Patents

Literature

24406results about How to "Improve breathability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

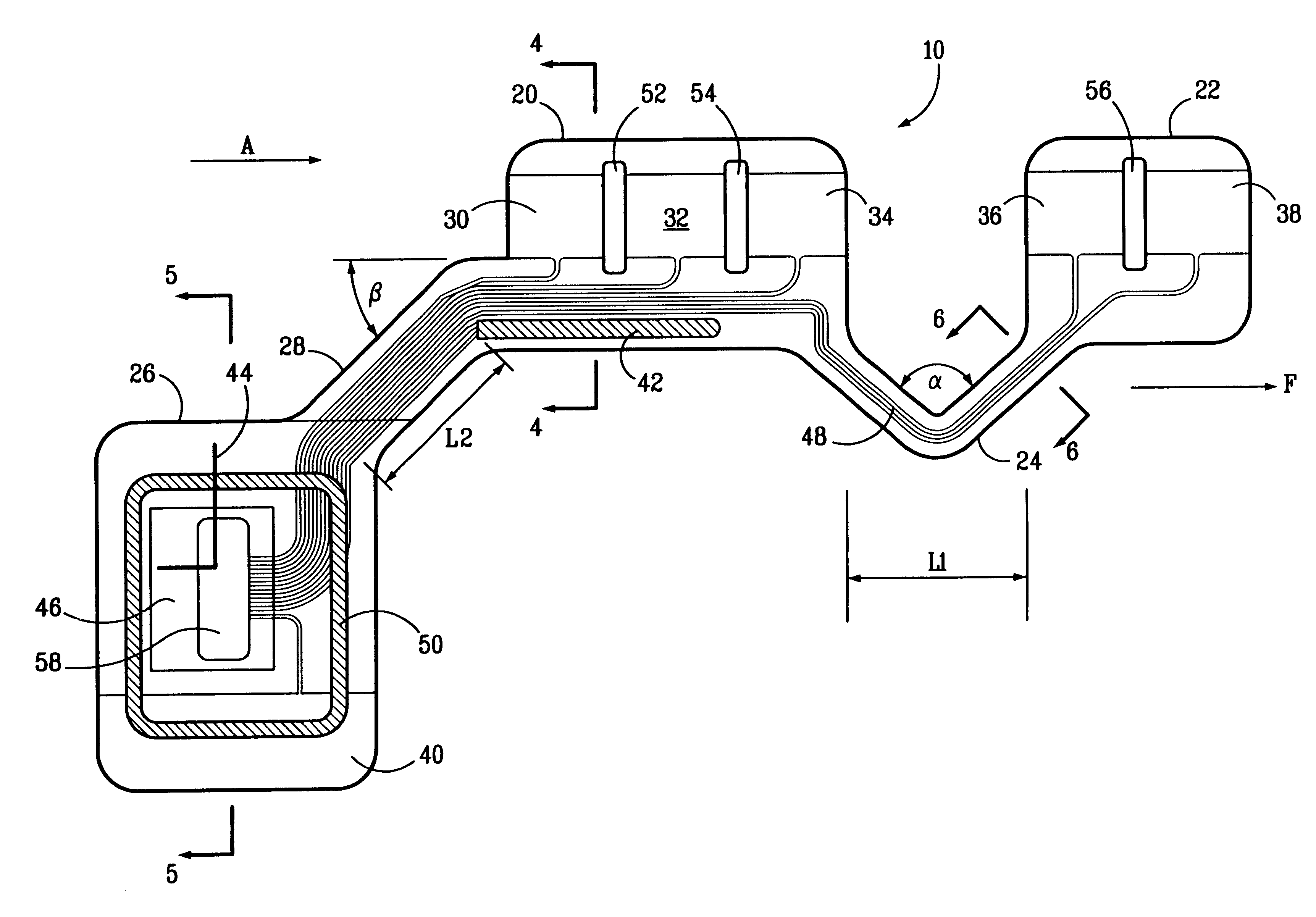

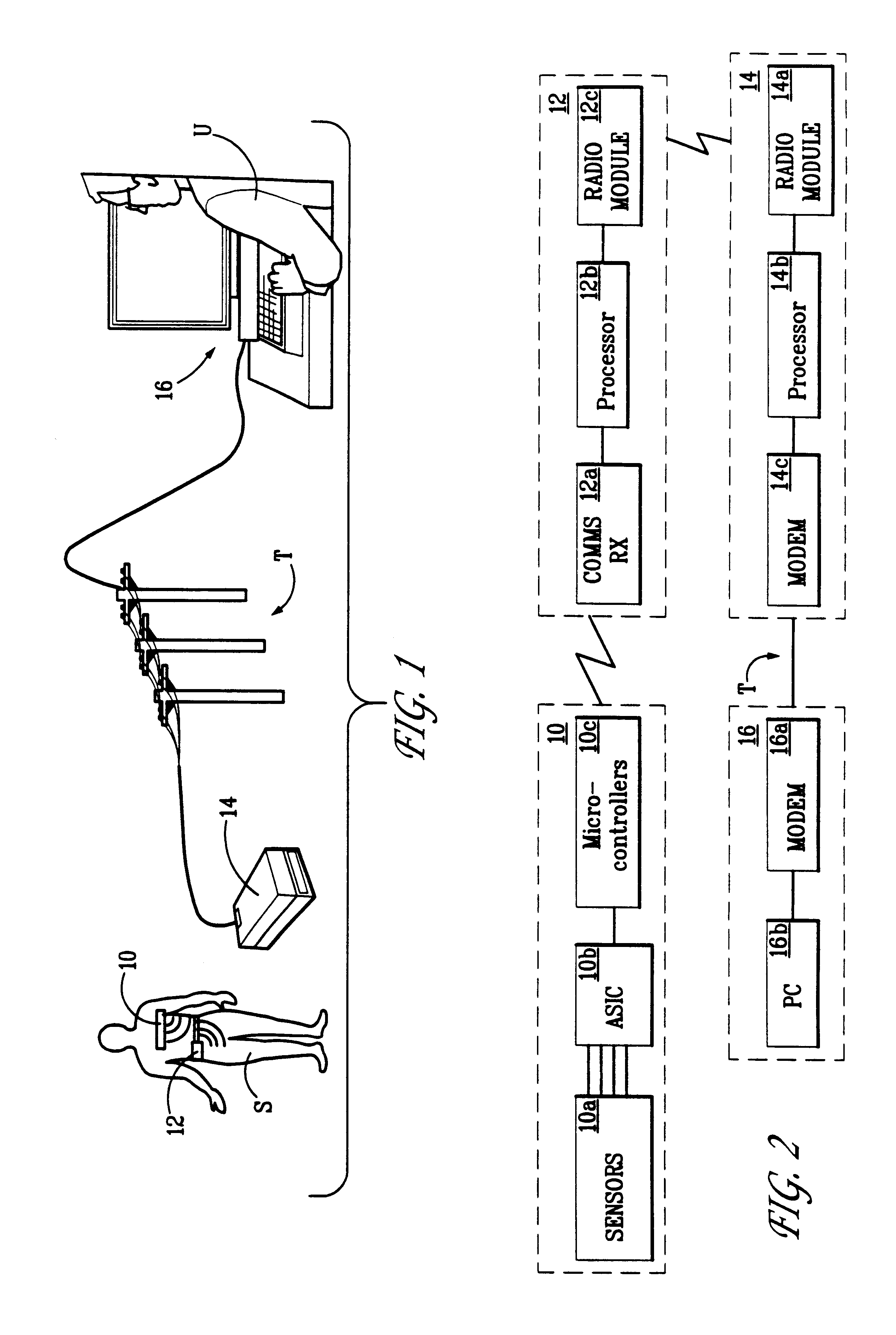

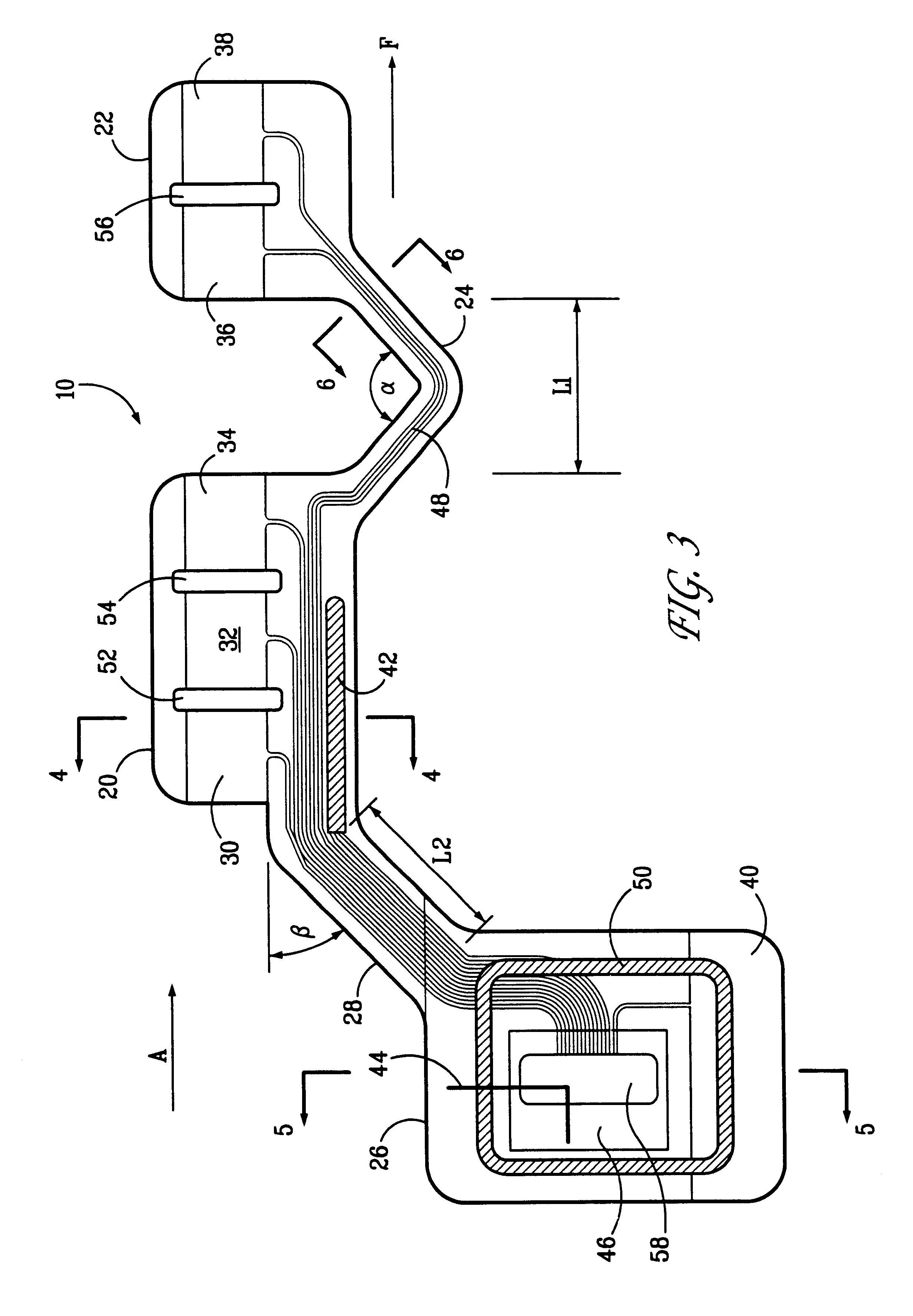

Physiological sensor device

InactiveUS6385473B1Improve breathabilityEasy to moveElectrocardiographySensorsEngineeringConductive materials

A physiological sensor device for attachment to a mammalian subject including first and second regions of sensors attachable to a subject in use, which first and second regions of sensors are separated by a flexible web adapted to enable variable separation of the first and second sensor regions from one another in use. The physiological sensor device is manufactured by forming a strip of electrically conductive material on a flexible electrically non-conductive substrate and cutting a slot through both the flexible substrate and conductive strip to define a pair of adjacent edges of conductive material separated by a non-conductive gap thereby also to define adjacent electrode sensors each having one of the pair of adjacent edges formed in the strip of conductive material. The physiological sensor device is attached to the subject for measurement of numerous physiological parameters for a period of time, such as 24 hours, and is then thrown away.

Owner:CLEARPATH PARTNERS

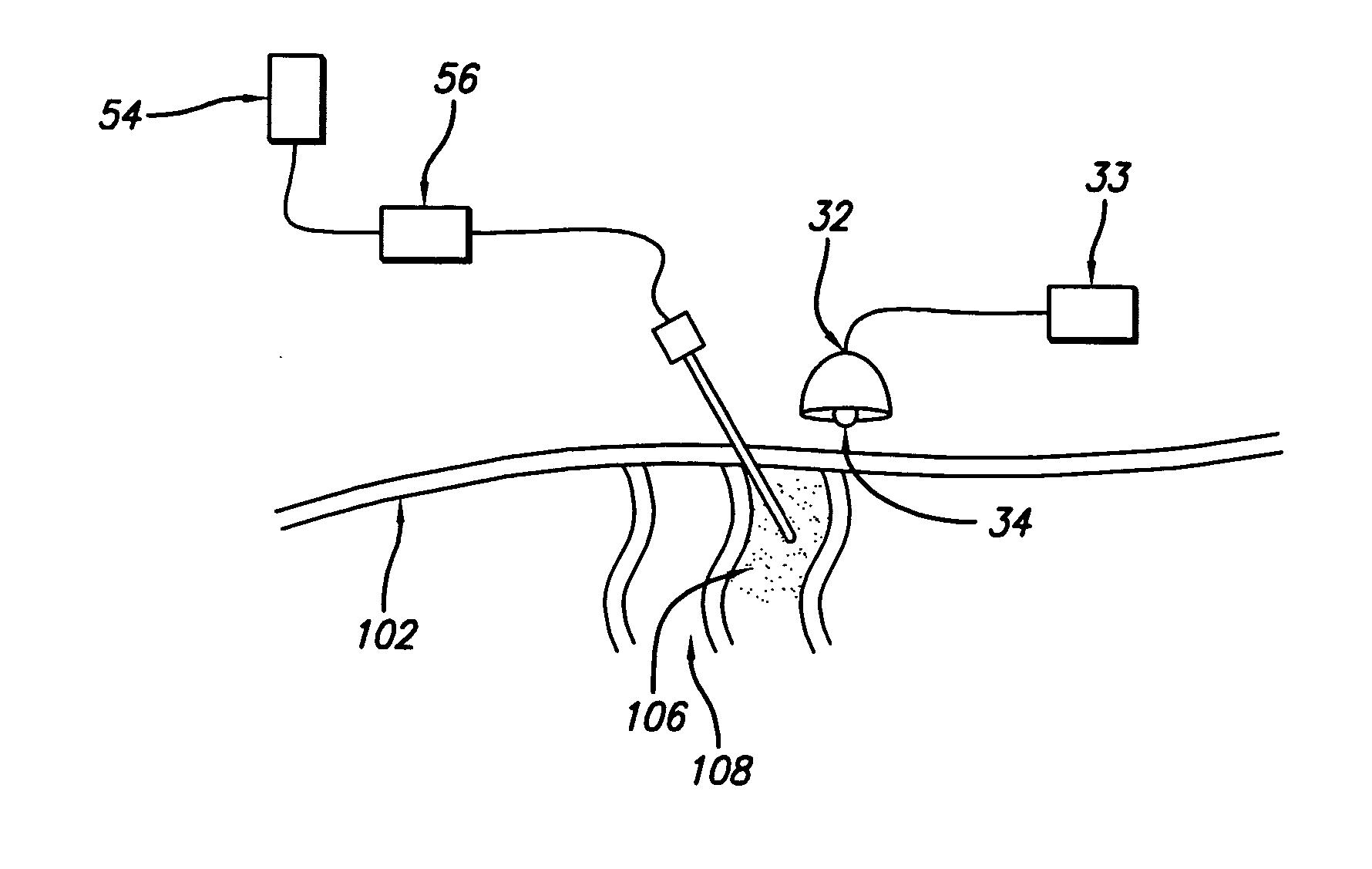

Apparatus and method for disrupting subcutaneous structures

InactiveUS20070060989A1Improve breathabilitySelective disruptionUltrasound therapyElectrotherapyDiseaseCellulite

Methods and apparatus are provided for disruption / destruction of subcutaneous structures in a mammalian body for the treatment of skin irregularities, and other disorders such as excess adipose tissue, cellulite, and scarring. Devices and methods include energy mediated applicators, microneedles, catheters and subcutaneous treatment devices for applying a treatment non-invasively through the skin, less invasively through the skin, or minimally invasively via a subcutaneous approach. Various agents to assist or enhance the procedures are also disclosed.

Owner:THE FOUNDRY INC

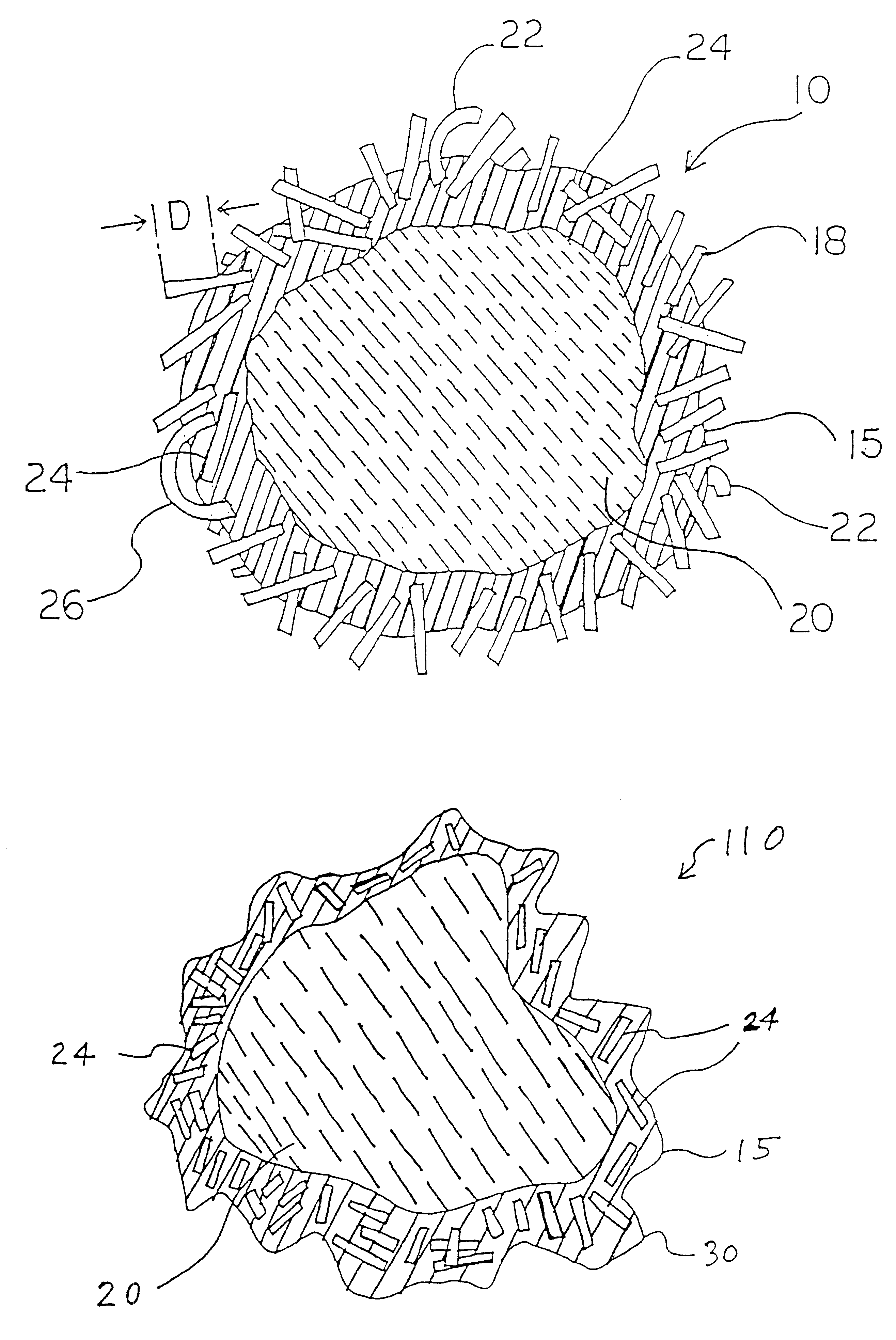

Proppants with fiber reinforced resin coatings

InactiveUS6528157B1High compressive strengthWithstanding stressCeramic layered productsDrilling compositionParticulatesResin coating

Coated particles made of particulate substrates having a coating of resin and fibrous material are provided for use in subterranean formations. The coated substrate particles are proppants useful to prop open subterranean formation fractures. The coated substrate particles are also useful for sand control, that is, acting as a filter or screen to prevent backwards flow of sand, other proppants or subterranean formation particles. Methods of making the coated particles are also disclosed.

Owner:HEXION INC

Microporation of tissue for delivery of bioactive agents

InactiveUS20050165393A1Improve throughputImprove breathabilitySonopheresisUltrasound therapyBiological bodyThermal energy

A method of enhancing the permeability of a biological membrane, including the skin or mucosa of an animal or the outer layer of a plant to a permeant is described utilizing microporation of selected depth and optionally one or more of sonic, electromagnetic, mechanical and thermal energy and a chemical enhancer. Microporation is accomplished to form a micropore of selected depth in the biological membrane and the porated site is contacted with the permeant. Additional permeation enhancement measures may be applied to the site to enhance both the flux rate of the permeant into the organism through the micropores as well as into targeted tissues within the organism.

Owner:ALTEA THERAPEUTIC CORP +1

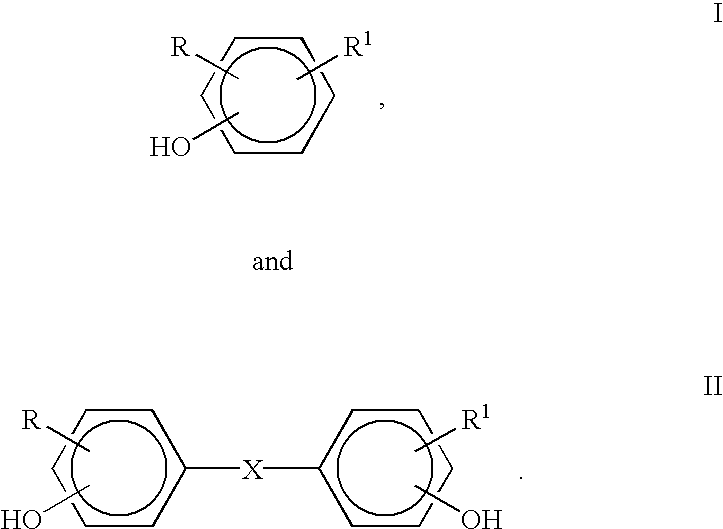

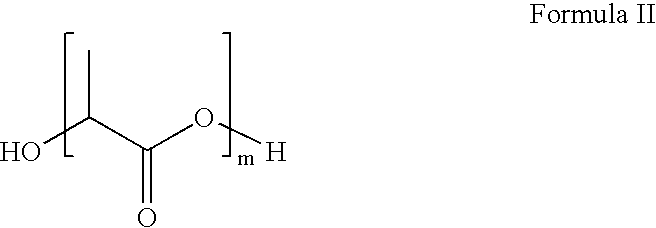

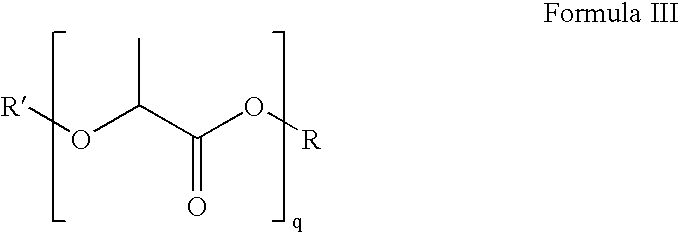

Breathable polyurethanes, blends, and articles

InactiveUS6897281B2Improve breathabilityImprove moisture vapor transmission rateSynthetic resin layered productsPolyurea/polyurethane coatingsGramSide chain

A breathable polyurethane having an upright moisture vapor transmission rate (MVTR) of more than about 500 gms / m2 / 24 hr comprises:(a) poly(alkylene oxide) side-chain units in an amount comprising about 12 wt. % to about 80 wt. % of said polyurethane, wherein (i) alkylene oxide groups in said poly(alkylene oxide) side-chain units have from 2 to 10 carbon atoms and are unsubstituted, substituted, or both unsubstituted and substituted, (ii) at least about 50 wt. % of said alkylene oxide groups are ethylene oxide, and (iii) said amount of said side-chain units is (i) at least about 30 wt. % when the molecular weight of said side-chain units is less than about 600 grams / mole, (ii) at least about 15 wt. % when the molecular weight of said side-chain units is from about 600 to about 1,000 grams / mole, and at least about 12 wt. % when the molecular weight of said side-chain units is more than about 1,000 grams / mole, and(b) poly(ethylene oxide) main-chain units in an amount comprising less than about 25 wt. % of said polyurethane.Coatings and films for textiles and other articles and applications using such polyurethanes have excellent breathability, i.e., high moisture vapor transmission rates (MVTR).

Owner:LUBRIZOL ADVANCED MATERIALS INC

Degraded agonist antibody

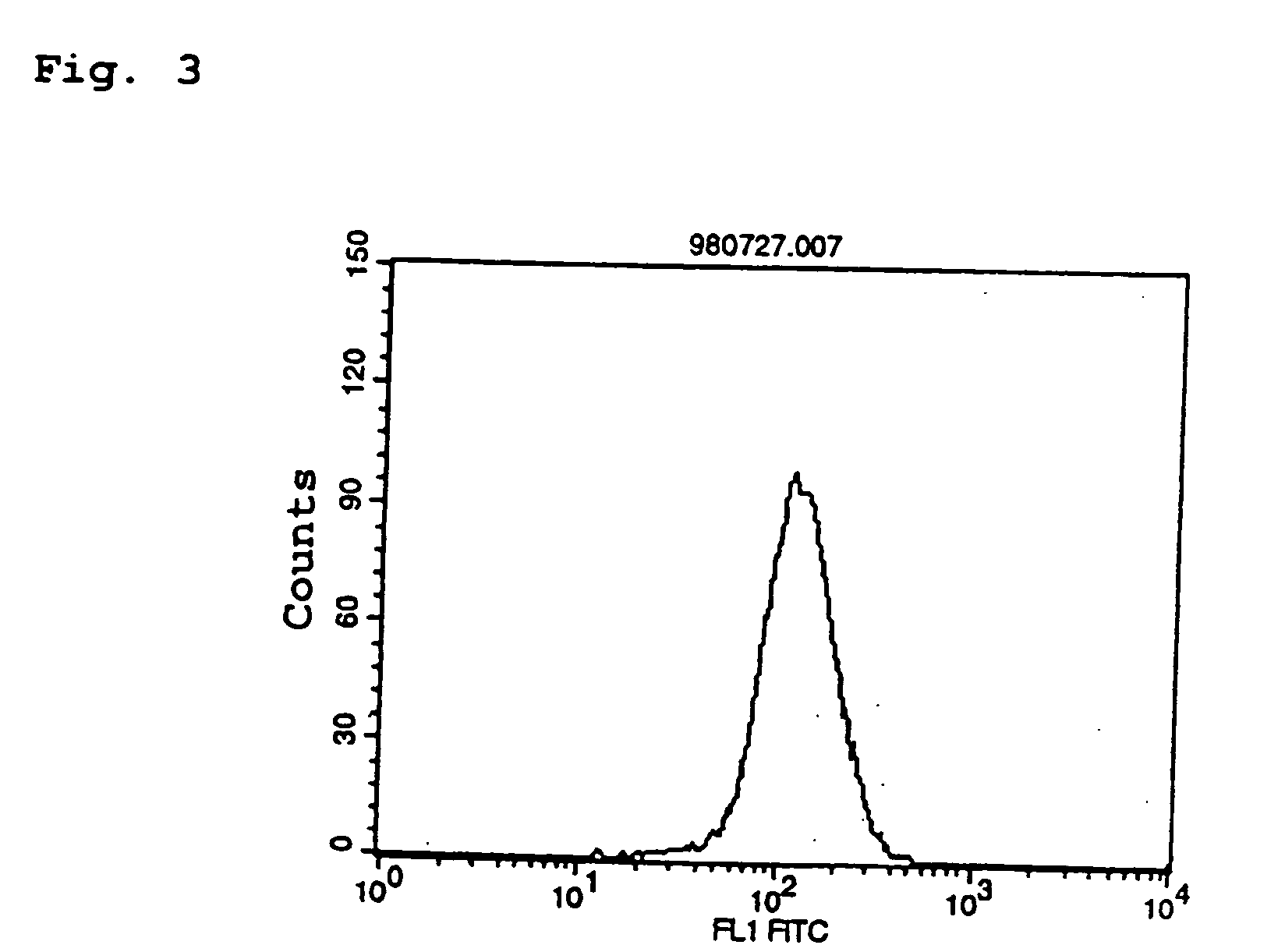

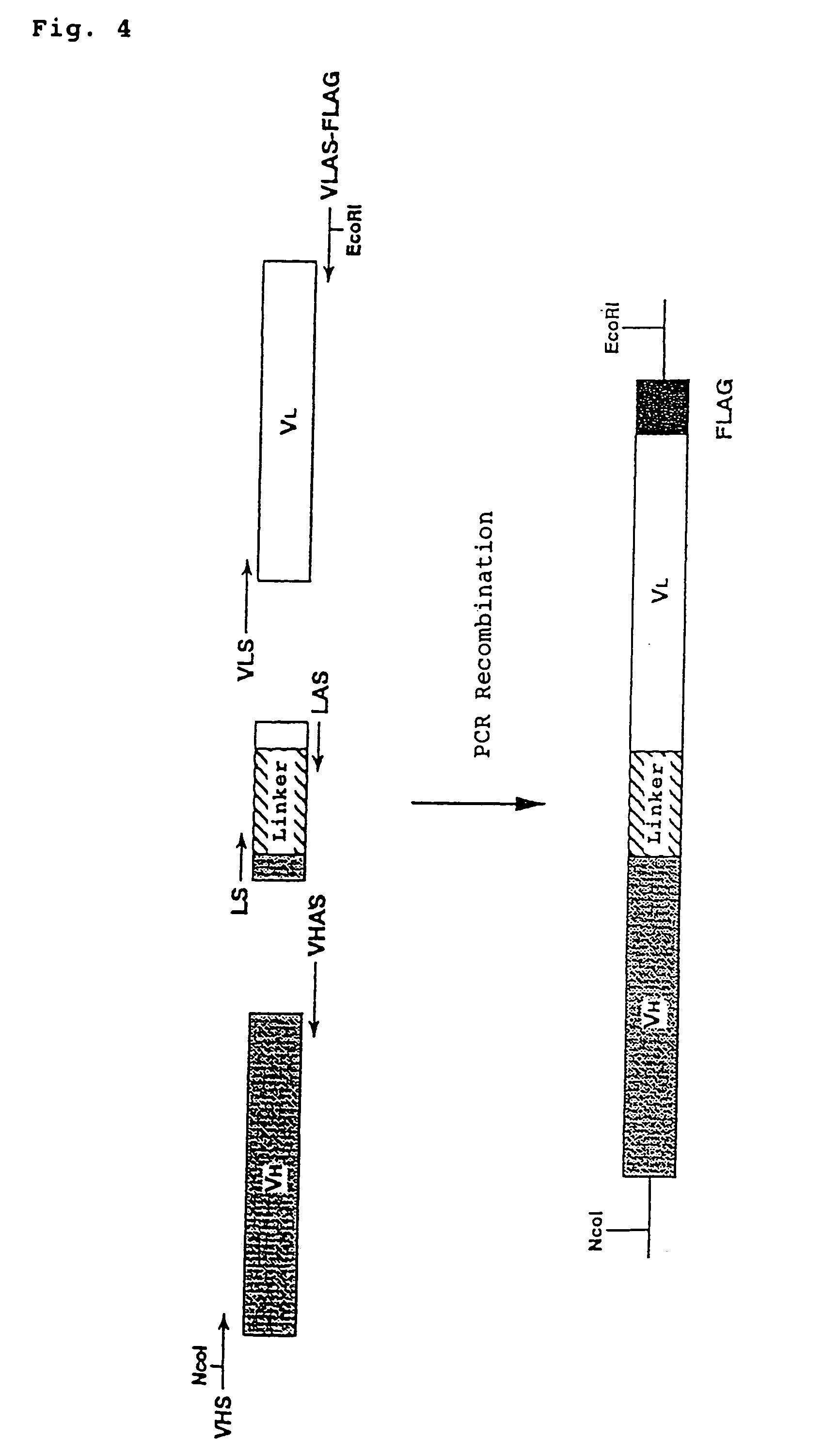

InactiveUS20040242847A1Excellent antigen-binding propertyExcellent agonist activityPeptide/protein ingredientsAntibody mimetics/scaffoldsDiseaseAntiendomysial antibodies

The invention relates to a modified antibody which contains two or more H chain V regions and two or more L chain V regions of monoclonal antibody and can transduce a signal into cells by crosslinking a cell surface molecule(s) to thereby serve as an agonist. The modified antibody can be used as a signal transduction agonist and, therefore, useful as a preventive and / or remedy for various diseases such as cancer, inflammation, hormone disorders and blood diseases.

