Patents

Literature

5121 results about "Deep hole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

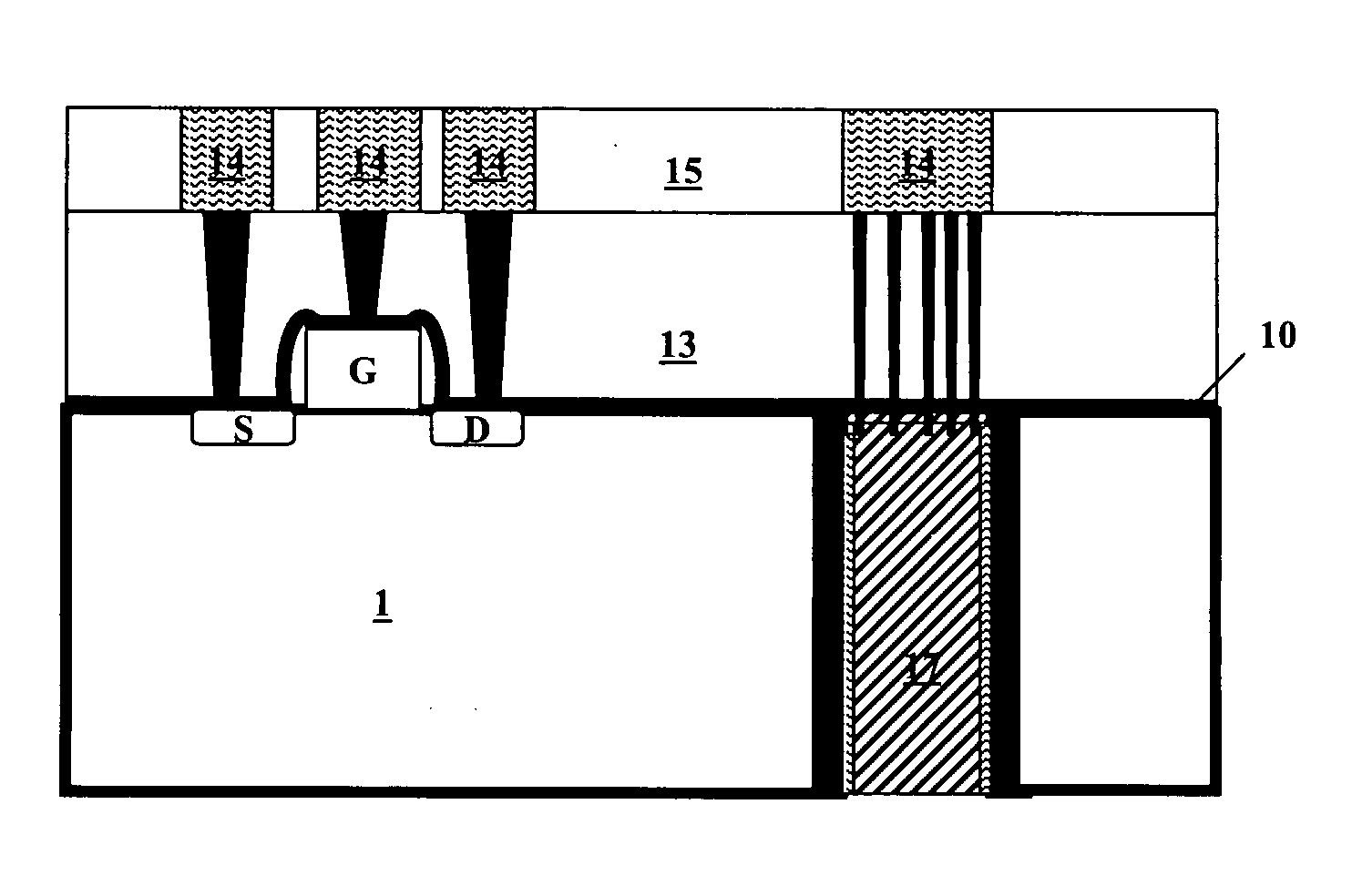

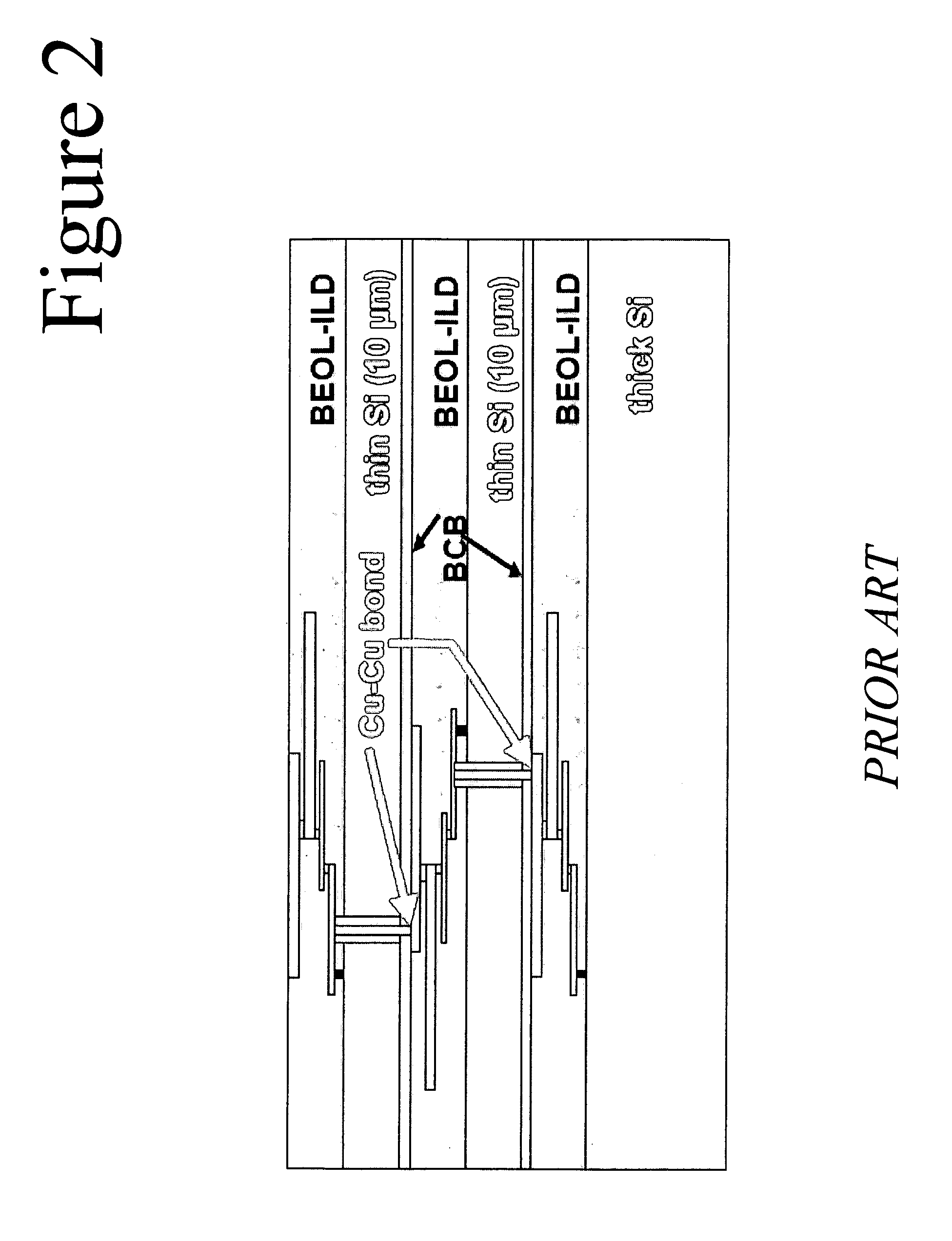

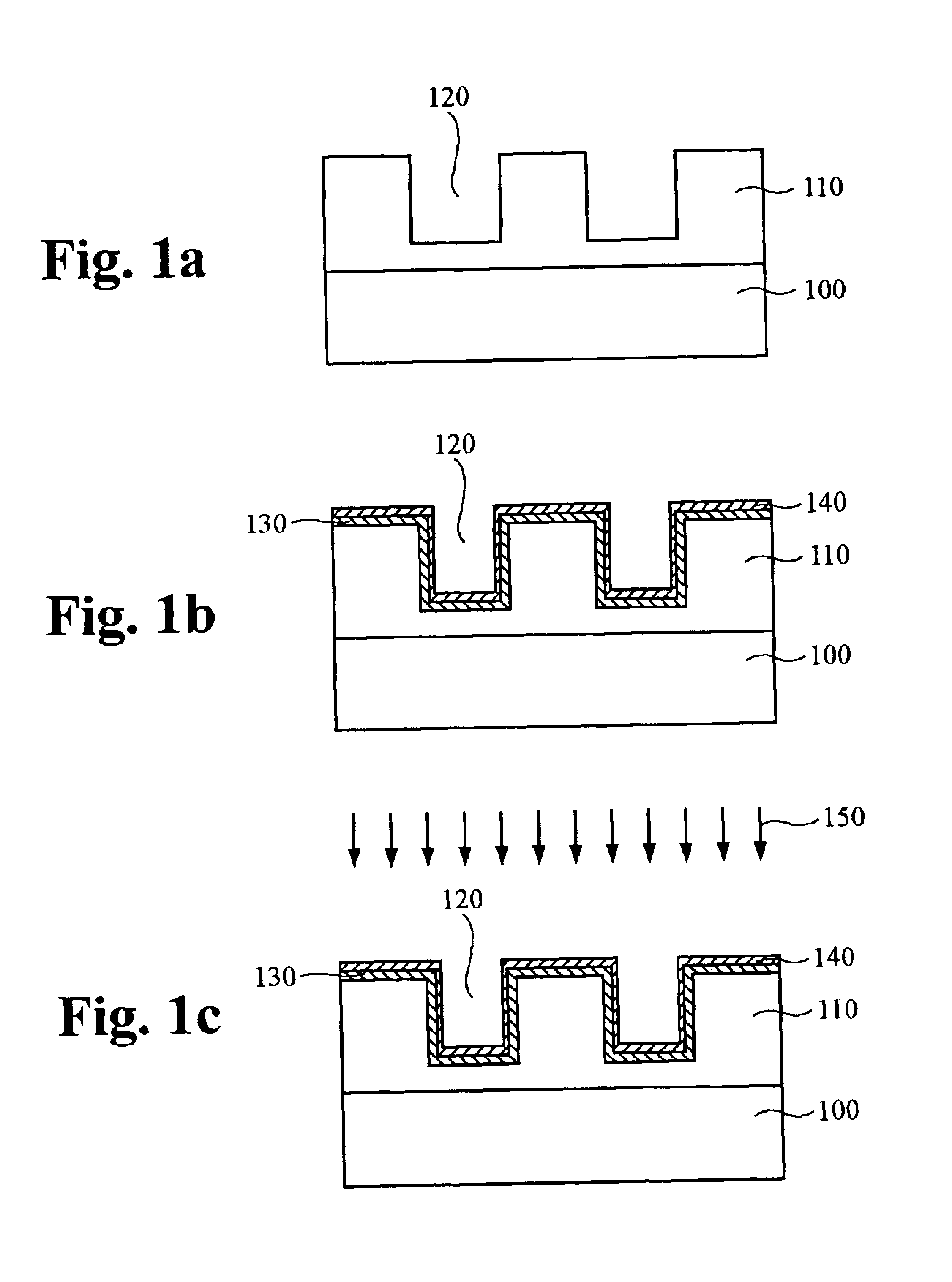

Formation of deep via airgaps for three dimensional wafer to wafer interconnect

InactiveUS20060223301A1Semiconductor/solid-state device detailsSolid-state devicesConductive materialsSemiconductor

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Method of forming copper interconnections and thin films using chemical vapor deposition with catalyst

InactiveUS6720262B2Semiconductor/solid-state device detailsSolid-state devicesCopper conductorSource material

A method of forming copper conductors for interconnecting active and passive elements as well as signal and power lines for circuits and devices on silicon wafers is disclosed. The method disclosed herein involves with using catalysts in conjunction with a chemical vapor deposition(CVD) process with typically using copper as a source material for forming interconnecting conductors. Interconnecting method for filling trenches, via holes, contacts, large trenches and holes for power devices and lines as well as for forming large passive elements is also disclosed. Disclosed herein are also a method of filling narrow and deep trenches and small in diameter and deep holes, and a method of forming very thin film on the flat top surface so that an etchback process, such as wet or dry etchback as well as plasma etchback processes, can be used for removing a thin film in preparation for subsequent processing steps, thereby rather expensive chemical mechanical polishing(CMP) process need not be used.

Owner:ASM KOREA LTD

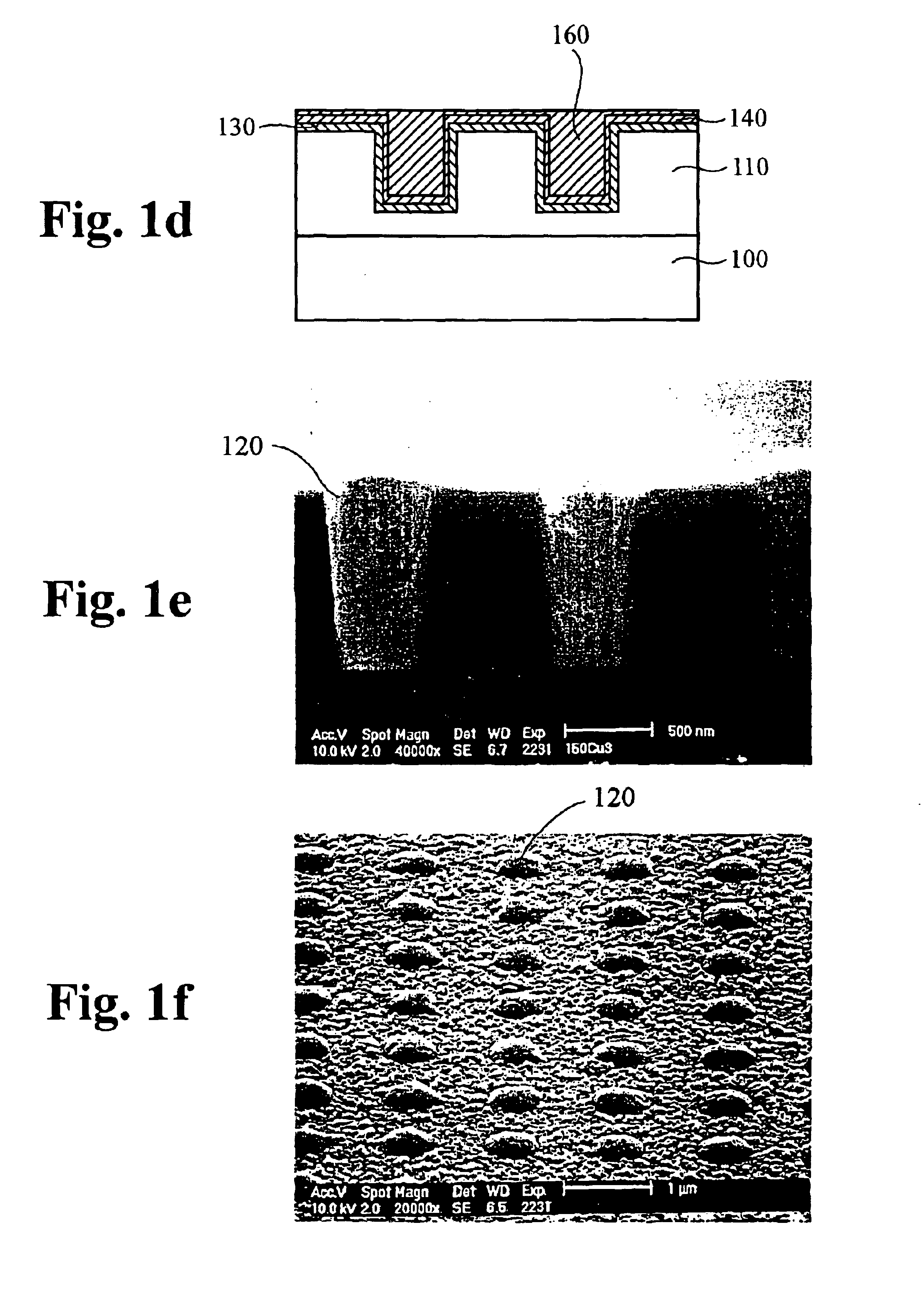

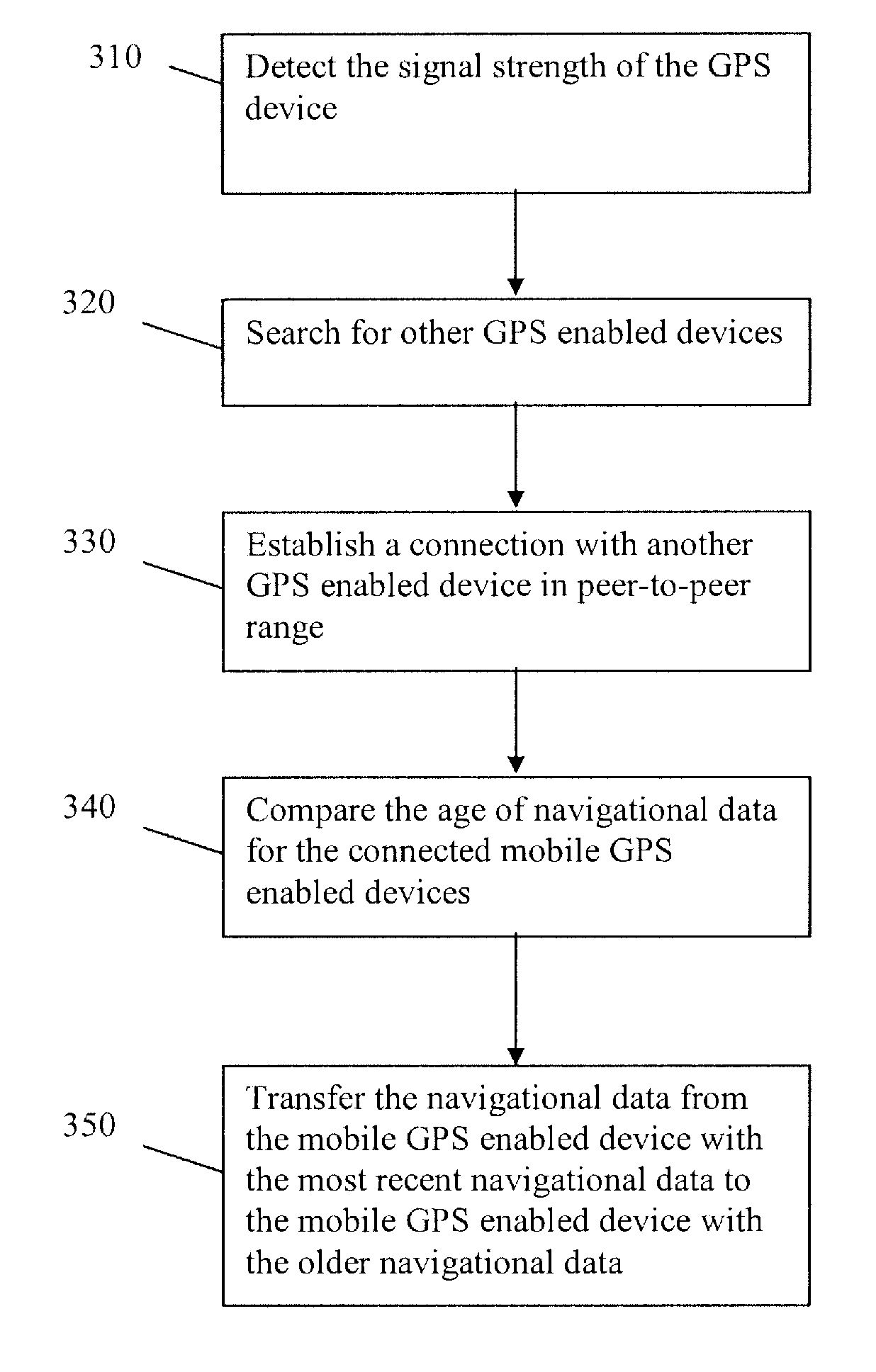

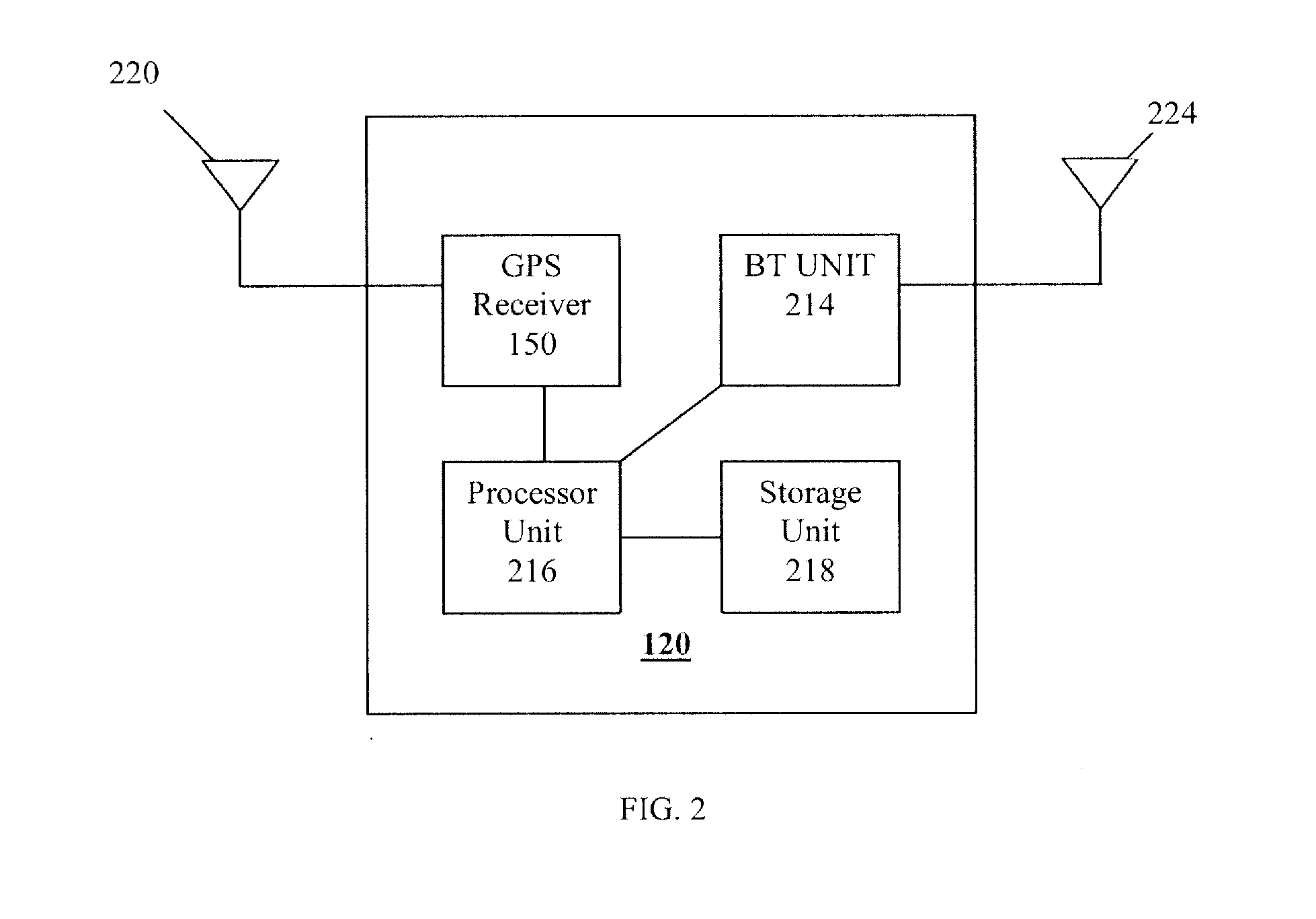

GPS with aiding from ad-hoc peer-to-peer bluetooth networks

InactiveUS20110163914A1Reduce the possibilityPosition fixationSatellite radio beaconingTime informationEphemeris

The present invention is related to location positioning systems, and more particularly, to a method and apparatus for providing an update of ephemeris information. According to one aspect, GPS enabled devices in the signal unavailable area monitors the state of its ephemeris data and time information. When the ephemeris data and time information become out of date, the GPS enable device uses an ad hoc Bluetooth network to retrieve ephemeris data and time information from another GPS enabled device with more current data. According to further aspects, a map of a deep hole region in which GPS and other cellular signals are not available, is generated to enable power reduction and cost saving measures.

