Patents

Literature

3181 results about "Mechanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanization is the process of changing from working largely or exclusively by hand or with animals to doing that work with machinery. In some fields, mechanization includes the use of hand tools. In modern usage, such as in engineering or economics, mechanization implies machinery more complex than hand tools and would not include simple devices such as an ungeared horse or donkey mill. Devices that cause speed changes or changes to or from reciprocating to rotary motion, using means such as gears, pulleys or sheaves and belts, shafts, cams and cranks, usually are considered machines. After electrification, when most small machinery was no longer hand powered, mechanization was synonymous with motorized machines. Extension of mechanization of the production process is termed as automation and it is controlled by a closed loop system in which feedback is provided by the sensors. It controls the operations of different machines automatically.

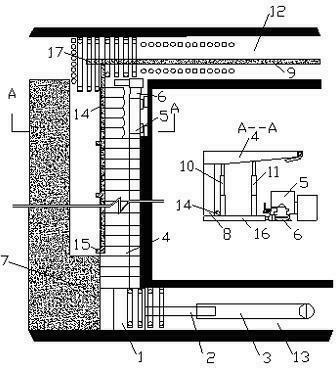

Upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method

ActiveCN106677780AImprove securityEnsure safetyUnderground miningTunnel/mines ventillationDetonationEngineering

The invention provides an upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method. The method includes the following steps that panels are divided in the ore direction, a stope preparation system is arranged, upward fan-shaped medium-depth blast holes are drilled from one side to the other side of a chamber, the blast holes are filled with explosives for detonation, and an undercut space is formed after detonation; cut grooves are formed through a VCR method, and as for ore above the undercut space, downward vertical deep holes are drilled in a drilling chamber at the top of the chamber, and the holes are filled with explosives for detonation with the cut grooves as a compensation space; the chamber in each panel is subjected to two-step backstoping, after ore removal of a first-step chamber is finished, the first-step chamber is filled with cementing materials, after the first-step chamber is filled and cured, a second-step chamber is subjected to backstoping, the backstoping steps of the second-step chamber are the same as those of the first-step chamber, and the second-step chamber is filled with cemented filling bodies and non-cemented filling bodies; and the steps are repeated in this way till backstoping of all chambers are completed. The upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method has the advantages that the rock drilling efficiency of the upward fan-shaped medium-depth blast holes is improved, the waste hole rate is lowered, efficient and safe bottom ore removal is achieved, and the mechanization level is high.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

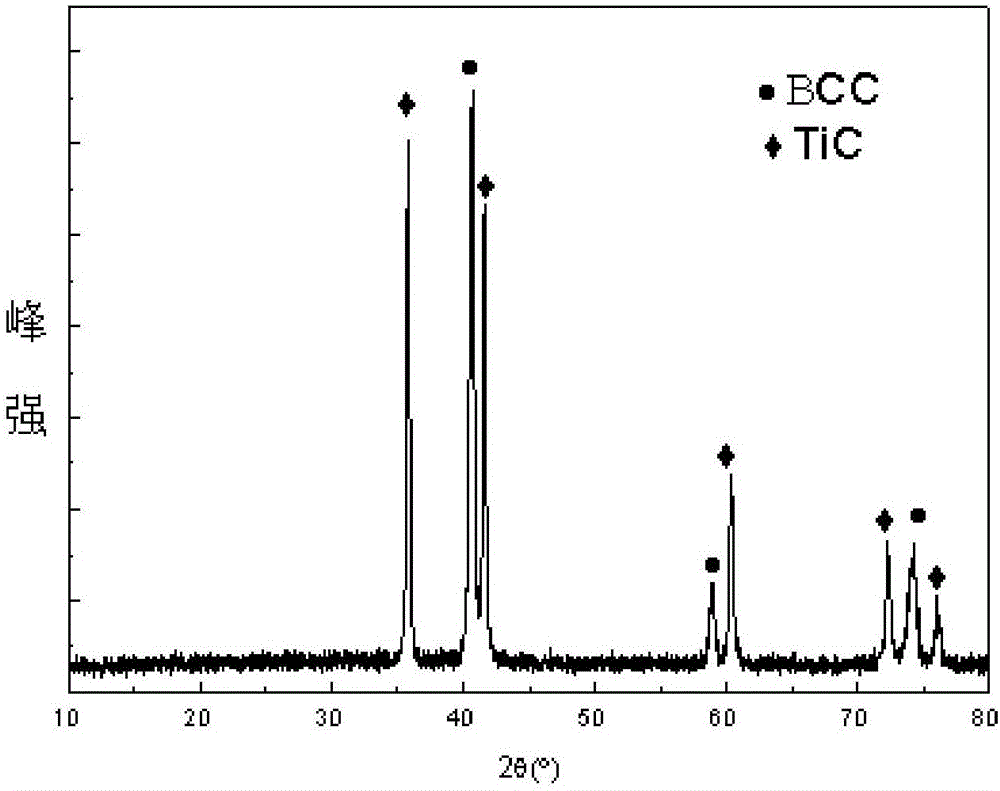

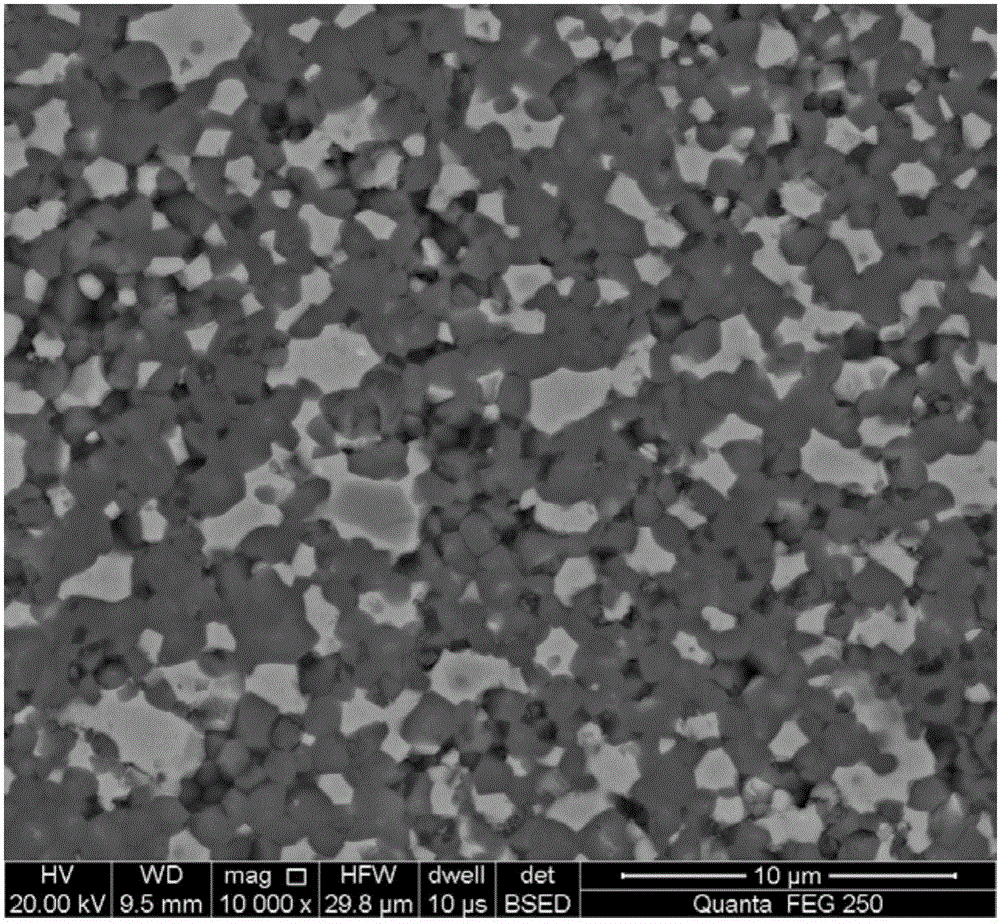

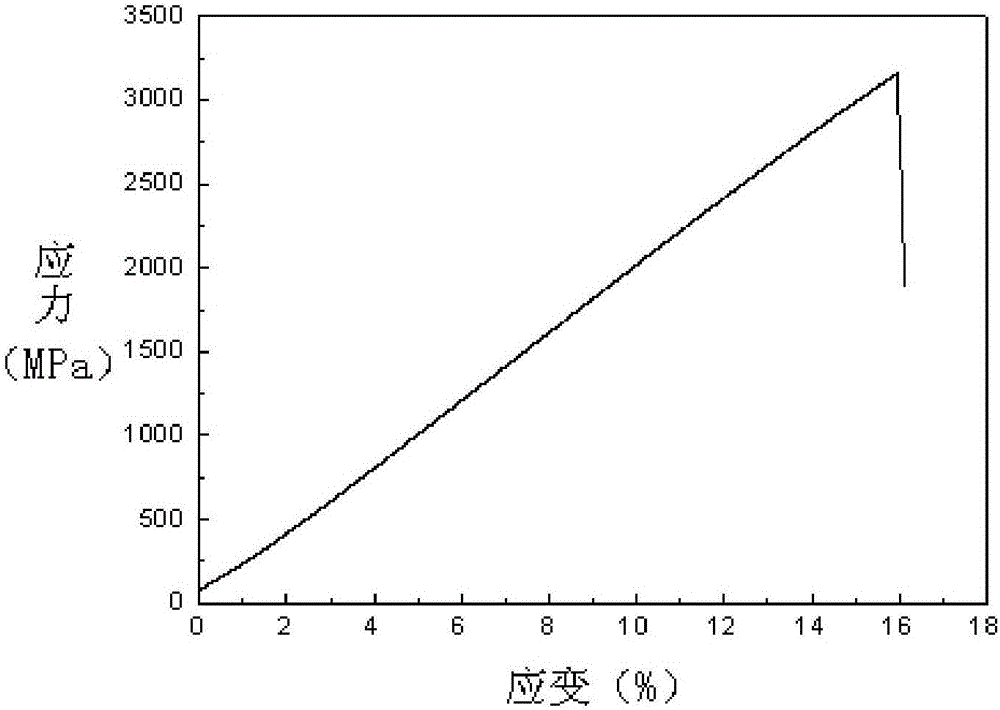

Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

The invention discloses a refractory high-entropy alloy / titanium carbide composite. A refractory high-entropy alloy serves as a matrix phase, and titanium carbide serves as a wild phase; and elements in the refractory high-entropy alloy are selected from at least four kinds of elements of W, Mo, Ta, Nb, V, Ti, Zr, Hf and Cr. A preparation method of the refractory high-entropy alloy / titanium carbide composite comprises the steps that at least four kinds of carbonization metal powder in tungsten carbide, molybdenum carbide, tantalum carbide, niobium carbide, vanadium carbide, the titanium carbide, hafnium carbide, zirconium carbide and chromium carbide are selected and mixed according to the equal molar ratio or the ratio close to the equal molar ratio to form high-entropy matrix powder; and after the high-entropy matrix powder and titanium powder are mixed, alloy mechanization is carried out, then spark plasma sintering or hot-press sintering is carried out, and the refractory high-entropy alloy / titanium carbide composite is obtained. The density and cost of the composite are reduced while the hardness of the composite is improved, excellent high-temperature performance is achieved, and the requirement for manufacturing a high-temperature structural component is met.

Owner:江西咏泰粉末冶金有限公司

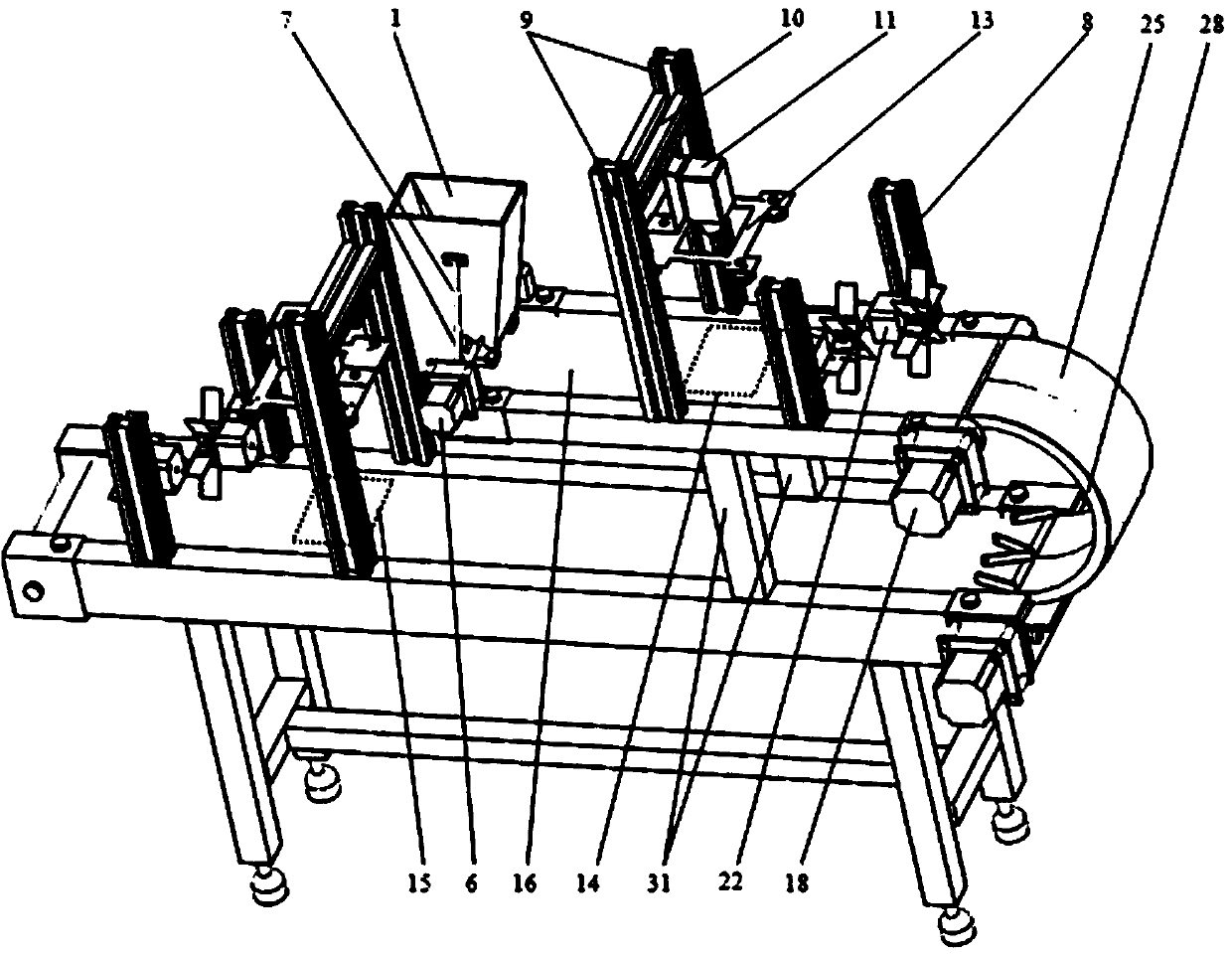

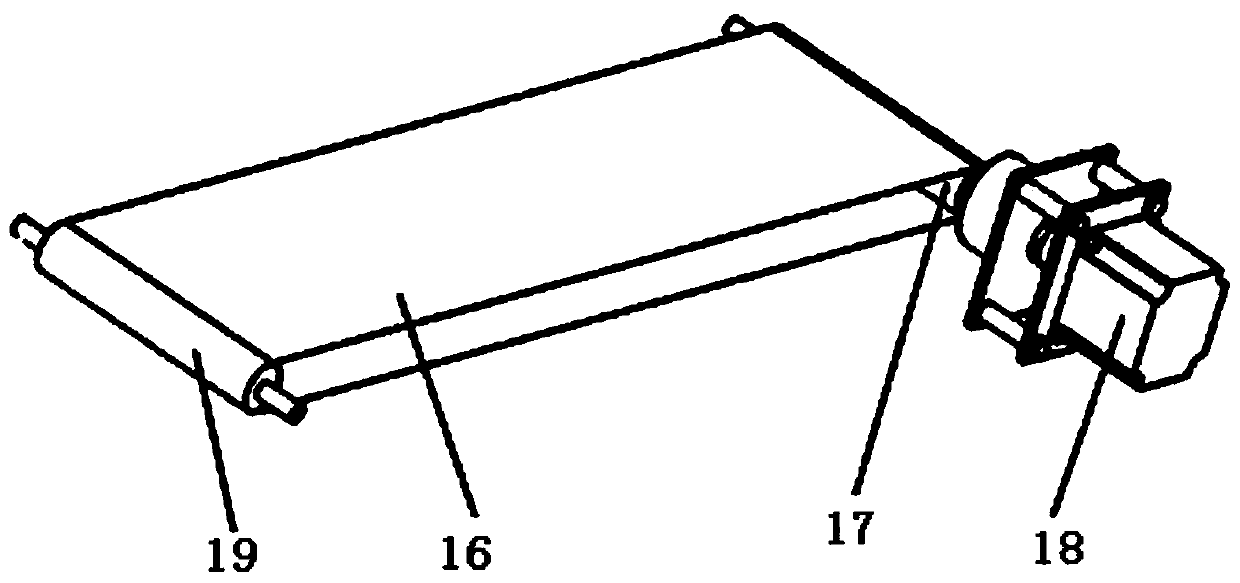

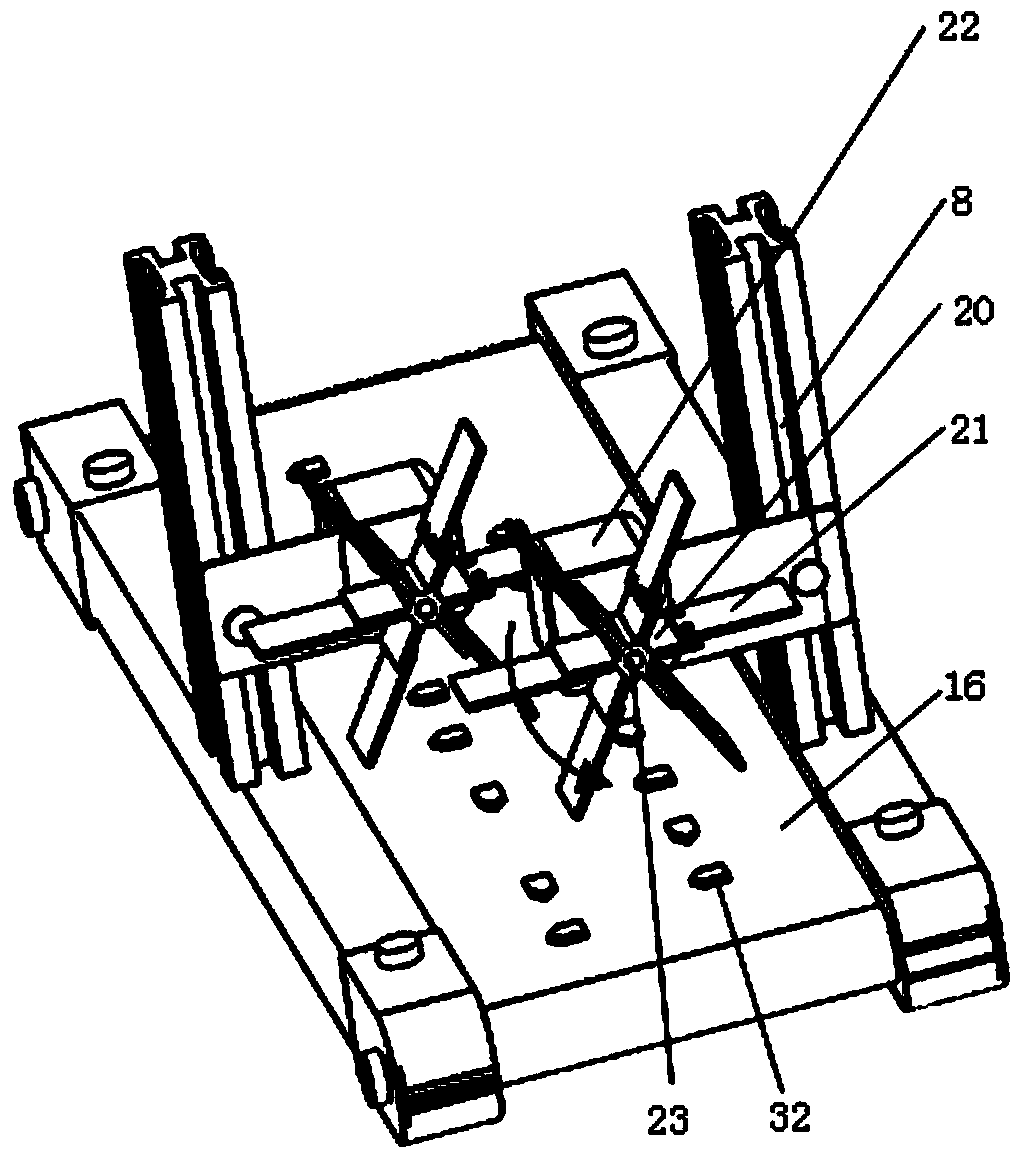

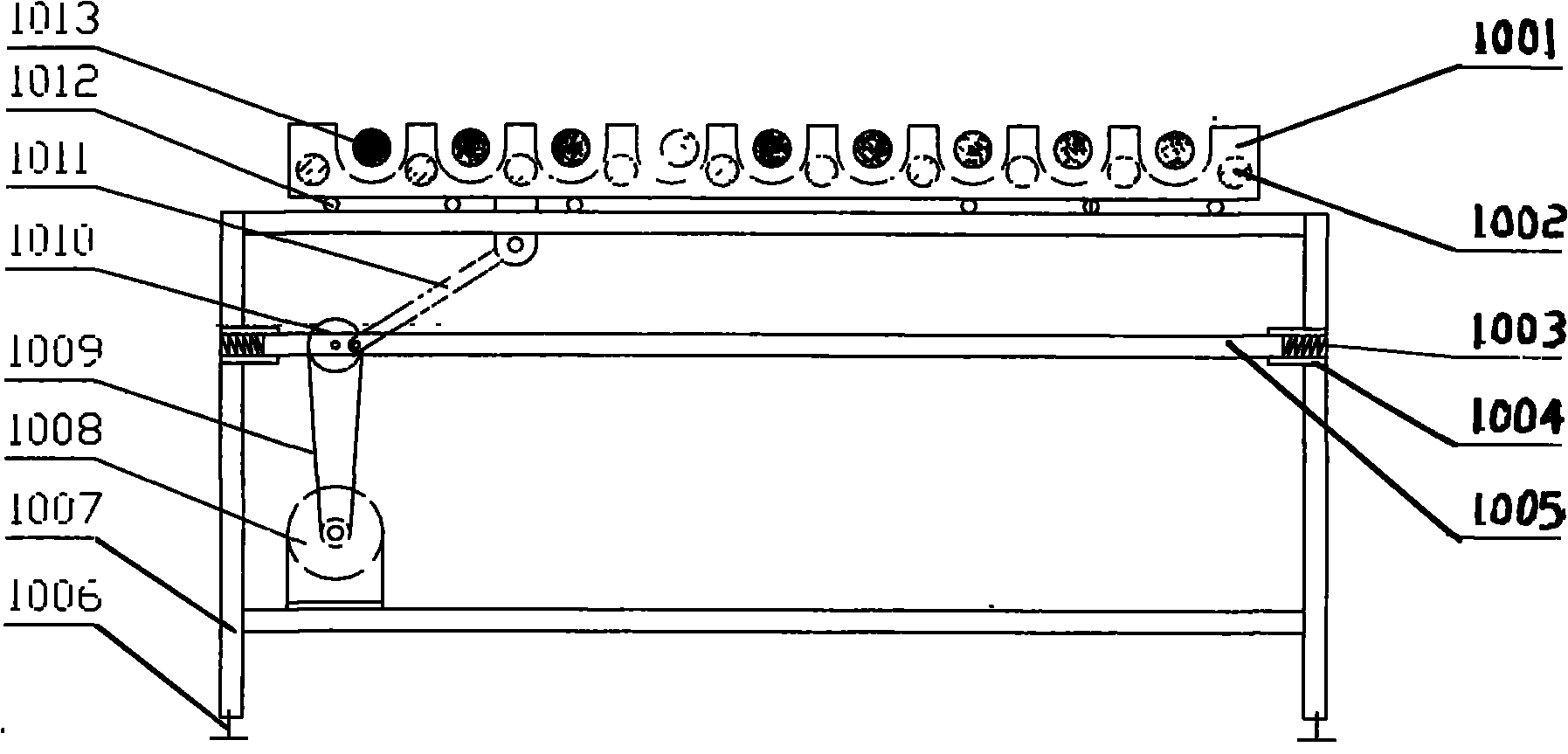

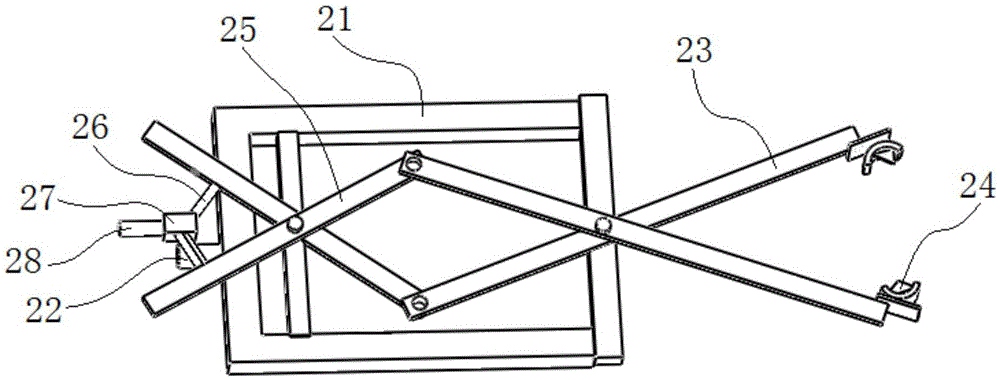

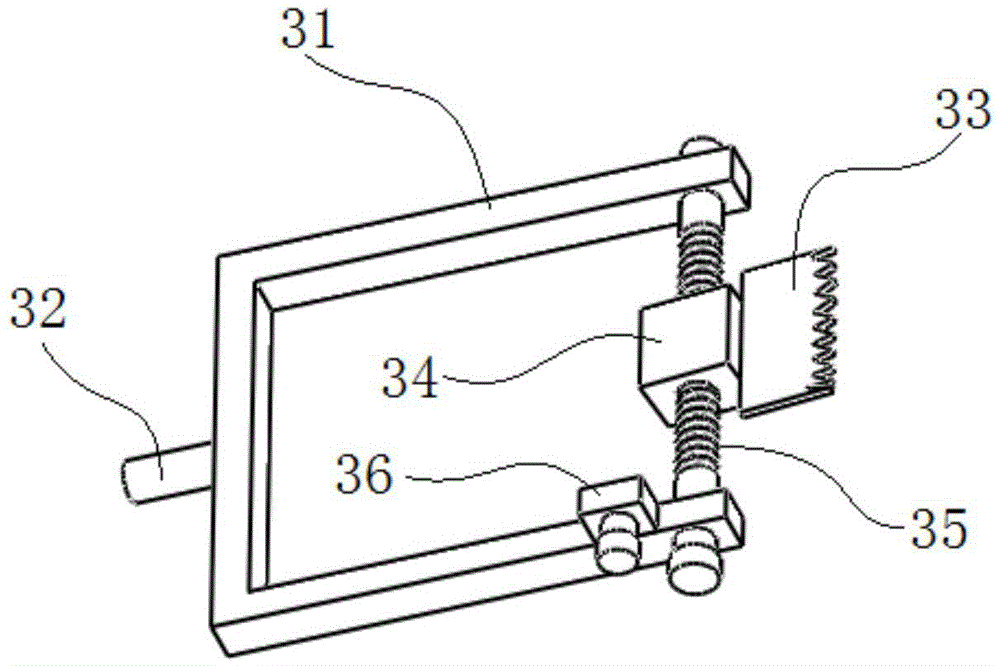

Corn-seed image carefully-choosing apparatus and usage method for apparatus

InactiveCN104084379AGuaranteed accuracyContinuous and even double row feedingSortingMachine visionImage detection

The invention relates to the technical field of visual inspection by using a machine, and concretely relates to an corn-seed image carefully-choosing apparatus and a usage method for the apparatus. The technical scheme is characterized in that the a practical efficient on-line carefully-choosing image detection algorithm for corn seeds is provided; a corn-seed turning-over mechanism is designed, which is capable of performing image detection determination on the front side and the reverse side of a corn seed and helps to guarantee accuracy of a detection result; an electromechanical sorting execution mechanism with simple structure is designed; and a novel double-row feeding mechanism is designed, which is capable of continuously uniformly performing double-row feeding on corn seeds. The corn-seed image carefully-choosing apparatus is simple in structure, precise and efficient, and is significant in guaranteeing enforcement of orientated precise sowing of corn, realizing careful choosing of corn seeds before sowing, promoting high quality, high yield and stable development of corn industry in our country and mechanization, automation and intelligentization level of agricultural-product detection.

