Patents

Literature

473 results about "Engine cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

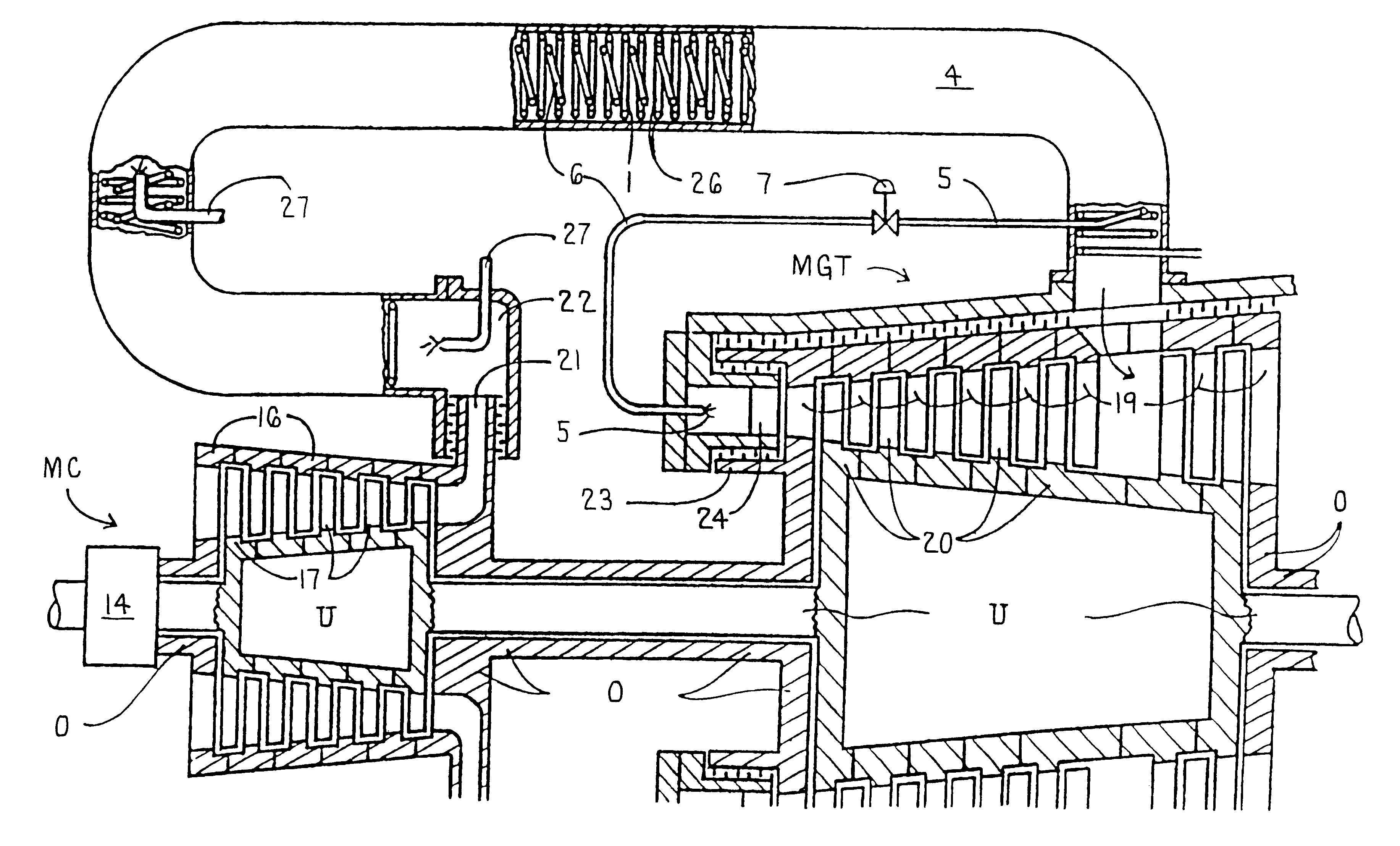

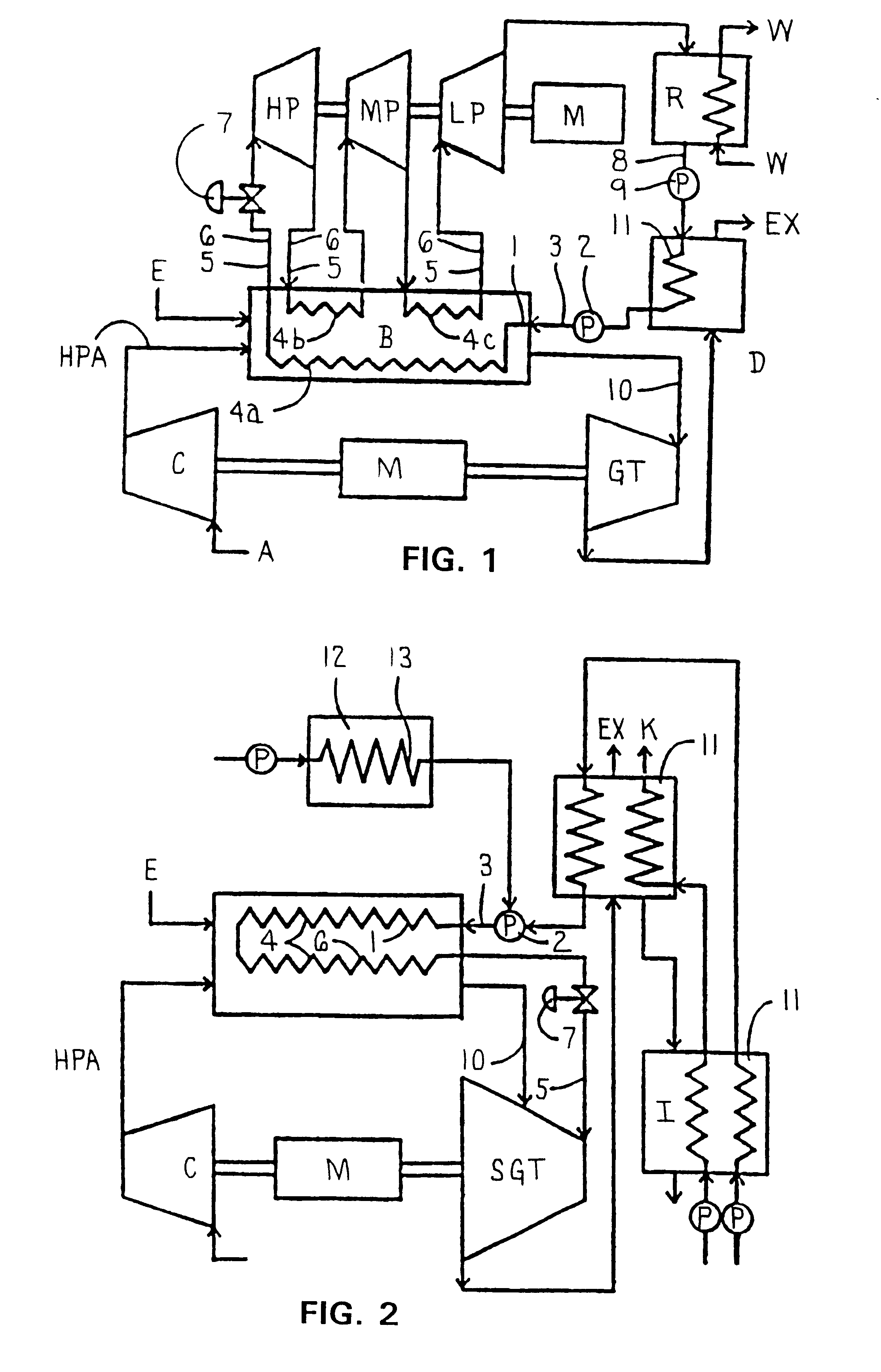

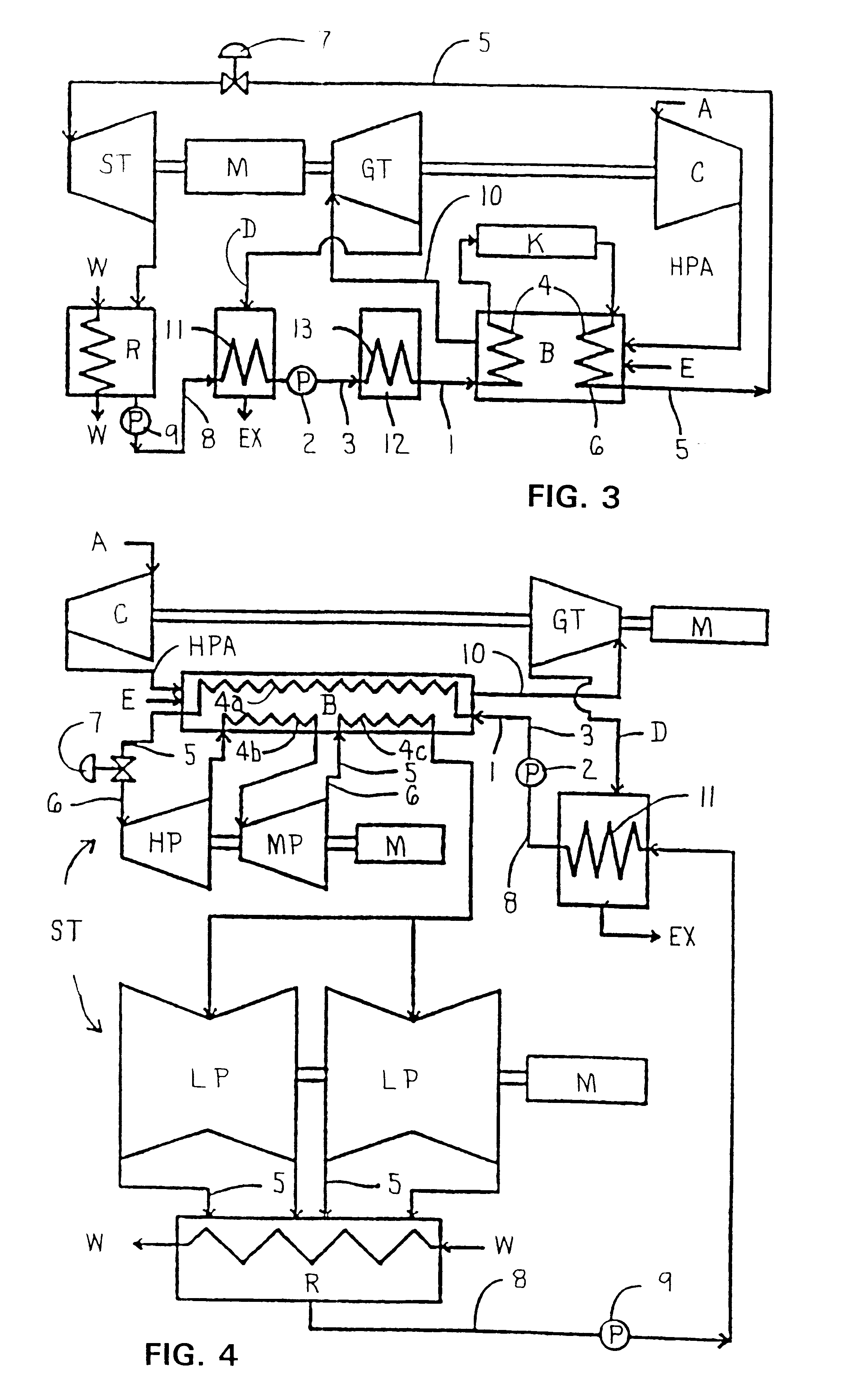

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

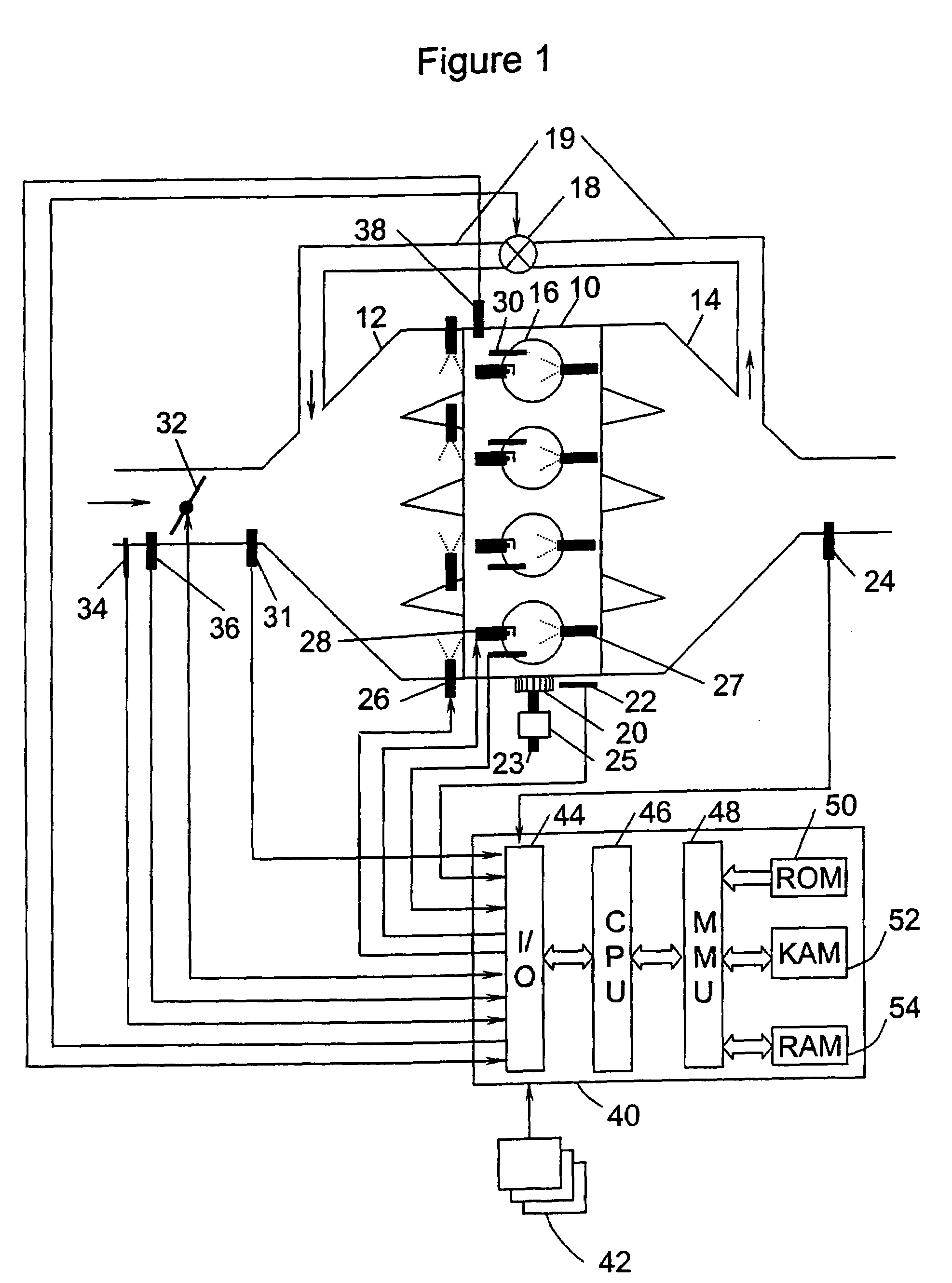

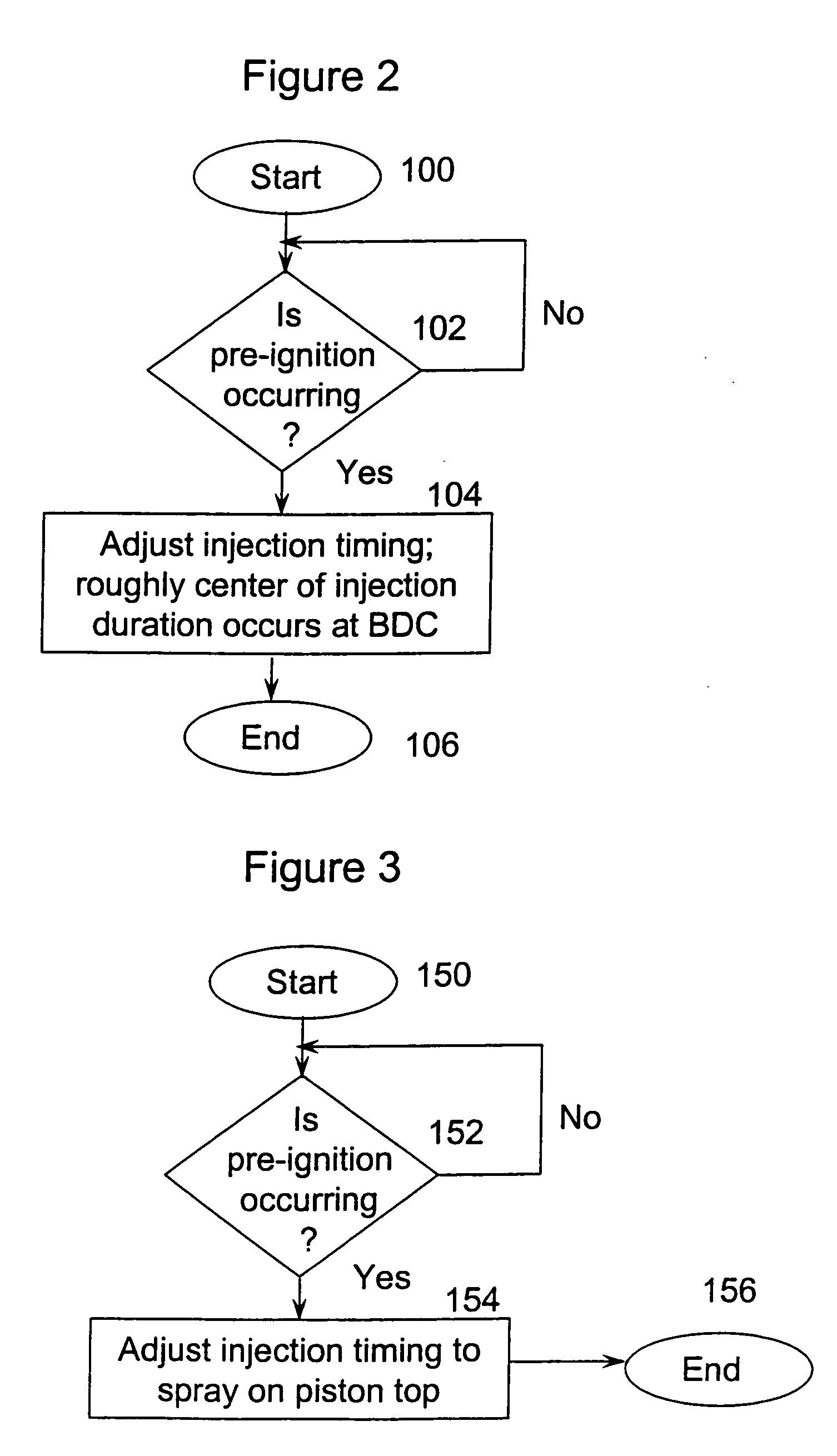

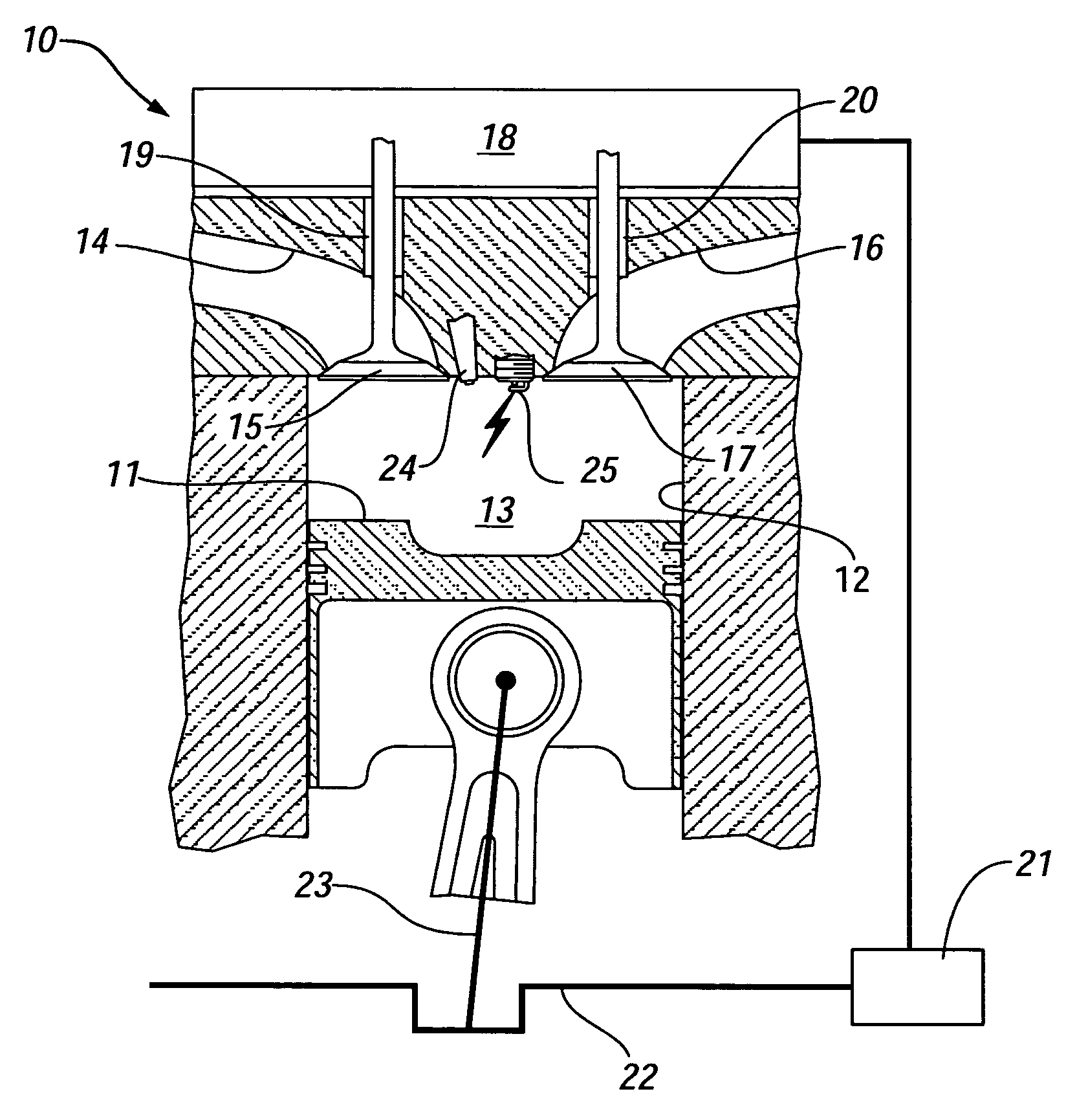

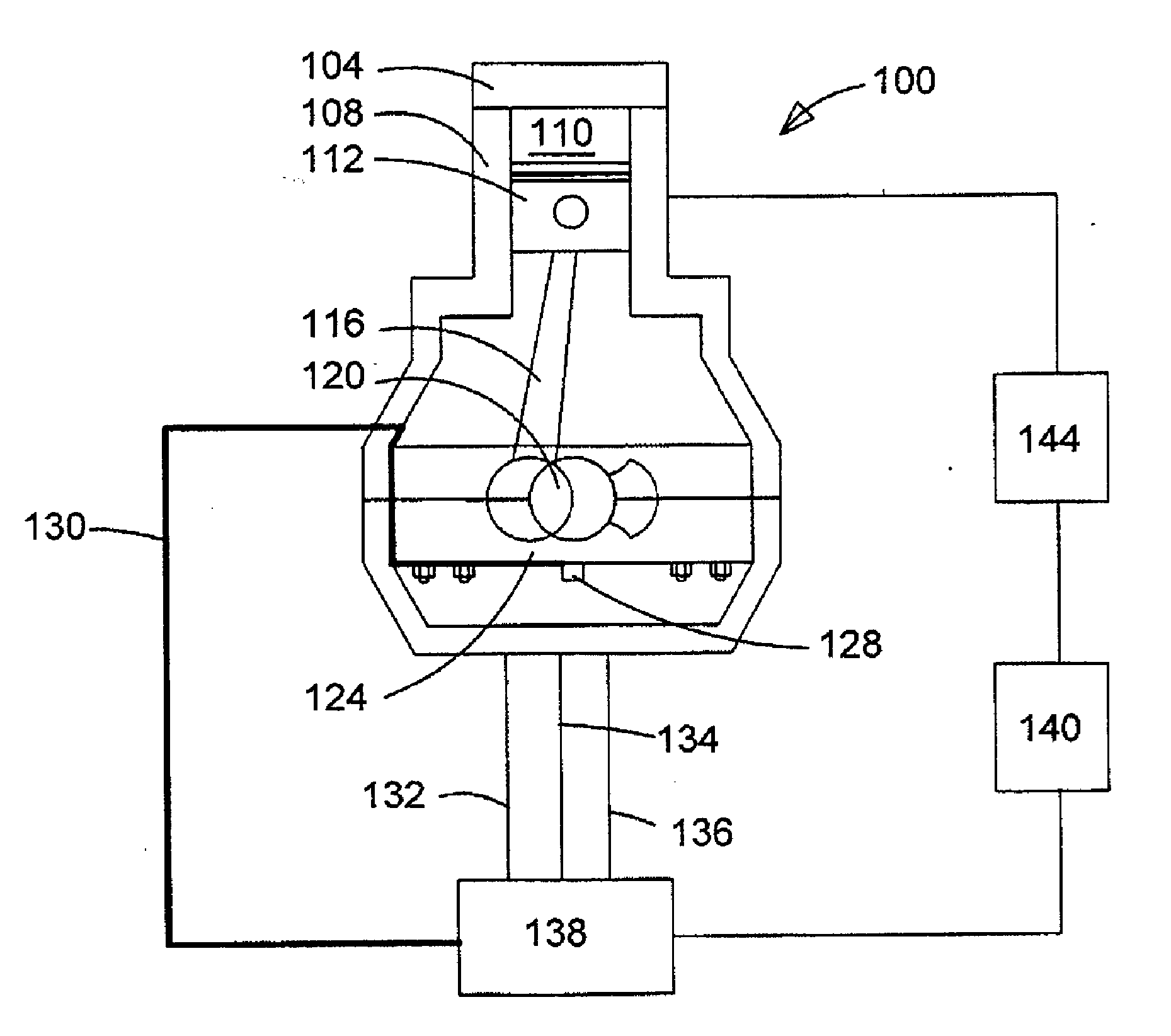

System and method to pre-ignition in an internal combustion engine

ActiveUS7178503B1Mitigate pre-ignitionReduce air densityAnalogue computers for vehiclesElectrical controlCombustion chamberAlcohol fuel

An engine system and method are disclosed for controlling pre-ignition of an alcohol fuel. In one embodiment, the fuel injection timing is adjusted to cause the fuel to avoid combustion chamber surfaces. In another embodiment, the fuel injection timing is adjusted to spray the fuel directly onto the piston surface to cool the piston. Also disclosed is a cylinder cleaning cycle in which engine knock is purposely caused for one to hundreds of engine cycles by adjusting the fuel content away from alcohol toward gasoline. Further measures to cause knock which are disclosed: adjusting spark timing, intake boost, exhaust gas fraction in the cylinder, cam timing, and transmission gear ratio.

