Bag type paste injection hole sealing device and its hole sealing method

A technology of sealing device and bag, applied in safety device, sealing/sealing, earth-moving drilling, etc., can solve the problem that the deformation and damage of drilling can not be effectively controlled, the compressible amount is large, and the concentration and concentration of gas drainage are affected. Extraction effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

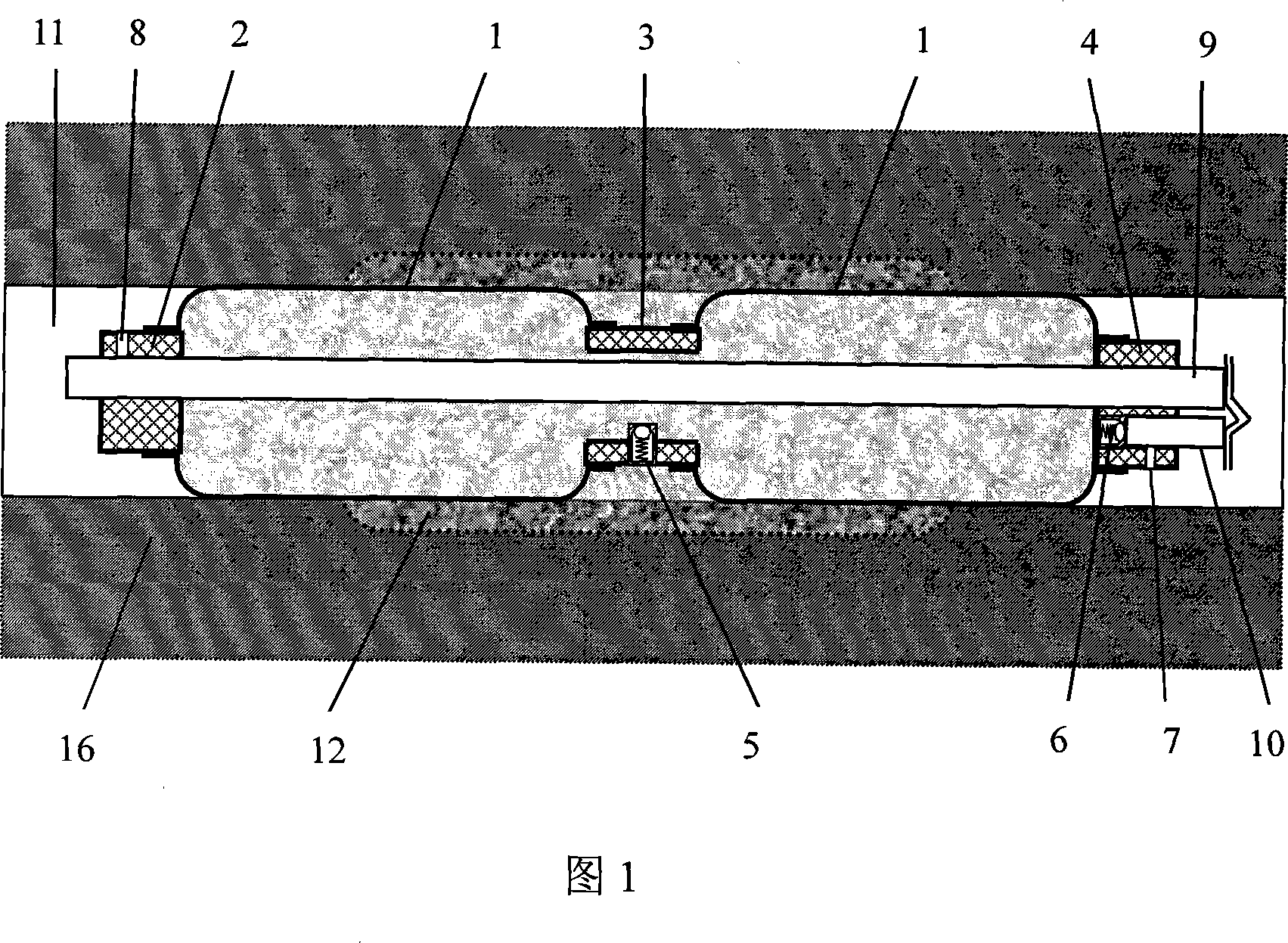

[0017] As shown in Figure 1, the bag-type grouting and sealing device includes a bag 1 and a drainage tube 9 passing through the bag 1, and the drainage tube 9 is equipped with an inner support 2 and an outer support. piece 4. The pouch 1 is made of elastic thin-walled material composed of sleeve cloth (thread cloth) and rubber, latex or other elastic materials, and can also be replaced by an existing expansion rubber tube on the market. The rubber makes the pouch 1 have sealing performance. The threaded cloth makes the pouch 1 have better tensile performance, and one or more layers of threaded cloth can be added separately on the outside of the pouch 1 to increase the tensile capacity of the pouch 1 . One end of the pouch 1 is fixed on the inner support member 2, the other end of the pouch 1 is fixed on the outer support member 4, and the middle part of the pouch 1 is fixed on the middle support member 3, which can be fixed by glue bonding or Secure with ties or hoops. The ...

