Patents

Literature

888 results about "Fuel line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fuel line is a hose used to bring fuel from one point in a vehicle to another or from a storage tank to a vehicle. It is commonly made of reinforced rubber to prevent splitting and kinking. The United States Environmental Protection Agency defines a fuel line as "all hoses or tubing designed to contain liquid fuel or fuel vapor. This includes all hoses or tubing for the filler neck, for connections between dual fuel tanks, and for connecting a carbon canister to the fuel tank. This does not include hoses or tubing for routing crankcase vapors to the engine's intake or any other hoses or tubing that are open to the atmosphere."

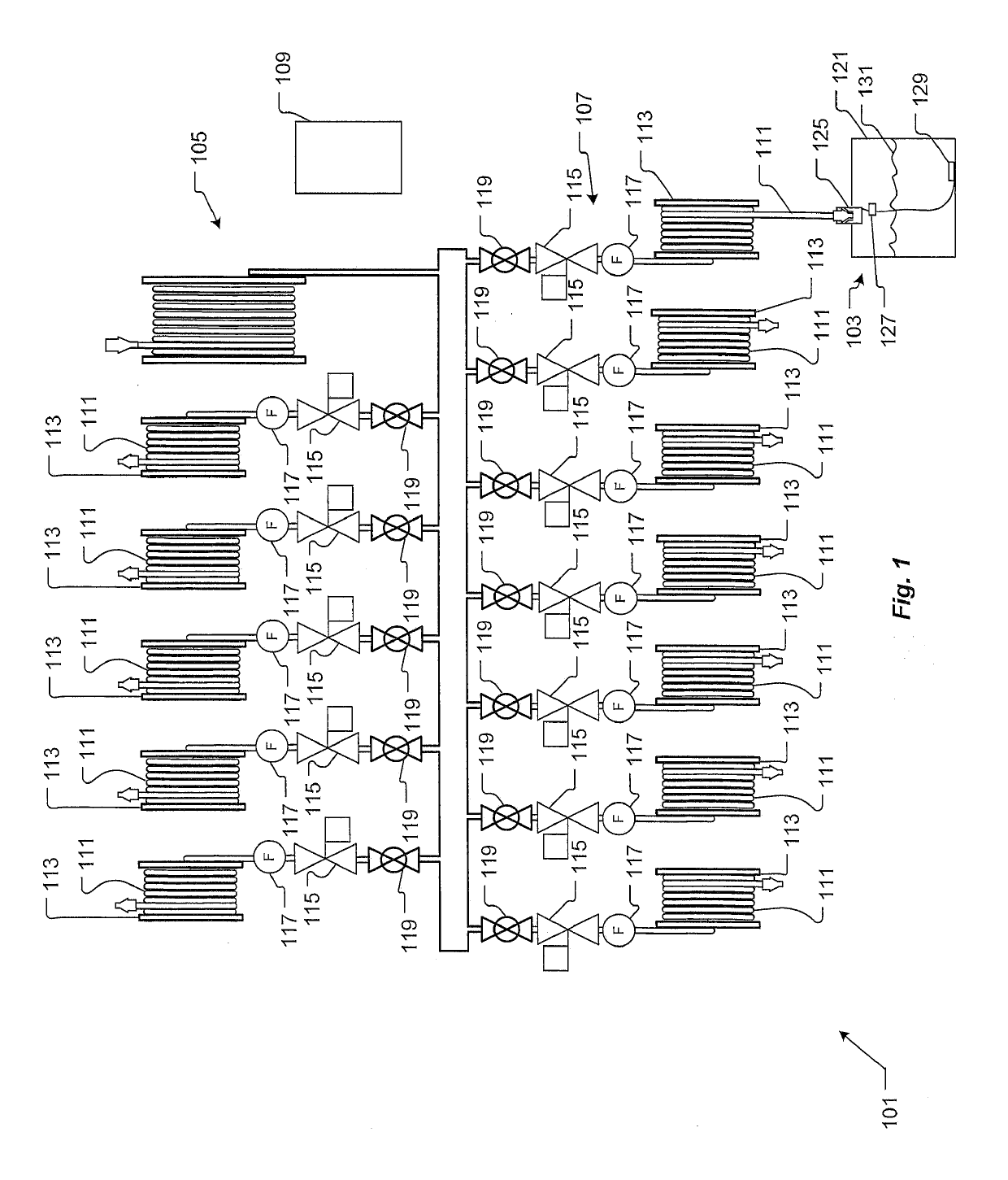

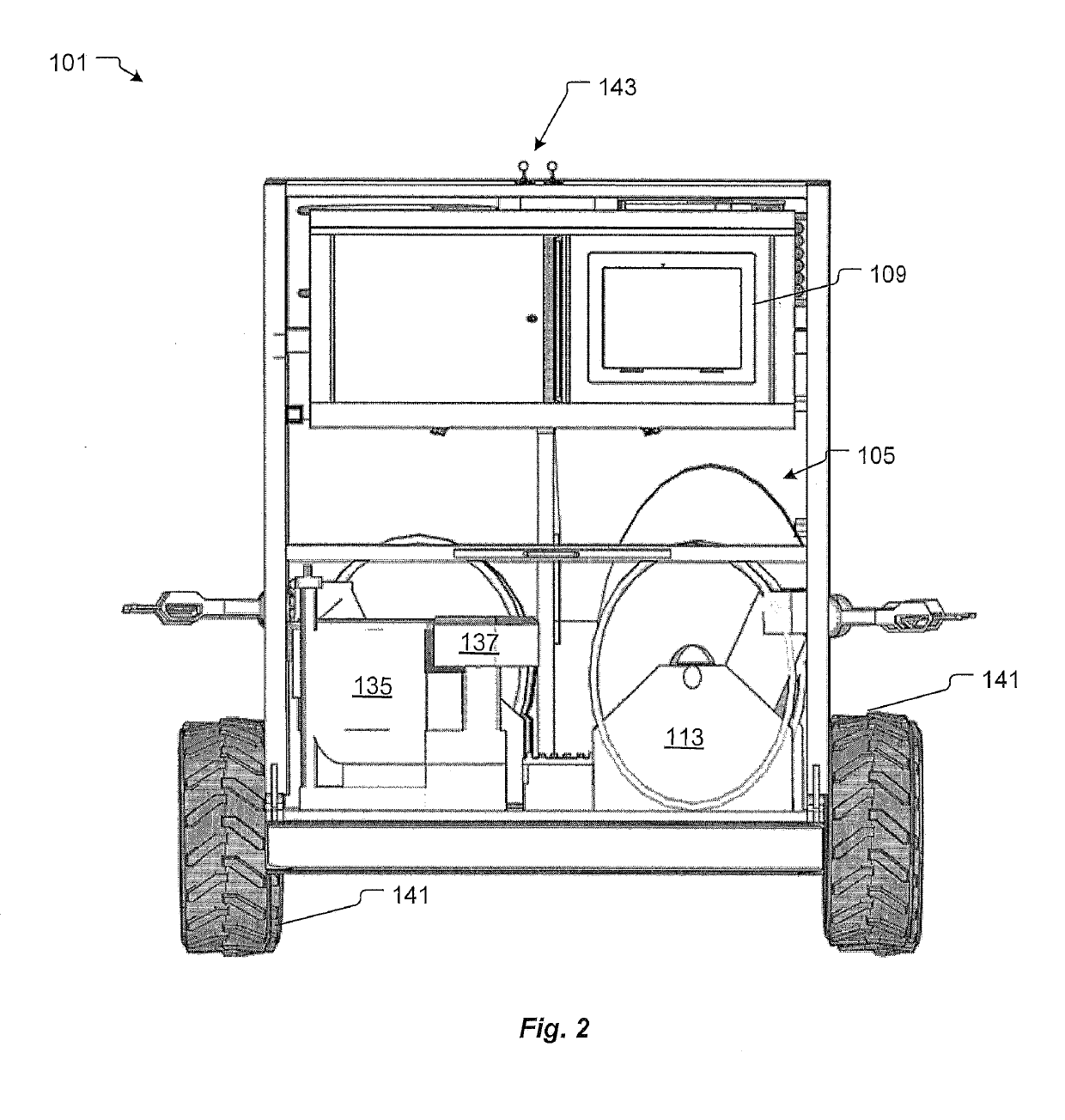

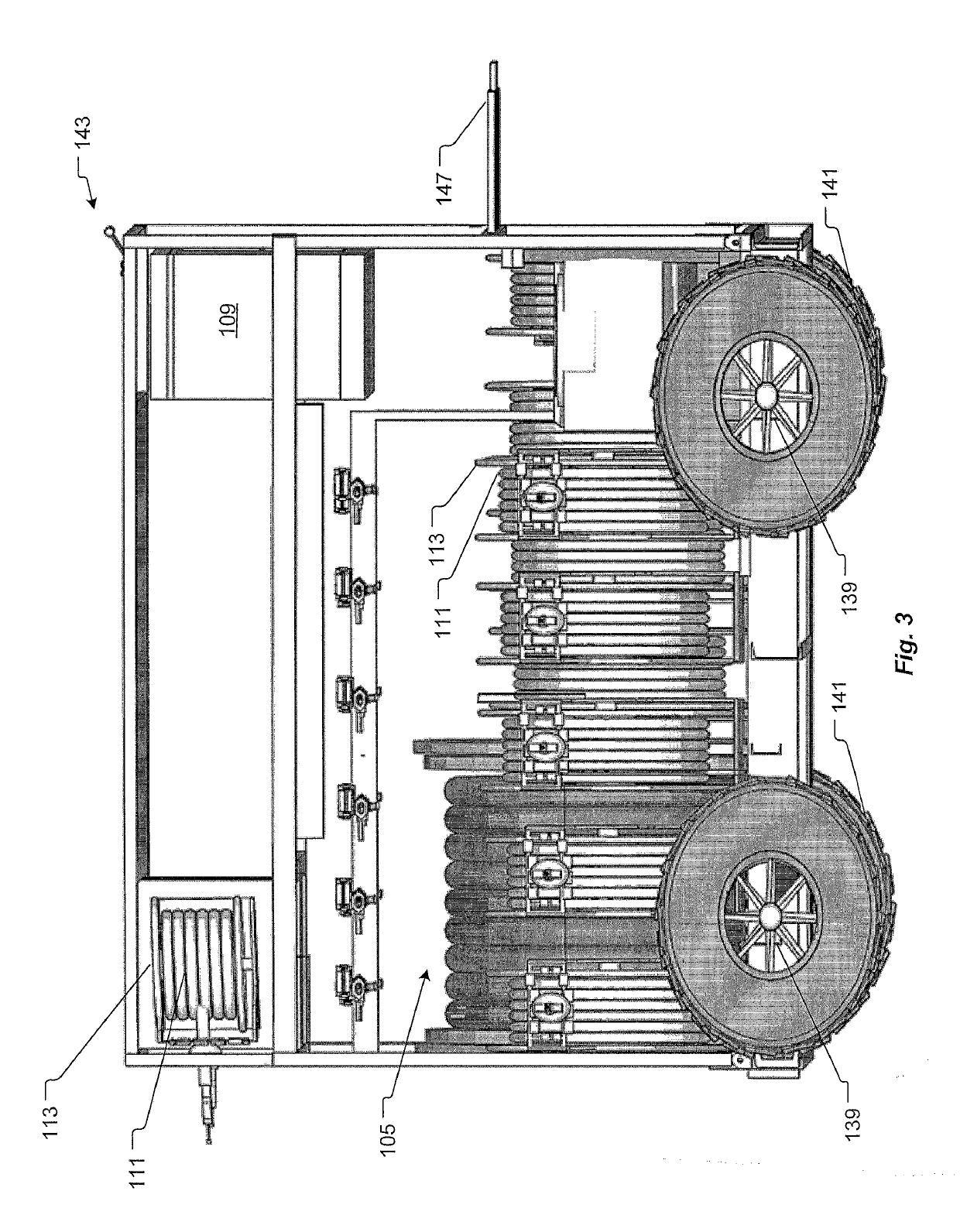

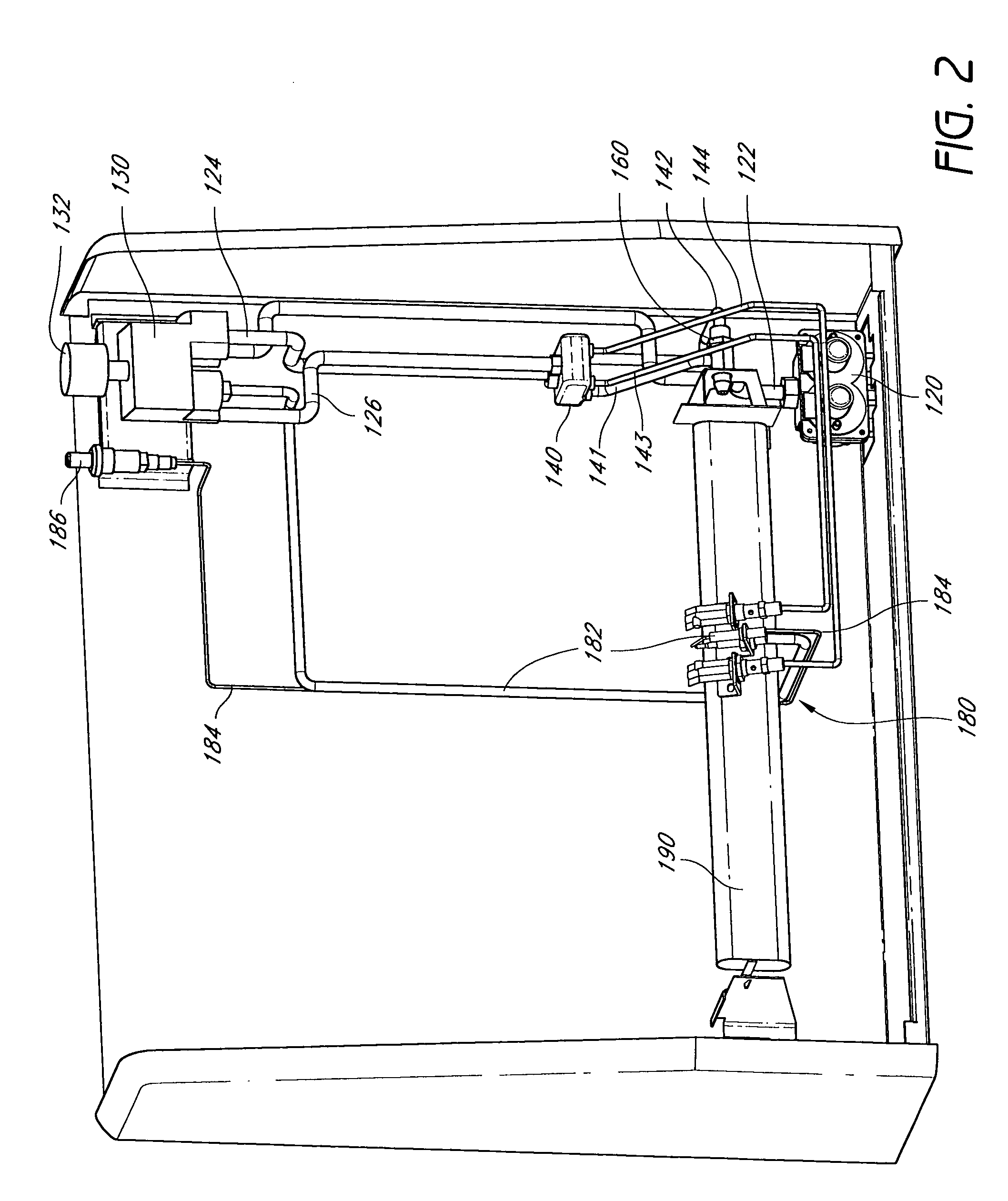

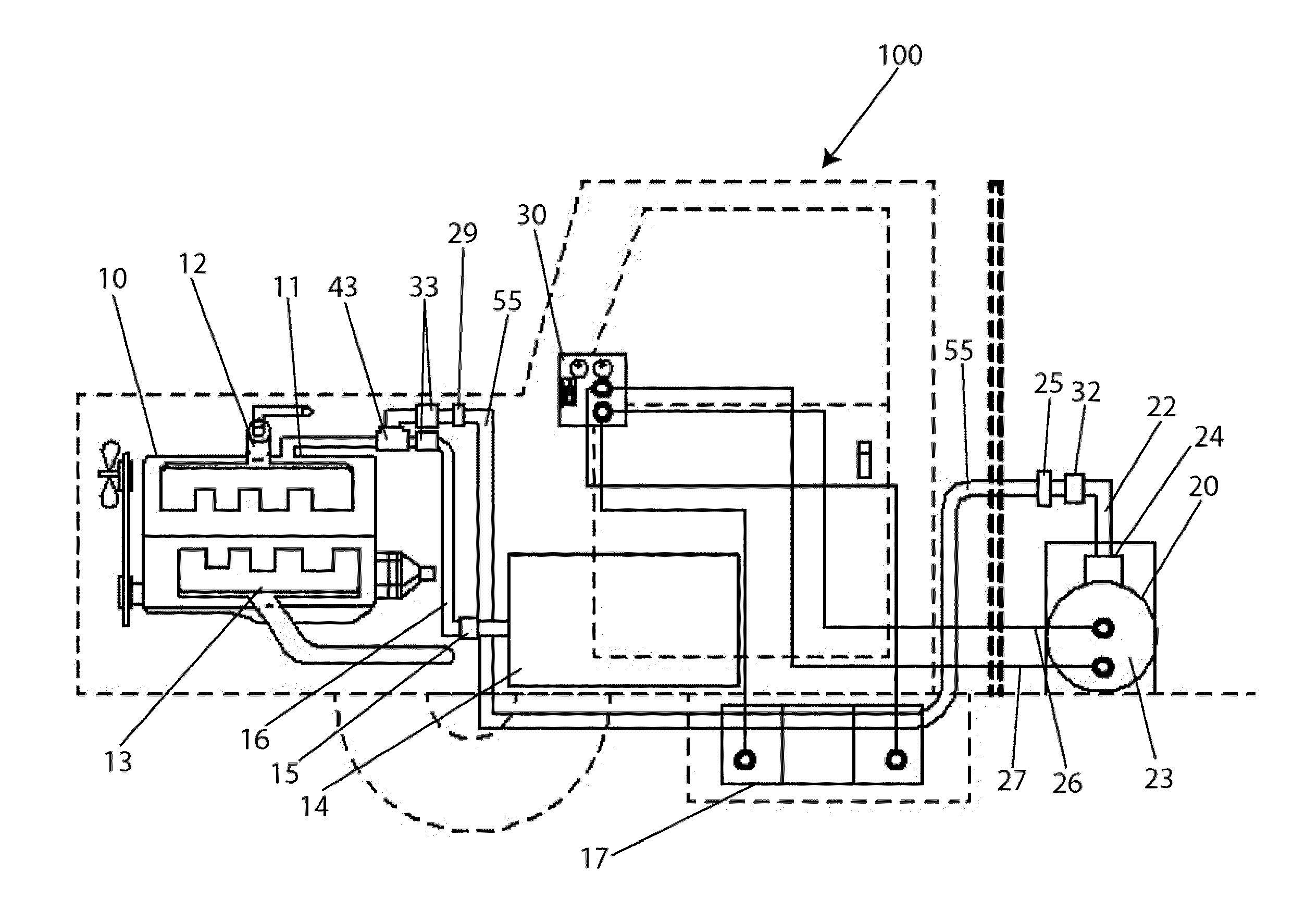

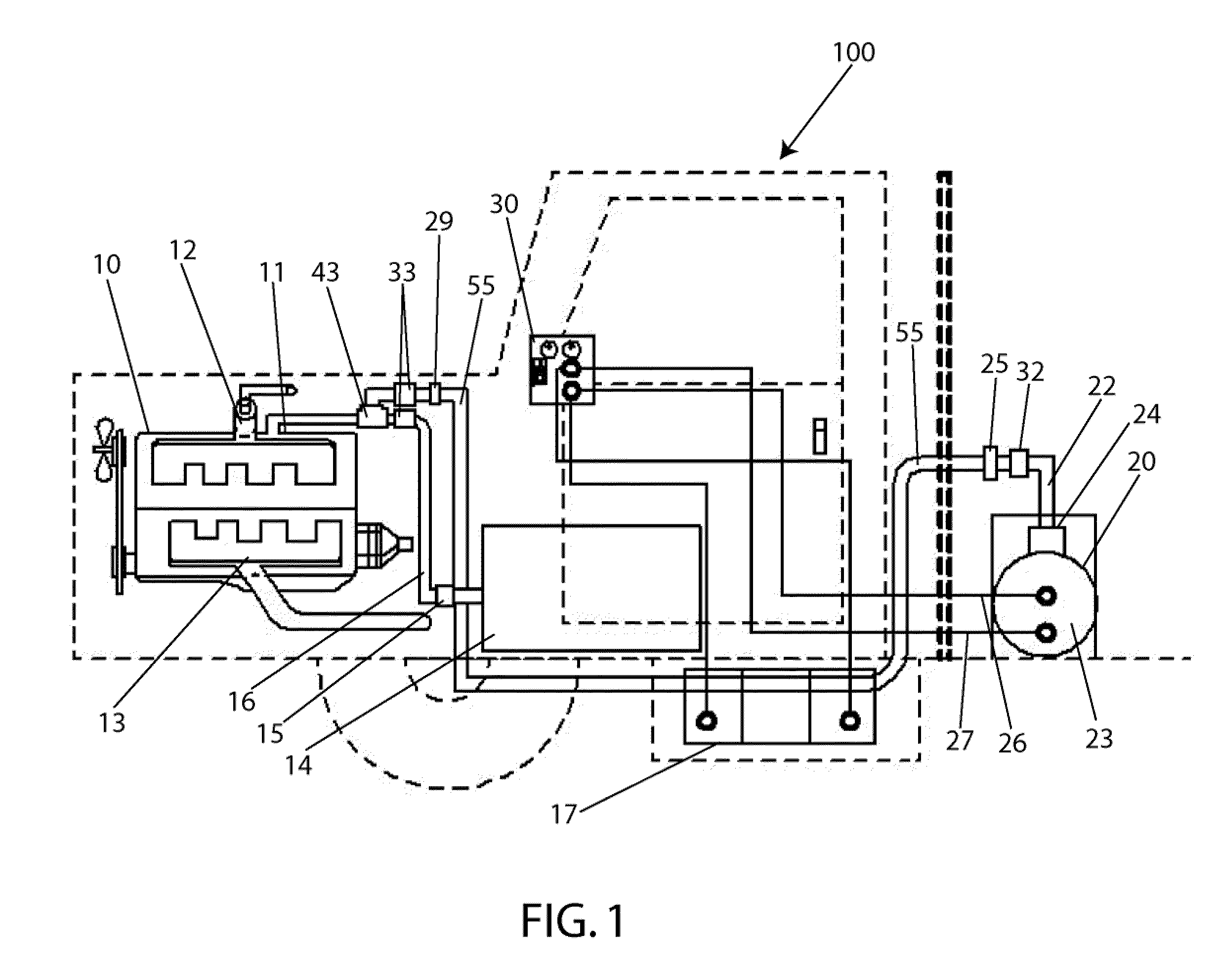

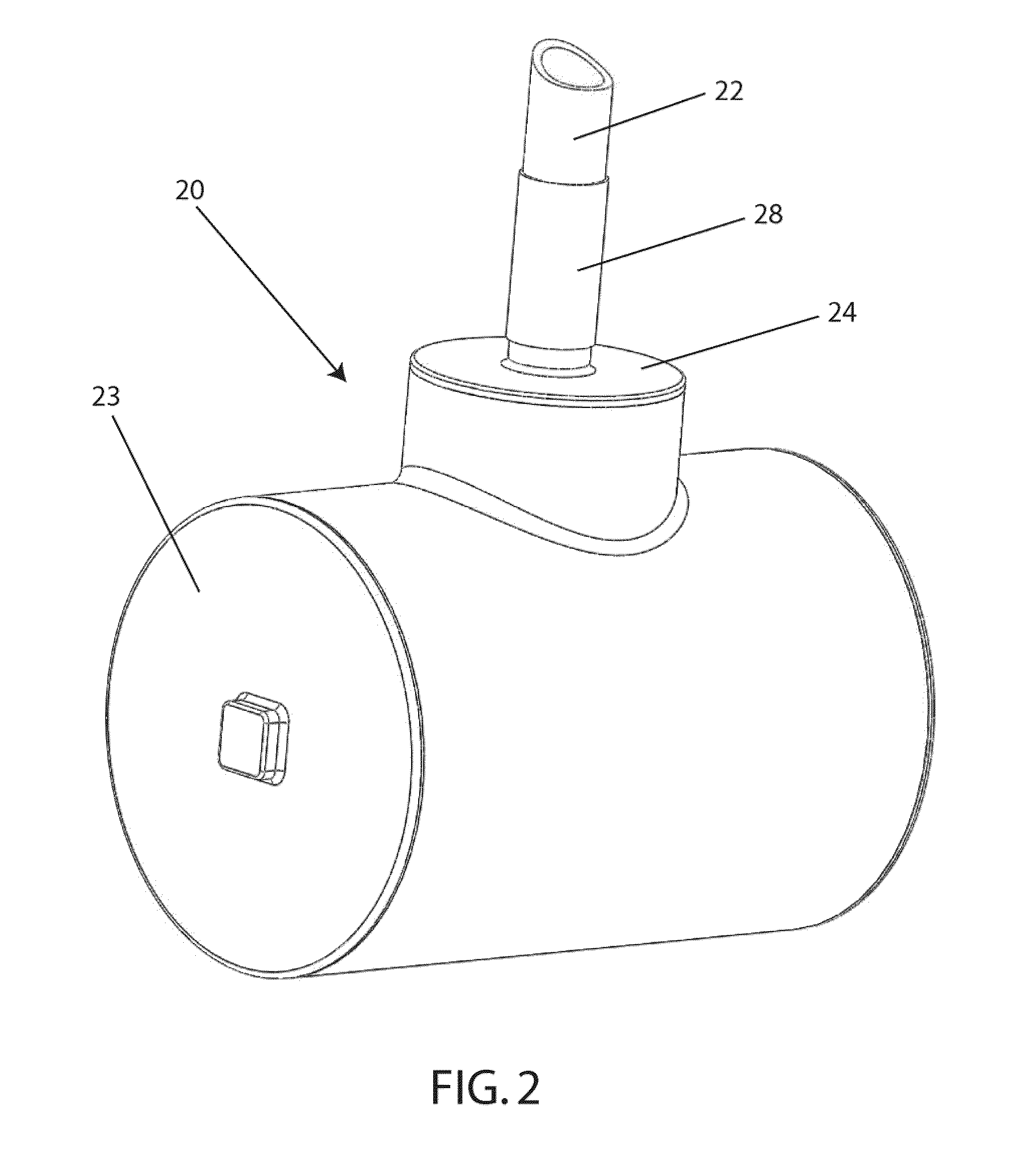

System and Method for Automatic Fueling of Hydraulic Fracturing and Other Oilfield Equipment