Owner:CSR TECH HLDG

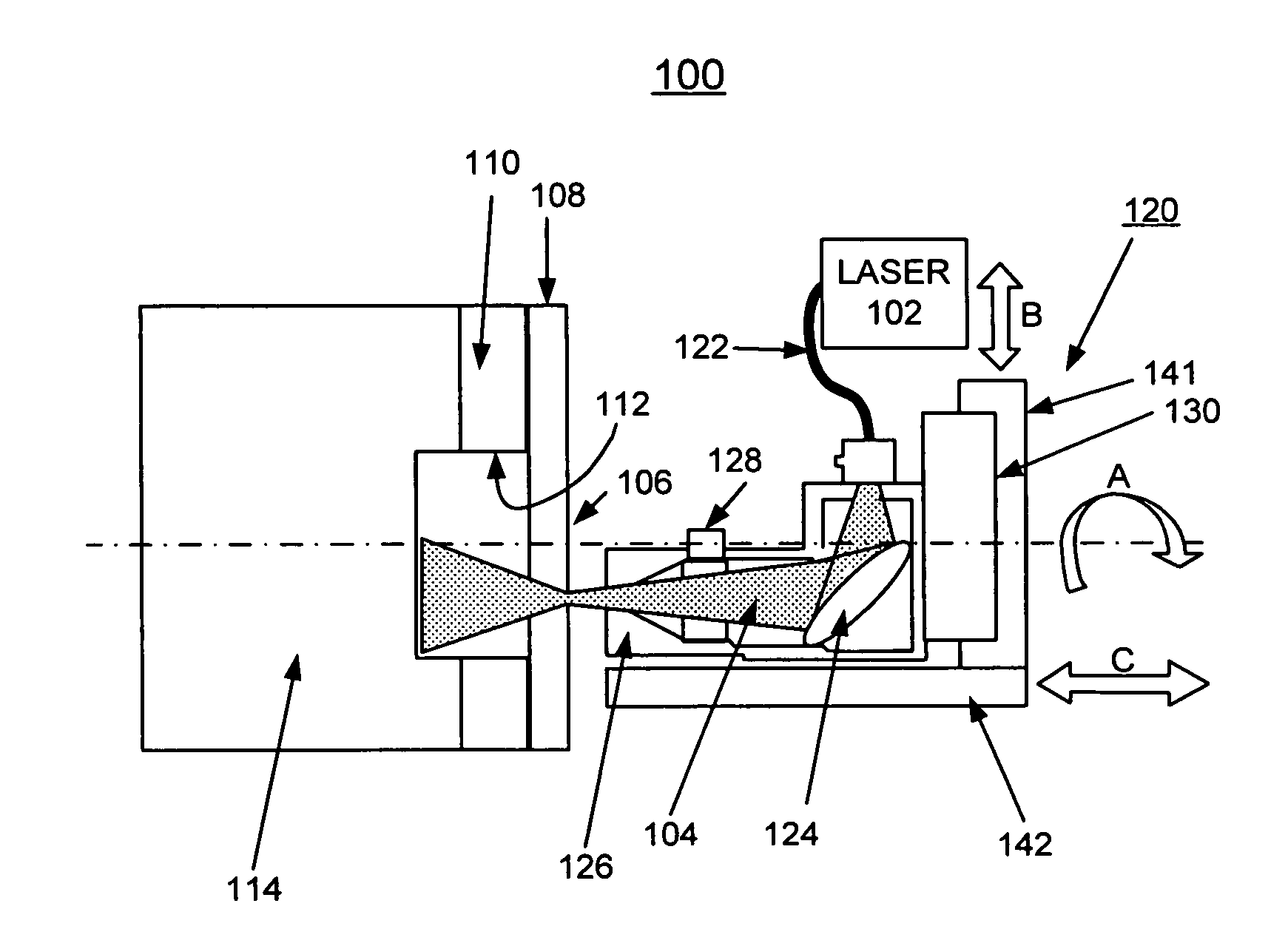

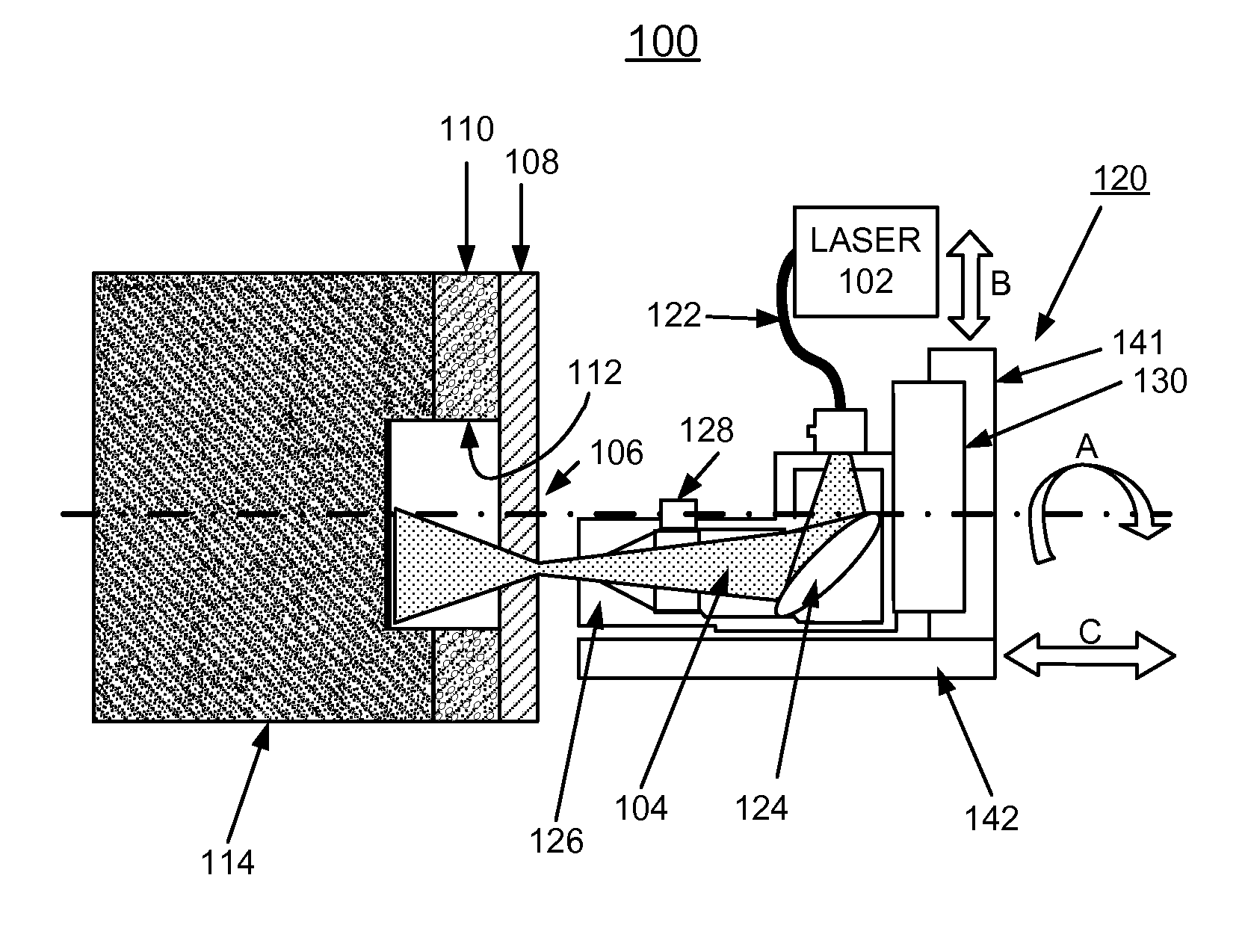

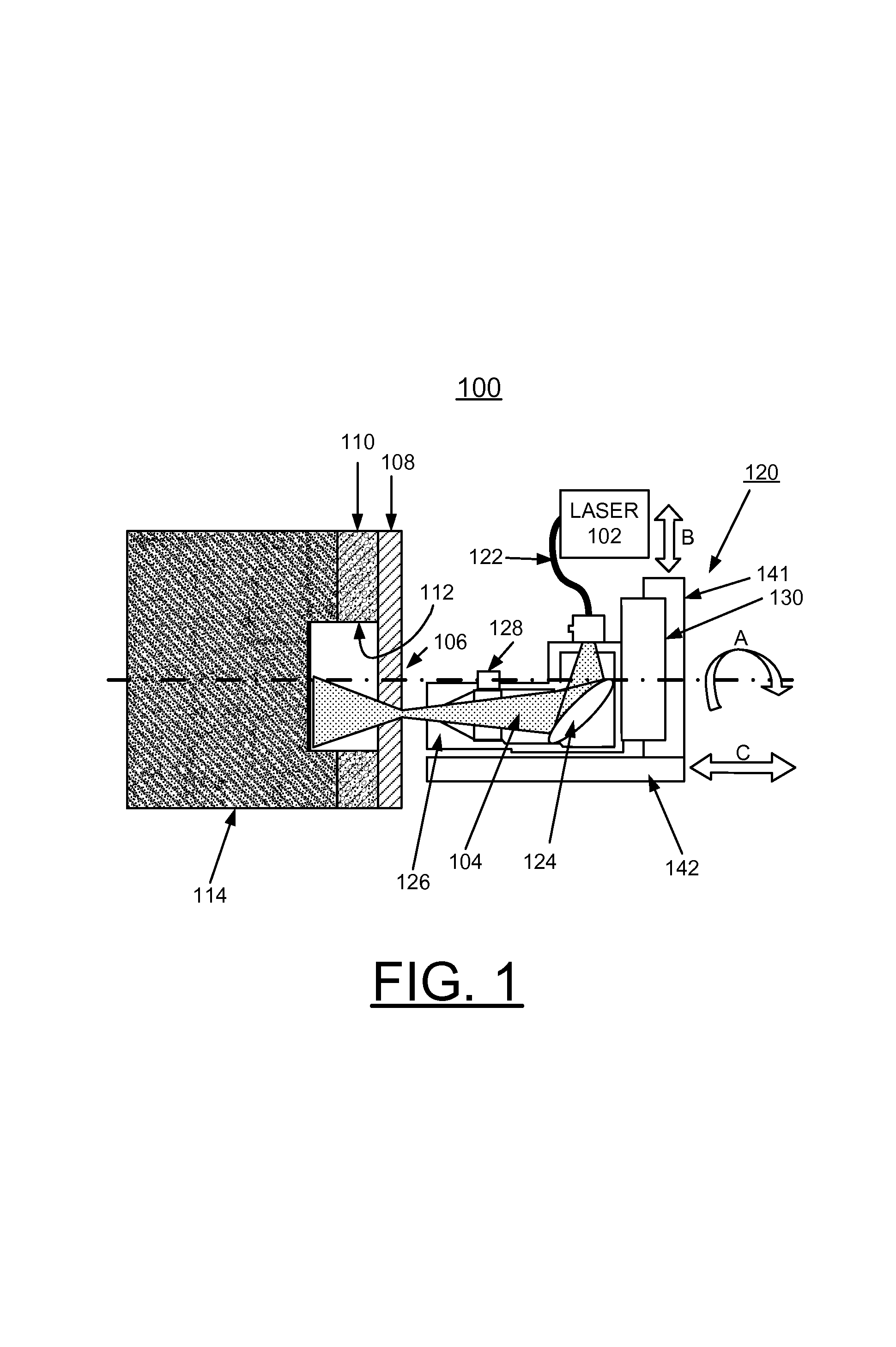

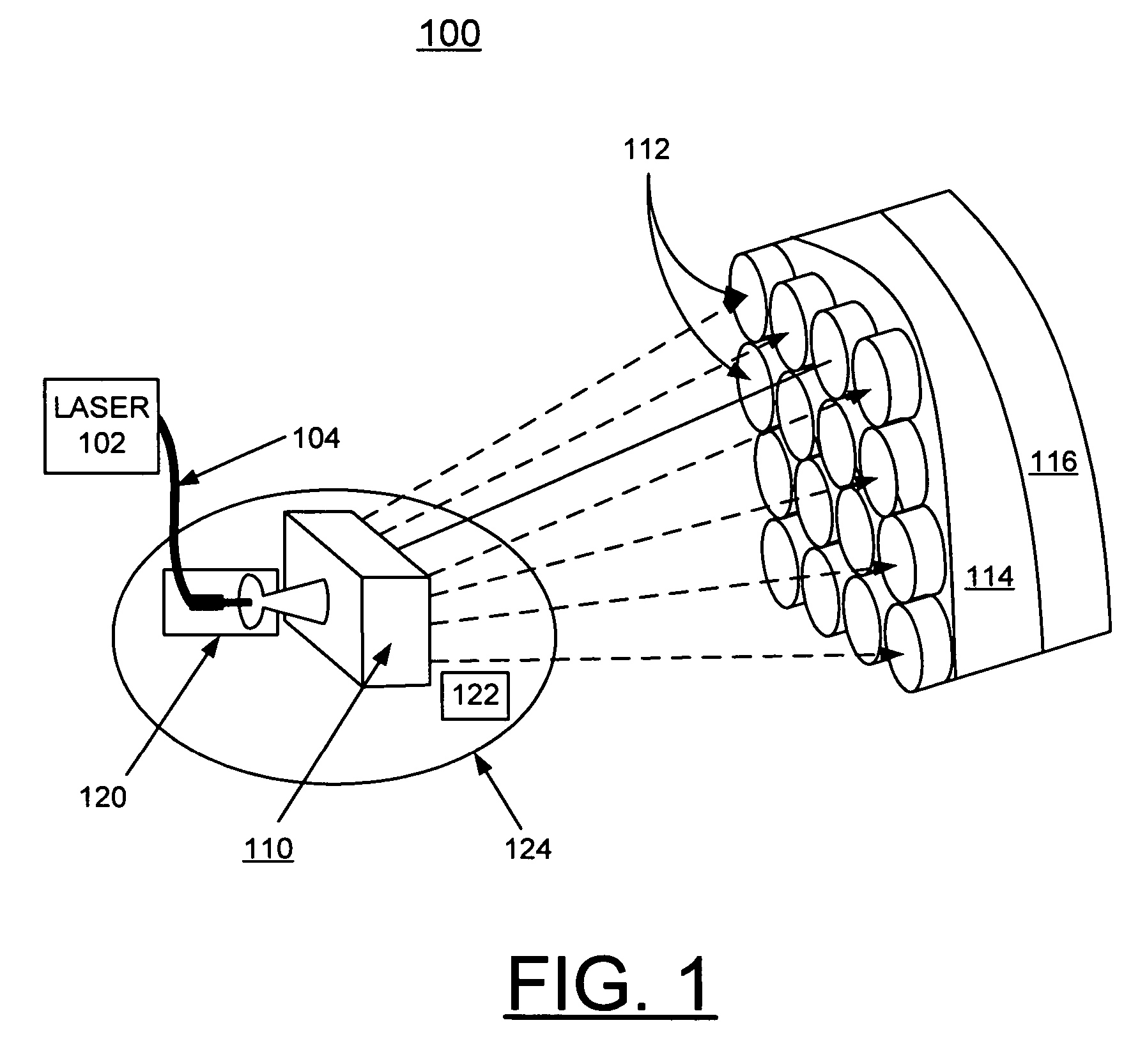

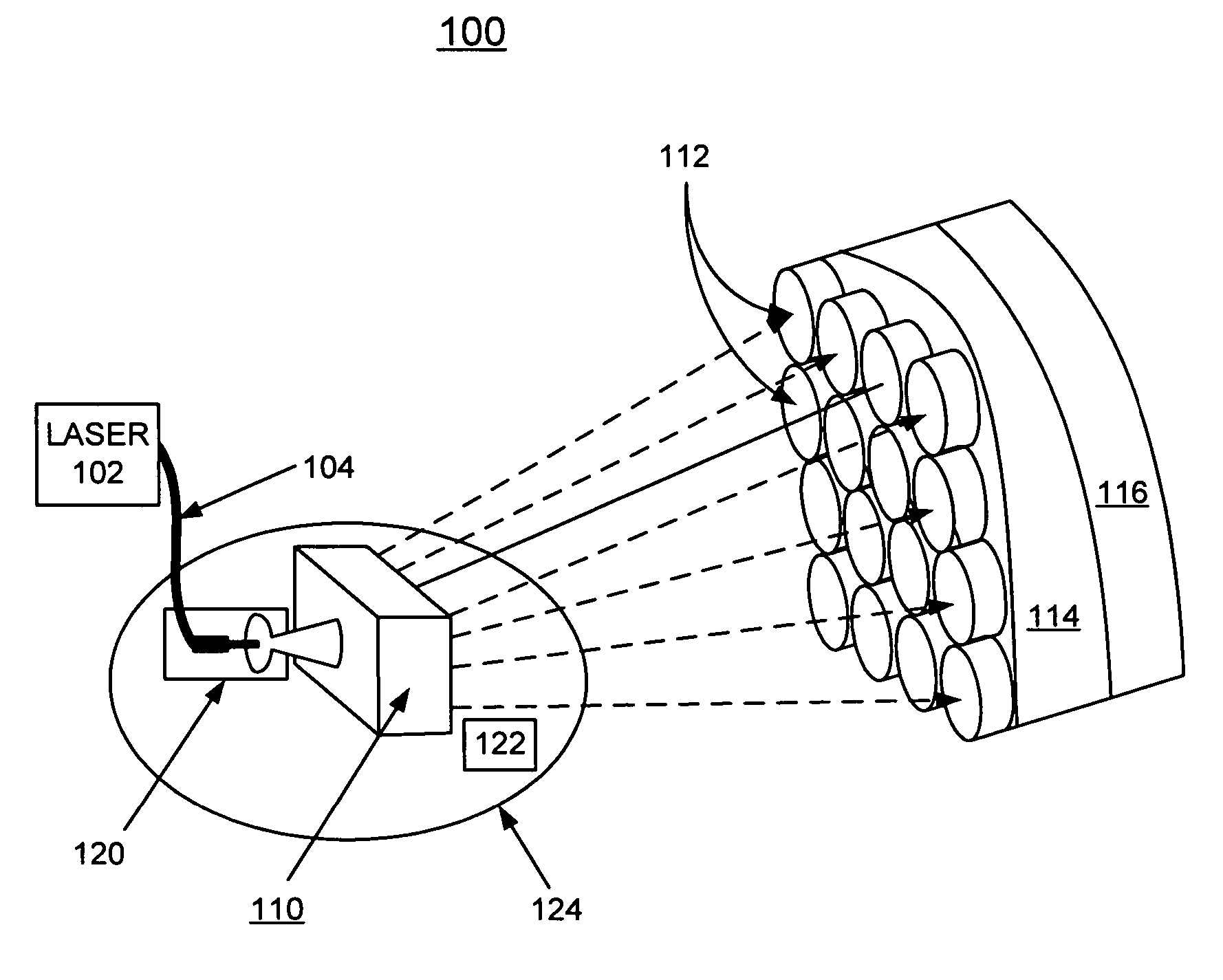

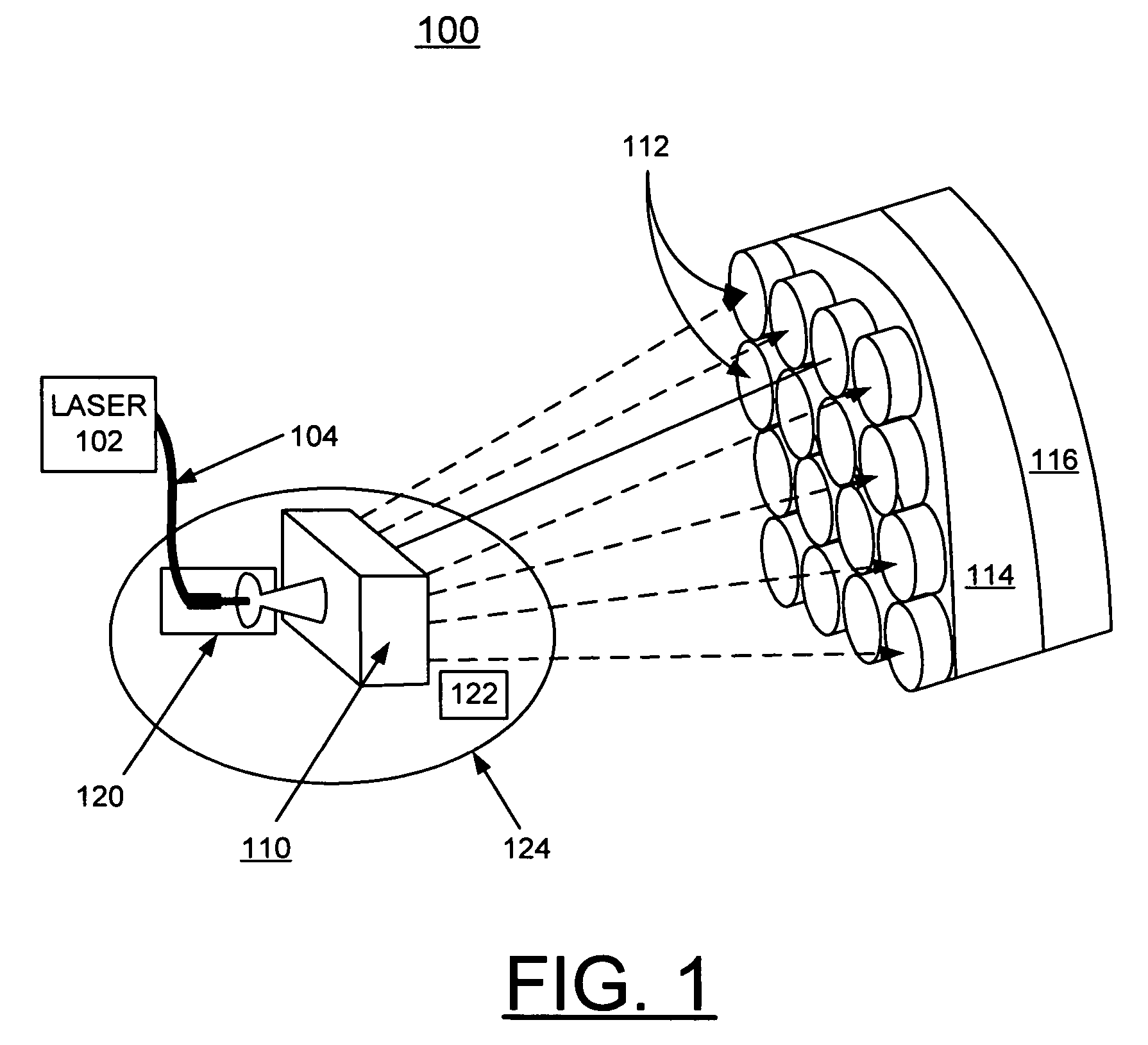

Methods of using a laser to perforate composite structures of steel casing, cement and rocks

ActiveUS20060231257A1Improve breathabilityReduce hole taperingDisloding machinesThermal drillingHigh power lasersSmall fragment

Apparatus and methods of using lasers are provided for the perforation of oil and gas well casings and rock formations. A rock removal process called laser spallation is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall or fracture the rock into small fragments that can then be easily removed from the rock formation. The use of high power laser beams of kilowatt level is provided to rapidly cut the steel casings and perforate into the formation. Techniques of the invention increase permeability and reduce hole tapering while perforating a deep hole in reservoir rock formations.

Owner:UCHICAGO ARGONNE LLC +1

Methods of using a laser to perforate composite structures of steel casing, cement and rocks

ActiveUS7487834B2Improve breathabilityReduce hole taperingDisloding machinesThermal drillingHigh power lasersSmall fragment

Owner:UCHICAGO ARGONNE LLC +1

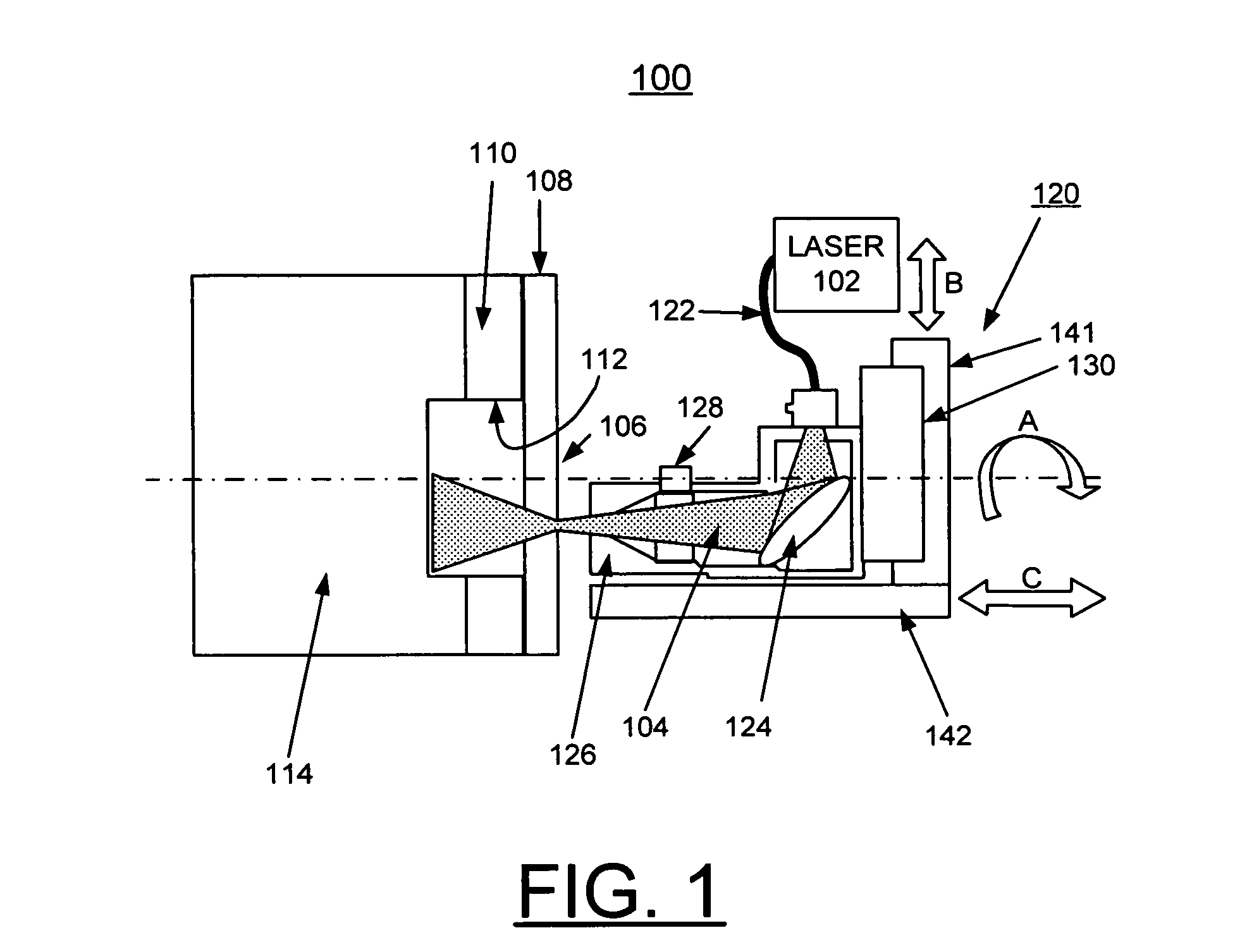

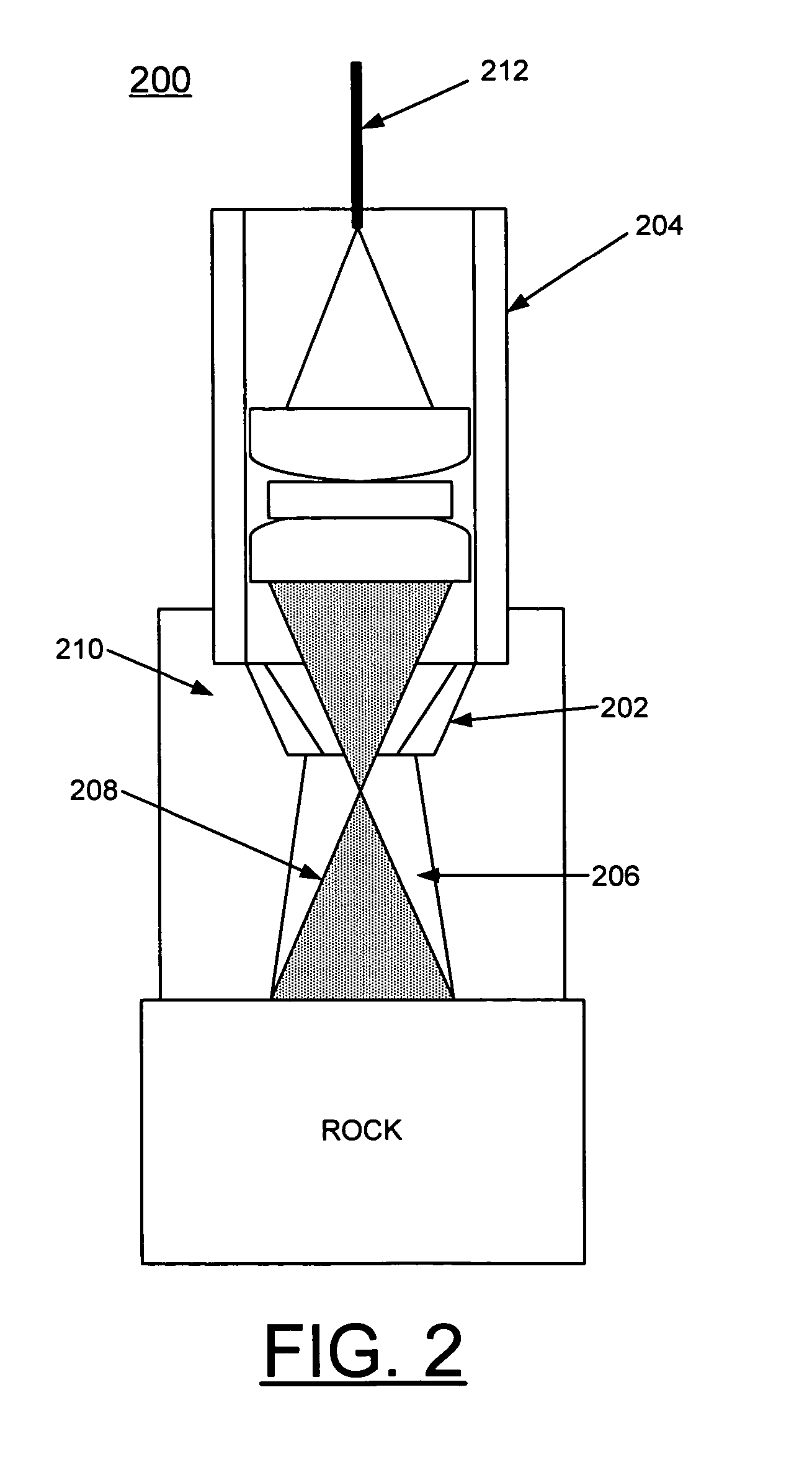

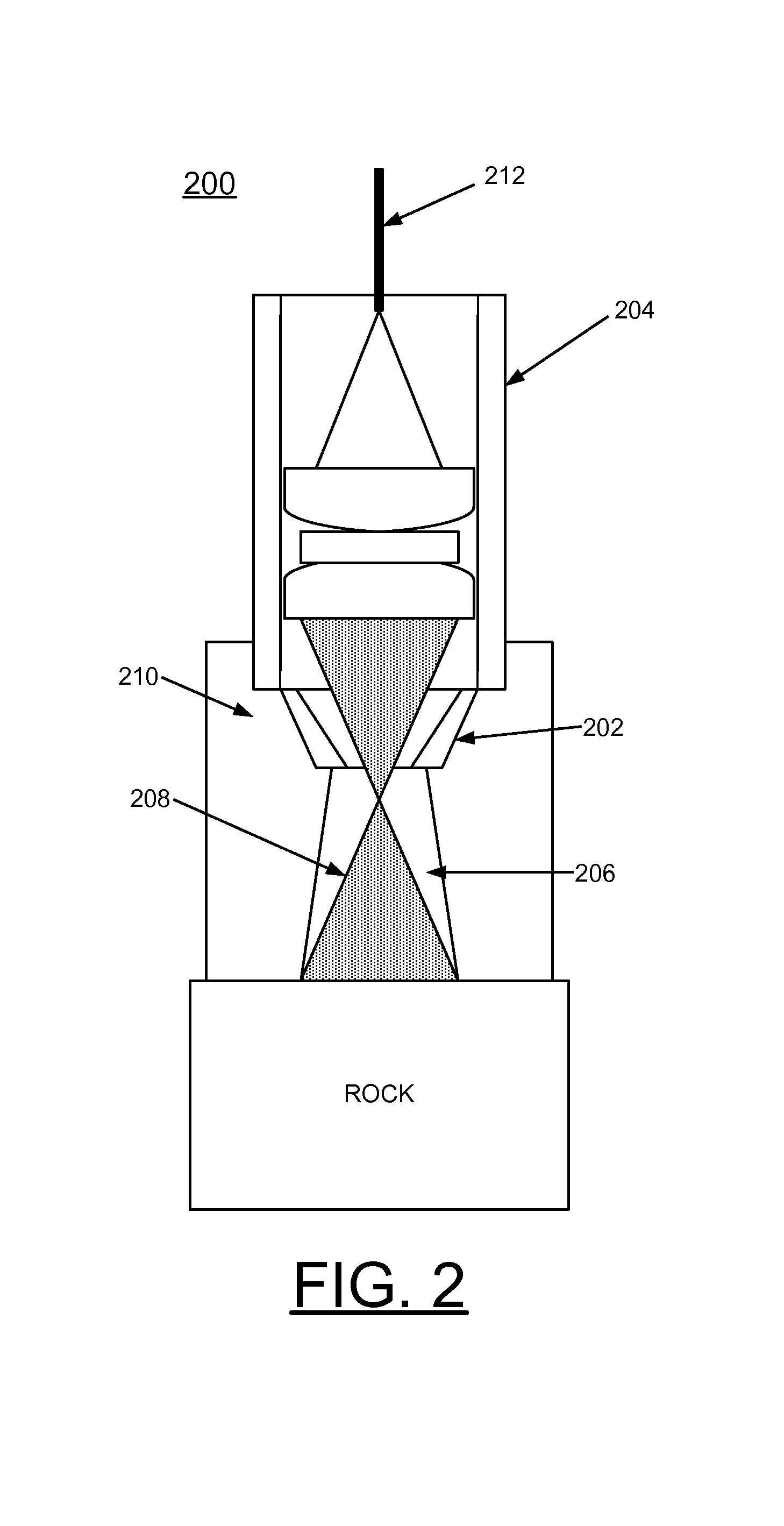

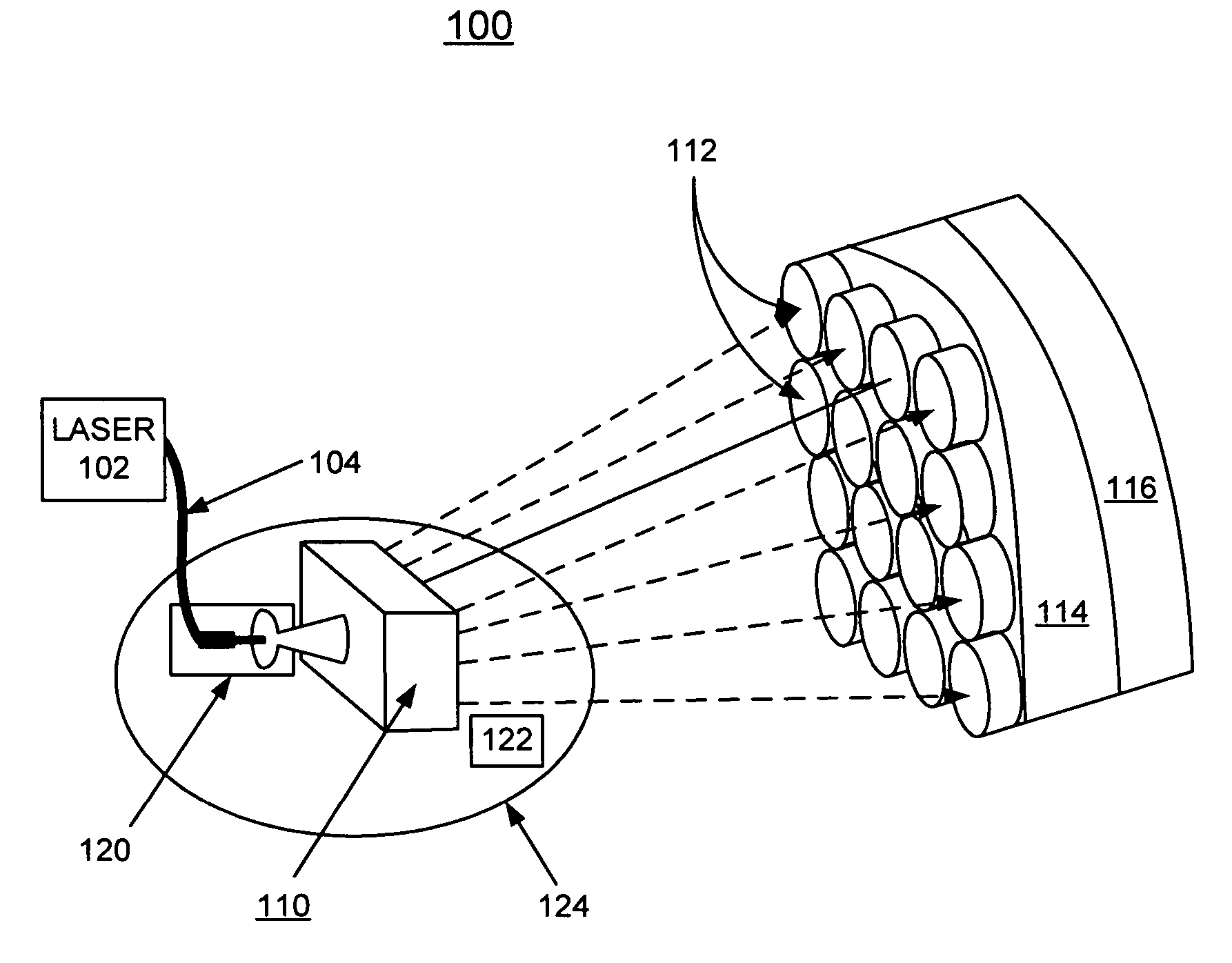

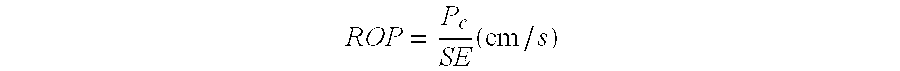

Methods of using a laser to spall and drill holes in rocks

ActiveUS20060237233A1Energy efficiencyProtection is necessaryEarth drilling toolsDisloding machinesSmall fragmentClassical mechanics

Apparatus and methods of using lasers are provided for spalling and drilling holes into rocks. A rock removal process is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall the rock into small fragments that can then be easily removed by a purging flow. Single laser beams of given irradiance spall rock and create holes having diameter and depth approximately equal to the beam spot size. A group of the single laser beams are steered in a controllable manner by an electro-optic laser beam switch to locations on the surface of the rock, creating multiple overlapping spalled holes thereby removing a layer of rock of a desired diameter. Drilling of a deep hole is achieved by spalling consecutive layers with an intermittent feed motion of the laser head perpendicular to the rock surface.