Owner:CHUGAI PHARMA CO LTD

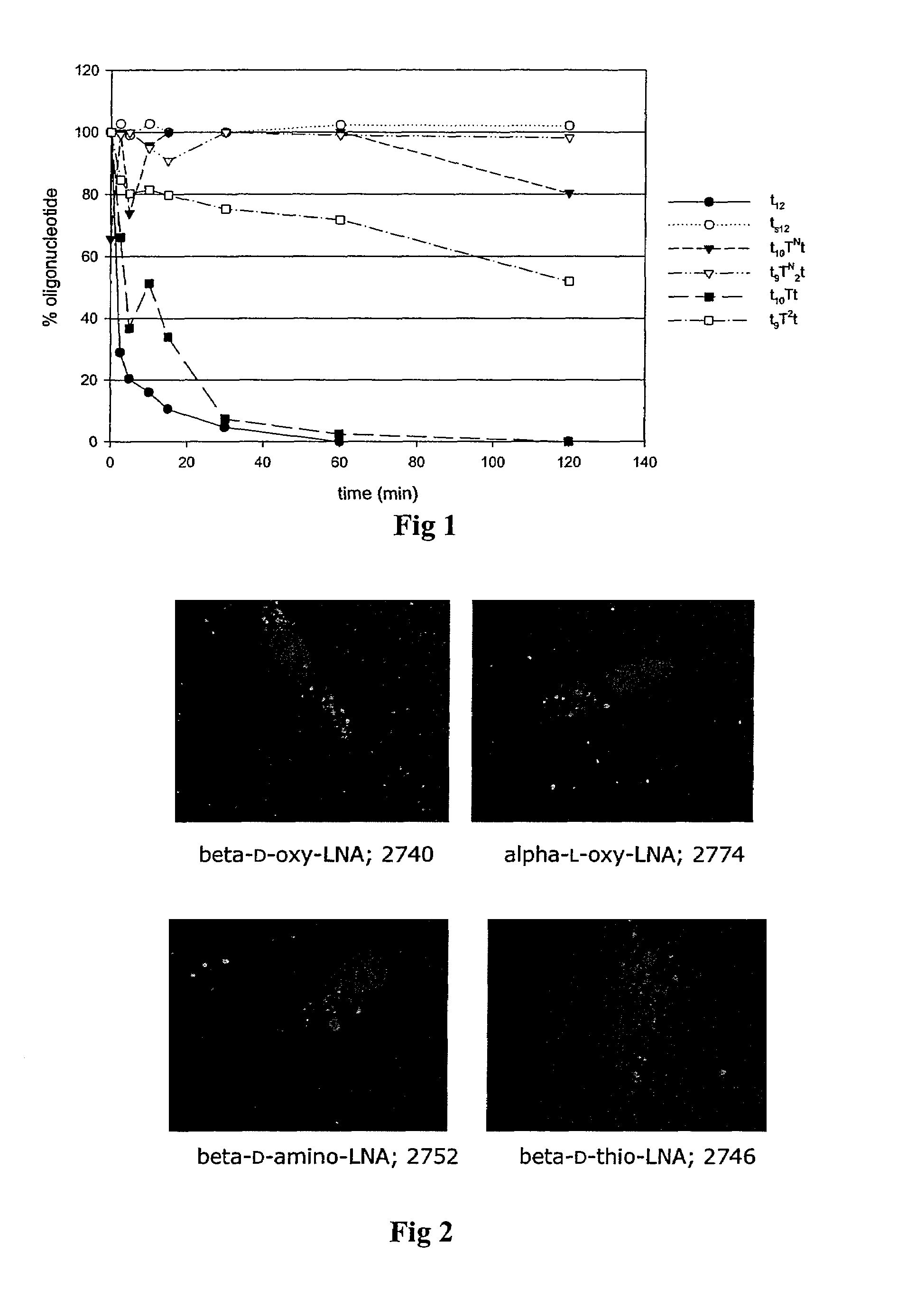

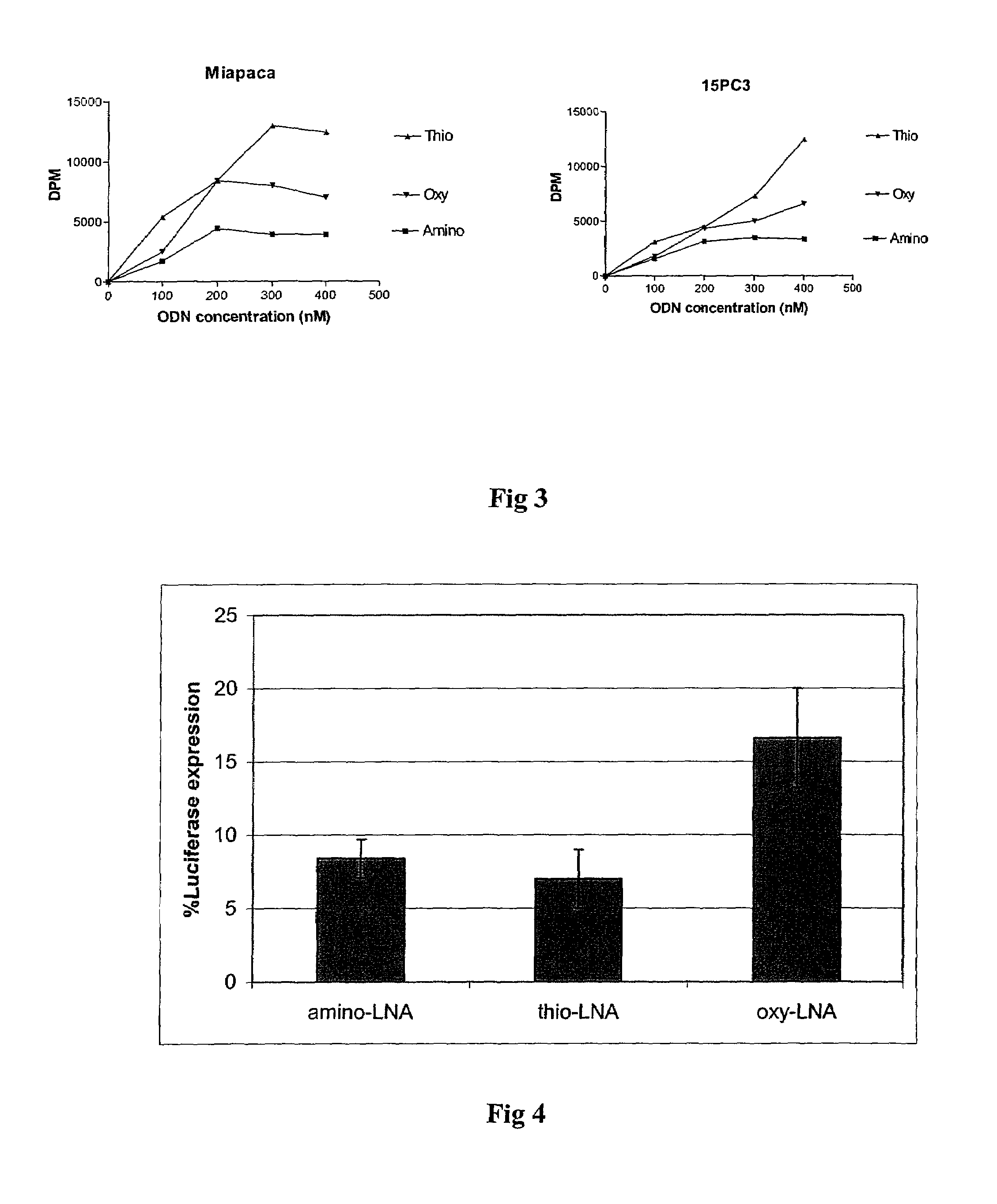

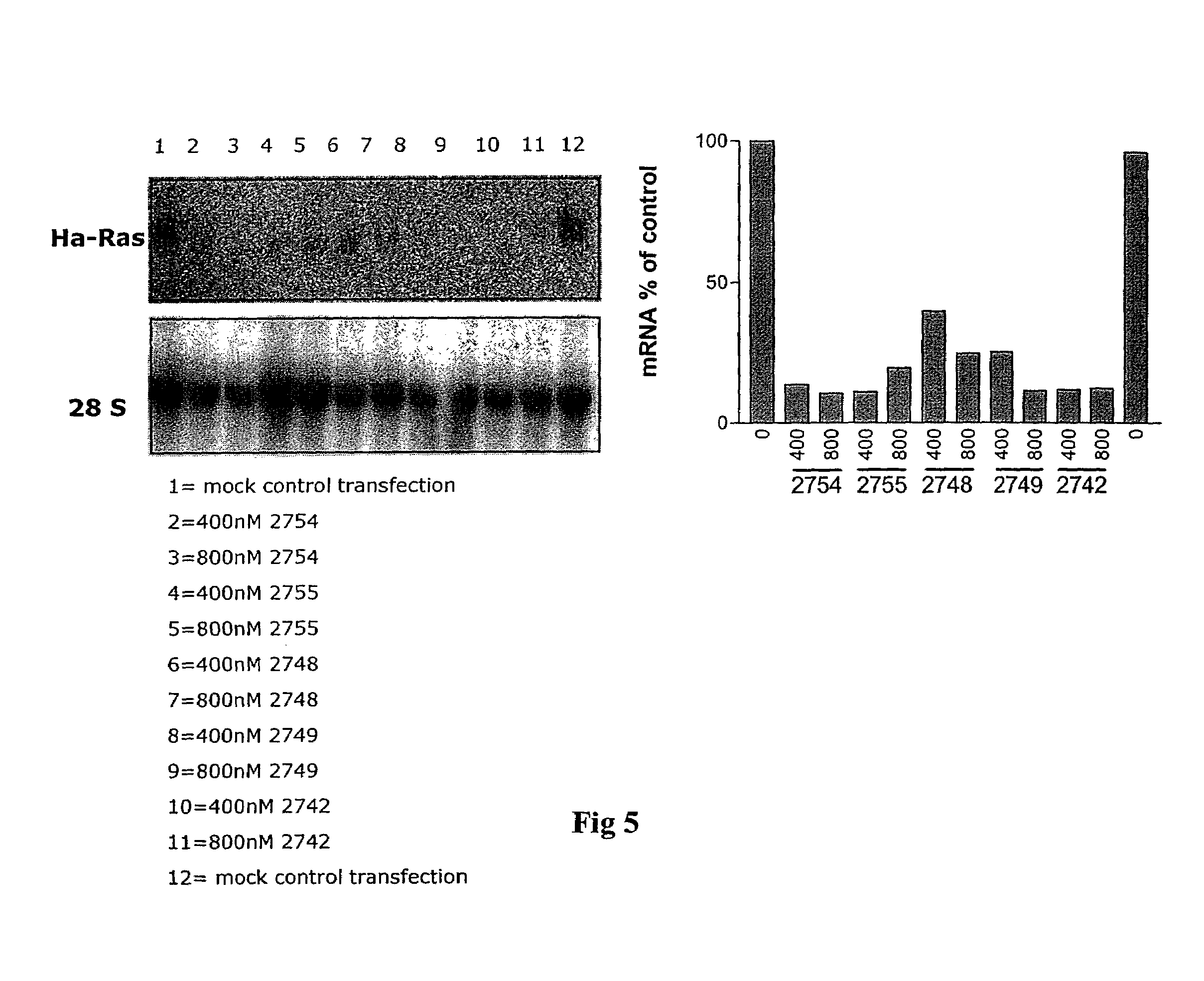

Oligonucleotides with alternating segments of locked and non-locked nucleotides

ActiveUS7687617B2Increased Design PossibilitiesEfficient substrateSugar derivativesActivity regulationNucleotideThio-

The present invention is directed to novel oligonucleotides with improved antisense properties. The novel oligonucleotides comprise at least one Locked Nucleic Acid (LNA) selected from beta-D-thio / amino-LNA or alpha-L-oxy / thio / amino-LNA. The oligonucleotides comprising LNA may also include DNA and / or RNA nucleotides. The present invention also provides a new class of pharmaceuticals which comprise antisense oligonucleotides and are useful in antisense therapy.

Owner:SANTARIS PHARMA AS

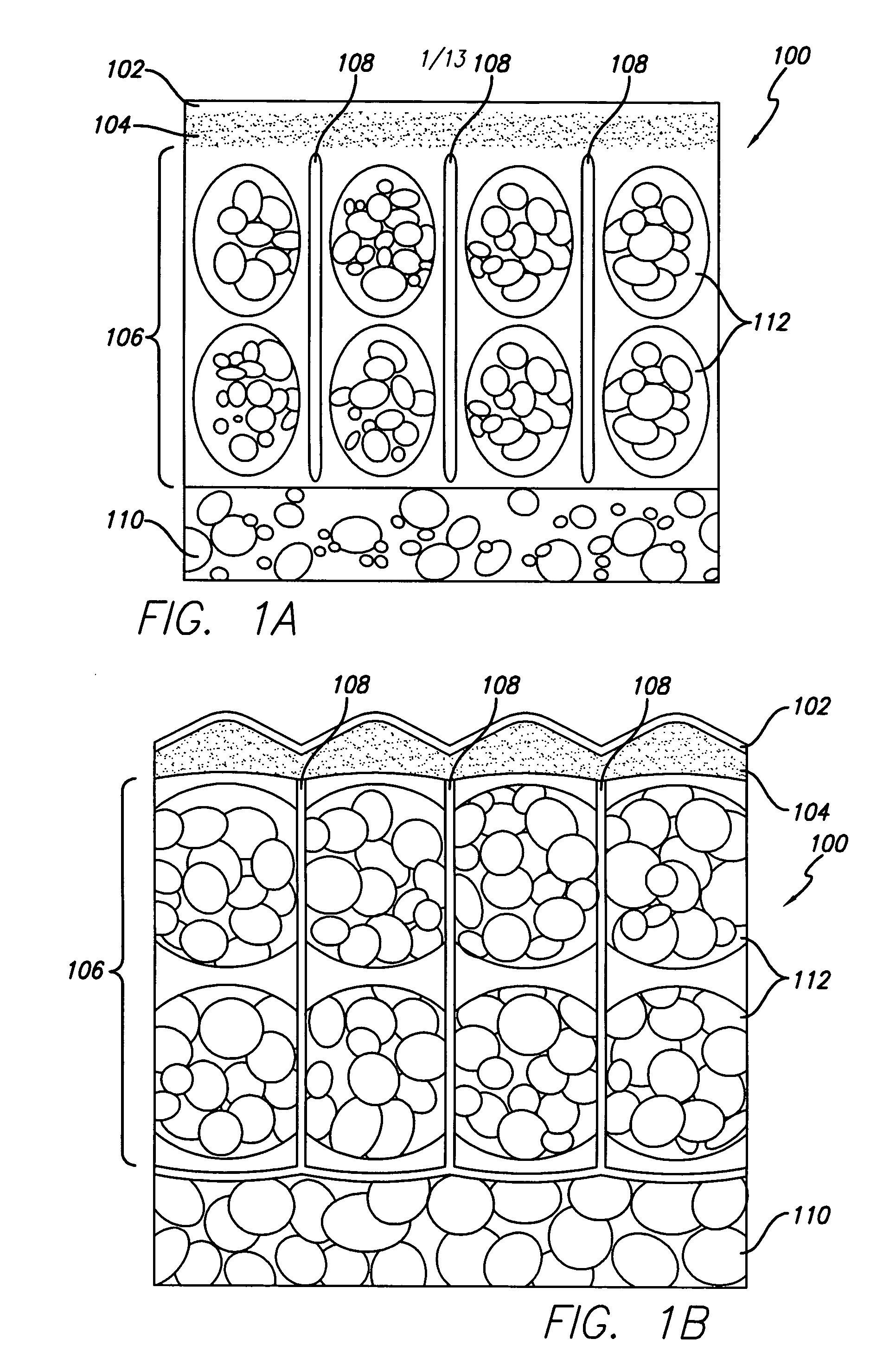

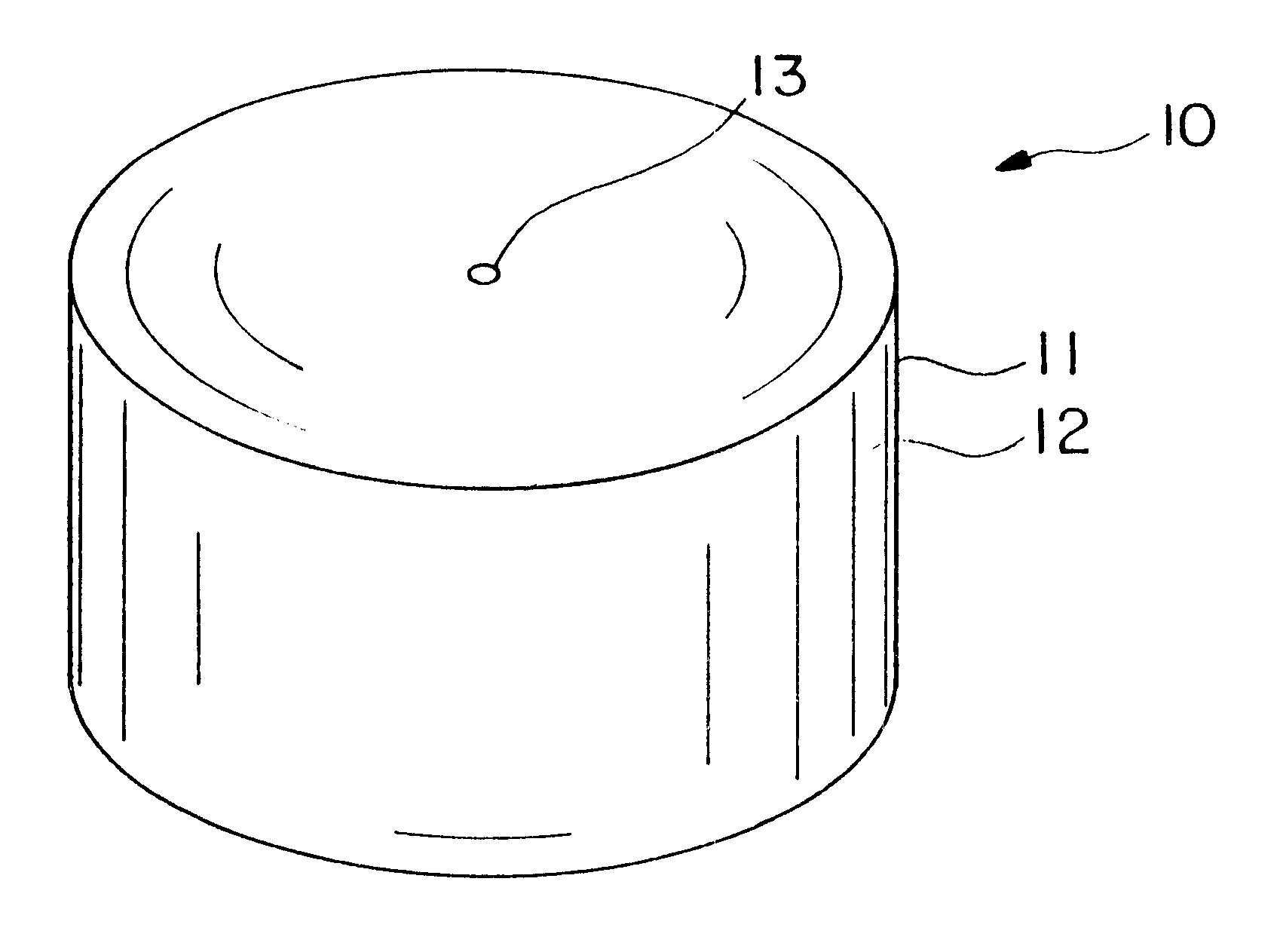

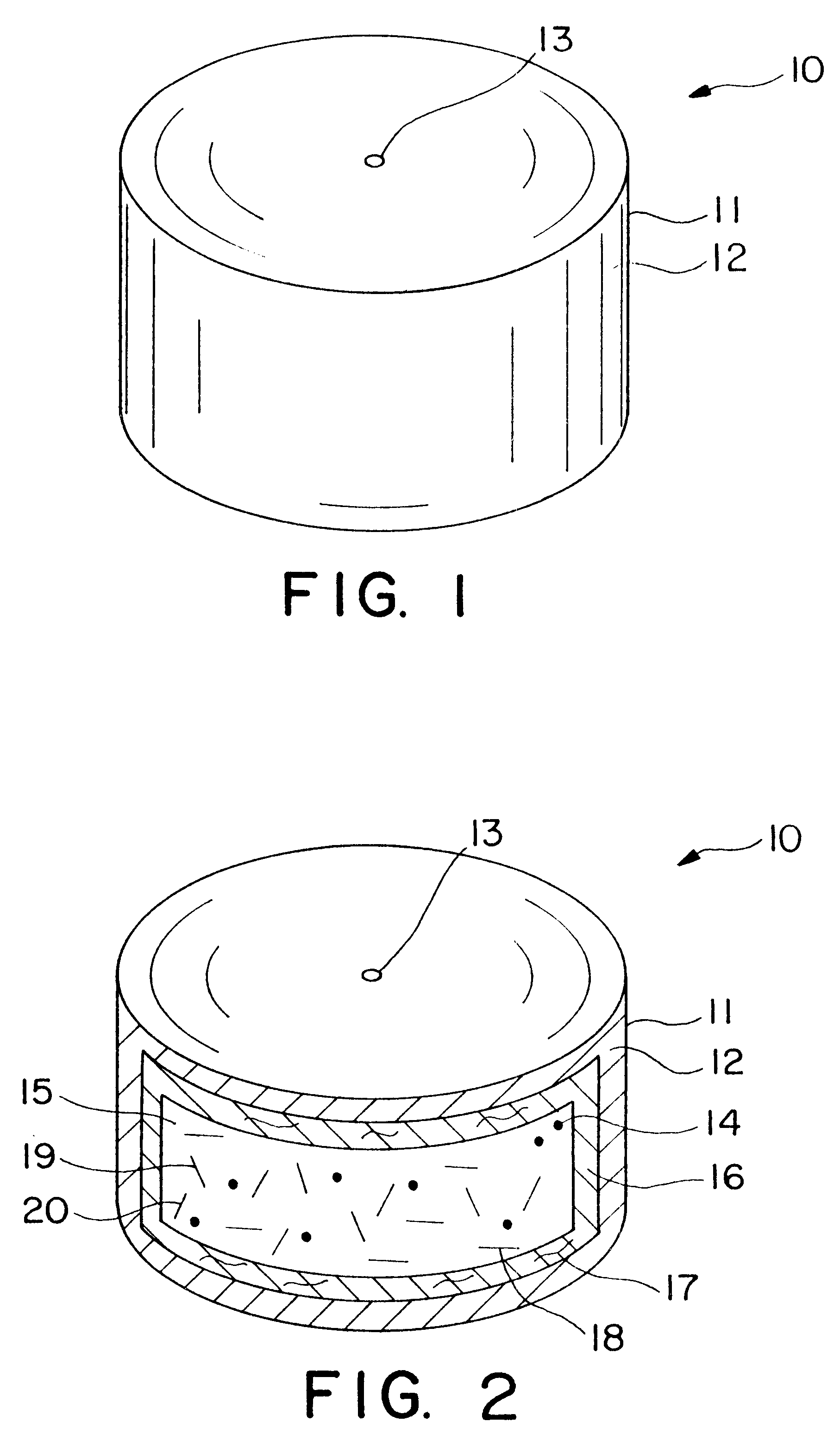

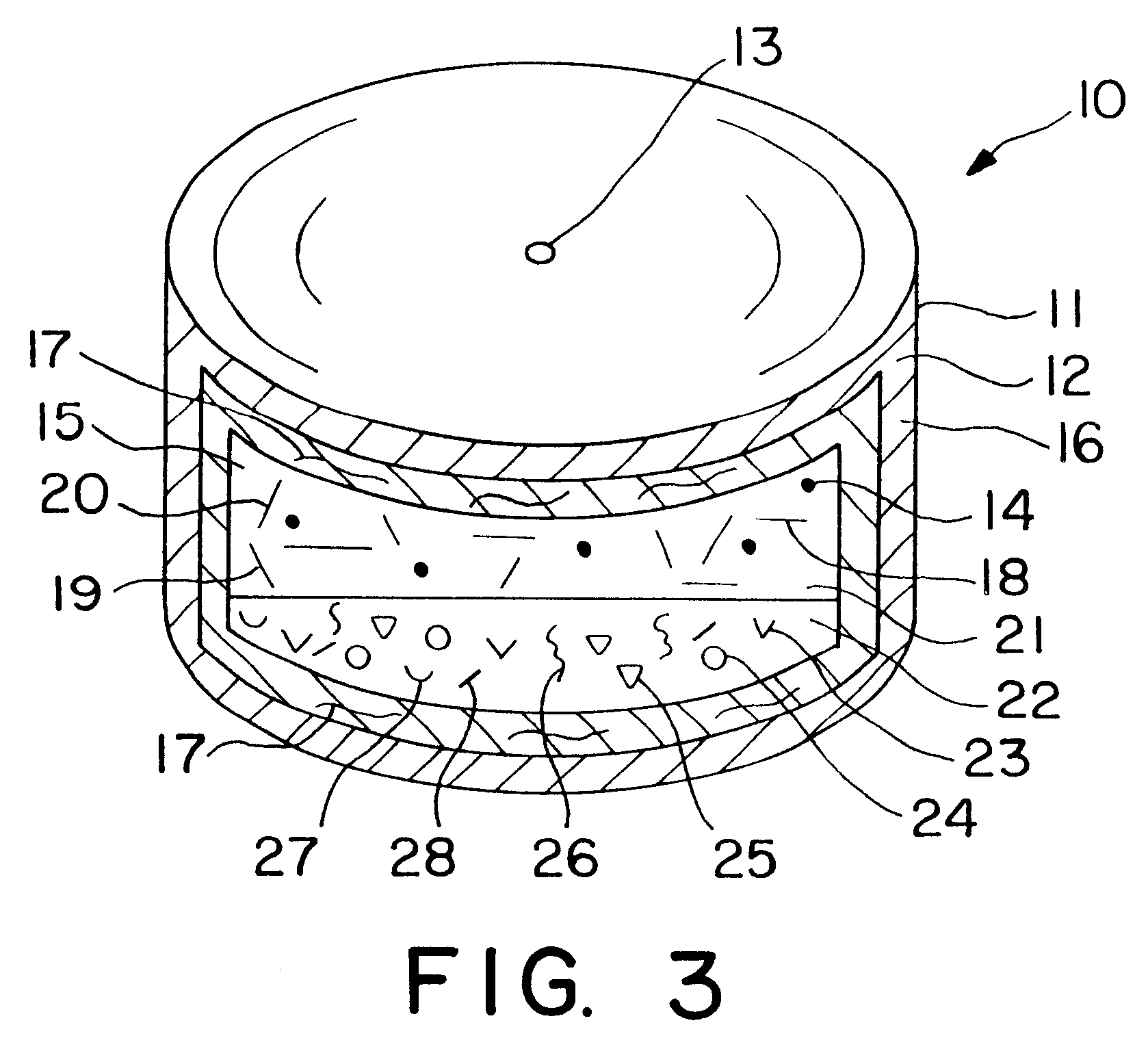

Dosage form having first and second coats

A dosage form comprising a composition comprising a drug surrounded by a first coat and a second coat with an exit for administering the drug to a patient; and a method of using the dosage form are disclosed for an indicated therapy.

