Patents

Literature

55167 results about "Heat exchanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

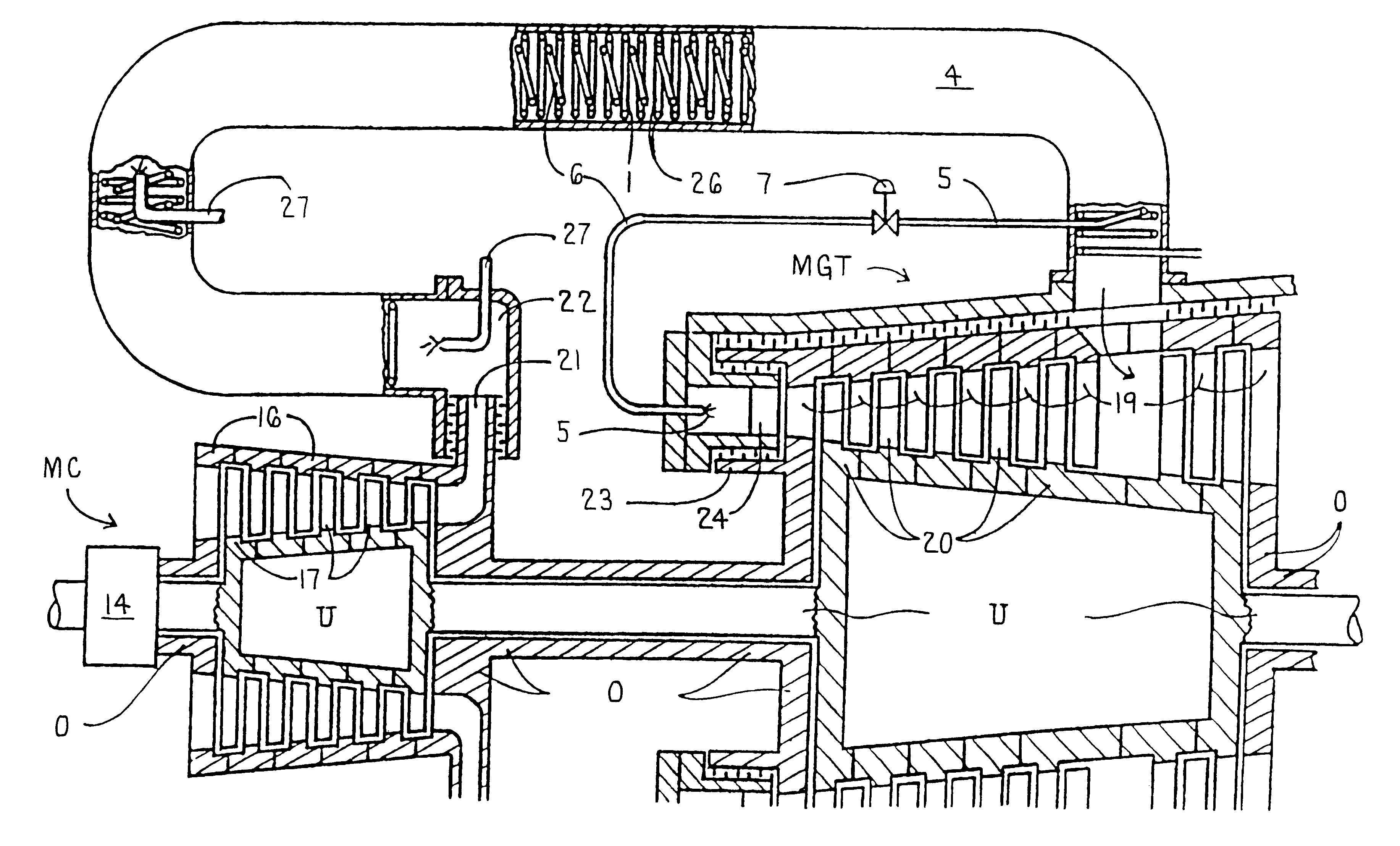

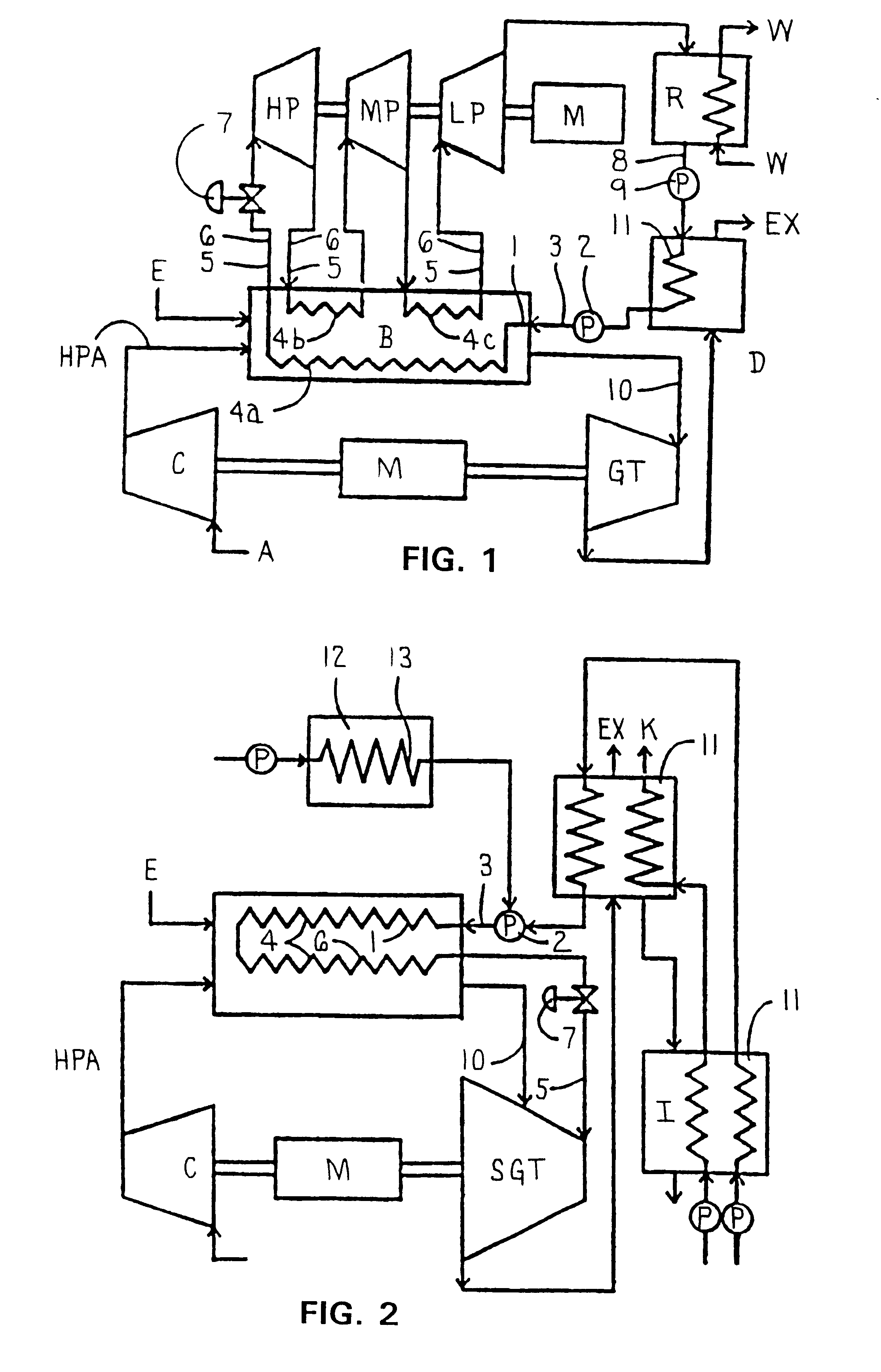

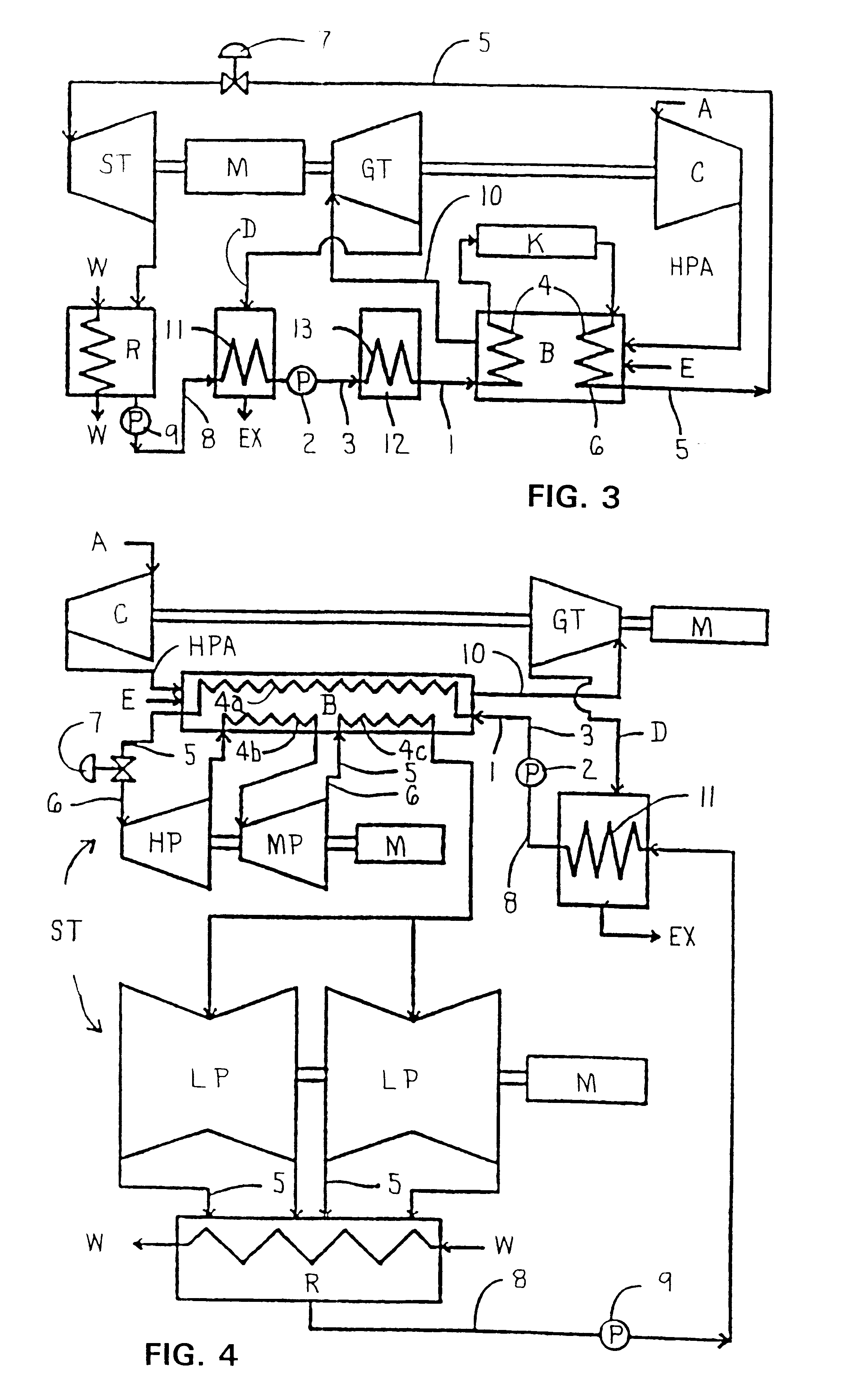

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

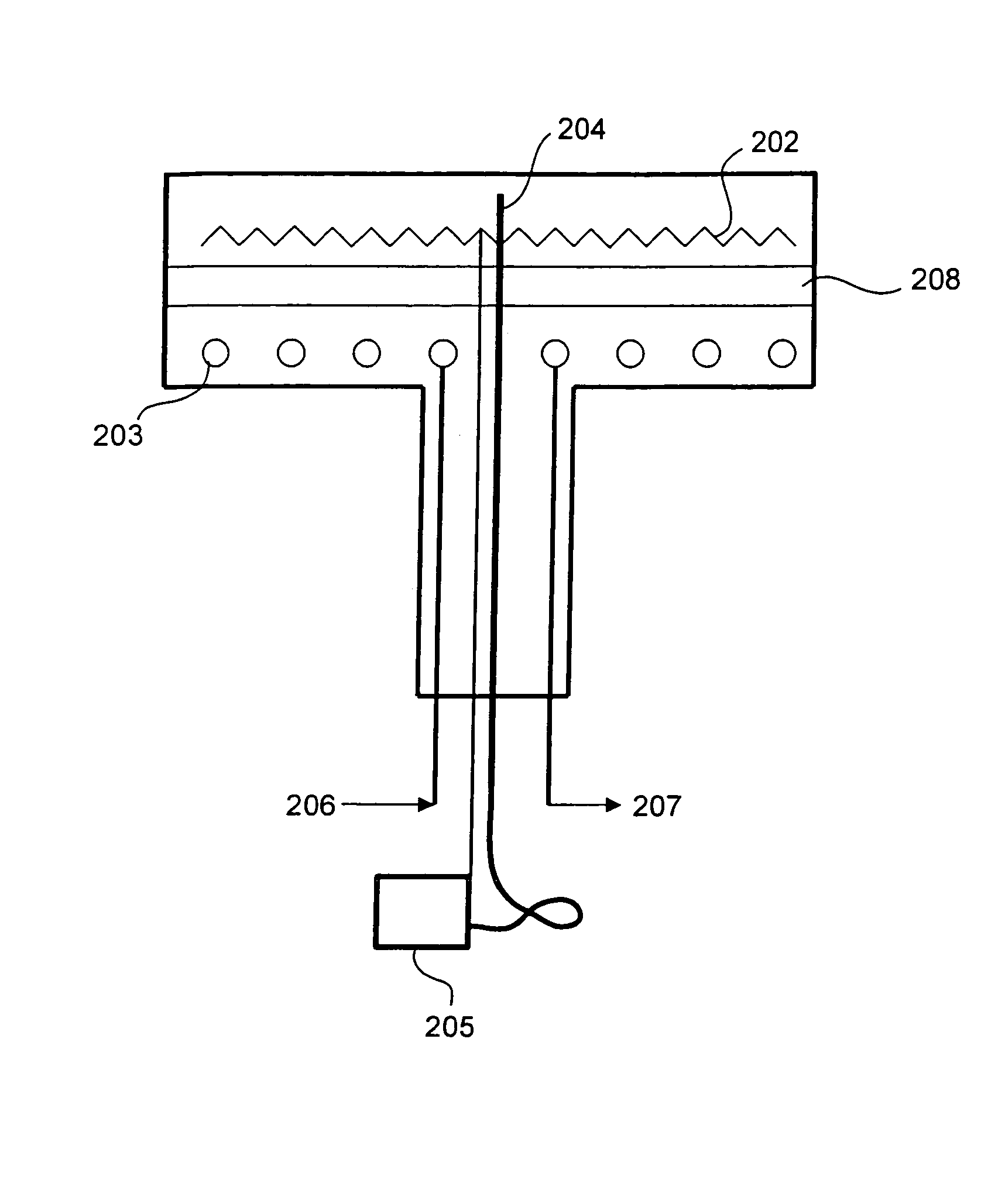

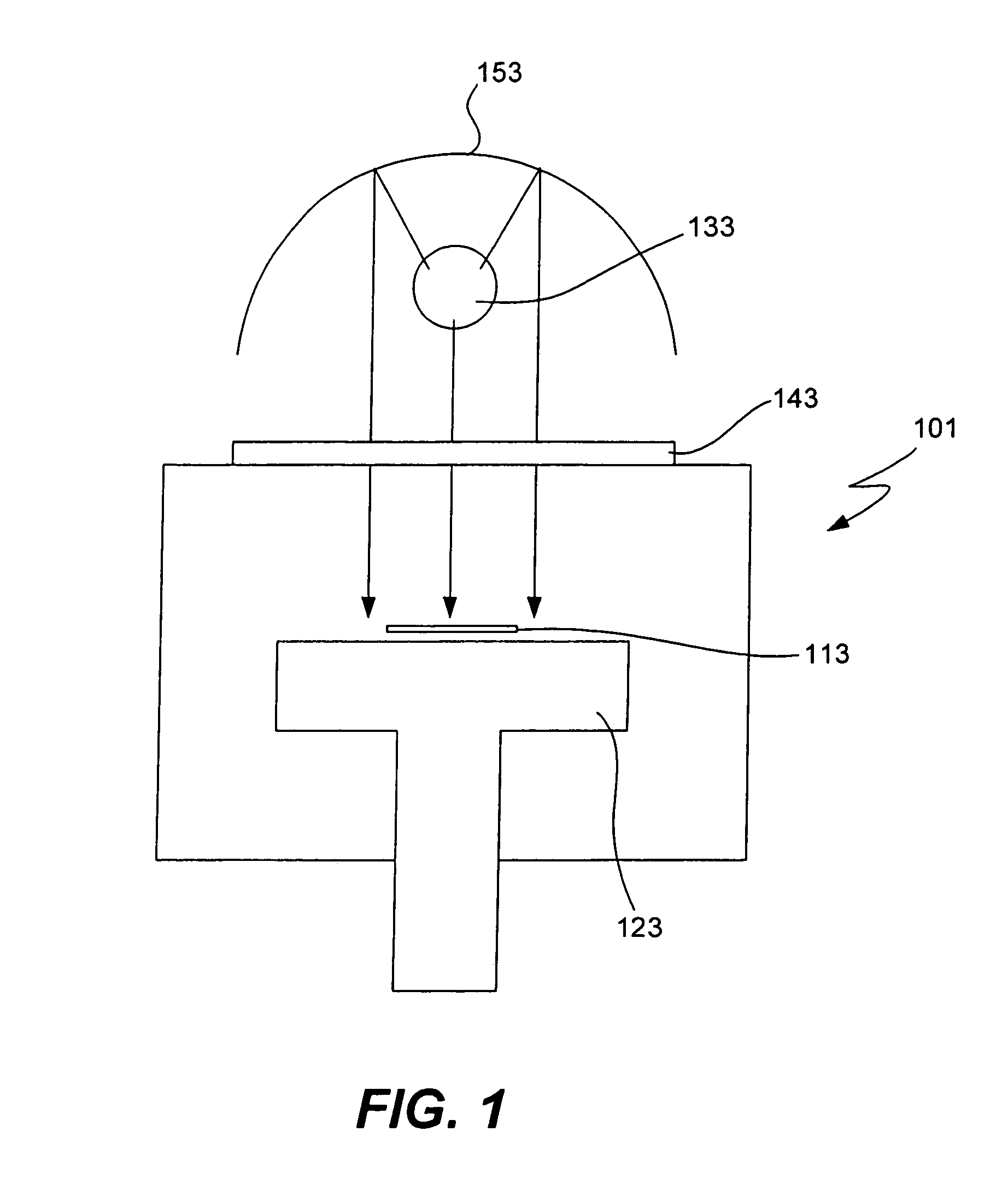

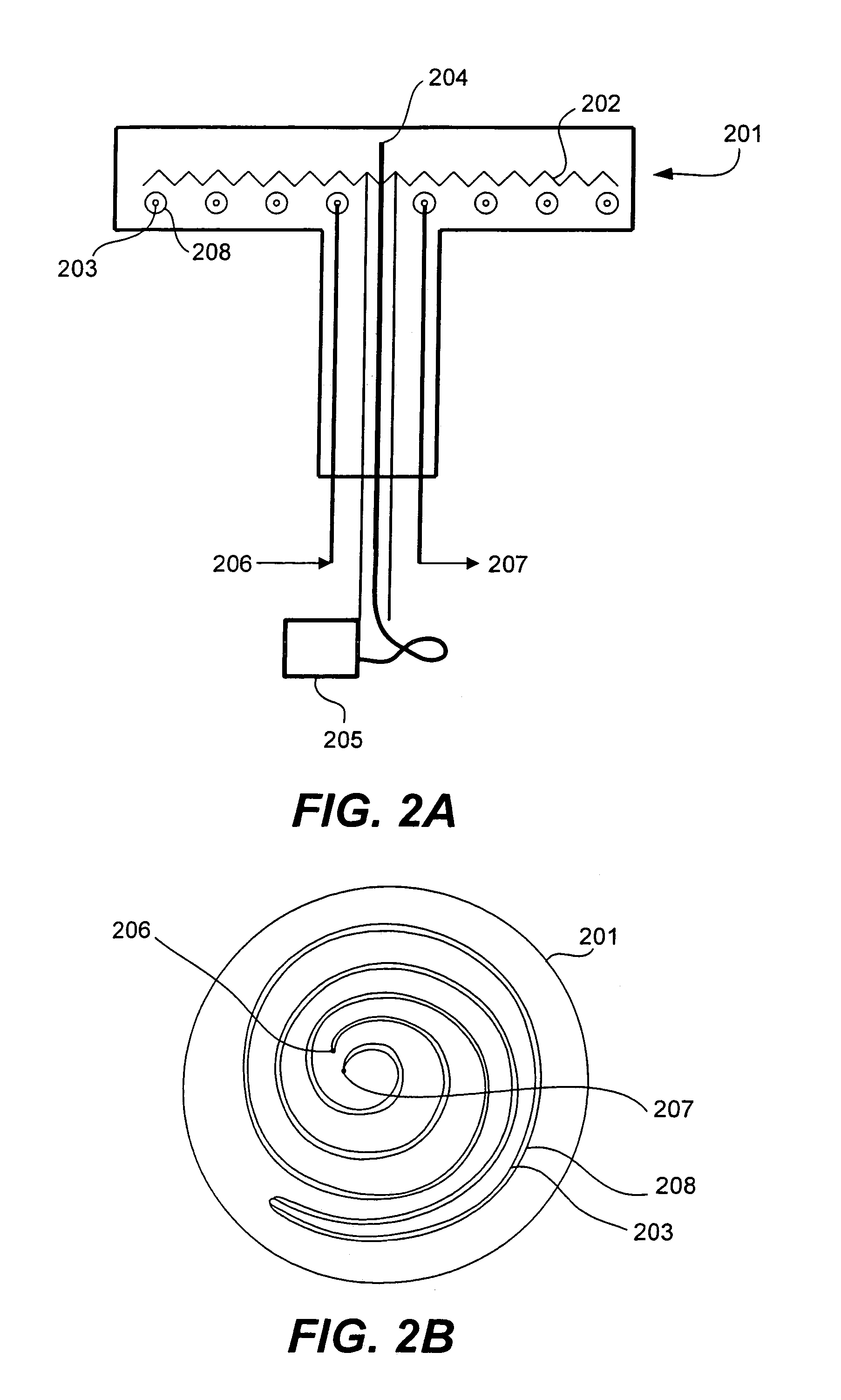

Cast pedestal with heating element and coaxial heat exchanger

ActiveUS7327948B1High-temperature gradientHeat resistantSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingHeat resistanceEngineering

The present invention provides a heat transfer assembly that, when coupled to an object, is capable of keeping the object at a uniform elevated temperature while removing large amounts of heat from an external source. The assembly may be contained in a pedestal for use in a UV-cure chamber. The heat transfer assembly includes a heating element to control the wafer temperature and a cooling element to remove incident IR heat from the wafer and pedestal. A heat resistant layer having a calibrated heat resistance is located between the heating and cooling elements and between the wafer and the cooling elements. The heat resistant layer is able to sustain high temperature gradient from the wafer to the coolant so that the coolant does not boil while permitting enough heat to be conducted away from the wafer to maintain the desired set-point temperature.

Owner:NOVELLUS SYSTEMS

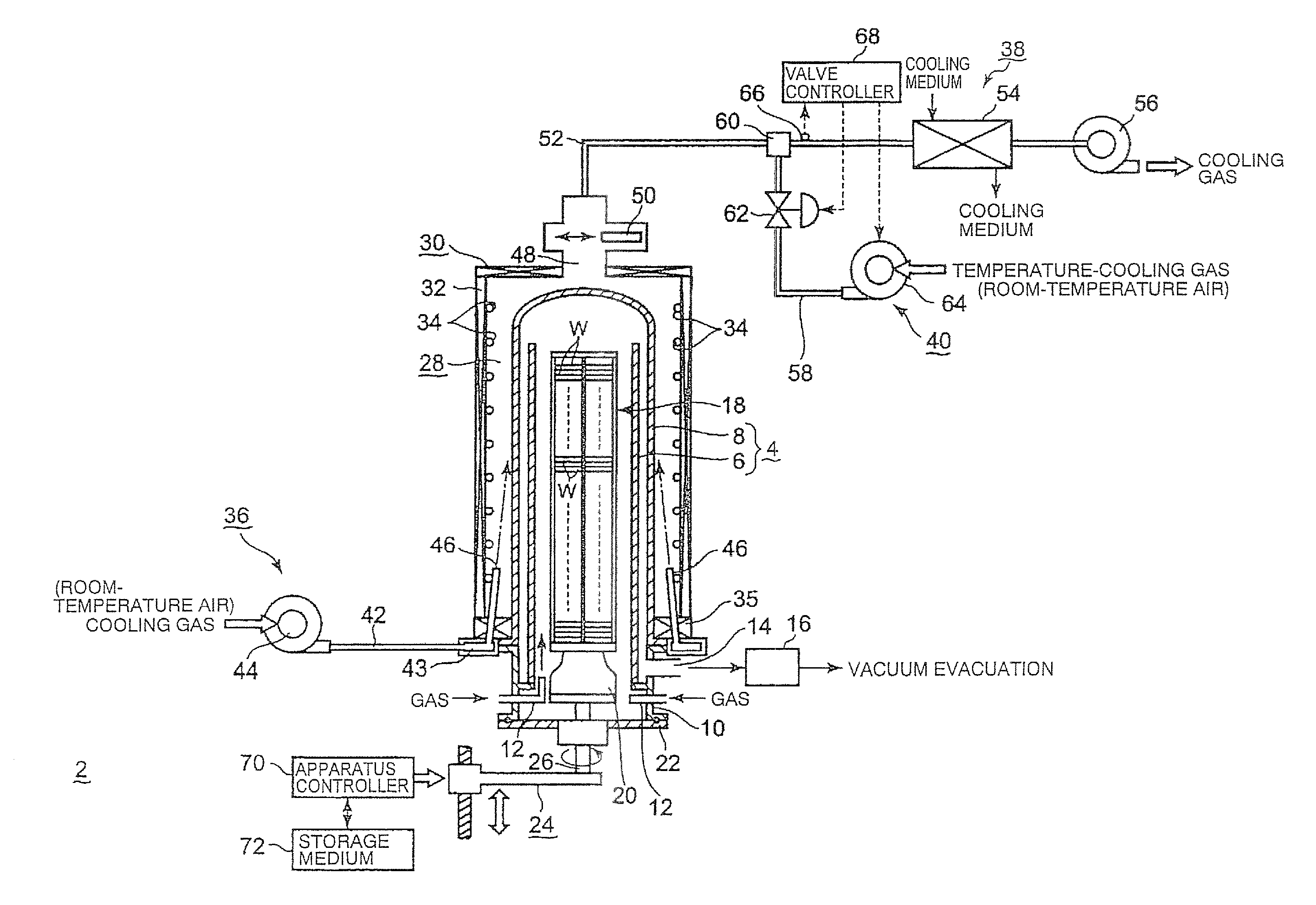

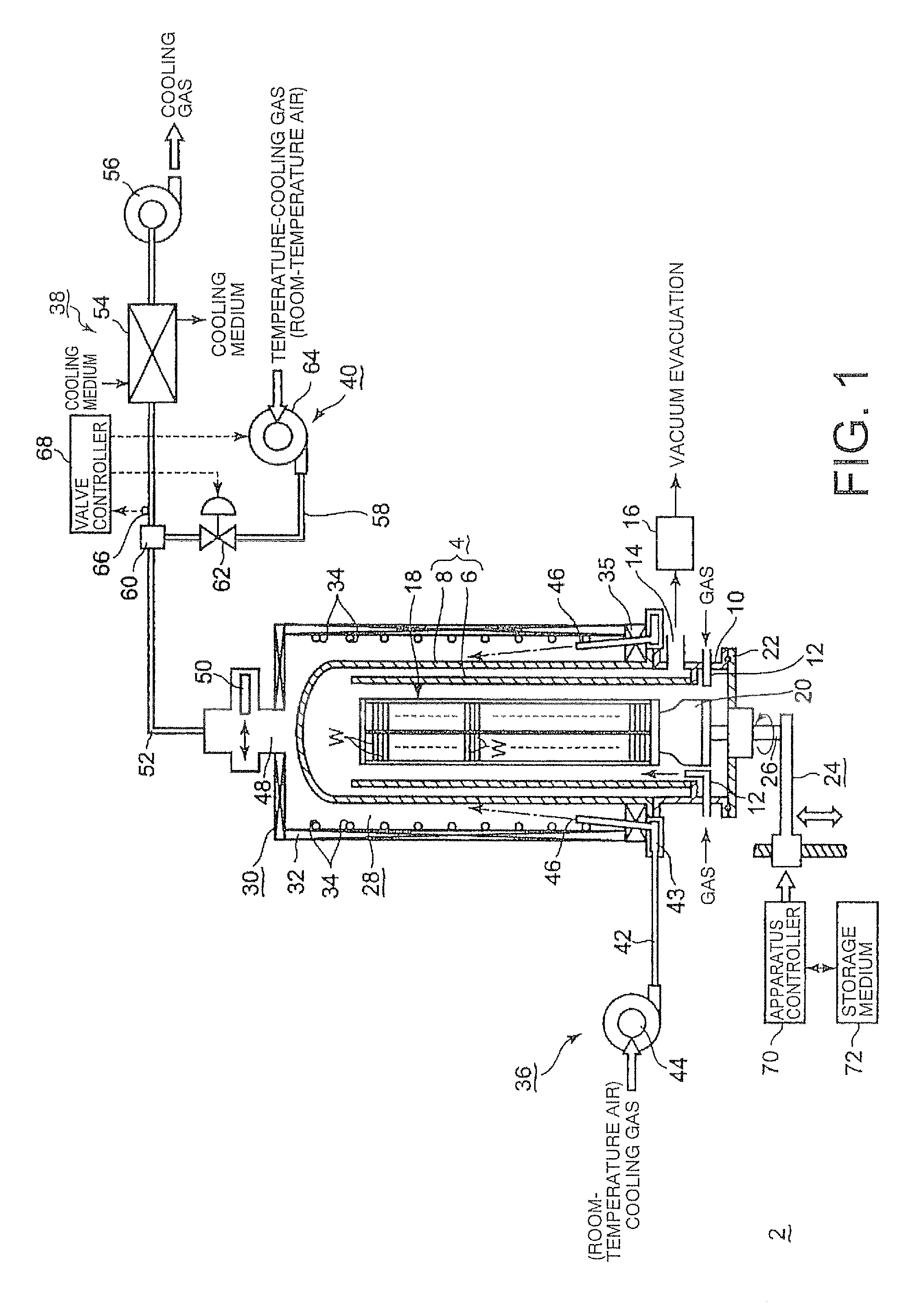

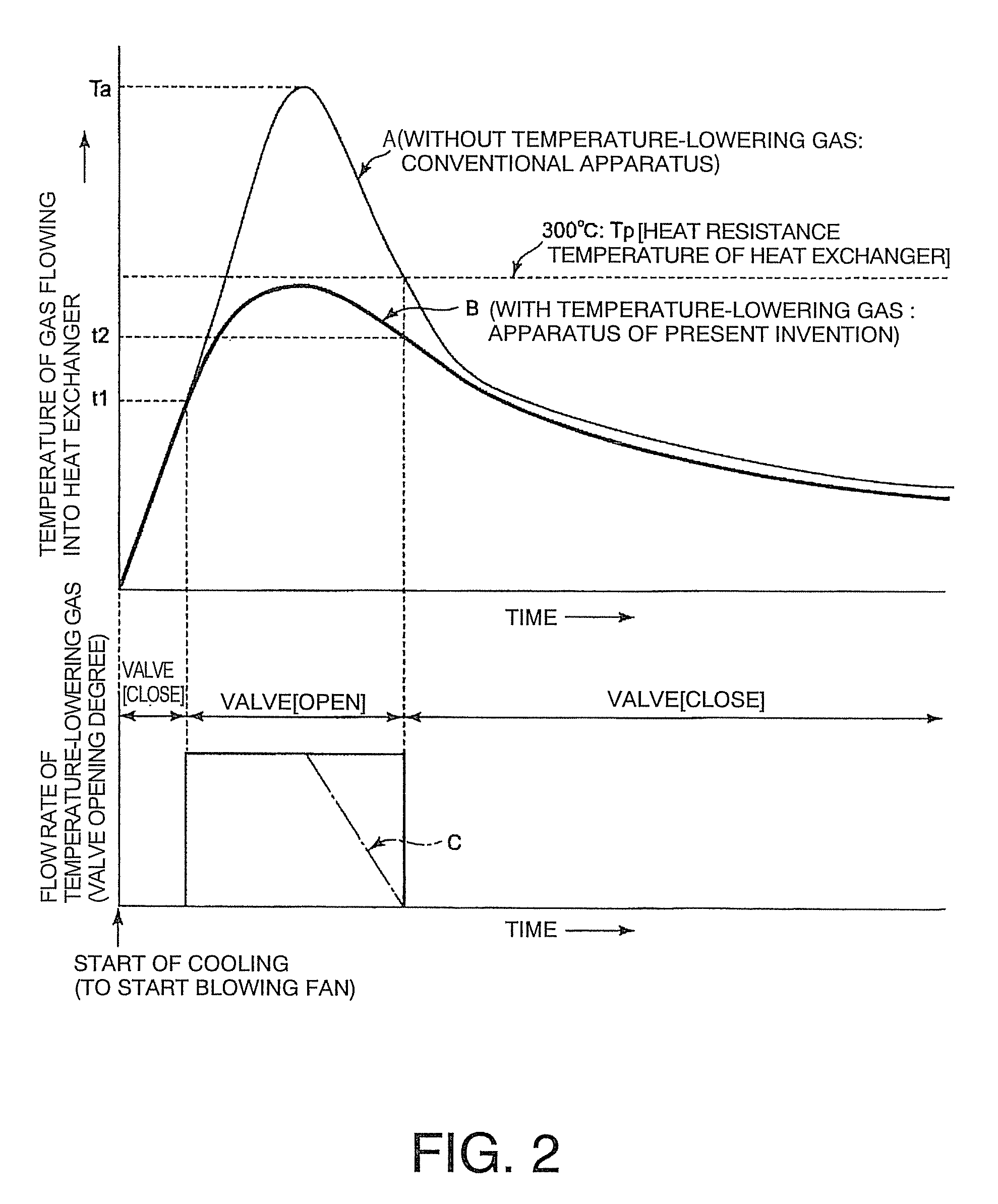

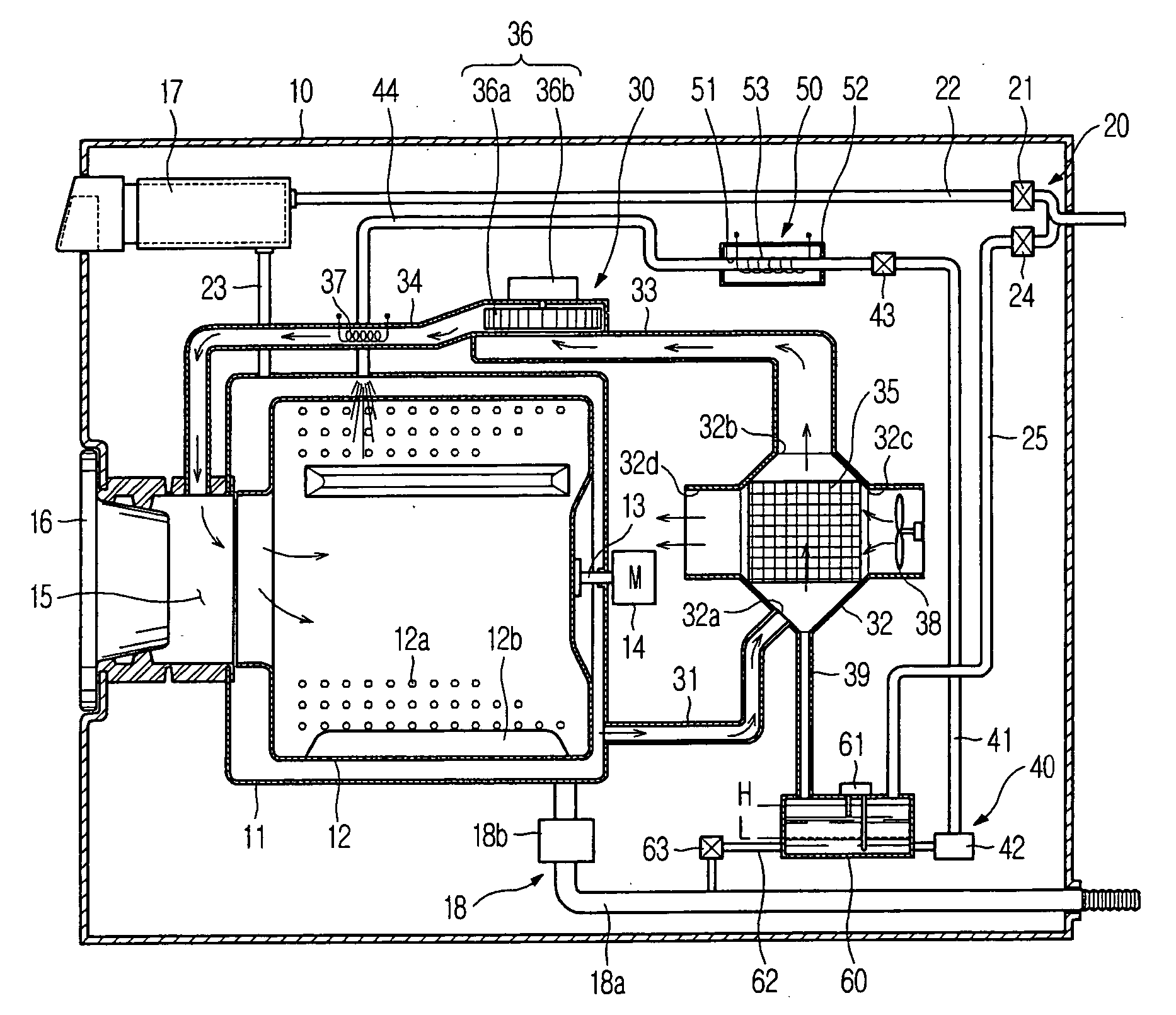

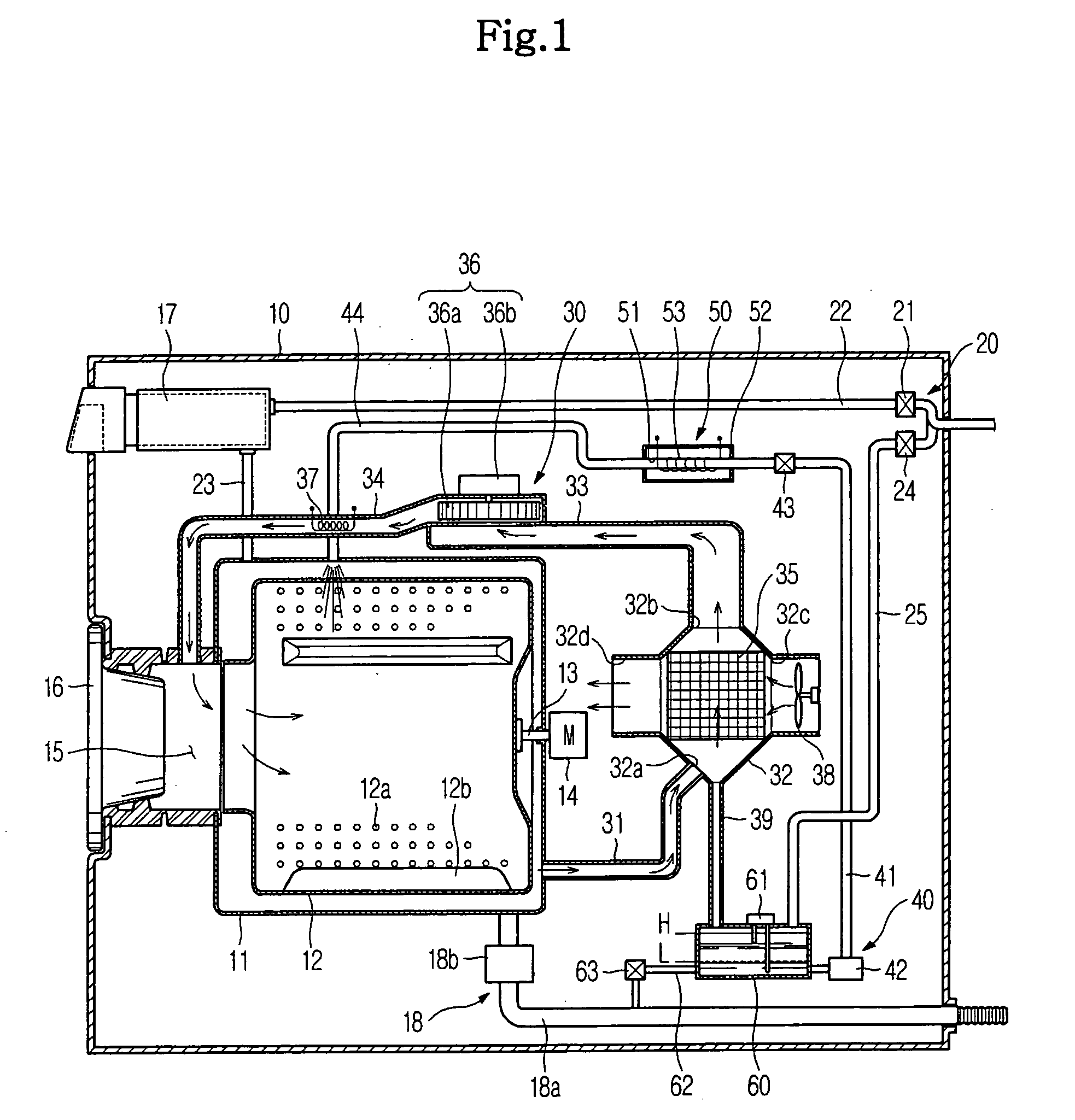

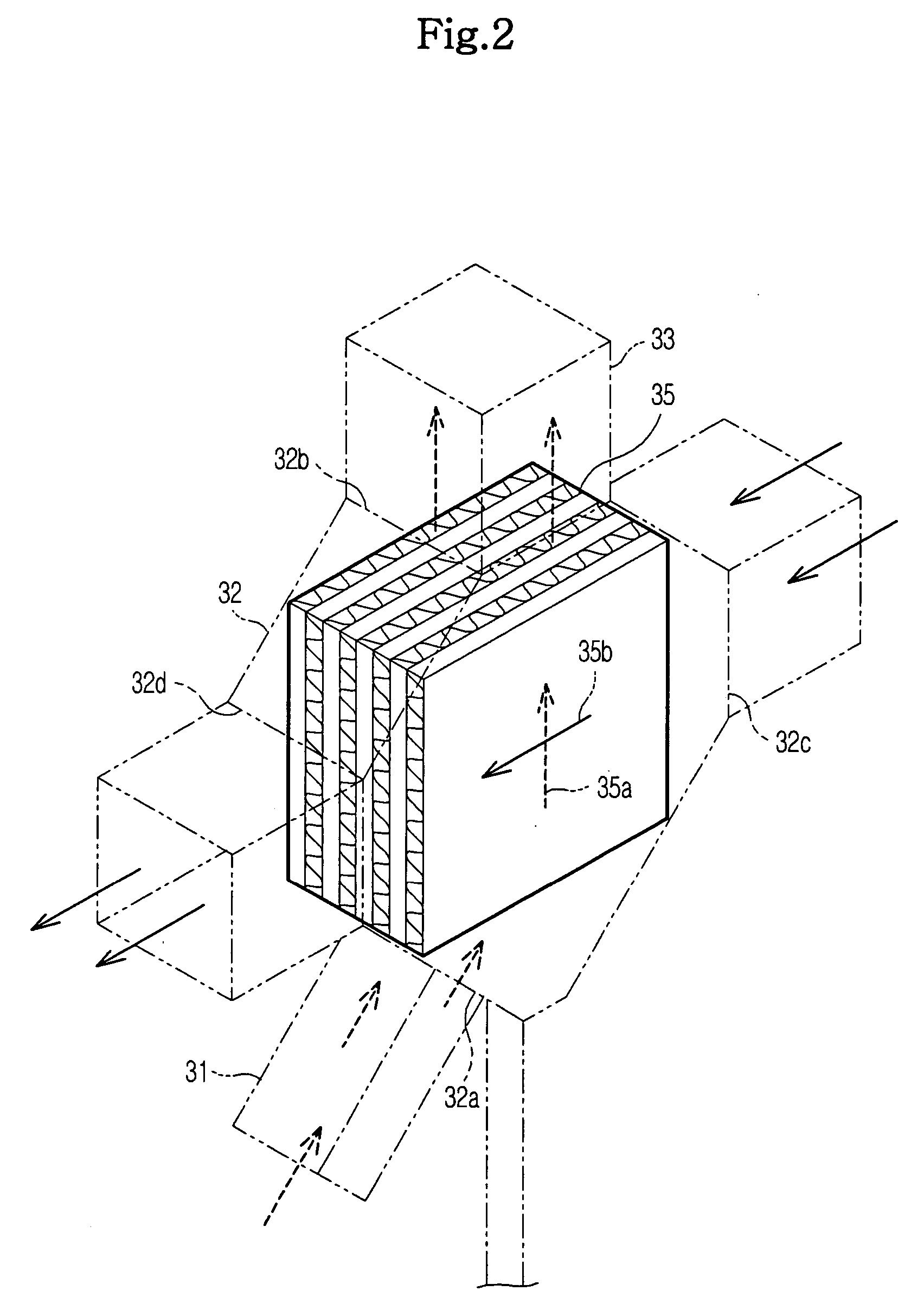

Thermal processing apparatus and cooling method

InactiveUS9099505B2Efficient solutionLow heat resistanceAfter-treatment apparatusSemiconductor/solid-state device manufacturingProcess engineeringHeating furnace

A thermal processing apparatus including: a cylindrical processing vessel; a support unit to be loaded into and unloaded from the vessel; and a heating furnace surrounding an outer periphery of the vessel, with a cooling space therebetween. The furnace is connected to a cooling-gas introduction unit, including a gas introduction passage to which a blowing fan is connected, for introducing a cooling gas into the cooling space during a temperature lowering operation after a thermal process. The furnace is connected to a cooling-gas discharge unit, including a heat exchanger, a suction fan, and a gas discharge passage, for discharging the cooling gas of a raised temperature from the cooling space. Connected to the gas discharge passage at a position upstream of the heat exchanger is a temperature-lowering gas introduction unit for introducing a temperature-lowering gas to the cooling gas of a raised temperature so as to lower its temperature.

