Patents

Literature

85results about How to "Withstanding stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

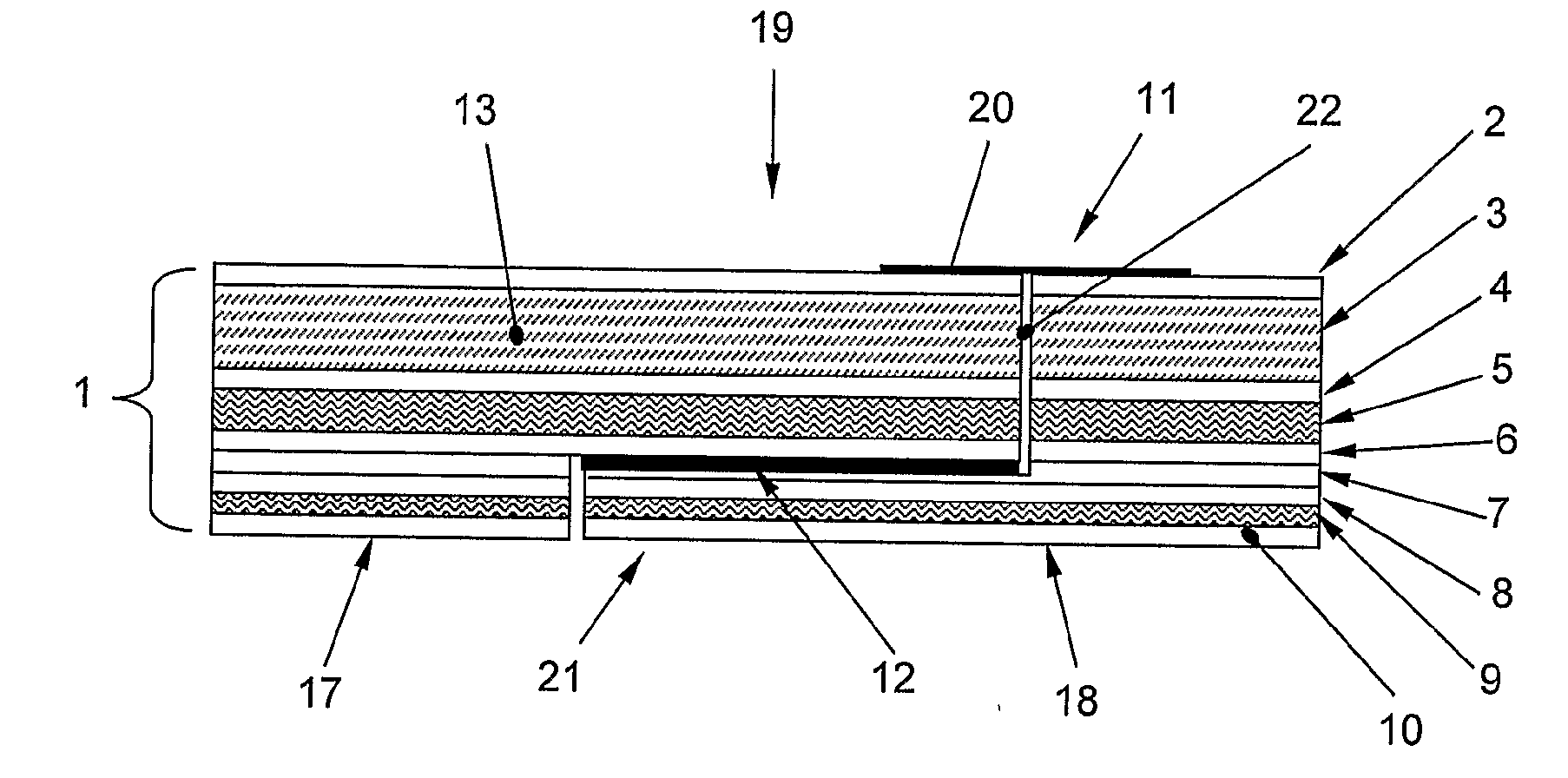

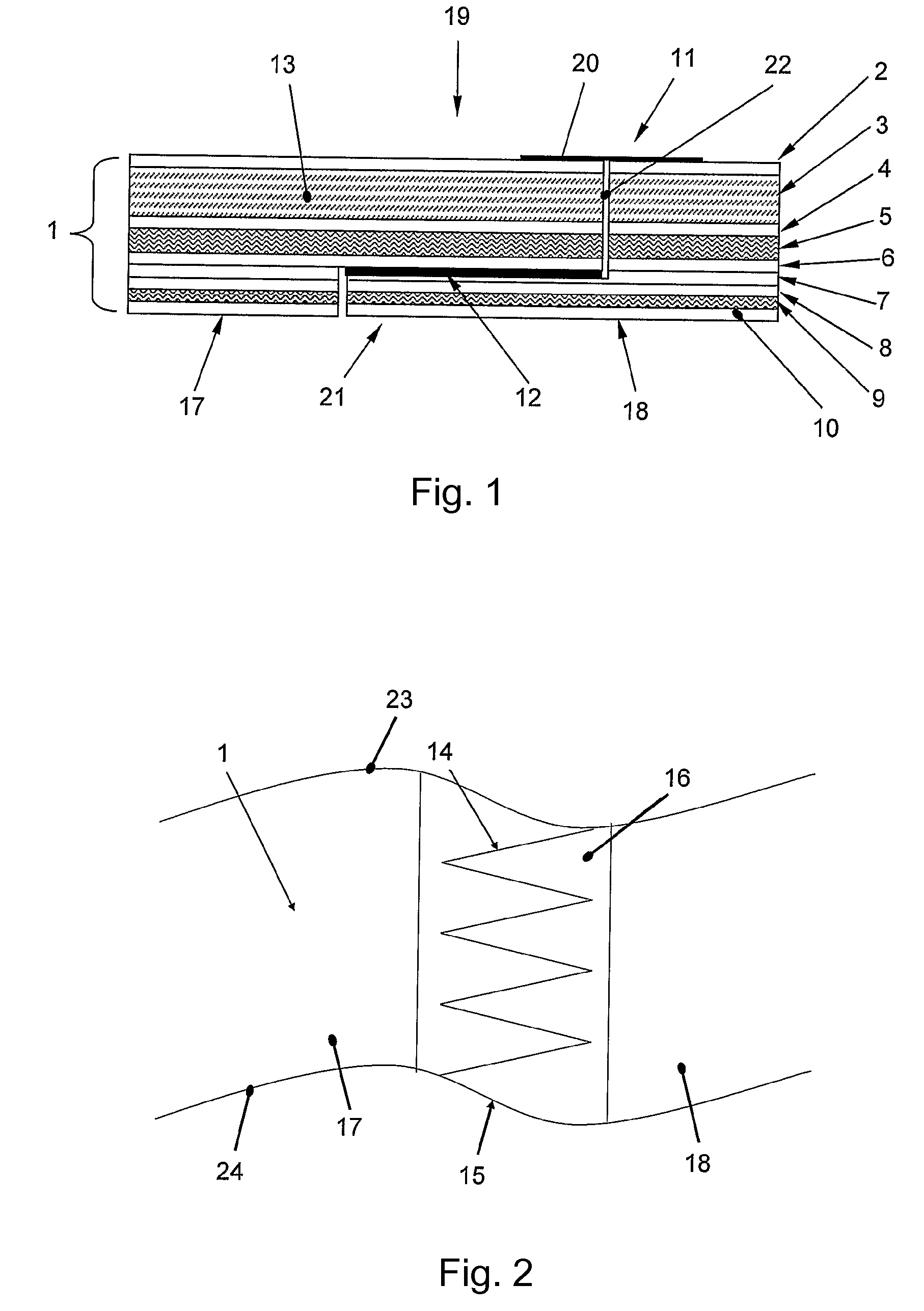

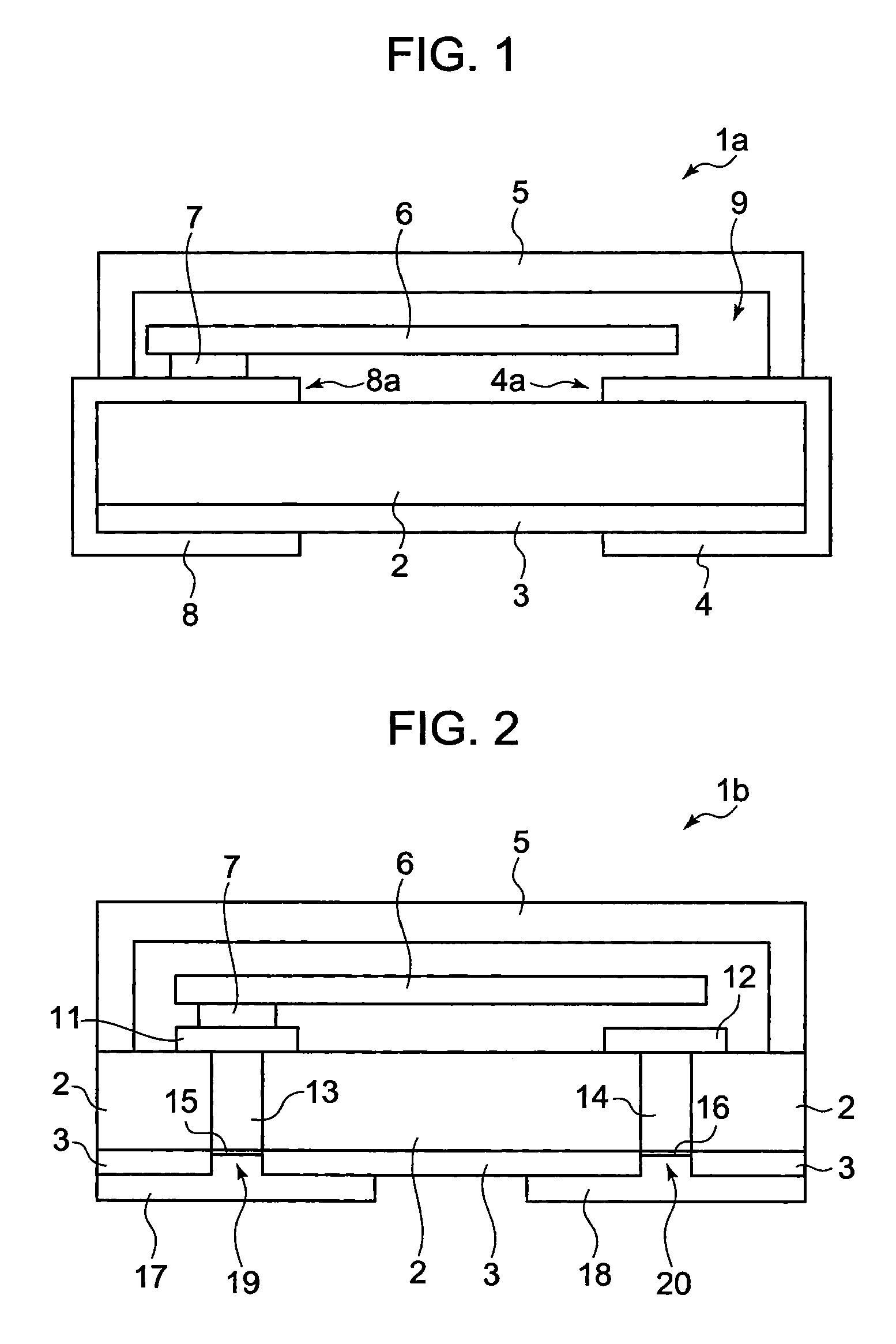

Multi-layered belt

InactiveUS20090098385A1Reliable and durable mechanical propertyReduce stress exertedConveyorsSynthetic resin layered productsEngineeringLeather belt

A multi-layered belt, in particular a continuous running and / or transport and / or processing belt, includes a traction layer and a functional layer that contains a gel. To reduce the stress placed on the transported goods, in particular persons, the gel is an unplasticized gel and the functional layer consist of a coating containing the interspersed gel. In addition, to a method for producing a belt of this type is provided, in which the gel is poured in a continuous method onto the traction layer and a mixer and delivery unit is guided back and forth in a reversible manner perpendicular to the displacement direction of the traction layer in such a way that a gel layer with a uniform thickness is applied to the traction layer. Furthermore, the use of said belt as a running belt for persons, in particular as a running belt for training and / or fitness equipment is described.

Owner:FORBO SIEGLING +1

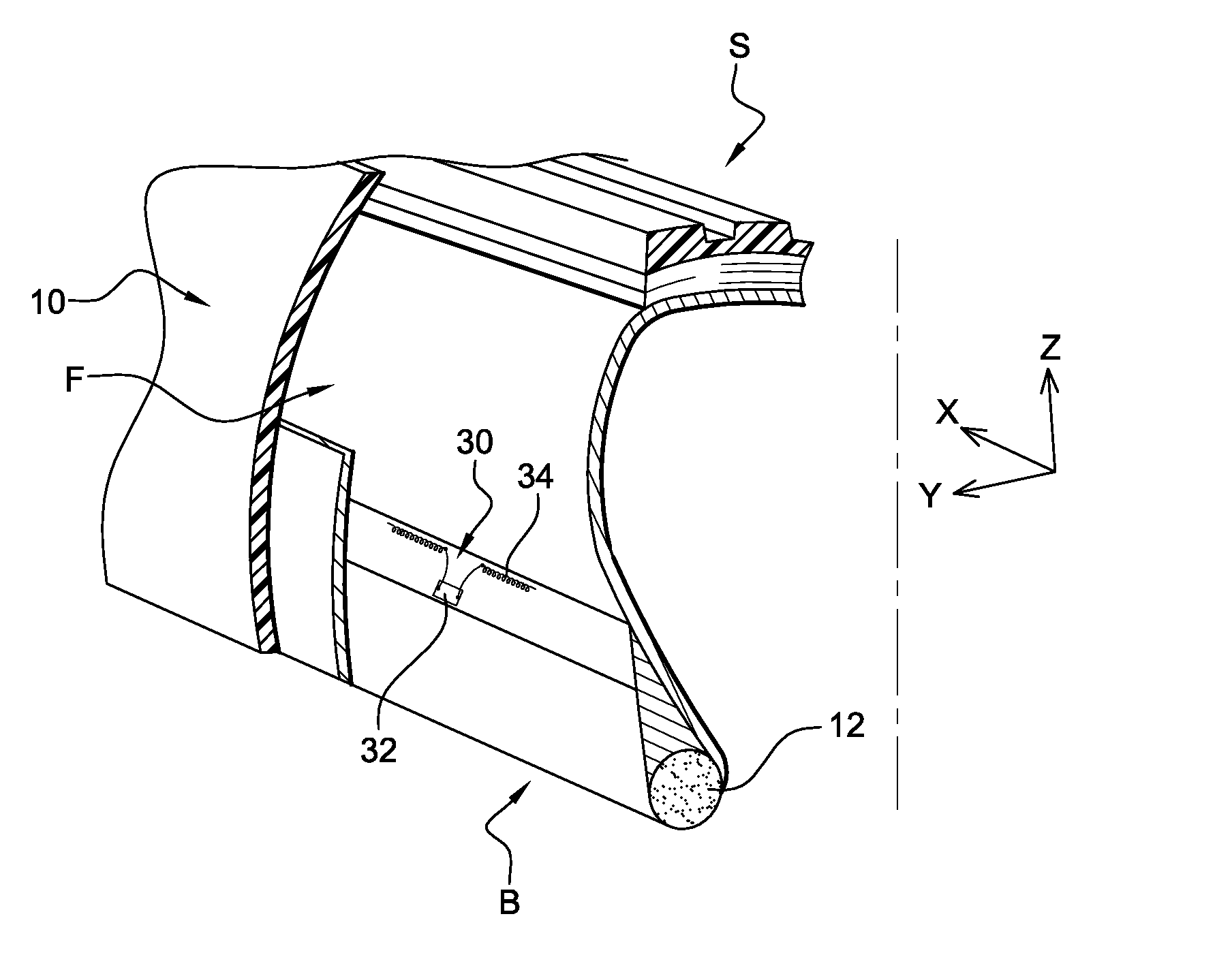

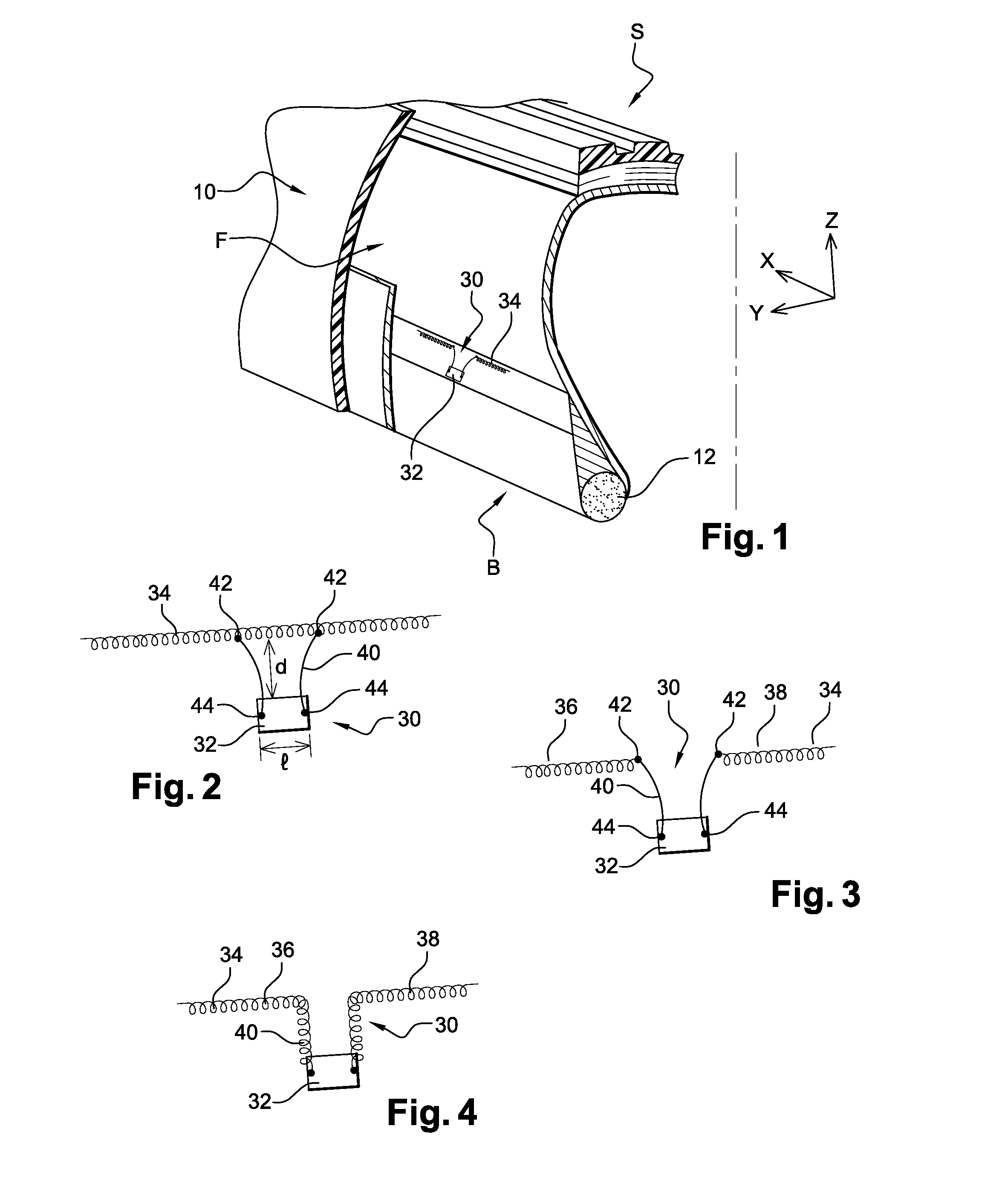

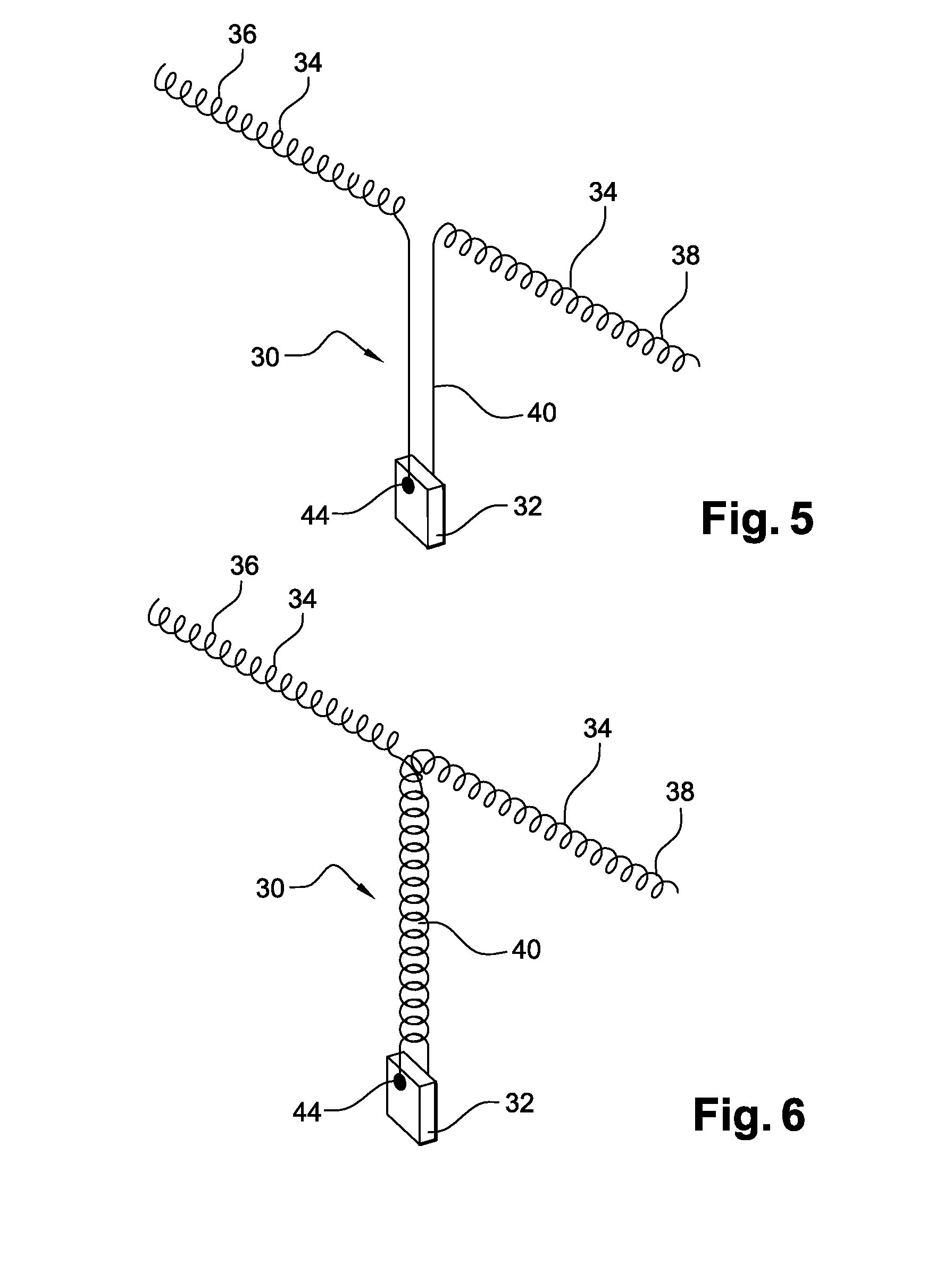

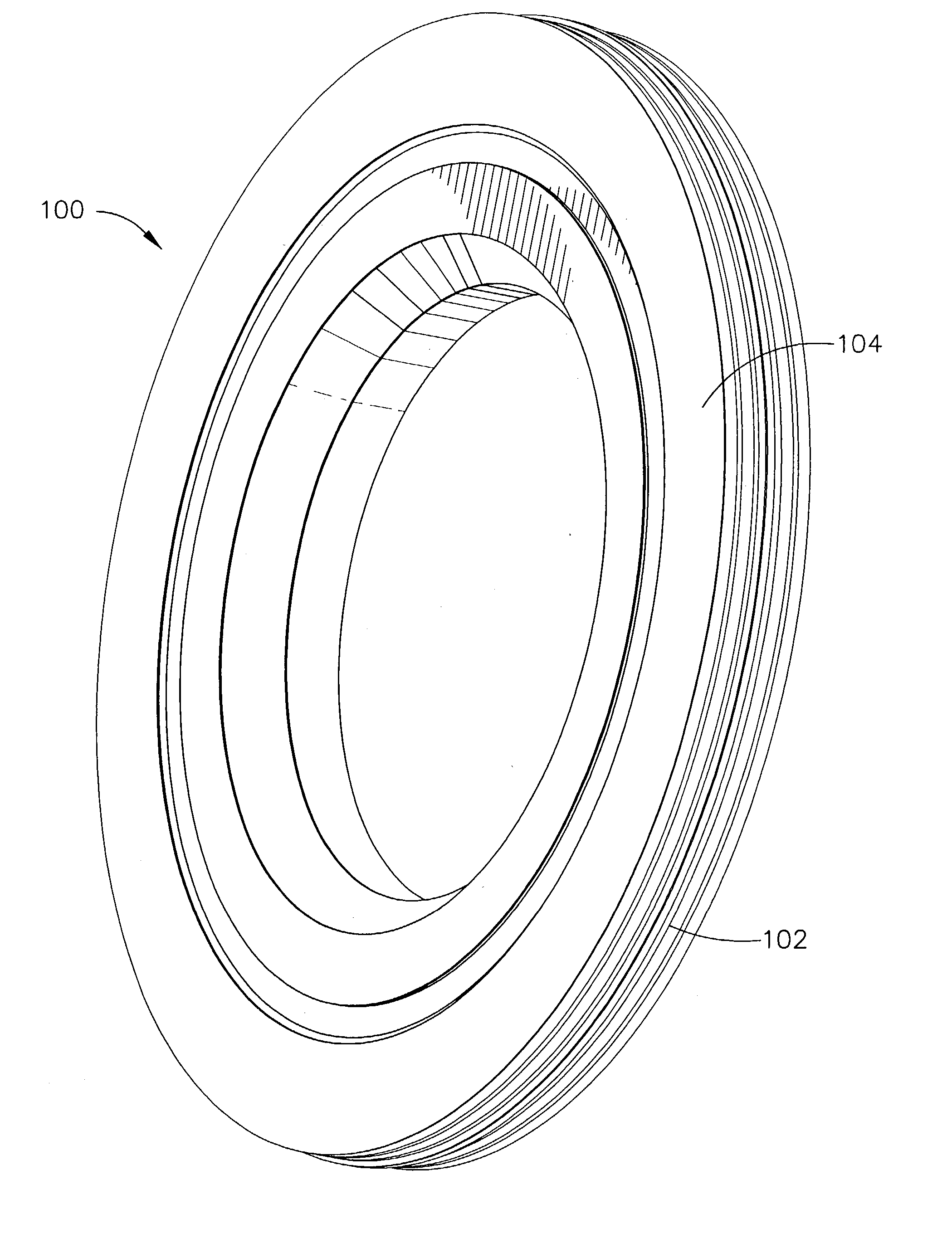

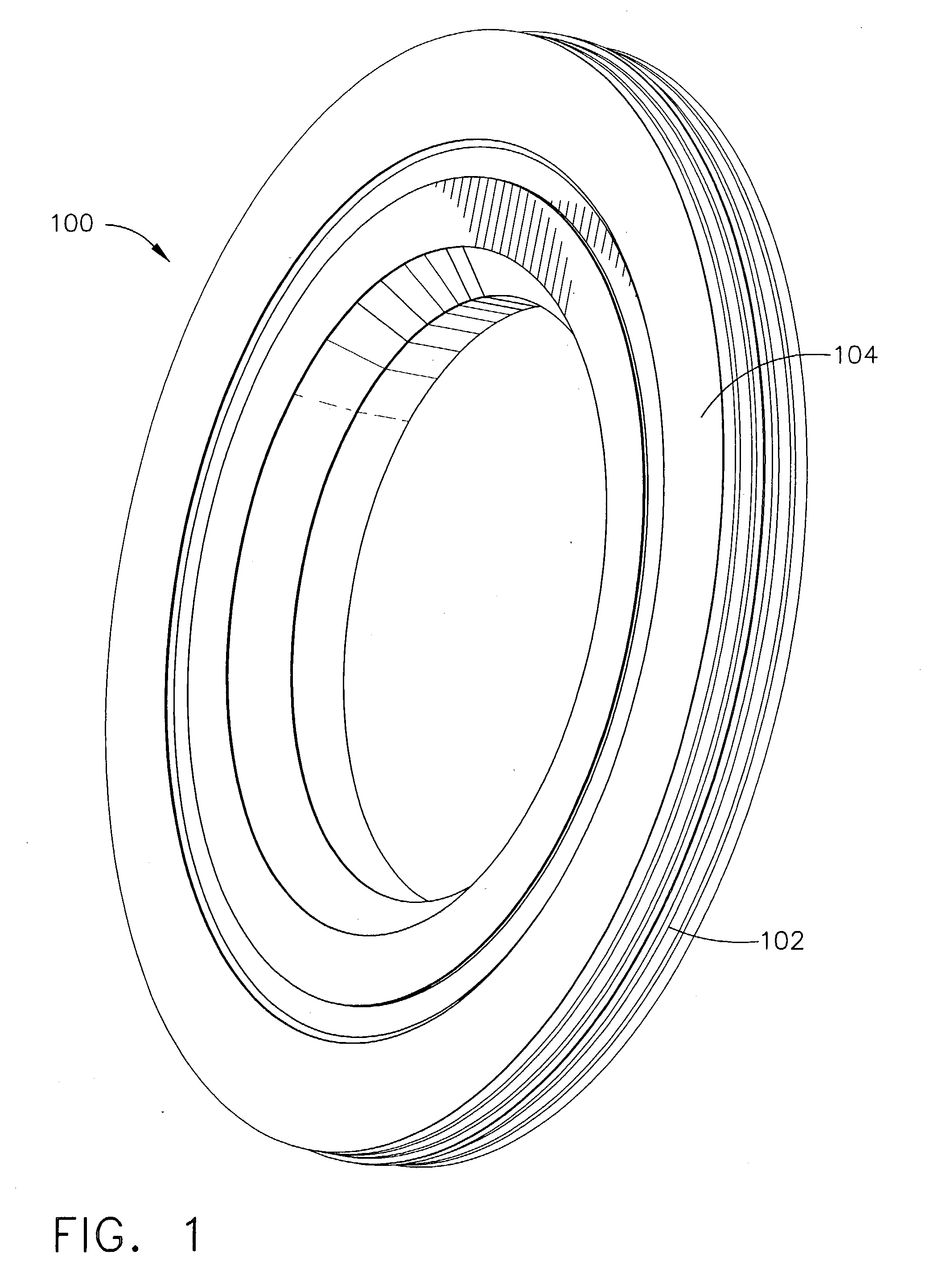

Tyre having a member with an offset antenna

ActiveUS20110175778A1Mitigate such drawbackWithstanding stressAntenna adaptation in movable bodiesTyresElectrical connectionWire antenna

A motor-vehicle tyre includes a sidewall and a member with an electronic device, a generally and substantially linear-shaped rectilinear wire antenna, and means of electrical connection between the wire antenna and the electronic device. The member is embedded in the sidewall in an arrangement such that the antenna is oriented circumferentially with respect to the tyre and the connection means is oriented in a radial direction of the tyre. The wire antenna is integrally offset radially on one side of the electronic device.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