Owner:CHINA AGRI UNIV

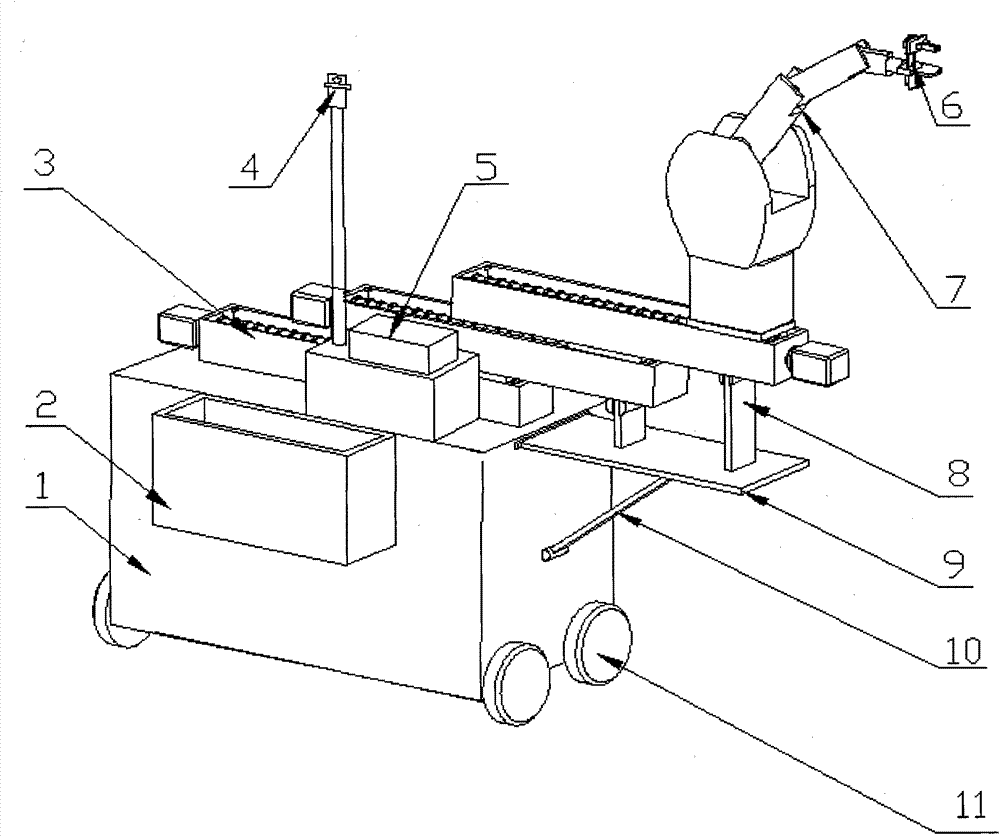

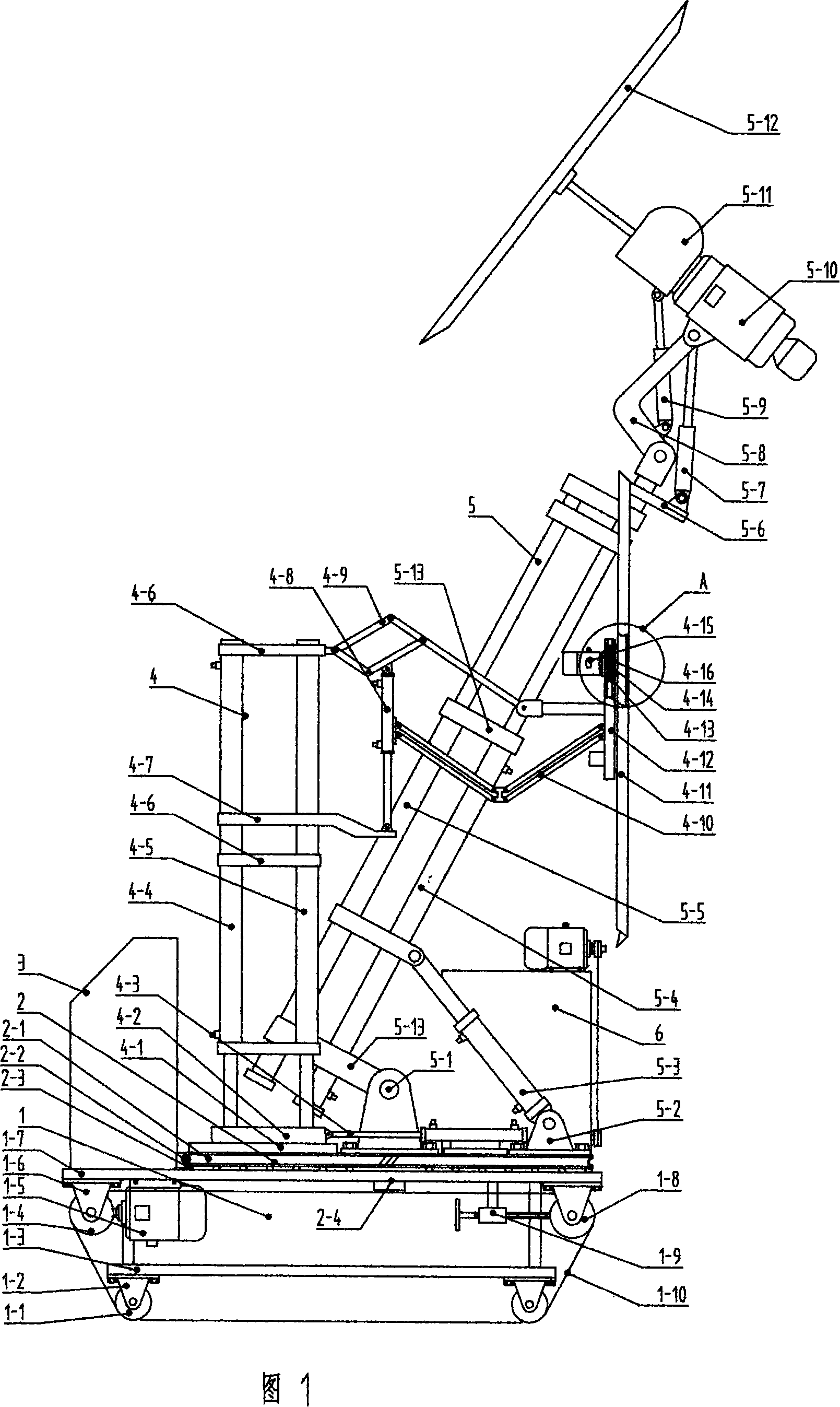

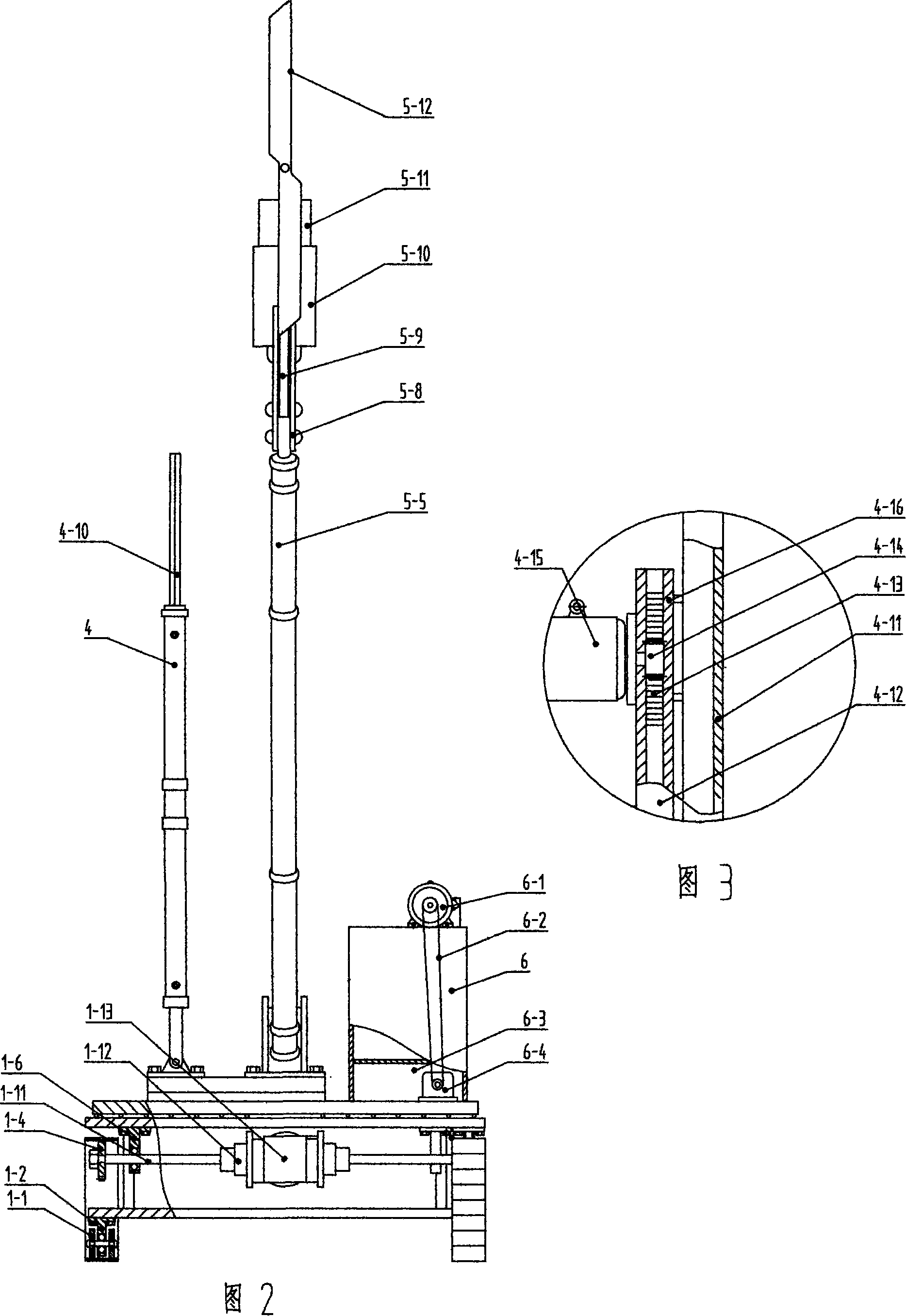

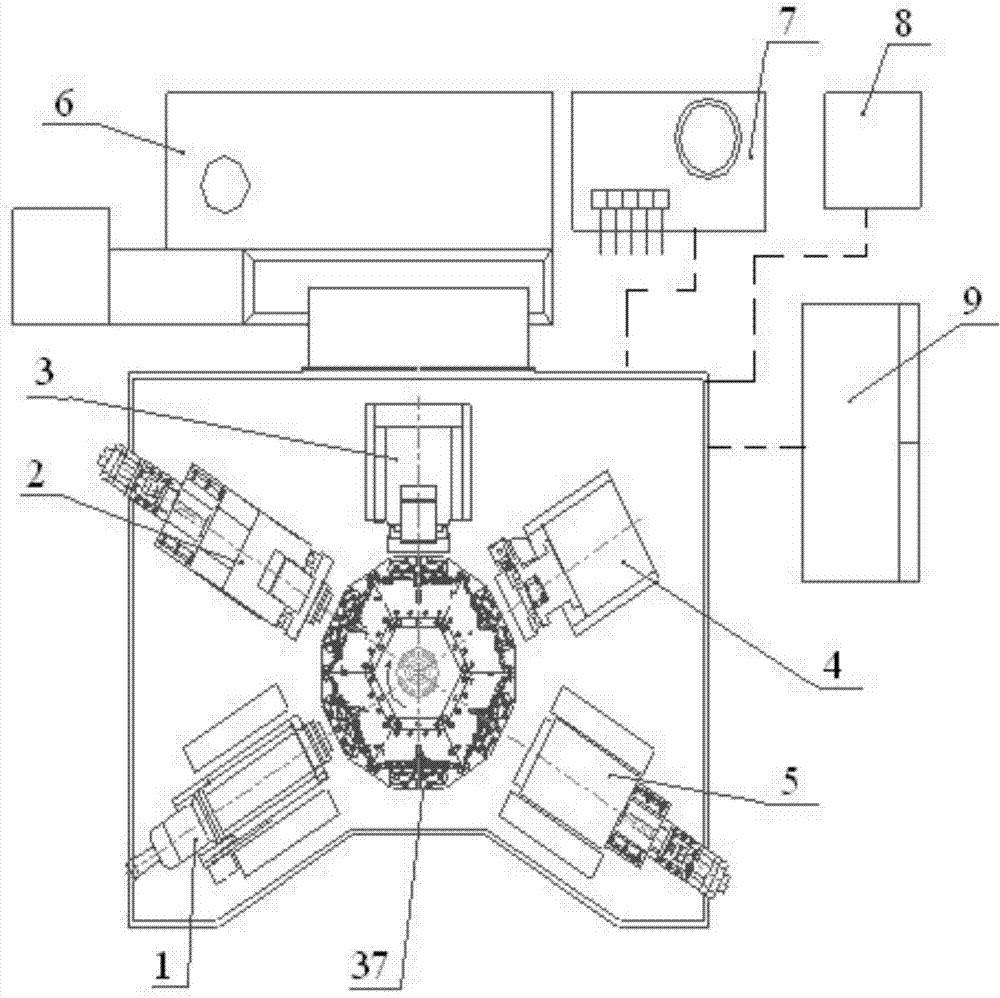

Picking robot and picking method for kiwi fruits

InactiveCN103749094AImprove environmental adaptabilityImprove work efficiencyPicking devicesActinidiaData acquisition

The invention discloses a picking robot and a picking method for kiwi fruits. The picking robot for the kiwi fruits comprises a machinery execution system and a control system, and is characterized in that the machinery execution system comprises a car body, a telescopic slide platform, a five freedom degree picking robot arm and a two finger type end actuator, and the control system comprises an industrial personal computer, a motion control card, a data acquisition card, an image acquisition card, a servo motor driver, a binocular video camera, an infrared sensor, a pressure sensor, an electric control cabinet and a control circuit. The picking robot and the picking method for the kiwi fruits use a building block design philosophy to integrate the two finger type end actuator, the five freedom degree picking robot arm, the telescopic slide platform and a sensor system together and integrate image acquisition and feature extraction of fruits and barriers, intelligent mobility of the telescopic slide platform, counterguard and fruit positioning of the five freedom degree picking robot arm and grab motions of the two finger type end actuator together, and therefore achieve mechanization and automation of picking of the kiwi fruits, improve labor productivity, reduce production cost, and guarantee harvest quality of the kiwi fruits.

Owner:NORTHWEST A & F UNIV

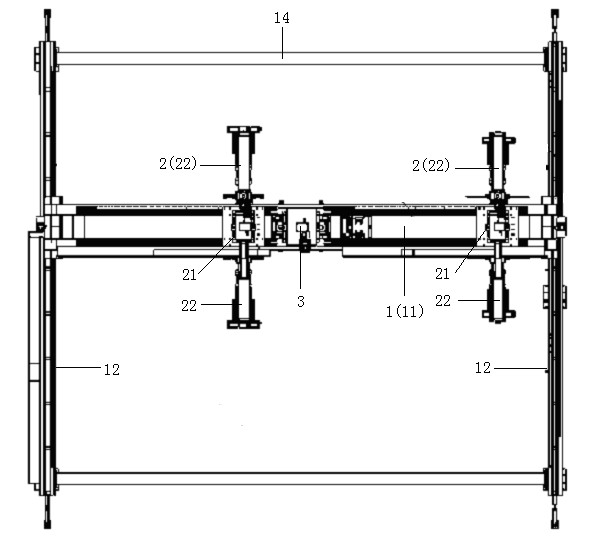

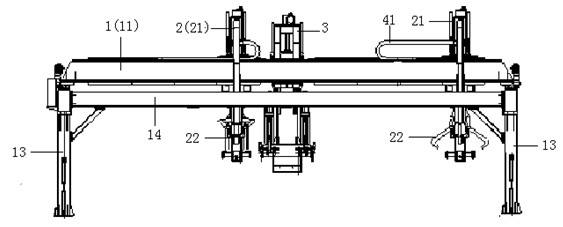

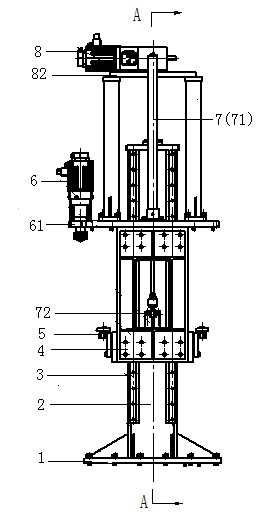

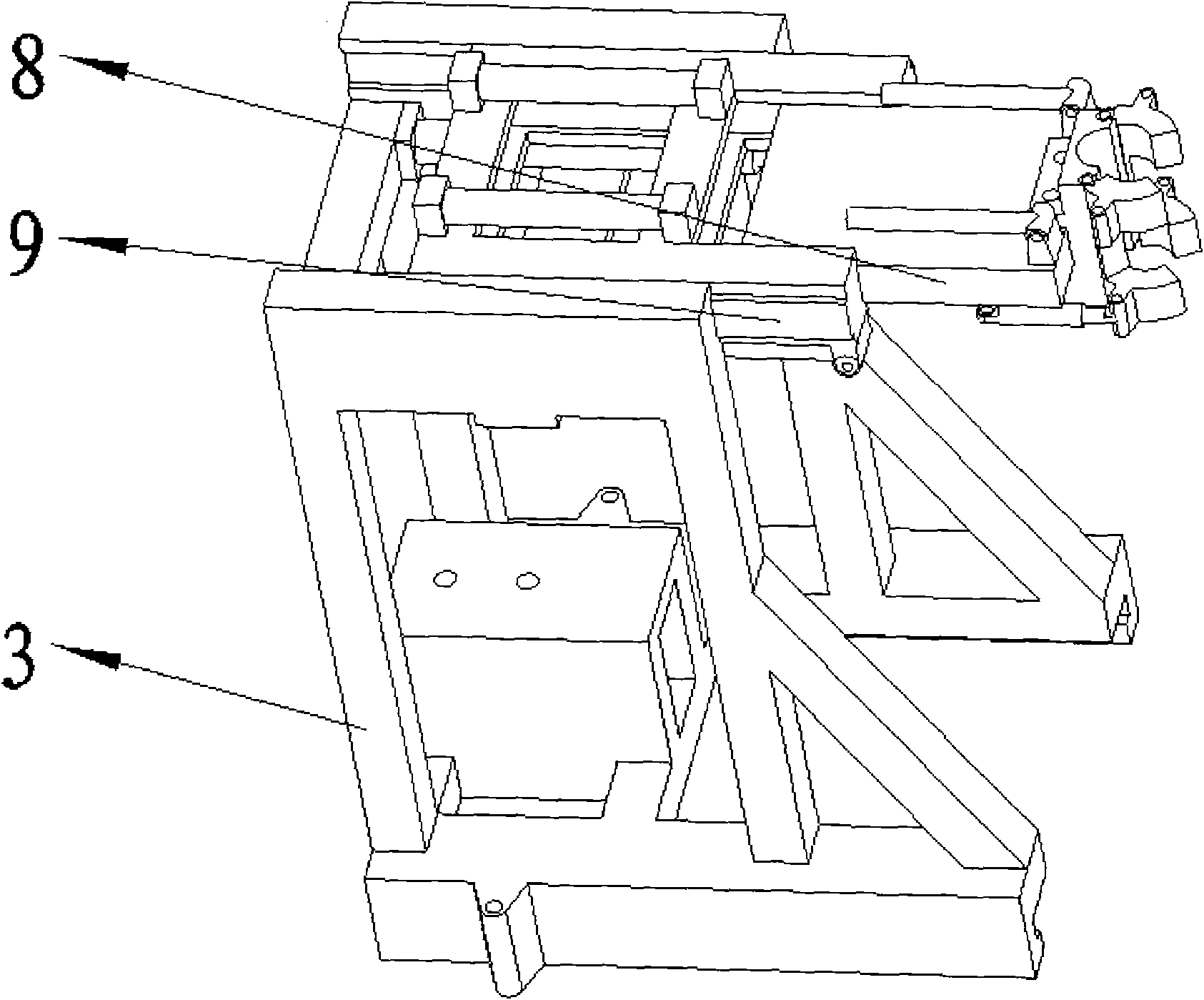

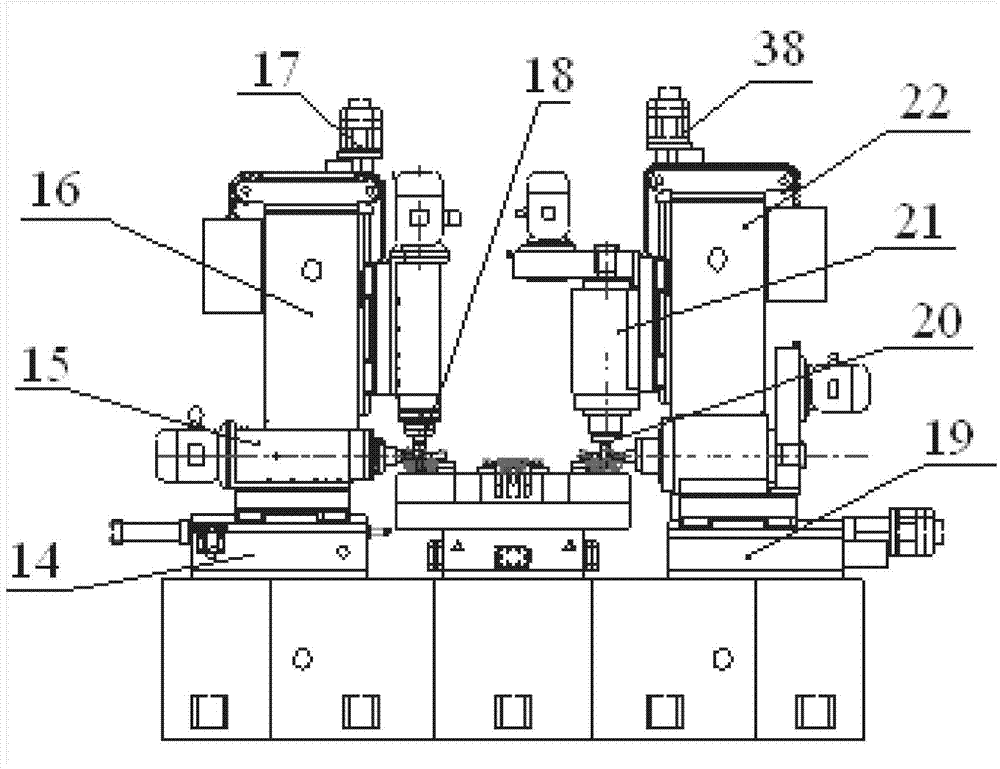

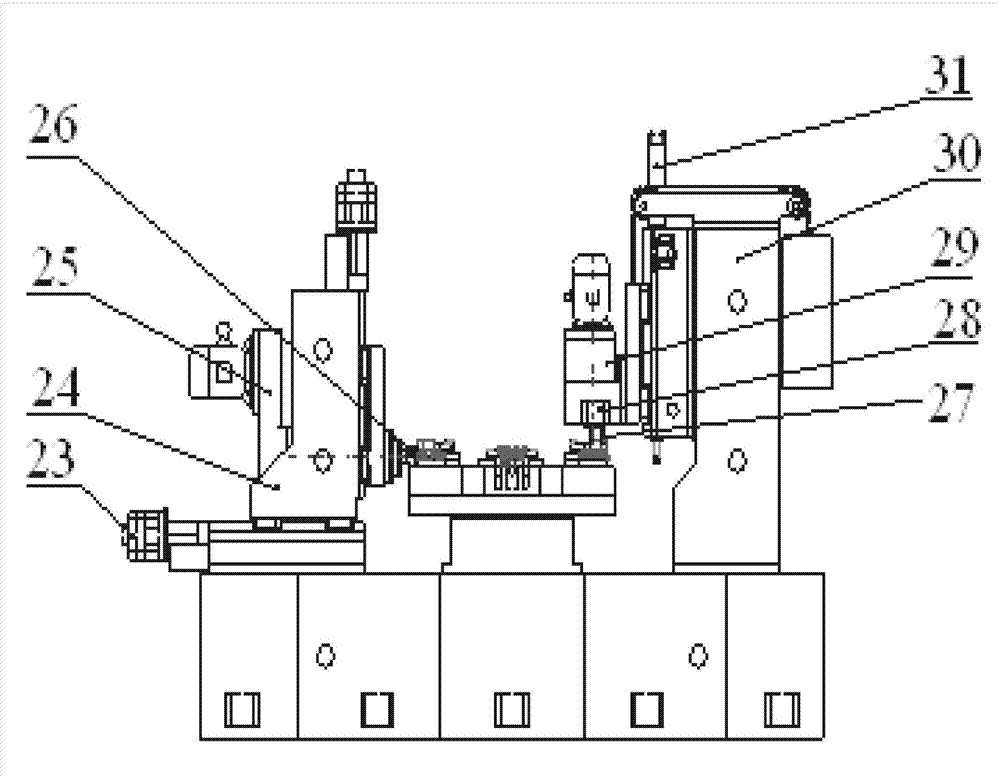

Special portal-type bolster frame assembly manipulator for truck bogie production line

