Patents

Literature

290 results about "Exhaust brake" patented technology

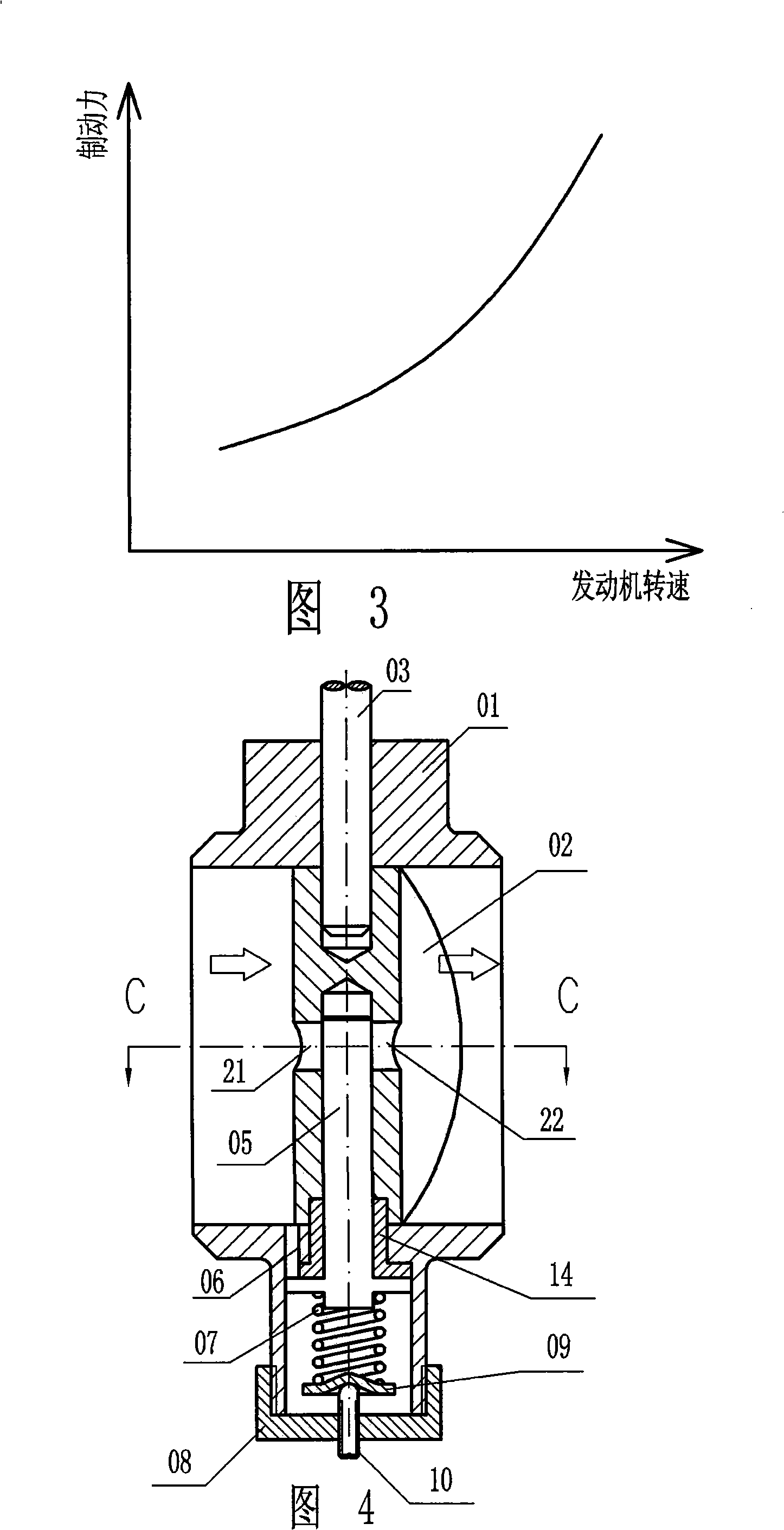

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

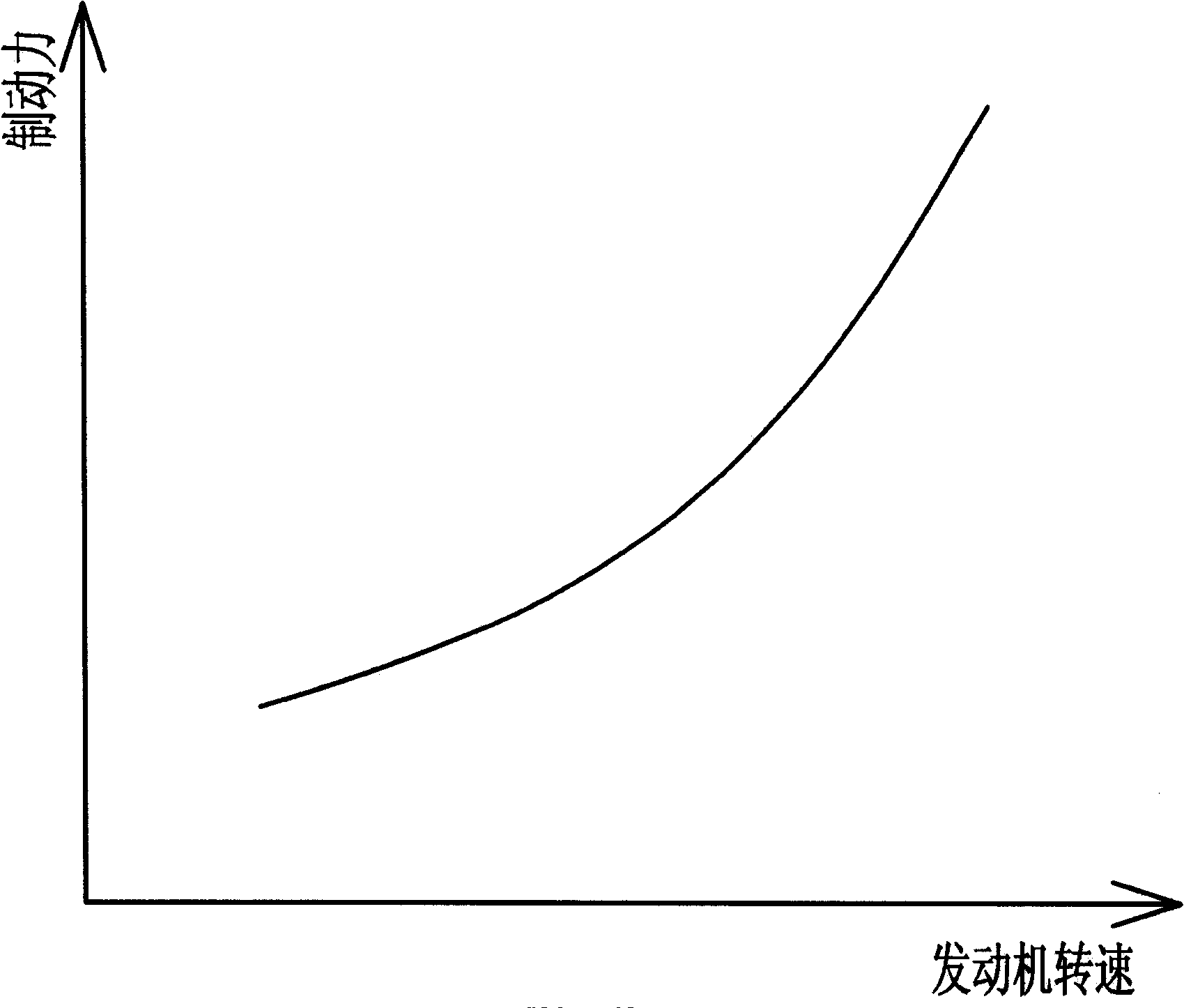

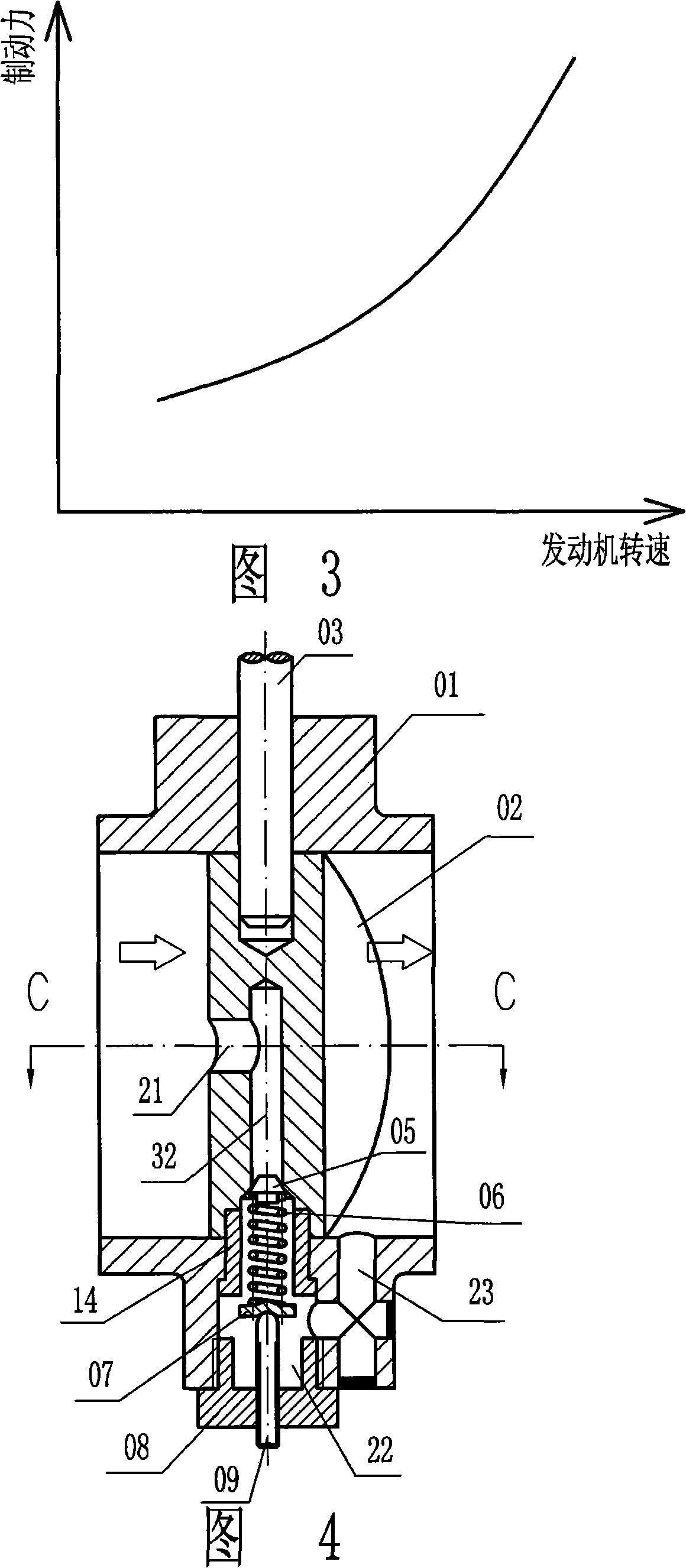

An exhaust brake is a means of slowing a diesel engine by closing off the exhaust path from the engine, causing the exhaust gases to be compressed in the exhaust manifold, and in the cylinder. Since the exhaust is being compressed, and there is no fuel being applied, the engine works backwards, slowing down the vehicle. The amount of negative torque generated is usually directly proportional to the back pressure of the engine.

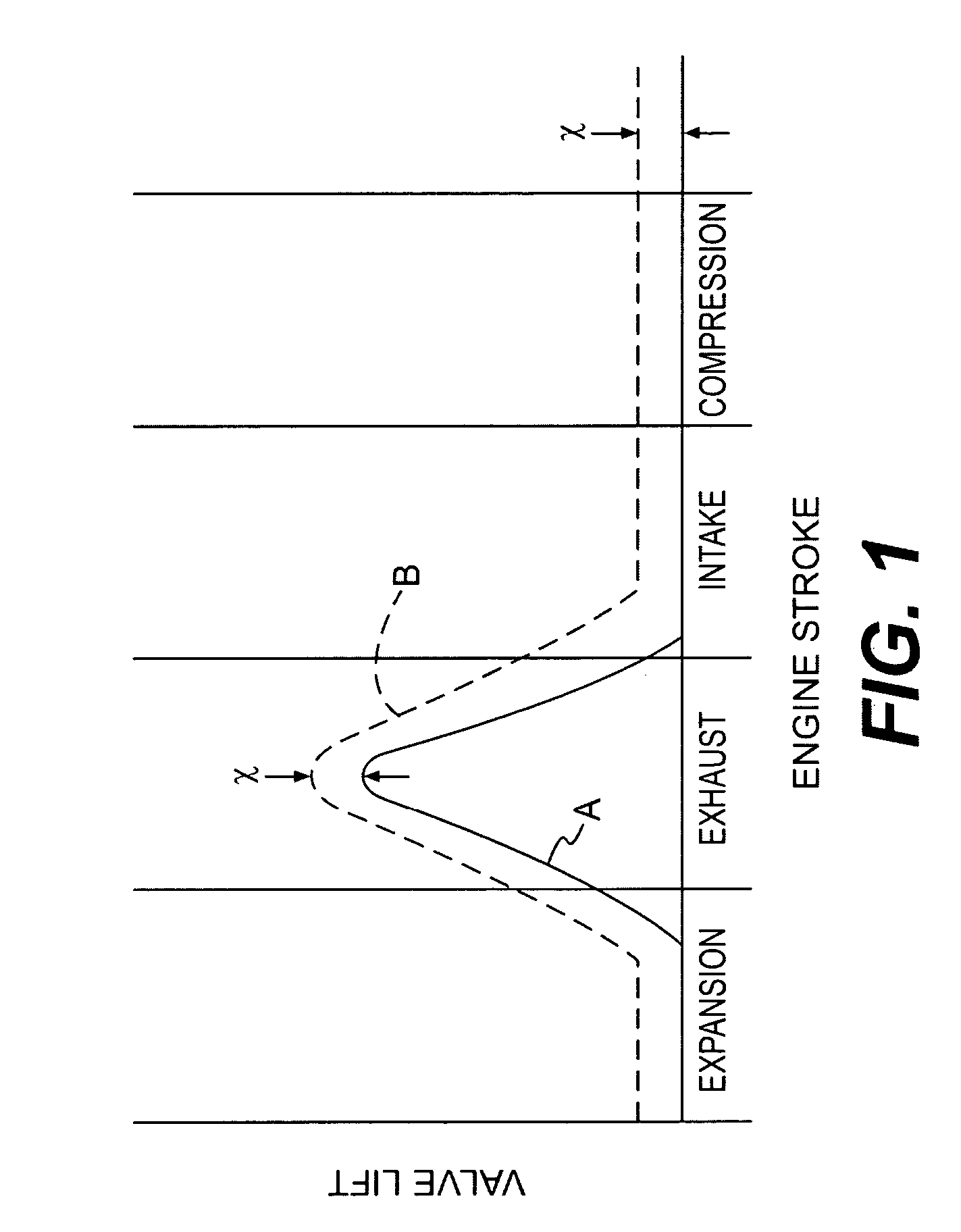

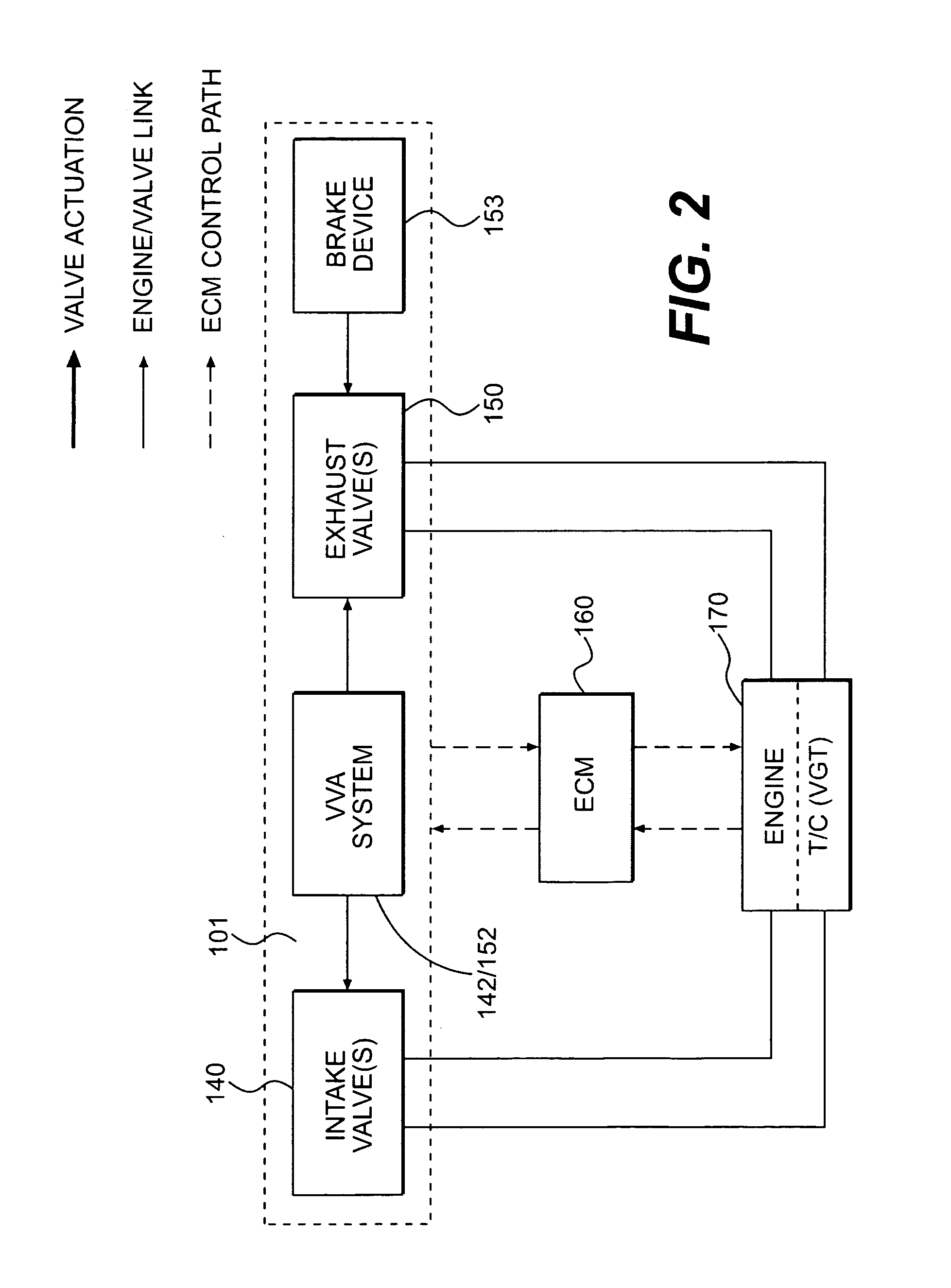

Modal variable valve actuation system for internal combustion engine and method for operating the same

ActiveUS6925976B2Improve fuel economyImprove power densityValve drivesOutput powerExhaust brakeInlet valve

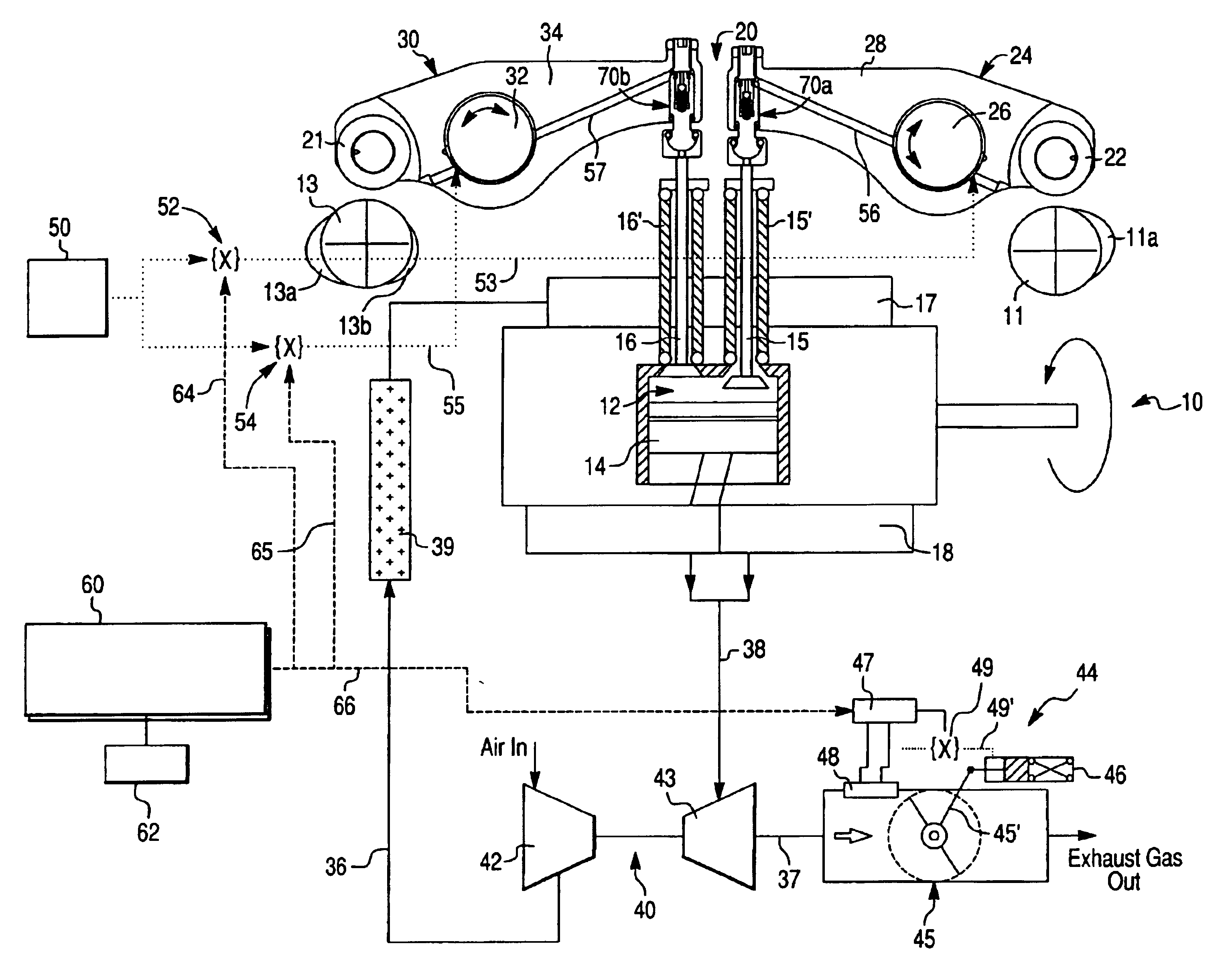

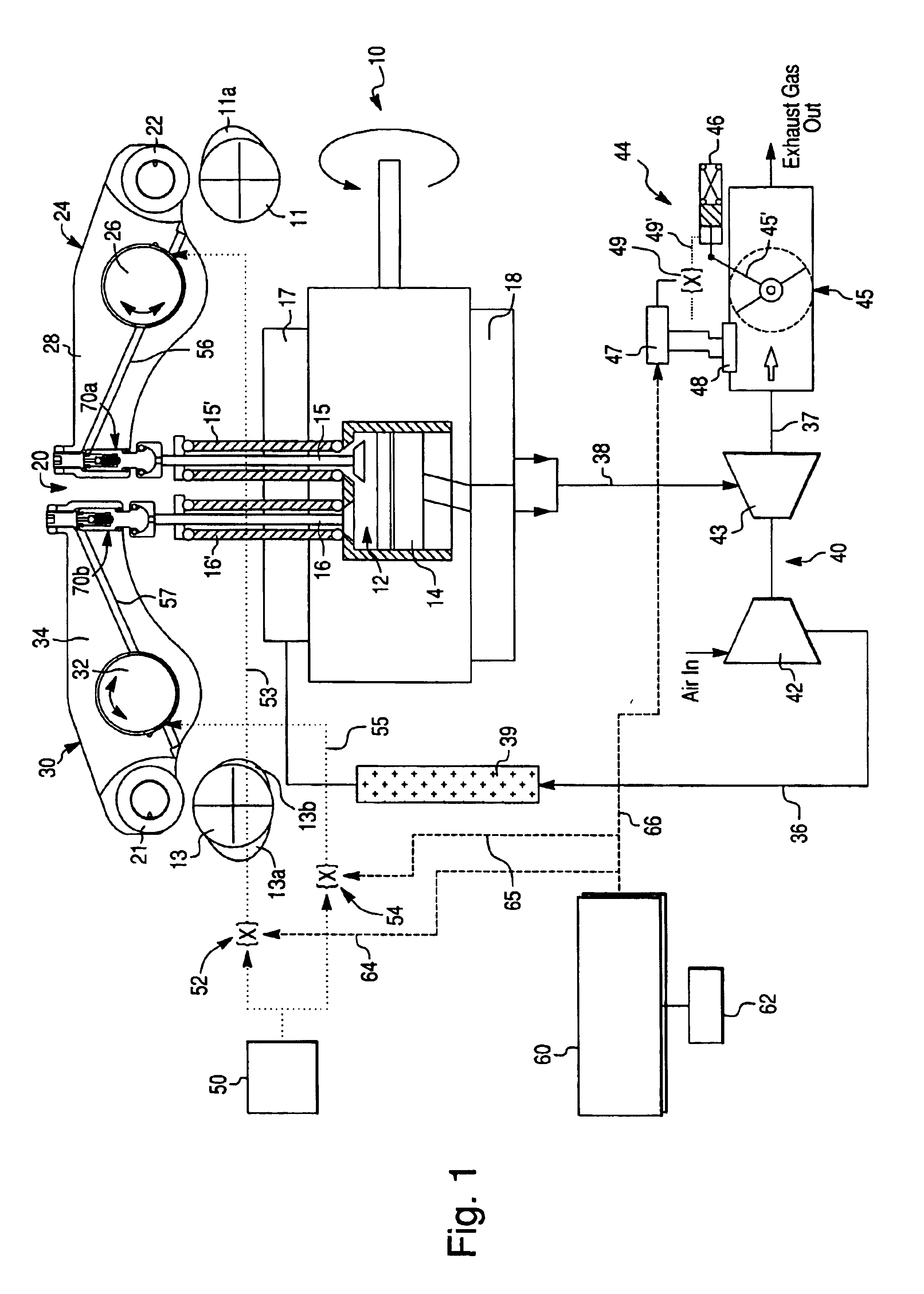

A variable valve actuation system for providing discrete exhaust and intake valve lift profiles for various operating modes of an internal combustion engine. The variable valve actuation system includes exhaust and intake rocker assemblies, exhaust and intake hydraulic extension devices operatively coupling corresponding rocker assemblies with respective engine valves and exhaust and intake control valves for selectively supplying the pressurized hydraulic fluid to the extension devices so as to independently switch them between a pressurized condition and a depressurized condition. The engine further includes an exhaust brake provided to initiate a small lift of the exhaust valve during the engine braking operation while the exhaust extension device maintains the exhaust valve open during a compression stroke for bleeder-compression release braking. The exhaust and intake valves can be adjusted independently to provide combinations of valve lift modes.

Owner:JENARA ENTERPRISES

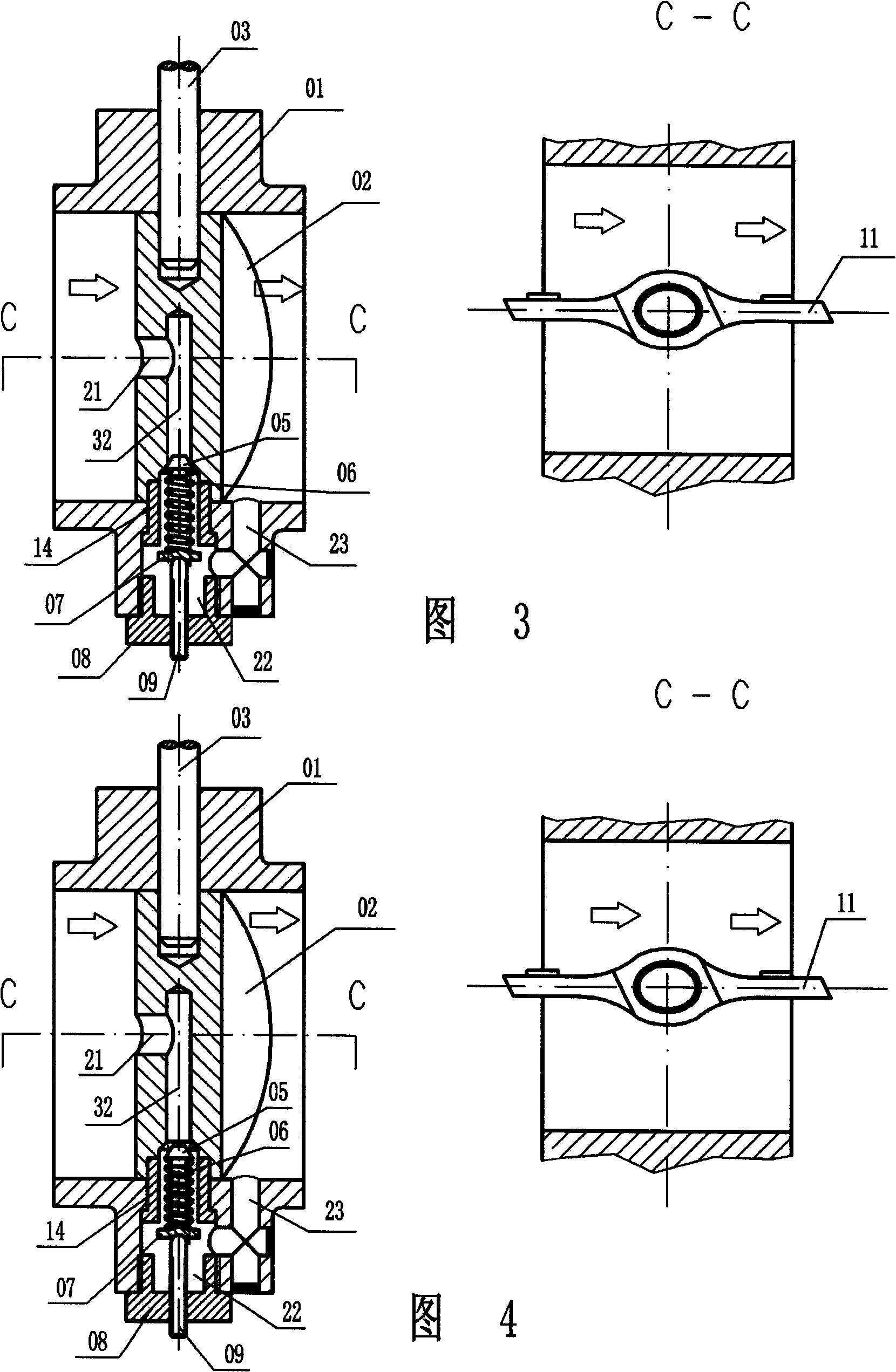

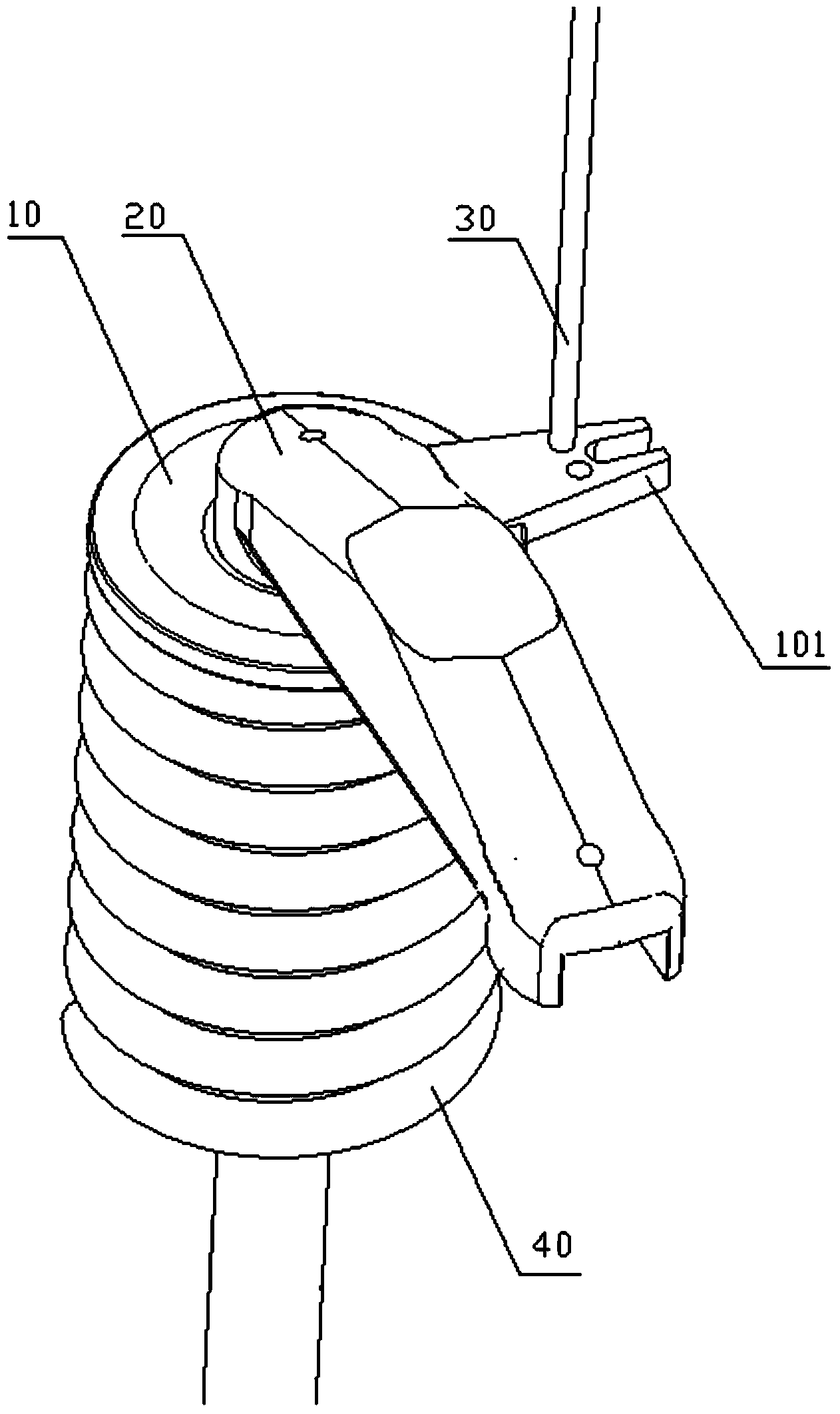

Exhaust brake capable of adjusting working pressure

InactiveCN101251049AAccurate control of back pressureResponsiveEngine controllersMachines/enginesWorking pressureExhaust brake

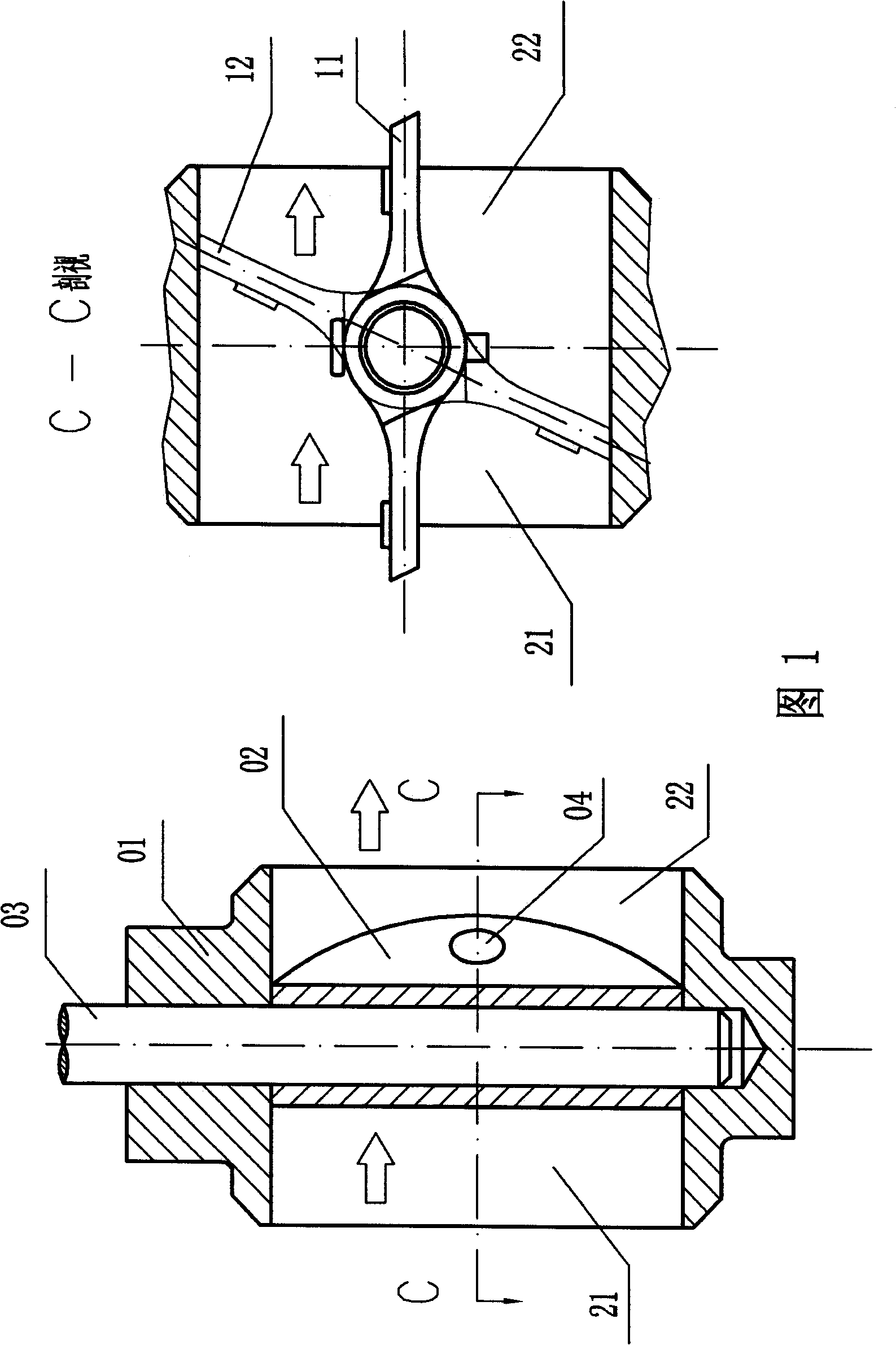

The invention relates to an exhaust brake with stable and adjustable operating pressure, stable brake and sensitive brake reaction, comprising a valve body, a disc, a supporting rod, a supporting sleeve, a control rod, a spring and an adjustable bolt without a pressure relief vent, wherein, the supporting rod and the supporting sleeve are used for fixing the disc, the control rod is used for controlling the on and off of an exhaust channel, the spring is used for adjusting the size of the operating back pressure of an assembly. The exhaust brake can release the excess pressure in time when the pressure surpasses the presetting value due to any unforeseen circumstances and guarantees the stable and reliable operating pressure; moreover, the exhaust brake with the decompressor has adjustable operating pressure, simple and convenient implementation and reliable performance.