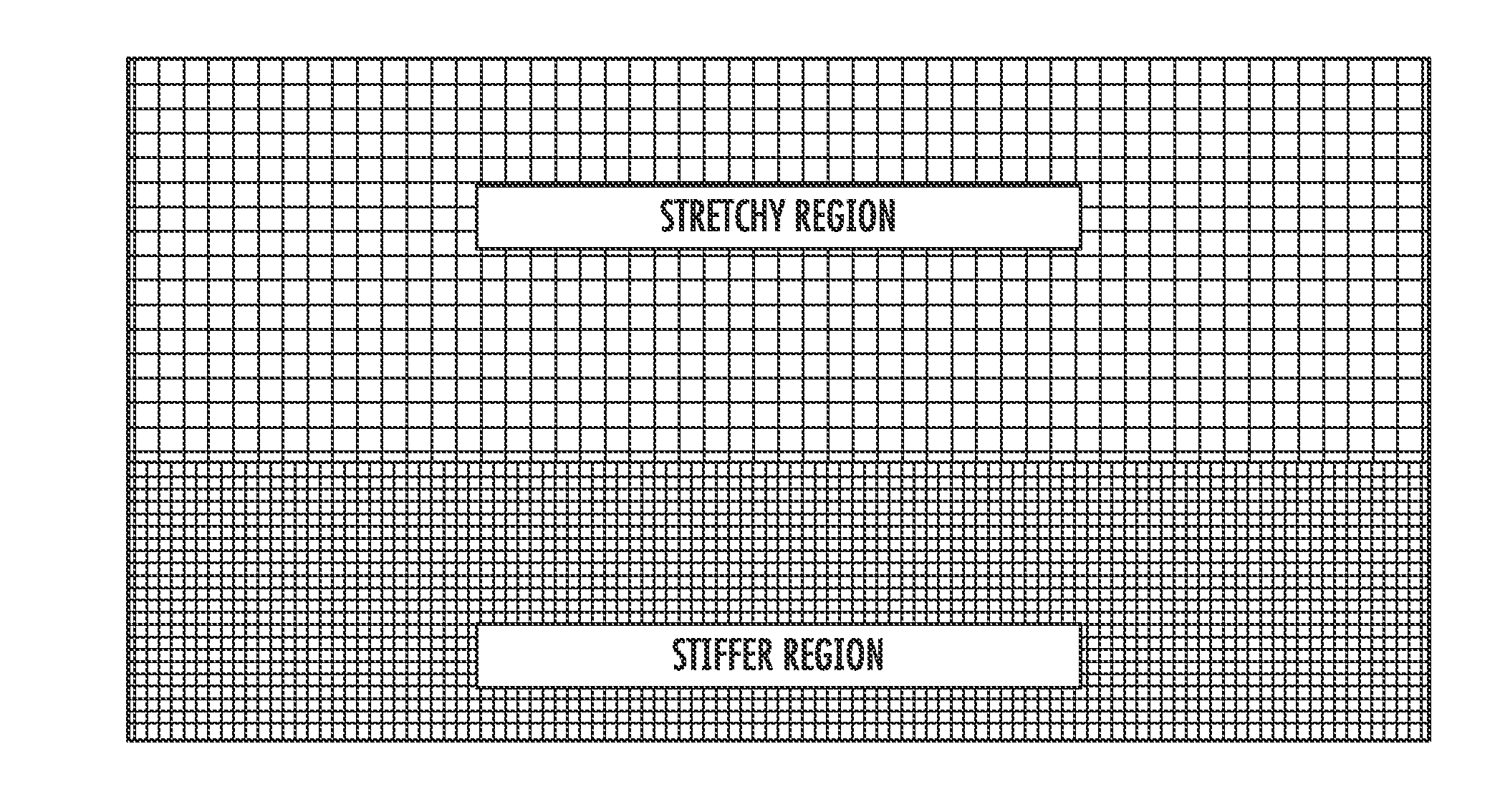

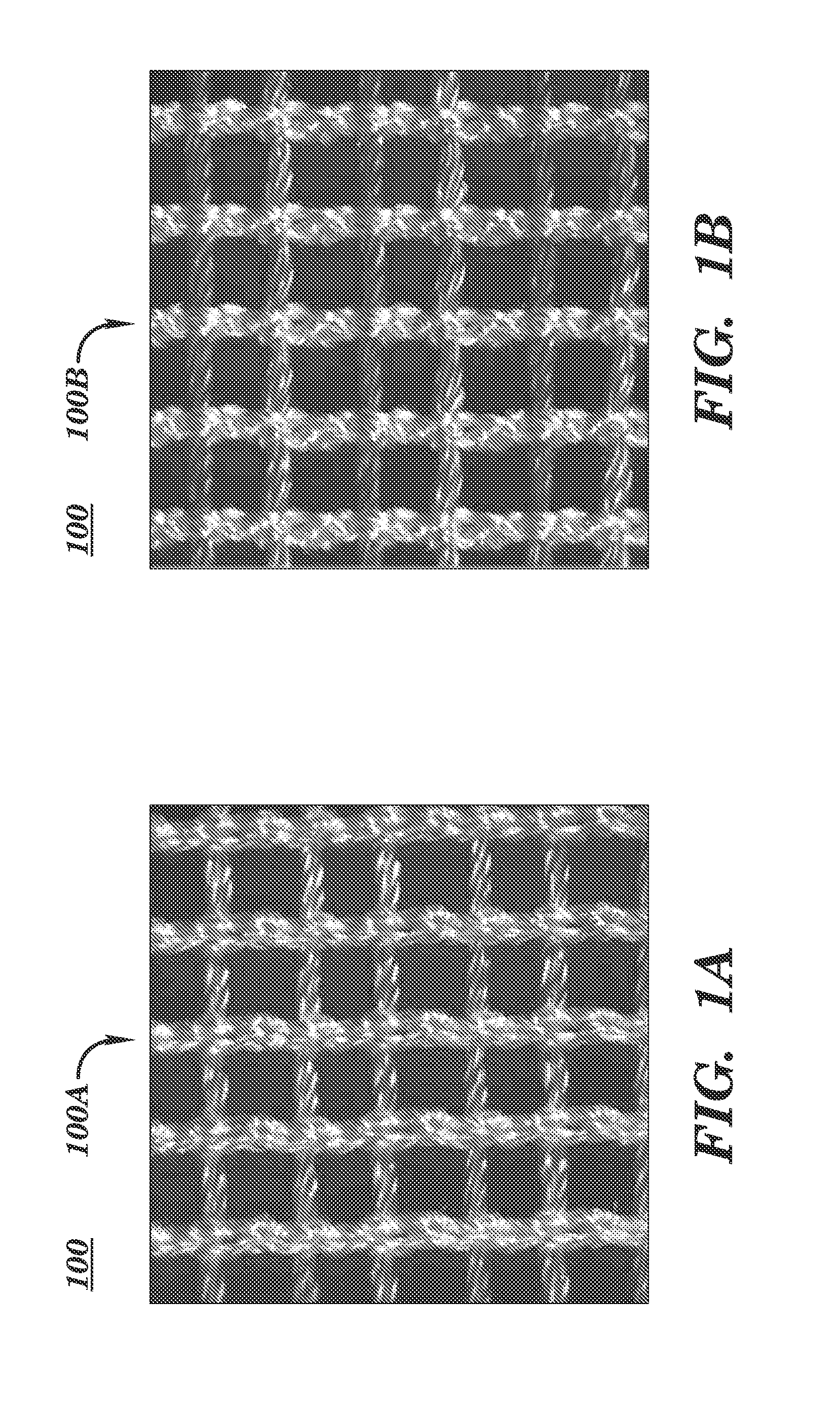

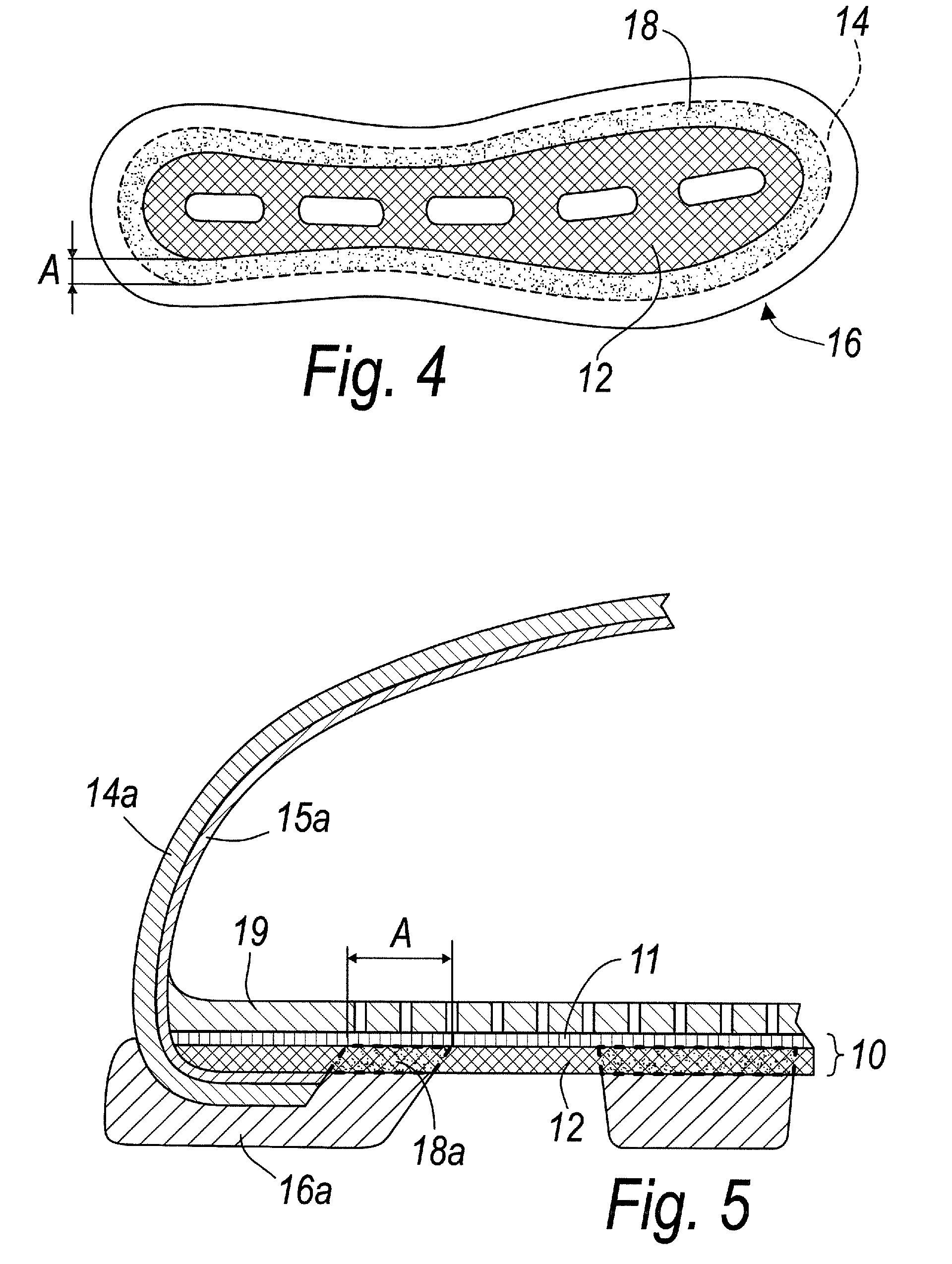

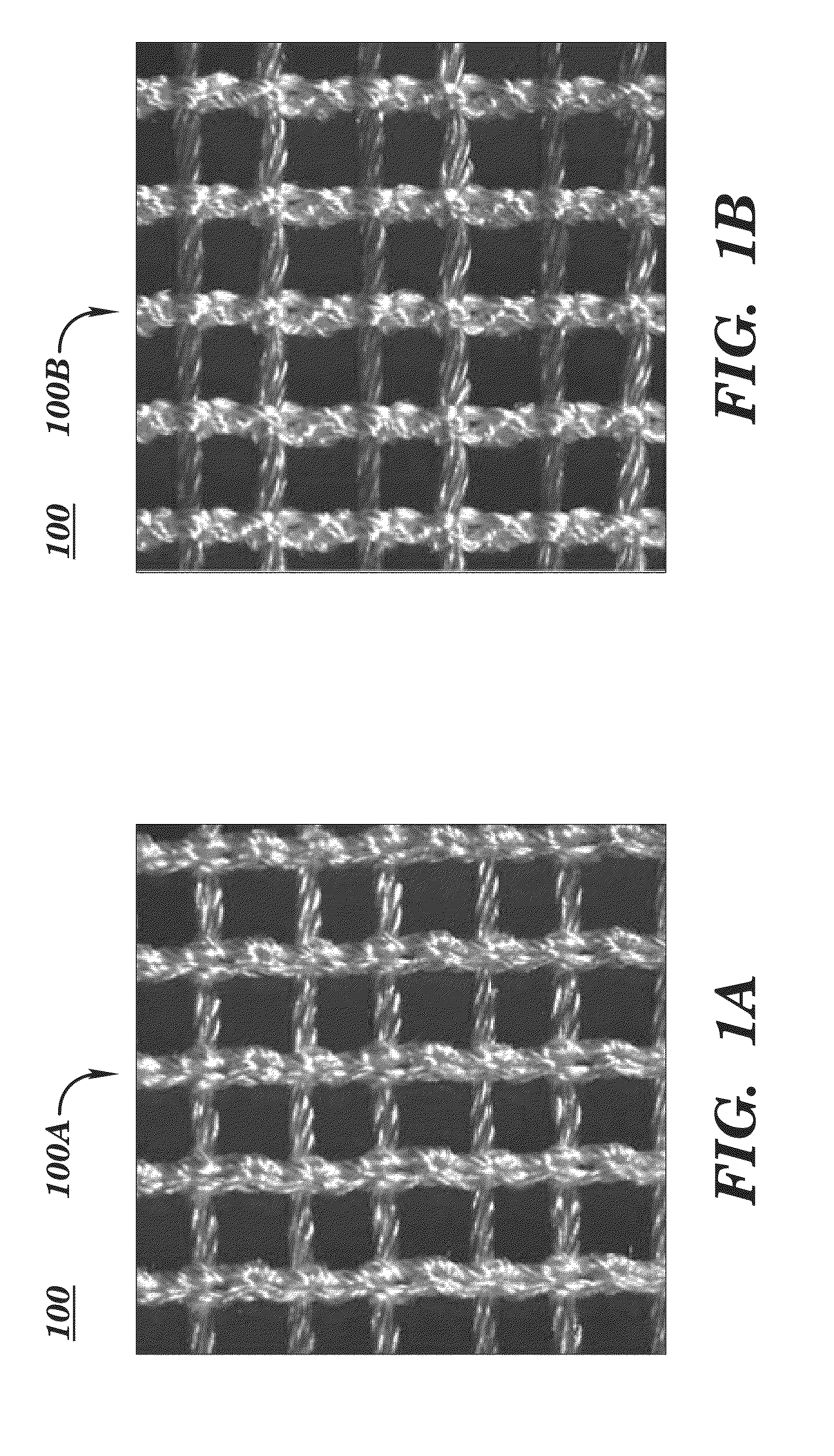

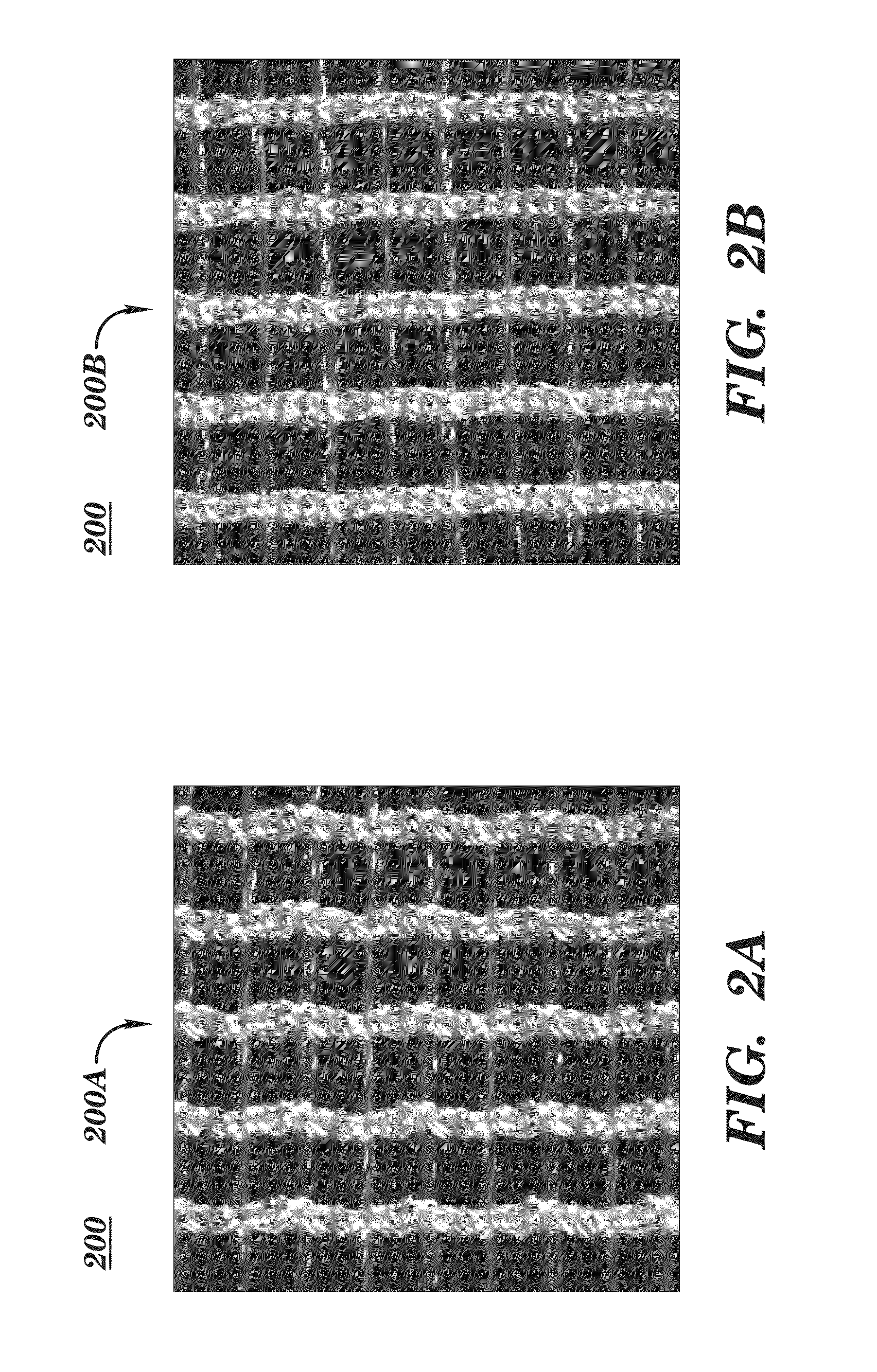

Prosthetic device having regions of varying stretch and method of manufacturing the same

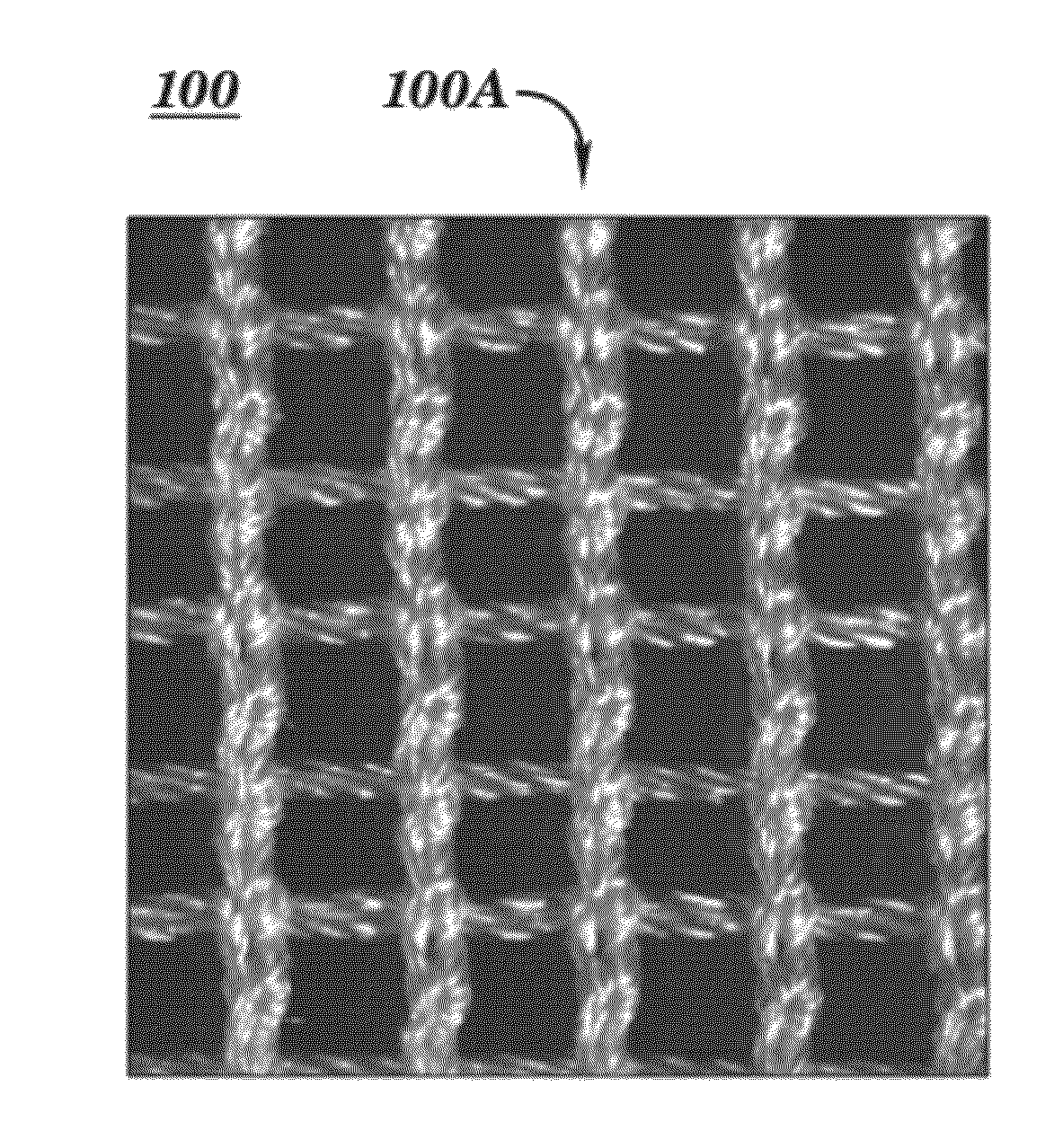

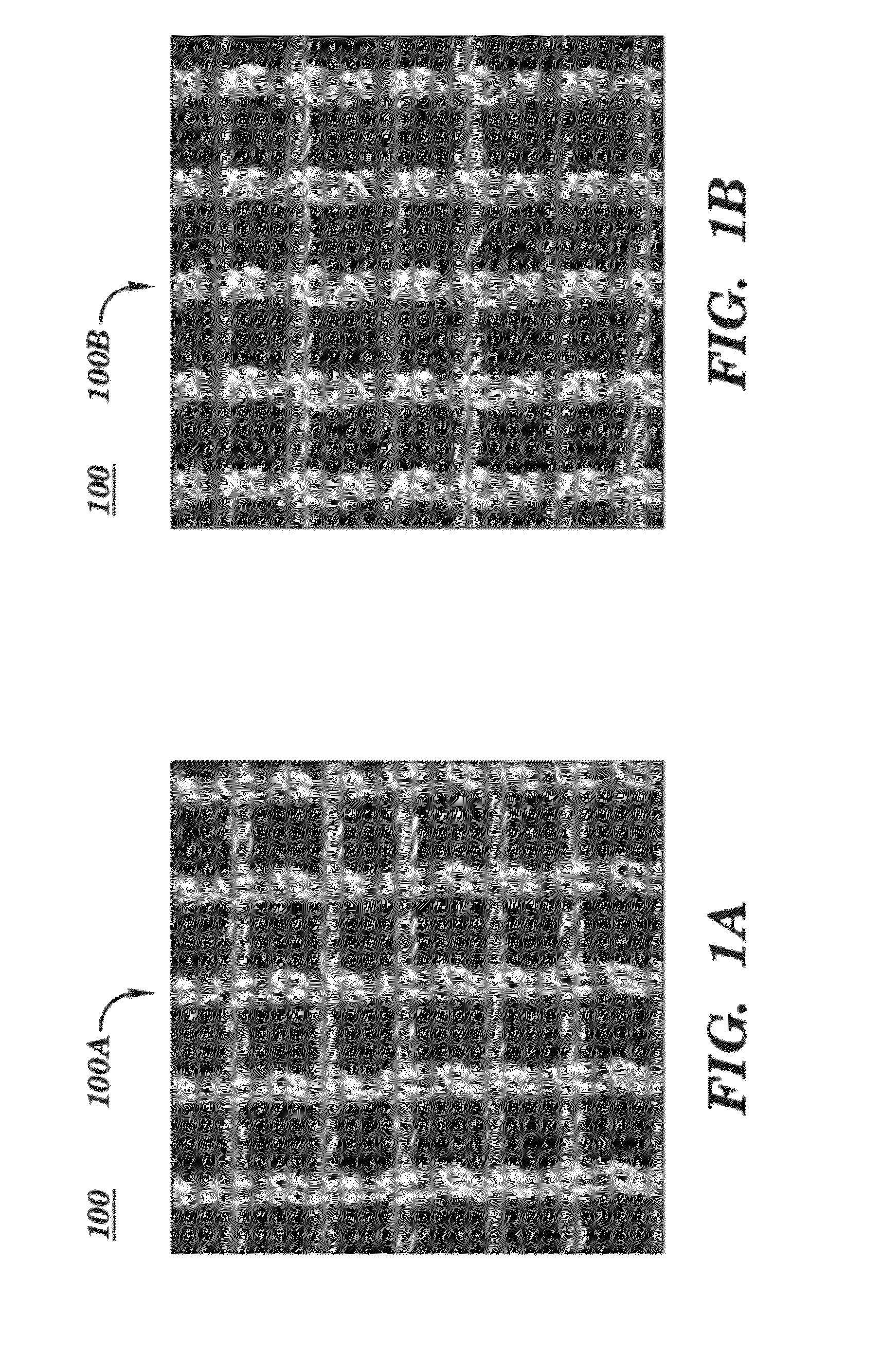

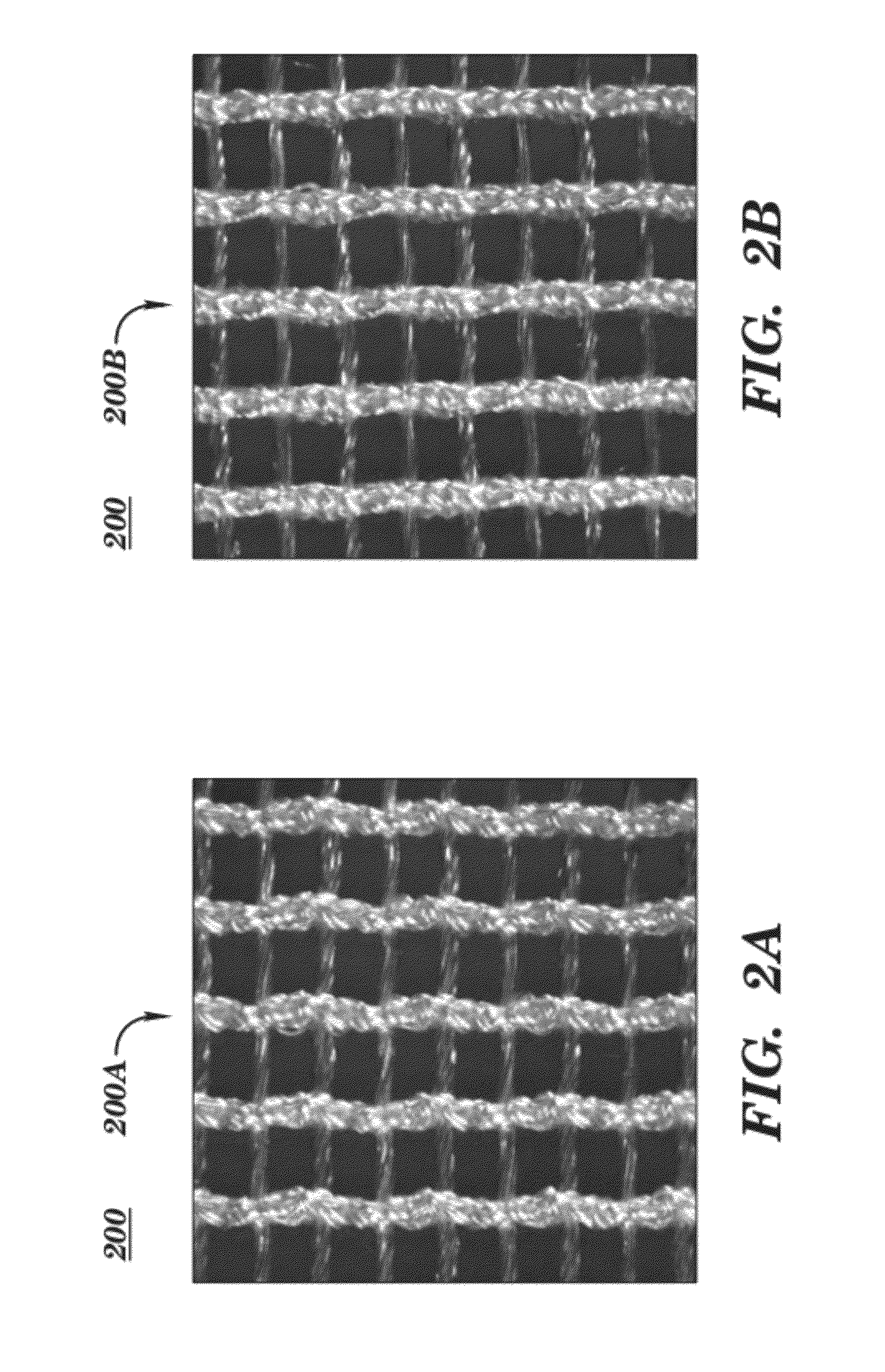

InactiveUS20110257761A1Minimizes adhesionsErosion minimizationMammary implantsWeft knittingYarnMechanical property

A biocompatible surgical scaffold made from a multi-filament silk yarn for soft tissue reconstruction. The scaffold incorporates regions of varying stretch having different physical and mechanical properties that allow contouring to the required soft tissue shape to be replaced or repaired. The porous structure allows tissue in-growth, while the mesh degrades at a rate which allows for a smooth transfer of mechanical properties to the new tissue from the silk scaffold.

Owner:ALLERGAN INC

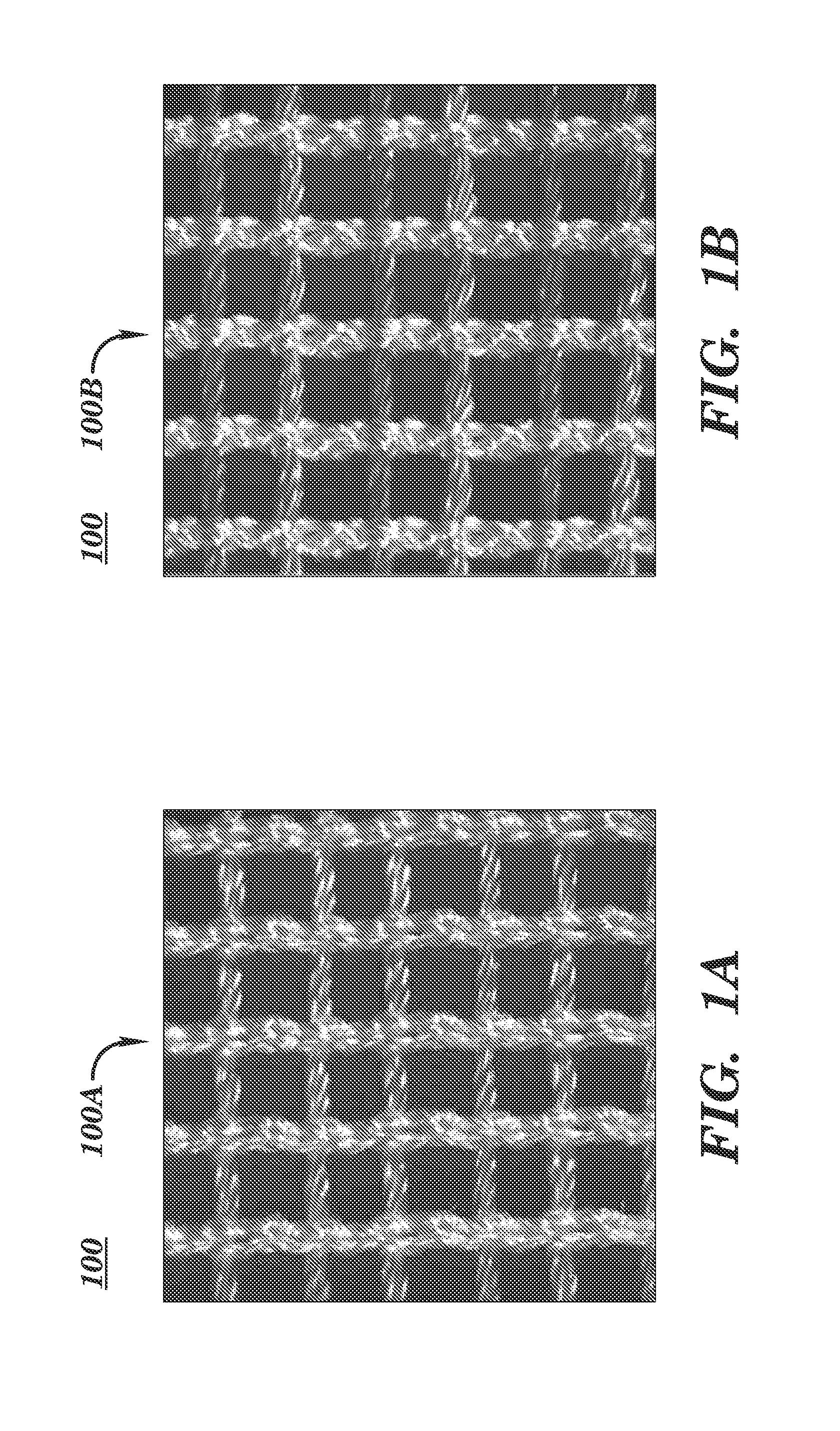

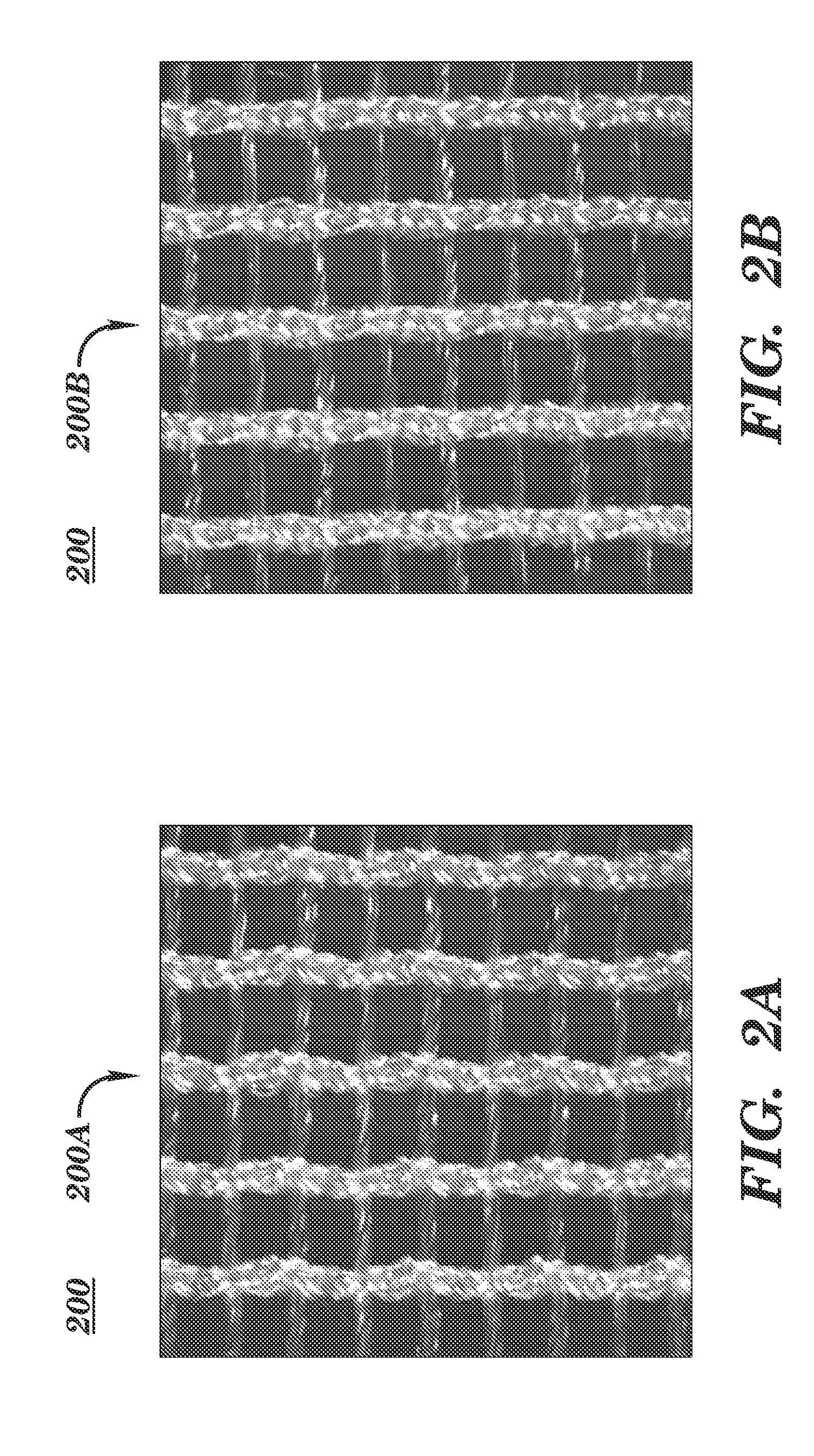

Implantable silk prosthetic device and uses thereof

InactiveUS20120150204A1Minimizes tissue erosionMinimizes fistulaMammary implantsWeft knittingYarnProsthesis

A method of using a biocompatible surgical silk mesh prosthetic device in body aesthetics and body contouring, the surgical mesh employing a knit pattern that substantially prevents unraveling and preserves the stability of the mesh device, especially when the mesh device is cut. An example prosthetic device employs a knitted mesh including at least two yarns laid in a knit direction and engaging each other to define a plurality of nodes. The at least two yarns include a first yarn and a second yarn extending between and forming loops about two nodes. The second yarn has a higher tension at the two nodes than the first yarn. the second yarn substantially prevents the first yarn from moving at the two nodes and substantially prevents the knitted mesh from unraveling at the nodes.

