Patents

Literature

2990 results about "High-temperature corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature corrosion is a mechanism of corrosion that takes place in gas turbines, diesel engines, furnaces or other machinery coming in contact with hot gas containing certain contaminants. Fuel sometimes contains vanadium compounds or sulfates which can form compounds during combustion having a low melting point. These liquid melted salts are strongly corrosive for stainless steel and other alloys normally inert against the corrosion and high temperatures. Other high-temperature corrosions include high-temperature oxidation, sulfidation and carbonization. High temperature oxidation and other corrosion types are commonly modelled using the Deal-Grove model to account for diffusion and reaction processes.

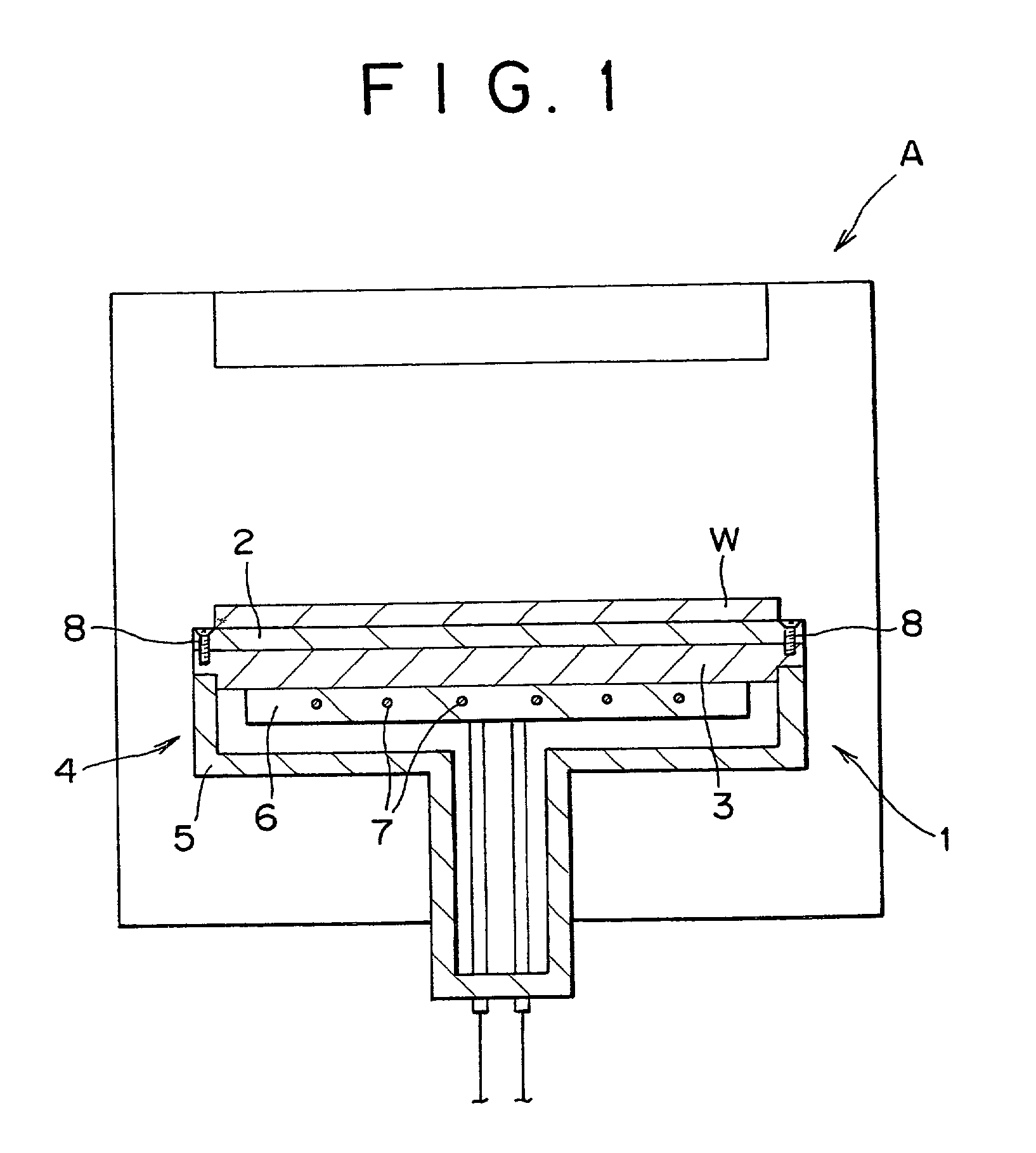

Chamber material made of Al alloy and heater block

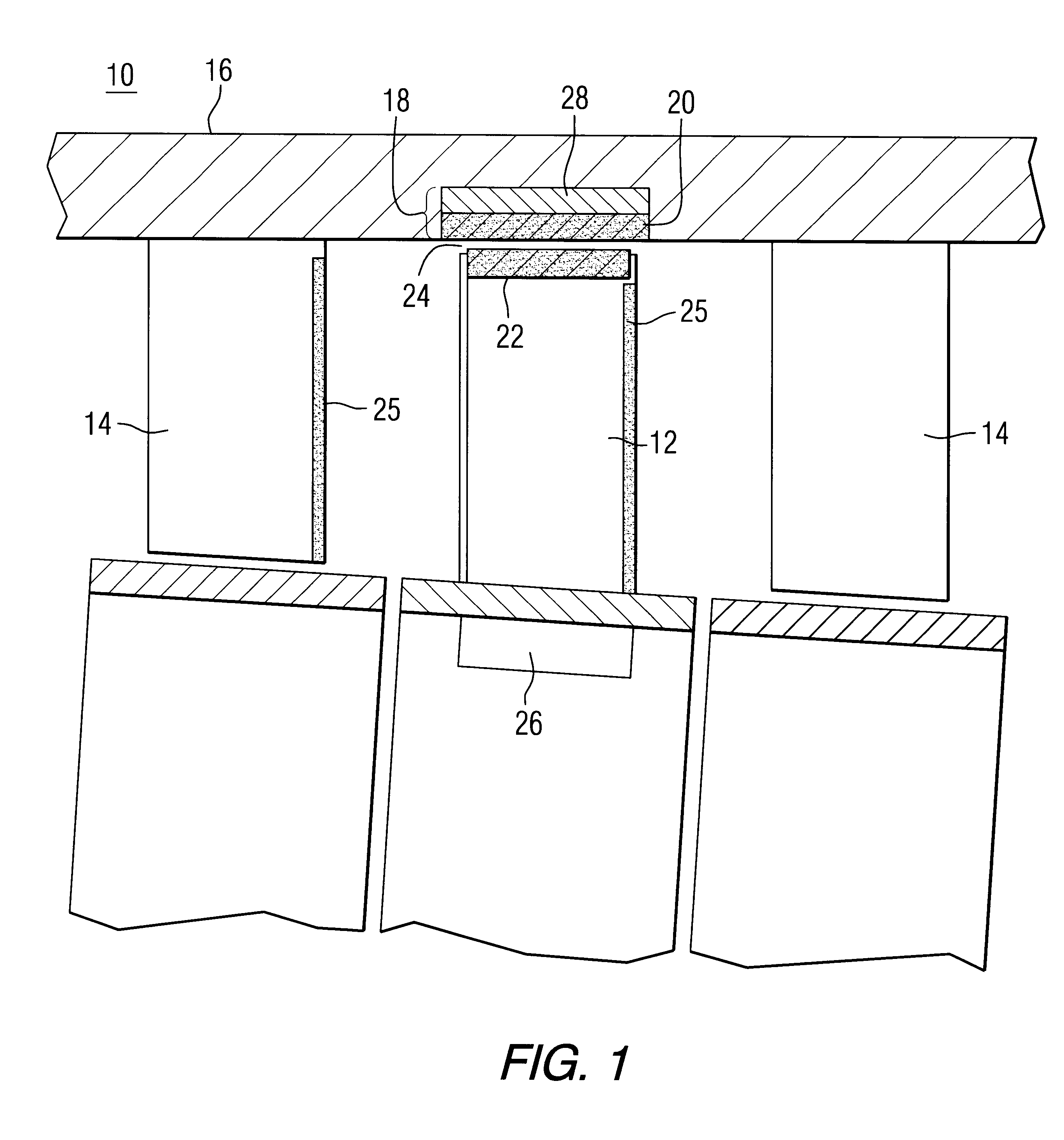

InactiveUS20010019777A1Not be restrictElectric discharge tubesSemiconductor/solid-state device manufacturingHigh-temperature corrosionContamination

A chamber material made of Al alloy excellent in thermal cracking resistance and chemical and / or physical corrosion resistance and capable of reducing contamination excellently and further having excellent and wide applicable brazing property in a high temperature corrosive circumstance, in which the substrate aluminum material for the chamber material made of Al alloy having an anodized film comprises 0.1 to 2.0% Si, 0.1 to 3.5% Mg, 0.02 to 4.0% Cu on the mass % basis and the balance of Al and impurity element with Cr in the impurity elements being less than 0.04%. Preferably, Fe is 0.1% or less and Mn is 0.04% or less in the impurity element and, further, the total sum of impurity elements other than Cr and Mn being restricted to 0.1$ or less. This invention can be utilized suitably to various materials used in high temperature corrosive circumstance, particularly, in high temperature corrosive gas or plasma atmosphere.

Owner:KOBE STEEL LTD

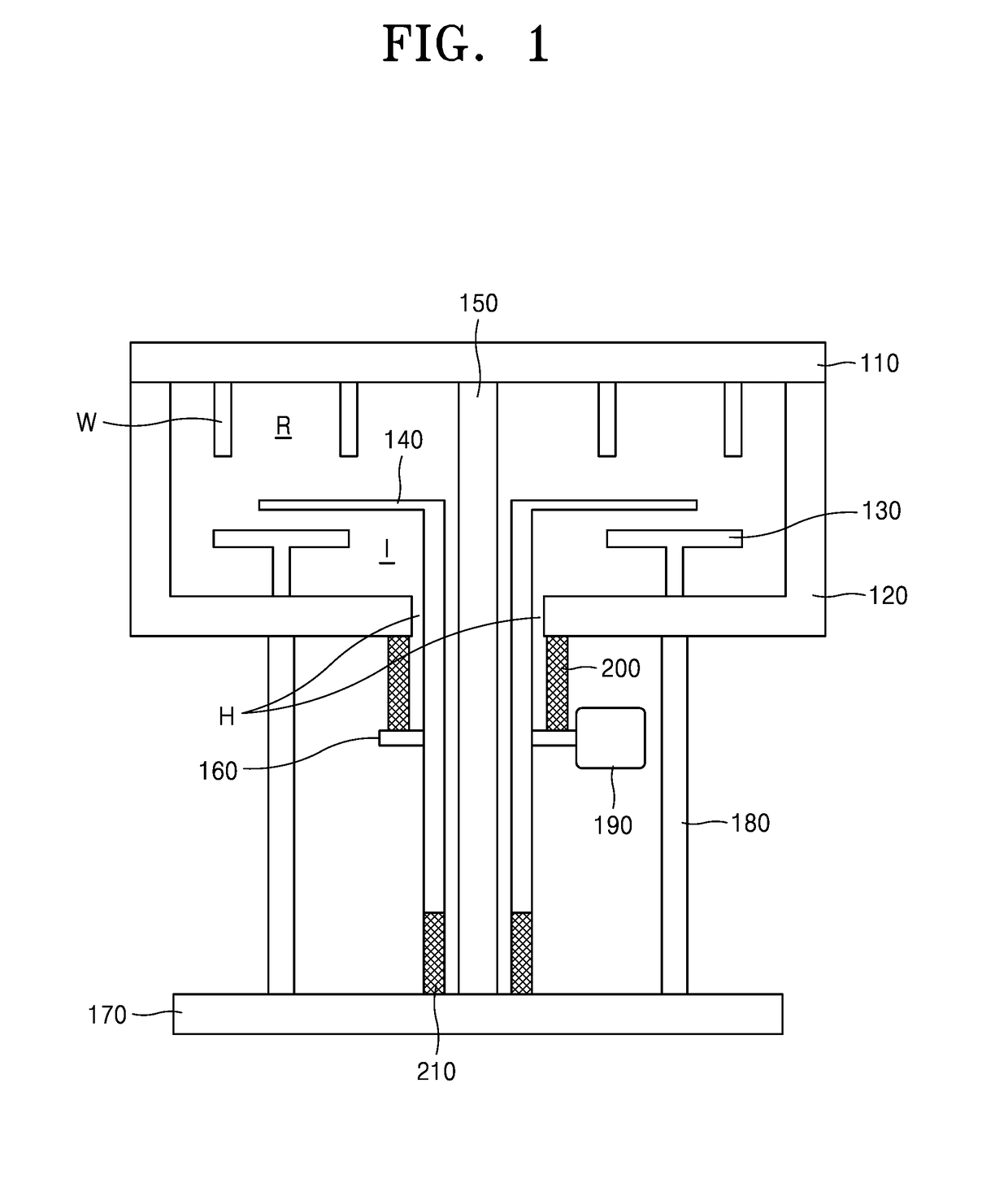

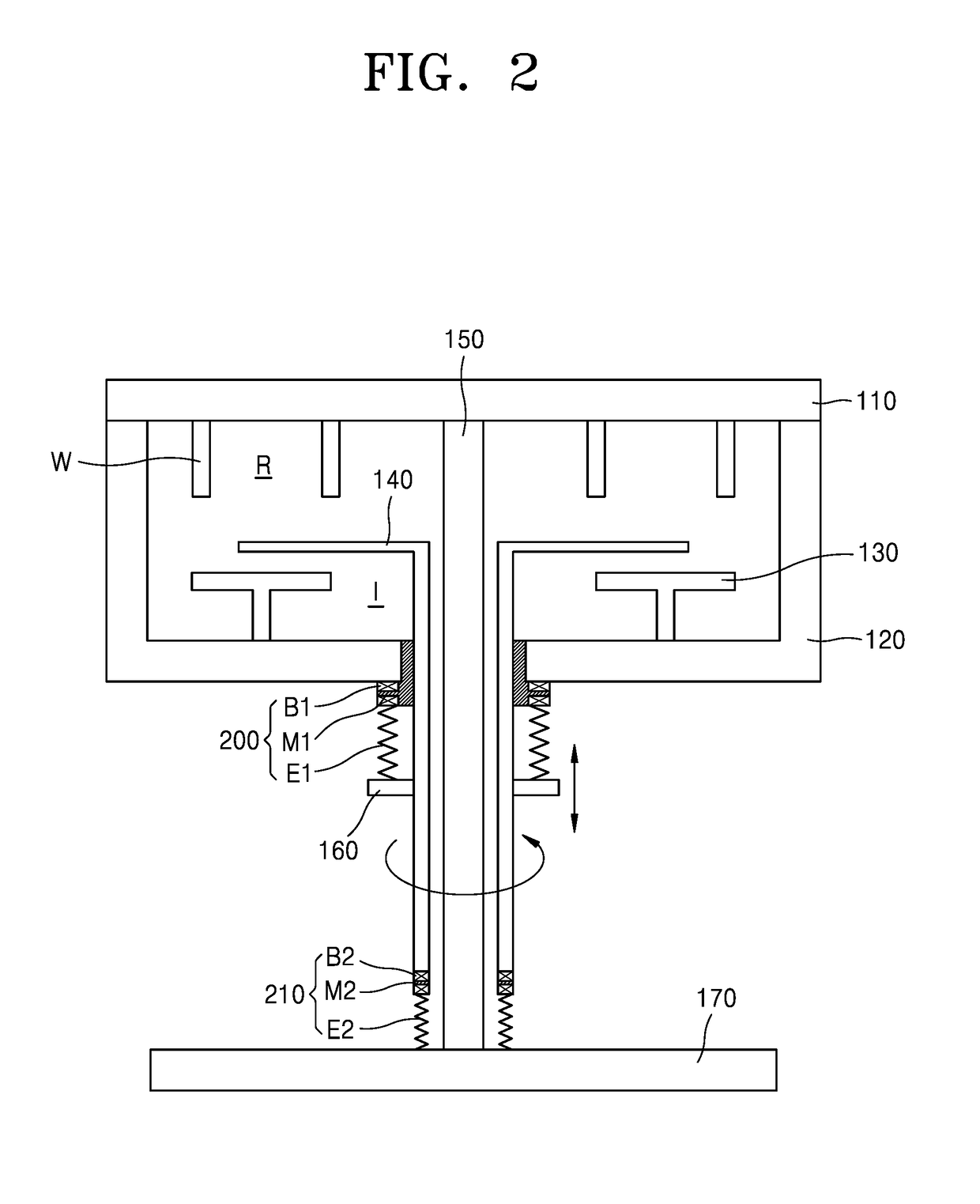

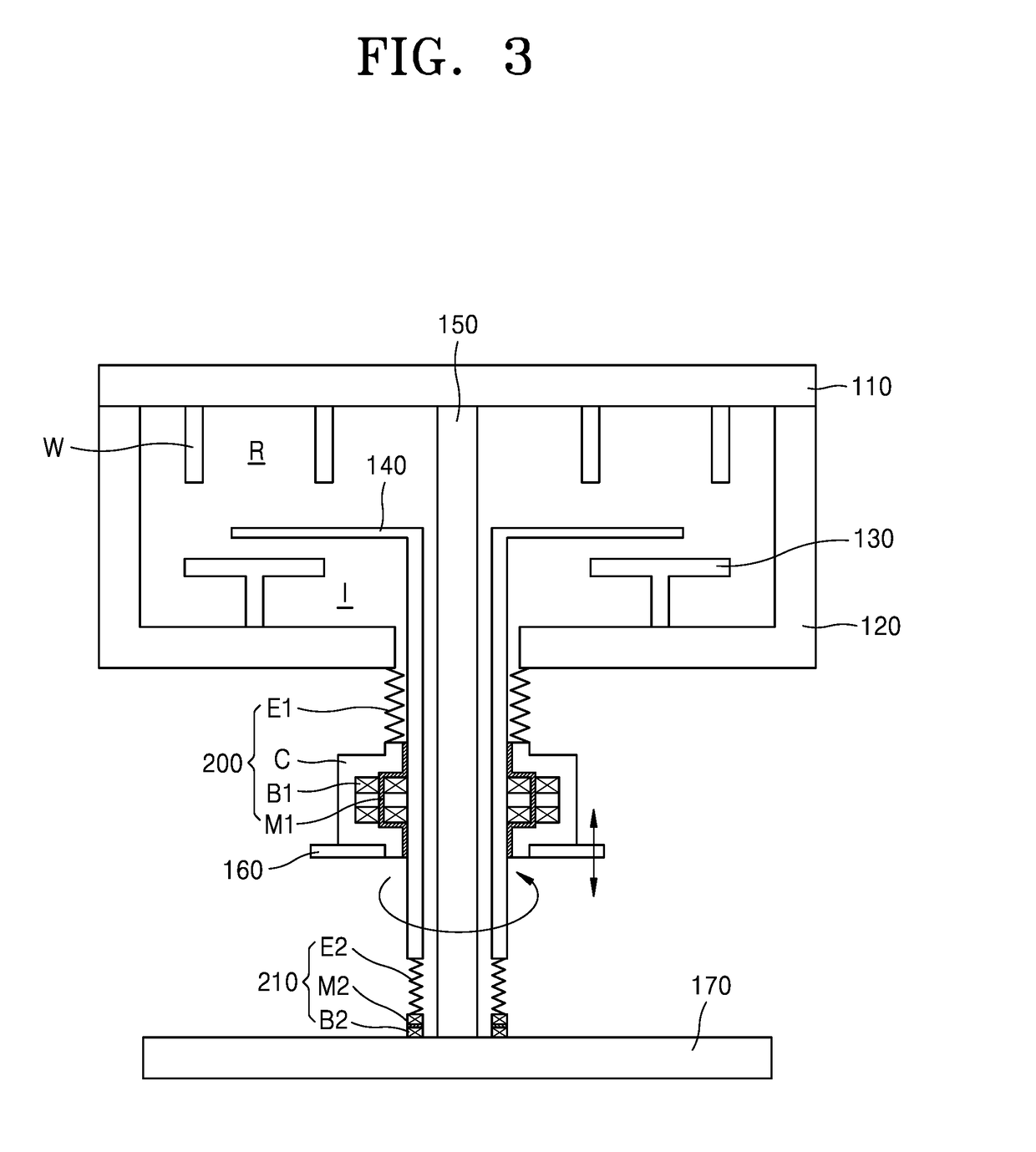

Substrate processing device

Provided is a substrate-processing device capable of preventing a top lid from sagging downward by the own weight of the substrate-processing device and / or a vacuum suction force generated by a vacuum pump and / or thermal shock at high temperature process, in a chamber including a plurality of reactors. Also, provided is a rotating shaft for transferring a substrate between the plurality of reactors.

Owner:ASM IP HLDG BV

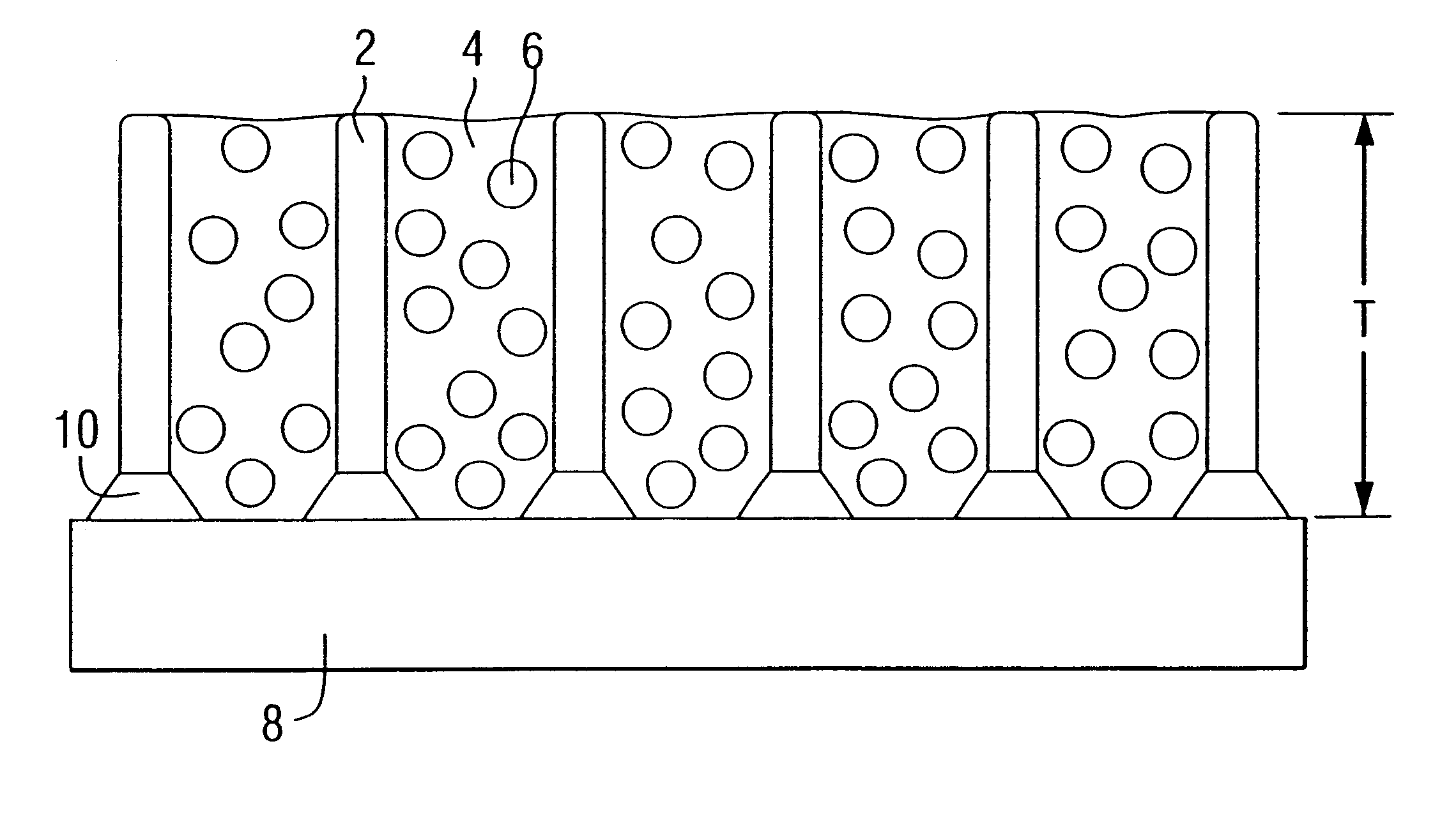

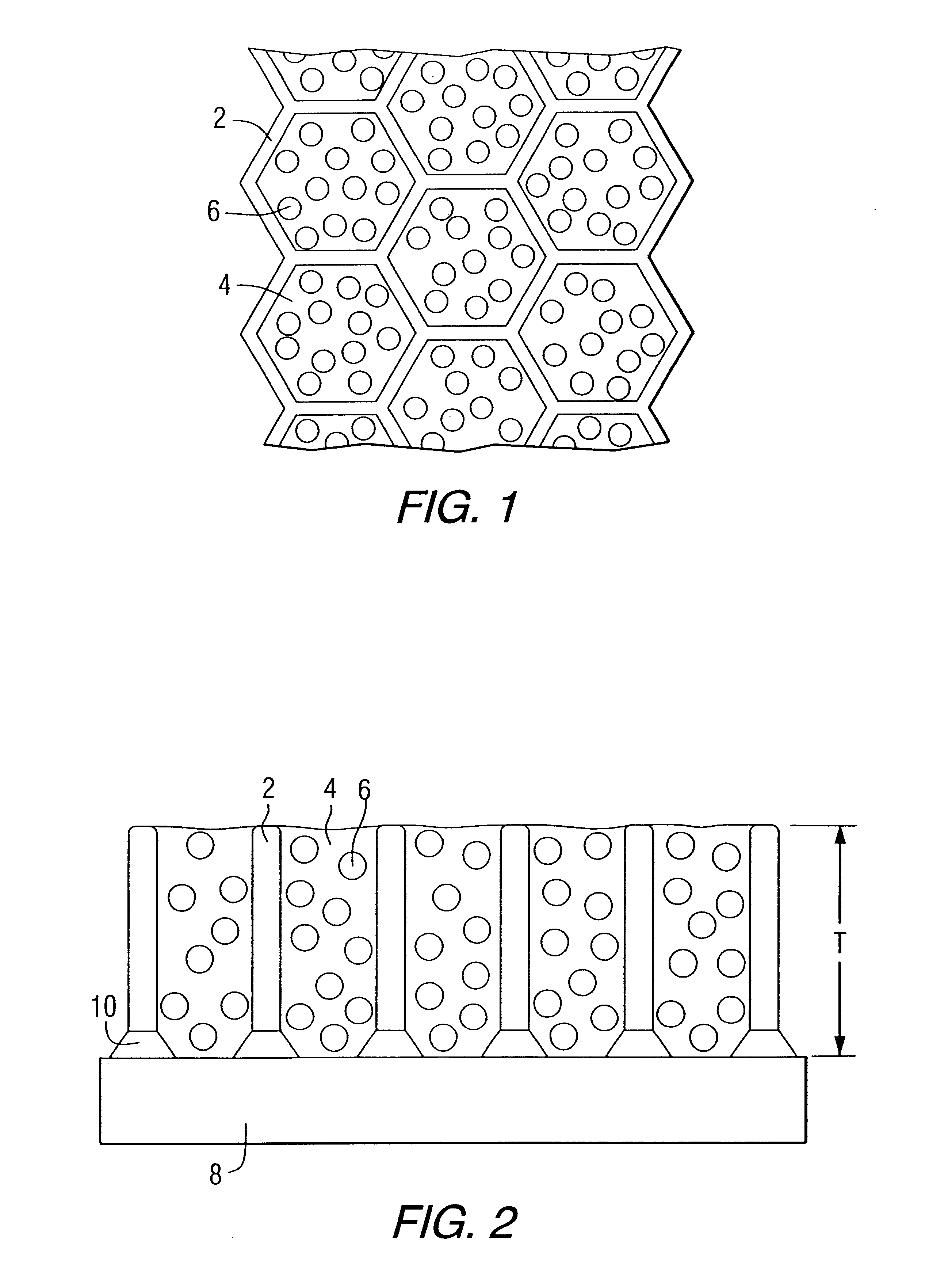

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

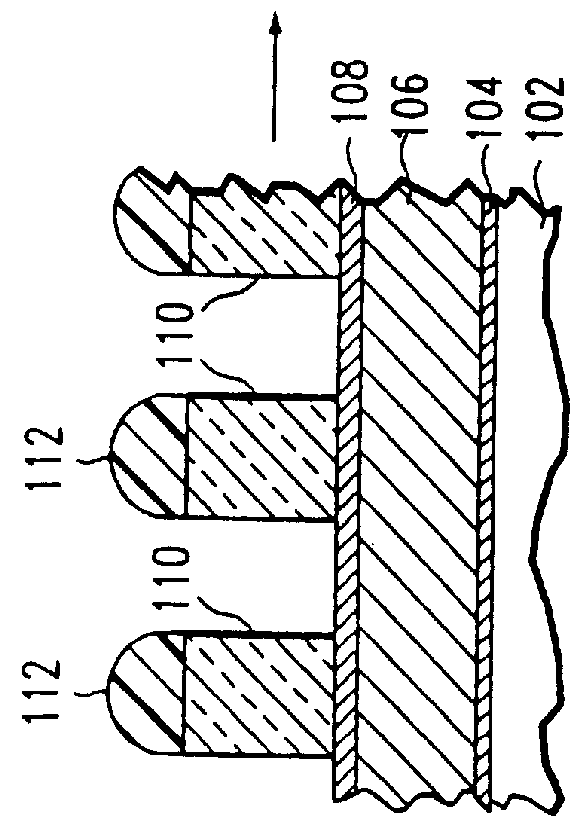

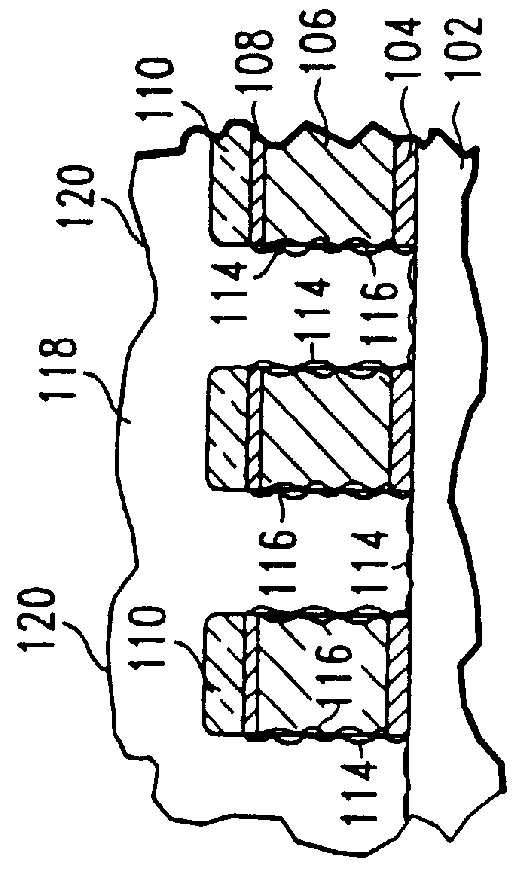

Method for high temperature etching of patterned layers using an organic mask stack

InactiveUS6143476APhotomechanical apparatusSemiconductor/solid-state device manufacturingOrganic baseHigh-temperature corrosion

The present disclosure pertains to a method of patterning a semiconductor device feature which provides for the easy removal of any residual masking layer which remains after completion of a pattern etching process. The method provides for a multi-layered masking structure which includes a layer of high-temperature organic-based masking material overlaid by either a layer of a high-temperature inorganic masking material which can be patterned to provide an inorganic hard mask, or by a layer of high-temperature imageable organic masking material which can be patterned to provide an organic hard mask. The hard masking material is used to transfer a pattern to the high-temperature organic-based masking material, and then the hard masking material is removed. The high-temperature organic-based masking material is used to transfer the pattern to an underlying semiconductor device feature.