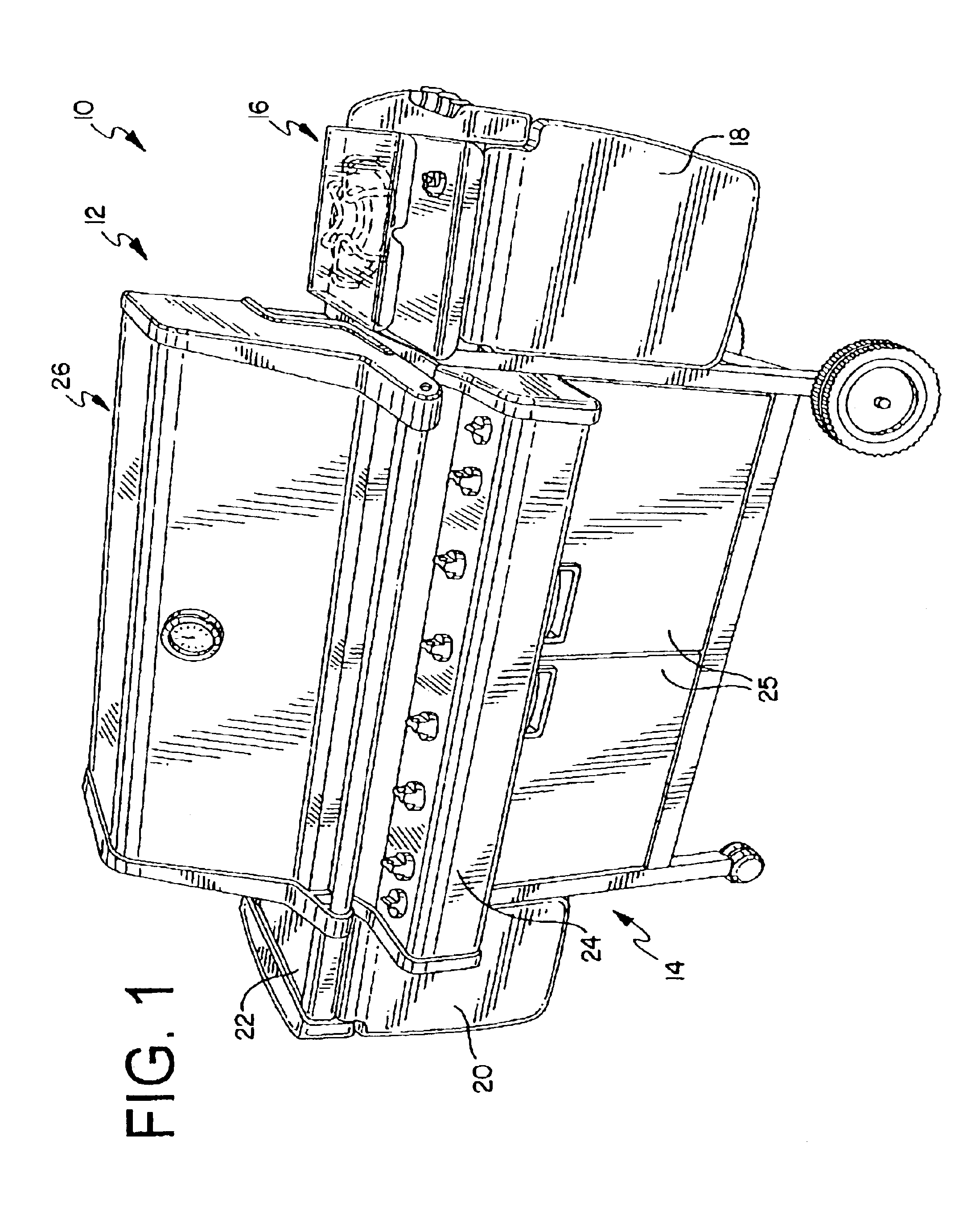

A system and method for fueling multiple saddle tanks of hydraulic fracturing equipment from a single self-propelled cart. The cart having multiple retractable fuel lines for providing and obtaining fuel. Each retractable fuel supply line uses a flowmeter, a ball valve, and an electrically actuated valve to provide remote control to a controller based on a user's selected fueling requirements. An electronic reporting system provides fuel data to operators and users. Fuel data such as fuel tank status, an amount of fuel usage over a stage level, a daily level, or job level along with a fill level of the fuel tank.

