Patents

Literature

101results about How to "Erosion minimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

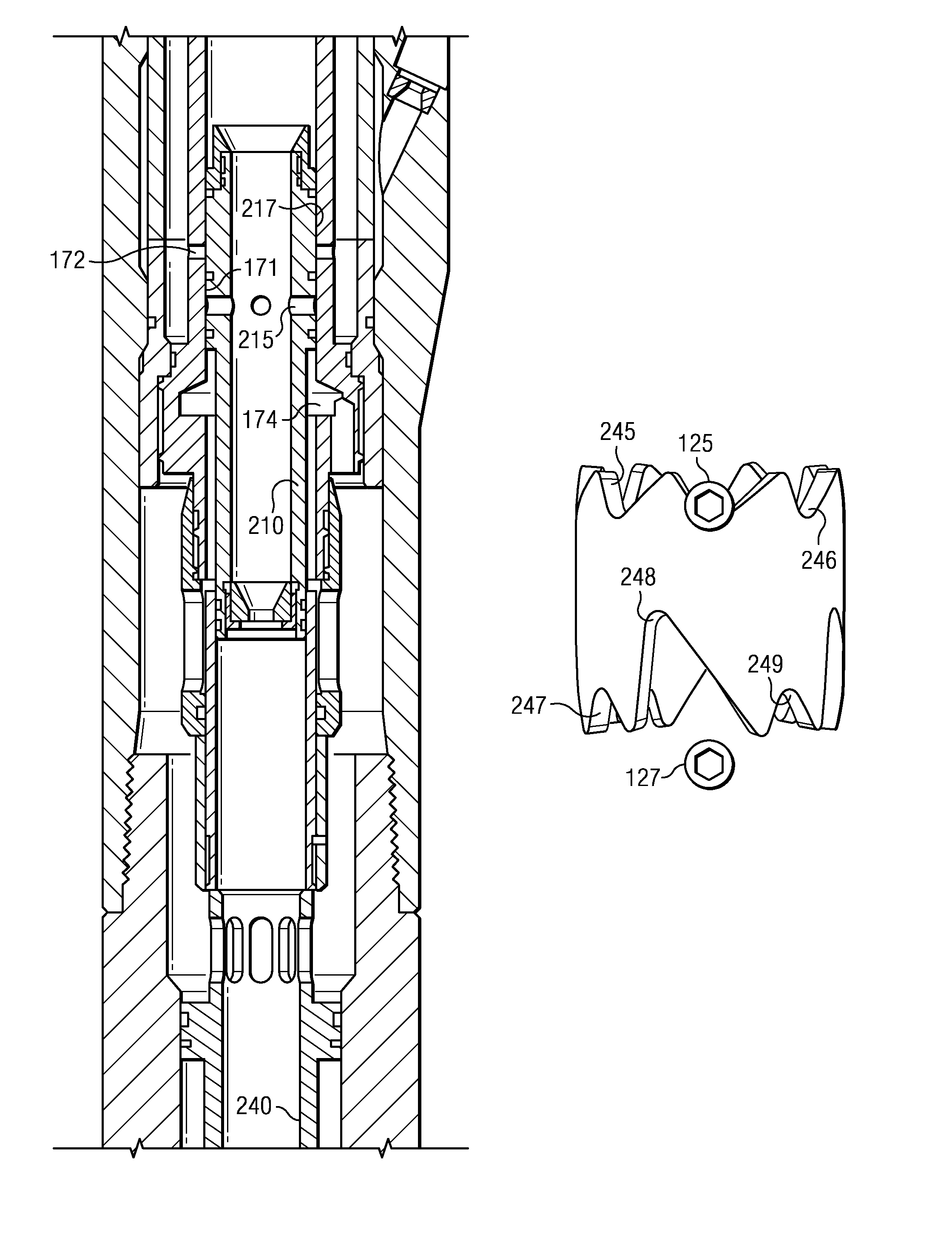

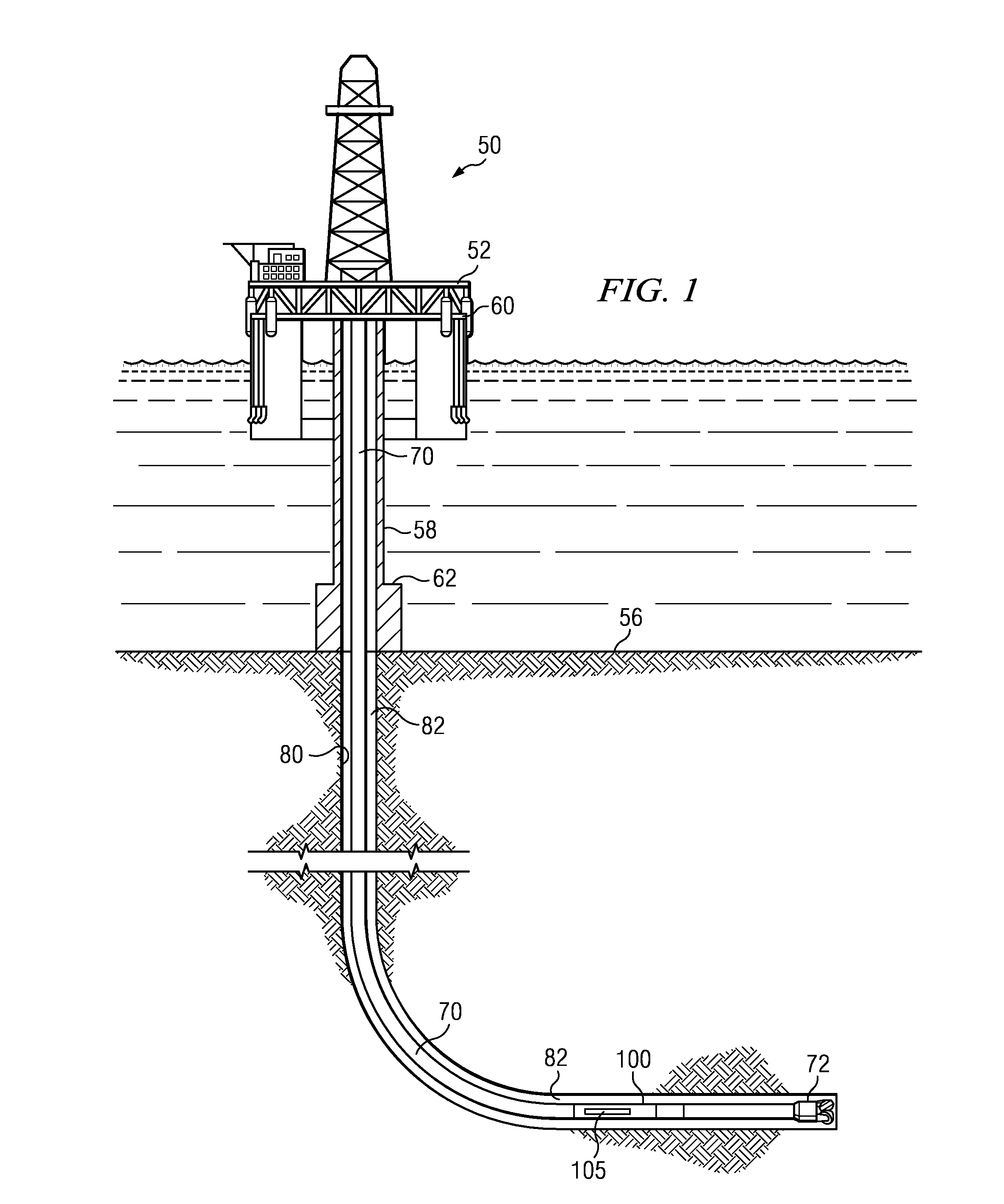

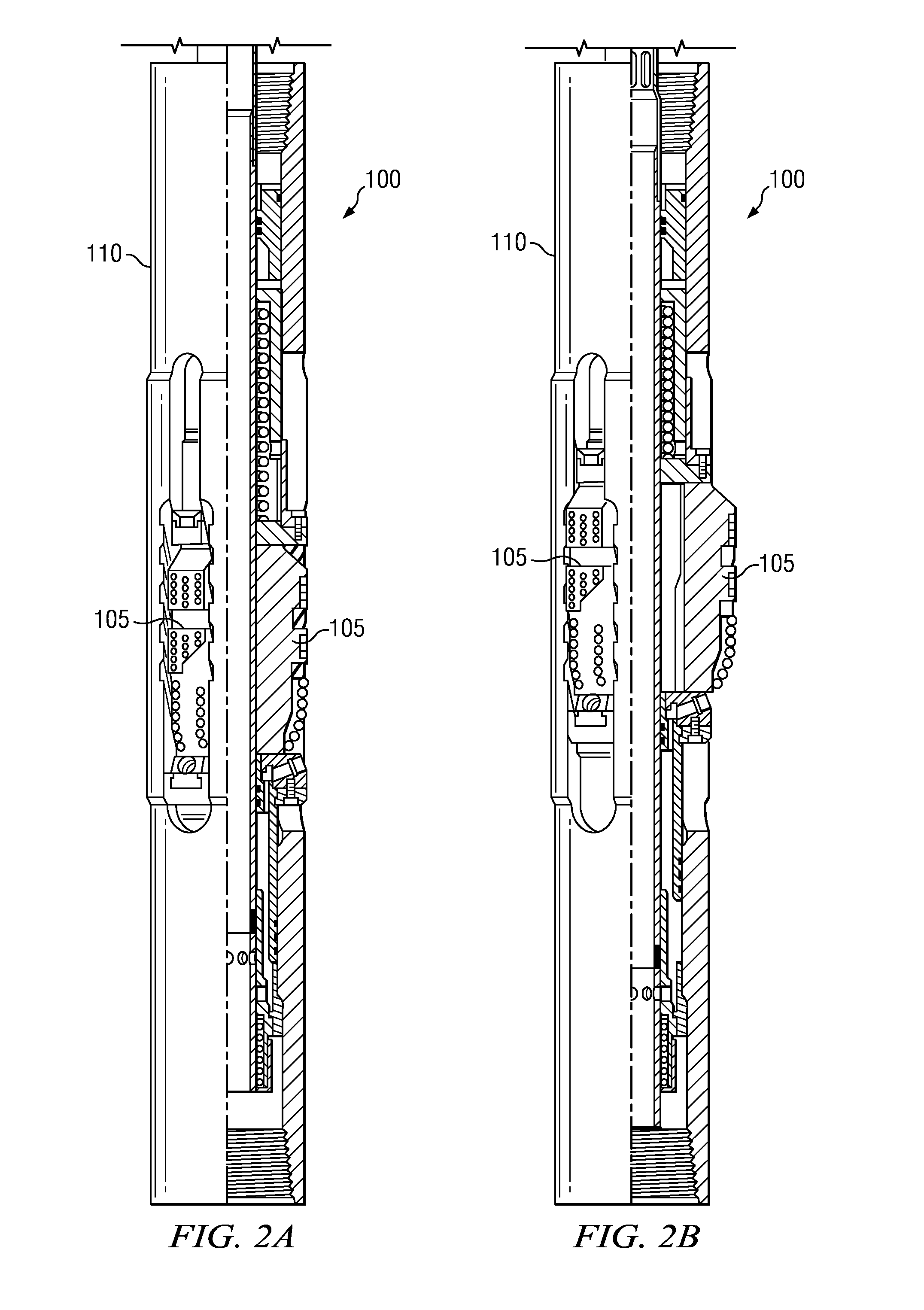

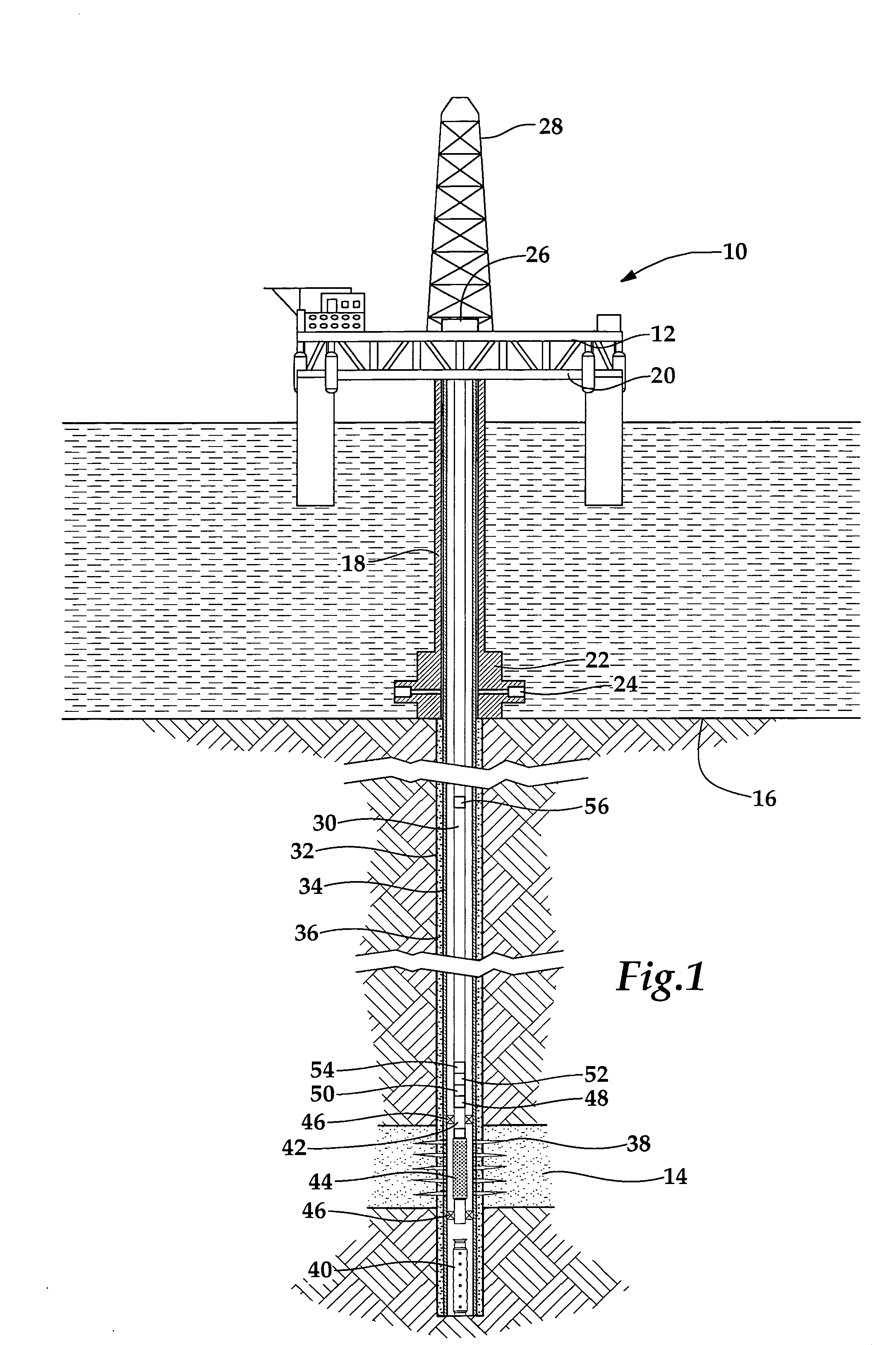

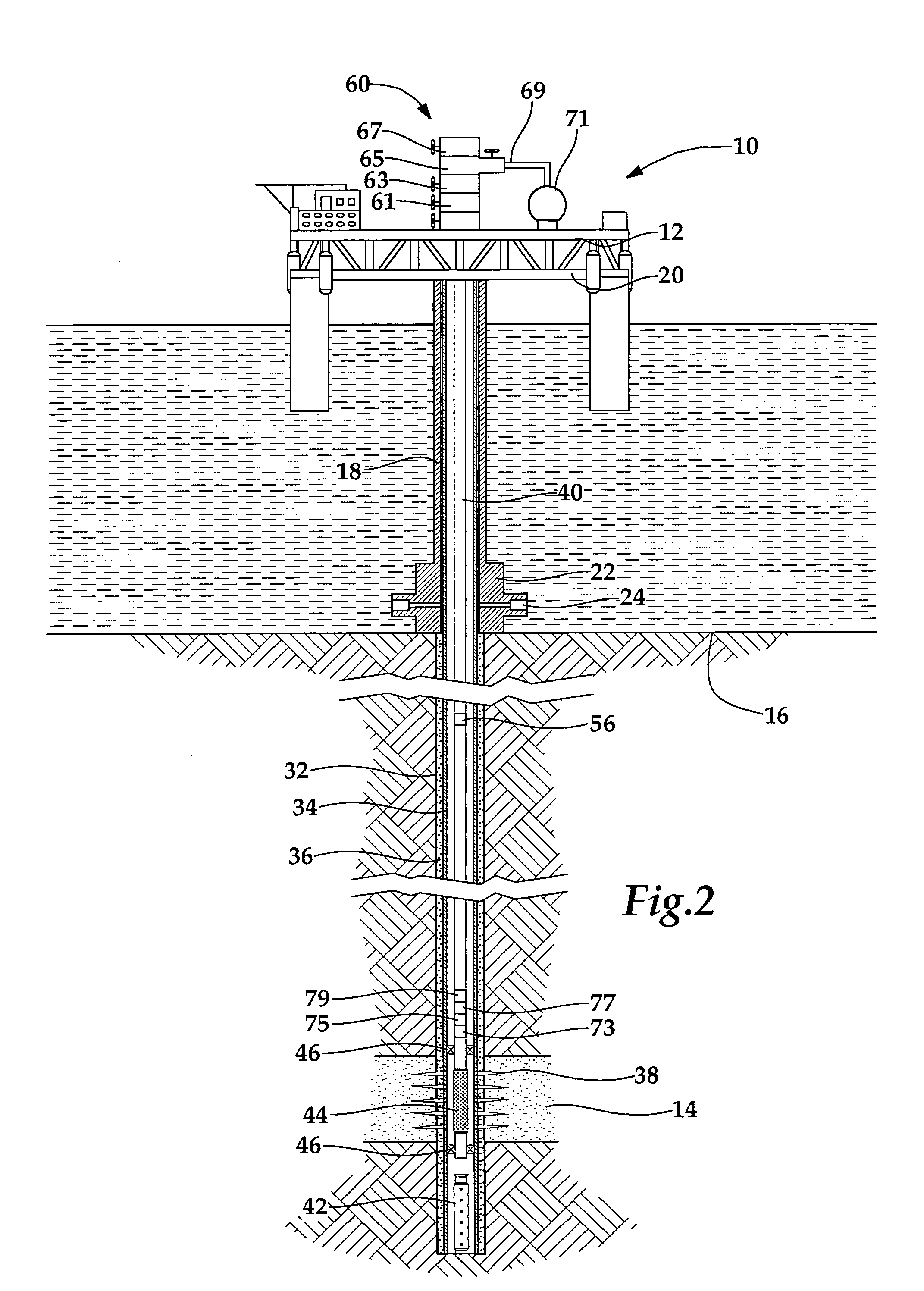

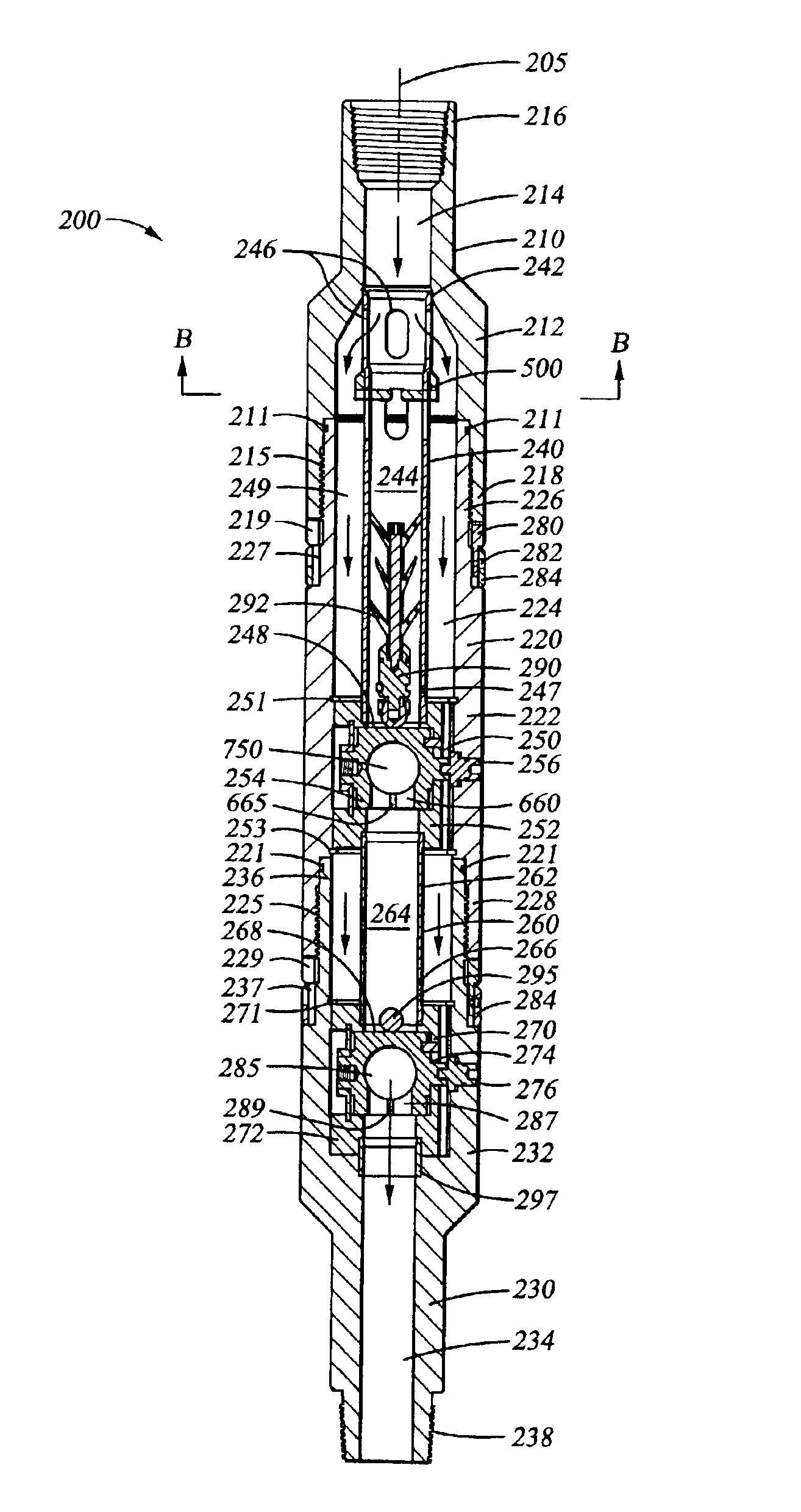

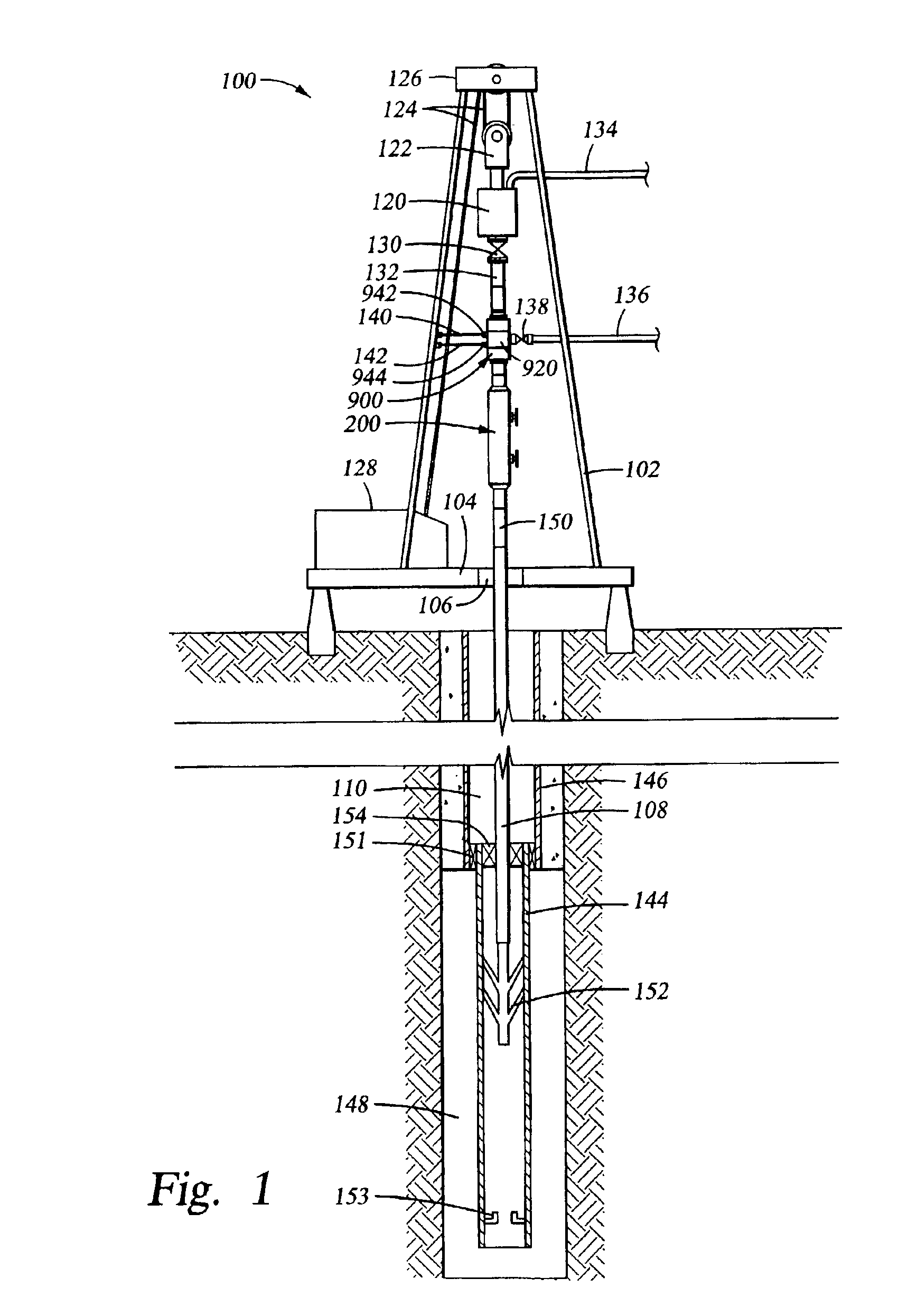

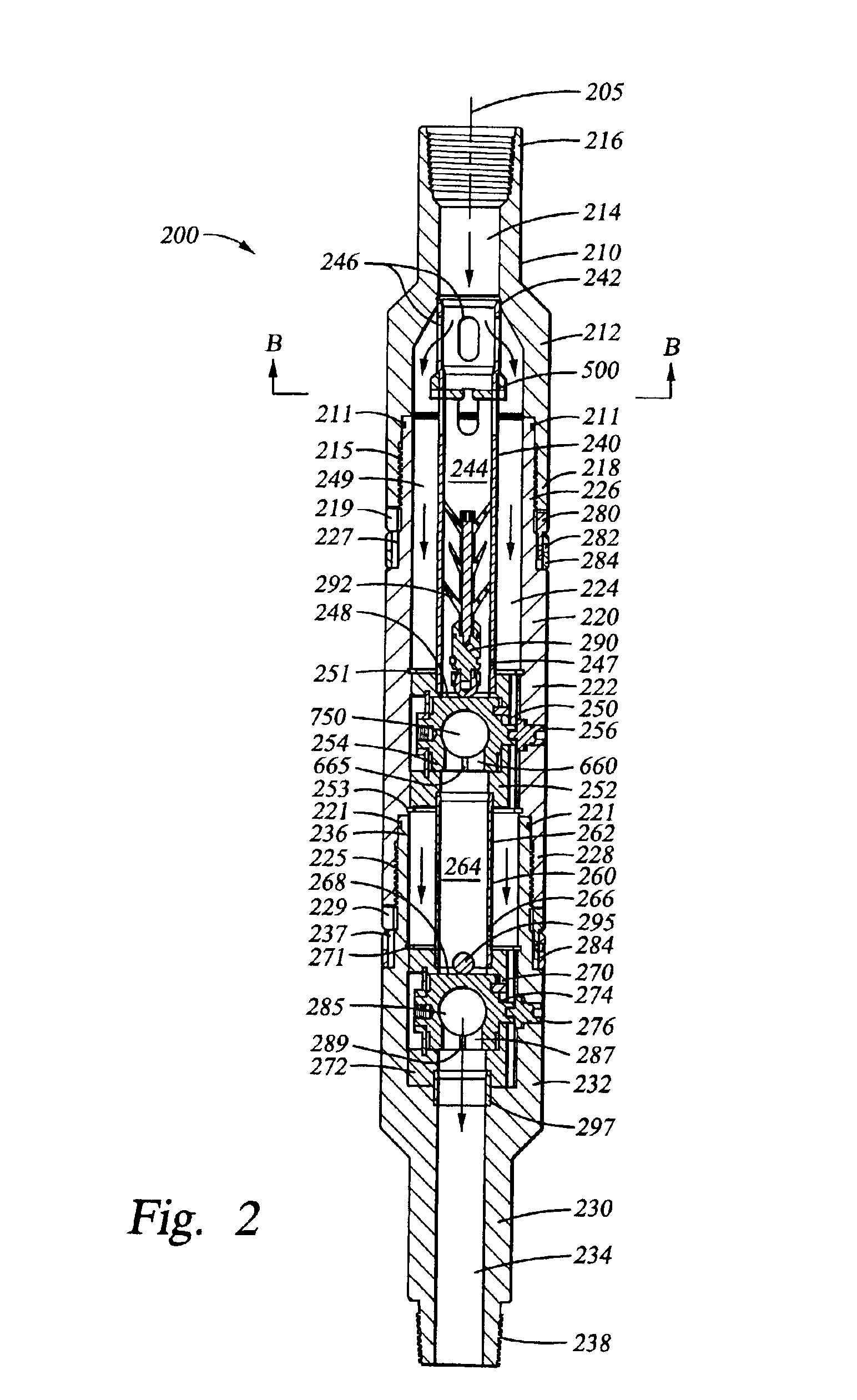

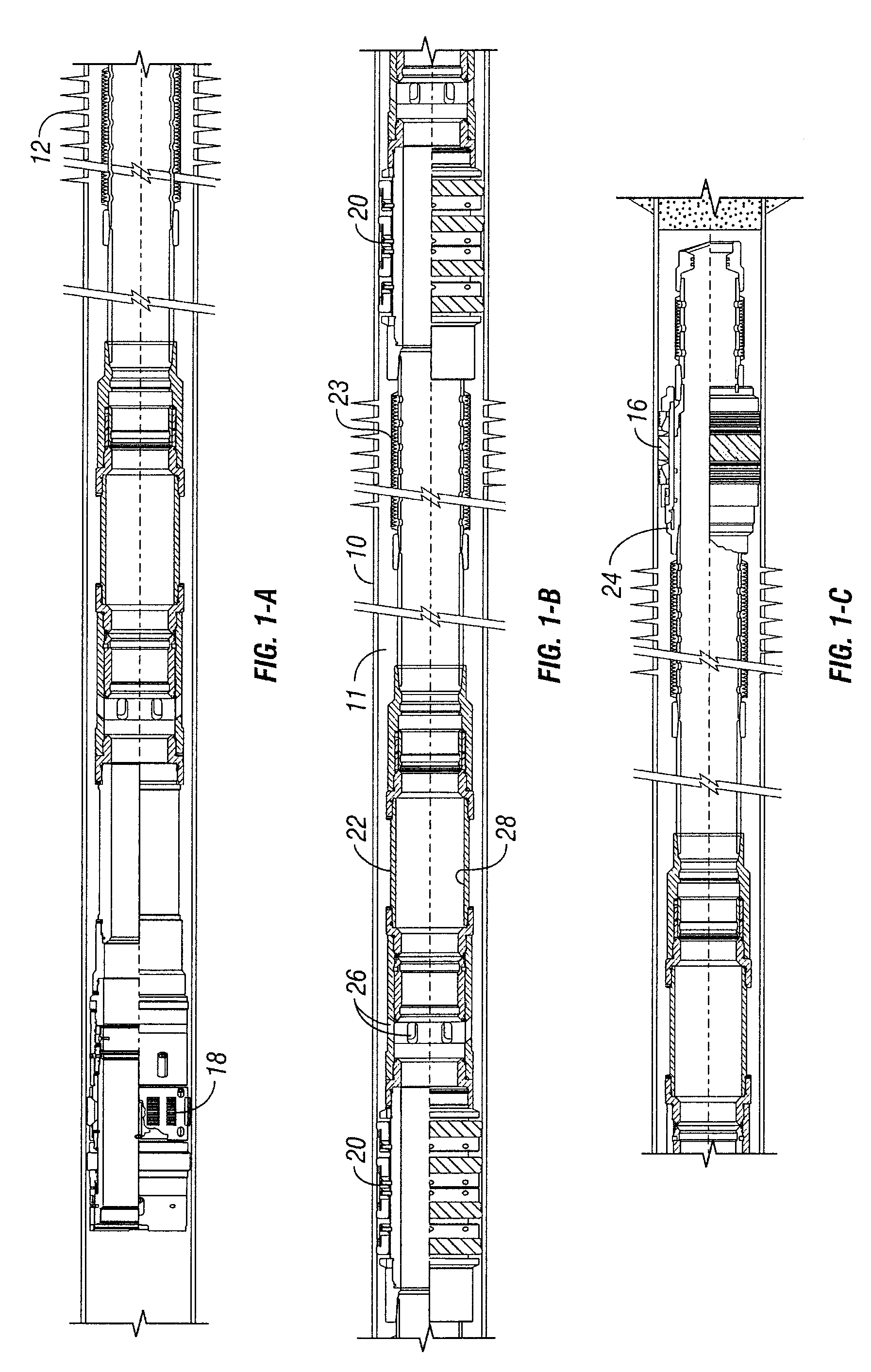

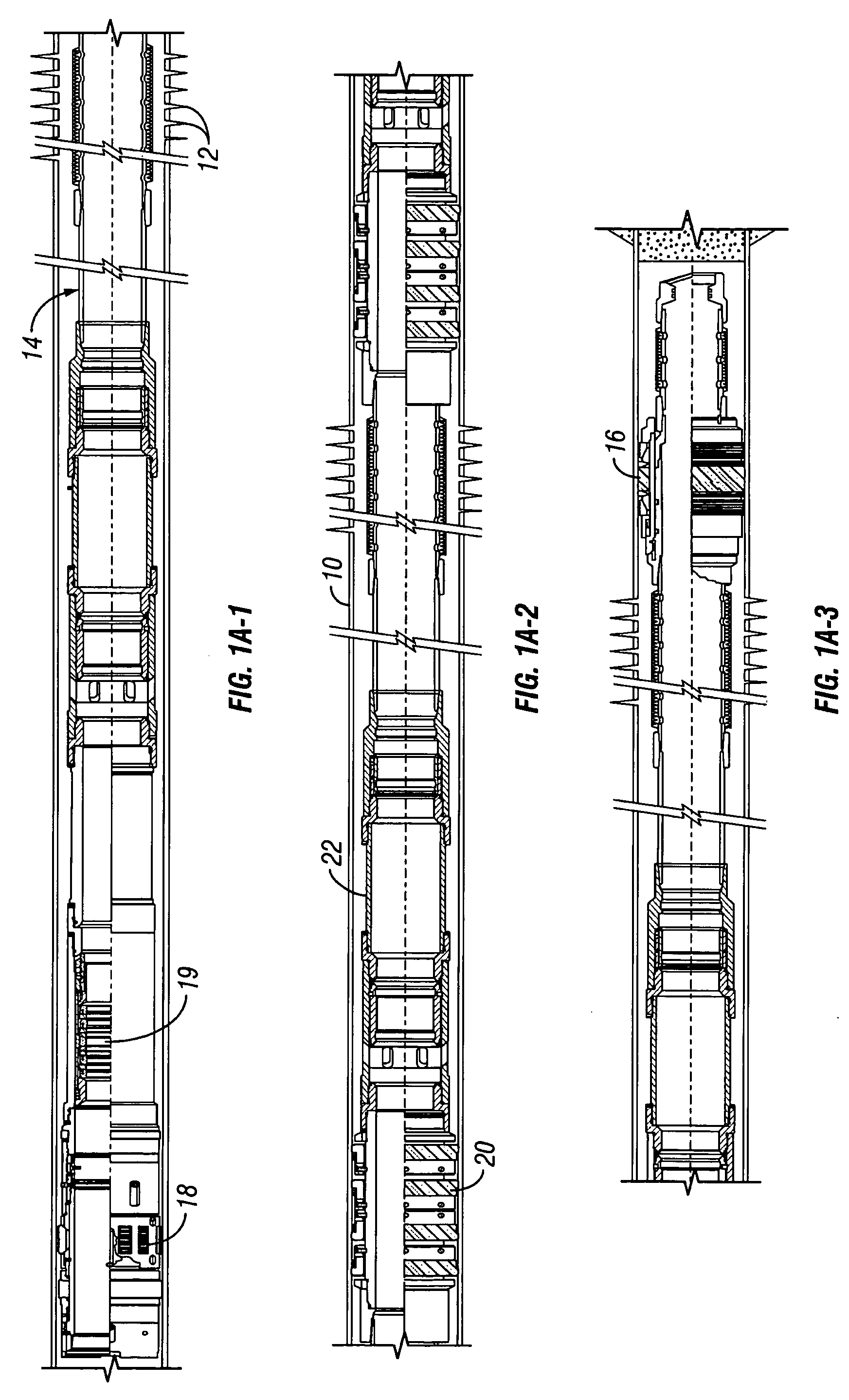

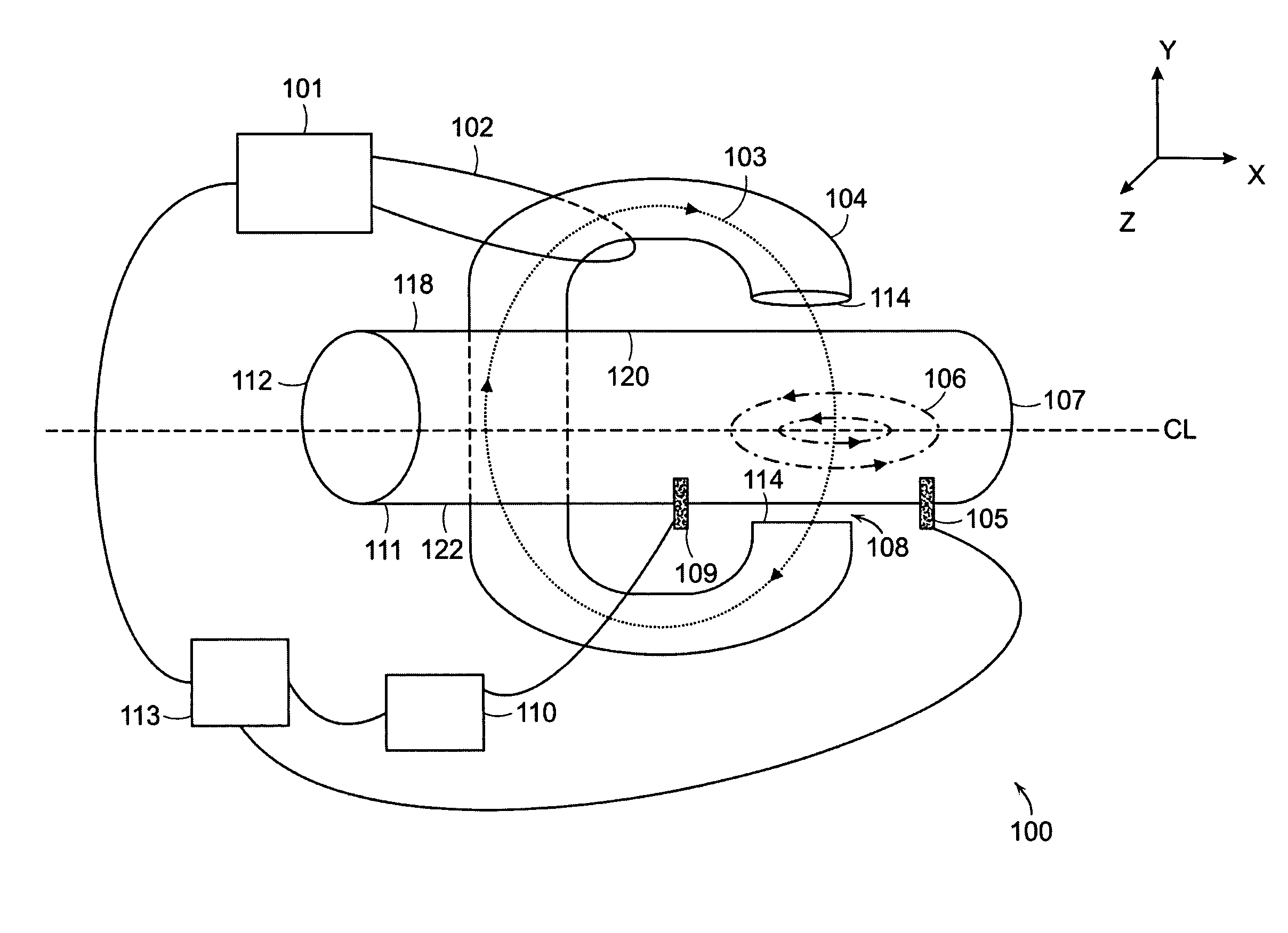

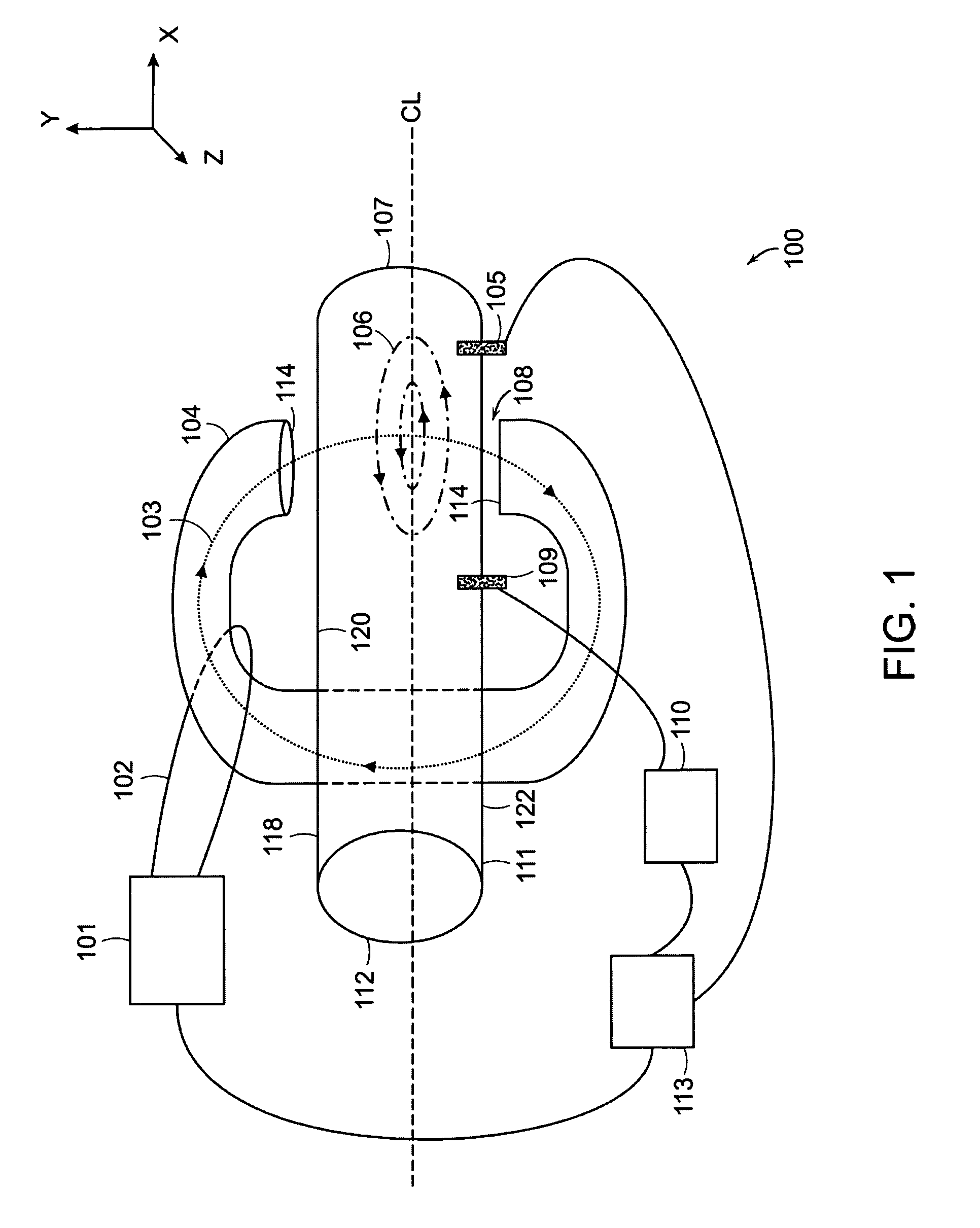

Hydraulic Actuation of a Downhole Tool Assembly

ActiveUS20110284233A1Improve reliabilityHighly serviceableDrill bitsFluid removalWell drillingReciprocating motion

A downhole tool assembly is configured for repeated and selective hydraulic actuation and deactuation. A piston assembly is configured to reciprocate axially in a downhole tool body. The piston assembly reciprocates between a first axial position and second and third axial positions that axially oppose the first position. The downhole tool is actuated when the piston assembly is in the third axial position and deactuated when the piston assembly is in either of the first or second axial positions. A spring member biases the piston assembly towards the first axial position while drilling fluid pressure in the tool body urges the piston assembly towards the second and third axial positions. Downhole tool actuation and deactuation may be controlled from the surface, for example, via cycling the drilling fluid flow rate.