Owner:APPLIED MATERIALS INC

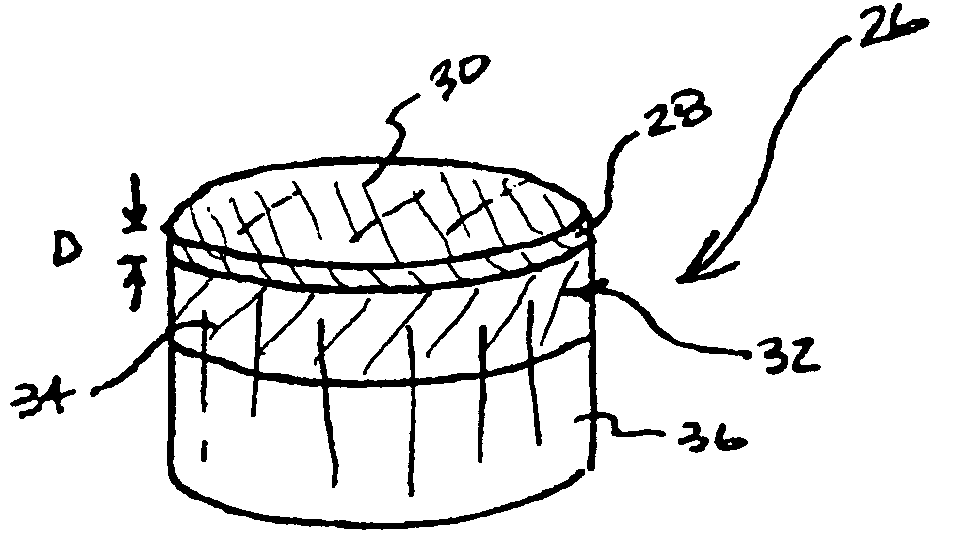

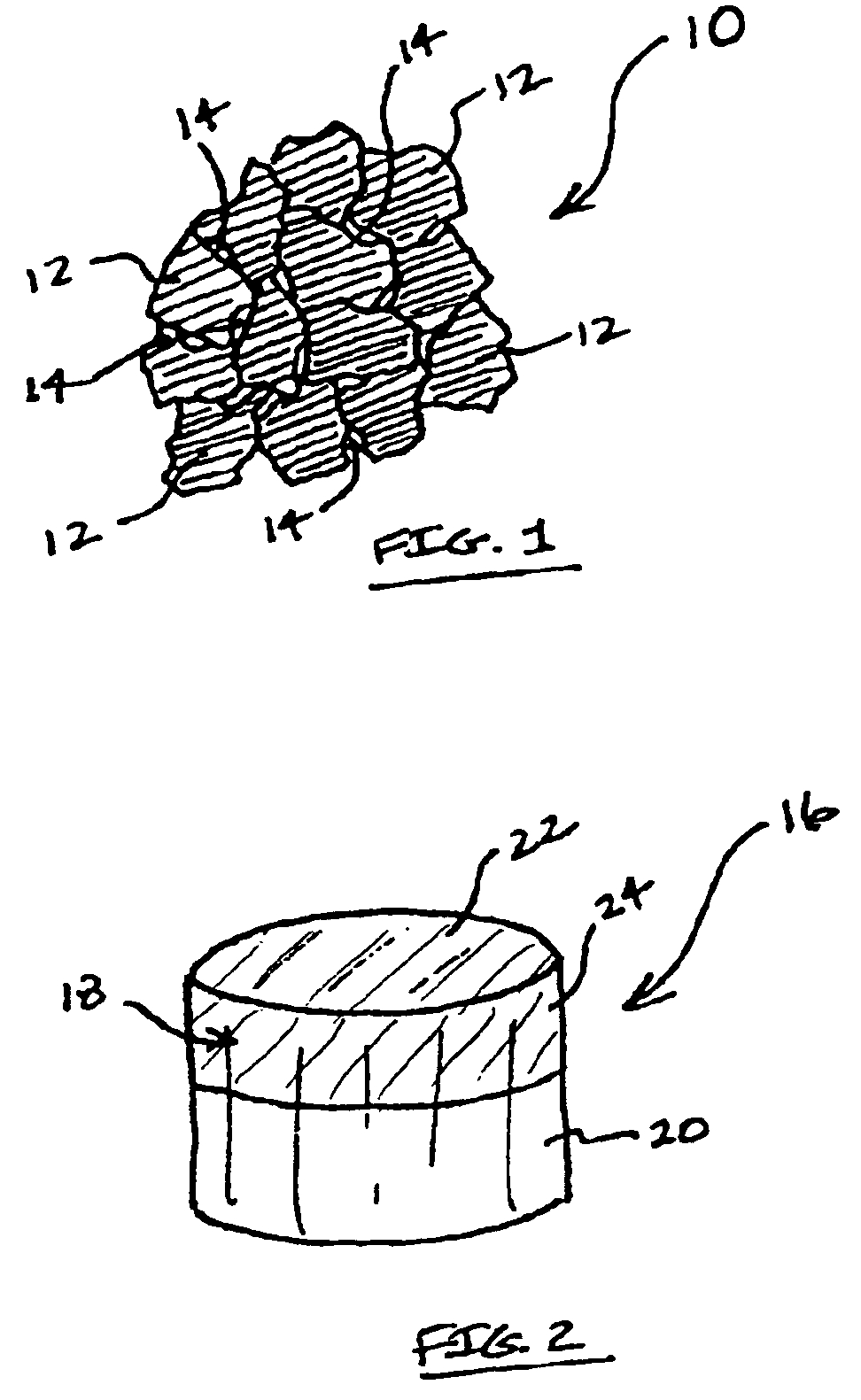

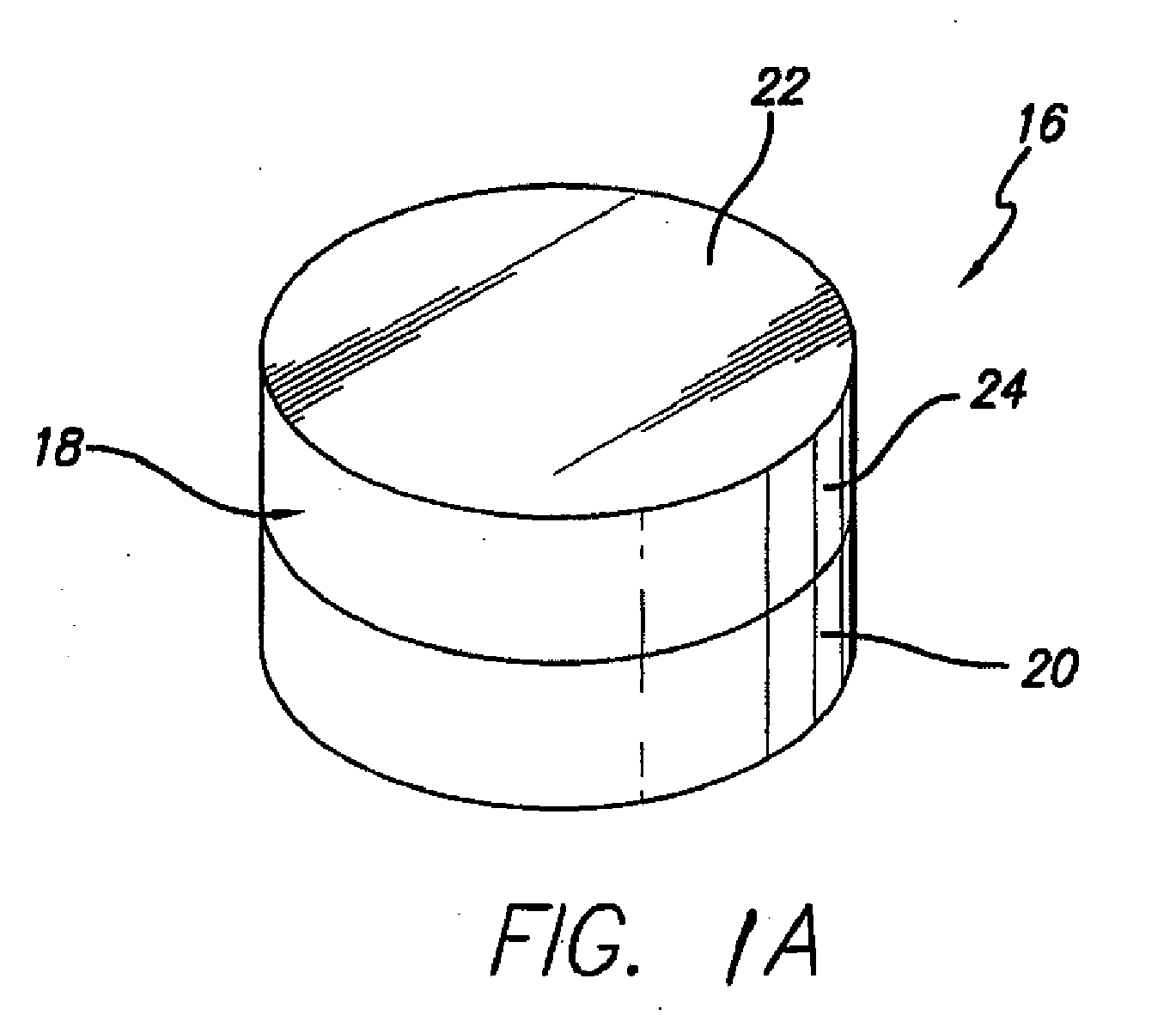

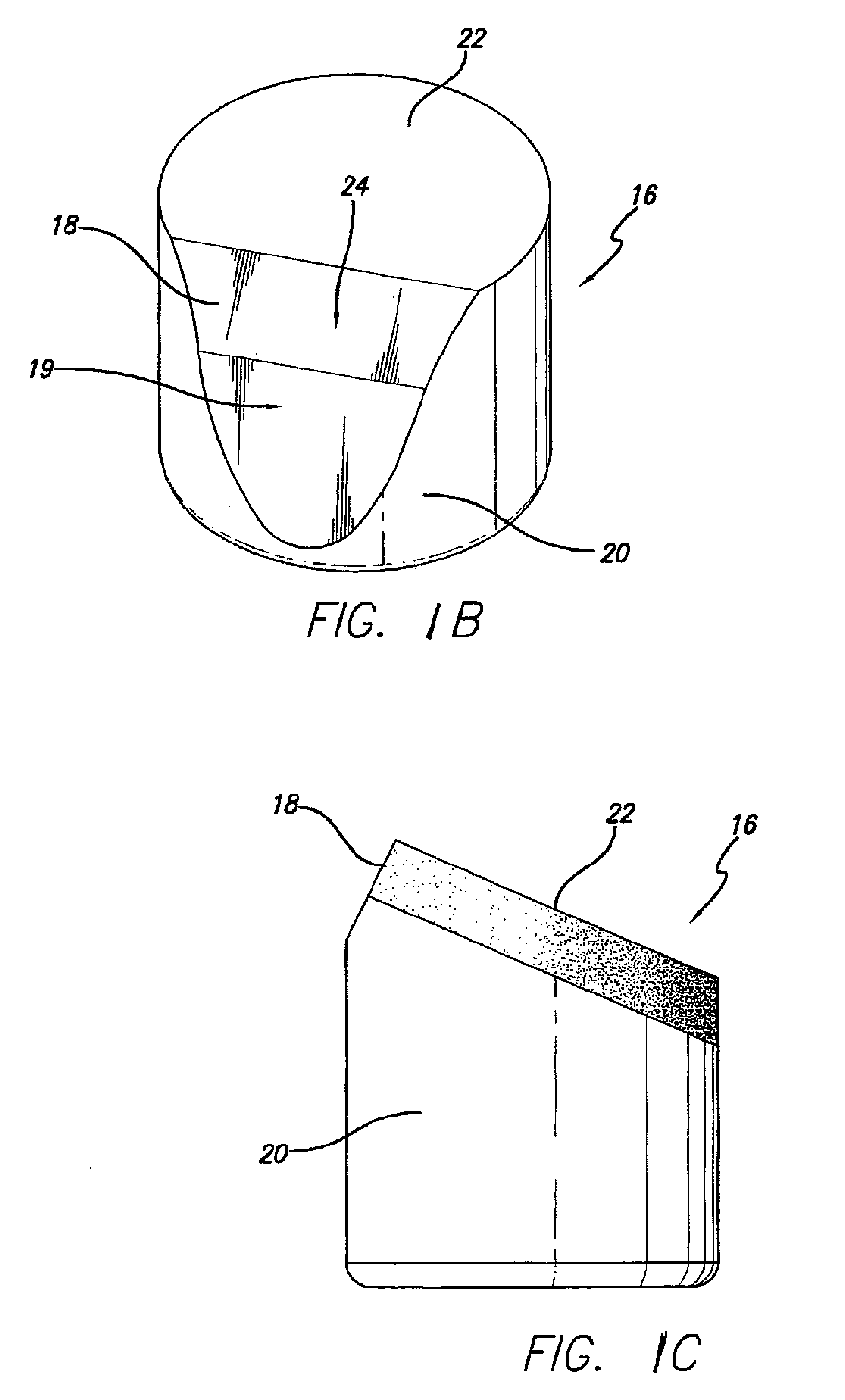

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

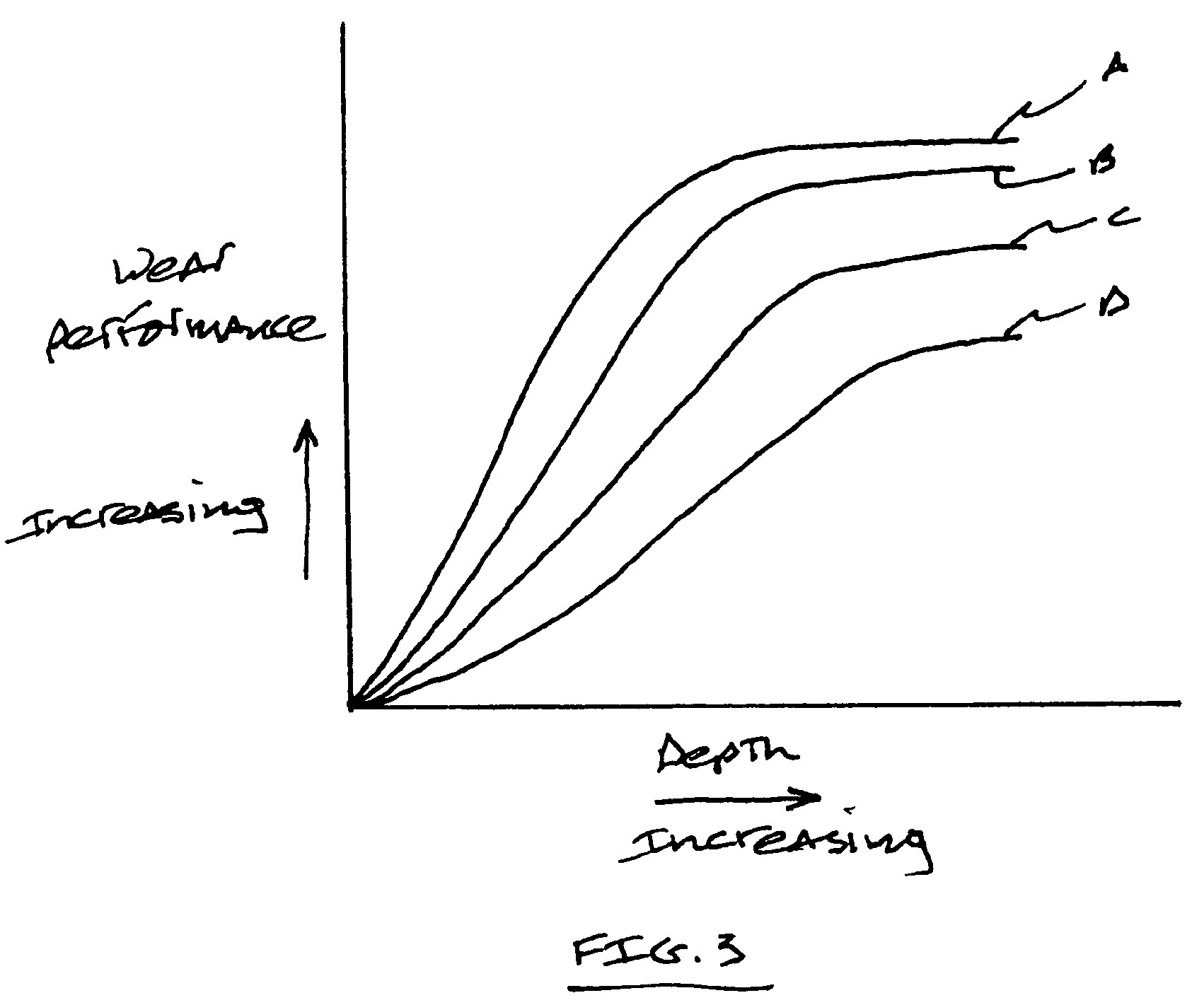

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

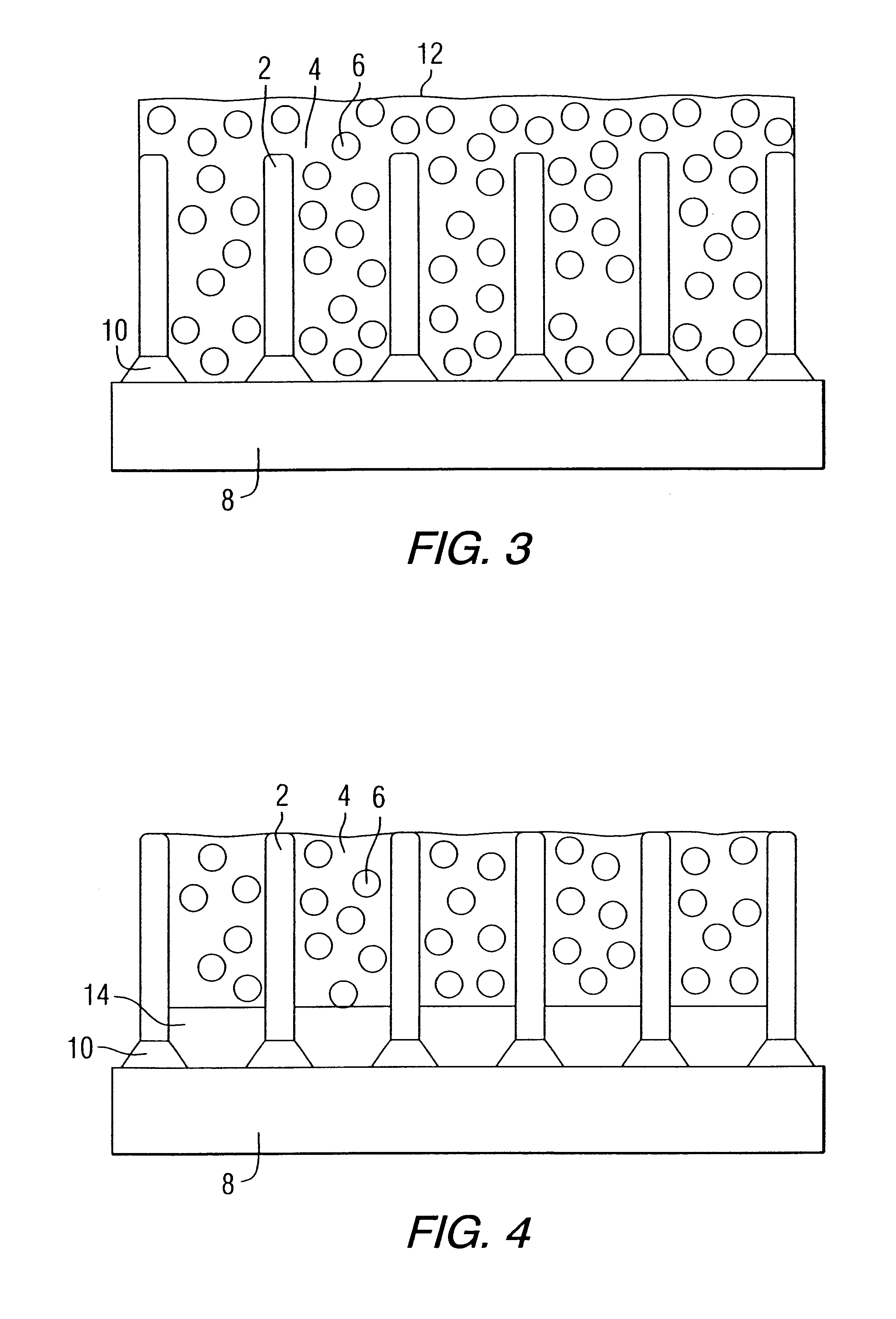

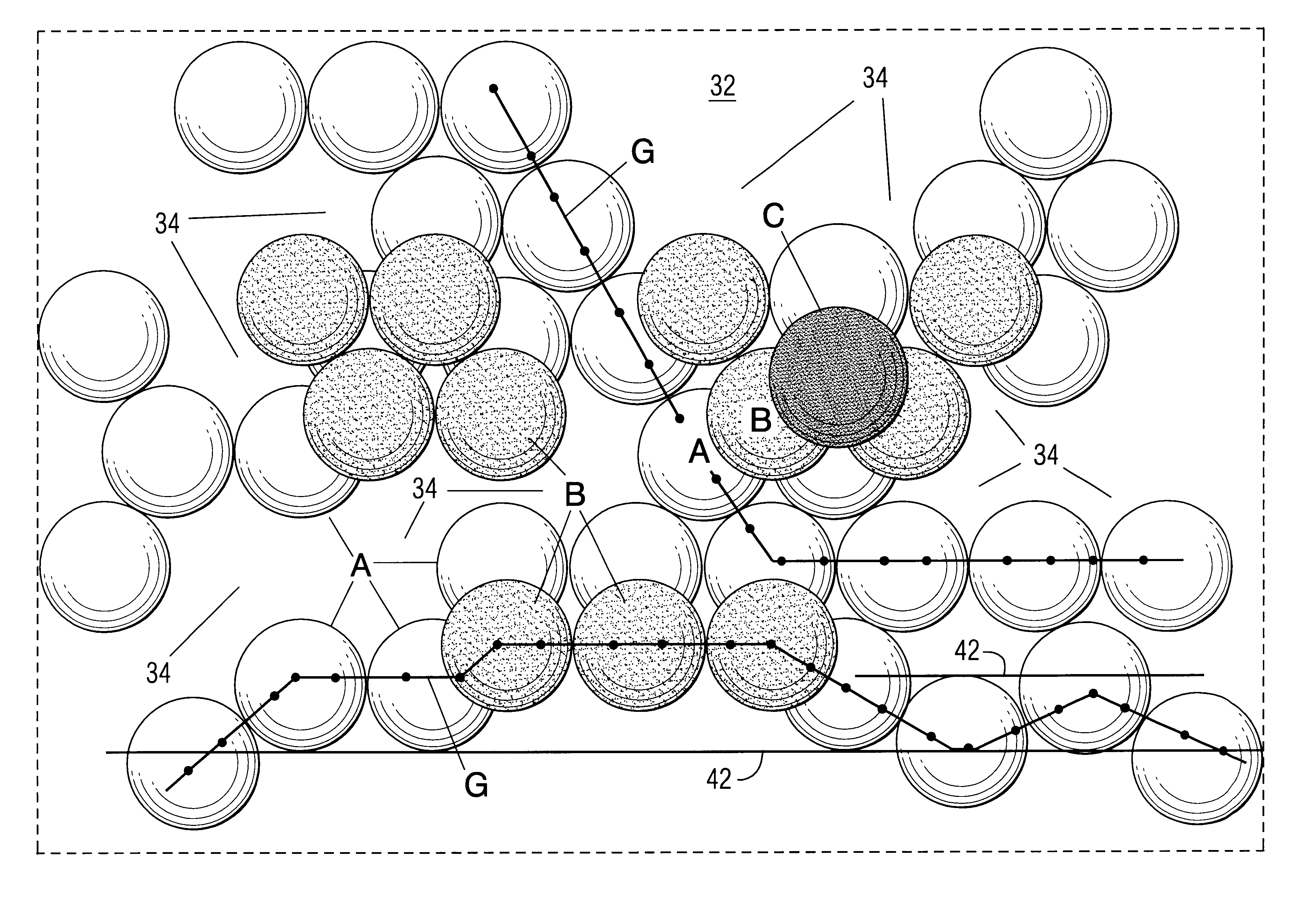

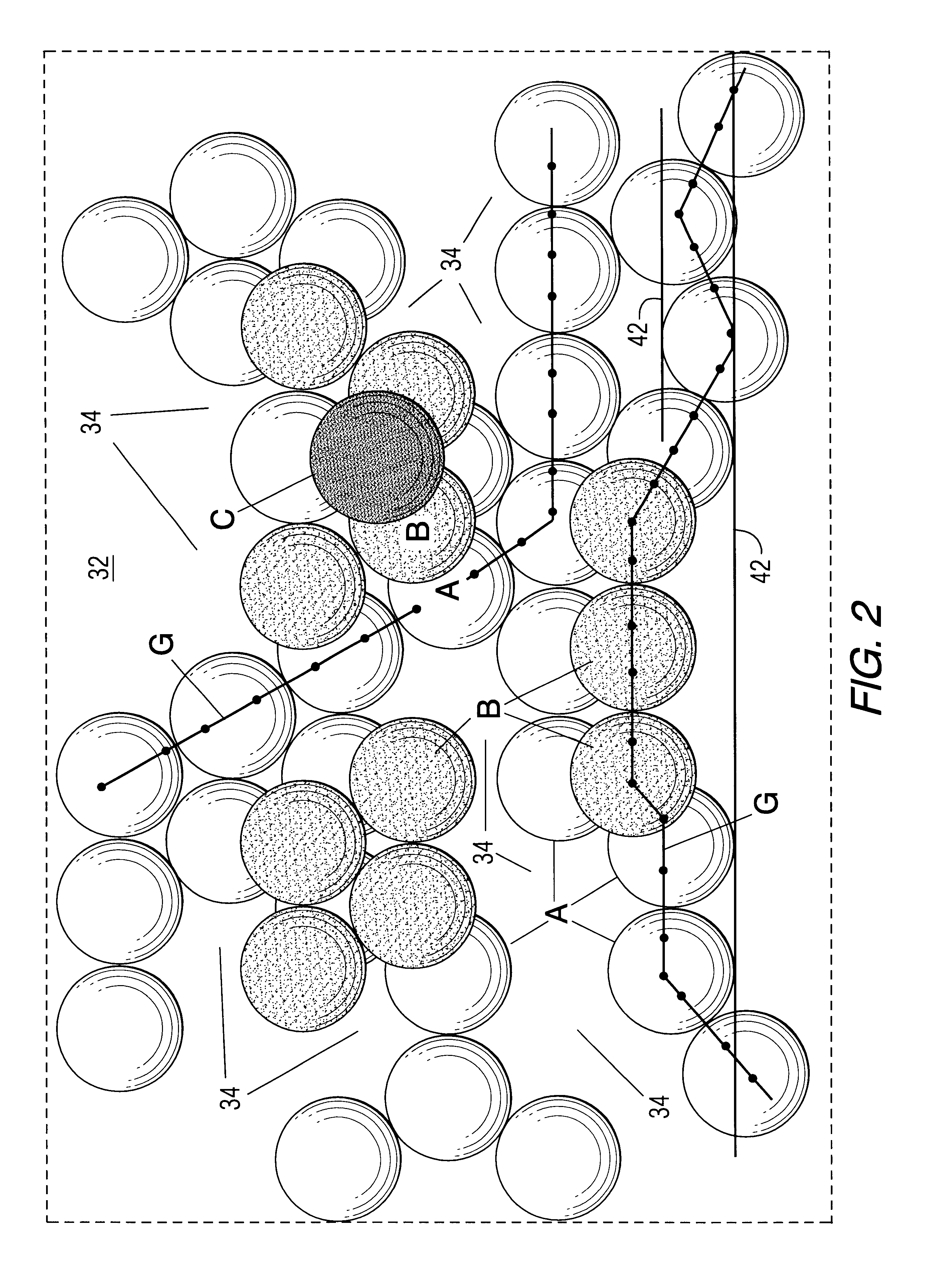

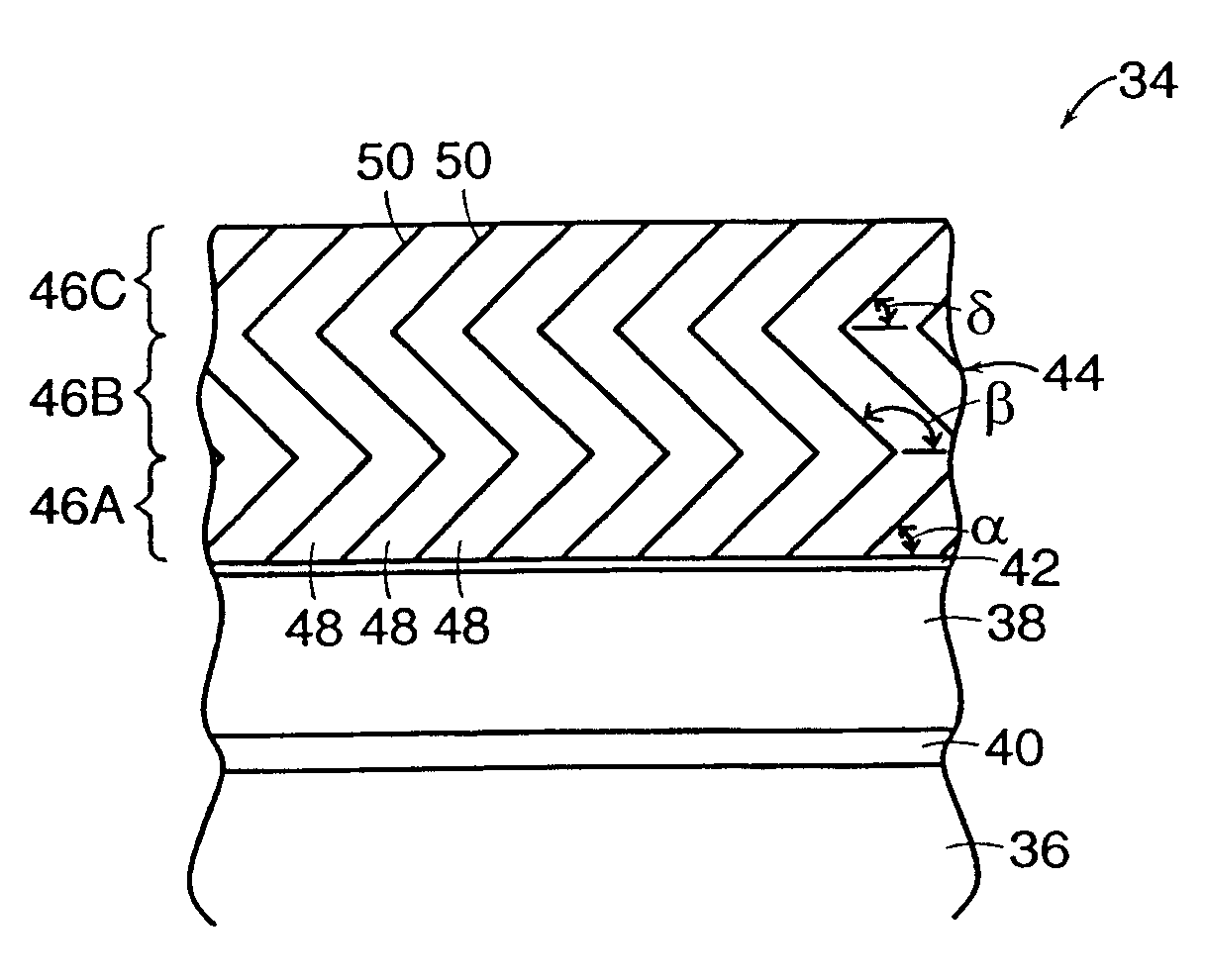

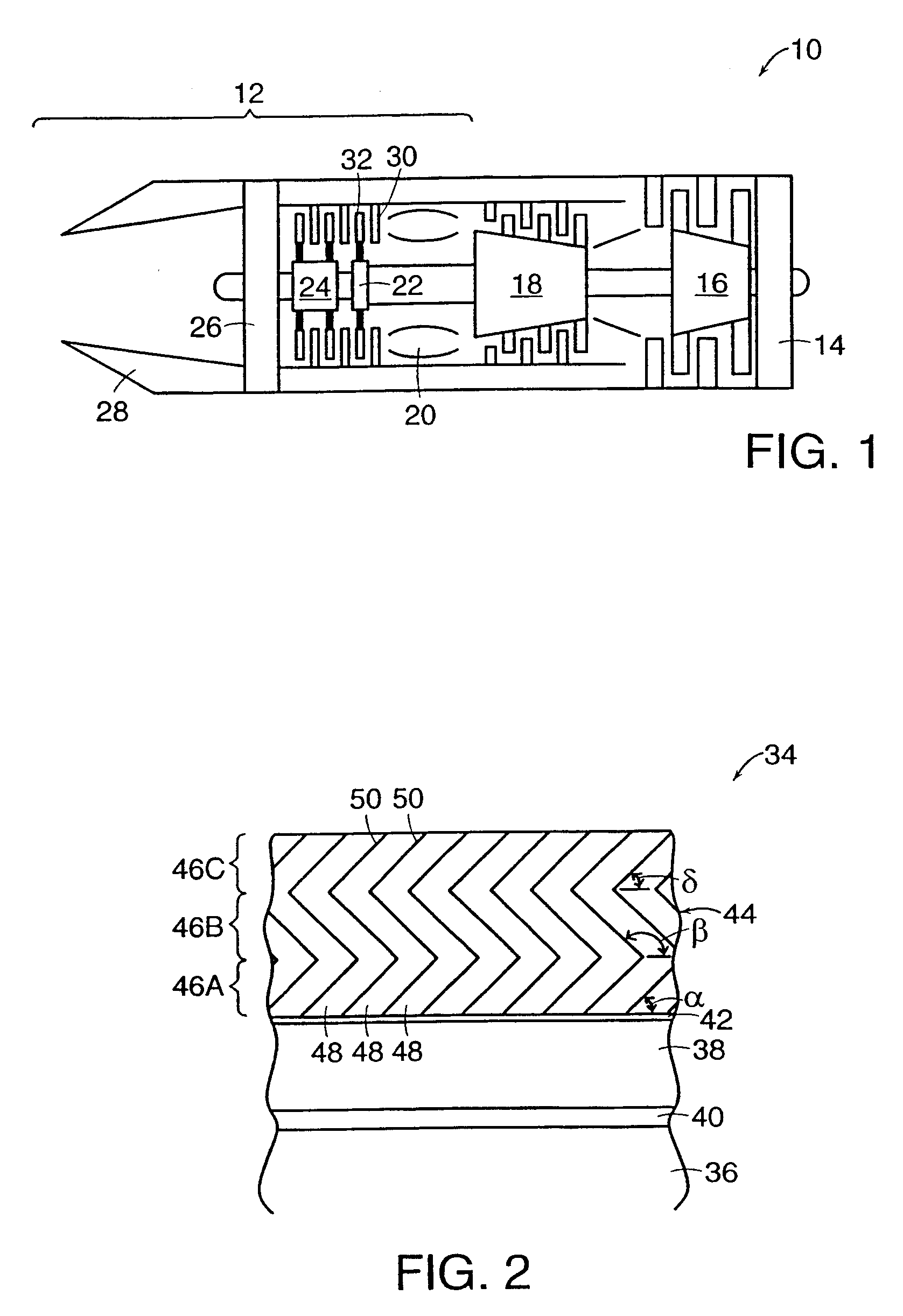

High temperature erosion resistant coating and material containing compacted hollow geometric shapes

InactiveUS6641907B1Improve corrosion resistanceReduce void volumeEngine manufactureBlade accessoriesPorosityMetallurgy

A material system (60) contains close packed hollow shapes (50, 70) having a dense wall structure (52, 66), which are bonded together and which may contain a matrix binder material (56) between the shapes, where the system has a stable porosity, and is abradable and thermally stable at temperatures up to possibly 1700° C., where such systems are useful in turbine apparatus.

Owner:SIEMENS ENERGY INC

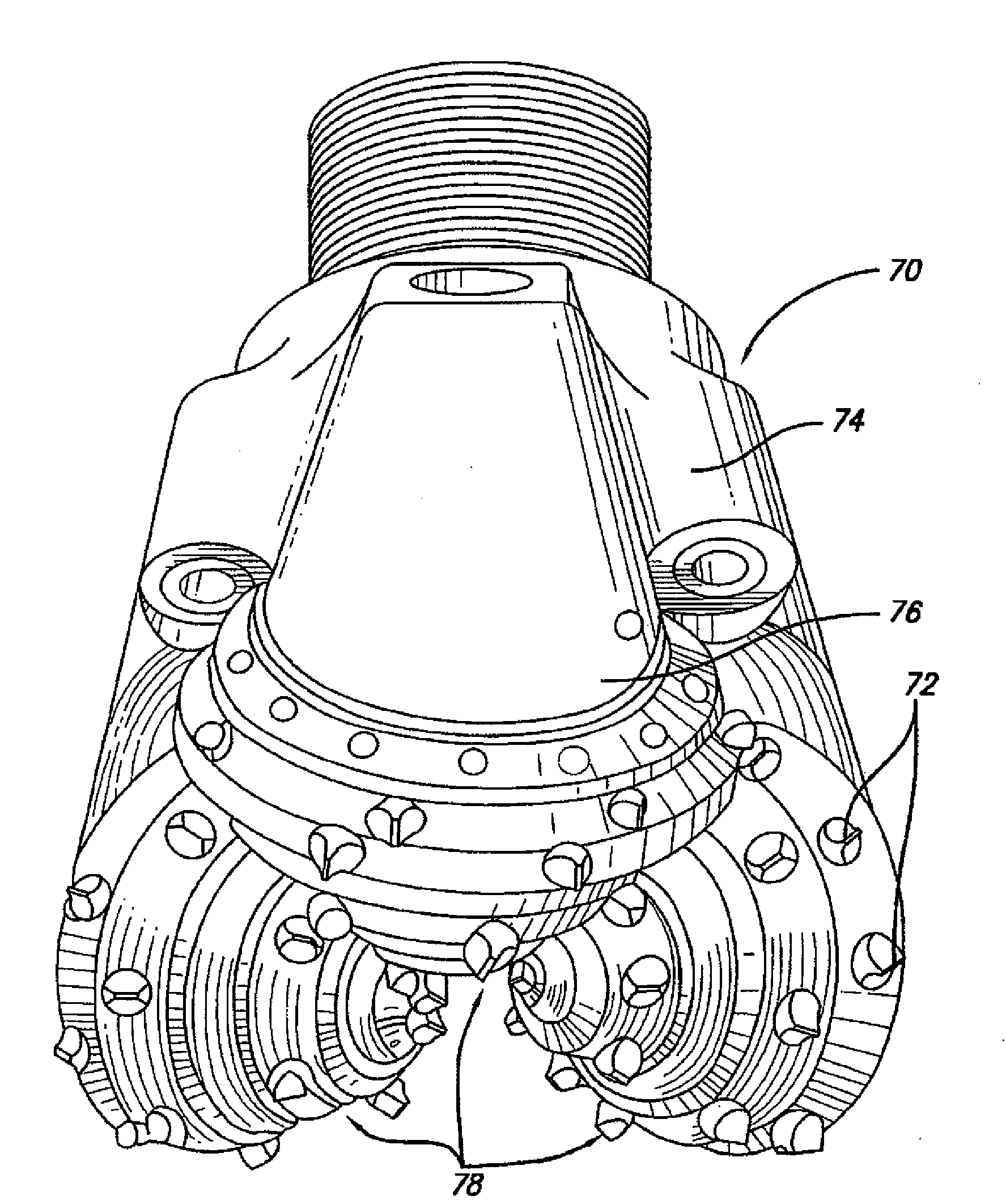

Polycrystalline diamond cutting elements having improved thermal resistance

InactiveUS20080302579A1Increase thermal resistanceGood adhesionDrill bitsConstructionsHeat resistanceDiamond crystal