ActiveCN102430906AEliminate potential safety hazardsImprove assembly qualityProgramme-controlled manipulatorMetal working apparatusBogieProduction line

The invention provides a special portal-type bolster frame assembly manipulator for a truck bogie production line, which is mainly composed of a frame, two side frame manipulators, a swing bolster manipulator and an electric control unit, wherein the side frame manipulators, swing bolster manipulator and electric control unit are installed on the frame; the frame is mainly composed of a cross beam, a support beam, a vertical support and a traveling beam which are connected with each other; the two side frame manipulators are installed on the cross beam, and each side frame manipulator is composed of a side frame transverse operating / vertical lifting unit and a side frame grabbing / clamping / turning unit; and the swing bolster manipulator is installed on the cross beam and positioned betweenthe two side frame manipulator. The invention provides an indispensable important apparatus of the key position bolster frame assembly for a truck bogie production line; the side frame manipulators can operate leftward and rightward or forward and backward to grab and lift the side frames transported by the transport vehicle, and smoothly align and assemble the side frame with the swing bolster grabbed by the swing bolster manipulator, and thus, the degree of mechanization and automation is high; and the invention has the advantages of labor saving, time saving and high assembly quality, and eliminates the potential safety hazard in the craning process.

Owner:江苏中创机械装备制造有限公司

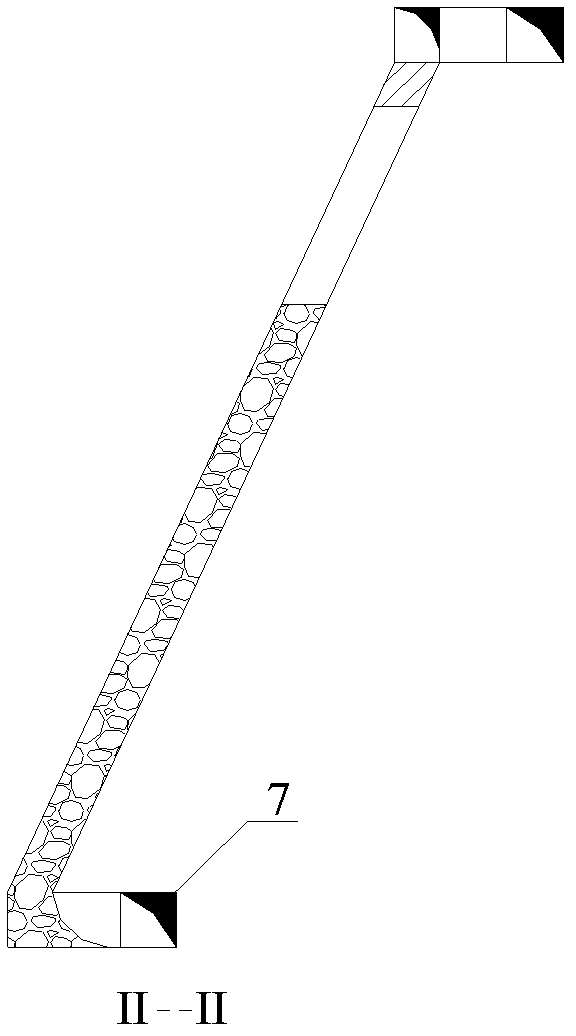

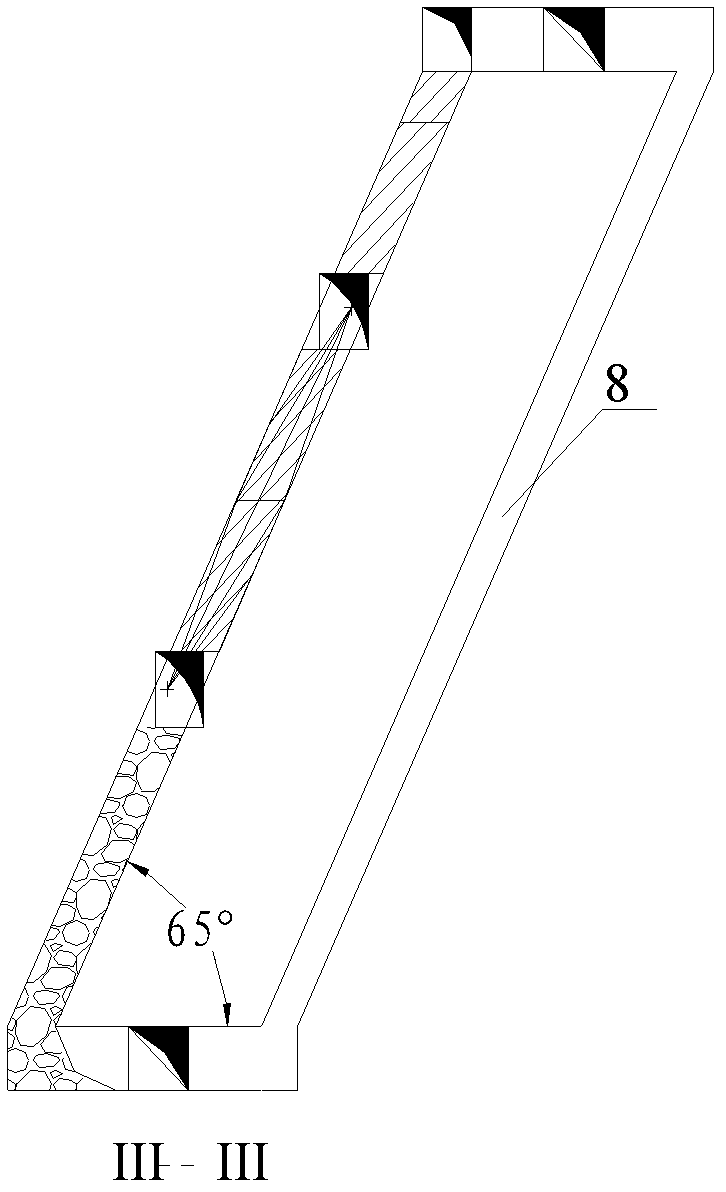

Medium-length hole mining method in multiple blasting free faces of high dipping thin veins

InactiveCN102635356AIncrease job securityStrong mining continuityUnderground miningSurface miningPunchingMineralogy

The invention discloses a medium-length hole mining method in multiple blasting free faces of high dipping thin veins. The medium-length hole mining method is characterized by comprising the steps of: arranging ore blocks along the trend of a core body, dividing the ore body into a medium section and a segment in the altitude; drilling a gate way in the segment and arranging in veins along the ore body; arranging a flat ore removal structure on the bottom along the veins; arranging a cutting raise from one ends of the ore blocks, arranging a manway at the other ends of the ore blocks; and upwards and downwards punching forwards leaning medium-length holes, with the cutting raise as free faces, and blasting caved ores in the segment by multiple free faces, and withdrawing the ore centrally at the bottom. The medium-length hole mining method has the remarkable characteristics of high mining safety, little resource dilution rate, good production continuity, high level of mechanization, low cost, high efficiency, low labor intensity and the like.

Owner:CENT SOUTH UNIV

Wall rendering robot

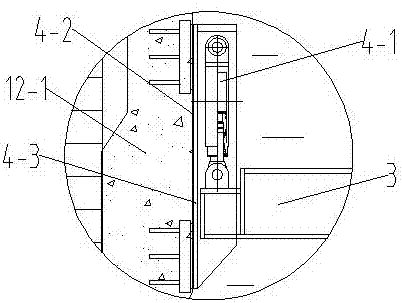

InactiveCN101144324AStraightness is easy to guaranteeQuality improvementBuilding constructionsElectromagnetic clutchDrivetrain

The invention relates to an improved equipment on the basis of an original patent wall side plastering machine (the patent number: ZL01218090.4), and the invention is that two groups of mutually independent plane plastering devices and reentrant and outside corners plastering devices are arranged on the revolution support of a crawler belt chassis. Improvement is done to a power driving system of the crawler belt chassis, and a half axis and an electromagnetic clutch are added. The revolution support adopts a gear worm to drive. The weight of a complete machine is reduced, in order to ensure that the whole mechanization is realized for the work of the complete machine such as the plastering, the roughening, the treatment of the reentrant and outside corners during the construction, the labor strength is greatly reduced, the production efficiency is improved, and the maintenance expense is reduced, as well as the service life is prolonged.

