Patents

Literature

12708 results about "Ball valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball's hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve's status.

Fluid pump

ActiveUS7238165B2ElectrocardiographyOther blood circulation devicesEngineeringCardiopulmonary bypass time

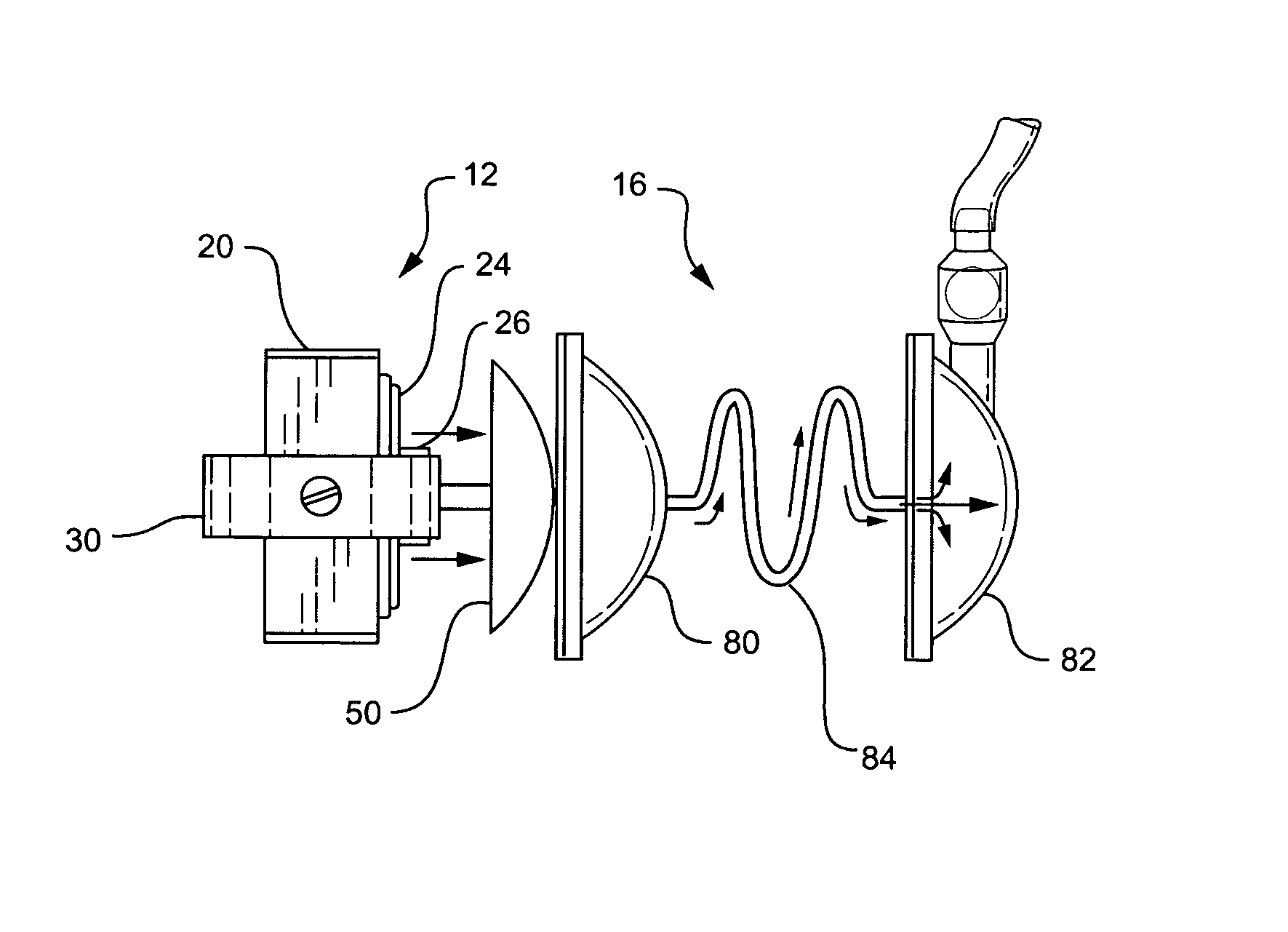

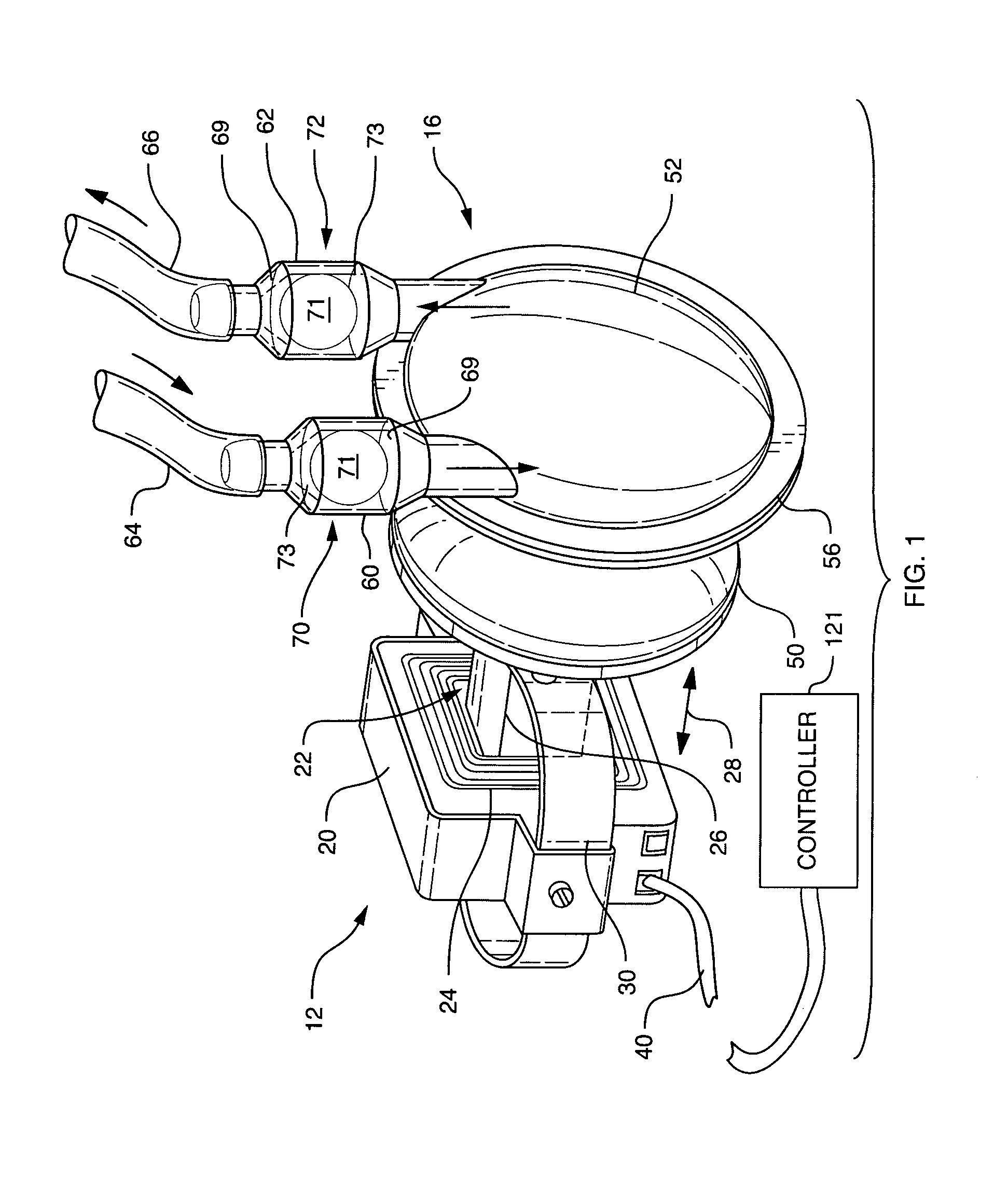

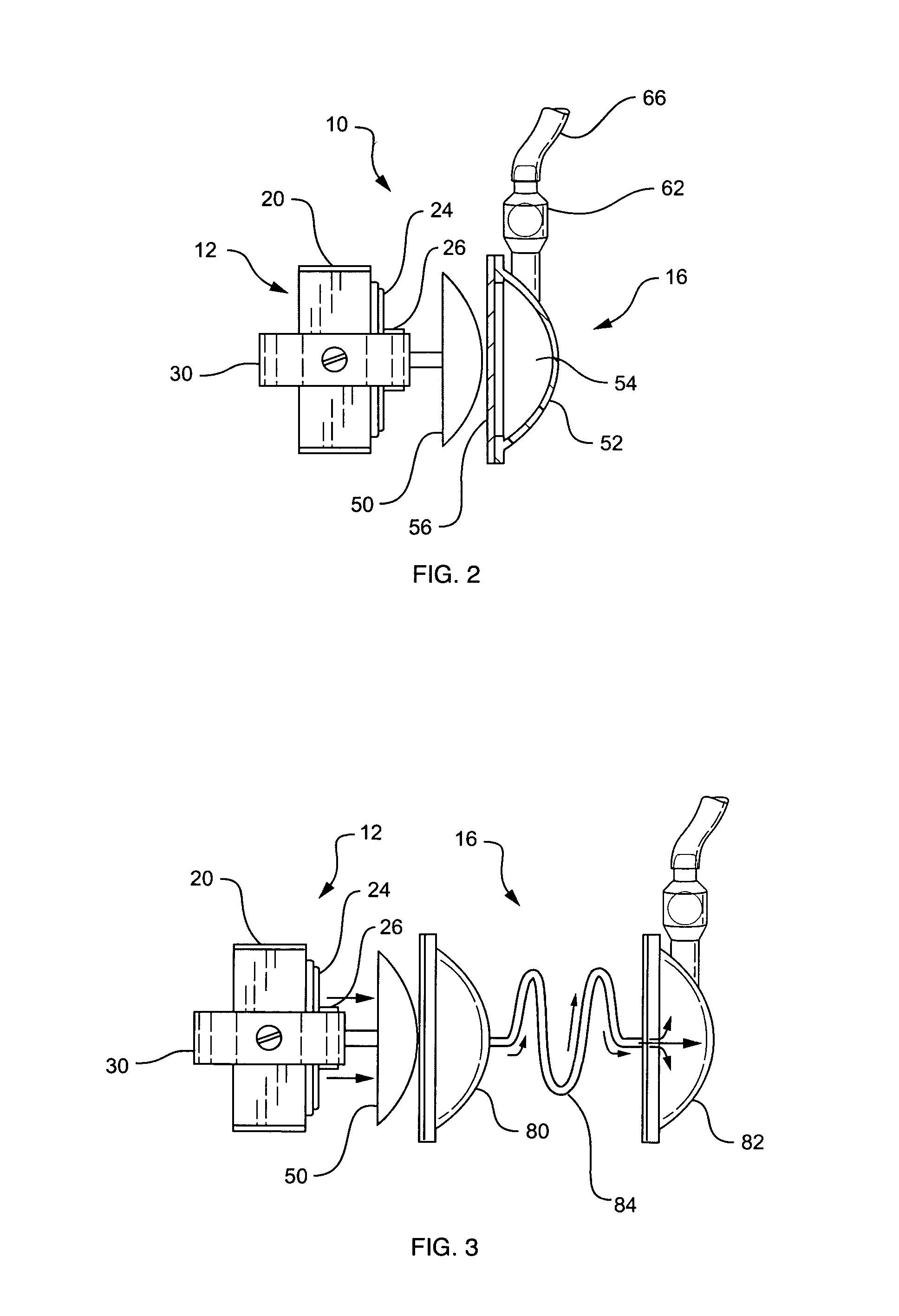

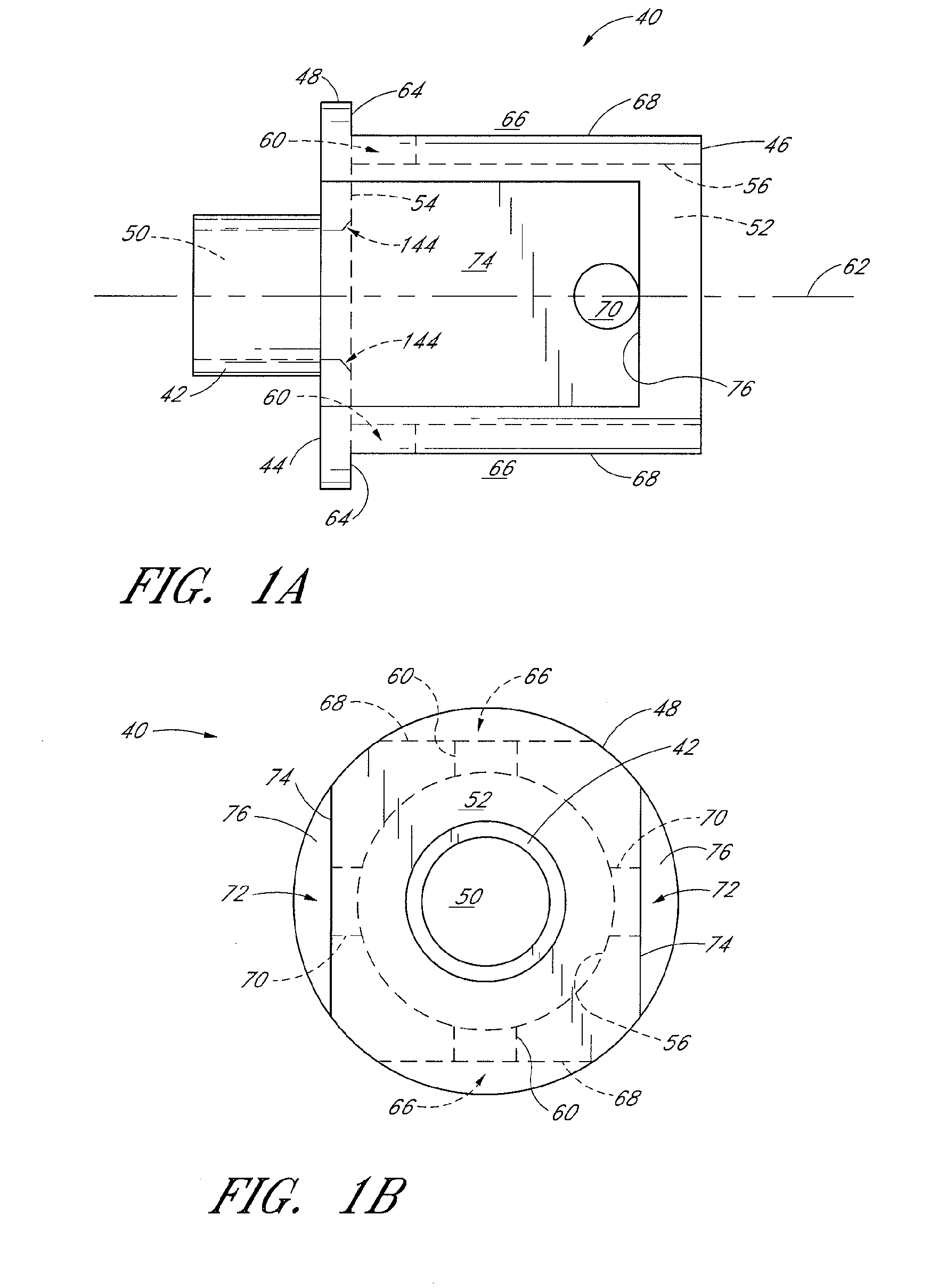

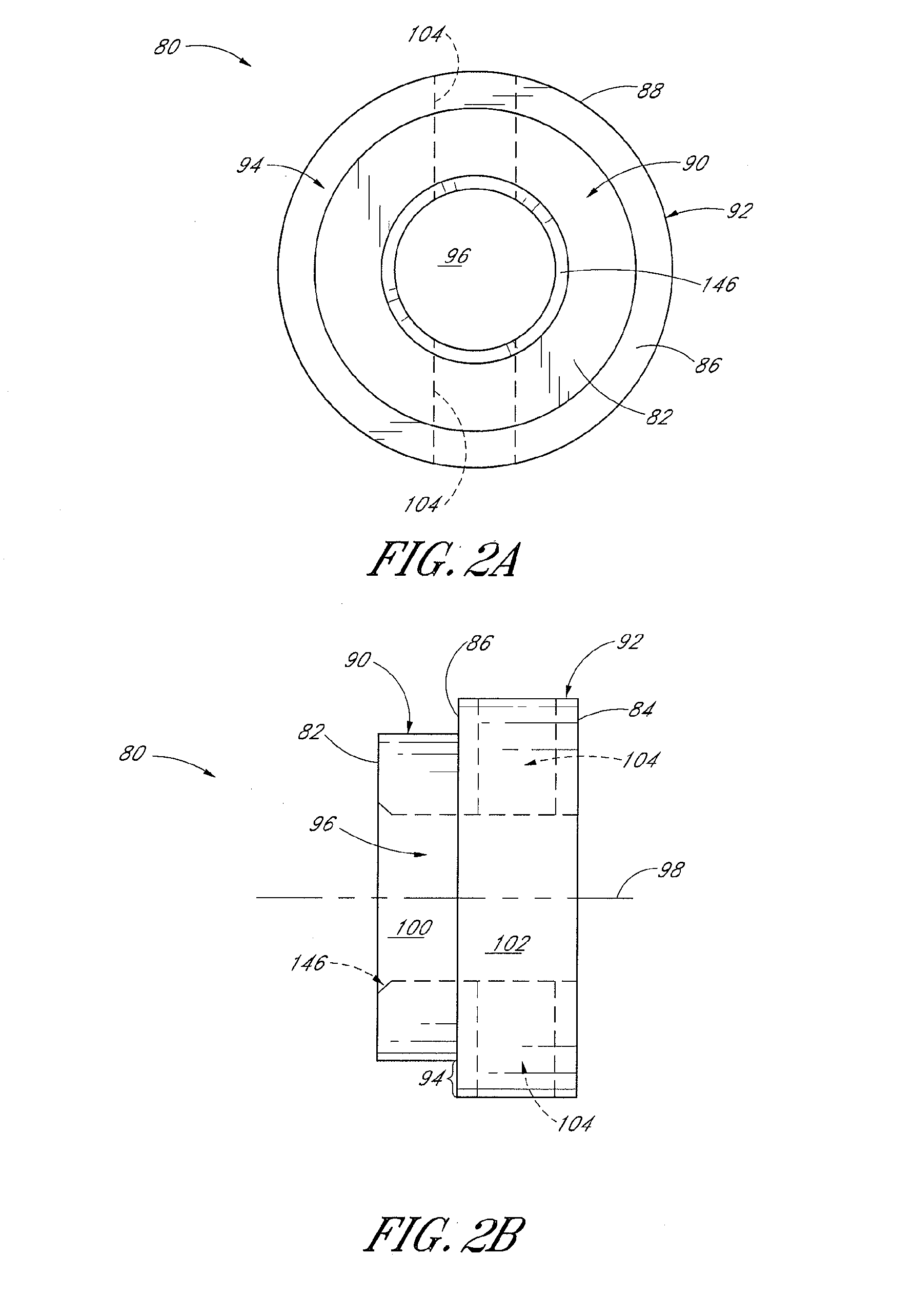

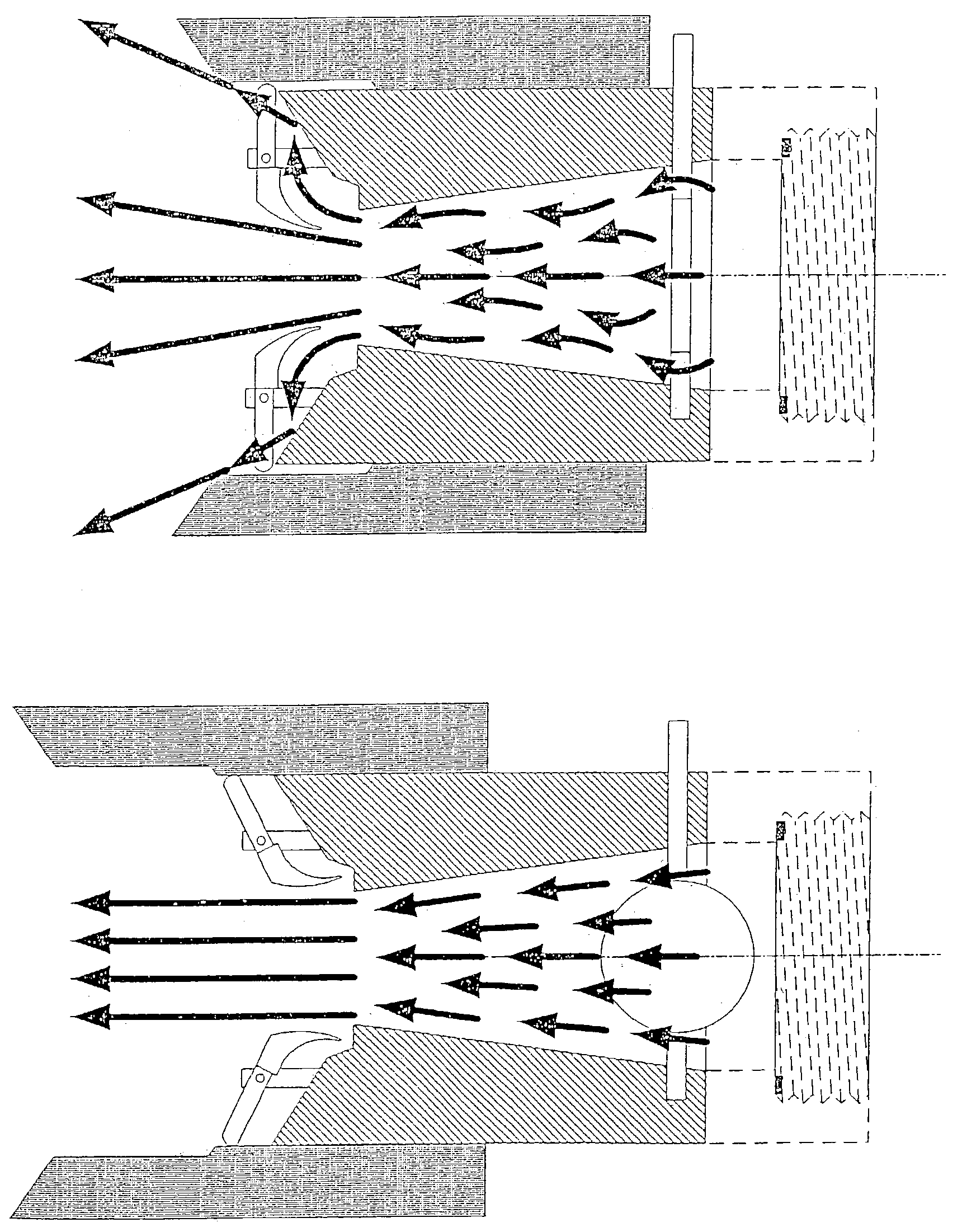

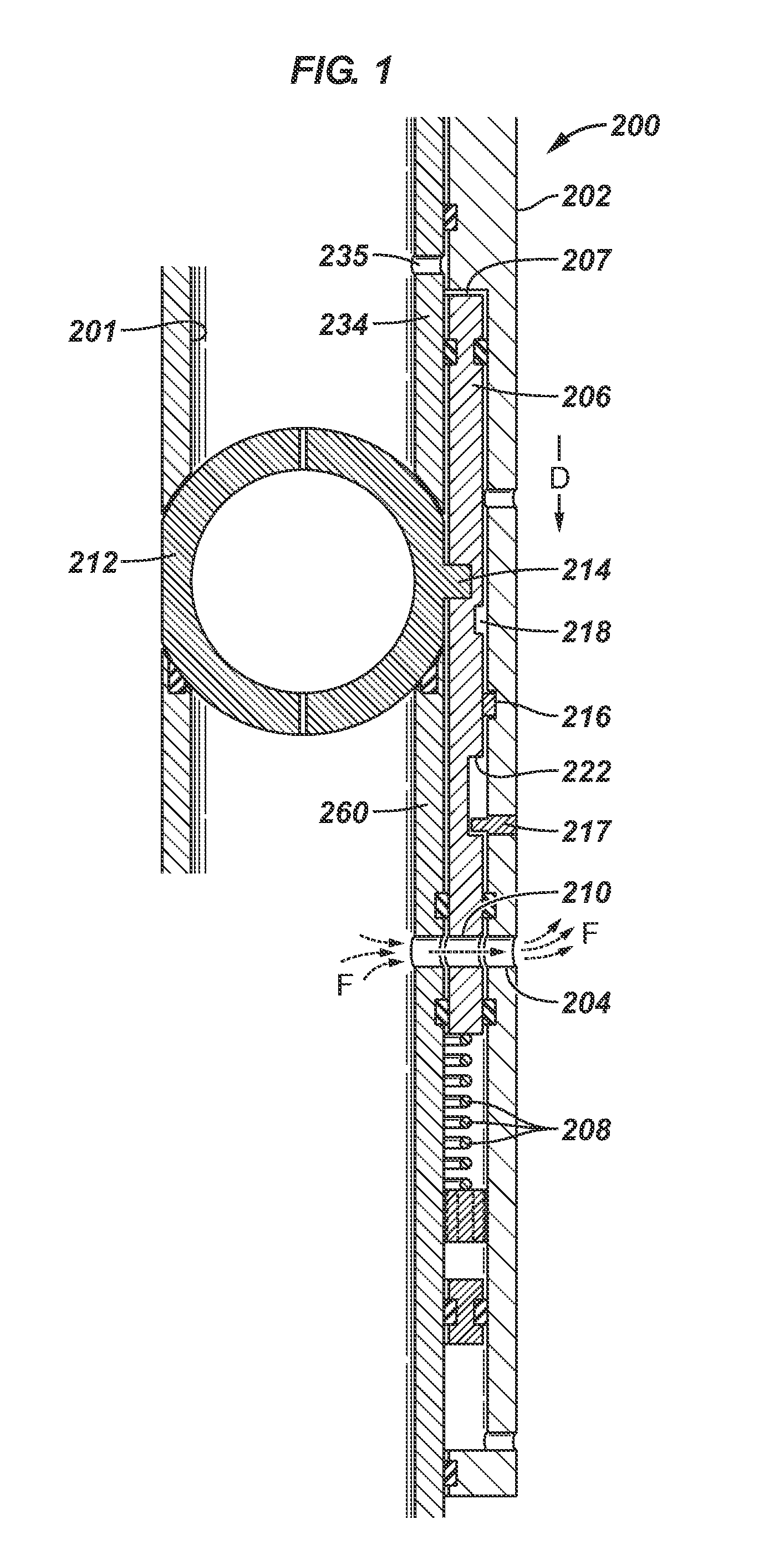

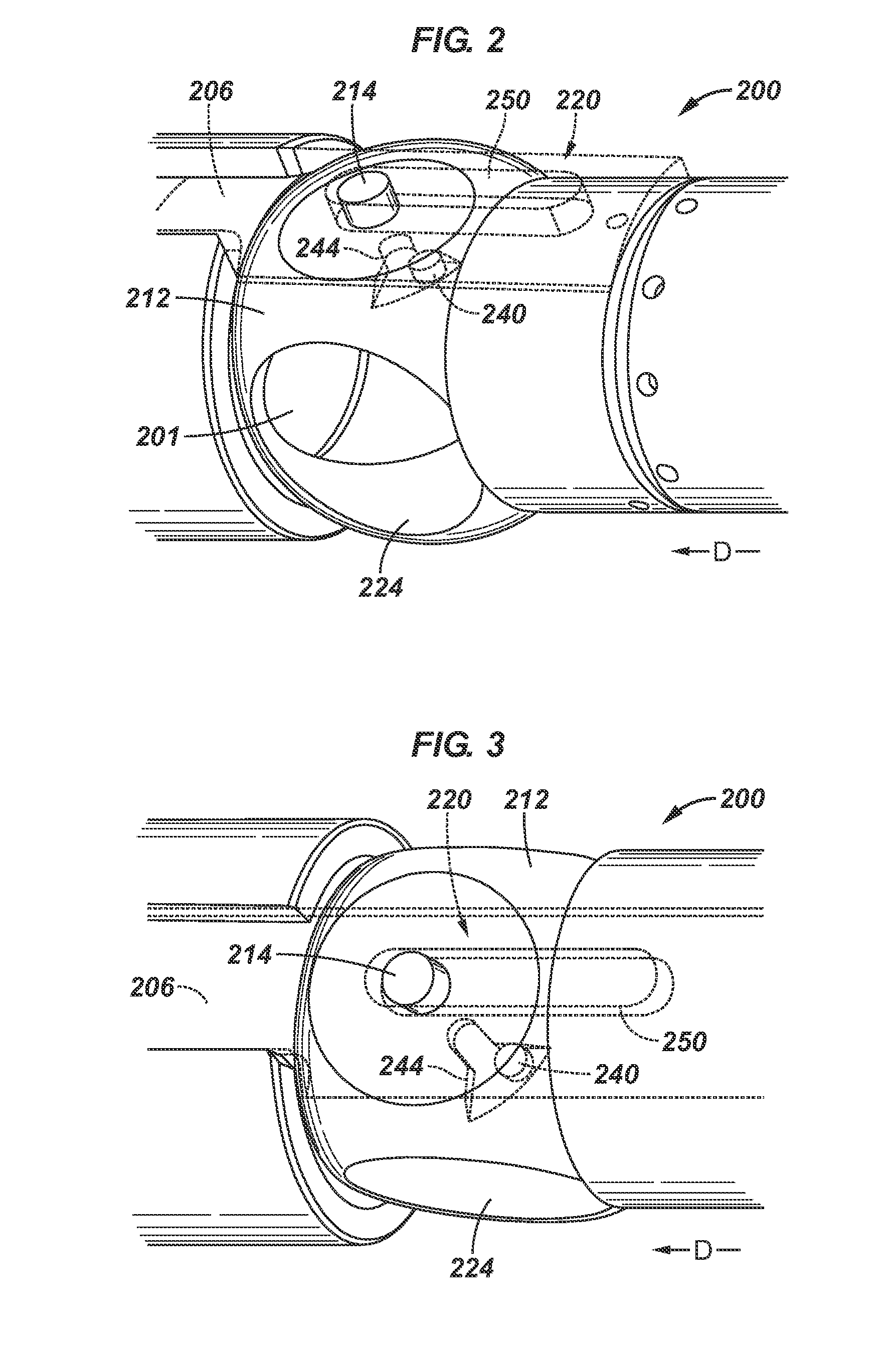

A pumping system 10 provides a physiological pulsatile flow and includes controller 121, a pump drive head 50 coupled to a motor 12 and a fluid housing 52 having at least one port 60. The port 60 includes a ball valve retainer region 69, a valve seat 73, and an occluder ball 71 disposed in the ball valve retainer region 69. During operation, the motor 12 forces the fluid in and out the fluid housing 52 and causes the occluder ball 71 to move from a first position whereby the fluid cannot pass through the port 60, to a second position whereby the fluid moves annular to and generally around the occluder ball 71. This movement creates a slight flow reversal that “breaks up” any blood clots that may form. The pumping system may be used as part of a cardiopulmonary bypass system, a ventricular assist device (VAD) and / or a heart pump.

Owner:DESIGN MENTOR

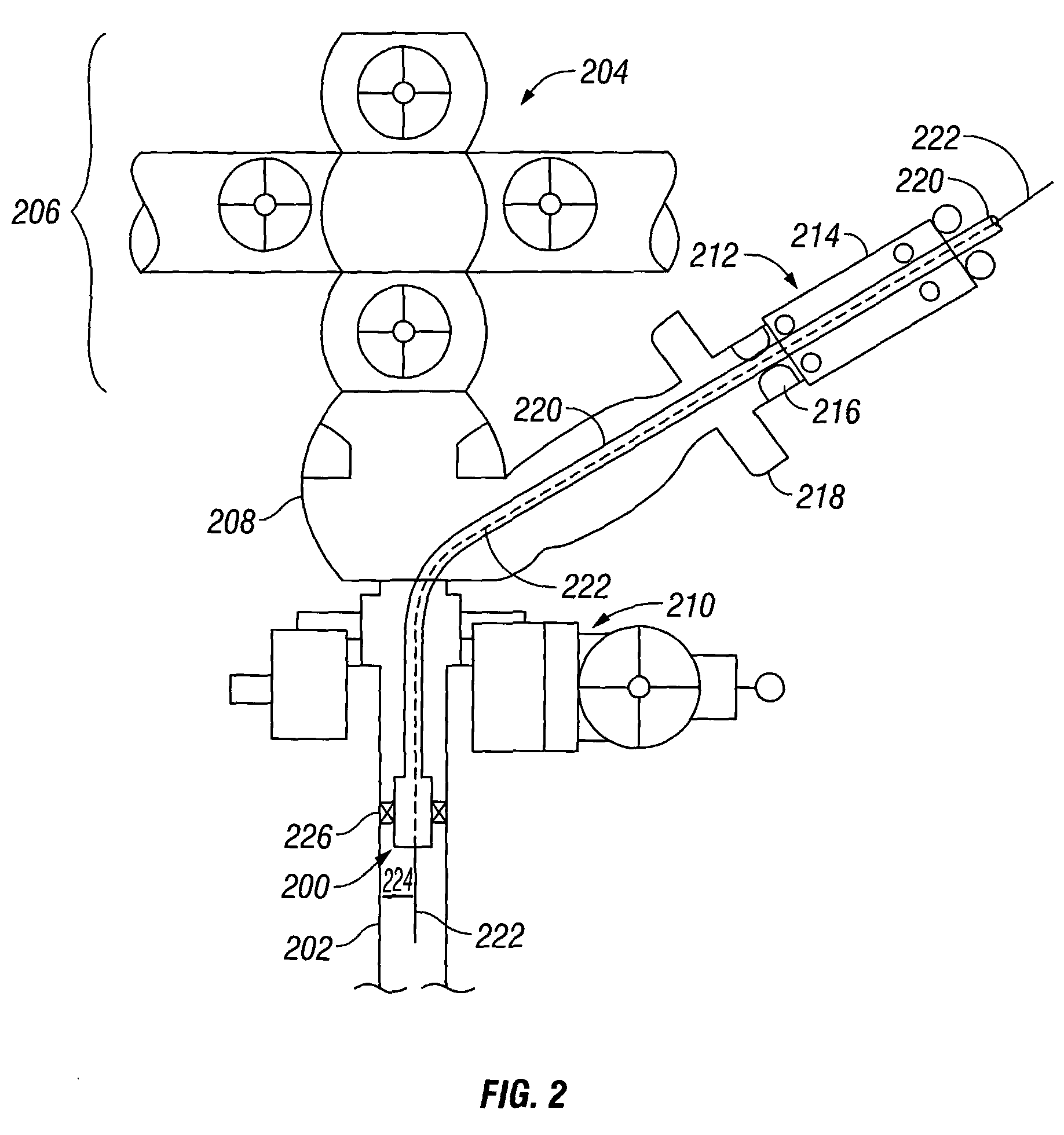

System and Method for Automatic Fueling of Hydraulic Fracturing and Other Oilfield Equipment