Owner:FORD GLOBAL TECH LLC

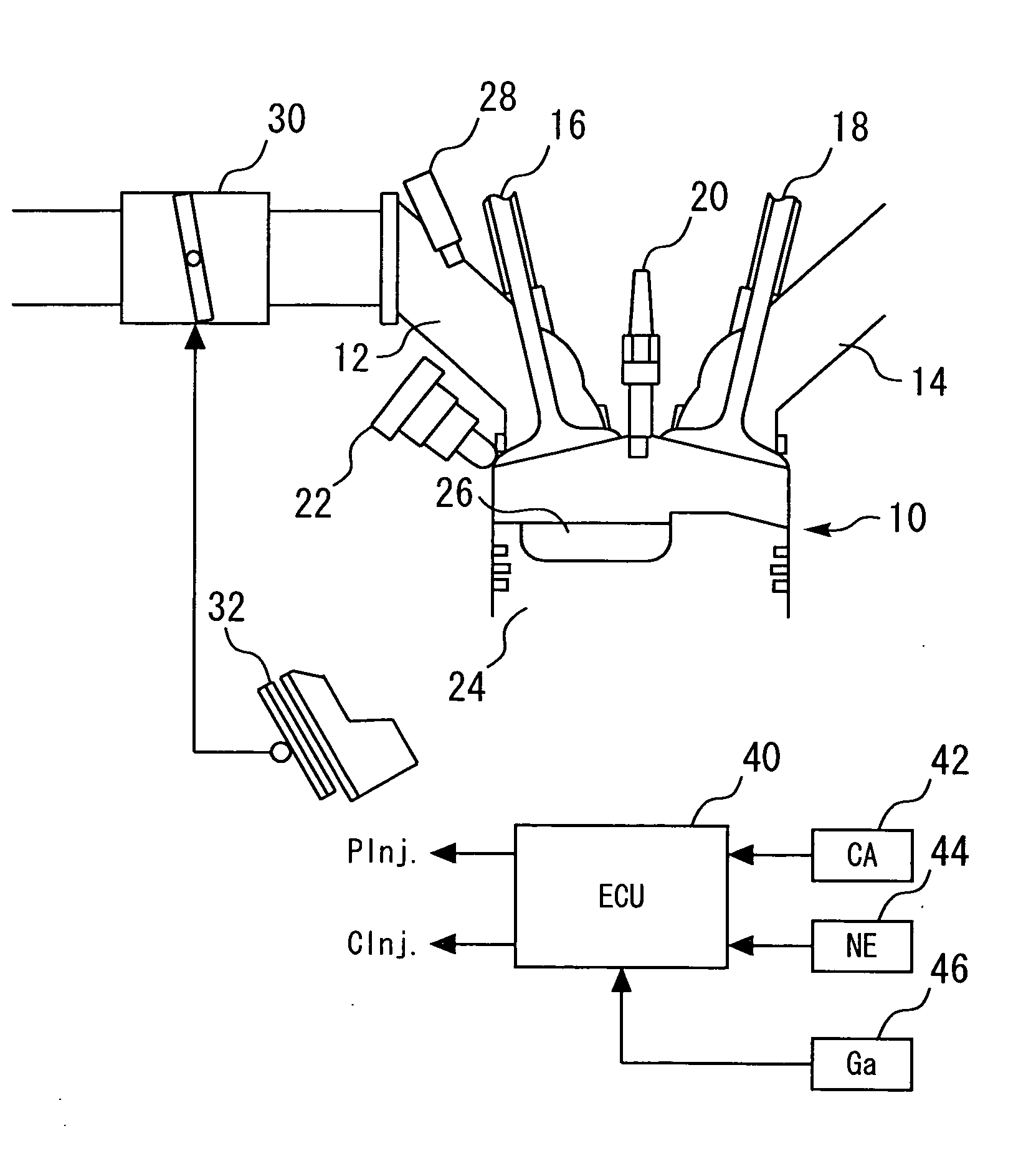

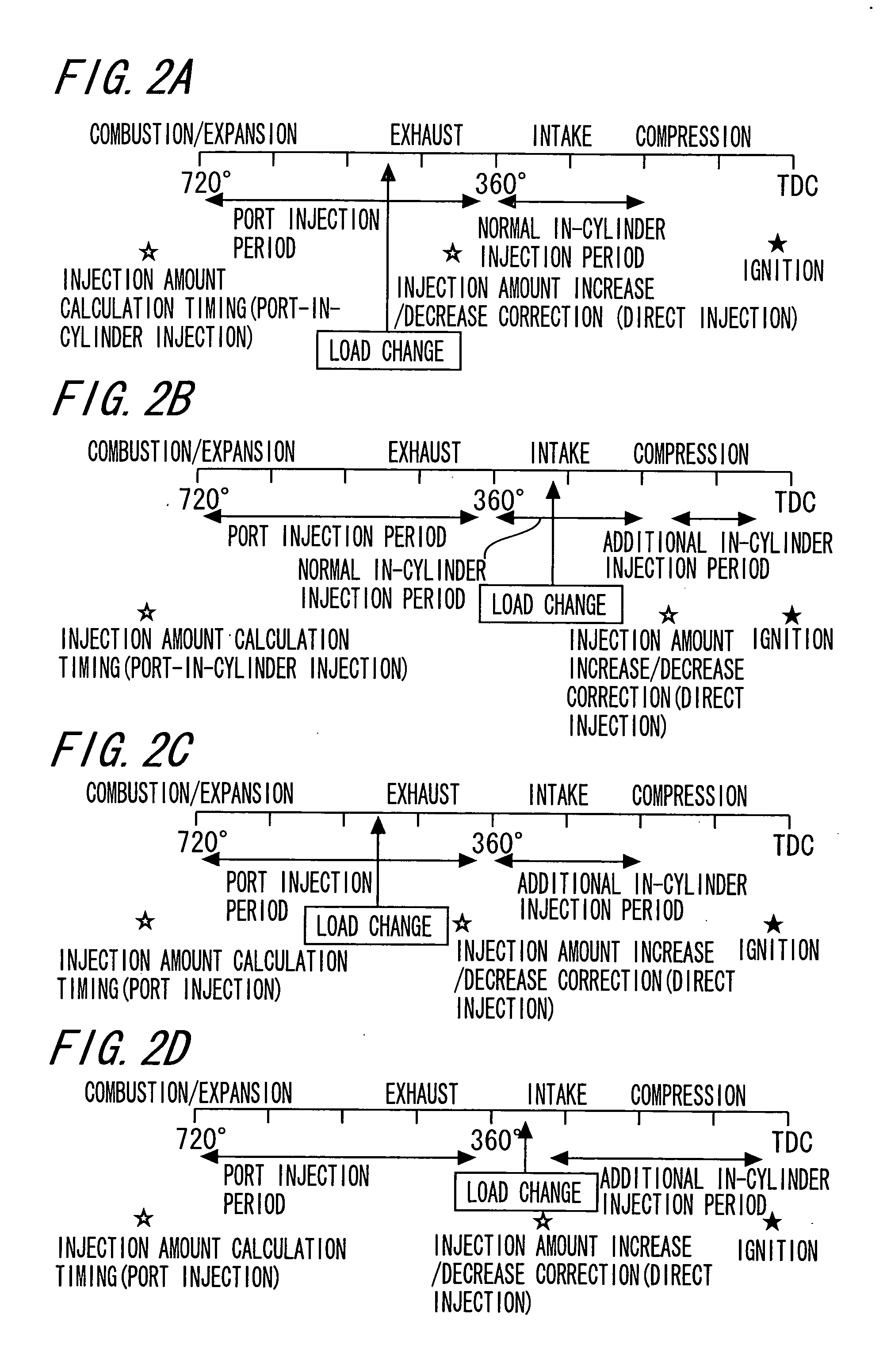

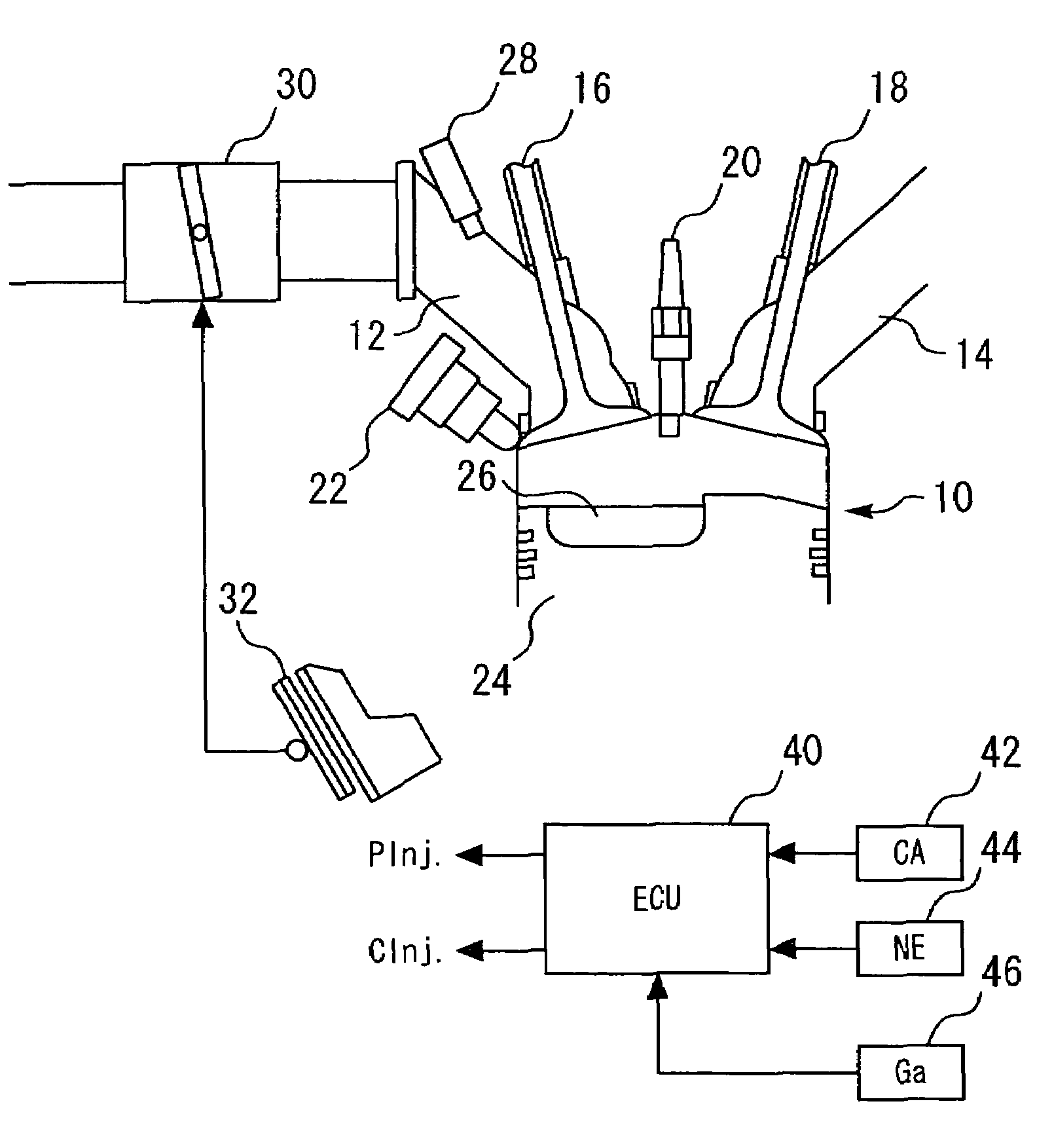

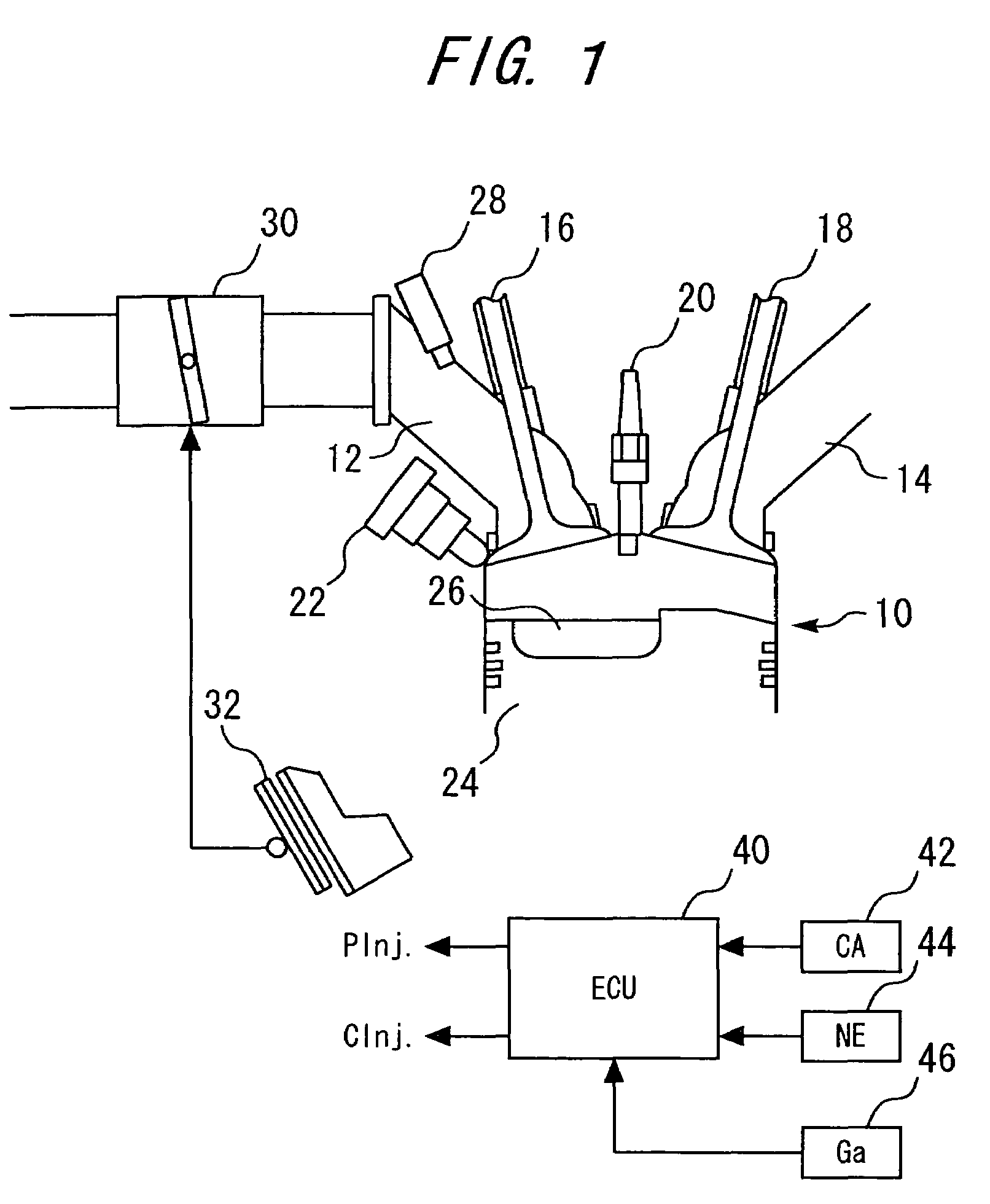

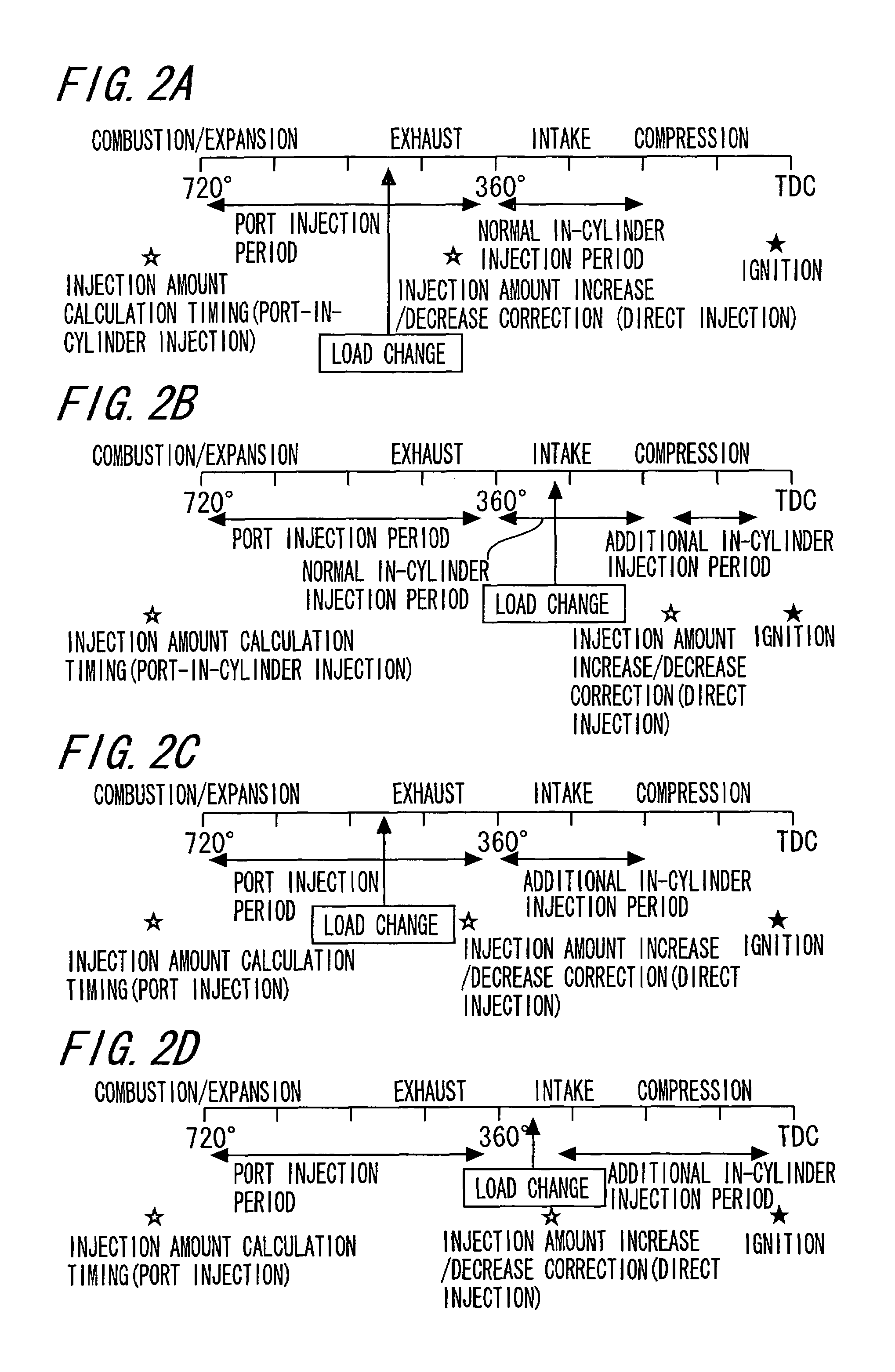

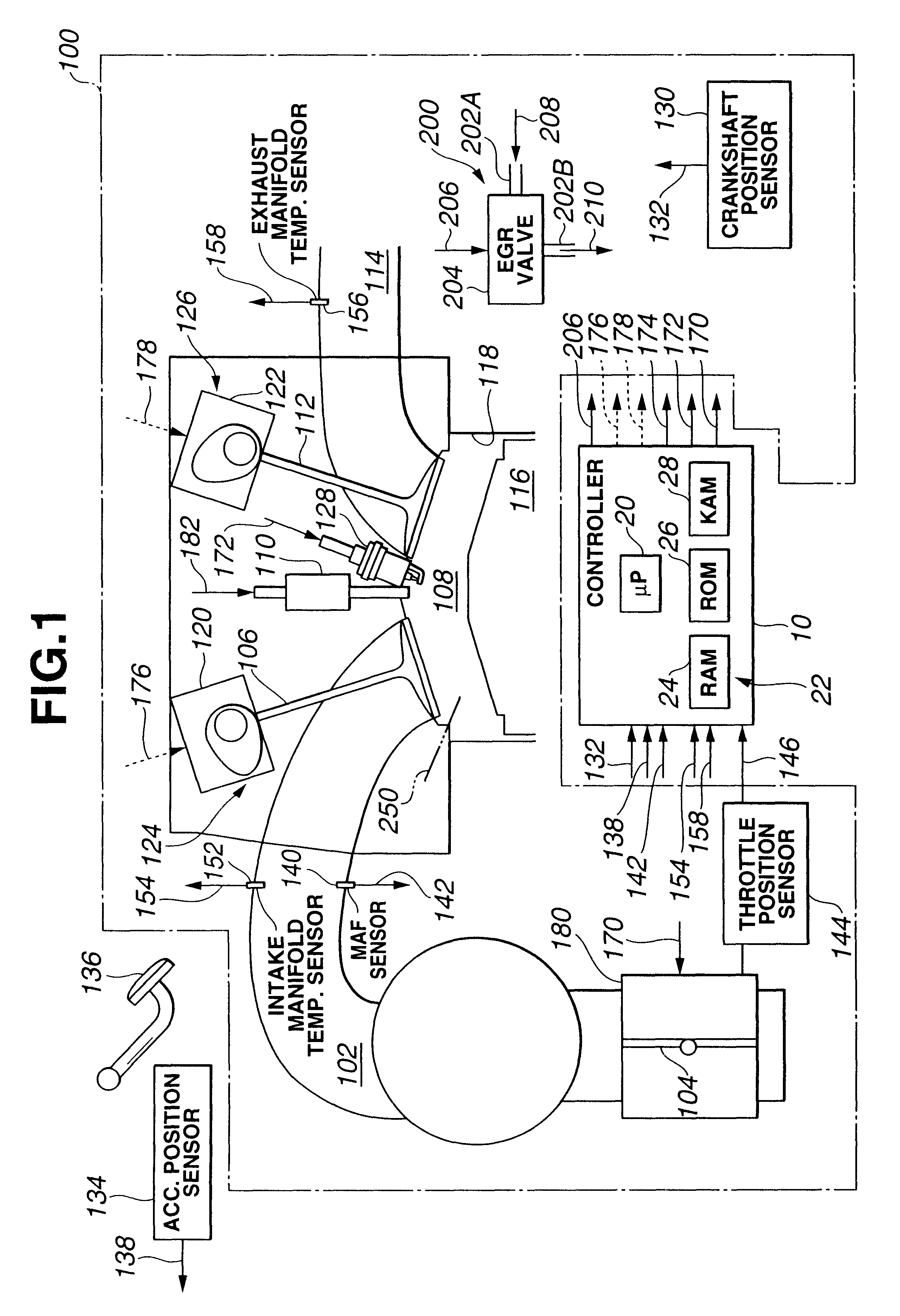

Fuel injection control device for internal combustion engine

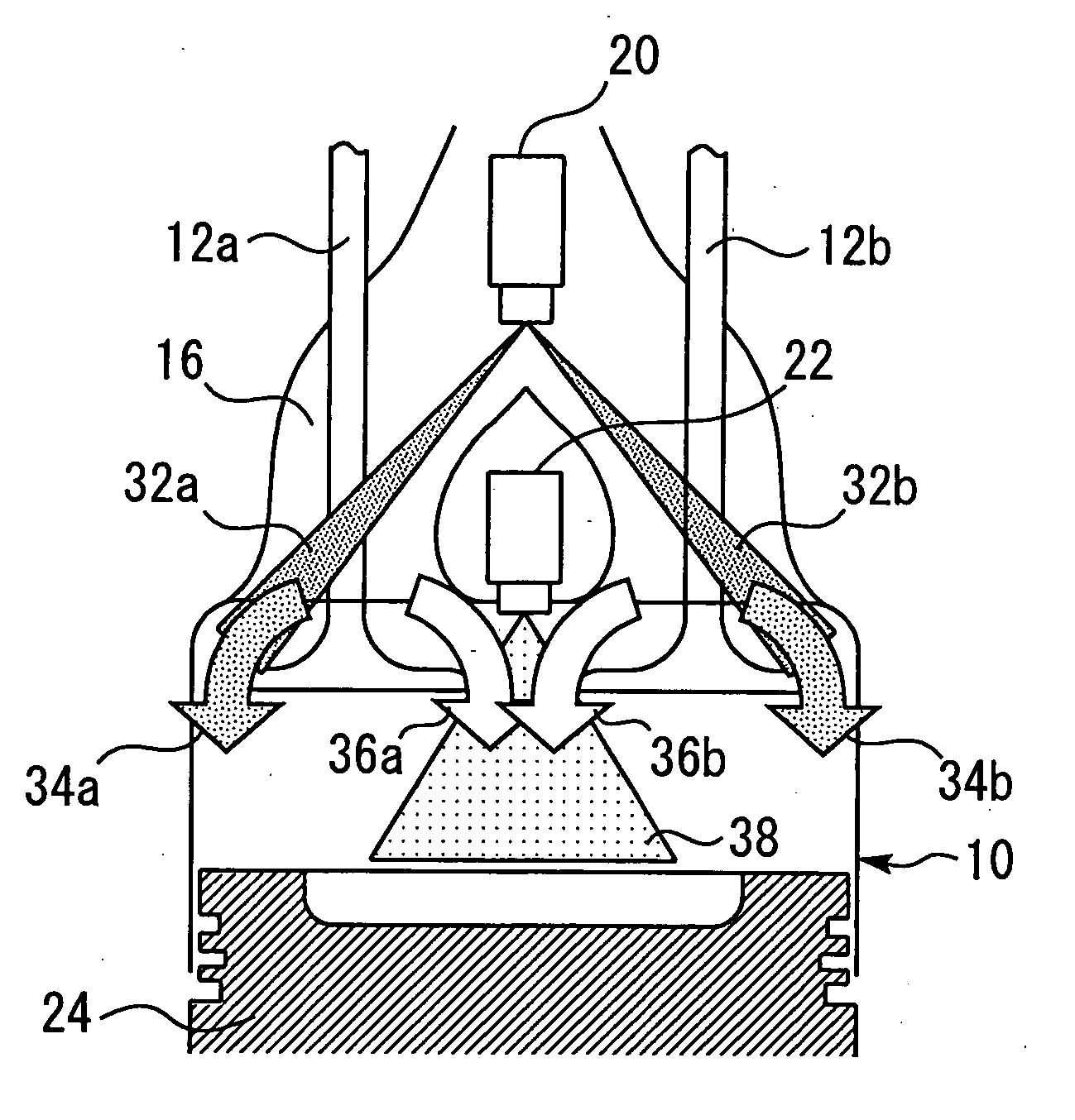

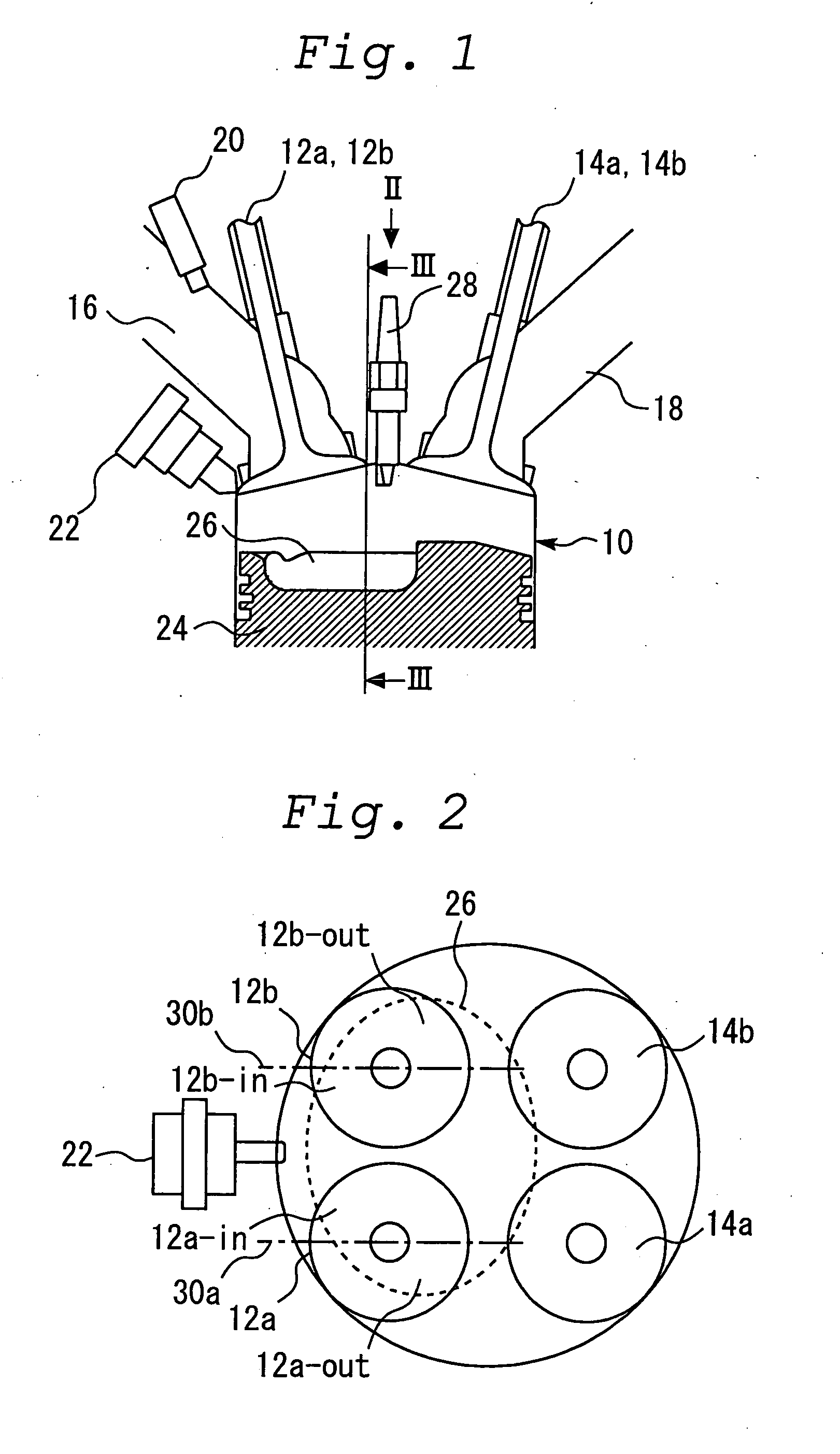

InactiveUS20050155578A1Good load changeElectrical controlInternal combustion piston enginesFuel injectionInjector

An internal combustion engine (10) is provided with a port injector (28) and an in-cylinder injector (22). Before a port injection is started, the total amount of fuel to be injected is calculated (at an injection amount calculation timing). The port injection fuel amount and the in-cylinder injection fuel amount are calculated by appropriately dividing the total amount between them. If a change of the operating load on the internal combustion engine (10) is detected after the injection amount calculation timing, the load change is reflected in the amount of fuel to be injected in the current engine cycle by increasing or decreasing the in-cylinder injection fuel amount.

Owner:TOYOTA JIDOSHA KK

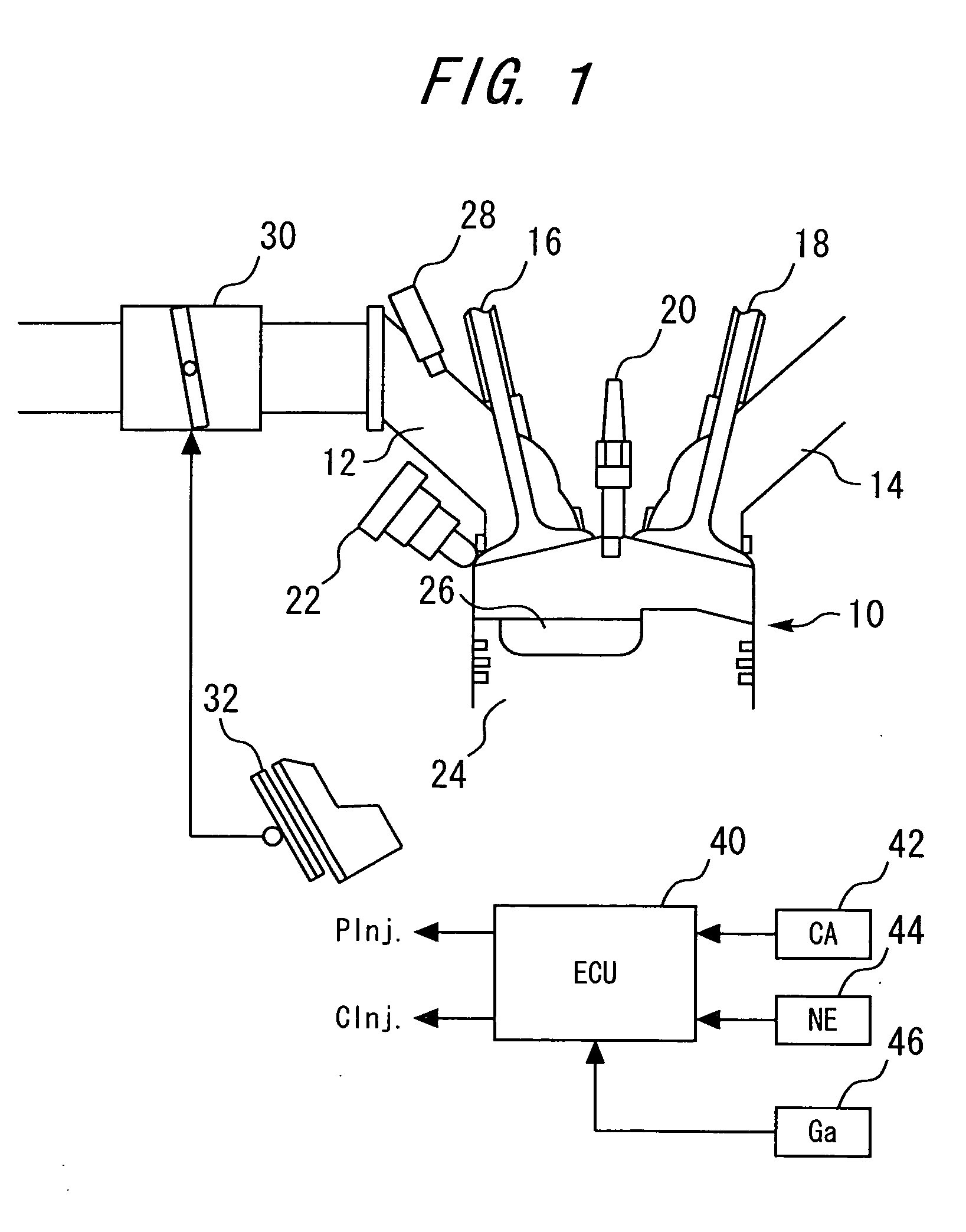

Fuel injection control device for internal combustion engine

InactiveUS6988485B2Good load changeElectrical controlInternal combustion piston enginesFuel injectionInjector

An internal combustion engine (10) is provided with a port injector (28) and an in-cylinder injector (22). Before a port injection is started, the total amount of fuel to be injected is calculated (at an injection amount calculation timing). The port injection fuel amount and the in-cylinder injection fuel amount are calculated by appropriately dividing the total amount between them. If a change of the operating load on the internal combustion engine (10) is detected after the injection amount calculation timing, the load change is reflected in the amount of fuel to be injected in the current engine cycle by increasing or decreasing the in-cylinder injection fuel amount.

Owner:TOYOTA JIDOSHA KK

Spark ignition internal combustion engine

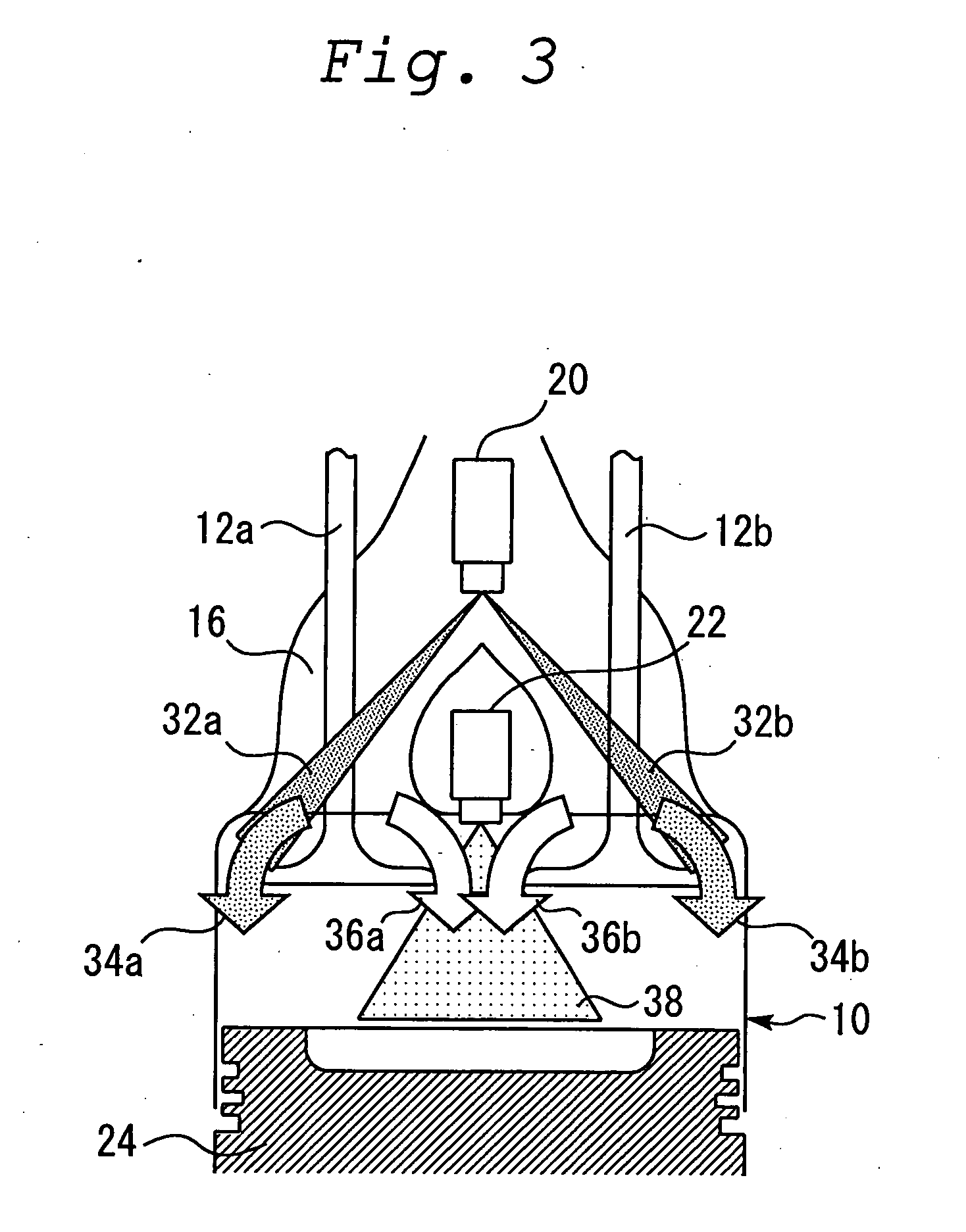

Each cylinder is provided with an ignition plug, two intake valves, an intra-cylinder fuel injector, and a port fuel injector. When homogeneous combustion is demanded, the intra-cylinder fuel injector and port fuel injector inject fuel on the same engine cycle. The port fuel injector is installed so that the amount of fuel directed toward outer regions of the intake valves is larger than that of fuel directed toward inner regions of the intake valves, thereby causing only fresh air to flow to regions near the inner regions of the intake valves.

Owner:TOYOTA JIDOSHA KK

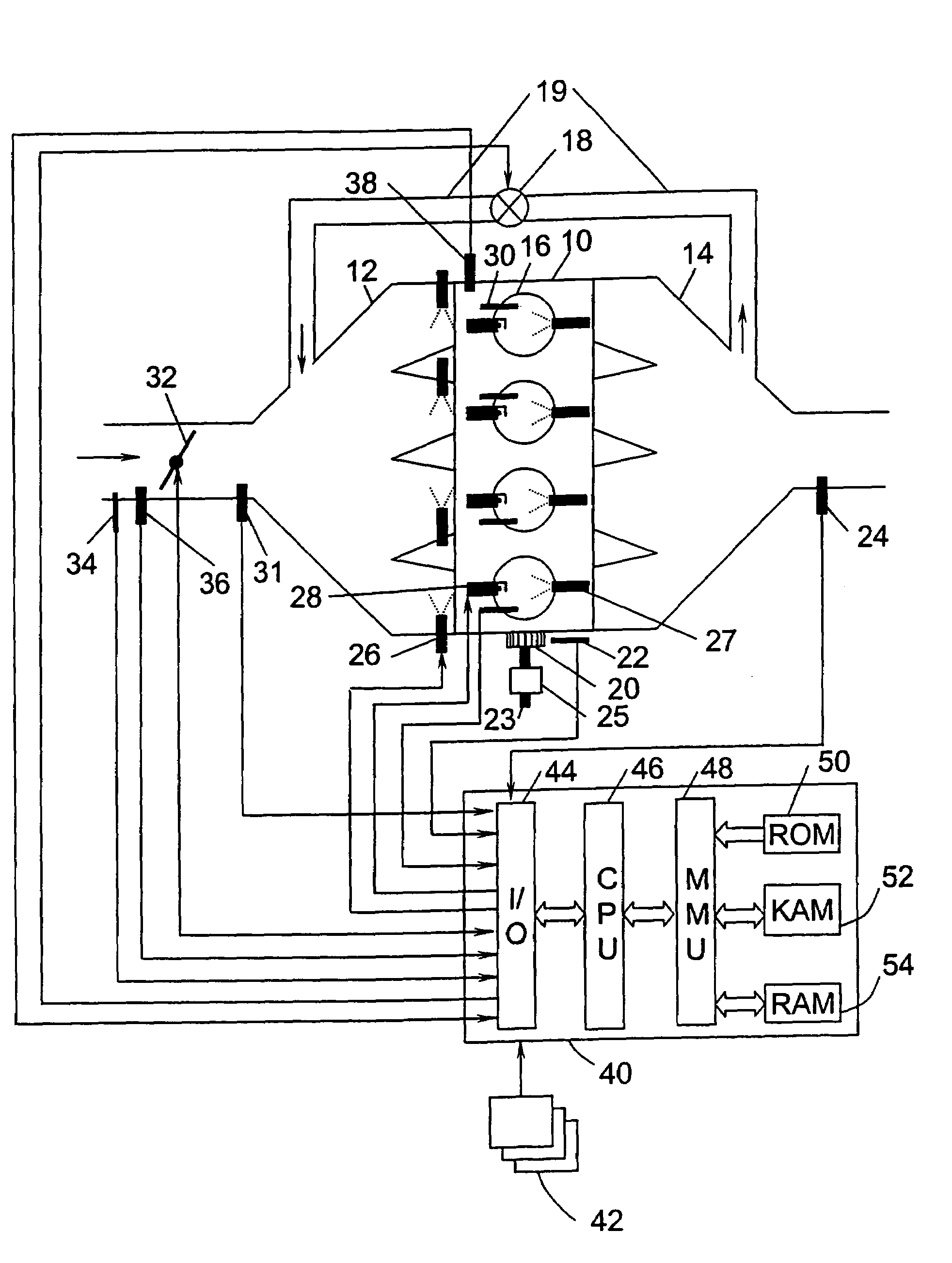

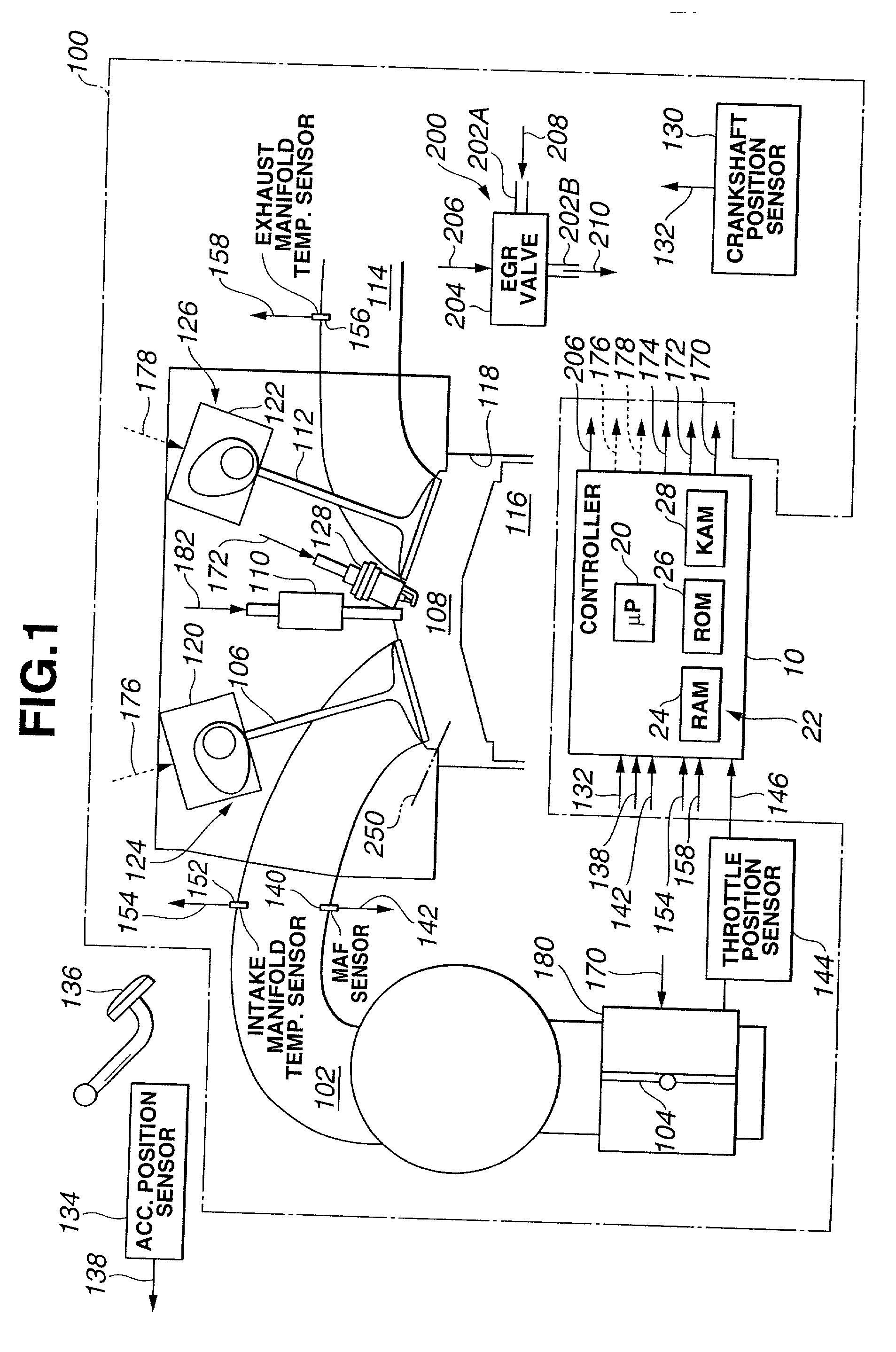

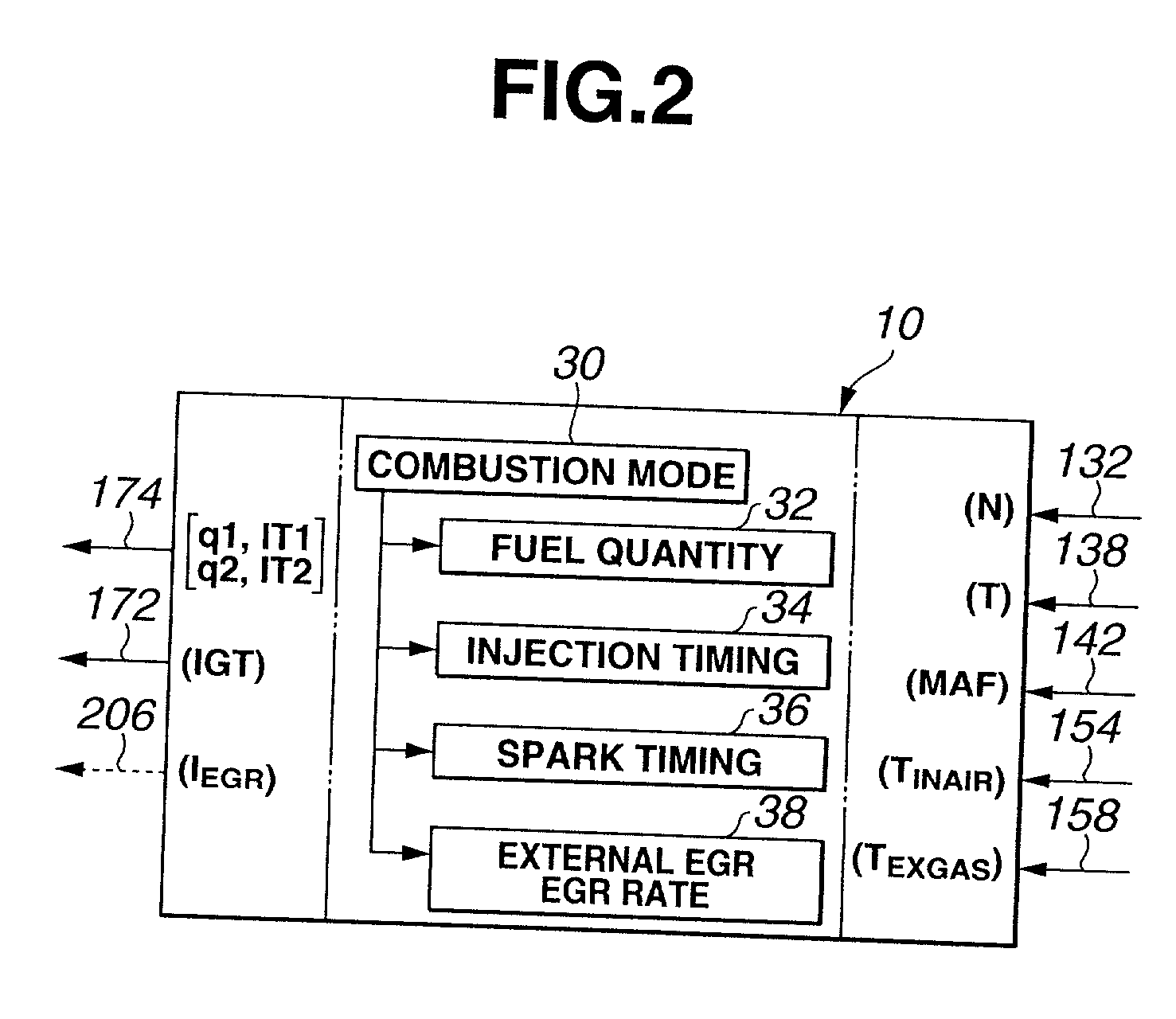

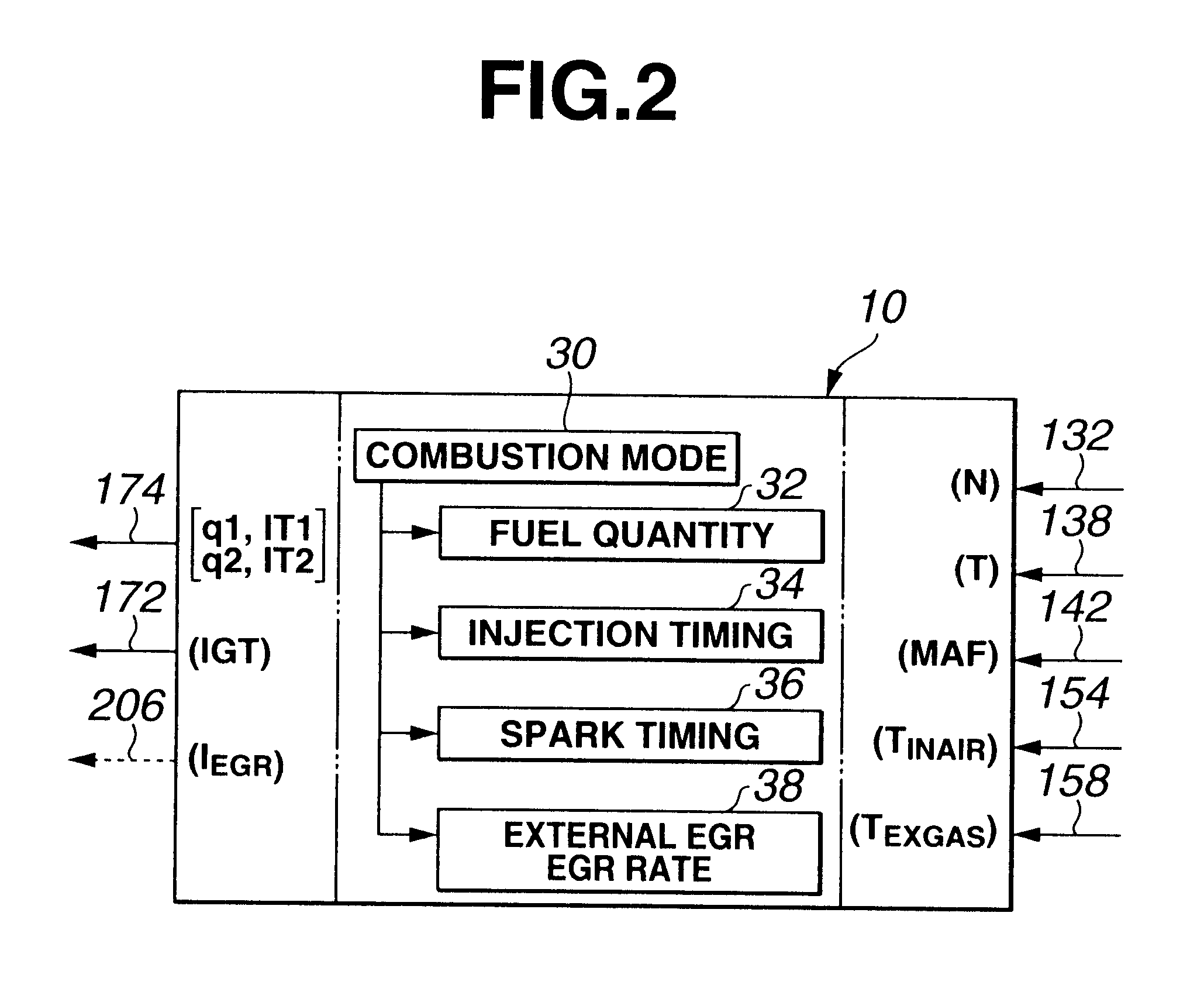

System and method for enhanced combustion control in an internal combustion engine

InactiveUS20020059914A1Electrical controlInternal combustion piston enginesExternal combustion engineStaged combustion

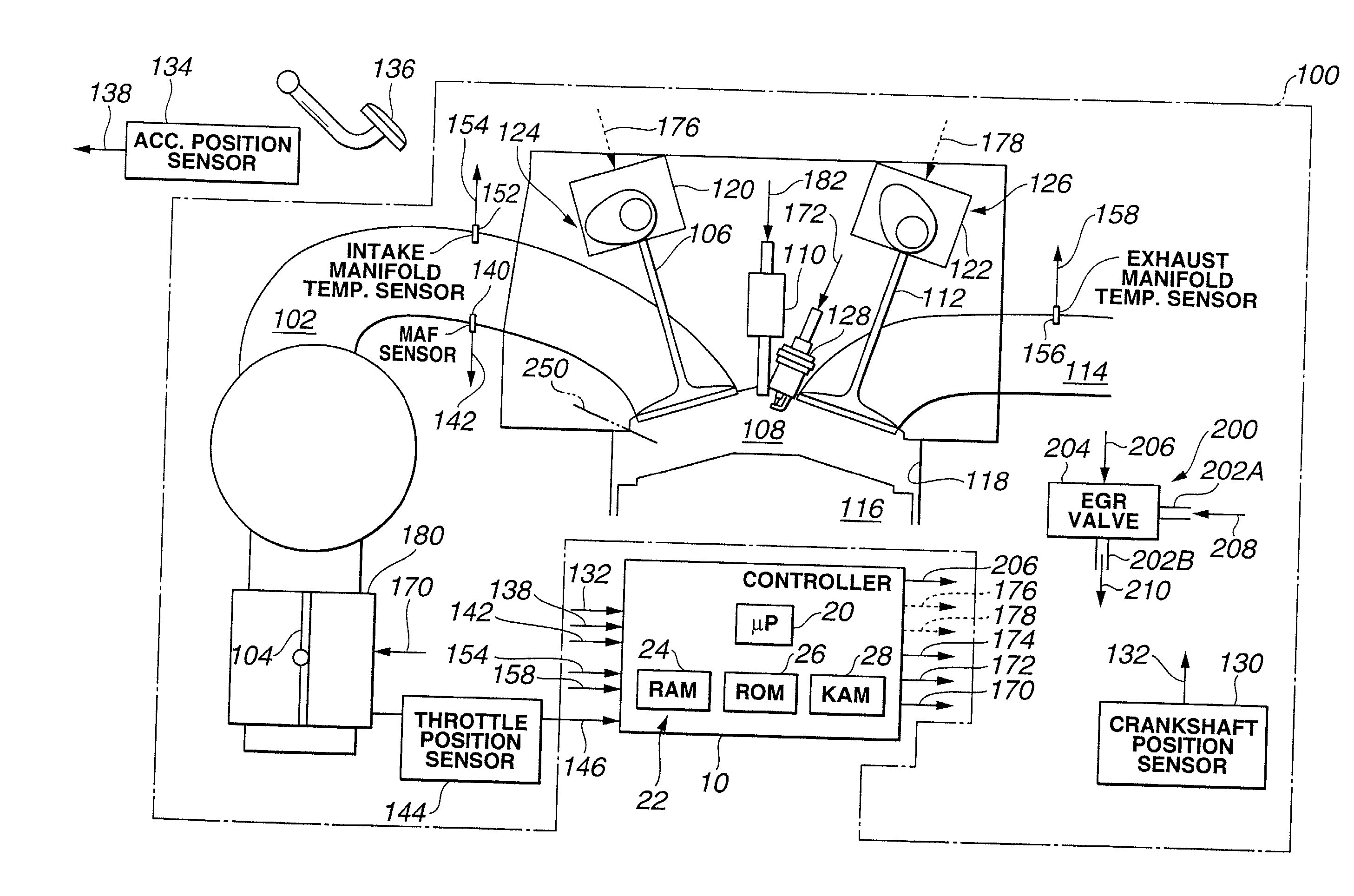

A system and method for enhanced combustion control in an internal combustion engine is disclosed. A fuel supply system has a fuel injector positioned to directly inject fuel into a combustion chamber, and it is capable of performing a split injection wherein a first fuel injection in each engine cycle precedes a second fuel injection that occurs during compression stroke in the same engine cycle. A spark plug produces a spark to ignite a first air / fuel mixture portion created due to the second fuel injection, initiating a first stage combustion. The first stage combustion raises temperature and pressure high enough to cause auto-ignition of a second air / fuel mixture portion surrounding the first air-fuel mixture portion, initiating a second stage combustion. An engine controller is programmed to perform control over initiation timing of the second stage combustion in response to at least one of the engine speed and load. This control is accomplished by varying at least one of a fuel injection timing of the first fuel injection, a fuel injection timing of the second fuel injection, spark timing, a proportion of fuel quantity of the second fuel injection to the total fuel injected in each engine cycle, and an EGR rate in response to at least one of engine speed and load.