Owner:SMITH INT INC

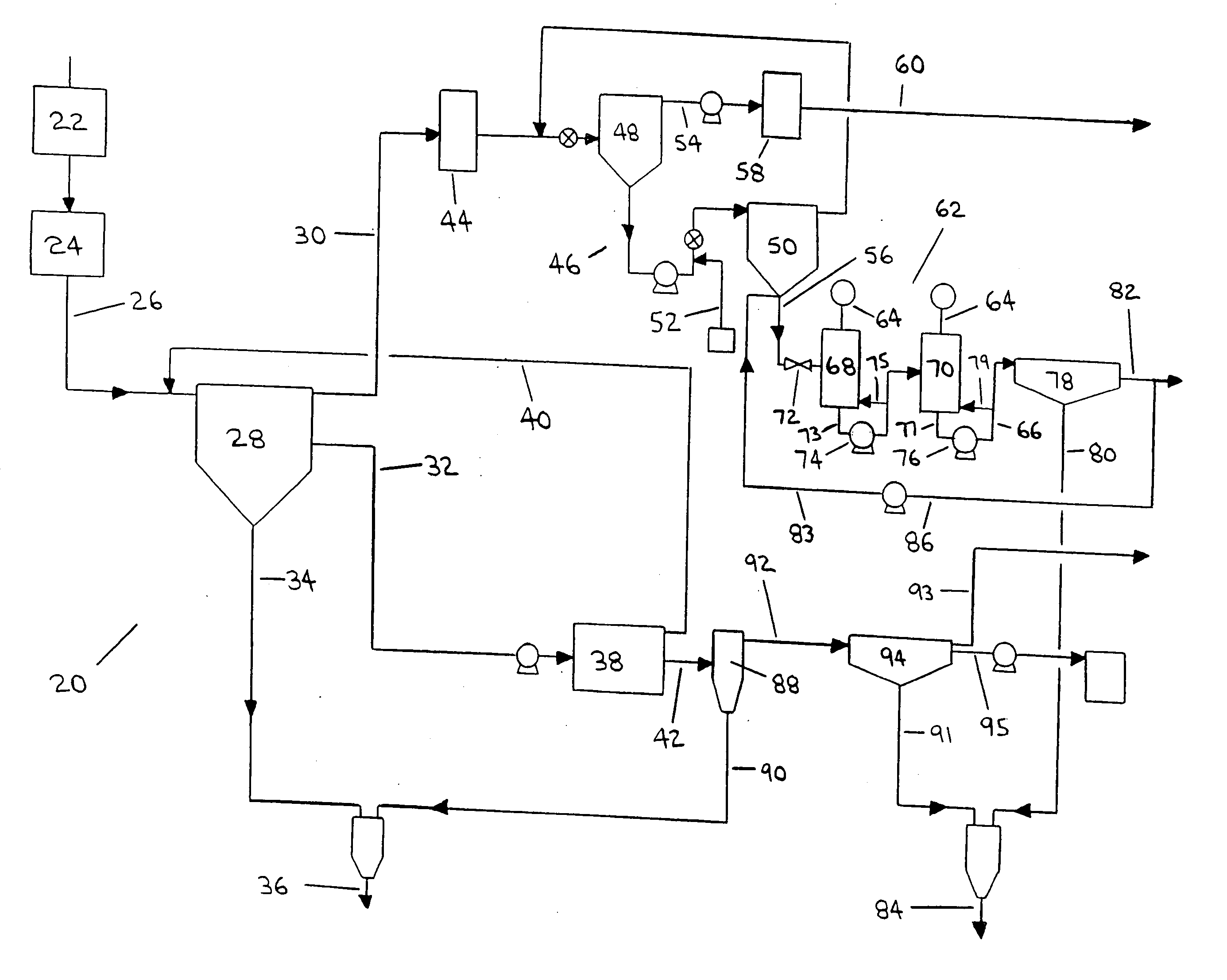

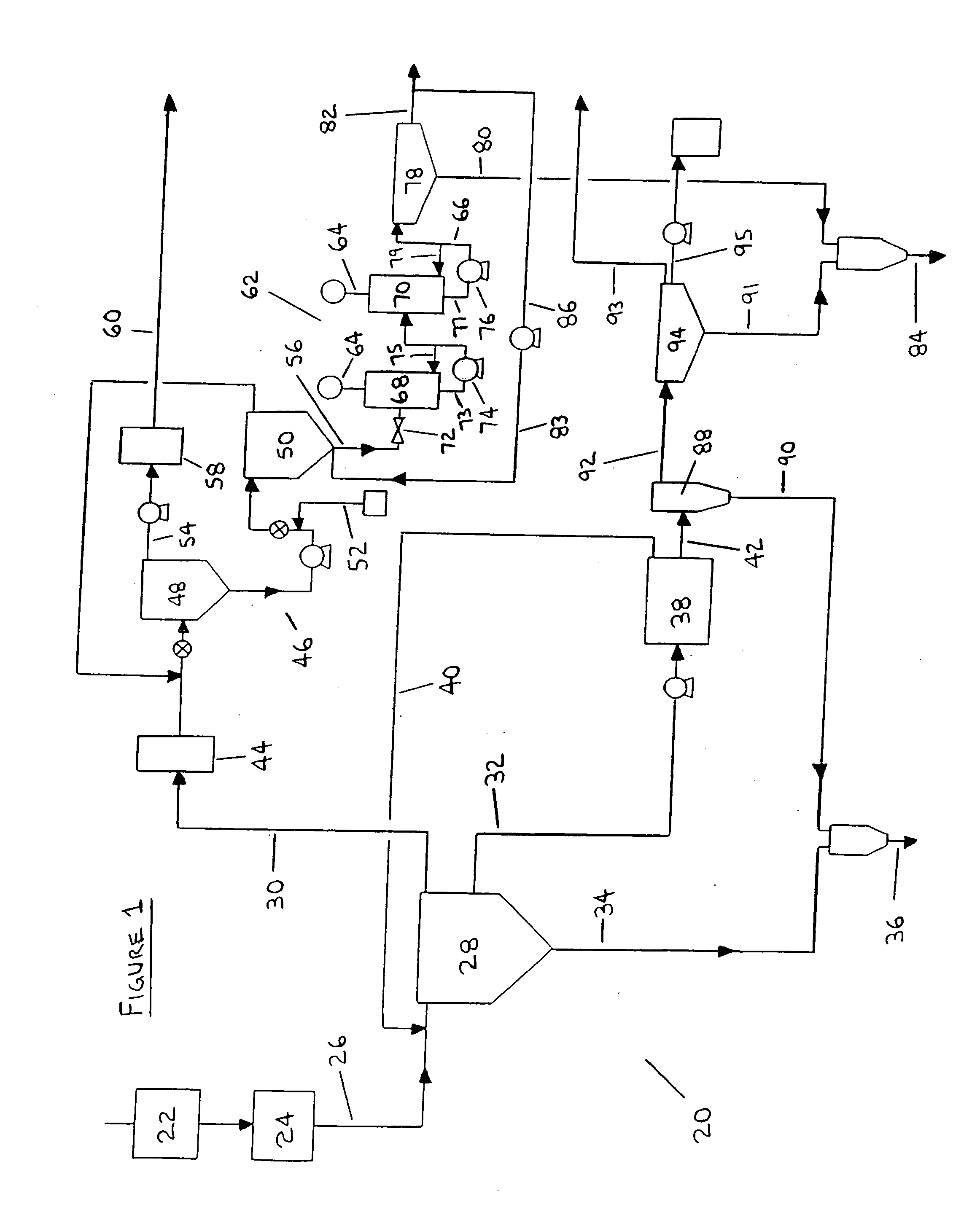

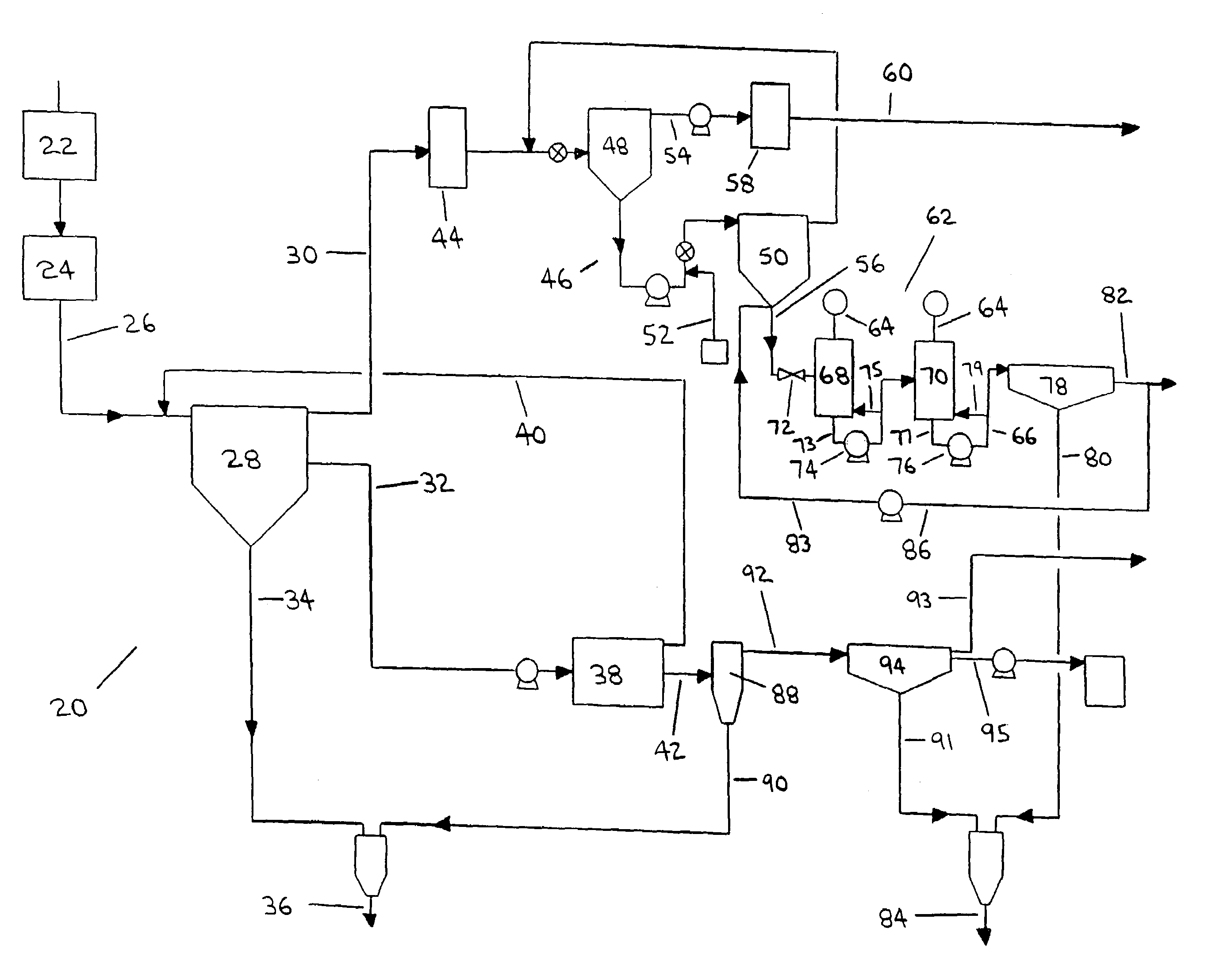

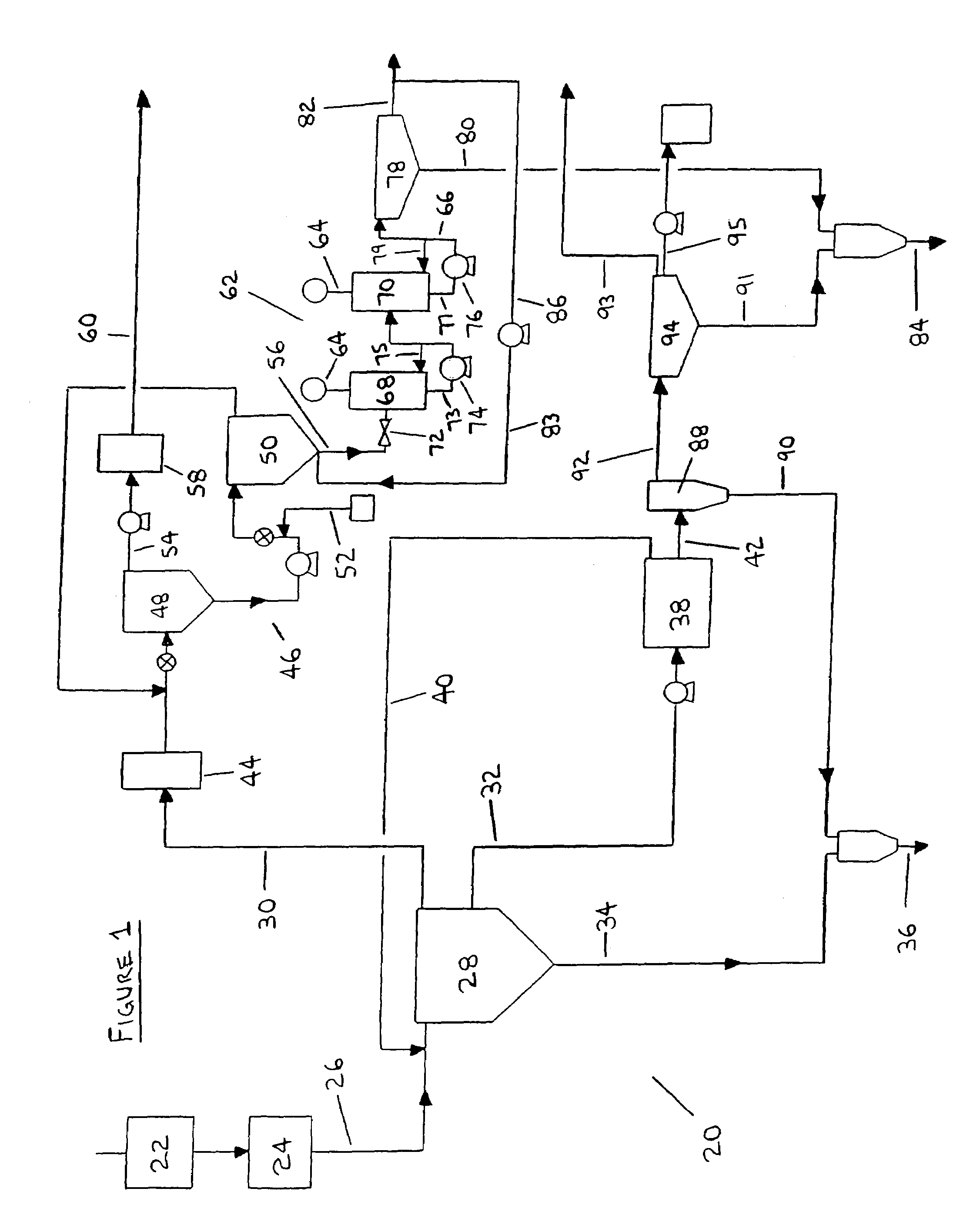

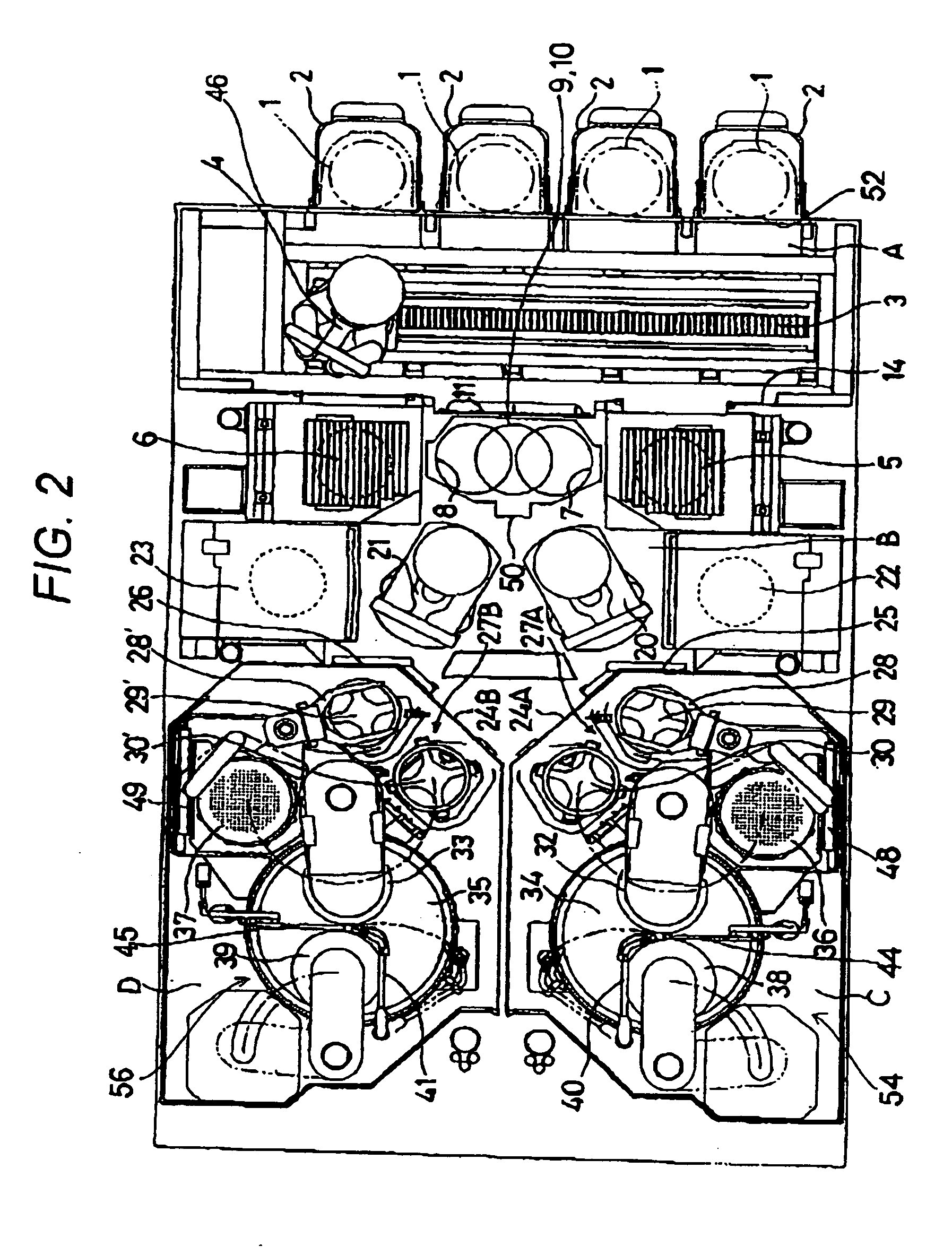

Process and apparatus for treating tailings

ActiveUS20050150844A1Easy to separateMaximize efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid separationSolventOil sands

Processes and apparatus for the treatment of product streams from mineral processing operations, including the treatment of tailings which result from oil sand processing operations. The processes and apparatus relate to the recovery of a diluent solvent from bitumen froth tailings and to the thickening of tailings from a bitumen froth stream and a middlings stream resulting from an oil sand extraction process. In one aspect the processes and apparatus relate particularly to the recycling of product streams to maximize process efficiencies. In a second aspect the processes and apparatus relate particularly to the thickening of tailings to produce an underflow component, a clarified overflow component and an unclarified overflow component.

Owner:TRUENORTH ENERGY CORP

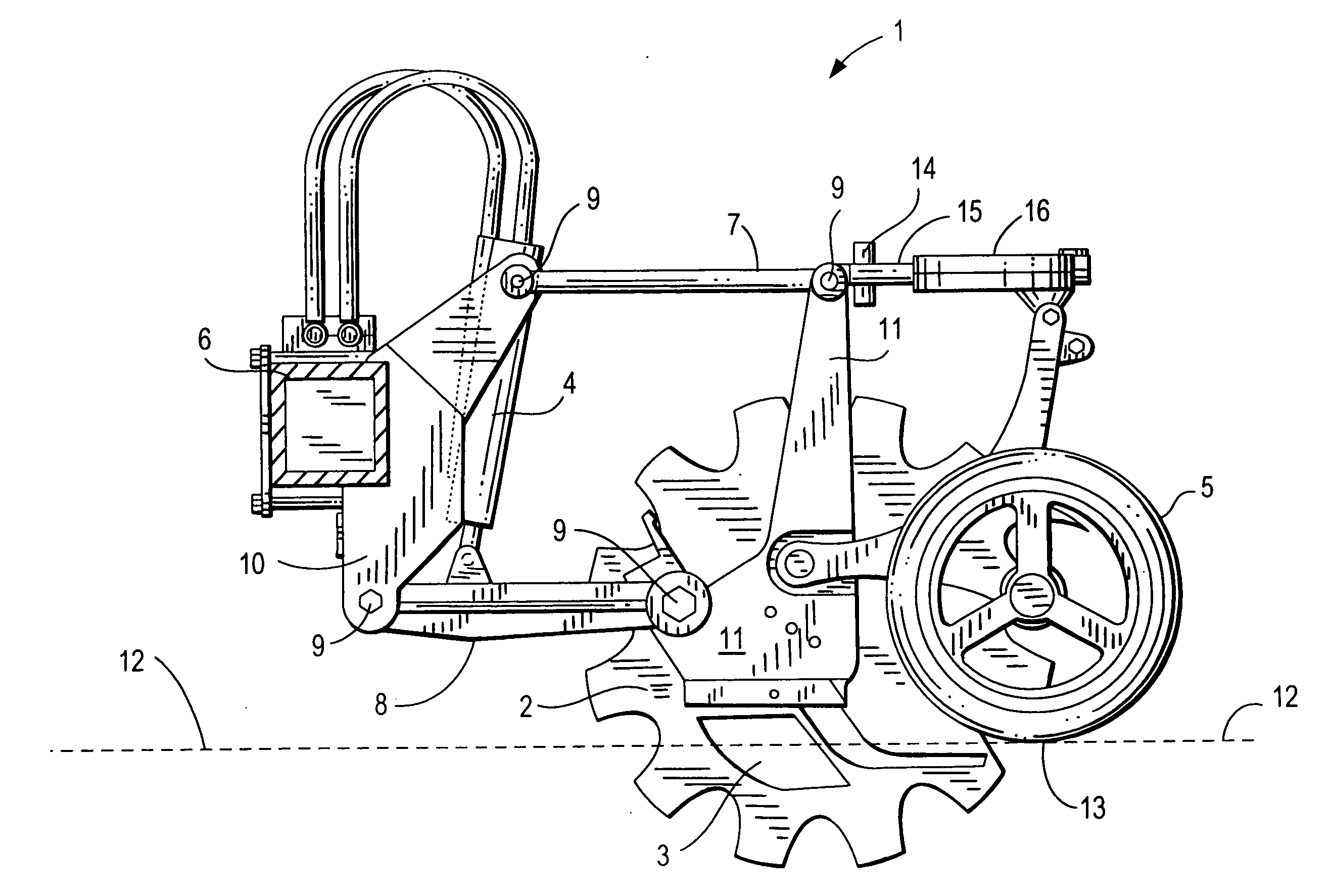

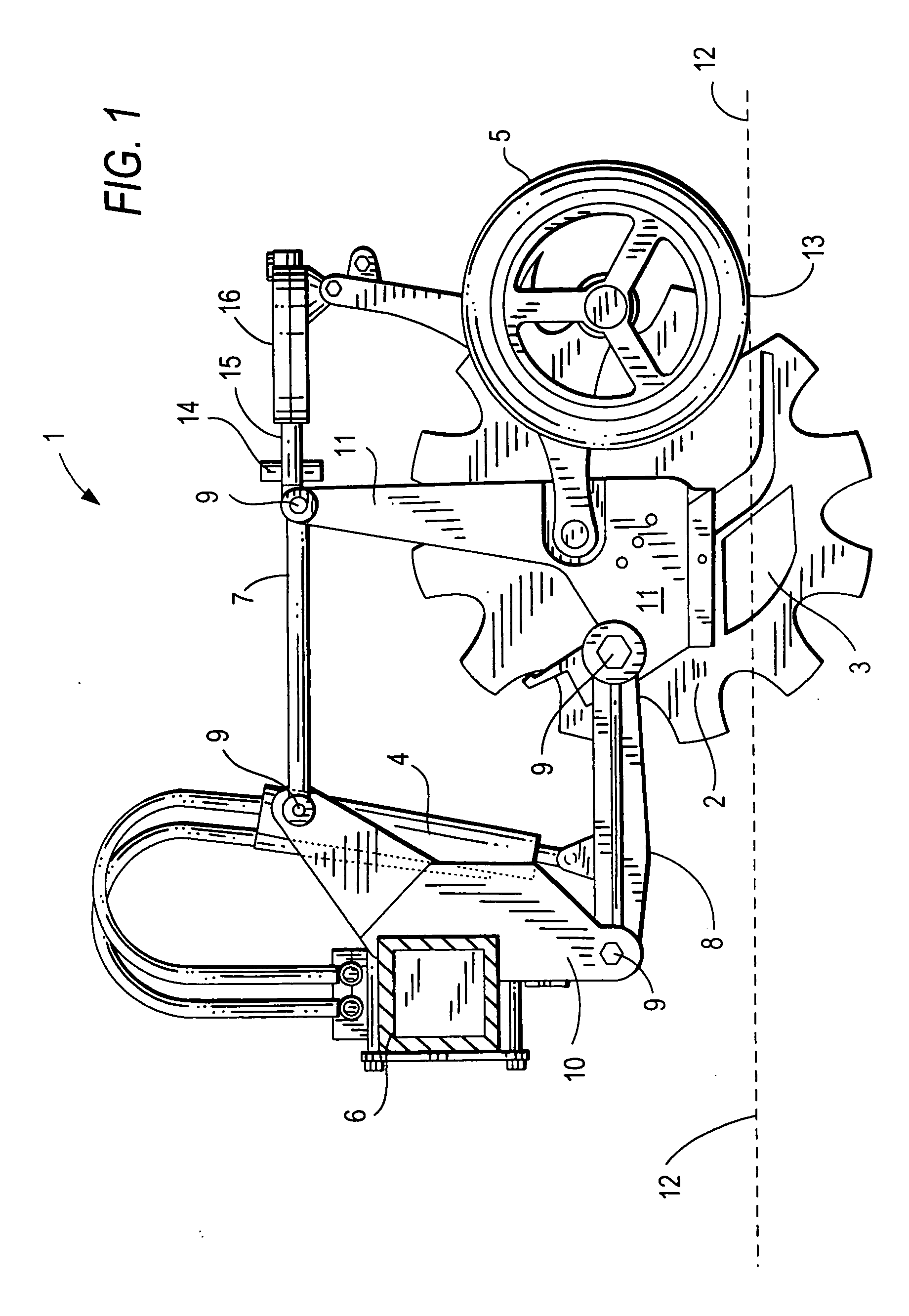

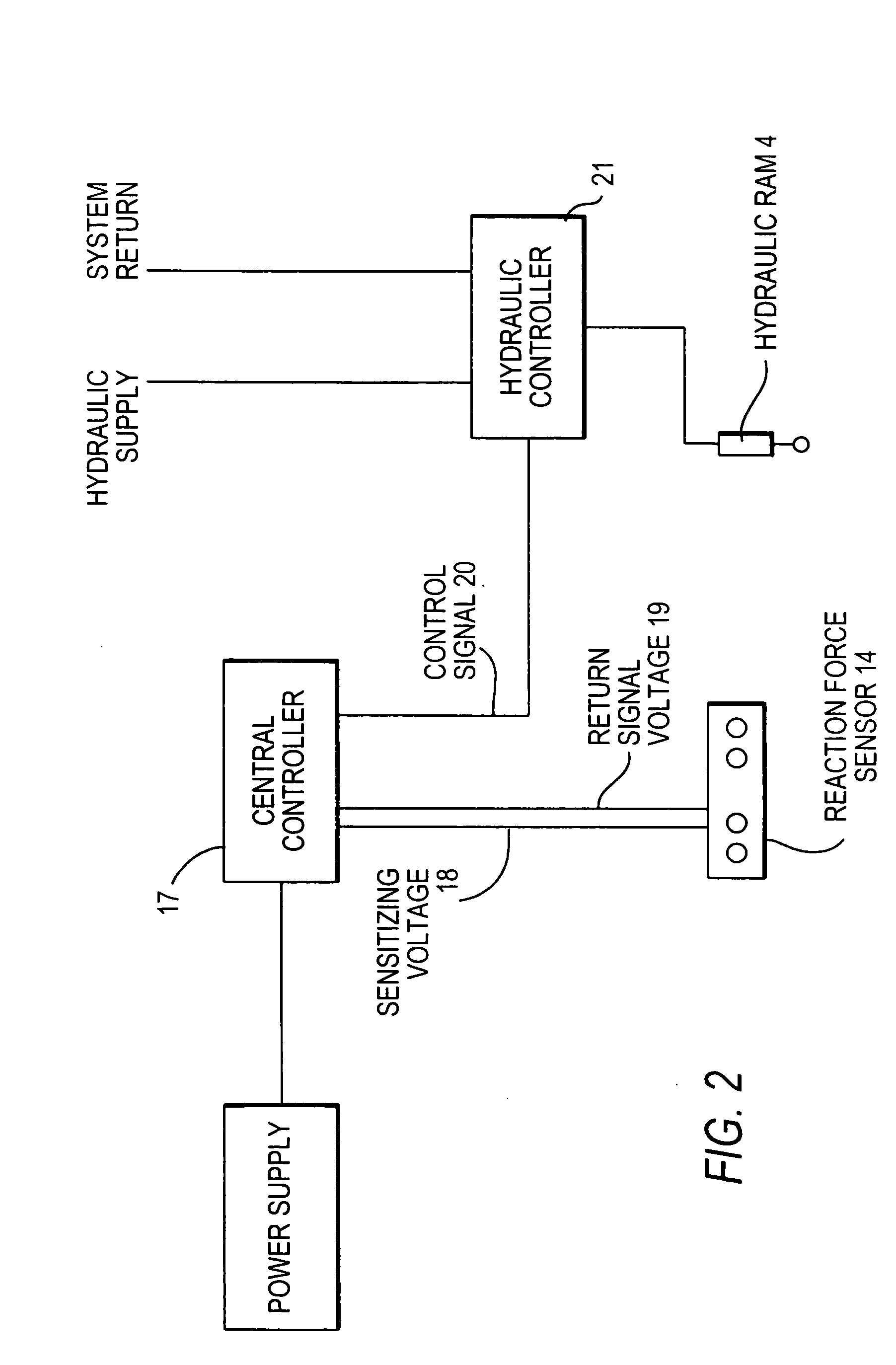

Ground opening device

InactiveUS20070272134A1Adjustable loadImprove variationPlantingAdjusting devicesEngineeringForce sensor

A ground opening device includes a ground-penetrating element configured to penetrate a ground surface, a down drive element configured to apply a downward force to the ground-penetrating element, a reaction force sensor configured to sense a ground reaction force in response to the action of the ground-penetrating element, and a controller configured to adjust the downward force on the ground-penetrating element in response to the sensed ground reaction force.

