Patents

Literature

758 results about "Pressure feedback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

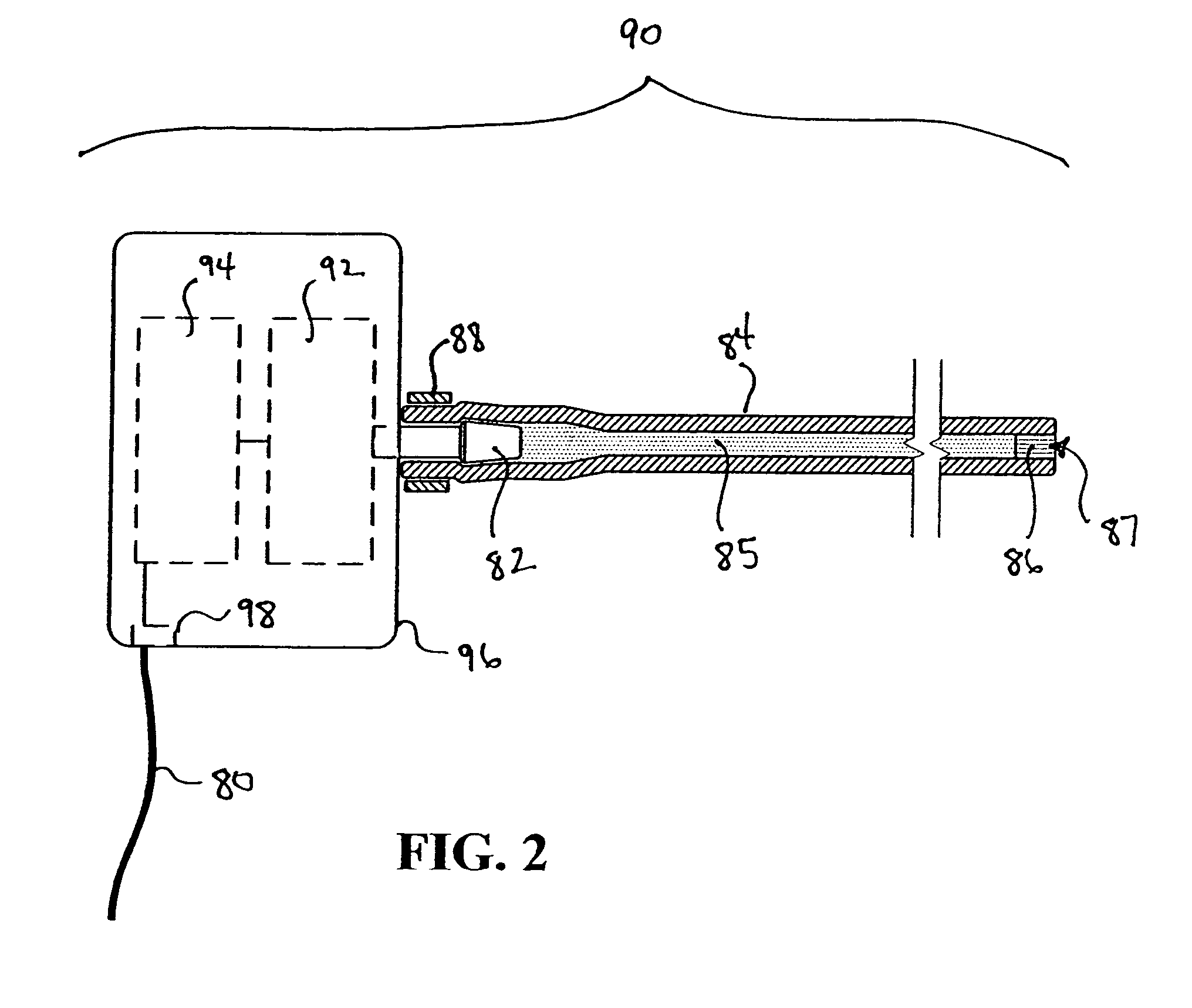

Portable wound treatment apparatus having pressure feedback capabilities

InactiveUS7670323B2Easy to remove and replaceLess-easy to determineWound drainsSurgeryWound sitePressure feedback

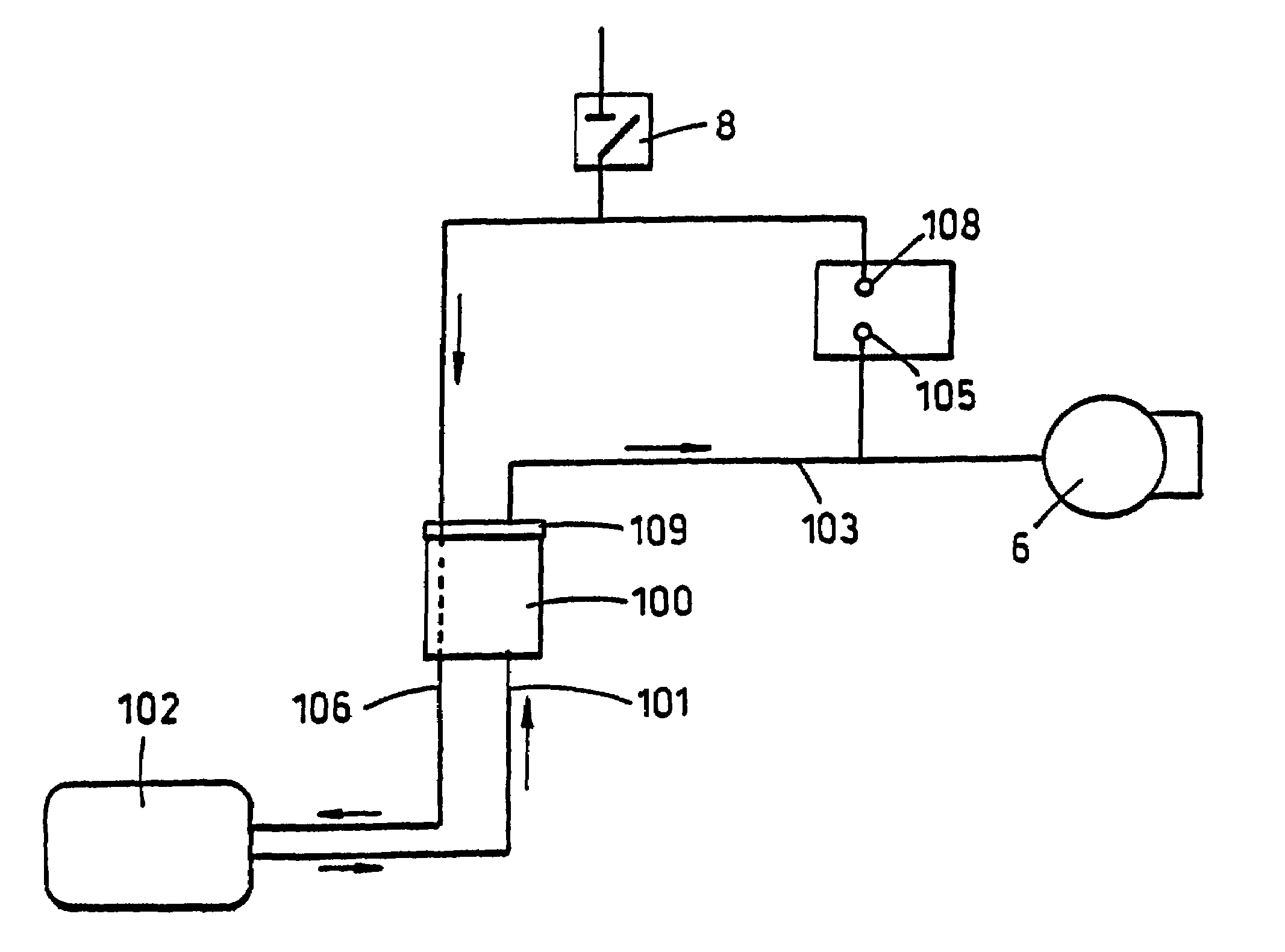

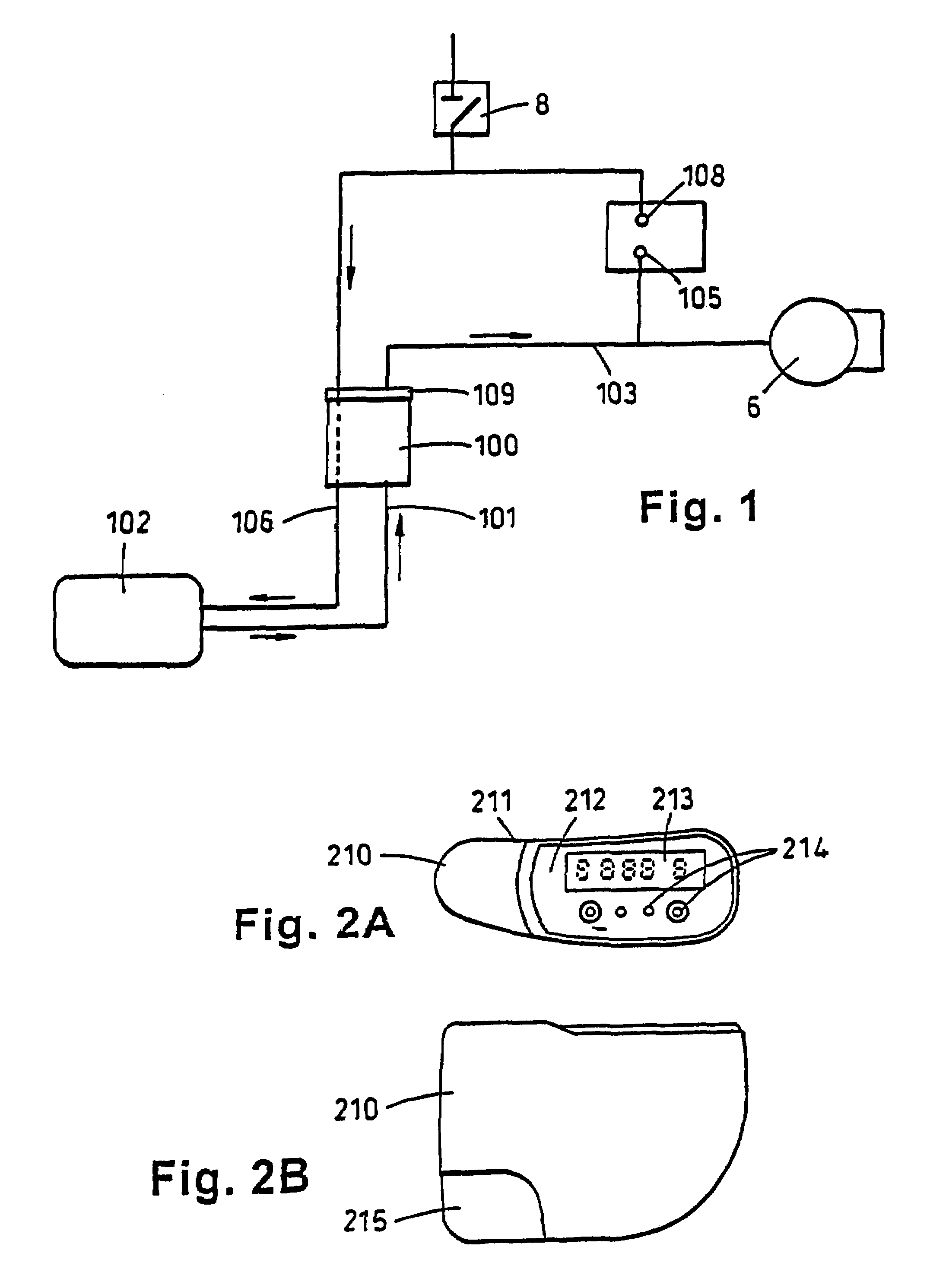

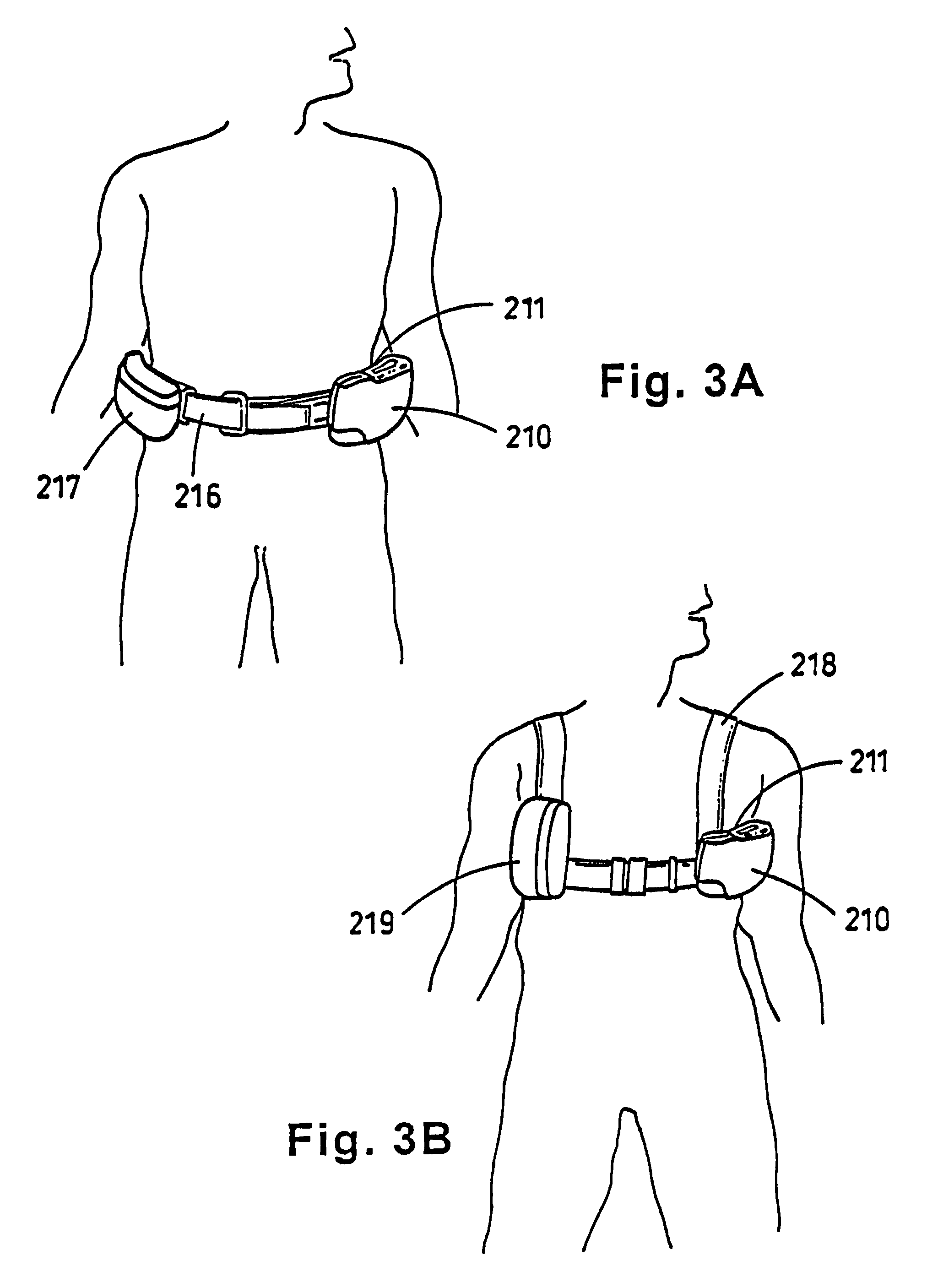

A reduced pressure treatment apparatus includes a drape for positioning over the wound site to create and maintain a substantially air-tight cavity between the wound site and the drape. A multi-lumen suction tube is provided to be attached to a reduced pressure source. The multi-lumen suction tube includes a center lumen and at least one outer lumen and is configured to deliver reduced pressure beneath the drape to the substantially air-tight cavity. The multi-lumen suction tube is adapted to allow fluid to be drawn from the wound site through the center lumen and pressure to be monitored at the wound site through the at least one outer lumen.

Owner:KCI LICENSING INC

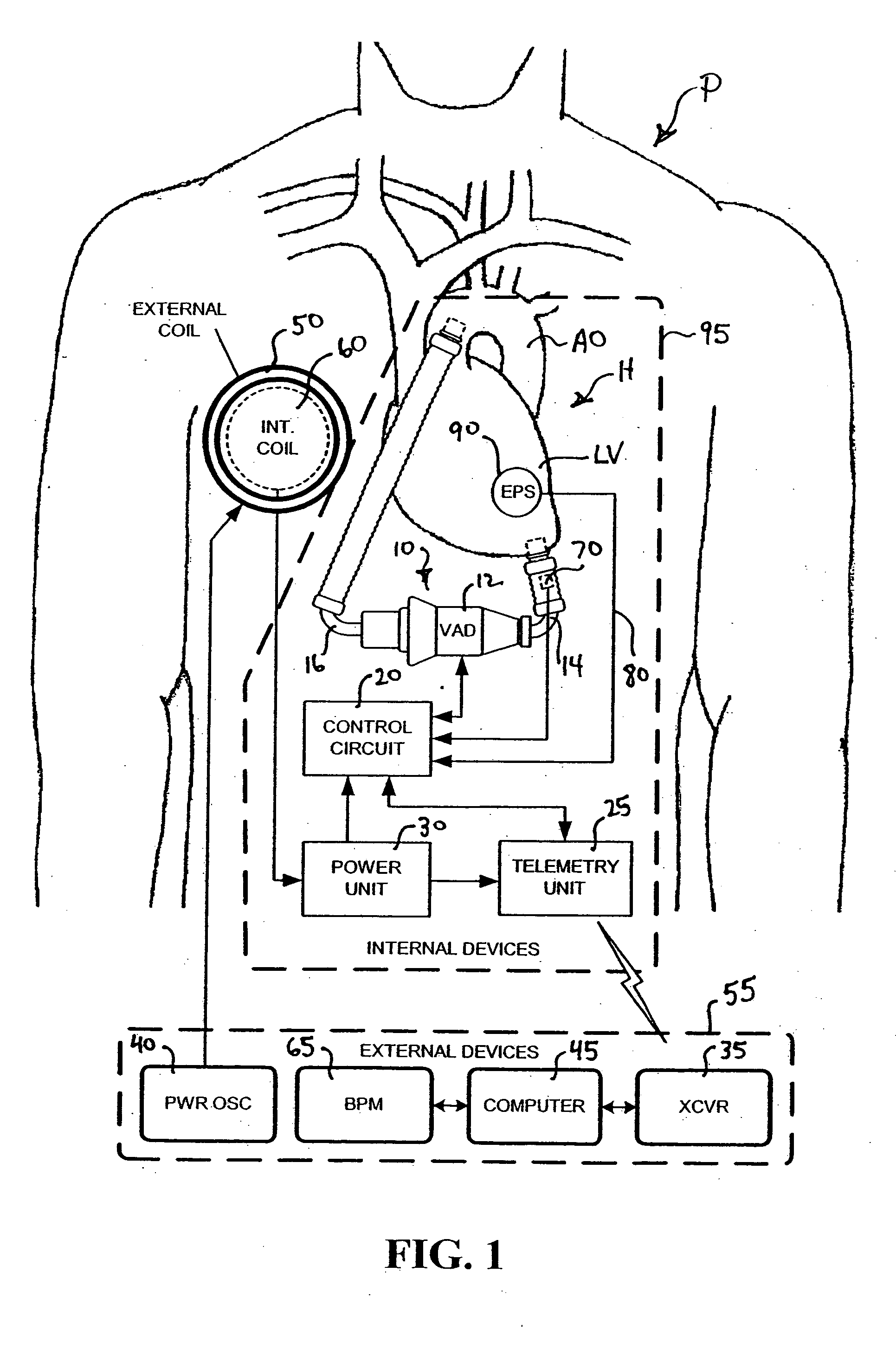

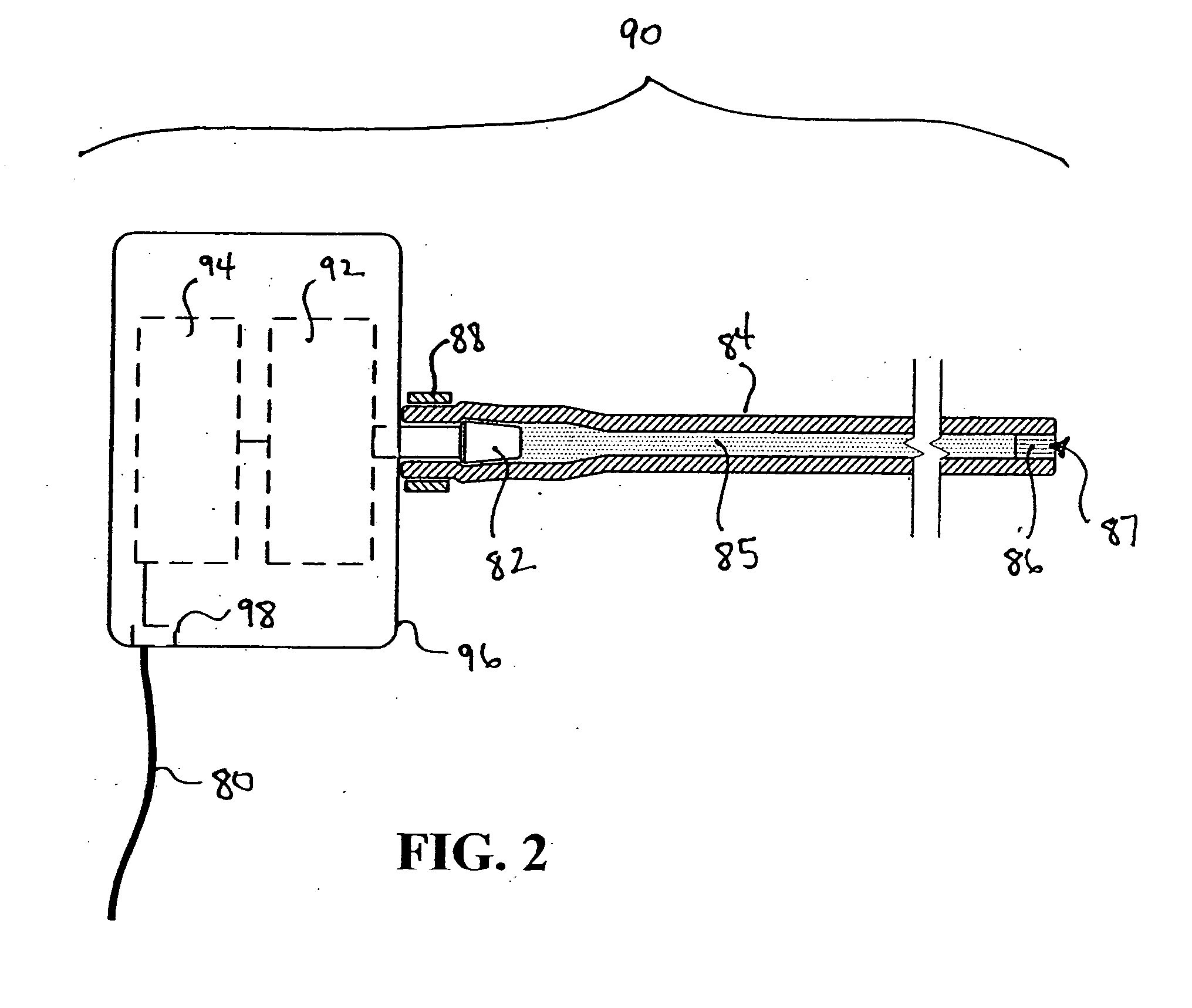

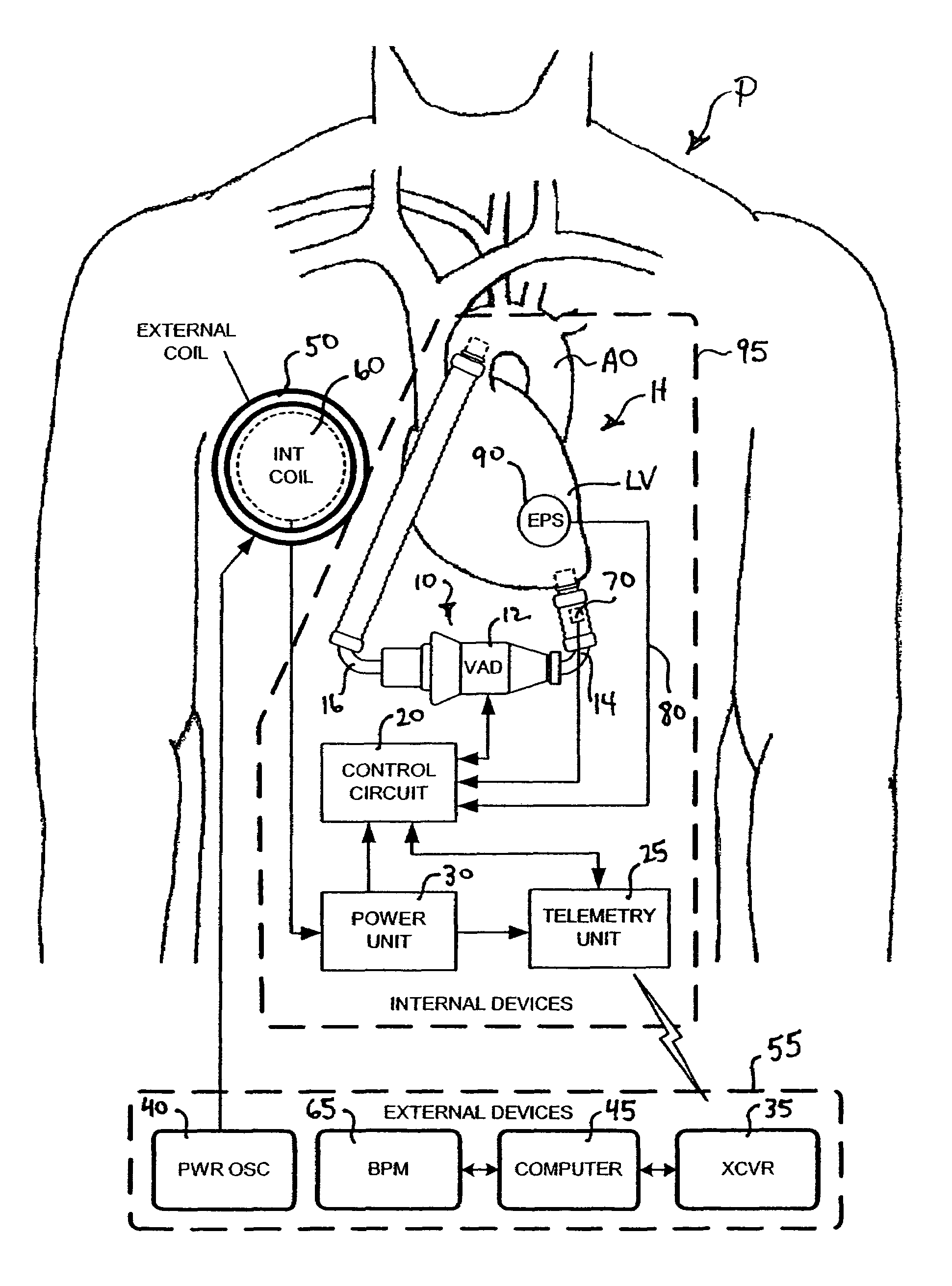

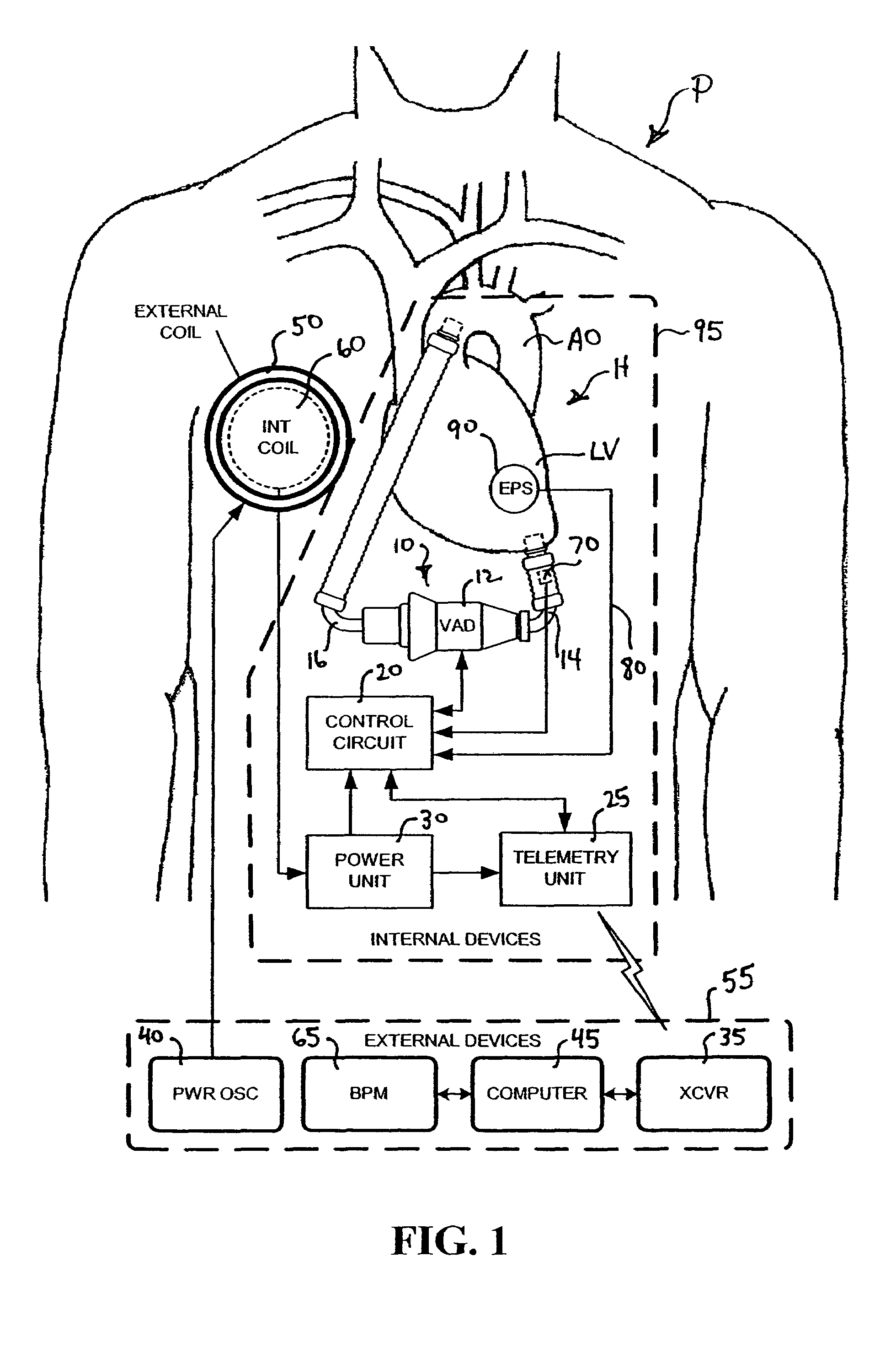

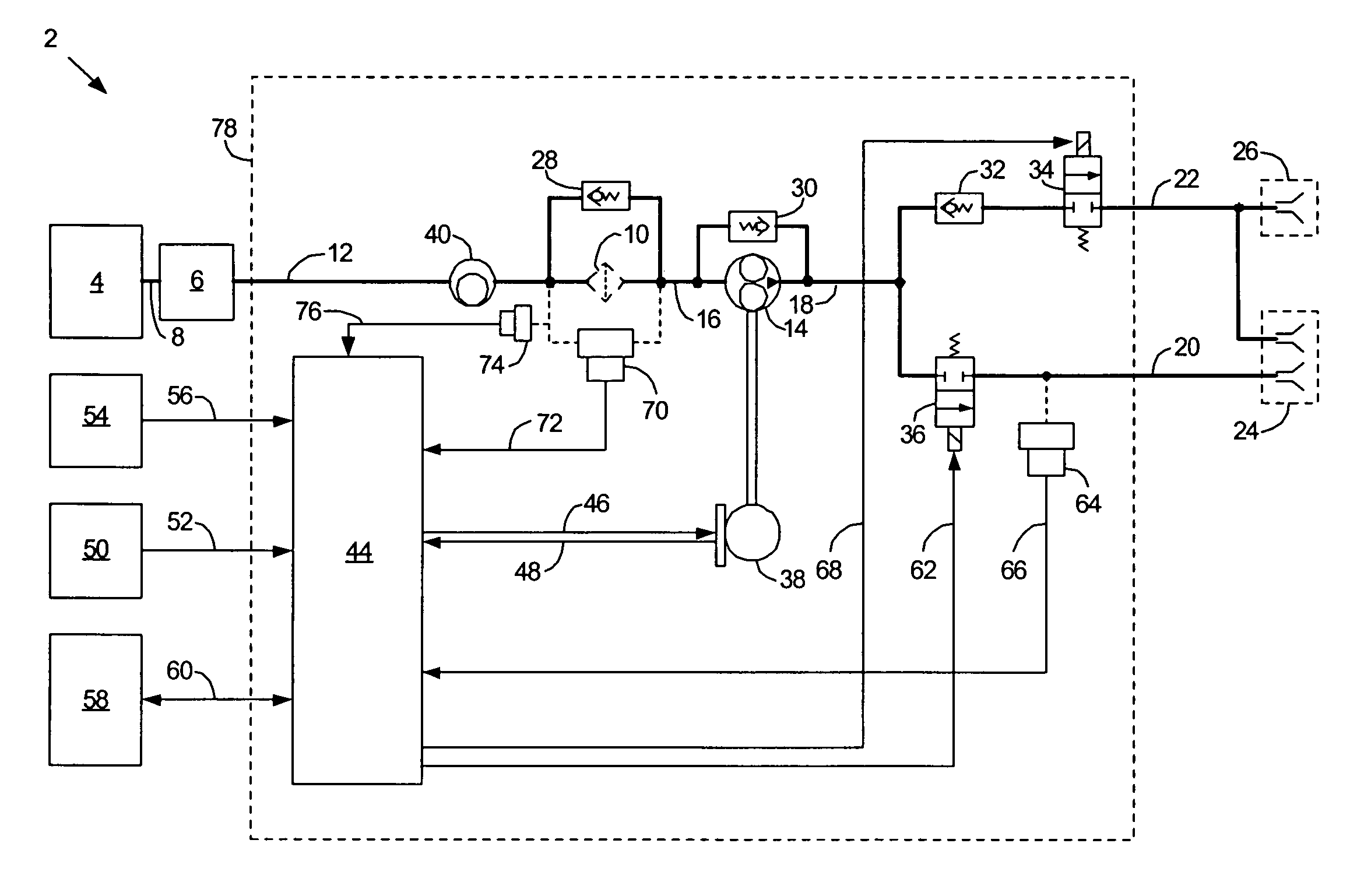

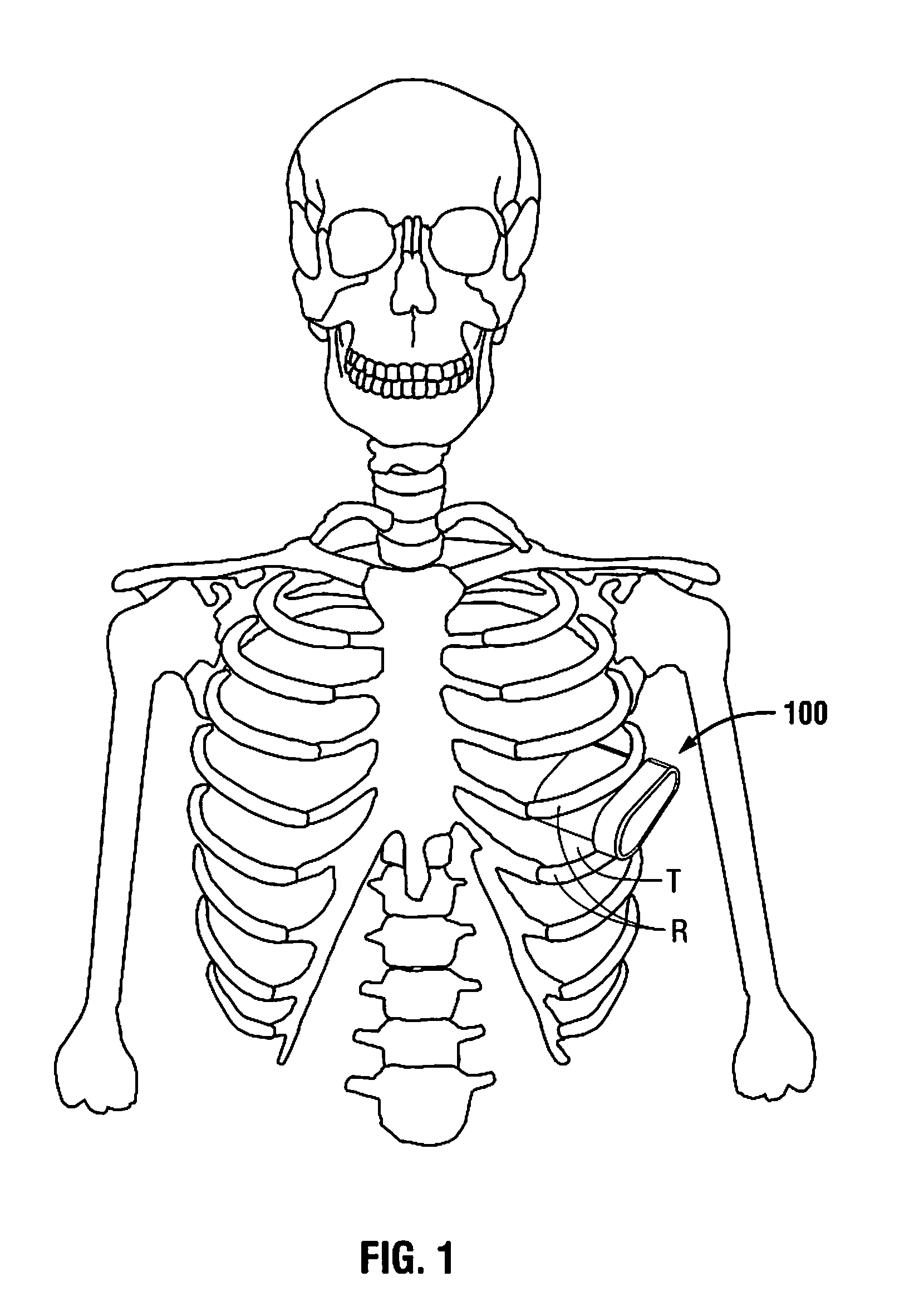

Feedback control of ventricular assist devices

InactiveUS20050107658A1Reliable and accurate pressure feedbackGood curative effectControl devicesBlood pumpsVentricular assistancePhysical therapy

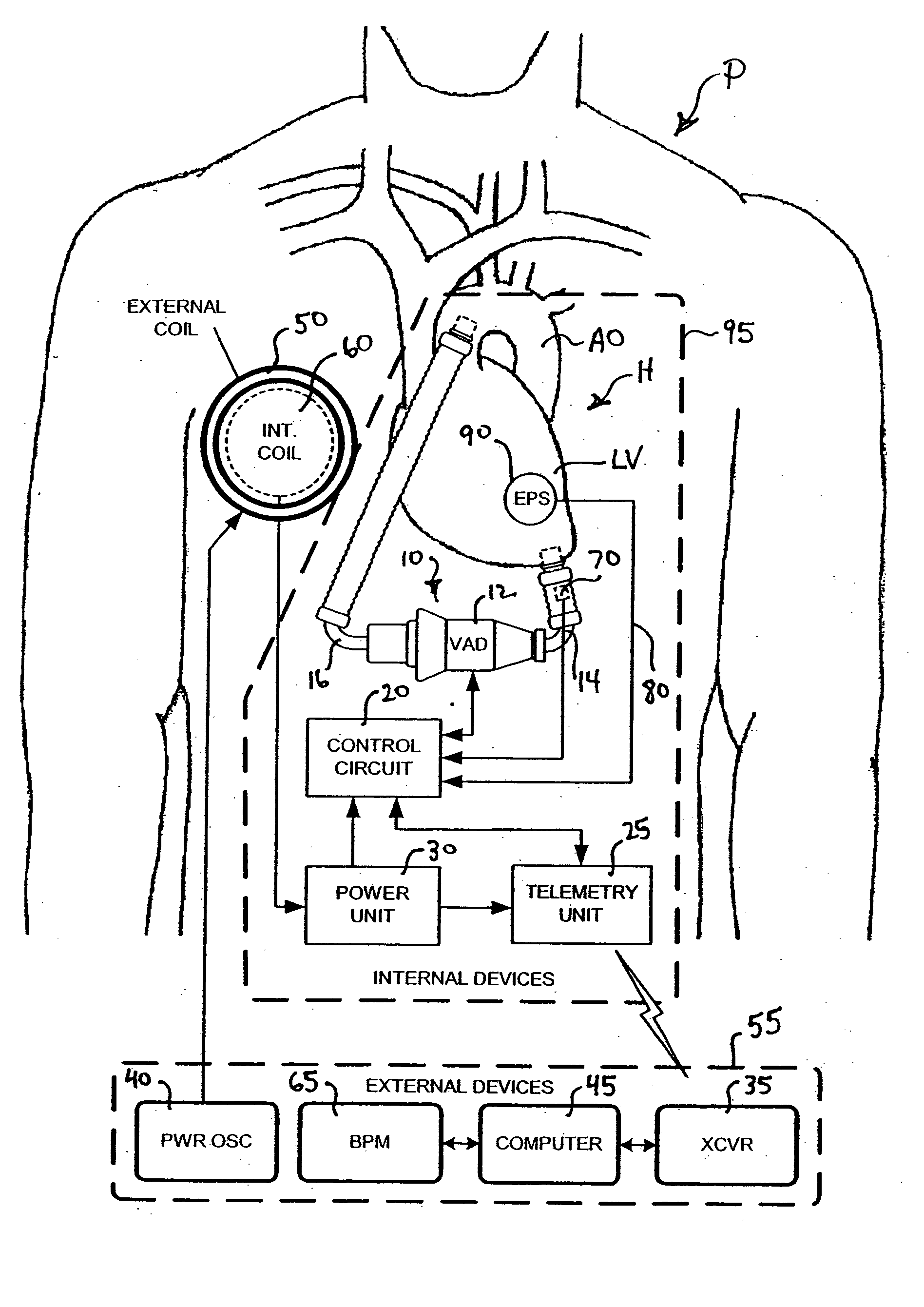

Various devices, systems and methods for providing effective, long term and reliable use of pressure feedback in VADs. Exemplary embodiments are described which provide for direct LV pressure measurement, non-invasive calibration techniques to detect ventricular collapse and recalibrate the feedback mechanism, improved pressure sensor designs with reduced drift, and barometric pressure correction schemes. These devices and methods may be used alone or in combination with each other, and may also be combined with other feedback mechanisms.