Owner:AMERICAN ENERGY INNOVATIONS LLC

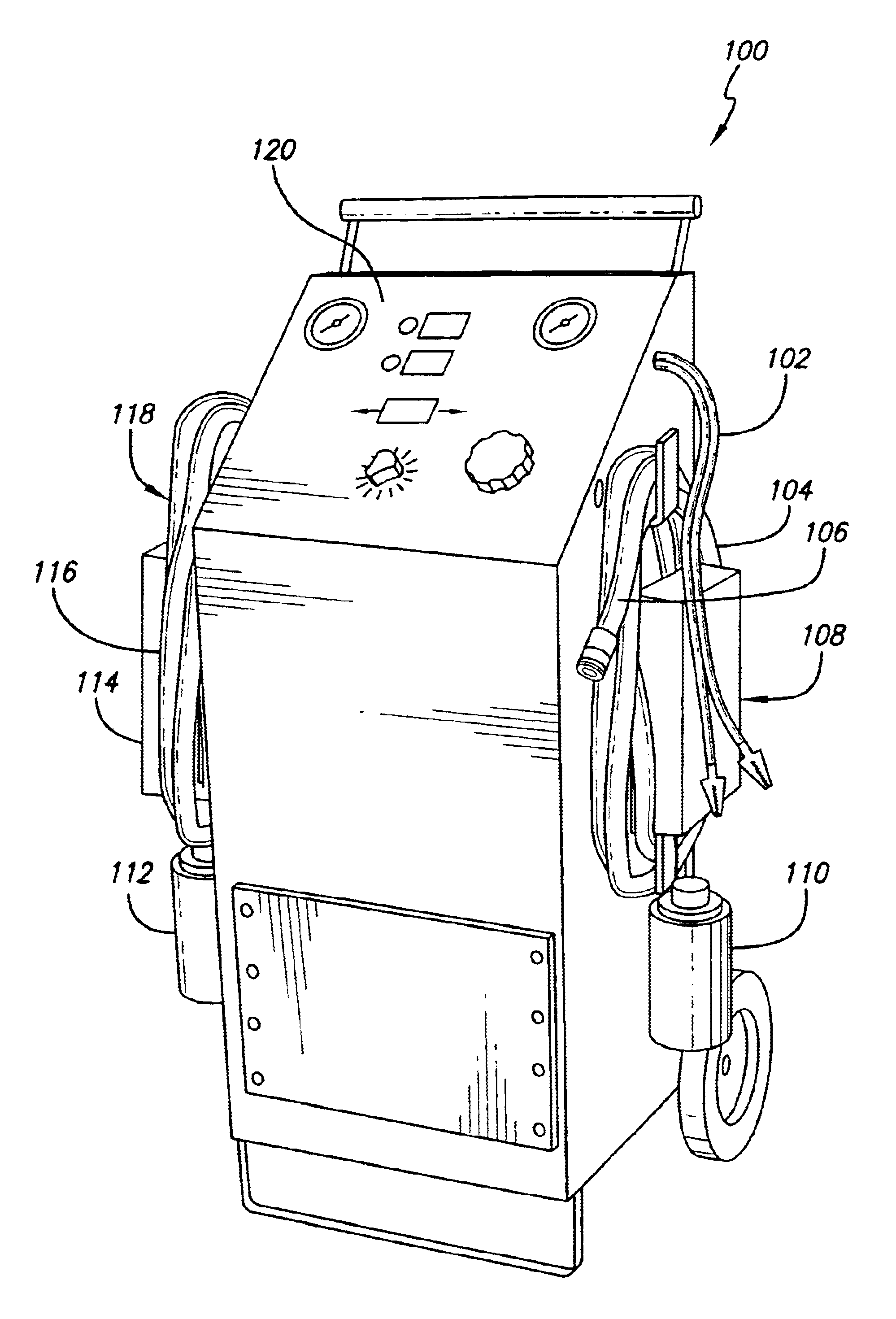

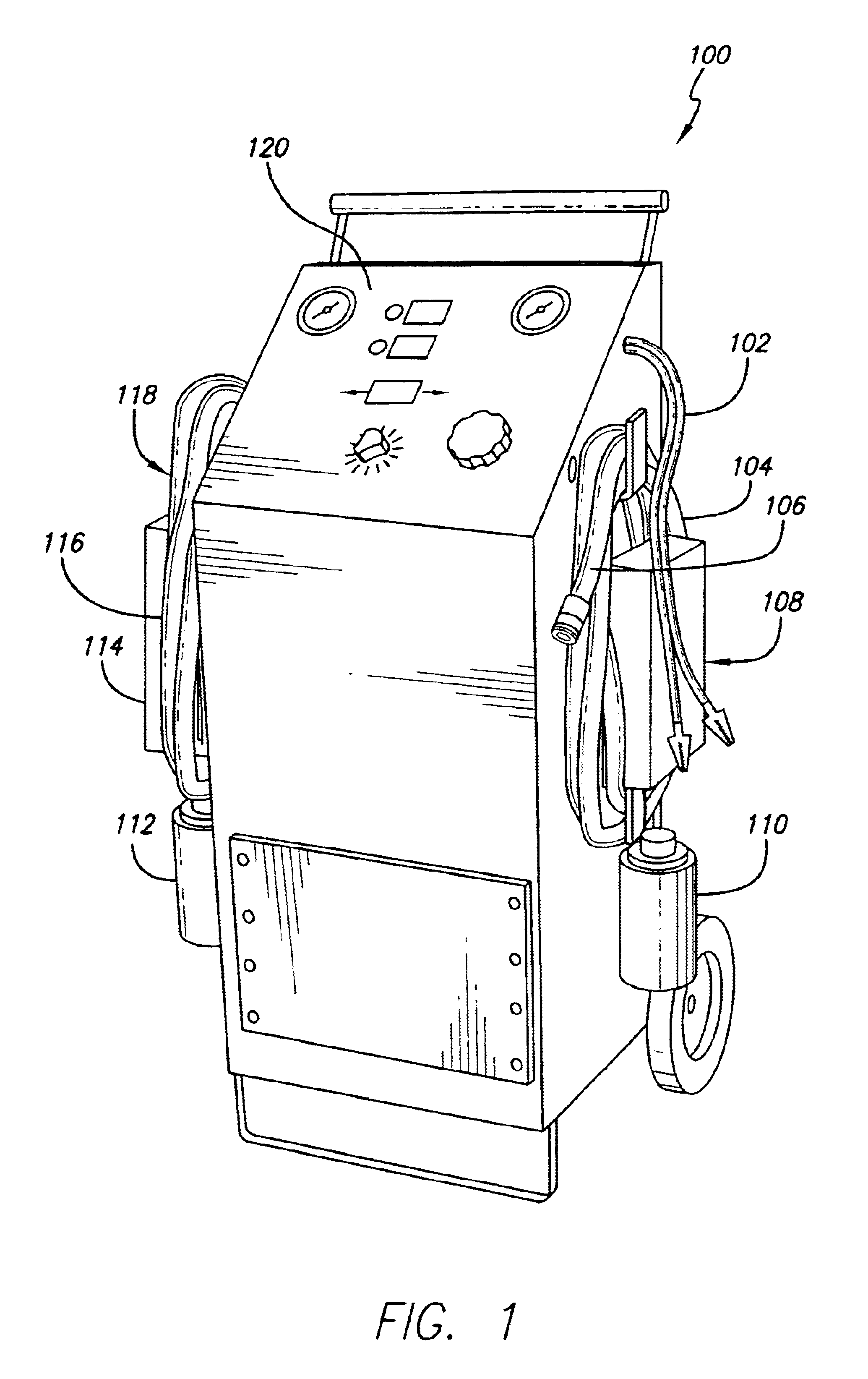

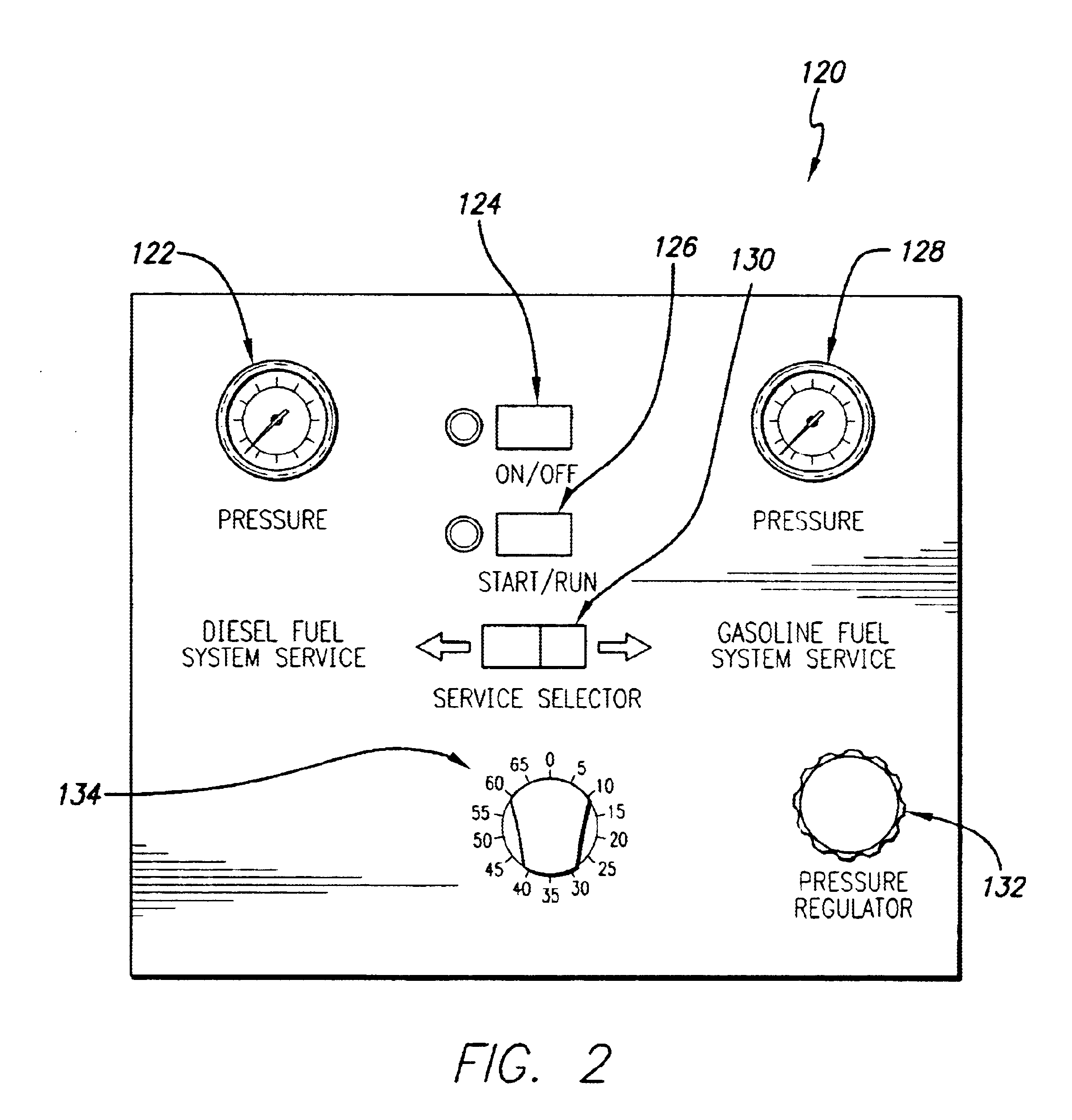

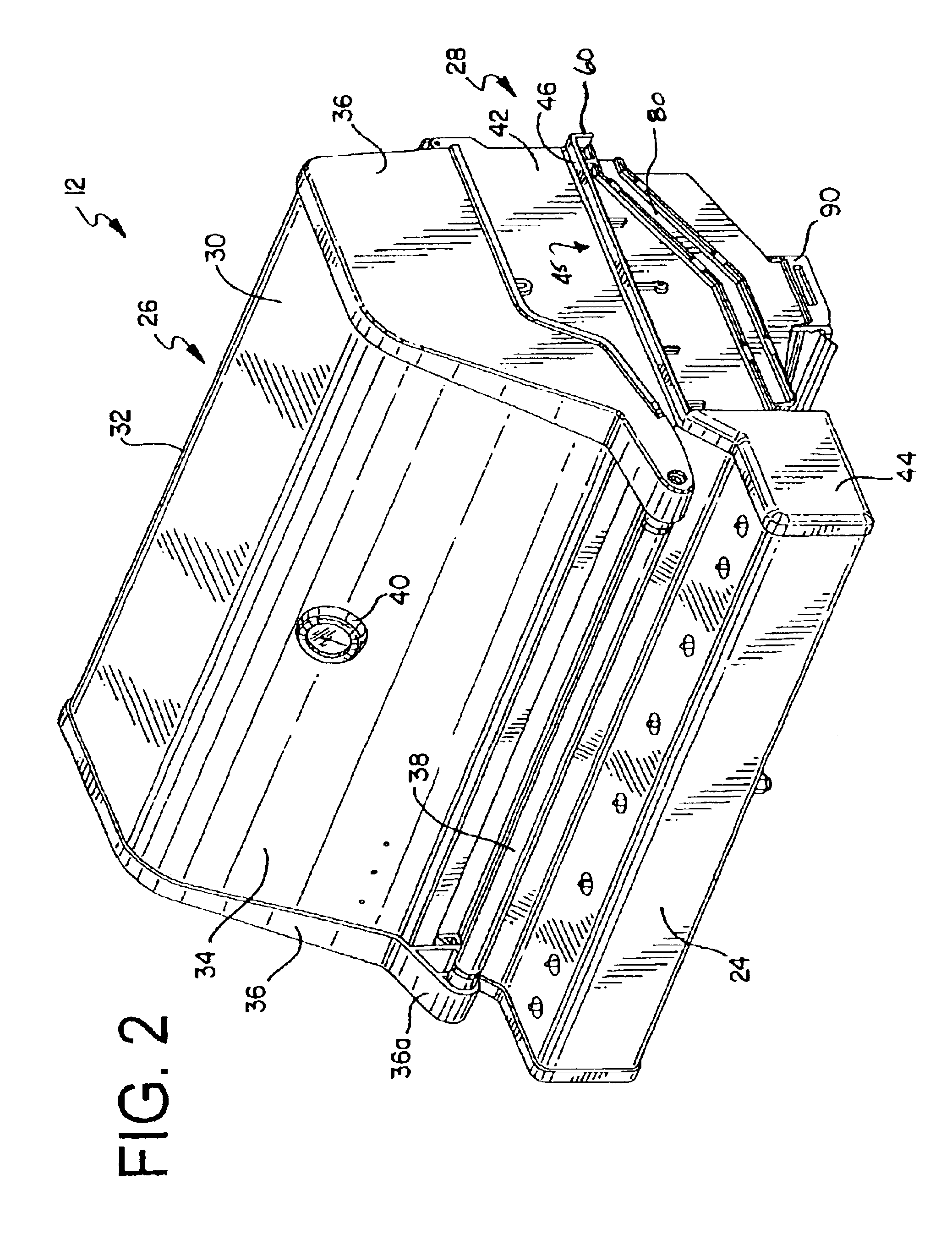

Automatic fuel system cleaner

An apparatus and method for cleaning either a diesel or a gasoline fuel system. The automatic fuel cleaner apparatus comprises a diesel service portion and a gasoline service portion. The diesel and gasoline service portions each includes a return hose having a first end capable of being coupled to a fuel line outlet of the fuel system. Each service portion further includes a detergent reservoir having an input connected to the return hose. Each service portion also includes a pump having an input connected to an output of the detergent reservoir. The diesel and gasoline service portions each further includes an output hose having a first end connected to a pump output and a second end capable of being coupled to a fuel line inlet. The gasoline service portion also comprises a pressure regulator connected to the output of the gasoline pump.