Owner:赵呈为 +1

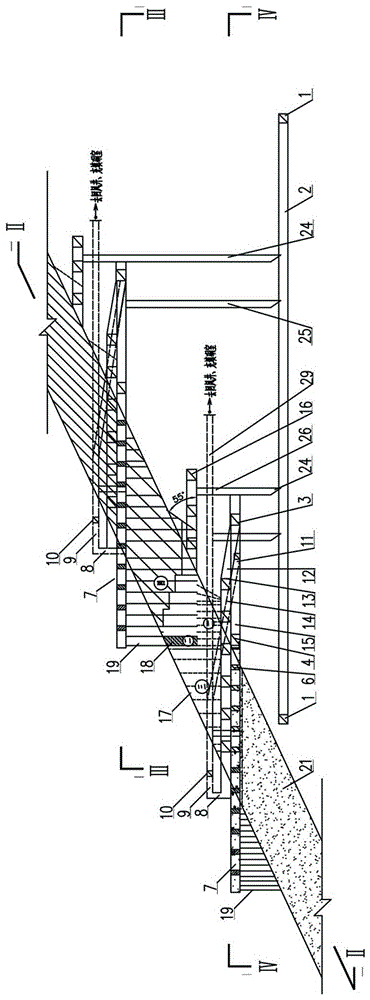

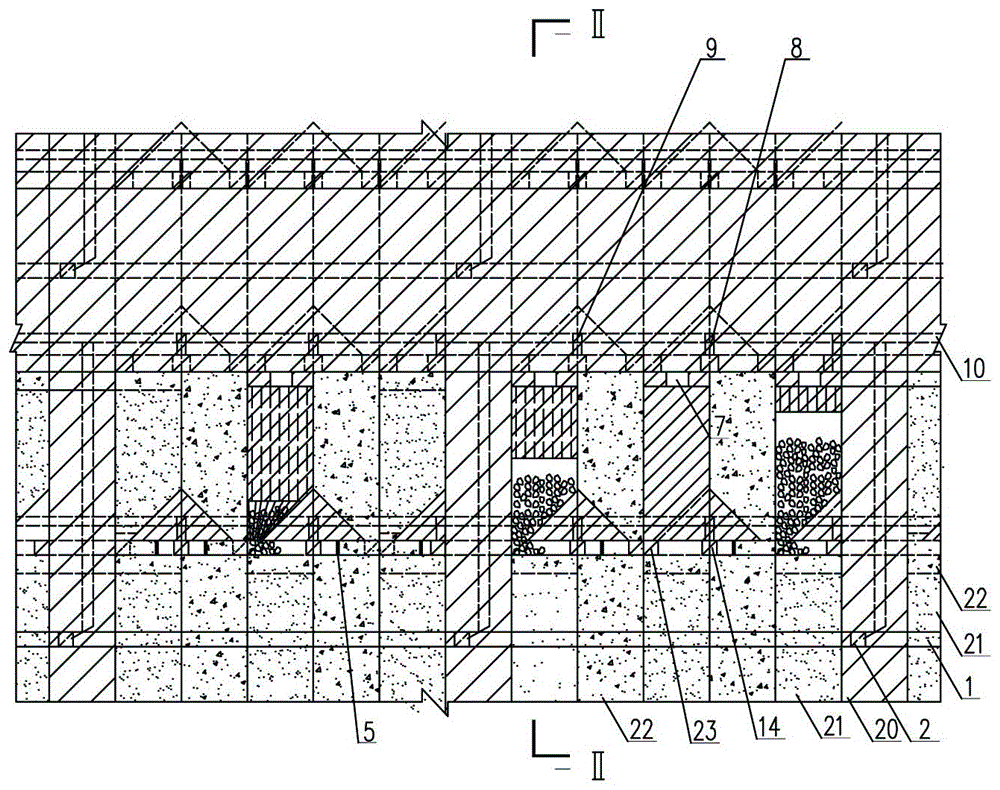

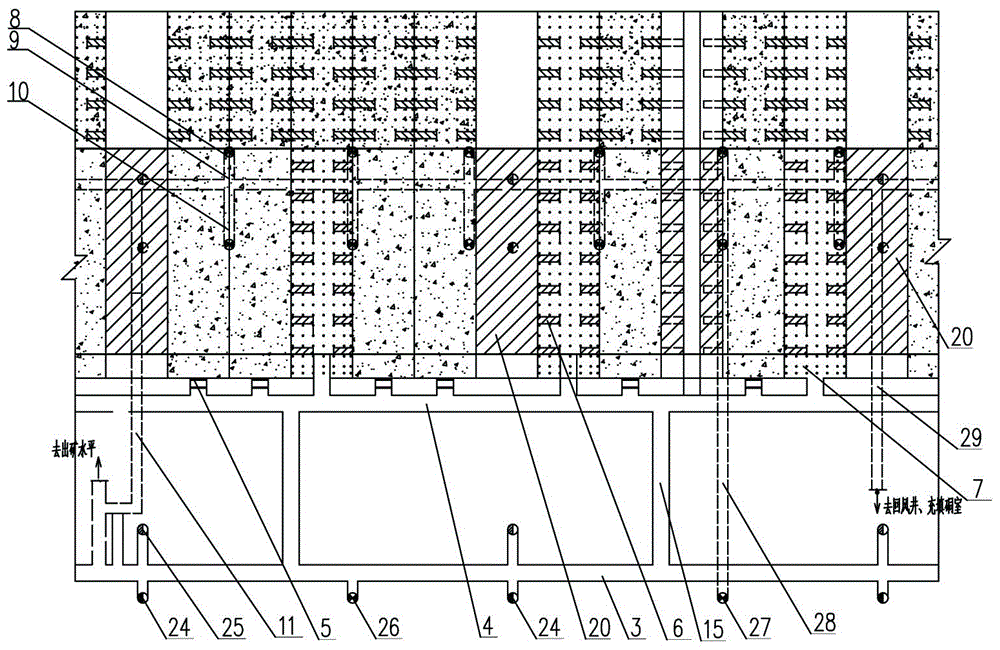

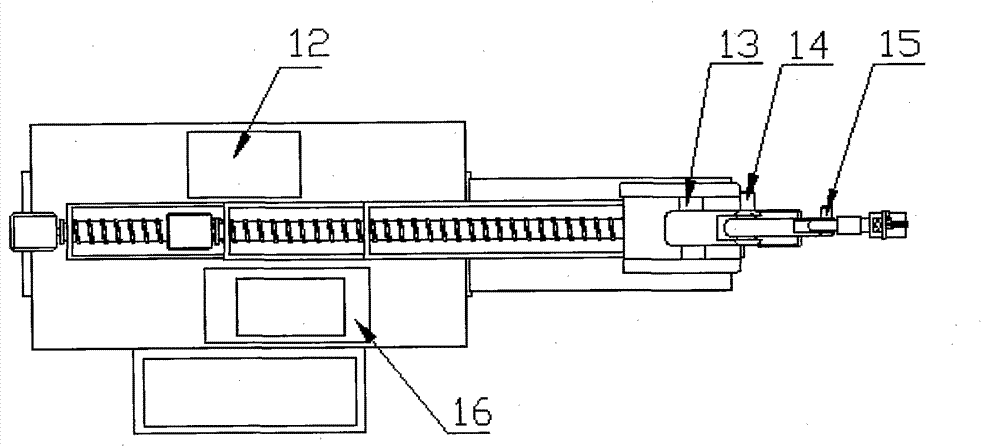

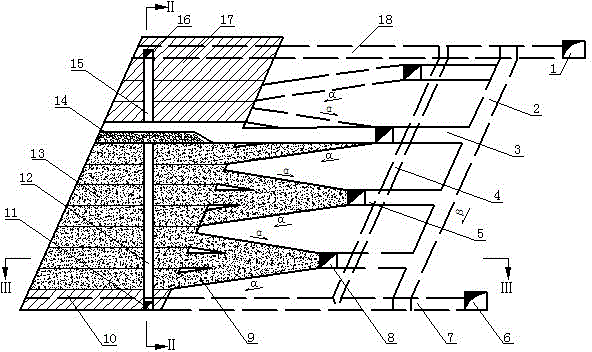

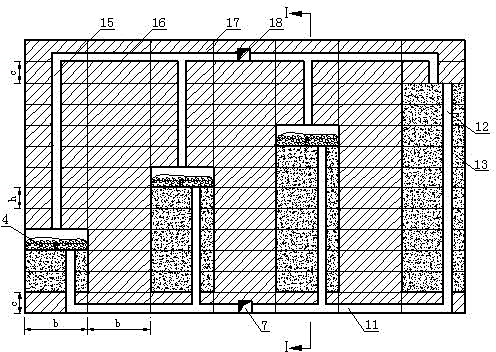

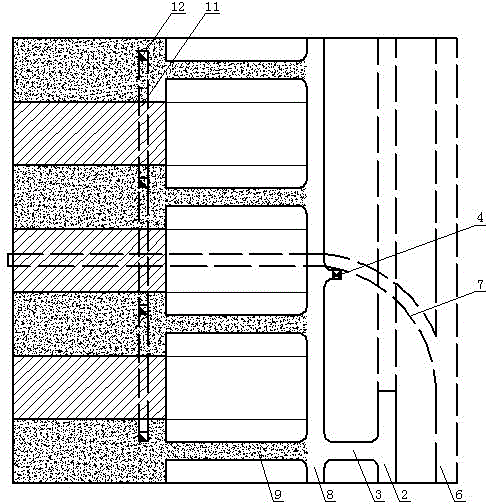

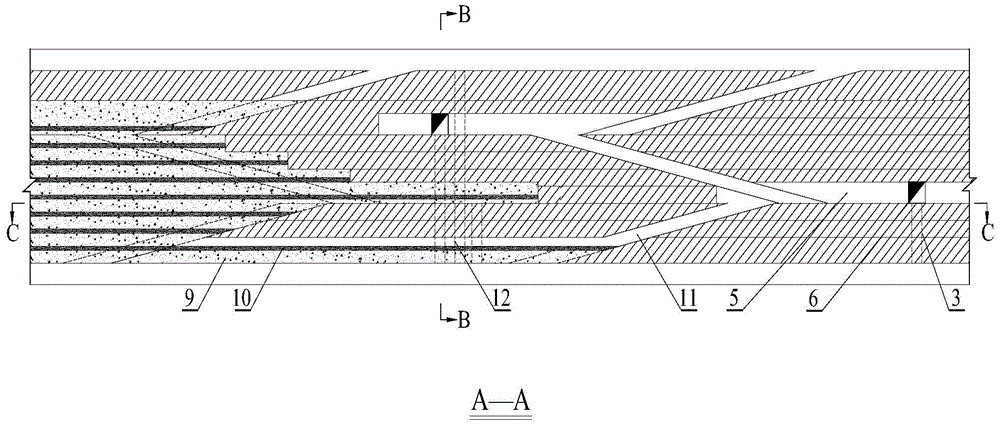

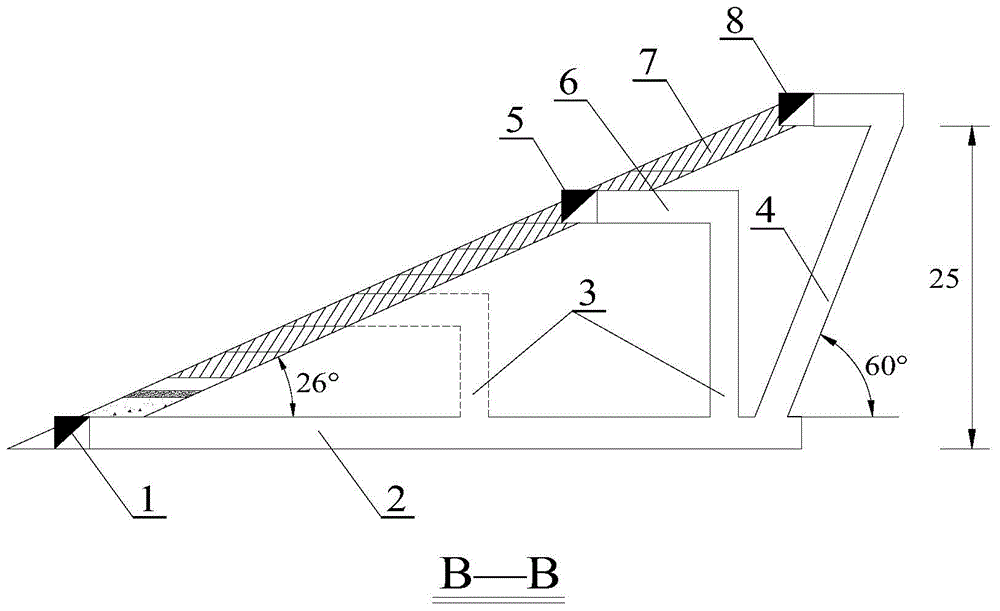

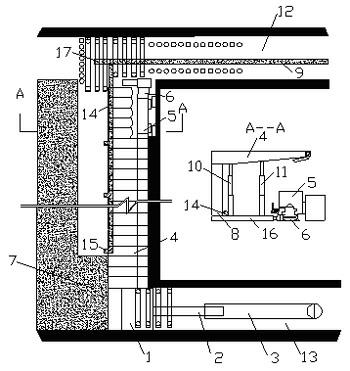

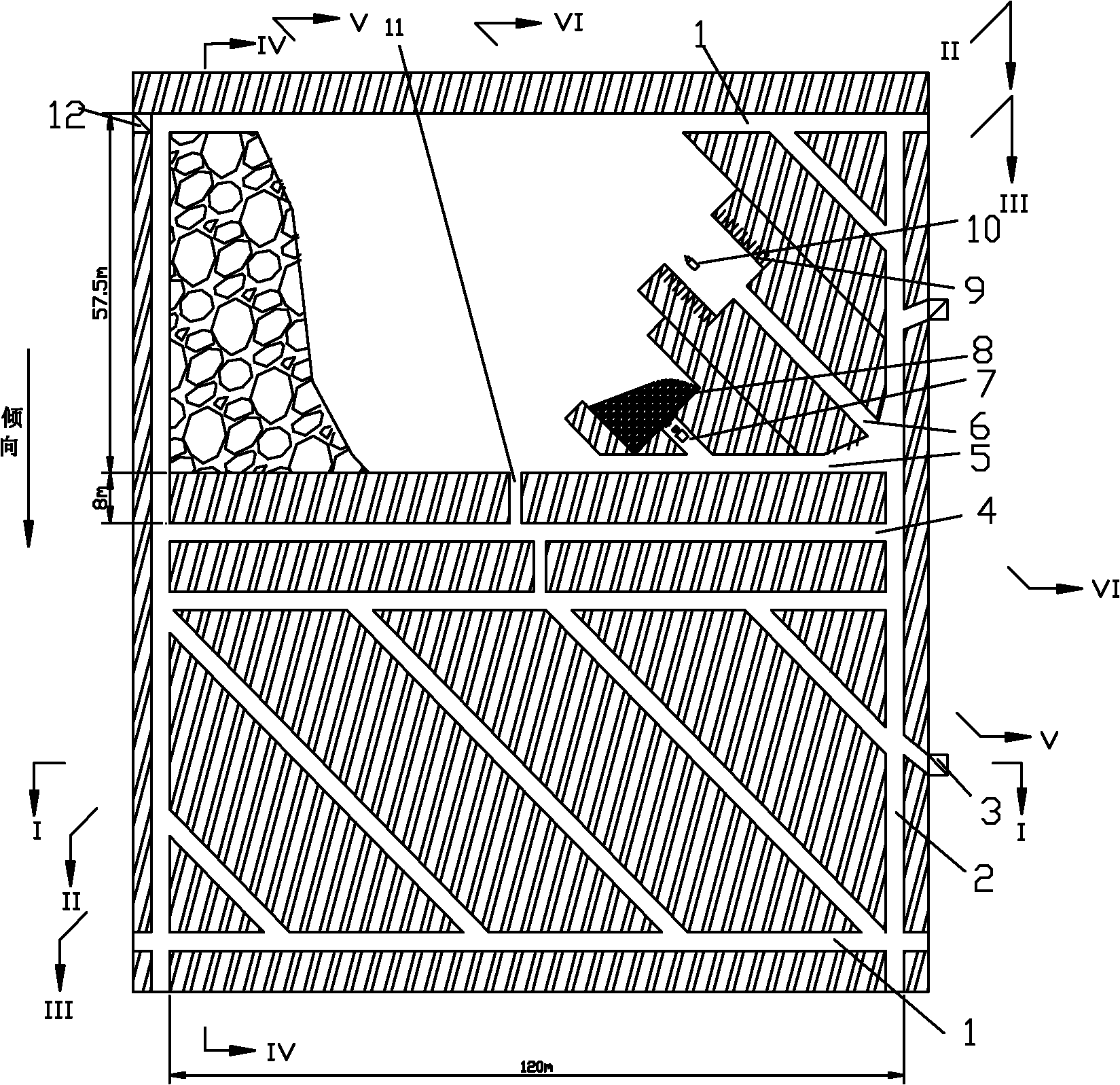

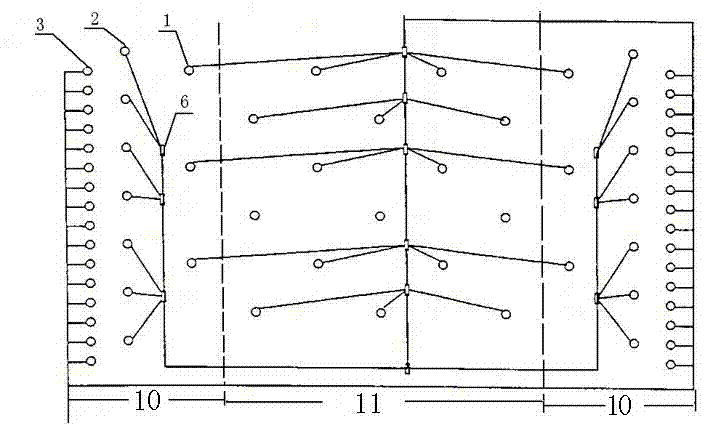

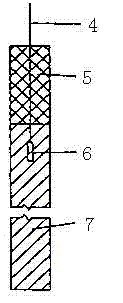

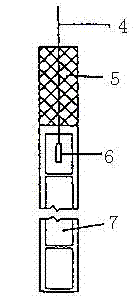

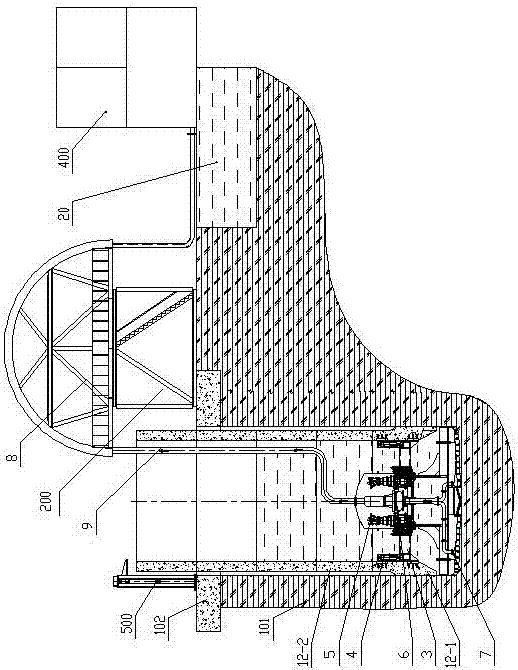

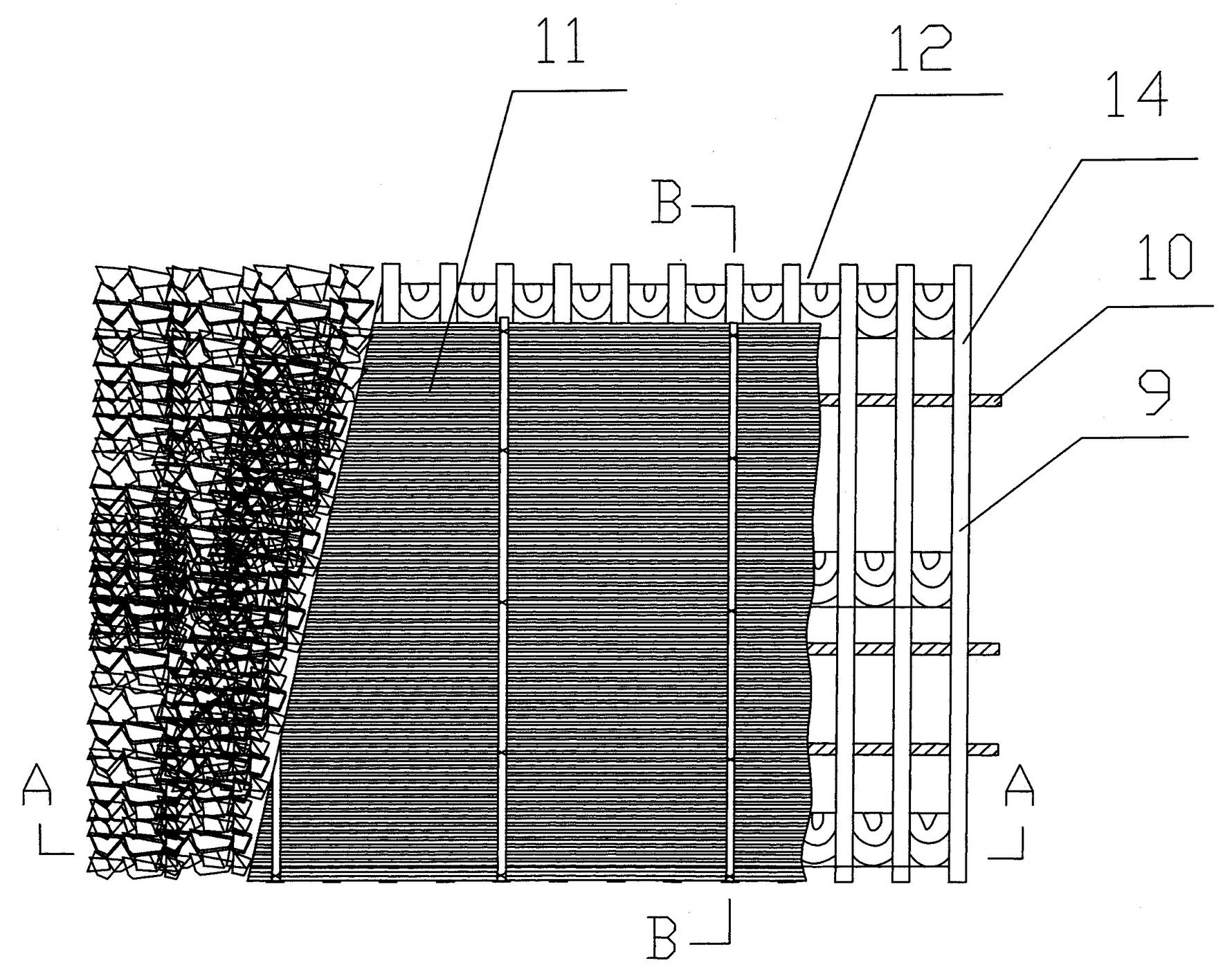

Panel mechanized centralized ore-pass upward horizontal cut-and-filling stoping method

InactiveCN103557002AIncrease production capacityHigh degree of mechanizationUnderground miningSurface miningFiltrationStructural engineering

The invention relates to a panel mechanized centralized ore-pass upward horizontal cut-and-filling stoping method. According to the technical scheme, an ore body is divided into panels in stages along the trend, and the panels are divided into chambers and studs at equal intervals according to the trend; a top pillar (17) and a bottom pillar (10) are left; the chambers and the studs are horizontally layered; a sublevel roadway (8), a pulse external slope ramp (2), a stope cross gateway (9) and a panel centralized ore-pass (4) are distributed on the panel lower plate to form a trackless stope preparation system; an upper-stage transverse drift (18) and a lower-stage transverse drift (7) pass through corresponding ventilation filling shaft cross gateway (16) and pedestrian water-filtration patio cross gateway (11) to be communicated with a ventilation filling shaft (15) and a pedestrian water-filtration patio (12) in each chamber or ore pillar. Mechanical mining is adopted, so that all chambers are stoped at the same time, and a mined-out area and the stope cross gateway (9) are filled when every layer is stoped; after the chamber mining is completed, the studs are stoped by using the same method, and the top pillar (17) and the bottom pillar (10) are finally stoped. The panel mechanization-centralized ore-pass upward horizontal cut-and-filling stoping method disclosed by the invention has the advantages of being high in production capability, high in stoping efficiency, simple in stoping process and good in operation safety.

Owner:WUHAN UNIV OF SCI & TECH

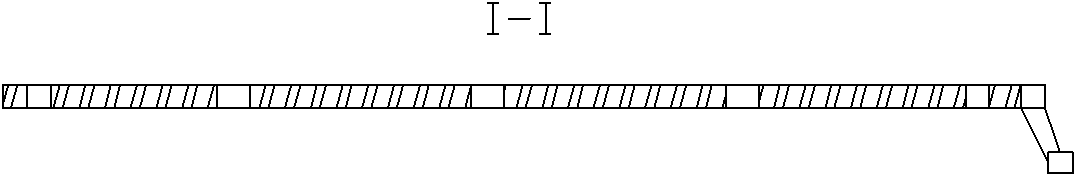

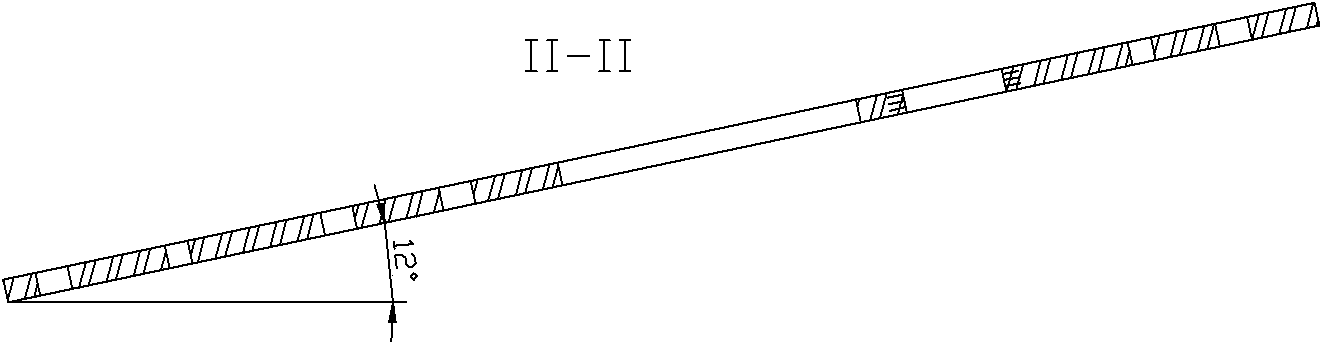

Upward cut-and-fill mining method for in-vein slope ramp of gentle dip thin vein

ActiveCN104060991AEnsure safetyImprove recovery efficiencyUnderground miningSurface miningVeinCut and fill

The invention discloses an upward cut-and-fill mining method for an in-vein slope ramp of a gentle dip thin vein. The method comprises the following steps: stoping layers of an ore body, tunneling a cross gateway from a bottom middle haulage drift to the ore body, tunneling a diagonal slope ramp along the vein to rise for certain height, and tunneling a slice drift, a reversing chamber and a sectional ore removal draw shaft forwards along the vein, wherein the reversing chamber and the sectional ore removal draw shaft are perpendicular to the slice drift; reversely tunneling the diagonal slope ramp along the vein from one side of the slice drift to rise for the certain height, and tunneling the slice drift, the reversing chamber and the sectional ore removal draw shaft along the vein; dividing a stope by using the diagonal slope ramp as the boundary, continuously propelling from one end of the vein to the other end of the vein, reaching all the layers of the ore body by virtue of the diagonal slope ramp which is tunneled in the vein, and sequentially stoping and filling from bottom to top by virtue of each layer stoping unit in the stope. The upward cut-and-fill mining method for the in-vein slope ramp of the gentle dip thin vein is high in mechanization degree, small in out-vein stope preparation engineering amount, low in labor intensity, low in ore dilution loss, safe to operate and high in efficiency.

Owner:河南发恩德矿业有限公司

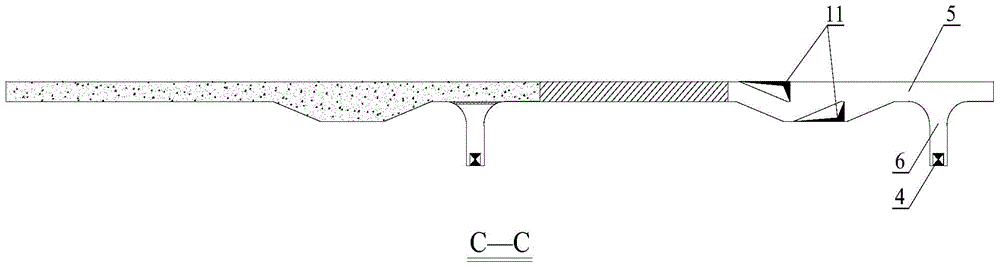

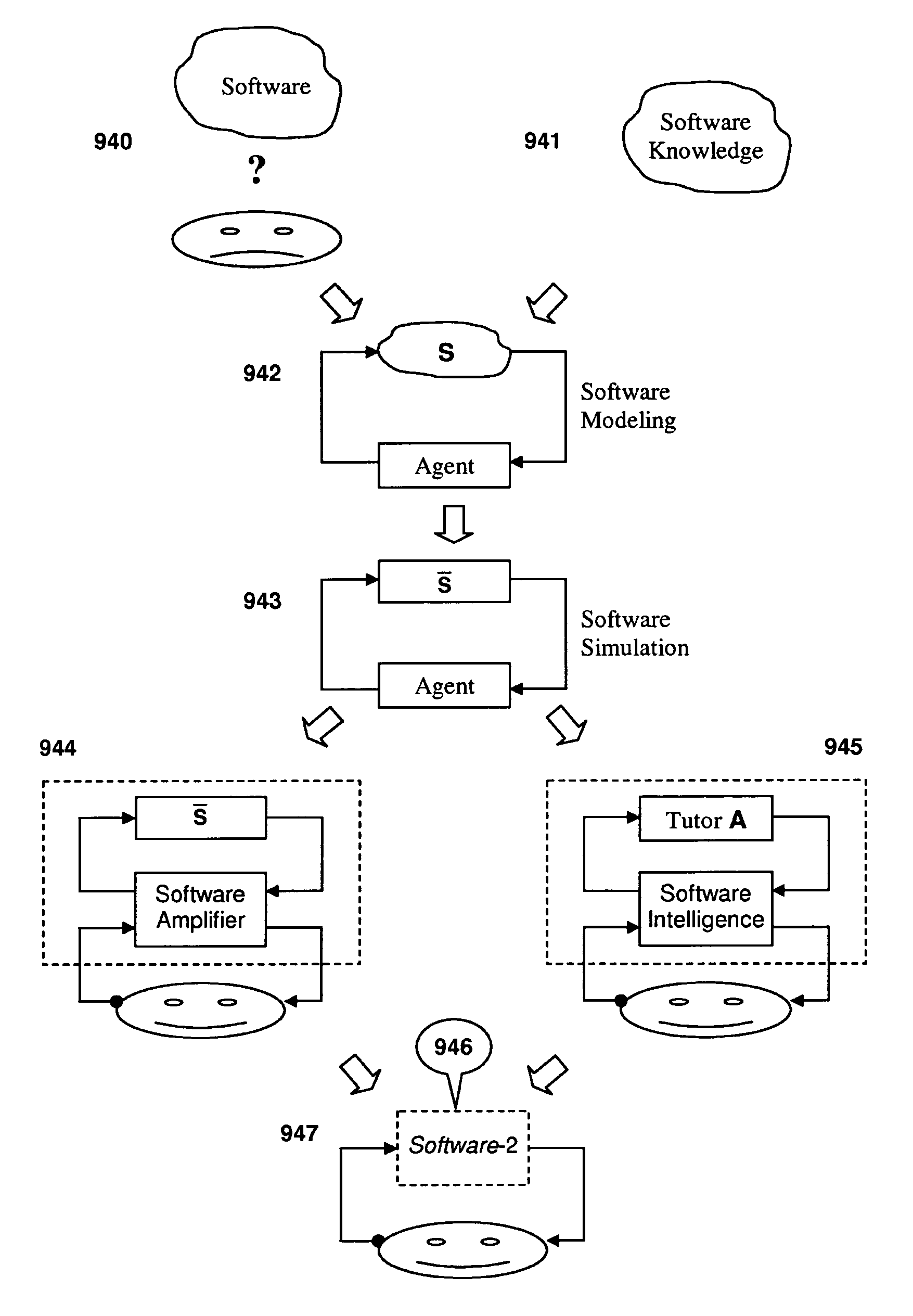

Mechanization of modeling, simulation, amplification, and intelligence of software

InactiveUS7490031B1High simulationImprove experienceSoftware engineeringSoftware simulation/interpretation/emulationAudio power amplifierModeling software

The invention models software as a physical device with causality. It develops interaction between software and user in a software dynamic system that connects software or modeled software with a software controller. The software is modeled with its input / output behavior on a discrete sampling domain and is controlled by the controller in a modeling software dynamic system while its behavior is observed real-time to identify its model. The modeled software is controlled by the same controller in a simulation software dynamic system, which can be augmented programmatically. Augmentations integrated with the controller construct a software amplifier coupling the modeled software and user interactively and automatically. The modeled software represents domain knowledge simulated in the augmented system as software intelligence. A software-2 including the modeled software, the software controller, and augmentations is created. Software-2 integrated with real-time communication distributes over Internet with a Master-Machine-Learner loop as a new interactive media.

Owner:QIU GANG

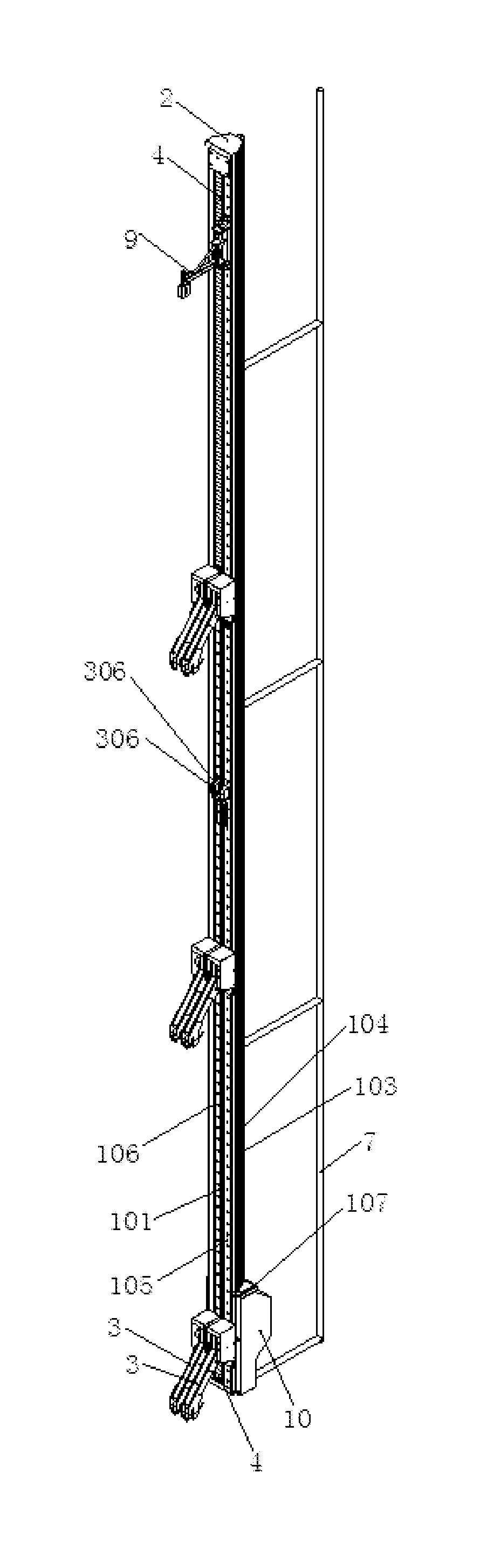

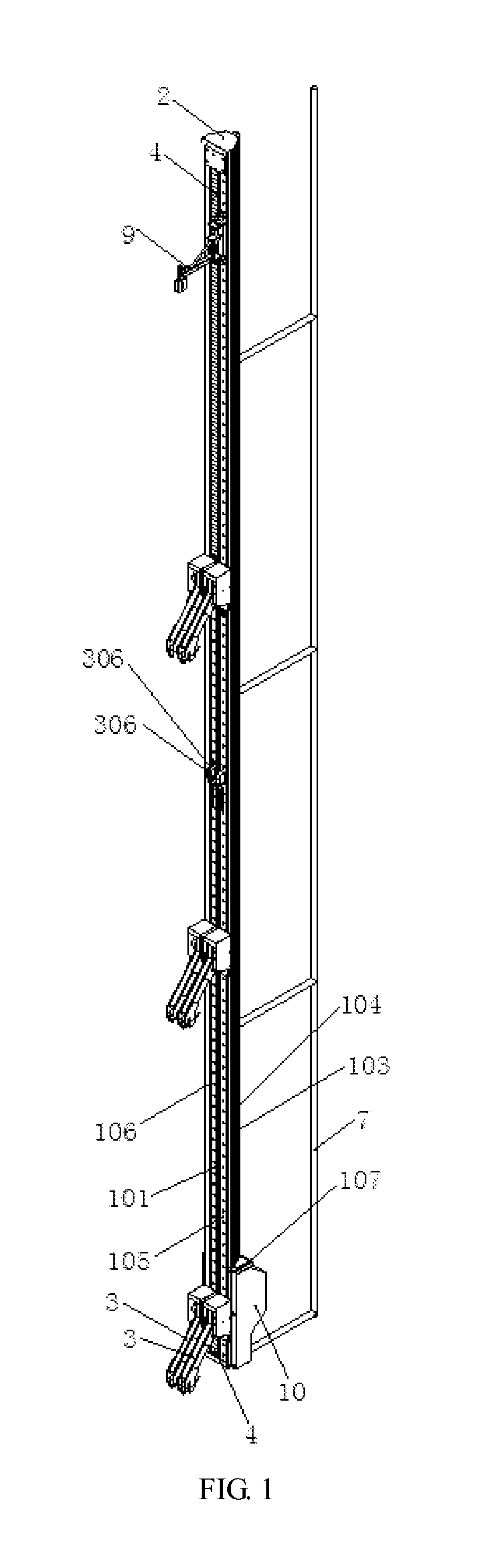

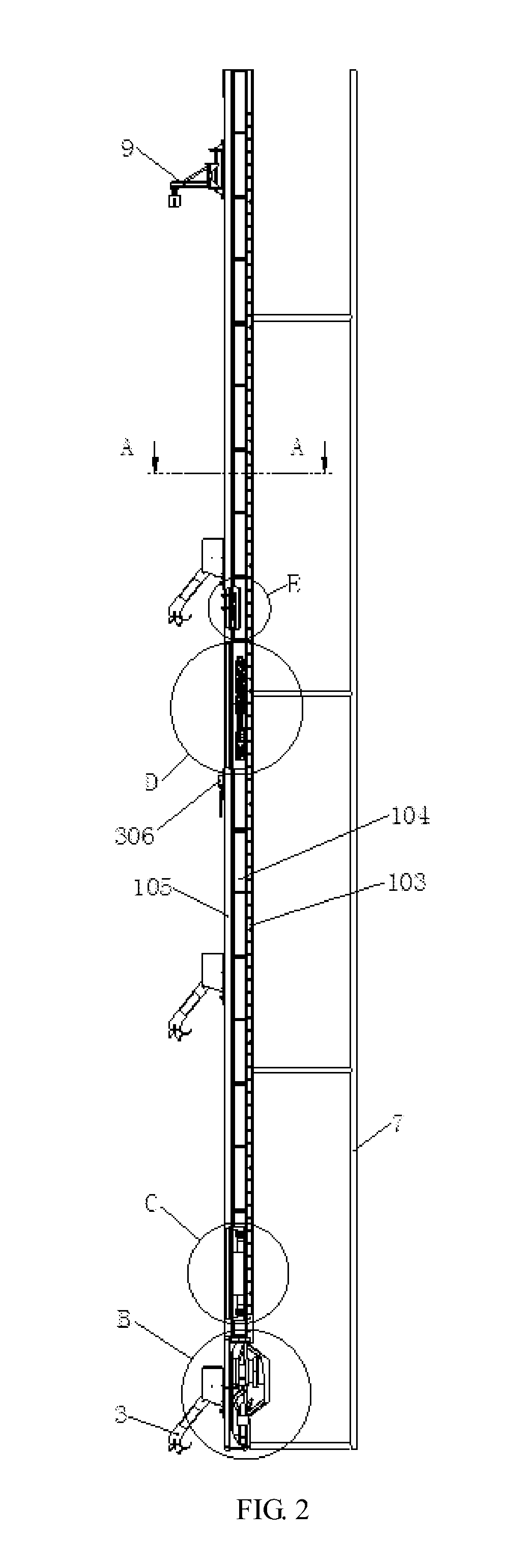

Sealed and integrated climbing scaffold and method for using the same

ActiveUS20150167326A1Improves level of mechanization and automationEasy to assembleForms/shuttering/falseworksScaffold accessoriesHigh riseDevice failure

The present application relates to a sealed and integrated climbing scaffold, comprising a hollow frame structure, a plurality of mechanical arm devices, a plurality of climbing fulcrums, a lifting system, and a construction operation platform structure; wherein, the hollow frame structure includes an inner guide rail and an outer guide rail, the inner guide rail and the outer guide rail are capable of sliding relative to each other; at least two of the mechanical arm devices are fixed on the outer guide rail, at least two of the mechanical arm devices are fixed on the inner guide rail. When implementing the sealed and integrated climbing scaffold of the present application, it improve the level of mechanization and automation in lifting platform of high-rise construction, improve the efficiency of construction, save the workforce, realize standardization and modularization, effectively protect the internal lifting system and decline equipment failure rate.