Owner:TOKYO ELECTRON LTD

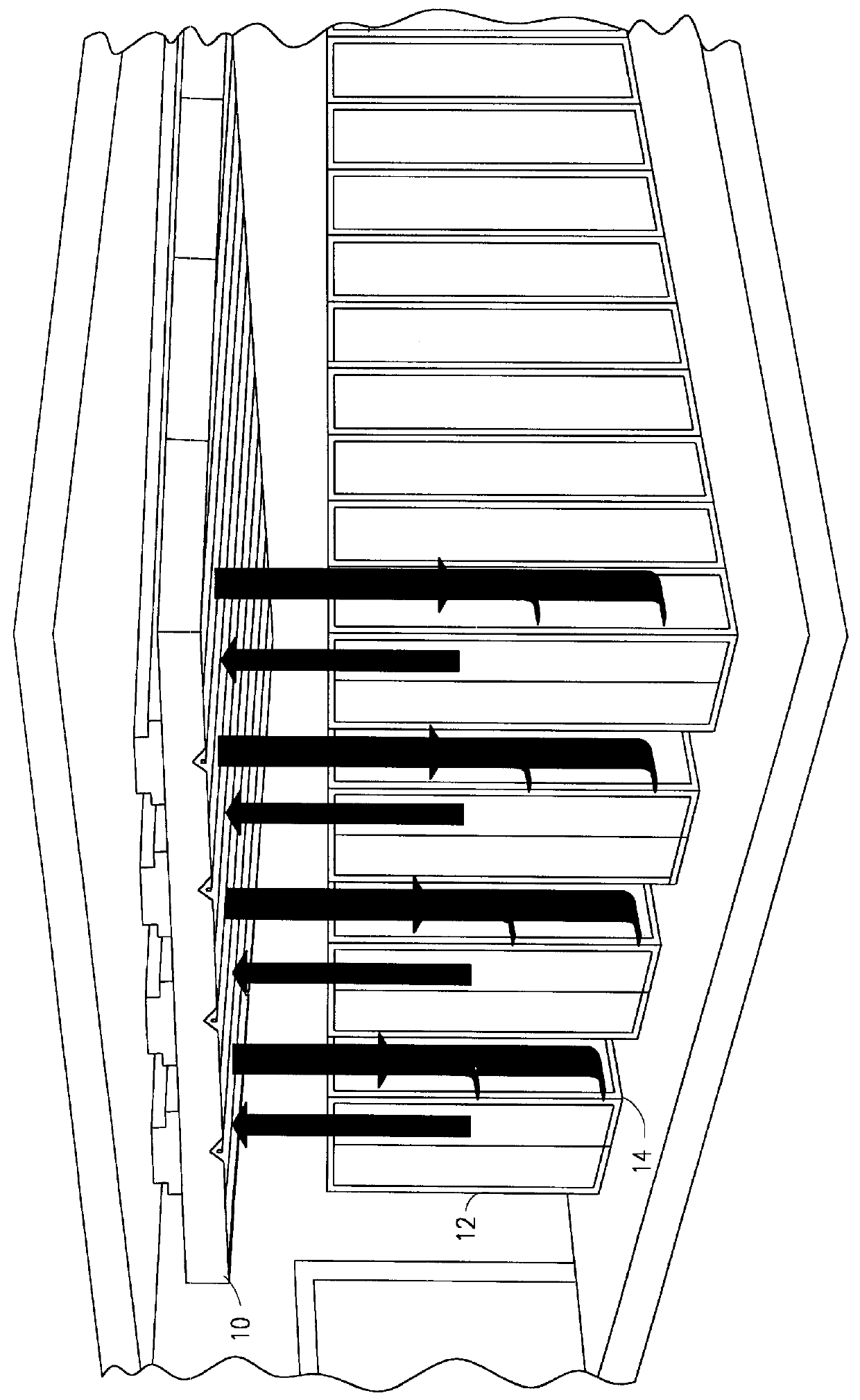

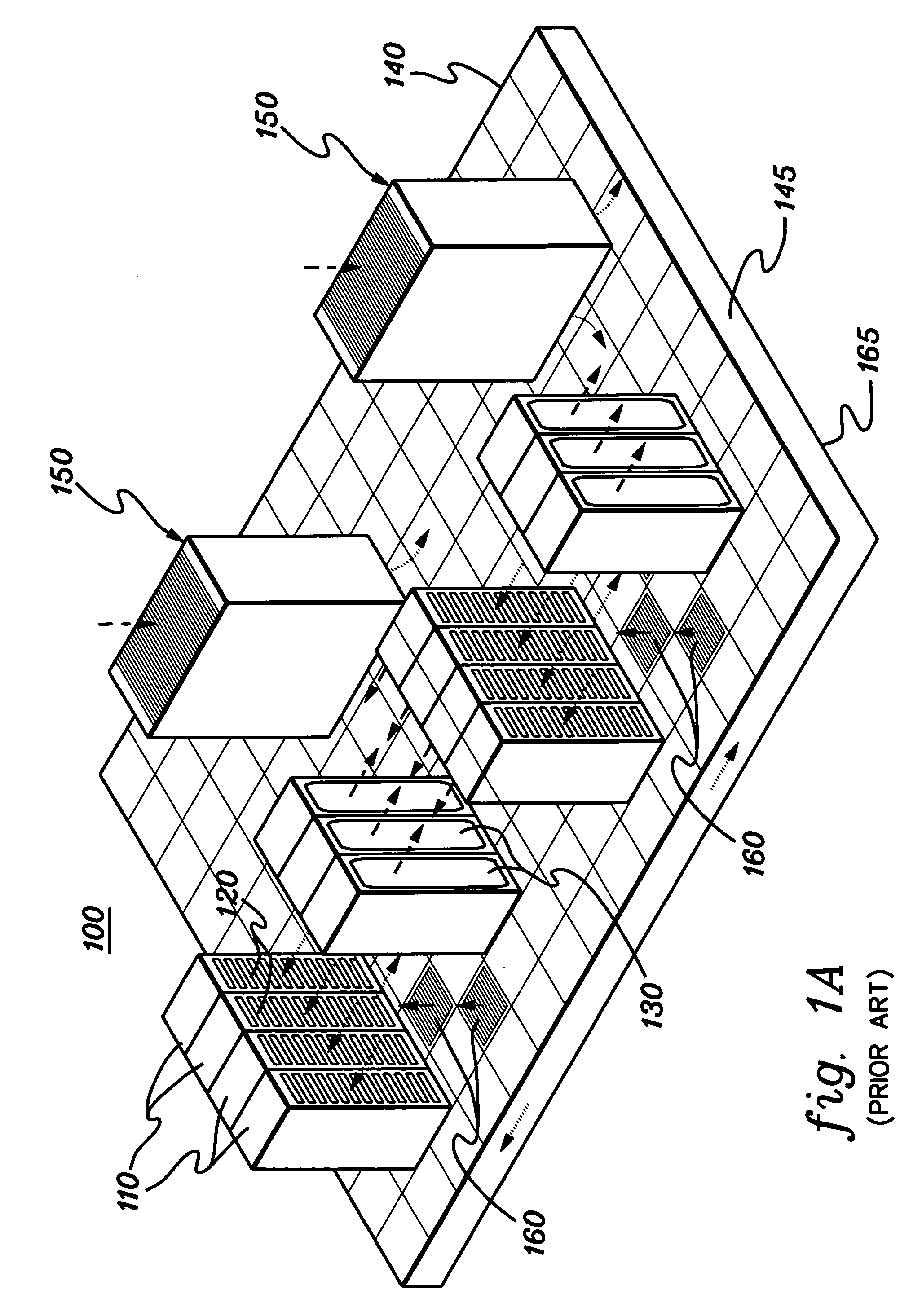

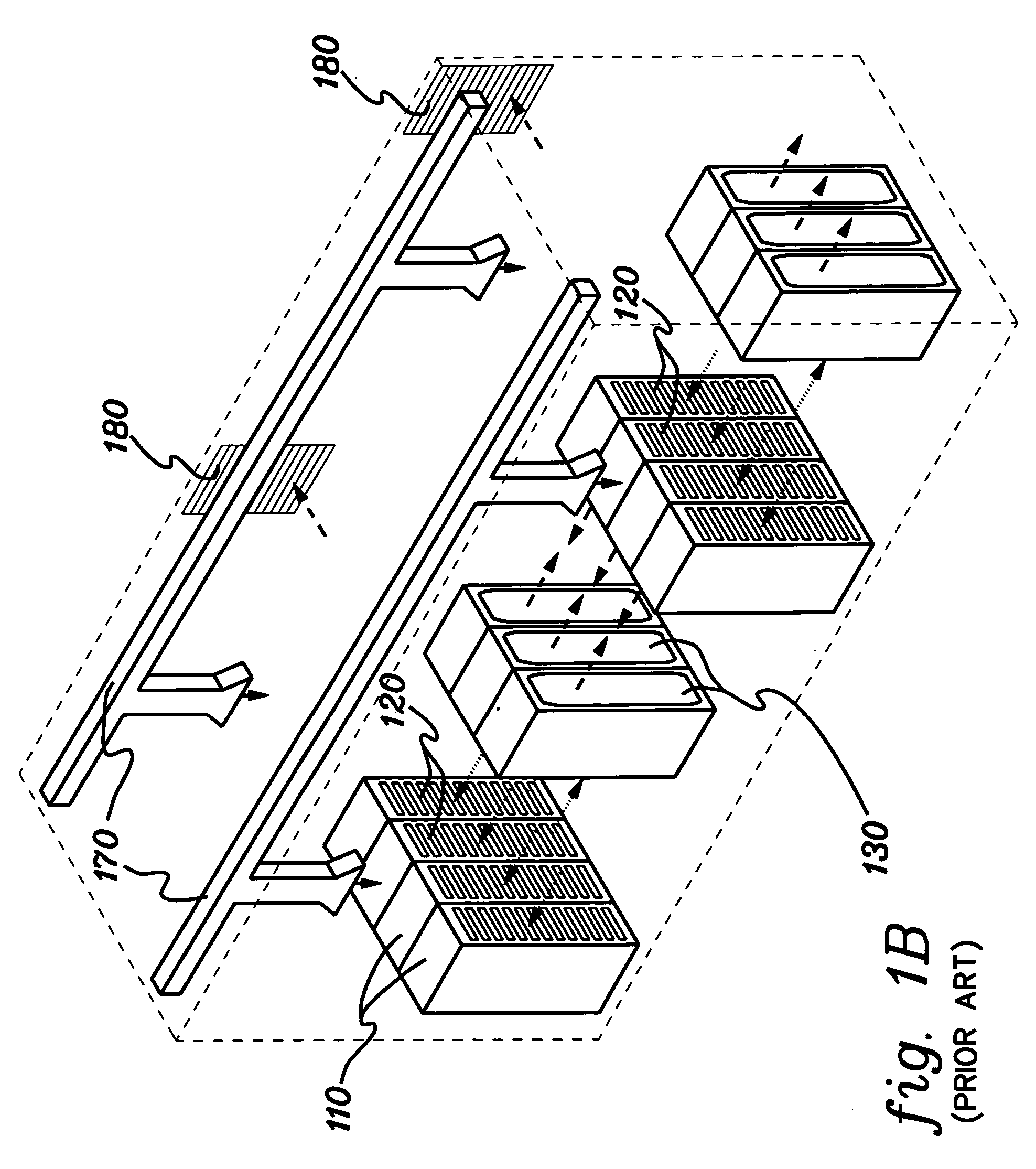

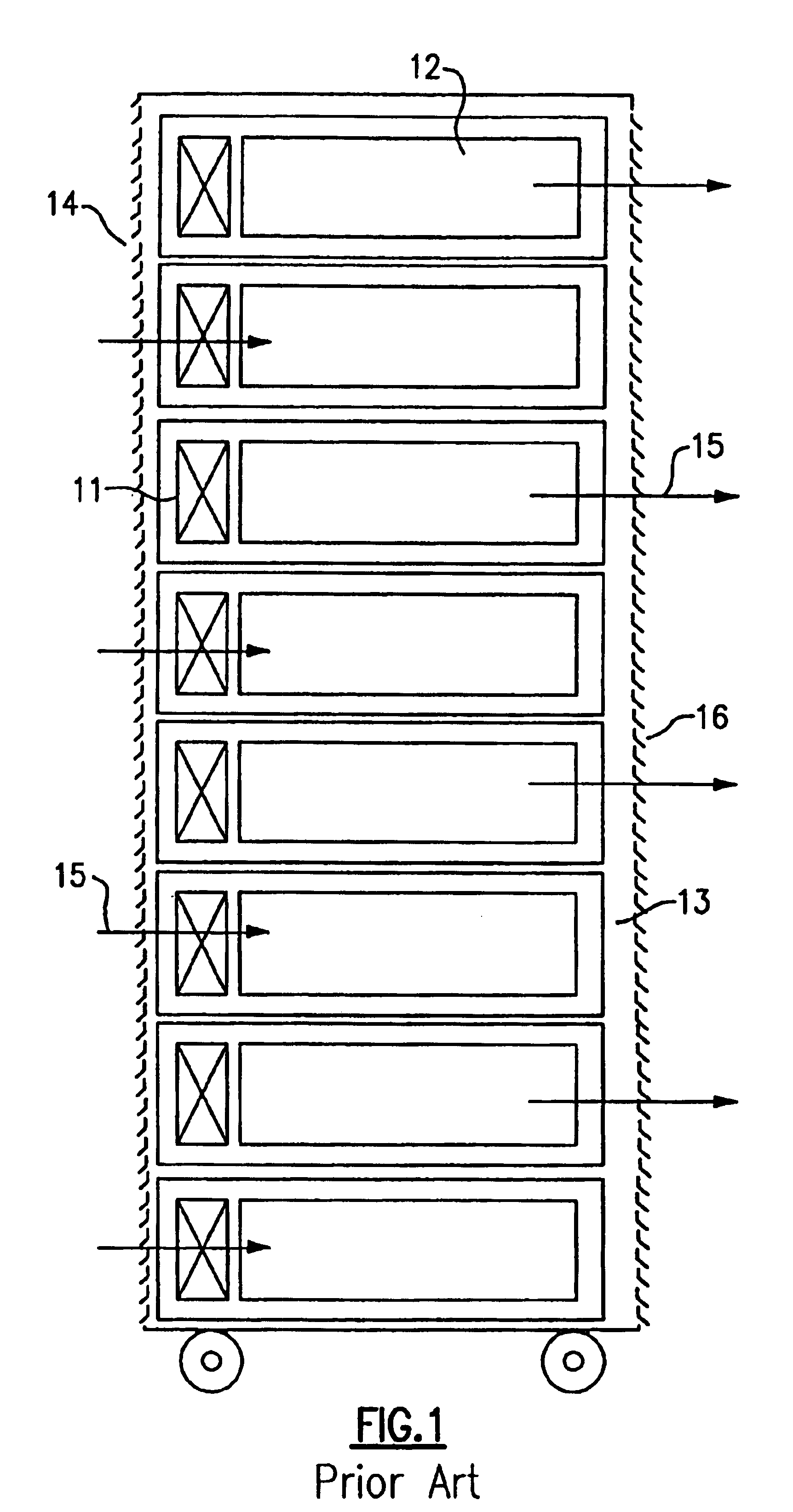

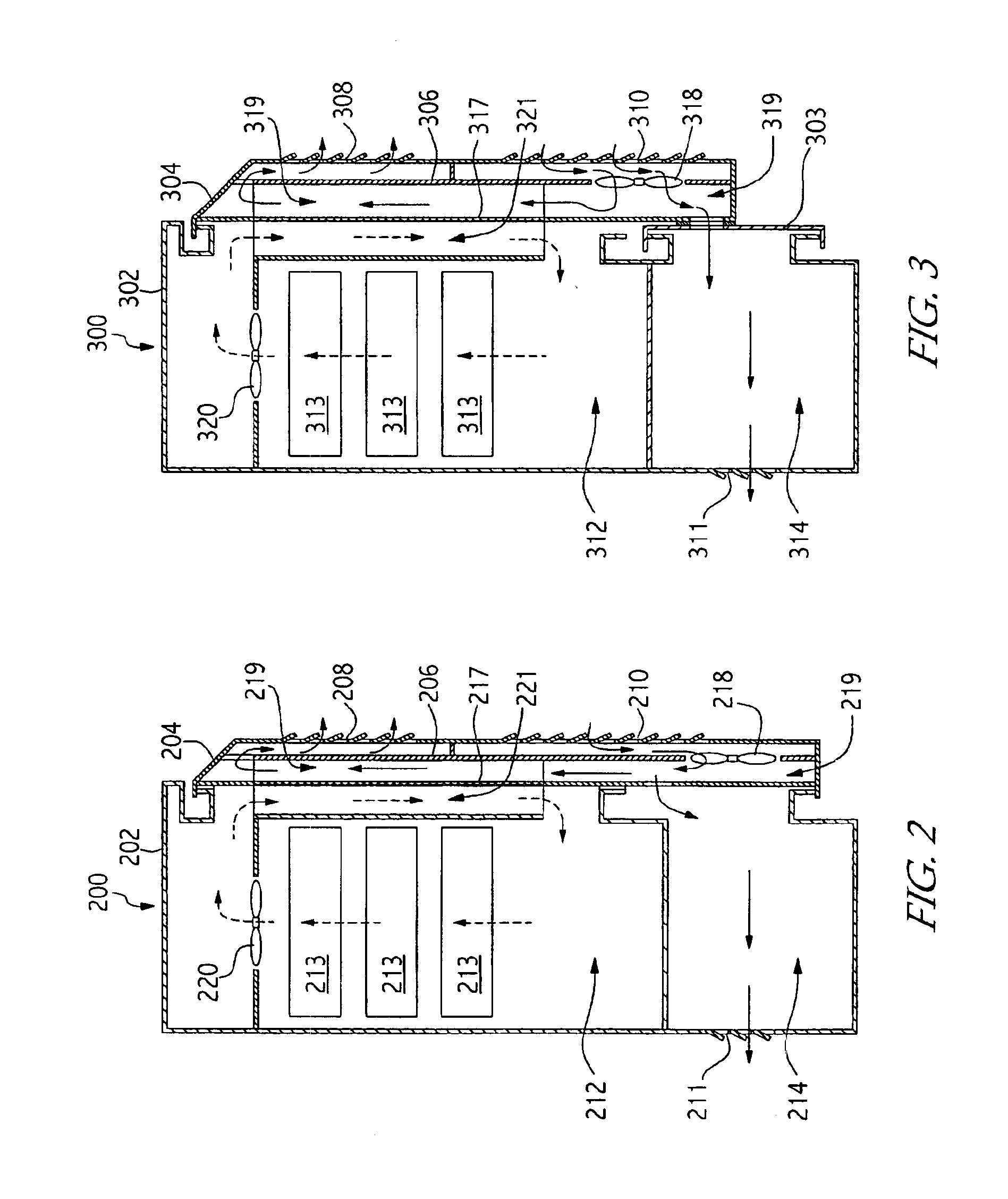

System and method for separating air flows in a cooling system

InactiveUS6034873AGreat and great efficiencyImprove efficiencyHeat exchange apparatusCooling/ventilation/heating modificationsMulti materialEngineering

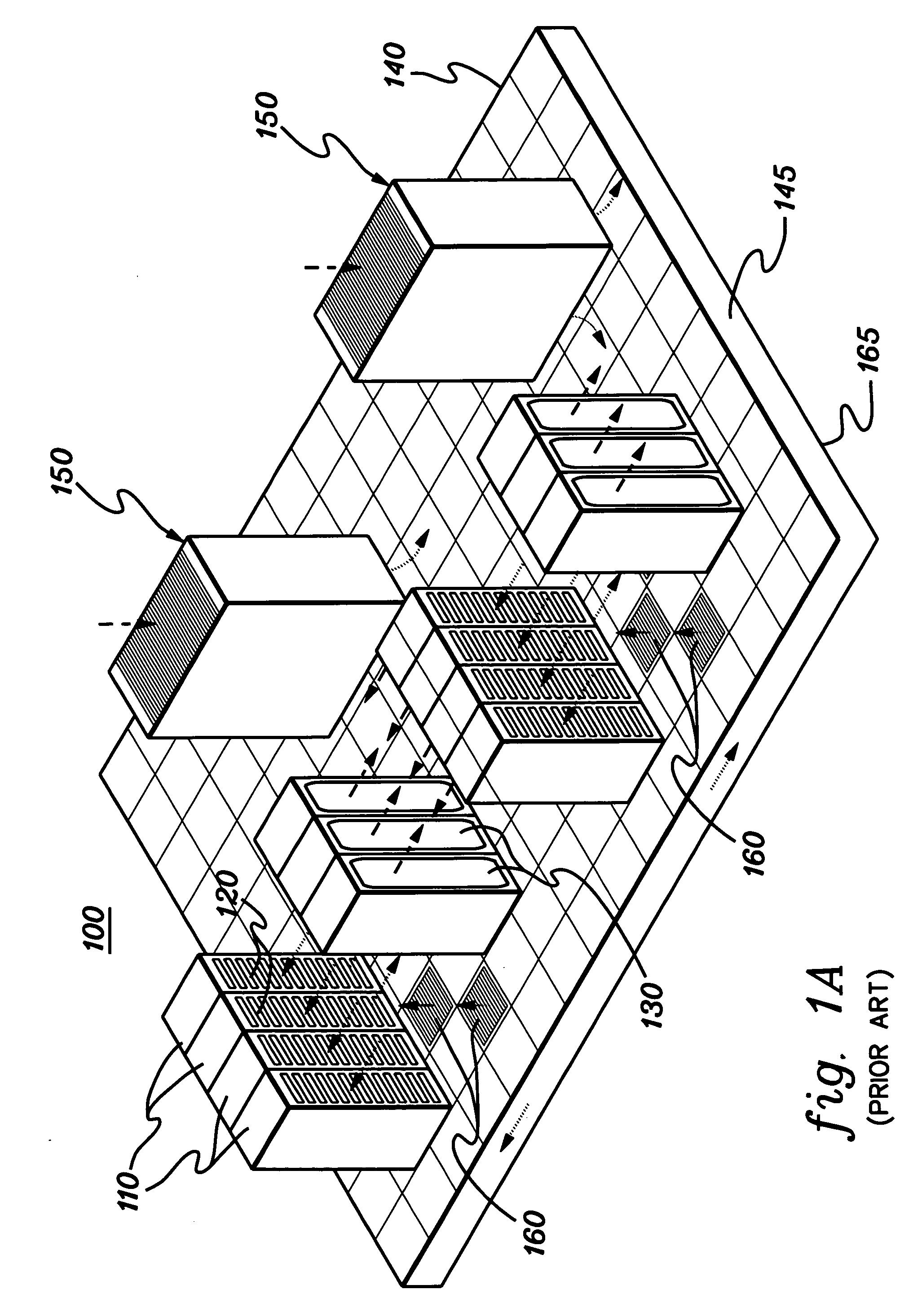

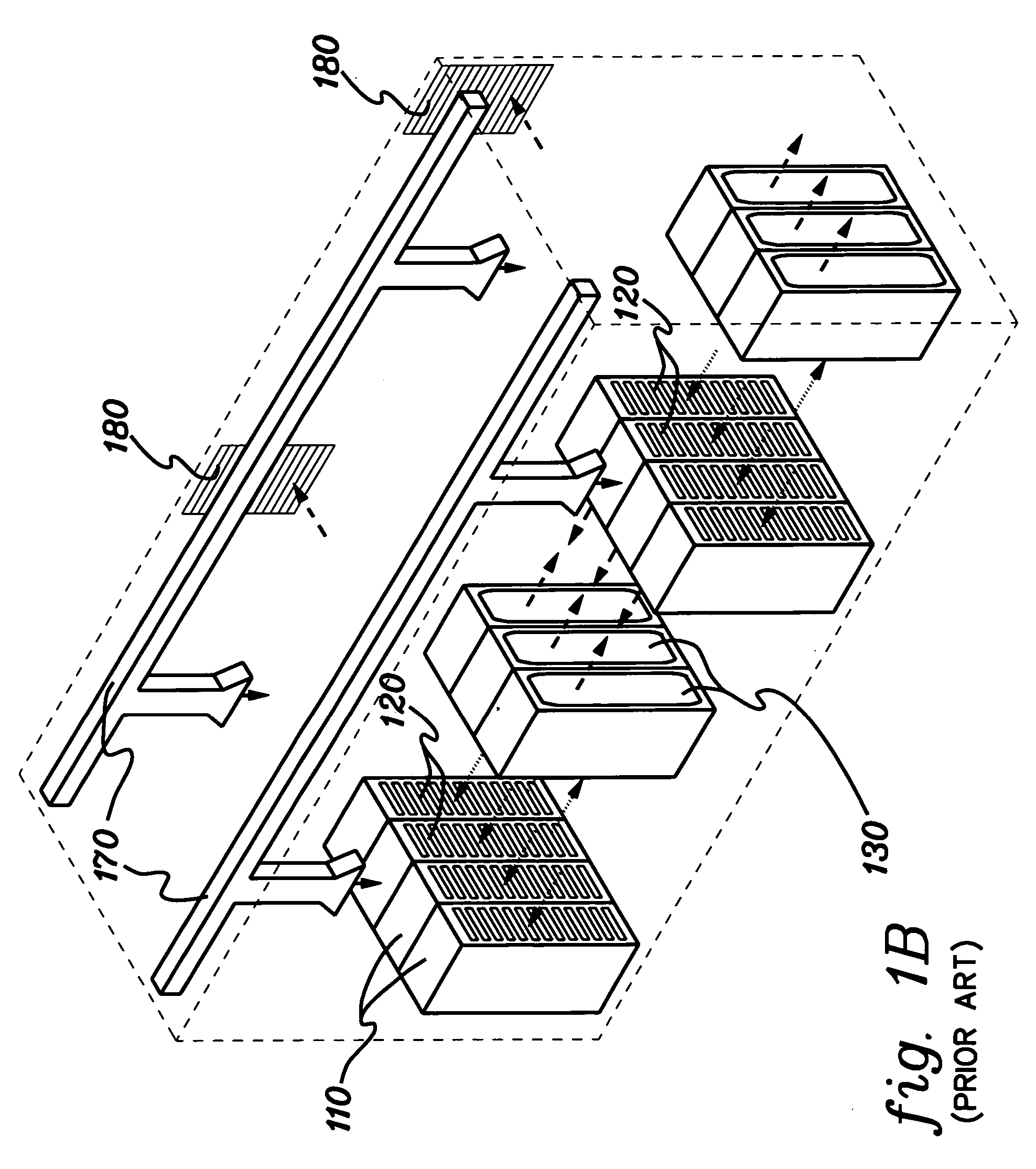

A cooling system and method employing separation chutes and baffles is disclosed. The separation chutes separate the cooled air descending from a heat exchanger positioned above heat-generating equipment in an equipment room from heated air ascending from the heat-generating equipment. Separation of the airflows reduces turbulence and increases cooling efficiencies. The separation chutes are made of a variety of materials, both rigid and flexible, for a variety of applications.

Owner:VERTIV CORP

Apparatus and method for heating subterranean formations using fuel cells

InactiveUS6684948B1Eliminate needAvoid inefficiencyFuel cell heat exchangeFuel cells groupingElectricityFuel cells

A fuel cell based subterranean heater for mineral extraction, in situ decontamination, or other applications. The fuel cells are preferably stacked within a casing which is then inserted into a hole bored, or otherwise formed, into the formation to be heated. Conduits within the casing, and preferably formed by adjacent, aligned holes formed through the plates of the individual fuel cells supply fuel and air and extract exhaust gases. An optional manifold is used to span the overburden without applying heat to it directly. The manifold may also function as a heat exchanger between incoming and exhaust gases. Preferably the fuel cell is fueled by gases produced by the formation and also generates electricity which is available for use or export.

Owner:IEP TECH INC

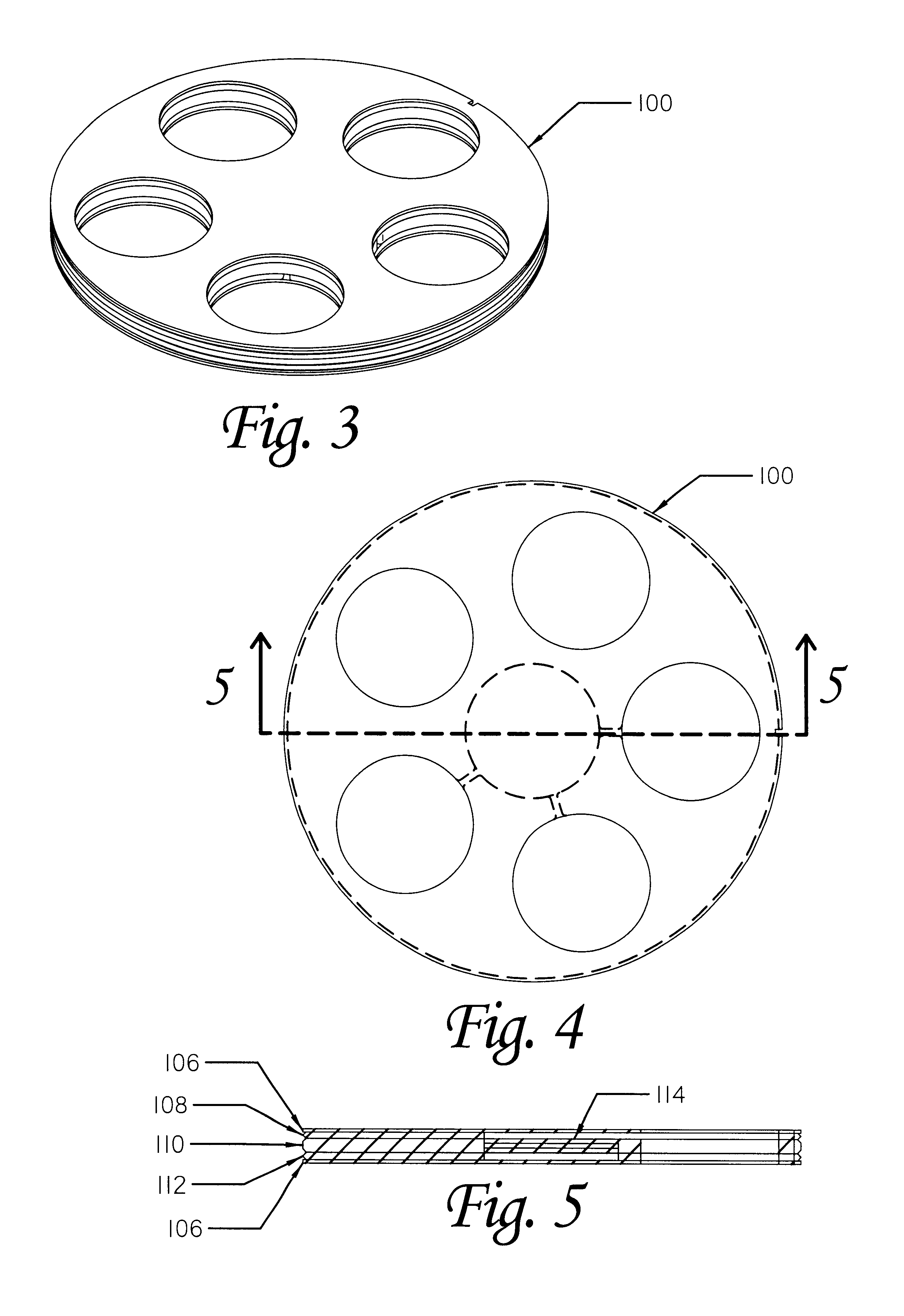

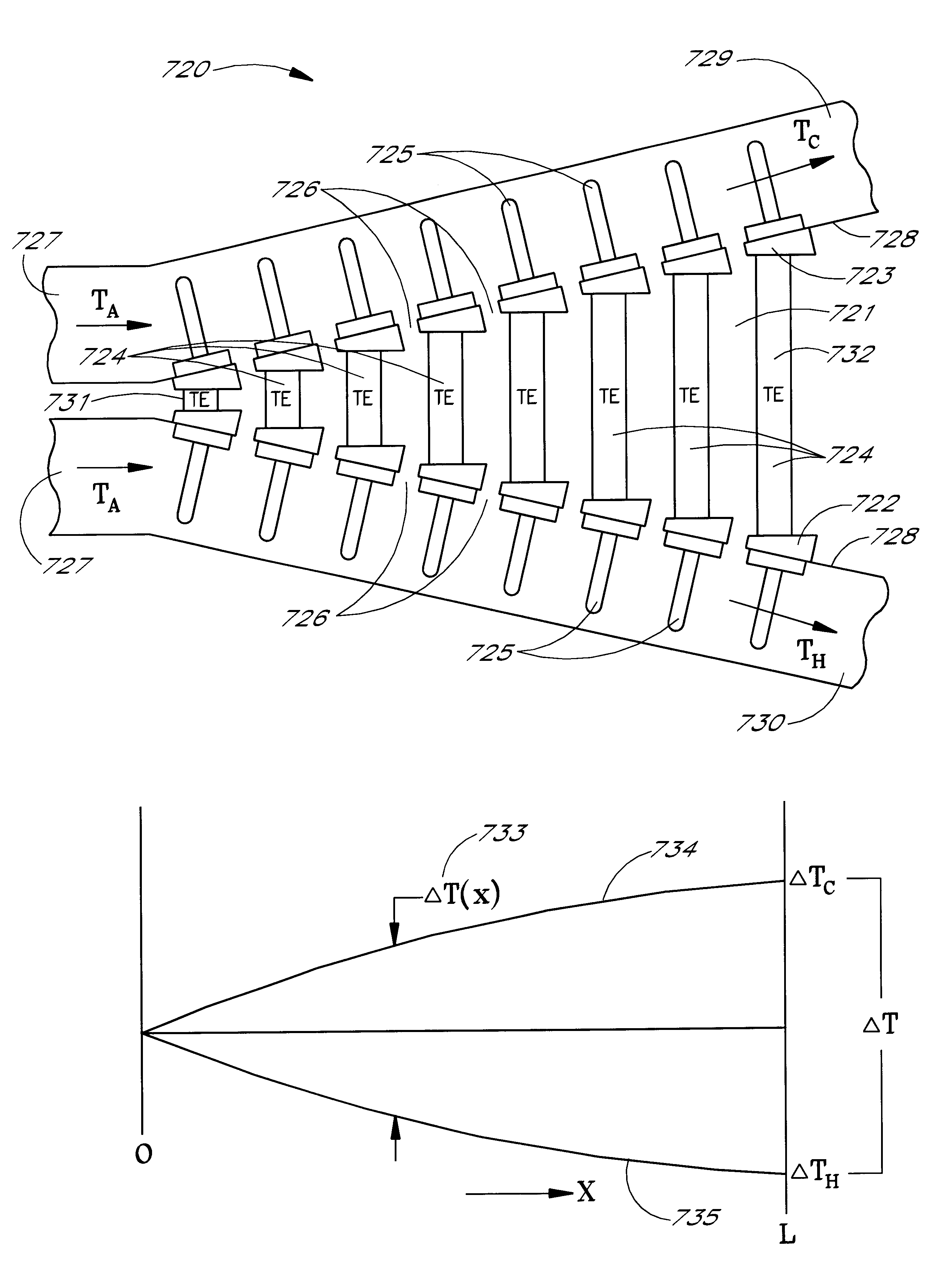

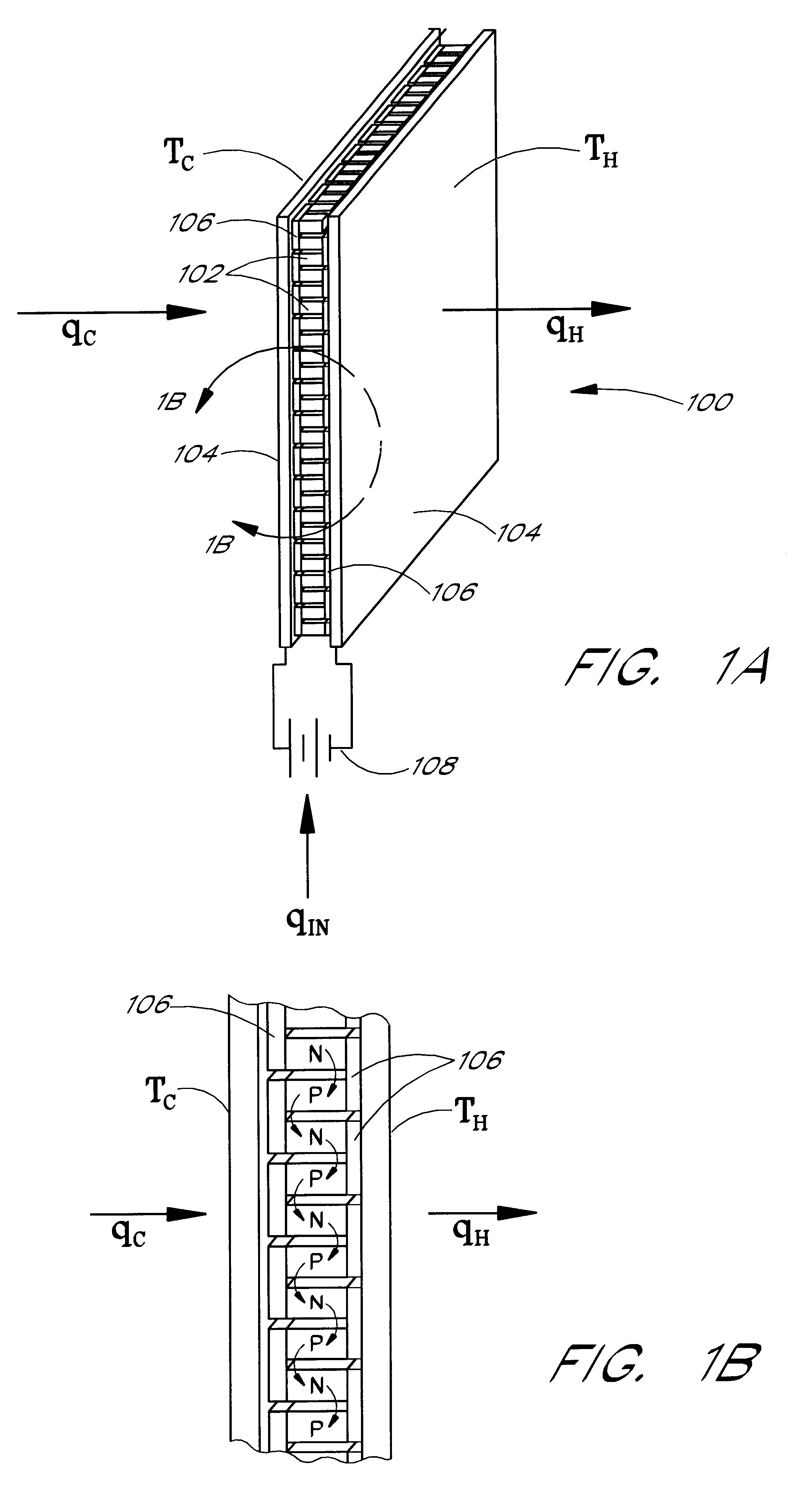

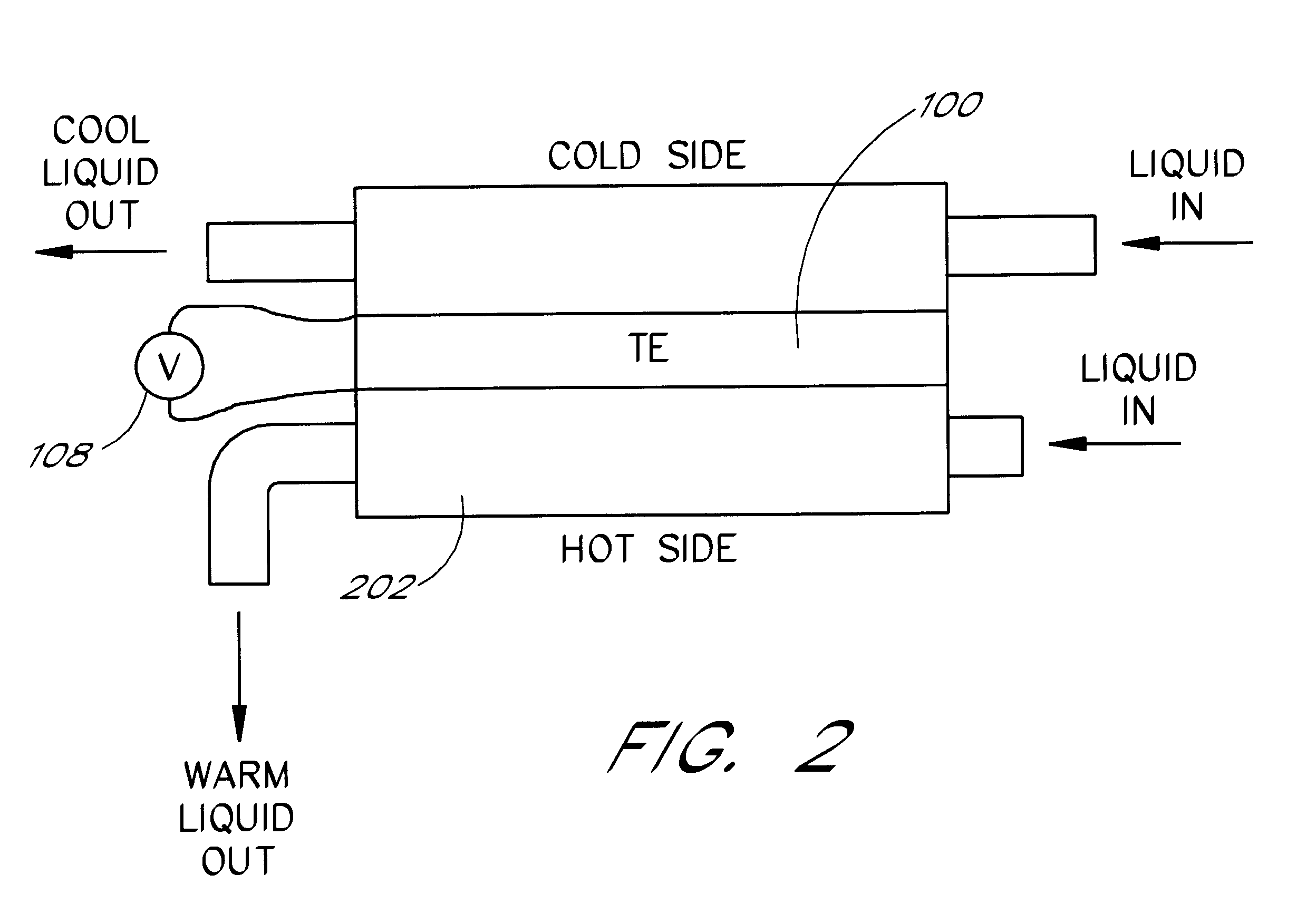

Efficiency thermoelectrics utilizing thermal isolation

InactiveUS6539725B2Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal isolationElectrical resistance and conductance

An improved efficiency thermoelectric system and method of making such a thermoelectric system are disclosed. Significant thermal isolation between thermoelectric elements in at least one direction across a thermoelectric system provides increased efficiency over conventional thermoelectric arrays. Significant thermal isolation is also provided for at least one heat exchanger coupled to the thermoelectric elements. In one embodiment, the properties, such as resistance or current flow, of the thermoelectric elements may also be varied in at least one direction across a thermoelectric array. In addition, the mechanical configuration of the thermoelectric elements may be varied, in one embodiment, according to dynamic adjustment criteria.