Owner:CPS PROD CANADA

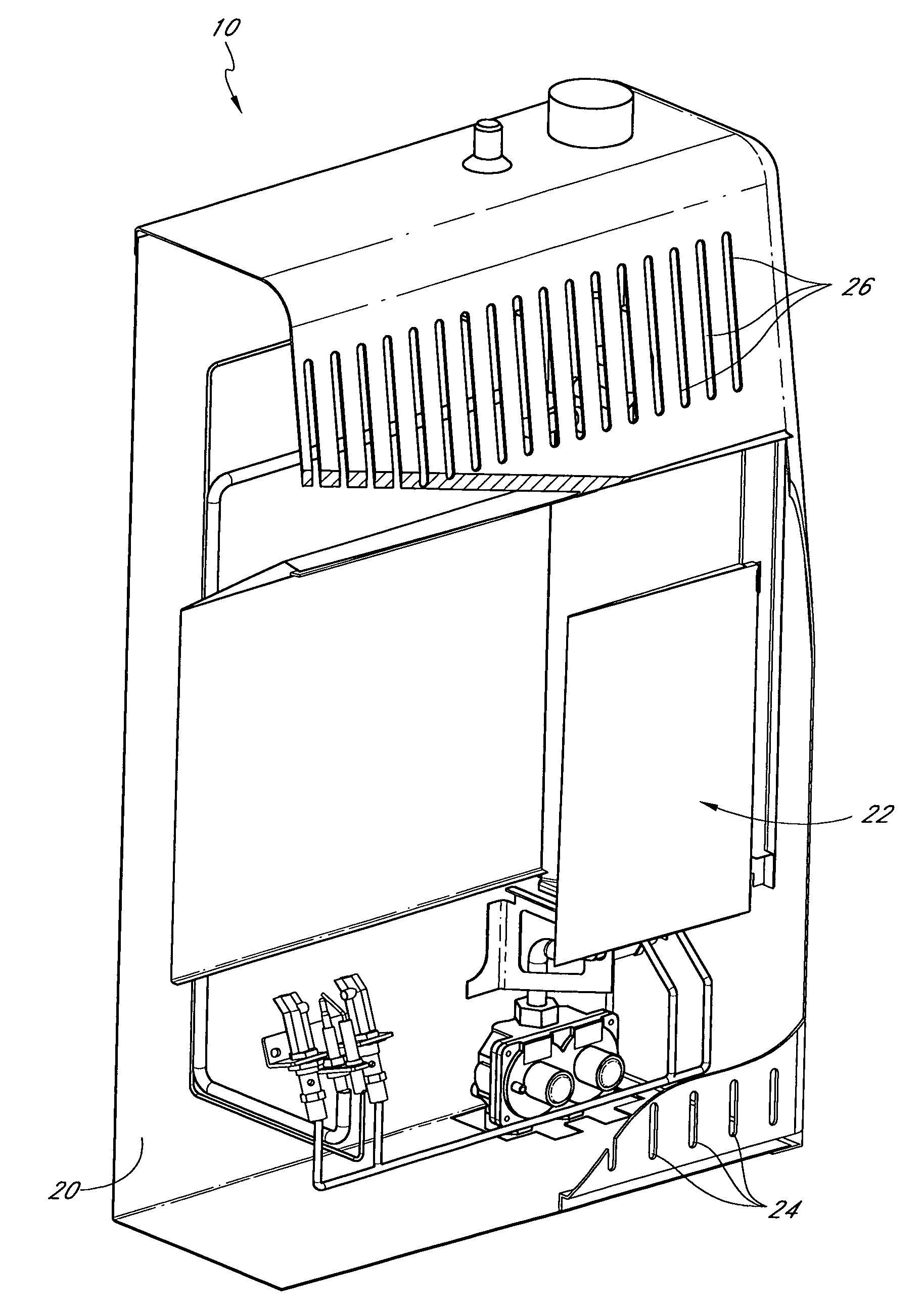

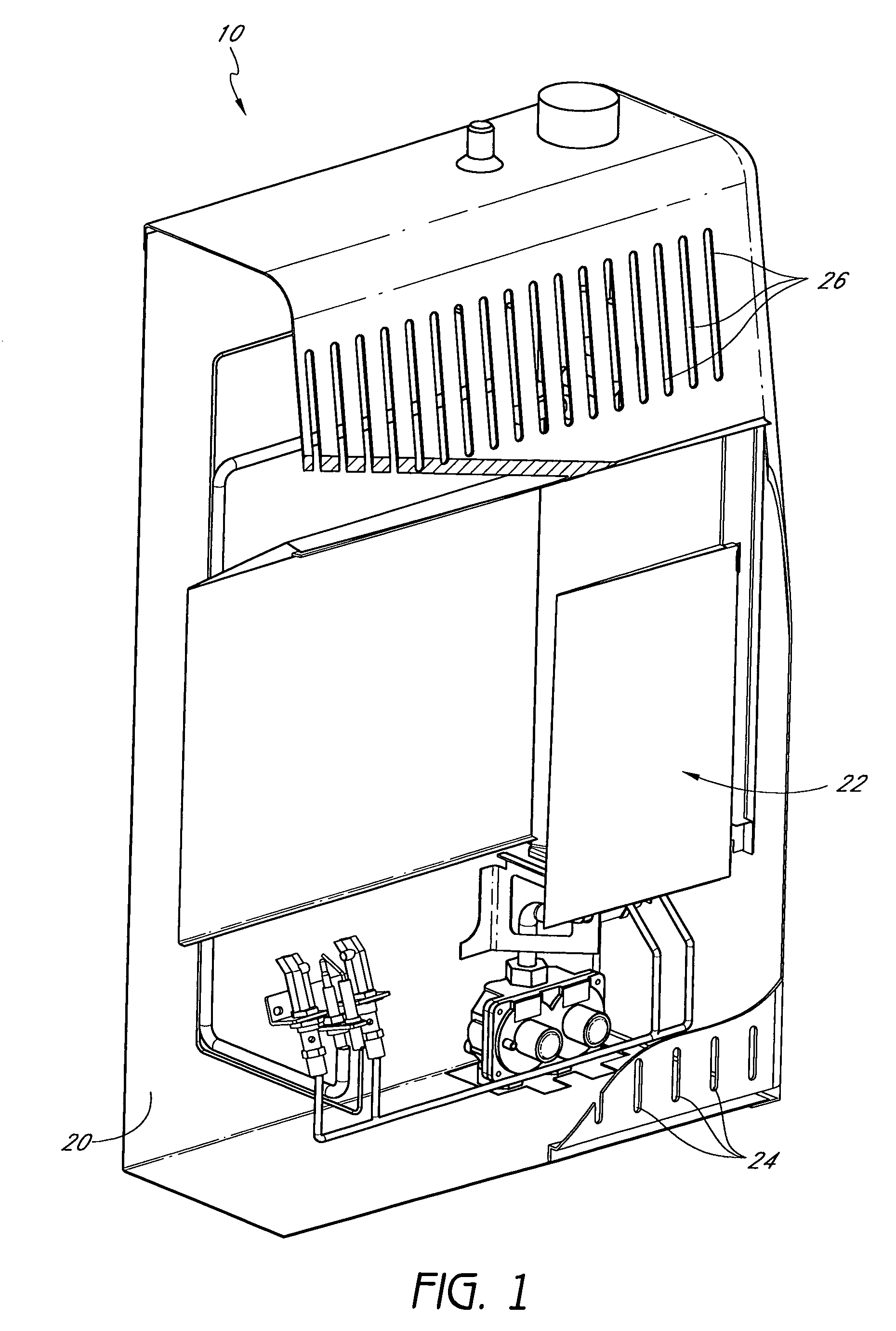

Dual fuel heater

ActiveUS7607426B2Fuel supply regulationDomestic stoves or rangesCombustion chamberNuclear engineering

In certain embodiments, a dual fuel heater has a pressure regulating device for selectively coupling with a first source or a second source operating at different pressures. The dual fuel heater can also include first and second fuel lines, a fluid flow controller, a combustion chamber and first and second oxygen depletion sensor nozzles. The fluid flow controller is configured to selectively permit flow of fuel to either the first fuel line or to the second fuel line. In some embodiments, the first fuel line is connected to the first oxygen depletion sensor nozzle and the second fuel line is connected to the second oxygen depletion nozzle.

