Patents

Literature

3958results about "Gas removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

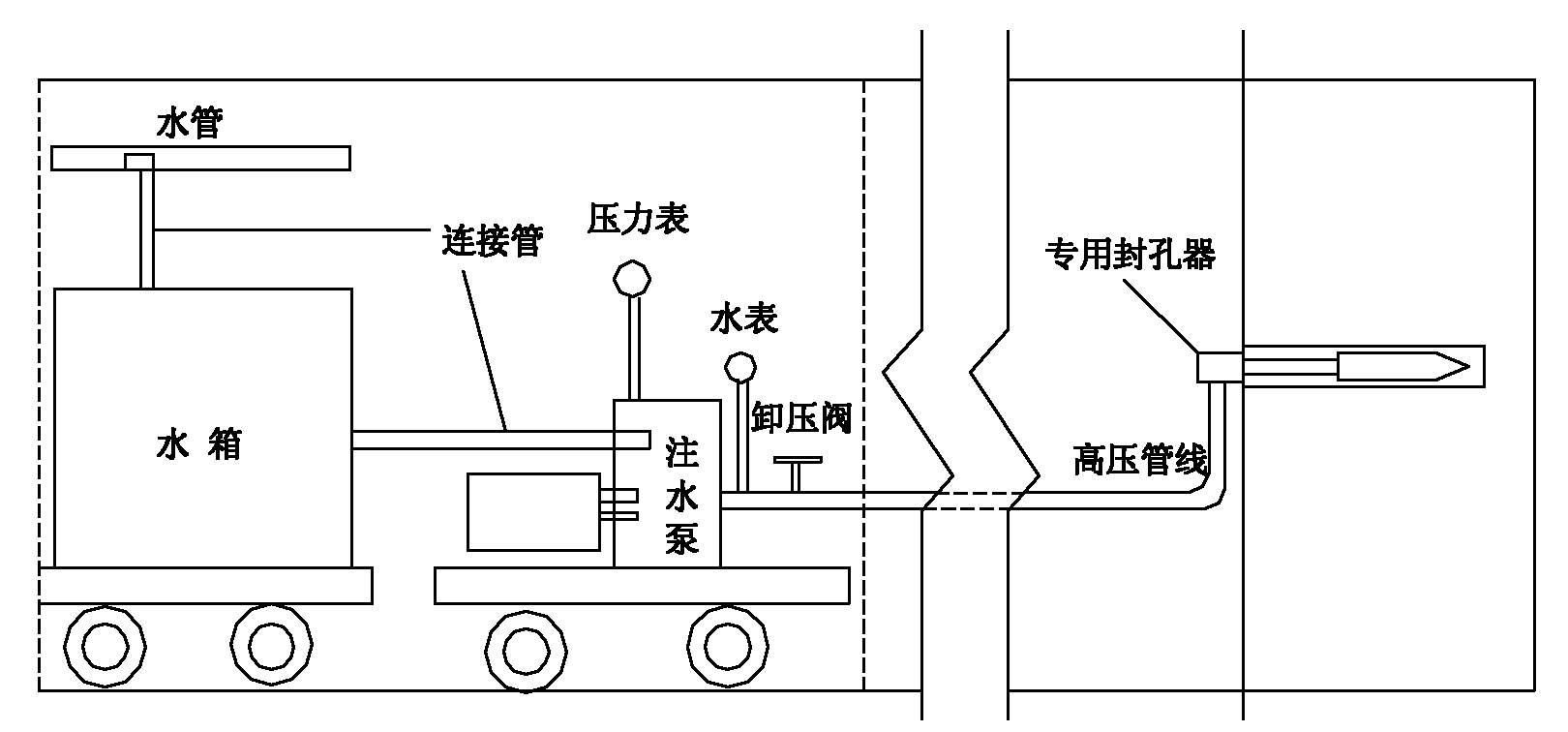

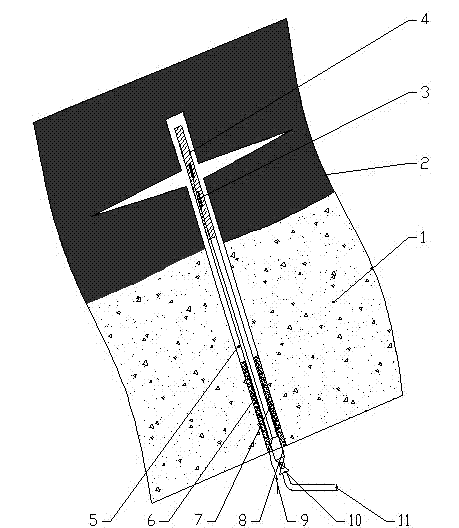

Coal mine down-hole drilling hydraulic fracturing anti-reflection mash gas extraction technique

ActiveCN101403314ALess gushEliminate disastersFluid removalGas removalDischarge efficiencyInjection pressure

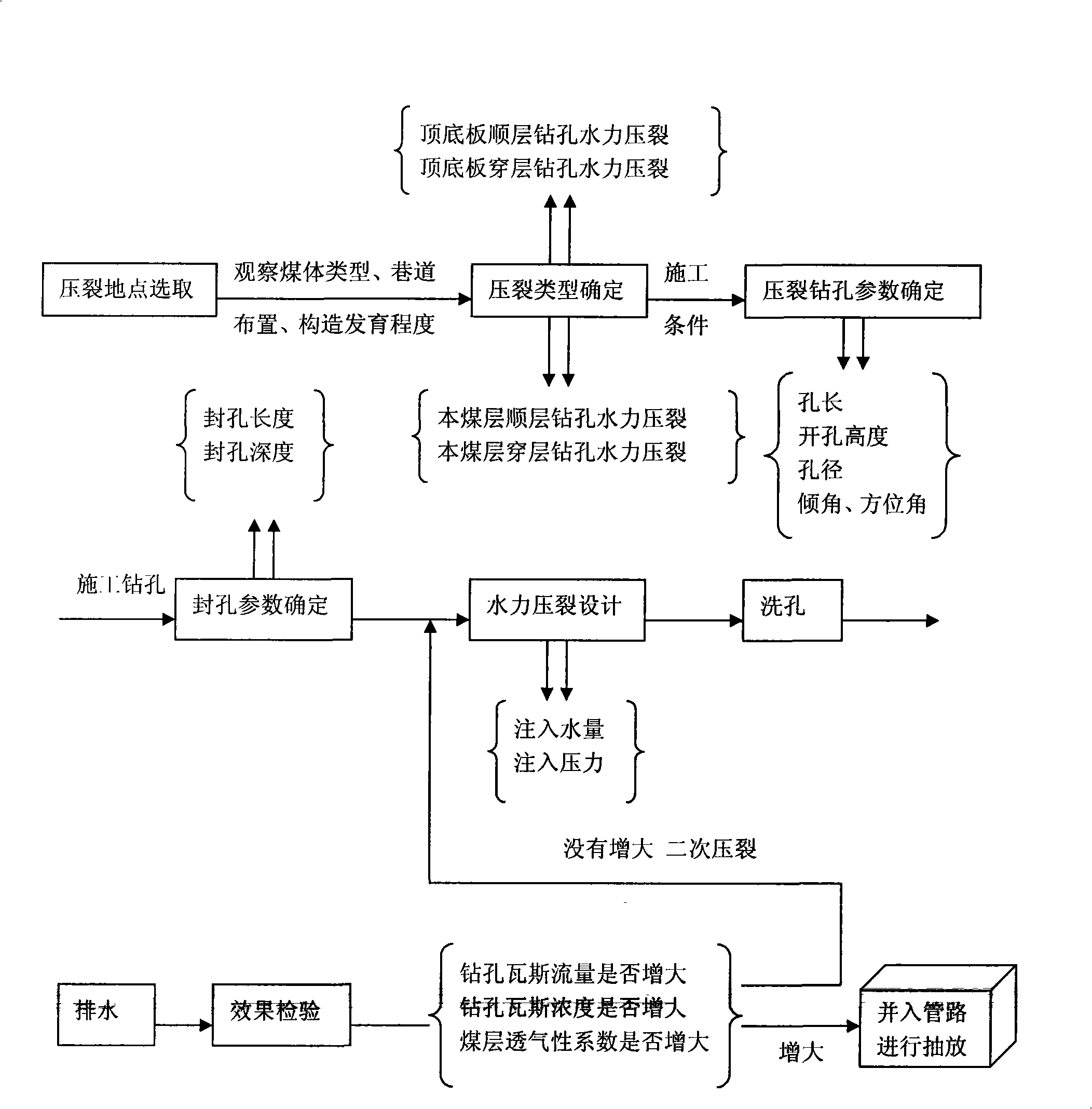

The invention relates to a hydraulic fracturing anti-reflection technology for pumping and exploring gas by drilling a hole in a coal mine well, comprising the following steps sequentially: (1) selecting a fracturing location; (2) determining the pressure type according to observed coal type, laneway arrangement and construction development degree, and ways of top soleplate bedding plane borehole hydraulic fracturing, top soleplate translamellar borehole hydraulic fracturing, the coal bed bedding plane borehole hydraulic fracturing or the coal bed translamellar borehole hydraulic fracturing can be adopted; (3) determining borehole parameters for constructing drilling, wherein, the borehole parameters include borehole length, borehole height, aperture, obliquity angle and azimuth angle; (4) designing the hydraulic fracturing, including injected water volume and injection pressure; (5) borehole washing; (6) draining; (7) examining the fracturing effect, if the fracturing effect is in accordance with the requirement, the following step is carried out, if not, turning to step (4); and (8) entering a pipeline for pumping and discharging. The technology enhances the air permeability of the coal bed, reduces the gas emission rate of an excavation working face, and obviously promotes the pumping and exploring capability and the pumping and exploring effect of the single borehole. The pumping and discharging efficiency is improved, the pumping and discharging time is shortened and the damage of the gas is maximally eliminated.

Owner:HENAN POLYTECHNIC UNIV

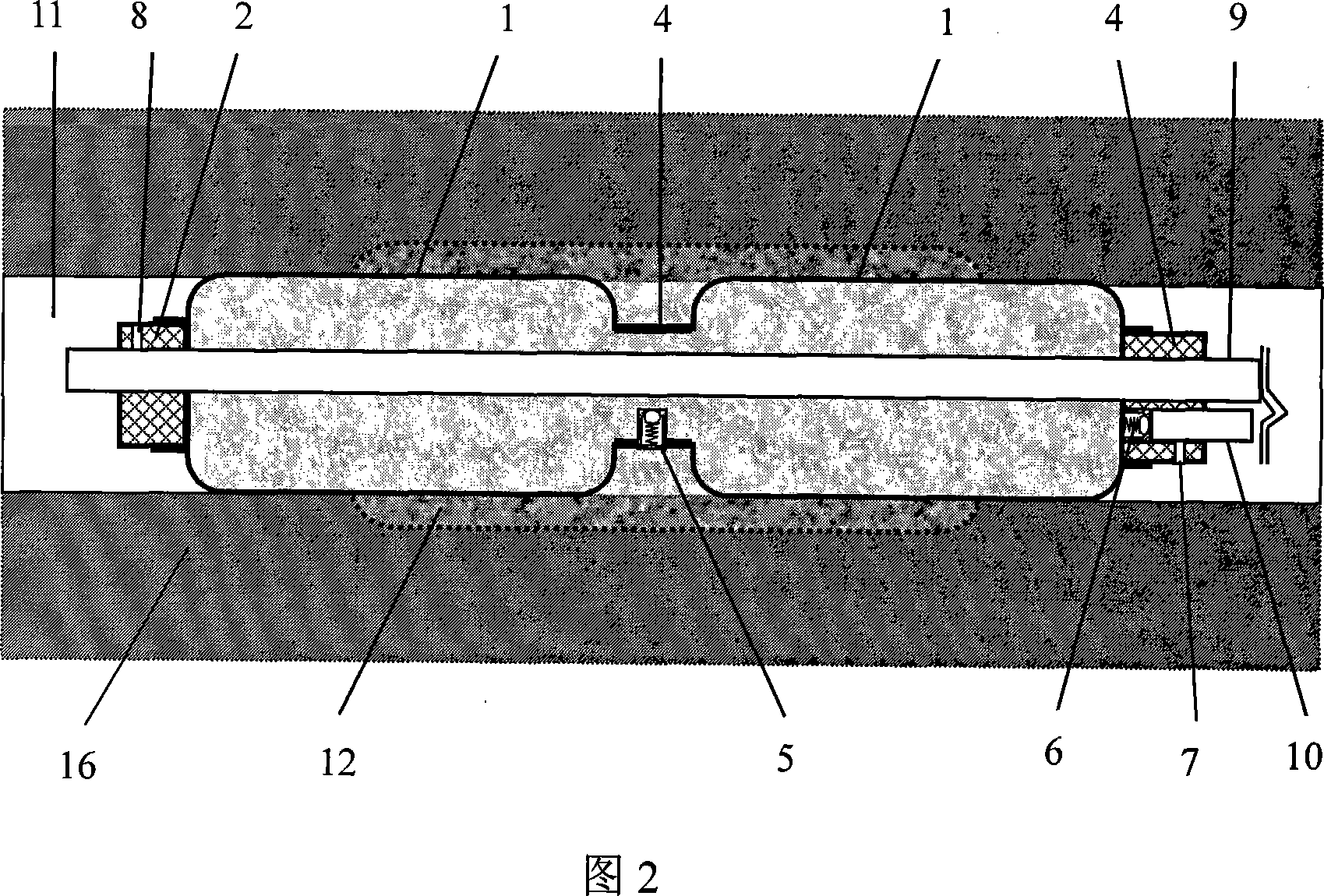

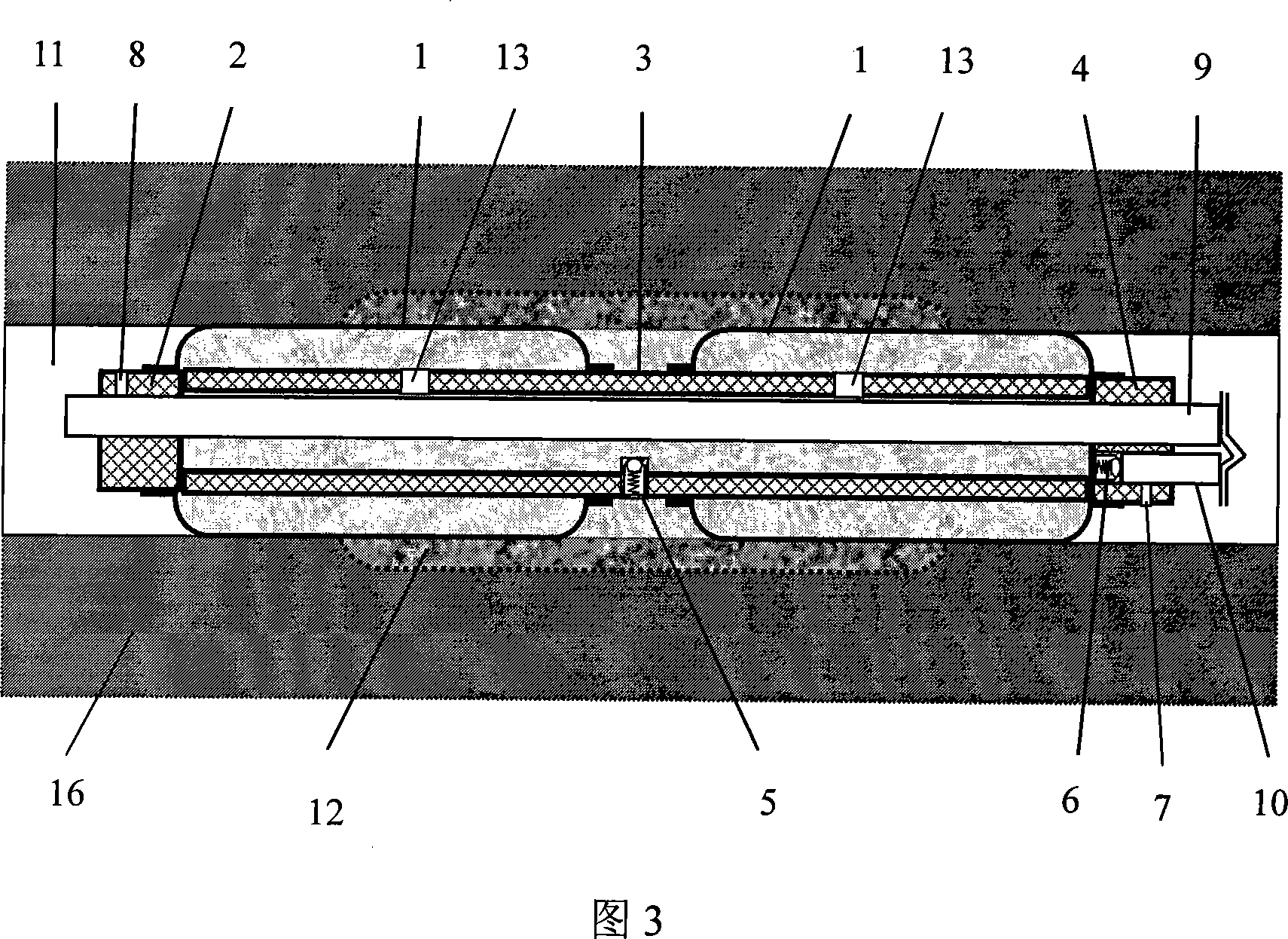

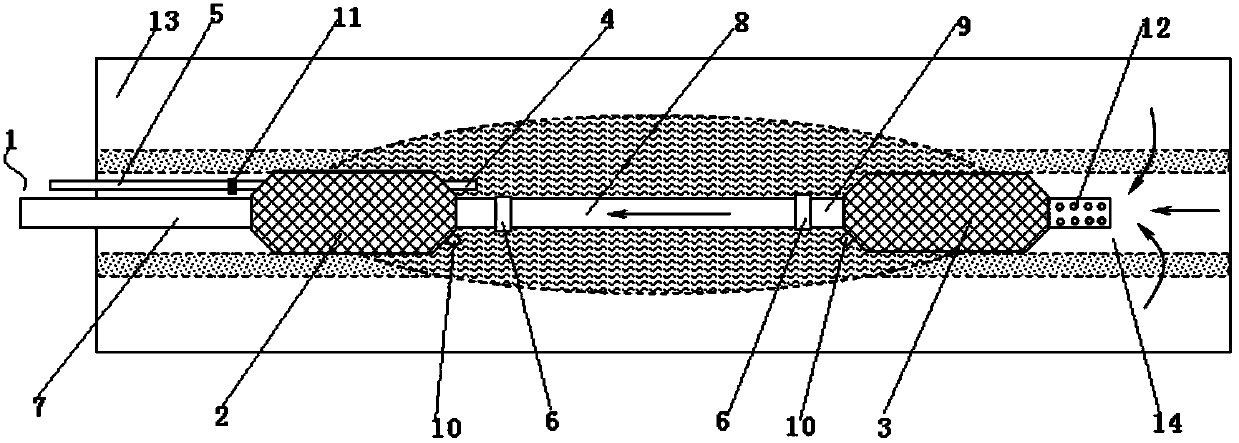

Bag type paste injection hole sealing device and its hole sealing method

InactiveCN101050696AGrouting and sealing are effectiveReduce air permeabilityGas removalSealing/packingSlurryControl valves

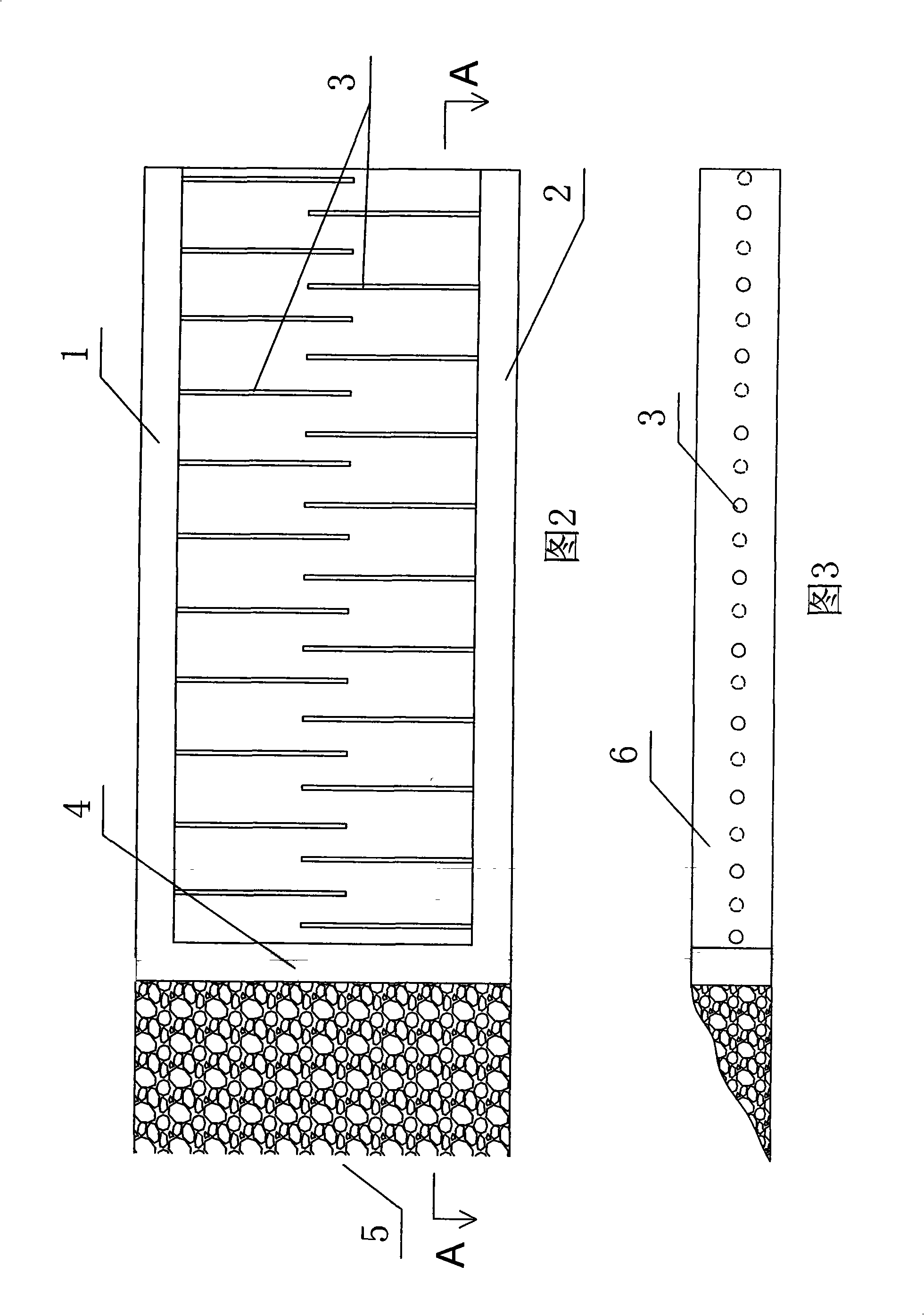

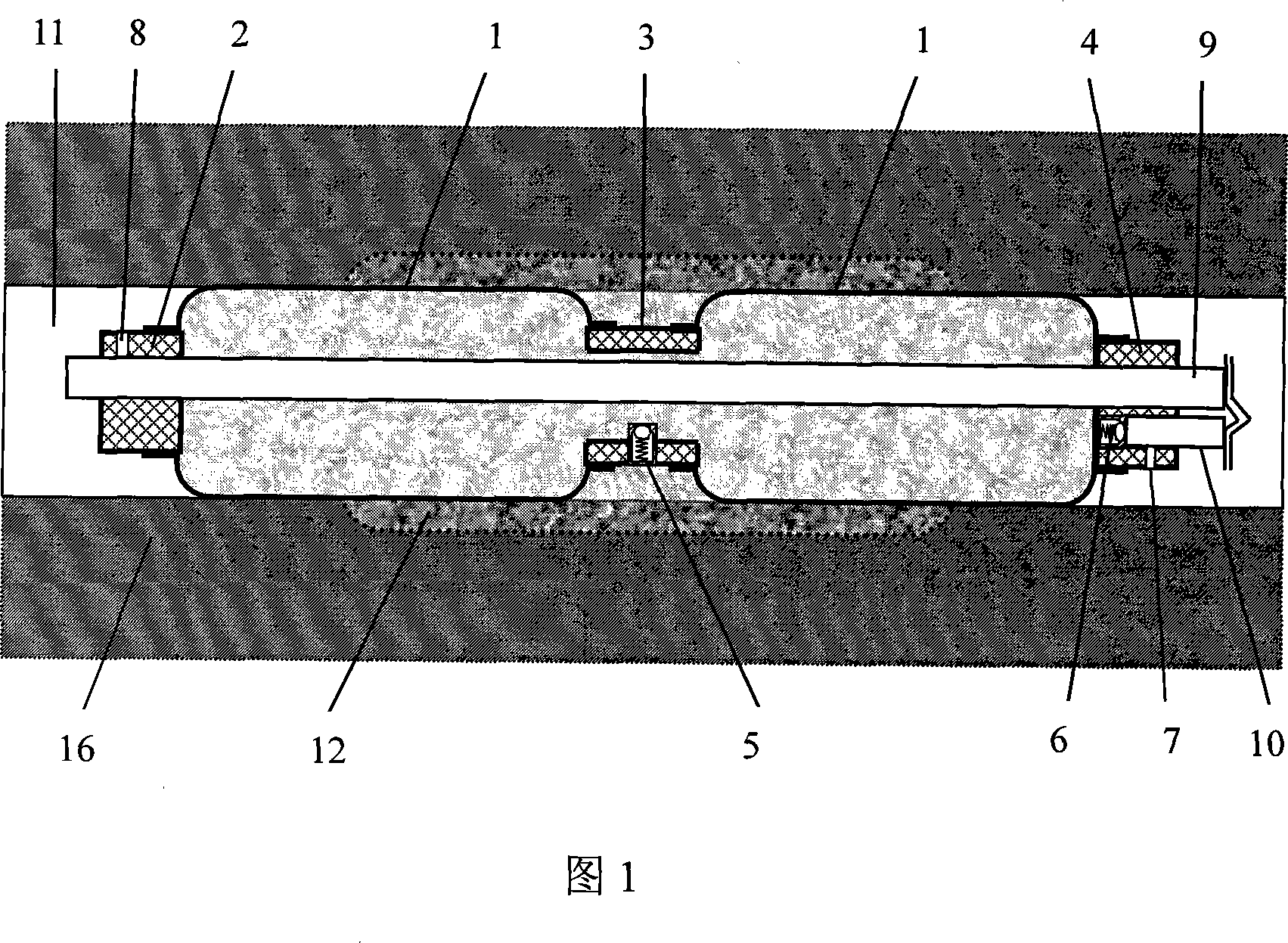

The present invention relates to a bag type paste-injecting hole-sealing equipment and its hole-sealing method. Said bag type paste-injecting hole-sealing equipment includes the following several portions: bag, internal end supporting component, middle portion supporting component, external end supporting component, paste injection control valve, reverse check valve and pressure control pin. Besides, said invention also provides the concrete steps of said hole-sealing method.

Owner:HENAN POLYTECHNIC UNIV

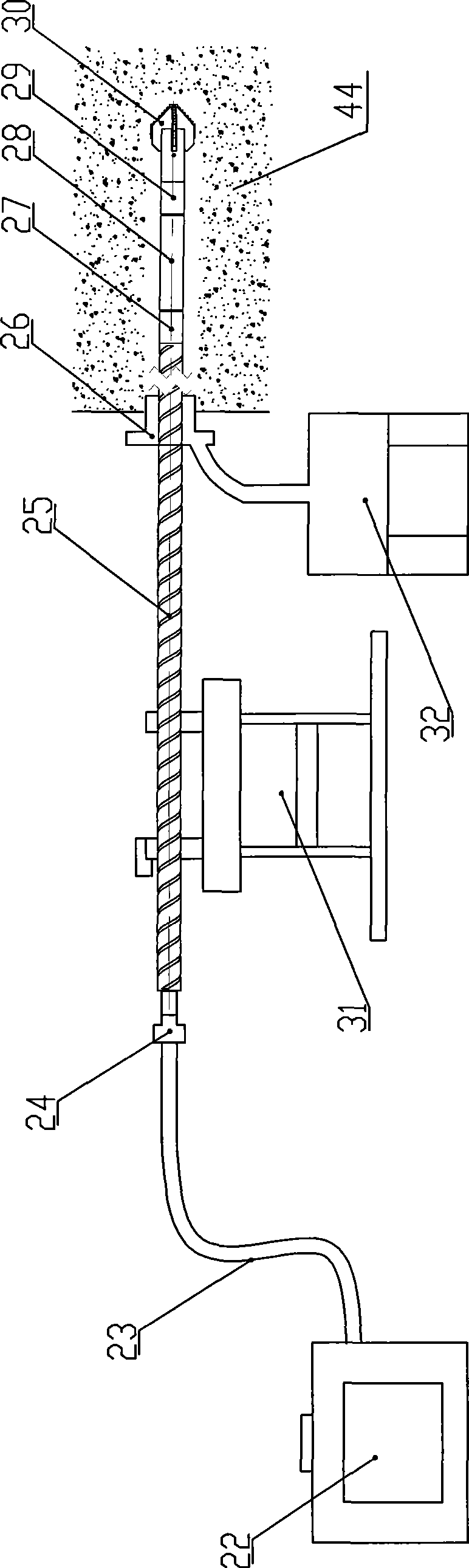

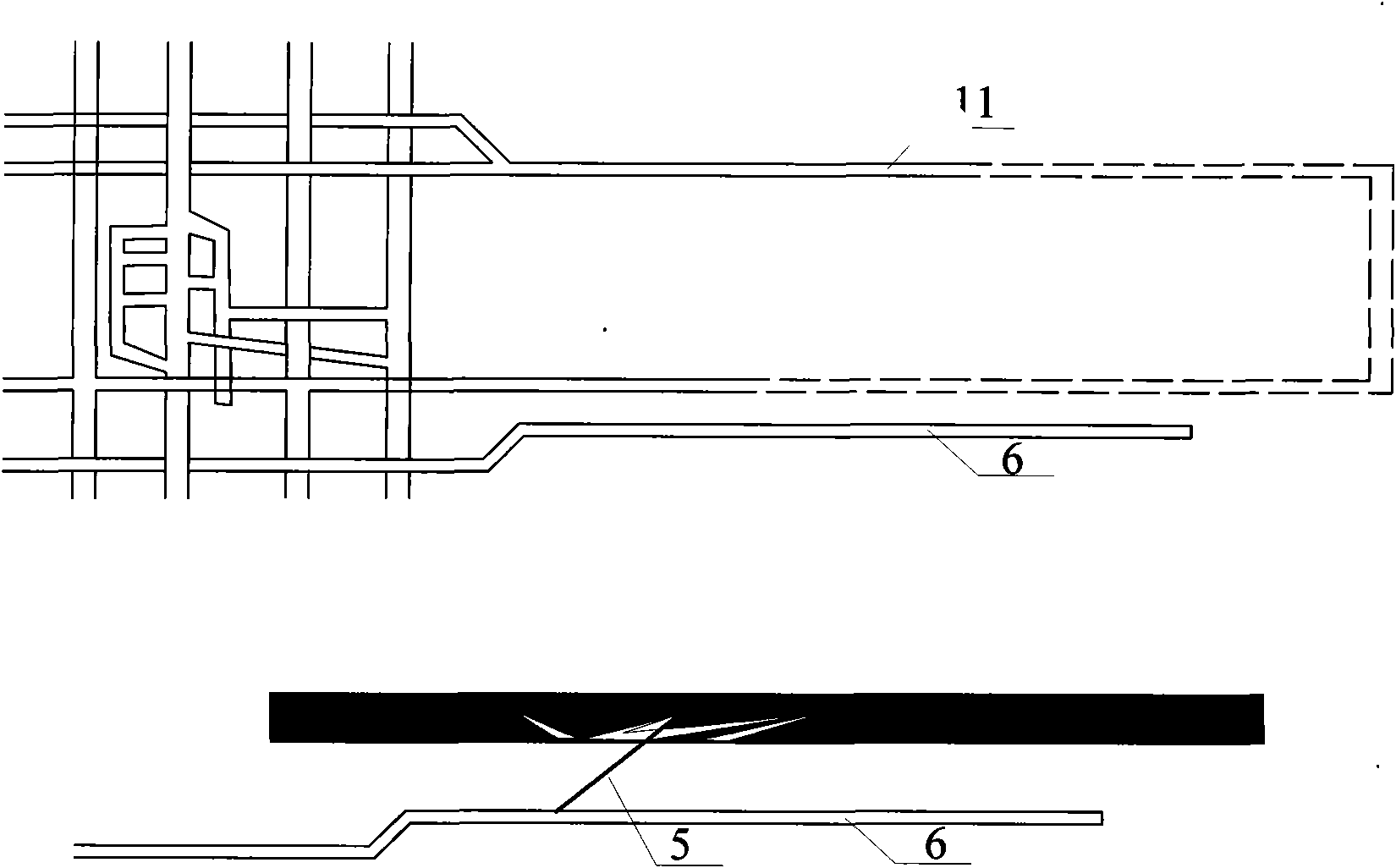

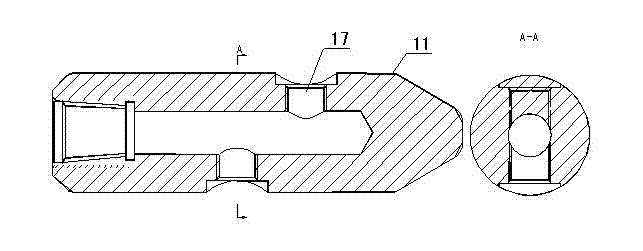

In-hole drilling tool integrating drilling, slotting and punching coal seam and using method thereof