Owner:SHENZHEN TECHEN SCI & TECH CO LTD

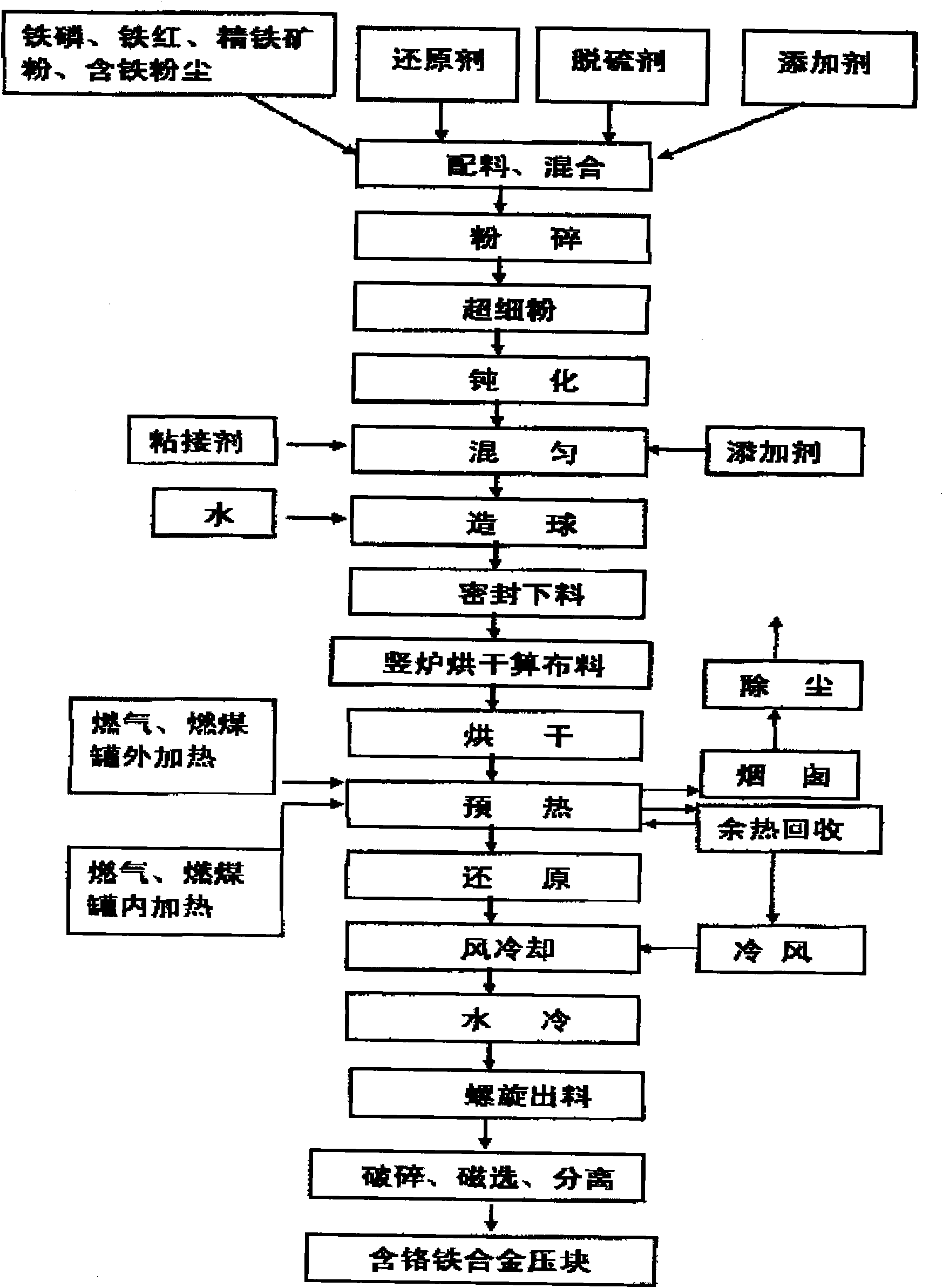

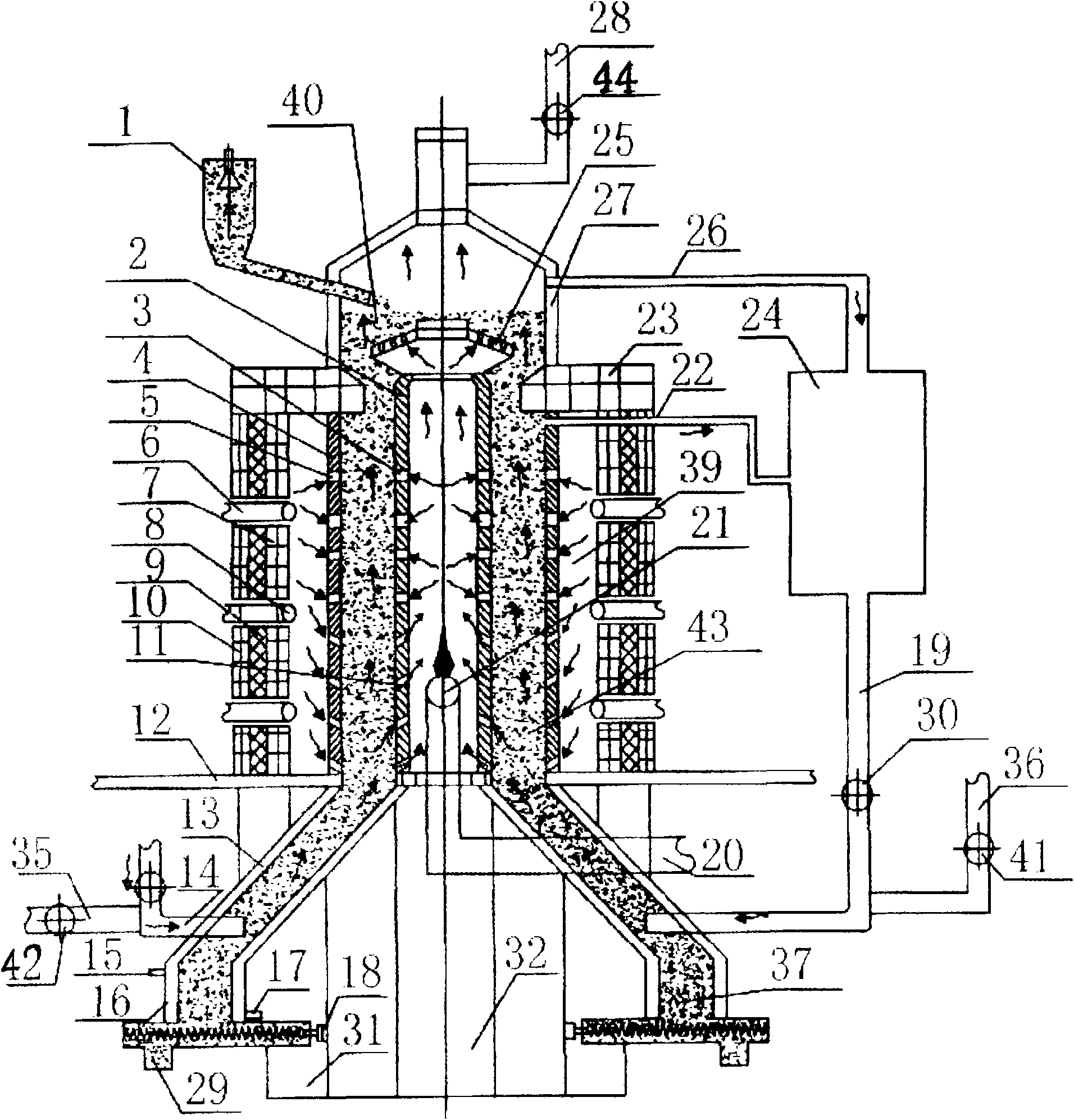

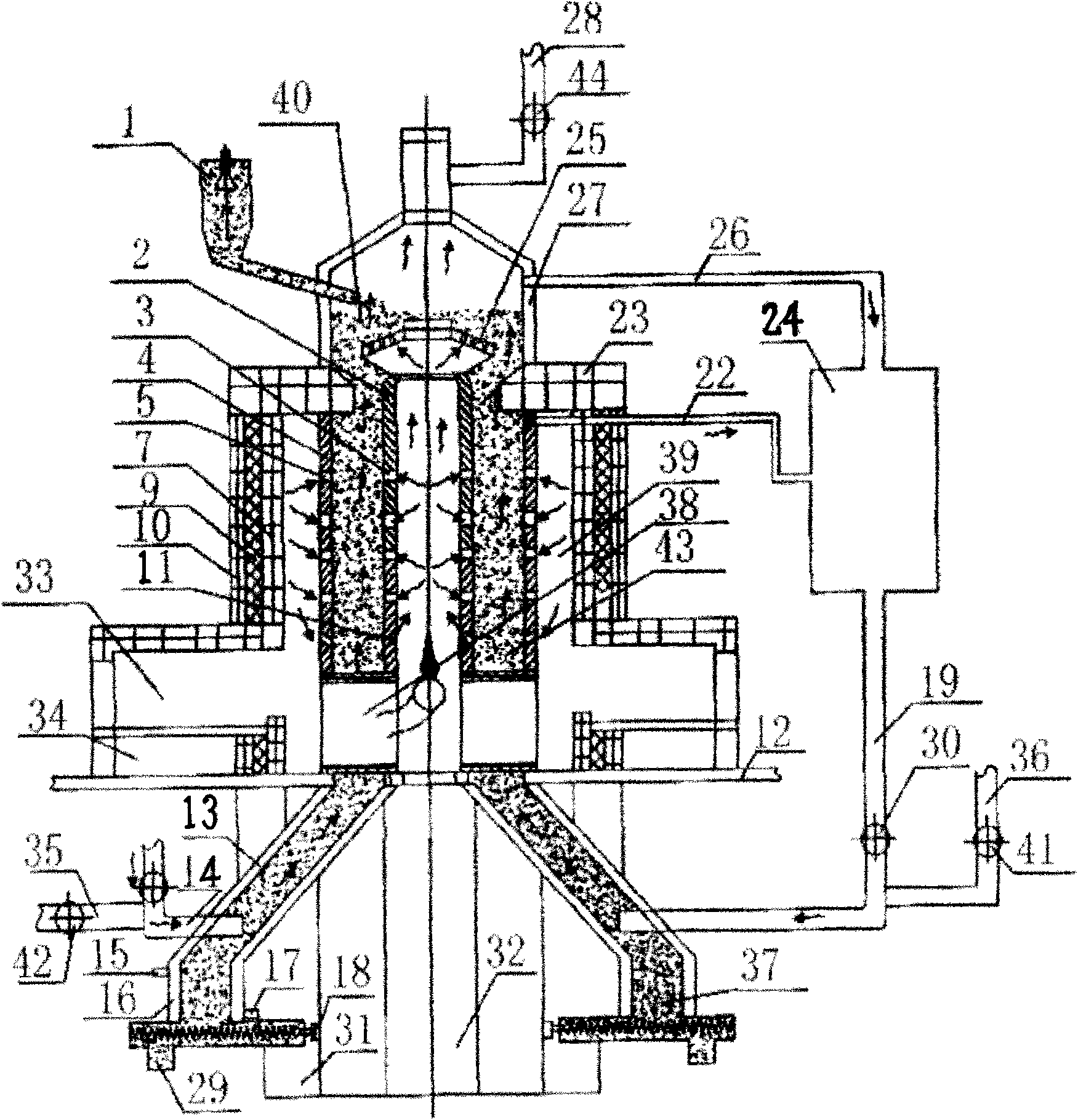

Preparation process and device of sponge iron

InactiveCN101538632AGuaranteed uniformityReduce wasteProcess efficiency improvementShaft furnaceResource consumptionUltra fine

The invention relates to a preparation process and a device of sponge iron, belonging to metallurgical industry steel-making raw material. The process comprises the following steps: mixing iron-containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, passivating and mixing to make pelletizing materials, sending the prepared pelletizing materials into a reducing furnace, drying and roasting, and obtaining sponge iron after the reduction reaction. The reducing device is connected with an upper furnace above a furnace base, a lower furnace body is connected to the downside of the furnace base, the upper end of the upper furnace body is connected with an upper furnace mantle, a drying bed grate is positioned at the upper end in the upper furnace body, a purifying device is connected with the upper furnace body and the lower furnace body through pipelines, and a residual heat circulating device is connected with the lower furnace body. The invention has the advantages that: firstly, the reduction temperature is reduced, the reduction speed is increased, the energy consumption is reduced, the production cost is lowered, the production efficiency is improved, and the uniformity of the quality is ensured; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is lowered, the environment pollution is reduced; and fourthly, the waste resource can be recycled so as to save the resource consumption.

Owner:丁家伟 +1

Method for fully mechanized continuously-filling coal mining of steeply pitching coal seam

InactiveCN102493838AIncrease the level of mechanizationReduce labor intensityUnderground miningSurface miningStopped workEngineering

The invention provides a method for fully mechanized continuously-filling coal mining of steeply pitching coal seams, which comprises the following steps: a stoping face is arranged as per the method of long-wall mining along the strike, and fully mechanized mining equipment for the steeply pitching coal seam is adopted; an air cushion and a working face filling pipeline are arranged on a base on the side of a mined out space of rear pillars of a fully mechanized mining support; whenever the working face advances for every 1.4 to 1.8 meters and after the support is moved, the working face filling pipeline is connected with an upper gateway filling main pipeline; the air cushion is filled with air, and auxiliary separation is arranged; paste is conveyed to a filling pipe branch sequentially from low to high so as to ensure filling and compacting, and finally the paste is conveyed to a supplementary filling pipe of the upper gateway; after the paste is coagulated, a portion of air in the air cushion is released, and the working face advances forward continuously; the steps are repeated until the stopping work for the whole working face and the filling work for the mined out space are finished. The method provided by the invention is convenient to operate and simple to carry out, can improve the mechanization level for mining the steeply pitching coal seams under buildings, railways and water bodies, improves the output of the working face, efficiently reduces the roof subsidence and the ground deformation, and realizes coal mining without the pillars and achieves Y type ventilation.

Owner:HUNAN UNIV OF SCI & TECH

Mechanical continuous mining method for gently inclined thin ore body

ActiveCN101975064ASolve the mining disasterResolutionUnderground miningSurface miningEngineeringDrill

The invention discloses a mechanical continuous mining method for a gently inclined thin ore body. Based on the principle of lengthening the slope distance to reduce the angle, ore blocks are arranged in an inclined way, so that an angle smaller than the original inclination angle can be formed between a working plane and the horizontal plane, thus creating an operating space for a drill jumbo and a scraper; a return air shaft is arranged at the corner of one ore room so as to be communicated with an upper horizontal return airway; each ore room is provided with an orepass used for the transmission of ores in the ore room; and a tunnel is respectively excavated along the strike direction above and below each ore room, the upper tunnel is used for ventilation connection, and the lower tunnel is used for ore removal connection. The invention is especially applicable to the mining of the gently inclined thin ore body of an underground mine, mining preparation has no requirements for undercutting projects, and the drill jumbos and scrapers are used for the operation, thereby achieving the characteristics of high degree of mechanization, high production efficiency, full-thickness continuous mining and low ore loss rate.

Owner:CENT SOUTH UNIV

Rice direct-seeding drip irrigation under mulch-film dry-farming cultivation method

ActiveCN101422120AIncrease profitImprove drought resistanceClimate change adaptationWatering devicesPunchingPesticide pollution

The invention discloses a drip irrigation dry-farming planting method under a rice direct seeding film, which belongs to a crop planting agriculture method. A timely seeding operation is carried out after the preparation before seeding is finished; the seeding operation is as follows: the operations of drip irrigation zone paving, film covering, punching, hole seeding and soil covering on a hole are accomplished by one time by a drip irrigation tube-paving film-paving fine seeder under the film; the drip irrigation zone is arranged on the lower surface of a plastic film and is connected with a water-carriage system; and timely and proper water dripping and fertilizing are carried out according to the growing demand of the crops. The drip irrigation dry farming planting method can be applied to save water by 60 to 70 percent, save the fertilizers by 30 percent, have high degree of mechanization, save labor, reduce the field management and reduce the pesticide pollution.

Owner:XINJIANG TIANYE GRP +1

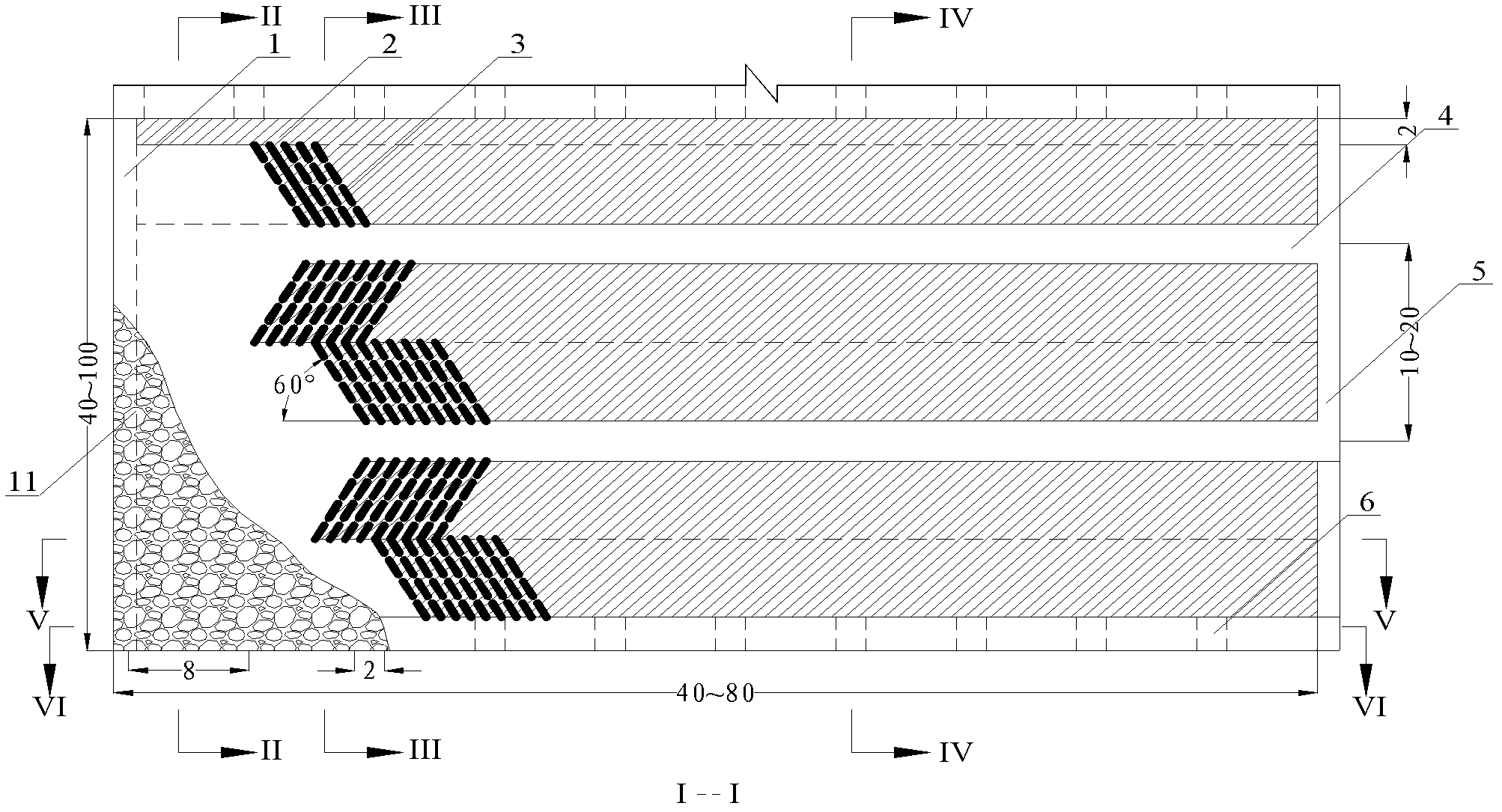

Multi-row micro-differential roadbed deep hole blasting construction method

The invention relates to a multi-row micro-differential roadbed deep hole blasting construction method, which comprises the following steps of: (1) selecting blasting parameters; (2) calculating security; (3) arranging a stair and a free face; (4) distributing holes and drilling holes; and (5) blasting. The blasting method is a multi-row deep hole millisecond micro-differential blasting method; and the blasting is performed by pull trough blasting and side slope blasting in a roadbed sequentially, wherein the pull trough blasting is loose blasting and the side slope blasting is precraking blasting. In the method, a shock conducting tube non-electric priming system micro-differential control blasting technology, a comprehensive blasting construction scheme of loose blasting, the deep hole millisecond micro-differential blasting technology and the roadbed side slope precraking blasting technology, and a wide-pitch and low-resistance hole distribution mode are adopted, so that explosivesand detonators are saved, the drilling mechanization degree is enhanced, the labor cost is reduced, the blasting effect is enhanced, the large rate of blast rocks is reduced, the material abandoning rate is reduced and harms of blasting vibration, impact waves, flying stones and the like are reduced; furthermore, when the blasting effect is enhanced and the stability of the blast roadbed side slope rocks is guaranteed, the absolute safety of blasting can be guaranteed.