Owner:ALZA CORP

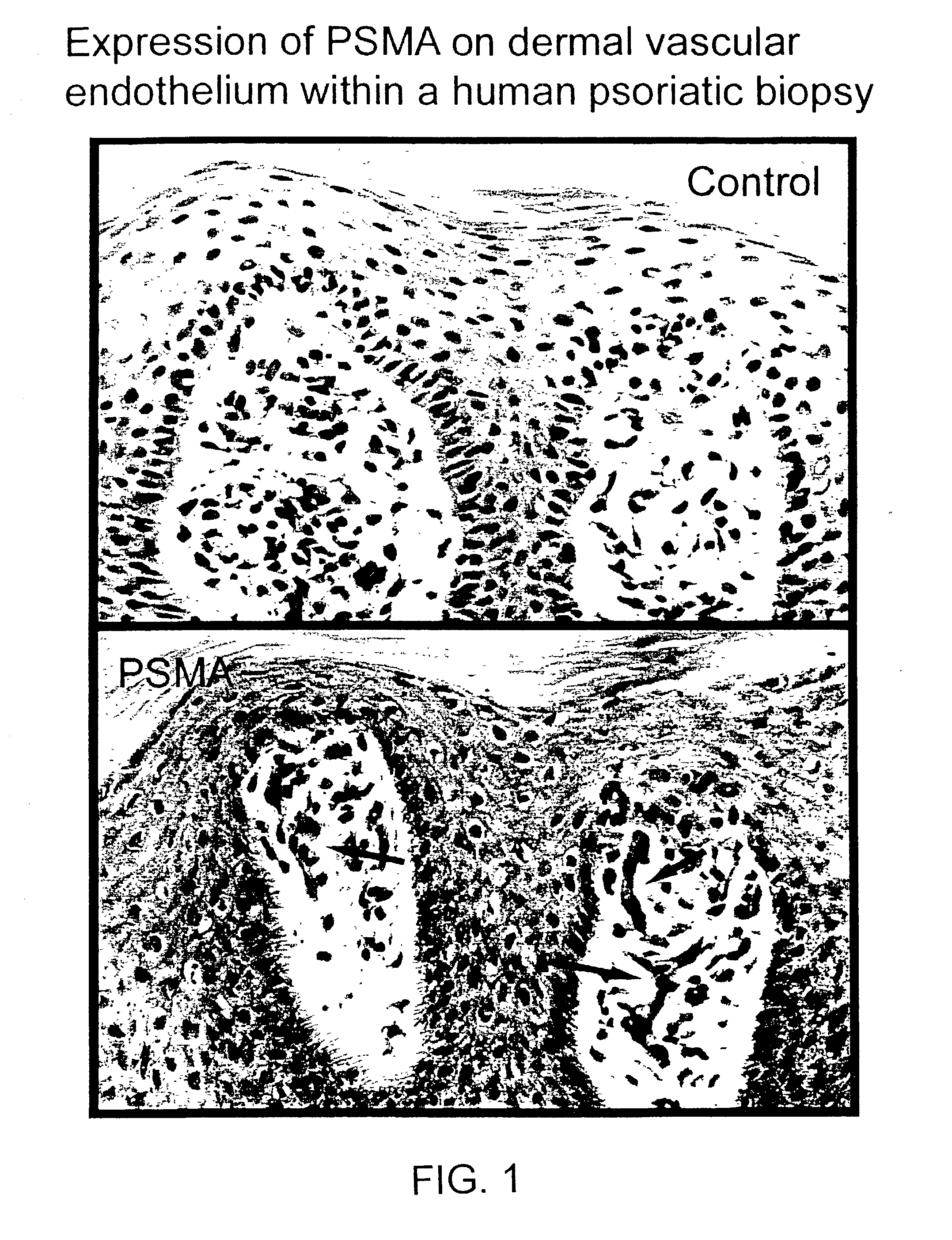

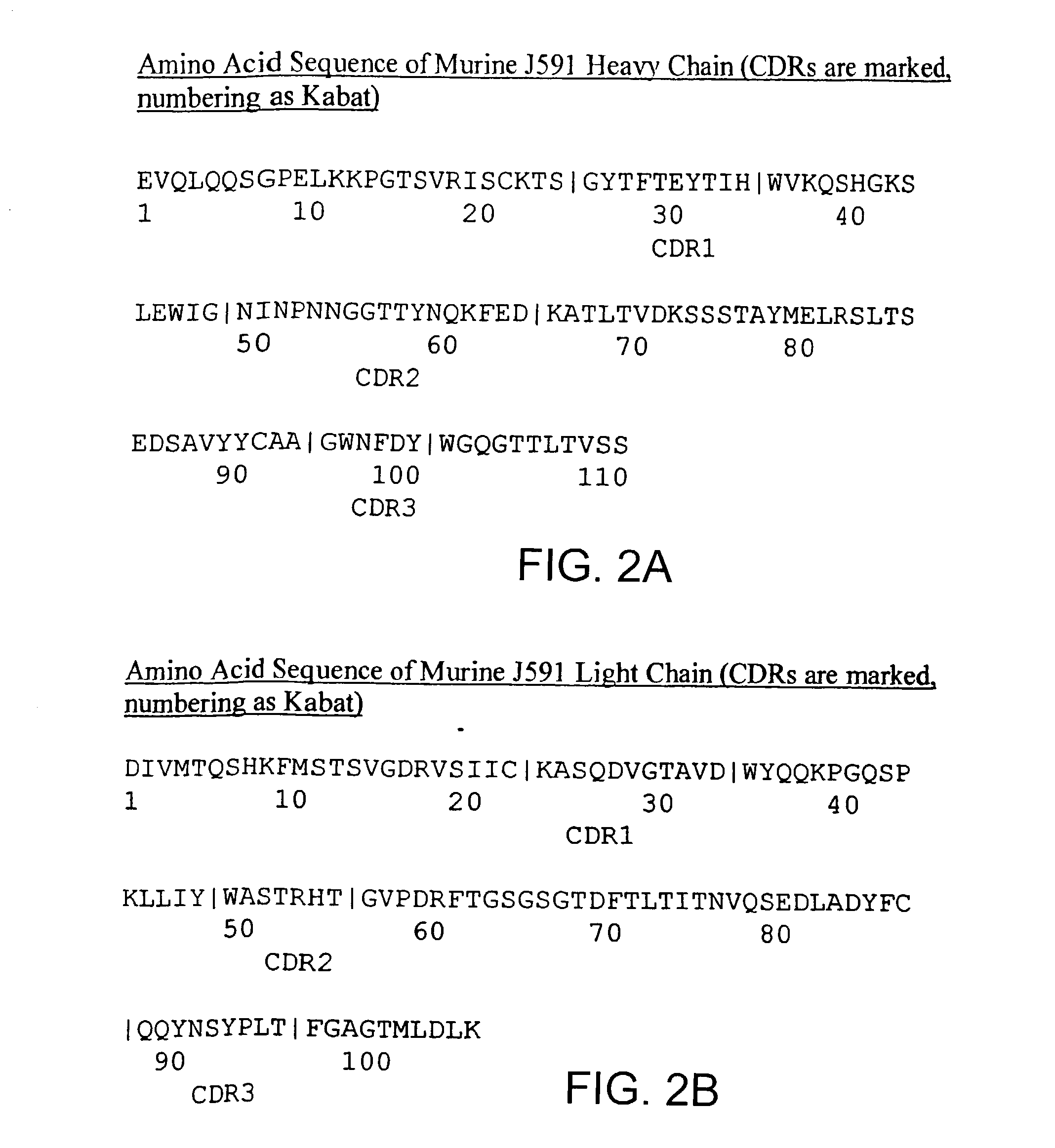

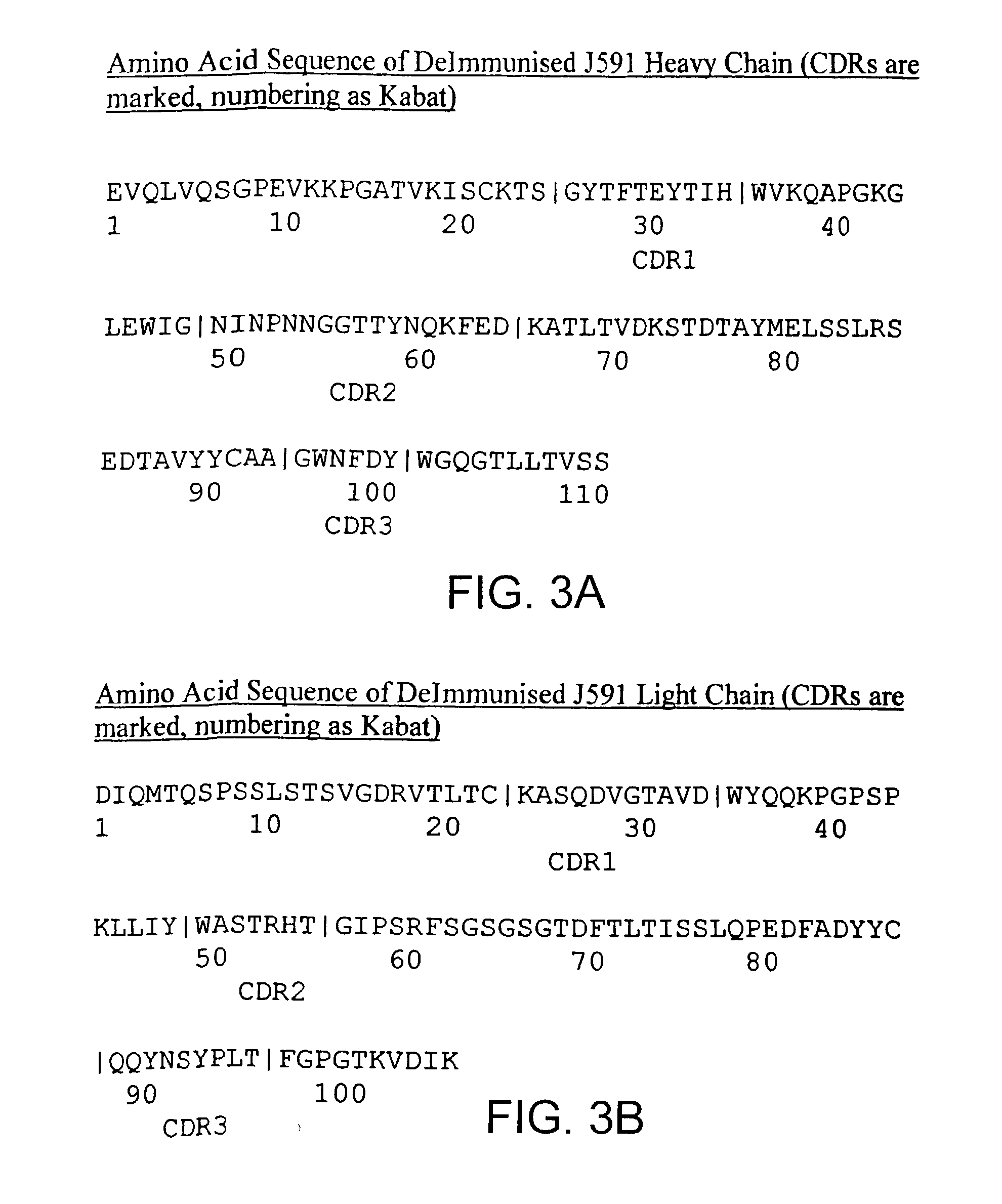

Methods and compositions for treating or preventing skin disorders using binding agents specific for prostate specific membrane antigen

InactiveUS7192586B2Reduce severityHigh expressionOrganic active ingredientsHybrid immunoglobulinsPsoriasisAntigen

Methods and compositions for treating, preventing, or diagnosing epidermal or dermal disorders, e.g., psoriasis, are disclosed. The methods and compositions of the invention use binding agents, e.g., antibodies, specific for the extracellular domain of human prostate specific membrane antigen (PSMA).

Owner:CORNELL RES FOUNDATION INC

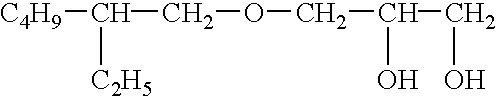

Gentle-acting skin disinfectants

InactiveUS6846846B2Minimize skin irritationUnexpected antimicrobial effectivenessCosmetic preparationsBiocideOctoxyglycerinMedicine

Antimicrobial compositions having synergistic combinations of octoxyglycerin and at least one other antimicrobial agent in formulations which are more effective than prior art compositions without causing increased irritation to the skin of the average user. In certain embodiments, skin irritation may be minimized by low concentrations of antimicrobials and / or the presence of soothing compounds such as zinc. Preferred embodiments include combinations of octoxyglycerin, a quaternary compound, and at least one other antimicrobial agent. Without being bound to any particular theory, it is hypothesized that the unexpected antimicrobial effectiveness of combinations of octoxyglycerin may result from an enhancement of the permeability of microbes to antimicrobials caused by octoxyglycerin.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

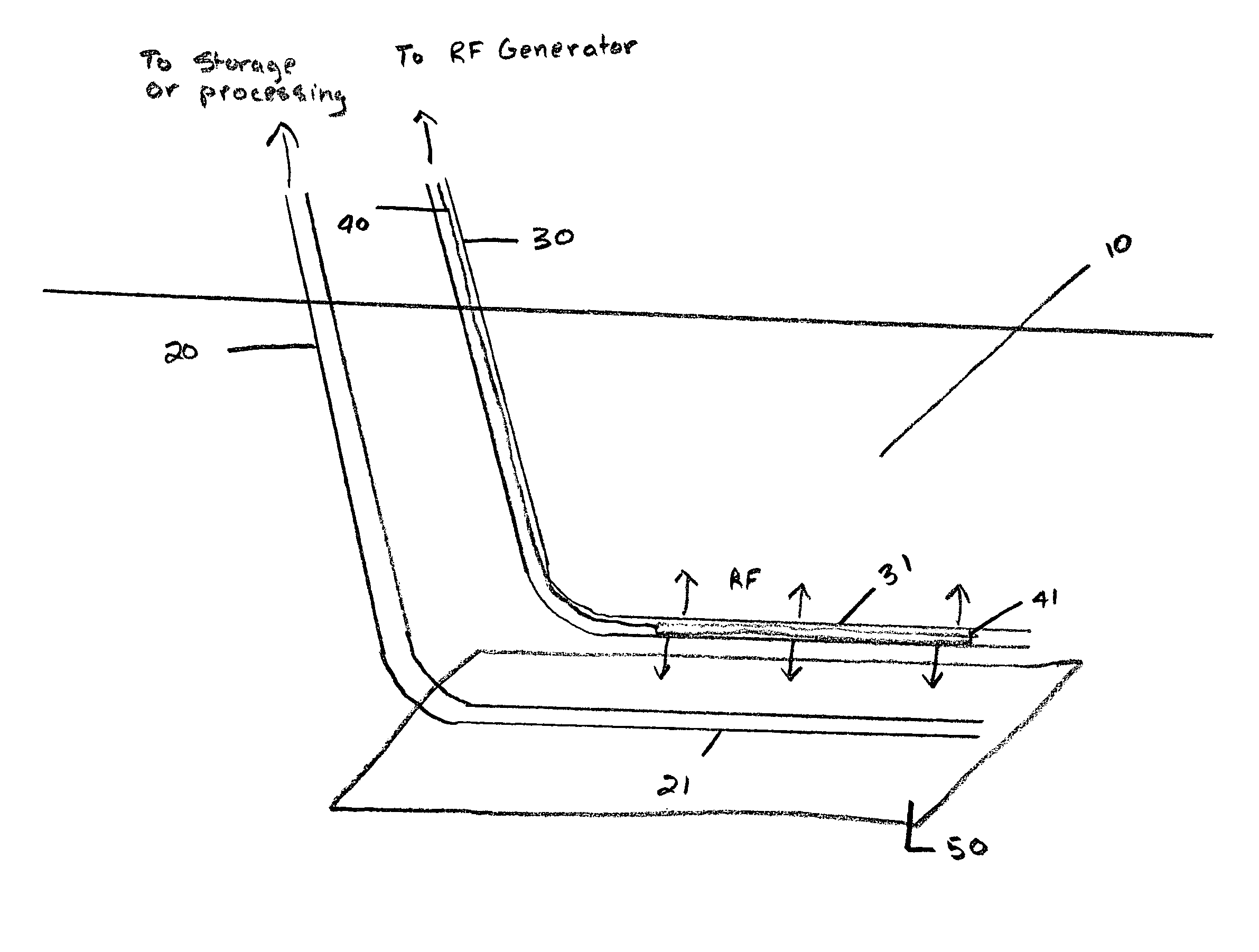

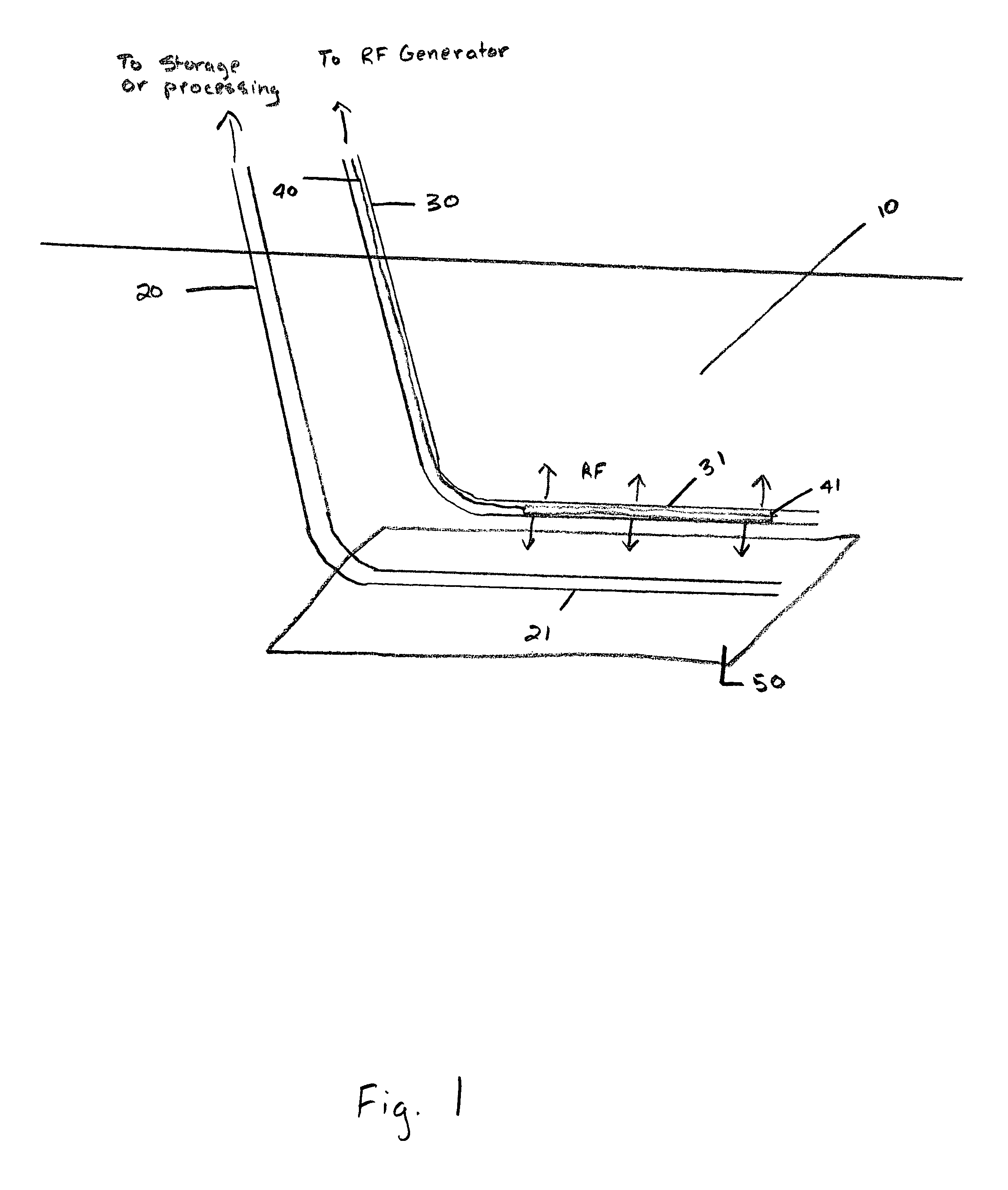

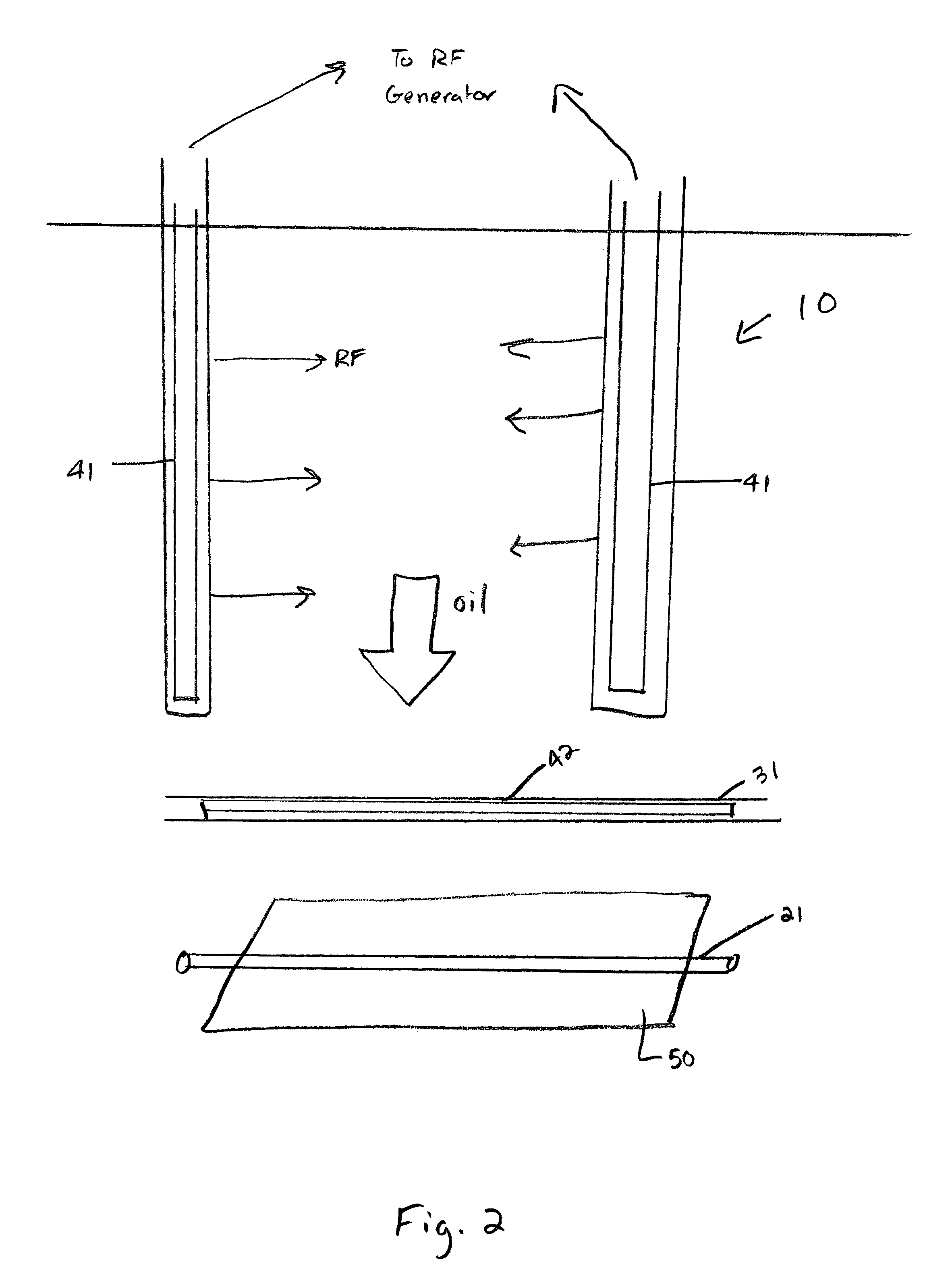

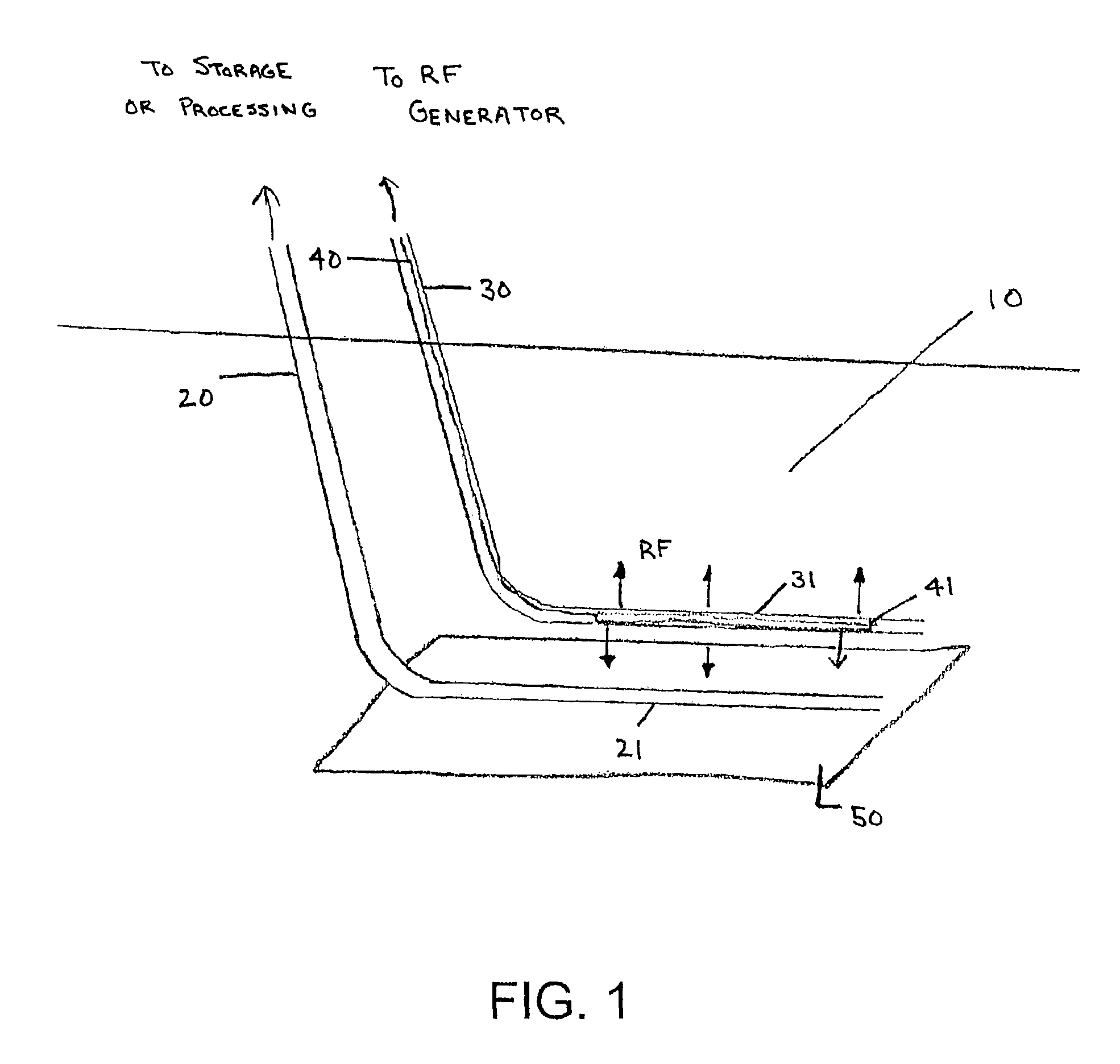

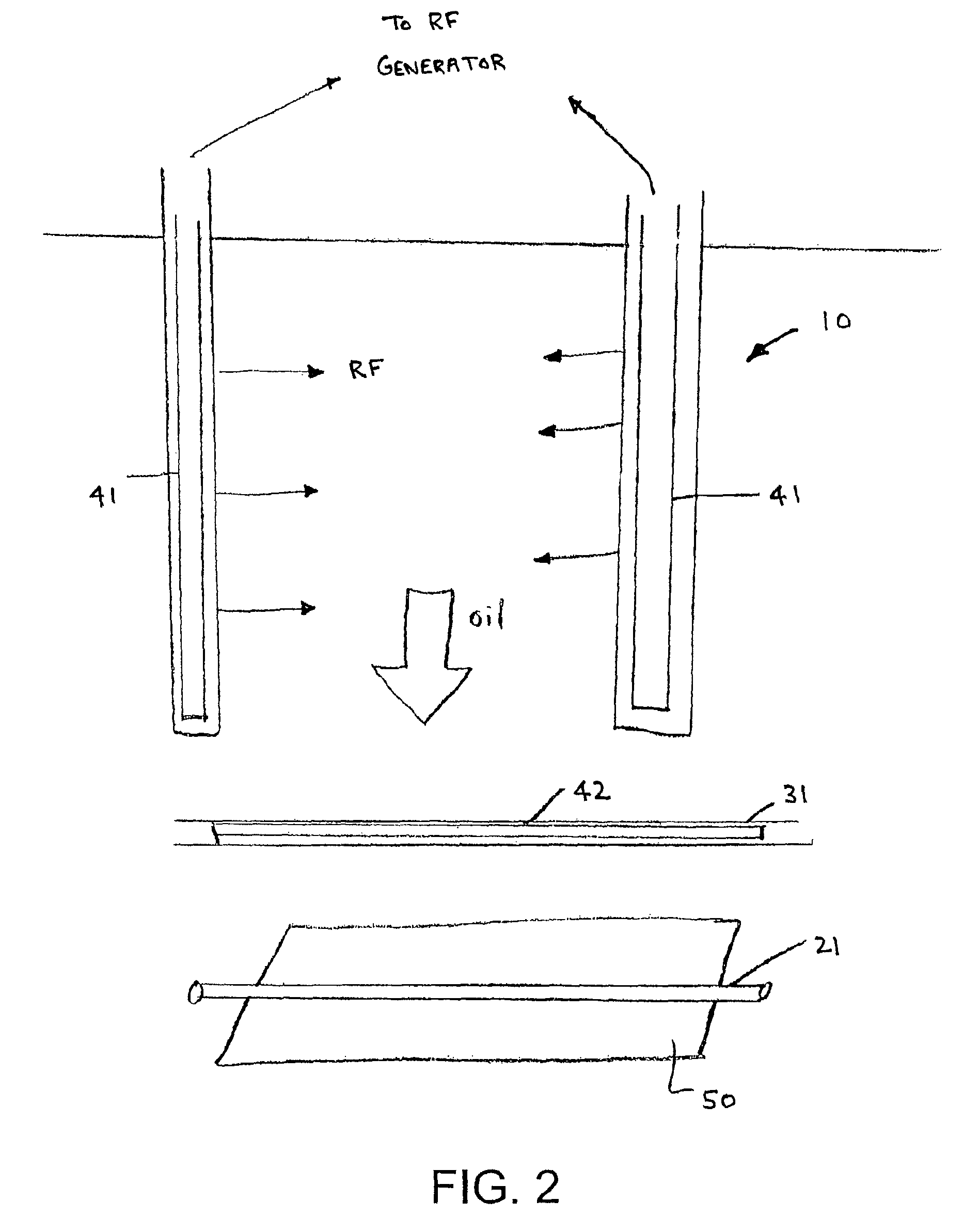

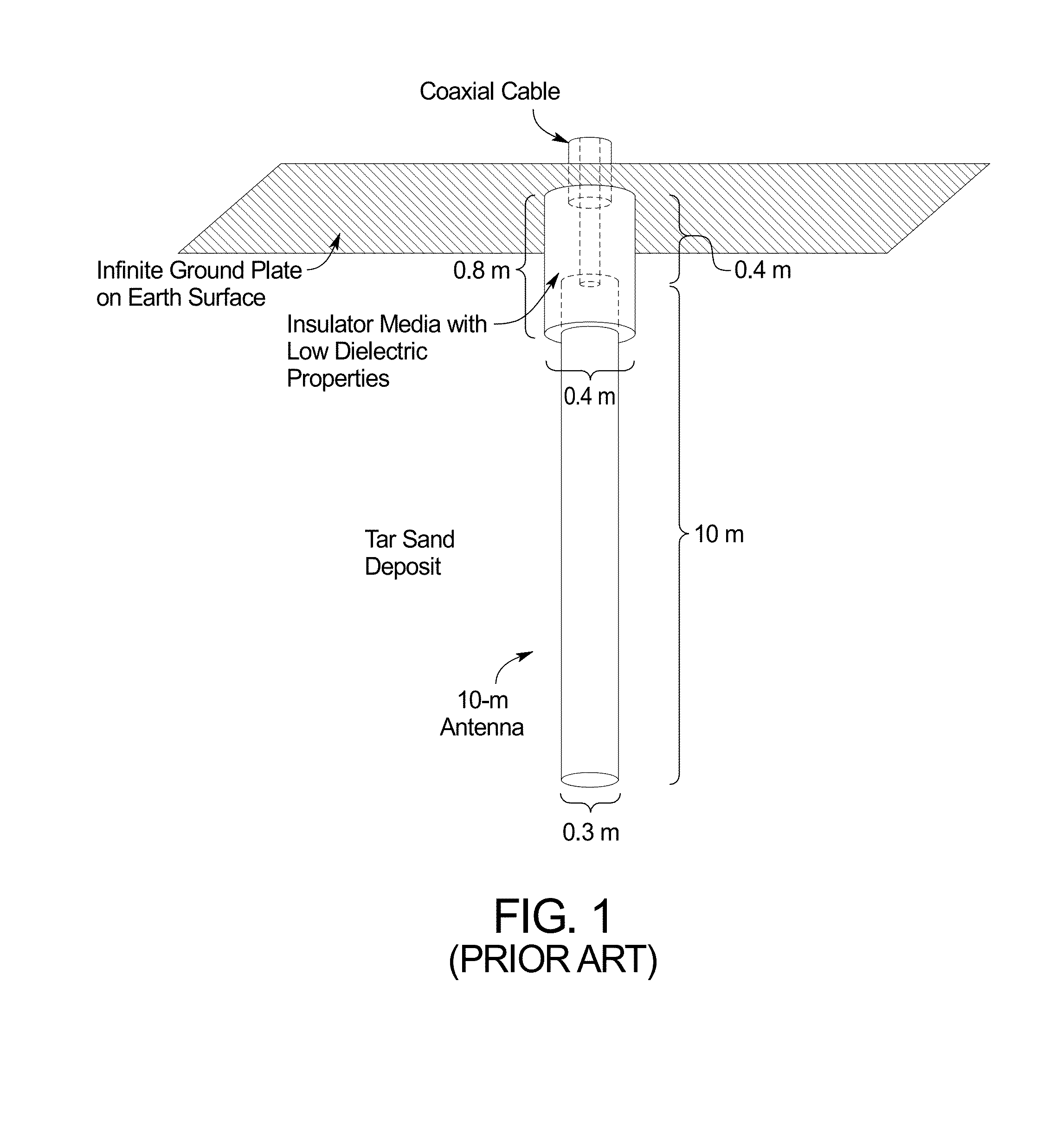

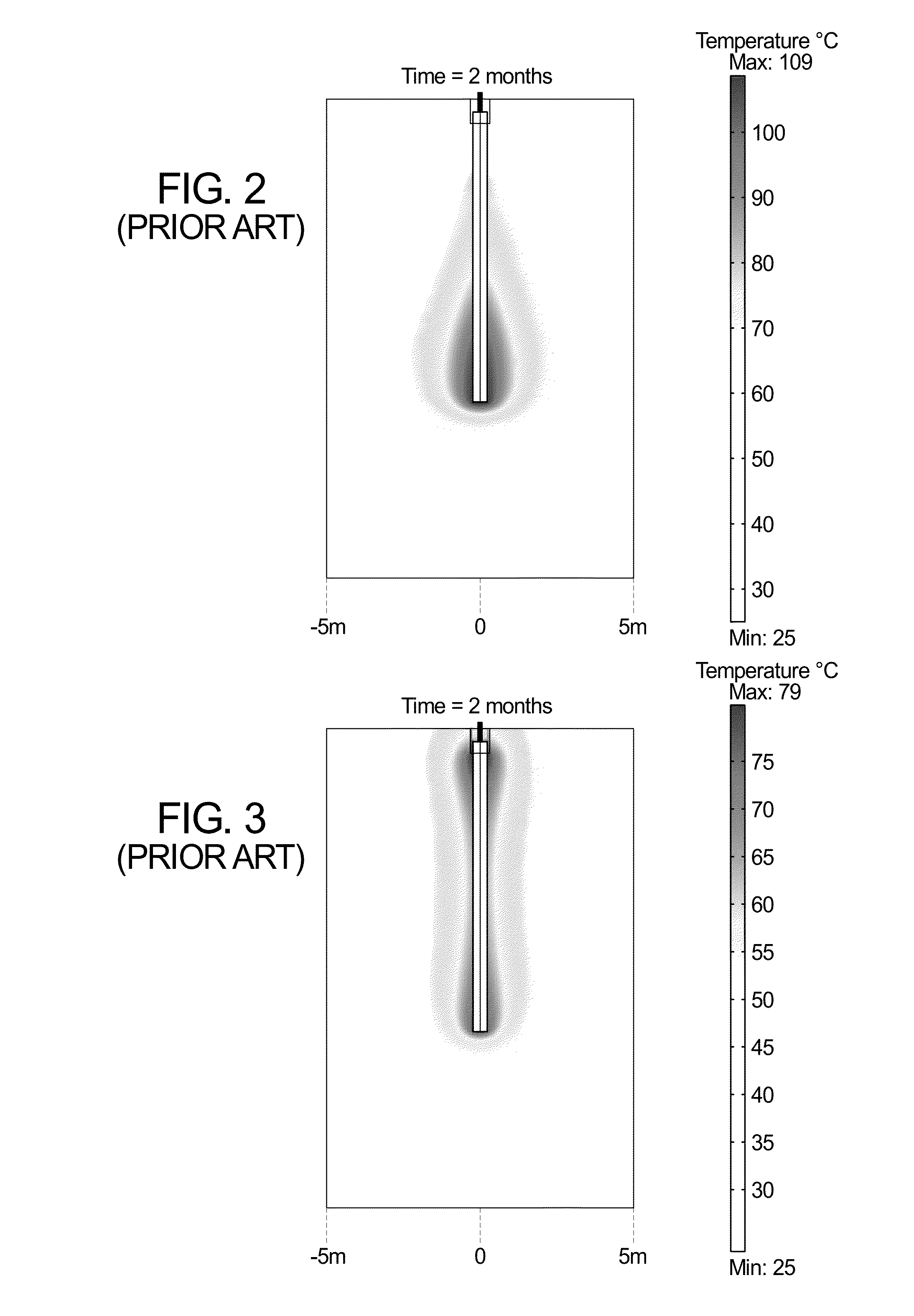

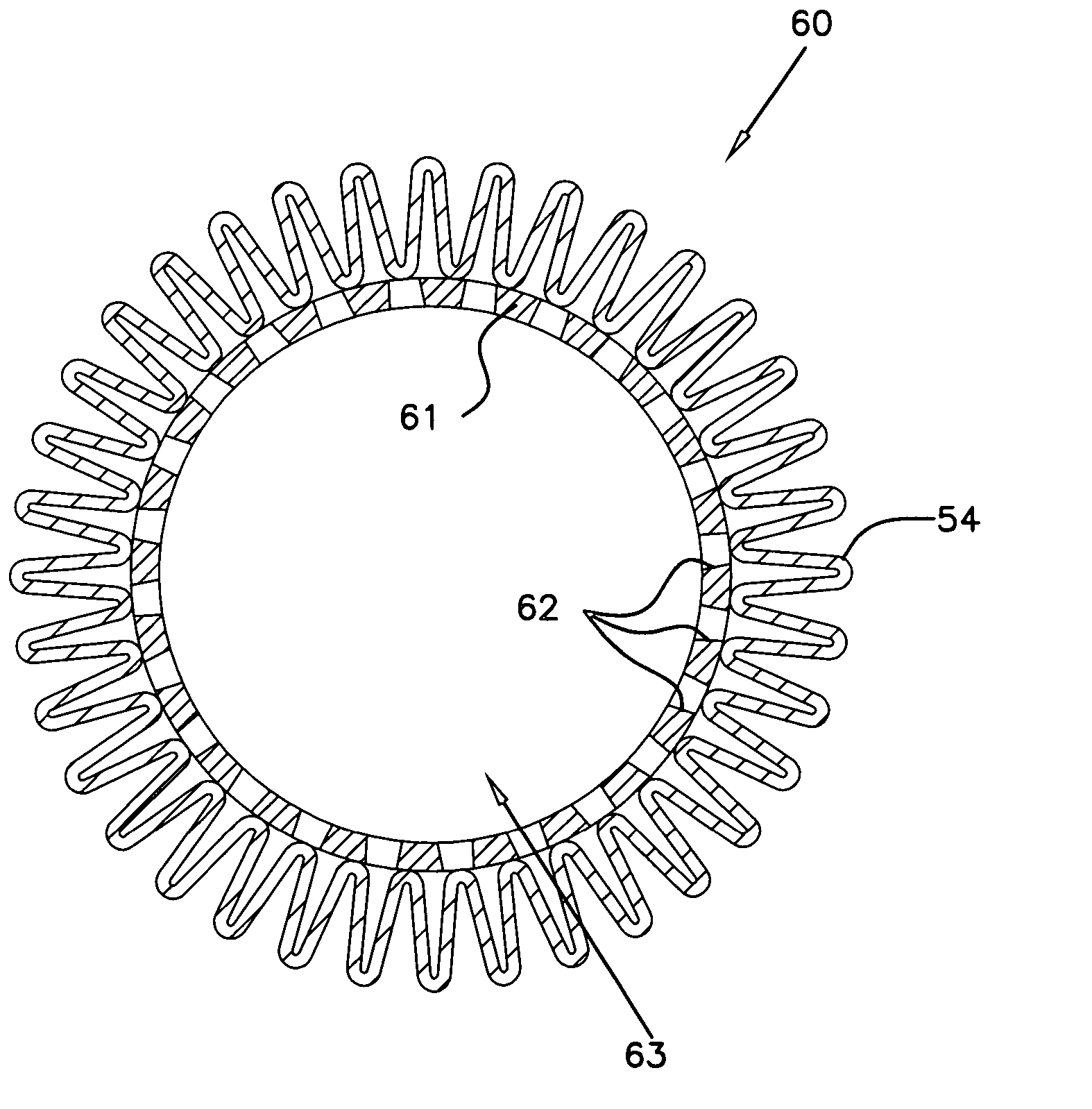

Method and apparatus for in-situ radiofrequency assisted gravity drainage of oil (RAGD)