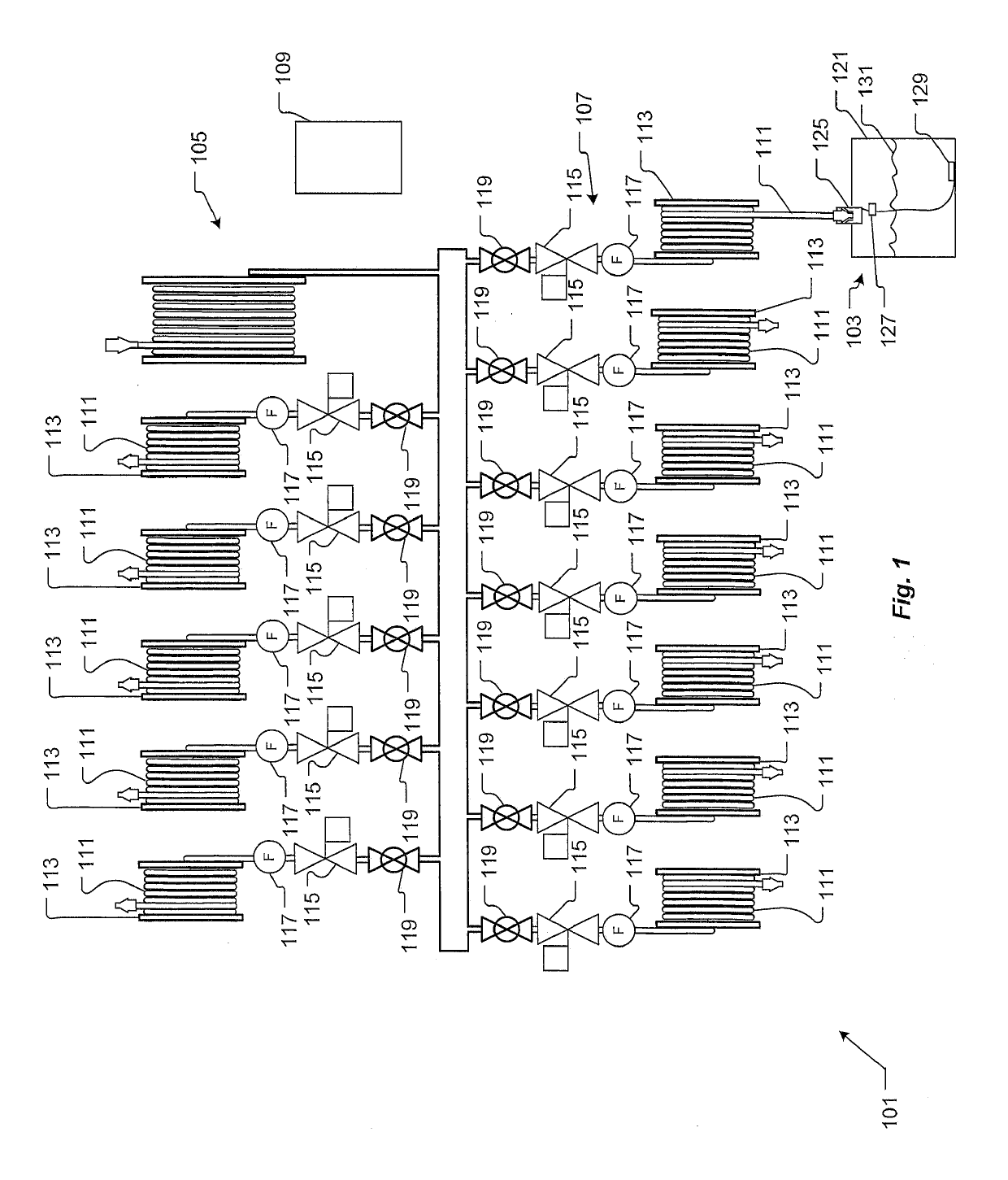

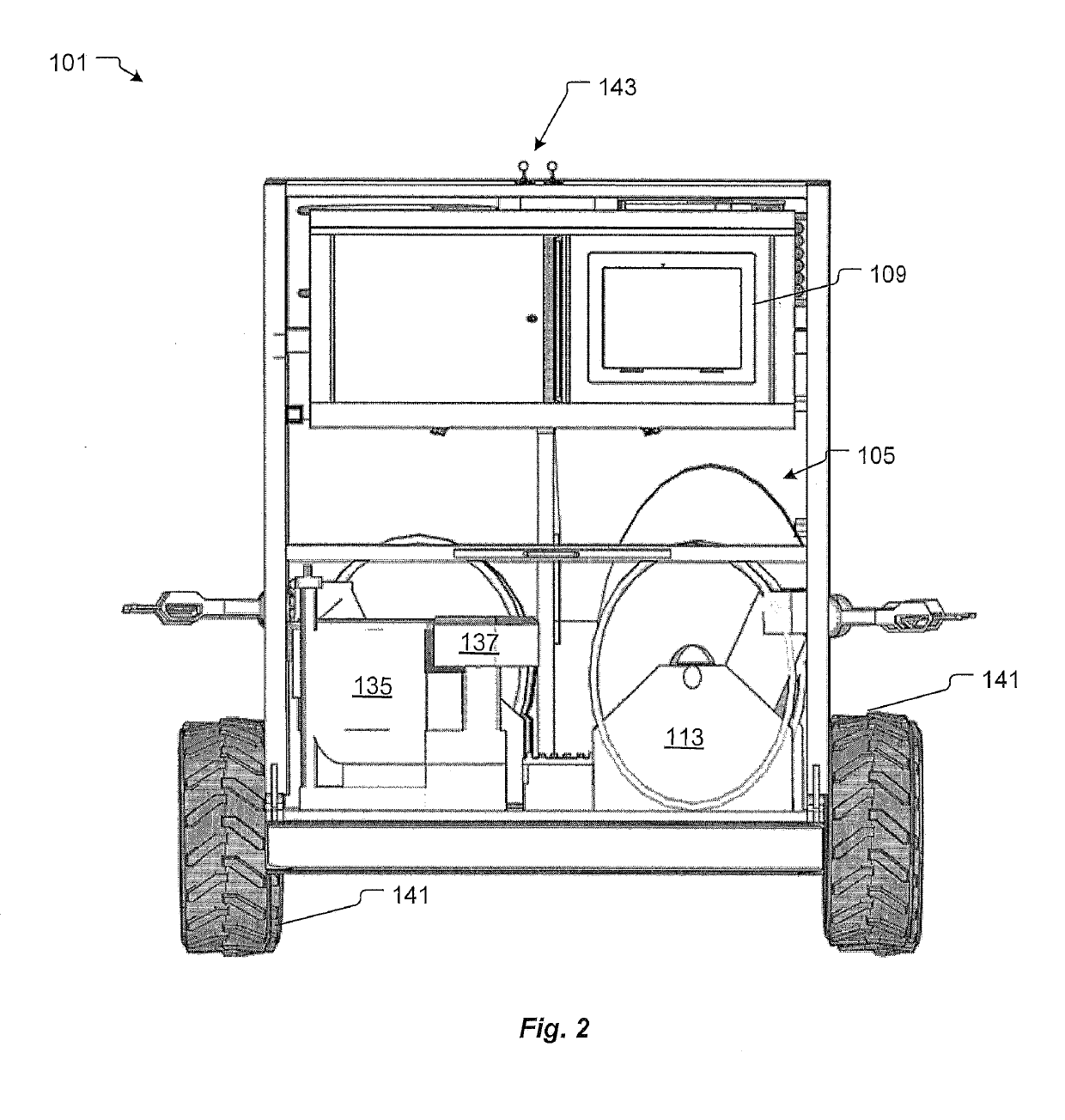

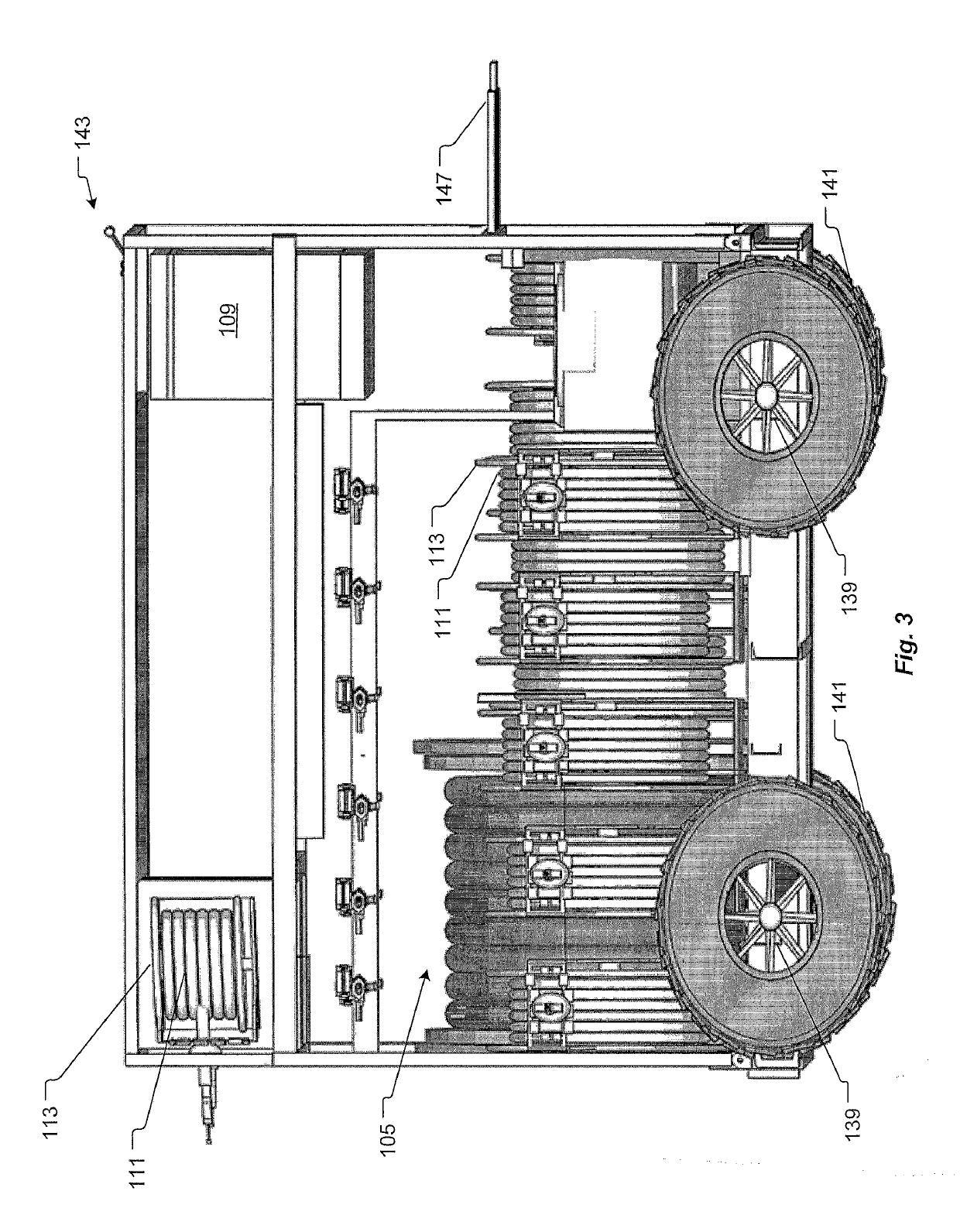

A system and method for fueling multiple saddle tanks of hydraulic fracturing equipment from a single self-propelled cart. The cart having multiple retractable fuel lines for providing and obtaining fuel. Each retractable fuel supply line uses a flowmeter, a ball valve, and an electrically actuated valve to provide remote control to a controller based on a user's selected fueling requirements. An electronic reporting system provides fuel data to operators and users. Fuel data such as fuel tank status, an amount of fuel usage over a stage level, a daily level, or job level along with a fill level of the fuel tank.

Owner:AMERICAN ENERGY INNOVATIONS LLC

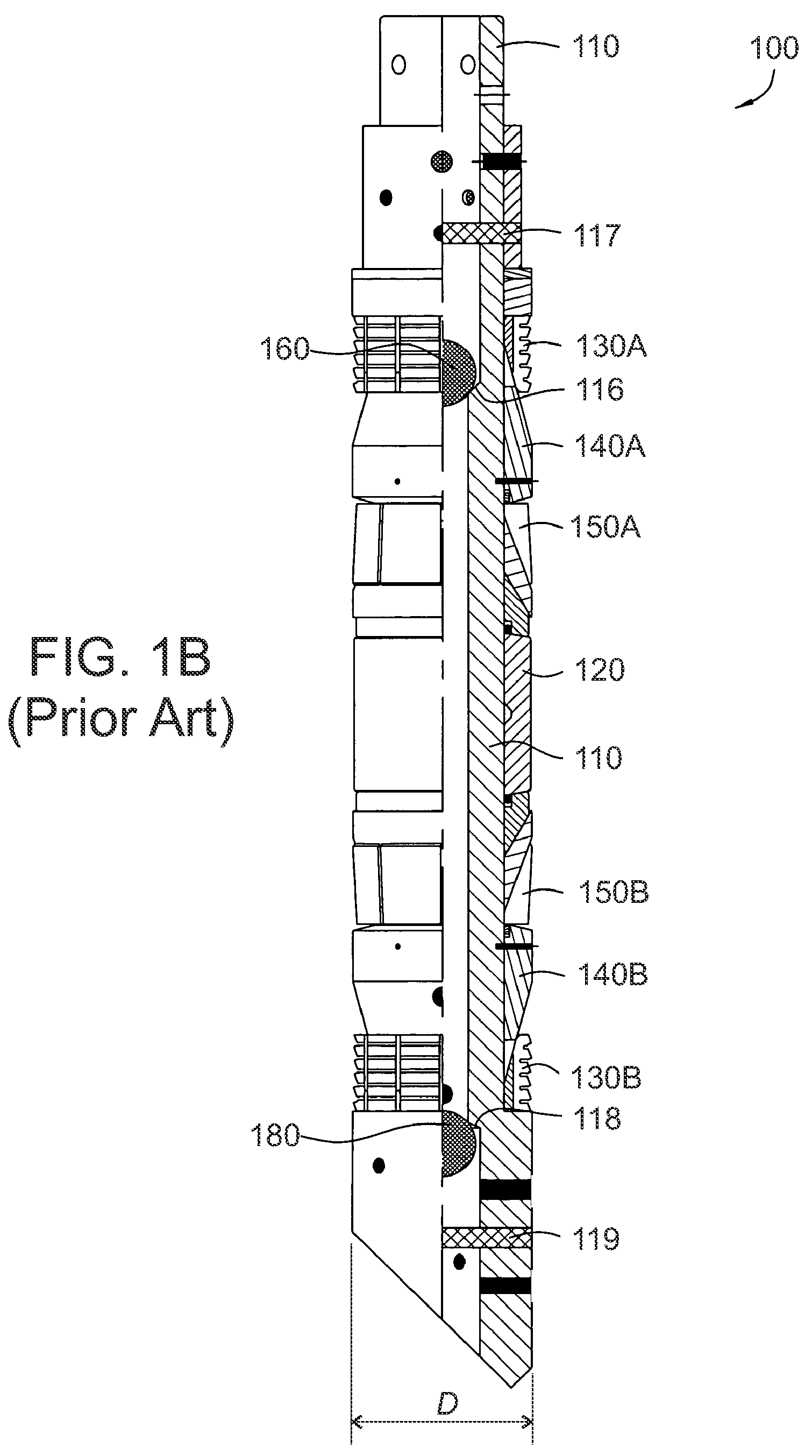

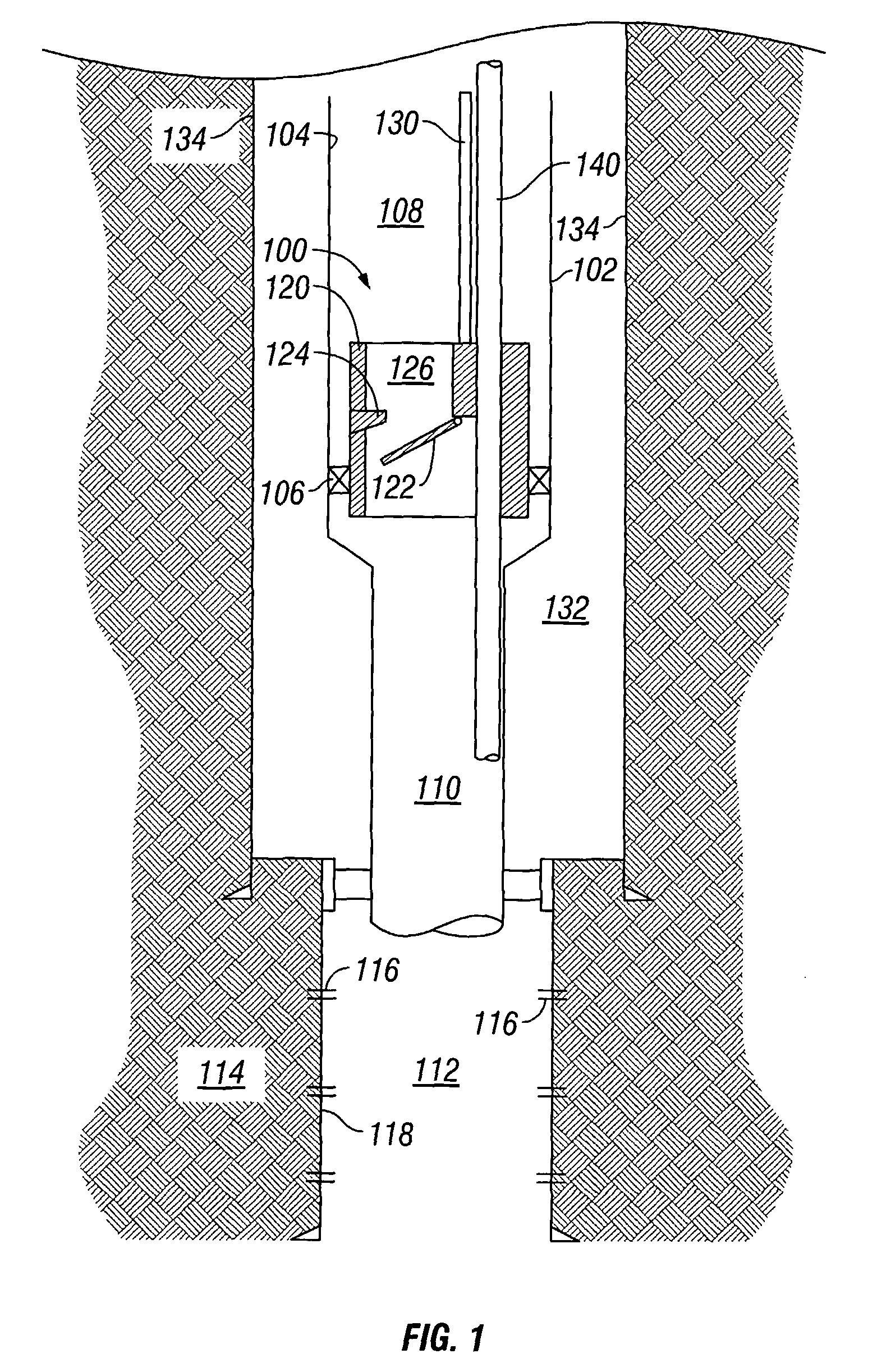

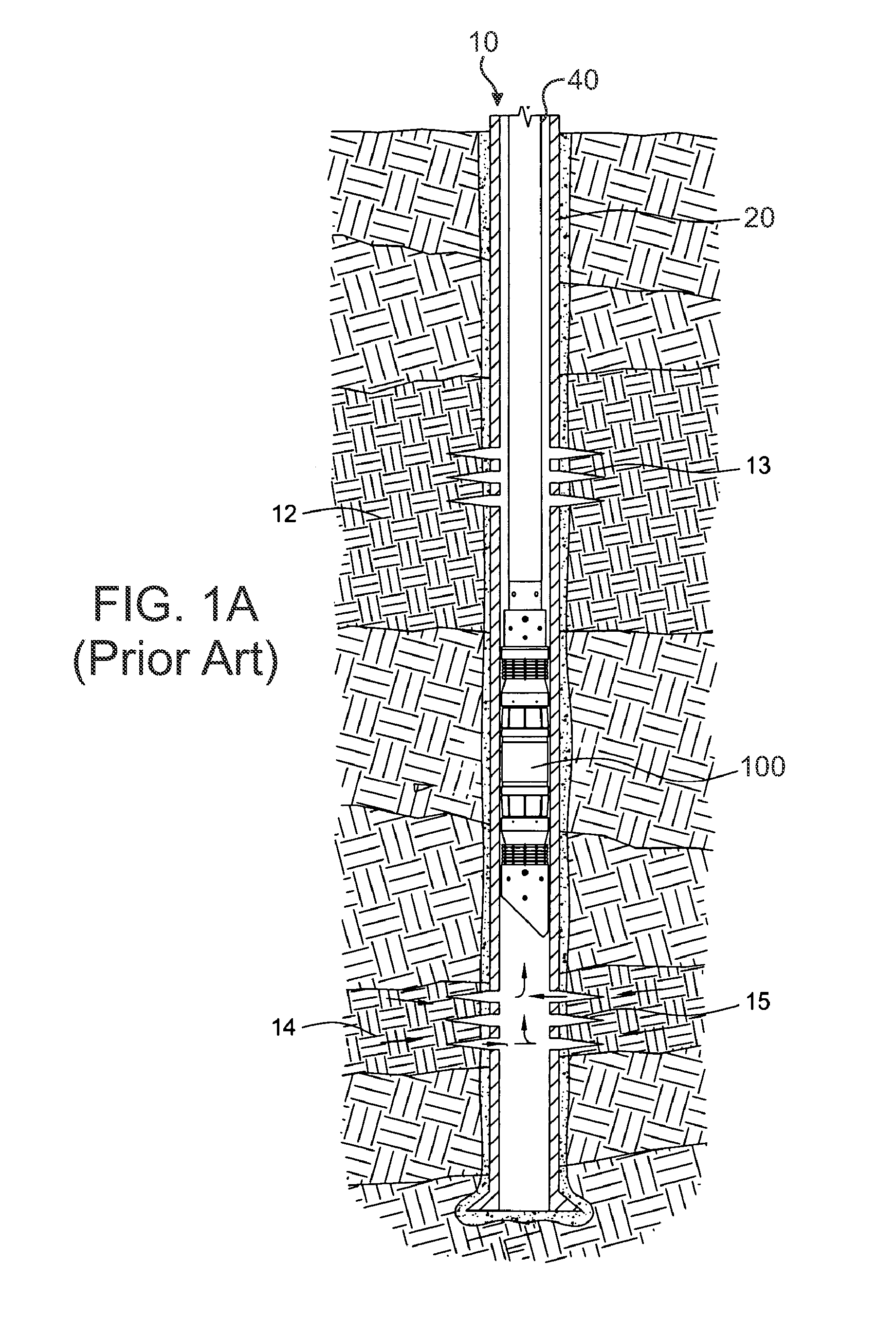

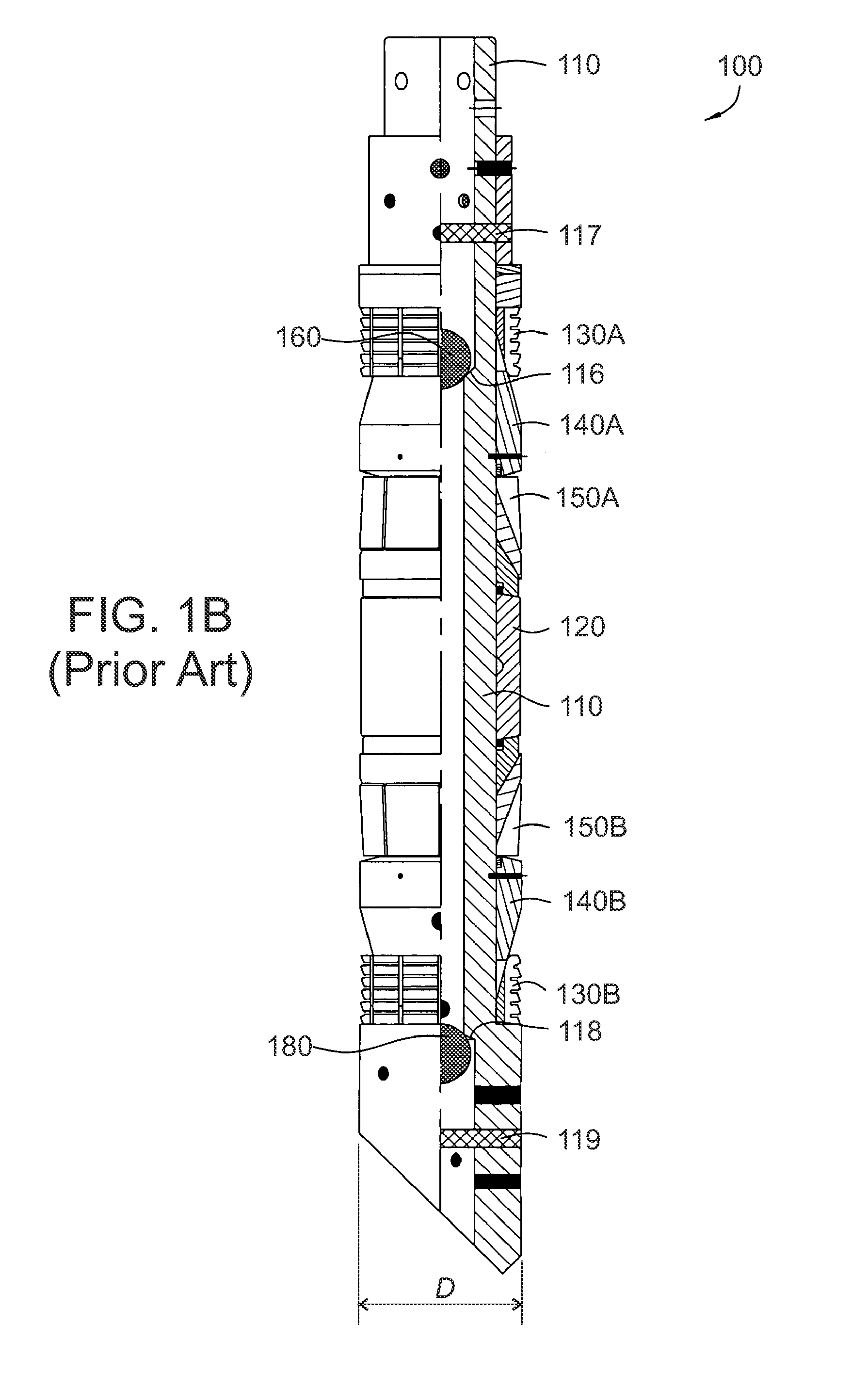

Pressure isolation plug for horizontal wellbore and associated methods

InactiveUS7690436B2Easy to deployIncrease the differential pressureDrilling rodsFluid removalTime segmentWellbore

A wellbore pressure isolation apparatus is deployed in a wellbore and has a sealing element that can be activated to seal against an interior surface of a surrounding tubular. Once set, a ball valve in the apparatus restricts upward fluid communication through the apparatus, and another ball valve in the apparatus can restrict downward fluid communication through the apparatus. These ball valve can have disintegratable balls intended to disintegrate in wellbore conditions after different periods of time. To facilitate deployment of the apparatus in a horizontal section of the well bore, the apparatus has a plurality of rollers positioned on a distal end. In addition, the apparatus has a ring disposed about the body between the distal body portion and an adjacent body portion. The ring has an outside diameter at least greater than that of the adjacent body portion to facilitate pumping of the apparatus in the wellbore.

Owner:WEATHERFORD TECH HLDG LLC

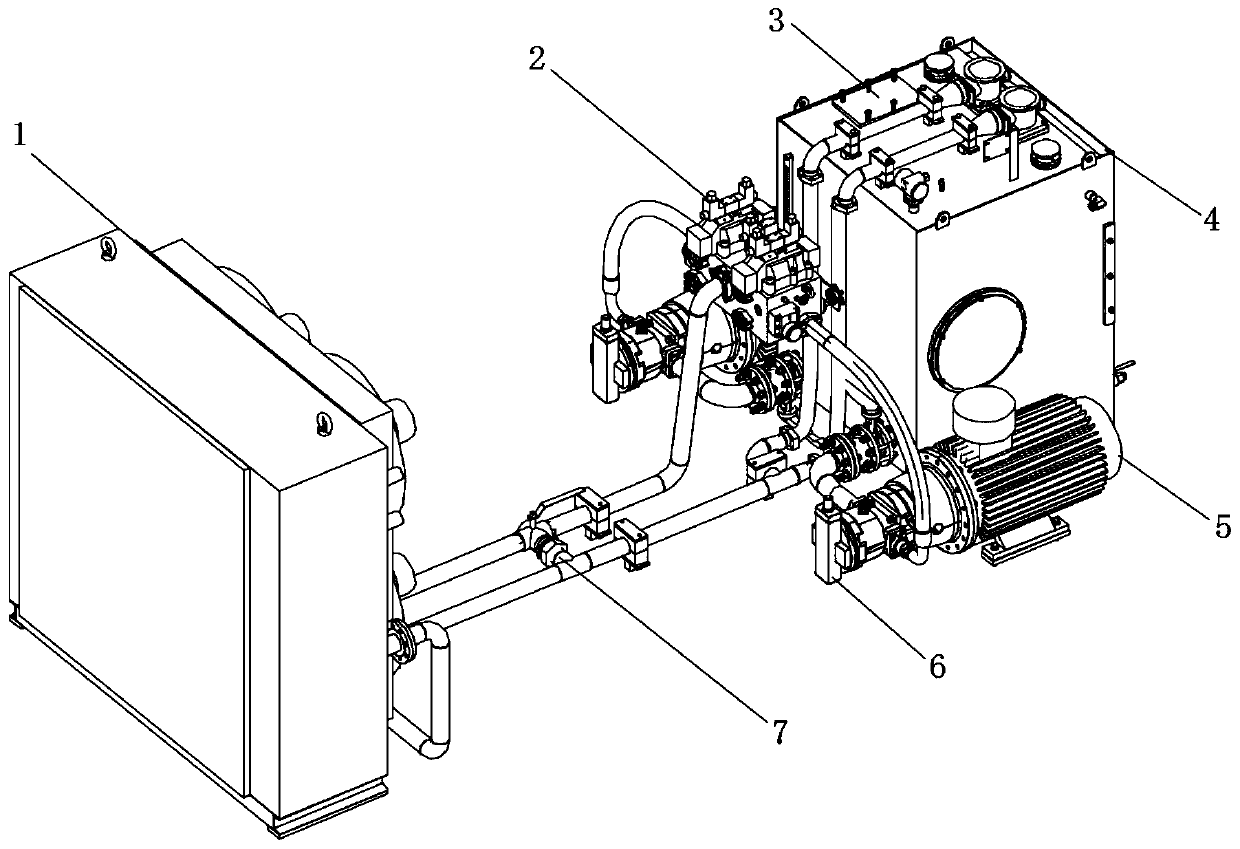

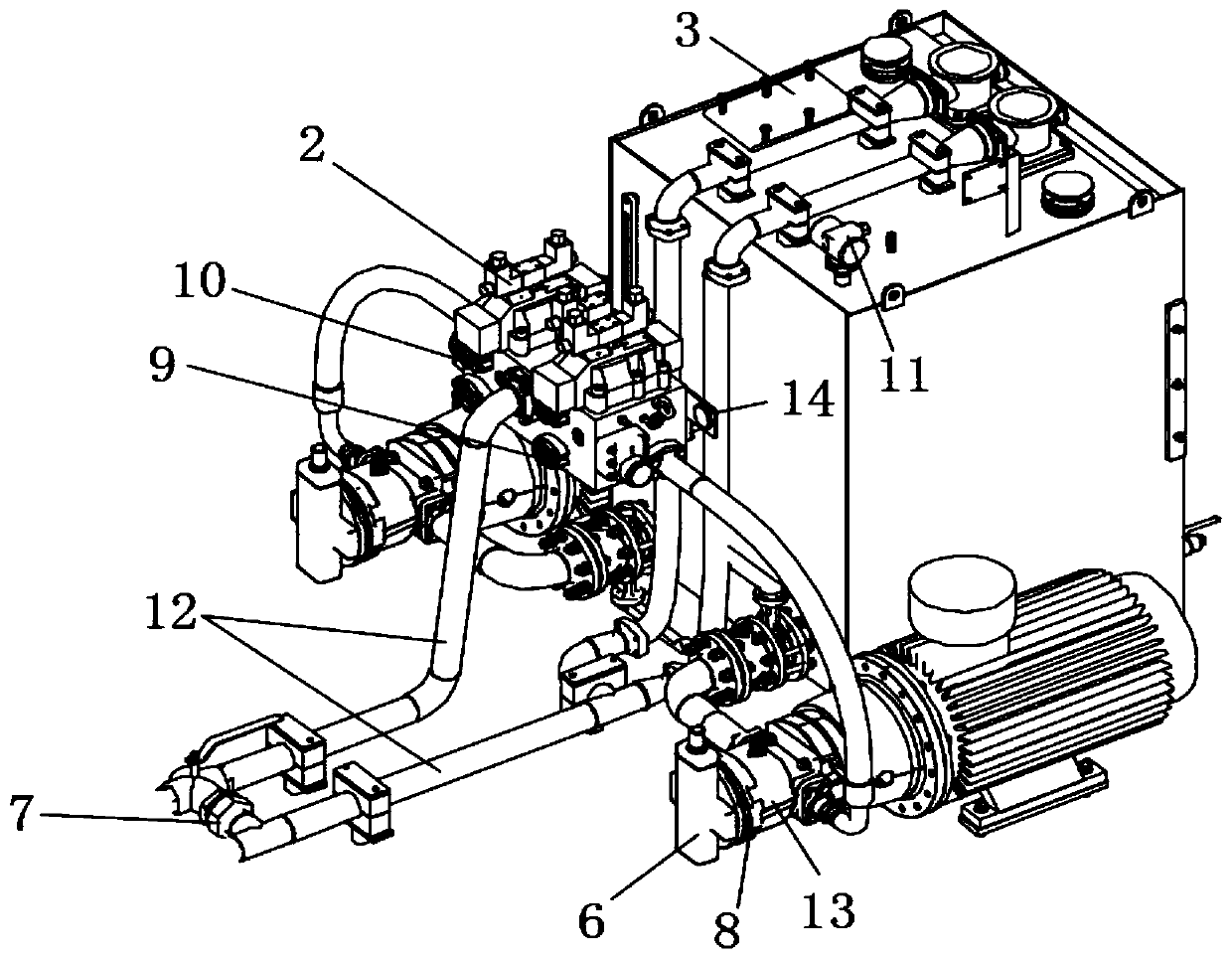

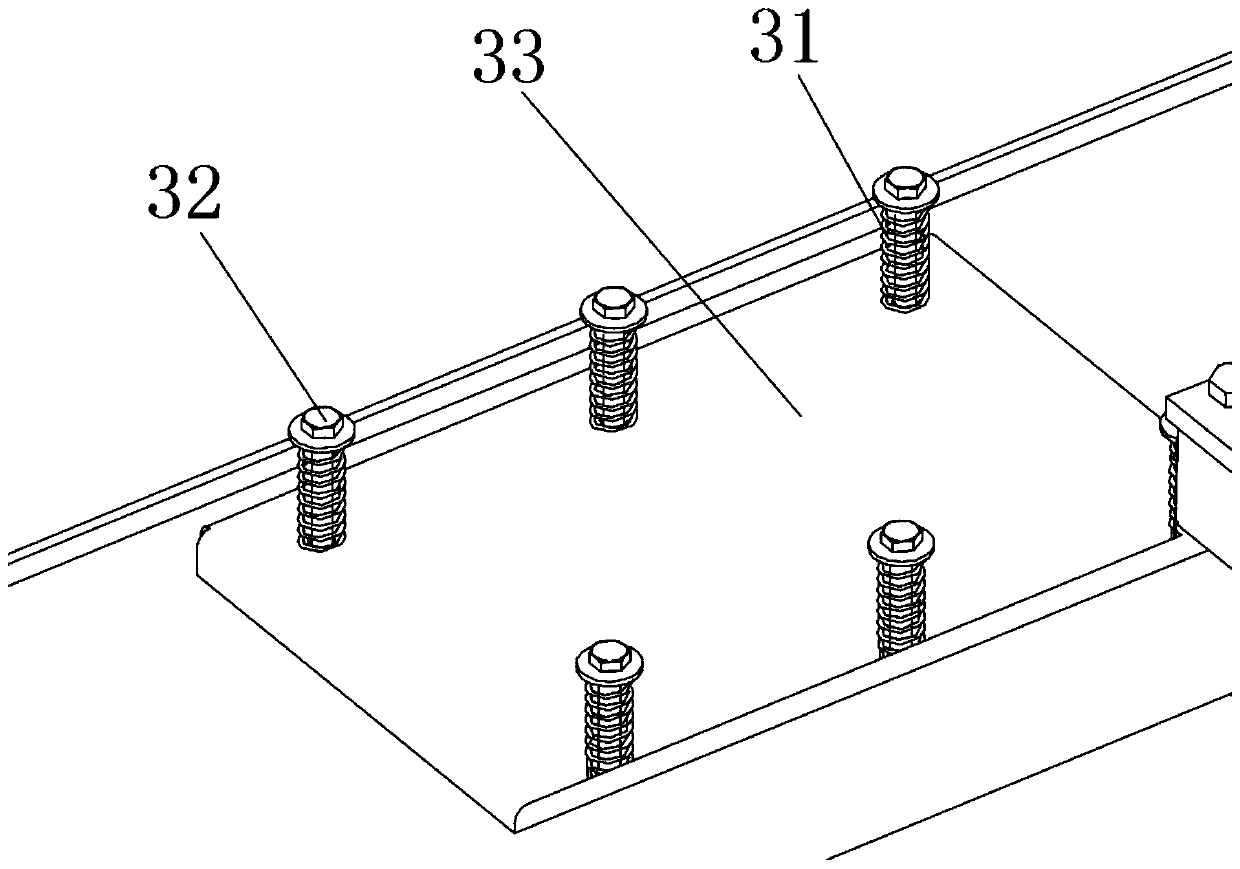

Integrated hydraulic station

InactiveCN110873093AAchieve high integrationRealize automatic control functionFluid-pressure actuator safetyFluid-pressure actuator componentsCompressed natural gasPressure difference

The invention belongs to the technical field of compressed natural gas filling, and particularly relates to an integrated hydraulic station which realizes high integration of an oil tank, plunger pumps, motors, a valve block, a cooler, an instrument and a sensor. The reversing function of hydraulic oil is provided through cooperation of an electro-hydraulic reversing valve and a proximity switch on a hydraulic cylinder, the functions of circulating heating of the low-temperature hydraulic oil, discharging of the high-pressure hydraulic oil and avoiding the hydraulic oil channeling back betweenthe double pumps are realized through cooperation of an unloading valve, a one-way valve and the electro-hydraulic reversing valve in the valve block, the high-pressure difference automatic stop function and the high-pressure gas discharging function are provided, combustible gas leakage and expansion deformation of the oil tank which cannot be recovered caused by high-pressure gas channeling back are avoided, the functions of low oil level monitoring alarm, temperature monitoring alarm and low oil temperature automatic circulating heating before starting of the hydraulic oil tank are provided, a three-way ball valve is adopted to replace an oil return valve block in the aspect of cooling oil return of the hydraulic oil, thus the oil return control function is realize, and the cost and space of the hydraulic station are also reduced.

Owner:JEREH OIL & GAS ENG

Bridge plug

A retrievable bridge plug assembly having an internal "pump through" bypass passage and a wedge assembly, slips and seals disposed thereon. A retrieving tool is provided for running, setting, releasing and retrieving the bridge plug assembly. A tubing sensor is included to prevent setting of the bridge plug assembly in improper size tubing. When the bridge plug is properly located, the wedge assembly can actuated by manipulation of the retrieving tool to force the slips radially outward into gripping engagement with the well tubular and to force the seals into sealing engagement with the well tubular. A ball valve on the bridge plug assembly is movable to selectively open and close the bypass passage. The retrieving tool can maintain the valve and passageway open to facilitate circulation during run in and setting and also open during retrieving for pressure equalization. A service packer can be connected to and run with the bridge plug assembly.