Owner:UCHICAGO ARGONNE LLC

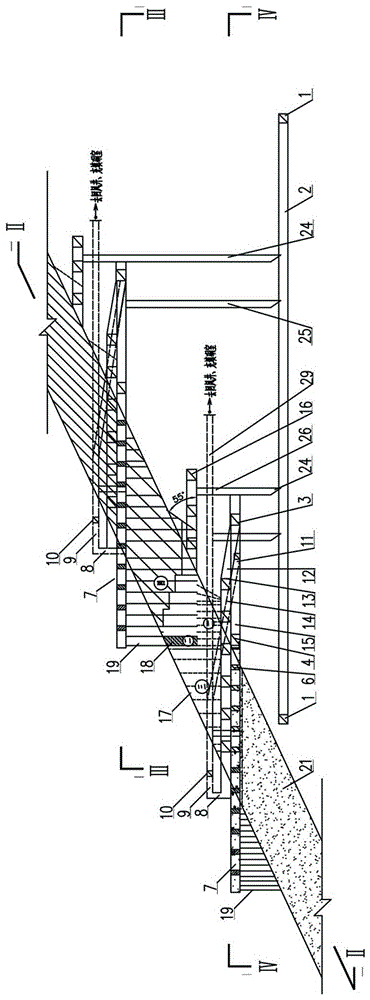

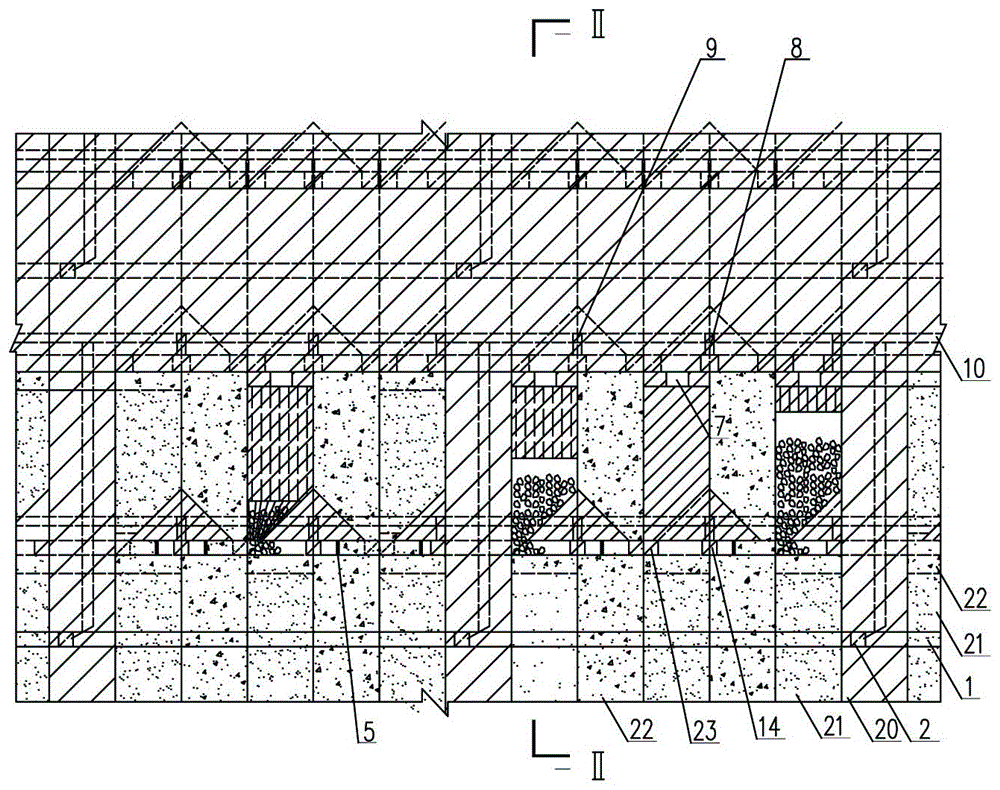

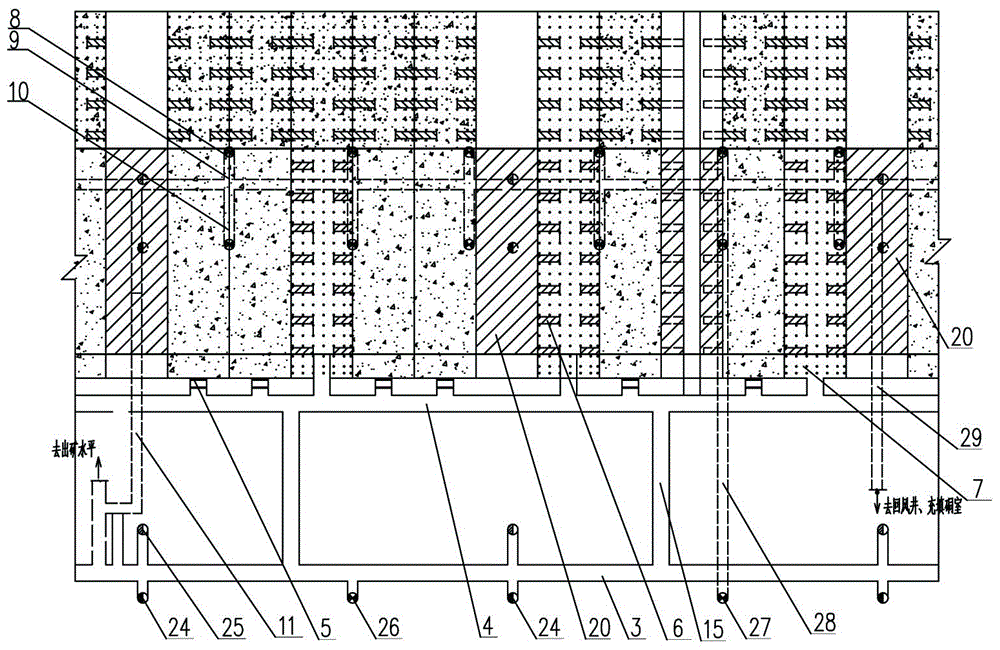

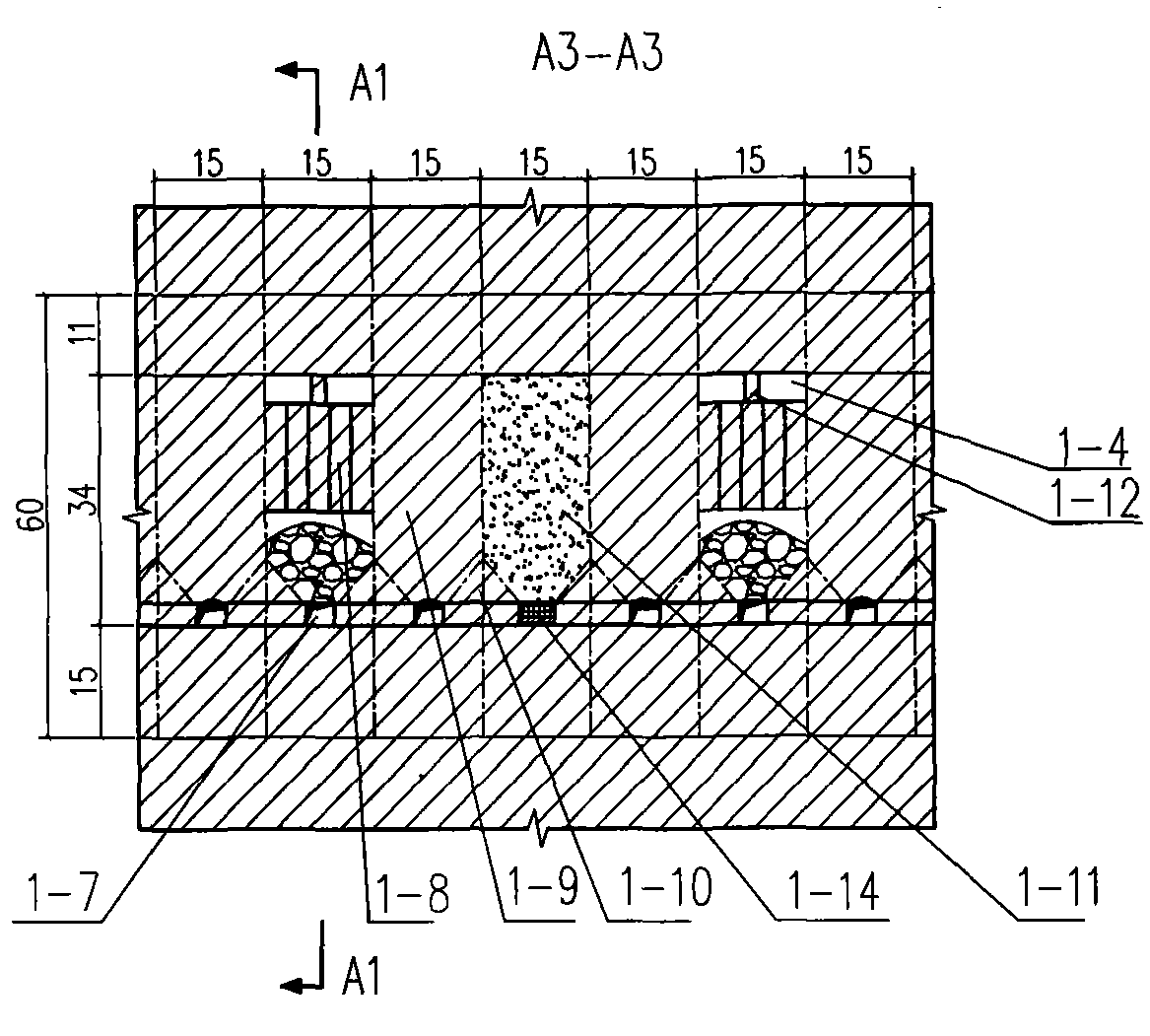

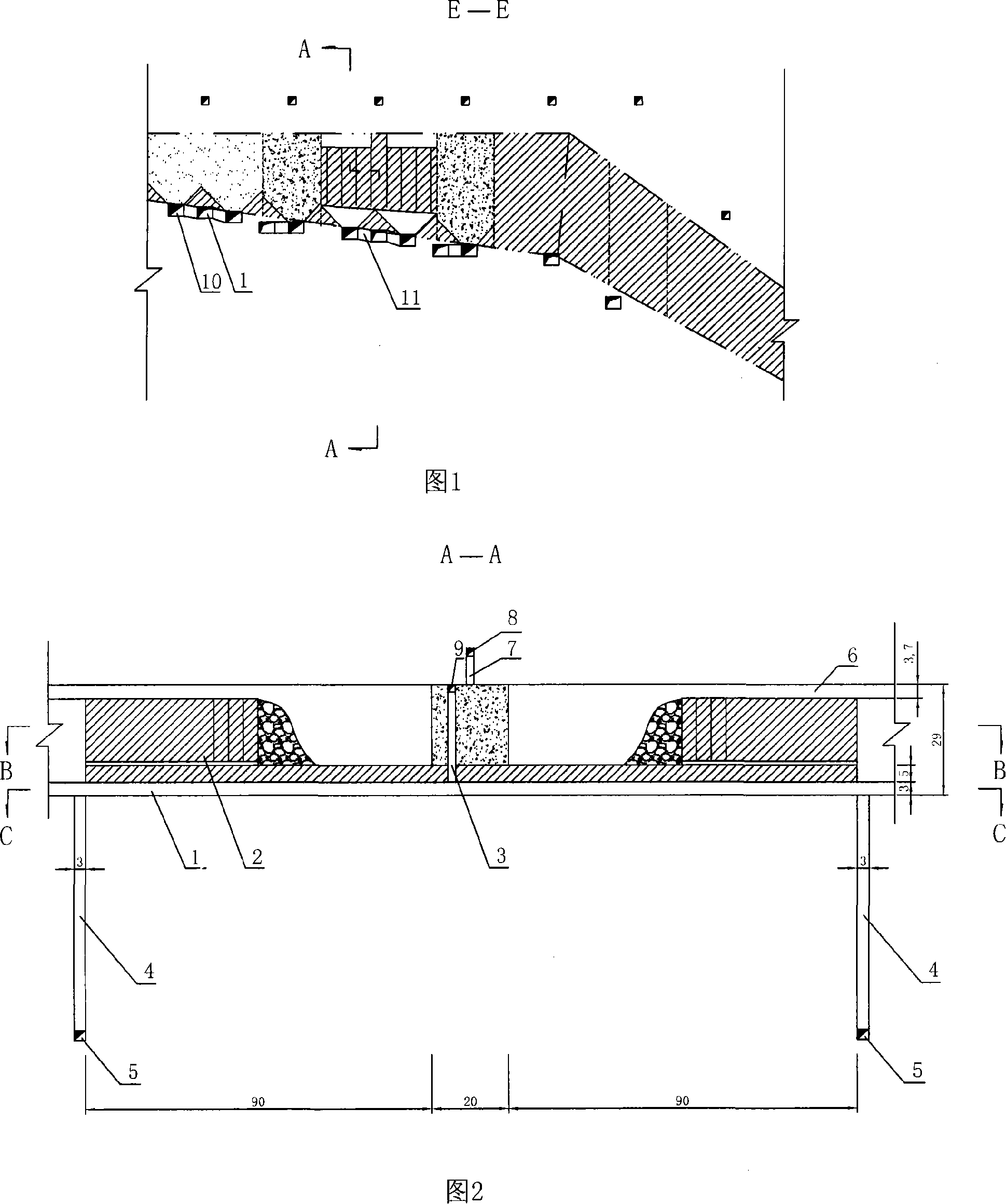

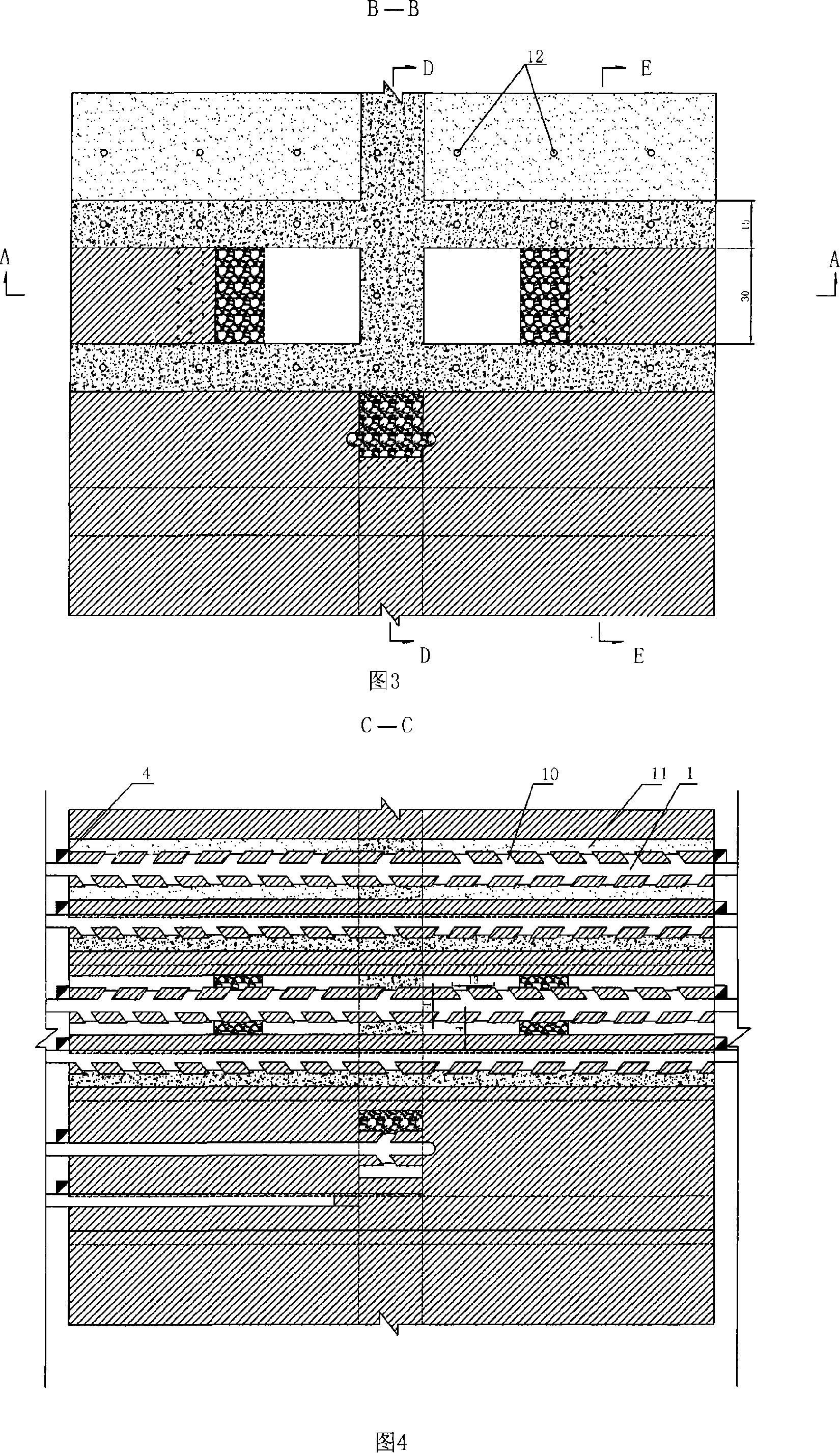

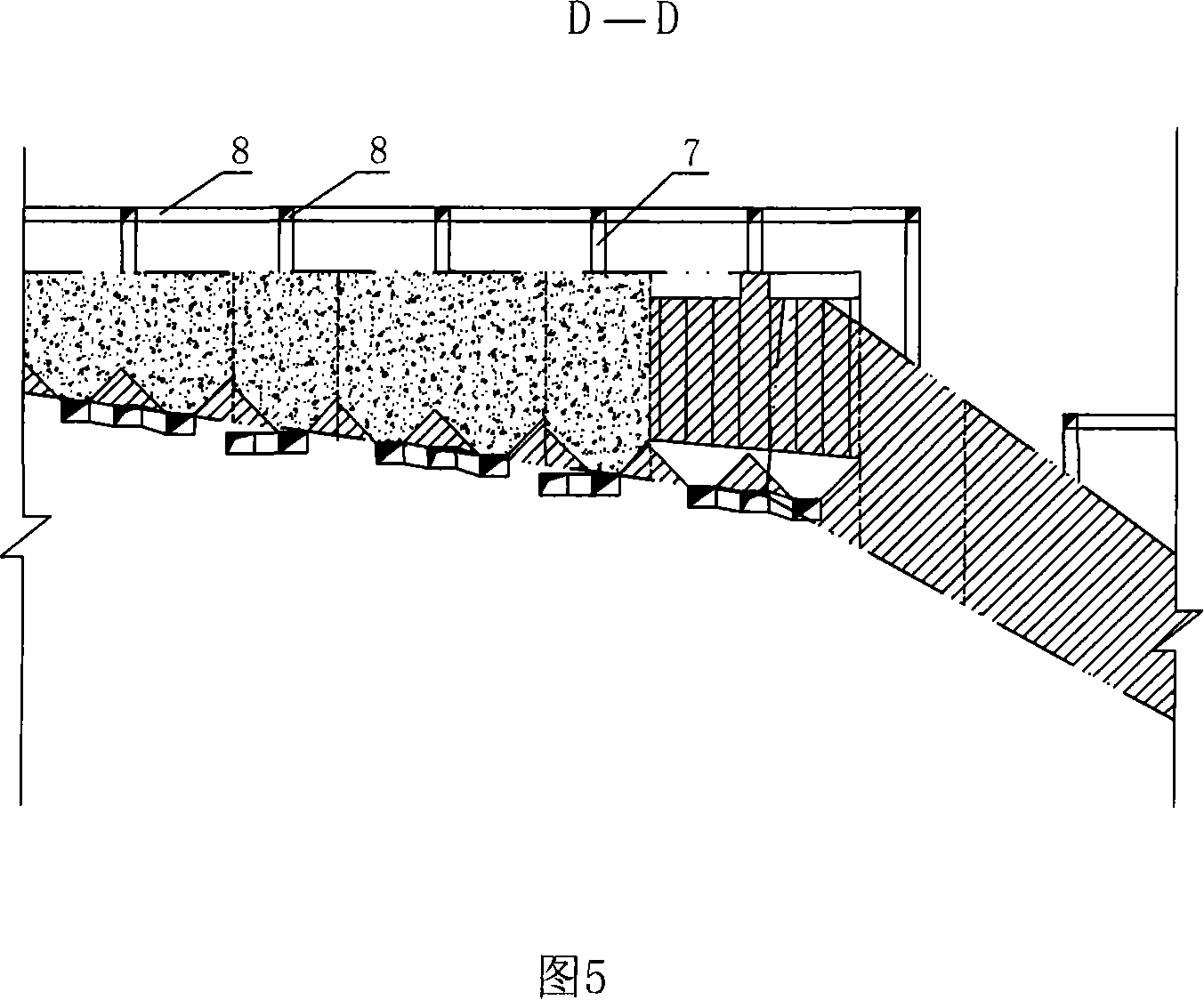

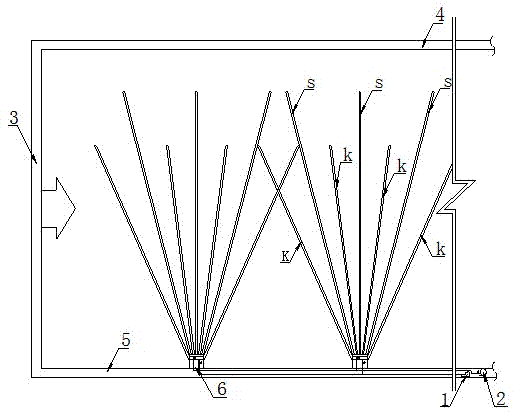

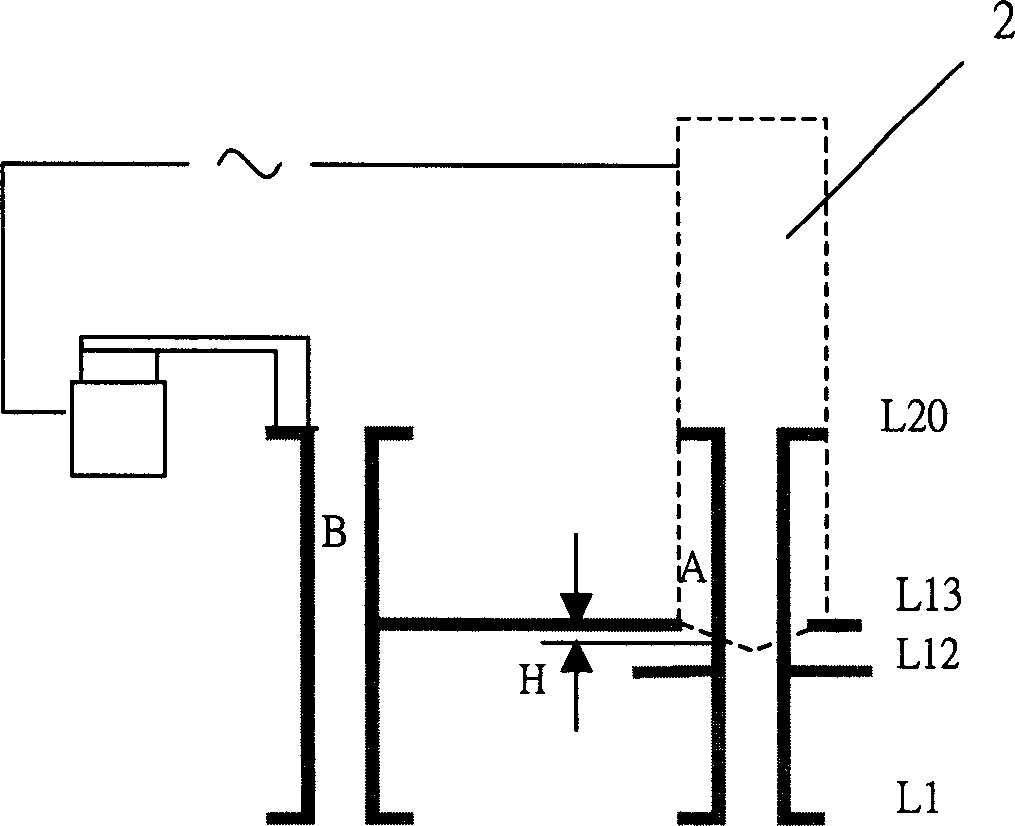

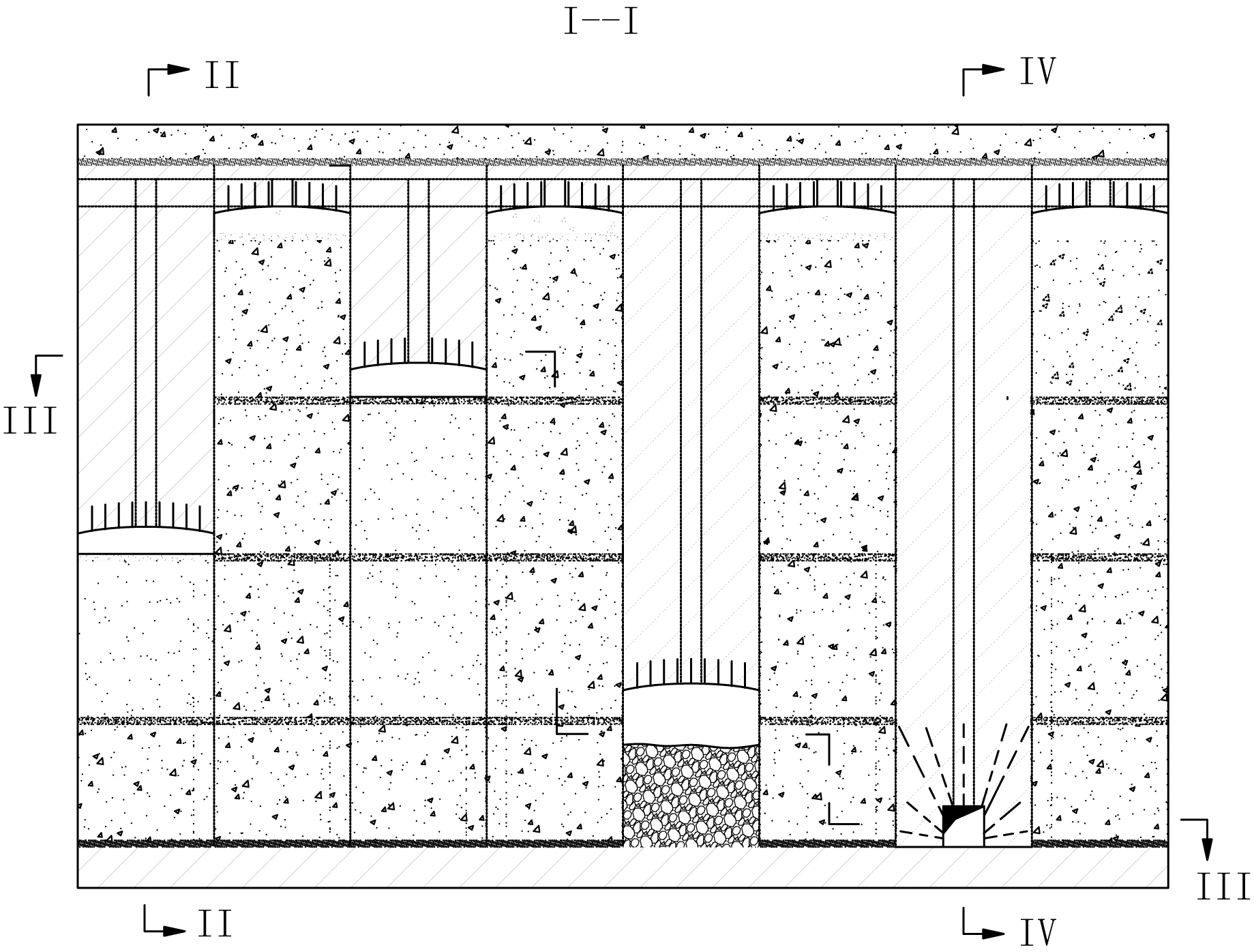

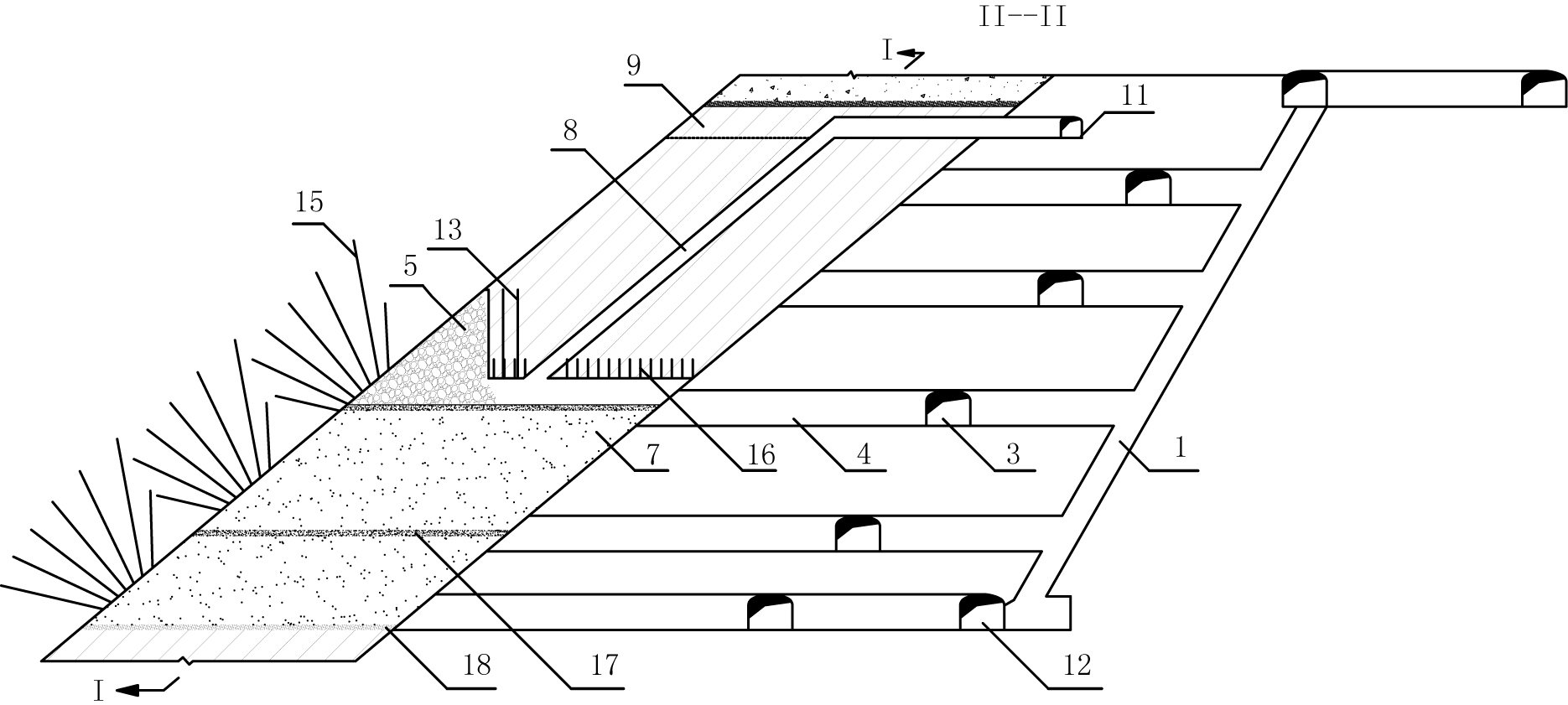

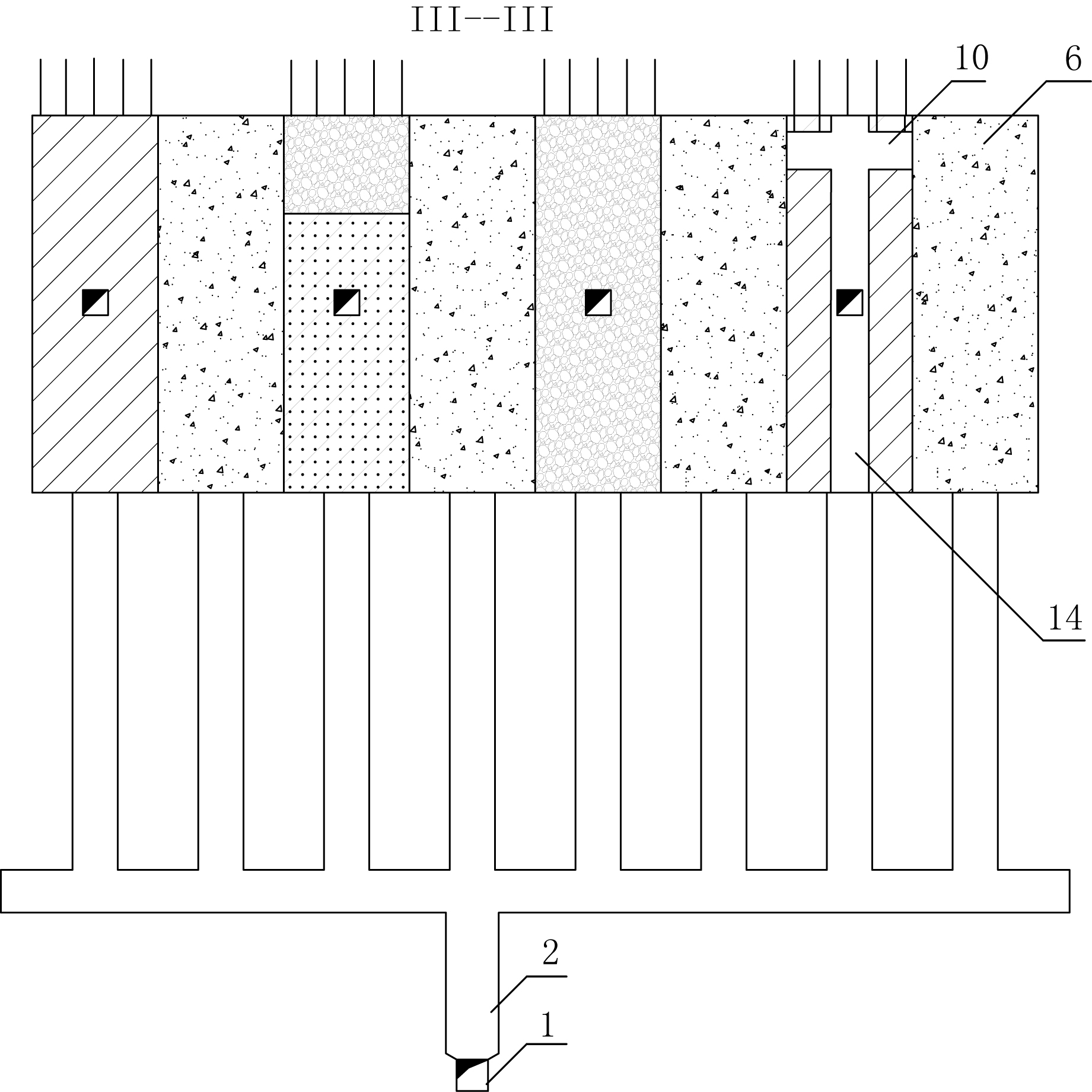

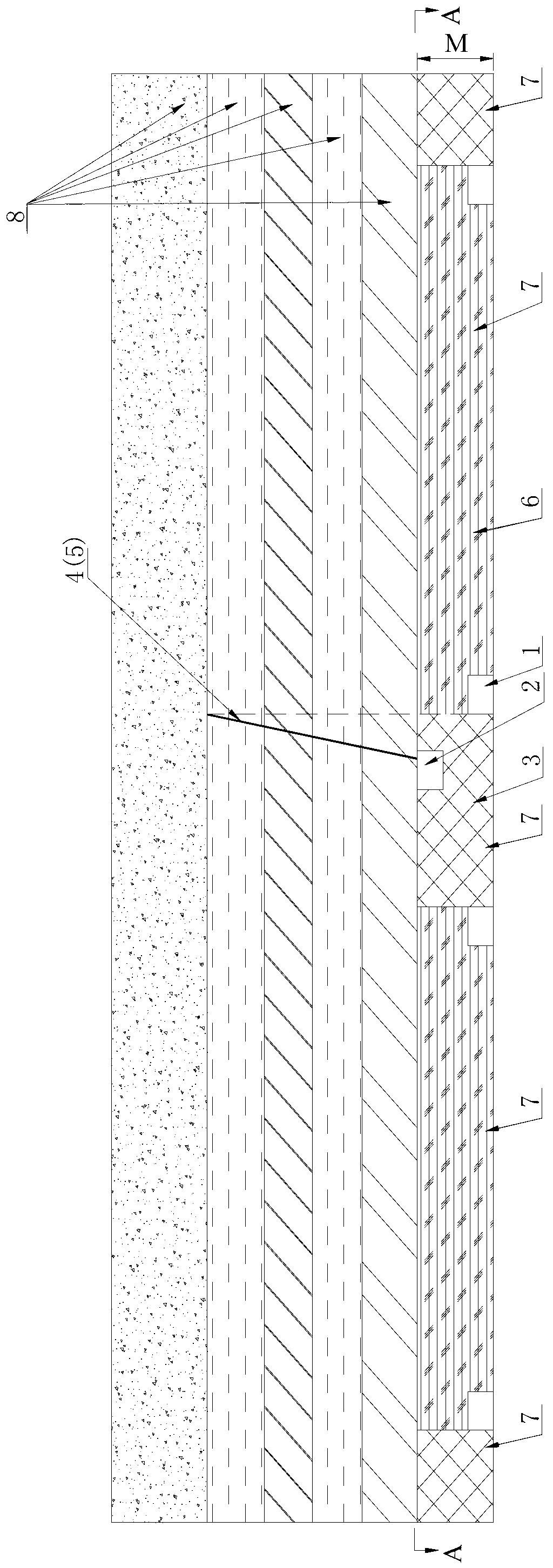

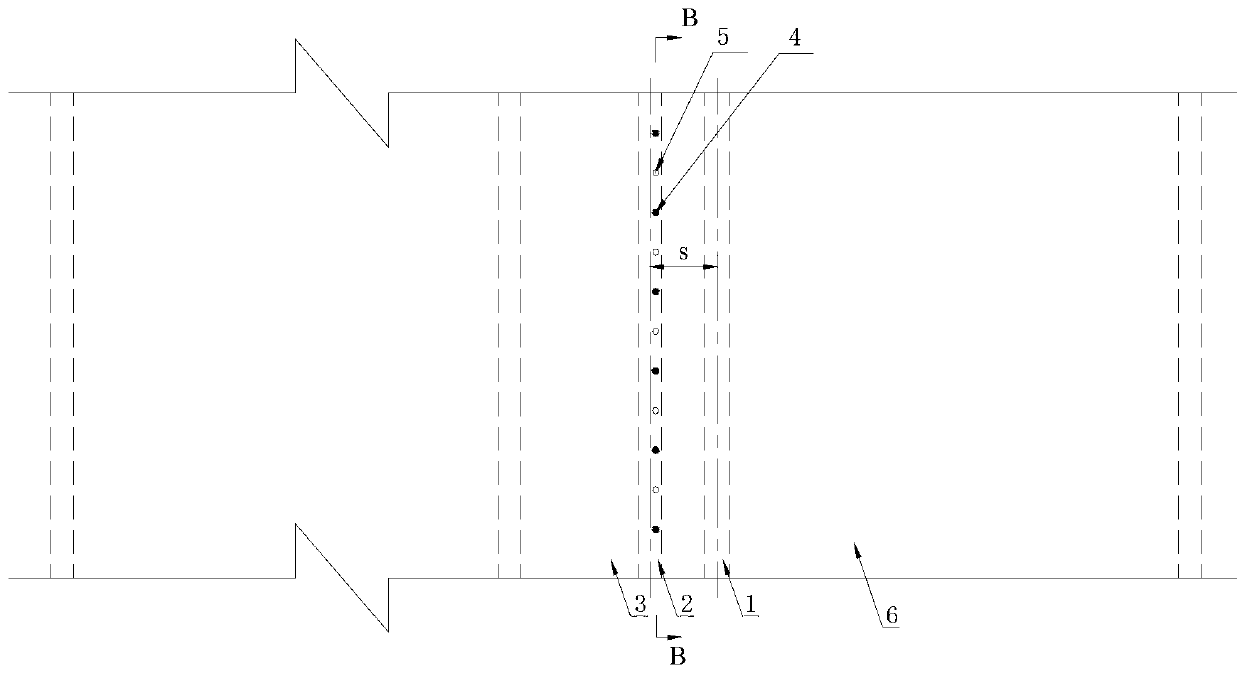

Upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method

ActiveCN106677780AImprove securityEnsure safetyUnderground miningTunnel/mines ventillationDetonationEngineering

The invention provides an upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method. The method includes the following steps that panels are divided in the ore direction, a stope preparation system is arranged, upward fan-shaped medium-depth blast holes are drilled from one side to the other side of a chamber, the blast holes are filled with explosives for detonation, and an undercut space is formed after detonation; cut grooves are formed through a VCR method, and as for ore above the undercut space, downward vertical deep holes are drilled in a drilling chamber at the top of the chamber, and the holes are filled with explosives for detonation with the cut grooves as a compensation space; the chamber in each panel is subjected to two-step backstoping, after ore removal of a first-step chamber is finished, the first-step chamber is filled with cementing materials, after the first-step chamber is filled and cured, a second-step chamber is subjected to backstoping, the backstoping steps of the second-step chamber are the same as those of the first-step chamber, and the second-step chamber is filled with cemented filling bodies and non-cemented filling bodies; and the steps are repeated in this way till backstoping of all chambers are completed. The upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method has the advantages that the rock drilling efficiency of the upward fan-shaped medium-depth blast holes is improved, the waste hole rate is lowered, efficient and safe bottom ore removal is achieved, and the mechanization level is high.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