Owner:HUITONG ROAD & BRIDGE CONSTR GROUP

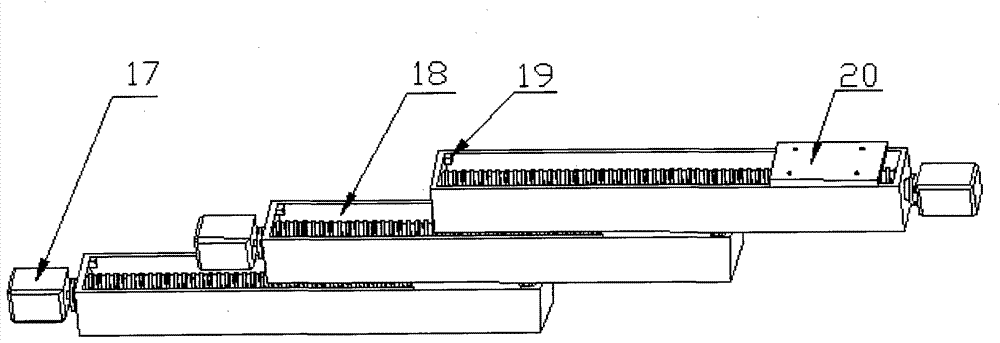

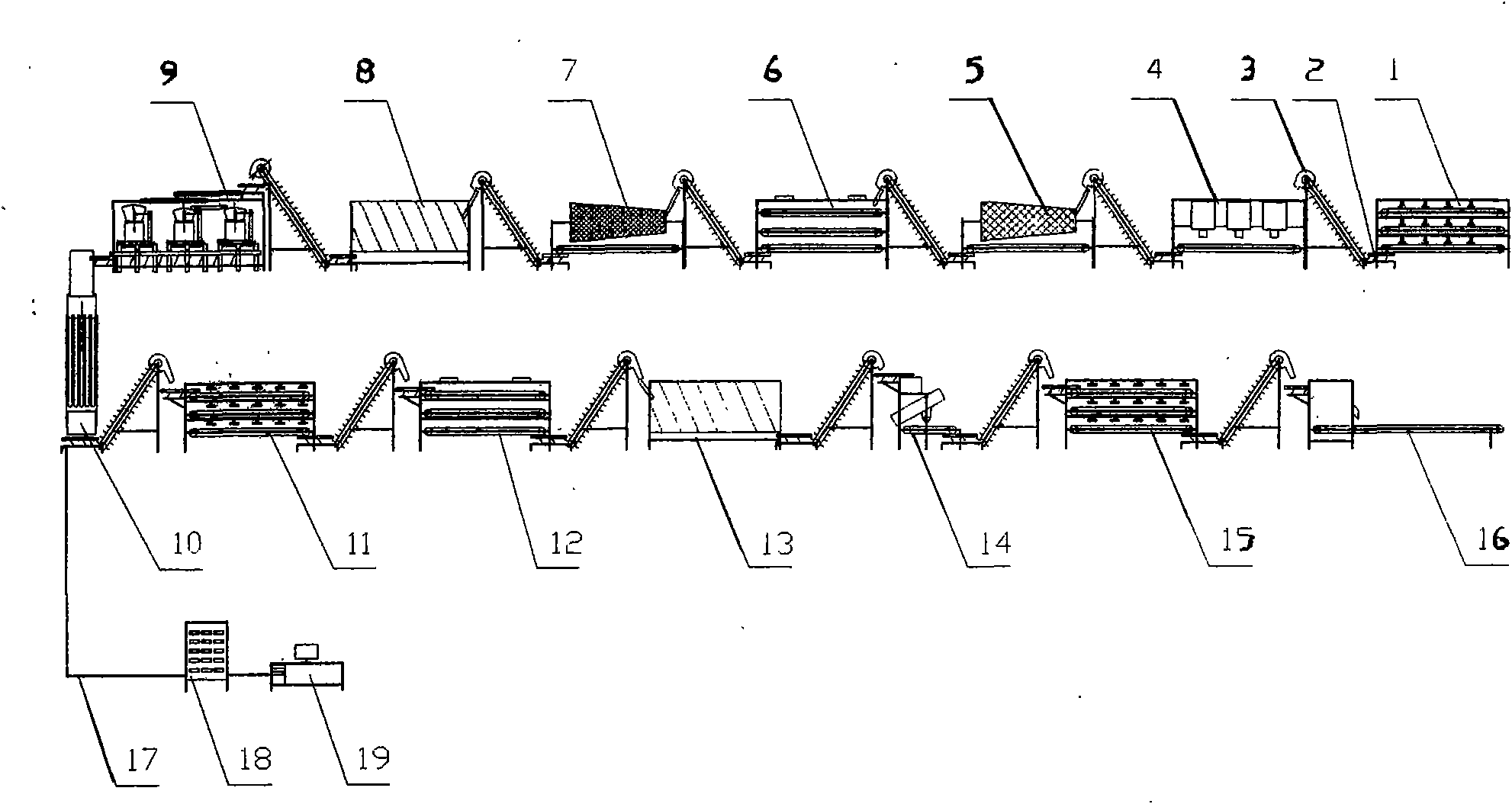

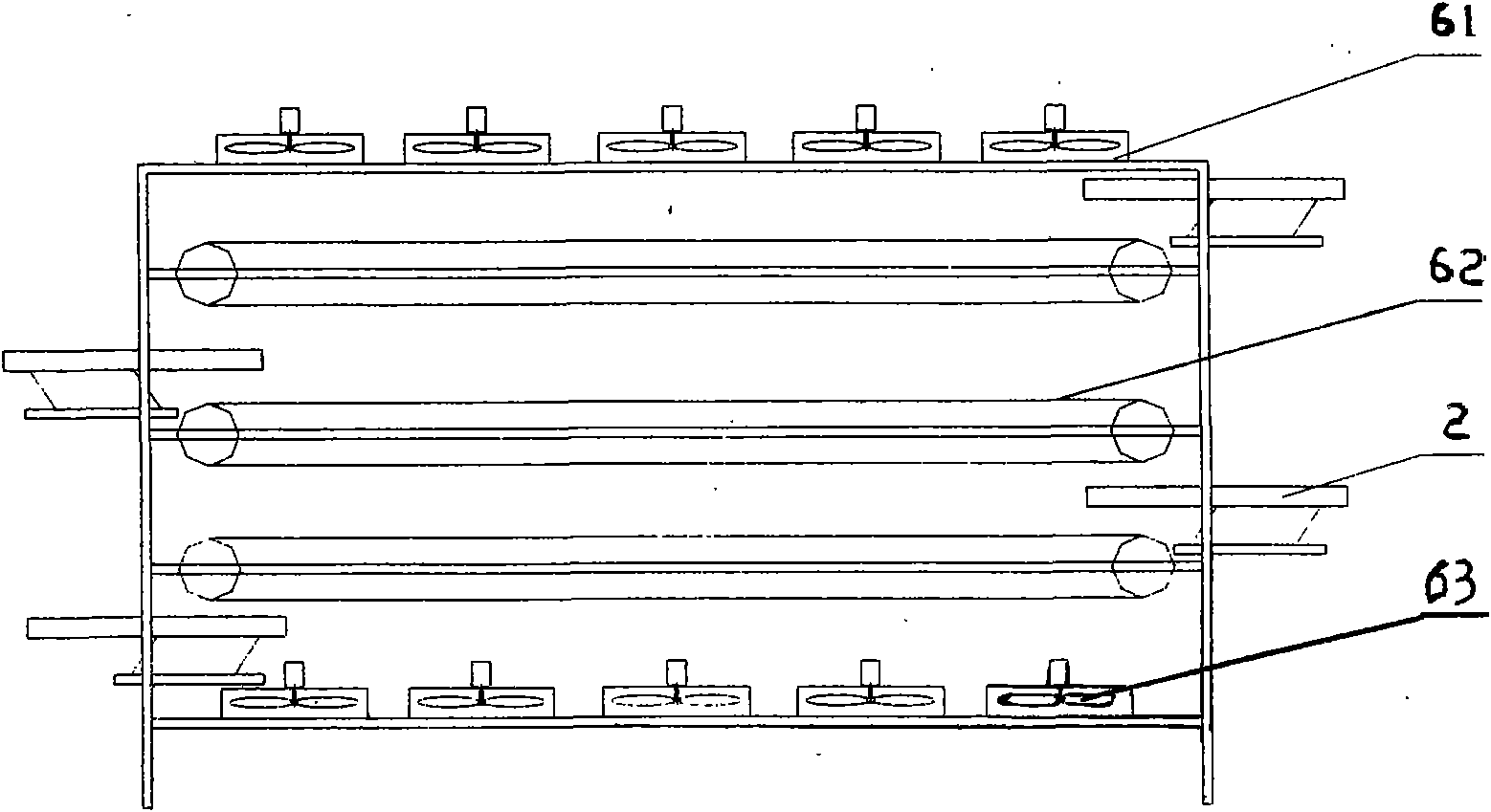

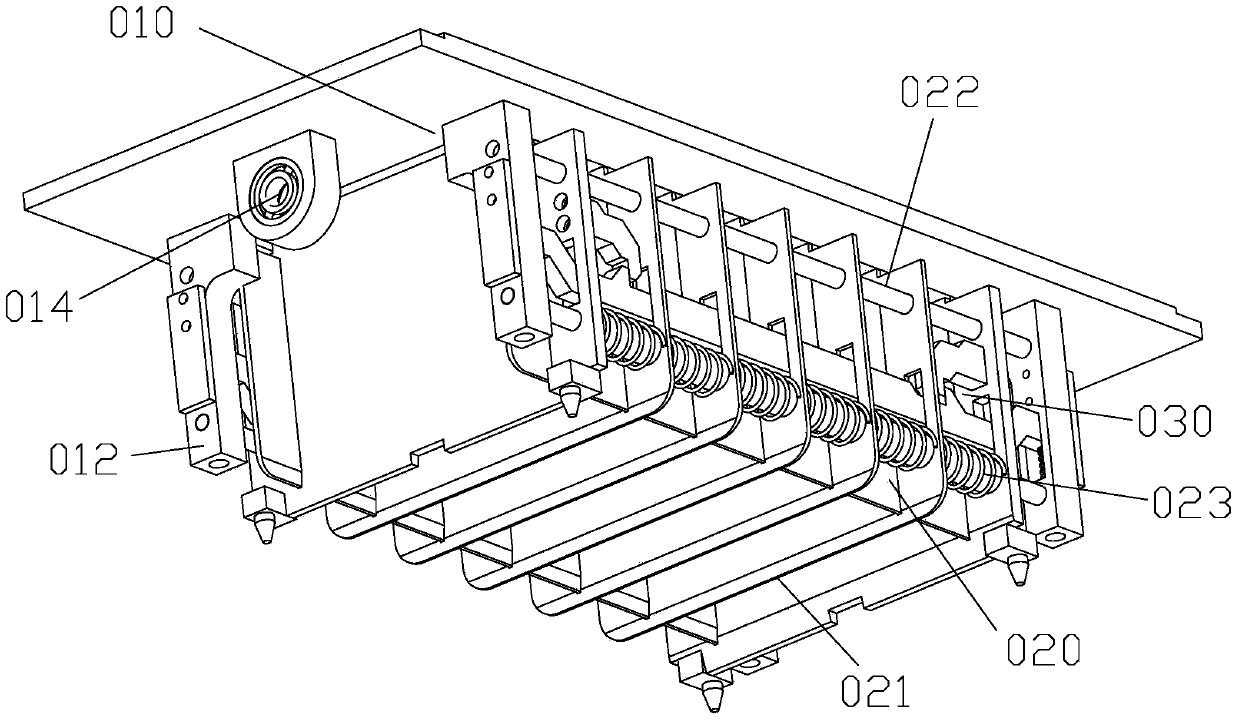

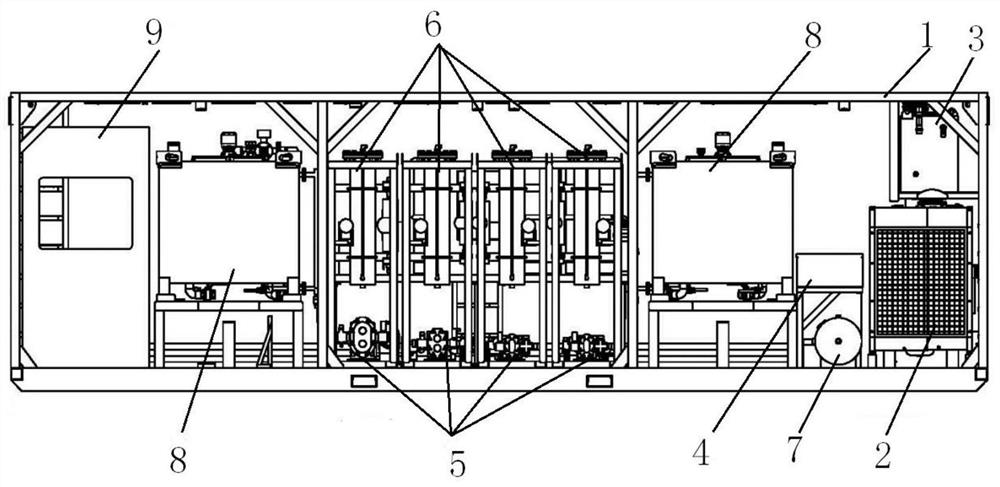

Tea mechanization and clean production line

InactiveCN101953405ASimple processing equipmentAvoid secondary pollutionPre-extraction tea treatmentMicrocomputerElectric machinery

The invention relates to a tea mechanization and clean production line, which belongs to the technical field of tea processing equipment. The invention provides a tea production line which is mechanized, standardized, automated, serialized, clean and dimensions scaled. The production line comprises various process devices which are composed of a cleaning machine, a dehydrater, a grader, a green-unfolding machine, a green-shaking machine, a rotary-drum removing green machine, a knead entwist machine, a multislot pot type continuous strip-managing machine, a low temperature far infared baker, a WXTL, a treating pot machine, a tea color sorter a high temperature far infared baker and a tea package mechanism, a material conveying mechanism composed of an elevator and a conveyor and a control mechanism composed of a microcomputer and a central control cabinet; the adjacent process devices are respectively connected by the conveyor and the elevator; electrical machines of the various process devices and the electrical machine of the material conveying mechanism both are variable frequency motors which are controlled by the control mechanism.

Owner:ANHUI AGRICULTURAL UNIVERSITY +1

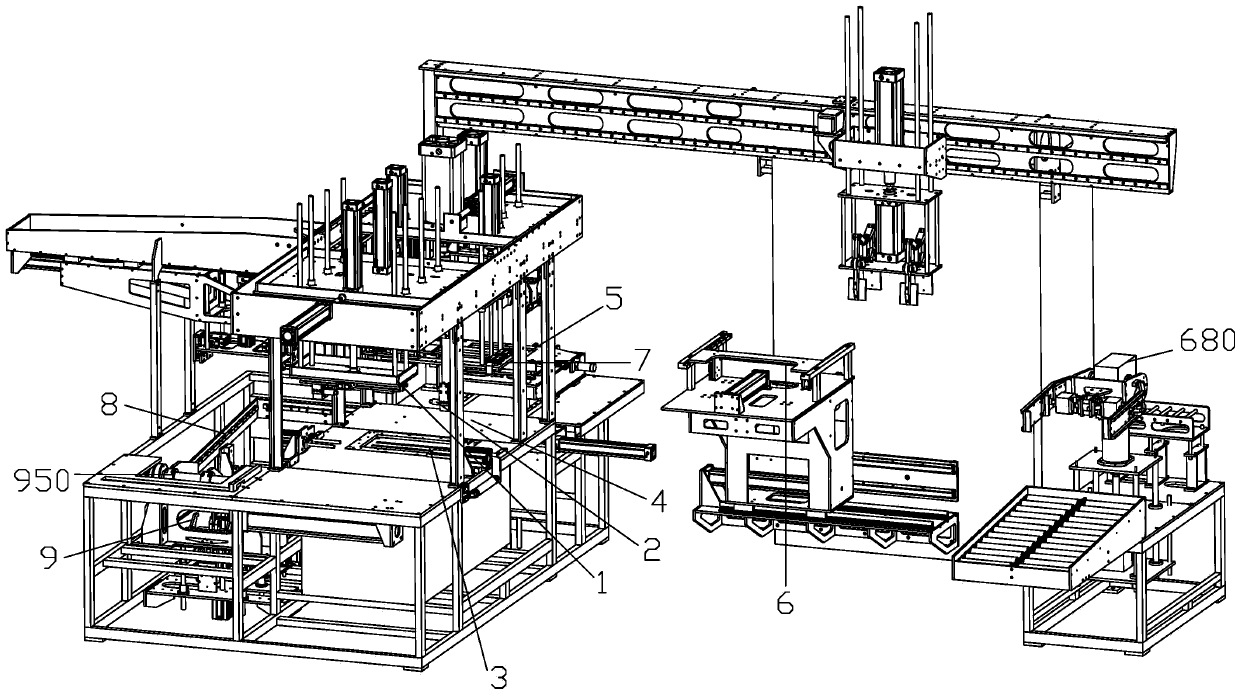

Full-automatic production device for assembling and cast-welding storage battery polar groups

ActiveCN104051741AIncrease productivityReduce labor costsElectrode carriers/collectorsInstabilityEngineering

The invention relates to a full-automatic production device for assembling and cast-welding storage battery polar groups. The full-automatic production device for assembling and cast-welding storage battery polar groups comprises a polar group fixture as well as a tab reshaping device, a fixture overturning device, a tab cutting device, a polar group feeding device, a tab pinching device as well as a tab cast-welding device, wherein the tab reshaping device, the fixture overturning device, the tab cutting device, the polar group feeding device, the tab pinching device and the tab cast-welding device are connected sequentially. The invention aims to provide the full-automatic production device for assembling and cast-welding the storage battery polar groups, which has the advantages that the production efficiency is improved, and the manual cost is saved. The full-automatic production device for assembling and cast-welding the storage battery polar groups, which is provided by the invention, has the advantages that firstly, the production efficiency greatly is greatly improved, and the manual cost is saved; secondly, the locking and unlocking operation of the polar group fixture can achieve mechanization; thirdly, due to the fixture overturning device, the automatic overturning of the polar group fixture can be realized, and the manual operation can be replaced; fourthly, the bodies of workers can be prevented from being damaged by lead fume in the manual welding process; the environmental pollution is alleviated; the quality instability generated by manual welding is overcome; the product quality is improved.

Owner:FUJIAN JIANYANG YAHENG MACHINERY MFG

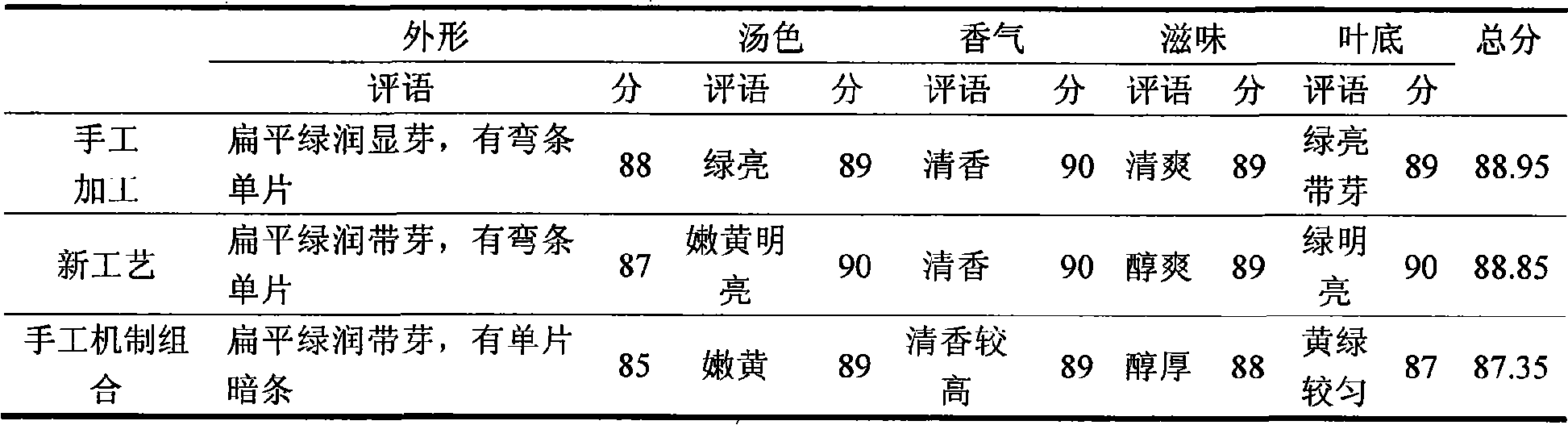

A flat famous green tea processing method

InactiveCN101548700ARealize mechanized processingGuaranteed qualityPre-extraction tea treatmentMicrowaveCool storage

The present invention provides a flat shape famous green tea processing method, which includes: firstly performing spreading and greening processing to fresh leaves, and then continuously performing roller de-enzyming, microwave tempering, automatic grounding, and then using a cooling storage machine for cooling the grounded leaves, frying drying after the leaves are cooled and enter in a flat tea frying machine, finally determining whether it is needed to enter a hexagon brightness dried machine for hair-off treatment or directly use far infrared perfuming machine to performing perfuming. The invention integrates the use of stacked-type multiple layer placing frame, roller de-enzyming, microwave de-enzyming machine, automatic tea carding machine, cooling storage machine, drying machines, hexagonal brightness drying machine / far-infrared perfuming machine and the like machining processes and equipment for integrated considering, so that the appearance of the obtained product is flat and smooth, fragrant, to realize mechanization machining of flat famous green tea.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