InactiveUS7441597B2Promote recoveryEnhanced overall recoveryInsulationFluid removalHeavy crude oilFuel oil

The present invention relates generally to the use of radiofrequency energy to heat heavy crude oil or both heavy crude oil and subsurface water in situ, thereby enhancing the recovery and handling of such oil. The present invention further relates to methods for applying radiofrequency energy to heavy oils in the reservoir to promote in situ upgrading to facilitate recovery. This invention also relates to systems to apply radiofrequency energy to heavy oils in situ.

Owner:KSN ENERGIES

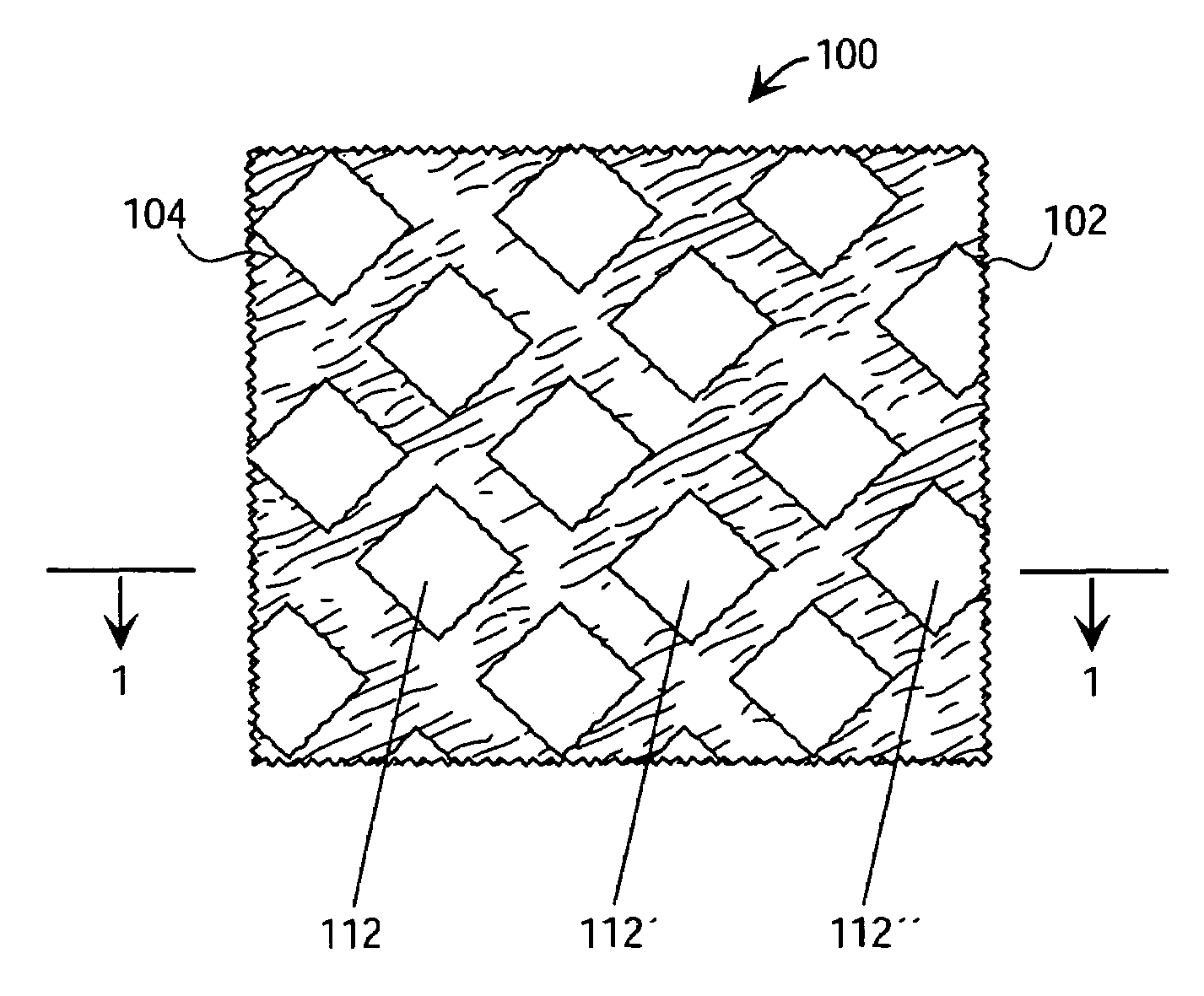

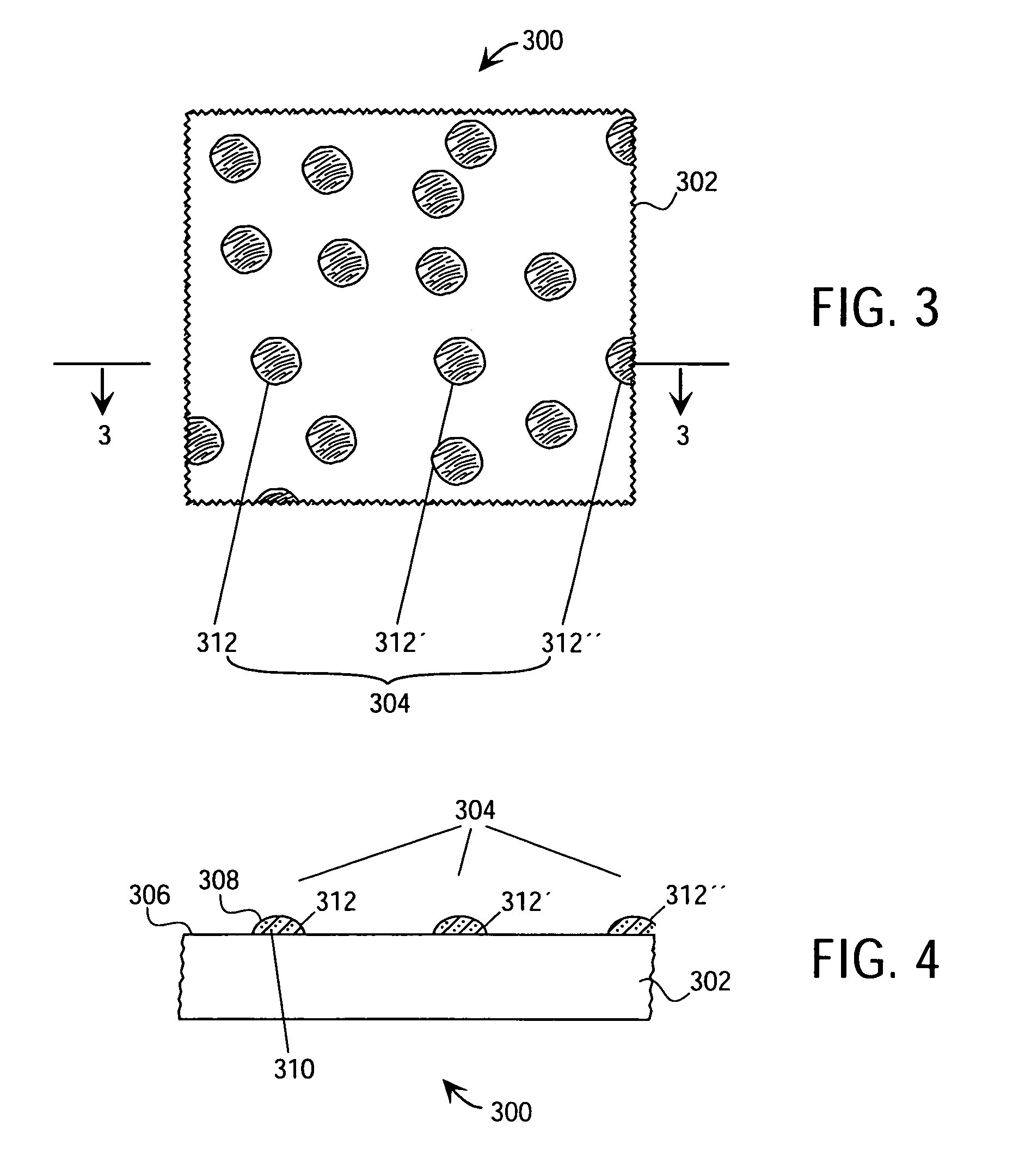

Coated articles having enhanced reversible thermal properties and exhibiting improved flexibility, softness, air permeability, or water vapor transport properties

InactiveUS7135424B2Enhanced reversible thermal propertyImprove breathabilityHeat storage plantsDecorative surface effectsWater vaporMedical product

The invention relates to a coated article having enhanced reversible thermal properties. The coated article comprises a substrate having a surface and a coating covering a portion of the surface and comprising a polymeric material and a temperature regulating material dispersed in the polymeric material. The coating is formed with a plurality of regions of discontinuity that are separated from one another and expose a remaining portion of the surface to provide improved flexibility, softness, air permeability, or water vapor transport properties. The coated article may be used in apparel, footwear, medical products, containers and packagings, building materials, appliances, and other products.

Owner:OUTLAST TECH LLC

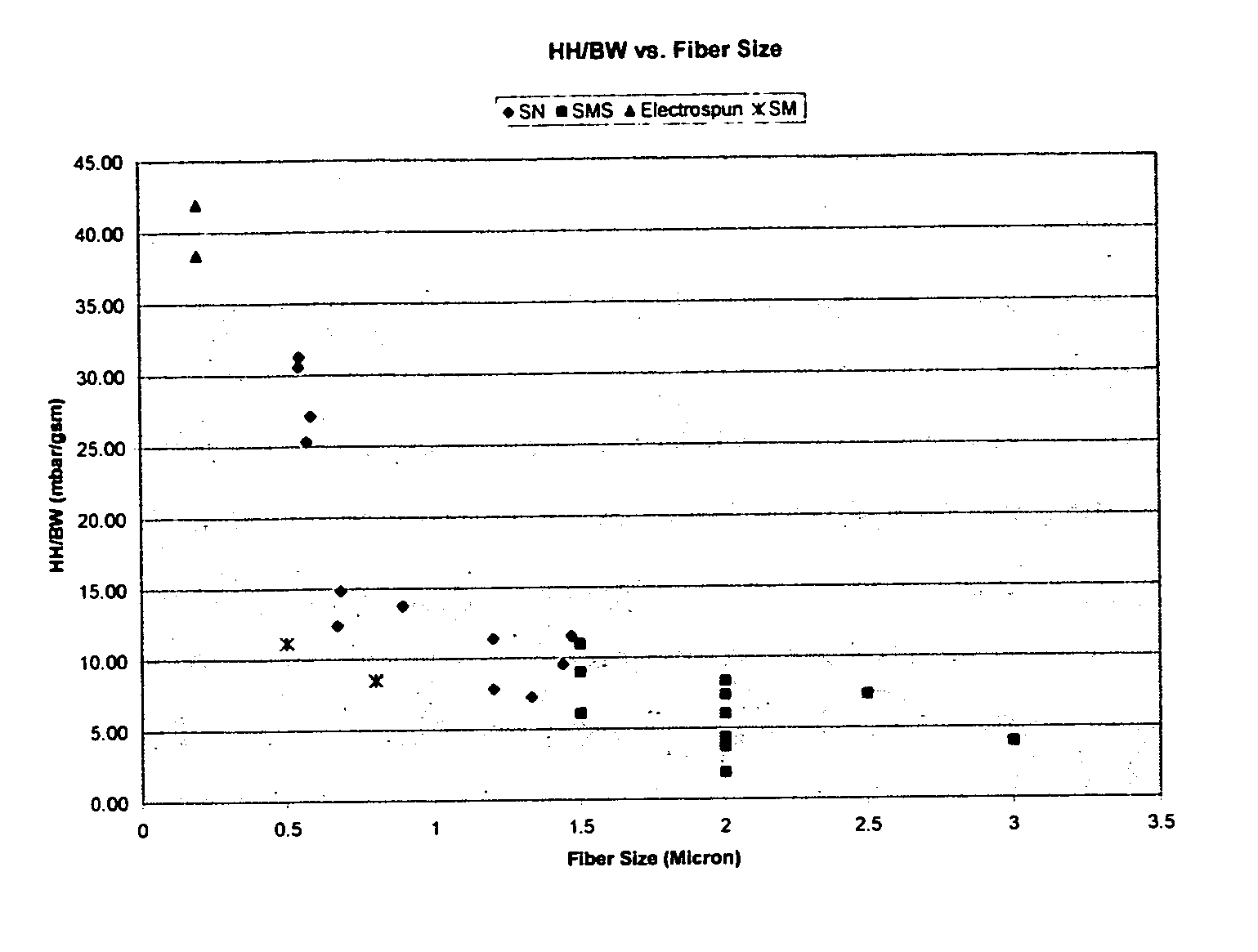

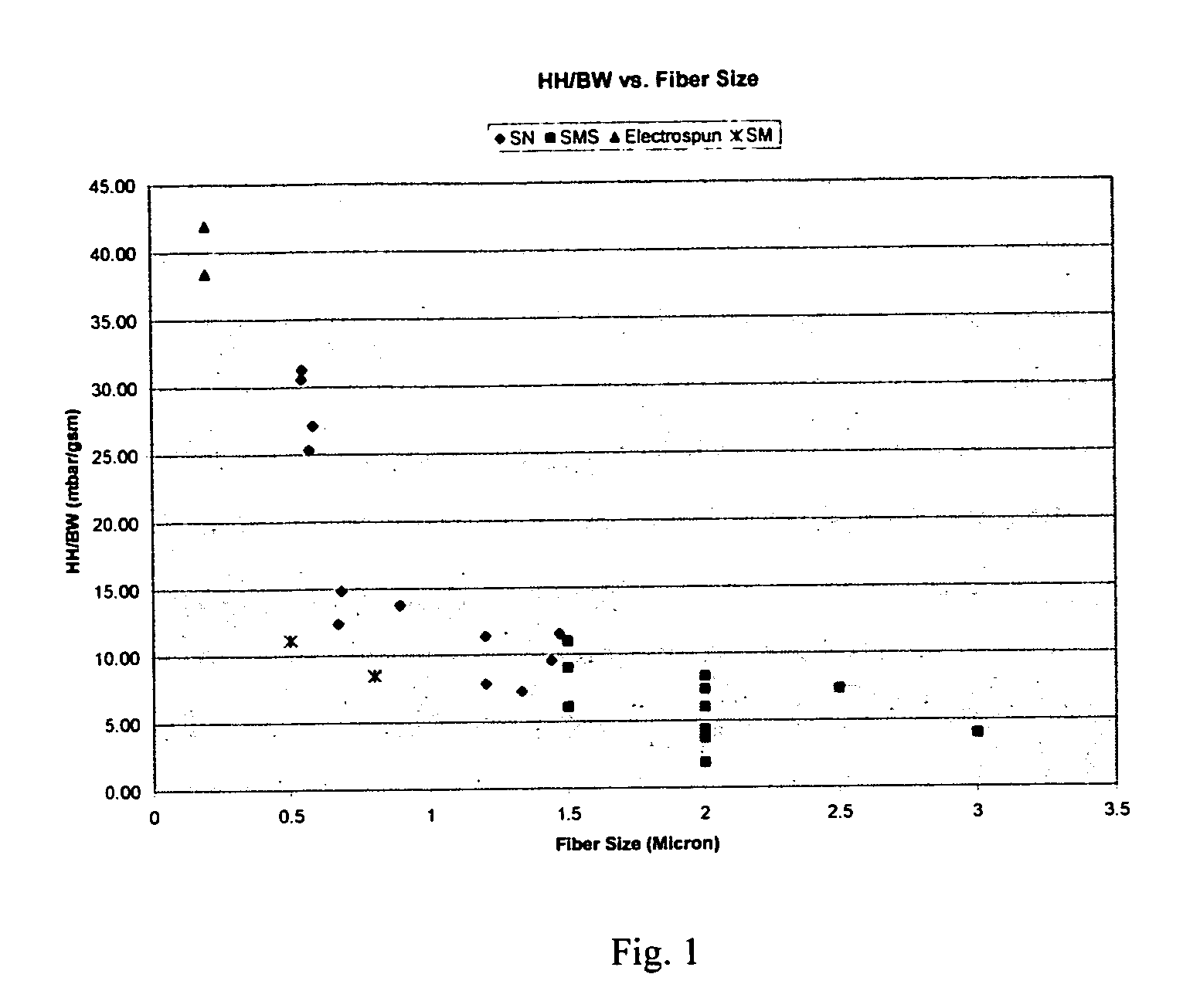

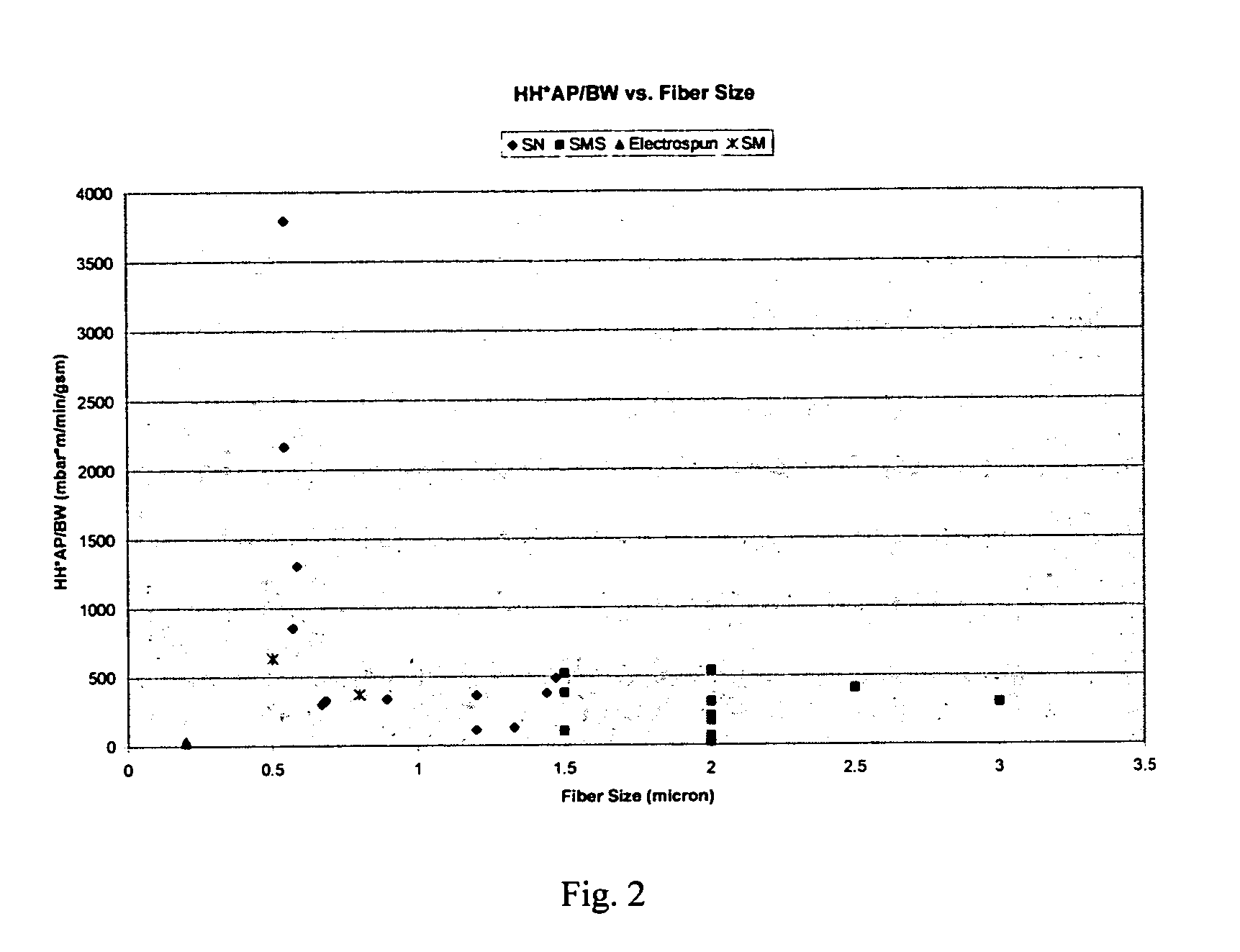

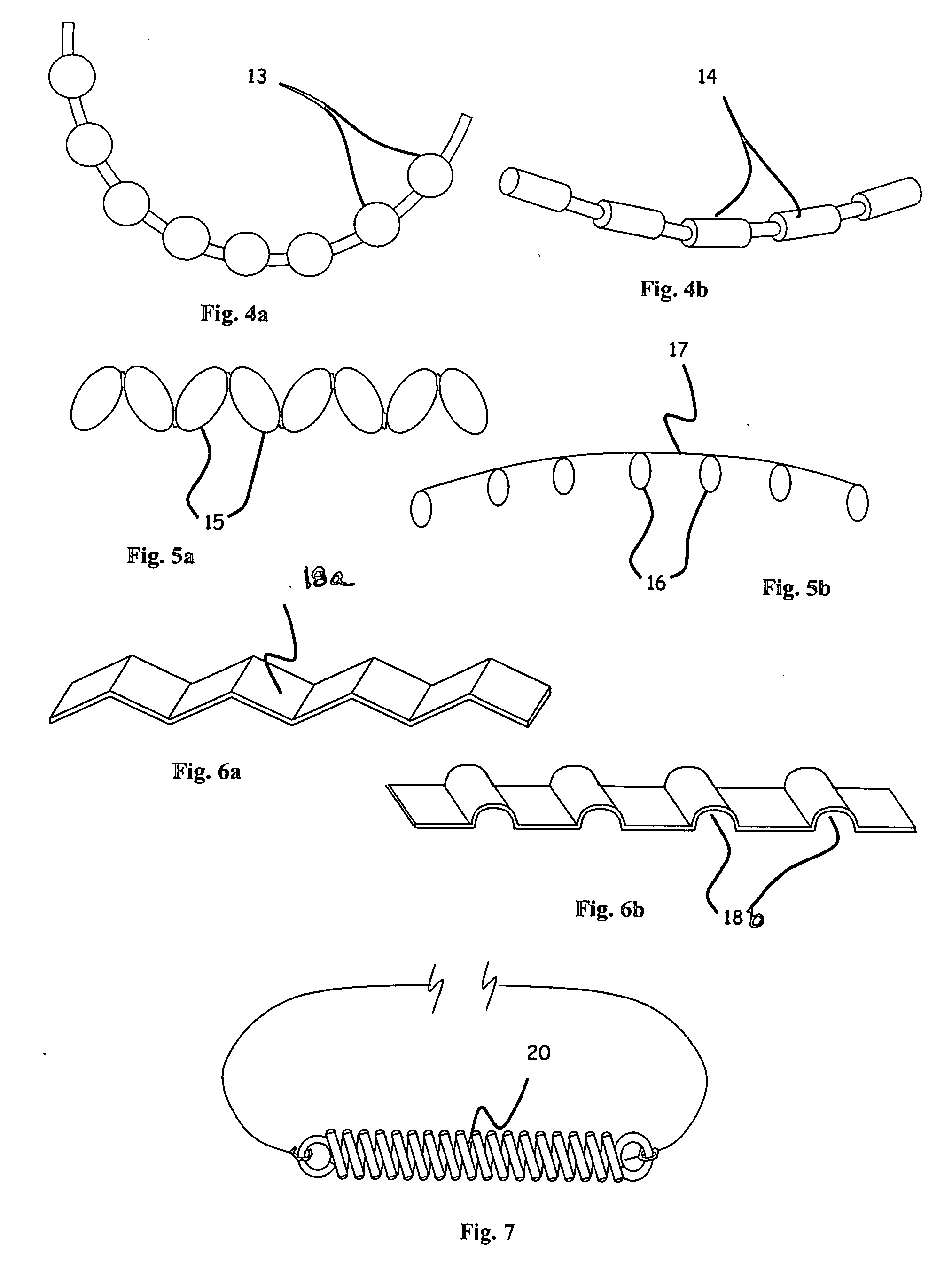

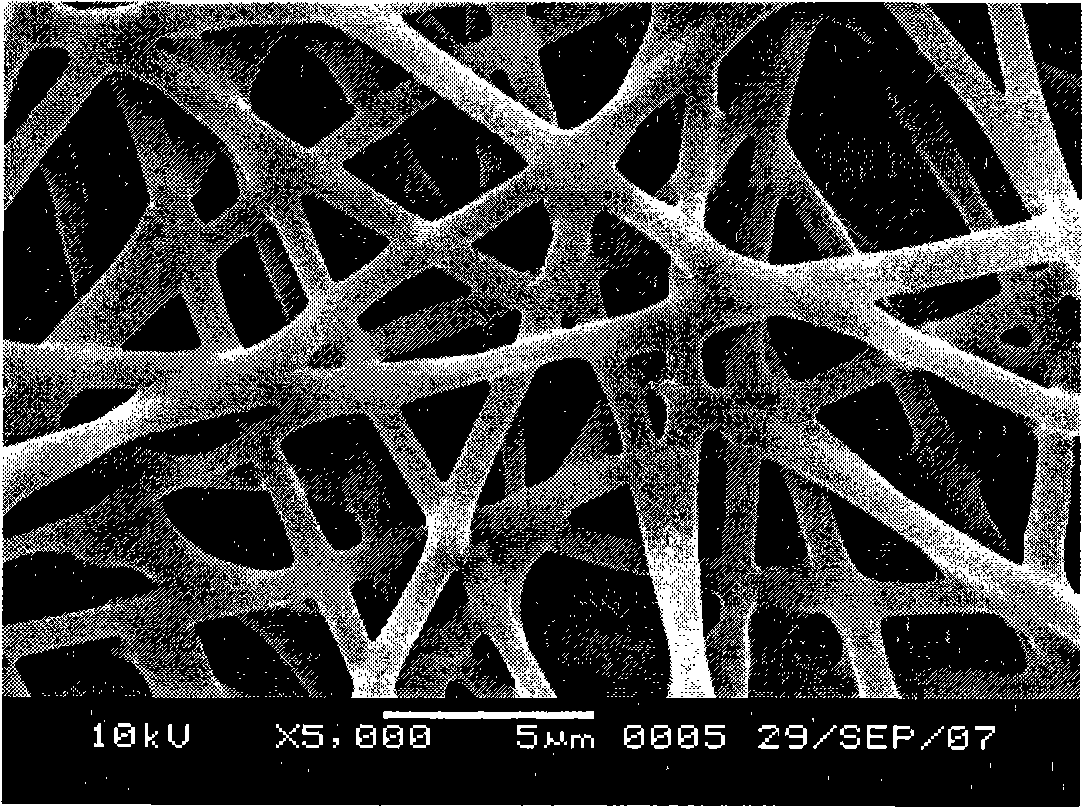

Articles containing nanofibers for use as barriers

ActiveUS20060014460A1Improve barrier propertiesReduce surface tensionSynthetic resin layered productsFilament/thread formingPersonal careFiber

The present invention is directed to articles comprising nanofibers. Preferred articles include diapers, training pants, adult incontinence pads, catamenials products such as feminine care pads and pantiliners, tampons, personal cleansing articles, personal care articles, and personal care wipes including baby wipes, facial wipes, body wipes, and feminine wipes. The nanofiber webs can be used as a barrier, wipe, absorbent material, and other uses. The nanofibers, having a diameter of less than 1 micron, must comprise a significant number of the fibers in at least one nanofiber layer of the nonwoven web. The nonwoven web may have a hydrohead to basis weight ratio of greater than about 10 mbar / gsm. The nanofibers may be produced from a melt film fibrillation process.