InactiveCN101532391AGuaranteed cleanlinessAvoid enteringDrill bitsLiquid/gas jet drillingHigh pressure waterHigh pressure

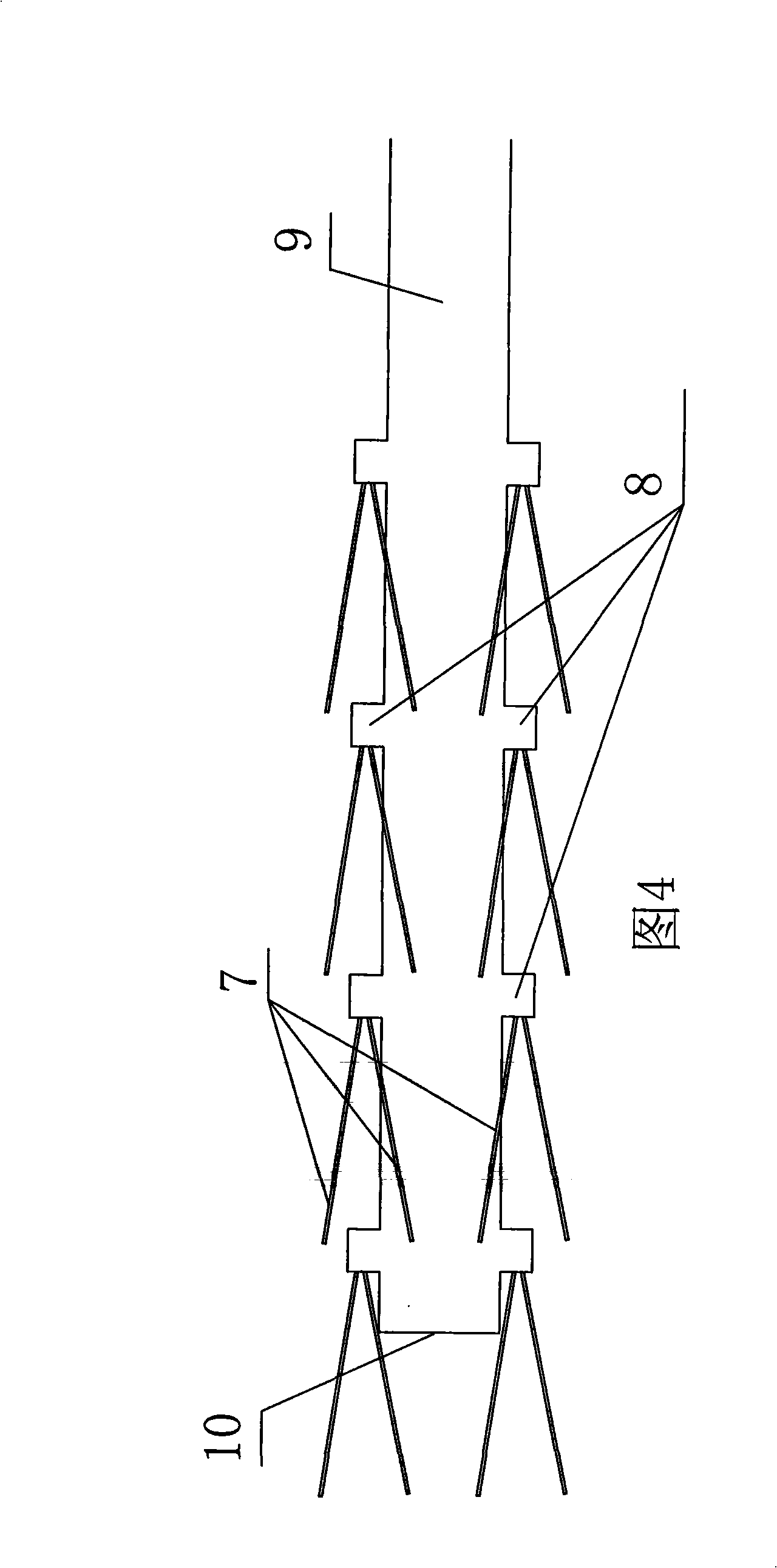

The invention discloses an in-hole drilling tool integrating drilling, slotting and punching a coal seam and a using method thereof. The in-hole drilling tool comprises a water supple device or an air supple device, a high-pressure sealing drill pipe, a slotting and punching valve and a drill bit. The water supply device and the air supply device are connected with the high-pressure sealing drill pipe at an orifice. The slotting and punching valve is installed between the high-pressure sealing drill pipe and the drill bit. The in-hole drilling tool is essentially used for drilling and anti-reflective outburst eliminating after drilling of soft outburst coal seam. The using method is as follows: after the drilling construction is finished, a water supplier with a pressure release valve is used for starting a high-pressure pumping station to improve the pressure and the flux for water supply; high-pressure water current at the pumping station drives the slotting and punching valve to act for closing an axial liquid passage and opening a radial liquid passage; and high-pressure jet current realizes slotting or punching through a cutting nozzle or a punching nozzle. The invention has novel design and easy operation, is safe and reliable, improves the outburst elimination efficiency and realizes the integrated operation of drilling, slotting or punching and outburst eliminating.

Owner:HENAN POLYTECHNIC UNIV

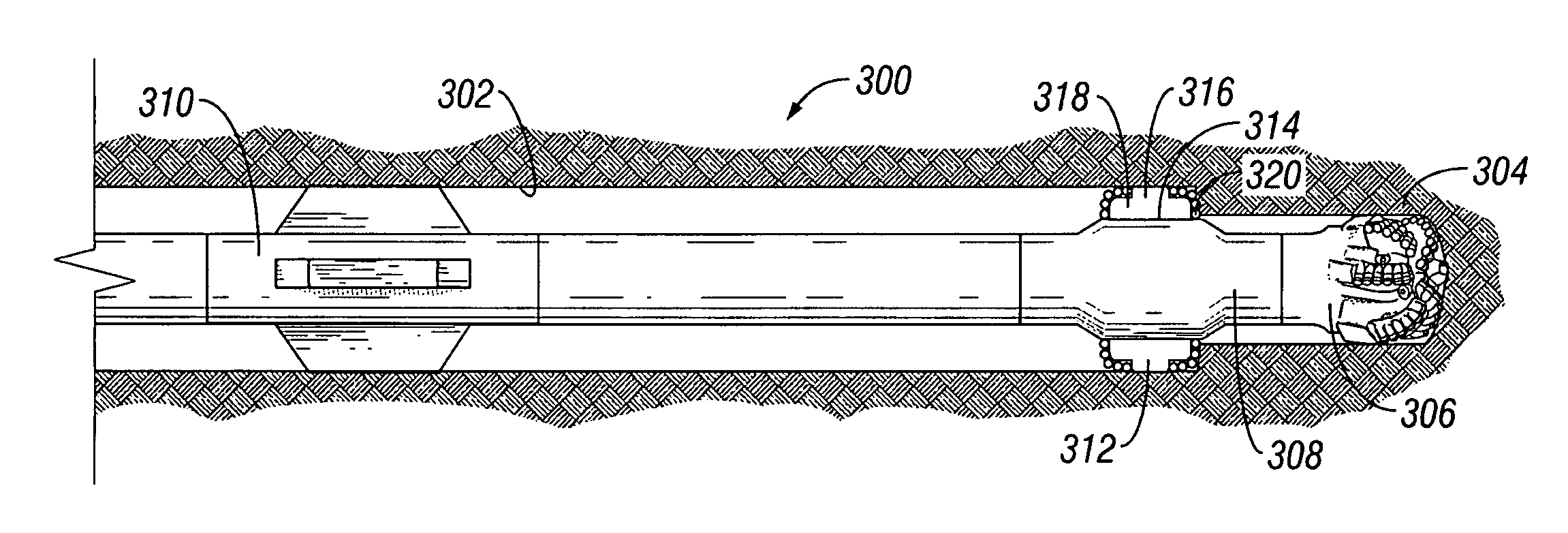

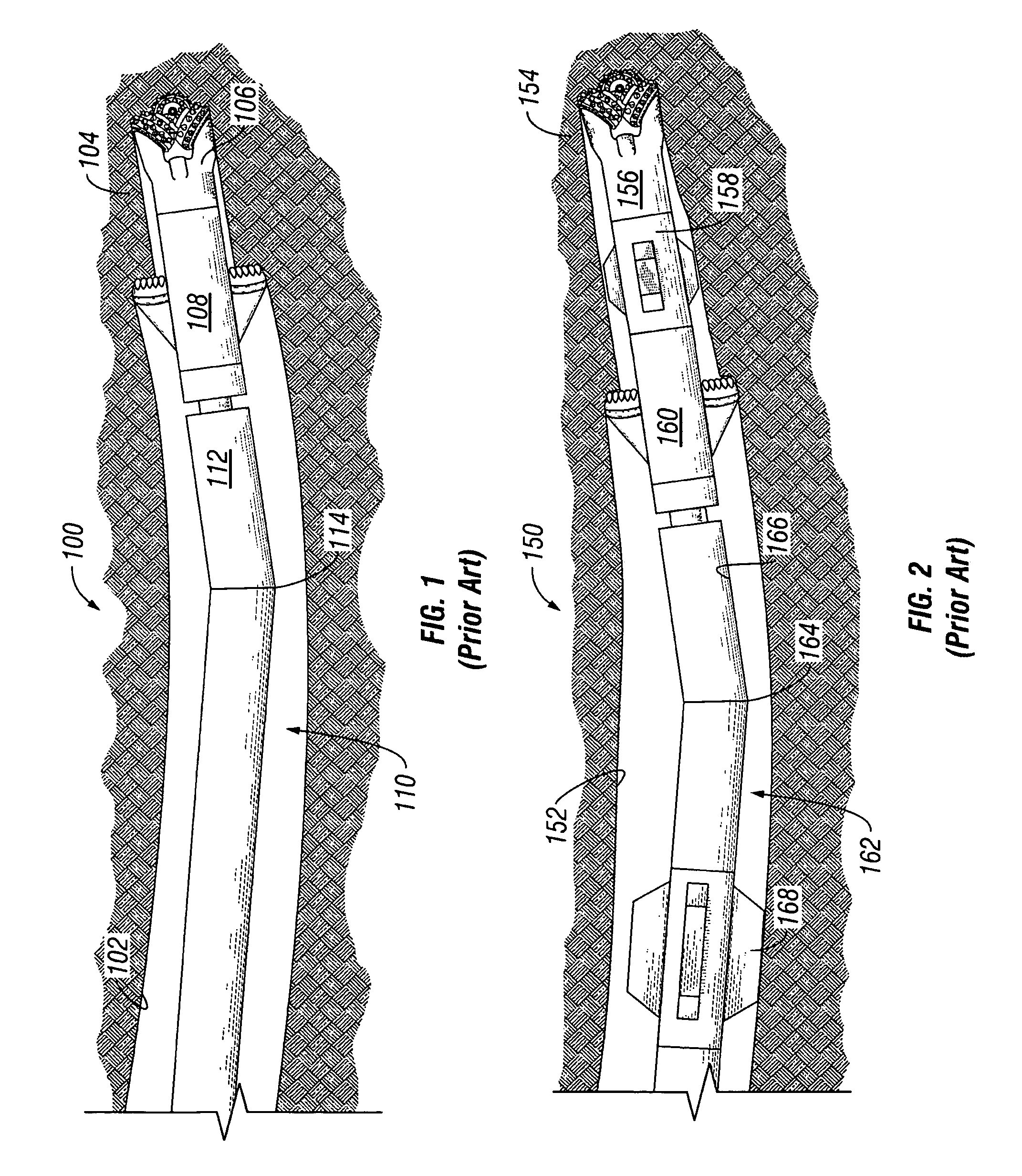

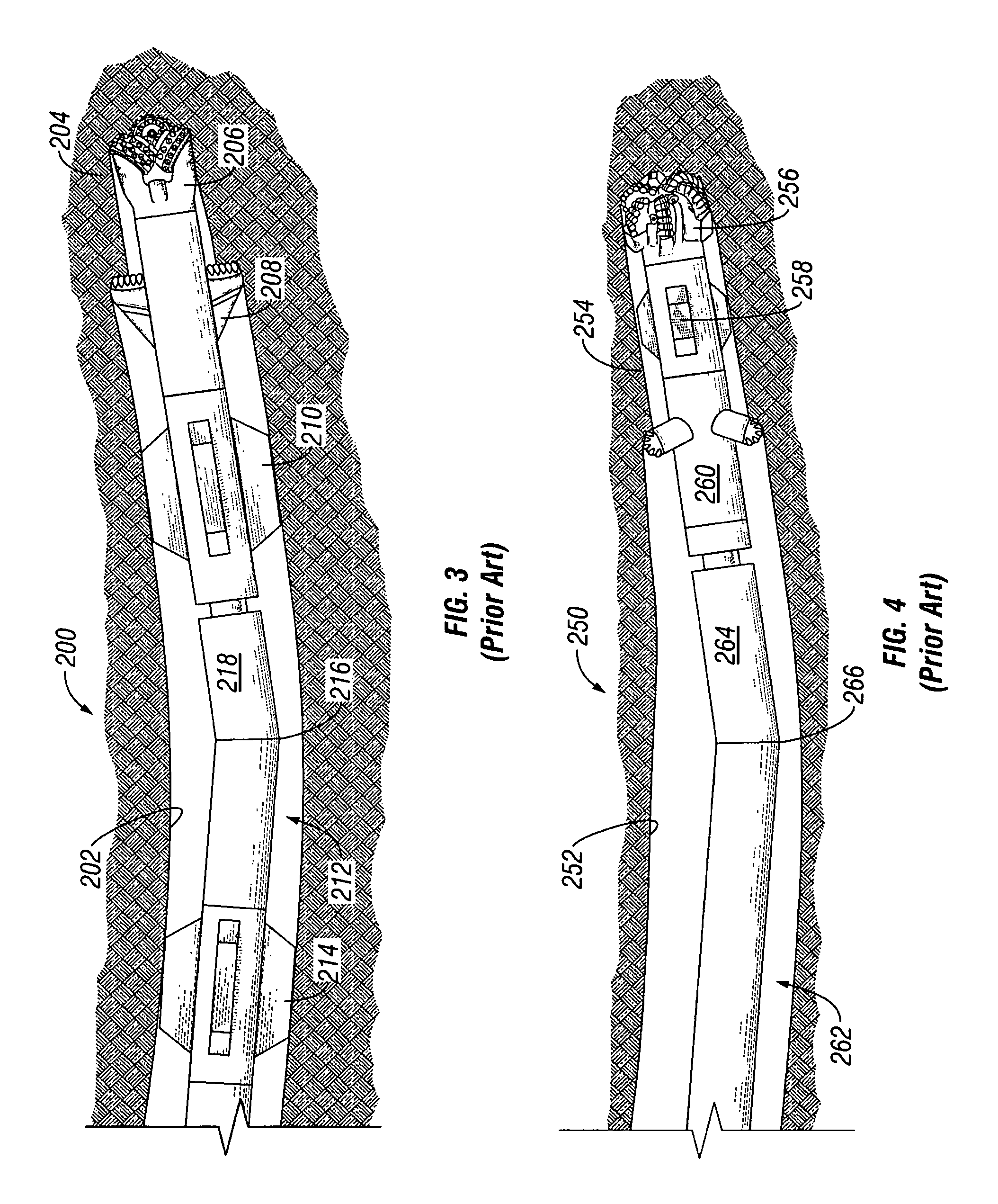

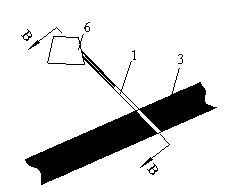

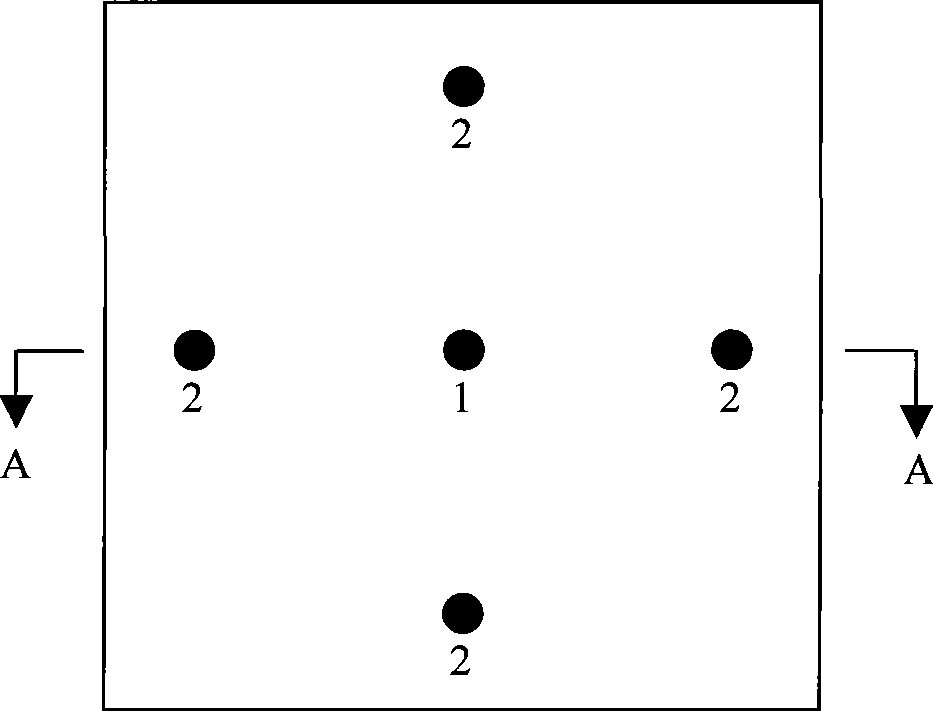

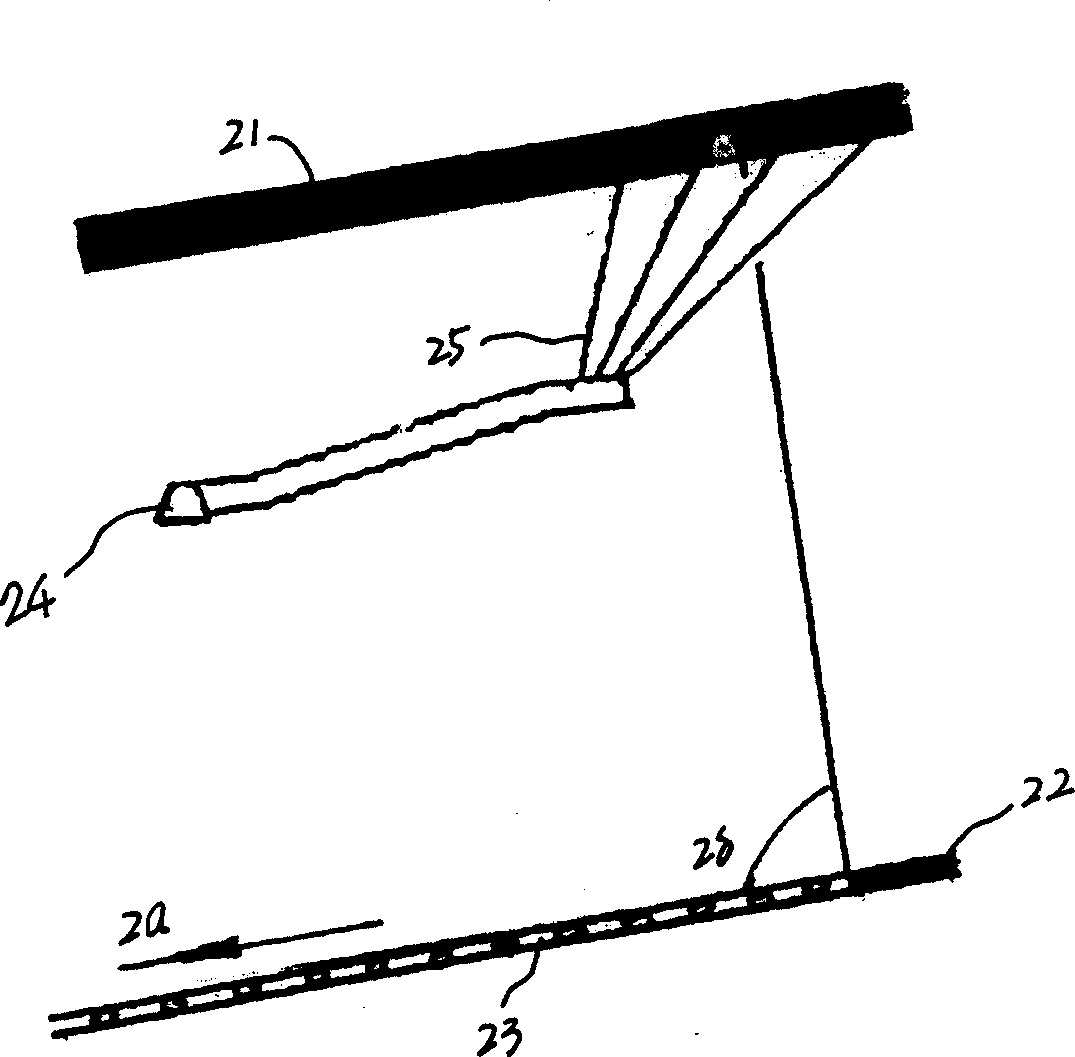

Steerable underreamer/stabilizer assembly and method

A bottom hole assembly includes a drill bit, a stabilized underreamer assembly located behind the drill bit, and a drilling assembly. A method to drill a formation includes positioning a stabilized underreamer assembly behind a drill bit, positioning a drilling assembly behind the stabilized underreamer assembly, and rotating the drill bit and stabilized underreamer assembly with the drilling assembly. A stabilized underreamer located between a directional drilling assembly and a drill bit includes at least one arm assembly extending from the stabilized underreamer assembly, wherein the arm assembly includes a stabilizer portion and an underreamer cutting structure.

Owner:SMITH INT INC

Method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection

ActiveCN102155254AChange mechanical propertiesImprove breathabilityFluid removalGas removalPulse pressureDischarge rate

The invention relates to a method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection, comprising the following steps: firstly using the blast-proof pulse-type coal layer high pressure water injector with adjustable frequency and pressure from the coal layer, high tunnel or low tunnel; using the pulse water effect generated by the periodical change of high pressure pulse water inside the drill hole of coal body, wherein the maximum pulse pressure is 35 MPa, the flow is about 300 L / min, and the pulse frequency is 0-1460 times / min; forcing the macroscopic fracture in the coal layer to be expanded and communicated; promoting the micro-pore fracture to be formed and extended; forming a new regeneration fracture net; providing a permeable channel of water inthe coal layer so as to achieve the effects of improving the mechanical property of the coal body, reducing the stress of the coal body in front of the working face and improving the discharge rate of the gas. Through the method, the pressure releasing range of the coal layer is enlarged, the whole pressure is adequately released, the radius of influence range of fracture can reach 10-40 m, and the air permeability of the coal body can be improved by 100-1000 times; and the method is simple, easy to operate and good in effect.