Owner:GENTHERM INC +1

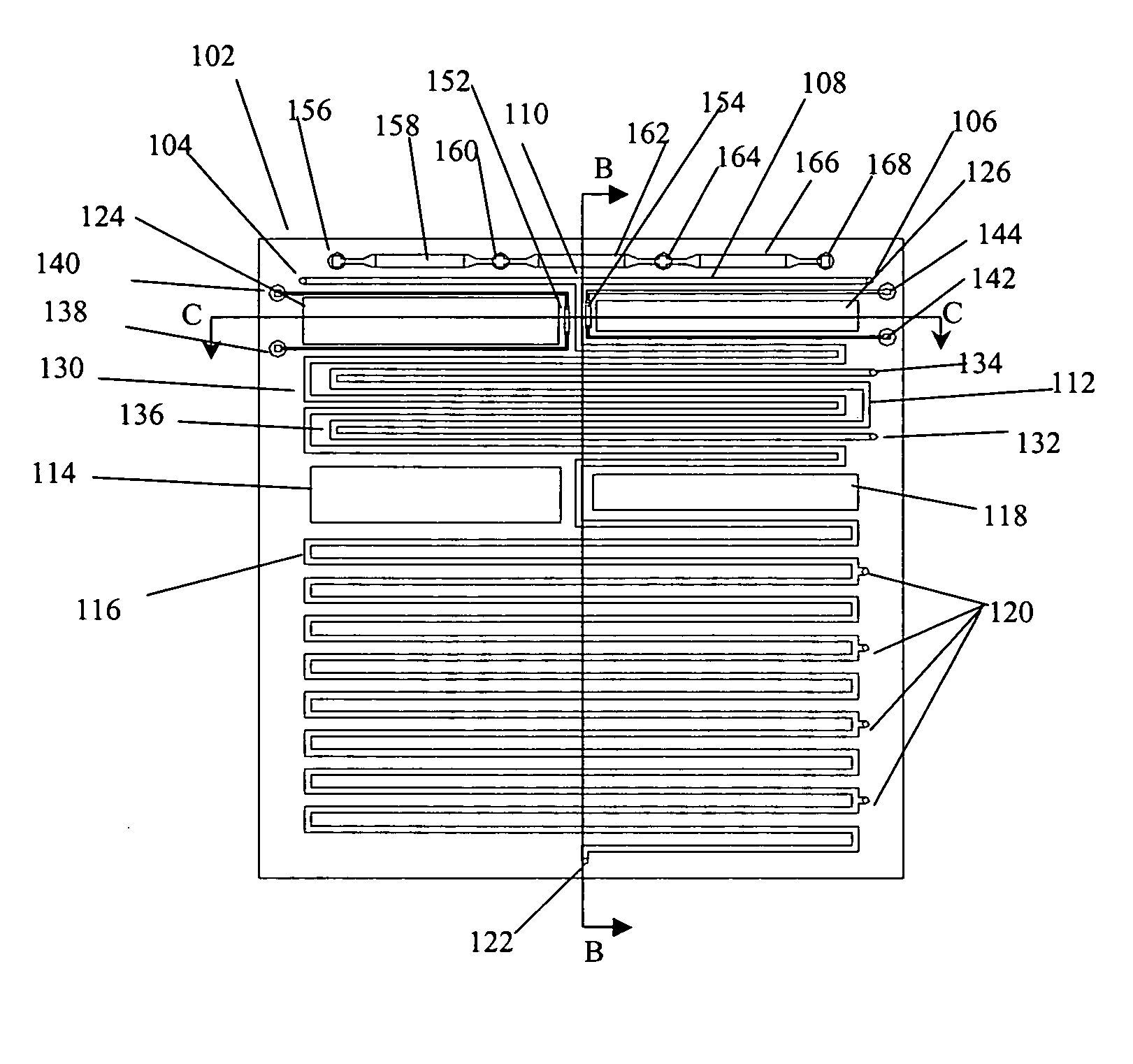

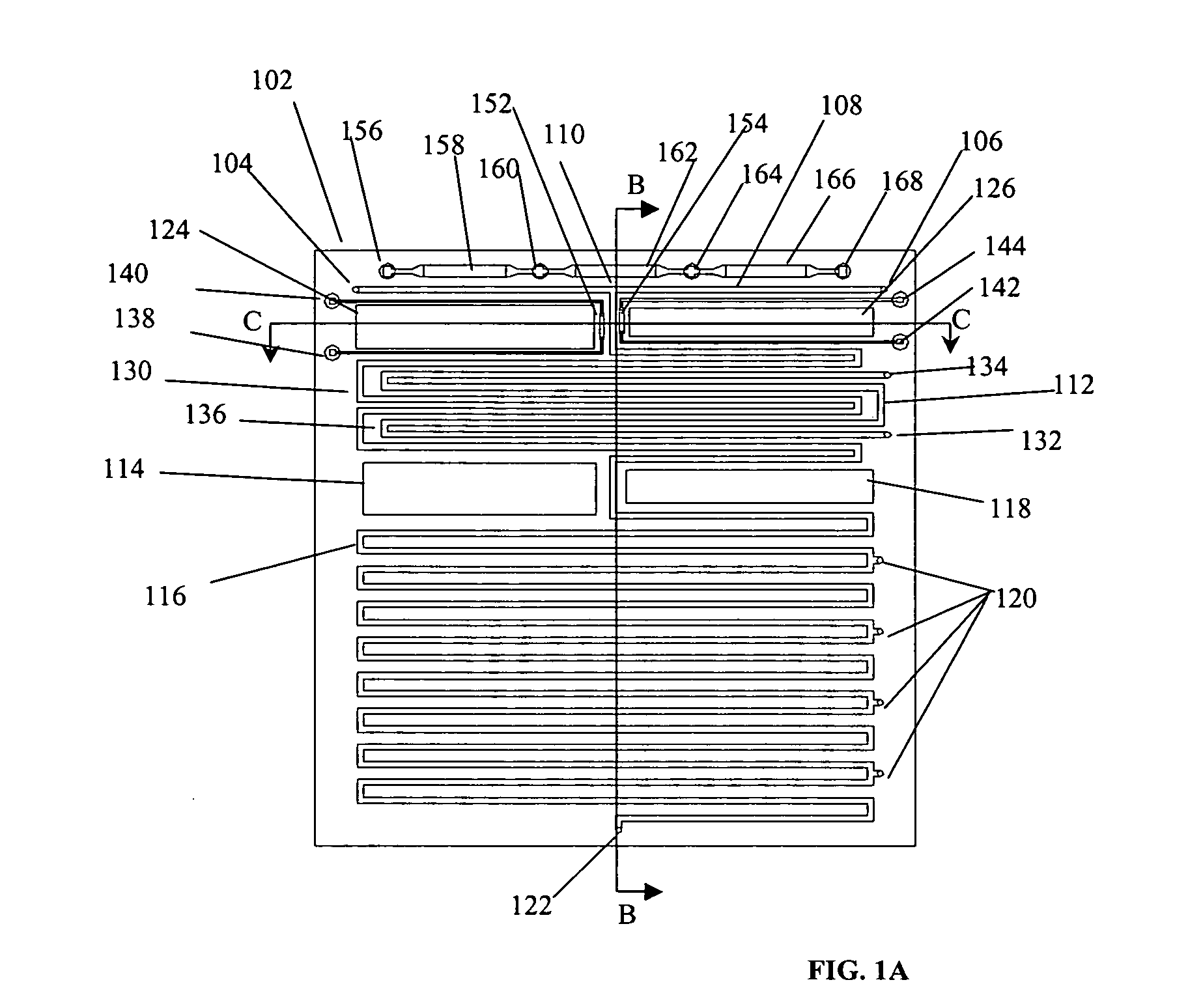

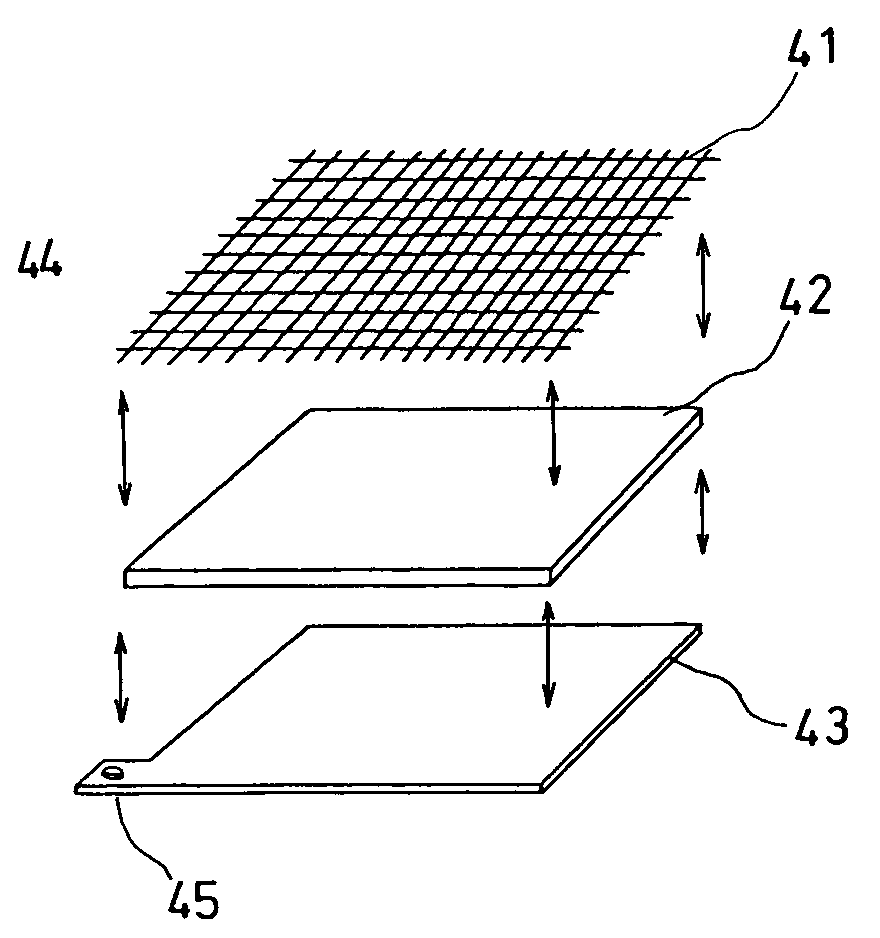

Microfluidic chemical reactor for the manufacture of chemically-produced nanoparticles

InactiveUS20050129580A1Maintain propertiesMaterial nanotechnologyPolycrystalline material growthProcess functionNanoparticle

The present invention discloses microfluidic modules for making nanocrystalline materials in a continuous flow process. The microfluidic modules include one or more flow path with mixing structures and one or more controlled heat exchangers to process the nanocrystalline materials and reagents in the flow path. The microfluidic modules can be interconnected to form microfluidic reactors that incorporate one or more process functions such as nucleation, growth, and purification.

Owner:LAKE SHORE CRYOTRONICS INC

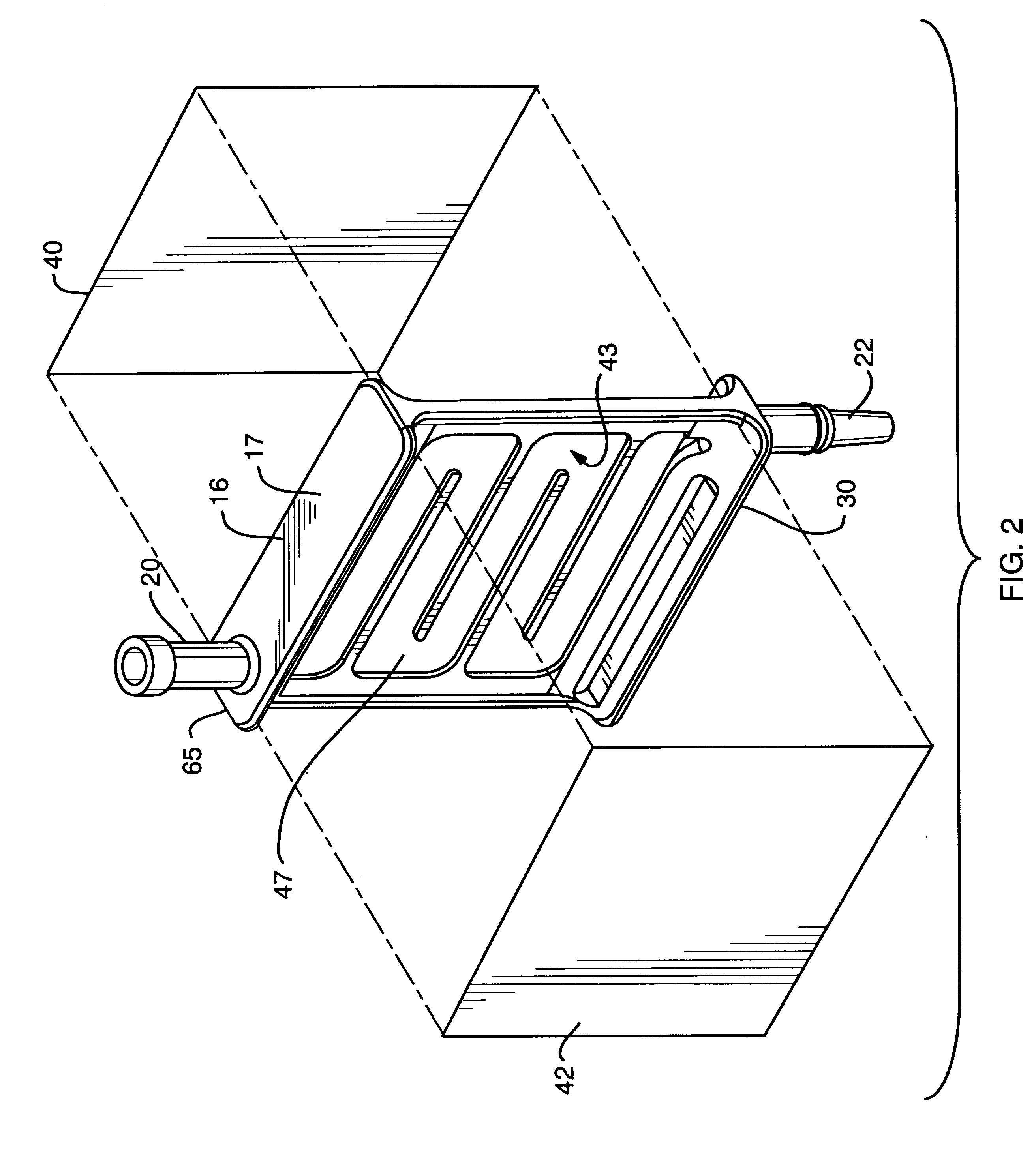

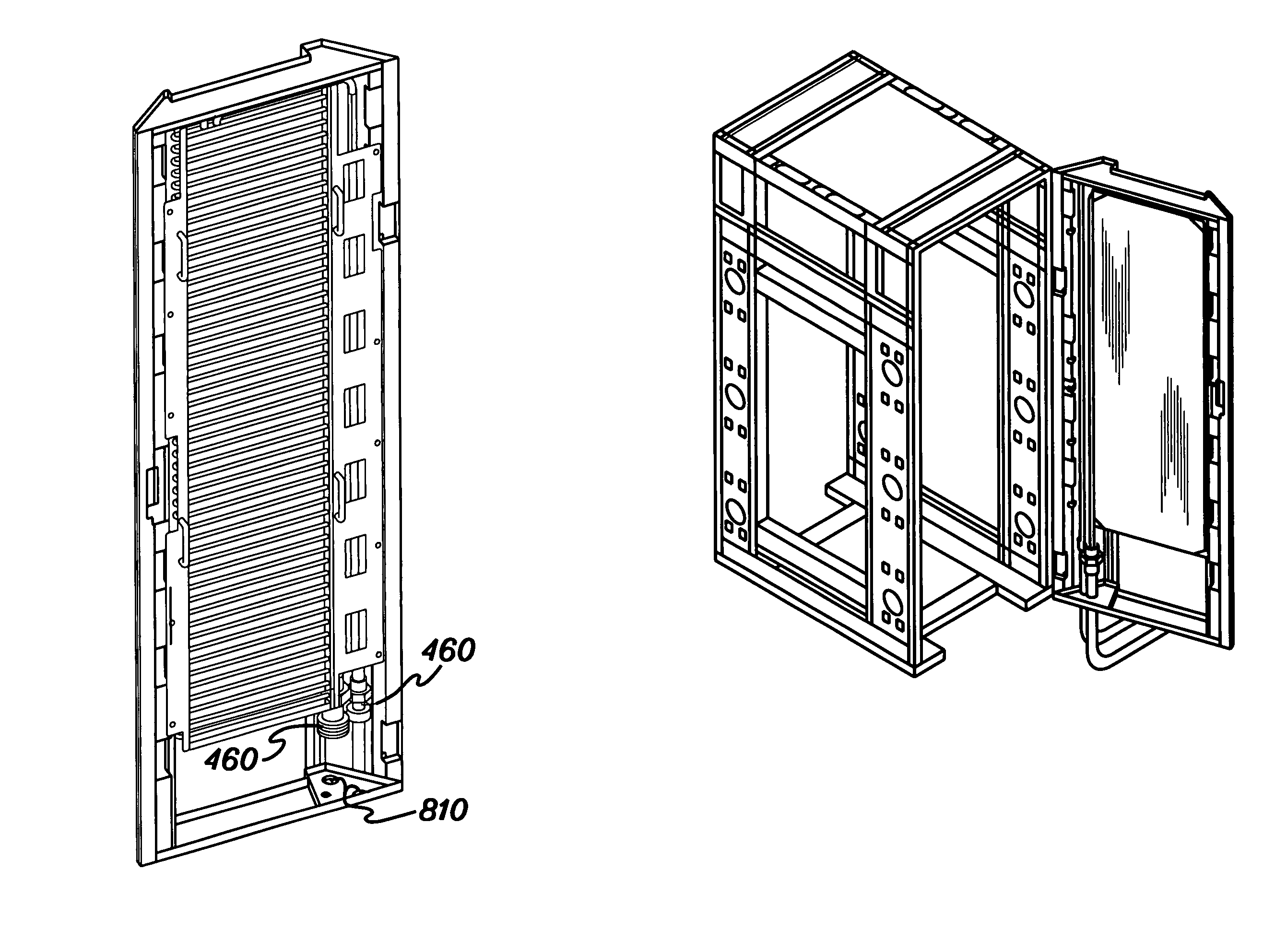

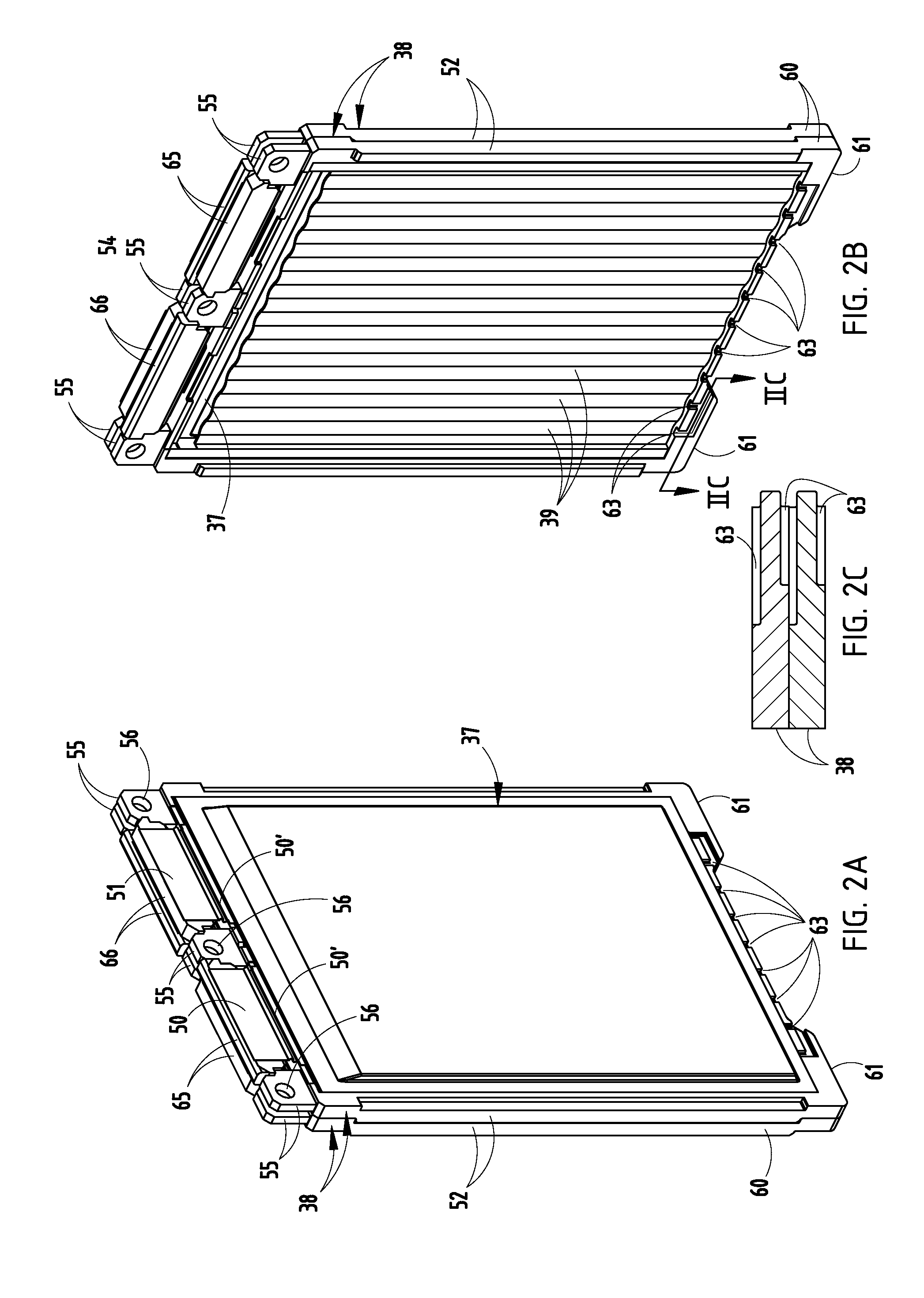

Apparatus and method for facilitating cooling of an electronics rack employing a heat exchange assembly mounted to an outlet door cover of the electronics rack

Apparatus and method are provided for facilitating cooling of an electronics rack employing a heat exchange assembly mounted to an outlet door cover hingedly affixed to an air outlet side of the rack. The heat exchange assembly includes a support frame, an air-to-liquid heat exchanger, and first and second perforated planar surfaces covering first and second main sides, respectively, of the air-to-liquid heat exchanger. The heat exchanger is supported by the support frame and includes inlet and outlet plenums disposed adjacent to the edge of the outlet door cover hingedly mounted to the rack. Each plenum is in fluid communication with a respective connect coupling, and the heat exchanger further includes multiple horizontally-oriented heat exchange tube sections each having serpentine cooling channel with an inlet and an outlet coupled to the inlet plenum and outlet plenum, respectively. Fins extend from the heat exchange tube sections.

Owner:VETTE TECH

Thermal management systems and methods

InactiveUS20050167169A1Increase heatCell temperature controlMachines/enginesThermal energyThermal energy storage

A thermal management system for a vehicle includes a heat exchanger having a thermal energy storage material provided therein, a first coolant loop thermally coupled to an electrochemical storage device located within the first coolant loop and to the heat exchanger, and a second coolant loop thermally coupled to the heat exchanger. The first and second coolant loops are configured to carry distinct thermal energy transfer media. The thermal management system also includes an interface configured to facilitate transfer of heat generated by an internal combustion engine to the heat exchanger via the second coolant loop in order to selectively deliver the heat to the electrochemical storage device. Thermal management methods are also provided.