Owner:BAKER

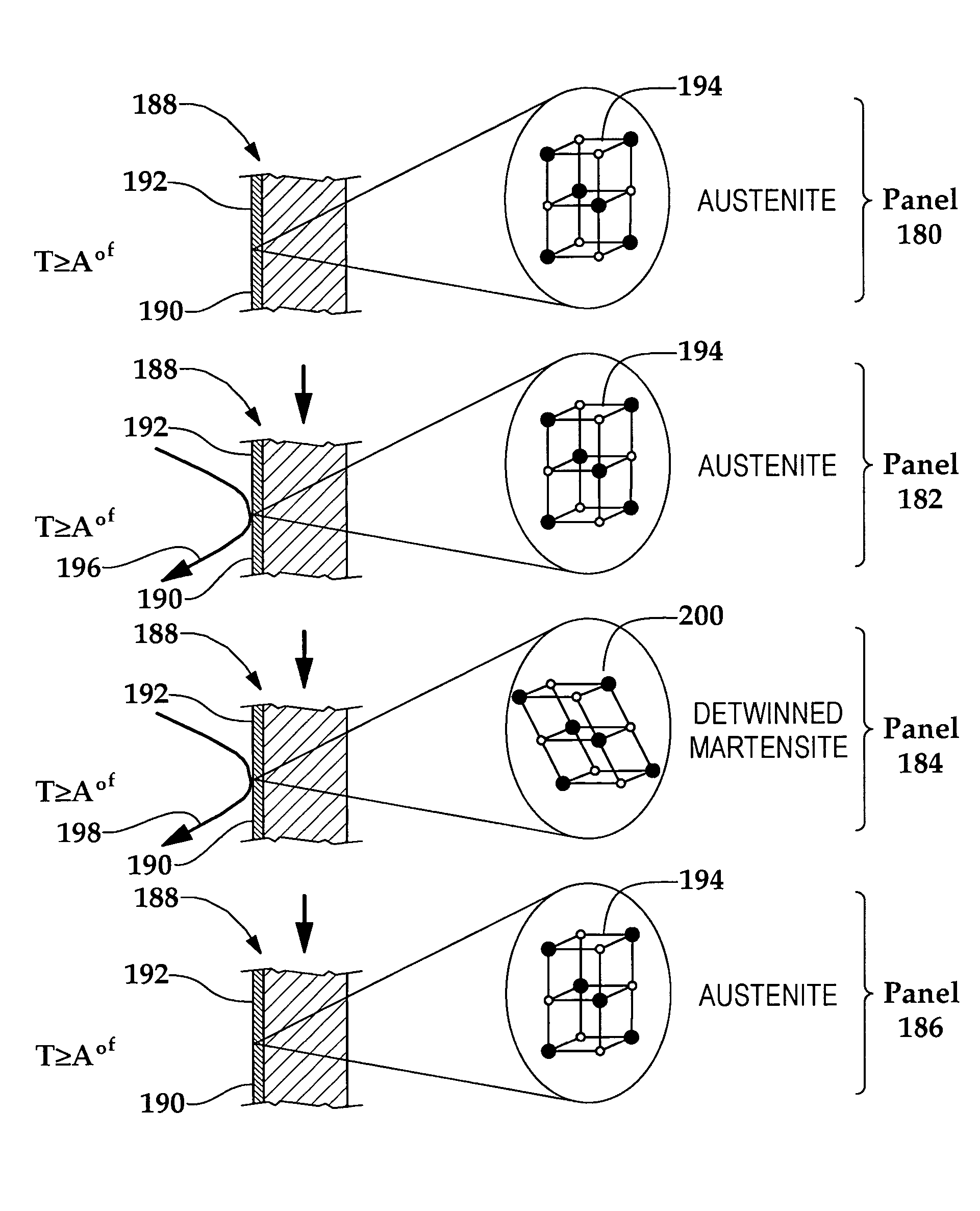

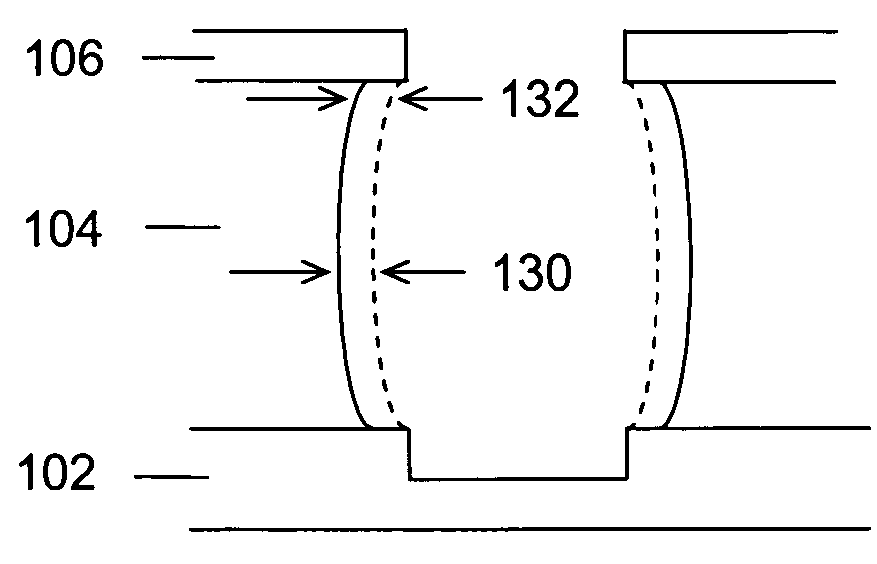

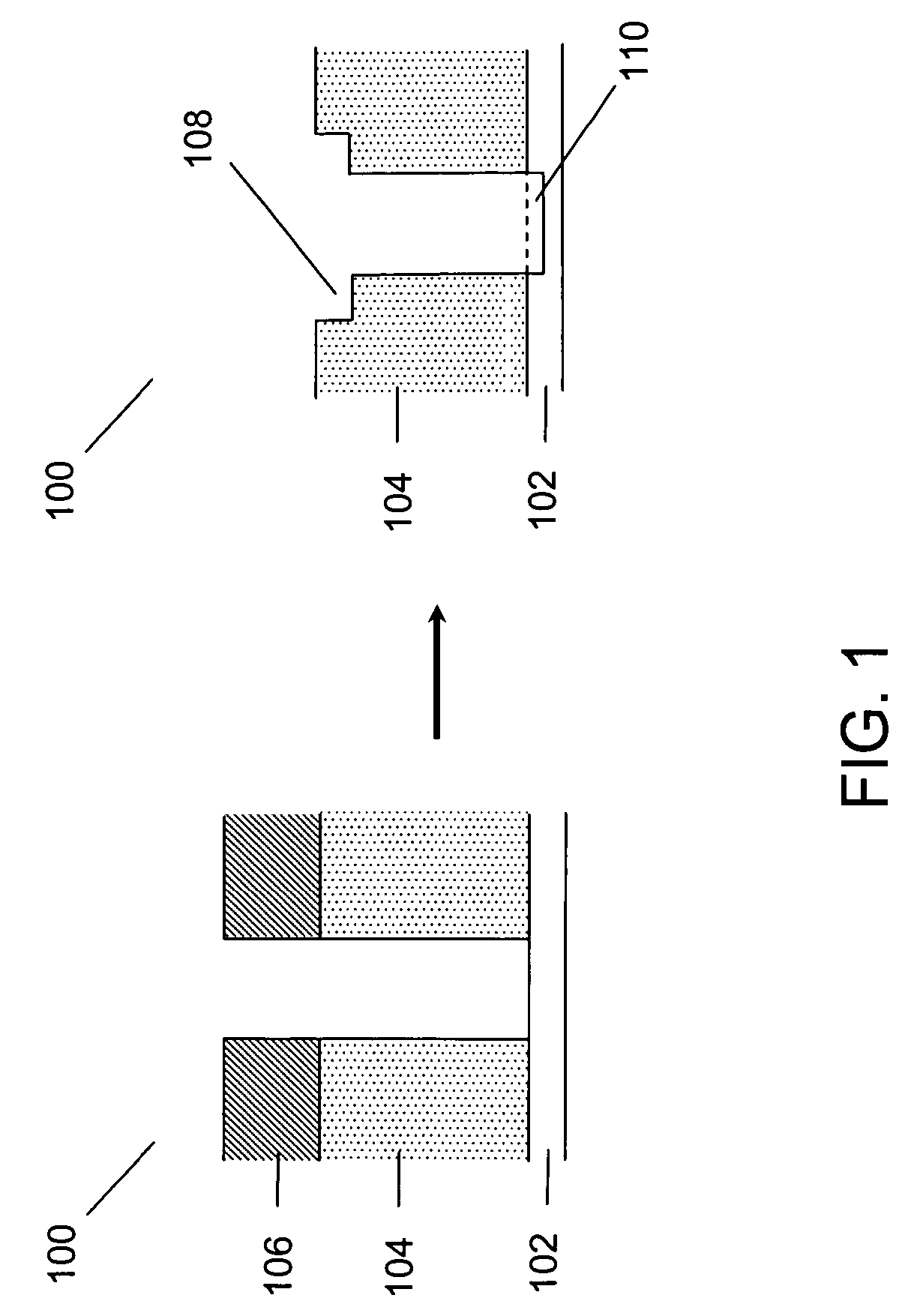

Shape memory alloy for erosion control of downhole tools

InactiveUS20060048936A1Minimize erosionErosion minimizationFluid removalWell/borehole valve arrangementsAusteniteShape-memory alloy

A downhole fluid flow control device (188) and method for minimizing erosion are disclosed. The downhole fluid flow control device (188) includes a downhole surface (190) subjectable to an erosive stress (196, 198) which may be a moving fluid or an erosive agent, for example. A shape memory alloy (192) is integrated with the downhole surface (190) in order to provide erosion resistance by reversibly transforming from an austenitic phase (194) to a martensitic phase (200) in response to the application of the erosive stress (196, 198). Further, the shape memory alloy (192) reversibly transforms from the martensitic phase (200) to the austenitic phase (192) in response to the presence of sufficient heat.

Owner:HALLIBURTON ENERGY SERVICES INC

Method of making iron and steel

InactiveUS6149709AEasy to getLess impurity contentProcess efficiency improvementElectric furnaceHigh energyRefractory

Molten iron is prepared by (1) providing iron oxide and a carbonaceous reducing agent, (2) preparing a shaped product from the carbonaceous reducing agent and the iron oxide, (3) preparing solid reduced iron from the shaped product, wherein the solid reduced iron has a metallization of at least 60%, a specific gravity of at least 1.7, and a carbon content of at least 50% of the theoretical amount required for reducing the iron oxide remaining in the solid reduced iron, and, (4) before substantial cooling occurs, heating the solid reduced iron in an arc heating-type melting furnace at a high temperature. The molten iron can be prepared efficiently from iron ores of relatively low iron content without causing erosion of refractories, at high energy and high reduction efficiencies, and by a simple operation in a simple facility.

Owner:KOBE STEEL LTD

Cementing manifold assembly

InactiveUS6904970B2Erosion minimizationFluid removalVibration devicesWell cementingMechanical engineering

A cementing manifold is disclosed that preferably includes: modular housings that can be stacked together and interconnected to add multi-dart or multi-sphere capability; identical, interchangeable valves; internal bypass capability; a minimum number of protrusions into the pressure containing components; and no externally mounted welded or threaded components.A cementing swivel is also disclosed that preferably includes connections that are formed integrally to the housing, redundant cement connections, angled cement ports, and seal assemblies that do not require individual placement of each seal.

Owner:SMITH INT INC

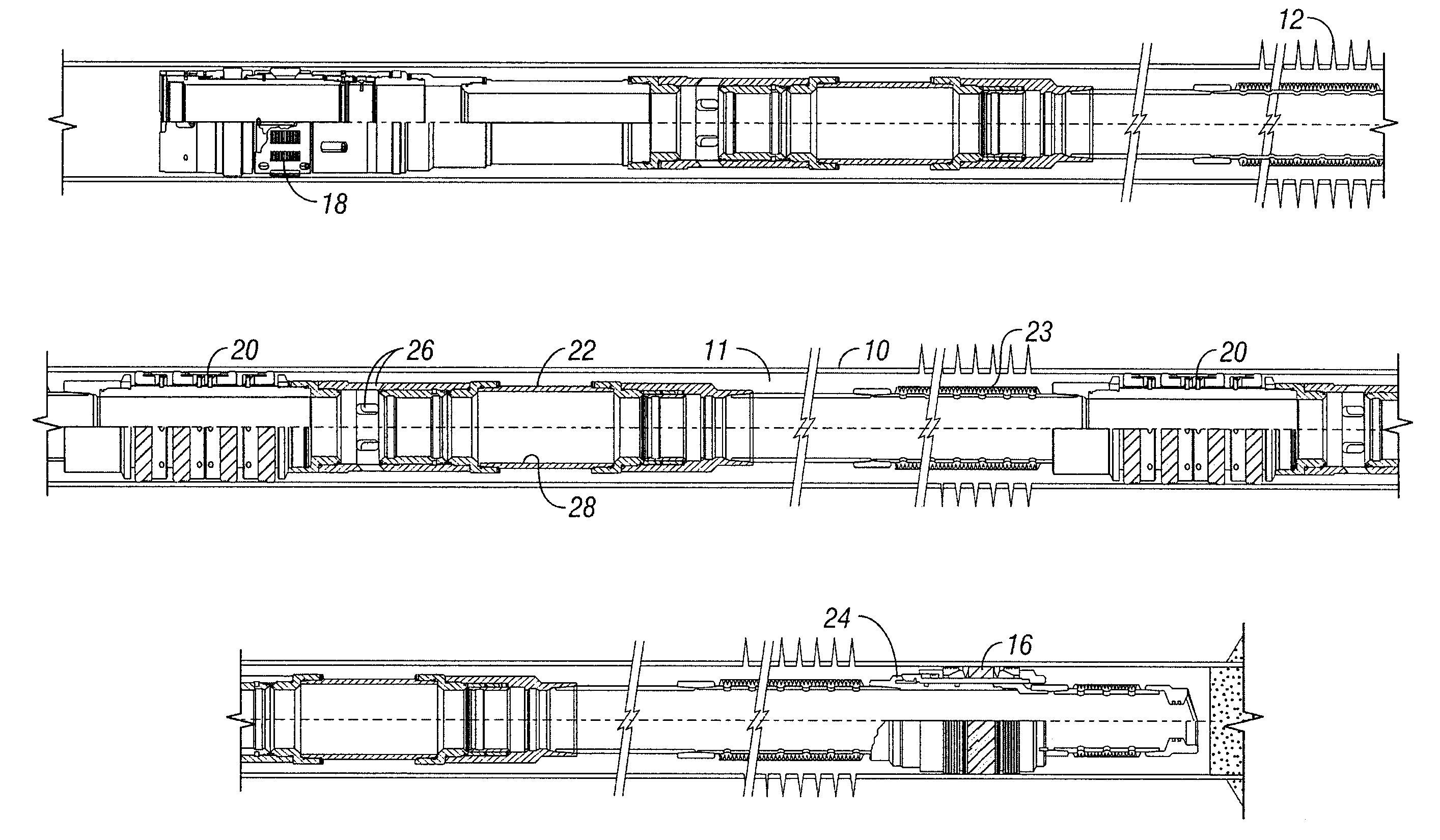

Method and apparatus for treating a subterranean formation

InactiveUS7066264B2Precise positioningMaintain positionFluid removalVibration devicesSleeve valveEngineering

A service / completion liner having a plurality of downhole selectable indicating tools and being used in sand control (gravel pack) placement systems in conjunction with a straddle packer service tools or with conventional crossover type service tools. Each indicating collar has a downhole selectable indicating collar providing a robust, landing profile for precisely locating and maintaining service tool position during well treatment operations. The landing collars accommodate hydraulic and / or thermal effects commonly referred to as tubing move effects which are the principle cause of tool position error and excessive seal wear. The landing collar is downhole convertible between a pass through (Go) and non pass through (No-go) condition by simple upward and downward cycling via the tool running and treatment fluid tubing and a shifting tool, which may also be referred to as a set down collet. The shifting / set down collet is also used to open and close a downhole sliding sleeve valve and may be an integral part of an injection tool or a tool for gravel or fracture packing. A sliding sleeve valve design and a straddle packer configuration that protects the primary PBRs in the gravel pack system and also protects the sliding sleeve while sand is placed in the screen casing annulus.