Owner:CHINA UNIV OF MINING & TECH

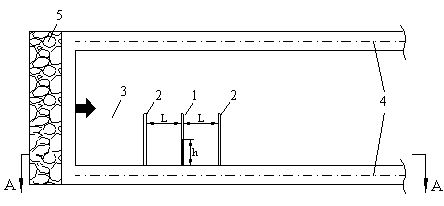

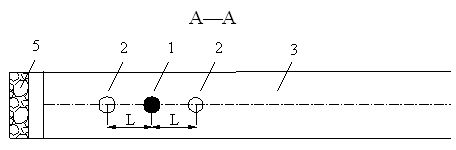

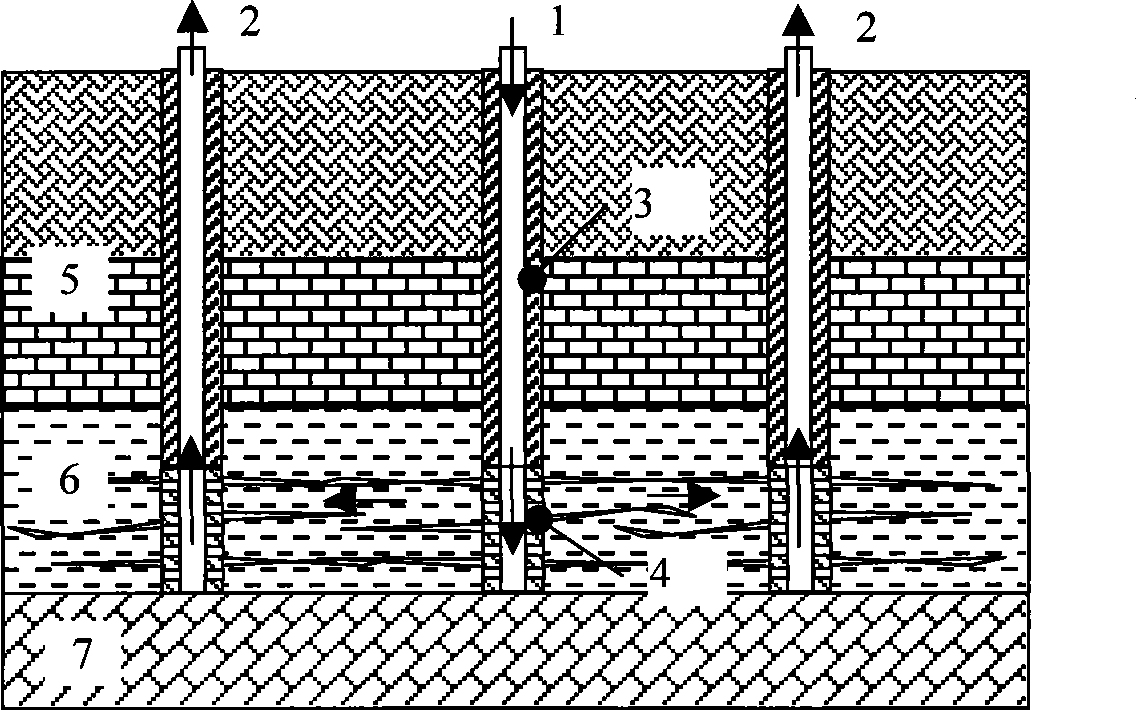

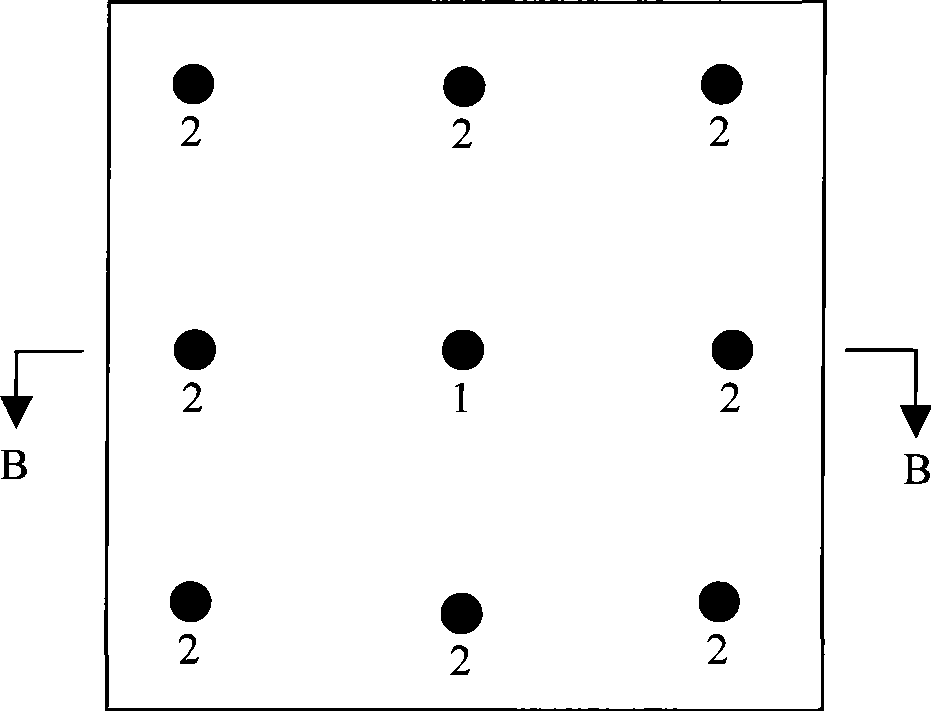

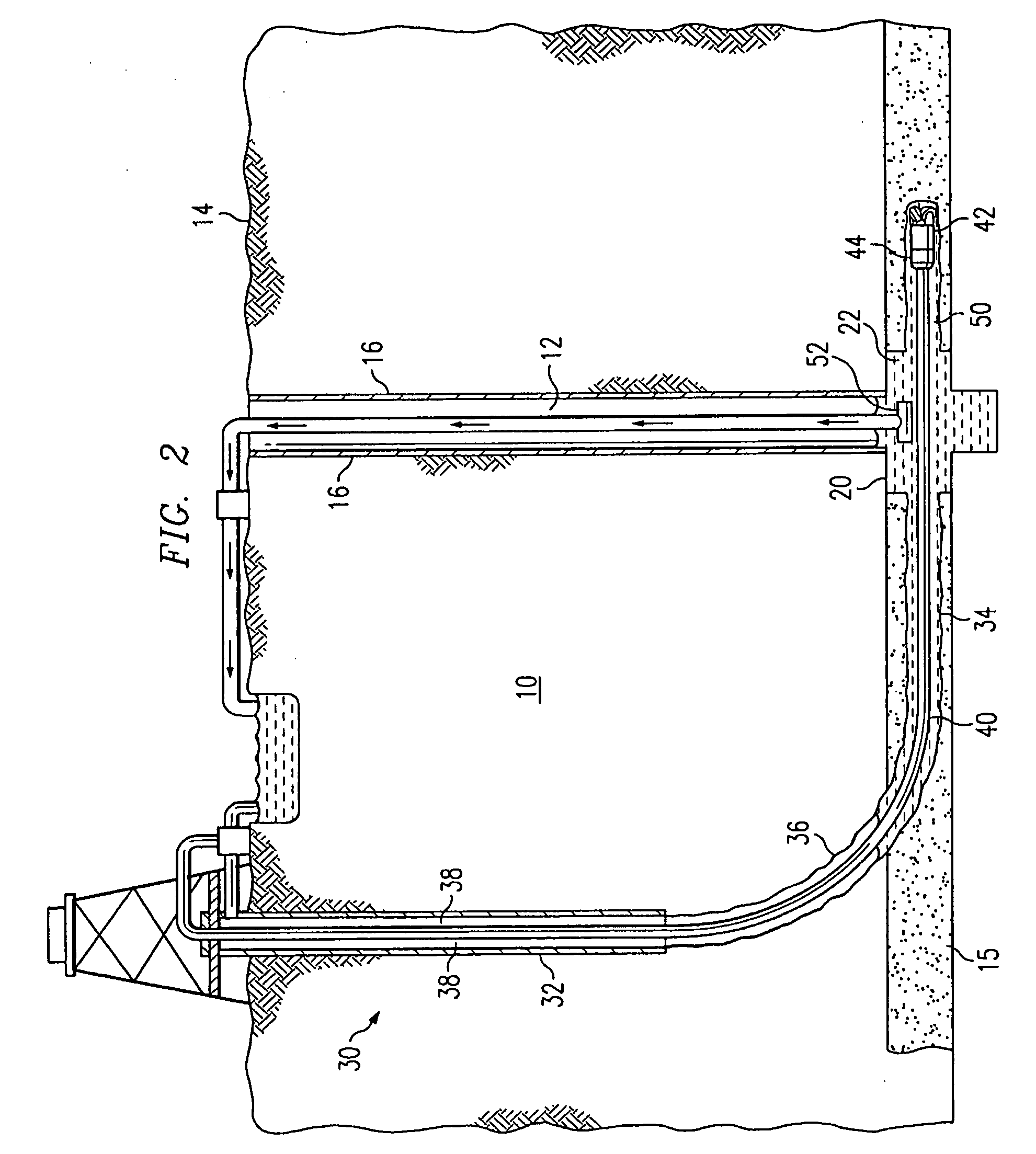

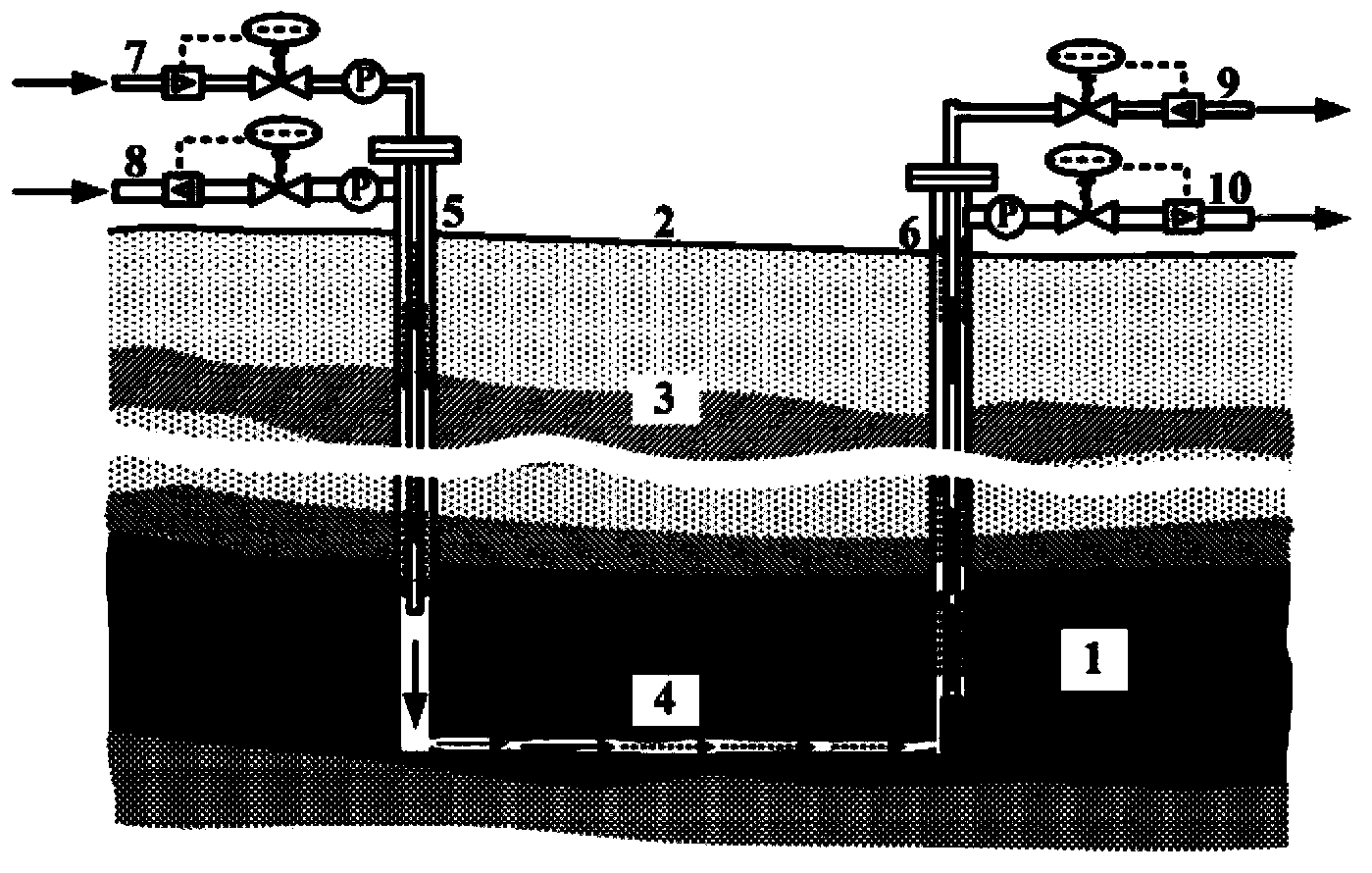

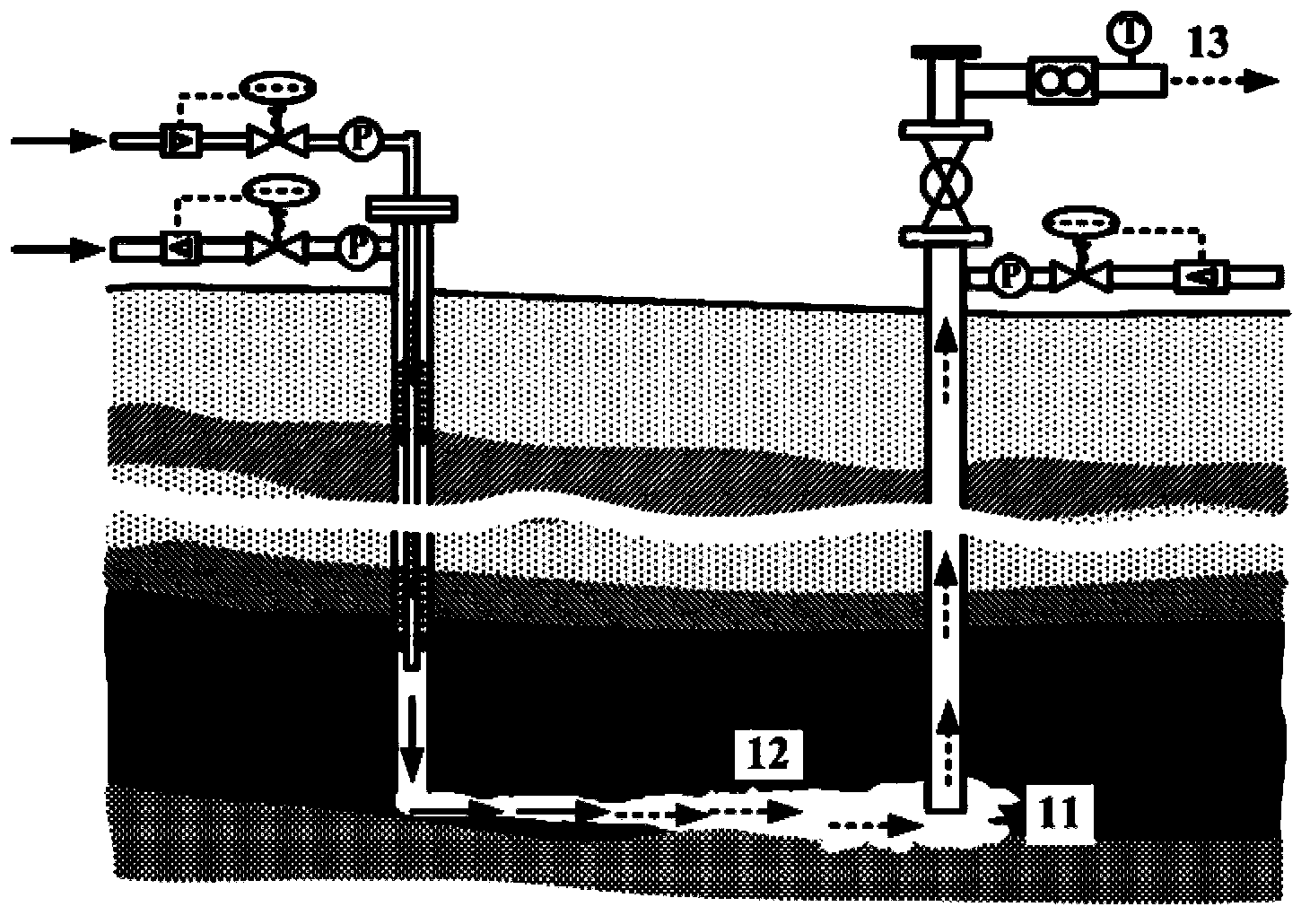

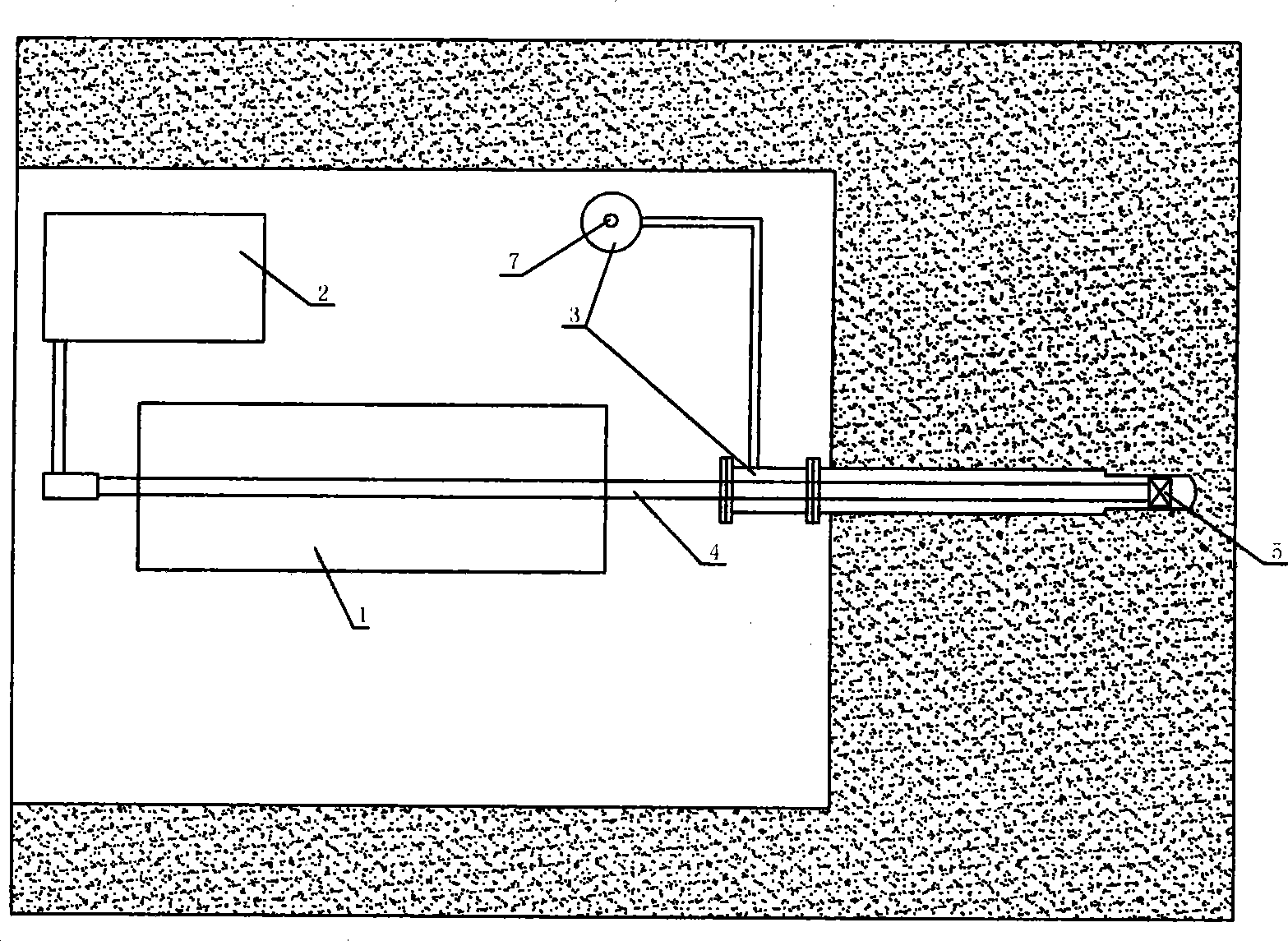

Method for pumping coalbed gas by heating coal bed

ActiveCN101418679AAchieve separationEfficient extractionFluid removalGas removalWater vaporDistilled water

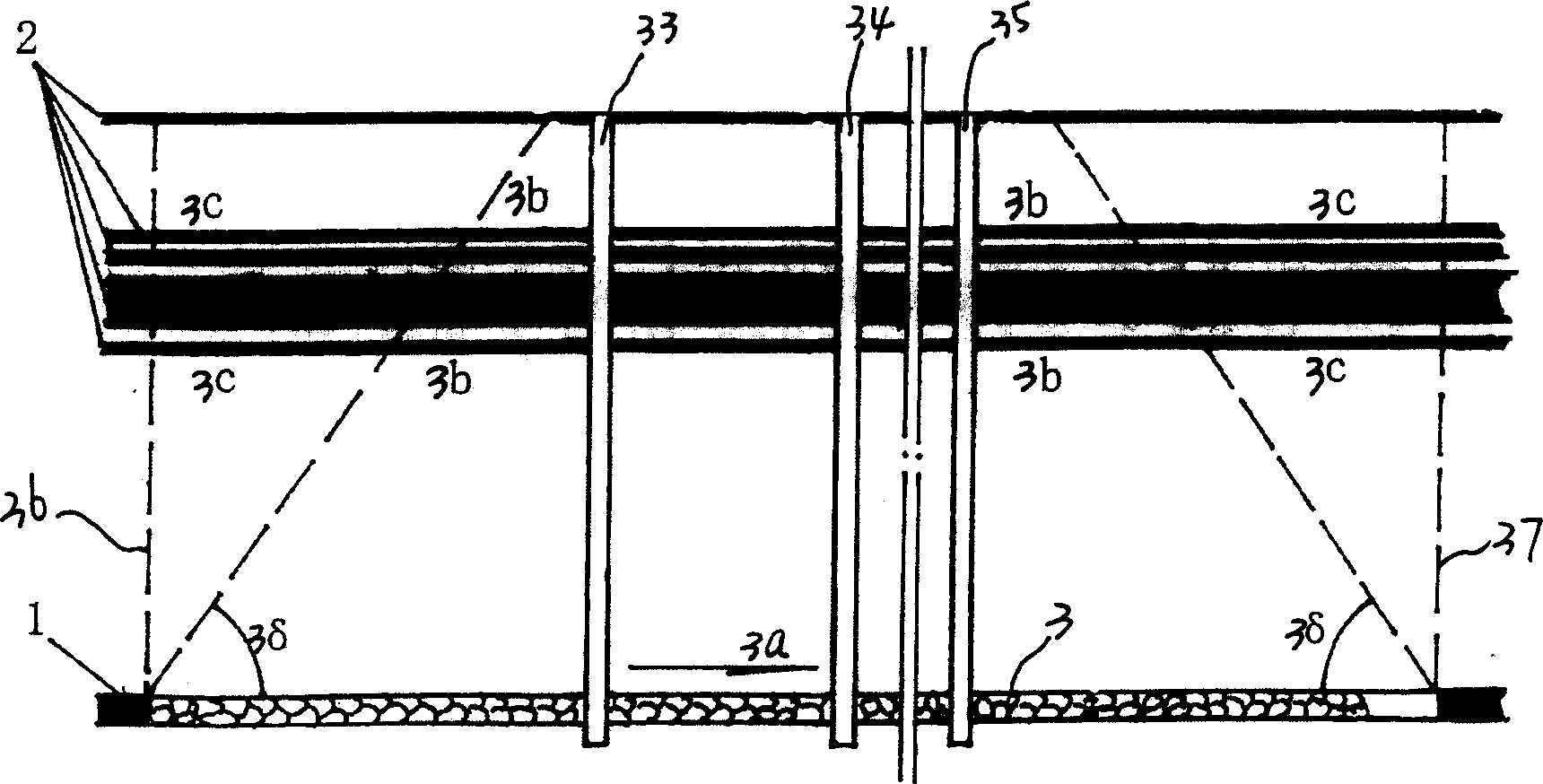

Provided is a method for heating coal seam and extracting coal seam gas. Firstly, a plurality of vertical wells are drilled from the ground to the coal seam, after the drilled well reached to the coal seam, the coal seam is inserted with a screen tube casing (4), the section above the coal seam is inserted with a heat insulation casing (31) and the well is correspondingly fixed. At least one well of the wells is selected to be a heat source injection well (1) and other wells are gas production wells (2), steam with high temperature and high pressure is injected into the heat source injection well (1) to perform fracturing to communicate all the wells in the network. Drainage and pressure reduction are performed to the gas production wells (2) to extract the mixed gas of the coal seam gas and steam. The mixed gas of the coal seam gas and steam is cooled by known cooling method so as to obtain gaseous coal seam gas and liquid distilled water to realize the separation of the mixed gas. According to the change of the coal seam temperature, the heat source injection well (1) and the gas production wells (2) are allocated to control the heated coal seam and extract coal seam gas. The method of he invention can effectively perform the extraction of the coal seam gas, accelerate the coal seam extraction speed, and improve the extraction rate.

Owner:TAIYUAN UNIV OF TECH

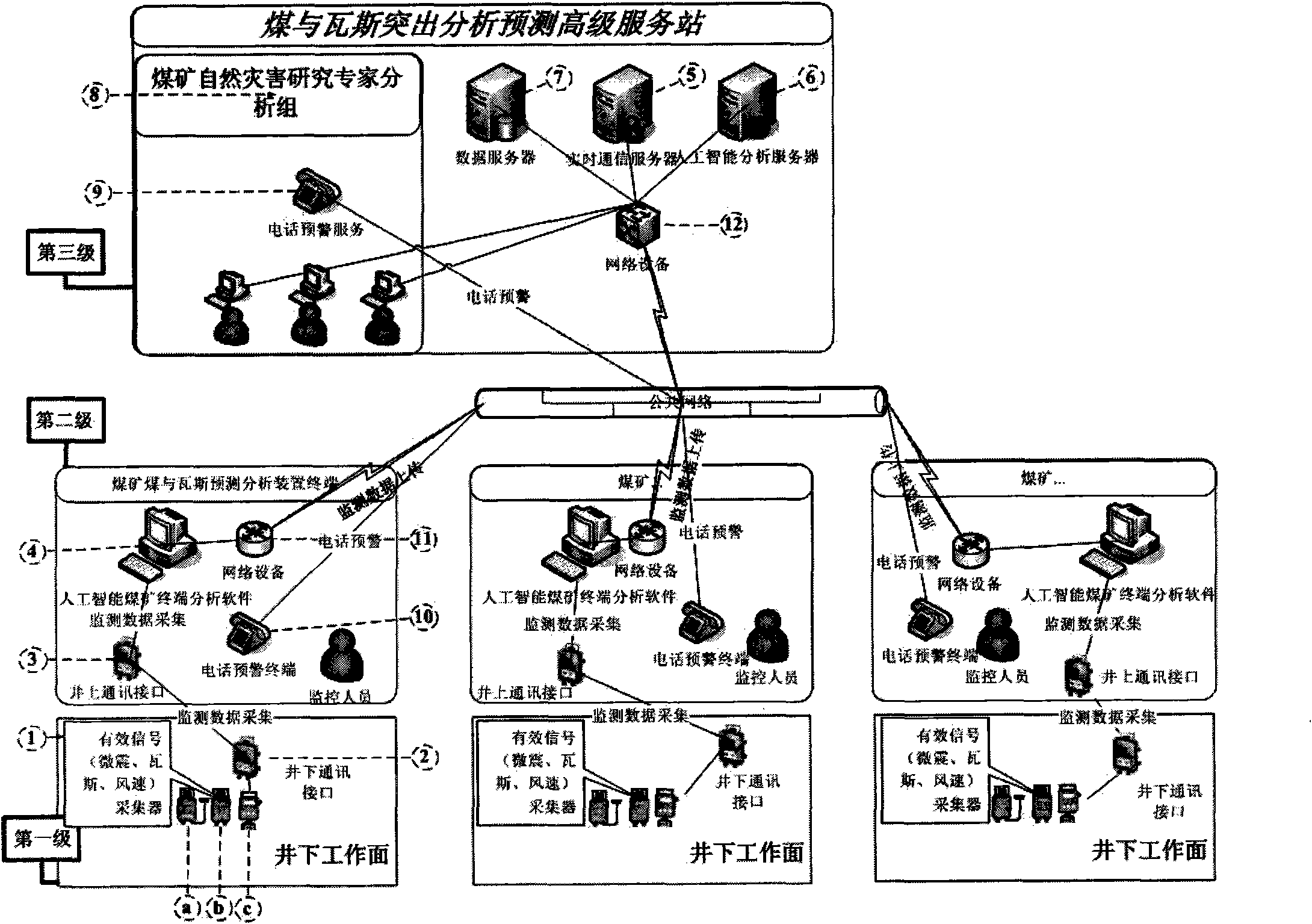

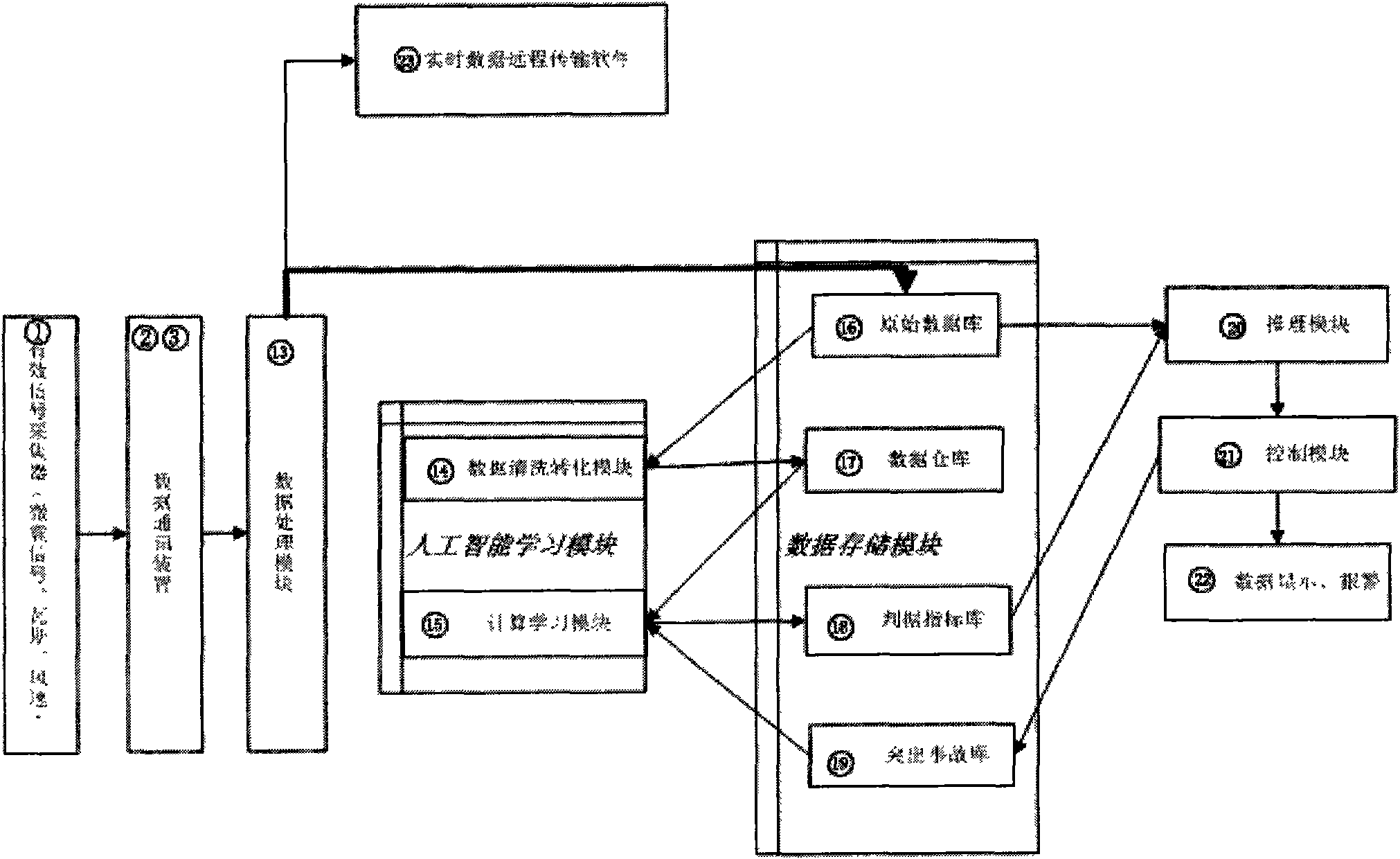

System and method for predicting coal and gas outburst risk of mine in real time

ActiveCN101787897ASolving the problem of varying hazard criteriaImprove forecast accuracyMining devicesGas removalReal-time dataNatural disaster

The invention provides a system and a method for predicting the coal and gas outburst risk of a mine in real time, which relate to a system and a method for judging mine natural disaster of coal and gas outburst risk degree through combination of artificial intelligence and expert analysis. The system uses a microseismic signal for reflecting the ground stress intensity and the gas outburst quantity for reflecting the gas change as analysis parameters to be combined with the expert experience, and can improve the predicting accuracy of the coal and gas outburst risk to high than 90 percent. The system and the method are characterized in that the system mainly consists of a data collection module, a data transmission module, a real-time data tracking and analysis center and an integrated early warning module, wherein after the data collection module collects underground data, the data is transmitted to the real-time data tracking and analysis center through the data transmission modulefor calculation, analysis and reasoning, and the integrated early warning module gives the early warning when a reasoning result shows that the risk occurs. The invention is applicable to similar mines with the coal and gas outburst risk.