Owner:BATTELLE ENERGY ALLIANCE LLC

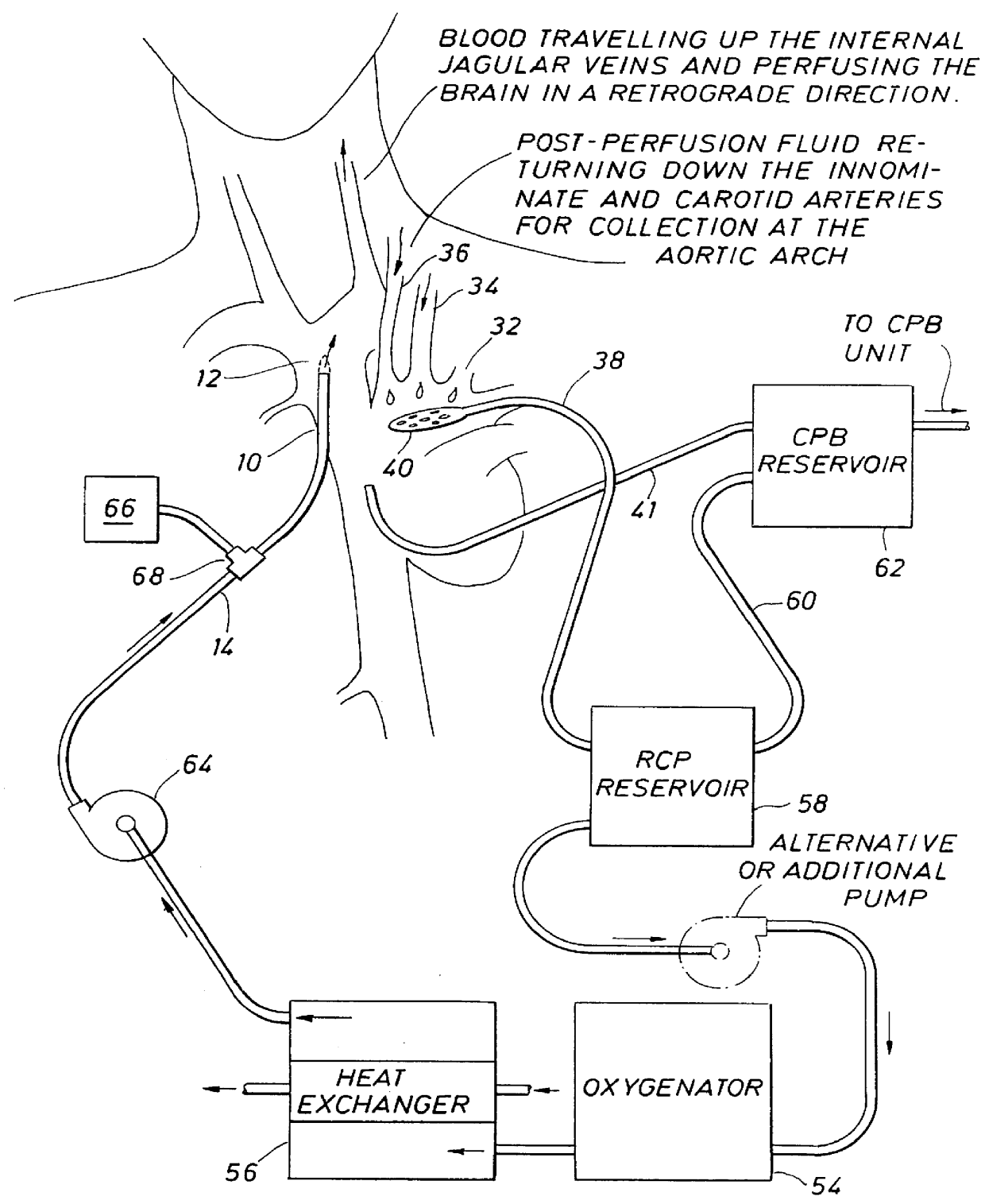

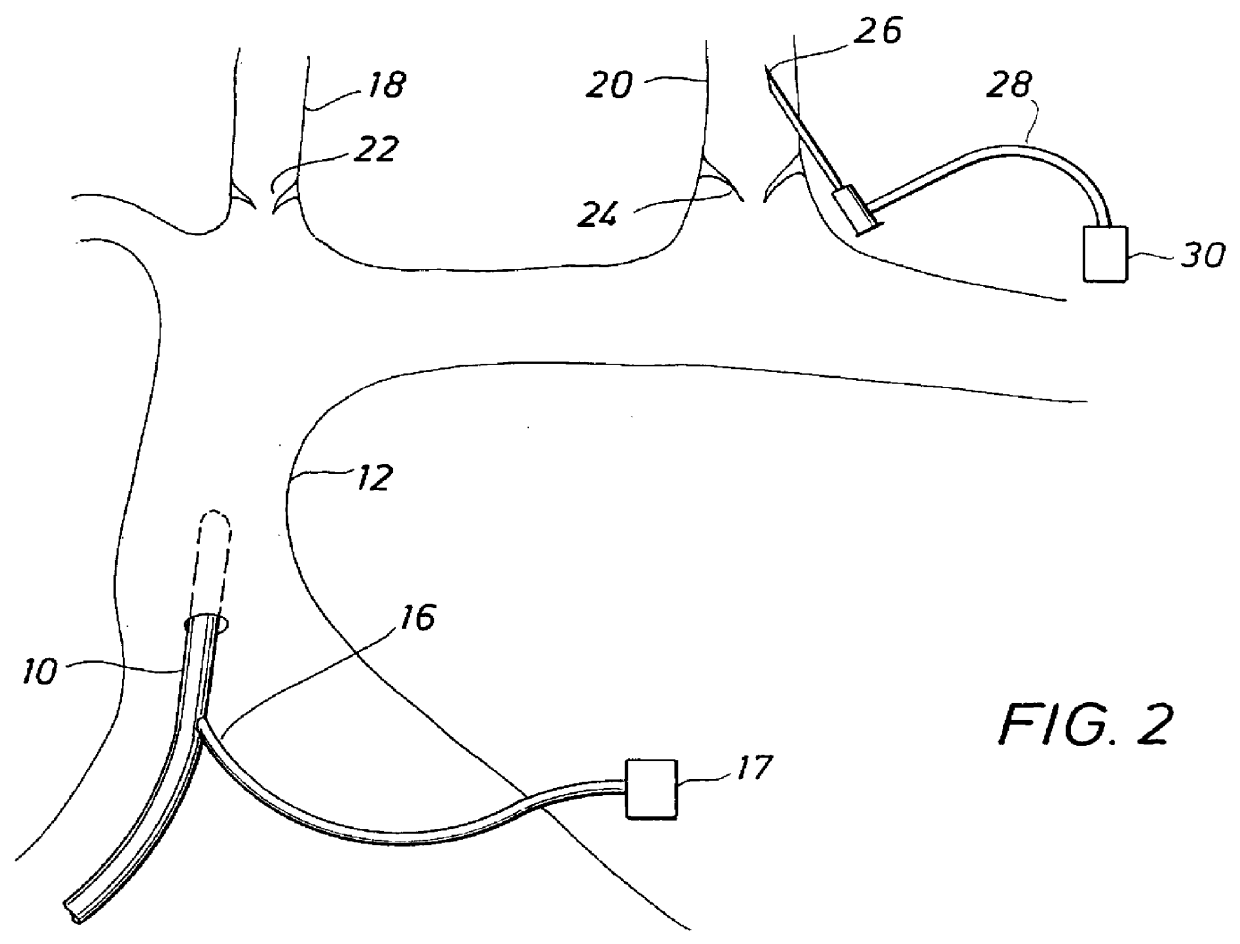

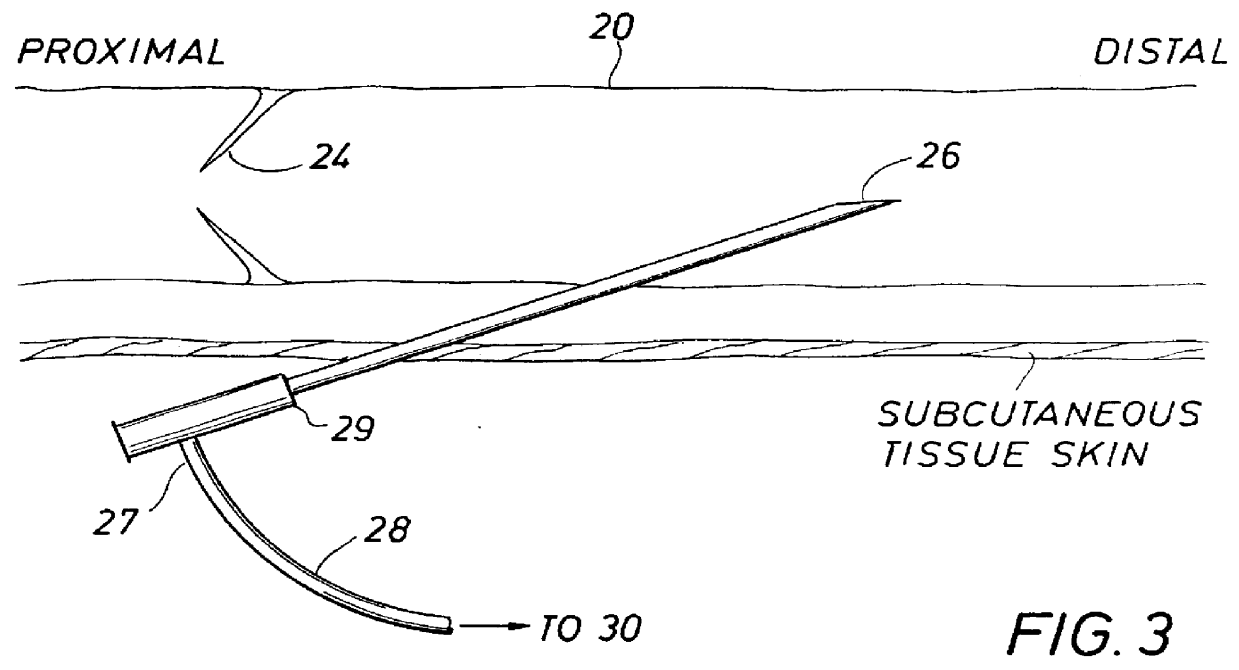

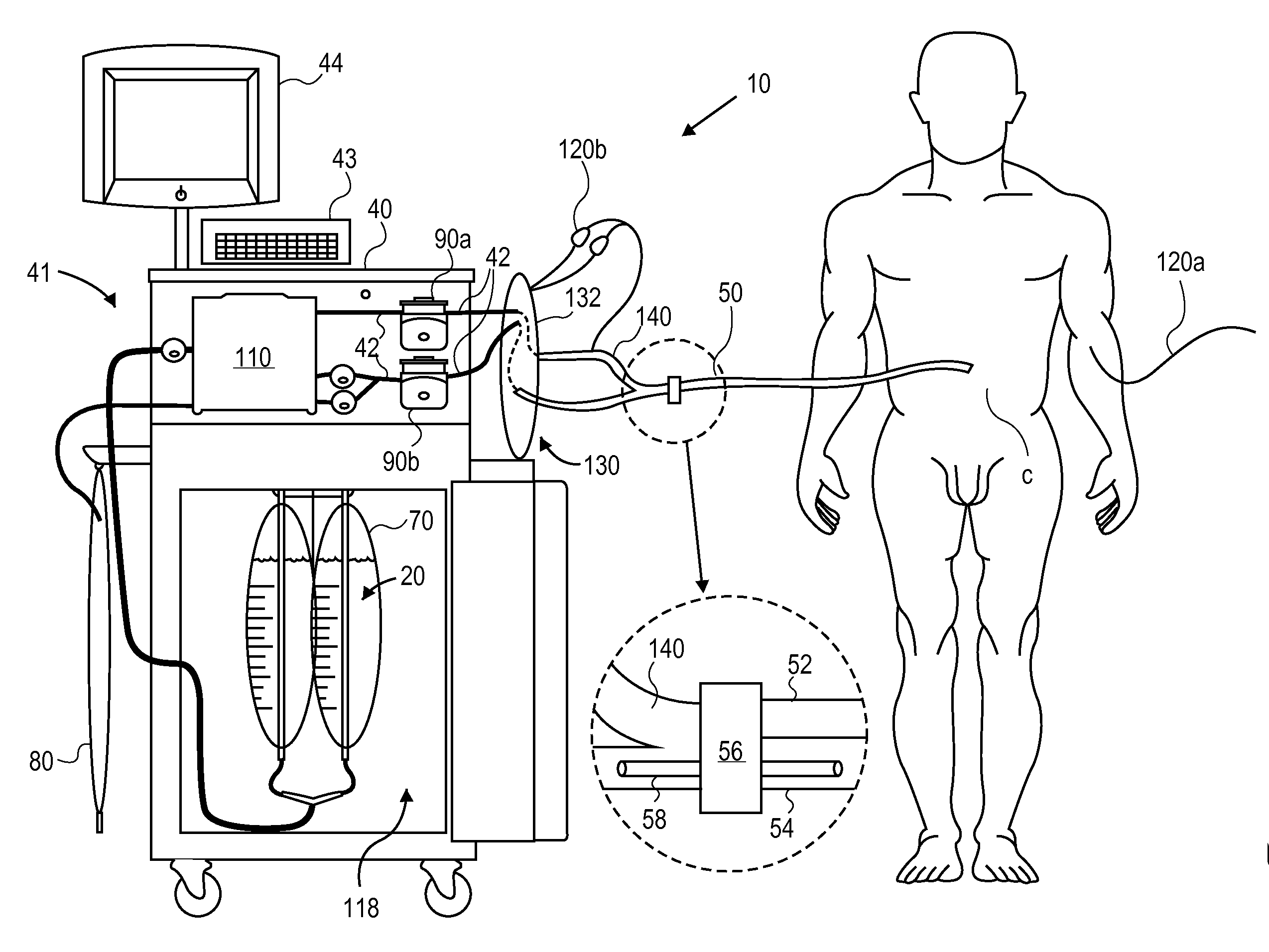

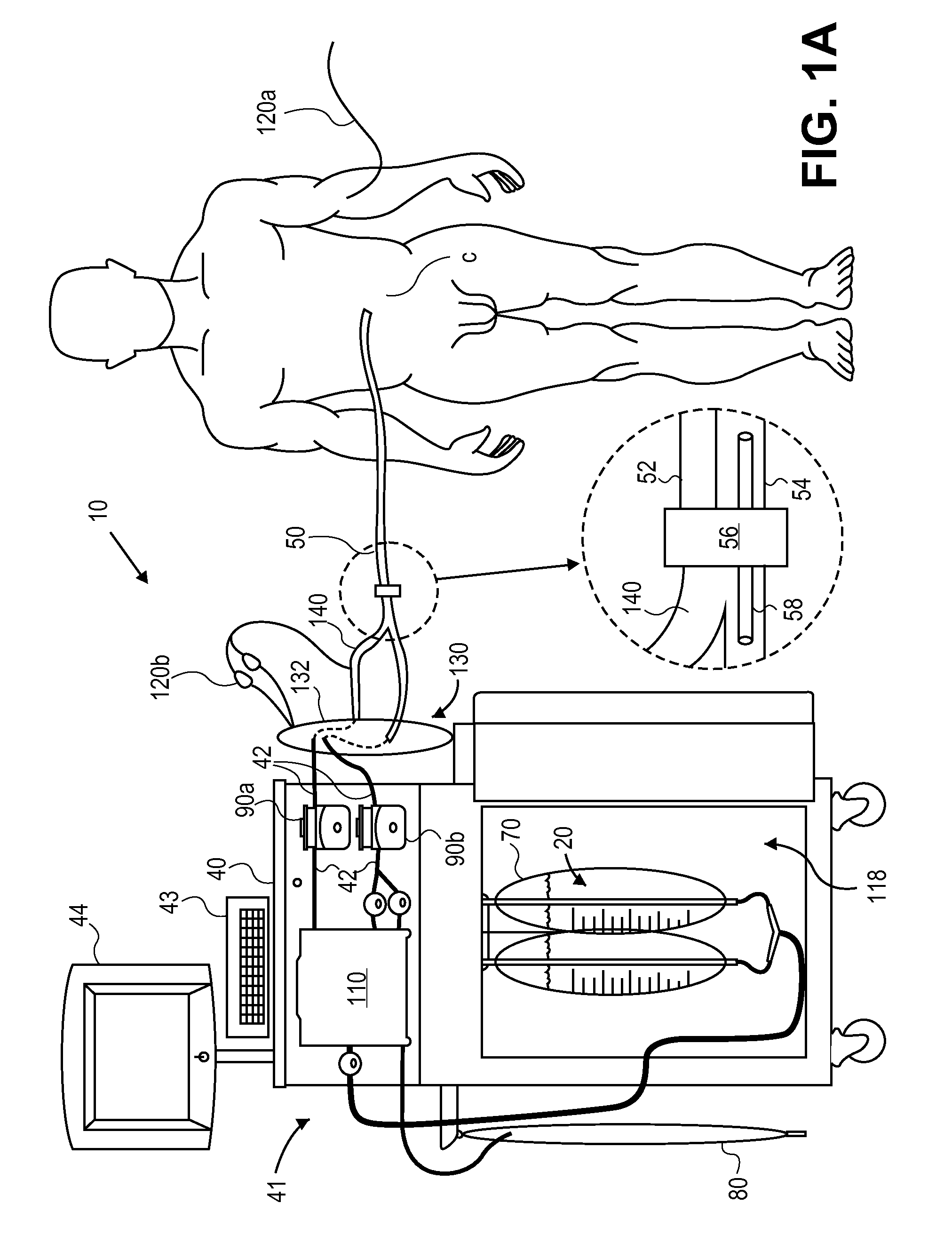

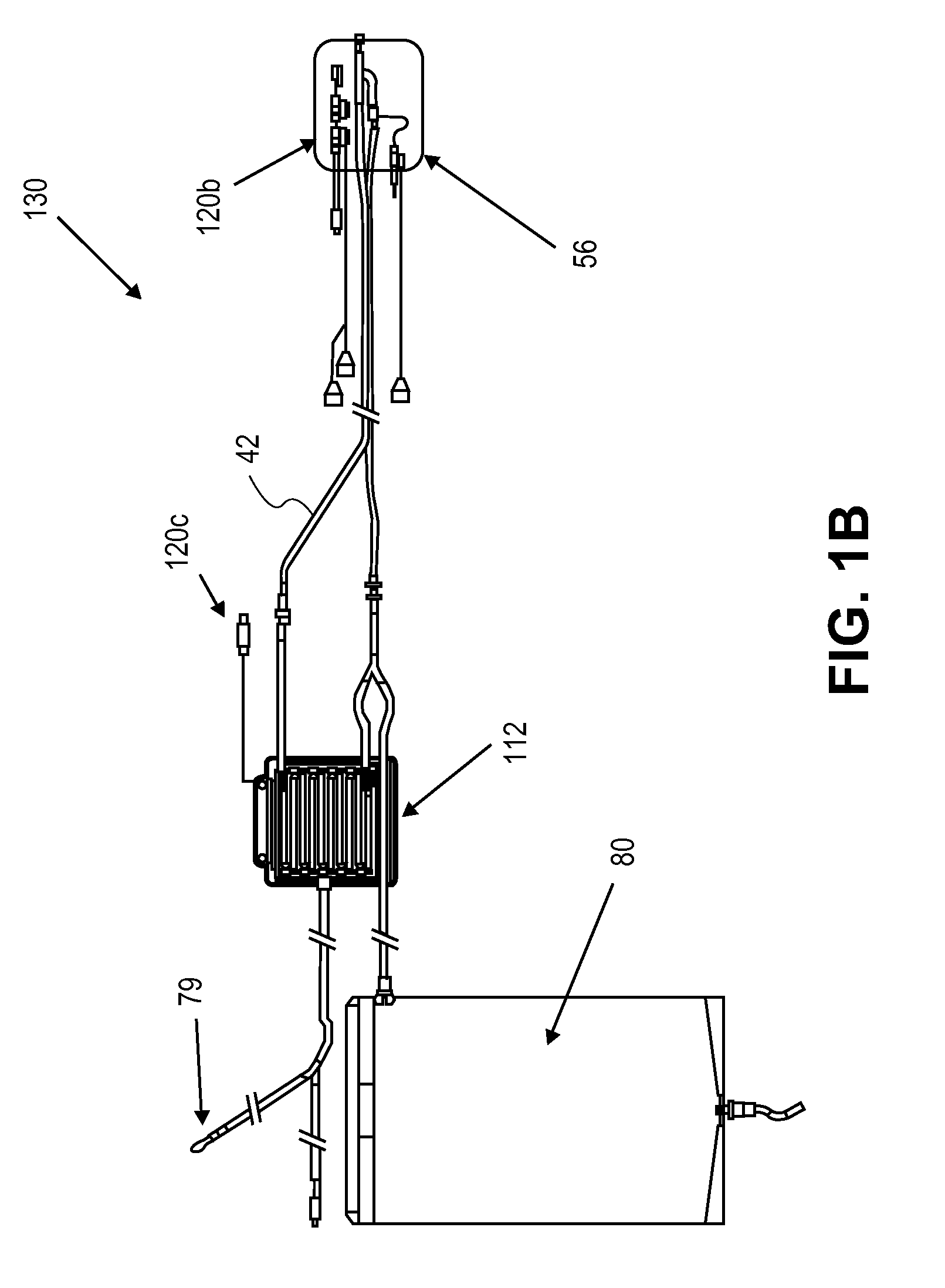

Retrograde perfusion monitoring and control system

InactiveUS6110139AOther blood circulation devicesDialysis systemsOrgan systemCardiopulmonary bypass time

Apparatus and methods for performing retrograde perfusion, especially during cardiopulmonary bypass operations, including dedicated pediatric scaled apparatus for retrograde perfusion of an adult human organ, organ system, or limb, especially the brain, employing small scale oxygenators and heat exchangers such as are designed for pediatric surgery; also including methods and apparatus for retrograde cerebral perfusion, using nonselective infravalvular cannulation of the superior vena cava, estimating the efficacy of cerebral perfusion by monitoring fluid flow across a valve of an internal jugular vein, modification of inflow pressure and administration of pharmacologic agents, and increasing fluid flow into a brain by occlusion of an inferior vena cava distal to its junction with an azygos vein.

Owner:LOUBSER PAUL GERHARD

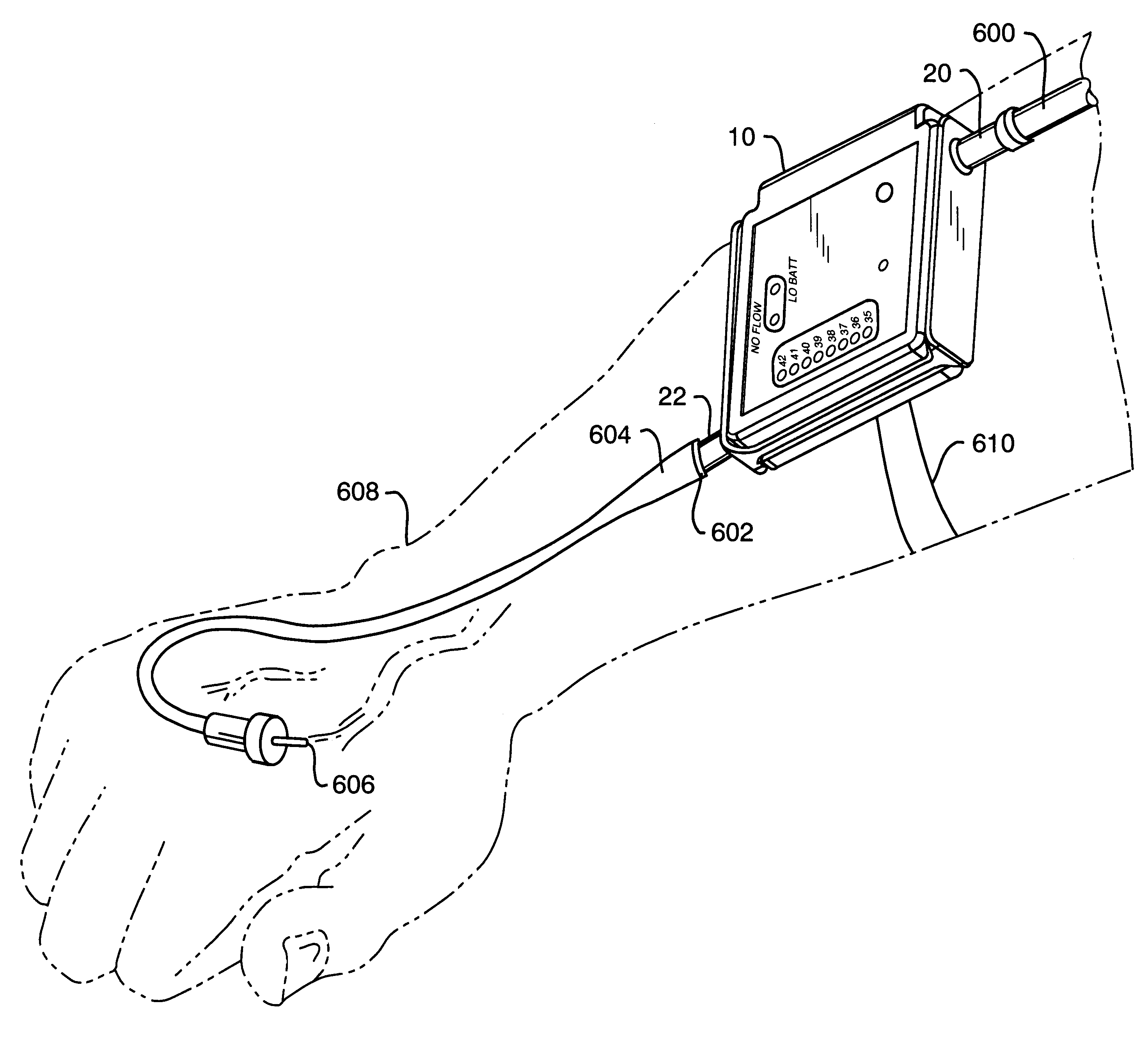

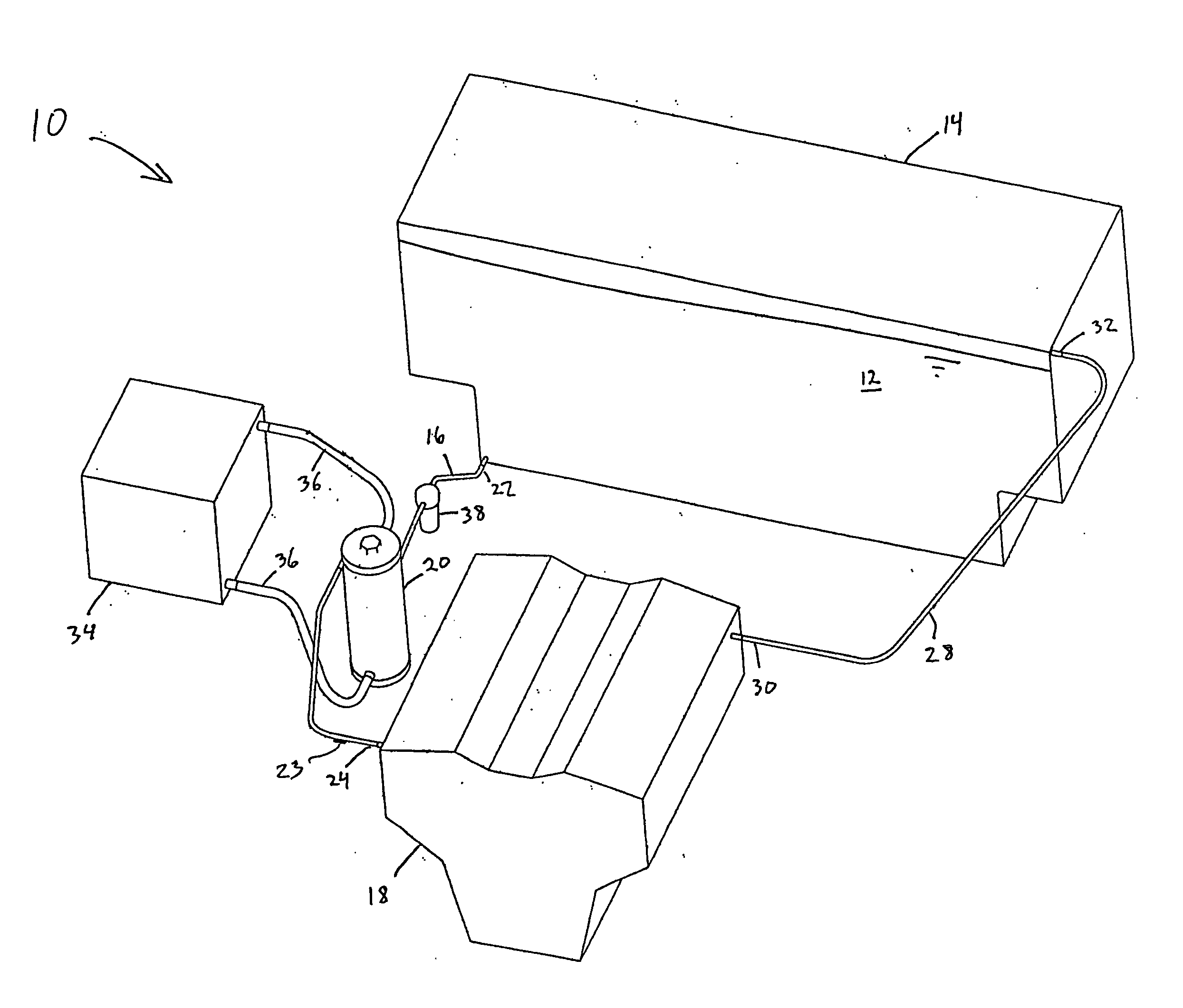

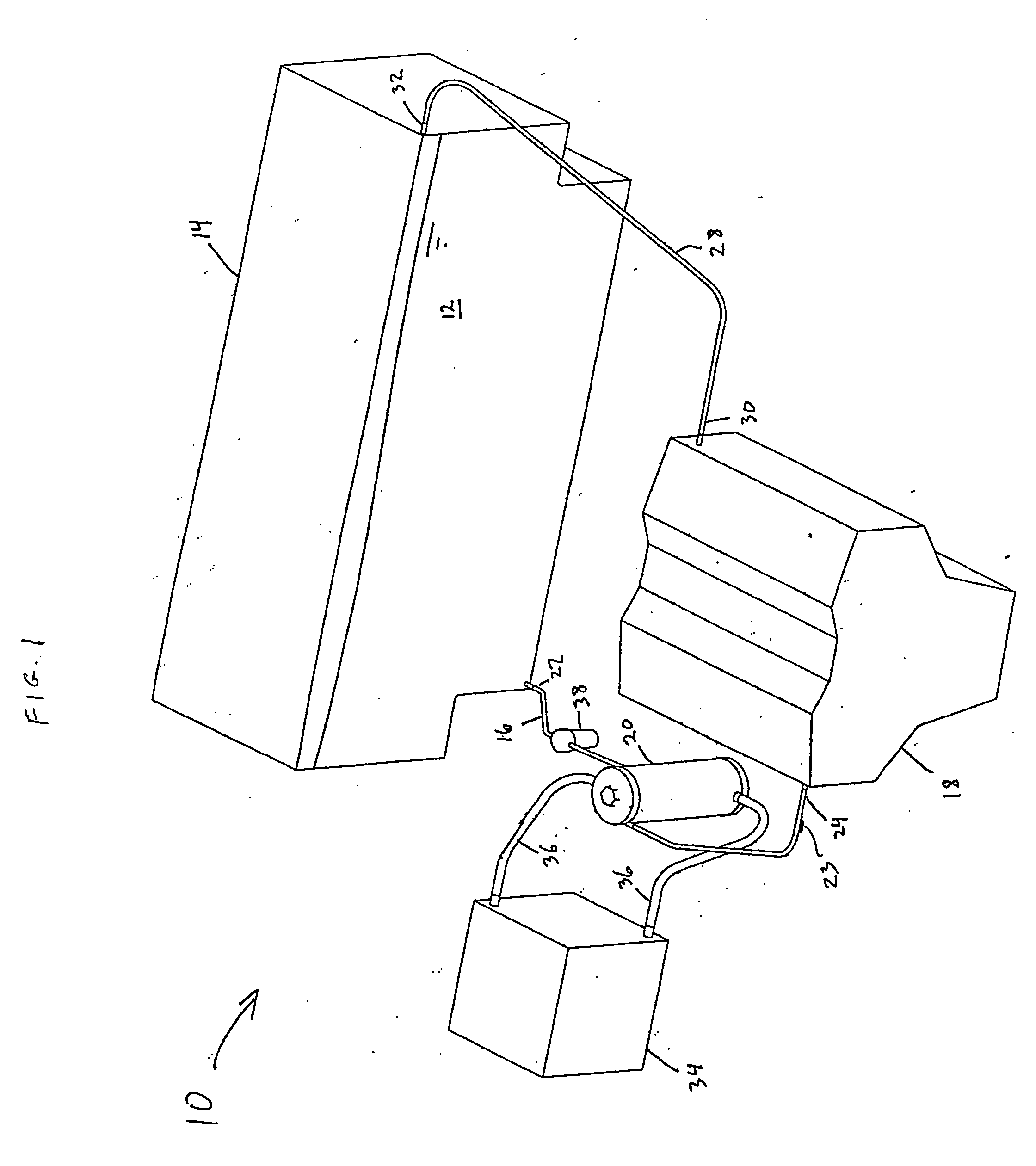

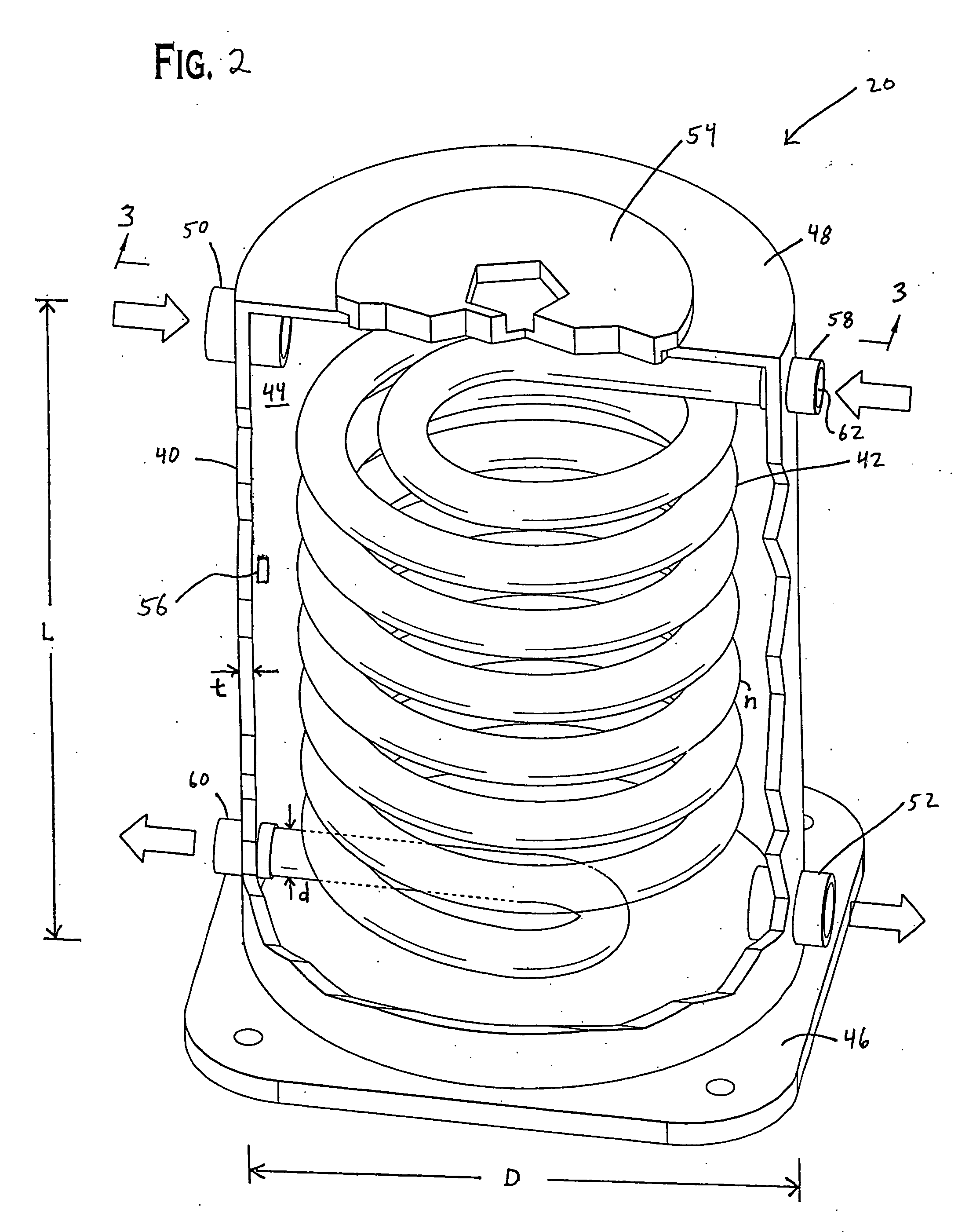

Wearable intravenous fluid heater

InactiveUS6175688B1Avoid contaminationReduce riskMedical devicesHeating element shapesTemperature controlEngineering

An intravenous fluid heater is provided that is dimensioned so as to be wearable adjacent a patient's intravenous fluid infusion situs. In one embodiment, the heater includes a heat exchanger for defining a flow path through the heater for fluid to be infused via the infusion situs. At least one controllable heating element is provided for heating the fluid in the flow path by heat conduction thereto through the heat exchanger. Sensors are included for sensing respective temperatures of entering and exiting fluids of the flow path. A controller controls, based upon the temperatures of the exiting fluids, heating of the fluid in the flow path by the heating element so as to cause the fluid in the flow path to be substantially uniformly heated to a desired infusion temperature prior to exiting the heater.

Owner:BELMONT INSTR LLC

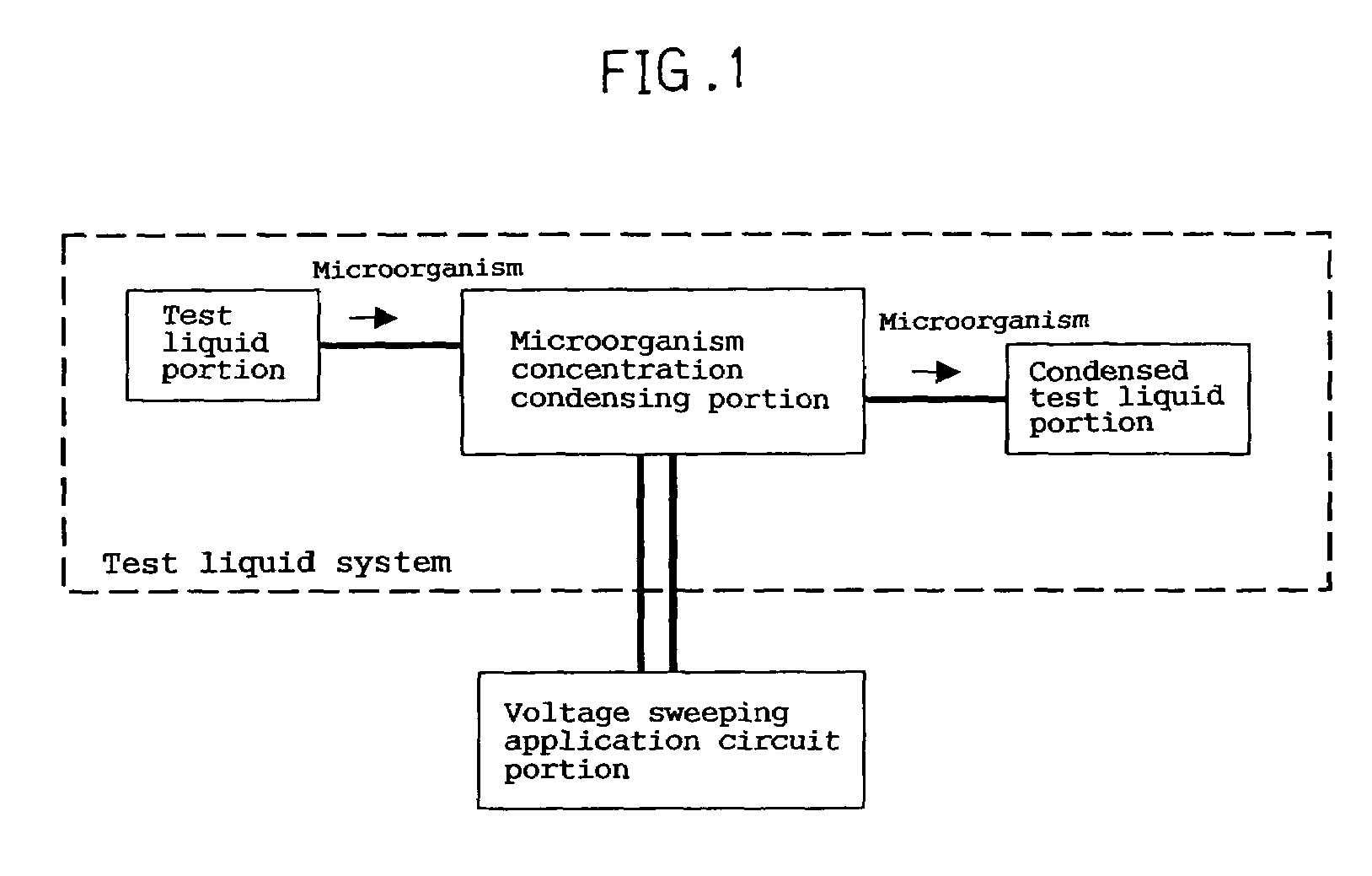

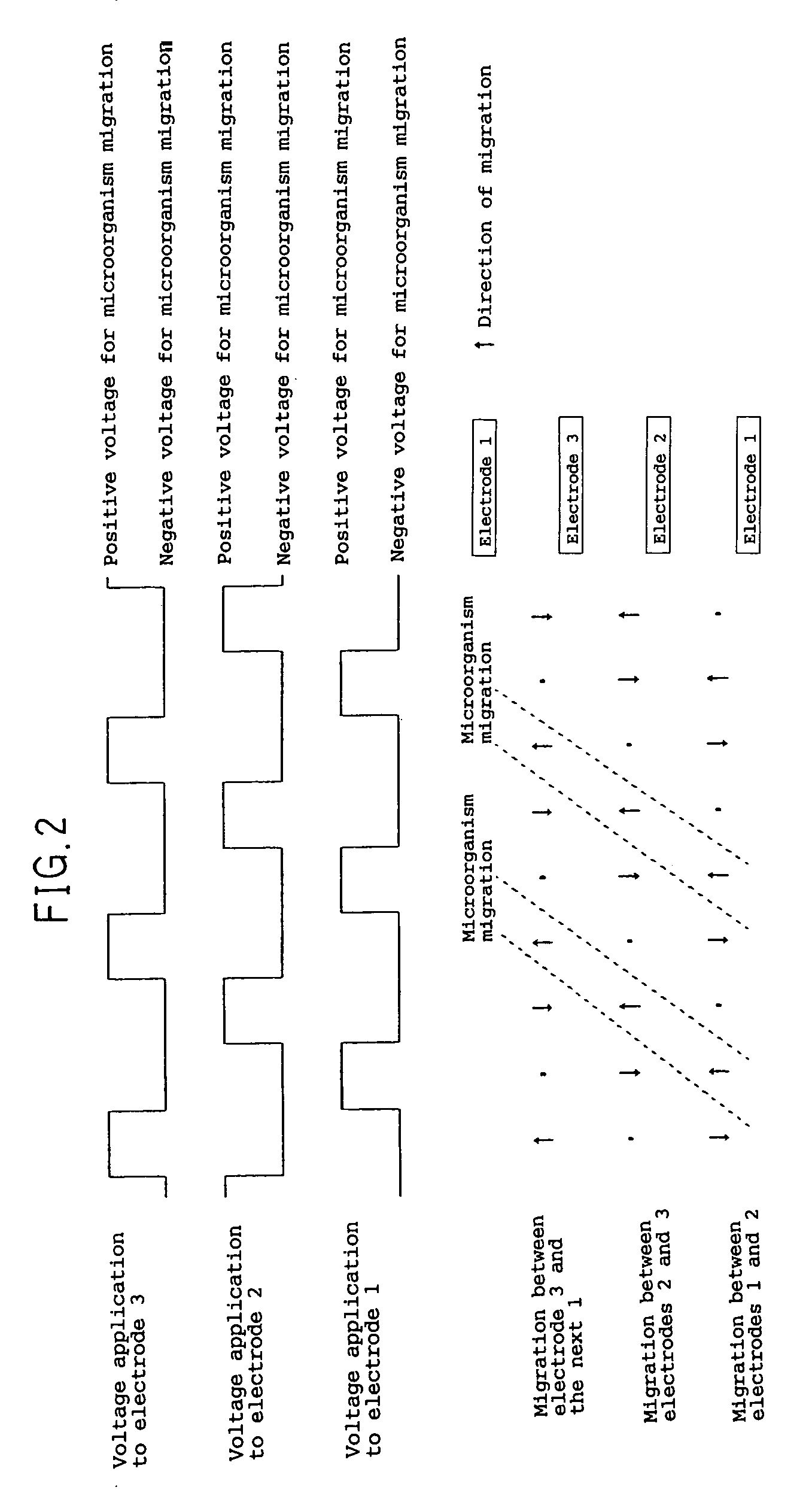

Electrochemical device for moving particles covered with protein

InactiveUS6972080B1Efficient disposalElectrostatic separatorsSludge treatmentBlood componentElectrolysis

An electrochemical device for moving particles covered with a protein is provided. The device includes at least two electrodes that are in contact with a liquid containing the protein-covered particles and a circuit that generates a potential difference in a range that does not cause electrolysis of the liquid between the electrodes. The particles are moved by electrophoresis in the direction of the arrangement of the electrodes. The invention provided herein has numerous applications, including use in a microorganism concentration condensing device, a blood component induction device, and / or a blood component induction method, and / or an electric appliance that decreases the concentration of microorganisms present on the surface of a heat exchanger.