Polycrystalline diamond constructions of this invention have a polycrystalline diamond body and a substrate attached thereto, wherein the diamond body has a material microstructure comprising a plurality of bonded-together diamond crystals forming a polycrystalline matrix phase, and second phase formed from different types of materials or sintering aids designed to reduce or eliminate the amount of free Group VIII elements therein. The use of such materials and the reduction and / or elimination of free Group VIII elements, in addition to graphitization, facilitates the sintering the construction at high pressure / high temperature conditions, e.g., greater than about 65 Kbar, to produce a construction having a high degree of thermal stability and / or thermal resistance when compared to conventional PCD materials. Polycrystalline diamond constructions of this invention are preferably configured as cutting elements that are disposed on drill bits used for drilling subterranean earthen formations.

Owner:SMITH INT INC

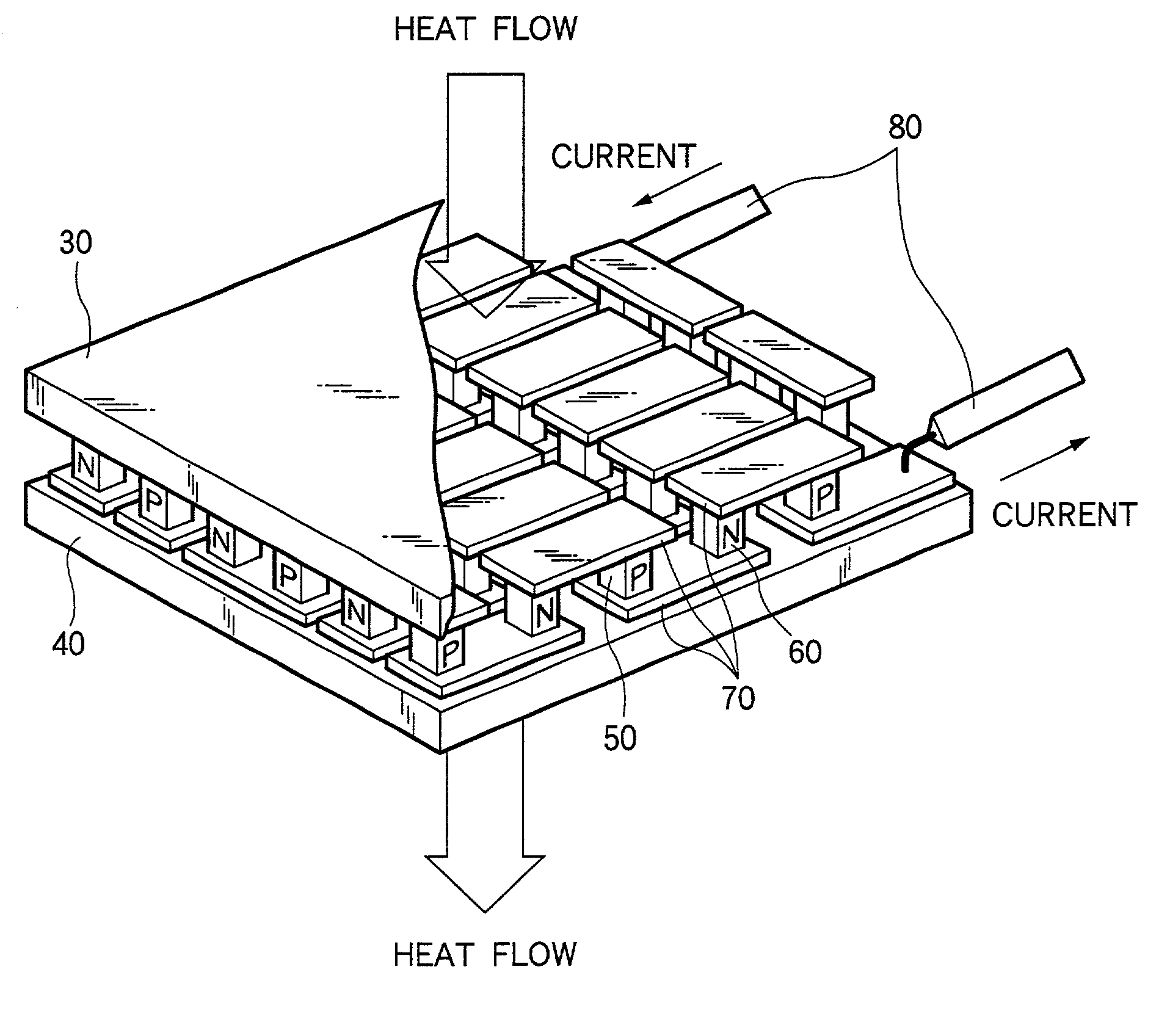

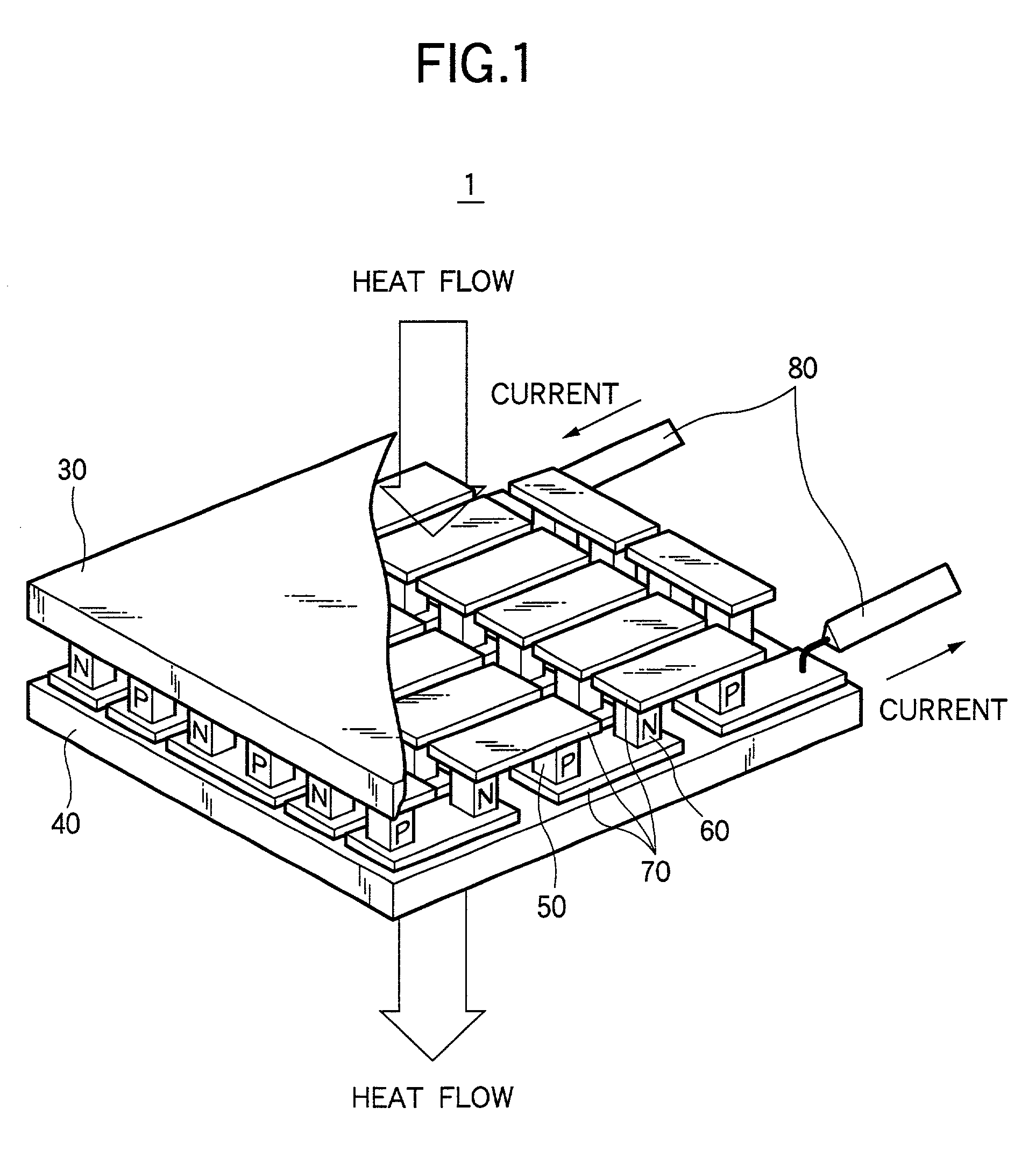

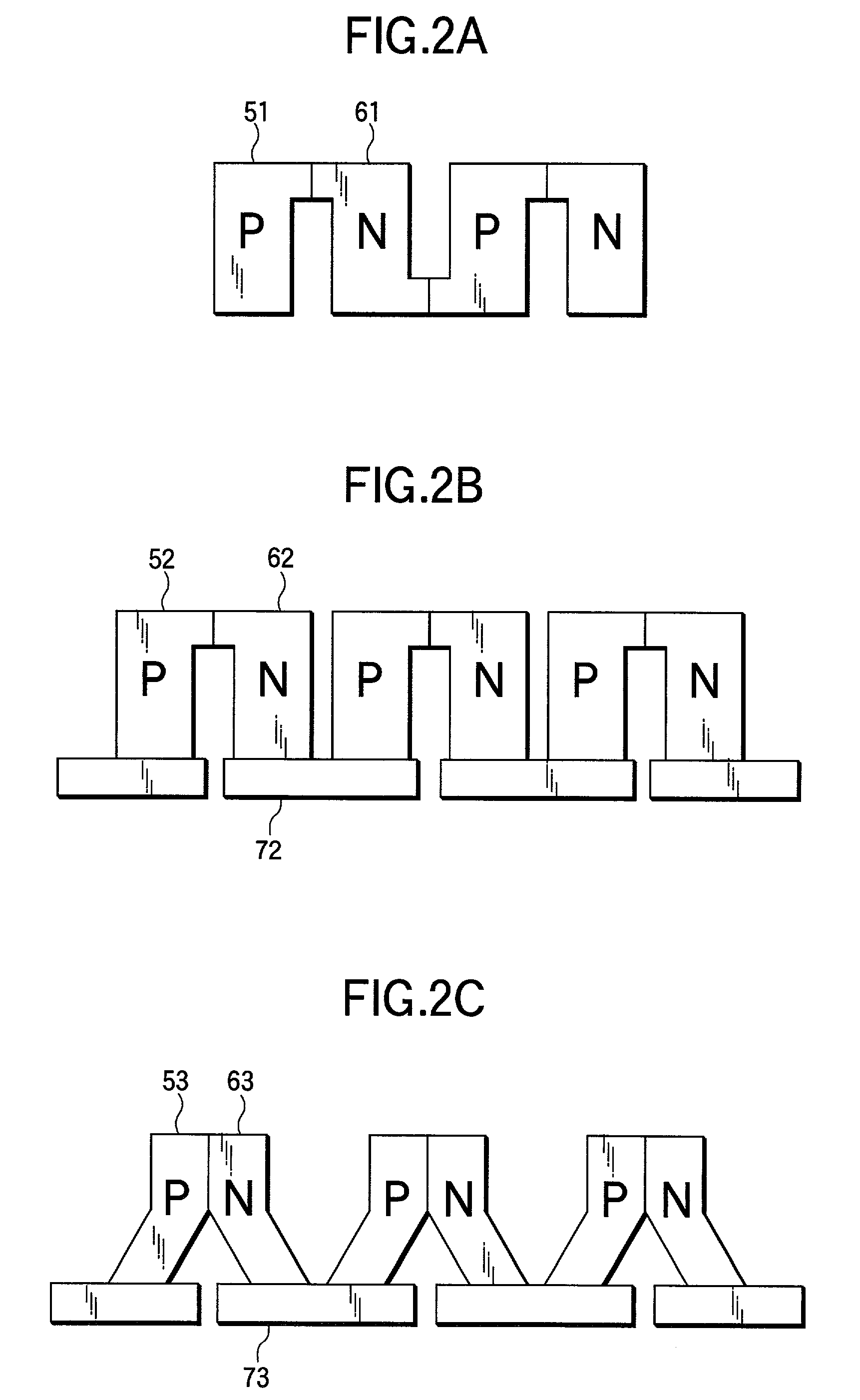

Thermoelectric module

InactiveUS20020024154A1Improve featuresSpeed up the conversion processThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsAtmospheric air