Owner:THE PROCTER & GAMBLE COMPANY

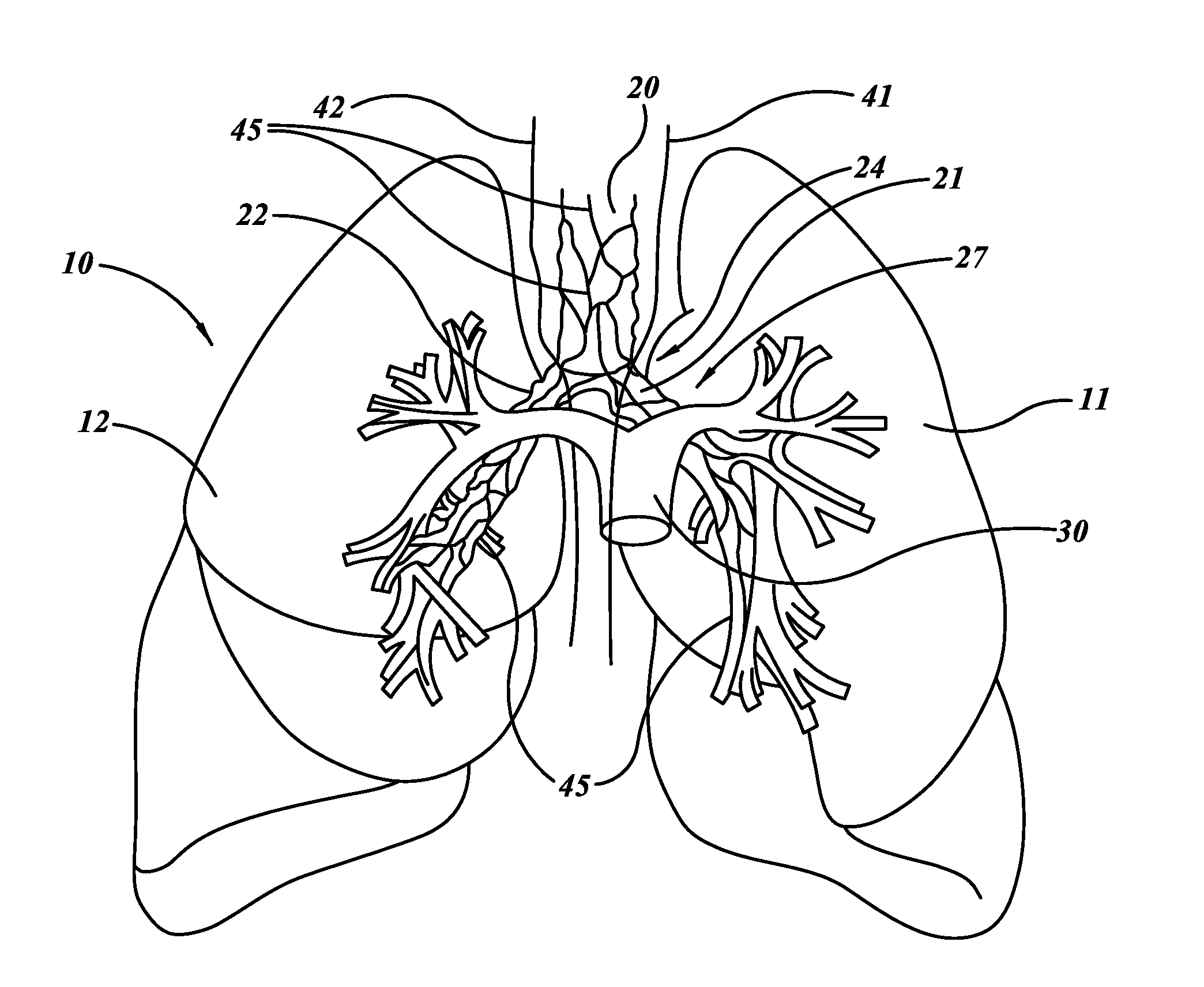

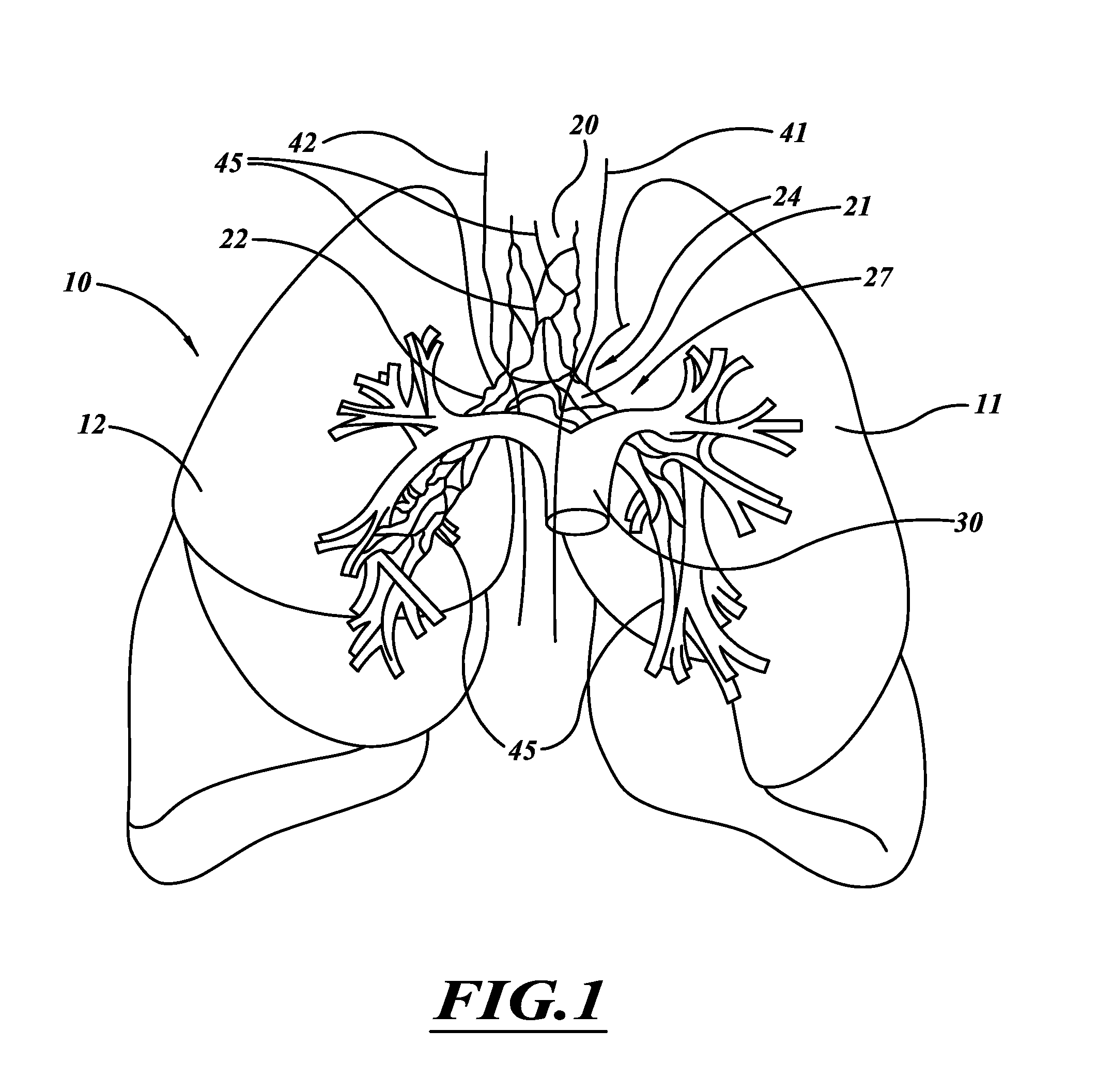

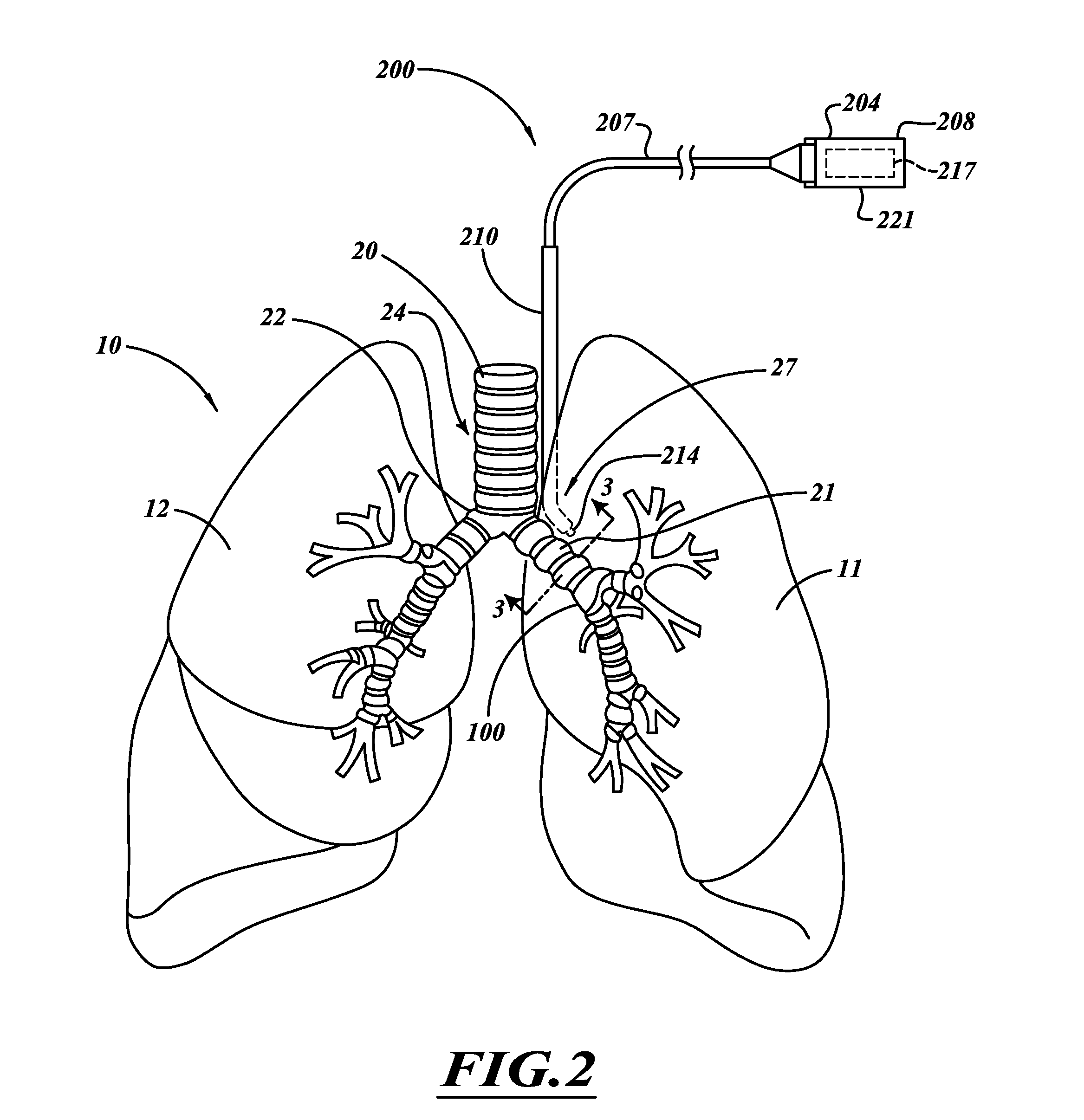

Non-invasive and minimally invasive denervation methods and systems for performing the same

ActiveUS20110118725A1Reduce harmReduce obstructionUltrasound therapySurgical needlesCOPDPartial denervation

A system and method can be used to denervate at least a portion of a bronchial tree. An energy emitter of an instrument is percutaneously delivered to a treatment site and outputs energy to damage nerve tissue of the bronchial tree. The denervation procedure can be performed without damaging non-targeted tissue. Minimally invasive methods can be used to open airways to improve lung function in subjects with COPD, asthma, or the like. Different sections of the bronchial tree can be denervated while leaving airways intact to reduce recovery times.

Owner:NUVAIRA INC

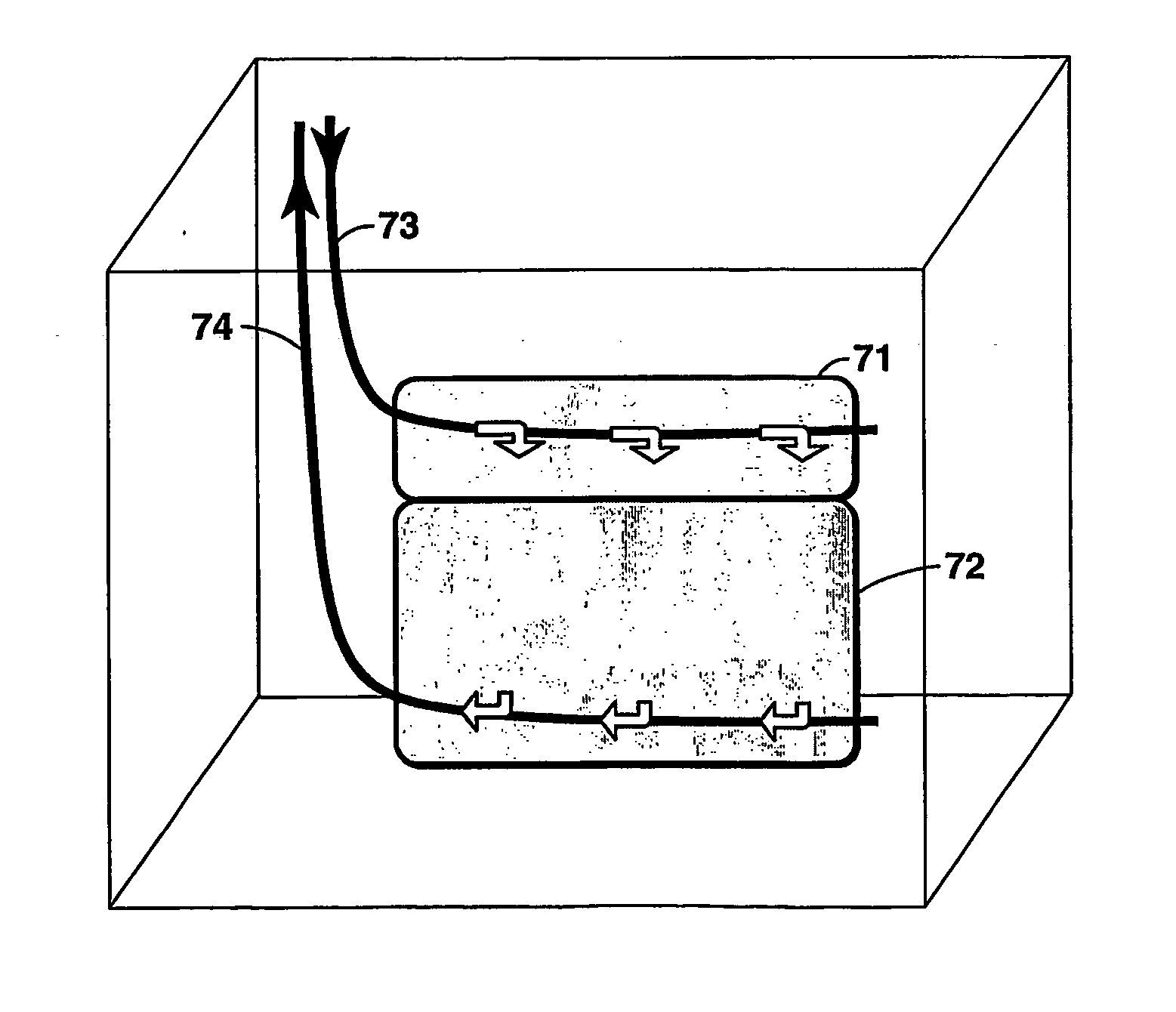

Method and apparatus for in-situ radiofrequency heating

InactiveUS7891421B2Promote recoveryEnhanced overall recoveryInsulationFluid removalElectricityNuclear engineering

Owner:TURBOSHALE INC

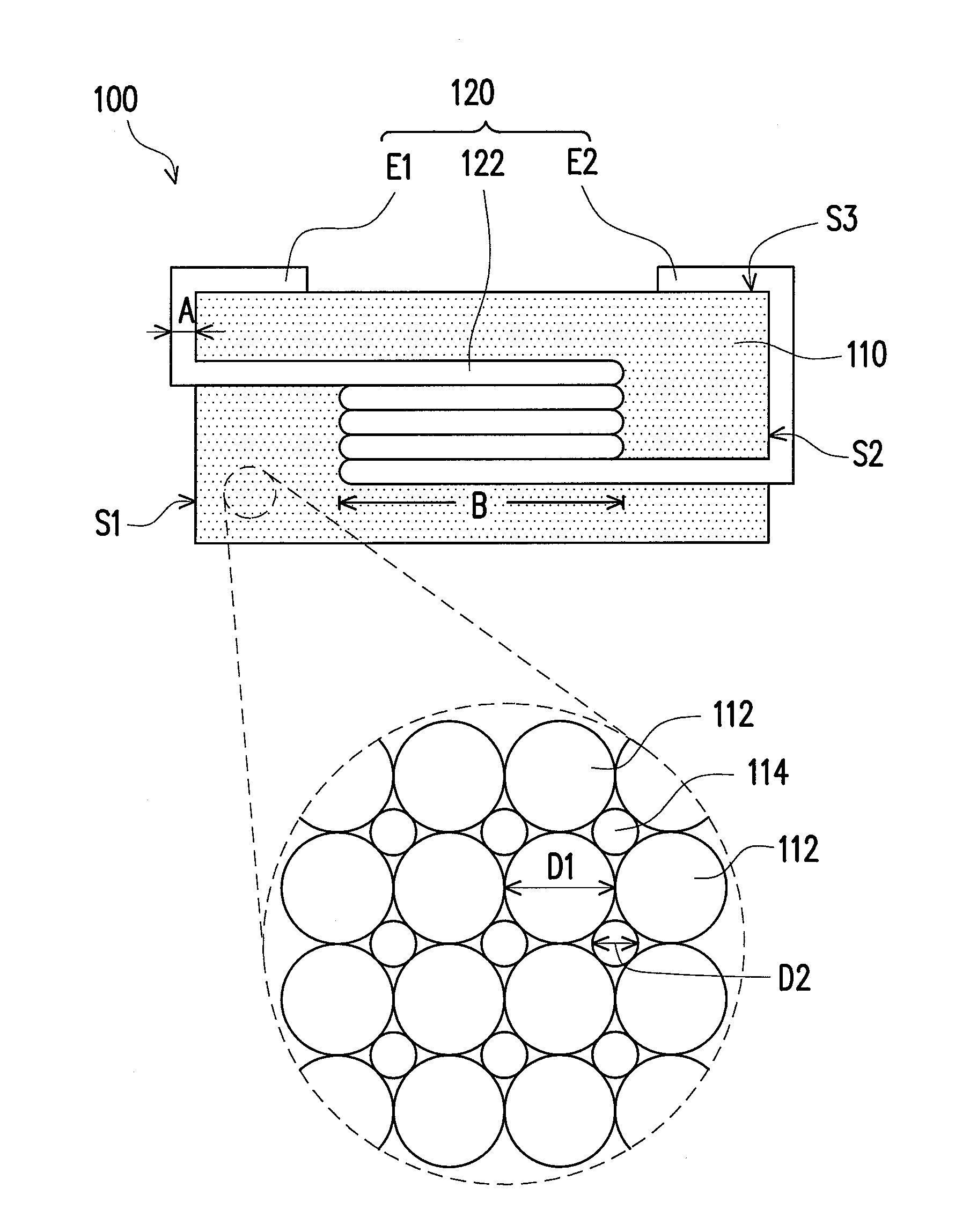

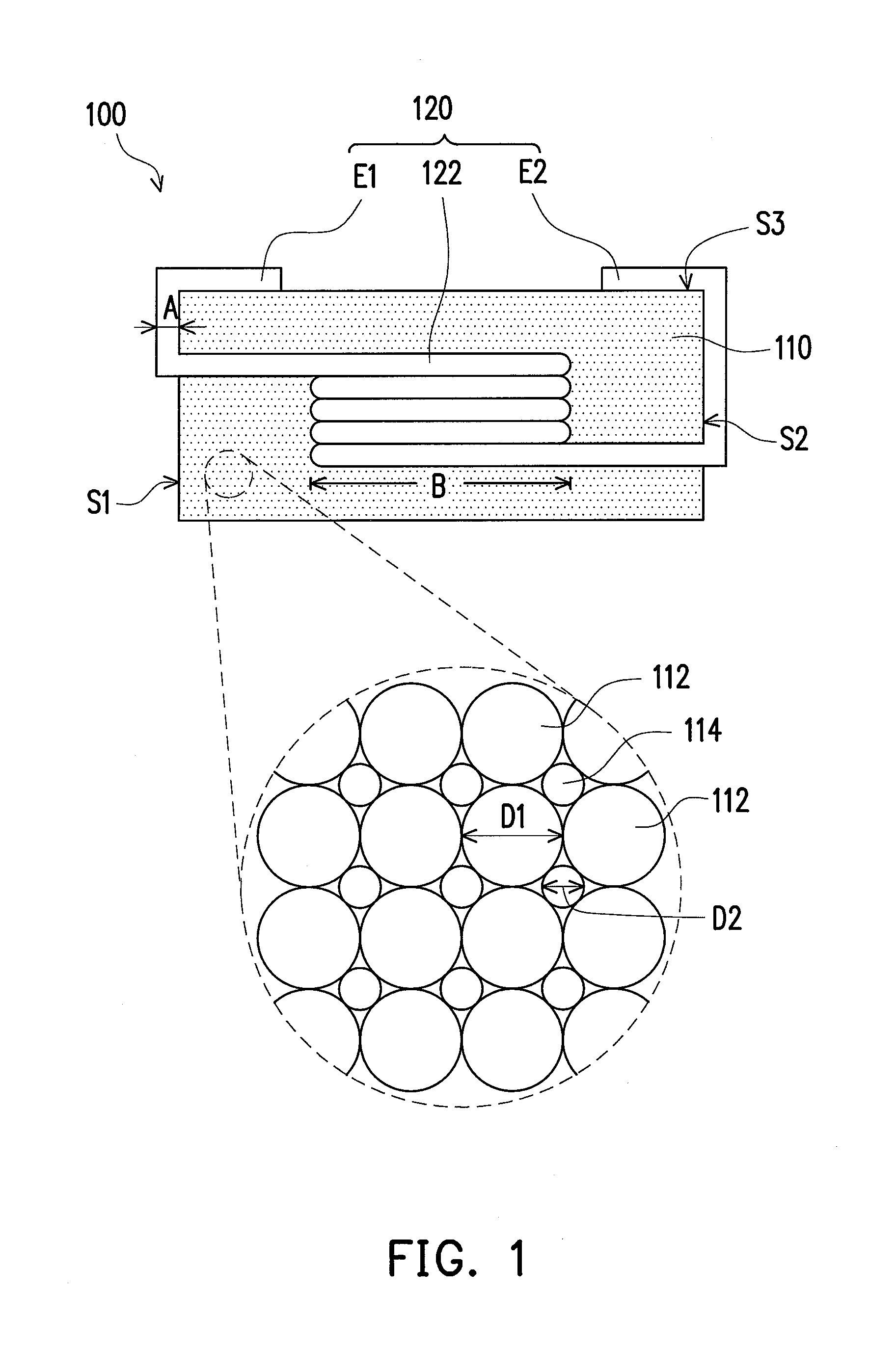

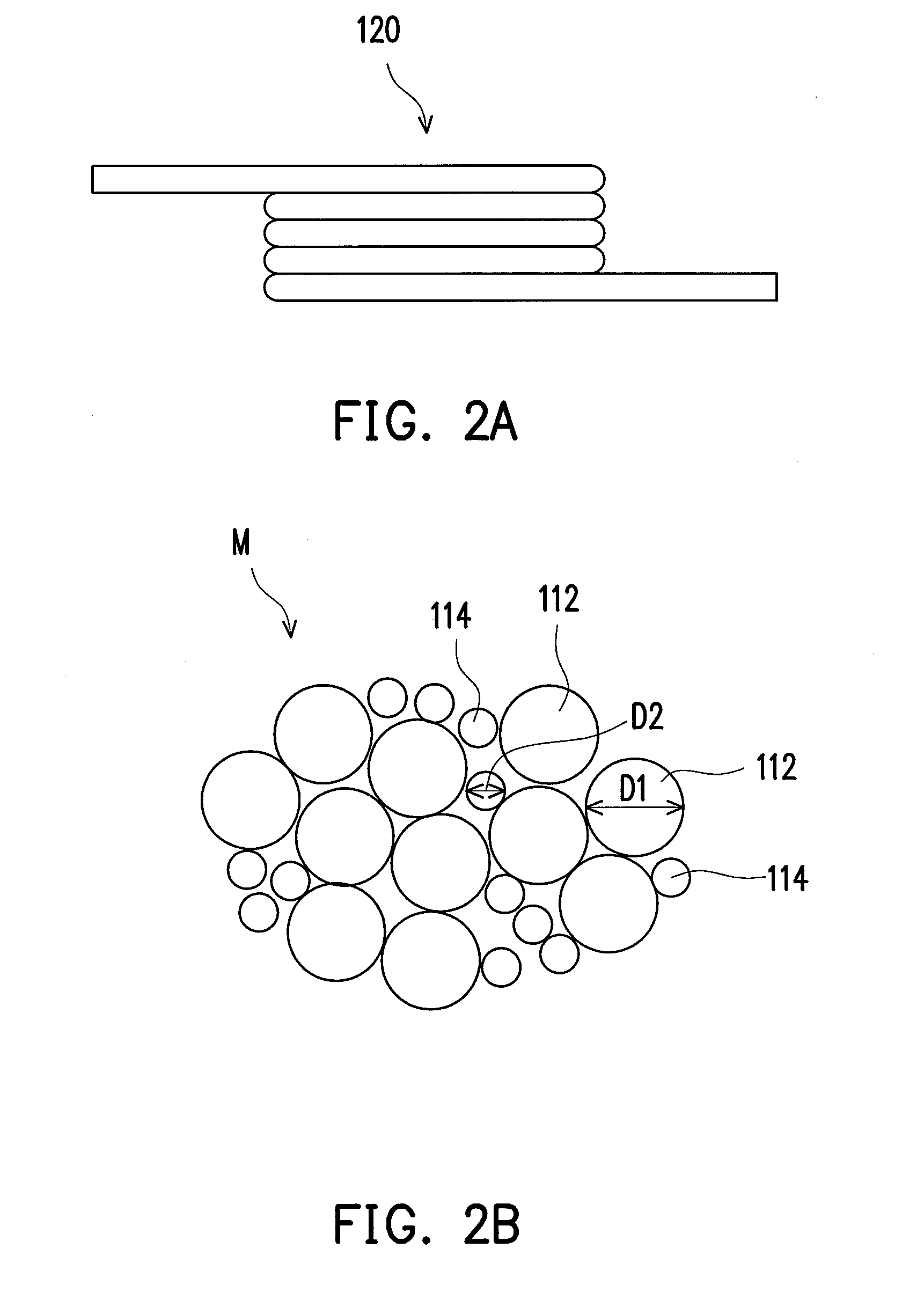

Electronic device and manufacturing method thereof

ActiveUS20100289609A1Improve breathabilityPrevent oxidationTransformers/inductances coils/windings/connectionsInorganic material magnetismMagnetic powderHardness

An electronic device including a magnetic body and a wire is provided. The magnetic body has a first magnetic powder and a second magnetic powder mixed with the first magnetic powder. The Vicker's Hardness of the first magnetic powder is greater than that of the second magnetic powder and the mean particle diameter of the first magnetic powder is greater than that of the second magnetic powder.

Owner:CYNTEC

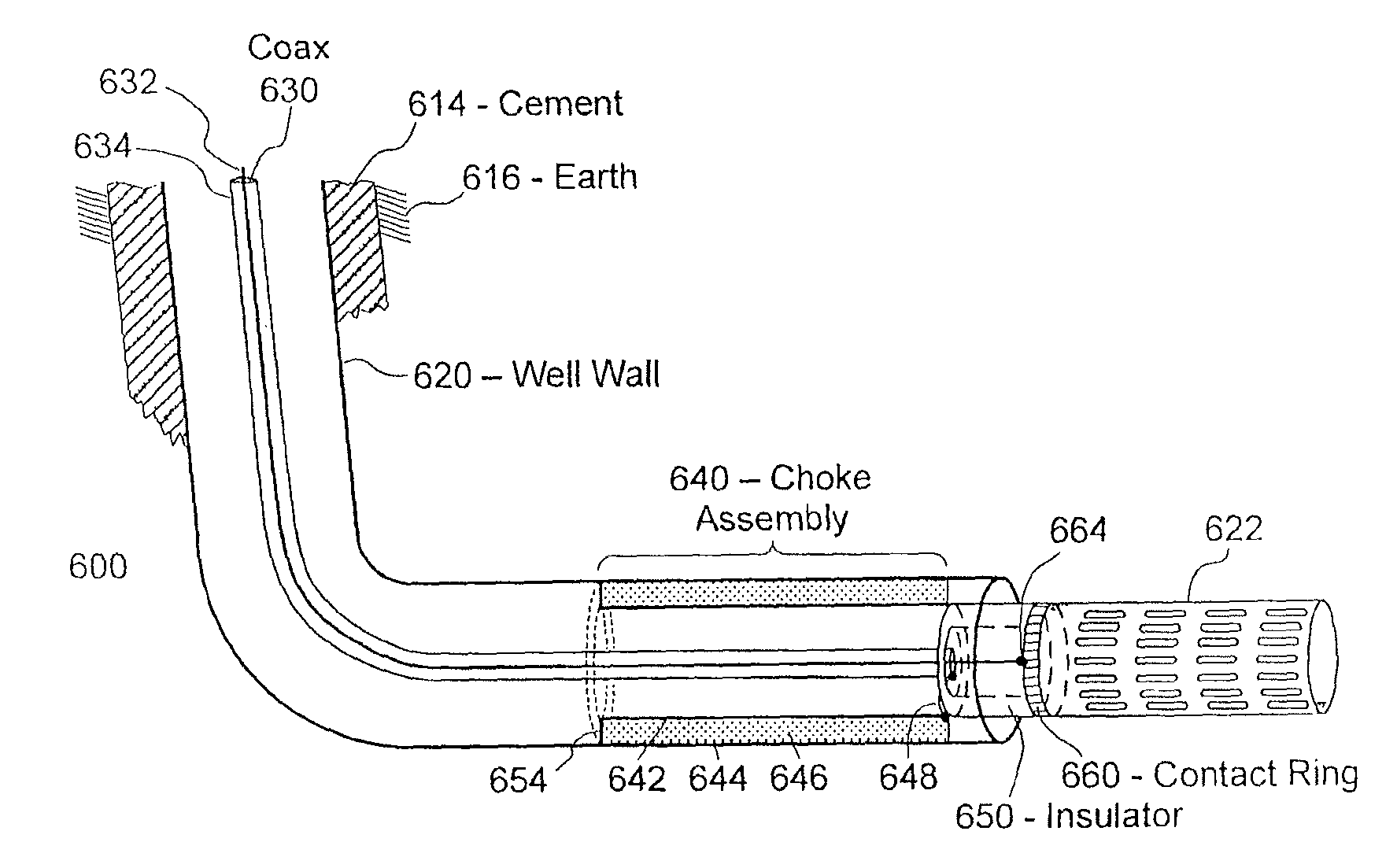

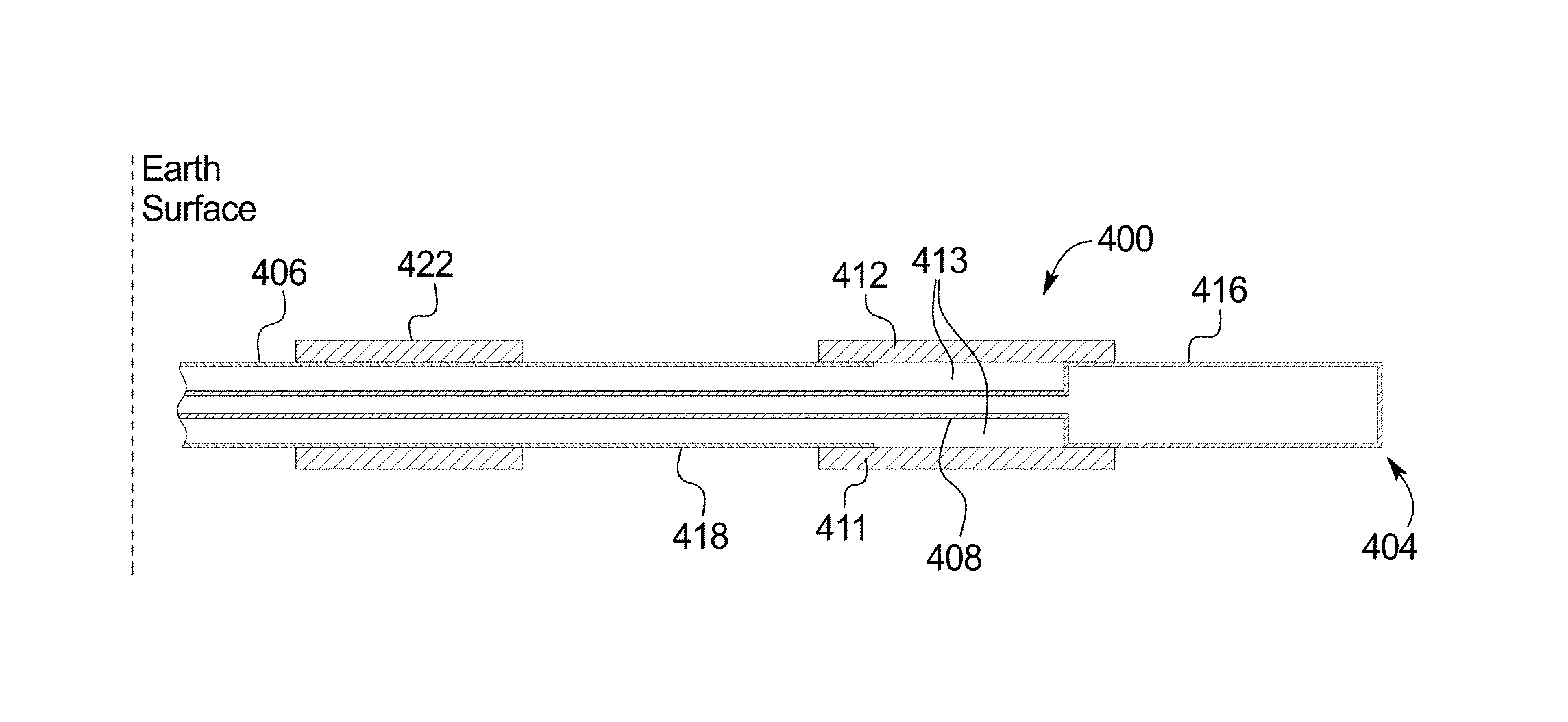

Stimulating production from oil wells using an RF dipole antenna

ActiveUS20140152312A1Reduced effectivenessLow thermal conductivityFluid removalDetection using electromagnetic wavesRf fieldElectrical conductor

A system emplaced in a subsurface formation configured to produce radio frequency (RF) fields for recovery of thermally responsive constituents includes coaxially disposed inner and outer conductors connected at an earth surface to an RF power source. The inner and outer conductors form a coaxial transmission line proximate said earth surface and a dipole antenna proximate said formation. The inner conductor protrudes from the outer conductor from a junction exposing a gap between the conductors to a deeper position within the formation. The RF power source is configured to deliver, via the conductors, RF fields to the formation. The system also includes at least one choke structure attached to said outer conductor at a distance at least ¼ wavelength above said junction. The choke structure is configured to confine a majority of said RF fields in a volume of said formation situated adjacent to said antenna.