Owner:PANASONIC CORP

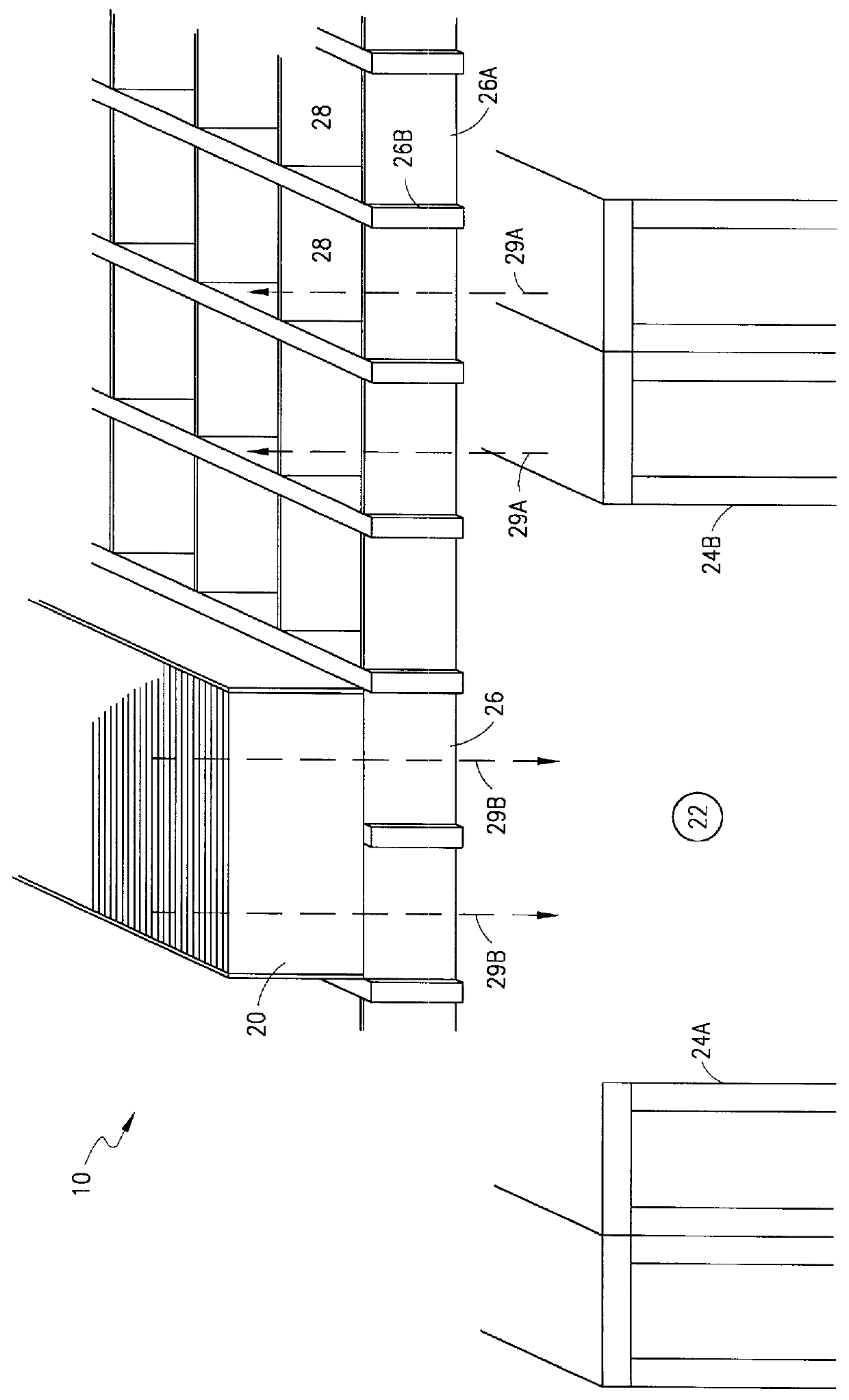

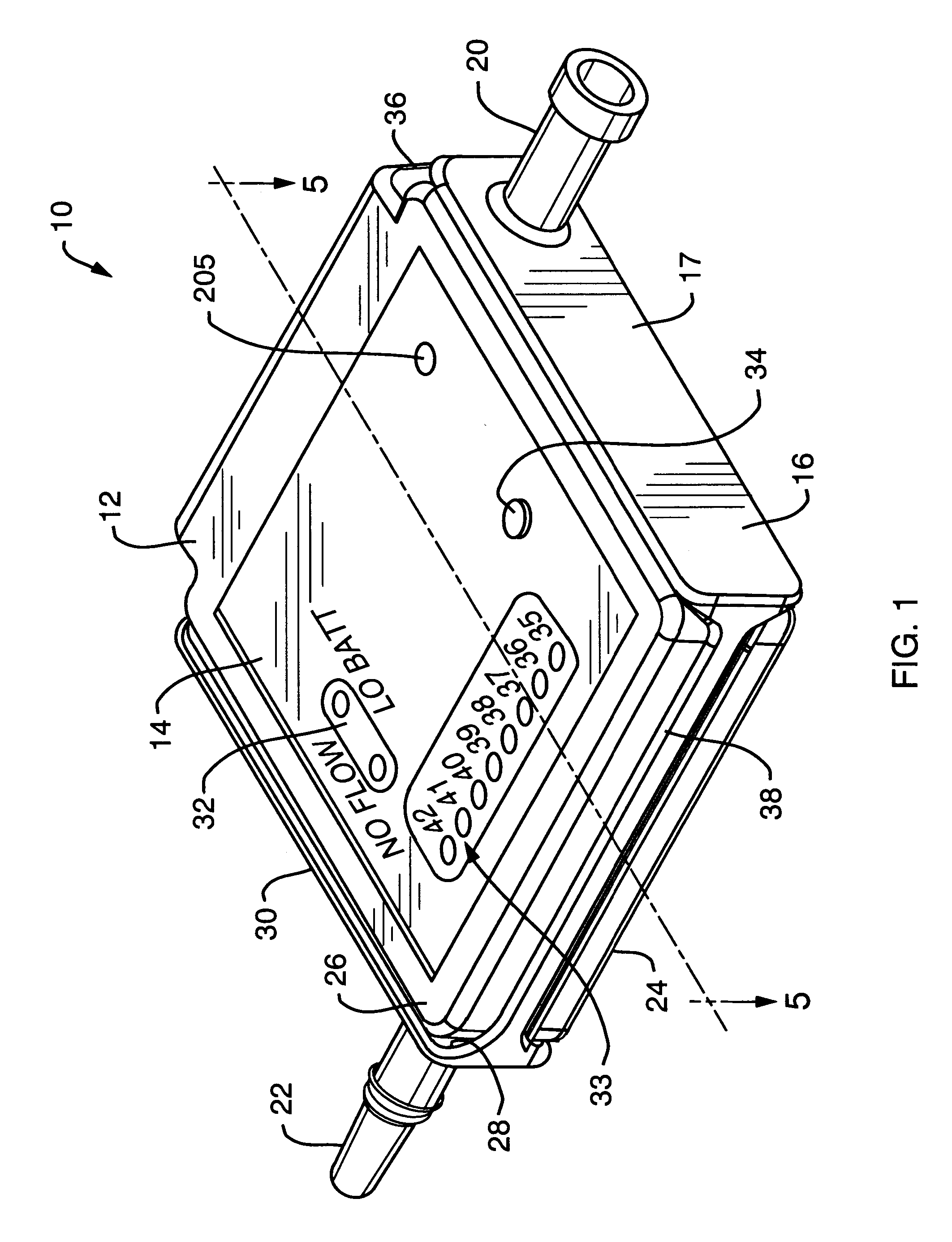

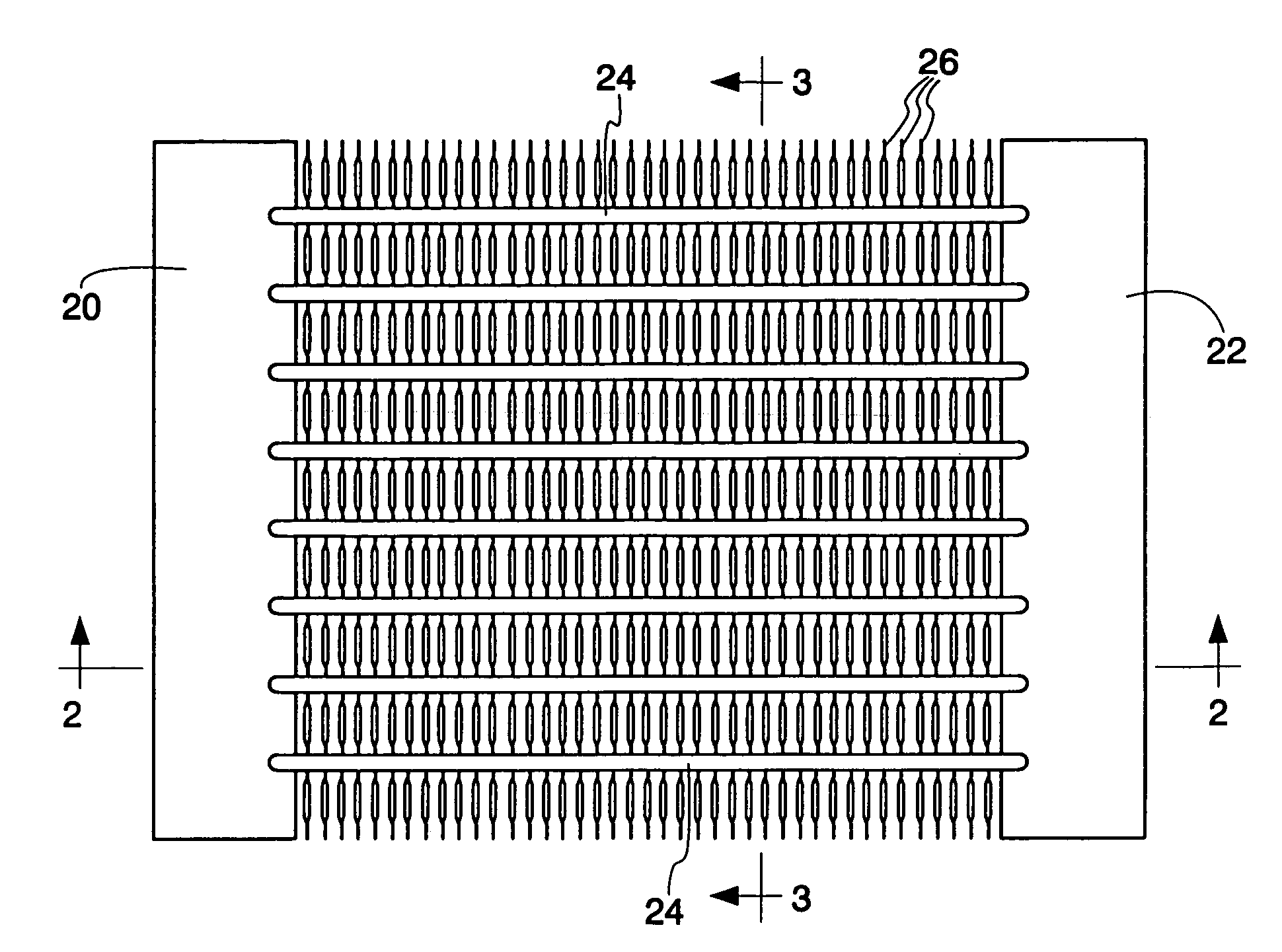

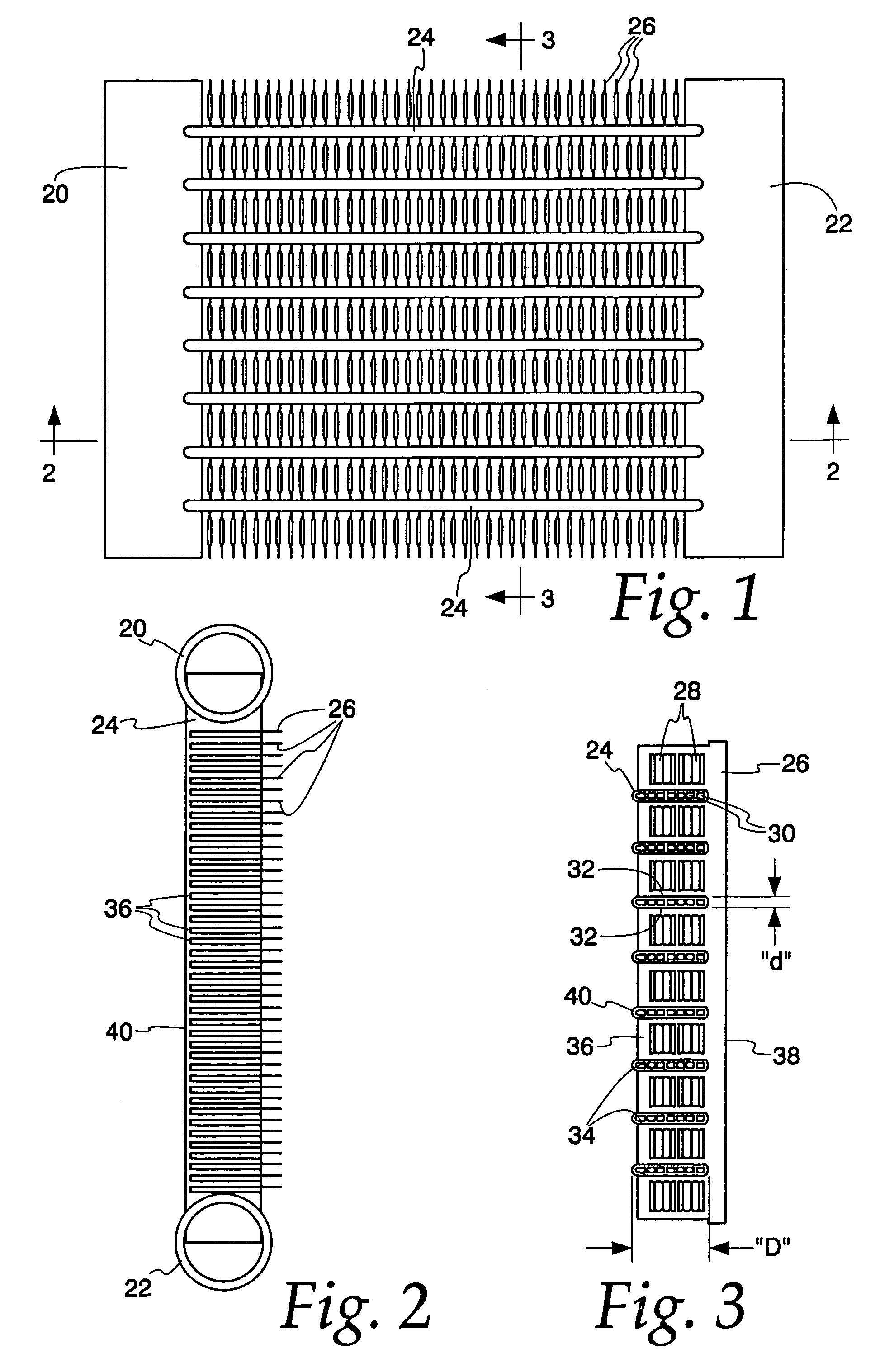

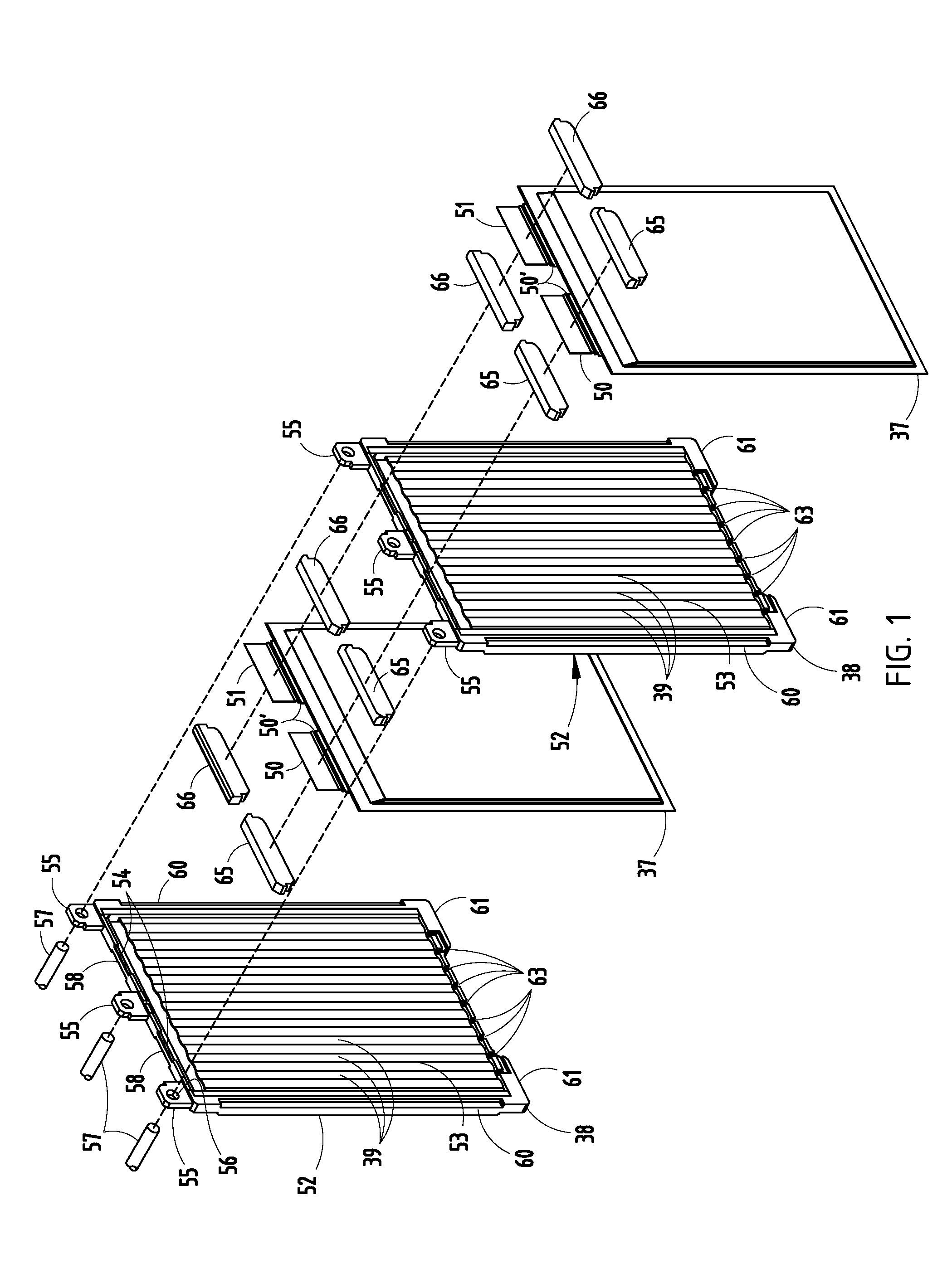

Heat exchanger

InactiveUS6964296B2Eliminate requirementsImprove relationshipSoldering apparatusHeat exhanger finsEngineeringMechanical engineering

Heat exchange inefficiencies found in round tube plate fin heat exchangers are eliminated in an aluminum heat exchanger that includes first and second headers (20), (22) and at least one flattened tube (24), (70) extending between the headers (20), (22). A plurality of generally parallel tube runs are defined and each has opposite edges. A plurality of plate fins (26), (50) are arranged in a stack and each has a plurality of open ended slots (34), one for each run of the tubes (24), (70). Each of the tube runs (24), (70) is nested within corresponding slots (26) and the fins (26), (50) with one of the edges (40) of the tube runs extending outwardly of the corresponding fin (34). The assembly is brazed together.

Owner:MODINE MFG CO

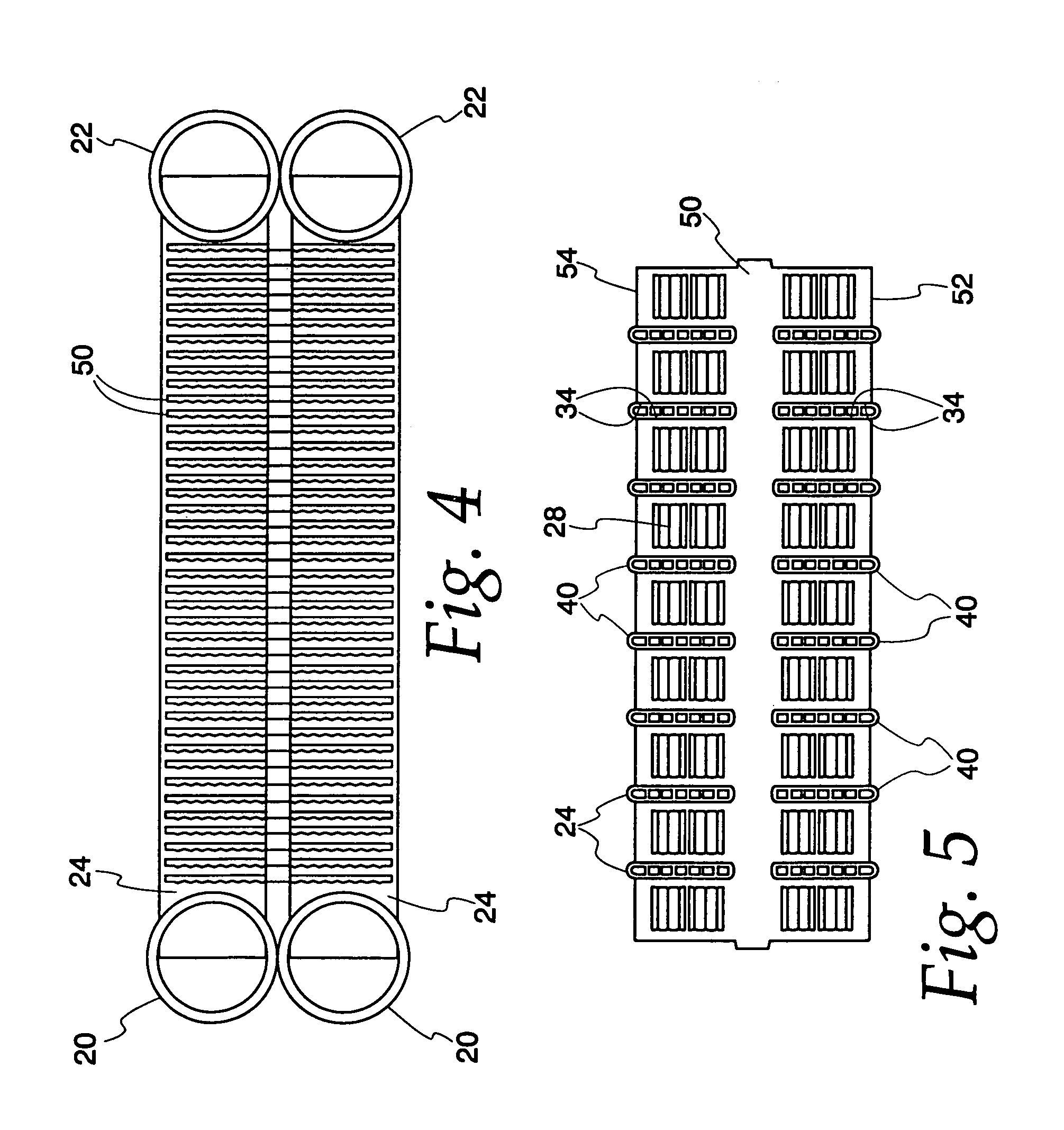

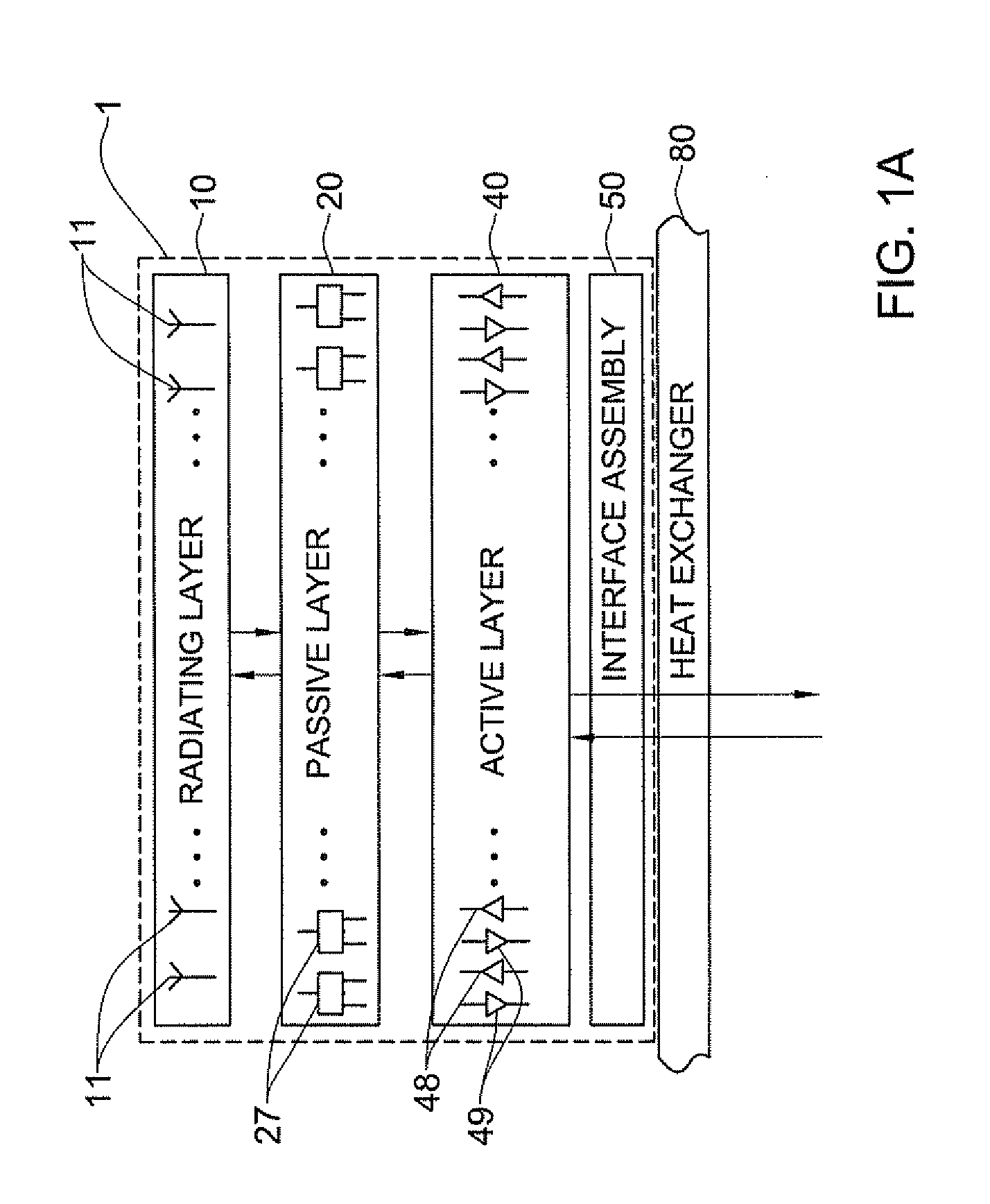

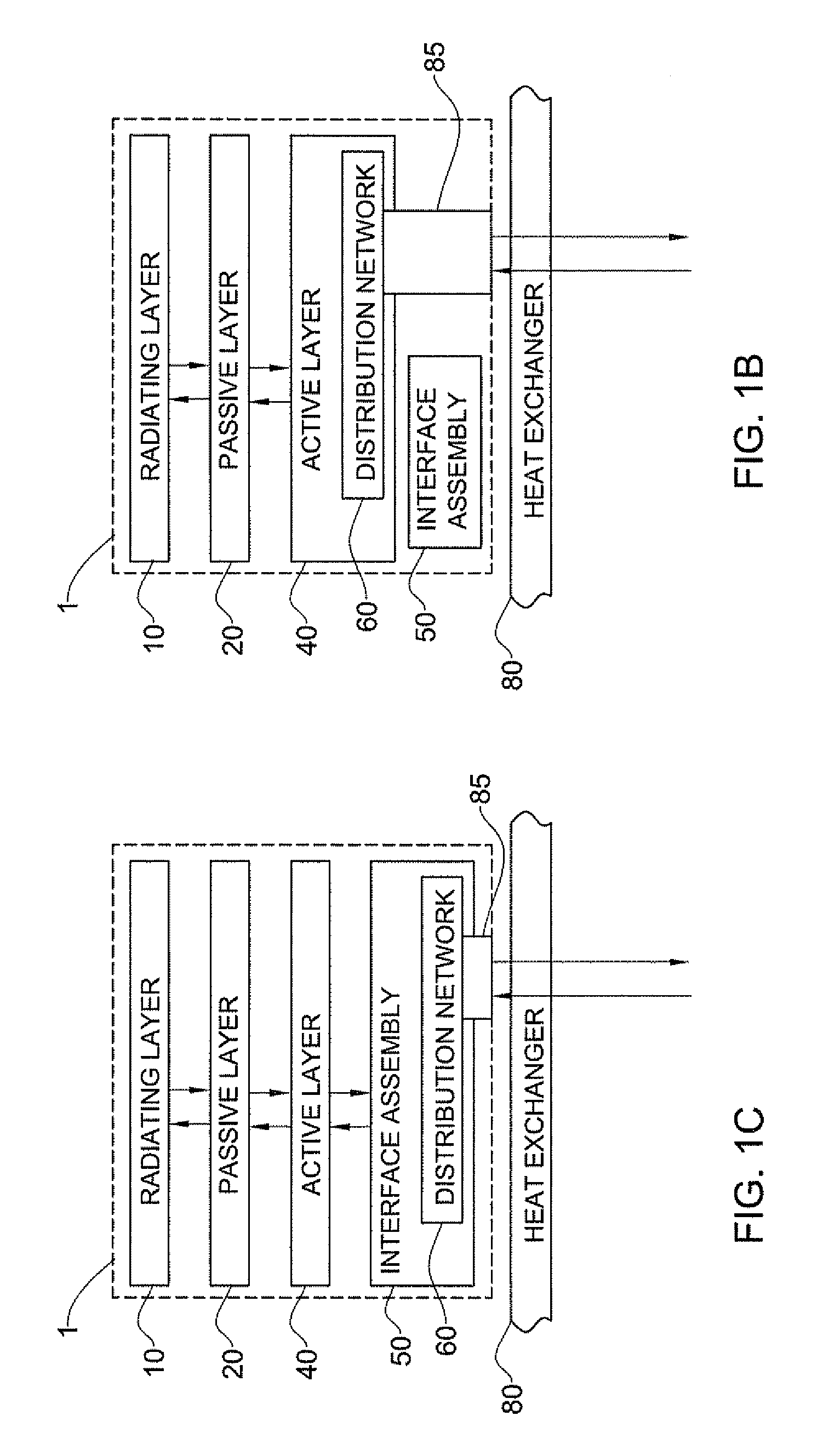

Phased array antenna and method for producing thereof

A vertically stacked array antenna structure is described. The structure comprises a radiating layer, a passive layer disposed under said radiating layer, an active layer disposed under said passive layer, and an interface assembly. The radiating layer comprises an array of radiating elements. The passive layer has only passive components. At least a part of the passive components includes an array of RF duplexers corresponding to the array of radiating elements. The active layer comprises RF amplifiers. The interface assembly comprises at least one metallic frame which is in direct thermal coupling with the RF amplifiers. The interface assembly is configured for providing thermal communication of the active layer with a heat exchanger.

Owner:ELTA SYST LTD

Apparatus and method for facilitating cooling of an electronics rack employing a heat exchange assembly mounted to an outlet door cover of the electronics rack

Apparatus and method are provided for facilitating cooling of an electronics rack employing a heat exchange assembly mounted to an outlet door cover hingedly affixed to an air outlet side of the rack. The heat exchange assembly includes a support frame, an air-to-liquid heat exchanger, and first and second perforated planar surfaces covering first and second main sides, respectively, of the air-to-liquid heat exchanger. The heat exchanger is supported by the support frame and includes inlet and outlet plenums disposed adjacent to the edge of the outlet door cover hingedly mounted to the rack. Each plenum is in fluid communication with a respective connect coupling, and the heat exchanger further includes multiple horizontally-oriented heat exchange tube sections each having serpentine cooling channel with an inlet and an outlet coupled to the inlet plenum and outlet plenum, respectively. Fins extend from the heat exchange tube sections.

Owner:VETTE TECH

Marine engine fuel cooling system

InactiveUS20060124113A1Internal combustion piston enginesThermal treatment of fuelNuclear engineeringFuel tank

A fuel cooling system for a marine inboard engine, including a fuel tank, a fuel supply conduit, and a heat exchanger. The fuel supply conduit includes first and second ends, and extends between the fuel tank and a fuel injection system for the engine. The heat exchanger is disposed intermediate the first and second ends of the fuel supply conduit, and includes a fuel passage in fluid communication with the fuel supply conduit, and a coolant passage in fluid communication with a coolant side of a closed-loop auxiliary cooling system.

Owner:ROBERTS FOREST G SR

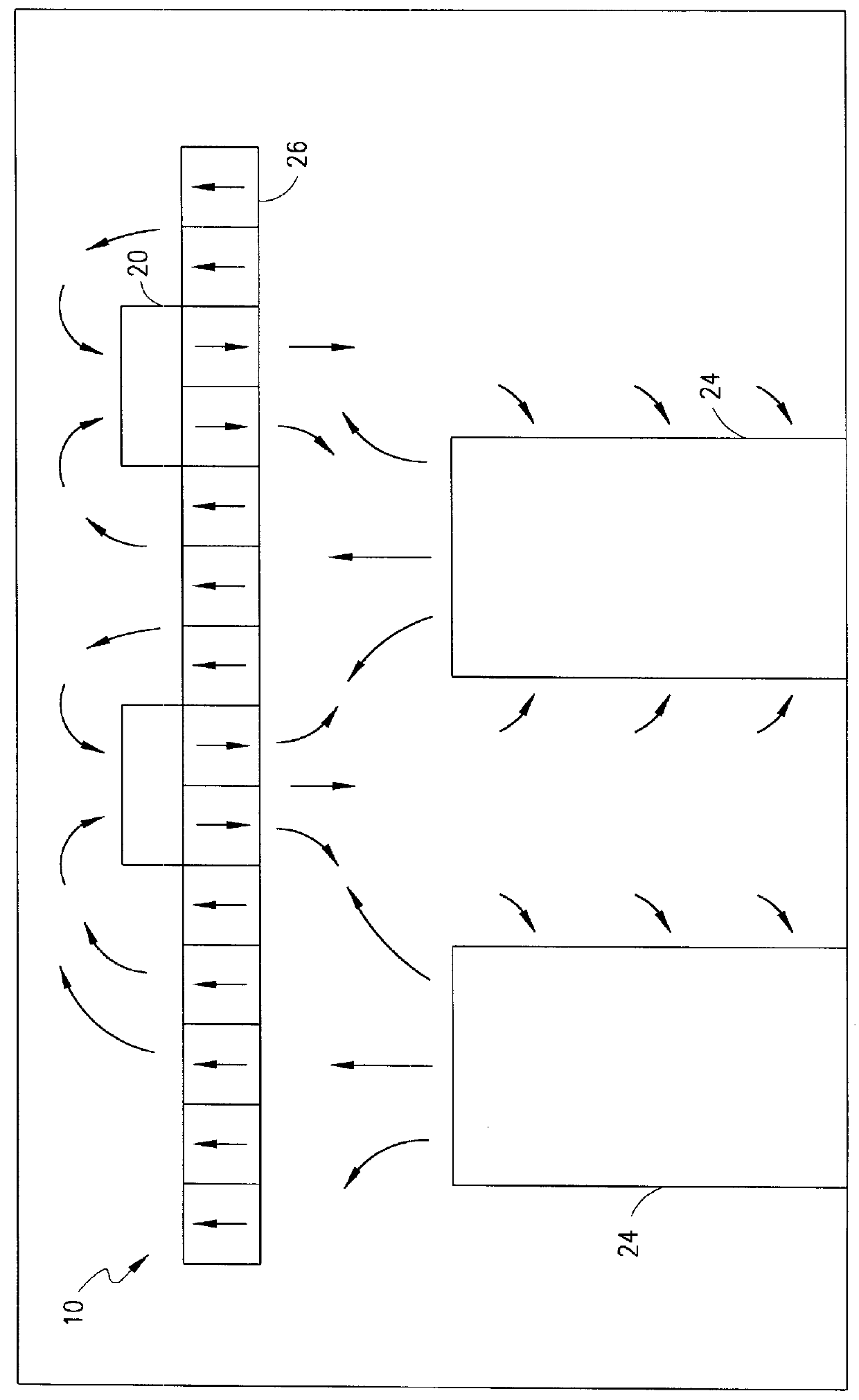

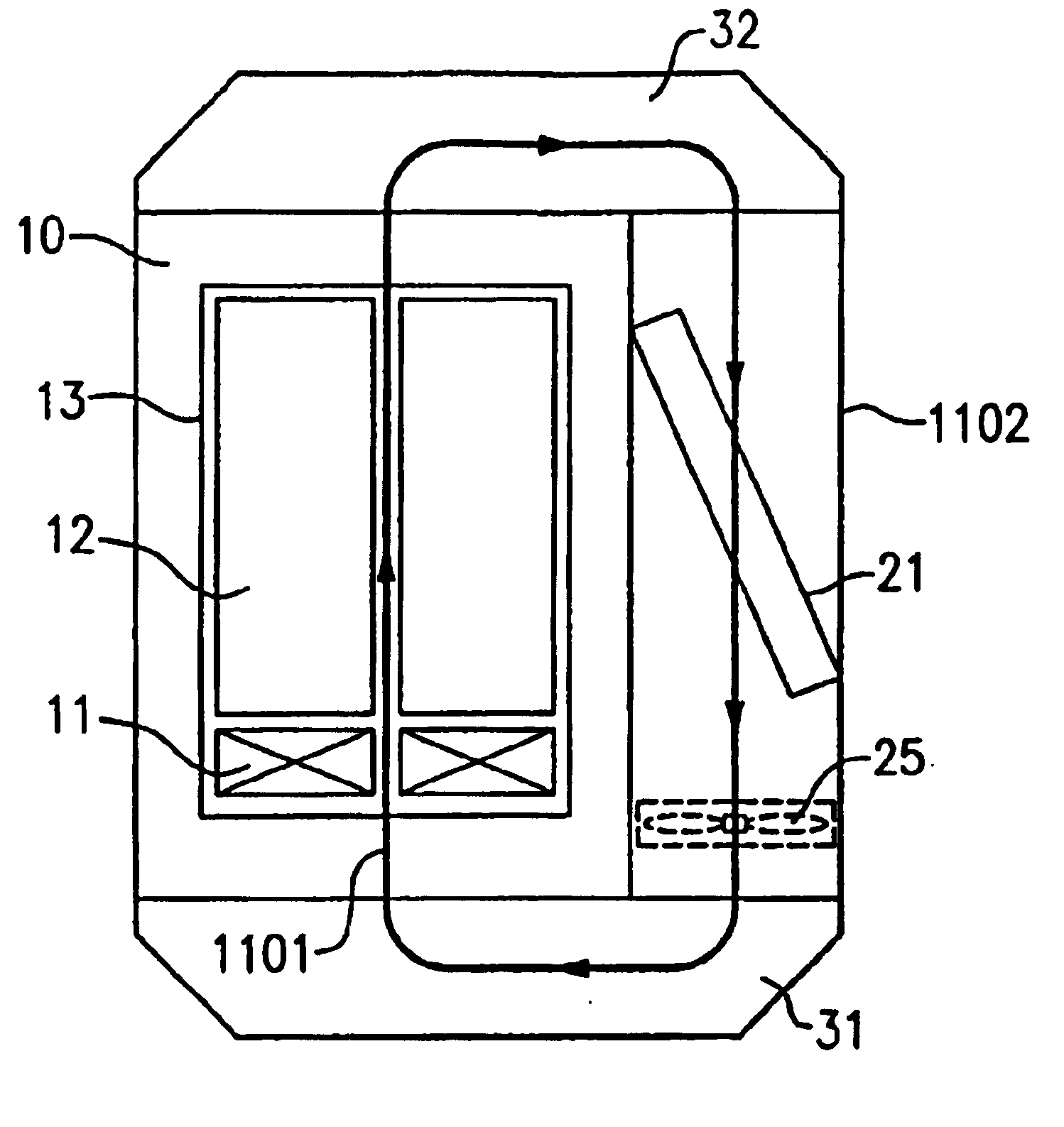

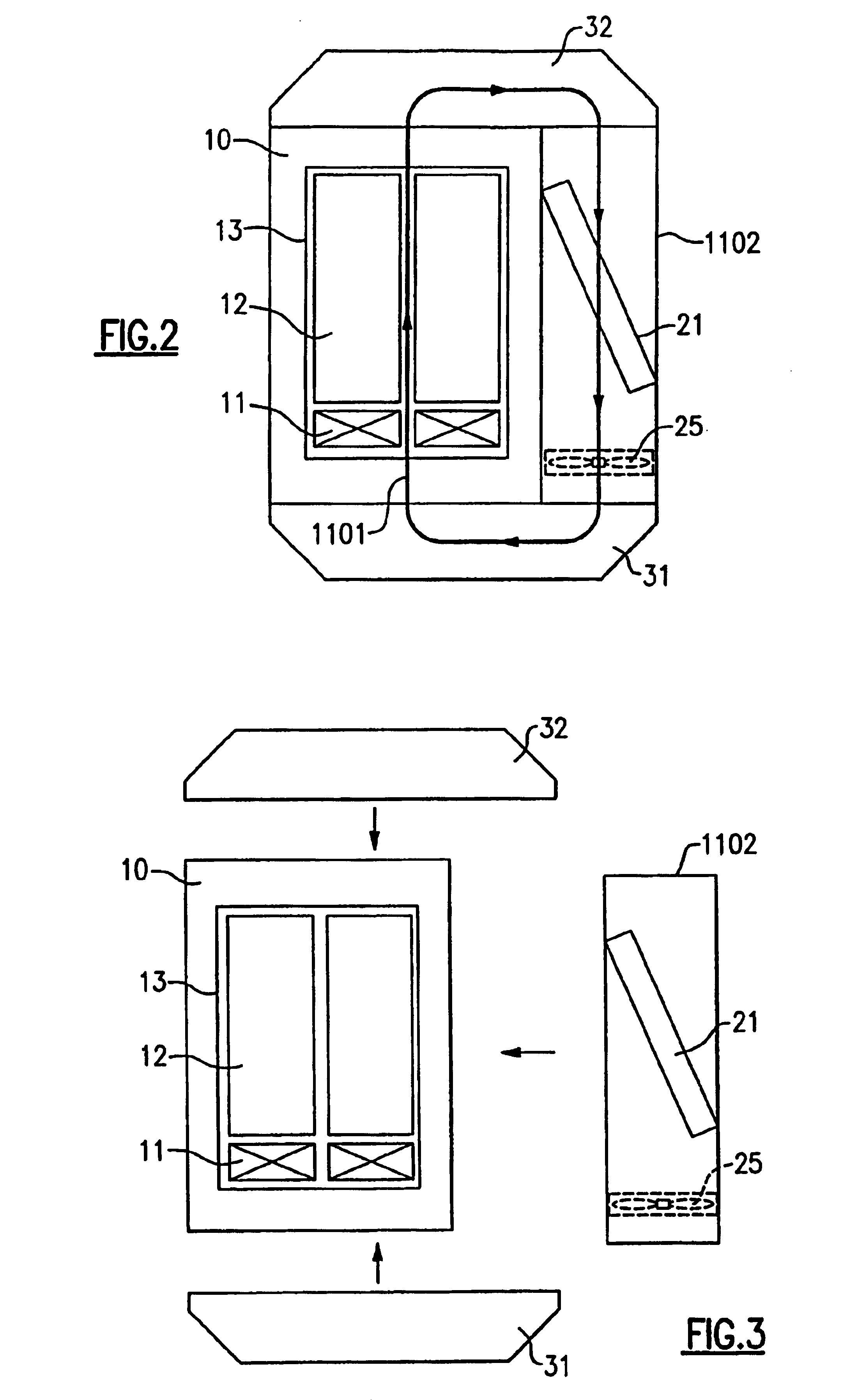

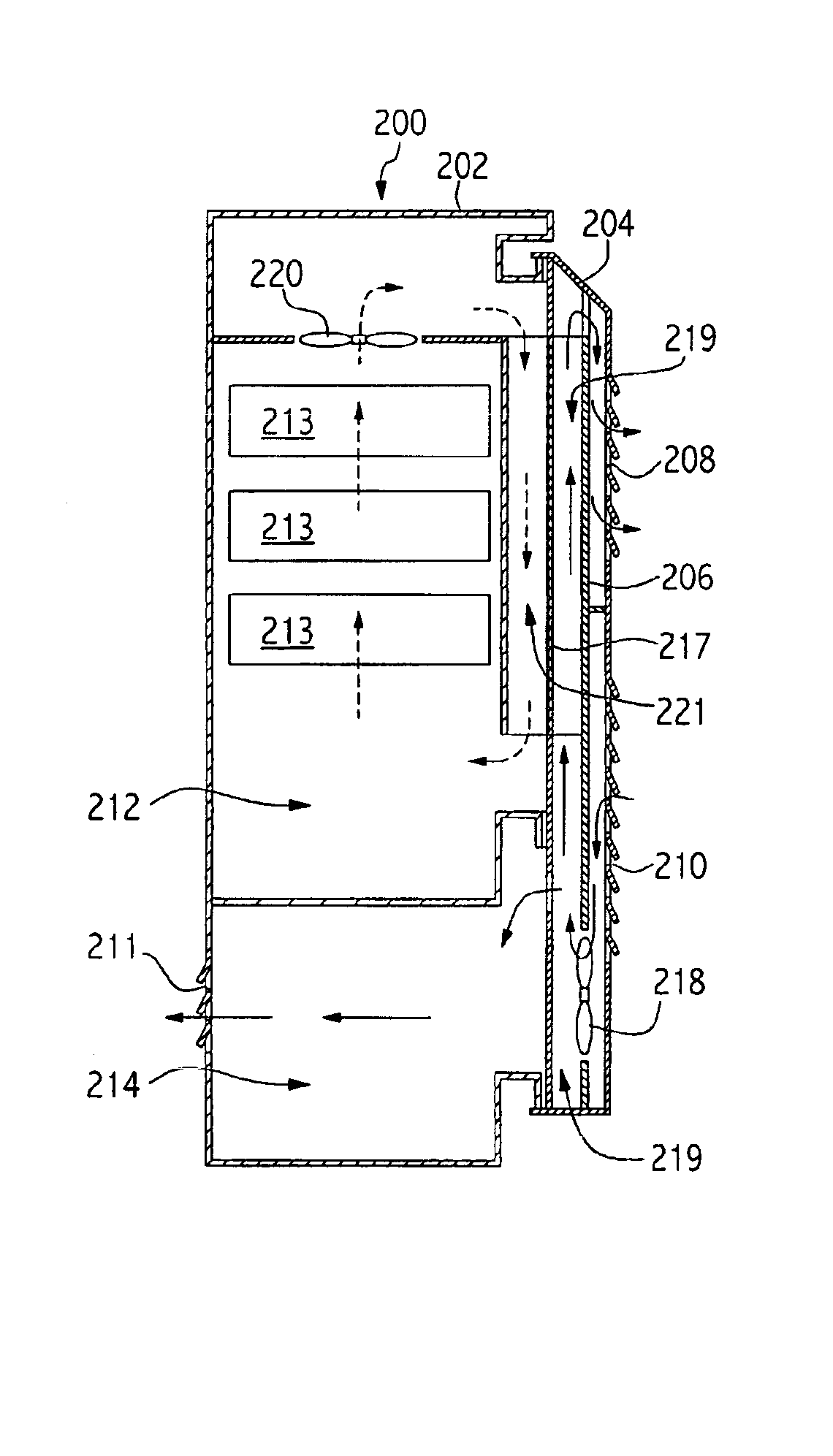

Method for combined air and liquid cooling of stacked electronics components

InactiveUS6924981B2Improve featuresReduce sensitivityDigital data processing detailsIndirect heat exchangersCombined methodElectronic component

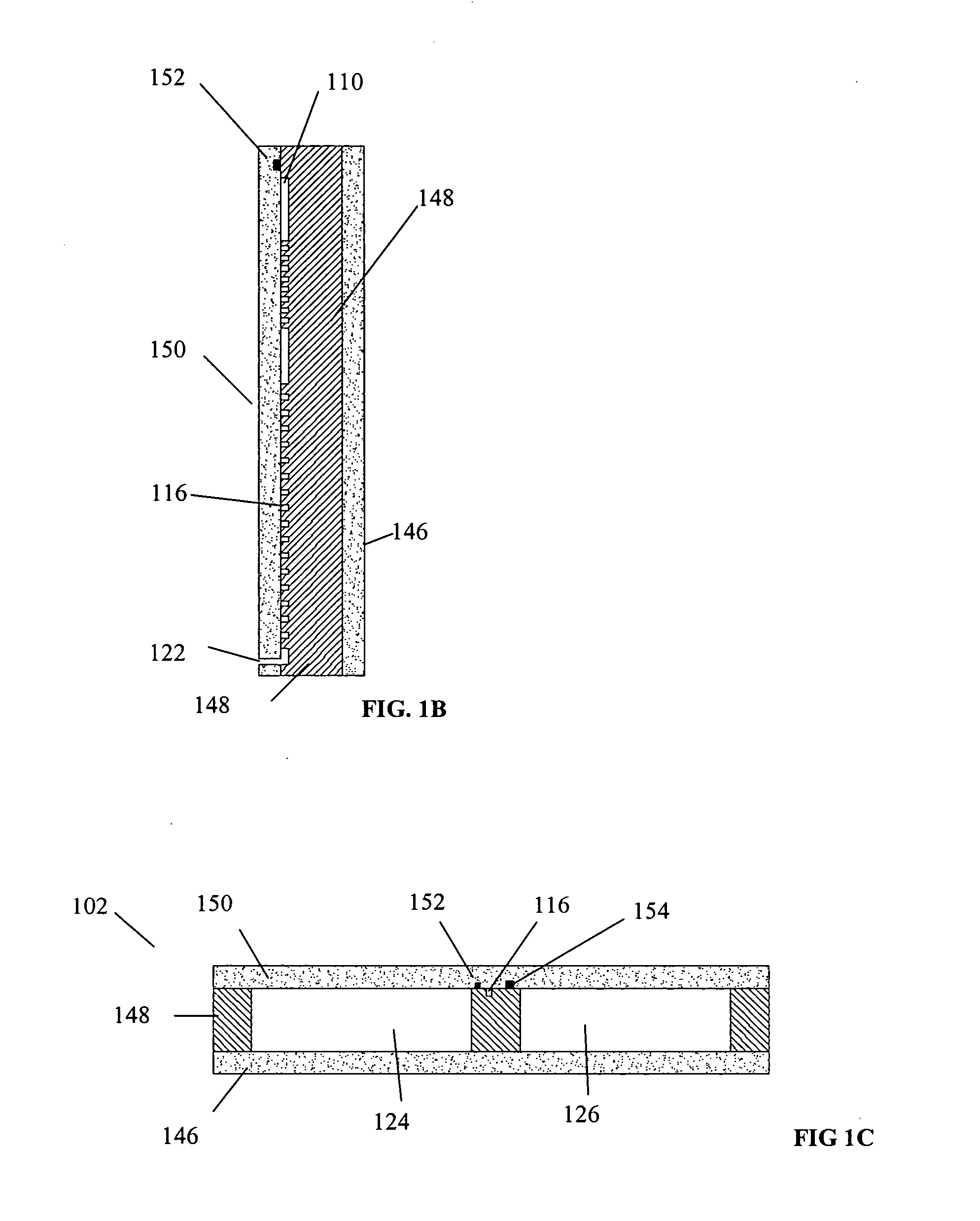

An enclosure apparatus provides for combined air and liquid cooling of rack mounted stacked electronic components. A heat exchanger is mounted on the side of the stacked electronics and air flows side to side within the enclosure, impelled by air-moving devices mounted behind the electronics. Auxiliary air-moving devices may be mounted within the enclosure to increase the air flow. In an alternative embodiment, air-to-liquid heat exchangers are provided across the front and back of the enclosure, and a closed air flow loop is created by a converging supply plenum, electronics drawers through which air is directed by air-moving devices, diverging return plenum, and a connecting duct in the bottom. In a variant of this embodiment, connecting ducts are in both top and bottom, and supply and return ducts are doubly convergent and doubly divergent, respectively. Auxiliary blowers may be added to increase total system air flow. The enclosure also may be provided with automatically opening vent panels to allow room air to circulate and cool in the event of an over-temperature condition. The design of the enclosure permits it to be constructed apart from the rack-mounted apparatus and subsequently attached to the rack, if desired, at the facility at which the rack had been previously operating.