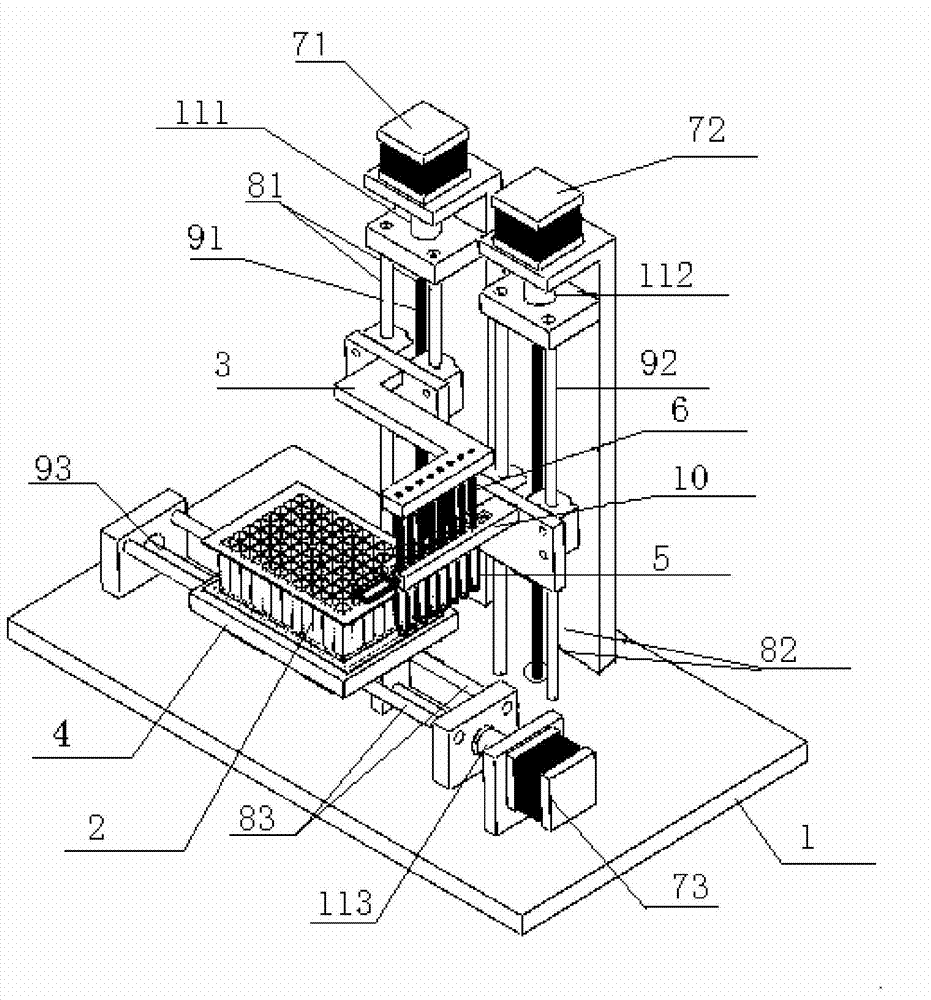

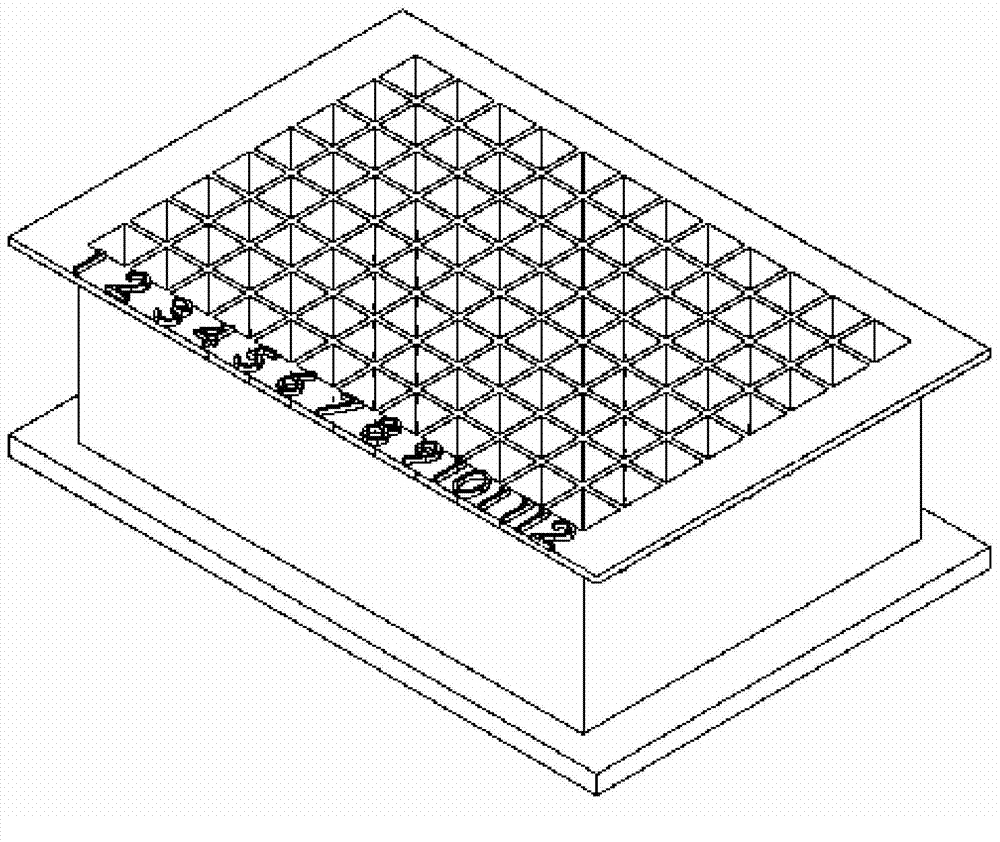

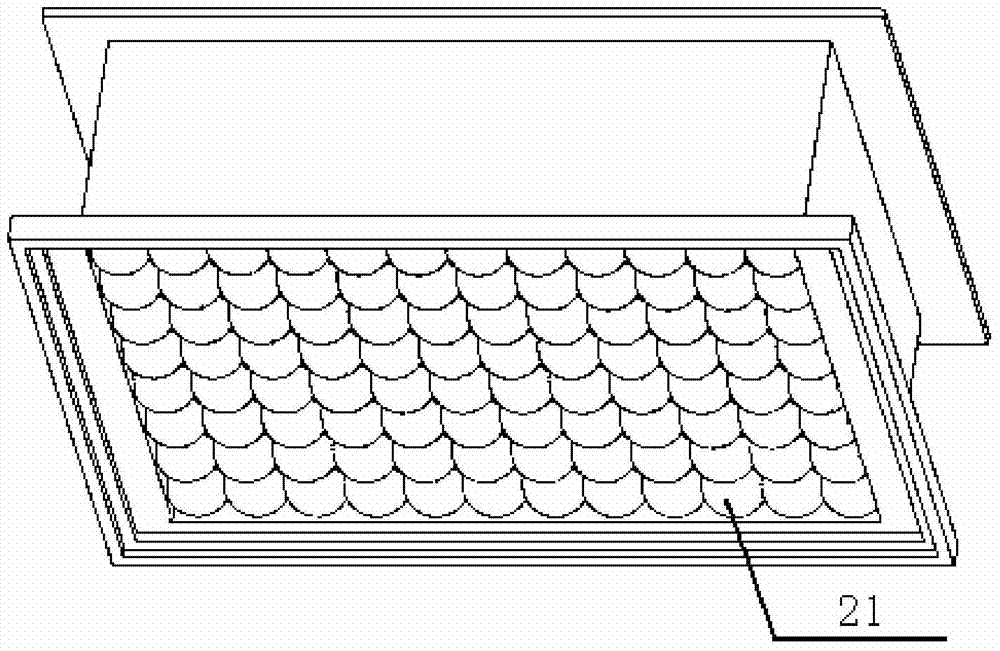

Automatic extraction device and method of nucleic acid based on nano magnetic beads

InactiveCN103897987AEnsure consistencyReduce human interferenceBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadEngineering

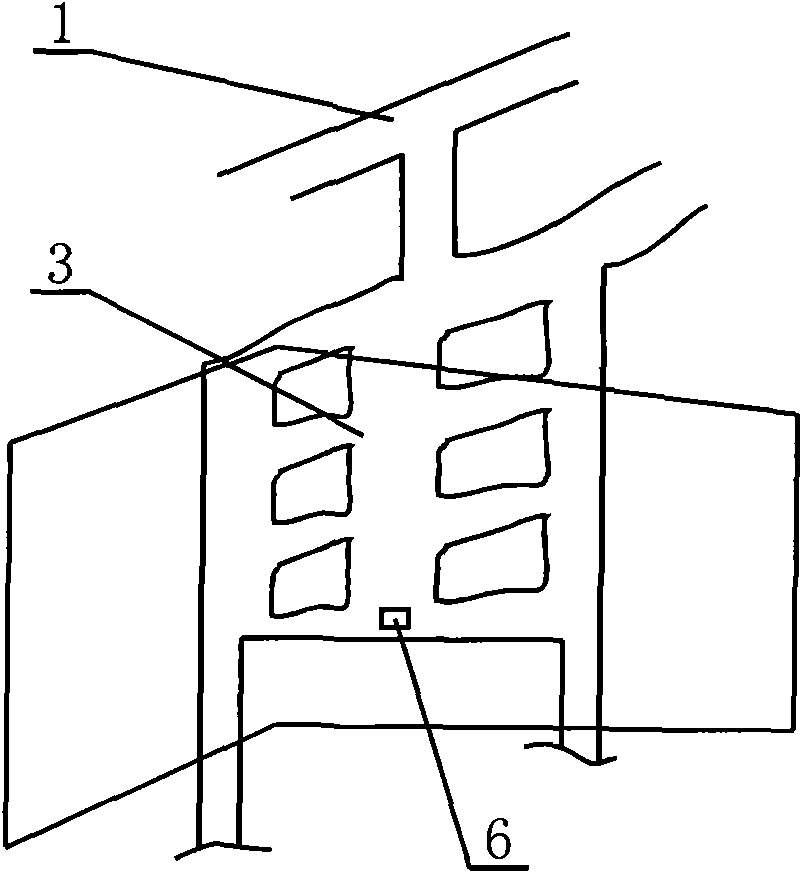

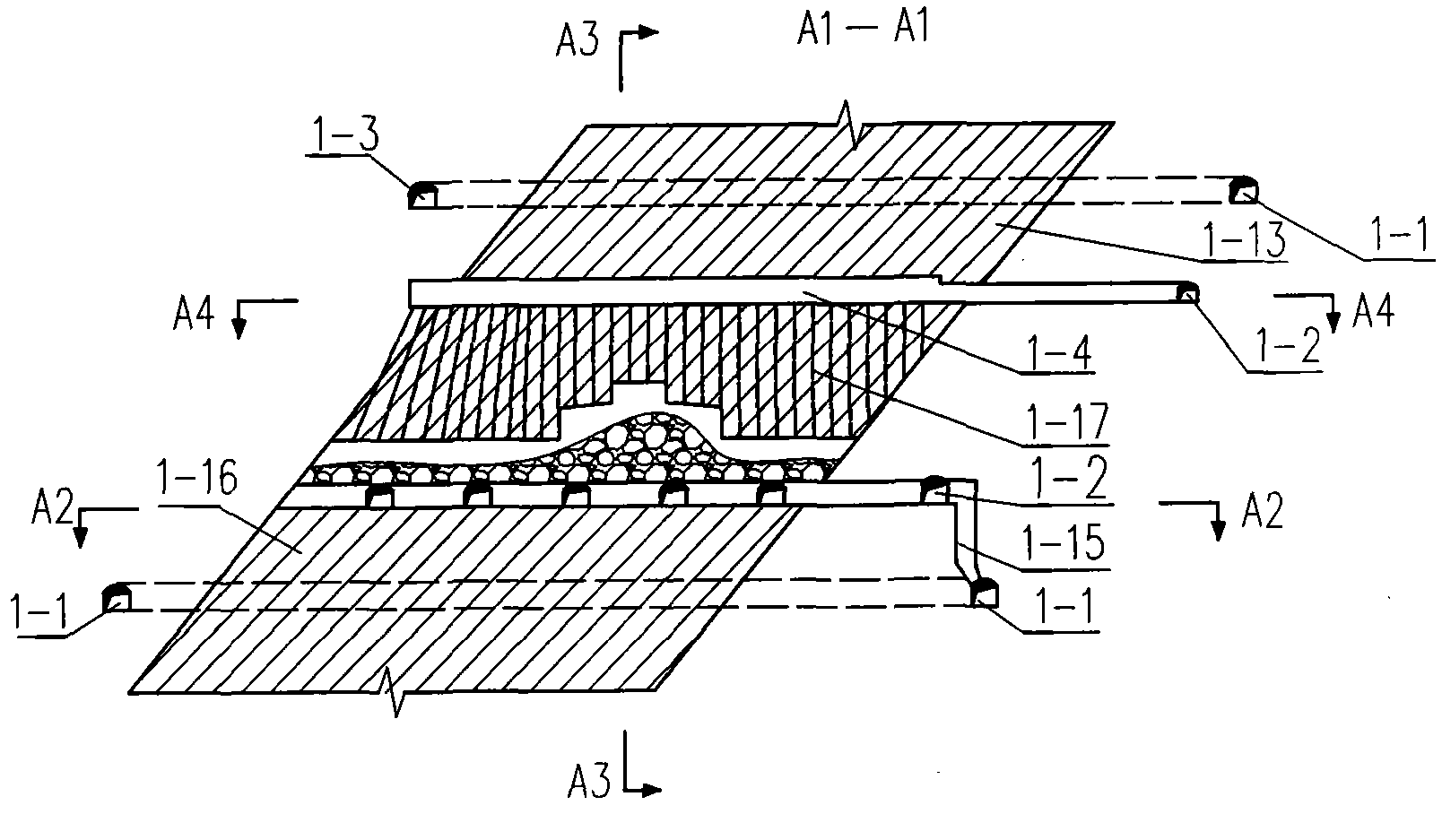

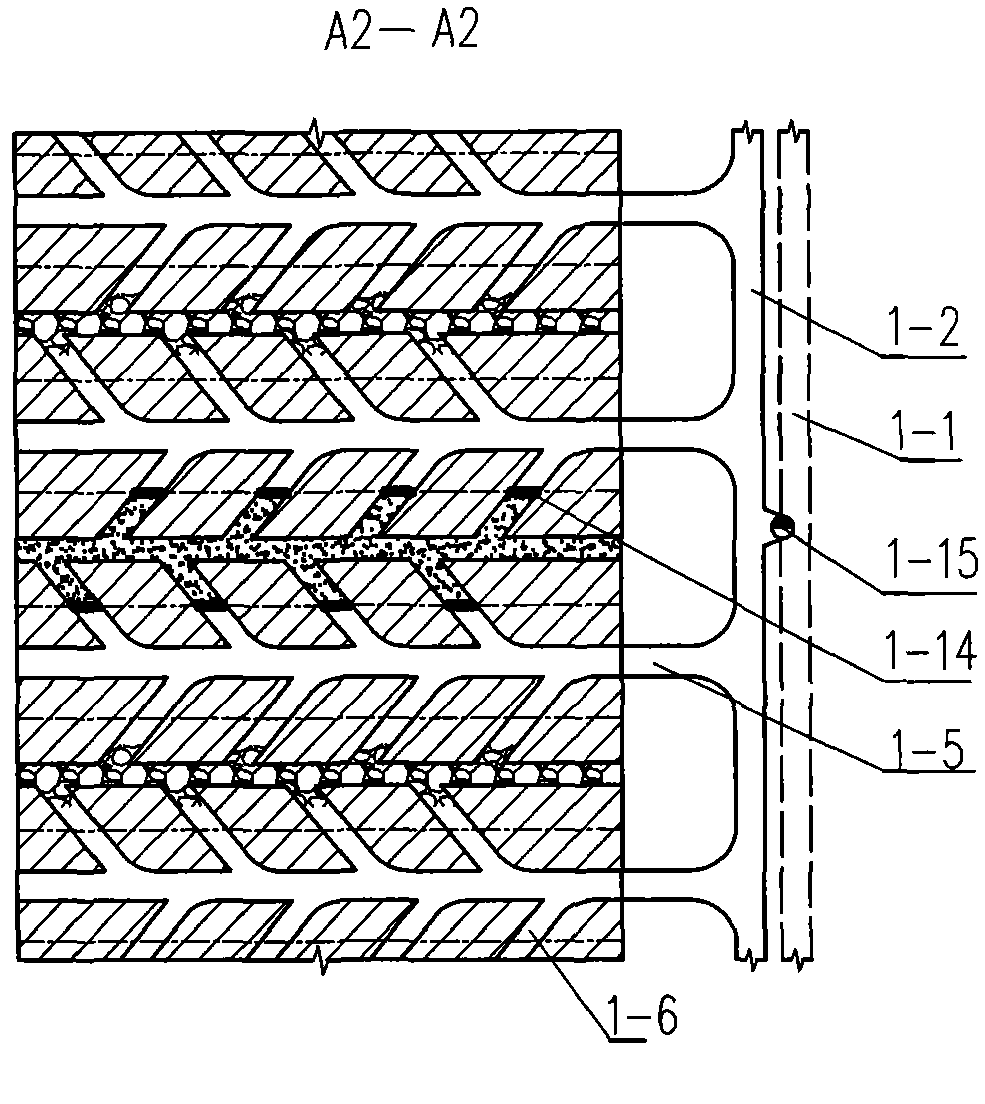

The invention provides an automatic extraction device and an automatic extraction method of a nucleic acid based on nano magnetic beads. The device comprises a base (1), as well as a motor, a magnetic bar (6), a magnetic bar clamping mechanism (3), a stirring sleeve (5), a stirring sleeve clamping mechanism (10), a deep hole plate (2), a control circuit and an upper computer which are arranged on the base (1). According to the device and the method which are provided by the invention, the nucleic acid is combined with the nano magnetic beads; and then, the nucleic acid is extracted from a nucleic acid cracking liquid under the attraction of the magnetic bar (6). Thus, the consistency of sample treatment is guaranteed to a great extent; the human interference is reduced; and the cross interference risk is decreased. The device and the method provided by the invention are suitable for the pretreatment of sample inspection in the medicinal field, the biological field, the agricultural field and the like.

Owner:CHINA AGRI UNIV

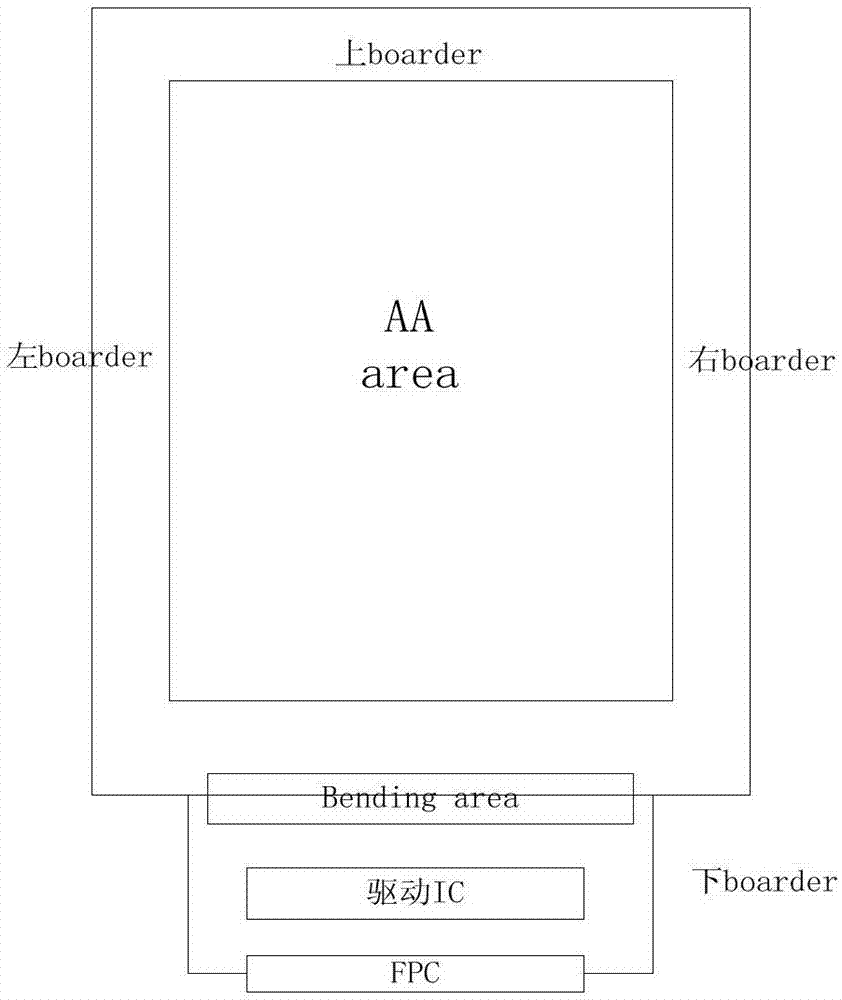

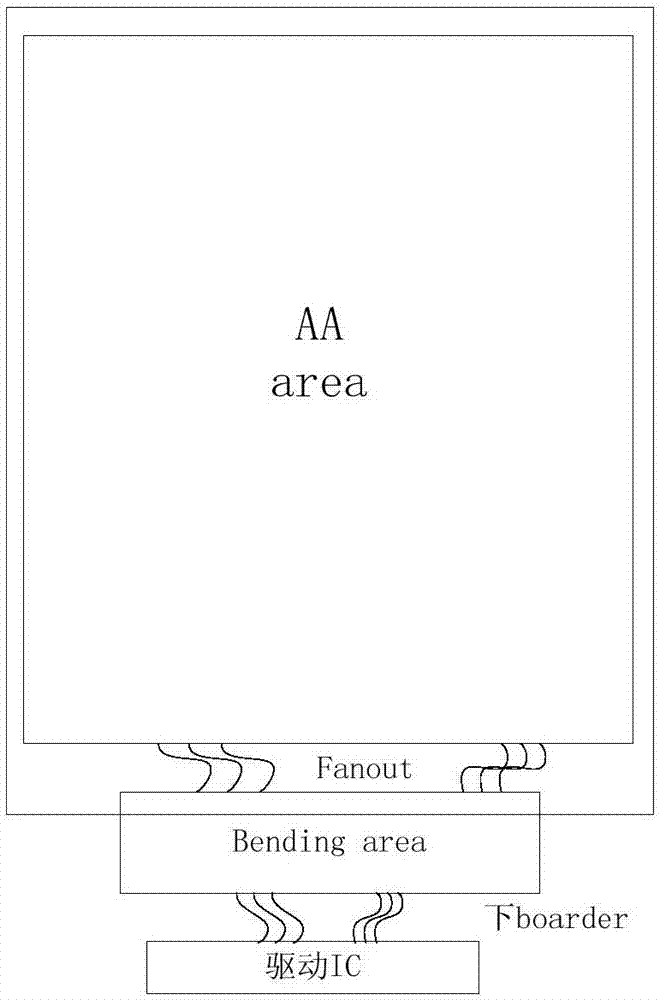

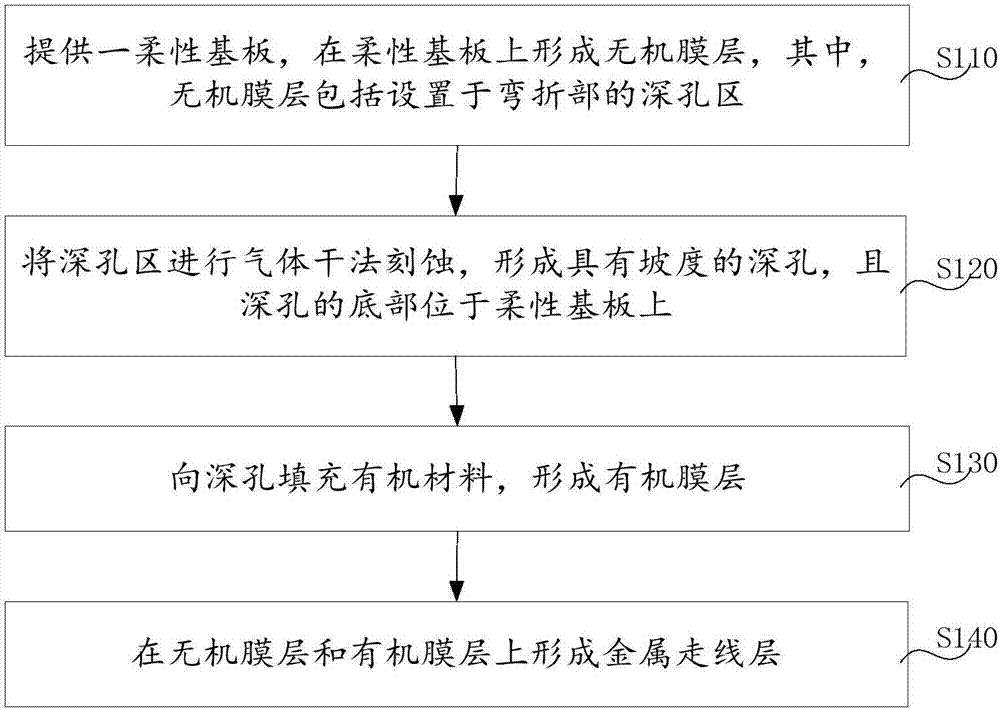

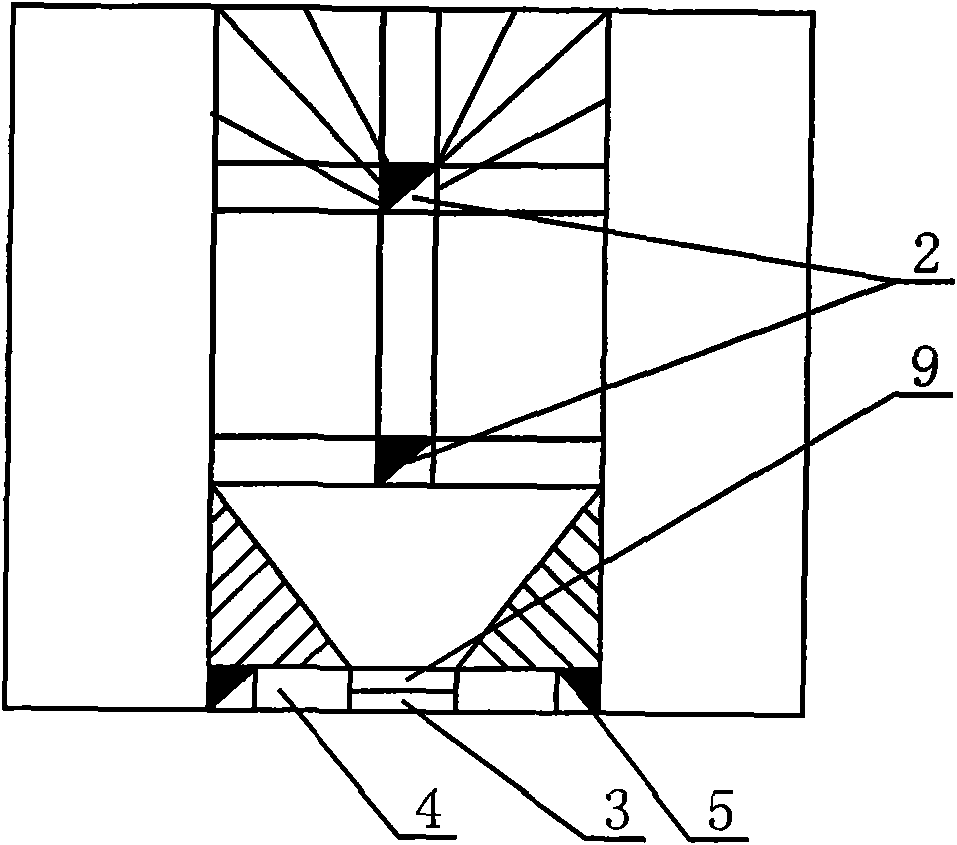

Bendable display panel and manufacturing method thereof

ActiveCN107994055AReduce or avoid electrical signal lossImprove qualitySolid-state devicesSemiconductor devicesOrganic filmEngineering