Owner:SCHLUMBERGER TECH CORP

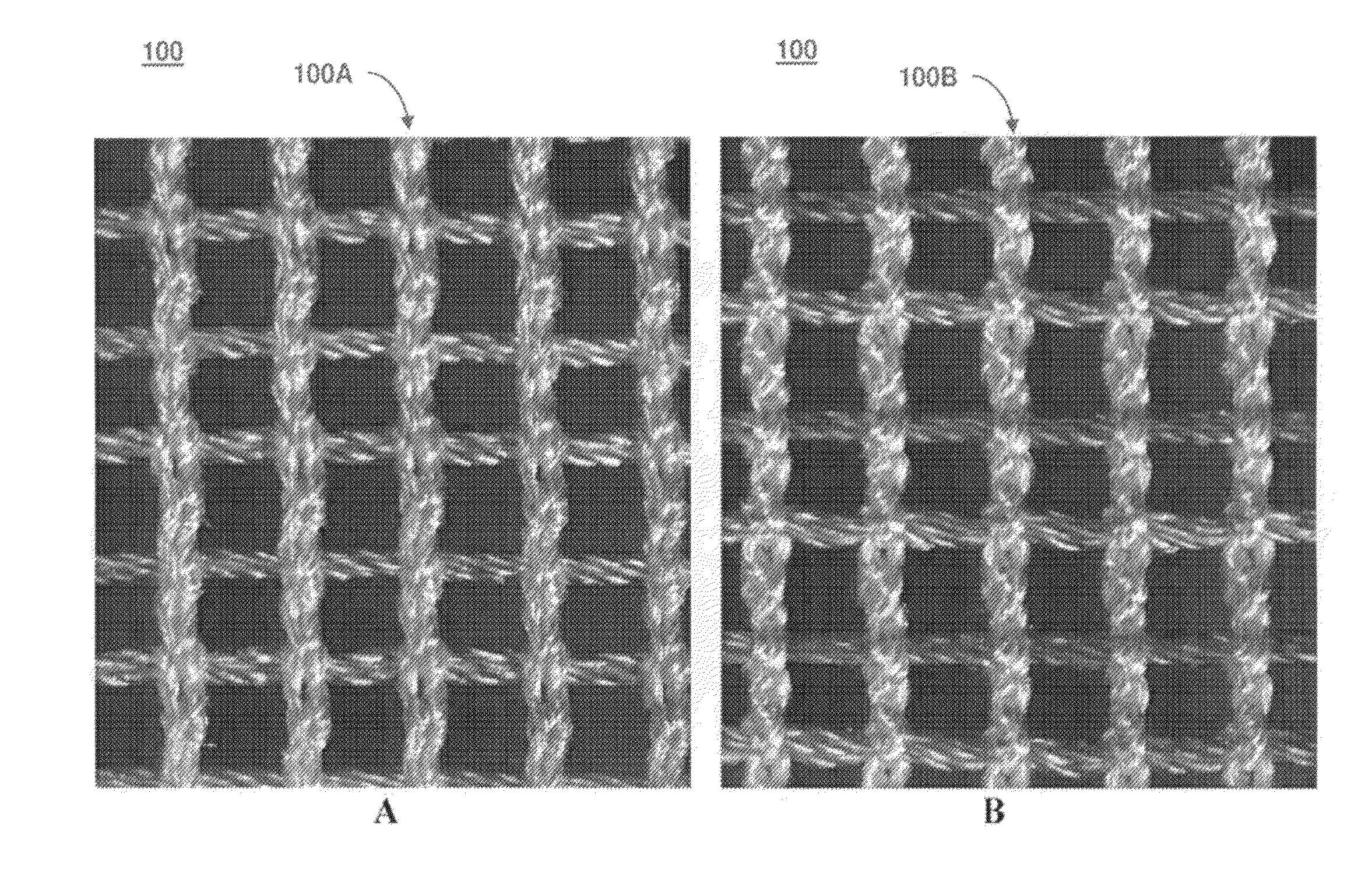

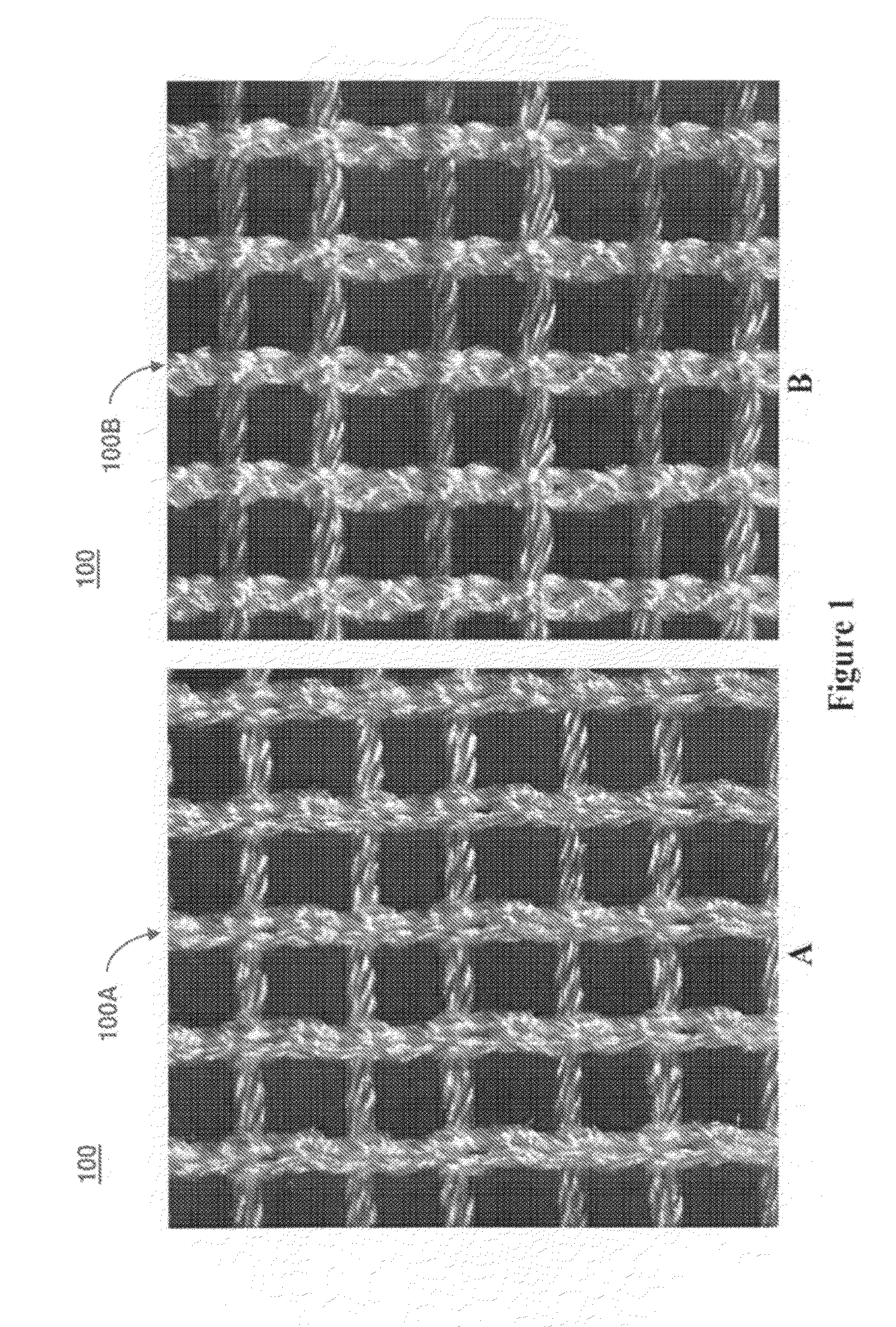

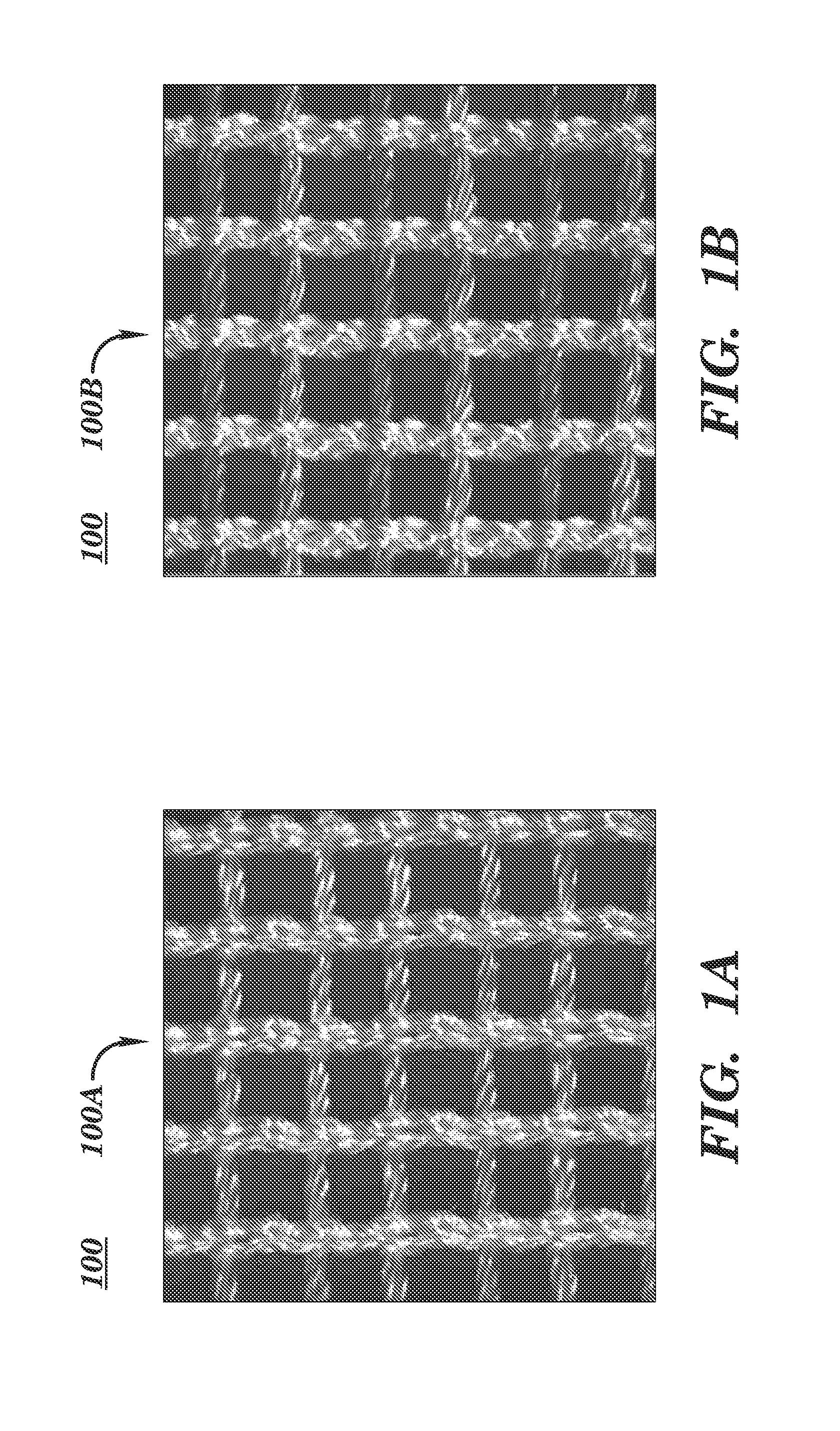

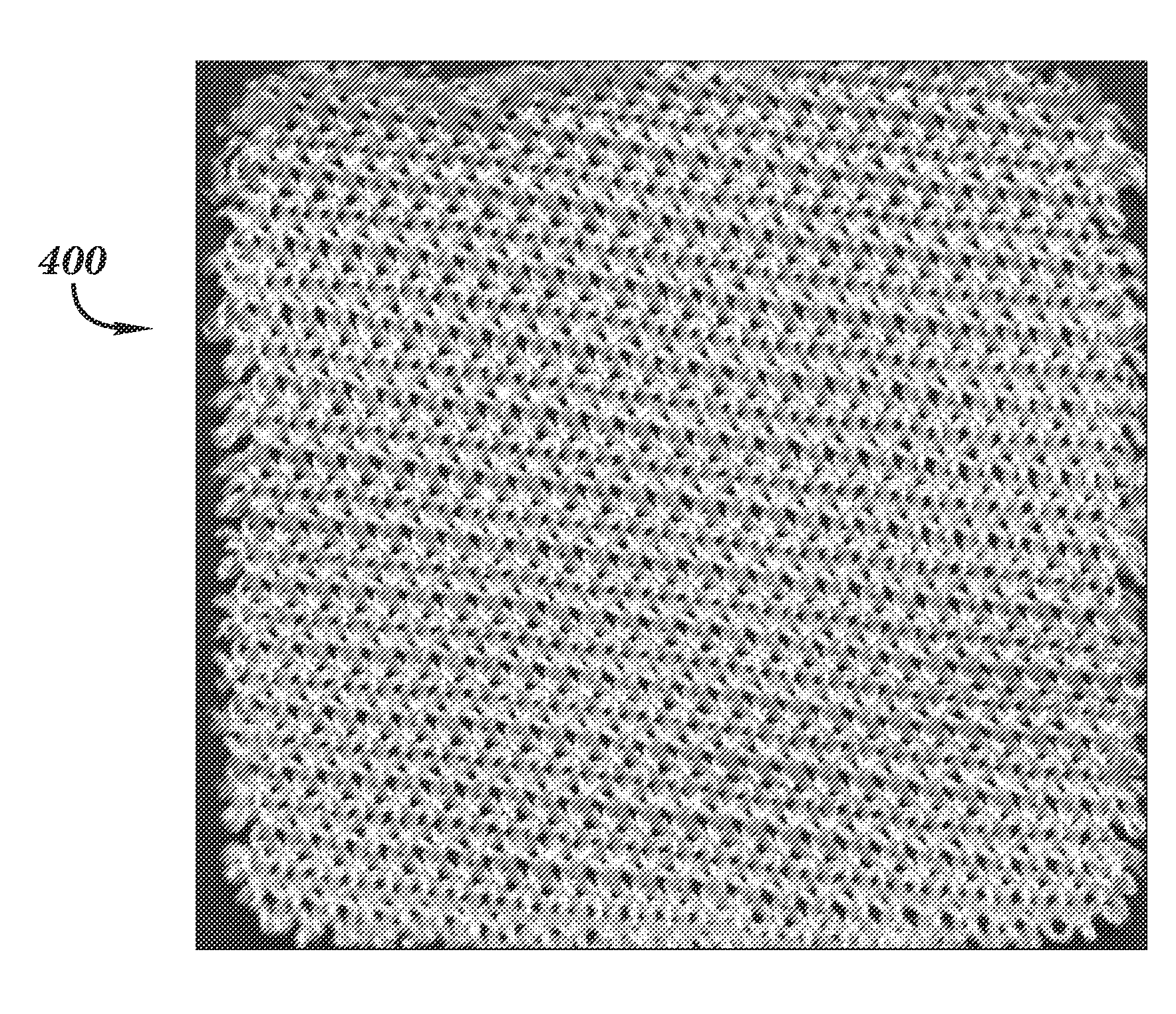

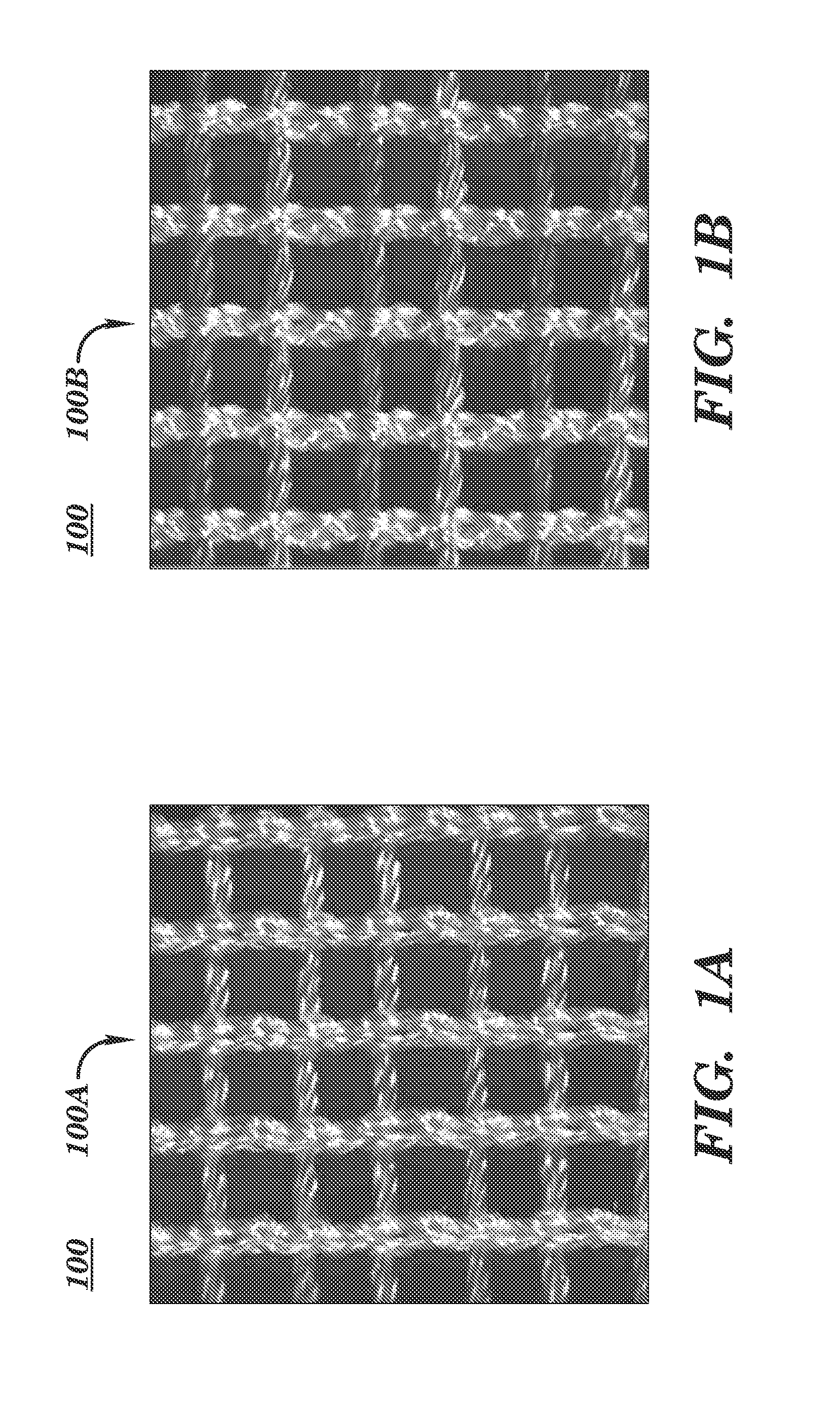

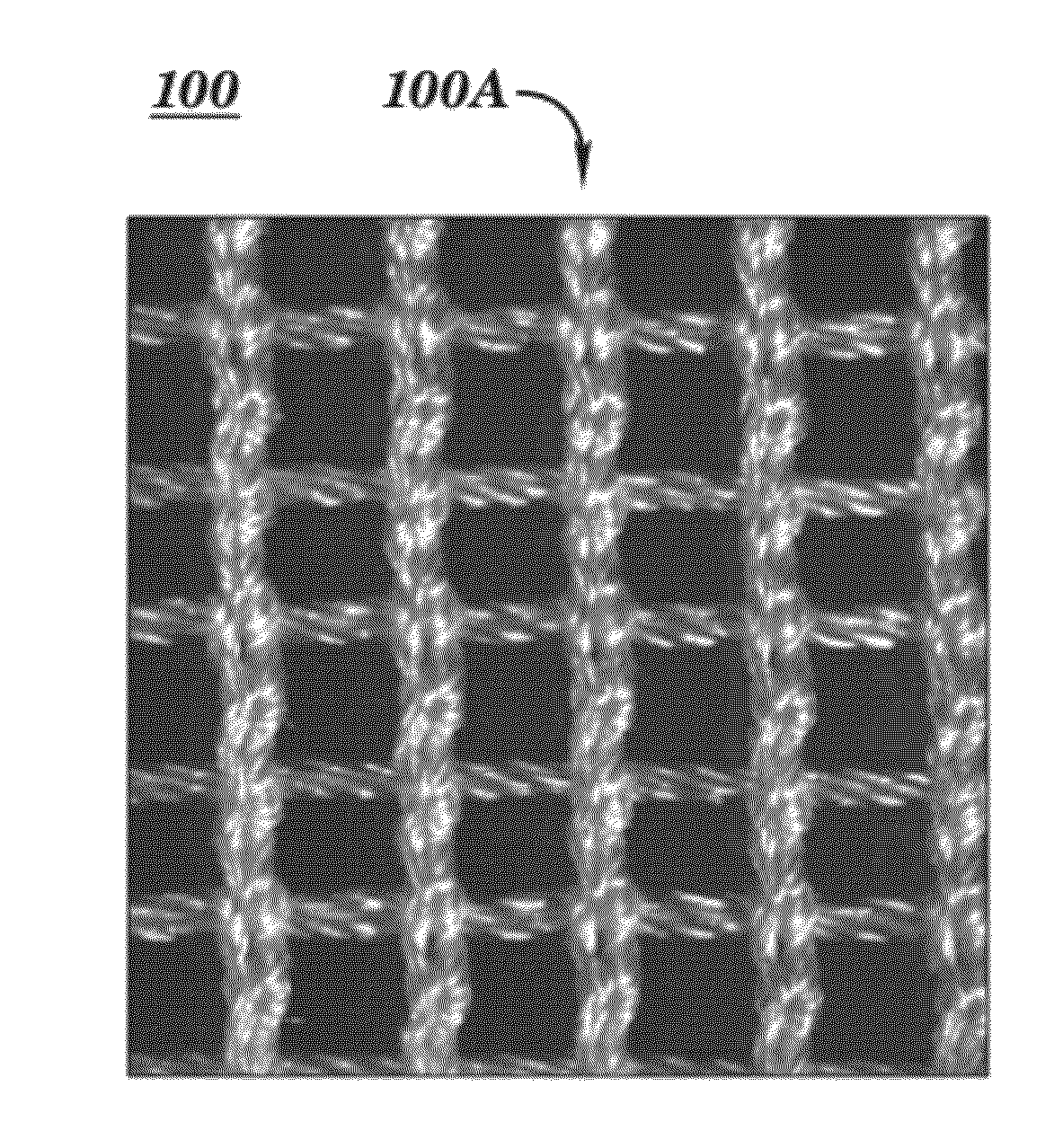

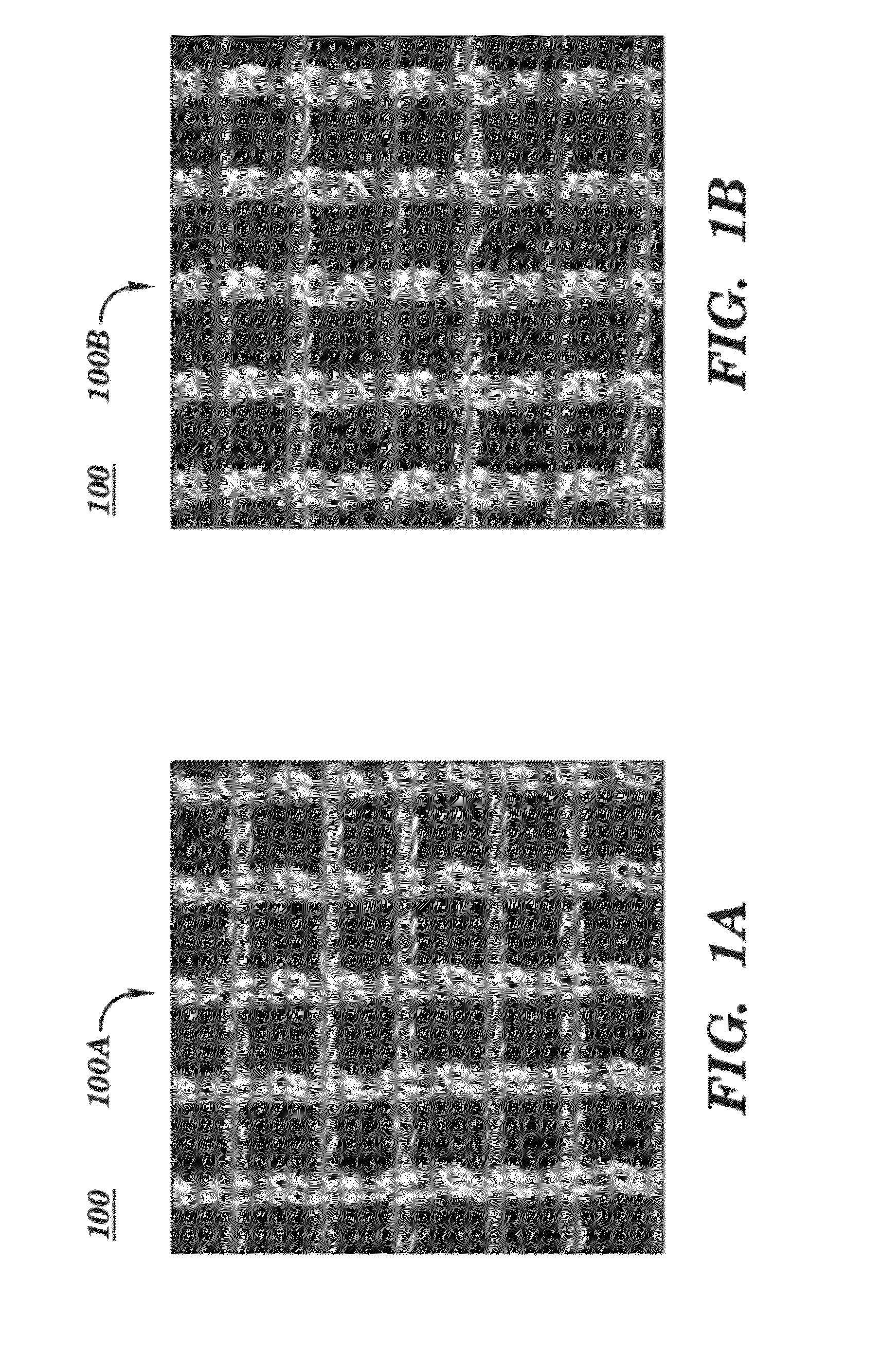

Prosthetic device and method of manufacturing the same

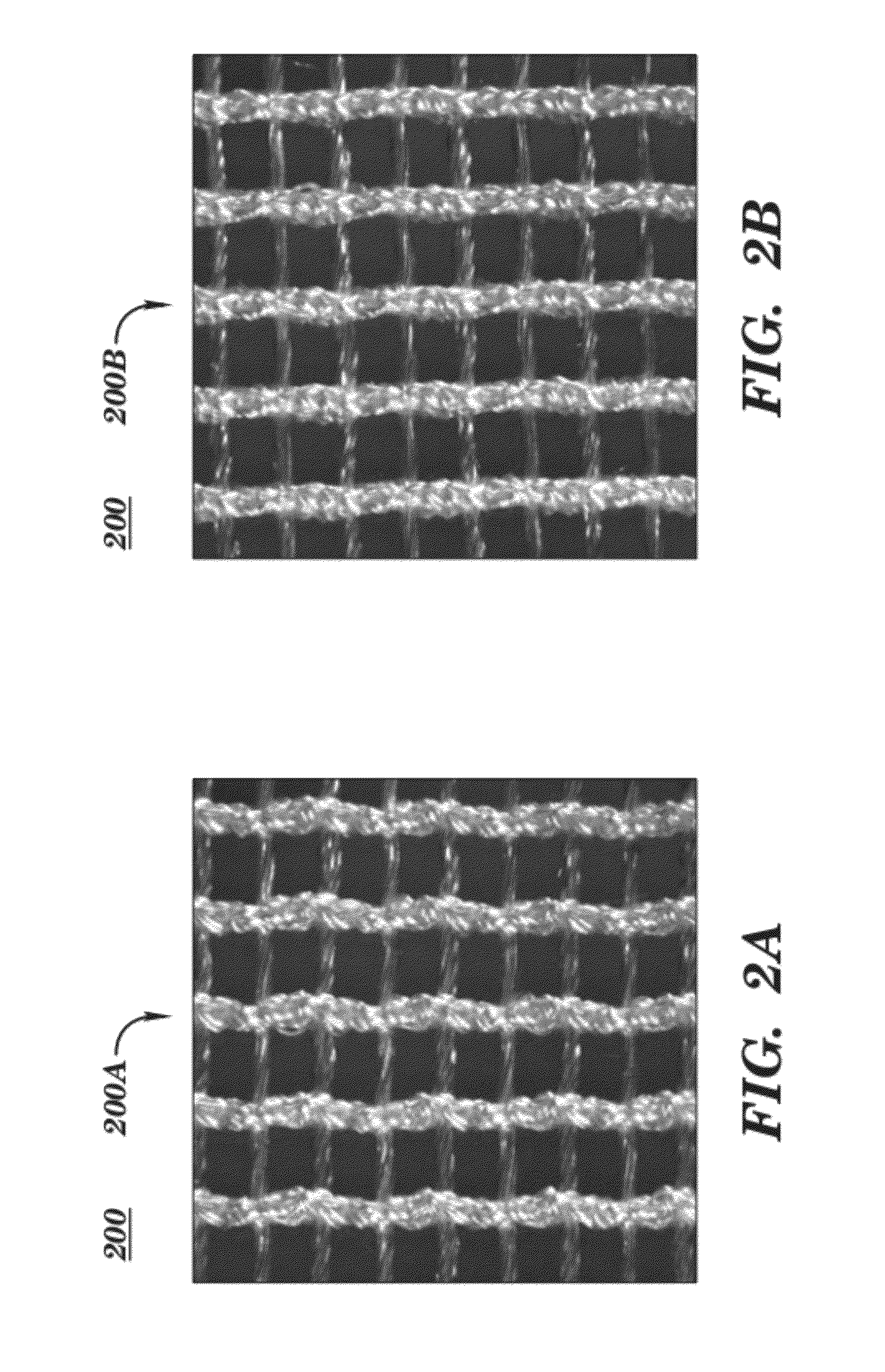

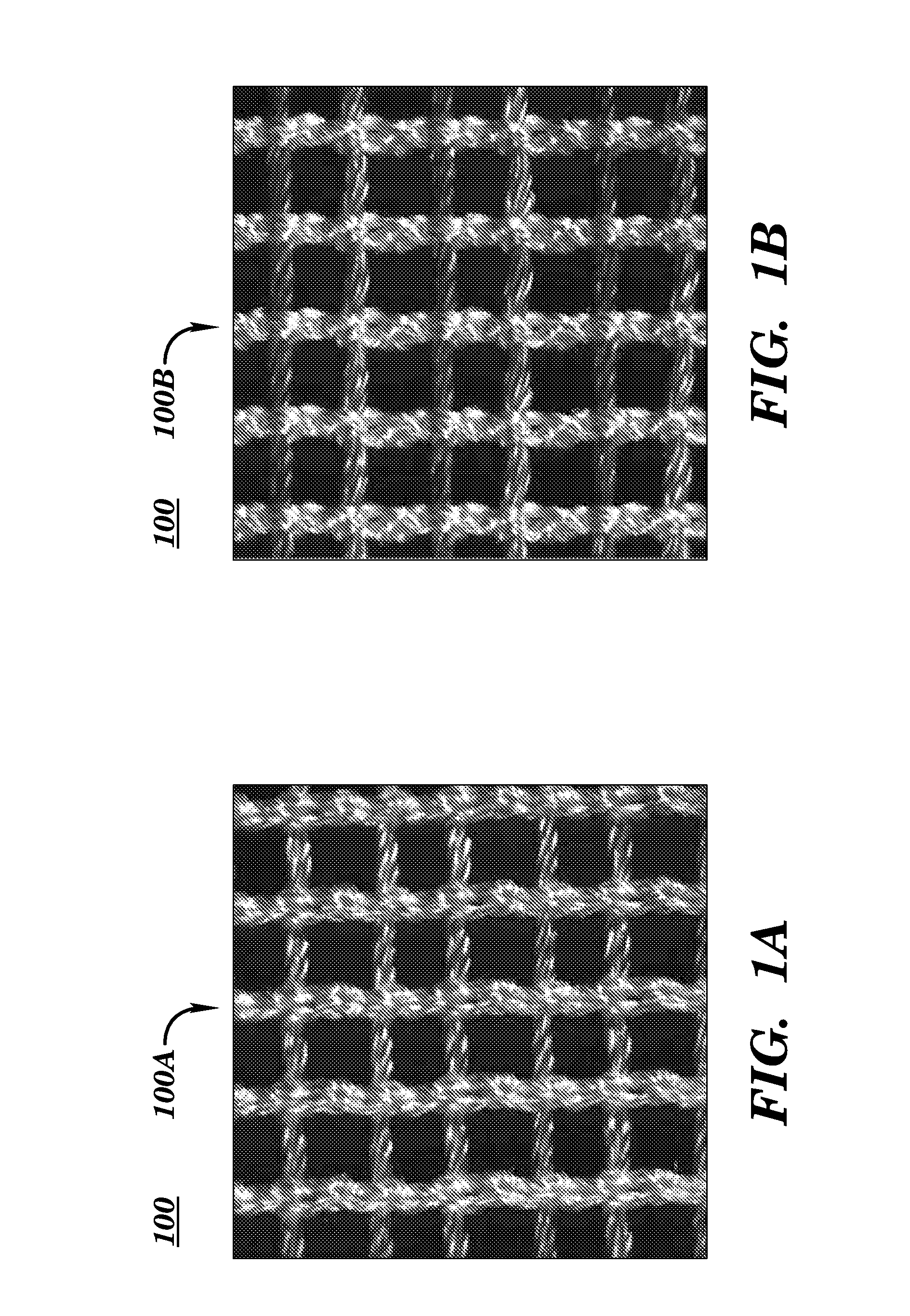

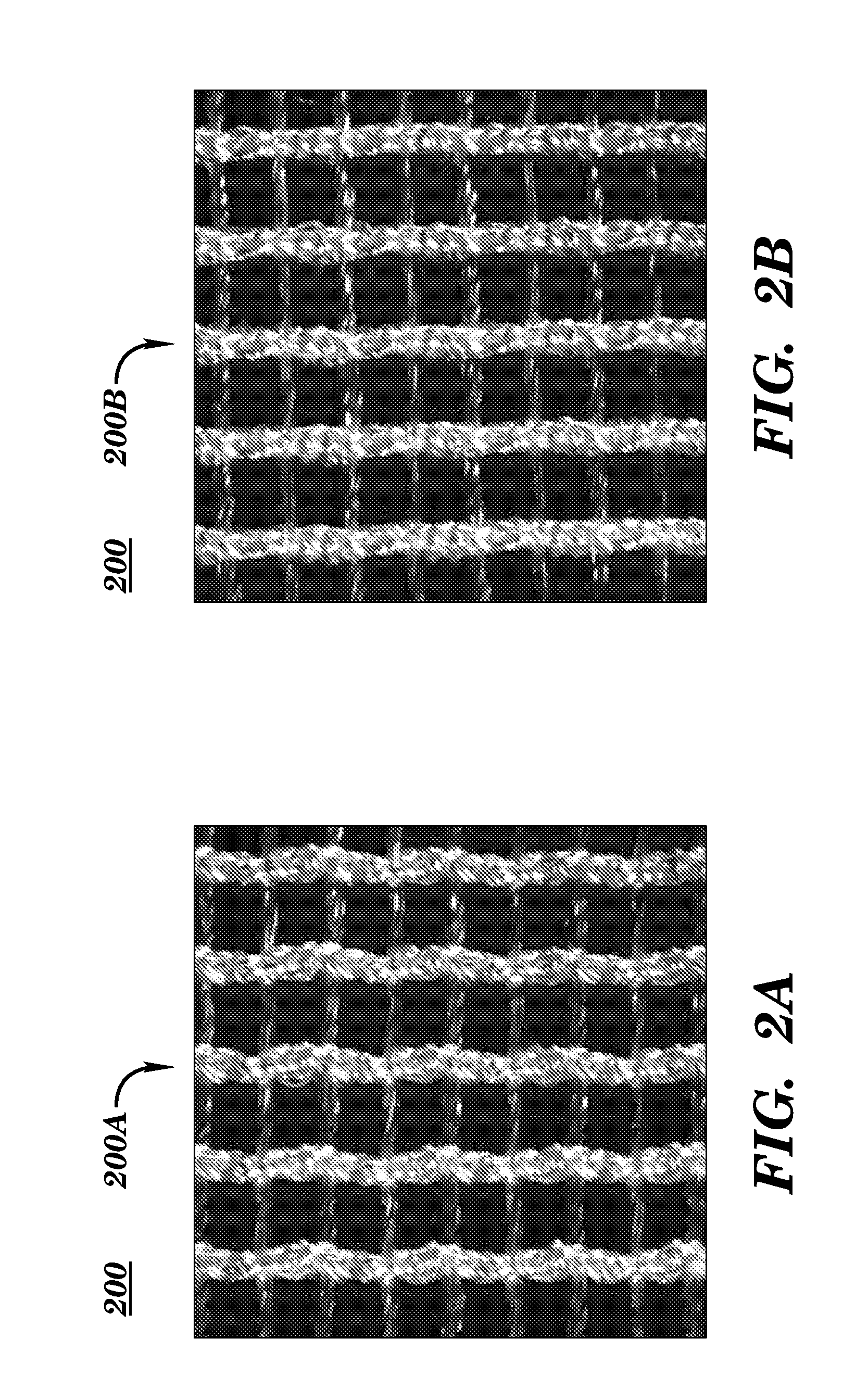

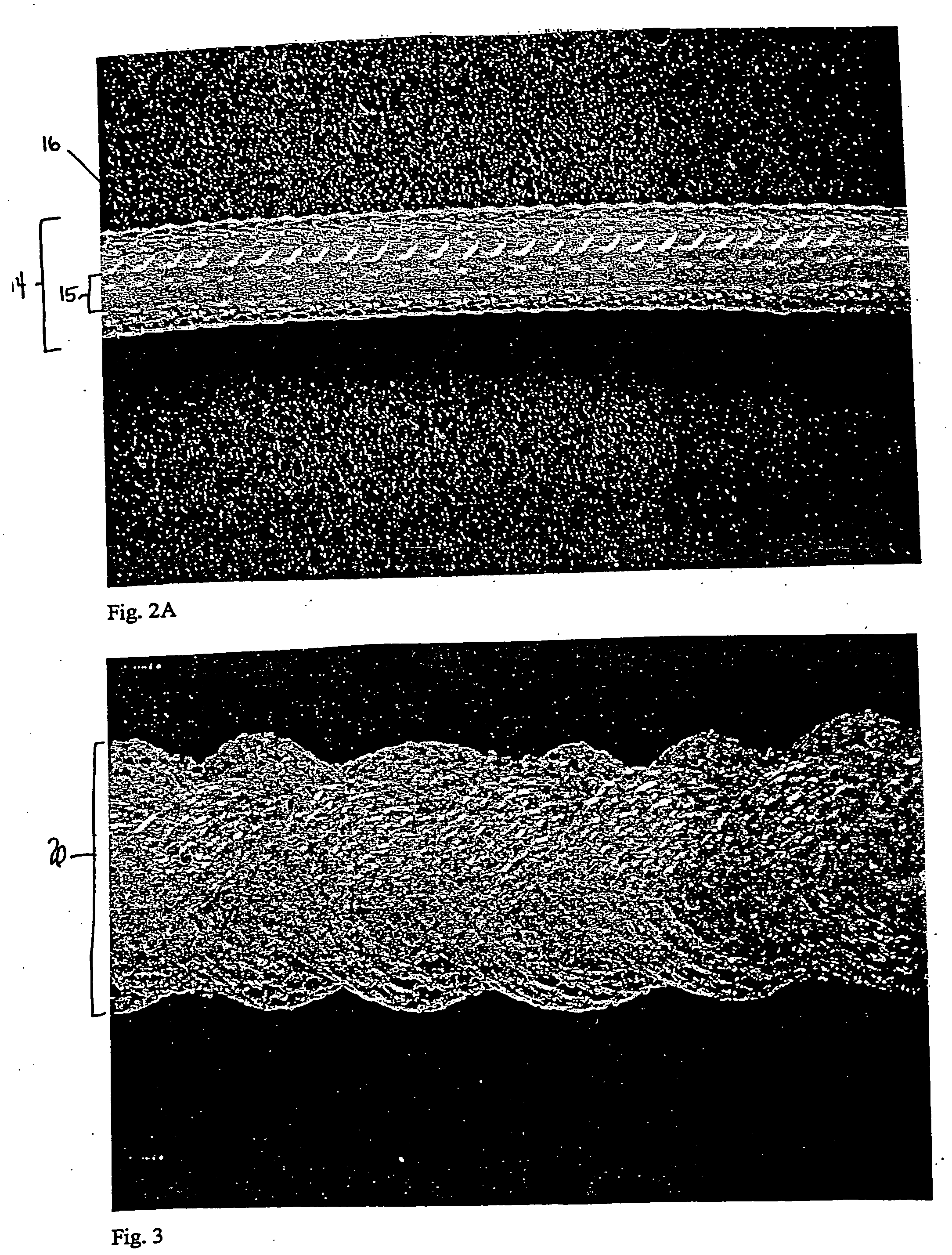

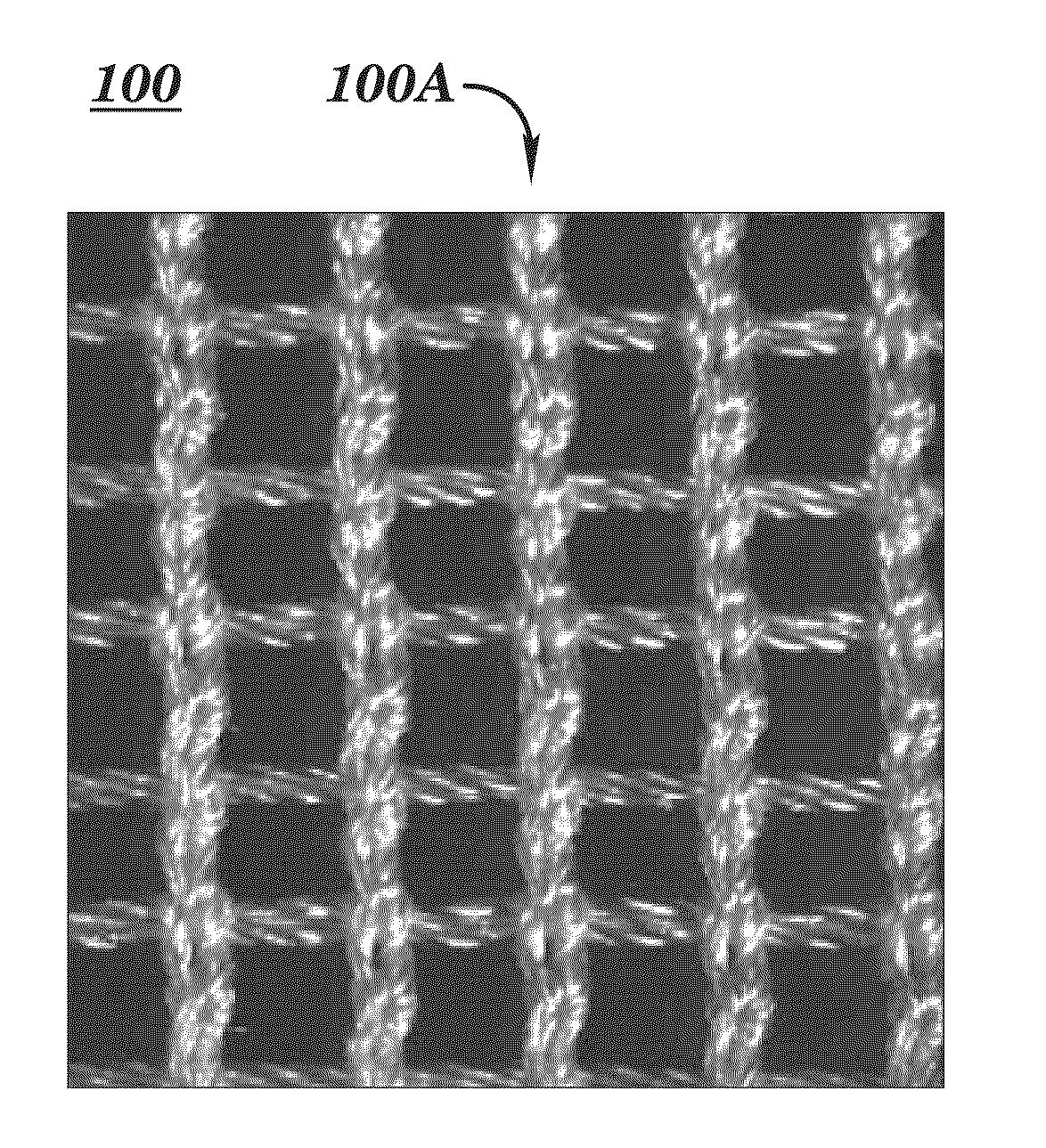

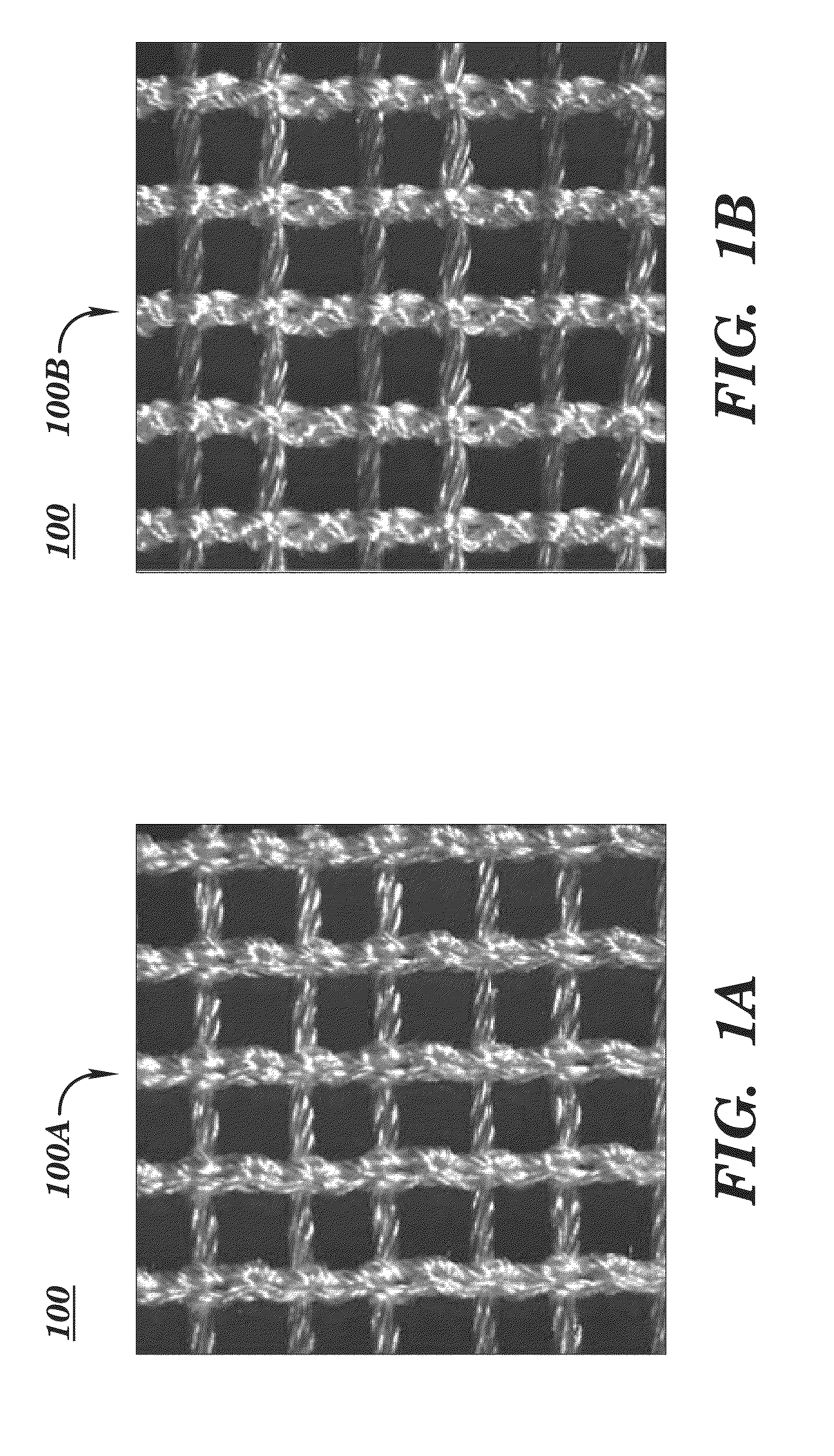

InactiveUS20120029537A1Minimizes tissue erosionMinimizes fistulaMammary implantsWarp knittingYarnDevice prosthetic

A biocompatible surgical silk mesh prosthetic device employs a knit pattern that substantially prevents unraveling and preserves the stability of the mesh device, especially when the mesh device is cut. An example prosthetic device employs a knitted mesh including at least two yarns laid in a knit direction and engaging each other to define a plurality of nodes. The at least two yarns include a first yarn and a second yarn extending between and forming loops about two nodes. The second yarn has a higher tension at the two nodes than the first yarn. the second yarn substantially prevents the first yarn from moving at the two nodes and substantially prevents the knitted mesh from unraveling at the nodes.

Owner:ALLERGAN INC

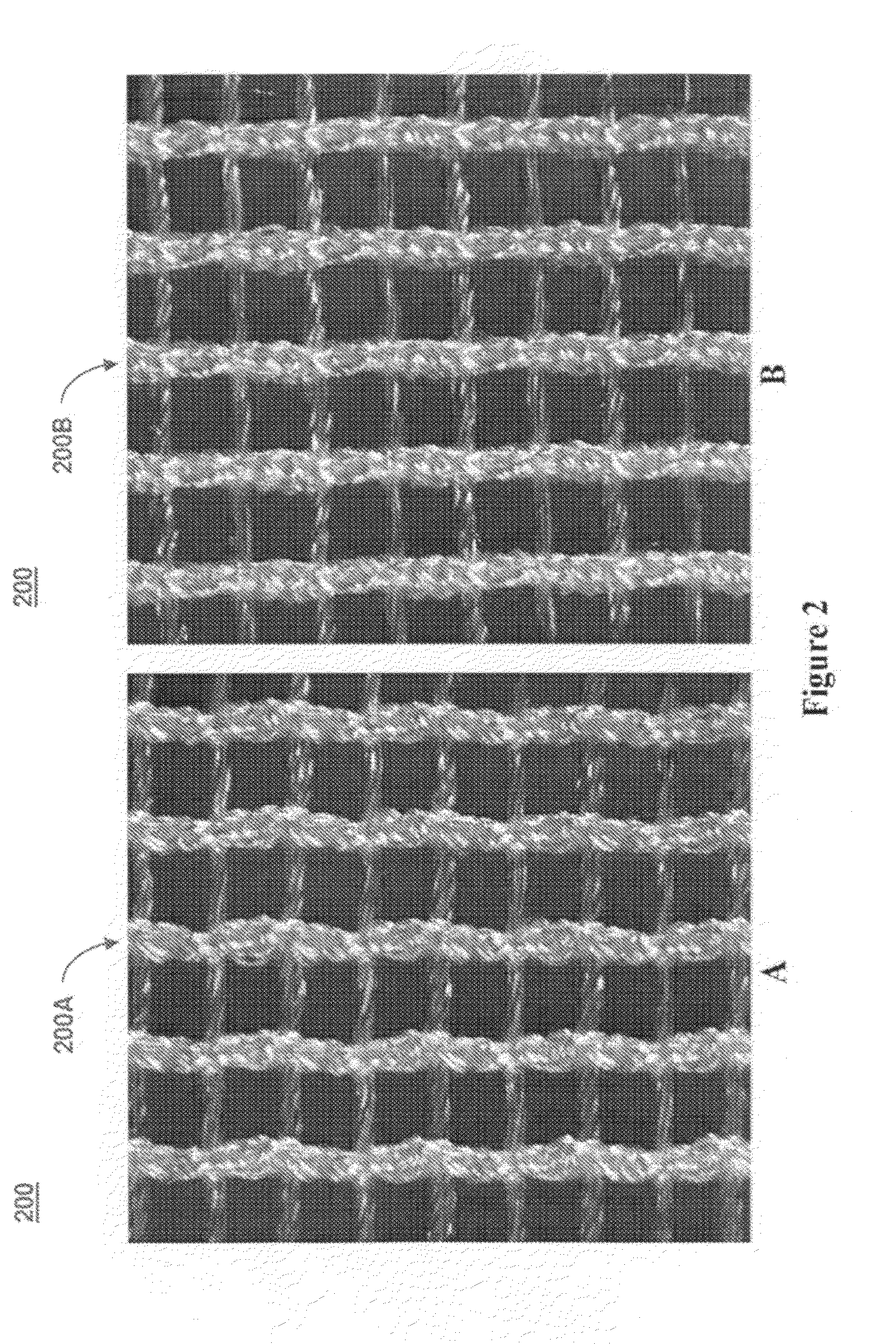

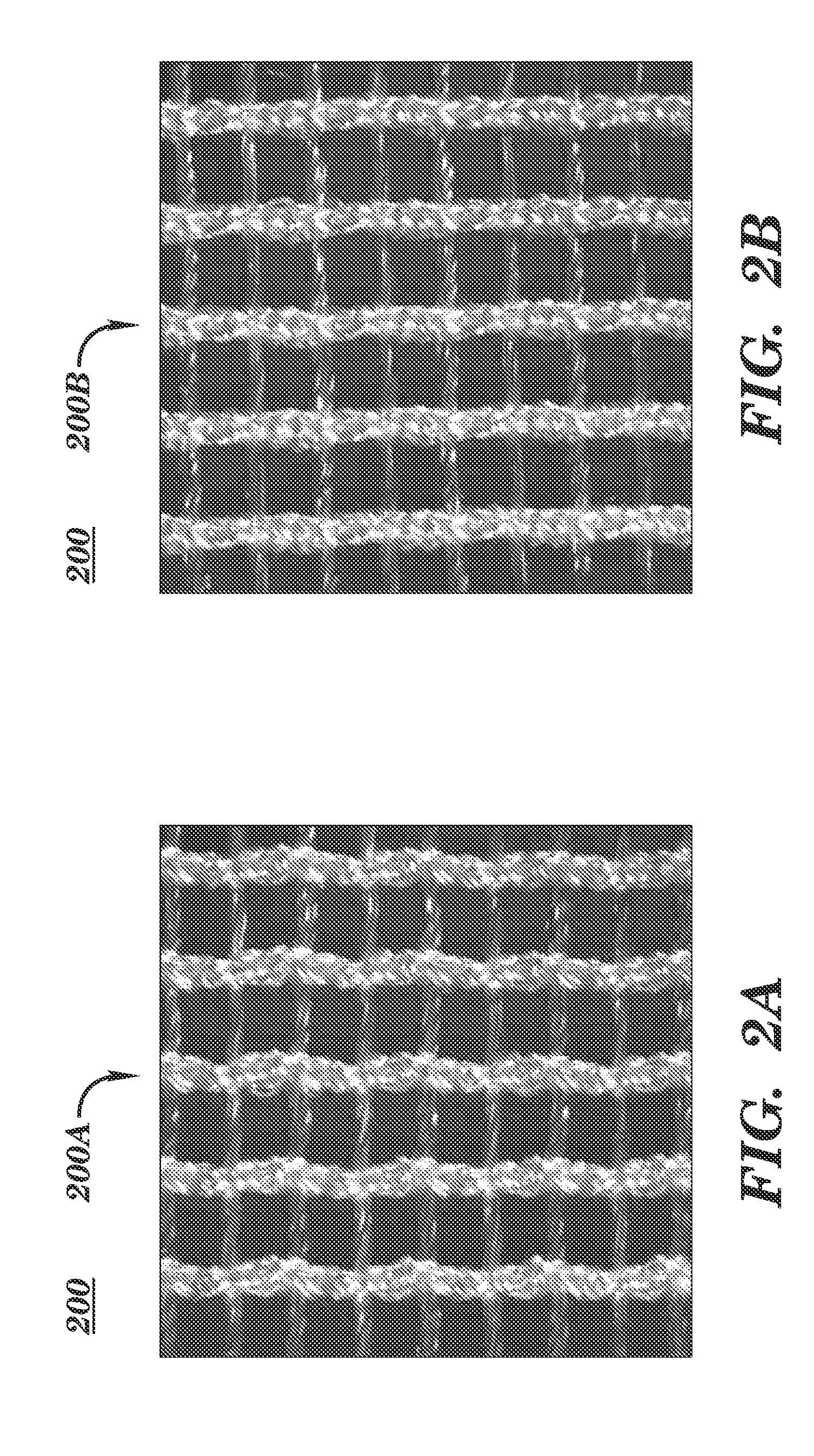

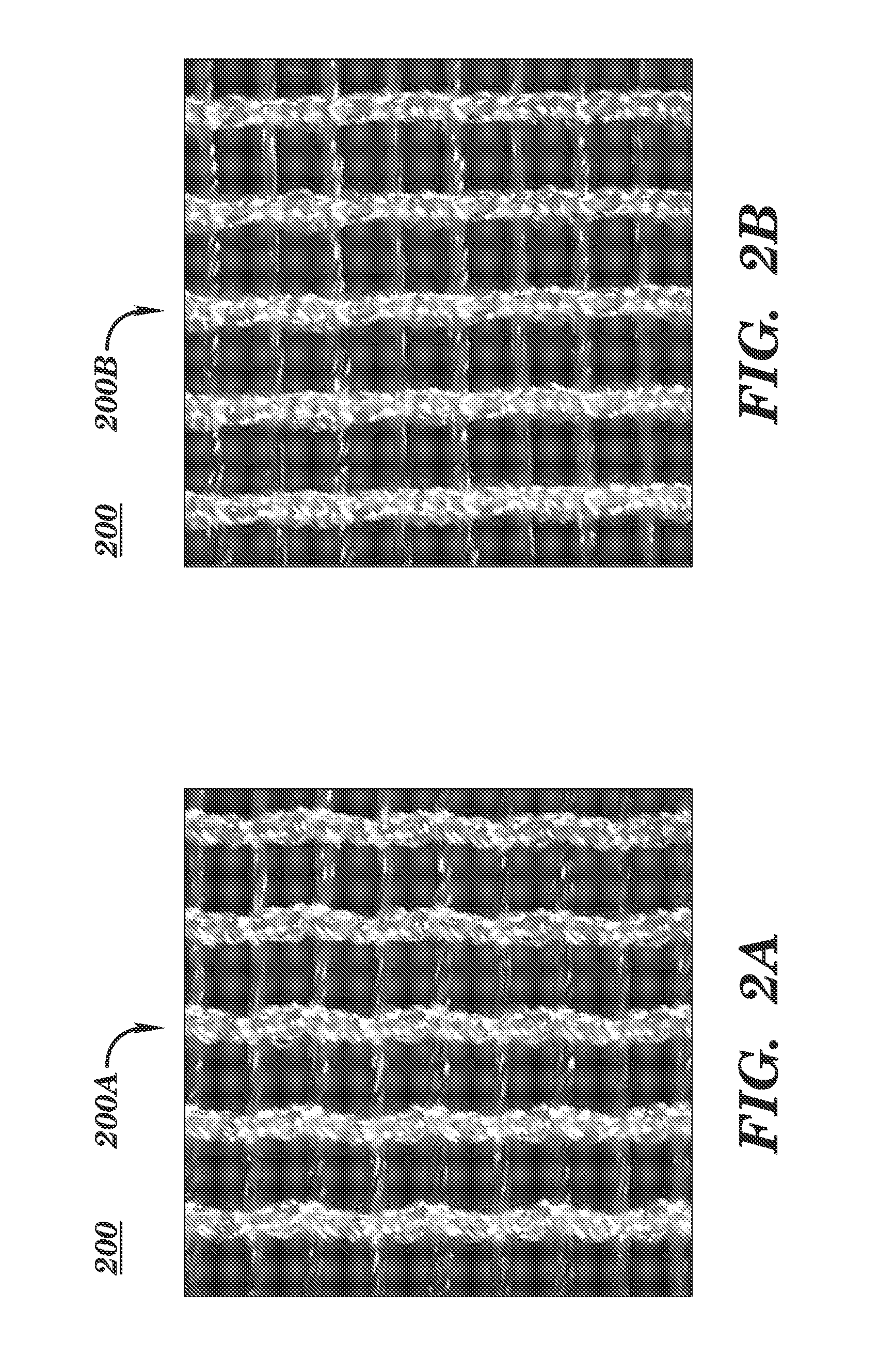

Prosthetic device having regions of varying stretch and method of manufacturing the same

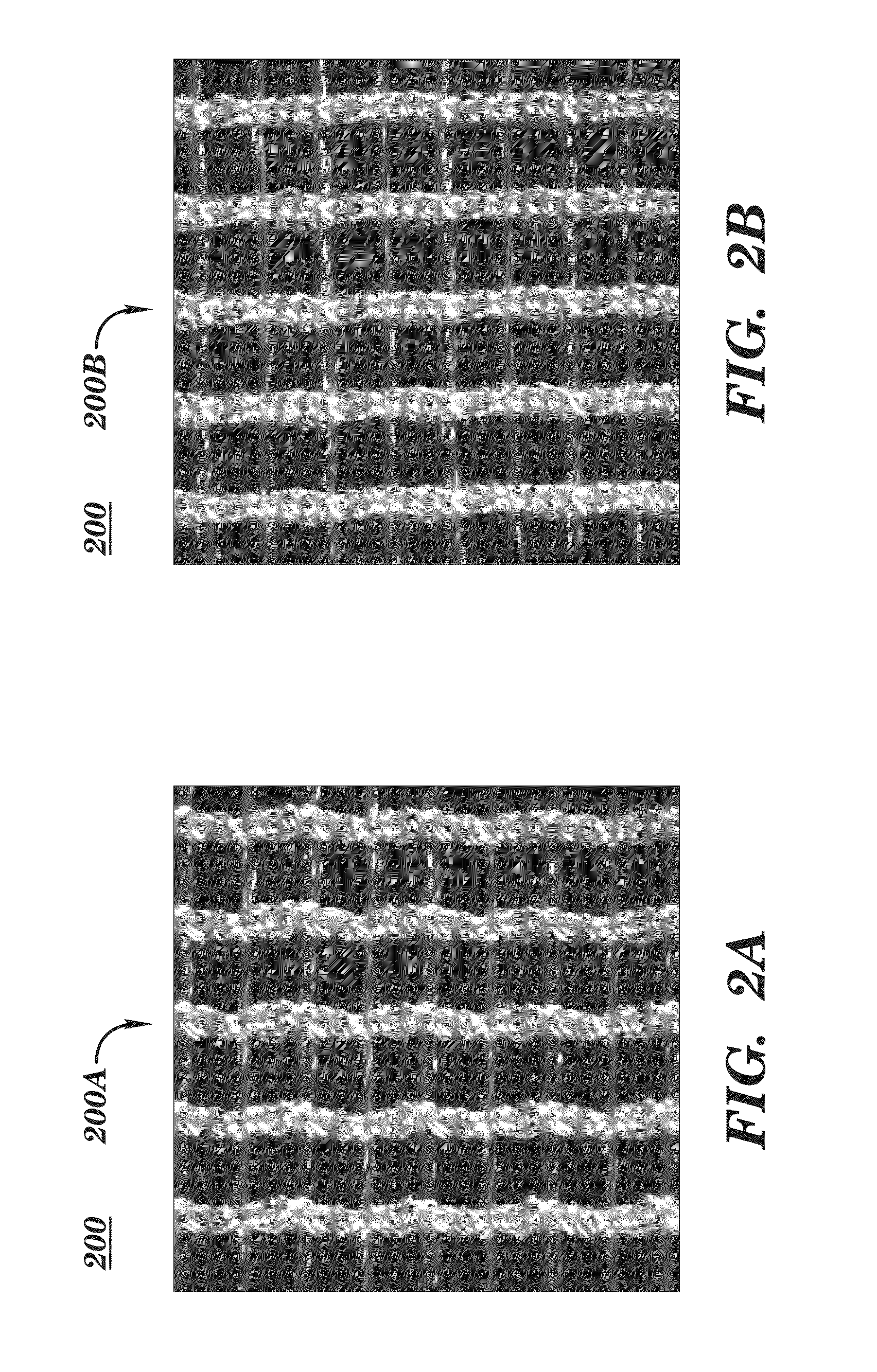

InactiveUS20110257761A1Minimizes adhesionsErosion minimizationMammary implantsWeft knittingYarnMechanical property

A biocompatible surgical scaffold made from a multi-filament silk yarn for soft tissue reconstruction. The scaffold incorporates regions of varying stretch having different physical and mechanical properties that allow contouring to the required soft tissue shape to be replaced or repaired. The porous structure allows tissue in-growth, while the mesh degrades at a rate which allows for a smooth transfer of mechanical properties to the new tissue from the silk scaffold.