Owner:ALLERGAN INC

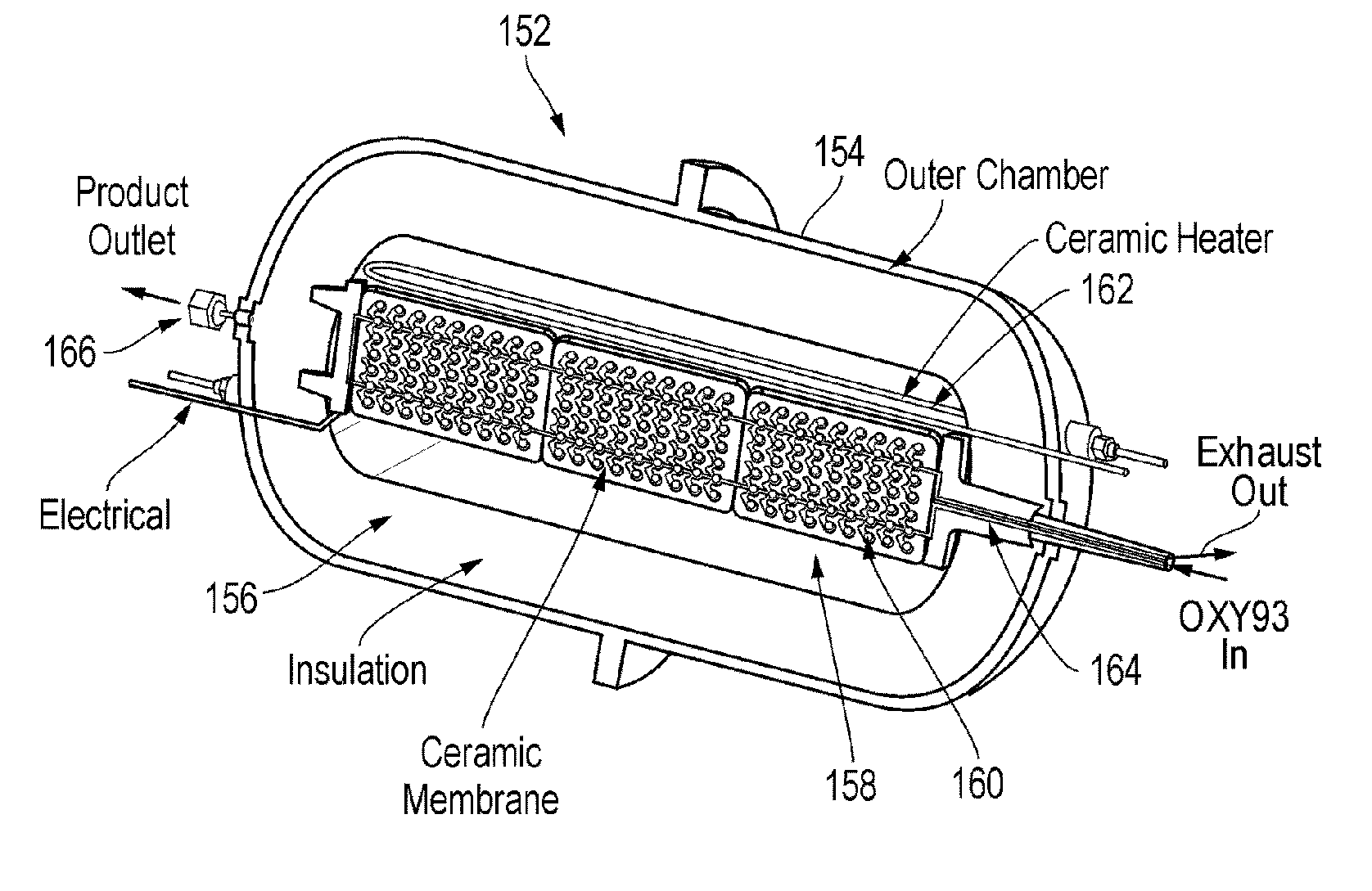

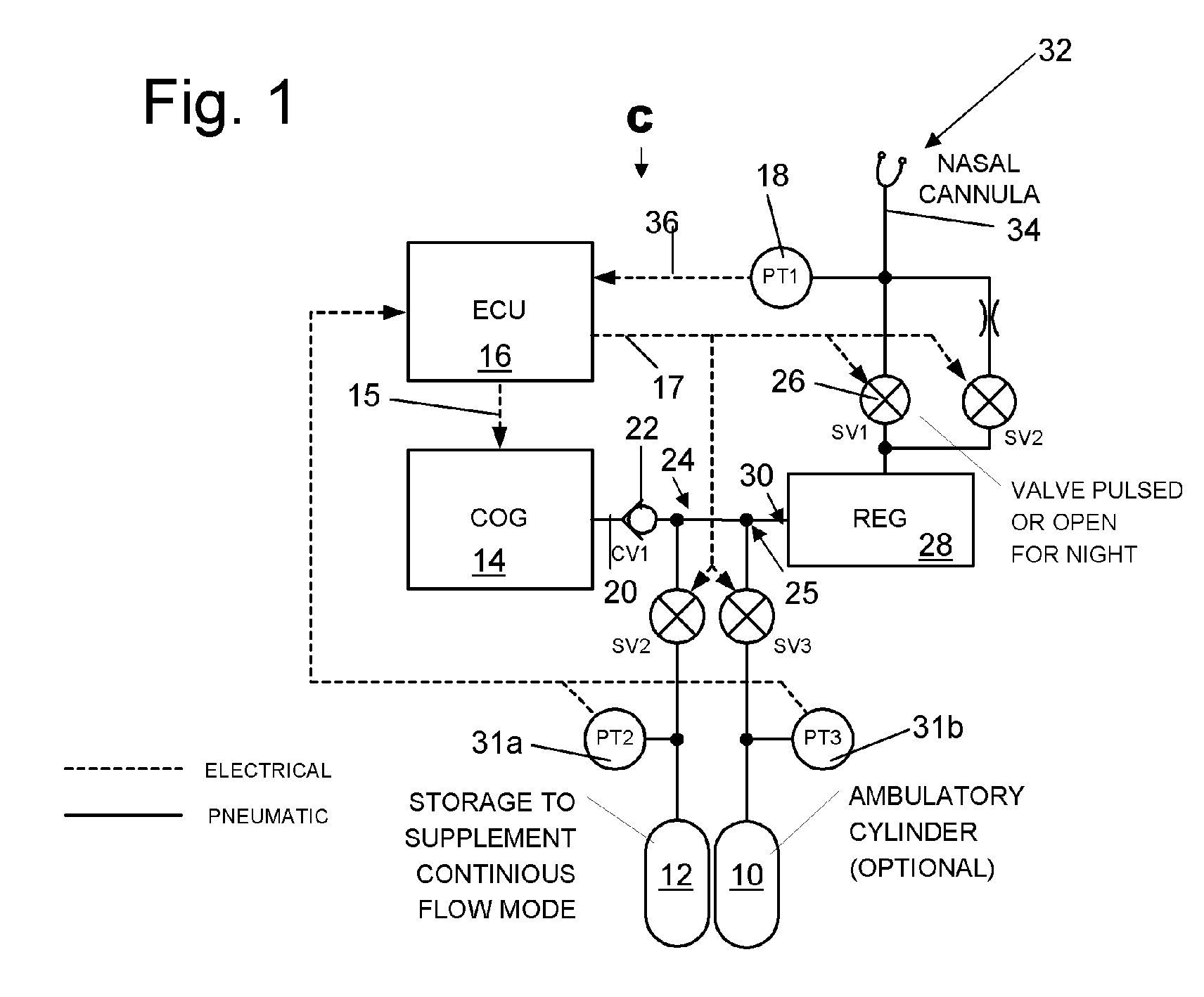

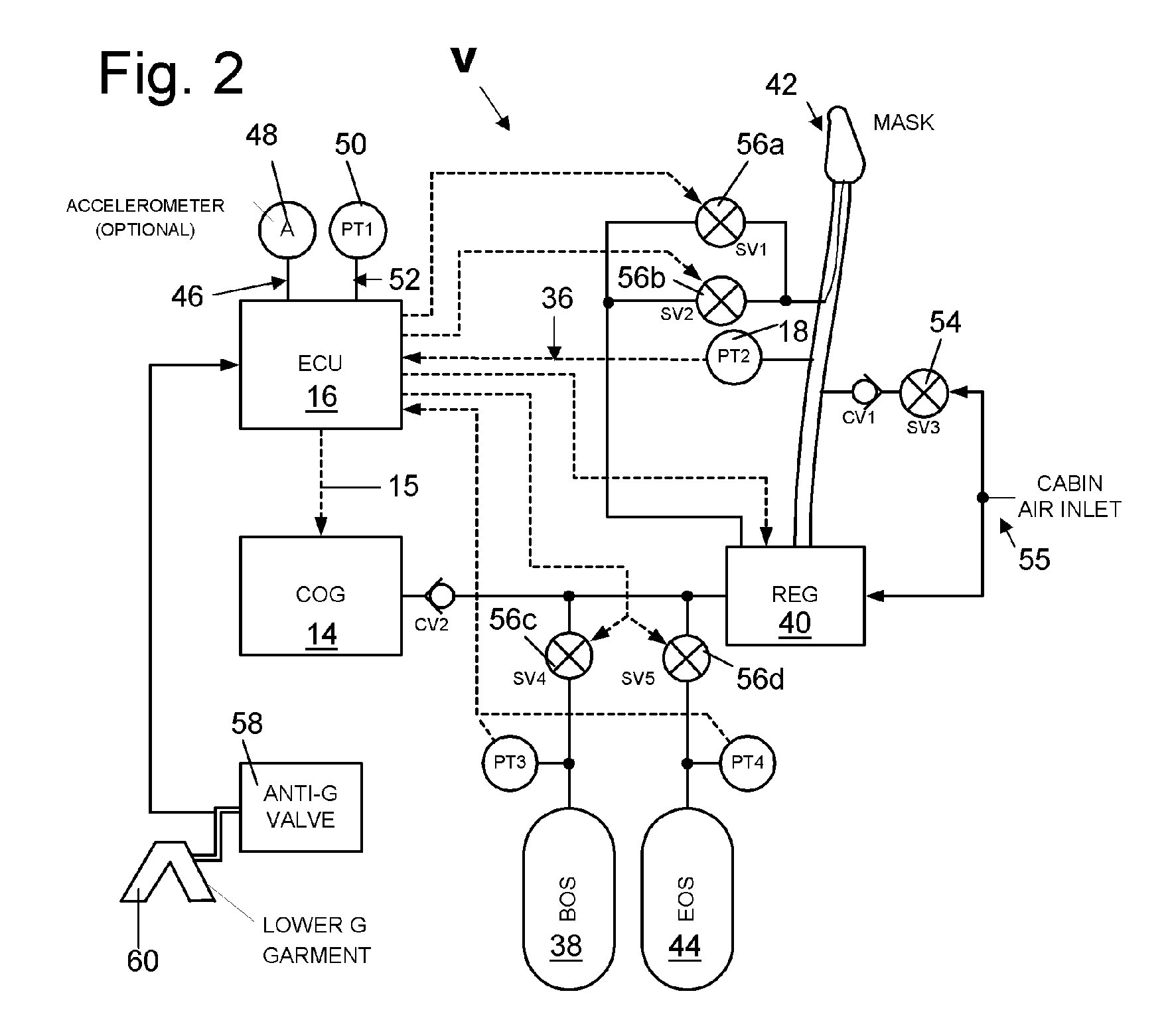

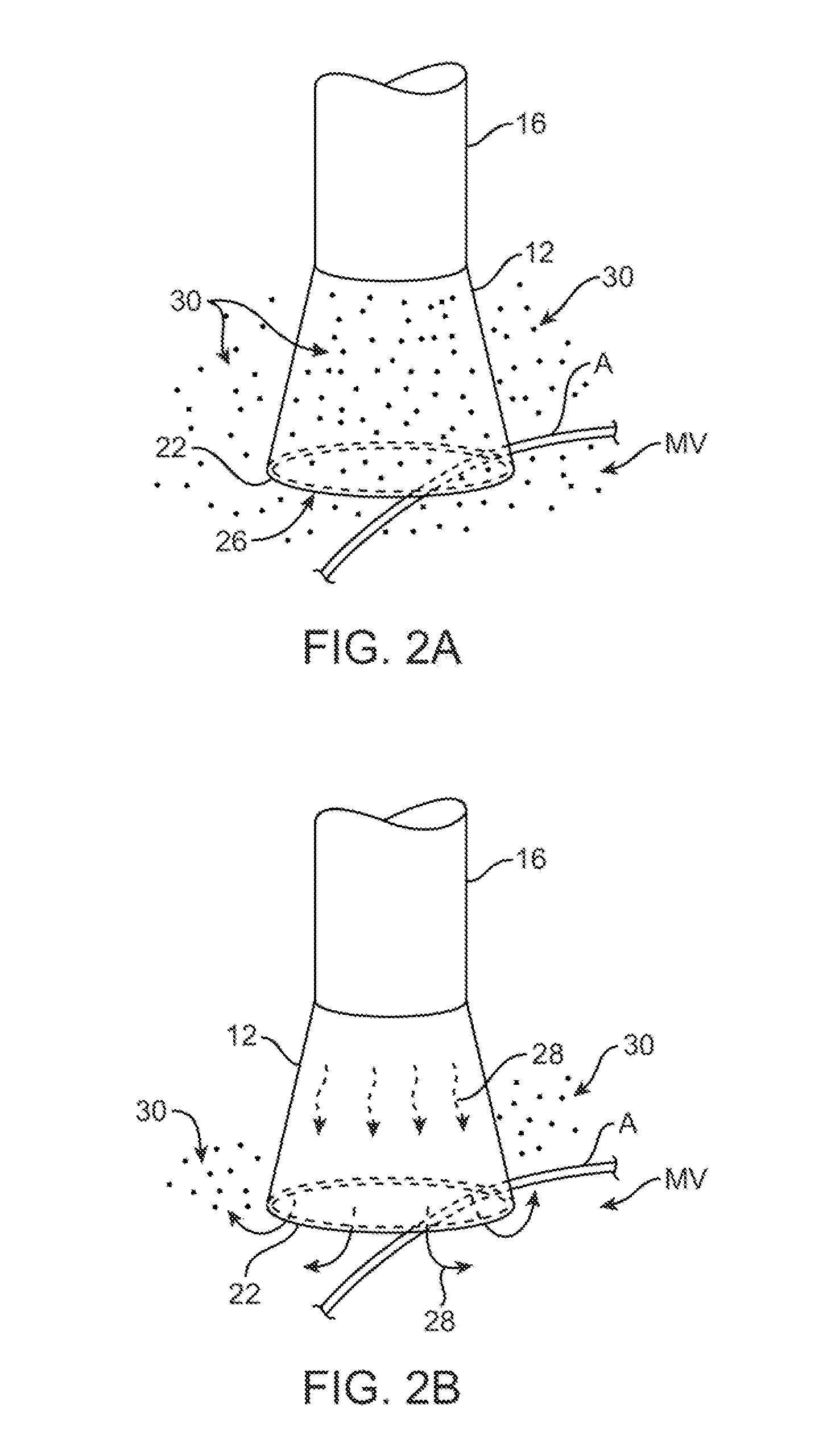

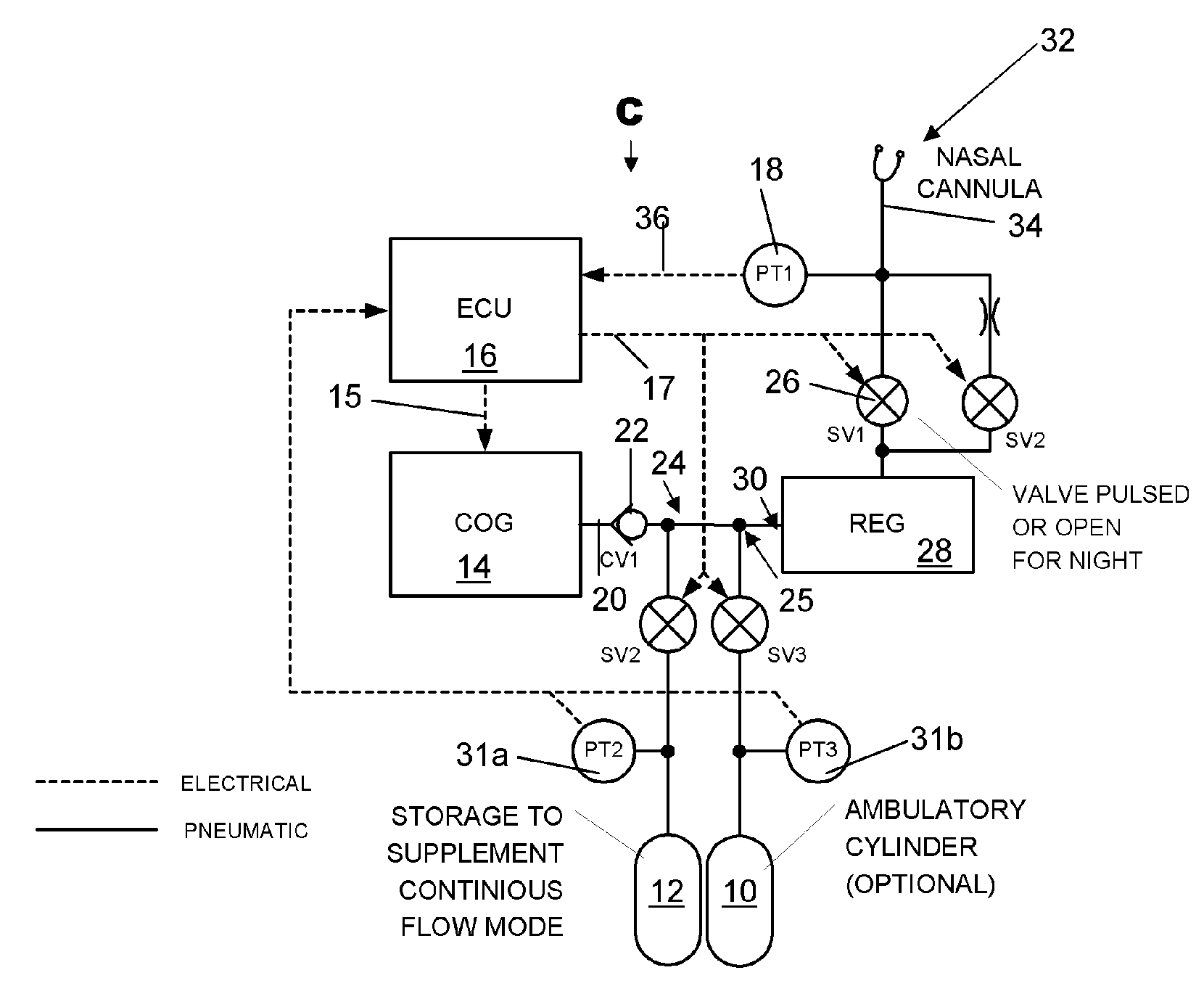

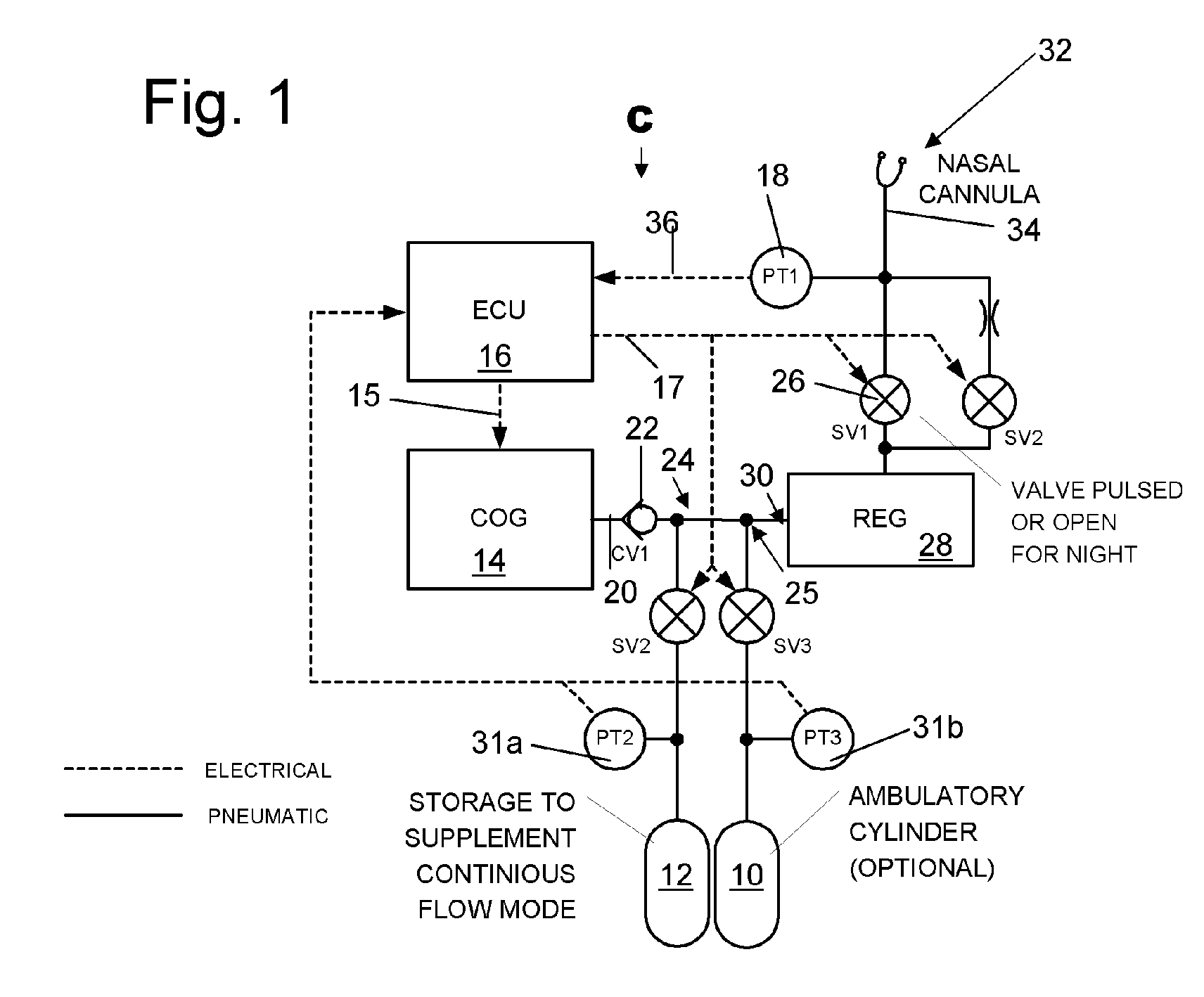

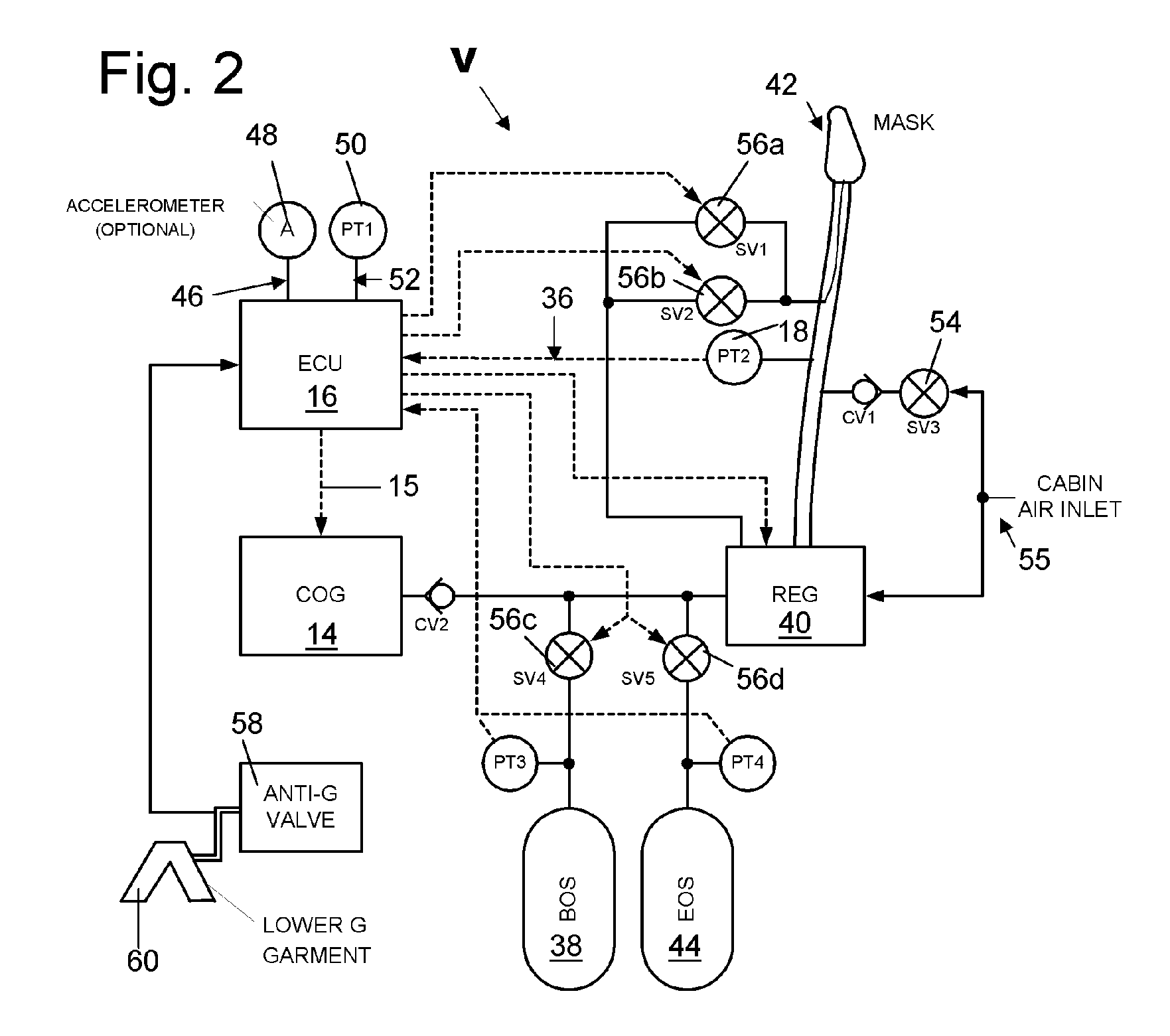

Oxygen generator with storage and conservation modes

ActiveUS20060062707A1Reduce decreaseIncrease productionCombination devicesAuxillary pretreatmentElectronic controllerEngineering

An electronic controller (16) controls the operation of an electrochemical oxygen generating system (14) producing a desired gas. The product gas is fed to a storage unit (12) or a regulator (28) and pulsing valve (28) controlling the gas flow to a user. A two-stage system (180) combines a low pressure 100 and a high pressure (150) gas generating subsystems. The low pressure subsystem (100) uses IMAT's (106) to pump oxygen from ambient air to generate a low-pressure. The high pressure subsystem (150) uses IMAT's (160) to pump oxygen to high-pressure oxygen storage devices (194).

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

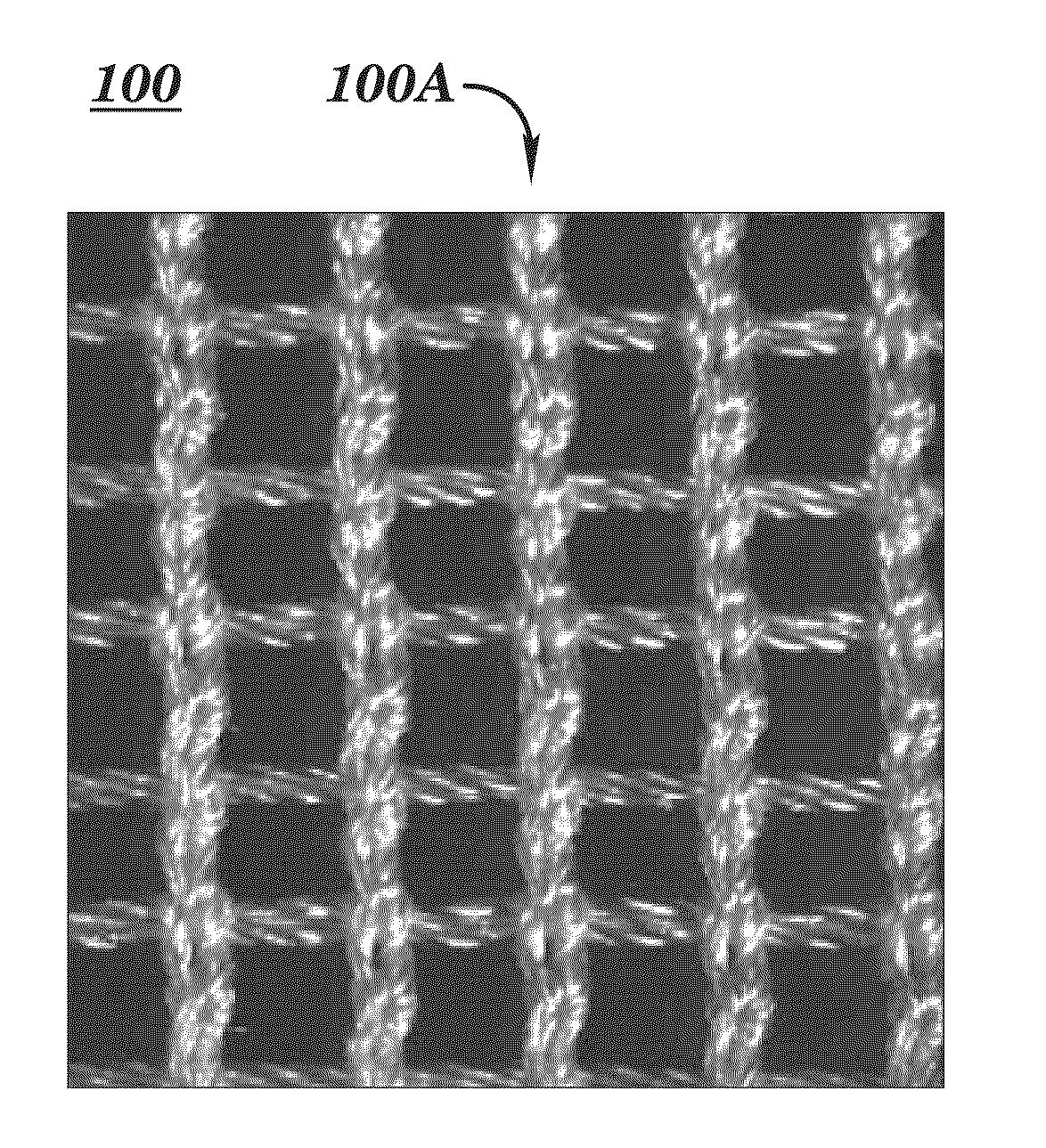

Prosthetic device and method of manufacturing the same

ActiveUS20110257665A1Minimizes tissue erosion and fistula and adhesionWithstanding stressMammary implantsWeft knittingMesh gridYarn

A biocompatible surgical silk mesh prosthetic device employs a knit pattern that substantially prevents unraveling and preserves the stability of the mesh device, especially when the mesh device is cut. An example prosthetic device employs a knitted mesh including at least two yarns laid in a knit direction and engaging each other to define a plurality of nodes. The at least two yarns include a first yarn and a second yarn extending between and forming loops about two nodes. The second yarn has a higher tension at the two nodes than the first yarn. the second yarn substantially prevents the first yarn from moving at the two nodes and substantially prevents the knitted mesh from unraveling at the nodes.

Owner:ALLERGAN INC

Prosthetic device having diagonal yarns and method of manufacturing the same

InactiveUS20110224703A1Minimize erosionMinimizes adhesionsMammary implantsMedical devicesYarnEngineering

A knitted scaffold comprising at least two silk yarns in a knit direction and a yarn member diagonal to the knit direction to thereby provide a knitted fabric or mesh for surgical use that can retain its shape and / or resist collapse when opposing forces are applied at an angle from the knit direction. The knitted scaffold may include at least two yarns laid in a knit direction and engaging each other to define a plurality of nodes. The at least two yarns can include a first yarn and a second yarn extending between and forming loops about two nodes. The second yarn has a higher tension at the two nodes than the first yarn. The second yarn substantially prevents the first yarn from moving at the two nodes and substantially prevents the knitted mesh from unraveling at the nodes.

Owner:ALLERGAN INC

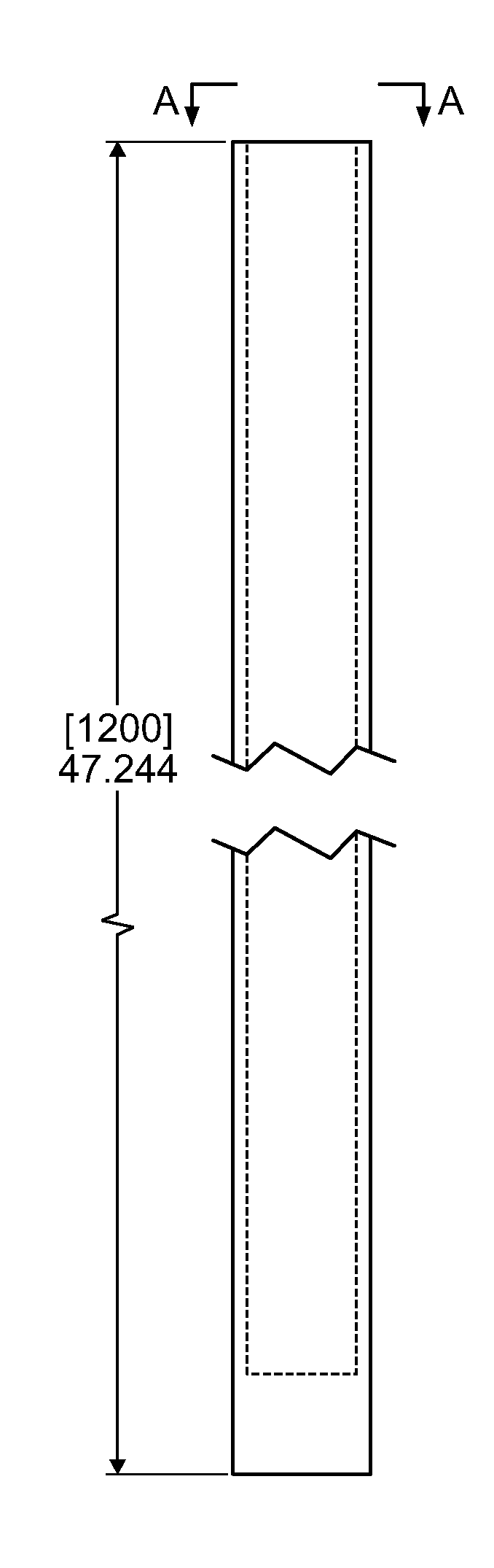

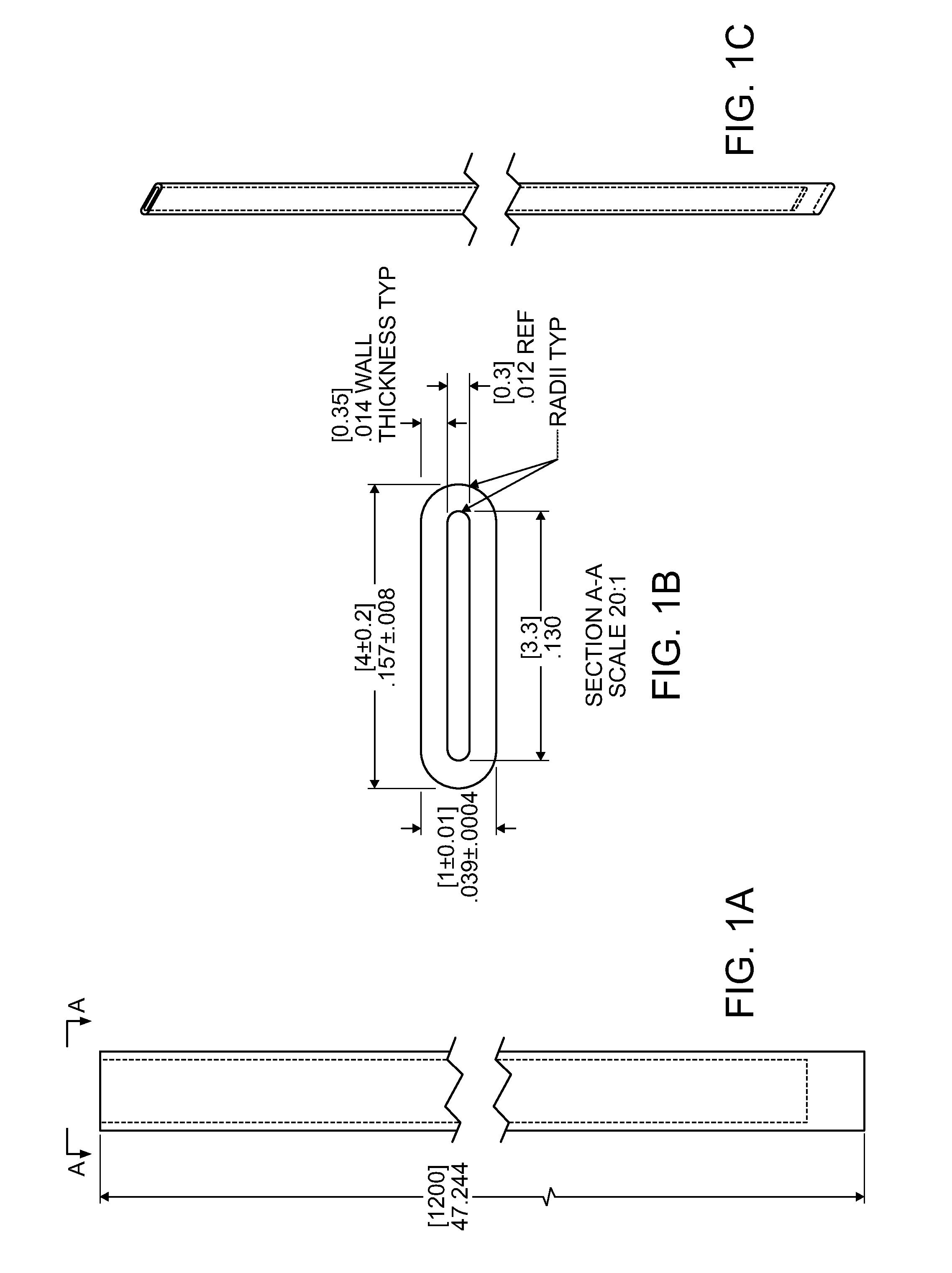

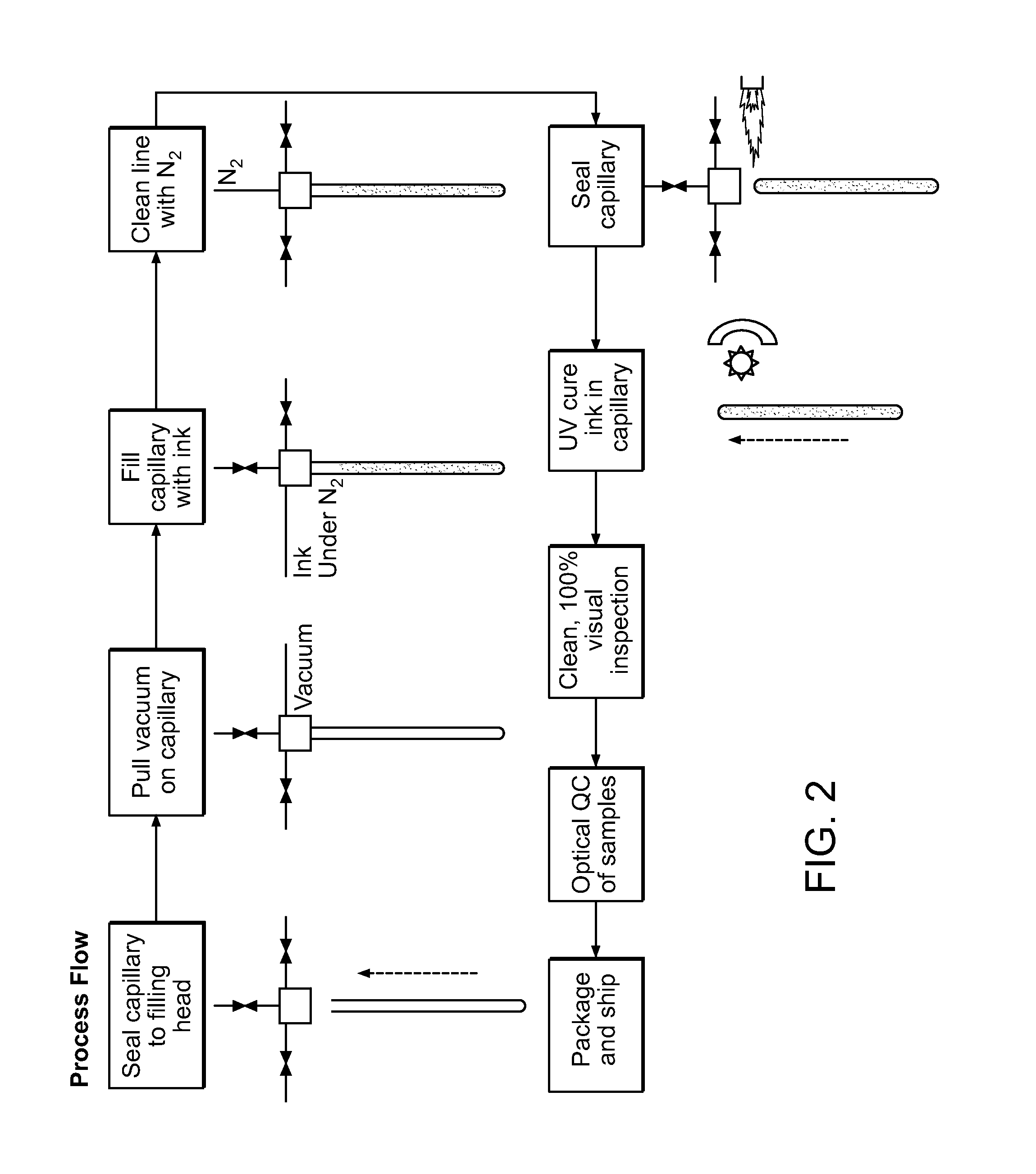

Stress-resistant component for use with quantum dots

ActiveUS20130148376A1Reduced optical performanceAvoid yellowingAircraft componentsLayered productsQuantum dotMaterials science

A glass tube including quantum dots in a polymerized matrix is described. An optical component and other products including such glass tube, a composition including quantum dots, and methods are also disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