Owner:西安西科测控设备有限责任公司

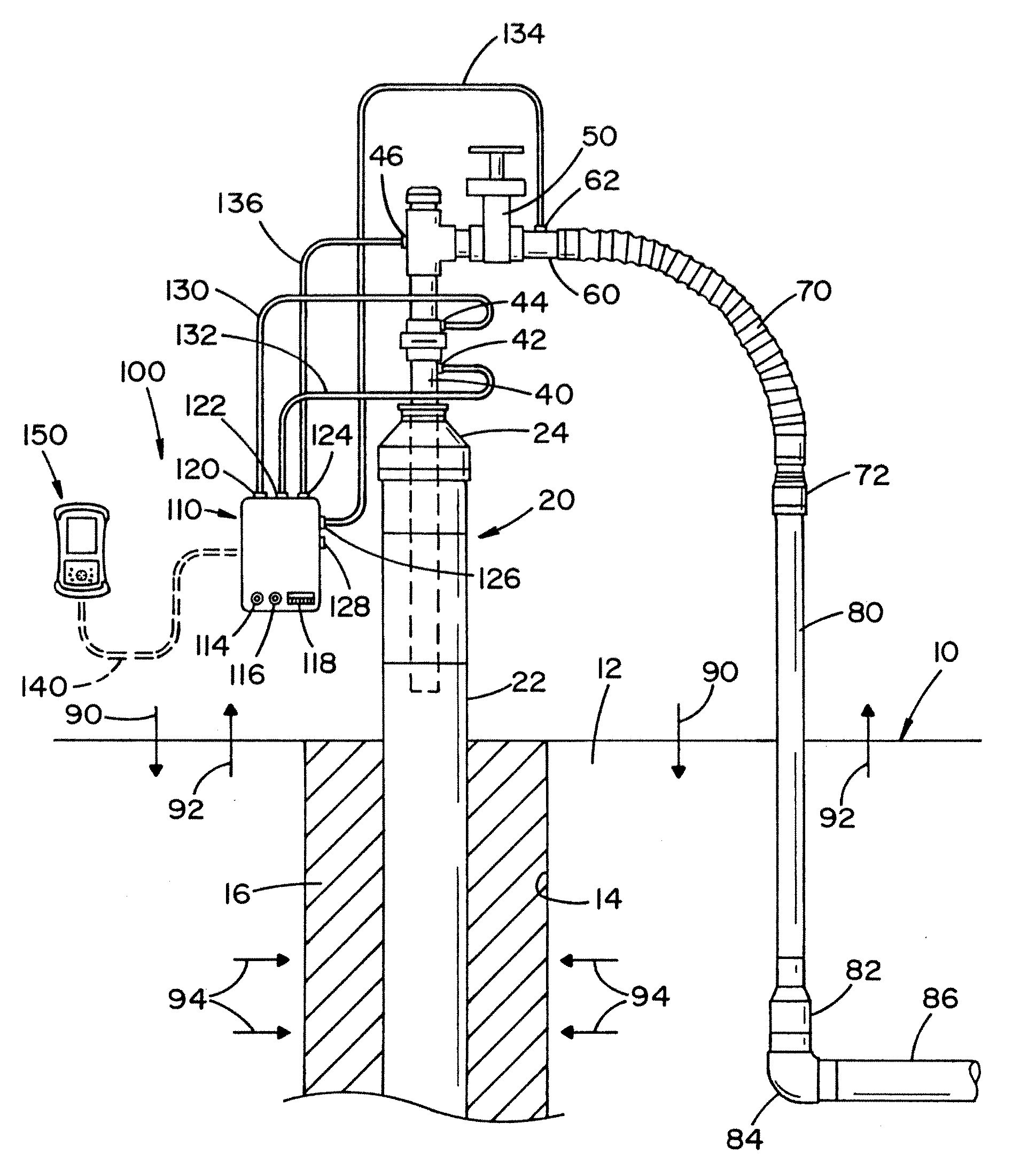

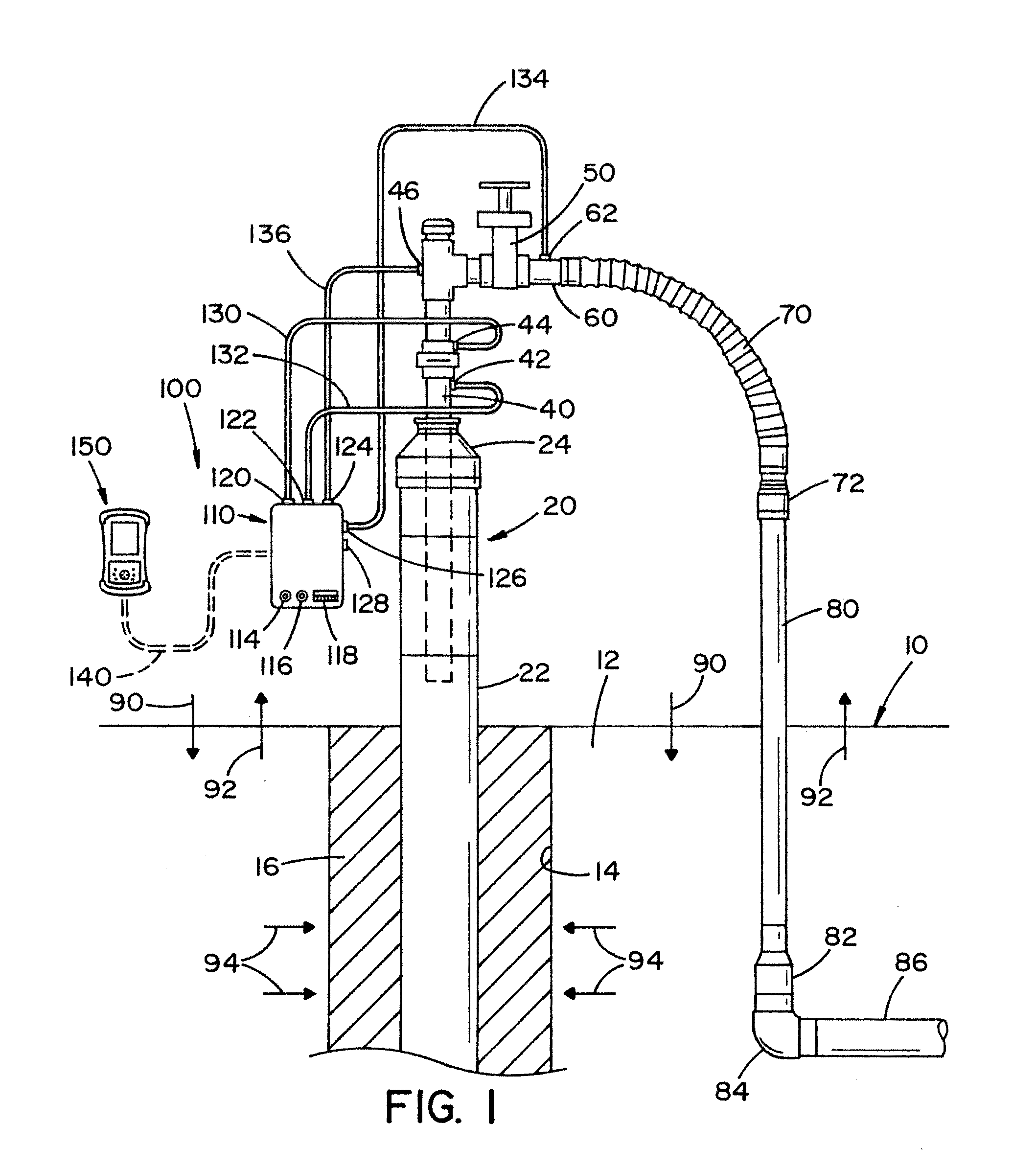

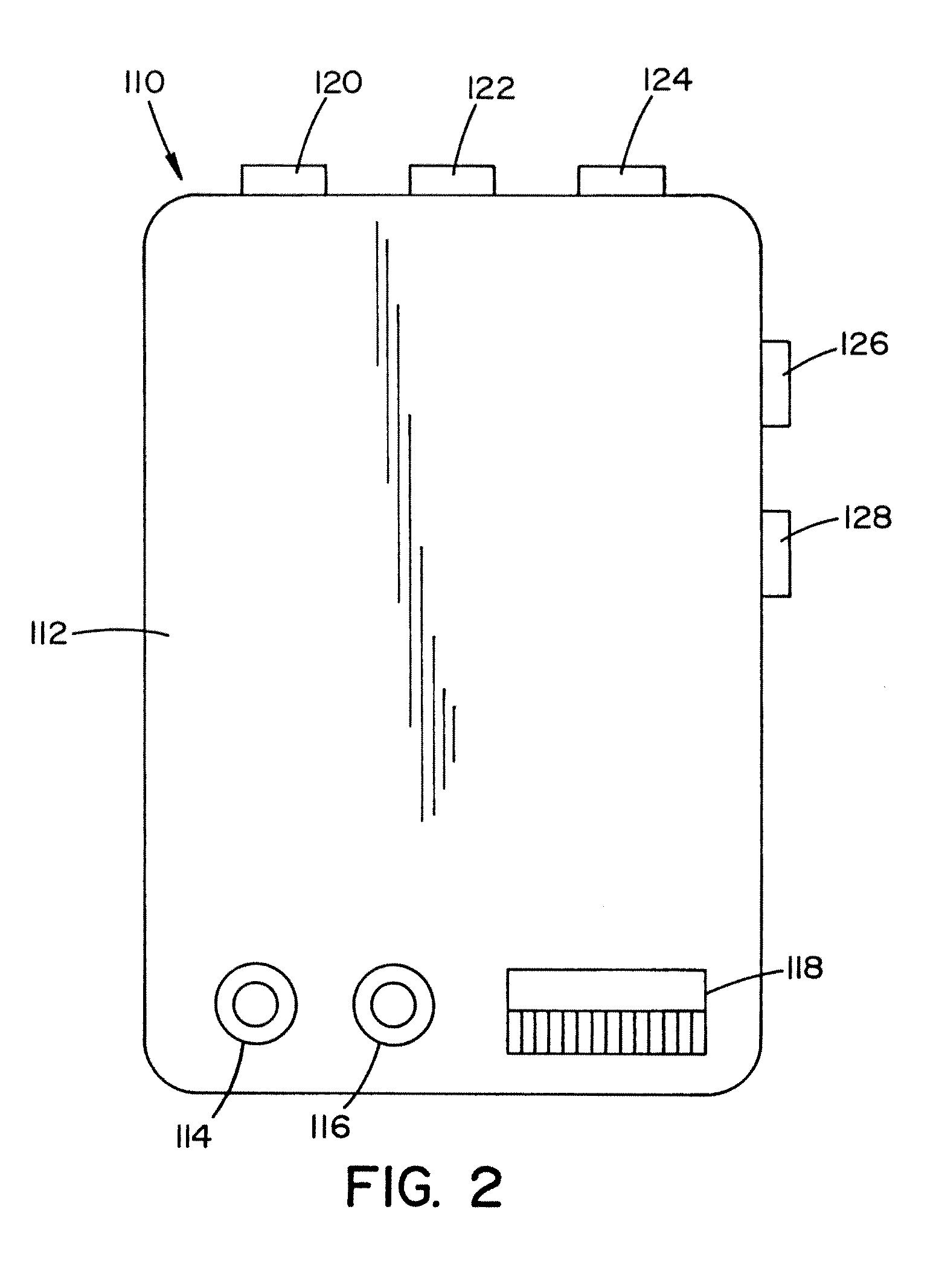

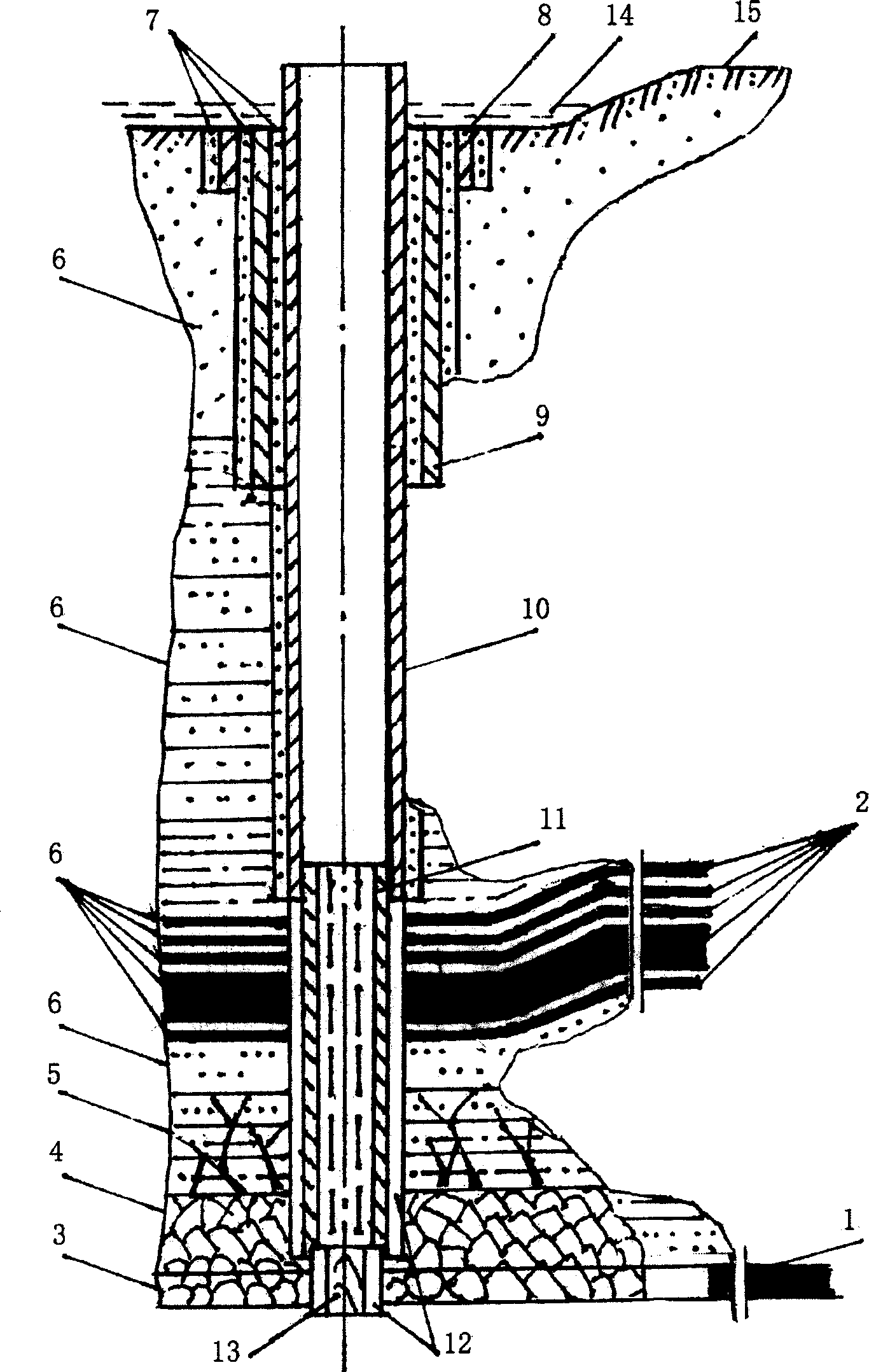

Portable gas monitor

InactiveUS20110231099A1Easy to identifyEasily obtain informationElectric/magnetic detection for well-loggingConstructionsEngineeringControl unit

A portable monitor used to measure landfill gas and landfill well parameters. The portable monitor includes a control unit and a measuring unit that can communicate wirelessly with one another. The control unit and / or measuring unit can include a heating arrangement to increase the temperature of one or more components in the control unit and / or measuring unit in cold environments.

Owner:ELKINS EARTHWORKS

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

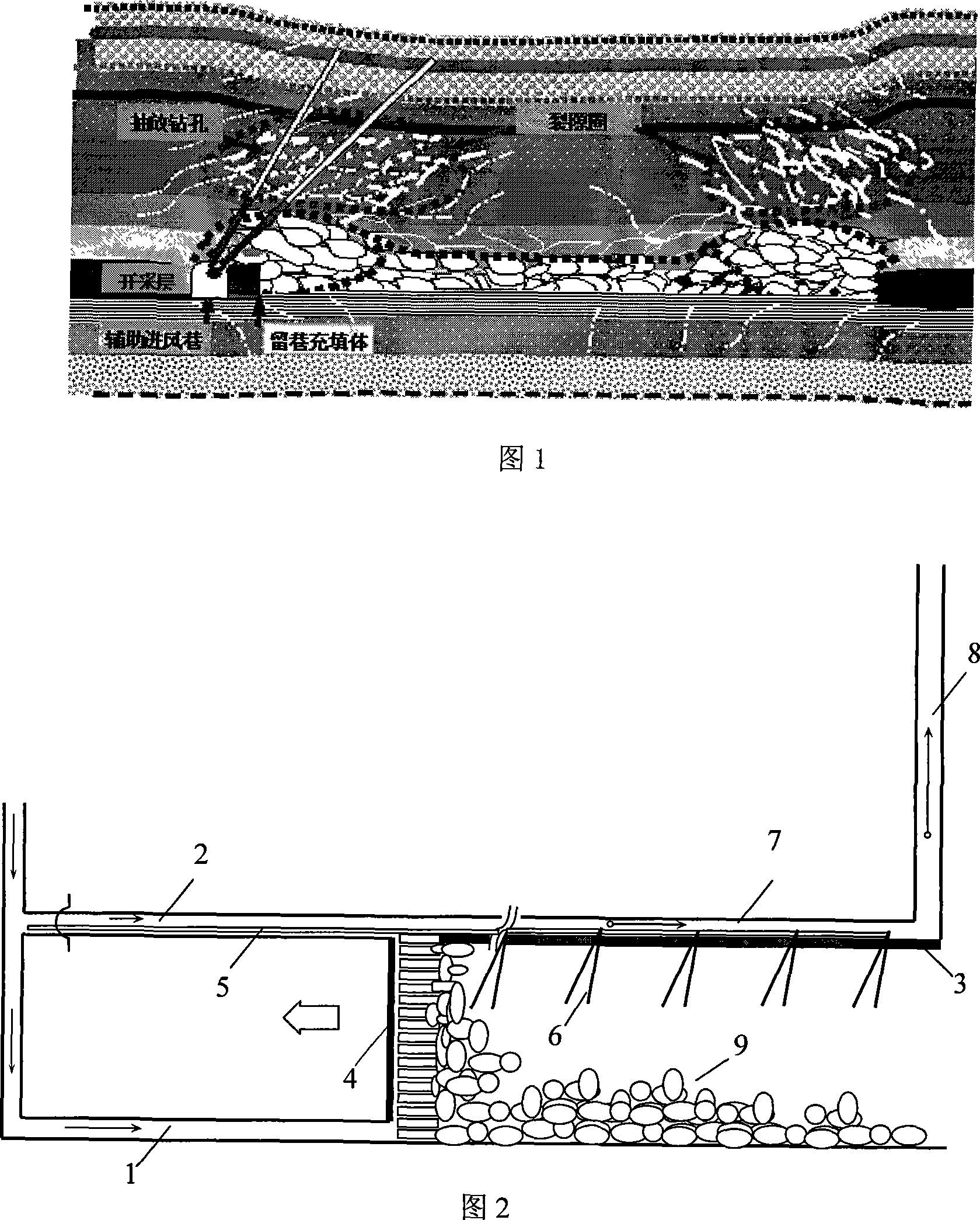

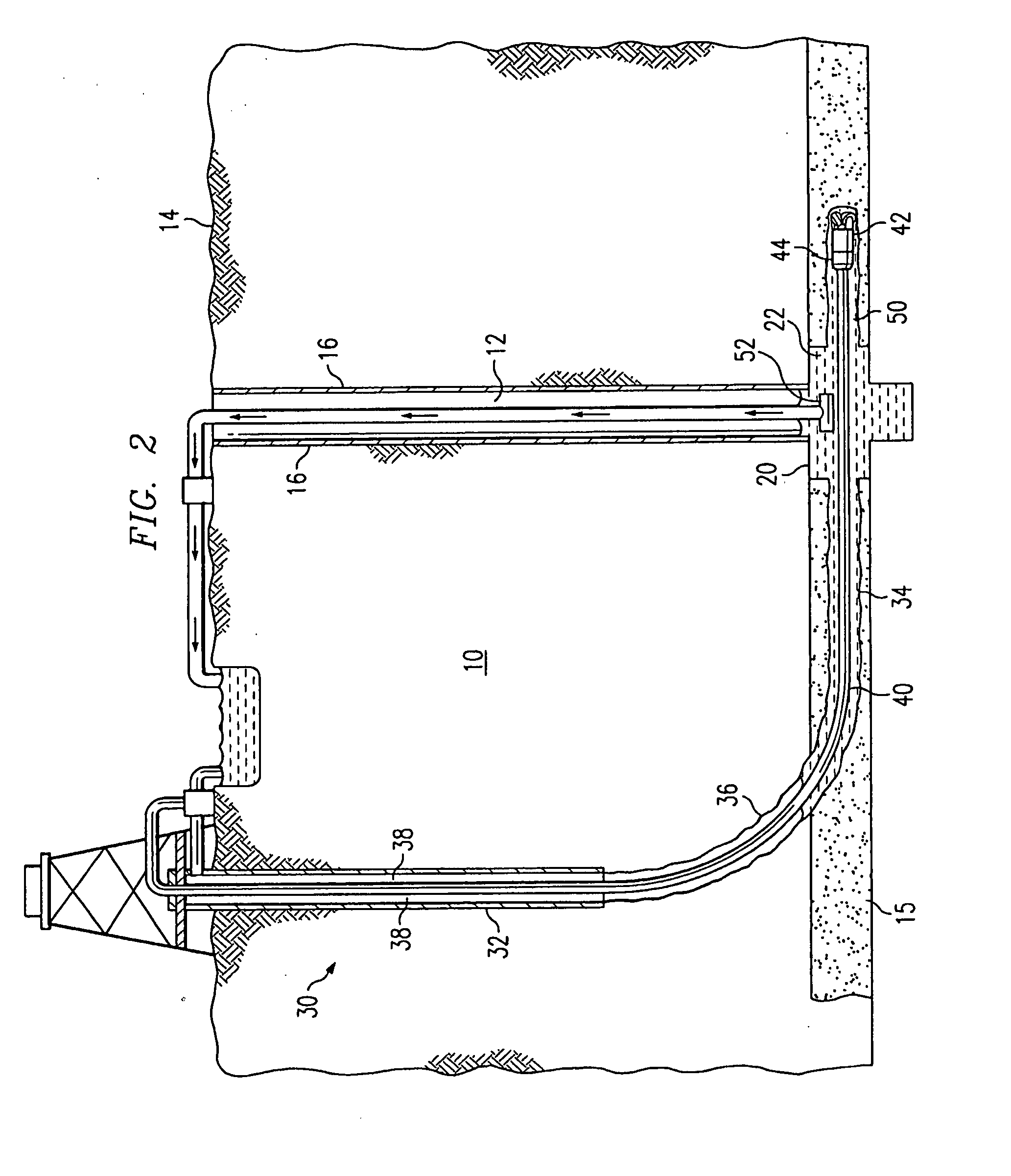

Gob-side entry retaining Y-type ventilation goaf top plate pressure relief gas pumping mining method

ActiveCN101082283ASolve the overrun problemReduce differential pressureTunnel/mines ventillationGas removalPlate pressureHigh density

A method to suck pressure relief firedamp along Y-shape ventilating gob roof of the empty tunnel is characterized in that: in the high-firedamp coal mining working-face pressure relief zone along the empty tunnel gob roof, it sucks the stripping and free firedamp from the exploiting and pressure relief layer which gathers in the gob upper part and the ring slit loop through the slit channel formed by the mining influence on the gob upper rock stratum through the dip sucking firedamp bore-hole which are distributed in the pressure relief ring slit loop. The pressure relief ring slit loop locates in the separation layer slit zone above the caving zone on the Y-shape ventilating working-face along the empty tunnel gob roof. The invention resolves the air firedamp overrun in the corner and the return airway on the coal mining working-face basically, realizes the sucking and application of the high density firedamp, improves the resource utilization ratio, exploits the high firedamp coal seam without coal wedges, improves the mine resource recovery and assures the high-efficiency and safe exploitation of the coal mining working-face.

Owner:HUAINAN MINING IND GRP +2

Method for integrated comprehensive management of gas in low-permeability single coal bed

InactiveCN102121395AReduce outstanding riskImprove breathabilityDrilling rodsFluid removalSocial benefitsHydraulic fracturing

The invention relates to a method for integrated comprehensive management of gas in a low-permeability single coal bed, which can effectively solve the problem of comprehensive management and utilization of the gas. A technical scheme of the method comprises the following steps of: firstly, drilling holes, wherein a high-torque drilling machine and a rifle or a trihedral drill stem are used for solving the phenomenon of clamping the drill stem caused by collapsing and jetting of the holes in the hole drilling process; and then, performing hydraulic fracturing permeability improvement on the coal body, drilling holes for pre-split blasting, performing gas drainage, and recycling the drained gas, thereby implementing the integrated management of the gas. With the method provided by the invention, the permeability of the coal body is improved, a pre-draining rate of the gas is improved, and the drained gas is recycled, so that the drilled holes are radically prevented from being blocked in the construction process, the problem of difficulties in draining the gas in the low-permeability coal bed with a drilling tool having insufficient capability in the drilling construction is solved, consequently, outburst risk of the coal and the gas is reduced, outburst accidents of the coal and the gas are reduced and even avoided, and mine production safety and lives of coal mine workers are ensured, so that the method brings great economic and social benefits.

Owner:平顶山天安煤业股份有限公司十矿

Directional fracturing permeability improvement outburst elimination method in coal mine and device thereof.

InactiveCN101575983AImprove breathabilityRapid and relatively long-lasting releaseFluid removalGas removalUltrasound attenuationFracturing fluid

The invention relates to a directional fracturing method in the coal mine and a fracturing permeability improvement outburst elimination device to ensure the coal-bed gas to release rapidly and continually in the coal mine. The method comprises the following steps: fracturing and drilling a bore on a preparing working face along the dip direction and strike direction of a coal bed, fixing a fracturing hole packer with an outer diameter matching with the pore diameter of a fracturing drilling bore into the fracturing drilling bore; connecting a fluid reservoir with a sand mixing machine, connecting the sand mixing machine with a fracturing pump package, and then connecting the fracturing pump package with the fracturing drilling bore; pumping formation fracturing fluid and proppant into the fracturing drilling bore to fracture the formation and sealing the fracturing drilling at above formation fracturing pressure, and completing directional fracturing permeability improvement outburst elimination in the coal mine, thus ensuring that the coal-bed gas discharges rapidly and continually relatively and solving the problems that drainage in low air permeability coal bed can only influence a limited range and the drainage attenuation period is short, improving the drainage rate by over 50% on primary base, decreasing the coal body dynamic phenomenon after fracturing and reginal stress influenced by fracturing, and having a significant effect for eliminating outburst.

Owner:河南省煤层气开发利用有限公司

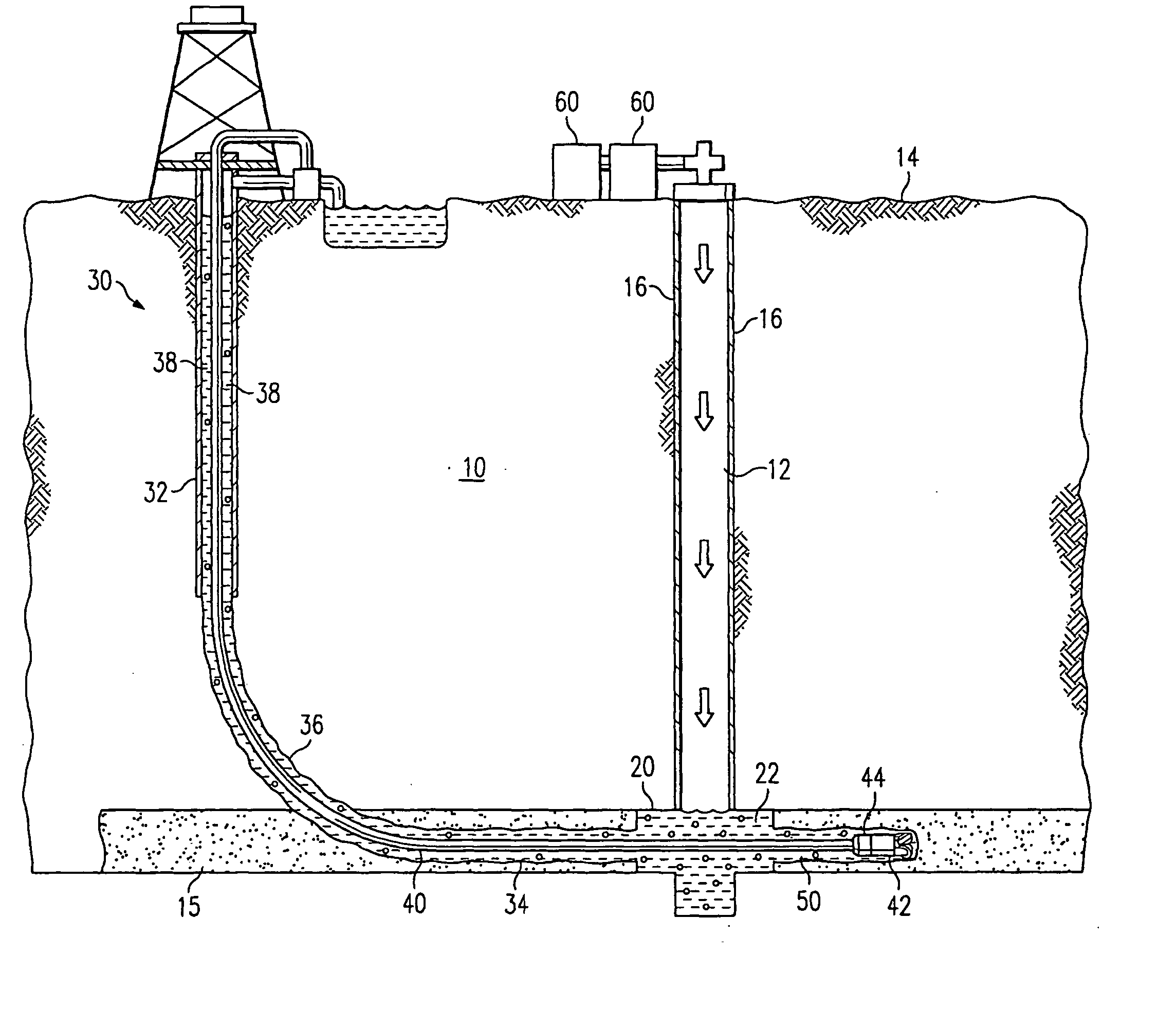

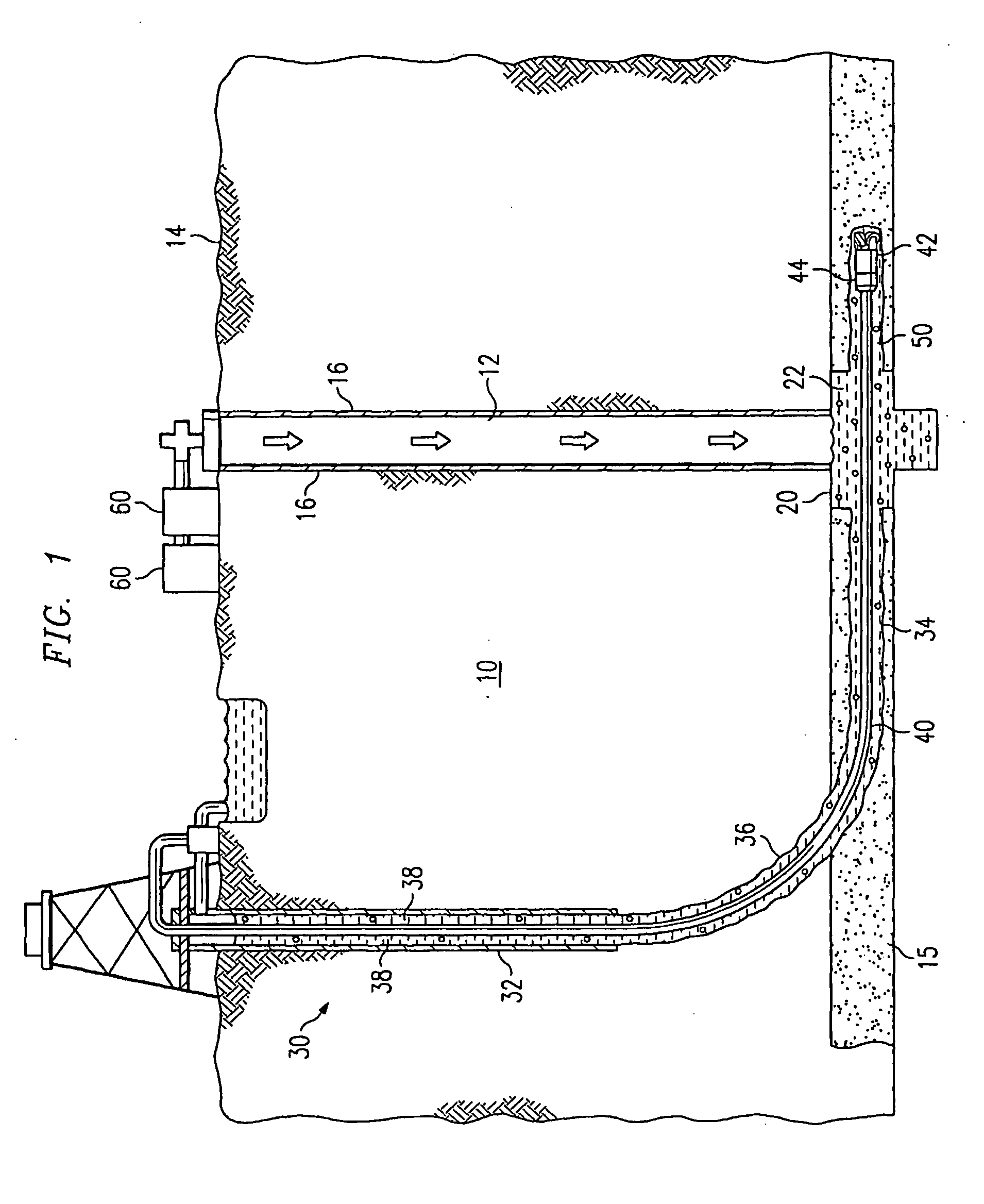

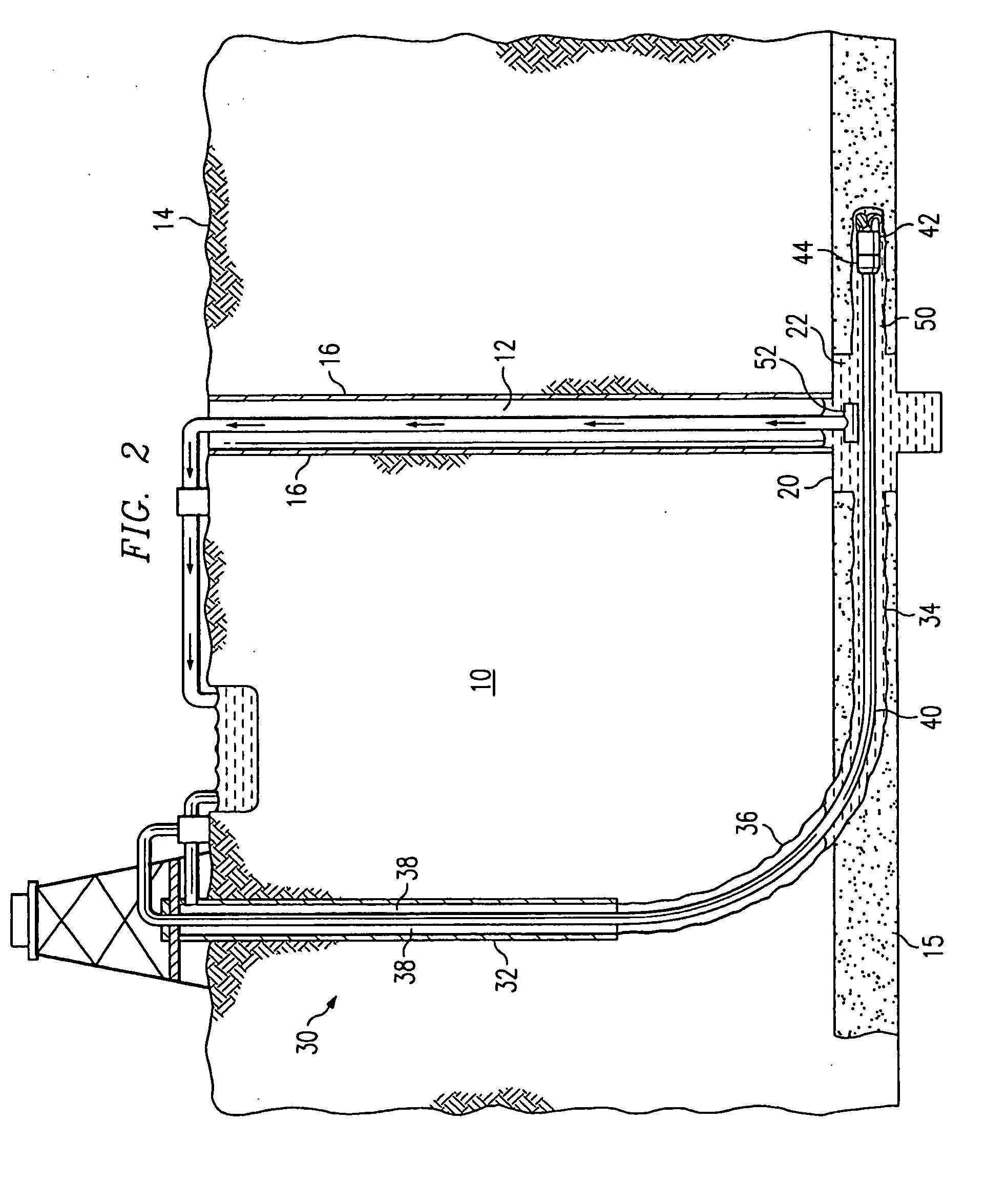

Method and system for accessing subterranean deposits from the surface and tools therefor

Owner:EFFECTIVE EXPLORATION

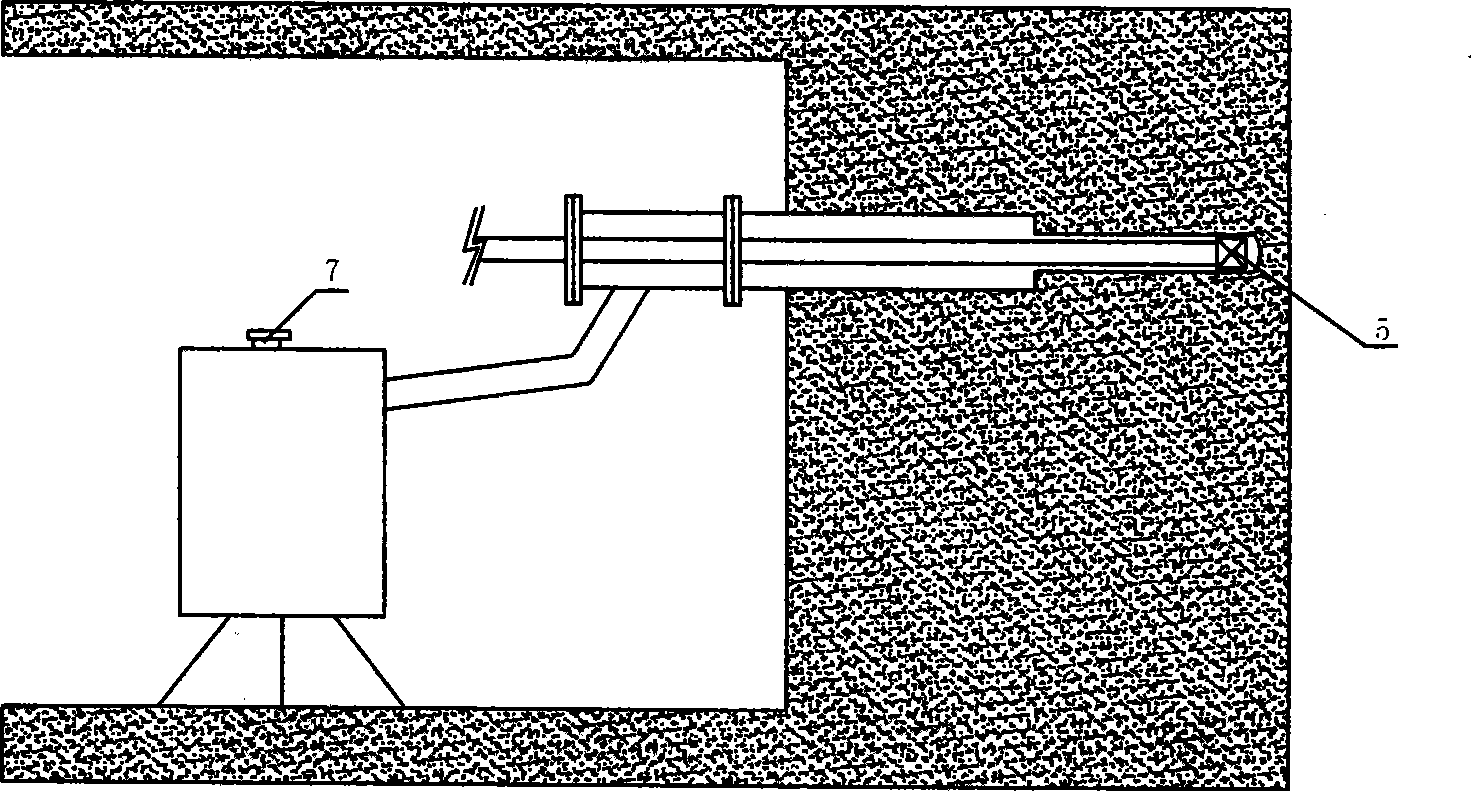

Gas pressure relief method of ground drilling extraction minery and goaf

InactiveCN1693654ARealize green co-miningAchieve destructive effectFluid removalGas removalWell drillingCoal

This invention discloses a method for depressuring gas in ground drilled well and mining area. Before extracting coal a ground drilling well is drilled from ground to long distance, low breathing, high gas, projecting and soft covered seams, then extracting down seam. The gas from the up covered seam is exhausted from pipe.