Owner:PROCOM HEATING

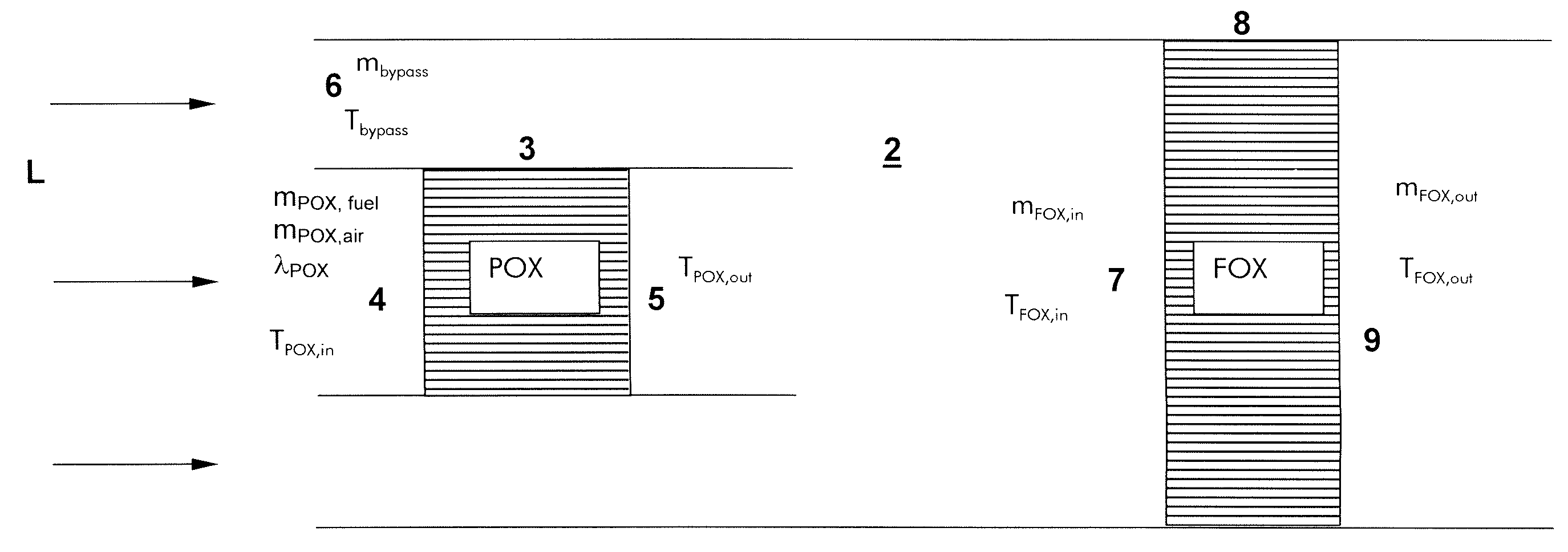

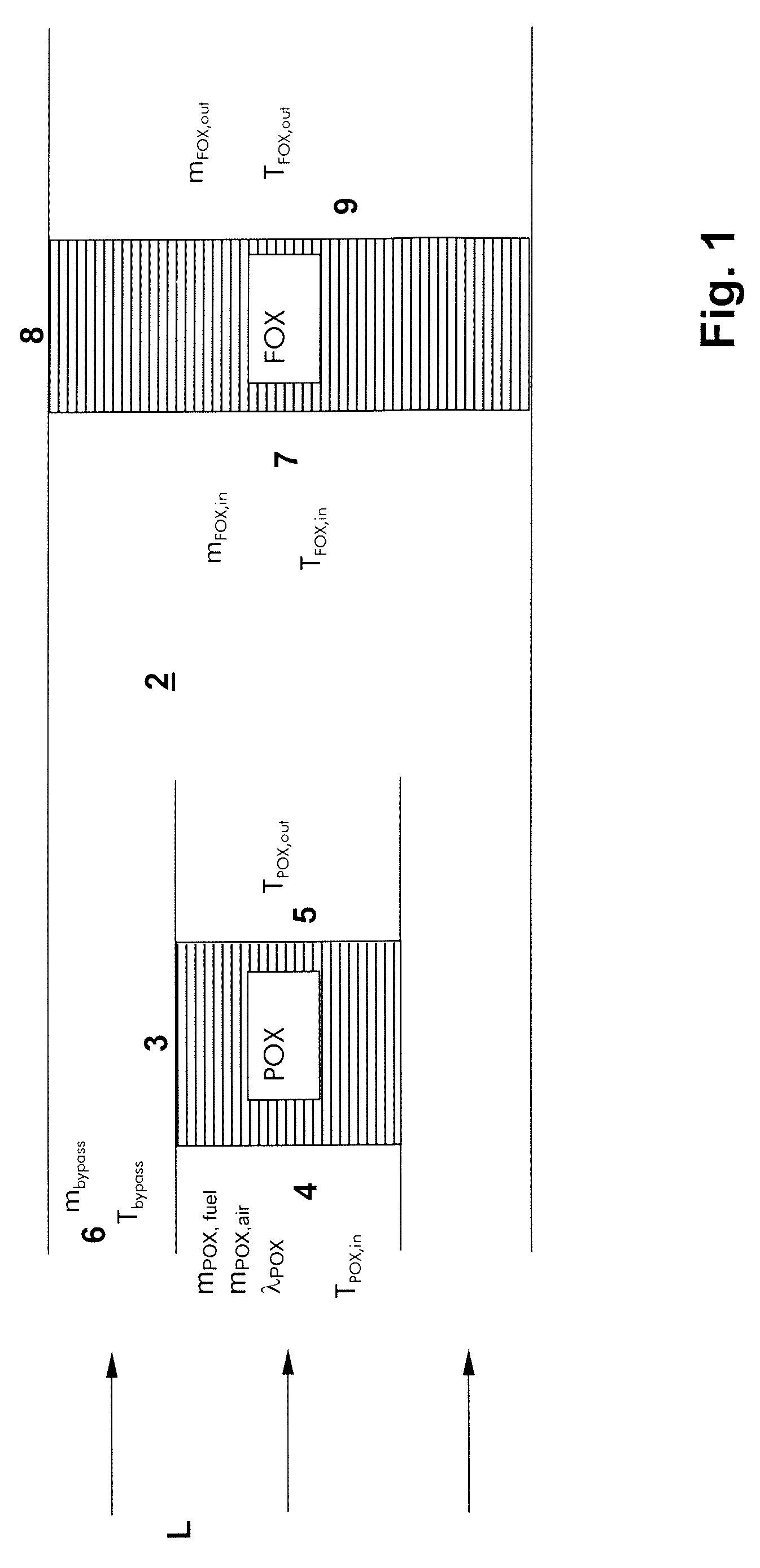

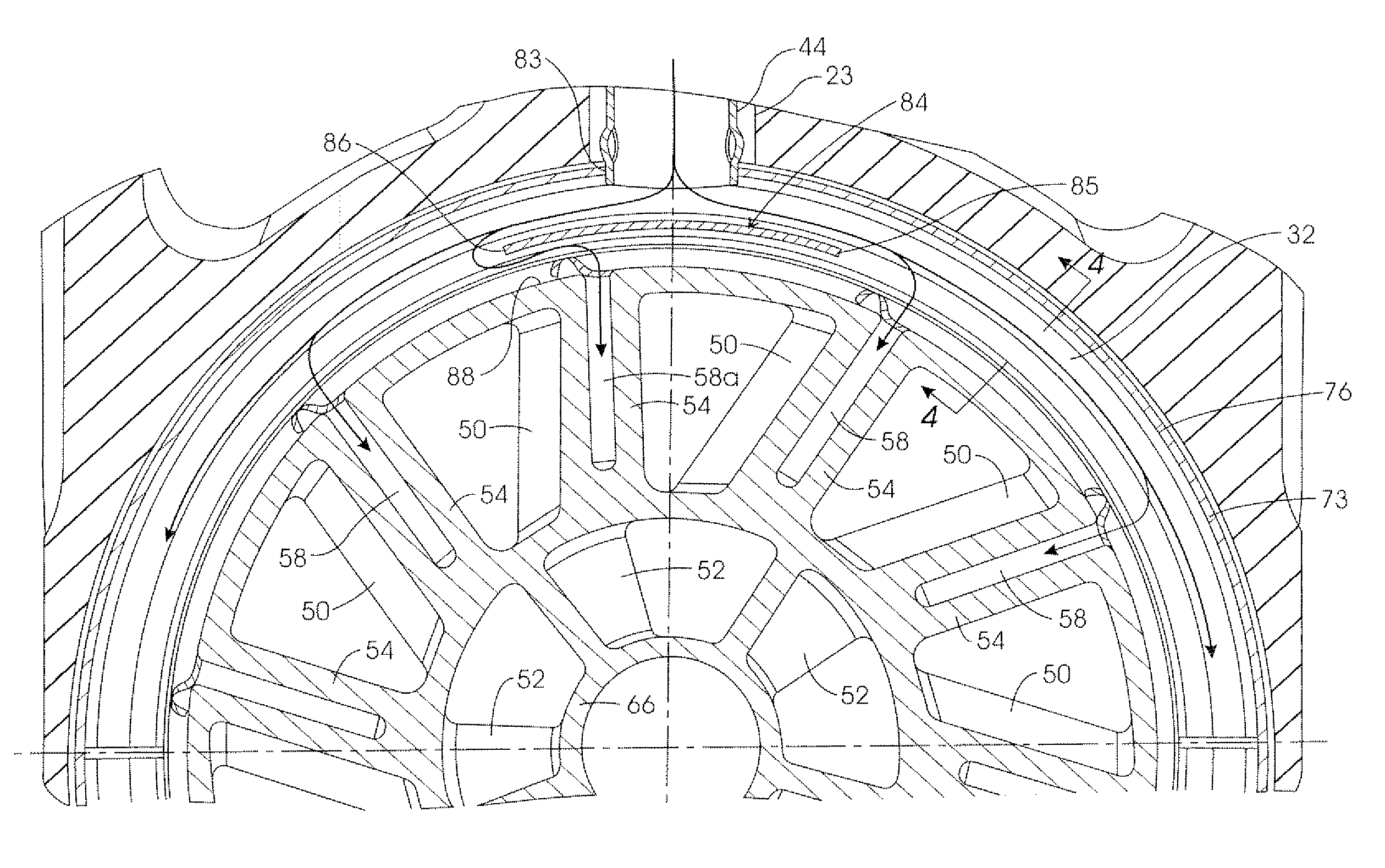

Device and method for flame stabilization in a burner

InactiveUS7467942B2Improve design flexibilityAccelerate emissionsFuel supply regulationContinuous combustion chamberCombustion chamberCombustor

A device and a method for flame stabilization in a burner (10), includes a burner housing at least partially enclosing a burner volume, into which may be introduced via at least one fuel line, fuel, and via at least one air feed means, air, forming an air / fuel mixture spreading in a preferred flow direction, which may be ignited in a combustion chamber (11) connecting downstream of the burner housing to form a stationary flame (13). Upstream of the flame (13), a catalyst arrangement (1) is provided through which an air / pilot fuel mixture (4), separate from the air / fuel mixture, is flowable. The catalyst arrangement (1) has at least two catalyst stages which are located one behind the other in the through-flow direction, of which the catalyst stage (3) located upstream, the so-called POX-catalyst, is flow-washable by the air / pilot fuel mixture (4) with an air / pilot fuel mixture ratio λ<1, by which catalyst stage (3) the air / pilot fuel mixture (4) is partially oxidized, and of which catalyst stages the downstream catalyst stage (8), the so-called FOX-catalyst, is flow-washable by a leaned air / pilot fuel mixture (7) with a mixture ratio λ>1, by which the leaned air / pilot fuel mixture is completely oxidized forming an inert hot gas flow (9).