Owner:HALLIBURTON ENERGY SERVICES INC

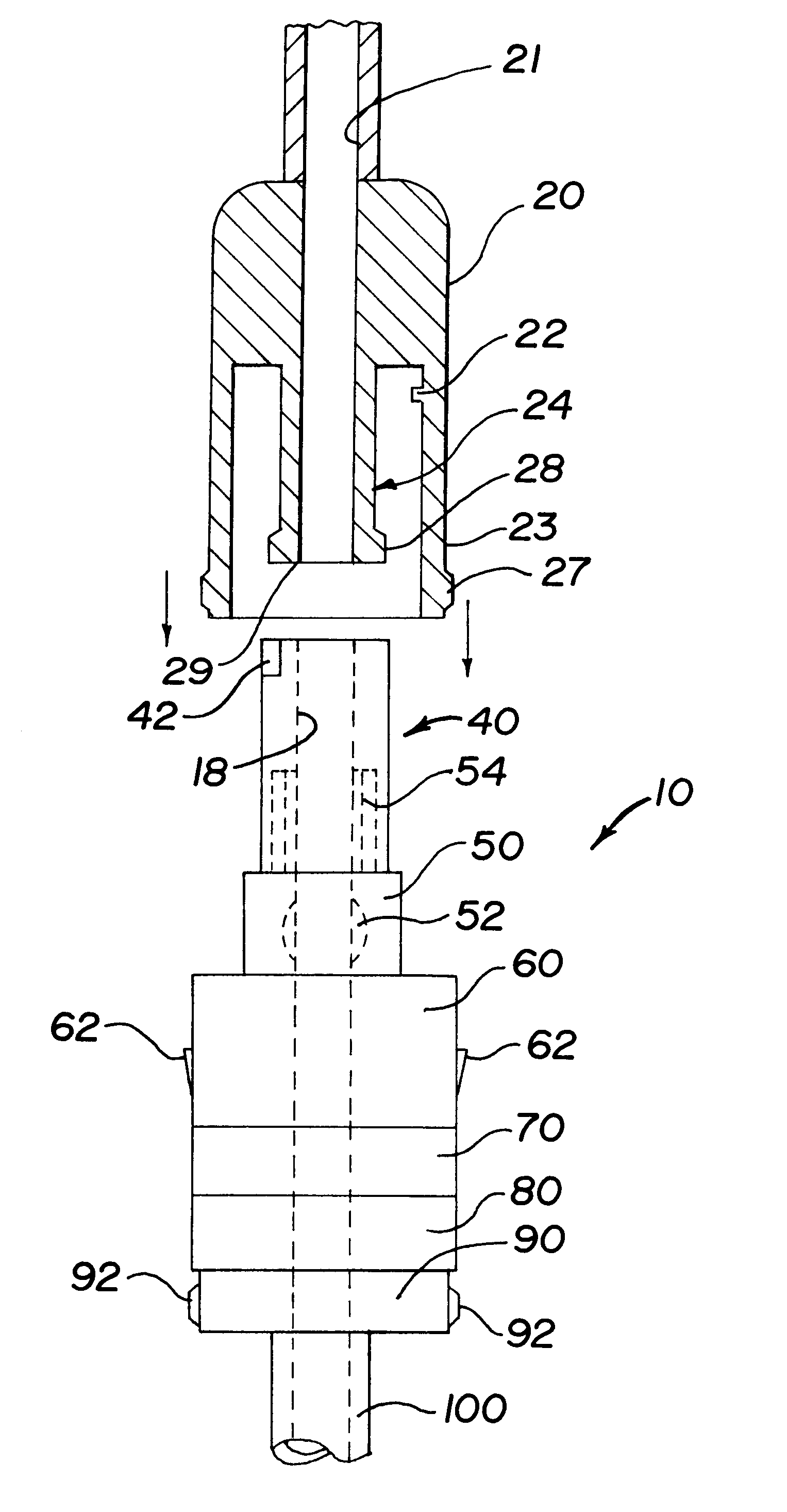

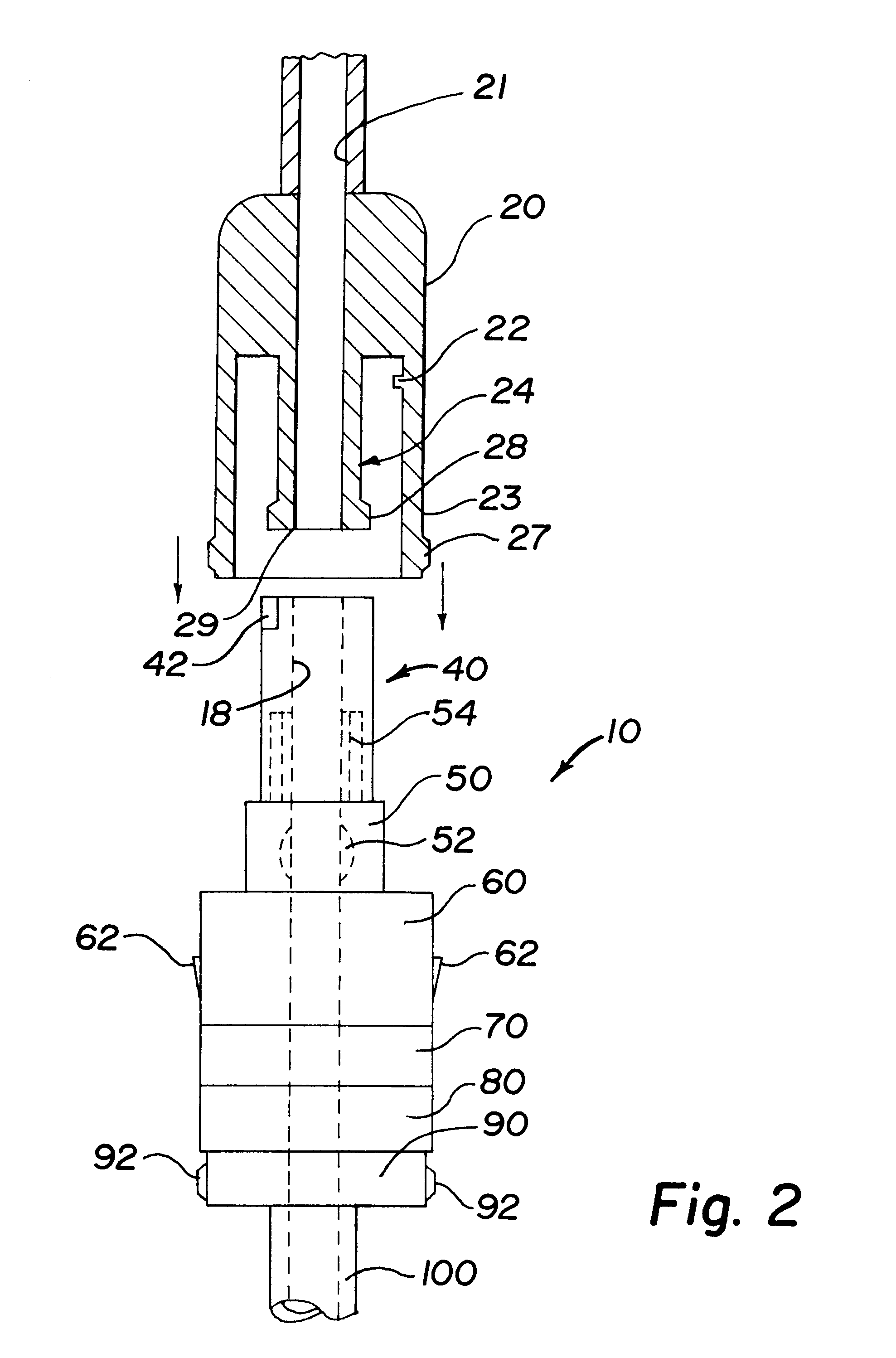

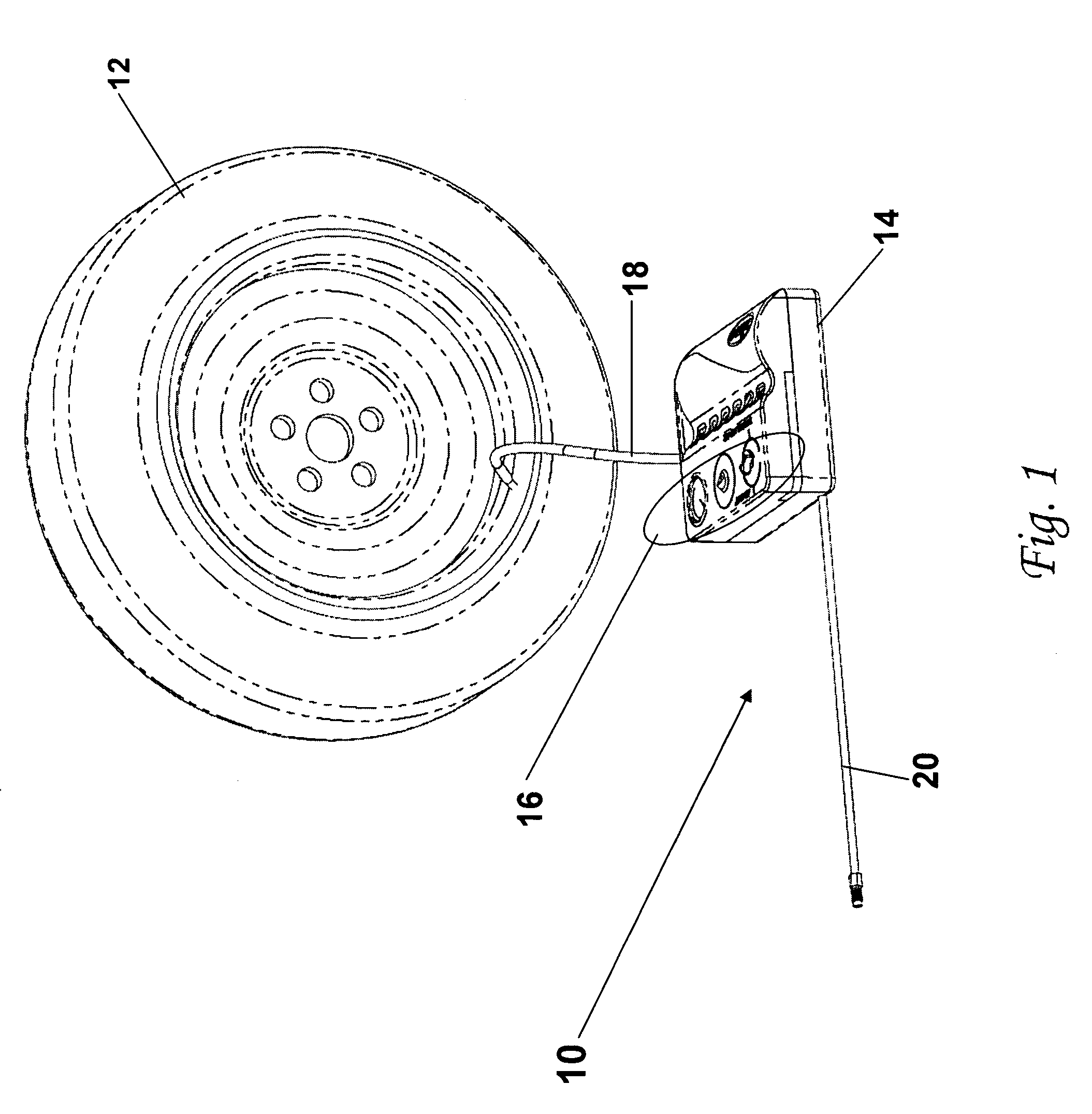

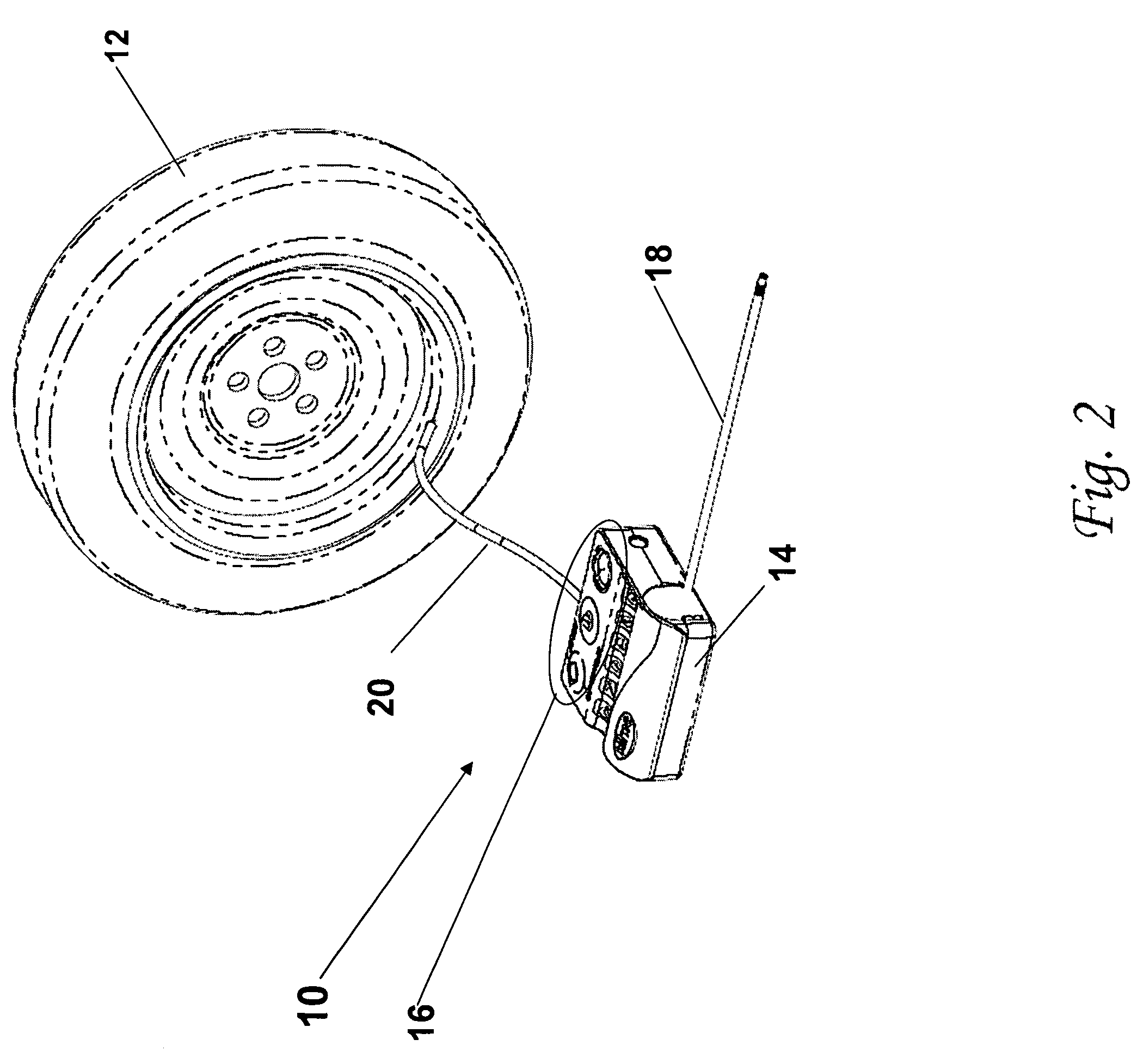

Integrated compressor-tire sealant injection device with large mouth sealant container

ActiveUS7798183B2More dispensing orientationsWide mouthLiquid fillingLiquid flow controllersLarge mouthComposite material

An integrated compressor-tire sealant injection device with a sealant container and a compressor is provided. The integrated compressor-tire sealant injection device has a compressor unit that has a compressor and a connector to a bottle of sealant integrated into the compressor unit so that a bottle of sealant is connectable to the device to inflate a tire wherein the connector has first and second ball valves.

Owner:ACCESSORIES MARKETING INC

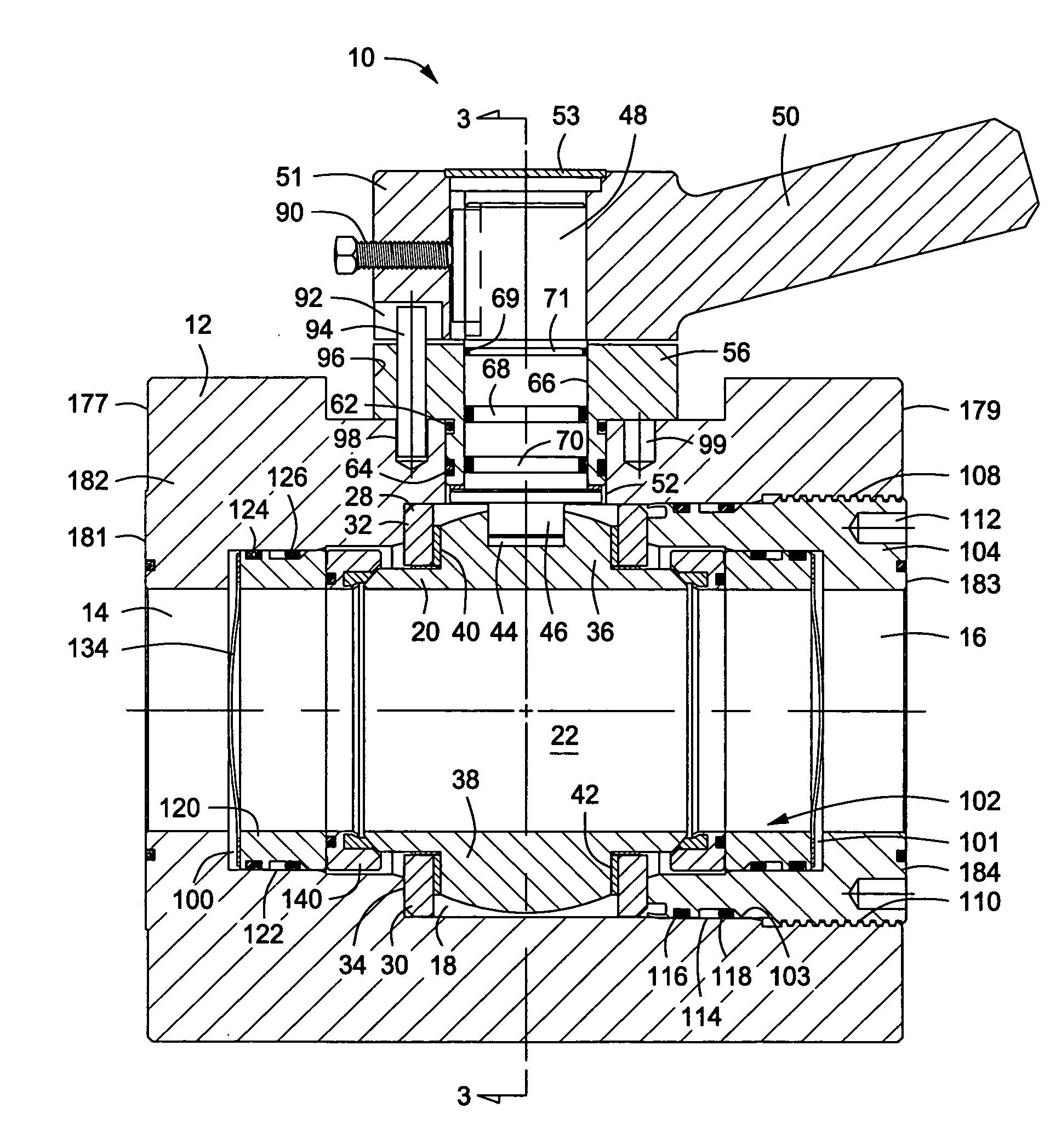

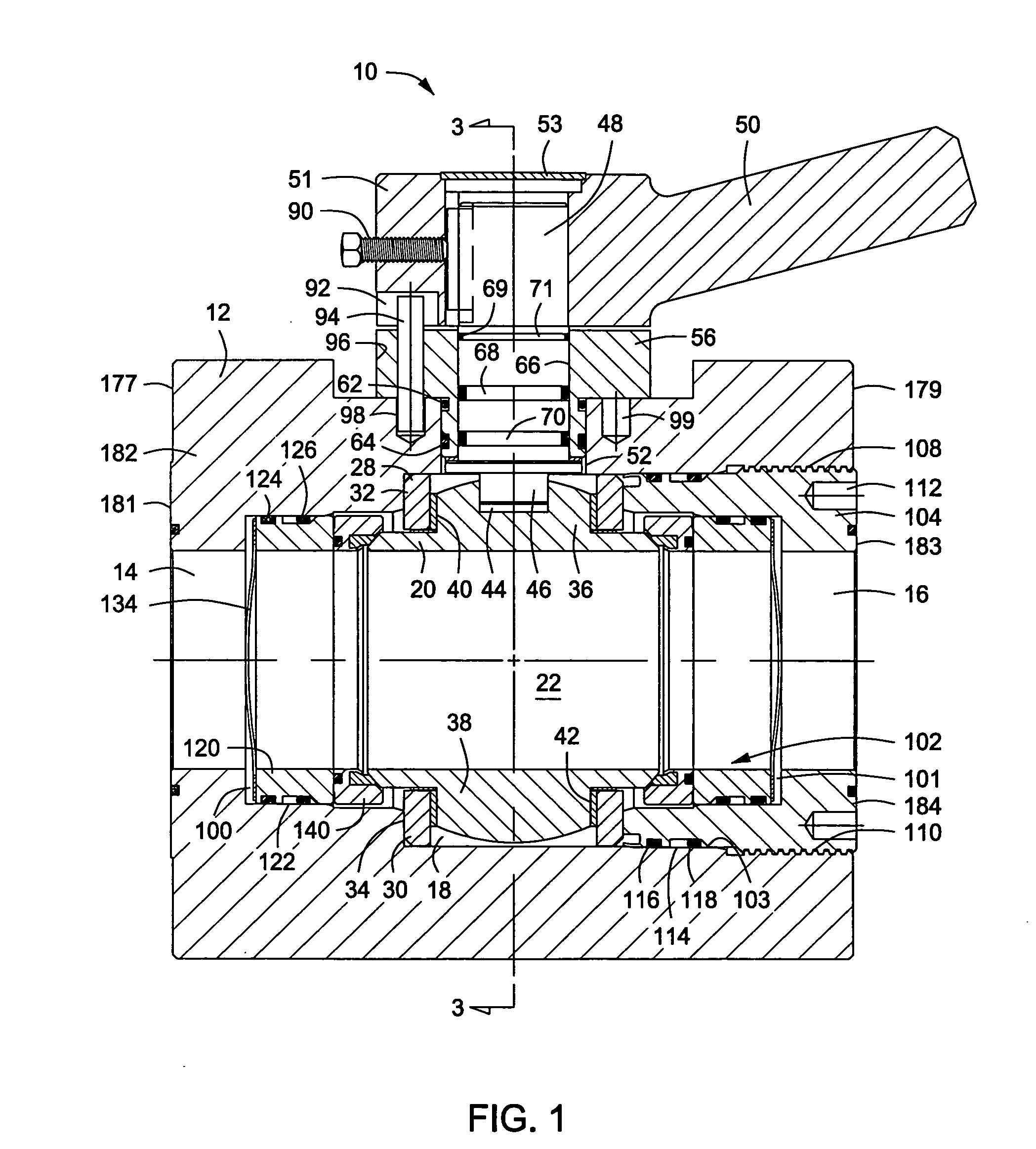

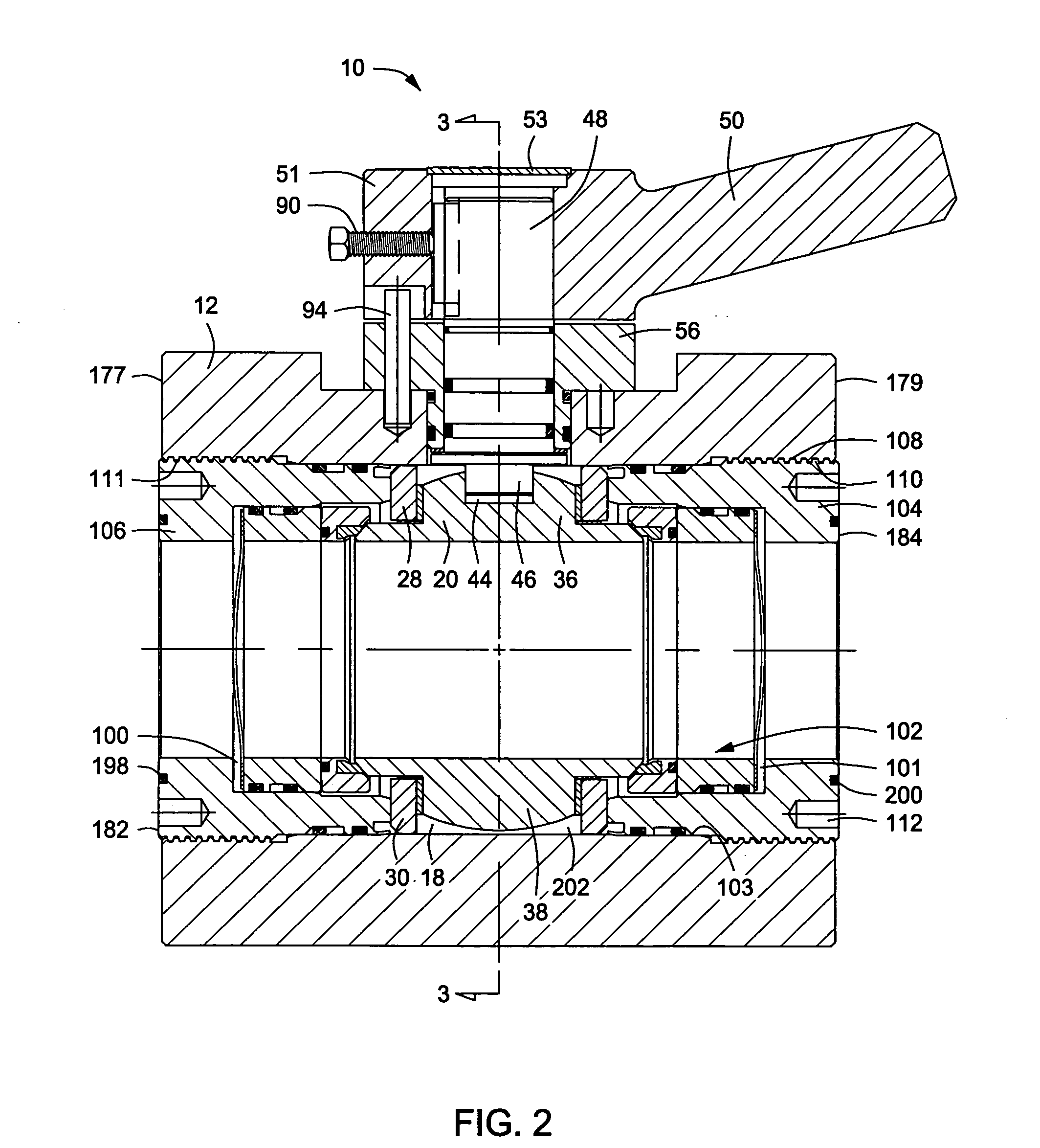

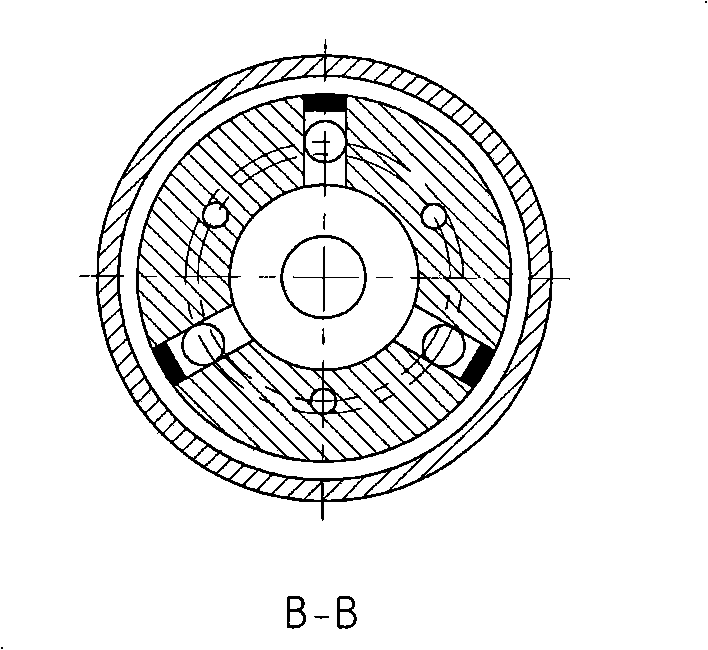

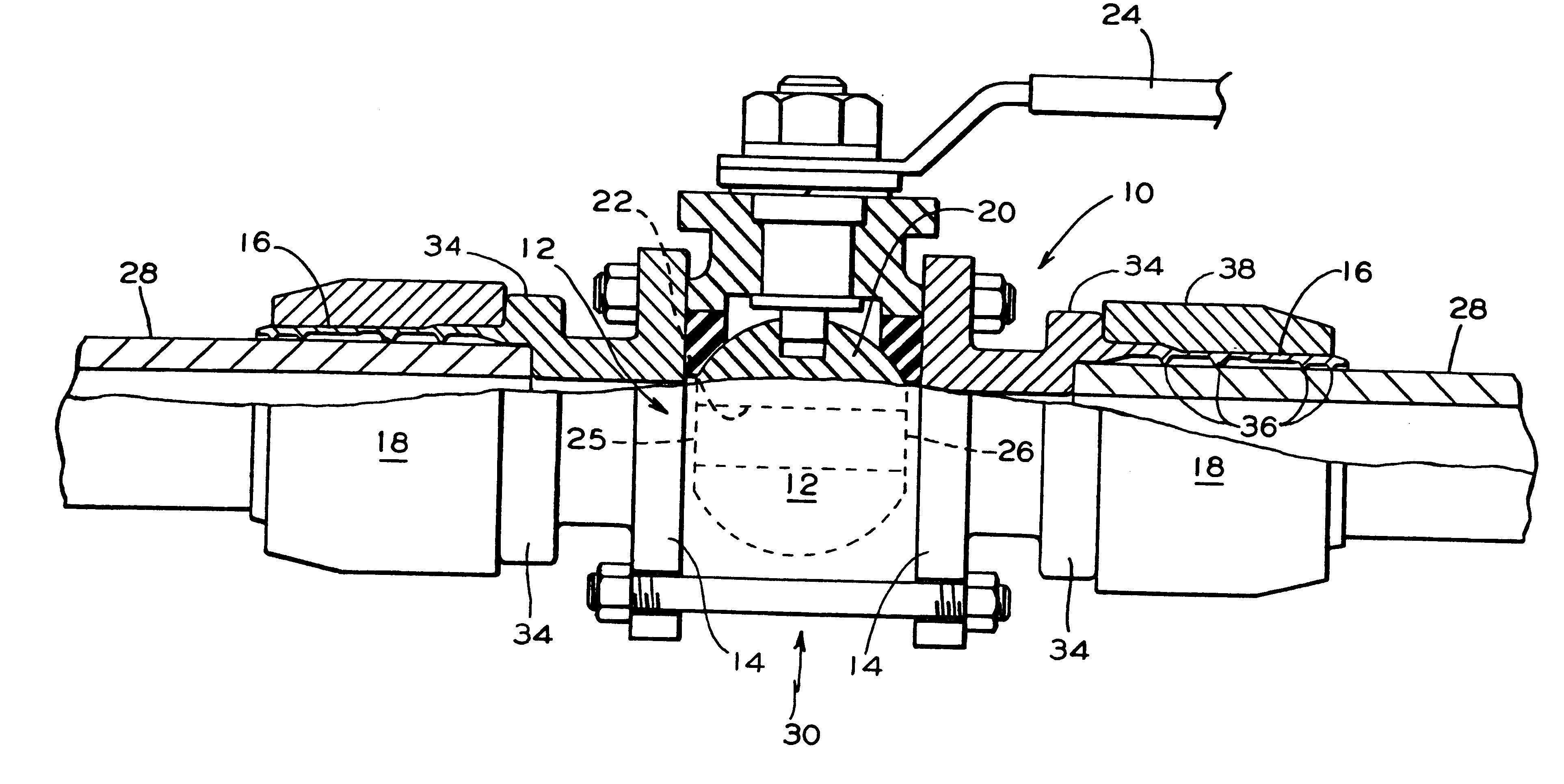

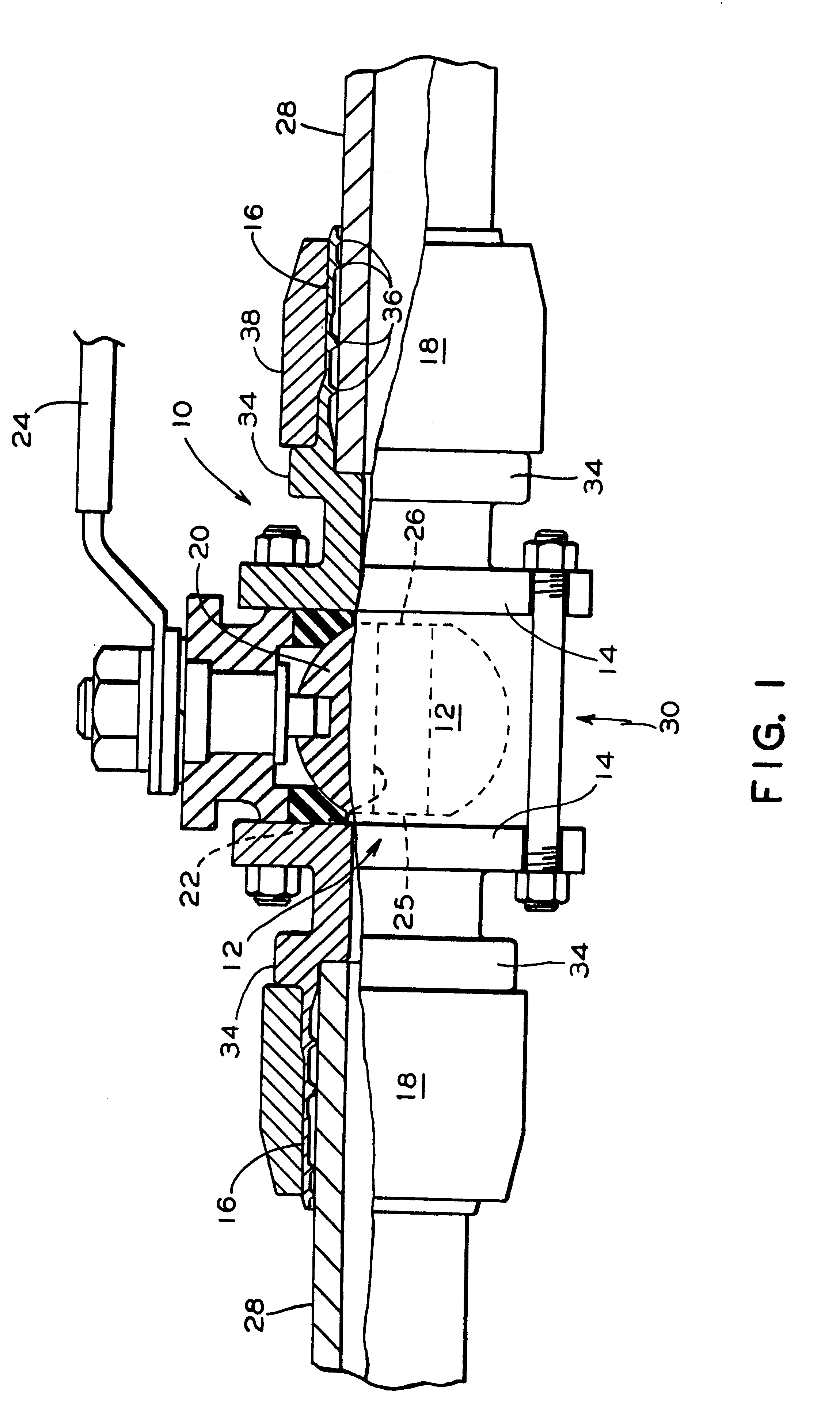

Ball valve having self-centering seats

InactiveUS20090095931A1Improve sealingAvoid small quantitiesPlug valvesValve housingsSpherical formTrunnion

A trunnion type ball valve having valve seats that are laterally moveable within seat recesses of the valve and establish sealing engagement with a valve ball member that is trunnion supported for rotational movement between open and closed positions. The valve seat members are self-centering for optimum sealing engagement with the spherical sealing surface of the ball member. The internal geometry of the seat assemblies are designed to permit optimum flow through the valve mechanism even under circumstances where the seat members are located in laterally off-center relation with respect to the centerline of the flow passages due to self-centering seat movement. The ball valve is readily adapted for fire-safe application via the use of heat resistant seals and metal-to-metal sealing of components to prevent or minimize leakage in the event of seal destruction or degradation by excess heat.