Owner:HUAINAN MINING IND GRP

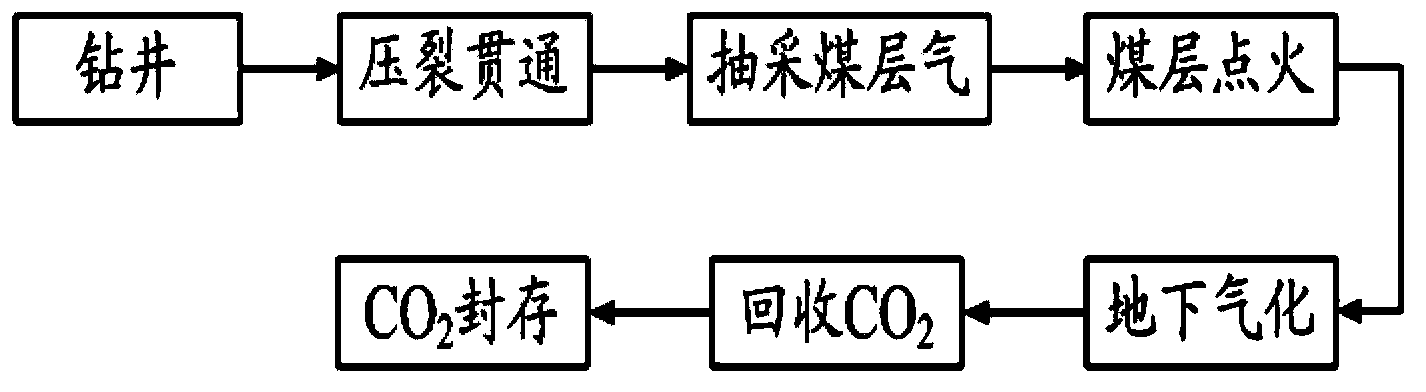

Method for extracting coalbed methane and coal together

ActiveCN103670338AImprove breathabilityEnhanced overall recoveryConstructionsFluid removalWell drillingCoal

The invention relates to a method for extracting coalbed methane and coal together. The method includes a well drilling step, a pressing crack cut-through step, a coalbed methane extracting step an ignition step and an underground gasification step. According to the method, an underground coal gasification technology and a coalbed methane extracting technology are combined, a coal bed can be heated by high temperature of underground gasification to improve breathability of the coal bed and increase extracting ratio of the coalbed methane, well drilling and pressing crack cut-through processes can be performed by the aid of the coalbed methane, and the underground gasification coal extraction efficiency is increased.

Owner:ENN SCI & TECH DEV

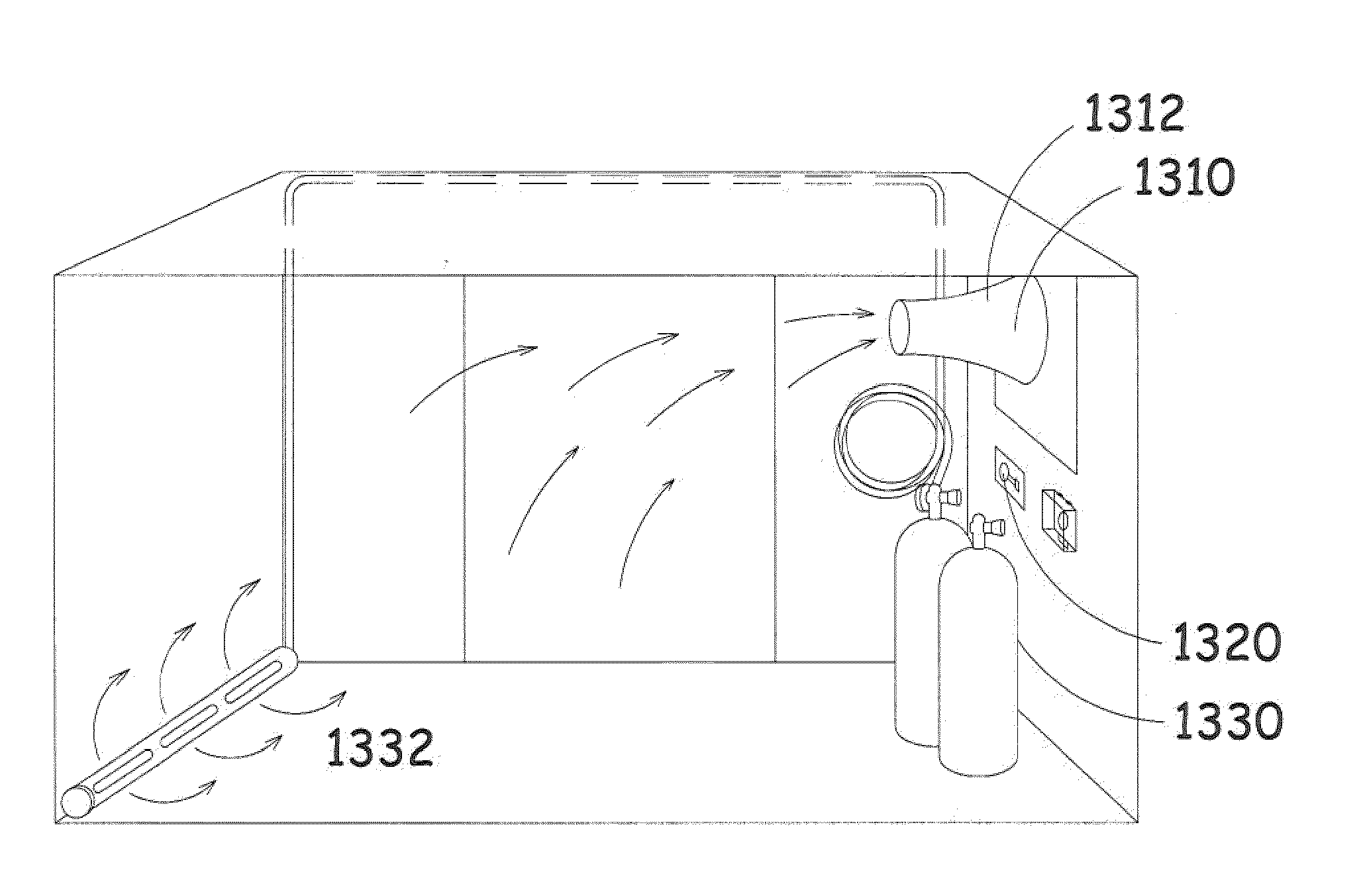

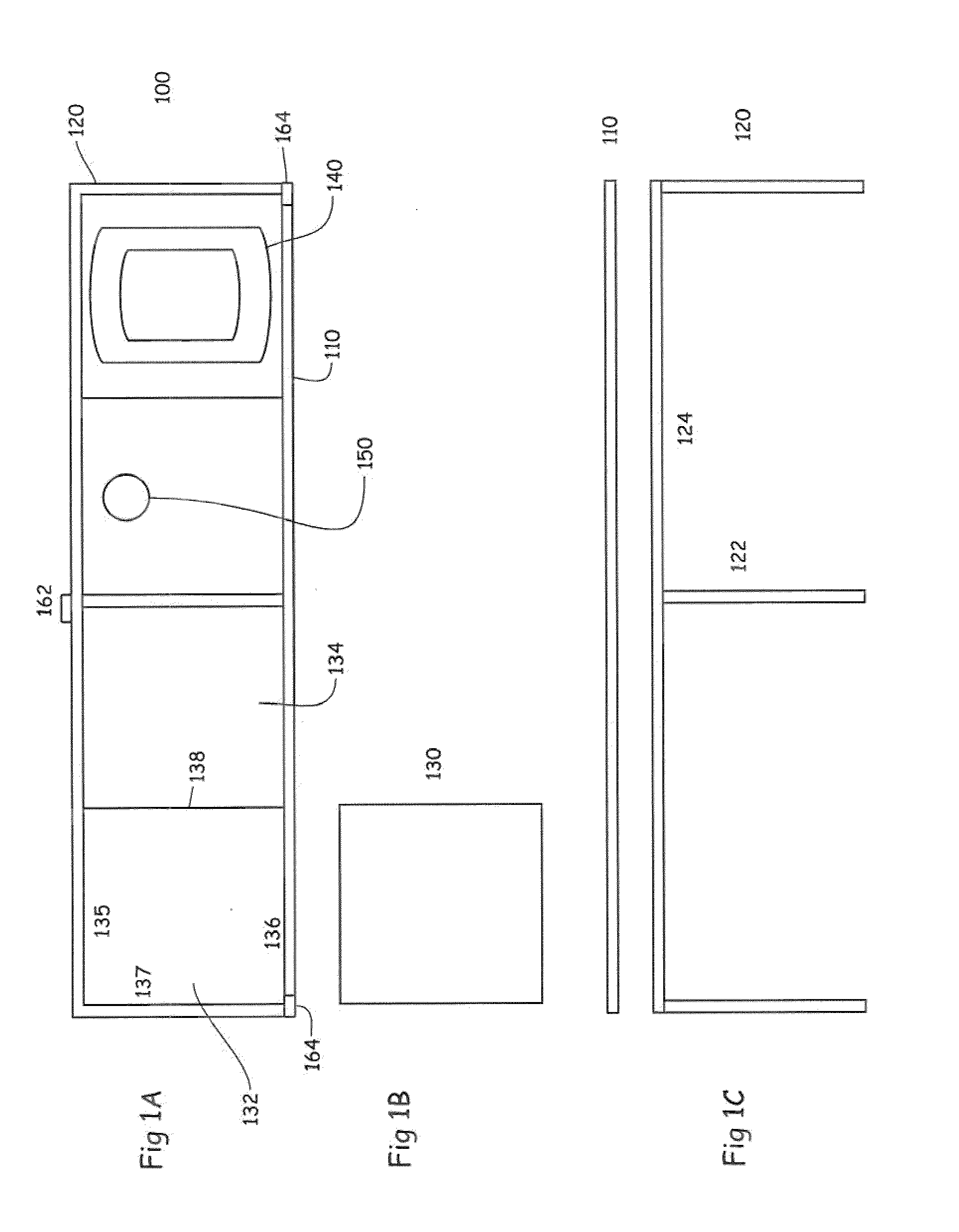

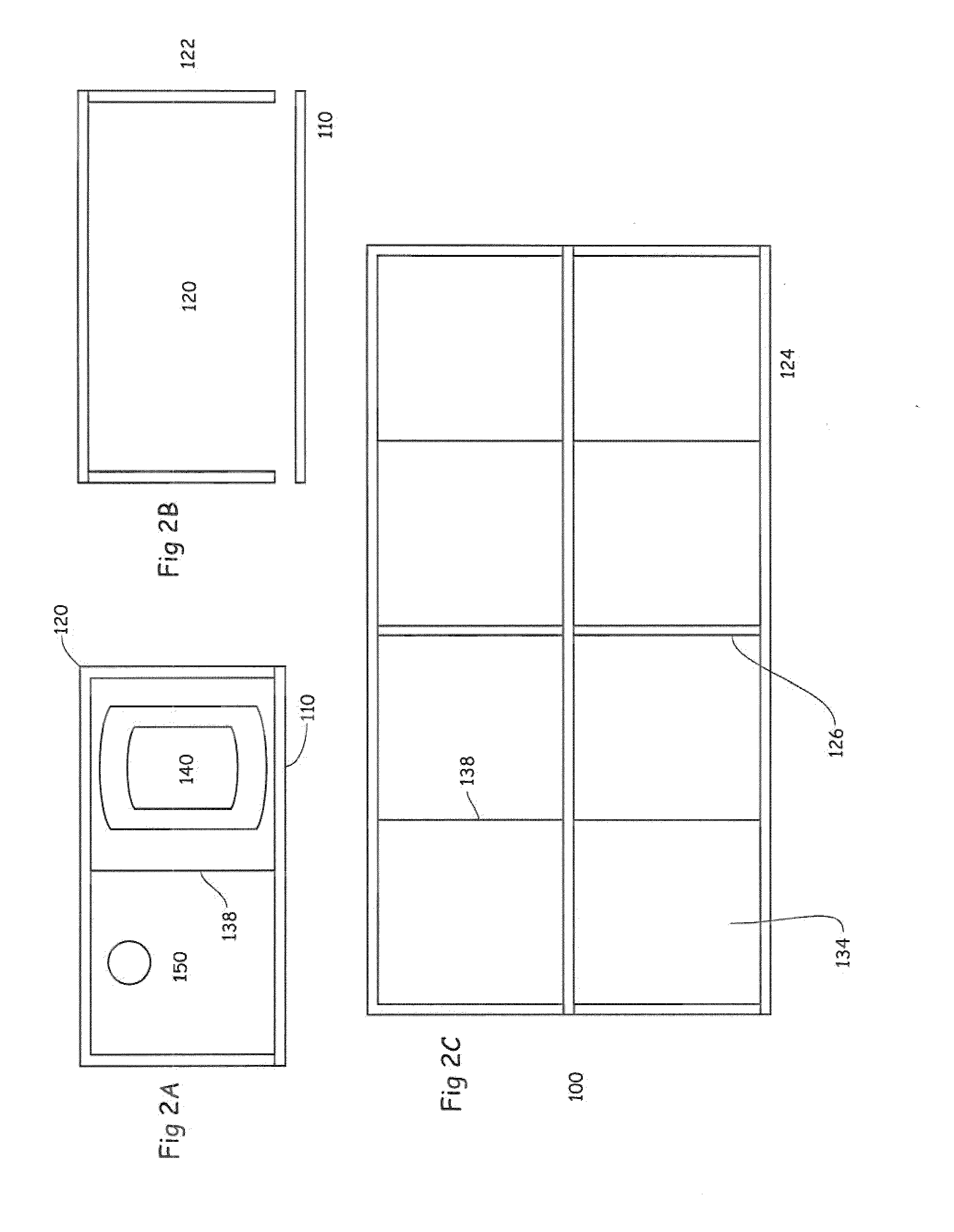

Mine haven

ActiveUS20100175334A1Easy maintenanceIncrease pressurePublic buildingsBuilding repairsWorking environmentAtmosphere

Systems and methods are provided for a modular shelter that is suited for use as a safety chamber in an underground working environment. The shelter includes at least two wall units connected along a substantially sealed seam, a base unit that extends substantially throughout a floor plan of the shelter, and a roll cage that surrounds an outer extent of the shelter above the floor plan. The shelter may be configured to maintain a pressurized state in a closed condition. Each of the at least two wall units may share a substantially common shape and substantially common dimension, and may form a part of a wall, ceiling, and floor of the shelter. The shelter can also include various atmospheric control, circulation, and purge systems, and exterior and soft seal doors to assist in maintaining a livable atmosphere in the safety chamber.

Owner:PSR GROUP

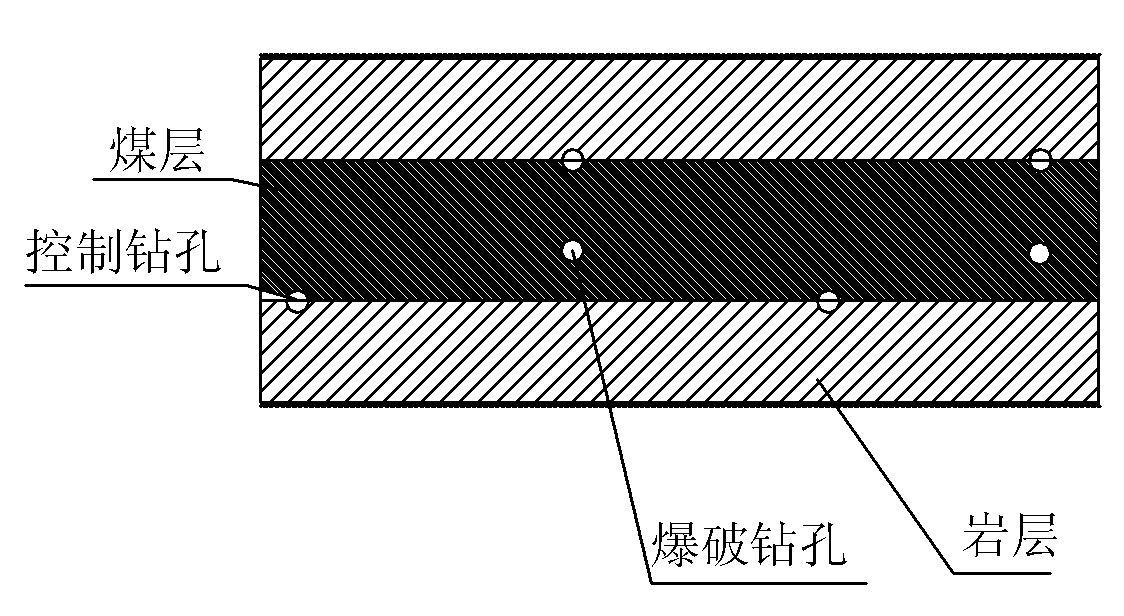

Directional water pressure blasting method for improving coal bed gas permeability

ActiveCN103195466ASolving difficult extraction problemsImprove breathabilityFluid removalGas removalDetonationPore water pressure

A directional water pressure blasting method for improving coal bed gas permeability includes utilizing water pressure blasting splitting to change the structure of the coal and rock mass, firstly drilling holes inside a coal bed, performing high-pressure hydraulic cutting seam, and forming a deep flat slot around the drilling holes of the coal bed after cutting; and filling explosive into the drilling holes of the coal bed, then injecting water and sealing the hole, detonating the explosive to perform water pressure blasting, and enabling the periphery of the drilling holes of the coal bed to generate directional expanding fractures under the function of detonation pressures. Performing water pressure blasting in a high-gas low gas permeability coal bed can organically combine the waterpower and the explosive force of the explosive fully and reasonably, the water pressure blasting enables the cracks generated by hydraulic cutting seam to further expand and a directional expanding cross fracture net is formed on the periphery of the drilling holes of the coal bed, so that the gas permeability of the coal bed is greatly improved, the problem that the gas of the coal bed is hard to extract due to the small number of the cracks can be effectively solved, the concentrated stress of the coal bed is transferred to the deep of the coal mass, and the capacity of gas emission is improved. The directional water pressure blasting method for improving the coal bed gas permeability is simple in process, convenient to operate, safe, reliable, and good in controllability and effects.

Owner:CHONGQING UNIV

Method for taking out and picking high gassy seam group dislodging gob-side entry retaining Y type ventilated decompression firedamp

The invention relates to a highly gassy coal seam group mining gob-side entry retaining Y-shaped ventilation and decompression gas extraction method. The invention is characterized in that: free desorption gas which comes from an adjacent decompression layer and is gathered into a roof plate decompression crack ring and a bottom plate decompression crack ring through crack channels which are formed by mining affection on roof plate coal seam and strata and bottom plate coal seam and strata is extracted in a gob-side entry through an upward extraction gas drill hole which is arranged inside the roof plate decompression crack ring and a downward extraction gas drill hole which is arranged inside the bottom plate decompression crack ring in a roof plate decompression area and a bottom plate decompression area of a gob-side entry retaining gob of a coal face of a primarily extracted coal seam of a highly gassy coal seam group. The highly gassy coal seam group mining gob-side entry retaining Y-shaped ventilation and decompression gas extraction method solves the problem of low extraction rate of the highly gassy low permeability coal seam group, simultaneously solves the ultralimit problem of airflow gas of spatial angles and return airways on the coal face of the primarily extracted coal seam of the highly gassy coal seam group, and realizes extraction utilization of high concentration gas and highly efficient and safe extraction of the highly gassy coal seam group without coal pillars.