Owner:ALLERGAN INC

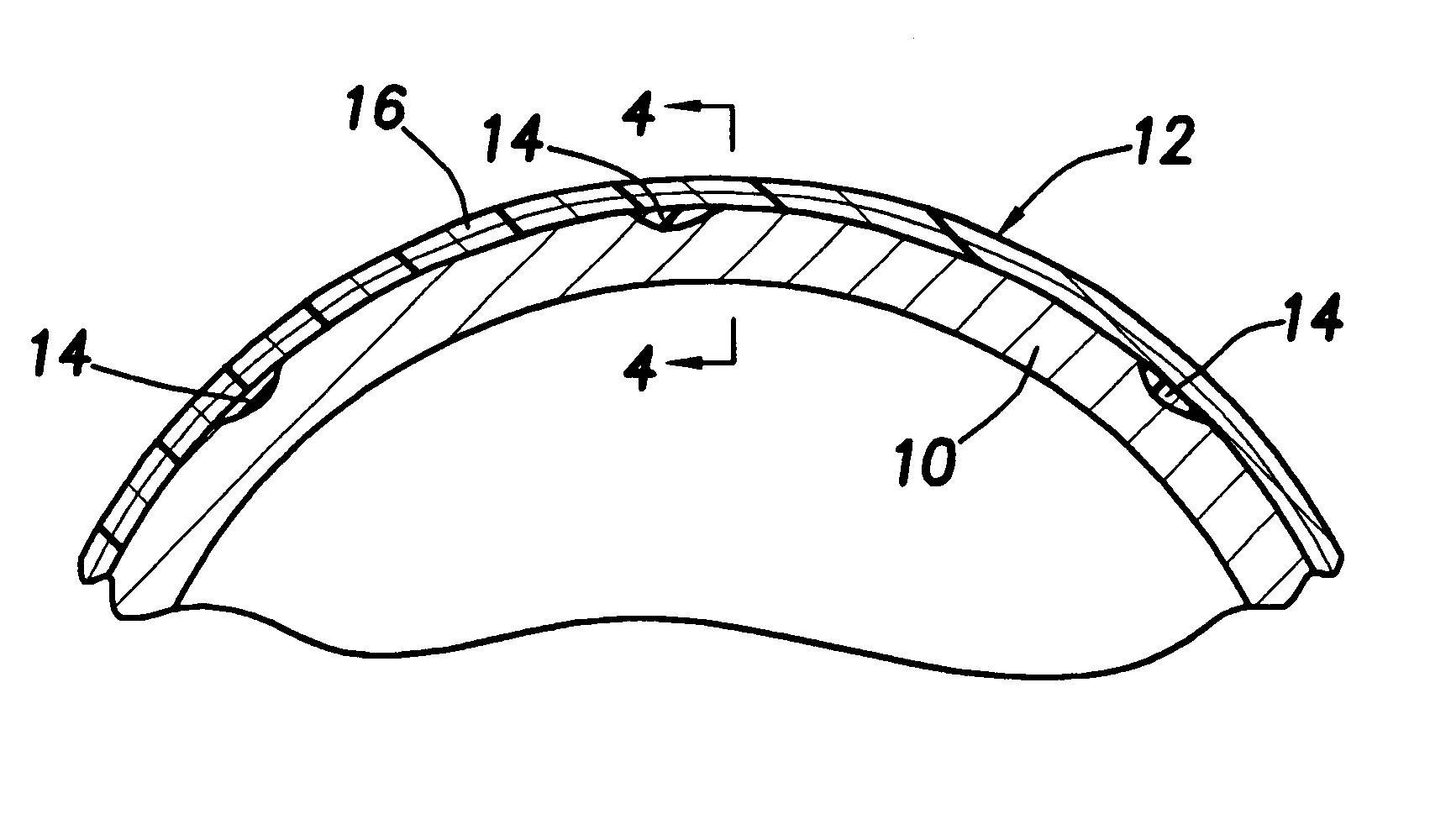

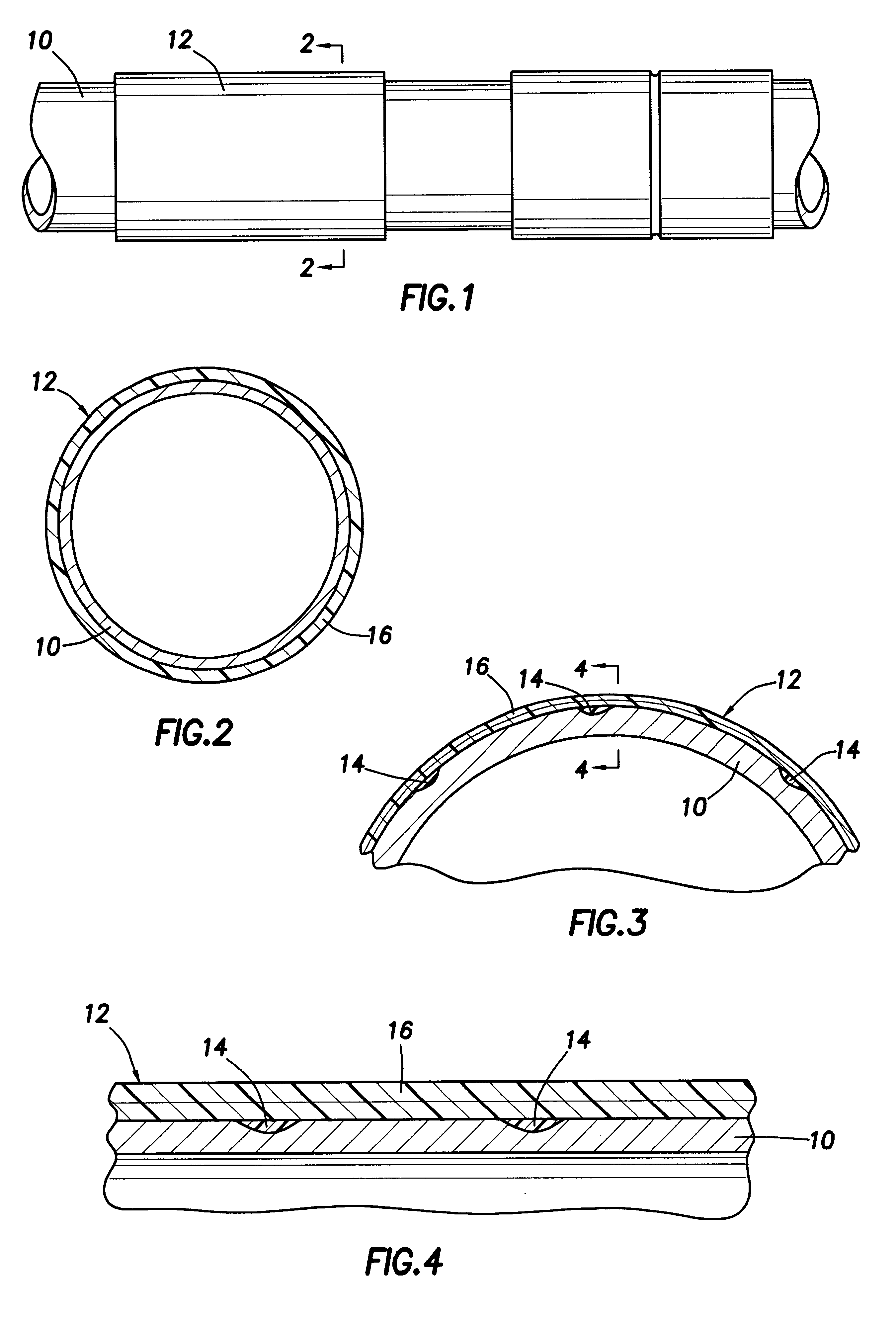

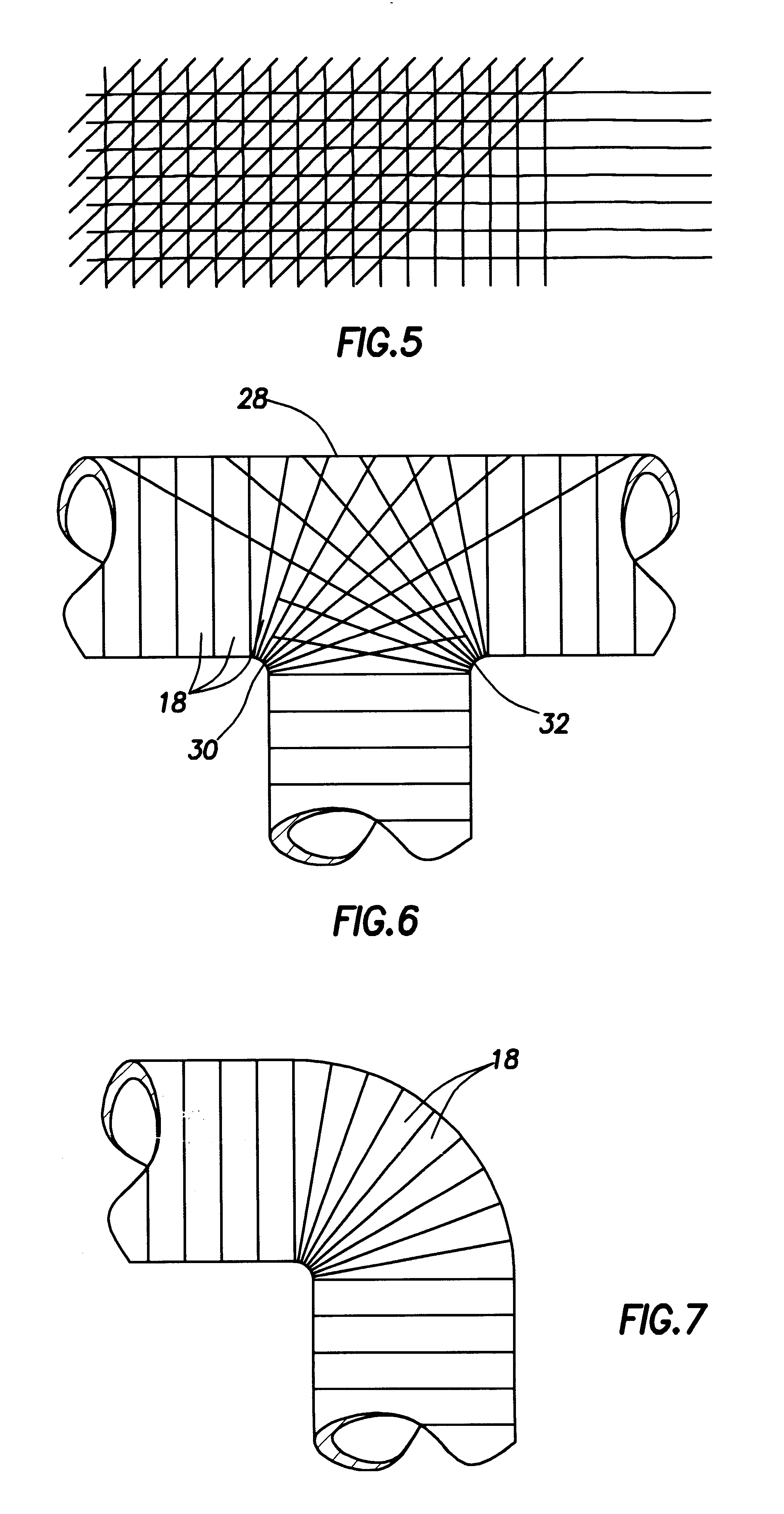

High temperature composite pipe wrapping system

InactiveUS6276401B1Improve stress resistanceMinimize dimensional changeLayered productsLaminationUnderlaySolvent

A method and apparatus for providing metal or non-metal vessels, including straight and curved pipes and various pipe connections, such as T's, elbows, swages, etc., and pressure containing vessels such as tanks, with an external composite lining of a webbing of biaxial or triaxial weave preferably composed of fiberglass which is pre-impregnated with a high temperature heat curable polymer composition capable of being heat cured at a temperature range of from about 275° F. to about 375° F. The vessel is prepared for bonding by abrasive cleaning and by solvent cleaning. Metal imperfections are then filled with an epoxy. A small amount a quick setting epoxy is employed to attach one end of the web to the external surface of the vessel in oriented position for wrapping of the web in intimate surface-to-surface contact with the vessel. During wrapping only enough tension is applied to the pre-impregnated webbing to eliminate any wrinkles. The number of layers of the impregnated webbing will be determined by the safe pressure containing capability of the pipe or vessel and its composite lining. An external heating element is then placed about the wrapping of pre-impregnated webbing material so as to be in substantially intimate relation therewith and is energized to apply sufficient heat for a sufficient period of time to completely cure the epoxy surface filler and to cure the polymer resin components of the pre-impregnated woven wrappings of webbing.

Owner:WILSON FRED D

Prosthetic device and method of manufacturing the same

ActiveUS20110257665A1Minimizes tissue erosion and fistula and adhesionWithstanding stressMammary implantsWeft knittingMesh gridYarn

A biocompatible surgical silk mesh prosthetic device employs a knit pattern that substantially prevents unraveling and preserves the stability of the mesh device, especially when the mesh device is cut. An example prosthetic device employs a knitted mesh including at least two yarns laid in a knit direction and engaging each other to define a plurality of nodes. The at least two yarns include a first yarn and a second yarn extending between and forming loops about two nodes. The second yarn has a higher tension at the two nodes than the first yarn. the second yarn substantially prevents the first yarn from moving at the two nodes and substantially prevents the knitted mesh from unraveling at the nodes.

Owner:ALLERGAN INC

Implantable silk prosthetic device and uses thereof

InactiveUS20120150204A1Minimizes tissue erosionMinimizes fistulaMammary implantsWeft knittingYarnProsthesis

A method of using a biocompatible surgical silk mesh prosthetic device in body aesthetics and body contouring, the surgical mesh employing a knit pattern that substantially prevents unraveling and preserves the stability of the mesh device, especially when the mesh device is cut. An example prosthetic device employs a knitted mesh including at least two yarns laid in a knit direction and engaging each other to define a plurality of nodes. The at least two yarns include a first yarn and a second yarn extending between and forming loops about two nodes. The second yarn has a higher tension at the two nodes than the first yarn. the second yarn substantially prevents the first yarn from moving at the two nodes and substantially prevents the knitted mesh from unraveling at the nodes.

Owner:ALLERGAN INC

Prosthetic device having diagonal yarns and method of manufacturing the same

InactiveUS20110224703A1Minimize erosionMinimizes adhesionsMammary implantsMedical devicesYarnEngineering

A knitted scaffold comprising at least two silk yarns in a knit direction and a yarn member diagonal to the knit direction to thereby provide a knitted fabric or mesh for surgical use that can retain its shape and / or resist collapse when opposing forces are applied at an angle from the knit direction. The knitted scaffold may include at least two yarns laid in a knit direction and engaging each other to define a plurality of nodes. The at least two yarns can include a first yarn and a second yarn extending between and forming loops about two nodes. The second yarn has a higher tension at the two nodes than the first yarn. The second yarn substantially prevents the first yarn from moving at the two nodes and substantially prevents the knitted mesh from unraveling at the nodes.

Owner:ALLERGAN INC

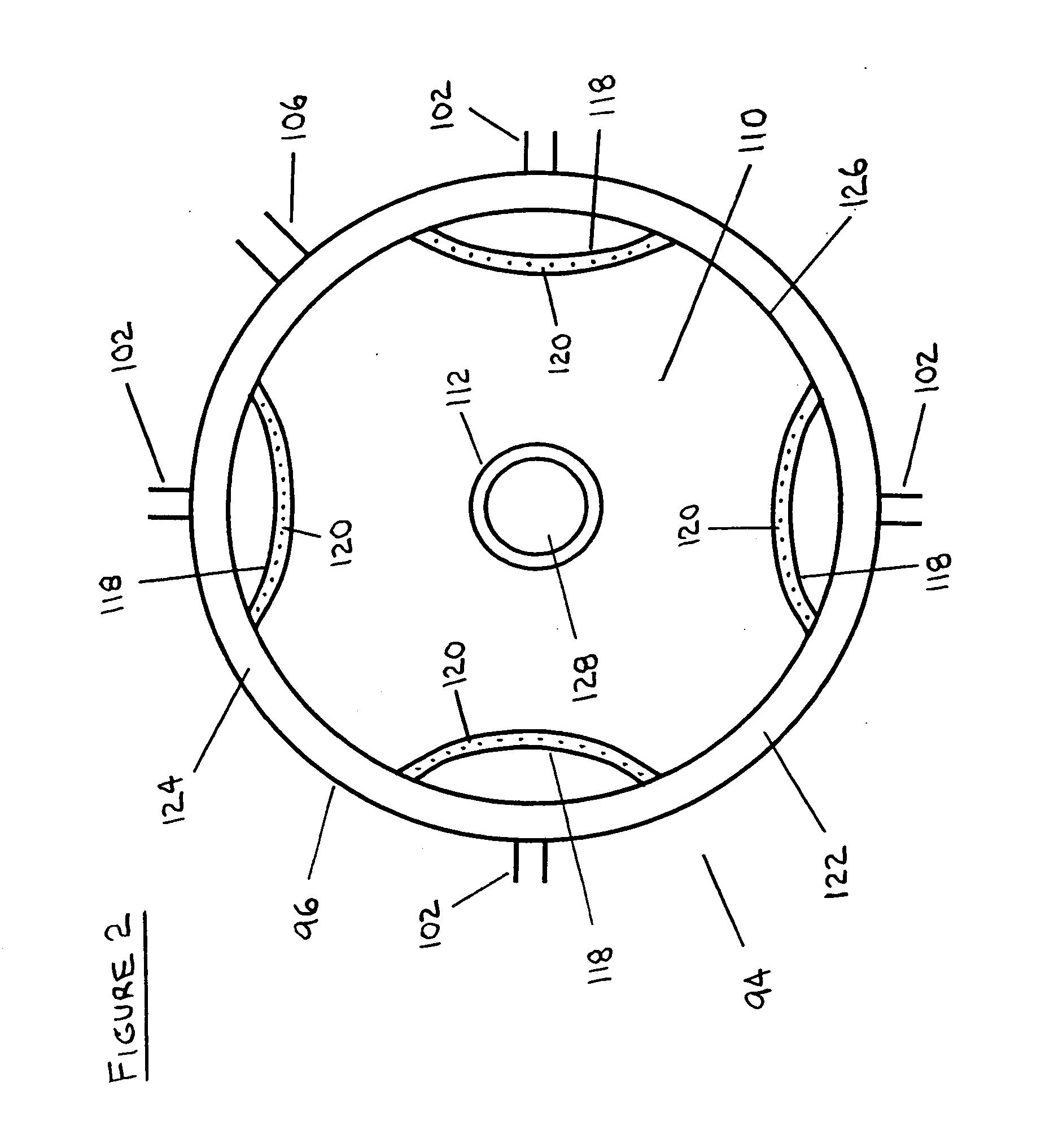

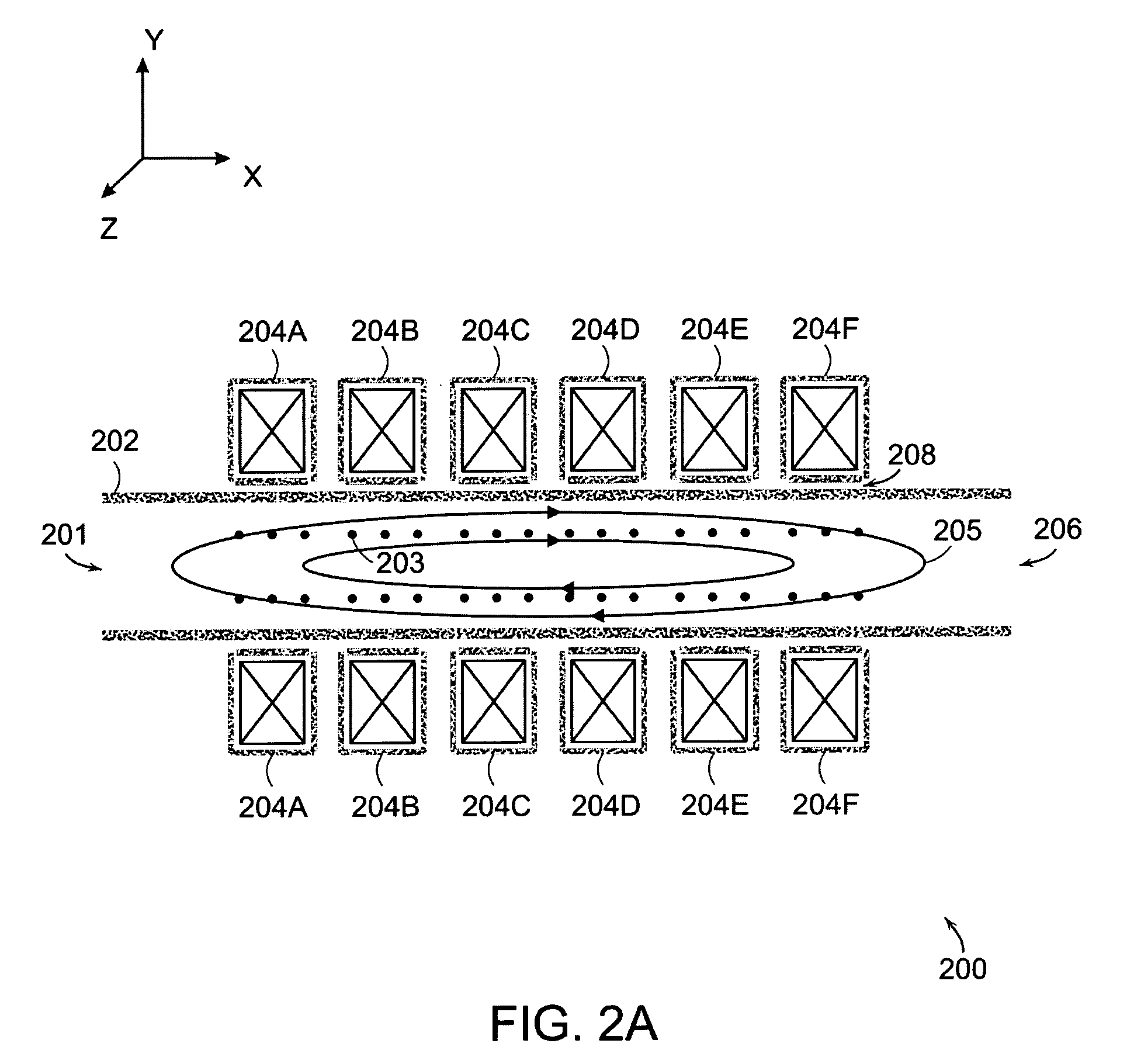

Inductively-coupled plasma source

ActiveUS7969096B2Energy efficiencyMaximize efficiencyElectric discharge tubesElectric arc lampsInductively coupled plasmaInductance

A method and apparatus for exciting gas that involves generating an alternating magnetic field unidirectionally through a magnetic core defining a gap, across the gap and through a plasma vessel that includes dielectric material. The magnetic field induces an electric field in the plasma vessel that generates the plasma.