Owner:PHOENIX COMPACT VALVES

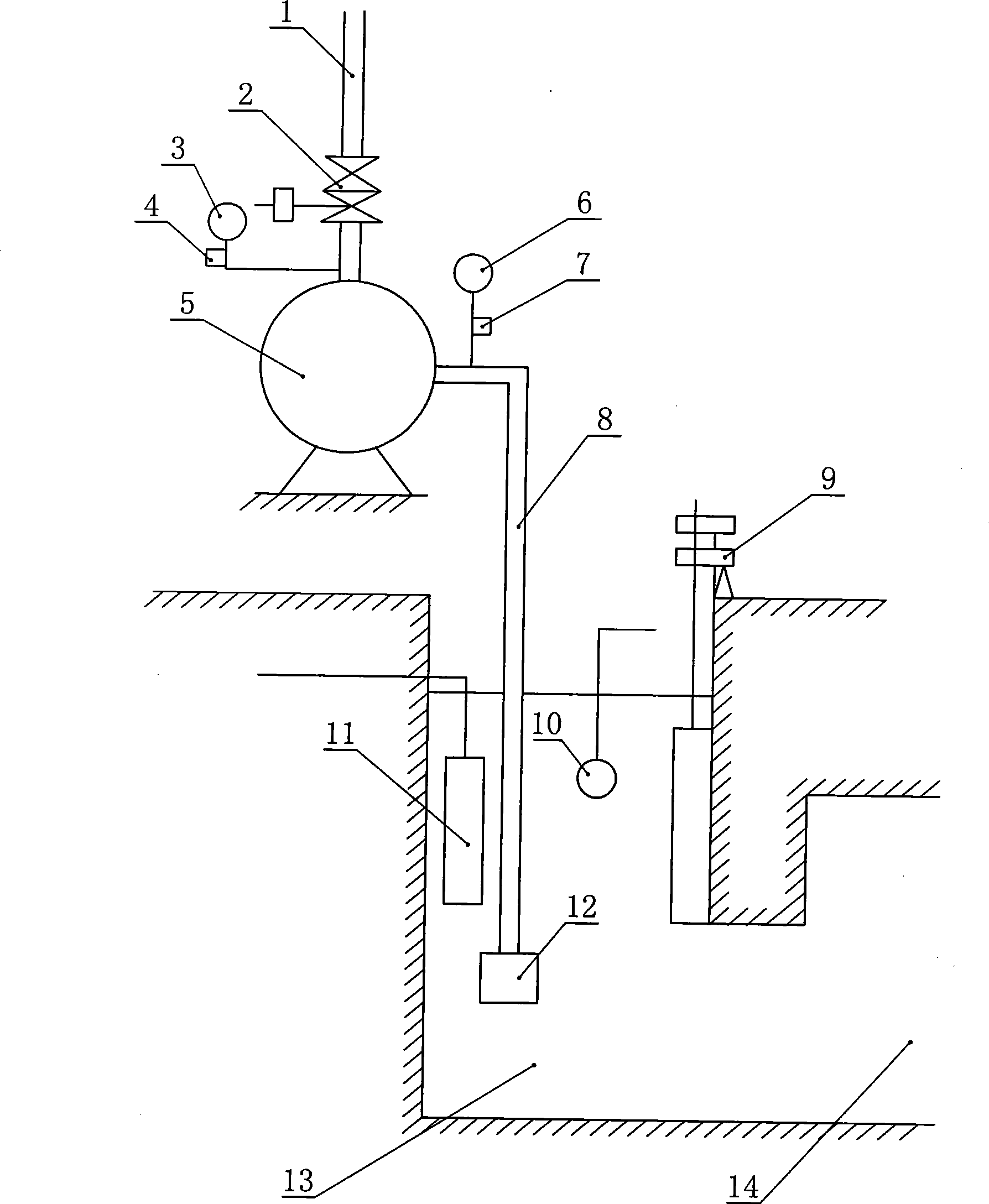

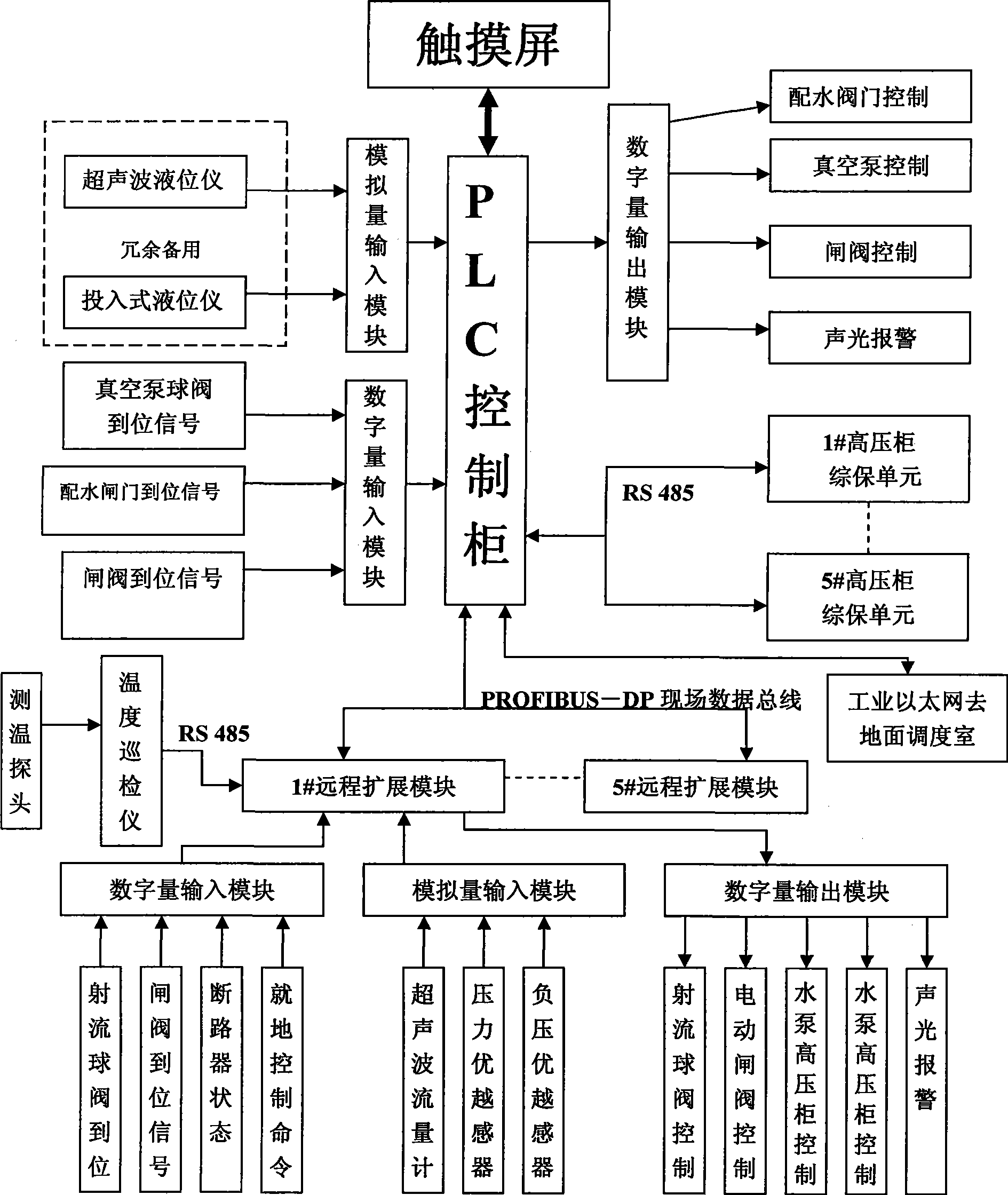

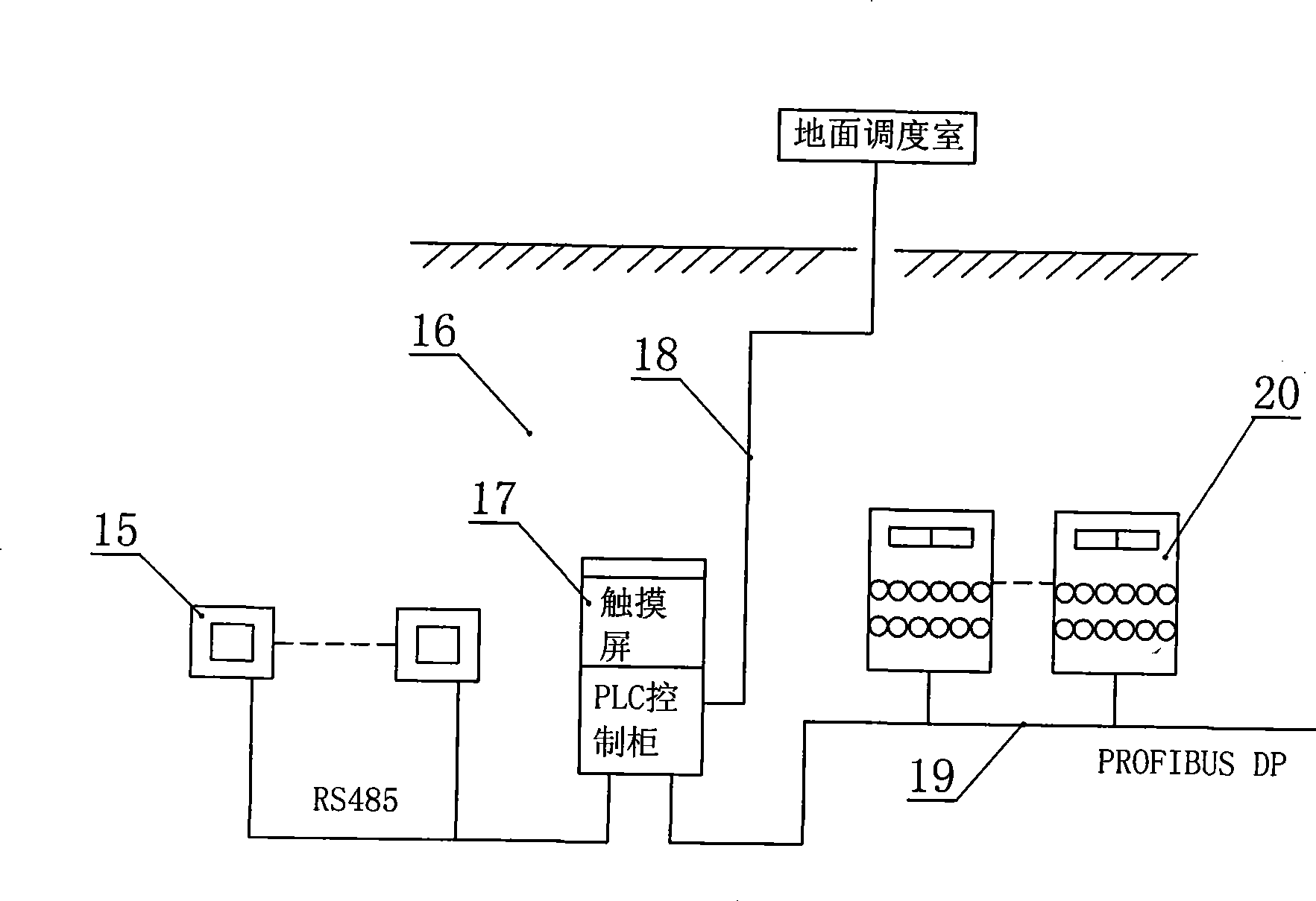

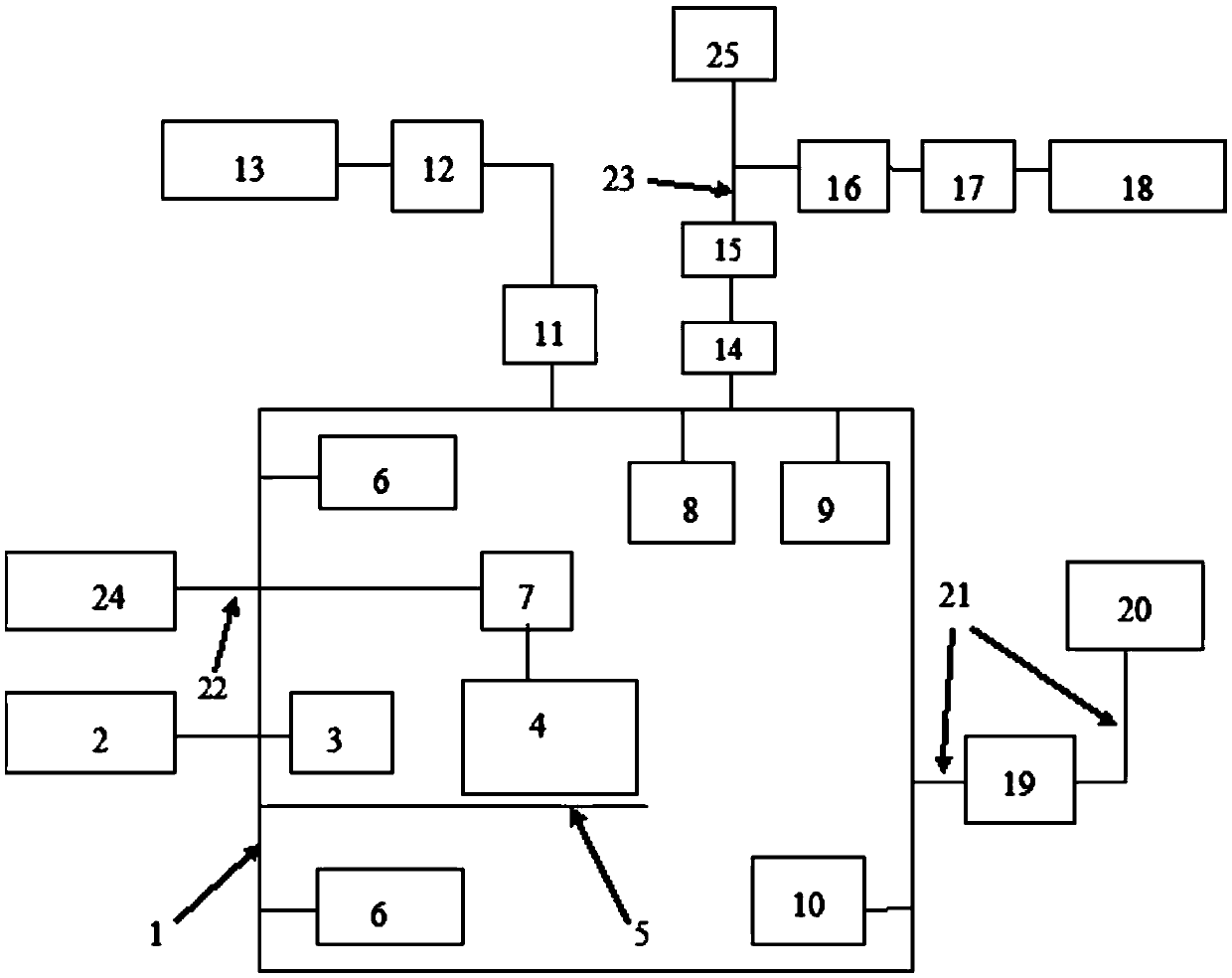

Automatic monitoring system for down-hole central pumping room drainage

The invention relates to an underground central pump room draining automatic monitoring system, which comprises a PLC control cabinet, a remote expanding module, a site data bus, a contact screen, an analog quantity and switching value input module, various monitoring probes, a travel switch, a level instrument and an executable section. A monitoring net adopts a form of combining a PROFIBUS DP site data bus and an industrial ethernet. A monitoring method for the system comprises: (1) monitoring the absorbing well water level; (2) monitoring the state for starting a high pressure switching cabinet by a water pump; (3) judging the valve levels of a gate valve, a ball valve of a water jet pumping device and a water distribution gate; (4) judging the valve levels of a vacuum pump ball valve; (5) measuring each equipment temperature measuring point; (6) measuring signals of a pressure sensor and a negative pressure sensor; (7) judging system faults; (8) automatically controlling the start-stop and operation numbers of the water pumps according to the absorbing well water level conditions; and (9) setting power supply peak avoiding time periods, and automatically selecting starting time and numbers of a pump. The system improves the system working reliability, reduces the equipment fault rate, and adopts a three-stage monitoring structure for a draining system.

Owner:BINHU COAL MINE ZAOZHUANG MINING GRP

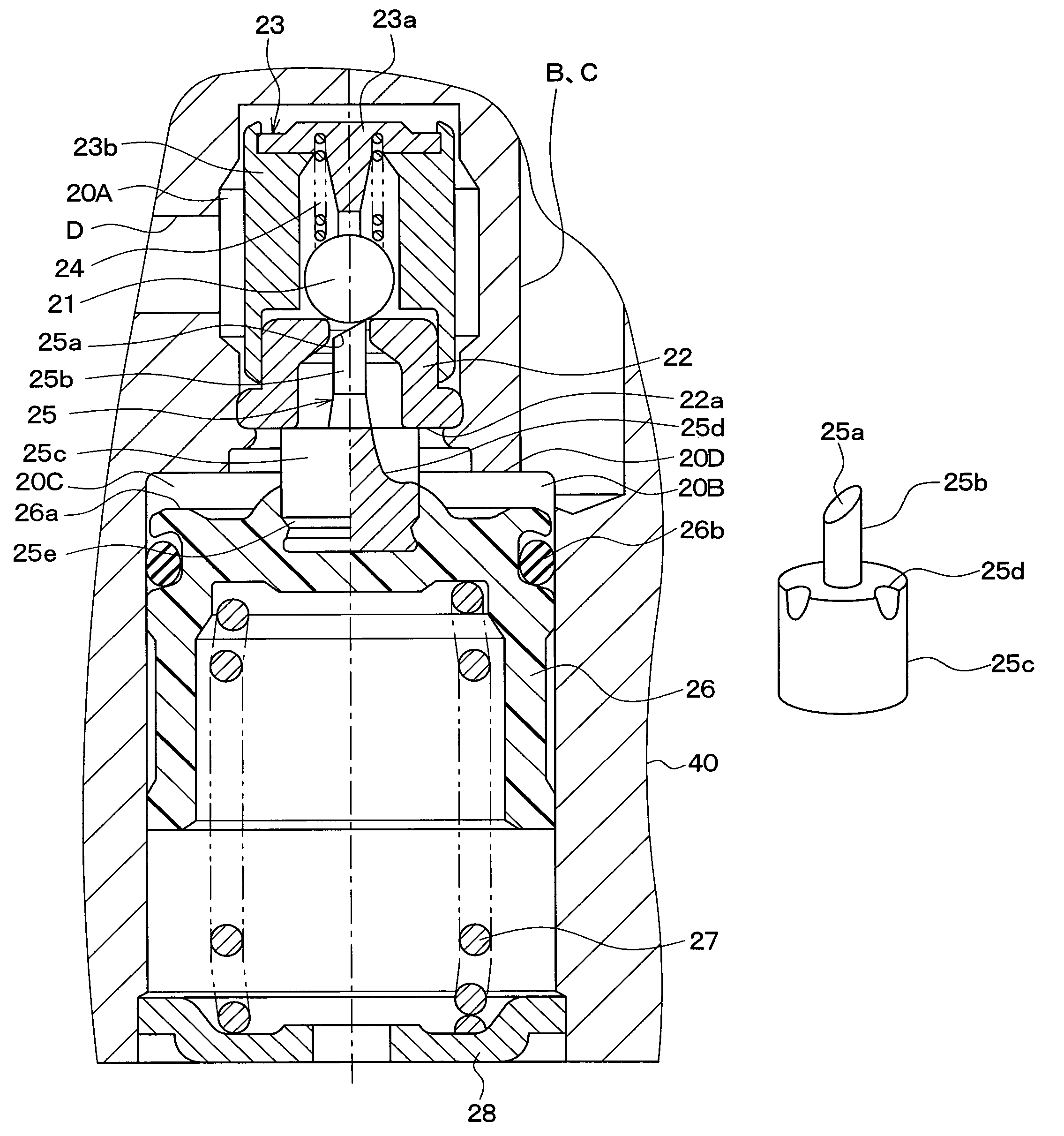

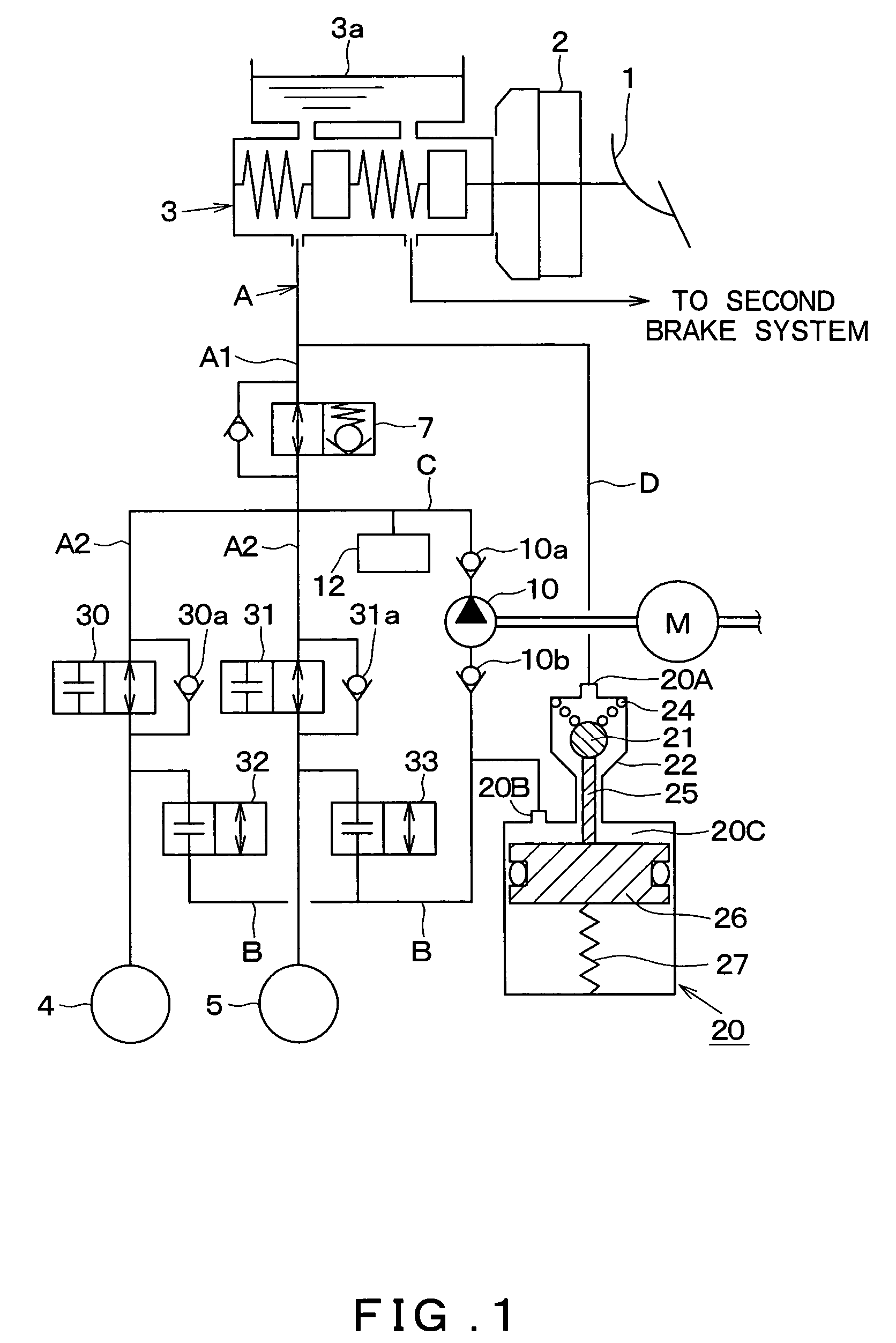

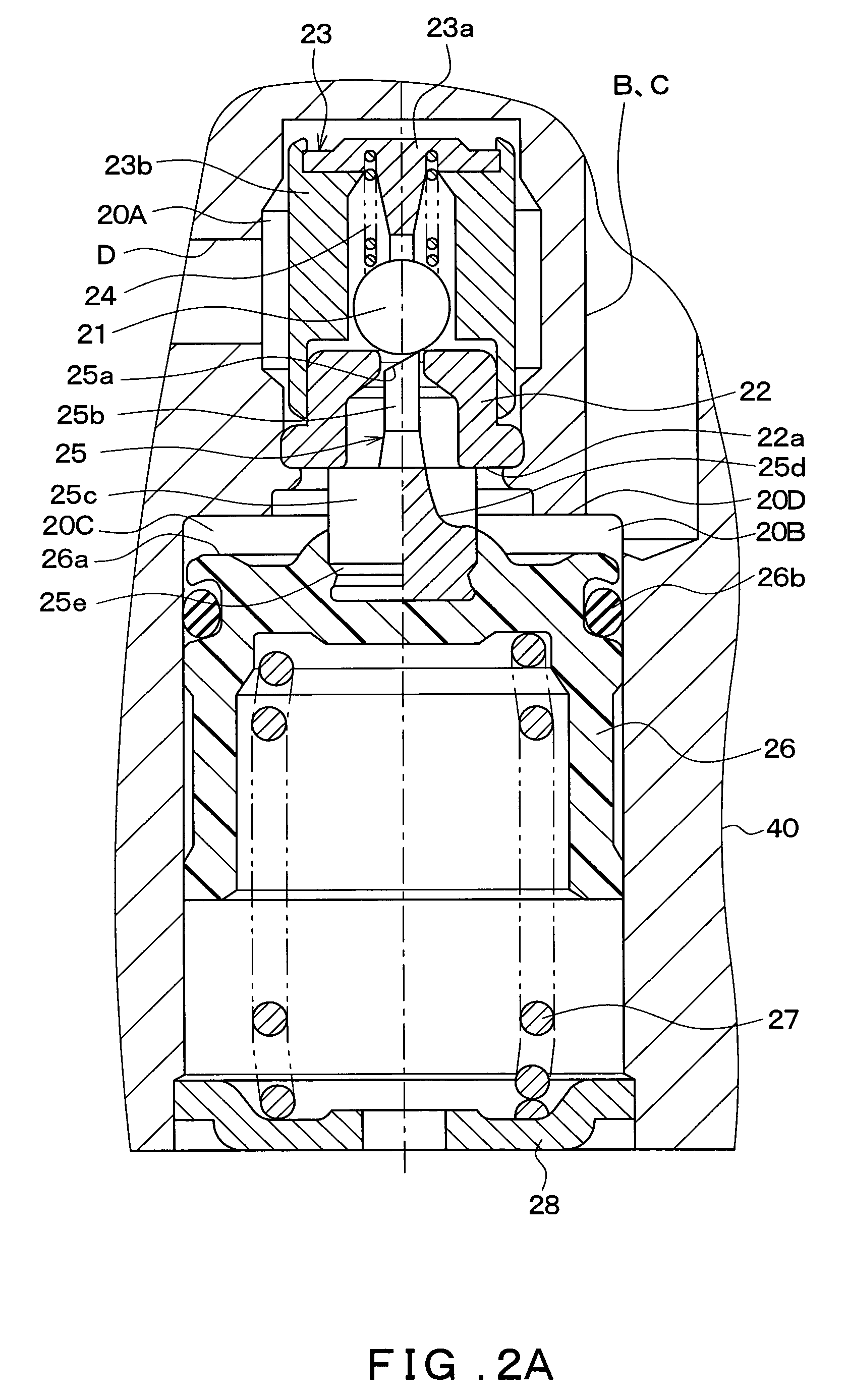

Pressure regulating reservoir and vehicular braking apparatus using it

A pressure regulating reservoir is structured such that a major diameter portion of a shaft contacts a bottom surface of a valve seat, whereas a top surface of a piston does not contact an upper end surface of a wall forming a reservoir chamber in a housing. Therefore, a lift amount of a ball valve can be set using a portion above the major diameter portion of the shaft that contacts the bottom surface of the valve seat. That is, the lift amount can be set using only a dimension in the axial direction of a minor diameter portion of the shaft.