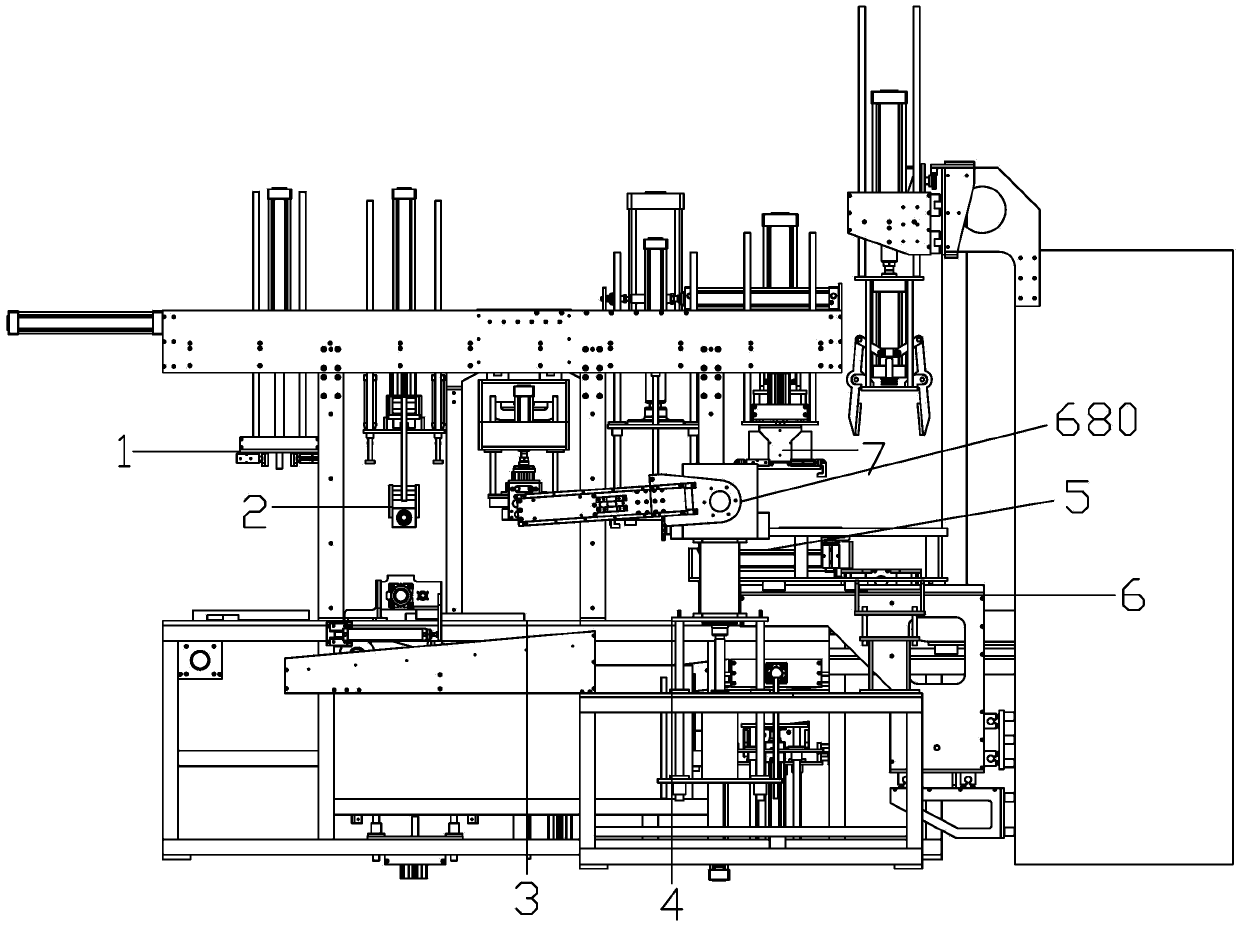

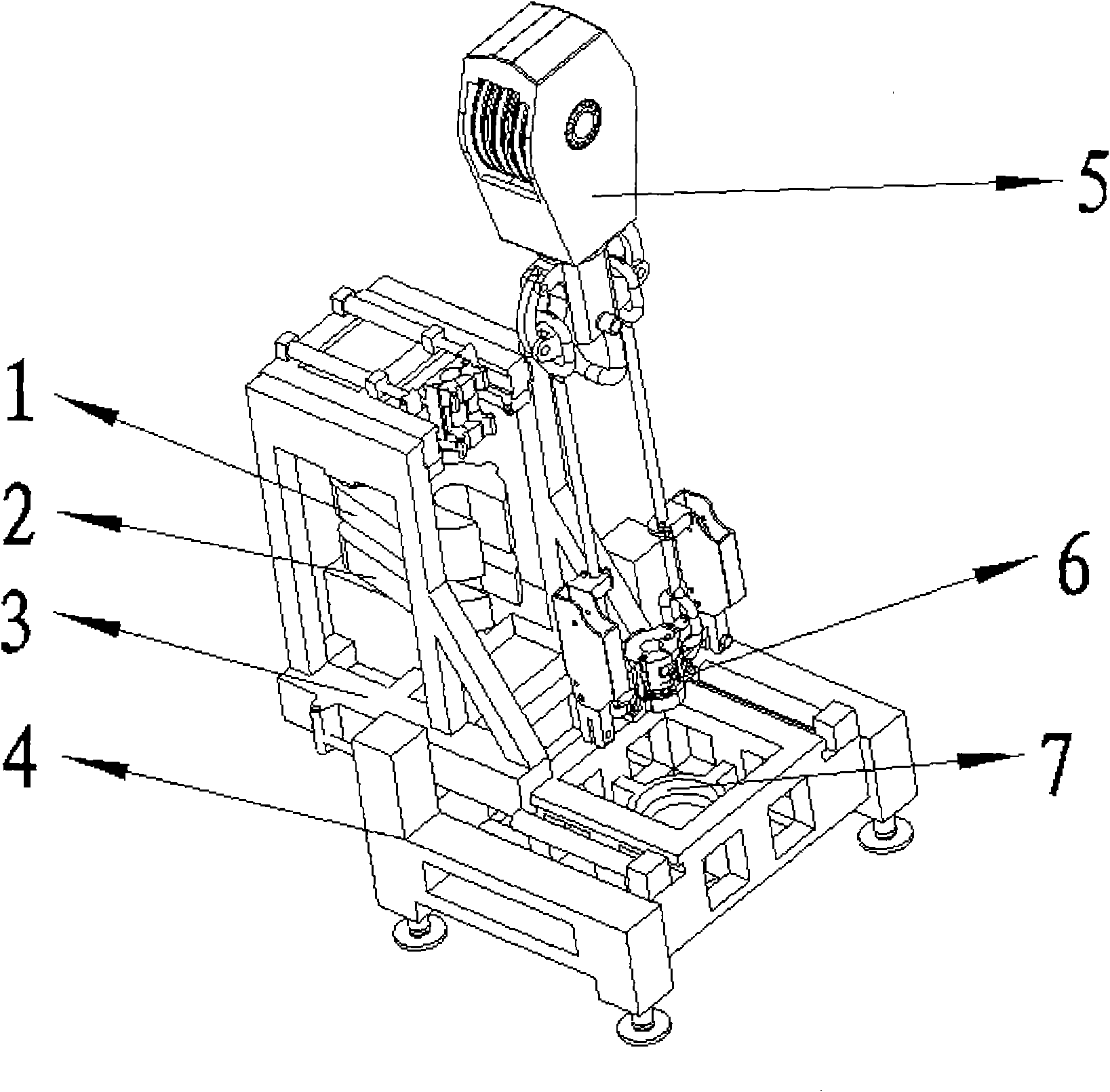

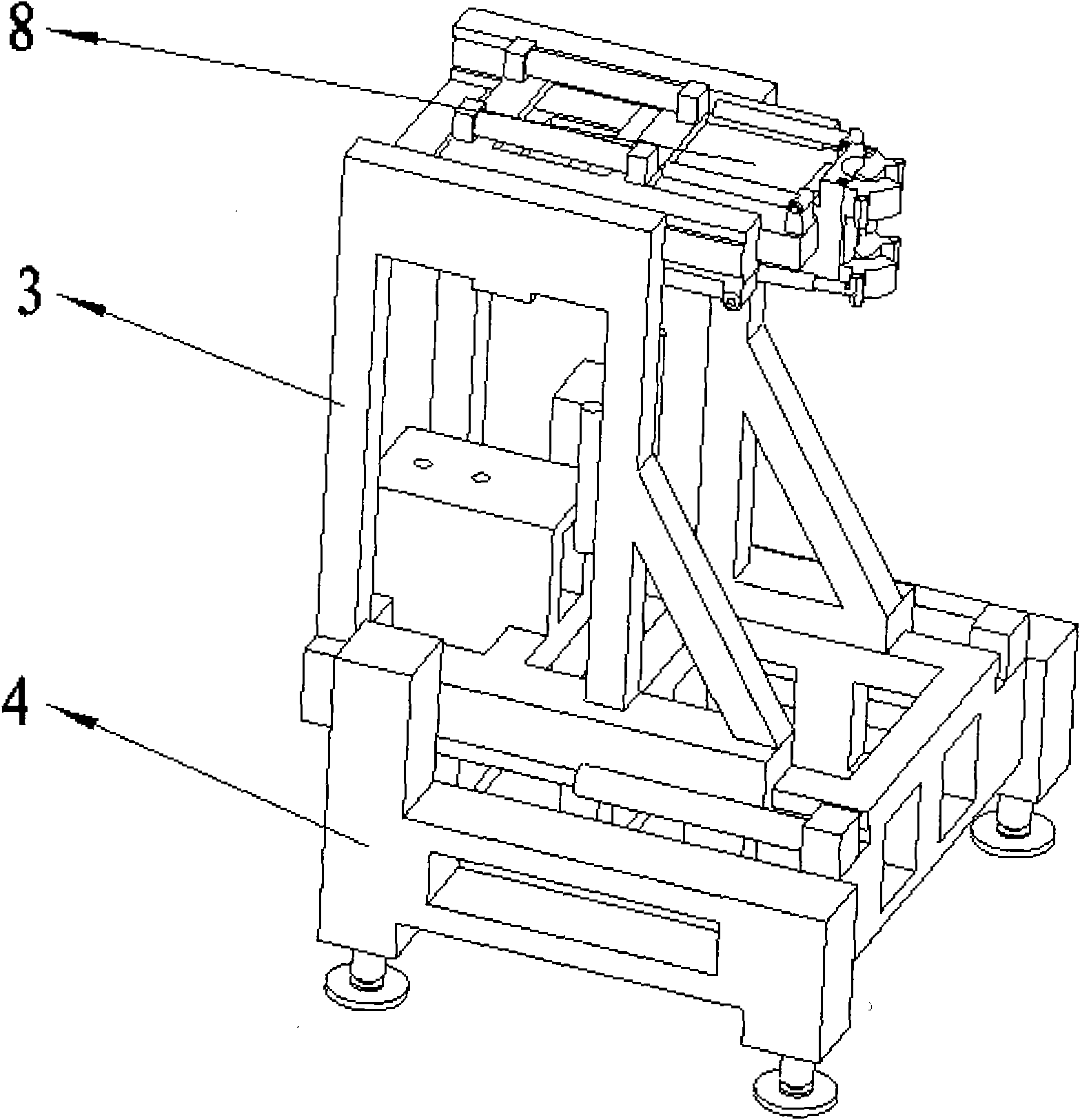

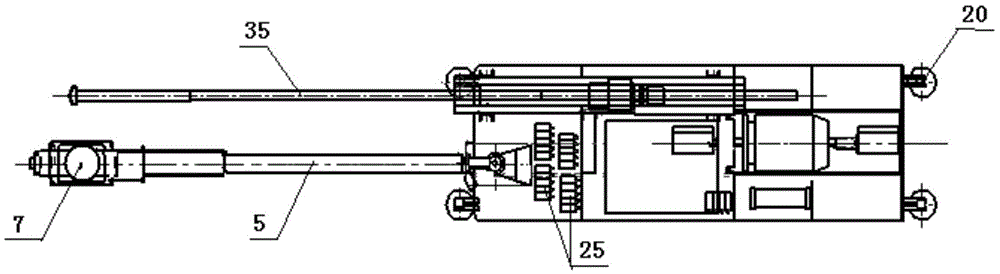

Workover operation mechanization system replacing well mouth manual operation

InactiveCN101672168AHigh degree of automationImprove mechanical propertiesDrilling rodsDrilling casingsEconomic benefitsRelative motion

The invention discloses a workover operation mechanization system replacing well mouth manual operation, which mainly solves the problem that mechanization and automation can not be realized when the well mouth operation is carried out in the existing well reparation. In the invention, an opening power tong, a power slip, a lift sub for conveying tubular column and a mobile mechanism of a conveying power tong are integrated; the power tong comprises a main tong and a backup tong, and is installed on the mobile mechanism; the lift sub is connected on a derrick through a big hook; the upper layer of a mobile mechanism is a working machine; the lower layer thereof is a base; the two layers can move relatively; the power tong is installed on the upper layer; the top part of the upper layer isprovided with a righting machine hand used for adjusting the position when the tubular column is loaded and uploaded; the movement of the power tong is finished through the mobile mechanism when the tubular column is loaded and uploaded; and the top part of the mobile mechanism is provided with a righting machine hand which is matched with the lift sub to move the tubular column when the tubular column is loaded and uploaded. The system of the invention improves automation degree of the tubular column loading and uploading, and improves the accuracy of the position of tubular column movement of the tubular column loading and uploading, and increases economic benefits.

Owner:DAQING GASOLINEEUM INST

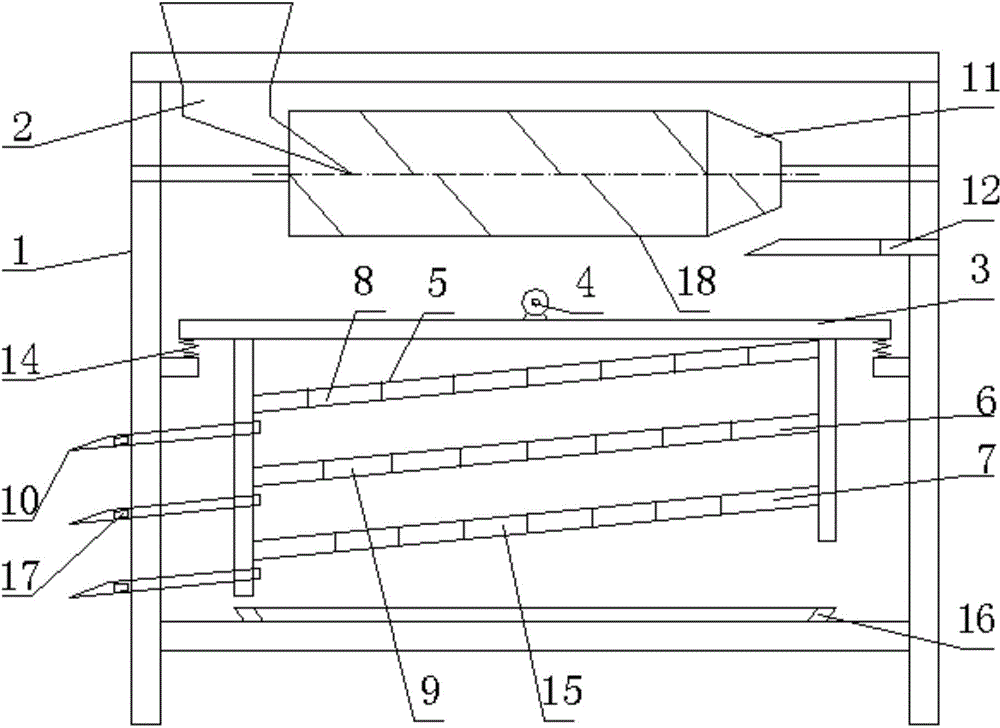

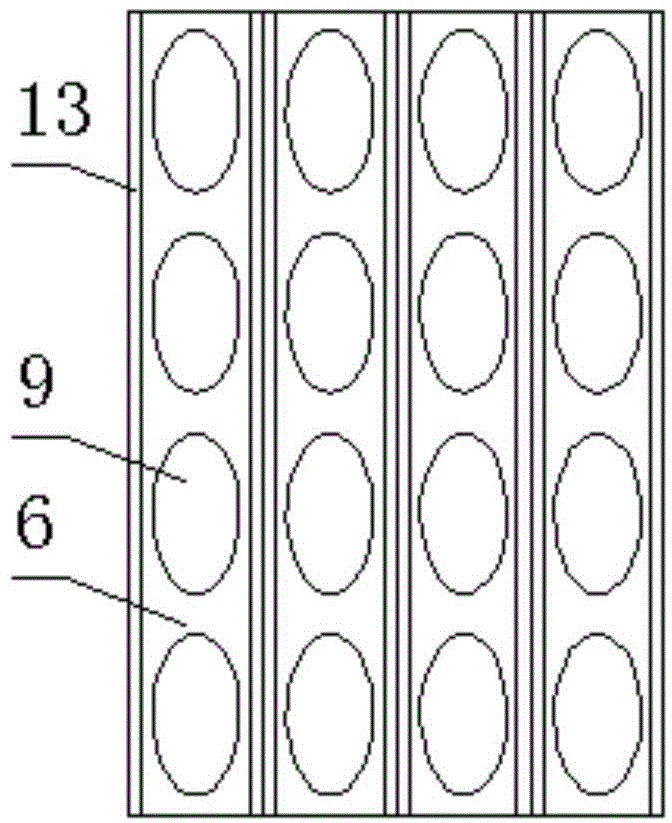

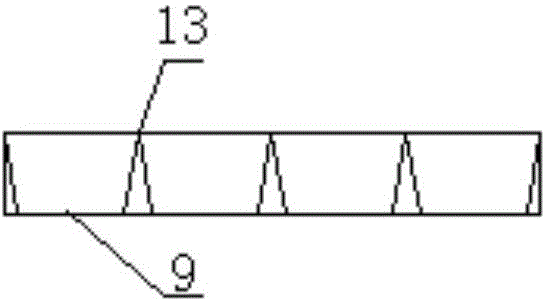

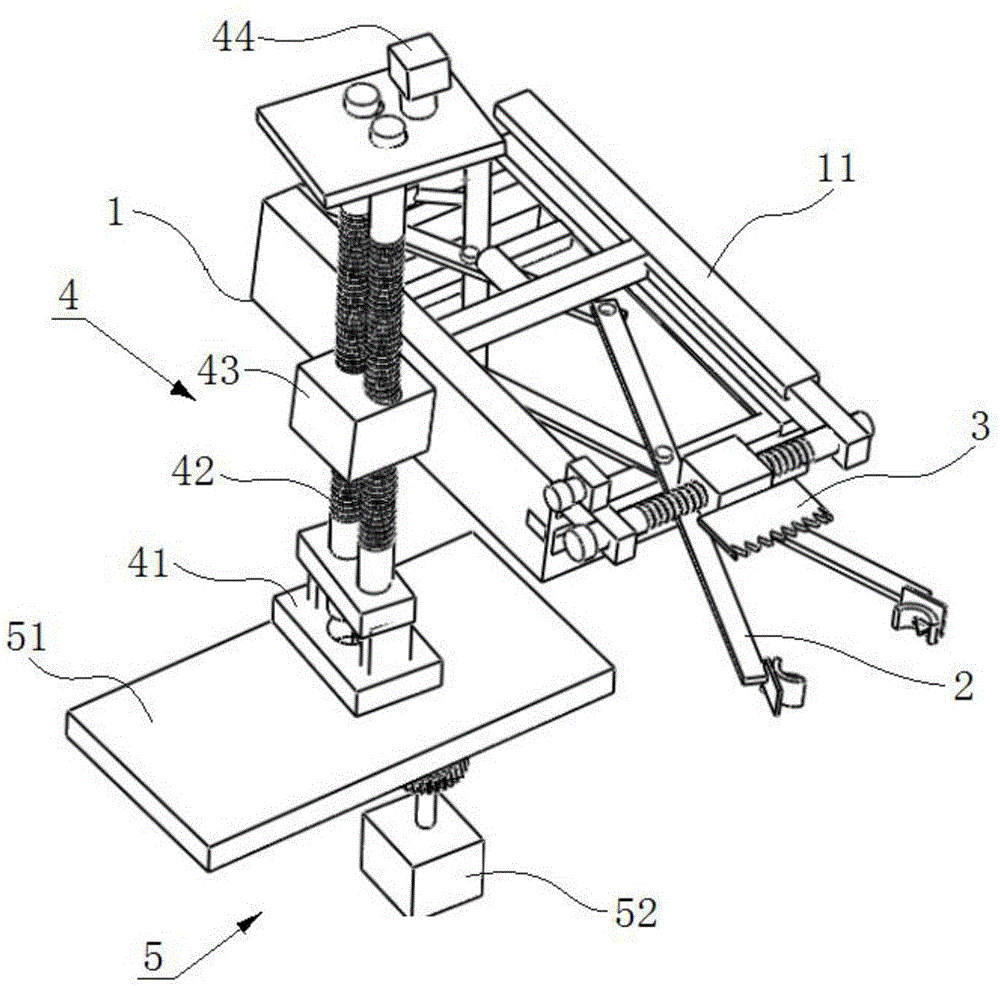

Coin separating device

The invention relates to coin sorting equipment, and discloses a coin separating device. The coin separating device comprises a casing (1), wherein a coin inlet (2) is formed in the top of the casing (1); a baffle rack (3) is arranged inside the casing (1); a vibrating motor (4) is connected into the baffle rack (3); the end part of the baffle rack (3) is connected with the casing (1) through springs (14); a first baffle (5), a second baffle (6) and a third baffle (7) are perpendicularly lapped on the baffle rack (3); flow guide ridges (13) are arranged on the bottom surface of each of the first baffle (5) and the second baffle (6); first coin separating holes (8) are formed in the bottom of the first baffle (5); second coin separating holes (9) are formed in the bottom of the second baffle (6). The coin separating device is small and exquisite in size and compact in structure, accurate and efficient screen separation of coins in the different currency value is realized through vibrating screen separation of the coins in different size, the whole screen separation process does not need too much manual operation, and the degree of mechanization and automation is high.

Owner:HANGZHOU NOAHS ARK NETWORK TECH

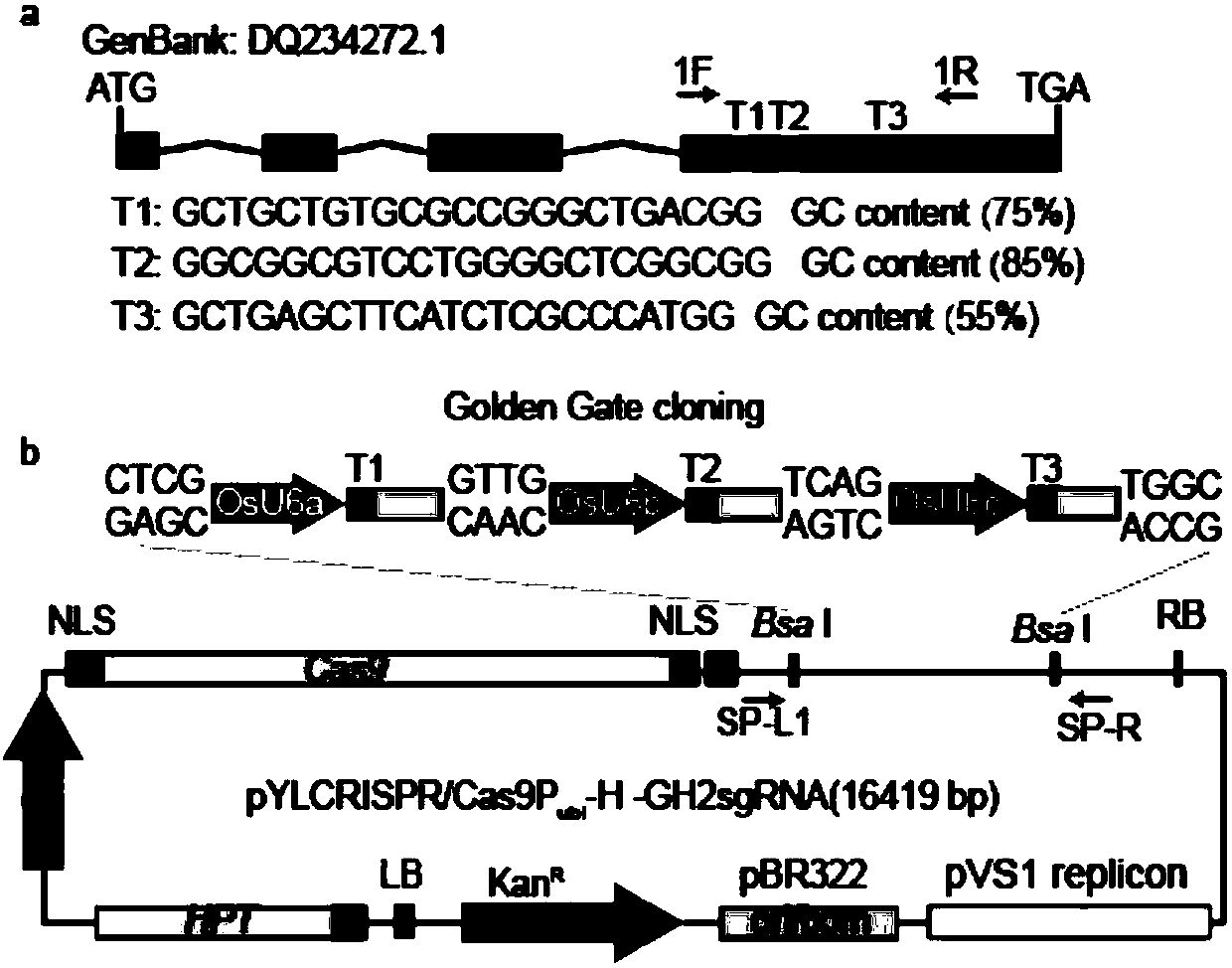

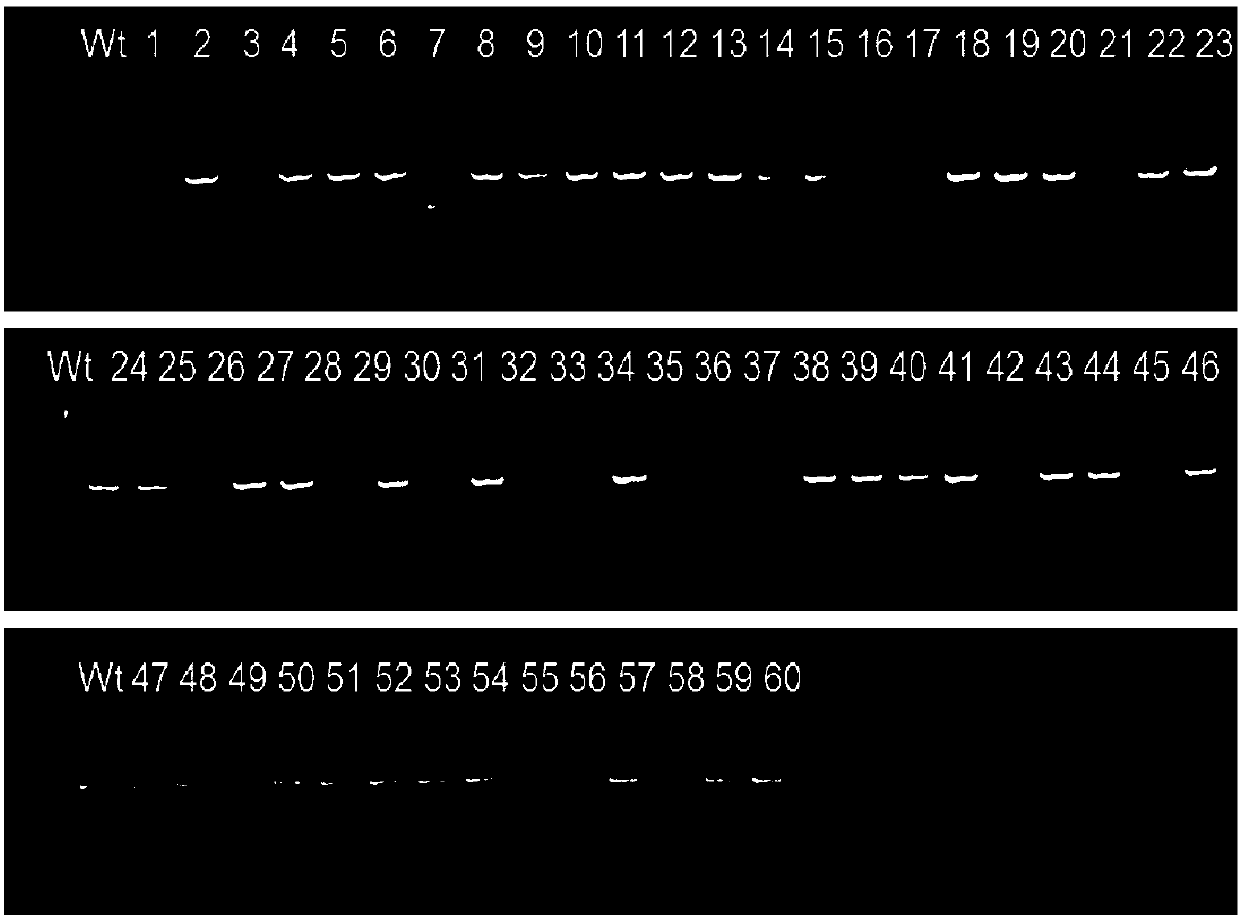

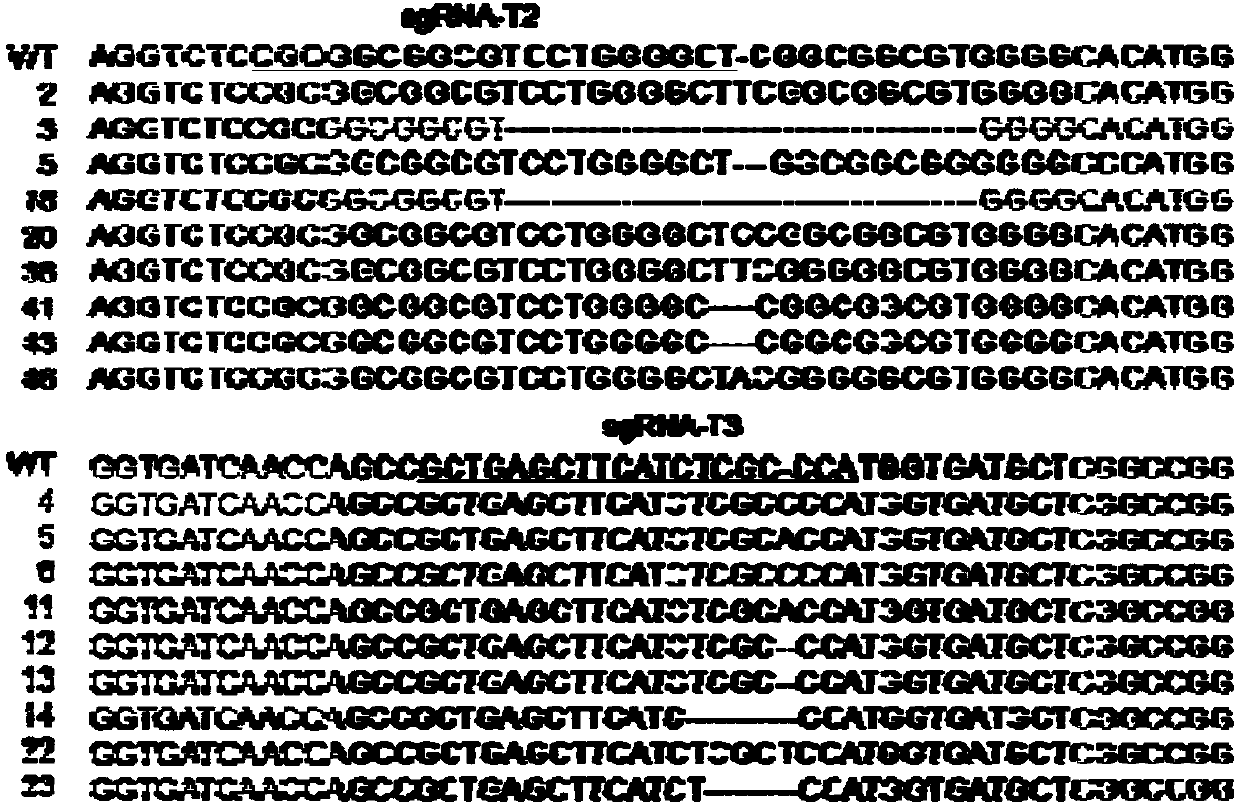

Vector sgRNA CRISPR/Cas9 relevant with character of rice reddish brown glume, vector construction and application

InactiveCN108034656AThe method is efficientSave time and costMicrobiological testing/measurementHorticulture methodsAlleleExon

The invention discloses a vector sgRNA CRISPR / Cas9 relevant with character of rice reddish brown glume, vector construction and application, for overcoming the defect that rice with reddish brown glume can be acquired only on the condition of mutation of two alleles OsCHi. The invention provides an sgRNA segment which comprises a gRNA of which specificity is targeted to the fifth exon of cinnamylalcohol dehydrogenase(CAD) gene of rice; the sgRNA refers to T1, T2 and T3 specifically. The invention further provides a CRISPR / Cas9 gene editing vector comprising the sgRNA and a construction methodof the vector. The vector can edit cinnamyl alcohol dehydrogenase(CAD) gene of rice. Besides, application of the segments and the vector in acquiring rice having characters of reddish brown glume andstem earing, and primer sequence for detecting CRISPR / Cas9-CAD gene reconstruction are also provided. According to the invention, conventional breeding cost can be reduced, mechanization level of hybrid rice seed production can be improved, and seeding cycle can be shortened.