Owner:NISSAN MOTOR CO LTD

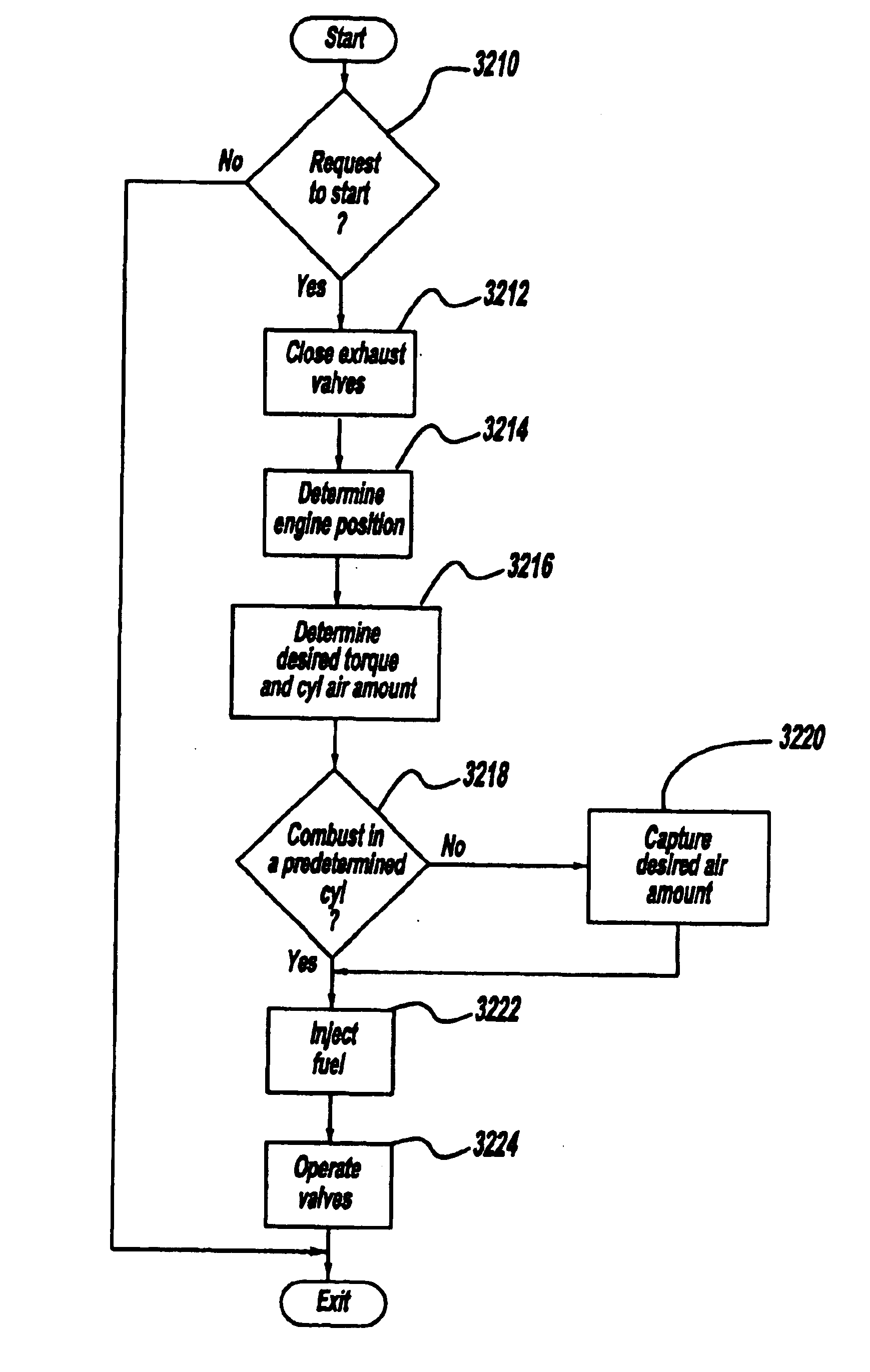

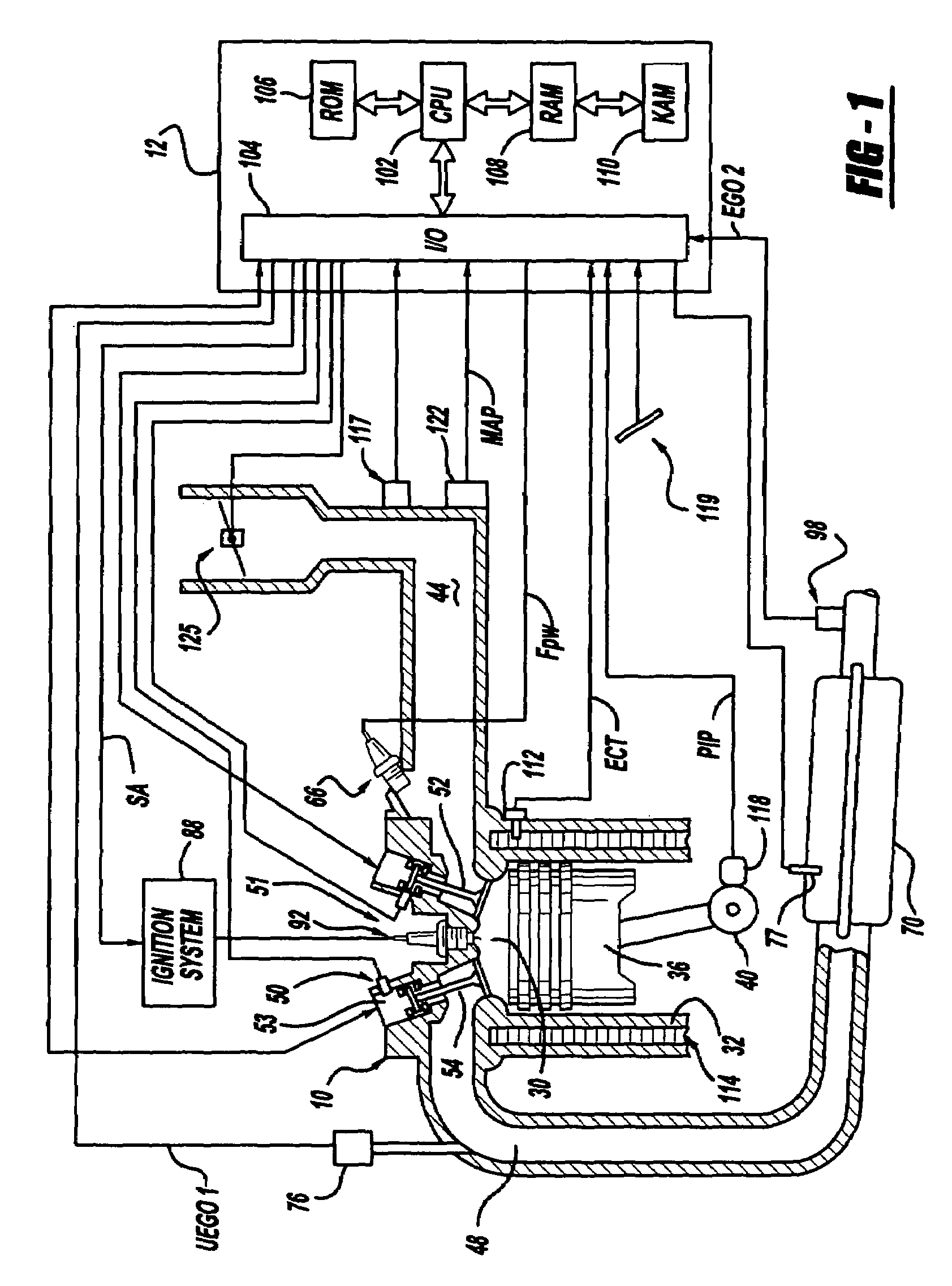

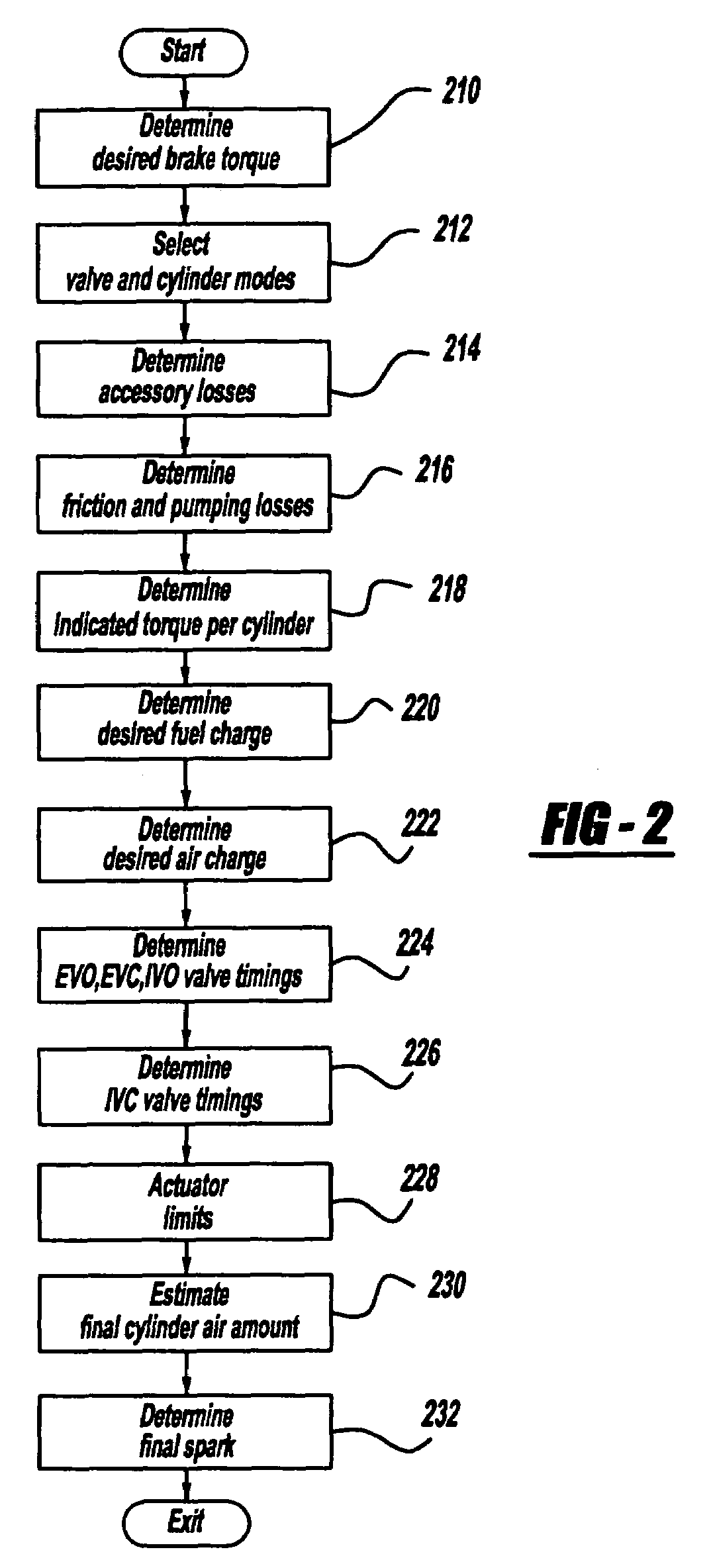

Starting an engine with electromechanical valves

ActiveUS6938598B1VariationLarge emissionsElectrical controlInternal combustion piston enginesControl mannerFour-stroke engine

A system and method to control engine valve timing to during the start of an internal combustion engine. Electromechanical valves are controlled in a manner to reduce engine vibration and hydrocarbon emissions during the start of an internal combustion engine. The method controls valves without an explicit four-stroke engine cycle during a start.

Owner:FORD GLOBAL TECH LLC

Dual Fuel Injection Compression Ignition Engine And Method Of Operating Same

A method of operating an electronically controlled dual fuel compression ignition engine includes injecting a pilot ignition quantity of liquid fuel into an engine cylinder from a dual fuel injector in an engine cycle during an auto ignition condition. An amount of gaseous fuel is also injected into the engine cylinder from the dual fuel injector in the same engine cycle. The amount of gaseous fuel is divided between a pre-mix quantity of gaseous fuel, which may be injected about 90° before top dead center, and a post ignition quantity of gaseous fuel that may be injected after top dead center, with both quantities being greater than zero. An engine controller may change a ratio of the pre-mix quantity of gaseous fuel to the post ignition quantity of gaseous fuel responsive to changing from a first engine speed and load to a second engine speed and load. The pilot ignition quantity of liquid fuel is compression ignited, which in turn causes the gaseous fuel to be ignited. A pre-mix quantity of liquid fuel may also be included in order to speed the combustion process at higher engine speeds.

Owner:CATERPILLAR INC

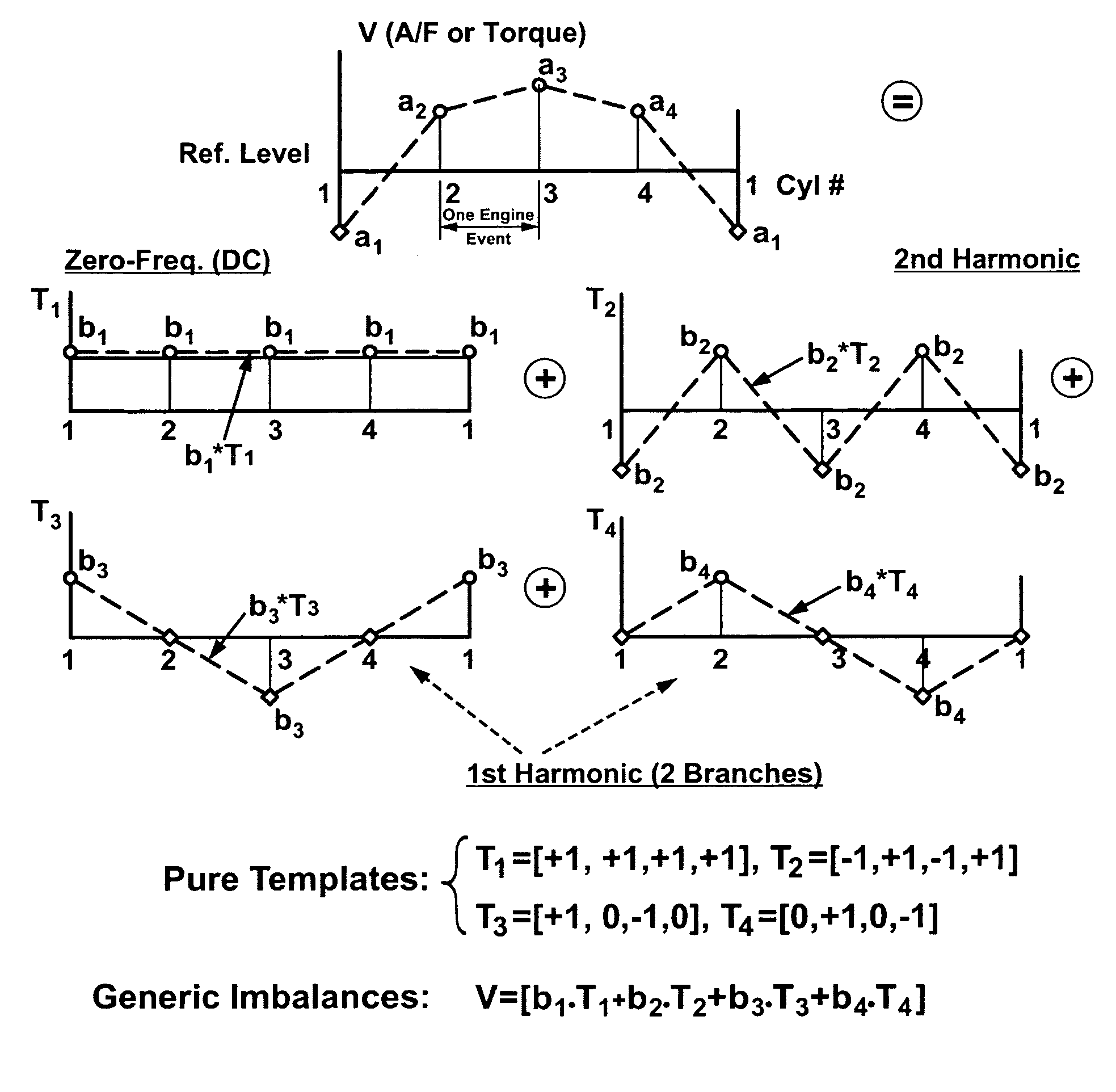

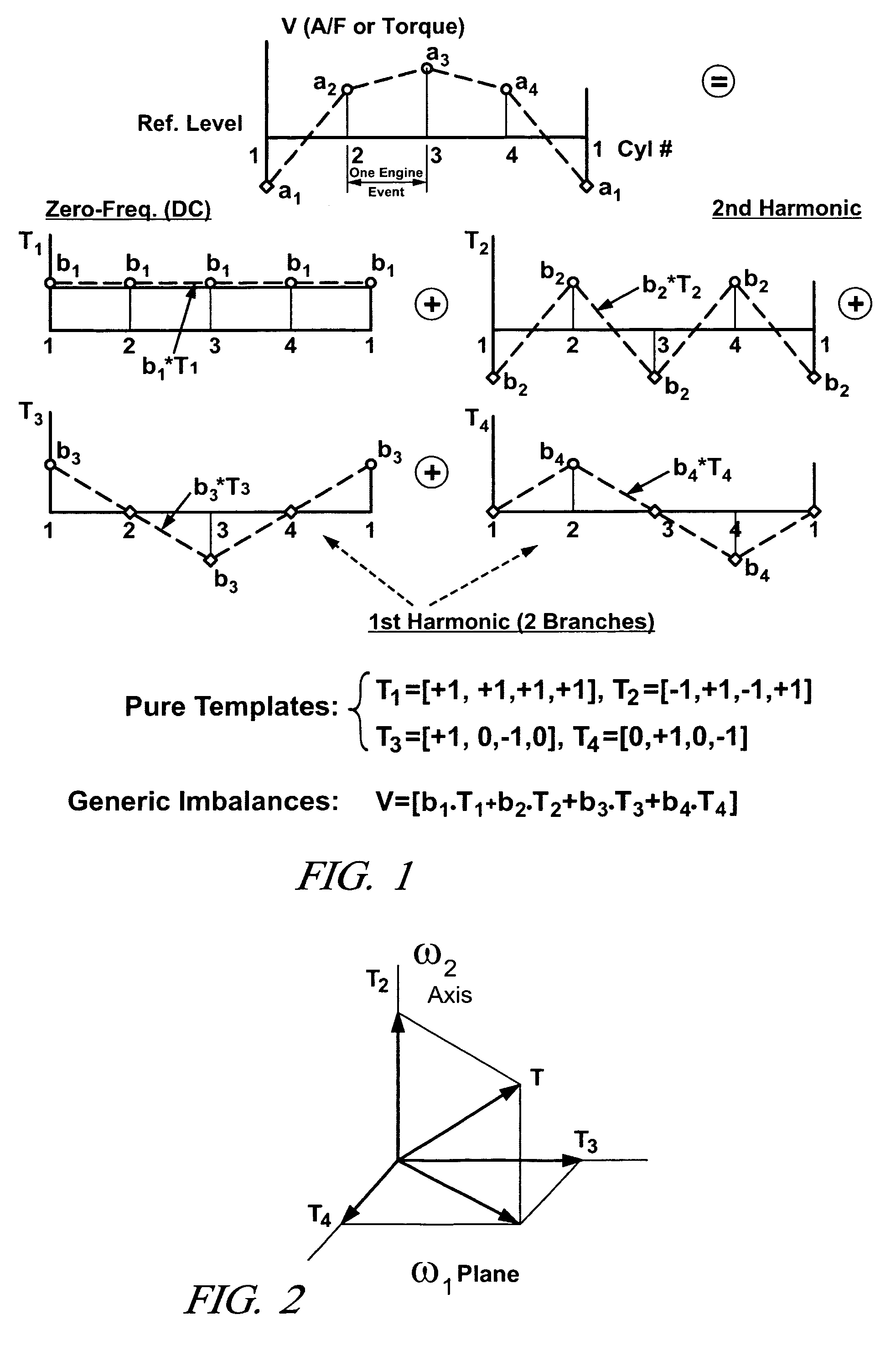

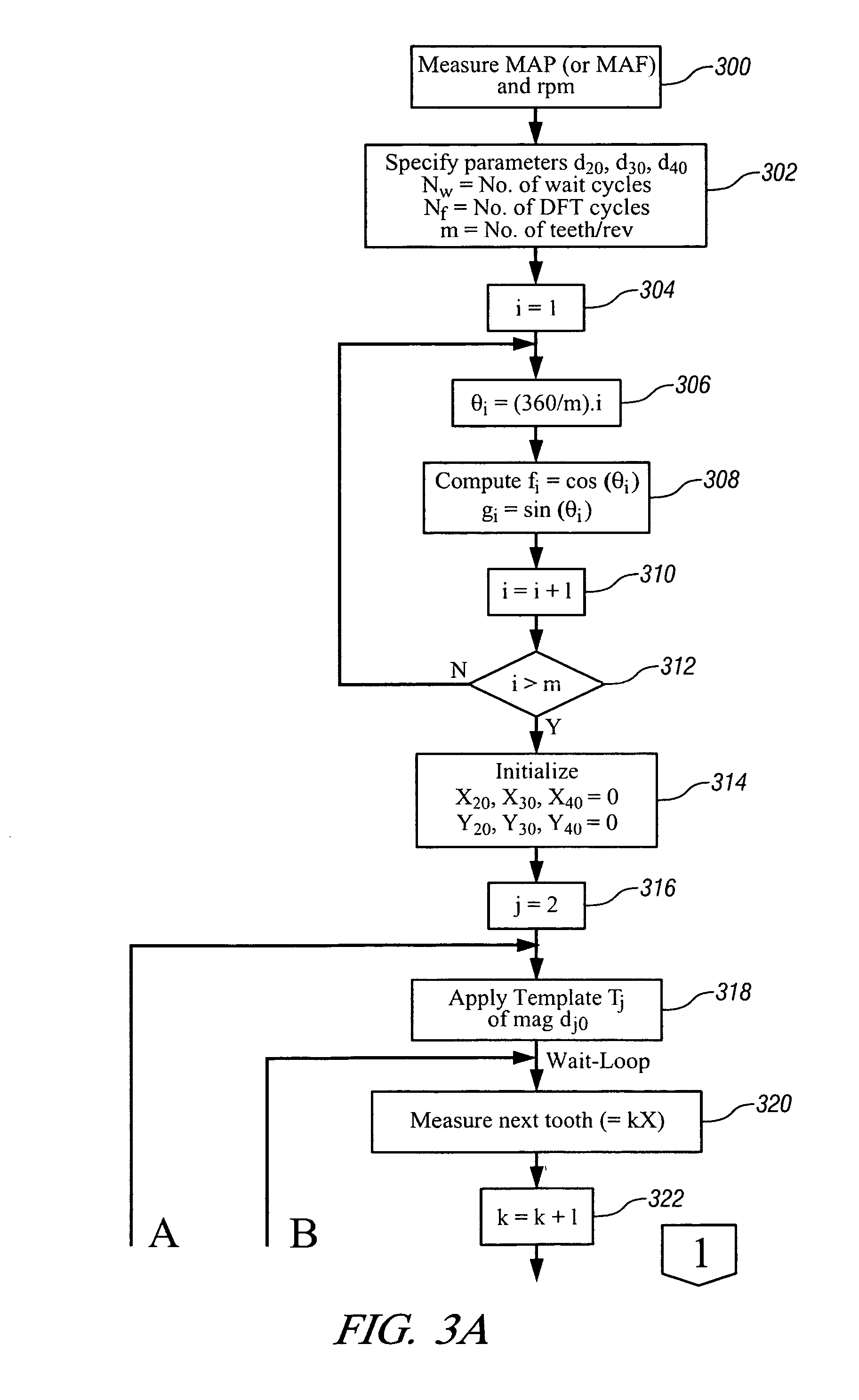

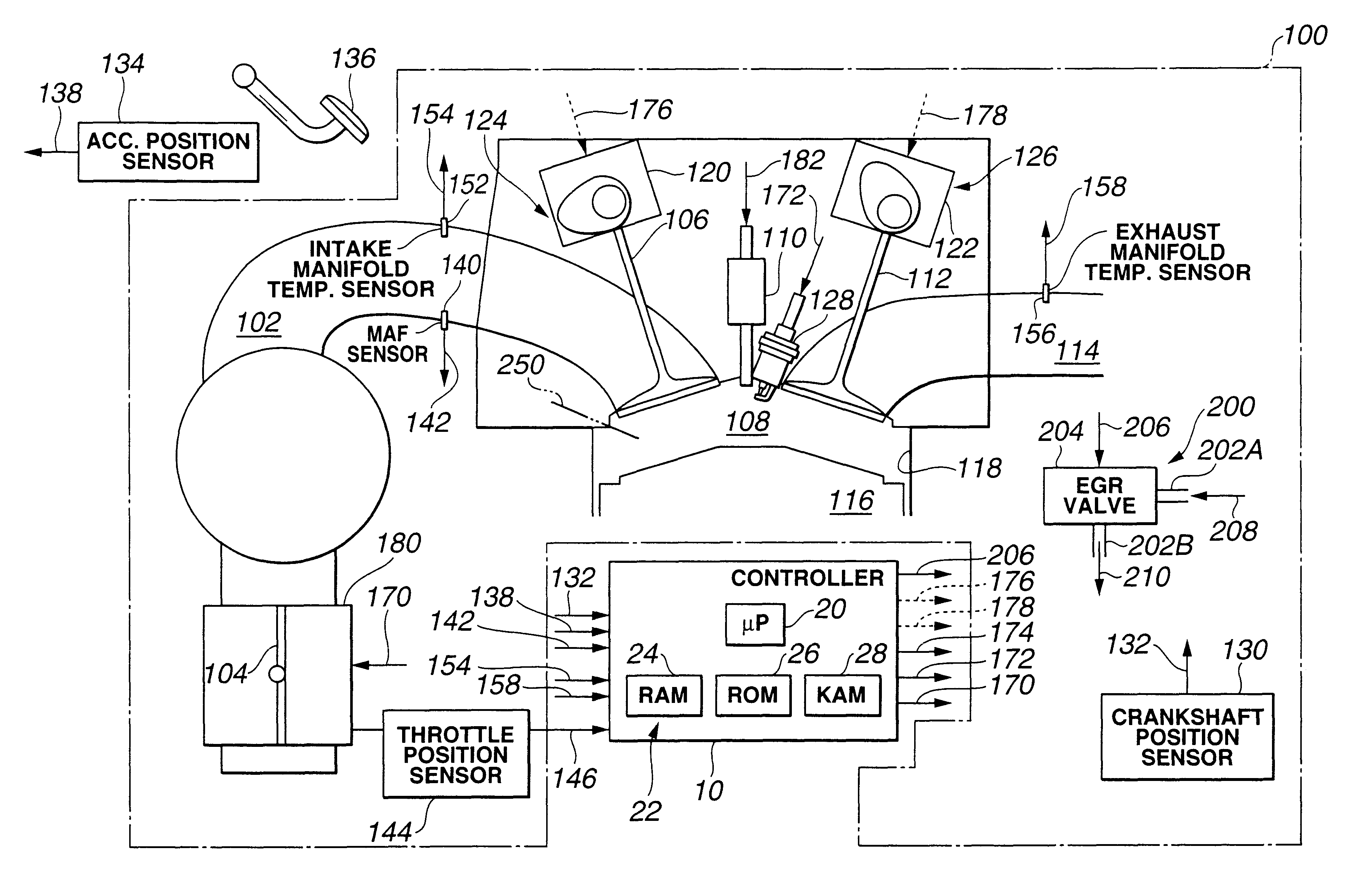

Individual cylinder controller for four-cylinder engine

A generic technique for the detection of air-fuel ratio (or torque) imbalances in a 4-cylinder engine equipped with either a production oxygen sensor or a wide-range A / F sensor (or a crankshaft torque sensor) is developed. The method is based on a novel frequency-domain characterization of pattern of imbalances and its geometric decomposition into four basic templates. Once the contribution of each basic template to the overall imbalances is computed, templates of opposite direction are imposed to restore air-fuel ratio (or torque) balance among cylinders. At any desired operating condition, elimination of imbalances is achieved within few engine cycles. The method is applicable to current and future engine technologies with variable valve actuation, fuel injectors and / or individual spark control.

Owner:GM GLOBAL TECH OPERATIONS LLC

System and method for enhanced combustion control in an internal combustion engine

InactiveUS6609493B2Electrical controlInternal combustion piston enginesExternal combustion engineEngineering

A fuel supply system has a fuel injector positioned to directly inject fuel into a combustion chamber, and it is capable of performing a split injection wherein a first fuel injection in each engine cycle precedes a second fuel injection that occurs during compression stroke in the same engine cycle. A spark plug produces a spark to ignite a first air / fuel mixture portion created due to the second fuel injection, initiating a first stage combustion. The first stage combustion raises temperature and pressure high enough to cause auto-ignition of a second air / fuel mixture portion surrounding the first air-fuel mixture portion, initiating a second stage combustion. This control is accomplished by varying at least one of a fuel injection timing of the first fuel injection, a fuel injection timing of the second fuel injection, spark timing, a proportion of fuel quantity of the second fuel injection to the total fuel injected in each engine cycle, and an EGR rate in response to at least one of engine speed and load.