Owner:ADVICS CO LTD

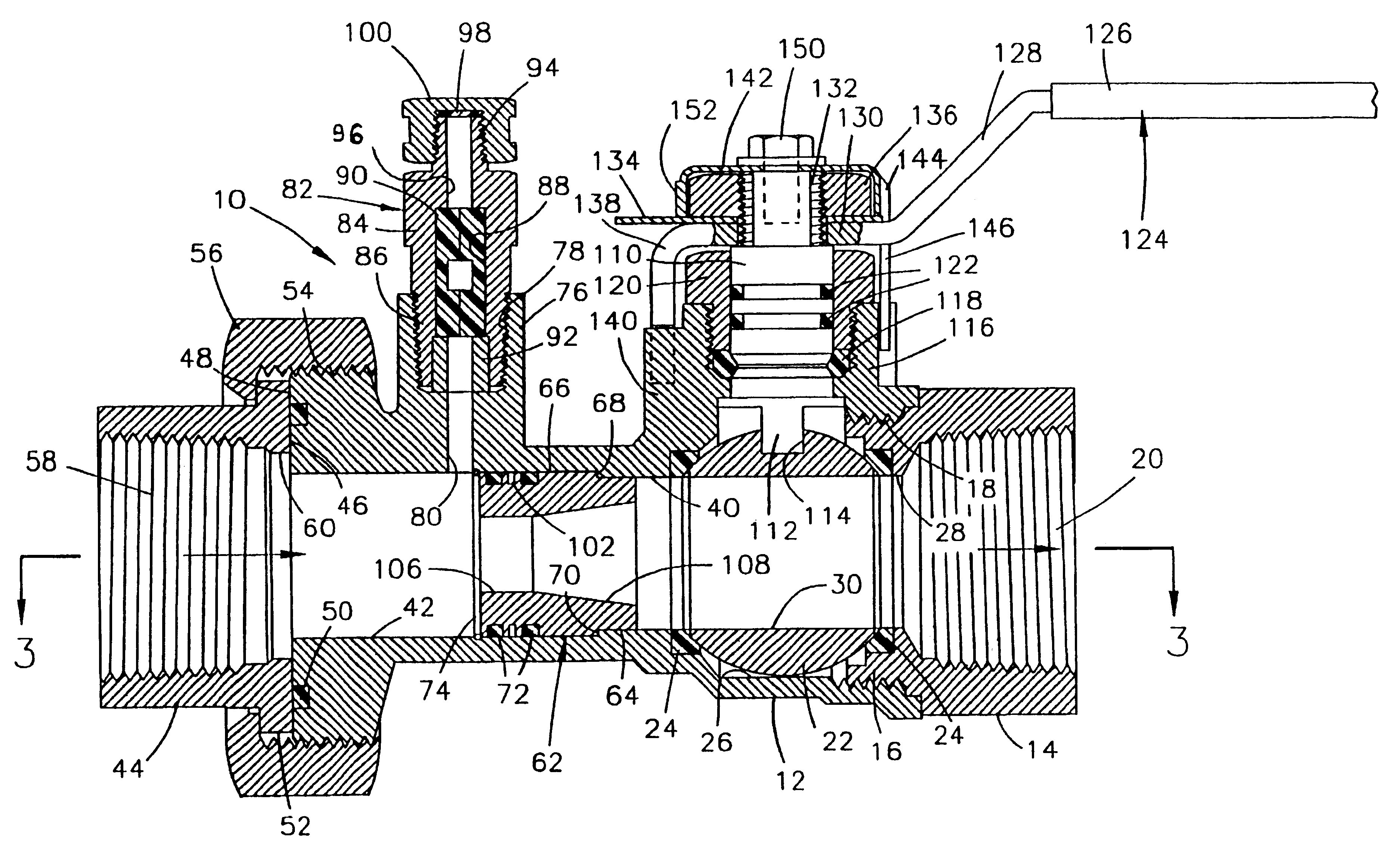

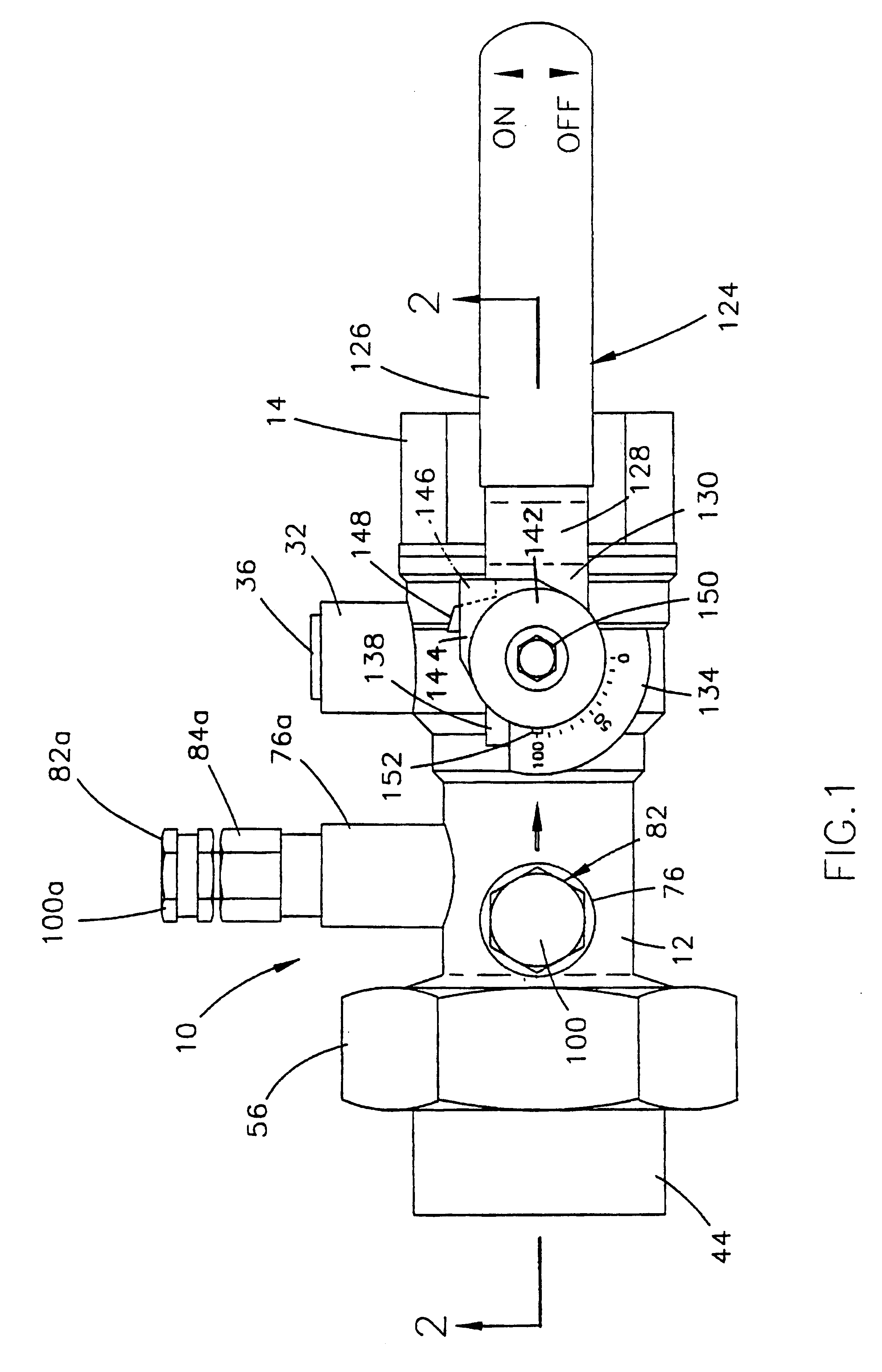

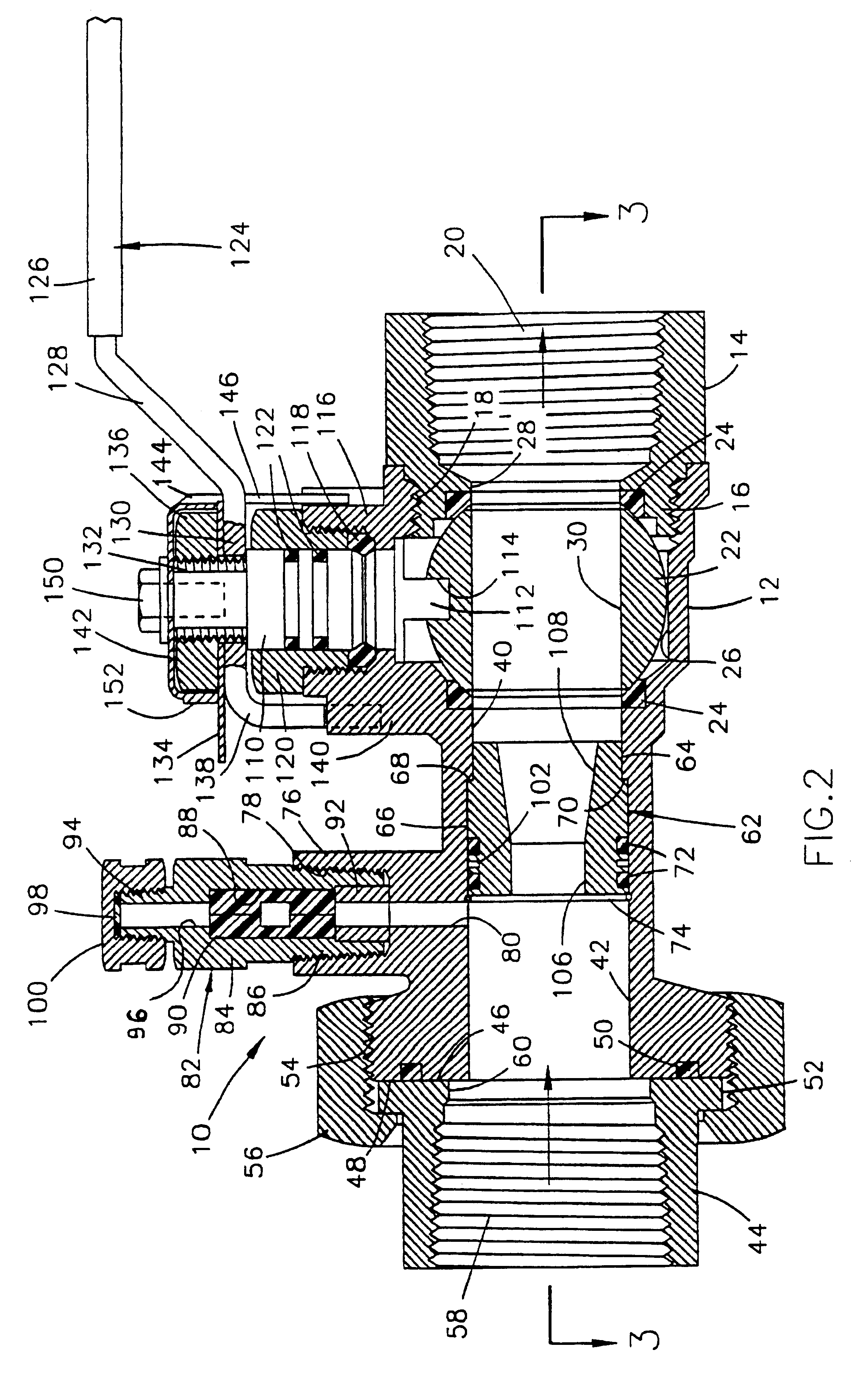

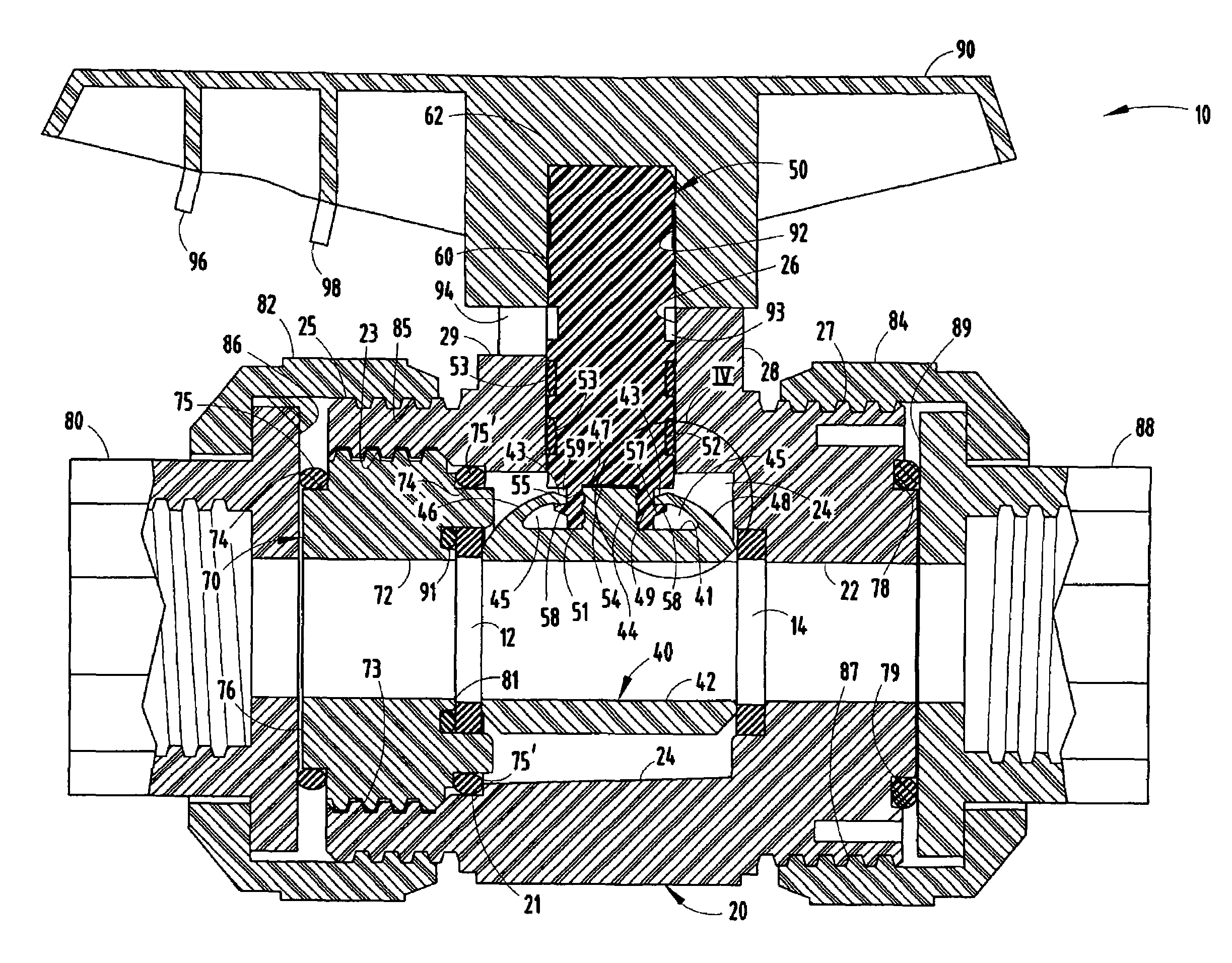

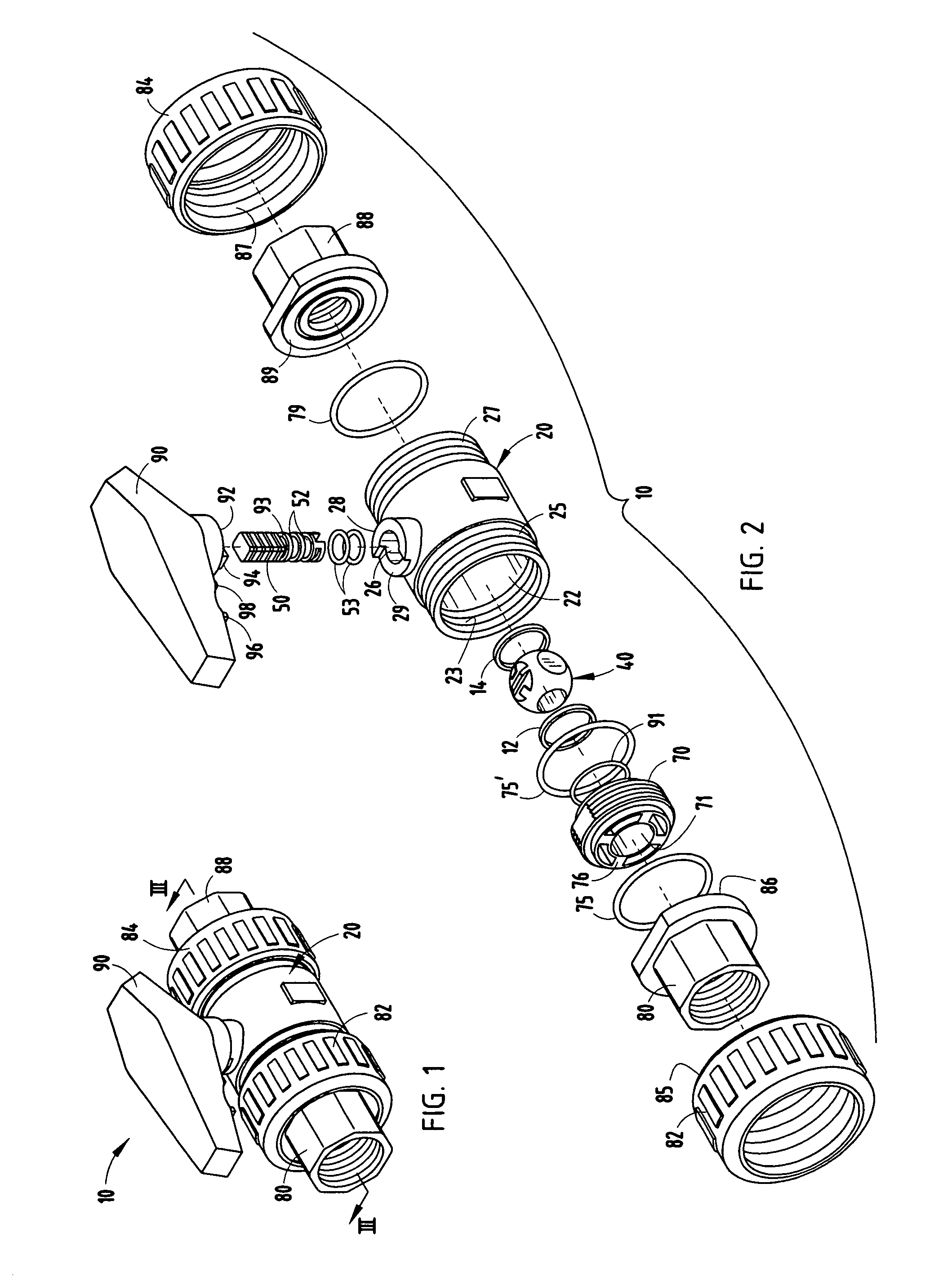

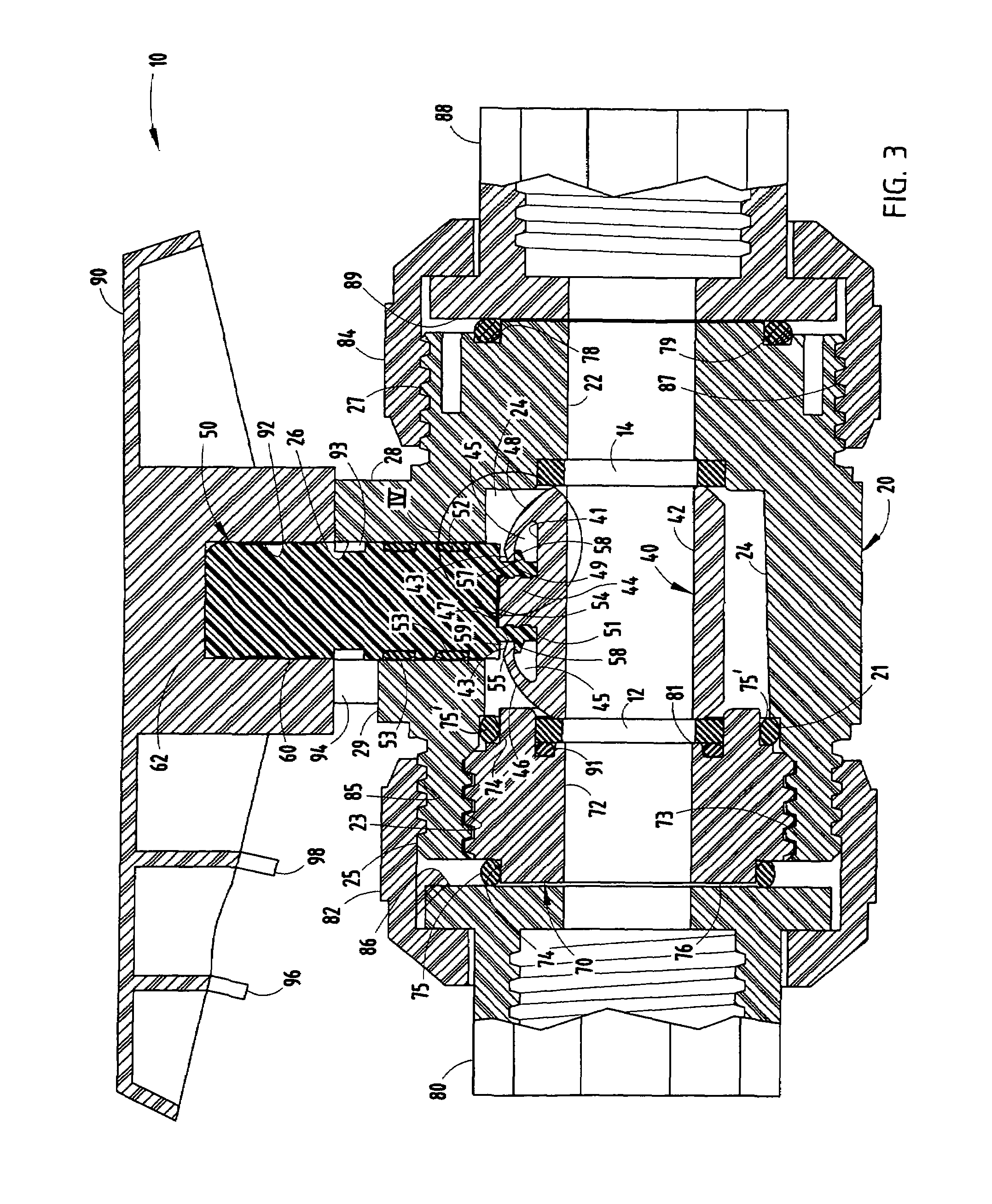

Ball valve with integrated removable flow venturi, flow balancing means, and pipe union means

InactiveUSRE37617E1Considerable timeEasy to installPlug valvesValve members for absorbing fluid energyEngineeringAir conditioning

A valve assembly for use in heating, ventilating and air conditioning systems. The valve assembly includes a valve body having a chamber in which is rotatably mounted a quarter-turn flow control ball valve. A valve body nut having an outlet port is threadably mounted on the valve body adjacent the outlet end of the valve body chamber. A flow venturi is removably mounted in the inlet end of the valve body. A pipe union tailpiece is detachably mounted on the inlet end of the valve body. A pair of pressure / temperature readout ports are mounted on the valve body for use in determining the rate of fluid flow through the venturi. A vent plug is mounted on the valve body for venting air from the ball valve chamber.

Owner:SHERMAN JOHN C

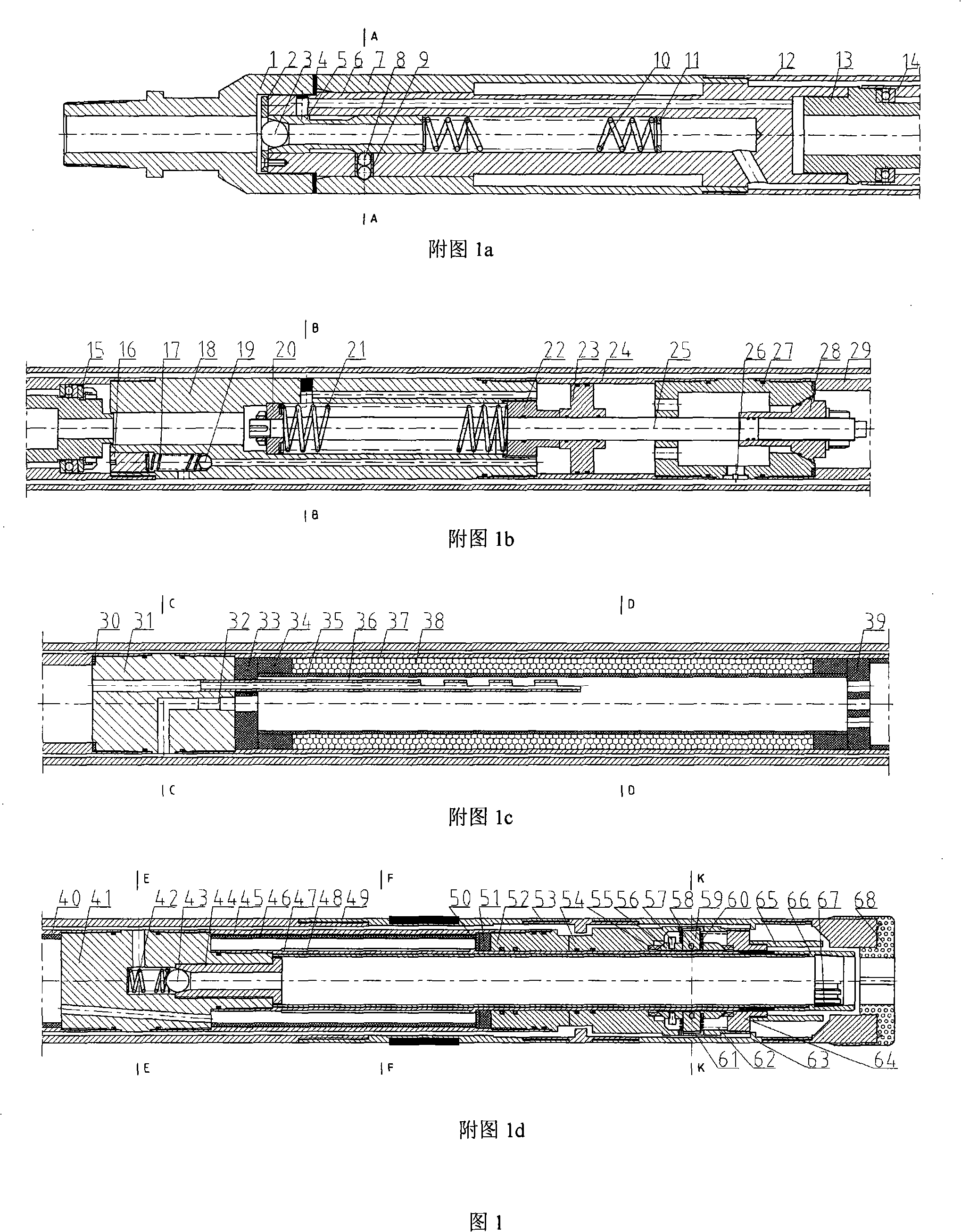

Dry ice sublimation hole bottom refrigerating and pressure keeping sampler and sampling method

InactiveCN101514614AAvoid destructionIncrease adoption rateWell/borehole valve arrangementsSealing/packingRock coreDry ice

The invention relates to a dry ice sublimation hole bottom refrigerating and pressure keeping sampler and a sampling method. The device is mainly composed of a suspension differential action mechanism, a single action mechanism, a control mechanism, a refrigerating mechanism and a pressure keeping mechanism. The method comprises: using dry ice as refrigerant, alcohol as refrigeration assisting catalyst and secondary refrigerant, and applying low temperature alcohol to the hole bottom to refrigerate the rock core; closing a ball valve to keep pressure of the rock sample so as to inhibite the decomposition of the hydrate rock core; dismounting a blocking tube and a drill bit when sampling, dismounting a clamp spring and a clamp spring seat, pulling out a half combining tube and the rock core from the rock core tube, and using a liquid nitrogen holdup vessel or a high pressure container to keep the rock core sample. When drilling for sampling the rock core, the external tube and the drill bit gyre, but the internal tube assembly does not gyre, thus avoiding the damage of mechanical force to the rock core caused by the gyrus of the drilling tool to a larger degree, improving the rock core sampling rate, integrity and representativeness more effectively, and realizing pure refrigeration sampling as well as a combination of refrigeration sampling and rock core pressure keeping; compared with the prior art, the invention has simple process, convenient operation and greatly reduces the cost.

Owner:JILIN UNIV

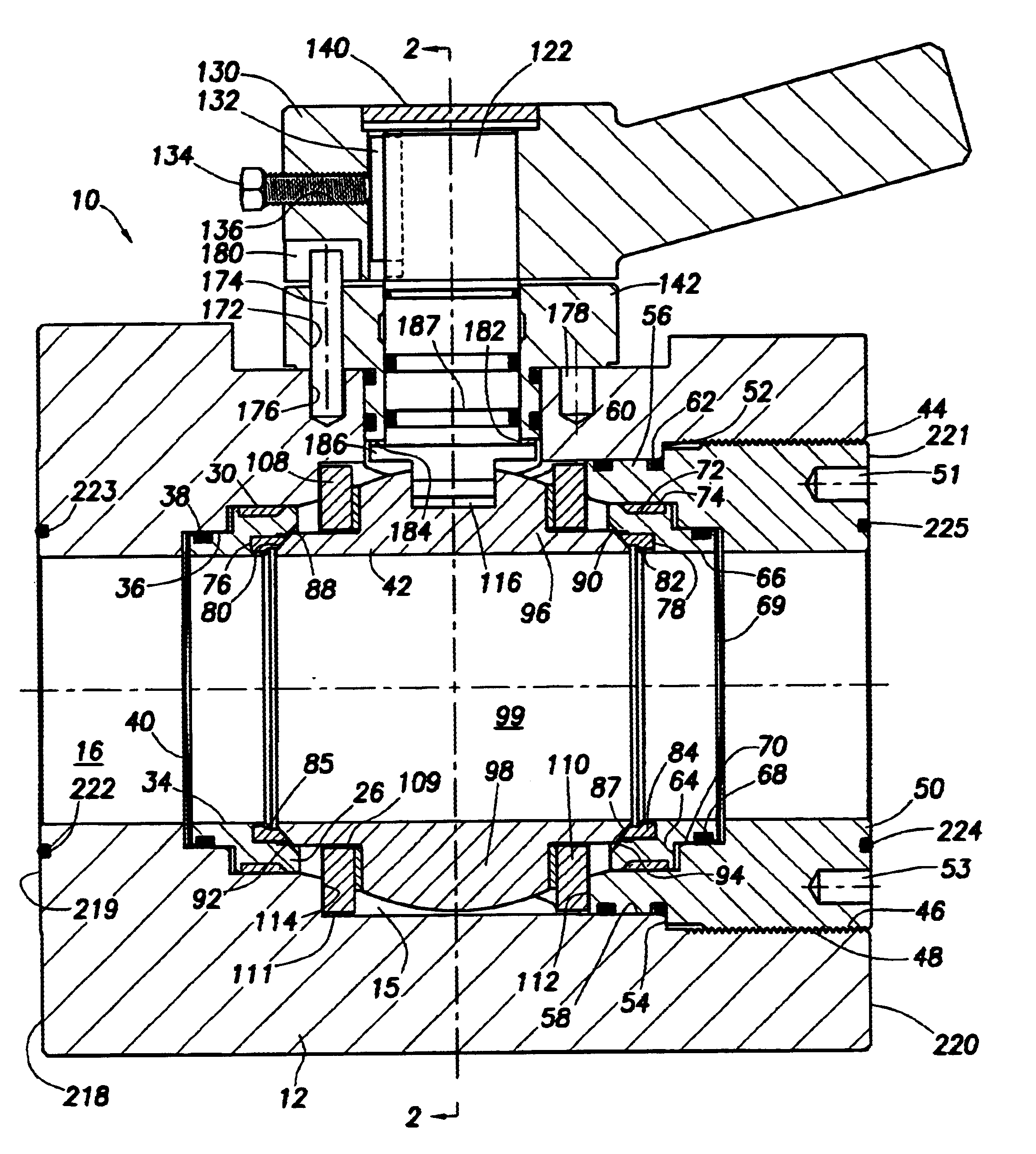

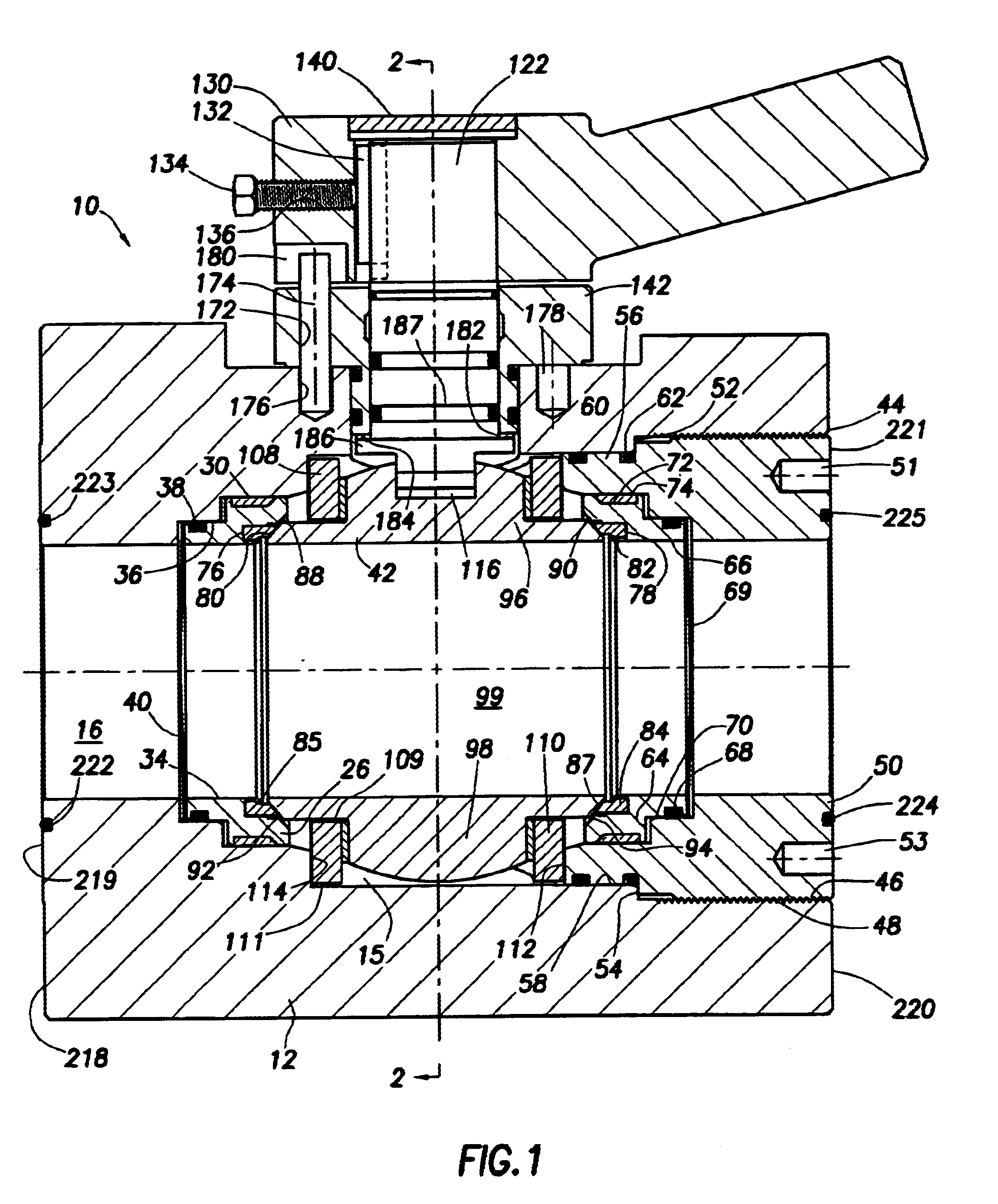

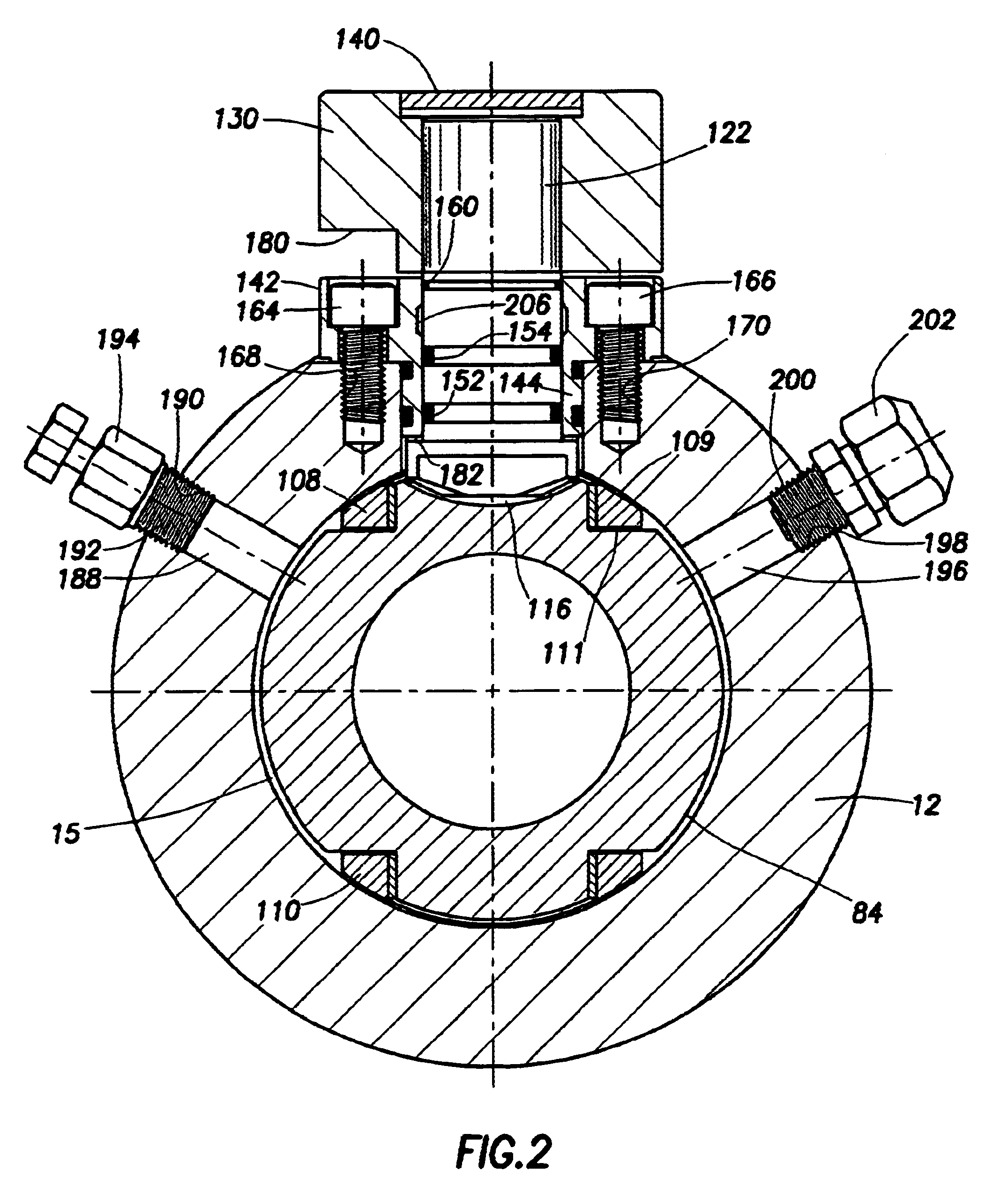

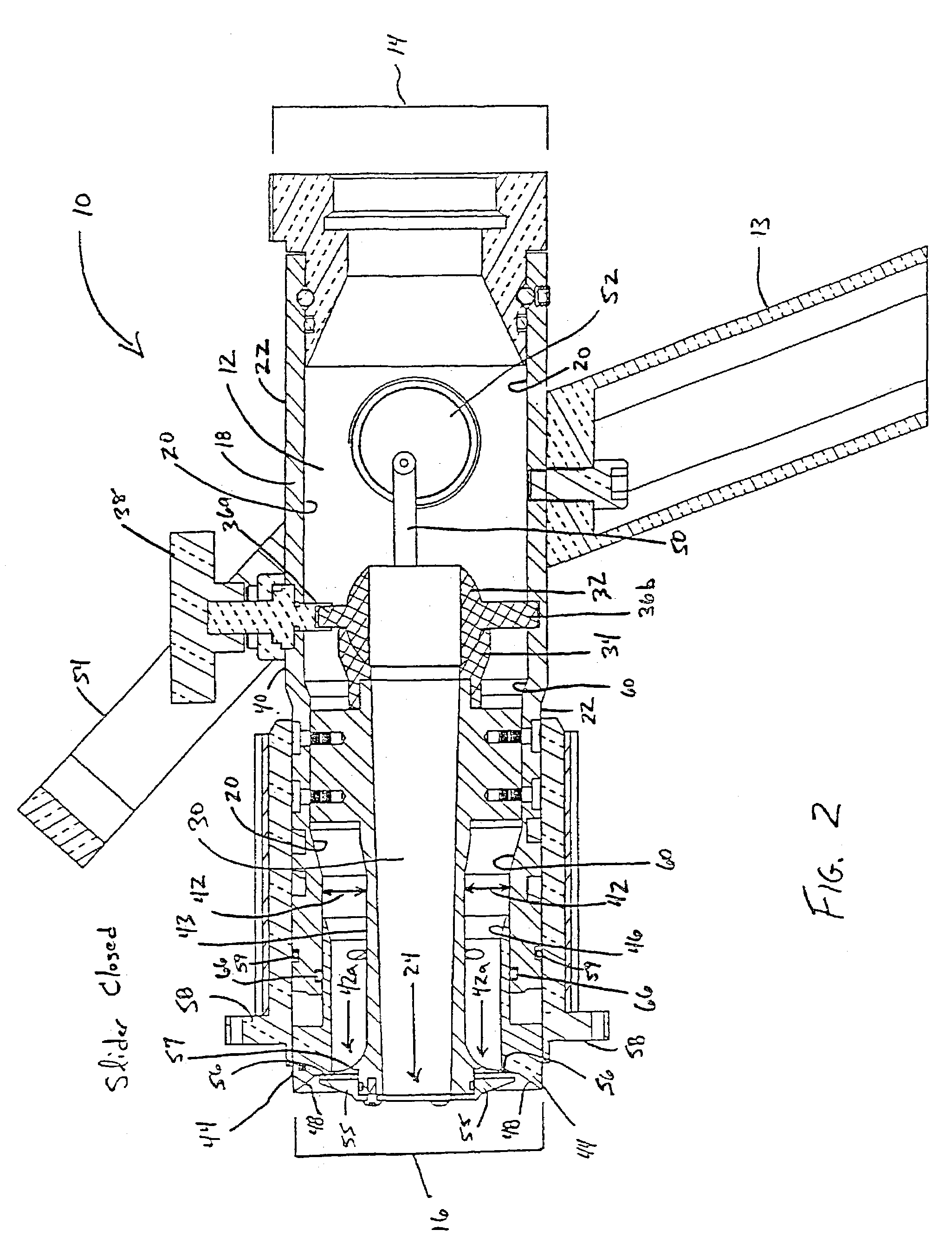

Compact manifold trunnion ball valve

A compact manifold ball valve having a valve body defining a valve chamber and having first and second ends and a first flow passage intersecting the valve chamber a cylindrical sealing surface defining a bonnet and valve stem passage also intersecting the valve chamber. A seat and ball retainer is threaded into the second end of the valve body and provides for support and positioning of a pair of trunnion support elements and a pair of seat assemblies. A valve ball having opposed trunnions is rotatable between open and closed positions within the valve chamber and is supported by the trunnion supports. A valve stem and bonnet assembly is secured and sealed to said valve body and is actuated to rotate the valve ball for opening and closing thereof. The valve seats are capable of metal-to-metal sealing with the valve ball in the event of heat destruction of said face seals to provide the valve with a fire-safe character. The seats incorporate high temperature graphite filament seals for fire-safe sealing between the valve seats and valve body in the event of heat destruction of said back seals. Other internal metal surfaces are arranged for metal-to-metal fire-safe sealing in the event the primary seals are destroyed by heat.