Owner:PYROPHASE INC

Coating on a balloon comprising a polymer and a drug

ActiveUS20100063570A1Rapid drug releaseGood mechanical integrityBiocidePeptide/protein ingredientsMedicineMedical device

Owner:ABBOTT CARDIOVASCULAR

Permeable cement and methods of fracturing utilizing permeable cement in subterranean well bores

InactiveUS20040261999A1Reduce hydrostatic pressureDesirable efficiencyAlkali metal silicate coatingsFluid removalFracturing fluidMaterials science

The present invention relates to methods of stimulating a subterranean formation. More particularly, but not by way of limitation, the present invention relates to methods of fracturing subterranean formations utilizing a fracturing fluid comprising a permeable cement composition that may be used as a propping agent. One method of stimulating a subterranean formation of the present invention comprises the following steps: preparing a permeable cement composition comprising a hydraulic cement, water, and a degradable material capable of undergoing an irreversible degradation downhole; injecting the permeable cement composition into the subterranean formation at a pressure sufficient to create a fracture in the subterranean formation; and allowing the permeable cement composition to form a proppant matrix having voids in the fracture.

Owner:HALLIBURTON ENERGY SERVICES INC

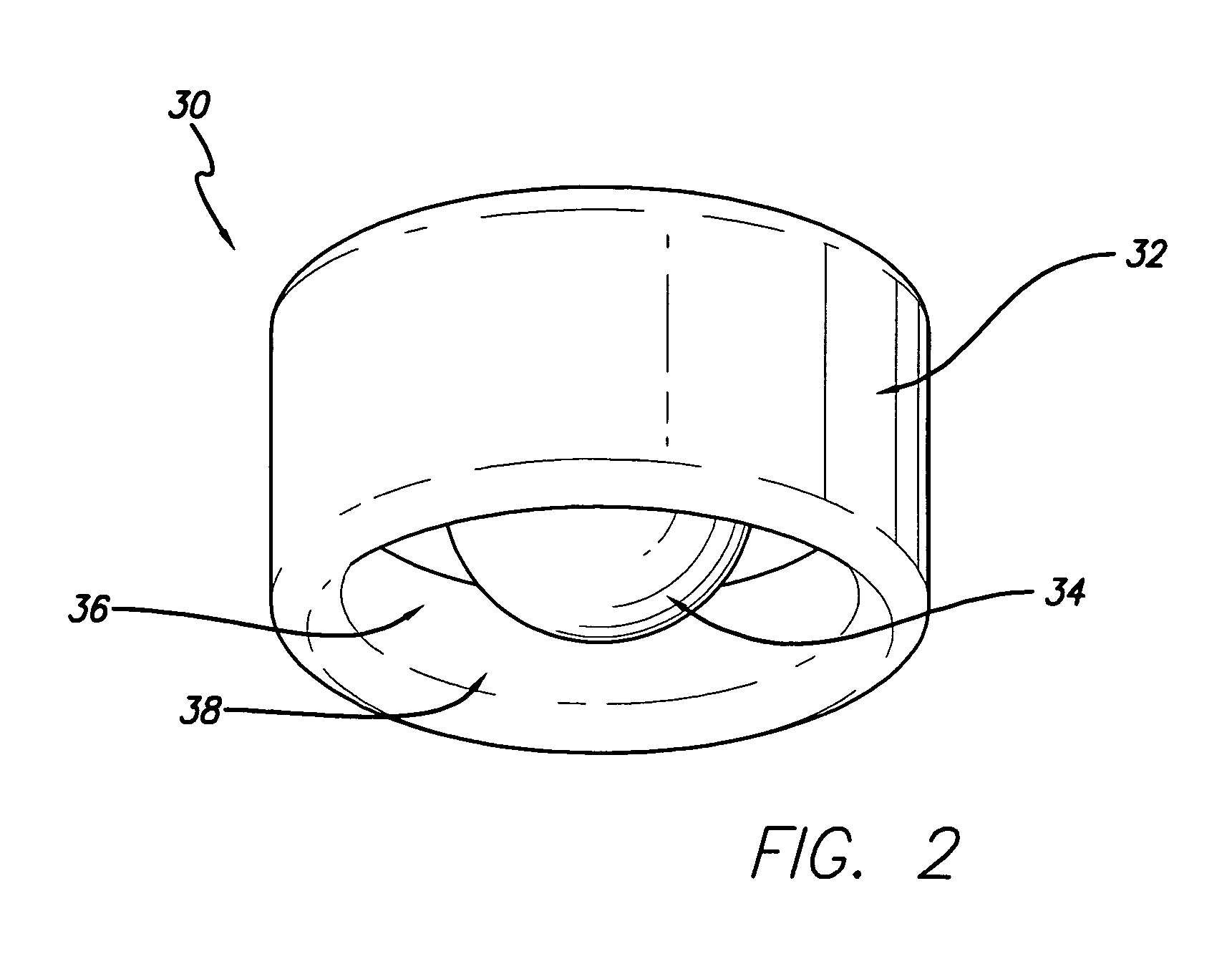

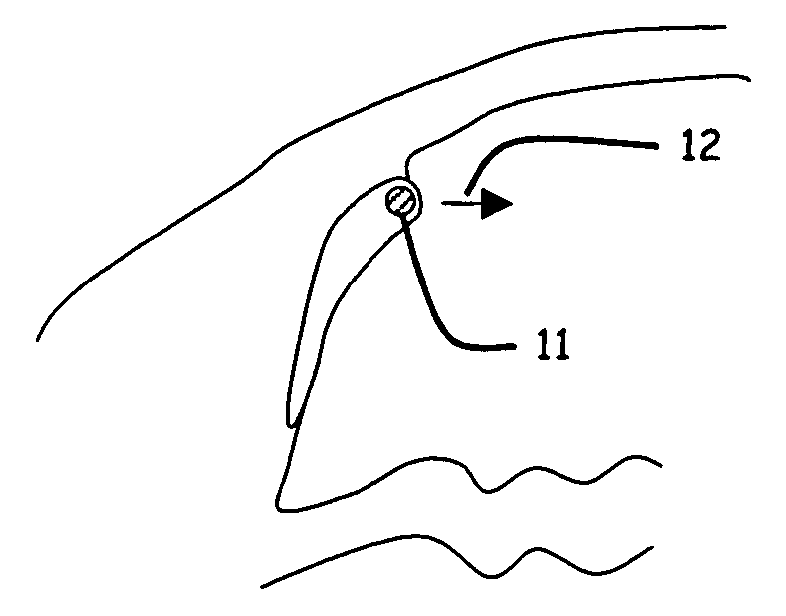

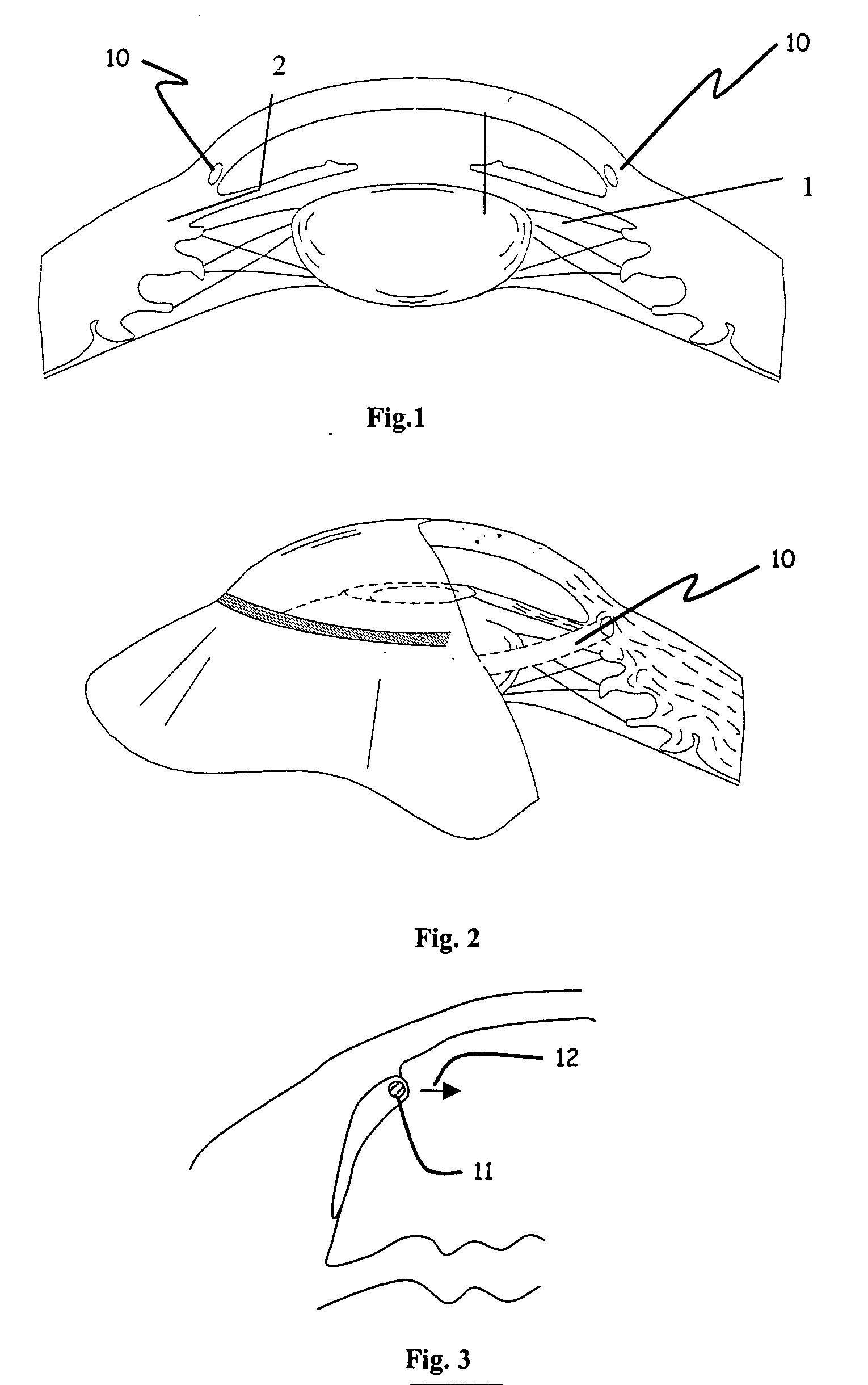

Ophthalmic implant for treatment of glaucoma

ActiveUS20060195187A1Increase outflowGood fluid permeabilityEye implantsEye surgeryOphthalmological implantSchlemm's canal

An implant is placed within Schlemm's canal of the eye and provides tension to the trabecular meshwork. The tension is continuous and increases the aqueous outflow without the necessity of administering cholinergic drugs to treat glaucoma.

Owner:NOVA EYE INC

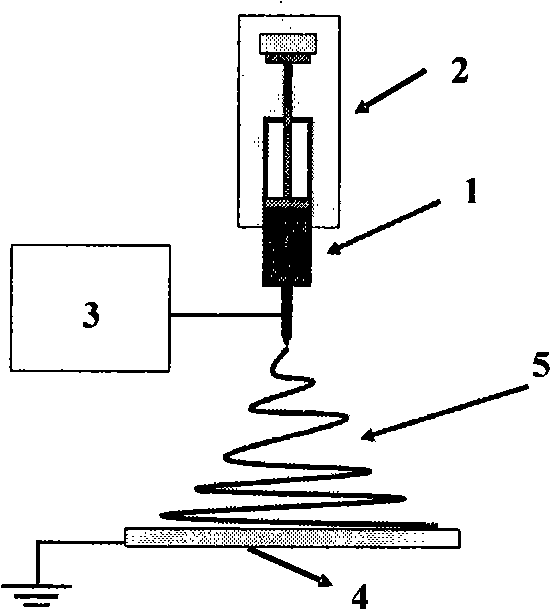

Antibacterial nano fiber material and preparation method thereof

InactiveCN101358382ANo side effects on the human bodyContinuous and stable releaseFilament/thread formingMacromolecular non-active ingredientsFiberSide effect

The invention relates to an antibacterium nano fiber material and a preparation method thereof; the material comprises polymer superfine fiber and antibacterial agent, and the weight ratio is 60 to 98: 2 to 40; the preparation method comprises the following steps: (1) the antibacterial agent is dissolved in distilled water to prepare solution; the polymer superfine fiber is dissolved in methylene dichloride or chloroform organic solvent, emulsifier is added to be mixed evenly, to obtain solution which is dispersed evenly; (2) the two types of solution are mixed to obtain even water-in-oil W / O latex, and then electrostatic spinning is conducted to the latex, to obtain the antibacterium nano fiber material. The nano fiber material has good ventilation property and filterability, still has bacteriostasis and sterilization functions for a long time after stably releasing the antibacterial agent, has simple preparation method, adopts the biodegradable and bioabsorbable polymer as carrier materials, can be absorbed by the human body after fully releasing, is not left, does not need secondary operation and has no side effect.

Owner:DONGHUA UNIV

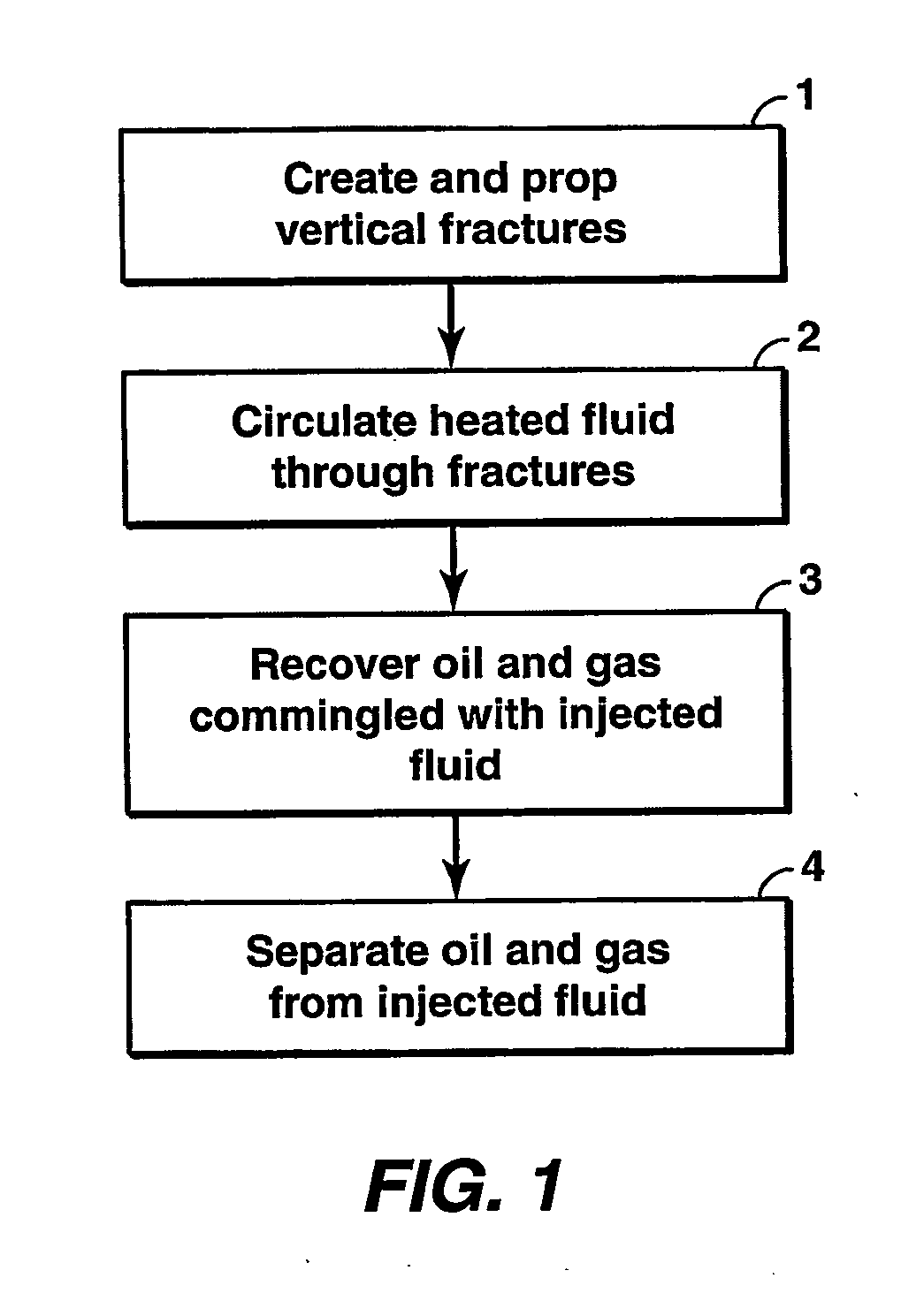

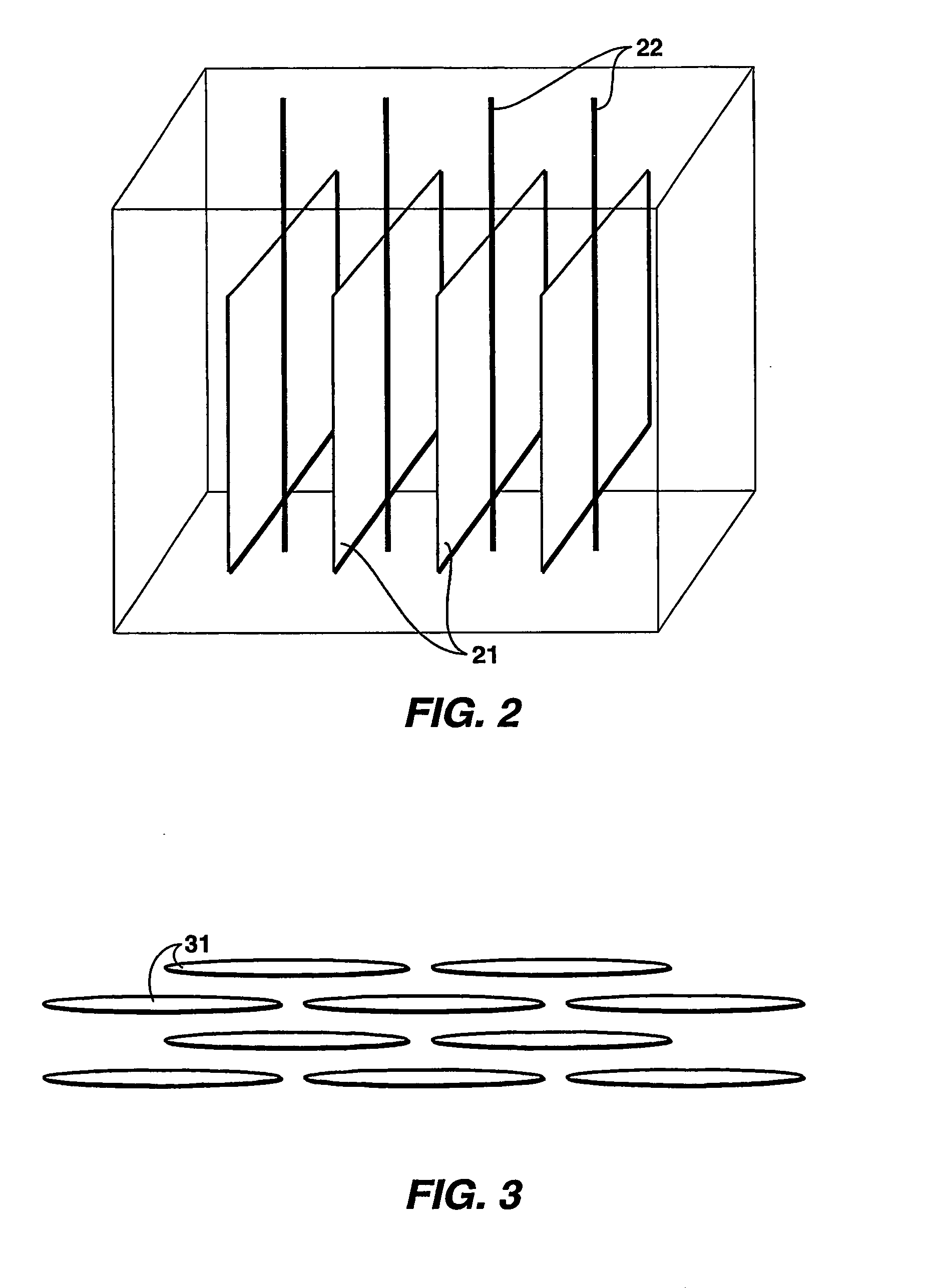

Hydrocarbon recovery from impermeable oil shales

InactiveUS20070023186A1Reduce penetrationAvoid insufficient heatingInsulationFluid removalKerogenCooling fluid

An economic method for in situ maturing and production of oil shale or other deep-lying, impermeable resources containing immobile hydrocarbons. Vertical fractures are created using horizontal or vertical wells. The same or other wells are used to inject pressurized fluids heated to less than approximately 370° C., and to return the cooled fluid for reheating and recycling. The heat transferred to the oil shale gradually matures the kerogen to oil and gas as the temperature in the shale is brought up, and also promotes permeability within the shale in the form of small fractures sufficient to allow the shale to flow into the well fractures where the product is collected commingled with the heating fluid and separated out before the heating fluid is recycled.

Owner:EXXONMOBIL UPSTREAM RES CO

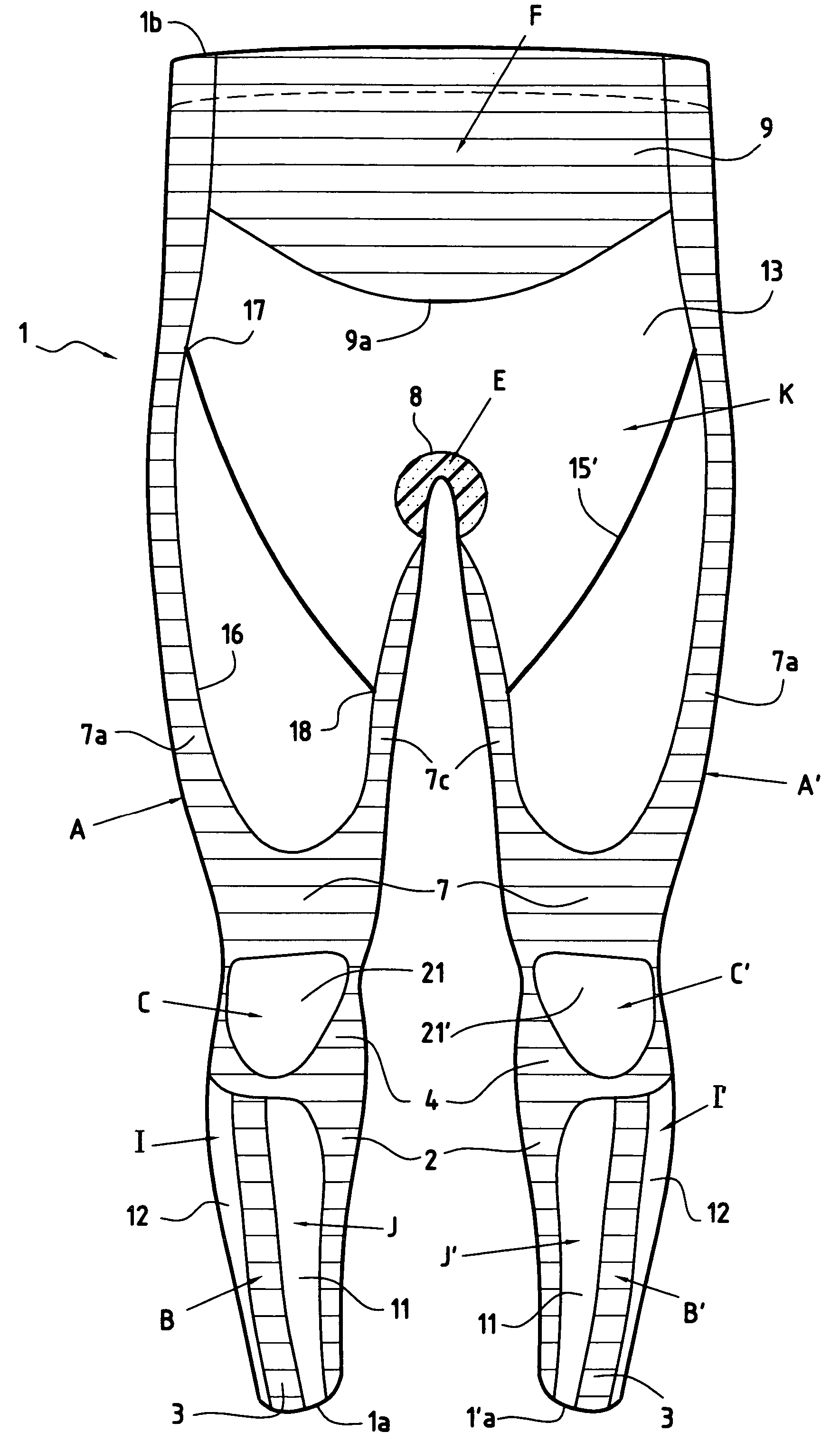

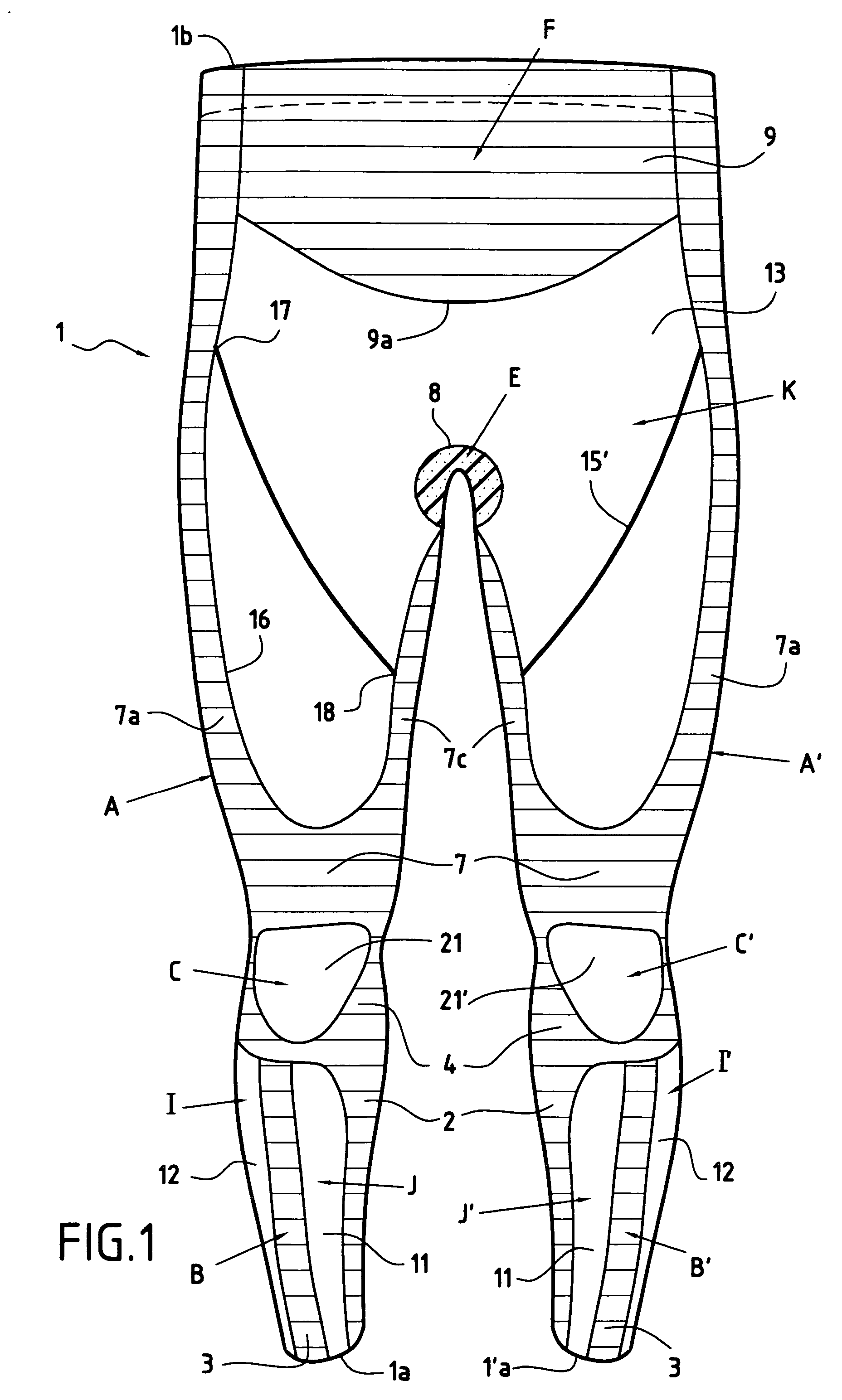

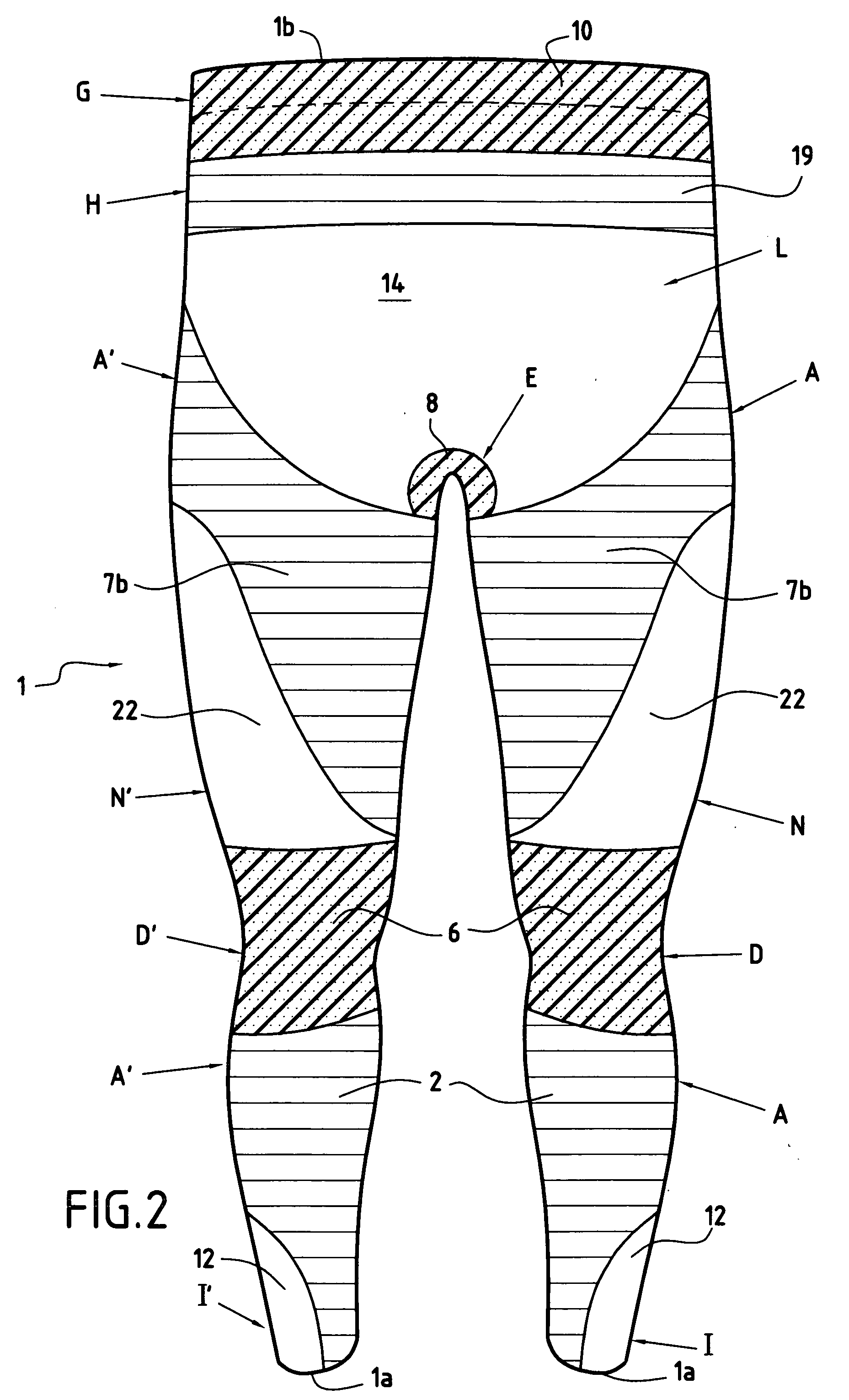

Tights presenting a localized compression effect for practicing a sport

InactiveUS20060169004A1Mitigate such drawbackNormal elasticityTrousersUndergarmentsEngineeringCycling

Tights having a localized compression effect for practicing a sport in which the legs are moved repetitively, in particular running or cycling, are constituted by stretchable textile pieces assembled to one another, namely first pieces having normal elasticity, second pieces providing a compression effect, and optionally third pieces having greater elasticity. When assembled together, all of the first and second pieces present substantially the same mean elasticity in the longitudinal direction of the tights, while the second pieces present, in the transverse direction, mean elasticity that is less than half the mean elasticity of the first pieces. Preferably, the difference in mean elasticity in the transverse direction between the first pieces and second pieces presenting the compression effect presents a ratio lying in the range 2 to 3.