Owner:NISSAN MOTOR CO LTD

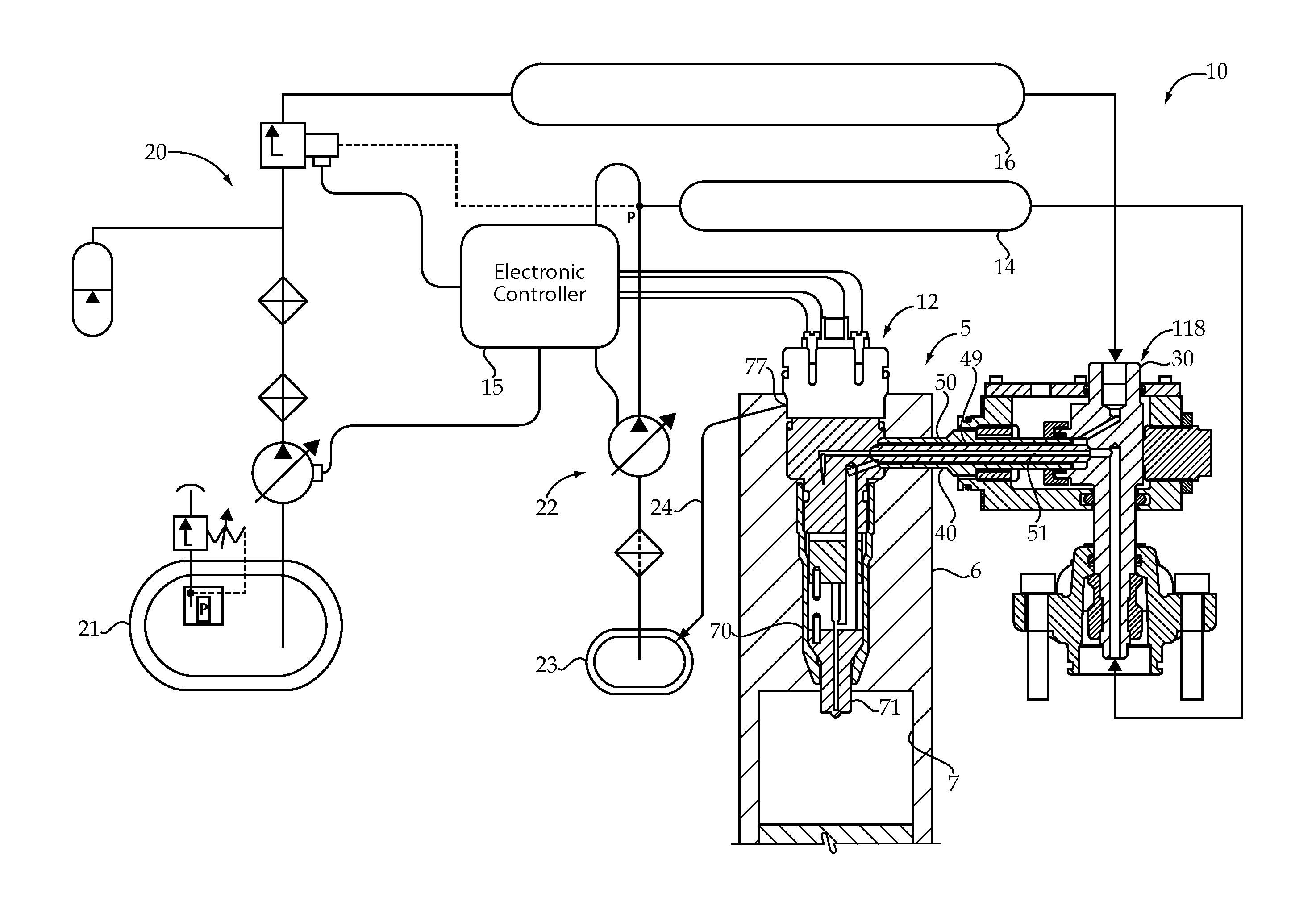

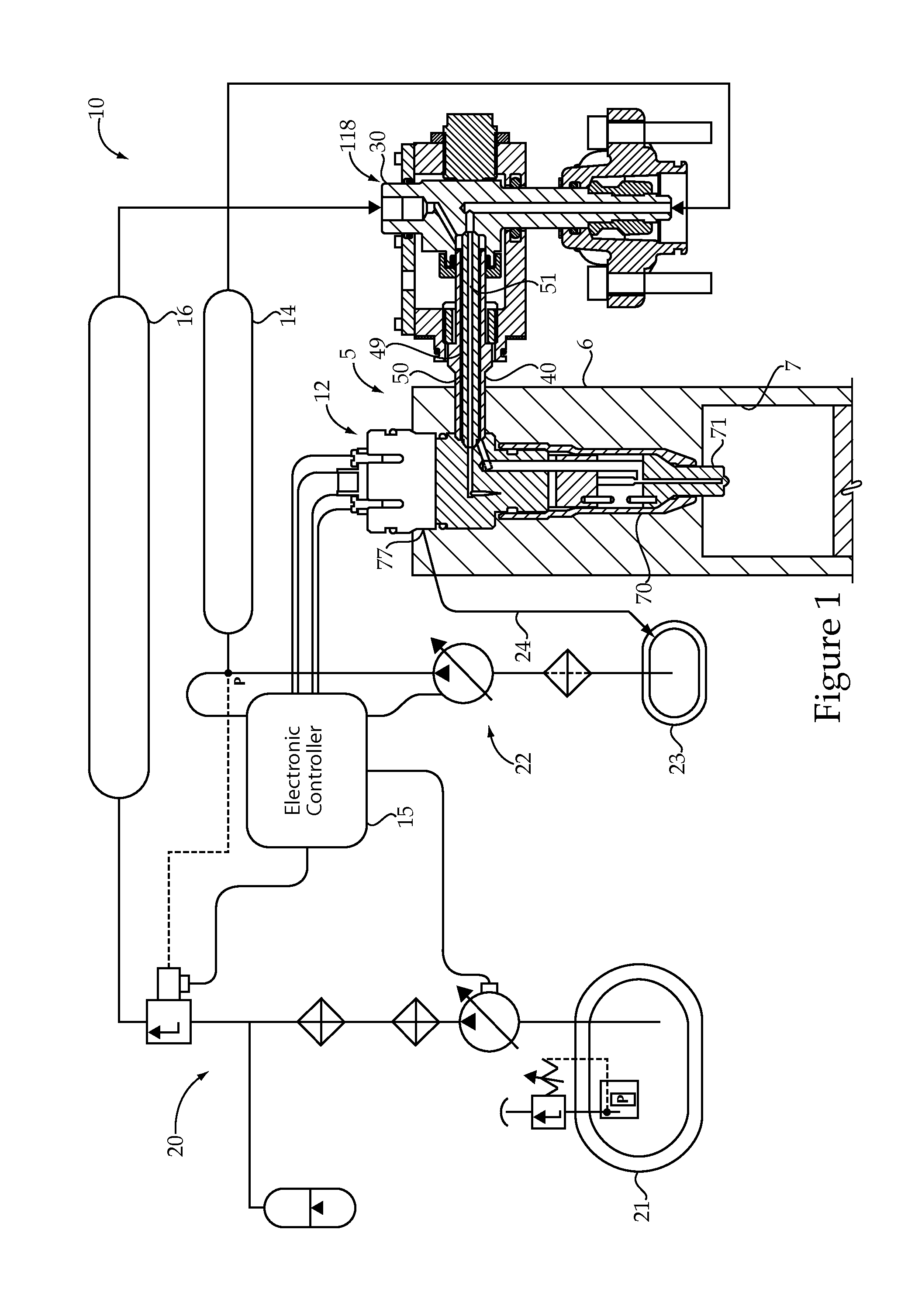

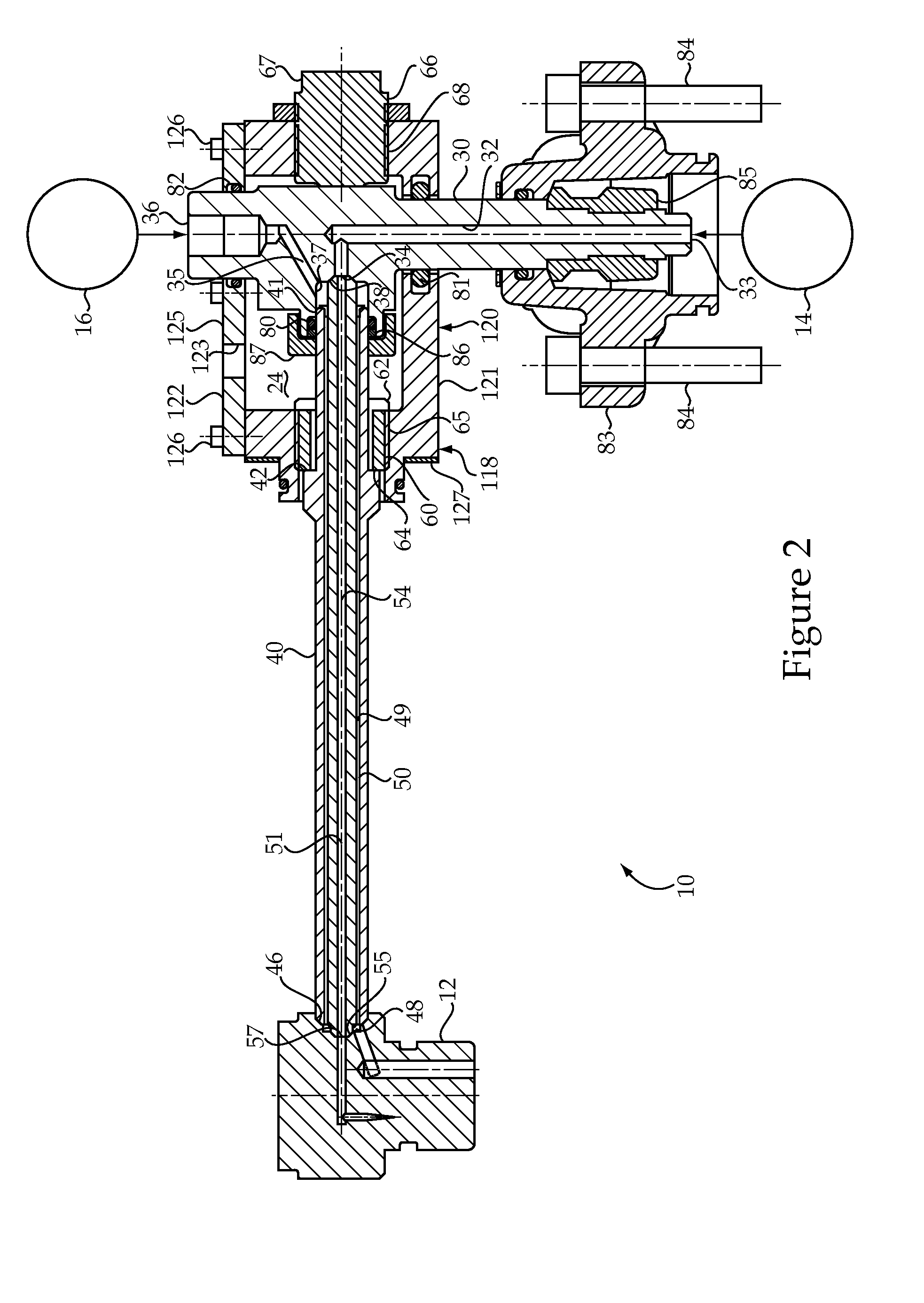

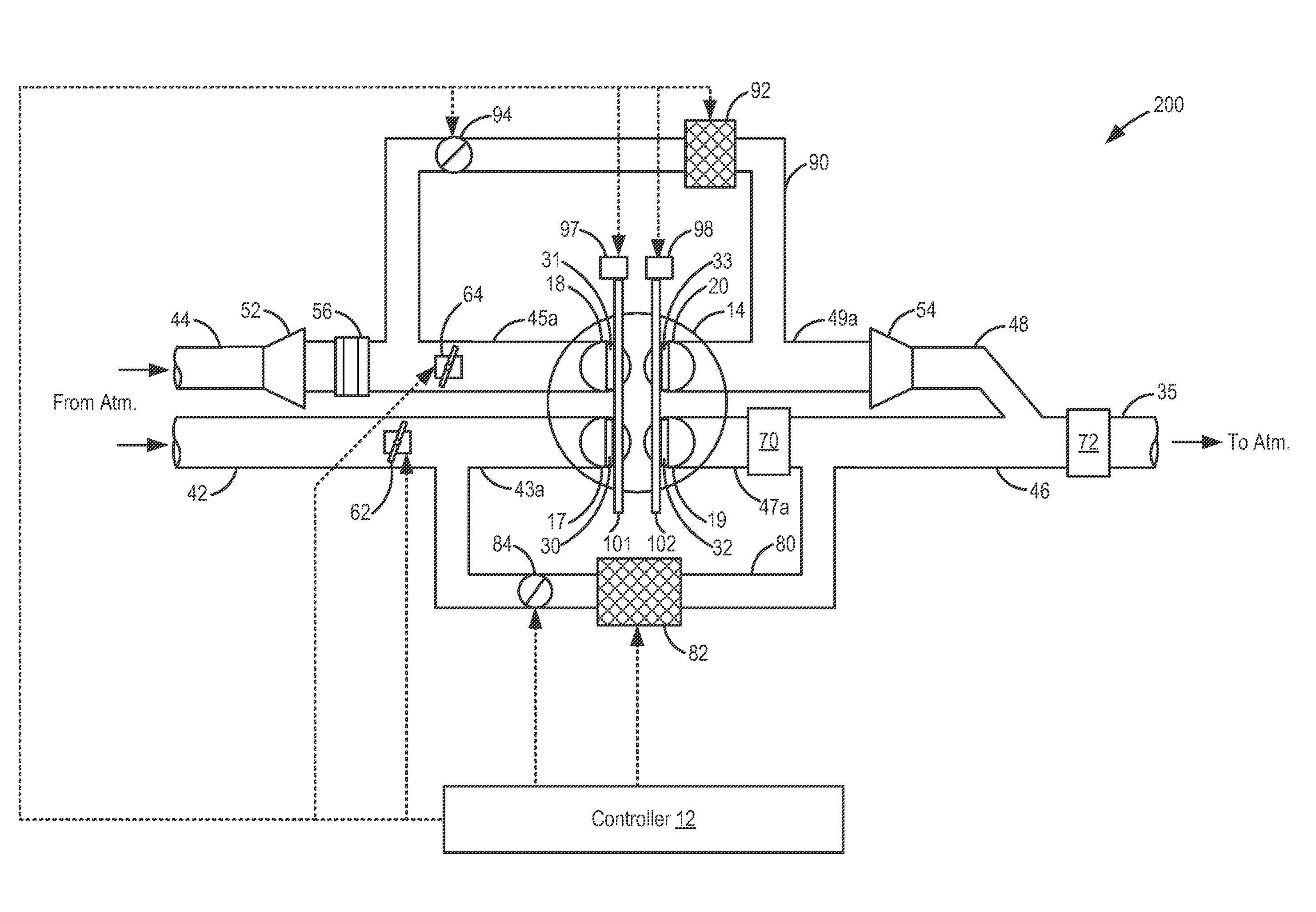

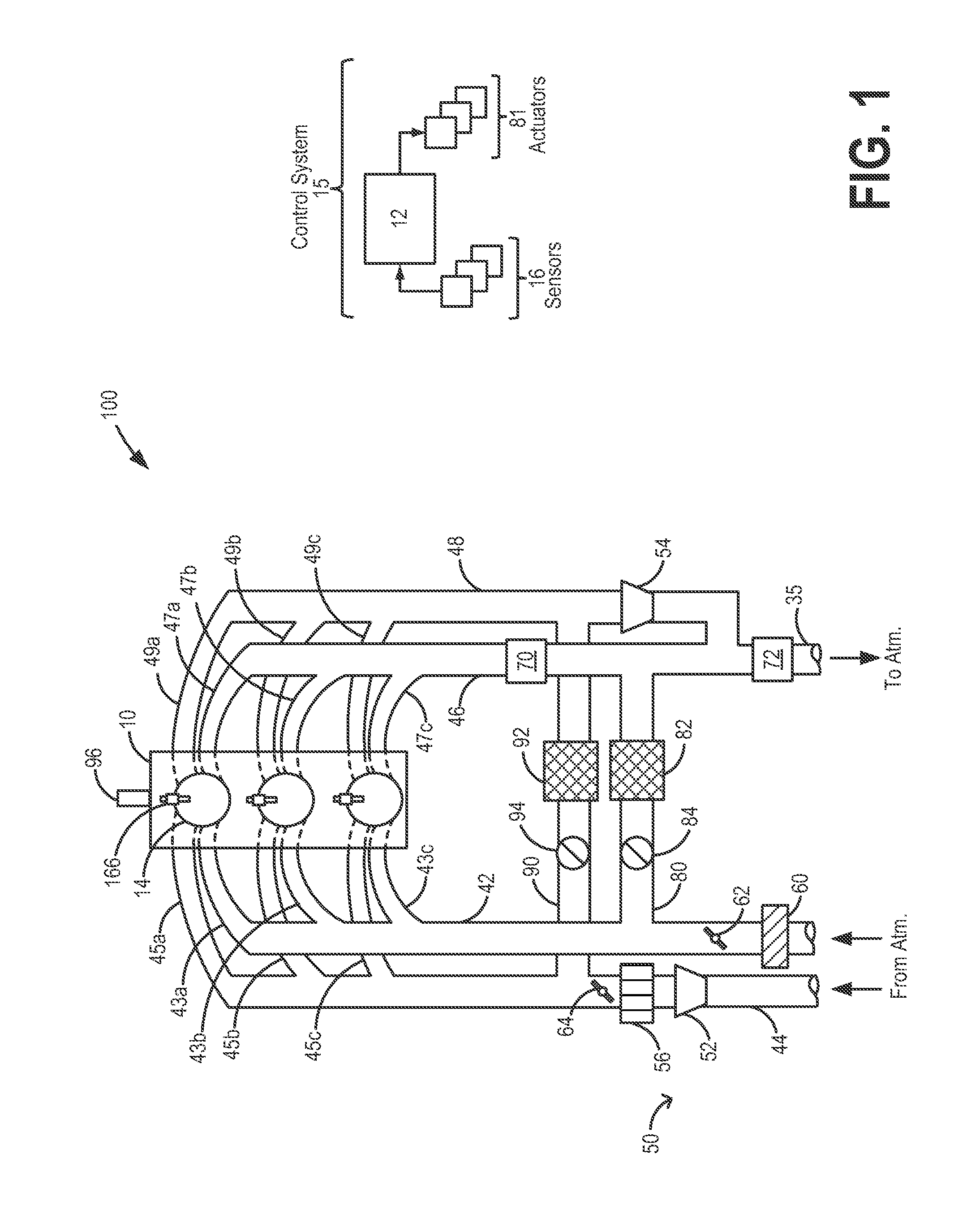

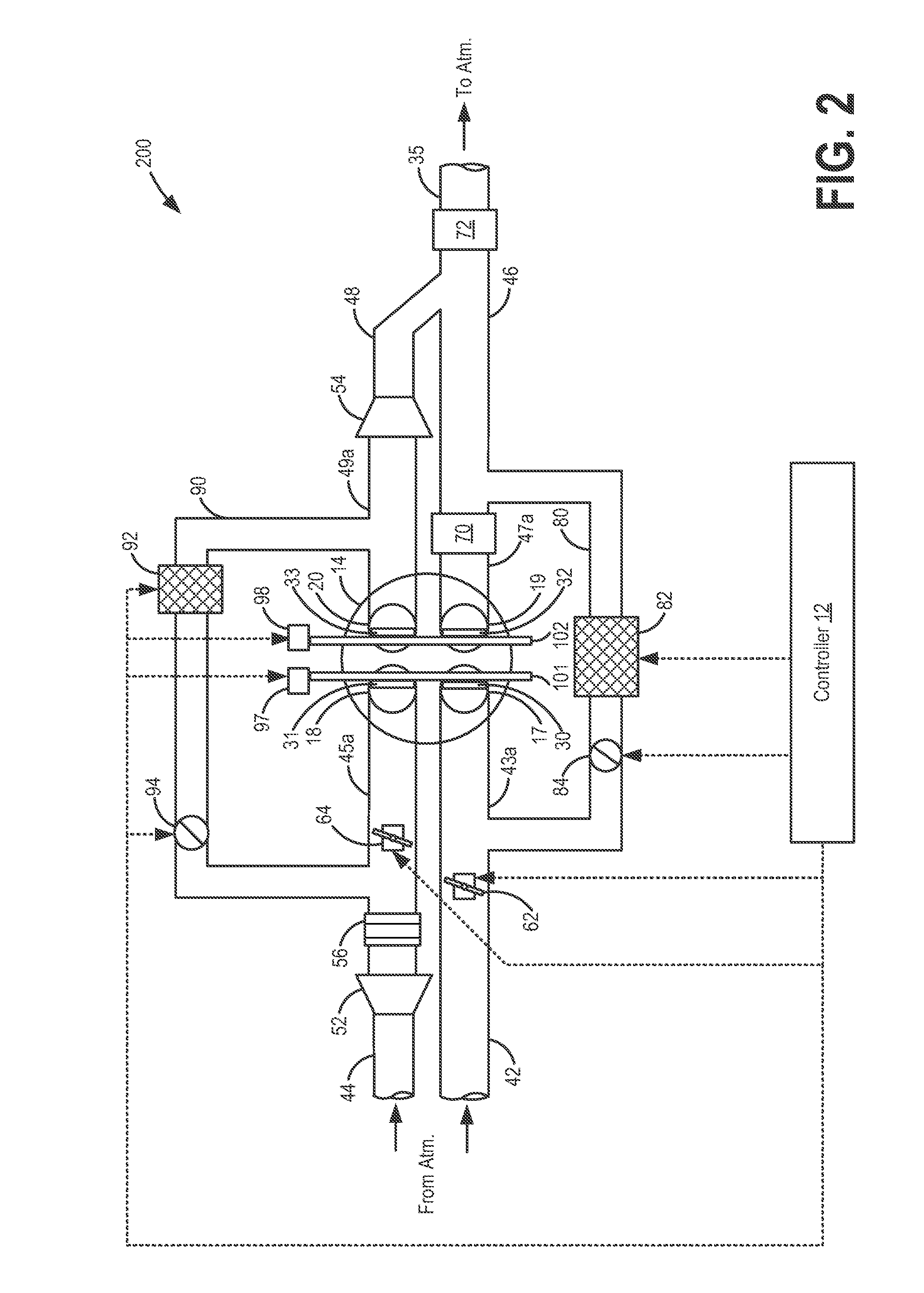

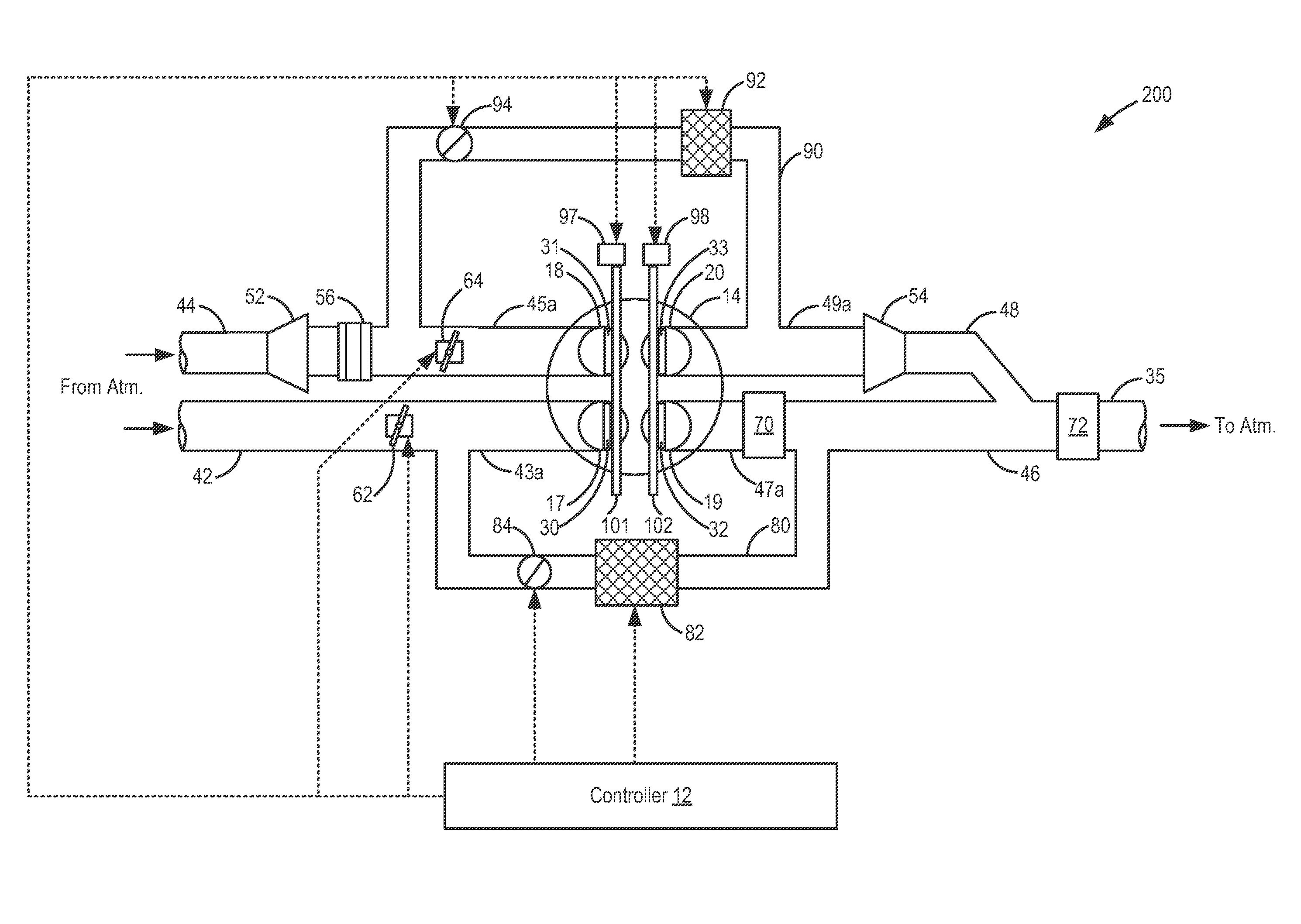

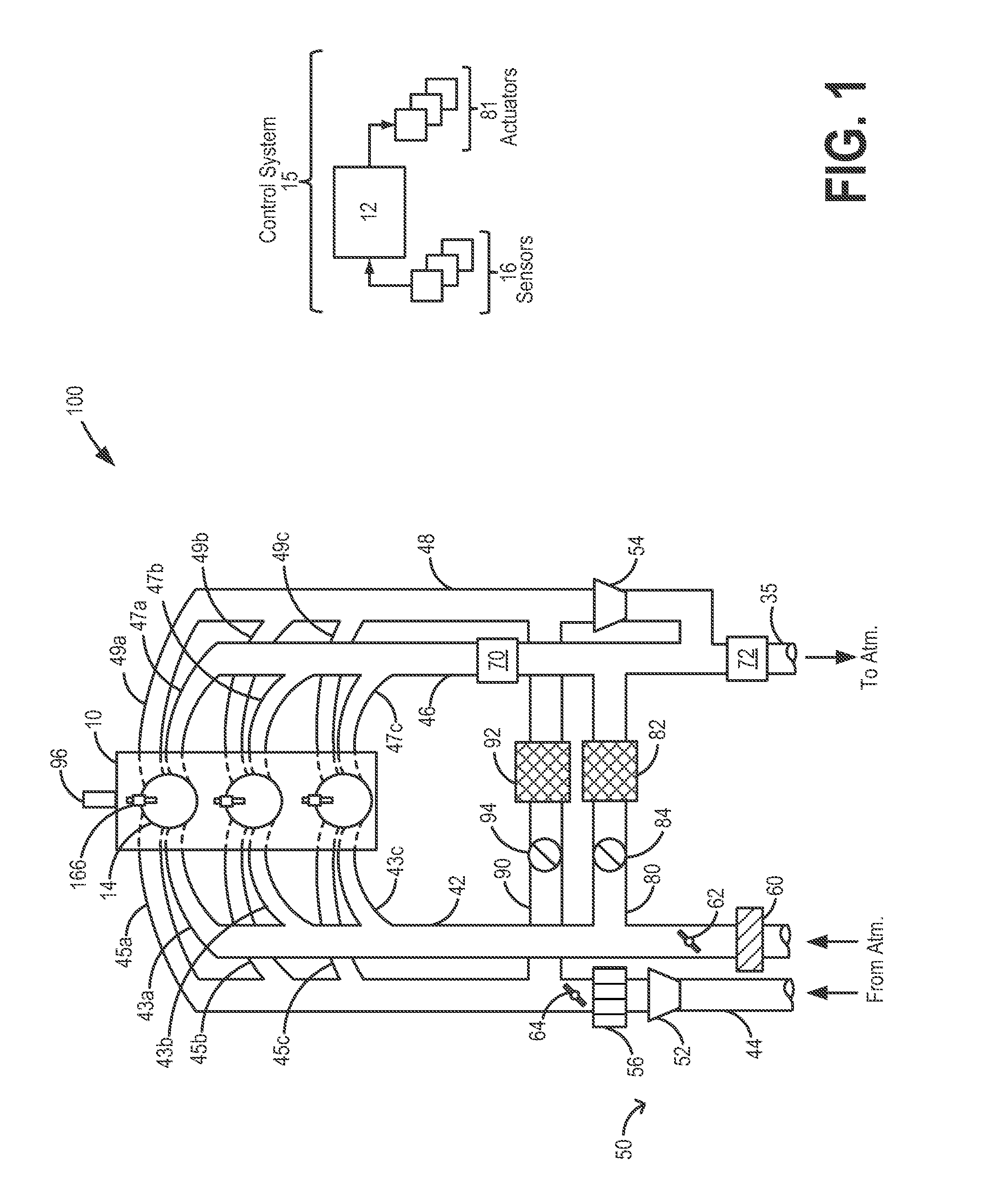

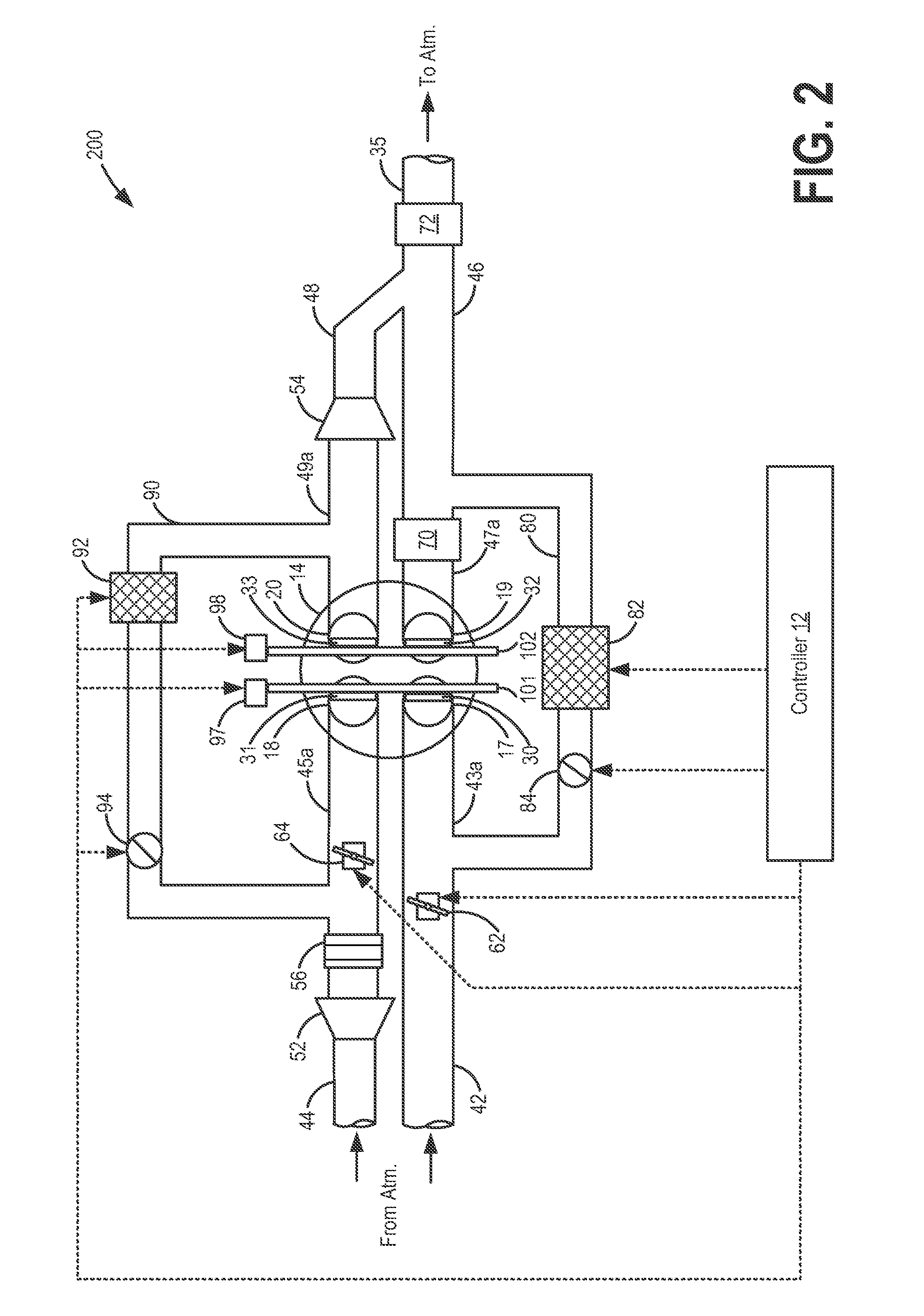

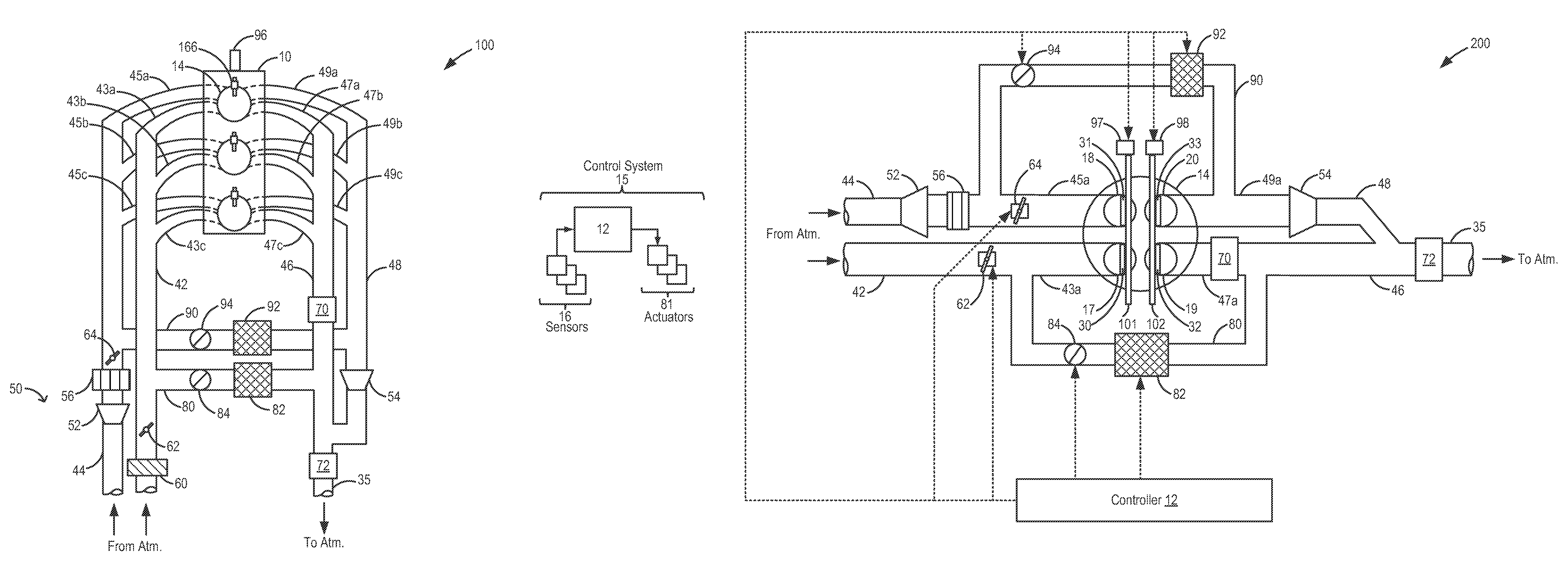

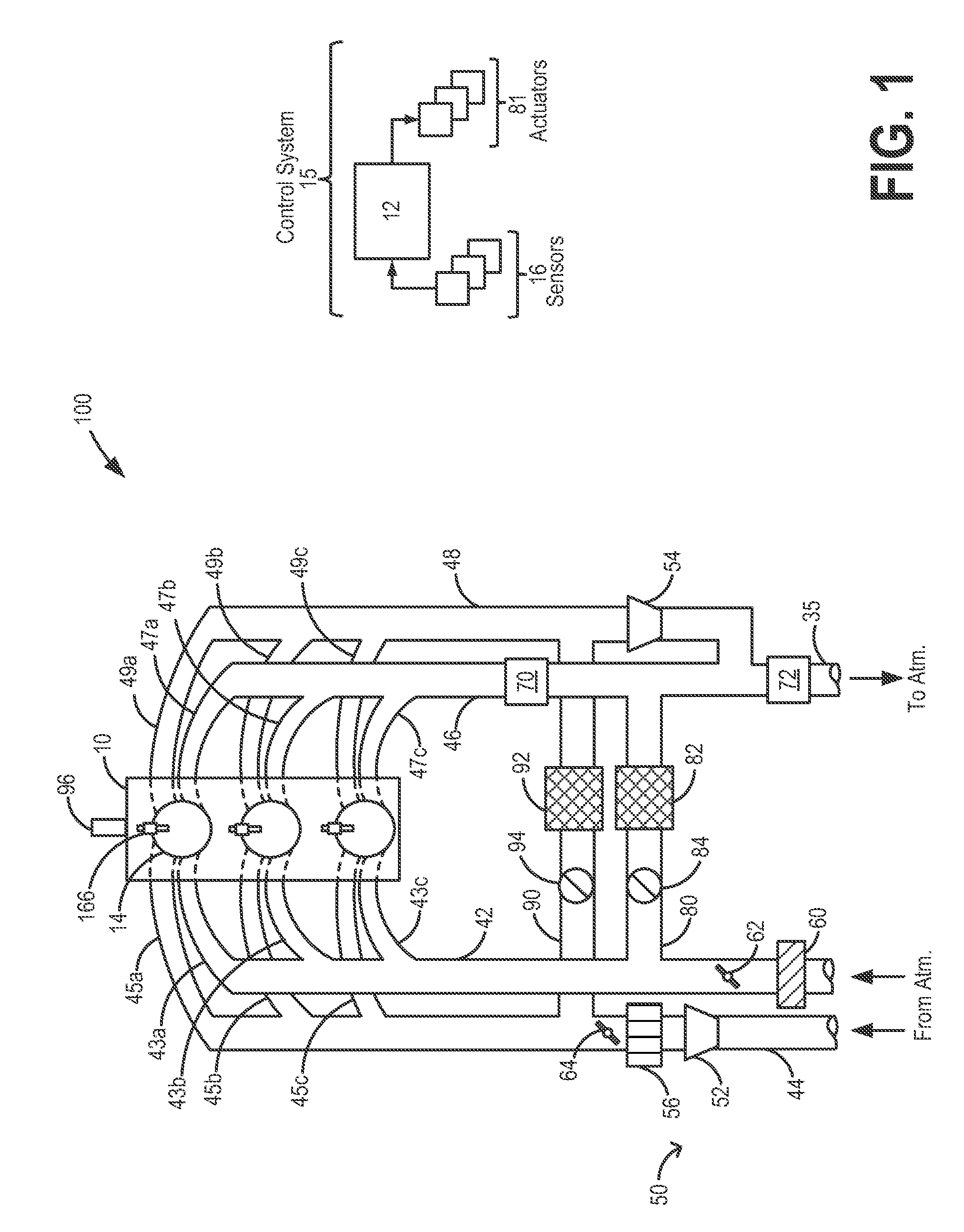

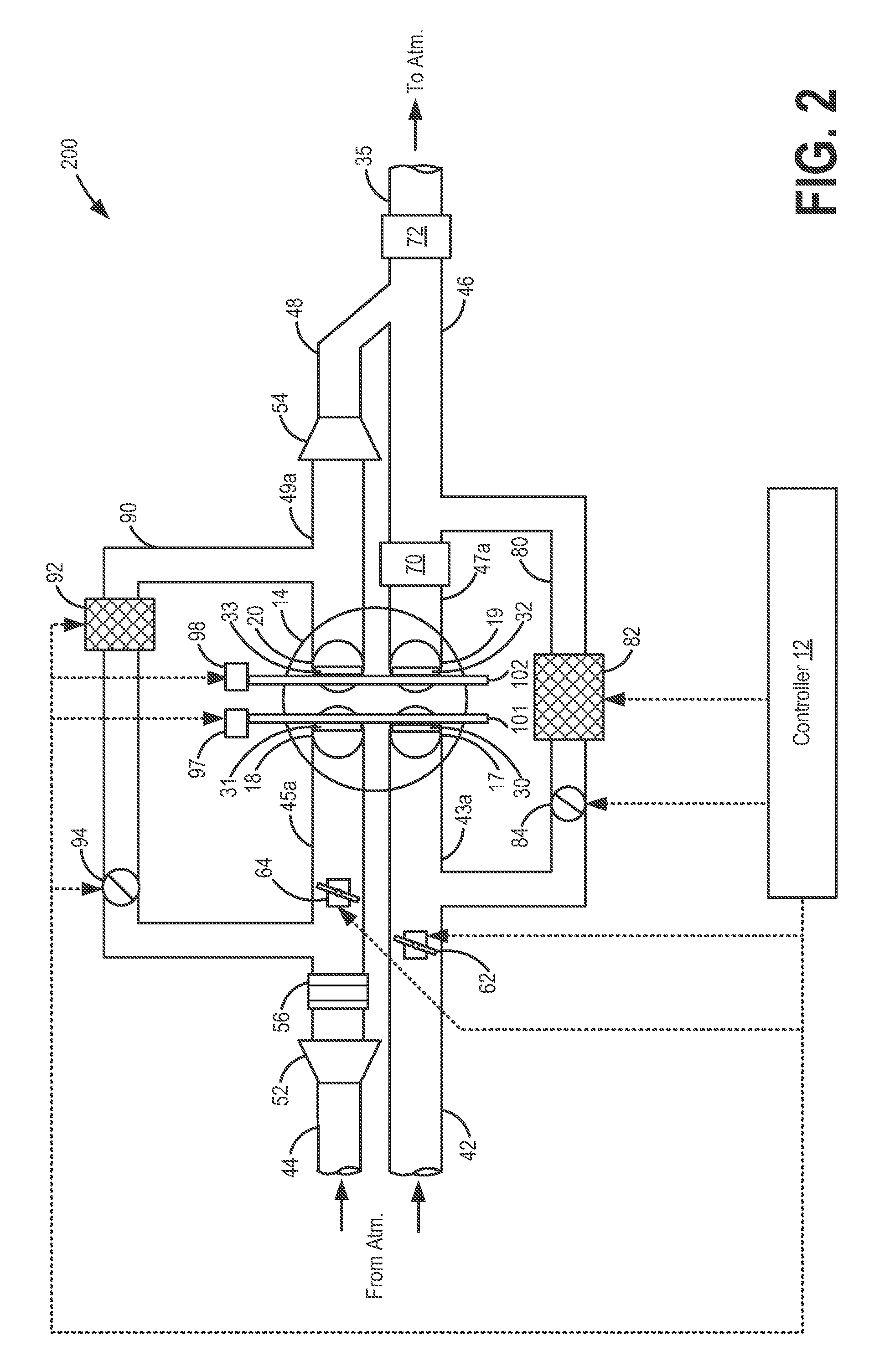

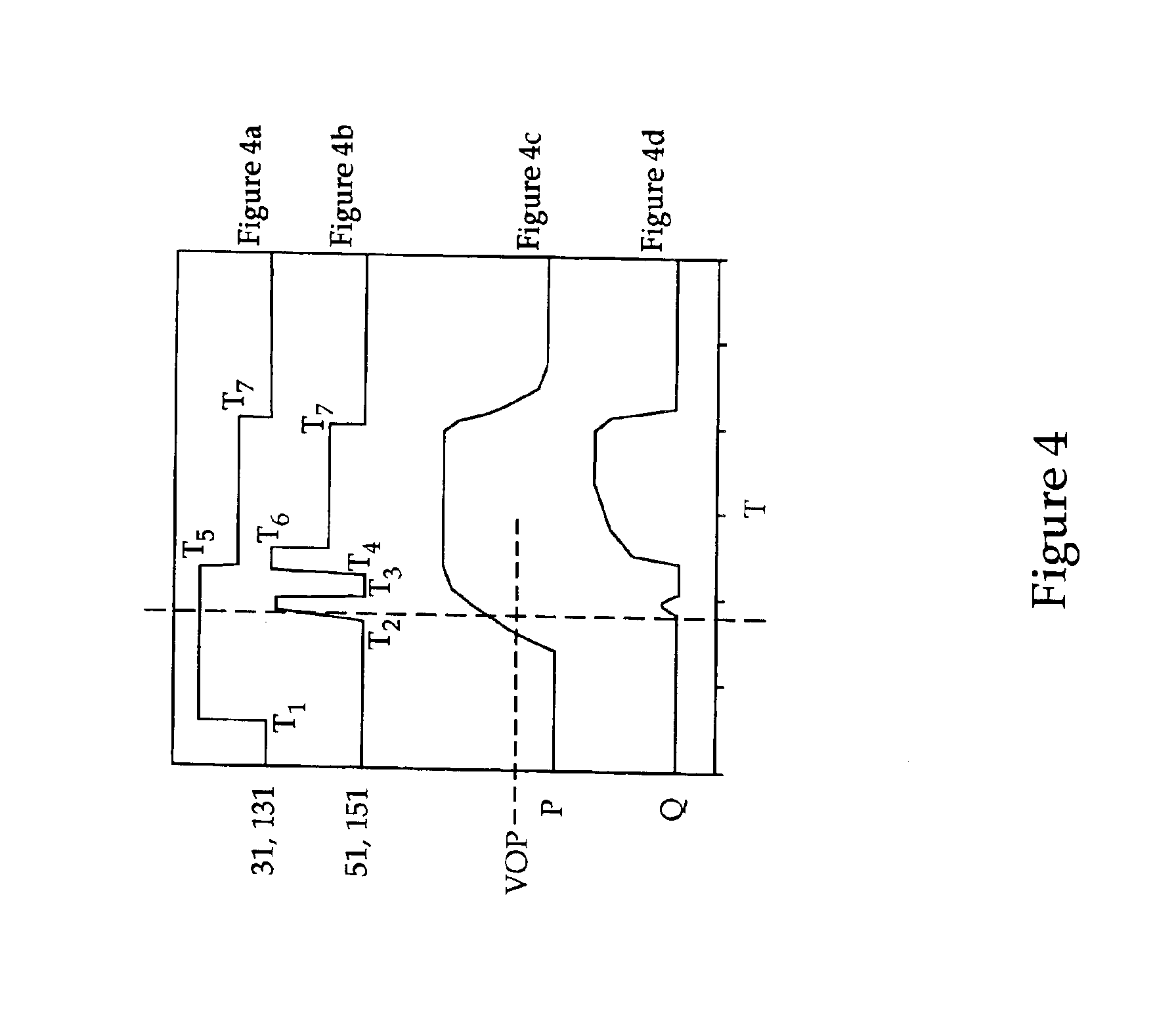

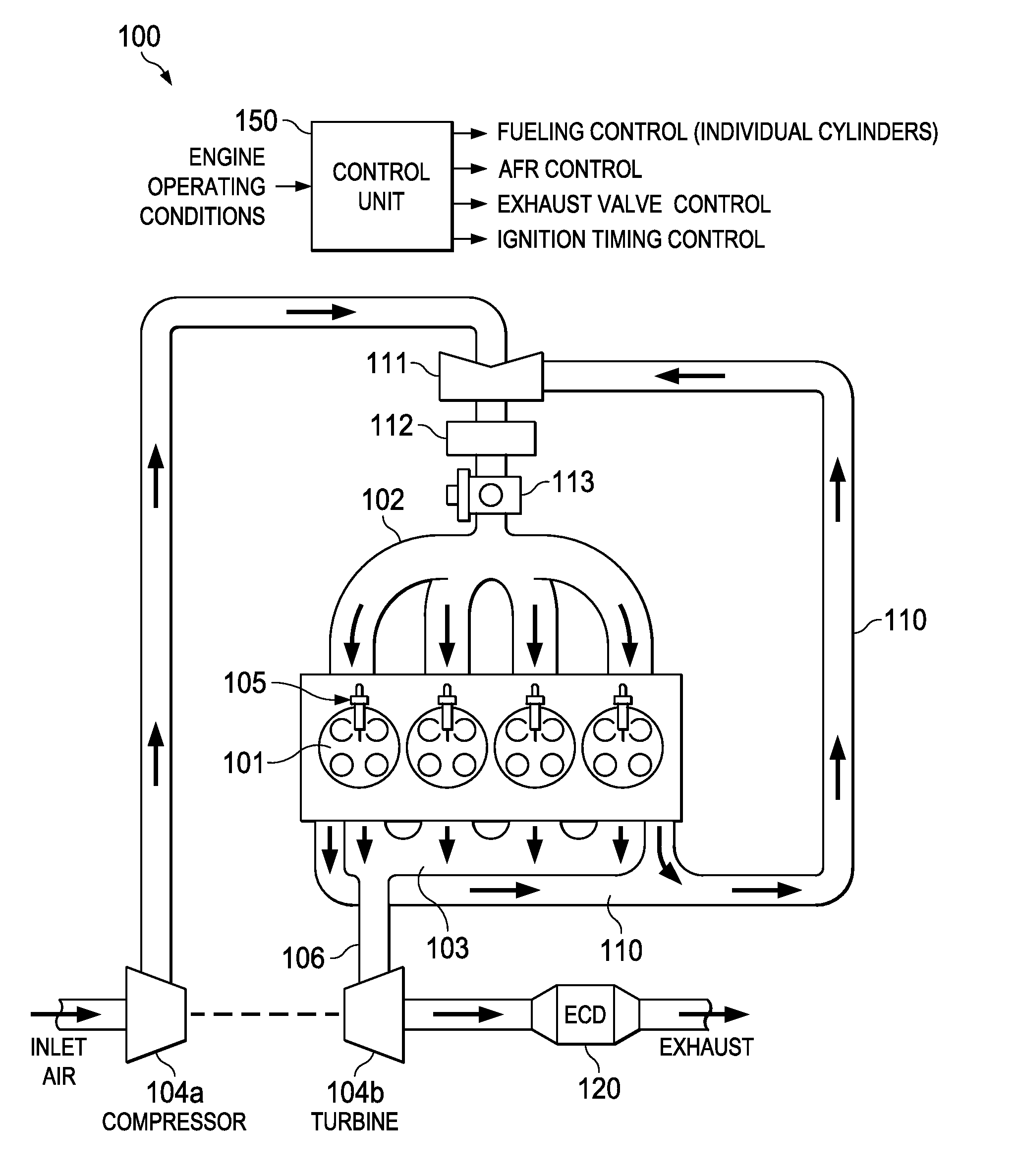

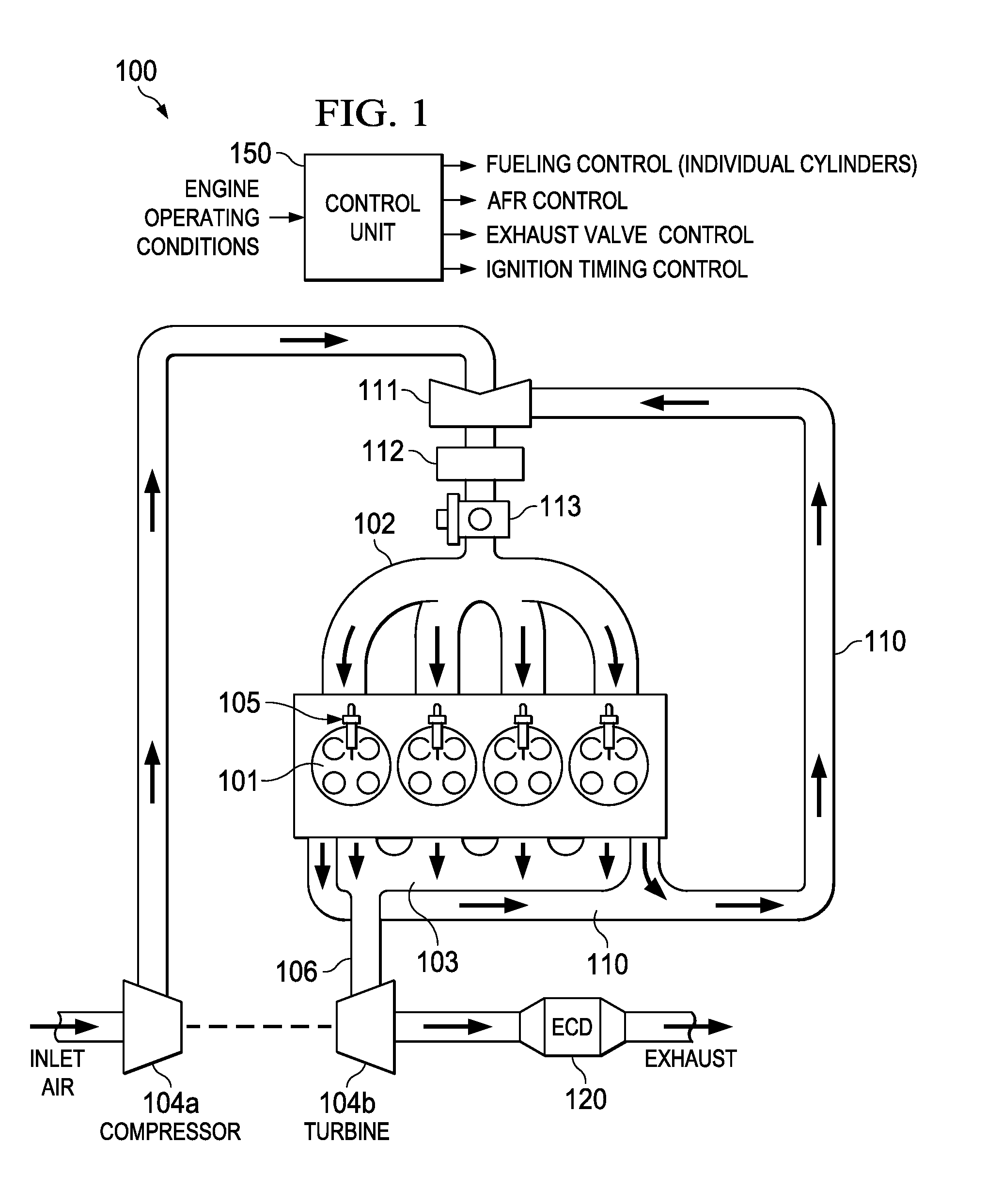

Method and system for a turbocharged engine

ActiveUS20120023935A1Improve compressor efficiencyFacilitates heat recoveryValve arrangementsElectrical controlEngine cycleAutomotive engineering

Methods and systems are provided for a boosted engine having a split intake system coupled to a split exhaust system. Aircharges of differing composition, pressure, and temperature may be delivered to the engine through the split intake system at different points of an engine cycle. In this way, boost and EGR benefits may be extended.