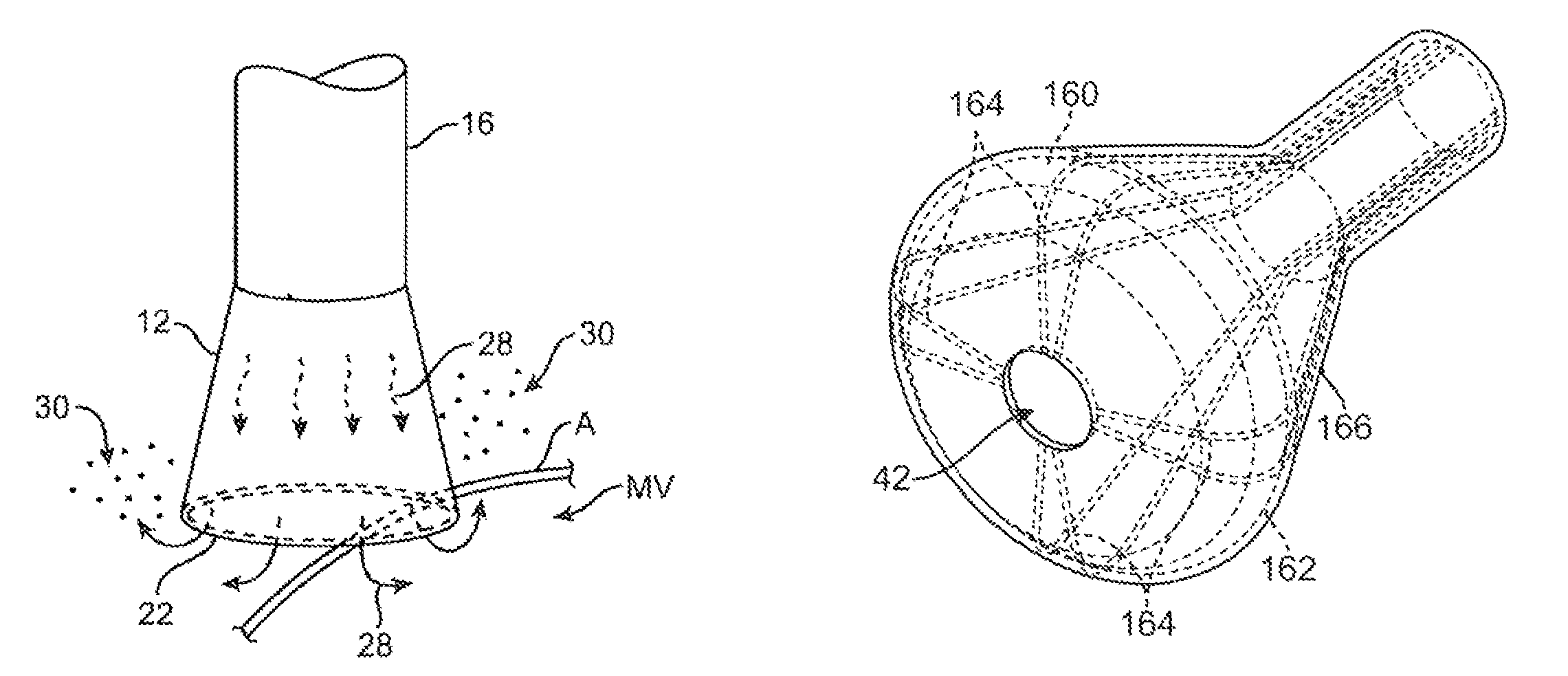

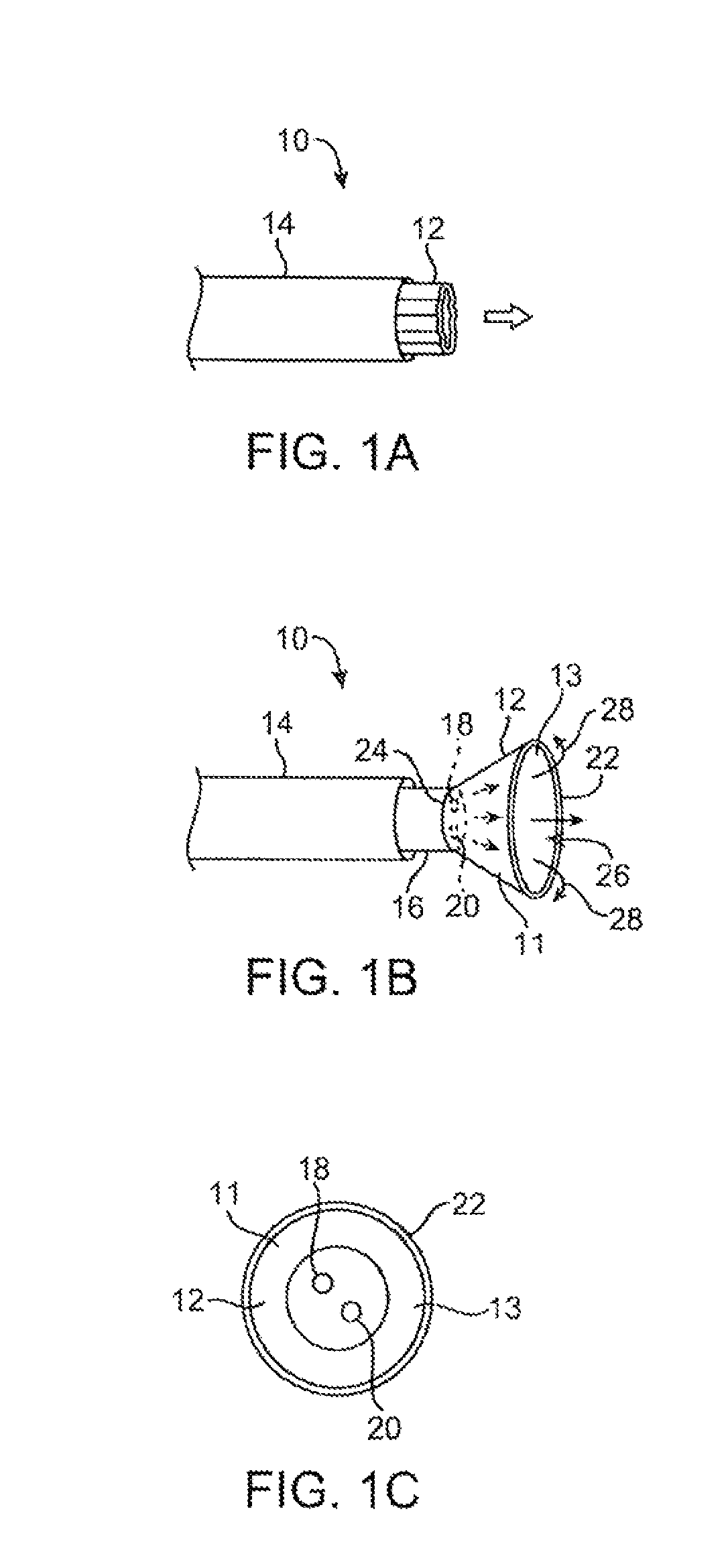

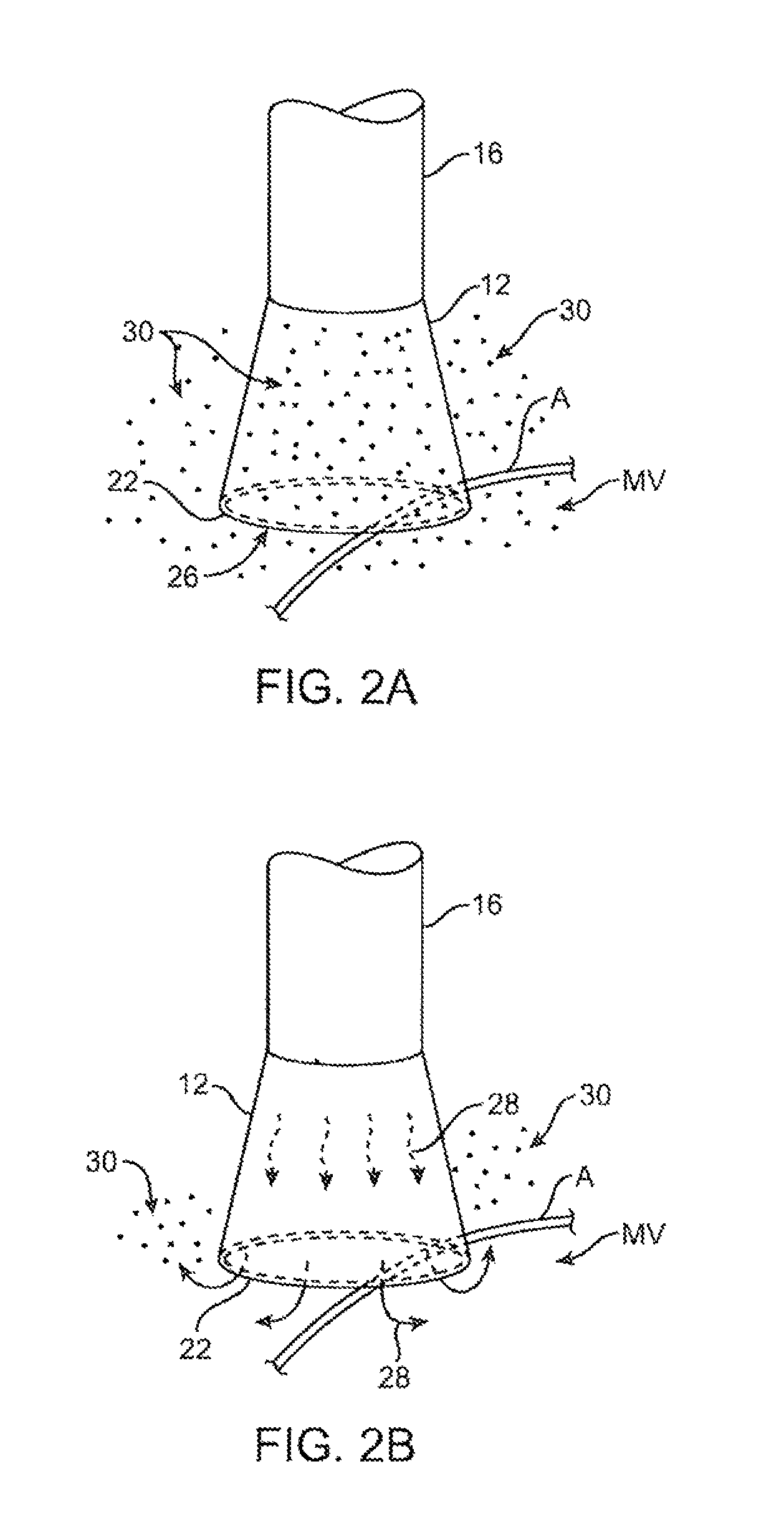

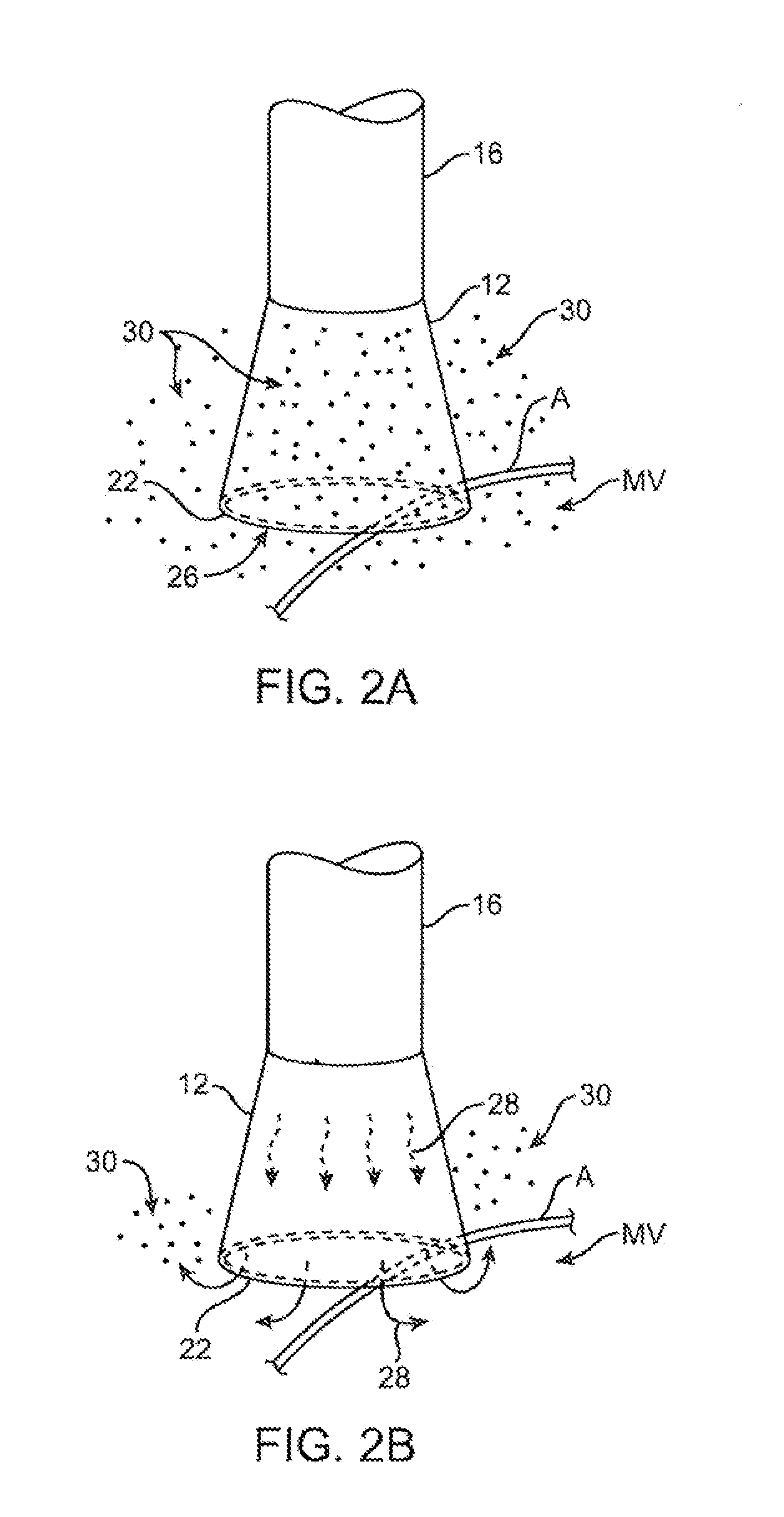

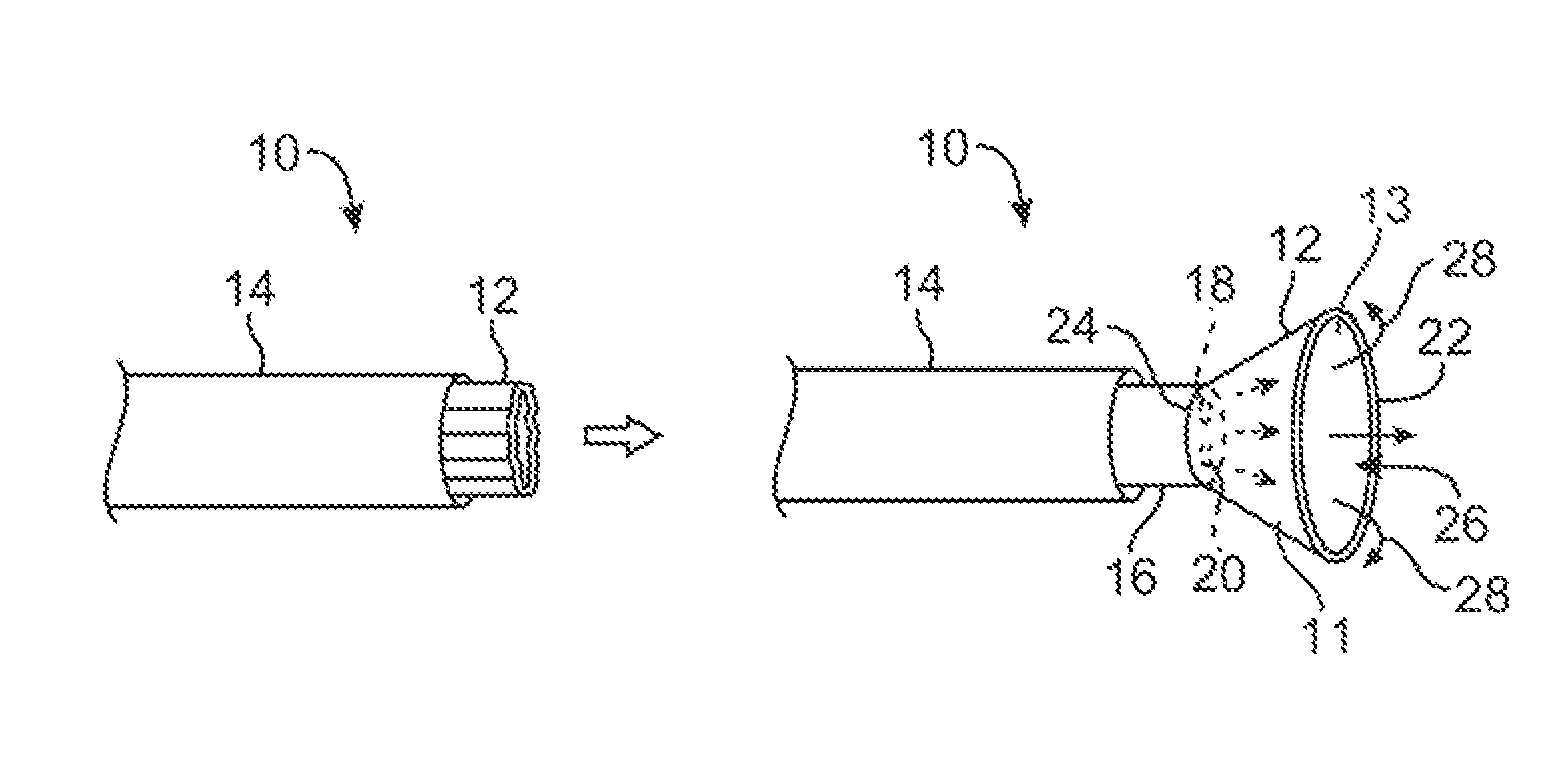

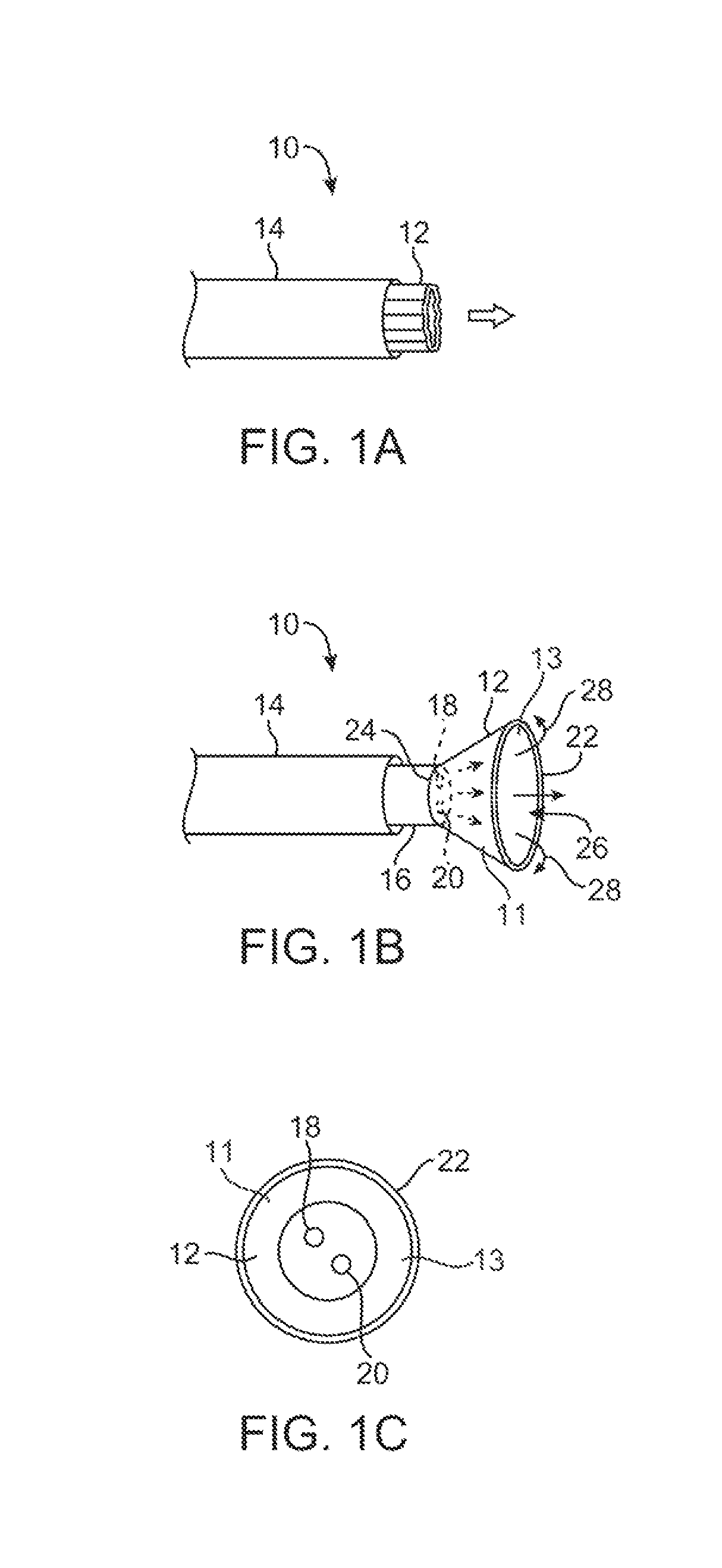

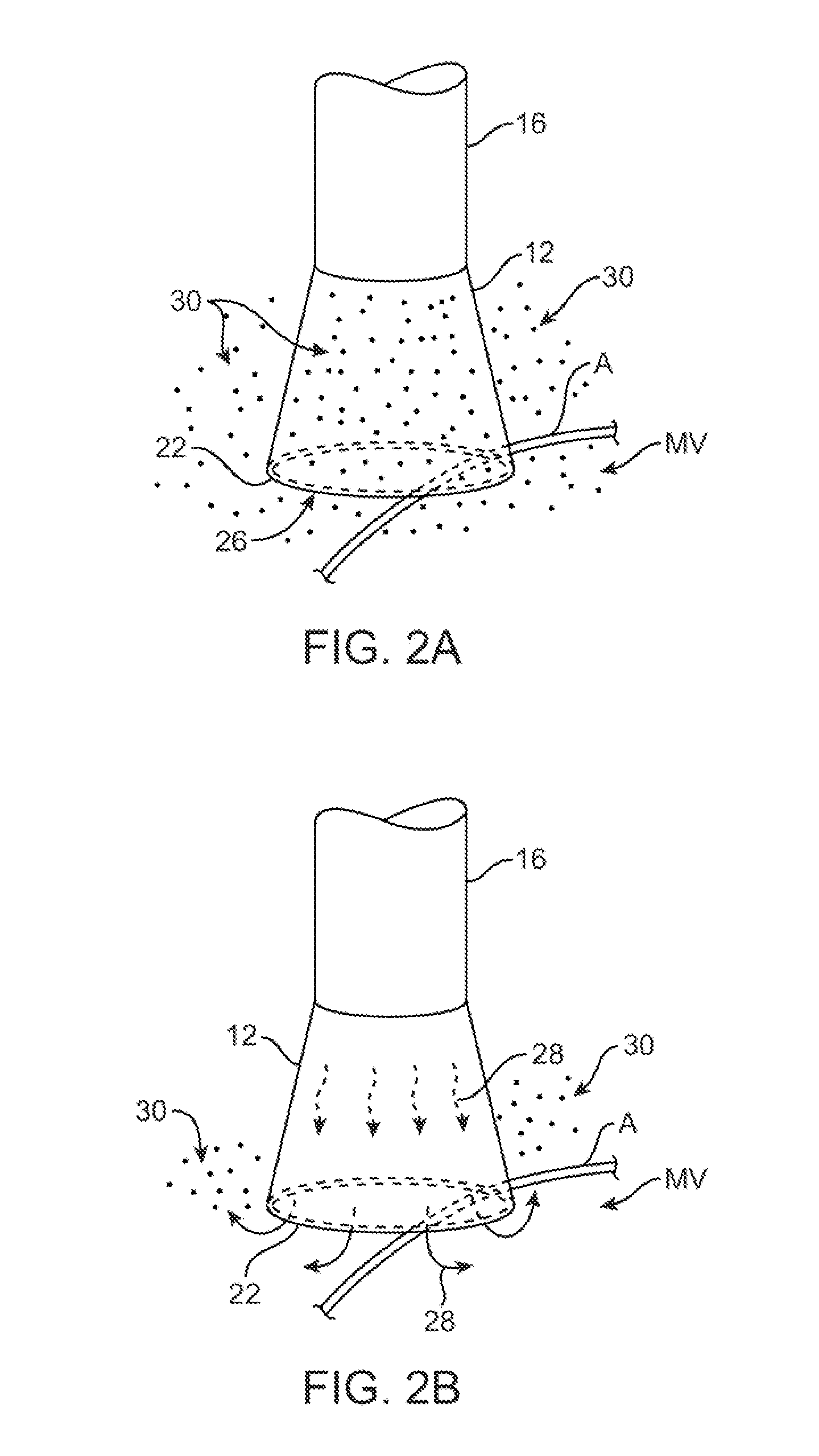

Method of forming electrode placement and connection systems

ActiveUS8333012B2Withstanding stressLine/current collector detailsSurgeryElectrode placementElectricity

Electrode placement and connection systems are described which allow for the electrical connection and maintenance of one or more electrodes positioned on a substrate which is subjected to a variety of mechanical stresses. Such a system may include an imaging hood having an aperture through which transparent fluid is flowed and one or more electrodes positioned along or about the hood. As the hood is configured between a low-profile and opened configuration, these electrodes may remain electrically coupled despite the mechanical stresses subjected to the electrodes and the connections thereto.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Electrode placement and connection systems

ActiveUS20100094081A1Easy to manufactureEnsures rigidityLine/current collector detailsInternal electrodesElectricityElectrode placement

Electrode placement and connection systems are described which allow for the electrical connection and maintenance of one or more electrodes positioned on a substrate which is subjected to a variety of mechanical stresses. Such a system may include an imaging hood having an aperture through which transparent fluid is flowed and one or more electrodes positioned along or about the hood. As the hood is configured between a low-profile and opened configuration, these electrodes may remain electrically coupled despite the mechanical stresses subjected to the electrodes and the connections thereto.

Owner:INTUITIVE SURGICAL OPERATIONS INC

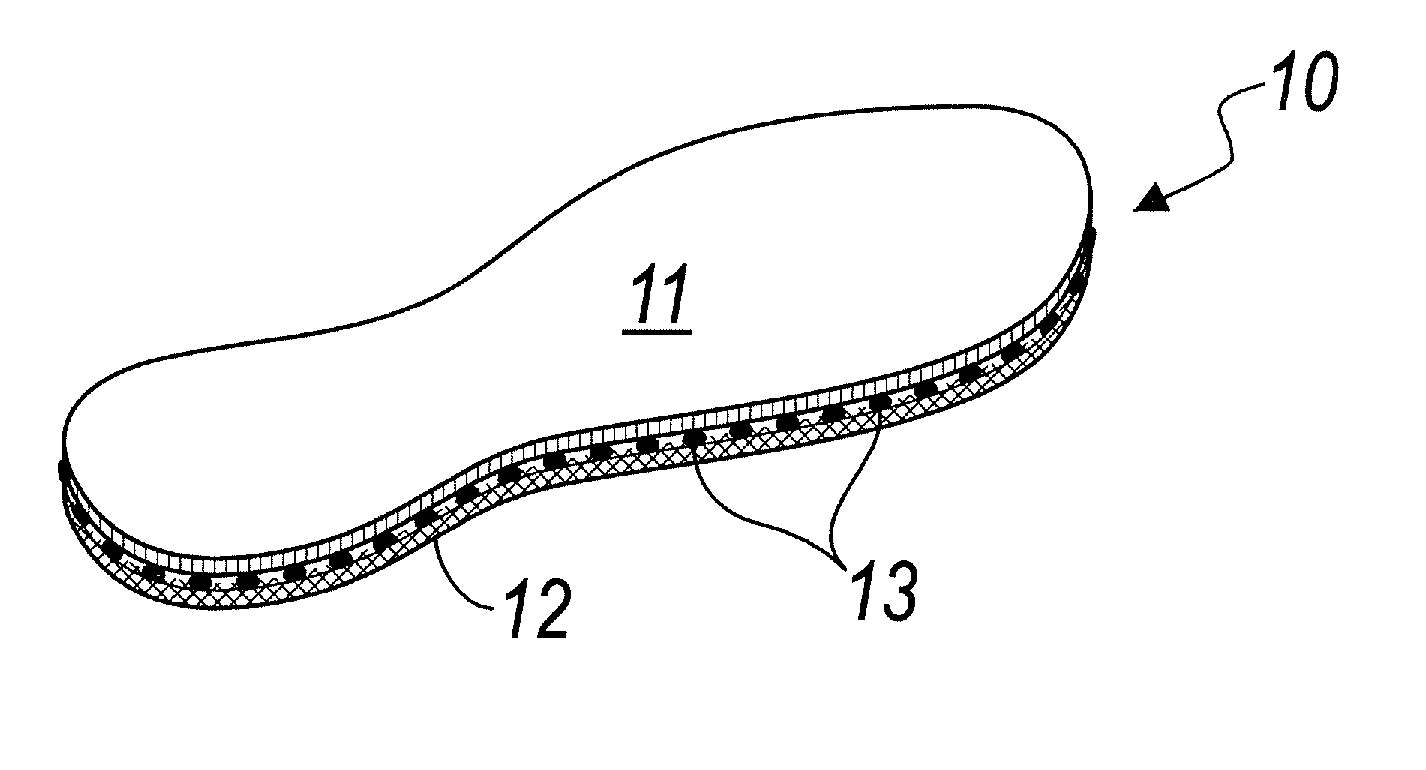

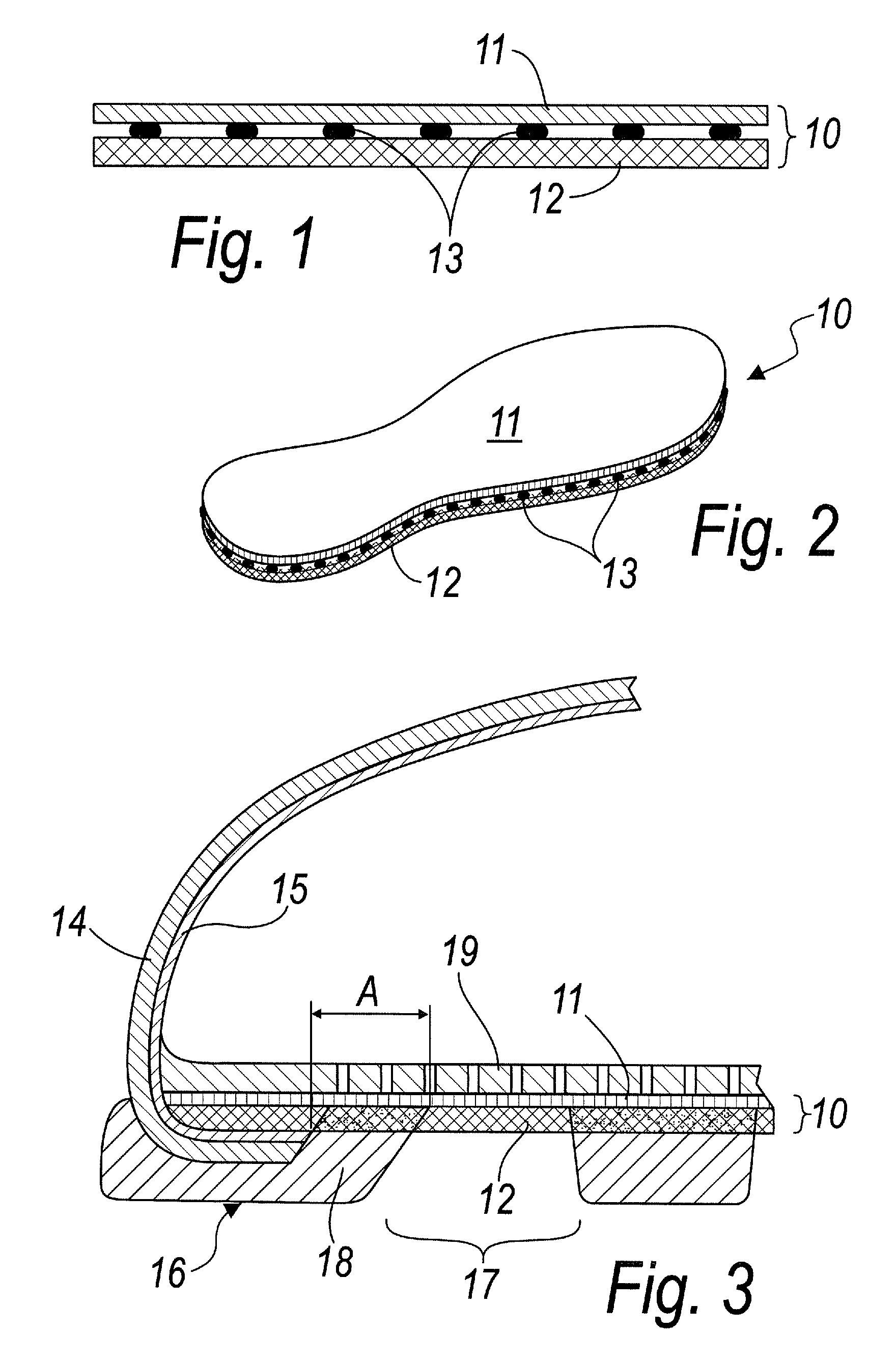

Waterproof and vapor-permeable assembly insole and shoe manufactured with such insole

ActiveUS20100050480A1Structure miniaturizationSimplify the manufacturing processSolesUpperTectorial membraneWater vapor

An assembly insole impermeable to water and permeable to water vapor, with a structure including a membrane impermeable to water and permeable to water vapor and arranged in an upward region, and a supporting layer arranged below the membrane, made of a material resistant to hydrolysis and vapor-permeable or diffusely perforated, and capable of acting as a support for the foot, as a manufacturing base for the shoe, as an element for protecting the membrane against the penetration of blunt objects, and of withstanding the stresses induced in the shoe during use. The membrane and the supporting layer are mutually joined so as to make, as a whole, the assembly insole impermeable to the passage of water and not compromise the vapor permeability of the membrane.