Owner:李瑞强

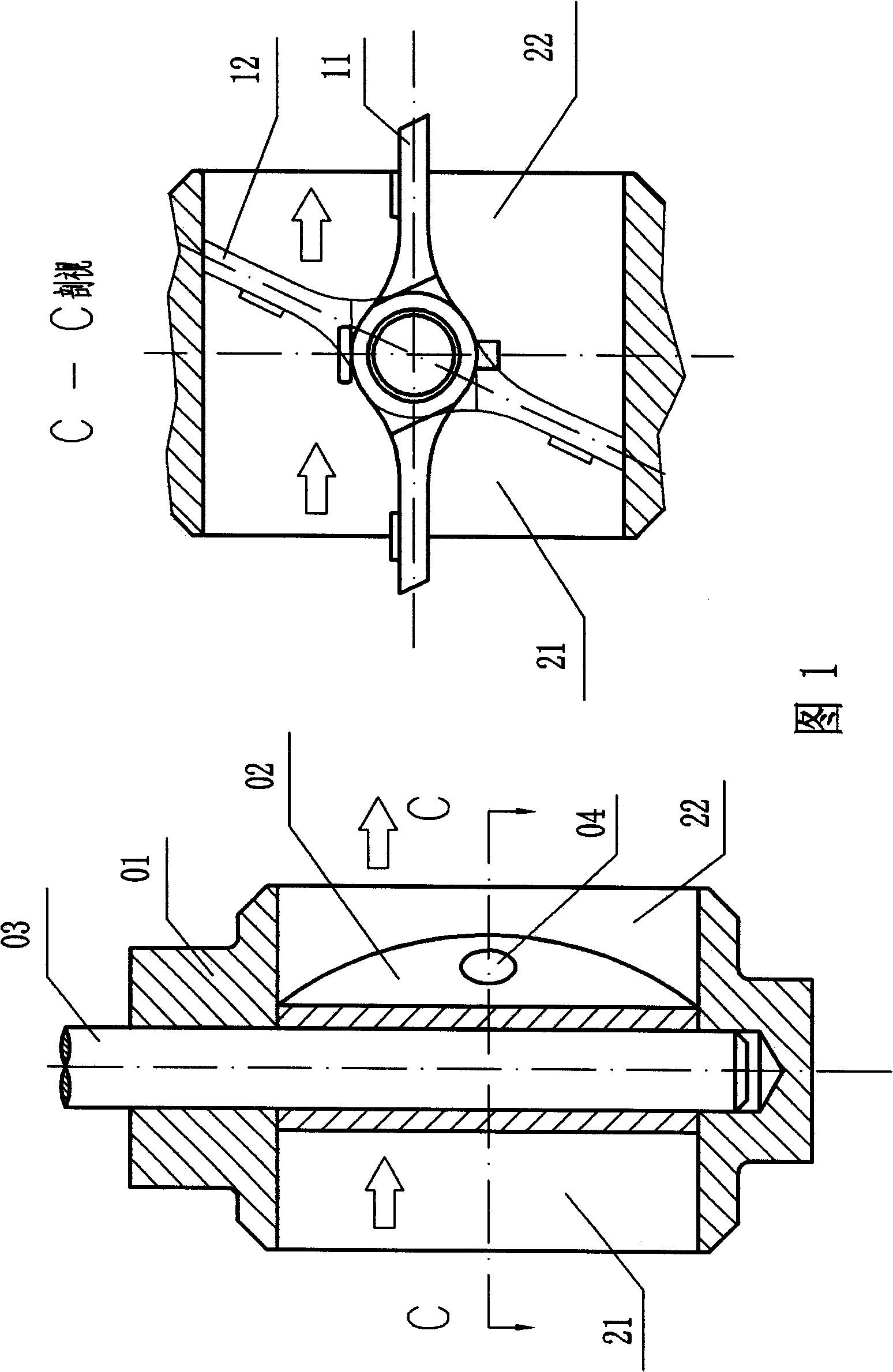

Operating pressure adjustable air exhausting brake

InactiveCN101307727AAccurate control of back pressureResponsiveValve arrangementsOutput powerWorking pressureExhaust brake

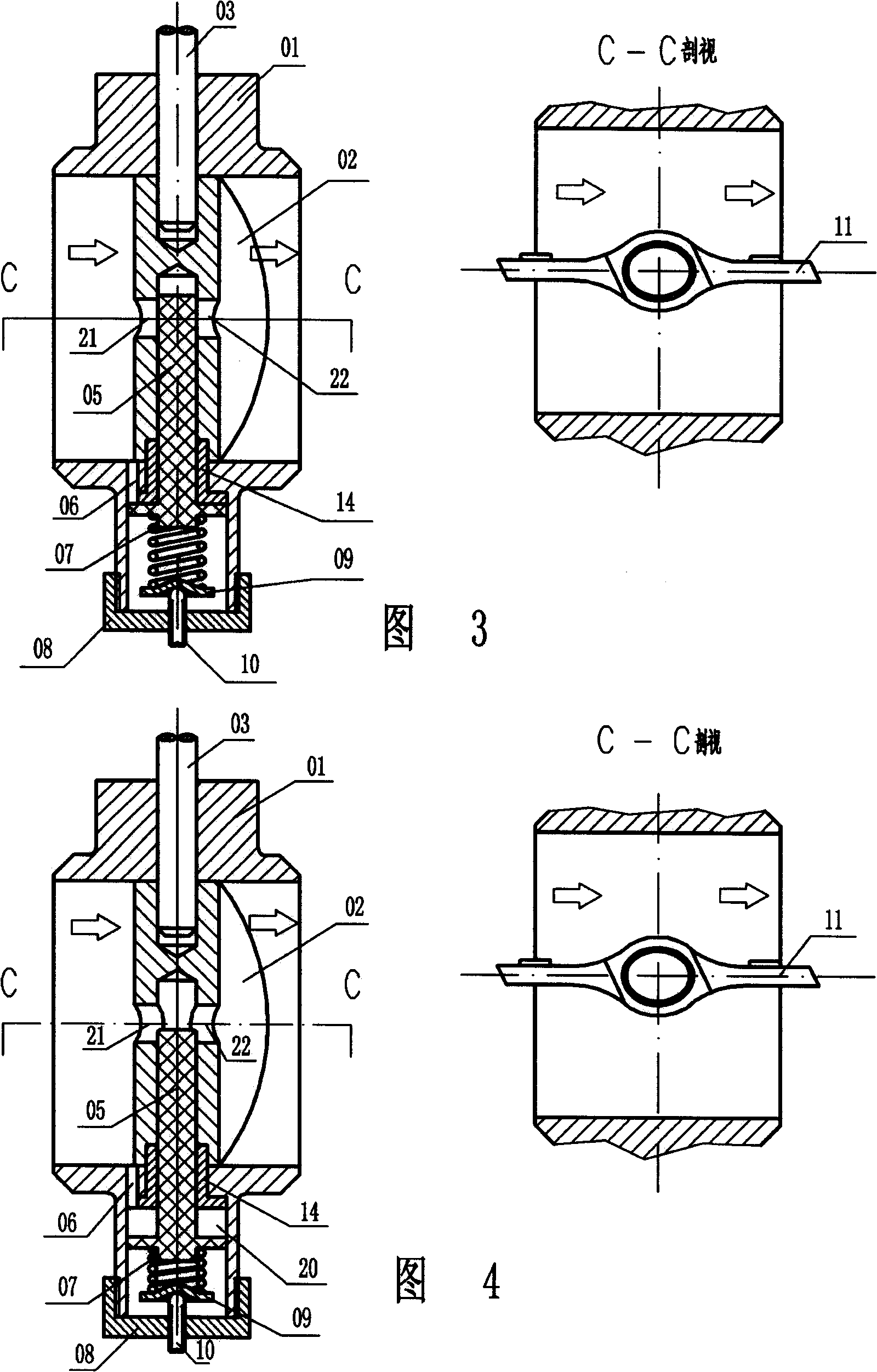

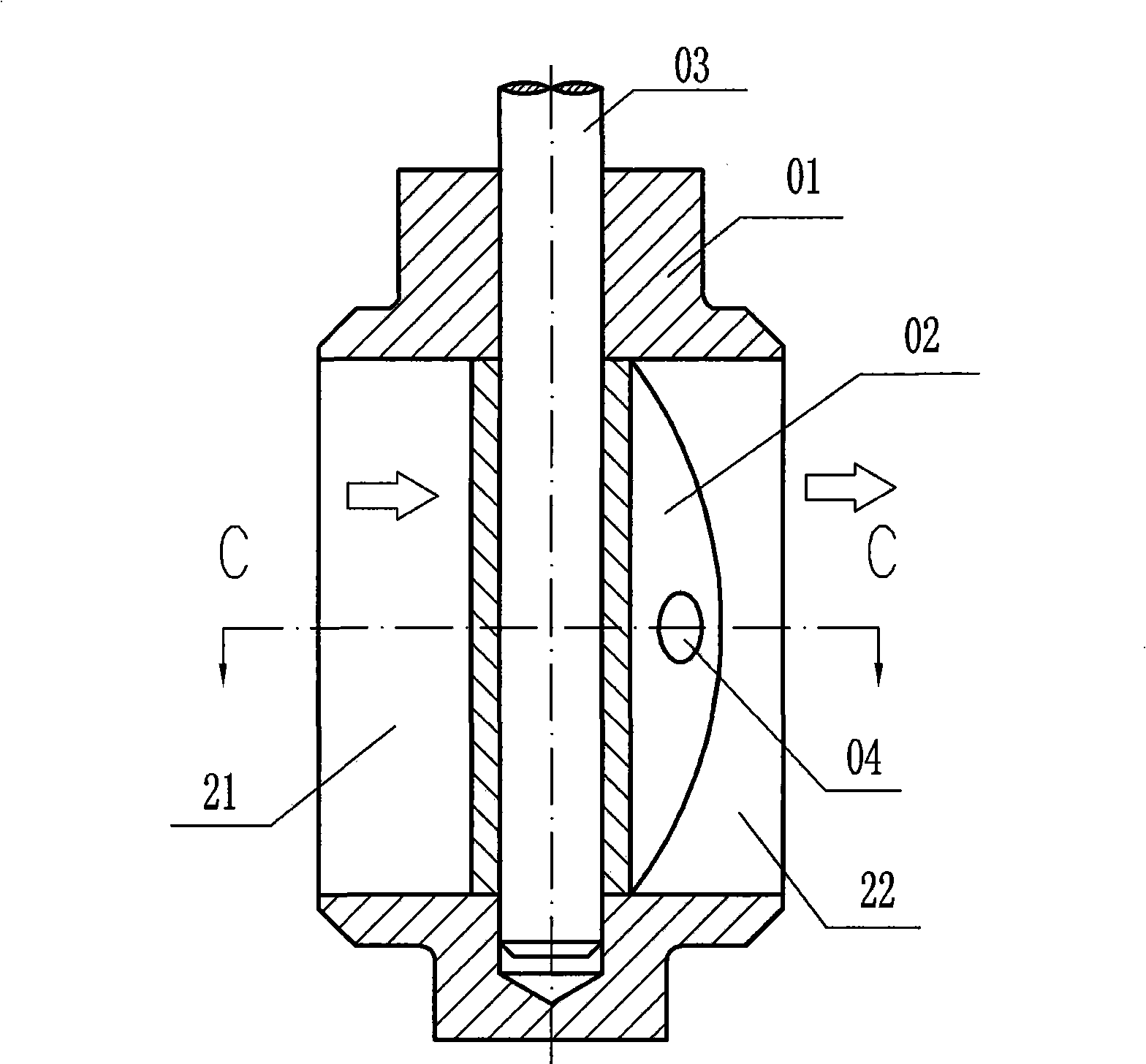

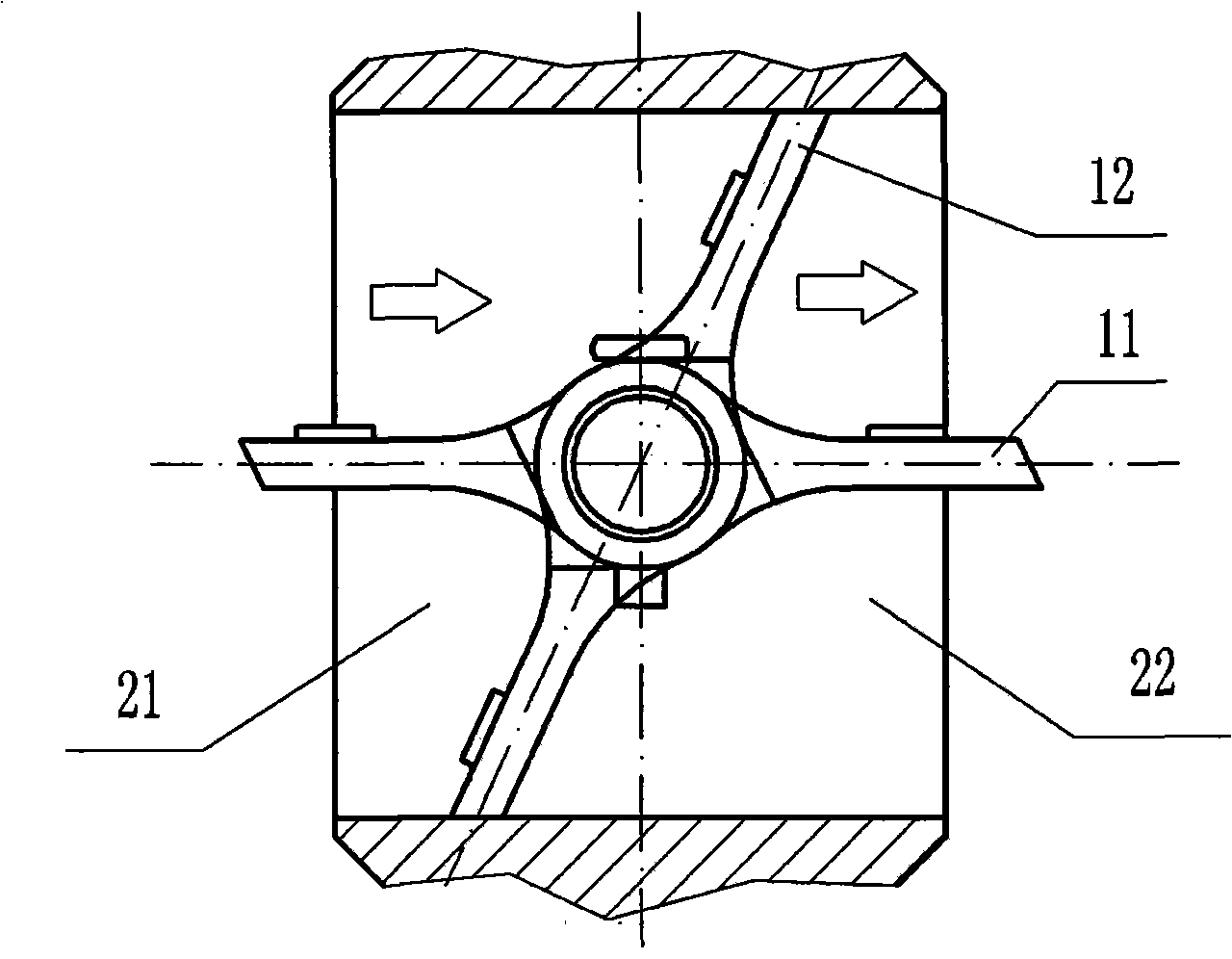

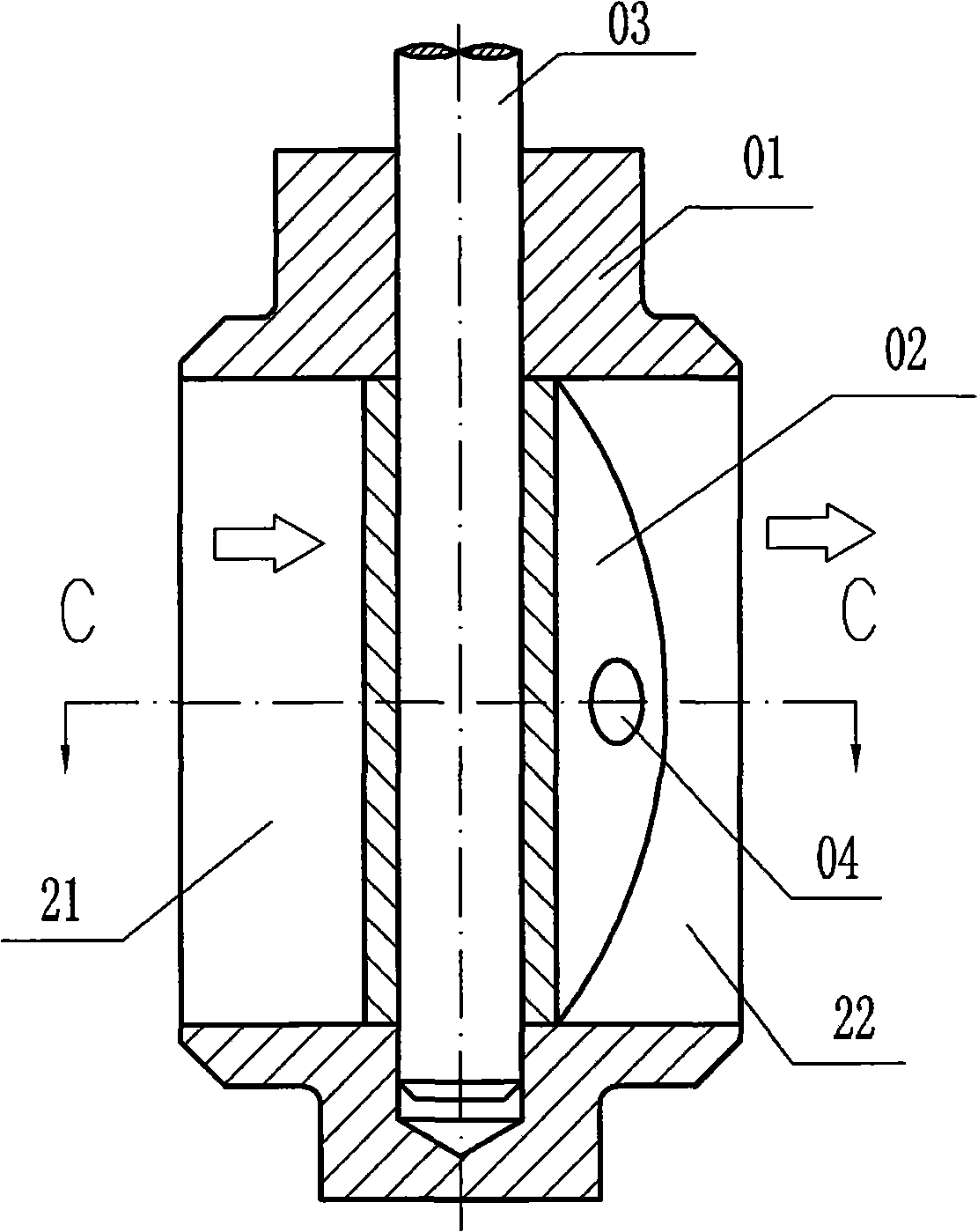

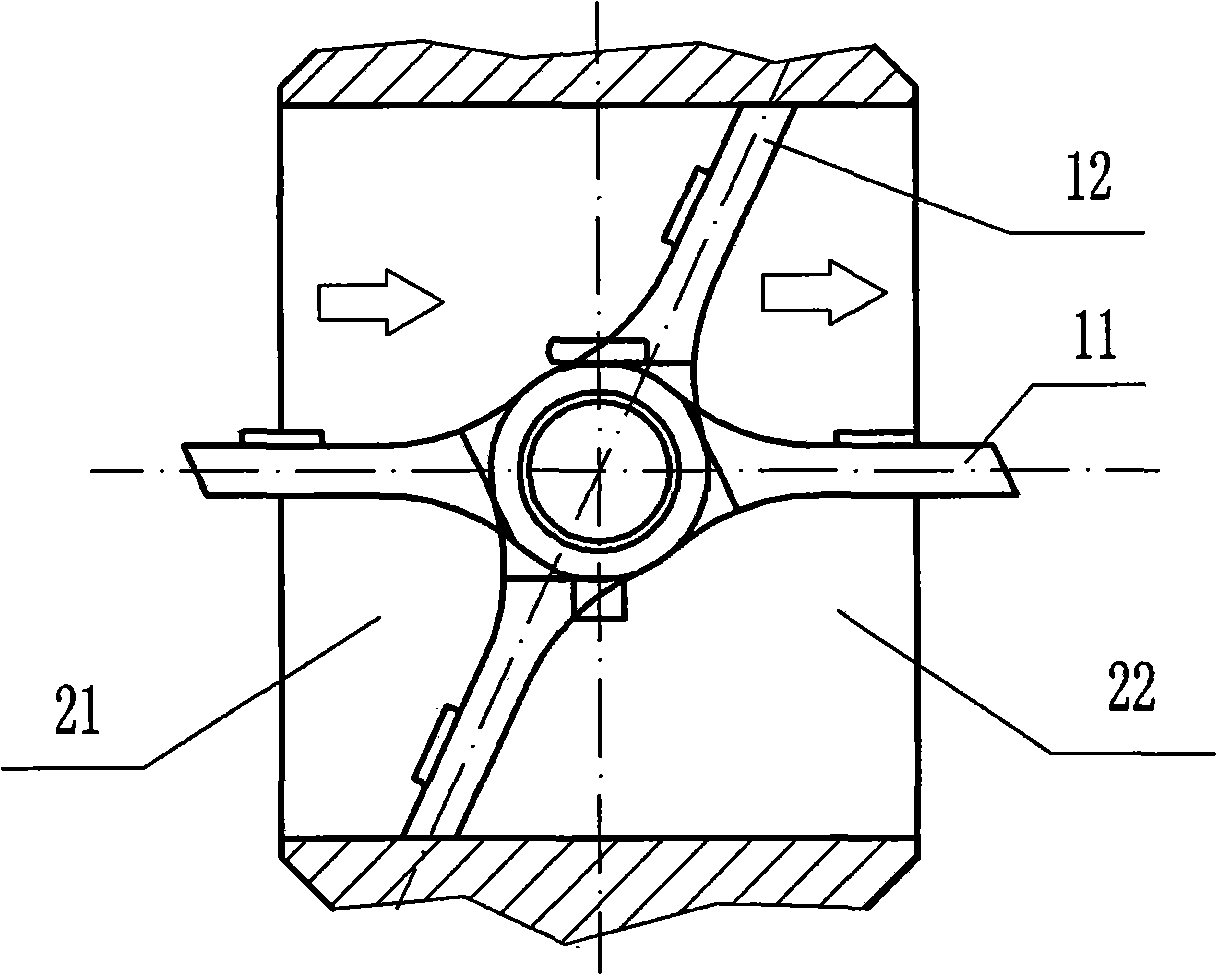

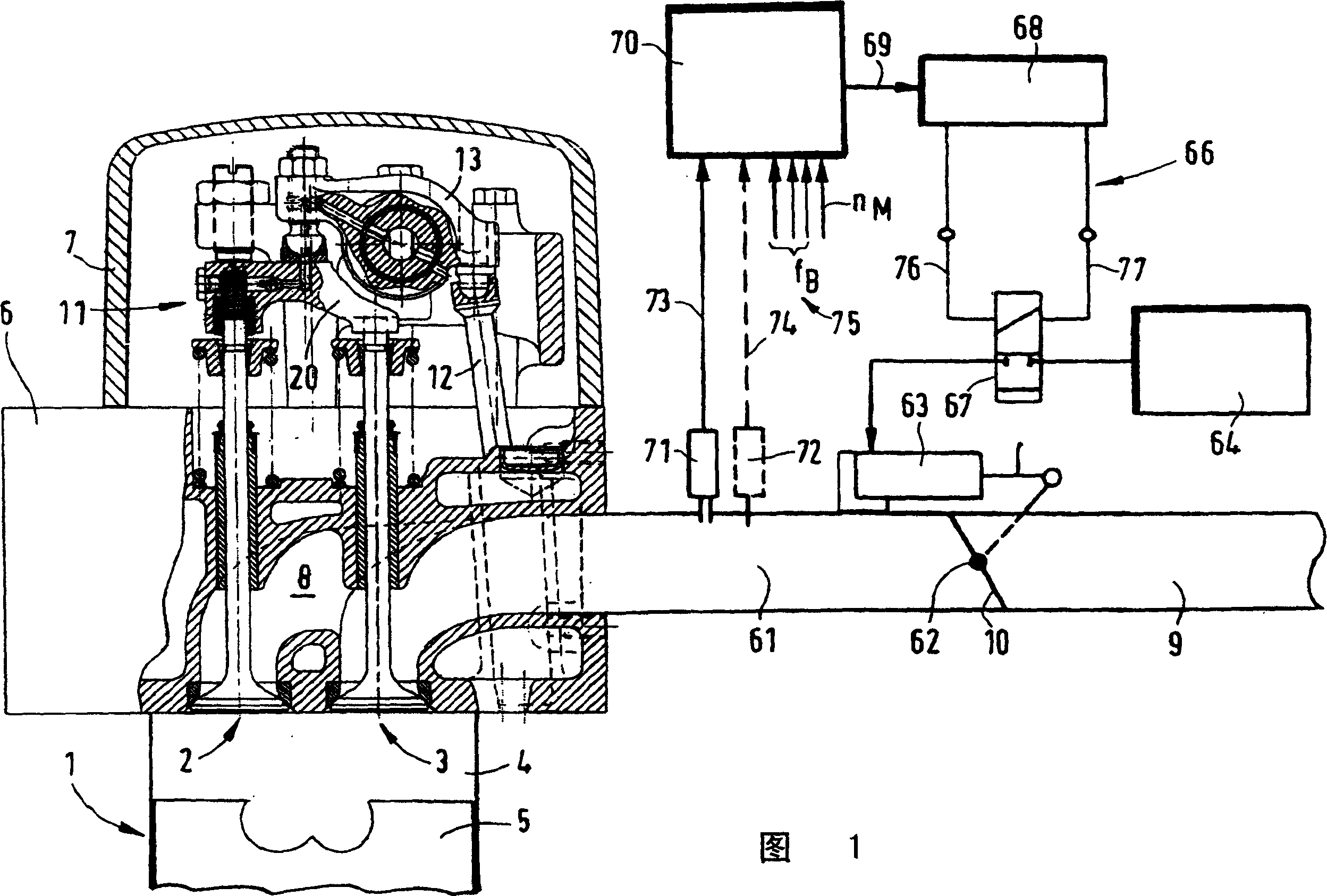

The invention relates to an exhaust arrester capable of adjusting working pressure. The exhaust arrester comprises a valve body (01), a disk (02), a support bar (03), a support sleeve (14), a control bar (05), an air pressure feedback passage (06), a spring (07), a press plate (09), an adjusting support (10) and a cover (08); the disk (02) is fixed on an appointed position of the valve body (01) by the support bar (03) and the support sleeve (14); the support bar (03) drives the disk (2) to rotate around the axes of the disk; the control bar (05) is used for controlling connection and disconnection of an exhaust gas passage and is fixed on the bottom of the support sleeve (14) by the spring (07), the press plate (09), the adjusting support (10) and the cover (08); the air pressure feedback passage (06) drives the control bar (05) to move; and the spring (07) is used for adjusting the working pressure of an exhaust arrester assembly. When the pressure exceeds a set value by any accidental situation, the exhaust arrester can release pressure in time, ensure that the working pressure is stable and reliable and has adjustable working pressure and simple and convenient implementation.