Owner:HUAINAN MINING IND GRP +2

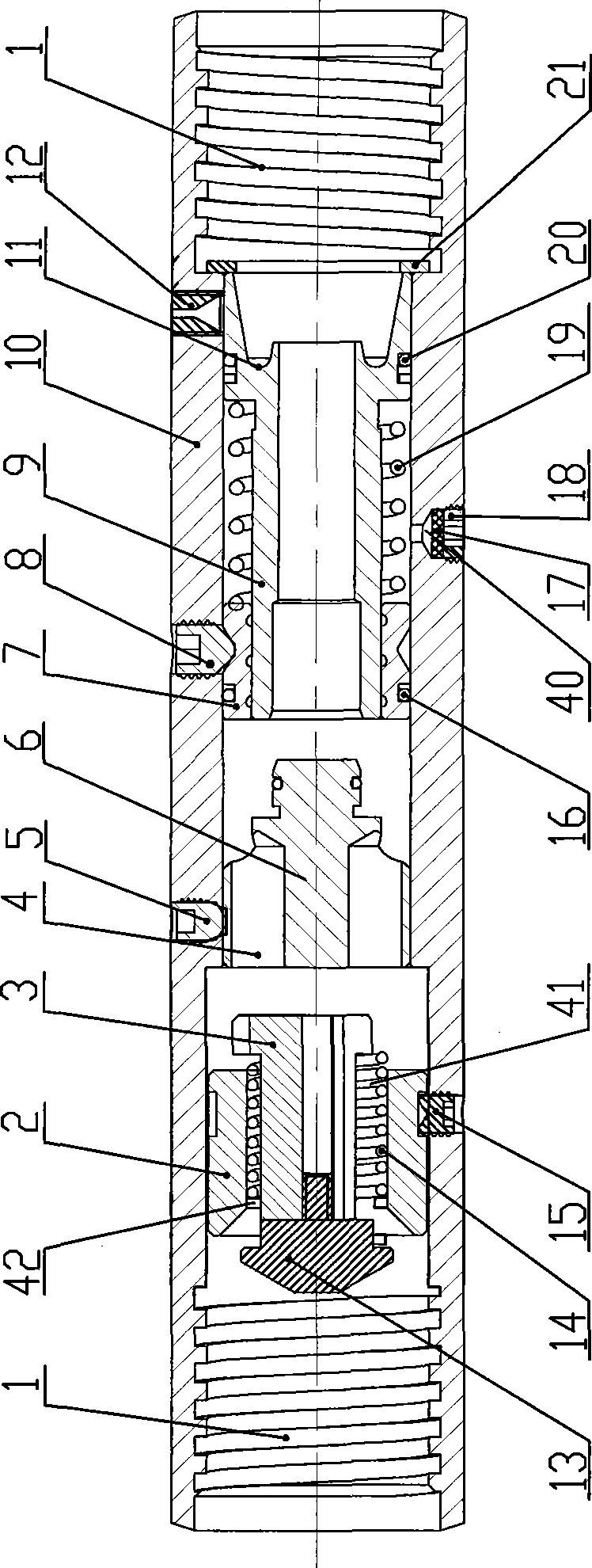

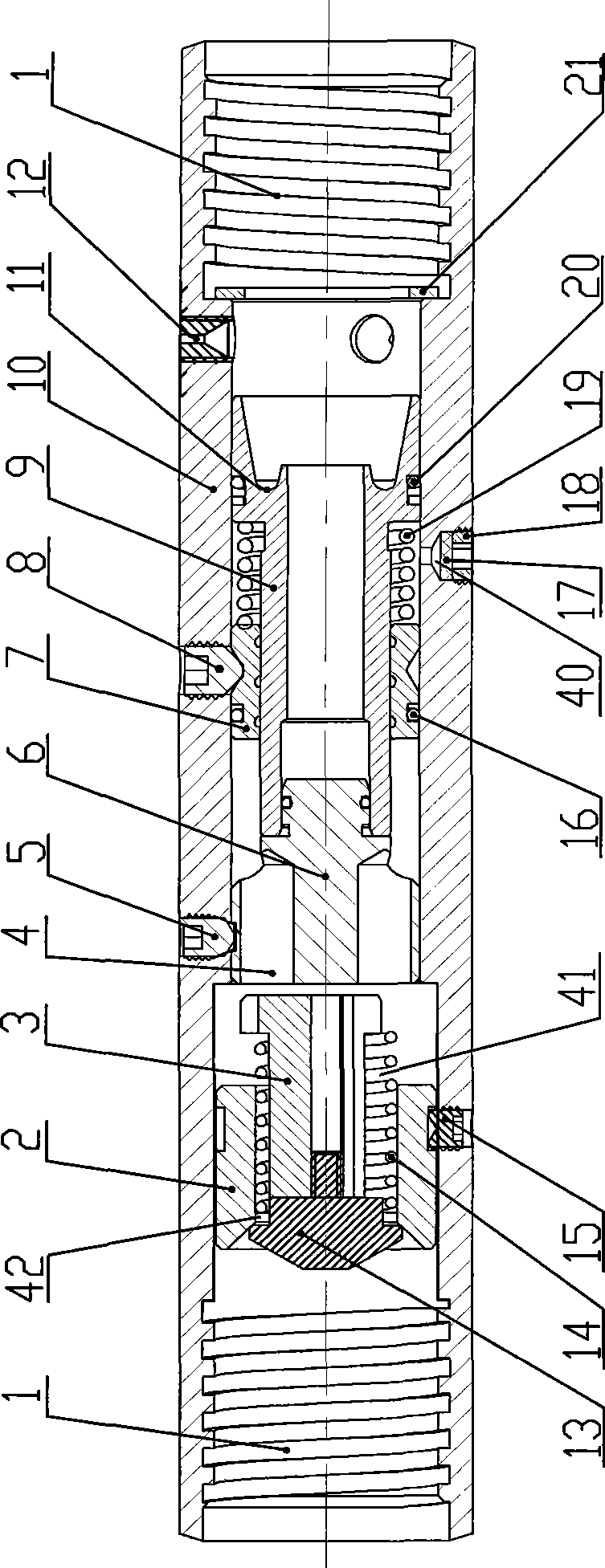

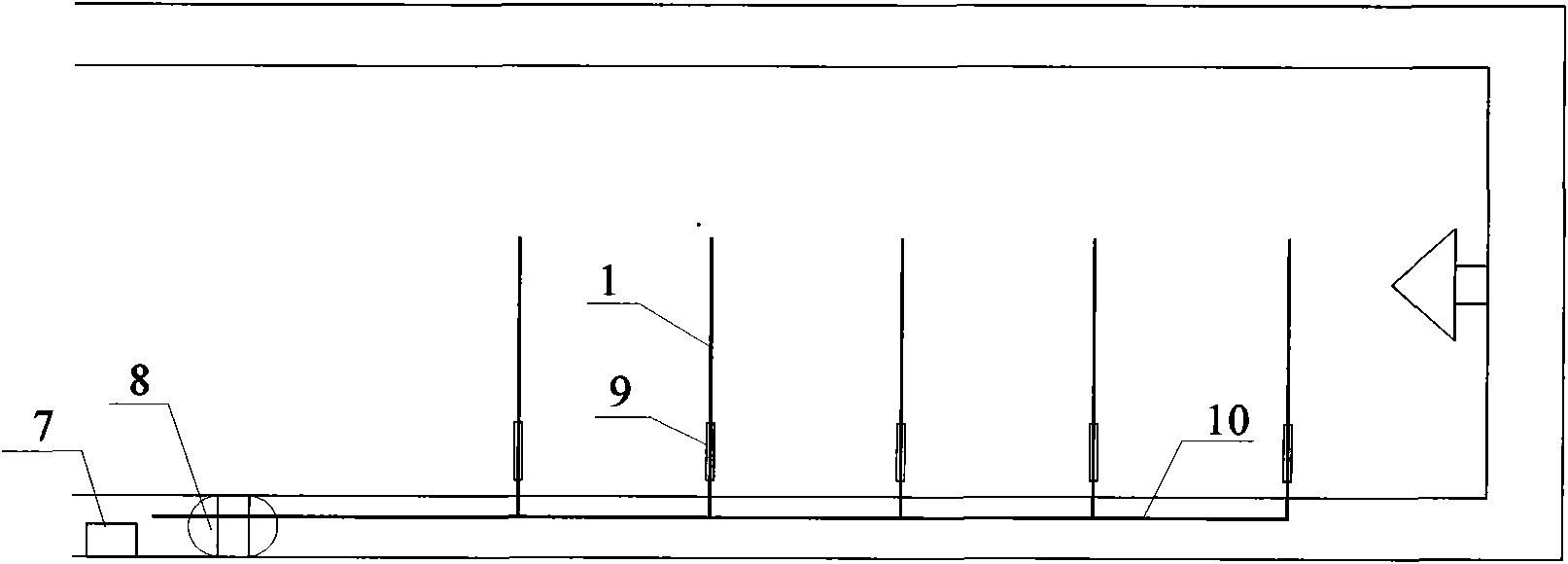

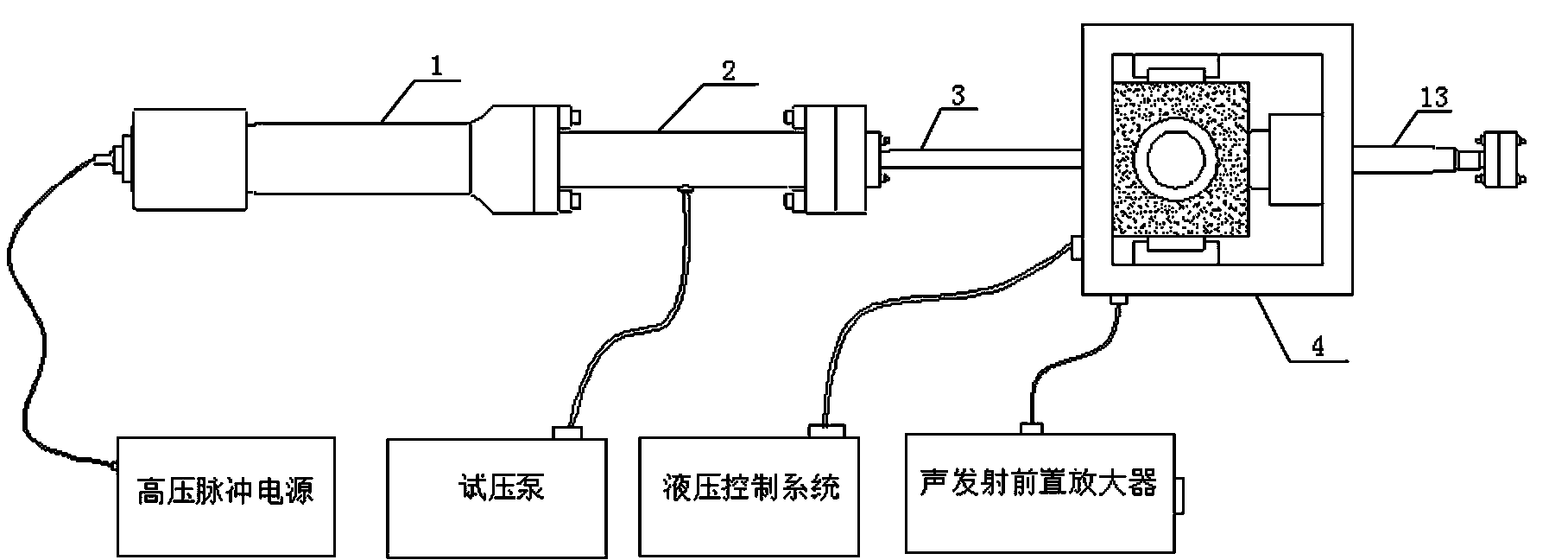

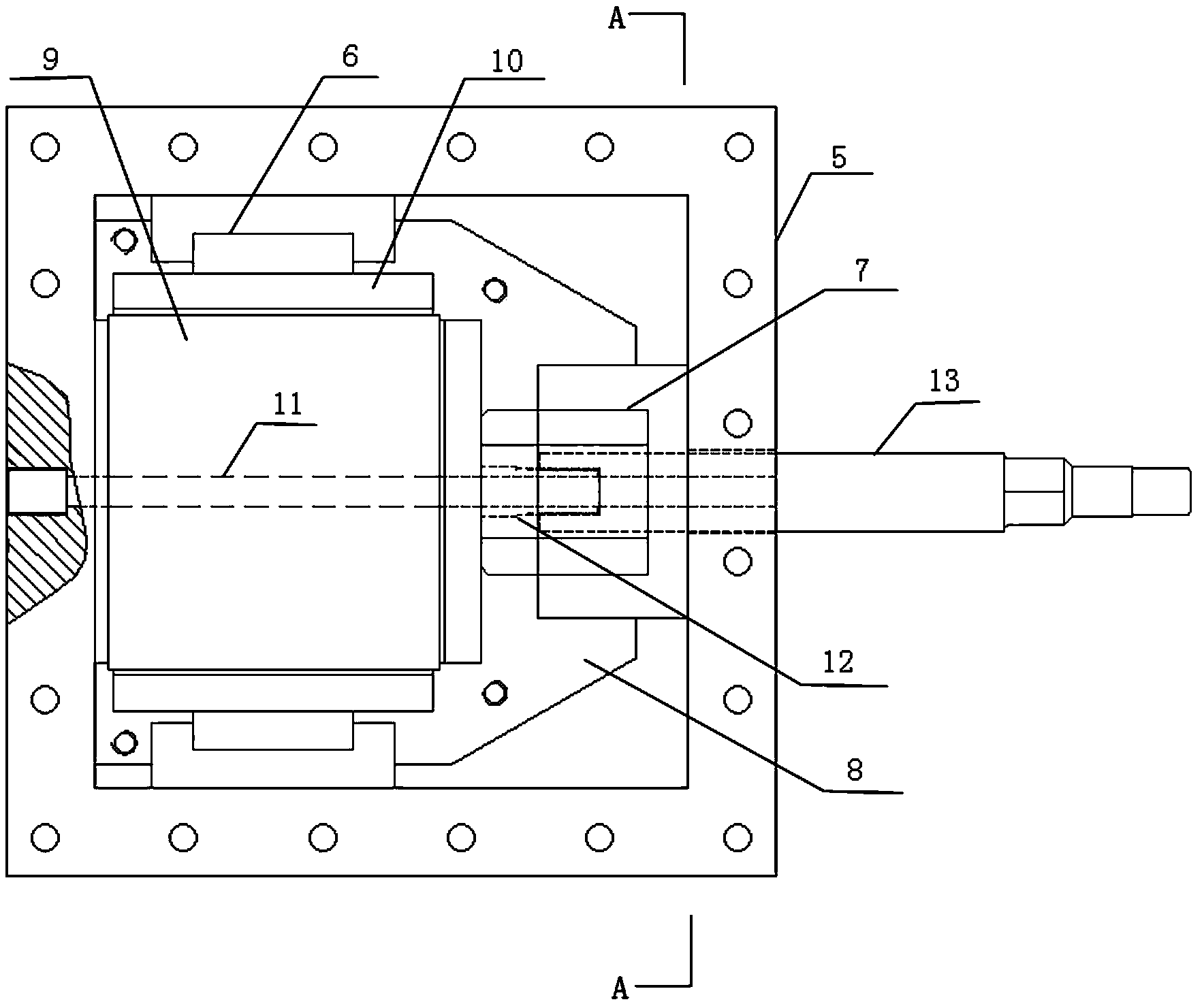

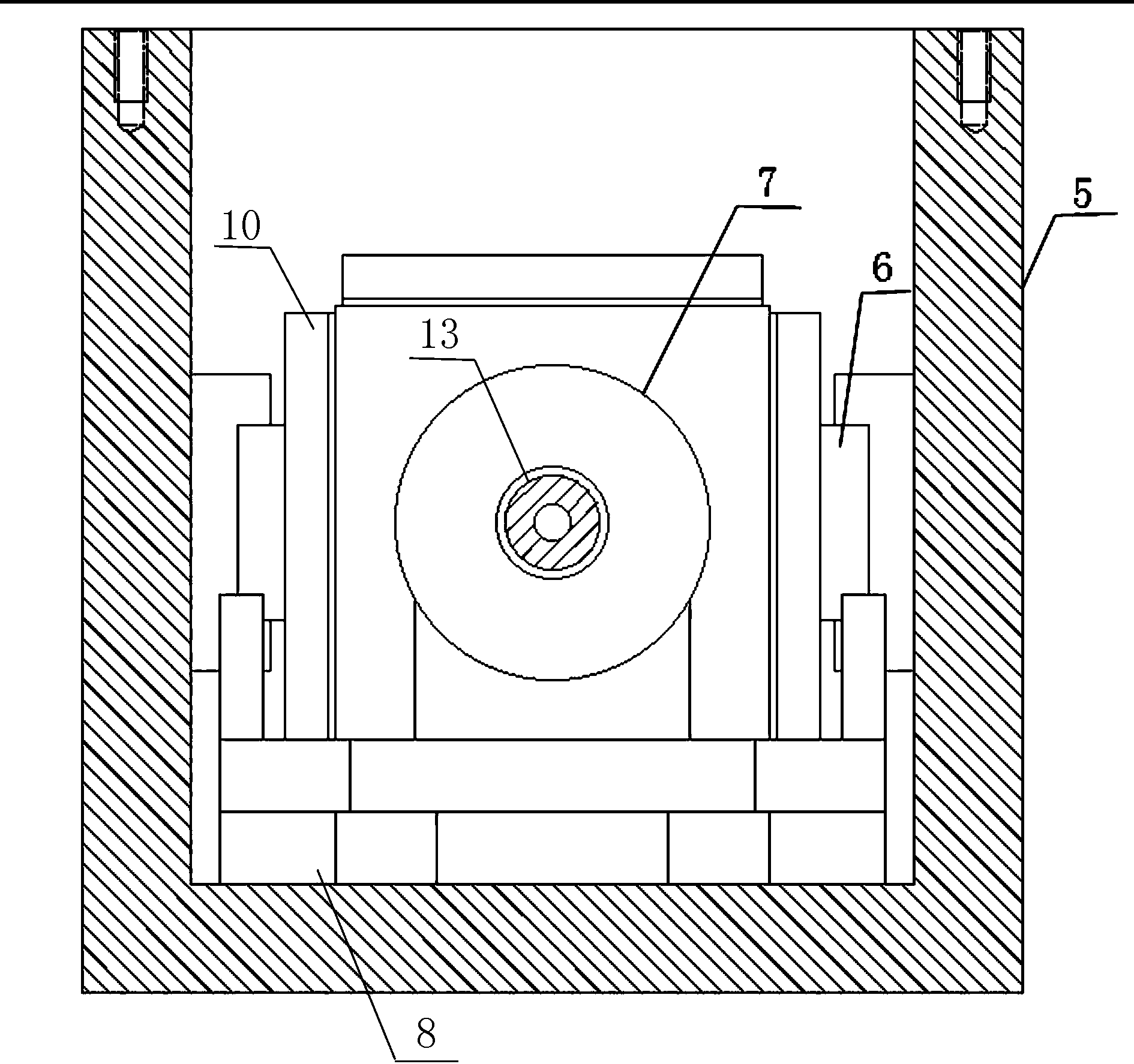

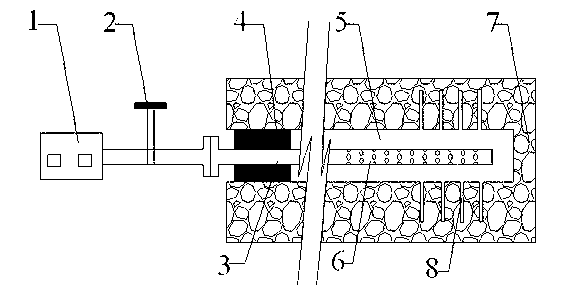

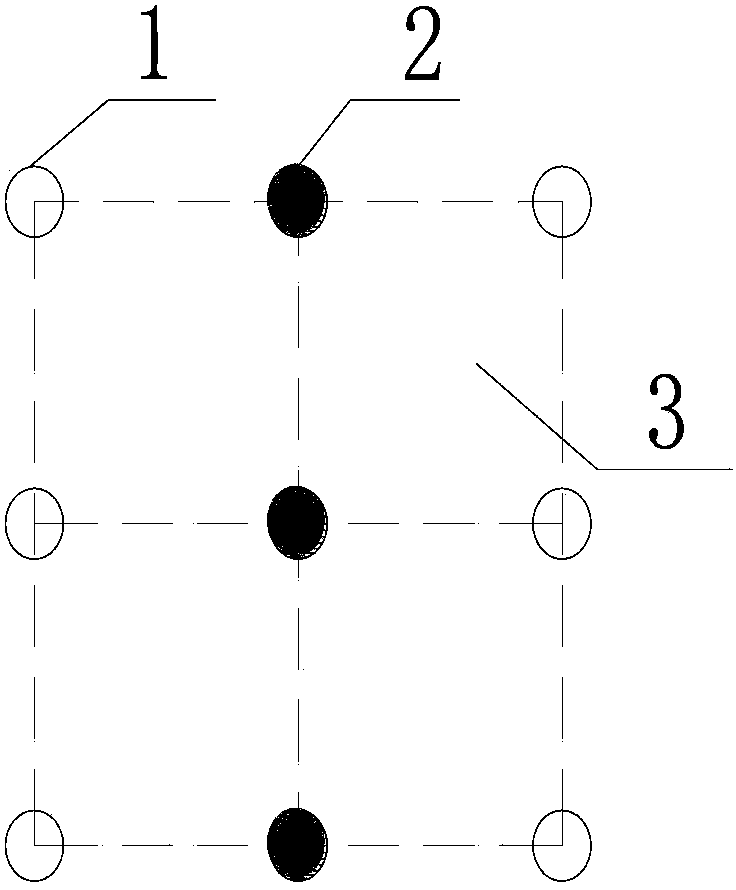

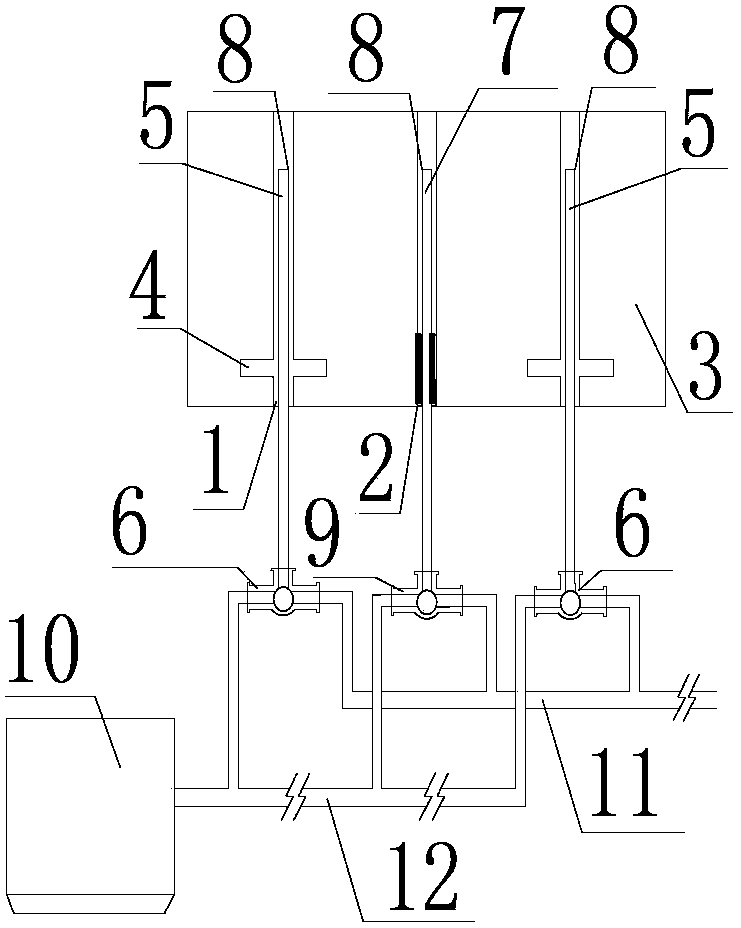

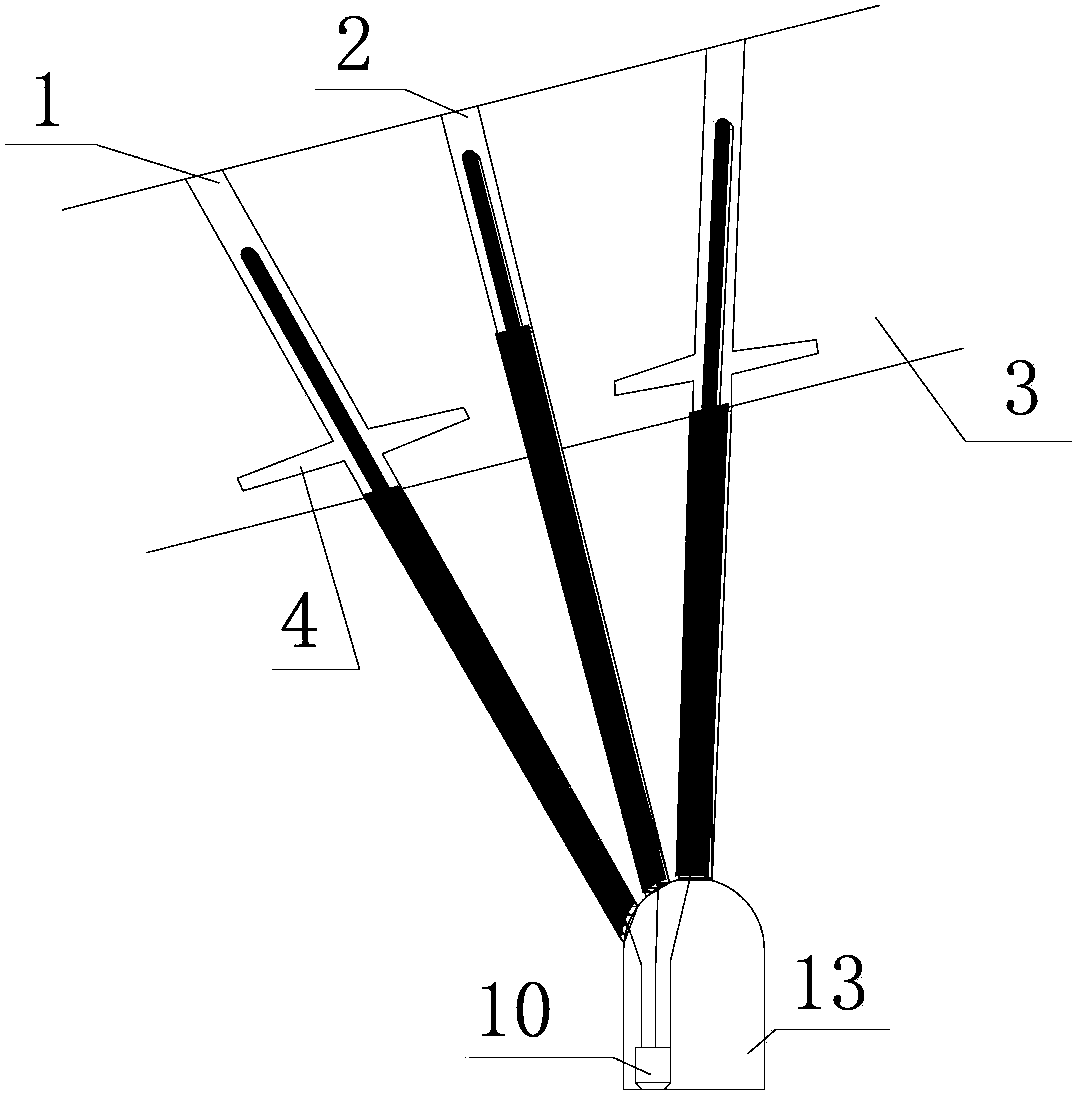

Coal seam anti-reflection experiment device based on high-voltage electric pulse

InactiveCN104061014ADetermine the impactDetermine the scopeFluid removalGas removalElectrical impulseEngineering

The invention relates to a device for performing experiments by combining high-voltage pulse discharging and the traditional coal seam anti-reflection technology, in particular to a coal seam anti-reflection experiment device based on high-voltage electric pulse. The coal seam anti-reflection experiment device based on high-voltage electric pulse comprises a high-voltage pulse power supply, a first tube body, a second tube body, a third tube body, a rigid triaxial pressure chamber, a pressure testing pump, a hydraulic control system and a sound reflection preamplifier, wherein the first tube body, the second tube body and the third tube body are connected in sequence. The traditional hydraulic fracturing technology is simulated in the rigid triaxial pressure chamber, the high-voltage pulse power supply supplies power to a discharging electrode, therefore, the positions around a through hole of a coal sample fracture, a fracturing positions and an expanding process of the fractures in the coal sample are monitored all the time, critical factors affecting fracture development of the coal sample and state transformation of gas, an actuating range and effect laws of pulse discharging on fracture development can be obtained through the later CT scanning and electron microscopy observation results, and a theoretical foundation is provided for practical application of high-voltage pulse discharging into underground coal seam anti-reflection.

Owner:TAIYUAN UNIV OF TECH

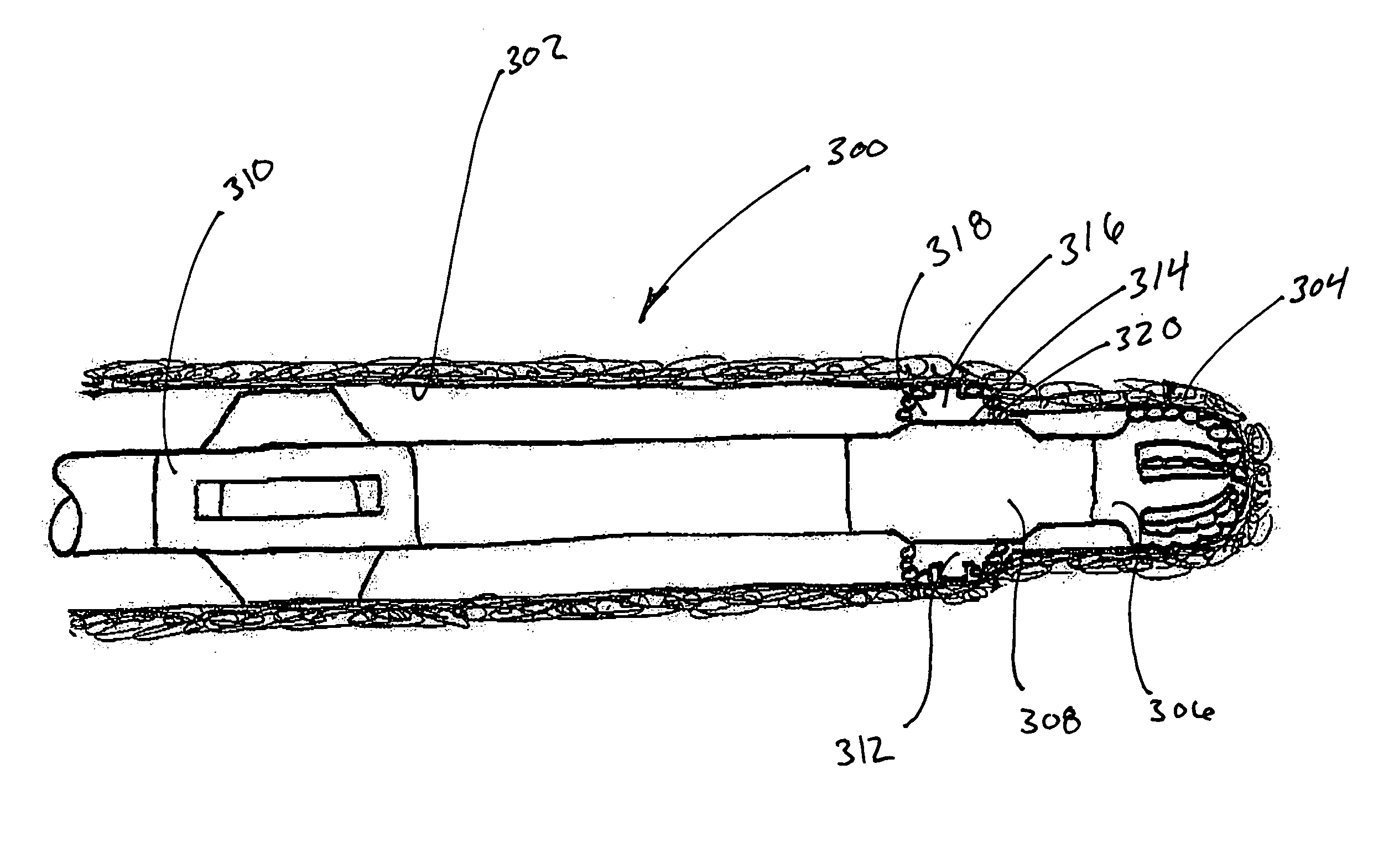

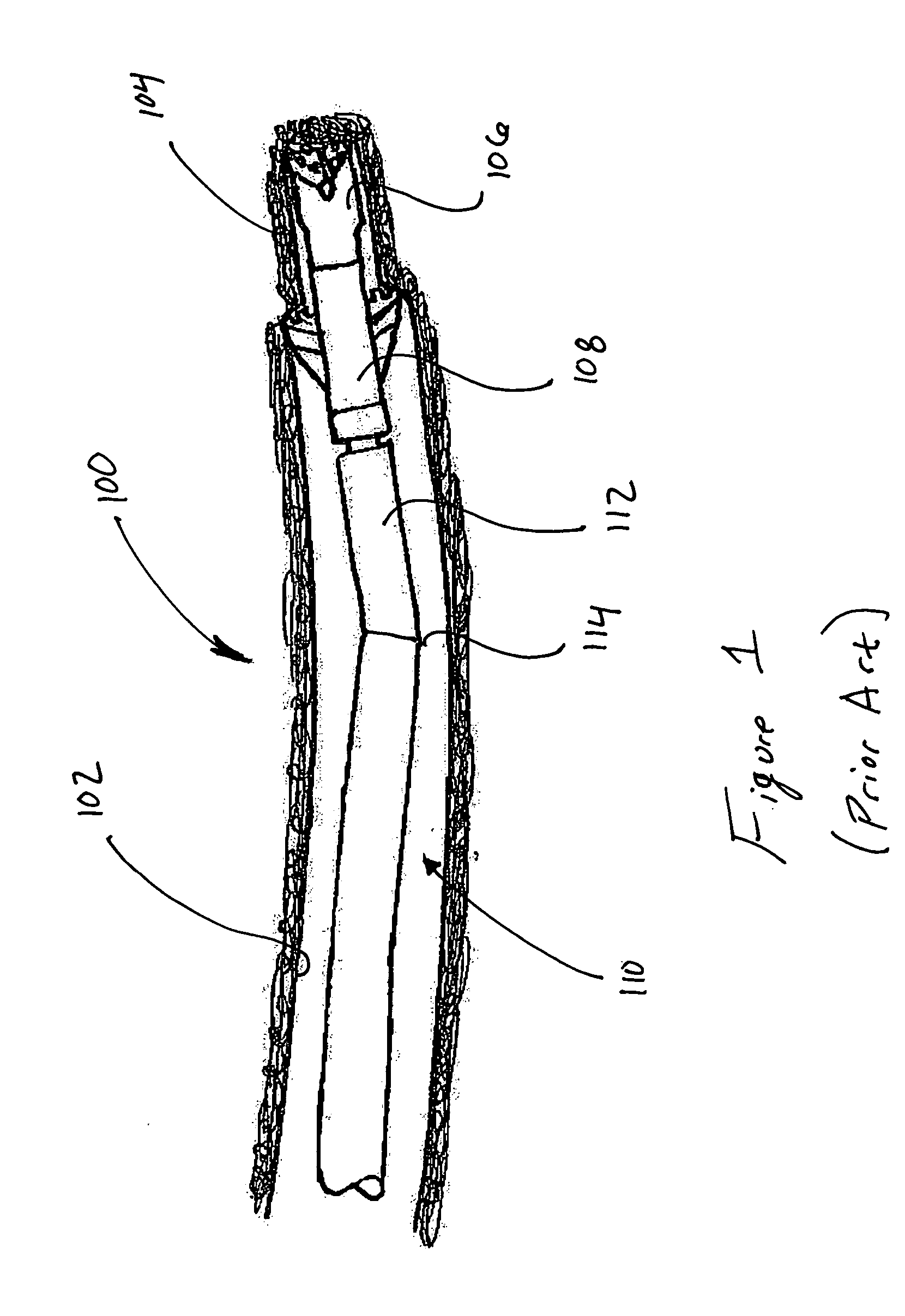

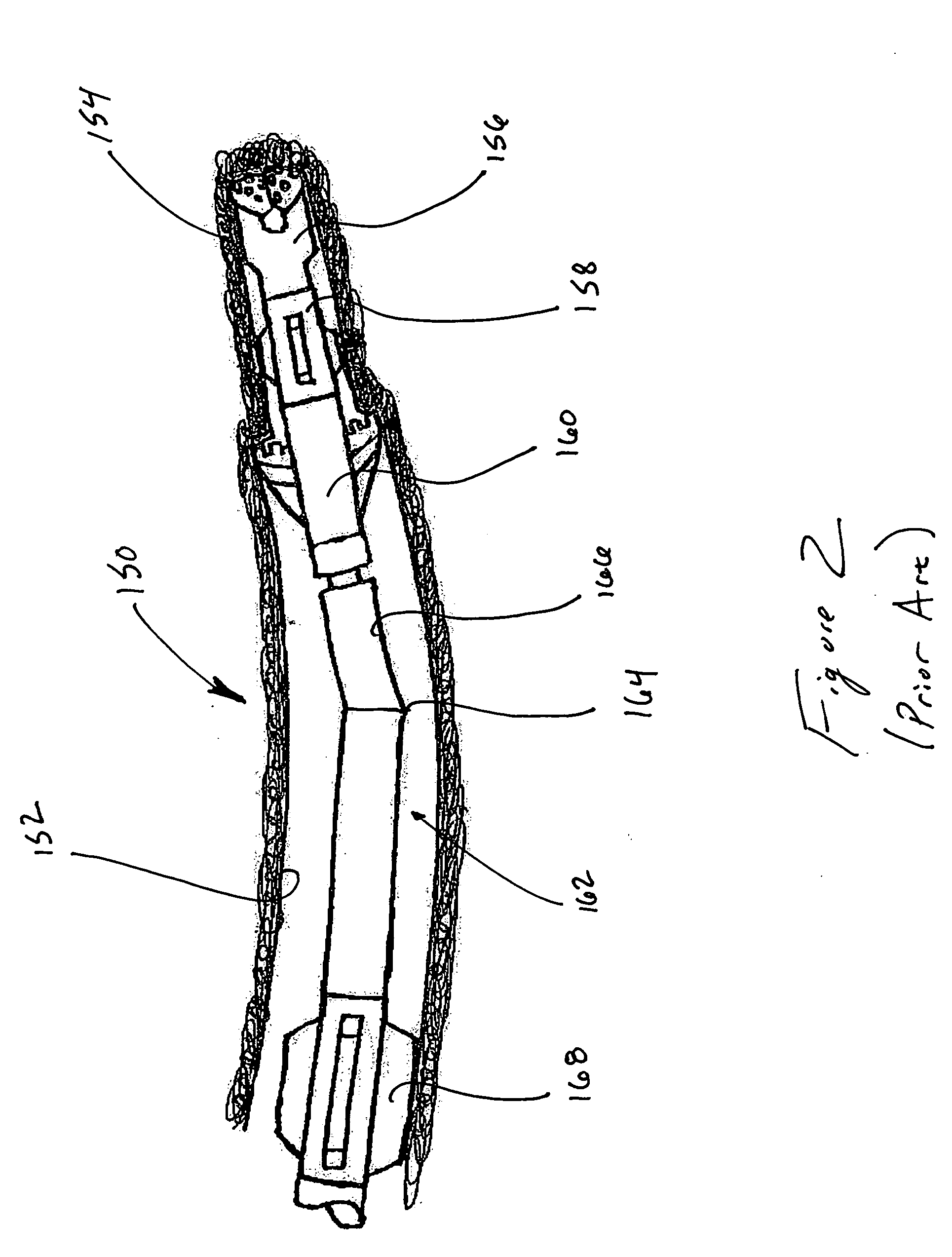

Steerable underreamer/stabilizer assembly and method

A bottom hole assembly includes a drill bit, a stabilized underreamer assembly located behind the drill bit, and a drilling assembly. A method to drill a formation includes positioning a stabilized underreamer assembly behind a drill bit, positioning a drilling assembly behind the stabilized underreamer assembly, and rotating the drill bit and stabilized underreamer assembly with the drilling assembly. A stabilized underreamer located between a directional drilling assembly and a drill bit includes at least one arm assembly extending from the stabilized underreamer assembly, wherein the arm assembly includes a stabilizer portion and an underreamer cutting structure.