Owner:GEOX SPA

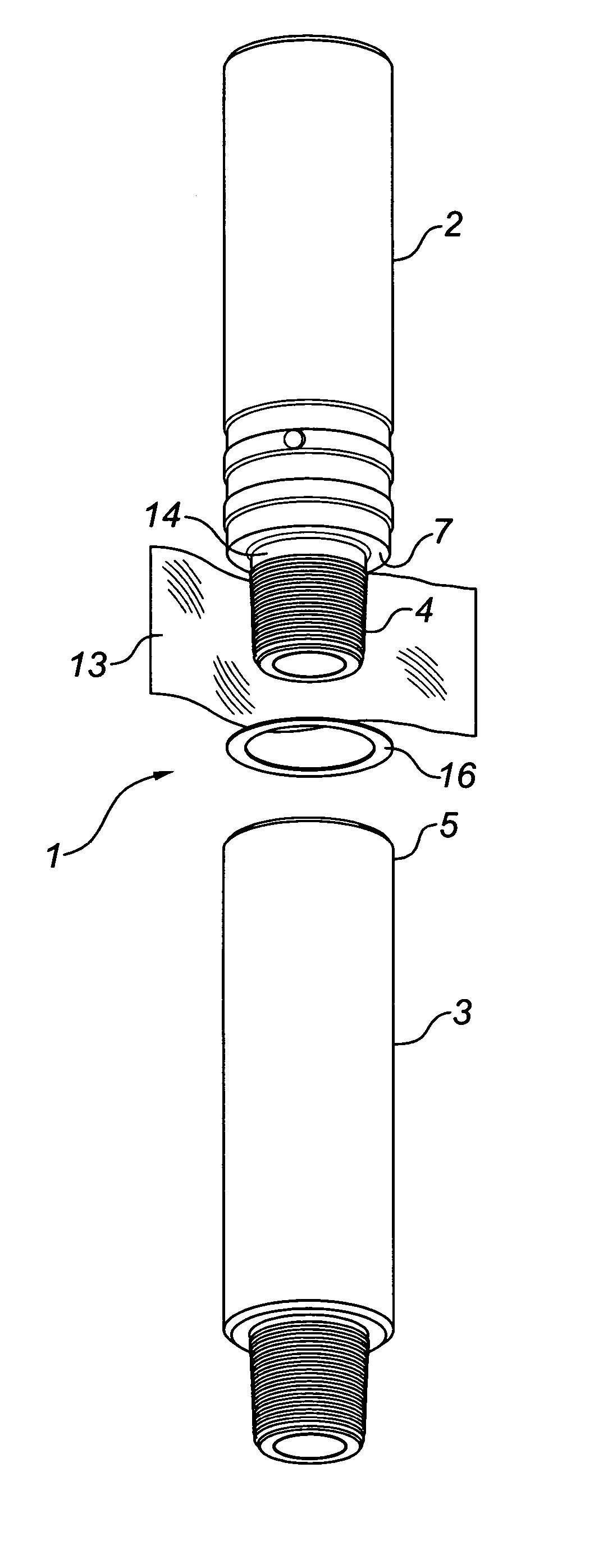

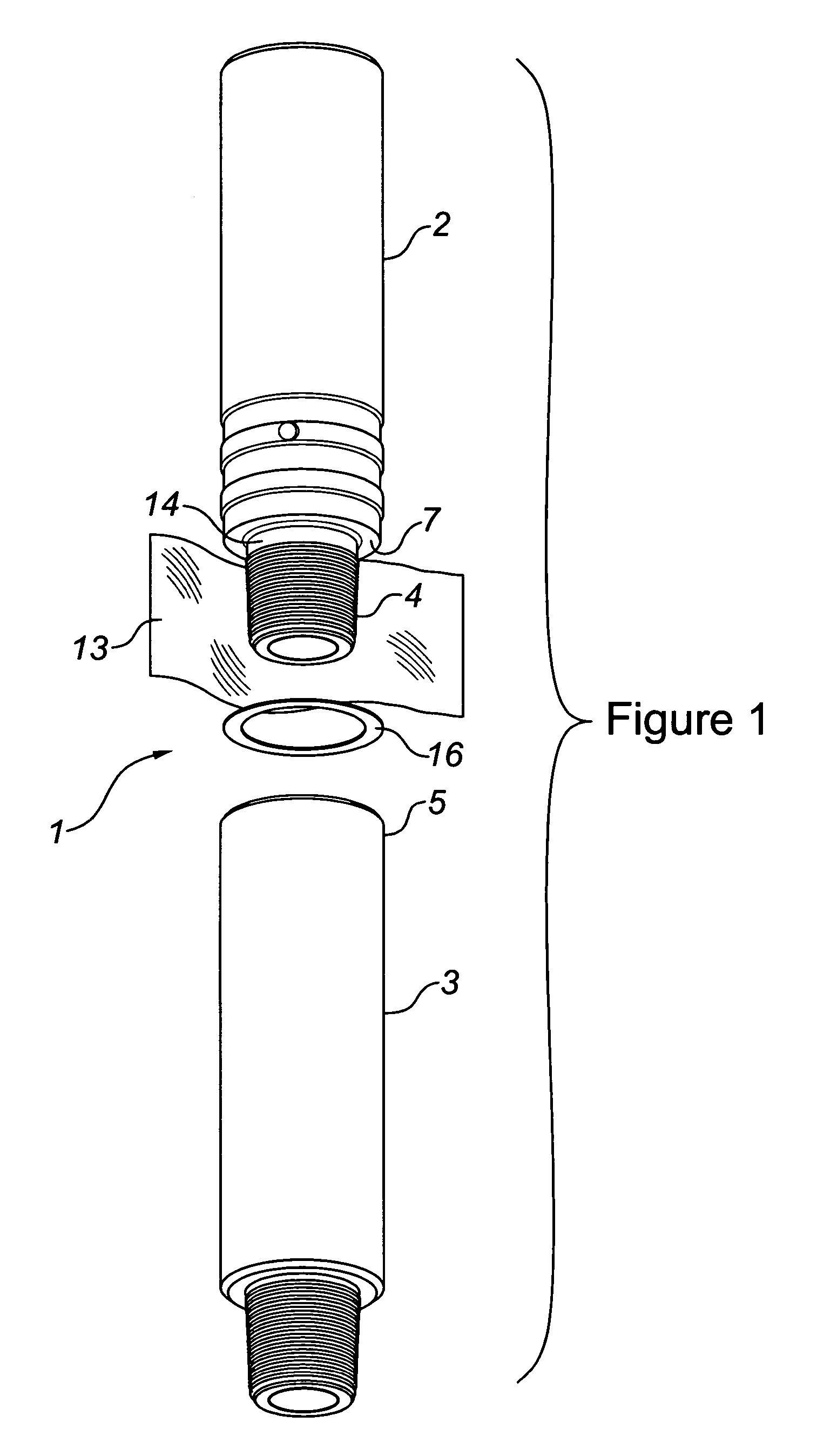

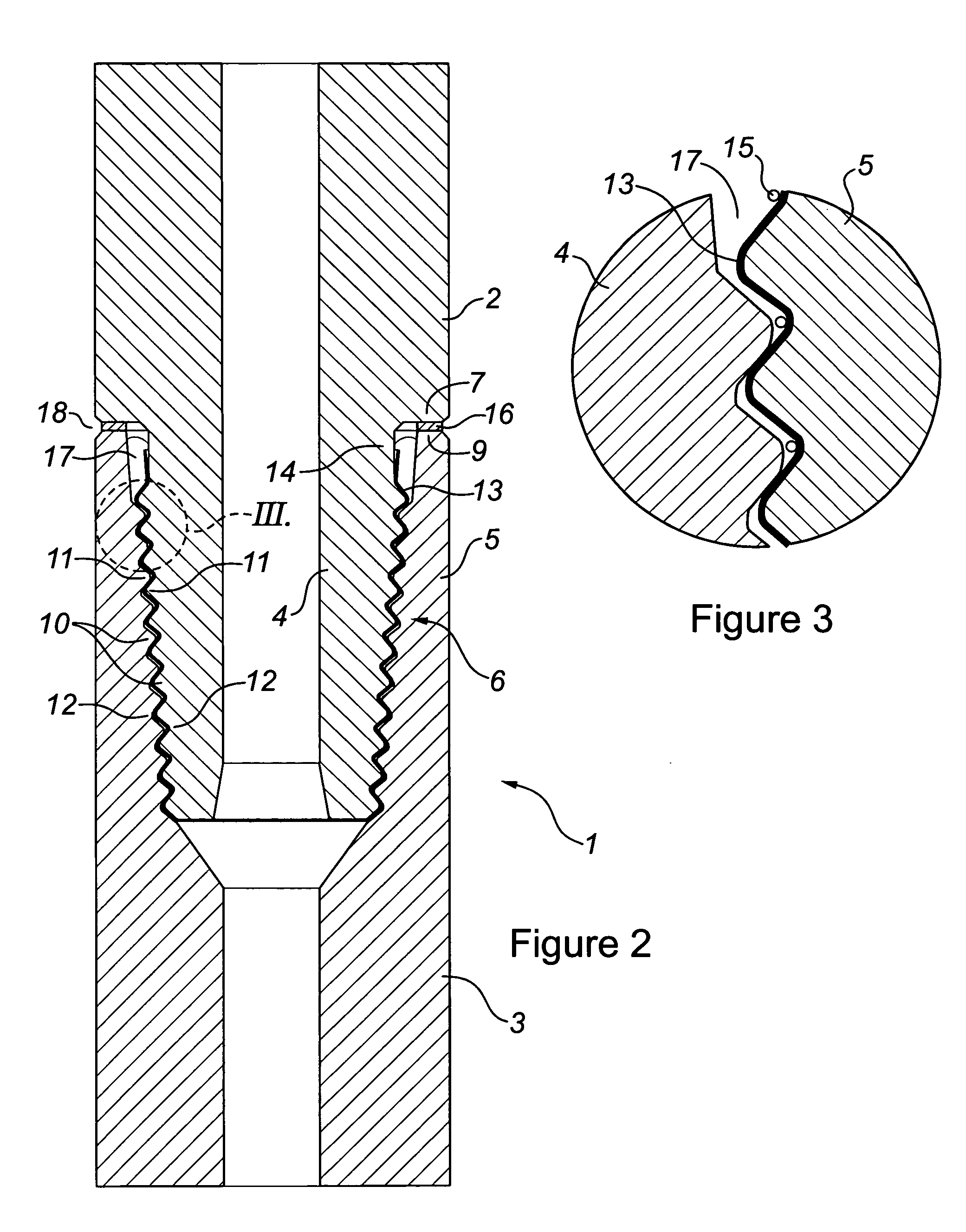

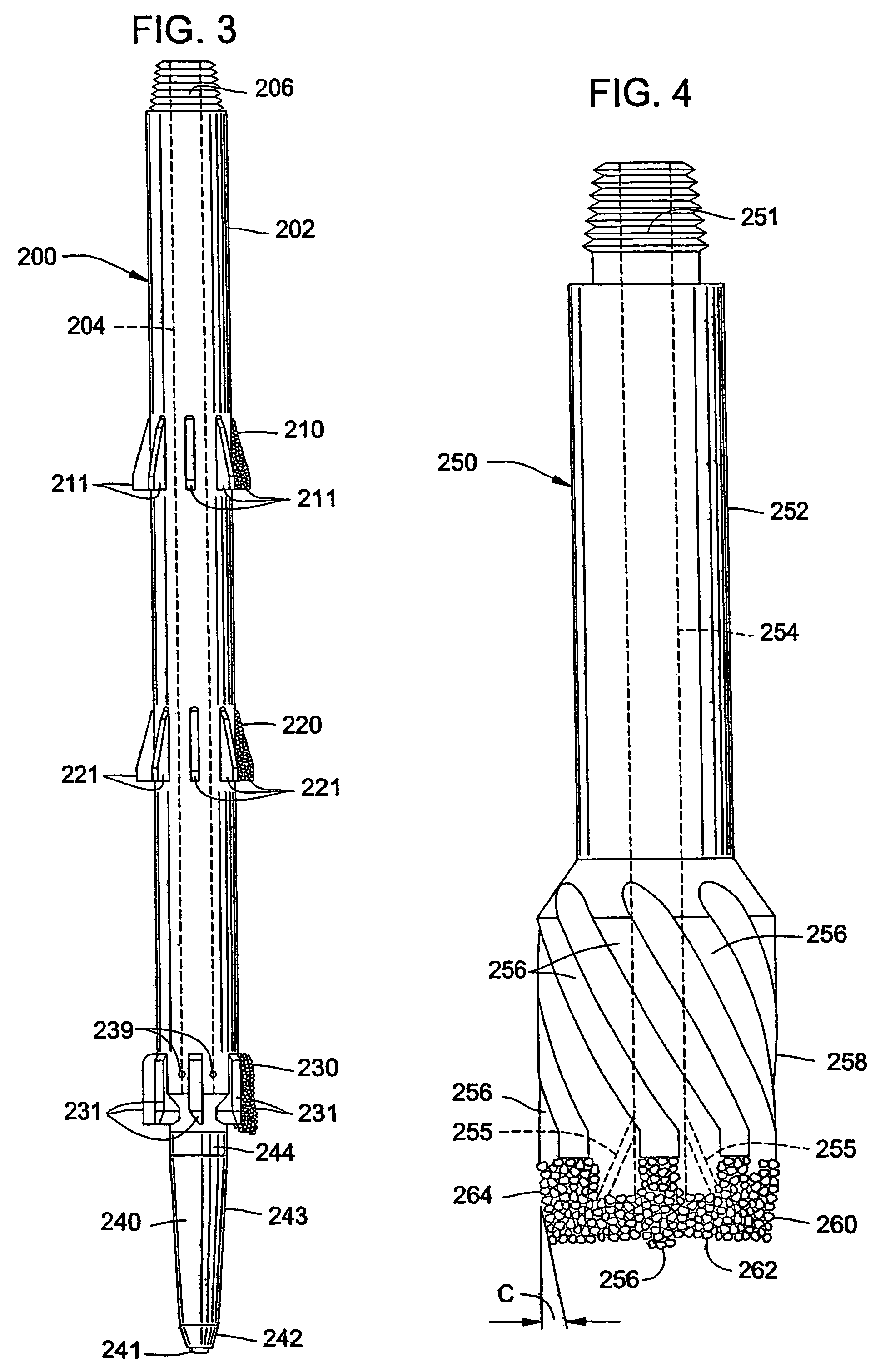

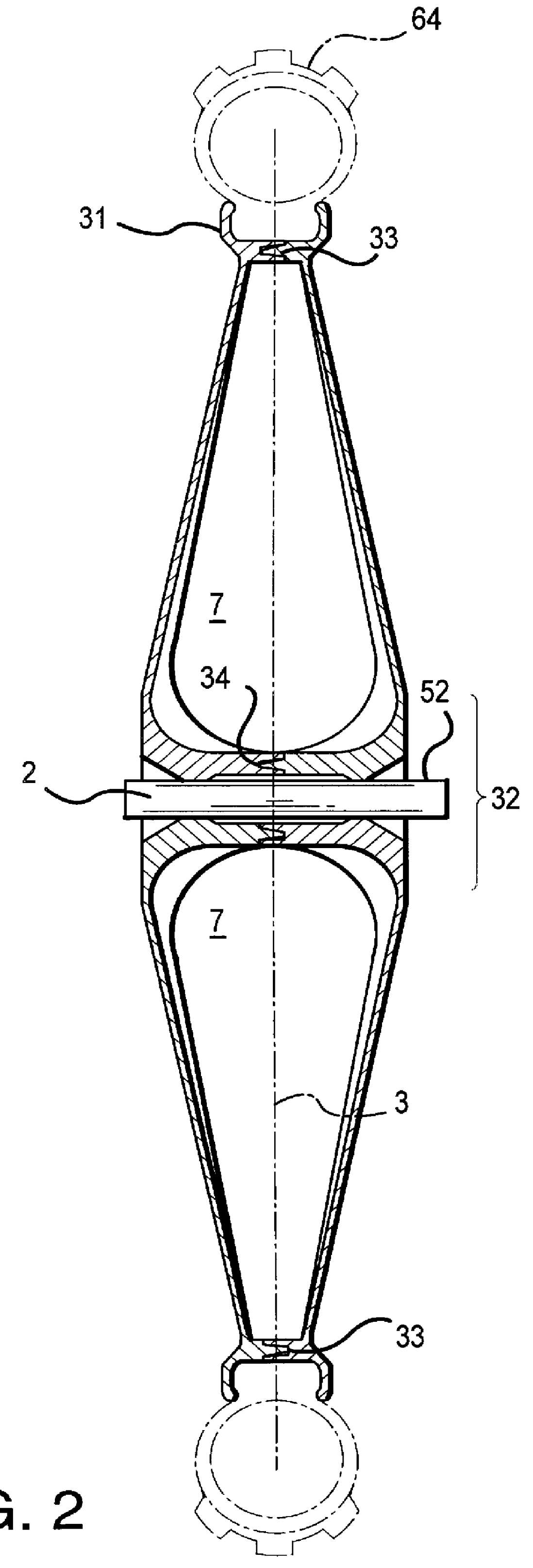

Gap sub assembly

ActiveUS7255183B2Withstanding make-up torqueWithstanding stressDrilling rodsFluid removalEngineeringElectrical and Electronics engineering

The gap sub assembly comprises a pair of electrically conductive subs. Each sub has a threaded pin and box. A pin and box are threaded together to form a connection. An electrically insulating, woven fabric overlies and conforms with the threads of the connection pin. An electrically insulating, annular washer separates the seal faces of the connection. The assembly functions to provide an electrical discontinuity when incorporated into a conductive drill string.

Owner:PHOENIX TECH SERVICES LP

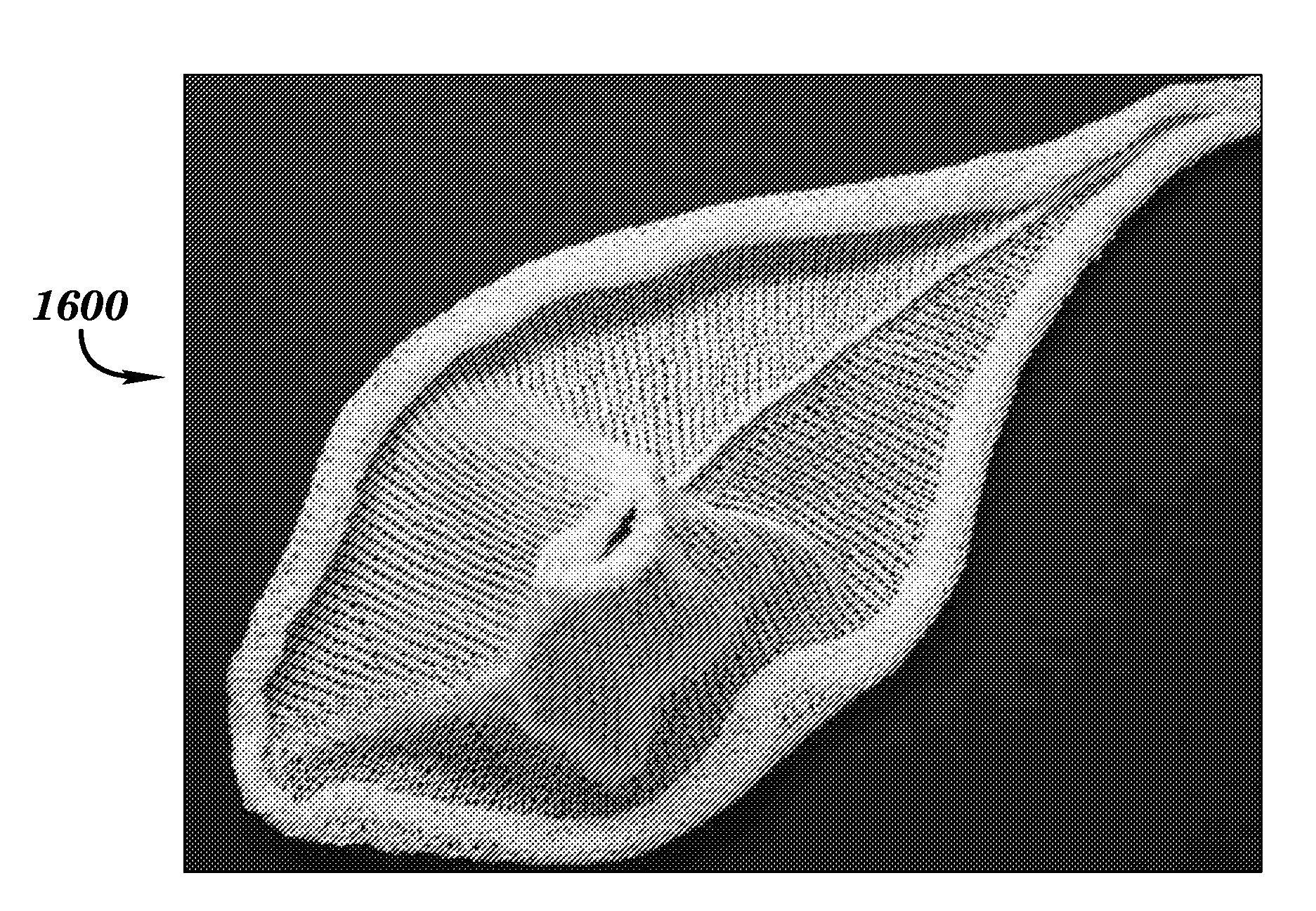

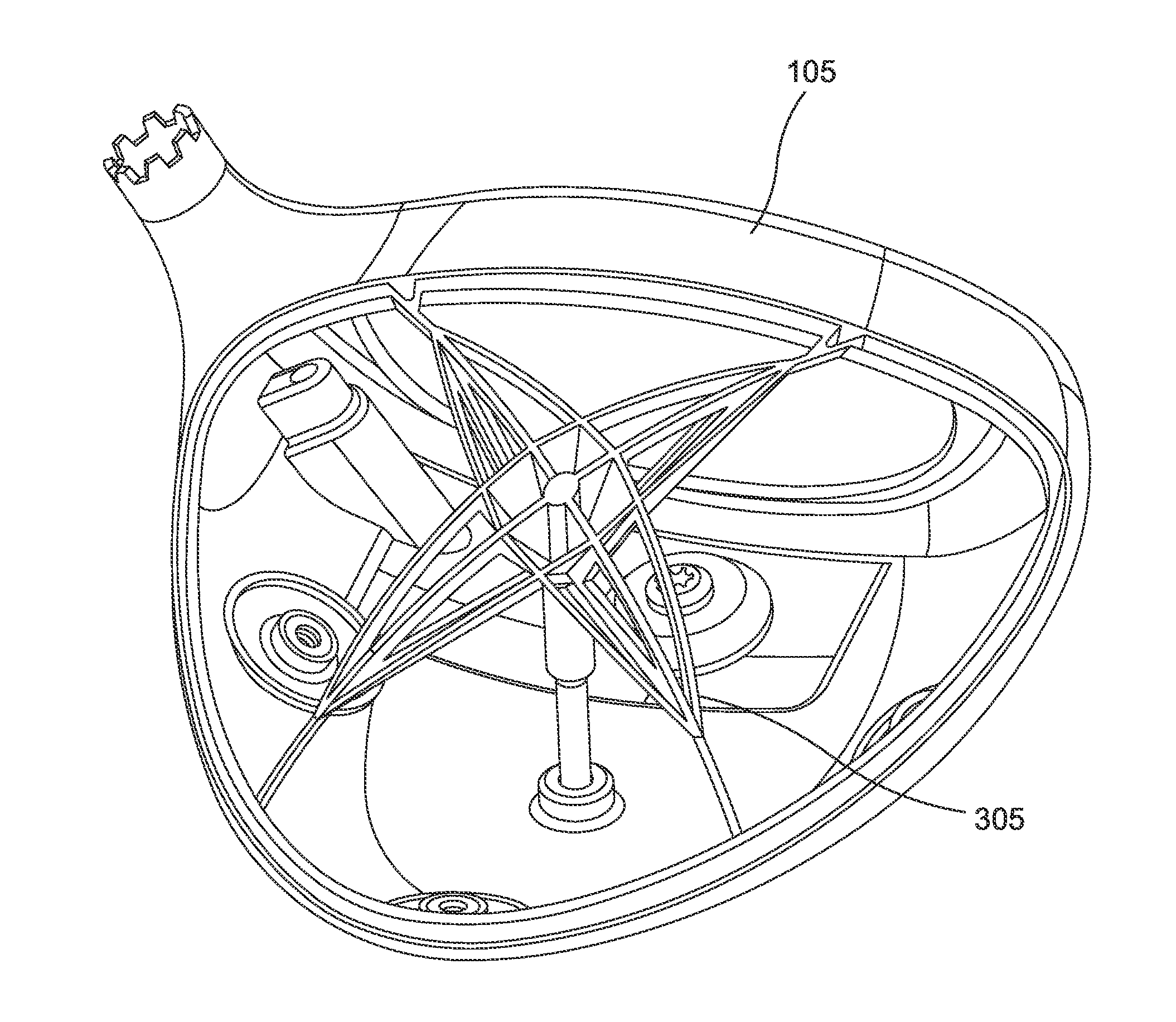

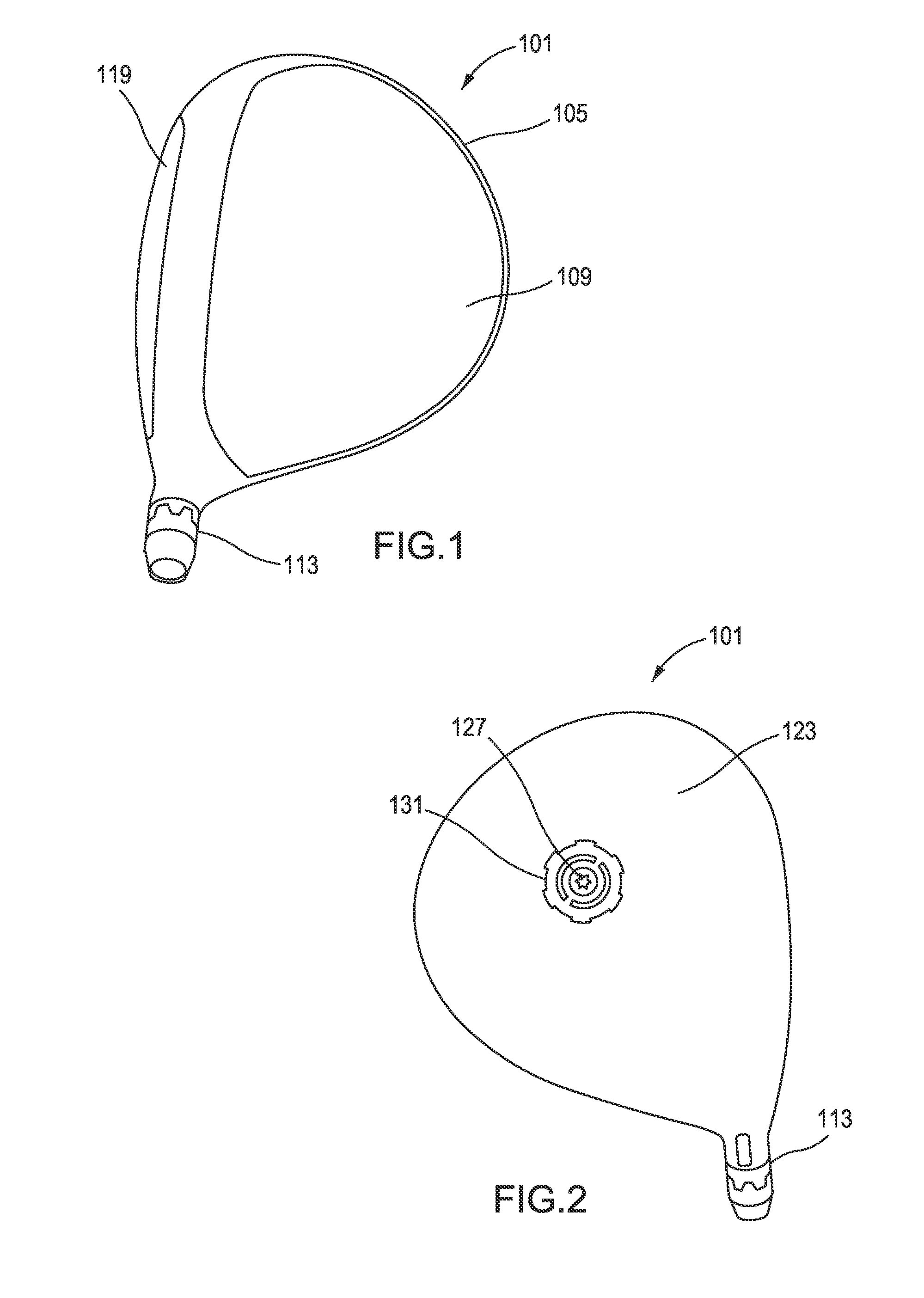

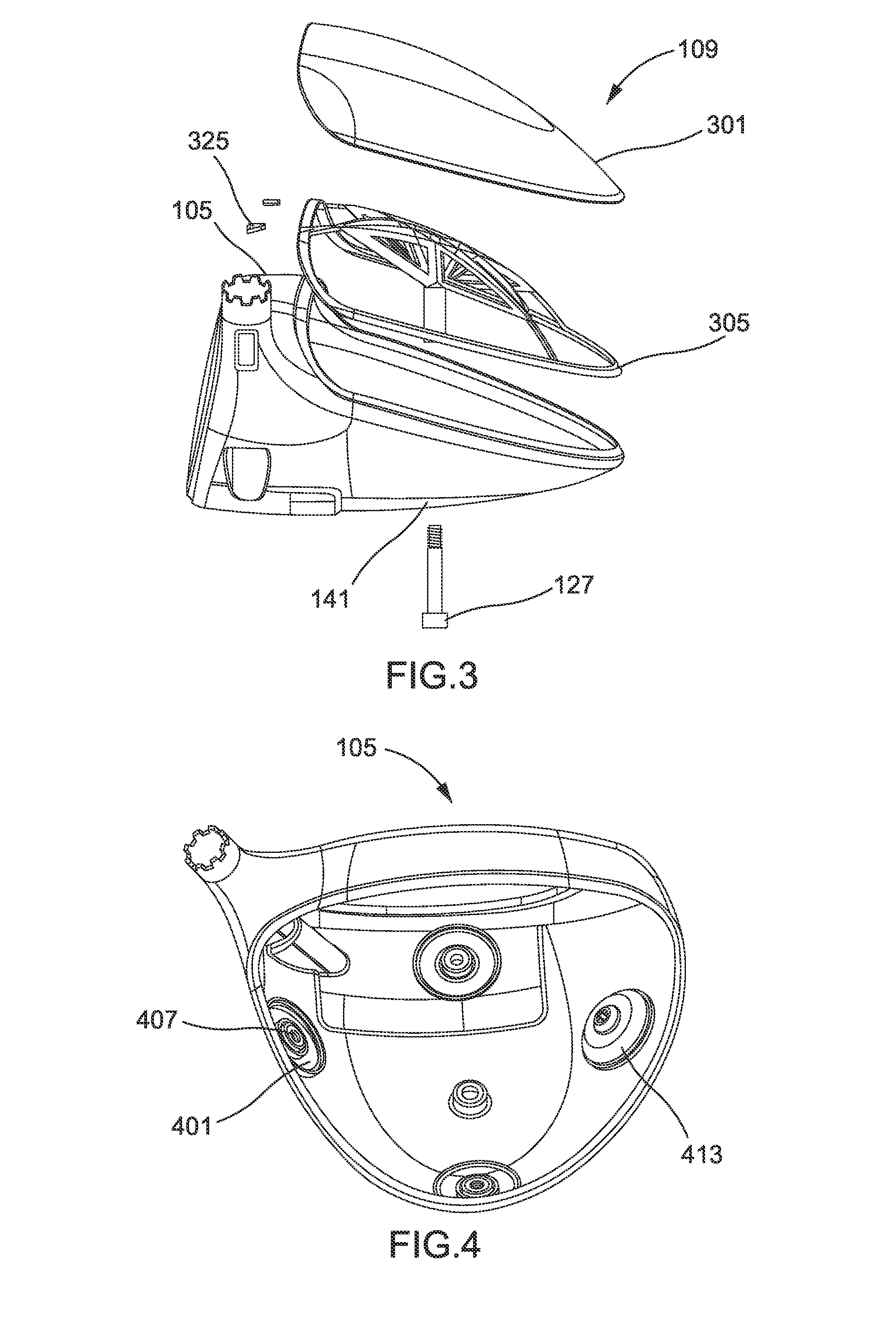

Golf club head with removable component

ActiveUS20140187346A1Highly effective for playing golfDurableGolf clubsRacket sportsWeight adjustmentEngineering

The invention provides a golf club head with a fully removable component that can withstand the stress of repeated hits. When assembled, the removable component is held in place by a fastening mechanism that includes structural elements that distribute the holding force across the component and tend to equalize the forces around the periphery where the component meets the body. The fastening mechanism may include a post that reaches across the open space within the hollow club head, pulling the removable component towards an opposed main club head body. Since a golf club of the present invention can be opened, it may include a mechanism on the inside for use by a golfer, such as an electronic device or an adjustment mechanism. The golf club may include a weight adjustment system that allows the club to be custom-fitted to a golfer.

Owner:COBRA GOLF

Integral electrode placement and connection systems

ActiveUS20100262140A1Avoid distortionWithstanding stressInternal electrodesLaproscopesElectrode placementElectricity

Electrode placement and connection systems are described which allow for the electrical connection and maintenance of one or more electrodes positioned on a substrate which is subjected to a variety of mechanical stresses. Electrodes may also be formed on flexible circuit assemblies integrated within or along the hood. The circuit assemblies may also provide structural support to the hood during delivery and / or deployment. Such a system may include an imaging hood having an aperture through which transparent fluid is flowed and one or more electrodes positioned along or about the hood. As the hood is configured between a low-profile and opened configuration, these electrodes may remain electrically coupled despite the mechanical stresses subjected to the electrodes and the connections thereto.

Owner:INTUITIVE SURGICAL OPERATIONS INC

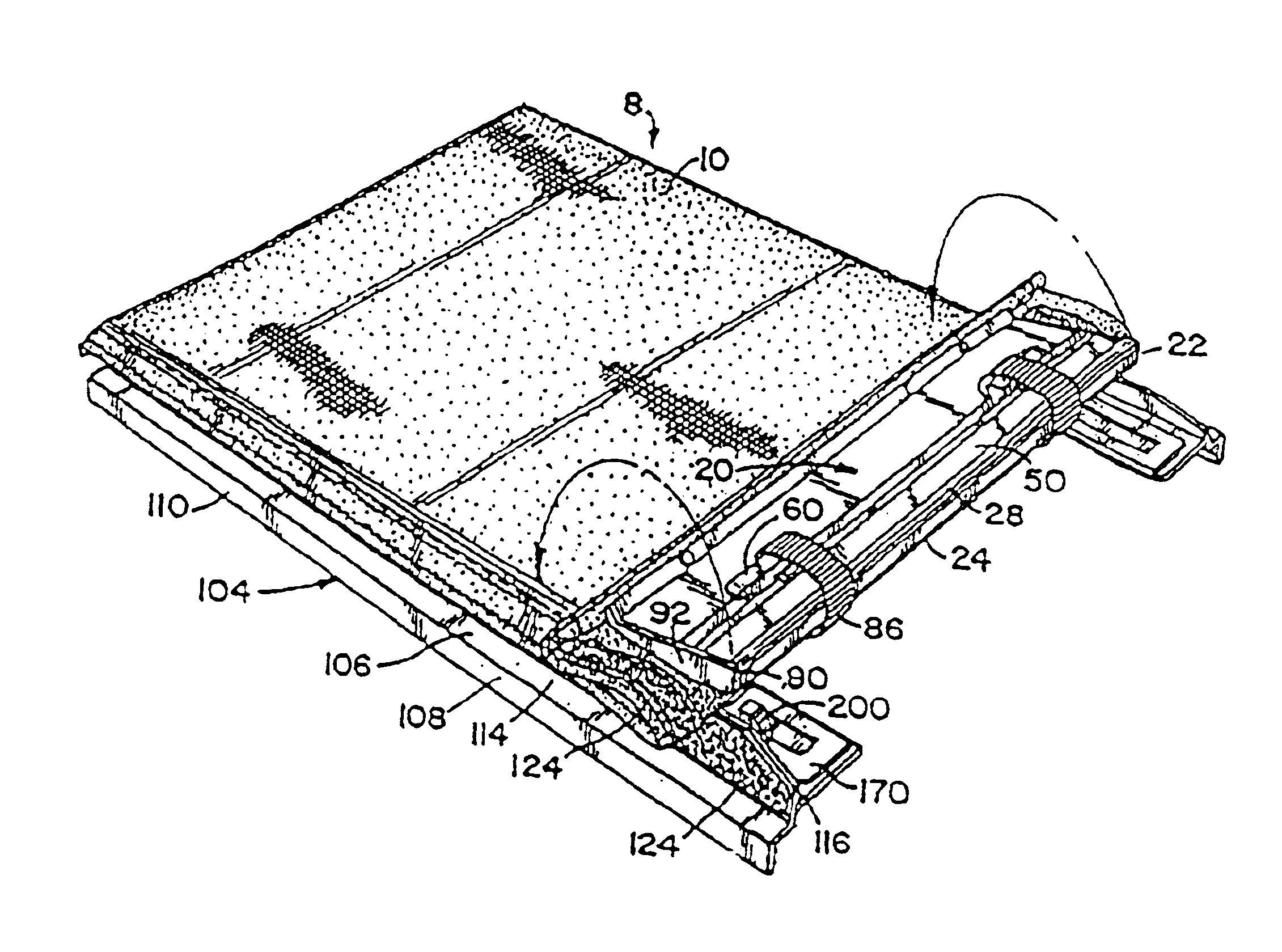

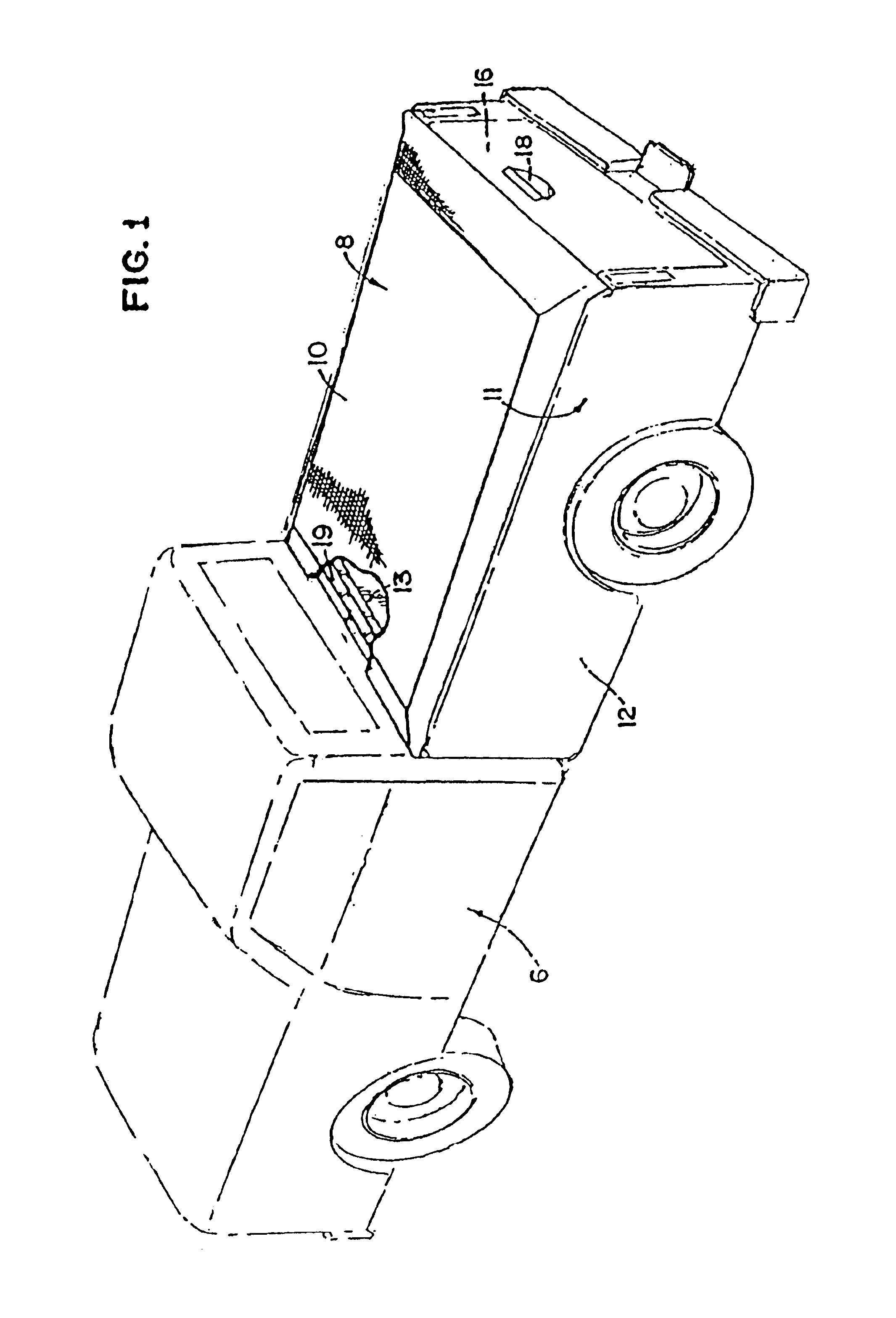

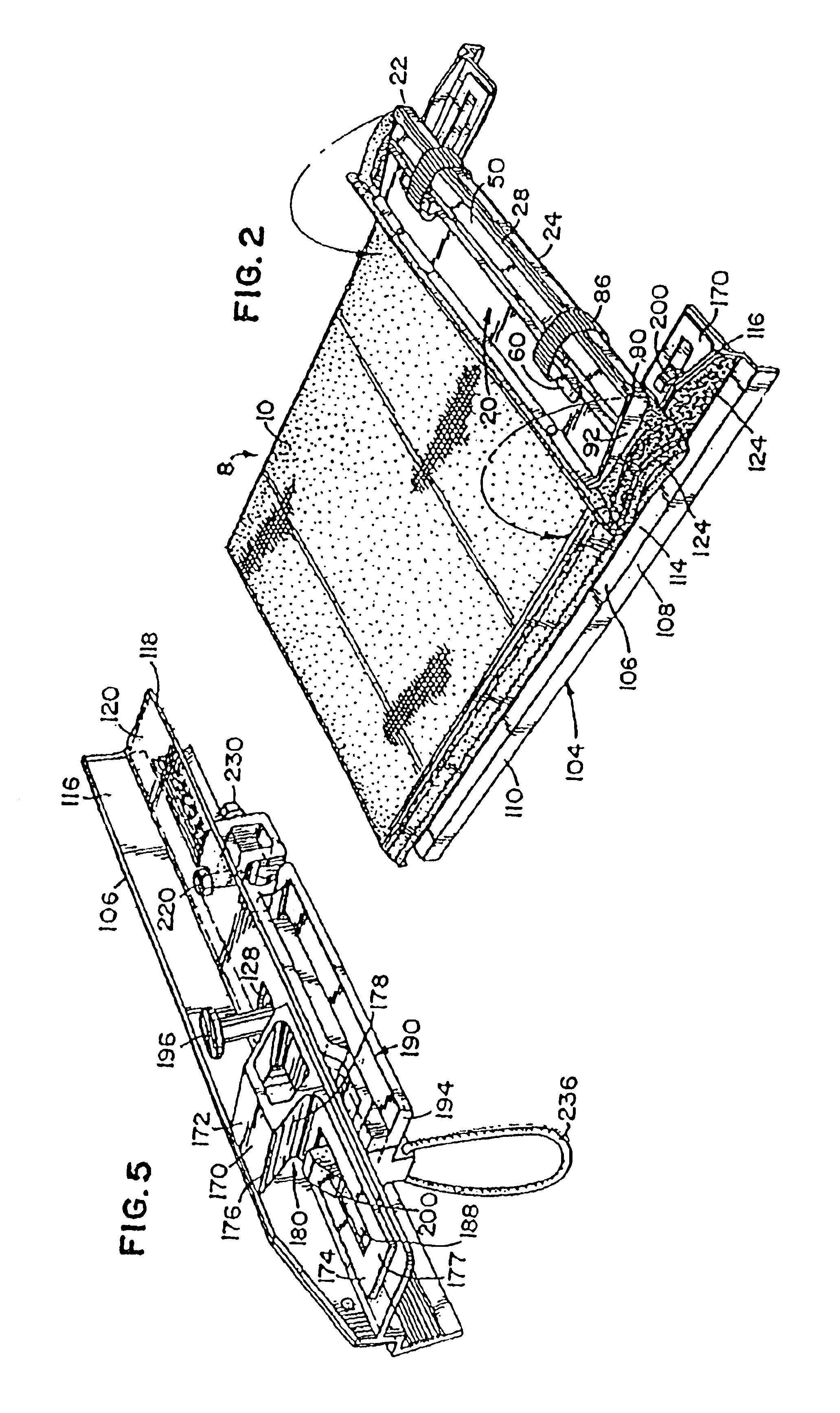

Tonneau cover apparatus having rear bar lock

InactiveUS6851738B1Maximize and simplify securementReduce areaBuilding locksTents/canopiesPickup truckBraced frame

A tonneau cover apparatus for attaching a flexible cover about a cargo box of a vehicle, preferably a pickup truck. The apparatus preferably includes, a support frame removably attached about the perimeter of a cargo box of the vehicle, an elongated end plate attached to an end of the flexible cover, an end plate engagement member attached to the support frame, preferably one on each side of the support frame, and a locking member movably attached to the end plate. The end plate is preferably attached to an end of the flexible cover and is configured to cooperatively engage and pivot with respect to the end plate engagement member or members into and out of a fixed stretching position wherein the flexible cover can be correspondingly be tensed and relaxed. The end plate may be retained in the fixed stretching position by the locking member, in alternate embodiments, a plurality of locking members are provided, preferably locking members that slide within a channel in the end plate. In preferred embodiments the locking member or members are spring biased toward a locking position where the locking member engages a flange of the support frame to prevent the end plate from moving out of the fixed stretching position.