Owner:李瑞强

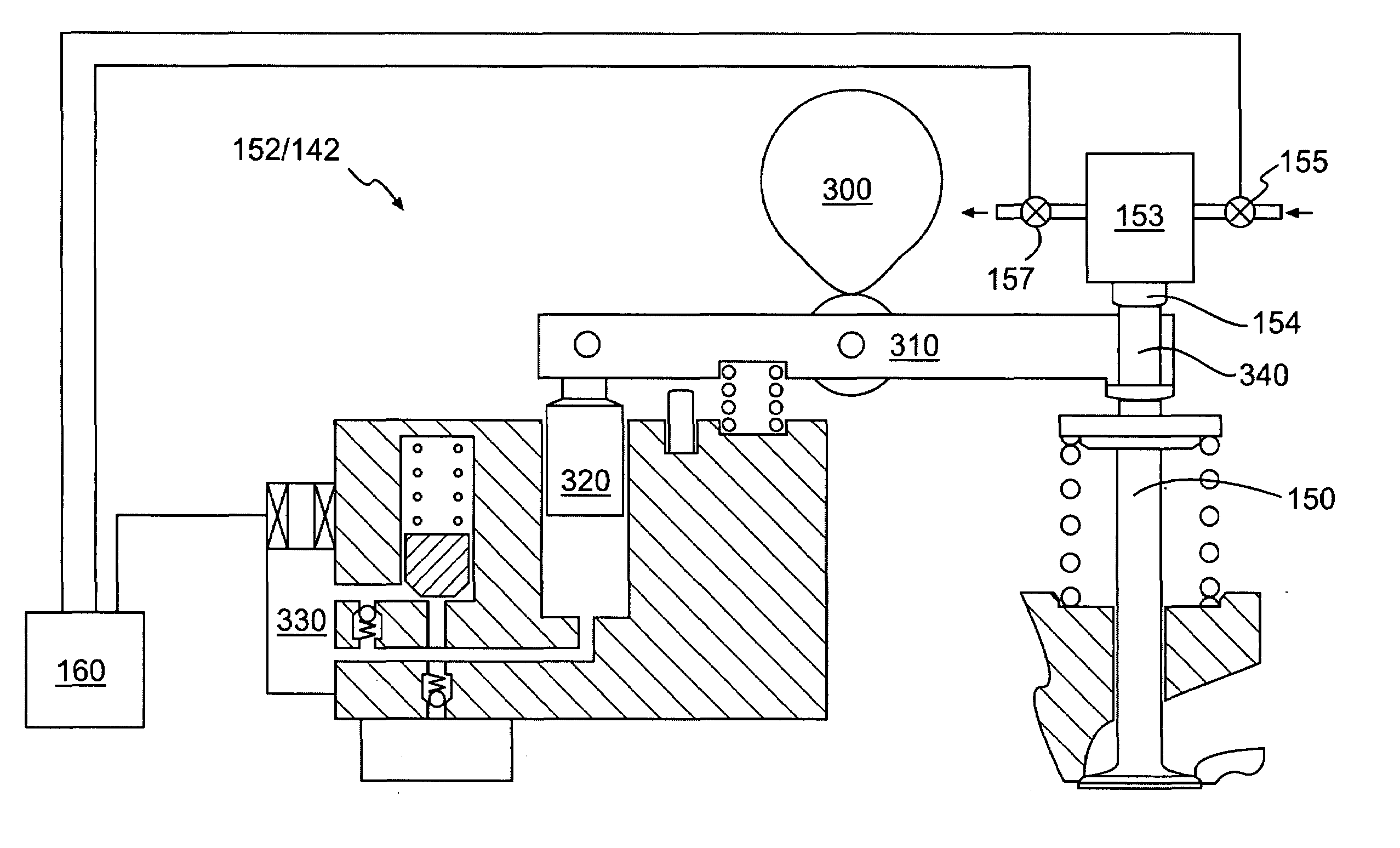

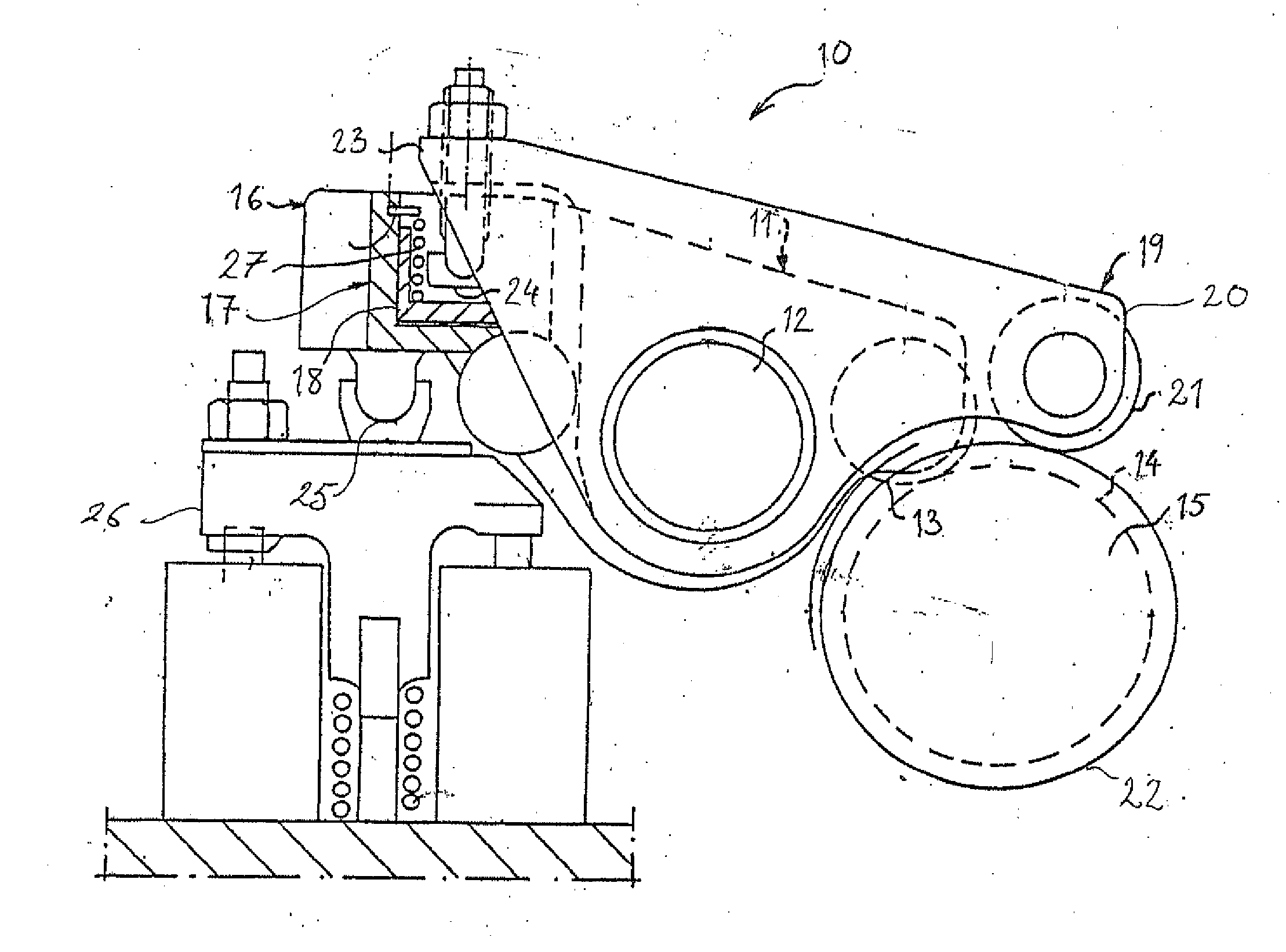

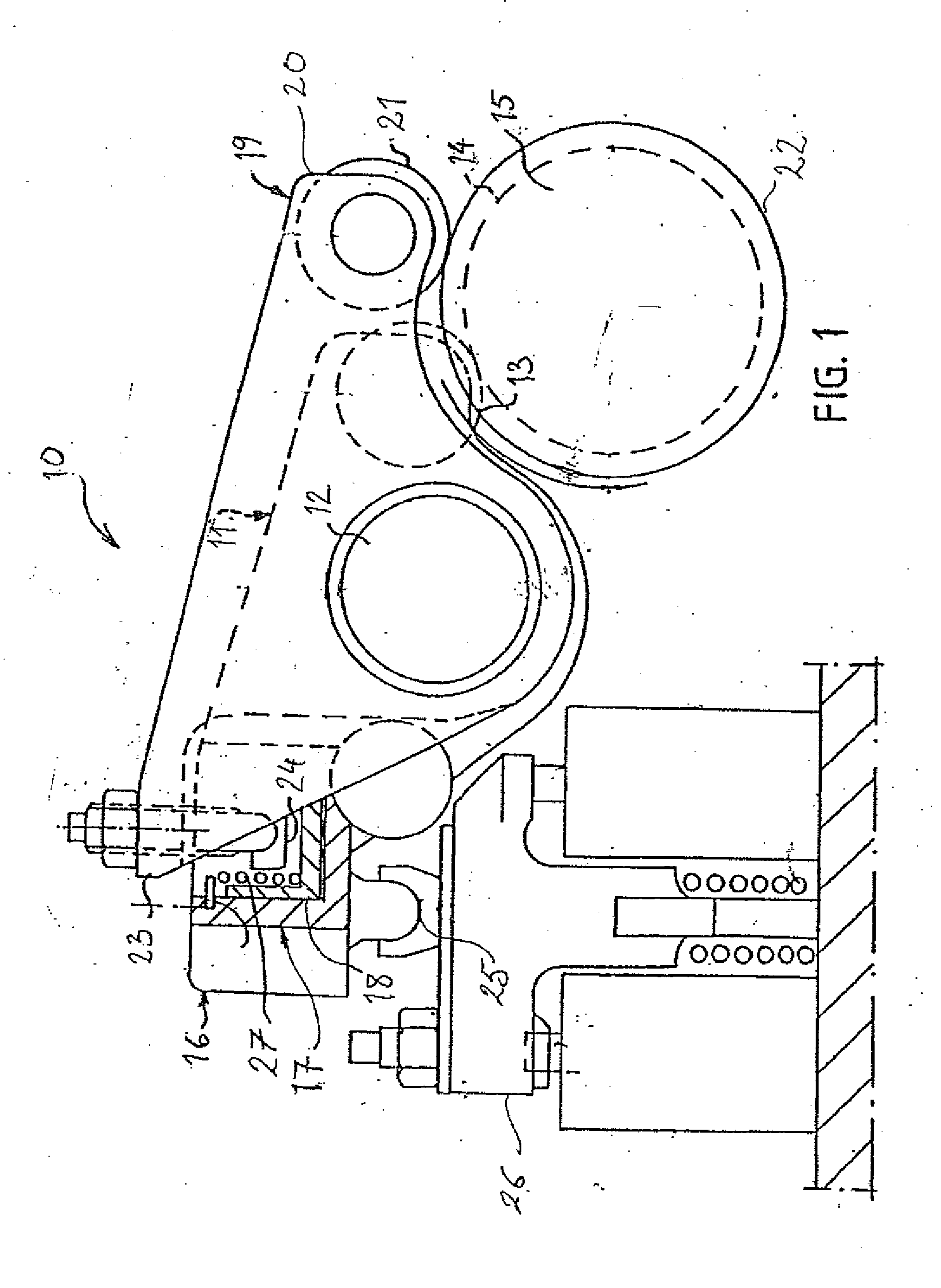

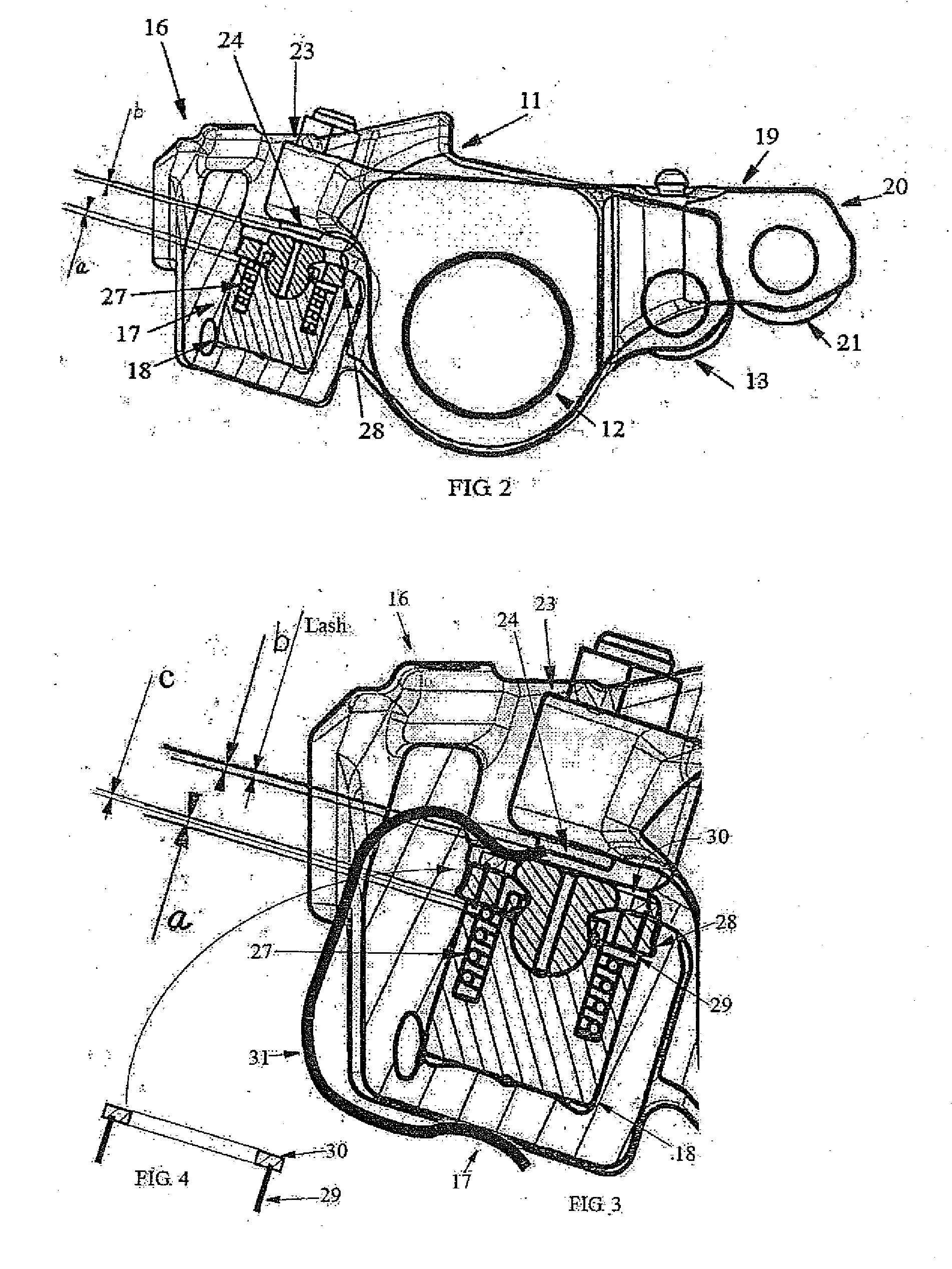

Engine braking methods and apparatus

ActiveUS7162996B2Constant liftNon-fuel substance addition to fuelInternal combustion piston enginesExhaust brakeVariable-geometry turbocharger

Methods and apparatus for providing bleeder-type and compression-release engine braking in an internal combustion engine are disclosed. For bleeder-type engine braking, the exhaust valve is maintained at a small and relatively constant lift throughout all or much of the engine cycle. The engine braking may be combined with exhaust gas recirculation, variable exhaust brake, and / or operation of a variable geometry turbocharger.

Owner:JACOBS VEHICLE SYST

Exhaust brake

InactiveCN101324207AStable brake working pressureResponsive brakingEngine controllersMachines/enginesWorking pressureExhaust brake

The invention relates to an exhaust brake, including a valve body (01), a disc piece (02), a supporting rod (03), a supporting sleeve (14), a pressure relief valve (05), a spring (06), an adjustment support (09) and a cover (08), wherein, the supporting rod (03) and the supporting sleeve (14) are used for fixing the disc piece (02) at the specified position on the valve body (01), and driving the disc piece (02) to rotate around the axis thereof; the disc piece (02) is opened with a first cavity (21) and a second cavity (22); the pressure relief valve (05) is pressed at the bottom of the second cavity (22) by the spring (06), a clamp (07), the adjustment support (09) and the cover (08); the spring (06) is used for adjusting the working pressure of the exhaust brake assembly. The exhaust brake of the invention can release the unnecessary pressure in time when the pressure exceeds a setting value caused by any contingency, so as to ensure the working pressure to be stable and reliable, the working pressure is adjustable, and the implementation is simple and convenient.

Owner:李瑞强 +2

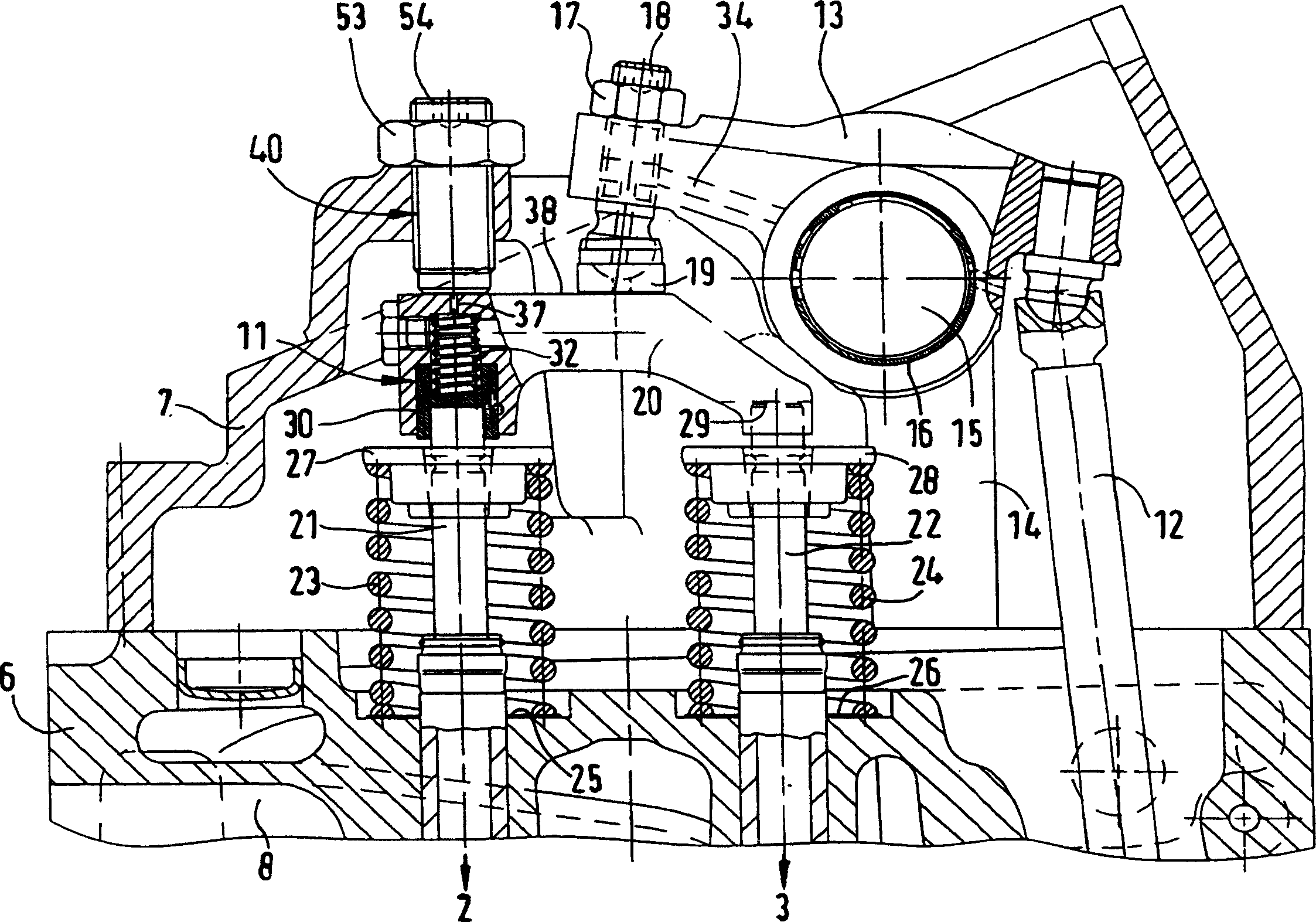

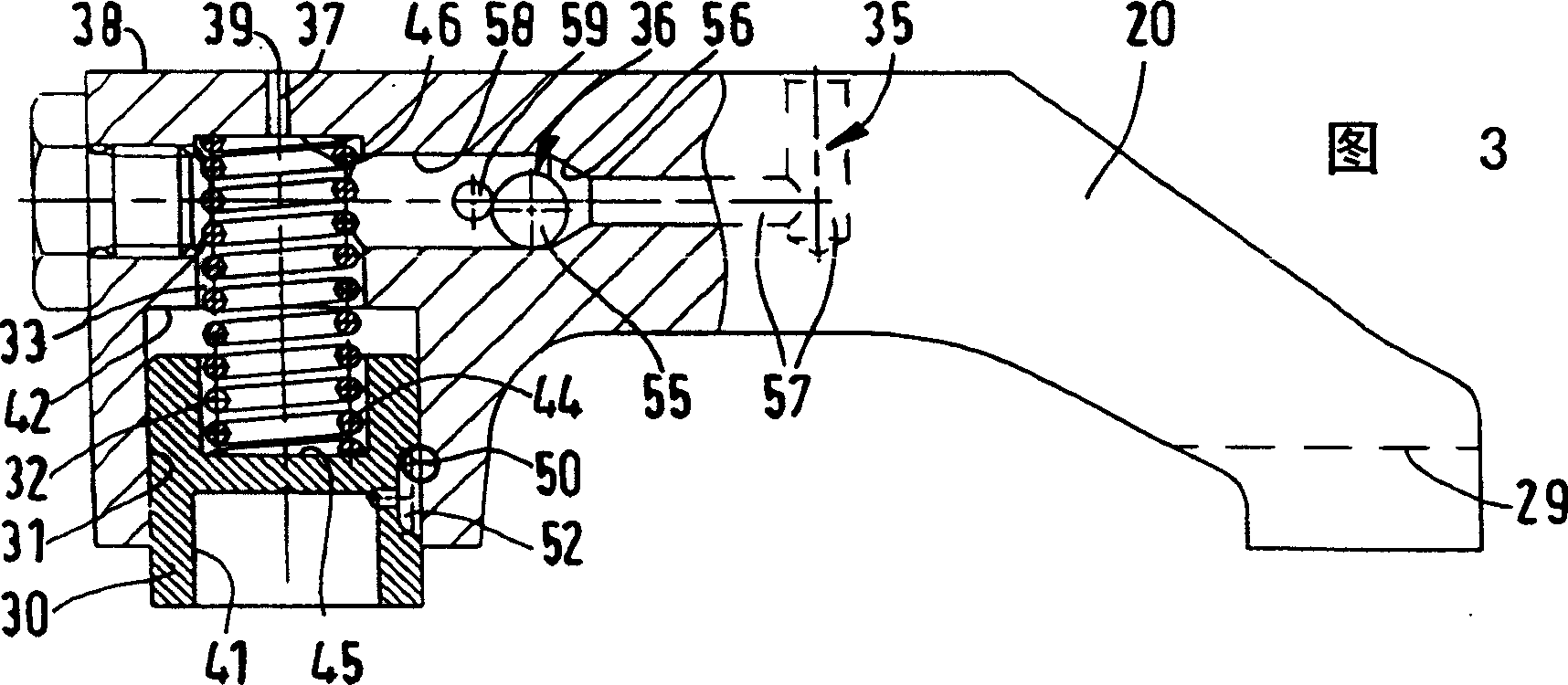

Exhaust braking device for a 4-stroke internal piston combustion engine

InactiveCN1609414AGuaranteed uptimeAvoid overall overheatingValve arrangementsExhaust apparatusExhaust valveCombustion

The purpose of this invention is to automatically perform predetermined open or close of an exhaust valve and to provide high engine brake power, by improving an engine control braking device of a 4-stroke internal piston combustion engine equipped with one intake valve and two exhaust valves 2 and 3 for each cylinder. A throttle device 10 for operating an engine brake is incorporated in an exhaust gas duct 9 so that the exhaust gas resistant pressure cooperating with a braking device 11 in an engine is formed in exhaust gas dammed up in the upstream of the throttle device. The braking device 11 is disposed in one exhaust valve 2 of the exhaust valves 2 and 3, and the other 3 is controlled conventionally. The braking device 10 has a control piston 30 incorporated in a valve bridge 20 pressed toward the exhaust valve 2 from a control pressure chamber 33 loaded by oil pressure. The control pressure chamber 33 is connected to a permanent pressure oil supply section, and is cut off and pressure-released via a pressure releasing passage 37 in relation to a motion or position of the valve bridge 20.

Owner:MAN TRUCK & BUS AG

Exhaust brake

InactiveCN101251048AAccurate control of working pressureResponsiveEngine controllersMachines/enginesWorking pressureExhaust brake

The invention relates to an exhaust brake with a decompressor and a method for preventing the formation of the overpressure in the exhaust brake. The operating pressure of the exhaust brake is reliable and adjustable. The exhaust brake comprises a valve body, a disc, a supporting rod, a supporting sleeve, a reducing valve, a spring and an adjustable bolt and does not have a pressure relief vent, wherein, the supporting rod and the supporting sleeve are used for fixing the disc, the reducing valve is used for stably activating the exhaust resistance, the spring is used for adjusting the size of the operating back pressure of an assembly. The exhaust brake with the decompressor can release the excess pressure in time when the pressure surpasses the presetting value due to any unforeseen circumstances and guarantees the stable and reliable operating pressure; moreover, the exhaust brake with the decompressor has adjustable operating pressure, simple and convenient implementation and reliable performance.

Owner:李瑞强 +2

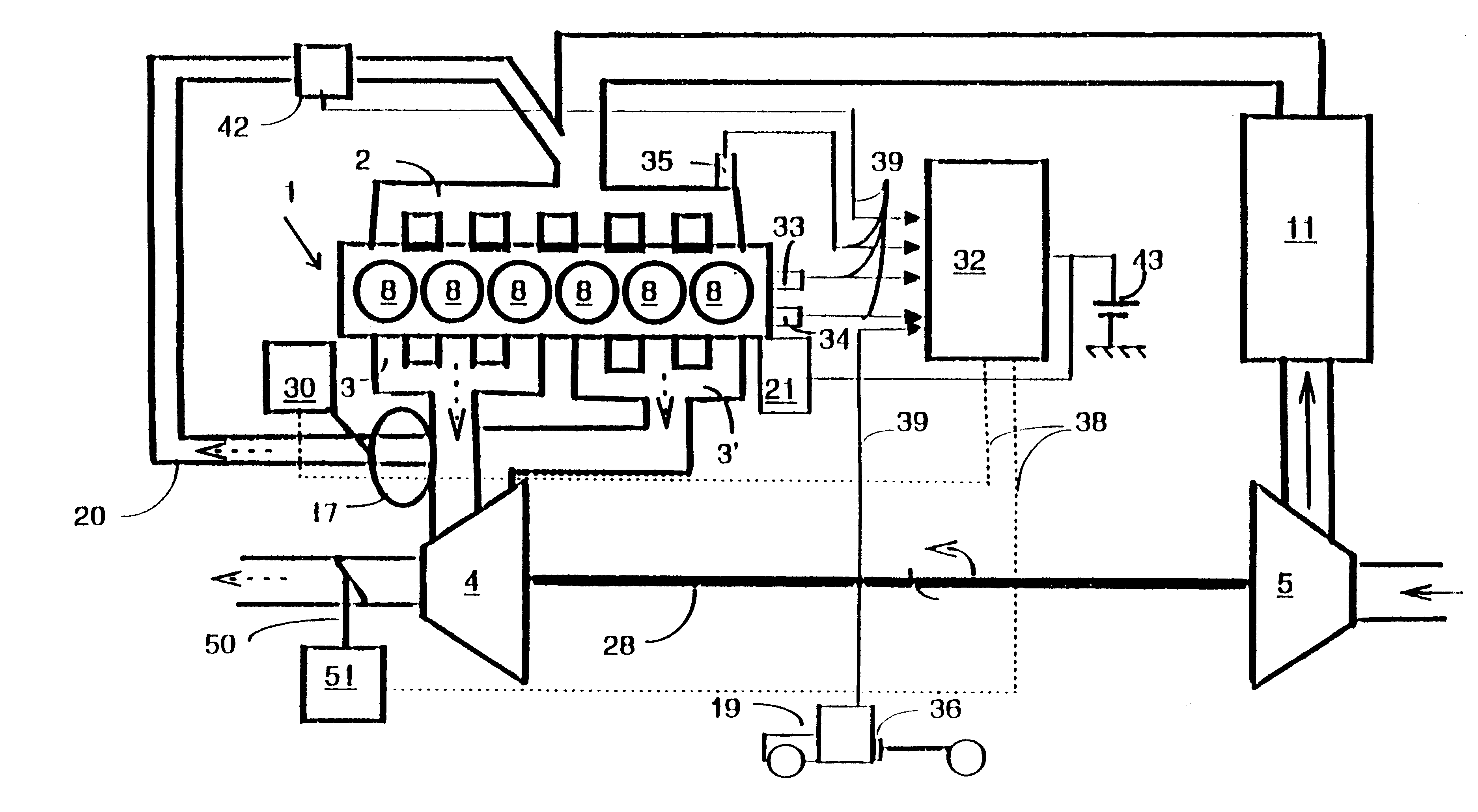

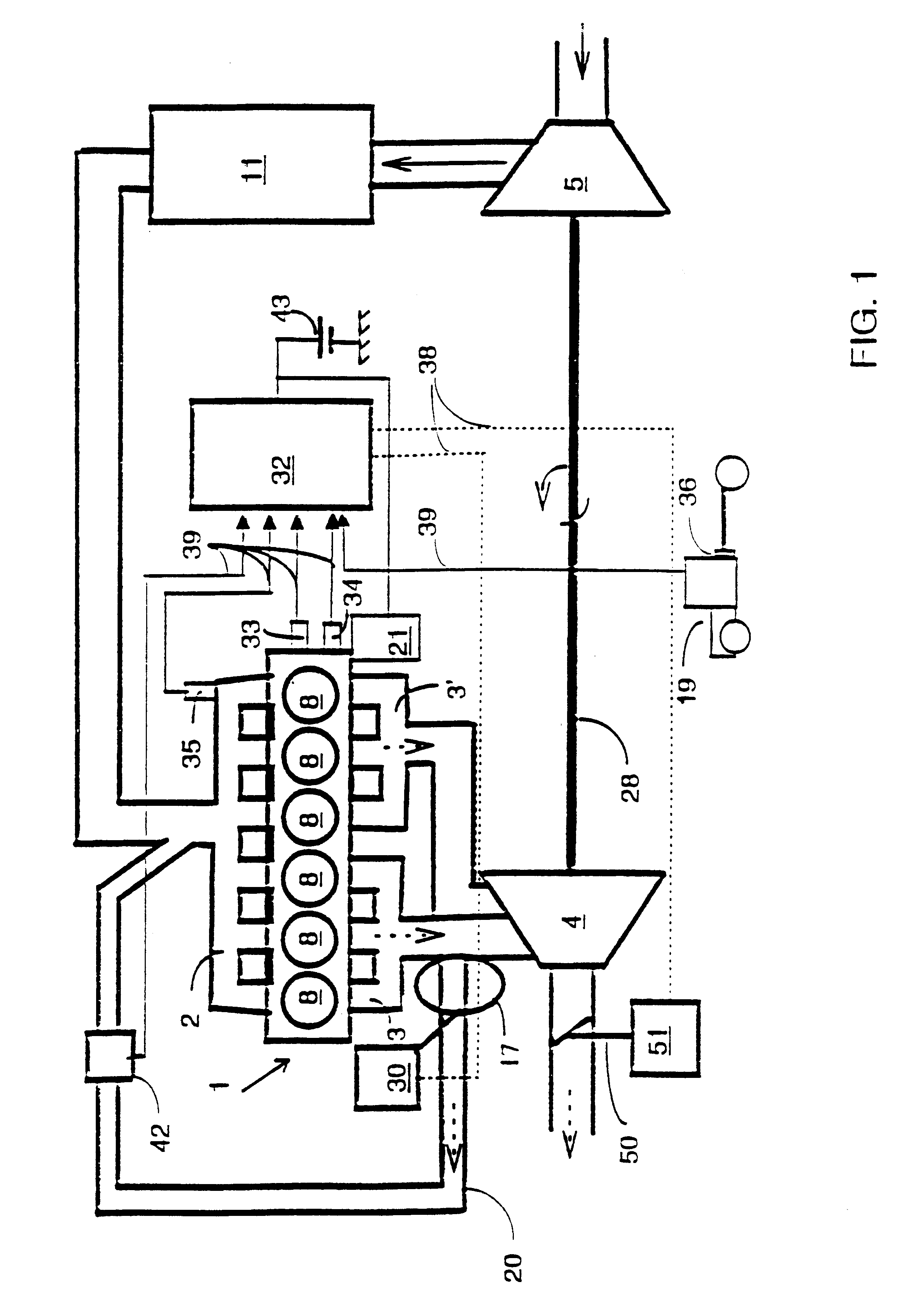

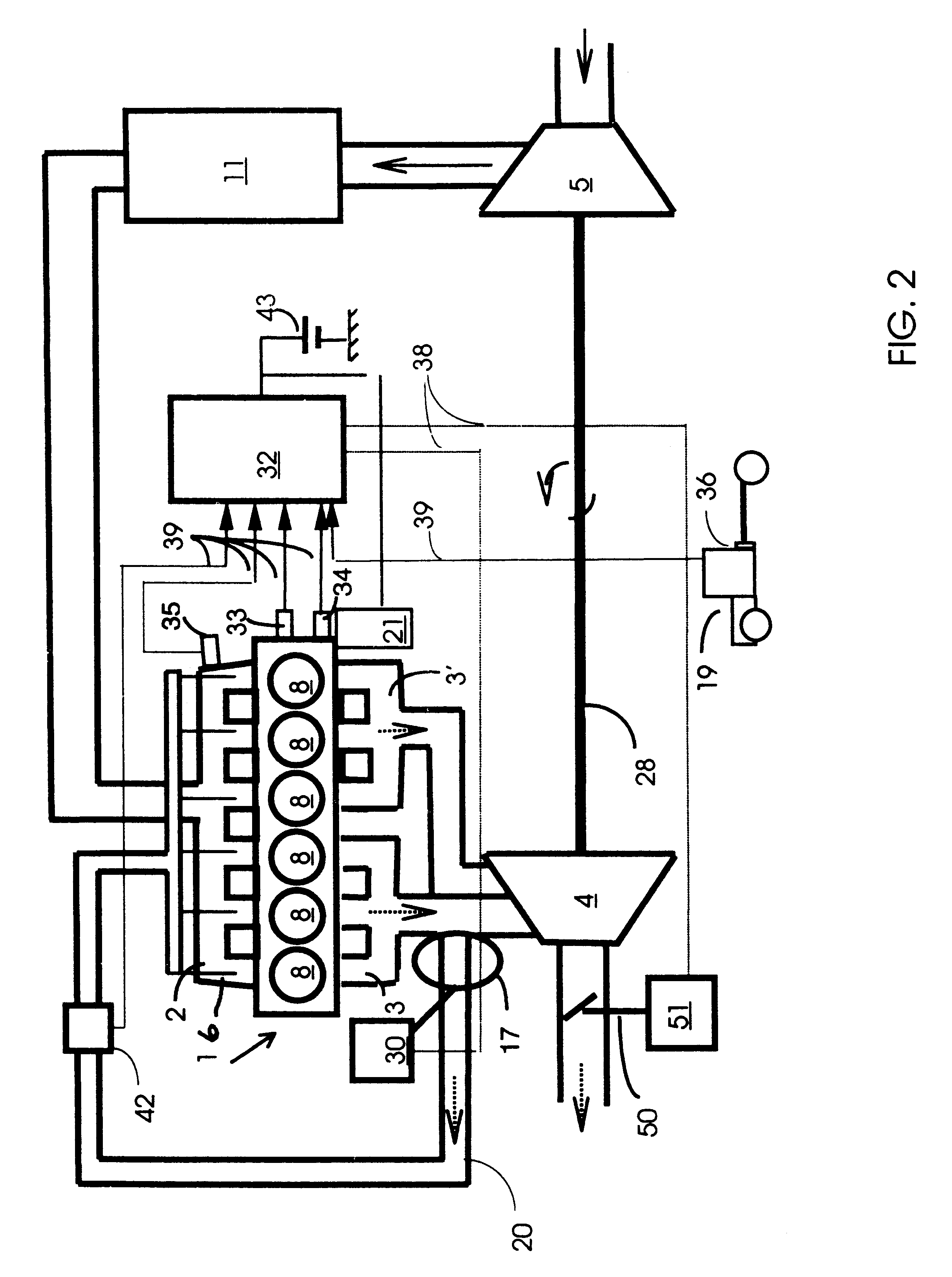

Combustion engine and method of controlling same

InactiveUS6230682B1Reduce exhaust emissionsEmission reductionElectrical controlNon-fuel substance addition to fuelCombustionControl system

A combustion engine has a line (20) for feeding exhaust gases back from the outlet system (3, 3) to the inlet system (2), an EGR valve (17) in the line (20), an exhaust brake valve (50) in the outlet system to increase the pressure in the outlet system upstream therefrom, and a control system (32) for controlling the degree of opening and closing of the valves (17, 50) on the basis of signals which represent the engine's operating state. The control system (32) holds the EGR valve (17) open and the exhaust brake valve (50) in a position which substantially throttles the exhaust gas flow so long as a first signal indicates that the engine has, during its starting, not yet reached a steady operating state. The result is a particularly simple way of appreciably shortening the time the engine takes to reach a steady operating state from a cold start and a corresponding reduction in discharge of emissions.