Owner:TRANSOMA MEDICAL

Feedback control and ventricular assist devices

InactiveUS7520850B2Reliable and accurate pressure feedbackGood curative effectControl devicesBlood pumpsVentricular assistanceAtmospheric pressure

Various devices, systems and methods for providing effective, long term and reliable use of pressure feedback in VADs. Exemplary embodiments are described which provide for direct LV pressure measurement, non-invasive calibration techniques to detect ventricular collapse and recalibrate the feedback mechanism, improved pressure sensor designs with reduced drift, and barometric pressure correction schemes. These devices and methods may be used alone or in combination with each other, and may also be combined with other feedback mechanisms.

Owner:TRANSOMA MEDICAL

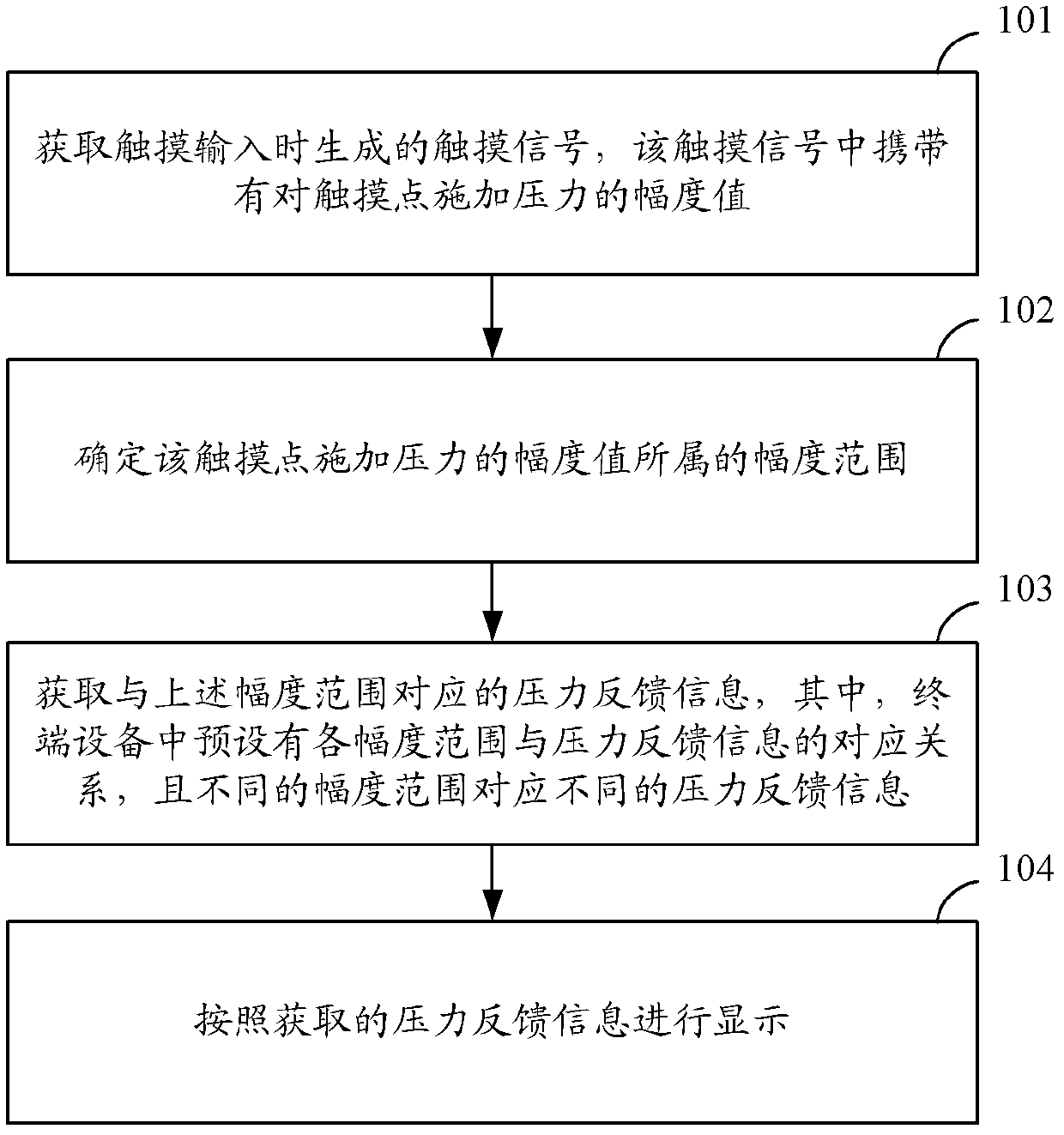

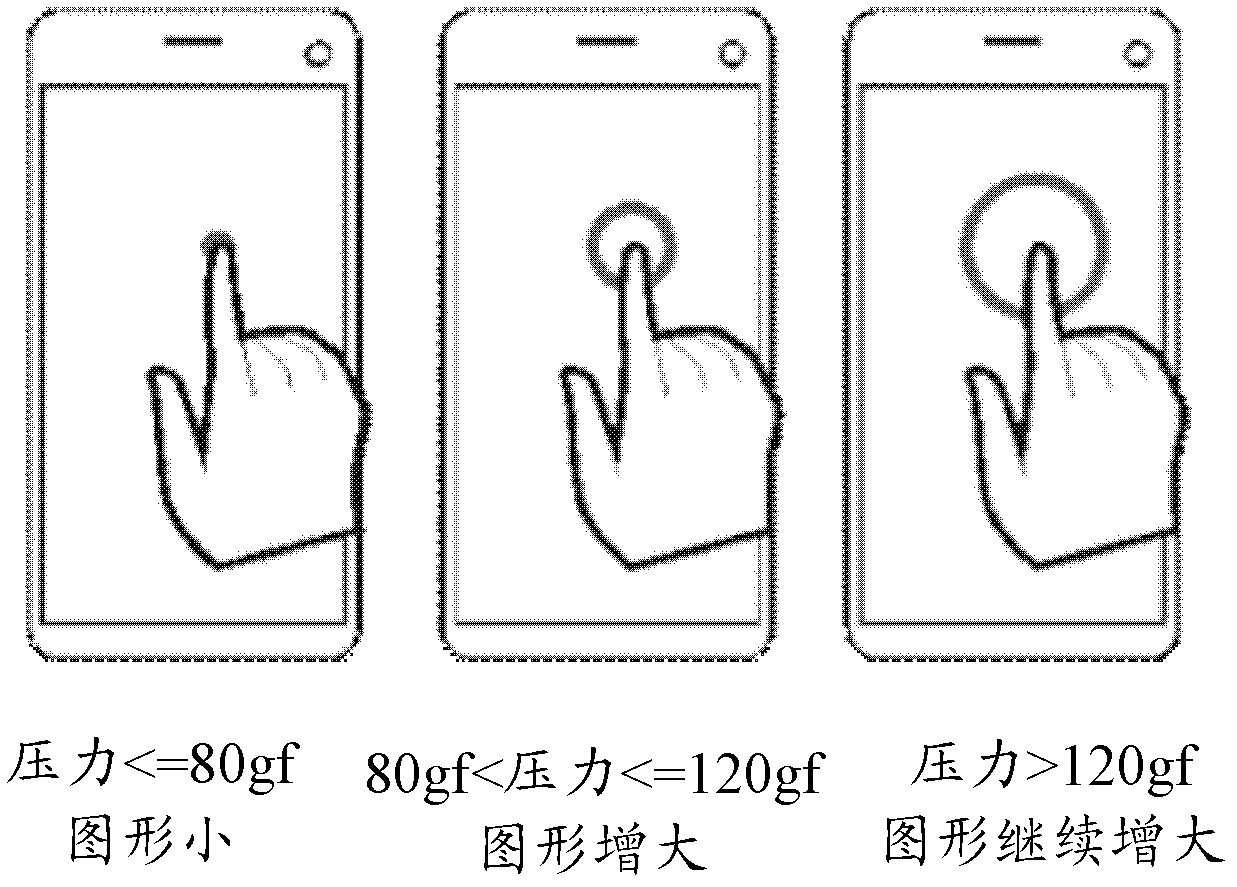

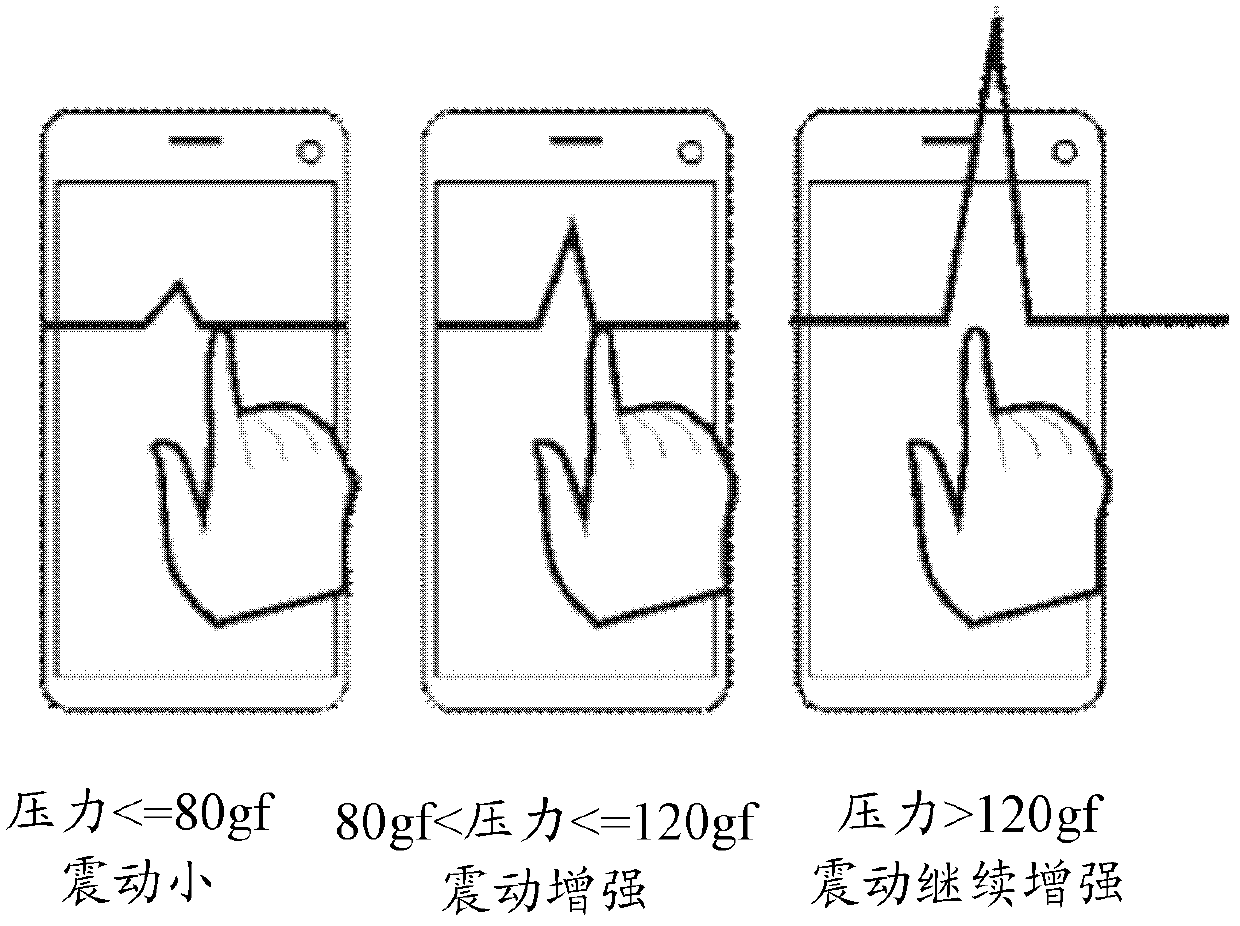

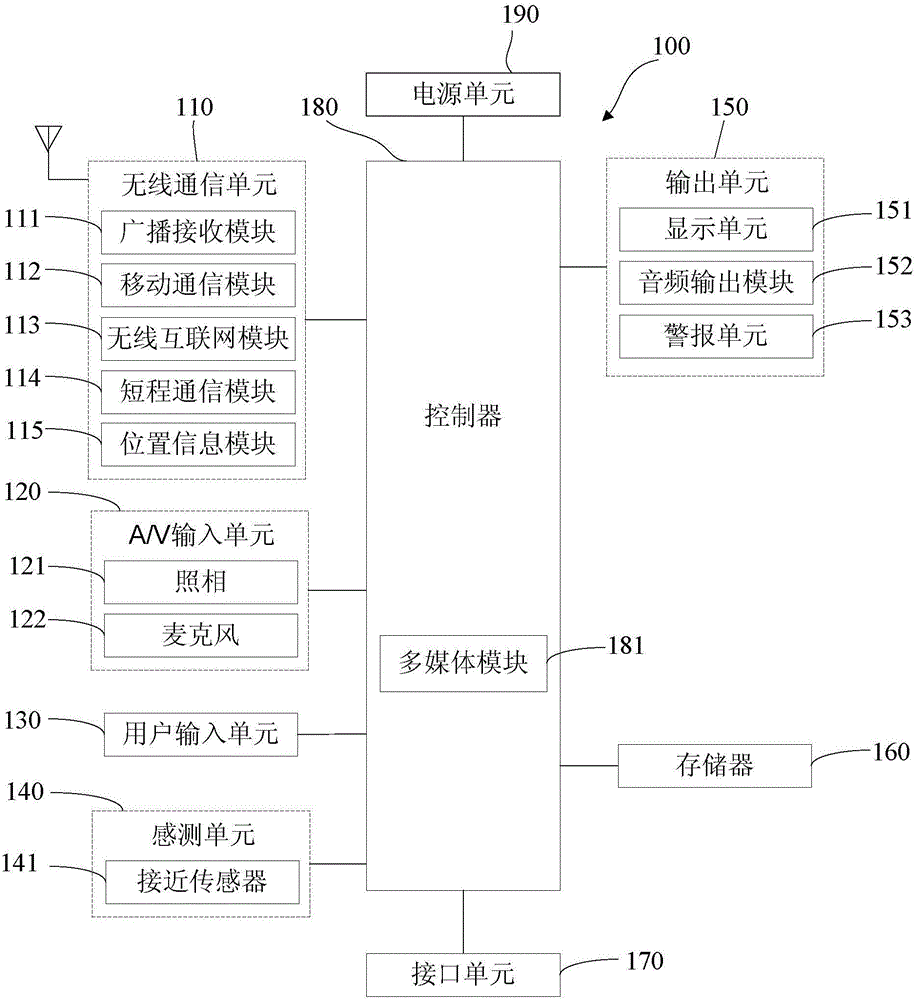

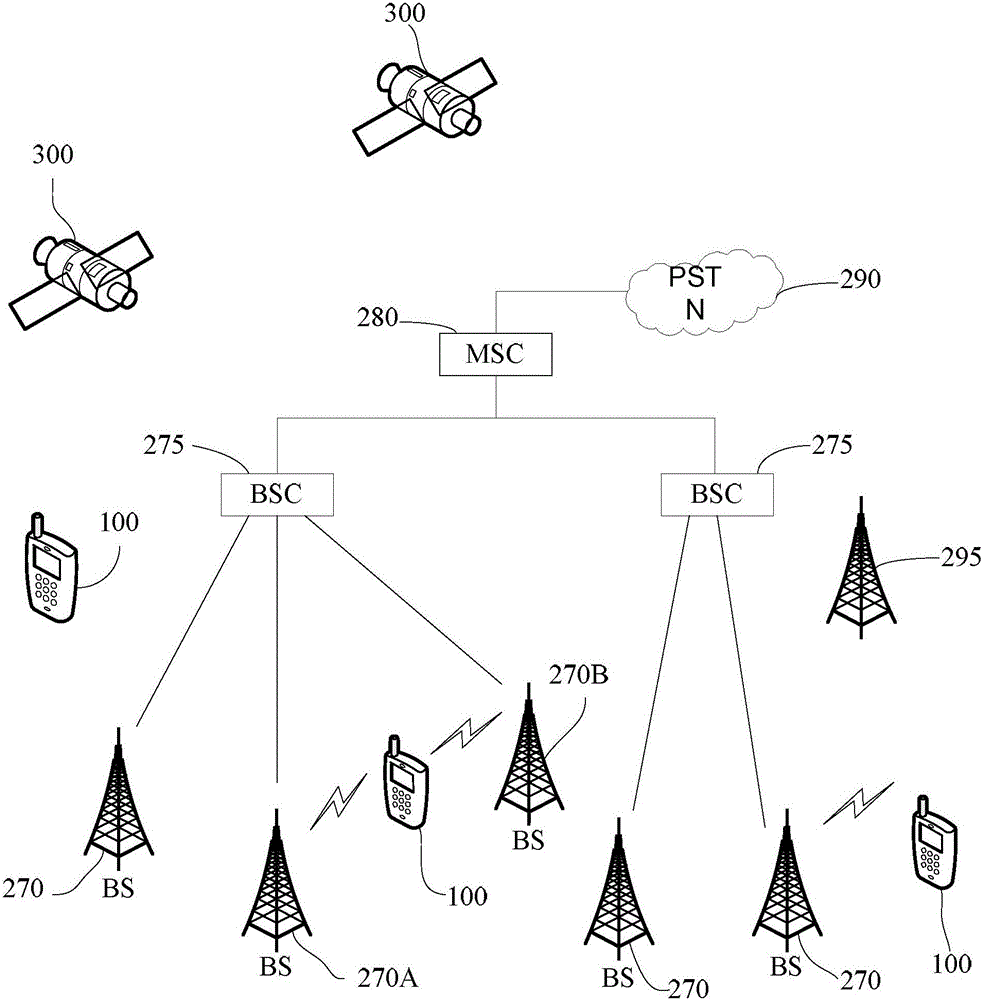

Terminal equipment and method for feeding back pressure by using same

ActiveCN103294183AEasy to operateImprove experienceInput/output for user-computer interactionGraph readingTerminal equipmentComputer terminal

The invention discloses terminal equipment and a method for feeding back pressure by using the same. The terminal equipment can present different information feedback to users according to the pressure born by the terminal equipment, so that the user can determine the pressure applied at present according to the feedback information and perform corresponding processing. The method comprises the following steps: sensing the applied pressure and determining the amplitude of the applied pressure; determining the amplitude range which the amplitude belongs to; acquiring pressure feedback information corresponding to the amplitude range, wherein the corresponding relationship between each amplitude range and the pressure feedback information is preset in the terminal equipment and different amplitude ranges correspond to different pressure feedback information; and performing feedback according to the acquired pressure feedback information. The invention also discloses another terminal equipment and method for feeding back pressure by using the same.

Owner:LENOVO (BEIJING) CO LTD

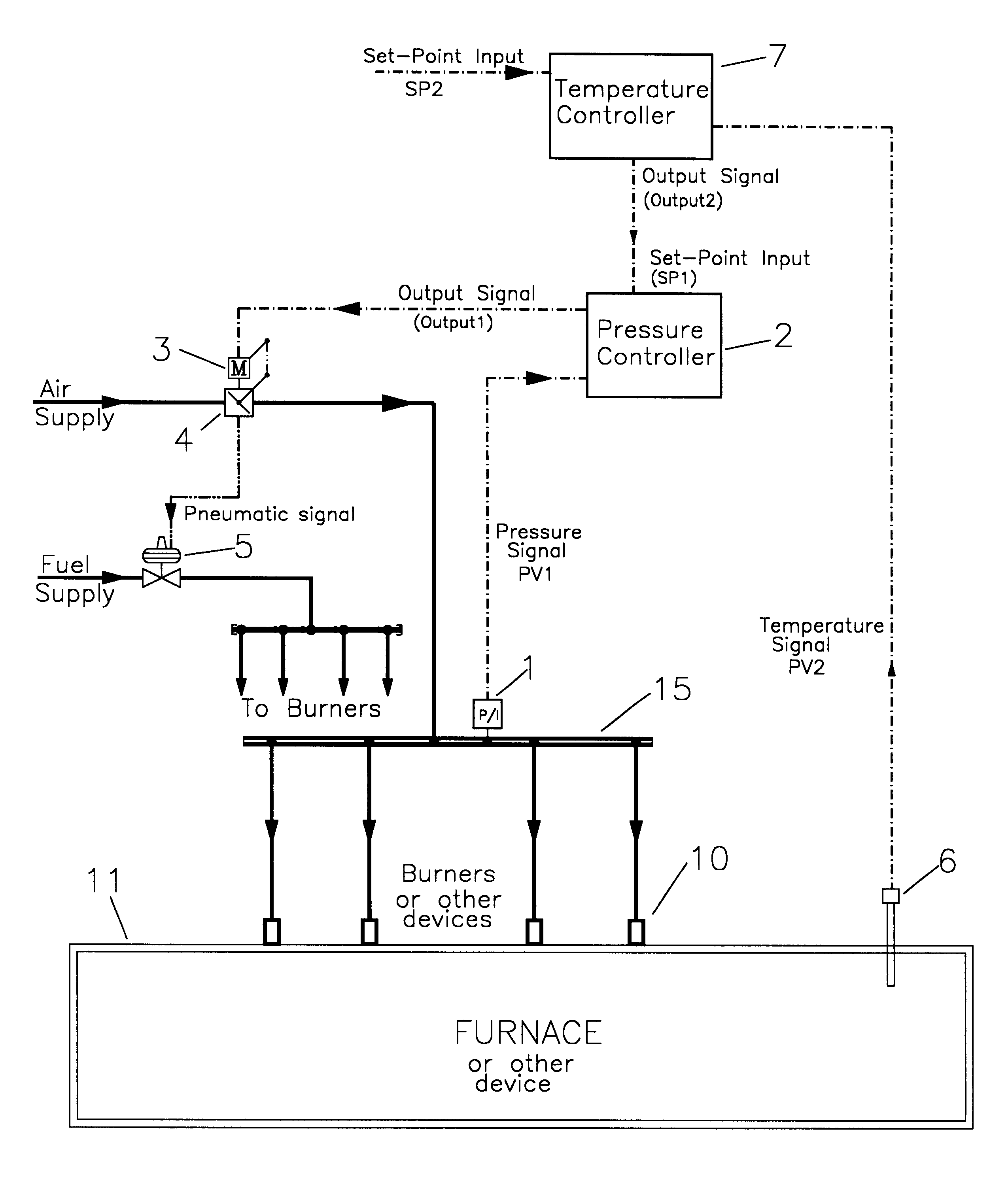

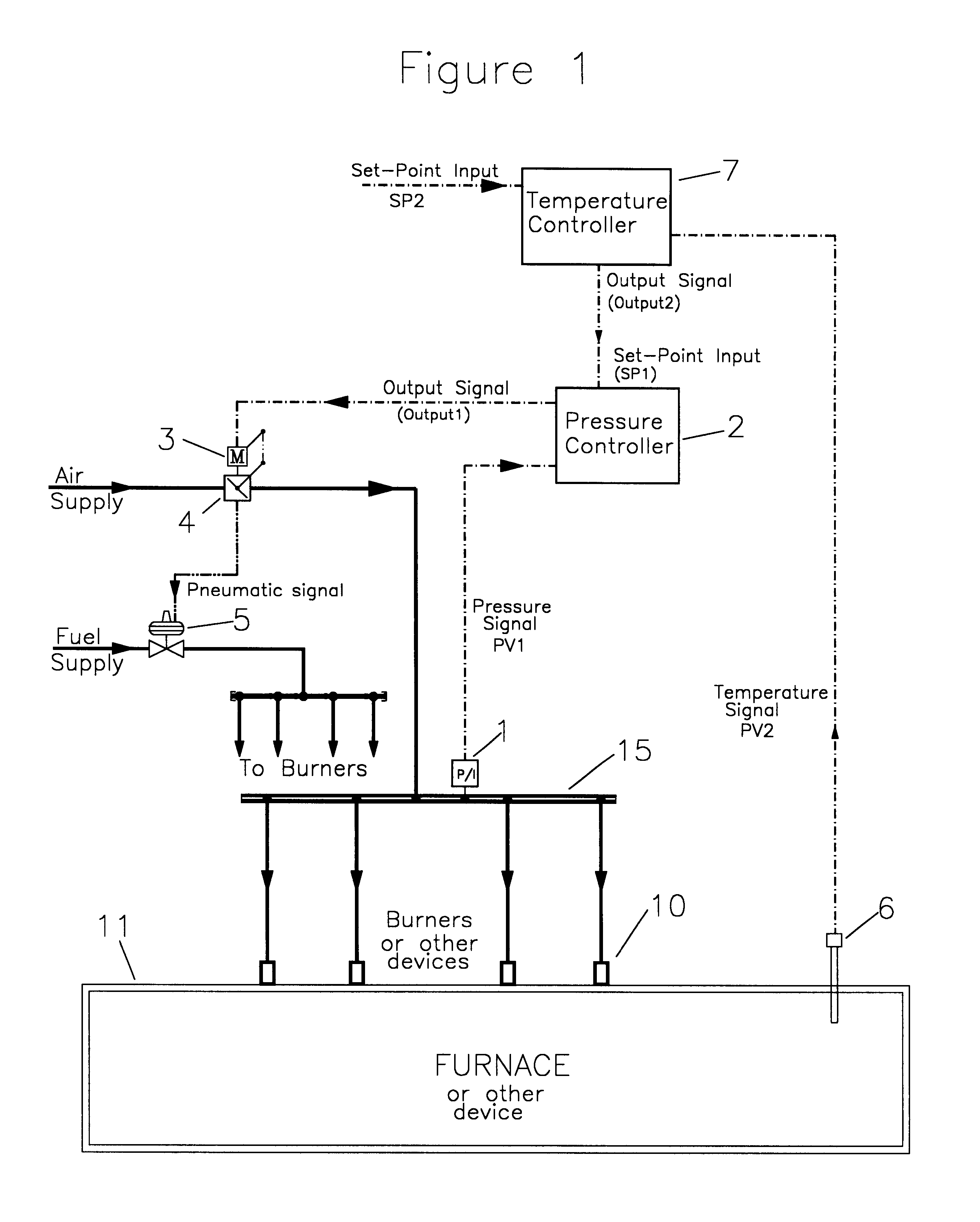

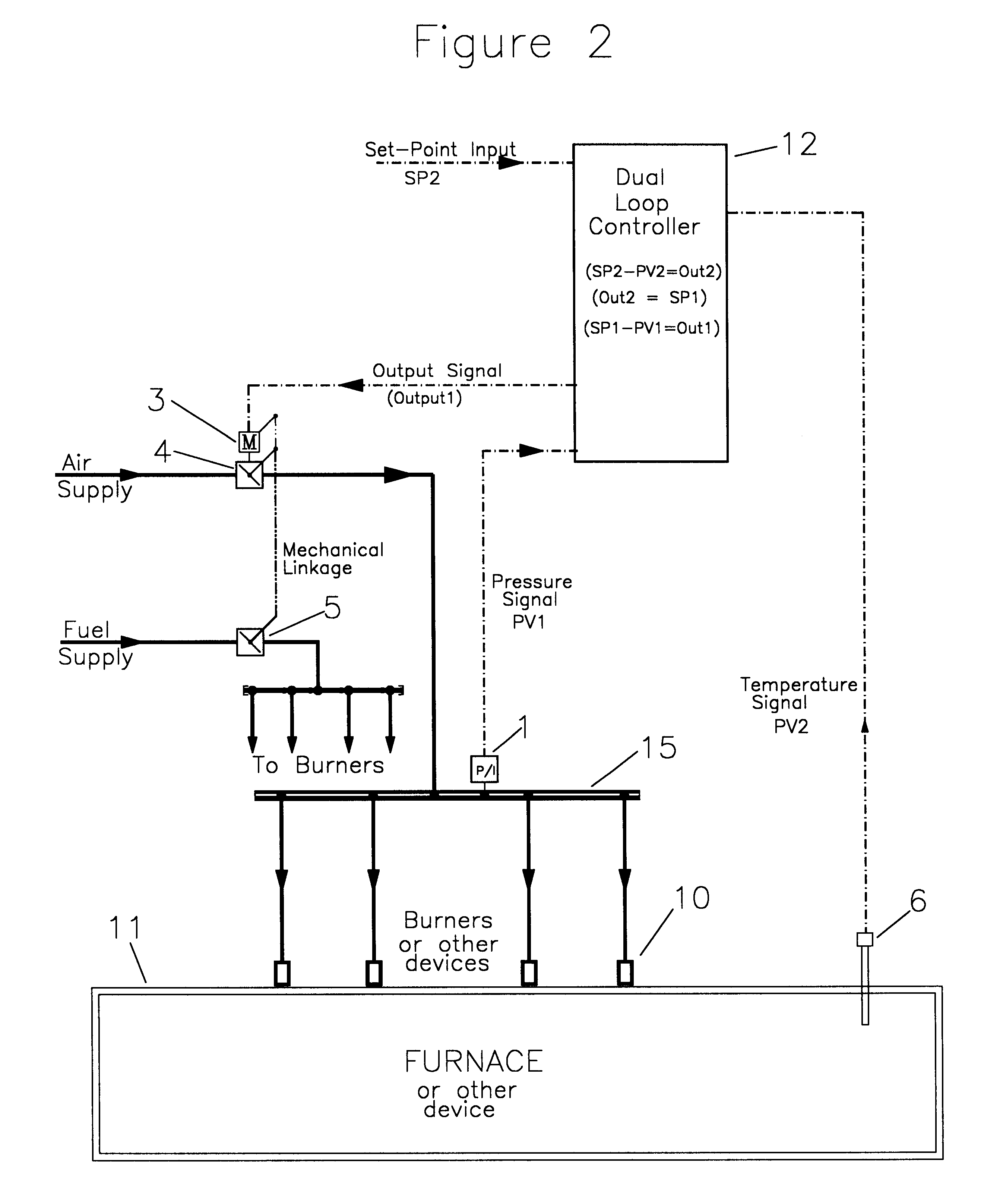

Pressure feedback signal to optimise combustion air control

InactiveUS6332408B2Fuel supply regulationCombustion regulation systemsFurnace temperatureRate change

A novel method of combustion air control for multiple burner furnaces, whereas a pressure transducer is located in the air piping downstream of each zone air flow control device. The pressure transducer sends a feedback signal to a pressure control loop that is in a logical cascade from the furnace temperature control loop. The pressure control loop repositions the air flow control device to compensate for changes in both downstream and upstream conditions. Output from the temperature control loop is interpreted by the pressure control loop as a changing remote set-point value. In one embodiment, the system is ideally suited to compensate for the pressure drop changes that occur across a zone air flow control valve, when flow rate changes occur as burners are started or stopped, thus providing a substantially higher turndown ratio and better control at low fire settings.

Owner:HOWLETT MICHAEL +2

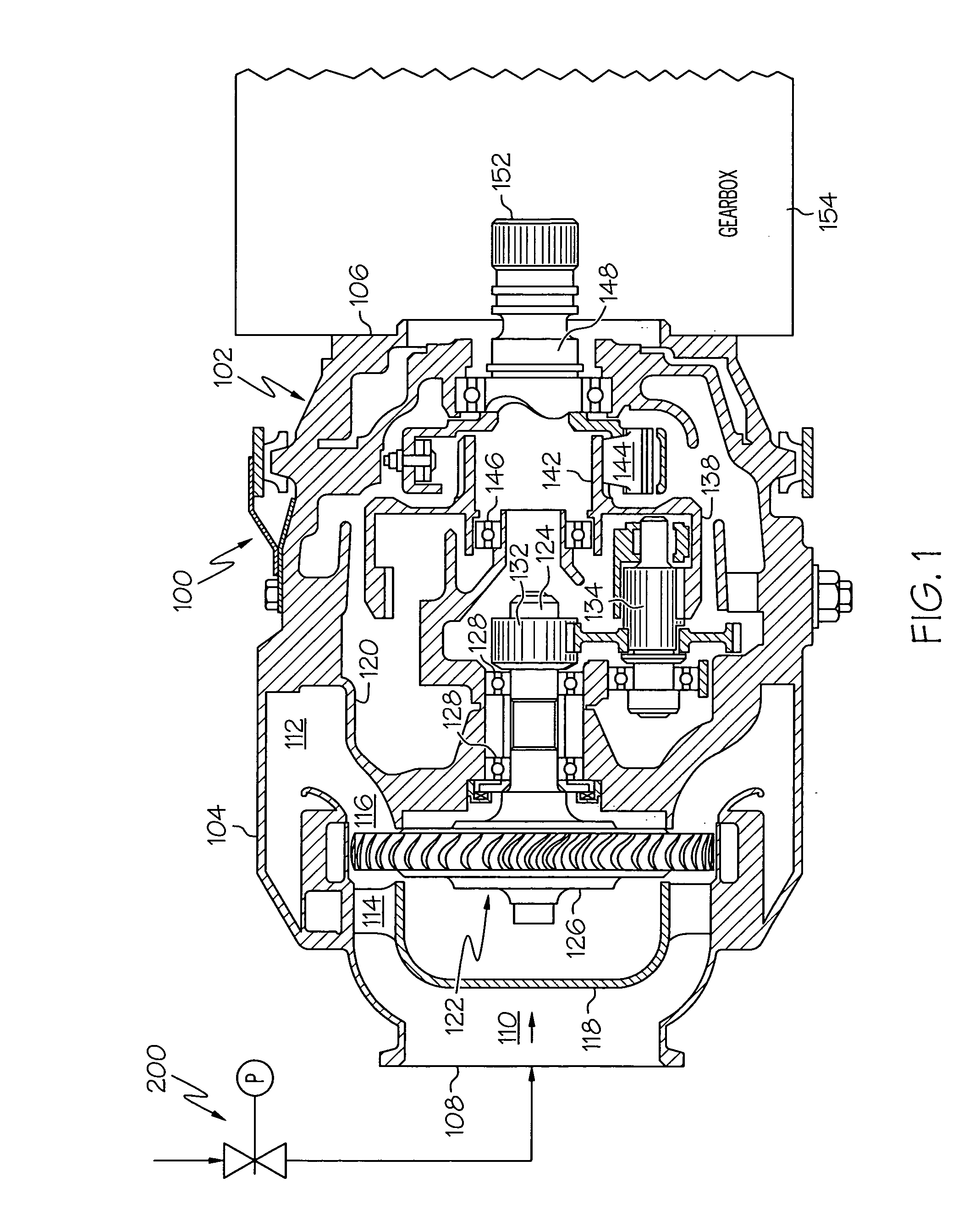

Smart fuel control system

A fuel control system uses a fuel pump powered by a variable speed pump motor controlled by a closed loop electronic feedback system that tracks motor speed and corrects fuel pump motor speed so that the fuel pump delivers flow according to a desired flow schedule based on the pressure feedback from the manifold.