Owner:AGRI COVER

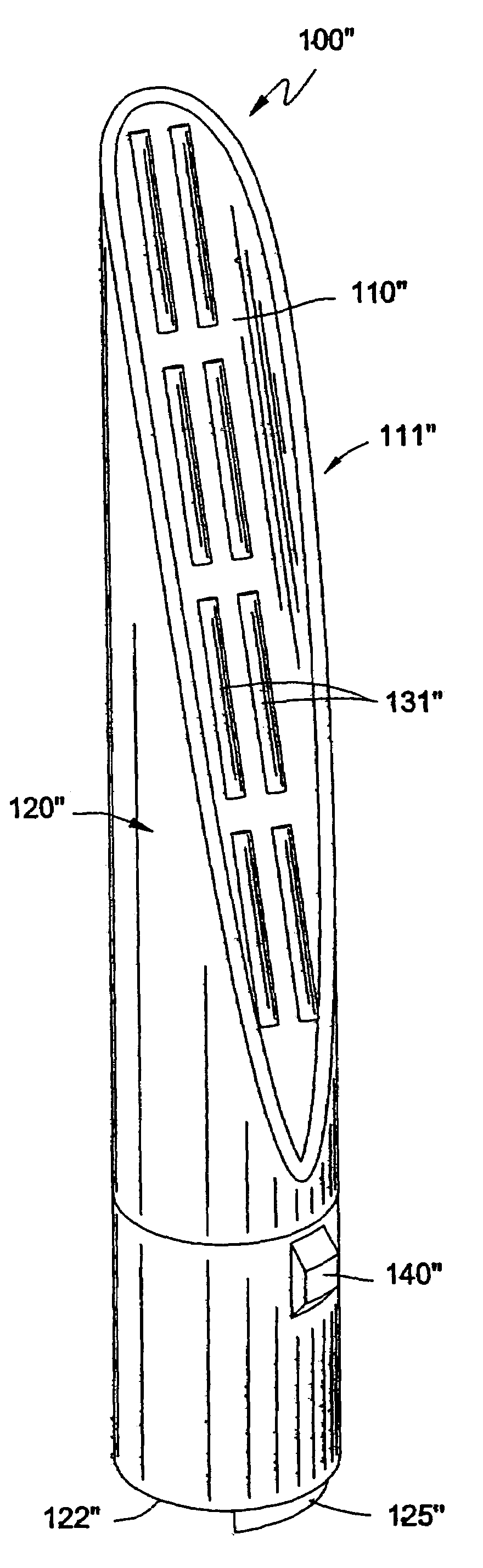

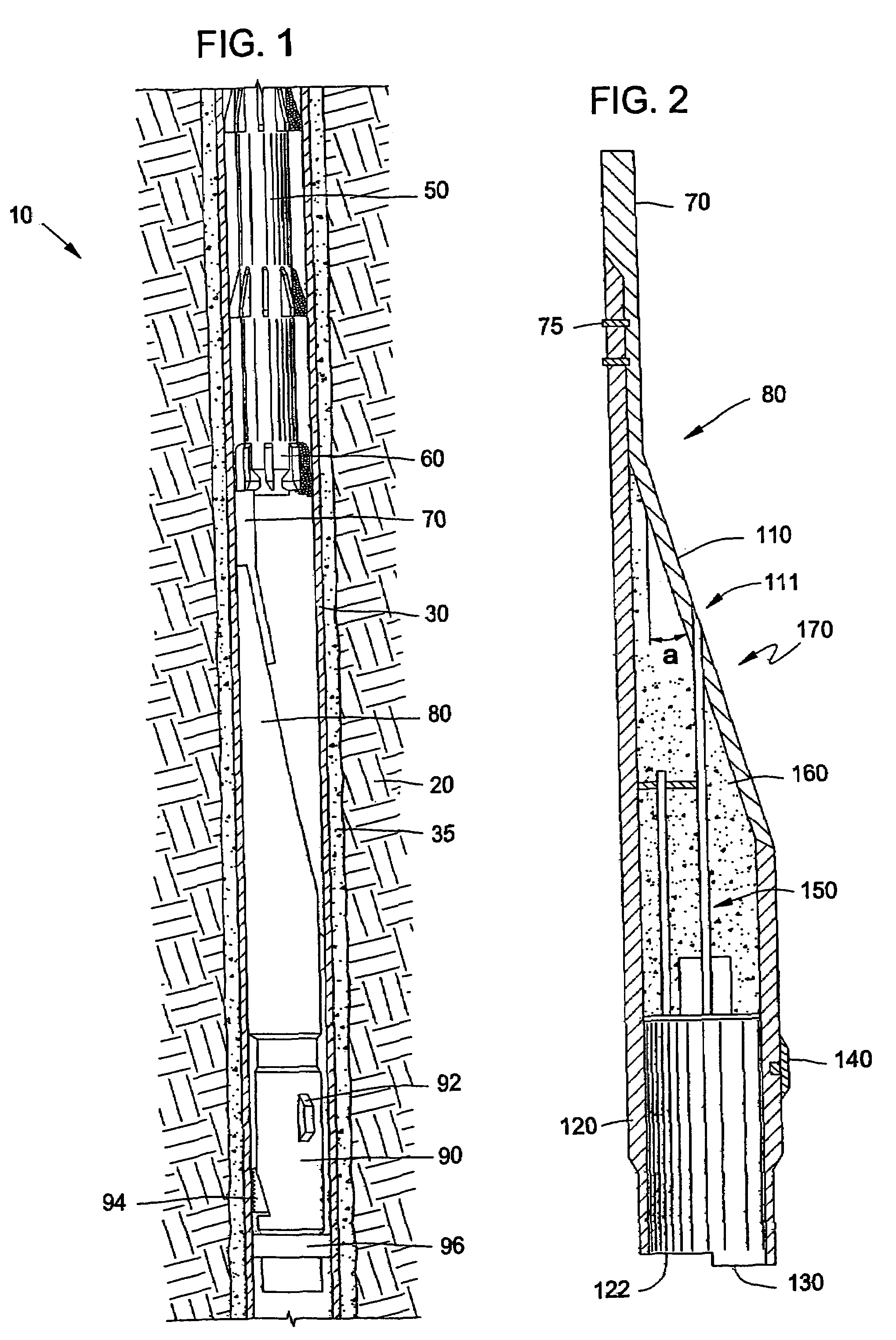

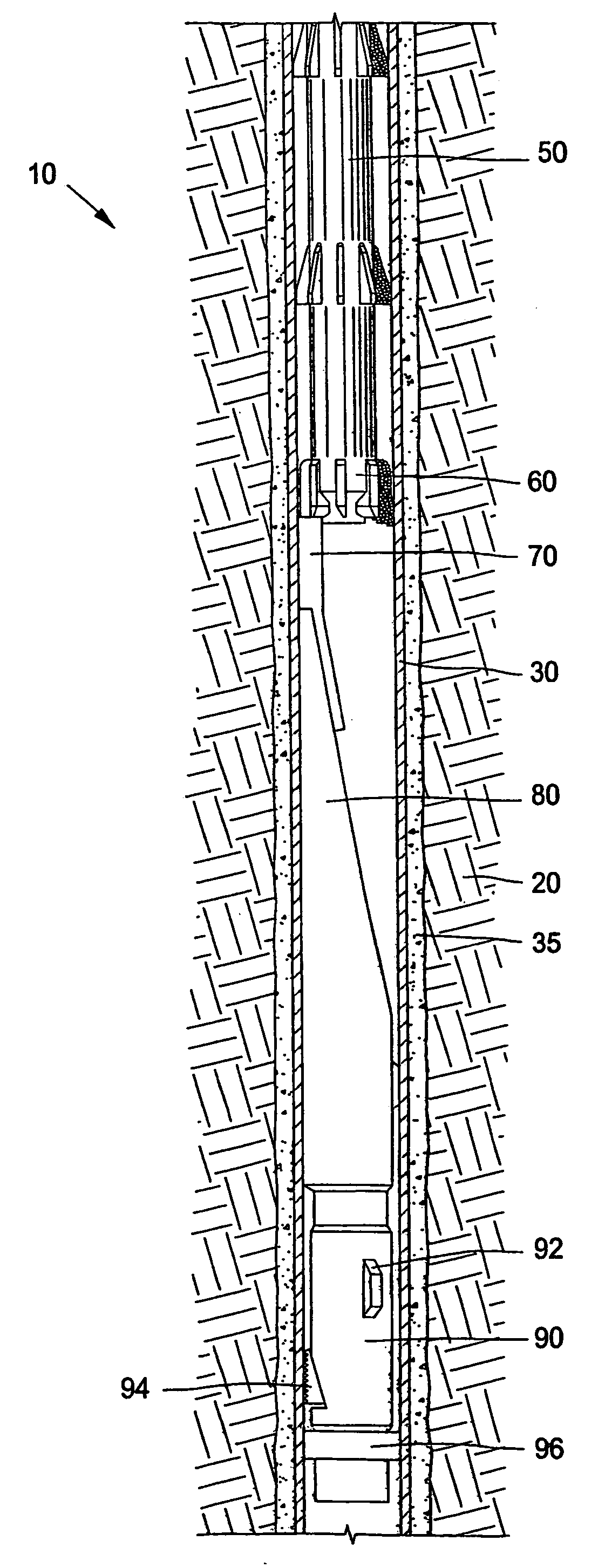

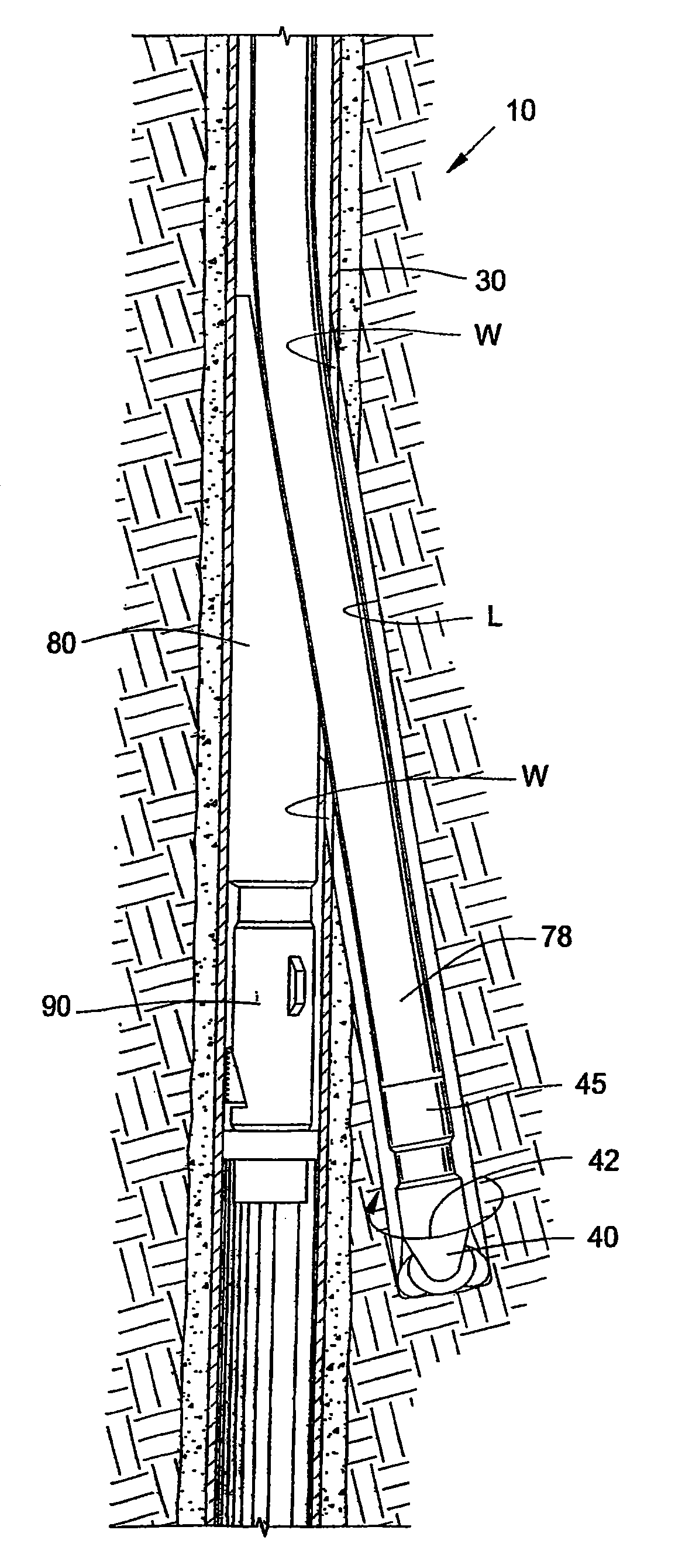

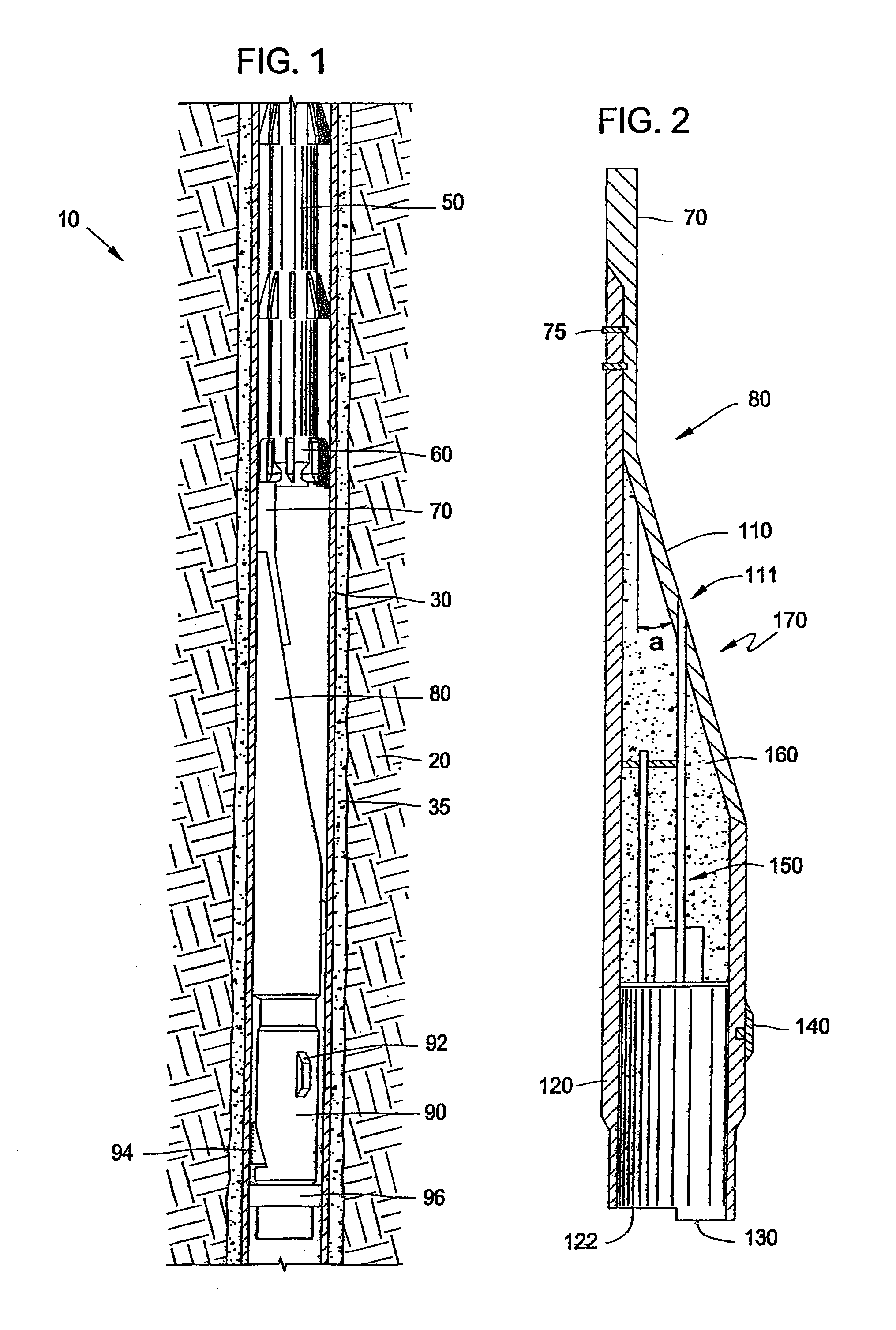

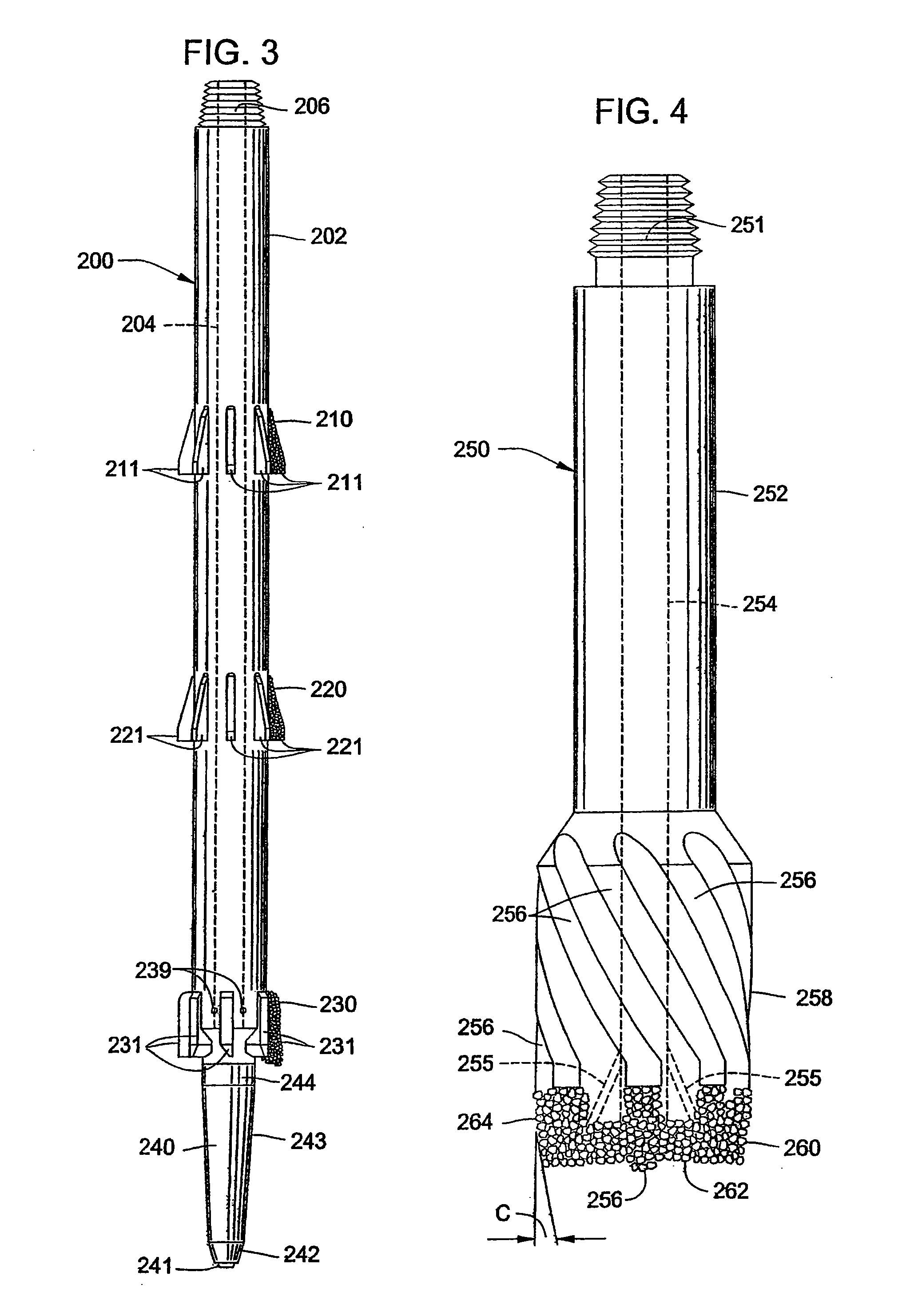

Whipstock assembly and method of manufacture

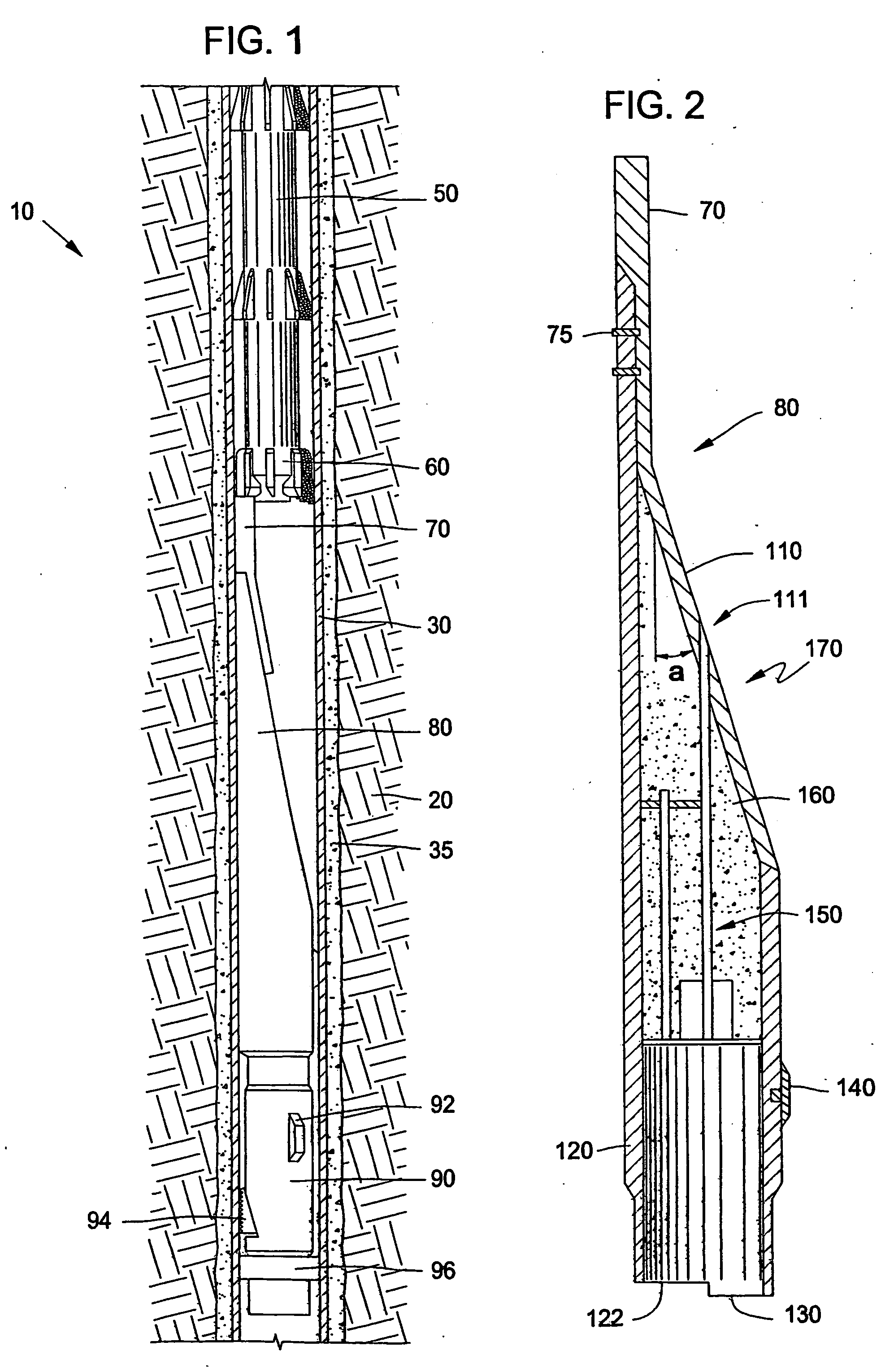

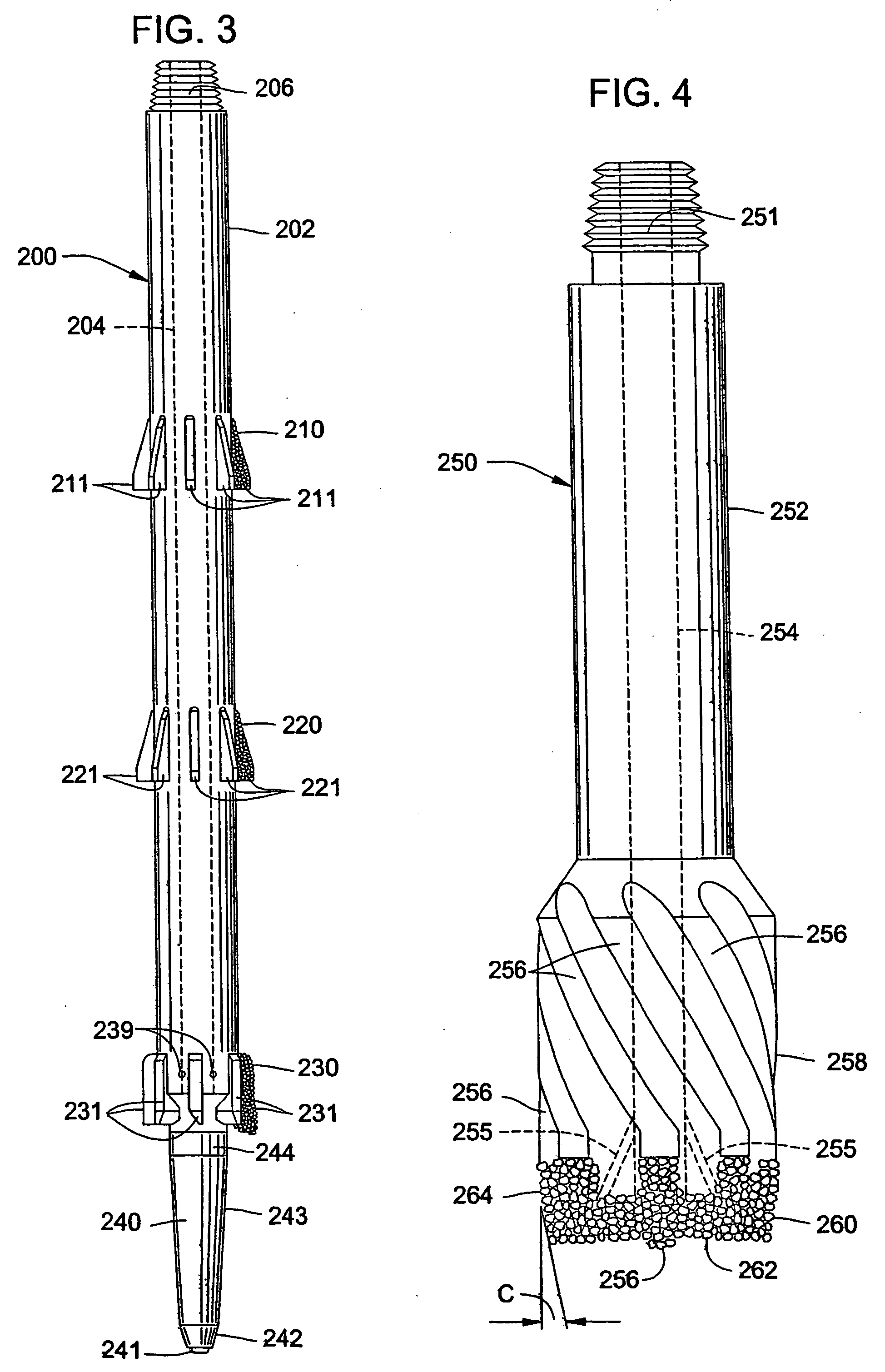

InactiveUS7353867B2Improve permeabilityWithstanding stressSurveyDrilling rodsEngineeringMechanical engineering

The present invention discloses a whipstock assembly (100) for use in forming a lateral borehole from a parent wellbore. The whipstock assembly comprises a body (122) and a deflection member 120) above the body. The deflection member includes a concave portion (111) for deflecting a milling bit during a milling operation. Disposed on a perforation plate (110) portion of the concave portion is a raised surface feature (116). The raised surface supports a milling bit above the perforation plate portion during a milling operation. This, in turn, substantially prevents frictional contact between the milling bits and the perforation plate portion during a milling operation. The present invention also provides a novel method for manufacturing a whipstock in which a cavity portion is formed behind the perforation plate by milling out the backside of the deflection member and then joining a second back cover member to the whipstock body to complete the assembly.

Owner:WEATHERFORD TECH HLDG LLC +1

Whipstock assembly and method of manufacture

InactiveUS20060027359A1Improve permeabilityWithstanding stressSurveyDrilling rodsDrill bitEngineering

The present invention discloses a whipstock assembly (100) for use in forming a lateral borehole from a parent wellbore. The whipstock assembly comprises a body (122) and a deflection member 120) above the body. The deflection member includes aconcave portion (111) for deflecting a milling bit during a milling operation. Disposed on a perforation plate (110) portion of the concave portion is a raised surface feature (116). The raised surface supports a milling bit above the perforation plate portion during a milling operation. This, in turn, substantially prevents frictional contact between the milling bits and the perforation plate portion during a milling operation. The present invention also provides a novel method for manufacturing a whipstock in which a cavity portion is formed behind the perforation plate by milling out the backside of the deflection member and then joining a second back cover member to the whipstock body to complete the assembly.

Owner:WEATHERFORD TECH HLDG LLC +1

Use of powder metal sintering/diffusion bonding to enable applying silicon carbide or rhenium alloys to face seal rotors

InactiveUS20030207142A1High to coatingImprove wear resistanceEngine sealsBearing componentsRheniumPowder mixture

A method for making aerospace face seal rotors reinforced by rhenium metal, alloy, or composite in combination with silicon carbide or other ceramic. The resulting rotor also is disclosed. Ceramic grains, preferably silicon carbide (SiC), are mixed with powdered metallic (PM) binder that may be based on a refractory metal, preferably rhenium. The mixture is applied to a rotor substrate. The combined ceramic-metal powder mixture is heated to sintering temperature under pressure to enable fusion of the ceramic in the resulting metal-based substrate. A load may then be applied under an elevated temperature. The resulting coated rotor can exhibit high hot hardness, increased durability and / or high hot wear resistance, as well as high thermal conductivity.

Owner:HONEYWELL INT INC

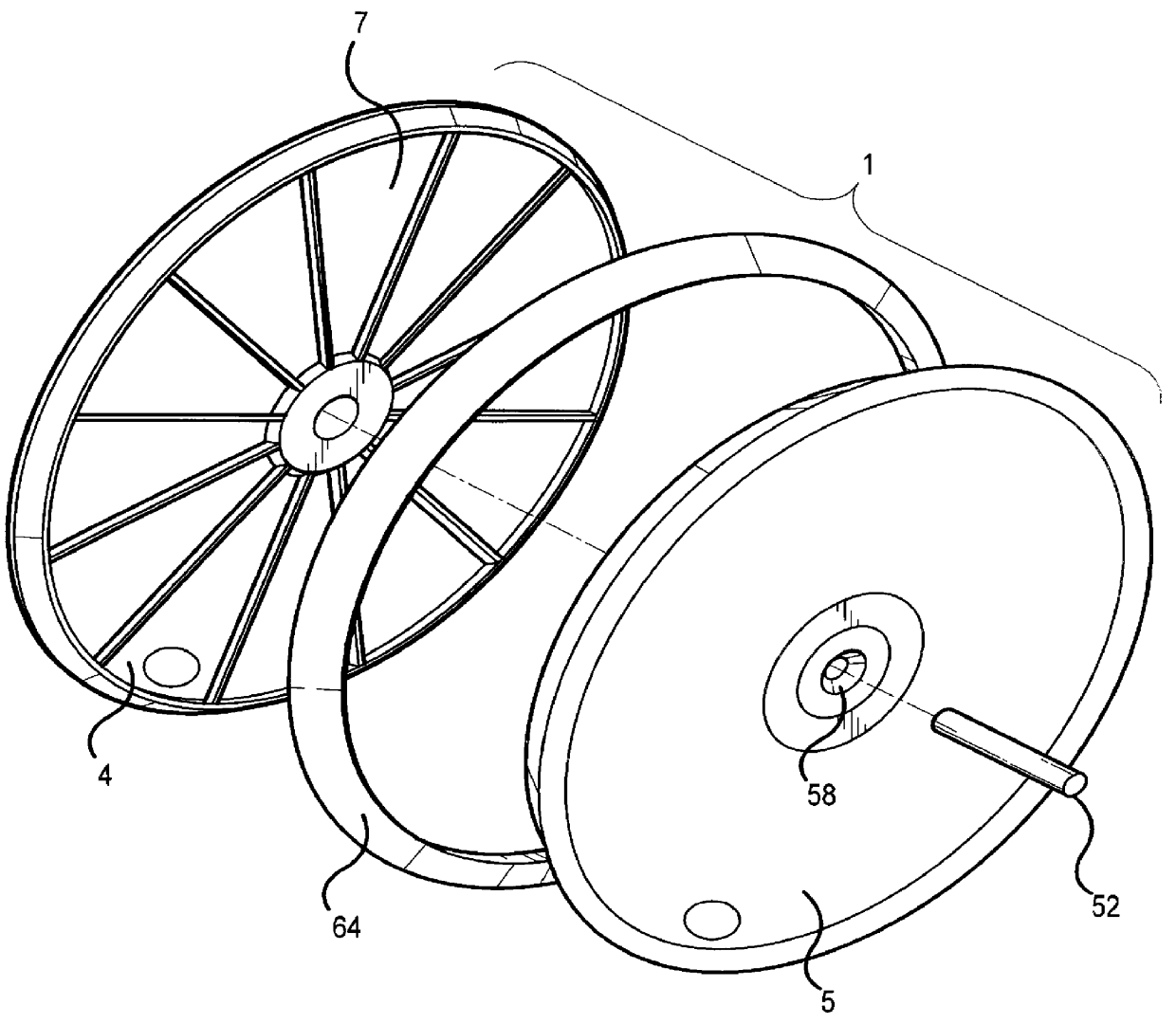

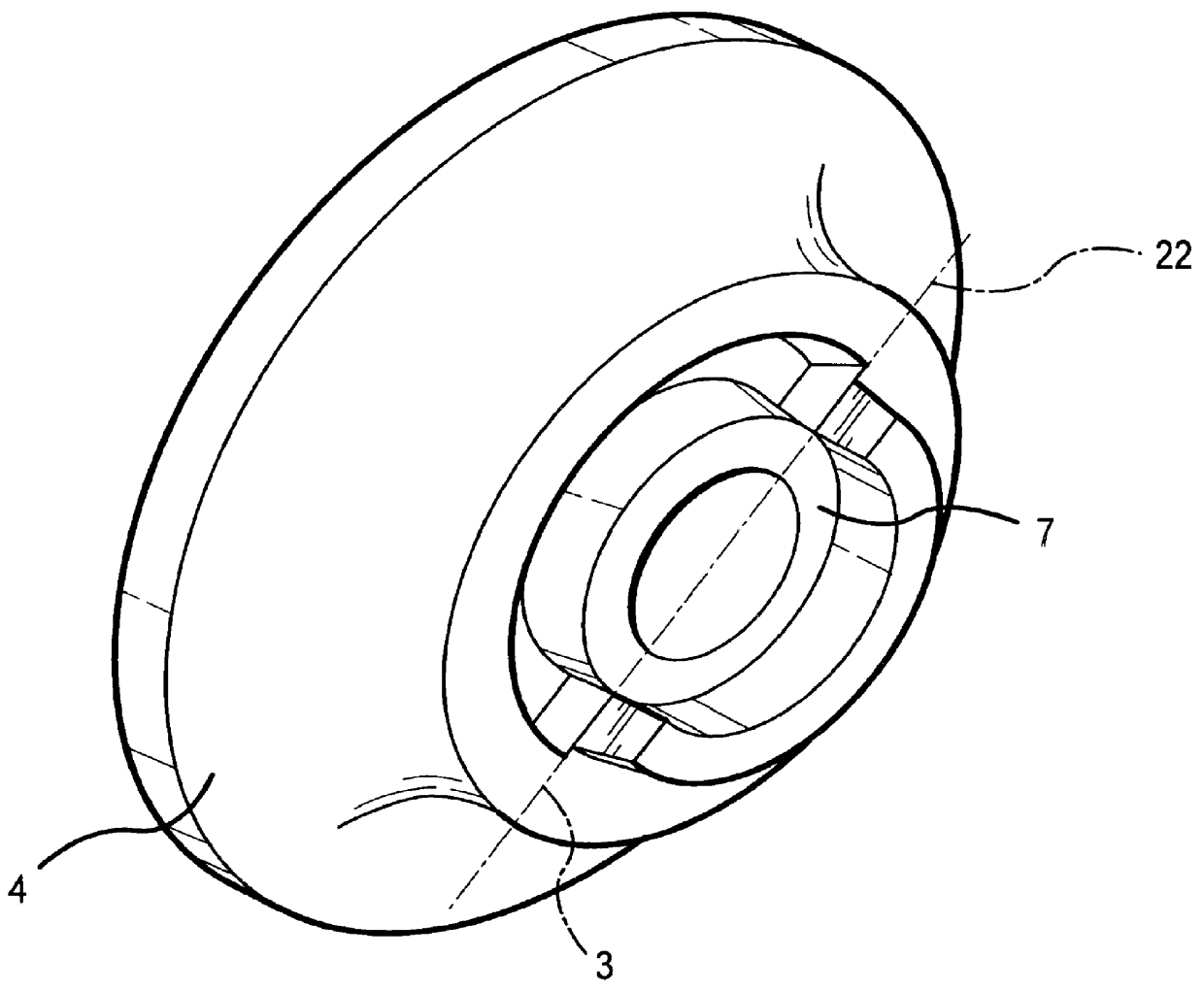

Shear-bonded molded bicycle component assembly

InactiveUS6139040AImproves Structural IntegrityIncrease bonding areaPassenger cyclesChildren cyclesVehicle frameShear bond

A molded structural bicycle component design, such as wheels and frames, which may incorporate complementary halves and at least one shear bond to allow efficient manufacturing and assembly. The molded design which may be applied in a host of different applications, including a bicycle frame and wheel, where demanding loads exist in normal use. Details of the joint and its design are provided. Integral bearings, foam tire adaptations, symmetrically opposite designs, and compression bonding techniques are described. Various cross sections may be made at different stress areas. A method of inserting a reinforcing tube in various high stress areas is also described. A host of bonding techniques including the use of electromagnetically active material are accommodated by the designs. The design may include the use of spacers in the vicinity where methods of retention of accessories or components require compressing from both sides such as the wheels, head tube, bottom bracket, and suspension attachment. The invention may include semicircular boundaries of a wheel assembly so as to define a valve stem hole after assembly.

Owner:DEMPSEY DOUGLAS E

Prosthetic device and method of manufacturing the same

ActiveUS9326840B2Minimizes adhesionsErosion minimizationMammary implantsWeft knittingYarnEngineering

Owner:ALLERGAN INC

Whipstock assembly for forming a window within a wellbore casing

InactiveUS20080185148A1Improve permeabilityWithstanding stressDrilling rodsConstructionsMechanical engineeringWellbore

The present invention discloses a whipstock assembly for use in forming a lateral borehole from a parent wellbore. The whipstock assembly comprises a body and a deflection member above the body. The deflection member includes a concave portion for deflecting a milling bit during a milling operation. Disposed on a perforation plate portion of the concave portion is a raised surface feature. The raised surface supports a milling bit above the perforation plate portion during a milling operation. This, in turn, substantially prevents frictional contact between the milling bits and the perforation plate portion during a milling operation. The present invention also provides a novel method for manufacturing a whipstock in which a cavity portion is formed behind the perforation plate by milling out the backside of the deflection member and then joining a second back cover member to the whipstock body to complete the assembly.