Owner:IBM CORP

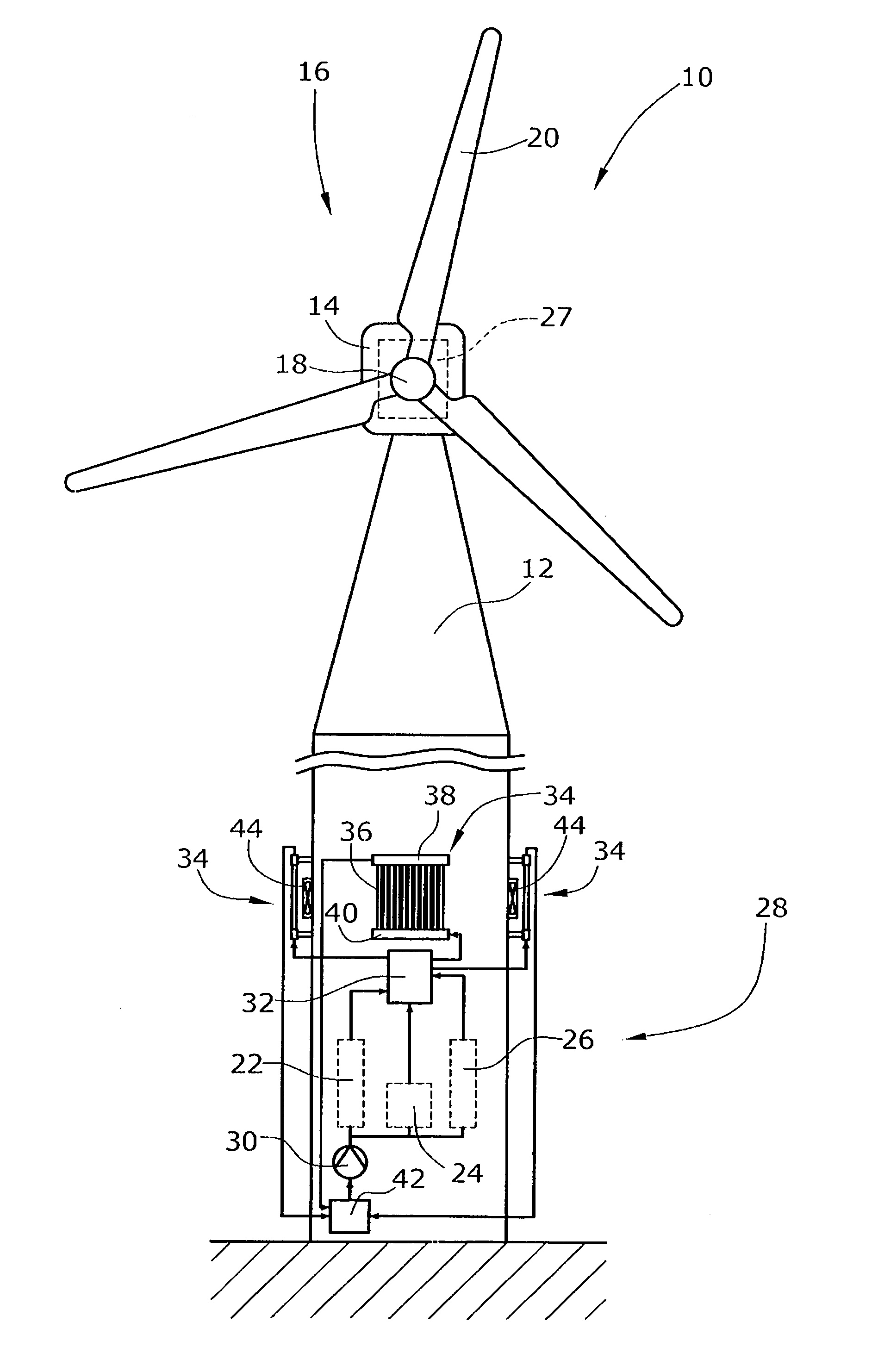

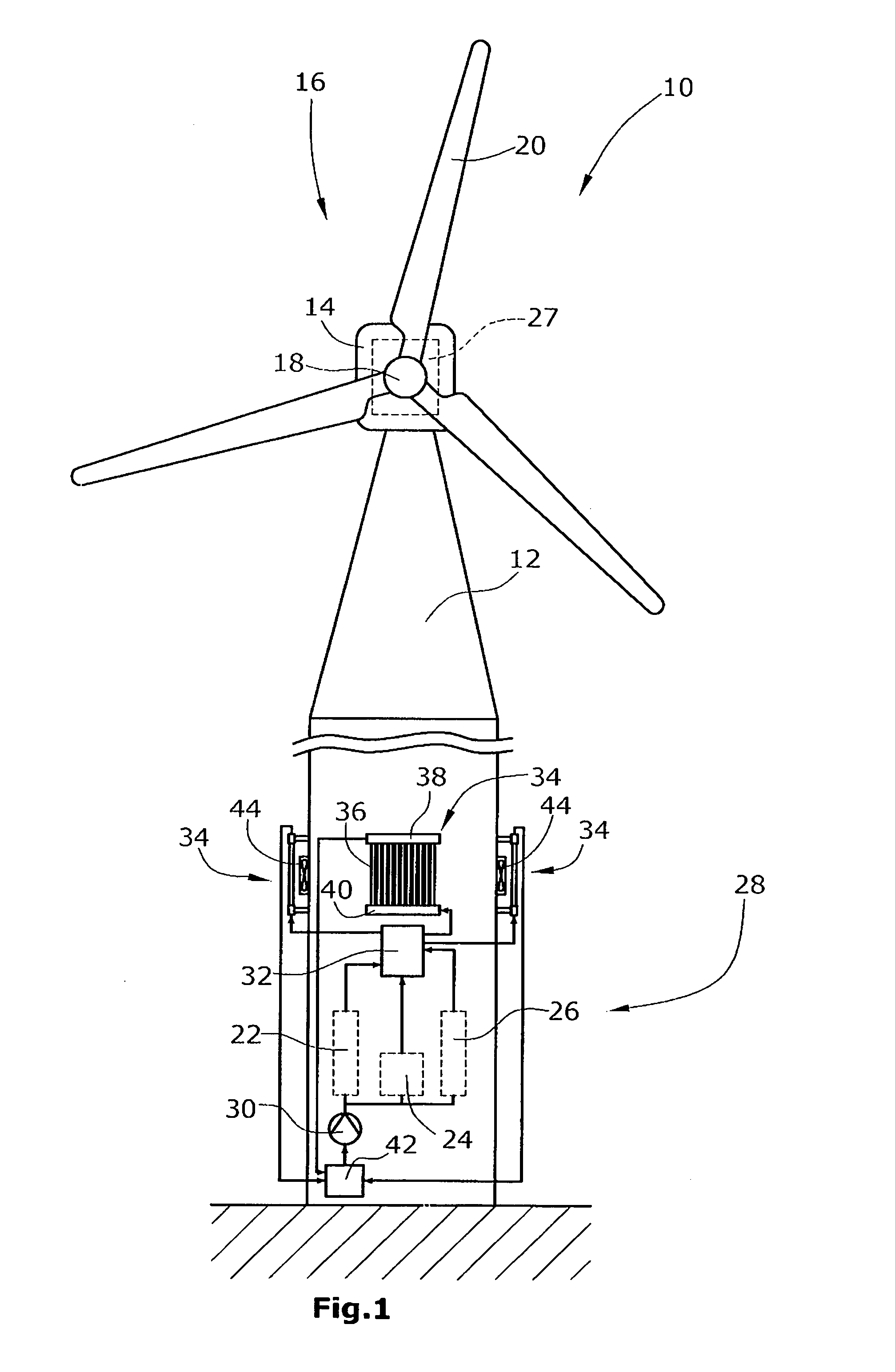

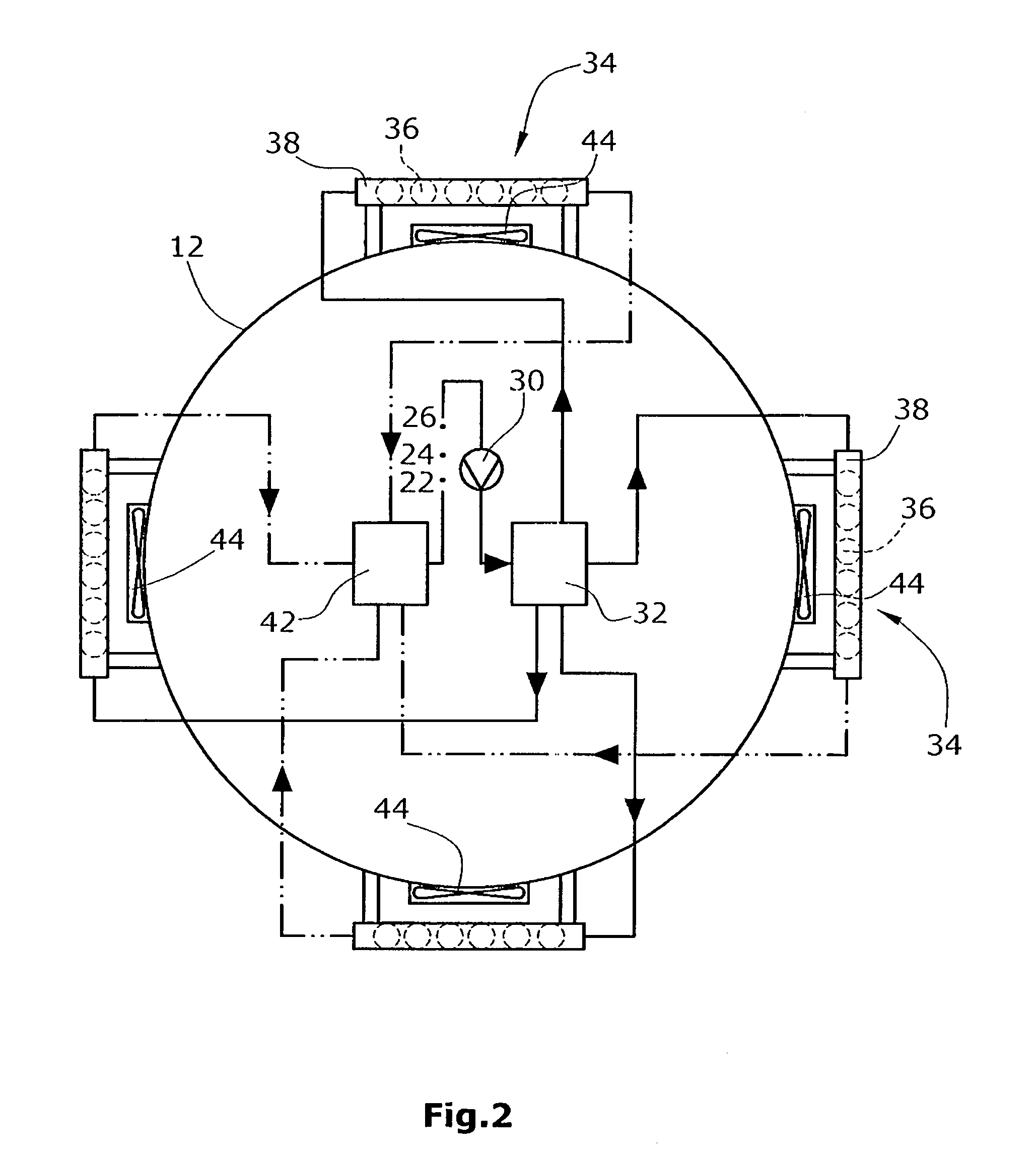

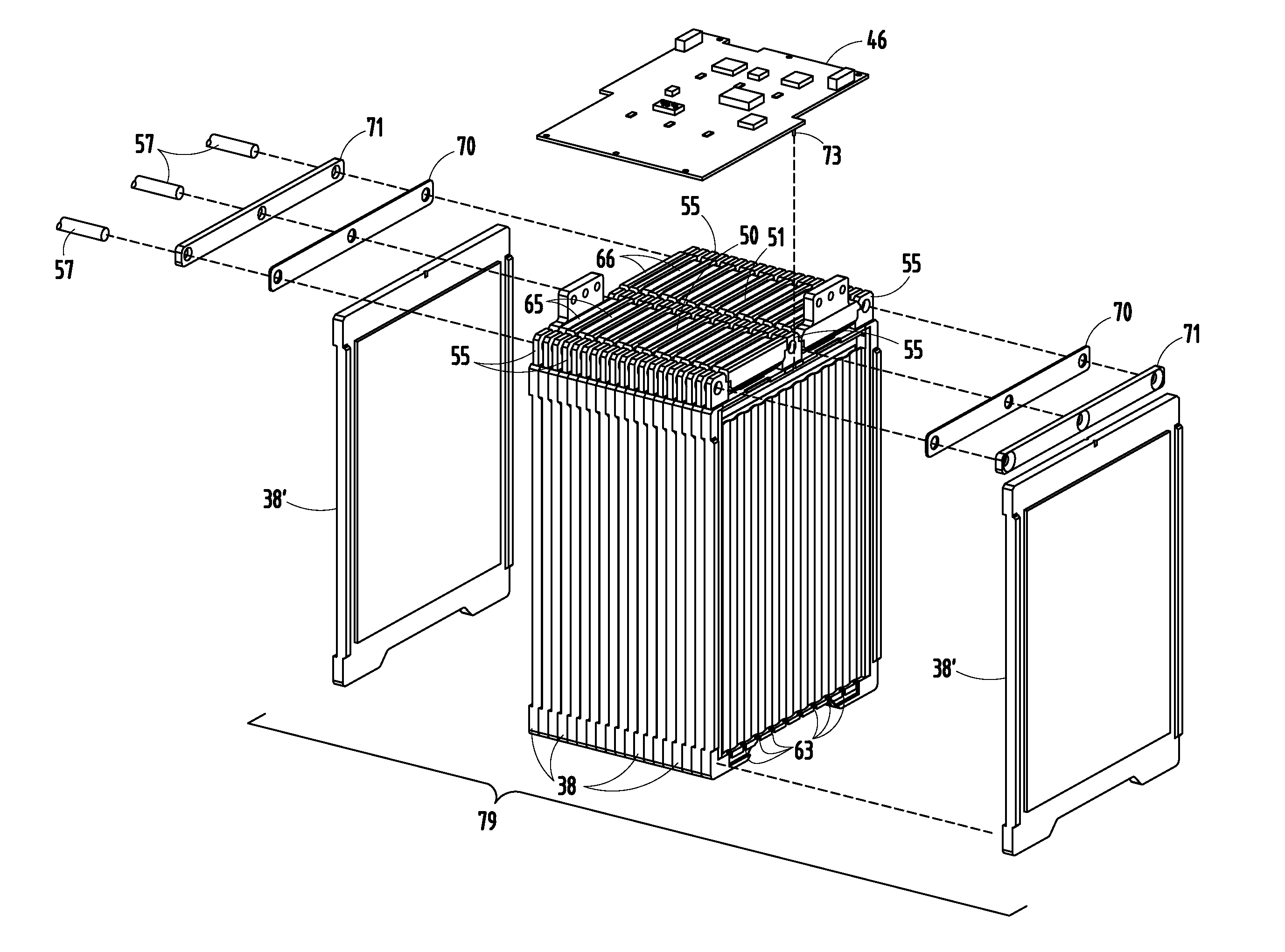

Wind energy turbine

A wind energy turbine includes a tower, a nacelle rotatably supported by the tower, a rotor rotatably supported by the nacelle, and at least one unit to be cooled and arranged in the tower and / or the nacelle. The unit is adapted to be cooled by a cooling medium flowing in a cooling circuit from the unit to at least one heat exchanger. The at least one heat exchanger is located outside of the tower and / or nacelle and configured to be cooled by ambient air.

Owner:GENERAL ELECTRIC CO

Temperature-controlled battery configuration

A vehicle includes a body adapted to carry passengers or cargo, an electric engine / motor, and a temperature-controlled battery configuration. The battery configuration includes a casing, and a plurality of alternating Lithium-ion cell packs and spacers defining vertical channels, the spacers supporting the cell packs in a hanging manner in the casing. The casing is flooded with a thermally-conductive electrically-insulating fluid flowing from the inlet under the cell packs, upwardly across the cell packs and out an outlet to a heat exchanger for controlling a temperature of the cell packs. A fluid pump connected to the engine / motor and a heat exchanger pumps the liquid through the system. A controller is provided for controlling the pump and fluid flow to control a temperature of the battery configuration to maintain the temperature in a desired temperature range.

Owner:EDGEWATER AUTOMATION

Method and Apparatus for Inducing Therapeutic Hypothermia

Methods and apparatus for delivering therapeutic hypothermia to a patient are provided which may include any number of features. One feature is a hypothermia system comprising a fluid source, a heat exchanger assembly, a catheter in fluid communication with the fluid source, and a pump system configured to infuse hypothermic fluid into a patient cavity and extract hypothermic fluid from the patient cavity. The hypothermia system can infuse and extract fluid automatically from the patient cavity. In one embodiment, the patient cavity is a peritoneal cavity. A safe access device to gain access to the patient cavity is also provided.

Owner:VELOMEDIX

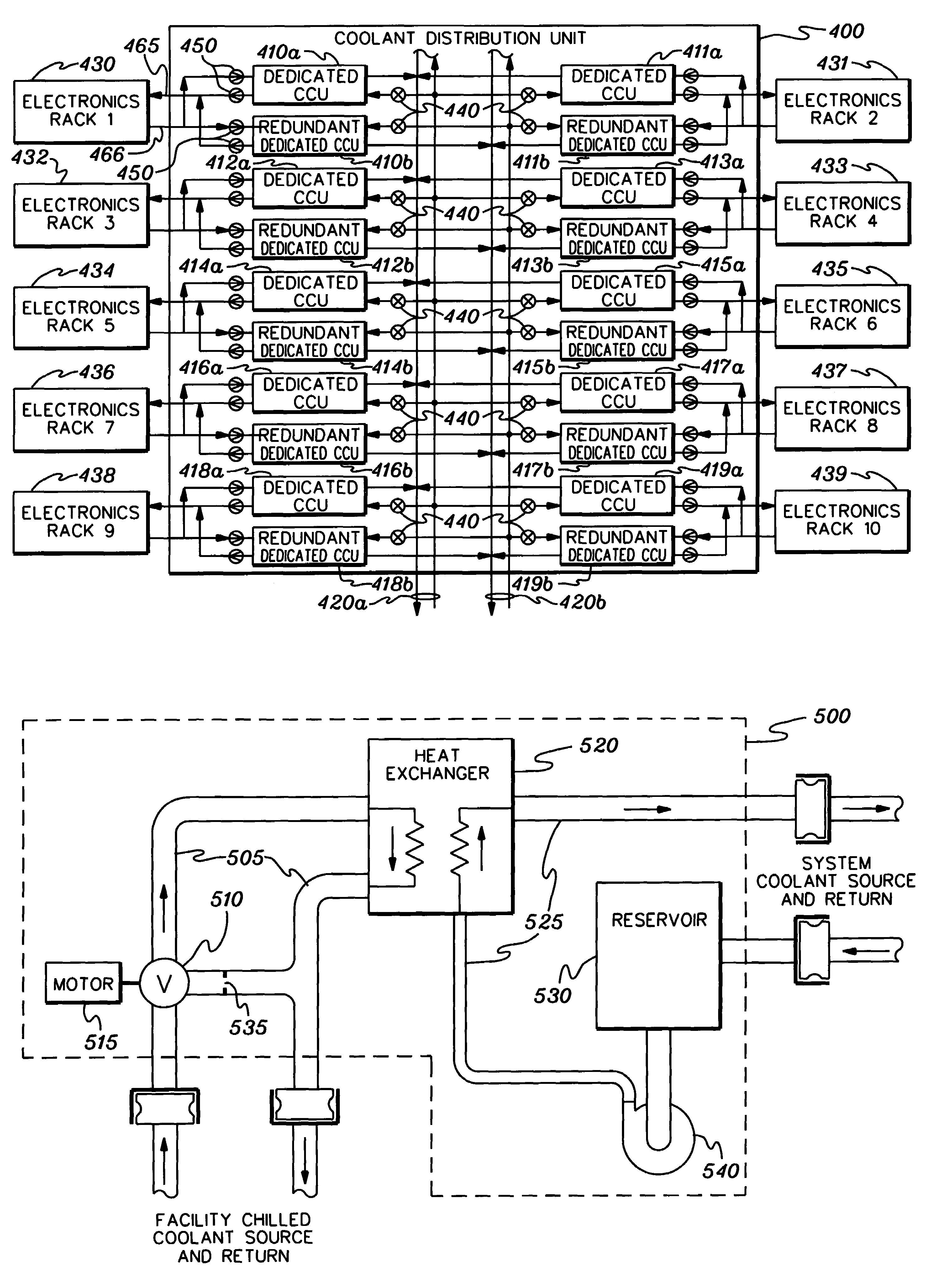

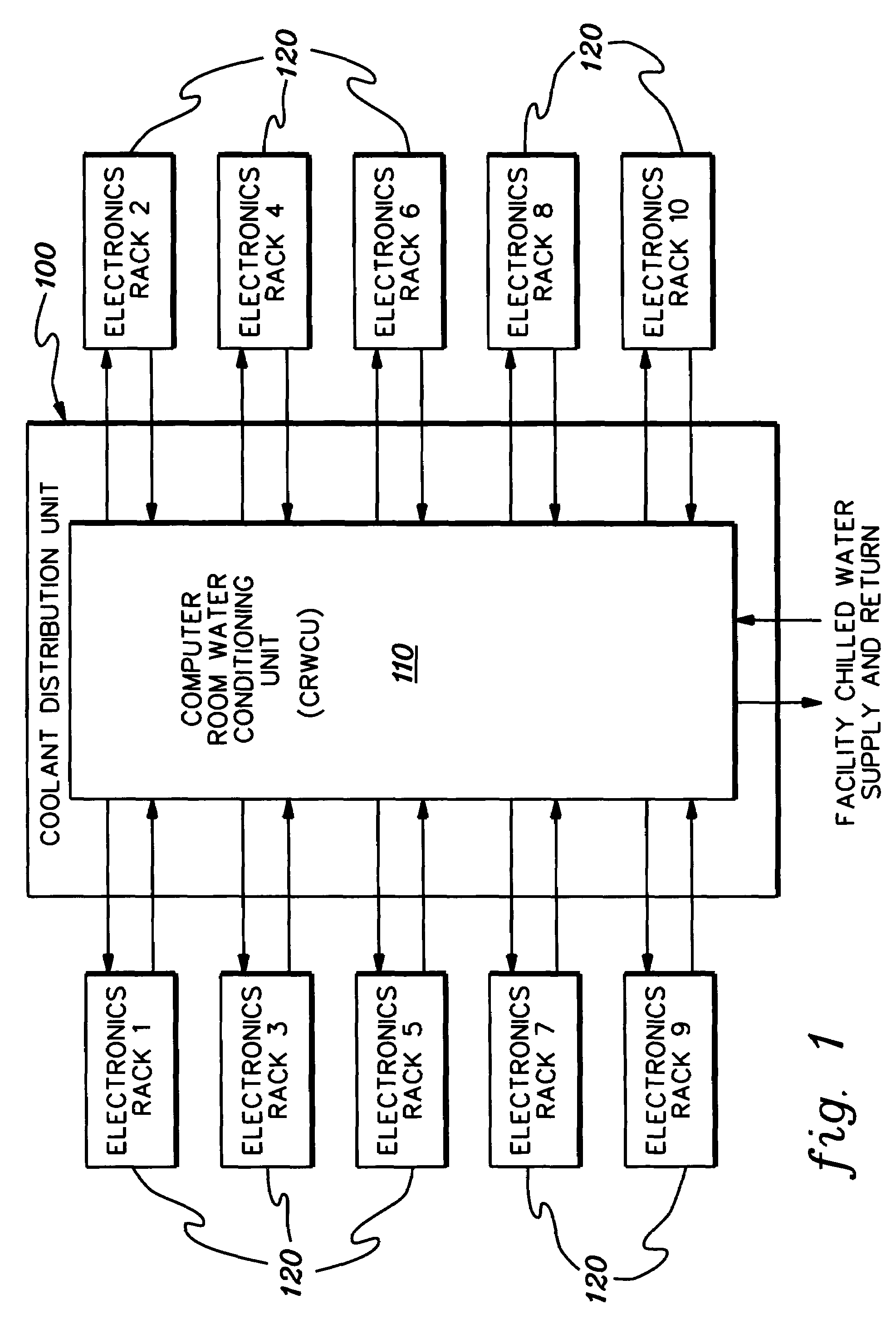

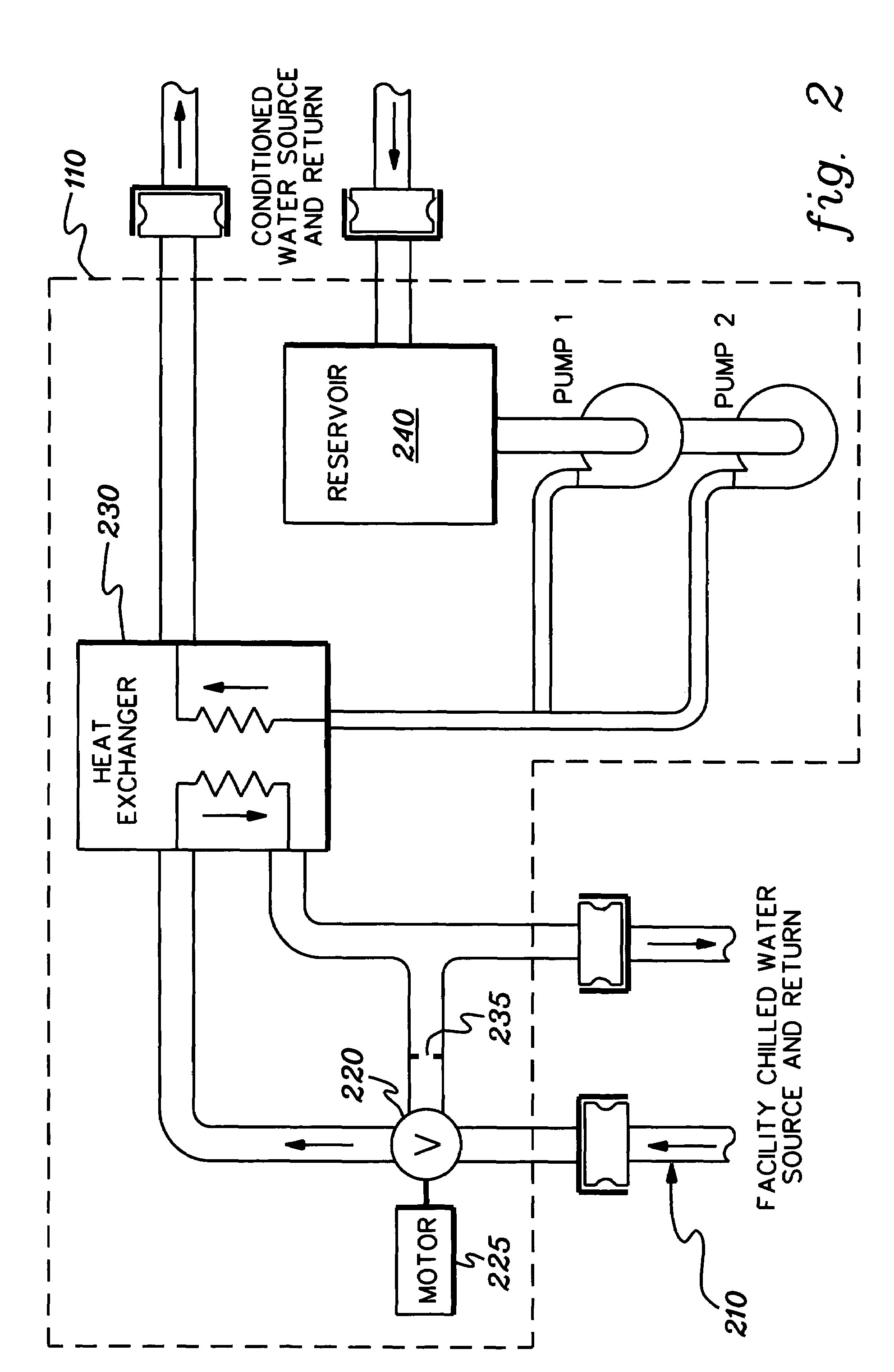

Cooling system and method employing multiple dedicated coolant conditioning units for cooling multiple electronics subsystems

InactiveUS7106590B2Superconductors/hyperconductorsDomestic cooling apparatusCoolant flowNuclear engineering

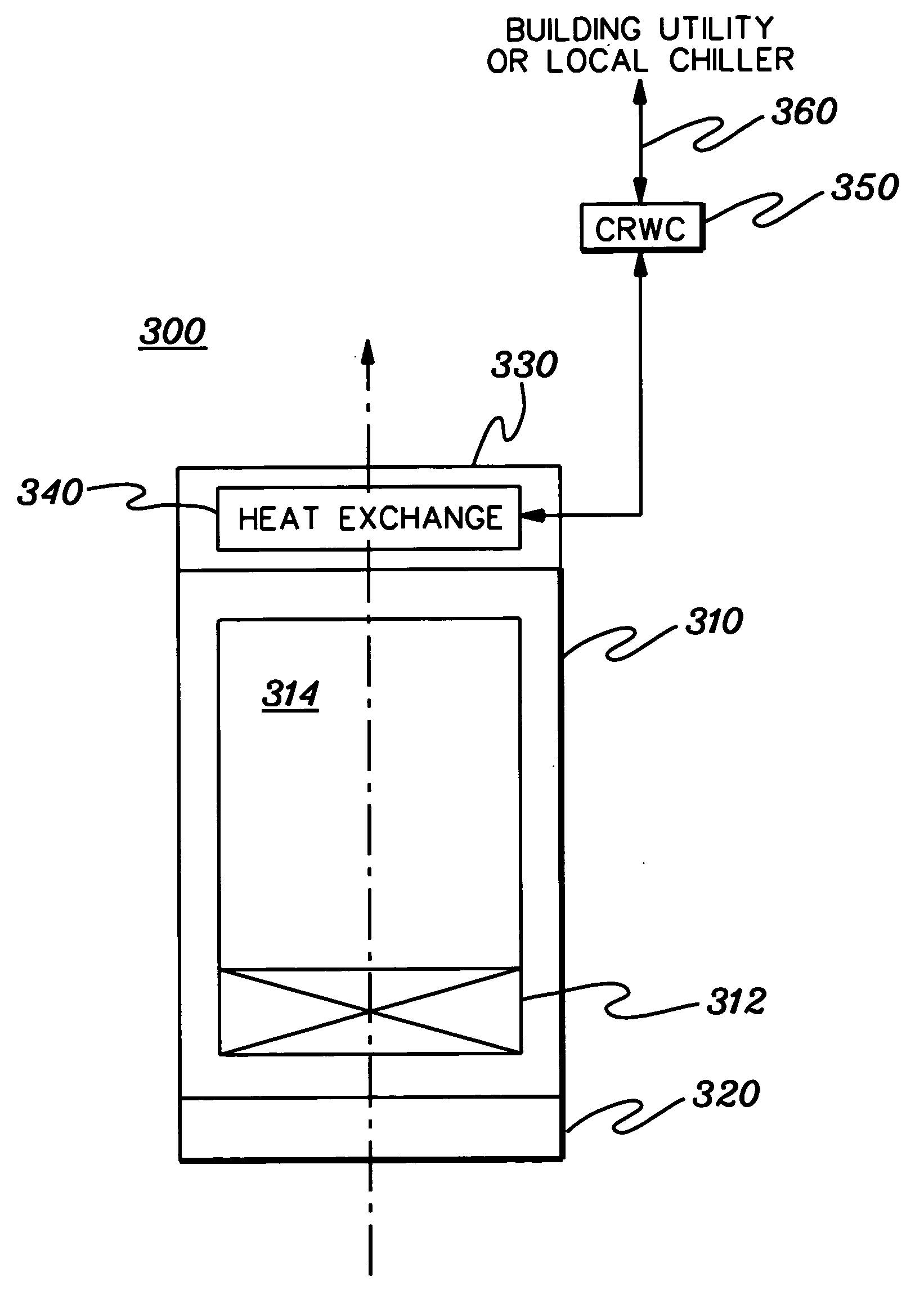

A cooling system is provided employing multiple coolant conditioning units (CCUs). Each CCU, which is coupled to a different, associated electronics rack of multiple electronics racks to be cooled, includes a heat exchanger, a first cooling loop with a control valve, and a second cooling loop. The first cooling loop receives chilled facility coolant from a source and passes at least a portion thereof via the control valve through the heat exchanger. The second cooling loop provides cooled system coolant to the associated electronics rack, and expels heat in the heat exchanger from the electronics rack to the chilled facility coolant in the first cooling loop. The control valve allows regulation of the facility coolant flow through the heat exchanger, thereby allowing independent control of temperature of the system coolant in the second cooling loop. Various CCU and associated component redundancies of the cooling system are also provided.

Owner:INT BUSINESS MASCH CORP

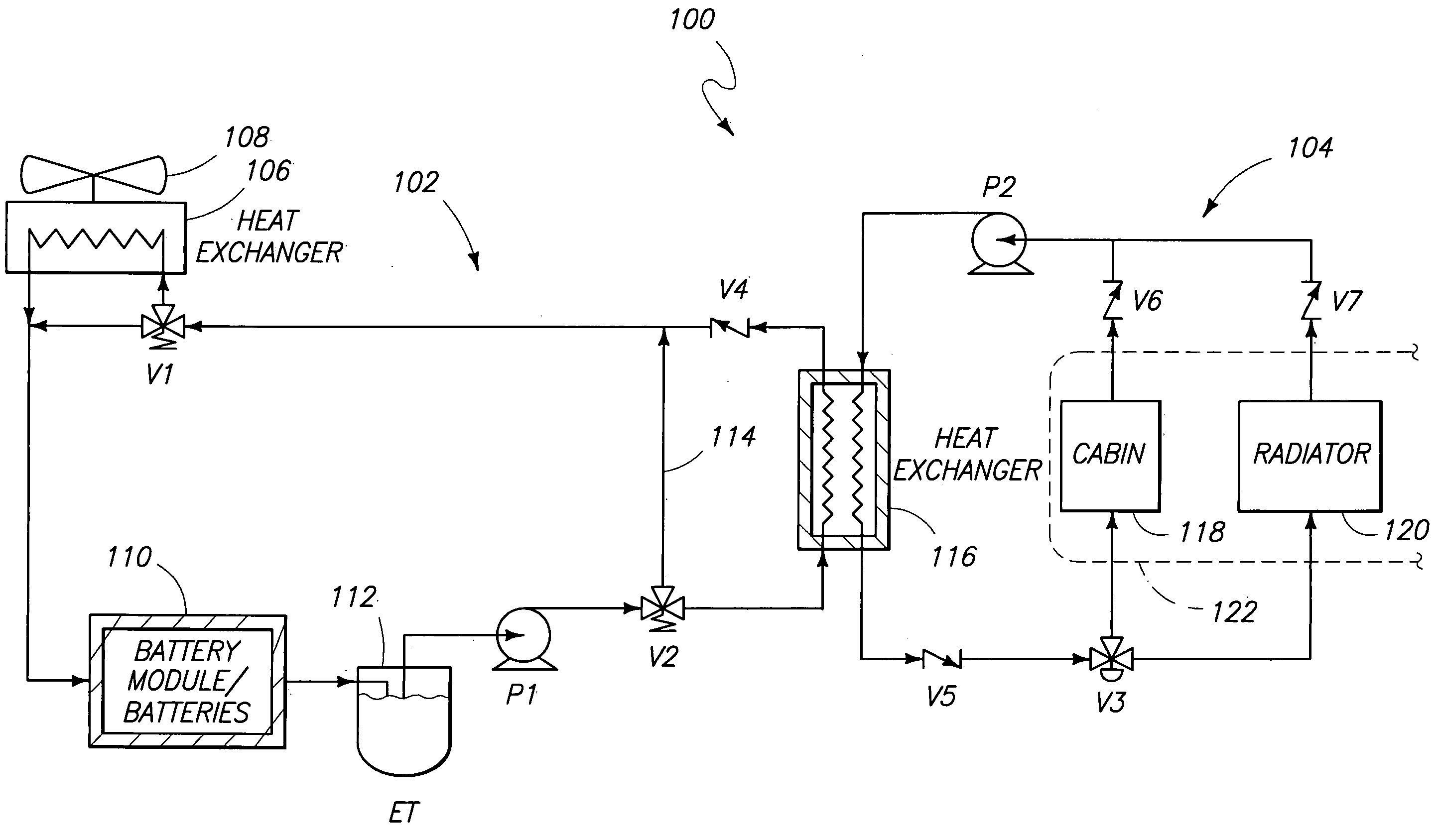

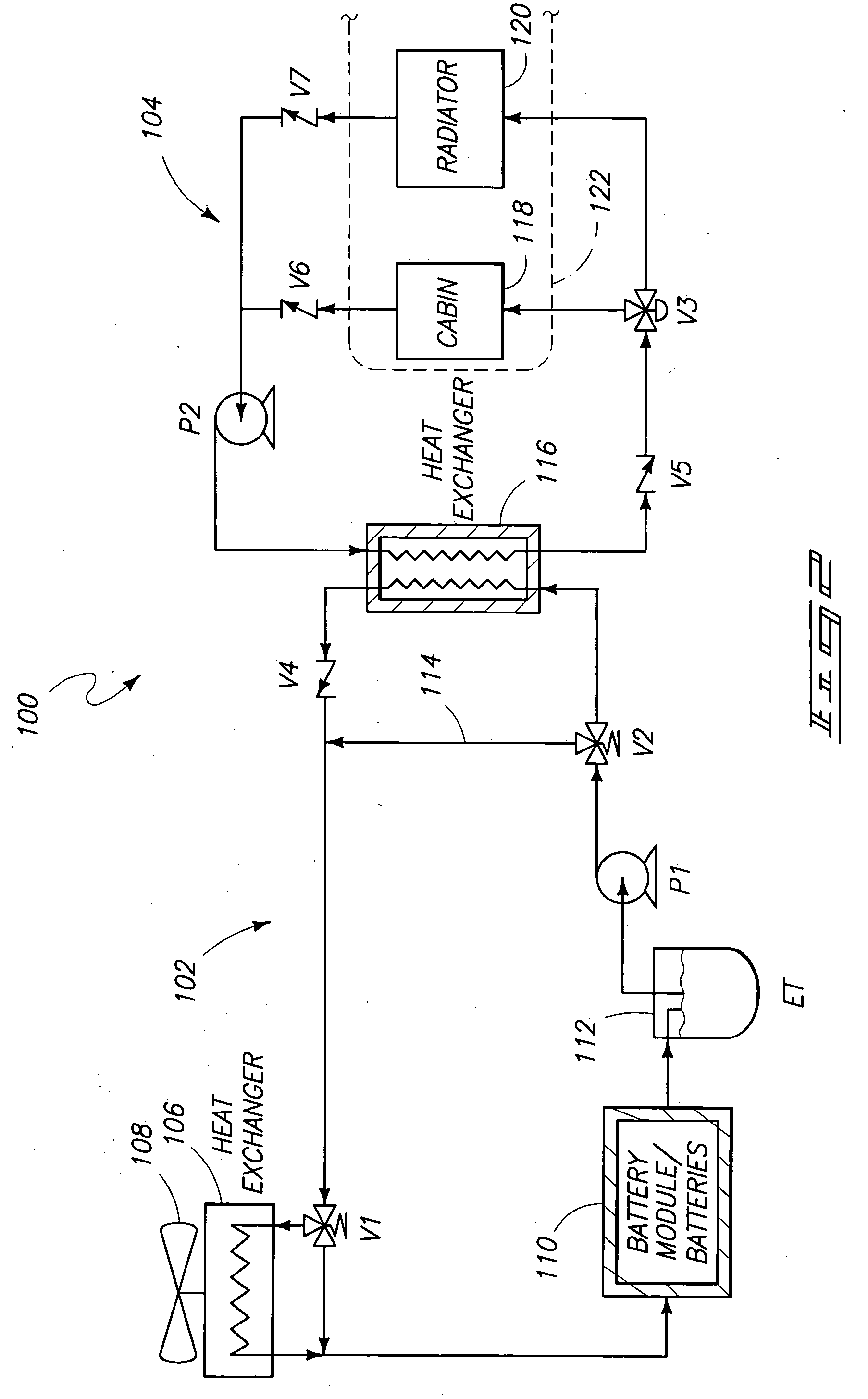

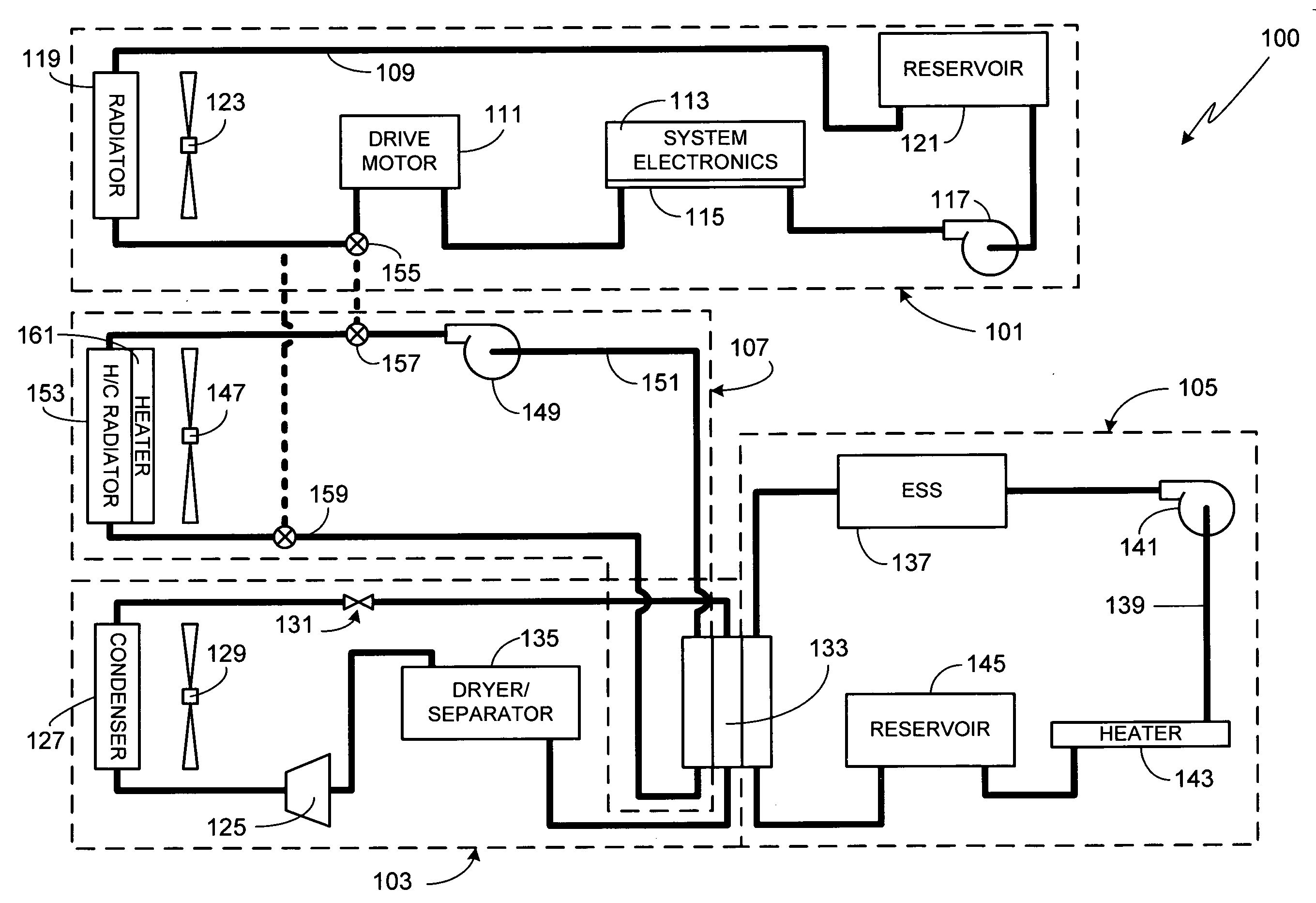

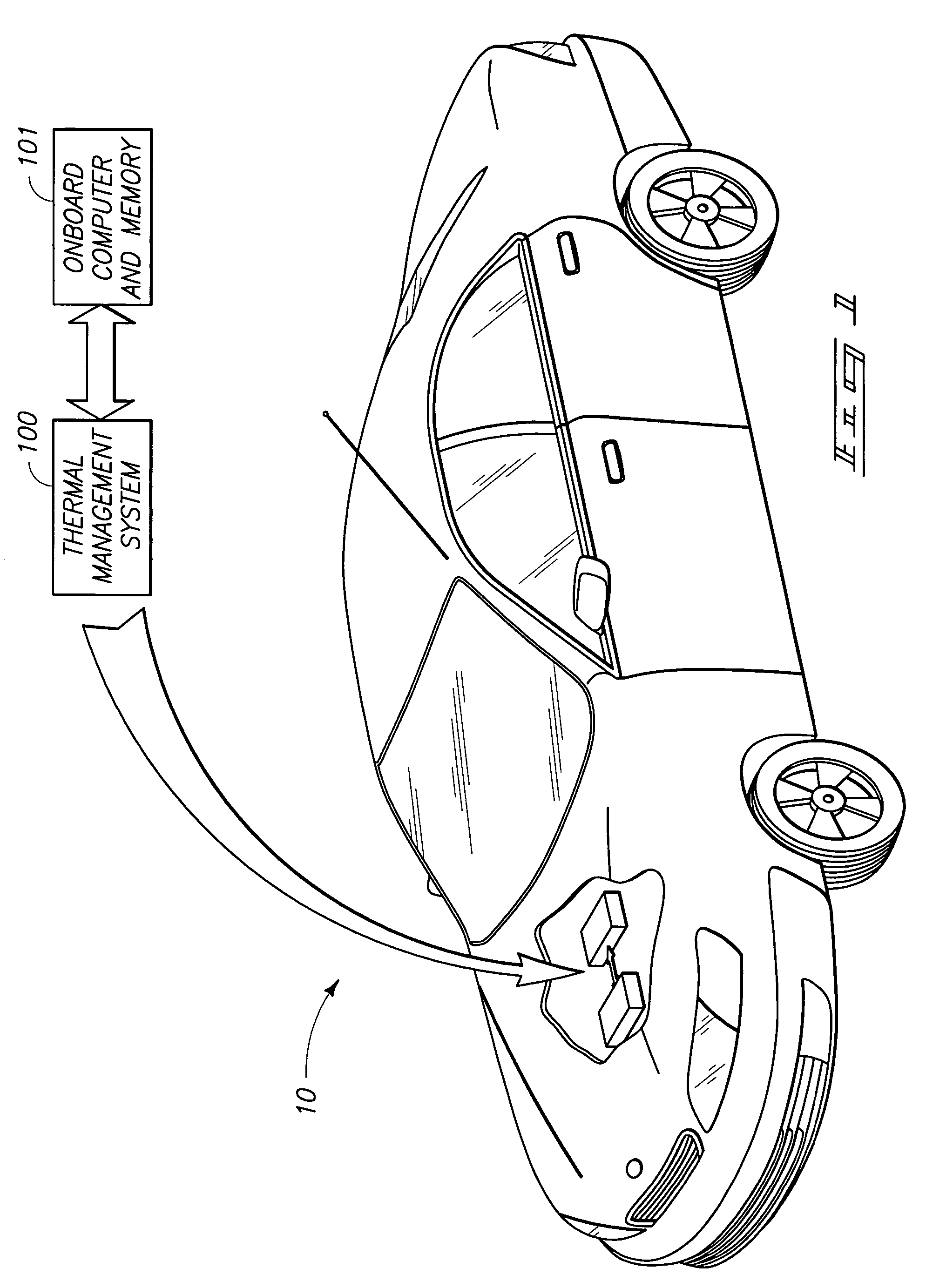

Electric vehicle thermal management system

ActiveUS20080251235A1Lighting and heating apparatusPower to auxillary motorsEngineeringThermal management system