The invention discloses a bendable display panel and a manufacturing method thereof. The manufacturing method comprises the steps of providing a flexible substrate and forming an inorganic film layeron the flexible substrate, wherein the inorganic film layer comprises a deep hole area arranged on a bending part; performing gas dry etching on the deep hole area to form deep holes with slopes, wherein the bottoms of the deep holes are positioned on the flexible substrate; filling the deep holes with an organic material to form an organic film layer; and forming a metal routing line layer on theinorganic film layer and the organic film layer. By virtue of the gas dry etching, the deep holes with slopes are formed, and through the etching method, the slopes of the deep holes can be controlled, thereby improving the metal routing line climbing capability, reducing or avoiding an electric signal losing phenomenon of the display panel caused by breaking of the metal routing line, and improving the quality of the display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

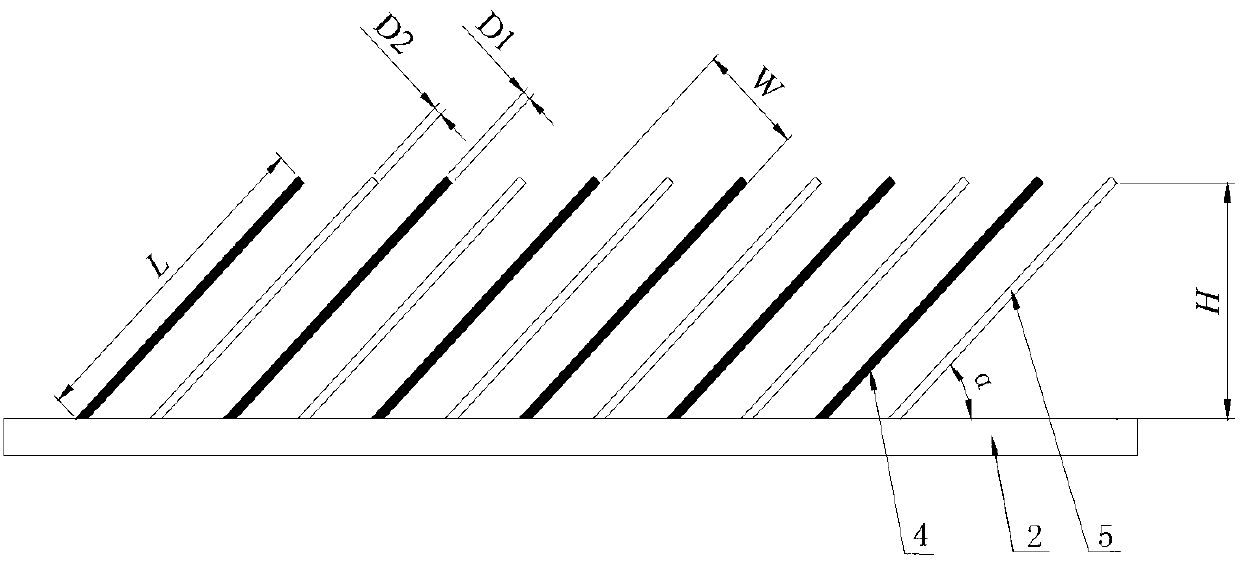

Efficient mining method for thick metal ore body in slanting

InactiveCN102182461ARealize continuous productionImprove mining efficiencyUnderground miningSurface miningEngineeringMetal

The invention relates to an efficient mining method for a thick metal ore body in slanting, comprising the following mining steps: constructing a transportation roadway outside a dike, constructing flat roadways for rock drilling by sections, constructing a cutting roadway, constructing a cutting well, constructing a cutting groove and reserving a temporary triangular ore pillar, constructing a trench, constructing a sector medium-deep hole and implementing blasting and ore removal, and recovering residual ore. The method realizes safe and efficient recovering of metal ore bodies with the inclination of 30 to 55 degrees and the average thickness of 4 to 15m by adopting a medium-deep hole blasting ore dropping valve under the circumstance without a filling condition, thereby further improving the mining recovery rate and the mining efficiency.

Owner:SHANDONG GOLD MINING LINGLONG

Method for filling and mining after ore caving

ActiveCN102587916AReduce impact damageImprove work efficiencyUnderground miningSurface miningSpelunkingMineral Sources

The invention discloses a method for filling and mining after ore caving, which includes the following steps: exploiting; mining quasi work; cutting work: including excavation of mine collection trench and patio cutting, cutting a patio at one end portion of a rock drilling chamber, cutting the patio by using a vertical deep hole ore falling stage chamber method, and enabling patio cutting to provide sufficient compensation space for actual mining; chamber extraction work: constructing a downward blasthole in the rock drilling chamber, filling and blasting, one-time blasting charging at the entire middle section height of the blasthole, and enabling blasting to adopt one-time lateral blasting and ore removal; filling and maintaining: closing all outlets communicated with a lower mine of the empty area, burying strainer pipes, leading in filling pipelines from the upper portion of the chamber, and filling and maintaining the chamber; and pillar recovery: recovering pillars after filling and maintaining the chamber, and the pillar recovery is the same as the chamber extraction work. The method for filling and mining after ore caving is high in recovery rate of mineral resources, small in blasting impact effect, low in cost and high in production efficiency.

Owner:金建工程设计有限公司

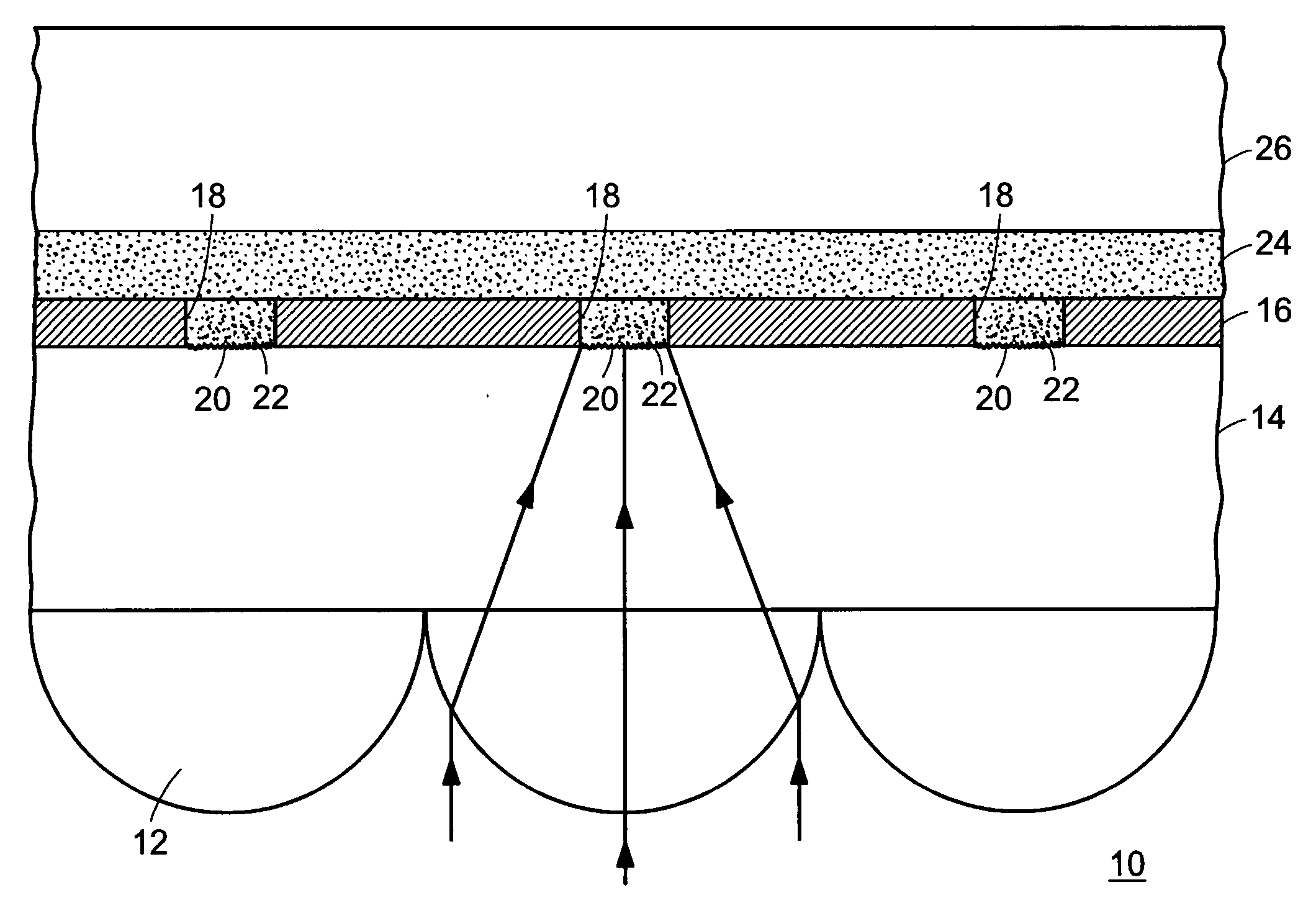

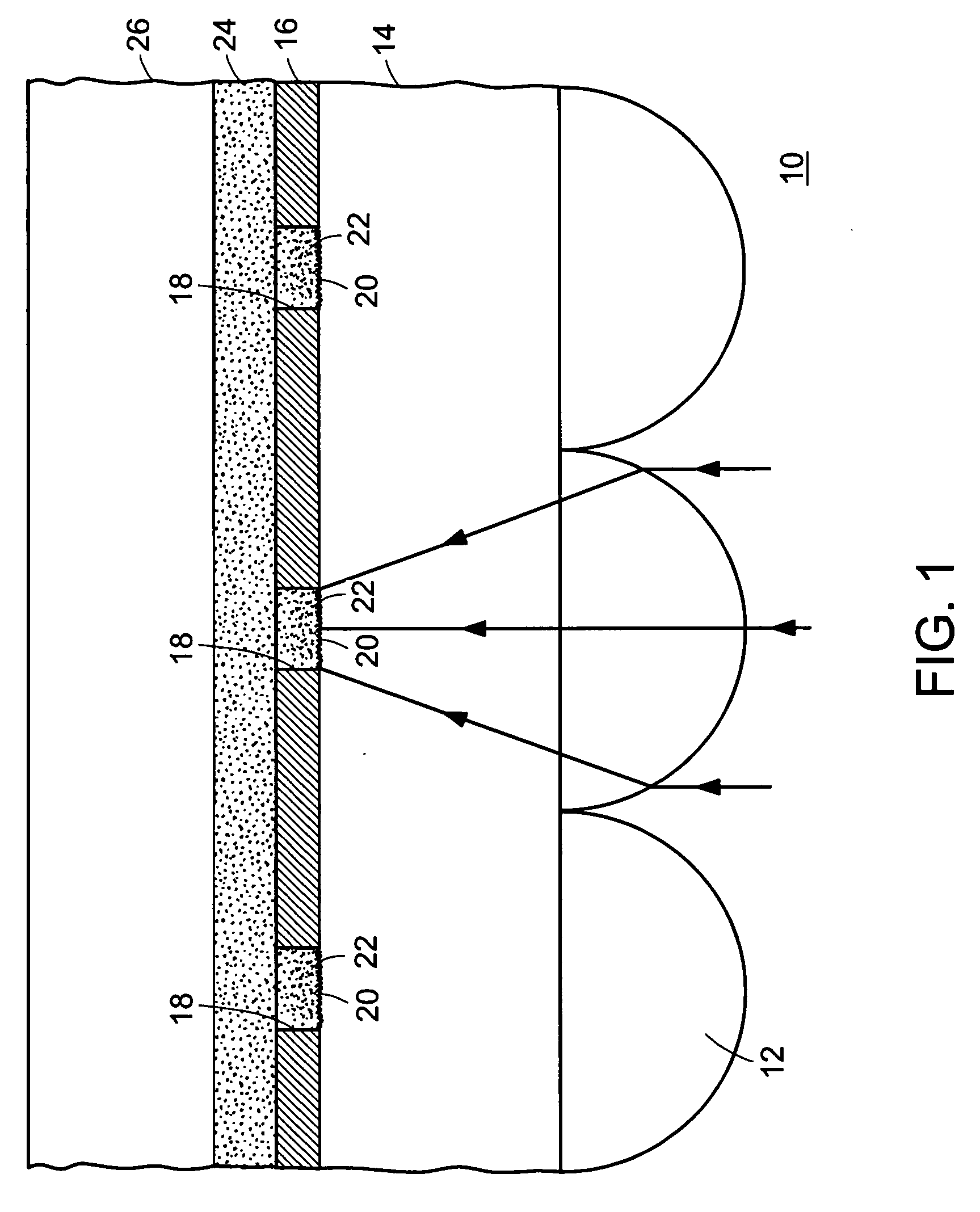

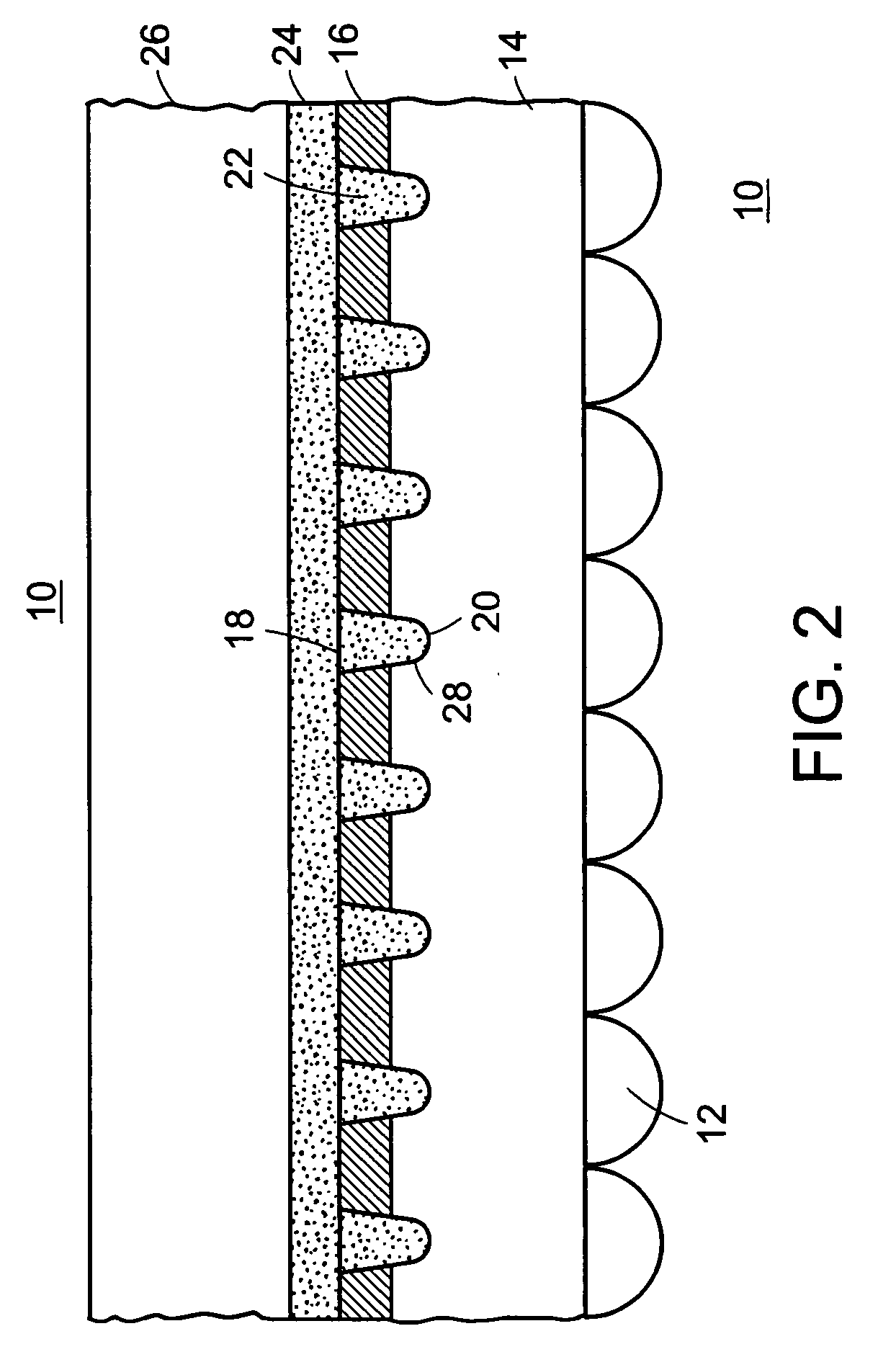

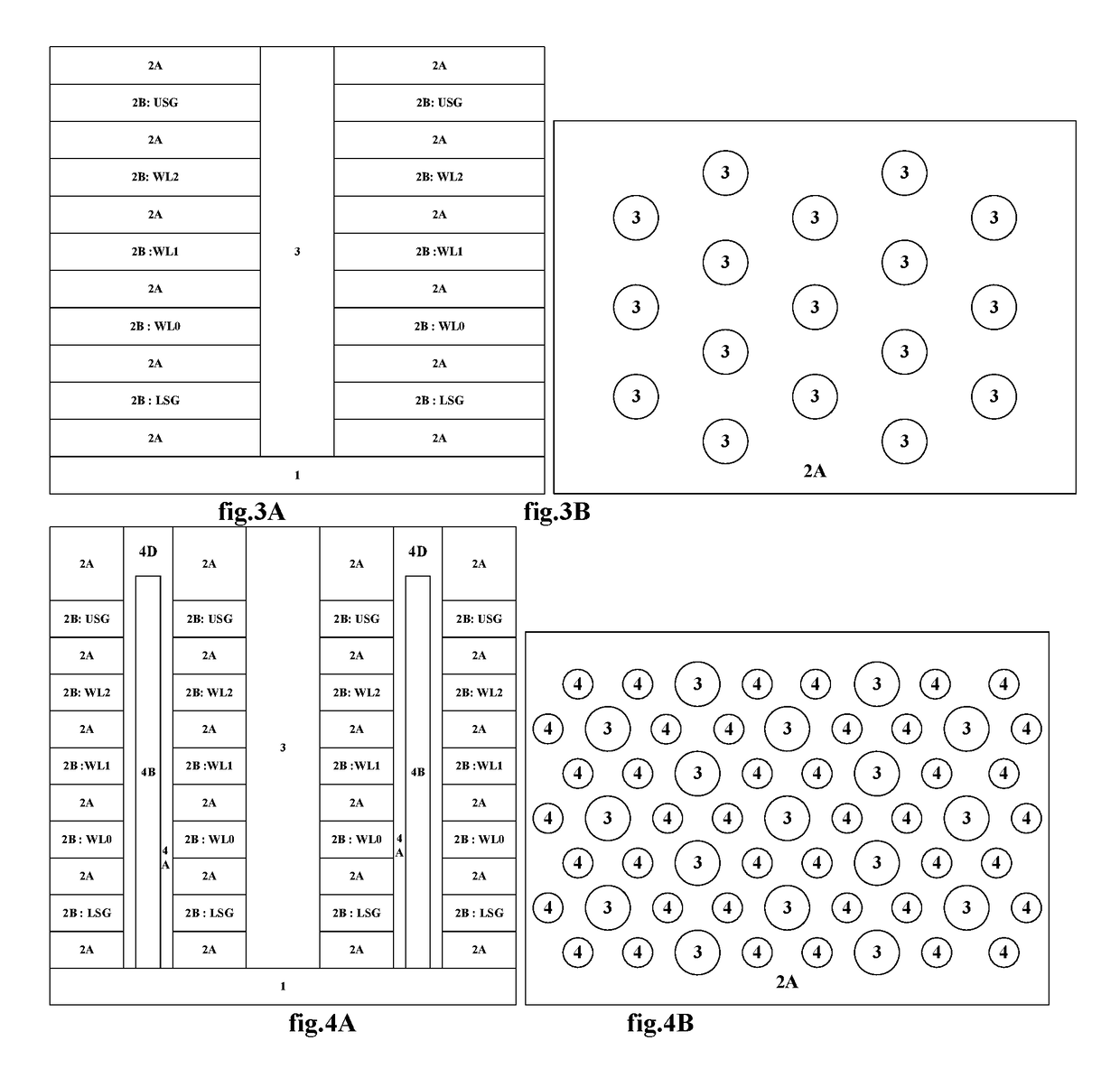

High performance rear-projection screen

A rear-projection screen and a method for forming same are provided. The screen can include a substrate including a first side and a second side, apertures disposed on the first side of the substrate, and an opaque layer disposed on the second side of the substrate. In a particular embodiment, the opaque layer includes a plurality of apertures therethrough. A surface relief diffuser can be provided in the substrate at the plurality of apertures. A bulk diffuser can be provided at the plurality of apertures to diffuse the projected image. A cover can be attached to the opaque layer, for example, with an adhesive. An overlayer can be provided on the opaque layer for providing deep apertures that can be filled with bulk diffuser to further diffuse the projected image. The overlayer disposed on the opaque layer can include a light-absorbing material in and / or on the overlayer.

Owner:REFLEXITE

Methods of using a laser to spall and drill holes in rocks

ActiveUS7416258B2Easy to disassembleProtection is necessaryEarth drilling toolsDisloding machinesSmall fragmentClassical mechanics

Apparatus and methods of using lasers are provided for spalling and drilling holes into rocks. A rock removal process is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall the rock into small fragments that can then be easily removed by a purging flow. Single laser beams of given irradiance spall rock and create holes having diameter and depth approximately equal to the beam spot size. A group of the single laser beams are steered in a controllable manner by an electro-optic laser beam switch to locations on the surface of the rock, creating multiple overlapping spalled holes thereby removing a layer of rock of a desired diameter. Drilling of a deep hole is achieved by spalling consecutive layers with an intermittent feed motion of the laser head perpendicular to the rock surface.

Owner:UCHICAGO ARGONNE LLC

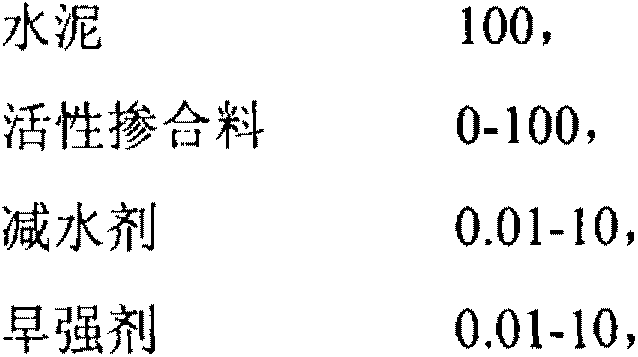

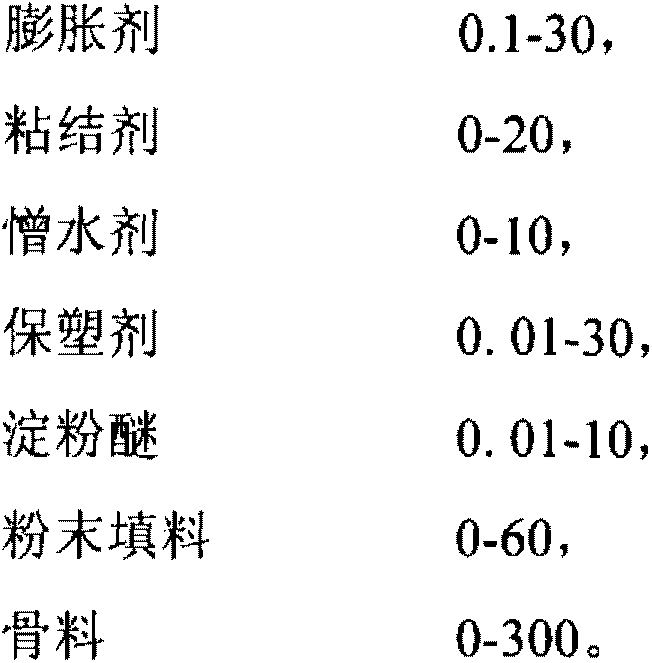

Cement-based shrinkage-free wall hole-penetrating blocking material and preparation method and construction method

ActiveCN103159440AGuaranteed tightnessPrevent infiltrationBuilding material handlingBuilding insulationsEtherFree wall

The invention relates to cement-based shrinkage-free wall hole-penetrating blocking materials and a preparation method and a construction method. The materials comprise, by weight, 100 cement, 0-100 active admixture, 0.01-10 water reducing agent, 0.01-10 early strength agent, 0.1-30 expanding agent, 0-20 adhesion agent, 0-10 water repellent, 0.01-30 plastic retaining agent, 0.01-10 starch ether, 0-60 power filler and 0-300 aggregate. Compared with the prior art, the cement-based shrinkage-free wall hole-penetrating blocking materials have the advantages of being good in construction performance, and long in operational time. New mixing slurry has good plasticity, adhesive power and anti-falling performance, a caulking gun or a caulking machine can be used for pressing, injecting or sealing holes, a flowing phenomenon cannot appear even big holes are filled, and the big holes can be filled until the big holes are full and until reaching the deep hole, and completely sealed, and the sealing materials can fully come into play.

Owner:杭州固特建筑加固技术工程有限公司

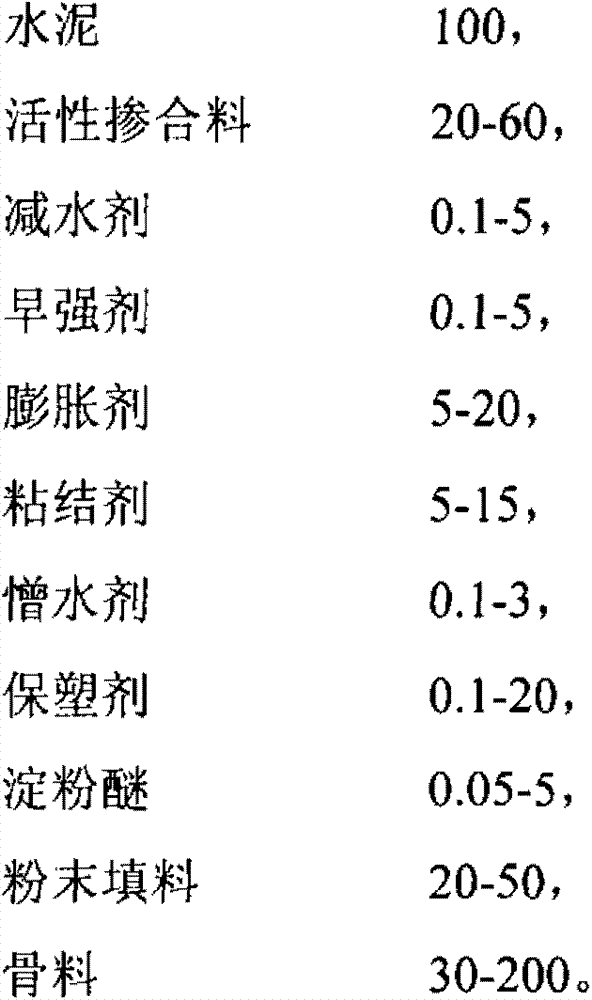

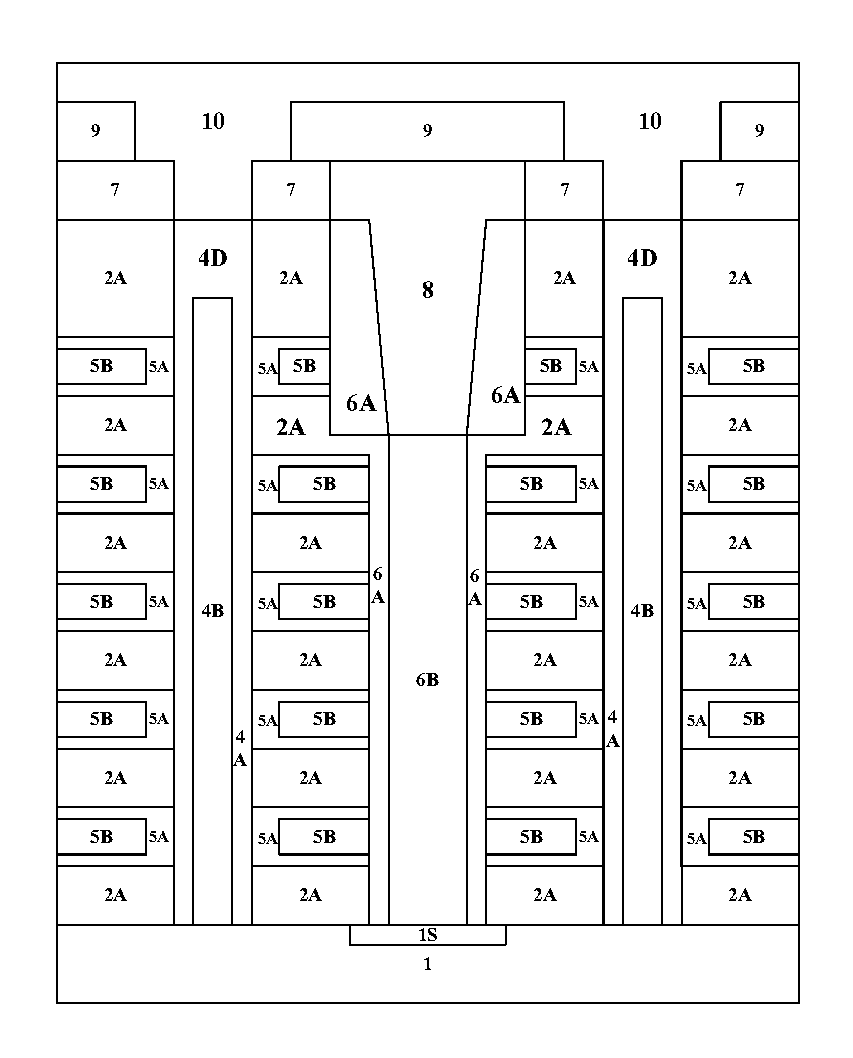

Three-dimensional Memory Device and Manufacturing Method Thereof

ActiveUS20170236836A1Improve integration densitySimplify the etch processSolid-state devicesSemiconductor devicesEtchingGate stack

A method for manufacturing three-dimensional memory, comprising the steps of: forming a stack structure composed of a plurality of first material layers and a plurality of second material layers on a substrate; etching the stack structure to expose the substrate, forming a plurality of first vertical openings; forming a filling layer in each of the first openings; etching the stack structure around each of the first openings to expose the substrate, forming a plurality of second vertical openings; forming a vertical channel layer and a drain in each of the second openings; removing the filling layer by selective etching, re-exposing the first openings; partially or completely removing the second material layers by lateral etching, leaving a plurality of recesses; forming a plurality of gate stack structure in the recesses; forming a plurality of common sources on and / or in the substrate at the bottom of each of the first openings. In accordance with the three-dimensional memory manufacturing method of the present invention, the deep trenches of word-line in the TCAT three-dimensional device are replaced with deep-hole etching to realize the same function, thereby improving the integration density, simplifying the etching process of stacked structure, and maintaining the control performance of the metal gate.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