Owner:ARRAY HLDG

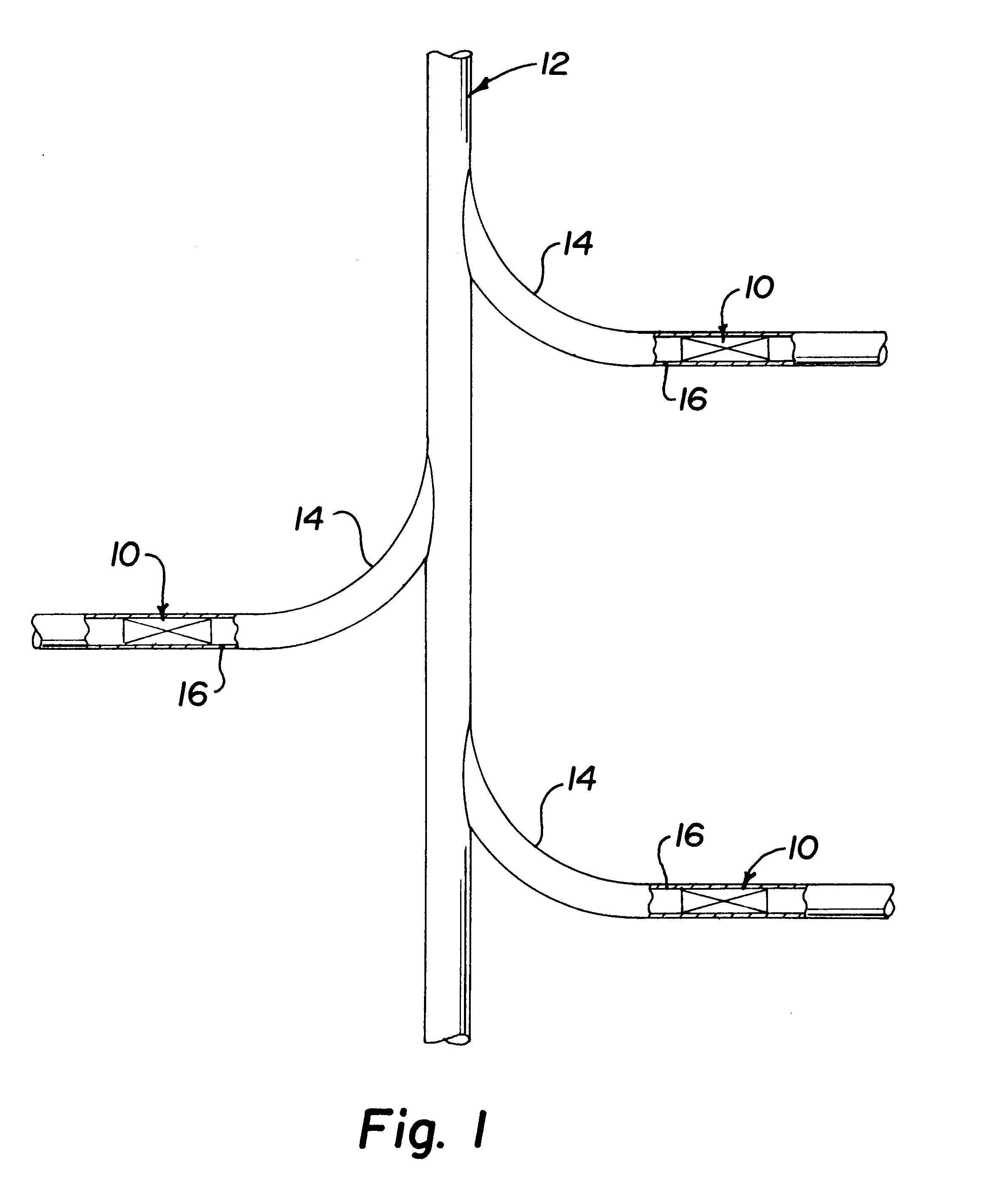

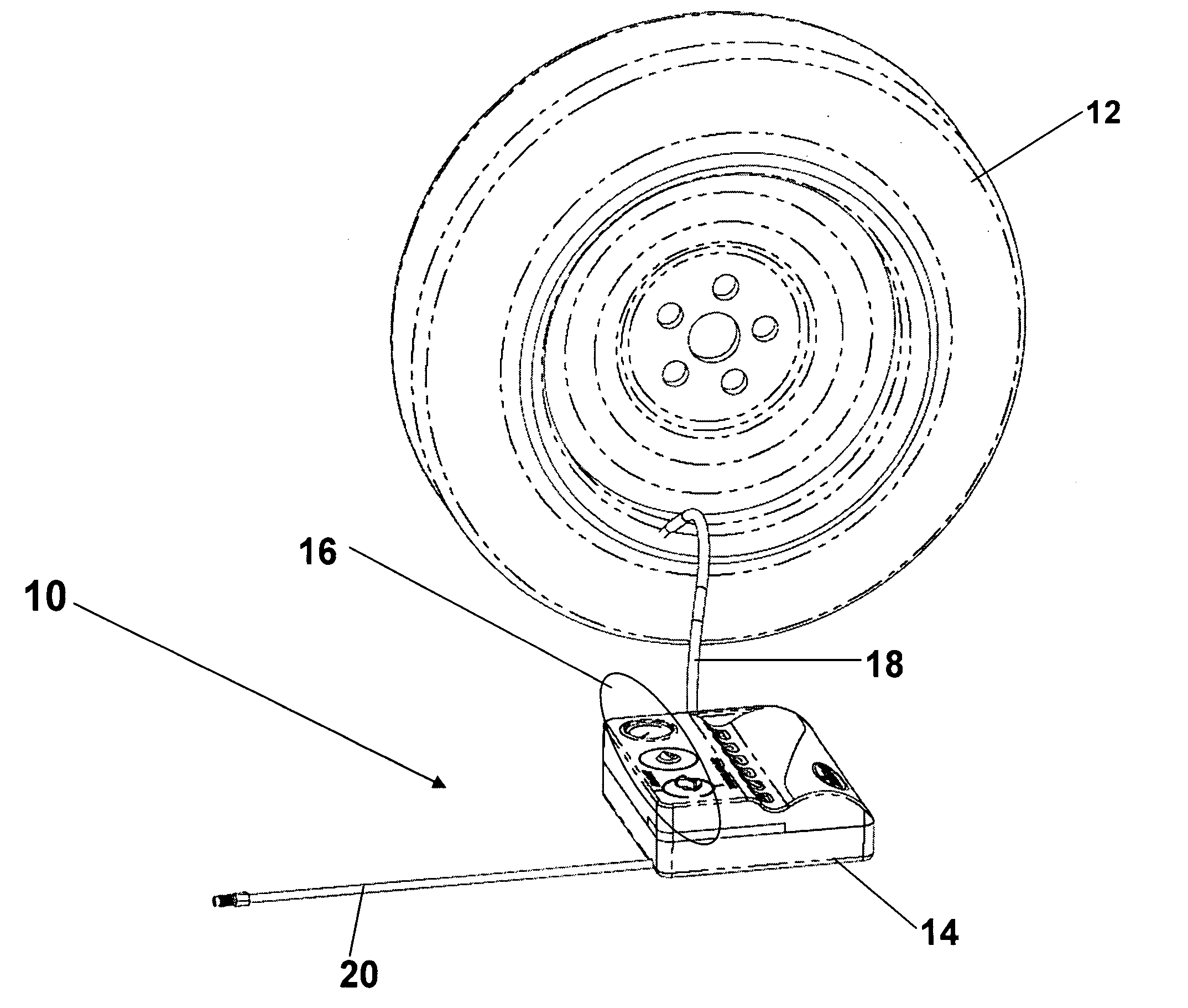

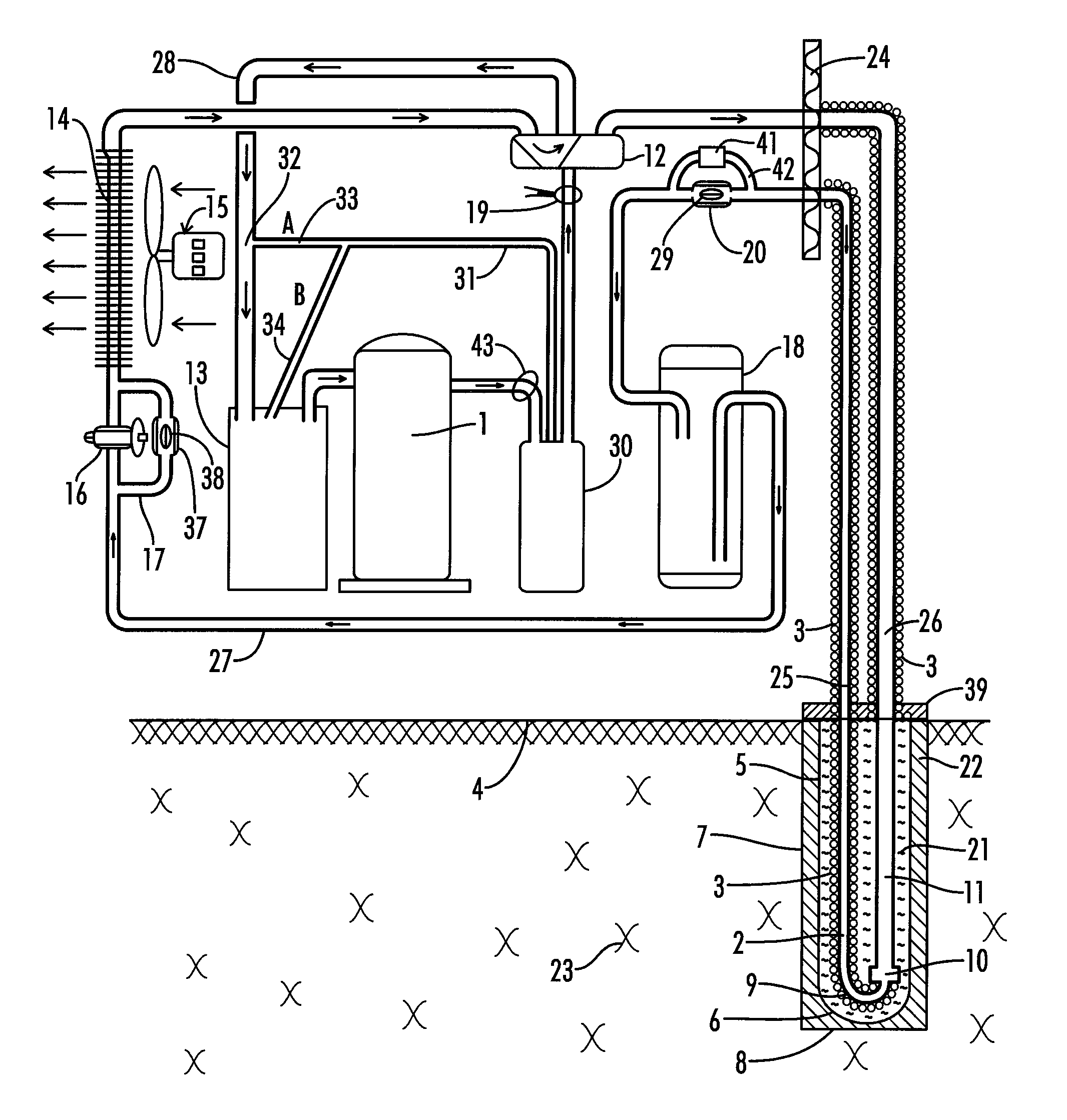

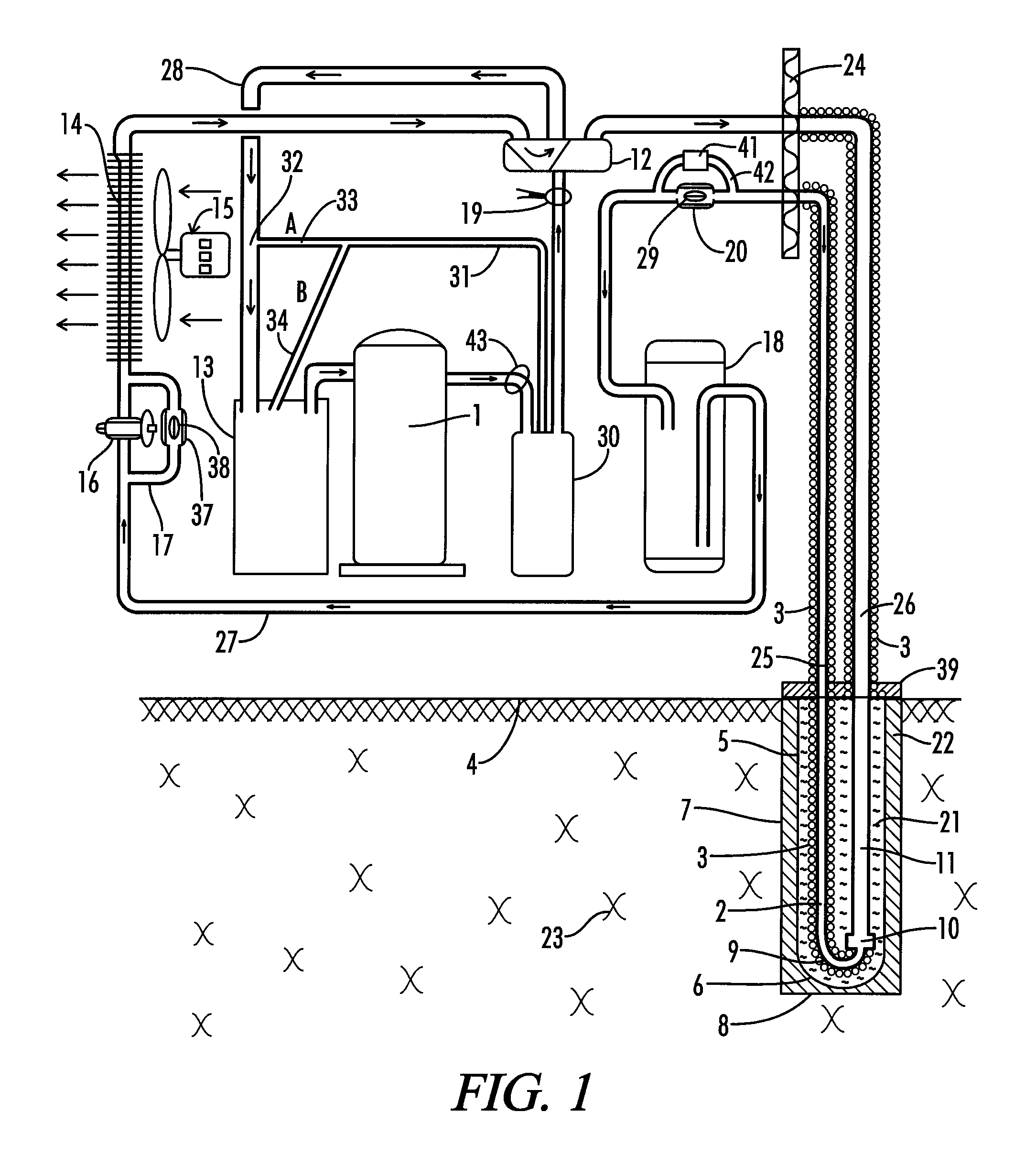

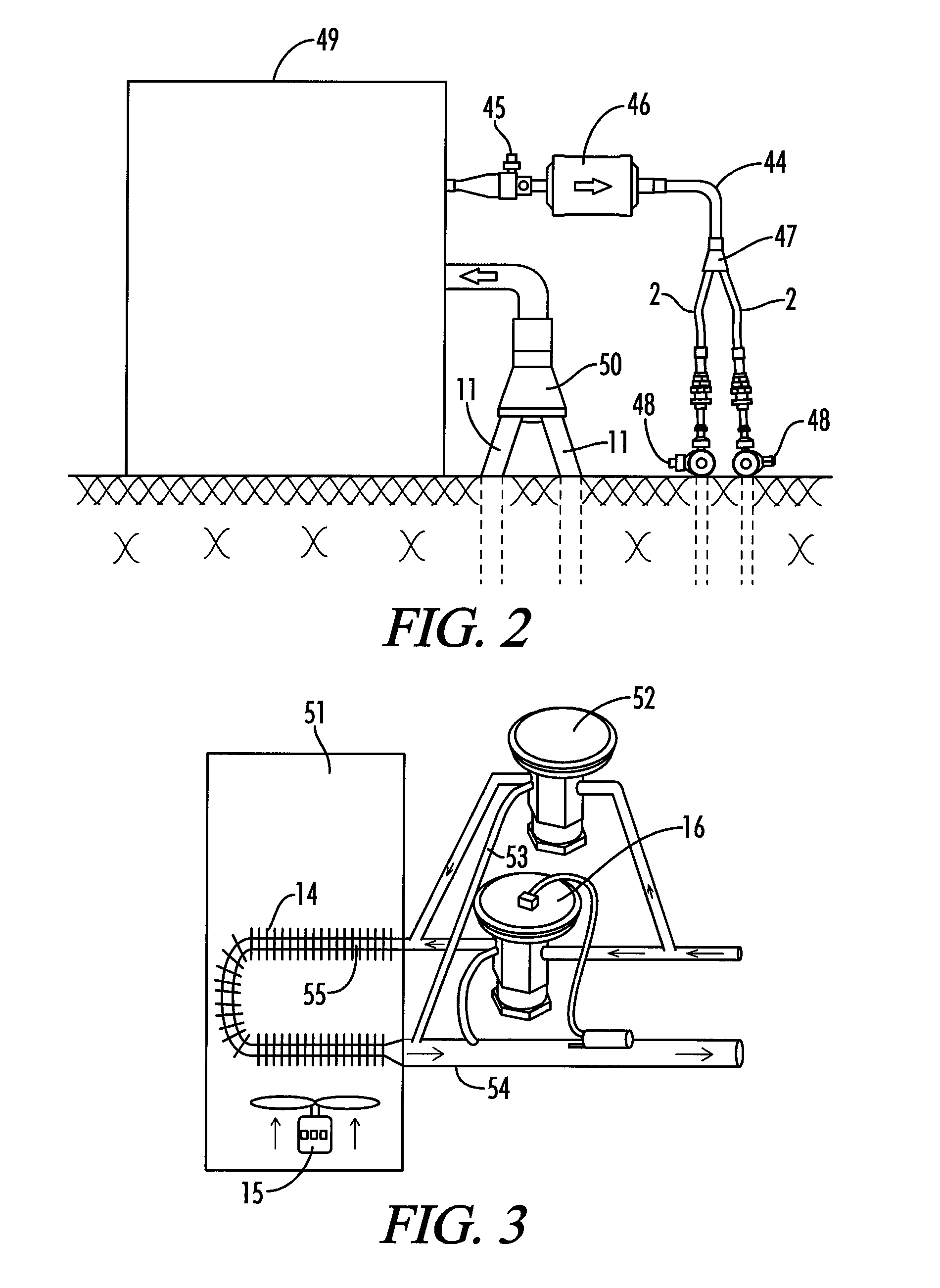

Advanced Direct Exchange Geothermal Heating/Cooling System Design

InactiveUS20080016894A1Shorten the timeEasy maintenanceDomestic cooling apparatusOther heat production devicesLiquid lineGeothermal heating

A direct expansion / direct exchange (“DX”) geothermal heating / cooling system having a plurality of pin restrictors positioned in housing units at ground accessible locations. The pin restrictors are preferably located near the compressor unit and on the field side of the distributor. Refrigerant is substantially equally distributed by a distributor to substantially equally sized line sets in the DX system with multiple wells. The distributors are place in either horizontal or vertical inclinations with the pin restrictors situated on the field side of the distributor in each individual liquid refrigerant transport line. A cut-off ball valve is located within the liquid refrigerant transport line on each side of the respective pin restrictor housing units. A filter / dryer is place within the same liquid refrigerant transport line segment as the pin restrictor(s) with a refrigerant flow shut-off valve being situated on each side of the liquid line segment containing the filter / dryer and the distributor.

Owner:EARTH TO AIR SYST

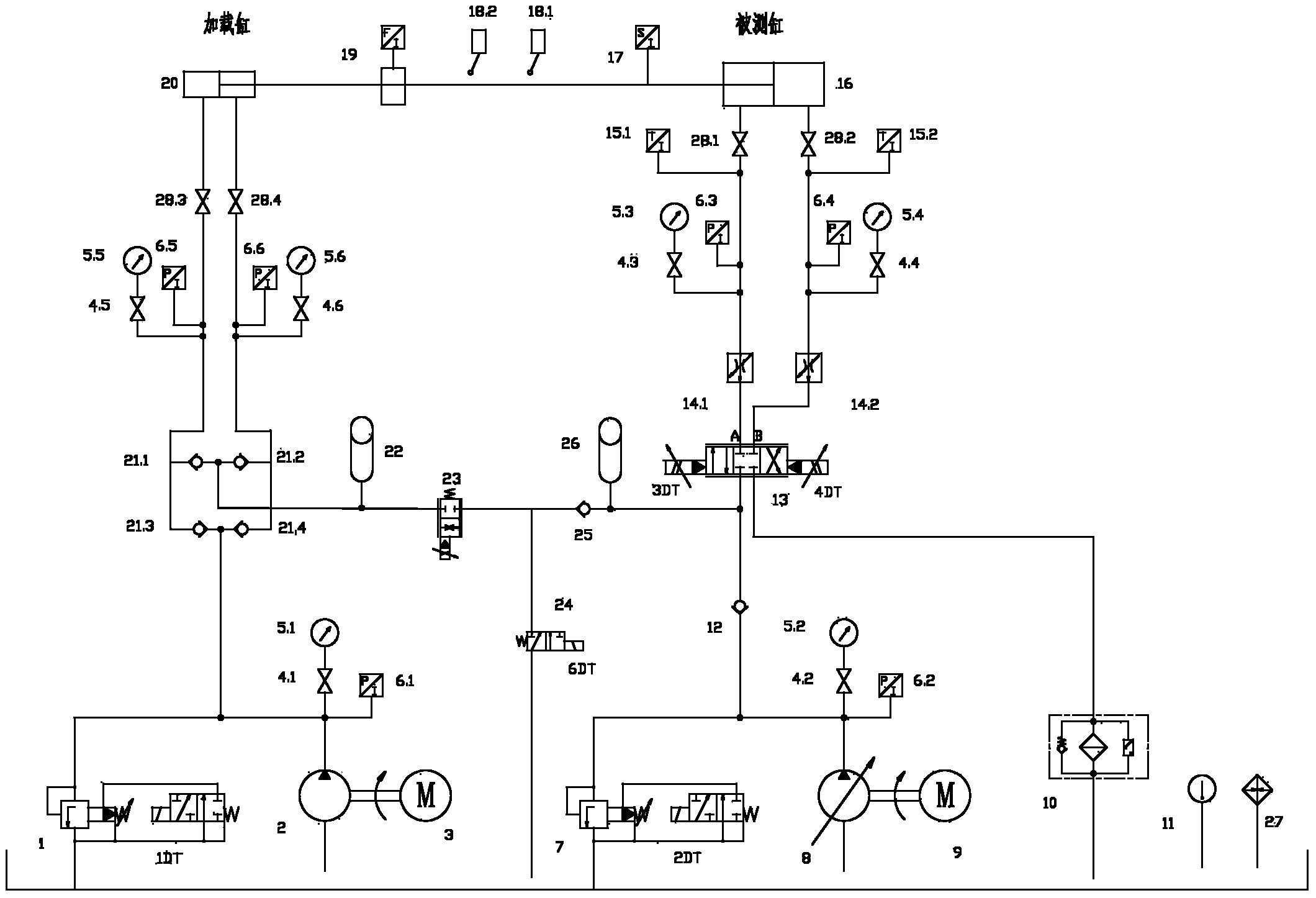

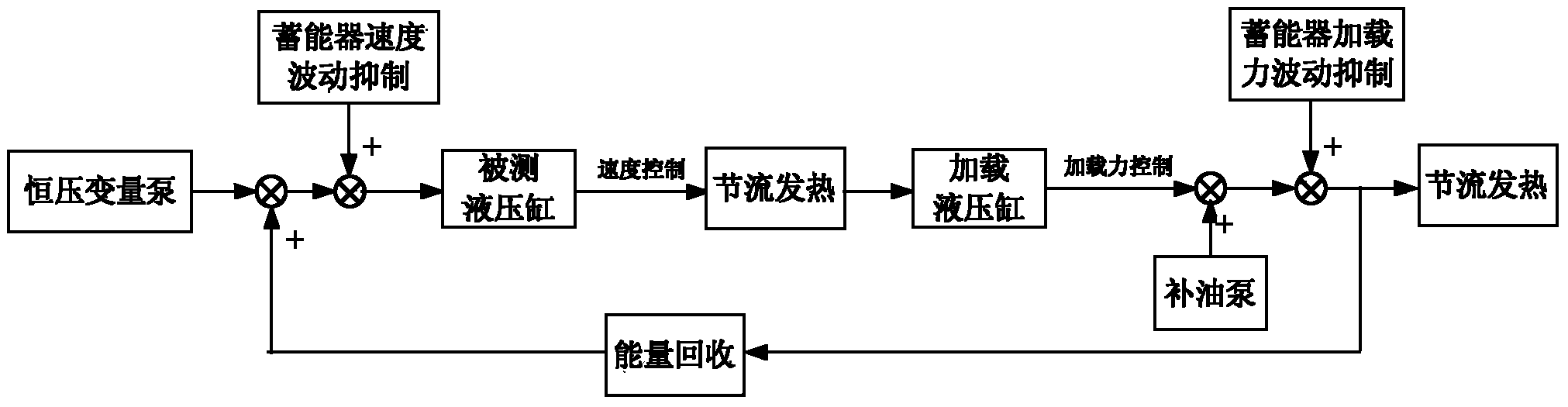

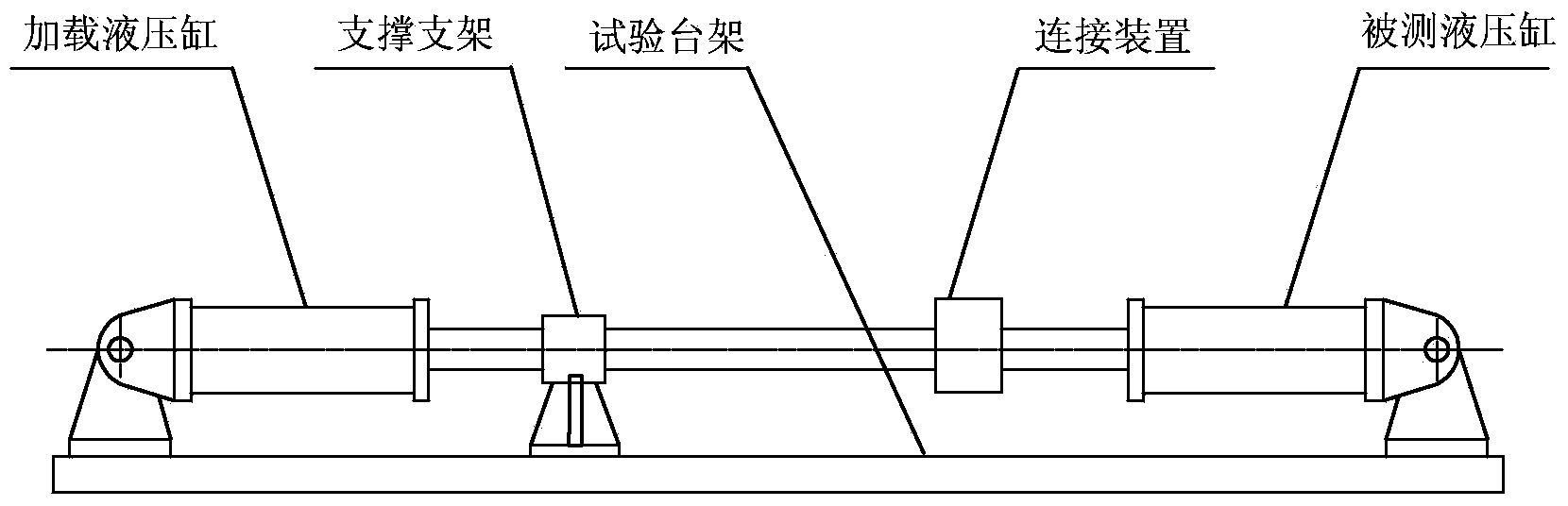

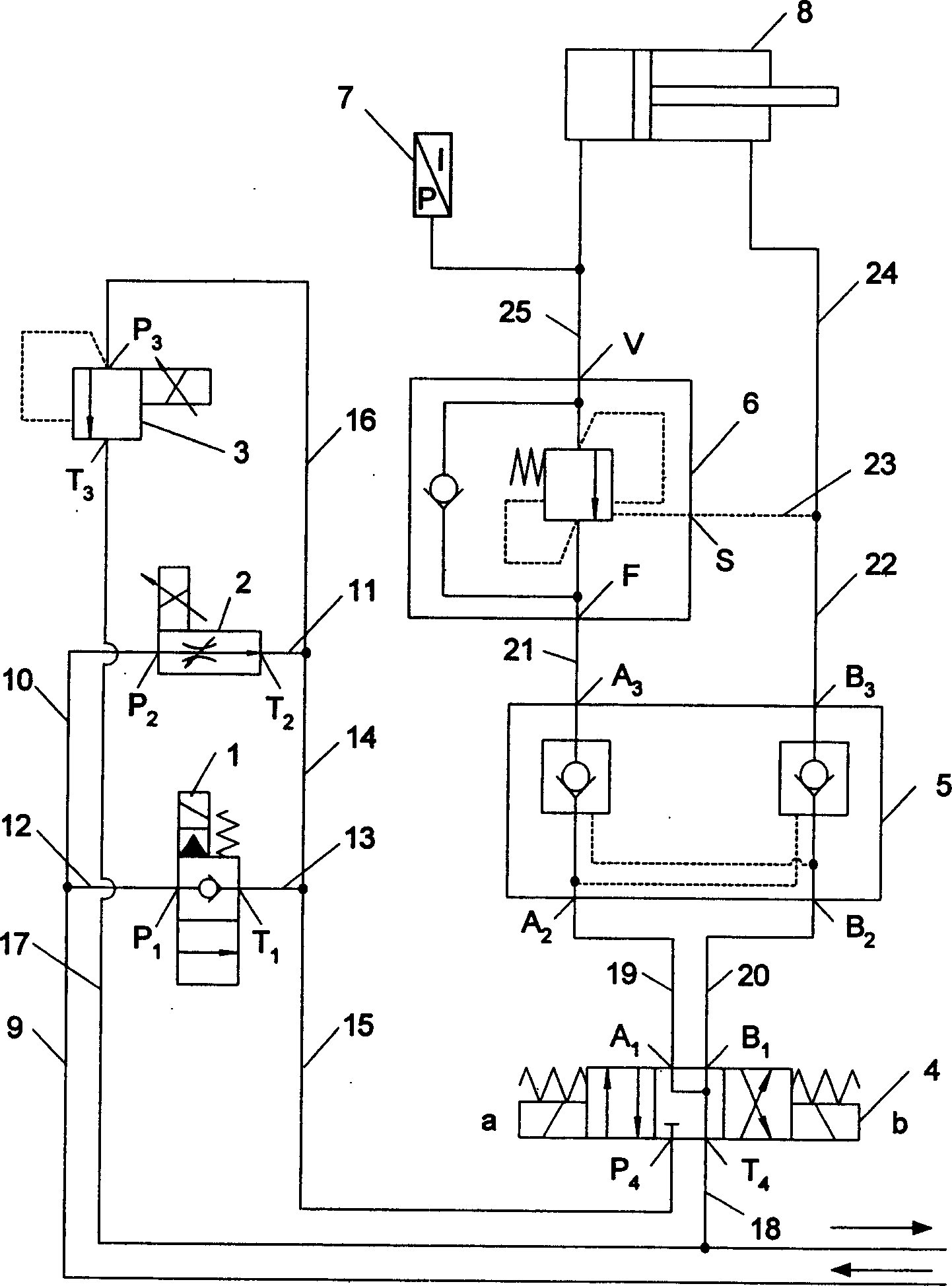

Energy-conservation and low-impact hydraulic cylinder test testbed hydraulic control system

InactiveCN103644151AStable energyRealize full working condition simulationFluid-pressure actuator testingLiquid temperatureFuel tank

The invention discloses an energy-conservation and low-impact hydraulic cylinder test testbed hydraulic control system. The system comprises a constant pressure variable pump, two electromotors, two electromagnetic unloading overflow valves, six check valves, two energy accumulators, an electrohydraulic proportional direction valve, two speed regulating valves, four ball valves, an oil supplementing pump, a proportional throttle valve, an electromagnetic reversing valve, a loading hydraulic cylinder, six pressure sensors, two temperature sensors, a displacement sensor, a force sensor, two travel switches, six pressure measuring connectors, six pressure gages, a heater, a liquid level liquid temperature gage, a filter and an oil tank. The energy-conservation and low-impact hydraulic cylinder test testbed hydraulic control system has the advantages that stable energy is provided for low-impact control over the speed of a tested hydraulic cylinder while energy is conserved, low-impact stable control over the loading force is achieved, meanwhile, the actual work condition that loads of the hydraulic cylinder probably change continuously in work can be simulated, all the work conditions of the loads of the hydraulic cylinder can be simulated, and power input is reduced.

Owner:YANSHAN UNIV

Hydraulic propelling system for mining tunnel driving machine controlled by ratio flow pressure

InactiveCN1560482AReal-time adjustment of propulsion speedAdjust pressure in real timeServomotor componentsTunnelsMachine controlEarth surface

The invention discloses a shield development machine hydraulic advancing system with proportion flow pressure compound control. It includes two bits two-way electromagnetic ball valve, proportion adjusting valve, proportion overflow valve, and three-bit four-way electromagnetic change valve, hydraulic lock, balancing valve, pressure sensor and hydraulic oil cylinder with inner shift sensor. The advancing system uses the proportion adjusting valve to control the advancing speed, uses proportion overflow valve to control the advancing pressure, it realizes the compound control of advancing speed and pressure with proper control tactics. Because the invention uses the compound control technology of the proportion flow pressure, it can realize the control to the advancing speed and advancing pressure in the advancing process of the shield development in real-time, thus realizes the control to the soil barn pressure, stratum stability and the ground sedimentation. The system in the invention can be adapted to each kind of stratums, realizes the control to the posture and direction precisely, the energy-saving effect of the system is good.

Owner:ZHEJIANG UNIV

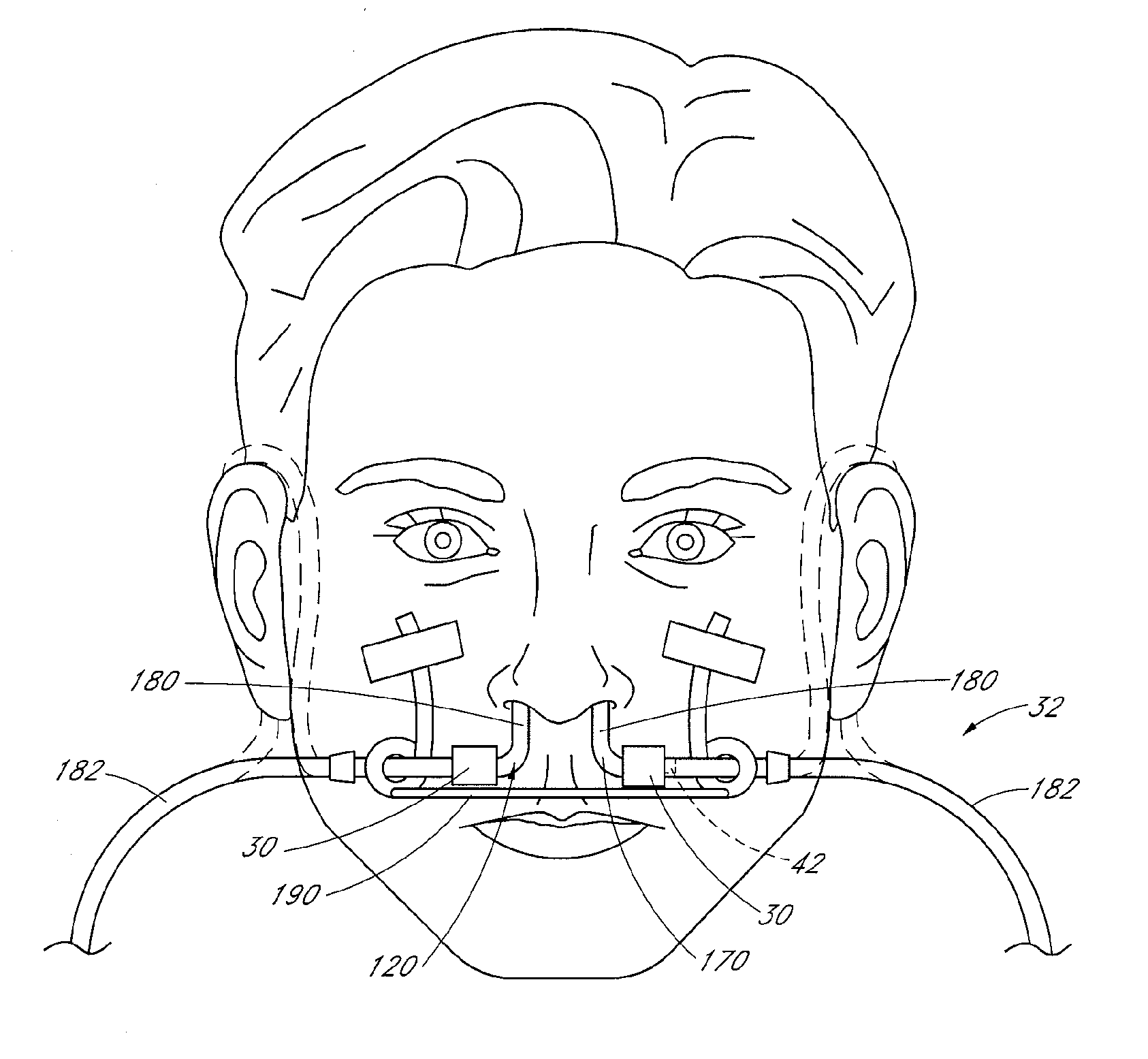

Breathing gas delivery system and method

A breathing gas delivery system and method provides a flow of breathing gas to a patient. The gas flow is purposely interrupted for the patient's exhale phase in order to minimize irritation and injury to nasal tissues due to constant, uninterrupted flows. Embodiments include an oscillating ball valve that interrupts oxygen supply during the patient's exhale phase, cannula tips that are shaped to minimize trauma, and a sleep apnea treatment system that interrupts breathing gas supply during the patient's exhale phase.

Owner:FACULTY PHYSICIANS & SURGEONS OF LLUSM +1

Hose nozzle apparatus and method

A device and method are provided for regulating two types of flow from a nozzle. The first flow is a deluge stream and the second flow is a fog spray. The deluge stream is controlled by the nozzle operator using a first flow control valve, such as a ball valve. The fog spray is controlled by the nozzle operator using a second flow control valve. The nozzle permits the nozzle operator to manually control the flow of the nozzle, thereby permitting quick regulation and adjustment of flow types and amounts to accommodate then existing fluid pressure and supply conditions to address fluid application needs.

Owner:WS ACQUISITION LLC

Unitary fitting and ball-valve

The present invention provides in combination with a ball-valve, an improvement comprising a threadless metallic fitting that incorporates both a male portion and a female portion formed as an integral unitary structure extending from at least one end wall of a housing portion of the ball-valve. The threadless metallic fitting includes a sleeve portion having a female interior surface adapted for receiving one of a tube and a pipe section therein and a male exterior surface having at least two distinct cylindrical sections. There is also a driver member having at least two distinct cylindrical sections for engaging the male exterior surface of the sleeve portion for deforming the sleeve portion and concurrently deforming such one of such tube and pipe section engaged within the sleeve portion when the driver member is forced longitudinally along the male exterior surface of the sleeve portion so as to effect an air tight seal between the pipe section and the female interior surface of the fitting.

Owner:LOKRING TECHNOLOGY

Liner hanger fluid diverter tool and related methods

A downhole fluid diverter tool includes a tool body having a central bore therethrough and a bypass port formed in an outer diameter thereof, a spring-biased piston disposed within the tool body, a piston port in the spring-biased piston configured to axially align with the bypass port to control fluid flow outward from the central bore, and a rotatable ball valve aligned within the central bore of the tool body and configured to control fluid flow through the central bore, wherein the bypass port and the ball valve are configured to be cycled multiple times between open and closed positions while in a wellbore.

Owner:SMITH INT INC

Valve seat and valve

A valve seat for a ball valve in an adjustable medical valve is described. The valve seat is formed as a cone in a manifold. The cone is formed by rotating a line that intersects a central axis of the valve seat around the central axis. The angle of the intersection between the line and the central axis is doubled to form the included angle of the valve seat. Generally, the narrower the included angle, the better the tolerance of the assembled valve for variations in the spring constant of the pressure regulating spring. Specifically, the present invention has included angles between 0 and 90 degrees with the preferred included angles being between 10 and 40 degrees. A valve embodying the valve seat is also disclosed.

Owner:MEDTRONIC INC

Ball valve with snap-in stem

InactiveUS7306010B2Facilitate snap insertionEnhanced couplingPlug valvesEqualizing valvesFlangeBall valve

Owner:NIBCO INC

Downhole safety valve apparatus and method

The application discloses a valve, which may include either a safety valve or a storm surge choke valve or the like, to isolate a zone below a valve from a string of production tubing. Preferably, the valve includes a flow interruption surface assembly, such as a flapper valve or a ball valve, displaced by an operating conduit extending from a surface location to the valve through the inside of the production tubing. The application also discloses a bypass-conduit inside the production tubing to allow communication from a surface location to the production zone when the valve is in either an open or a closed location.

Owner:BAKER HUGHES INC

System for testing thermal performance of vehicle power battery

InactiveCN105372291AStable temperatureUniform temperatureComponent separationMaterial heat developmentAutomotive batteryElectrical battery

A system for testing thermal performance of a vehicle power battery belongs to the field of electric vehicle batteries. The system includes a high-temperature explosion-proof box; a pressure sensor, a temperature sensor, a heating and cooling device, a battery module and a circulating fan are arranged in the high temperature explosion-proof box; the circulating fan is connected with a circulating motor; the high temperature explosion-proof box is provided with an exhaust hole; the exhaust hole, a ball valve, a sampling port, a cut-off valve and a gas chromatograph are connected in sequence; the ball valve is connected to a gas collecting bag through an air exhaust pipe; the pressure sensor and the temperature sensor are connected to the computer through a data collector; a charge-discharge machine is connected to the battery module through a socket; the high temperature explosion-proof box is provided with an observation window; and the observation window is connected to a camera through an endoscope. The system can perform thermal property test of the battery, battery discharge analysis and thermal runaway test of the battery. The system has the advantages of simple structure and low cost, can carry out test on multiple functions of the lithium ion battery, so as to realize design optimization on the structure of the battery pack; and the system has broad market prospects.

Owner:BEIJING UNIV OF TECH

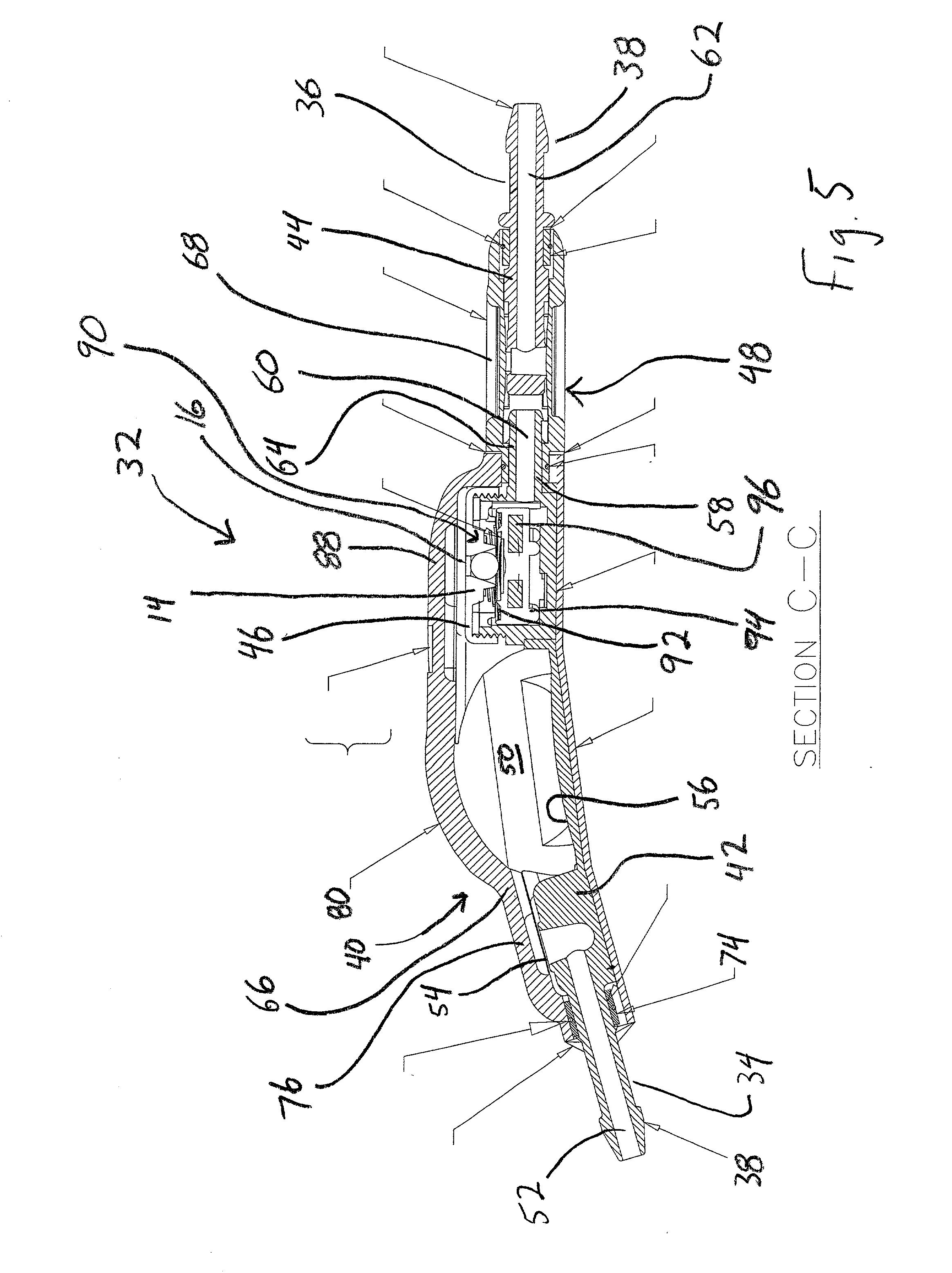

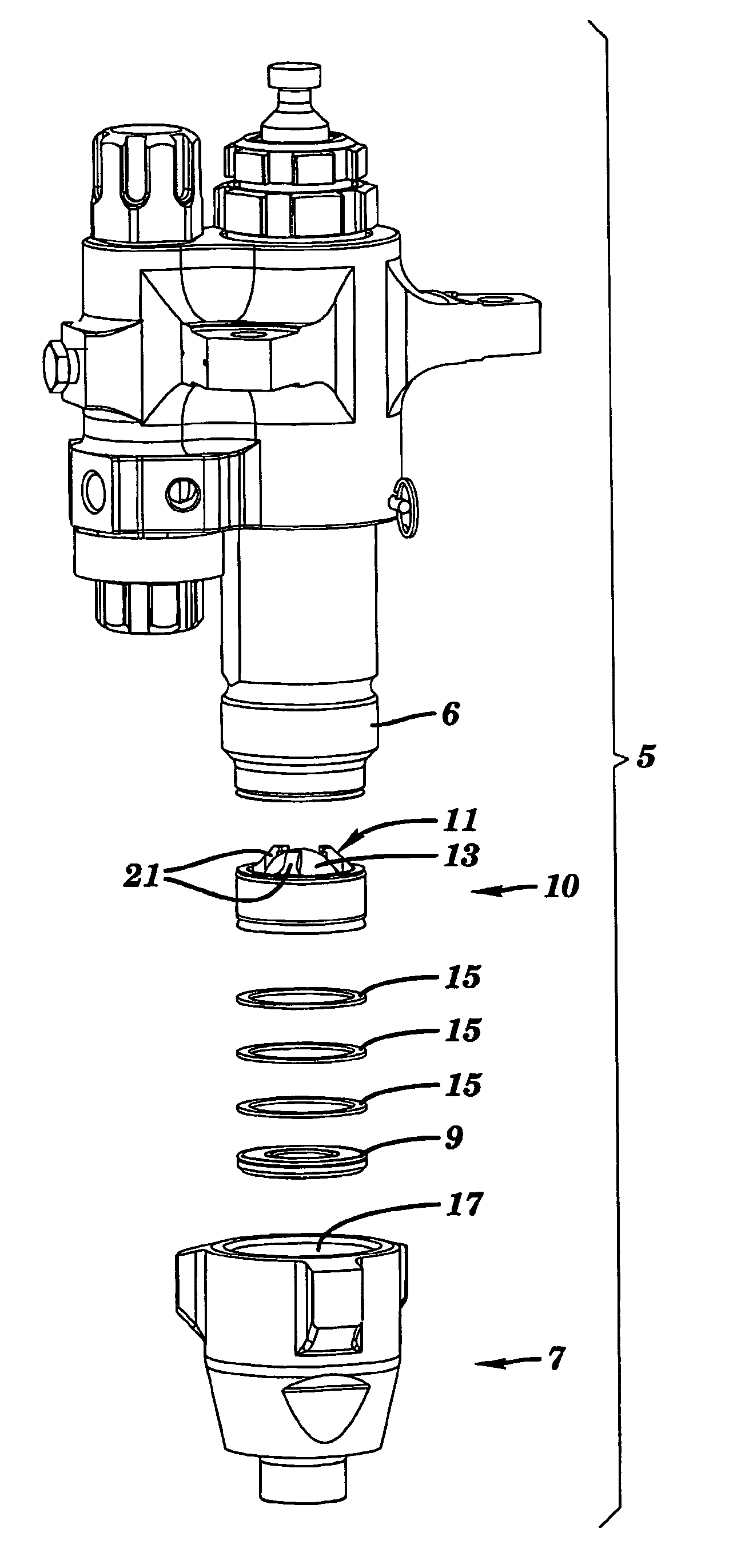

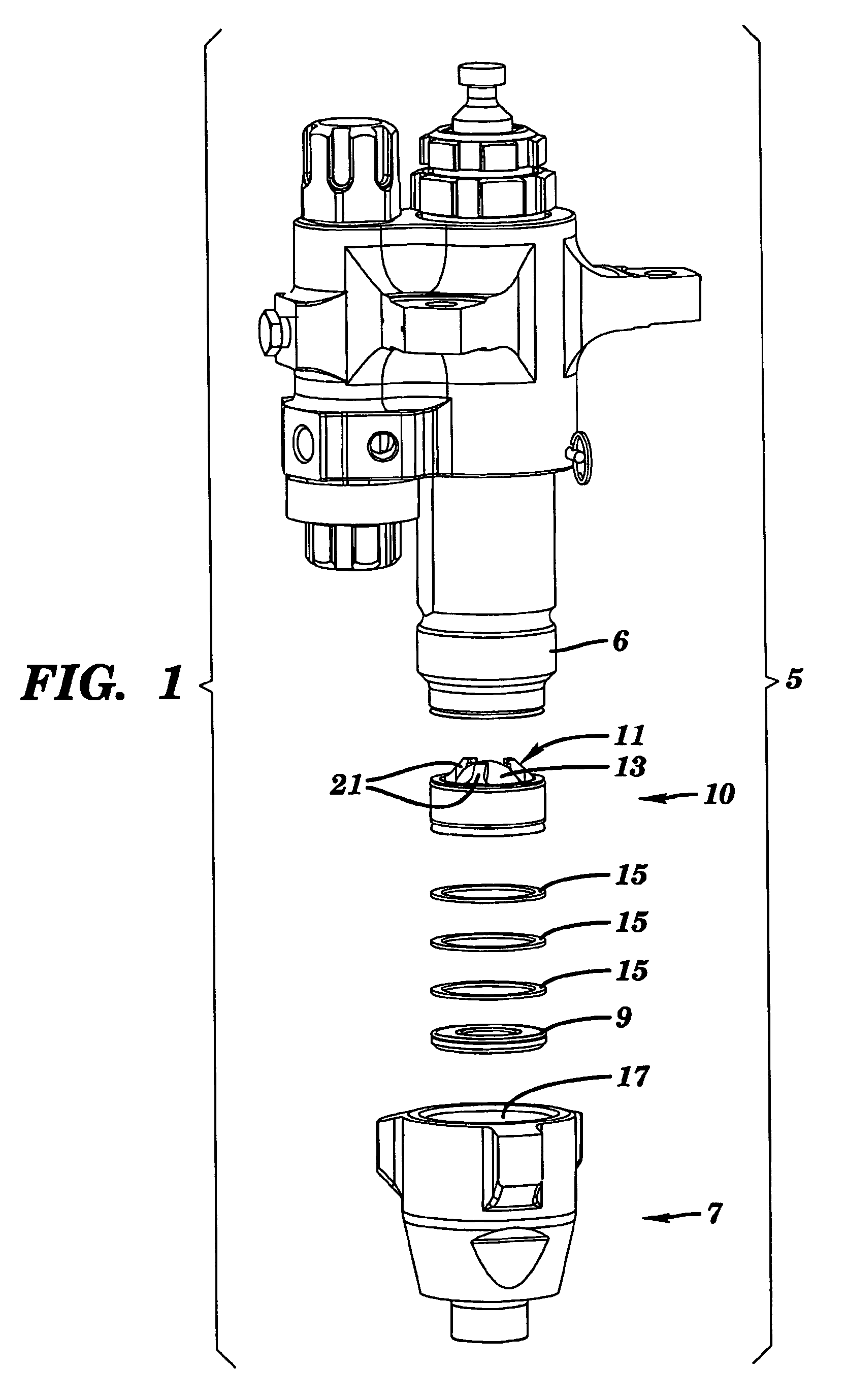

Reciprocating piston pump adjustable inlet ball travel

InactiveUS7025087B2Accurate placementImprove efficiencyPositive displacement pump componentsServomotor componentsInlet valveGlobe valve