Owner:MKS INSTR INC

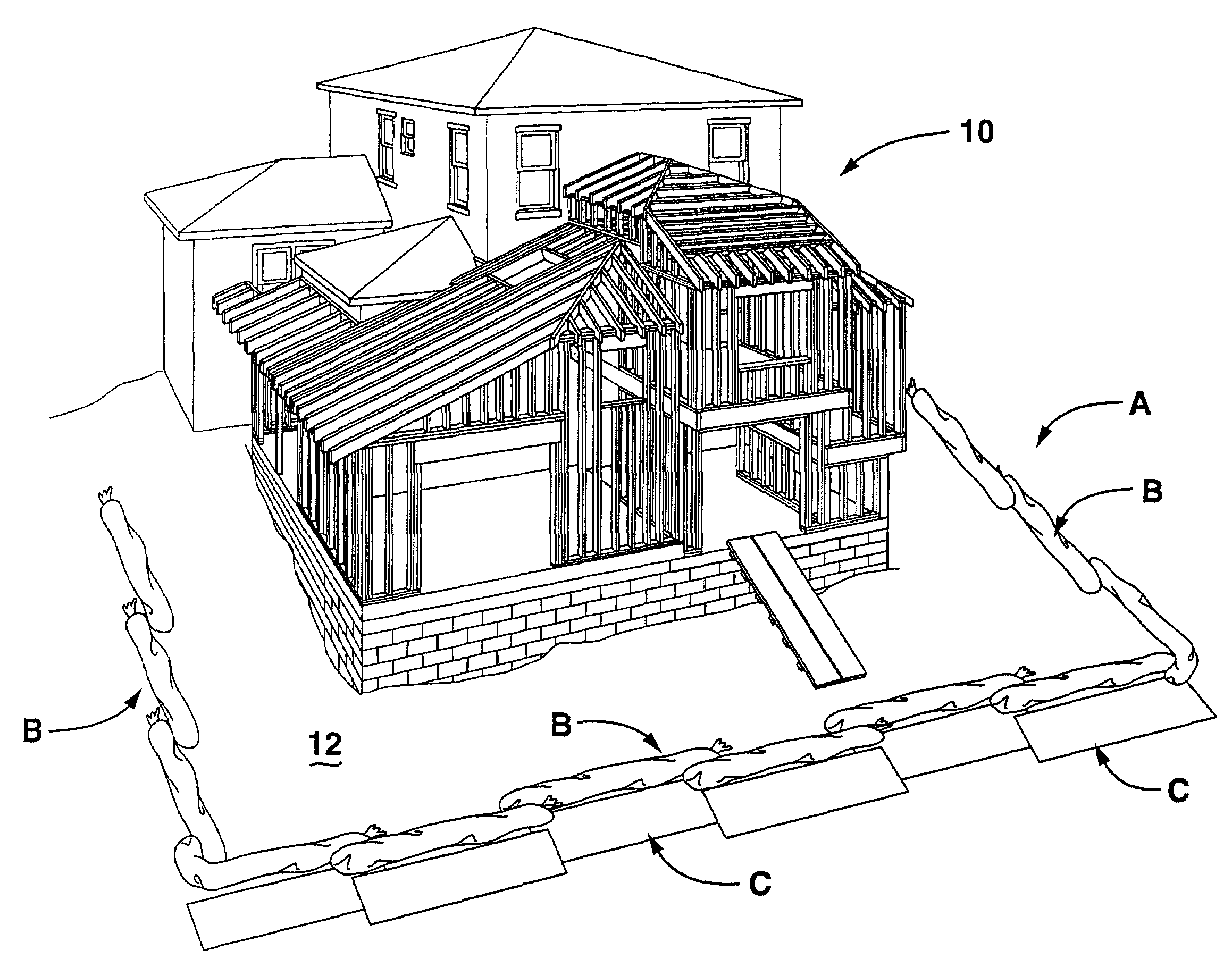

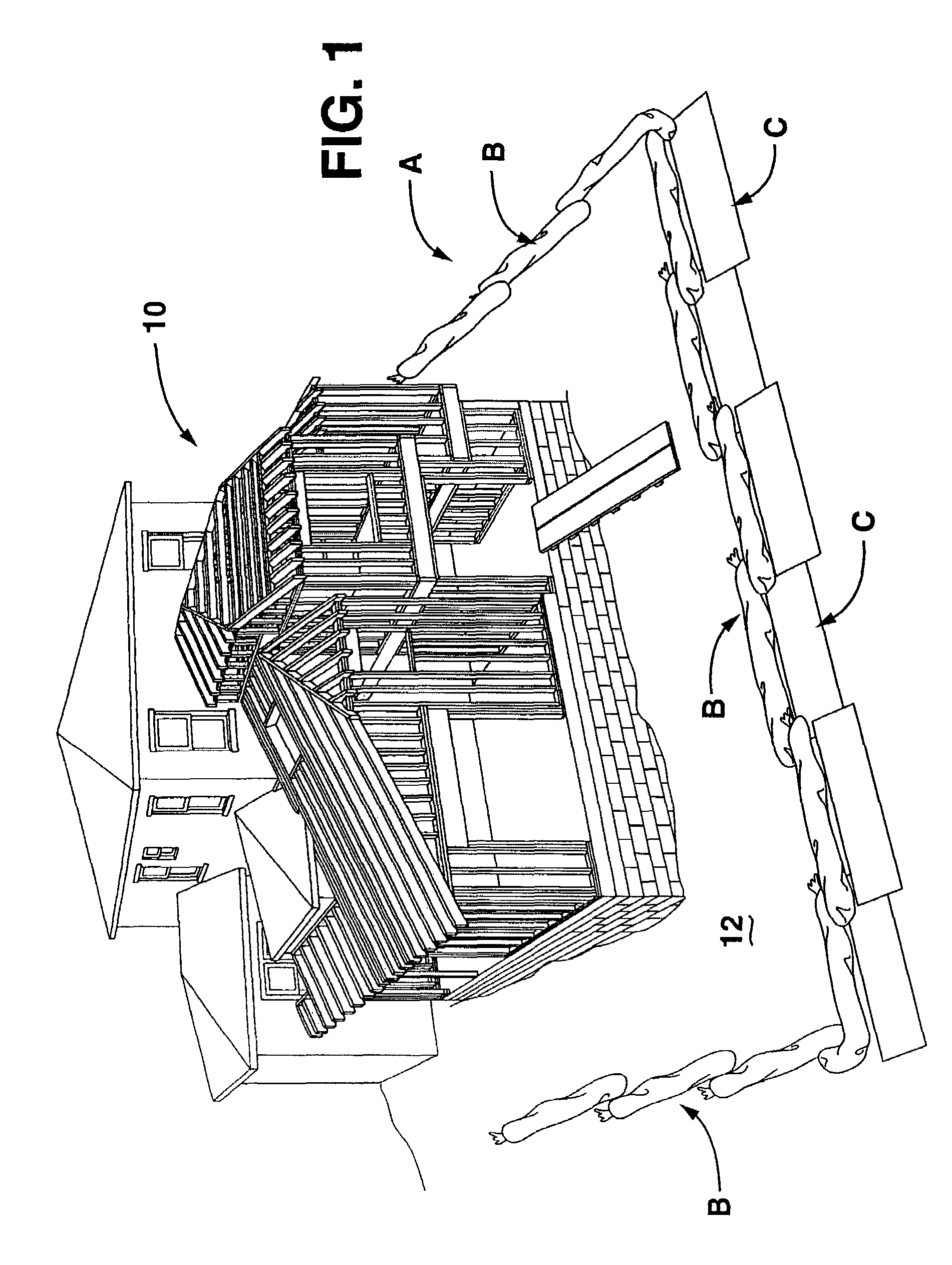

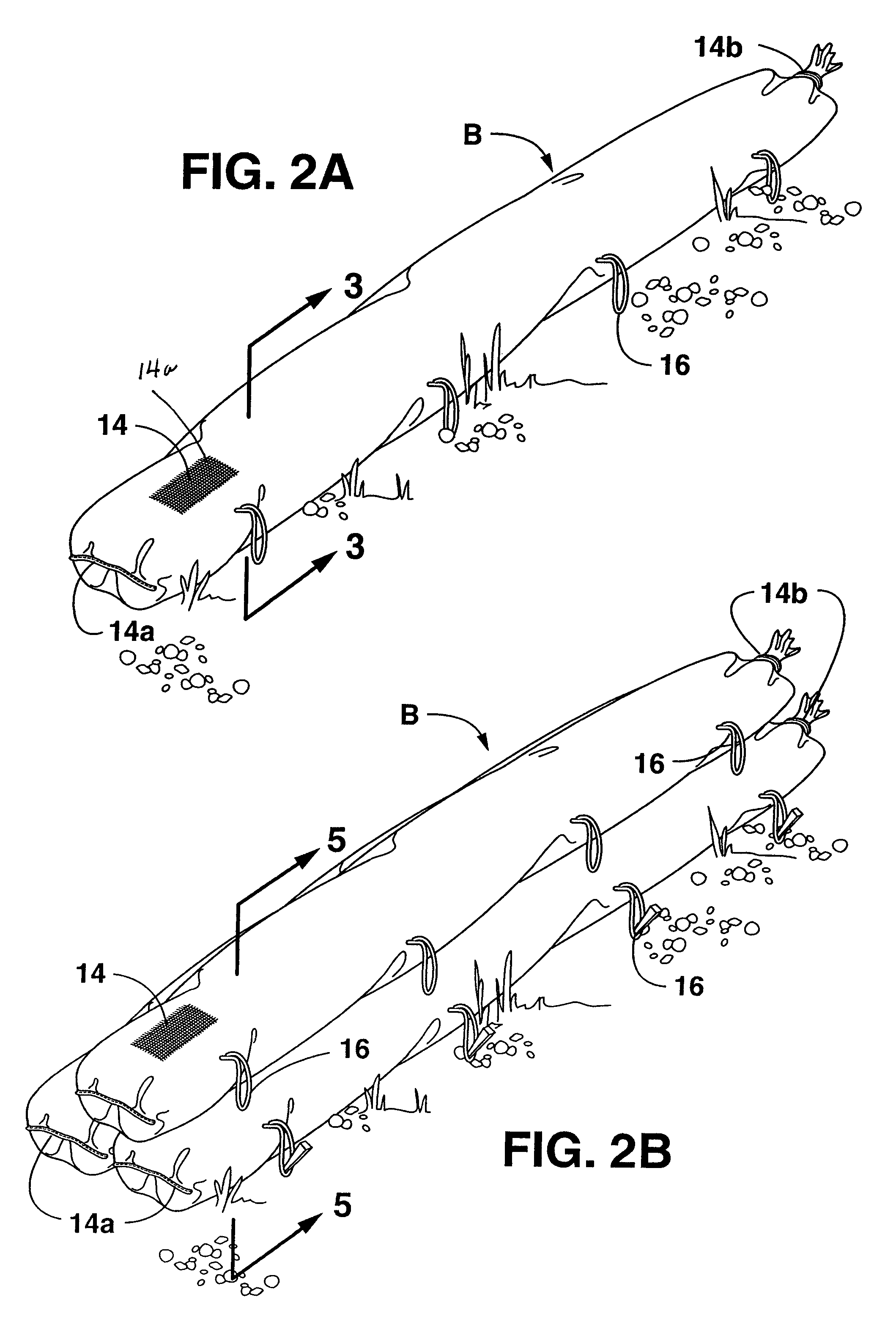

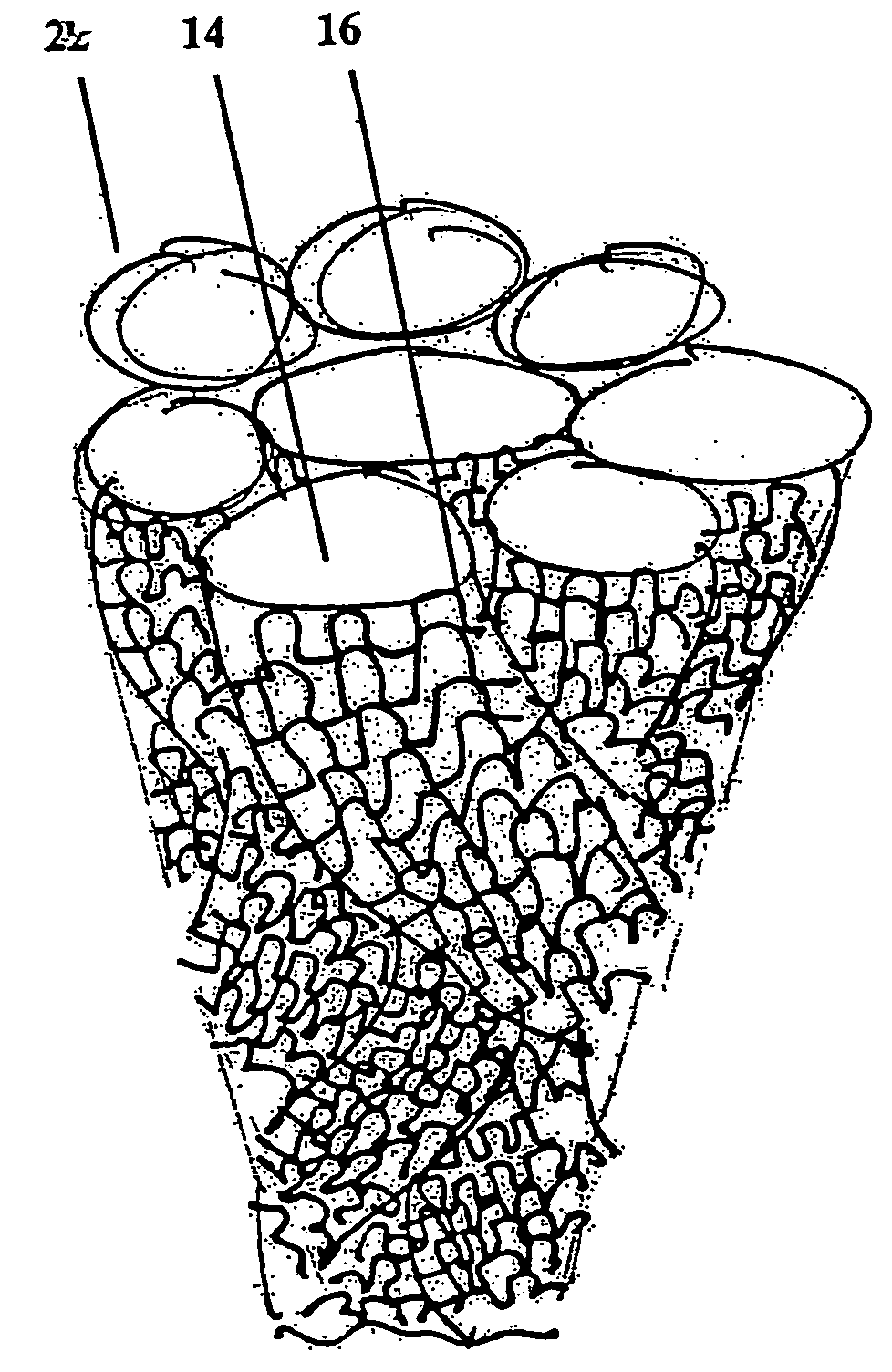

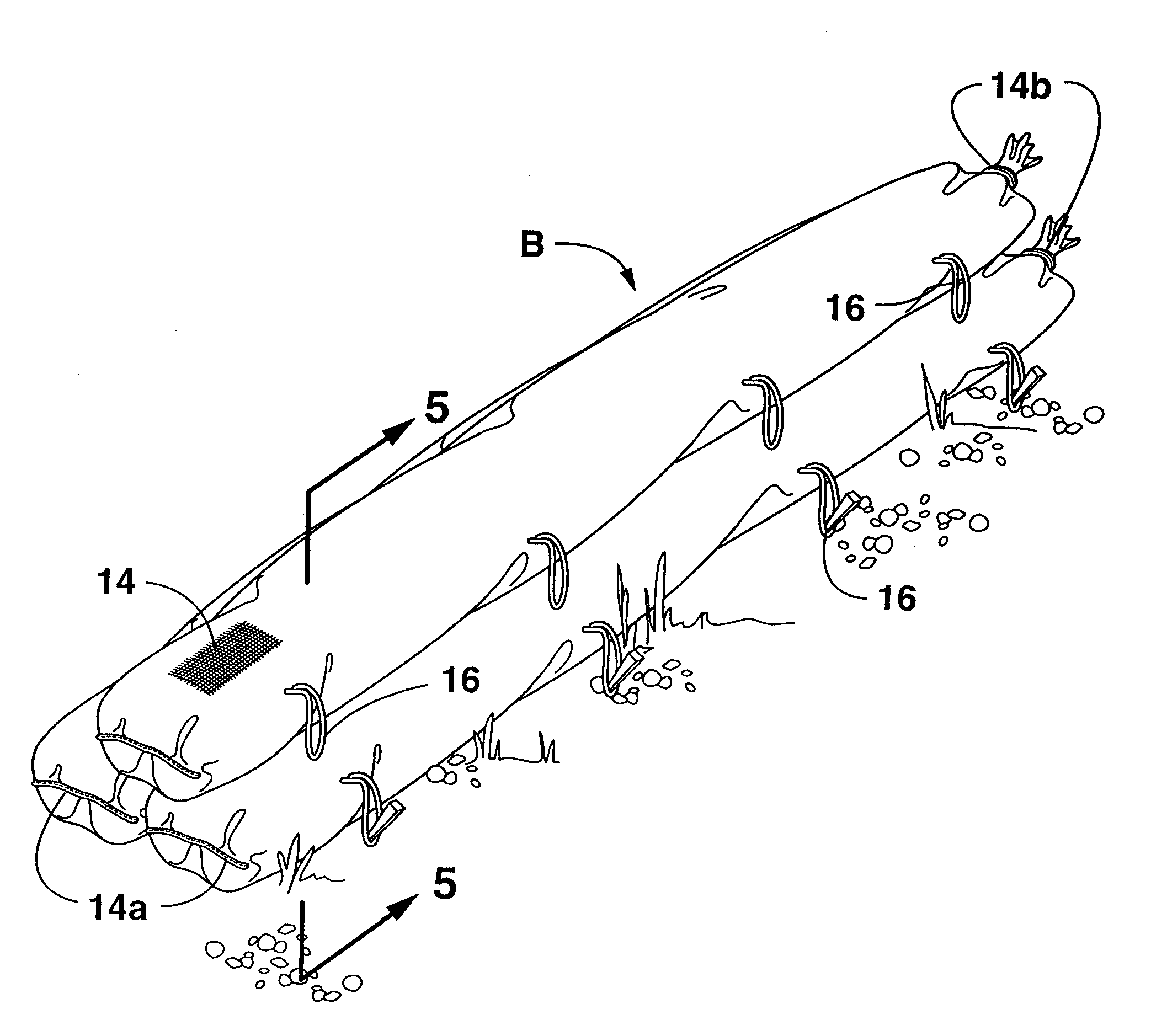

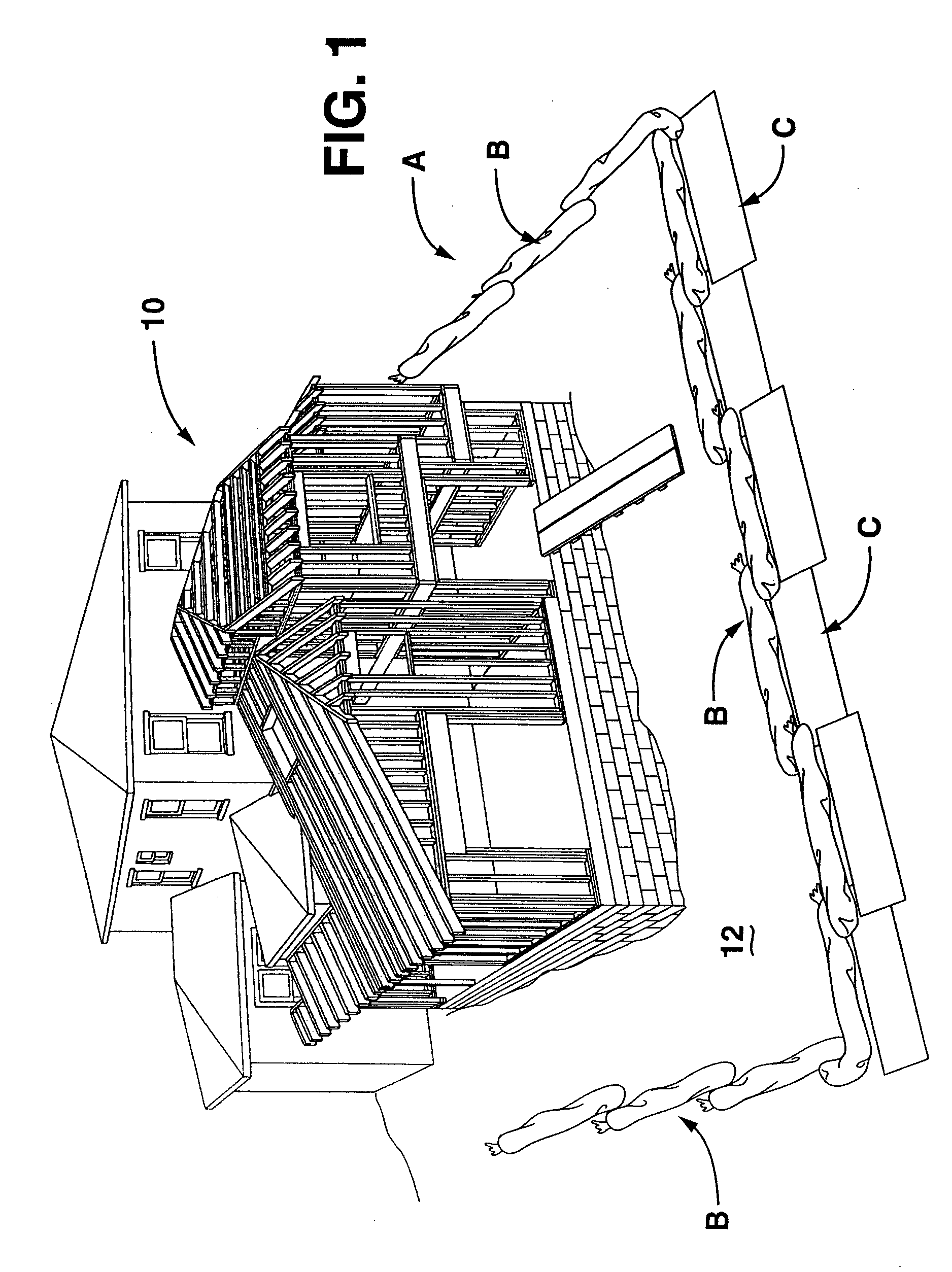

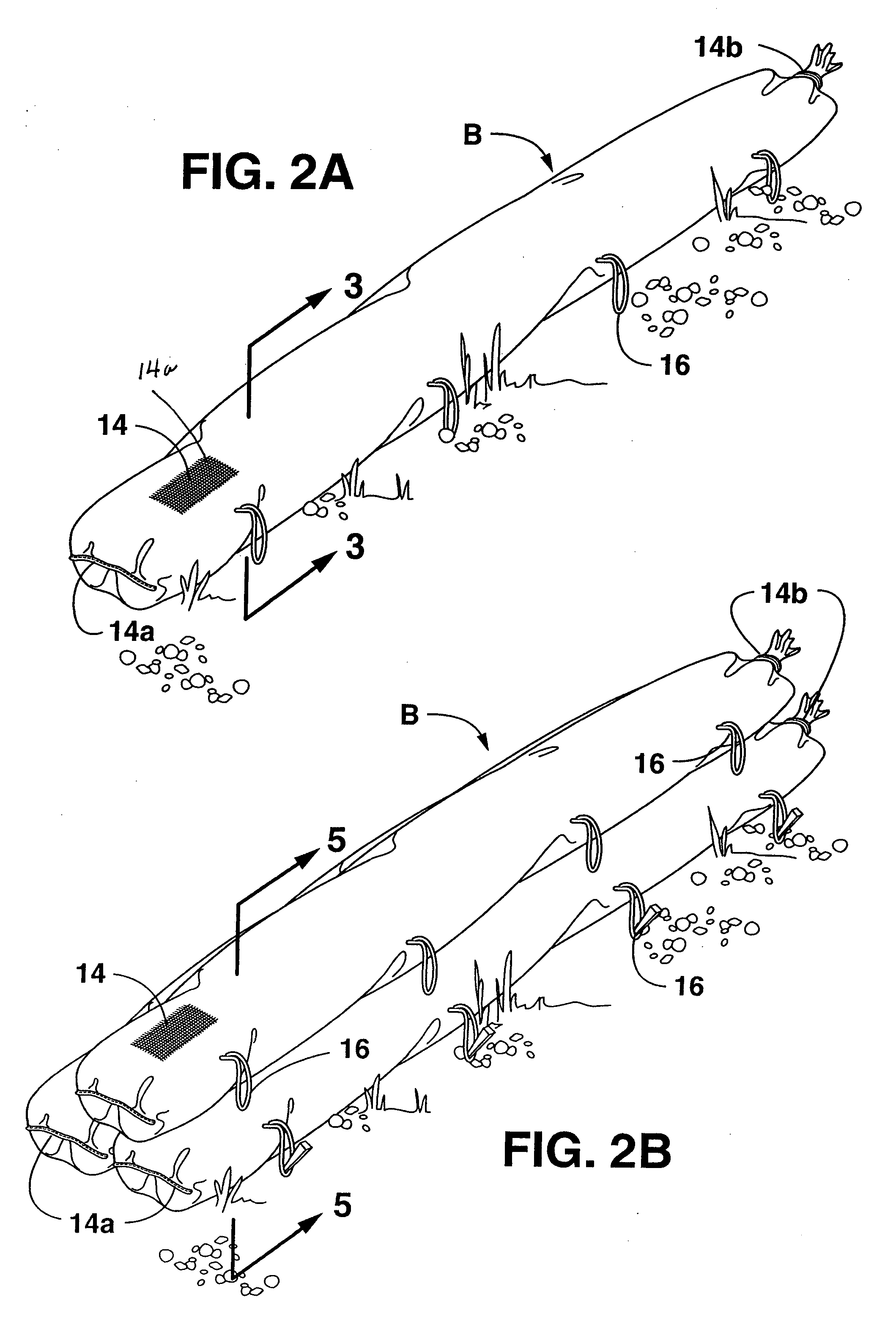

Water filtration and erosion control system

ActiveUS7449105B2Useful in erosion controlErosion minimizationLoose filtering material filtersCartridge filtersPondingControl system

An erosion control system and method wherein a fabric filter bag is embedded with and / or filled with a flocculating polymer and is positioned on a sloping soil surface to dam and pond water flowing thereacross for settling of the particles in the water, and as the ponding water seeps into the bag the colloidal particles will be filtered or agglomerated for settling. The water then passes through and out of the bag and is further subjected to agglomeration and filtering by a skirt of filter material also impregnated with flocculating polymer, said skirt being anchored to the bag or stacked to maintain the position adjacent and downslope from the bag.

Owner:DENNY HASTINGS FLP 14

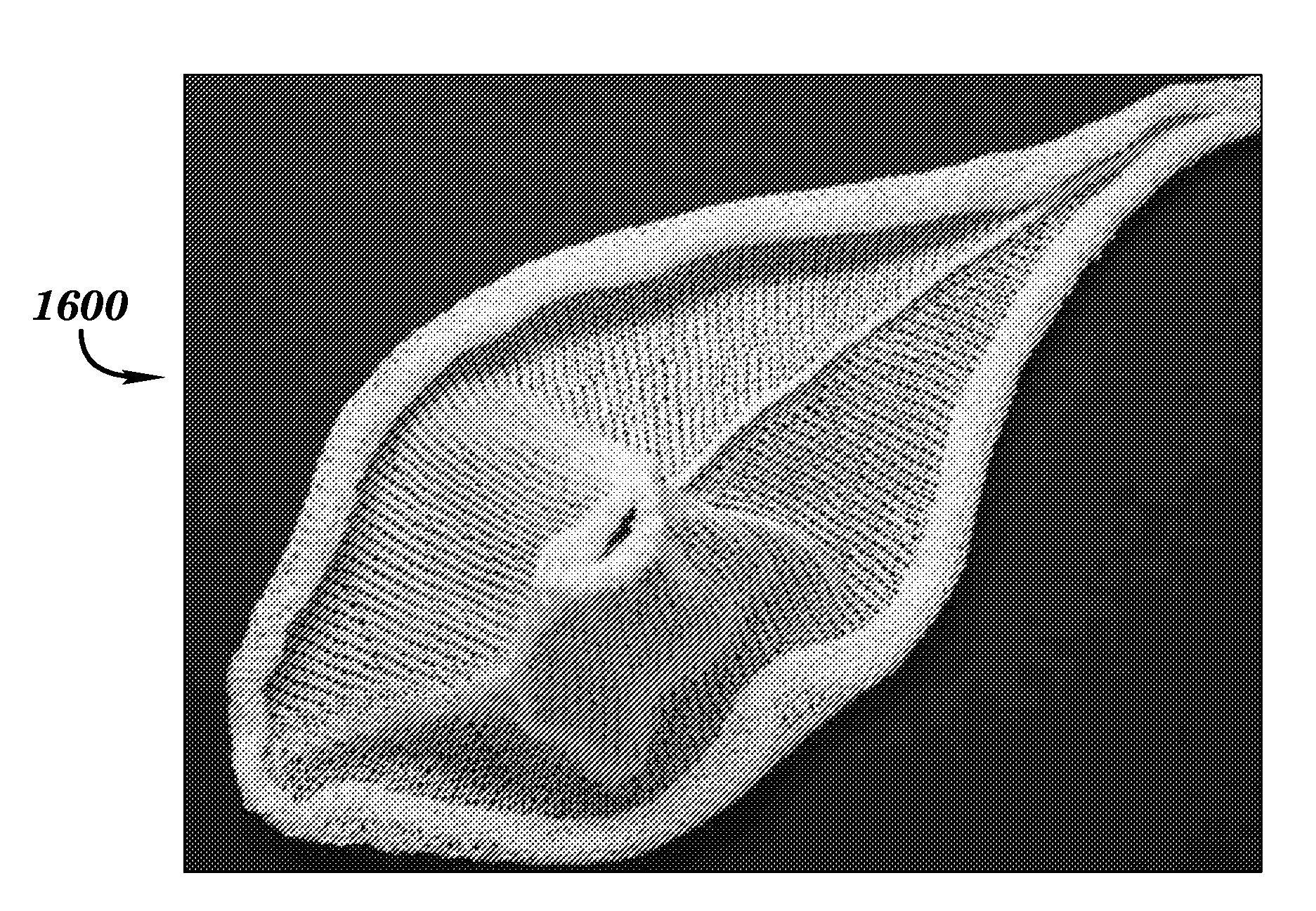

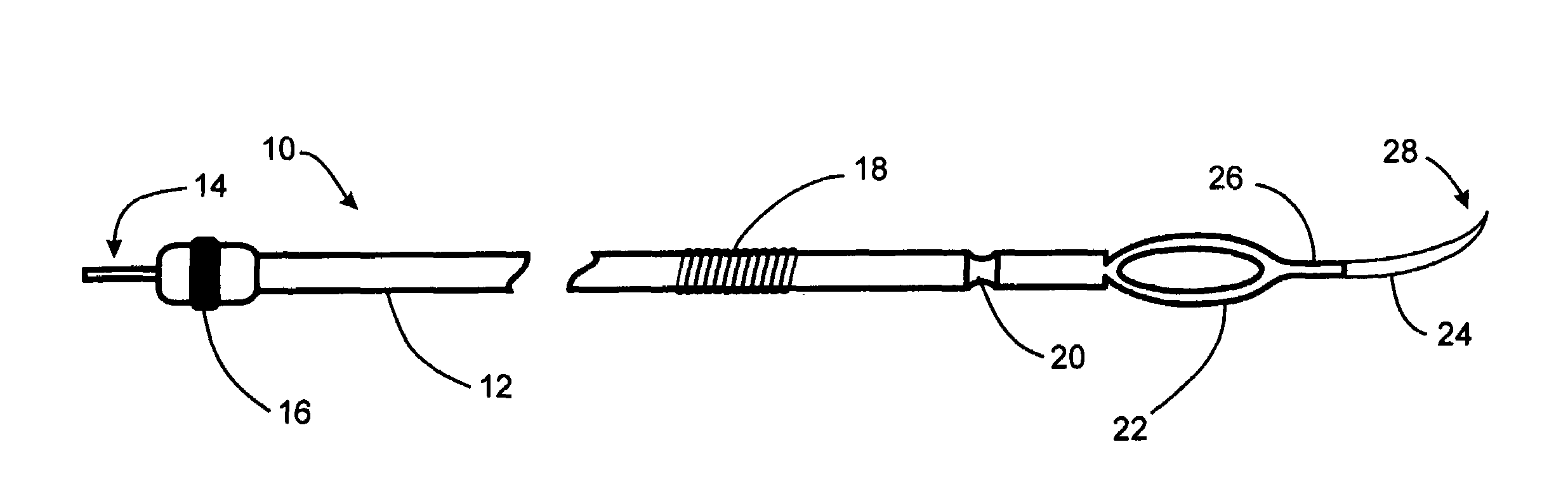

Three dimensional implant

InactiveUS20060106419A1Low densityLow implant surface area ratioStentsBlood vesselsLow densityTissue ingrowth

Implants (20, 22) and methods of making the implants for treating bodily defects or remodeling tissue. The implants have a low density and open pores (49) which may permit tissue ingrowth.

Owner:PROXY BIOMEDICAL

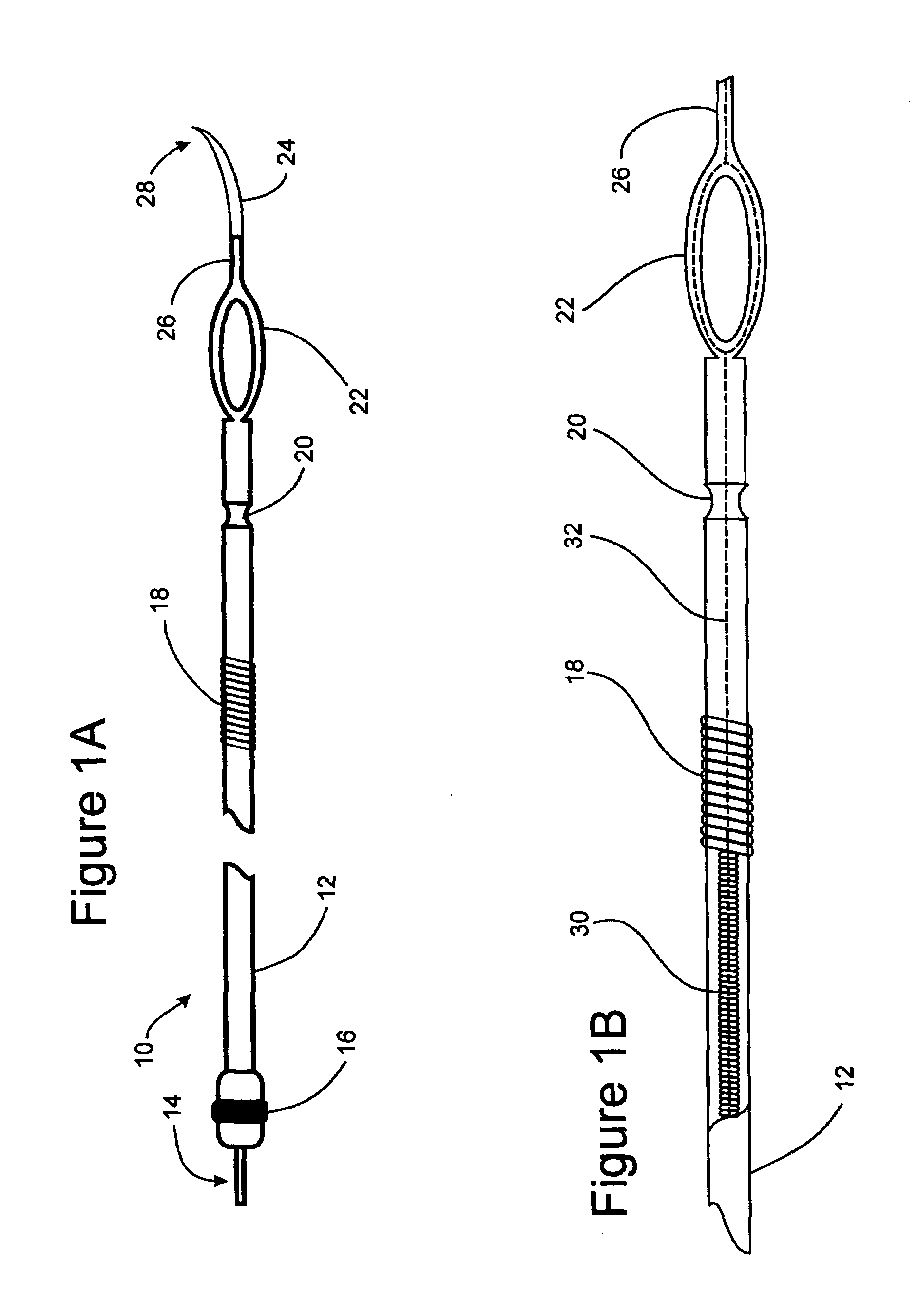

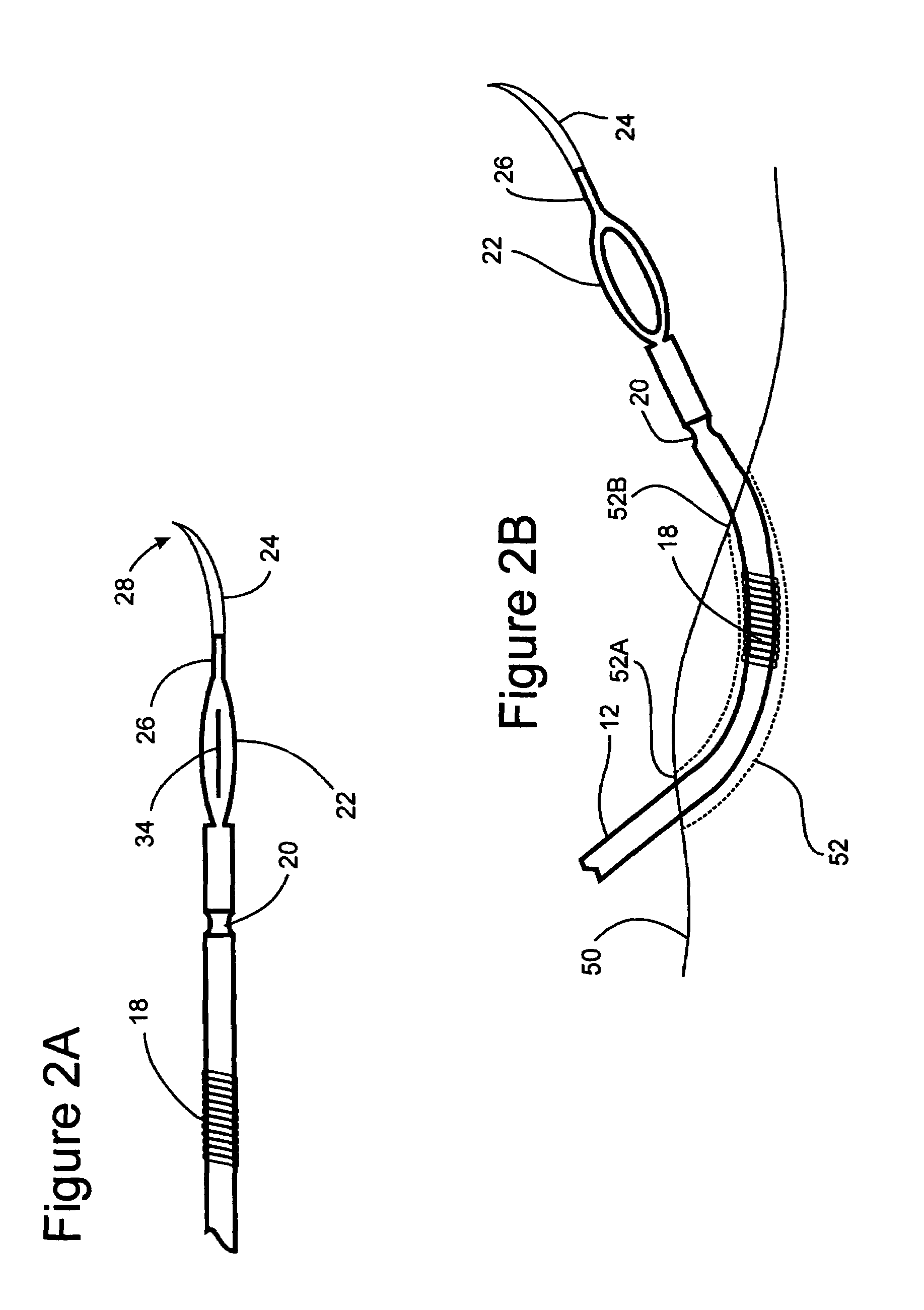

Gastrointestinal stimulation lead

ActiveUS7519433B2Flexible propertyErosion minimizationInternal electrodesDiagnostic recording/measuringStress concentrationElectrode erosion

Owner:MEDTRONIC TRANSNEURONIX

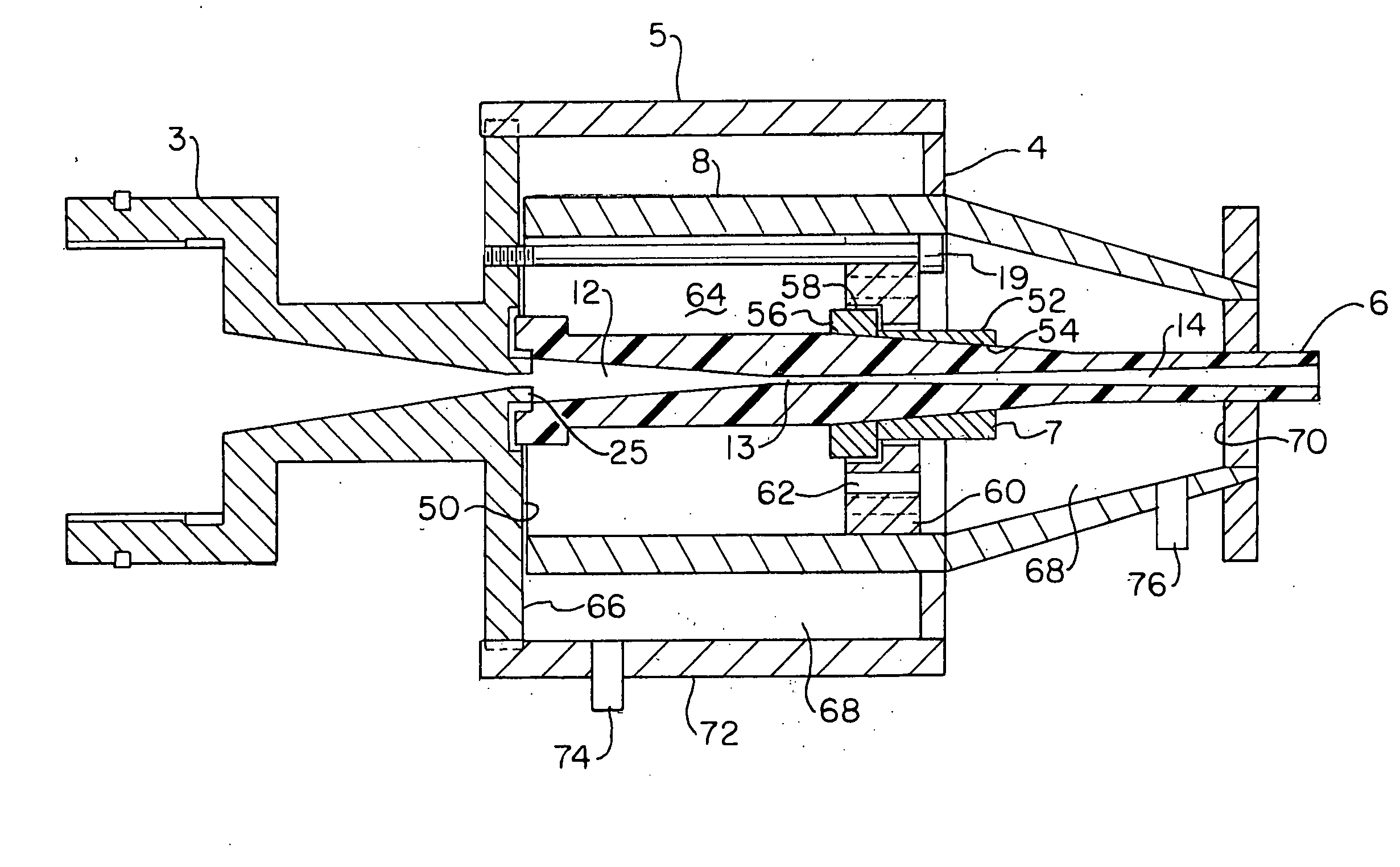

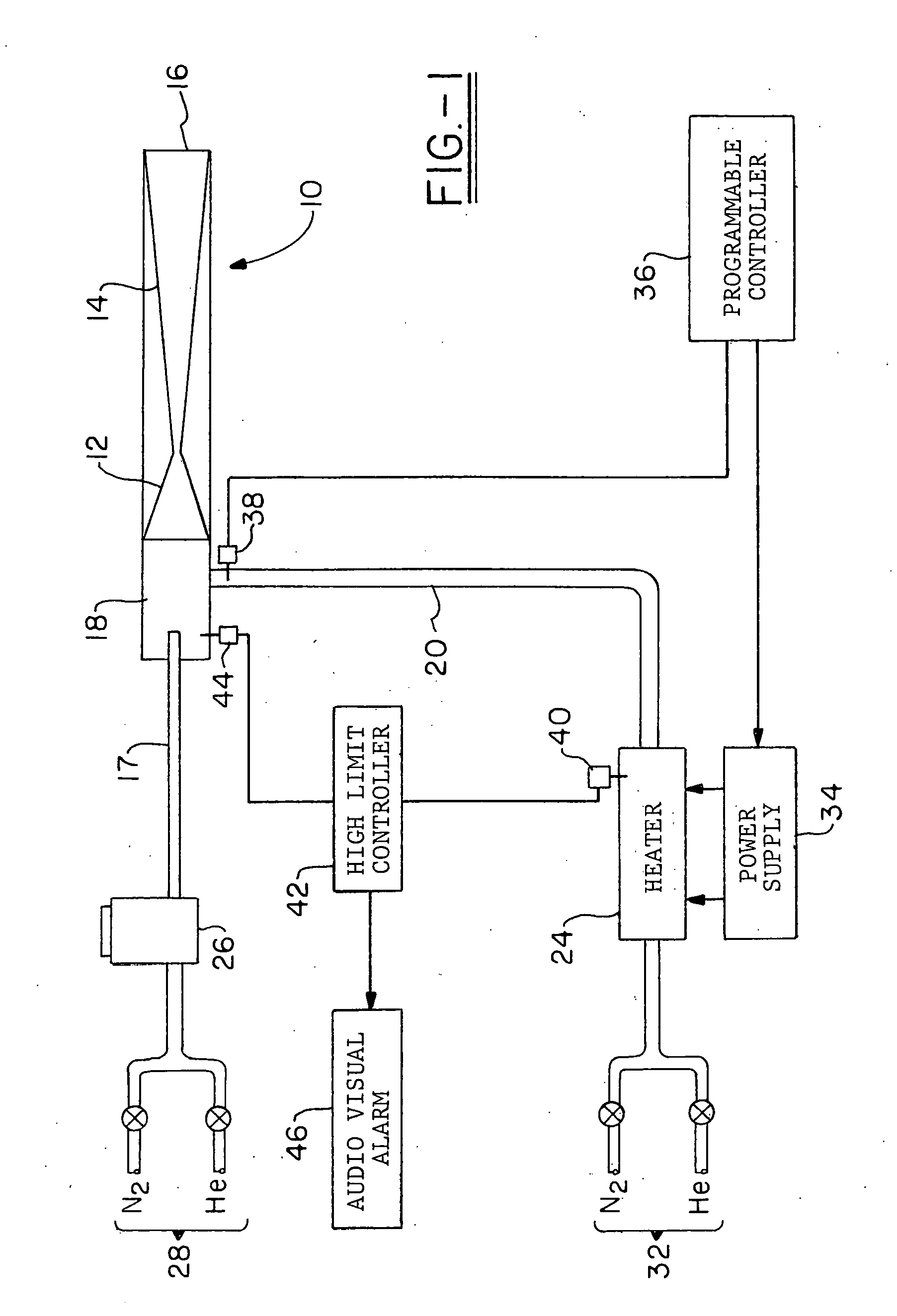

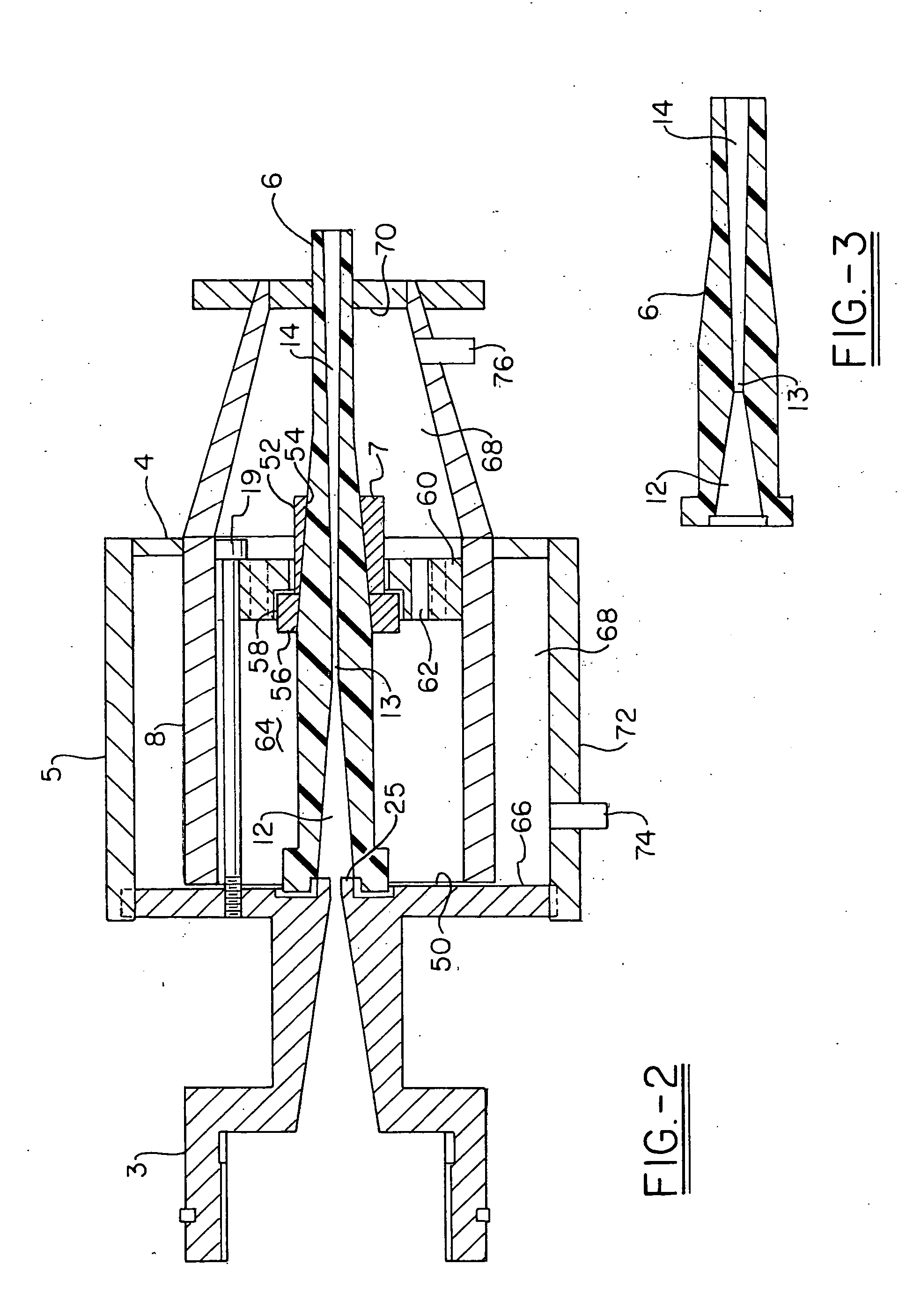

Spray nozzle assembly for gas dynamic cold spray and method of coating a substrate with a high temperature coating

InactiveUS20100136242A1Erosion minimizationMinimizes degradationPretreated surfacesSpray nozzlesHigh-temperature corrosionPolymer

The invention relates to an improved design for a spray gun and application system for cold gas dynamic spraying of a metal, alloy, polymer, or mechanical mixtures thereof. The gun includes a rear housing comprising a powder inlet and a gas inlet, a front housing removably affixed to the rear housing and comprising an mixing cavity therein for mixing of the powder and gas and an exit therefrom, a nozzle holder having a bore disposed therethrough and removably affixed to the front housing, and a polymeric nozzle positioned within the nozzle holder, an interior taper of the nozzle holder bore complementing an exterior taper of the nozzle. The nozzle having an initially converging, subsequently diverging centrally disposed bore therein adapted to receive the mixed powder and gas from the mixing chamber and the nozzle holder including a cooling jacket which is thermally coupled to the nozzle adjacent the nozzle inlet and mechanically coupled downstream of the nozzle inlet.