Owner:FORD GLOBAL TECH LLC

Method and system for a turbocharged engine

InactiveUS8701409B2Reduce exhaust emissionsImprove fuel economyValve arrangementsElectrical controlEngine cycleAutomotive engineering

Methods and systems are provided for a boosted engine having a split intake system coupled to a split exhaust system. Aircharges of differing composition, pressure, and temperature may be delivered to the engine through the split intake system at different points of an engine cycle. In this way, boost and EGR benefits may be extended.

Owner:FORD GLOBAL TECH LLC

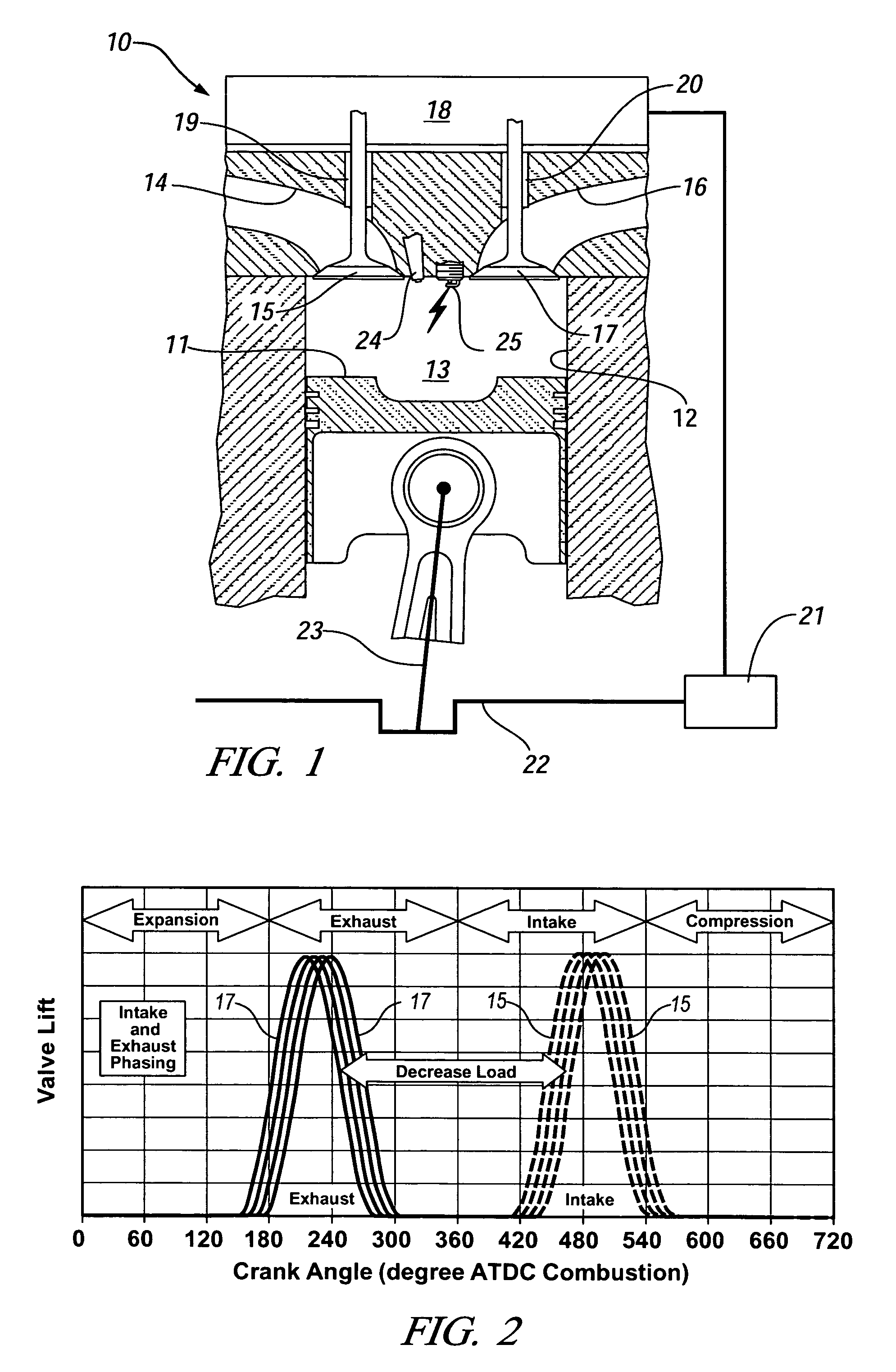

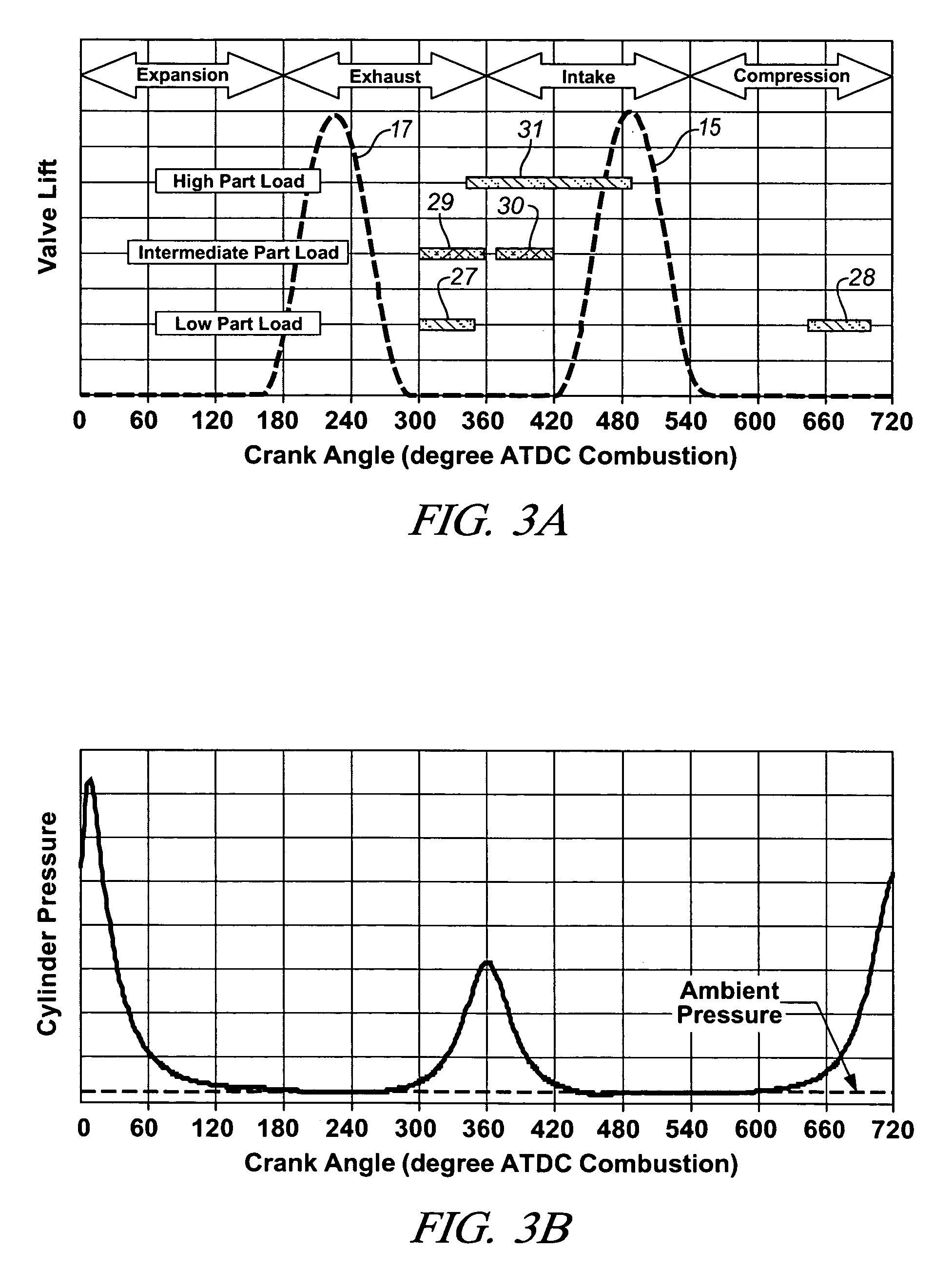

Load transient control methods for direct-injection engines with controlled auto-ignition combustion

InactiveUS20060196467A1Electrical controlNon-fuel substance addition to fuelHomogeneous charge compression ignitionLow load

A direct injection controlled auto-ignition engine is operated at steady state, within a homogeneous charge compression-ignition (HCCI) load range and with fuel-air-diluent mixtures at predetermined conditions, for each speed and load, of engine control inputs, including at least fueling mass flow rate, injection timing (FI), spark timing (SI) and exhaust recompression obtained by negative valve overlap (NVO). During load change rates below a predetermined threshold, SI, FI and NVO change rates are synchronized to current changes in the fueling mass flow rate. For fast load increases above the threshold, the cylinder charge is temporarily enriched by increasing the percentage of residual gas or reducing the percentage of fresh air mass in the charge sufficiently to maintain auto-ignition temperature during the load change. This may be done by delaying NVO action for a predetermined speed-dependent number of engine cycles. At very low loads, stable fuel rate reduction may require an alternate method involving deceleration fuel cut-off followed by a step change during refire.