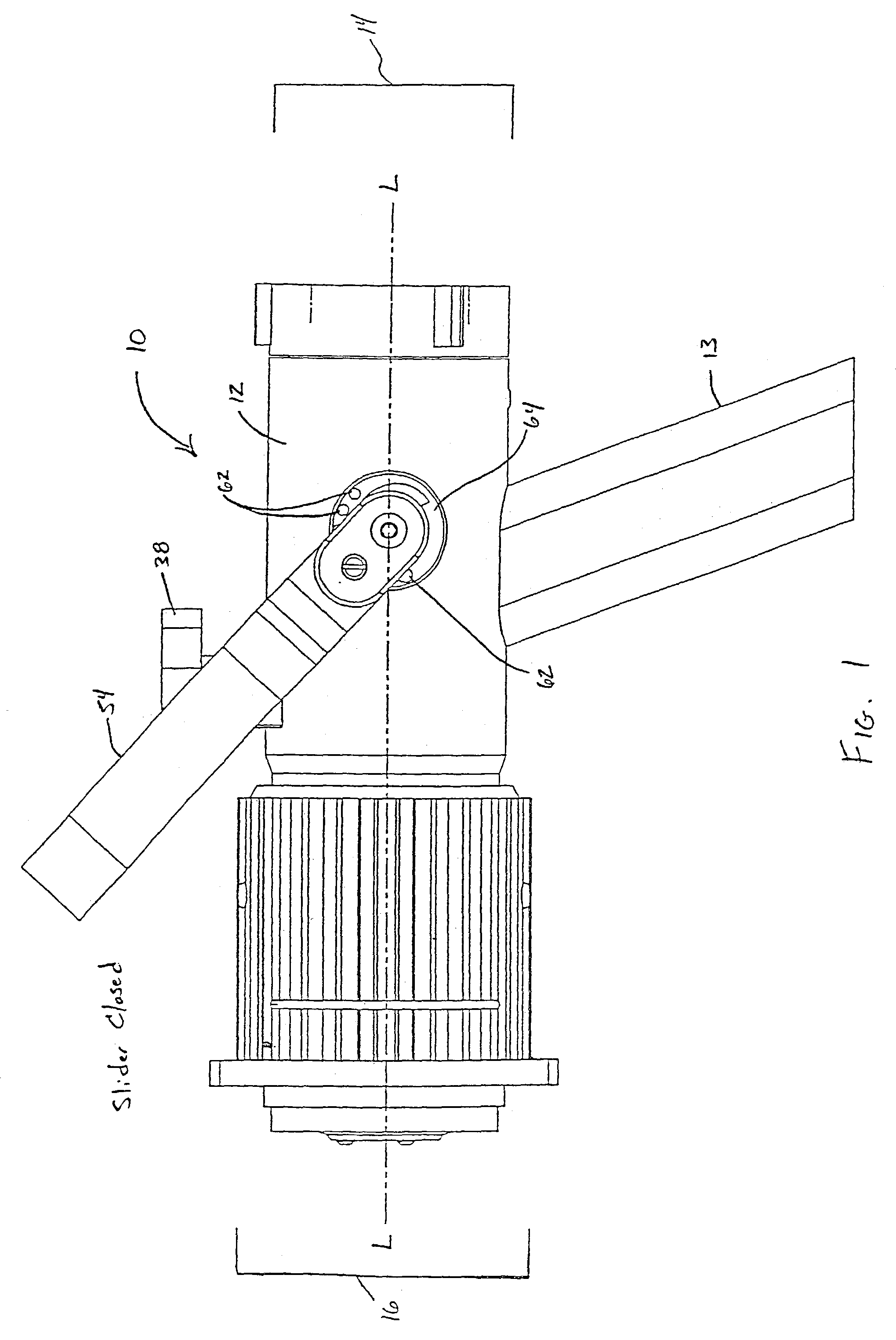

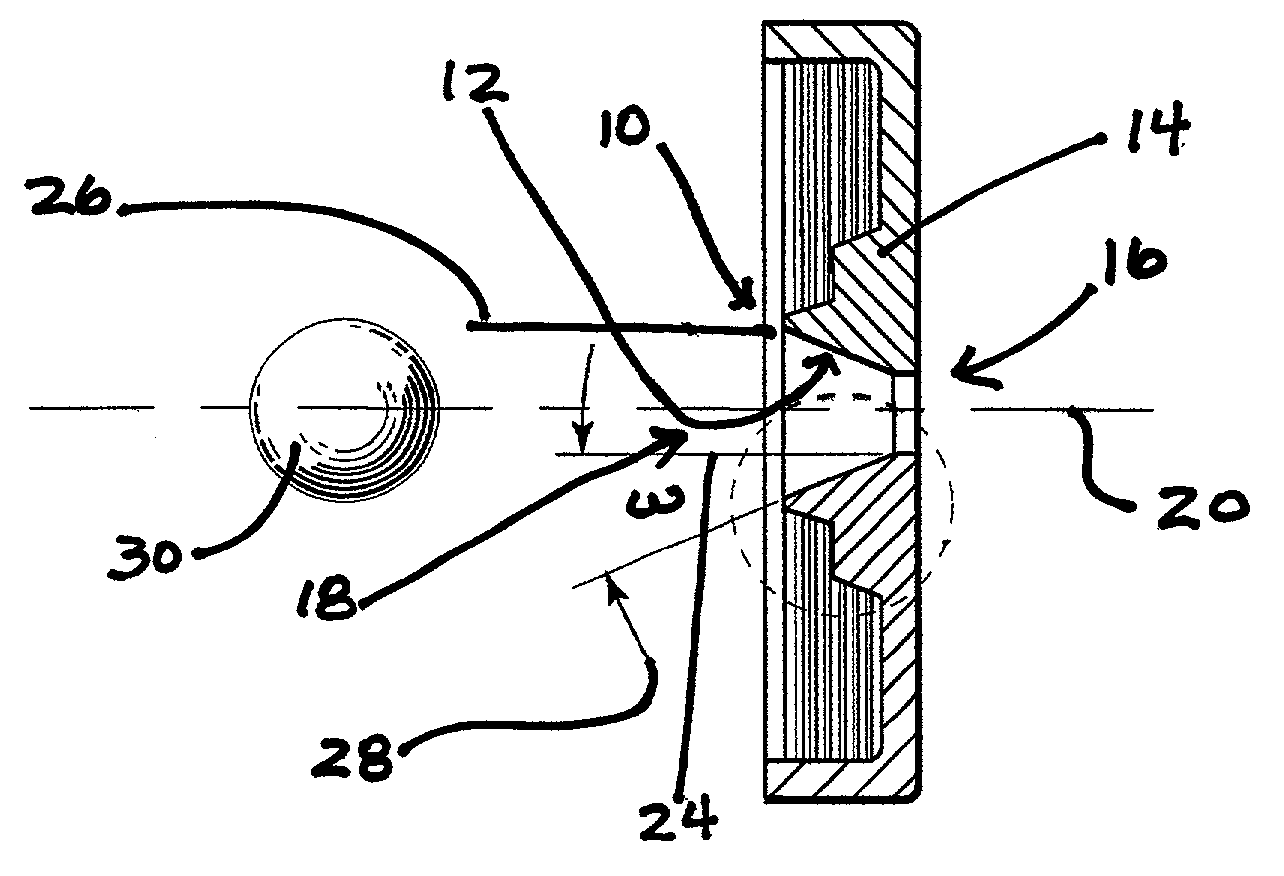

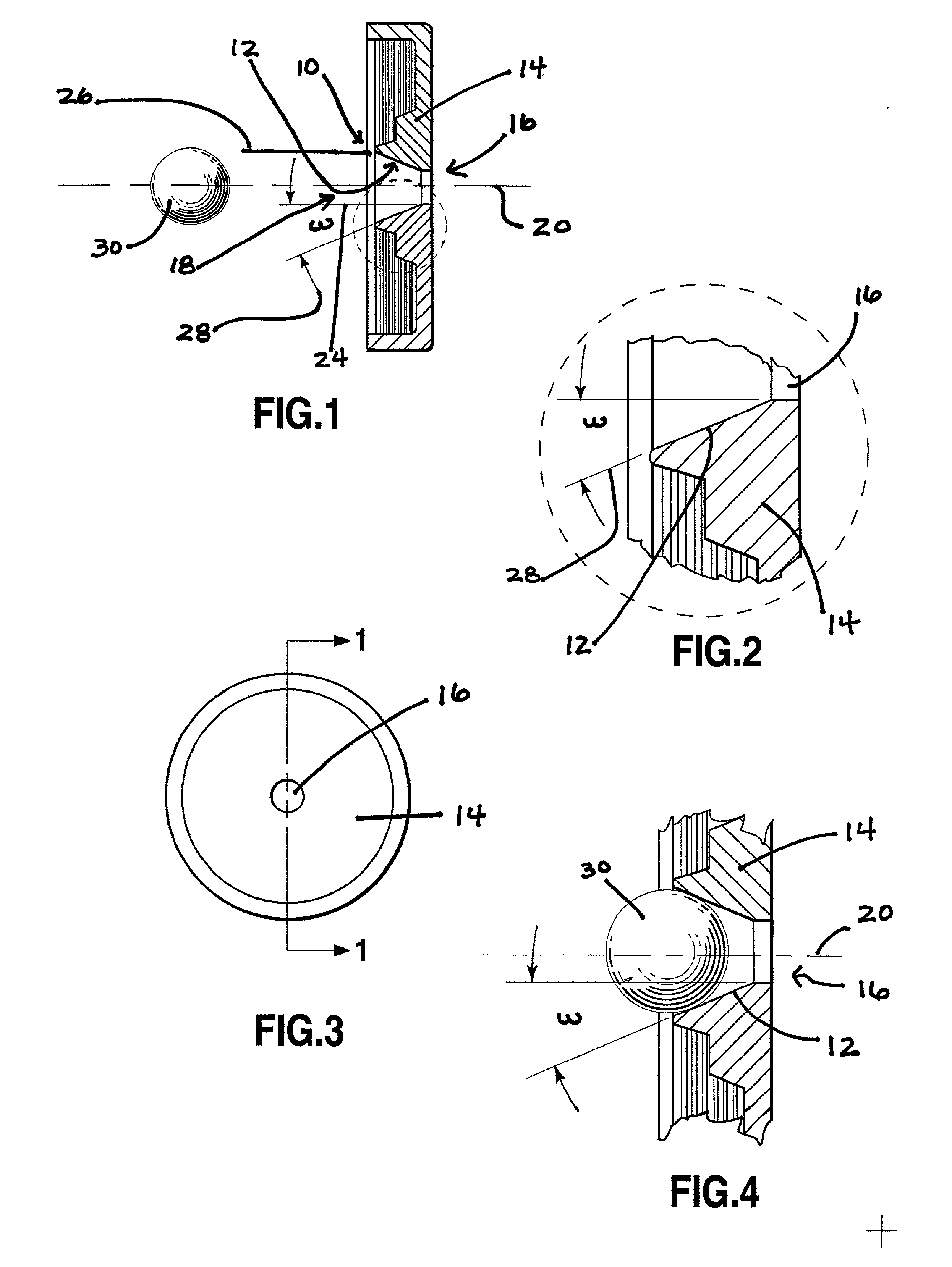

A ball stop valve (10) allows liquid to enter a reciprocating piston pump when internal suction is great enough to raise the ball (13) and create a space between the ball (13) and a seat (9). This invention allows the user to easily insert or remove rings (15) into the ball inlet valve, either above or below the ball (13), so that the space between the ball (13) and the seat (9) can be adjusted. The valve (10) is easily accessible to the user and all components of the ball valve (10) are removable.

Owner:GRACO INC

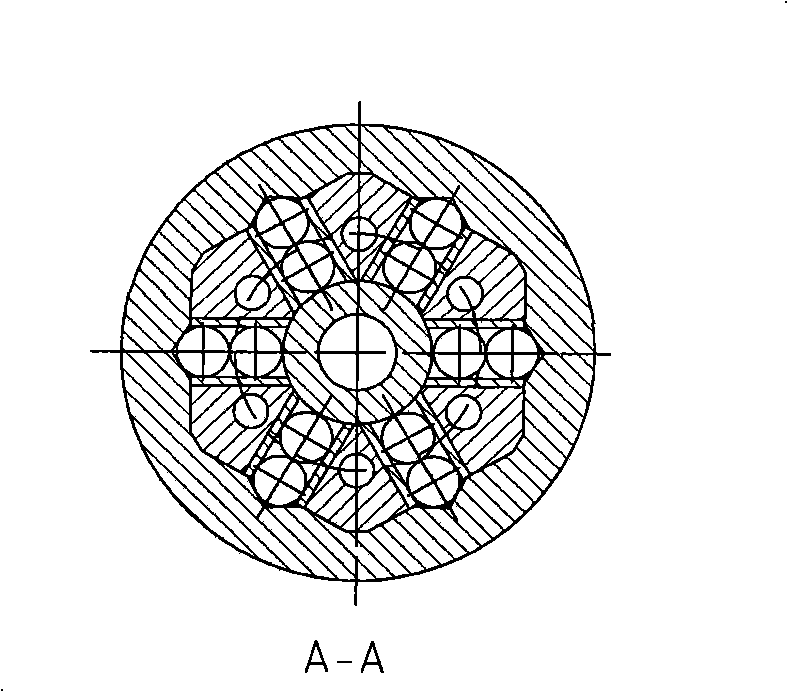

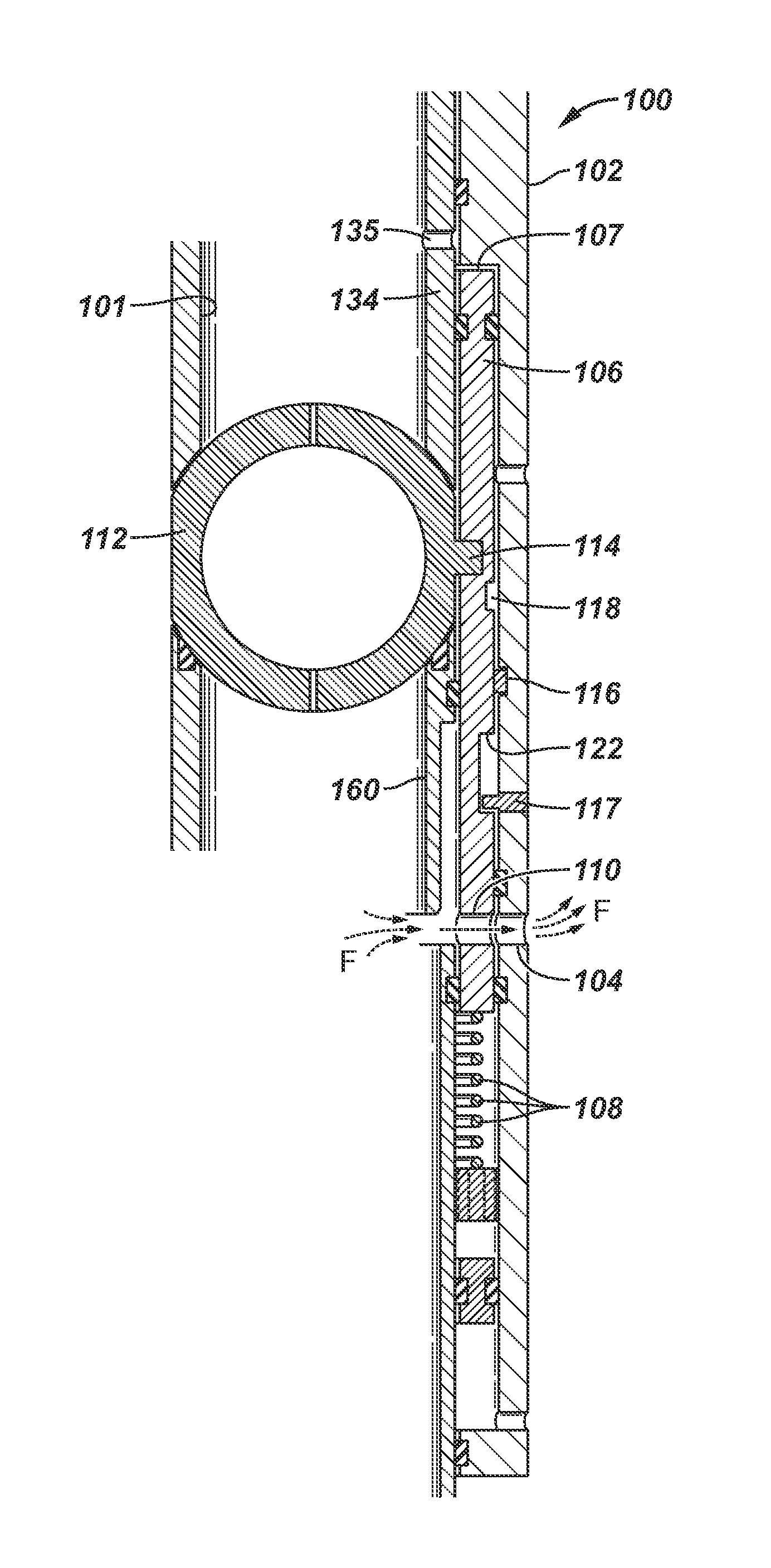

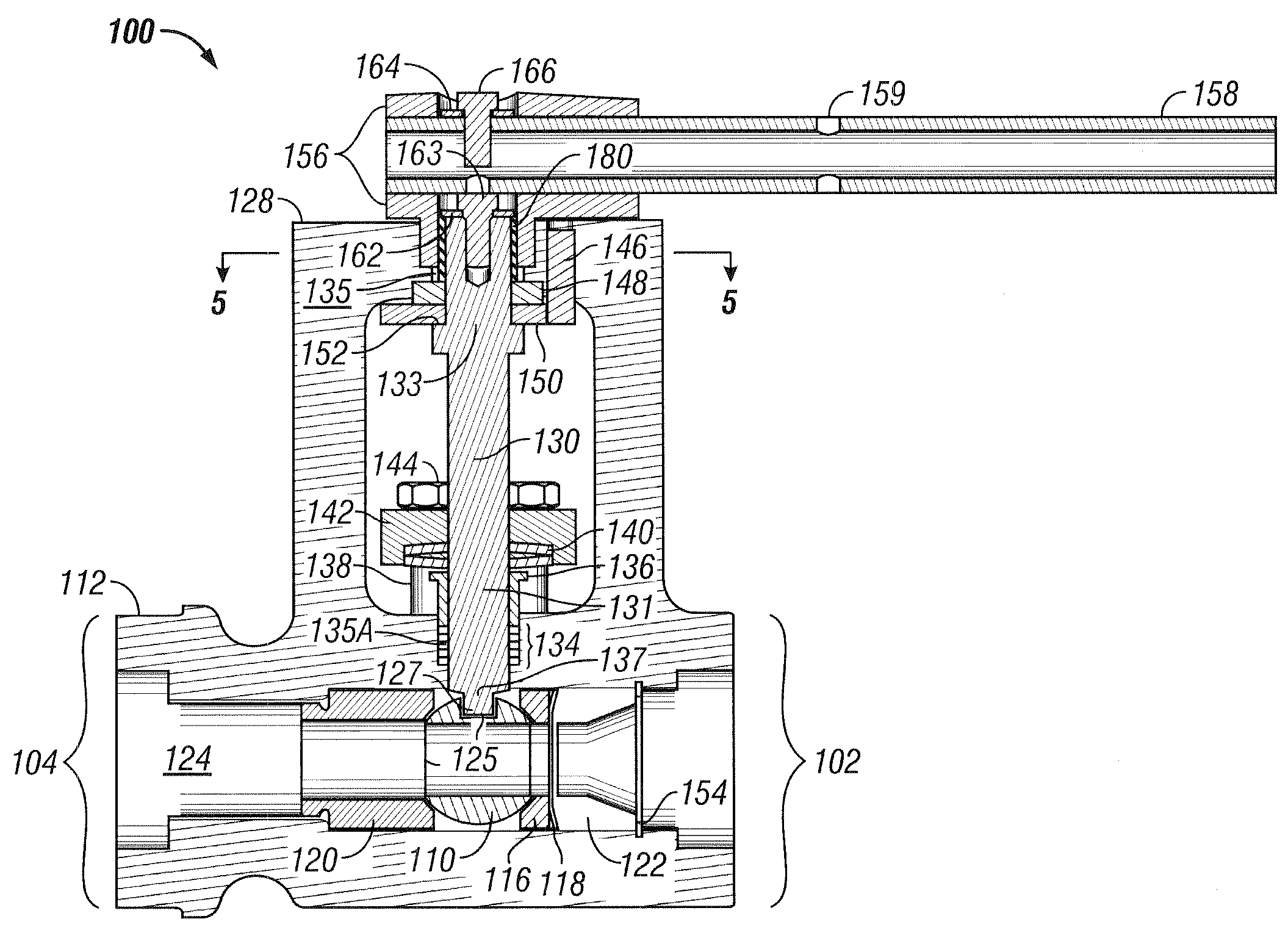

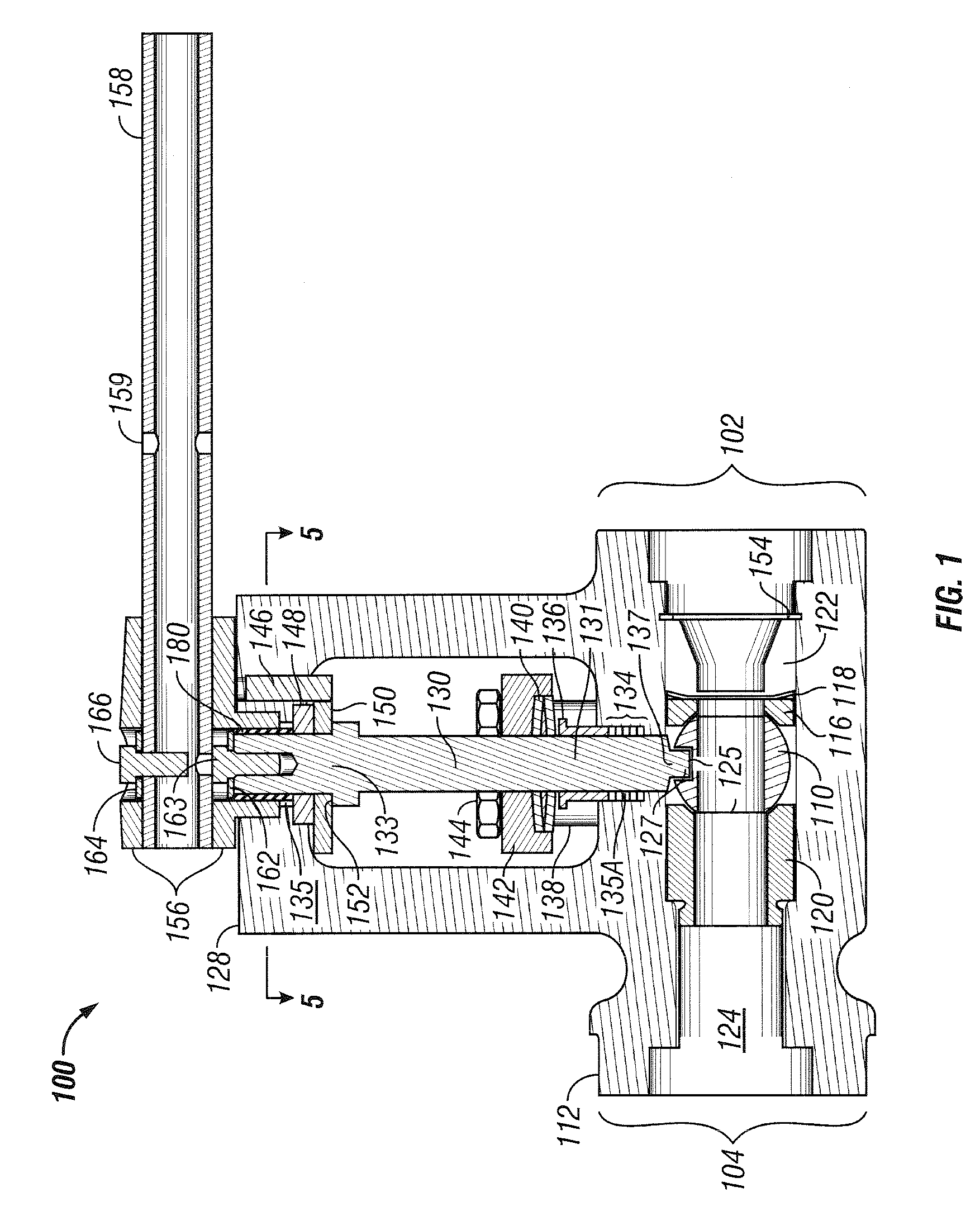

Ball valve with shear bushing and integral bracket for stem blowout protection

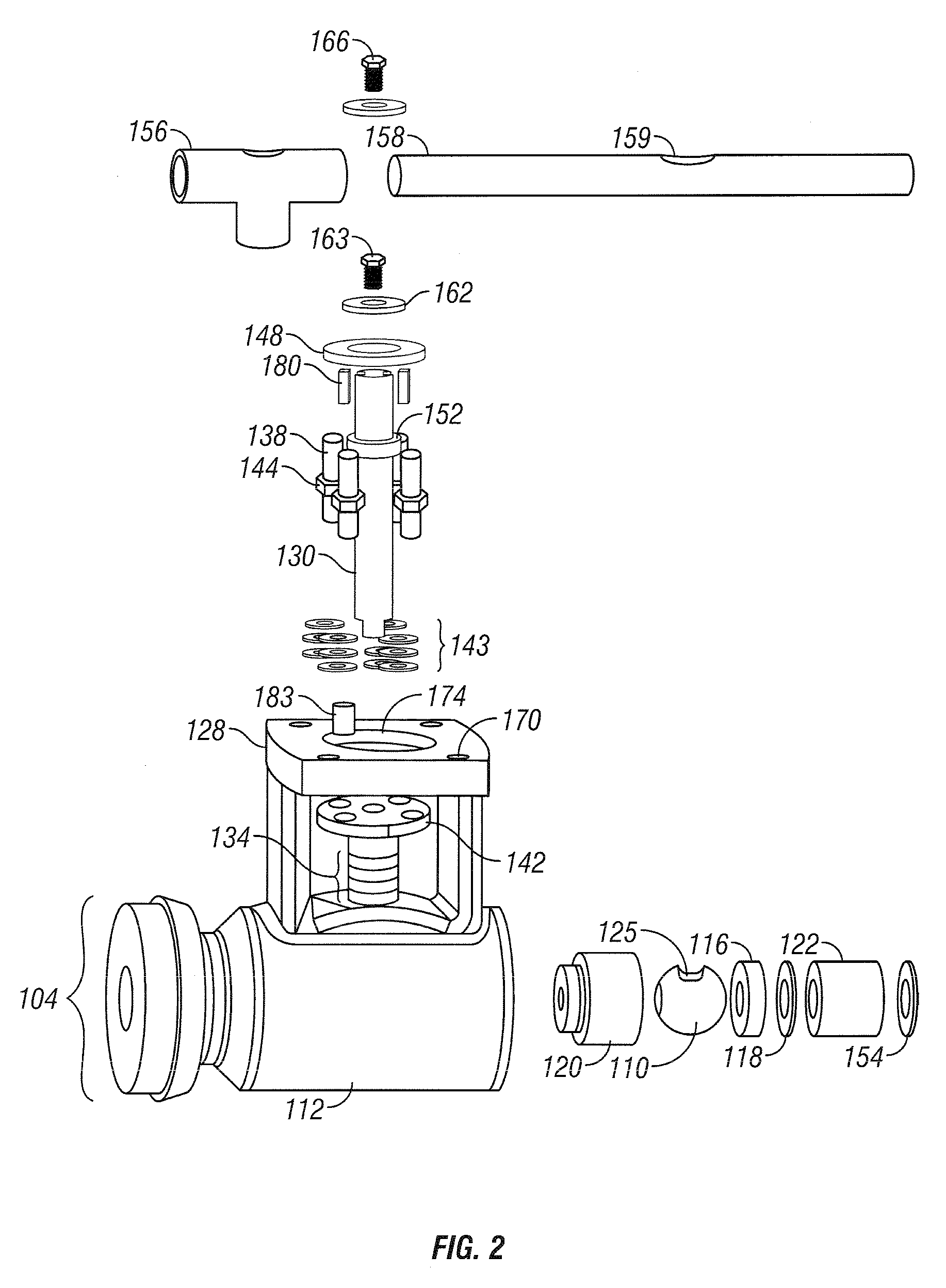

ActiveUS7093819B1Blowout preventionPrevent removalPlug valvesOperating means/releasing devices for valvesEngineeringValve stem

A valve 100 comprising a one piece valve body 112 having an axial fluid bore 124 and a rotatable fluid control element 110. The body 112 includes an integral bracket 128 which provides an open access area between the bracket 128 and the main body 112 of the valve 100. A valve stem 130 is disposed within a stem bore 135, and 137 extending from the valve body 112 to the bracket 128, and engaging the flow control element 110. A contiguous single piece gland flange 142 secures packing 134 disposed between a valve body bore 137 and the stem 130. The stem 130 includes an enlarged shoulder 152 which engages a contiguous single piece shear bushing 148 having a diameter greater than the diameter of the stem bore 130, thereby preventing removal and / or blowout of the stem 130 without prior removal of the shear bushing 148.