Owner:ASB INDS

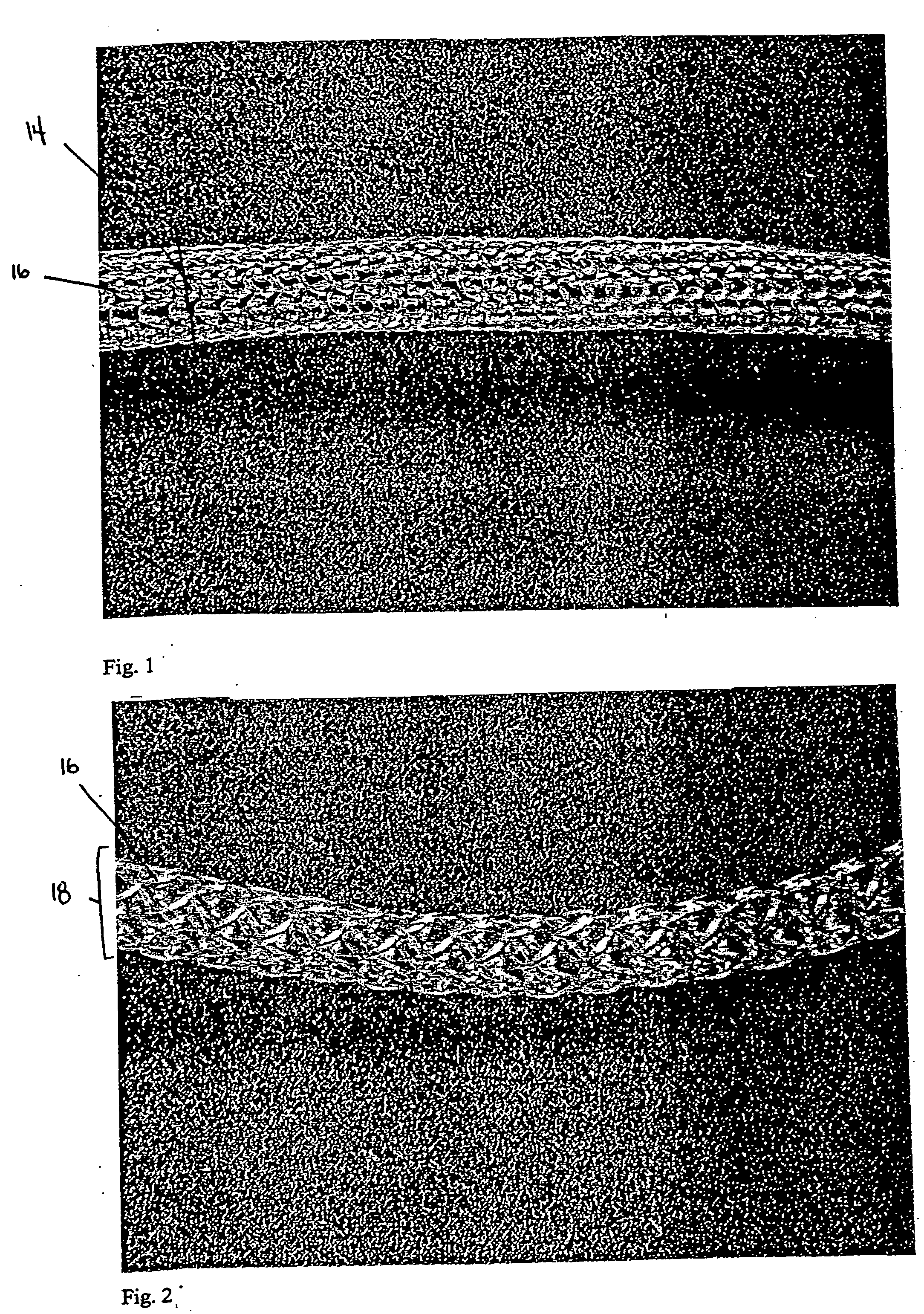

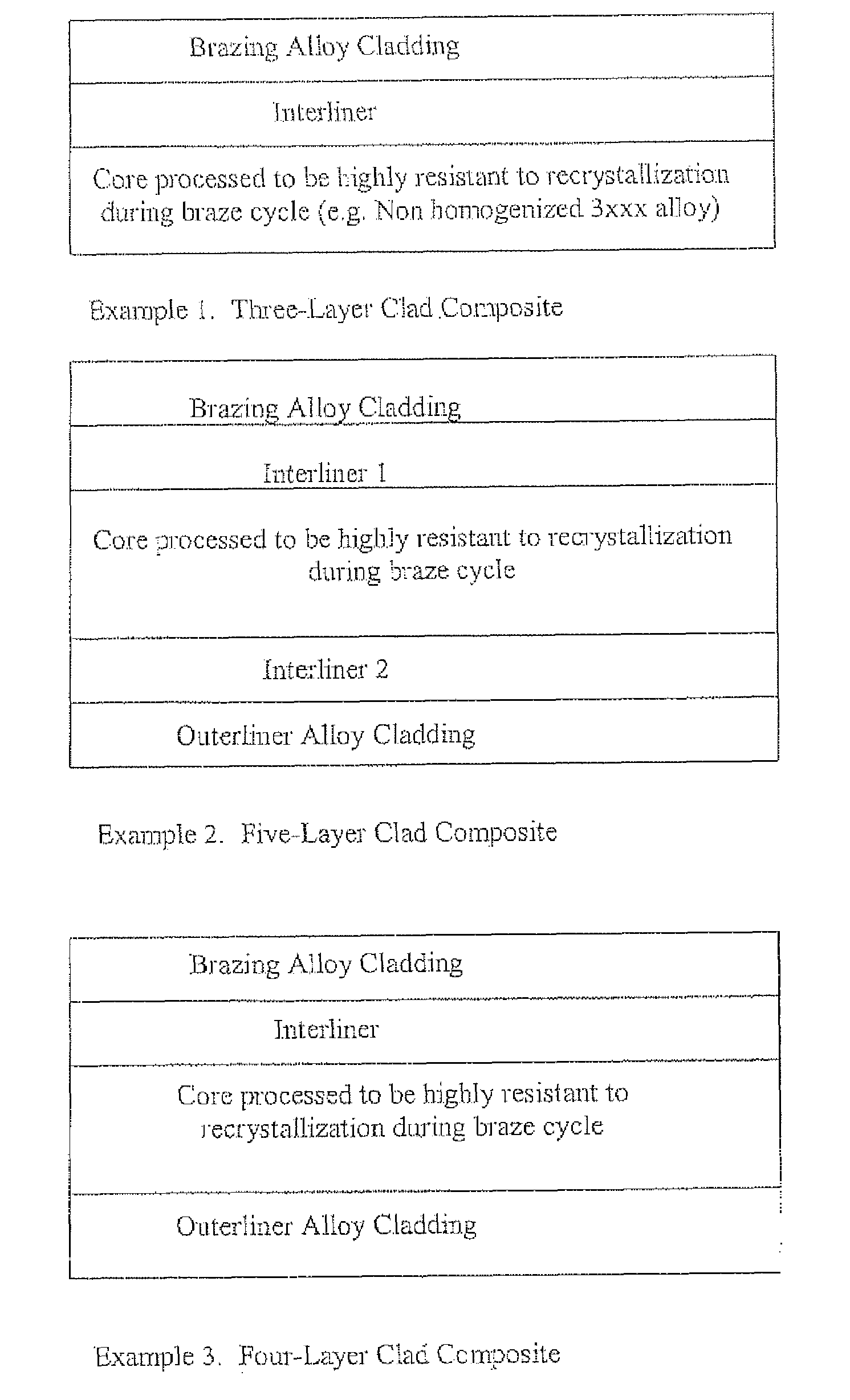

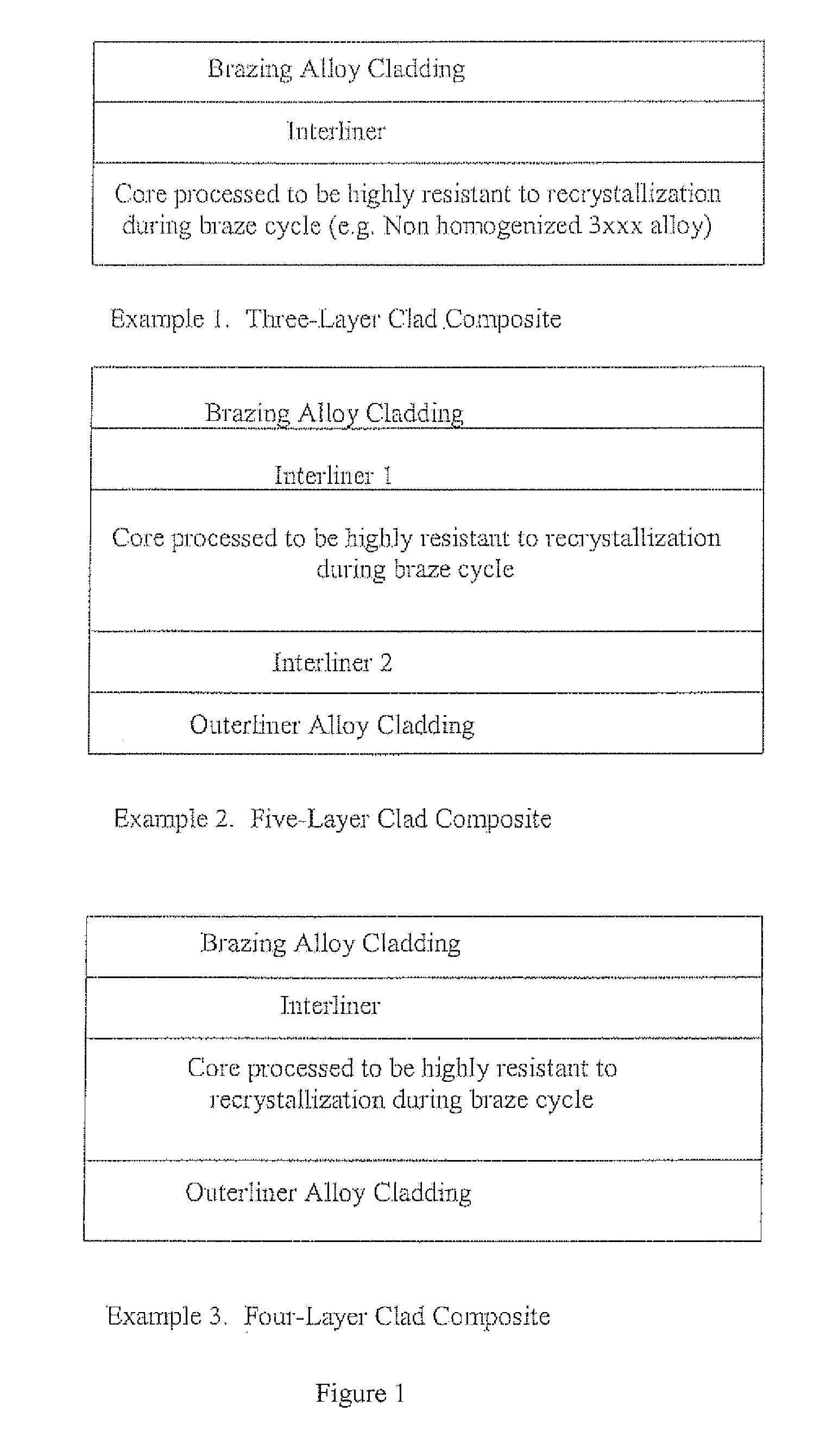

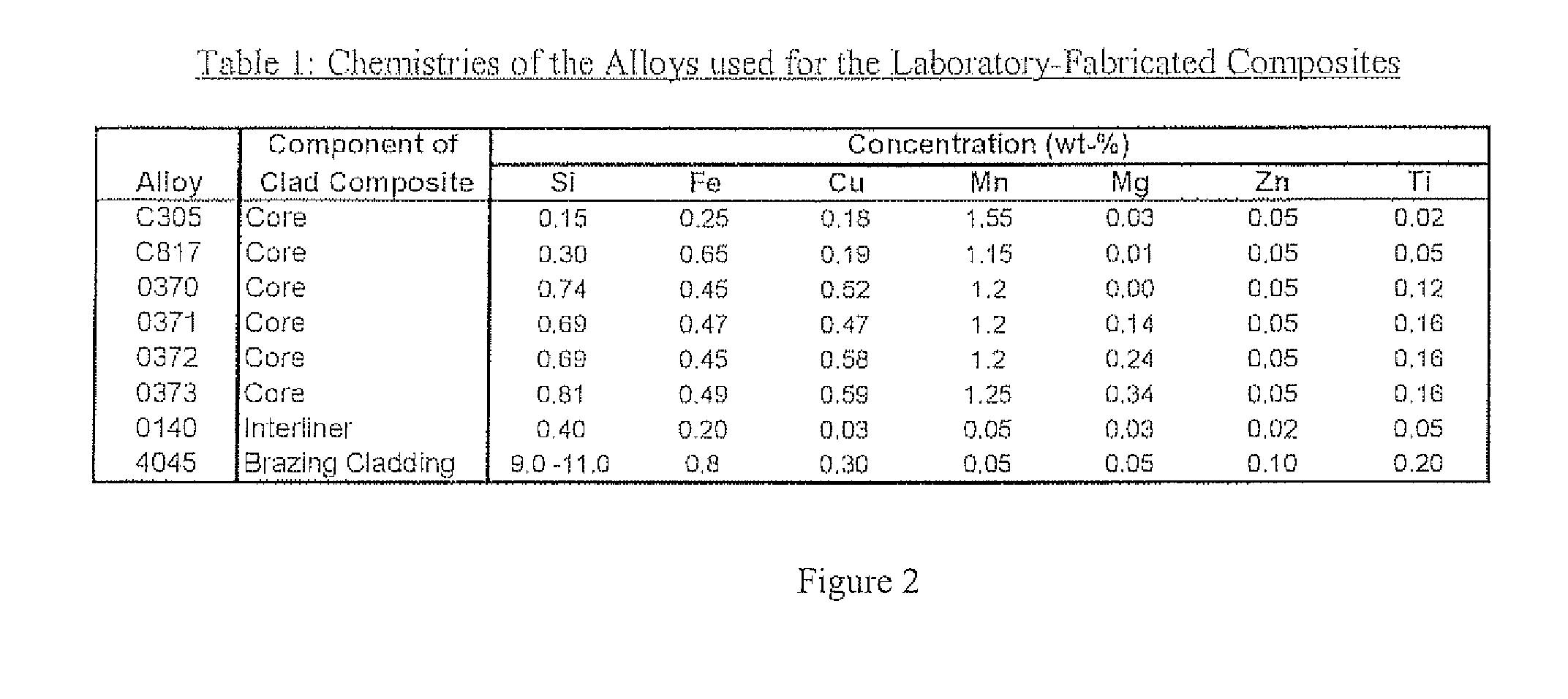

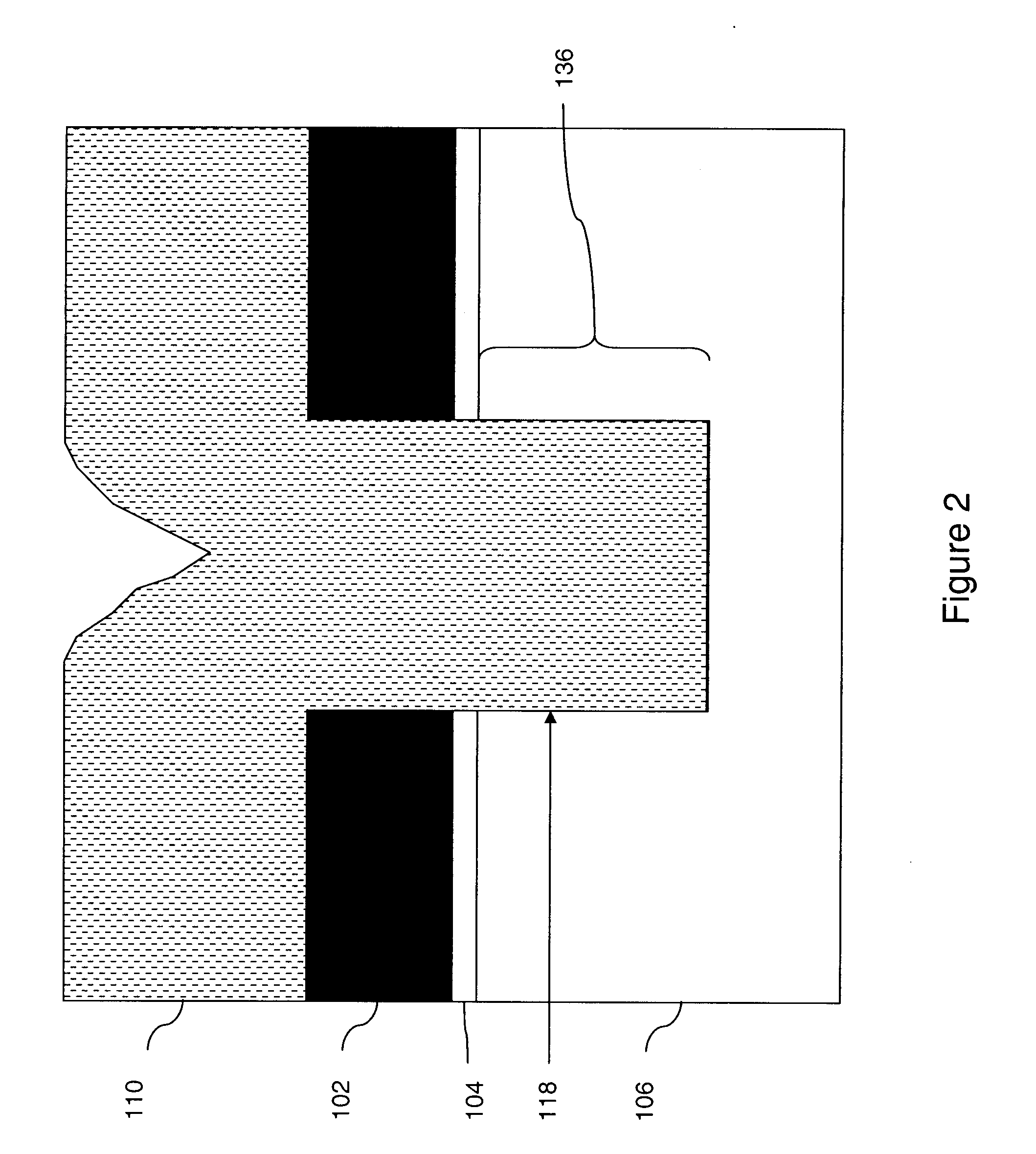

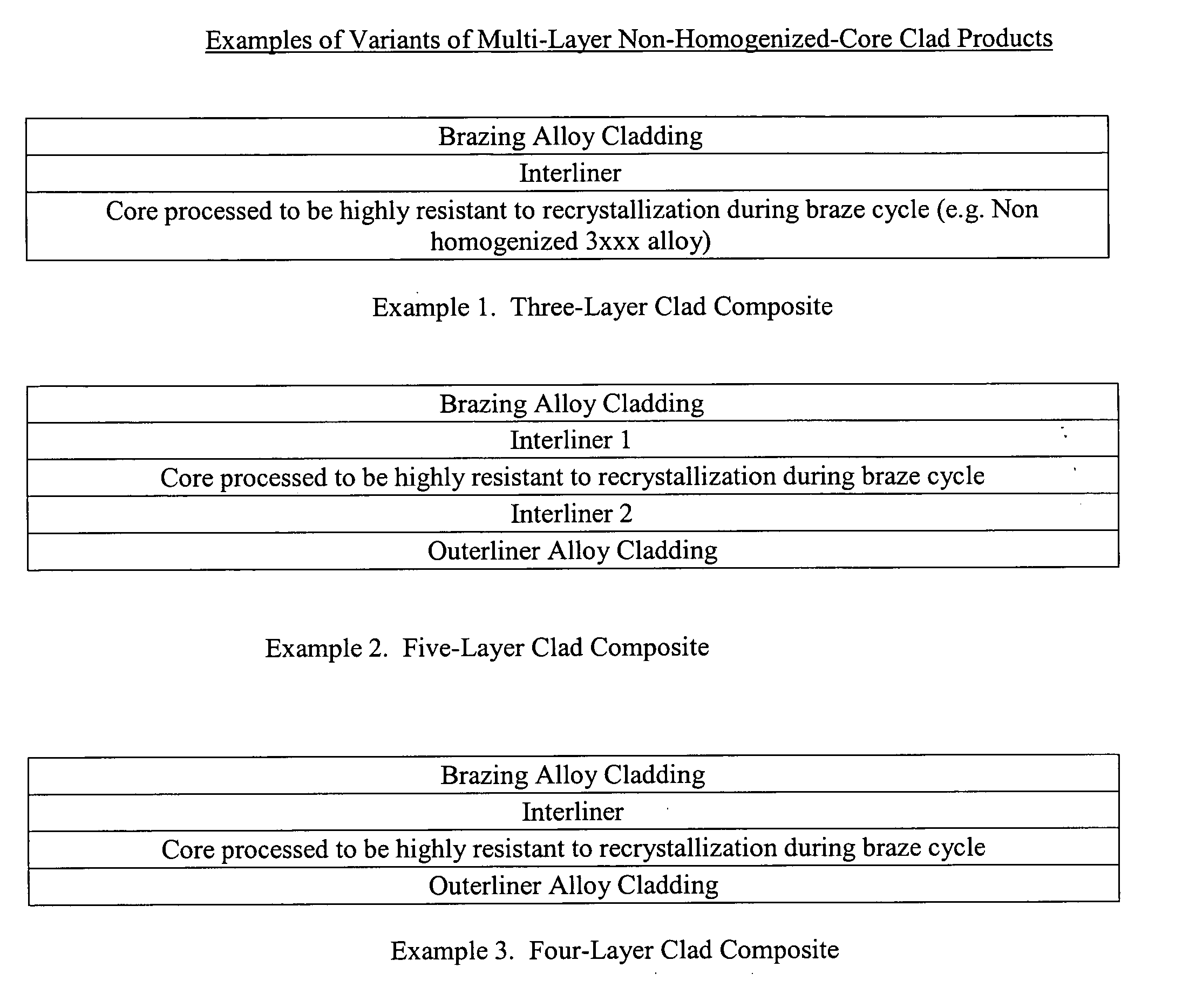

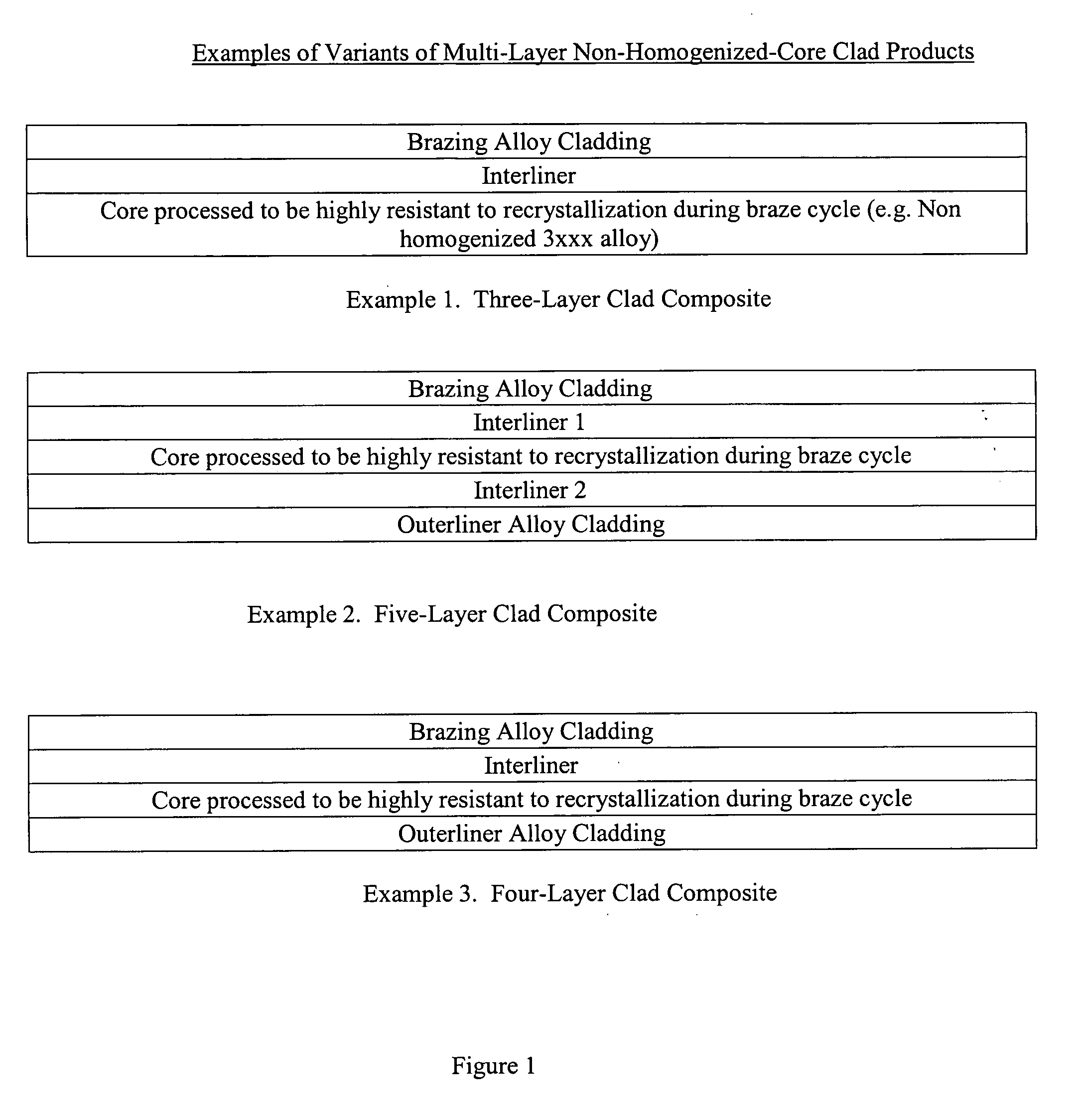

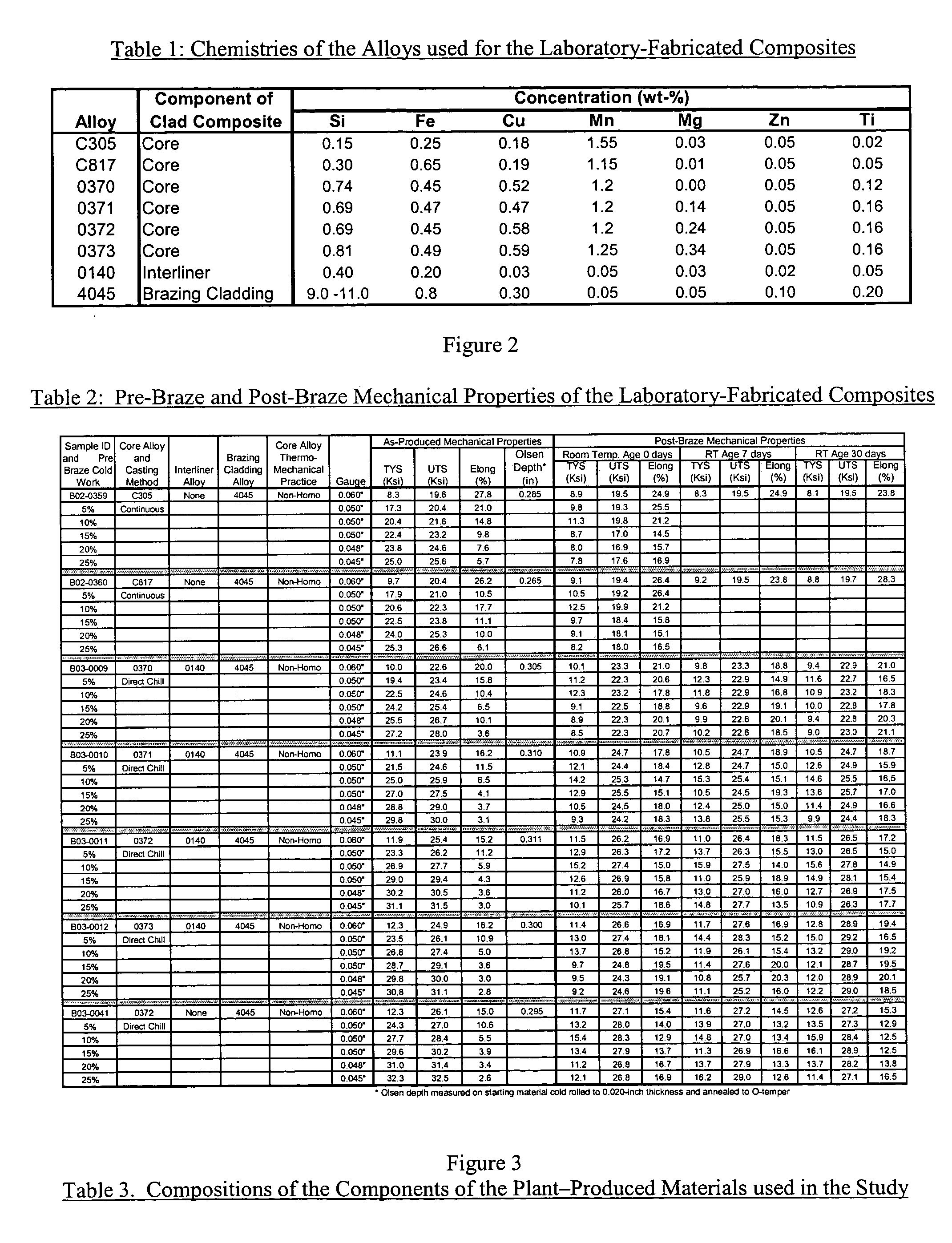

Recovered high strength multi-layer aluminum brazing sheet products

InactiveUS20080274367A1Excellent brazeabilityHigh post-braze tensile strengthWelding/cutting media/materialsThin material handlingIngot castingHigh intensity

A multi-layer metallurgical product comprising a core aluminum alloy, purposefully tailored through chemistry and processing route to resist recrystallization during the brazing cycle to intentionally exploit the higher strengths immediately after brazing of a deformed and recovered microstructure, the core aluminum alloy being positioned on one side to an aluminum alloy interliner designed to be resistant to localized erosion, which, in turn, is adjacent to a 4xxx cladding alloy. The multi-layer product can be fabricated at least in part via any multi-alloy ingot casting processes such as the Simultaneous Multi-Alloy Casting process or the Unidirectional Solidification of Castings process.

Owner:ARCONIC INC

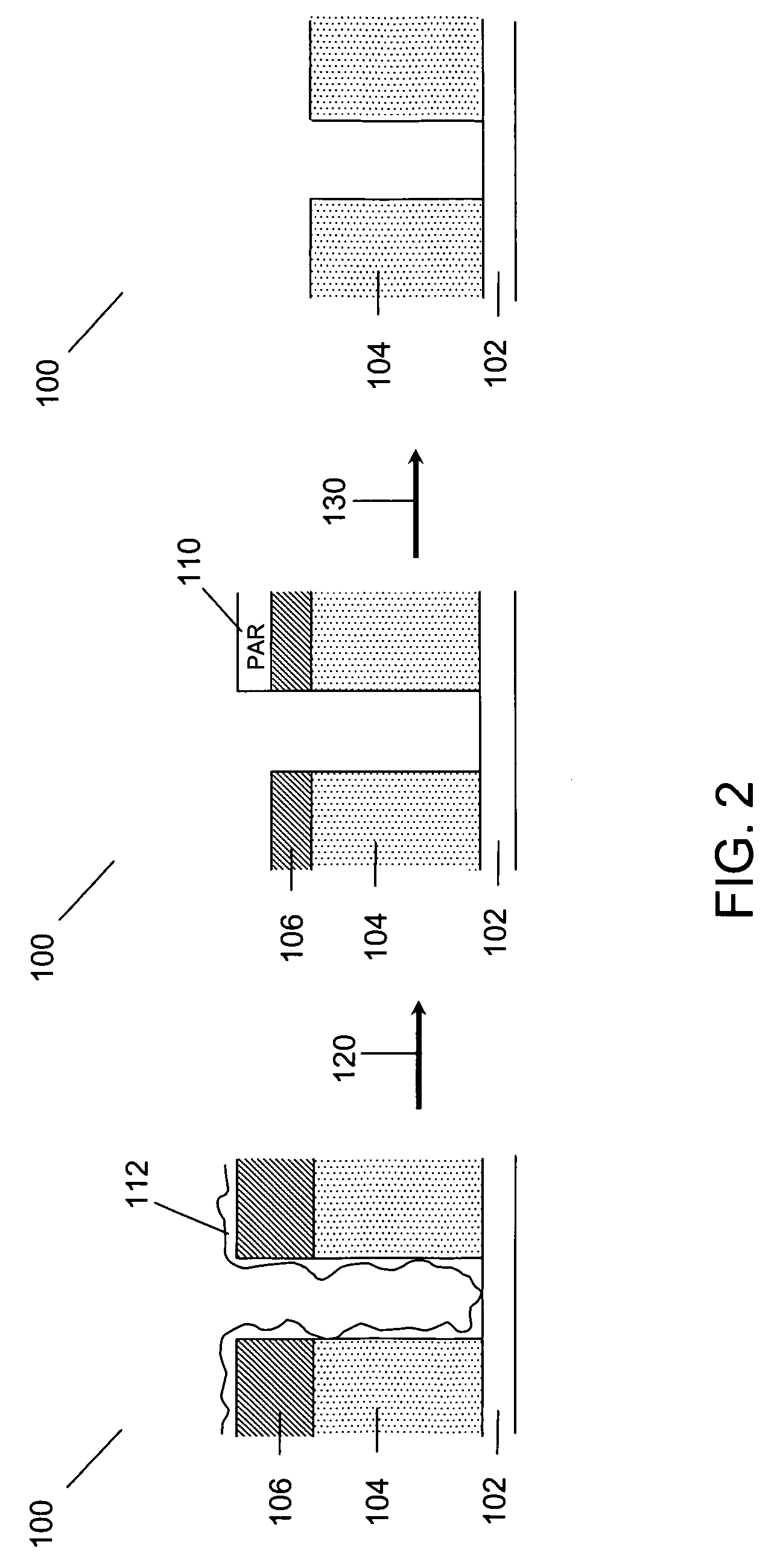

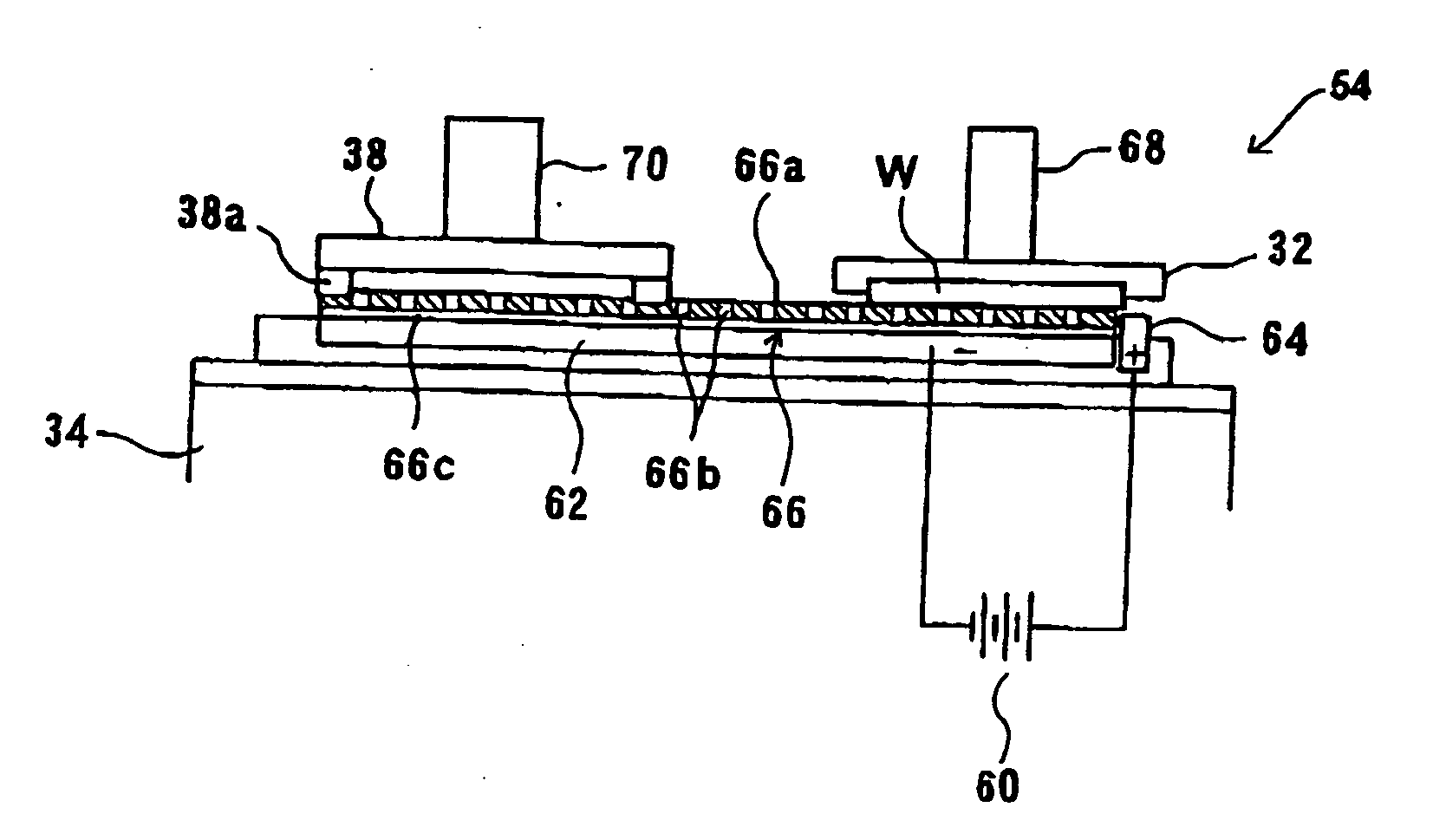

Low-pressure removal of photoresist and etch residue

ActiveUS7344993B2Reduce erosionErosion minimizationSemiconductor/solid-state device testing/measurementElectric discharge tubesResistHydrogen

A method is provided for plasma ashing to remove photoresist remnants and etch residues formed during preceding plasma etching of dielectric layers. The ashing method uses a two-step plasma process involving a hydrogen-containing gas, where low or zero bias is applied to the substrate in the first cleaning step to remove significant amount of photoresist remnants and etch residues from the substrate, in addition to etching and removing detrimental fluorocarbon residues from the chamber surfaces. An increased bias is applied to the substrate in the second cleaning step to remove the remains of the photoresist and etch residues from the substrate. A chamber pressure less than 20 mTorr is utilized in the second cleaning step. The two-step process reduces the memory effect commonly observed in conventional one-step ashing processes. A method of endpoint detection can be used to monitor the ashing process.

Owner:TOKYO ELECTRON LTD

Water filtration and erosion control system and method

ActiveUS20080019780A1Useful in erosion controlErosion minimizationBarrages/weirsLoose filtering material filtersPondingControl system

An erosion control system and method wherein a fabric filter bag is embedded with and / or filled with a flocculating polymer and is positioned on a sloping soil surface to dam and pond water flowing thereacross for settling of the particles in the water, and as the ponding water seeps into the bag the colloidal particles will be filtered or agglomerated for settling. The water then passes through and out of the bag and is further subjected to agglomeration and filtering by a skirt of filter material also impregnated with flocculating polymer, said skirt being anchored to the bag or stacked to maintain the position adjacent and downslope from the bag.