Owner:HAMILTON SUNDSTRAND CORP

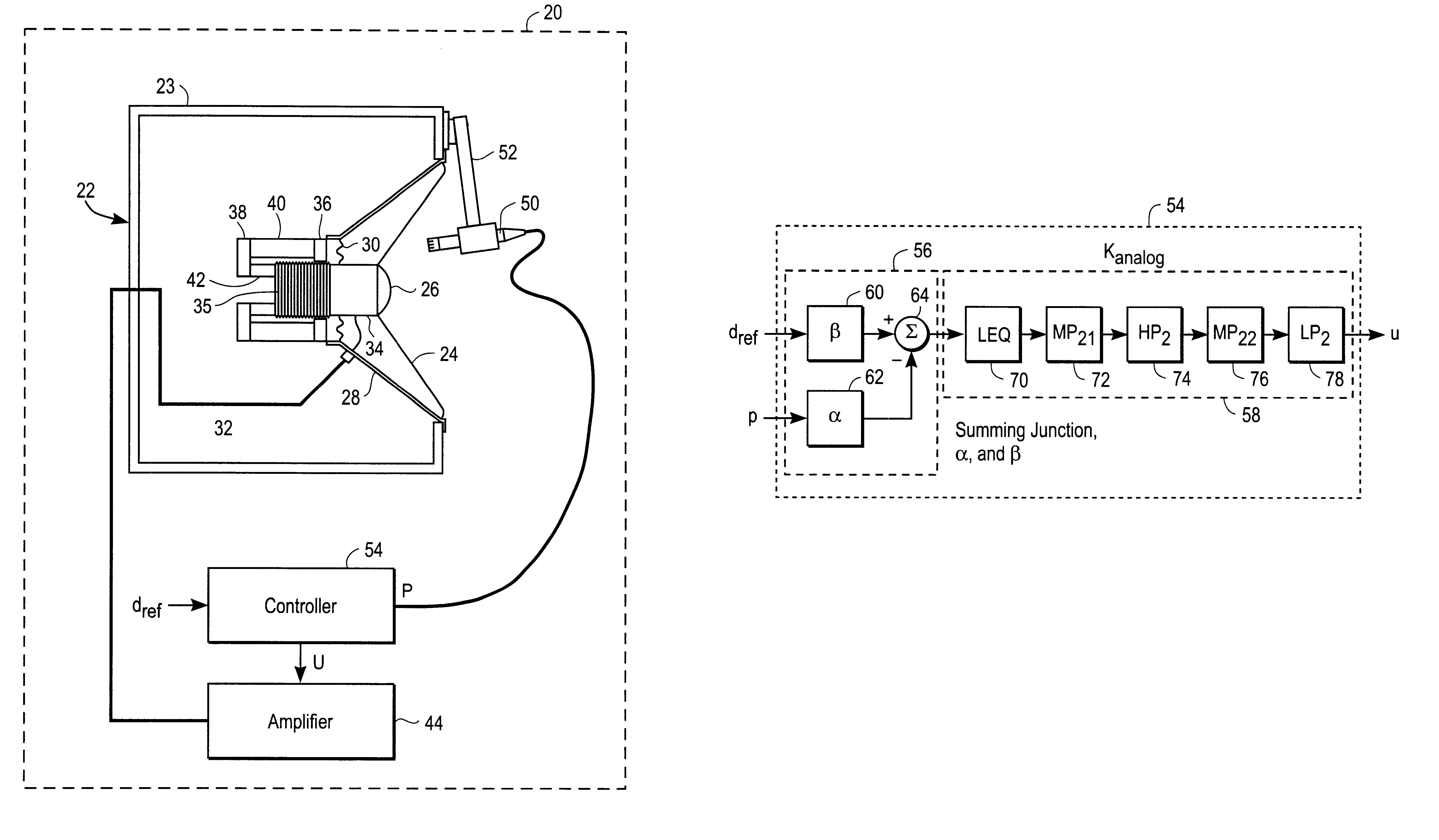

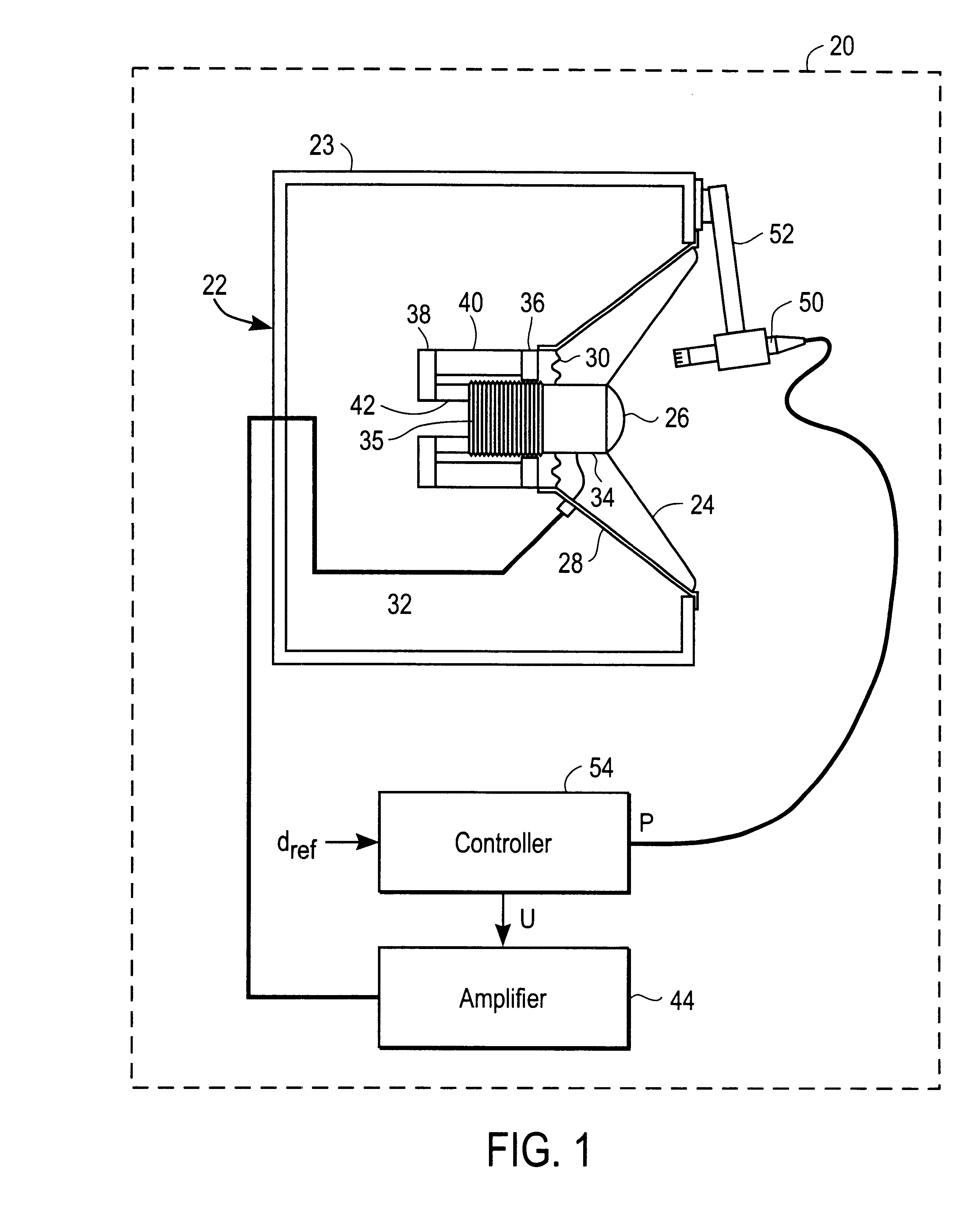

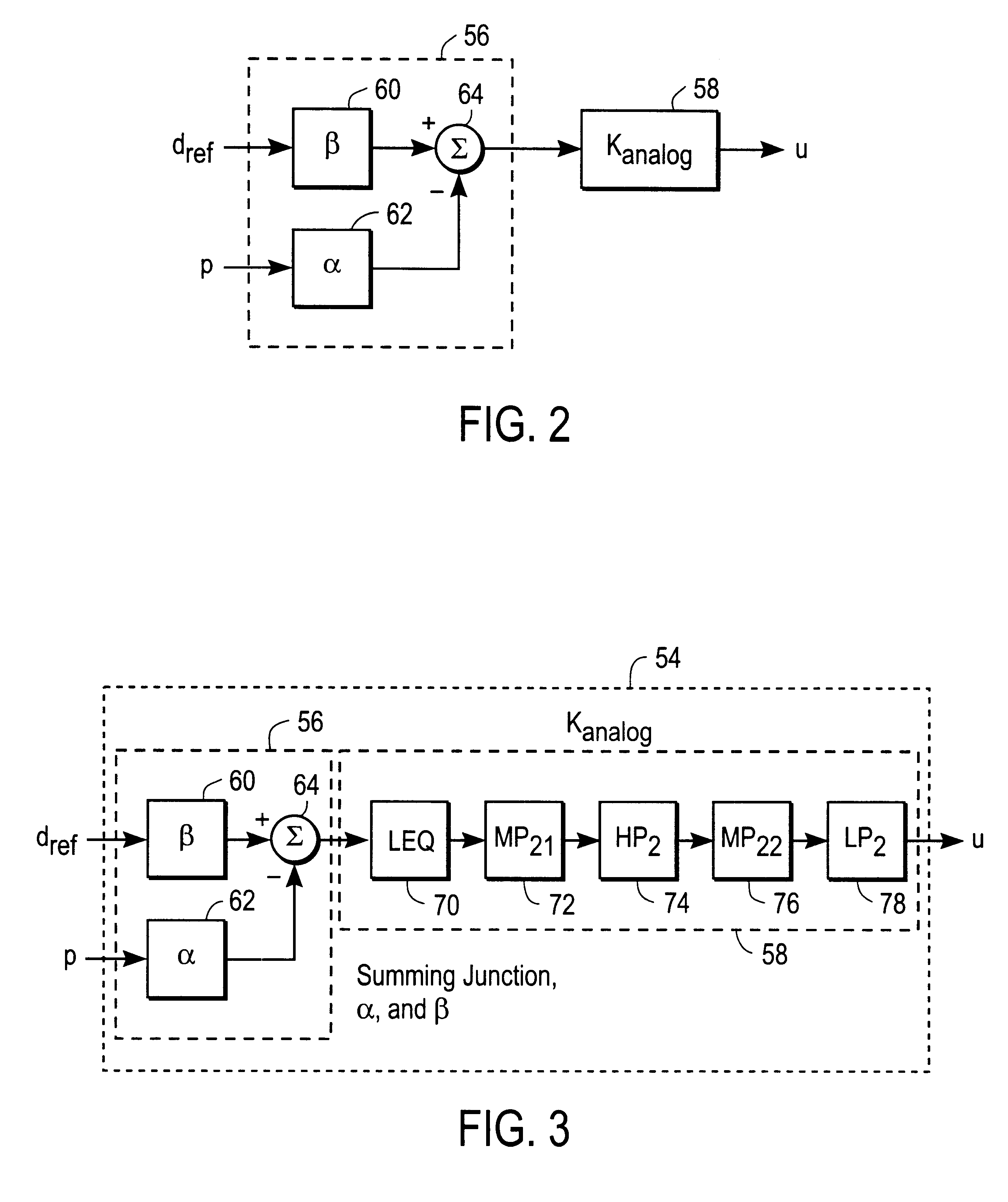

Loudspeaker system with feedback control for improved bandwidth and distortion reduction

InactiveUS6584204B1Improves Sound Pressure Level (SPL) frequency responseReduce distortion problemsGain controlTransducer circuit dampingControl signalDistortion reduction

A sound producing system includes a loudspeaker to generate an audible signal. A transducer generates a pressure feedback signal from the audible signal. A controller produces a controlled signal for application to the loudspeaker. The controller derives the controlled signal from the pressure feedback signal and an audio input signal. The controlled signal improves the Sound Pressure Level (SPL) frequency response and reduces distortion within a selected bandwidth of the loudspeaker.

Owner:RGT UNIV OF CALIFORNIA

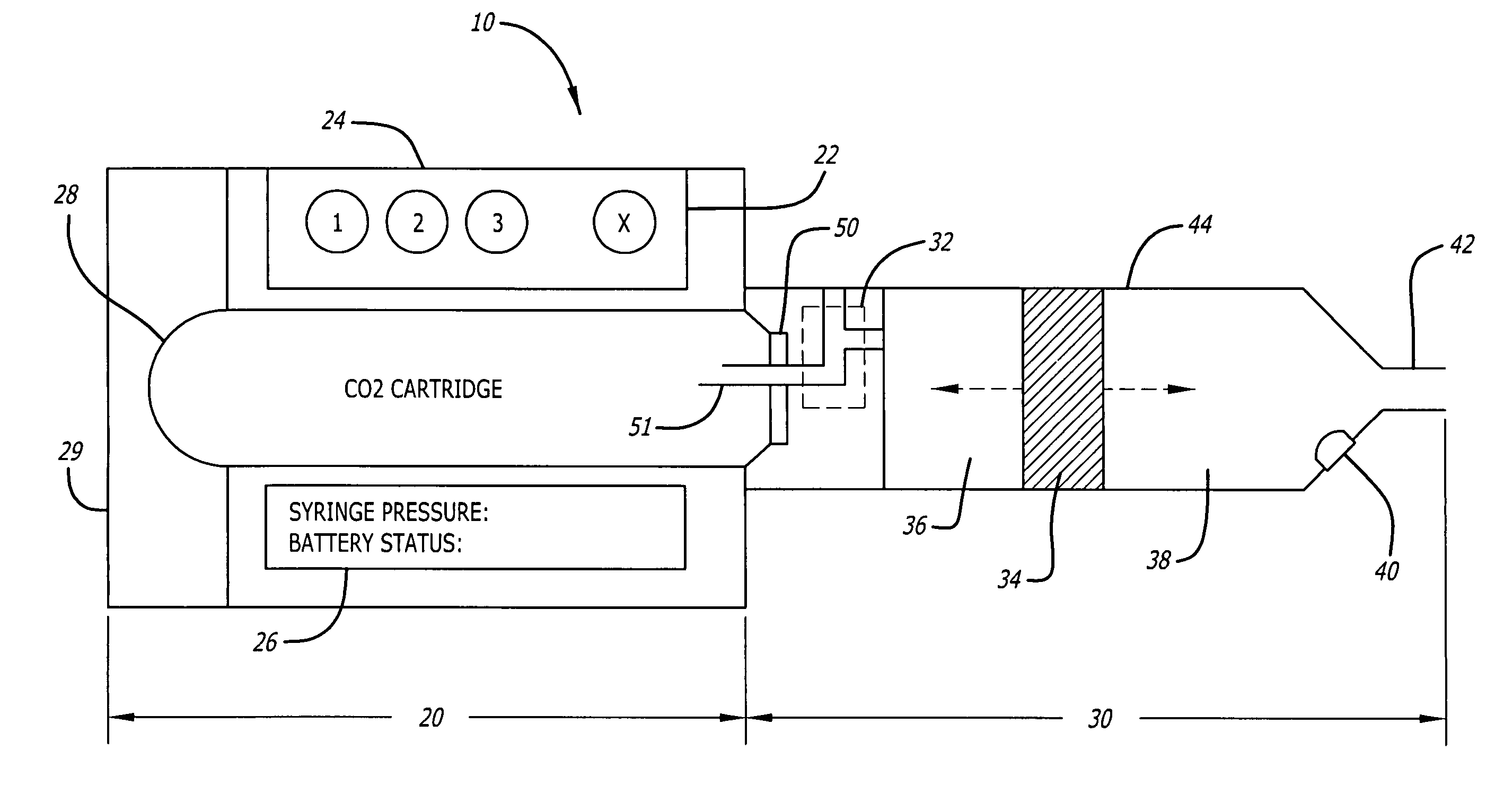

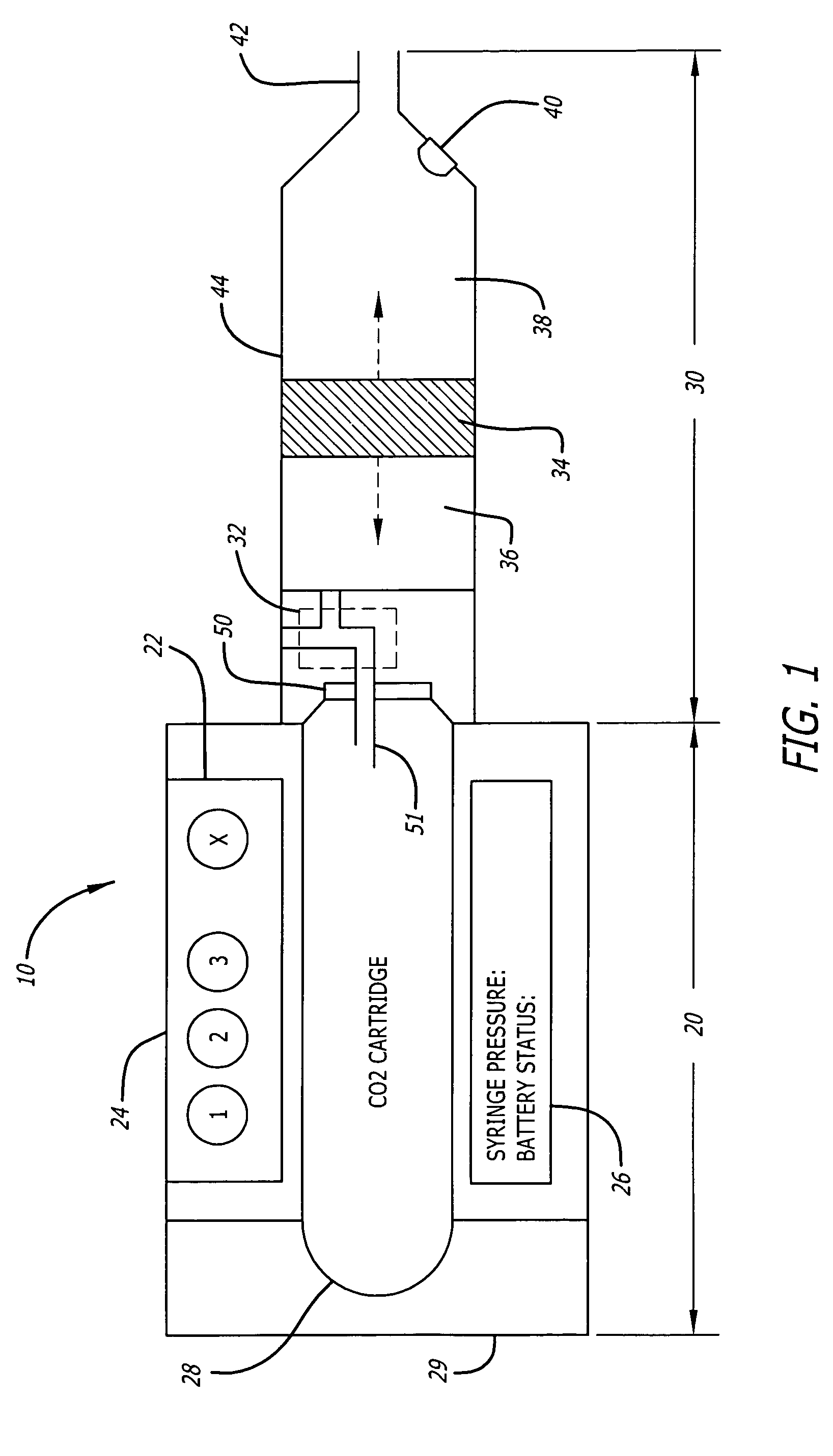

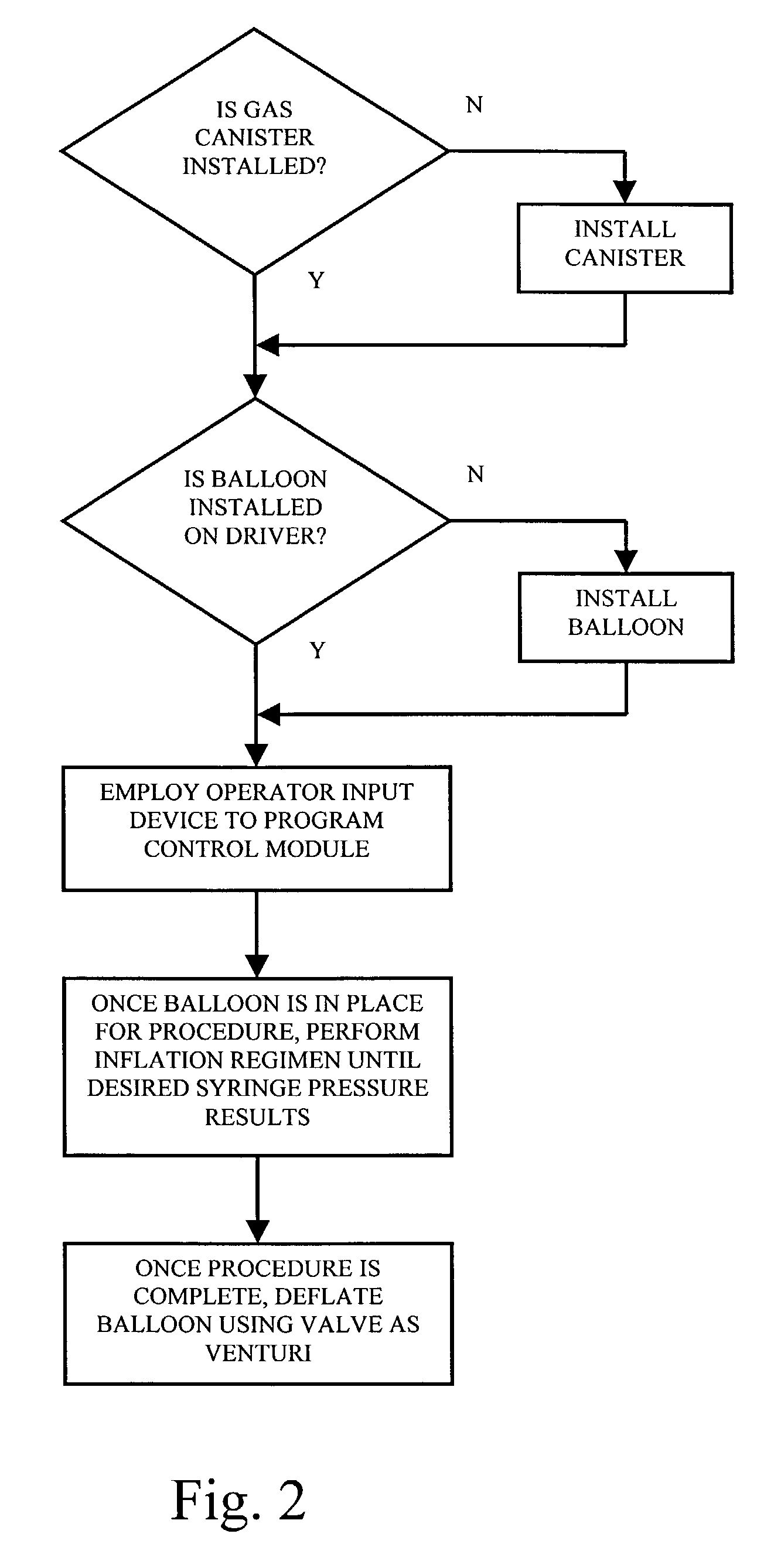

Pneumatic syringe driver

A pneumatic syringe driver having a control module for regulating pressure applied to the plunger of an associated syringe is disclosed. The syringe driver is adapted for receiving a compressed gas canister and for enabling the selective release of gas from the canister into a chamber, one wall of which being formed by the syringe plunger via a three-way valve. The valve also enables the selective venting of gas from the canister into the atmosphere, thereby forming a venturi which reduces the pressure in the chamber and causes the syringe plunger to be withdrawn into the chamber. A pressure sensor in communication with the control module is provided for pressure feedback. Pushbuttons or switches in communication with the control module are provided for defining the syringe driver operation. The device is suited for the selective inflation and deflation of a balloon attached to the syringe driver for a balloon angioplasty procedures.

Owner:CARDINAL HEALTH SWITZERLAND 317 S A R L

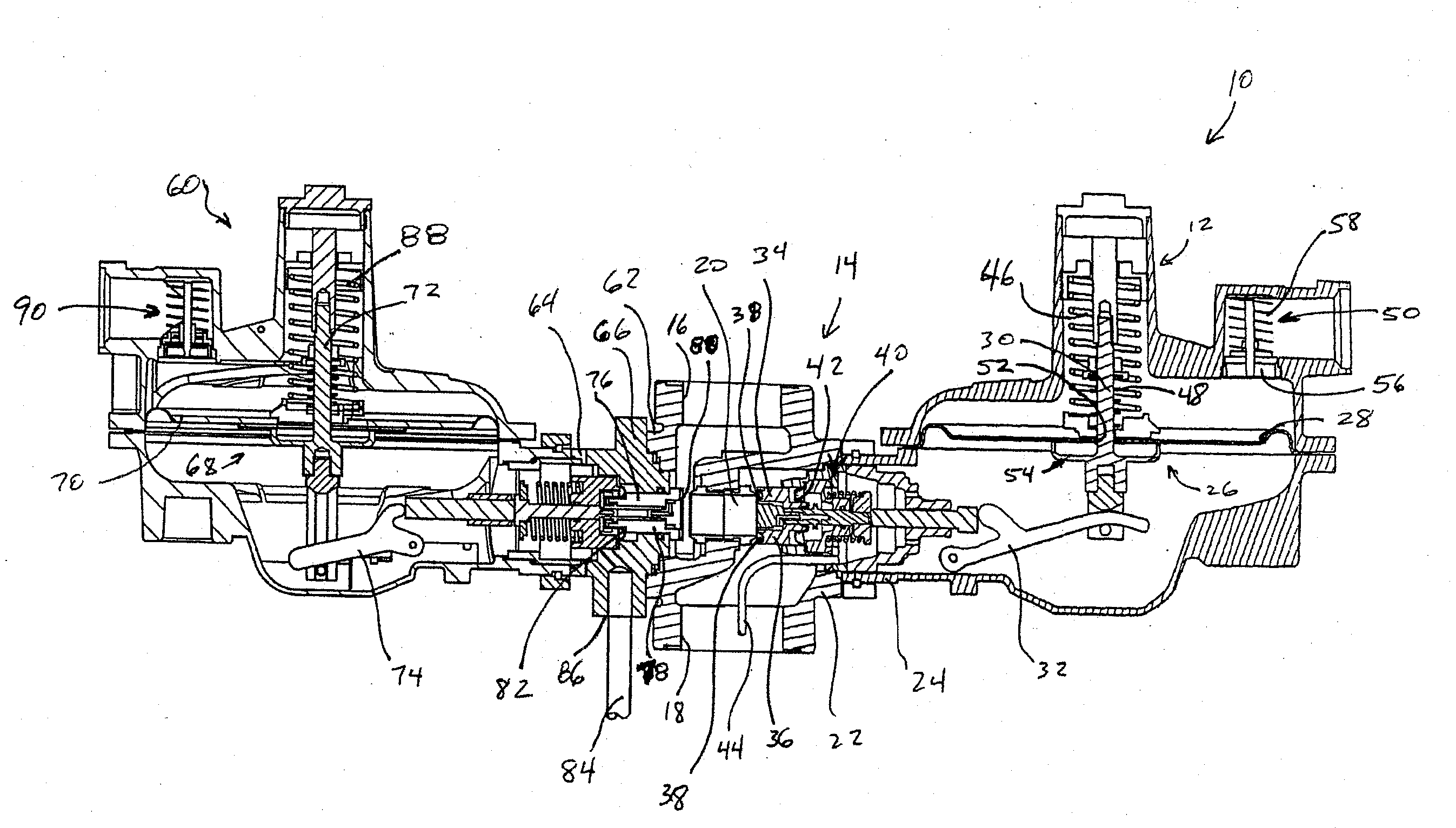

Valve Body with Dual Sense Mechanism

ActiveUS20090260697A1Operating means/releasing devices for valvesEqualizing valvesEngineeringActuator

A gas regulator includes an actuator, a regulator valve, and a secondary device. Downstream pressure feedback is provided to the actuator and the secondary device via a Pitot tube disposed within an outlet of the regulator valve. The Pitot tube has a first branch having an end connected to the actuator to place the actuator control cavity and diaphragm in fluid communication with downstream pressure within the outlet for maintaining the outlet pressure at an actuator setpoint pressure. The Pitot tube also has a second branch having an end connected to the secondary device to place the interior of the secondary device in fluid communication with downstream pressure within the outlet for responding to changes in the downstream pressure when the outlet pressure diverges from a predetermined normal operating pressure range.

Owner:EMERSON PROCESS MANAGEMENT REGULATOR TECH INC

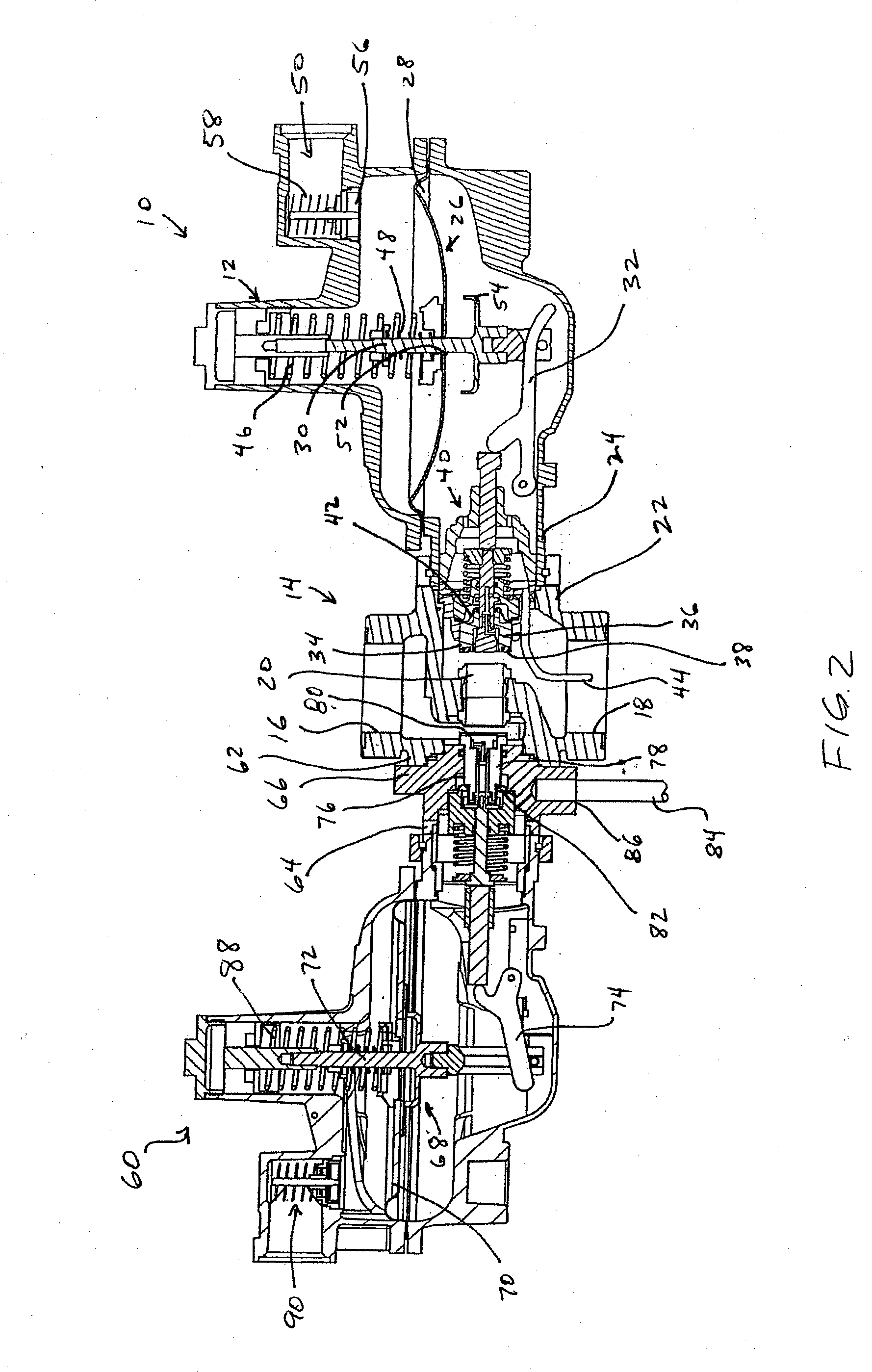

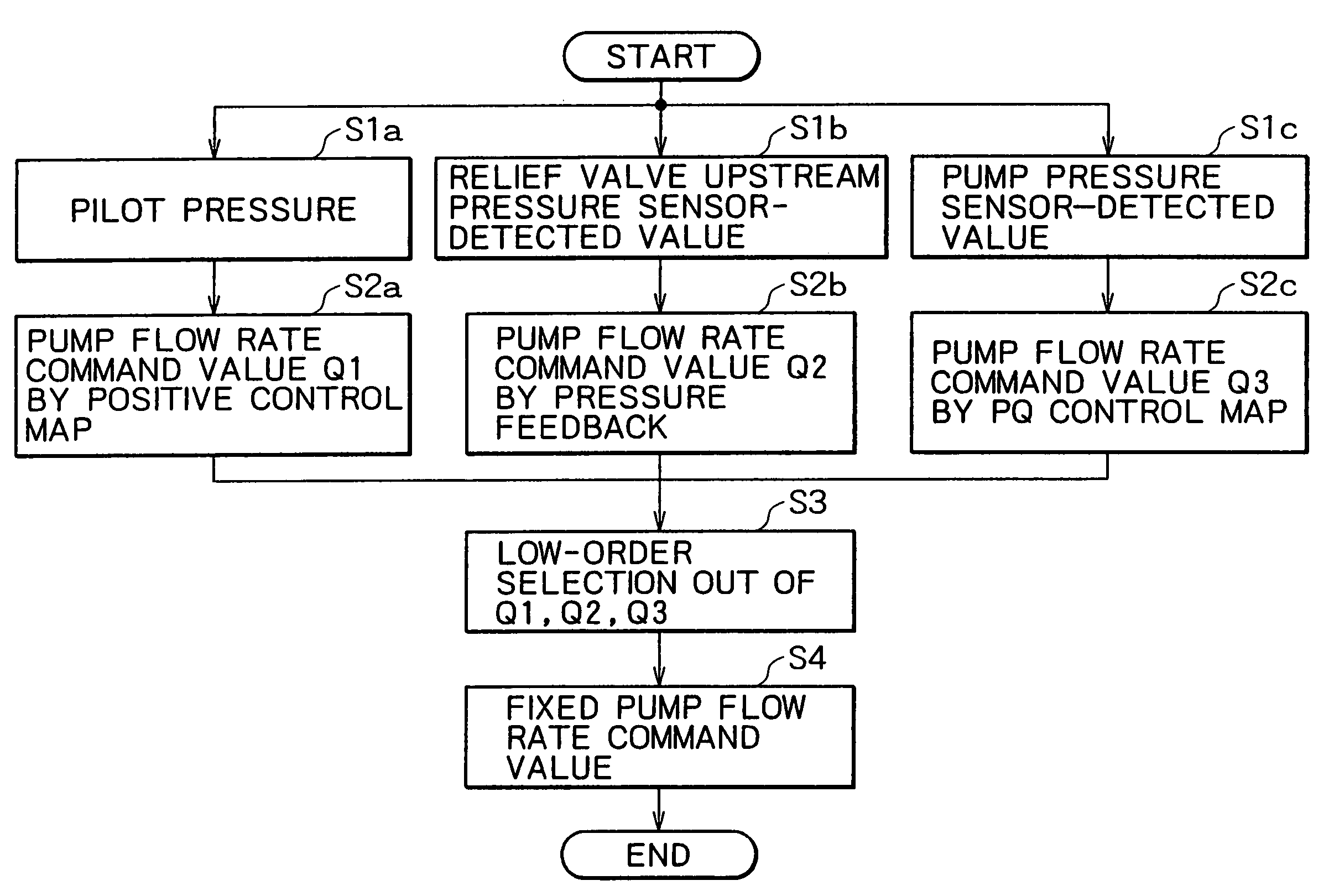

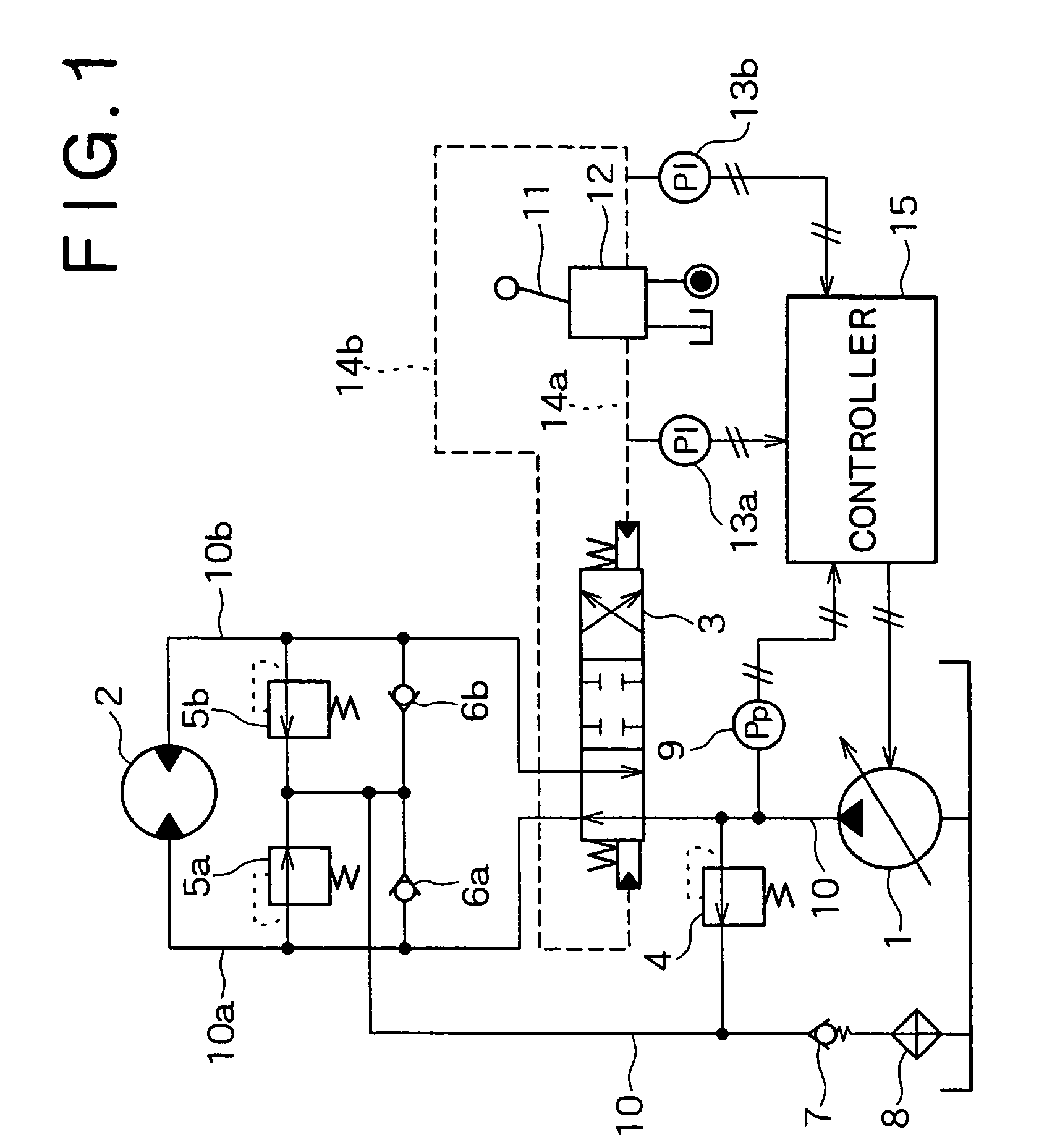

Hydraulic control system for working machine

ActiveUS7392653B2Decrease a relief lossImprove energy efficiencyFluid couplingsServomotorsControl systemHydraulic pump

A hydraulic control system for a working machine according to the present invention comprises a hydraulic pump for supplying working oil to a hydraulic actuator through a control valve, a relief mechanism disposed on the discharge side of the pump, the relief mechanism assuming an open state when a pump discharge pressure which varies according to the pump flow rate exceeds a predetermined pressure and assuming a closed state when the pump discharge pressure becomes the predetermined one or lower, an ordinary control means for controlling the pump flow rate in accordance with working information, and a pressure feedback control means for controlling the pump flow rate in accordance with the pump discharge pressure. In this system, out of controls performed by both control means, control wherein the flow rate by one control becomes smaller than that of the other is selected, thereby opening / closing control of the relief mechanism is performed. According to this, it is possible to decrease the relief loss and improve the energy efficiency while making the most of the ordinary control.