Owner:GM GLOBAL TECH OPERATIONS LLC

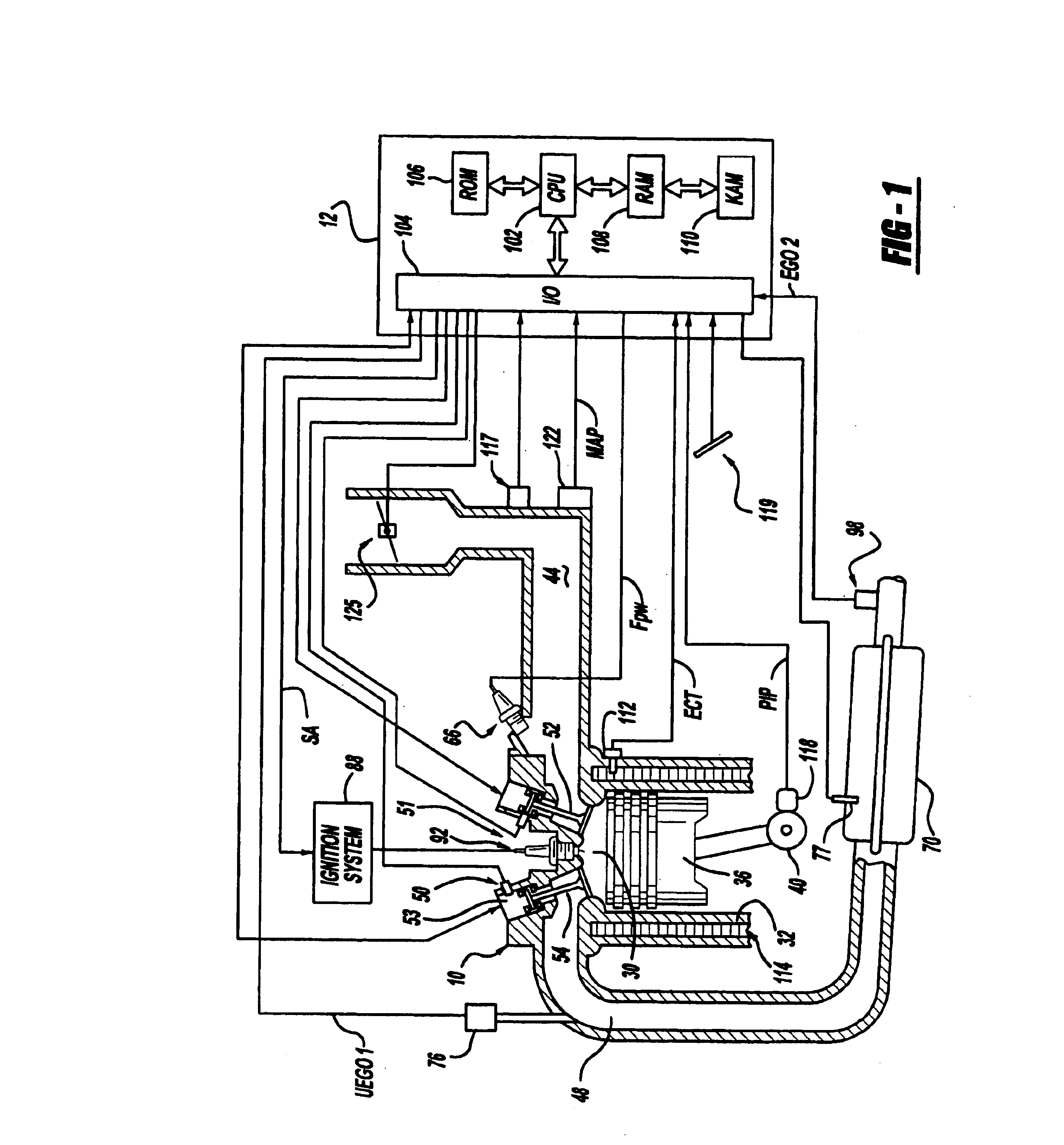

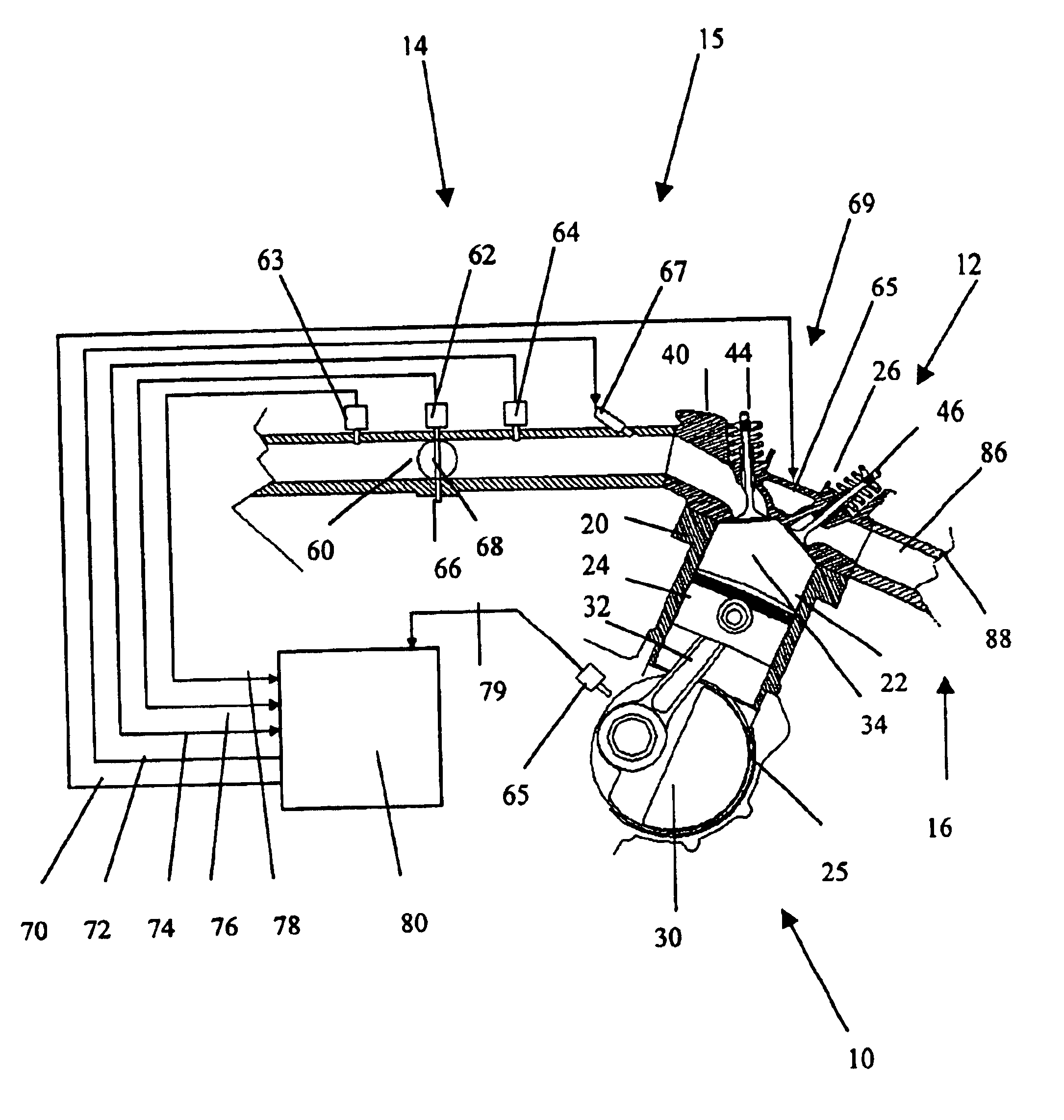

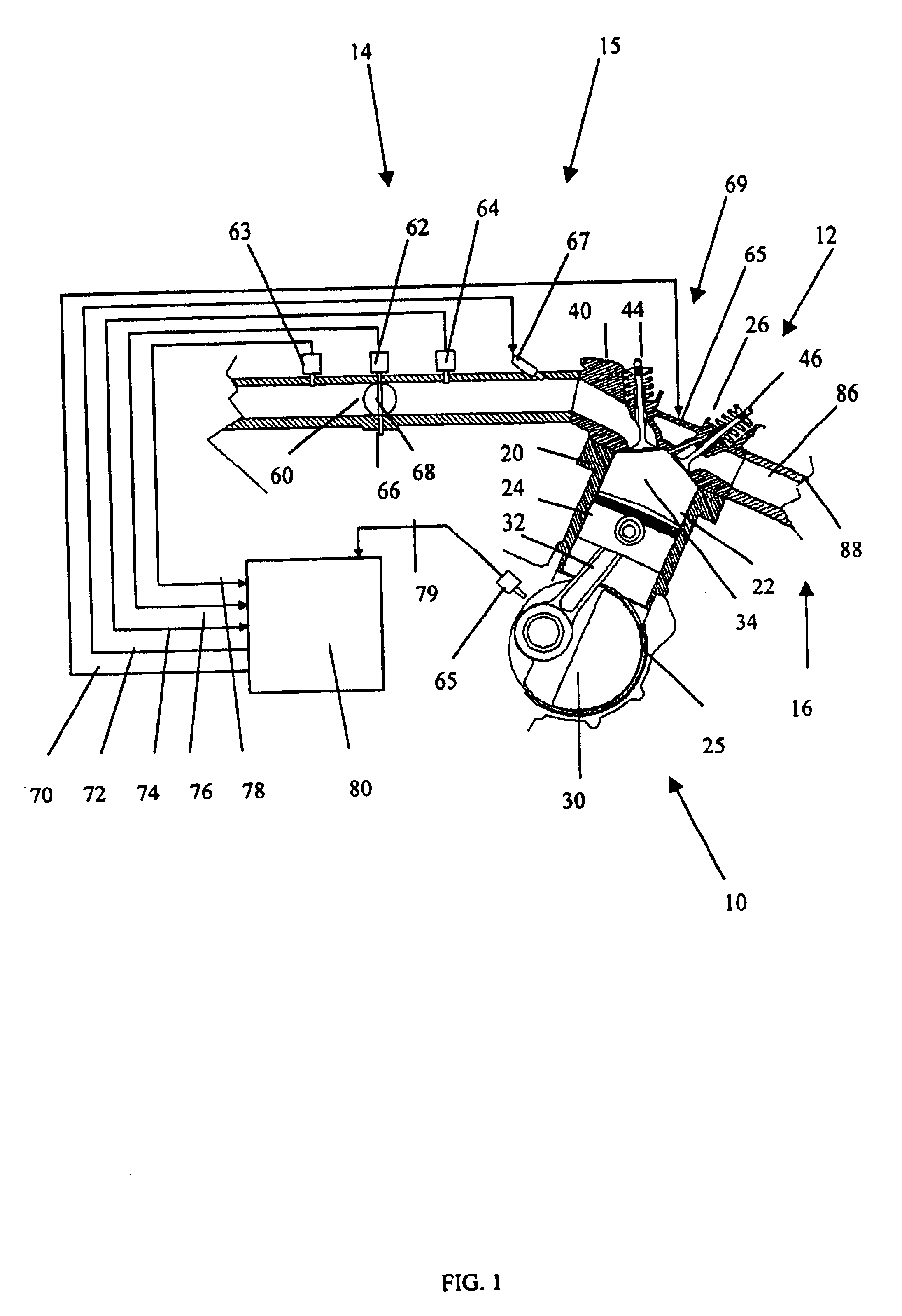

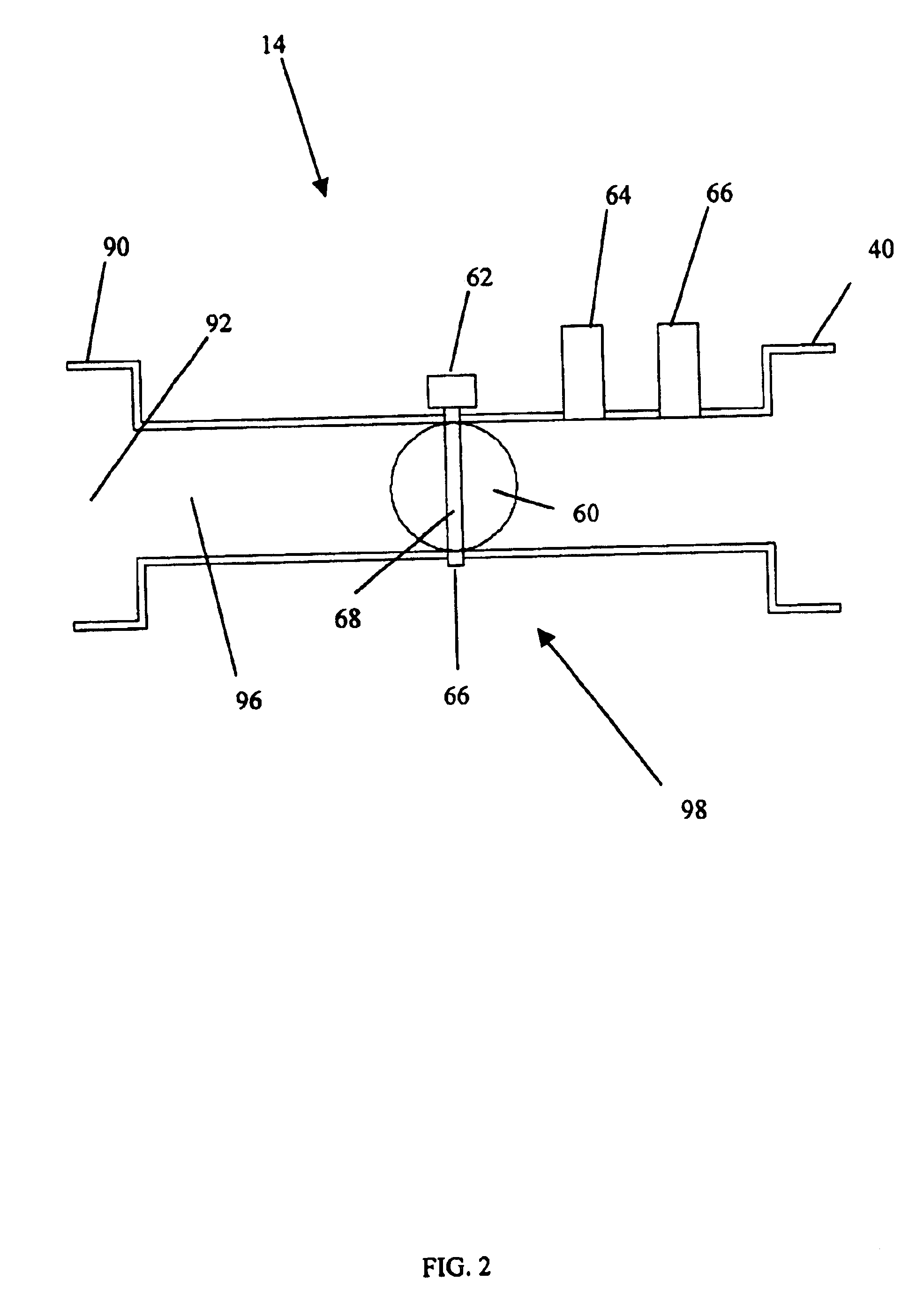

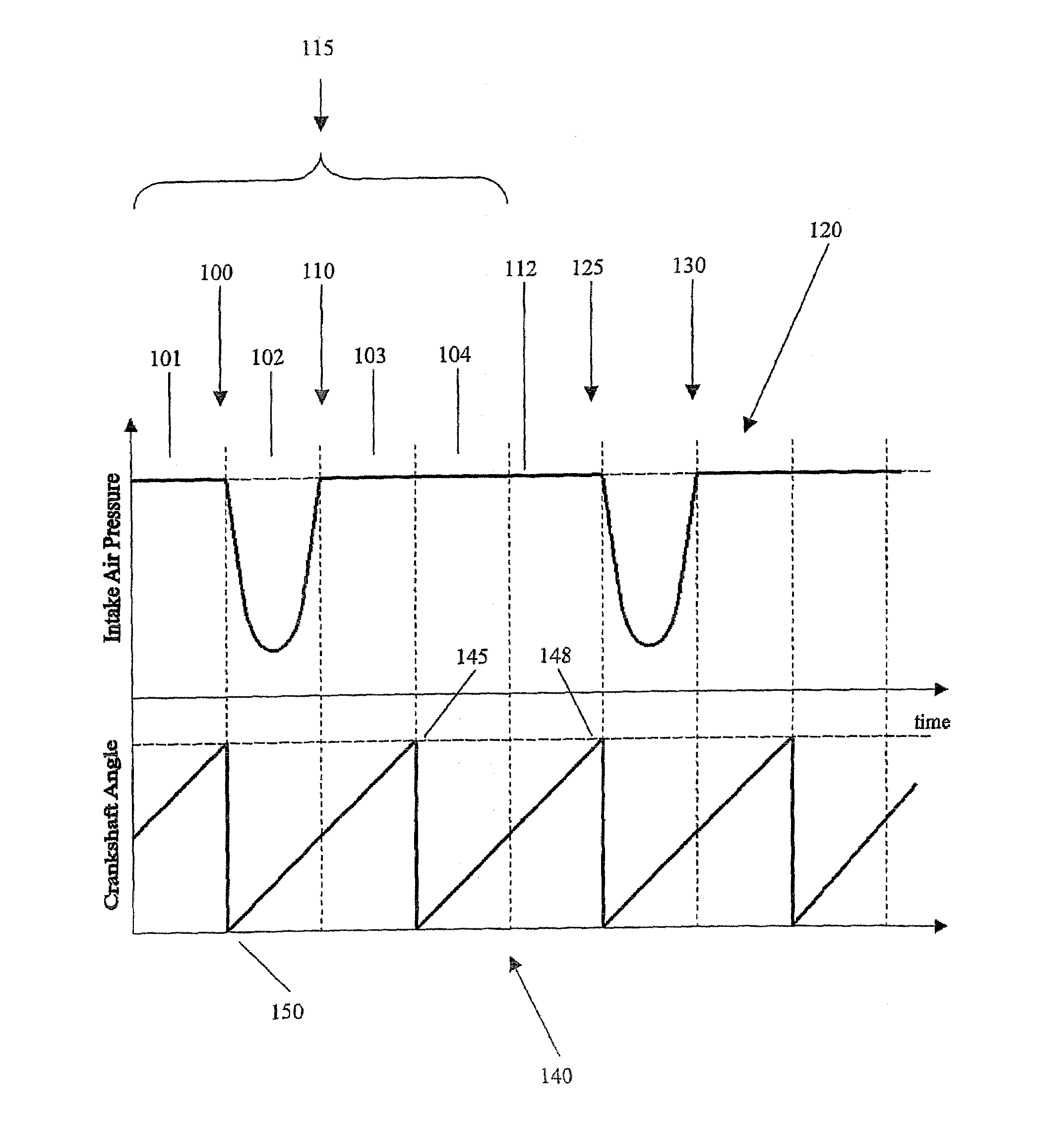

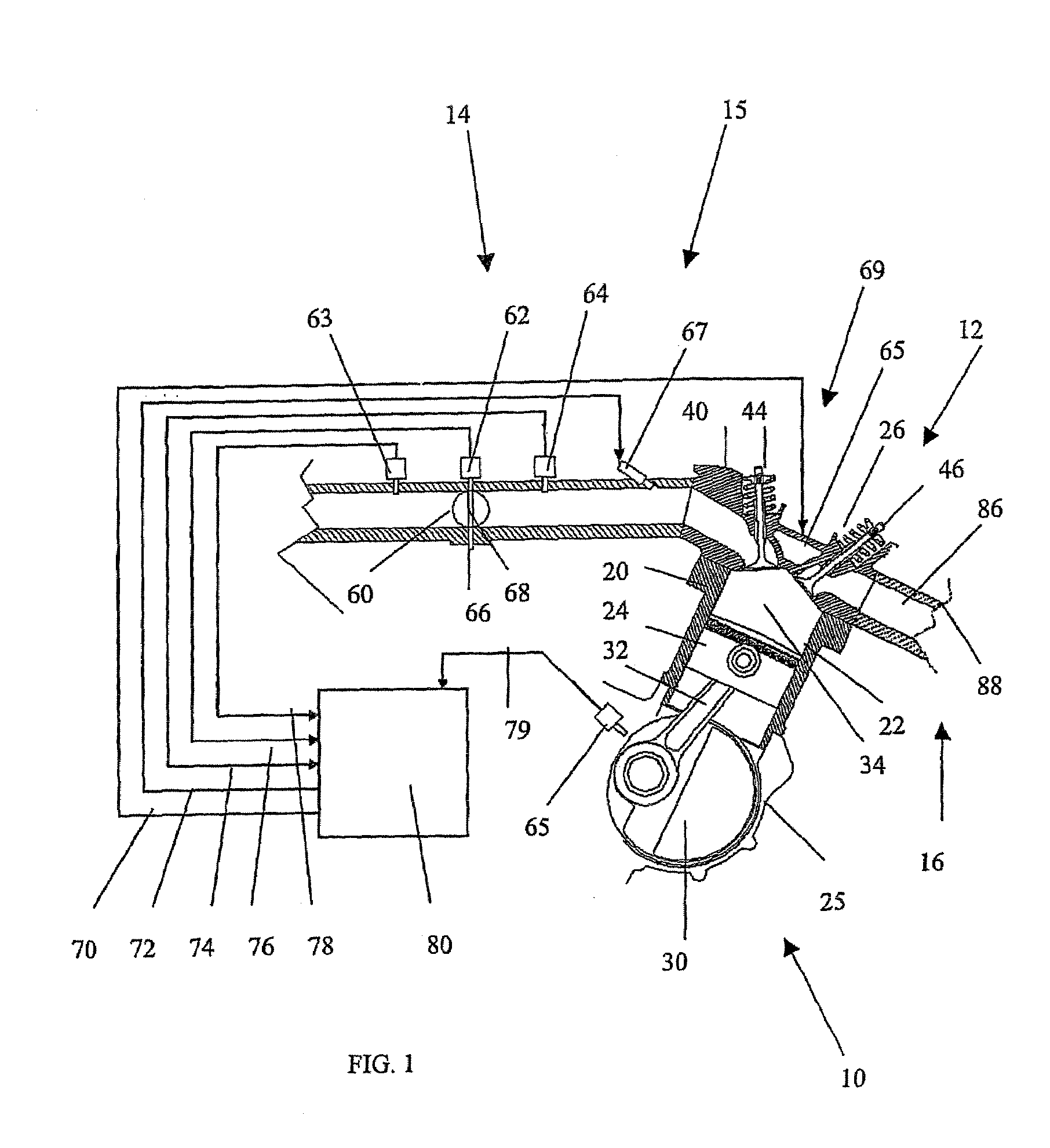

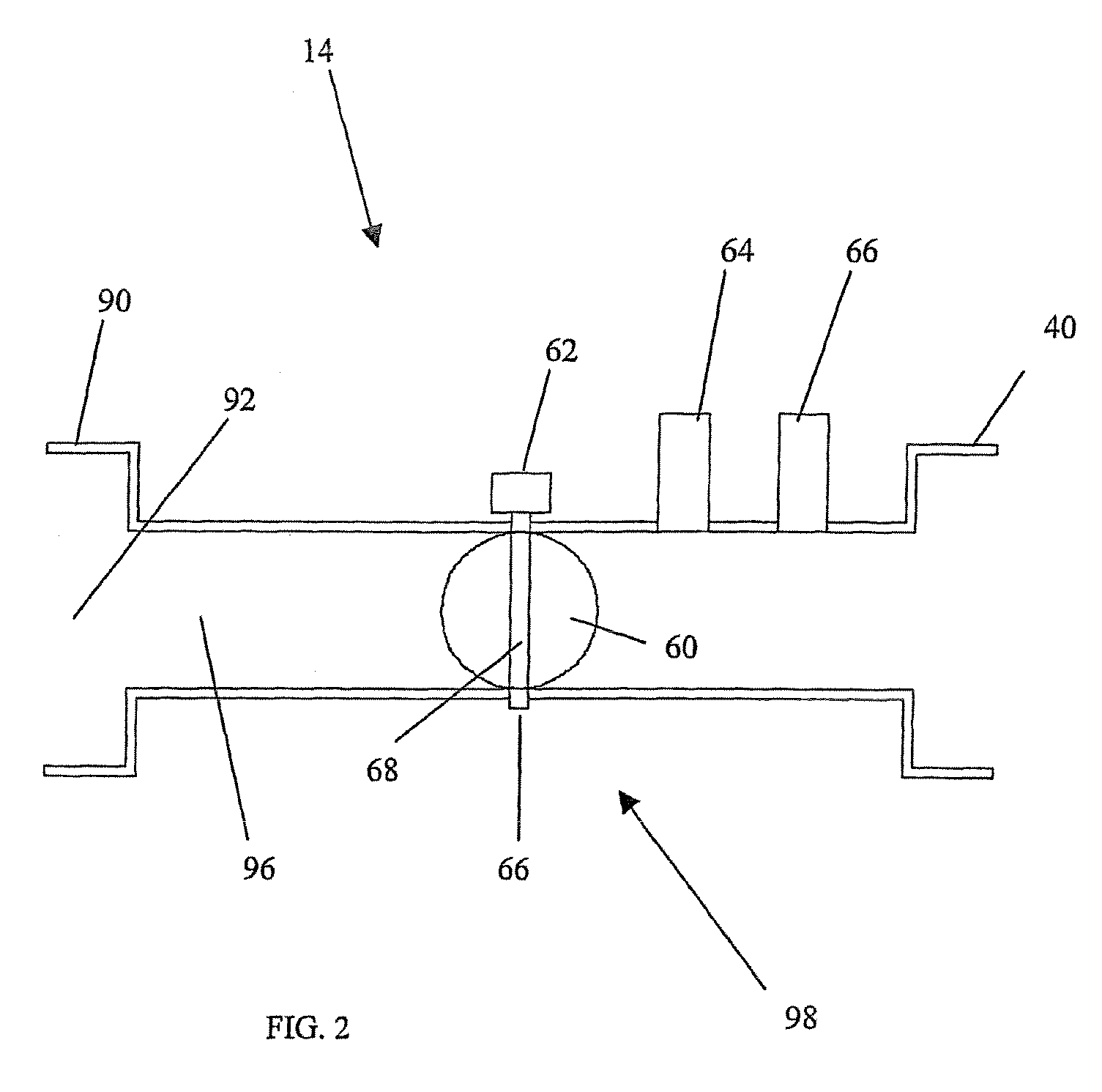

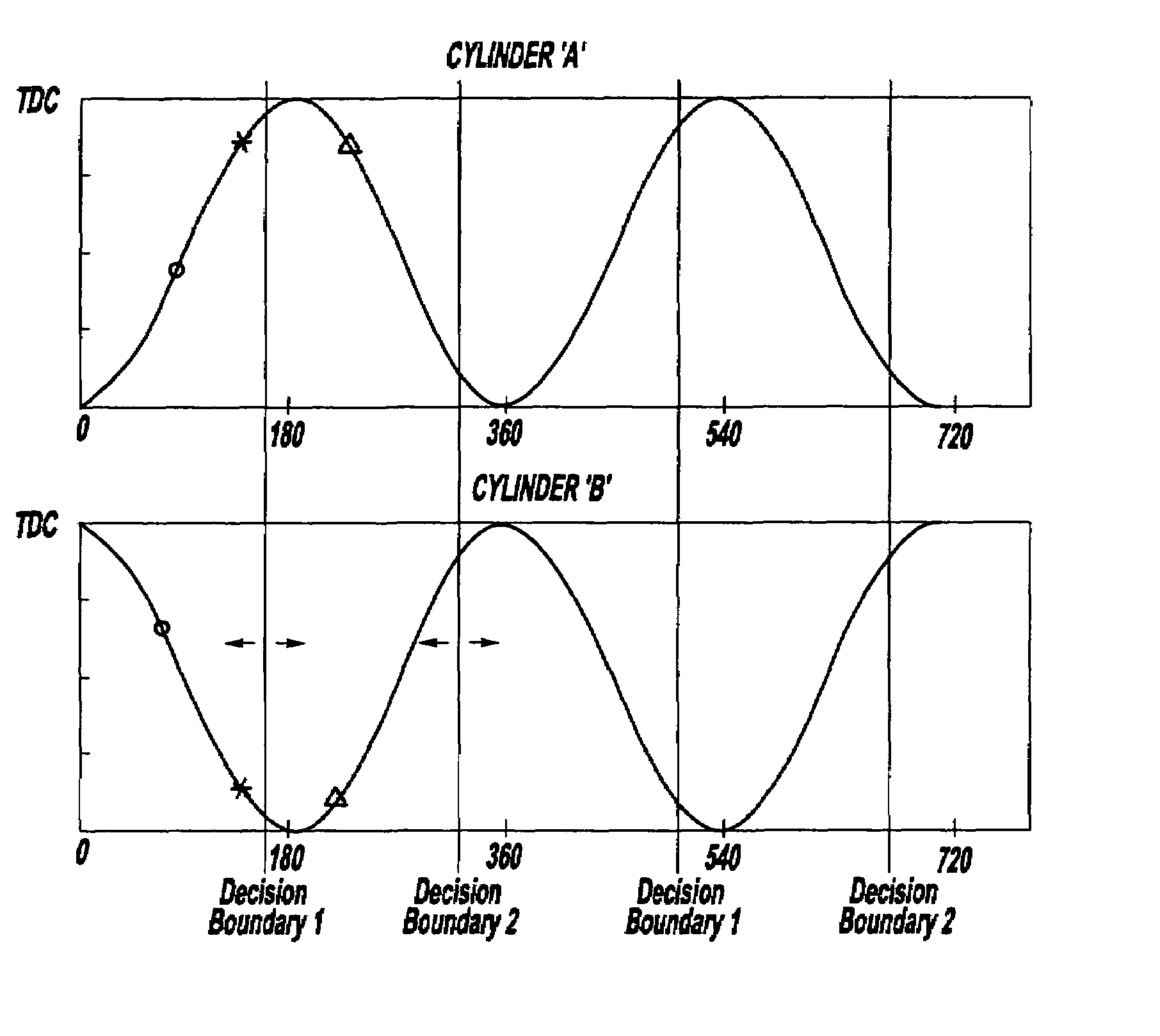

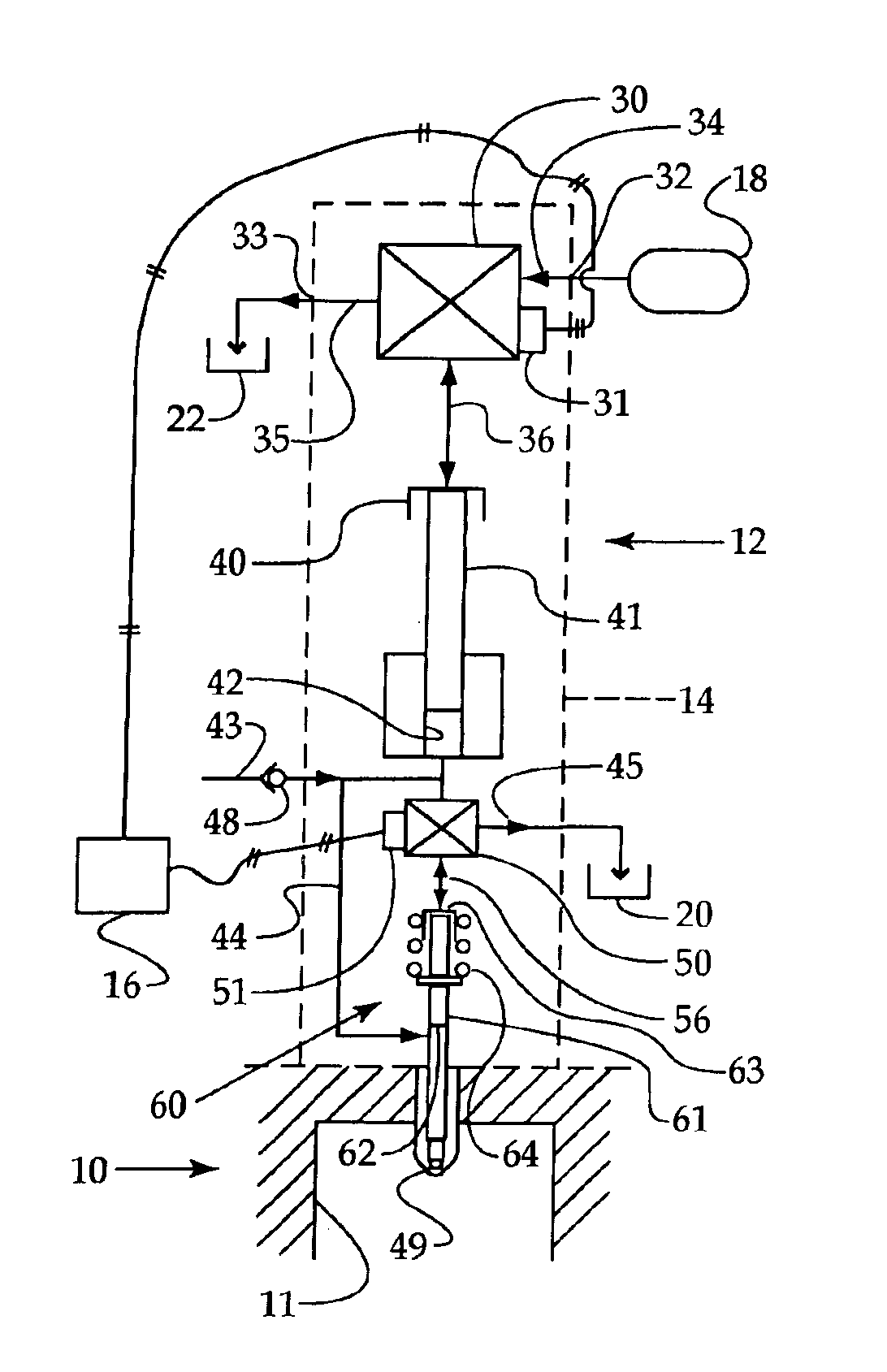

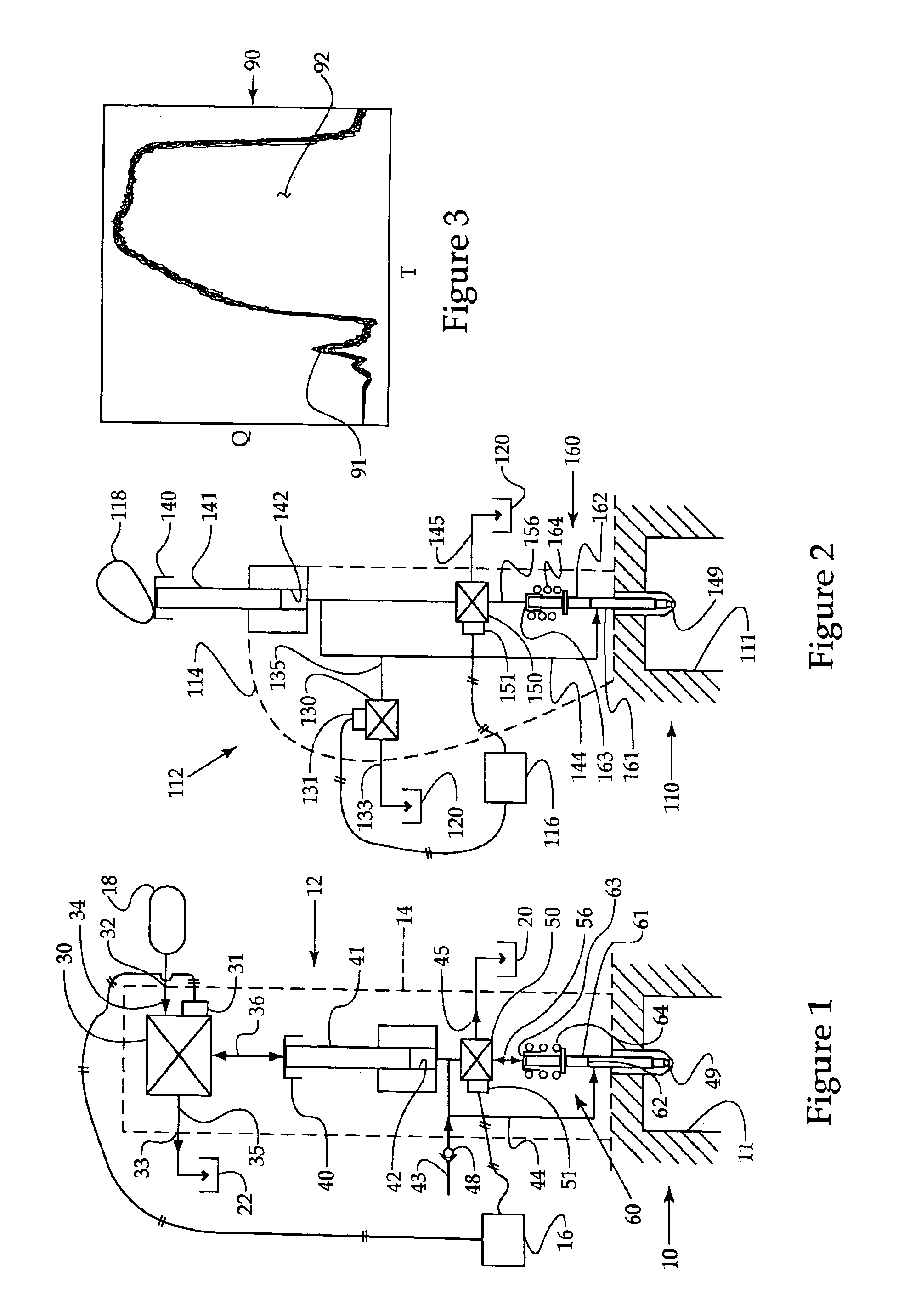

Engine timing control with intake air pressure sensor

InactiveUS6804997B1Reduce in quantityRobust implementationElectrical controlEngine testingExternal combustion engineInlet valve

An engine control apparatus is disclosed for determining crankshaft position and engine phase of an internal combustion engine (10) through monitoring intake air pressure fluctuations (120). The opening of the intake valve (44) is mechanically linked to the crankshaft position of an engine. When the intake valve (44) opens it creates air pressure fluctuations in the air induction system (14) of the engine (10). The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event (100 to 110) and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure fluctuations to increase resolution in determination of crankshaft position.

Owner:ELECTROJET TECH INC

Method and system for a turbocharged engine

ActiveUS8479511B2Without compromising boost performanceBoosted airchargeValve arrangementsElectrical controlEngine cycleAutomotive engineering

Methods and systems are provided for a boosted engine having a split intake system coupled to a split exhaust system. Aircharges of differing composition, pressure, and temperature may be delivered to the engine through the split intake system at different points of an engine cycle. In this way, boost and EGR benefits may be extended.

Owner:FORD GLOBAL TECH LLC

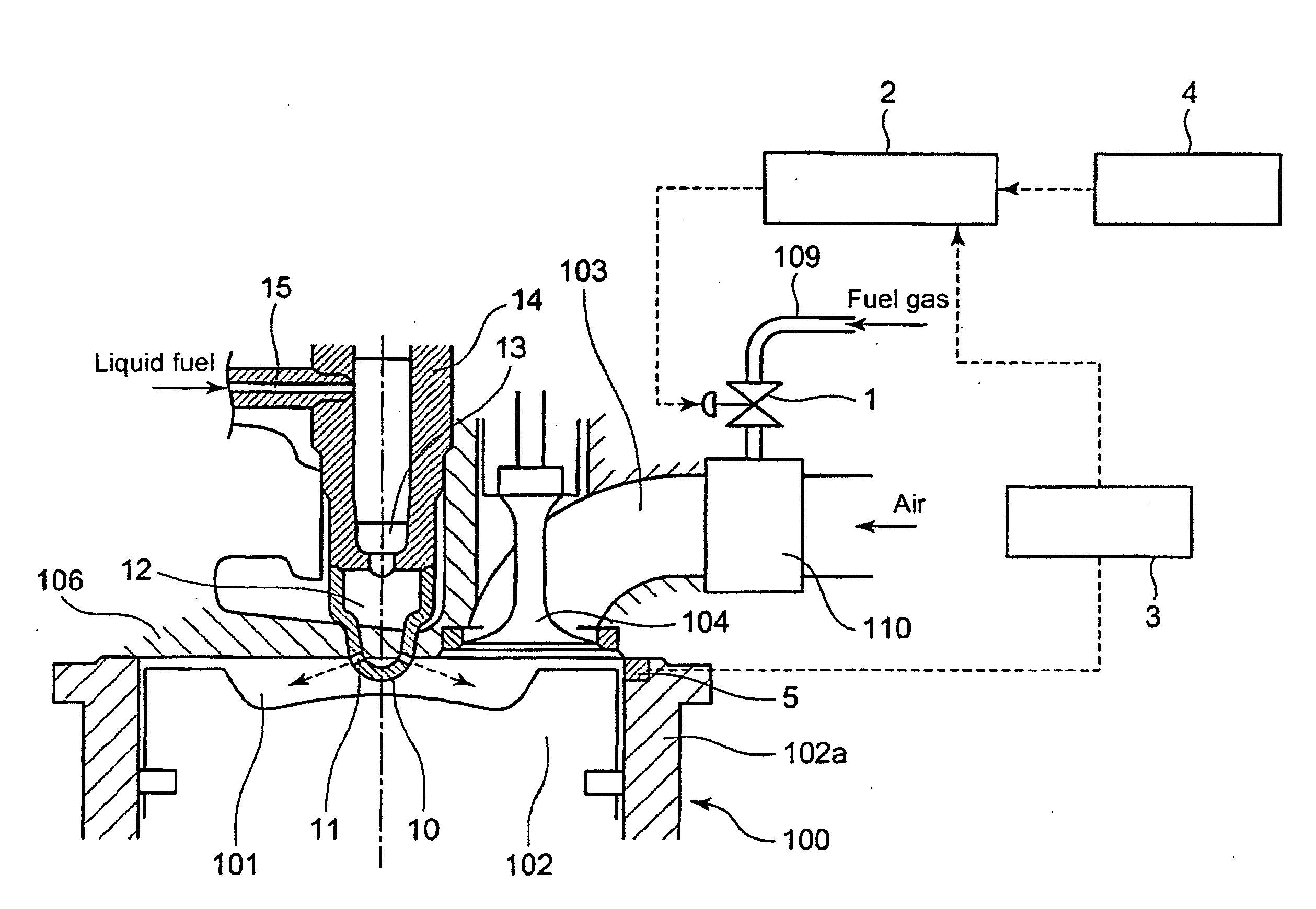

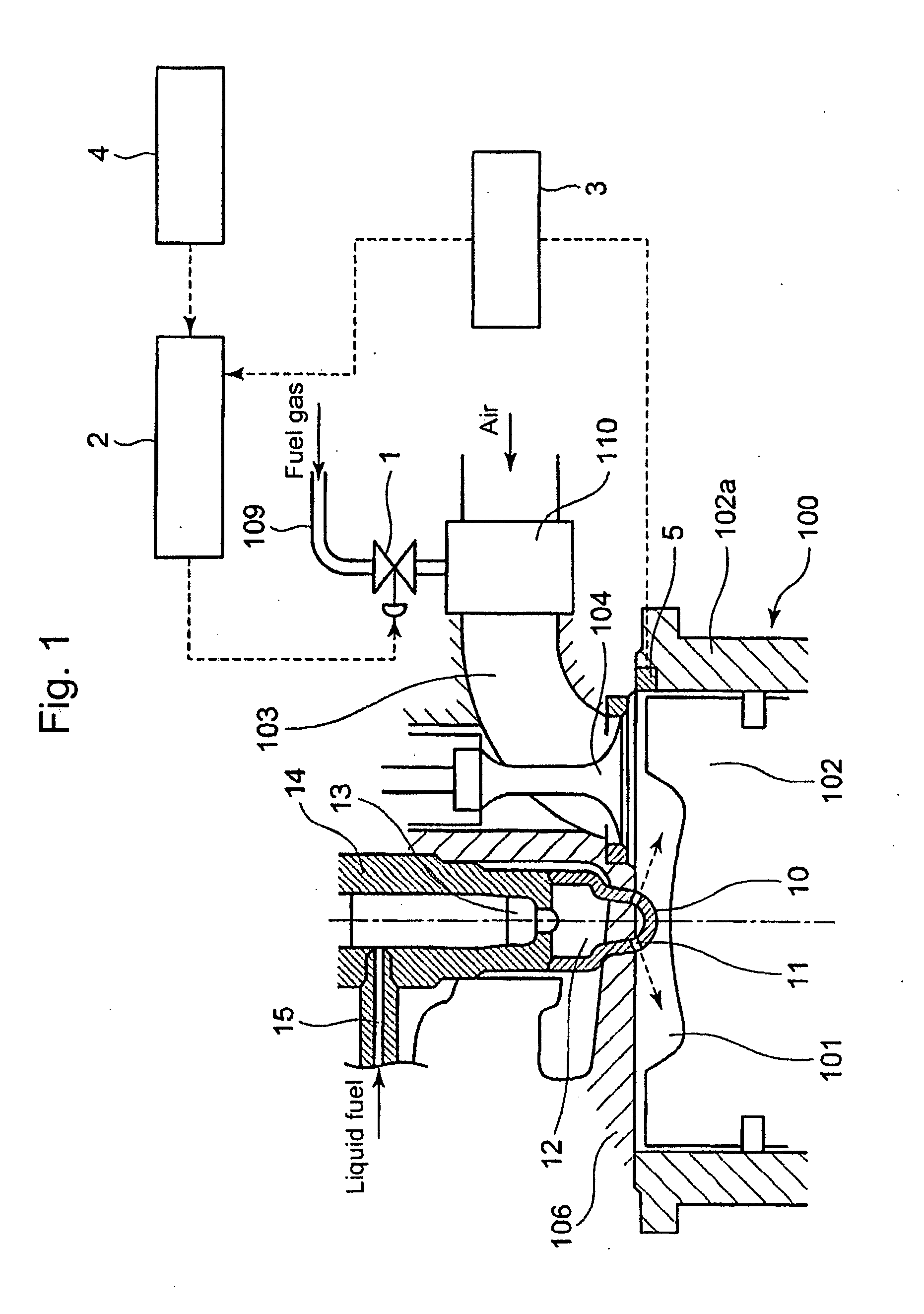

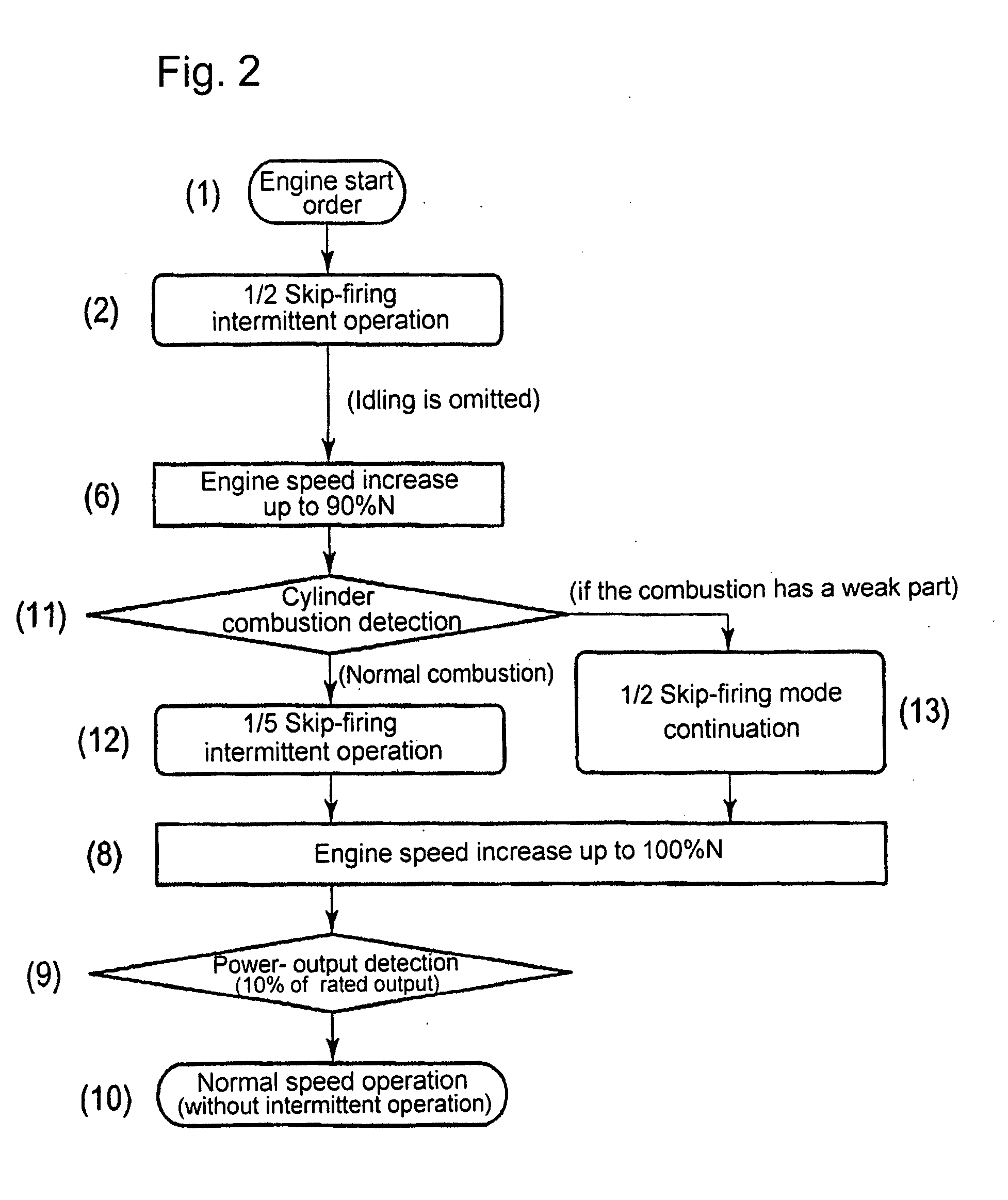

Micro-pilot injection ignition type gas engine

ActiveUS20100043744A1High precisionIdle timeValve arrangementsElectrical controlFuel supplyAir–fuel ratio

What is disclosed is a micro-pilot injection ignition type gas engine, whereby an air fuel ratio control in starting the engine is executed with enhanced precision, by means of introducing skip-firing intermittent operations which reflect the engine operation conditions, while an idling time span can be shortened or omitted.The engine includes: a gas valve that opens and closes a fuel-gas passage in front of each cylinder, so as to arbitrarily control the throat area as well as the opening-closing time span of the gas valve; an engine speed detecting unit to detect the engine speed; a combustion diagnosis unit to detect an engine combustion state through a cylinder pressure distribution along elapsed time, as to each cylinder; an opening-closing control unit as to the gas valve, so as to control the intermittent opening-closing of the gas valve according to the levels of the detected engine speed as well as the cylinder pressure distribution; whereby, in starting the engine, the intermittent opening-closing of the gas-valve enables at least one skip-firing mode that brings an enhanced fuel-supply pressure-pulsation with which a relatively large amount of fuel-gas is supplied per engine cycle with firing so that the air fuel-gas ratio of each cylinder reaches a prescribed target value.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

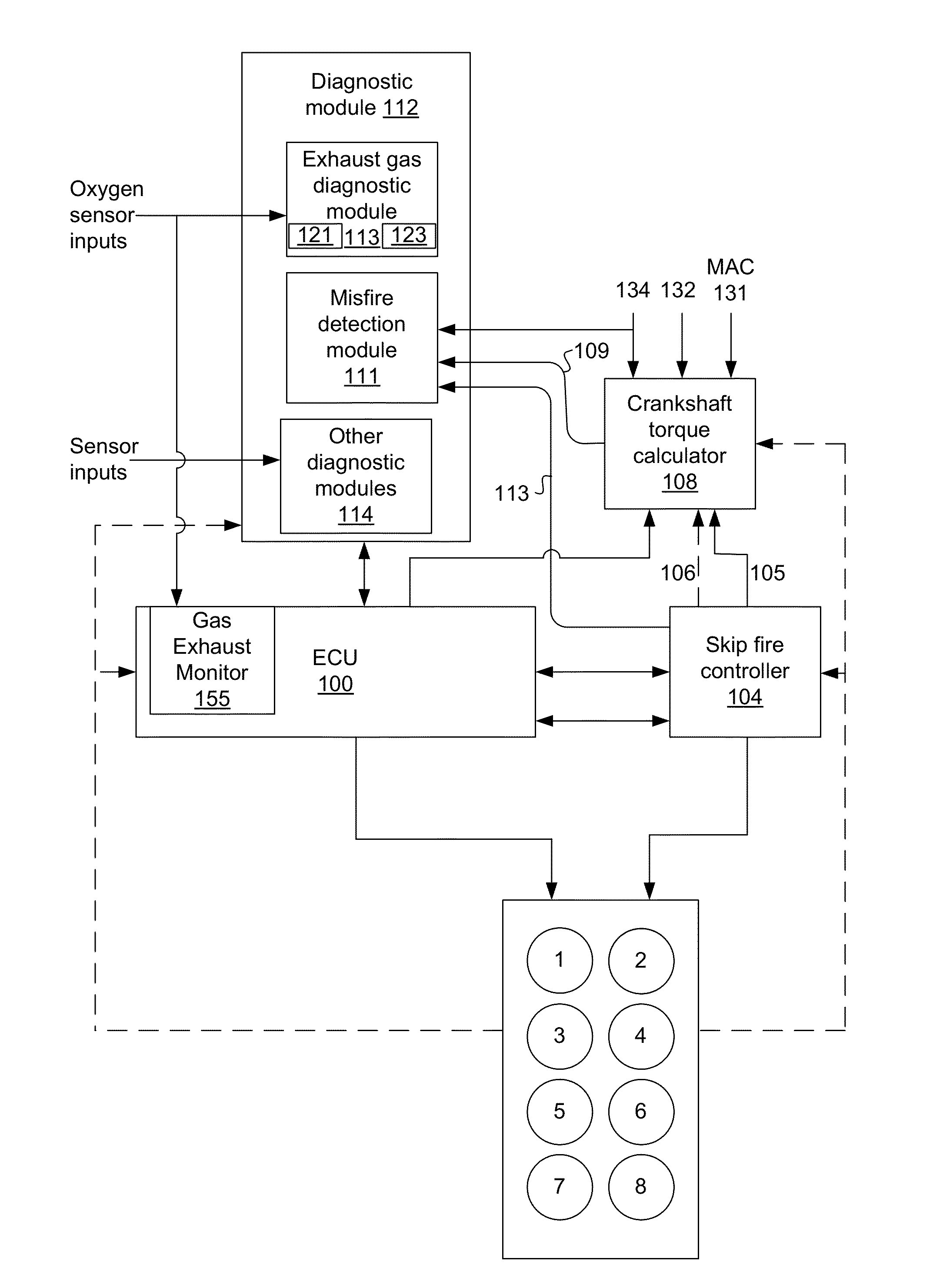

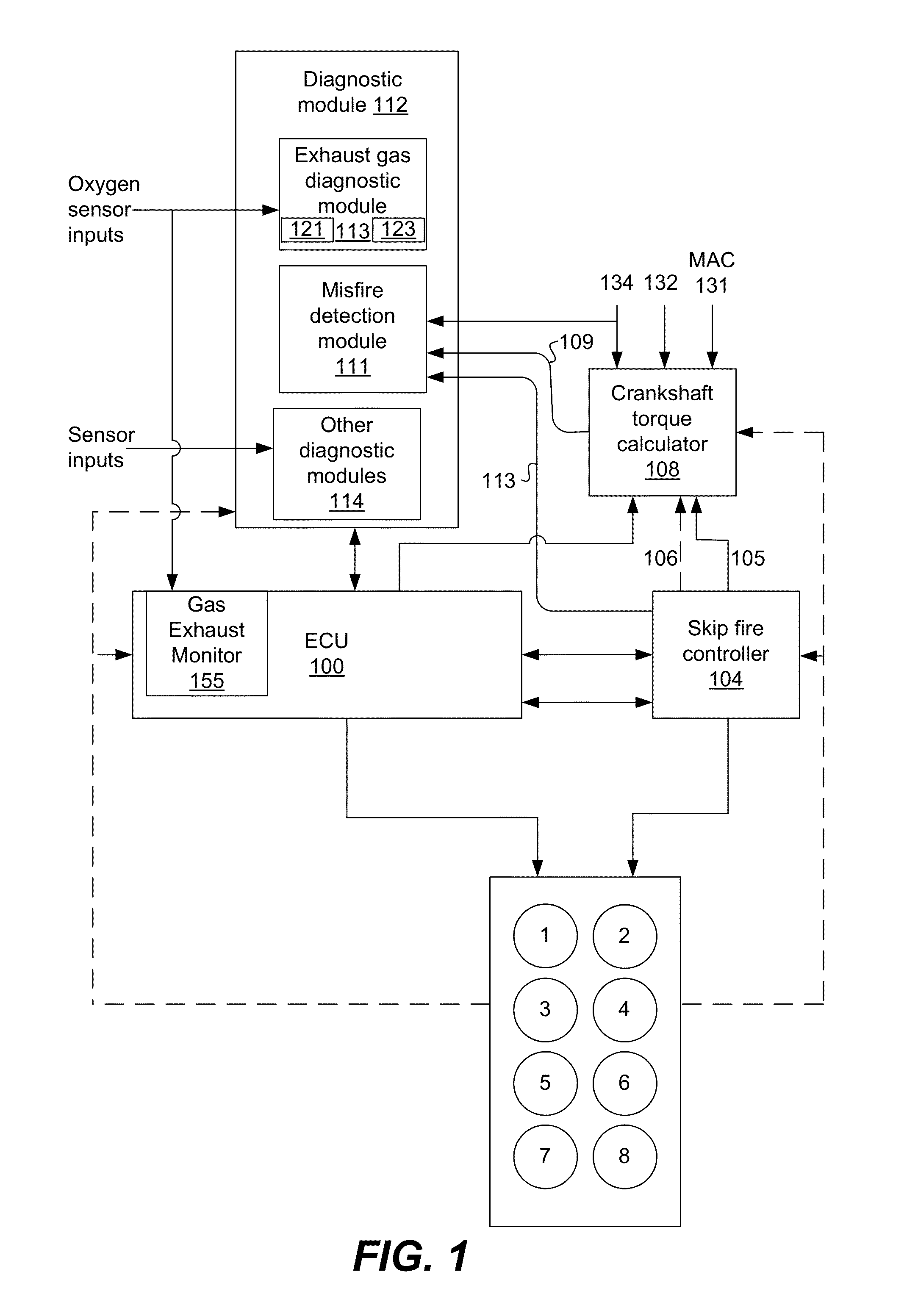

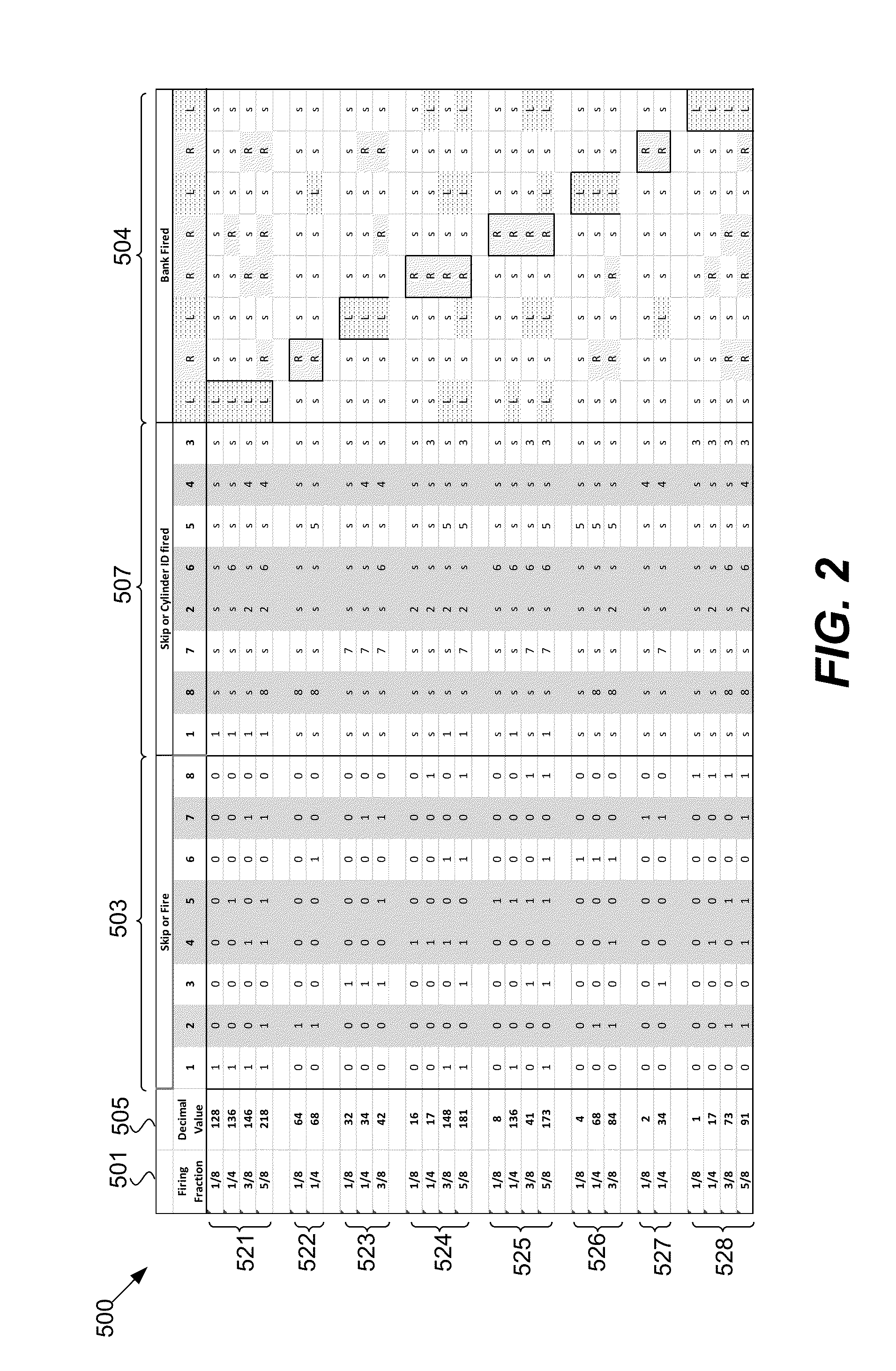

Engine diagnostics with skip fire control

Methods and devices are described for performing engine diagnostics during skip fire operation of an engine while a vehicle is being driven. Knowledge of the firing sequence is used to determine appropriate times to conduct selected diagnostics and / or to help better interpret sensor inputs or diagnostic results. In one aspect, selected diagnostics are executed when a single cylinder is fired a plurality of times in isolation relative to a sensor used in the diagnosis. In another aspect, selected diagnostics are conducted while the engine is operated using a firing sequence that insures that no cylinders in a first cylinder bank are fired for a plurality of engine cycles while cylinders in a second bank are at least sometimes fired. The described tests can be conducted opportunistically, when conditions are appropriate, or specific firing sequences can be commanded to achieve the desired isolation or skipping of one or more selected cylinders.

Owner:TULA TECH INC

Engine timing control with intake air pressure sensor

InactiveUS7225793B2Reduce complexityLow costElectrical controlVolume/mass flow by thermal effectsExternal combustion engineInlet valve

An engine control apparatus is disclosed for determining crankshaft position and engine phase of an internal combustion engine through monitoring intake air pressure fluctuations. The opening of the intake valve is mechanically linked to the crankshaft position of an engine. When the intake valve opens it creates air pressure fluctuations in the air induction system of the engine. The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure fluctuations to increase resolution in determination of crankshaft position. A circuit is provided for simultaneously measuring intake temperature using a single bridge type pressure sensor in order to calculate air mass flow rate.

Owner:ELECTROJET TECH INC

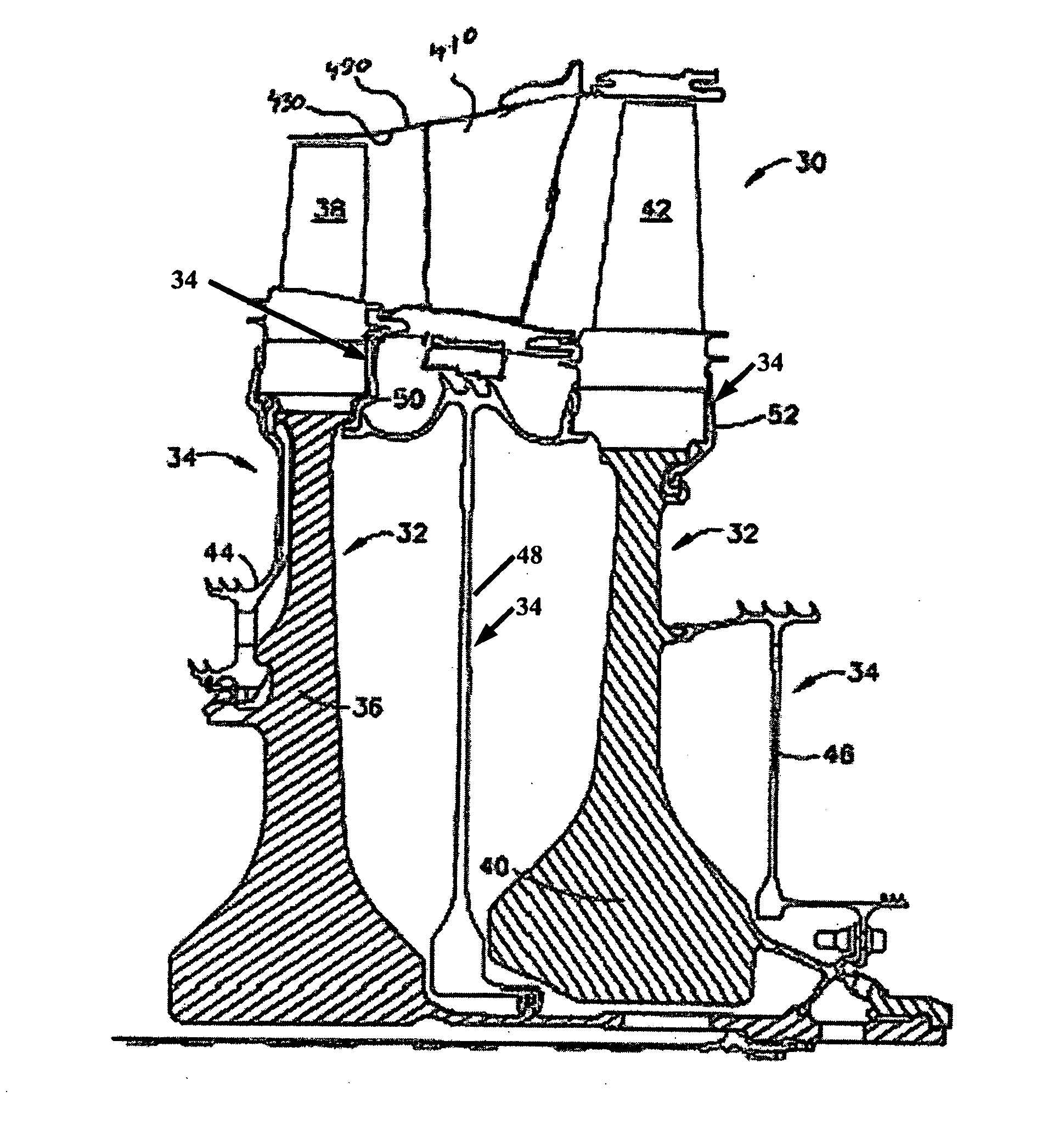

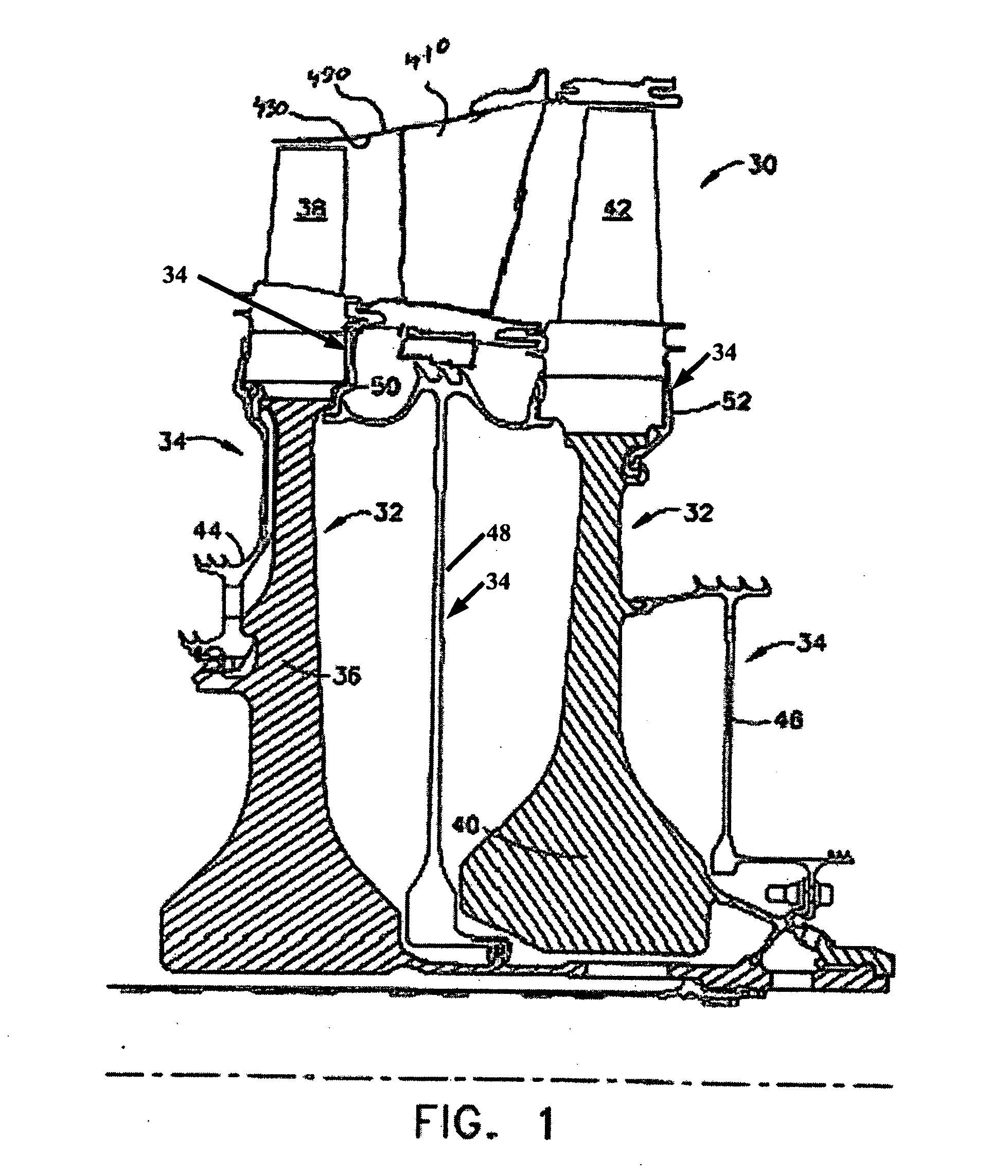

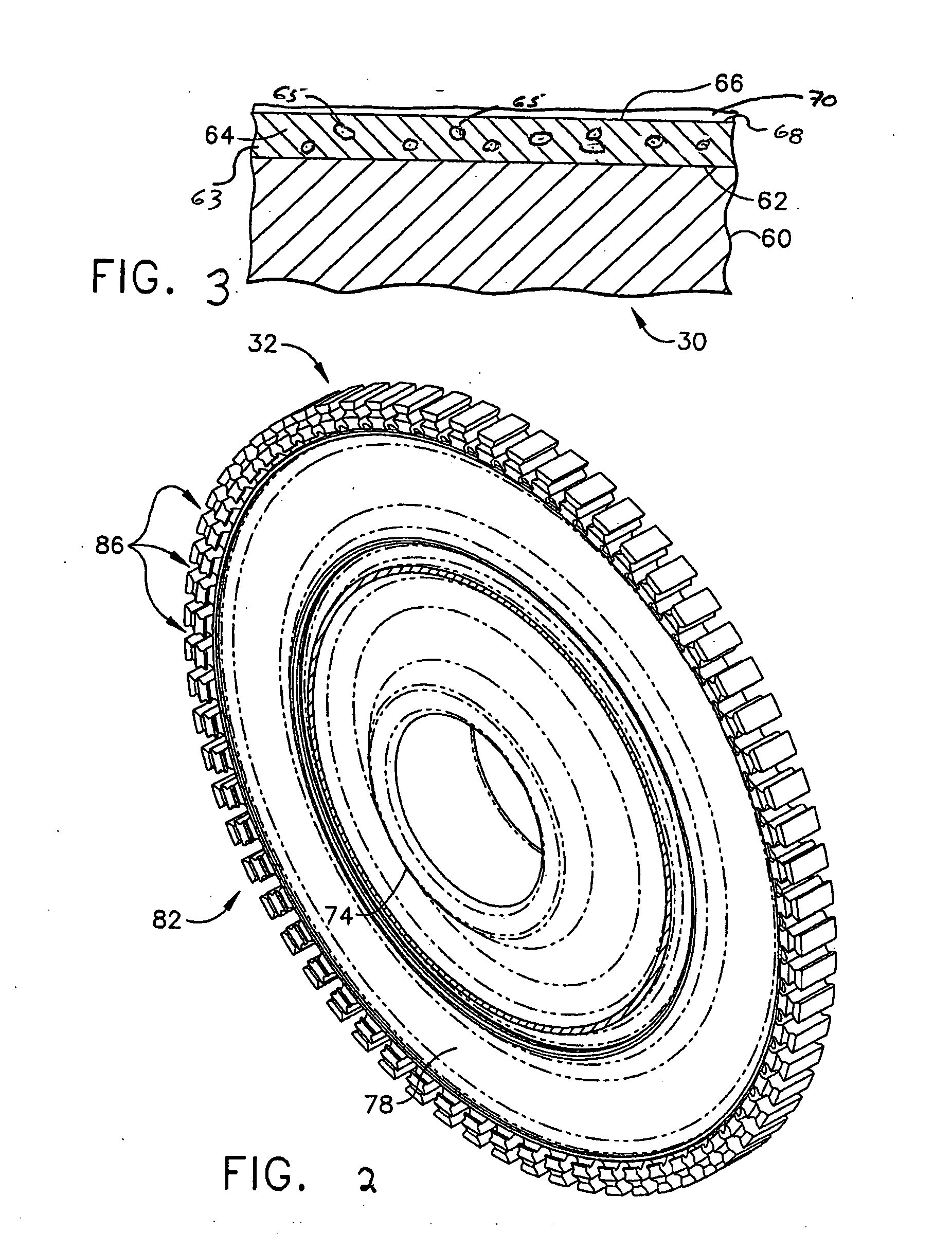

Corrosion inhibiting ceramic coating and method of application

InactiveUS20070128447A1Reduce thermal stressCarefully controlledPretreated surfacesEfficient propulsion technologiesCeramic coatingTurbine blade