A thermoelectric module comprising an N-type thermoelectric element having excellent characteristics in atmospheric air even when the temperature rises to a medium-to-high temperature region of about 500° C. and, further, improving the conversion efficiency of a thermoelectric module, by the combination of an excellent P-type thermoelectric material and an excellent n-type thermoelectric material containing a compound having a skutterudite structure, the module comprising an N-type thermoelectric elements each containing a compound having a skutterudite structure, P-type thermoelectric elements each connected directly or by way of a metal member to the N-type thermoelectric elements and containing an Mn-Si series compound,

Owner:KOMATSU LTD

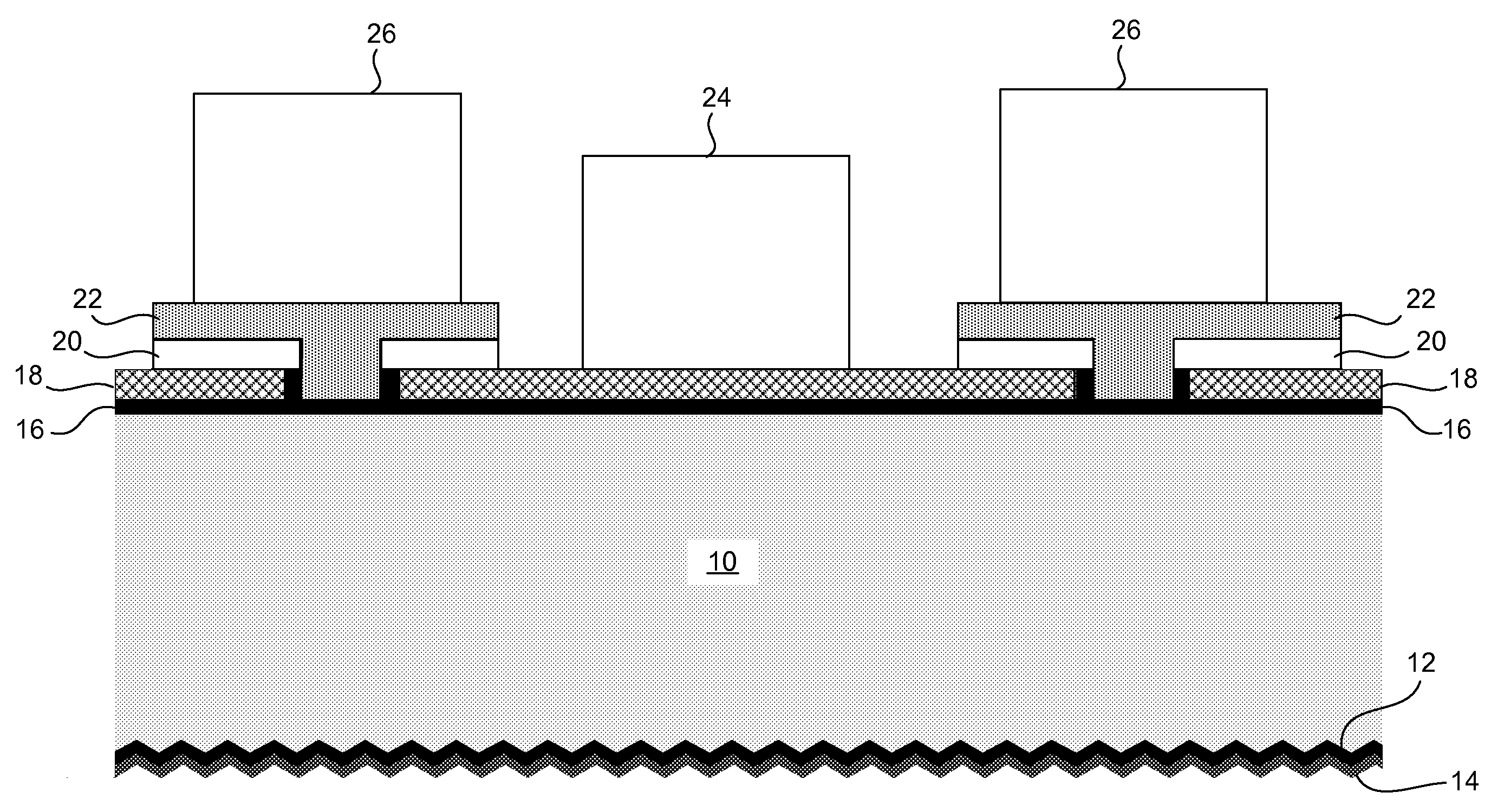

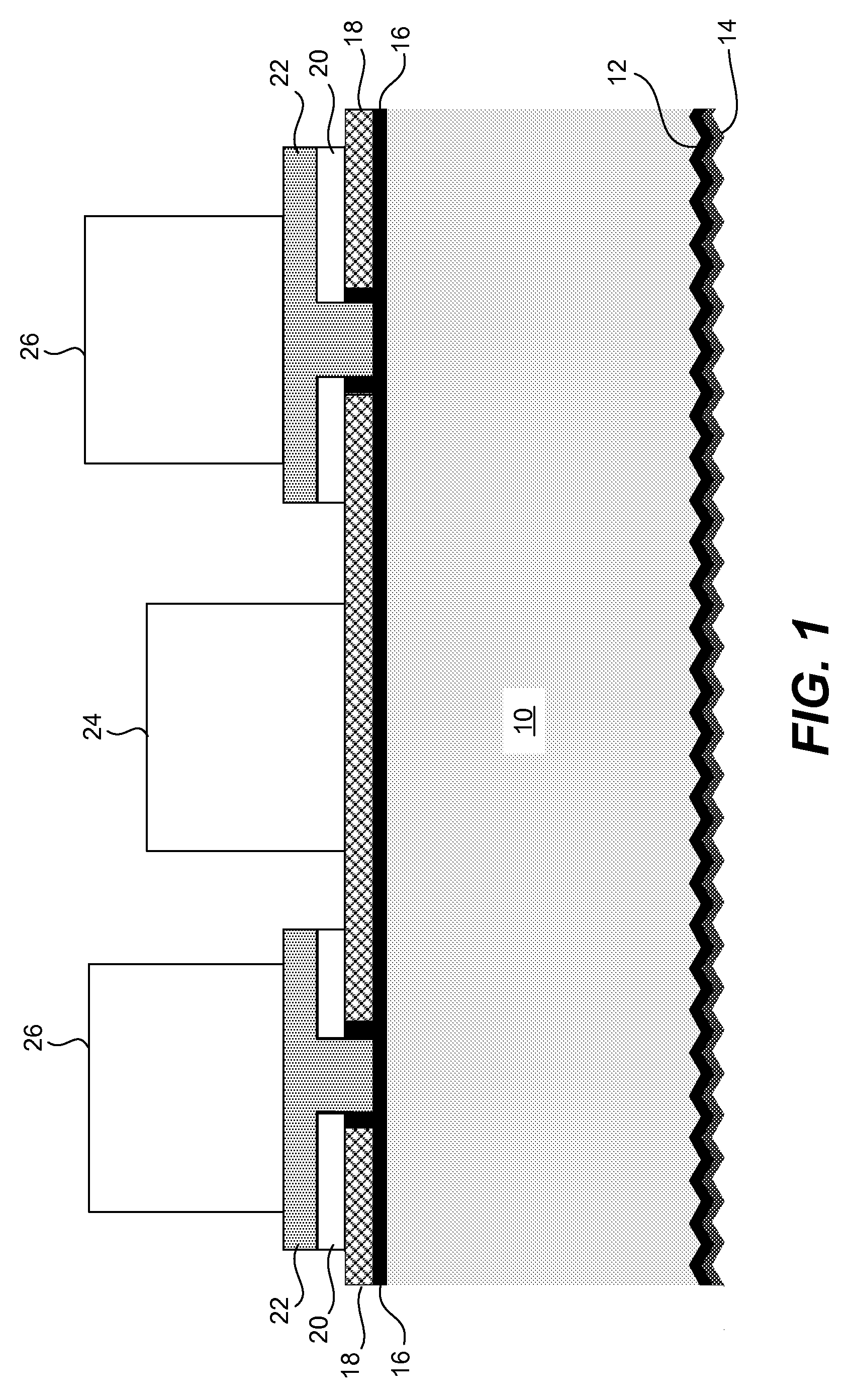

Solar cell having doped semiconductor heterojunction contacts

A silicon solar cell has doped amorphous silicon contacts formed on a tunnel silicon oxide layer on a surface of a silicon substrate. High temperature processing is unnecessary in fabricating the solar cell.

Owner:MAXEON SOLAR PTE LTD

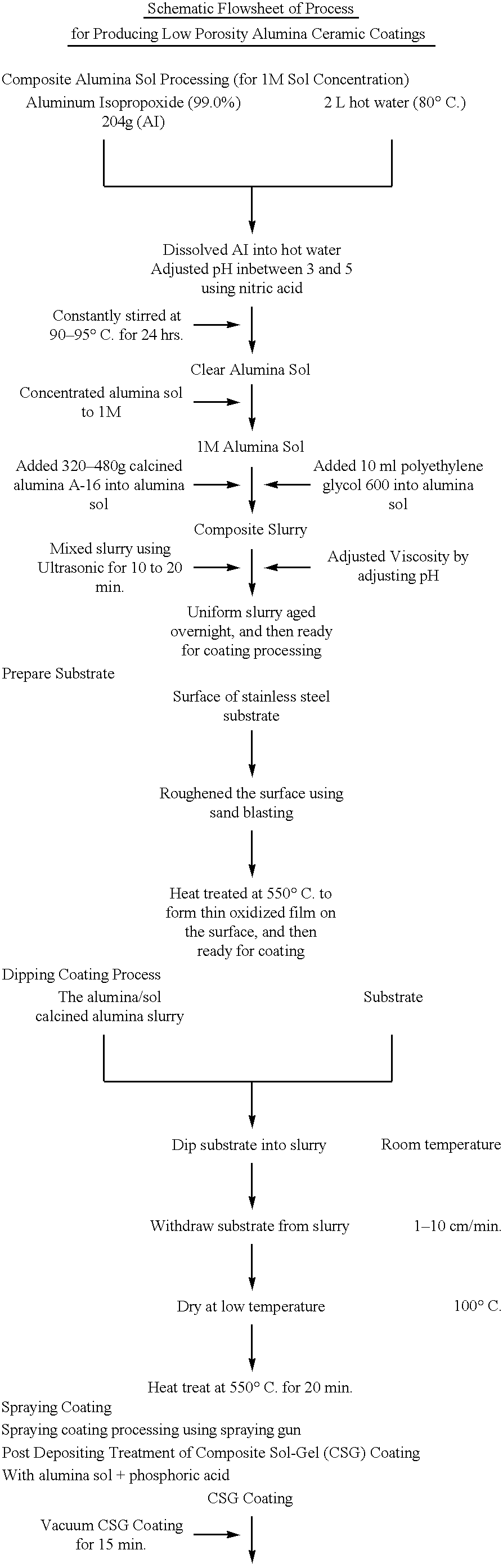

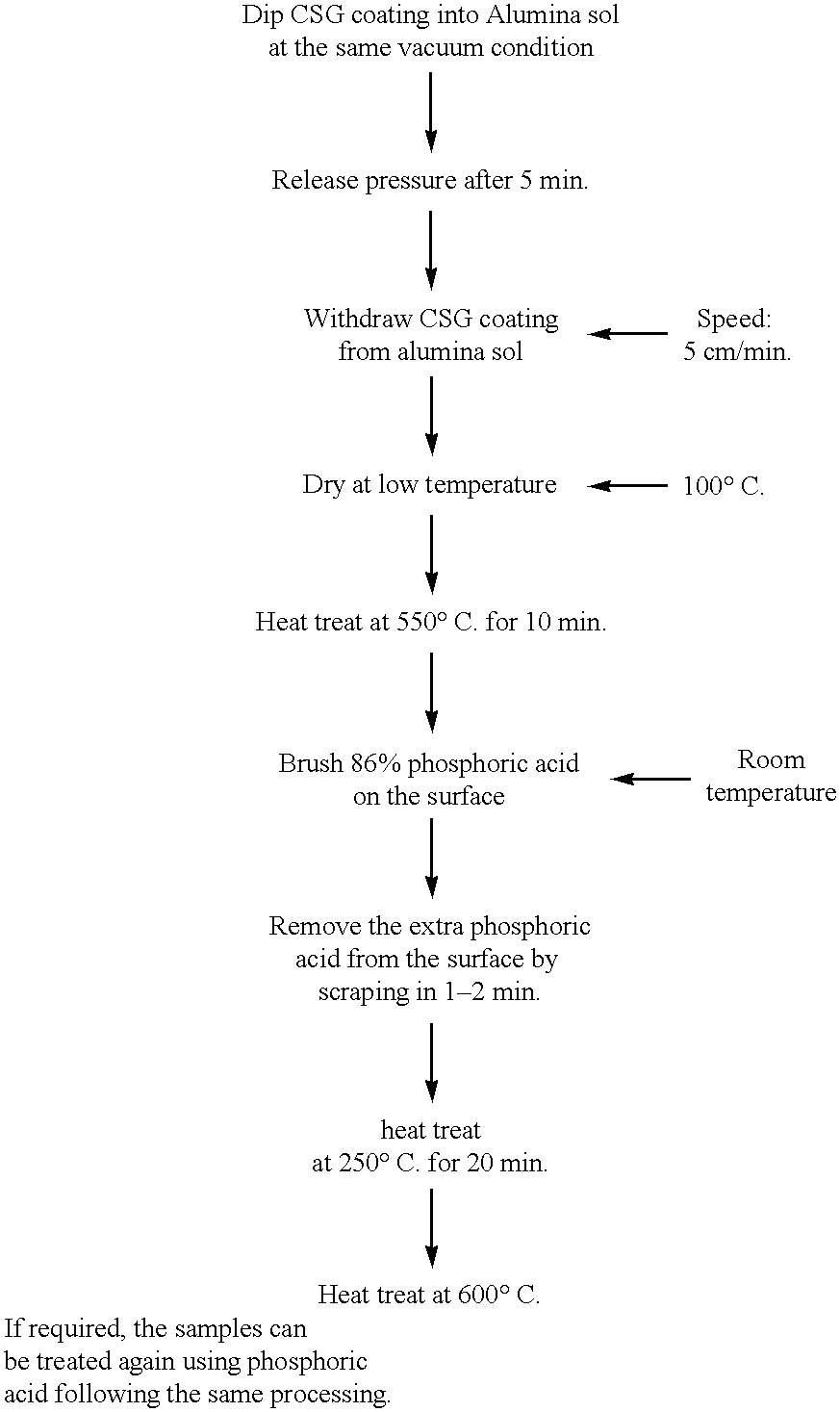

Process for making chemically bonded sol-gel ceramics

InactiveUS6284682B1Liquid/solution decomposition chemical coatingSuperimposed coating processPorosityCeramic coating

This invention relates to a novel method of decreasing porosity of ceramics produced by sol-gel processing. The process of preparing chemically bonded sol-gel ceramics comprises phosphating a sol-gel derived oxide or hydrated oxide and polymerizing the phosphated product with heat treatment. Such combined sol-gel / chemical bonding process can be used to fabricate dense, thick ceramics or ceramic coatings for a variety of applications, including high temperature corrosion protection, wear resistance, dielectric properties, non-sticky surfaces, bio-active ceramics, thermal barrier ceramics, non-wetted surfaces, and others.

Owner:THE UNIV OF BRITISH COLUMBIA

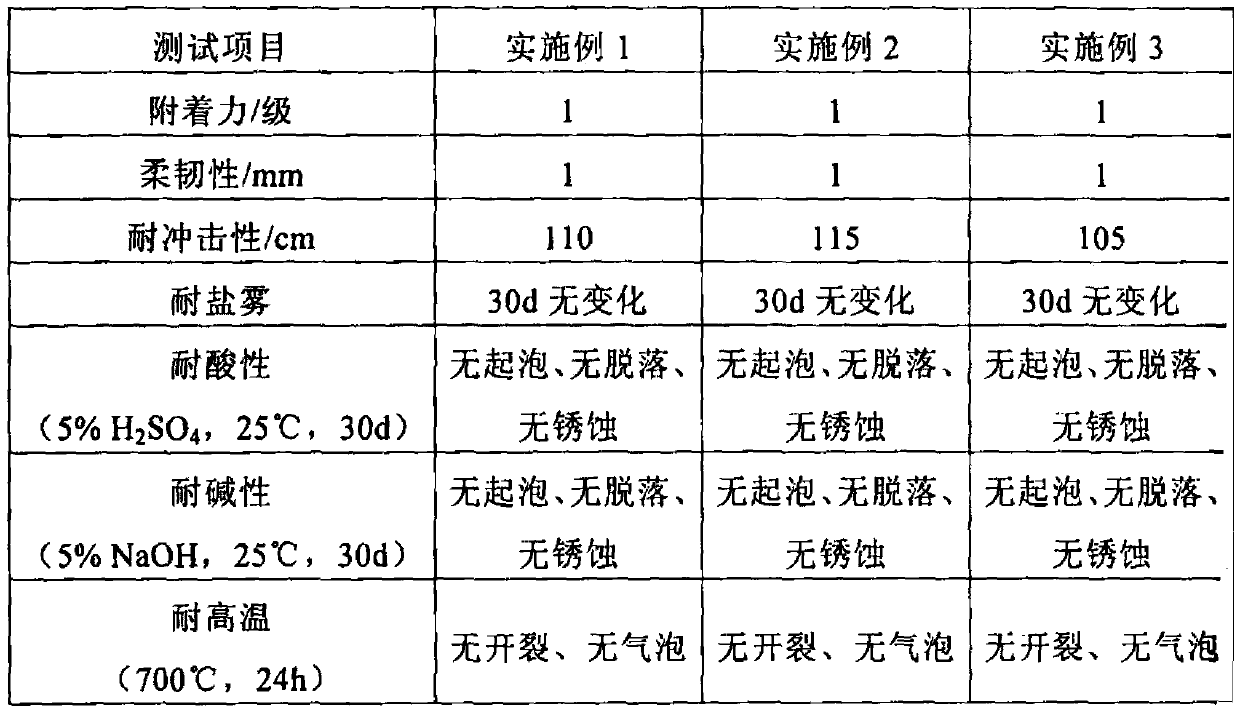

High temperature resistant anticorrosion coating based on graphene and preparation method thereof

InactiveCN103589281AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

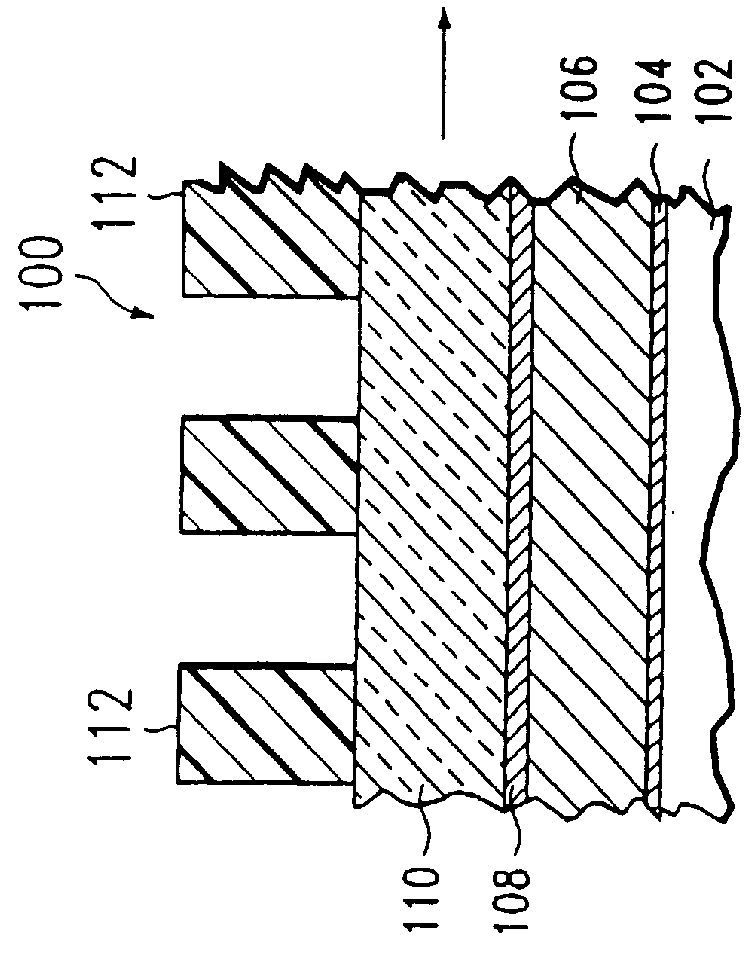

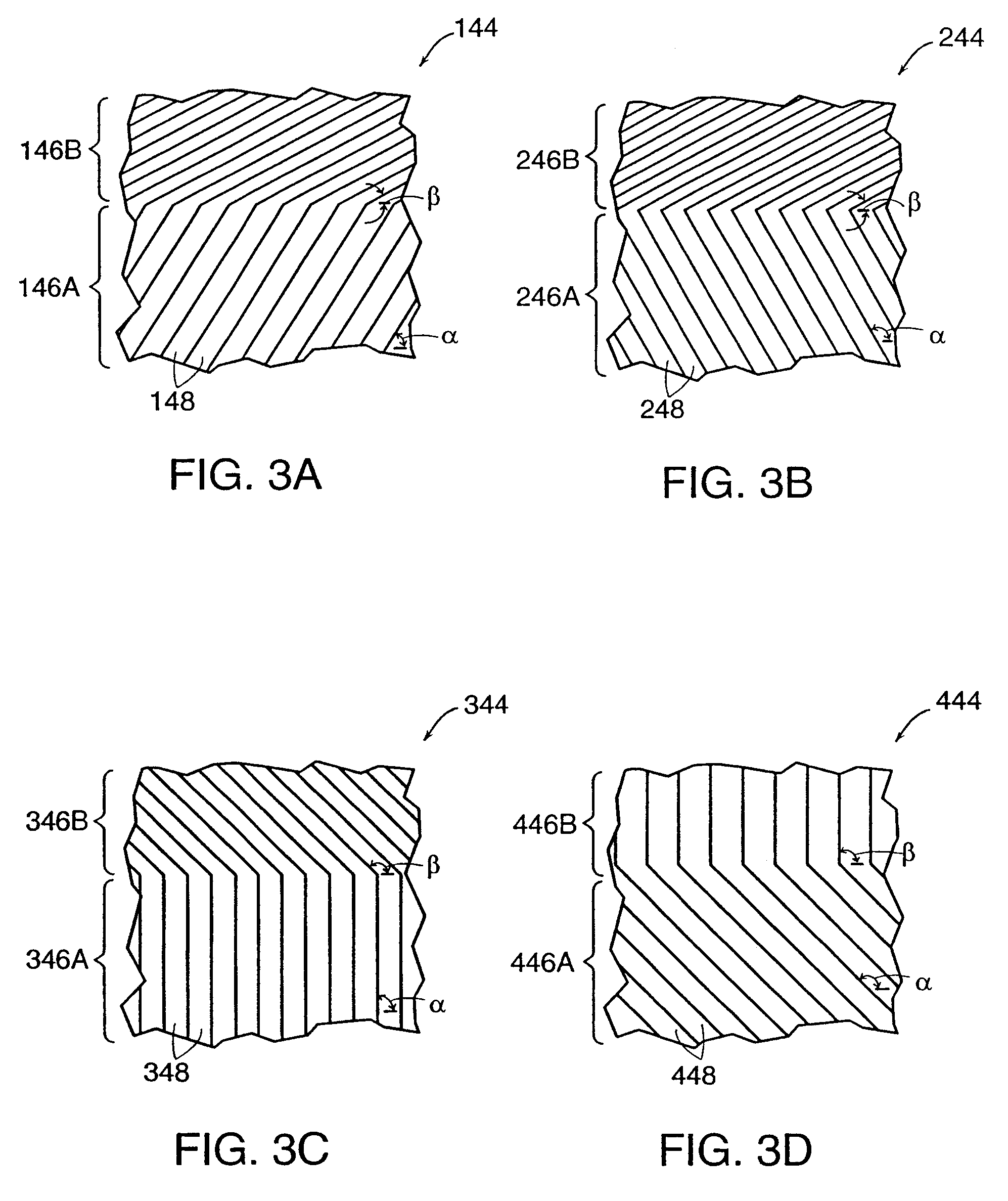

Thermal barrier coating ceramic structure

InactiveUS6455173B1PropellersSurface reaction electrolytic coatingElectron beam physical vapor depositionVapor cloud

A multilayered ceramic topcoat of a thermal barrier coating system is useful for high temperature corrosive applications such as hot section components in gas turbine engines. The ceramic topcoat includes at least two layers, each having generally columnar grain microstructures with different grain orientation directions. A preferred method of producing the multilayered ceramic topcoat includes positioning a superalloy substrate at a first angled orientation relative to a ceramic vapor cloud in an electron beam physical vapor deposition apparatus for a time sufficient to grow a first ceramic layer. The substrate is then reoriented to a second, different angled orientation for a time sufficient to grow a second ceramic layer. The ceramic layers exhibit columnar microstructures having respective grain orientation directions which are related to the first and second substrate orientations. For uniformly coating a complex contoured surface such as a turbine blade airfoil, the blade can be rotated during coating deposition at each angled orientation. Alternatively, the article may be continuously reoriented according to a predetermined speed cycle to produce generally arcuate, sinusoidal, helical, or other columnar grain microstructures.

Owner:MARIJNISSEN GILLION HERMAN +4

Low cost high-pressure sensor

InactiveUS20070095144A1Low costLess materialFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesPressure senseHigh pressure

A pressure sensing apparatus including a thin disc of a metal having a ceramic material layer and piezoresistive elements formed thereon. A surface of the disc is bonded to a diaphragm assembly on a pressure port base constructed of a low cost metal. The bonding process is performed at low temperatures, (<700° C.), so that the diaphragm assembly and pressure port do not require high temperature corrosion resistance, and can thus be formed of less expensive materials. The inventive apparatus provides a lower cost alternative to conventional high pressure sensors since less material is used, less expensive materials are used, and fabrication is less complex. The inventive apparatus is also more reliable and exhibits greater thermal stability than conventional high pressure sensors.