Owner:KOBELCO CONSTR MASCH CO LTD

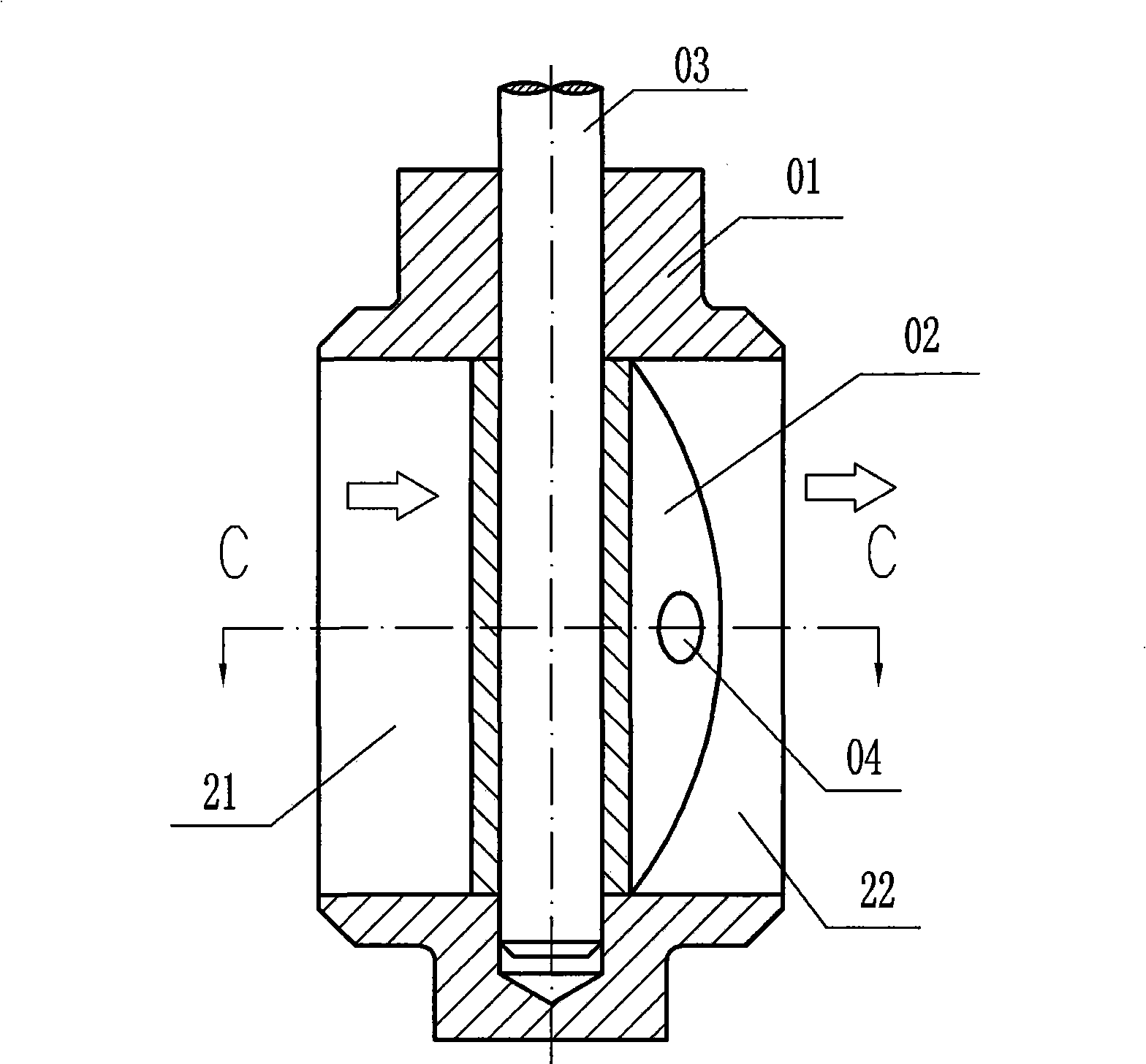

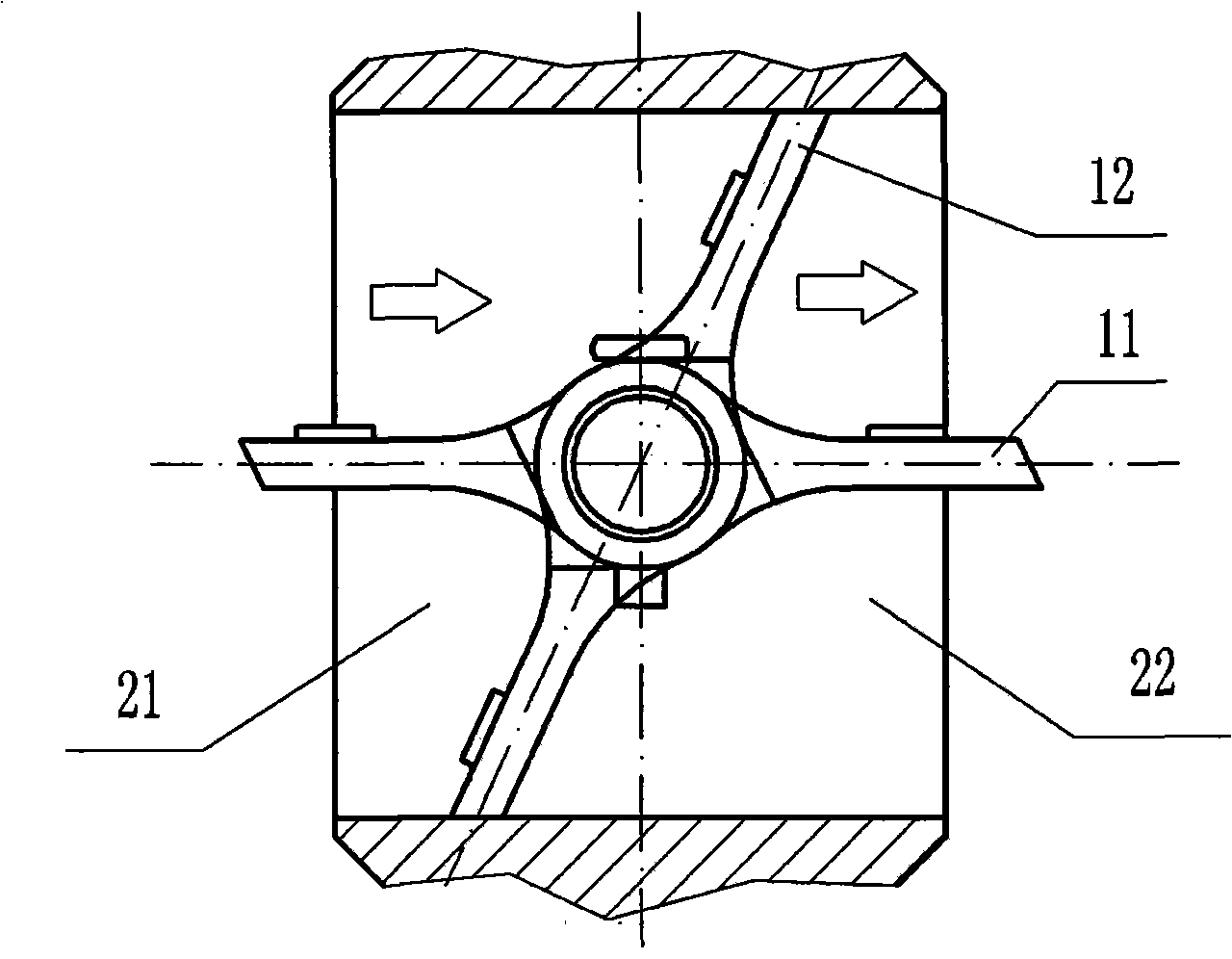

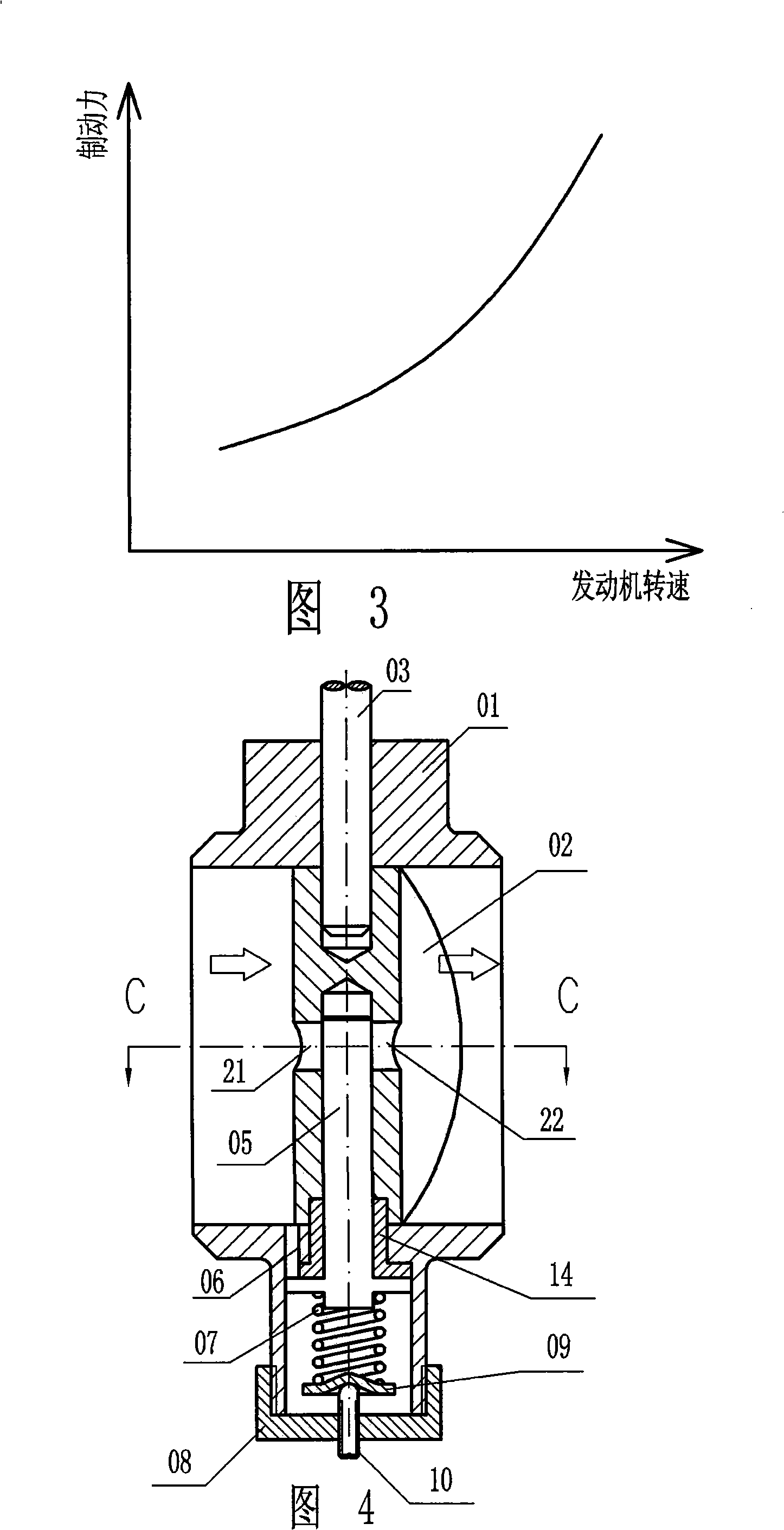

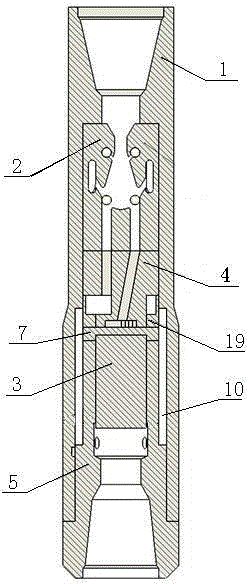

Operating pressure adjustable air exhausting brake

InactiveCN101307727AAccurate control of back pressureResponsiveValve arrangementsOutput powerWorking pressureExhaust brake

The invention relates to an exhaust arrester capable of adjusting working pressure. The exhaust arrester comprises a valve body (01), a disk (02), a support bar (03), a support sleeve (14), a control bar (05), an air pressure feedback passage (06), a spring (07), a press plate (09), an adjusting support (10) and a cover (08); the disk (02) is fixed on an appointed position of the valve body (01) by the support bar (03) and the support sleeve (14); the support bar (03) drives the disk (2) to rotate around the axes of the disk; the control bar (05) is used for controlling connection and disconnection of an exhaust gas passage and is fixed on the bottom of the support sleeve (14) by the spring (07), the press plate (09), the adjusting support (10) and the cover (08); the air pressure feedback passage (06) drives the control bar (05) to move; and the spring (07) is used for adjusting the working pressure of an exhaust arrester assembly. When the pressure exceeds a set value by any accidental situation, the exhaust arrester can release pressure in time, ensure that the working pressure is stable and reliable and has adjustable working pressure and simple and convenient implementation.

Owner:李瑞强

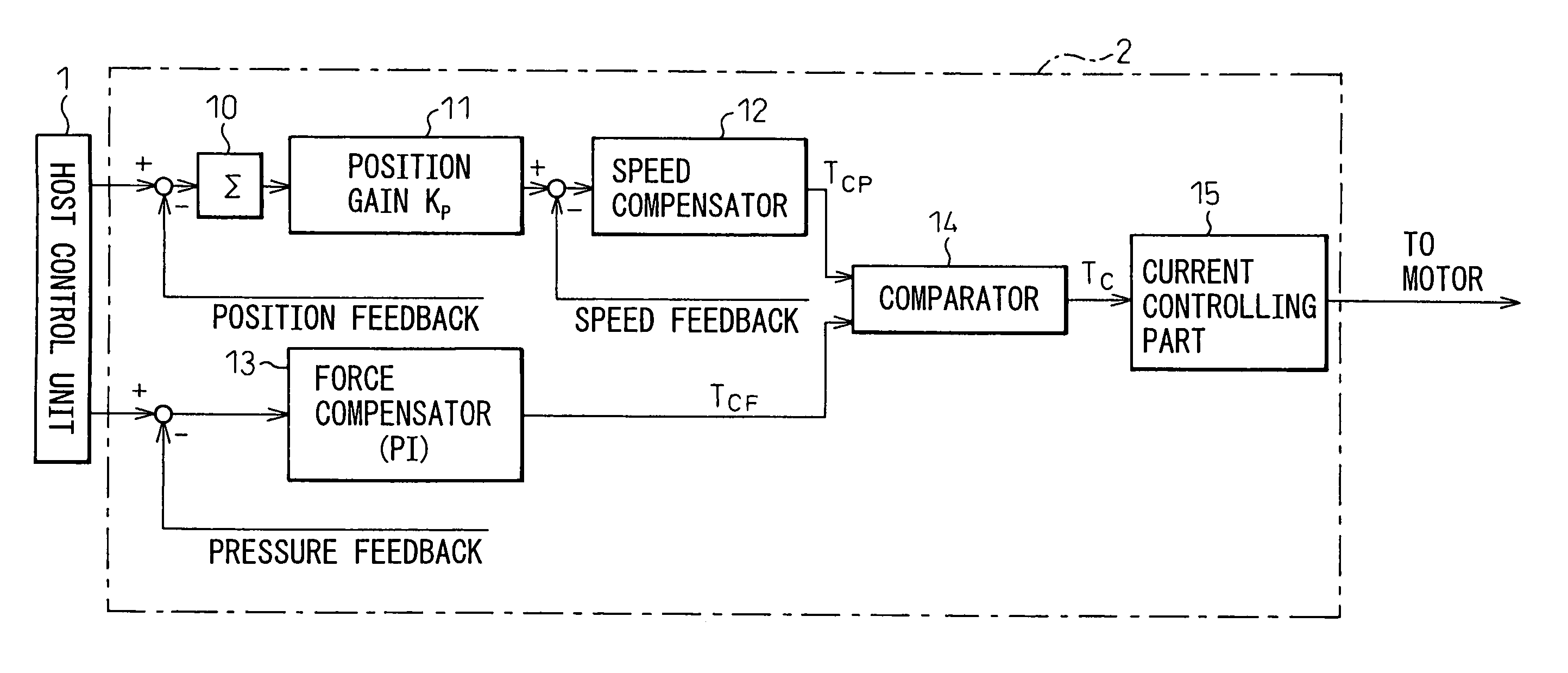

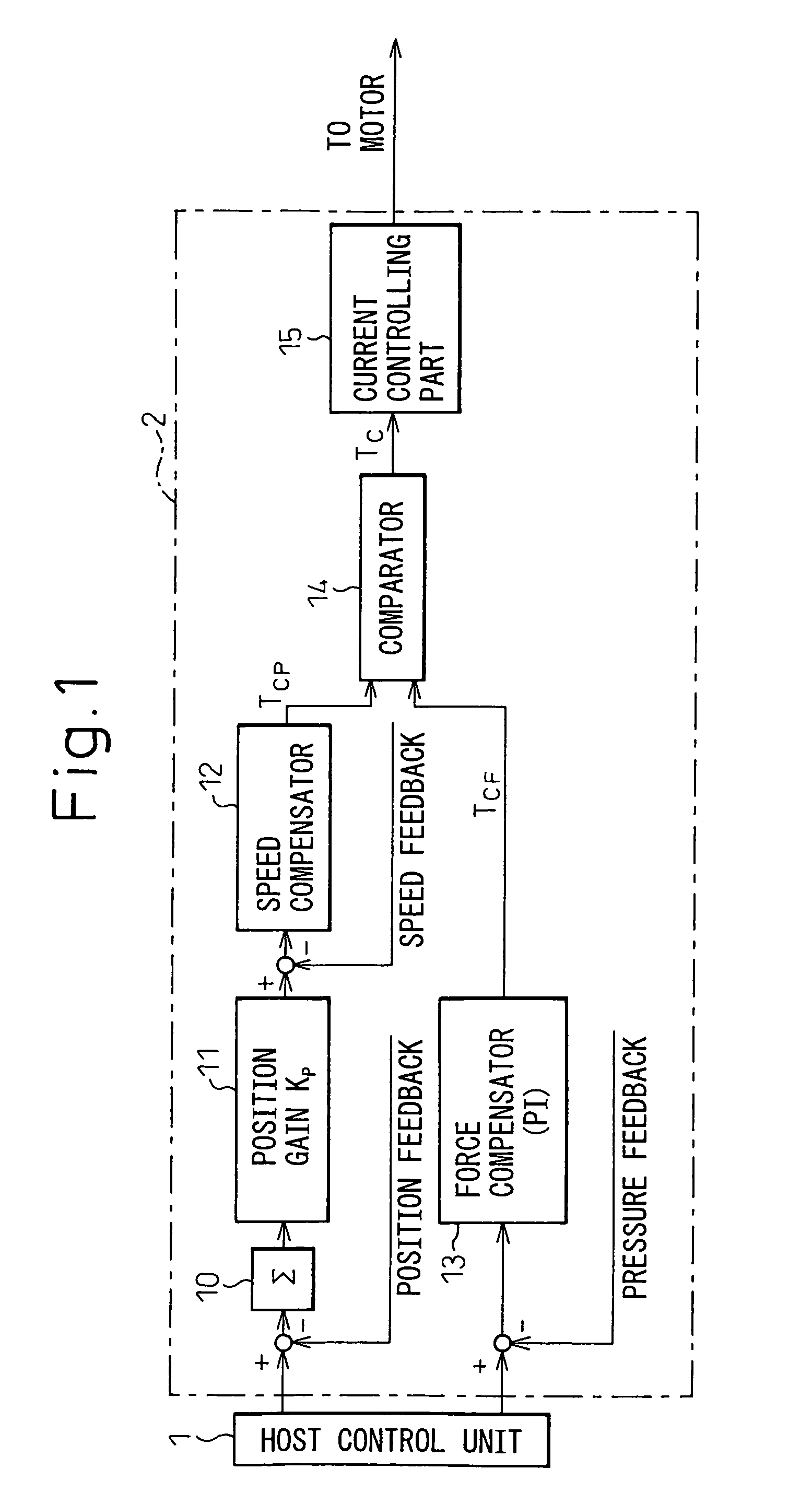

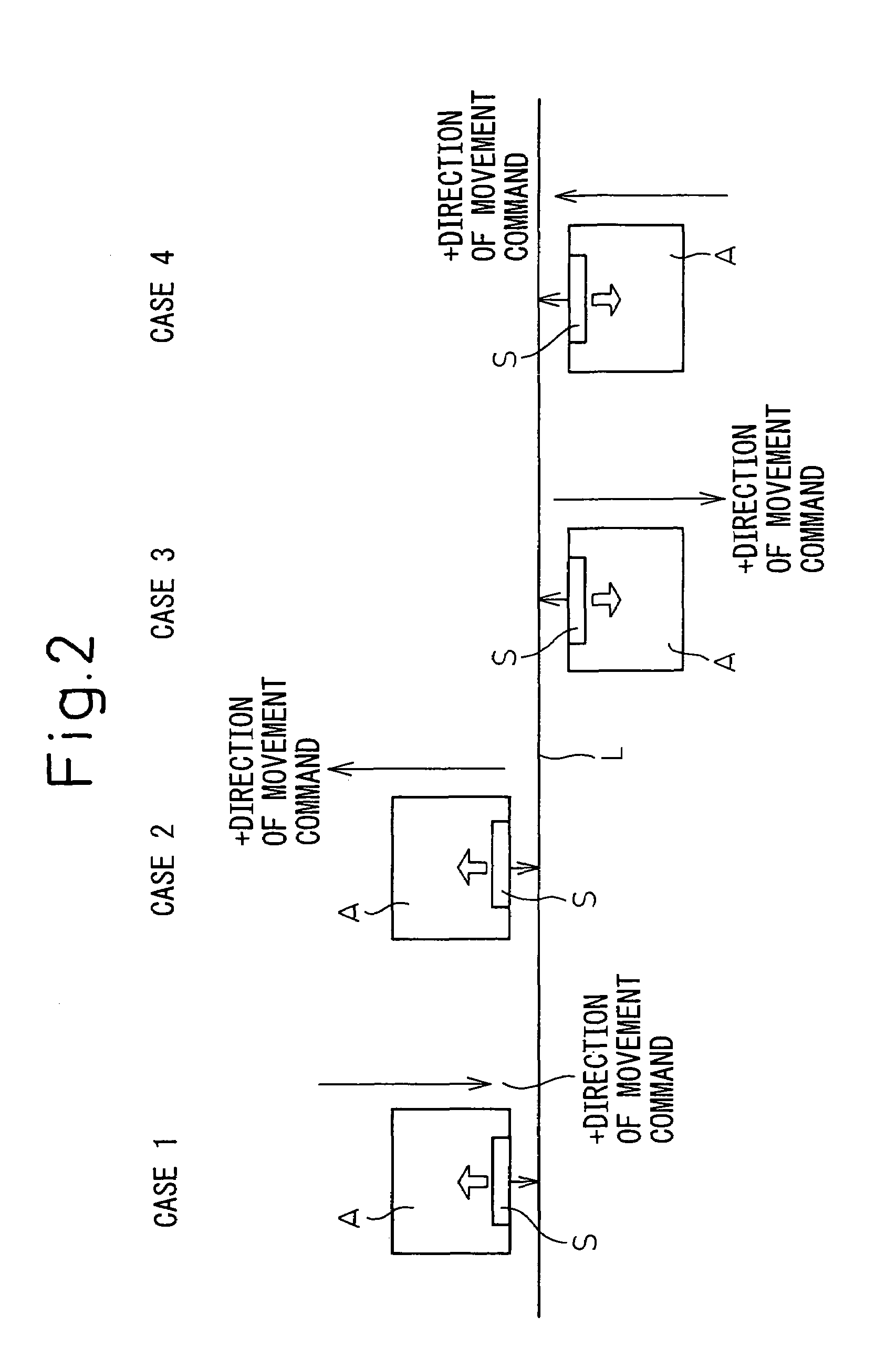

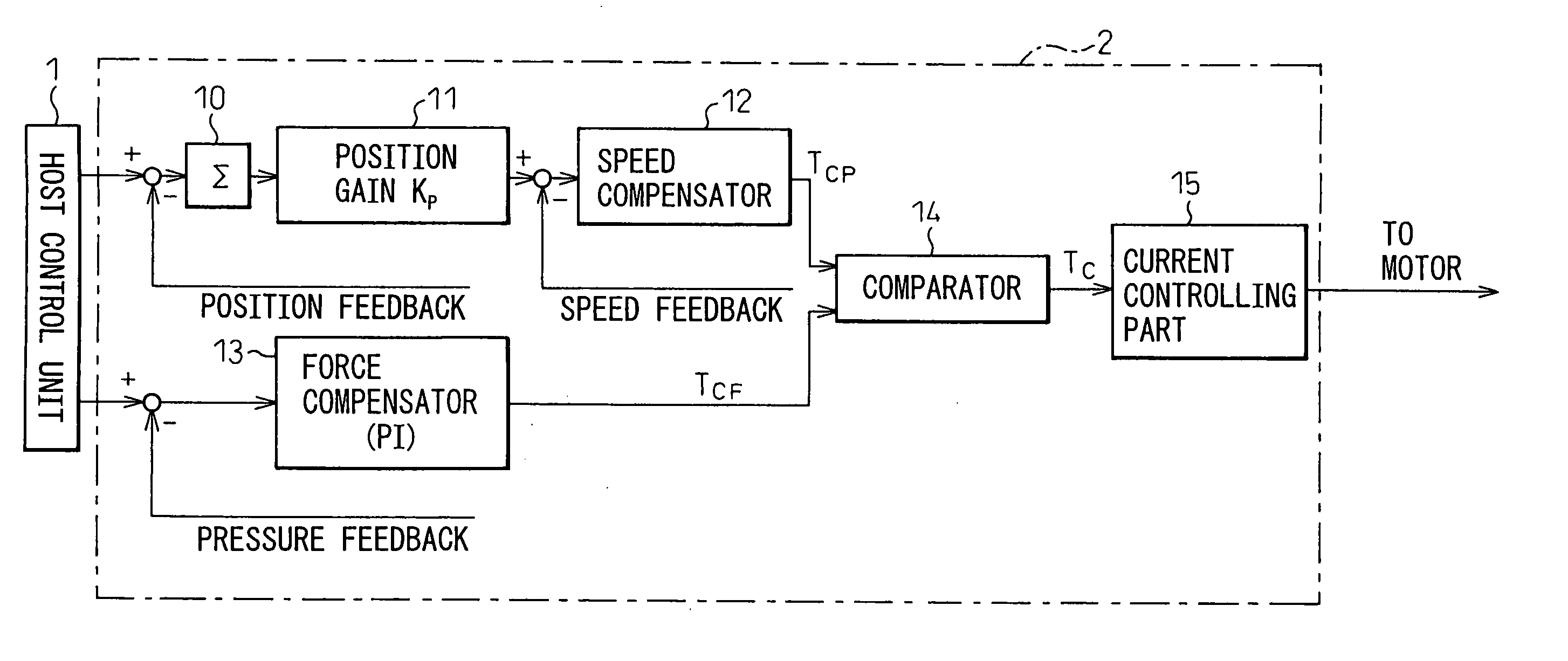

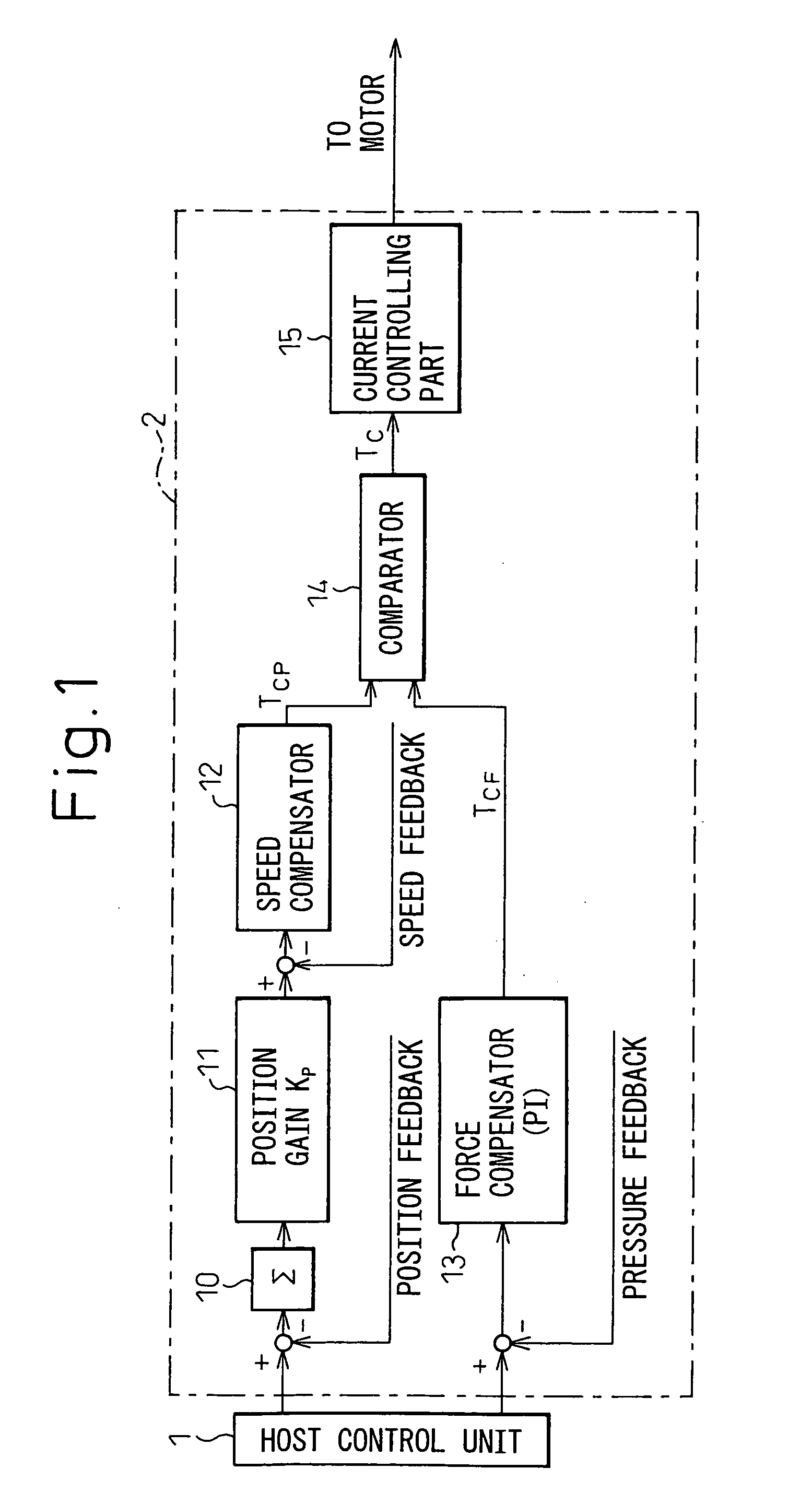

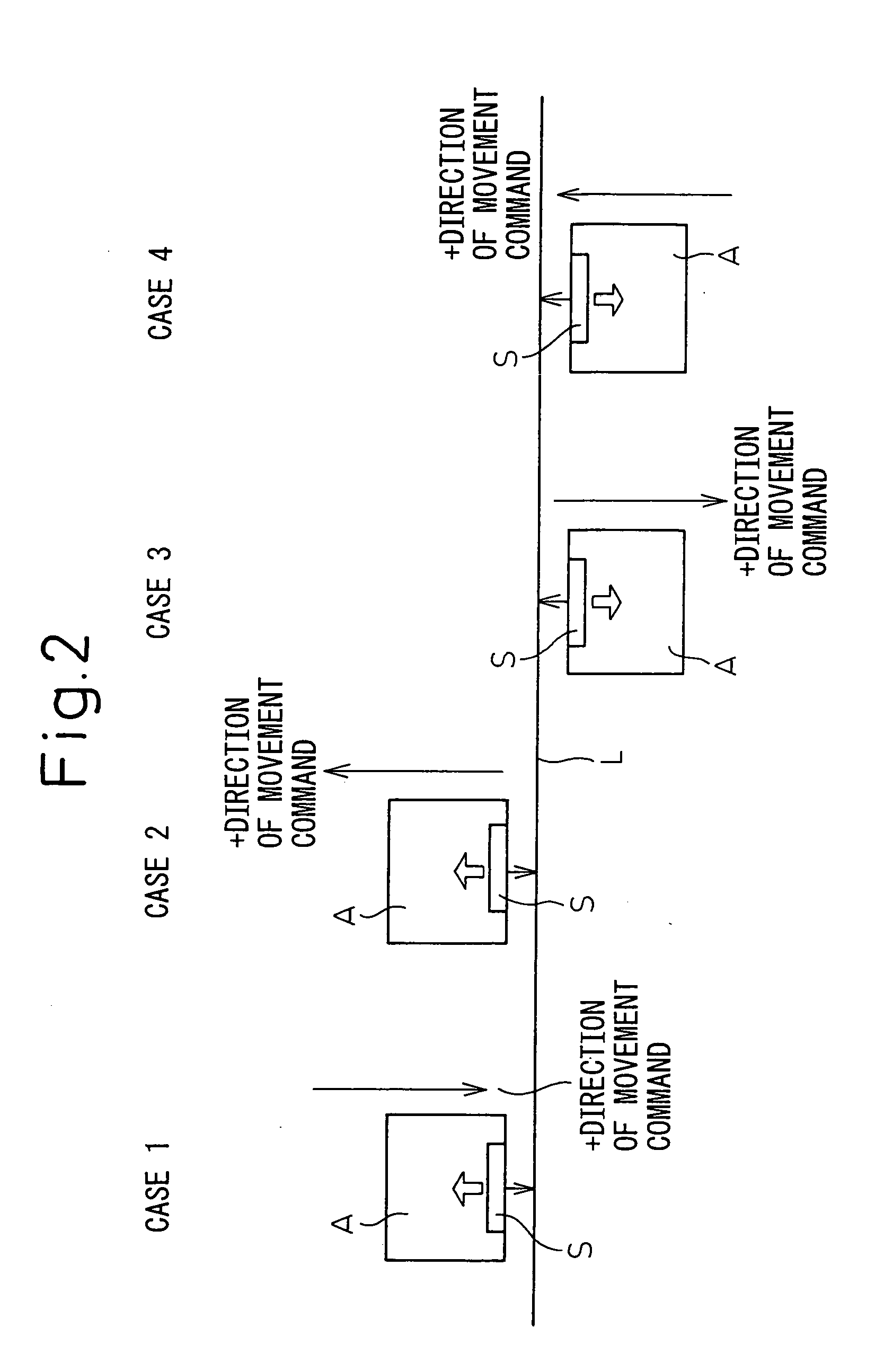

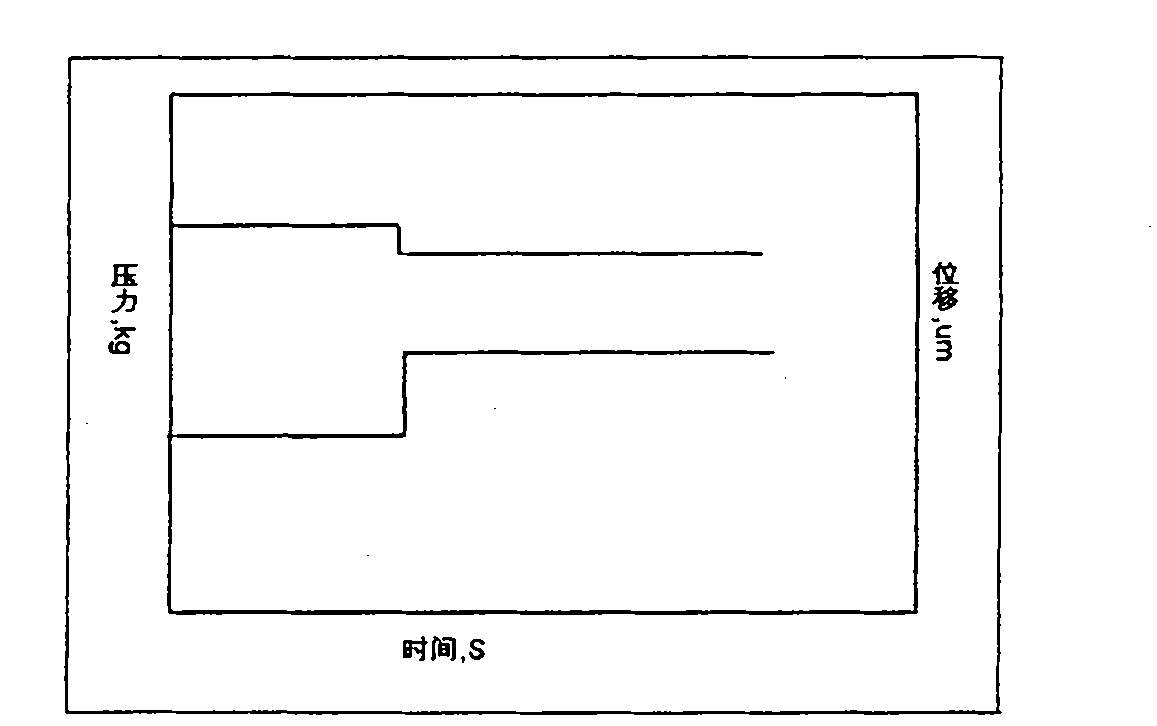

Servo motor control unit for press-forming machine

A servo motor for driving a die is provided with position and speed detectors. Further, a pressure sensor for detecting the pressure applied to a workpiece is provided. In the servo motor control unit, the smaller one of the speed command obtained by feedback control of the position and the speed command obtained by the pressure feedback control is selected as an output of a comparator. Based on the speed command output from the comparator, feedback control of the speed is performed and the servo motor is driven. In the state where the die does not press against the workpiece, a pressure error is large, the speed command by pressure control becomes large, and the speed command by position control becomes small. Therefore, position control is performed. When the workpiece is pressed, the position error increases, and the pressure error decreases, a speed command by pressure control is employed and pressure control is performed.