A corrosion resistant coating for engine components such as turbine disks, turbine seal elements and turbine shafts. This coating may also find application to other turbine components that are subjected to high temperatures and corrosive environments, such as turbine components located within or on the boundary of the gas fluid flow path, including for example turbine blades, turbine vanes, liners and exhaust flaps. The corrosion resistant coating of the present invention in service on a gas turbine component includes a glassy ceramic matrix wherein the glassy matrix is silica-based and particles selected from the group consisting of refractory oxide particles, MCrAlX particles and combinations of these particles, substantially uniformly distributed within the matrix. The refractory oxide and / or the MCrAlX provides the coating with corrosion resistance. Importantly the coating of the present invention has a coefficient of thermal expansion (CTE) greater than alumina. The CTE of the coating is sufficiently close to the substrate material, that is, the component to which it is applied, such that the coating does not spall after frequent engine cycling at elevated temperature

Owner:GENERAL ELECTRIC CO

Quick starting engine with electromechanical valves

ActiveUS7055483B2Improve trustReduce noiseElectrical controlOutput powerExhaust valveFour-stroke engine

Owner:FORD GLOBAL TECH LLC

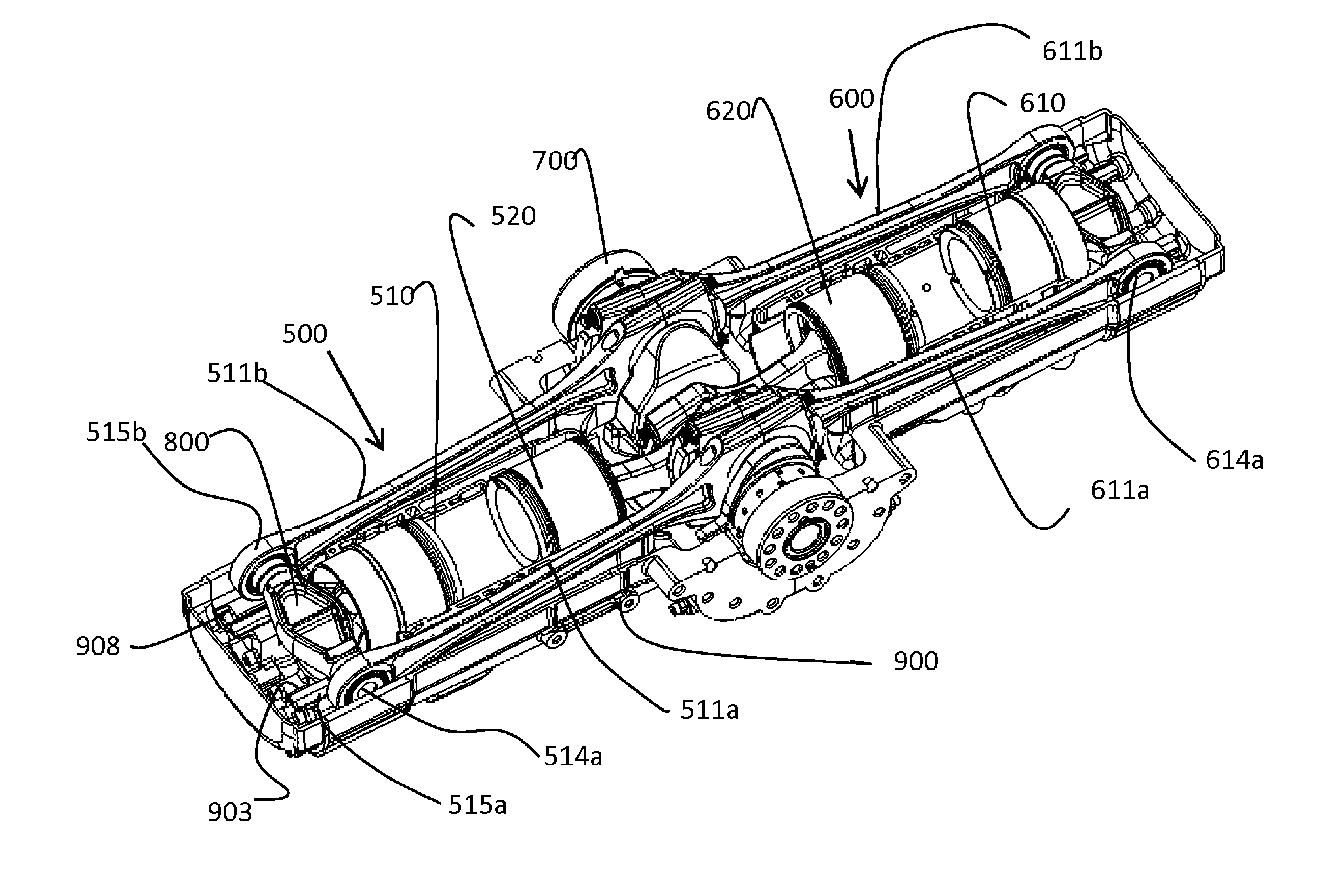

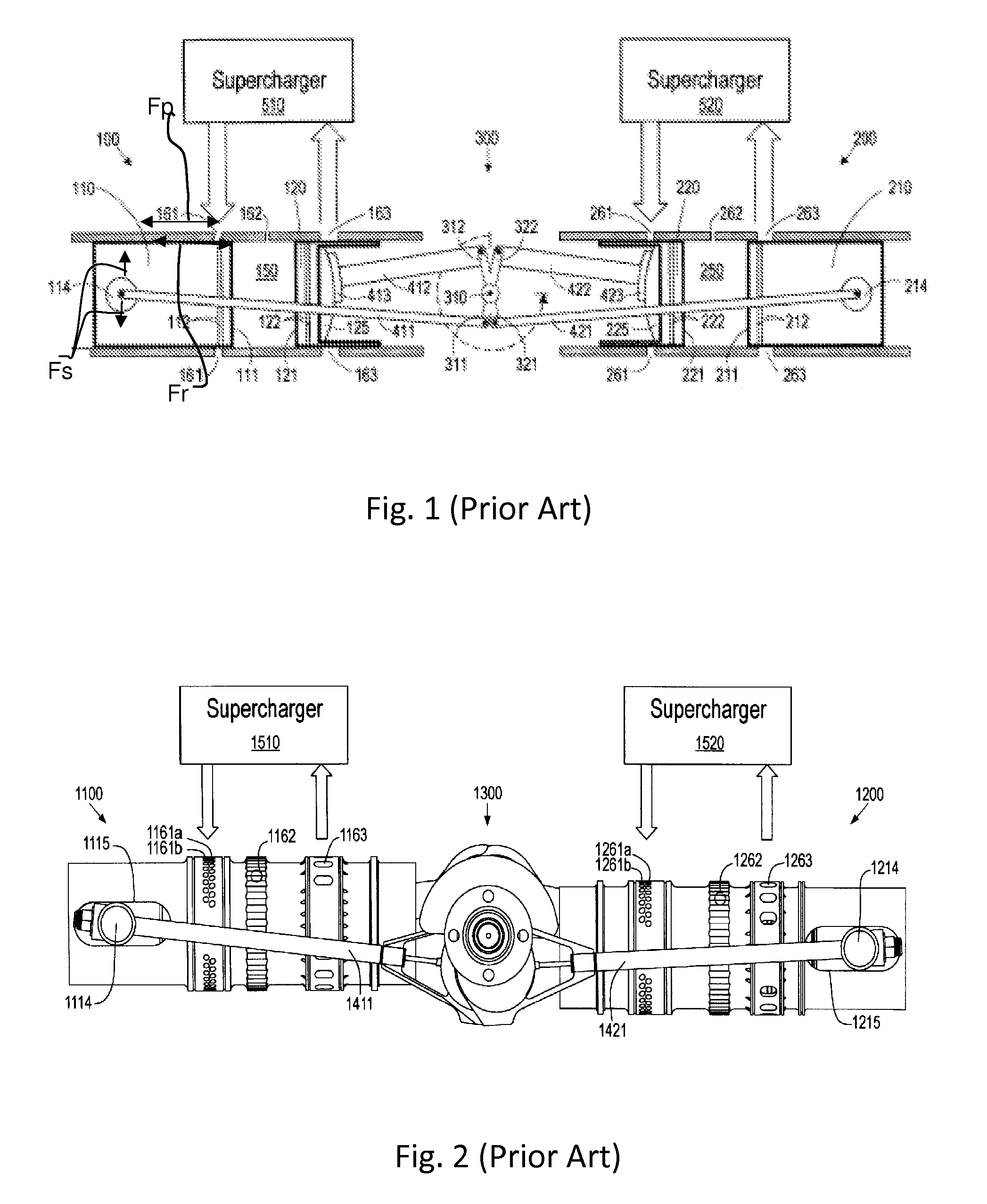

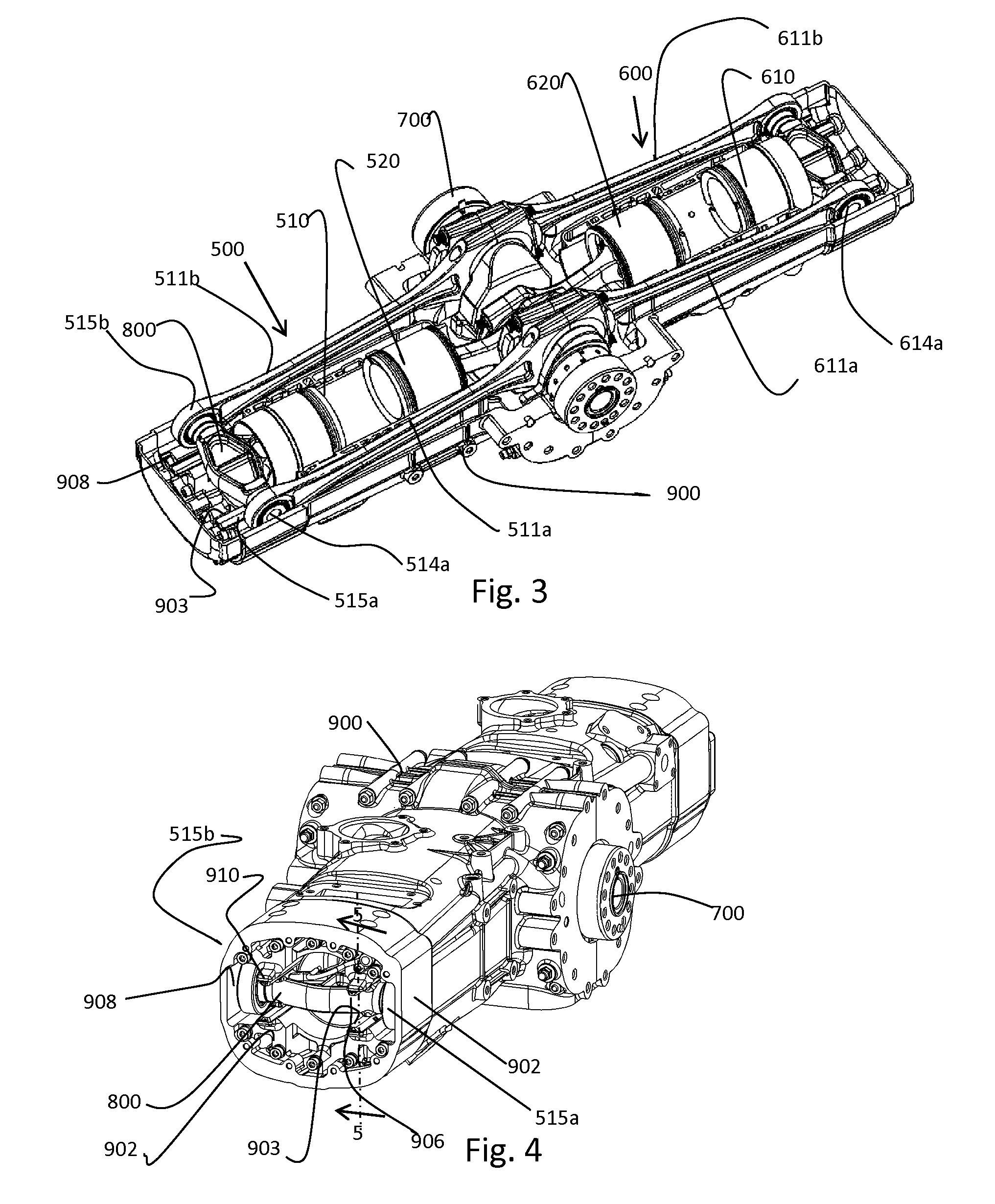

Guided bridge for a piston in an internal combustion engine

InactiveUS20100229836A1Reduce frictionImprove efficiencyPistonsReciprocating piston enginesPistonEngine cycle

An improved configuration for internal combustion engine that reduces side forces on pistons during the engine cycle. The improvement is an intermediate and guided bridge element located between pull rods and pistons with articulated connections that allow side forces to be dissipated away from the pistons.

Owner:ECOMOTORS INT +1

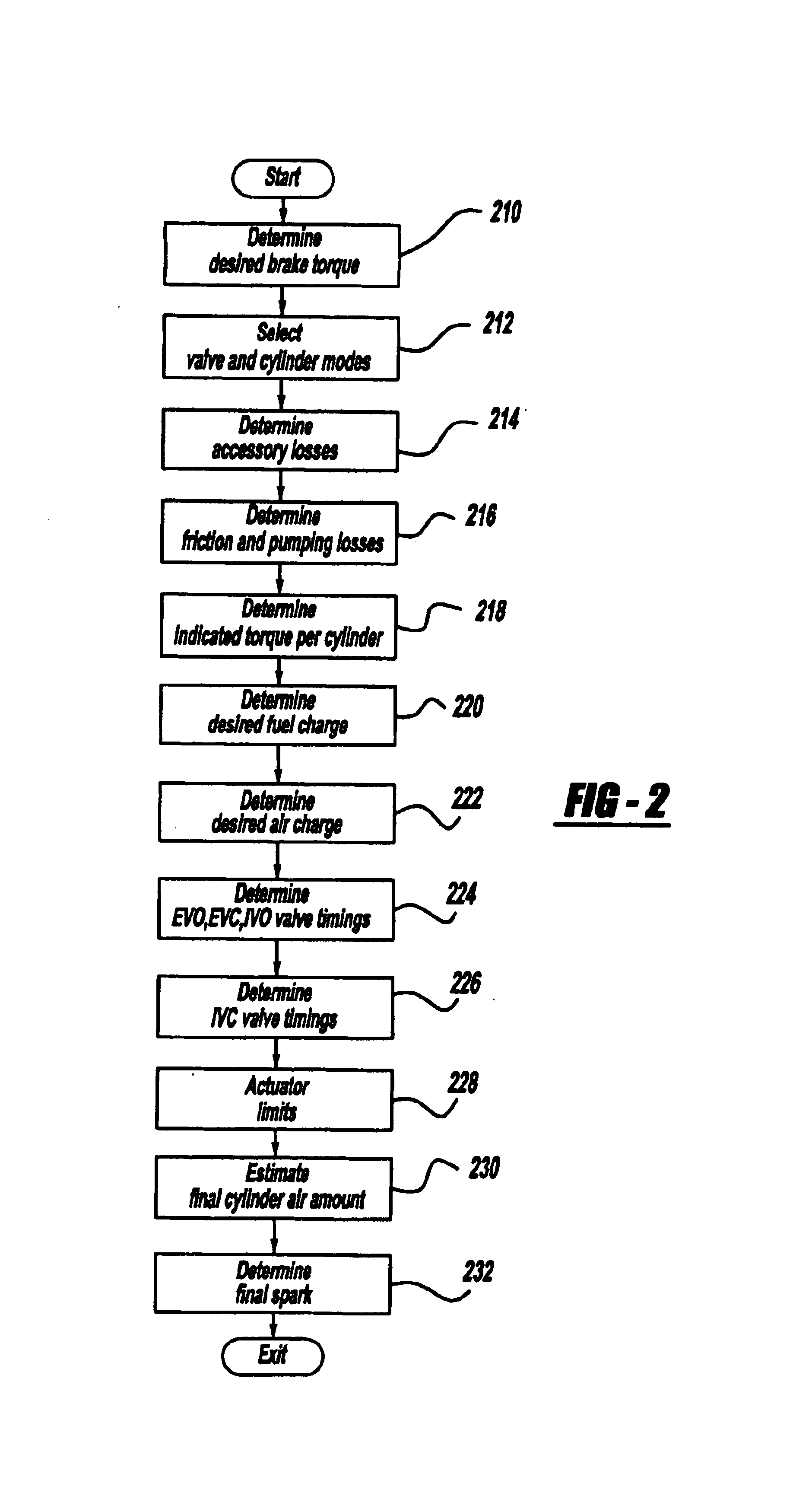

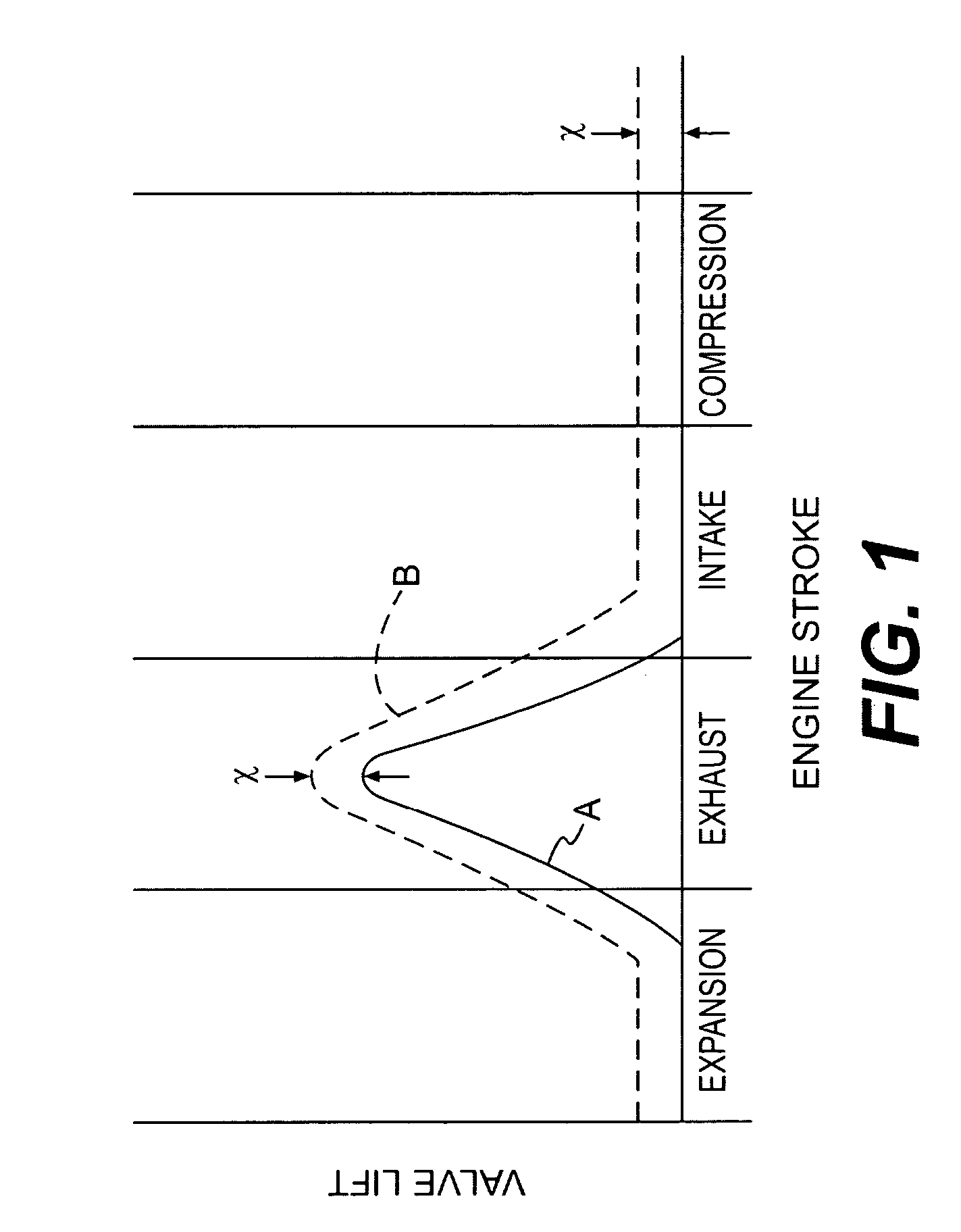

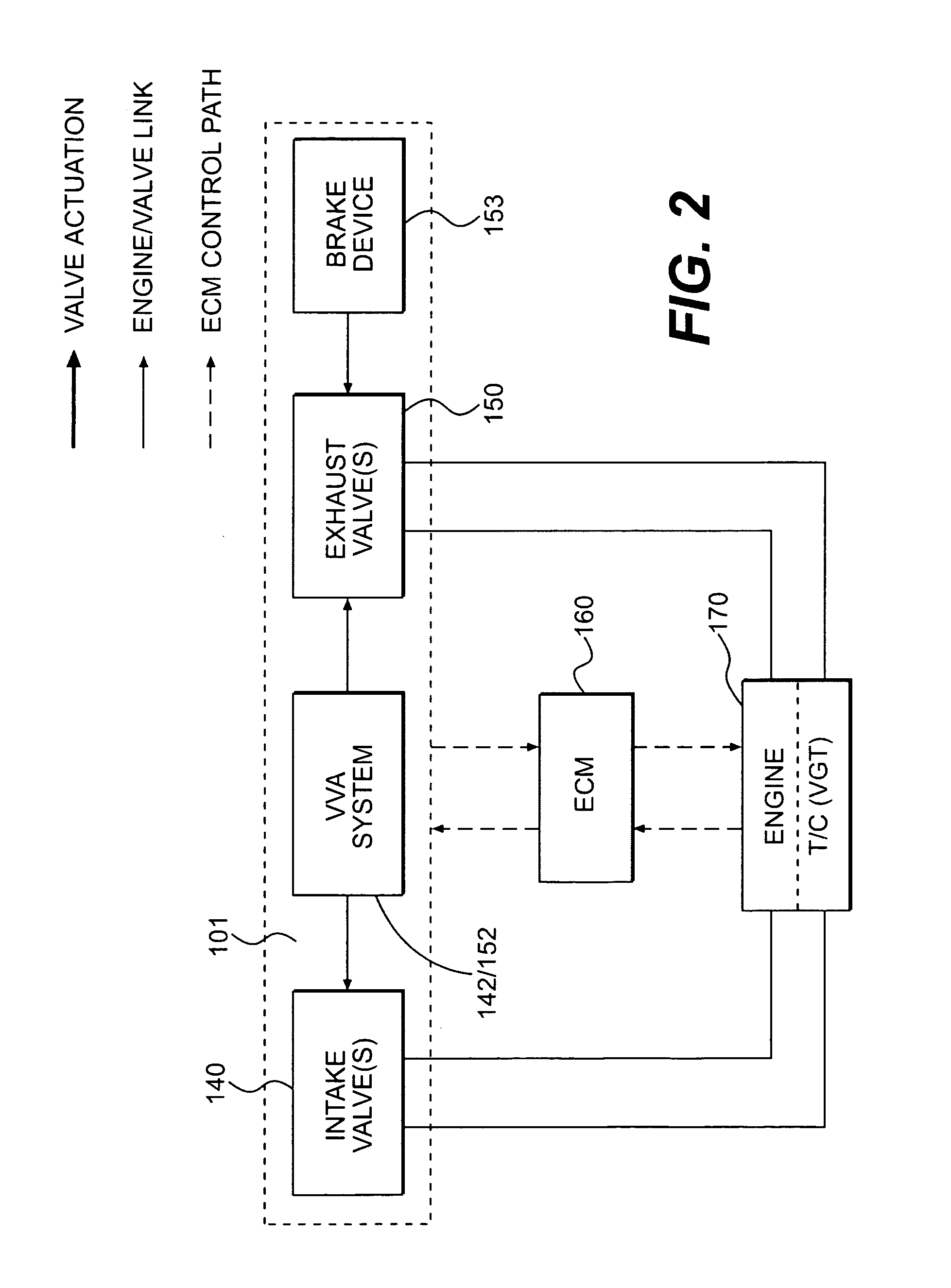

Engine braking methods and apparatus

ActiveUS7162996B2Constant liftNon-fuel substance addition to fuelInternal combustion piston enginesExhaust brakeVariable-geometry turbocharger

Methods and apparatus for providing bleeder-type and compression-release engine braking in an internal combustion engine are disclosed. For bleeder-type engine braking, the exhaust valve is maintained at a small and relatively constant lift throughout all or much of the engine cycle. The engine braking may be combined with exhaust gas recirculation, variable exhaust brake, and / or operation of a variable geometry turbocharger.

Owner:JACOBS VEHICLE SYST

Directly controlled fuel injector with pilot plus main injection sequence capability

InactiveUS6910462B2Reduce pressureImprove accuracyElectrical controlCombustion enginesCommon railEngineering

Owner:CATERPILLAR INC

EGR Rate Control For Internal Combustion Engine With Dual Exhaust-Ported Cylinders

ActiveUS20140190458A1Electrical controlNon-fuel substance addition to fuelExhaust gas recirculationEngine cycle

A method of using exhaust gas recirculation (EGR) in an internal combustion engine. At least two of the cylinders are “dual exhaust-ported cylinders” having two exhaust ports. For each of these cylinders, one of the exhaust ports is connected to the EGR loop and the other of the exhaust ports is connected to the main exhaust line. These cylinders are controlled such that one exhaust port is open and the other exhaust port is closed during each engine cycle, and are operated, on a cycle-by-cycle basis so that all of the exhaust produced by a cylinder may be delivered to the EGR loop at any cycle. The number of cylinders operating as EGR cylinders per engine cycle is in response to a desired EGR rate.

Owner:SOUTHWEST RES INST

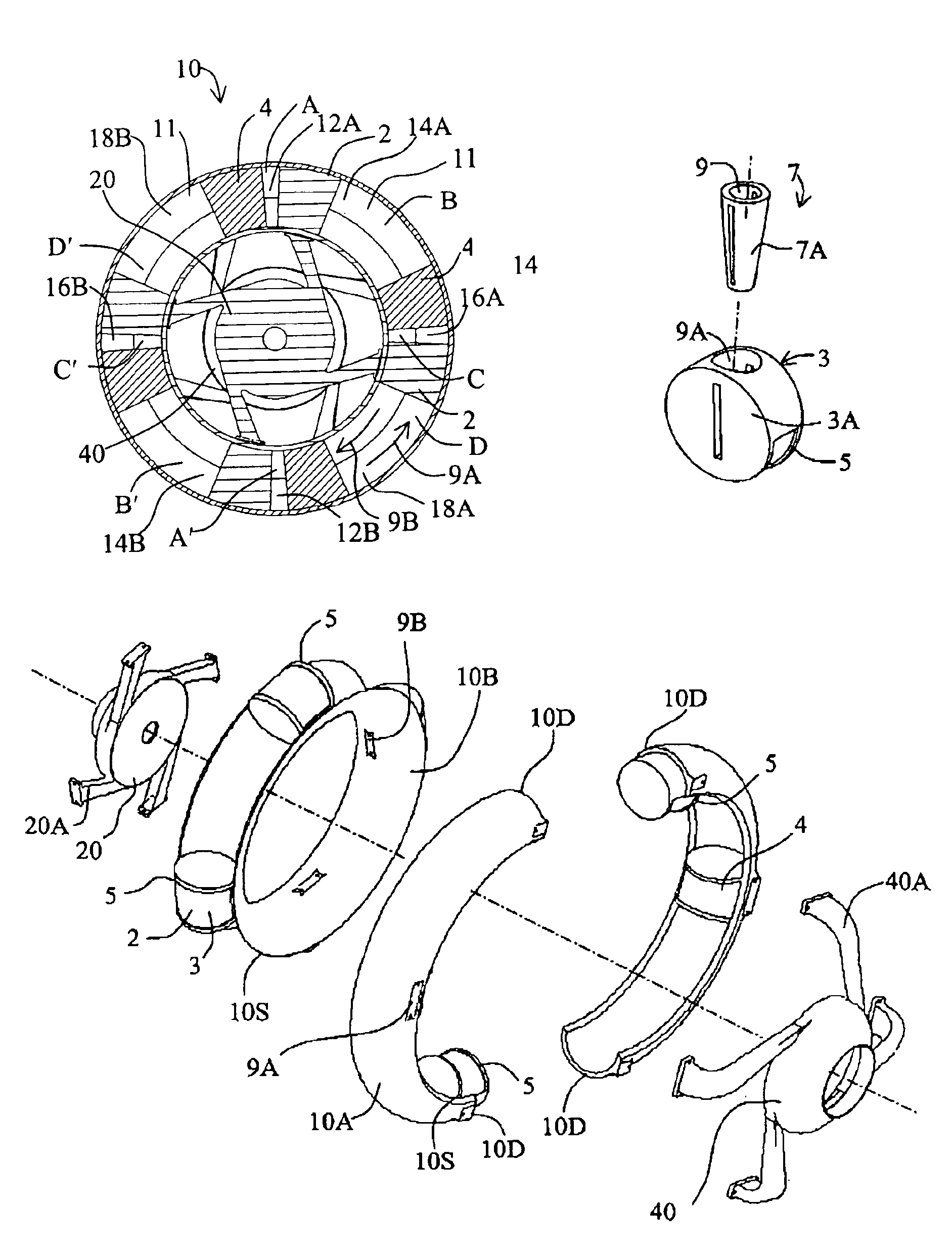

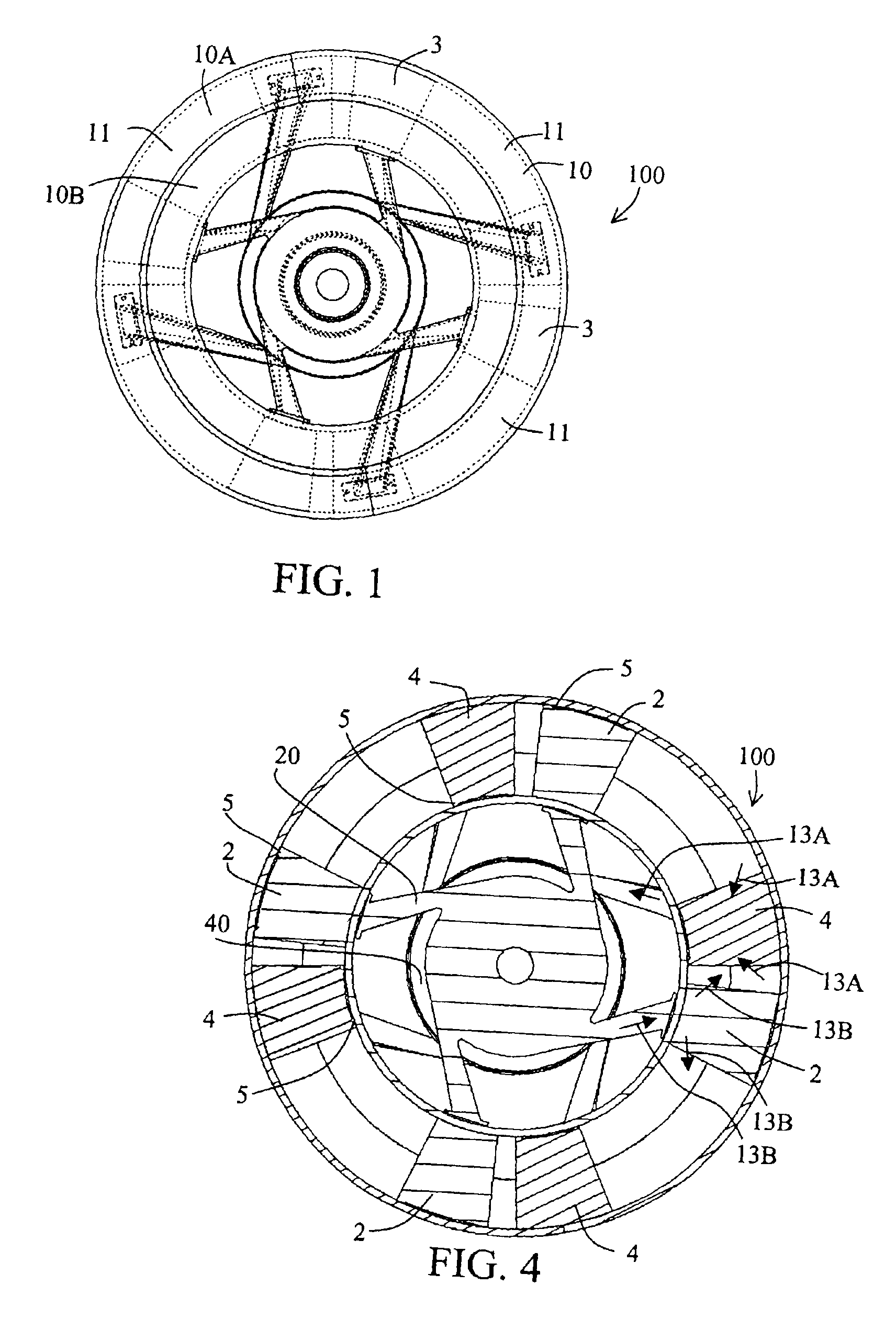

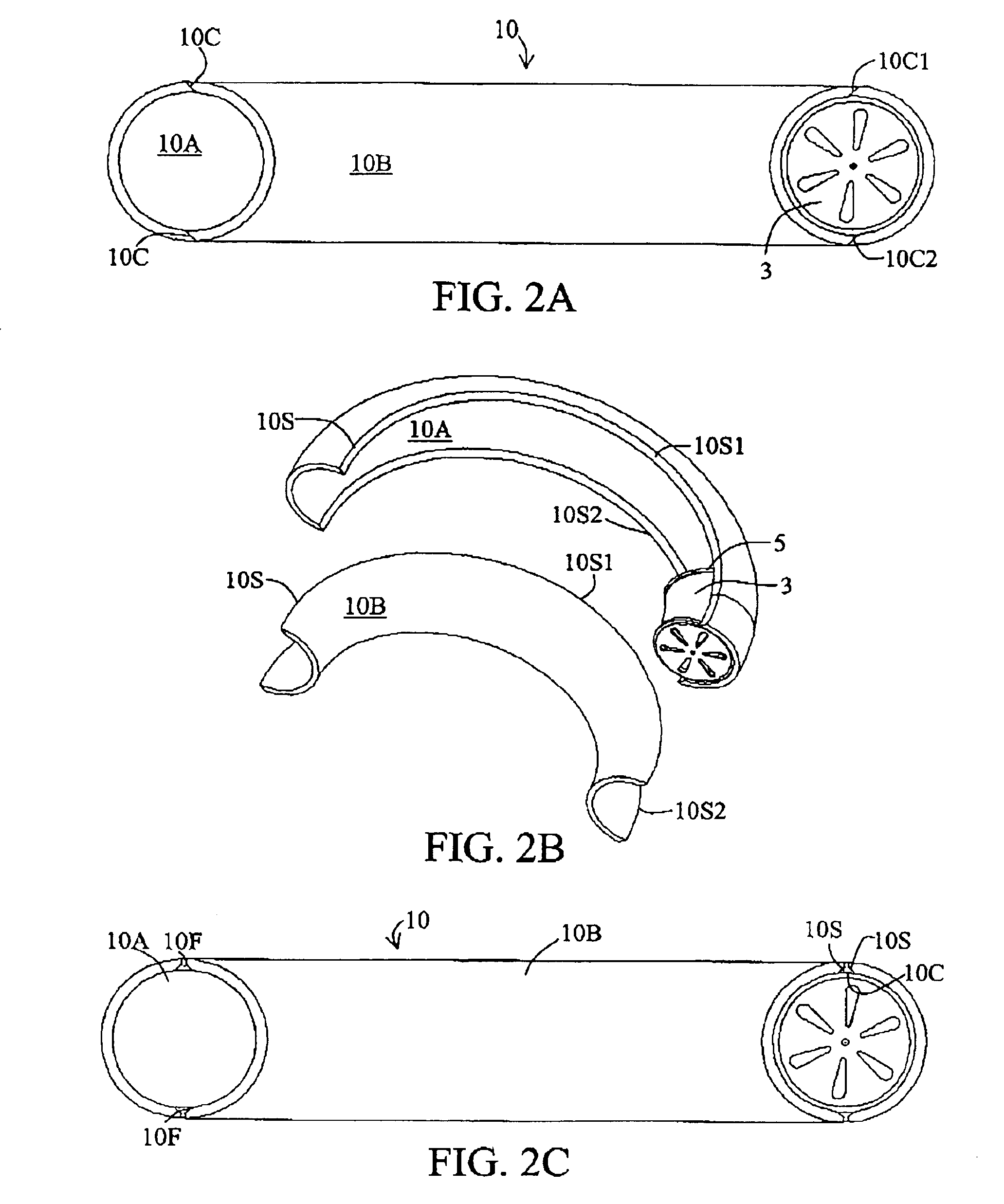

Toroidal internal combustion engine

InactiveUS6880494B2Improve performanceEmission reductionInternal combustion piston enginesEngine of arcuate-engagement typeExhaust valveInlet valve

Toroidal internal combustion engine comprising two concentric engine rings. Intake valves are assembled in two faces of one set of pistons and exhaust valves in two faces of the second set of pistons. The intake-valve pistons are fixedly attached to one of the engine rings and the exhaust-valve pistons to the other engine ring. The face of one intake-valve piston and the face of one adjacent exhaust-valve piston form boundaries of an engine chamber. Combustion forces on the piston faces force the two concentric engine rings to counter-rotate. The intake-valve piston and the adjacent exhaust-valve piston sweep the same chamber volume at different strokes of the engine cycle. The engine is constructed of CRC material and mounted on a central shaft, with the intake manifold and the exhaust manifold mounted on each side of the engine, providing a lightweight, self-lubricating, highly fuel efficient, and dynamically balanced engine.