example 2

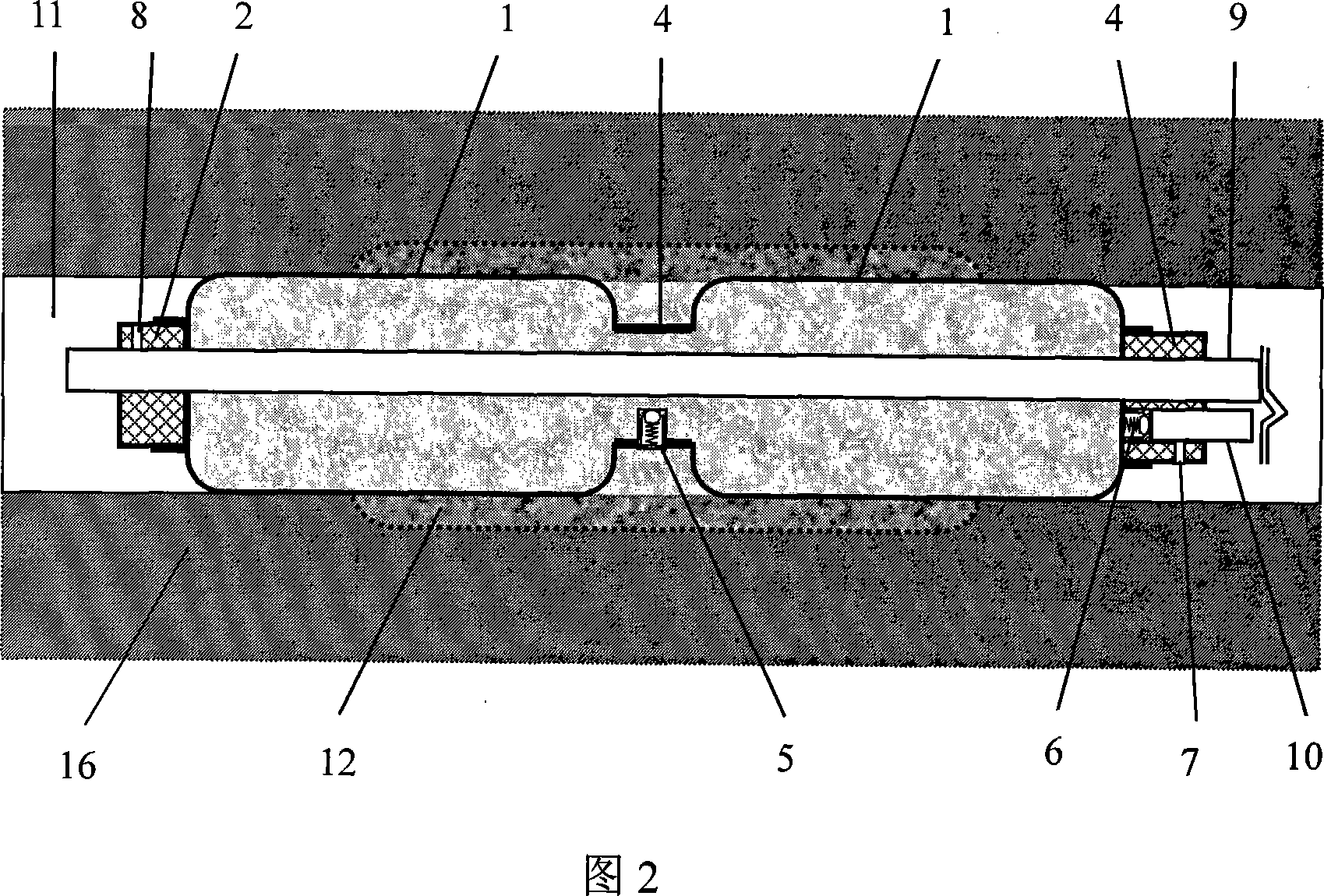

[0021] As shown in Figure 2, this embodiment is basically the same as Embodiment 1 shown in Figure 1, the difference is that the middle support 3 shown in Figure 2 is no longer a plastic or metal part, but a control panel is compounded in the middle of the pouch 1. The expansion control ring 4 expanded in the middle of the pouch 1, the expansion control ring 4 is a flexible sleeve made of fiber, the expansion of the expansion control ring 4 is less than that of the pouch 1, and the expansion control ring 4 is bonded to the pouch 1 It is used to control the expansion of the bag 1, and the slurry control valve 5 is installed on the expansion control ring 4. The method step of sealing hole is the same as embodiment 1.