Owner:FANUC LTD

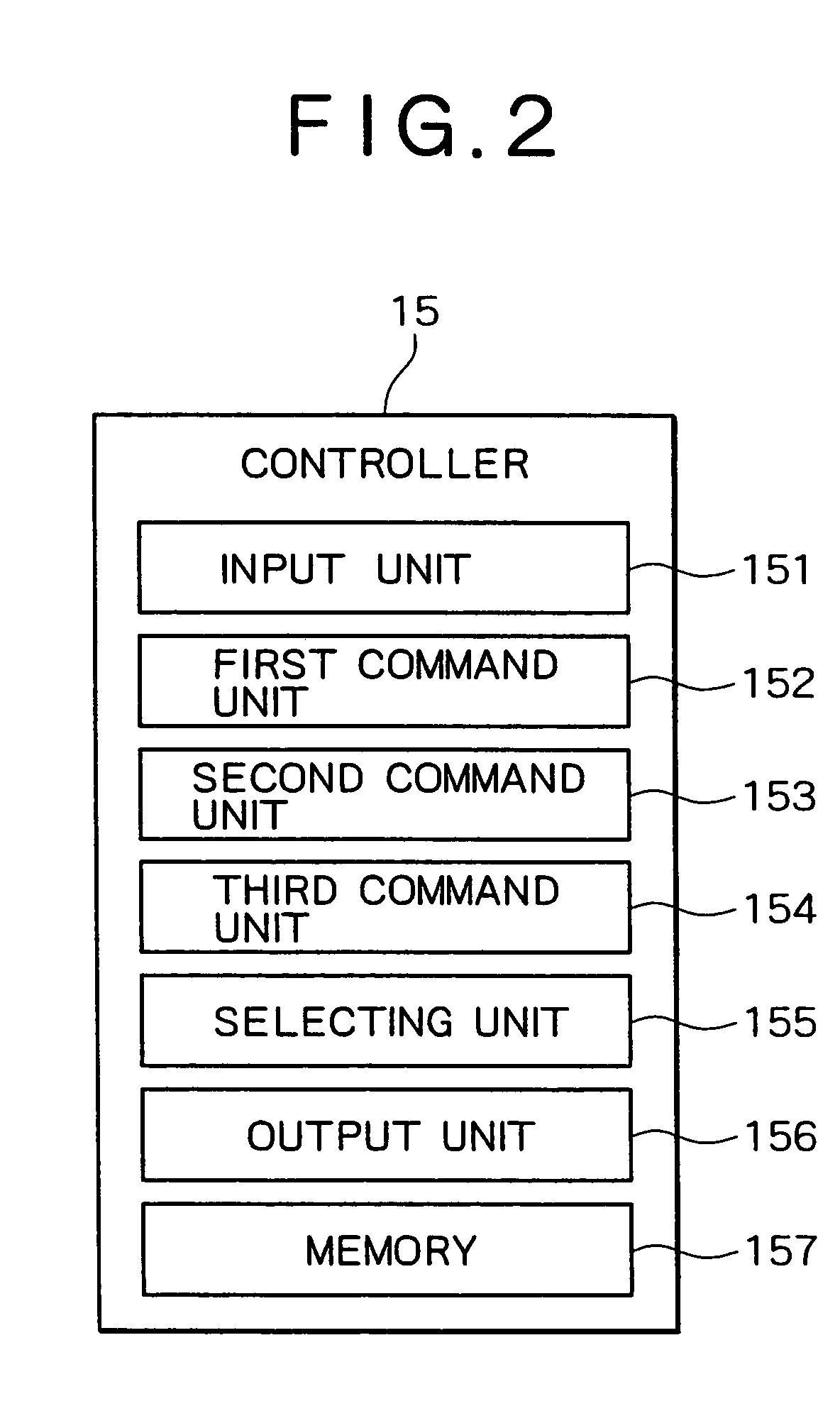

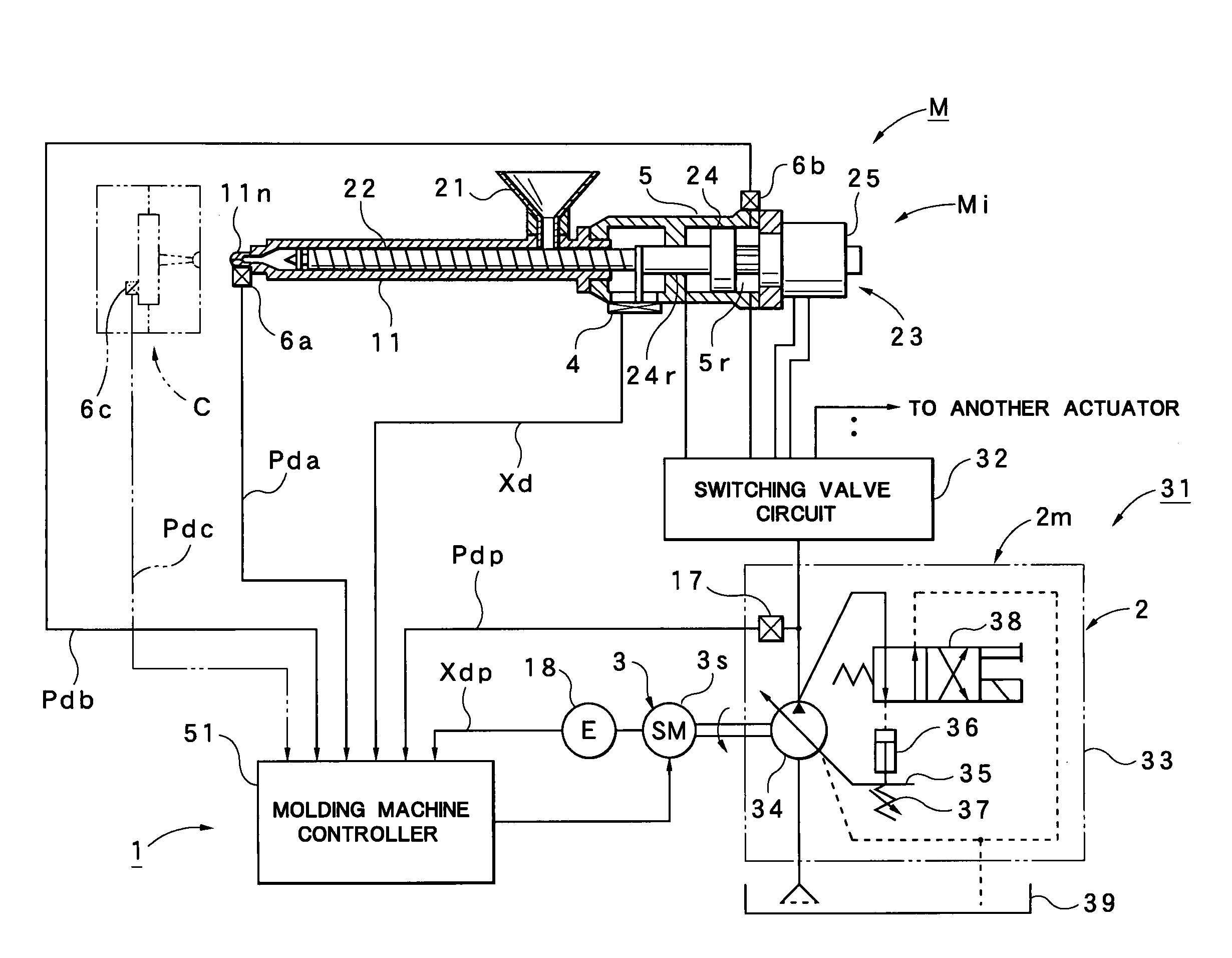

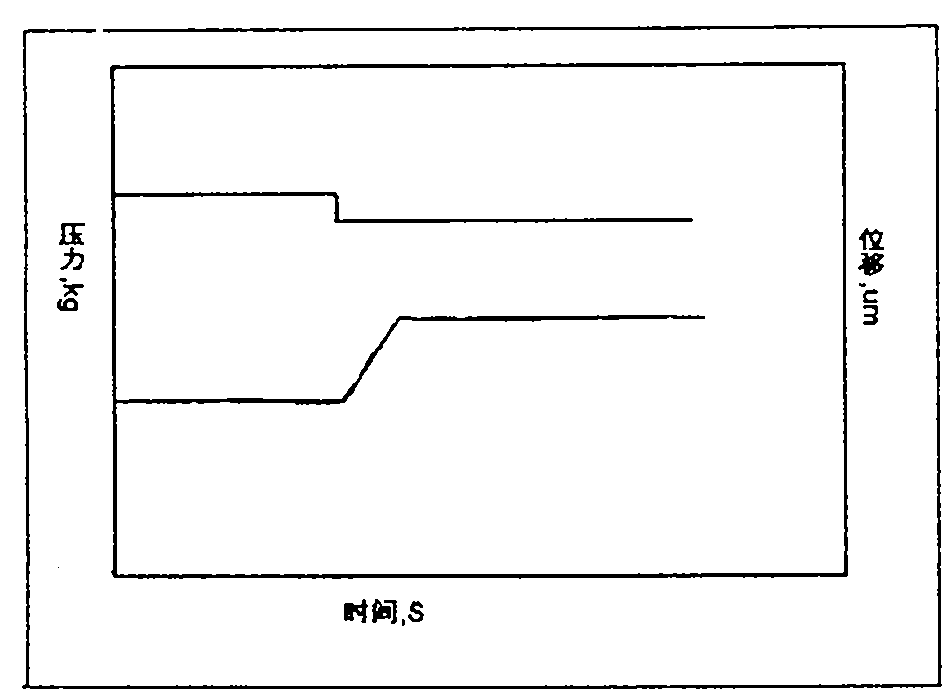

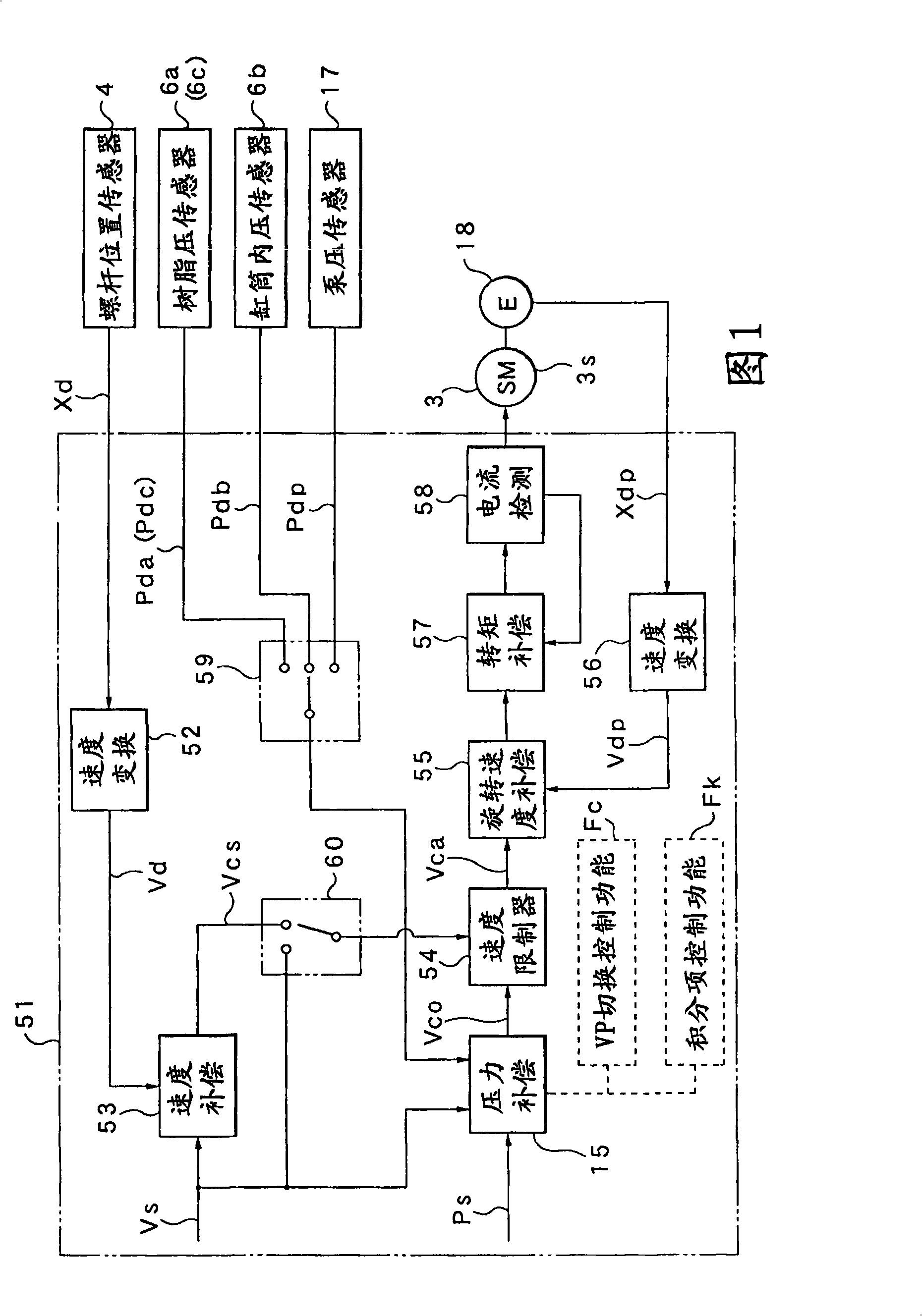

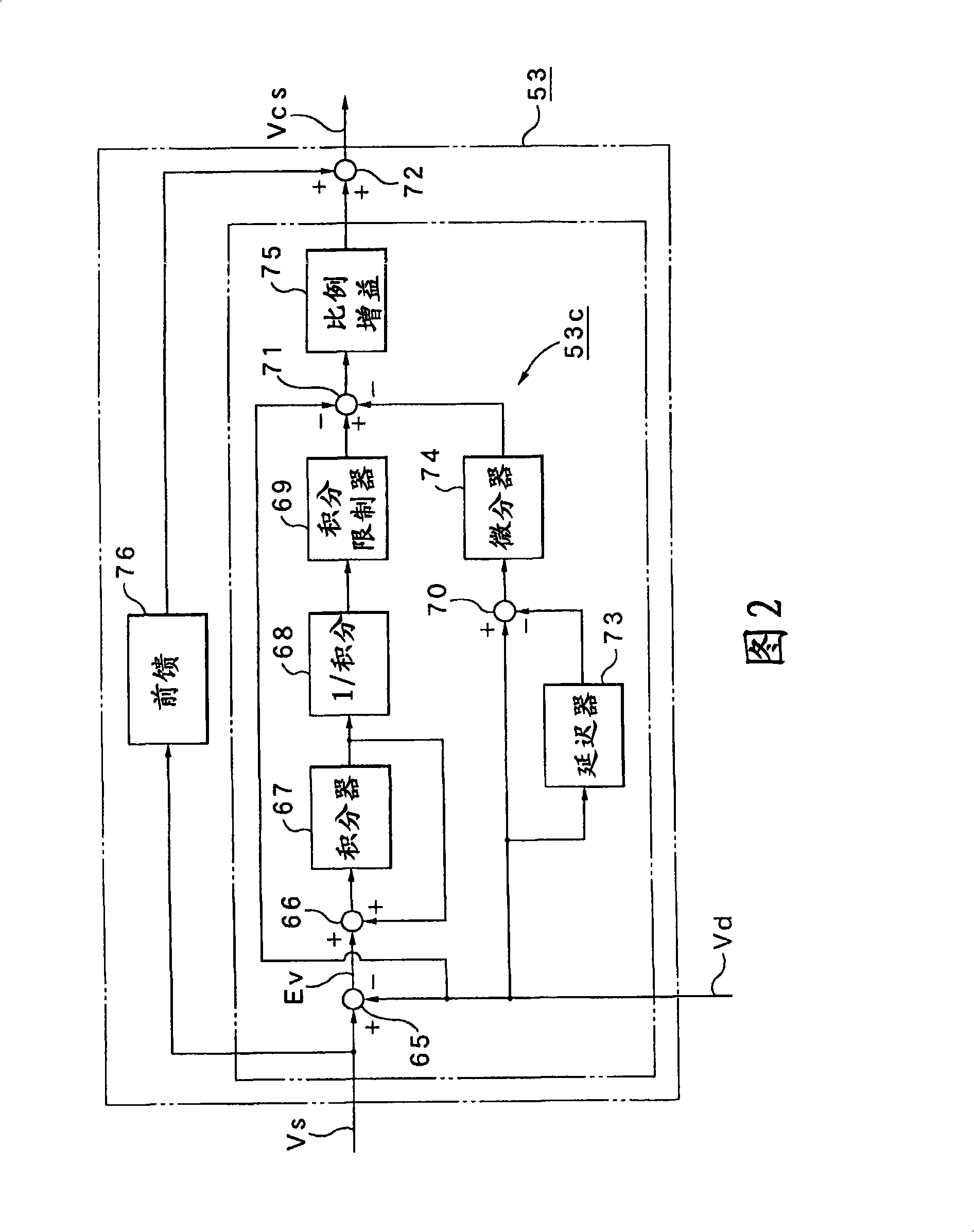

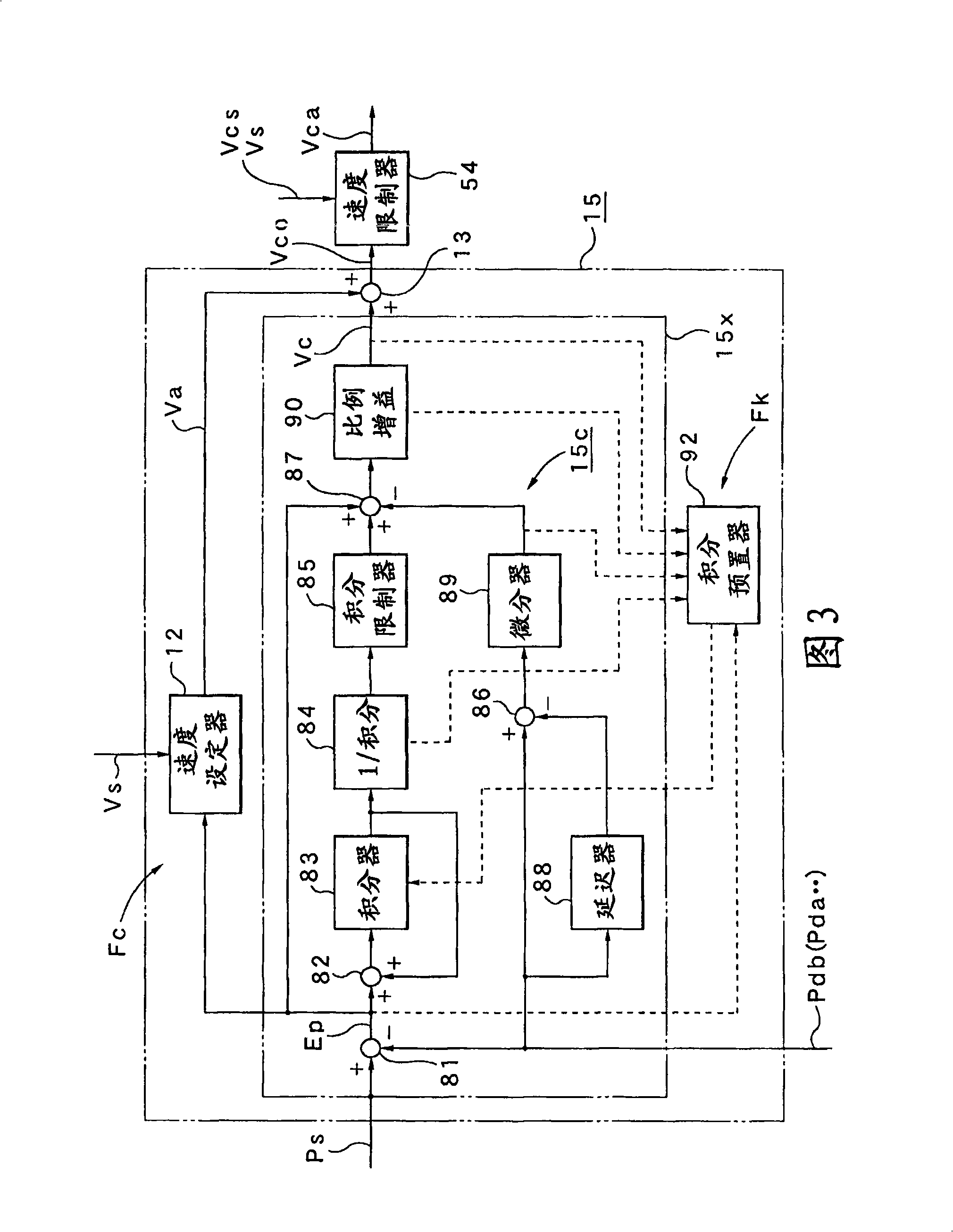

Controller of injection molding machine

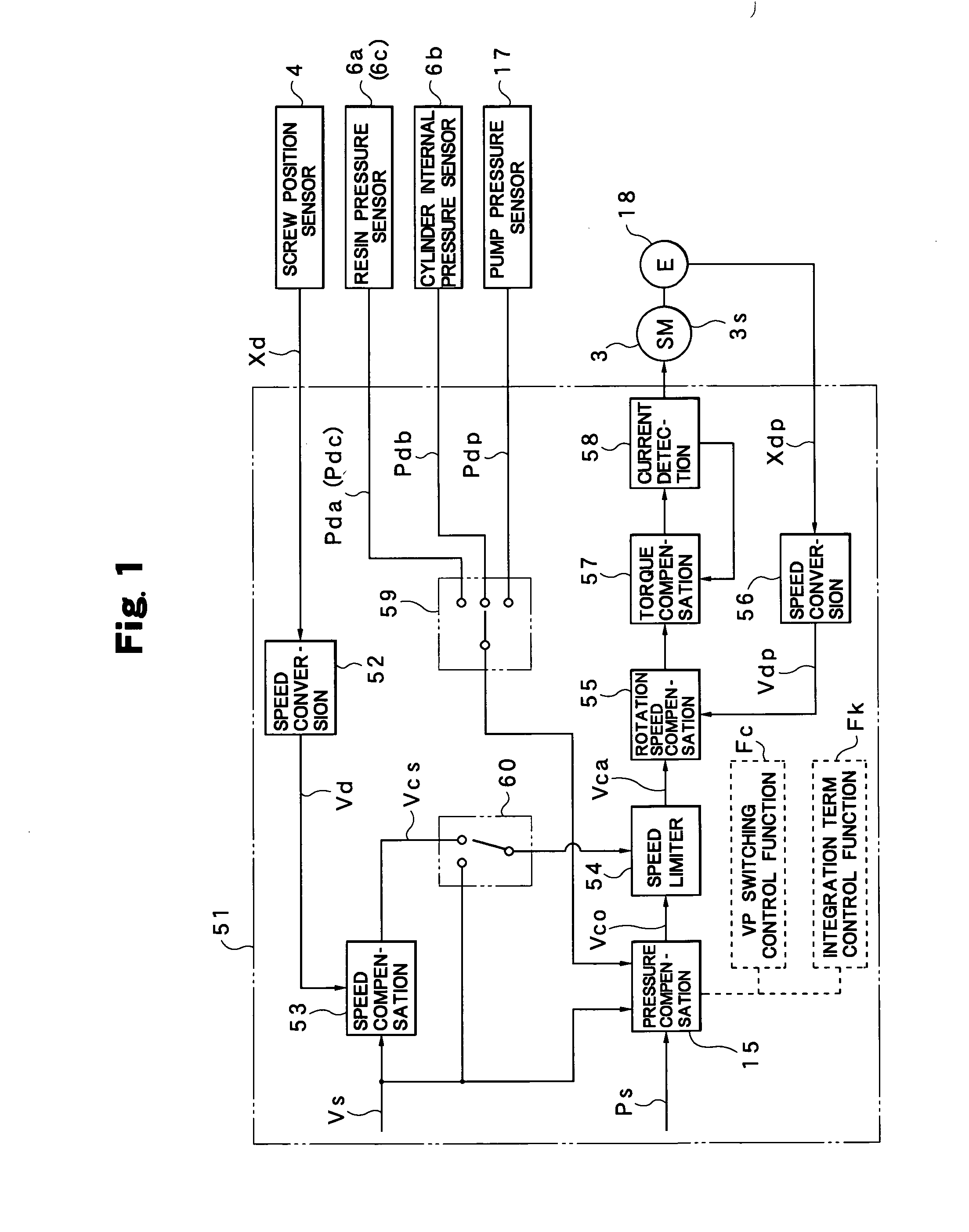

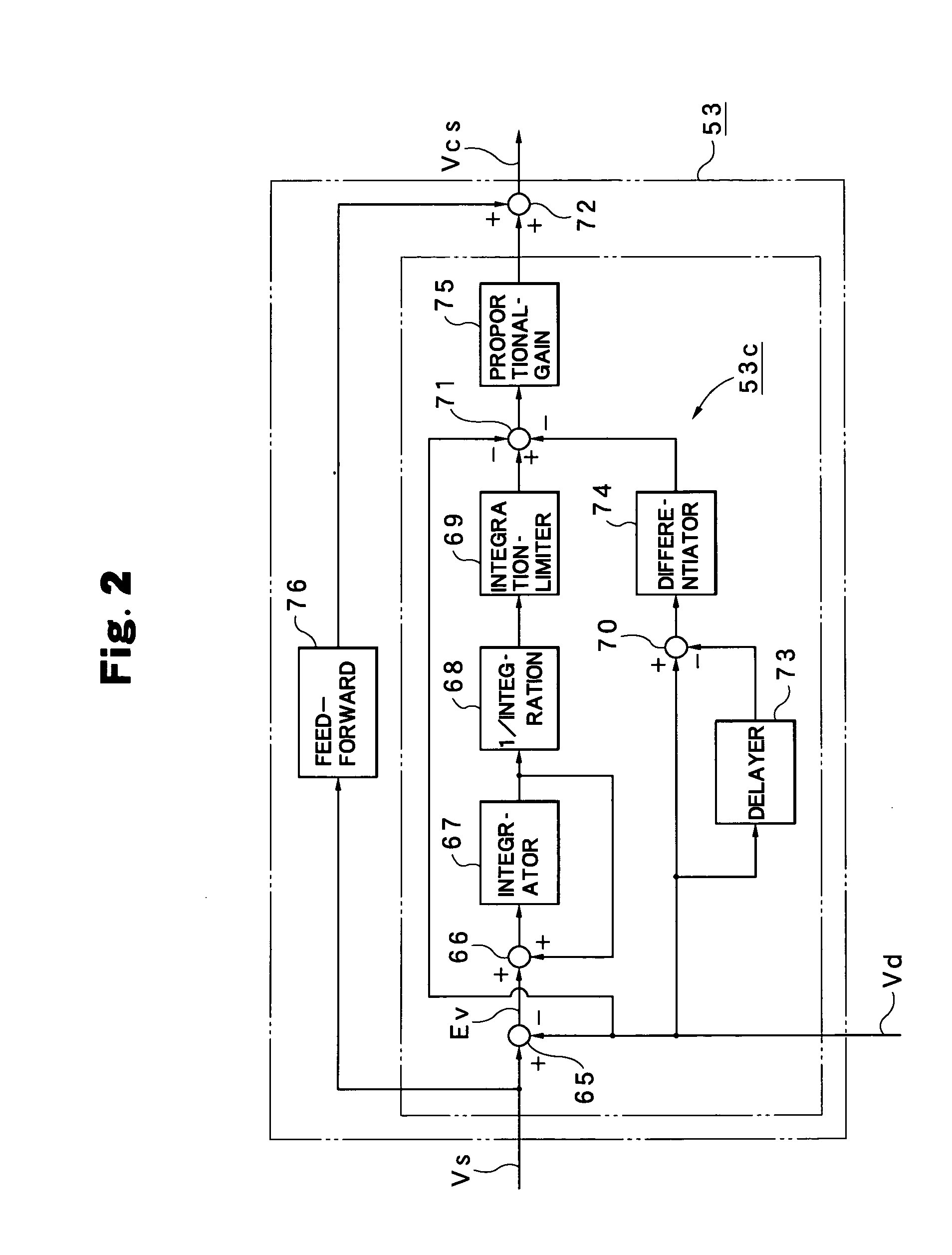

ActiveUS20090087510A1Significant changeSolve unqualifiedAuxillary shaping apparatusInjection pressureScrew position

The present invention comprises a speed feedback control system for carrying out speed feedback control on the basis of a speed detected value Vd obtained by converting a position detected value Xd obtained from a screw position sensor 4, a pressure feedback control system for carrying out a pressure feedback control on the basis of a pressure detected value Pdb obtained from an injection pressure sensor 6b, and a VP switching control function portion Fc for carrying out switching from a speed control region to a pressure control region Zp when a pressure deviation Ep between a preset pressure set value Ps and the pressure detected value Pdb becomes a preset switching determination value Eps or less and carrying out the switching to the pressure control region Zp after control of a speed command value in the speed control region Zv by a predetermined control pattern Dp at this switching.

Owner:NISSEI PLASTIC IND CO LTD

Smart fuel control system

Owner:HAMILTON SUNDSTRAND CORP

Servo motor control unit for press-forming machine

ActiveUS20060012326A1Improve processing qualityImprove machine efficiencySafety arrangmentsTemperatue controlElectric machineMotor control

A servo motor for driving a die is provided with position and speed detectors. Further, a pressure sensor for detecting the pressure applied to a workpiece is provided. In the servo motor control unit, the smaller one of the speed command obtained by feedback control of the position and the speed command obtained by the pressure feedback control is selected as an output of a comparator. Based on the speed command output from the comparator, feedback control of the speed is performed and the servo motor is driven. In the state where the die does not press against the workpiece, a pressure error is large, the speed command by pressure control becomes large, and the speed command by position control becomes small. Therefore, position control is performed. When the workpiece is pressed, the position error increases, and the pressure error decreases, a speed command by pressure control is employed and pressure control is performed.

Owner:FANUC LTD

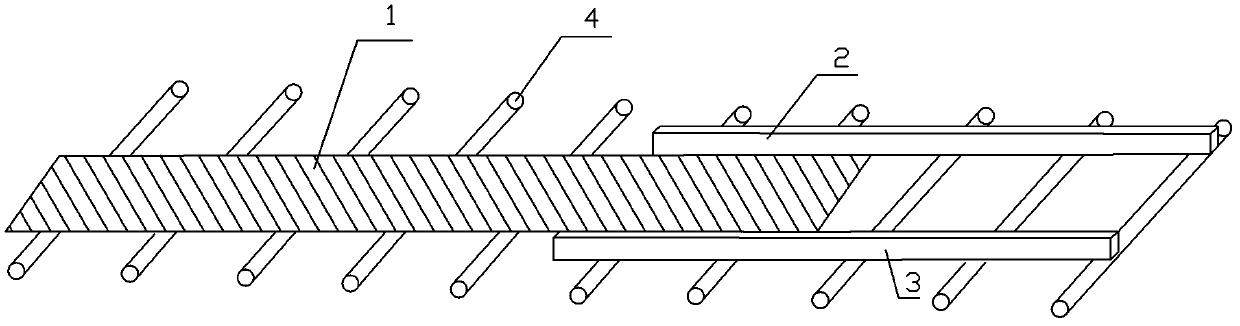

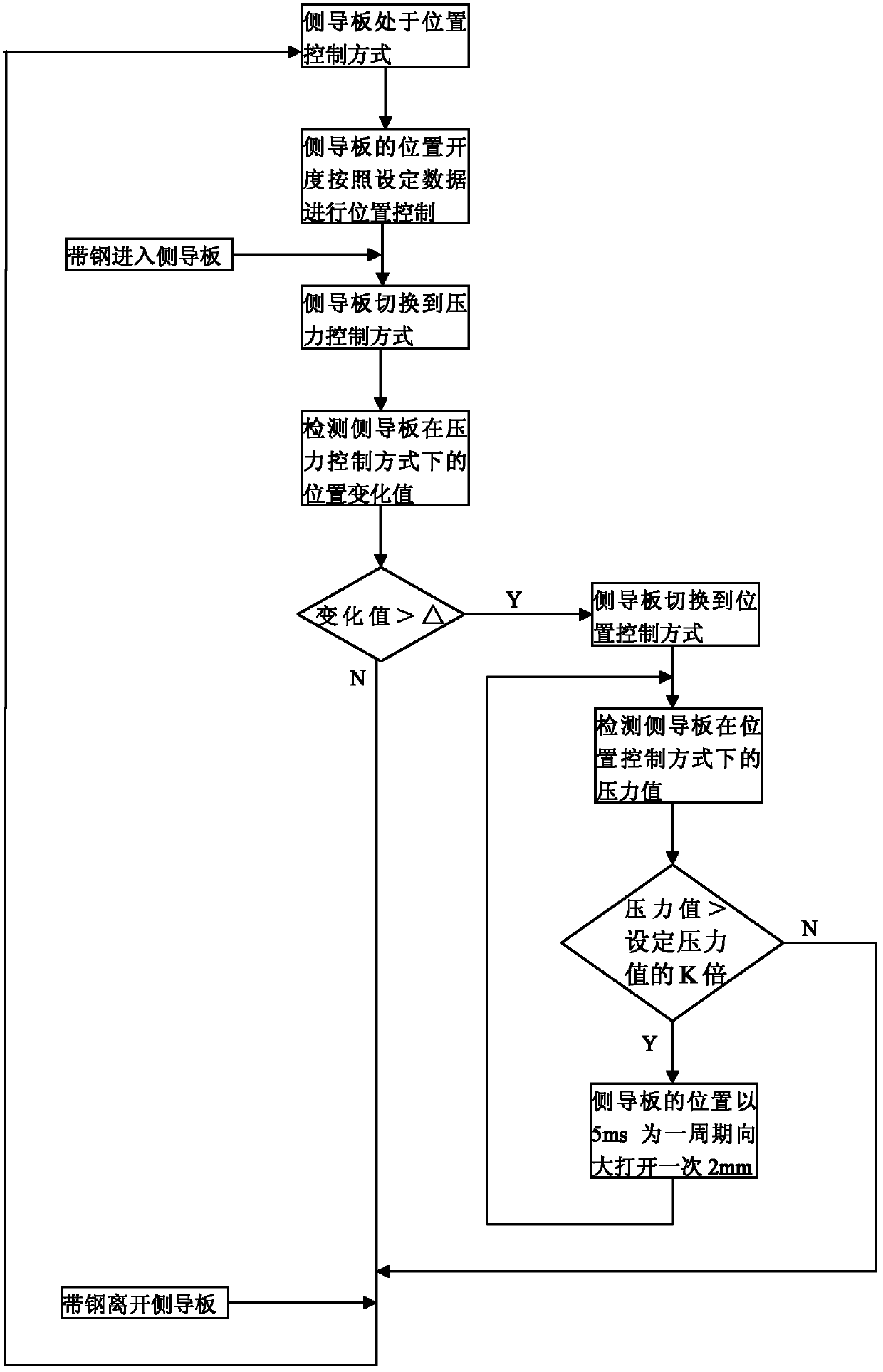

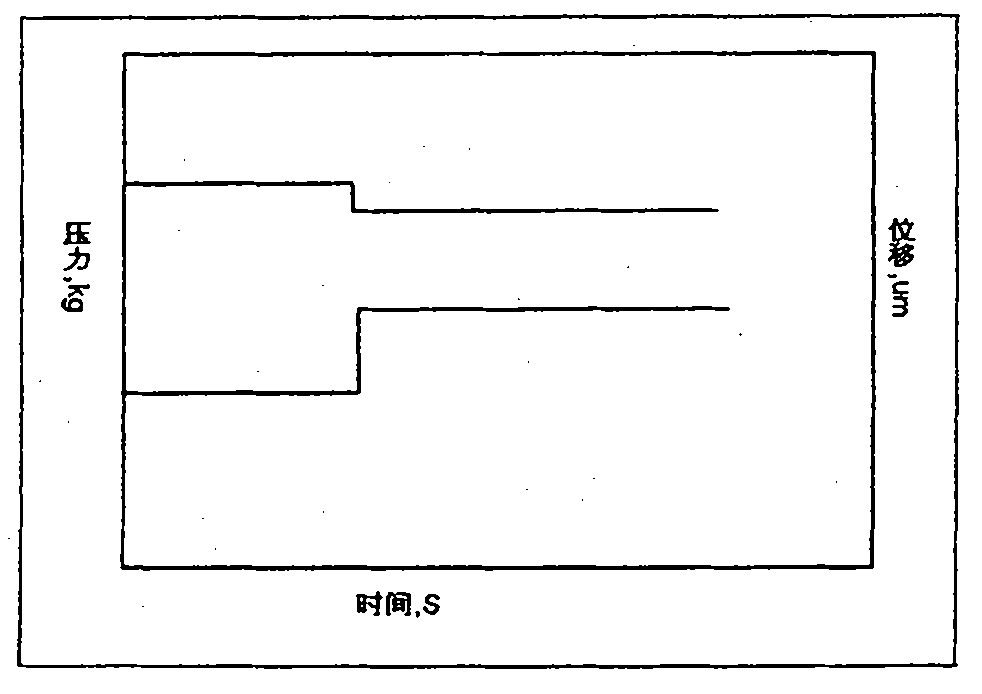

Control method of hot-rolling rolled side guide plate for improving hot-rolling roll shape quality

ActiveCN102896180AReduce the amount of reworkReduce manufacturing costControl mannerPressure feedback

The invention relates to a control method of a hot-rolling side guide plate in the metallurgy field, and relates to a control method of a hot-rolling rolled side guide plate for improving hot-rolling roll shape quality. The side guide plate is in a position ring control mode before the band steel enters into the rolling side guide plate; the control mode of side guide plate is switched to a pressure control mode from the position control mode after the band steel enters into the side guide plate; during the pressure control process, when the detected position change of the side guide plate exceeds [Delta]X mm, the control mode of side guide plate is switched to the position control mode from the pressure control mode; and if the position change does not exceed [Delta]X mm, the side guide plate is at the pressure control mode all the time; after the control mode of side guide plate is switched to the position control mode from the pressure control mode, a pressure feedback value of the side guide plate is detected; if the pressure feedback value exceeds K times of a pressure setting value in the pressure control mode, the position of the side guide plate is opened 2 mm with 5 s as a period, until the pressure feedback value of the side guide plate is lower than K times of a pressure setting value in the pressure control mode; and when the band steel leaves the side guide plate; the side guide plate enters into the position control mode. The method effectively solves the problems of quality defects such as layer offset, edge protrusions and edge cracks of roll shapes when rolling supplied material of the band steel swims or has cambers.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