Owner:SCANIA CV AB

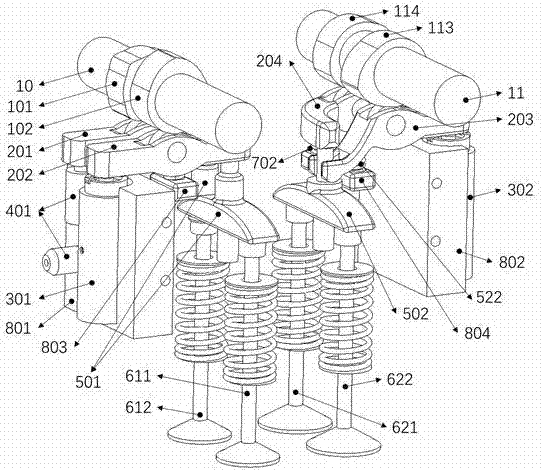

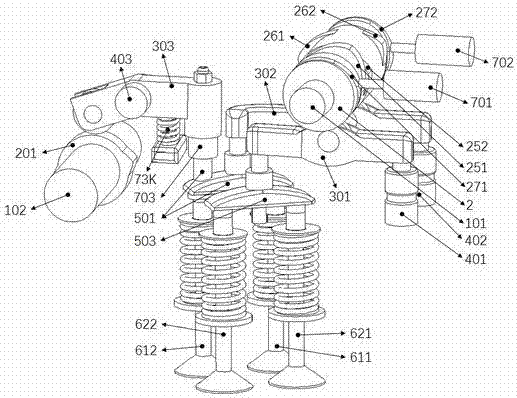

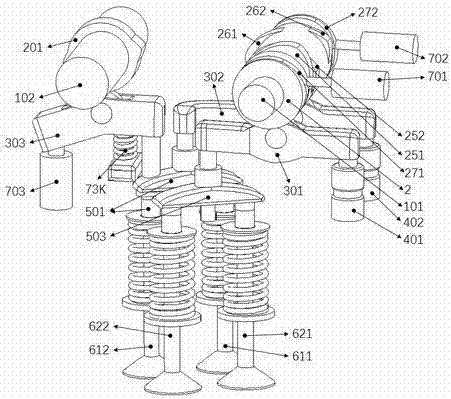

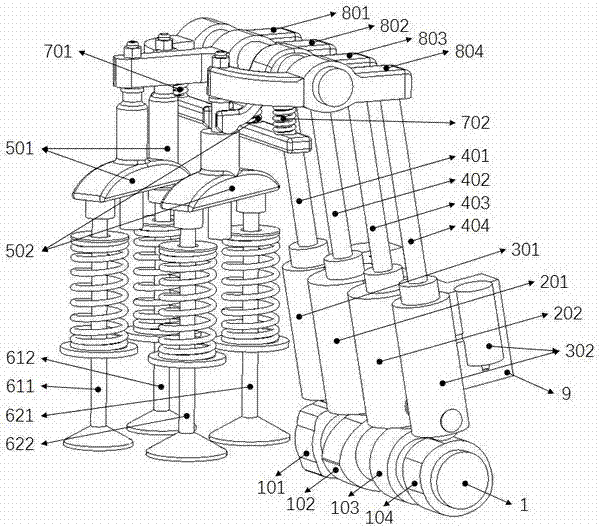

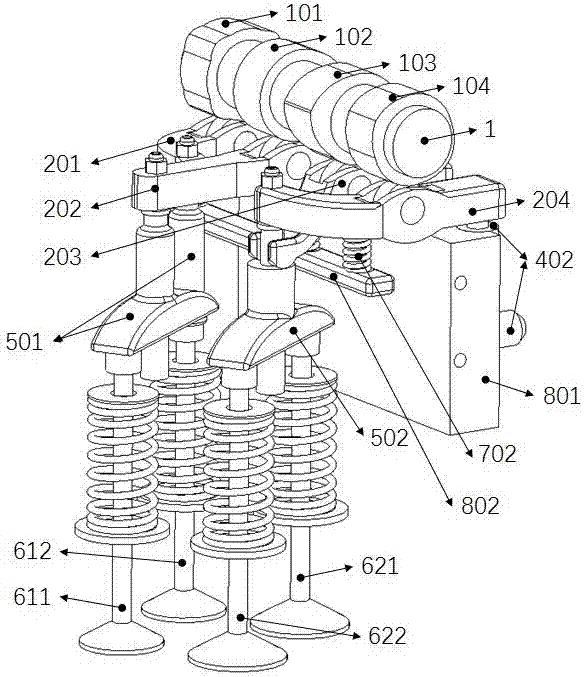

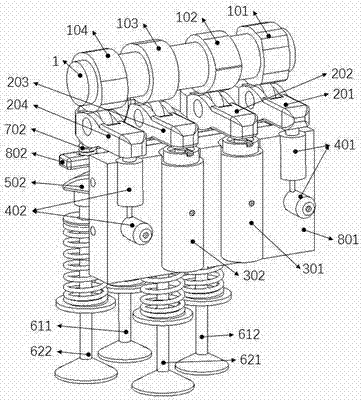

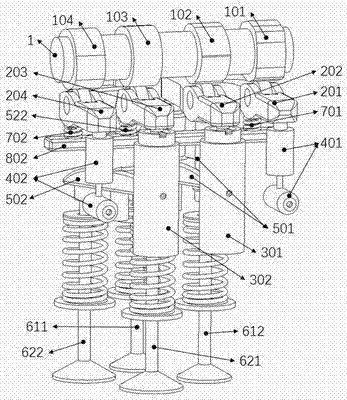

Double-cam-shaft switch supporting point type mode-switching valve driving system

ActiveCN107060941AReduce fuel consumptionEmission reductionMachines/enginesNon-mechanical valveExhaust valveExhaust brake

The invention discloses a double-cam-shaft switch supporting point type mode-switching valve driving system and belongs to the field of engine valve driving, cylinder deactivation and auxiliary braking. The system mainly comprises an intake valve assembly, an exhaust valve assembly, an exhaust braking cam, an exhaust driving cam, an intake driving cam, an intake braking cam, an exhaust braking rocker arm, an exhaust driving rocker arm, an intake driving rocker arm, an intake braking rocker arm, an exhaust braking supporting point assembly, an exhaust driving supporting point assembly, an intake driving supporting point assembly and an intake braking supporting point assembly. By controlling the states of all supporting points, various modes of four-stroke driving, two-stroke braking, cylinder deactivation and the like are achieved, and low-oil-consumption, low-emission and efficient braking is achieved. The double-cam-shaft switch supporting point type mode-switching valve driving system is oriented to actual application, the number of moving parts is small, the structure is simple and compact, the reliability is high, the cost is low, and the energy consumption is low.

Owner:DALIAN UNIV OF TECH

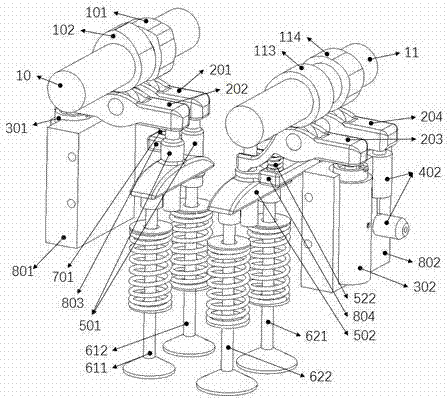

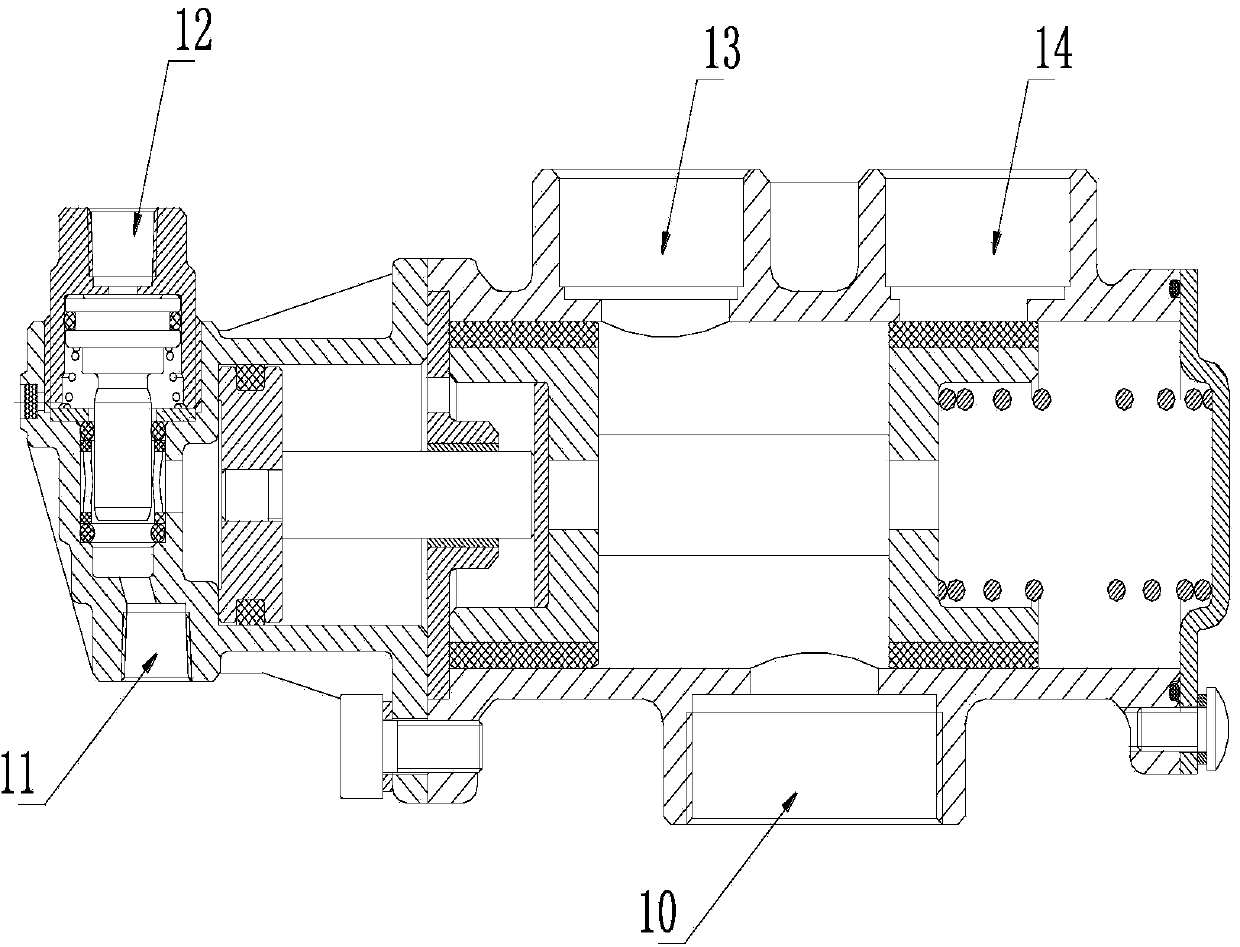

Compact multi-mode valve driving system

ActiveCN107060942AReduce fuel consumptionIncrease fuel consumptionMachines/enginesNon-mechanical valveExhaust brakeEngineering

The invention discloses a compact multi-mode valve driving system and belongs to the field of engine valve driving, stroke changing and auxiliary braking. The compact multi-mode valve driving system comprises a first cam shaft provided with a shaft sleeve, a second cam shaft provided with an exhaust braking cam, switching assemblies, a braking switch and the like. The shaft sleeve is provided with an intake four-stroke cam, an intake two-stroke cam, an exhaust four-stroke cam, an exhaust two-stroke cam and two switching grooves. The axial position of the shaft sleeve is controlled through the two switching assemblies, and two-stroke and four-stroke seamless switching is achieved; and the driving modes and the braking modes are switched through only one braking switch. By means of the compact multi-mode valve driving system, the four modes including the four-stroke driving mode, the two-stroke driving mode, the four-stroke braking mode and the two-stroke braking mode are flexibly switched, and high-power, low-oil-consumption, low-emission and efficient graded braking is achieved. The compact multi-mode valve driving system is simple and compact in structure, high in reliability, low in cost and high in response speed.

Owner:DALIAN UNIV OF TECH

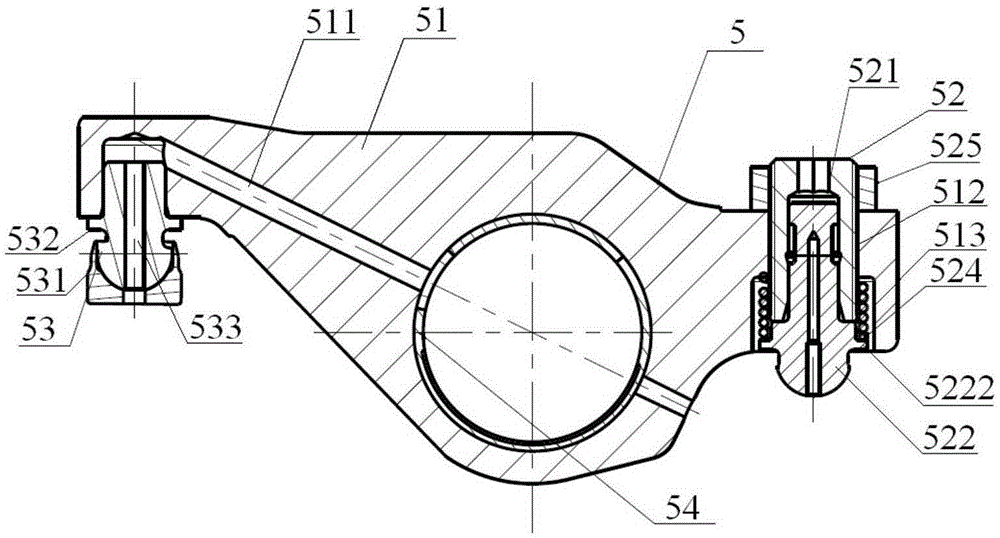

Engine exhaust brake system

ActiveCN105351026ASave layout spaceReduce weightValve drivesMachines/enginesExhaust valveExhaust brake

The invention relates to the technical field of engines, and in particular to an engine exhaust brake system. The engine exhaust brake system comprises a cam, a rocker shaft, an exhaust rocker assembly, a valve bridge assembly and a sealing device. The cam is provided with a base circle, an exhaust lift and a brake lift. The rocker shaft is provided with a brake oil path capable of being connected and disconnected. A rocker body of the exhaust rocker assembly is provided with a first oil way communicated with the brake oil path. An adjusting screw assembly is provided with a brake lift gap adjusting structure. A ball pin assembly is provided with a second oil way which penetrates a first ball pin and an elephant foot and is communicated with the first oil way. A valve bridge body of the valve bridge assembly is provided with an exhaust valve, a main piston, an auxiliary piston and an oil releasing hole. A main piston installing hole is communicated with an auxiliary piston installing hole. The sealing device capable of sealing the oil releasing hole is arranged in the oil releasing hole. A step cavity of the main piston is communicated with the second oil way. An installing hole for installing a brake exhaust valve is formed in the lower end of the auxiliary piston. By means of cooperation of the cam, the rocker assembly and the valve bridge assembly, an engine achieves the two work states of doing positive work and braking.

Owner:WEICHAI POWER CO LTD

Exhaust valve mechanism for an internal combustion engine

ActiveUS20100186710A1Increase exhaust temperatureLess torqueValve arrangementsOutput powerExhaust valveExhaust brake

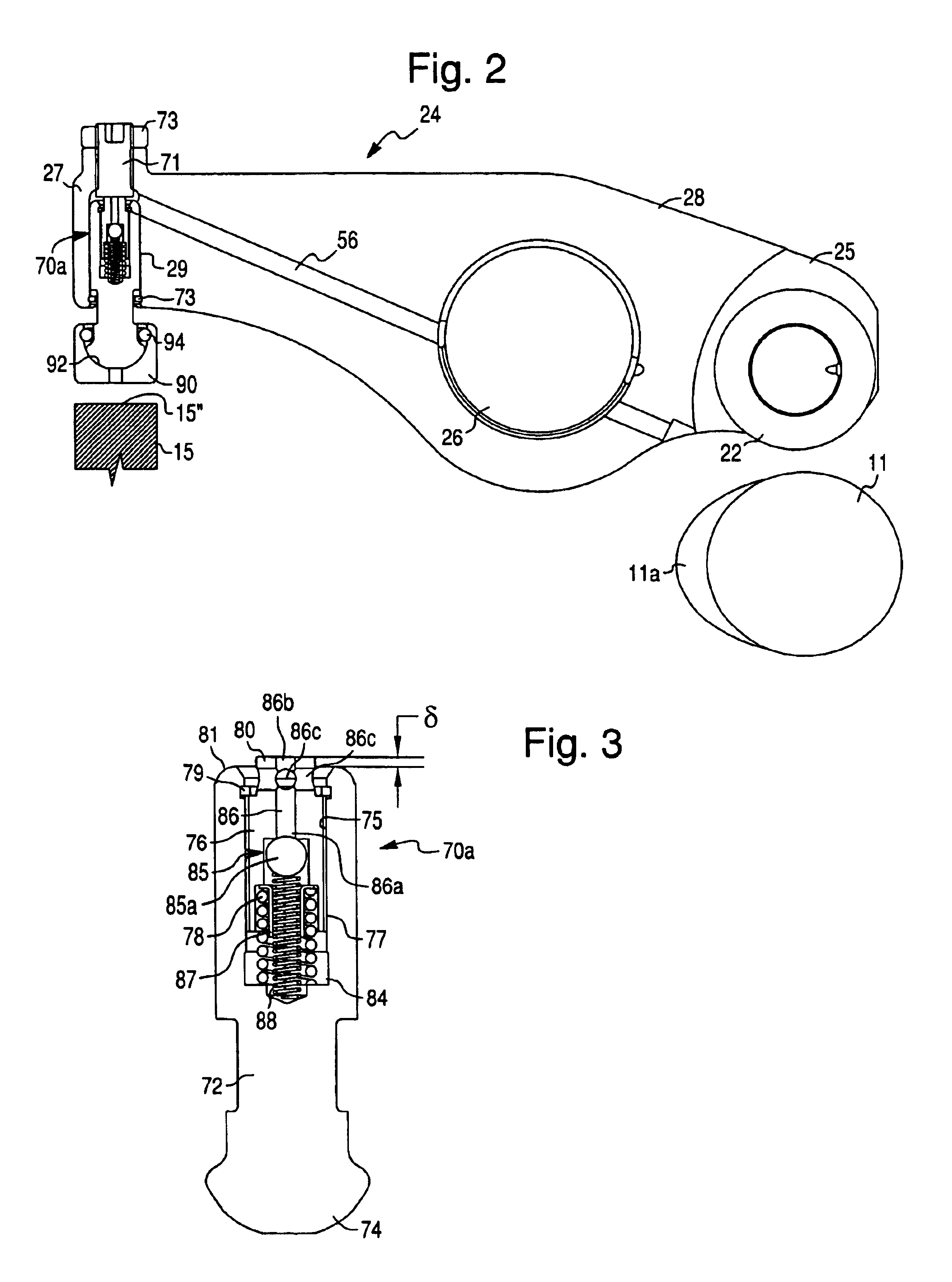

In an exhaust valve mechanism for an internal combustion engine the main rocker arm is mounted on a rocker arm shaft for normal valve operation via a cam element. A secondary rocker arm is mounted on the shaft for activation of an exhaust brake mode. The activation is achieved through supply of hydraulic pressure to a piston cylinder arrangement acting between the main and secondary rocker arms. A master piston and a slave piston are connected by a hydraulic-link allowing activation by increased hydraulic pressure. When activating the exhaust gas temperature increasing mode, the master piston is moved to an active position for part of its stroke against the force of a first resilient member. When activating the exhaust brake mode, the master piston is moved the full movement of its stroke against the combined forces of the first resilient member and a second resilient member as active position. The end of the first stroke length defines a position for the master piston allowing activation of an extra valve event.

Owner:VOLVO LASTVAGNAR AB

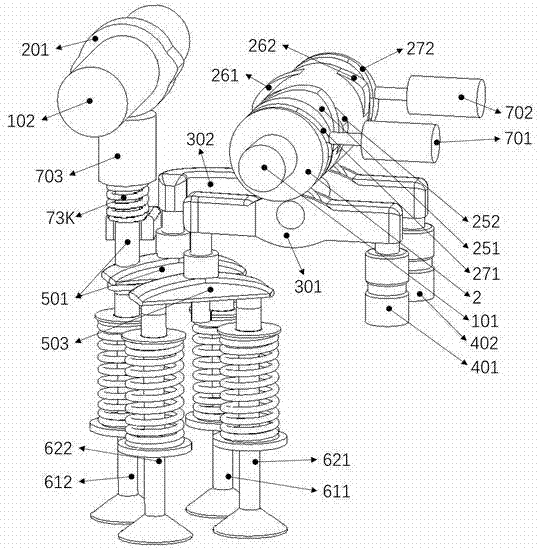

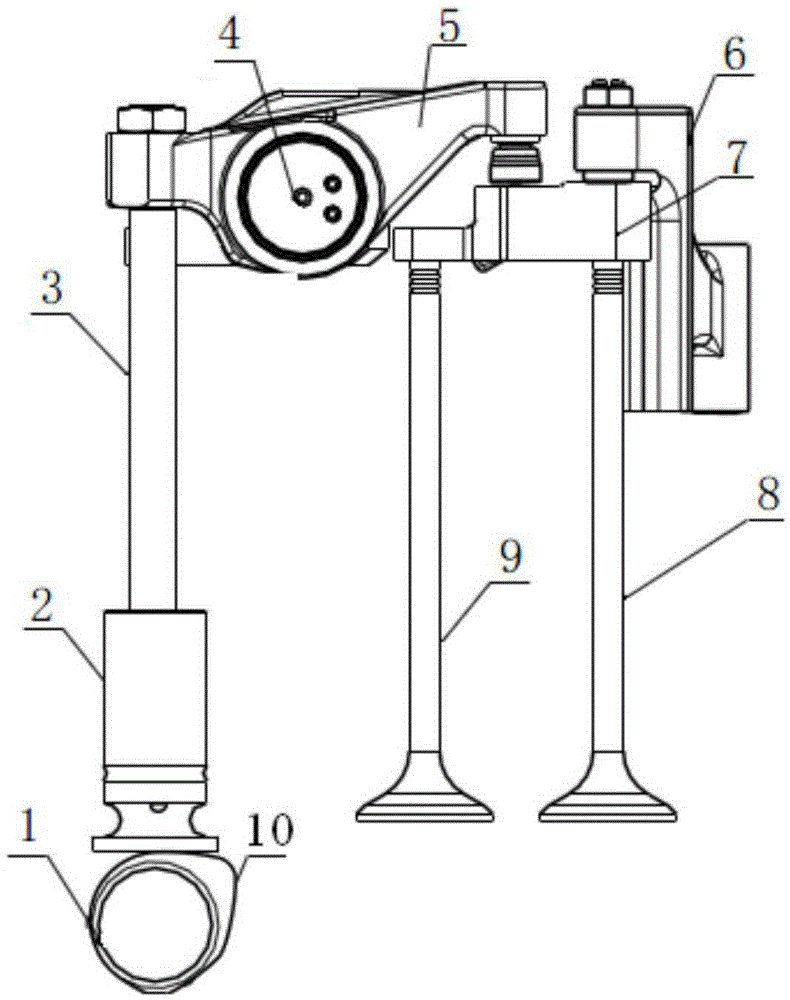

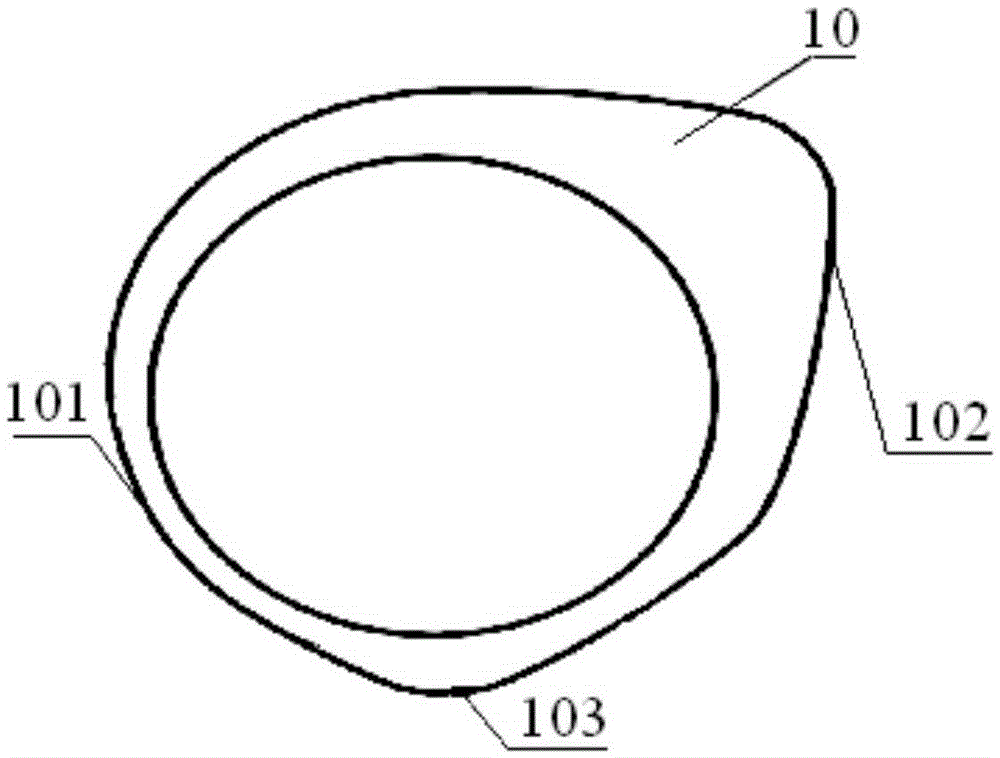

Variable-mode valve driving system

ActiveCN107023342AReduce fuel consumptionEmission reductionMachines/enginesNon-mechanical valveExhaust brakeEngine valve

The invention discloses a variable-mode valve drying system and belongs to the field of engine vale driving, cylinder stopping and auxiliary braking. The variable-mode valve driving system comprises an exhaust braking cam, an exhaust drive cam, a gas inlet drive cam and a gas inlet braking cam, wherein all the cams drive a valve through push rods, rocker arms and the like. The variable-mode valve driving system further comprises an exhaust braking fulcrum assembly, an exhaust drive fulcrum assembly, a gas inlet drive fulcrum assembly and a gas inlet braking fulcrum assembly which are arranged between all the cams and correspond valve assemblies or all the cams and corresponding valve bridge assemblies. Modes of four-stroke driving, two-stroke braking, cylinder stopping and the like are achieved by controlling the states of all the fulcrums, and the purposes of low oil consumption, low emission and efficient braking are achieved. The variable-mode valve driving system is compact in structure, high in reliability and low in cost.

Owner:DALIAN UNIV OF TECH

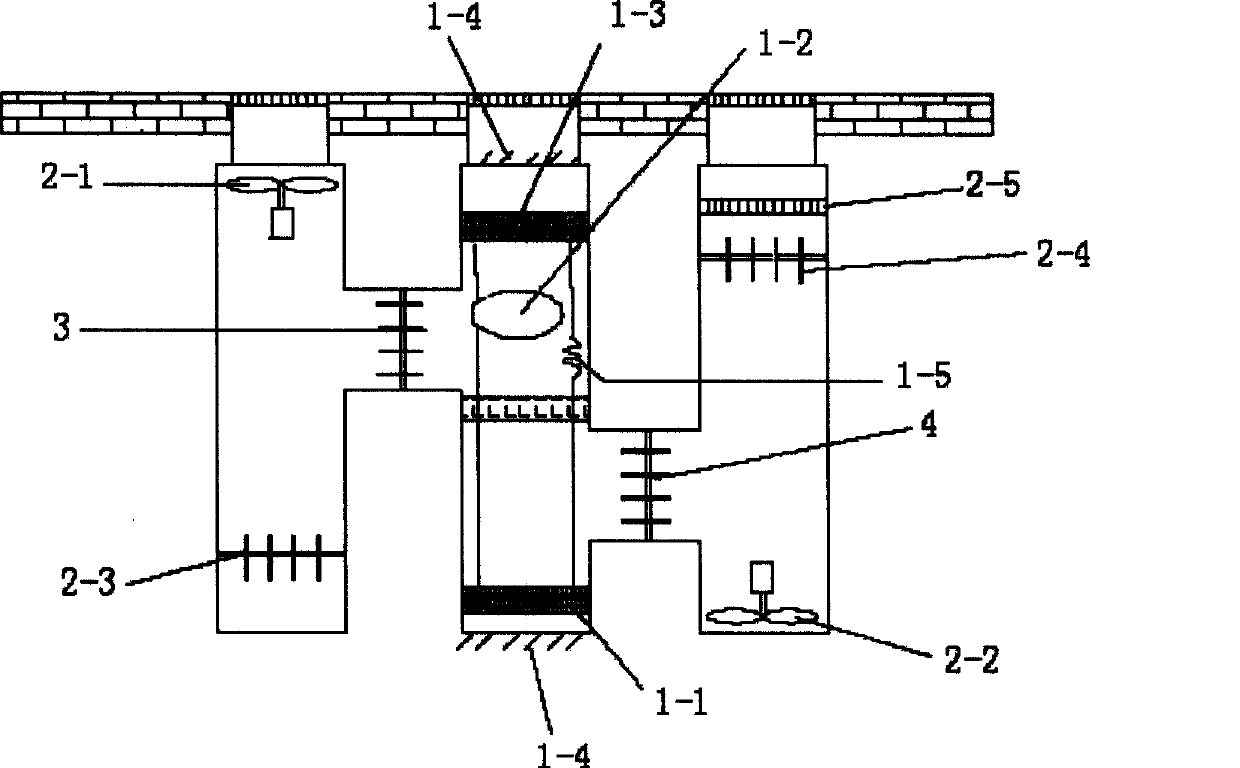

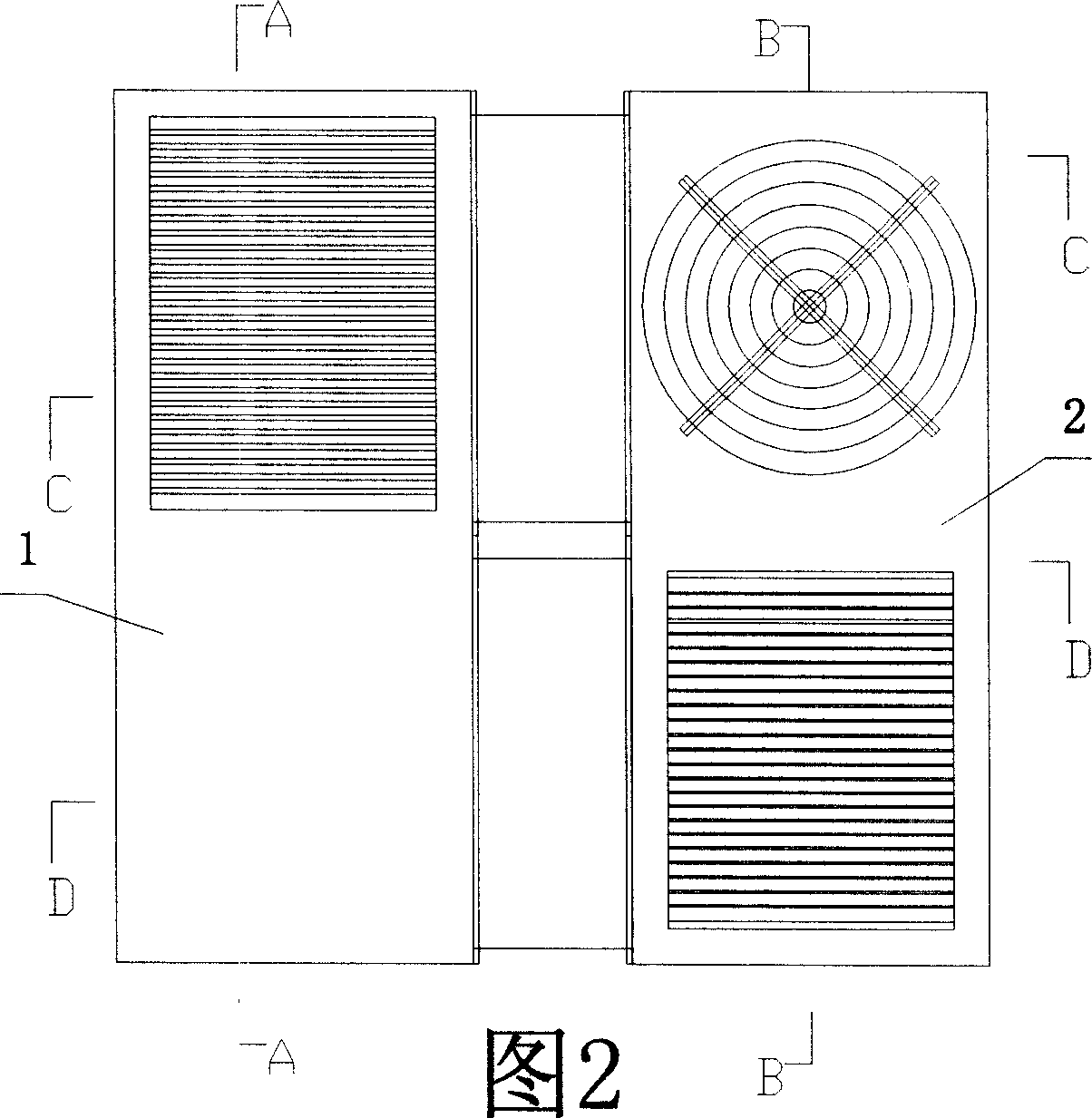

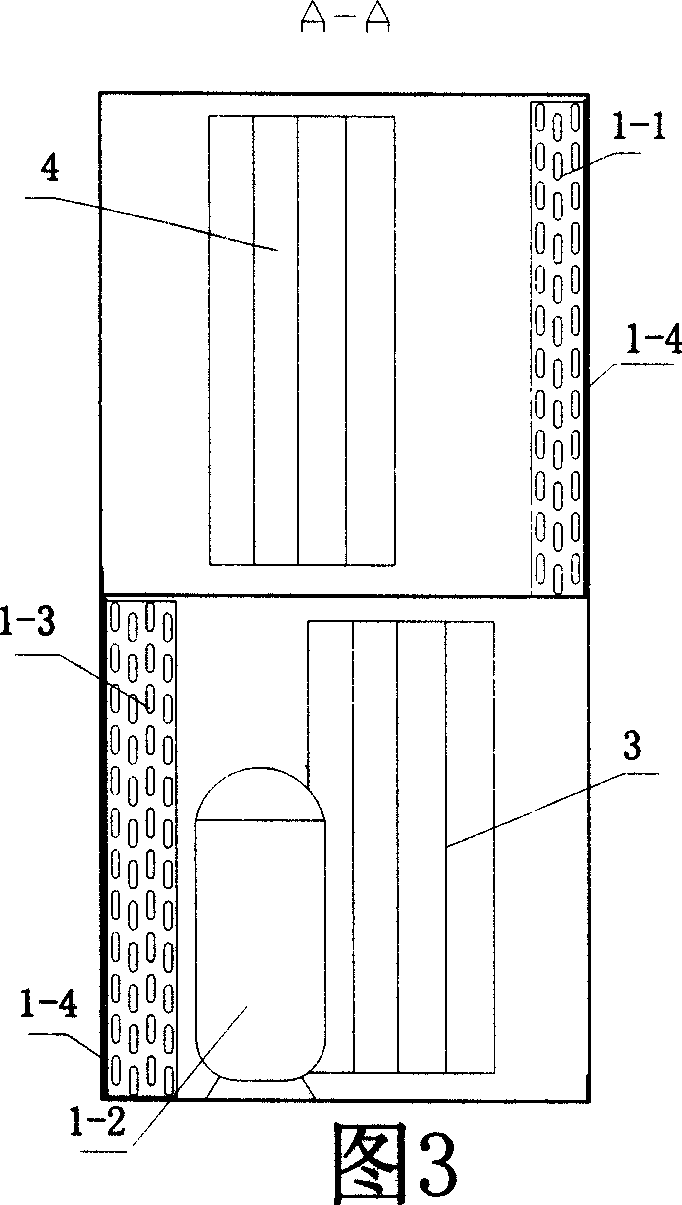

Fresh air integral energy-saving air conditioner unit special for machinery room

InactiveCN101373087AImprove insulation effectIncrease temperatureLighting and heating apparatusAir conditioning systemsBusiness efficiencyFresh air

The invention relates to a fresh air integral-type air conditioning unit used particularly in an energy-saving equipment room. The unit comprises an air conditioner, an automatic air brake, a controller and a fresh air machine, wherein, a compressor, a condenser, an evaporator, a capillary throttle pipe and a connecting pipe are assembled to form an integral air conditioner which is divided into an upper layer and a lower layer by a clapboard; the fresh air machine comprises an automatic air inlet brake, an automatic air exhaust brake, an air inlet fan and an air exhaust fan; the fresh air machine is divided into an upper layer and a lower layer corresponding to the air conditioner; the automatic air inlet brake and the air inlet fan are arranged on the upper layer of the fresh air machine; the automatic air exhaust brake and the air exhaust fan are arranged on the lower layer of the fresh air machine; the fresh air machine is respectively connected through the pipe with the upper and the lower layer of the air conditioner to form a whole; an automatic air brake is respectively arranged at the connecting part between the upper layer of the air conditioner and the fresh air machine and the connecting part between the lower layer of the air conditioner and the fresh air machine; and the controller is respectively connected with the automatic air exhaust brake, the automatic air inlet brake, the air exhaust fan, the air inlet fan, two automatic air brakes, and the air conditioner. The air conditioning unit is characterized in that the energy efficiency ratio between fresh air cooling and fresh air heating is particularly high; furthermore, the air conditioning unit can be integrally installed in the equipment room for security concern, or outside the equipment room for reducing noise and occupied space.