Owner:HONEYWELL INT INC

anti-corrosion coating

InactiveCN102260450AStrong adhesionEasy constructionAlkali metal silicate coatingsAnti-corrosive paintsMetal coatingSolvent

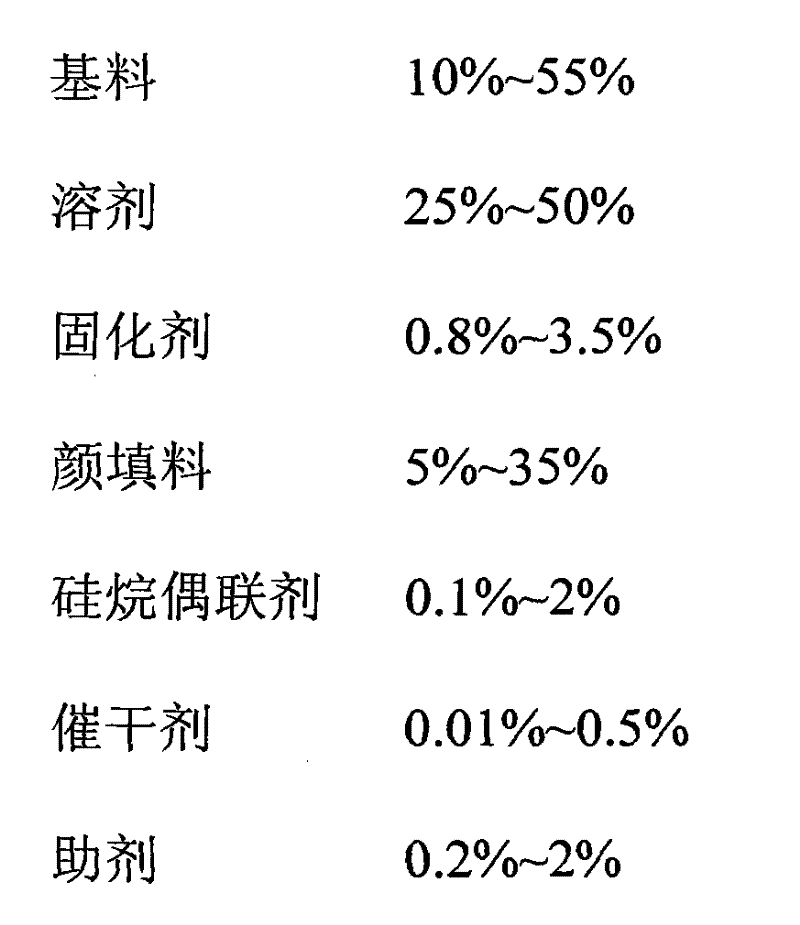

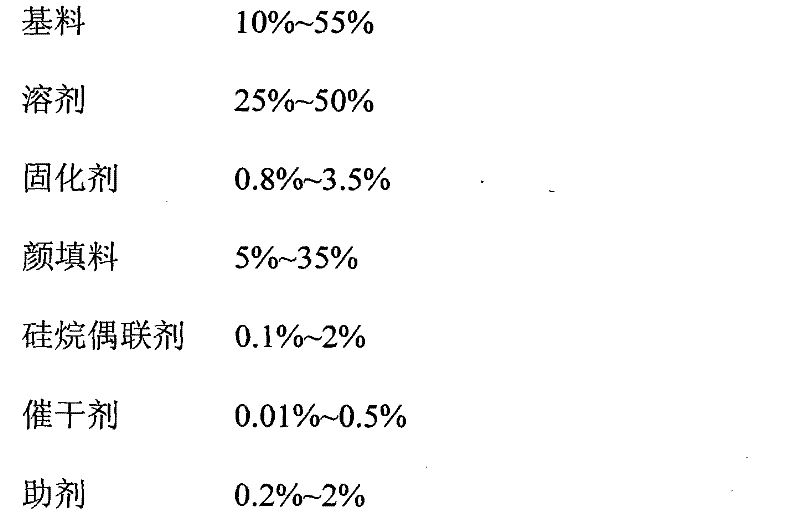

The invention belongs to the field of metal coatings, and in particular relates to a coating that can be used at high temperatures and is corrosion-resistant; the technical problem to be solved by the invention is to provide a coating that still has strong mechanical strength, strong adhesion, Corroded paint; in order to solve the above problems, the technical solution provided by the present invention is: a high-temperature anti-corrosion paint, including base material, solvent, curing agent, pigment and filler, silane coupling agent, drier, auxiliary agent; the present invention The beneficial effect is that: it has good adhesion, impact resistance and mechanical strength, the thickness of the coating film is 50 μm, the coating can withstand the temperature of 600 ° C, and has good corrosion resistance.

Owner:SNTO TECH GRP

Laser Cladding on Low Heat Resistant Substrates

InactiveUS20080226843A1Sufficient powerMolten spray coatingVacuum evaporation coatingMetal alloyLength wave

This invention relates to laser cladding of components used in high temperature-corrosive applications, such as those associated with metallurgical vessels' lances, nozzles and tuyeres, for extending their service life under such severe conditions. In particular, this invention relates to a method for applying a high melting point material onto a substrate, said substrate having a melting point temperature below the melting point temperature of the high melting point material, comprising: (a) moving a laser beam generated from a laser over the surface of said substrate, said laser beam comprised of wavelengths from about 300 to about 10,600 nanometers; (h) providing a metal, alloy, or metal-alloy composite powder to the surface of said substrate; and (c) generating sufficient power to the laser to superficially heat said substrate and to effect a fusion bond between the metal, alloy or metal-alloy composite powder and the surface of said substrate.

Owner:PRAXAIR ST TECH INC

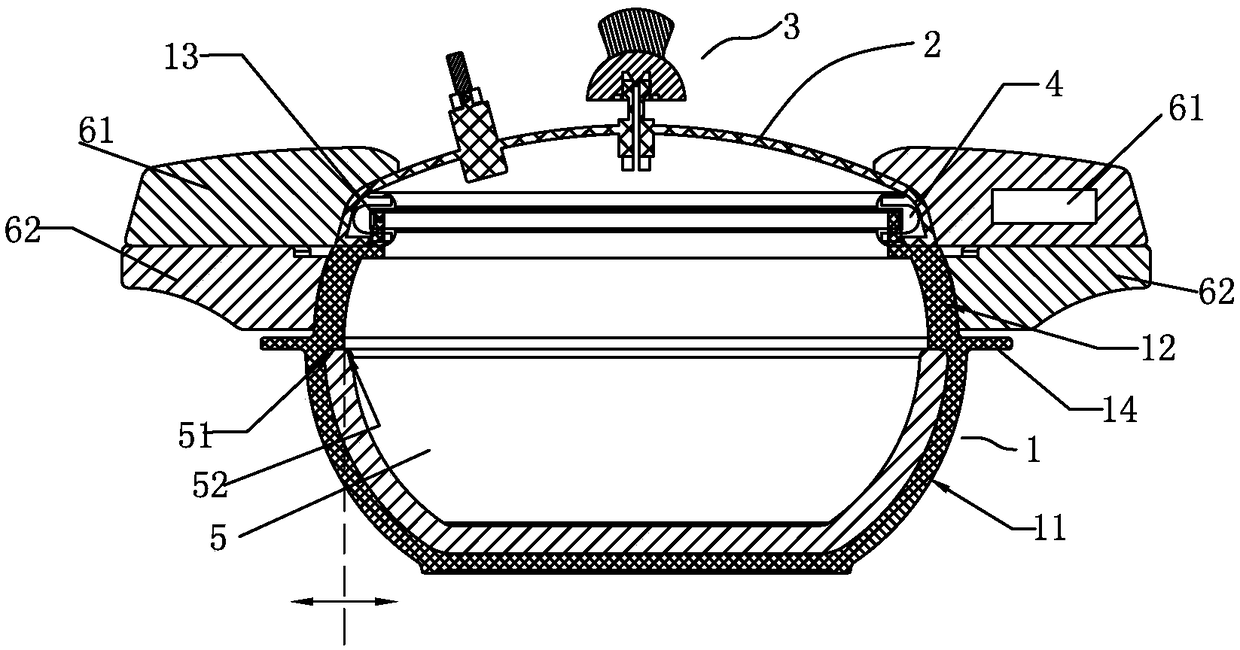

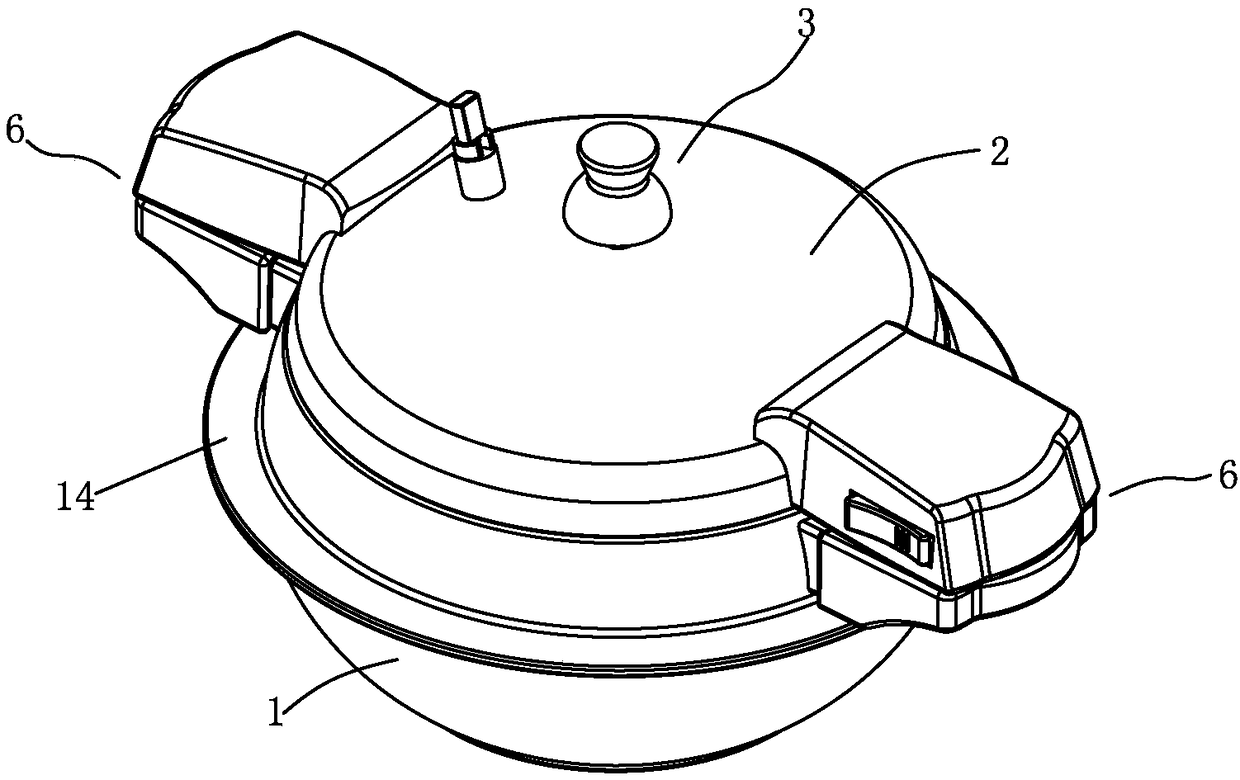

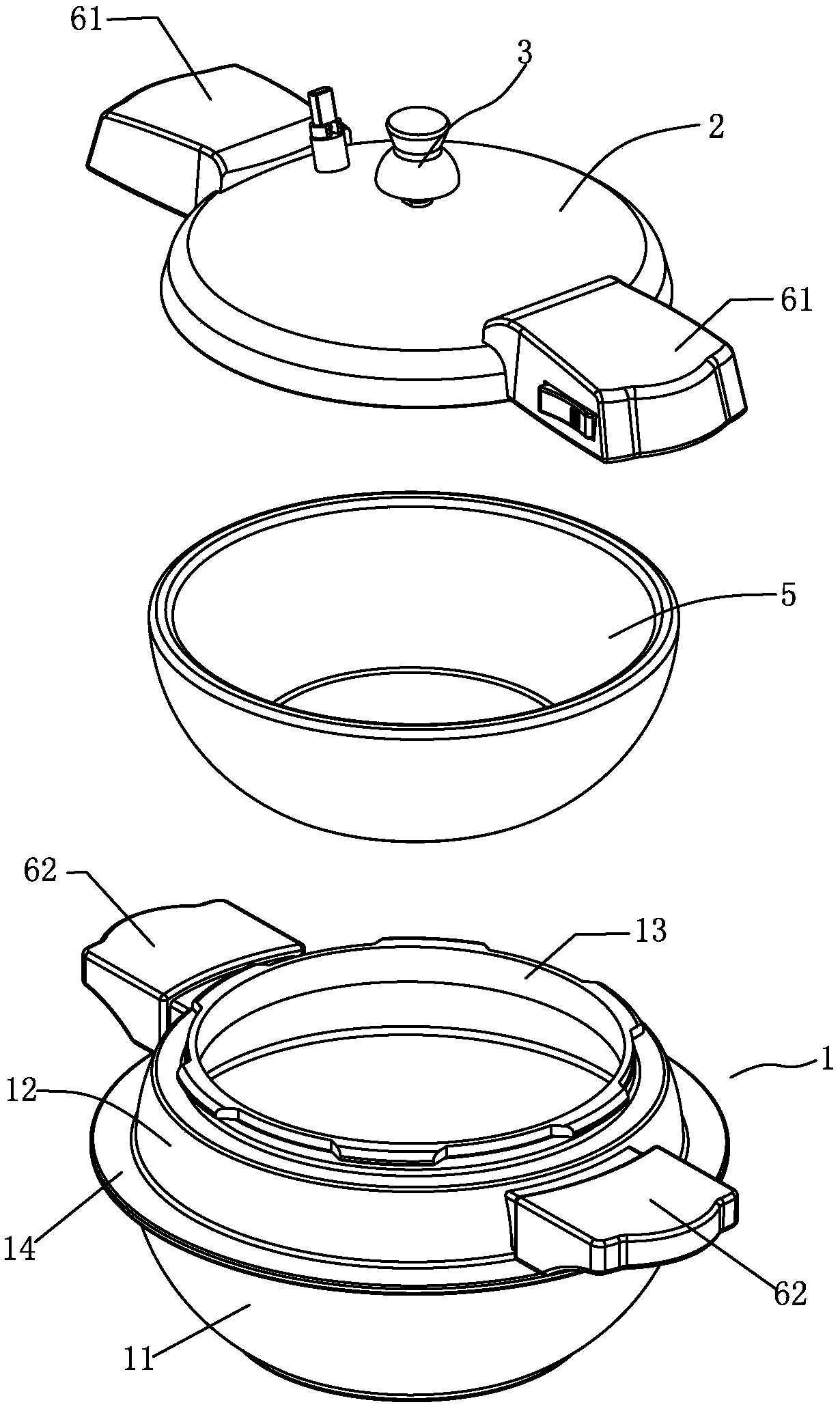

Pressure cooker

PendingCN108652431AKeep the smellPlay a role in breaking the wallCooking-vessel materialsPressure-cookersCooking & bakingMetallic materials

A pressure cooker comprises a body, a lid, a pressure relief valve arranged on the lid and a sealing ring arranged on the lid. Upper fastening threads of the lid are in screw fit with lower fasteningthreads on an opening in the body. The cooker further comprises an inner pot opening up and made of a non-metallic material and a heat conductive material. The body is made of aluminum or aluminum alloy with certain ductility, and comprises a lower wrapping portion, a steam chamber portion and an upper interface portion. The upper interface portion is provided with the lower fastening threads. Theinner pot is embedded in the lower wrapping portion. During use, a food material is located in the inner pot, a high temperature cooking area is formed in the inner pot, a high pressure high temperature heat source area is formed in the steam chamber portion, and a secondary high pressure and high temperature area is formed in the lid. During use, the high temperature cooking area is formed in the inner pot, a high temperature high pressure hot baking area is formed in a steam chamber, and a secondary high temperature high pressure hot baking area is formed in the lid. The inner pot is heatedto emit infrared rays, and the infrared rays break the long starch protein in the food material and achieve a wall-breaking effect. The original flavor of the food material can be effectively maintained, and the taste is effectively improved.

Owner:中山市家冠电气有限公司

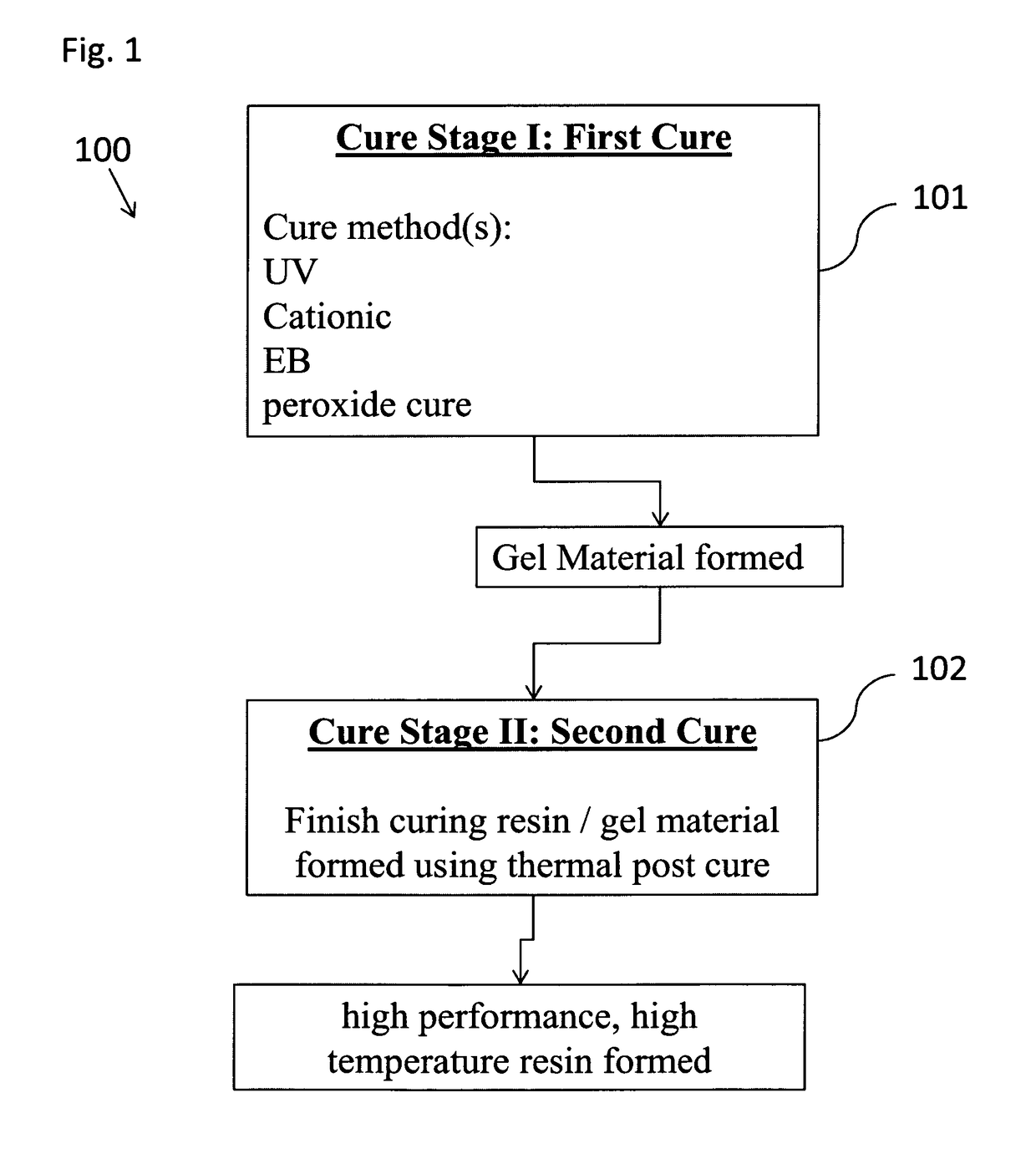

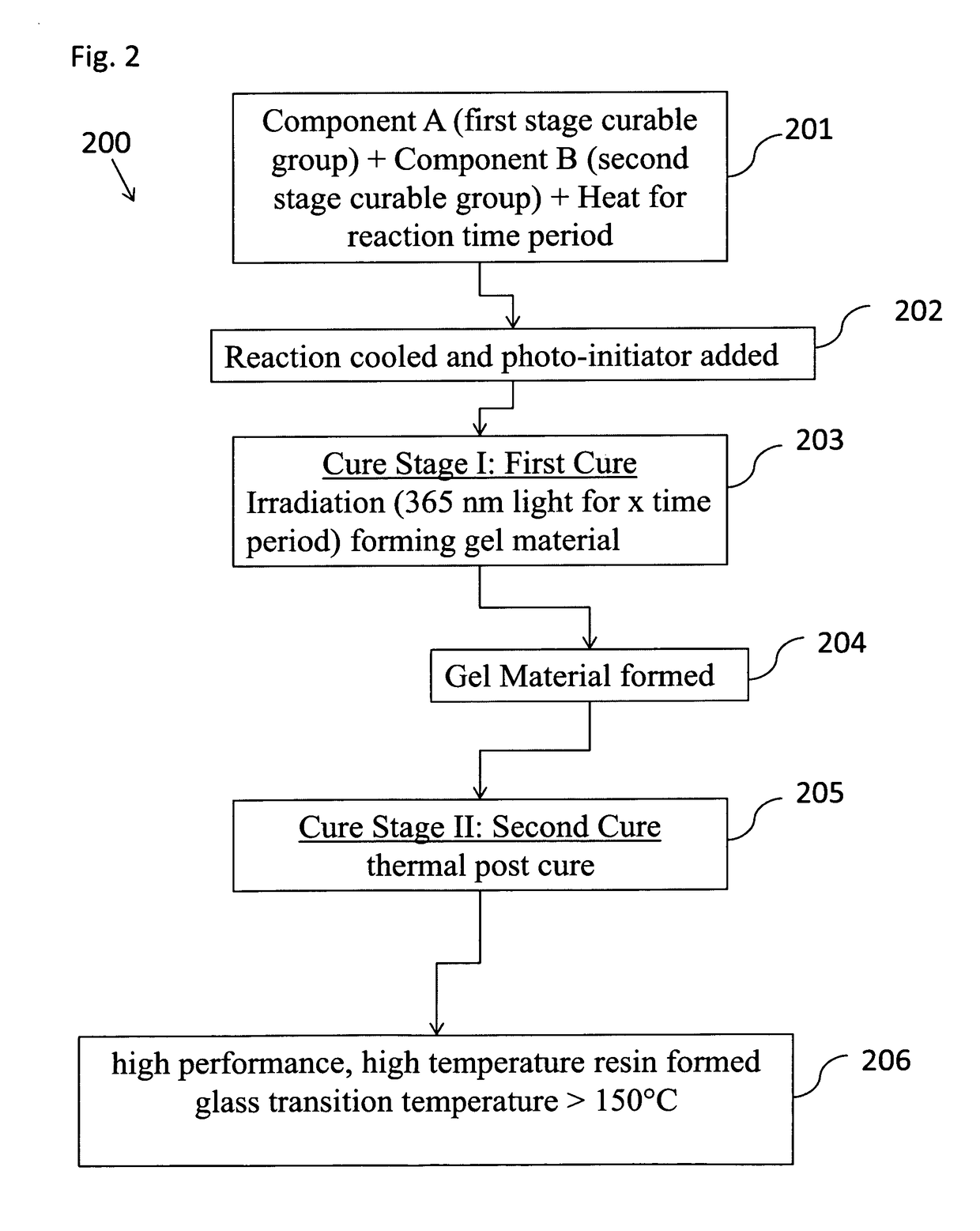

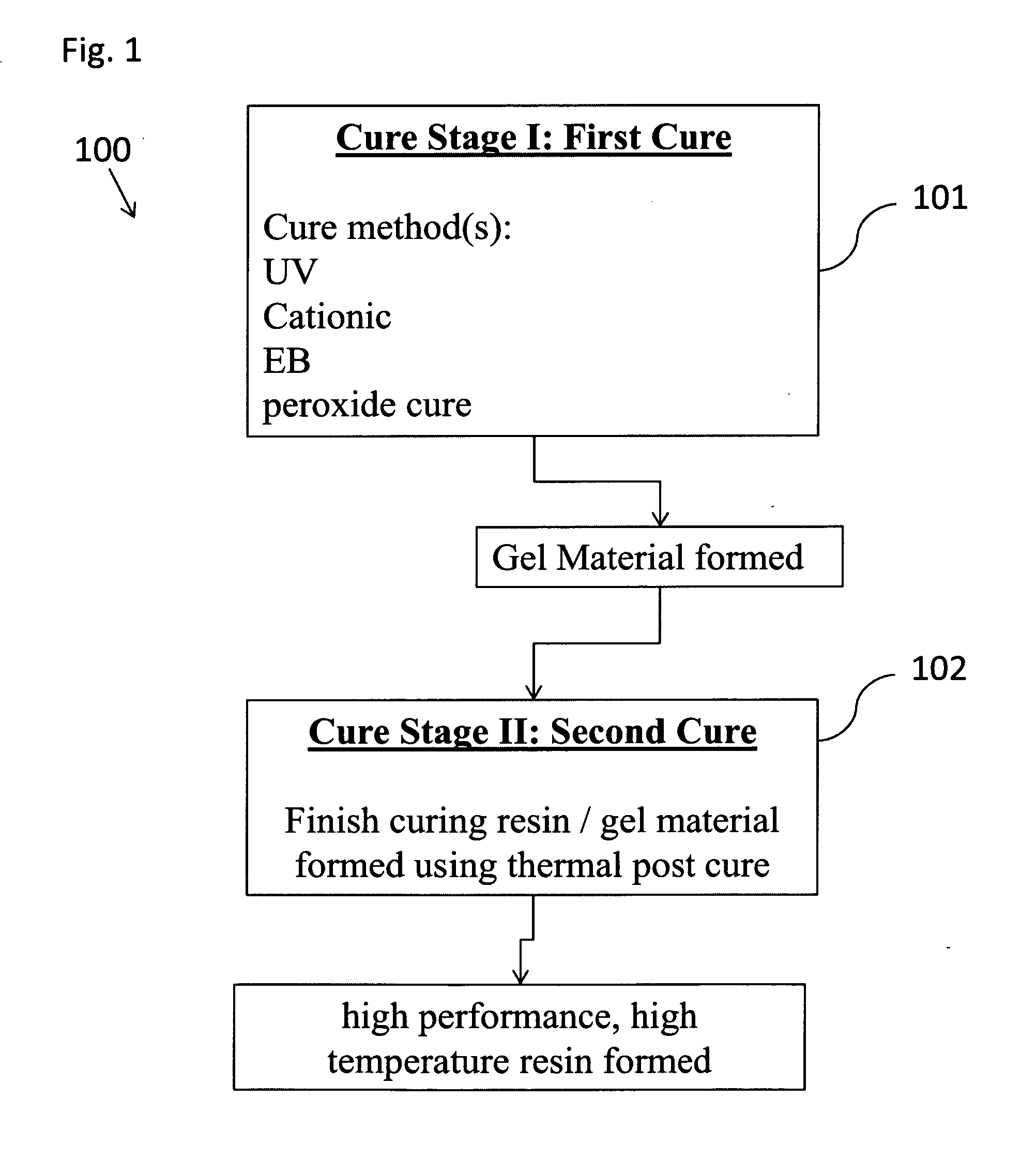

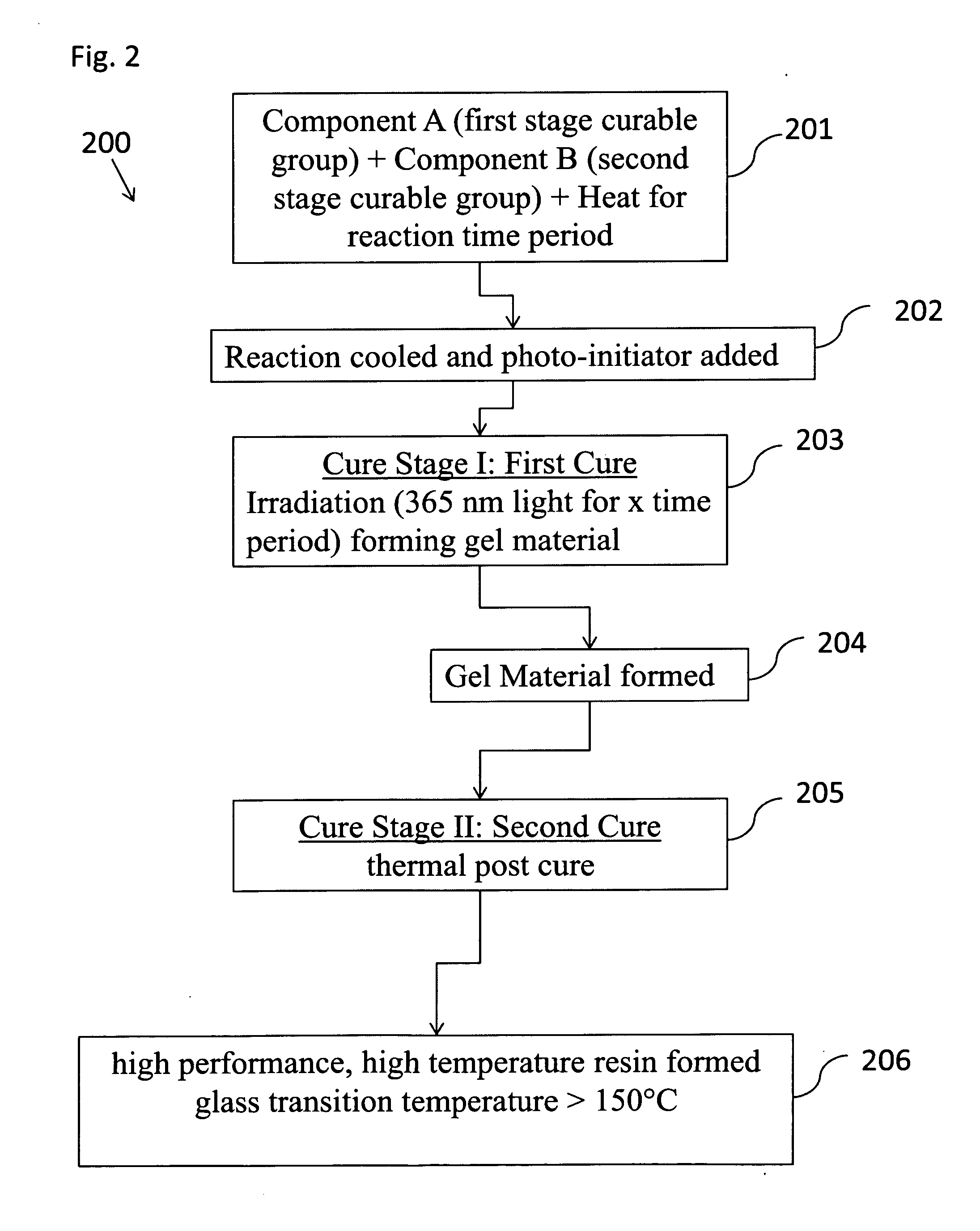

High temperature three dimensional printing compositions

ActiveUS9708440B2Improve performanceHigh-temperature resinAdditive manufacturing apparatusMetal catalystRoom temperature

A thermosetting resin composition has particular applications in three dimensional (3-D) printing. The thermosetting resin composition exhibits high performance and is characterized by a high temperature two stage cure resin composition. The thermosetting resin composition comprises cyanate esters and other high temperature resins, photo curable monomers, photo initiator, metal catalyst or ionic liquid catalyst. The thermosetting resin composition cures at room temperature to form 3-D objects and upon further post cure these objects exhibit high temperature properties enabling use at temperatures exceeding 150 C.