Owner:ALSTOM TECH LTD

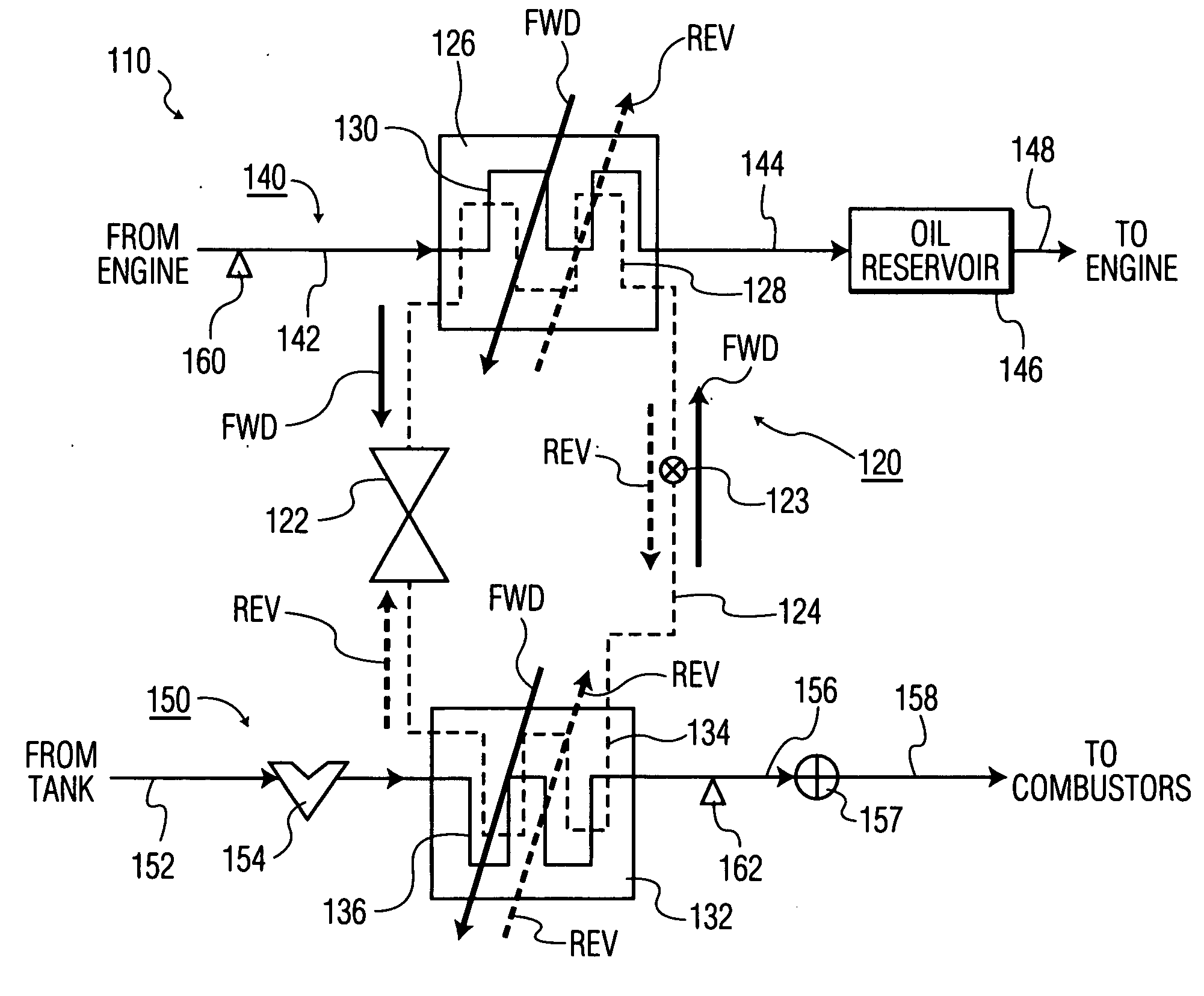

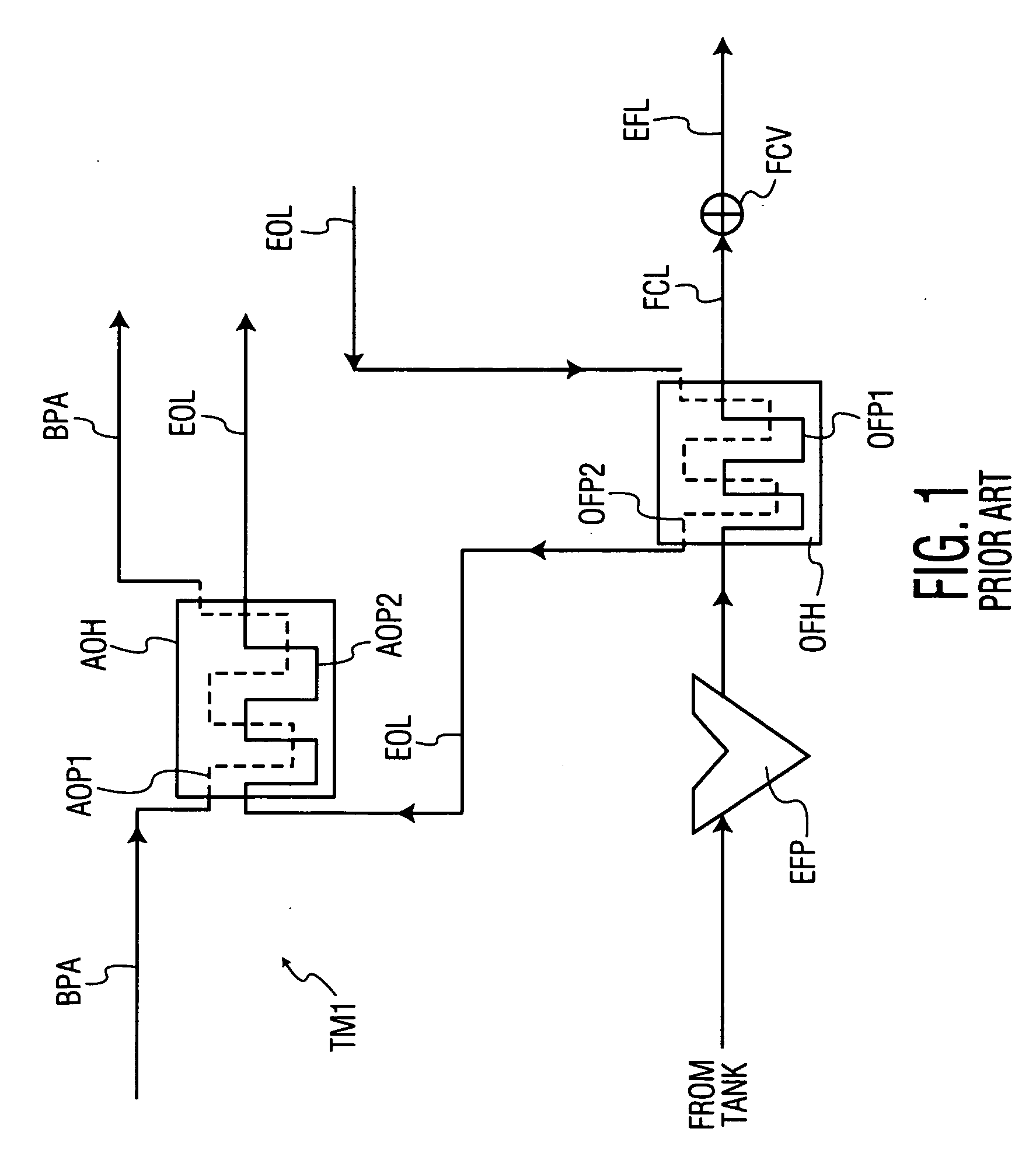

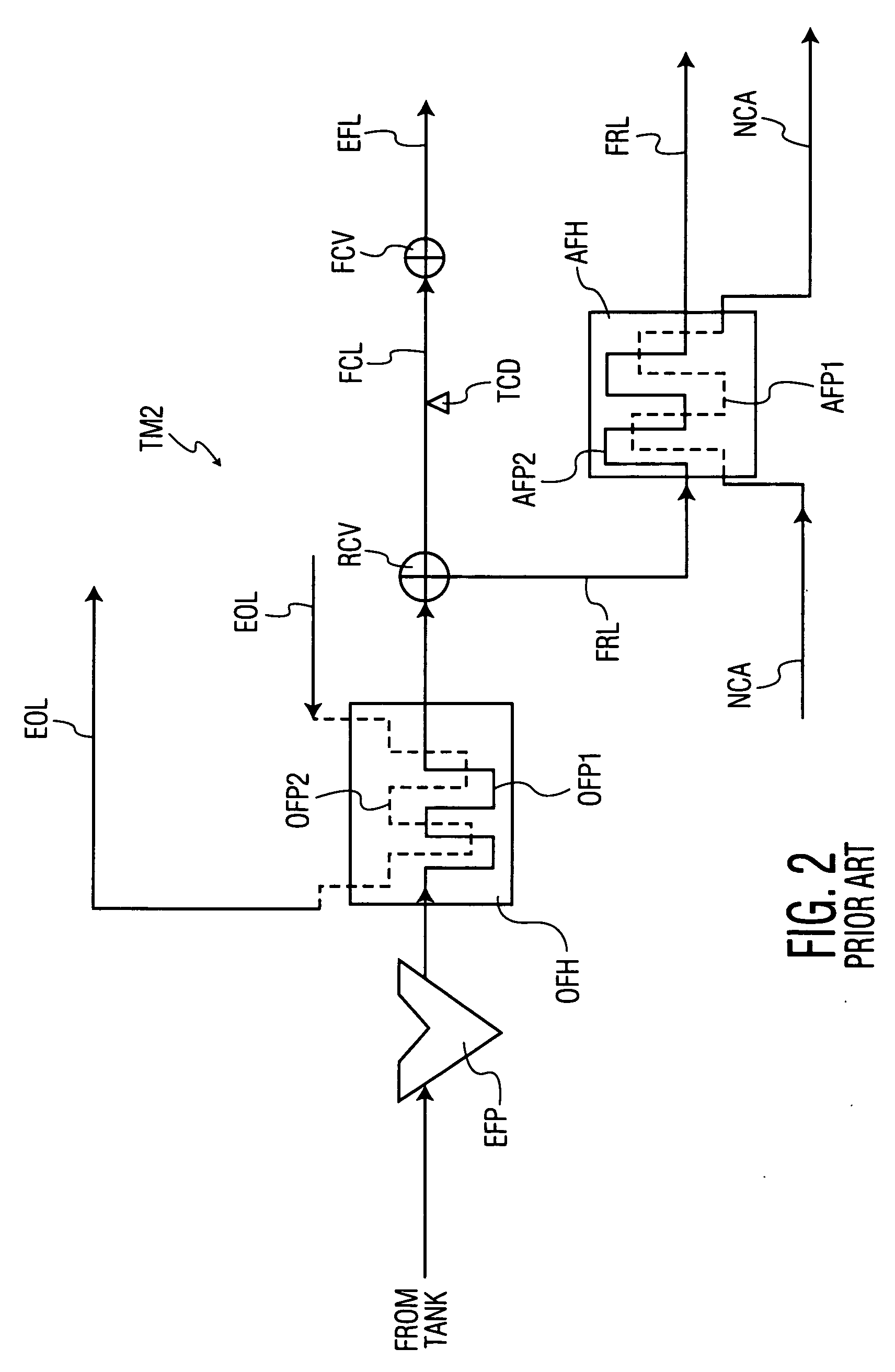

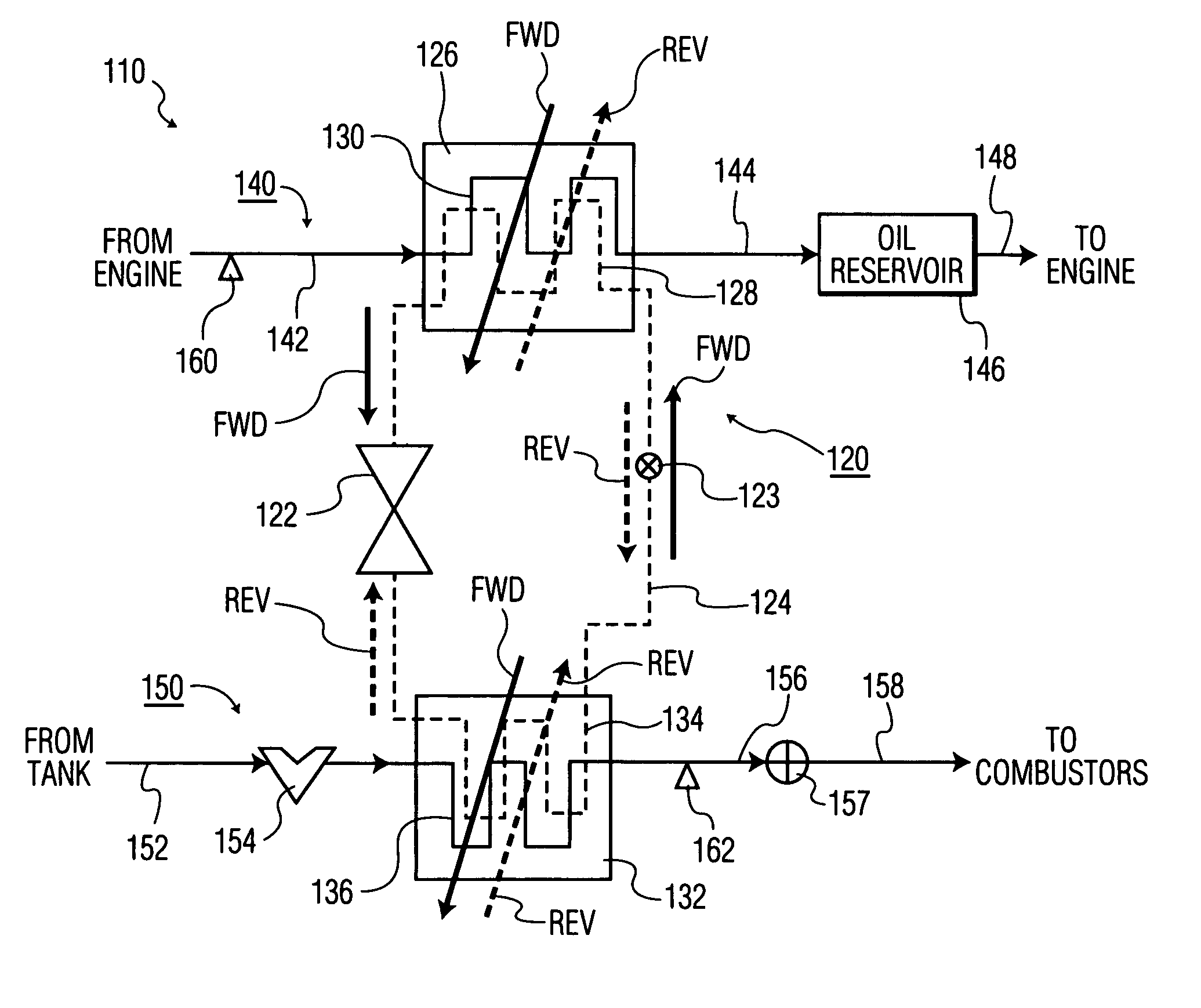

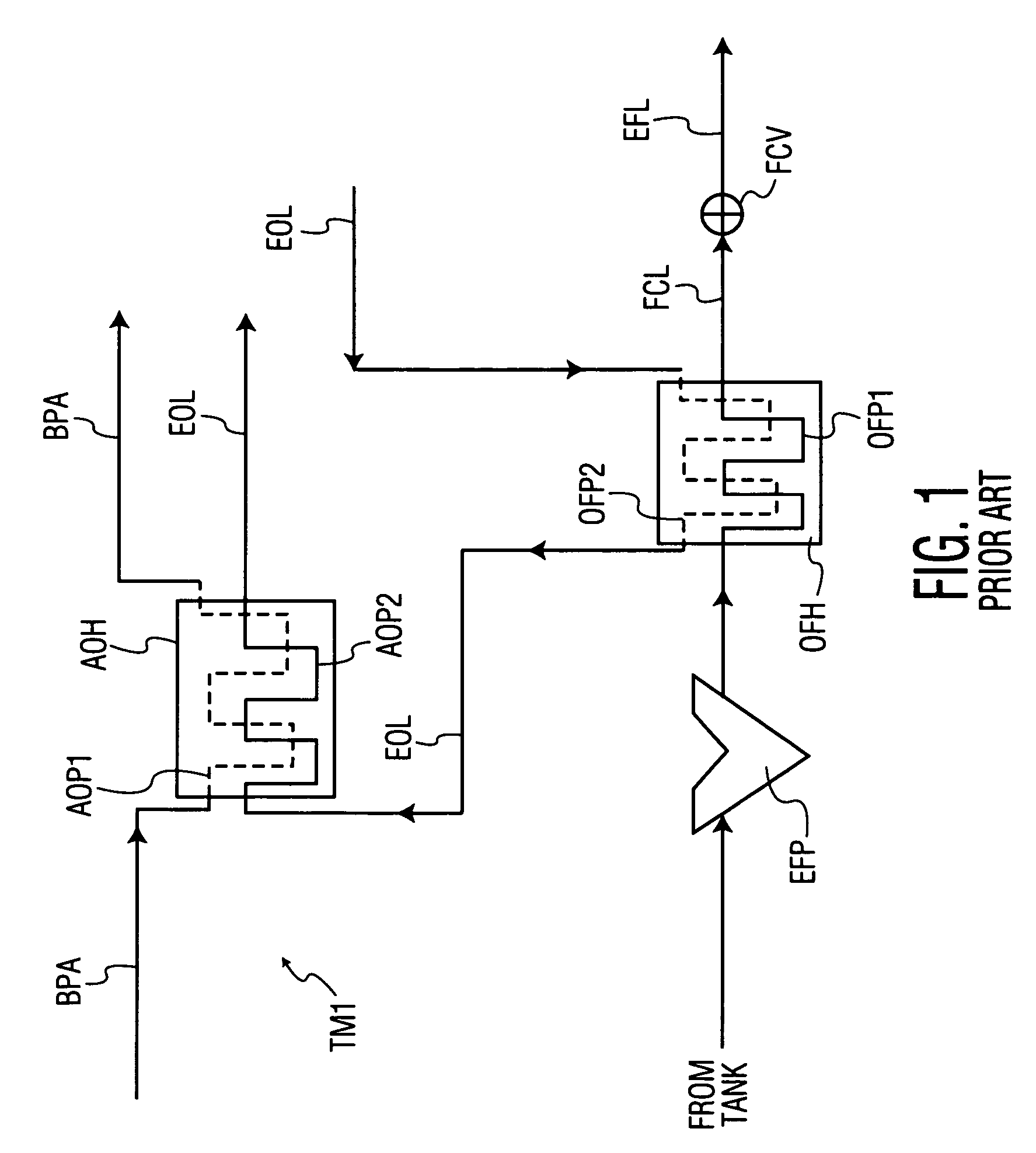

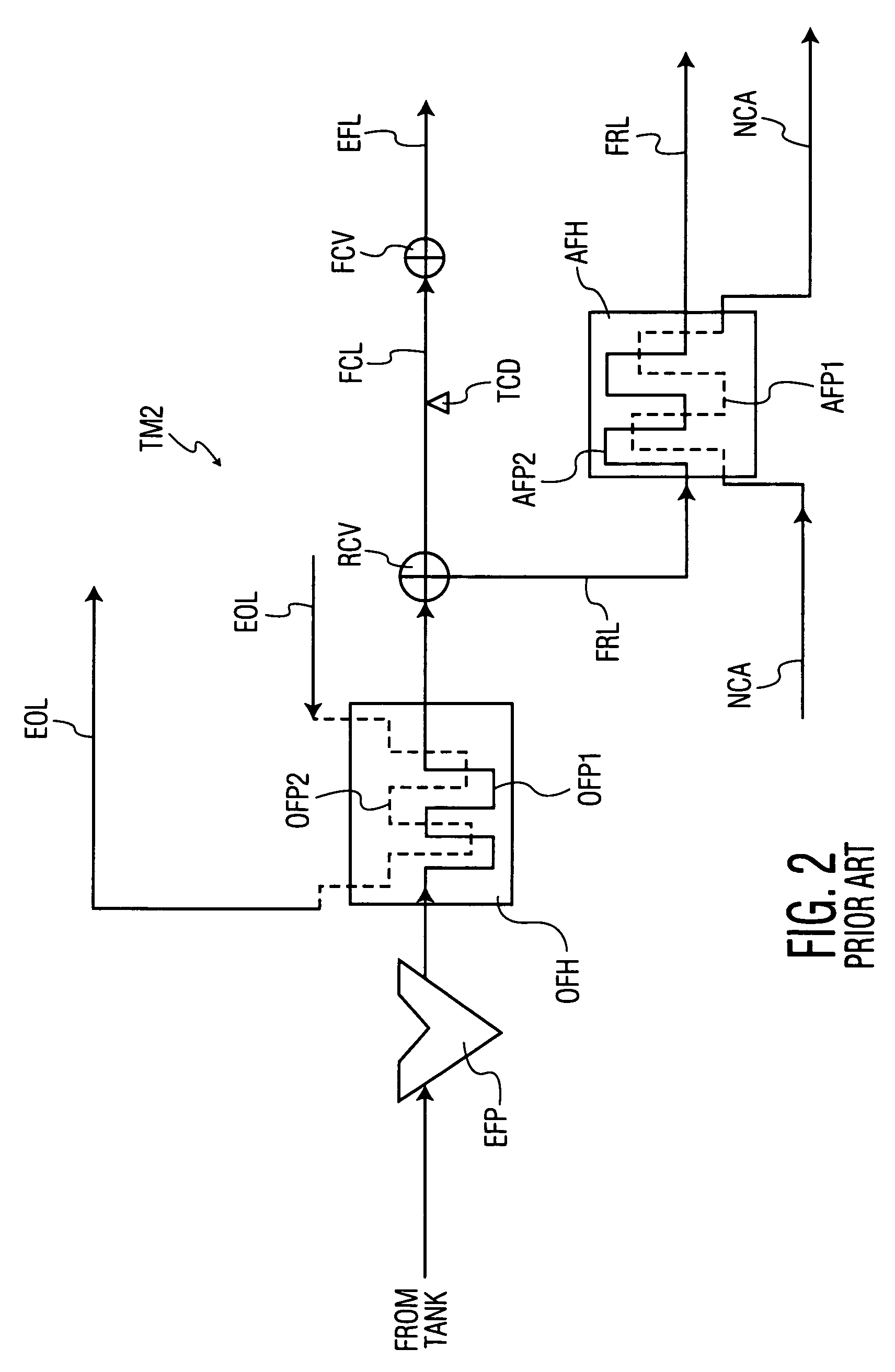

Systems and methods for thermal management in a gas turbine powerplant

InactiveUS20100107603A1Minimize impactReduce coke depositionAnalogue computers for vehiclesTurbine/propulsion engine coolingWorking fluidThermal management system