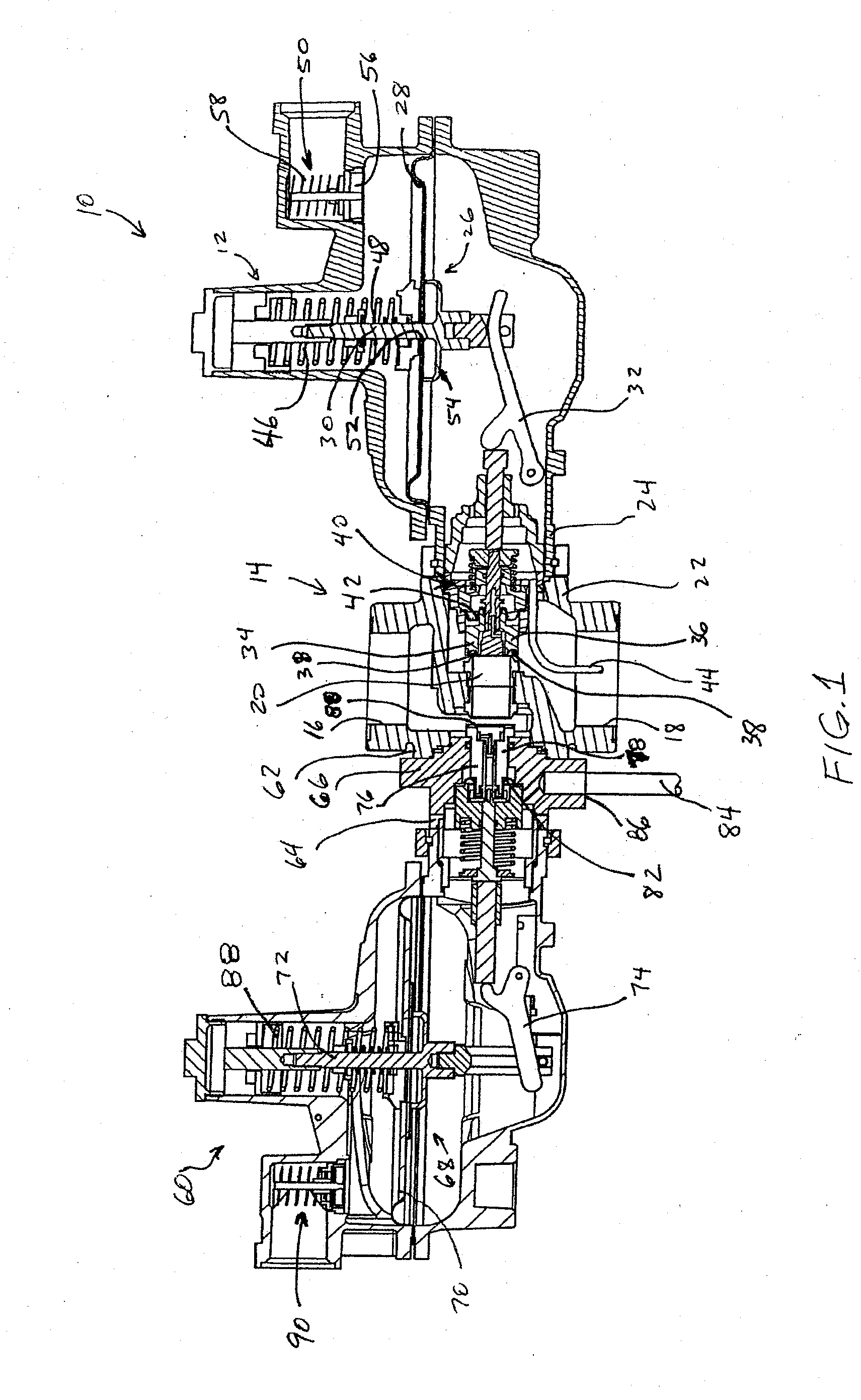

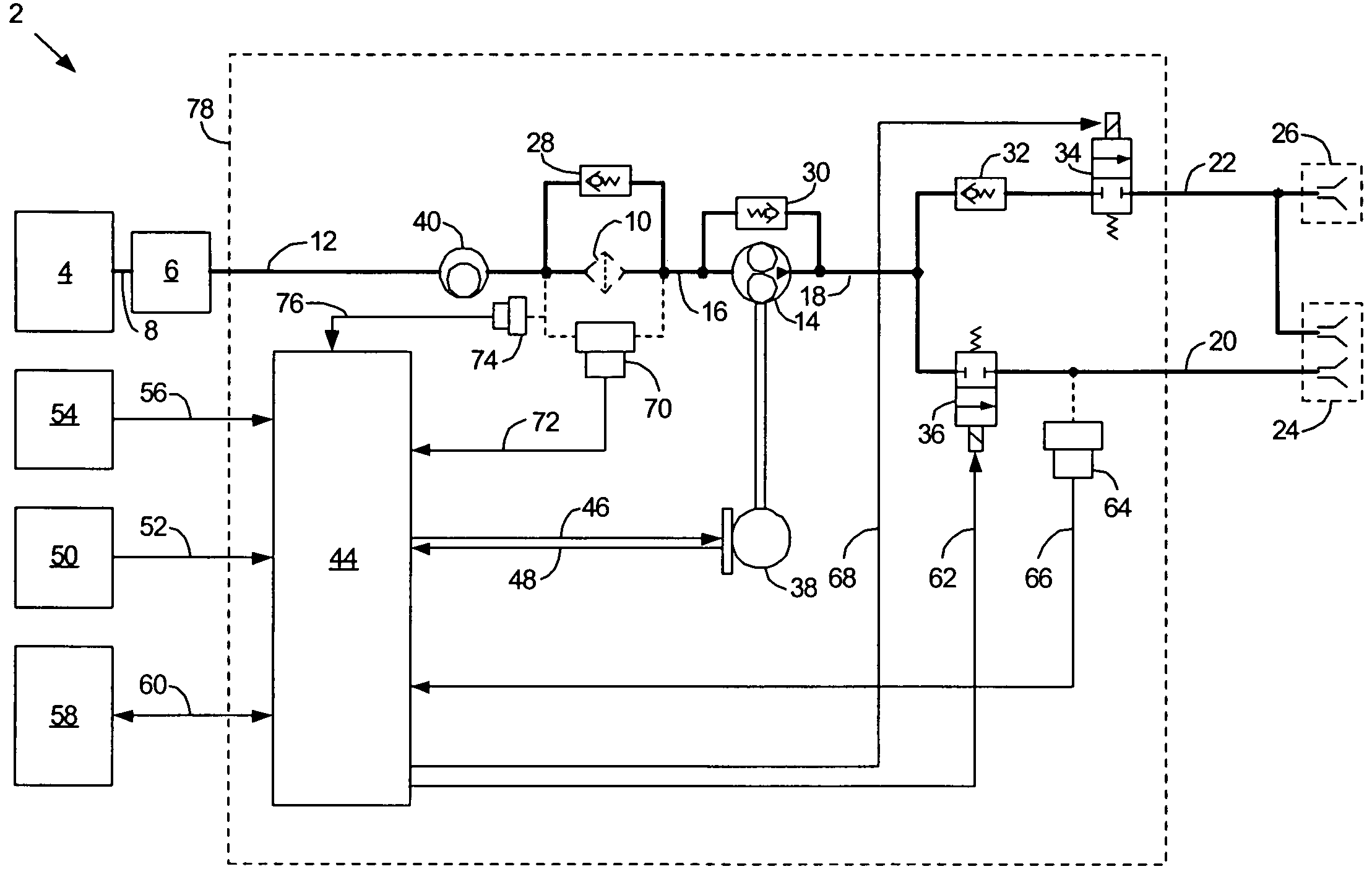

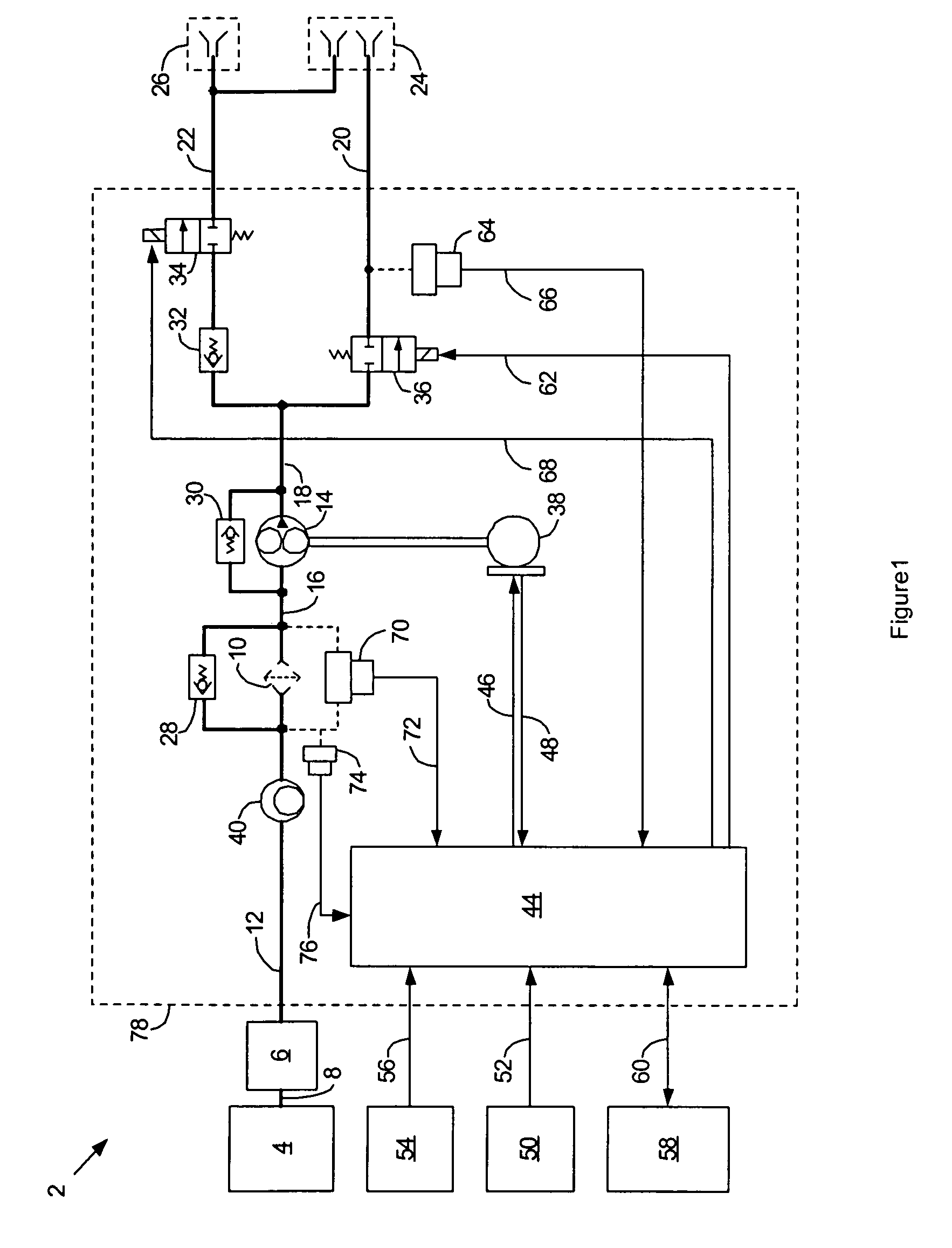

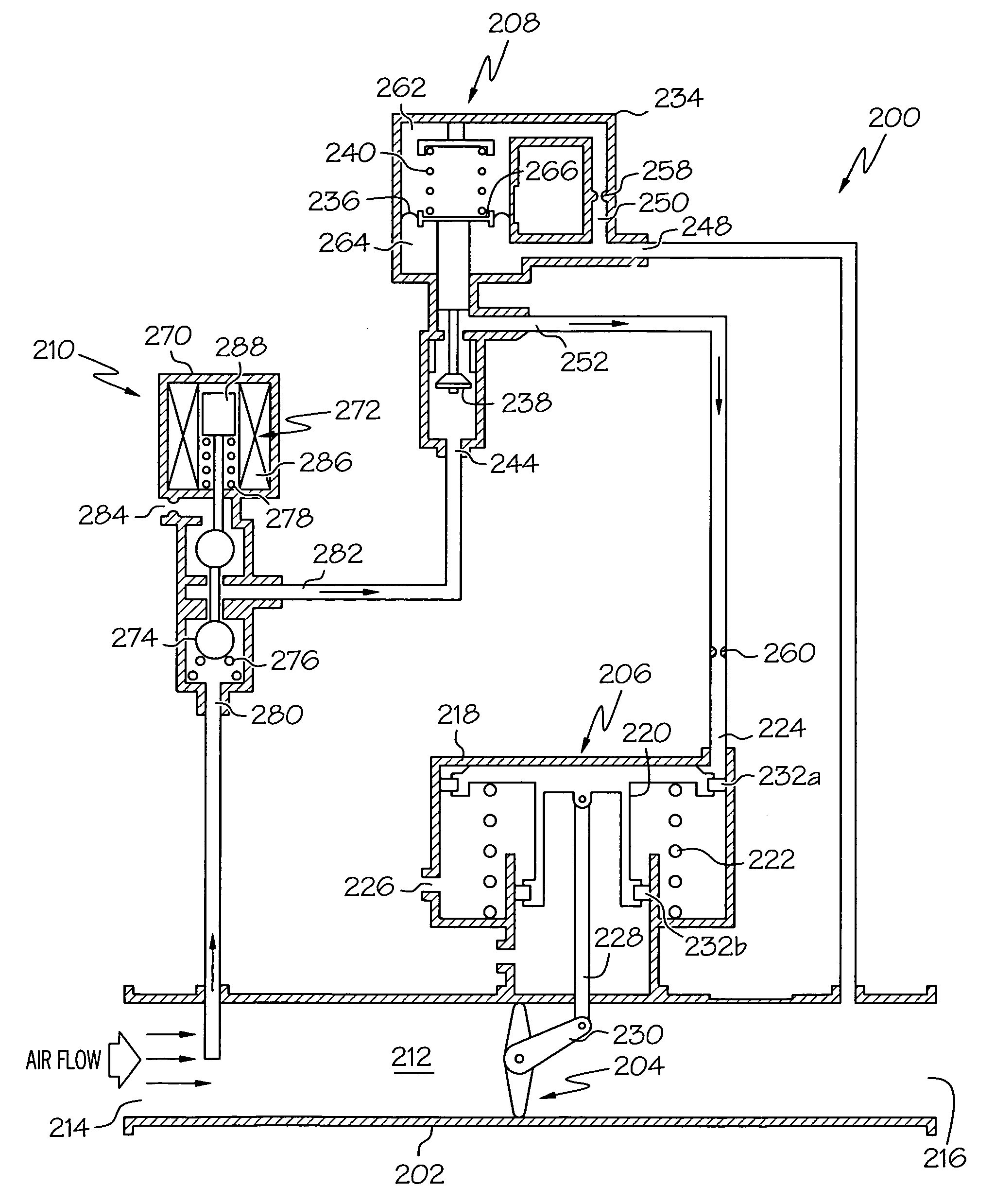

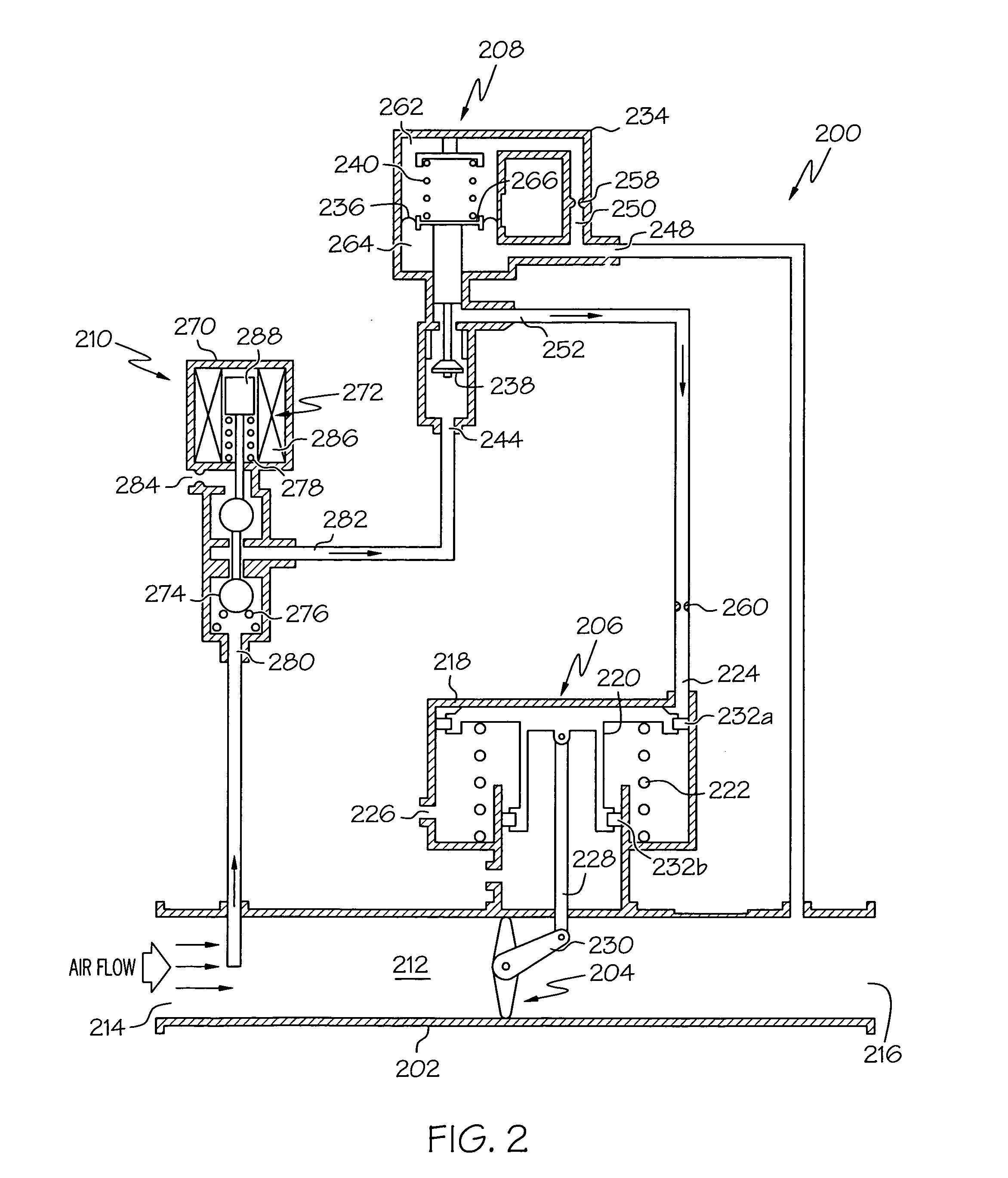

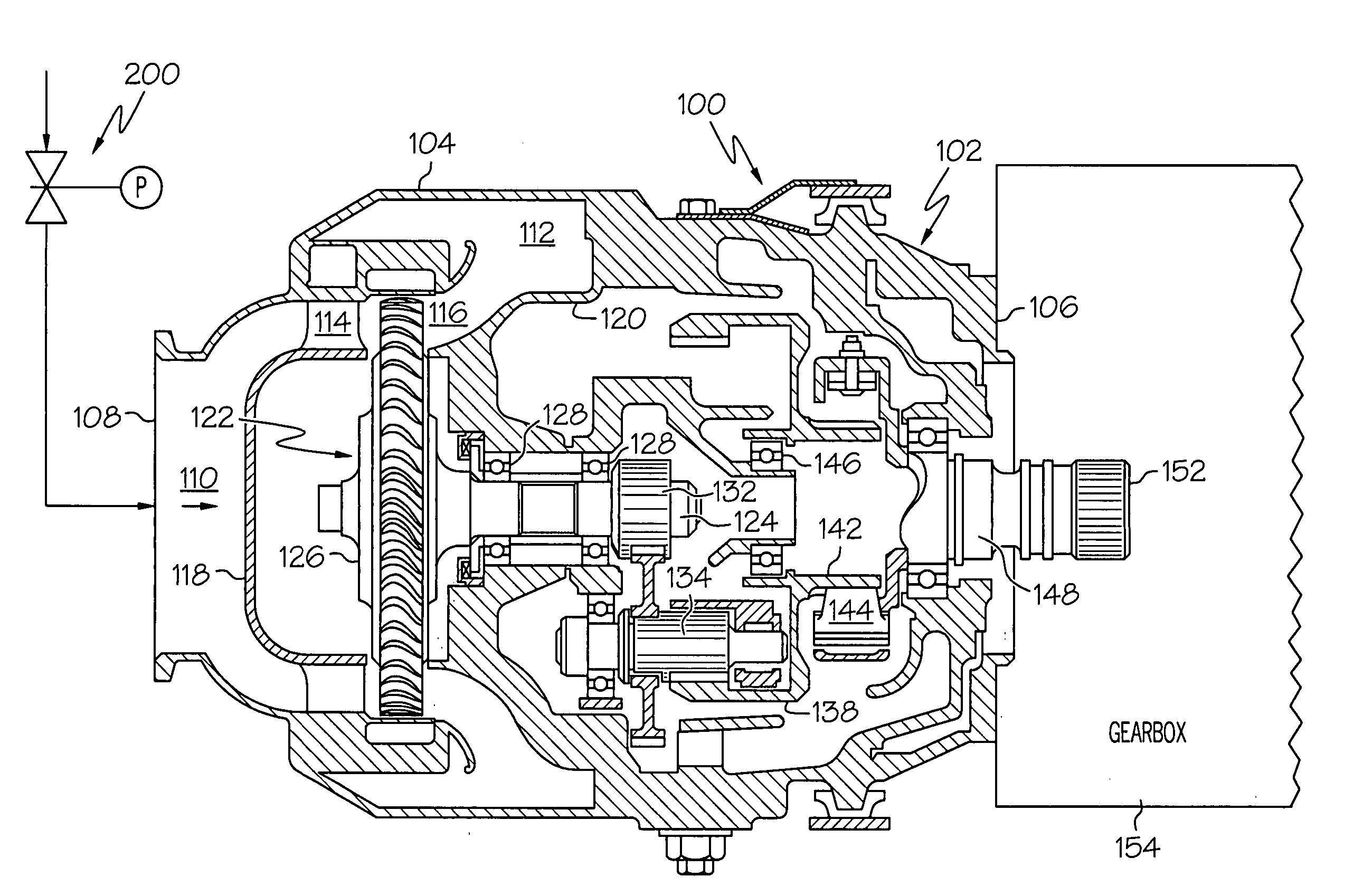

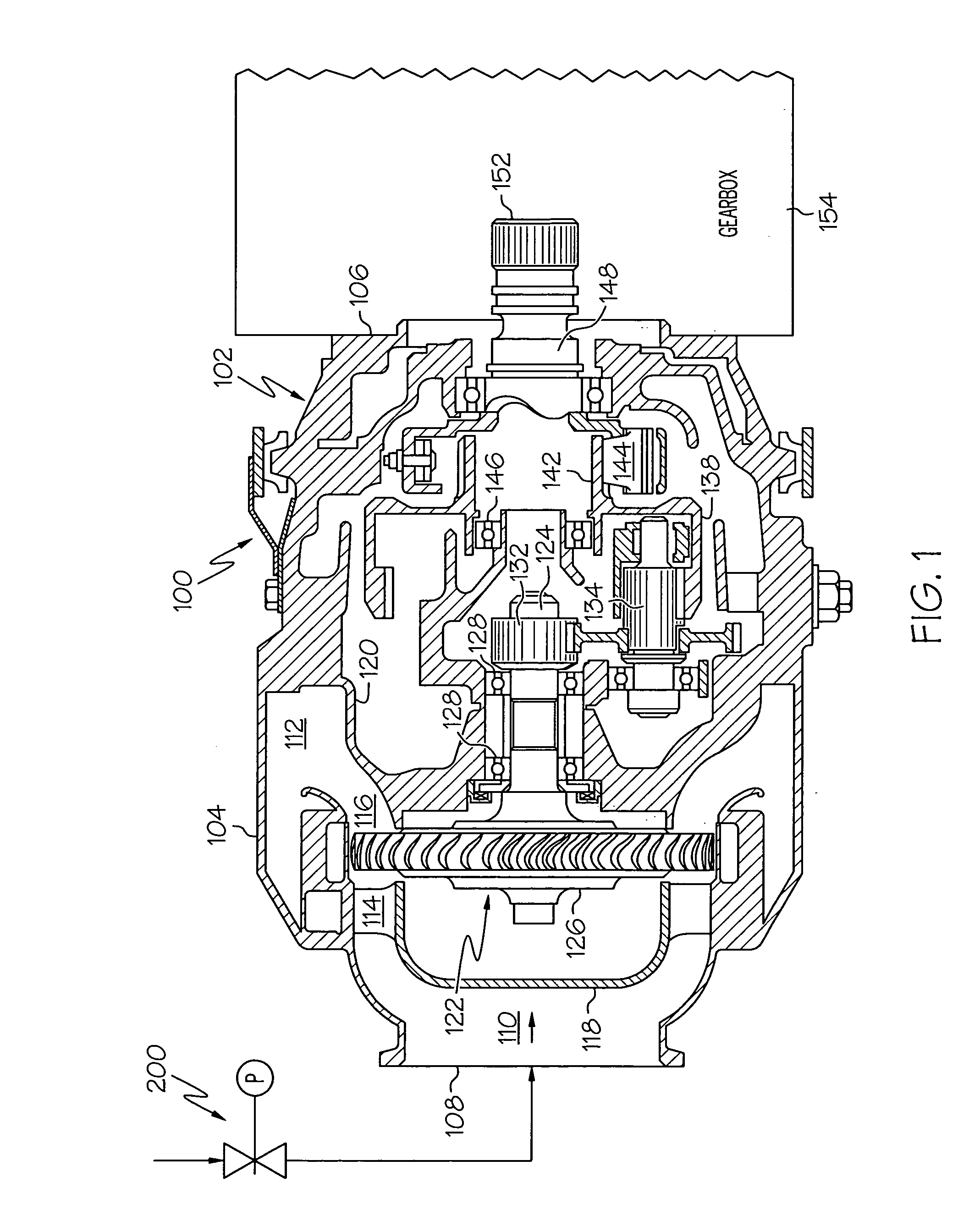

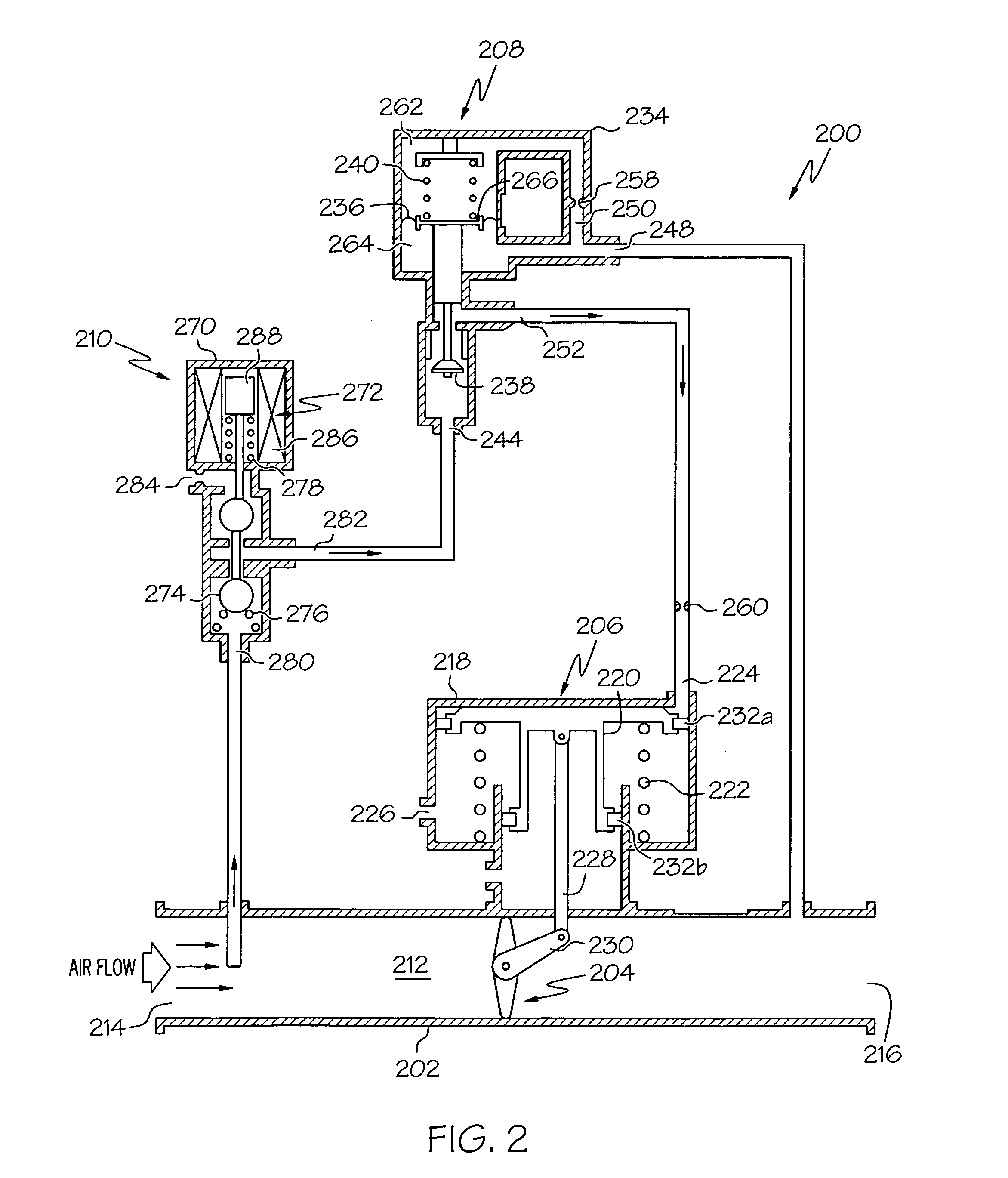

Pneumatic valve control using downstream pressure feedback and an air turbine starter incorporating the same

A starter air valve assembly includes a valve body, a flow control valve, a rate control servo mechanism, and a valve actuator. The valve body defines a flow passage having at least an inlet port and an outlet port. The valve is disposed at least partially within the flow passage and is moveable between an open position and a closed position. The rate control servo mechanism is adapted to receive pressurized fluid and is configured, upon receipt of the pressurized fluid, to supply a controlled flow of the pressurized fluid. The valve actuator is coupled to the valve and is in fluid communication with the rate control servo to thereby receive the controlled flow of the pressurized fluid. The valve actuator is configured, upon receipt of the controlled flow of the pressurized fluid, to move the valve between the closed position and the open position at a substantially controlled rate.

Owner:HONEYWELL INT INC

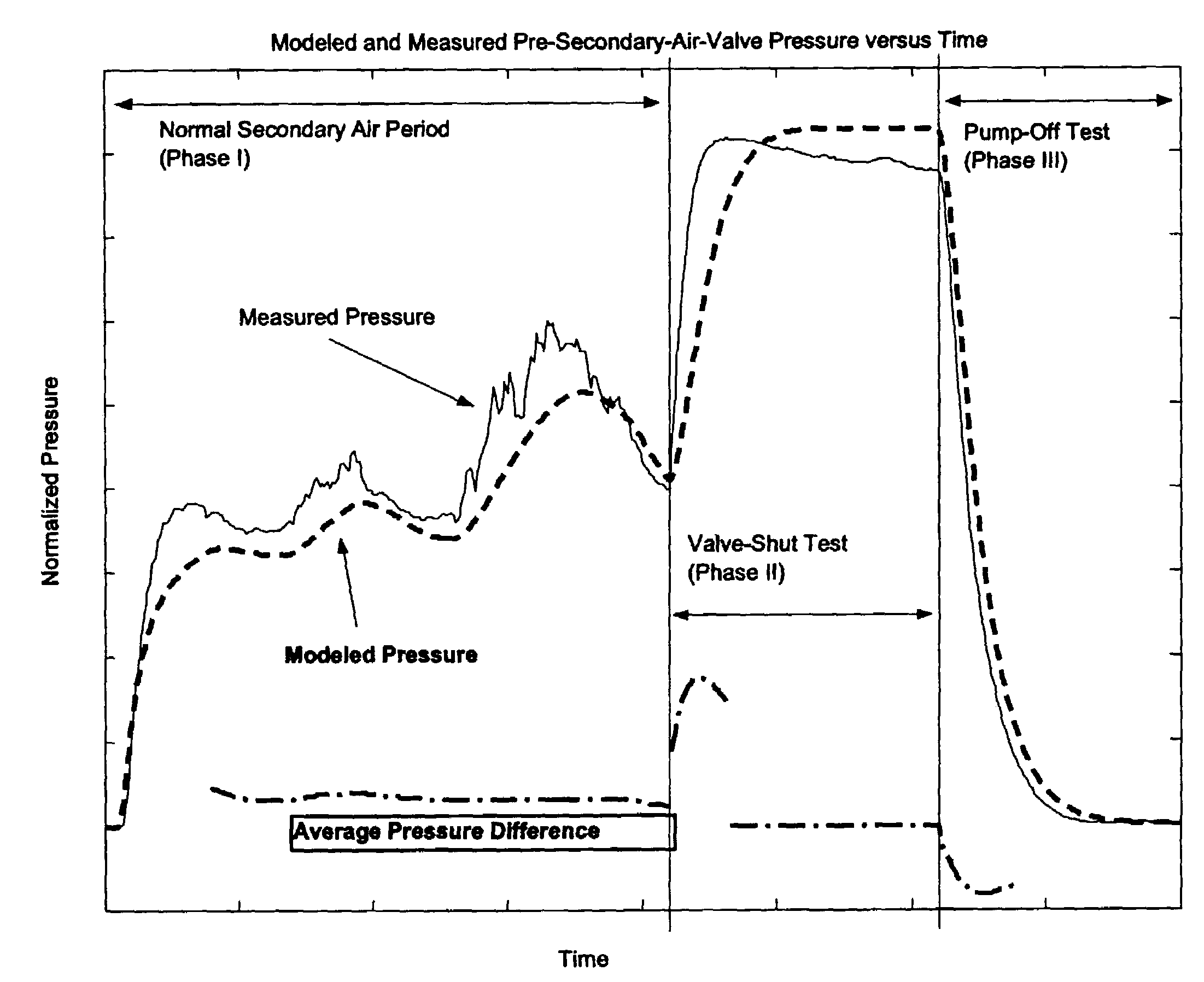

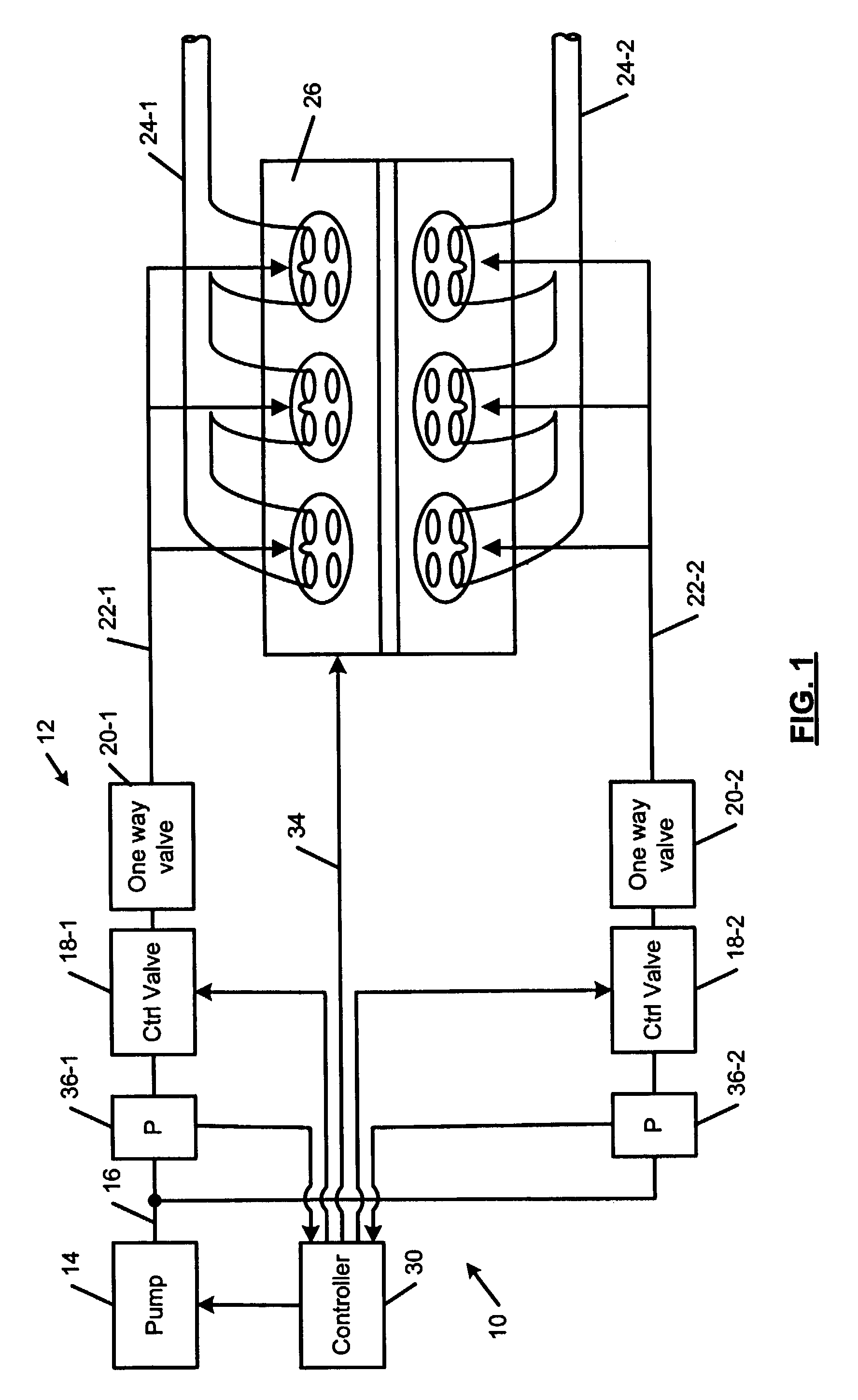

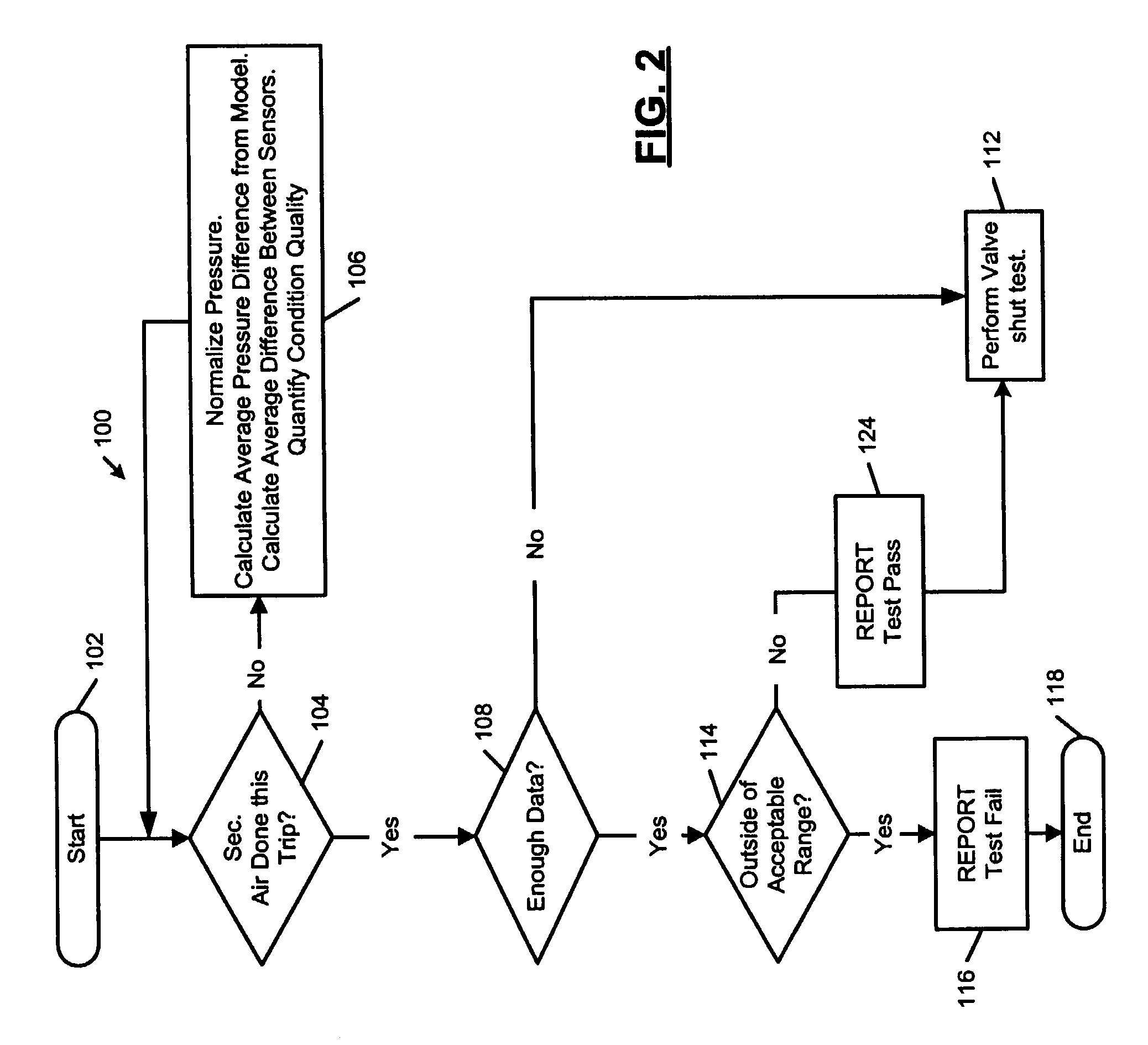

Secondary air injection diagnostic system using pressure feedback

InactiveUS6983590B2Reduce vehicle emissionInternal combustion piston enginesExhaust apparatusEngineeringSystem failure

A diagnostic system according to the present invention diagnoses system failure of a secondary air injection system. The secondary air injection system includes a pump that provides air to an exhaust system via a conduit and a valve that controls the flow of air through the conduit. A pressure sensor measures pressure in the conduit. A controller predicts pressure in the conduit during first, second and third operational phases of the secondary air injection system. The controller compares the measured pressure to the predicted pressure to evaluate operation of the secondary air injection system. During the first phase, the secondary air injection system is used to reduce vehicle emissions. During the second phase, the valve is shut while the pump is on. During the third phase, the pump is turned off while the valve is closed.