Owner:SMITH INT INC

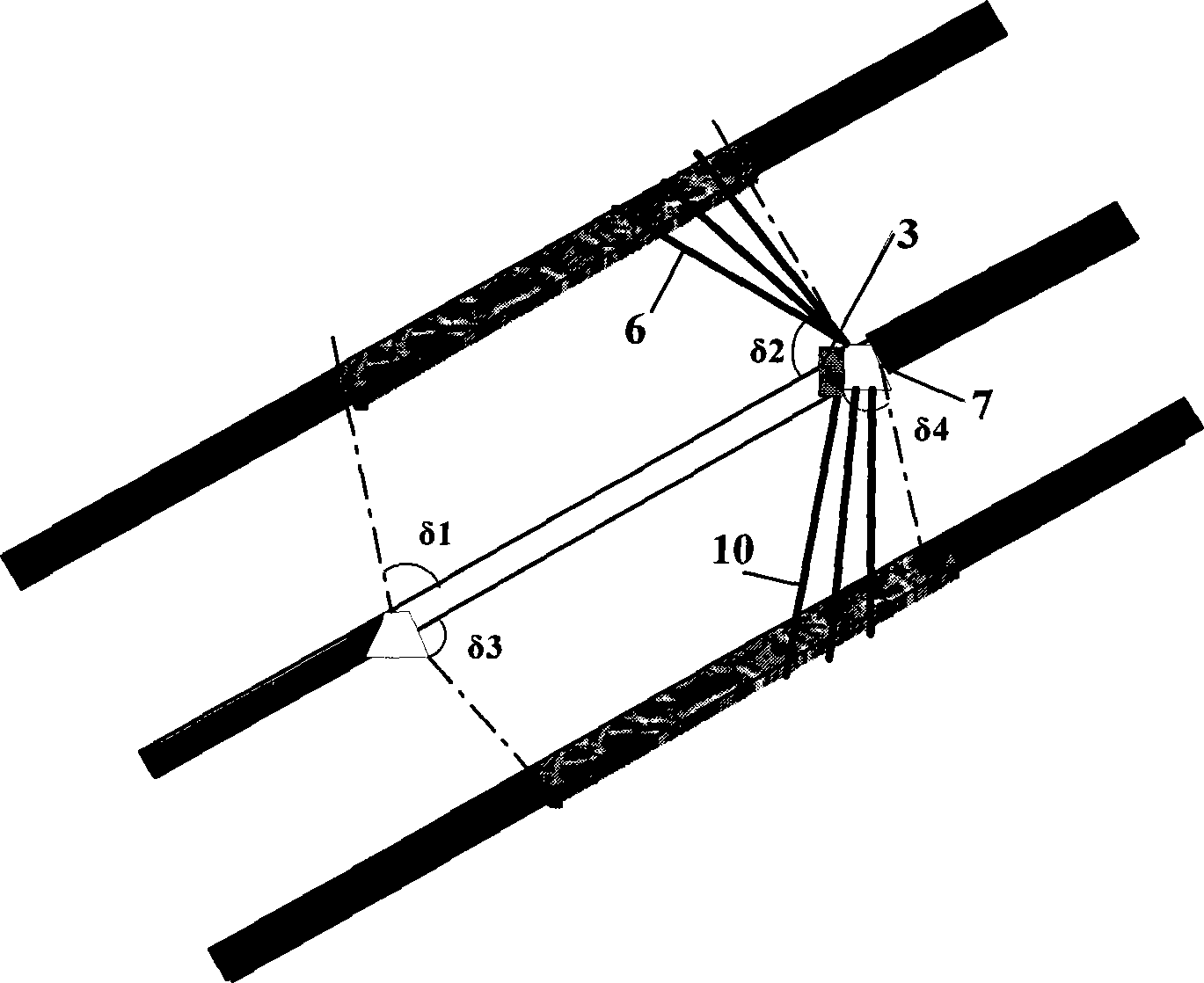

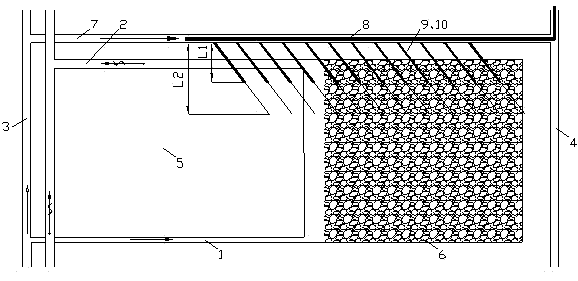

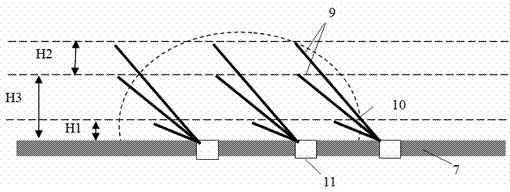

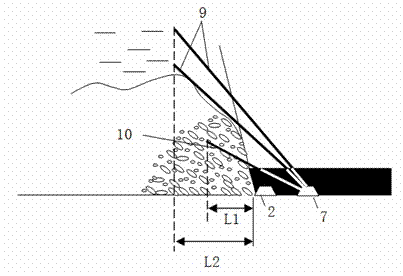

Gas extraction method of cross hole drilling area of gas discharge laneway

ActiveCN102226413AEffective interceptionEffective gush controlDirectional drillingGas removalDrill siteOblique angle

The invention discloses a gas extraction method of a cross hole drilling area of a gas discharge laneway, comprising the following steps: tunnelling an mining area return airway parallel to a mining area track roadway at the tail part of the gas discharge laneway; arranging drill sites on the gas discharge laneway along the roof of a coal seam at intervals; respectively constructing multiple high-level drilling holes with different oblique angles and different lengths and a low-level hole in a worked out area direction in the middle and upper part of each drill site; arranging an extraction pipe after hole drilling construction in each drill site is finished; sealing the holes; and connecting the drilling holes in each drill site into the extraction pipe of the gas discharge laneway through an upper confluence pipe and a lower confluence pipe for extraction, thus realizing the safe production of a gas coal seam group. The method is safe and reliable, can effectively intercept pressure relief gas at an upper neighbor layer, effectively controls the gas from flowing out from a stope face, lowers the gas concentration of an upper corner, and ensures the safe production of the stope face.

Owner:CHINA UNIV OF MINING & TECH

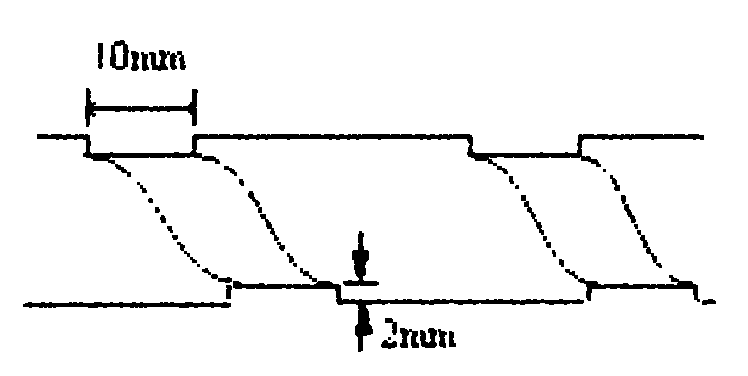

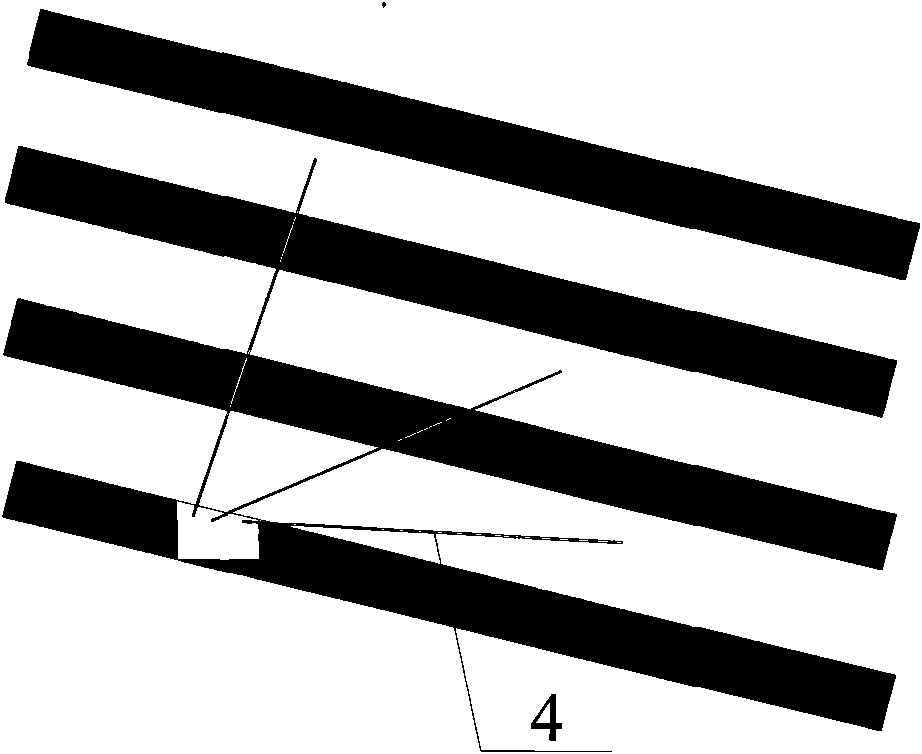

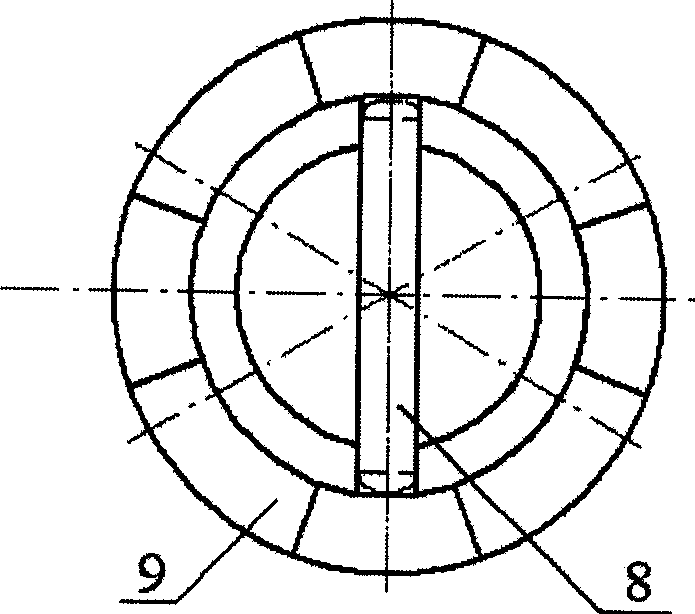

Coal seam reaming system using three-dimensional (3D) swirling water jet and reaming and fracturing method for permeability enhancement

InactiveCN102213077AEasy to crackLarge range of pressure reliefDrill bitsConstructionsHydraulic pumpHigh pressure water

The invention relates to coalmine gas extraction and permeability enhancement equipment and technology, and discloses a coal seam reaming system using three-dimensional (3D) swirling water jet. The system is connected to a high-pressure rotary joint through a high-pressure hose provided with a stop valve by virtue of a high-pressure hydraulic pump station and is characterized by being connected to a high-pressure water jet drill stem through a drilling machine, wherein the front end of the high-pressure water jet drill stem is connected with a high-pressure water jet head with nozzle bases; and high-pressure swirling water jet nozzles are arranged on the nozzle bases. The invention further discloses a coal seam reaming and fracturing method for permeability enhancement using the 3D swirling water jet. In the coal seam reaming method using the 3D swirling water jet, coal is sheared so as to lower the hydraulic pressure loss, improve the cutting efficiency and increase the cracks and bore diameter of the coal; high-pressure water is injected so as to fracture the coal between a hydraulic reamed hole and control bored holes; and a coal seam is fully depressurized within a large range so as to shorten the pre-extraction time of the coal seam.

Owner:CCTEG SHENYANG RES INST +1

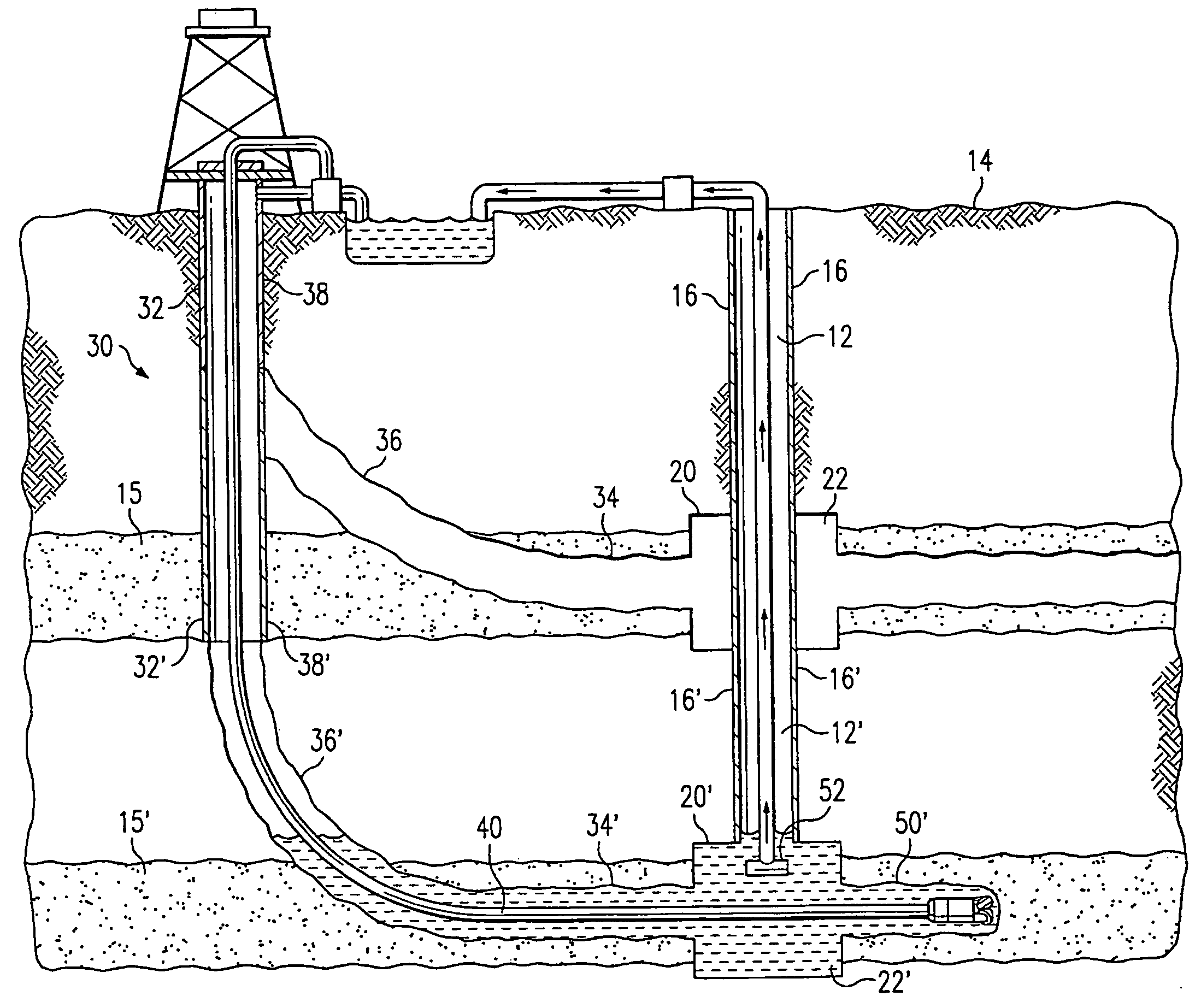

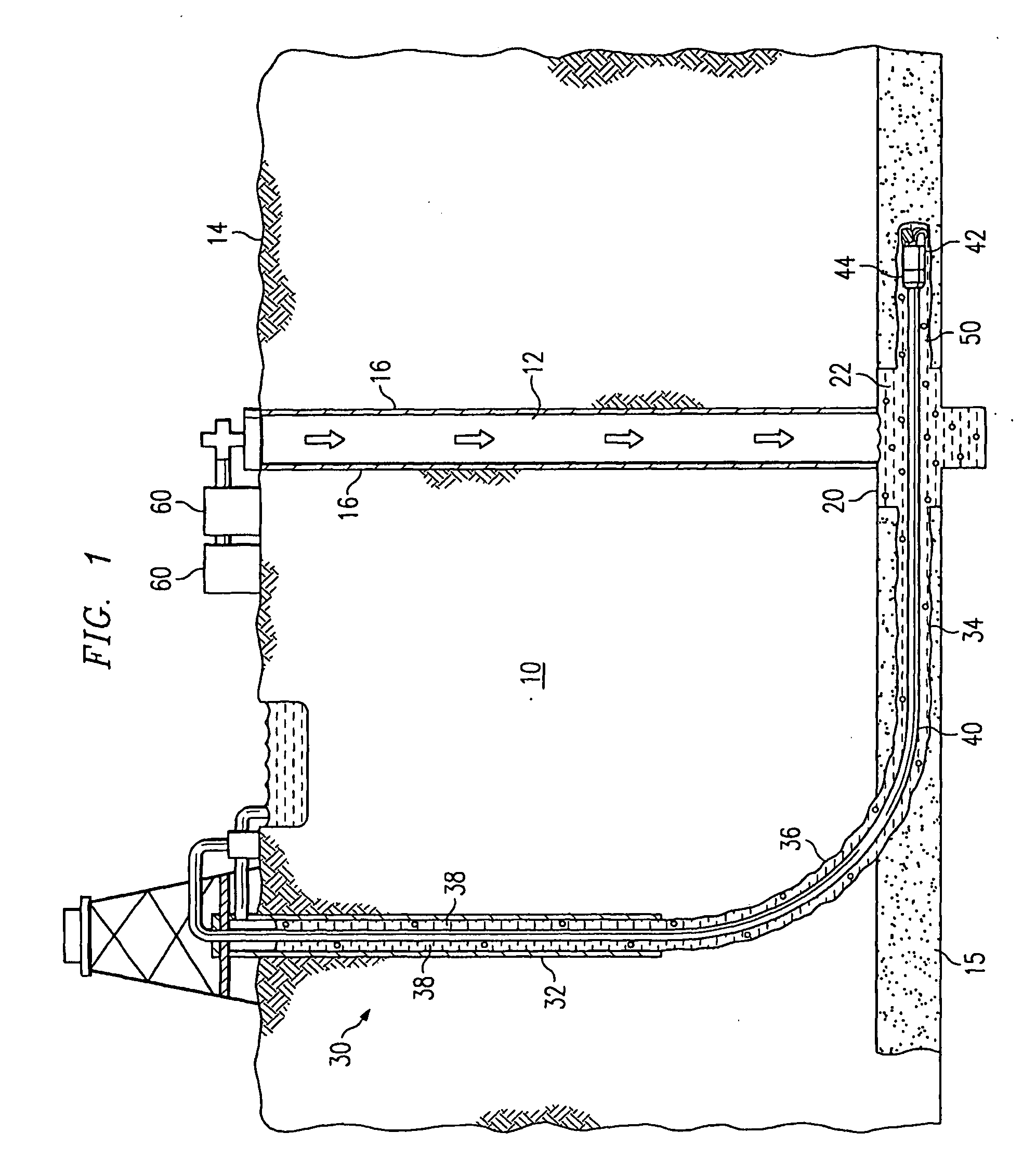

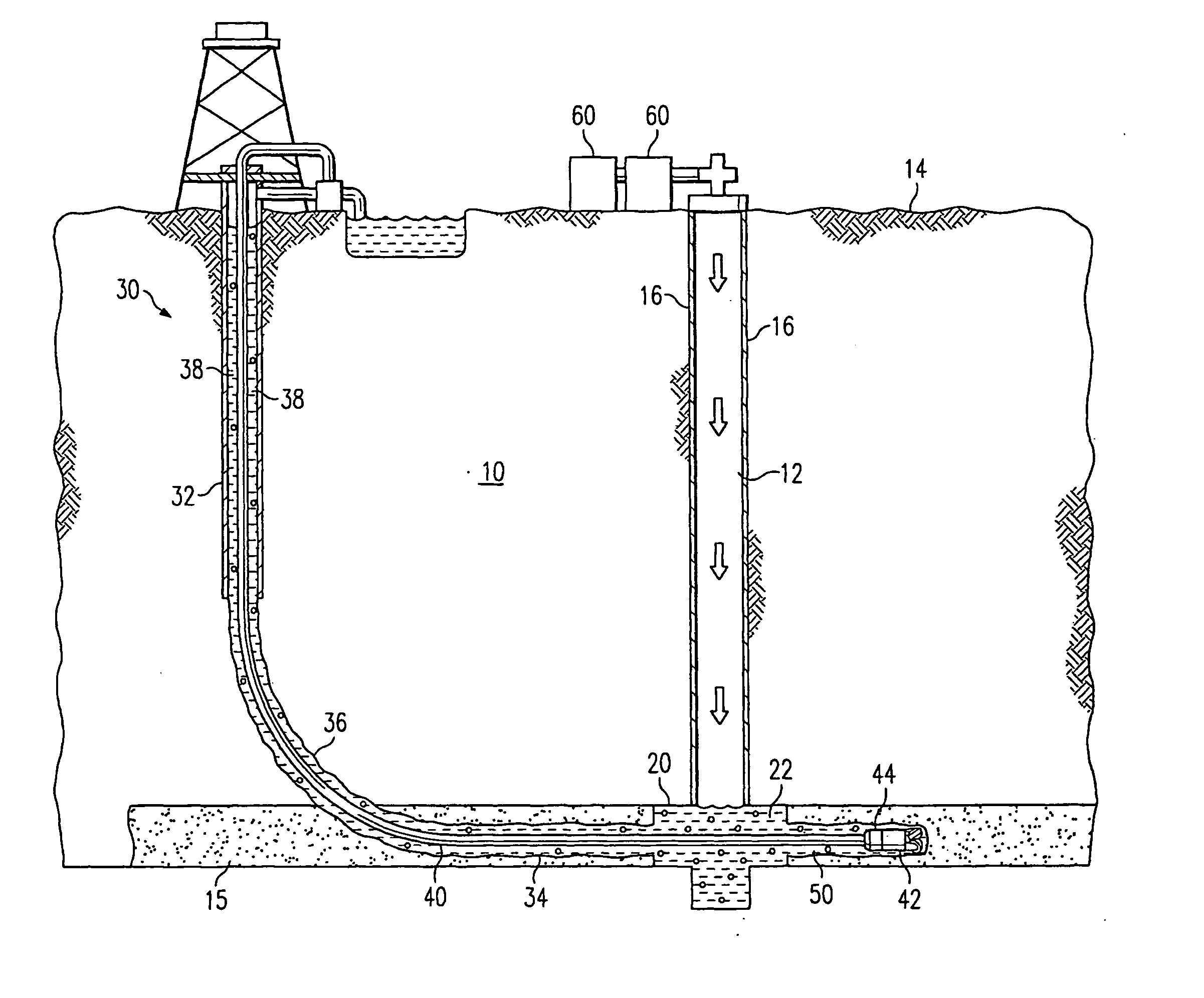

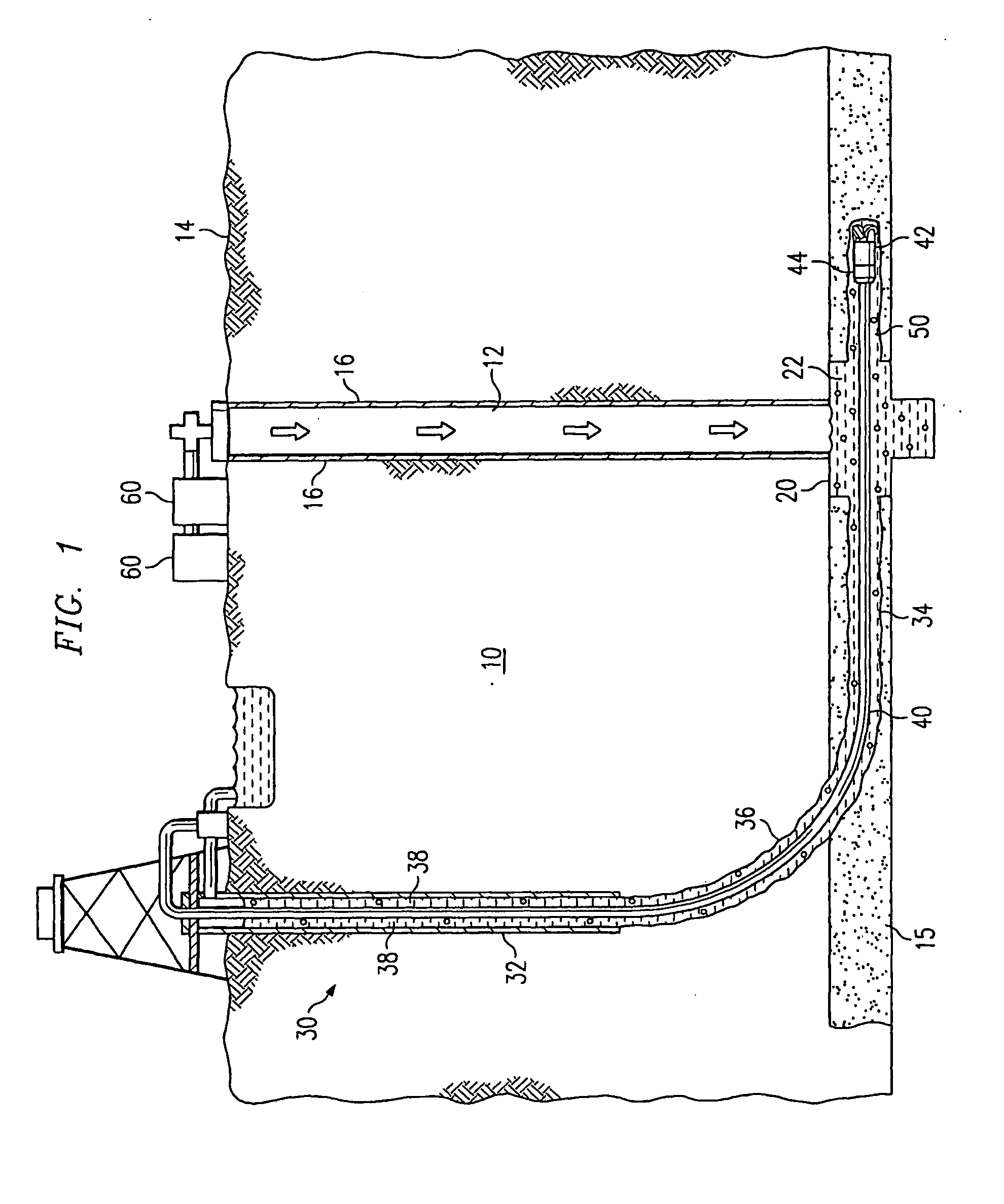

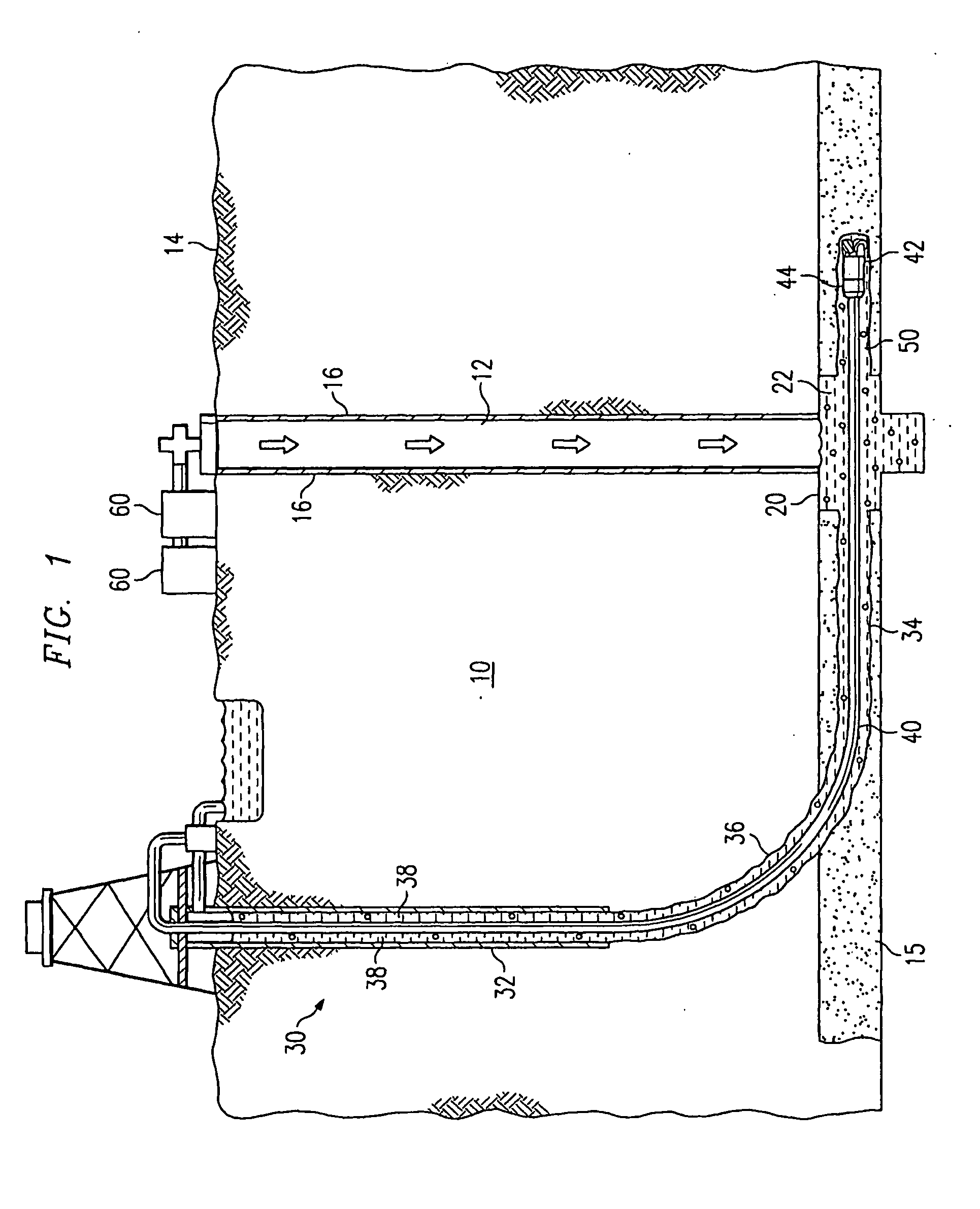

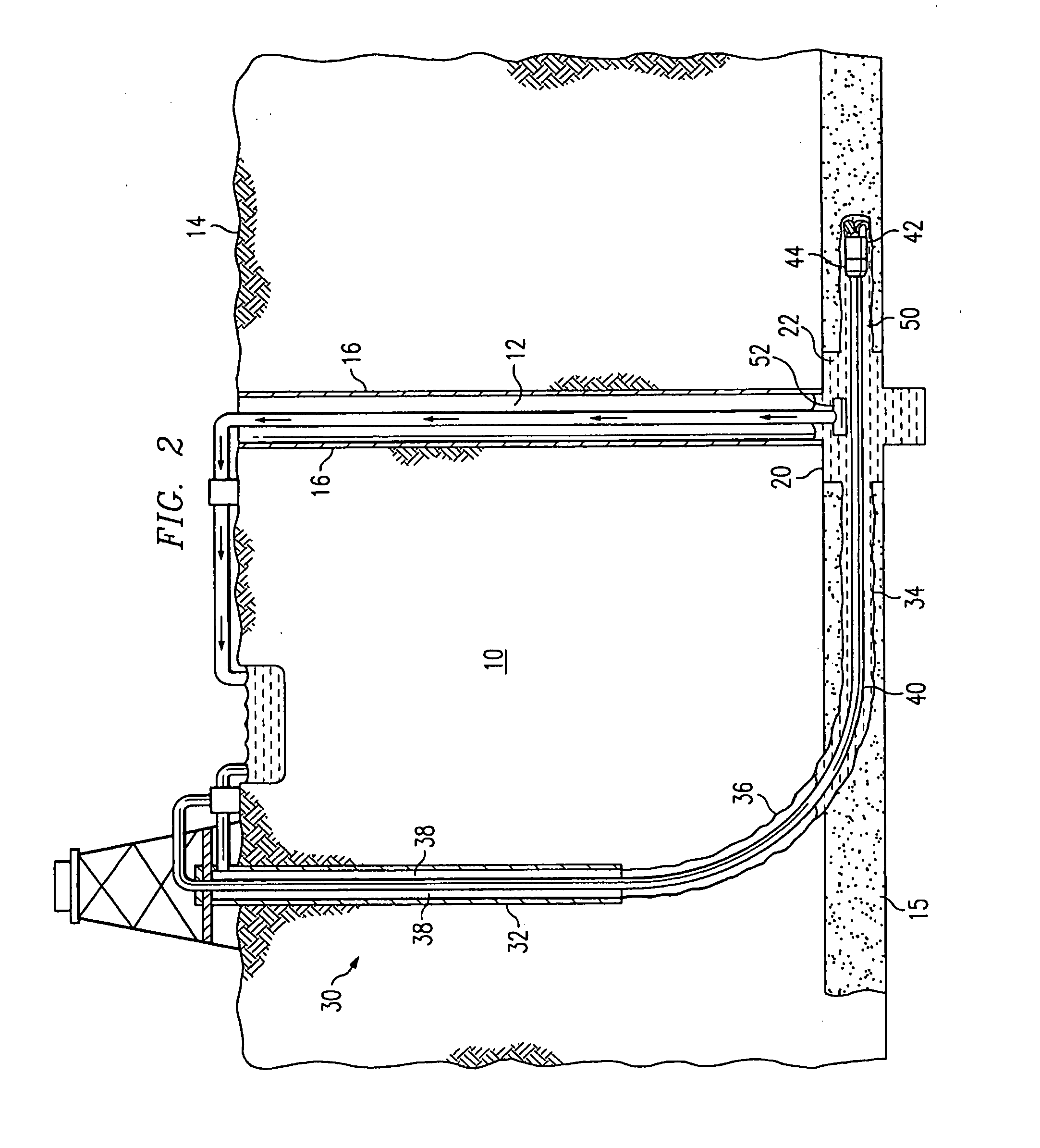

Method and system for accessing subterranean deposits from the surface and tools therefor