example 3

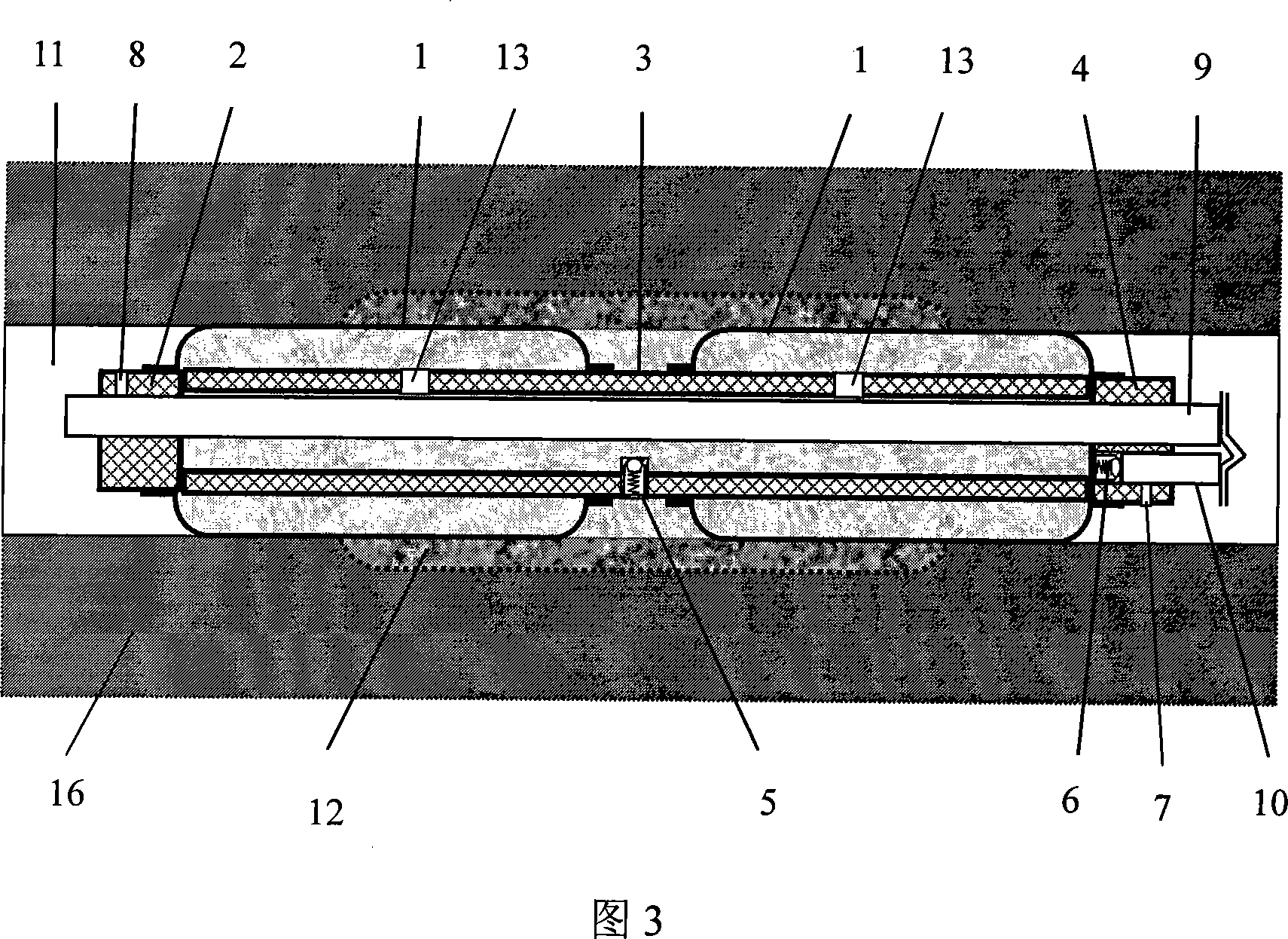

[0023] As shown in Figure 3, this embodiment is basically the same as Embodiment 1 shown in Figure 1, the difference is that the inner end support member 2, the middle support member 3 and the outer end support member 4 are connected by bonding method or screw connection method. In one piece, the middle support 3 penetrates into the inside of the pouch body, and the two ends are respectively connected to the inner support 2 and the outer support 4, and the middle support 3 covered by the pouch 1 is radially opened with a slurry outlet 13 . The two ends of the middle support member 3 can also leave a gap with the inner support member 2 and the outer support member 4 to form a slurry outlet. The method step of sealing hole is the same as embodiment 1. The cost of this embodiment is higher than that of Example 1 and Example 2, but it can reduce the axial tensile force of the bladder 1 and has certain advantages when the grouting pressure is relatively high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com