Owner:GM GLOBAL TECH OPERATIONS LLC

Pneumatic valve control using downstream pressure feedback and an air turbine starter incorporating the same

ActiveUS20050276685A1Improved valve opening characteristicImprove featuresWind motor controlPump componentsControl flowValve actuator

A starter air valve assembly includes a valve body, a flow control valve, a rate control servo mechanism, and a valve actuator. The valve body defines a flow passage having at least an inlet port and an outlet port. The valve is disposed at least partially within the flow passage and is moveable between an open position and a closed position. The rate control servo mechanism is adapted to receive pressurized fluid and is configured, upon receipt of the pressurized fluid, to supply a controlled flow of the pressurized fluid. The valve actuator is coupled to the valve and is in fluid communication with the rate control servo to thereby receive the controlled flow of the pressurized fluid. The valve actuator is configured, upon receipt of the controlled flow of the pressurized fluid, to move the valve between the closed position and the open position at a substantially controlled rate.

Owner:HONEYWELL INT INC

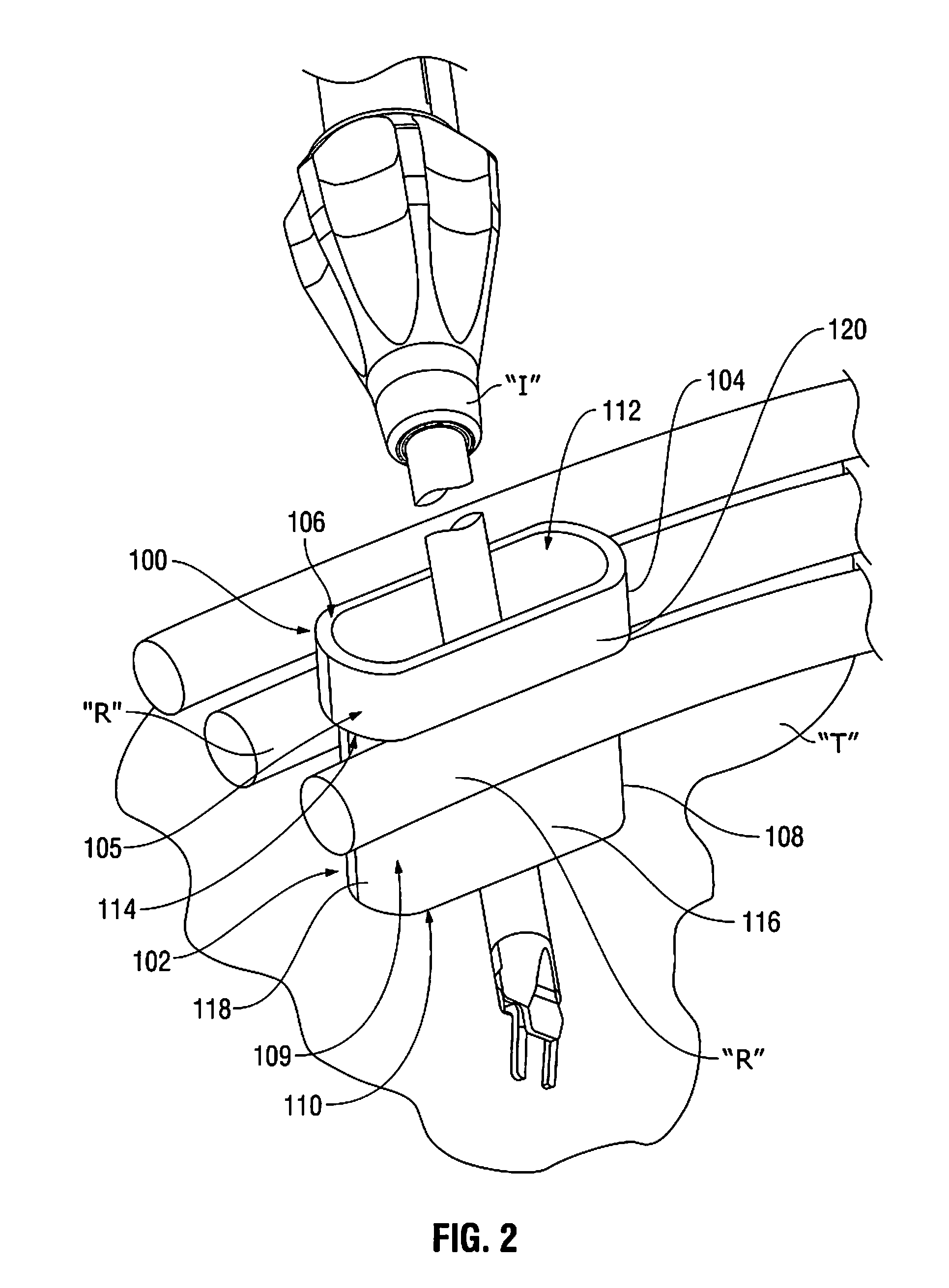

Pressure feedback access ports for minimally invasive surgery

A surgical access port configured and dimensioned for positioning within an opening in tissue for providing access to an internal surgical site includes a body portion defining a passageway therethrough. The body portion includes an outer surface. A pressure feedback indicator is disposed on at least a portion of the outer surface of the body portion. The pressure feedback indicator is configured for providing a visual indication to a user where an applied pressure is greater than a predetermined threshold.

Owner:TYCO HEALTHCARE GRP LP

Dynamic soft reduction method for detecting tail end of solidified liquid core of casting blank based on pressure feedback

The invention relates to a dynamic soft reduction method for detecting the tail end of a solidified liquid core of a casting blank based on pressure feedback, belonging to the technical field of metallurgy continuous casting control. The method comprises the following steps of: firstly, establishing a control platform for remotely and automatically adjusting roll gaps of all sector sections on a continuous casting machine, and calculating the stress of the casting blank in different sector sections by utilizing the detection result of pressure sensors installed on all the sector sections; detecting the stress difference of the casting blank in each sector section during roll gap variation by changing the roll gap contraction size of each sector section; judging the position of the tail end of the solidified liquid core of the casting blank according to the stress difference between the casting blank with the liquid core and the casting blank without the liquid core; and finally, dynamically adopting different reduction quantities in all sector sections of a casting machine by using a soft reduction control system according to the position of the tail end of the liquid core judged by the method. The method for judging the tail end of the solidified liquid core of the casting blank is directly obtained by calculating the real-time stress of the casting blank. Because the calculation of casting blank surface temperature and blank shell thickness does not need a large quantity of mathematical models, the calculation method is simple and effective and ensures the stability and the execution efficiency of a casting machine control system.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

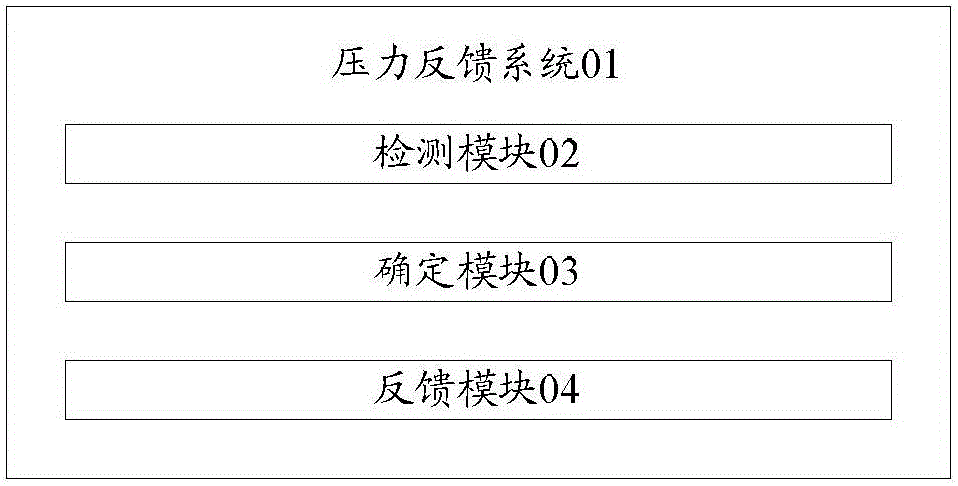

Pressure feedback system and pressure feedback method

InactiveCN105100492AReal Feedback ExperienceDetailed feedback experienceSubstation equipmentInput/output processes for data processingComputer terminalEngineering

The invention discloses a pressure feedback system and a pressure feedback method. The pressure feedback system comprises a detection module, a determination module and a feedback module, and is characterized in that the detection module is used for detecting pressure applied to a terminal; the determination module is used for determining pressure parameters of the pressure; and the feedback module is used for controlling the terminal to provide different feedbacks according to different feedback parameters corresponding to the different pressure parameters. Through the scheme disclosed by the invention, real, detailed and omni-directional feedback experience can be provided for a user in allusion to pressure operations of the user.

Owner:NUBIA TECHNOLOGY CO LTD

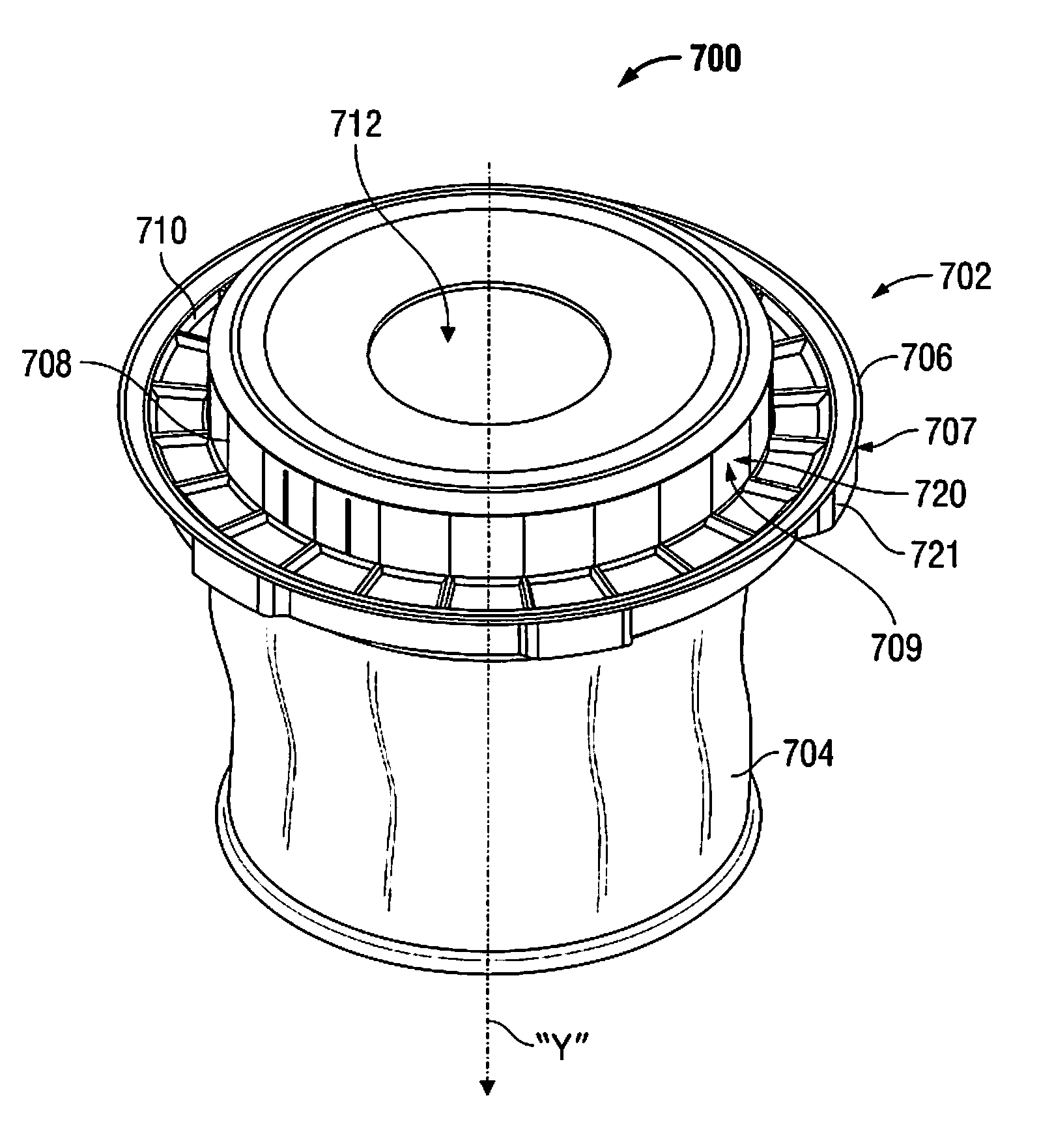

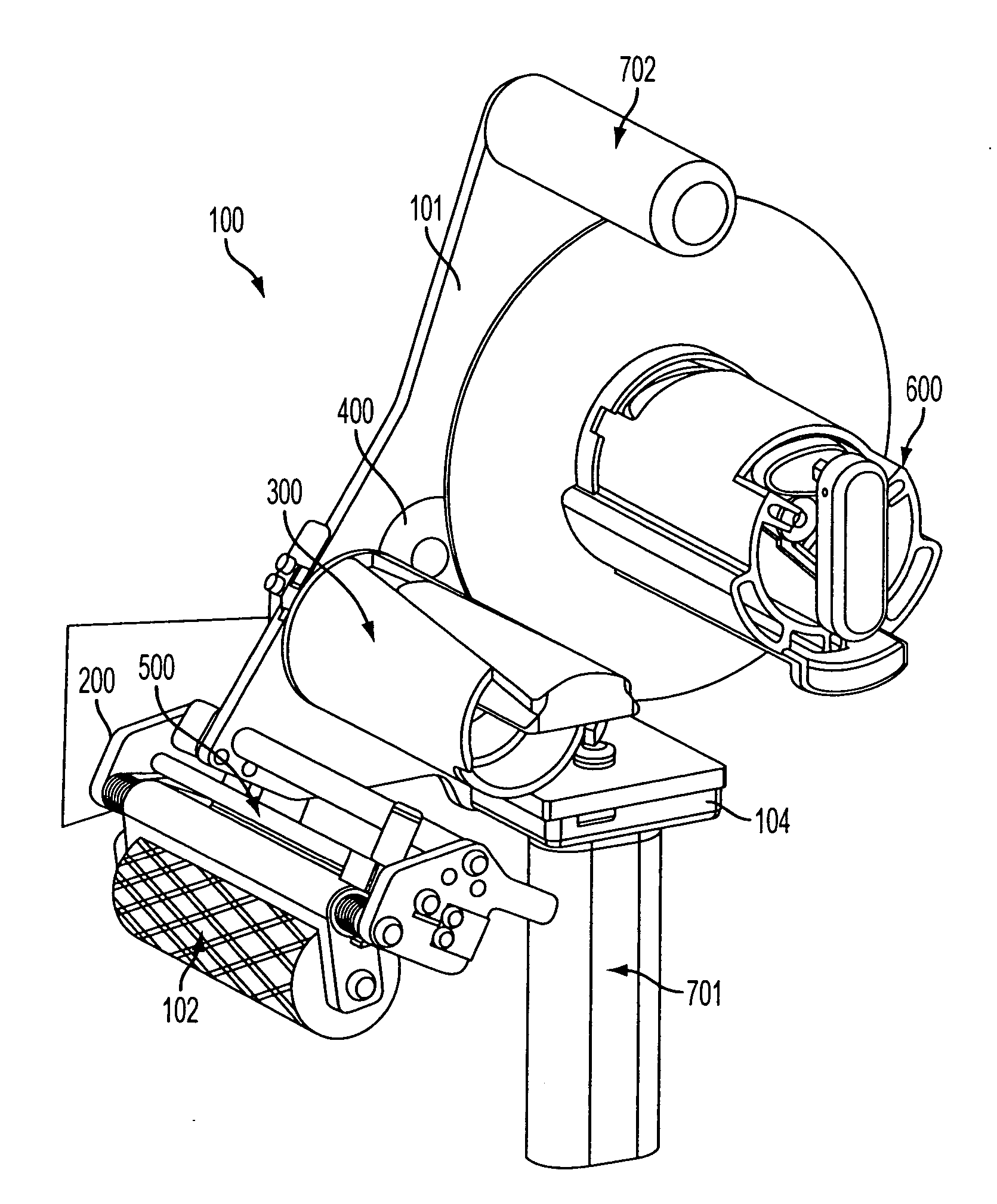

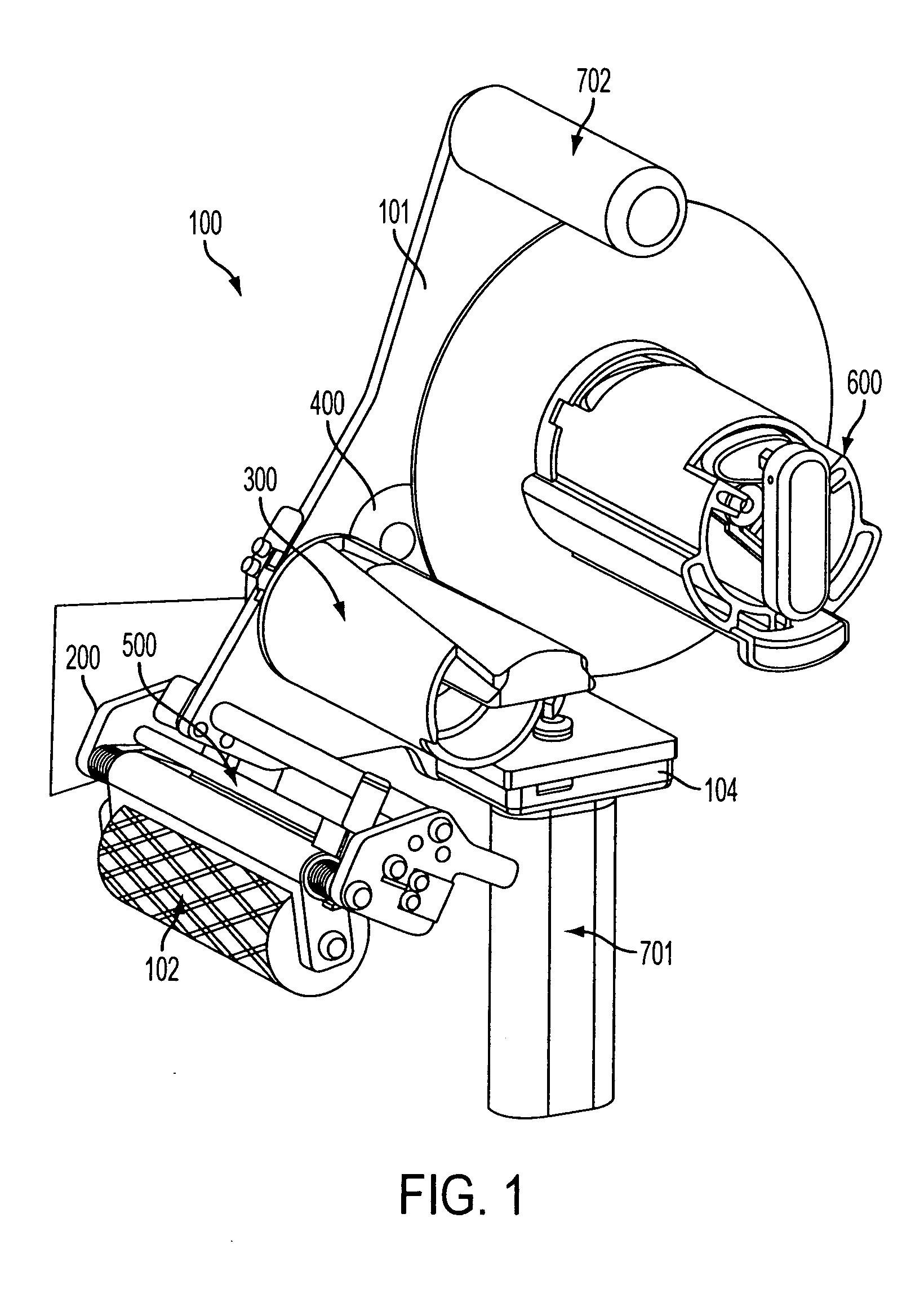

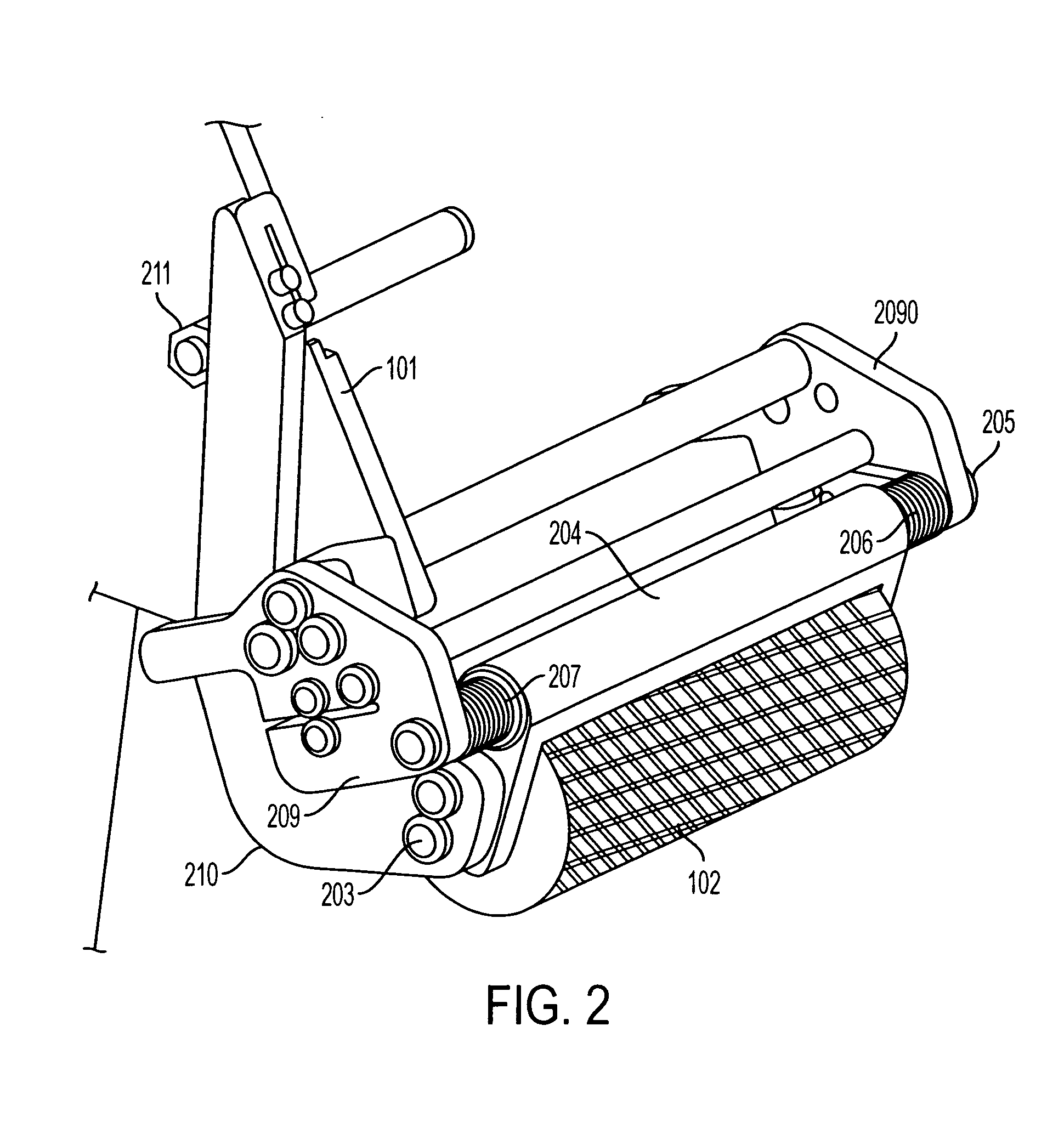

Handheld tape applicator and components thereof, and their methods of use

InactiveUS20070125474A1Reduce user-applied forceIncrease pressureCovering/liningsWallsHand heldPressure feedback

A hand-grippable adhesive tape applicator is provided for building construction and other environments. Pressure feedback and integrated slidable cutting mechanism features are included which provide improved tape application performance. Unique tape supply spool and take-up reel assemblies also are provided which enhance tape applicator performance. A patterned applicator roller also is provided to allow tape application to be performed with reduced user-applied force.

Owner:HUBER ENGINEERED WOODS

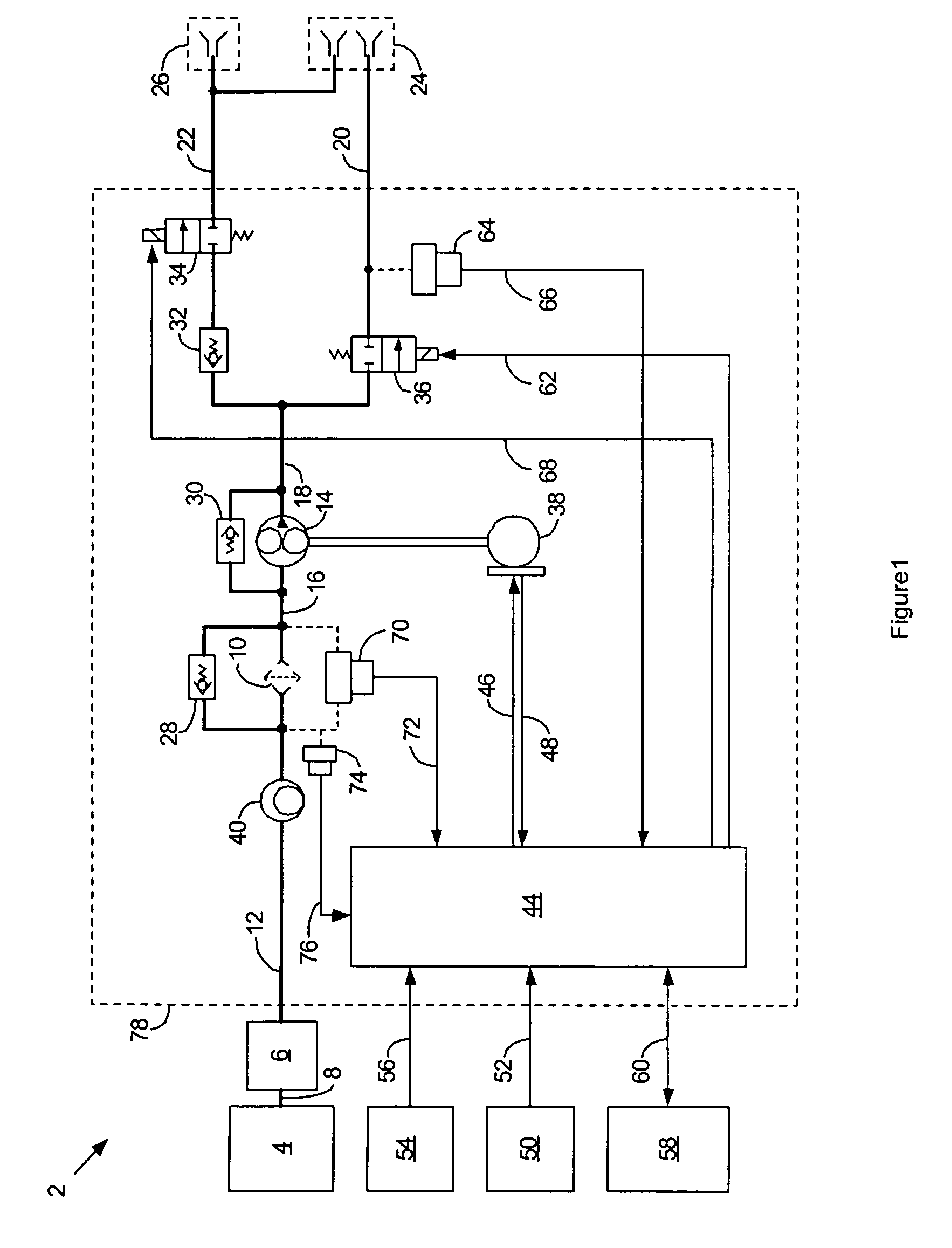

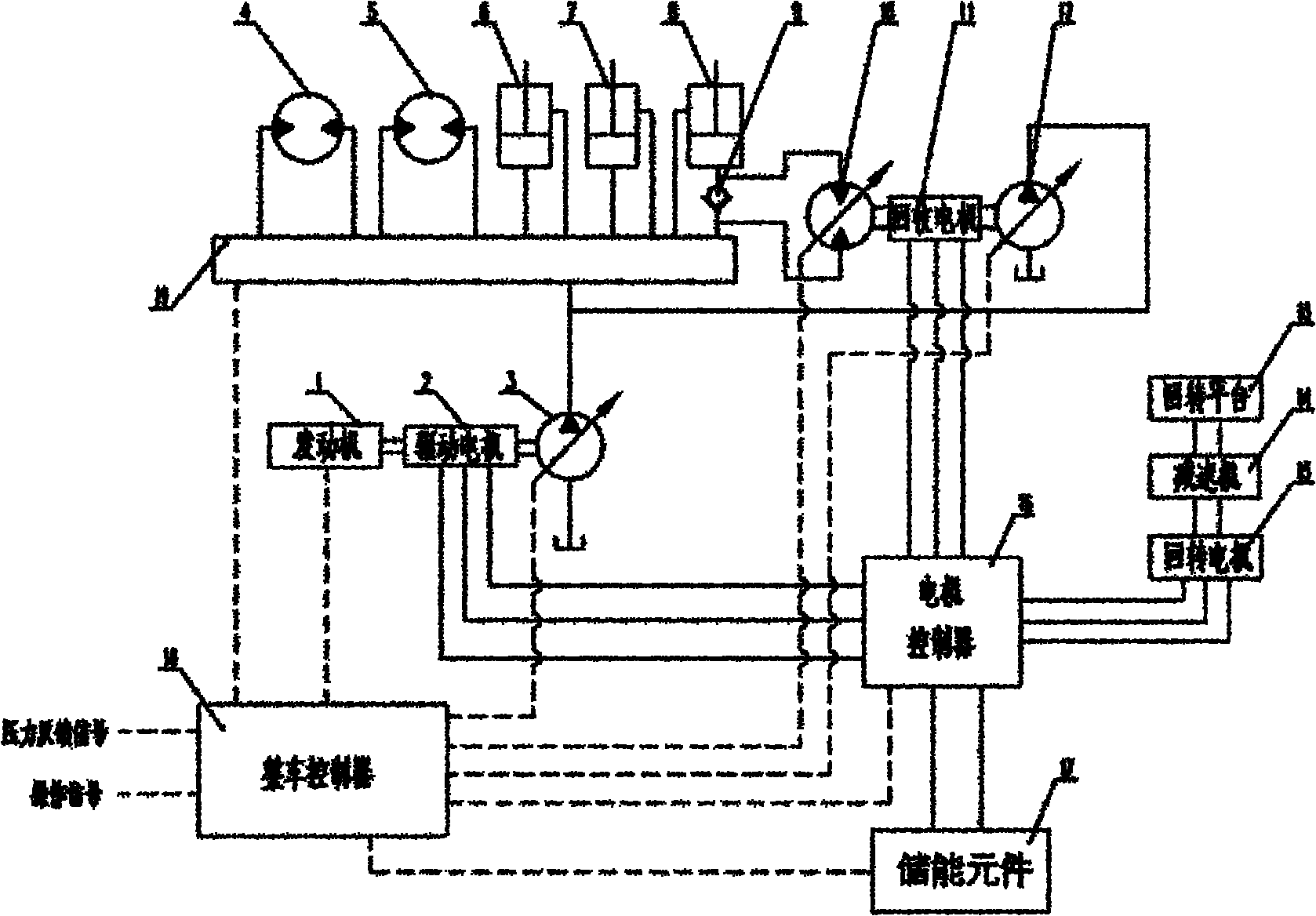

Driving and energy recovery system for hybrid excavator

ActiveCN101973271AReduce conversion linksImprove recycling efficiencyHybrid vehiclesSoil-shifting machines/dredgersDrive motorMotor controller

The invention discloses a driving and energy recovery system for a hybrid excavator, which is characterized in that a master valve, an engine, a master variable pump, a recovery motor, an auxiliary variable pump, a motor controller and an energy storage element are all connected with a hybrid control unit; the hybrid control unit is also provided with an operating signal input interface and a pressure feedback signal input interface; and a driving motor, a recovery motor, a turning motor and the energy storage element are all connected with the motor controller. The driving and energy recovery system for the hybrid excavator can recover energy comprehensively, has good energy-saving effect and can not affect the stable operation of the engine.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