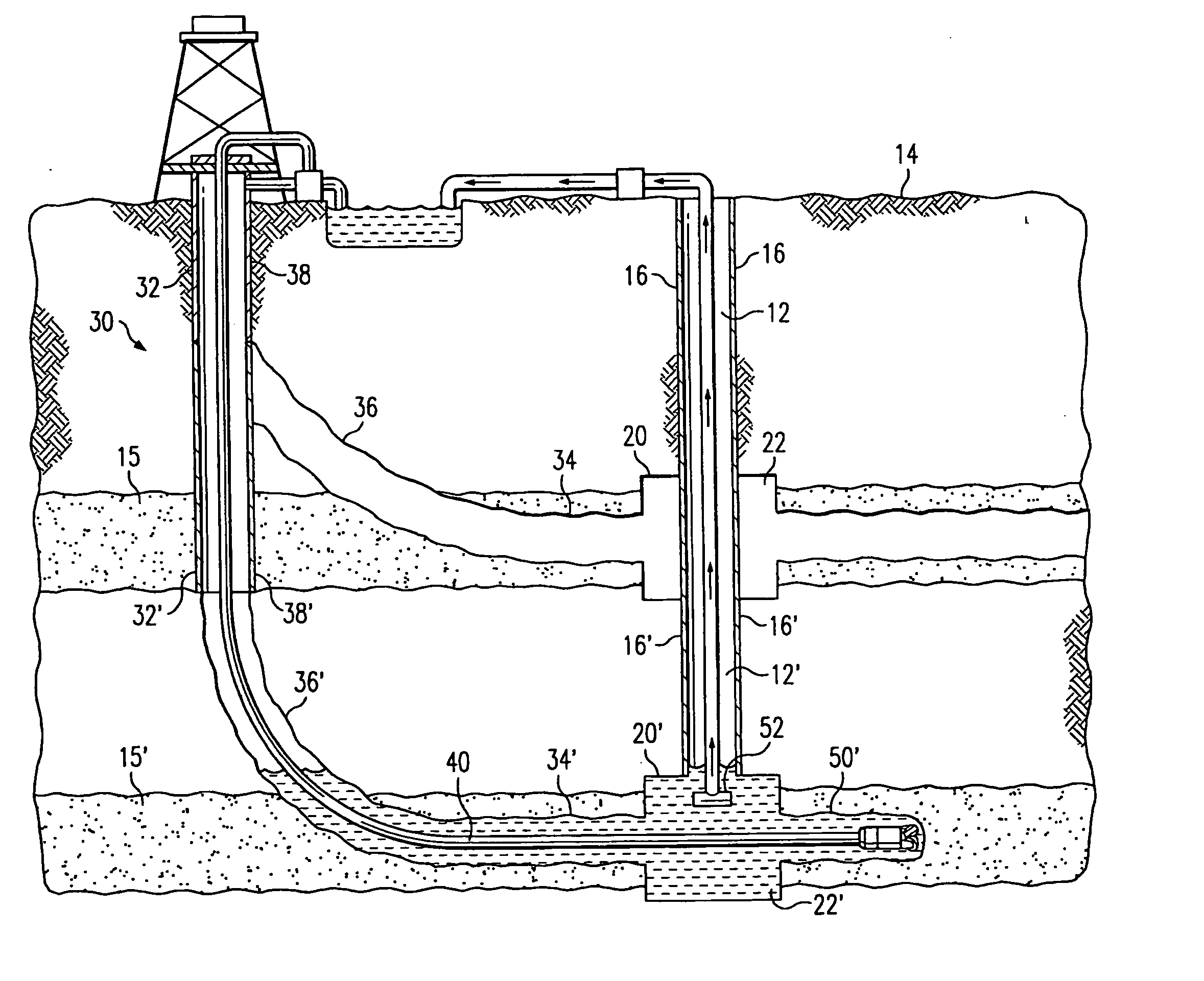

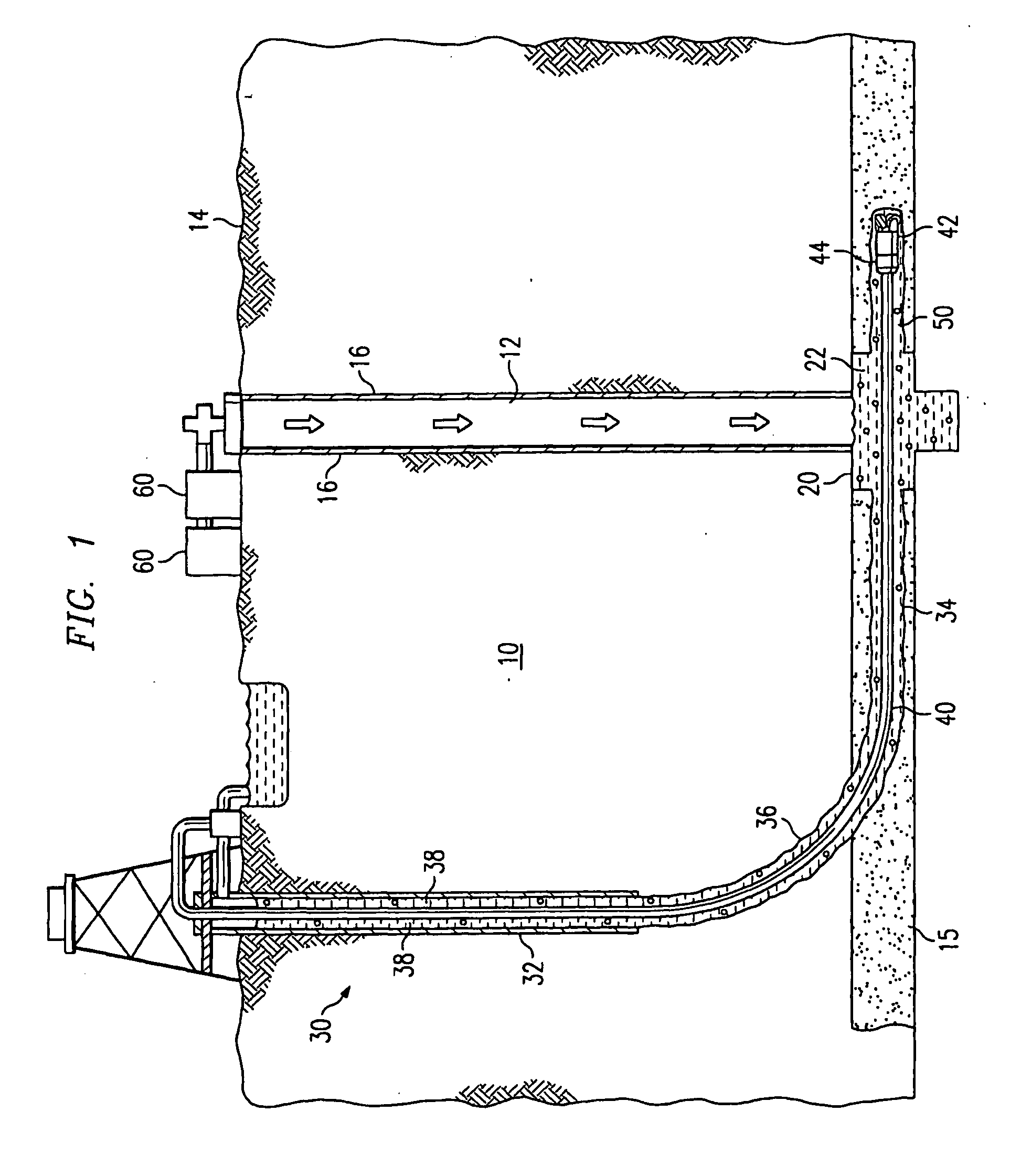

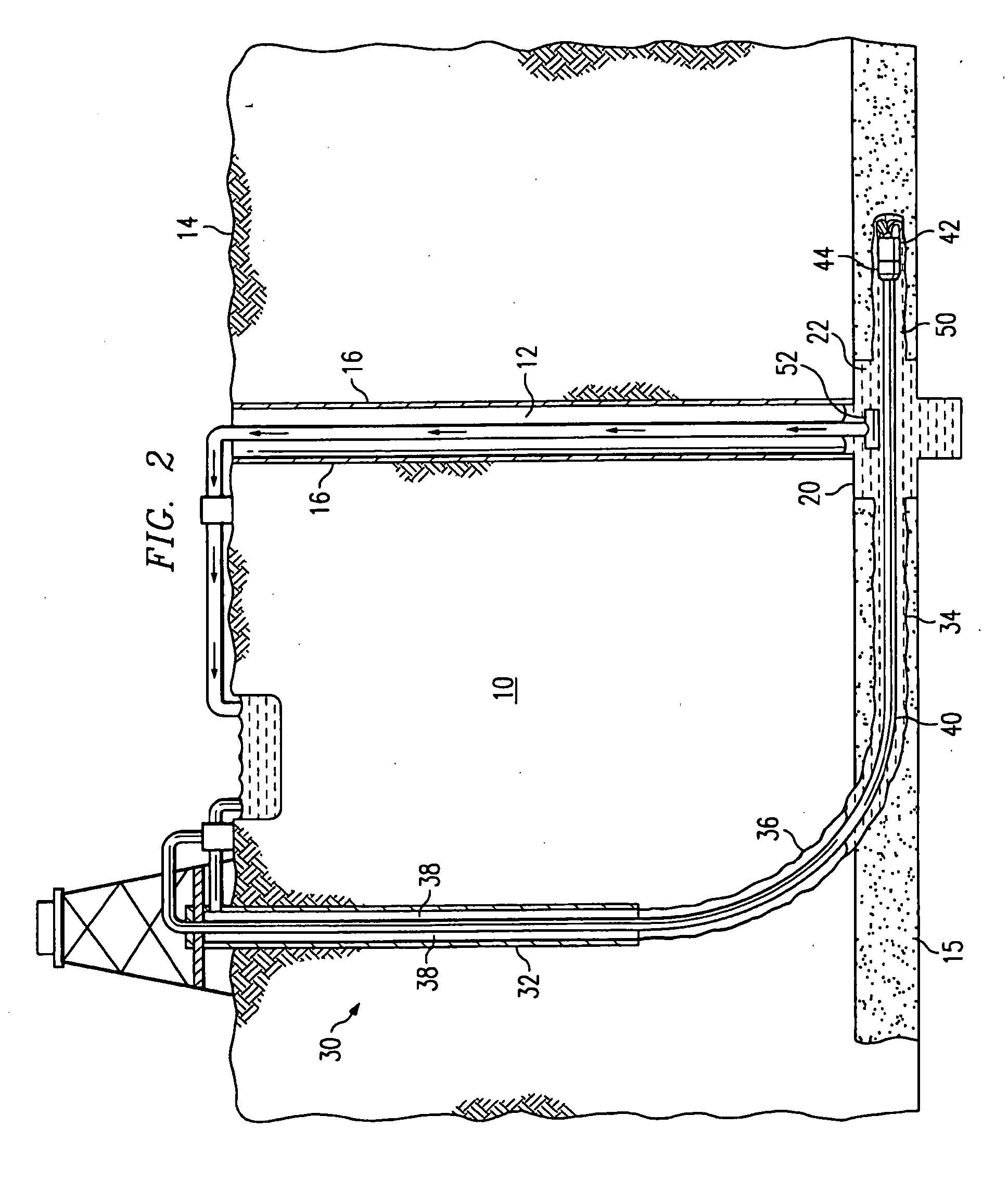

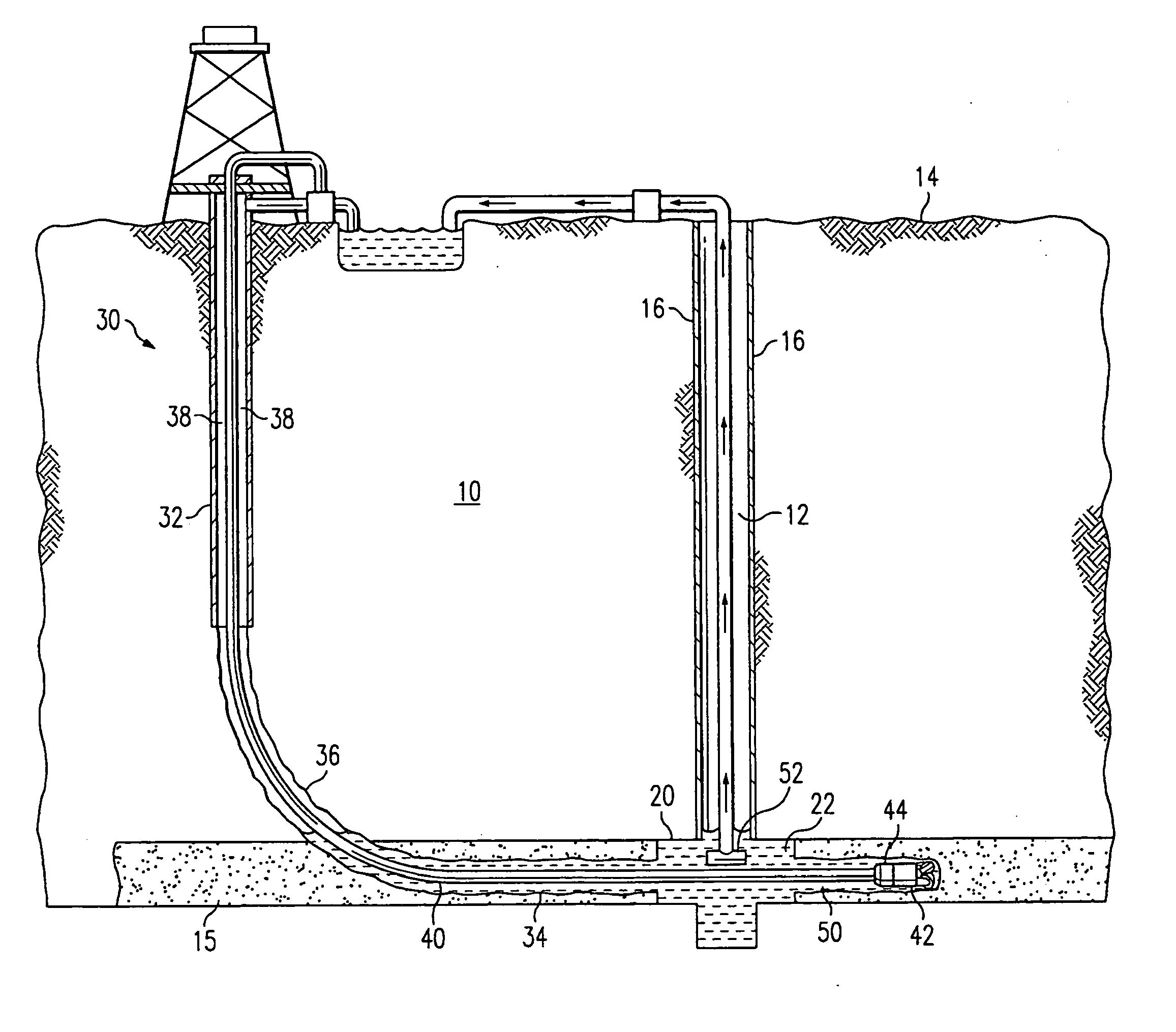

According to one embodiment, a system for accessing a subterranean zone from the surface includes a well bore extending from the surface to the subterranean zone, and a well bore pattern connected to the junction and operable to drain fluid from a region of the subterranean zone to the junction.

Owner:EFFECTIVE EXPLORATION

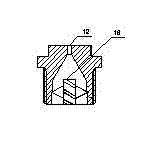

Under-pressure grouting hole sealing device and method for gas extraction drill air bag blocking

The invention relates to an under-pressure grouting and hole sealing device and method for gas extraction drill air bag blocking. The device is characterized in that the device comprises an extraction pipe, a first tip air bag, a second tip air bag, a slurry outlet pipe and a grouting pipe, wherein the extraction pipe is composed of a first extraction pipe body, a second extraction pipe body and a third extraction pipe body, the first extraction pipe body is sleeved with the first tip air bag, a one-way needle valve is arranged on the first tip air bag, the slurry outlet pipe with a one-way check valve arranged inside penetrates through the first tip air bag, the outer end of the slurry outlet pipe is communicated with the grouting pipe, the third extraction pipe body is sleeved with the second tip air bag, a one-way needle valve is arranged on the second tip air bag, the two ends of the second extraction pipe body are connected with one end of the first extraction pipe body and one end of the third extraction pipe body respectively, the tip of the other end of the third extraction pipe body is provided with a plurality of sieve holes which allow gas to inflow, and the first tip air bag and the second tip air bag are filled with expansion agents in advance. The device and the method can be widely applied to permanent hole sealing for coal mine underground gas extraction hole drilling.

Owner:NORTH CHINA INST OF SCI & TECH

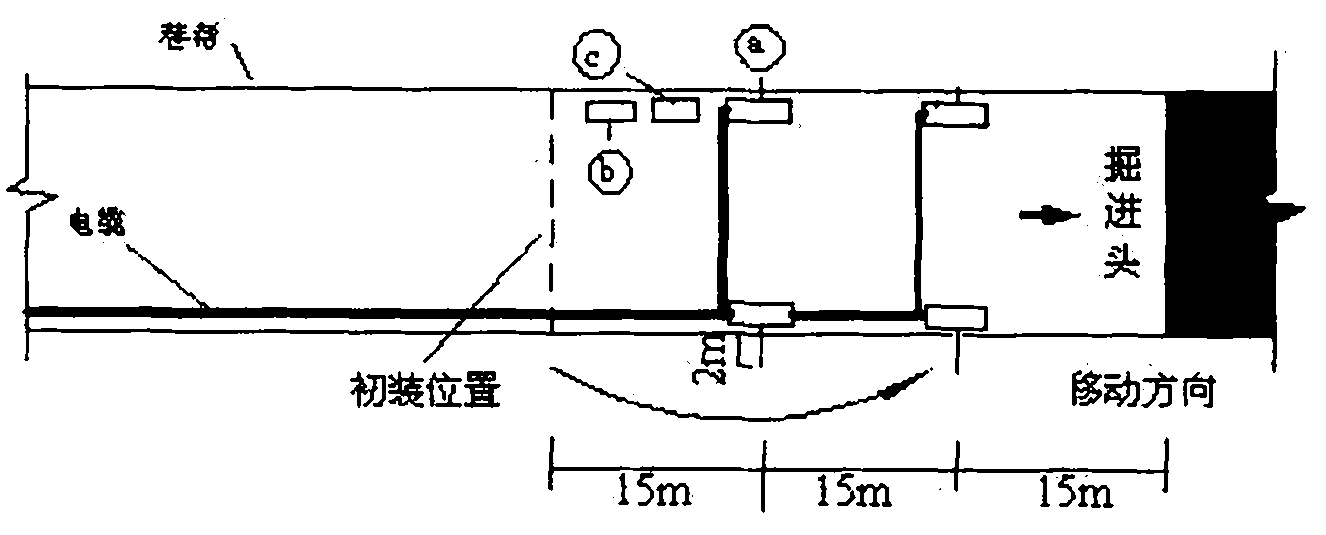

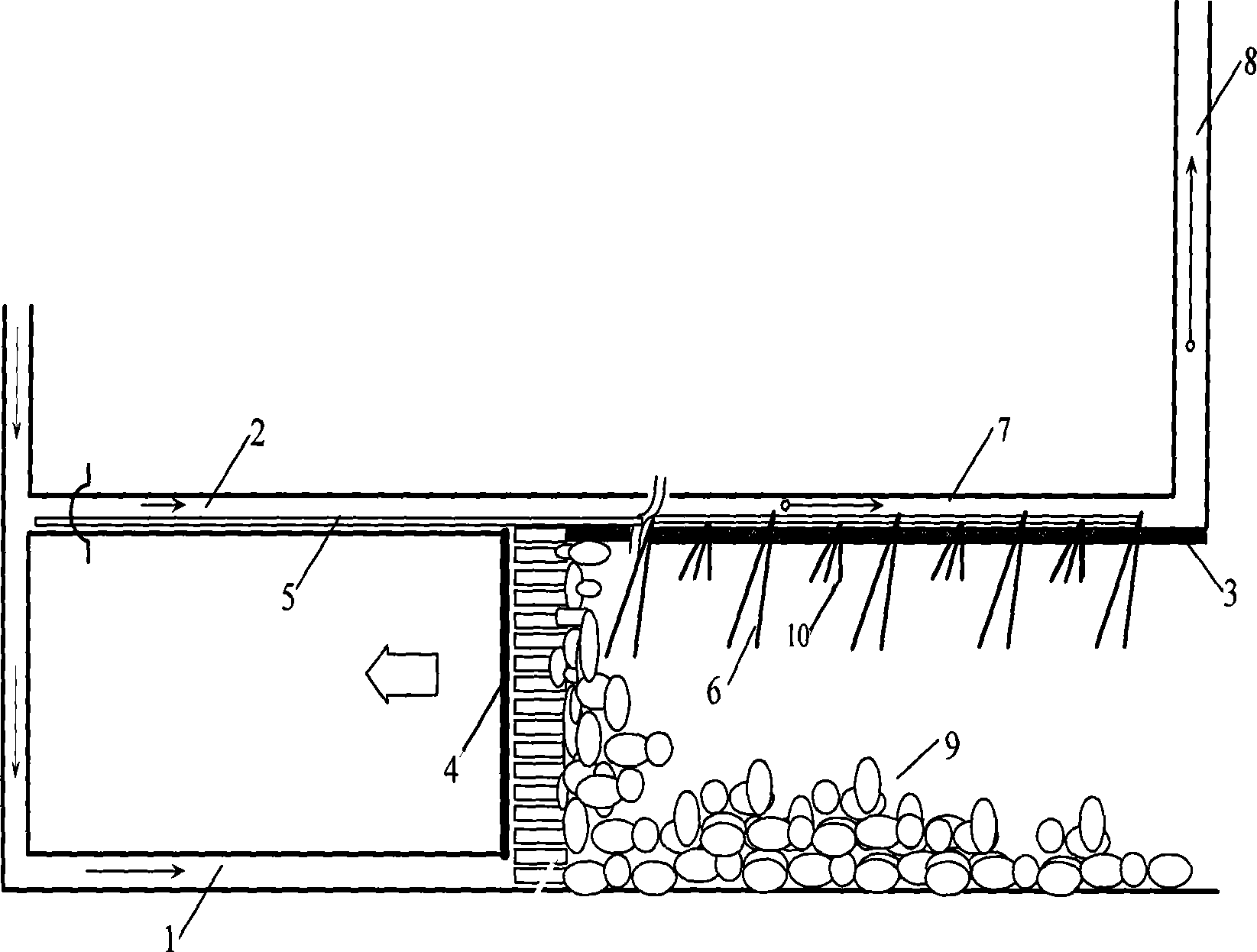

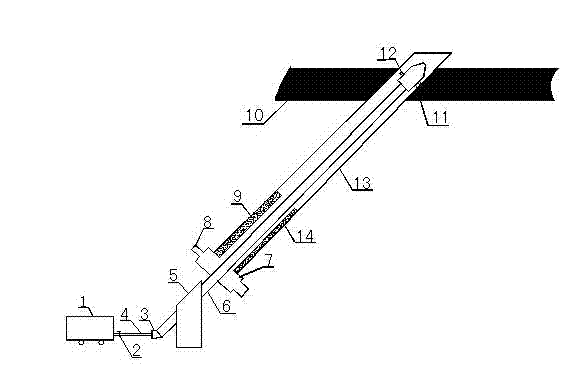

Wind pressure air drilling equipment in downhole soft outbursting coal bed and process matched therewith

ActiveCN101446178ADrill normalImprove governance efficiencyGas removalDrilling machines and methodsExplosion protectionHigh intensity

The invention relates to wind pressure air drilling equipment in a downhole soft outbursting coal bed and a process matched therewith. At present, as the consequent layer drilling characterized by high construction speed, low cost and high gas extraction efficiency becomes the primary option for coal control and gas control in coal mines, for soft outbursting coal beds, the gas extraction efficiency is directly dependant upon the pore-forming rate of the consequent layer drilling. The equipment comprises a boring machine, an air compressor, an orifice dust collection and dust removal device, a high-strength large through-hole drill rod, a drill bit with an inner core which can automatically fall off, and an antistatic explosion-protection PVC sieve tube; the boring machine which has large power and large torque supplies power to drilling construction; the orifice dust collection and dust removal device collects and eliminates slack carried out by wind from the orifice during drilling; and the antistatic explosion-protection PVC sieve tube is transferred from the interior of the high-strength large through-hole drill rod to the bottom of the orifice without lifting a drill on the completion of drilling, and at last remains in the orifice, thereby ensuring the completeness of drilling. The equipment and the process matched therewith provided by the invention has the advantages of increasing the pore-forming rate of the consequent layer drilling in soft outbursting coal beds, improving the effect of gas extraction, improving the working atmosphere of downhole air drilling, and protecting the production safety of outbursting coal mines.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Method and system for accessing subterranean deposits from the surface and tools therefor

According to one embodiment, a system for accessing a subterranean zone from the surface includes a well bore extending from the surface to the subterranean zone, and a well bore pattern connected to the junction and operable to drain fluid from a region of the subterranean zone to the junction.

Owner:EFFECTIVE EXPLORATION

Method and system for accessing subterranean deposits from the surface and tools therefor

According to one embodiment, a system for accessing a subterranean zone from the surface includes a well bore extending from the surface to the subterranean zone, and a well bore pattern connected to the junction and operable to drain fluid from a region of the subterranean zone to the junction.

Owner:EFFECTIVE EXPLORATION

Method and system for accessing subterranean deposits from the surface and tools therefor

According to one embodiment, a system for accessing a subterranean zone from the surface includes a well bore extending from the surface to the subterranean zone, and a well bore pattern connected to the junction and operable to drain fluid from a region of the subterranean zone to the junction.

Owner:EFFECTIVE EXPLORATION

High-pressure pneumatic blasting pressure relieving and transmission increasing method

ActiveCN102852506ARealize pressure relief and anti-reflectionRelief and anti-reflection achieveDisloding machinesFluid removalEngineeringHigh pressure water

The invention provides a high-pressure pneumatic blasting pressure relieving and transmission increasing method, comprising the steps of constructing a blasting drill hole in a coal layer, and carrying out high-pressure water jet seam cutting operation in the blasting drill hole at intervals, so that a lead seam groove is formed in a coal body around the blasting drill hole; feeding a blasting steel pipe with plugged top part into the blasting drill hole, forming a plurality of air vents at the front part of the blasting steel pipe, and sealing a section inside a hole opening of the blasting drill hole by 8-10 m, so as to form a cement plug; and connecting the blasting steel pipe with a high-pressure air station through a pipeline at the exposed end of the blasting steel pipe, and opening a valve arranged on the pipeline to inject high-pressure gas, so that the high-pressure gas is jetted by the blasting steel pipe from the air vents. On the basis of forming cracks and fractures formed in the fractures and cutting grooves of the original coal body, the high-pressure gas instantly impacts the blasting effect, so that the cracks and the fractures can be continuously expanded, and a lot of new fractures can be generated. Finally, a mutually communicated large fracture screen is formed in the coal body by using the blasting drill hole as a center, so that the purpose of pressure relief and transmission increase of the coal body can be realized. Furthermore, the high-pressure pneumatic blasting pressure relieving and transmission increasing method has the advantages of simple operation, easiness of realization and obvious effect.

Owner:CHINA UNIV OF MINING & TECH

Pressure alternate gas exhausting method by slotting and fracturing coal seams

ActiveCN103362538AExpand the scope of influenceIncrease profitFluid removalGas removalSocial benefitsHigh pressure water

A pressure alternate gas exhausting method by slotting and fracturing coal seams is applicable to the gas control of complex coal seams in a high-gas-content high-ground-stress area, aims to improve the air permeability of coal bodies and the capacity of drilling gas exhausting, and realizes continuous and efficient drilling gas exhausting of the complex coal seams. According to the pressure alternate gas exhausting method, drill holes to-be-slotted and drill holes to-be-fractured are formed by drilling coal seams to a coal floor; pressure-relief annular slots are formed in the bottom area of a coal seam section by virtue of the rotation of high pressure water jets in the drill holes; ground stress around the drill holes is manually discharged, and internal energy of coal seam gas is released; drilling pressure alternate gas exhausting is performed through designed drilling gas exhausting pipes which can shift the functions of gas exhausting and water injection fracturing; the water injection fracturing of the slotted drill holes and the gas exhausting of the fractured drill holes are performed simultaneously (or the water injection fracturing of the fractured drill holes and the gas exhausting of the slotted drill holes are performed simultaneously). Through alternate and repeated operations, the capacity of continuous and efficient drilling gas exhausting is increased; the effective influence range of drilling gas exhausting is increased by 2-4 times; the air permeability coefficient of coal bodies around the drill holes is increased by 200-500 times; the quantity of exhausted gas of drill holes with lengths of 100 m is increased by 2-5 times, so that the pressure alternate gas exhausting method has higher field application value and social benefits.

Owner:CHINA UNIV OF MINING & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com