Owner:SAAS BIOTECH & NUCLEAR TECH RES INST

Industrialized production method of primitive brown sugar

ActiveCN103993106ARetract lowPromote recoverySugar crystallisationPurification by physical meansSlagMicrofiltration

The invention discloses an industrialized production method of primitive brown sugar. The method comprises the steps of with cane sugar factory mixed juice as a raw material, adding lime milk to regulate the pH value to 5.8-6.6; sieving and filtering; heating, floating and removing floating slag; removing impurities through microfiltration; evaporating and concentrating to obtain syrup with the concentration of 60-65-degree Bx; boiling sugar at the temperature of 125-130 DEG C at normal pressure to obtain syrup with the concentration of 95-98-degree Bx; sanding and forming to realize industrialized production of the primitive brown sugar. When used for producing brown sugar, the industrialized production method disclosed by the invention is safe and reliable in production process, high in mechanization degree, capable of realizing large-scale production of the primitive brown sugar and stable in product quality.

Owner:GUANGXI UNIV +1

Banana picking mechanism

InactiveCN105580557AMechanizationImprove work efficiencyPicking devicesEngineeringMechanical engineering

The invention discloses a banana picking mechanism. The banana picking mechanism comprises a workbench, a clamping mechanism and a cutting device, wherein the clamping mechanism comprises a clamping bench and two clamping arms, the clamping bench is arranged on the workbench in a forward-backward slidable mode and driven by a clamping bench sliding mechanism to slide, the front end of each clamping arm is provided with a clamping jaw, and the two clamping arms are arranged at the front end of the clamping bench and driven by a clamping driving mechanism to be closed or opened so that the two clamping jaws can move close to or depart from each other; the cutting device comprises a cutting bench and a cutting tool, the cutting bench is arranged on the workbench in a forward-backward slidable mode and driven by a cutting bench sliding mechanism to slide, and the cutting tool is arranged at the front end of the cutting bench in a leftward-rightward slidable mode and driven by a cutting tool sliding mechanism to slide. By means of the banana picking mechanism, mechanization of banana picking can be achieved, work efficiency of banana picking can be improved, labor intensity is lowered, and mechanical damage to bananas can be further reduced.

Owner:GUANGXI UNIV

Crankcase vertical-horizontal composite type multi-station combined machine tool

ActiveCN103921118AReduce clampingReduce positioningMeasurement/indication equipmentsOther manufacturing equipments/toolsEngineeringCrankcase

The invention discloses a crankcase vertical-horizontal composite type multi-station combined machine tool which comprises a base (10), a hydraulic rotation workbench (11), a rotary table expansion plate (12), a cooling chip removing system (6), a lubricating system (7), a oil press (8) and an electric system (9). The hydraulic rotation workbench (11) and the rotary table expansion plate (12) are mounted on the base (10). The cooling chip removing system (6) is connected with the hydraulic rotation workbench (11). The crankcase vertical-horizontal composite type multi-station combined machine tool has the advantages that the machine tool is reasonable in structural design, simple to operate, high in mechanization degree, high in work efficiency and low in machining cost; the whole combined machine tool adopts the hydraulic rotation workbench with six machining stations which can machine at the same time and load and unload workpieces, the whole machine process only needs clamping and positioning once, machining error caused by inconsistent clamping and positioning can be reduced, and machined products can be accurate in size and good in quality.

Owner:江苏丰成实业有限公司

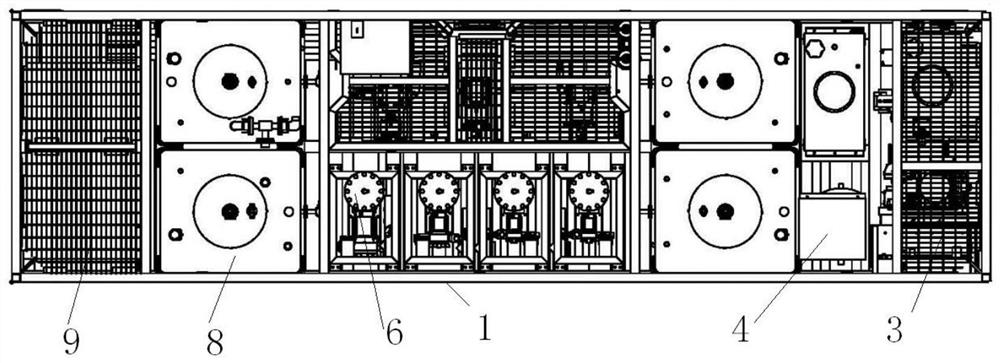

Full-automatic liquid adding device for fracturing construction and adding calibration method

PendingCN112196508AStable structureStructure, stable installationMass flow measurement devicesTransportation and packagingTransfer caseControl engineering

The invention belongs to the technical field of fracturing construction mechanization, and particularly provides a full-automatic liquid adding device for fracturing construction and an adding calibration method. The full-automatic liquid adding device comprises a prying frame, an engine, a transfer case, a hydraulic device, a liquid adding pump, a metering calibration tank, a liquid additive tank, a liquid supply pump and a control unit, wherein the input ends of the engine, the transfer case and the hydraulic device are sequentially connected; the output end of the hydraulic device is connected with the liquid supply pump and the liquid adding pump; the liquid supply pump is connected with an inlet of the liquid additive tank; an outlet of the liquid additive tank is sequentially connected with inlets of the metering calibration tank, the liquid adding pump and the liquid additive tank; the control unit is electrically connected with the engine, the transfer case, the hydraulic device, the liquid adding pump, the metering calibration tank, the liquid supply pump and the liquid additive tank; and the current situation that in the fracturing construction process, the liquid additive adding precision is large in adding difficulty and discontinuous is avoided, the mechanization and automation degree of fracturing construction is improved, meanwhile, the construction quality and potential safety hazards are effectively eliminated, and the construction success rate is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

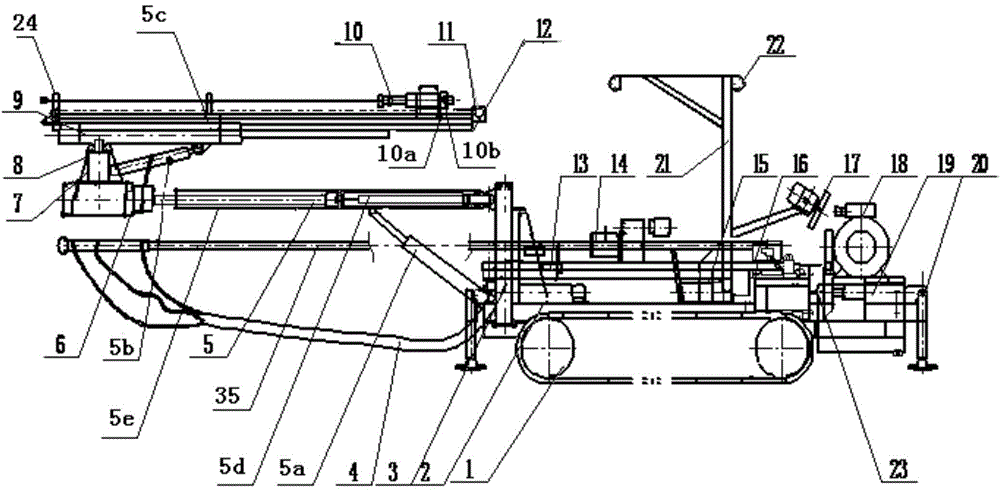

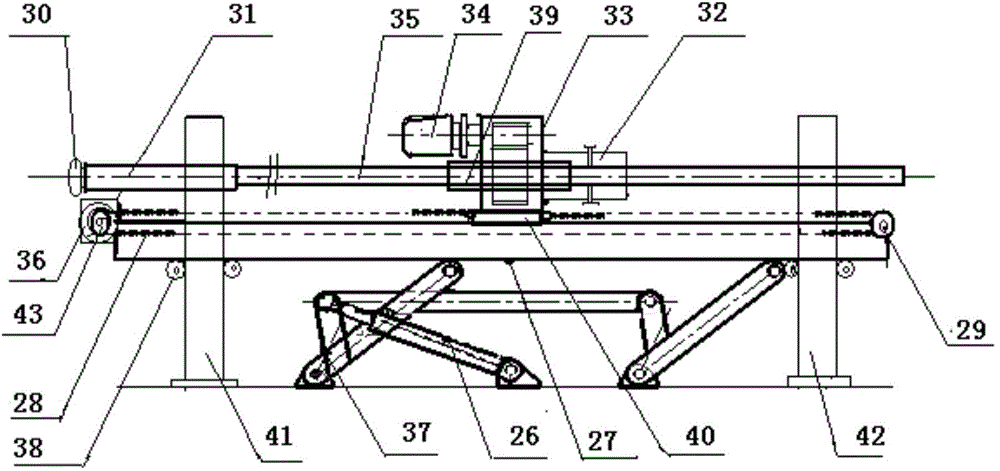

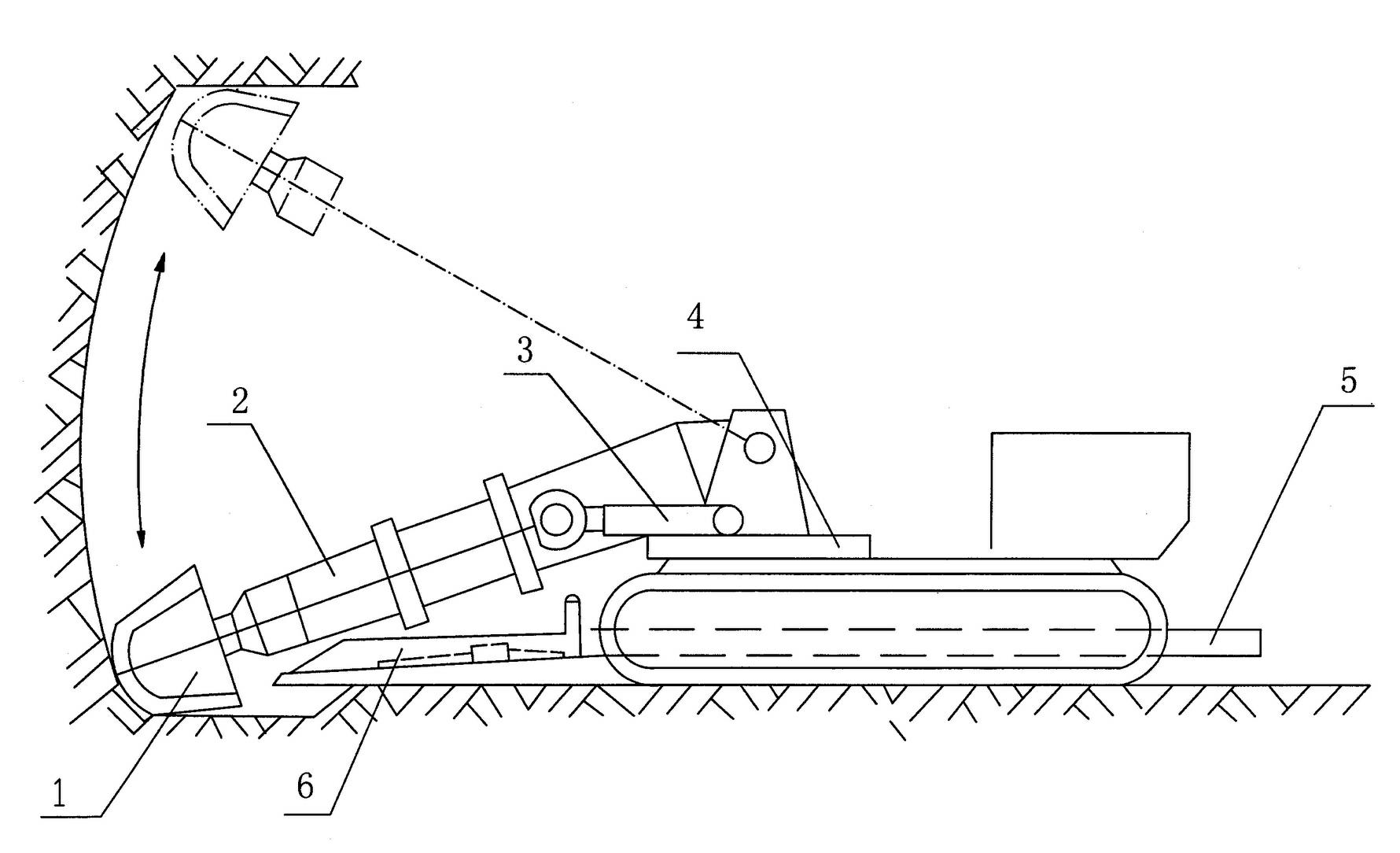

Whole-section quick-drilling drill carriage for parallel cut blasting of large empty holes in roadway

ActiveCN104612586ACompact chassisCompact structureDerricks/mastsDrilling drivesHydraulic motorReducer

The invention discloses a whole-section quick-drilling drill carriage specially used for parallel cut blasting of large empty holes in a roadway. The drill carriage is composed of a walking mechanism, a carriage frame, a hydraulic system, an electrical system and two drilling devices, wherein the first drilling device is used for drilling common blasting holes, and the second drilling device is used for drilling cut holes with the diameter of 100 mm or more. In the operating process of the drill carriage, a hydraulic motor drives a main chain wheel of a crawler-type walking chassis to rotate through a speed reducer; after a carriage body is stabilized, the first drilling device and the second drilling device are manipulated to select hole locations respectively; after the first drilling device and the second drilling device are located, the common blasting holes and the empty holes with the diameter of 100 mm or more can be drilled in rock simultaneously. The drill carriage is suitable for the roadway with the minimum section of 8 square meters and the maximum section of 23 square meters; by the adoption of a building block structural design, the drill carriage is convenient and fast to disassemble and assemble and convenient to transport; as a result, the drill carriage can be used when the length of the roadway under tunneling construction is seven meters or more, and accelerates tunneling mechanization and quick and efficient tunneling modernization.

Owner:SHANDONG UNIV OF SCI & TECH +1

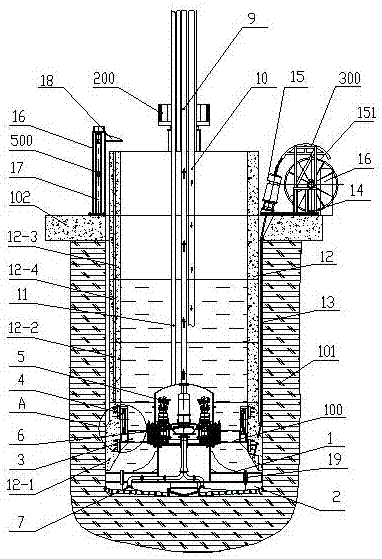

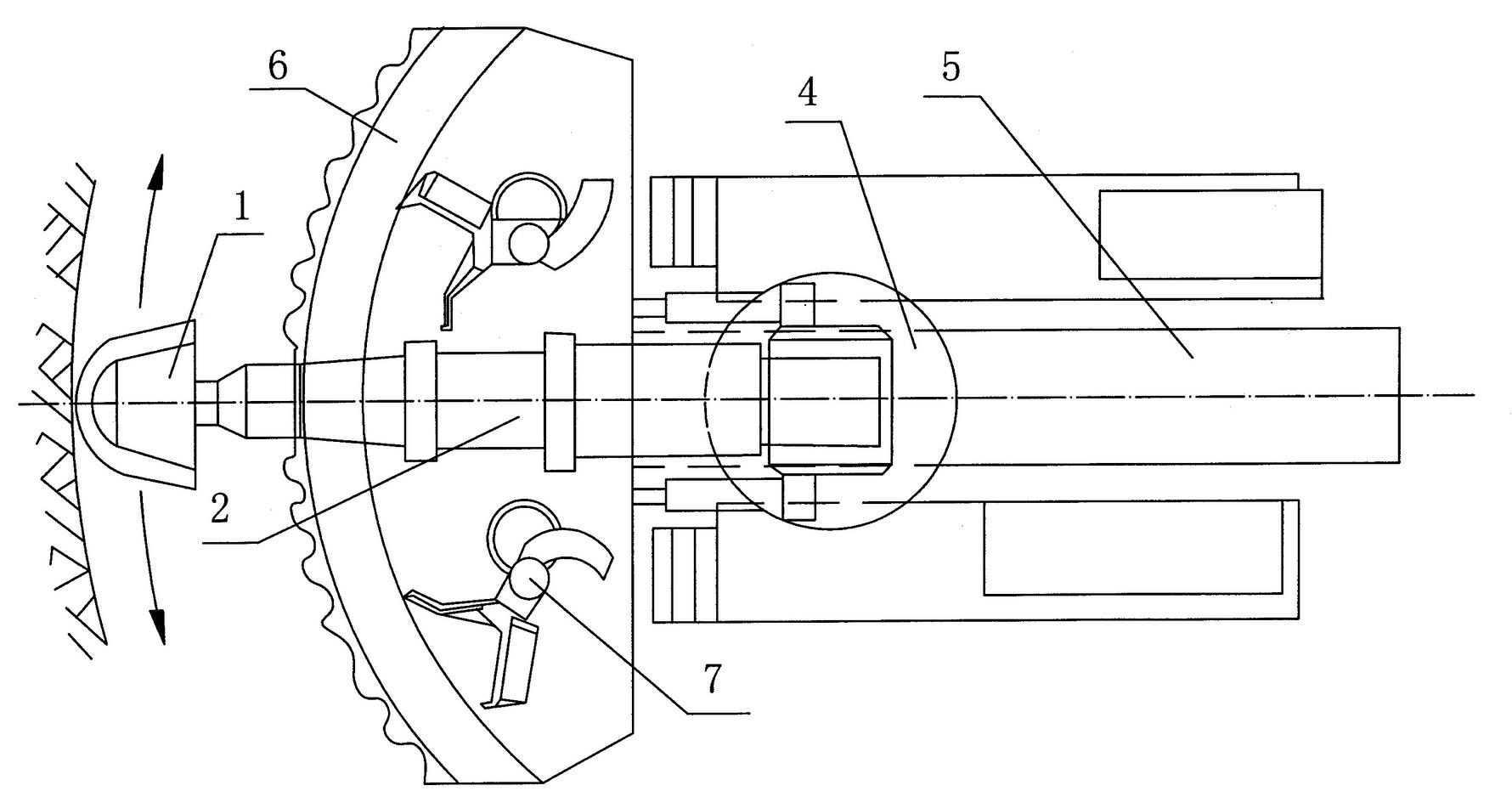

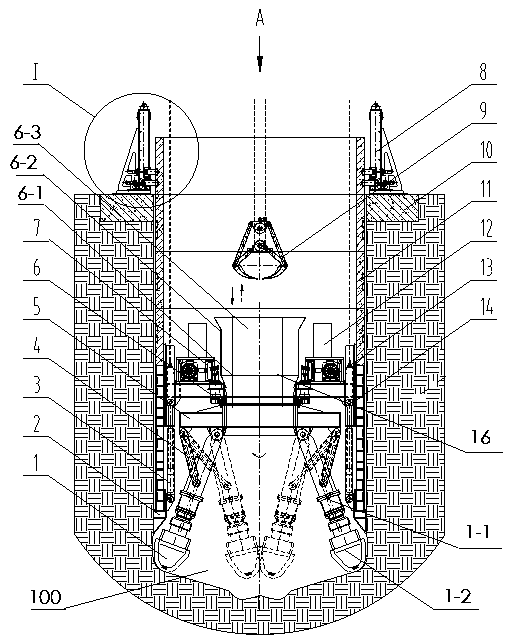

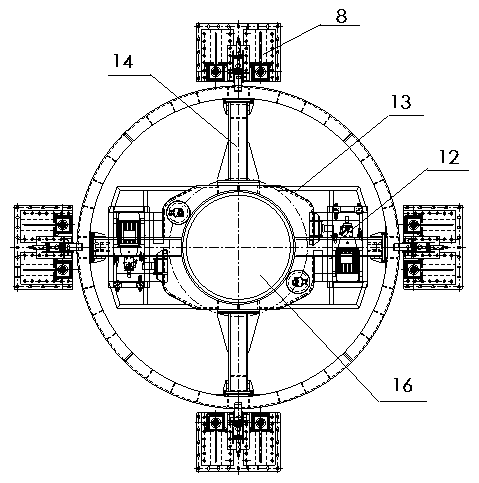

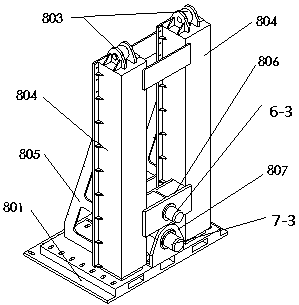

Vertical shaft tunnel boring machine by shaft sinking method and construction method of tunnel boring machine

ActiveCN107461197AChange the method of excavationReduce construction riskHydro energy generationShaft sinkingSludgeArchitectural engineering

The invention provides a vertical shaft tunnel boring machine by a shaft sinking method and a construction method of the tunnel boring machine, and solves the problems of low mechanization degree and efficiency, high risk and the like of devices and construction methods in the prior art. The tunnel boring machine comprises a tunneling mechanism, a pipe arrangement mechanism, a shaft lifting mechanism, a slurry separation system and an auxiliary pressure mechanism are mutually connected, the pipe arrangement mechanism, the shaft lifting mechanism, the slurry separation system and the auxiliary pressure mechanism are positioned on an over-ground wellhead ring beam, the tunneling mechanism comprises a tunneling shell, a cutter head is arranged at the front end of the tunneling shell, a driving fixing frame is arranged at the rear end of the tunneling shell, a feeding device and a driving device are arranged on the driving fixing frame, and the feeding device and the cutter head are connected with the driving device. The tunnel boring machine has mechanized excavation, sludge discharge and support functions and is operated on the ground, safe and reliable, underground operators are omitted in the working process of the vertical shaft tunnel boring machine, traditional shaft bottom excavation modes are changed, construction risks are greatly reduced, and operating efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Method for mechanically mining coal by using steep seam pseudo inclination bracing type retractable flexible shield support

InactiveCN102562066ARealize mechanized miningStrong thicknessUnderground miningSlitting machinesHigh probabilityWorking environment

The invention discloses a method for mechanically mining coal by using a steep seam pseudo inclination bracing type retractable flexible shield support. By the method, a steep seam coal mining machine and a bracing type retractable flexible shield support are provided. The method comprises the following steps of: 1, mining, namely mining by arranging the coal mining machine on a pseudo inclination working surface; 2, loading and transporting the coal, namely raking a falling coal body to a conveying mechanism and conveying the falling coal body to the rear part of the coal mining machine by using left and right gathering arms of the coal mining machine, sliding the falling coal body to a coal sliding hole truck loading point through a sliding chute, loading and transporting; 3, supporting an operating area, namely arranging the bracing type retractable flexible shield support in the operating area; 4, ventilating the working surface; 5, atomizing for dust removal; 6, exploiting upper triangle coal; and 7, recycling lower triangle coal, namely dredging a finishing cut, lowering the shield support to a horizontal position gradually, disassembling and decomposing the coal mining machine, transporting to the next stoping working surface and completely recycling the shield support when the working surface is propelled to a place neara district rise hole. By the method, the problems of low recovery ratio, low mechanization degree, low single yield of the working surface, severe working environment, high probability of malignant accidents and the like in domestic and oversea steep seams can be radically solved.

Owner:袁野 +2

Drop-shaft-sinking-based shaft well tunneller and construction method thereof

PendingCN109139017AEasy maintenanceEasy to operateShaft sinkingHydro energy generationSlagControl system

The invention discloses a drop-shaft-sinking-based shaft well tunneller and a construction method thereof so that problems of shaft well excavation mechanization, low automation degree and high risk coefficient in the prior art can be solved. The drop-shaft-sinking-based shaft well tunneller comprises a tunneling system, a control system and a detection system. The tunneling system includes an excavation device and a well wall lifting and pressing device. A bottom pipe joint and a guiding base are arranged in a starting shaft well; the bottom pipe joint is arranged below the guiding base; anda driving fixation rack is arranged at the guiding base and the lower part of the driving fixation rack is connected with the bottom pipe joint by a propulsion cylinder. A rotating device is arrangedat the driving fixation rack; a rotation rack is arranged at the lower part of the rotating device; and an excavating device is connected with the rotation rack. A hydraulic pump station, a driving device and a slag discharging device are arranged at the rotating device; and the slag discharging device corresponds to a lifting grab bucket. The drop-shaft-sinking-based shaft well tunneller is a modular shaft well tunneling machine that is used for mechanical excavation and support of a shaft well; the excavation precision and excavation speed of the whole process are improved; the mechanical automatic construction is realized; and the work efficiency and construction safety factor are increased.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com