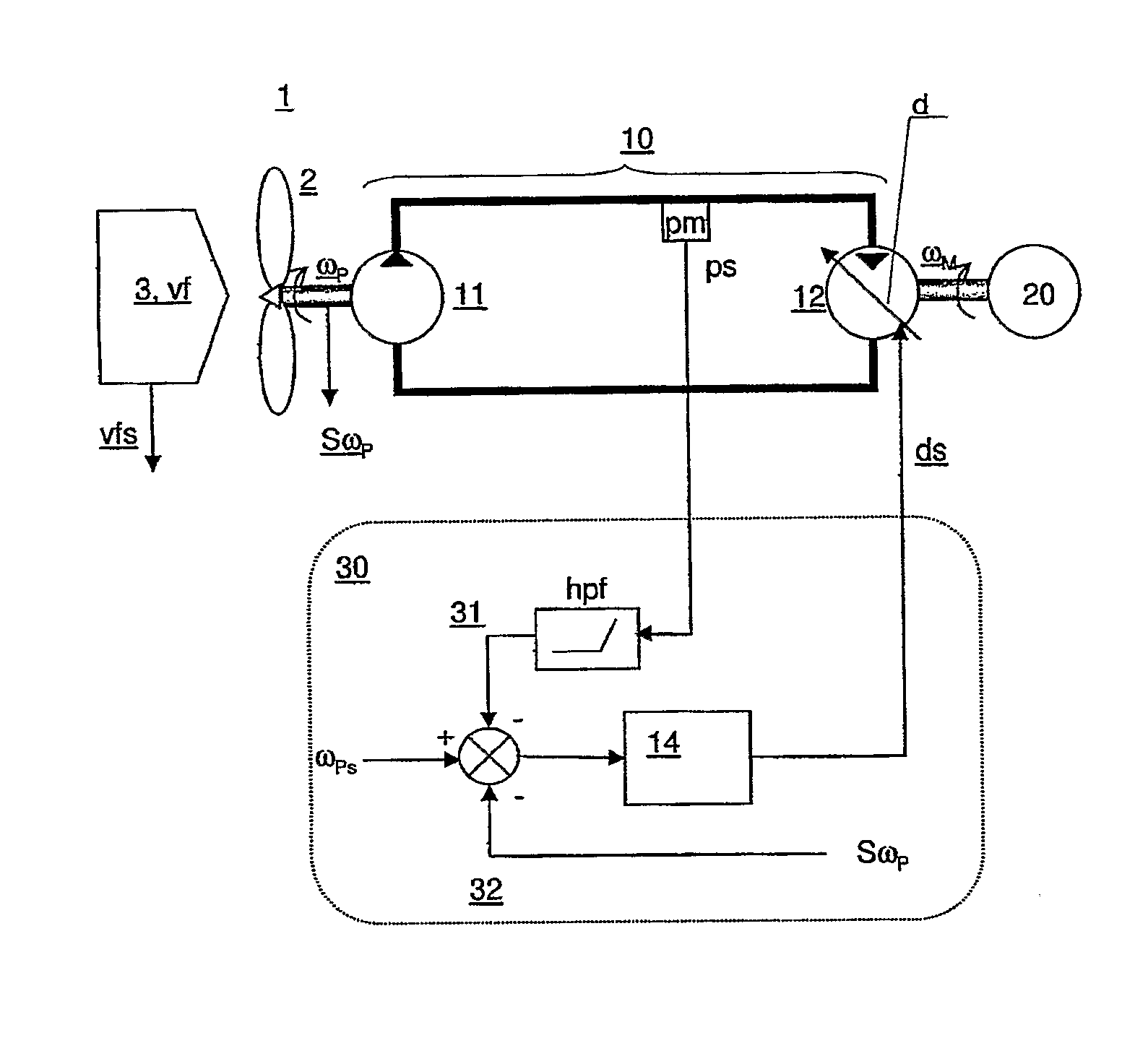

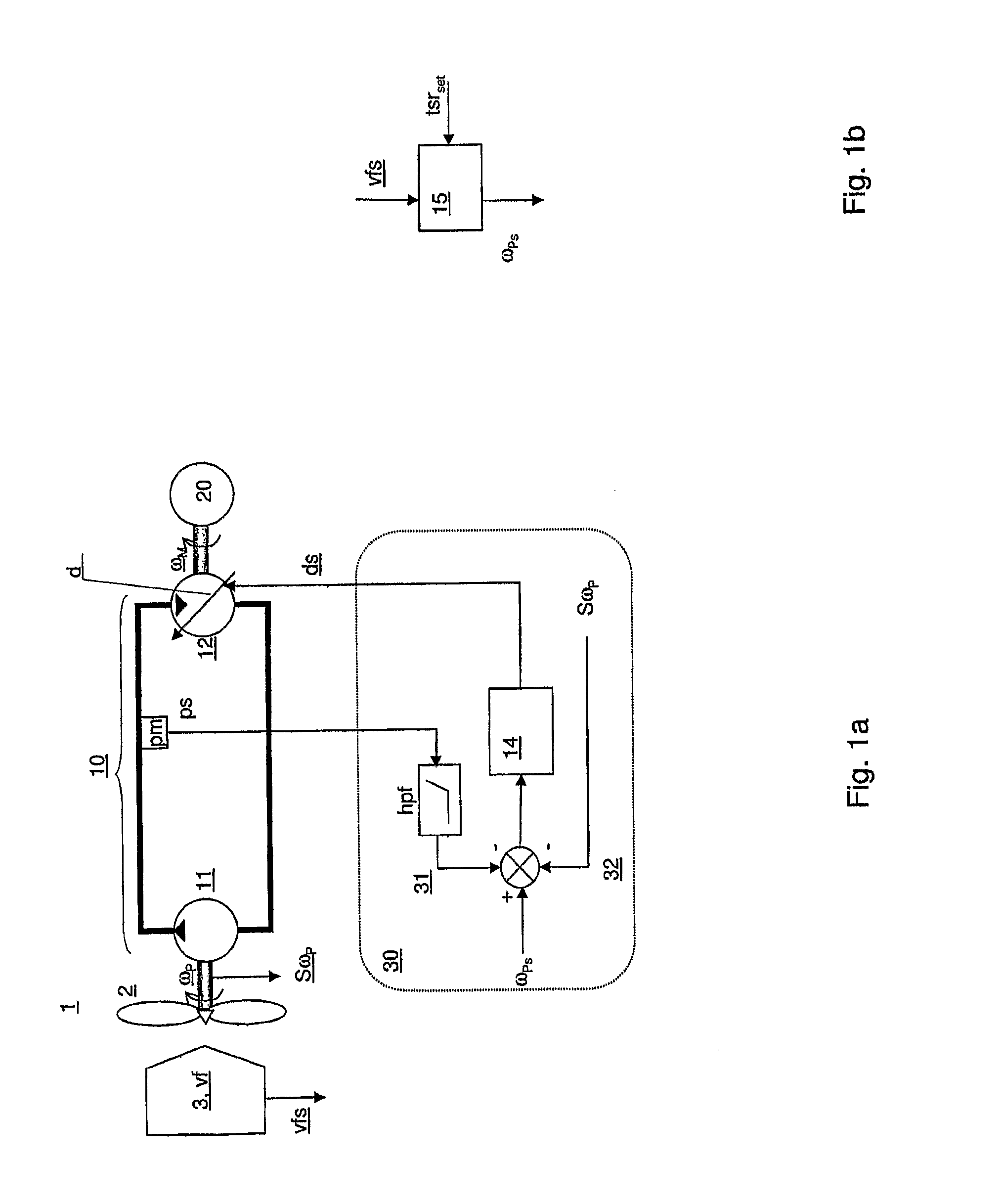

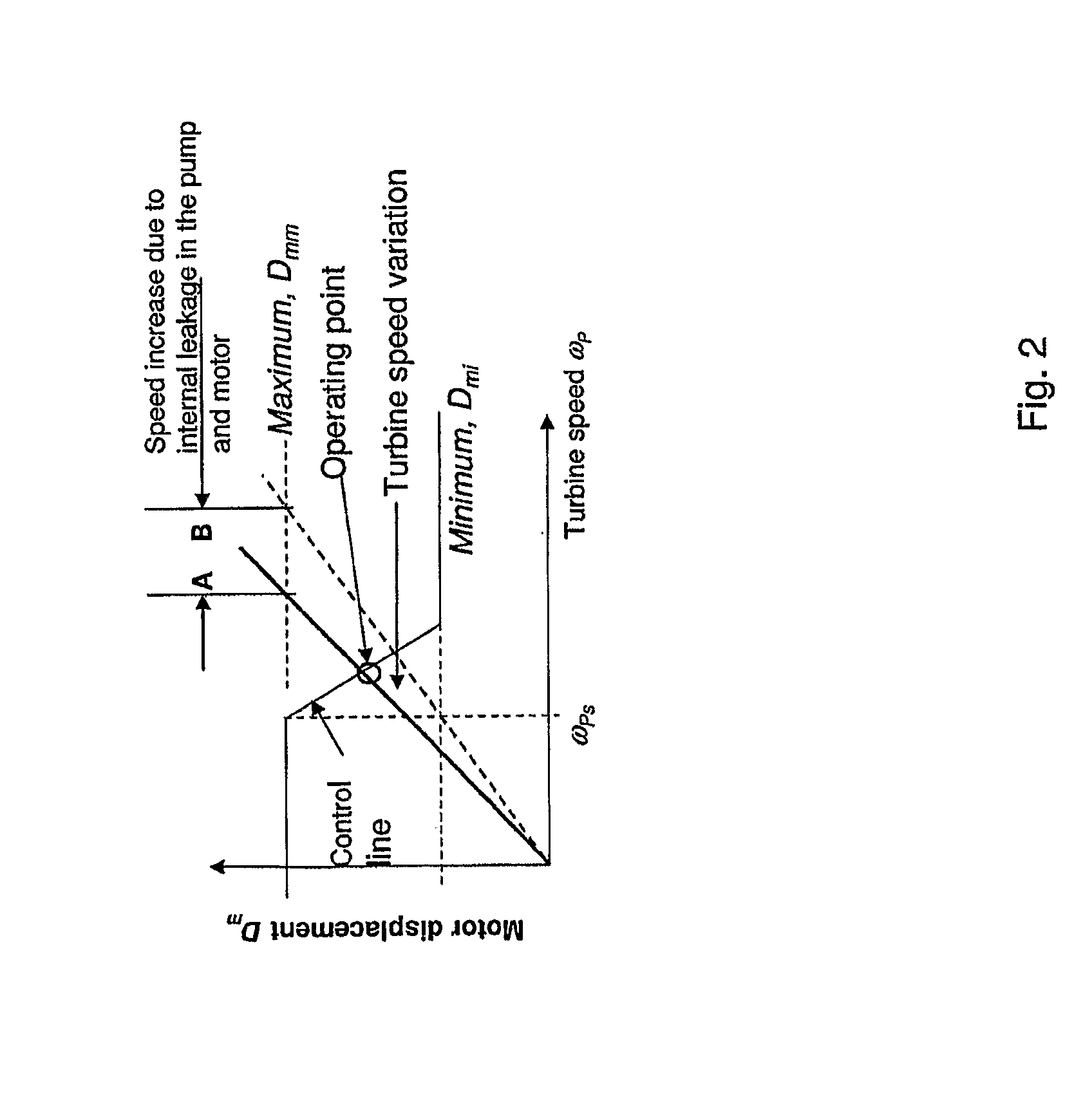

Turbine speed stabilisation control system

InactiveUS20120161442A1Reduce variationImprove stabilityRotational speed controlWind motor controlClosed loopDisplacement control

A closed loop turbine speed control system for a turbine power production system including a closed loop hydrostatic transmission system for the transfer of energy from a wind turbine rotor to a generator. A displacement actuator is arranged for receiving a displacement control signal from the control system and for controlling a displacement of the displacement motor. The control system includes a turbine rotor speed feedback control loop for calculating the displacement control signal based on deviations of a turbine rotor actual rotational speed from a turbine rotor set rotational speed. In addition a hydraulic pressure meter measures the hydraulic pressure of the hydrostatic system and provides a hydraulic pressure signal as an input to a pressure feedback control loop for stabilizing the displacement control signal based on the hydraulic pressure signal.

Owner:CHAPDRIVE AS

Controller of injection molding machine

The present invention discloses a control device of an injection molding machine, which comprises a speed feedback control system for carrying out speed feedback control on the basis of a speed detected value Vd obtained by converting a position detected value Xd obtained from a screw position sensor 4, a pressure feedback control system for carrying out a pressure feedback control on the basis of a pressure detected value Pdb obtained from an injection pressure sensor 6b, and a VP switching control function portion Fc for carrying out switching from a speed control region to a pressure control region Zp when a pressure deviation Ep between a preset pressure set value Ps and the pressure detected value Pdb becomes a preset switching determination value Eps or less and carrying out the switching to the pressure control region Zp after control of a speed command value in the speed control region Zv by a predetermined control pattern Dp at this switching.

Owner:NISSEI PLASTIC IND CO LTD

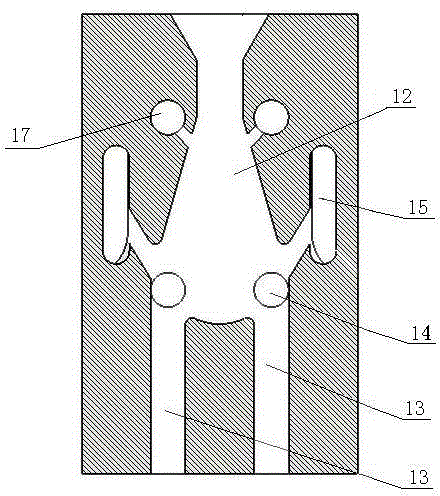

Flow distributing type hydraulic oscillation circumferential impactor

ActiveCN104963624AImprove rock breaking efficiencyReduce the impact of drillingLiquid/gas jet drillingBorehole drivesEngineeringPressure feedback

The invention relates to a flow distributing type hydraulic oscillation circumferential impactor. The flow distributing type hydraulic oscillation circumferential impactor comprises a shell connector, a double-bus jet generator, a flow distributor, a gland, a hydraulic drive hammer and a transmission short joint. The double-bus jet generator abuts against the interior of the shell connector. The hydraulic drive hammer is installed at the upper portion of the transmission short joint. The flow distributor and the gland are located between the double-bus jet generator and the hydraulic drive hammer. The transmission short joint is screwed in the lower end of the shell connector and abuts against the gland. An annular groove and a flow releasing channel are formed in the inner wall of the shell connector. The annular groove corresponds to a returned liquid outlet in the outer wall of the double-bus jet generator, and a drainage hole is formed in the transmission short joint. The double-bus jet generator is a cylinder with a center runner. The center runner is divided into a left branch runner and a right branch runner through a check block. The inlet and the outlet of a pressure feedback channel in the double-bus jet generator are communicated with the center runner. Each branch runner is divided into two parts through the flow distributor. The hydraulic drive hammer is provided with symmetric arc bosses. Arc cavities contain the arc bosses. According to the flow distributing type hydraulic oscillation circumferential impactor, no weak part exists, the service life is long, and the impact effect is good.

Owner:NORTHEAST GASOLINEEUM UNIV

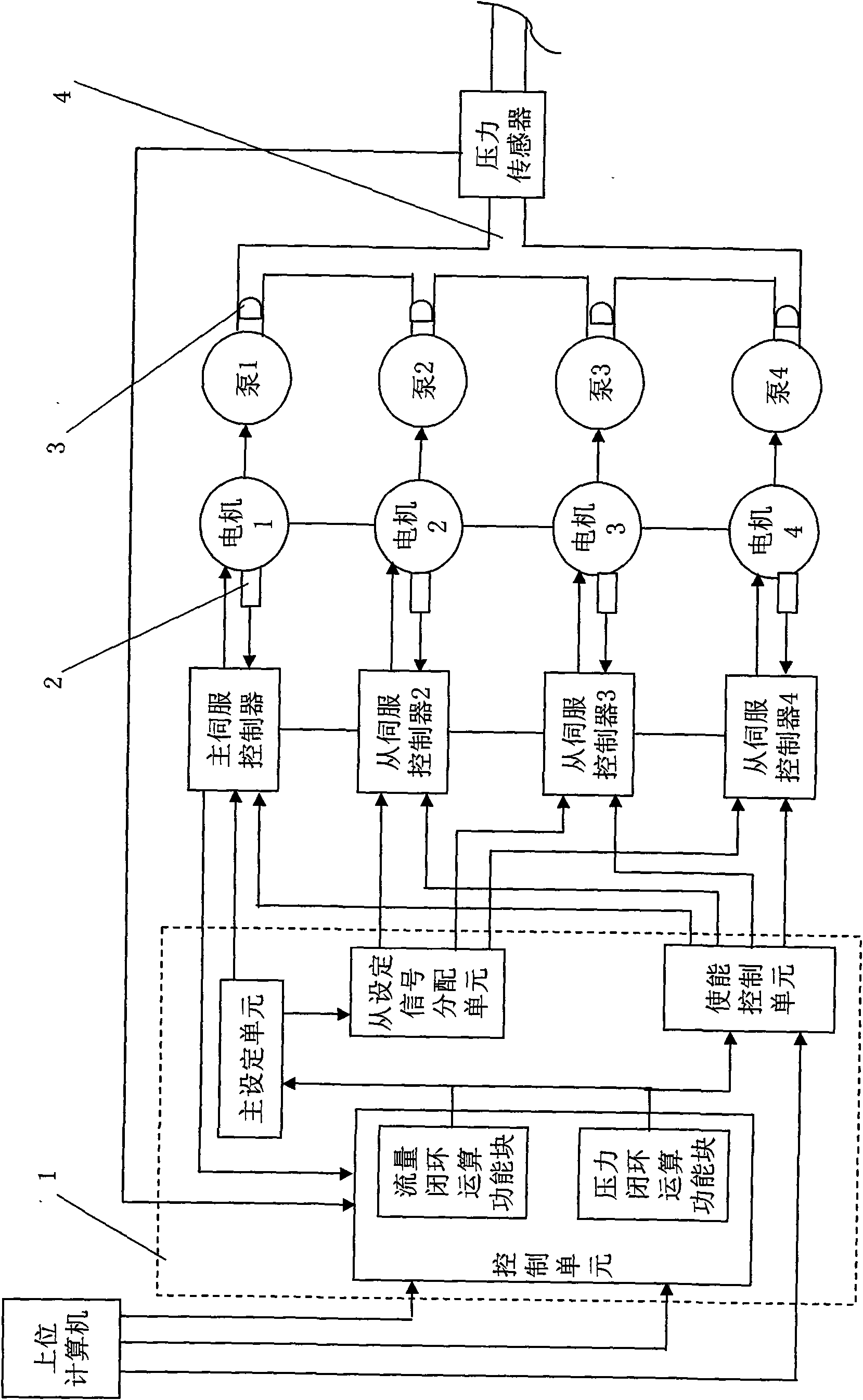

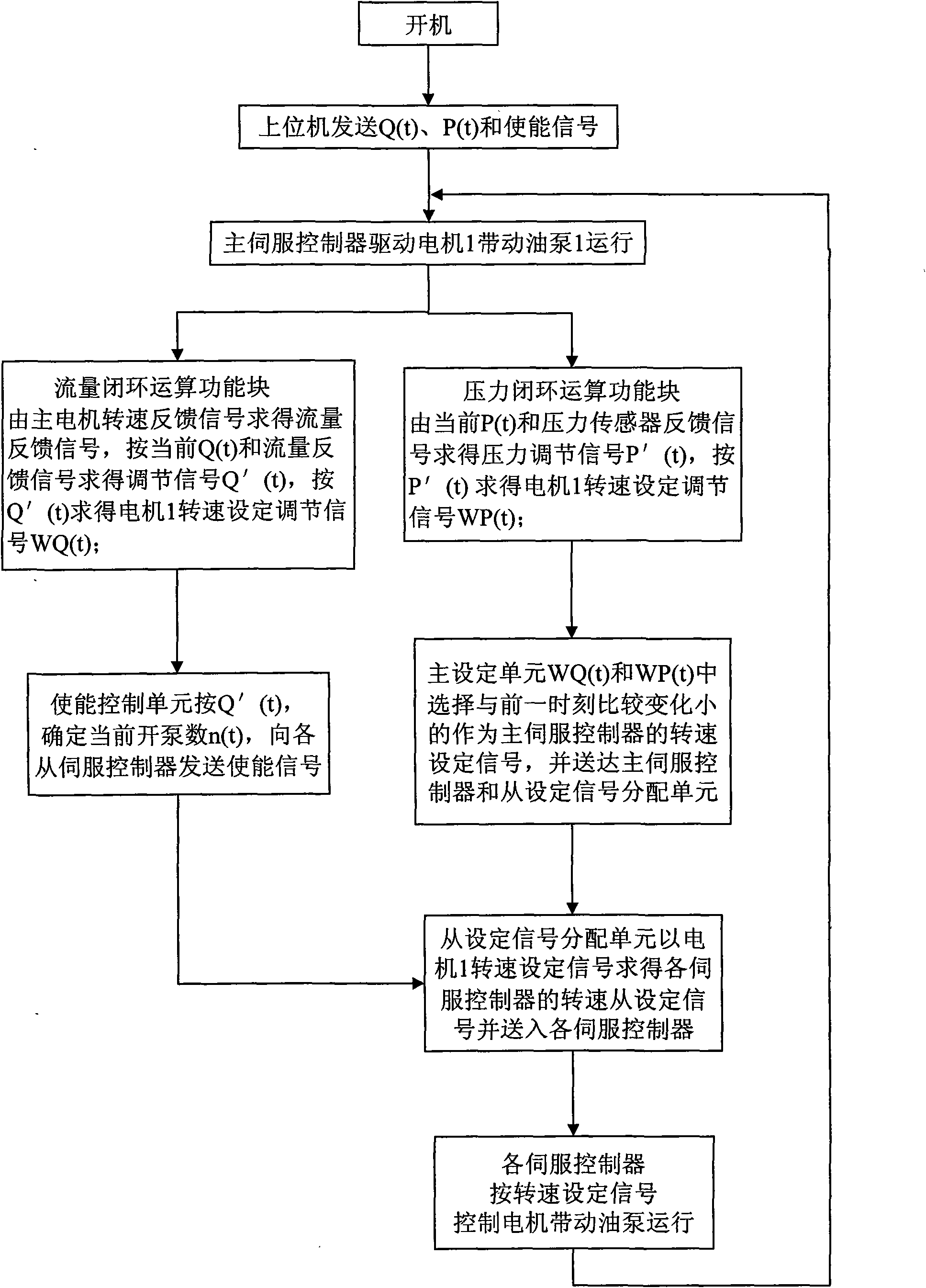

Energy-saving servo hydraulic control system for injection machine and control method thereof

The invention discloses an energy-saving servo hydraulic control system for an injection machine with multi-pump confluence and a control method thereof. The system comprises N branches, and each branch comprises a servo controller, a servo motor, an oil pump and a check valve, and accesses to an injection machine hydraulic loop in a gathering way. A main control template is connected with a host control computer and each servo controller. Each motor is provided with a speed measurement element which is connected with the servo controller thereof, rotational speed feedback signals of a main servo controller access to a control unit, and the hydraulic loop is provided with a pressure sensor. The control method comprises the following steps: a host computer provides flow and pressure set signals according to an injection molding flow; regulating signals of the flow and the pressure are obtained by the system according to a command of the host computer and the rotational speed and pressure feedback signals to solve the amount of starting motors and the rotational speed of the motors; and a plurality of pumps are controlled to cooperatively work to cause total flow of the hydraulic loop to follow the flow set signals and total pressure of the hydraulic loop to follow the pressure set signals. The invention satisfies the requirements of high-power running and low-power running of equipment, has accurate and agile control, and is obvious to save the energy.

Owner:桂林星辰科技股份有限公司

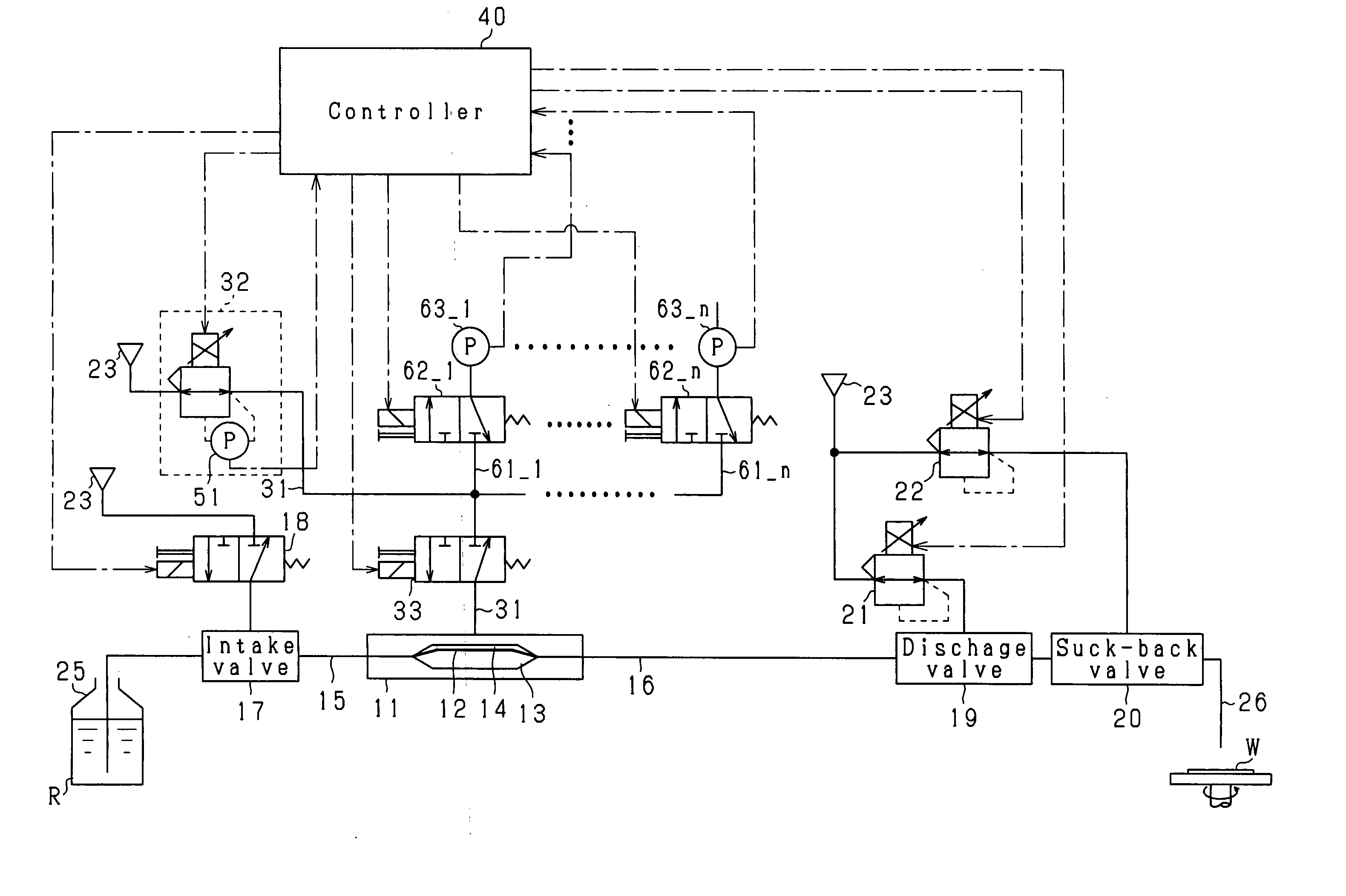

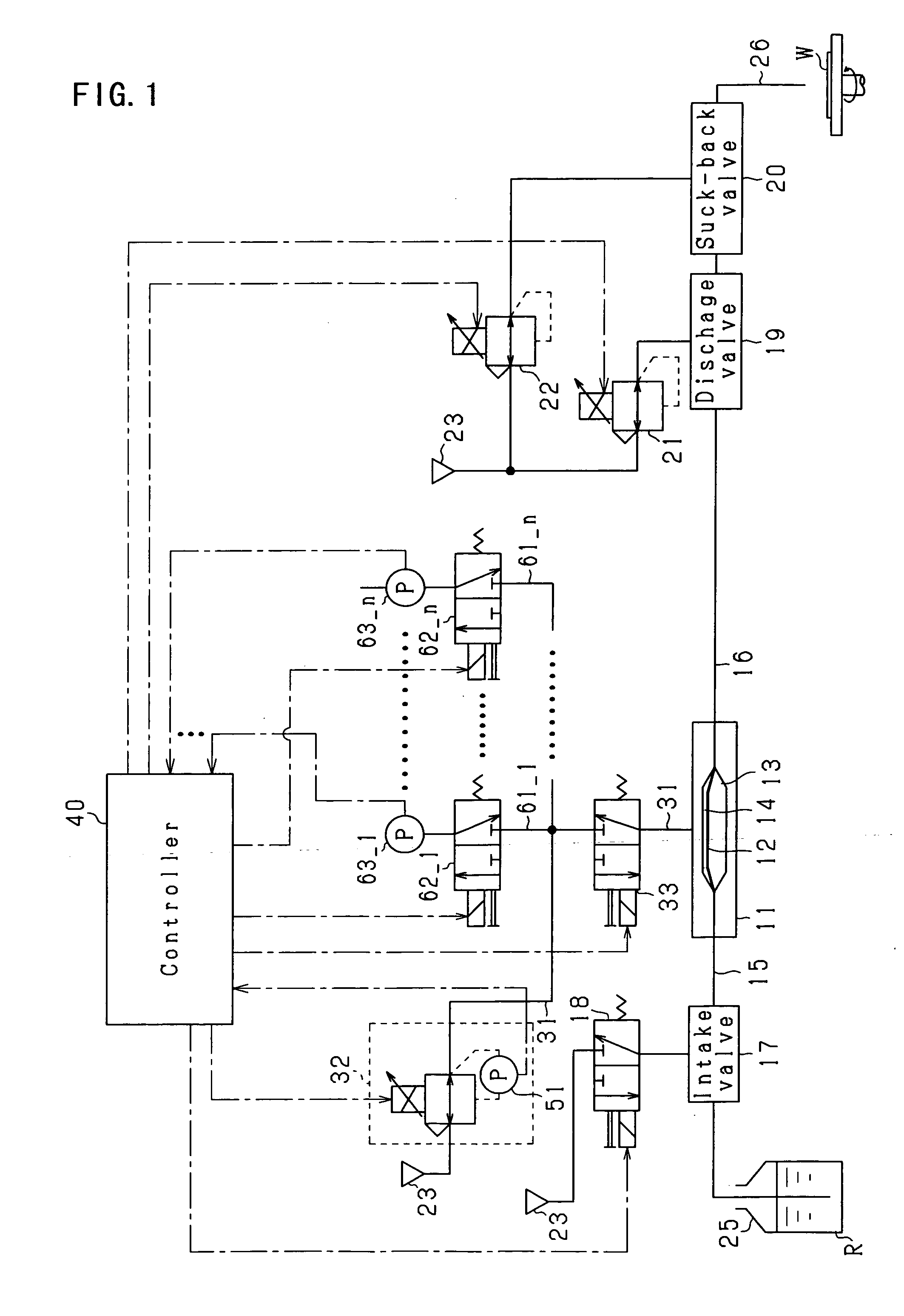

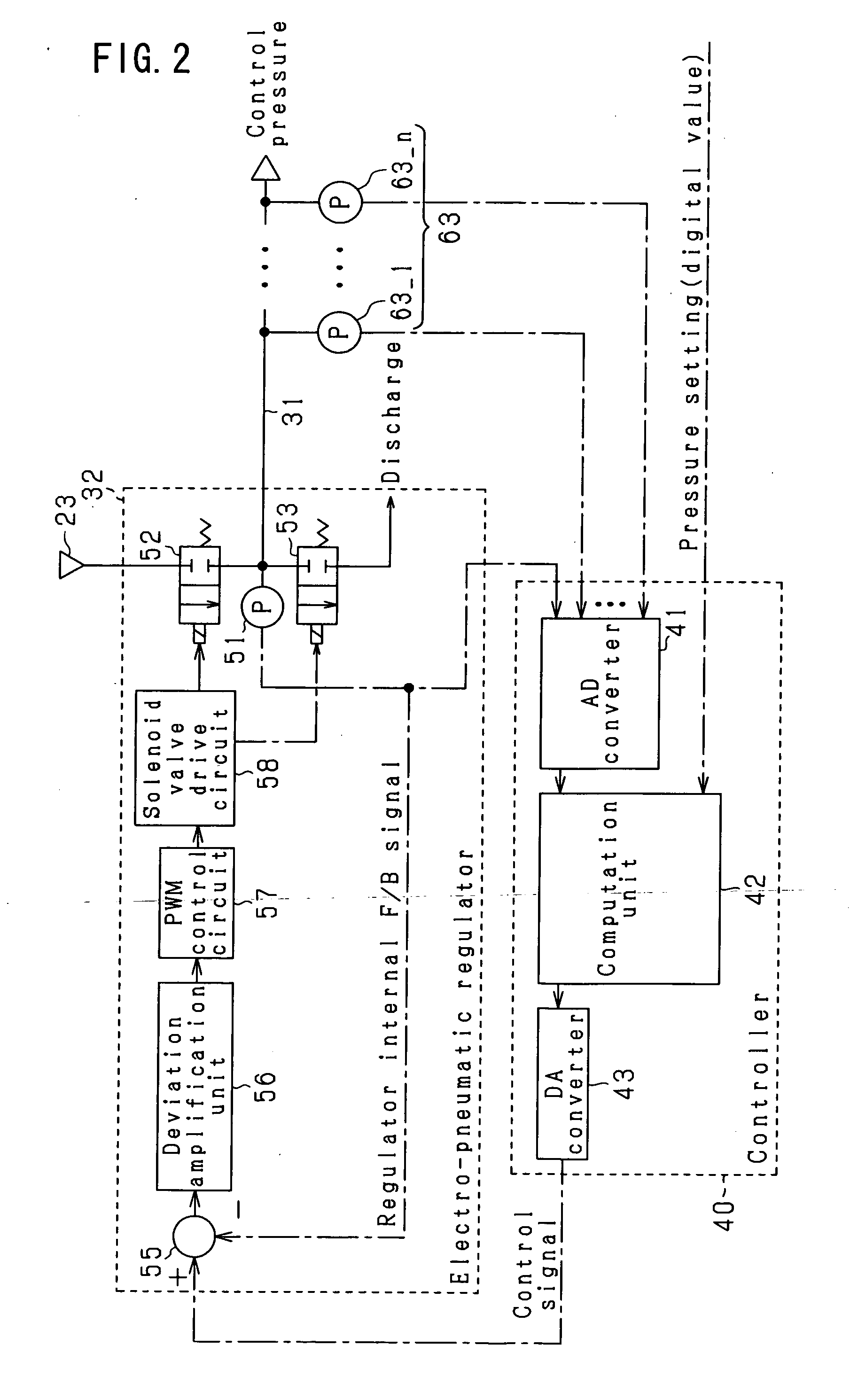

Liquid chemical supply system having a plurality of pressure detectors

ActiveUS20070122291A1Small sizeLow costFlexible member pumpsSemiconductor/solid-state device manufacturingPump chamberCompound (substance)

[Problem] To always perform accurate pressure feedback control, and control the discharge flow rate of liquid chemical with high precision, even in situations in which the pressure setting value of the operation pressure differs due to changes in the type of liquid chemical, etc. [Means of solution] A pump 11 has a pump chamber 13 and an operation chamber 14 separated by a diaphragm 12 comprised of a flexible membrane, and performs the intake and discharge of liquid chemical in accordance with the change in pressure inside the operation chamber 14. An electro-pneumatic regulator 32 supplies operation air to the operation chamber 14. In addition, in the present system, a plurality of pressure sensors 51, 63 having different pressure detection ranges is provided as pressure detection means for detecting the operation air pressure. A controller 40 selectively employs any of the detection results of the plurality of sensors 51, 63 in accordance with the pressure setting value of the operation air that is set for each use, and performs pressure feedback control.

Owner:OCTEC INC +1

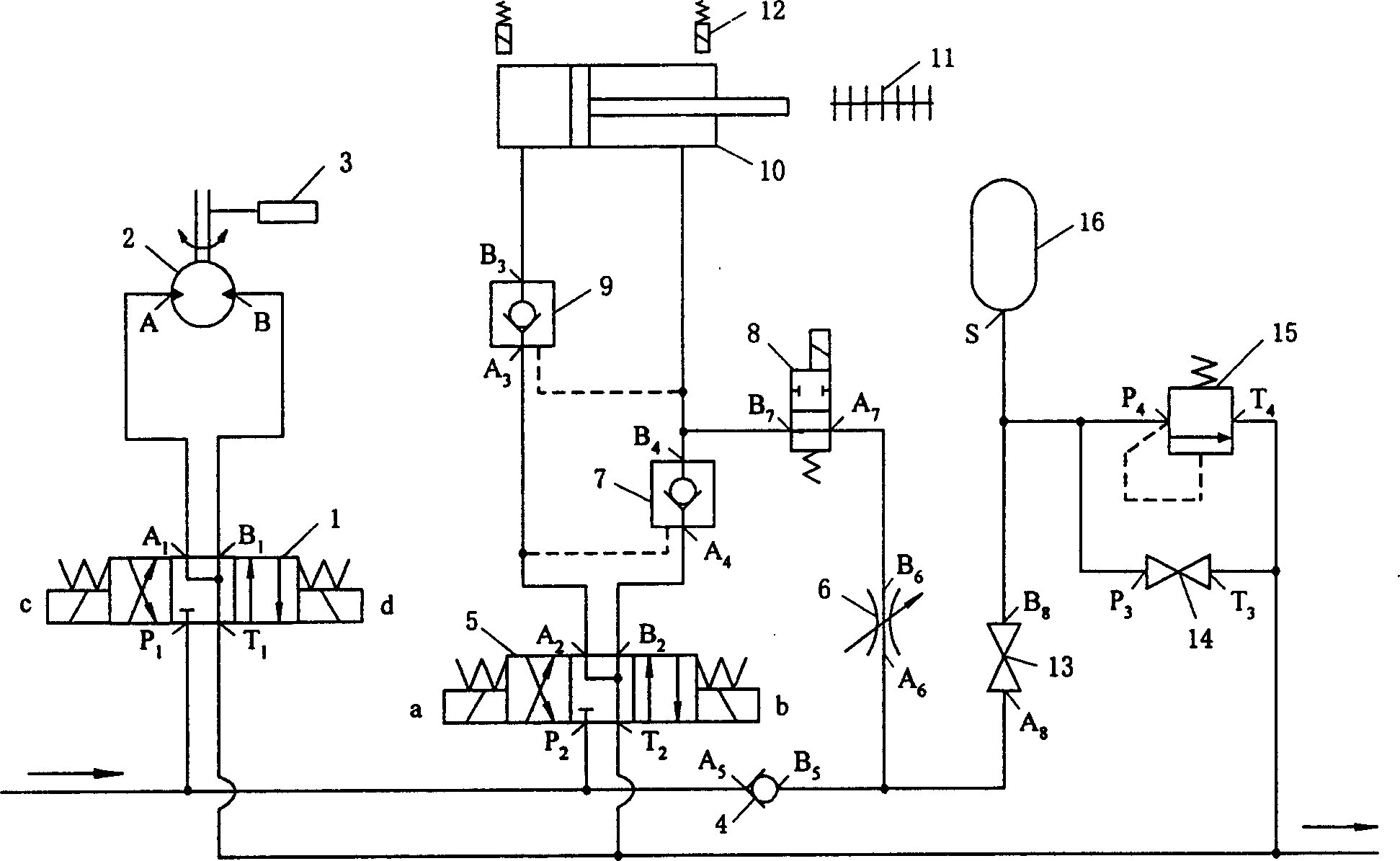

Shielding spiral conveyor hydraulic system with proportional feedback control and accumulator oil supplementary

InactiveCN1584346AControl disturbanceAdjustable speedFluid-pressure actuator safetyServomotorsEarth surfaceShuttle valve

A hydraulic system of shield spiral conveying machine with ratio feedback control and energy storing device for oil supplement consists of a three-position and four-way solenoid change valve, a motor, a rotation sensor, a one-way valve, a liquid-controlled one-way valve, a throttle valve, a two-position and two-way solenoid reversal valve, a shift sensor, a hydraulic cylinder, a range switch, a stop ball valve, a unloading valve, an overflow valve and an energy storing device. The machine has a sensor to monitor rotation and makes variable pump controlled according soil cabin pressure so as to control soil discharge volume and to achieve a hydraulic control system of a continuous real time controllable spiral-conveying machine. The energy-storing device is used oil supplement to close exhaust outlet reliably when accident occurs to guarantee safety for tunnel engineering. The electric feedback and ratio feedback are used to control turbulence to soil body when shield tunneling and reduce settlement of earth surface. The machine can be adaptable for various strata reliably.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com