Owner:DECATHLON SA

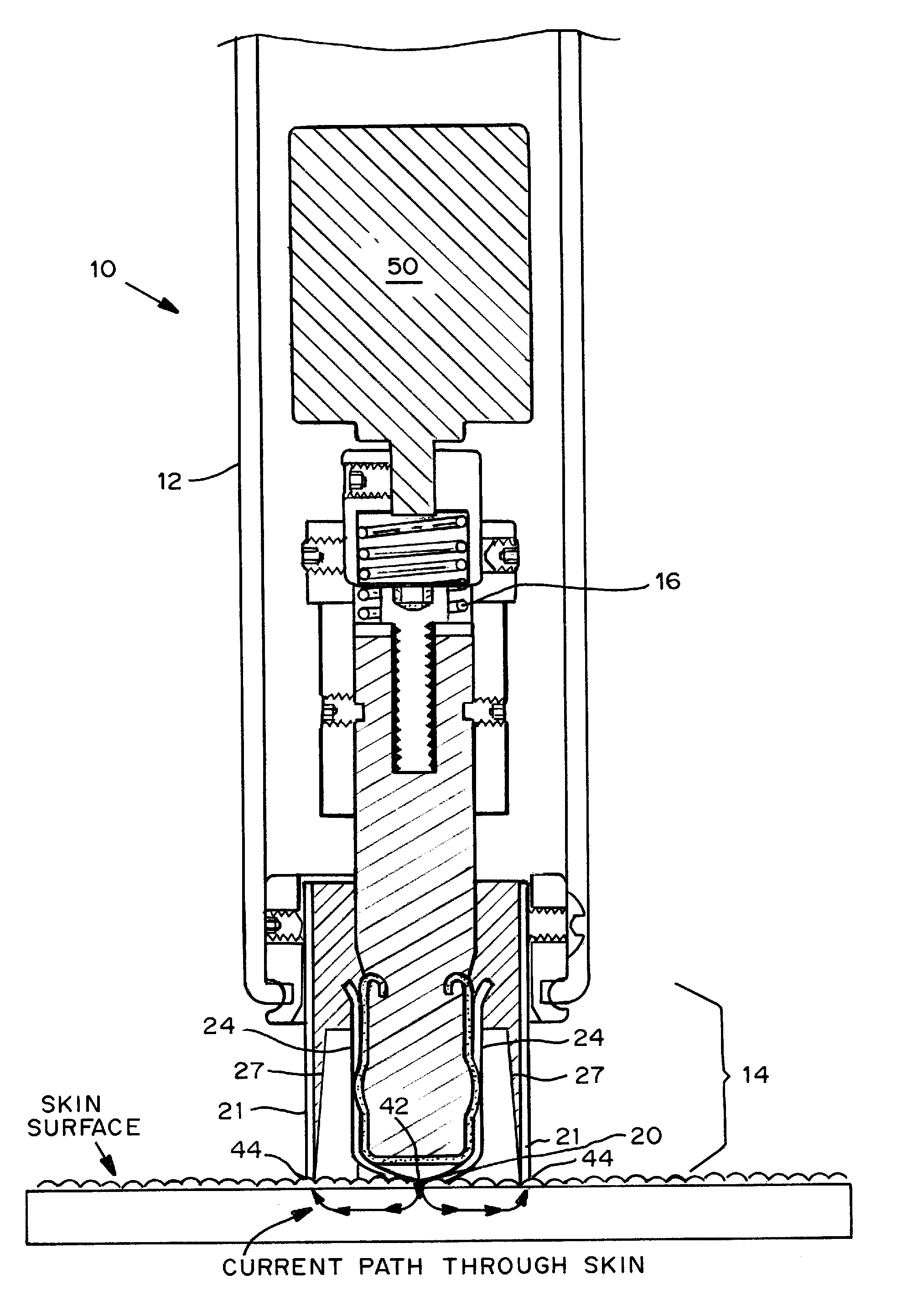

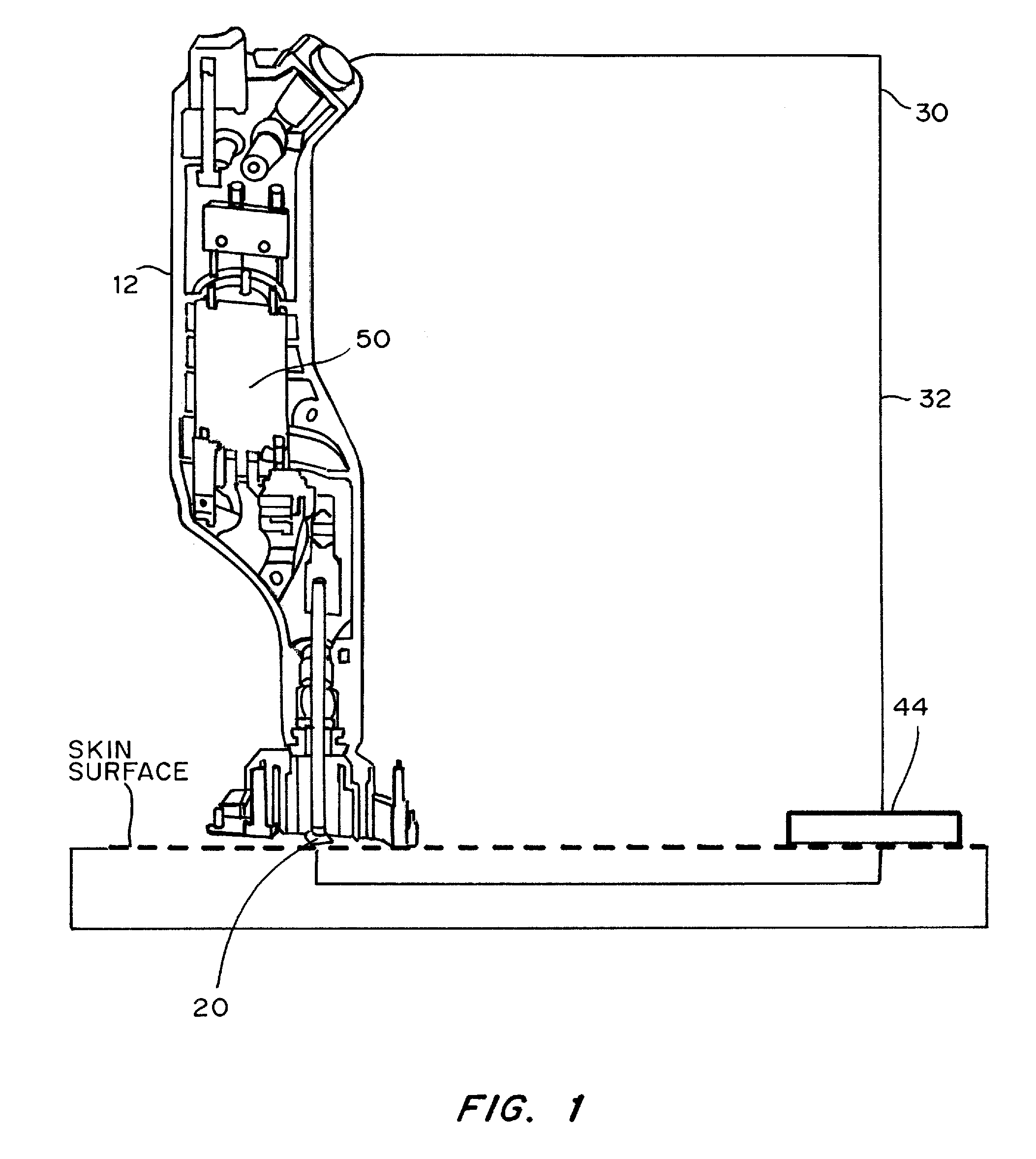

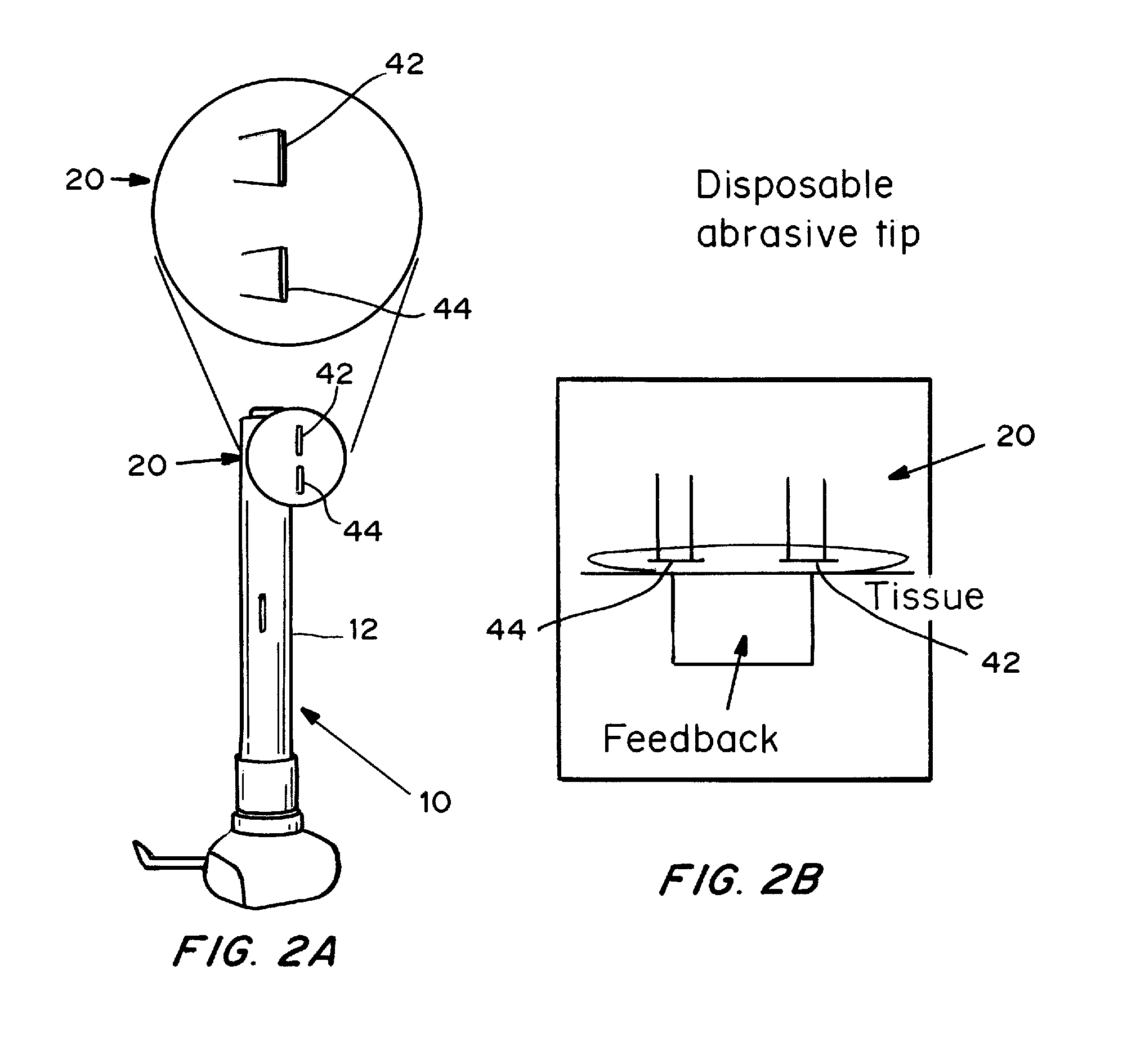

Skin permeation device for analyte sensing or transdermal drug delivery

Devices, systems, kits and methods for increasing the skin's permeability controlled by measured skin electrical parameter are described herein. They may be used for transdermal drug delivery and / or analyte extraction or measurement. The controlled abrasion device contains (i) a hand piece, (ii) an abrasive tip, (iii) a feedback control mechanism, (iv) two or more electrodes, and (v) an electrical motor. The feedback control mechanism may be an internal feedback control mechanism or an external feedback control. The kit contains the controlled abrasion-device, one or more abrasive tips, optionally with a wetting fluid. The method for increasing the skin's permeability requires applying the controlled abrasion device to a portion of the skin's surface for a short period of time, until the desired level of permeability is reached. Then the abrasion device is removed, and a drug delivery composition or device or an analyte sensor is applied to the treated site.

Owner:ECHO THERAPEUTICS INC

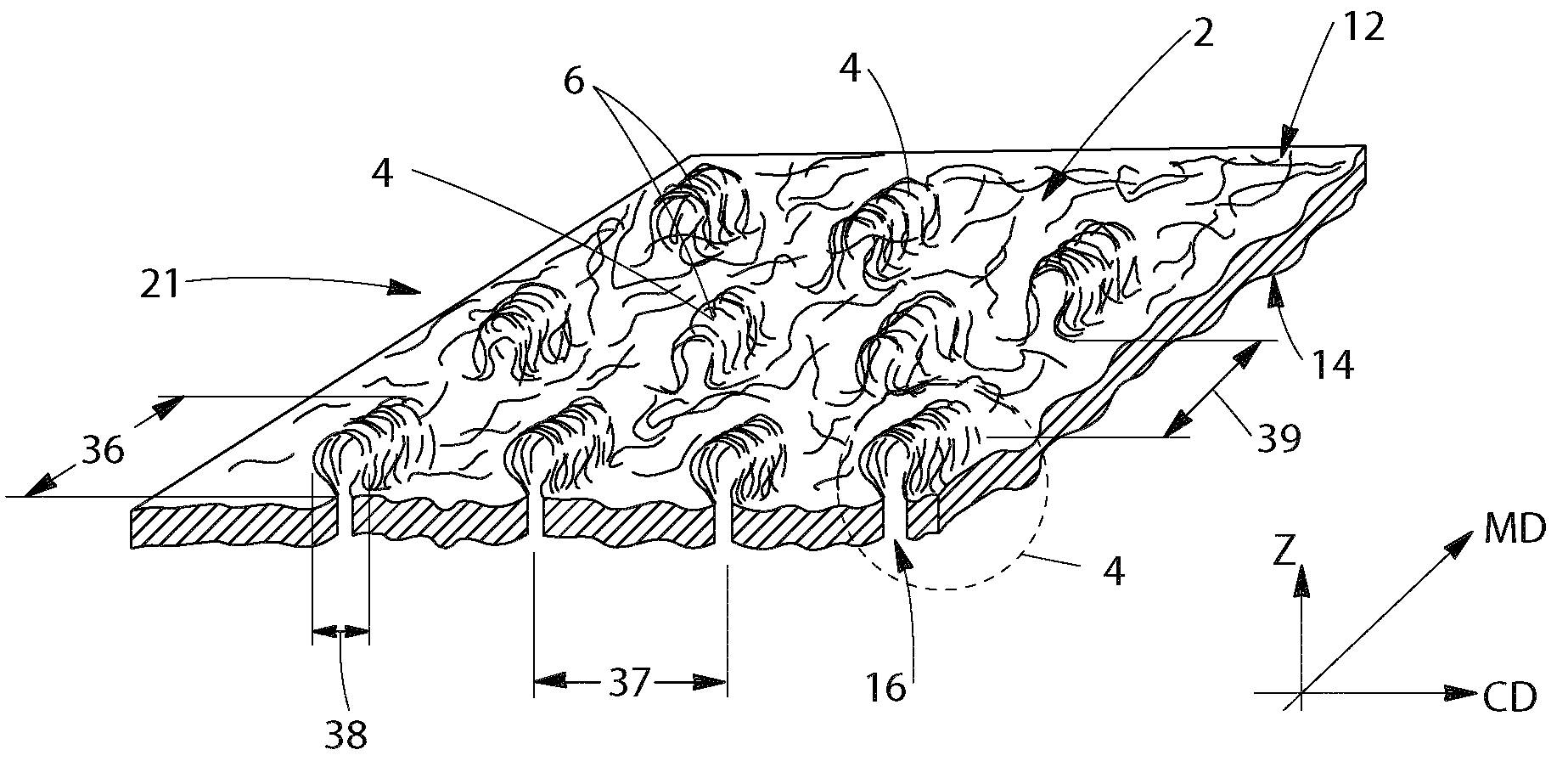

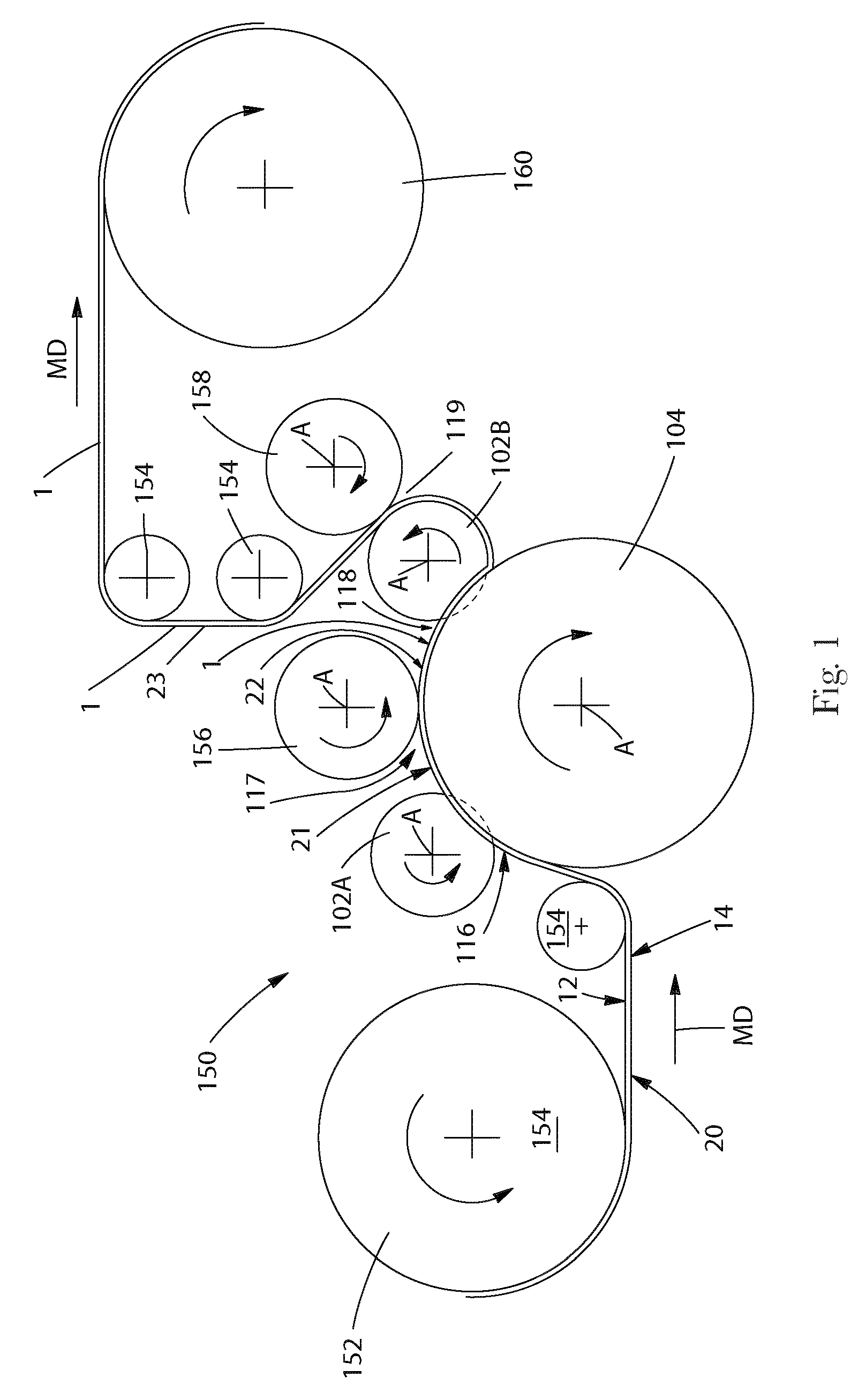

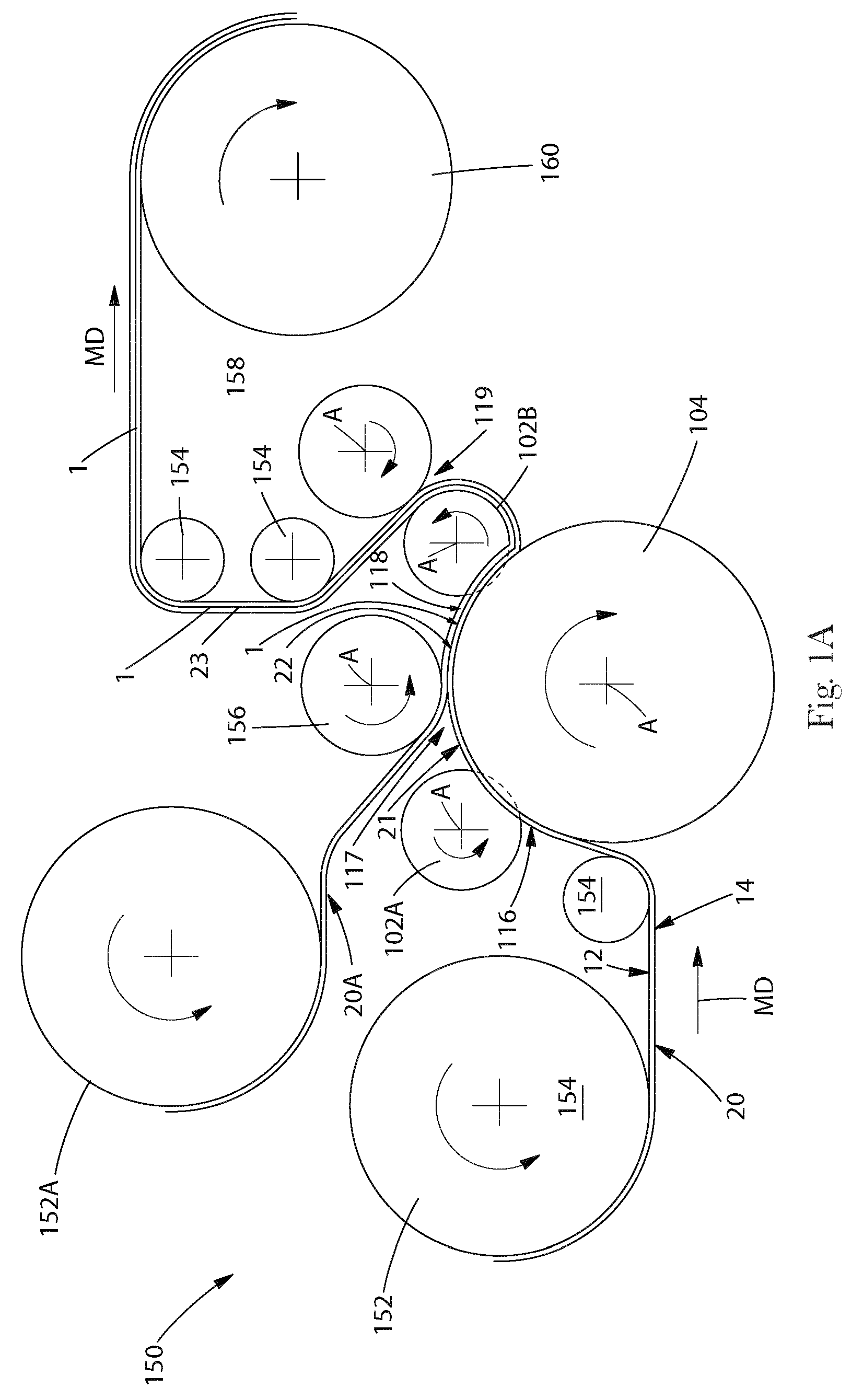

Fluid Permeable Structured Fibrous Web

InactiveUS20100312208A1Increase fiber surface areaImprove abilitiesBaby linensTamponsFiberEngineering

The present disclosure is directed to a disposable absorbent article comprising a fluid permeable structured fibrous web, the fibrous web comprising thermally stable, fibers that are thermally bonded together using heat producing a base substrate that is thermally stable. The base substrate is textured via mechanical treatment producing a structured fibrous web having an aged caliper of less than 1.5 mm, a vertical wicking height of at least 5 mm, a permeability of at least 10,000 cm2 / (Pa·s) and a specific volume of at least 5 cm3 / g. The structured fibrous web provides optimal fluid wicking and the fluid acquisition capabilities and is directed toward fluid management applications.