Owner:姚京生

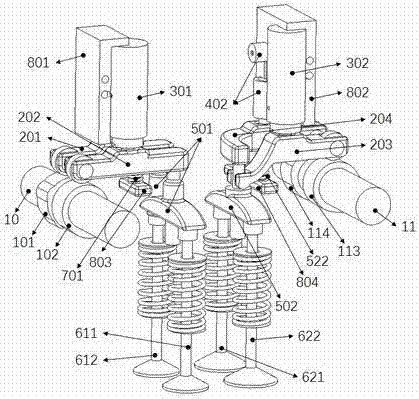

Single-cam-shaft switch pivot type variable-mode air valve driving system

ActiveCN107100686AReduce fuel consumptionEmission reductionValve drivesMachines/enginesExhaust valveExhaust brake

The invention discloses a single-cam-shaft switch pivot type variable-mode air valve driving system, and belongs to the field of engine valve driving, cylinder deactivation and auxiliary braking. The single-cam-shaft switch pivot type variable-mode air valve driving system comprises an exhaust valve assembly, an exhaust braking cam, an exhaust driving cam, an air intake driving cam, an air intake braking cam, an exhaust braking rocker arm, an exhaust driving rocker arm, an air intake driving rocker arm, an air intake braking rocker arm, an exhaust braking pivot assembly, an exhaust driving pivot assembly, an air intake driving pivot assembly, an air intake braking pivot assembly and the like. By control over states of all pivots, four-stroke driving, two-stroke driving, cylinder deactivation and other modes are realized, thus fulfilling the aims of low oil consumption, low emission and efficient braking. The number of moving pieces is small, and the system is compact in structure, high in reliability, low in cost, low in energy consumption and leakage-free.

Owner:DALIAN UNIV OF TECH

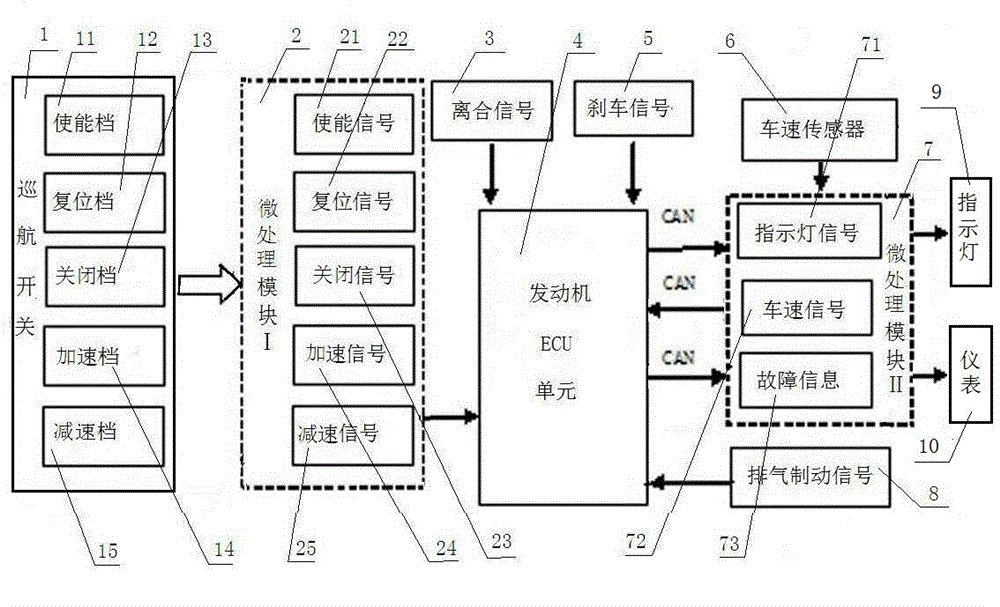

Automobile cruise control system and method

ActiveCN104385919AEasy to operateReduce work intensityVehicle fittingsSpeed/accelaration controlArea networkControl signal

The invention discloses an automobile cruise control system and method and belongs to the automobile manufacturing technical field. The automobile cruise control system comprises a first micro processing module I which is connected with an engine ECU (Electronic Control Unit); the first micro processing module I is connected with a cruise switch; the engine ECU is connected with a second micro processing module II through a CAN (Controller Area Network) bus; the second micro processing module II is connected with a speed sensor. The automobile cruise control method comprises receiving a speed signal through the second micro processing module and transmitting the speed signal to the engine ECU through the CAN bus; receiving a control signal and a clutch signal and an exhaust braking signal through the engine ECU and performing analysis on the signals; controlling the speed state through the engine ECU according to the control requirements when the cruise control conditions are met and transmitting a cruise control state signal to the second micro processing module II to control the working state of an indicator lamp. According to the automobile cruise control system and method, the problems of the automobile cruise control and abnormal prompts can be solved.

Owner:DONGFENG LIUZHOU MOTOR

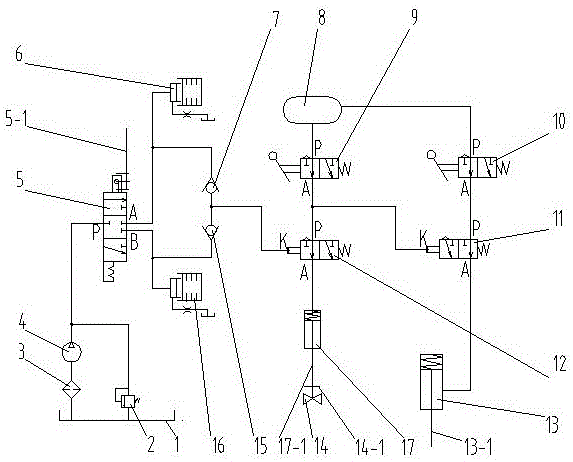

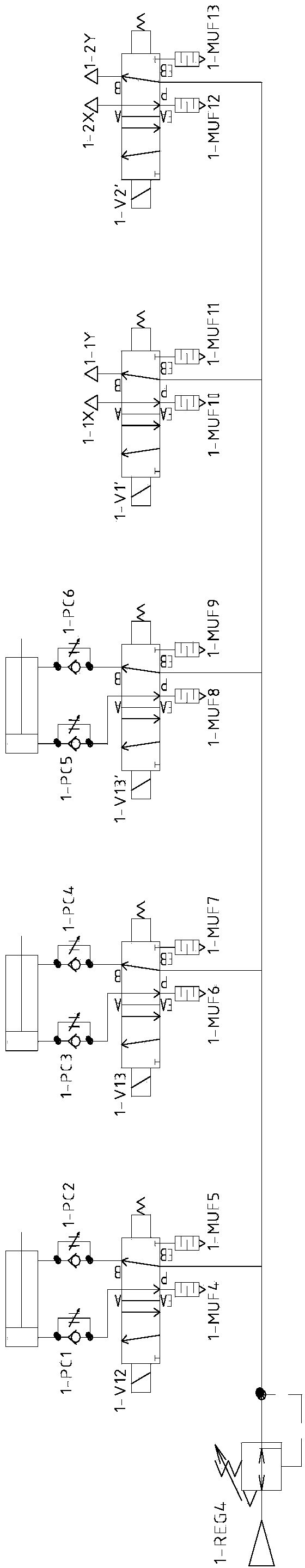

Flameout system of vehicle during exhaust brake

The invention discloses a flameout system of a vehicle during exhaust brake. The flameout system comprises a fuel tank, a filter, a hydraulic pump, a gear choosing operating valve, a forward gear clutch, a first one-way valve, an air bag, an exhaust butterfly valve switch, a flameout switch, a pneumatic control valve, a hydraulic control air valve, a flameout cylinder, an exhaust butterfly valve, a second one-way valve, a backward gear clutch and a butterfly valve cylinder, wherein the gear choosing operating valve comprises an operating lever; and the operating lever is connected with a gear selector positioned in a cab through a flexible shaft. According to the flameout system of the vehicle during exhaust brake, the drying safety is high, the vehicle can automatically flame out during exhaust brake.

Owner:HUBEI ZHENGXING EQUIP MFG

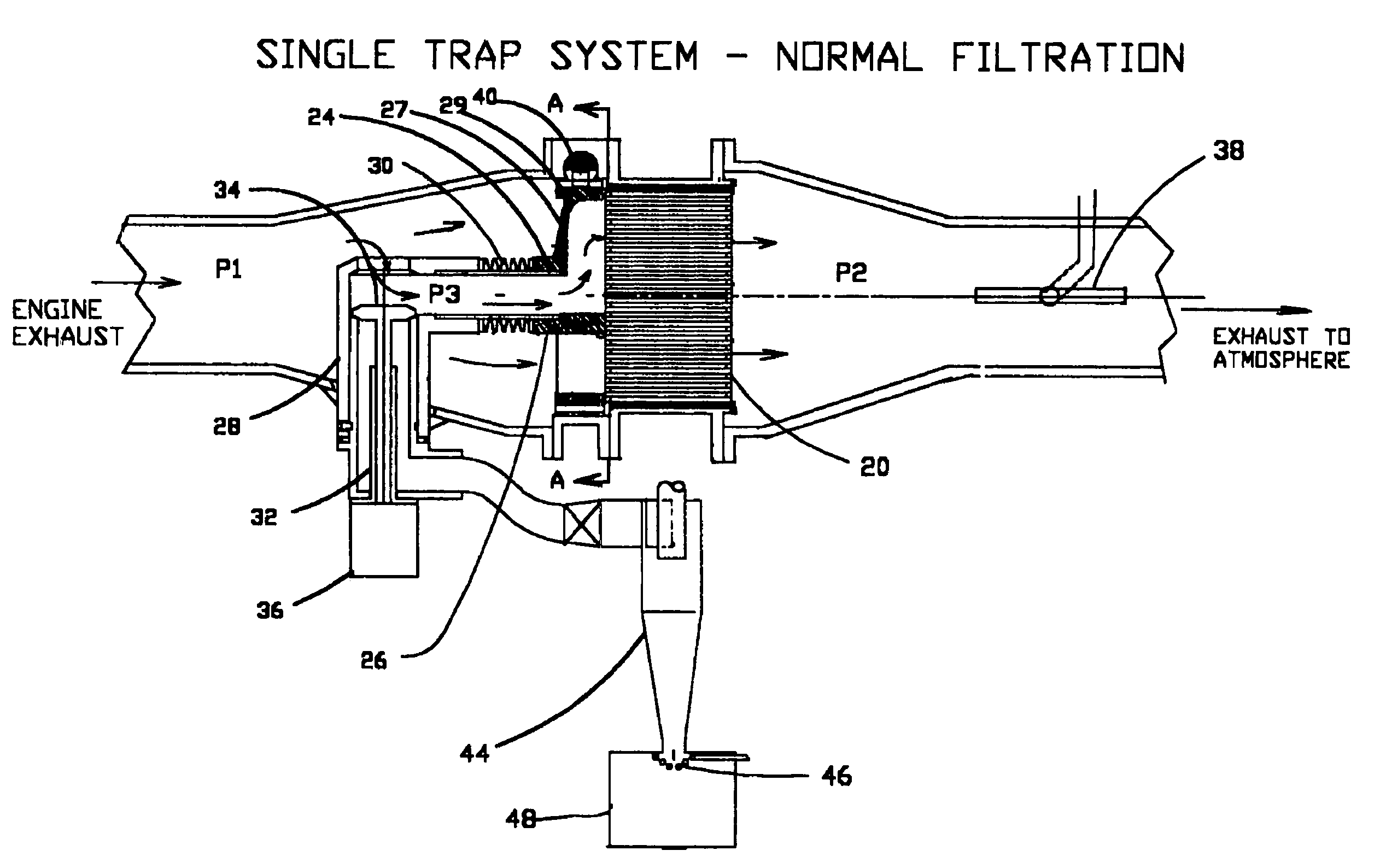

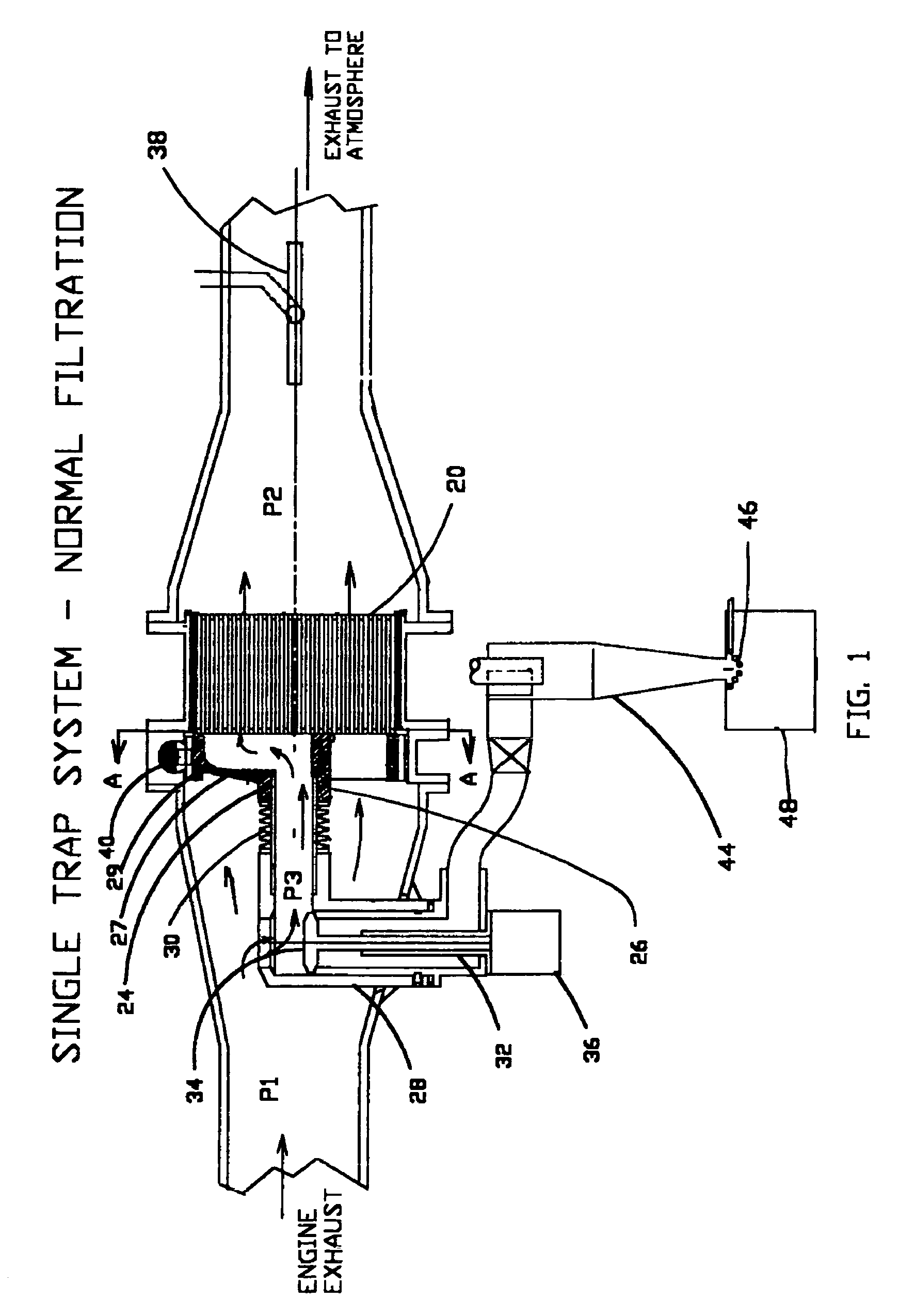

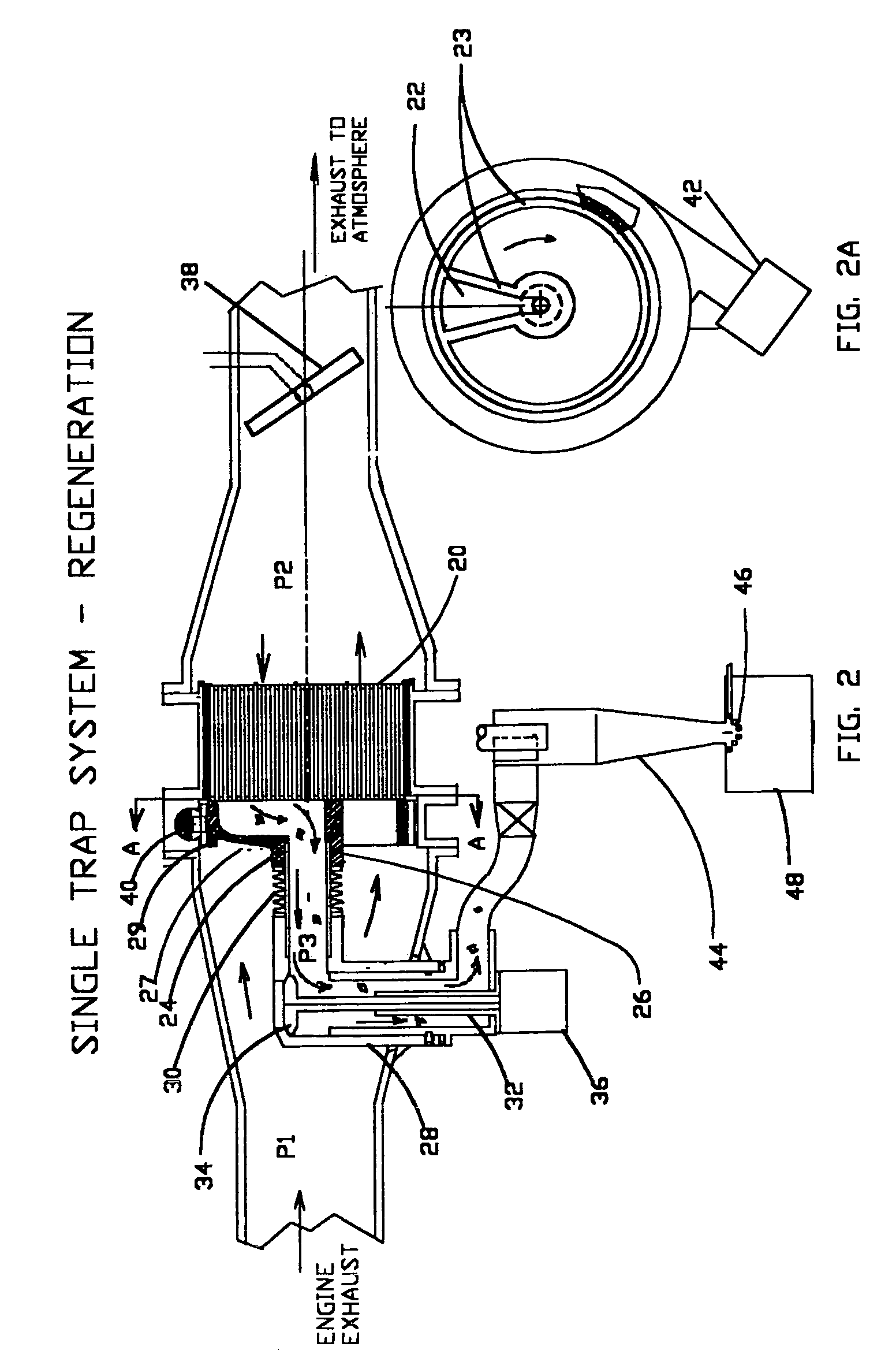

Particulate trap system and method

A particulate trap system for an internal combustion engine includes a plurality of contiguous porous walls, and a remotely actuated relief valve downstream of said trap for periodically creating a reverse pressure throughout the exhaust system upstream of the relief valve and including said trap. A reversing apparatus periodically creates a reverse pressure drop across a portion of the contiguous porous walls of said trap to dislodge accumulated particulate and cause a portion of the filtered exhaust gas to flow back through said portion of the contiguous porous walls to remove particulate therefrom. A control system actuates the relief valve and the reversing apparatus. In one embodiment the system is utilized on a vehicle and the reversing apparatus includes a relief valve that is also operative as an exhaust brake. Regeneration includes the steps of: creating a backpressure in the entire exhaust system from a location downstream of the trap; creating a reverse pressure drop across only a portion of the porous walls to dislodge accumulated particulate therefrom; and causing a portion of filtered exhaust gas to flow back through said portion of the porous walls to carry the dislodged particulate out of the trap.

Owner:ILLINOIS VALLEY HLDG

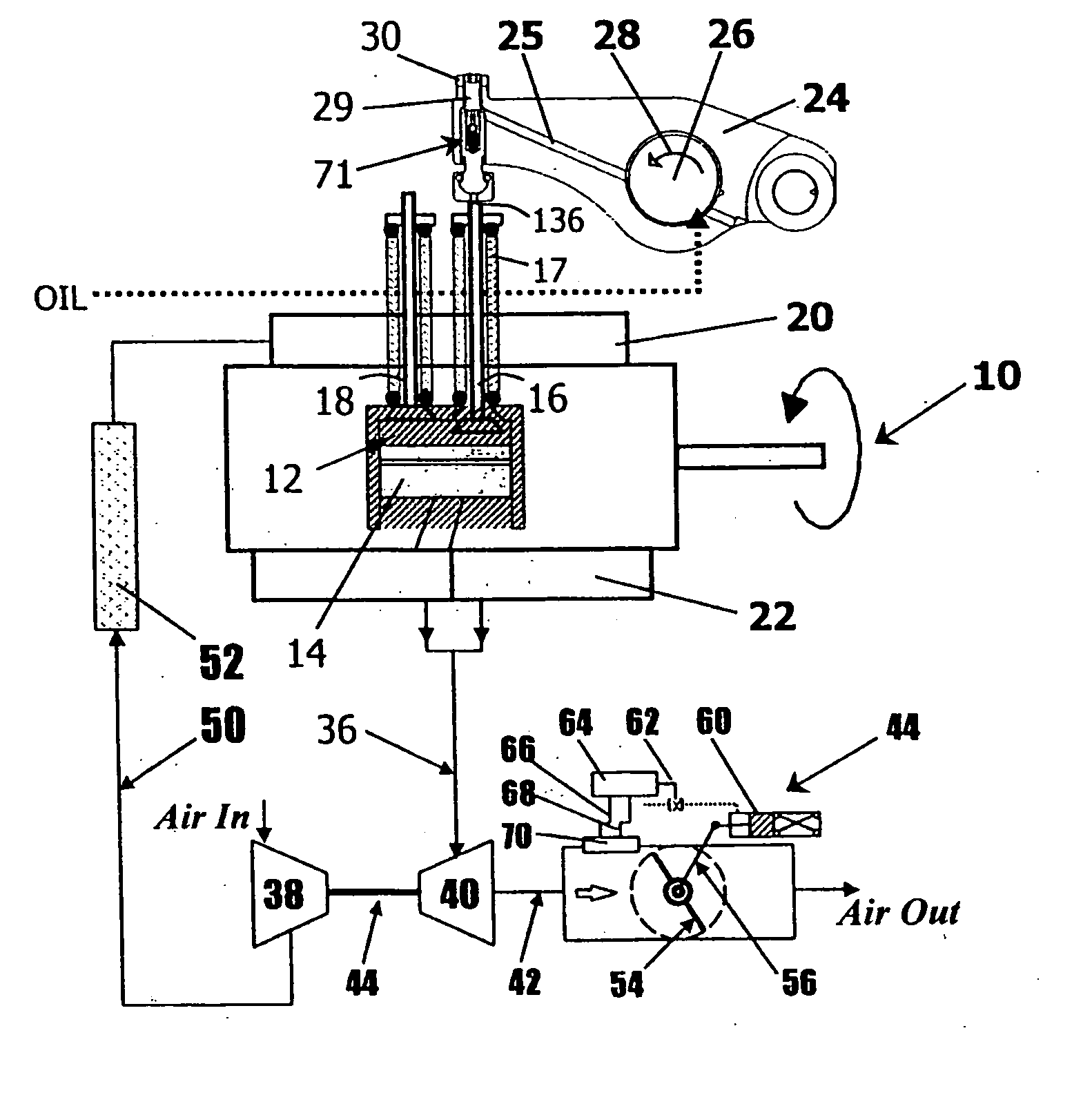

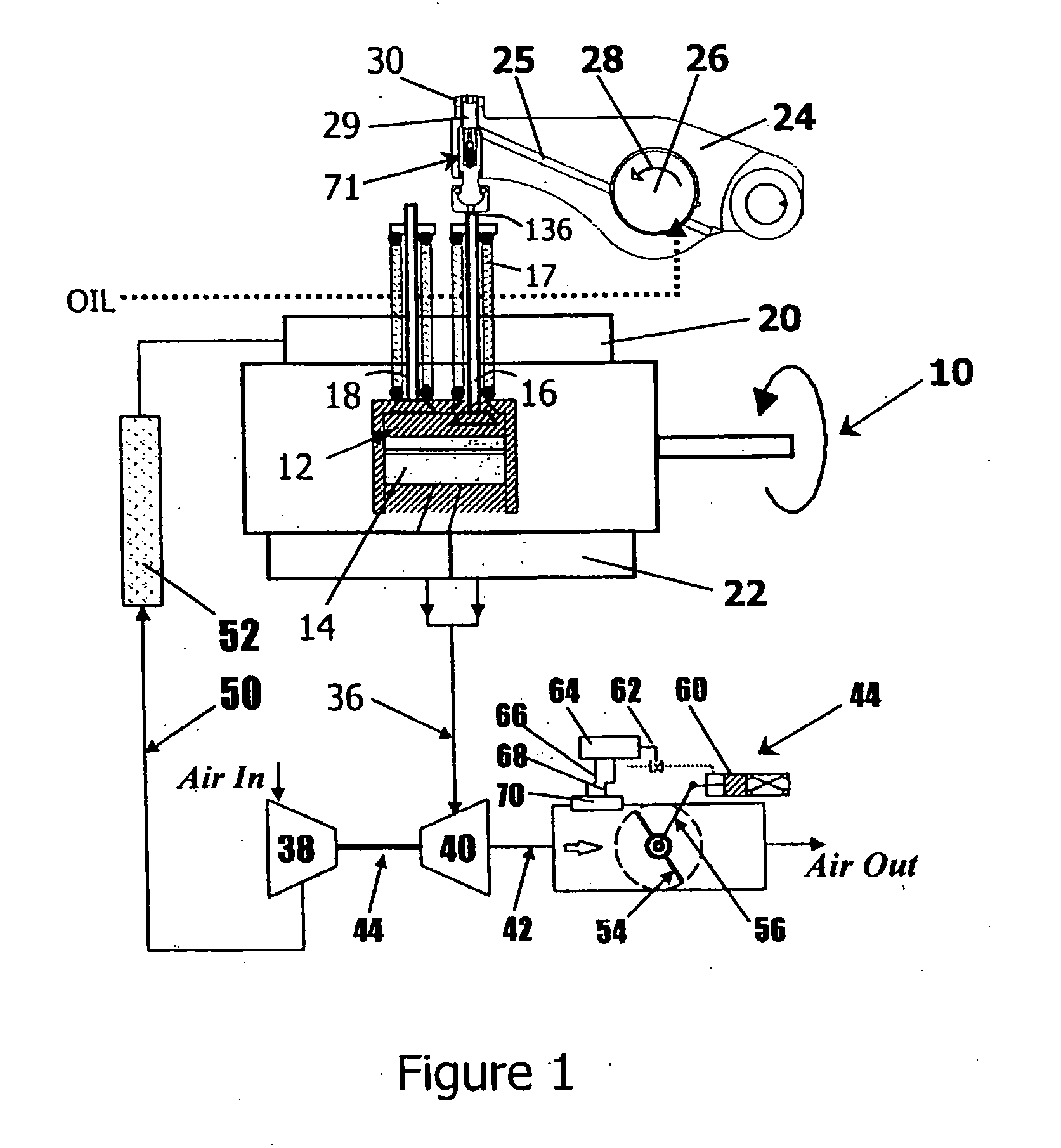

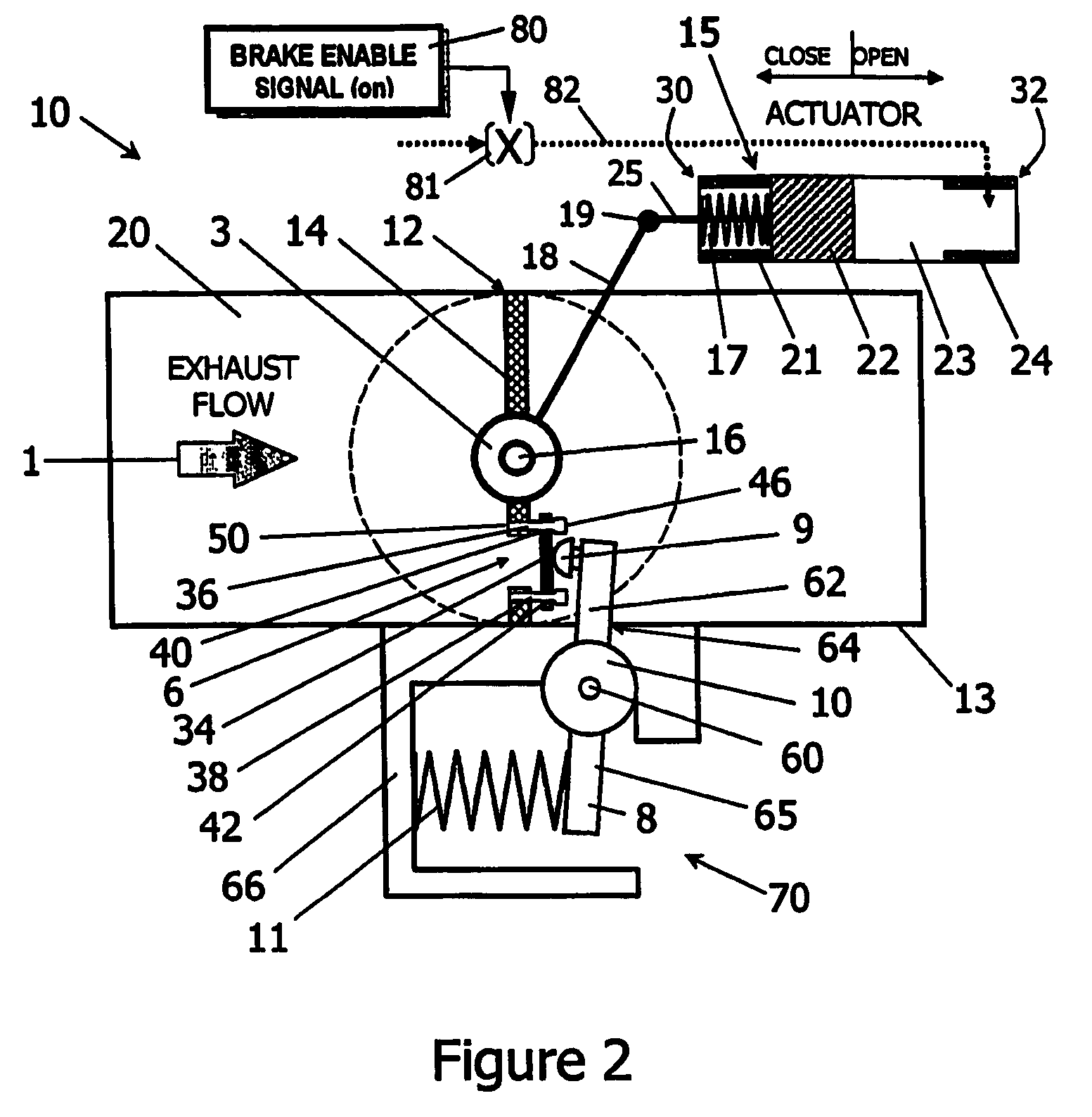

Apparatus and method for retarding an engine with an exhaust brake and a compression release brake

An apparatus and method for retarding an engine having a cylinder with an exhaust valve, an intake valve, an intake stroke, an exhaust stroke, a compression stroke and an expansion stroke. The apparatus includes an exhaust brake and a compression release brake. The exhaust brake includes a variable exhaust restrictor, a pressure sensor for sensing pressure of exhaust gases and a controller operatively connected to the pressure sensor and to the exhaust restrictor. Opening of the exhaust restrictor is adjusted during operation of the apparatus so exhaust pressure is sufficient to cause exhaust valve float prior to bottom dead center of intake strokes of the cylinder, thereby enhancing operation of the compression release brake.