Owner:NOVOSET

High-temperature wearable composite dope for electric power boiler flue

The invention relates to a high-temperature wear-resistant composite coating for the flue of an electrical furnace, belonging to the high-temperature coating field. The invention enhances the strength and toughness of the material, improves the high-temperature performance of the material and forms mullite net compound structure under high temperature condition by using modern composite material principle and a coupling method by particle enhancing and fiber toughness increasing and adding high-performance material and using nano-compound powder as bonding and using hard high-strength particle as enhancer, further, the invention can also improves the volume stability and the rear resistant performance in high temperature, and prolongs service life. The invention is especially suitable for the flue of a furnace, and has the advantages of high refractoriness, wear-resistant performance, excellent high temperature performance, stable volume, high strength, good toughness, prolonging service life of the material, reducing maintenance times for the flue, and labor saving.

Owner:LUOYANG KENAI HIGH TEMPERATURE MATERIAL

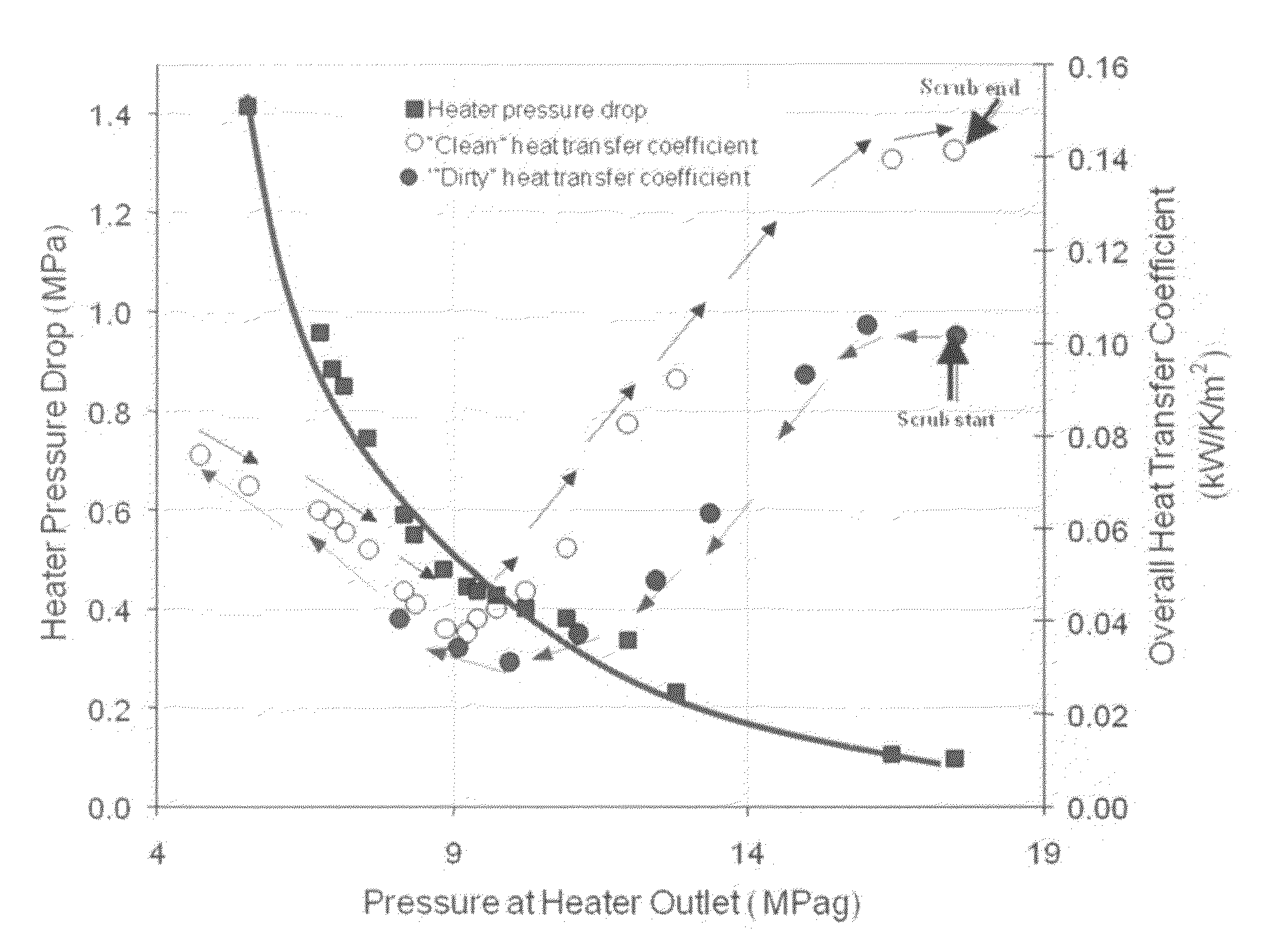

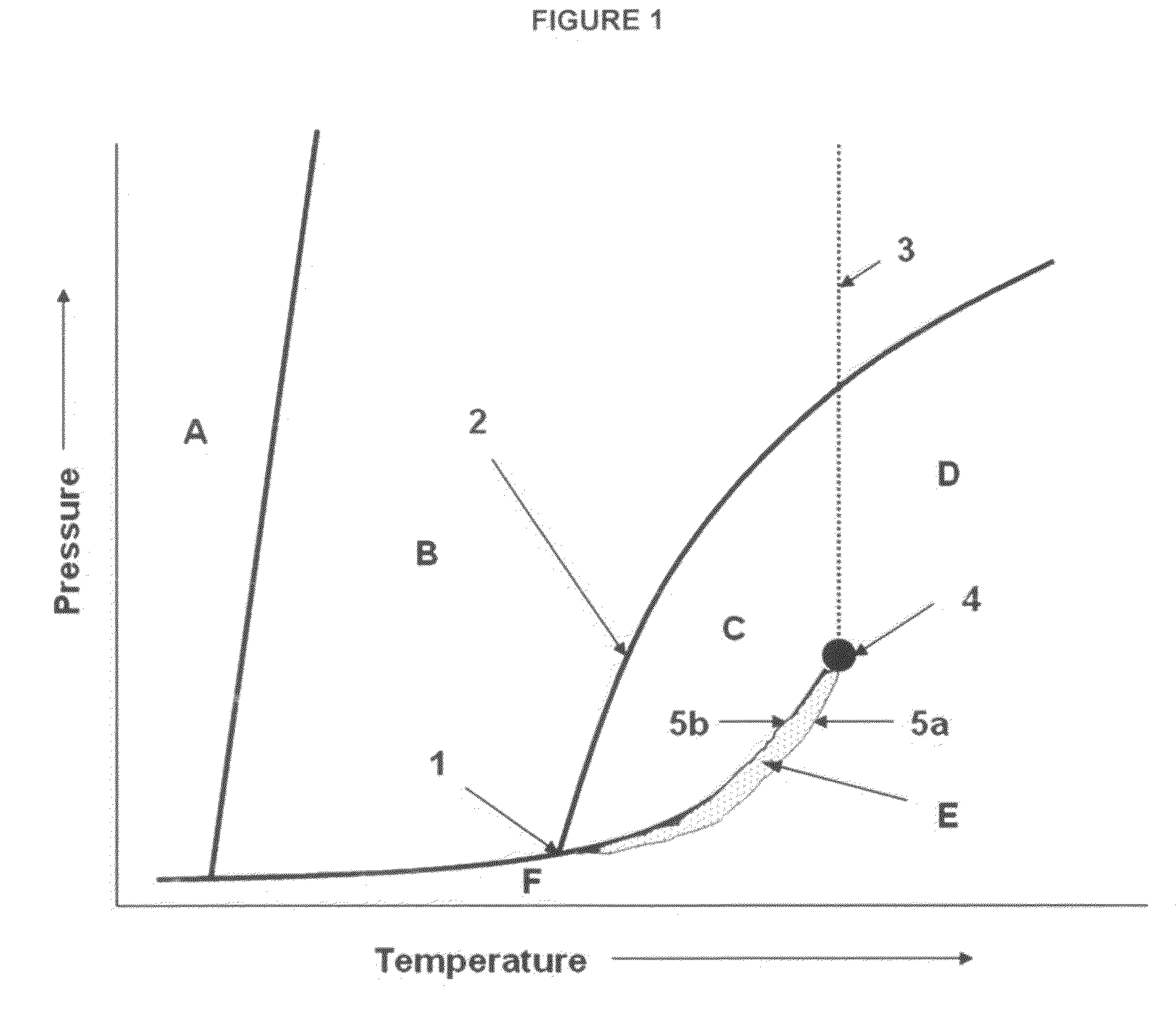

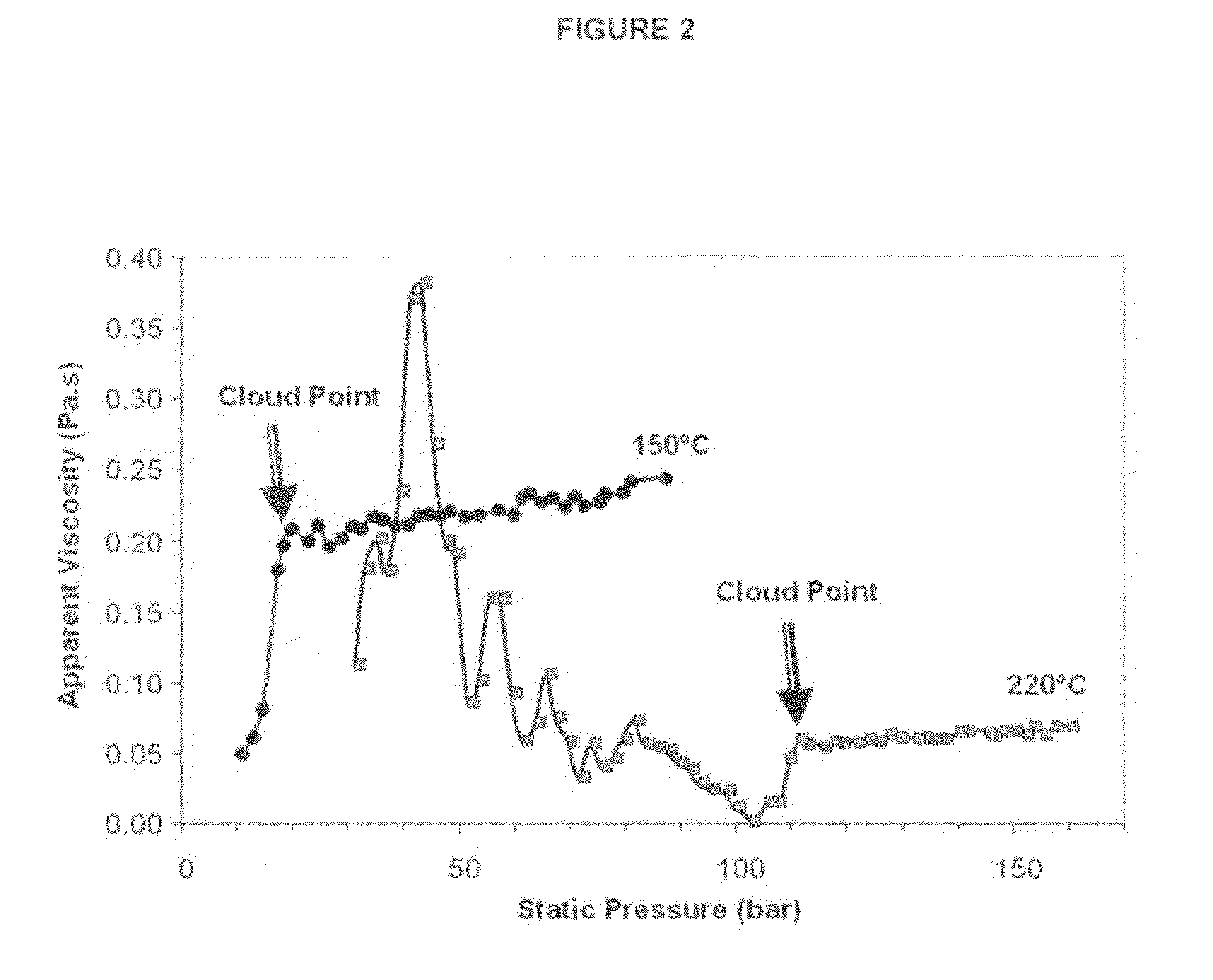

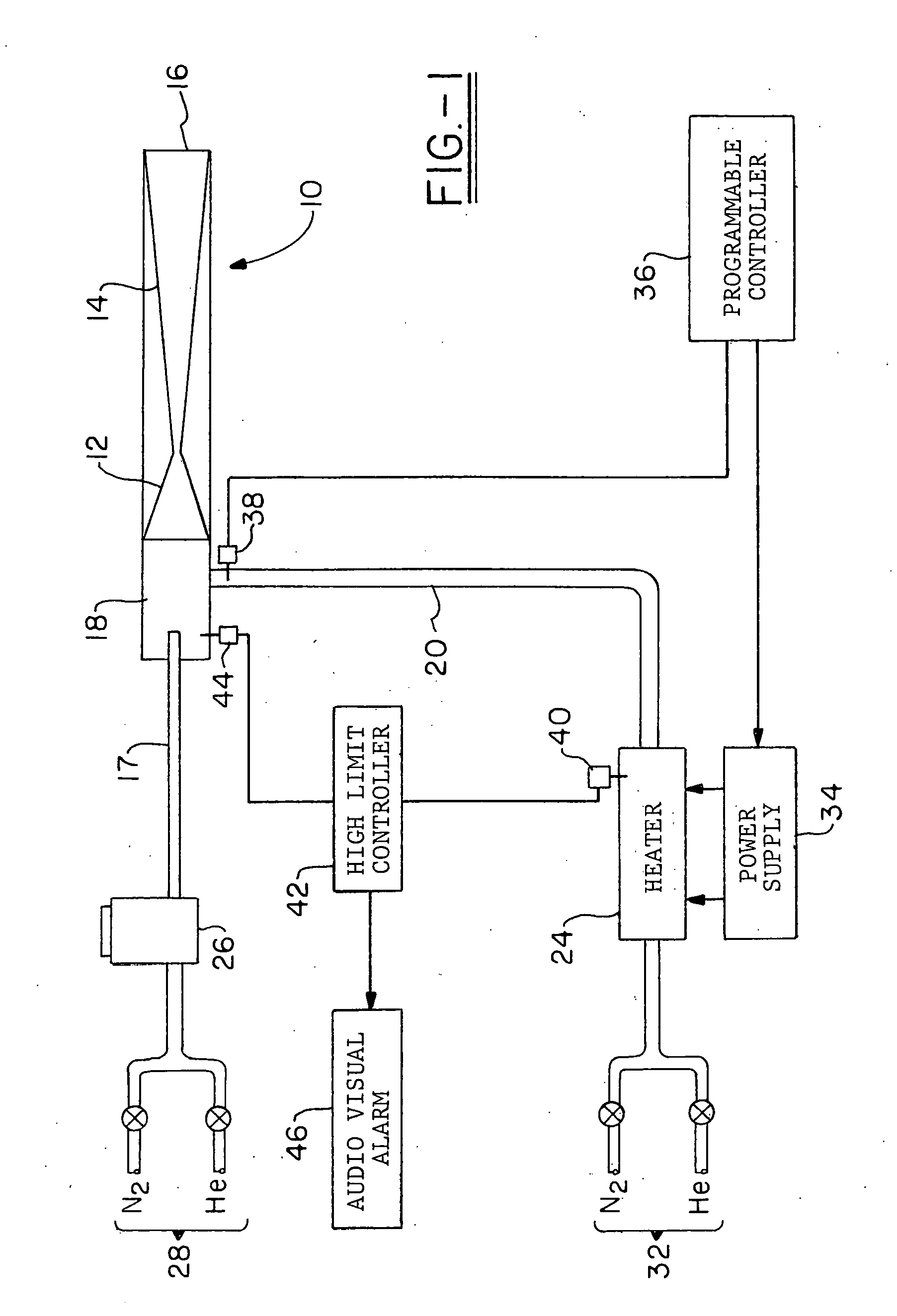

High temperature process for solution polymerization

ActiveUS7650930B2Avoid accumulationIncrease forceHollow article cleaningVapor condensationPlate heat exchangerEmulsion polymerization

A process for the solution polymerization of olefins with improved on-stream time is provided. The solution polymerization process of the current invention comprises a method for the on-line removal of foulant material from one or more heat exchangers downstream of a polymerization reactor. Removal of foulant material is accomplished by deliberately applying a positive pressure differential across a heat exchanger. In the process of the current invention, reactor shut down is not required for the purpose of cleaning foulant material from a heat exchanger.

Owner:NOVA CHEM (INT) SA

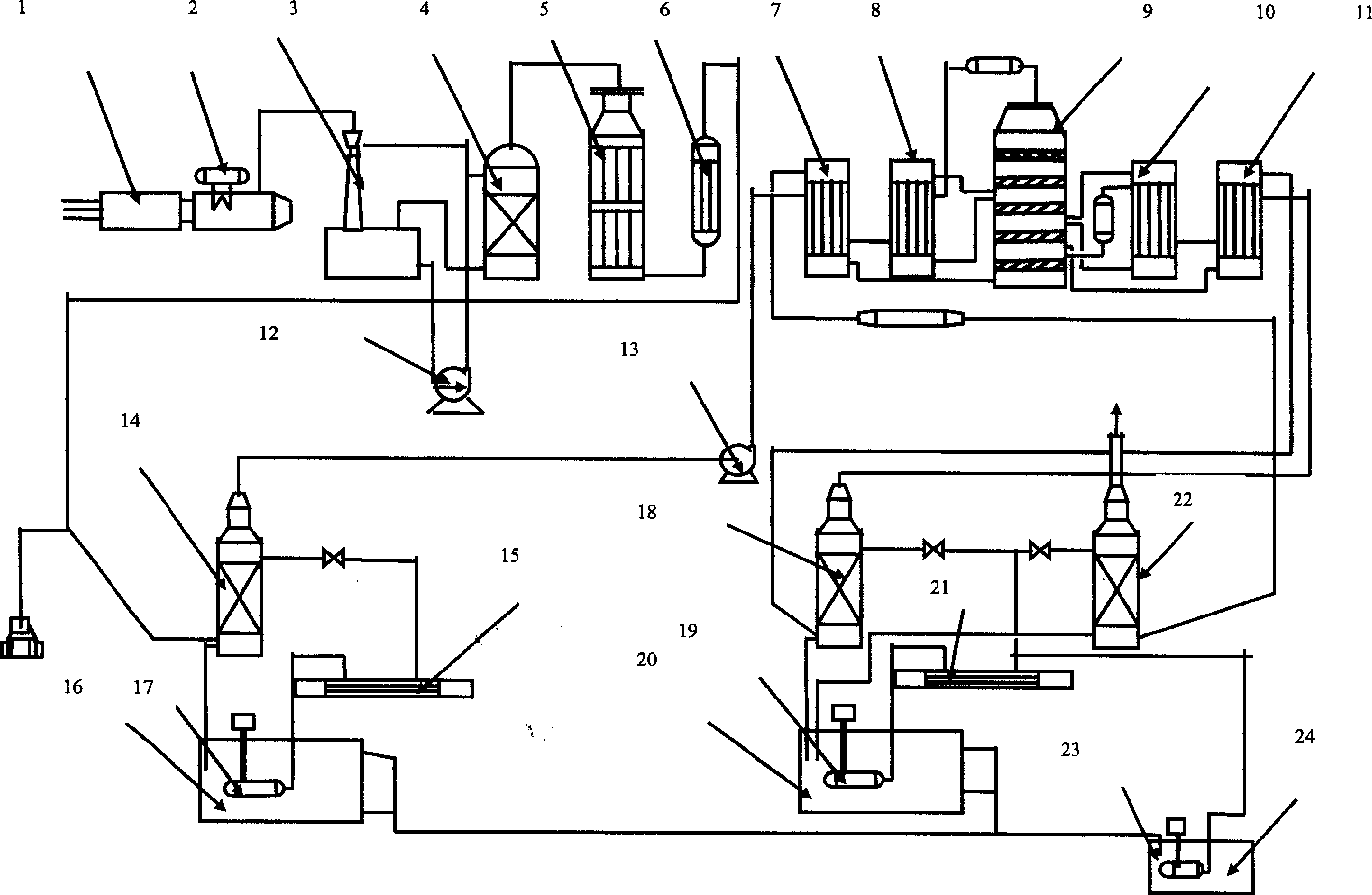

Treatment technology of producing sulfuric acid from alkylated spent sulfuric acid through high temperature decomposition

ActiveCN1751984ARealize lysis treatmentAvoid secondary pollutionSulfur-trioxide/sulfuric-acidDecompositionContact method

A process for preparing sulfuric acid from used alkylating sulfuric acid by high-temp cracking includes such steps as heating to 1000-1100 deg.C, cracking, acid washing for cleaning, converting twice by contact method, and absorbing twice to obtain qualified sulfuric acid for reuse. It has high recovering rate.

Owner:PETROCHINA CO LTD

Porous ceramic material and preparation method thereof

The invention discloses a porous ceramic material and a preparation method thereof. The invention comprises 5-50 portions of ceramic polishing waste, 20-50 portions of ceramic waste, 0-20 portions of ceramic clay, 0-15 portions of high temperature sand, 0-15 portions of low temperature sand by weight; the raw materials are mixed and water of 10-60 percent of the total weight of the raw materials is added, then 0-3 portions of grinding aids and 0-3 portions of binders are added and wet ball-milling is carried out; the mixture is pressed into a ceramic brick body and the invention can be obtained after the ceramic brick body is put into a ceramic roller kiln to be burned. The invention makes full of the ceramic waste and self foaming mechanism of the polishing brick waste, needs no foaming agent and can produce the porous ceramic material with light weight, low thermal conductivity and high strength. The invention has simple technique, the operation is easy to be controlled and the product has the functions of insulation, heat insulation, sound proof and fire proof, etc.

Owner:SOUTH CHINA UNIV OF TECH

High temperature resistant and pressure change resistant fireproof flame retardant thermal insulation material and preparation method and application thereof

The invention discloses a high temperature resistant and pressure change resistant fireproof flame retardant thermal insulation material and a preparation method and application of the high temperature resistant and pressure change resistant fireproof flame retardant thermal insulation material. The high temperature resistant and pressure change resistant fireproof flame retardant thermal insulation material comprises the following components in parts by weight: 20-45 parts of a matrix material, 15-40 parts of a reinforcing material, 10-30 parts of thermal insulation filler, 5-25 parts of a flame retardant, 2-10 parts of a lubricant, 1-5 parts of a coupling agent, 0-2 parts of a vulcanizing agent and 0-5 parts of other additives. The invention further provides a thermal insulation plate and a battery pack, wherein the thermal insulation plate is made of the high temperature resistant and pressure change resistant fireproof flame retardant thermal insulation material. The battery pack comprises a plurality of batteries arranged together, and the adjacent batteries of the battery pack are separated by the thermal insulation plate. The high temperature resistant and pressure change resistant fireproof flame retardant thermal insulation material has the excellent properties of pressure change resistance at the high temperature, thermal insulation at the high temperature, flame retardancy, rapidly porcelain preparation and the like.