Owner:WEATHERFORD TECH HLDG LLC

Oxygen generator with storage and conservation modes

ActiveUS7694674B2Withstanding stressIncrease pressureCombination devicesAuxillary pretreatmentElectronic controllerProduct gas

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

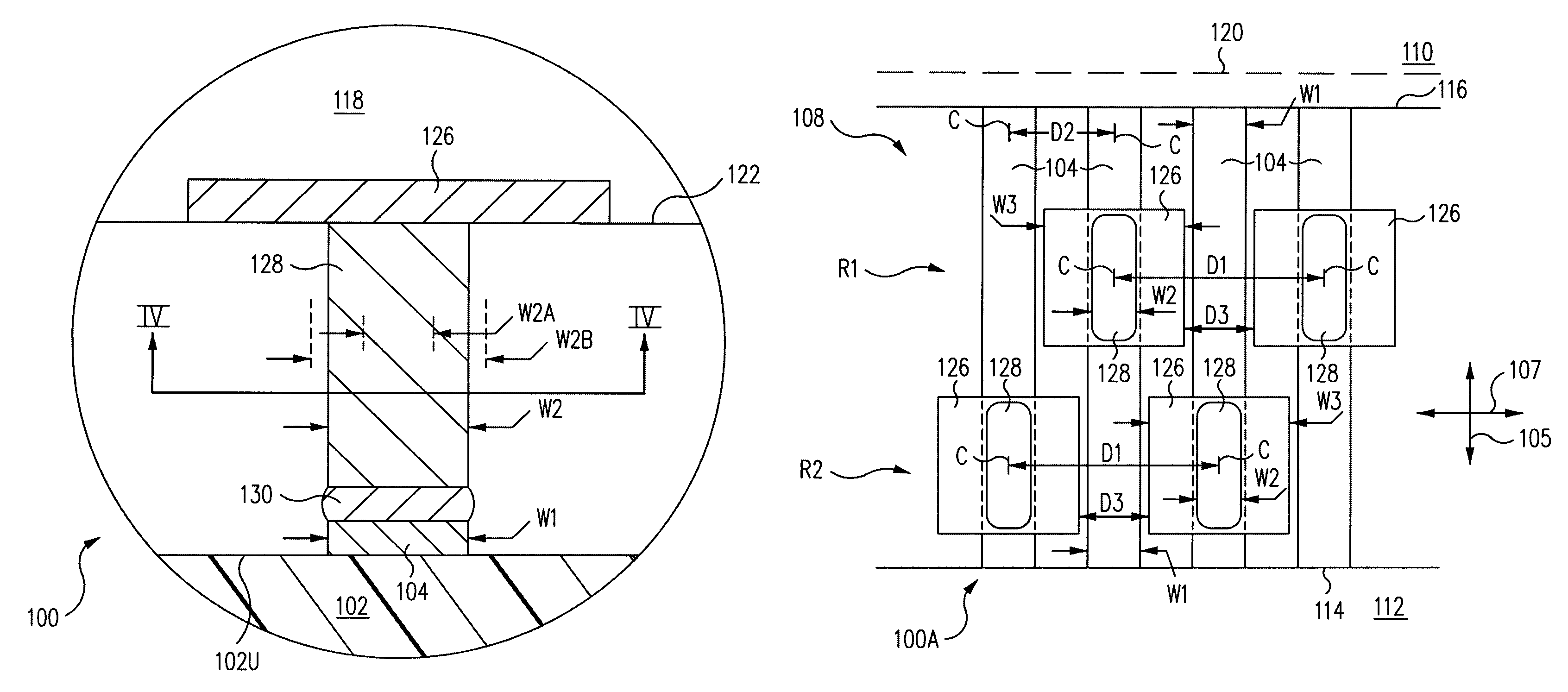

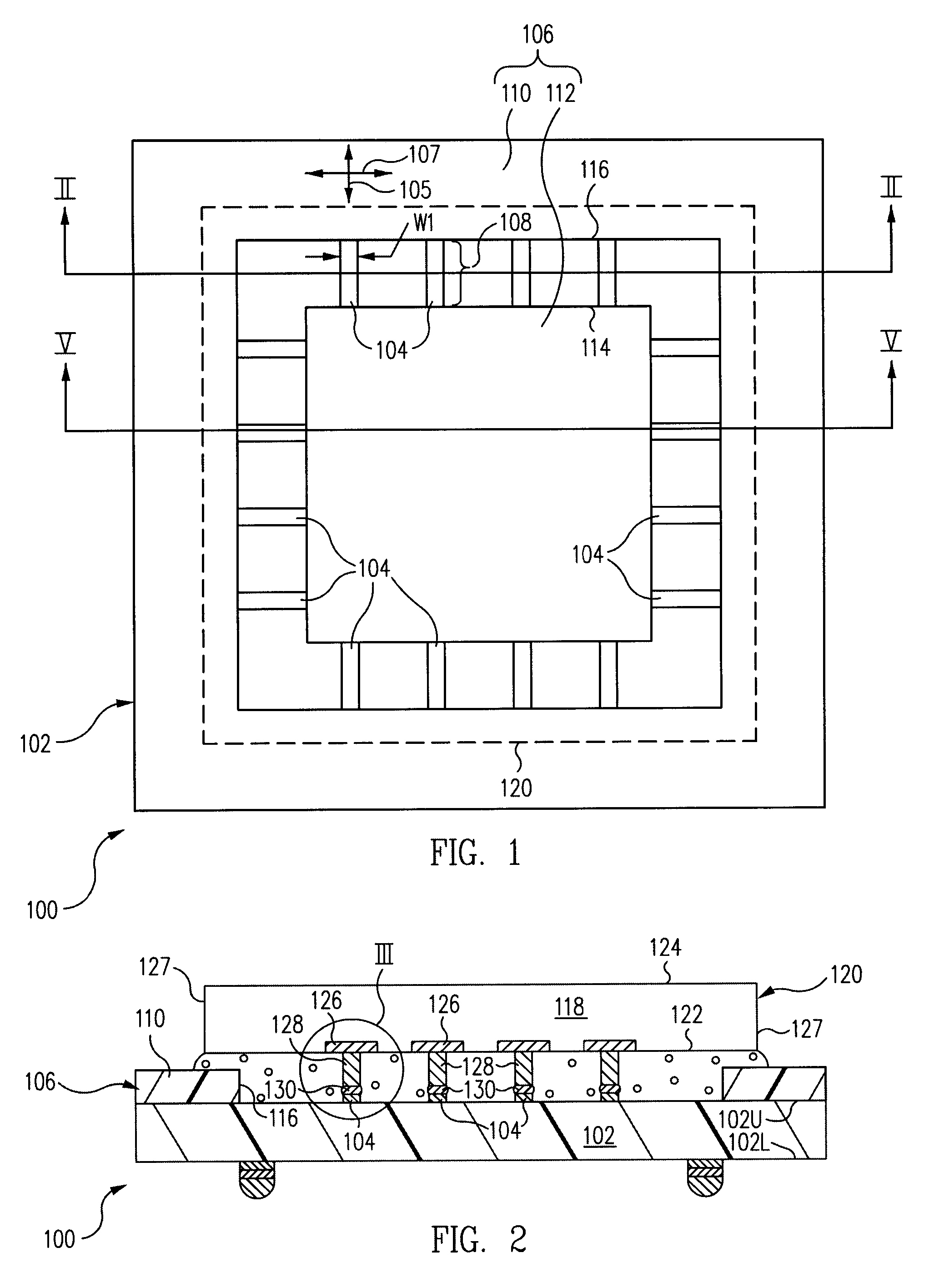

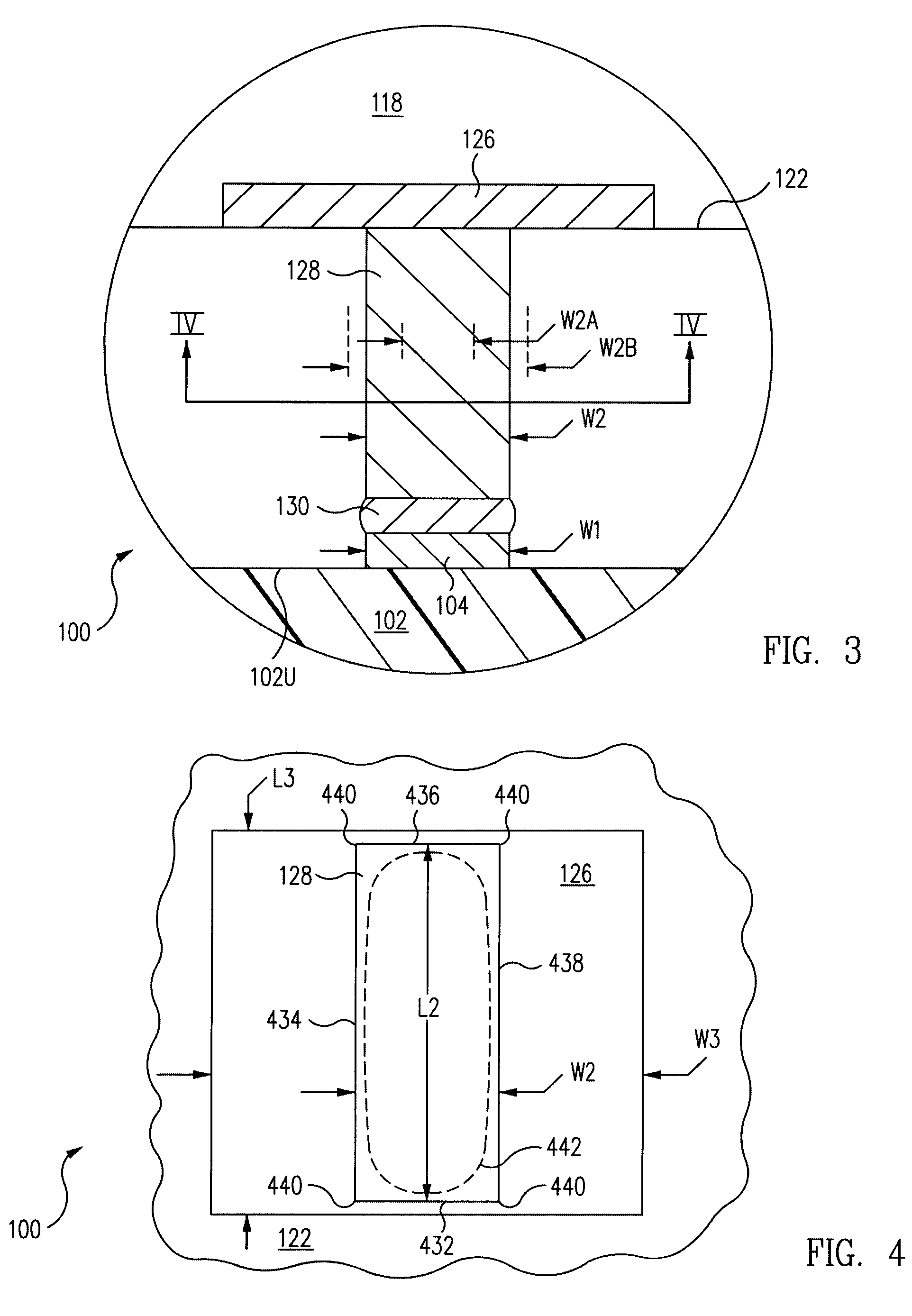

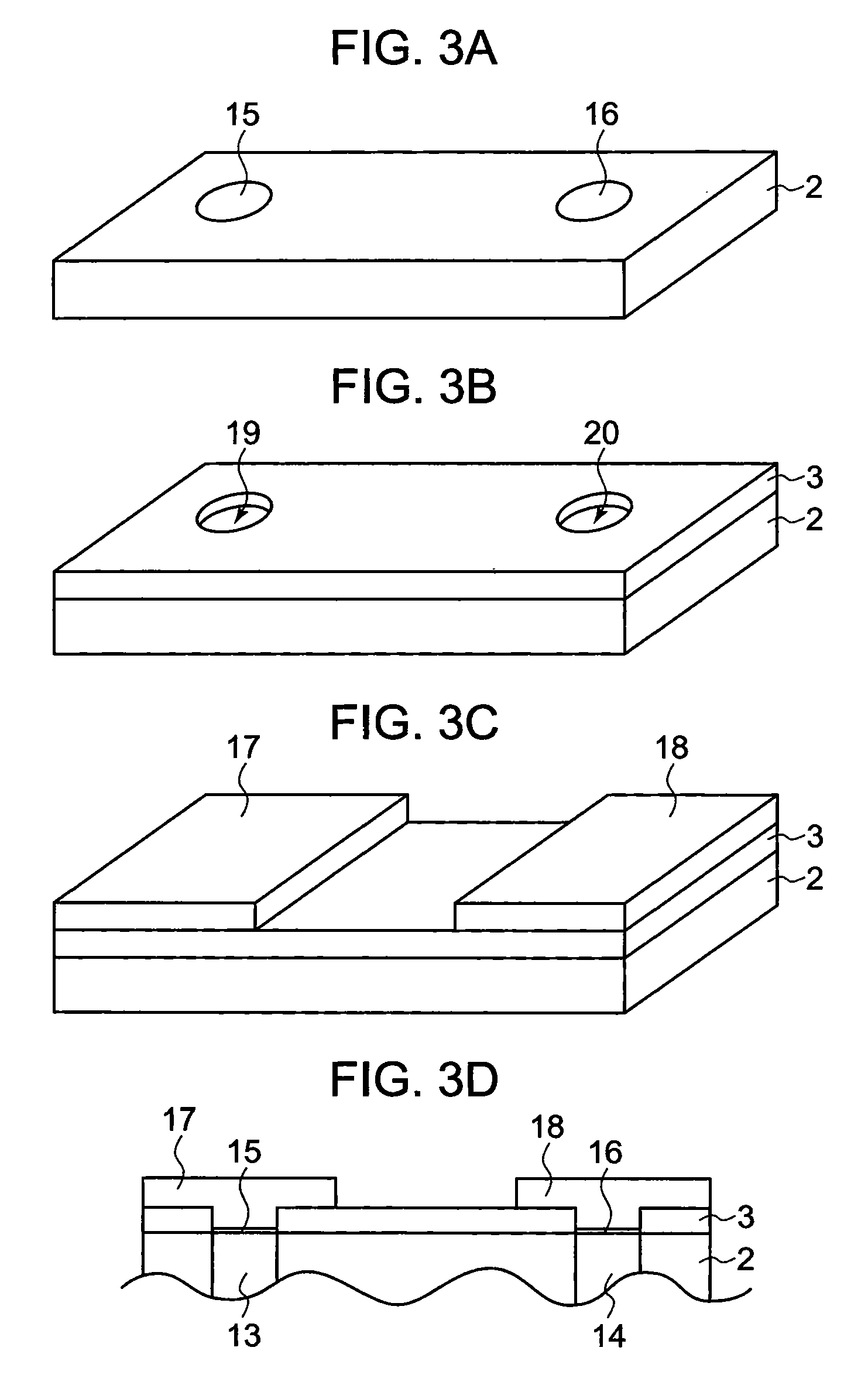

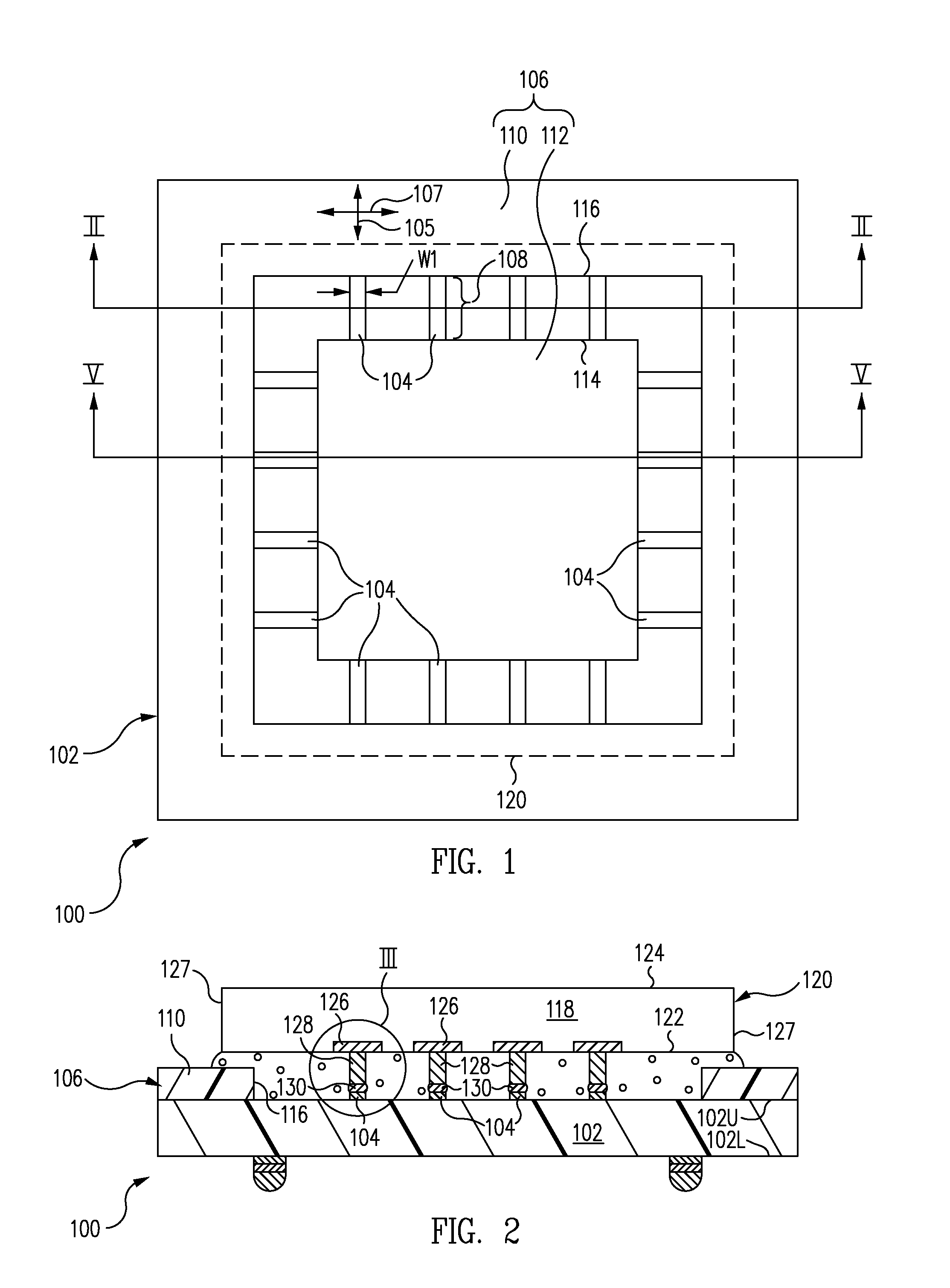

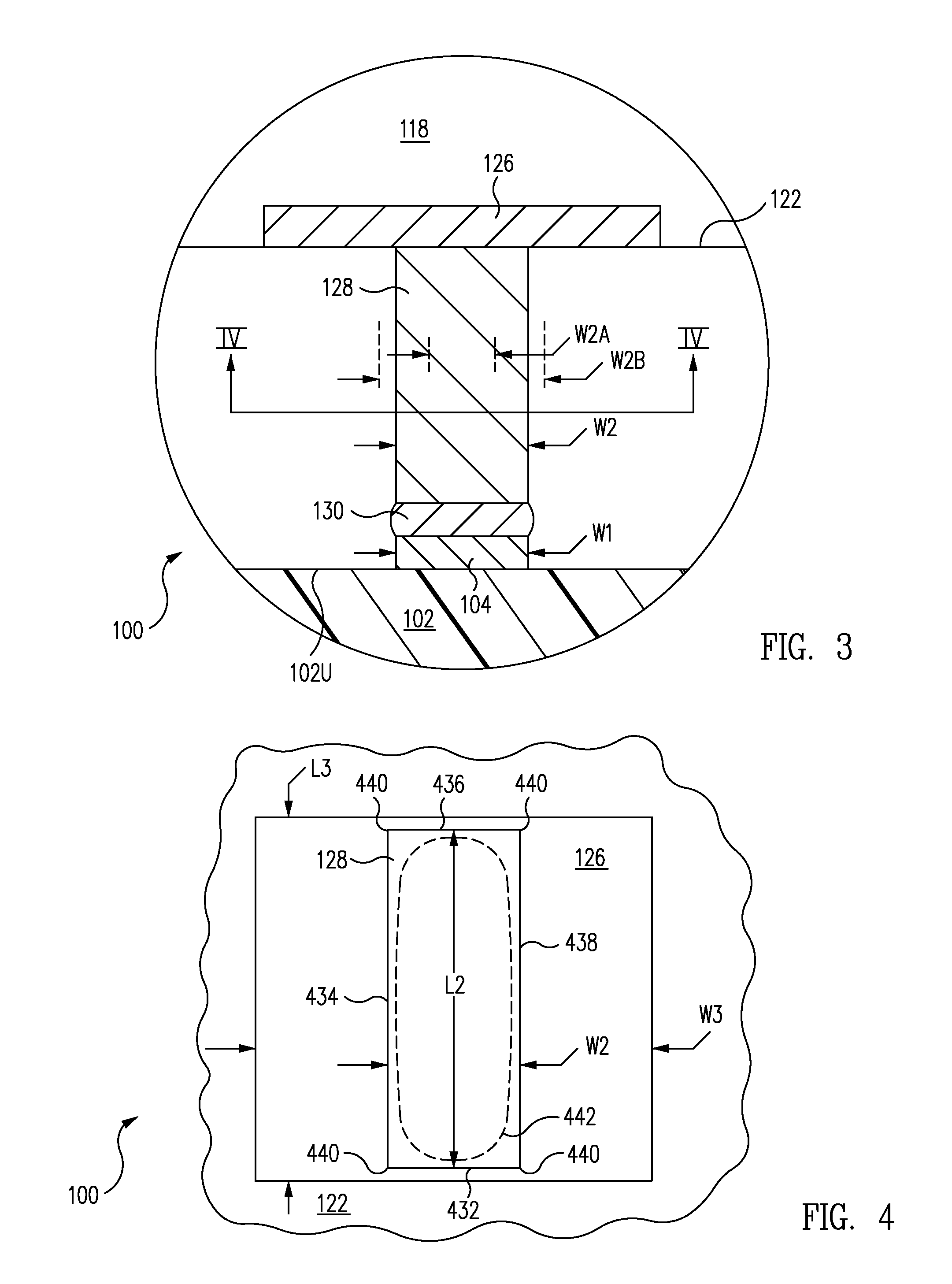

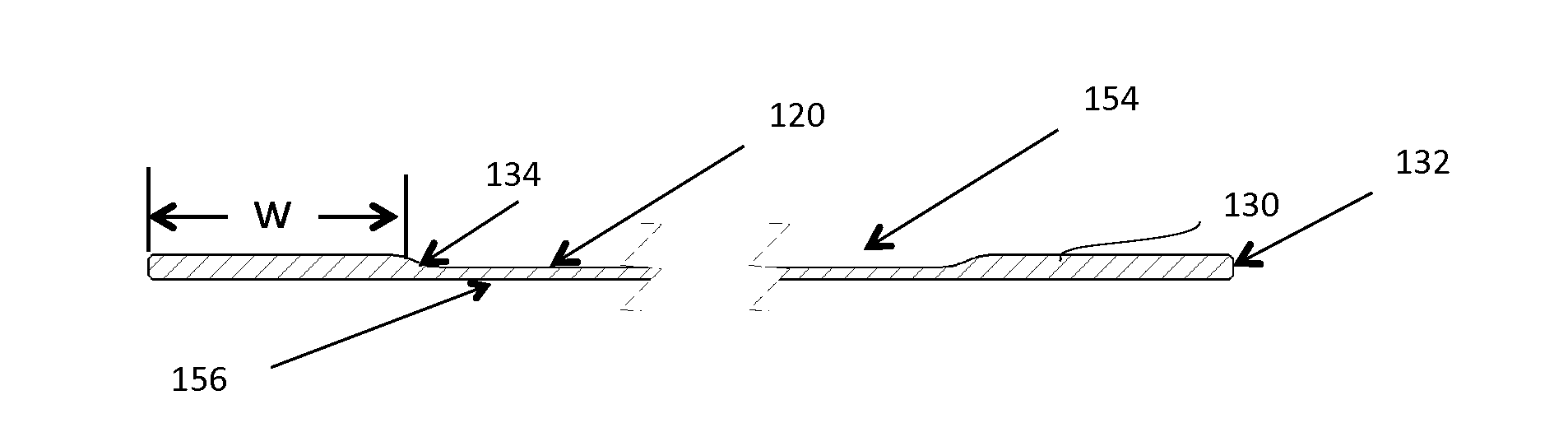

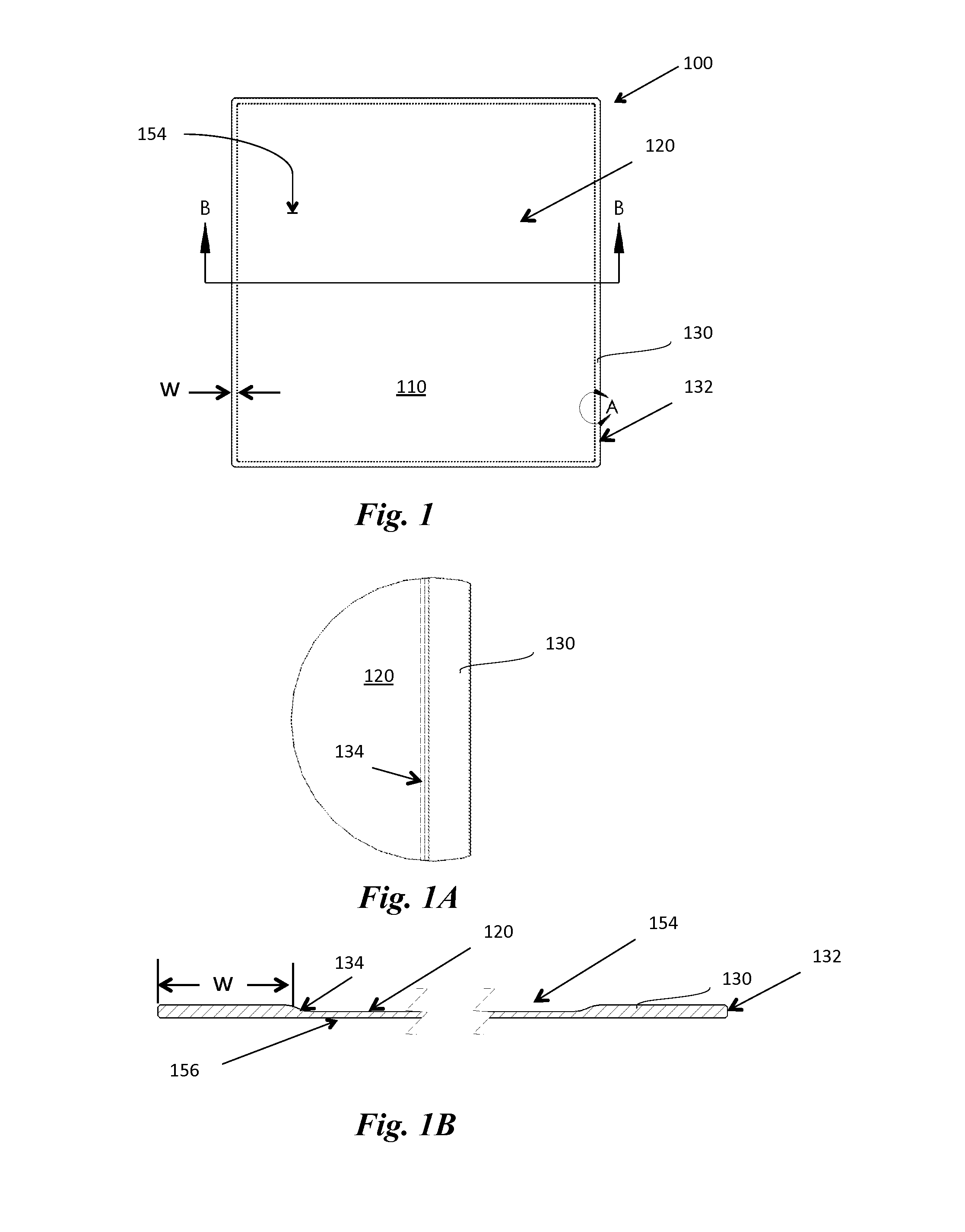

Fine pitch copper pillar package and method

ActiveUS8536458B1Maximizing load bearing areaRobust interconnectionFinal product manufactureSemiconductor/solid-state device detailsEngineeringElectronic component

An electronic component package includes a substrate having an upper surface. Traces on the upper surface of the substrate extend in a longitudinal direction. The traces have a first latitudinal width in a latitudinal direction, the latitudinal direction being perpendicular to the longitudinal direction. Rectangular copper pillars are attached to bond pads of an electronic component, the copper pillars having a longitudinal length and a latitudinal second width. The latitudinal second width of the copper pillars is equal to and aligned with the first latitudinal width of the traces. Further, the longitudinal length of the copper pillars is parallel with the longitudinal direction of the trace and equal to the length of the bond pads. The copper pillars are mounted to the traces with solder joints.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Integral electrode placement and connection systems

Electrode placement and connection systems are described which allow for the electrical connection and maintenance of one or more electrodes positioned on a substrate which is subjected to a variety of mechanical stresses. Electrodes may also be formed on flexible circuit assemblies integrated within or along the hood. The circuit assemblies may also provide structural support to the hood during delivery and / or deployment. Such a system may include an imaging hood having an aperture through which transparent fluid is flowed and one or more electrodes positioned along or about the hood. As the hood is configured between a low-profile and opened configuration, these electrodes may remain electrically coupled despite the mechanical stresses subjected to the electrodes and the connections thereto.

Owner:INTUITIVE SURGICAL OPERATIONS INC

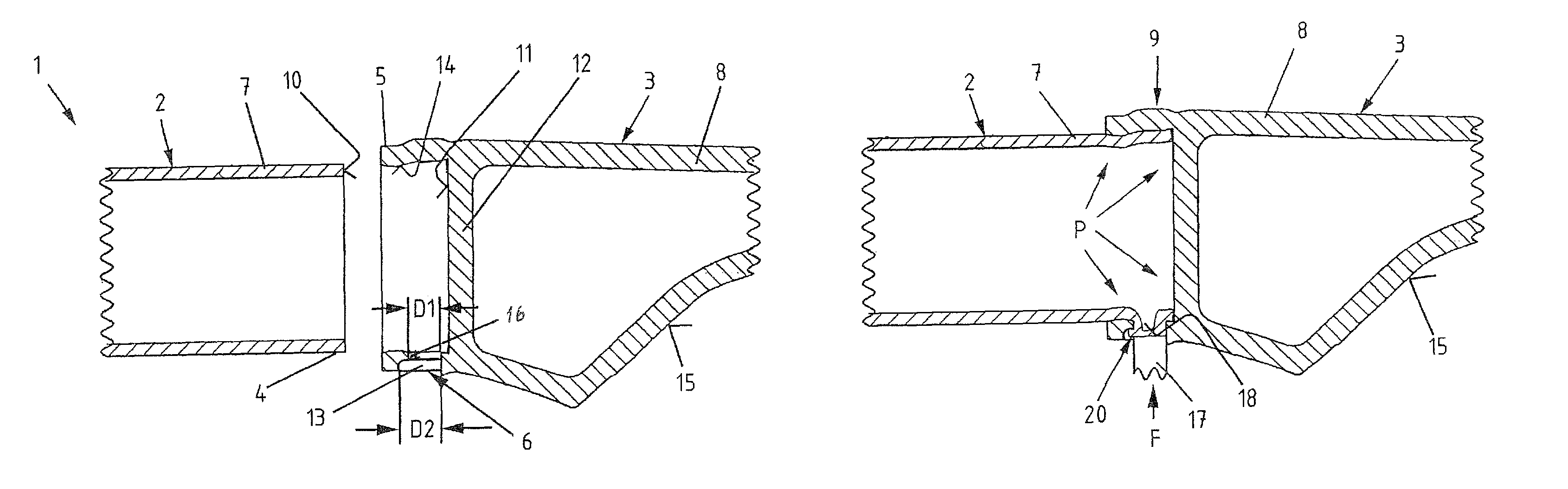

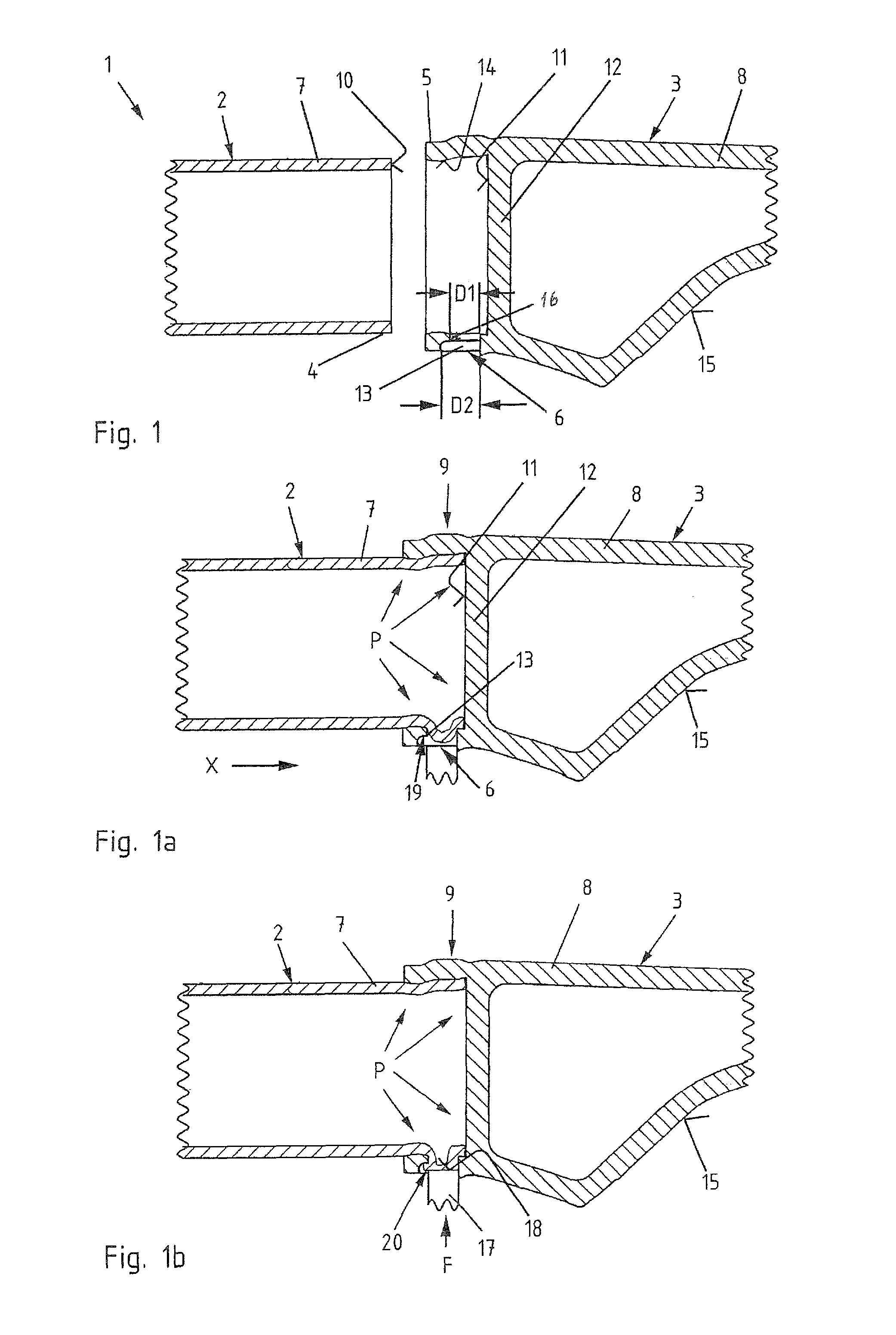

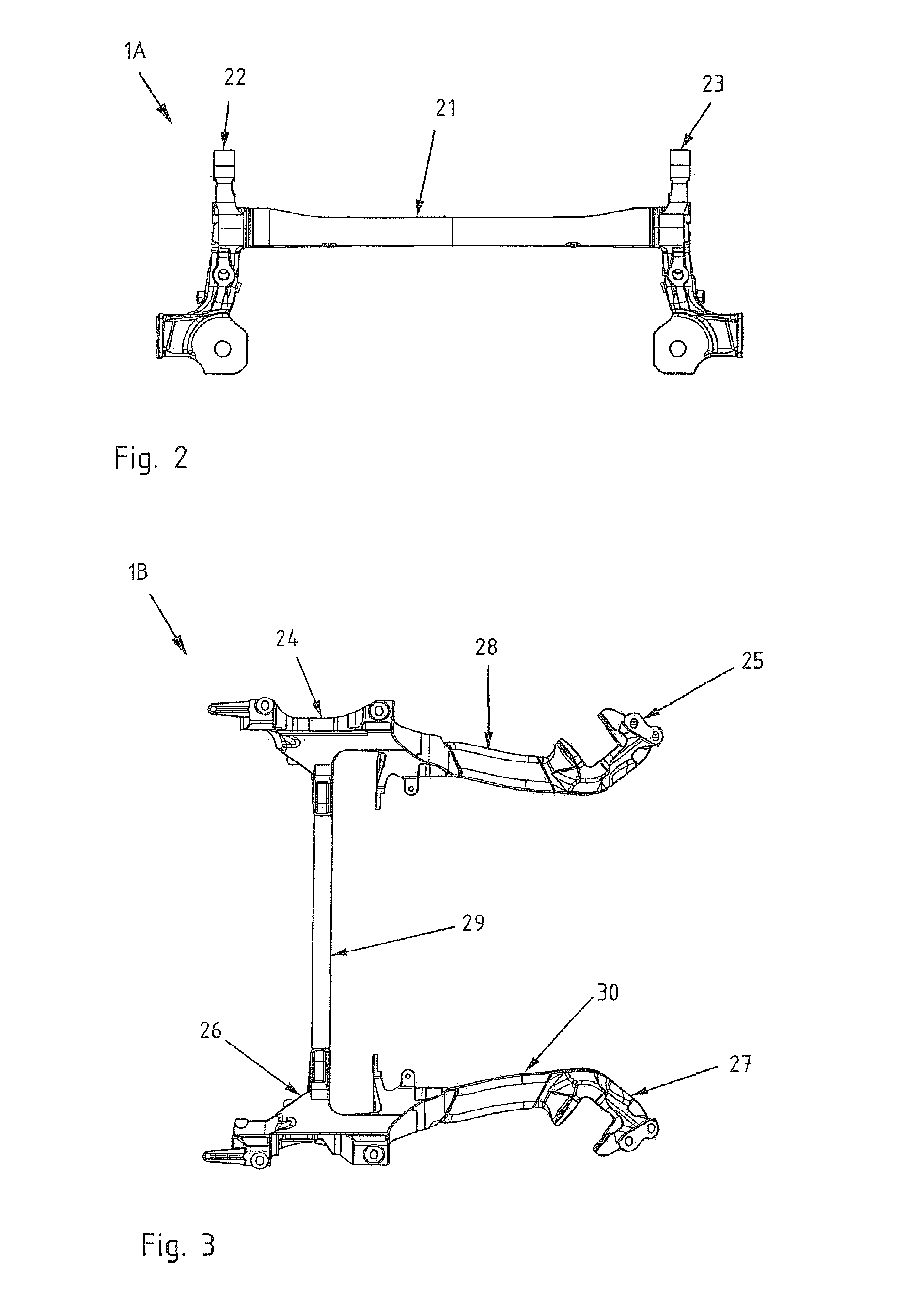

Method of connecting chassis parts, and a chassis assembly

InactiveUS8286319B2Simple processReadily suitedJoints with sealing surfacesRopes and cables for vehicles/pulleyOverlap zoneInterference fit