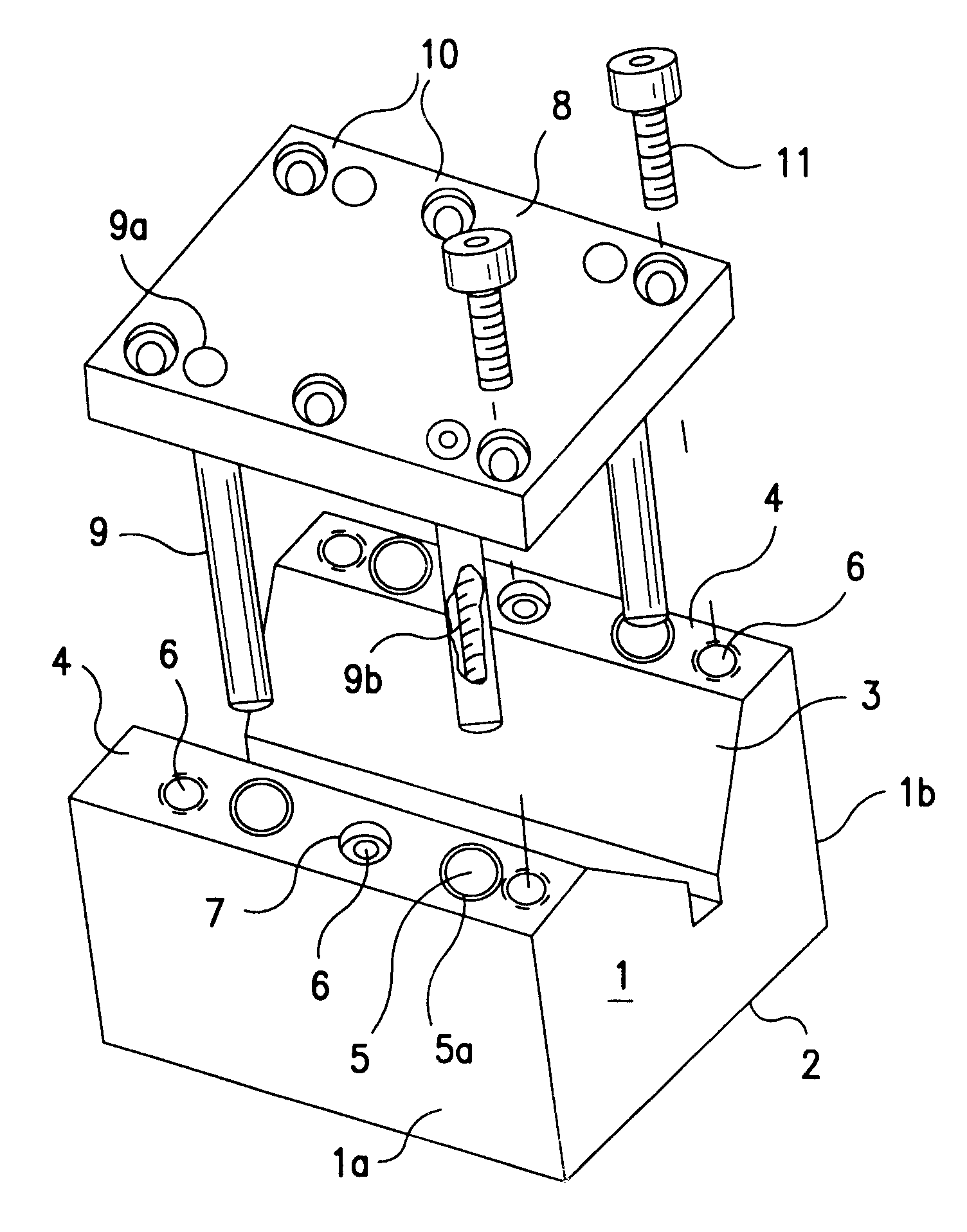

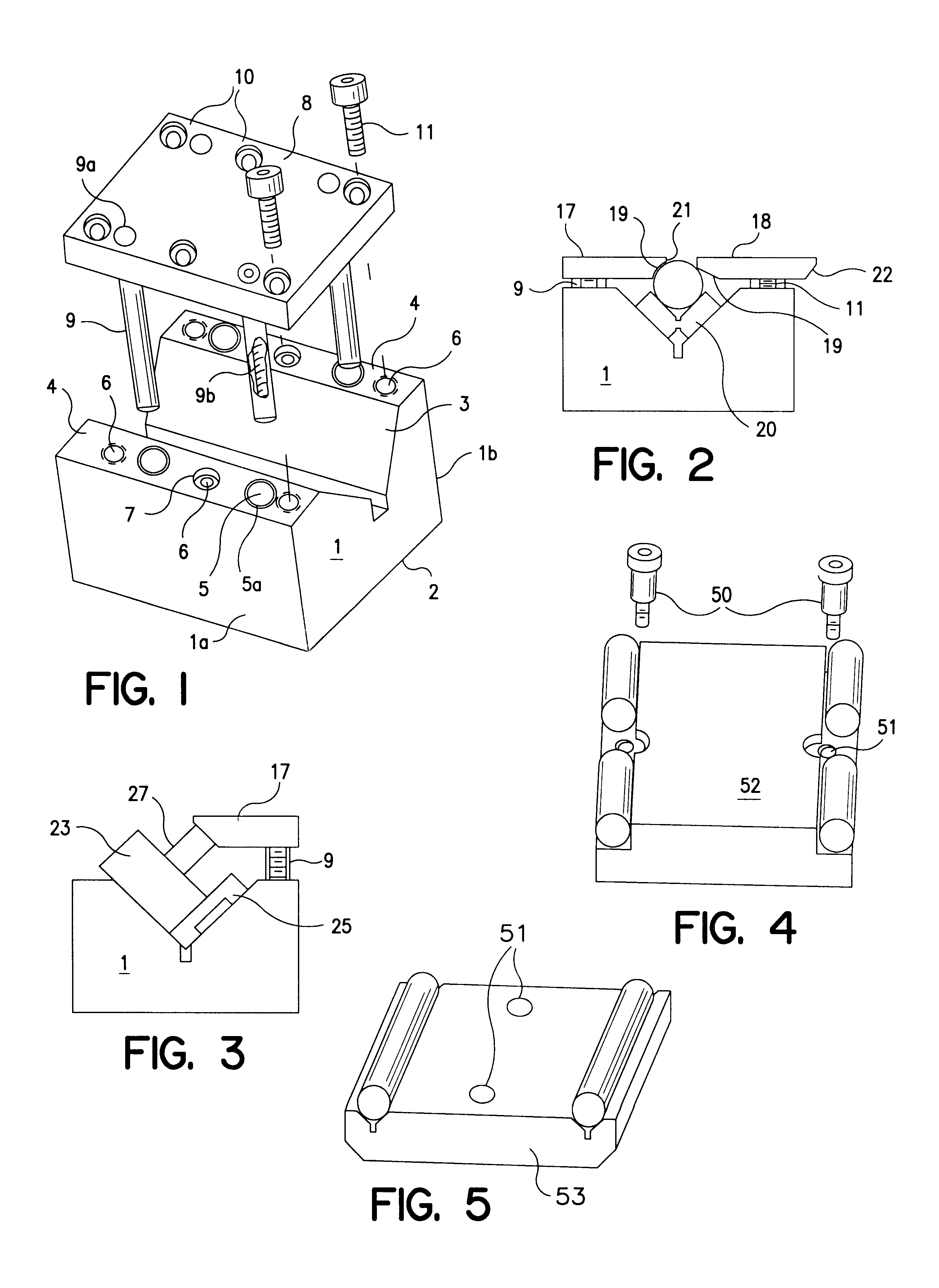

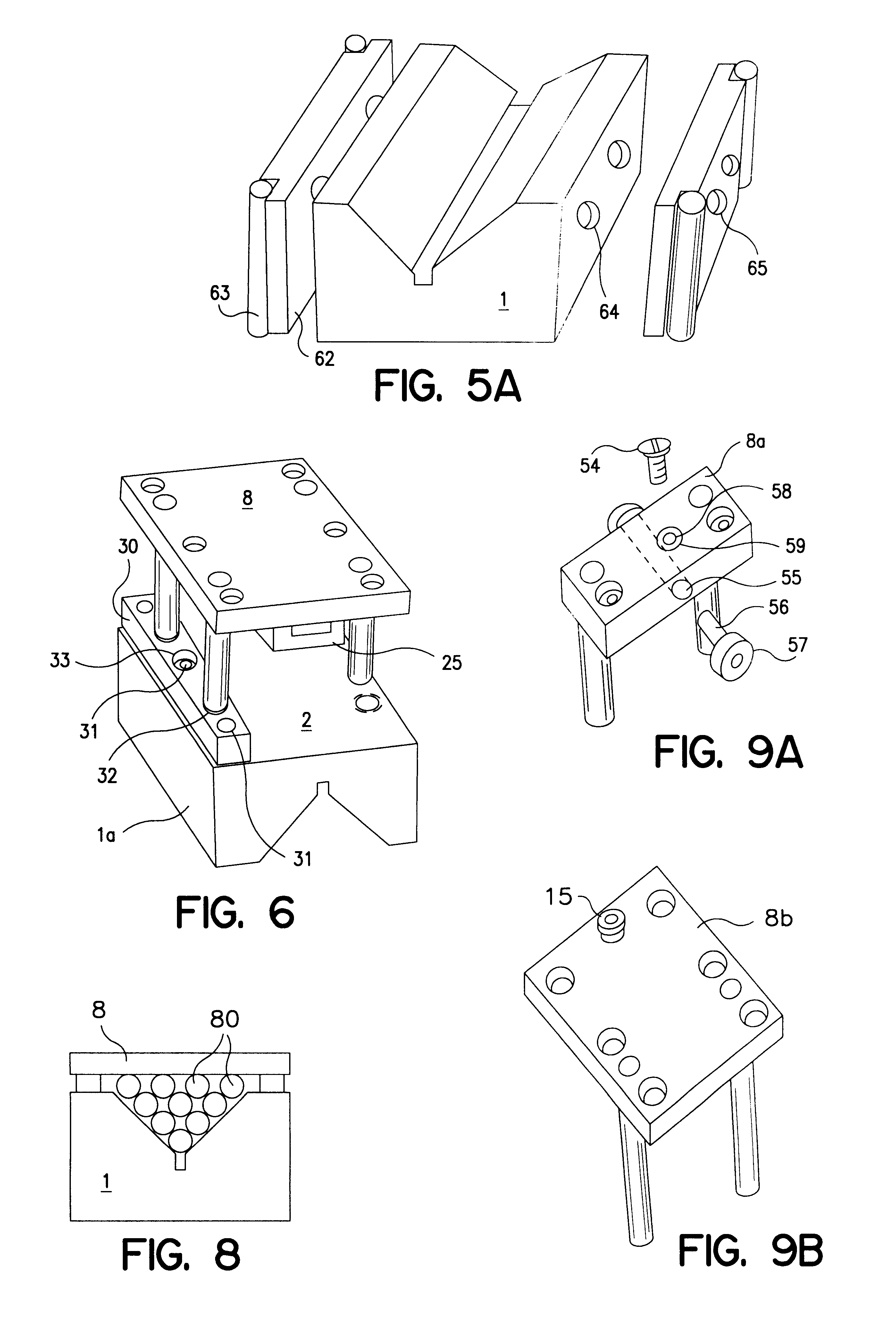

Universal workholding V fixture convertable to other applications

Owner:ANDRONICA RANDALL C

Strengthening and reinforcing method of high-ground-pressure soft rock laneway by hierarchical grouting

InactiveCN101864967AImprove the strengthening effectWill not blockUnderground chambersTunnel liningSlurryHigh pressure

The invention relates to a strengthening and reinforcing method of a high-ground-pressure soft rock laneway by hierarchical grouting. Aiming at the deformation damage and crack distribution rules of laneway wall rock of high-ground-pressure soft rock, a hierarchical grouting mode for a shallow layer and a deep layer is adopted to hierarchically and emphatically strengthen and reinforce the shallow layer and the deep layer by grouting. The method comprises the following steps of: firstly, carrying out shallow-hole low-pressure grouting to a laneway shallow-layer gap development zone and then carrying out deep-hole high-pressure grouting to deep rock bodies; constructing shallow-hole grouting with small grouting pressure so that grout is scarcely diffused into the deep part, and grouting passages, such as a deep gap of the deep part and the like, are well preserved without blockage; and adopting a double-component chemical grout malisan with easy dispersion and strong permeability in constructing deep-hole grouting to realize deep high-pressure grouting on the basis of a formed grout-stopping shielding shell formed by former-period shallow-hole grouting so that the distribution compactness and the dispersion evenness of the grout in the deep grouting are improved, and the strengthening effect of the deep grouting on the wall rock is effectively improved. The method is simple and easy to implement.

Owner:CHINA UNIV OF MINING & TECH

Medium-length hole mining method in multiple blasting free faces of high dipping thin veins

InactiveCN102635356AIncrease job securityStrong mining continuityUnderground miningSurface miningPunchingMineralogy

The invention discloses a medium-length hole mining method in multiple blasting free faces of high dipping thin veins. The medium-length hole mining method is characterized by comprising the steps of: arranging ore blocks along the trend of a core body, dividing the ore body into a medium section and a segment in the altitude; drilling a gate way in the segment and arranging in veins along the ore body; arranging a flat ore removal structure on the bottom along the veins; arranging a cutting raise from one ends of the ore blocks, arranging a manway at the other ends of the ore blocks; and upwards and downwards punching forwards leaning medium-length holes, with the cutting raise as free faces, and blasting caved ores in the segment by multiple free faces, and withdrawing the ore centrally at the bottom. The medium-length hole mining method has the remarkable characteristics of high mining safety, little resource dilution rate, good production continuity, high level of mechanization, low cost, high efficiency, low labor intensity and the like.

Owner:CENT SOUTH UNIV

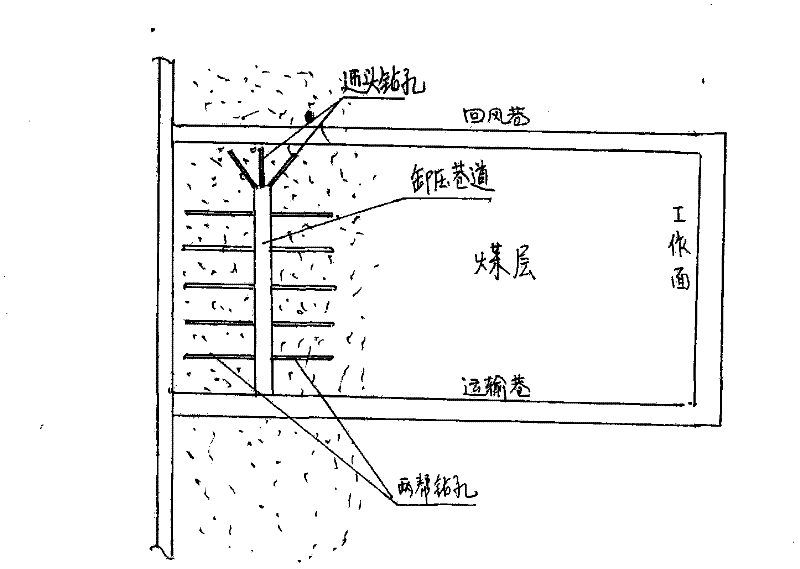

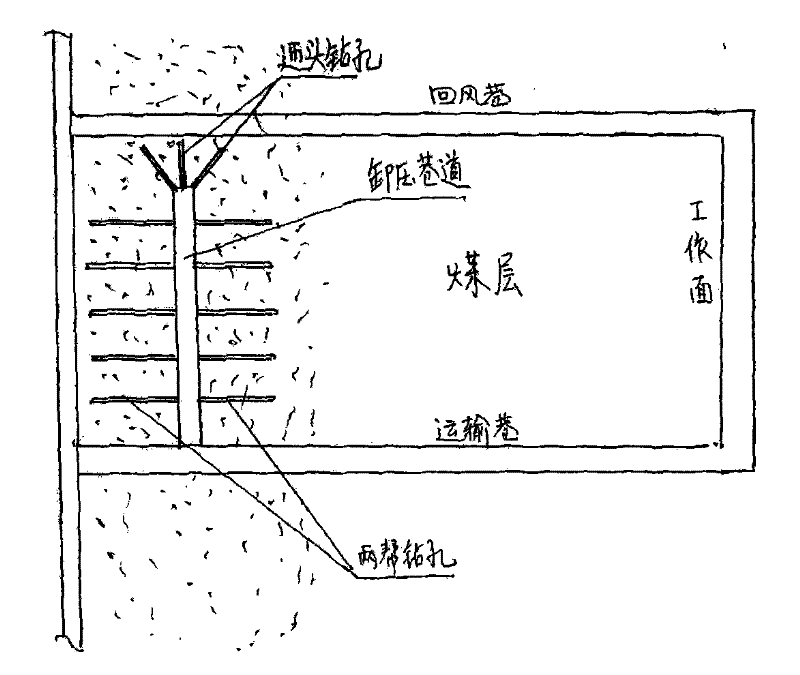

Method for Prevention and Control of Rockburst by Man-made Spatial Defects

InactiveCN102296958AReduce intensityPlay a role in isolationUnderground miningSurface miningStress distributionHead-hitting

The invention discloses a method for preventing and controlling rockburst by an artificial space defect body. Firstly, one or more pressure relief roadways are excavated in the high stress dangerous area of rockburst, and three boreholes are drilled in the head of the pressure relief roadway. The boreholes are drilled along the centerline of the roadway, and the holes on both sides are drilled obliquely forward at an angle of 30° based on the centerline of the roadway, so that the coal seam can be relieved by deep hole blasting; Drilling, and finally blasting from the head of the roadway to the back of the roadway. The invention changes the stress distribution by creating a large defect space in the high-stress coal body, the stress is far away from the roadway, the coal body around the roadway is destroyed, the energy is greatly released, and the risk of impact is fundamentally reduced.

Owner:SHANDONG UNIV OF SCI & TECH

Long barrel internal and external wall spiral type helical swinging built up welding method and equipment

InactiveCN1475323AImprove corrosion resistanceWelding/cutting auxillary devicesArc welding apparatusEngineeringCast iron pipe

A spirally oscillating wrap build-up welding method and equipment for long cylindrical body, such as the mould of long (14m) large-diameter (500 mm) nodular cast iron pipe, rotary drum type ball grinder, cylindrical container, etc features that the included spiral angle between wide welded band and cylinder's axis is 30-60 deg, welding gun is oscillating by 30-100 mm for ampletude and 30-50 times / min for frequency, and the adjacent welded bands are overlapped by 10 mm.

Owner:傅成

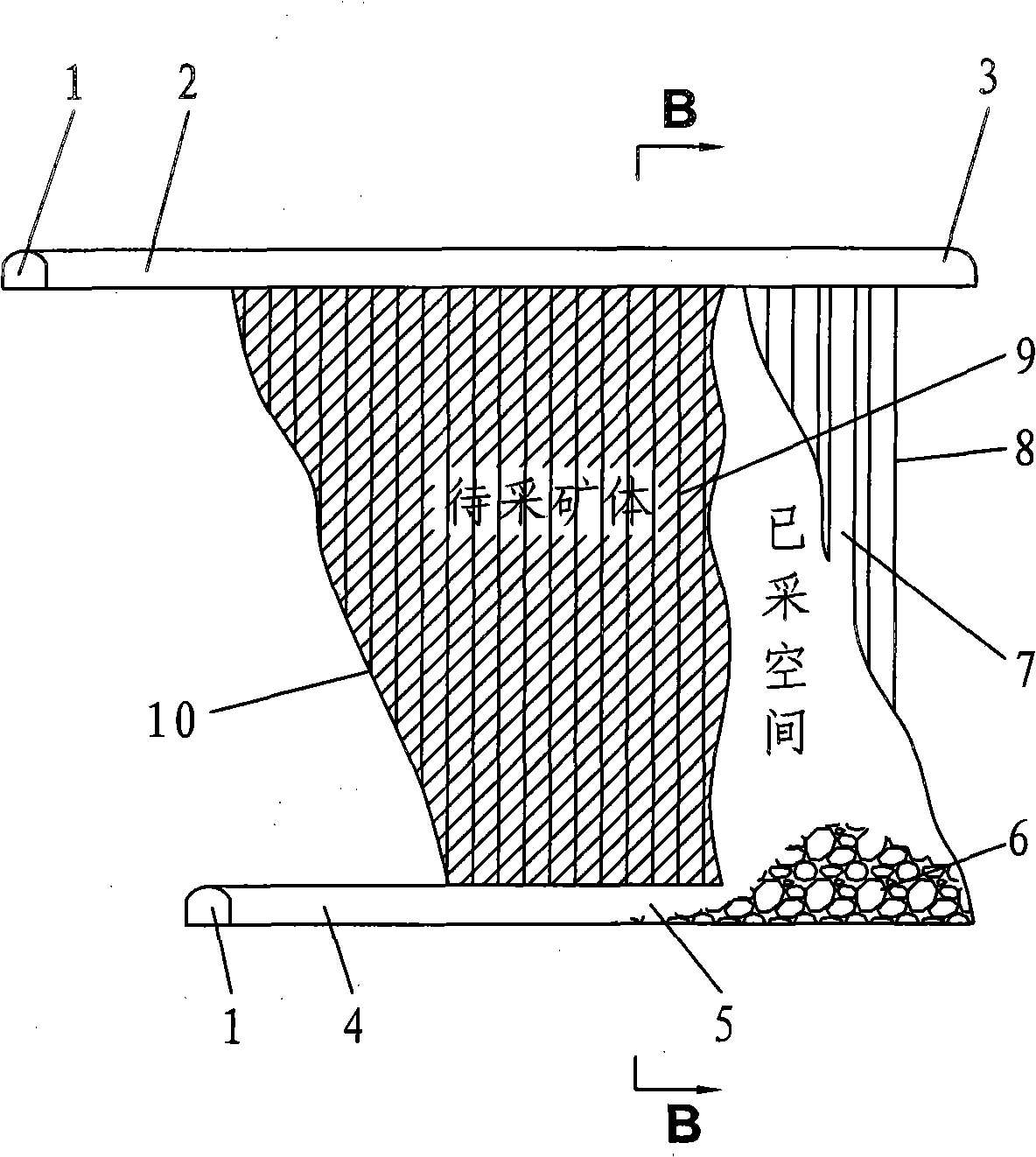

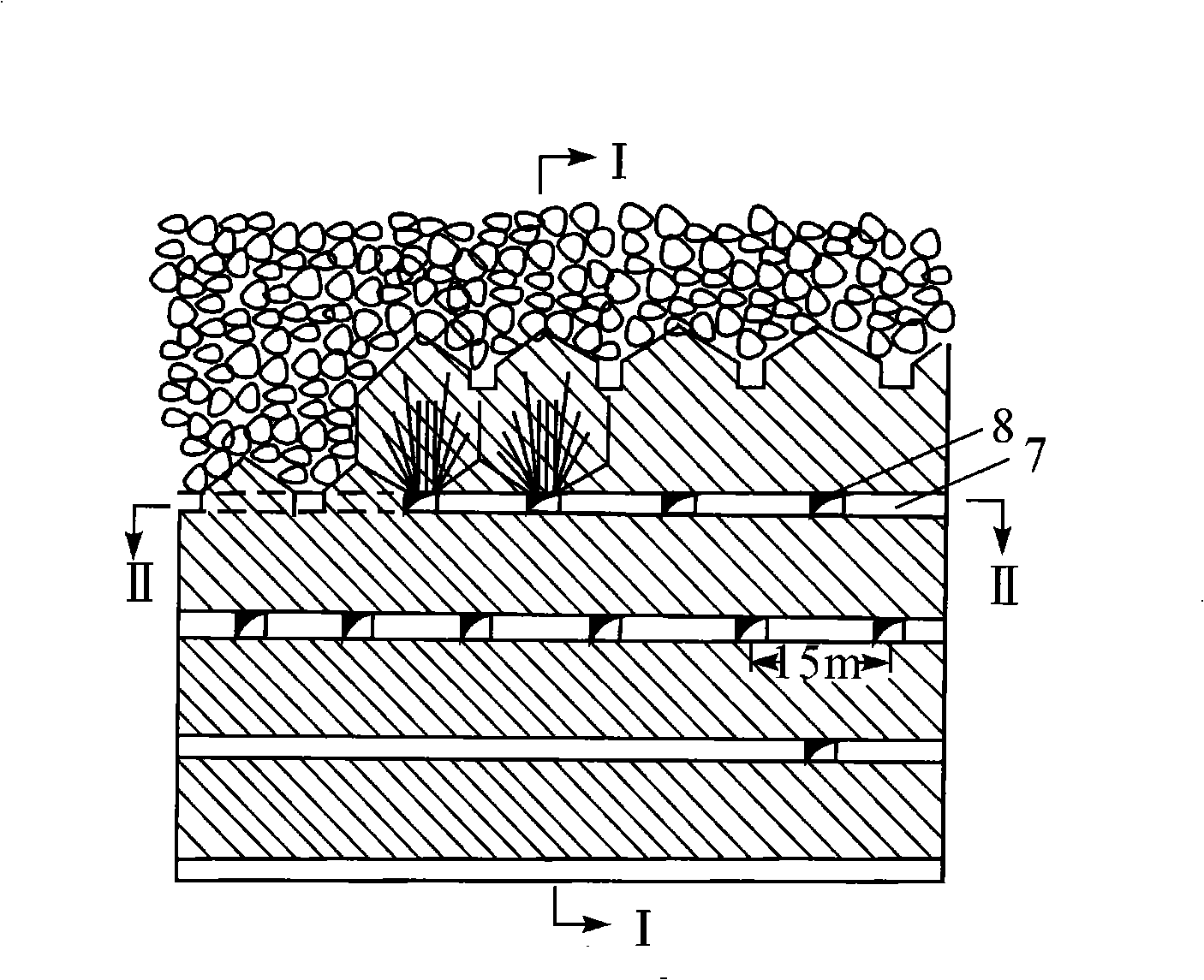

Mining environment reconstructed continuous mining afterwards filling mining method

InactiveCN101105129AHigh recovery rateImprove productivityUnderground miningSurface miningProduction rateMineralogy

The invention discloses a method of continuous mining followed by filling with mining environment reconstruction. The method comprises mining strip ore section in the middle part of the ore body, mining ore section with proper width extending towards two sides of the site that is perpendicular to and has proper distance far away the strip ore section followed by cementation filling to the mined-out area to form a continuous crisscross cementation filling top plate support frame structure. The frame structure meanwhile separates the ore body into several spaced and independent ore sections to reconstruct a new mining environment in the ore body. In such environment, performing spacedly or parallelly second mining with independent ore sections as second mining units followed by non-cementation filling to the mined-out area to realize continuous mining in the overall ore body, performing ore breaking in lateral direction with downward parallel and vertical deep holes, loading ore with double-trench or single-trench as bottom structure along ore blocks direction, landing down to the main gangway in the next stage through stage drop shaft, and transporting out of the mine by downhole locomotive. The invention has the advantages of safe and reliable mining environment, remarkably improved ore recovery rate and productivity, effectively controlled loss, and remarkably reduced production cost.

Owner:CENT SOUTH UNIV

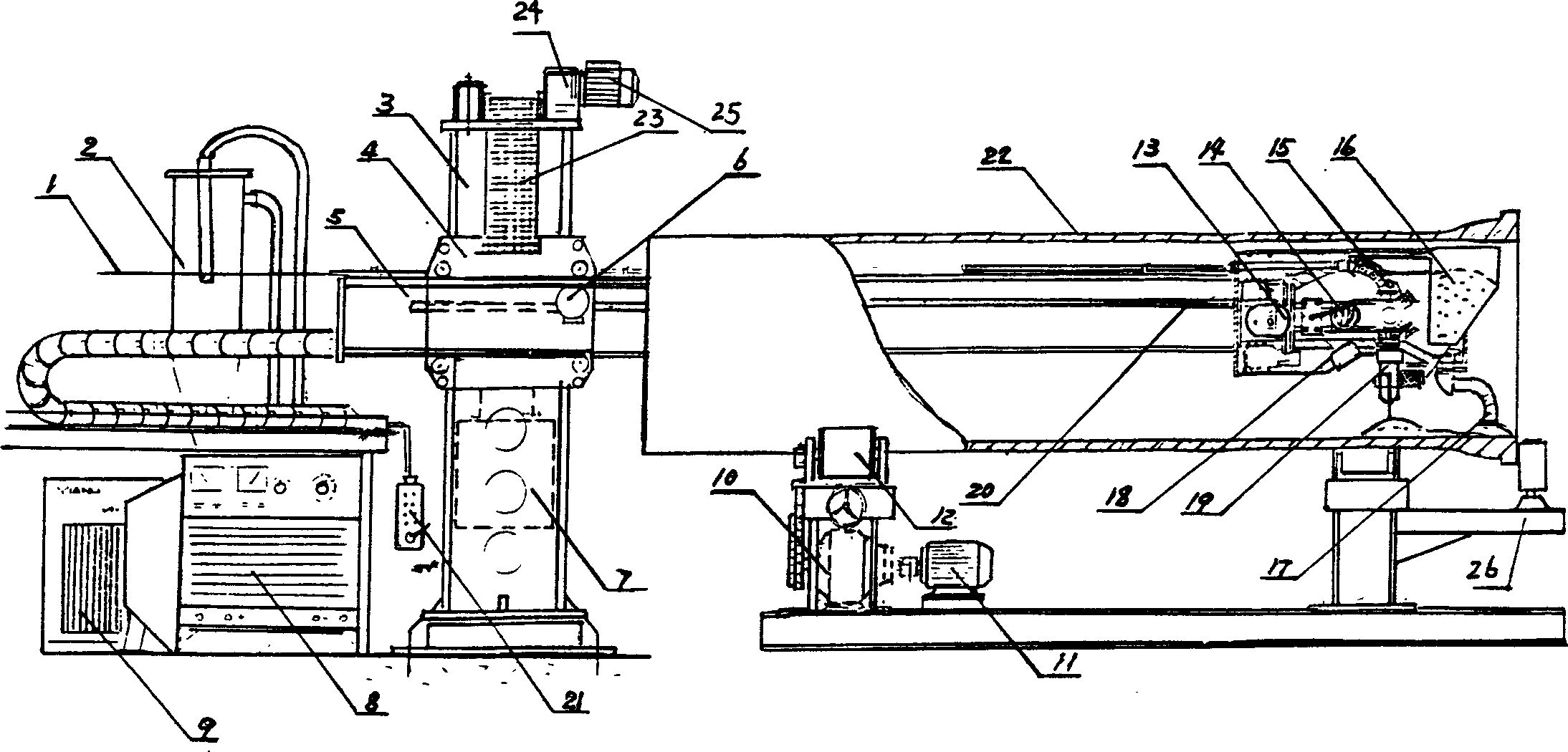

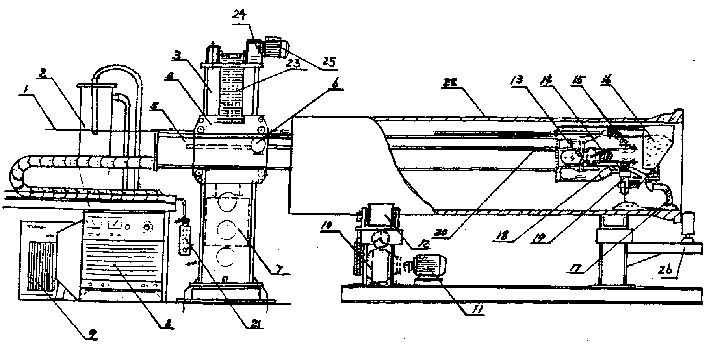

Refection reducing and outburst eliminating method for deep-hole hydraulic fracture driving gas shallow hole extraction

InactiveCN102383828AHigh extraction rateRelieve pressureFluid removalGas removalEngineeringHigh pressure water

The invention discloses a refection reducing and outburst eliminating method for deep-hole hydraulic fracture driving gas shallow hole extraction. The method comprises the following steps of: gradually and alternately constructing hydraulic fracture holes and gas extraction holes in the coal bed direction in a coal mining working face tunnel, an airway or a tunneling working face, and performing high-pressure water injection and gas extraction; stopping injecting water after the water is injected into the hydraulic fracture holes for 0.5 to 5 hours, and changing gas extraction pipe joints to extract gas; after the hydraulic fracture hole or gas extraction concentration is lower than 5%, changing water injection pipes to perform static pressure water injection; and when the coal mining working face is recovered to the position 5 meters away from the static pressure water injection holes or the tunneled working face is tunneled again, stopping a pump or closing a static pressure water valve to stop water injection. According to the method, refection reduction of the gas-containing coal bed is realized, the gas extraction rate is improved, the gas in the mining space is effectively prevented from exceeding the limit, outburst risks of coal and gas are reduced, and safe and efficient recovery of coal is ensured. The method is simple and good in effect.