Owner:JENARA ENTERPRISES

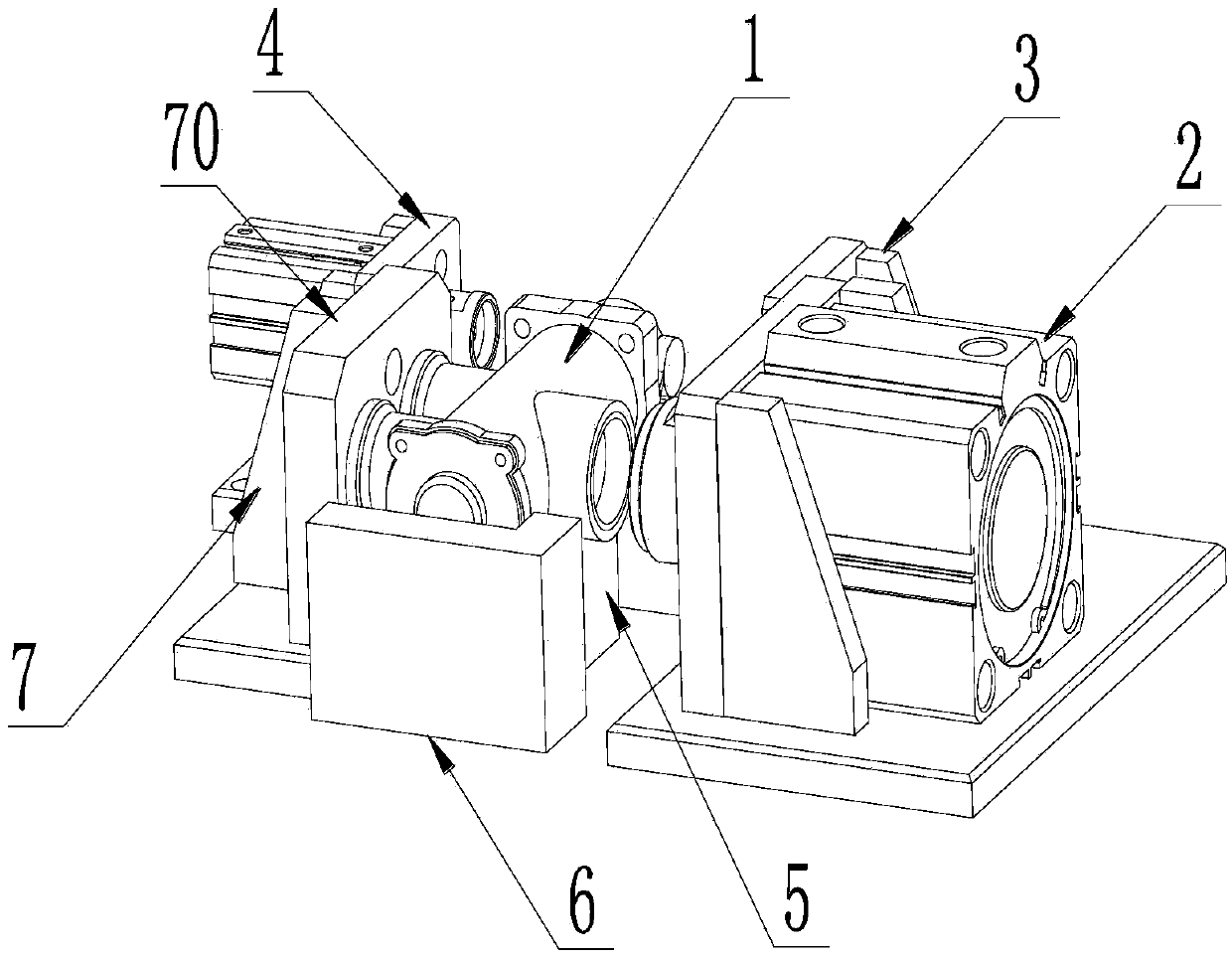

Gas control reversing valve detection device and detection method

InactiveCN104155093AImprove test efficiencyImprove test accuracyMachine part testingTest efficiencyTurbocharger

The invention discloses a gas control reversing valve detection device which is fixed on a rack. The device comprises a cylinder tooling which blocks a 2 port of an air compressor air inlet interface of a gas control reversing valve, a right cylinder tooling which blocks a 41 port of a pressure regulating valve air inlet interface of the gas control reversing valve, and a left cylinder tooling which blocks a 42 port of an exhaust brake valve control interface of the gas control reversing valve. Each cylinder is provided with a plug. The air inlet of each cylinder carries out air inlet, and a plug which is connected with the cylinder to stretch forward to block an interface of the gas control reversing valve. A positioning seat which fixes the gas control reversing valve is arranged on the rack. A spacing seat is arranged on one end of the positioning seat. A blocking tooling is arranged on one side of the positioning seat. A blocking plate which is corresponding to an 11 port of an air cleaner interface and a 12 port of a turbocharger interface of the gas control reversing valve is arranged on the blocking tooling. The invention further provides a pressure circuit and a detection method of the gas control reversing valve detection device. The detection device provided by the invention has the advantages of high test efficiency and test precision, simple and practical fixation component structure and high clamp precision.

Owner:CHINA JILIANG UNIV

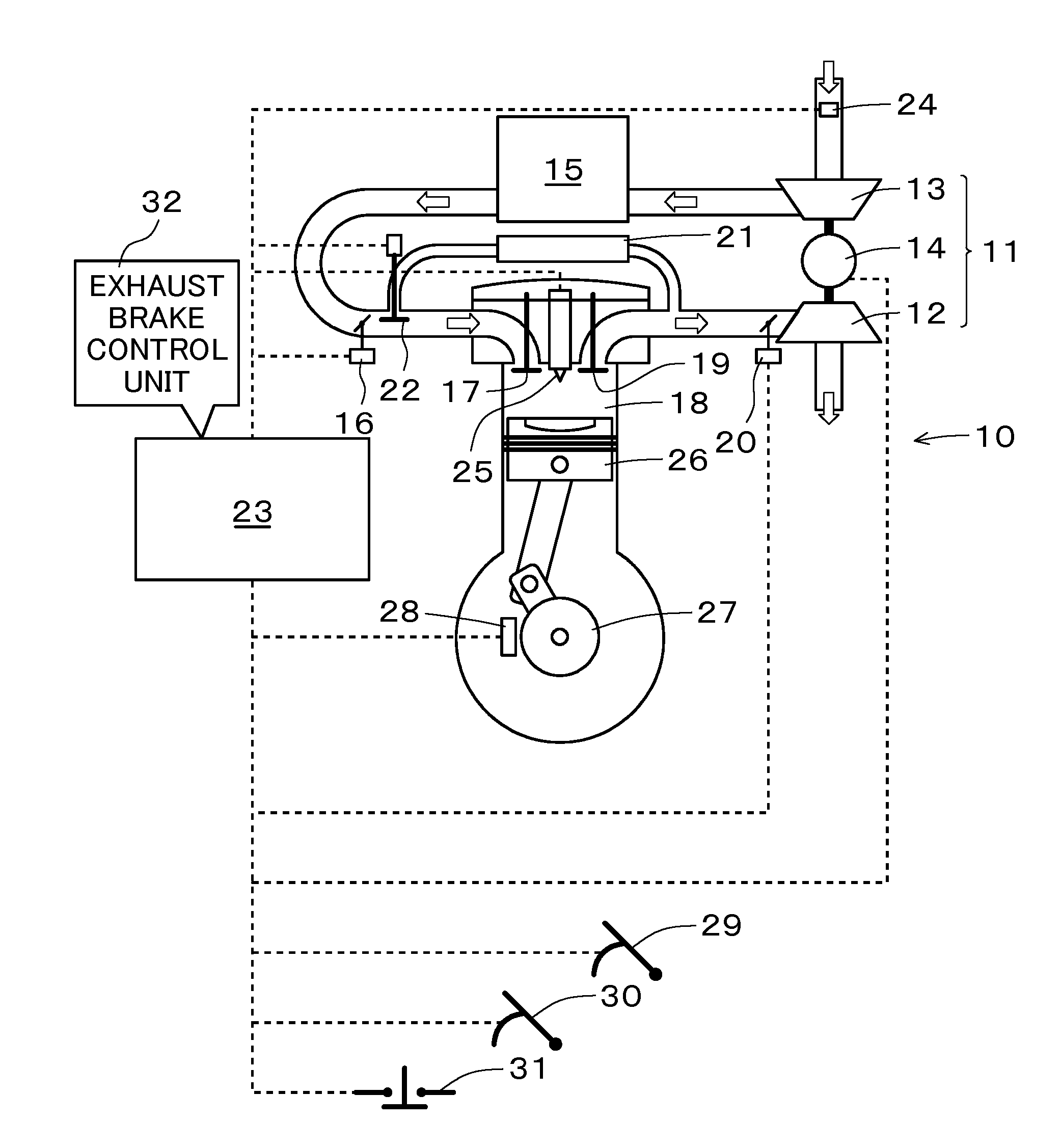

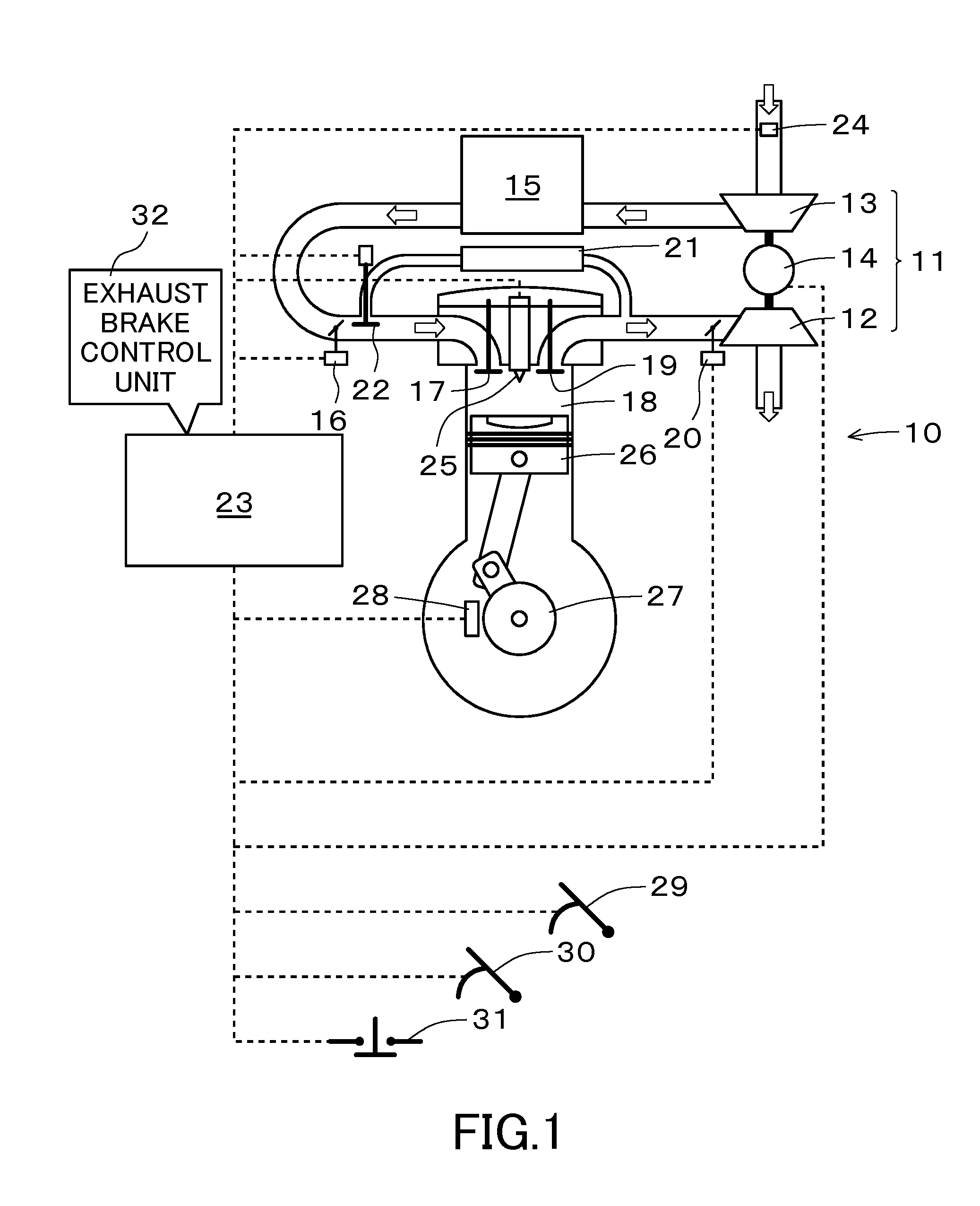

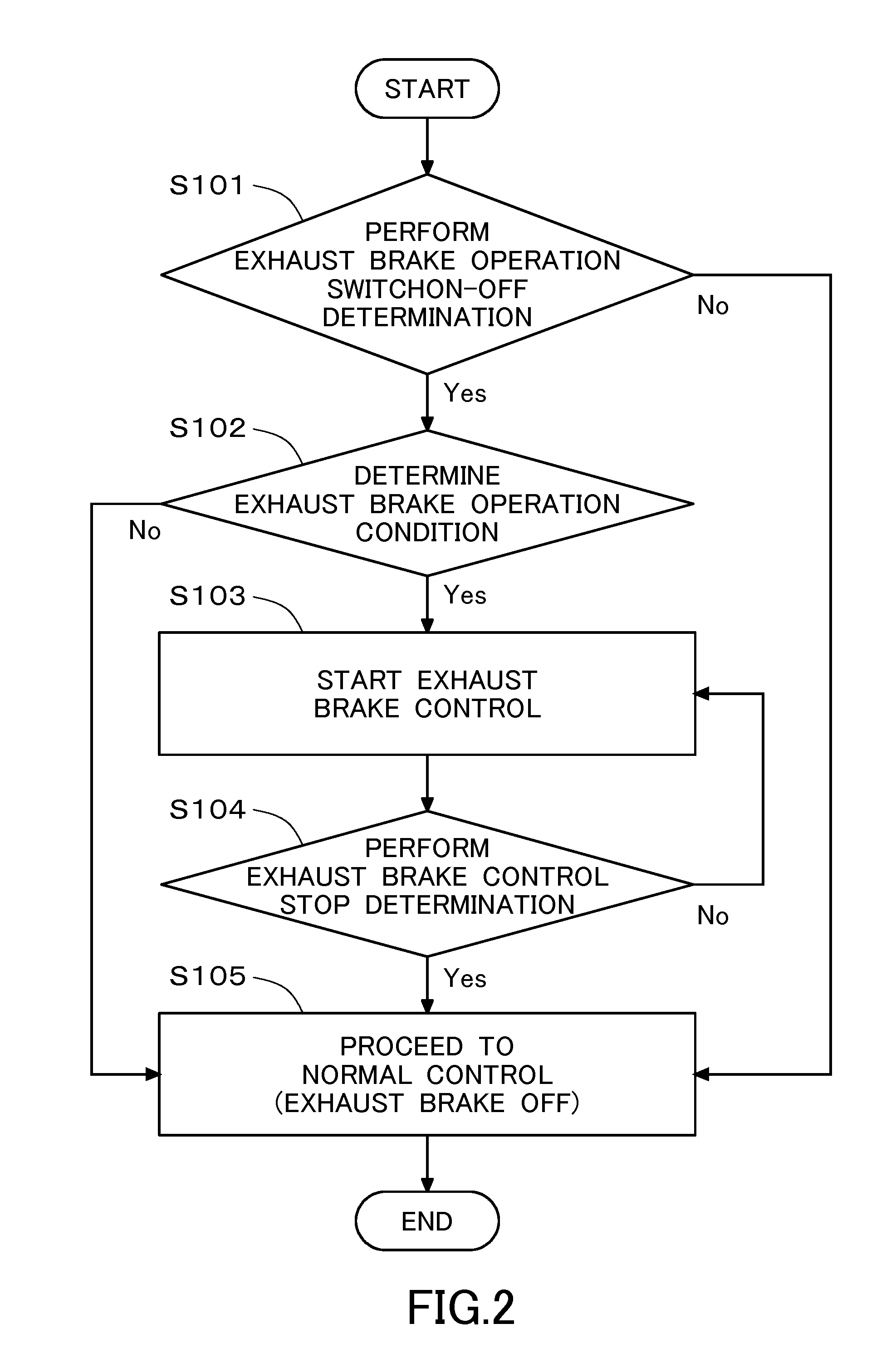

Internal combustion engine exhaust brake control method and device

InactiveUS20130213350A1Increase braking powerElectrical controlInternal combustion piston enginesInternal pressureTurbocharger

An internal combustion engine exhaust brake control method for increasing a braking force by increasing an exhaust pipe internal pressure when performing exhaust brake control by a vehicle in which an electric turbocharger is connected to an intake system of an engine. The method drives an electric turbocharger to increase a compressor rotation speed to a predetermined rotation speed and to increase an intake air amount when performing exhaust brake control by the vehicle in which the electric turbocharger is connected to the intake system of the engine.

Owner:ISUZU MOTORS LTD

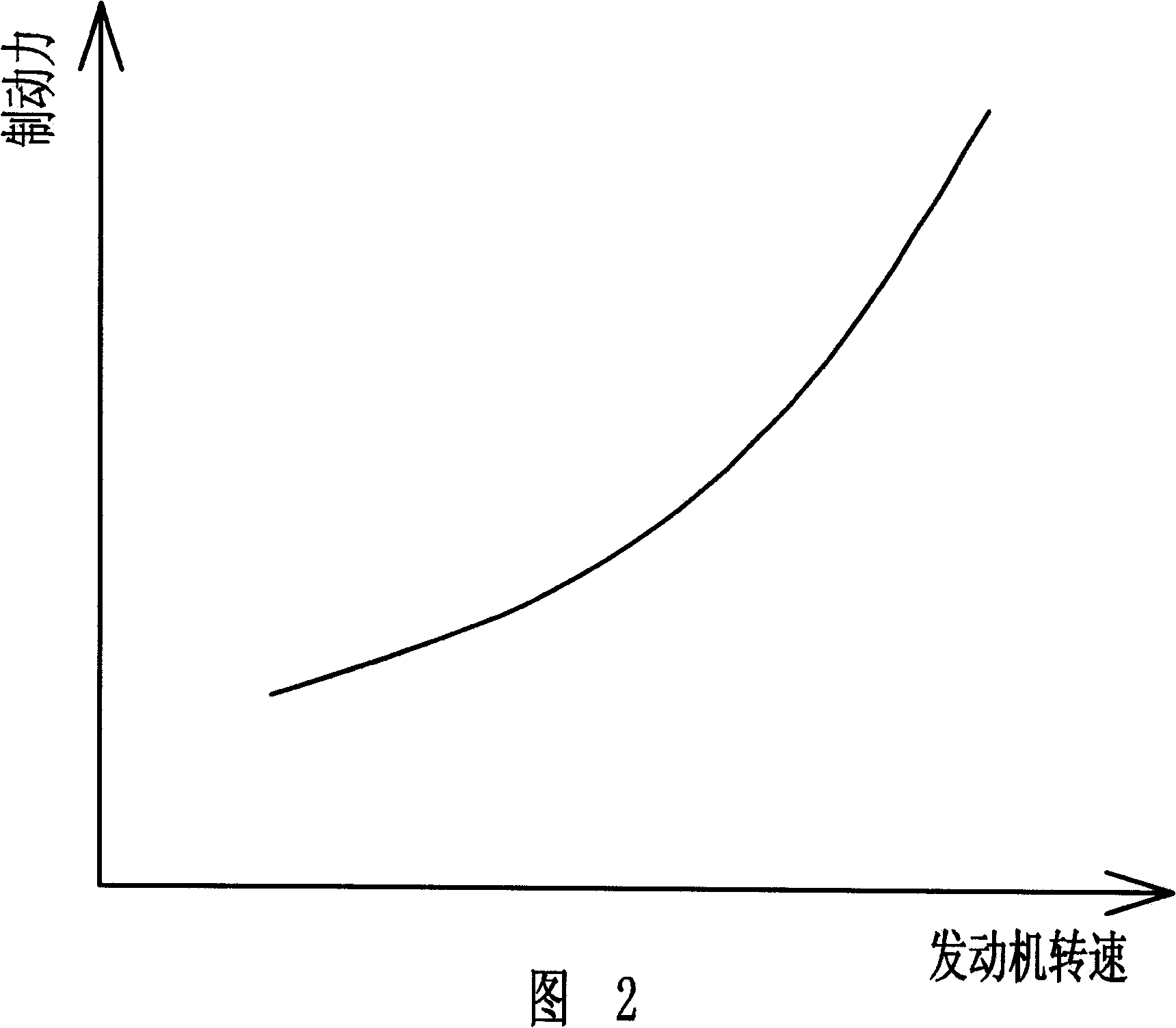

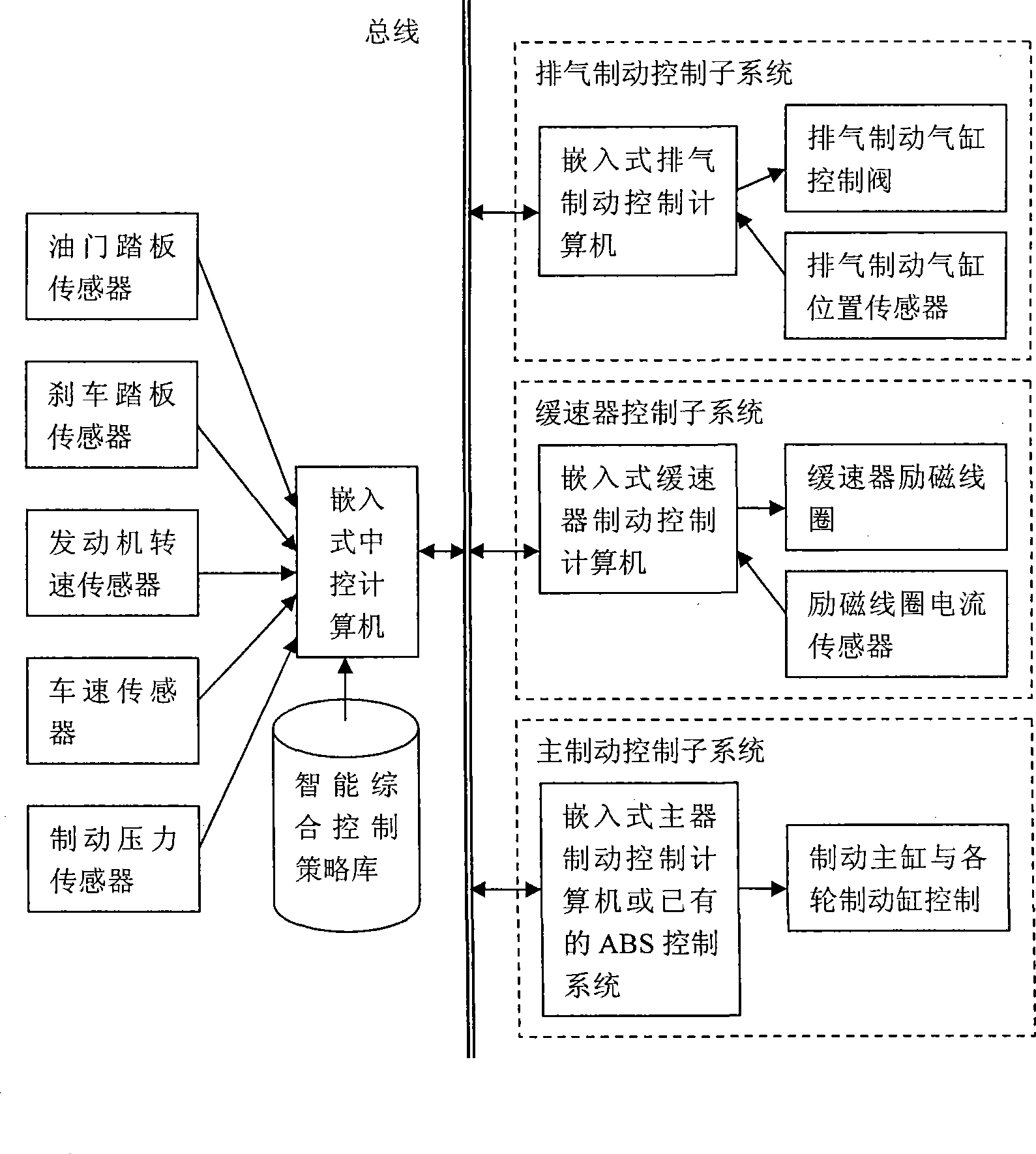

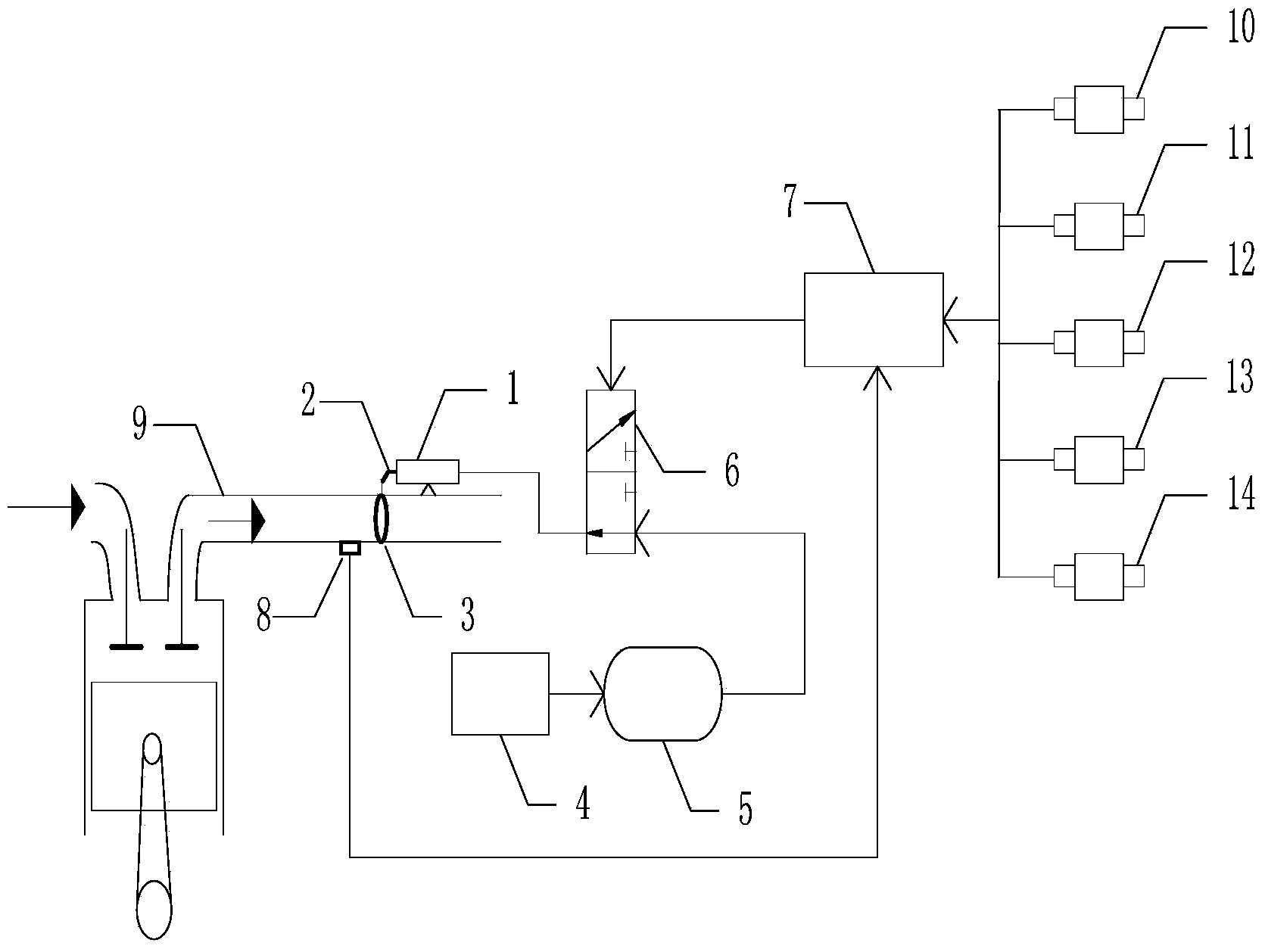

Large-sized vehicle intelligent synthetic brake control system

InactiveCN101474990AOptimal timingStrength optimizationElectric/fluid circuitBrake safety systemsControl systemExhaust brake

The invention discloses a large-scale automotive intelligent comprehensive braking control system, which comprises an accelerator pedal sensor, a brake pedal sensor, an engine rotating speed sensor, a vehicle speed sensor, a braking pressure sensor, an exhaust braking control subsystem, a retarder control subsystem, and a main braking control subsystem. The system is characterized in that the exhaust braking control subsystem, the retarder control subsystem, and the main braking control subsystem are connected with an embedded central control computer through a bus; the accelerator pedal sensor, the brake pedal sensor, the engine rotating speed sensor, the vehicle speed sensor, and the braking pressure sensor are also connected with the embedded central control computer respectively, and an intelligent comprehensive control policy library used for calculating the starting opportunity and braking strength of the subsystems is arranged in the embedded central control computer. The system has the characteristics of realizing the linkage of main braking, exhaust braking and retarder braking, reducing braking energy consumption, and improving braking safety.