Owner:APPLIED THERMAL SCI

Method And Apparatus For Reconstructing In-Cylinder Pressure And Correcting For Signal Decay

ActiveUS20120150414A1Increase system costImprove accuracyTesting/calibration apparatusDigital data processing detailsSignal-to-noise ratio (imaging)Engineering

A method comprises steps for reconstructing in-cylinder pressure data from a vibration signal collected from a vibration sensor mounted on an engine component where it can generate a signal with a high signal-to-noise ratio, and correcting the vibration signal for errors introduced by vibration signal charge decay and sensor sensitivity. The correction factors are determined as a function of estimated motoring pressure and the measured vibration signal itself with each of these being associated with the same engine cycle. Accordingly, the method corrects for charge decay and changes in sensor sensitivity responsive to different engine conditions to allow greater accuracy in the reconstructed in-cylinder pressure data. An apparatus is also disclosed for practicing the disclosed method, comprising a vibration sensor, a data acquisition unit for receiving the vibration signal, a computer processing unit for processing the acquired signal and a controller for controlling the engine operation based on the reconstructed in-cylinder pressure.

Owner:WESTPORT FUEL SYST CANADA INC

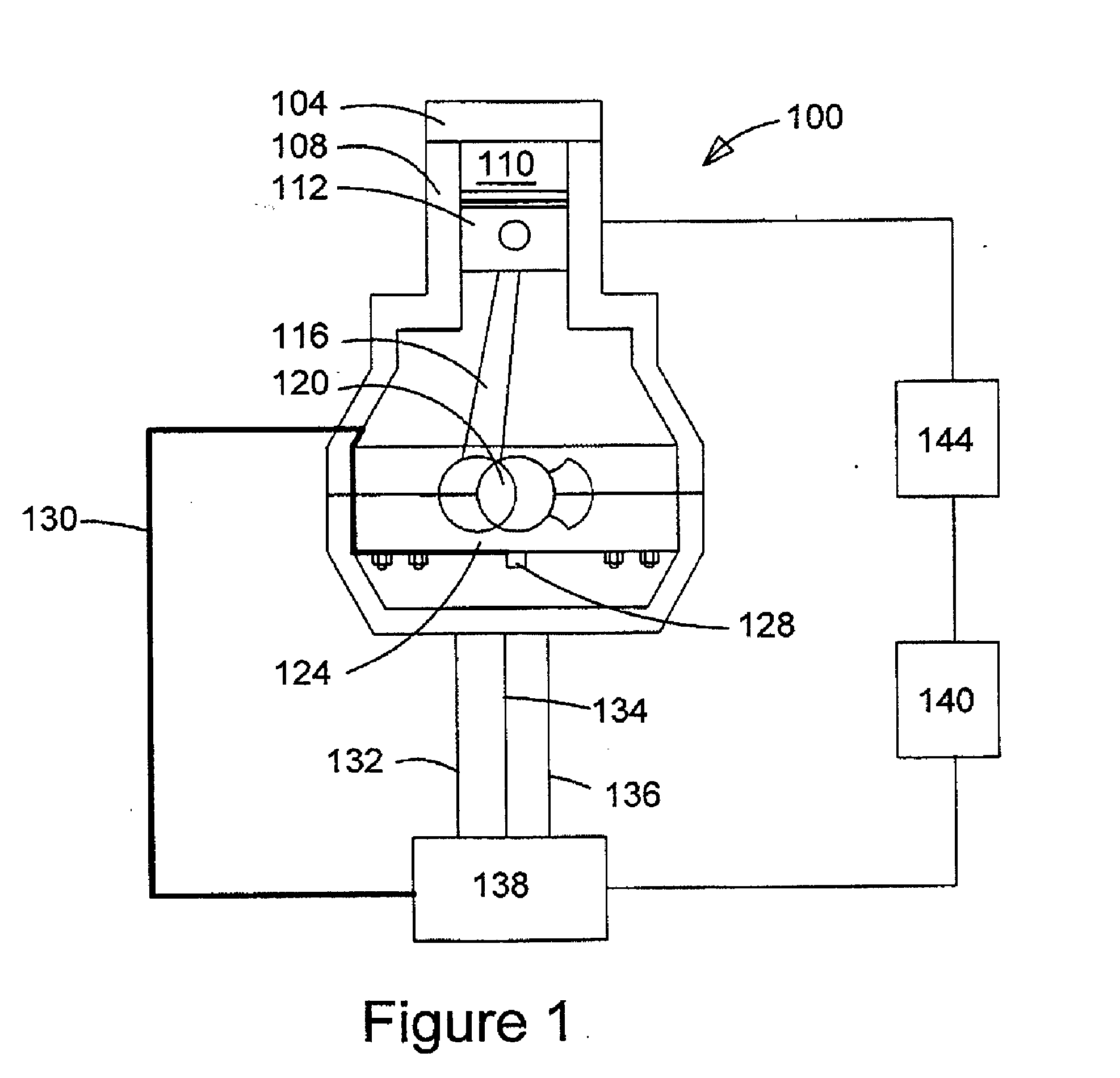

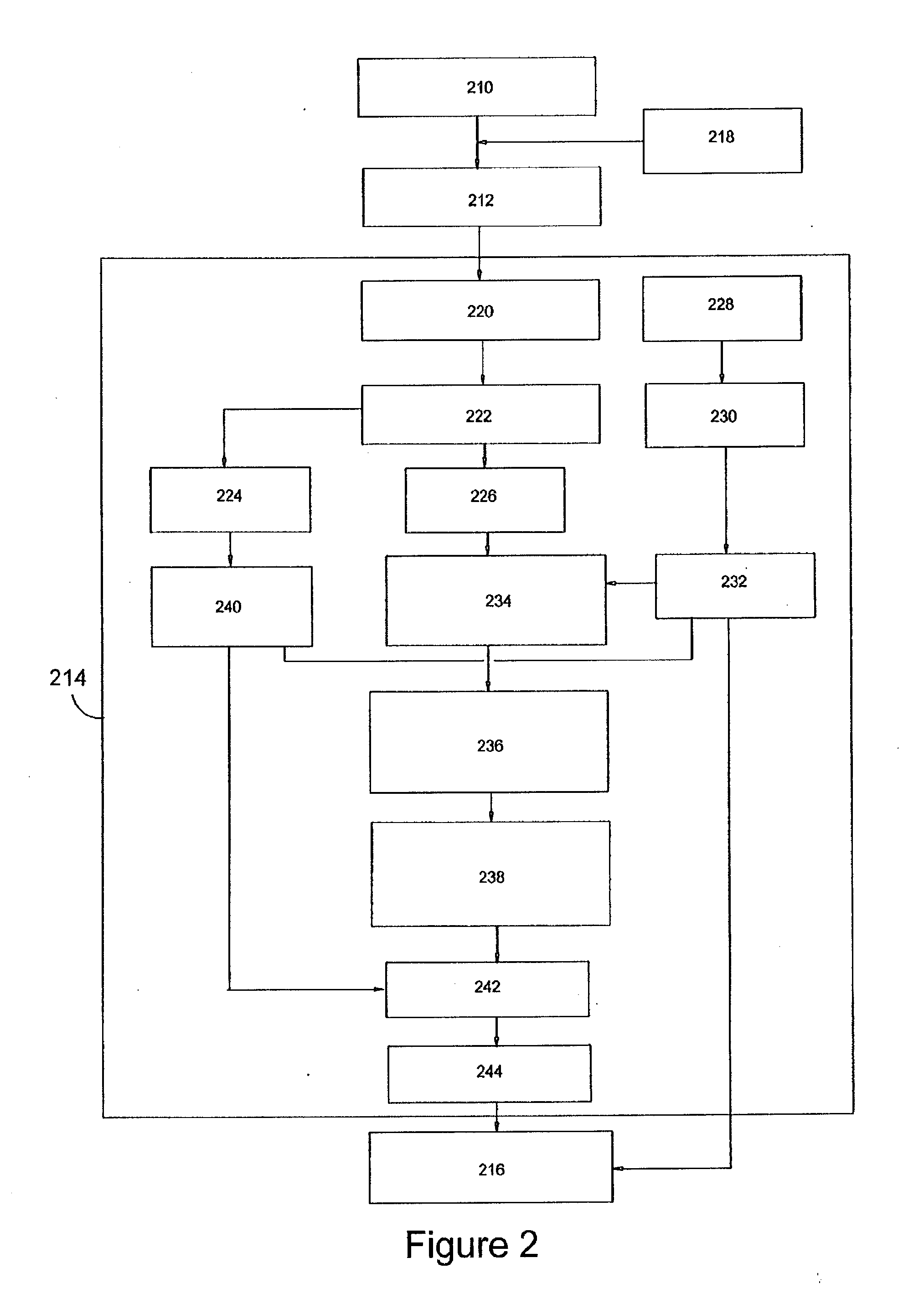

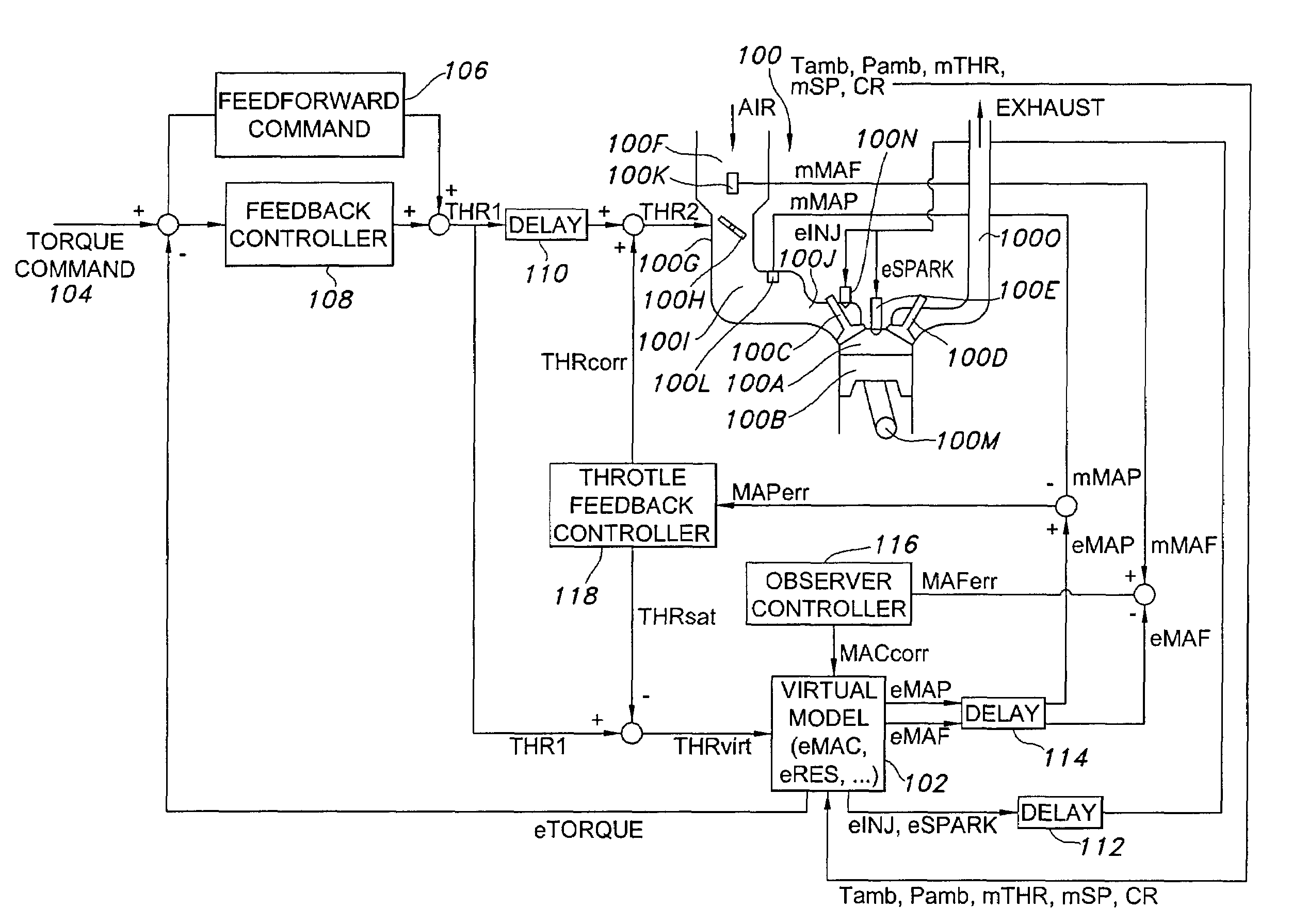

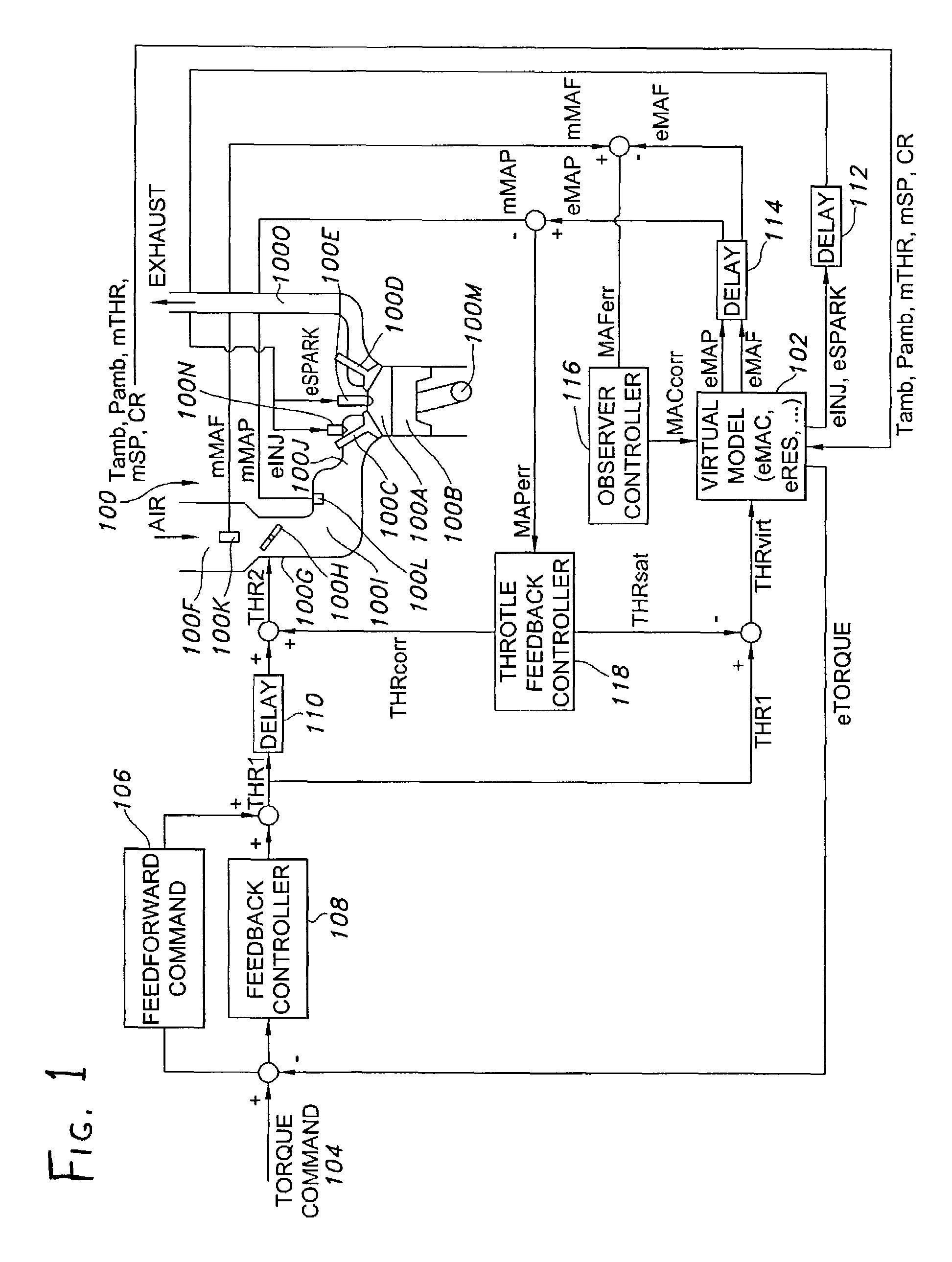

Internal combustion engine control system

InactiveUS7275426B2Improper engine operationImprove performanceElectrical controlNon-fuel substance addition to fuelControl systemExternal combustion engine

A control system for an internal combustion engine includes a virtual engine model which mathematically represents the states of the engine in real time, but which is programmed to provide the engine's states at least a fraction of an engine cycle (and preferably at least one-fourth of an engine cycle, i.e., one stroke) to several engine cycles in advance of the real engine. The mass flow entering and leaving the cylinder is modeled, allowing parameters such as the mass of air per cylinder (MAC) and residual exhaust gas to be computed, and thereafter used to generate engine control commands related to fuel injection (air / fuel ratio), spark advance, and so forth.

Owner:WISCONSIN ALUMNI RES FOUND +1

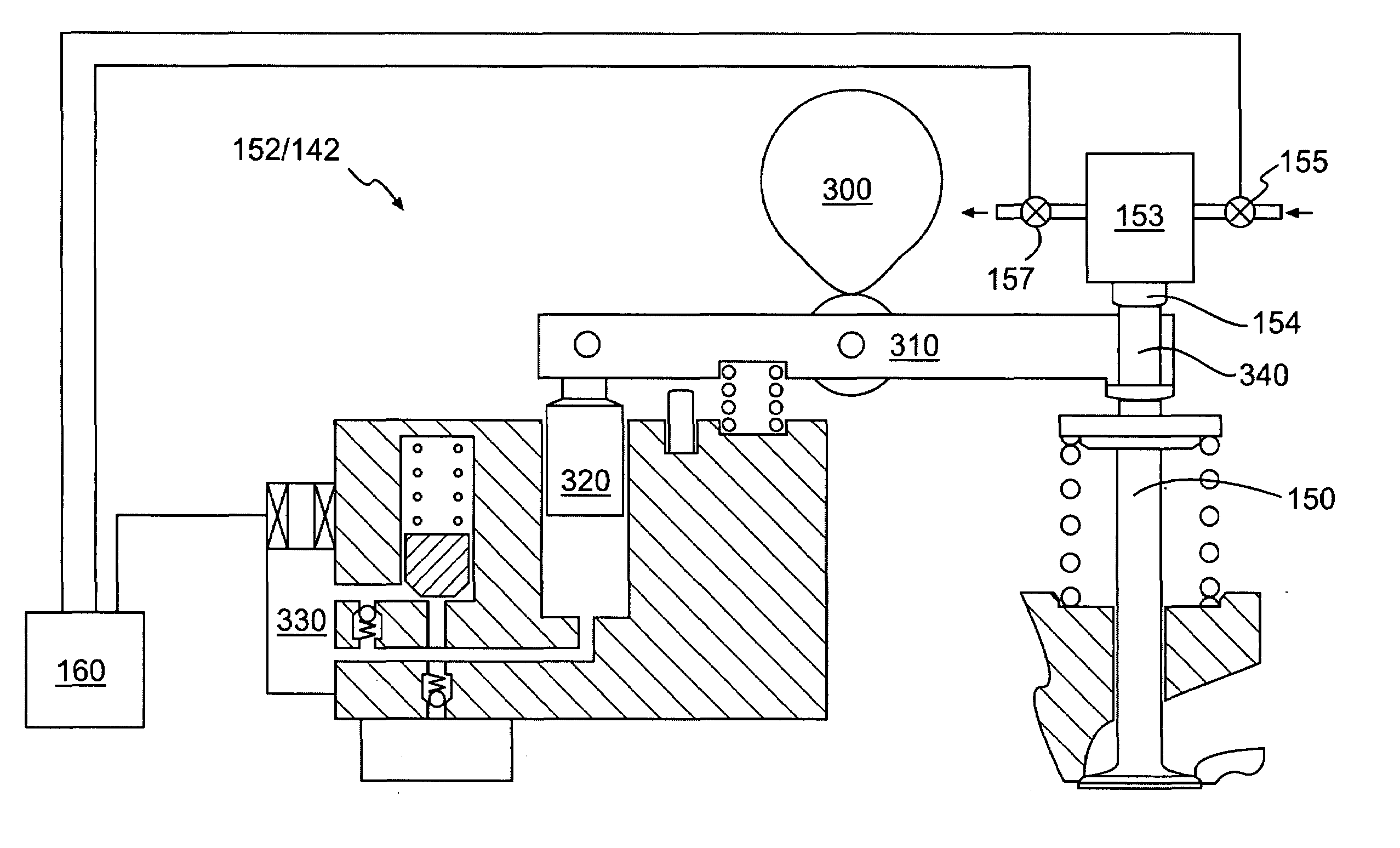

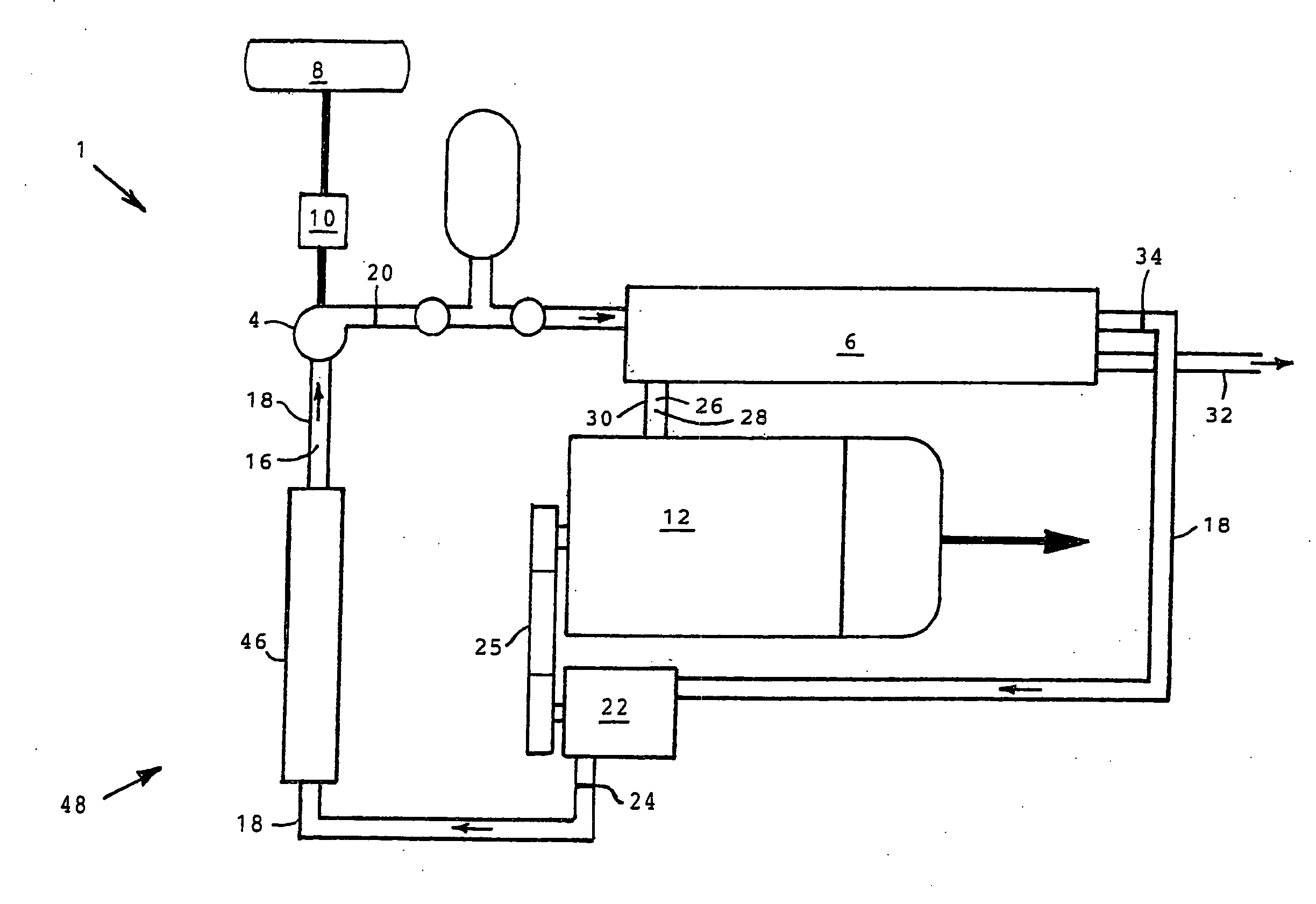

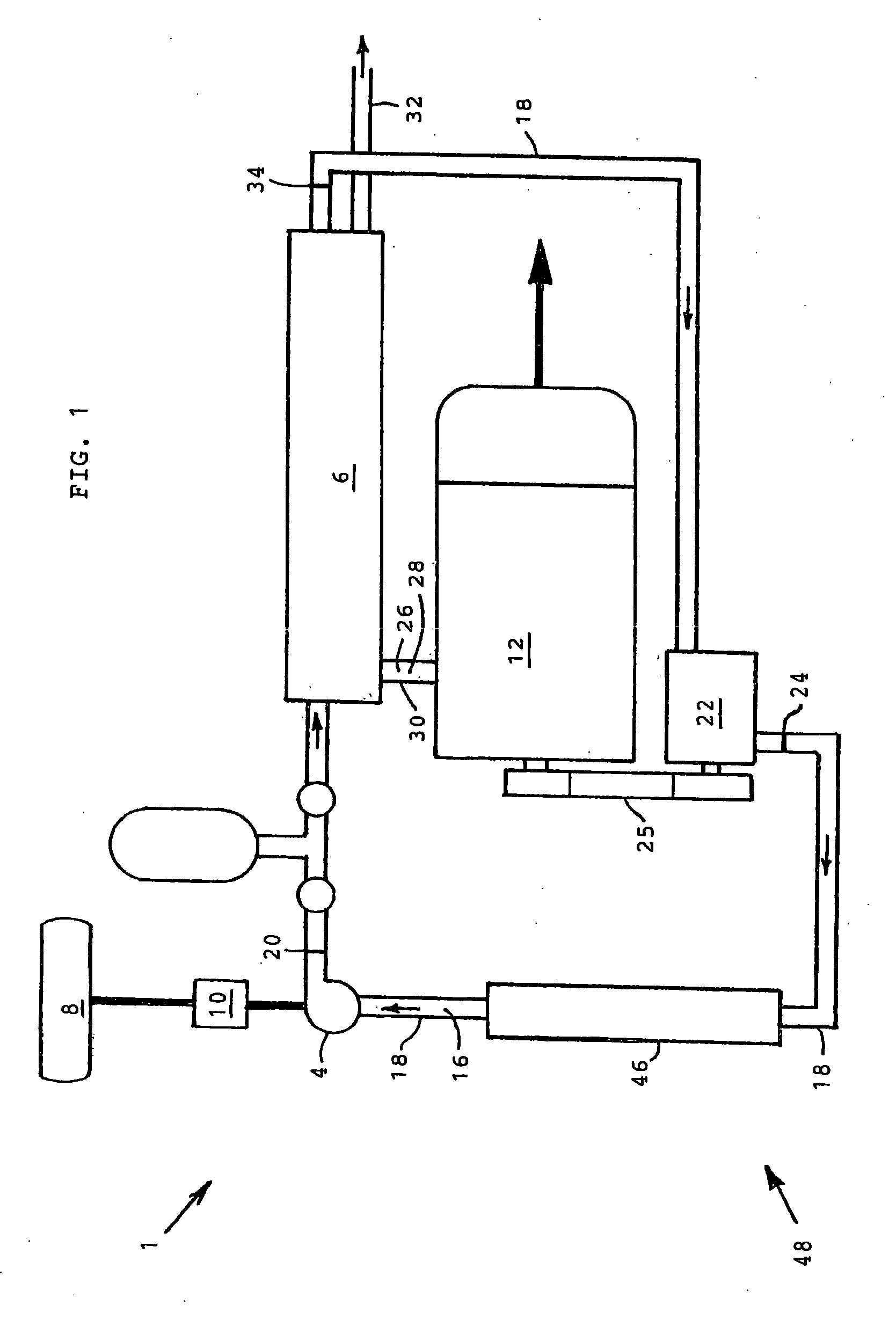

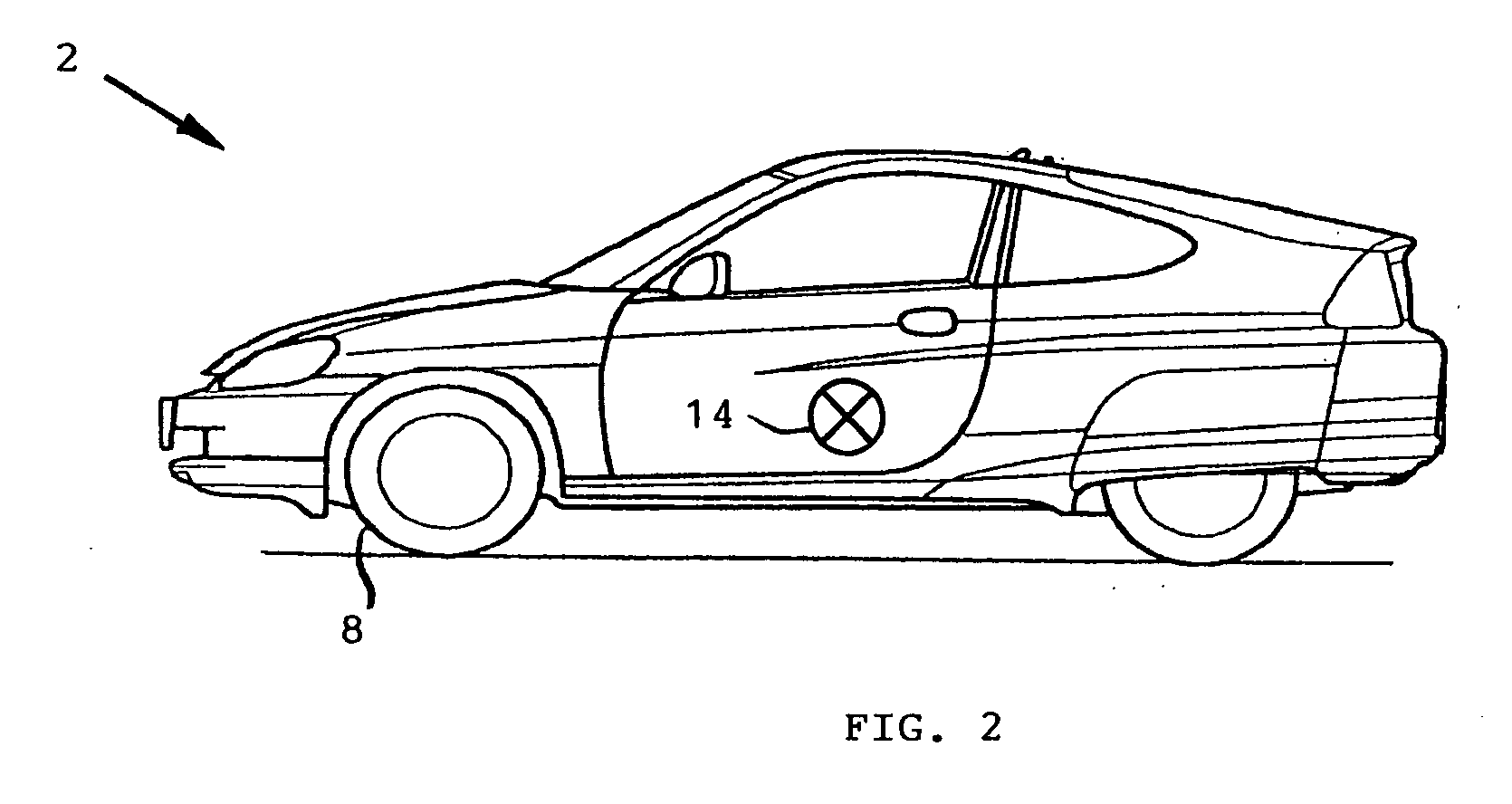

Hydraulic hybrid power system

InactiveUS20100133031A1Big economyLow costAuxillary drivesElectrodynamic brake systemsHigh pressureHydraulic pressure

According to the present invention a pump is driven by one or more wheels of a hydraulic hybrid vehicle during braking. The inertial energy of the vehicle powers the pump during braking of the vehicle, and the pump pumps a hydraulic liquid into an hydraulic accumulator that stores the fluid at its elevated pressure. When additional power is required by the vehicle, the liquid is released into a heat exchanger that transfers heat from the exhaust gas of the engine to the liquid causing at least a portion of the liquid to become gaseous. The heated fluid is then fed into an expander that generates shaft power by expanding the pressurized and heated gaseous and / or liquid fluid mixture. The preferred embodiment of the present invention operates under the Rankine cycle or steam engine cycle where the liquid compression function is performed using power from regenerative braking, and the liquid heating and vaporization function is performed using exhaust gas waste heat. The present invention shows potential for more than tripling the regenerative braking power of hydraulic hybrid vehicles, thereby providing a large improvement in vehicle fuel economy.

Owner:MENDLER EDWARD CHARLES

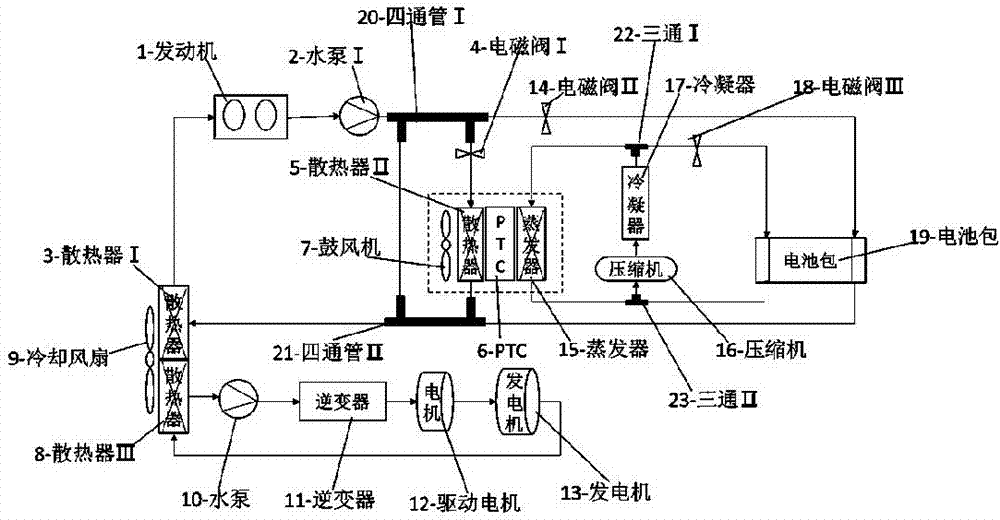

Heat management system of range-extending type electric automobile, and control method

ActiveCN107351640ASolve the problem of greatly shortened driving mileageImprove cooling effectAir-treating devicesElectric propulsion mountingHeat managementThermal management system

The invention relates to the technical field of electric automobiles, in particular to a heat management system of a range-extending type electric mobile, and a control method. The heat management system comprises an engine circulation subsystem, a drive motor circulation subsystem and an air conditioner refrigeration circulation subsystem, wherein the engine circulation subsystem comprises a range-extending engine, a circulation water pump I, a heat radiator I, a cooling fan, an electromagnetic valve I, a heat radiator II, an air blower, a PTC heater, an electromagnetic valve II and a battery pack; the drive motor circulation subsystem comprises a circulation water pump II, an inverter, a drive motor, a range-extending engine and a heat radiator III; the air conditioner refrigeration circulation subsystem comprises a compressor, a condenser, an electromagnetic valve III, a battery pack, an evaporator and an air blower. The heat management system is safe and reliable and is good in heat management effects.

Owner:HOZON NEW ENERGY AUTOMOBILE CO LTD

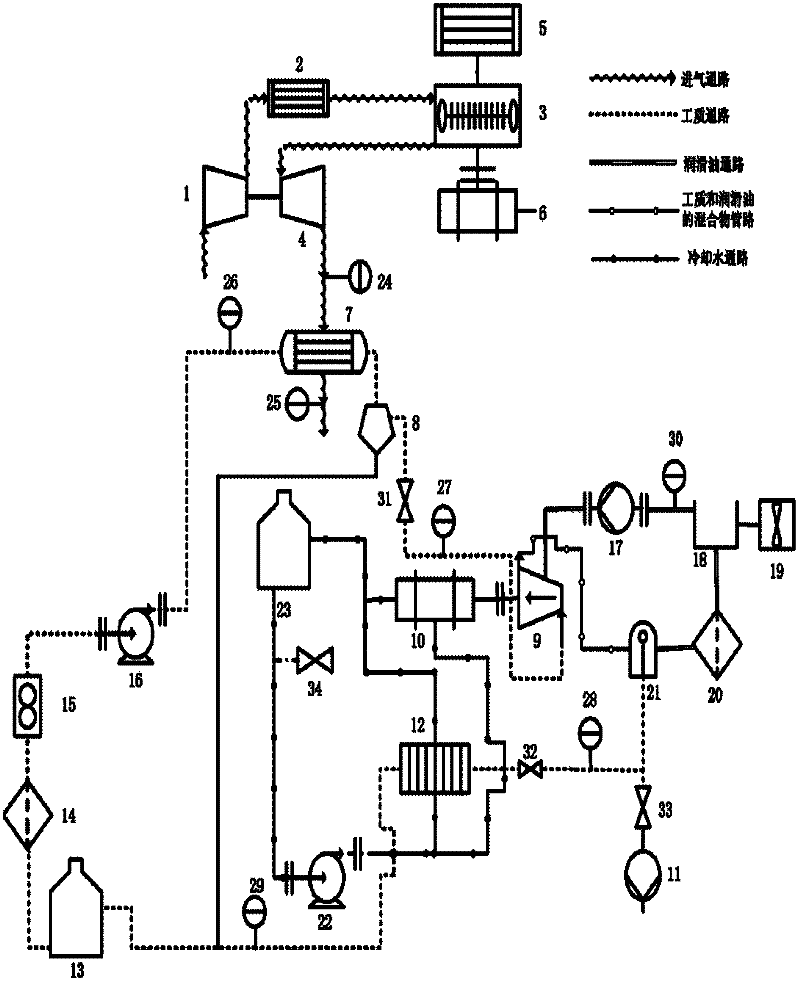

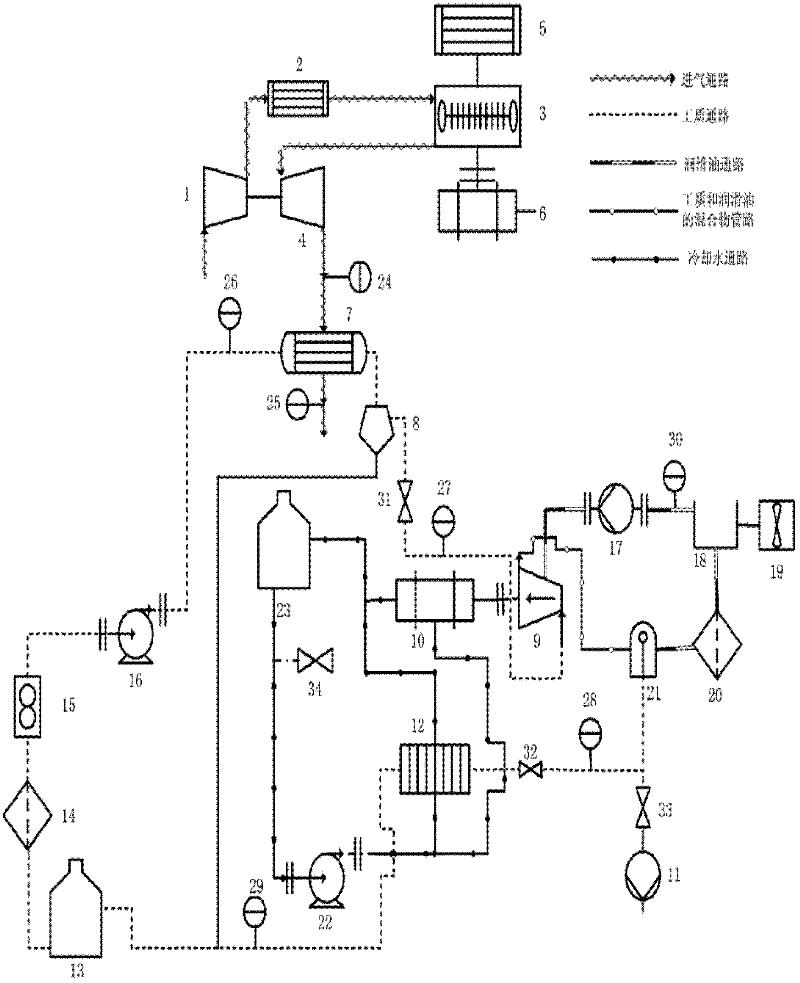

Engine exhaust gas waste heat recovery and control system and method based on organic rankine cycle

InactiveCN102410054ADoes not affect work performanceReasonable workLiquid coolingPressure lubrication with lubrication pumpOrganic Rankine cycleControl system

The invention discloses an engine exhaust gas waste heat recovery and control system and method based on organic rankine cycle, and belongs to the field of energy conservation and emission reduction. In the invention, a waste heat recovery system comprises engine cycle, organic rankine cycle, cooling water cycle and lubrication oil cycle which are coupled together; by means of reasonable control, the system can be convenient to start, stable to operate and rapid to stop according to the operation of the engine under different working conditions; in case of a system failure, the system can be emergently braked; and under the condition of no influence on the normal operation of the engine, the optimal performances of the system can be obtained finally, and the utilization ratio of the engine exhaust gas waste heat is improved greatly, thus thermal pollution of the engine exhaust gas to the environment is improved.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com