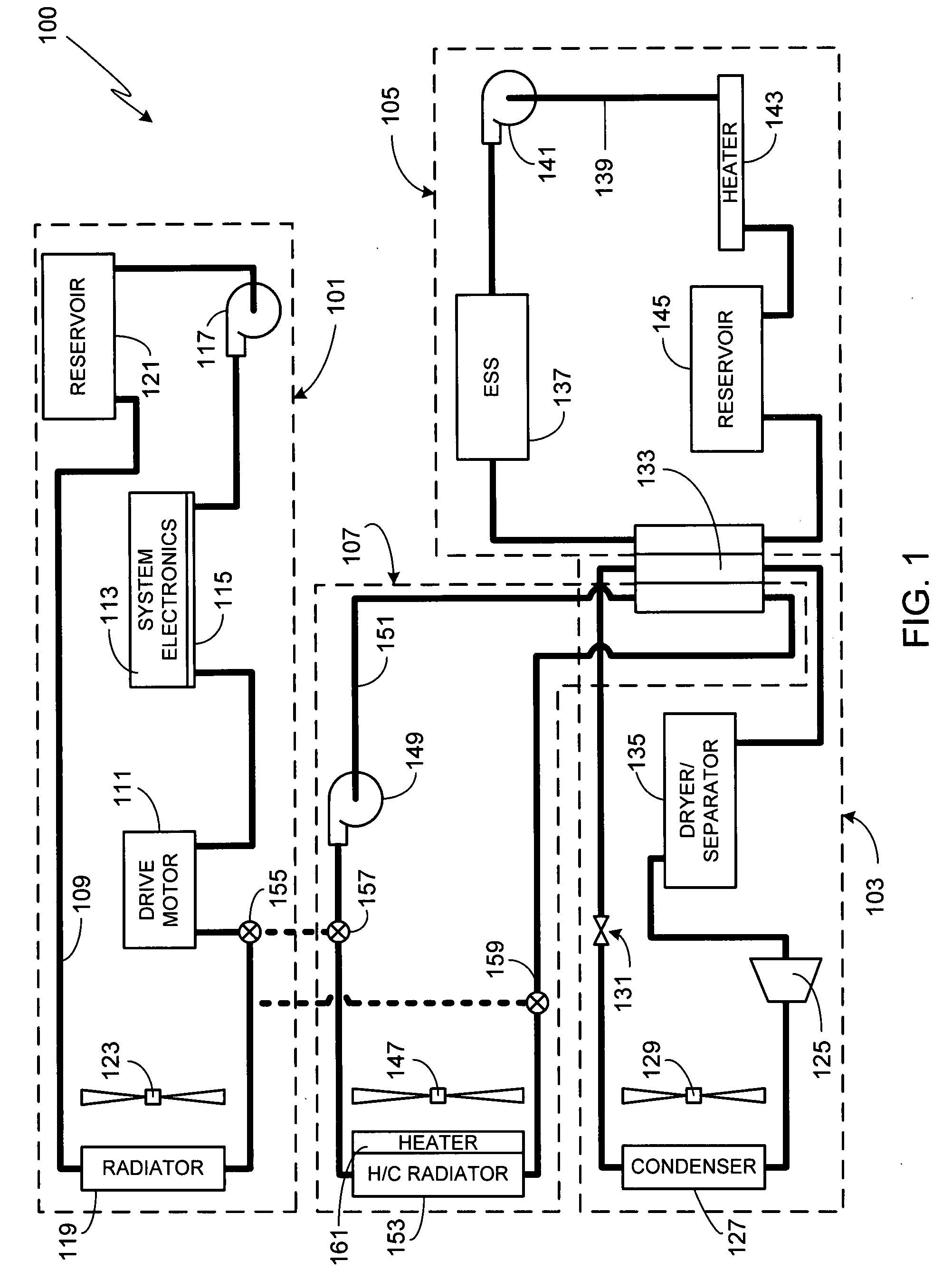

An efficient thermal management system (100) that utilizes a single heat exchanger (133) is provided. A refrigeration subsystem (103) cools the heat exchanger (133). A first coolant loop (139) in thermal communication with the heat exchanger (133) is used to cool the energy storage system (137). A second coolant loop (151) corresponding to the HVAC subsystem (107) is also in thermal communication with the heat exchanger (133). Preferably a third coolant loop (109) corresponding to the drive motor cooling subsystem (101) is coupleable to the HVAC coolant loop (151), thus providing an efficient means of providing heat to the HVAC subsystem (107).

Owner:TESLA INC

Thermal management systems and methods

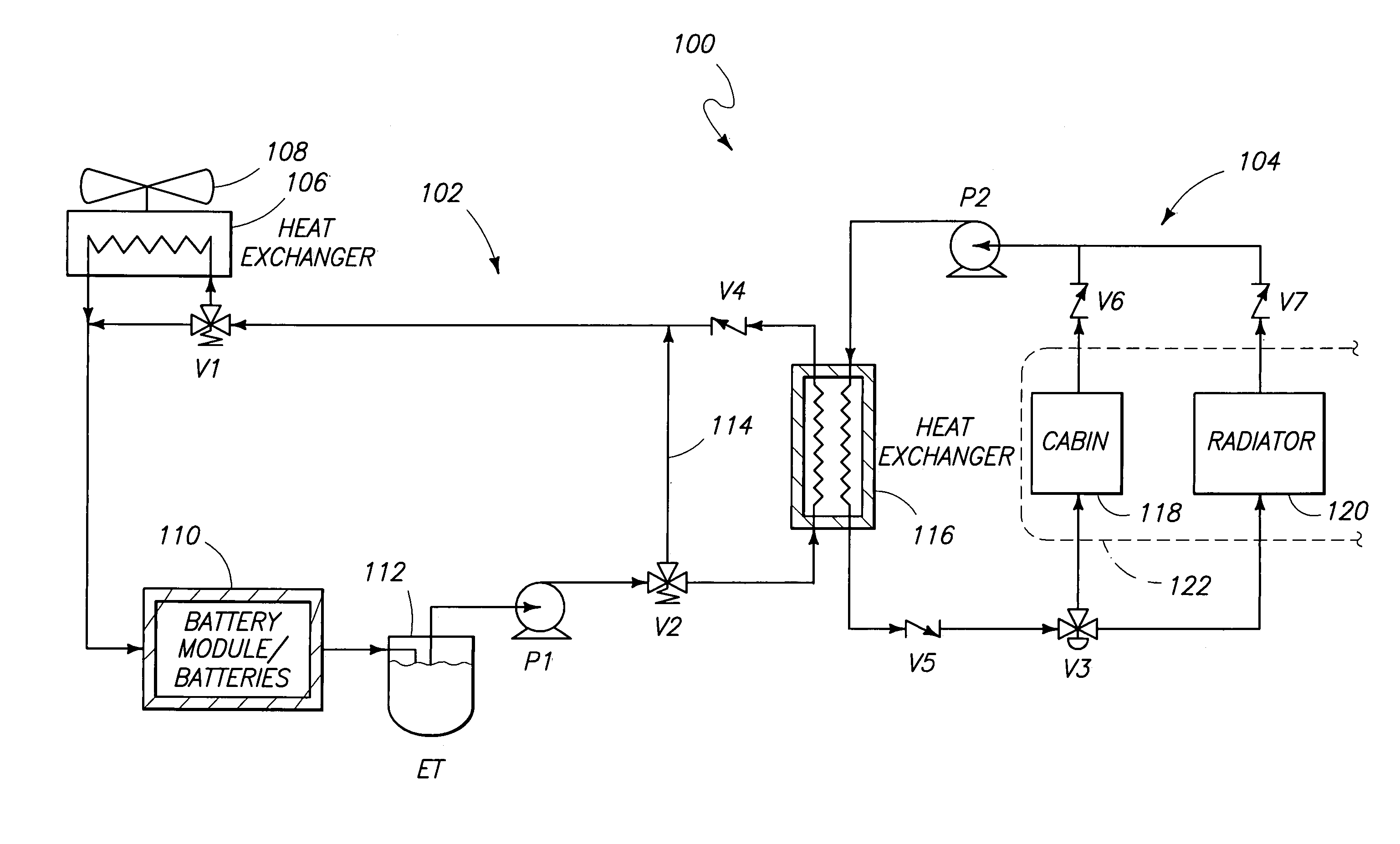

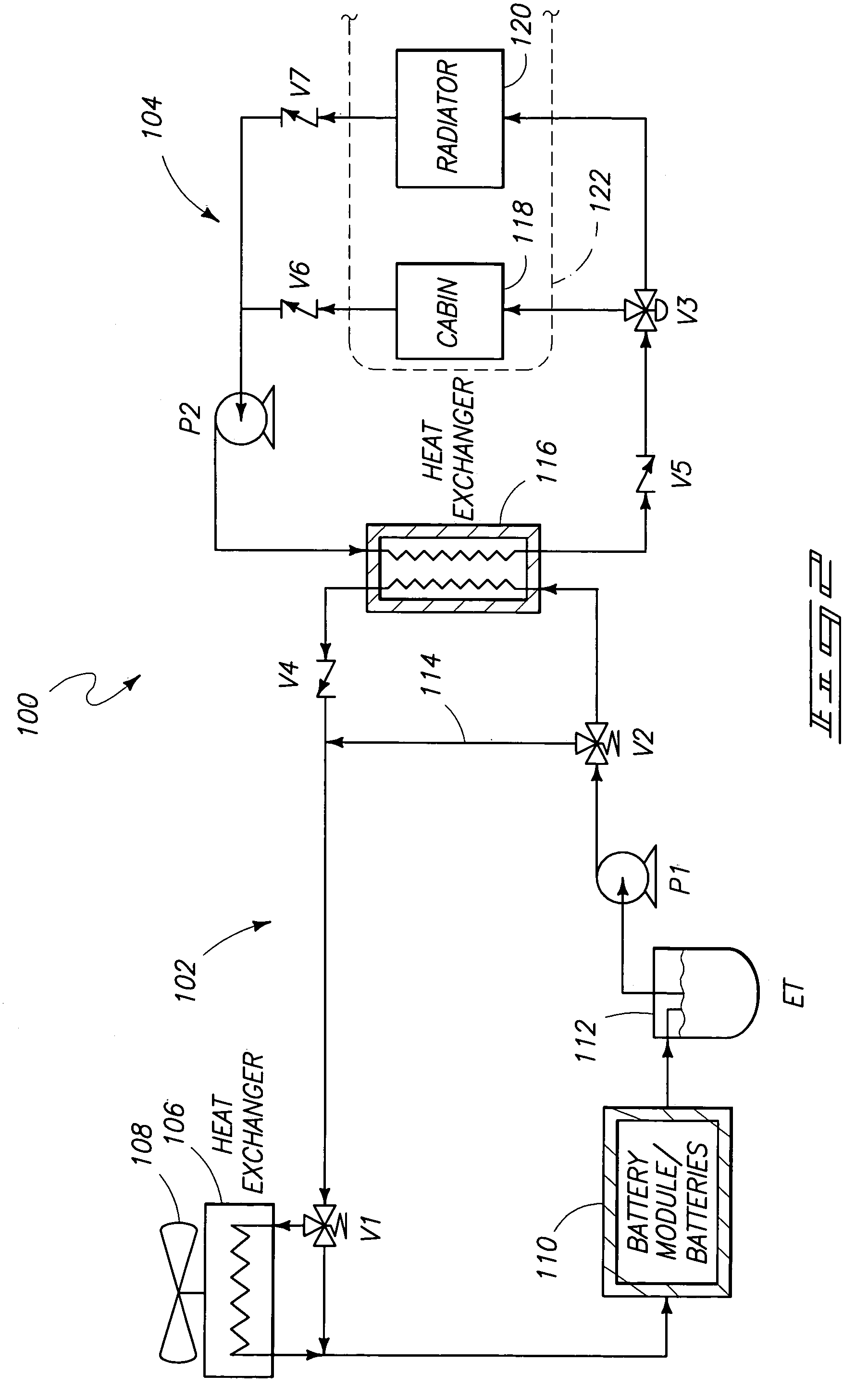

InactiveUS7147071B2Increase heatCell temperature controlMachines/enginesThermal energyThermal energy storage

A thermal management system for a vehicle includes a heat exchanger having a thermal energy storage material provided therein, a first coolant loop thermally coupled to an electrochemical storage device located within the first coolant loop and to the heat exchanger, and a second coolant loop thermally coupled to the heat exchanger. The first and second coolant loops are configured to carry distinct thermal energy transfer media. The thermal management system also includes an interface configured to facilitate transfer of heat generated by an internal combustion engine to the heat exchanger via the second coolant loop in order to selectively deliver the heat to the electrochemical storage device. Thermal management methods are also provided.

Owner:BATTELLE ENERGY ALLIANCE LLC

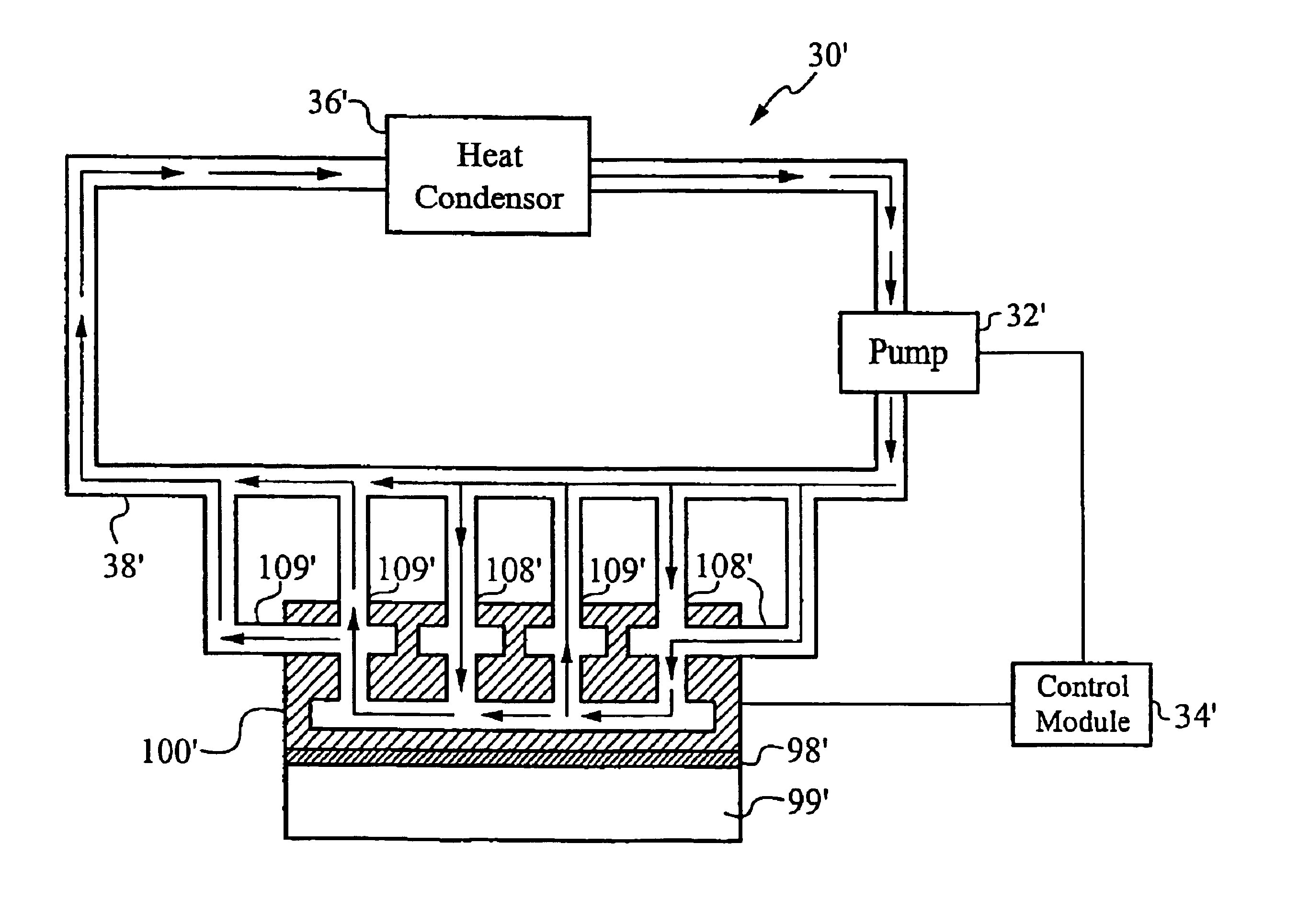

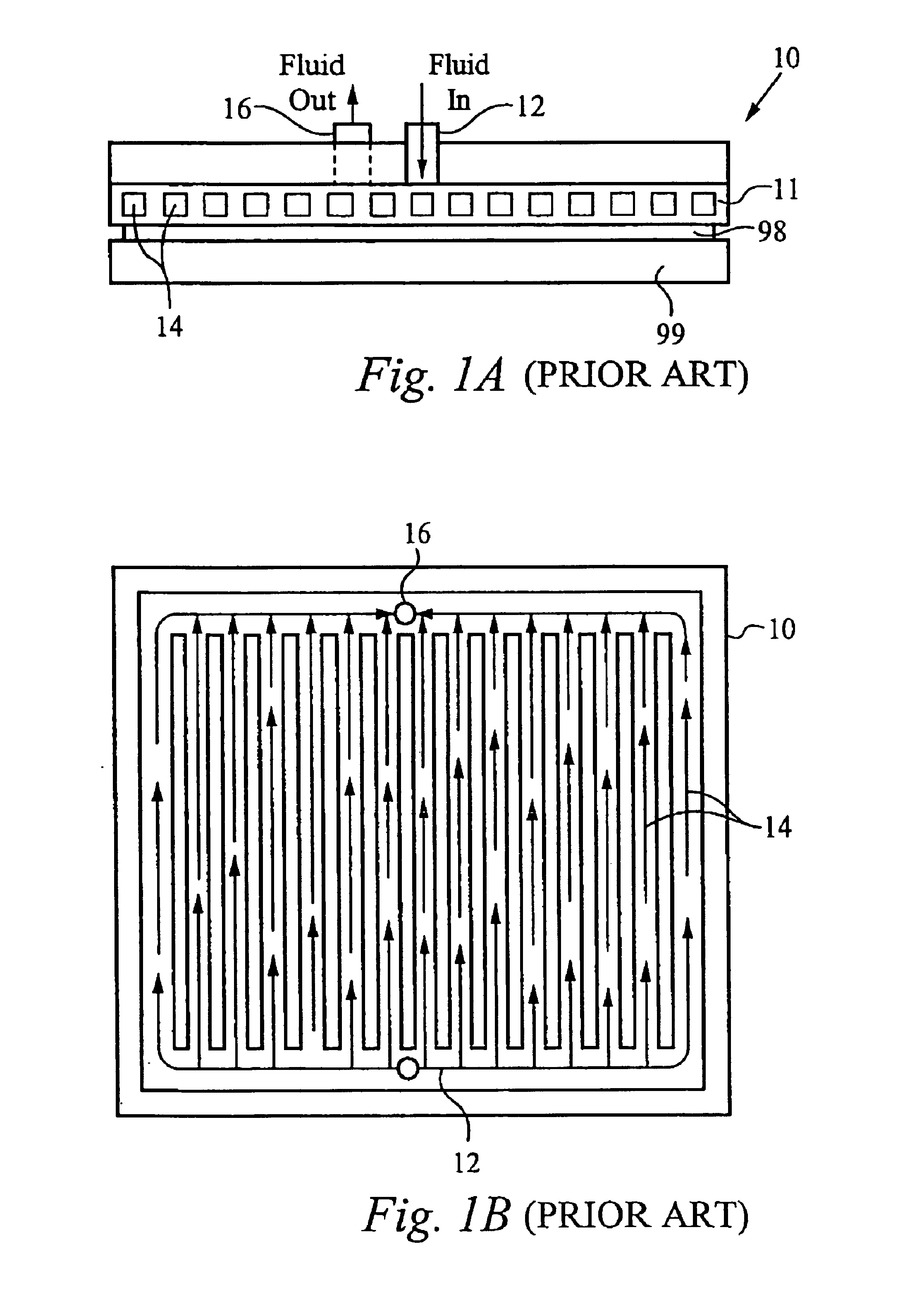

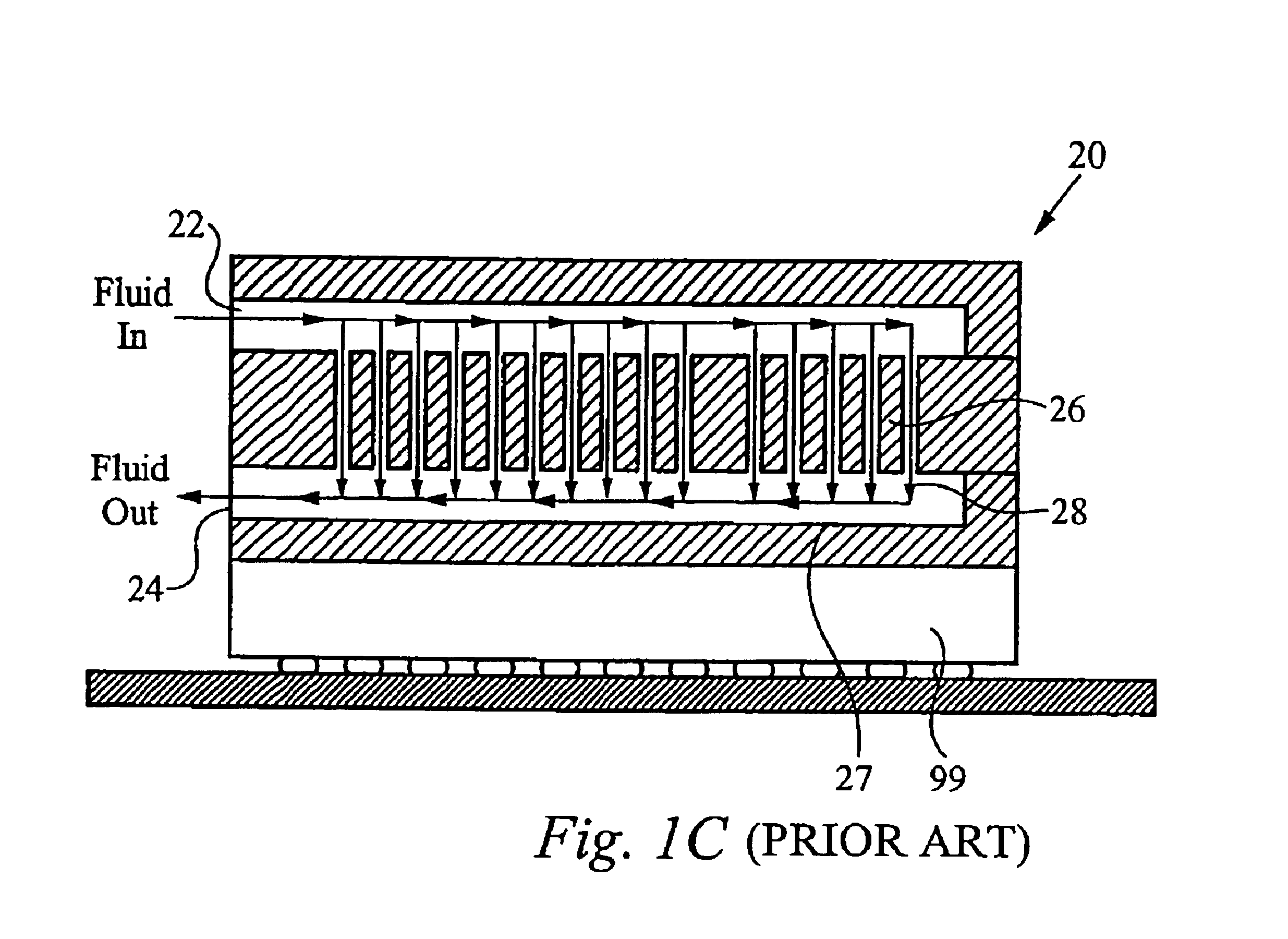

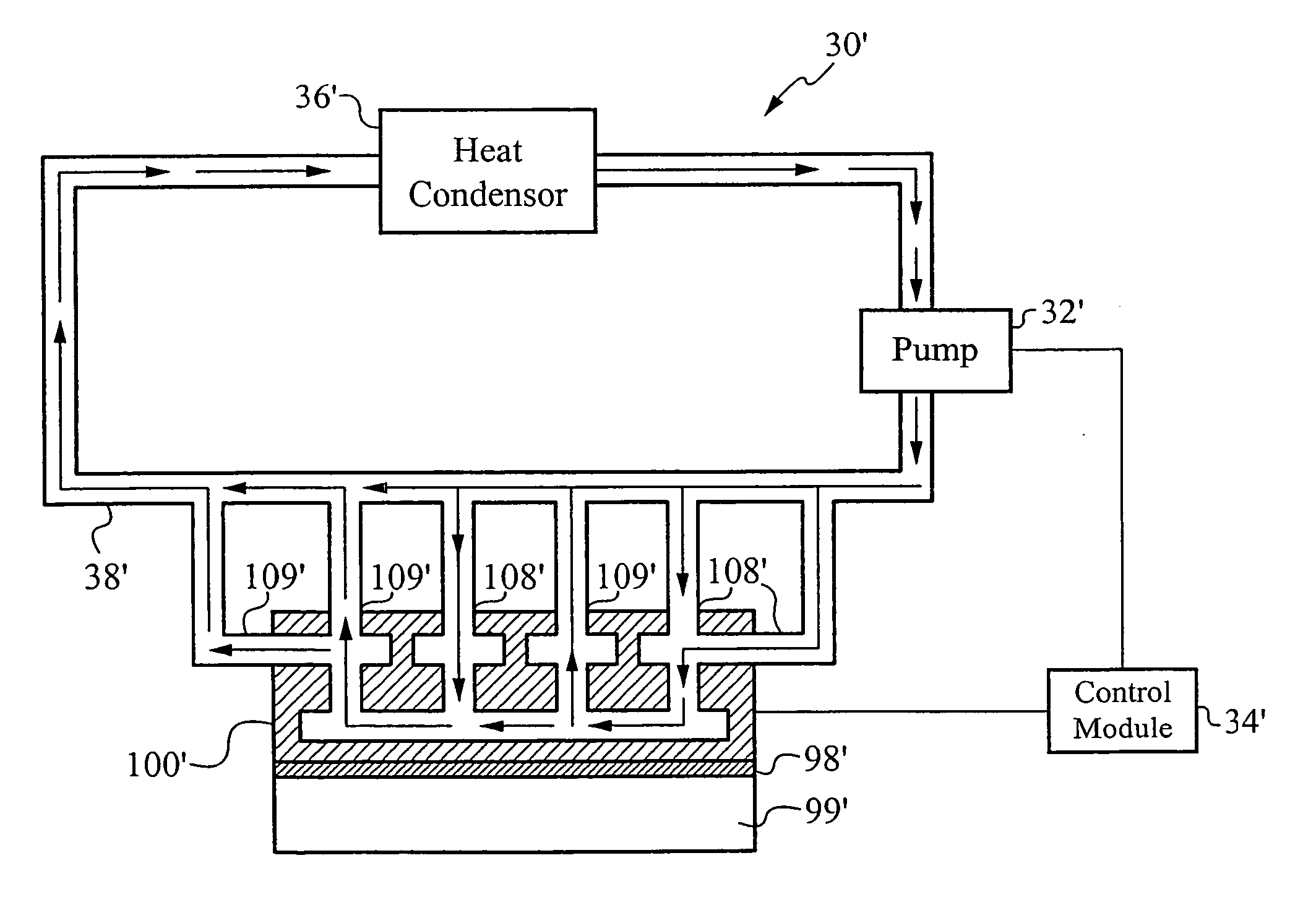

Method and apparatus for efficient vertical fluid delivery for cooling a heat producing device

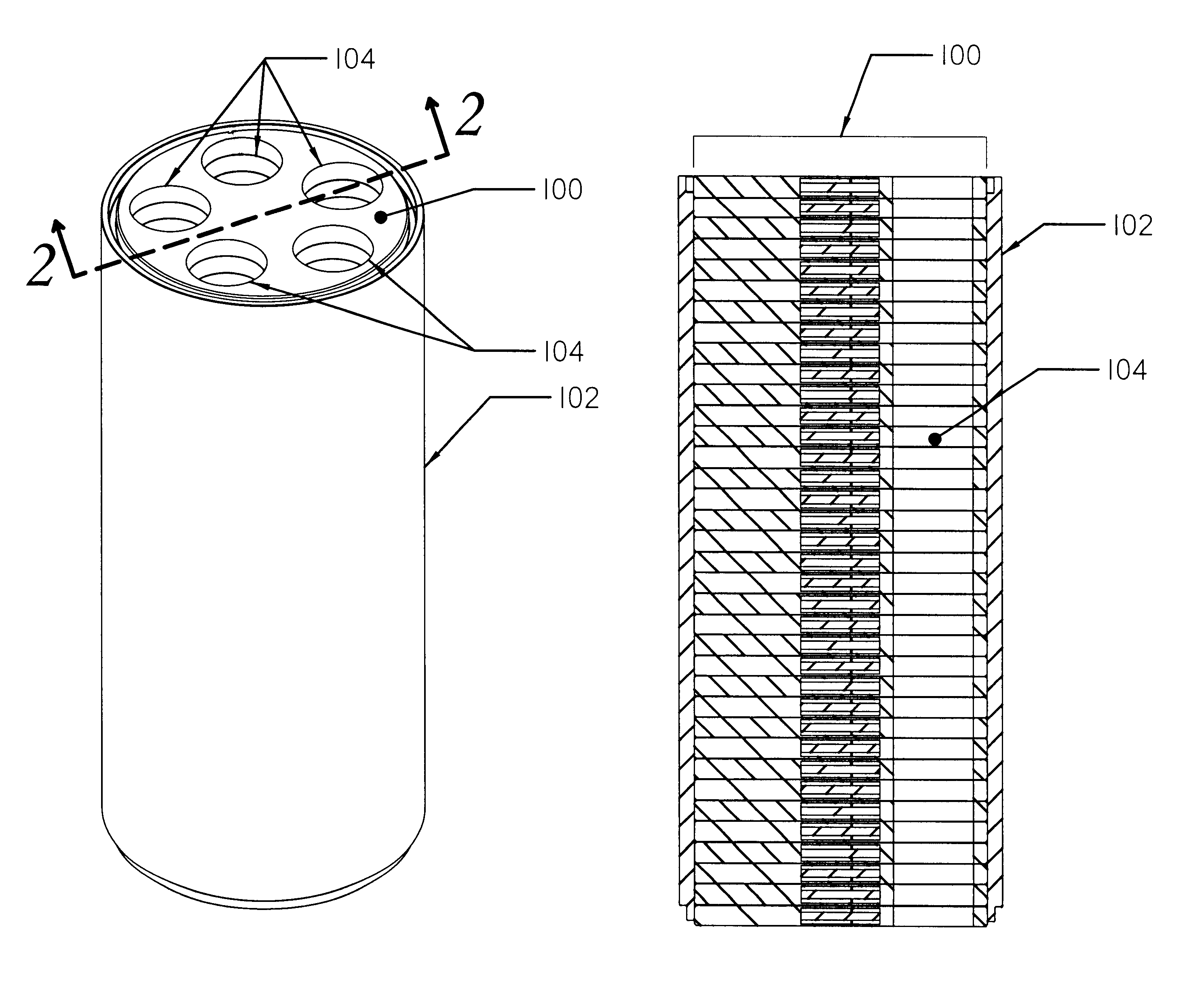

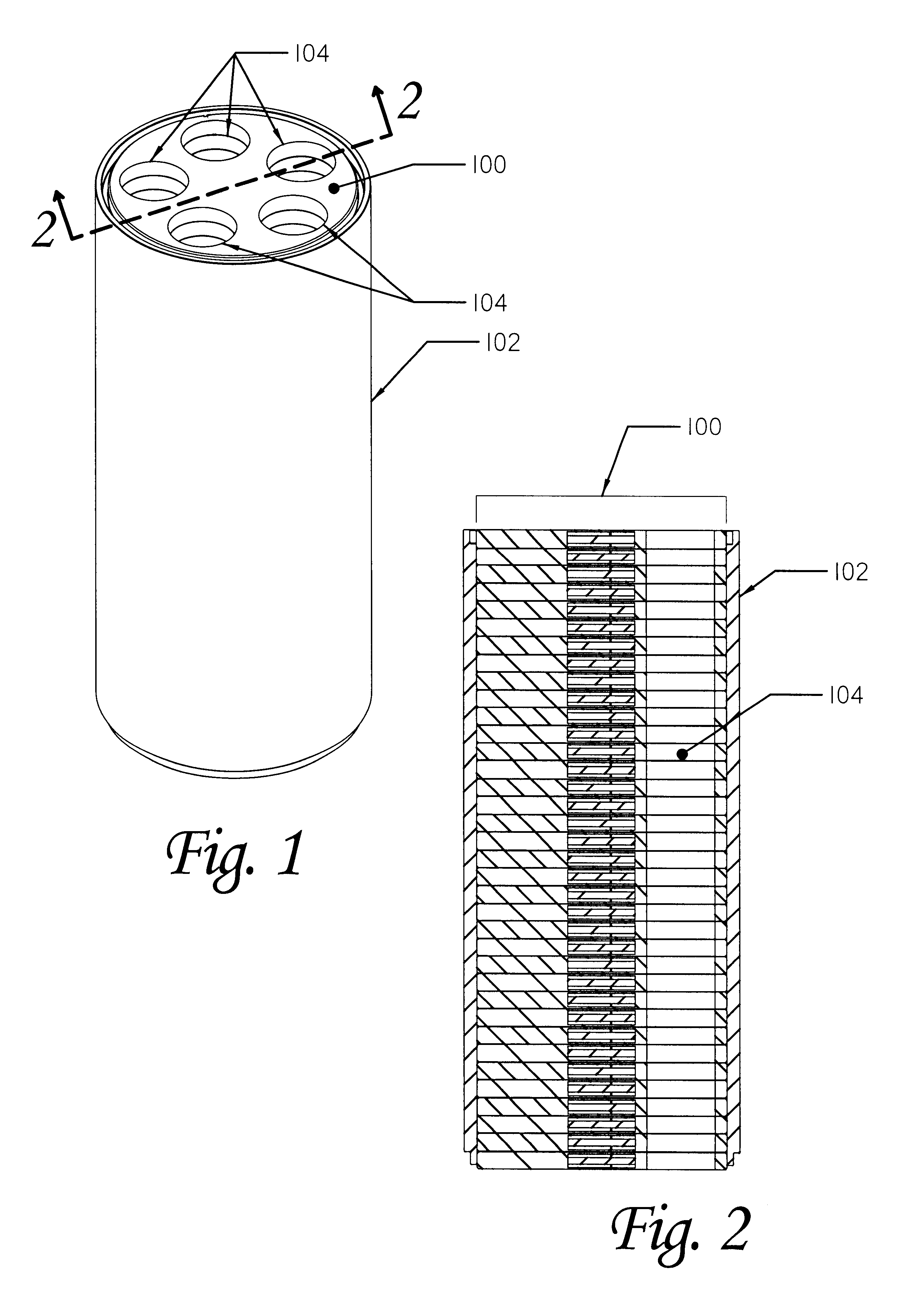

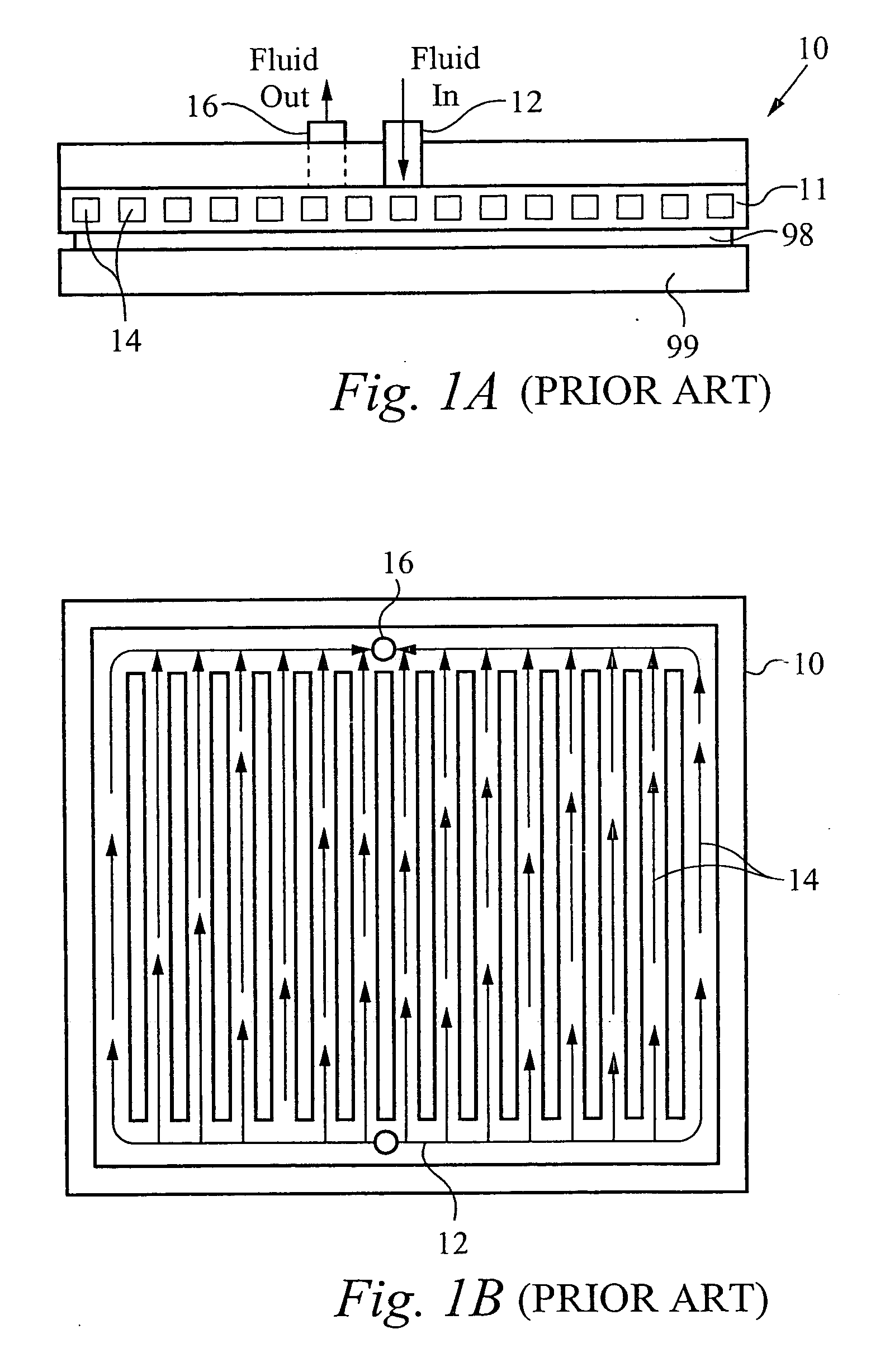

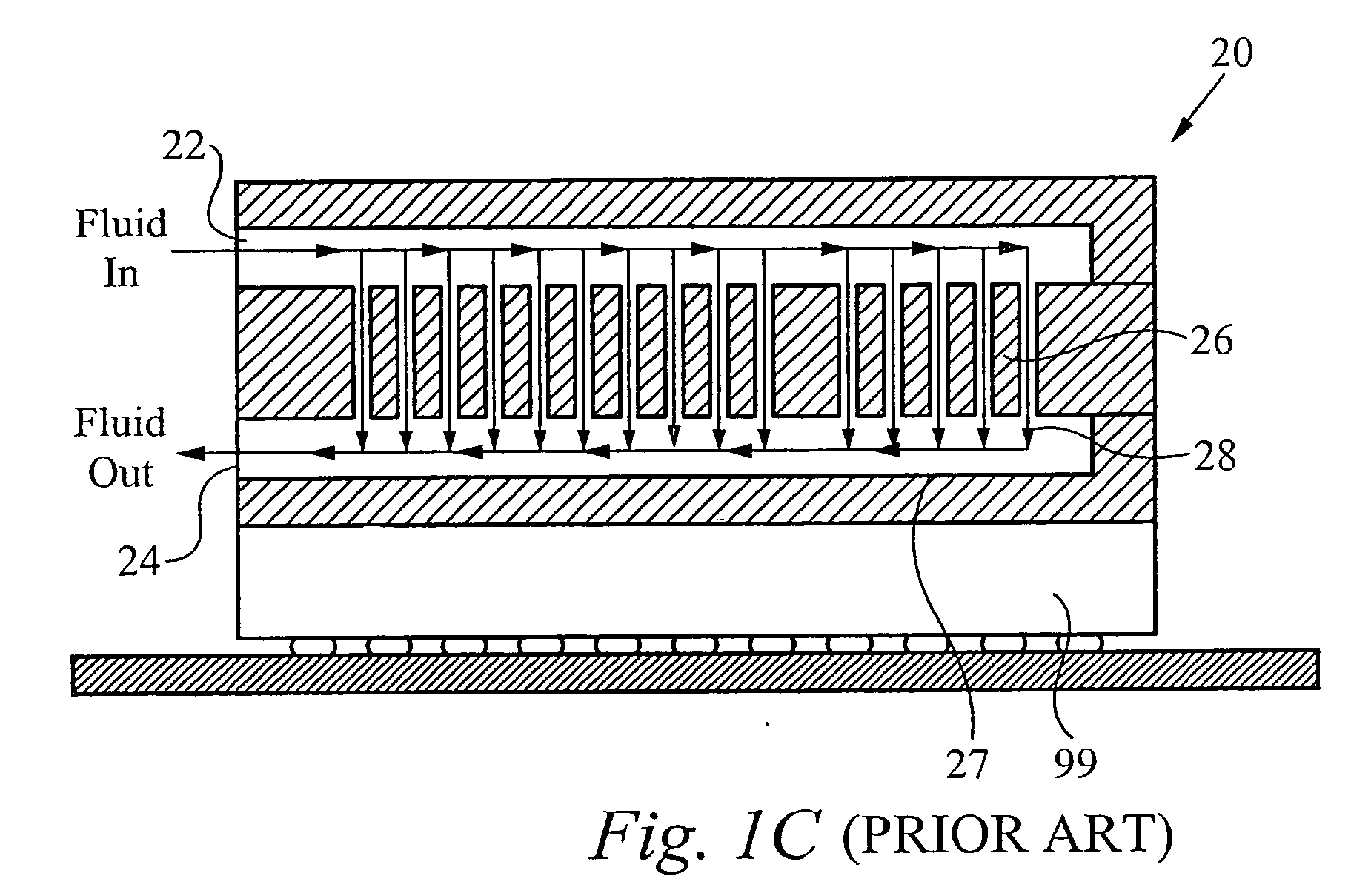

InactiveUS7000684B2Minimized fluid path distanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesInterface layerPath distance

A heat exchanger and method of manufacturing thereof comprises an interface layer for cooling a heat source. The interface layer is coupled to the heat source and is configured to pass fluid therethrough. The heat exchanger further comprises a manifold layer that is coupled to the interface layer. The manifold layer includes at least one first port that is coupled to a first set of individualized holes which channel fluid through the first set. The manifold layer includes at least one second port coupled to a second set of individualized holes which channel fluid through the second set. The first set of holes and second set of holes are arranged to provide a minimized fluid path distance between the first and second ports to adequately cool the heat source. Preferably, each hole in the first set is positioned a closest optimal distance to an adjacent hole the second set.