Owner:常州市沃科科技有限公司

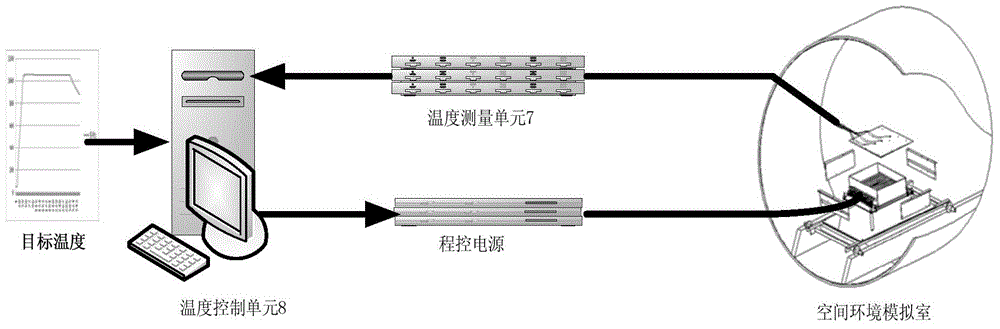

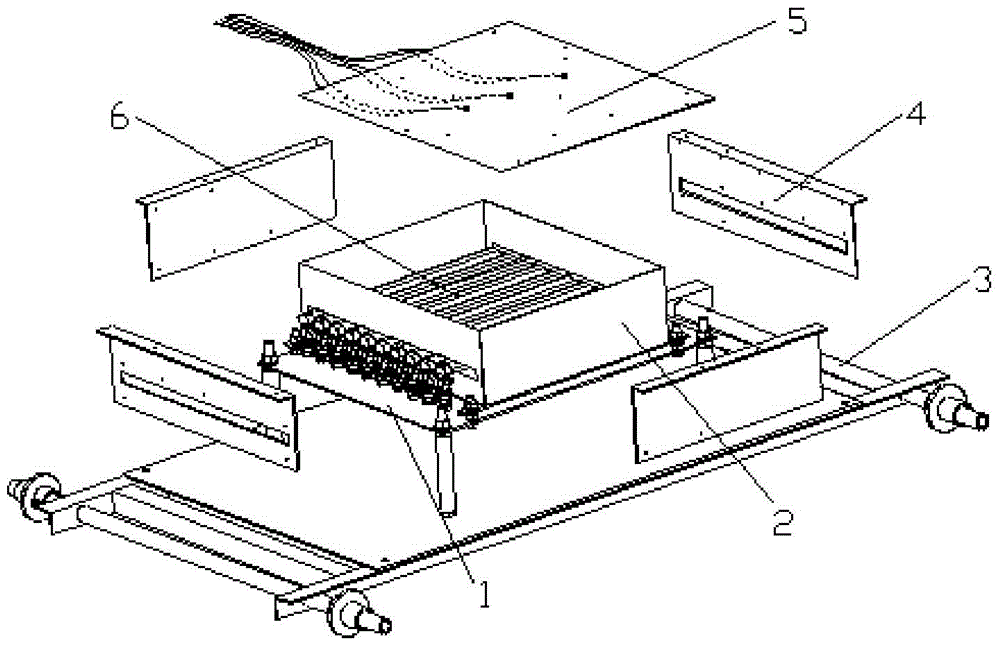

High heat flow simulator for spacecraft vacuum heat tests

InactiveCN103600851ASolve high temperatureSolve the technical difficulties of high heat flow simulationCosmonautic condition simulationsAircraft components testingHeat fluxInfrared lamp

The invention discloses a high-temperature high heat flow simulator for spacecraft vacuum heat tests in a space environment simulating chamber. The simulator mainly comprises infrared light arrays, a high-temperature insulation component unit, moving units, a temperature measuring unit and a temperature controlling unit. A plurality of infrared lights in the infrared light arrays are provided with reflective screens, the infrared lights are arrayed and combined to form the infrared light arrays according to requirements of heat flux density and uniformity, baffles surround the periphery of the infrared light arrays, high-temperature multi-layer insulation components are mounted among the infrared lights, a mounting baseplate and the baffles, and a high temperature region is limited in region formed through specimen irradiated face and the infrared light array high-temperature insulation components. According to the high-temperature high heat flow simulator, by means of unique design of the infrared light arrays and the high-temperature insulation components, technical difficulties of high-temperature high heat flow simulation when vacuum heat tests are performed on a spacecraft are solved, high-temperature high heat flow space environment can be simulated when vacuum heat tests are performed on spacecrafts in series of deep space exploration and space shuttles, and the spacecrafts can be tested.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

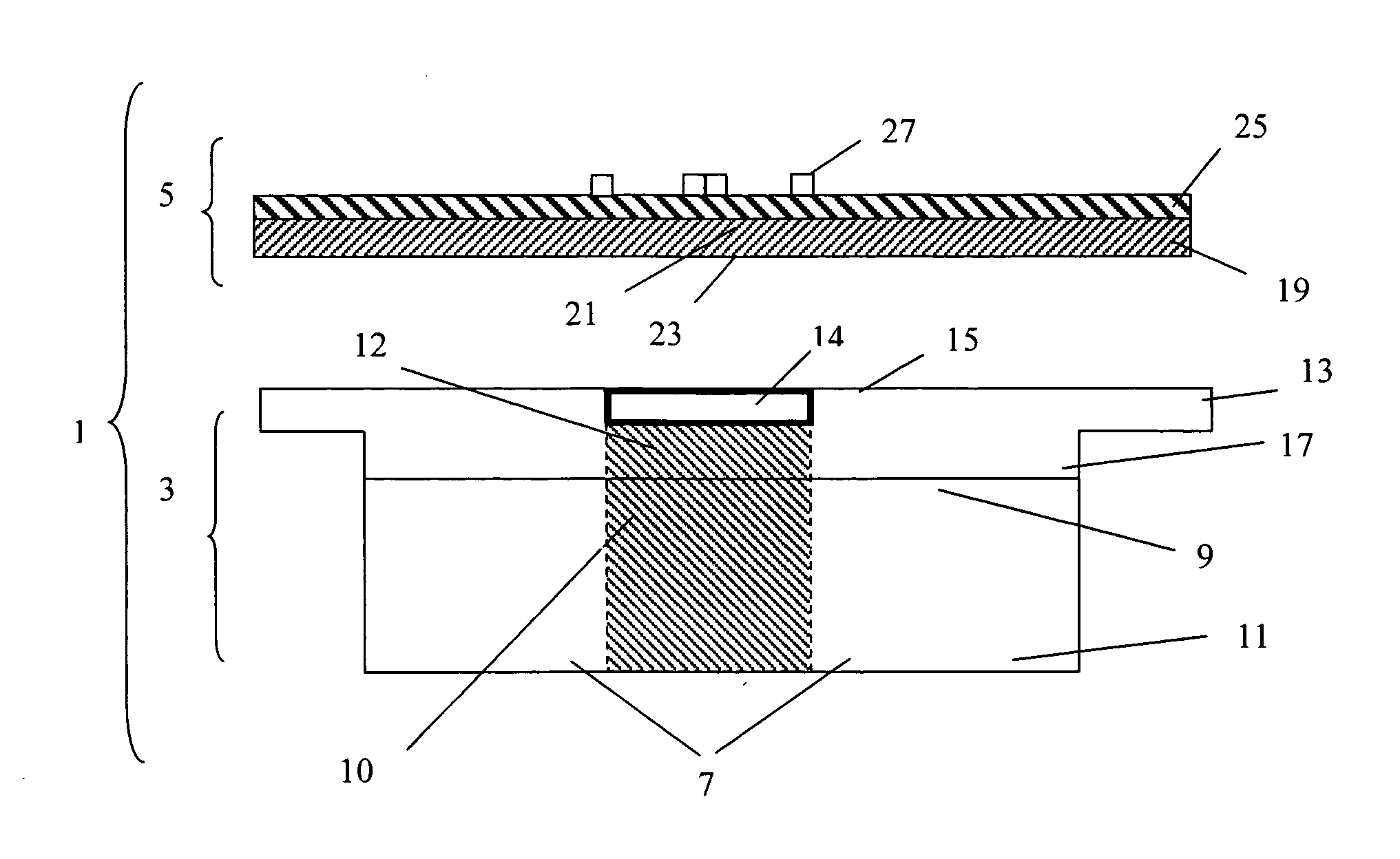

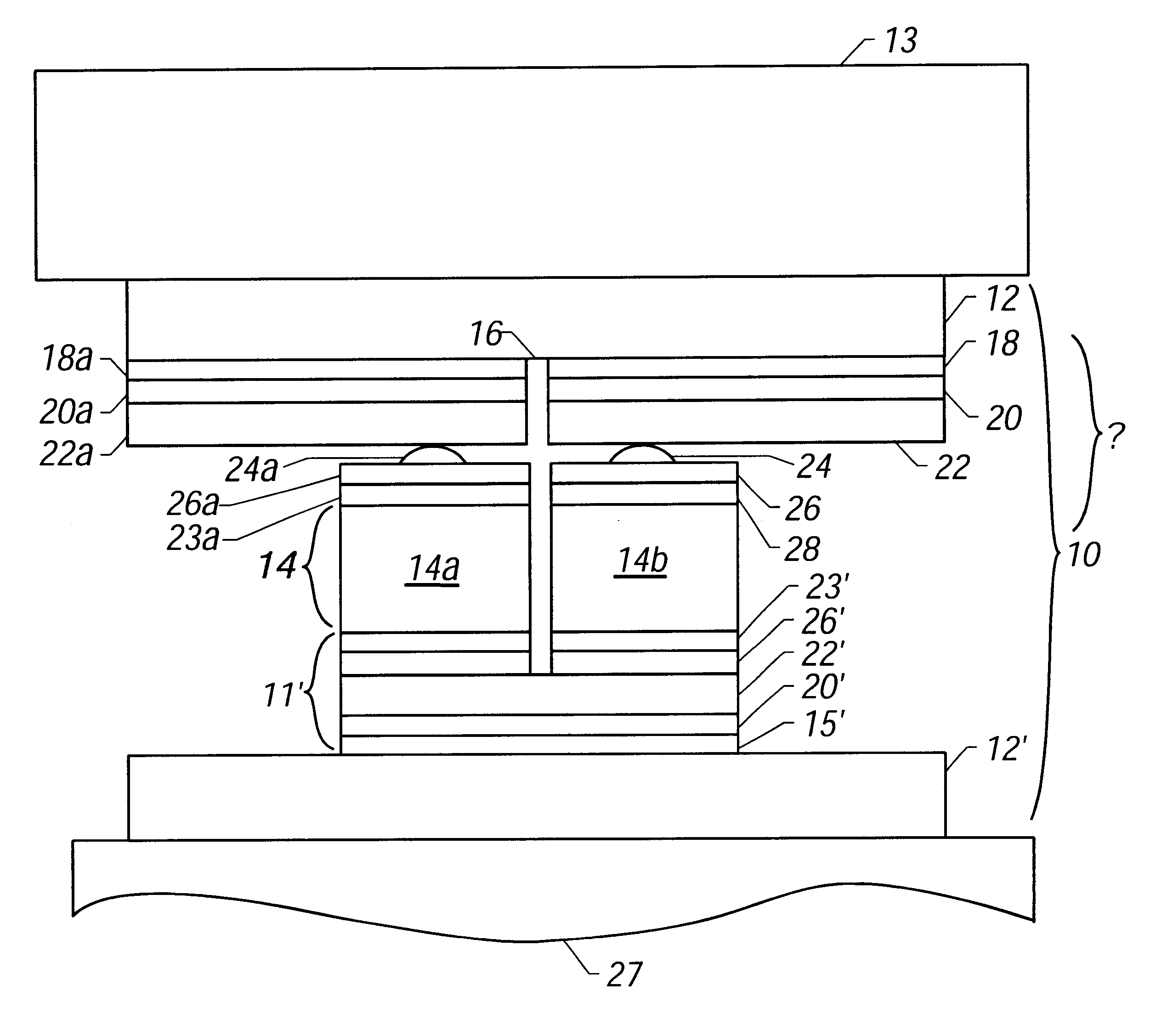

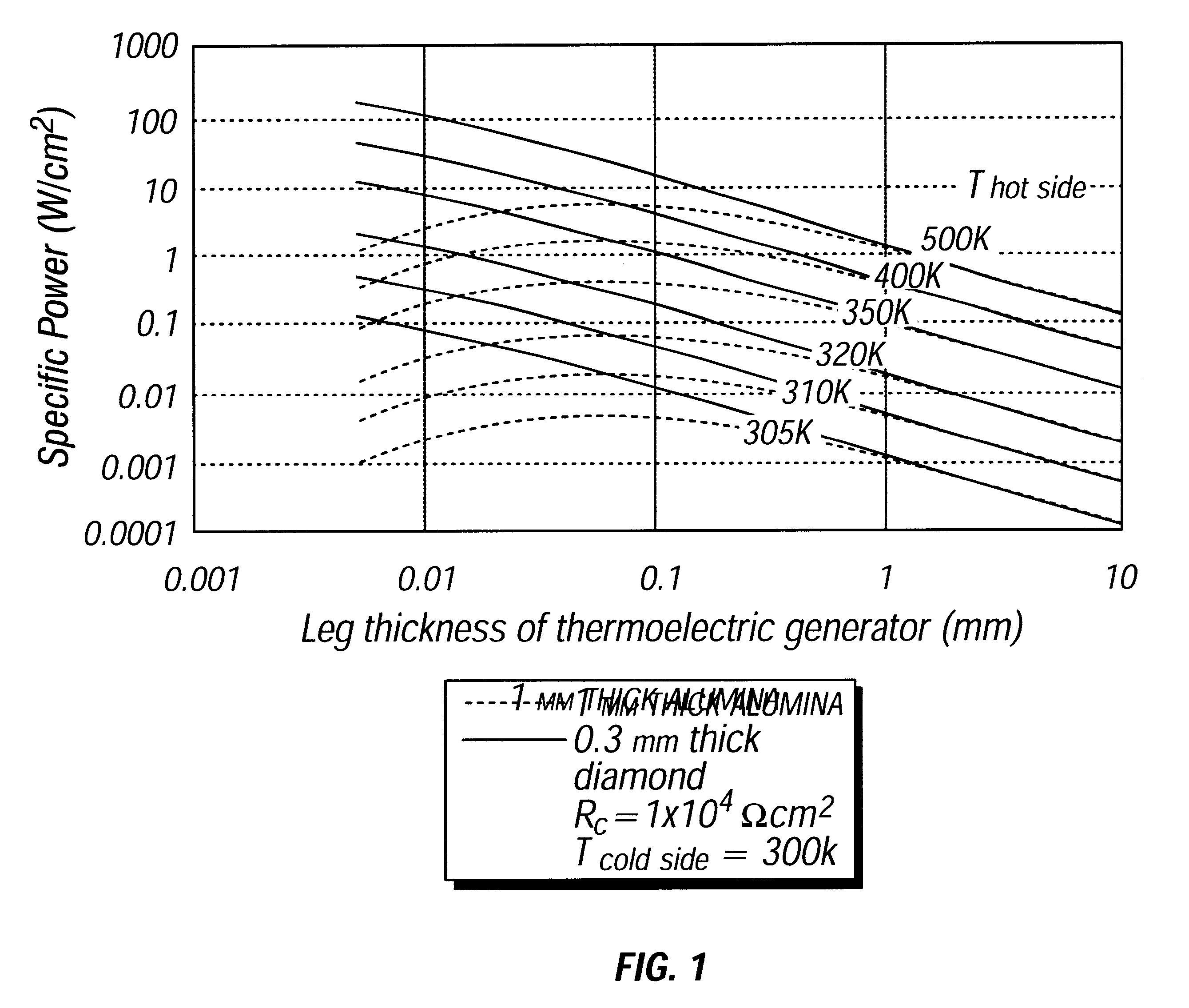

Electronic device featuring thermoelectric power generation

InactiveUS6288321B1Small sizeThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsHeat conducting

A device for generating power to run an electronic component. The device includes a heat-conducting substrate (composed, e.g., of diamond or another high thermal conductivity material) disposed in thermal contact with a high temperature region. During operation, heat flows from the high temperature region into the heat-conducting substrate, from which the heat flows into the electrical power generator. A thermoelectric material (e.g., a Bi2Te3-based film or other thermoelectric material) is placed in thermal contact with the heat-conducting substrate. A low temperature region is located on the side of the thermoelectric material opposite that of the high temperature region. The thermal gradient generates electrical power and drives an electrical component.