Owner:THE PROCTER & GAMBLE COMPANY

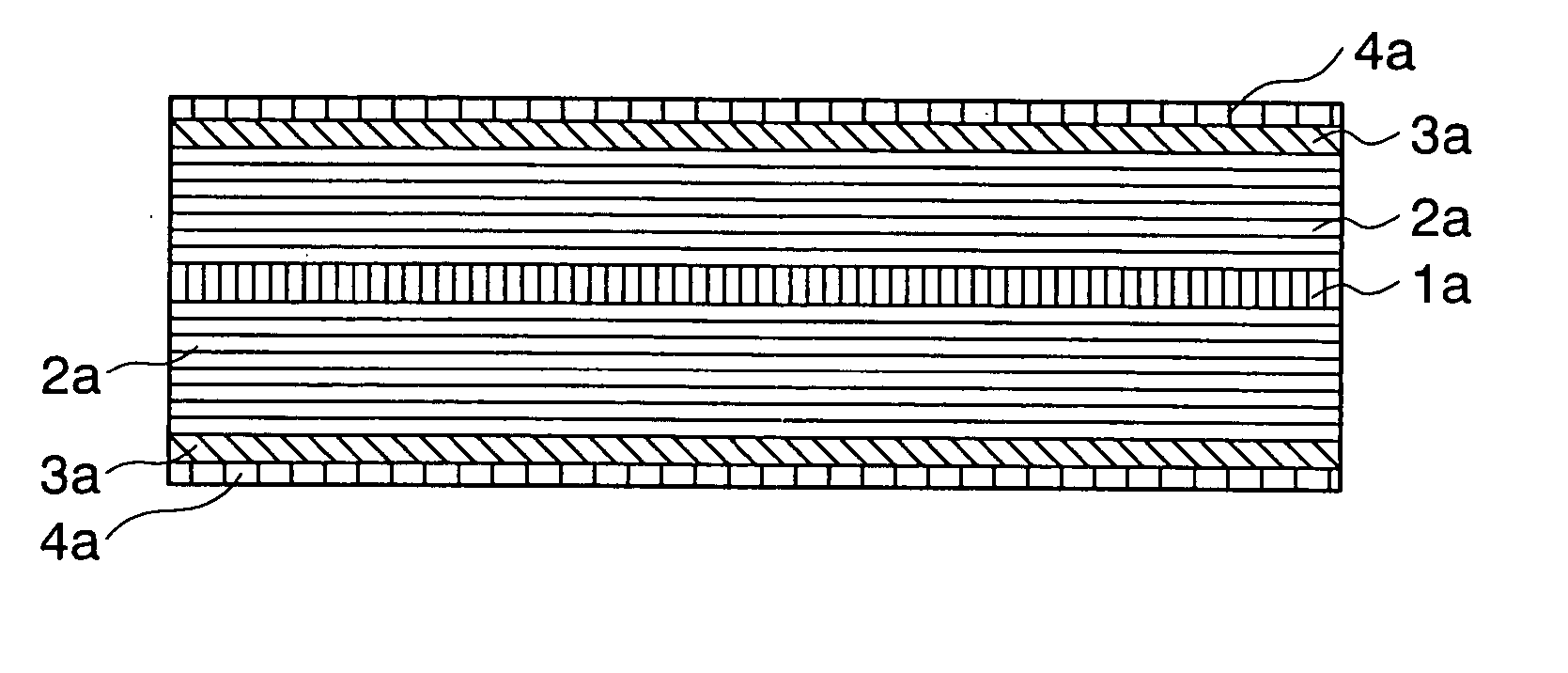

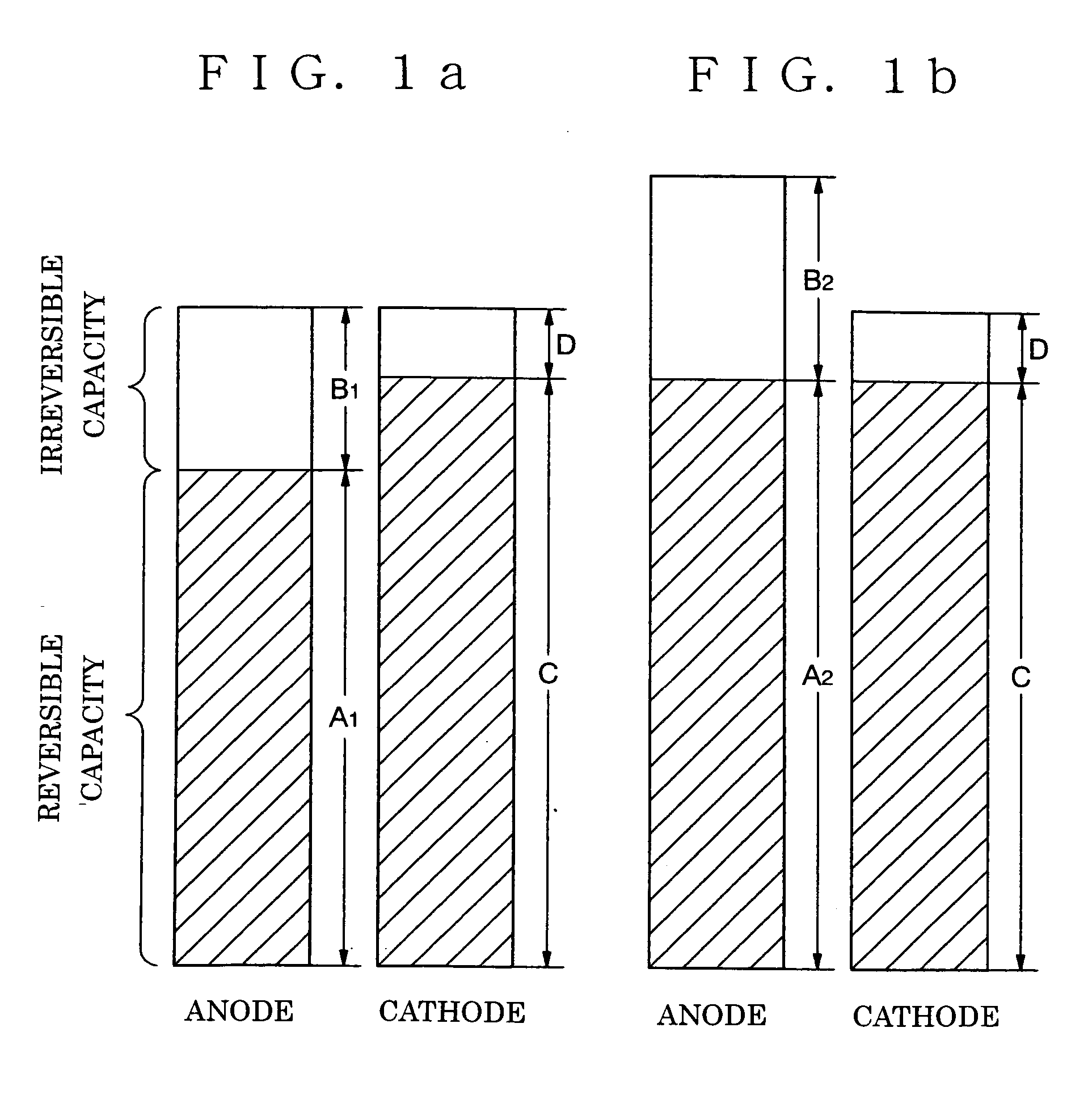

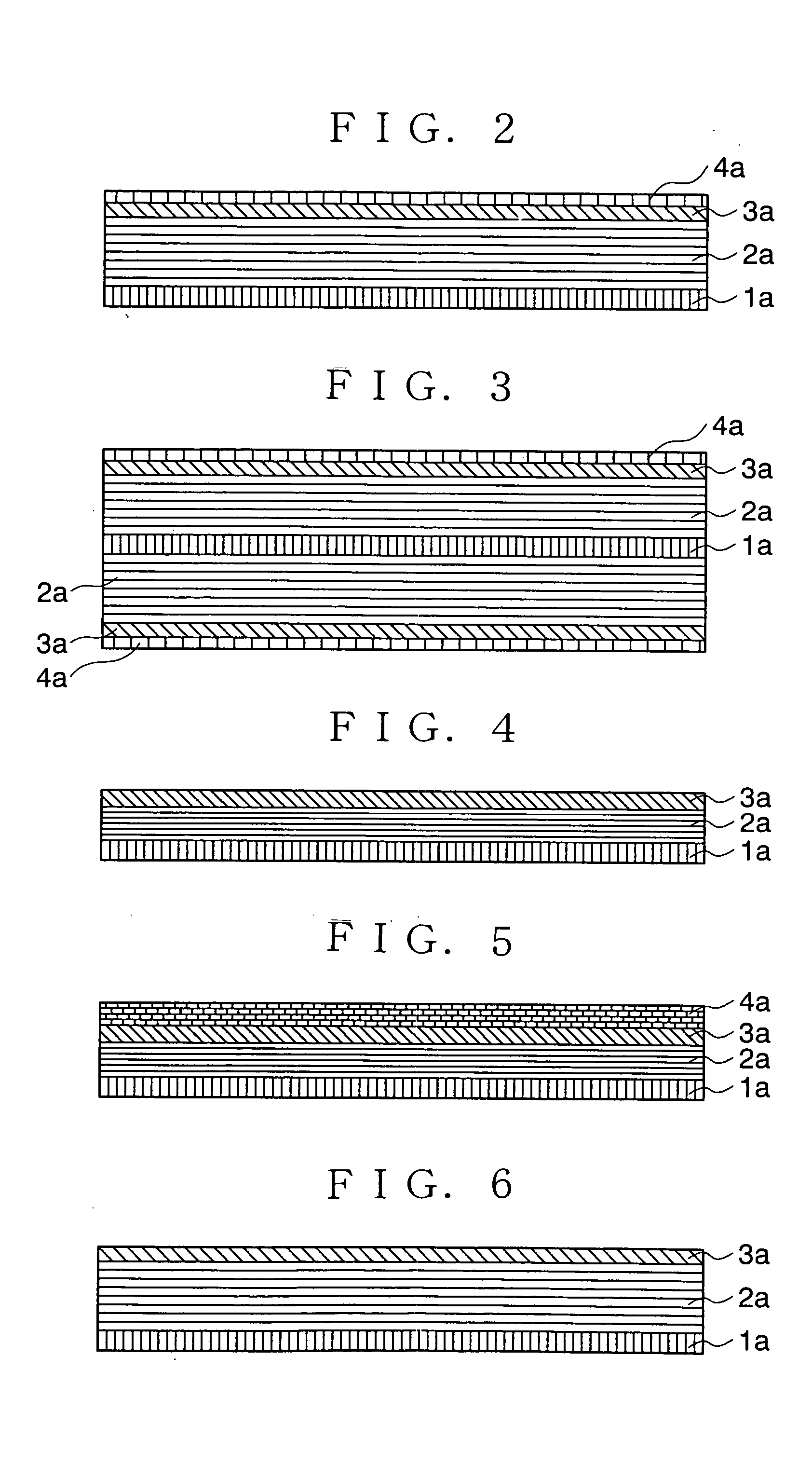

Negative pole for a secondary cell, secondary cell using the negative pole, and negative pole manufacturing method

ActiveUS20040175621A1High reversible capacityImprove cycle performanceVacuum evaporation coatingSputtering coatingDischarge efficiencySodium-ion battery

An anode for a secondary battery capable of inserting and extracting a lithium ion having a multi-layered structure including a first anode layer (2a) containing carbon as a main component; a second anode layer (3a) made of a film-like material through which a lithium component passes; and a third anode layer (4a) containing lithium and / or a lithium-containing compound as a main component. The battery capacity of the lithium ion battery is substantially increased while the higher charge-discharge efficiency and the stable cycle performance are maintained.

Owner:NEC CORP

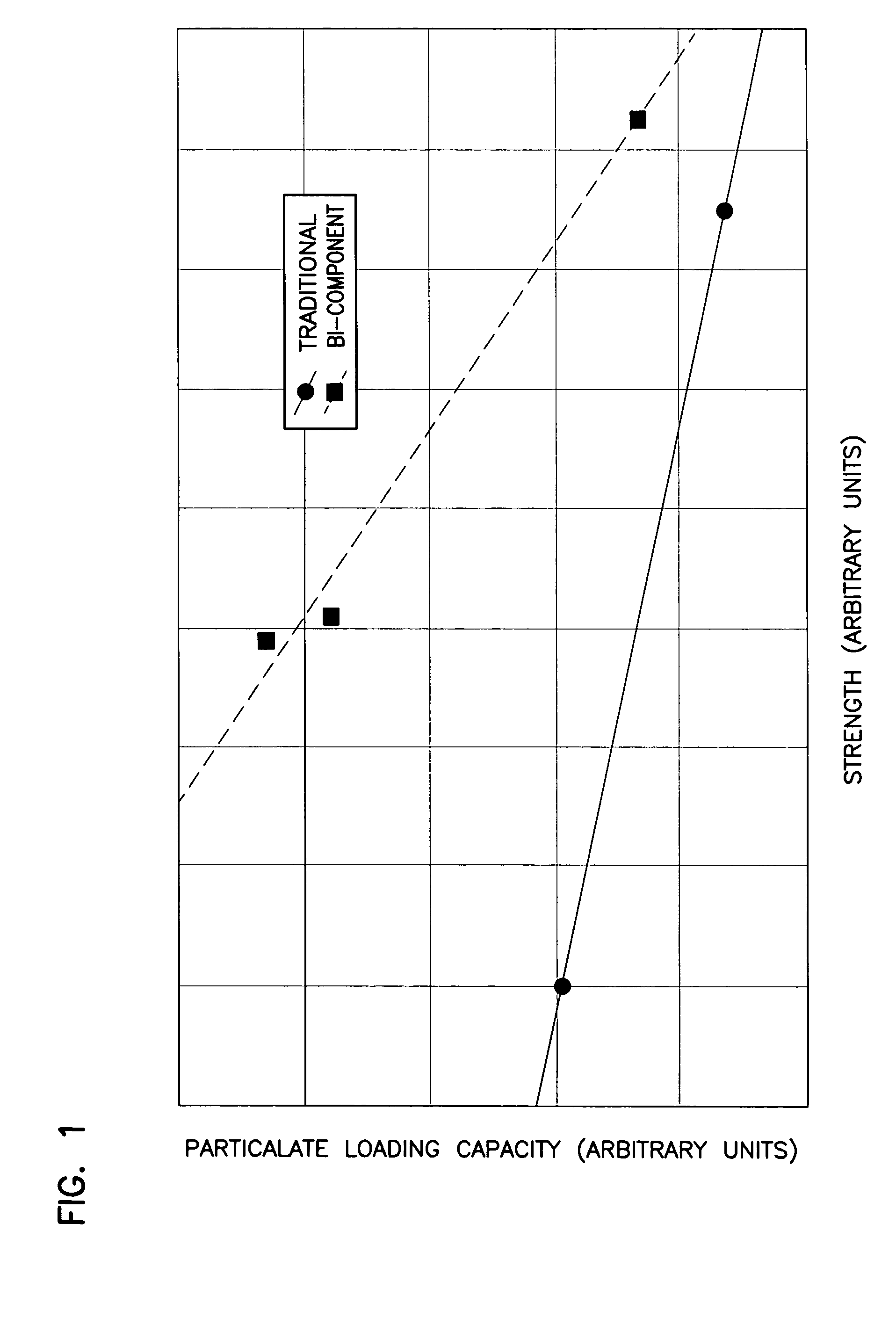

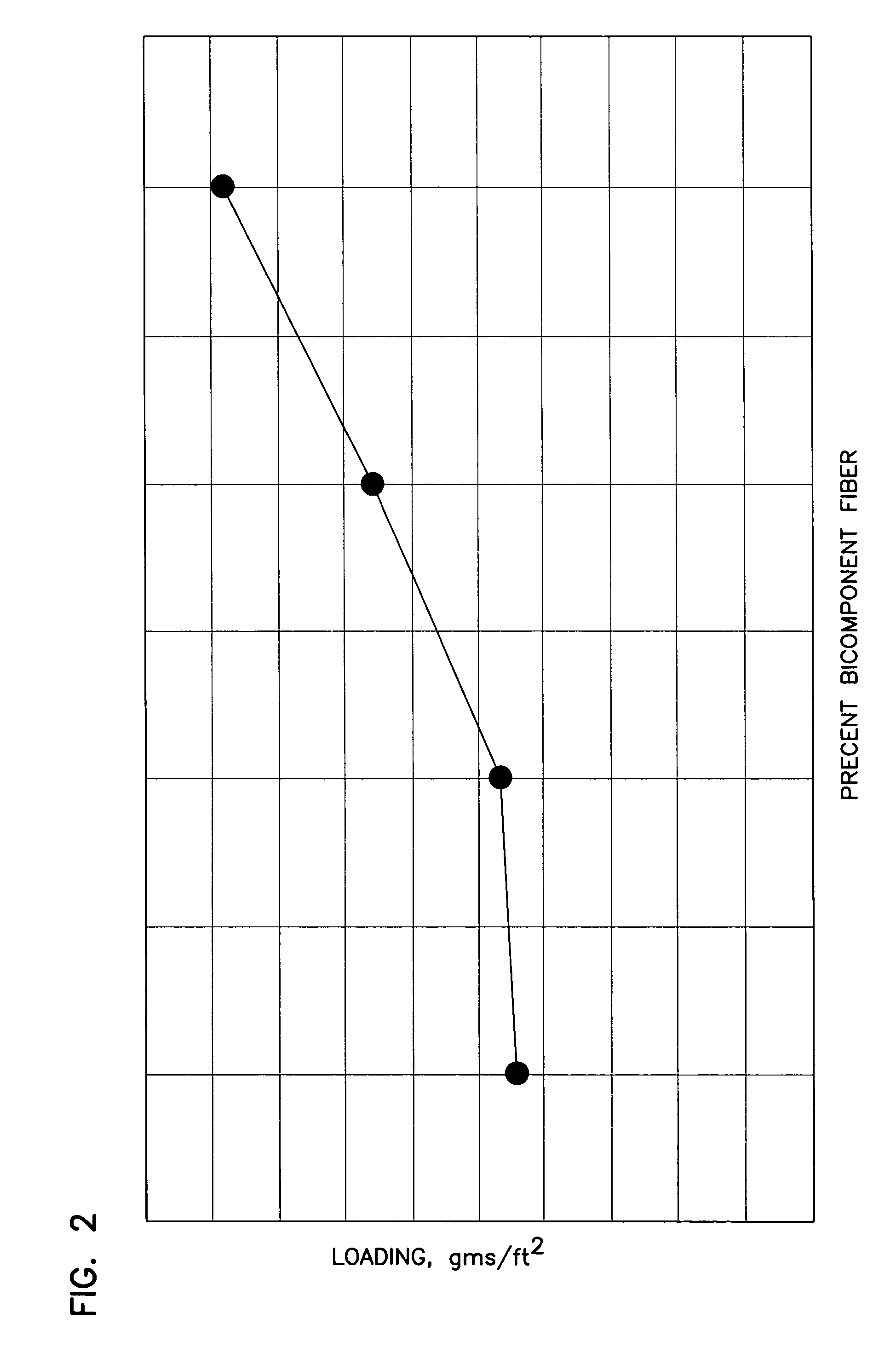

High strength, high capacity filter media and structure

ActiveUS20060096932A1Substantial flow capacity , permeabilityHigh strengthCombination devicesSemi-permeable membranesHigh intensityMechanical failure

In the filtration of fluid materials, the removal of particulate from the moving stream requires substantial pressure to maintain flow and substantial capacity for removing particulate. The filters of the invention are rugged, high wet strength materials having a basis weight, permeability and efficiency suitable to obtain substantial reduction in particulate loading from liquid streams without plugging or mechanical failure. In particular, the filters of the invention permit the removal of substantial proportions of particulate from non-aqueous streams including lubricant oils, hydraulic fluids and other contaminated streams.

Owner:DONALDSON CO INC

Encapsulation of sensitive liquid components into a matrix to obtain discrete shelf-stable particles

InactiveUS7201923B1Improve hydrophobicityPrevent and delays penetration of waterPowder deliveryBiocideSolid particleHeat sensitive

A liquid encapsulant component which contains an active, sensitive encapsulant, such as a live microorganism or an enzyme dissolved or dispersed in a liquid plasticizer is admixed with a plasticizable matrix material. The matrix material is plasticizable by the liquid plasticizer and the encapsulation of the active encapsulant is accomplished at a low temperature and under low shear conditions. The active component is encapsulated and / or embedded in the plasticizable matrix component or material in a continuous process to produce discrete, solid particles. The liquid content of the liquid encapsulant component provides substantially all or completely all of the liquid plasticizer needed to plasticize the matrix component to obtain a formable, extrudable, cuttable, mixture or dough. Removal of liquid plasticizer prior to extrusion is not needed to adjust the viscosity of the mixture for formability. Release of an active component from the matrix may be delayed or controlled over time so that the active component is delivered when and where it is needed to perform its intended function. Controlled release, discrete, solid particles which contain an encapsulated and / or embedded component such as a heat sensitive or readily oxidizable pharmaceutically, biologically, or nutritionally active component are continuously produced without substantial destruction of the matrix material or encapsulant.

Owner:GENERAL MILLS INC

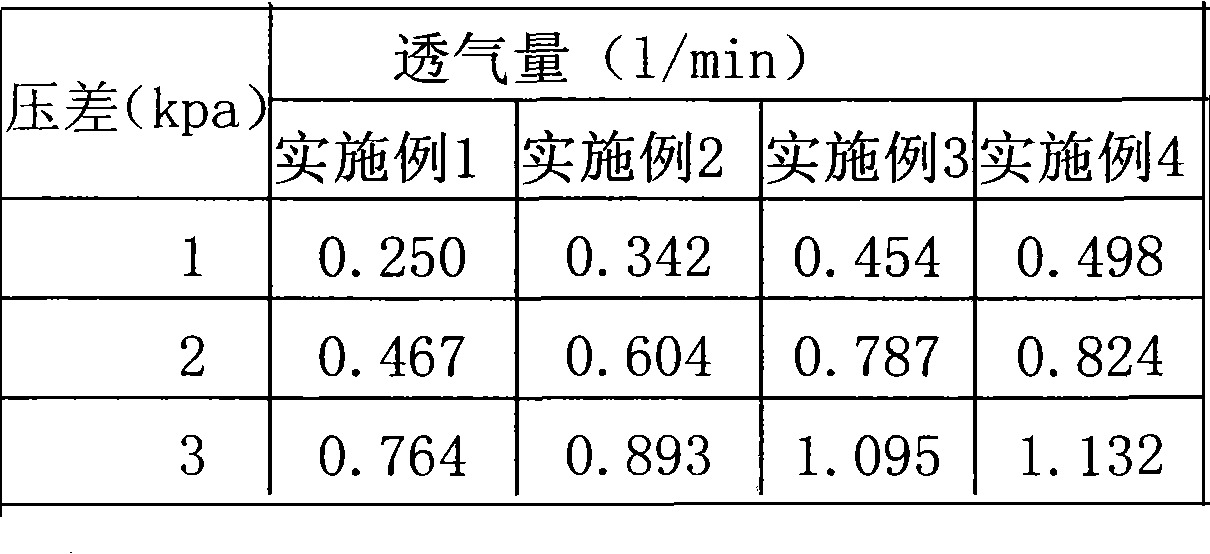

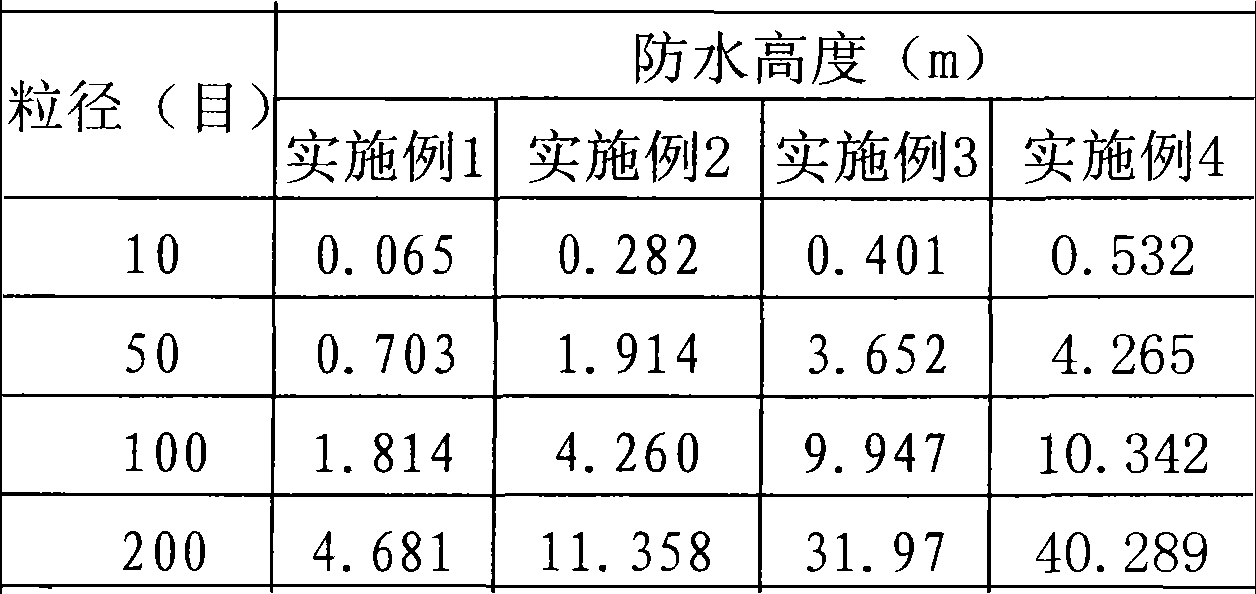

Hydrophobic granule and preparation method thereof, and waterproof breathable structure and forming method thereof

ActiveCN101838116AImprove hydrophobicityImprove water resistanceSolid waste managementSoil conditioning compositionsEpoxyPolyresin

The invention relates to a hydrophobic granule and a preparation method thereof, and a waterproof breathable structure and a forming method thereof. The hydrophobic granule comprises aggregate and a hydrophobic resin film coated on the aggregate, wherein the aggregate size is 6-300 meshes, and the hydrophobic resin film is made of one or a plurality of hydrophobic epoxy resin, bakelite, polyurethane resin and silicone resin, and coated on the aggregate. The preparation method of the hydrophobic granule comprises the following steps: heating the aggregate to 50-400 DEG C; adding the hydrophobic resin, evenly stirring so that a film is coated on the aggregate surface; and cooling, crushing and screening to obtain the hydrophobic granules. The hydrophobic granule can be widely used as a waterproof breathable layer in desert planting, lake bottom seepage-proofing, river course seepage-proofing, landscape water system bottom seepage-proofing, and has favorable waterproof and breathable properties.

Owner:北京仁创科技发展有限公司

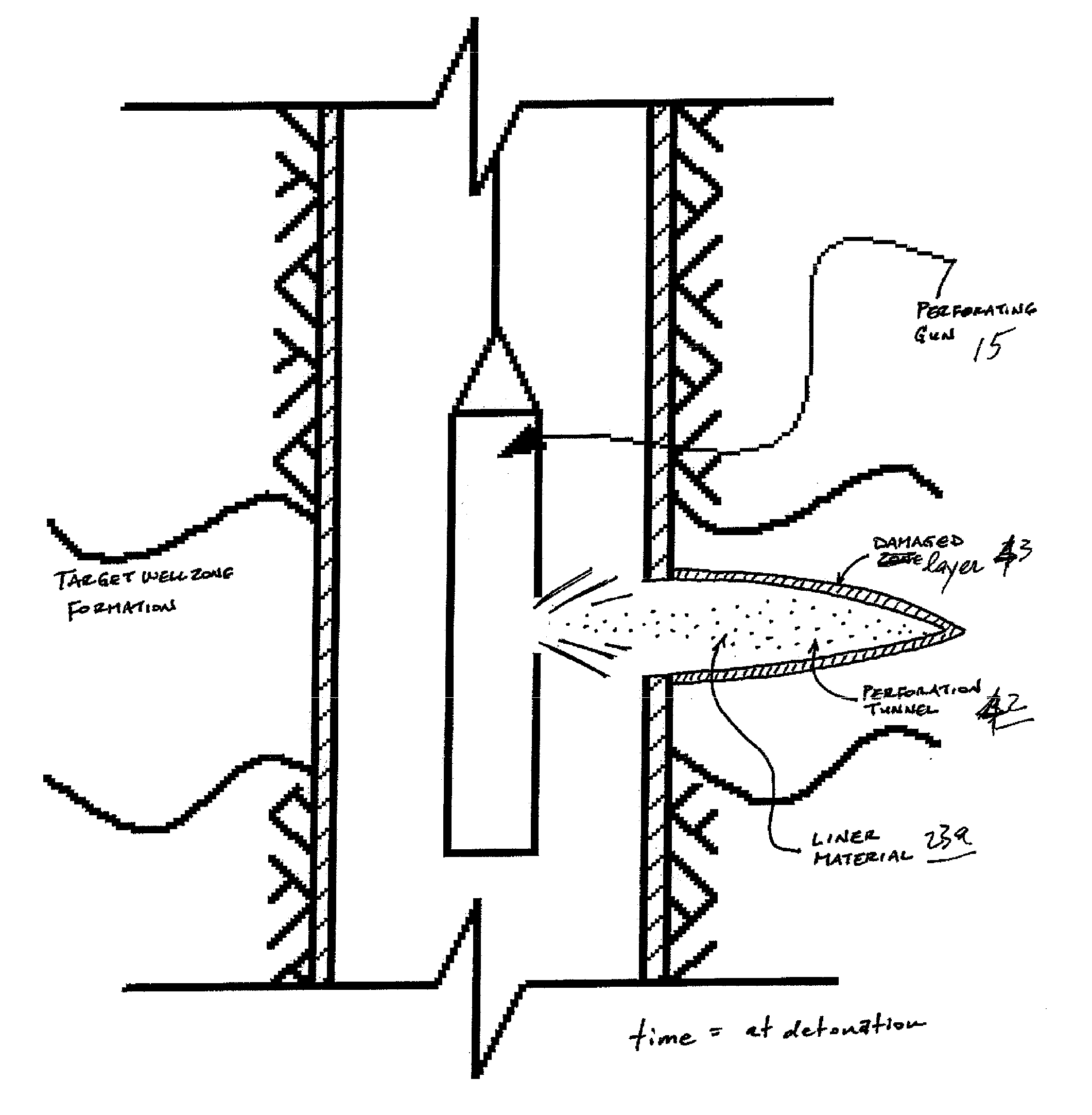

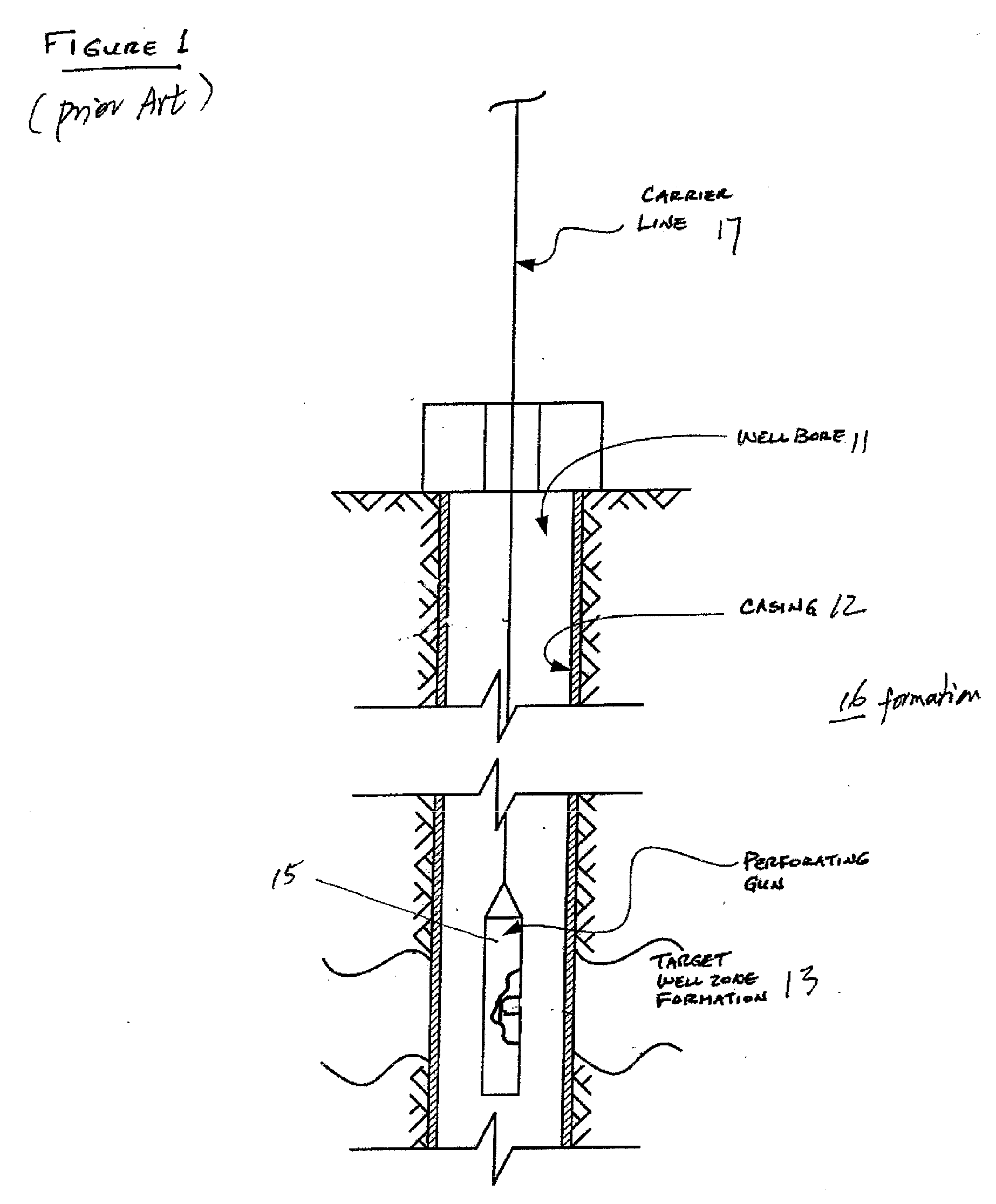

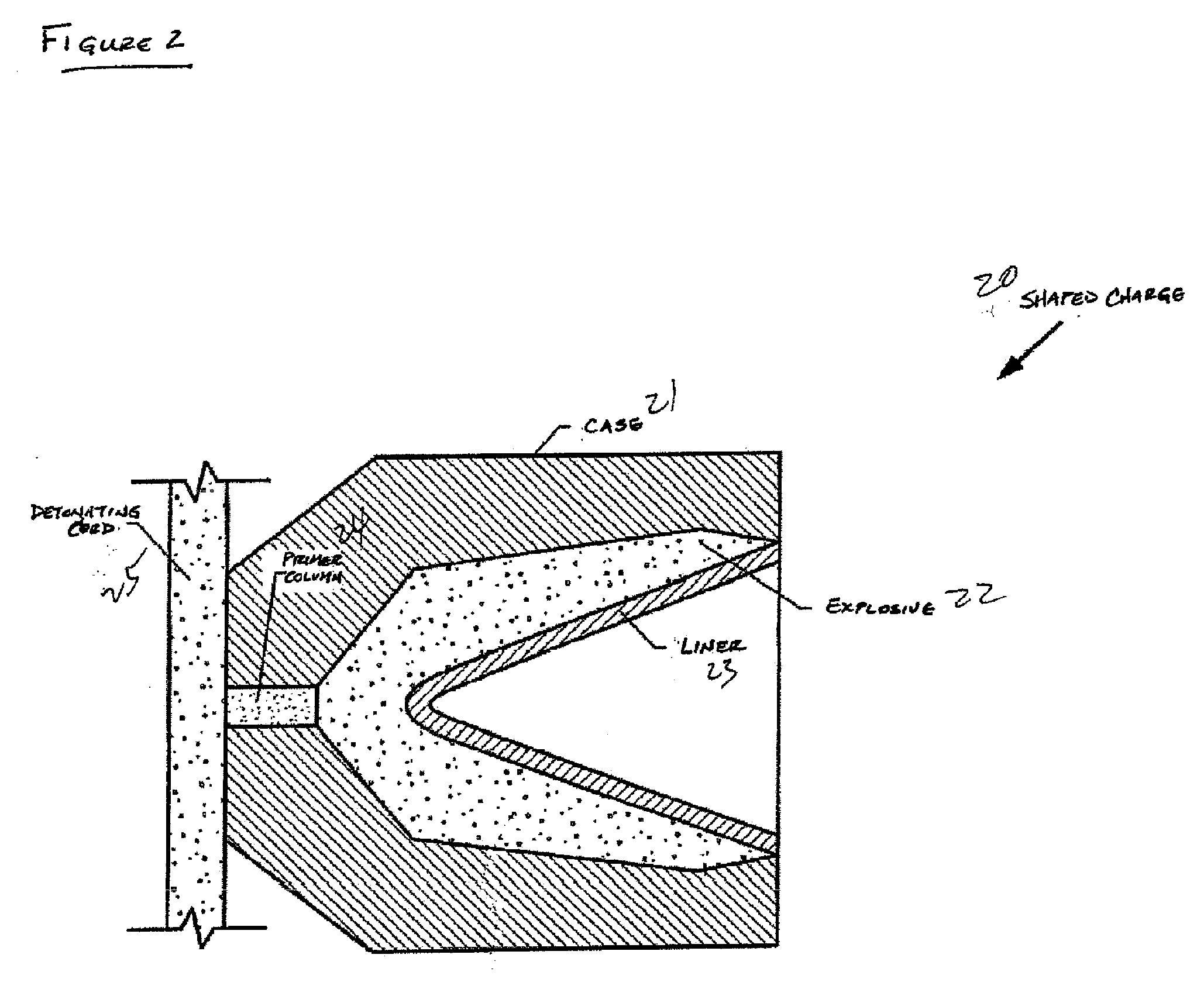

Shaped Charges for Creating Enhanced Perforation Tunnel in a Well Formation

ActiveUS20060266551A1Reduce penetrationDecrease productivityNuclear explosivesFluid removalShaped chargeEngineering

A shaped charge includes a charge case; an explosive disposed inside the charge case; and a liner for retaining the explosive in the charge case, wherein the liner comprises a material reactive with a component of an earth formation. A method for perforating in a well includes disposing a perforating gun in the well, wherein the perforating gun comprises a shaped charge having a charge case, an explosive disposed inside the charge case, and a liner for retaining the explosive in the charge case, wherein the liner includes a material that can react with a component of an earth formation; detonating the shaped charge to form a perforation tunnel in a formation zone; and allowing the material comprising the liner to react with the component of the earth formation.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com