Owner:LUDONG UNIVERSITY

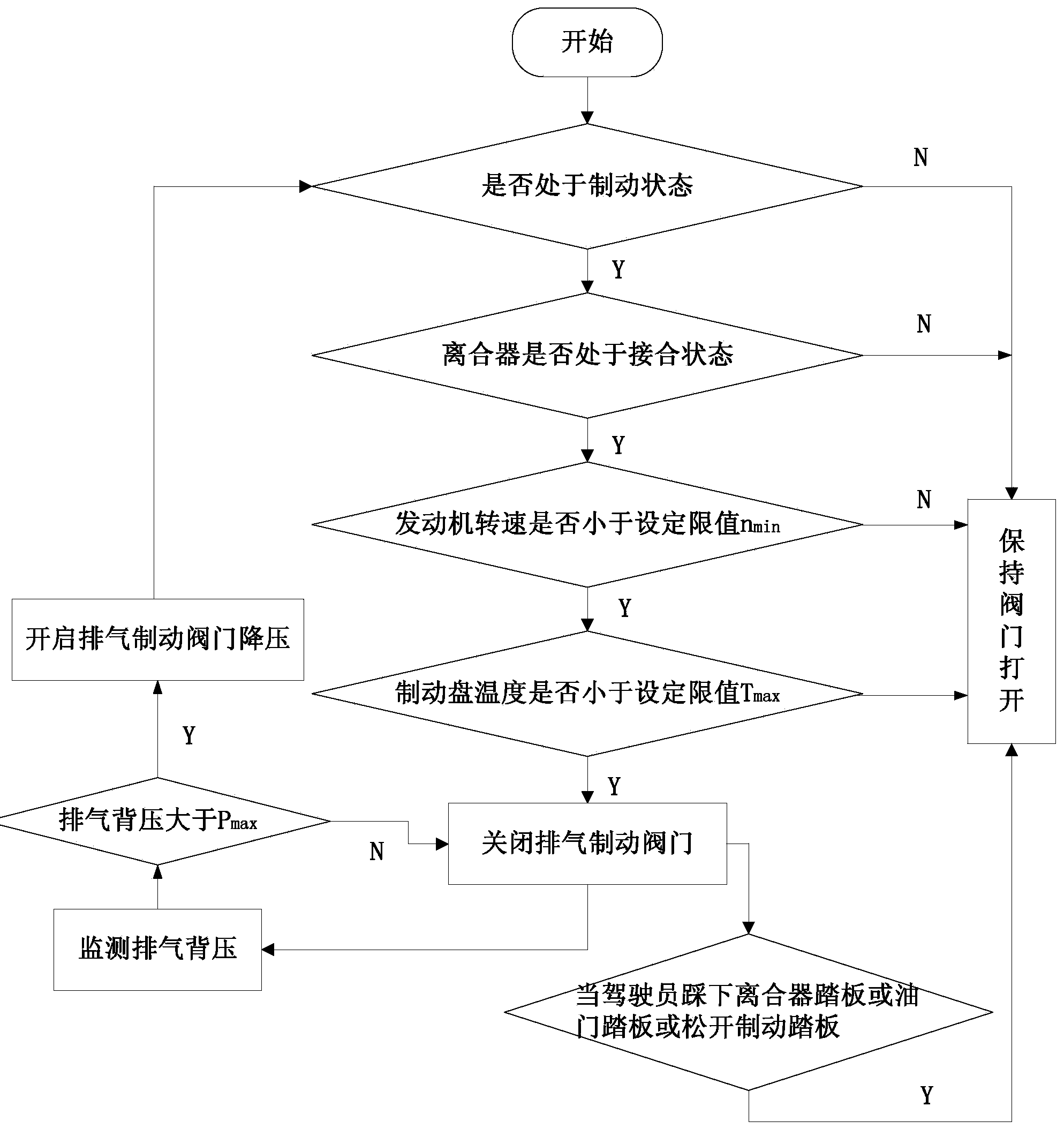

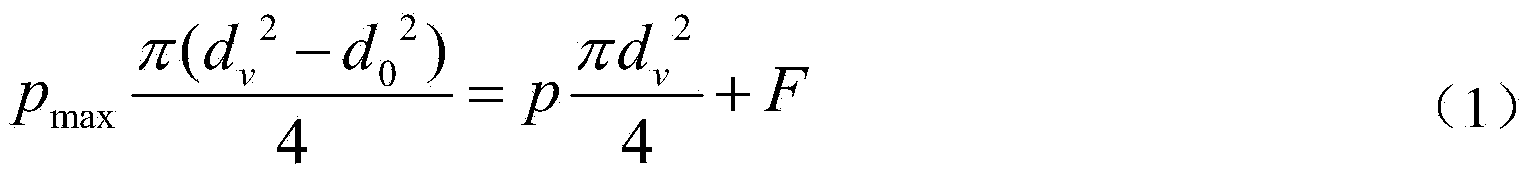

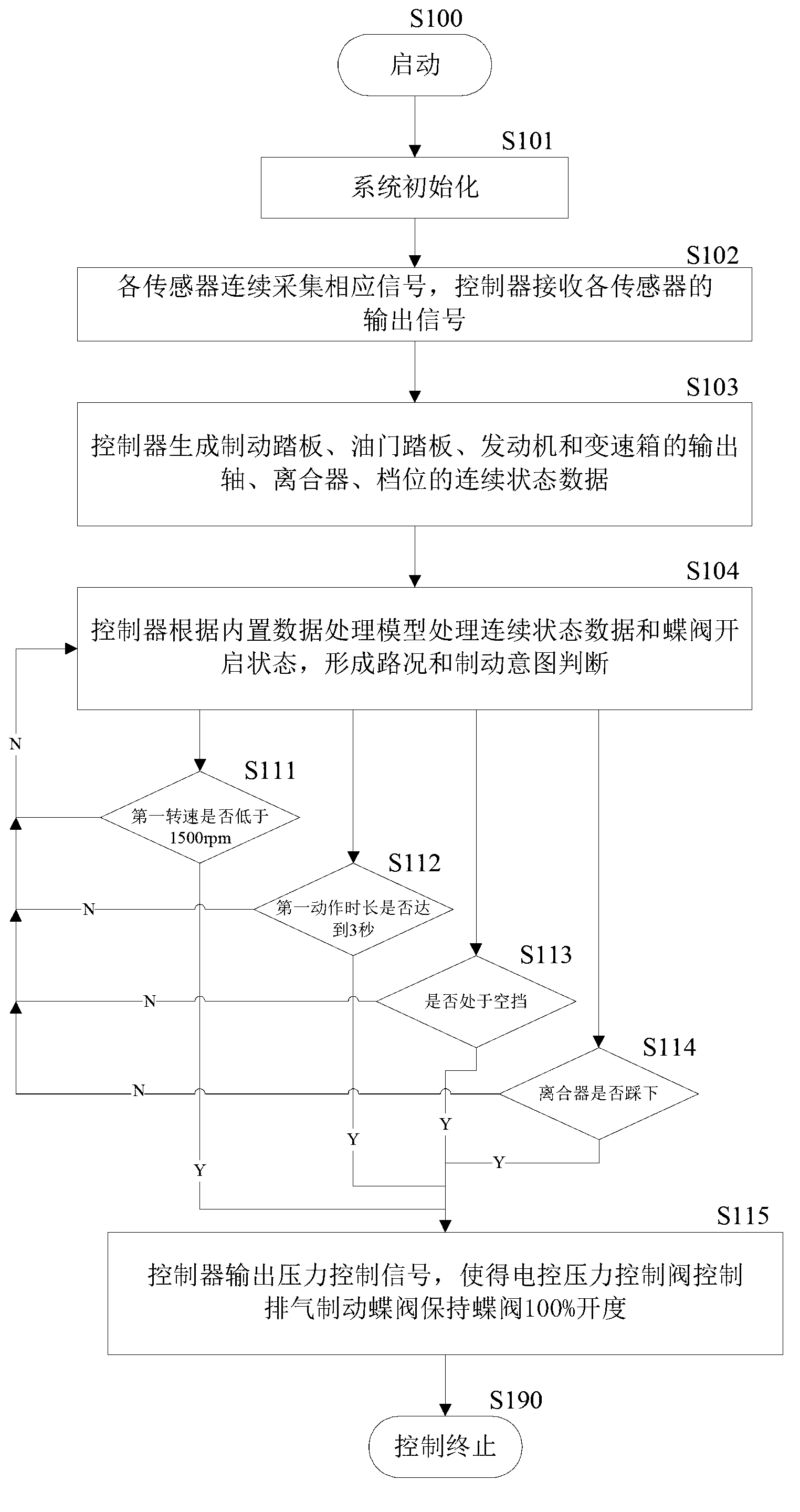

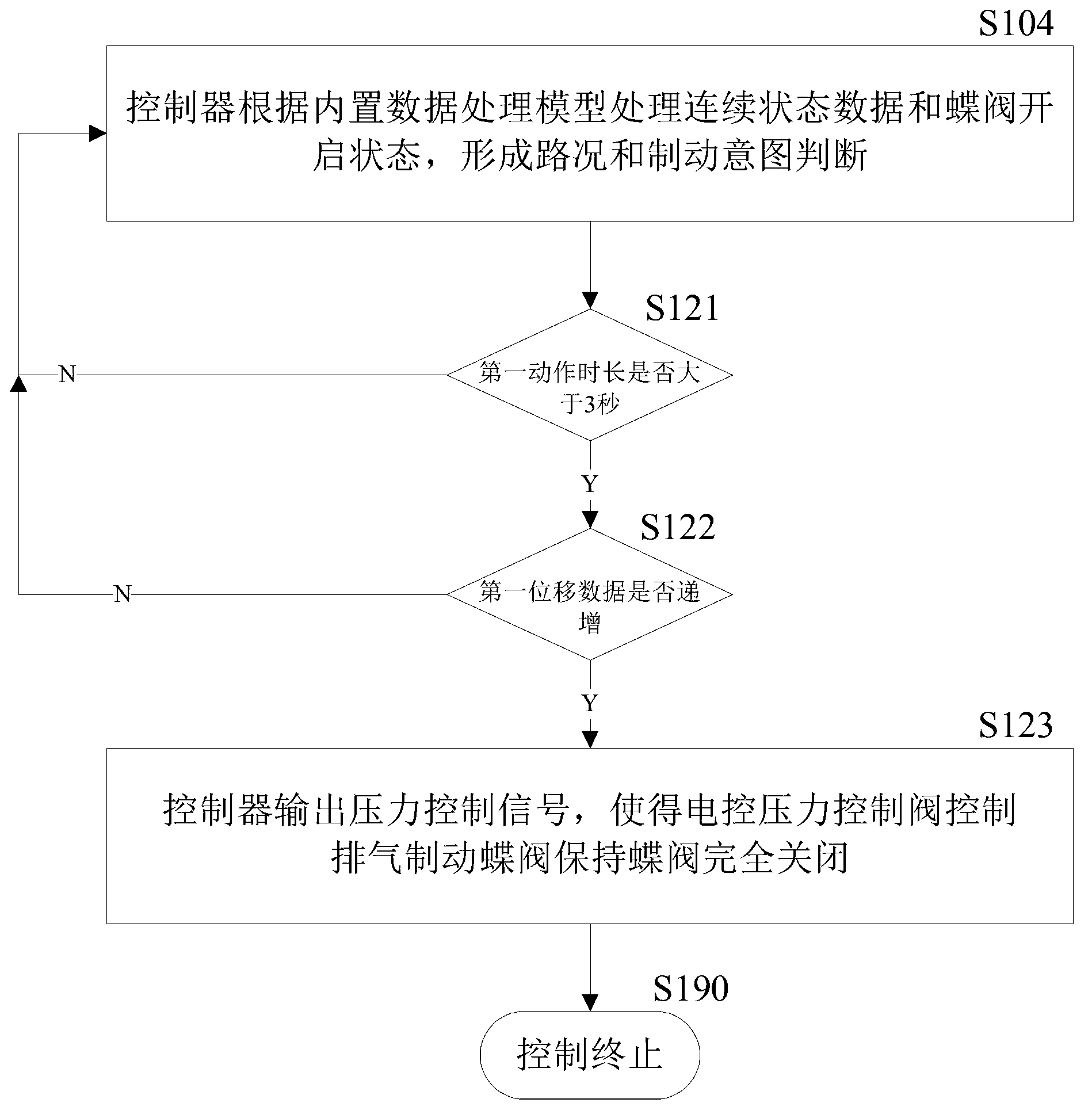

Engine exhaust brake control system and control method

InactiveCN103452676AControl auto-onControl offInternal combustion piston enginesEngine controllersAutomatic controlExhaust valve

The invention discloses an engine exhaust brake control system and a control method. According to the invention, in the automatic exhaust brake opening control process, under the brake state and the condition that a clutch is not separated, a control unit is used for collecting an engine rotation speed and a brake disc temperature signal, when the engine rotation speed is lower than a set limiting value and the brake disc temperature exceeds a set limiting value, the control unit controls an electromagnetic valve to act, so as to realize automatic closing of a butterfly valve; in the pressure regulation feedback control process, after the butterfly valve is closed, the control unit collects an exhaust pipe back pressure signal, and when the exhaust pipe back pressure exceeds a limiting value, the control unit controls the butterfly valve to be opened, and after the pressure is reduced, the automatic exhaust brake opening control process is performed again; in the automatic exhaust brake completing process, when the control unit collects any signal that a driver steps on a clutch pedal or an accelerator pedal or the driver loosens a brake pedal, the butterfly valve is opened, and the exhaust brake is ended. According to the invention, automatic control about exhaust brake is realized, the control accuracy is high, secondary opening of an exhaust valve is avoided, and the braking efficiency is improved.

Owner:DALIAN UNIV OF TECH

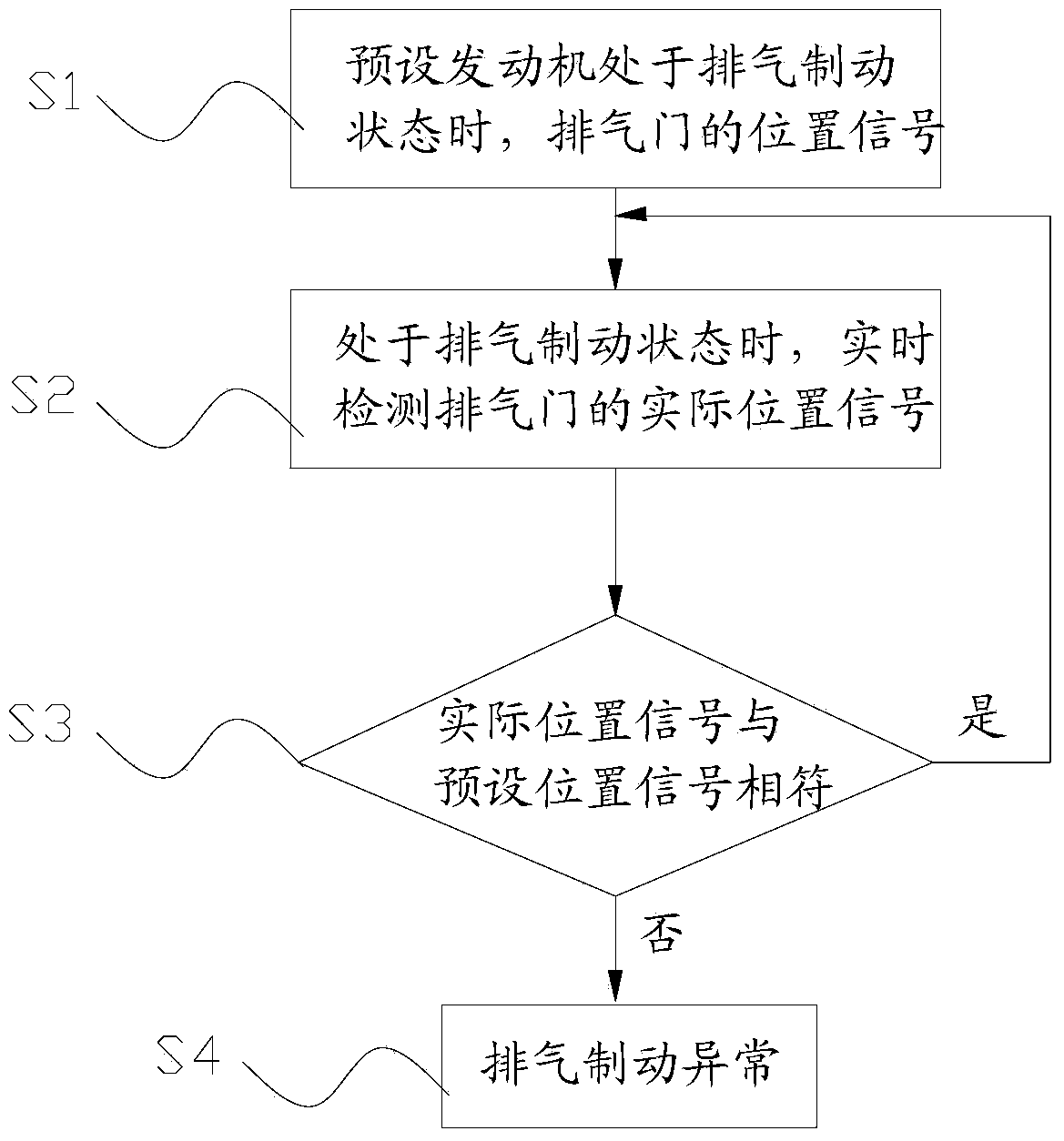

Method and system for monitoring exhaust brake state of engine

The invention discloses a method and system for monitoring the exhaust brake state of an engine. The monitoring method includes the following steps of presetting a position signal of an exhaust valve in the exhaust brake state; detecting an actual position signal of the exhaust valve in real time in the exhaust brake state; judging whether the actual position signal of the exhaust valve conforms to the preset position signal or not, and if not, judging exhaust brake to be abnormal. By means of the monitoring method and the monitoring system, a driver can monitor the exhaust brake state of the engine in the whole process, and therefore auxiliary brake can be reasonably controlled, and the safety coefficient of driving is increased.

Owner:WEICHAI POWER CO LTD

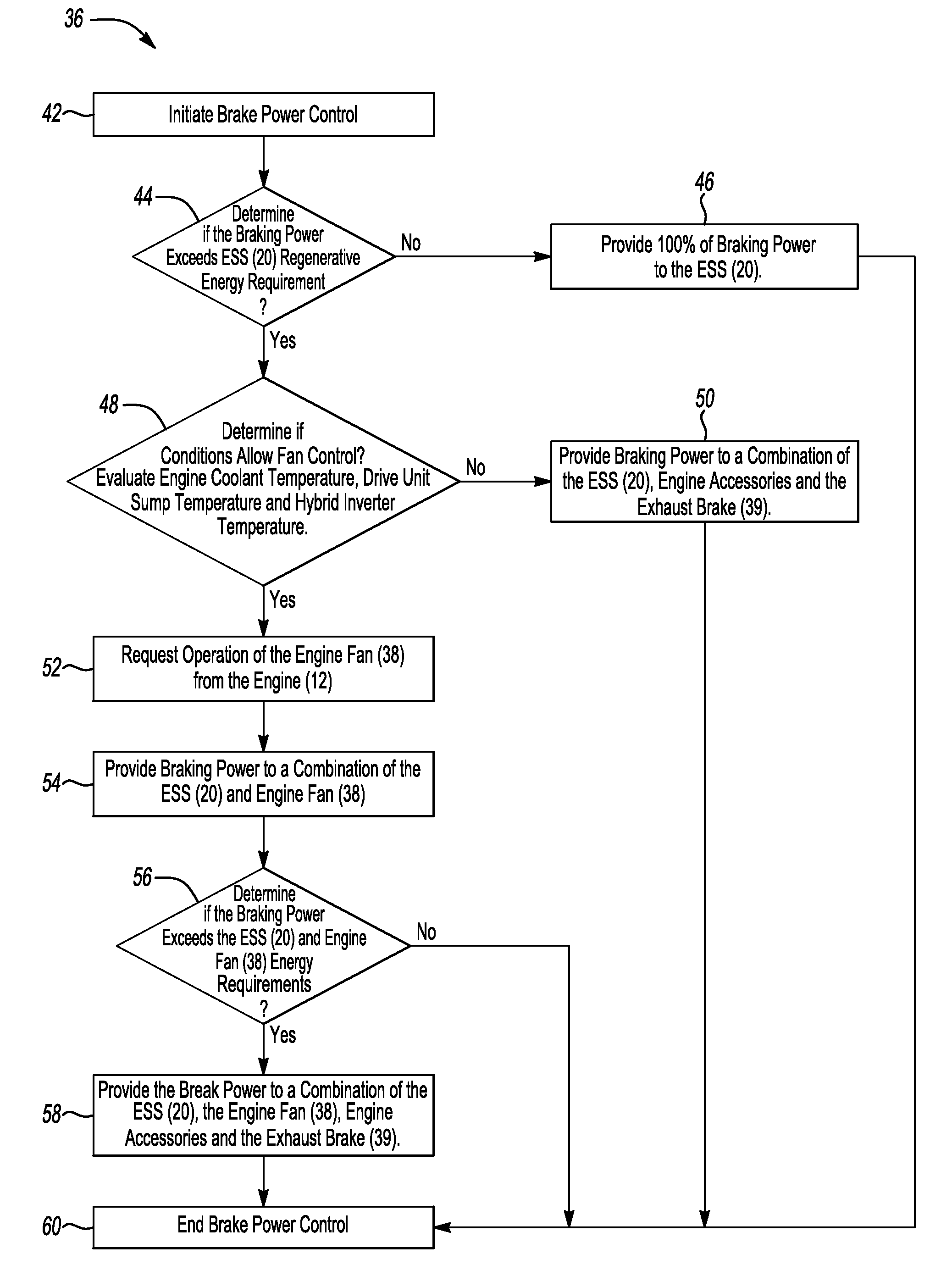

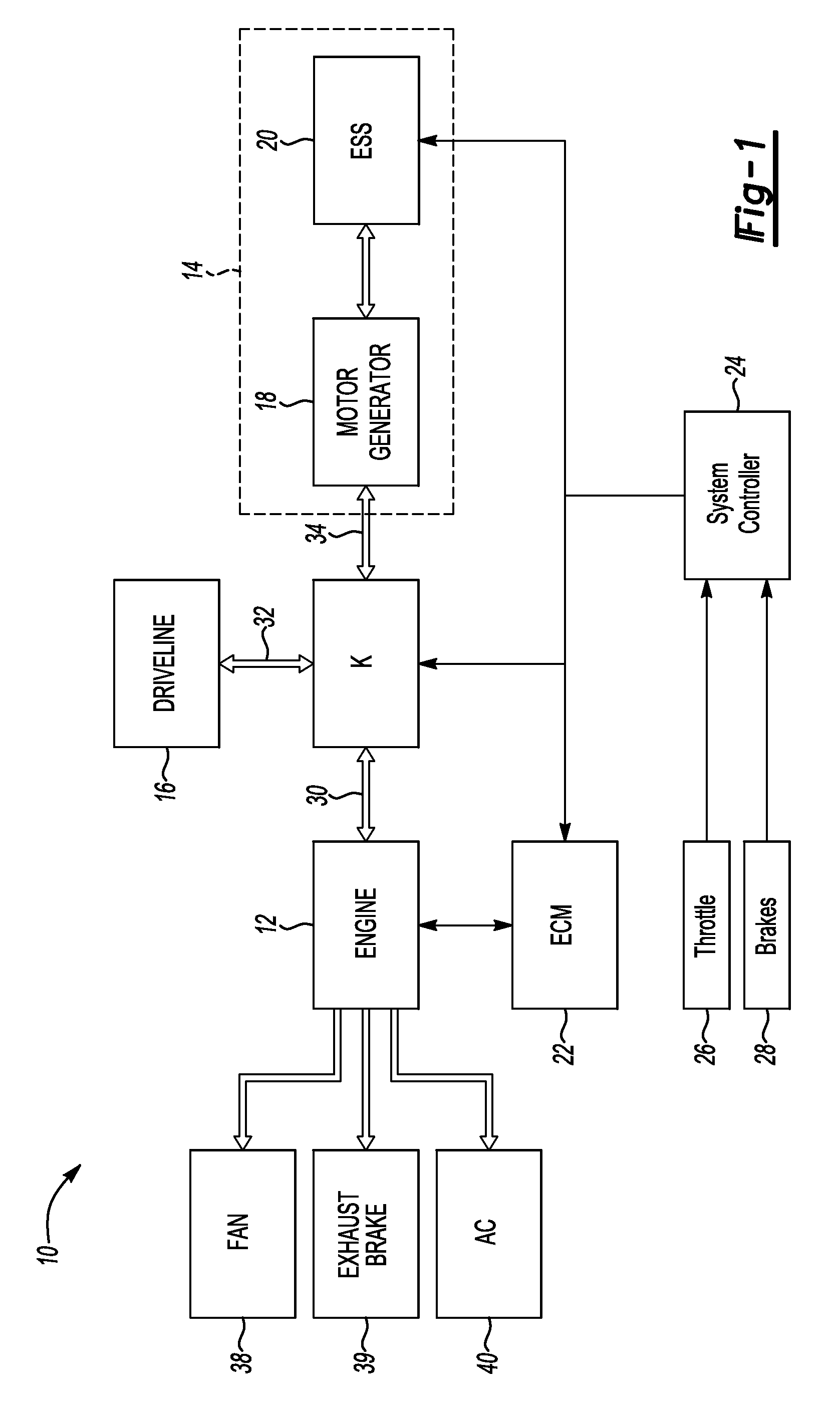

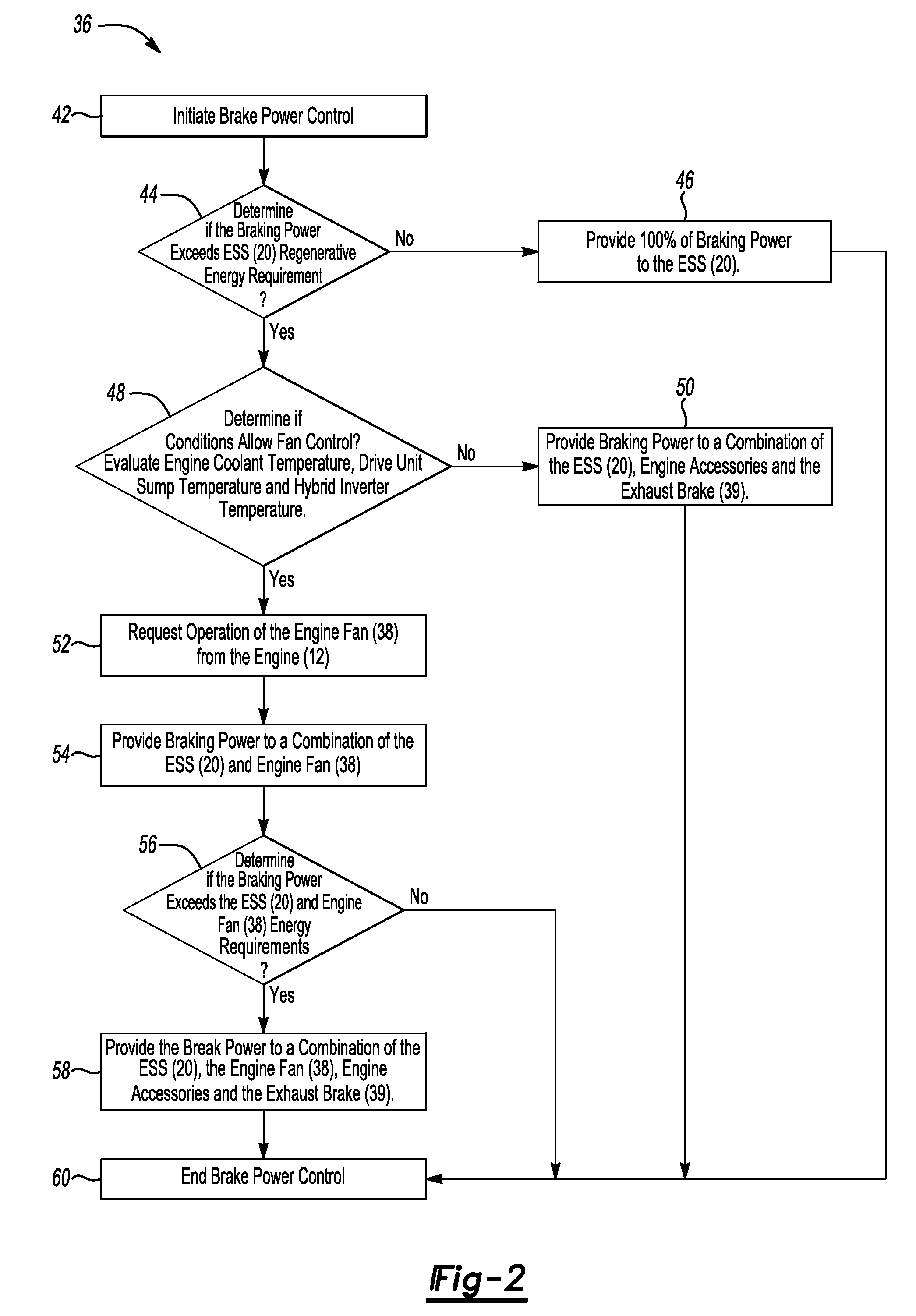

Method of controlling brake power for a vehicle with an electrically variable transmission

A method of controlling brake power flow for a vehicle with an electrically variable transmission is provided. When the brake power exceeds a power absorption capability of the energy storage system, then vehicle conditions are evaluated to determine if control of an engine fan is allowable. When conditions allow for fan control then the remaining brake power is provided for operation of the engine fan. Any excess brake power is dissipated through the exhaust brake or used by other vehicle accessories.

Owner:GM GLOBAL TECH OPERATIONS LLC

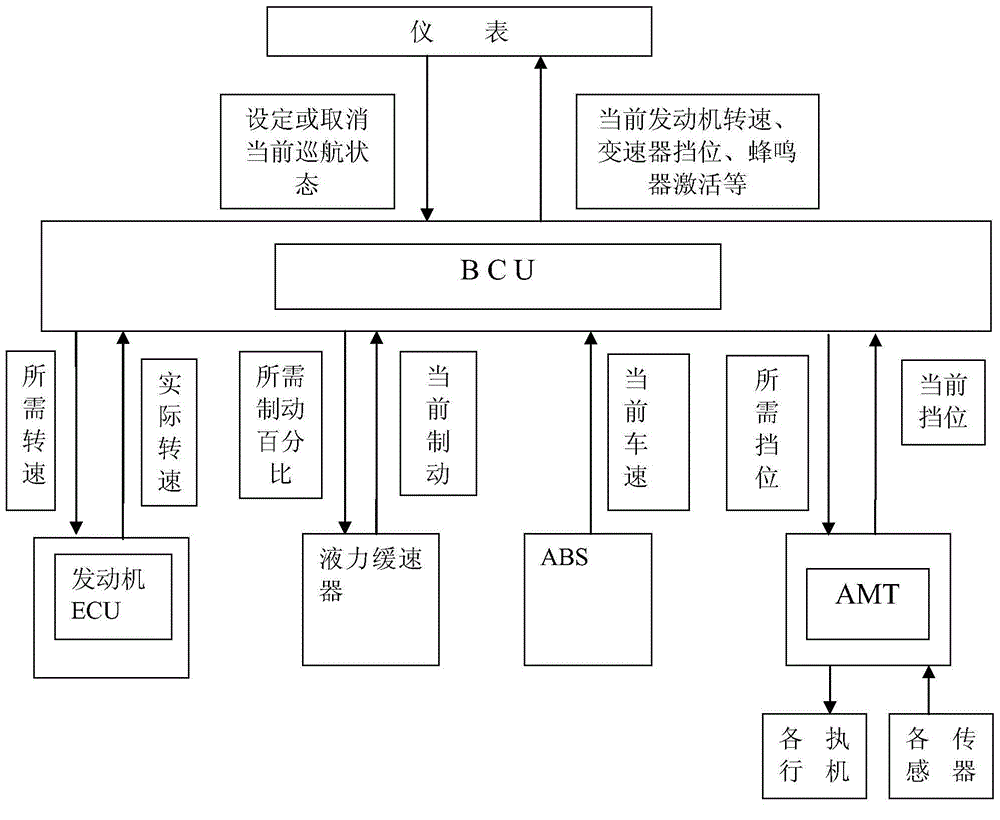

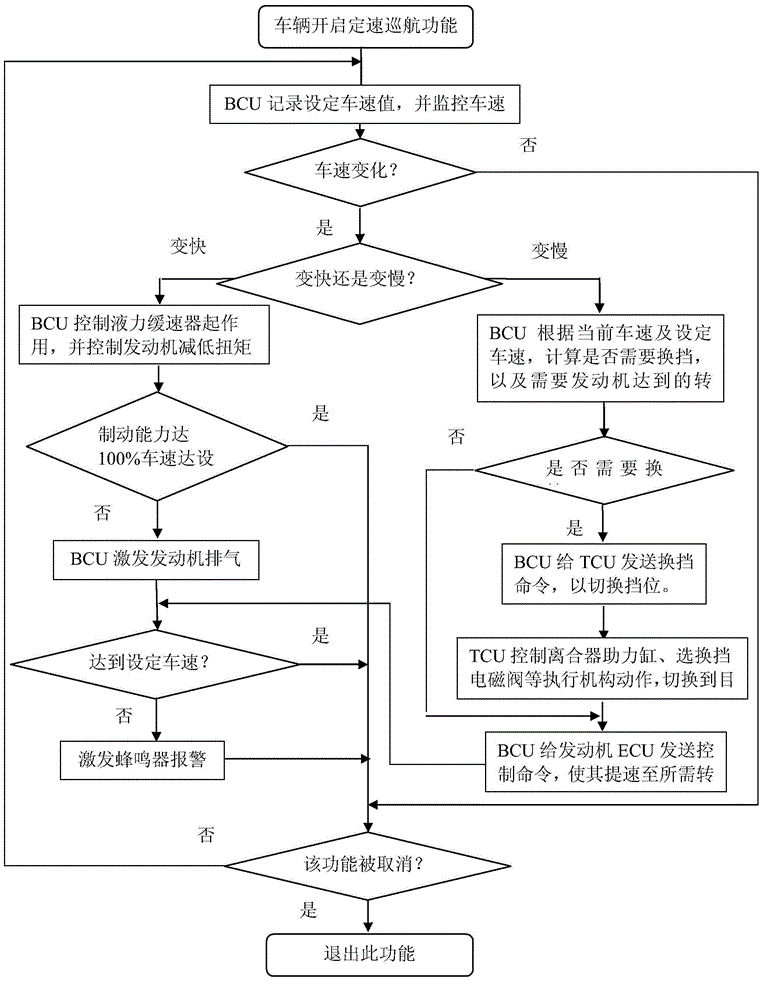

AMT (automated mechanical transmission) vehicle model CCS (cruise control system) based on hydrodynamic retarder as well as method

The invention discloses an AMT (automated mechanical transmission) vehicle model CCS (cruise control system) based on a hydrodynamic retarder as well as a method. The control system comprises an ECU (engine control unit), an ABS (anti-lock braking system), the hydrodynamic retarder, an AMT, a meter and a vehicle BCU (body control unit), wherein the ECU, the ABS, the hydrodynamic retarder, the AMT and the meter are connected with the vehicle BCU through a CAN (controller area network) bus. The AMT vehicle model CCS based on the hydrodynamic retarder has the benefits as follows: auxiliary braking equipment such as the hydrodynamic retarder, engine exhaust brake and the like is sufficiently utilized, the braking effect is better when the vehicle speed exceeds the cruise vehicle speed and speed reduction is required, that is, the safety guarantee is higher when a vehicle is driven particularly on a macroslope or a long slope; when the vehicle speed is lower than the cruise vehicle speed and acceleration is required, due to the fact that automatic gear shift is realized by AMT, the vehicle enables the engine to work in an economic rotating speed area under the premise of sufficient power, accordingly, the fuel economy of the whole vehicle is improved, the cruise control function is more reliable, and meanwhile, the fuel economy of the vehicle is improved.

Owner:SINO TRUK JINAN POWER

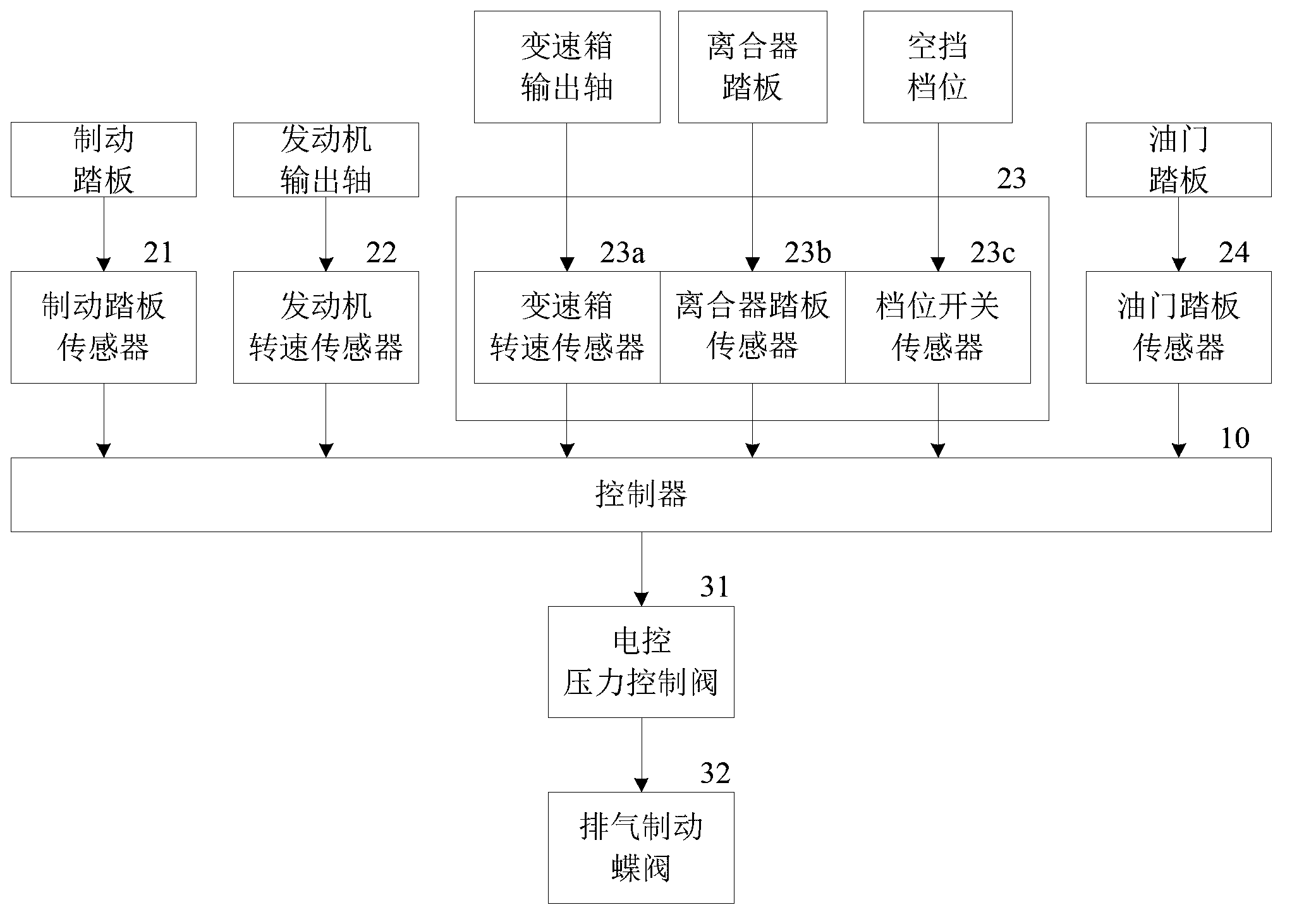

Intelligent control system and control method for continuous adjustment of automobile exhaust brake braking force

InactiveCN103061895AGood linkageTimely adjustment of braking forceEngine controllersMachines/enginesControl signalExhaust brake

An intelligent control system for continuous adjustment of automobile exhaust brake braking force comprises a brake pedal sensor, an engine speed sensor, a gearbox information sensor, an accelerator pedal sensor, a controller, an electronic control pressure control valve and an exhaust brake butterfly valve. The controller forms pressure control signal output of the electronic control pressure control valve according to displacement data, action duration data, rotation speed data, rotation speed duration data, clutch data and neutral gear data, the electronic control pressure control valve is used for receiving pressure control signals and changing pressure output of an air outlet, and the exhaust brake butterfly valve is used for outputting pressure change along with the air outlet and controlling corresponding opening angle of the butterfly valve. The intelligent control system for continuous adjustment of the automobile exhaust brake braking force is capable of continuously controlling an existing exhaust brake butterfly valve, timely adjusting exhaust brake braking force and improving linkage efficacy of exhaust brake and main brake. The invention further relates to a control method for the system.