Owner:CALIFORNIA INST OF TECH

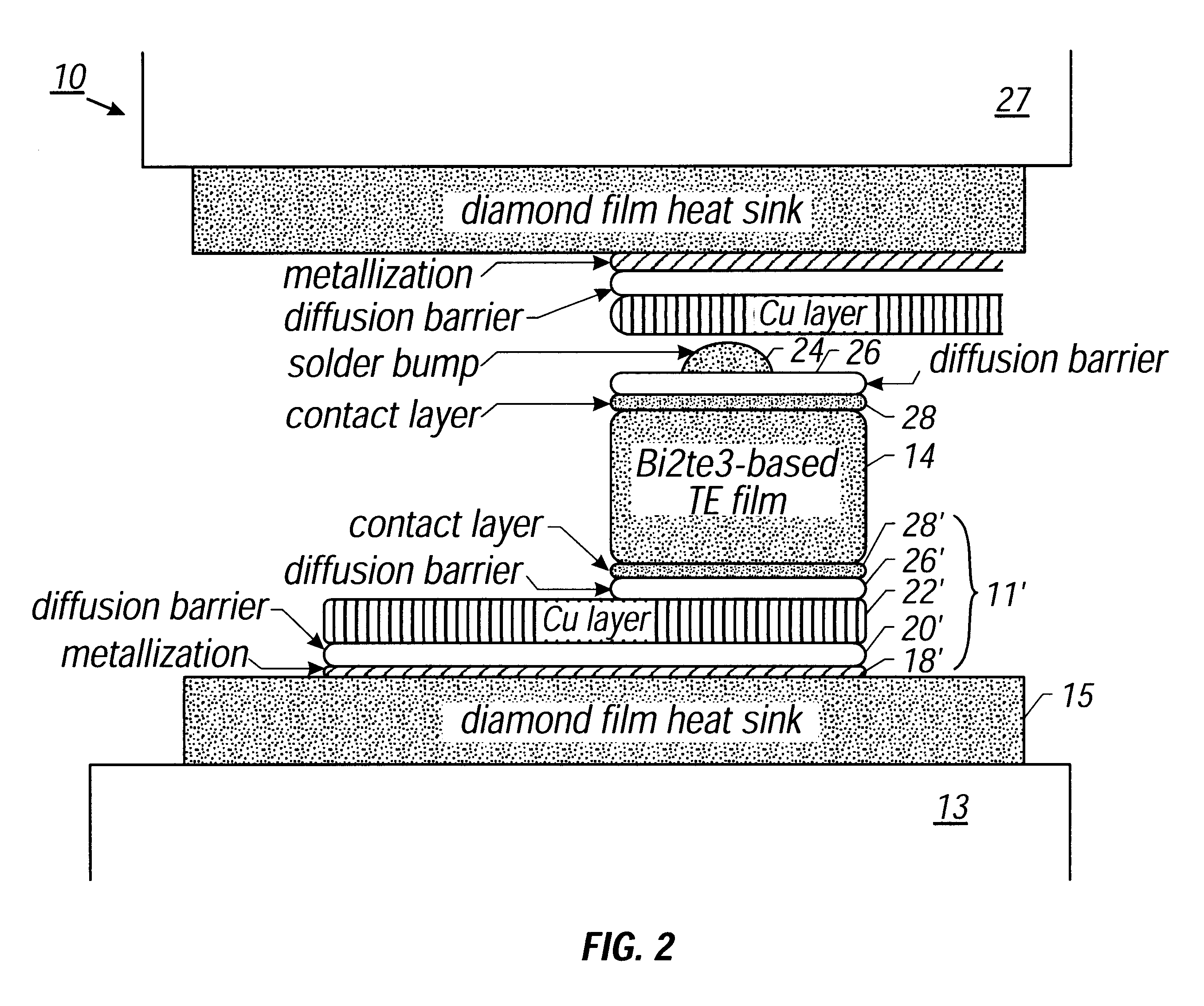

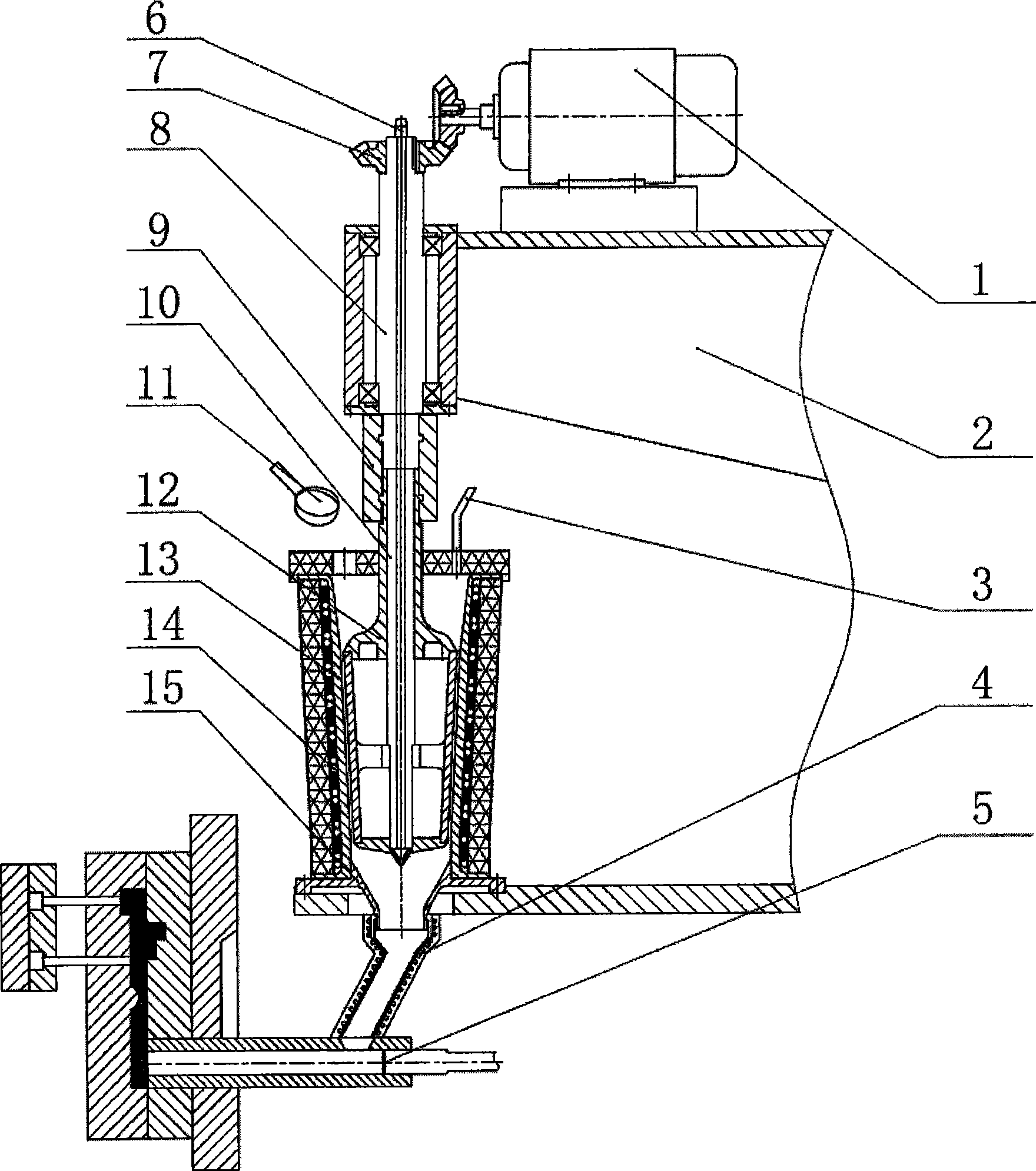

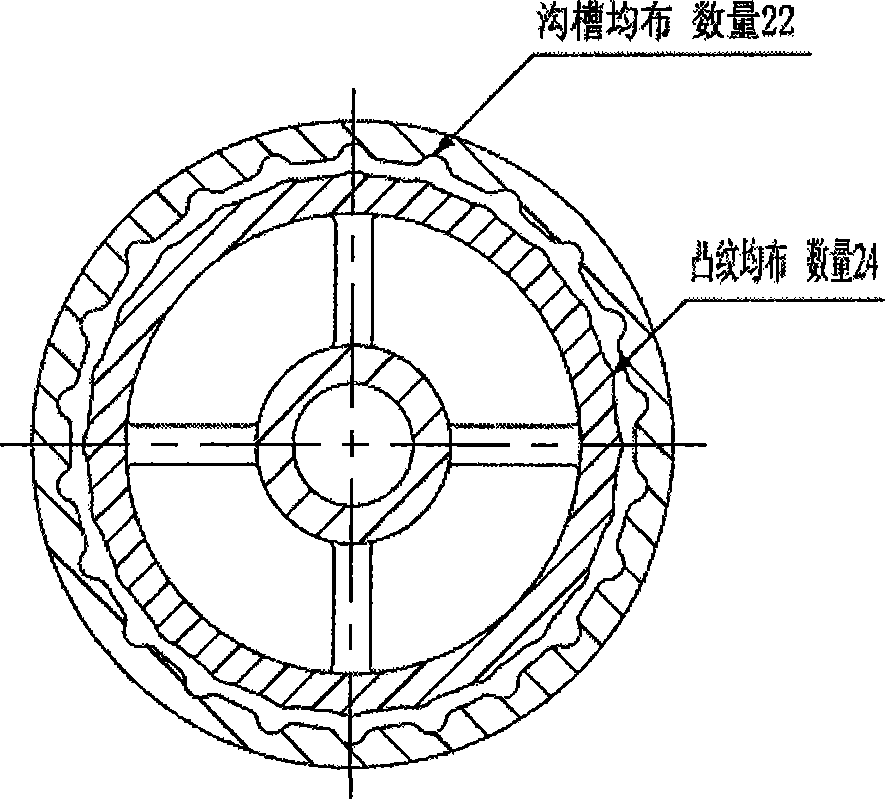

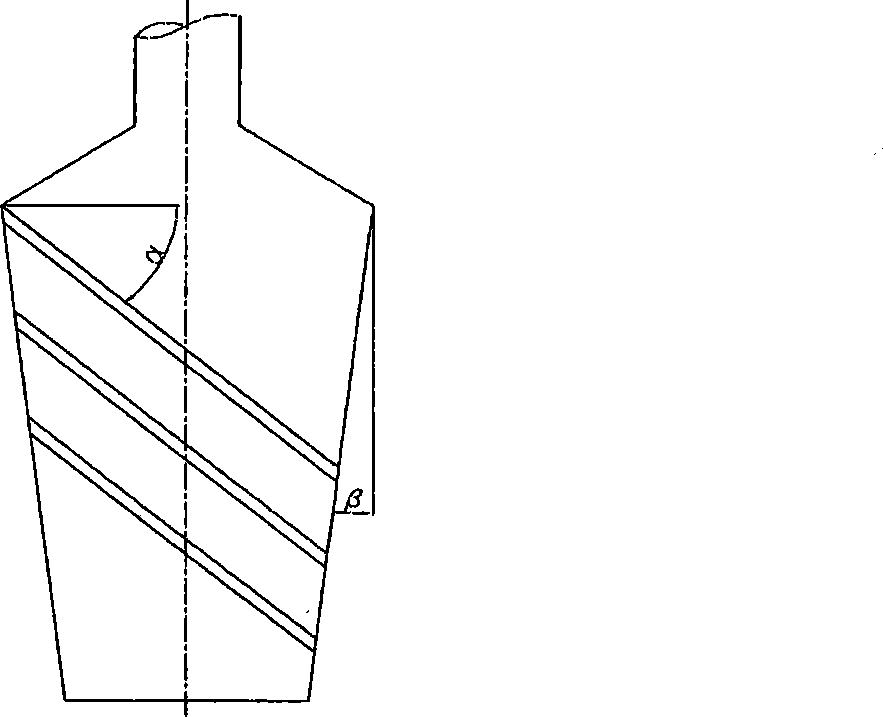

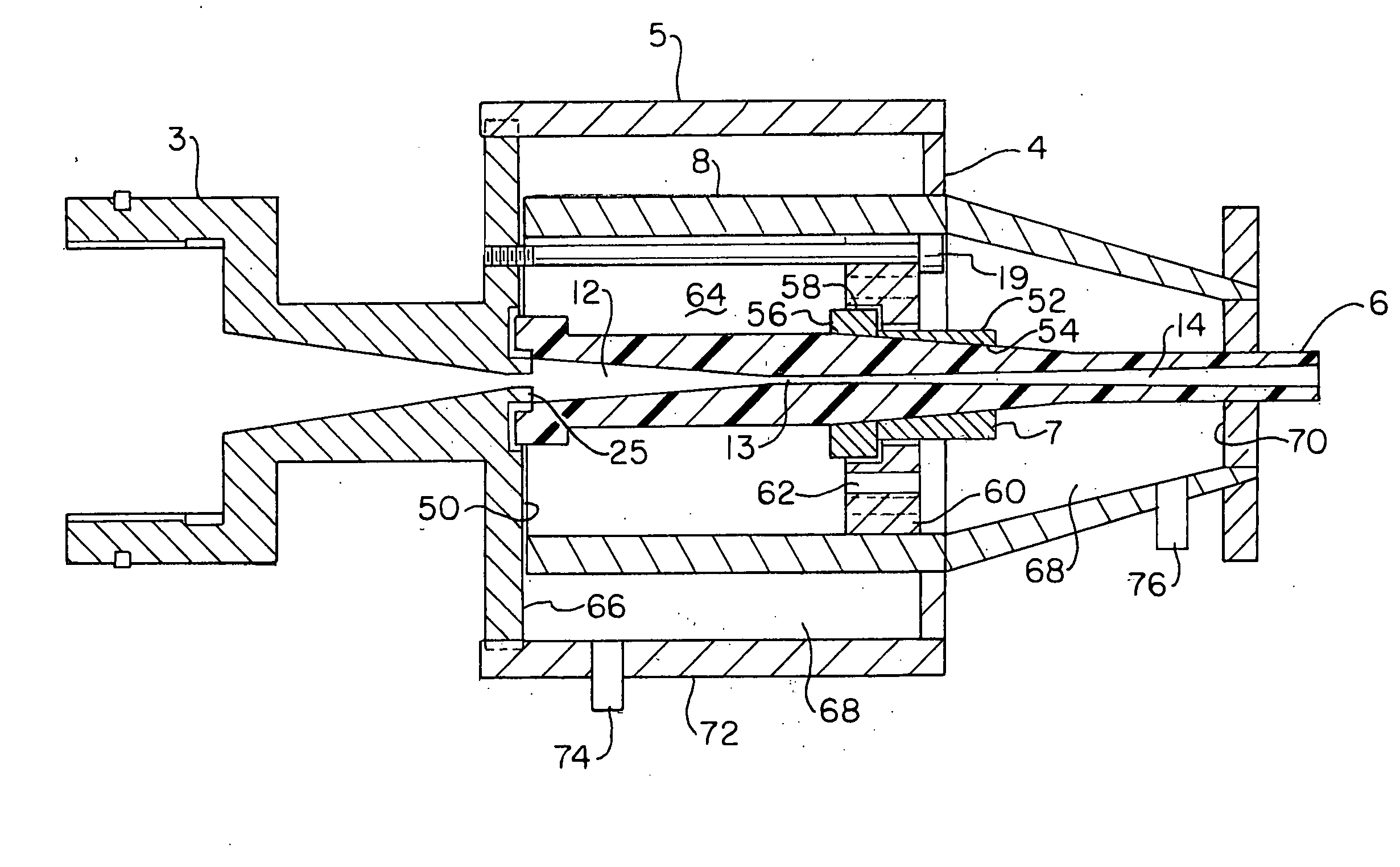

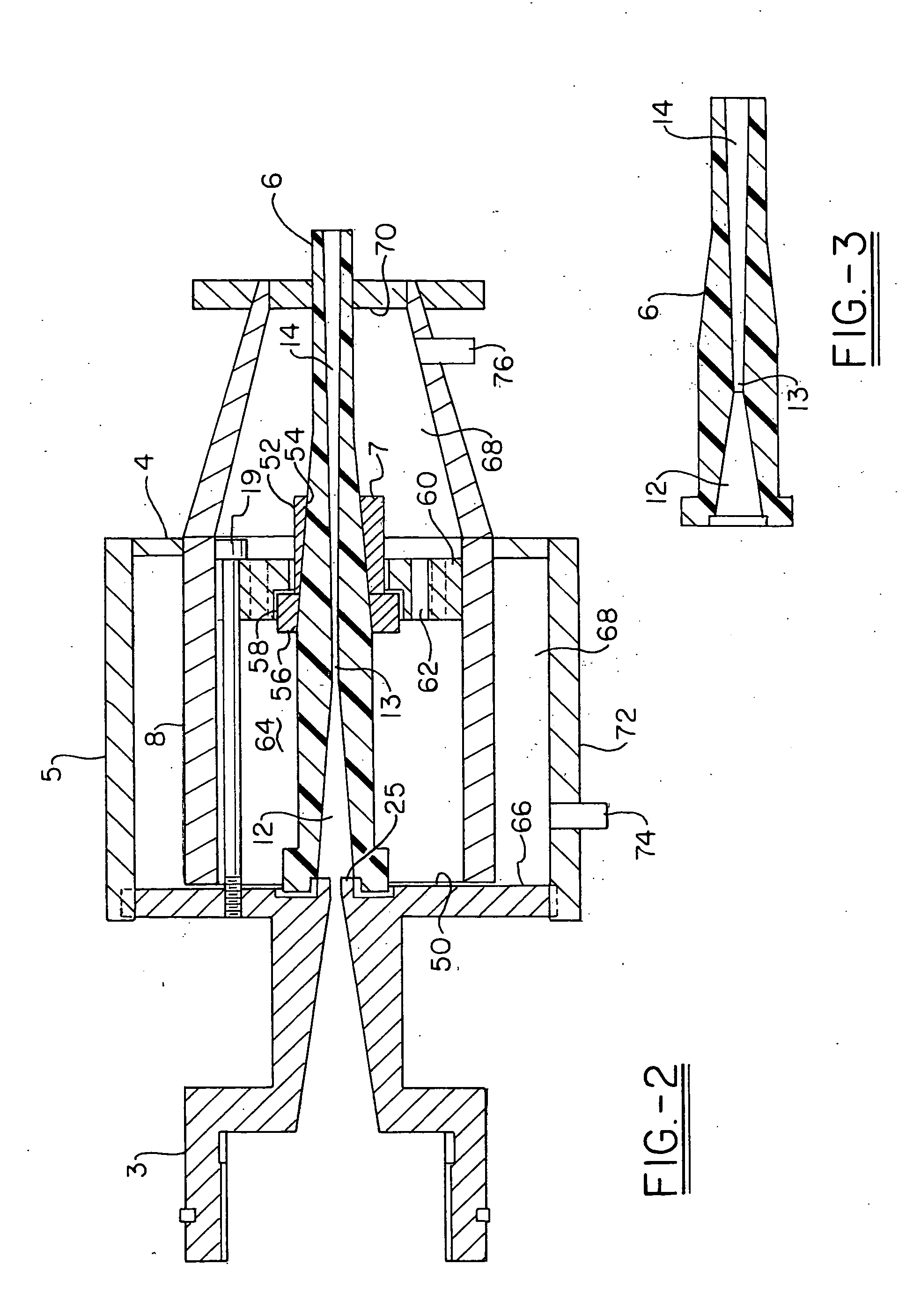

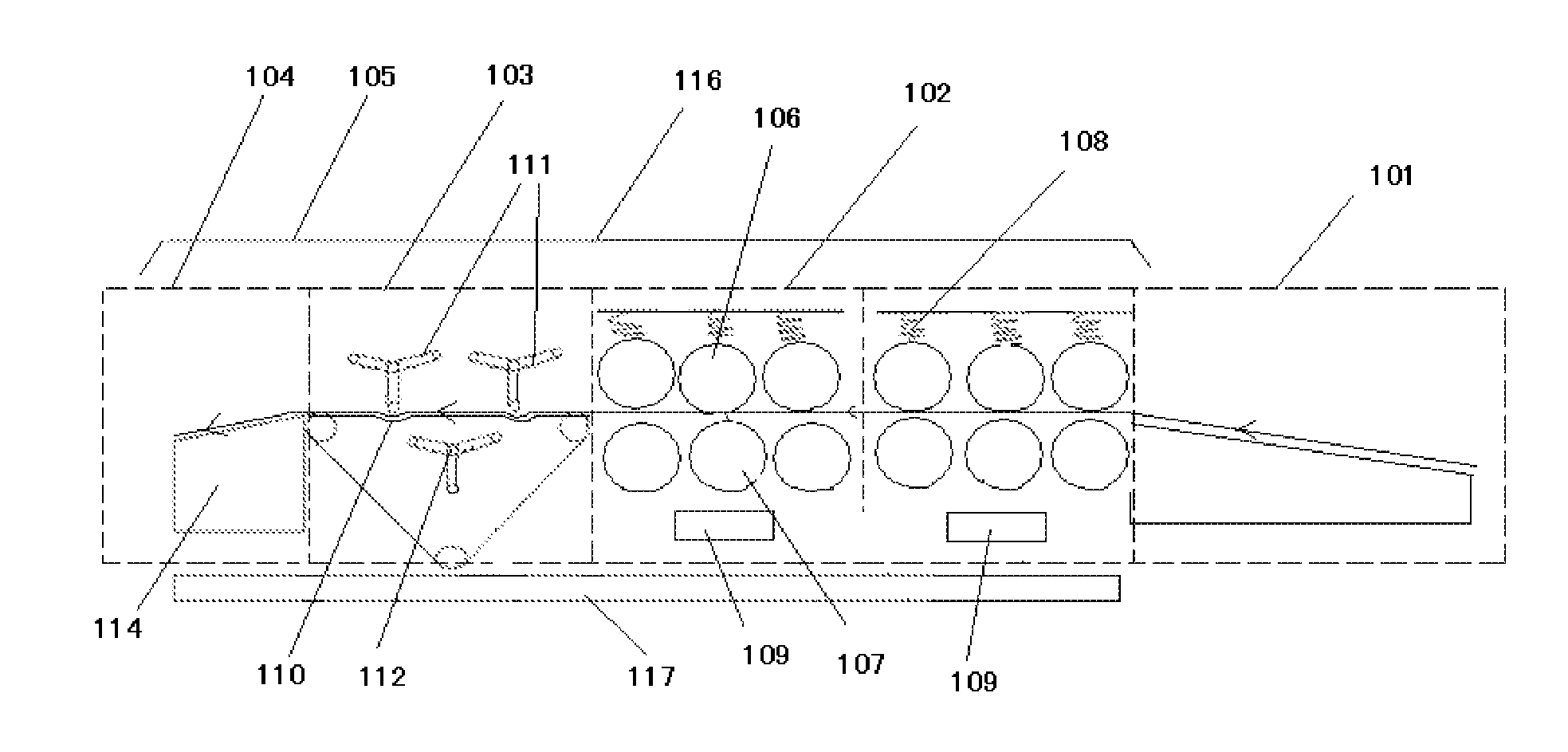

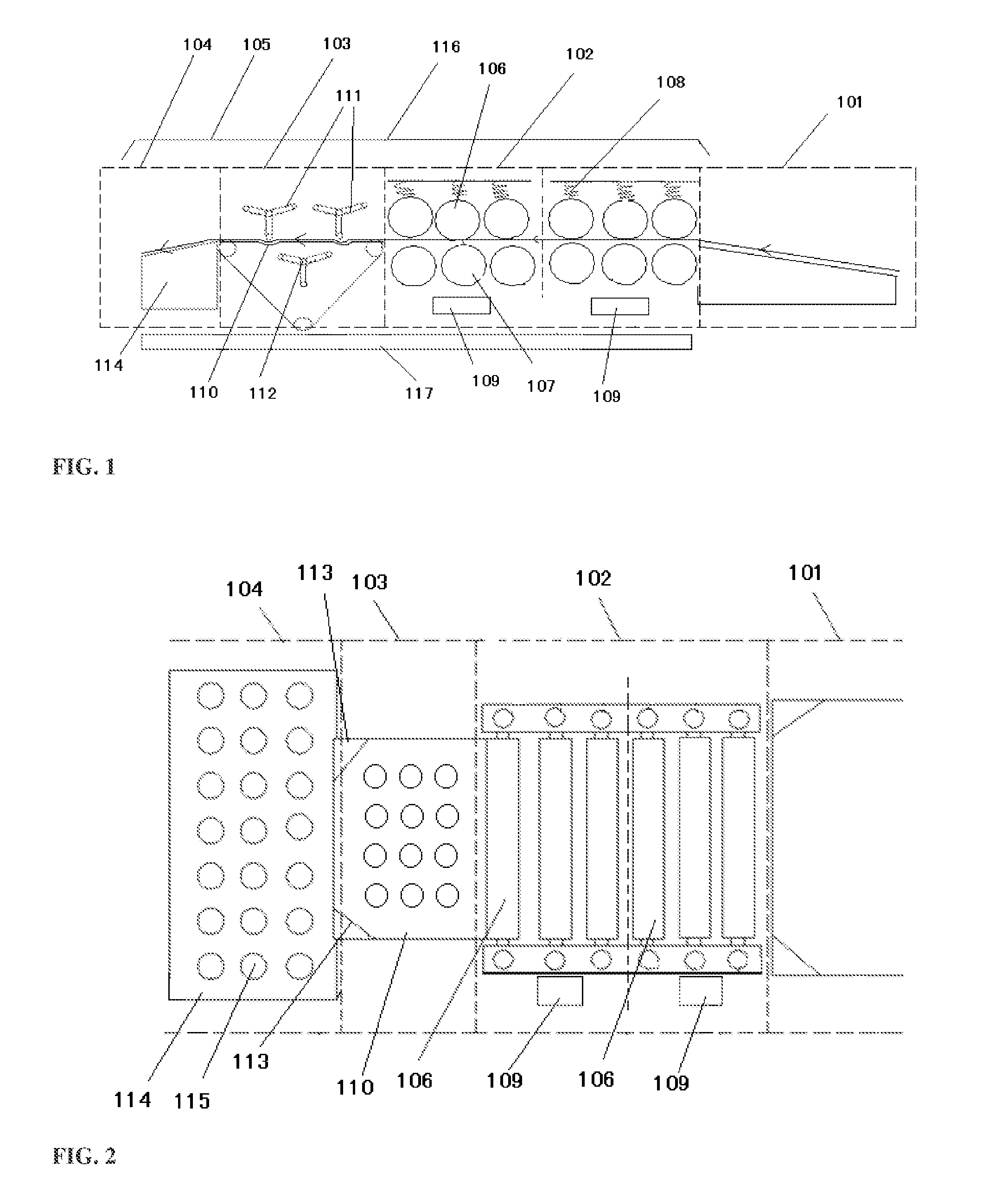

Suspension cone bucket type semi-solid metal slurry preparation and conveyor device

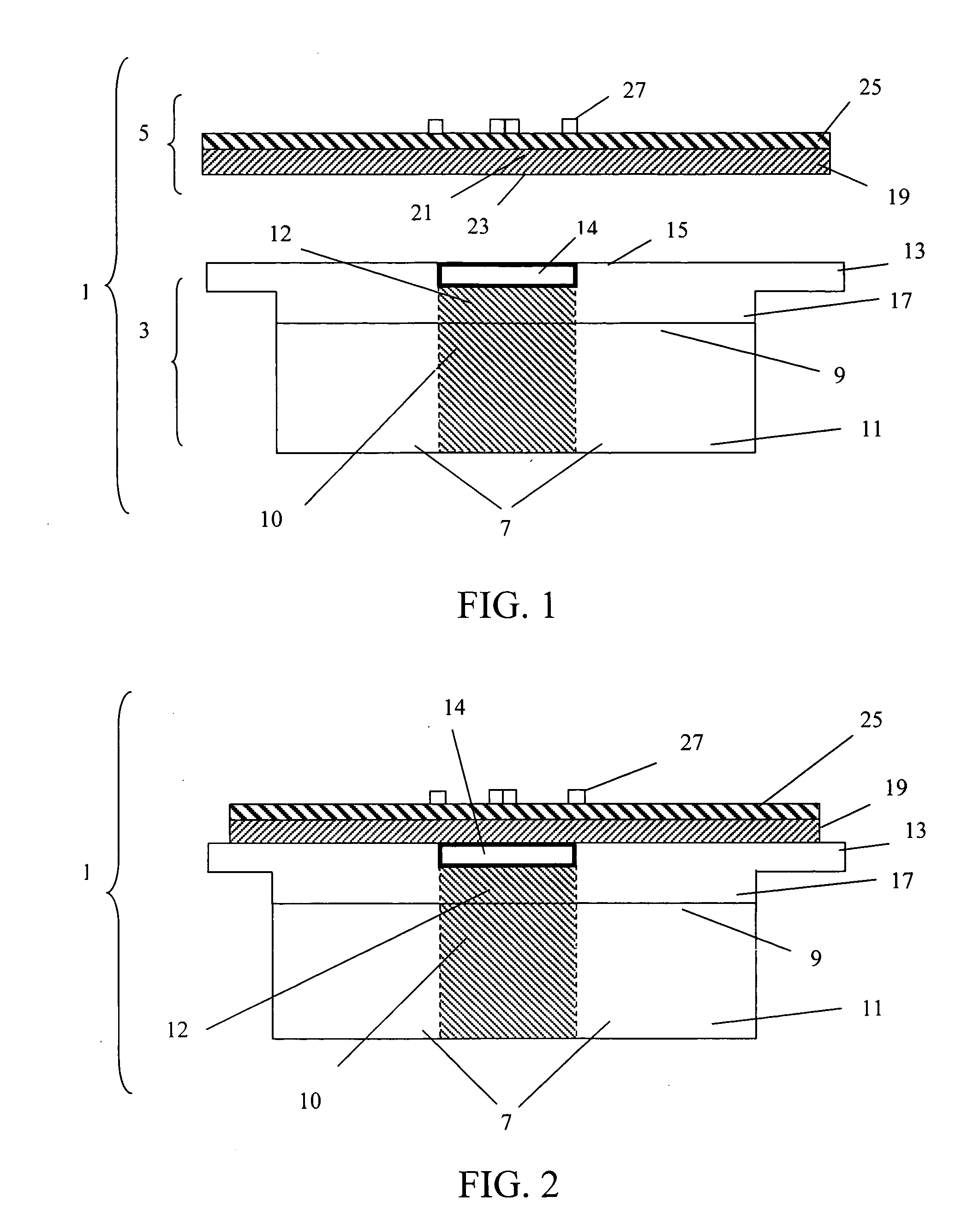

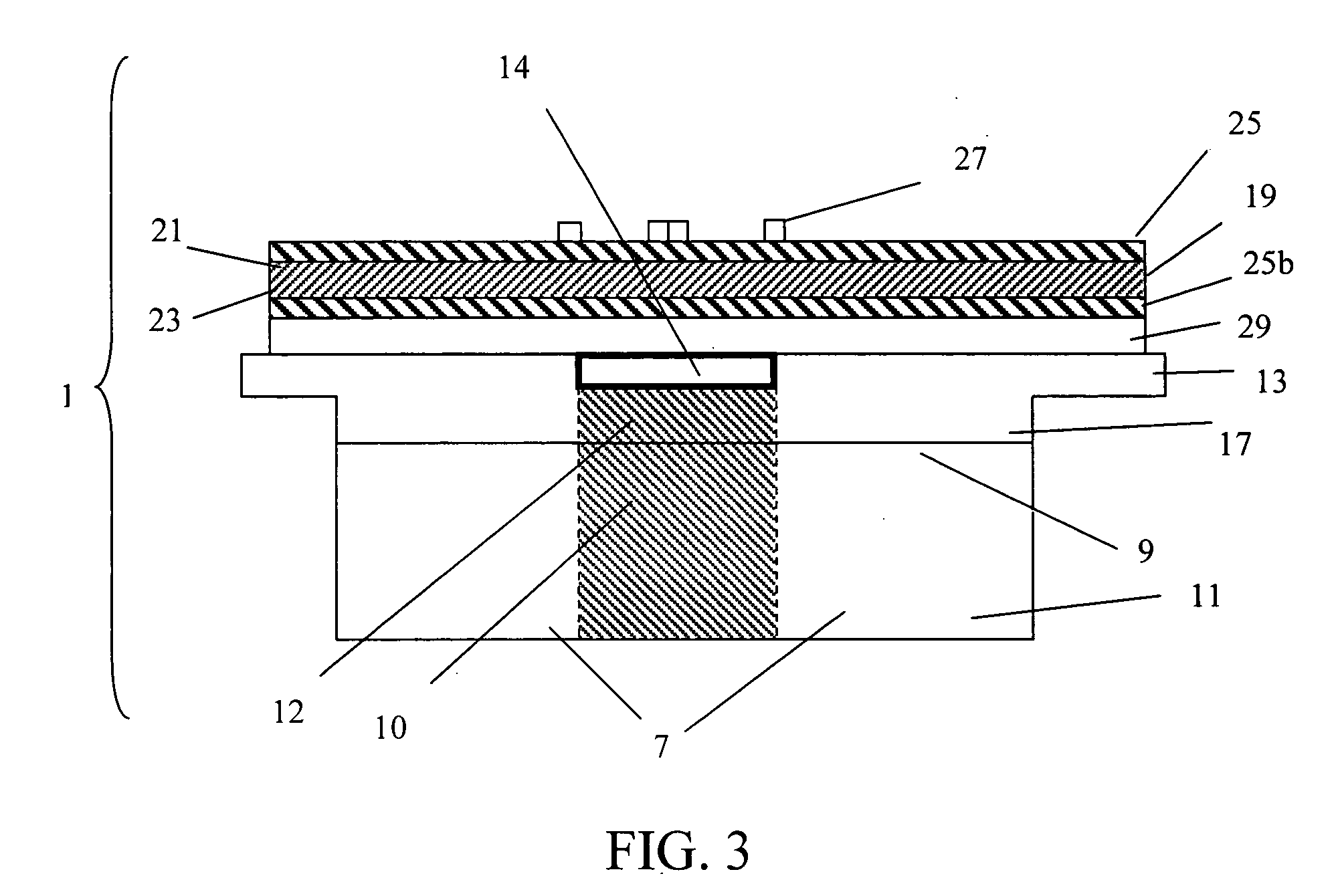

Disclosed is a suspending tapered bucket type semisolid metal slurry preparation and conveying apparatus, which belongs to the technique field semisolid metal machining. The apparatus comprises an adjustable speed motor 1, an elevating mechanism 2, an air pipe 3, a connecting device 4, a press-casting machine injection chamber 5, an air port 6, a transmission bevel gear 7, a mandrel 8, a coupling 9, an air pipe 10, a pony ladle 11, an inner tapered bucket 12, an outer tapered bucket 13, a heating and cooling element 14, a flanged disc 15 and the like. When in semisolid metal slurry preparation, according to the shearing deformation principle, the purpose of forming fine and even semisolid metal slurry can be achieved through the intense shearing function when the liquid state metal passes through gaps between the rotating inner tapered bucket and the outer tapered bucket which are inscribed with specific grooves, and the prepared semisolid metal slurry is conveyed to the press-casting machine injection chamber through the connecting device to realize the rheological die-casting molding. The invention has the advantages of: simple and compact equipment structure and light weight; high temperature control precision; convenient and reliable operation, and easy realization from semisolid metal slurry preparation, conveying to die-casting molding; and convenient maintenance and repair and industrialized continuous production.

Owner:UNIV OF SCI & TECH BEIJING

High temperature three dimensional printing compositions

ActiveUS20160369040A1High modulusHigh elongationAdditive manufacturing apparatusPolymer scienceMetal catalyst

A thermosetting resin composition has particular applications in three dimensional (3-D) printing. The thermosetting resin composition exhibits high performance and is characterized by a high temperature two stage cure resin composition. The thermosetting resin composition comprises cyanate esters and other high temperature resins, photo curable monomers, photo initiator, metal catalyst or ionic liquid catalyst. The thermosetting resin composition cures at room temperature to form 3-D objects and upon further post cure these objects exhibit high temperature properties enabling use at temperatures exceeding 150C.

Owner:NOVOSET

Spray nozzle assembly for gas dynamic cold spray and method of coating a substrate with a high temperature coating

InactiveUS20100136242A1Erosion minimizationMinimizes degradationPretreated surfacesSpray nozzlesHigh-temperature corrosionPolymer

The invention relates to an improved design for a spray gun and application system for cold gas dynamic spraying of a metal, alloy, polymer, or mechanical mixtures thereof. The gun includes a rear housing comprising a powder inlet and a gas inlet, a front housing removably affixed to the rear housing and comprising an mixing cavity therein for mixing of the powder and gas and an exit therefrom, a nozzle holder having a bore disposed therethrough and removably affixed to the front housing, and a polymeric nozzle positioned within the nozzle holder, an interior taper of the nozzle holder bore complementing an exterior taper of the nozzle. The nozzle having an initially converging, subsequently diverging centrally disposed bore therein adapted to receive the mixed powder and gas from the mixing chamber and the nozzle holder including a cooling jacket which is thermally coupled to the nozzle adjacent the nozzle inlet and mechanically coupled downstream of the nozzle inlet.

Owner:ASB INDS

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

High efficiency self-stripping high temperature oxidation-prevention/decarbonization coating material

The invention relates to a coating material for metal heat treatment process, especially a protective coating material for preventing oxidation / decarburization of steel workpieces during heat treatment heating. Composed of binder and its formula by weight percentage is: 10-20% glass powder, 33-30% quartz sand, 23-20% silica sand, 24-20% Al2O3, 2-10% C; this high-efficiency self-stripping High-temperature anti-oxidation / decarburization coating material, widely applicable to anti-oxidation / decarburization of various steels when heated at 800-1200°C / 4-10 hours, and can be naturally peeled off in the subsequent cooling process. The surface of the steel workpiece after heat treatment still has the original metallic luster, and the surface layer of the steel workpiece still maintains the original chemical composition; this coating material is easy to use, has excellent anti-oxidation / decarburization effects, strong natural peeling ability, and wide applicability .

Owner:CENT SOUTH UNIV

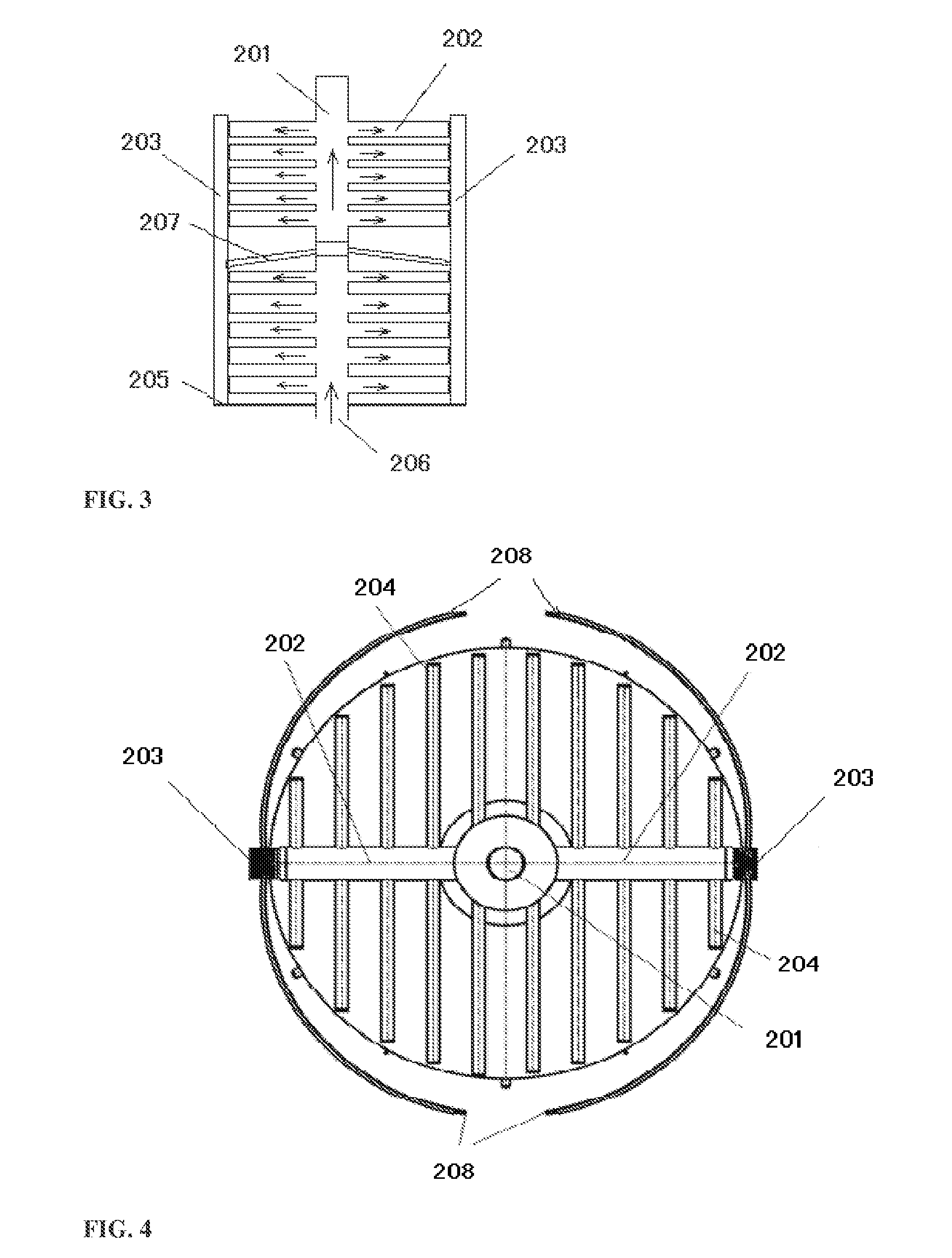

Desulfurization process containing H*S acidic gas

InactiveCN101530727AThe process idea is clear and simpleEasy to operate and manageDispersed particle separationCombustionSulfur

The invention relates to a desulfurization process containing acidic gas H2s, comprising the following steps: high temperature cross reaction is carried out in a combustion furnace; 3 cross reactions of varying levels are respectively carried out in a primary transformation reactor, a secondary transformation reactor and a tertiary transformation reactor; a ferric oxide desulfurization reaction is carried out in a fourthly oxidation sweetening reactor; wherein, process gas produced after the high temperature cross reaction and 3 cross reactions of varying levels passes through a primary cooler, a secondary cooler, a tertiary cooler and a fourthly condenser for hydrocooling; condensed liquid sulfur is collected; in the ferric oxide desulfurization reaction, ferric oxide is used as desulfurization catalyst for reaction, then the liquid sulfur enters the fourthly condenser, and the condensed liquid sulfur is collected; the process gas is discharged after removing sulfur fog drops. The invention can be used to carry out desulfurization treatment on acidic gas of oil refining devices, natural gas production devices or other industrial devices containing H2S acidic gas.

Owner:BEIJING HANGXINGSHIJI TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com