Owner:CHINA UNIV OF MINING & TECH +1

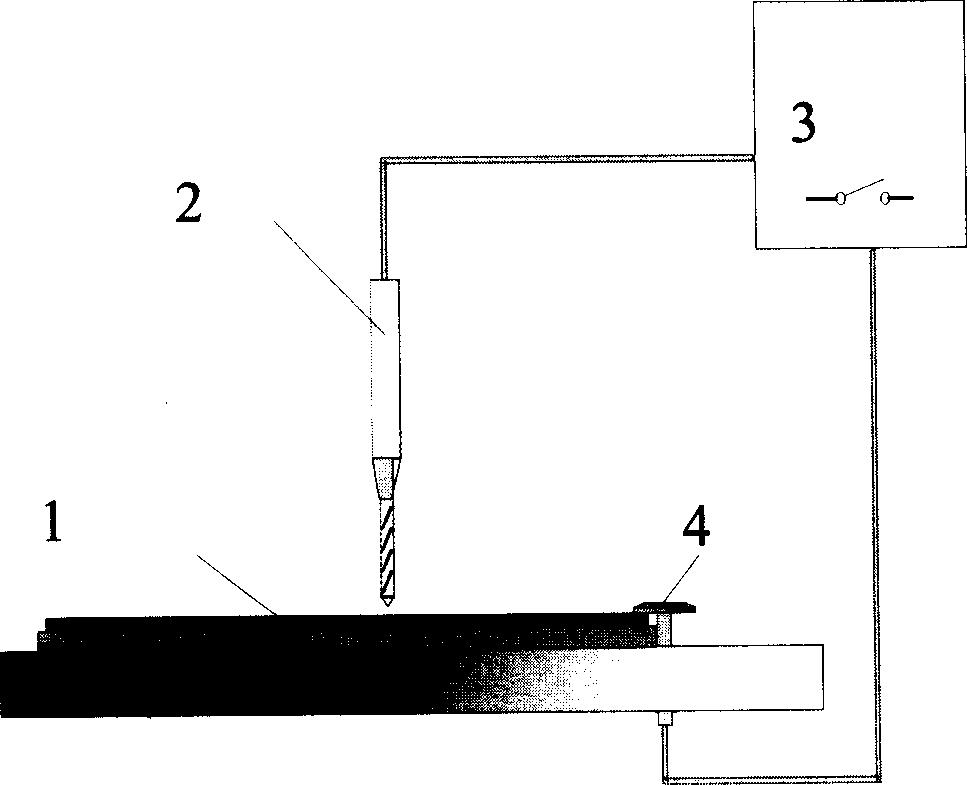

Method for drilling deep hole and PCB product obtained by same method

InactiveCN1787726AControl drilling depthReduce the impactConductive material mechanical removalEngineeringControl software

This invention discloses a new method for deep drilling and PCB products got from it, which sets the platform control loop on the POWER layer in the board and begins computing the designed depth from the place contacting the POWER by the drilling pin or drills the test holes of Z1,Z2 and Z3 on the necessary drilled regions of the upper surface, the upper target layer and the lower target layer then adds G87, G88 and G89 functional instructions on the control software of the platform to detect the depth values of Z1 and Z2 and judges the drilled depth value based on their positions, finally the platform adds a compensation value of a drill point to the depth of (Z2+Z3) / 2 to drill.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

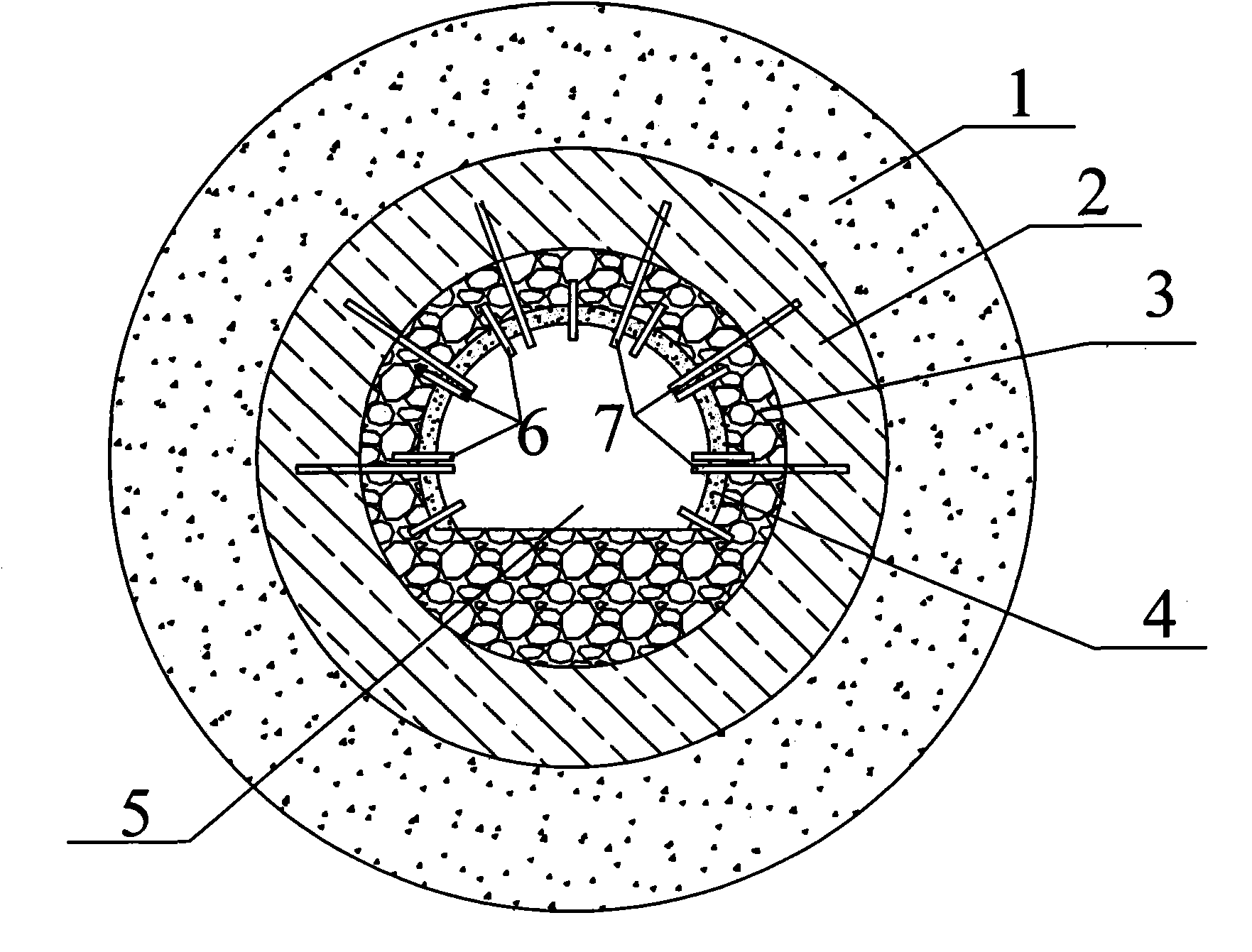

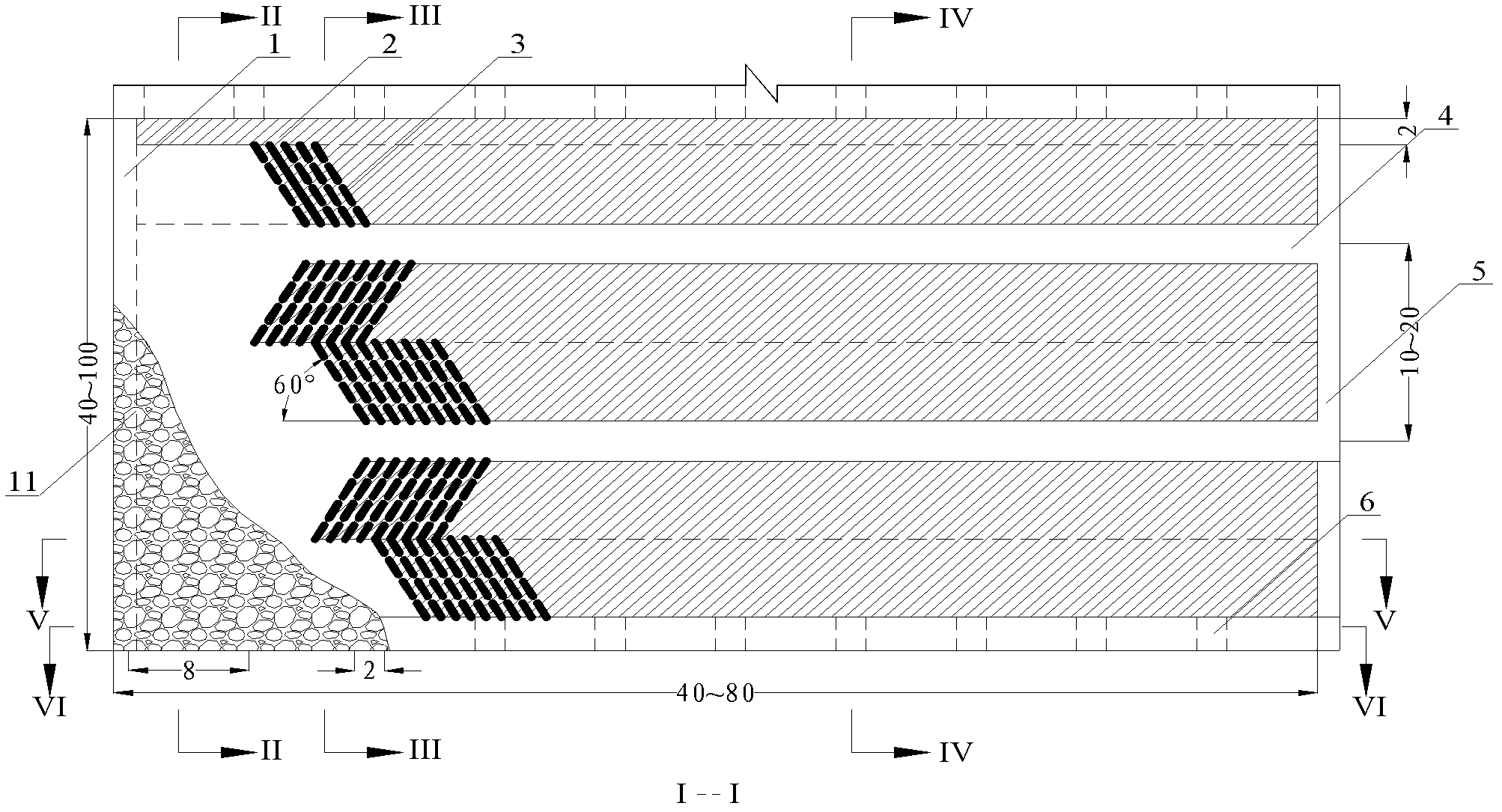

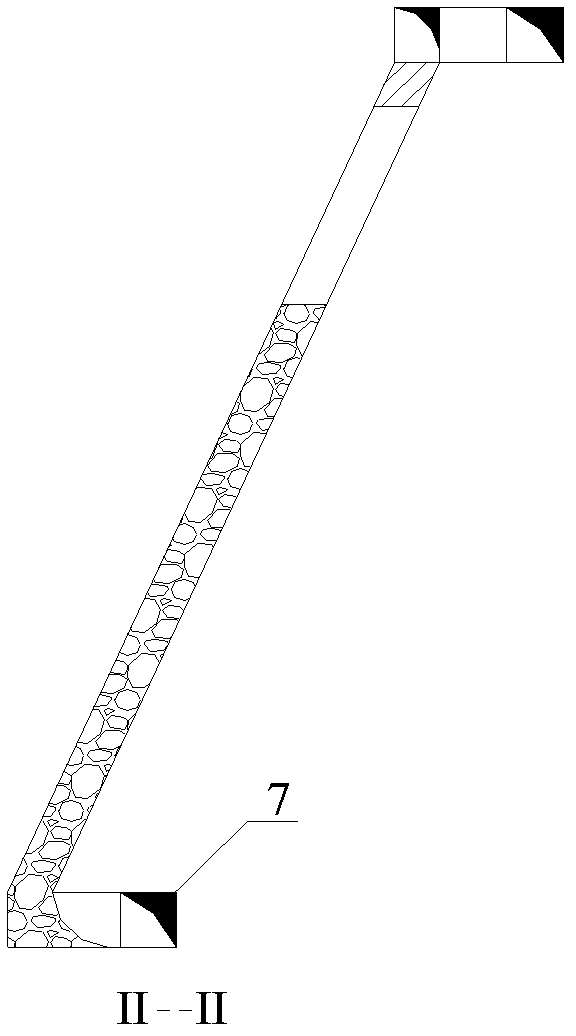

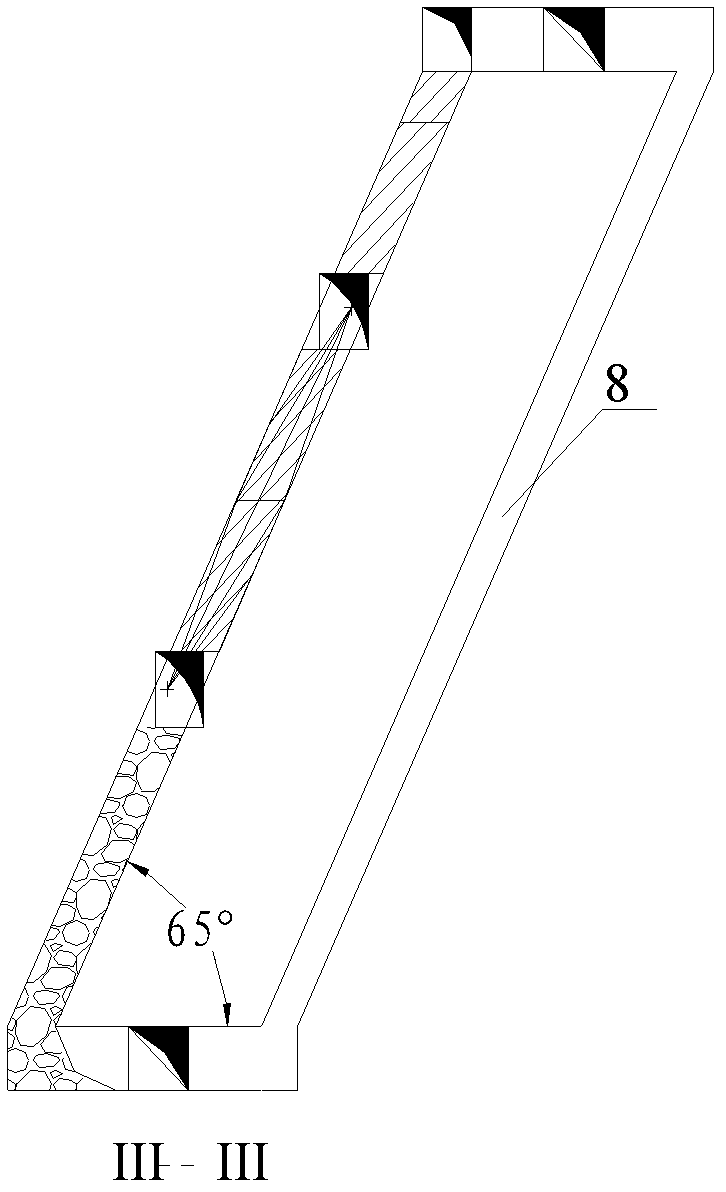

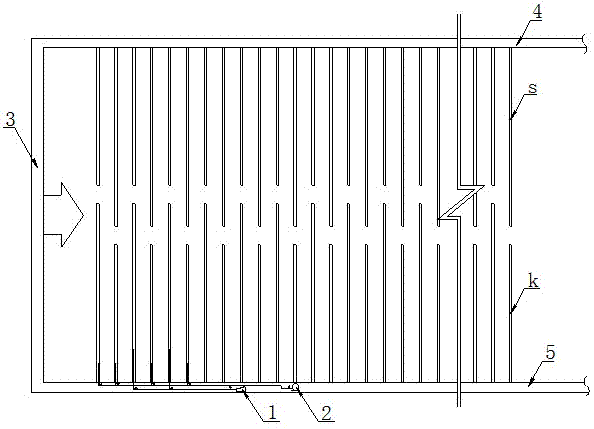

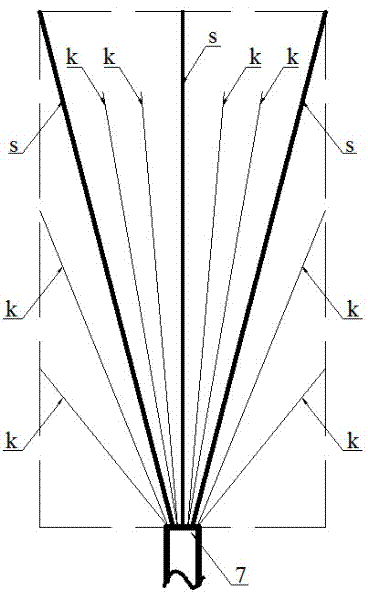

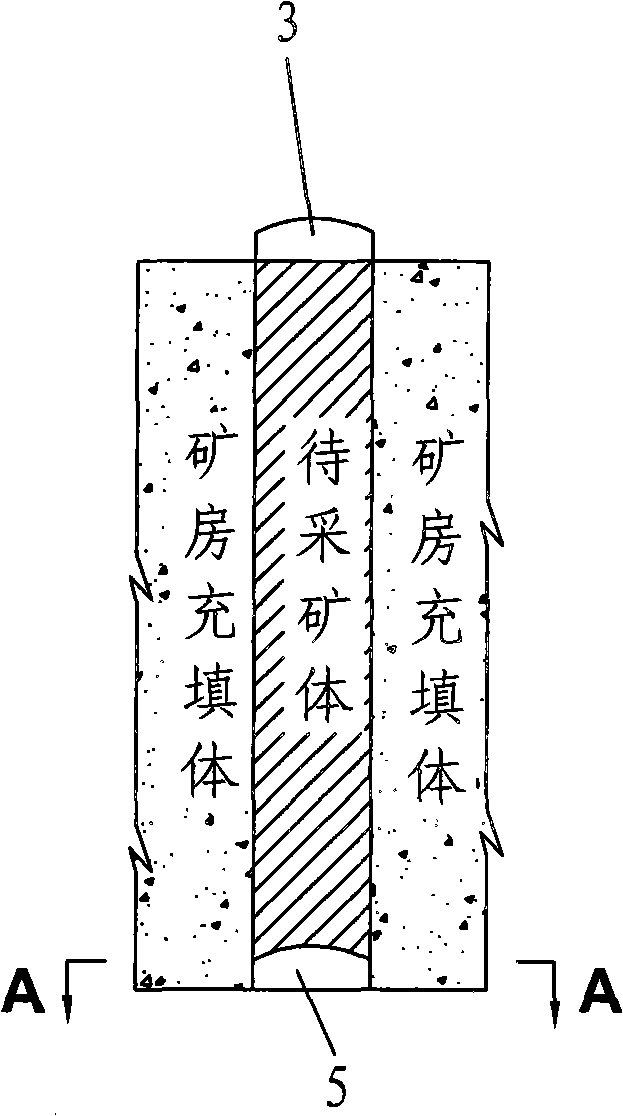

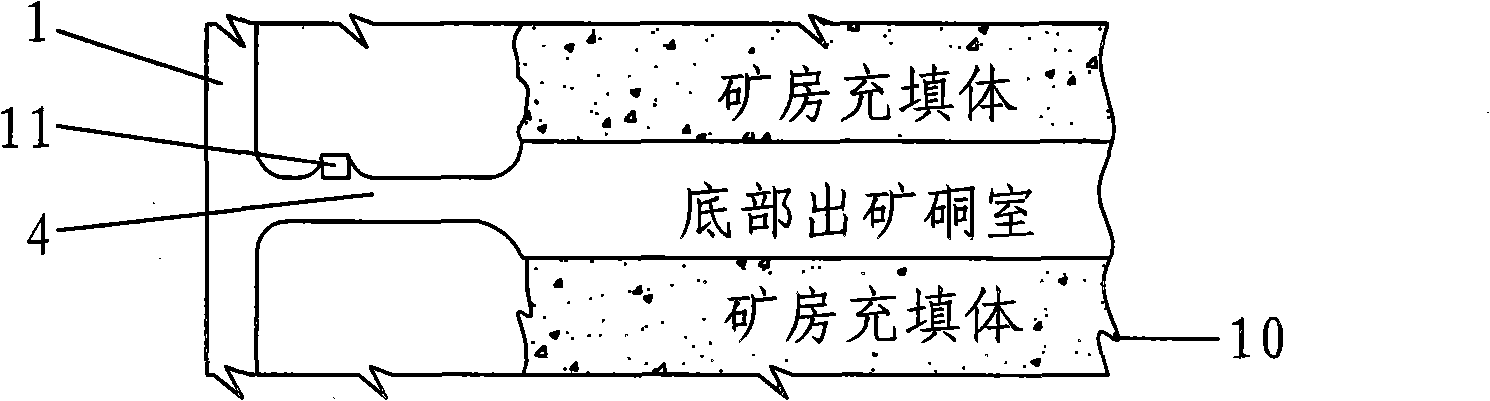

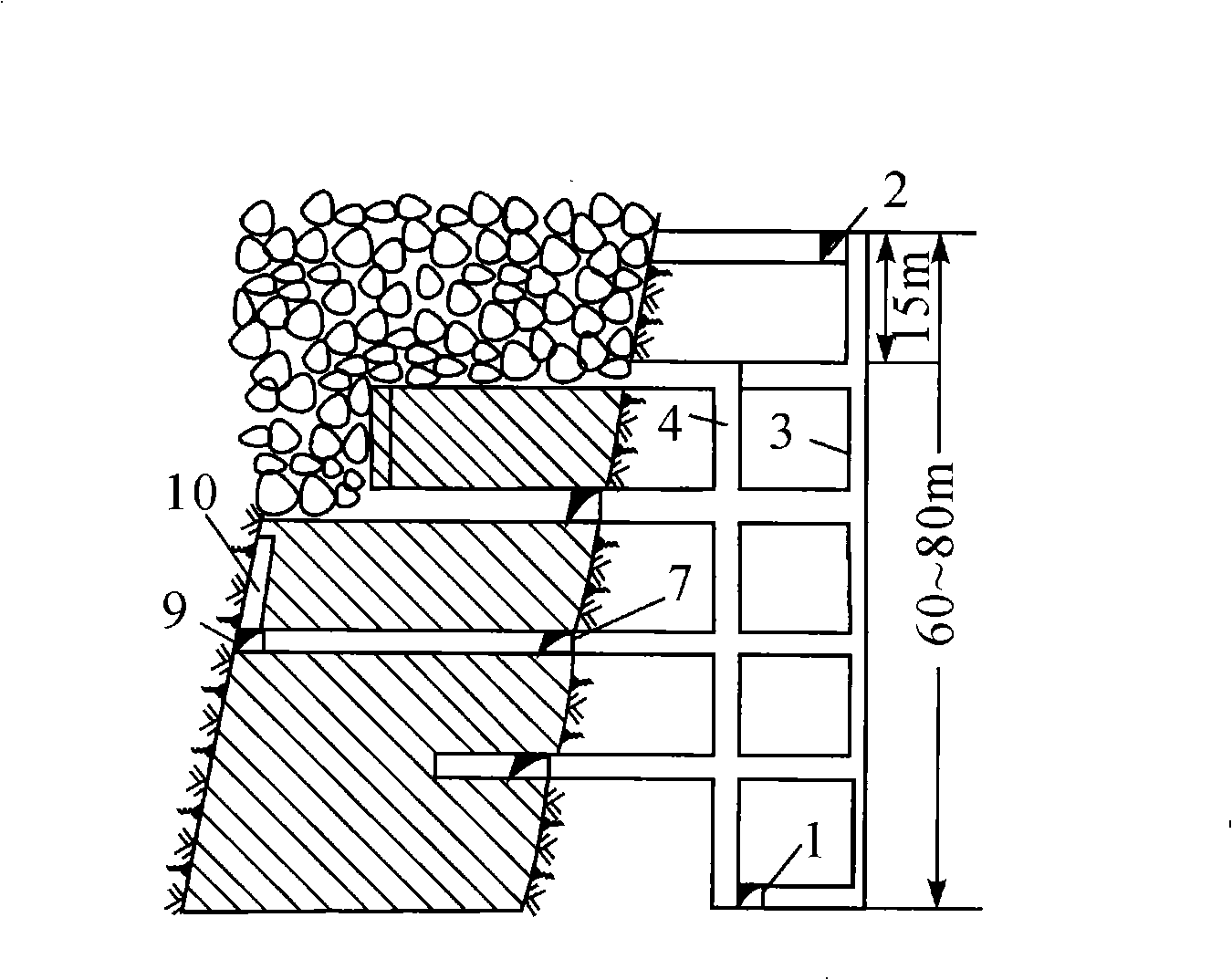

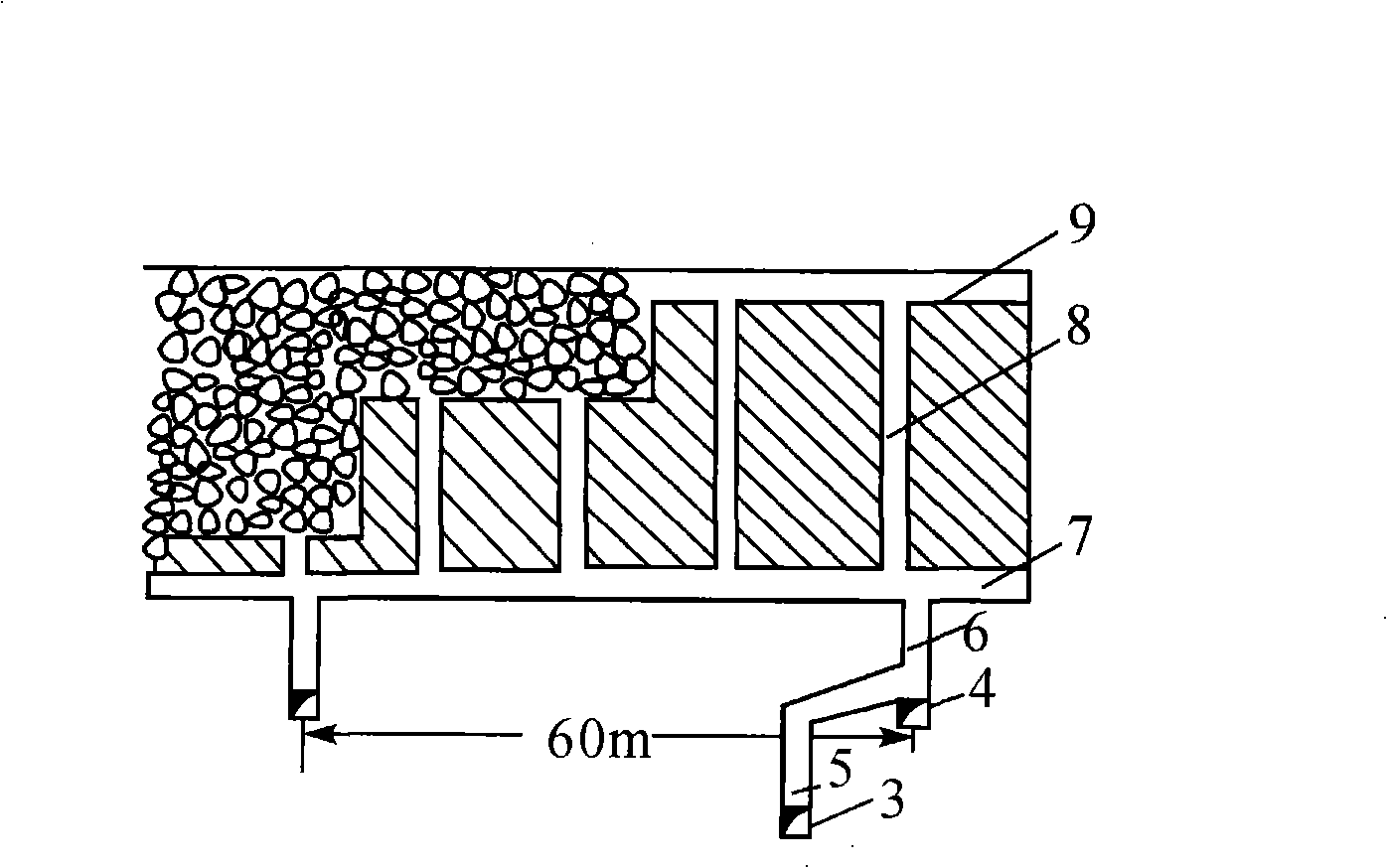

Non-bottom pillar deep hole falling-back type mining method

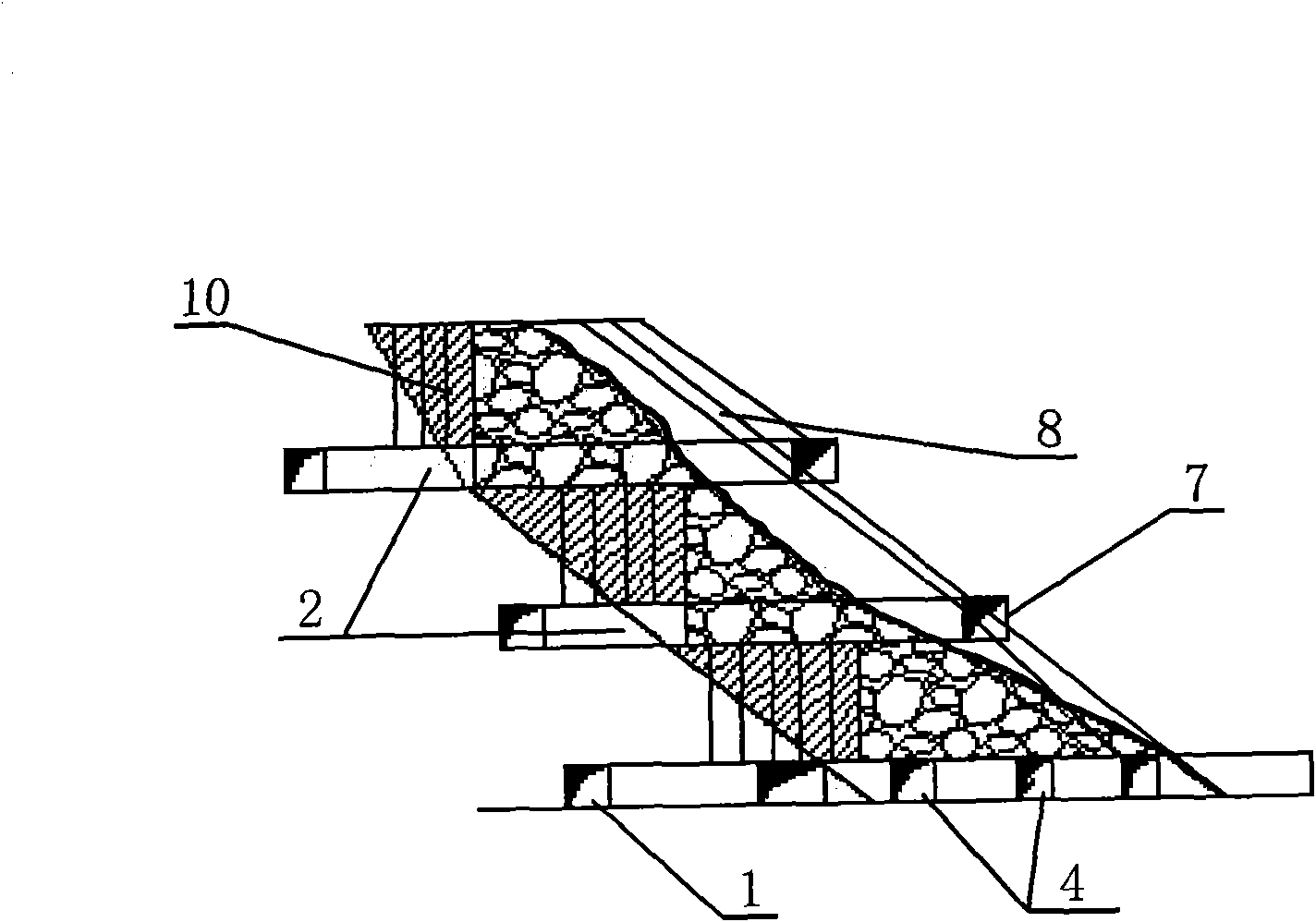

The invention relates to a non-pillar deep-hole backing-type mining method. The method is suitable for that: the digging height is between 10 and 50 m; the length of a stope is between 40 and 80 m; the width of the stope is between 7 and 9 m; the dip angle of an ore body is between 68 and 90 degrees; the height of a bottom ore removal chamber is between 2.5 and 3.5 m; the height of an upper part rock drilling chamber is between 3.4 and 3.8 m; meanwhile, an explosive charge structure, an explosion initiating sequence, stope side lacing and top plate control are determined according to the conditions of the stope, and a remote-control scraper and a remote-control crushing trolley are jointly used to treat large ore materials for ore removal. The mining method has the advantages of small mining-cutting engineering quantity, simple mining-cutting process, high rock drilling efficiency, good blasting effect, safe and efficient ore removal process, can effectively improve the wide-spacing stoping safety for underground metal mines nationwide, can upgrade the mining technical level for the underground metal mines in China, can promote the development of nationwide underground metal mine mining technology, and can reduce the dilution rate and loss rate of nationwide underground metal mine spacing stoping stopes, so as to promote the maximal recycling of metal resources.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿

Layered top-controlling filling mining method for residual ores in deep hole in diskless area

ActiveCN102678121AImprove mining safetyReduce unit consumptionUnderground miningSurface miningMineralogyDeep hole

The invention discloses a layered top-controlling filling mining method for residual ores in a deep hole in a diskless area. An ore body is divided into ore room ore columns which are arranged at intervals along the travelling direction, and production is preformed by taking 6 to 8 ore room ore columns as a unit; a mountain outer oblique slope, a mountain outer sectional stulm, a sectional contact way and a mountain outer middle-section orepass form a mountain outer rail-free mining preparation system; after bursting and ore falling in medium and deep holes are performed in the ore room ore columns, a part of ores is shoveled out, and the other ores are temporarily left in a stope to form an ore pile of which the top is provided with a hollow top space with the diameter of 1.5 to 2m; a layer of mine body with the thickness of 2.0 to 2.5m is exploited from the ore pile, a 1 / 4 three-center arc top plate is formed by a control burst method, the out ores are pressed and exploited on the ore pile, and surrounding rocks are crushed on an anchoring rod or an anchoring net supporting and protecting top plate and a long anchoring rope supporting and protecting upper disc; the ores are taken out in a concentrating way after the top is protected, and cement and tailings are glued and filled to a 3.5-4m position; and the steps are repeated until ore blocks are completely stoped and the top is connected and filled. The method has the characteristics of safety, high efficiency, low barren loss, low cost and the like.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU +1

Roof-cutting pressure relief method in hard-roof deep-hole pre-splitting blasting

The invention relates to a roof-cutting pressure relief method in hard-roof deep-hole pre-splitting blasting, belongs to the technical field of blasting pressure relief, relates to a method of controlling coal pillar stress concentration and intense gob-side entry strata behaviors caused by suspension of gob hard roofs in thick seams and super high seams, and solves such problems of coal pillar stress concentration and intense gob-side entry strata behaviors caused by suspension of gob hard roofs in thick seams and super high seams. The method is effective and widely applicable and includes the steps of firstly, reserving a roof-cutting roadway in coal pillars along a seam roof before working face extraction in case of the seam being the super high seam; if the seam is the thick seam, directly using a mining roadway as a roof-cutting roadway; secondly, if the seam is the super high seam, longitudinally reserving blast holes in the roof strata above the roof-cutting roadway; and thirdly, loading explosives, sealing the holes and allowing for roof-cutting blasting.