In a method of connecting chassis parts to produce a chassis assembly, at least one end of a first chassis part is connected with a second chassis part in an overlap zone by a form fit and an interference fit through an internal high pressure joining process. The second chassis part serves hereby a seal of the one end of the first chassis element.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

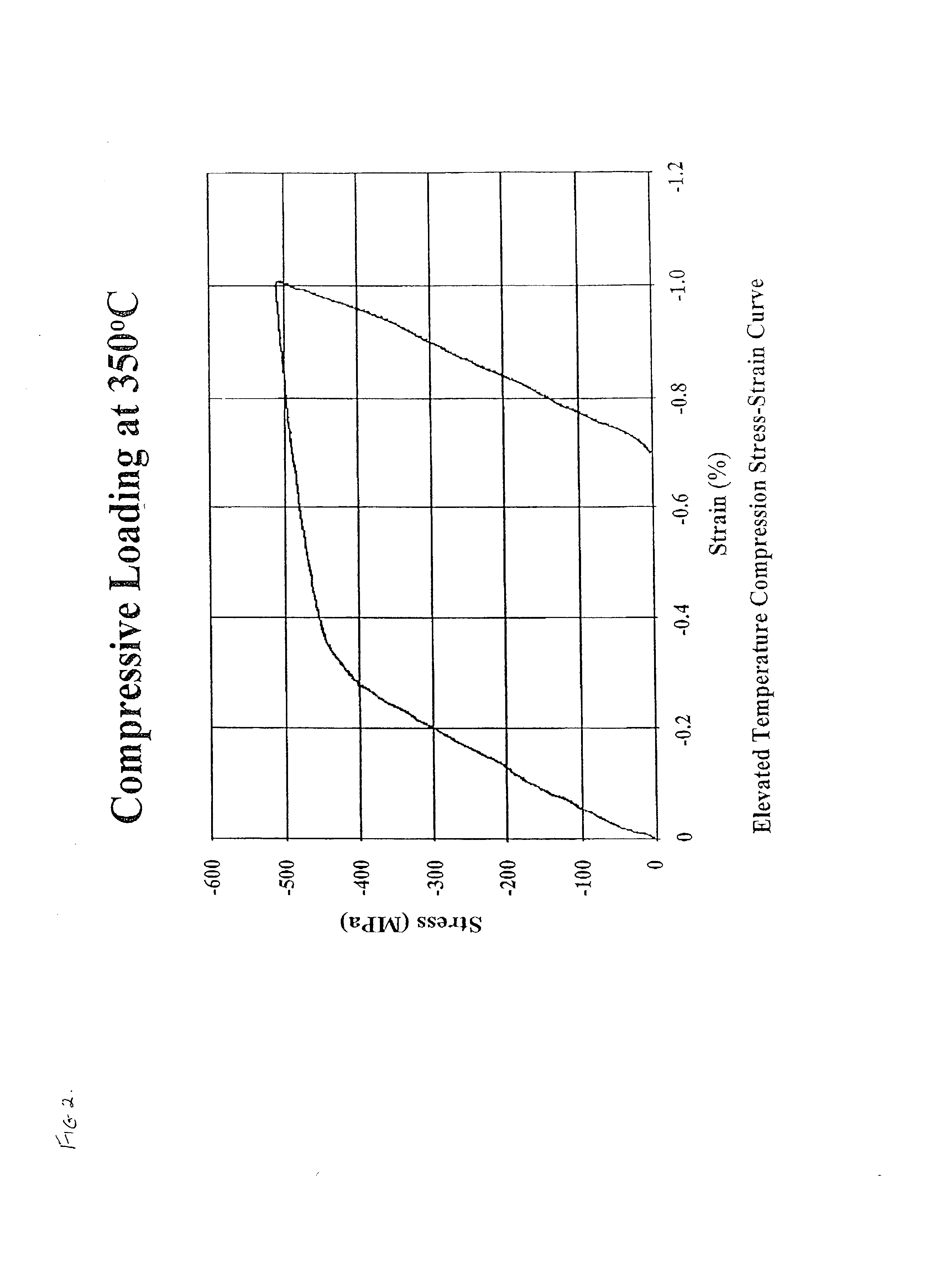

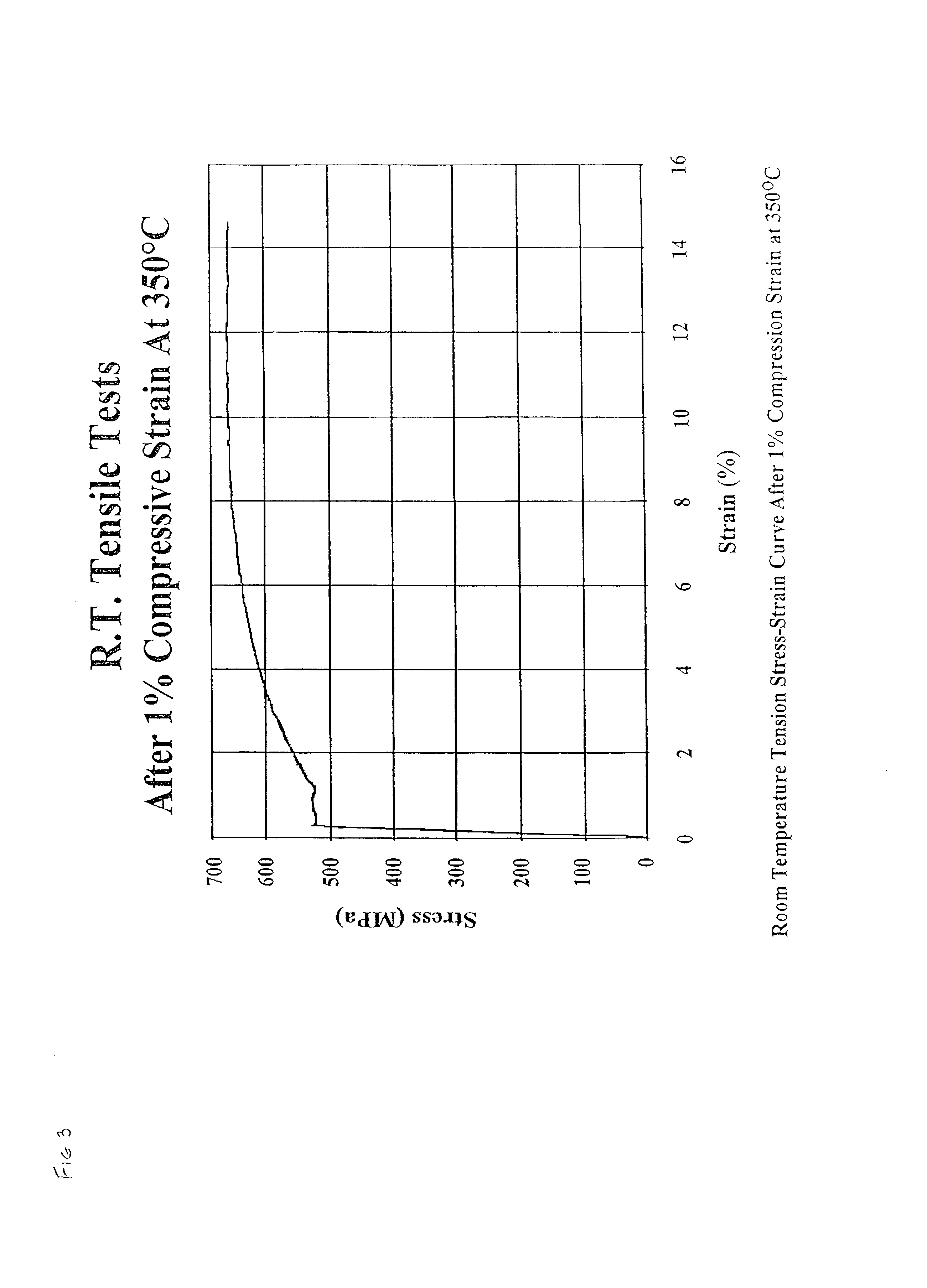

Hydrogen-induced-cracking resistant and sulphide-stress-cracking resistant steel alloy

The invention relates to a quench-and-temper steel alloy for use in casing for oil and gas wells wherein such casing is exposed to low pH environments. The steel alloy has a carbon range by weight of 0.15% to 0.35%, a manganese range by weight of 0.60% to 1.10%, a molybdenum range by weight of 0.15% to 0.65%, and a sulphur range by weight of less than 0.002%. The steel alloy has a quench-and-temper micro-structure and features precipitated spheroidal molybdenum carbides in manganese- and carbon-rich bands. The steel alloy also has, by weight, a chromium range of less than 0.50%, an aluminum range of less than or equal to 0.08% and a calcium range of less than or equal to 0.0045%.

Owner:IPSCO ENTERPRISES

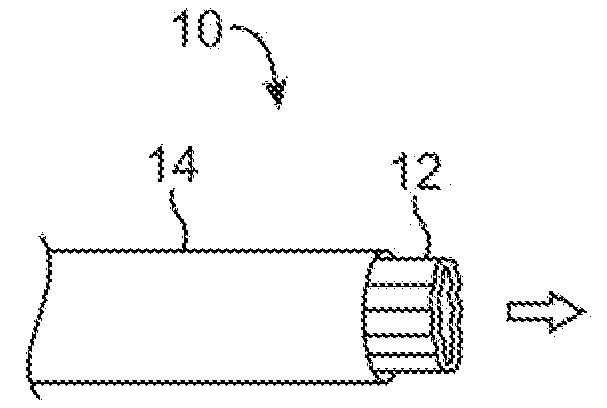

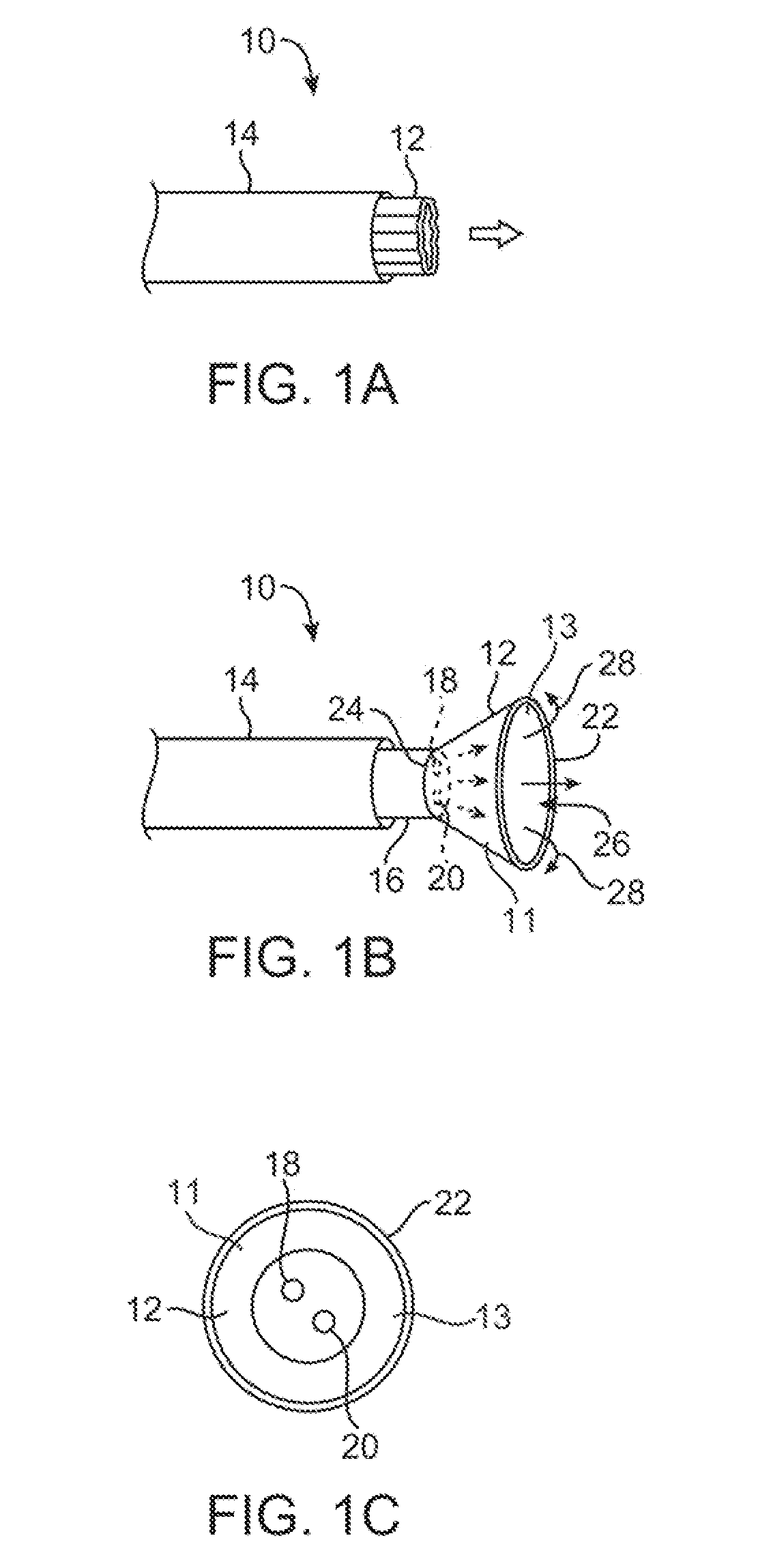

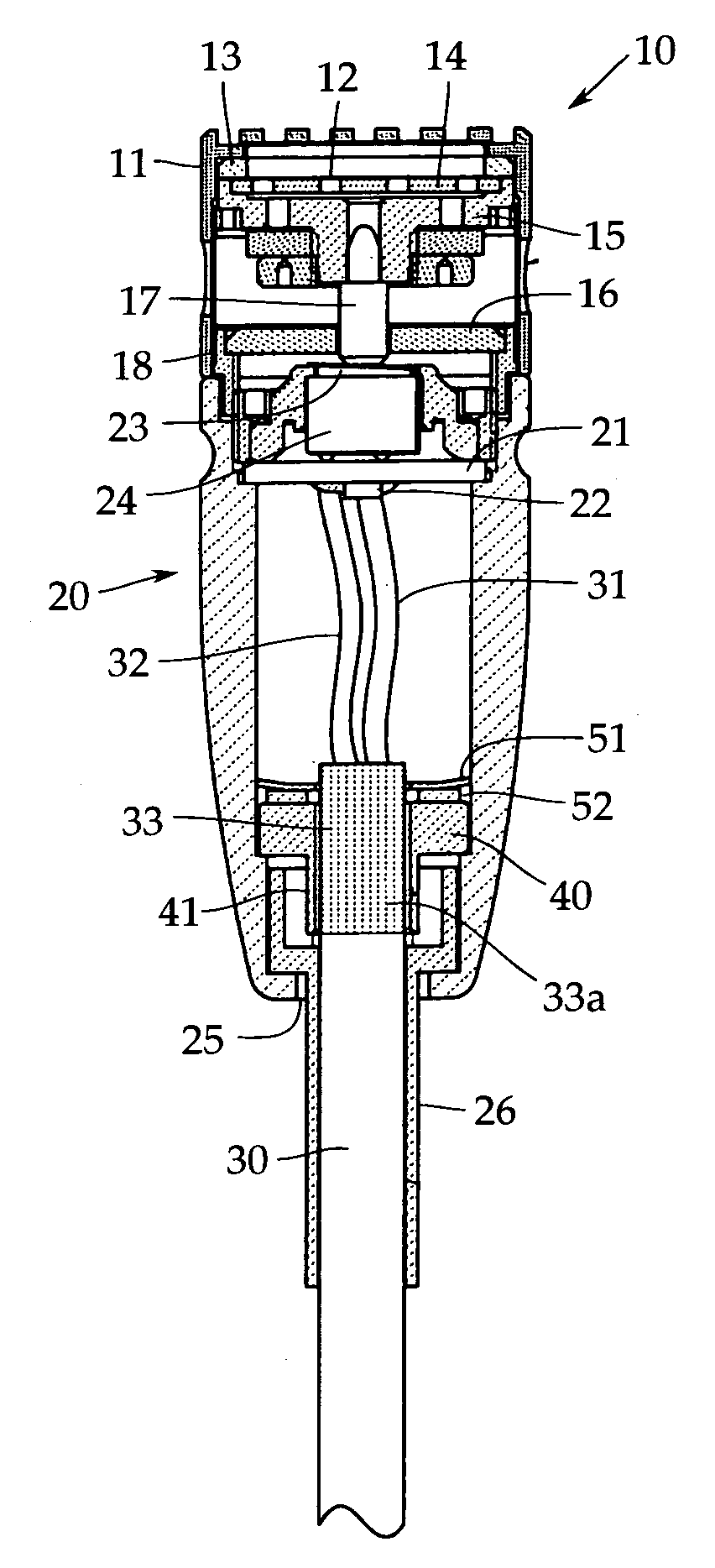

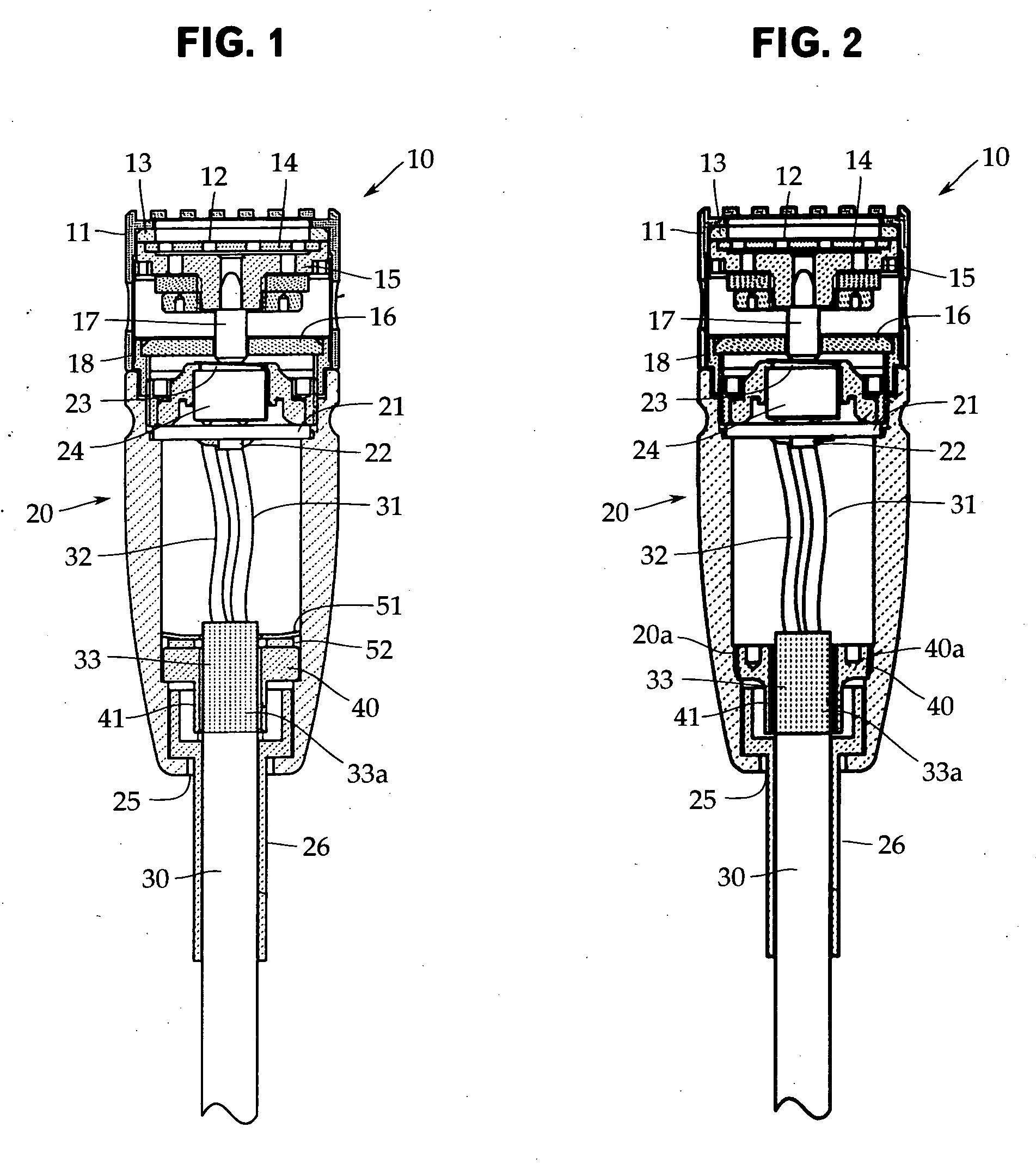

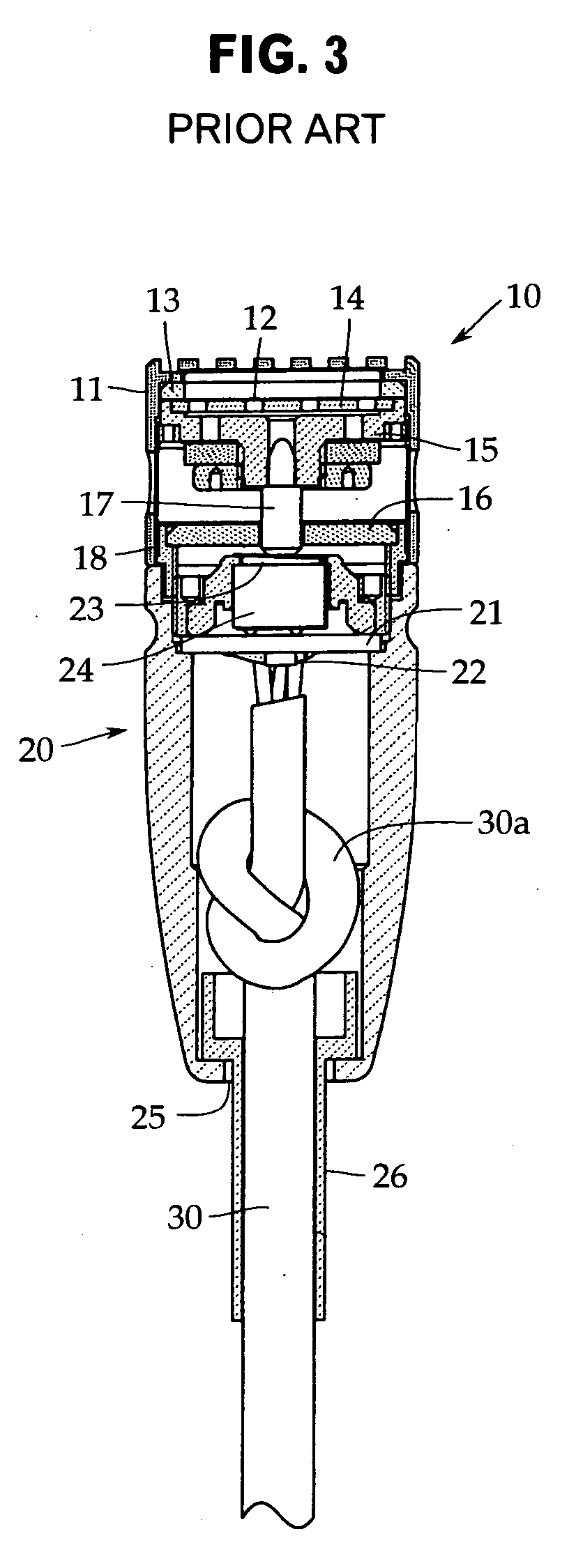

Condenser microphone

ActiveUS20060045302A1Improve reliabilityWithstanding stressPiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesCapacitanceEngineering

In a condenser microphone unit connected to an output module section via a dedicated microphone cord, the generation of noise caused by strong electromagnetic waves sent from a cellular phone etc. is effectively prevented by a simple configuration. In the condenser microphone unit in which a microphone capsule 10 is supported, for example, exchangeably on a support enclosure 20 and a microphone cord 30 consisting of a two-core shield covering line for connecting the condenser microphone unit to the output module section is pulled into the support enclosure 20, a shield covering line exposure portion 33a, in which a shield covering line 33 is stripped off, is provided in a portion in which the microphone cord 30 is pulled into the support enclosure 20, and a fixing member 40 formed into a doughnut shape is fixed to the shield covering line exposure portion 33a by staking, by which the shield covering line 33 is connected to the support enclosure 20 via the fixing member 40.

Owner:AUDIO-TECHNICA

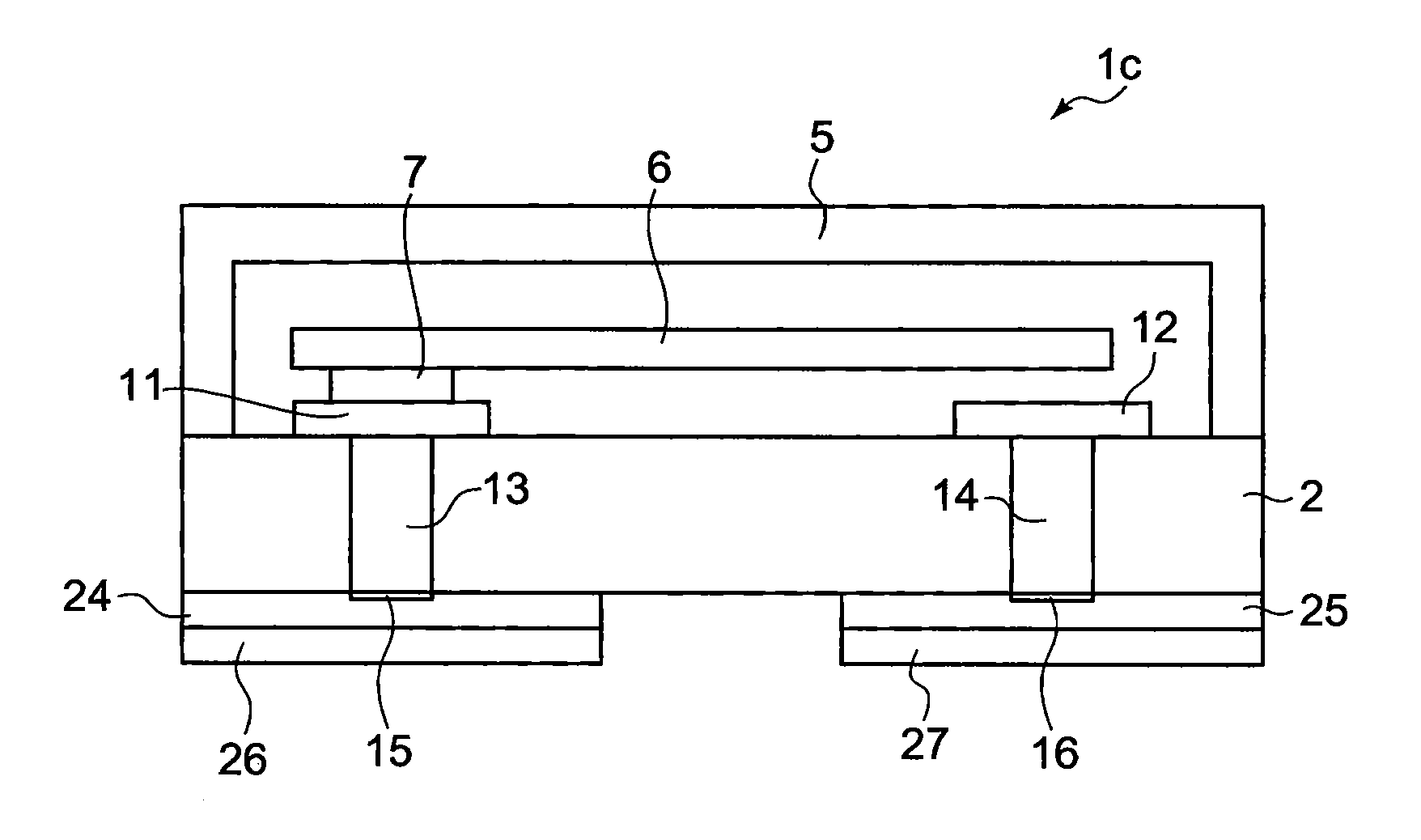

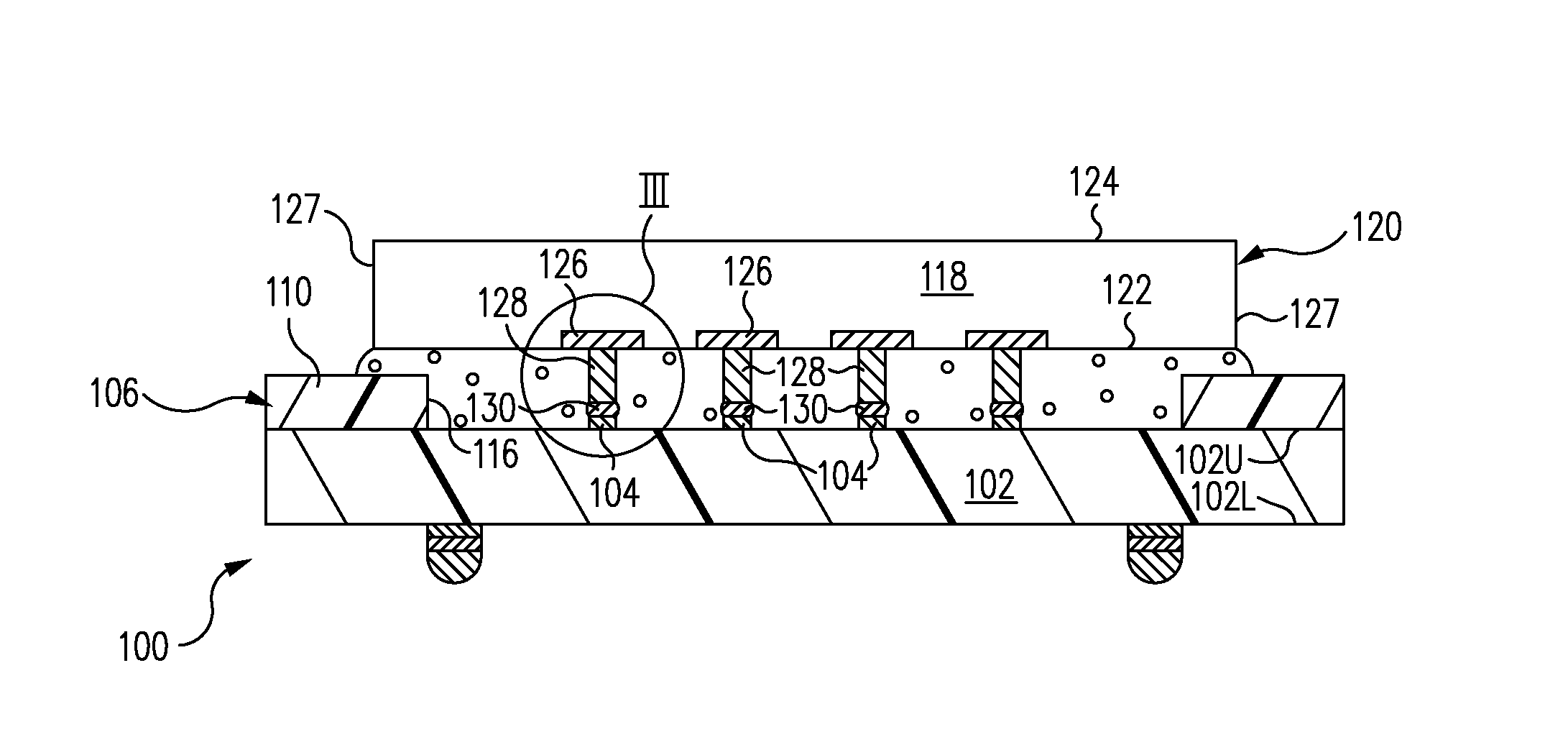

Electronic package having stress buffer layer on mounting surface thereof, and method for manufacturing same

InactiveUS7923904B2Withstanding stressPiezoelectric/electrostriction/magnetostriction machinesImpedence networksSurface mountingEngineering

An electronic component capable of withstanding stress from a printed circuit board or the like is provided. In an electronic component, a cavity hermetically sealed by a base and a lid is formed. In the cavity, a crystal resonator is supported by a supporting member over the top surface of the base. The base is made of glass. A stress buffer layer made of a conductive resin or the like is formed over the whole bottom surface of the base. An external electrode and an external electrode that are in continuity with the electrodes of the crystal resonator individually extend to the bottom surface of the stress buffer layer via the side surfaces of the base and stress buffer layer. The thus configured electronic component is surface-mounted by, for example, soldering the external electrode and external electrode formed on the bottom surface of the stress buffer layer to a printed circuit board.

Owner:SEIKO INSTR INC

Fine pitch copper pillar package and method

ActiveUS9462690B1Maximizing load bearing areaRobust interconnectionFinal product manufactureSemiconductor/solid-state device detailsEngineeringElectronic component

An electronic component package includes a substrate having an upper surface. Traces on the upper surface of the substrate extend in a longitudinal direction. The traces have a first latitudinal width in a latitudinal direction, the latitudinal direction being perpendicular to the longitudinal direction. Rectangular copper pillars are attached to bond pads of an electronic component, the copper pillars having a longitudinal length and a latitudinal second width. The latitudinal second width of the copper pillars is equal to and aligned with the first latitudinal width of the traces. Further, the longitudinal length of the copper pillars is parallel with the longitudinal direction of the trace and equal to the length of the bond pads. The copper pillars are mounted to the traces with solder joints.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

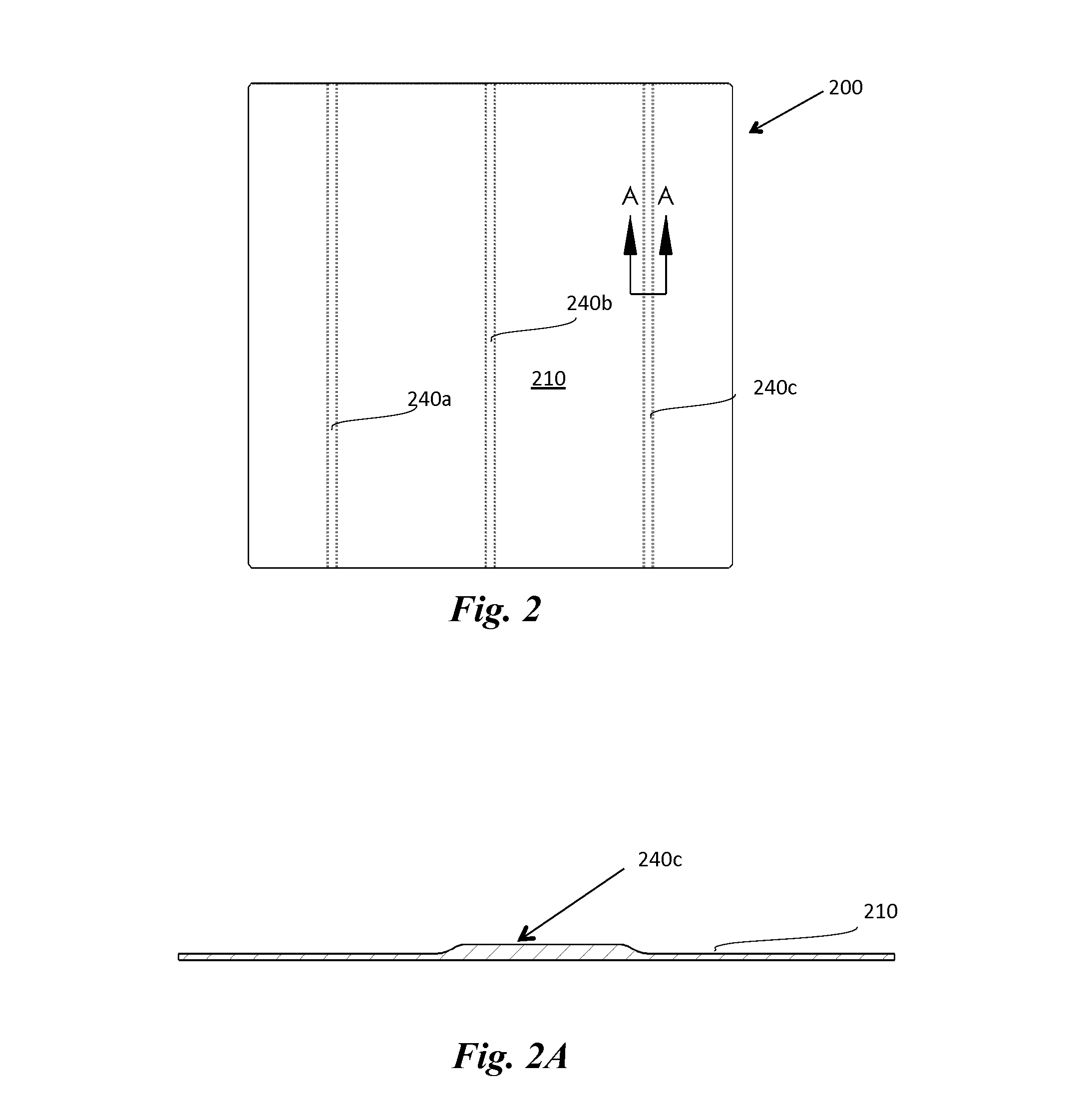

Methods and apparati for making thin semi-conductor wafers with locally controlled regions that are relatively thicker than other regions and such wafers

ActiveUS20170051429A1Increasing the thicknessWithstanding stressPolycrystalline material growthFinal product manufactureCouplingEngineering

Semi-conductor wafers with thin and thicker regions at controlled locations may be for Photovoltaics. The interior may be less than 180 microns or thinner, to 50 microns, with a thicker portion, at 180-250 microns. Thin wafers have higher efficiency. A thicker perimeter provides handling strength. Thicker stripes, landings and islands are for metallization coupling. Wafers may be made directly from a melt upon a template with regions of different heat extraction propensity arranged to correspond to locations of relative thicknesses. Interstitial oxygen is less than 6×1017 atoms / cc, preferably less than 2×1017, total oxygen less than 8.75×1017 atoms / cc, preferably less than 5.25×1017. Thicker regions form adjacent template regions having relatively higher heat extraction propensity; thinner regions adjacent regions with lesser extraction propensity. Thicker template regions have higher extraction propensity. Functional materials upon the template also have differing extraction propensities.

Owner:CUBICPV INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com