Owner:DENNY HASTINGS FLP 14

Prosthetic device and method of manufacturing the same

ActiveUS9326840B2Minimizes adhesionsErosion minimizationMammary implantsWeft knittingYarnEngineering

Owner:ALLERGAN INC

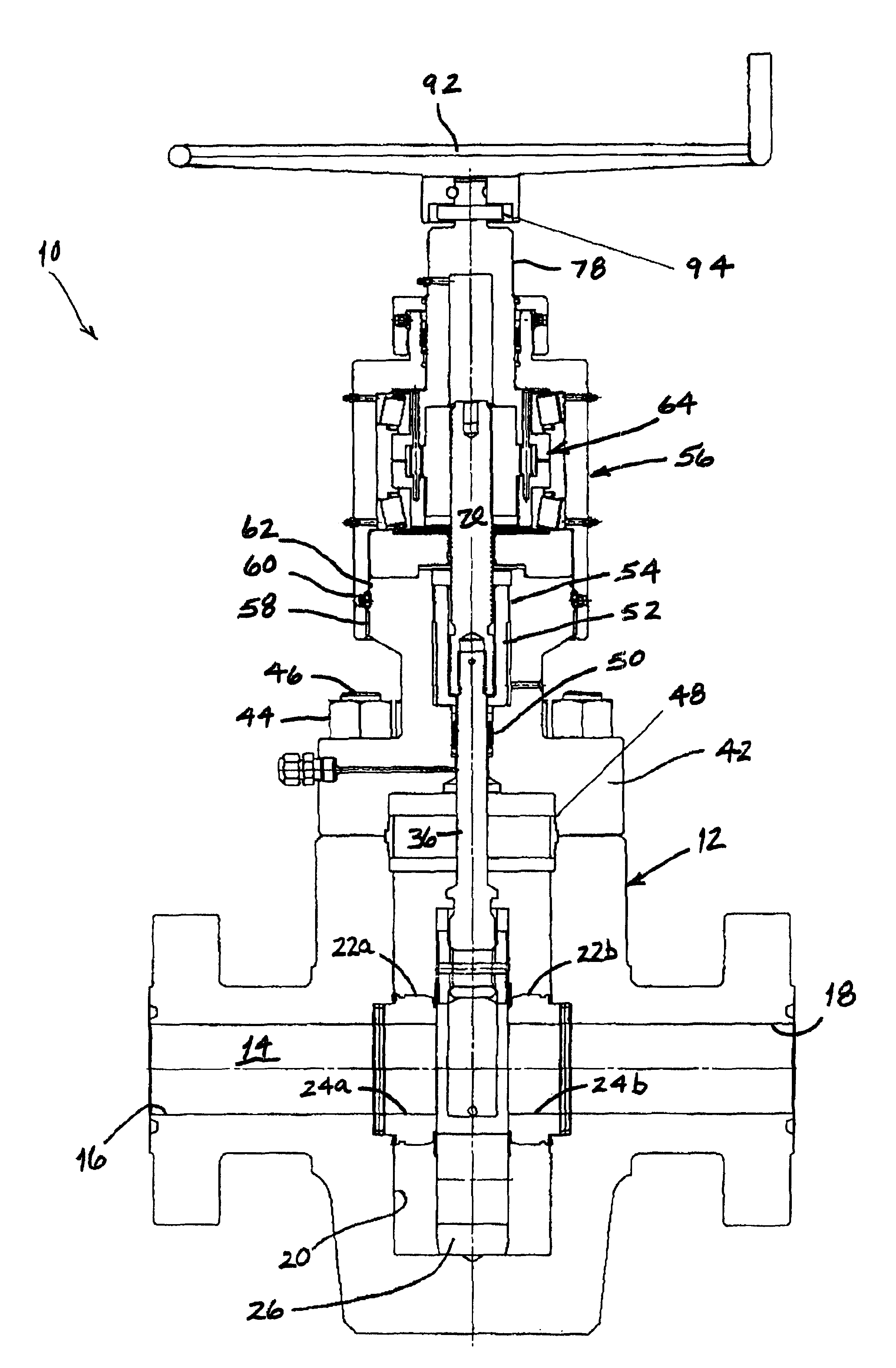

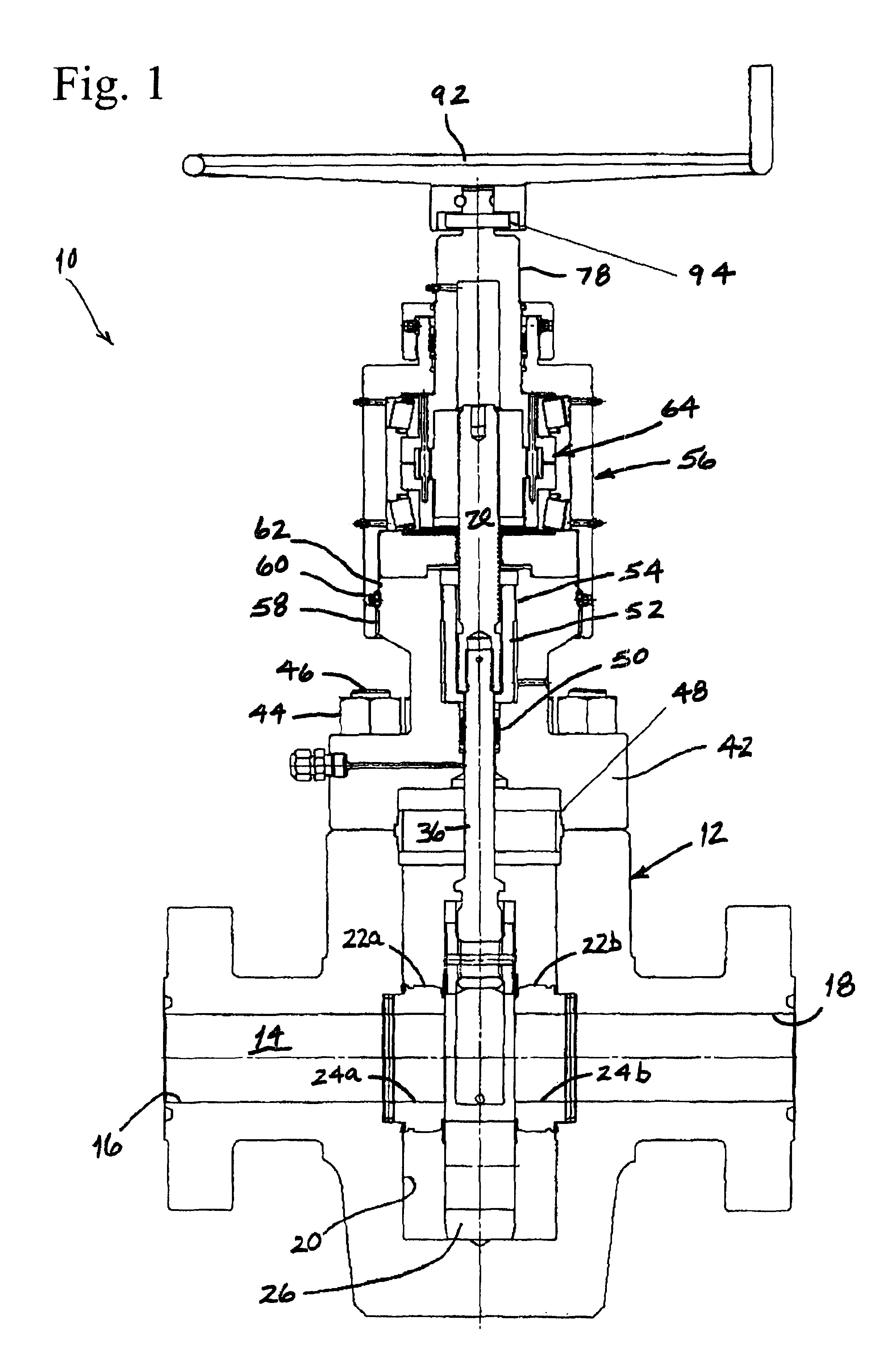

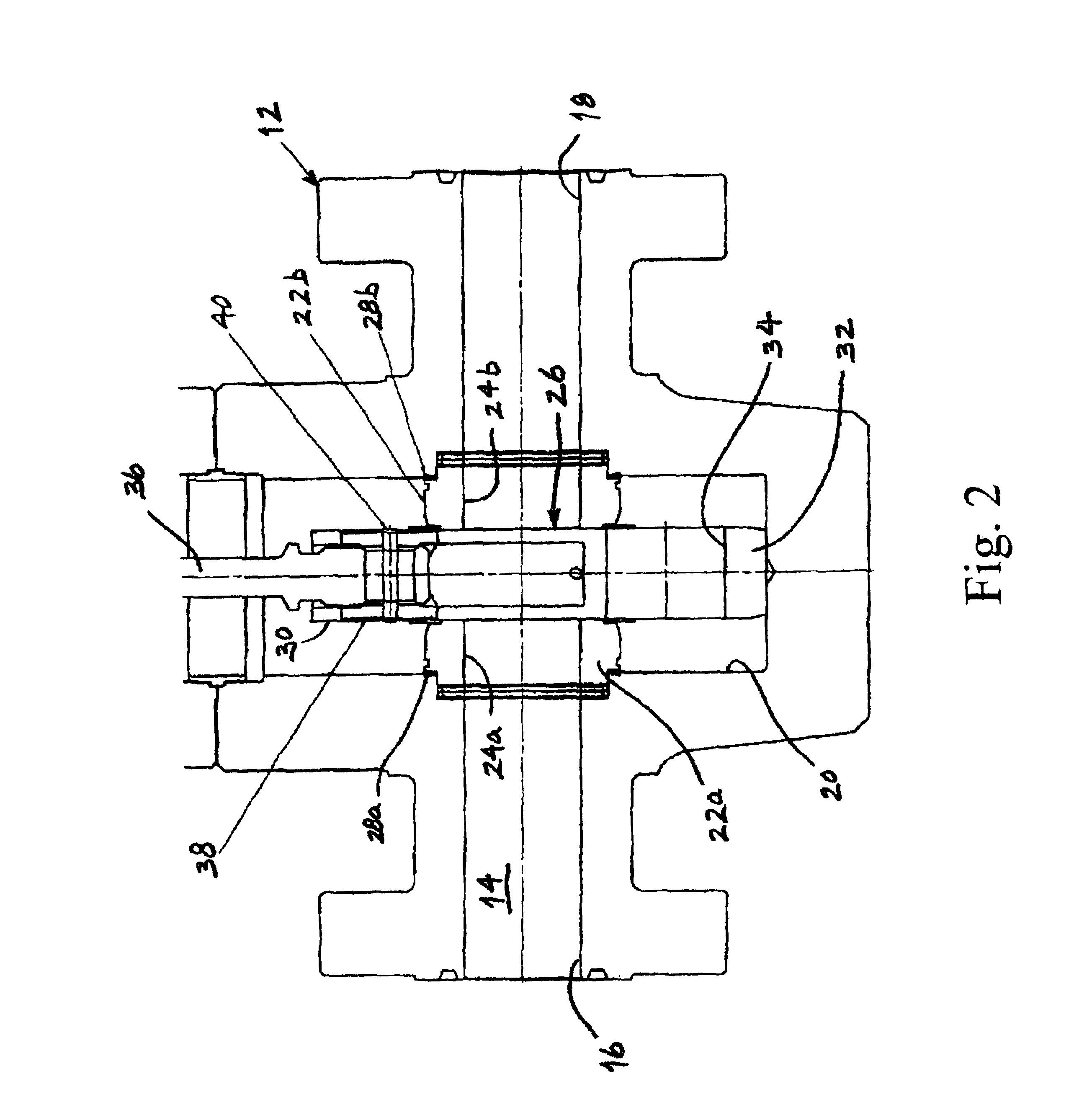

Reduced torque gate valve with roller screw

InactiveUS6918574B2Low gateGrow fastOperating means/releasing devices for valvesSlide valveRoller screwValve stem

A gate valve is disclosed which comprises a valve body which includes a flow bore that extends completely therethrough and a gate cavity that extends partially therethrough and intersects the flow bore, a bonnet which is connected to the valve body over the gate cavity, a gate which is disposed in the gate cavity across the flow bore and includes a transverse opening that extends completely therethrough, a valve stem which includes a first portion that is connected to the gate and a second portion that extends through the gate cavity, a handwheel, and a roller screw assembly which is connected between the handwheel and the second portion of the valve stem and which converts rotation of the handwheel into translation of the valve stem. In this manner, translation of the valve stem raises or lowers the gate to bring the opening into or out of alignment with the flow bore to either open or close the gate valve, respectively.

Owner:FMC TECH INC

Process and apparatus for treating tailings

ActiveUS7569137B2High trafficAvoid accumulationWorking-up pitch/asphalt/bitumen by selective extractionSolid separationProcess efficiencySolvent

Processes and apparatus for the treatment of product streams from mineral processing operations, including the treatment of tailings which result from oil sand processing operations. The processes and apparatus relate to the recovery of a diluent solvent from bitumen froth tailings and to the thickening of tailings from a bitumen froth stream and a middlings stream resulting from an oil sand extraction process. In one aspect the processes and apparatus relate particularly to the recycling of product streams to maximize process efficiencies. In a second aspect the processes and apparatus relate particularly to the thickening of tailings to produce an underflow component, a clarified overflow component and an unclarified overflow component.

Owner:TRUENORTH ENERGY CORP

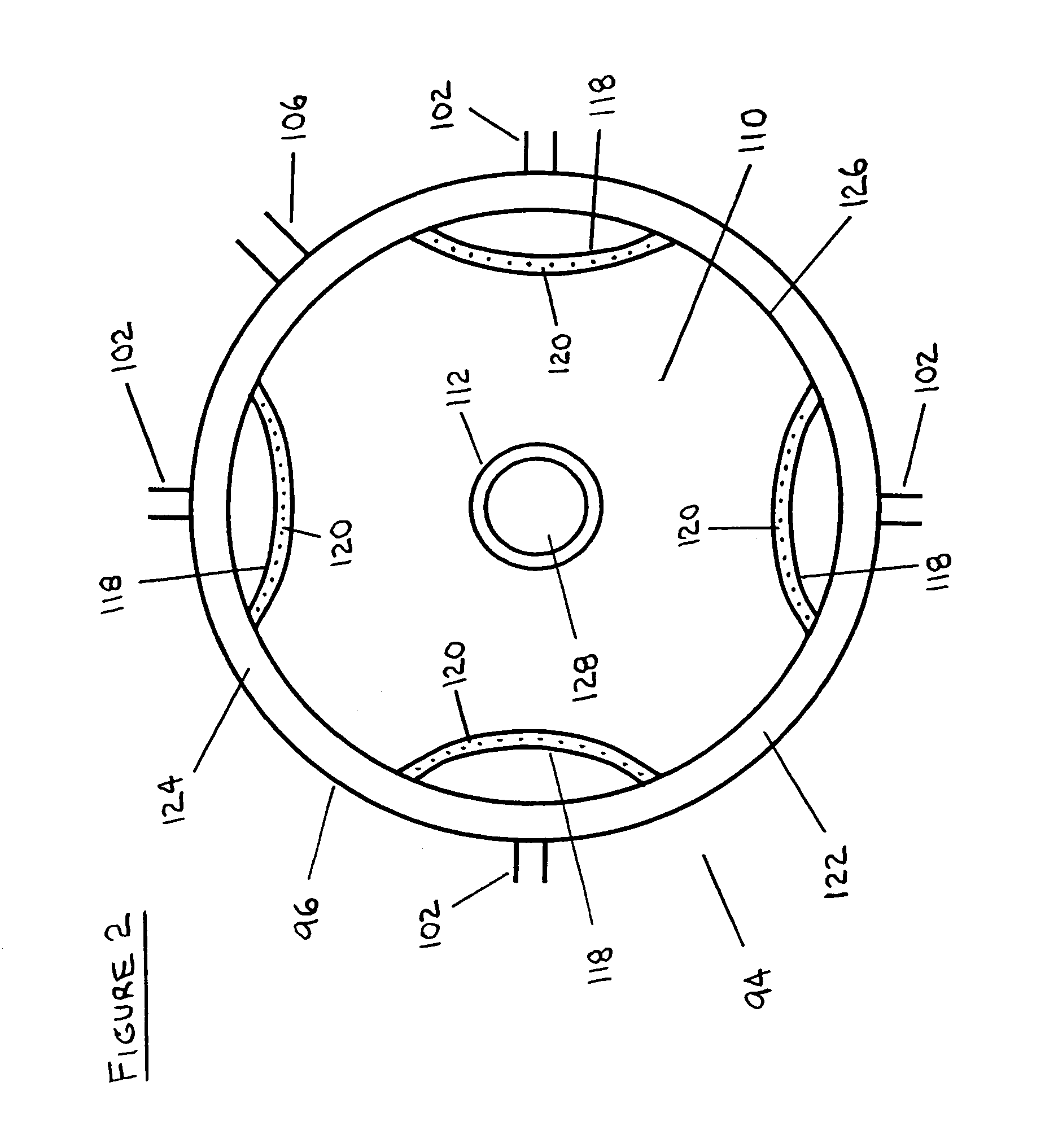

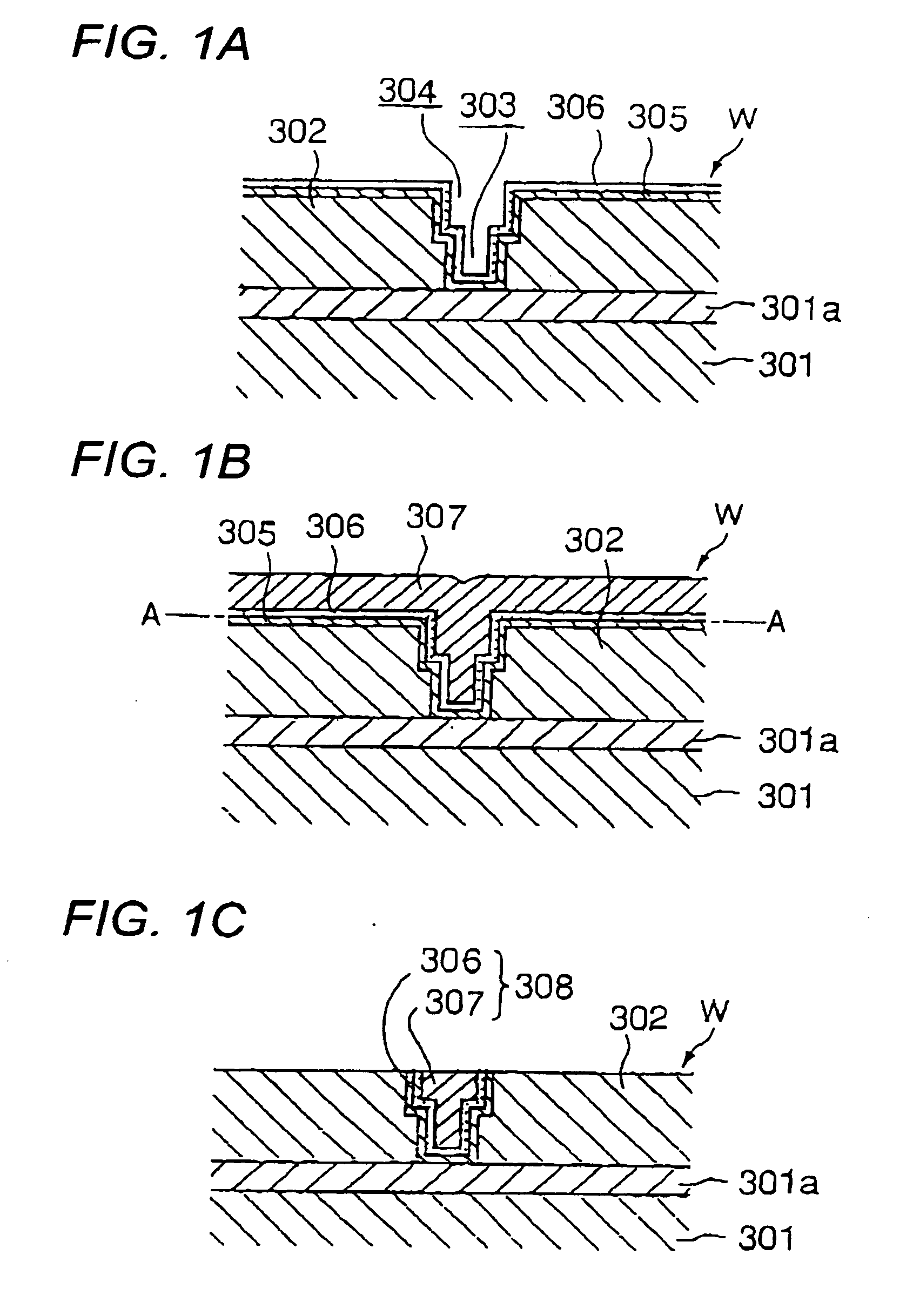

Polishing pad and polishing apparatus

InactiveUS20070135024A1Avoid it happening againReduce harmPolishing machinesRevolution surface grinding machinesEngineeringAperture ratio

A polishing pad enables efficient removal of a polishing product and an “old polishing liquid” remaining on a surface (polishing surface) or in through-holes of a polishing pad. The polishing pad has a polishing surface and a plurality of through-holes extending in the thickness direction, which communicate with each other by communication grooves. The through-holes have a diameter of, e.g., 2 to 5 mm. The aperture ratio of the through-holes is, e.g., 10 to 50% of the surface area of the polishing surface of the polishing pad. The depth of the communication grooves is, e.g., 40 to 60% of the thickness of the polishing pad. The width of the communication grooves is, e.g., 10 to 50% of the diameter of the through-holes.

Owner:EBARA CORP

Methods of Minimizing Etch Undercut and Providing Clean Metal Liftoff

ActiveUS20090111061A1Inhibition effectAdequate step coverageSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistOxygen

A method of minimizing etch undercut and providing clean metal liftoff in subsequent metal deposition is provided. In one embodiment a bilayer resist mask is employed and used for etching of underlying substrate material and subsequent metal liftoff. In one embodiment, the top layer resist such as positive photoresist which is sensitive to selected range of energy, such as near UV or violet light, is first patterned by standard photolithography techniques and resist development in a first developer to expose portion of a bottom resist layer which is sensitive to a different selected range of energy, such as deep UV light. The exposed portion of the bottom layer resist is then removed by anisotropic etching such as oxygen reactive ion etching using the top layer resist as the etch mask to expose portion of the underlying substrate. This minimizes the undercut in the bottom resist around the top photoresist opening. The resultant patterned bilayer resist stack is then used as the etch mask for the subsequent etching of the exposed portion of the underlying substrate material. Because there is no undercut in the bottom resist layer, the etch undercut in the substrate material is also minimized relative to the edges of the top photoresist opening.

Owner:TRIQUINT SEMICONDUCTOR

Compositions for dust suppression and methods

InactiveUS8052890B2Erosion minimizationImprove propertiesOther chemical processesCentrifugesDisposal wasteEvaporation

Owner:3M INNOVATIVE PROPERTIES CO

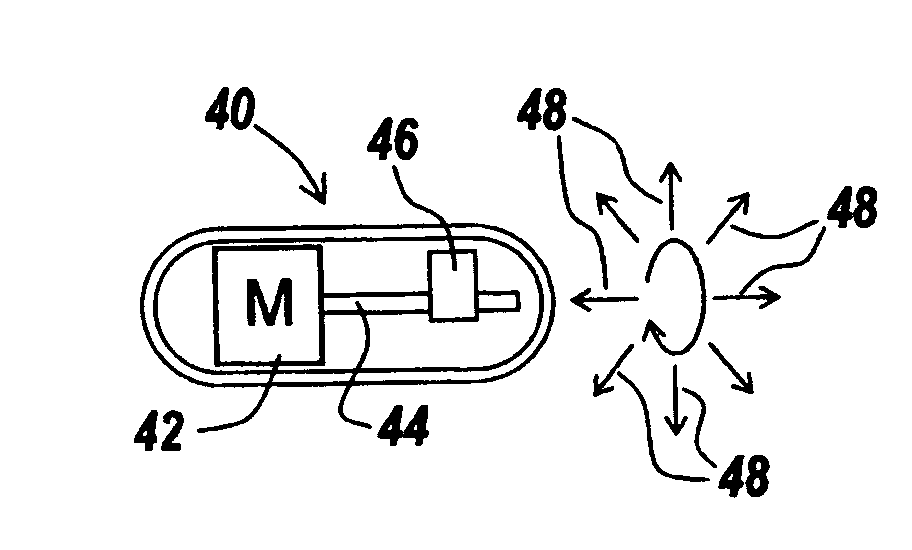

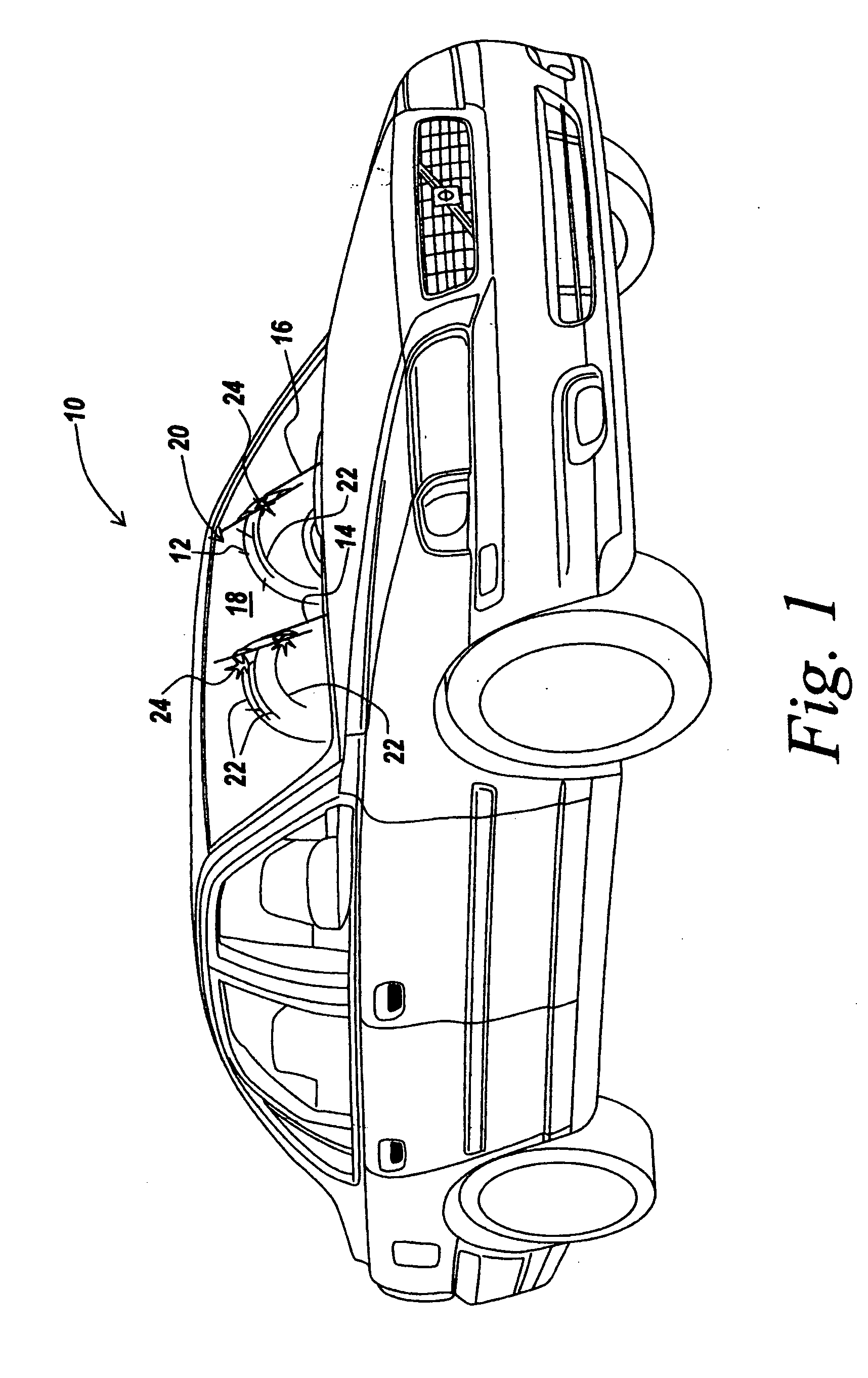

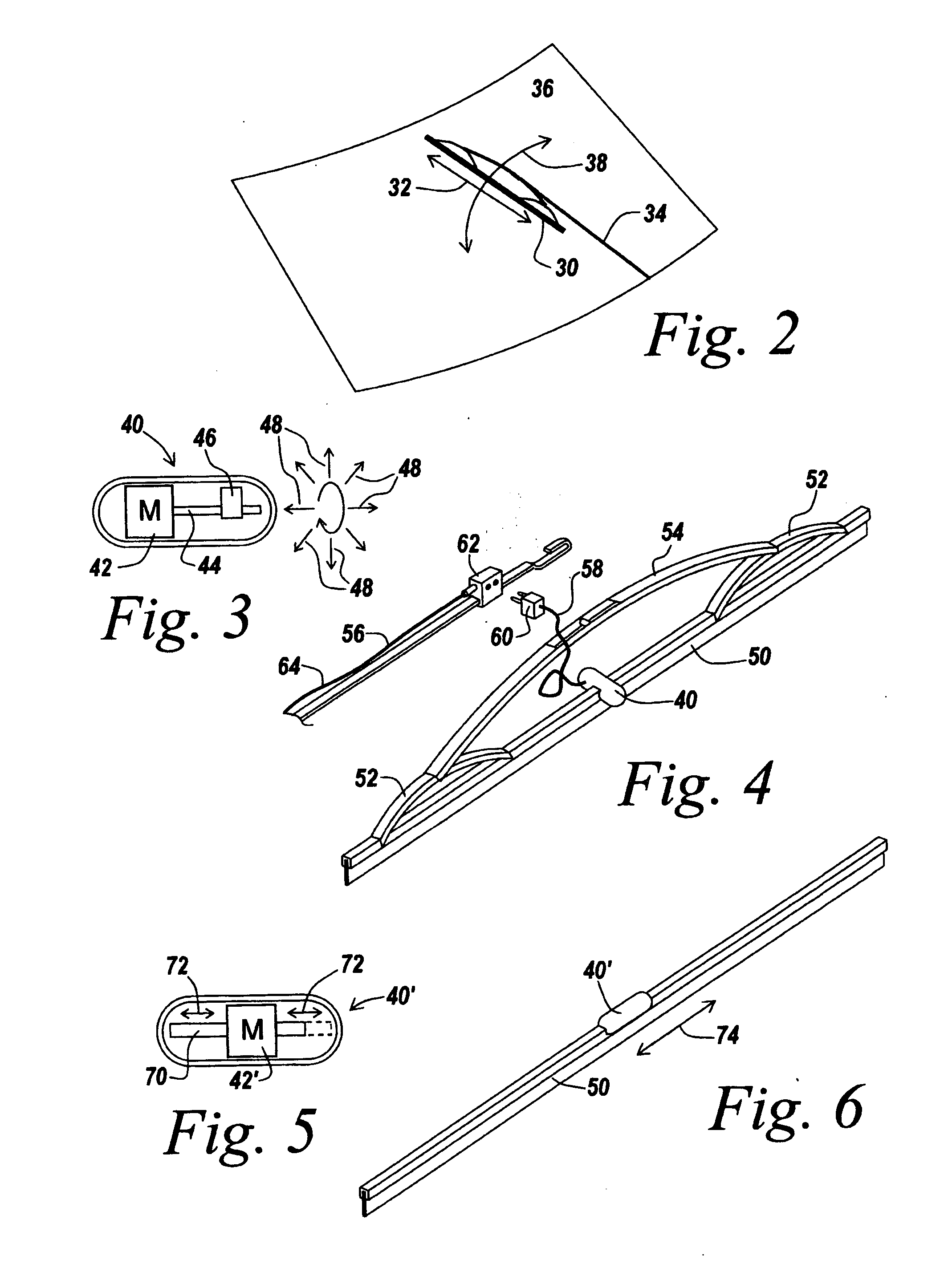

Method and apparatus for improving windshield wiper performance using a vibrating windshield wiper blade

InactiveUS20070022558A1Improve abilitiesAvoid excessive wearWindow cleanersVehicle cleaningVisibilityEngineering

A method is provided for improving the wiping capabilities of a windshield wiper by causing the windshield wiper blade to vibrate or oscillate in a direction parallel to the longitudinal centerline of the blade during a windshield wiper sweep. The vibrating mode causes less wear on the blade due to windshield abrasion since the blade edge does not contact the same eroded point on the windshield all the time. Secondly, any debris that is caught underneath the blade is quickly ejected due to the vibrating action. In one embodiment, an electromechanical vibrating unit is secured at one or more positions to the blade, with the actuator being driven by a 12-volt source and provided with a quickie disconnect at the center of the blade support structure. The vibrating actuator may be an electromechanically drive off-centered weight, a vibrating linear actuator, an ultrasonic vibrator, or a vibrator in the form of a piezoelectric crystal, with the primary mode of oscillation translating the blade along its centerline. The result is that debris underneath the blade is thrown out, including leaf stems, leaves and particulate matter, with the periodic translation of the blade providing more uniform water removal during the wiping operation to provide clearer visibility through the windshield regardless of the amount of water on the windshield, whether it be from a sporadic sprinkle or a torrential downpour. Wiper life is extended since the blade edge's position on the windshield is constantly varied during wiper sweeps.

Owner:ACOM INT

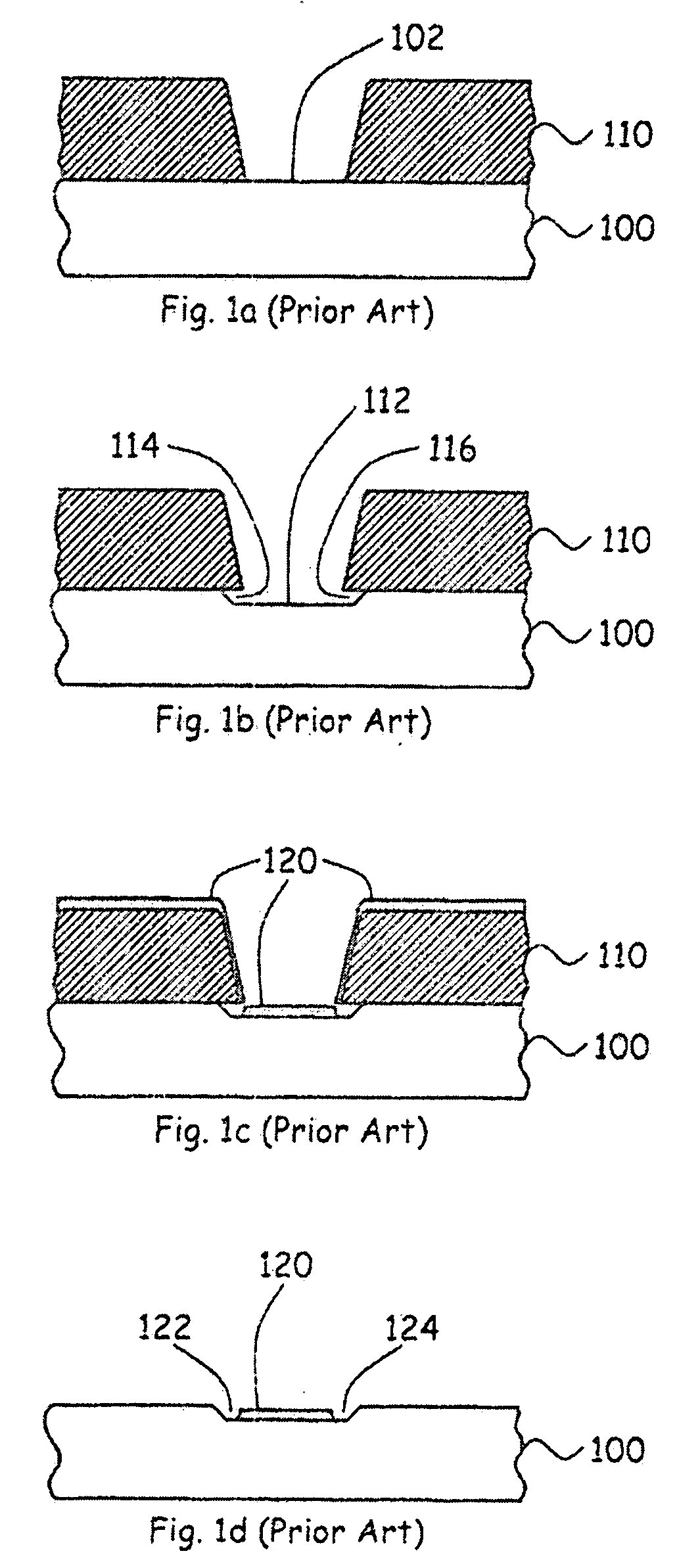

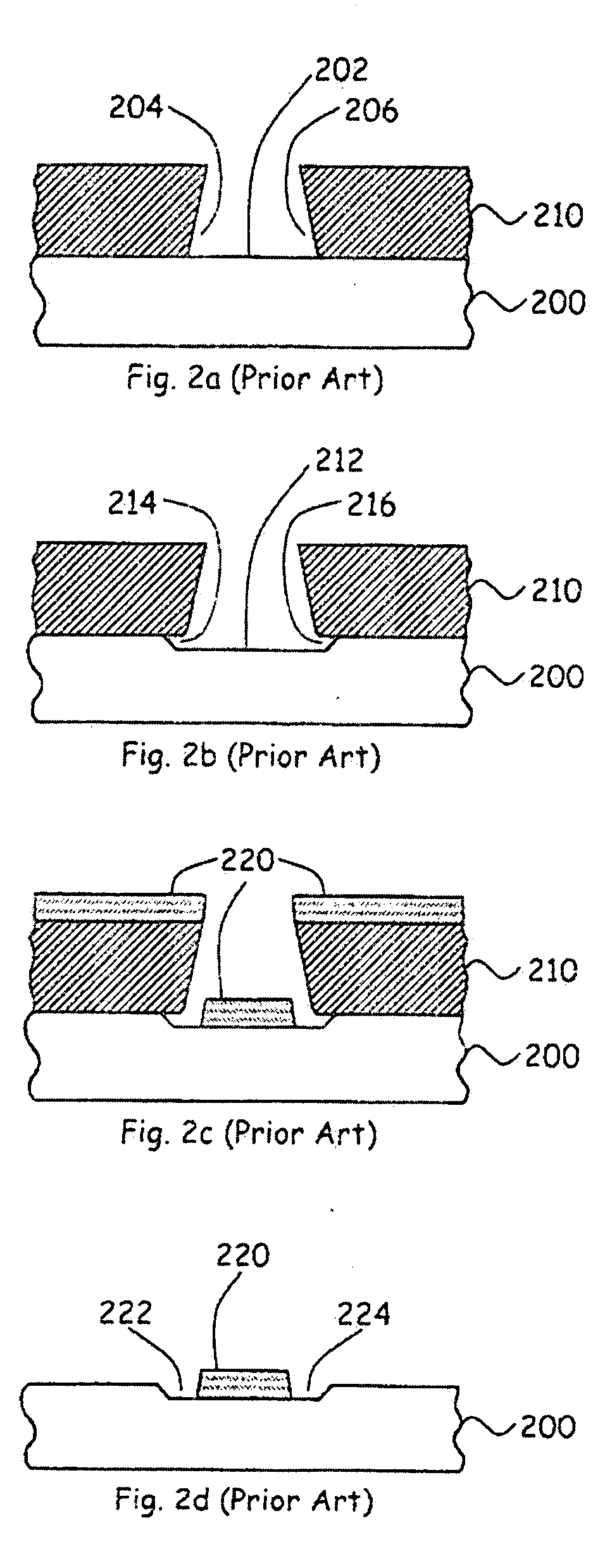

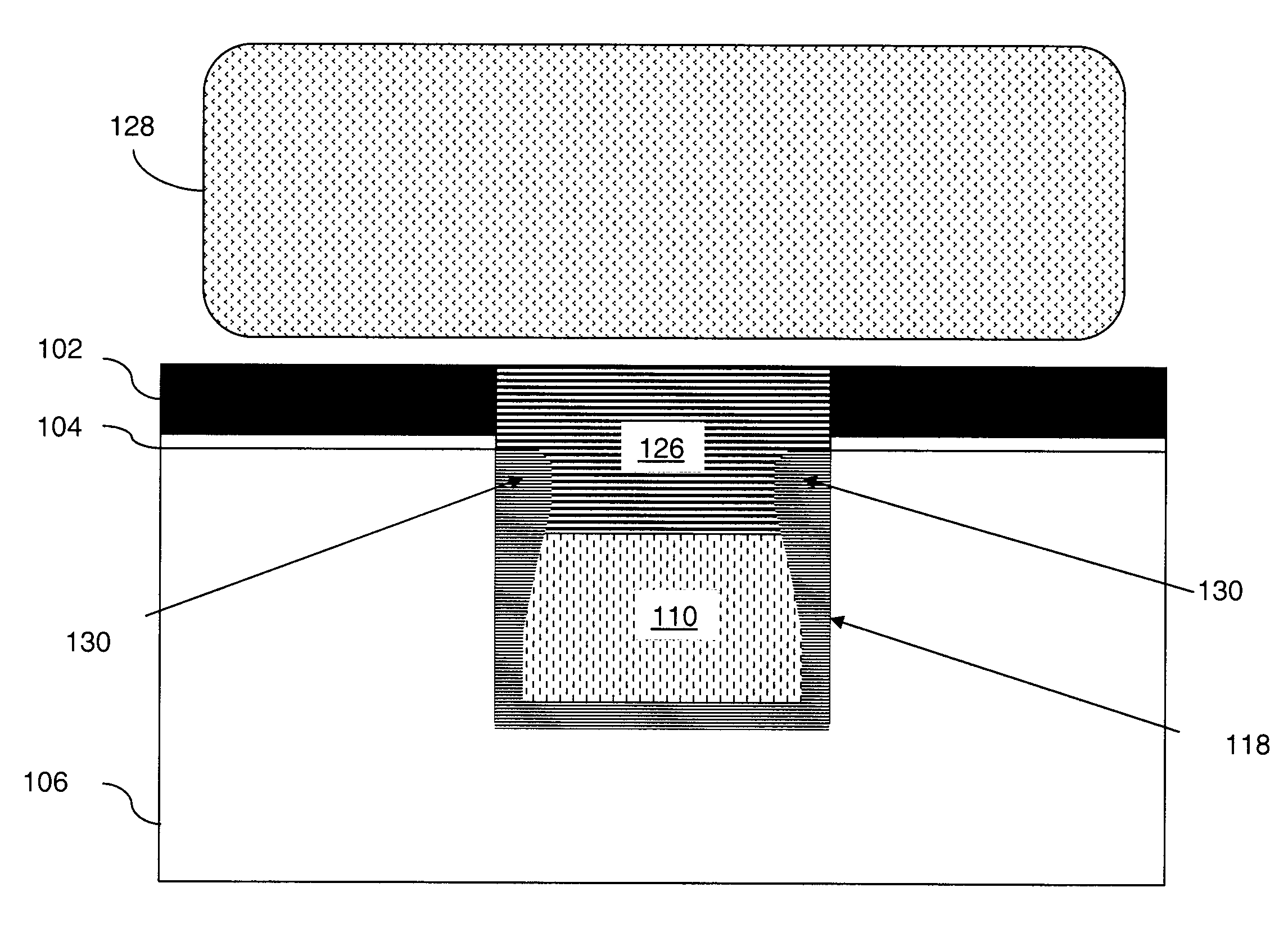

Nitridation of STI fill oxide to prevent the loss of STI fill oxide during manufacturing process

InactiveUS20060160322A1Reduce erosionReduce formationTransistorSemiconductor/solid-state device manufacturingHigh concentrationEtching

A method and structure for an improved shallow trench isolation (STI) structure for a semiconductor device. The STI structure incorporates an oxynitride top layer of the STI fill. Optionally, the STI structure incorporates an oxynitride margin of the STI fill adjacent the silicon trench walls. A region of the oxynitride margin near the upper edges of the silicon trench walls includes oxynitride corners that are relatively thicker and contain a higher concentration of nitrogen as compared to the other regions of the oxynitride margin. The oxynitride features limit the STI fill height loss and also reduce the formation of divots in the STI fill below the level of the silicon substrate cause by hydrofluoric acid etching and other fabrication processes. Limiting STI fill height loss and the formation of divots improves the functions of the STI structure. The method of forming the STI structure is particularly compatible with standard semiconductor device fabrication processes, including chemical mechanical polishing (CMP), because the method incorporates the use of a pure silicon dioxide STI fill and plasma and thermal nitridation processes to form the oxynitride top layer and oxynitride margin, including the oxynitride corners, of the STI fill.

Owner:IBM CORP

Recovered high strength multi-layer aluminum brazing sheet products

InactiveUS20060078728A1Minimizes localized erosionExcellent brazeabilityElectrography/magnetographyWelding/cutting media/materialsHigh intensityUltimate tensile strength

A metallurgical product consists essentially of a core aluminum alloy, purposefully tailored through chemistry and processing route to resist recrystallization during the brazing cycle to intentionally exploit the higher strengths immediately after brazing of a deformed and recovered microstructure, the core aluminum alloy being bonded on one side to an aluminum alloy interliner designed to be resistant to localized erosion, which, in turn, is bonded to a 4xxx calling alloy.

Owner:ARCONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com