Owner:VERTIV CORP

Cooling systems incorporating heat exchangers and thermoelectric layers

ActiveUS20070034356A1Thermoelectric device with peltier/seeback effectDigital data processing detailsEngineeringThermal contact

A method and system for cooling a heat source are presented. The system includes a fluid heat exchanger, a pump, a thermoelectric device having a cooling portion and a heating portion, and a heat rejector configured to be in thermal contact with at least a portion of the heating portion of the thermoelectric device. The pump is coupled with the fluid heat exchanger and configured to pass a fluid therethrough. The thermoelectric device is configured along with the heat exchanger in a cooling system to enhance the cooling efficiency of the system.

Owner:VERTIV CORP

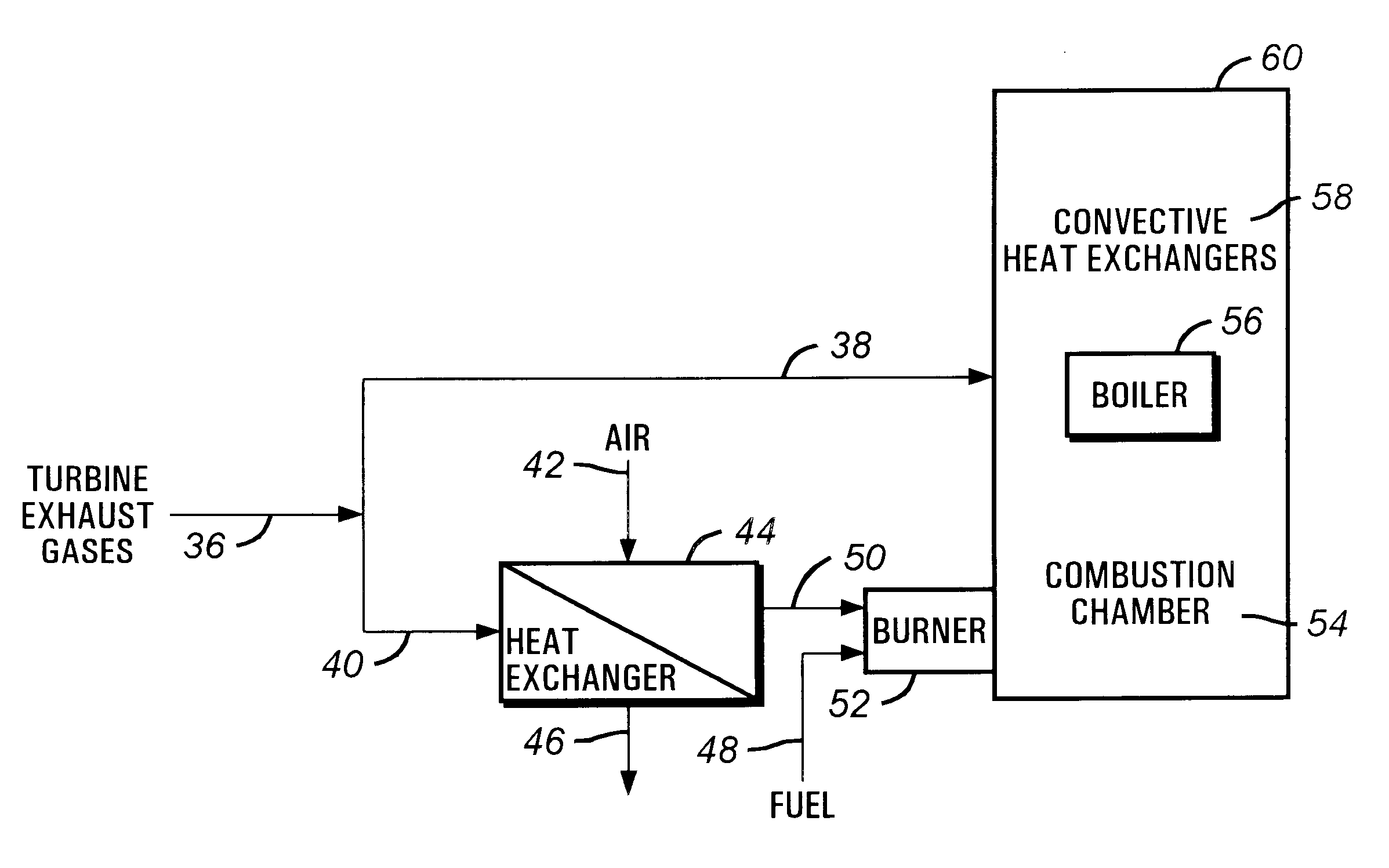

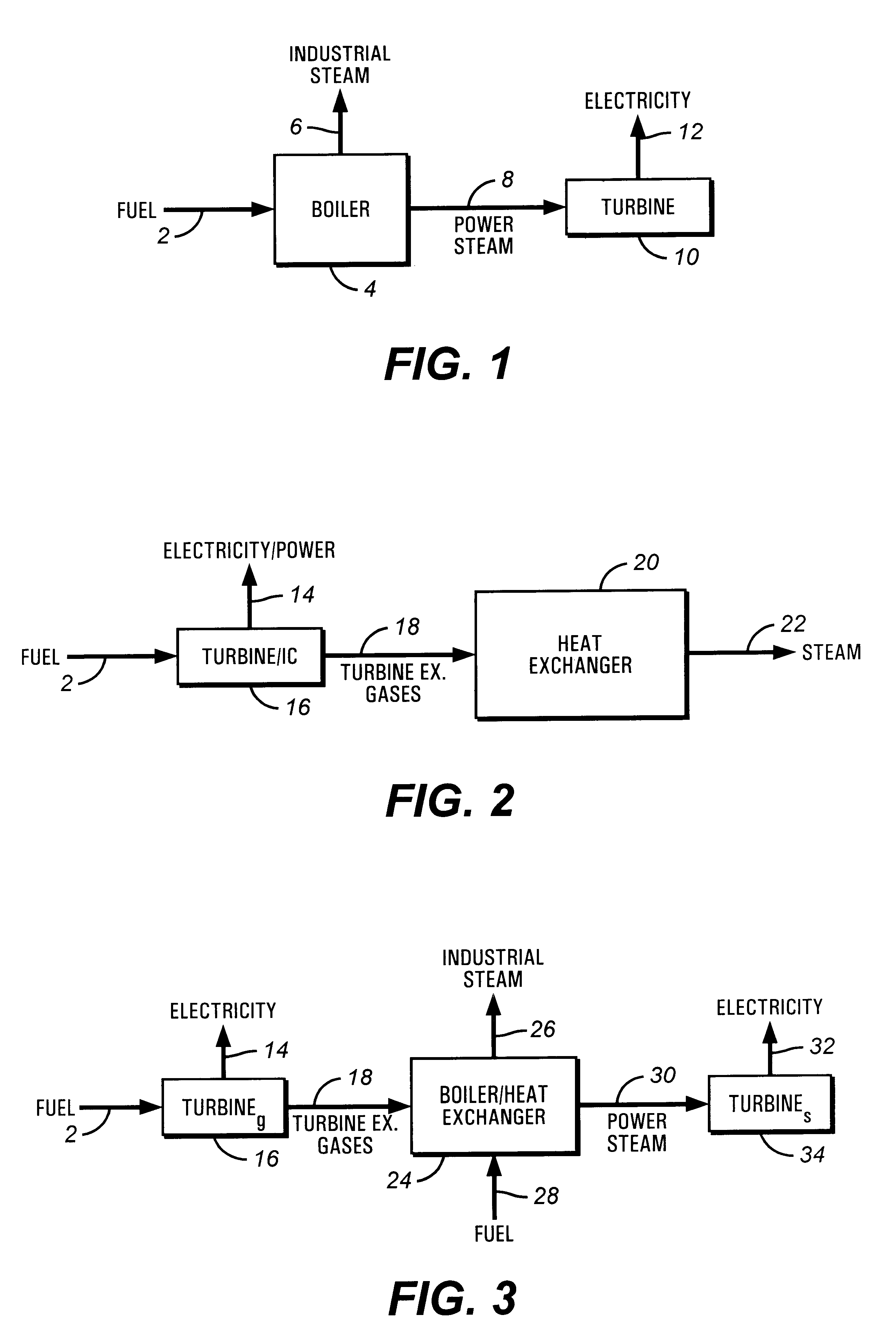

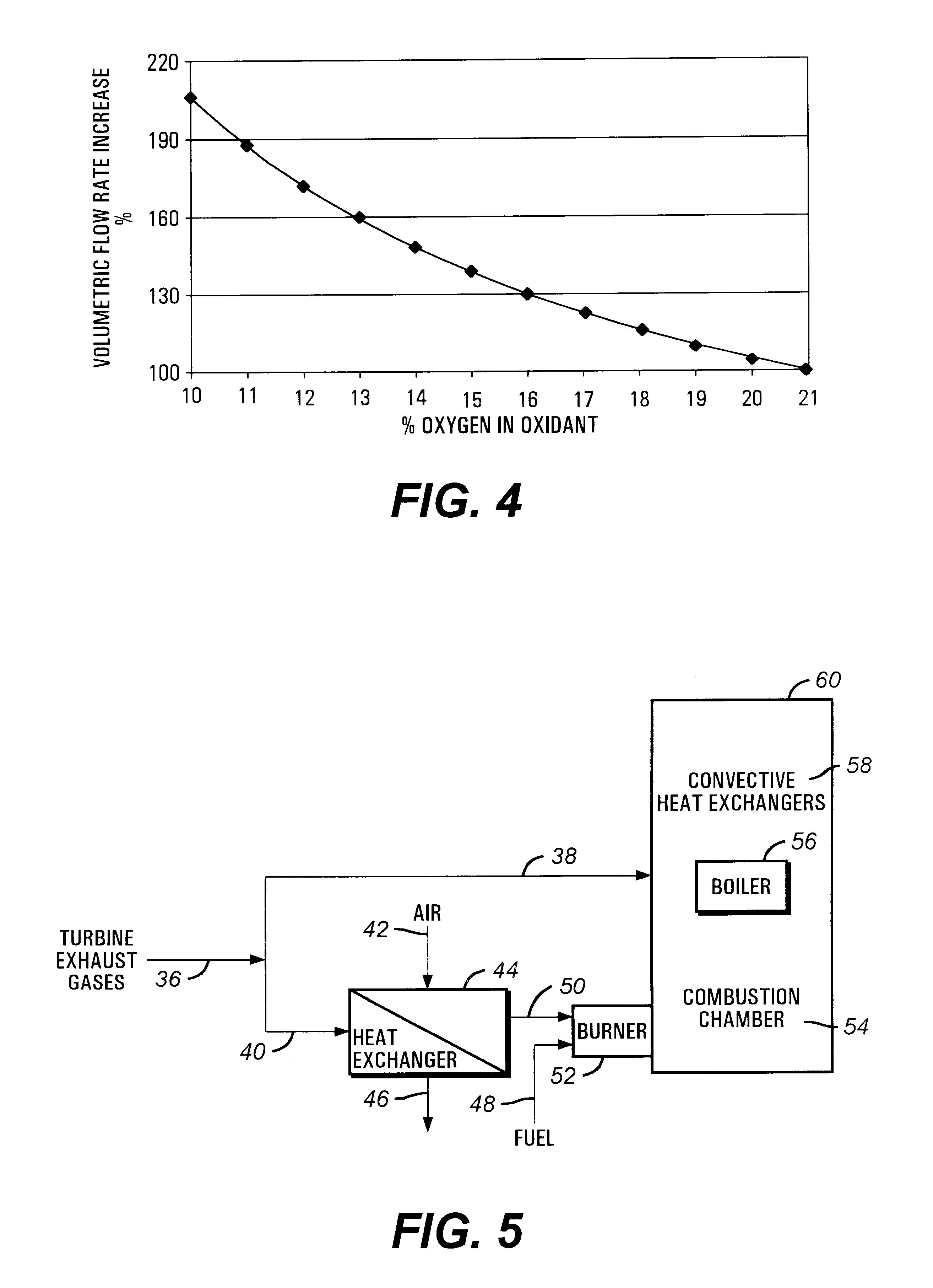

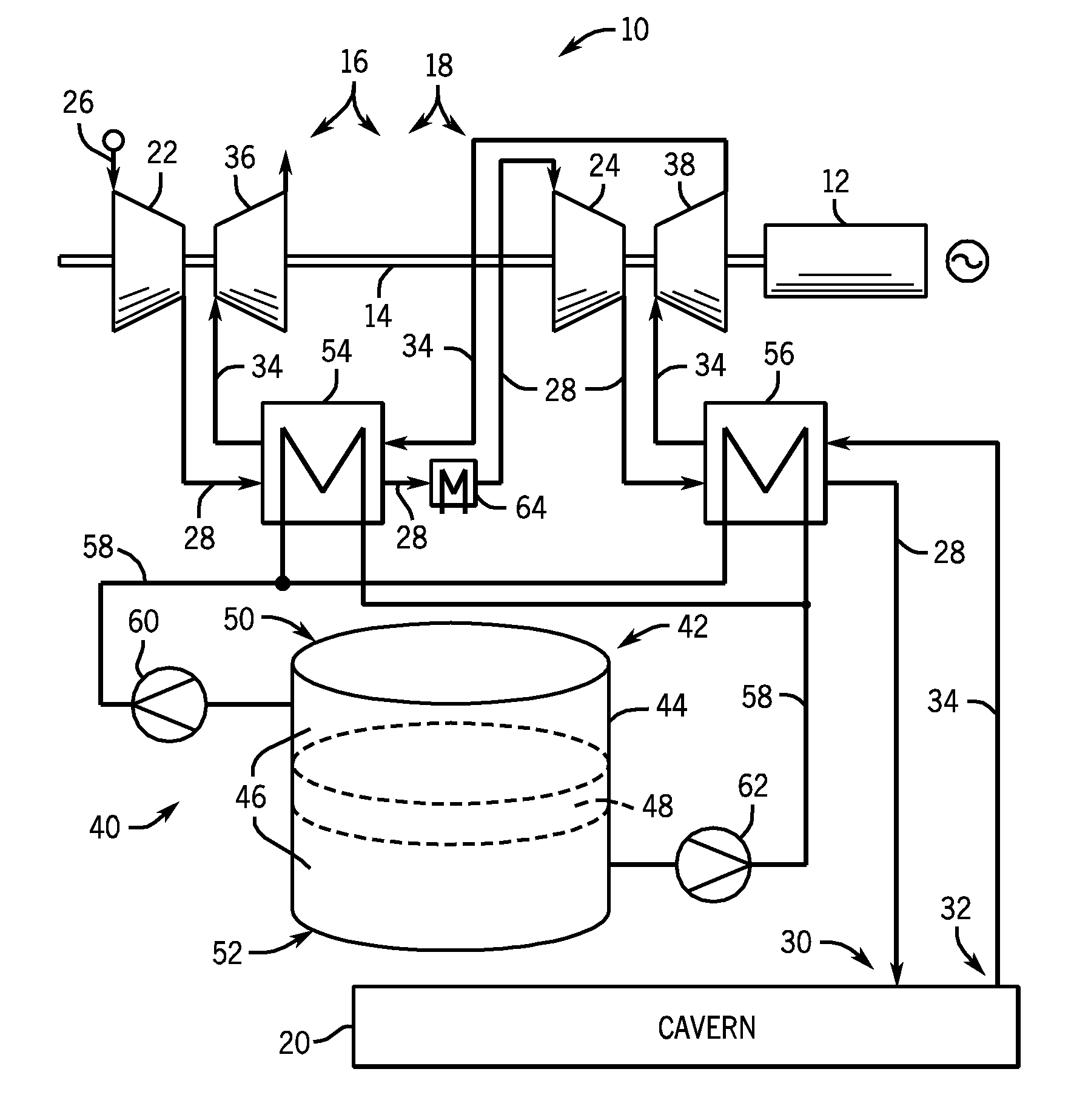

Oxidant control in co-generation installations

InactiveUS6247315B1Steam regenerationIndirect carbon-dioxide mitigationControl system designCogeneration

This invention is related to so-called combined cycle co-generation installations, and it addresses present concerns of the industry. Among these, combustion stability, corrosion (due to large water content in the flue gases), large heat transfer areas, and the like. In some embodiments, an additional heat exchanger is added to heat combustion air with a portion of the exhaust gases resulting from an engine, preferably a gas turbine. As a result, the efficiency of the cycle will improve, the oxidant will be enriched by above 50% oxygen, the combustion process will be enhanced, and the dimensions of the boiler may be reduced. It is considered that the combustion air will require between 10% and 80% of the total flue gas volume, more preferably between 20% and 40%. This is the portion of the flue gases sent through the heat exchanger. A control system designed to optimize the flow of the different streams is also presented. Other inventive embodiments forego heat exchanges in lieu of precise control of two flows of exhaust gas, with preferred addition of additional oxidant to the boiler bumers.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

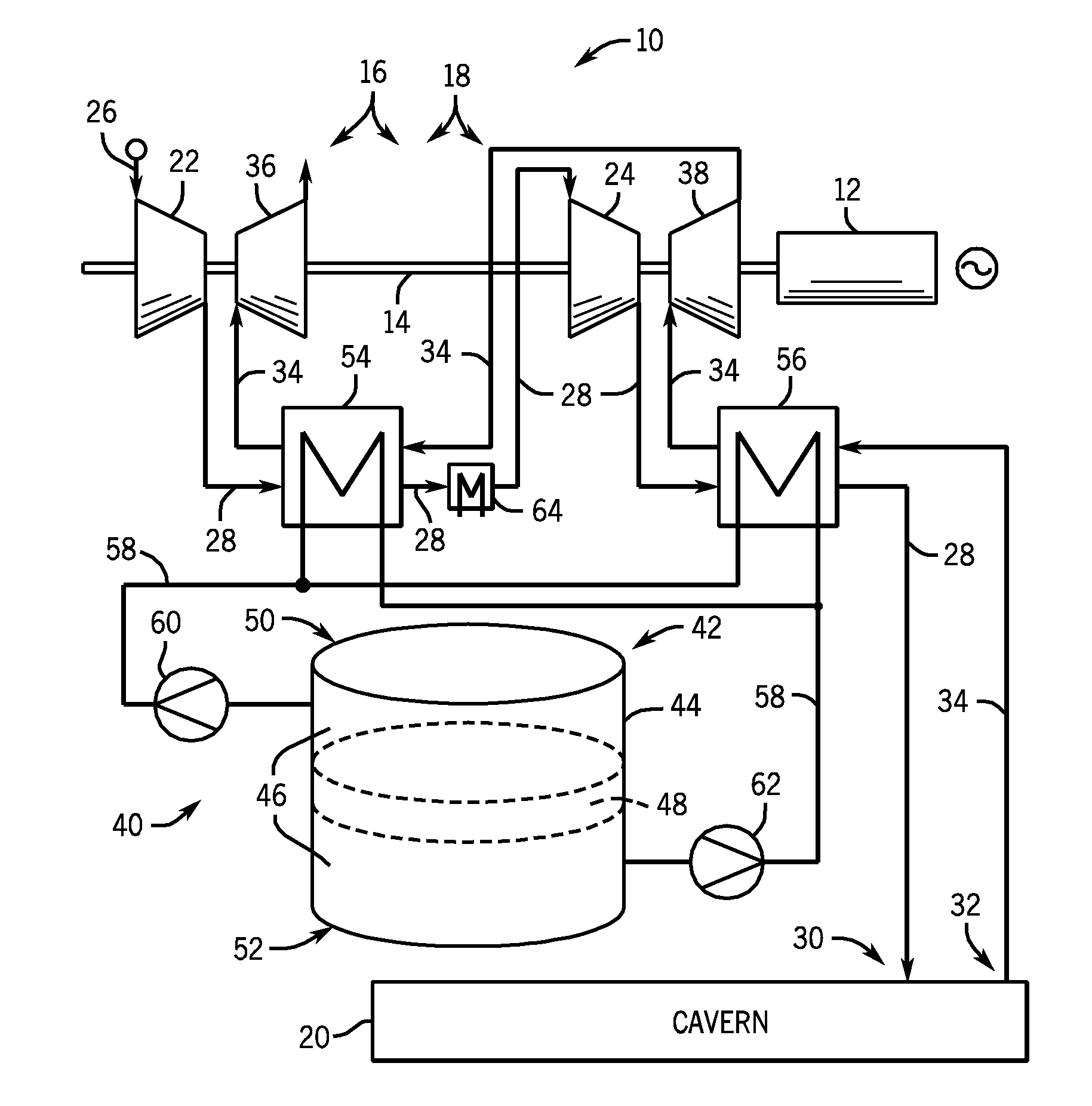

Adiabatic compressed air energy storage system with liquid thermal energy storage

InactiveUS20110100010A1Reciprocating combination enginesCombination enginesThermal energyThermal energy storage

An adiabatic compressed air energy storage (ACAES) system includes a compressor system, an air storage unit, and a turbine system. The ACAES system further includes a thermal energy storage (TES) system that includes a container, a plurality of heat exchangers, a liquid TES medium conduit system fluidly coupling the container to the plurality of heat exchangers, and a liquid TES medium stored within the container. The TES system also includes a plurality of pumps coupled to the liquid TES medium conduit system and configured to transport the liquid TES medium between the plurality of heat exchangers and the container, and a thermal separation system positioned within the container configured to thermally isolate a first portion of the liquid TES medium at a lower temperature from a second portion of the liquid TES medium at a higher temperature.

Owner:GENERAL ELECTRIC CO

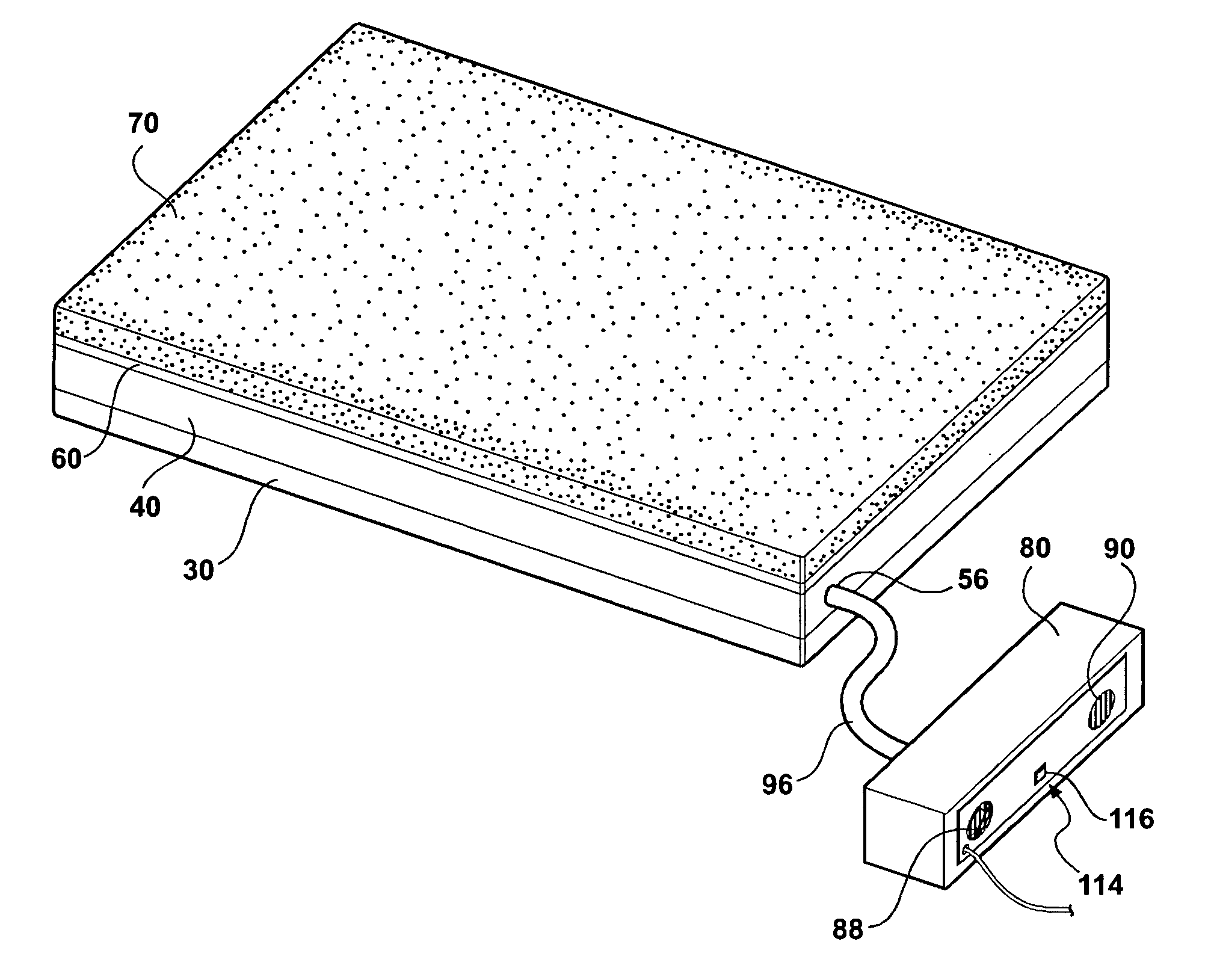

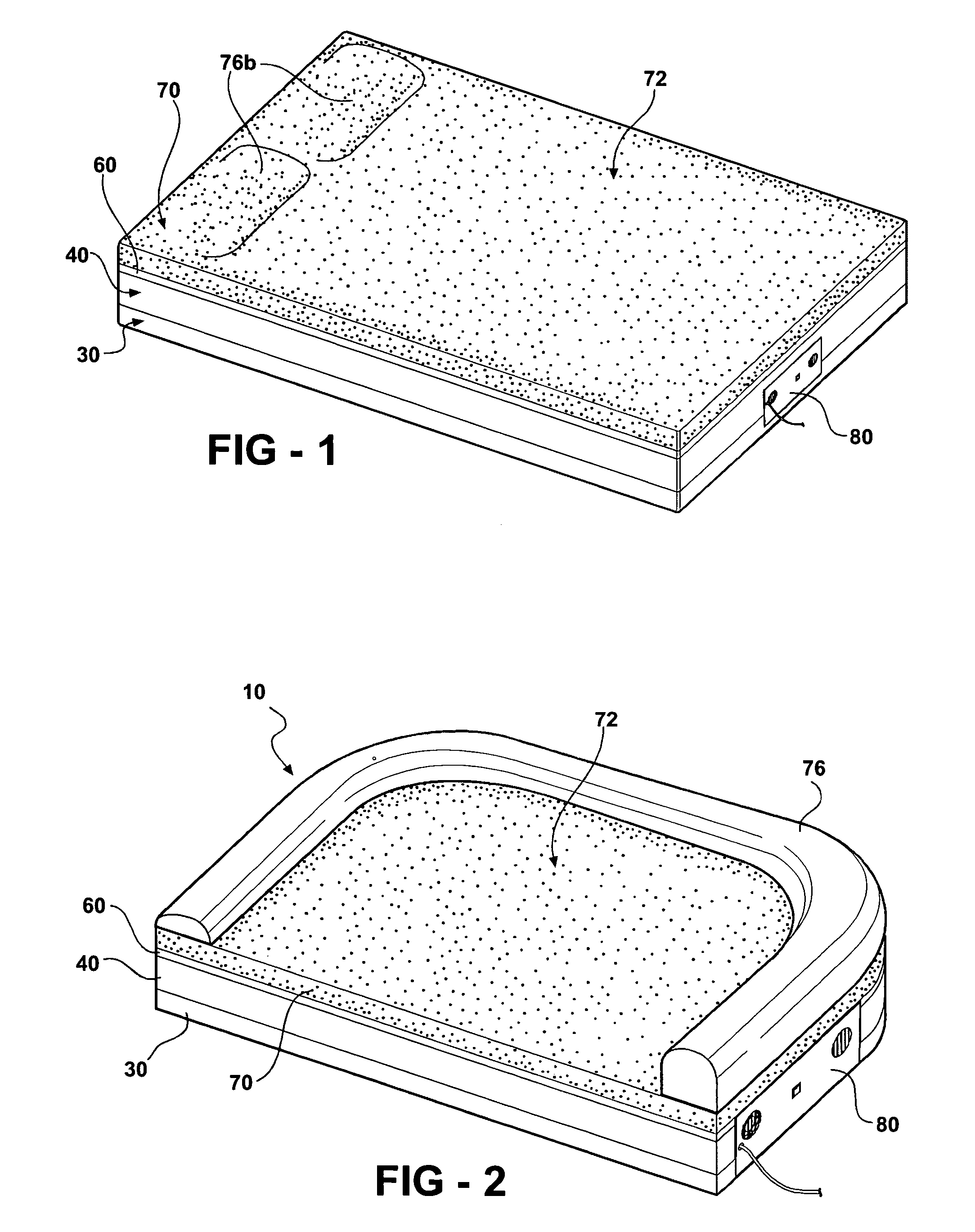

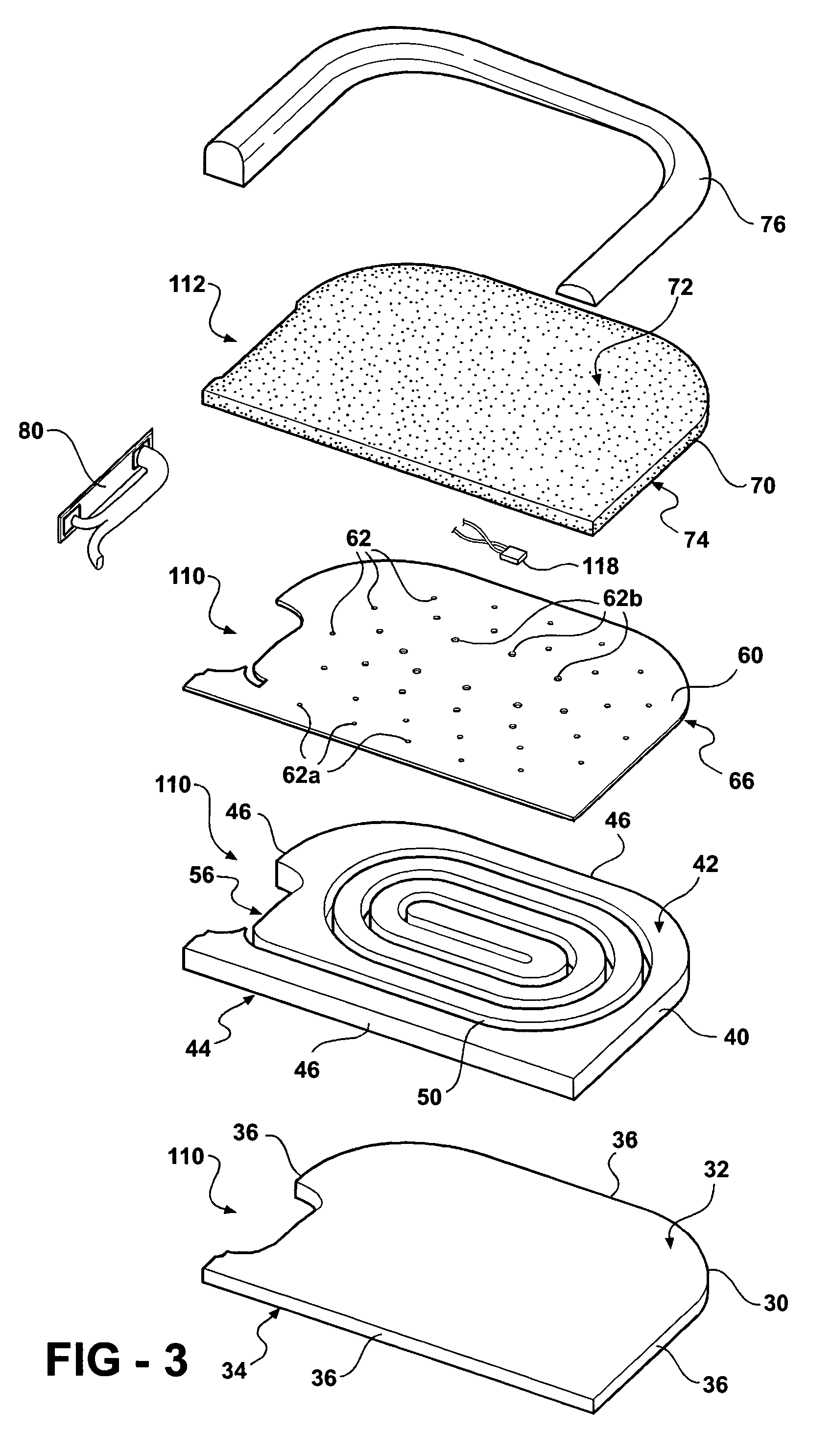

Comfort product

An improved comfort product that uses an airflow through a heat exchanger and into the comfort product to selectively heat or cool an occupant has a support layer contacting and supporting a channel layer. The channel layer has at least one channel with an opening to accept air. The channel layer contacts and supports an engineered distribution layer that has numerous small holes making it air permeable. The engineered distribution layer contacts and supports an air permeable comfort layer that is of such size and shape to support an occupant of the comfort product. The comfort product also has a heat exchanger assembly for supplying heated or cooled air to the opening in the channel. The heat exchanger assembly includes an air intake having an intake fan, an exhaust outlet and a heat exchanger for selectively heating or cooling air flowing through the heat exchanger resulting in selectively heated or cooled supply air and exhaust air. The intake fan forces air through the heat exchanger where some of the air is selectively heated or cooled to be supplied to the comfort product and some air is used as exhaust air (to remove the unwanted heat if the supplied air is cooled or to warm the exhaust side of the heat exchanger if the supply air is warmed.). The selectively heated or cooled supply air then moves through the channels in the channel layer and the exhaust air exits through the exhaust vent. The selectively heated or cooled supply air then moves through the engineered distribution layer where the numerous small holes diffuse the air and then the selectively heated or cooled air then moves through the comfort layer where the air is further diffused and where the selectively heated or cooled air can selectively heat or cool an occupant of the comfort product.

Owner:RIVERPARK INC A IN THE STATE OF INDIANA

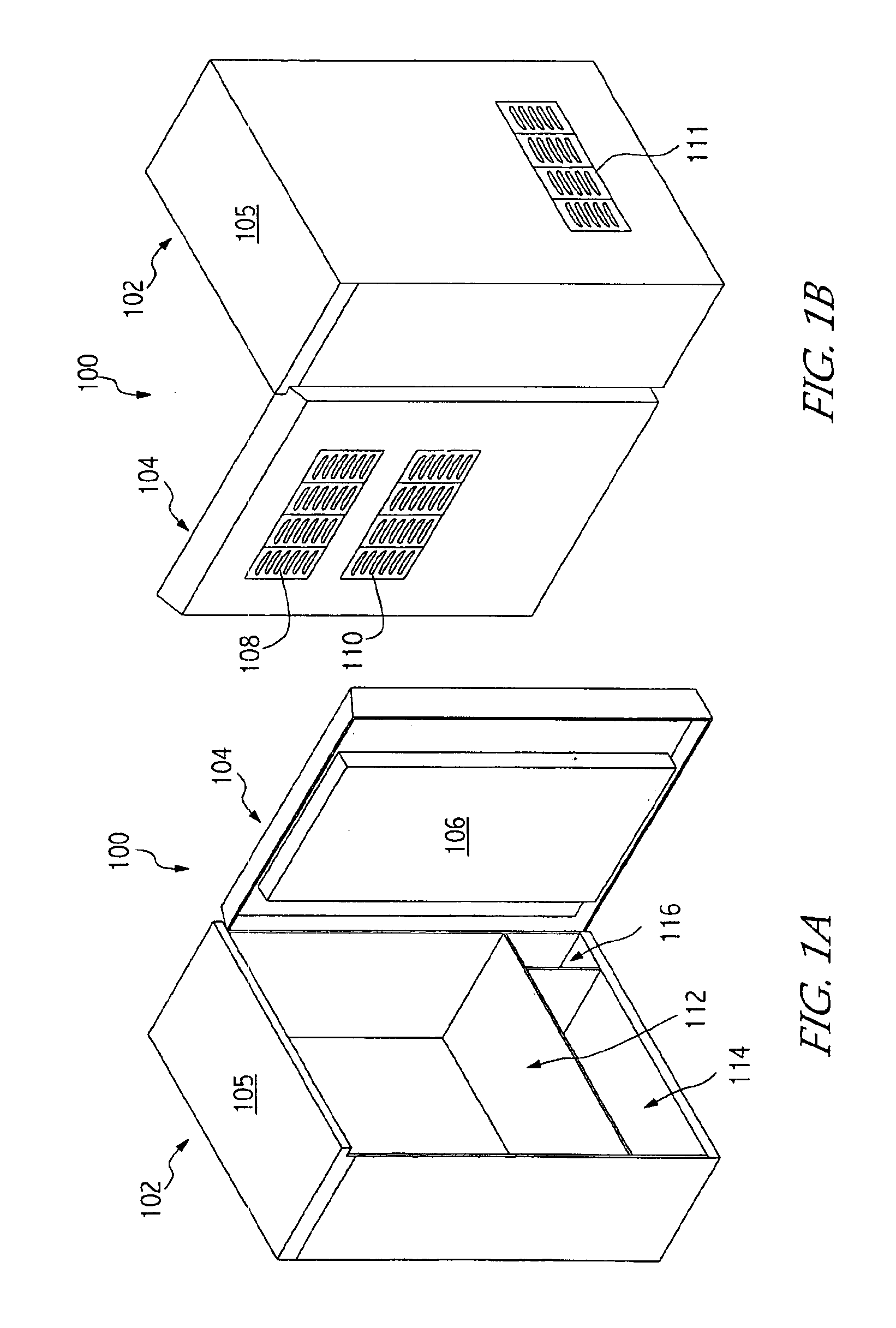

Systems and methods for weatherproof cabinets with multiple compartment cooling

A weatherproof cabinet with multiple-compartment cooling includes a housing and a door attached to the housing. The door includes a heat exchanger core, a first duct located at least partially between the heat exchanger door and an exterior of the door, and a second duct located at least partially between the heat exchanger door and an electronics compartment. The door also includes an inlet vent and an outlet vent that are pneumatically interconnected with the first duct. A fan is located at least partially within the first duct and is operative to draw external air into the first duct via the inlet vent, direct at least the first portion of the external air across the heat exchanger core, and then direct the first portion of the external air out of the first duct via the outlet vent. A partition is located within the first duct and separates the inlet vent from the outlet vent so that external air is not drawn into the first duct via the outlet vent during operation of the fan.

Owner:COMMSCOPE INC

Washing machine and control method thereof

InactiveUS20060277690A1Minimizing formation of scaleOther washing machinesControl devices for washing apparatusProcess engineeringHeat exchanger

Disclosed herein are a washing machine and a control method thereof that is capable of supplying condensed water generated while laundry is dried to a steam generating unit to generate steam, thereby minimizing formation of scale in the steam generating unit. The washing machine includes a drying unit having a heat exchanger to dehumidify air in a washing tub, a steam generating unit to supply steam to the washing tub, a condensed water tank to collect condensed water from the heat exchanger, and a steam-purpose water supplying unit to supply the water from the condensed water tank to the steam generating unit.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com