Owner:LUDONG UNIVERSITY

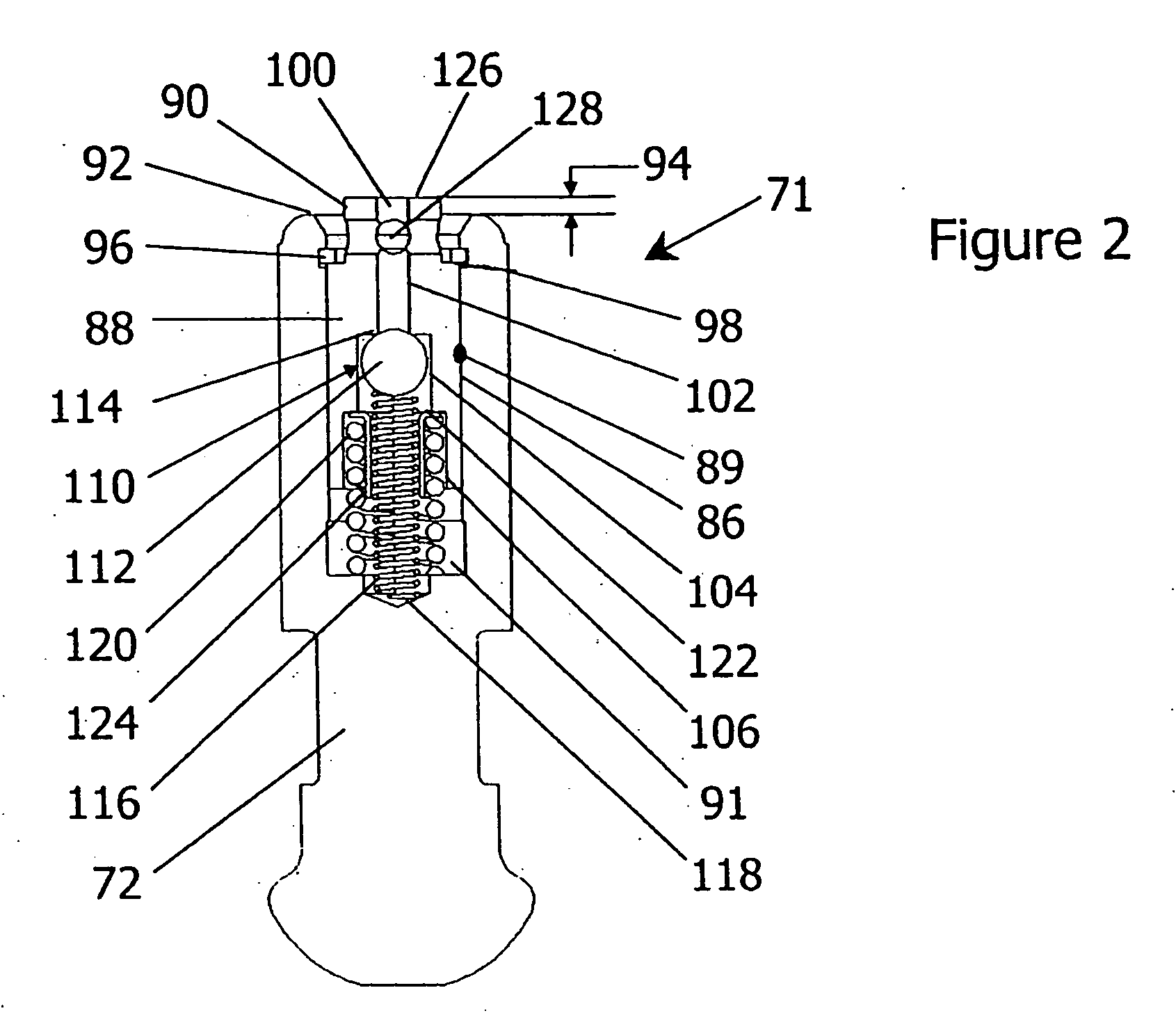

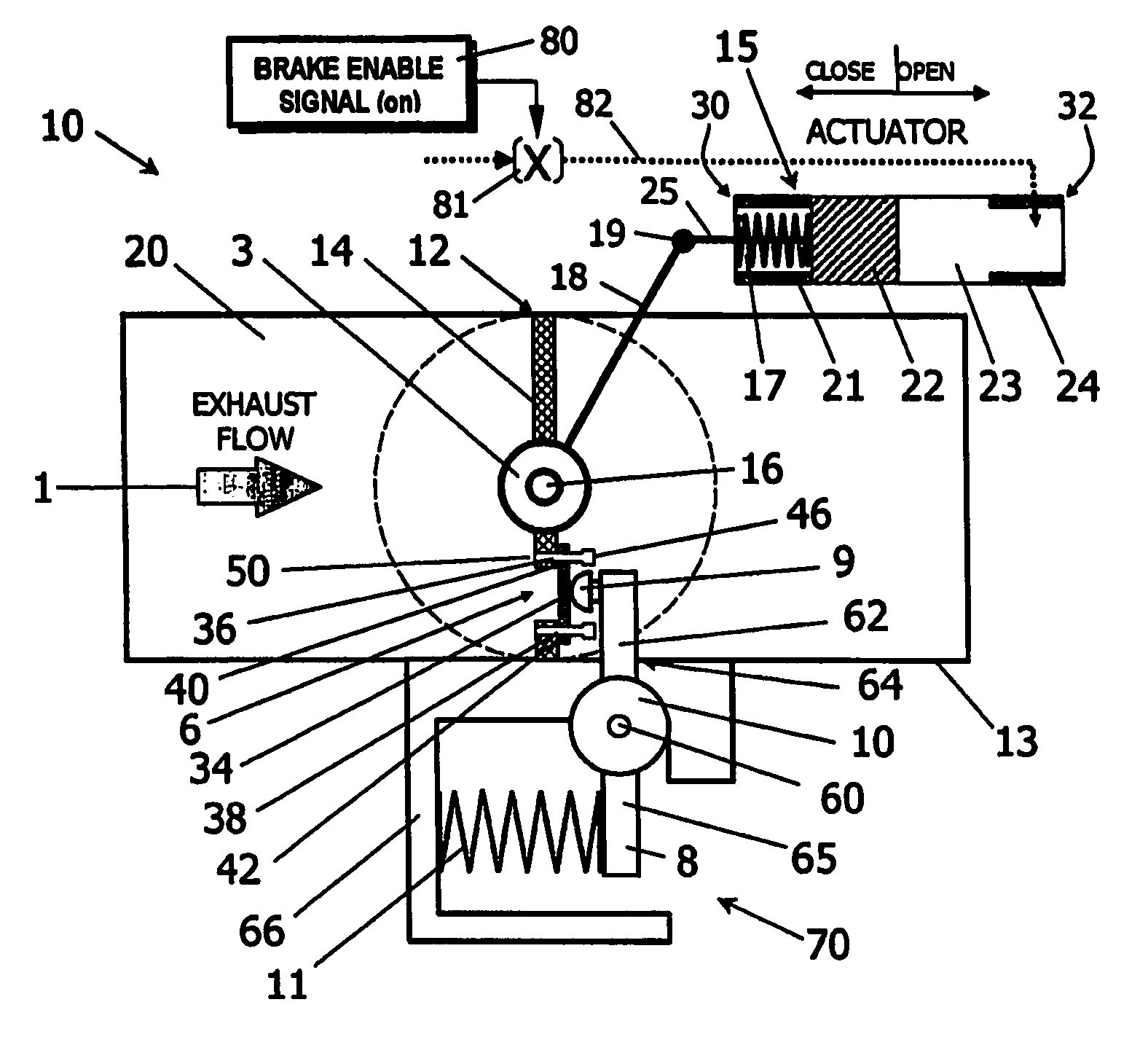

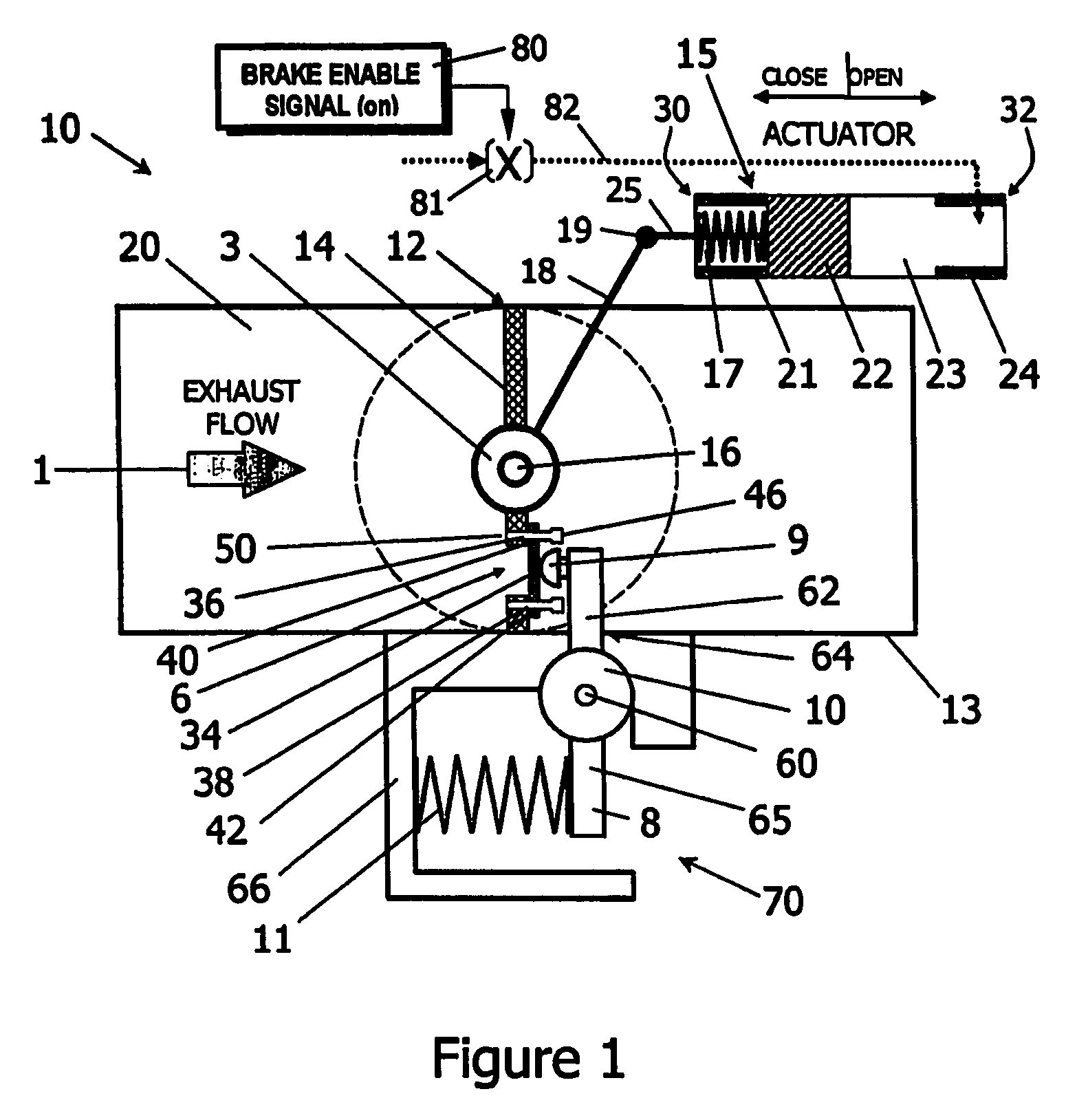

Apparatus and method for pressure relief in an exhaust brake

An exhaust brake has a body with a passageway for exhaust gases therein. A valve member is movably located within the passageway for selective movement between an open position where the valve member opens the passageway and exhaust gases are free to move through the passageway and a closed position where the valve member blocks the passageway and the passage of exhaust gases through the passageway. The valve member has an aperture therethrough to permit a limited flow of exhaust gases through the aperture when the aperture is open. An exhaust valve actuator mechanism is coupled to the valve member for moving the valve member between the open position and the closed position. A closure member is positioned adjacent to the aperture. The closure member has an open position where the closure member is spaced apart from the valve member and permits a flow of exhaust gases through the aperture and the closure member having a closed position where the closure member contacts the valve member about the aperture and inhibits a flow of exhaust gases through the aperture, An actuator member operatively engages the closure member. There is a relief actuator mechanism, the relief actuator mechanism including an actuator member that operatively engages the closure member. The relief mechanism brings the closure member into operative engagement with the valve member with sufficient force, when the valve member is closed, to maintain the closure member in the closed position when the exhaust gases are below a predetermined pressure.

Owner:JENARA ENTERPRISES

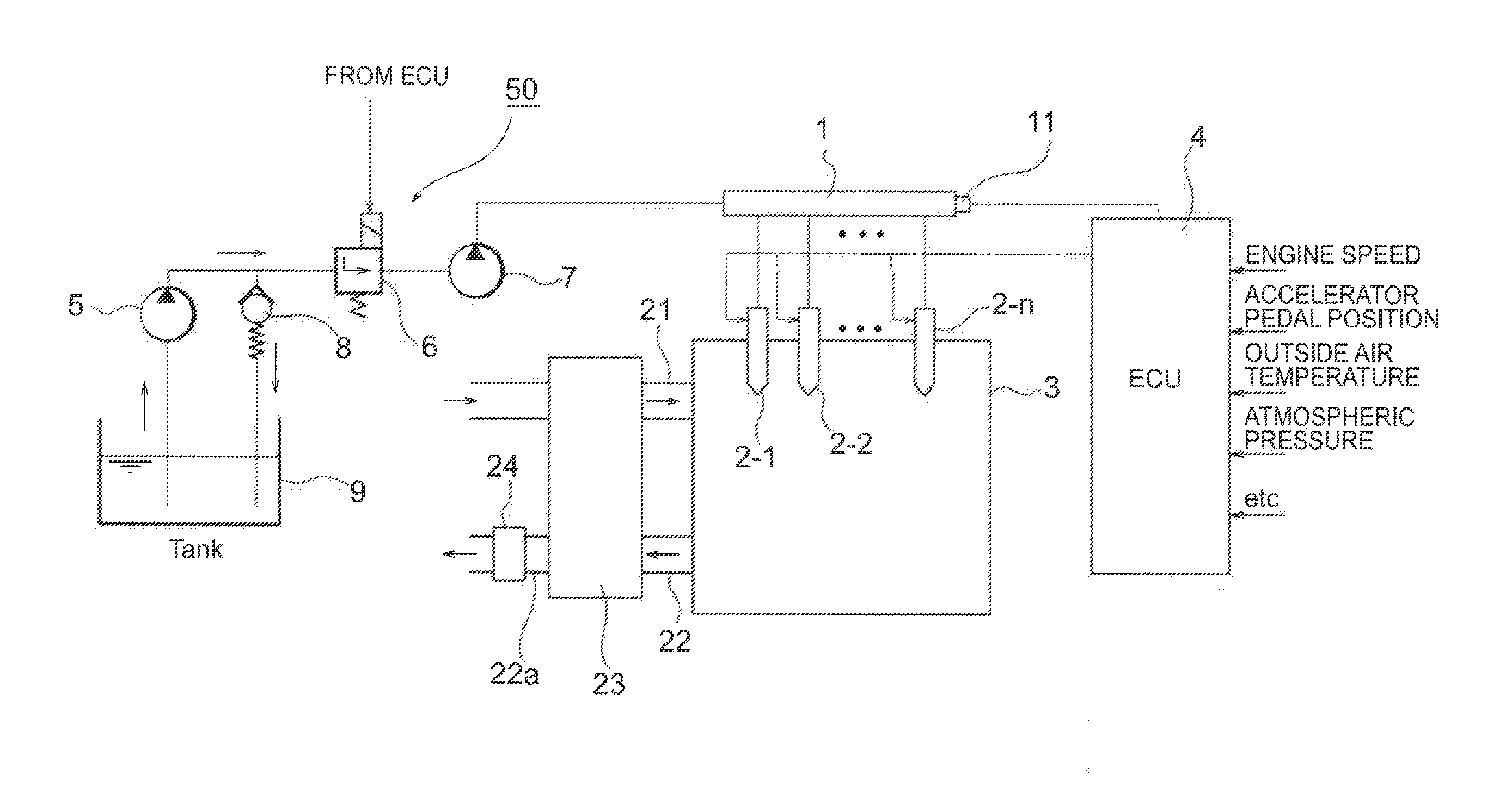

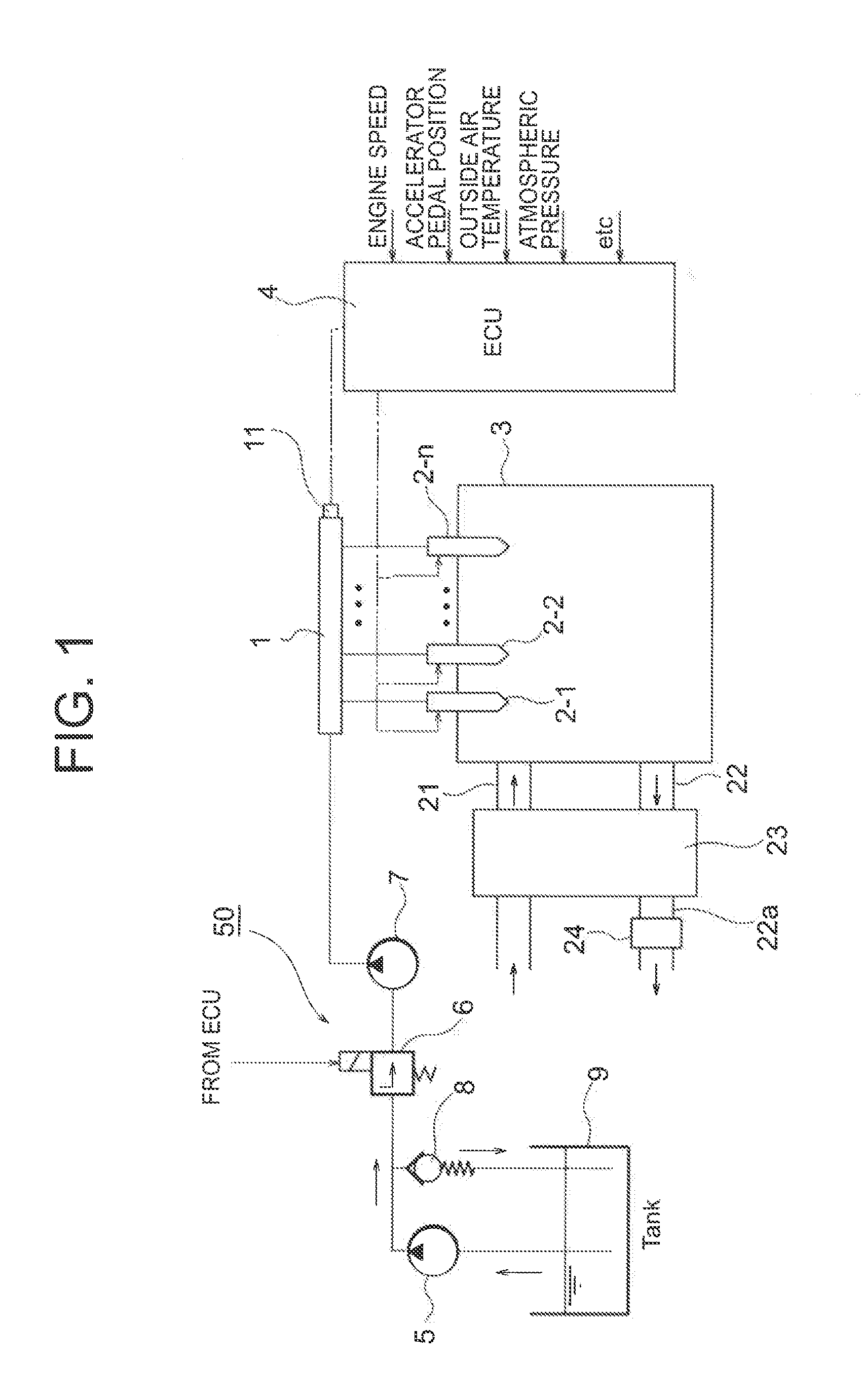

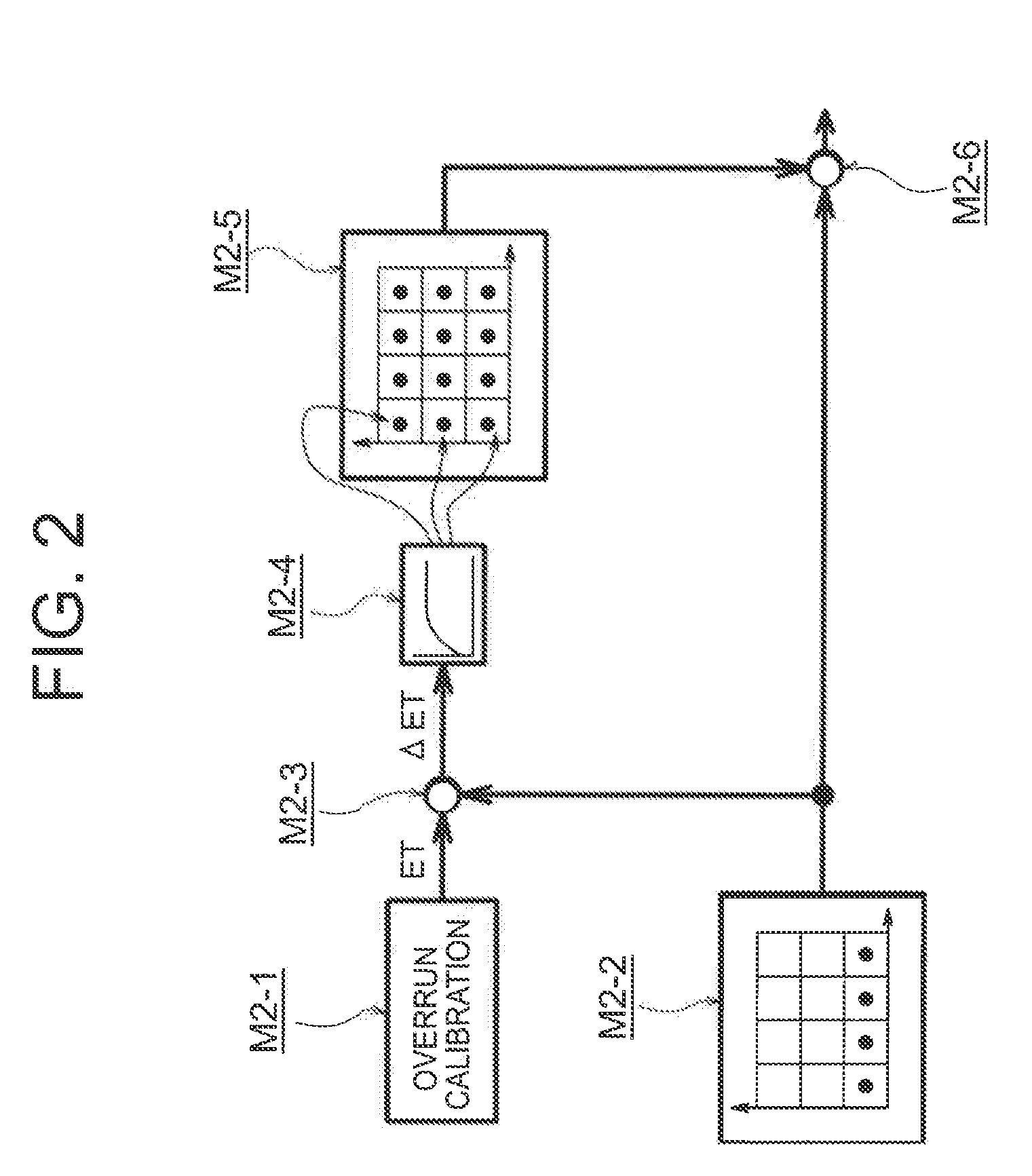

Method for correcting fuel injection amount in common-rail-type fuel injection control device and common-rail-type fuel injection control device

InactiveUS20120234294A1Reliable calibrationReliable of fuel injectionElectrical controlMachines/enginesCommon railExhaust brake

A common-rail-type fuel injection control device where an error in the correction of a fuel injection amount when an exhaust brake is used is eliminated enabling a more reliable correction of a fuel injection amount.A minute injection is performed plural times in a non-injection state. A difference between a reference energizing time, which becomes the reference for a fuel injection valve, and an actual energizing time based on a frequency component corresponding to a variation in an engine speed which is generated in the minute injection is learned. A correction control corrects an energizing time and timing. The correction control is corrected corresponding to a presence or non-presence of an operation of an exhaust brake and a magnitude of a supercharging pressure, and an amount of variation in an engine speed calculated based on a rotational variation frequency component.

Owner:BOSCH CORP

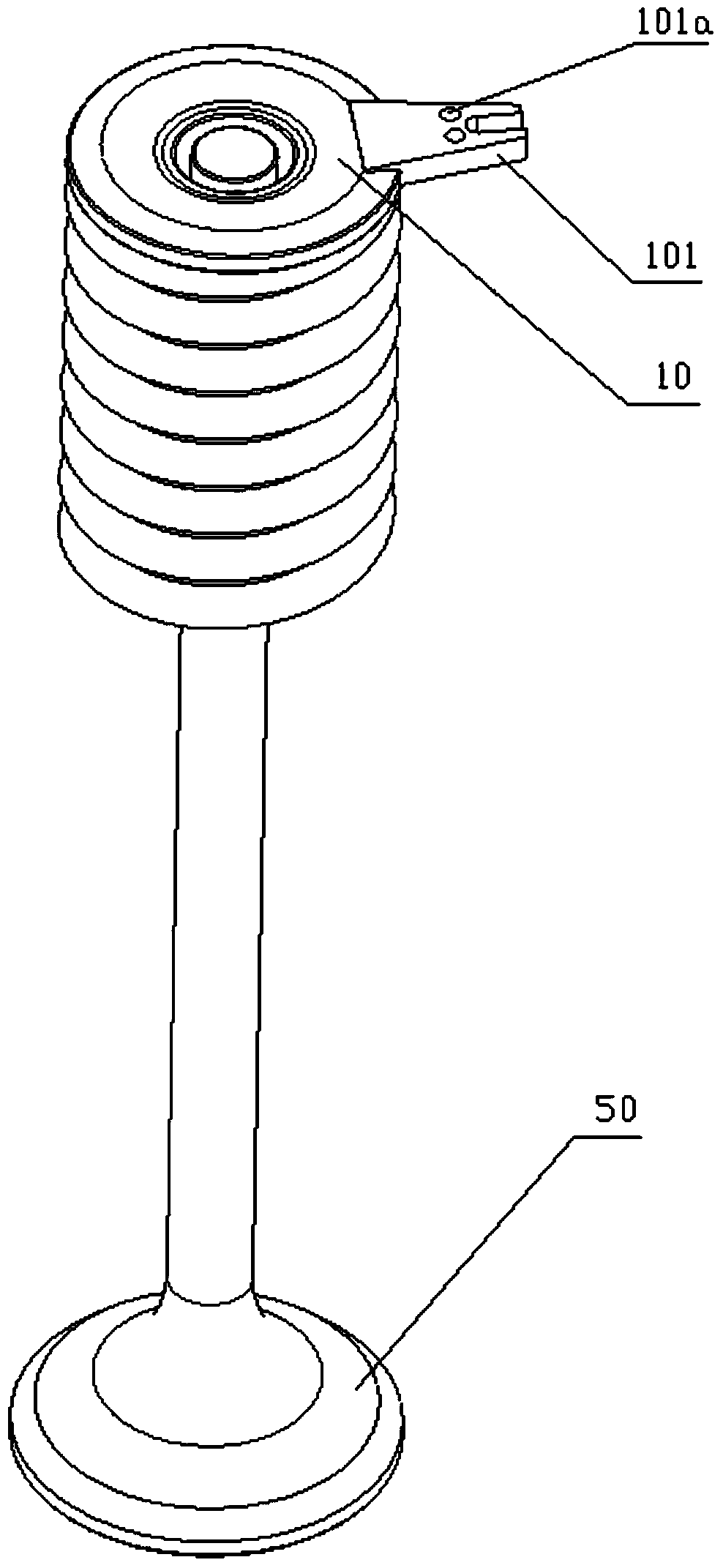

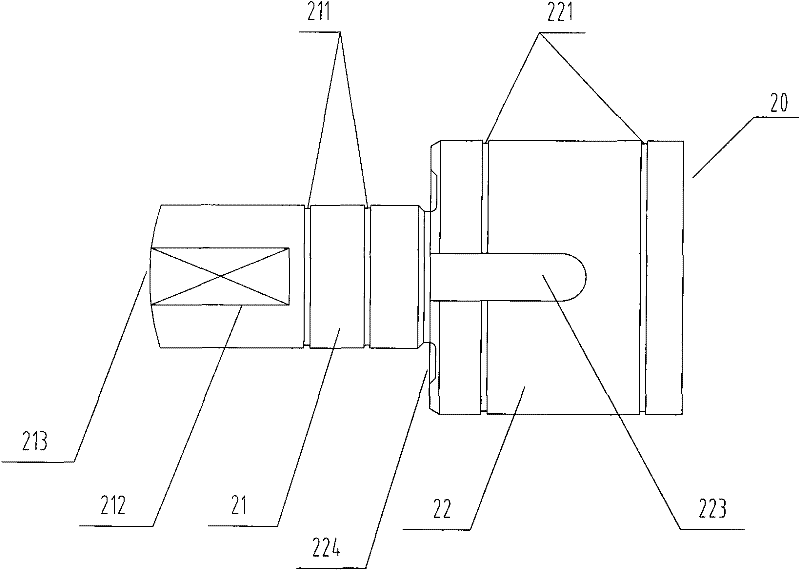

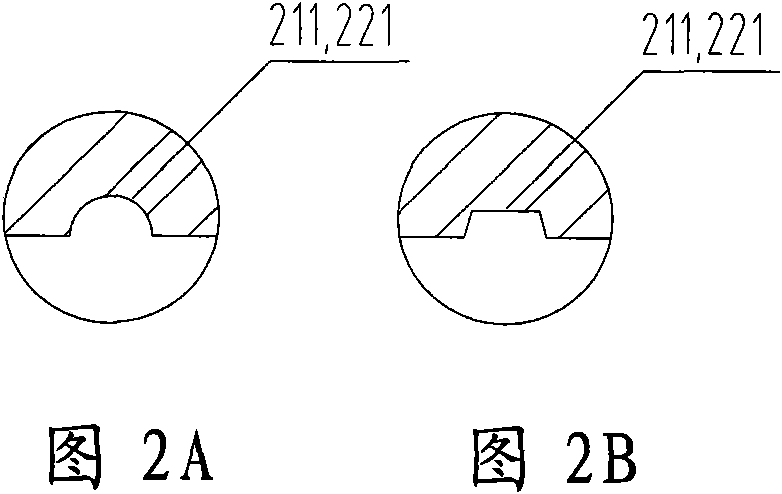

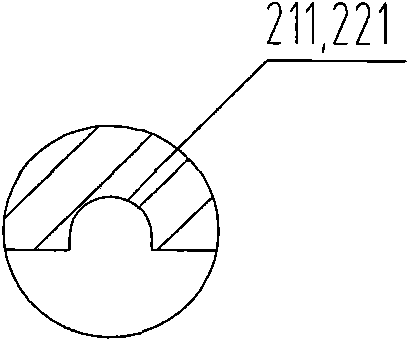

Pressure limiting seal piston and exhaust brake butterfly valve thereof

InactiveCN102182563ALow movement resistanceReduce leakagePlungersEngine controllersExhaust brakeEngineering

The invention relates to a pressure limiting seal piston which comprises a step-shaped piston body, wherein the step-shaped piston body comprises a tappet rod (21) and a support seat (22); a first annular groove (211) is arranged on the outer surface of the tappet rod (21); the pressure limiting seal piston (20) is slidably installed in a pressure limiting device shell (8) on the side wall of a valve body (1) of an exhaust brake butterfly valve; the tappet rod (21) convexly extends to an inner cavity of the valve body (1) by a through hole (100) arranged in the inner wall of the valve body (1) and is correspondingly inserted into a pressure relief notch (31); the support seat (22) is arranged on the pressure limiting device shell (8); static pressure holes (9) are also arranged outside the through hole (100) and in the air inlet cavity wall; the first annular groove (211) is positioned inside the through hole in the inner wall of the valve body; the bottom of the support seat (22) is provided with a pressure limiting spring (7); and the pressure limiting spring (7) is butted against a spring end cover (40). The invention has the advantages of simple and compact structure, less pressure limiting seal piston motion resistance, less waste gas leakage and capability of effectively controlling the position and the motion stroke of the piston.

Owner:ZHEJIANG EASUN PNEUMATIC SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com