Owner:LIAONING TECHNICAL UNIVERSITY

Non-pillar sublevel caving mining method for direct loading for ore

InactiveCN101338674AImprove limitationsHigh recovery rateUnderground miningBlastingMineralogyDeep hole

The present invention relates to a non-pillar sublevel caving method. The non-pillar sublevel caving method which loads and transports ores directly is characterized by comprising the steps as follows: two or more dipheads are tunneled downwards at the position of an orebody near a heading side along the orebody tendency and are used as main haulageways; segmented haulageways are tunneled from the dipheads to divide the orebody into segments; a stoping drift is tunneled from the segmented haulageways; the inner end of the stoping drift is tunneled a cutting roadway and a cutting winze; a vertical upward or oblique upward cutting slot medium and deep hole is drilled at the top plate of the cutting roadway, and the cutting slot is explored and formed on the cutting winze as a free surface; a mining medium and deep hole is drilled in the whole stoping drift, and the mining medium and deep hole of the stoping drift is explored on the cutting slot as the free surface to break ores; the ores are drawn under overlying rocks at the end of the stoping drift, and the ores are loaded on a tramcar directly to be transported out; when stoping, the processed of exploring the mining medium and deep hole, ore drawing and transporting out the ores are processed in the stoping drift, and the retreating mining is circulated until the stoping drift is mined completely. The non-pillar sublevel caving mehod has low cost, high ore recovery ratio, safe production and wide application range.

Owner:WUHAN UNIV OF TECH

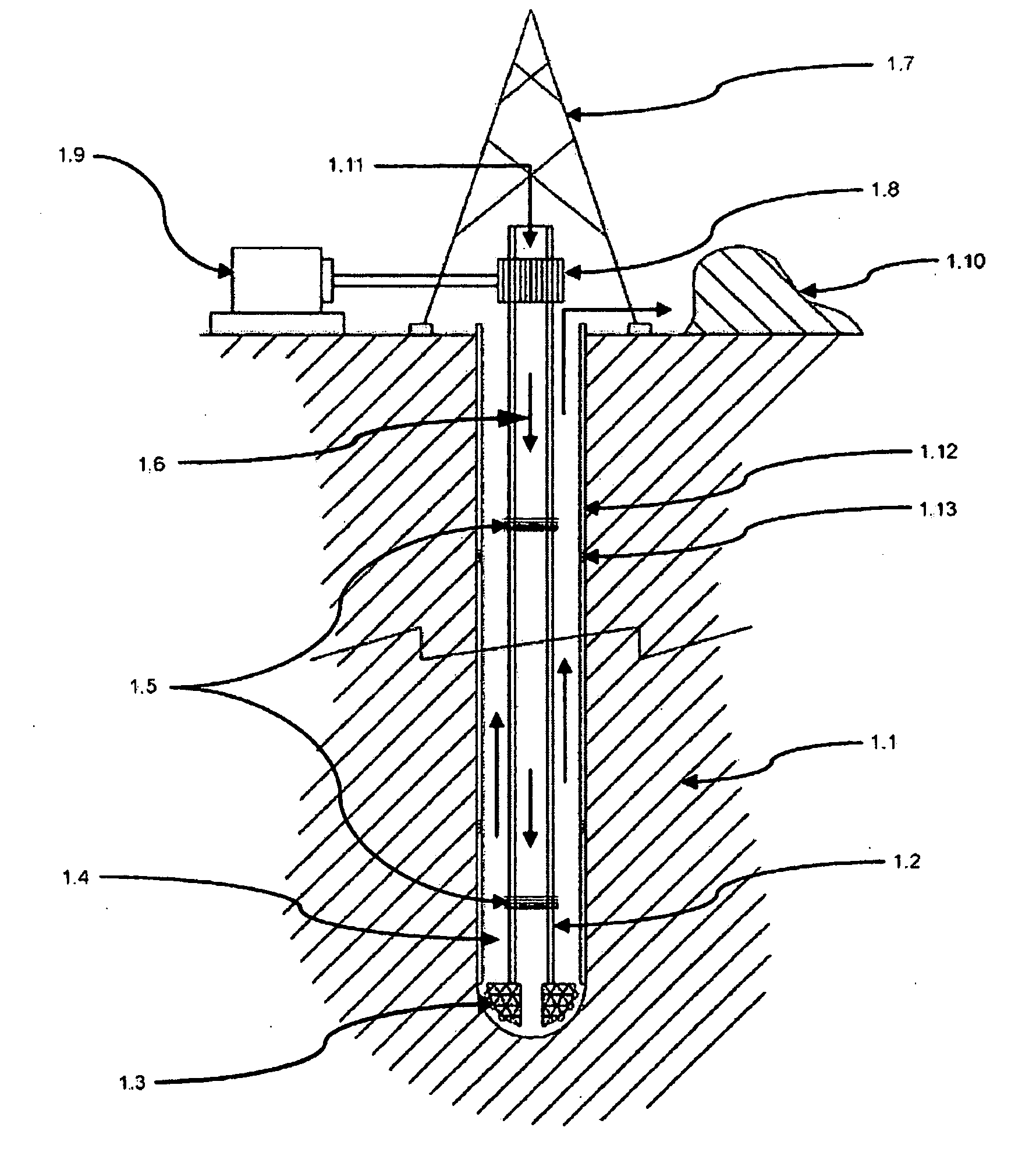

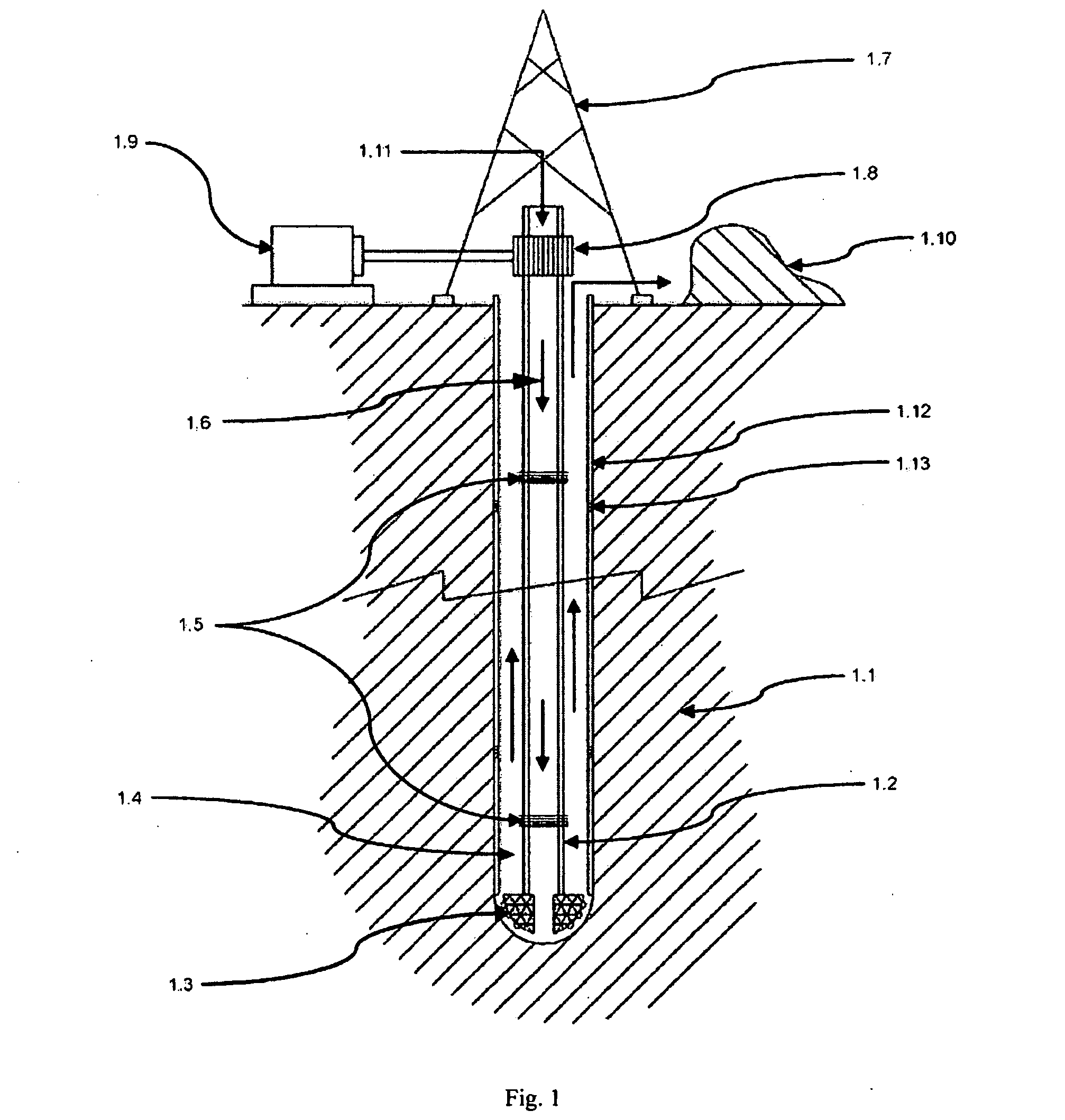

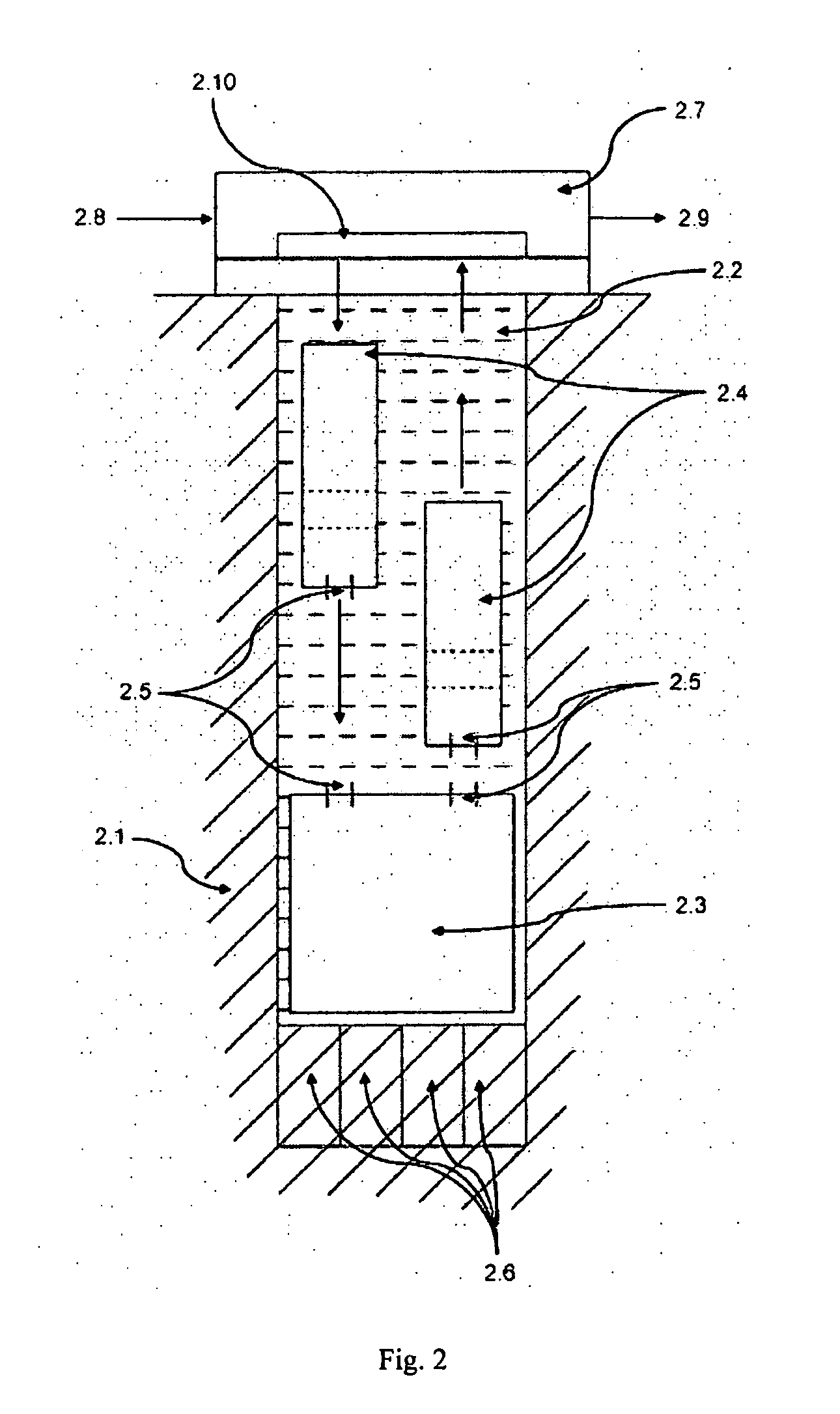

Equipment for excavation of deep boreholes in geological formation and the manner of energy and material transport in the boreholes

InactiveUS20100224408A1Considerable energy savingLarge boreholeDisloding machinesThermal drillingEngineeringEnergy depletion

Utilisation of geothermal energy in depths above 5 km could contribute considerably to resolving the global problems related to a lack of energy and to glasshouse gases from fossil fuels. The invention describes innovative equipment which makes deep holes in geological formations (rock) by disintegrating the soil into blocks carried to the land surface through the excavated hole filled with liquid, using transport modules yielded up by gas buoyancy interaction in the transport module utilising supercavitation. In an opposite direction—by help of negative buoyancy—the necessary energy carriers, materials and components, or entire devices required for rock excavation, are carried to the bottom. The opportunity to transport rock in entire blocks reduces energy consumption considerably, because the rock is disintegrated in the section volumes only. Some of the extracted rock and material carried from the surface is used to make a casing of the hole using a part of the equipment. The equipment also allows the generation of the necessary high pressure of liquid at the bottom of the hole, to increase permeability of adjacent rock. The equipment as a whole allows by its function that there is almost linear dependence between the price and depth (length) of the produced hole (borehole).

Owner:GA DRILLING AS

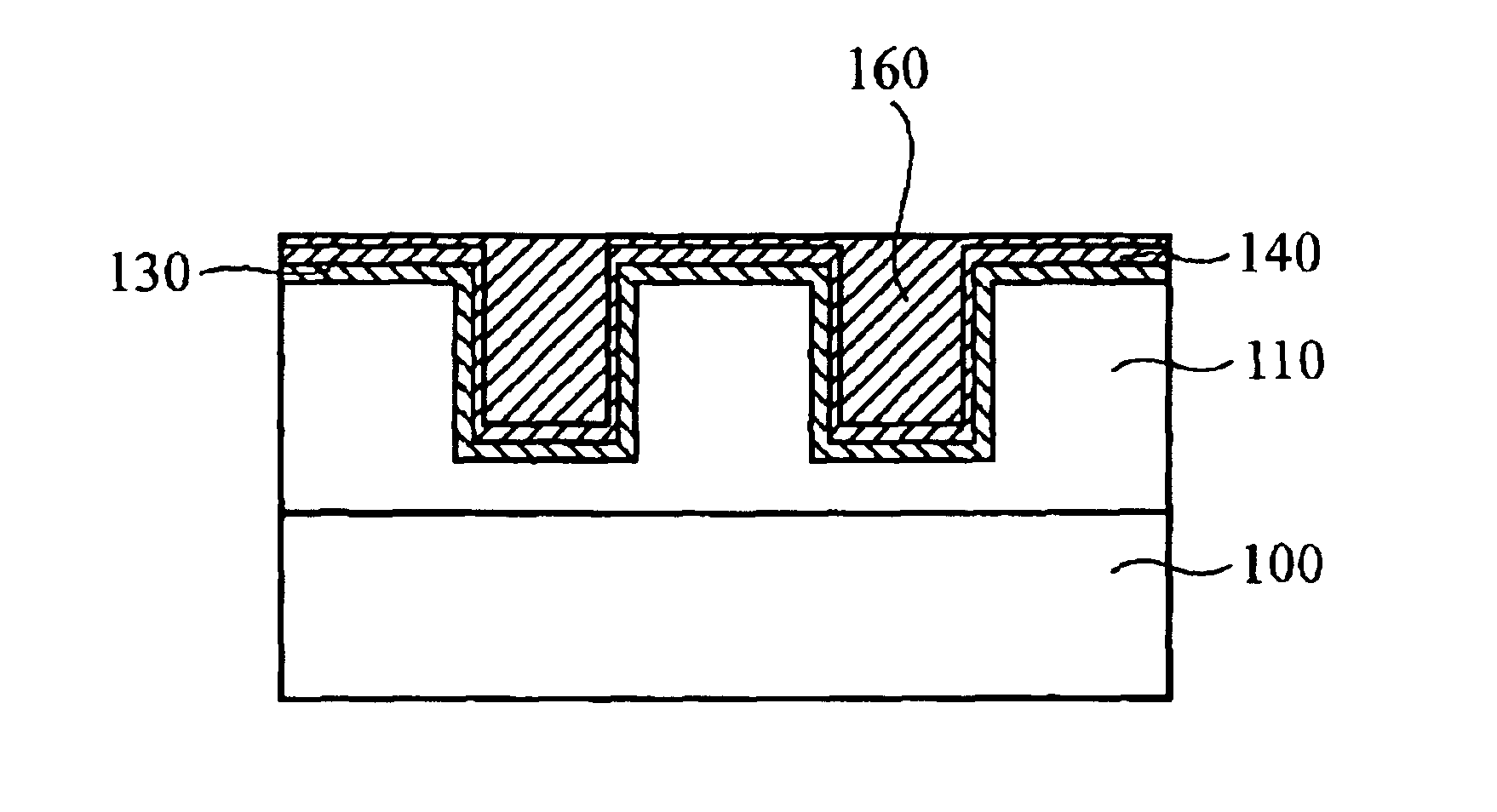

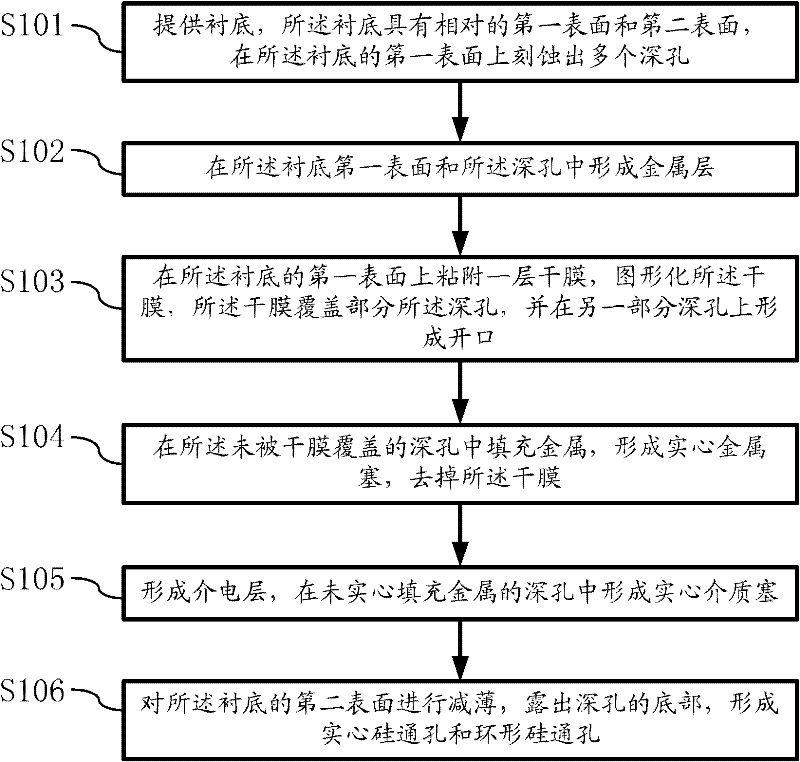

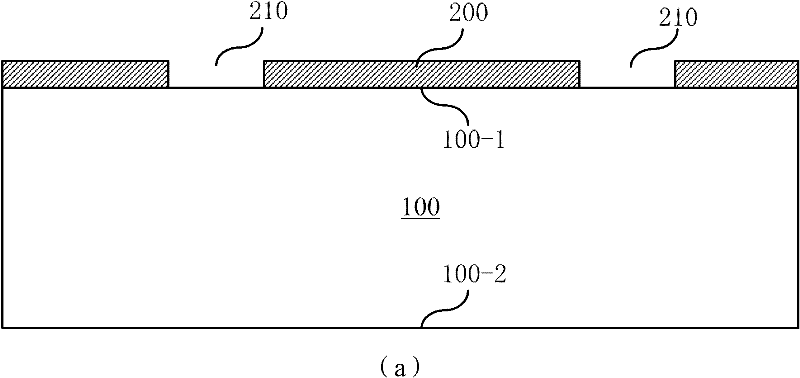

Semiconductor structure with through holes and manufacturing method thereof

InactiveCN102214624AImprove integrityIncrease stressSemiconductor/solid-state device detailsSolid-state devicesDielectricSemiconductor structure

The invention discloses a semiconductor structure with through holes and a manufacturing method thereof. The semiconductor structure comprises a substrate, a plurality of annular through holes and a plurality of solid through holes; the annular through holes and the solid through holes are embedded in the substrate; the solid through holes are through holes filled by metal; and the annular through holes are through holes filled by solid dielectric plugs and metal rings surrounding the solid dielectric plugs. The manufacturing method comprises the steps of: (1) etching a plurality of deep holes on a first surface of the substrate; (2) forming a metal layer; (3) attaching a dry film on the first surface of the substrate and patterning the dry film such that the dry film generates openings on one part of deep holes; (4) filling metal in the deep holes with the openings on the dry film, and removing the dry film; (5) filling dielectric in the remaining deep holes to form the solid dielectric plugs; and (6) thinning a second surface of the substrate. The solid through holes of the semiconductor structure disclosed by the invention can be used for the heat radiation of laminated chips to improve the completeness of a power supply; and the annular through holes can be used for solving the problems, such as stress, warping deformation and the like of the through hole structures.

Owner:PEKING UNIV

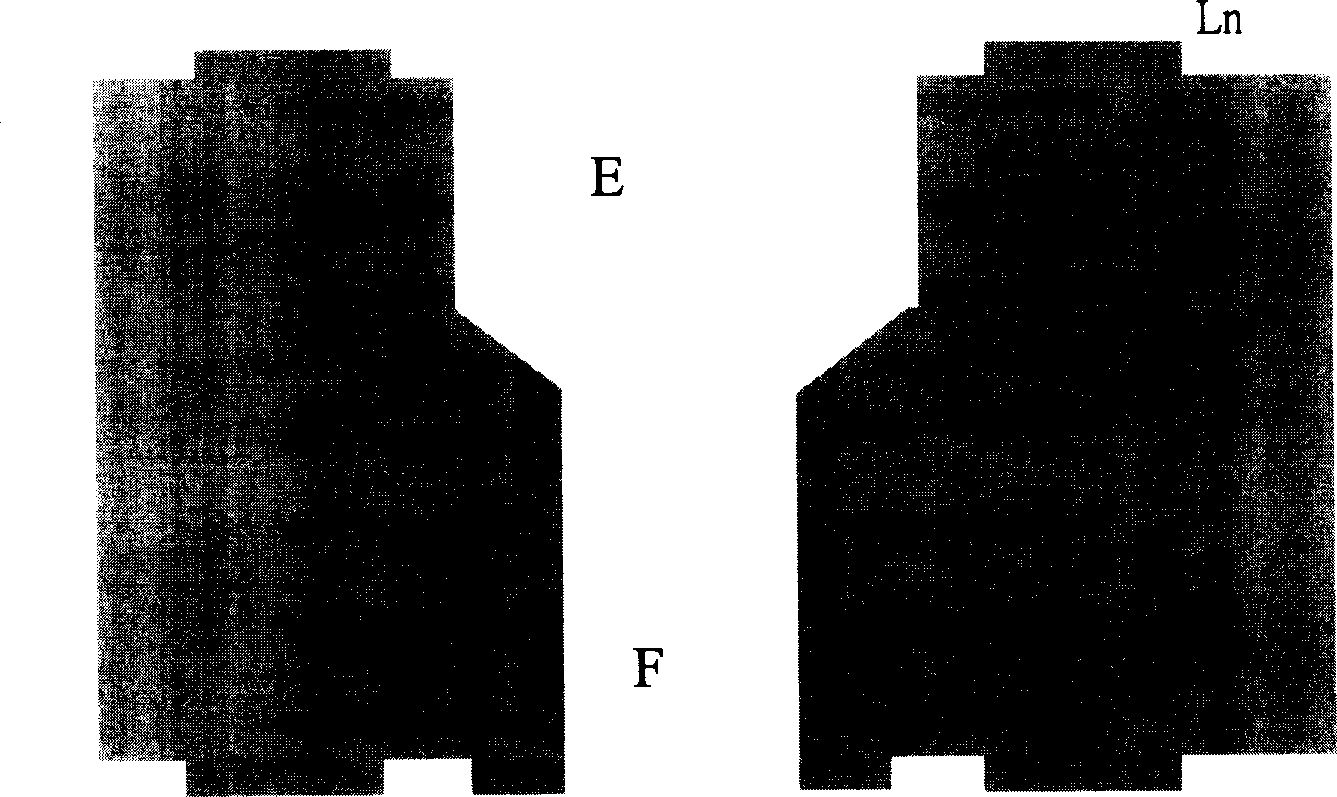

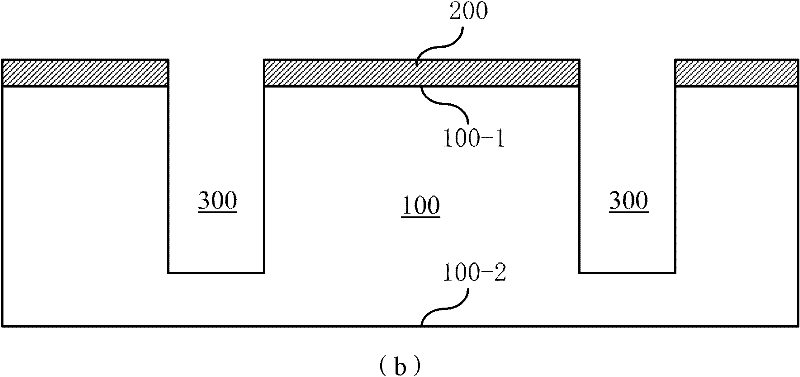

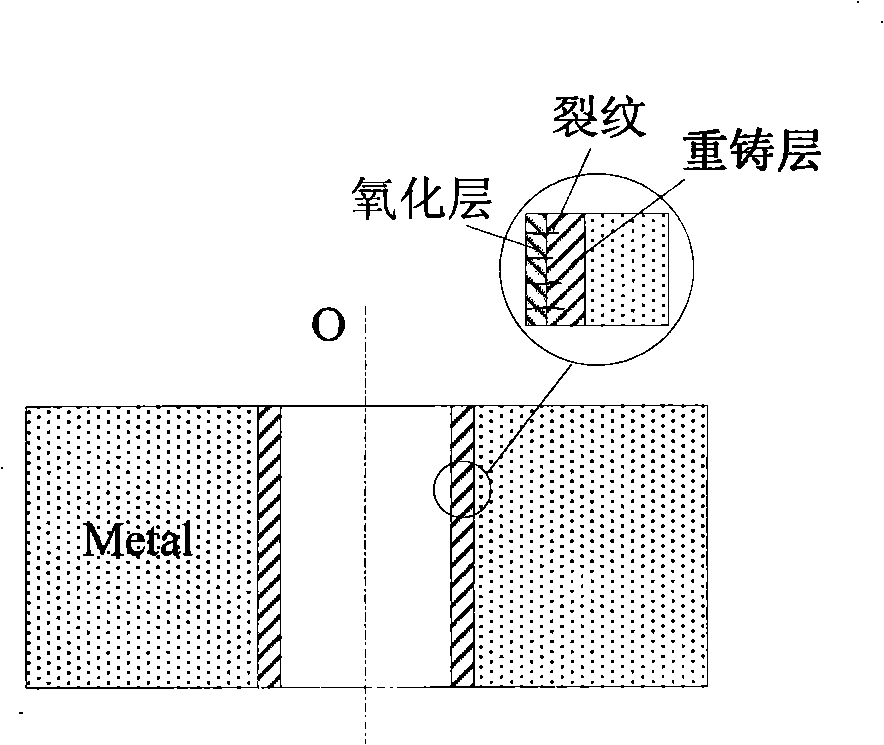

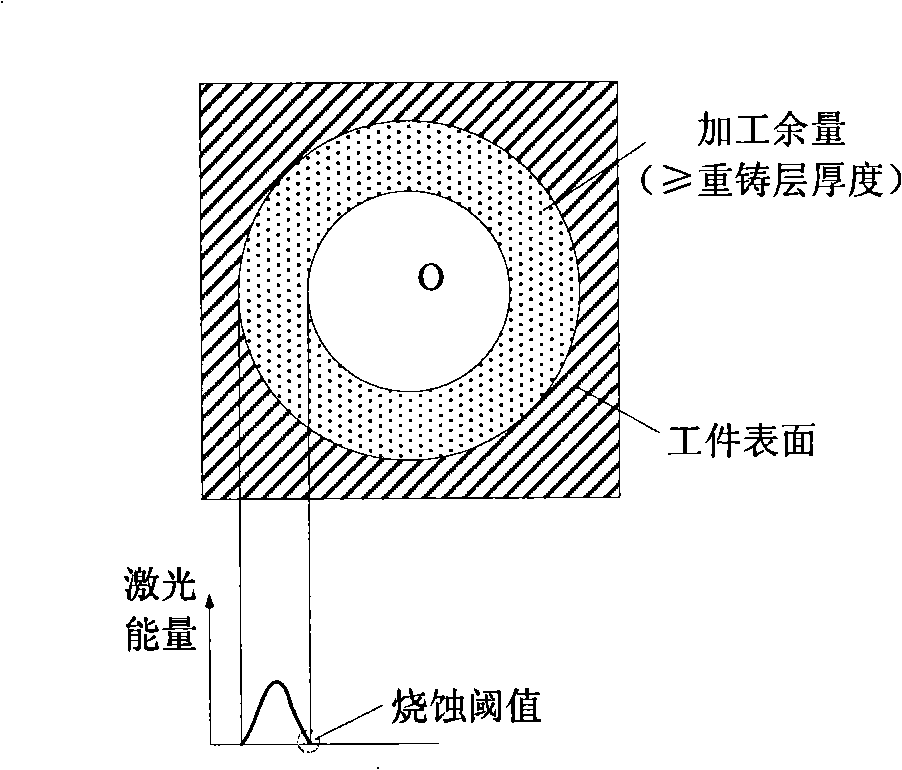

Laser compound processing and modifying method of no-recasting-layer micro deep-hole

ActiveCN101332559AEfficient solutionSolve processabilityLaser beam welding apparatusLong-focus lensHigh power lasers

The invention discloses a laser combined machining and profile modification method of a micro deep borehole without a recast layer. The method of the invention includes the following steps: first, a micro deep cooling borehole of a turbine blade is roughly machined by high power laser or electric sparks, and the like; the allowance for finish of the aperture is more than the thickness of the recast layer produced by using the machining method; and femtosecond laser is used for the secondary finish machining and profile modification of the micro deep cooling borehole; while femtosecond impulse laser is used for performing the finish machining and profile modification of the primarily machined micro deep borehole, under the precondition of guaranteeing the laser energy acting with the recast layer of a workpiece is higher than the ablation threshold of the material, a light beam is inclined for certain angle according to the spiral drilling mode; and the recast layer of the internal wall of the borehole is machined to remove erosion and profile modification by combining the method of lengthening the focal depth by a long focus lens. The concept of the combined machining method and the specific machining technology are used for solving the high-efficiency and high-precision machining problems of micro deep borehole groups of turbine blades.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com