Owner:MOGAS IND

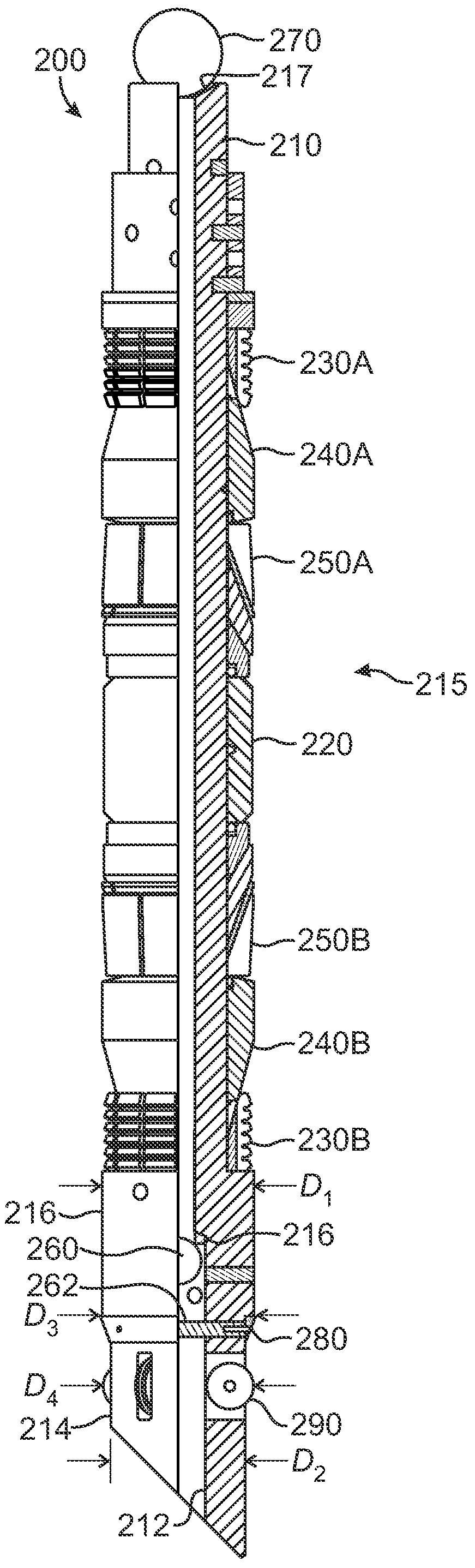

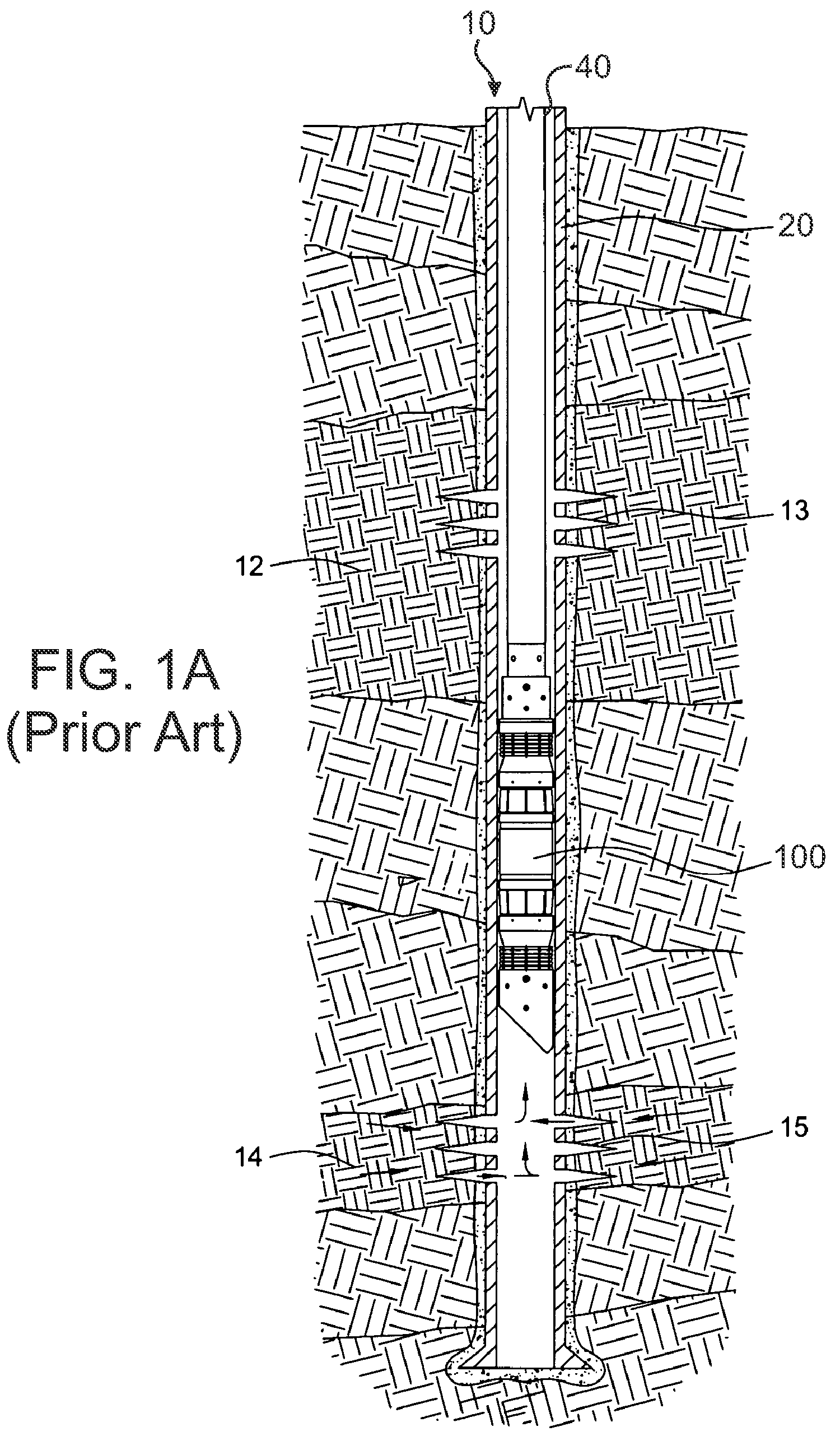

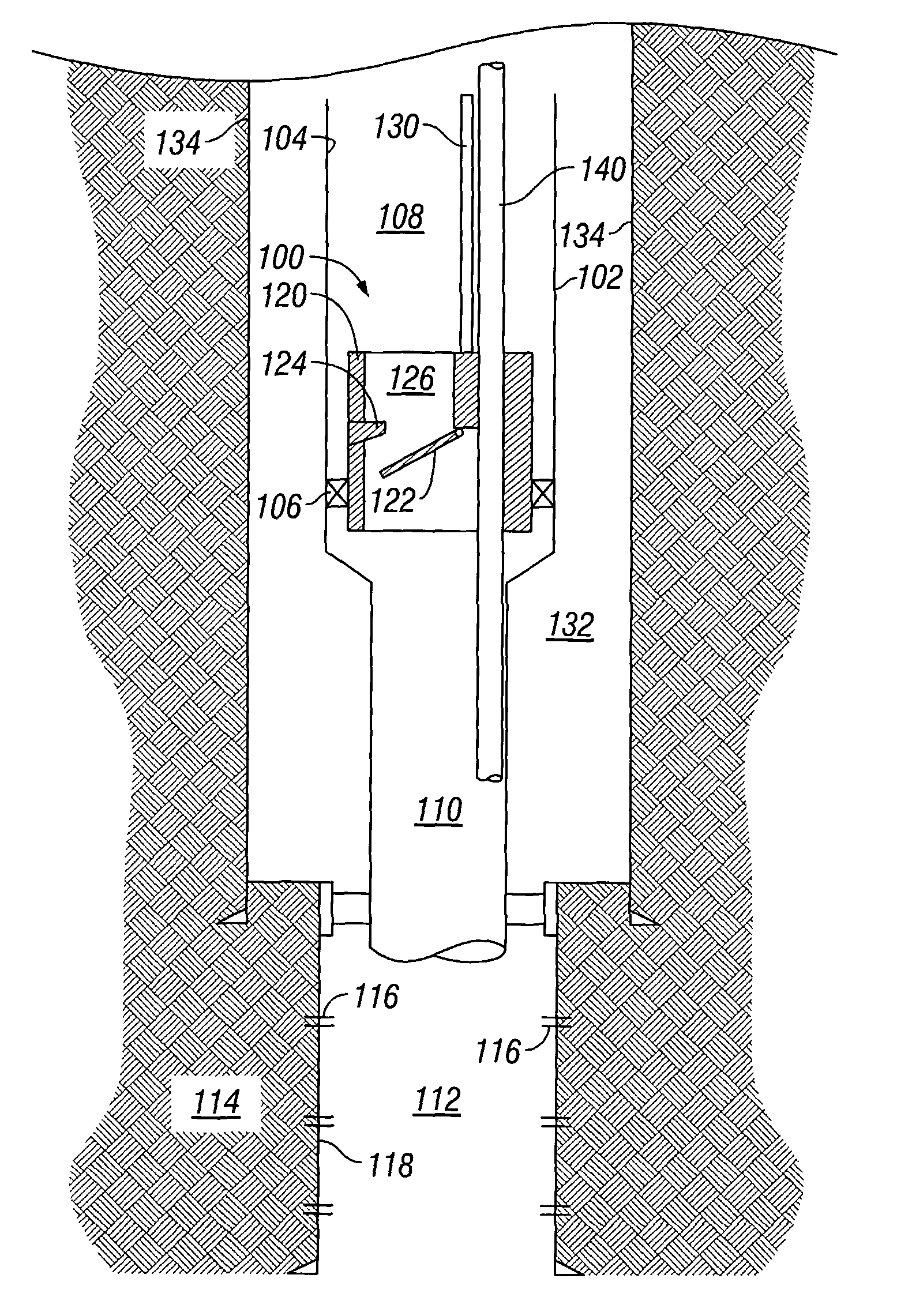

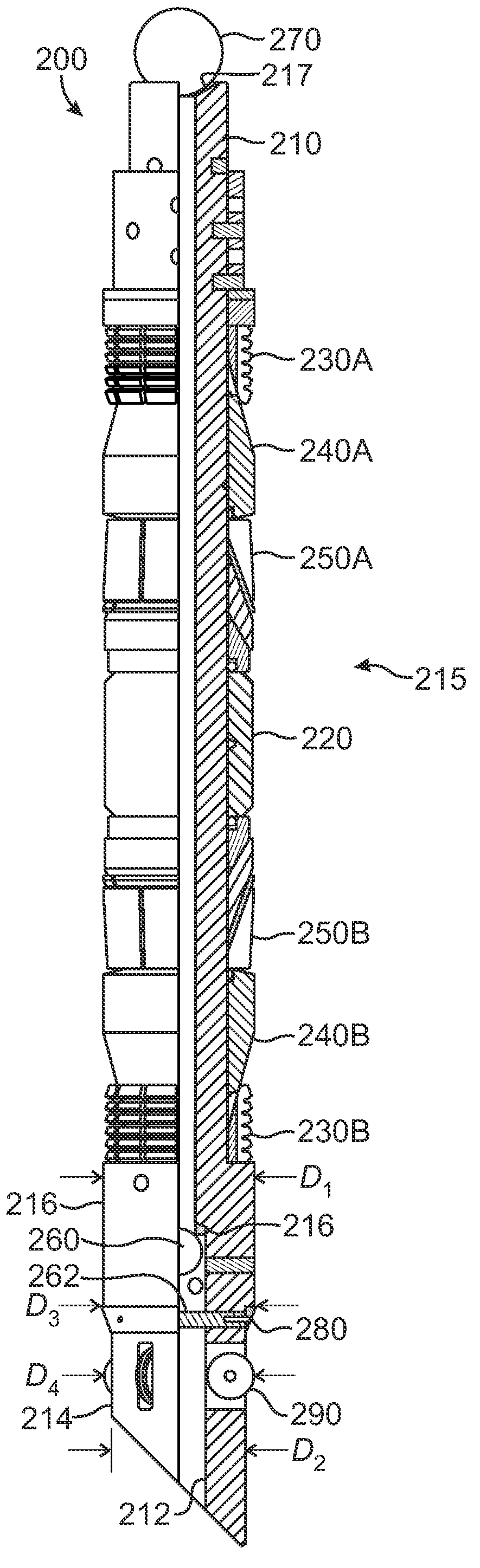

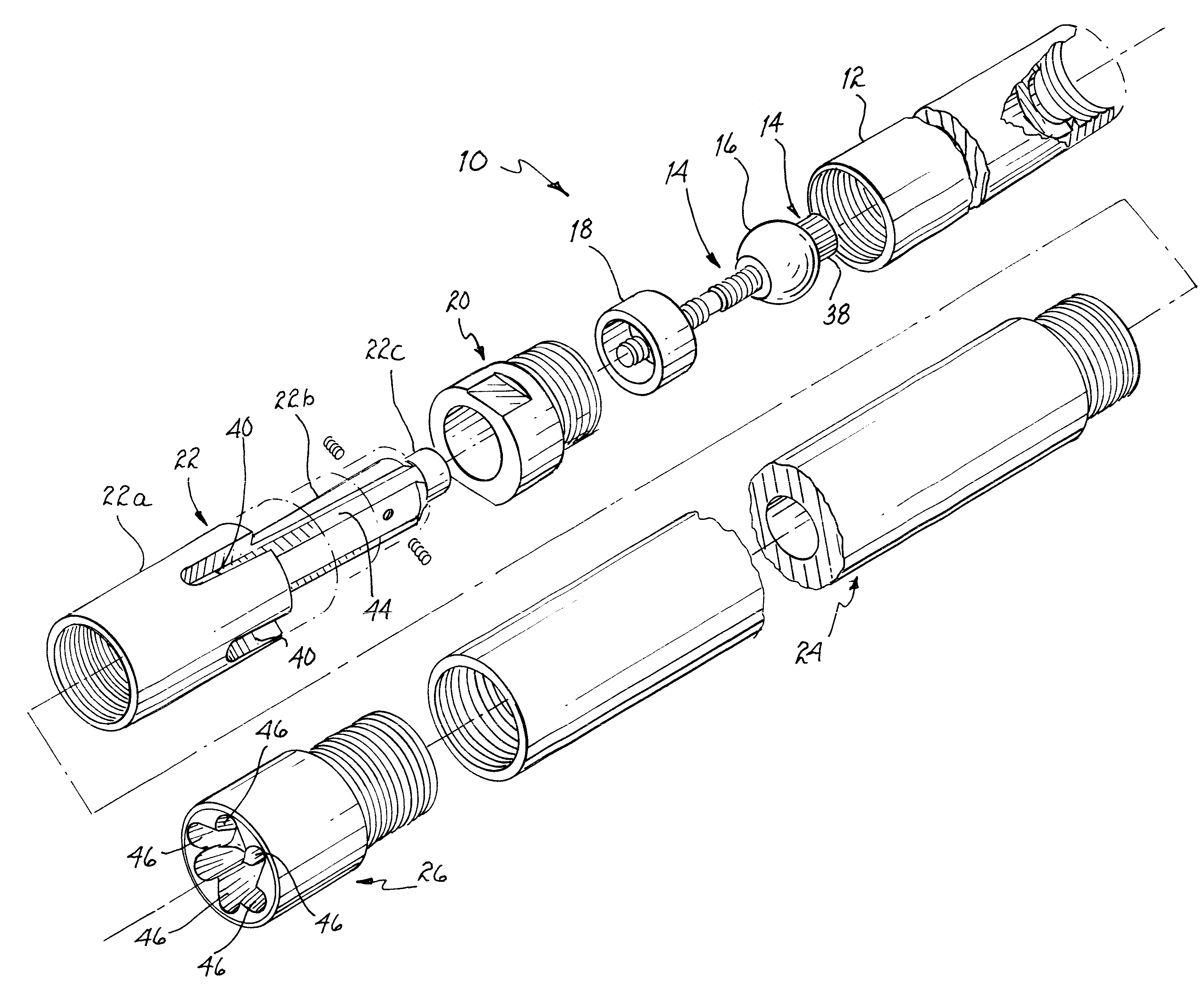

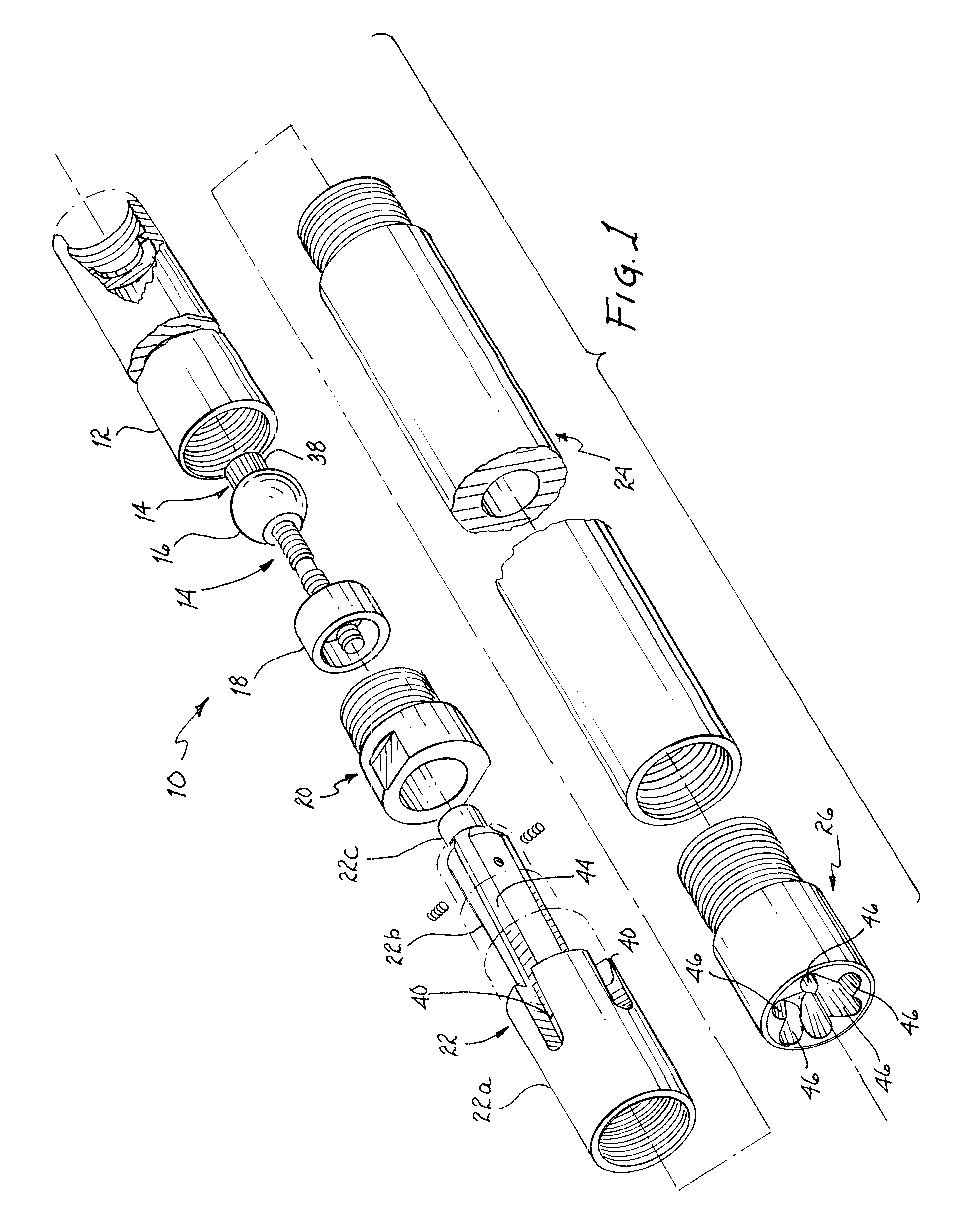

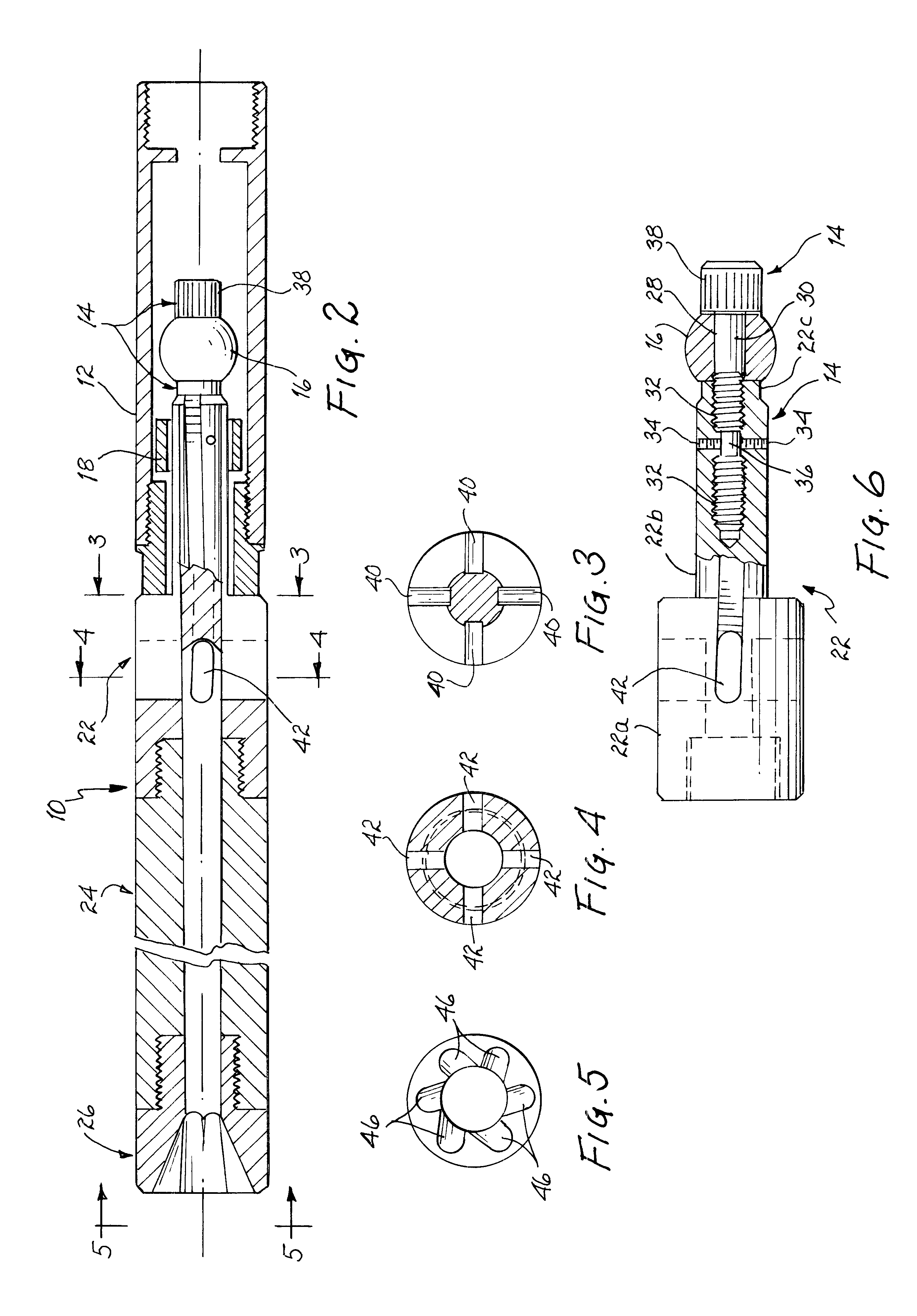

Pressure Isolation Plug for Horizontal Wellbore and Associated Methods

InactiveUS20080271898A1Easy to deployIncrease the differential pressureDrilling rodsFluid removalTime segmentEngineering

A wellbore pressure isolation apparatus is deployed in a wellbore and has a sealing element that can be activated to seal against an interior surface of a surrounding tubular. Once set, a ball valve in the apparatus restricts upward fluid communication through the apparatus, and another ball valve in the apparatus can restrict downward fluid communication through the apparatus. These ball valve can have disintegratable balls intended to disintegrate in wellbore conditions after different periods of time. To facilitate deployment of the apparatus in a horizontal section of the well bore, the apparatus has a plurality of rollers positioned on a distal end. In addition, the apparatus has a ring disposed about the body between the distal body portion and an adjacent body portion. The ring has an outside diameter at least greater than that of the adjacent body portion to facilitate pumping of the apparatus in the wellbore.

Owner:WEATHERFORD TECH HLDG LLC

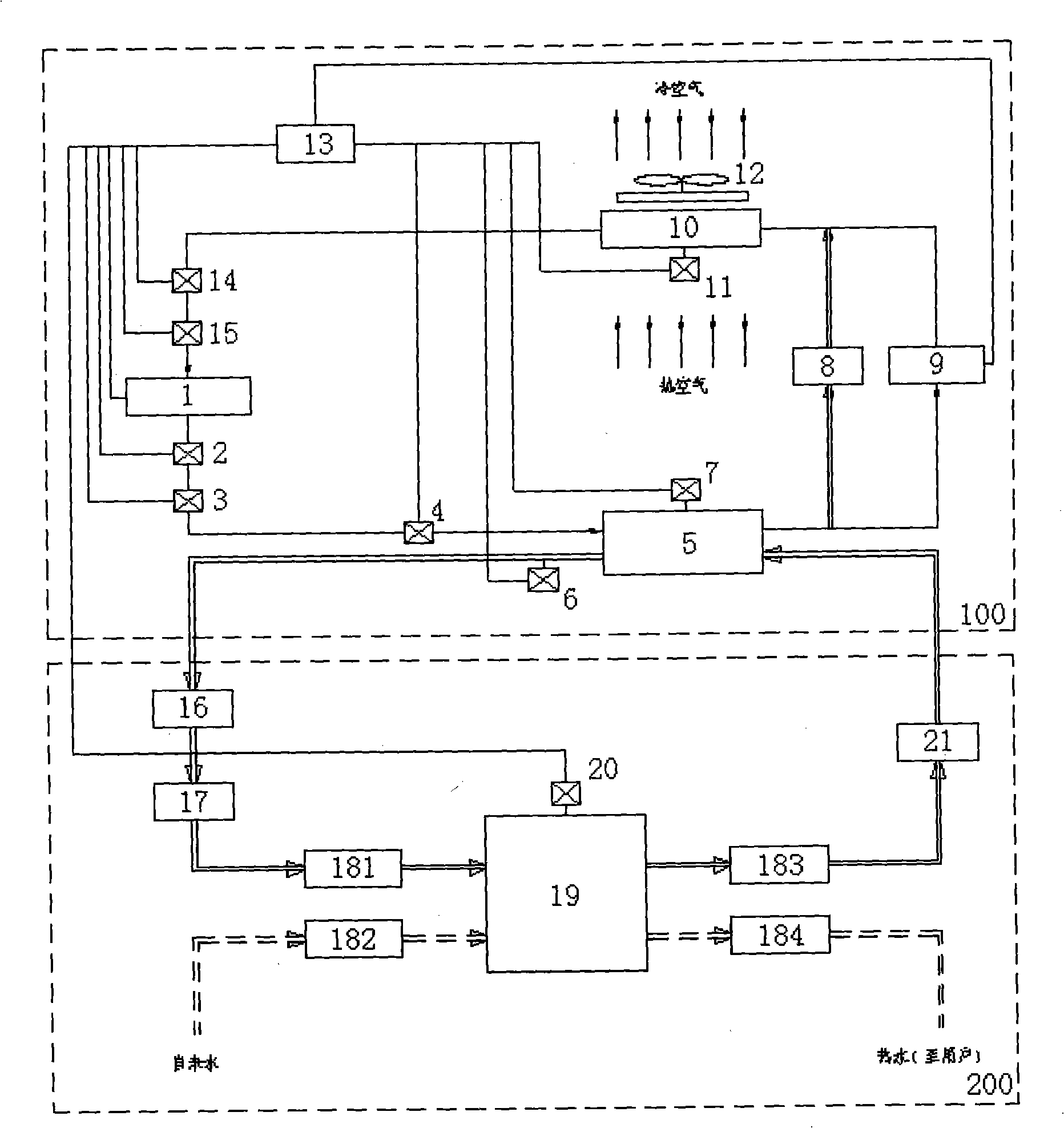

Frequency-variable flux-changing heat pump water heater

InactiveCN101319818AGood performance parametersFestive stream statusFluid heatersFuel oilEngineering

The invention provides a frequency and flow changing heat pump water heater, relates to a liquid heater with a heat generation device by using a heat pump. The frequency and flow changing heat pump water heater comprises a unit part, a water circulating part, water tubes and communication lines connected inside the water circulating part. The unit part comprises a frequency-changing compressor, a cross tee change valve, a double pipe condenser, an unloading valve, an electronic expansion valve, an evaporator, a fan, a controller, various temperature sensors and pressure sensors. The water circulating part comprises a pump, an outlet valve, a ball valve, a water tank, a water temperature sensor and a filter. The frequency and flow changing heat pump water heater takes the frequency-changing compressor as the power source of the system, takes the electronic expansion valve as a throttling device and uses the water temperature sensor to prevent freezing. Compared with combustion gas, fuel oil, coal or electronic water heater, the frequency and flow changing heat pump water heater has safety, environmental protection and energy saving properties. Compared with the heat pump hot water units, the throttling of which uses rated frequency compressor and thermostatic expansion valve or capillary tubes, the frequency and flow changing heat pump water heater has high heating output power, good heating effect and good environmental adaptability.

Owner:SHANGHAI MO & ELECTRICAL APPLIANCE

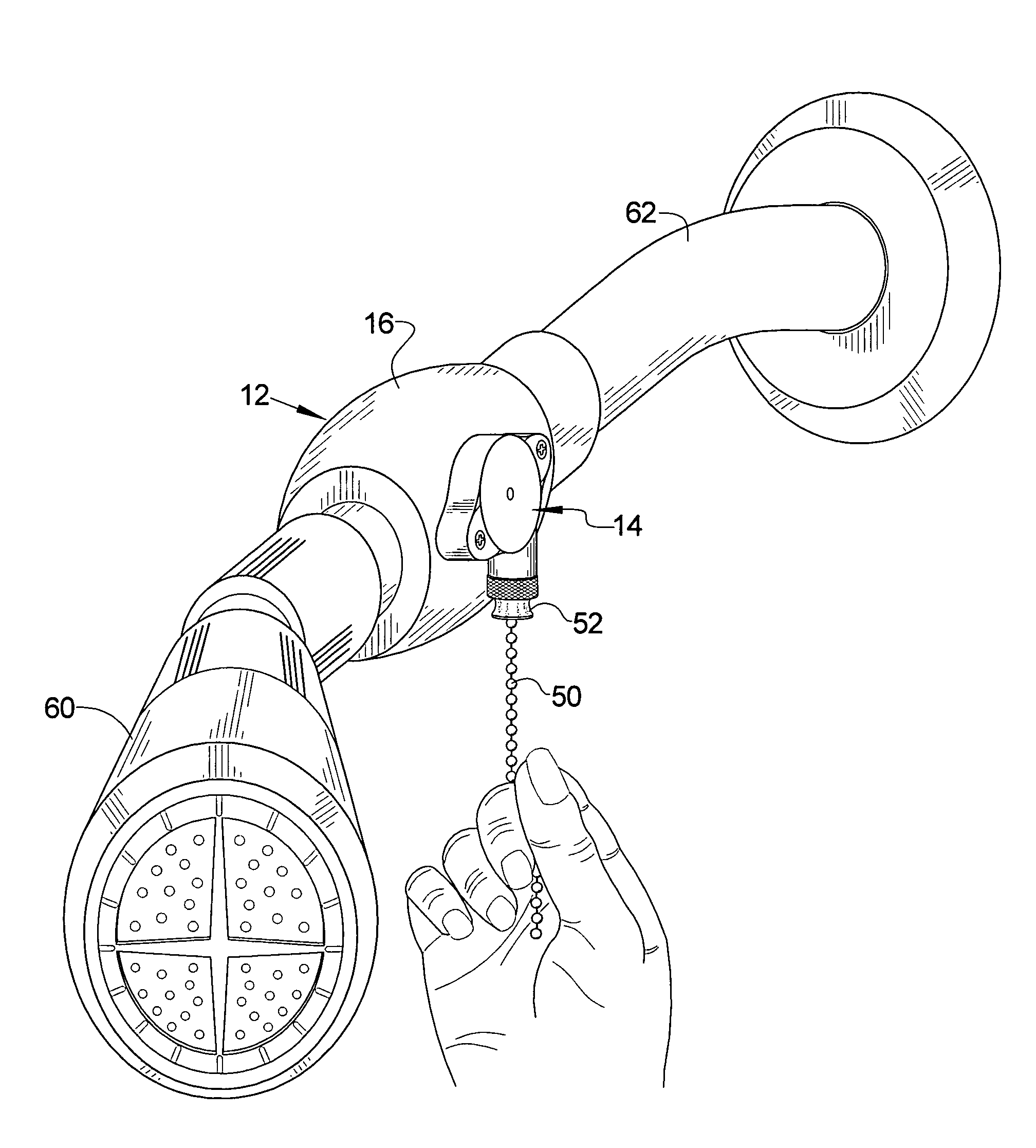

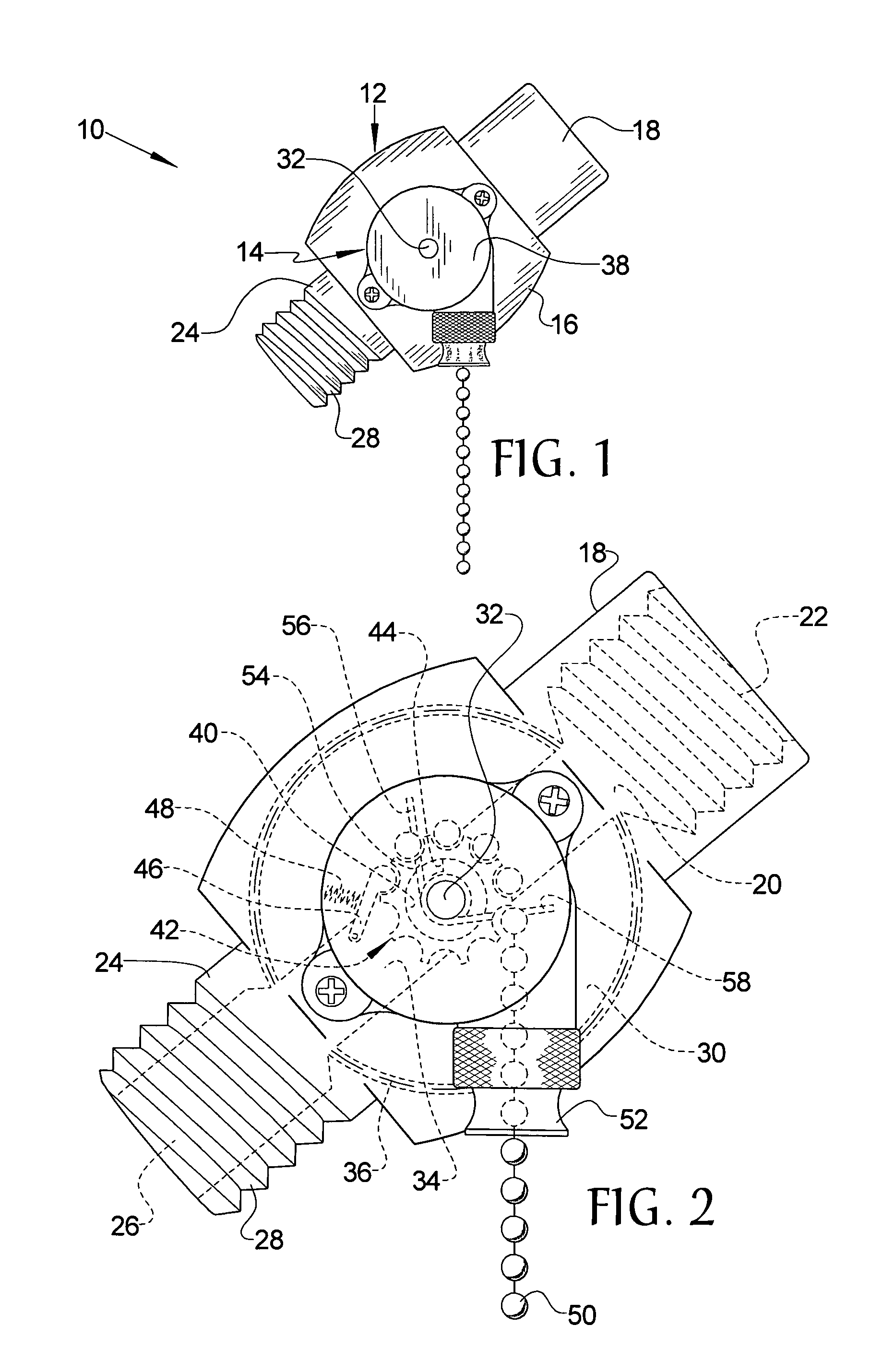

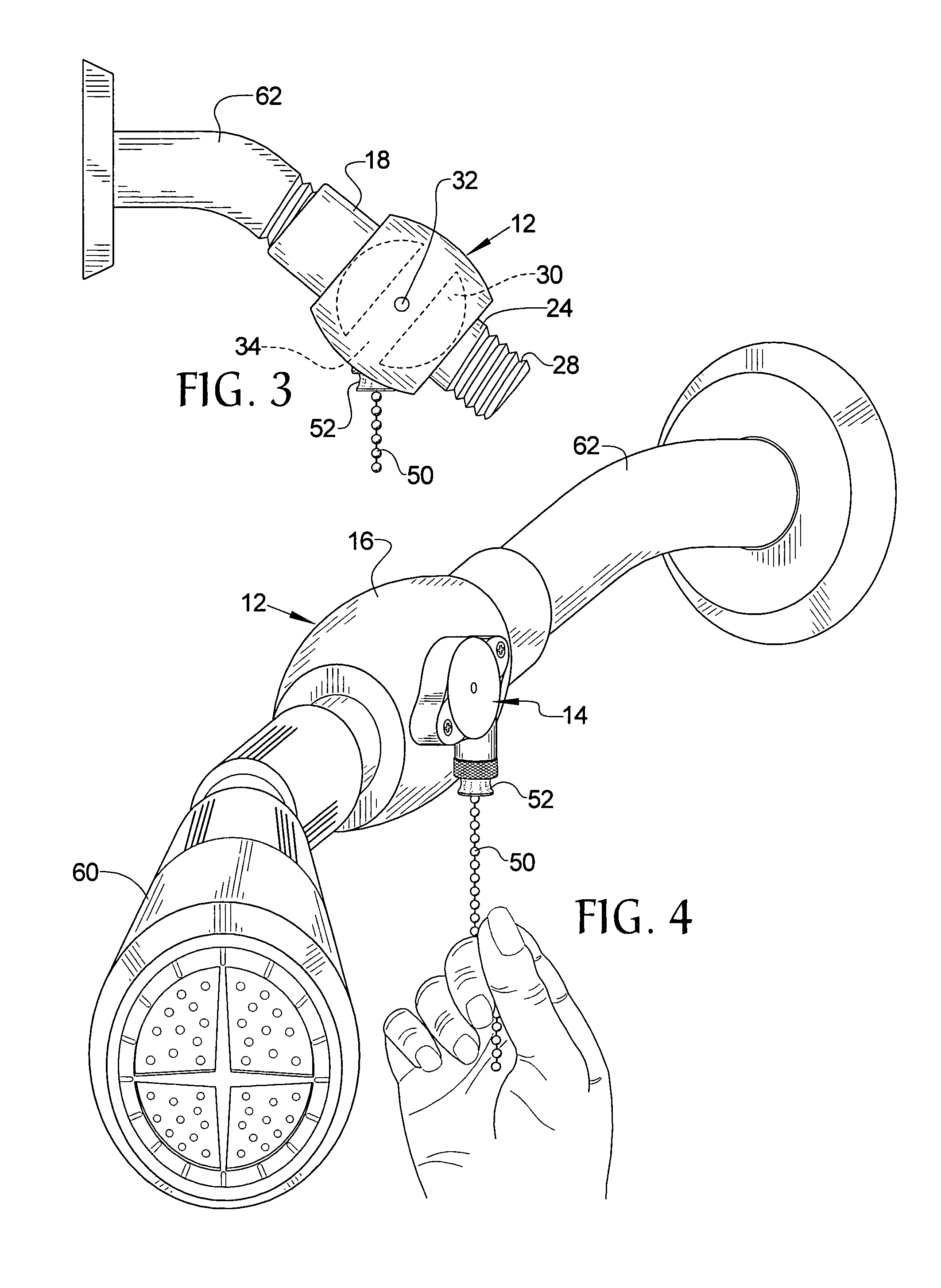

Pull-chain shower valve

InactiveUS7694359B1Simple designEasy constructionPlug valvesOperating means/releasing devices for valvesPull forceWater flow

A pull-chain shower valve is interposed between a pipe stub and a shower head of a typical shower and allows a user to turn the water on and off at the shower head assembly without the need to use the main valve controls of the shower. The device uses a ball valve that articulates between an open position wherein water flows out of the shower head and a closed position wherein water does not flow out of the shower head. A standard pull-chain assembly is used to articulate the ball valve between its open position and its closed position. A pull-chain of the pull-chain assembly is pulled in order to advance the ball valve to its next position. Each sufficient pull of the pull-chain advances the ball valve exactly 90 degrees. If the pull-chain is not pulled sufficiently, the ball valve resets to its prior position. A reset mechanism is provided for the pull-chain.

Owner:HALL LEATON

Travelling valve for a pumping apparatus

An improved travelling valve has a ball which is positioned on a seal stem, so that the ball is reliably centered when seated on the valve seat, reducing damage to the ball and seat from improper seating and providing increased efficiency for deviated or non-vertical pumping operations and the pumping of highly viscous fluids such as heavy crude. The improved travelling valve is constructed so that a lower portion of the valve rotates during pumping, and thereby imparts rotational movement to the fluid passed therethrough. Such rotational movement of the valve and fluid helps reduce gas lock, and reduces damage to the ball, seat, and valve exterior from impurities in the pumped fluid. Preferably, rotational movement is caused by angled channels in an interior portion of a vein rotator positioned at the bottom of the travelling valve, working in combination with angled channels in the seal stem.

Owner:FORD MICHAEL BRENT

PVC material and preparation thereof

InactiveCN101486820AReduce foulingHigh low temperature impact resistanceProcedure AgentsFood sanitation

The invention discloses a PVC material and a preparation method thereof. The PVC material comprises the following substances according to parts by weight: 100 parts of PVC, 2-8 parts of stabilizer, 2-6 parts of processing agent, 1.5-2.5 parts of lubricants, 4-12 parts of filler, and 0.05-1 part of colorant. Compared with the prior art, the invention adopts food sanitation-level or nontoxic raw materials; the mobility of the manufactured material is good, and the molding temperature and molding pressure of tubular products and pipe fittings can be reduced, thus preventing the PVC material from pyrolyzing. The PVC-U water supply tubular products, pipe fittings and pressure-proof ball valves made from the material have good acid and alkali resistance, inoxidability and ageing resistance, and the pressure resistance of the pressure-proof ball valve is more than or equal to 2.5MPa (the pressure resistance of similar products is only more than 1.6MPa), thus fully meeting food and chemical use requirements.

Owner:黄山琦源塑管阀门有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com