A thermal management system for a gas turbine powerplant with an engine oil line and an engine fuel line incorporates a heat transfer control module that includes a reversible heat pump with a heat pump compressor for circulating working fluid in forward and reverse directions through a working fluid line of the heat pump. The heat control module also includes a first heat exchanger having a heat exchange path for the working fluid between the compressor and a heat pump expansion valve and another heat exchange path for the engine oil. A second heat exchanger has a heat exchange path for the working fluid between the compressor and the expansion valve and another heat exchange path for the engine fuel. The heat pump can be operated in forward or reverse directions depending on whether heat is to be transferred from the engine oil or the fuel to the heat pump working fluid. In another embodiment an engine oil reservoir located between the first heat exchanger and the engine collects the oil before it is introduced to the engine and thus acts as a heat capacitor for the system.

Owner:PROPULSION GAS TURBINE & ENERGY EVALUATIONS

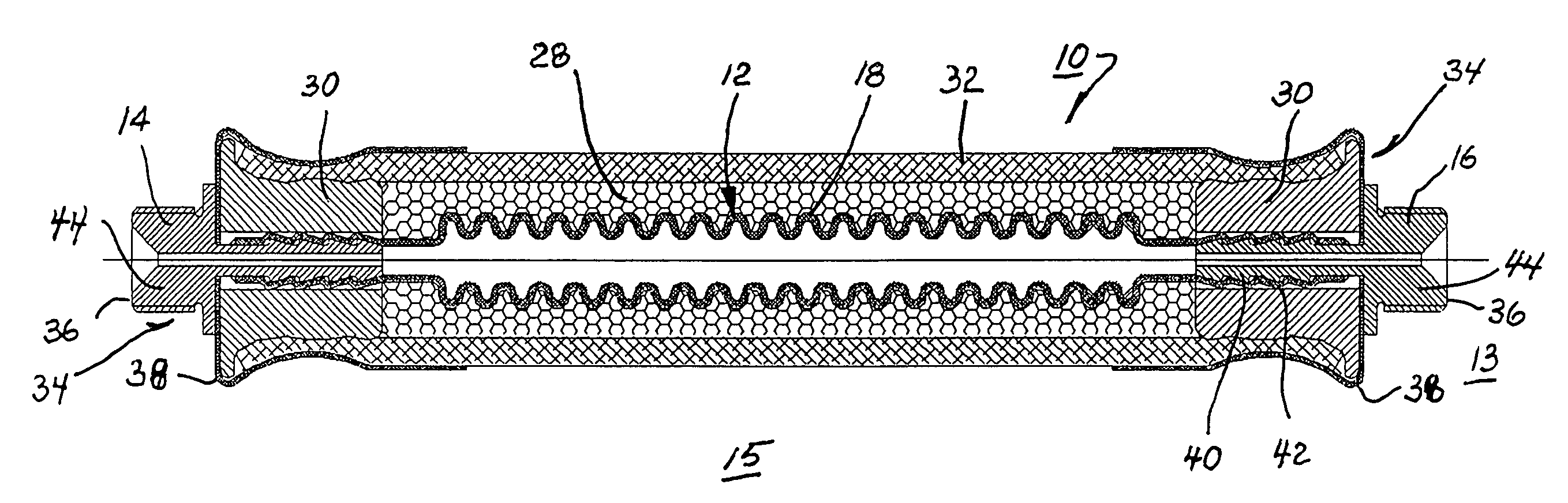

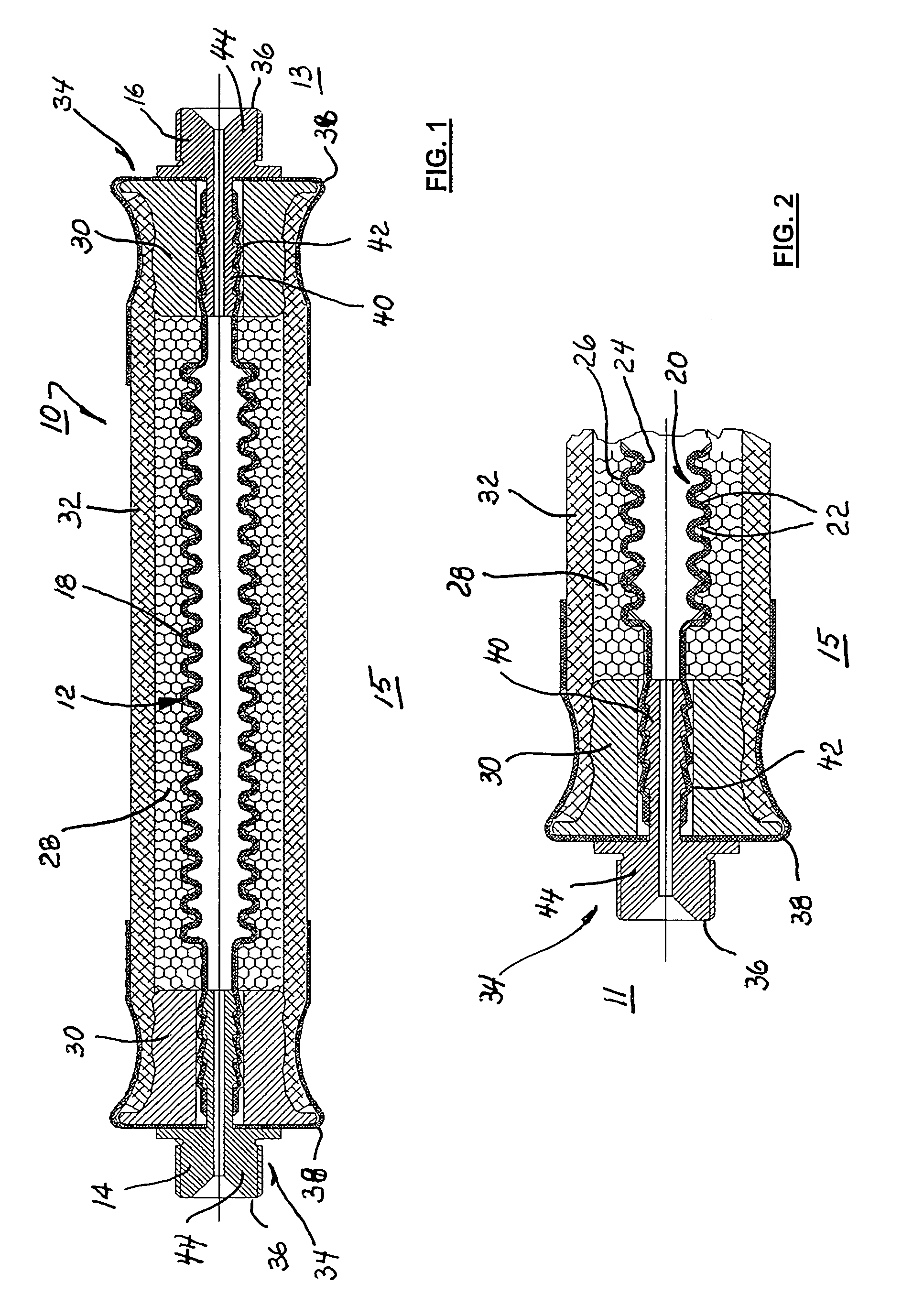

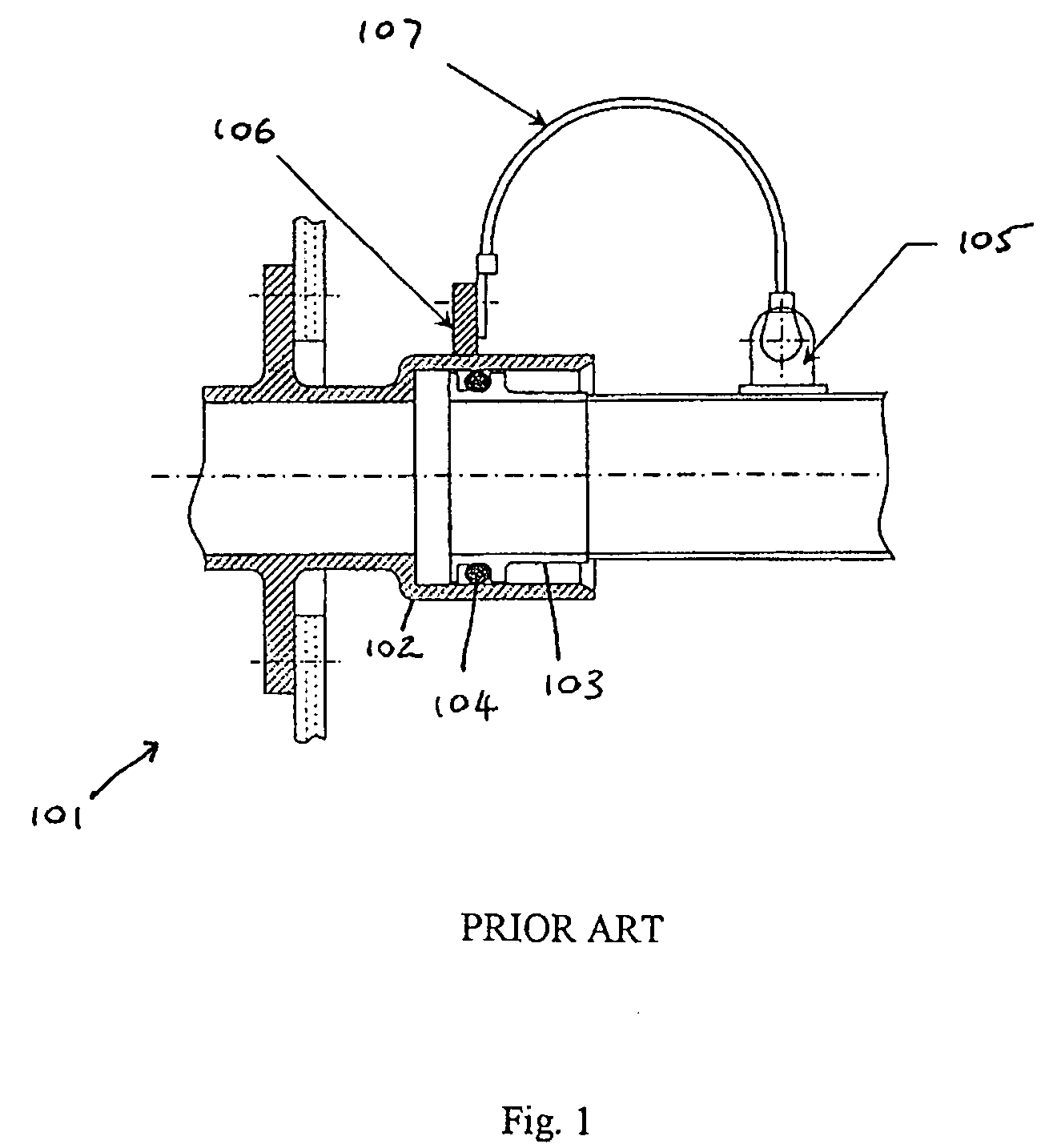

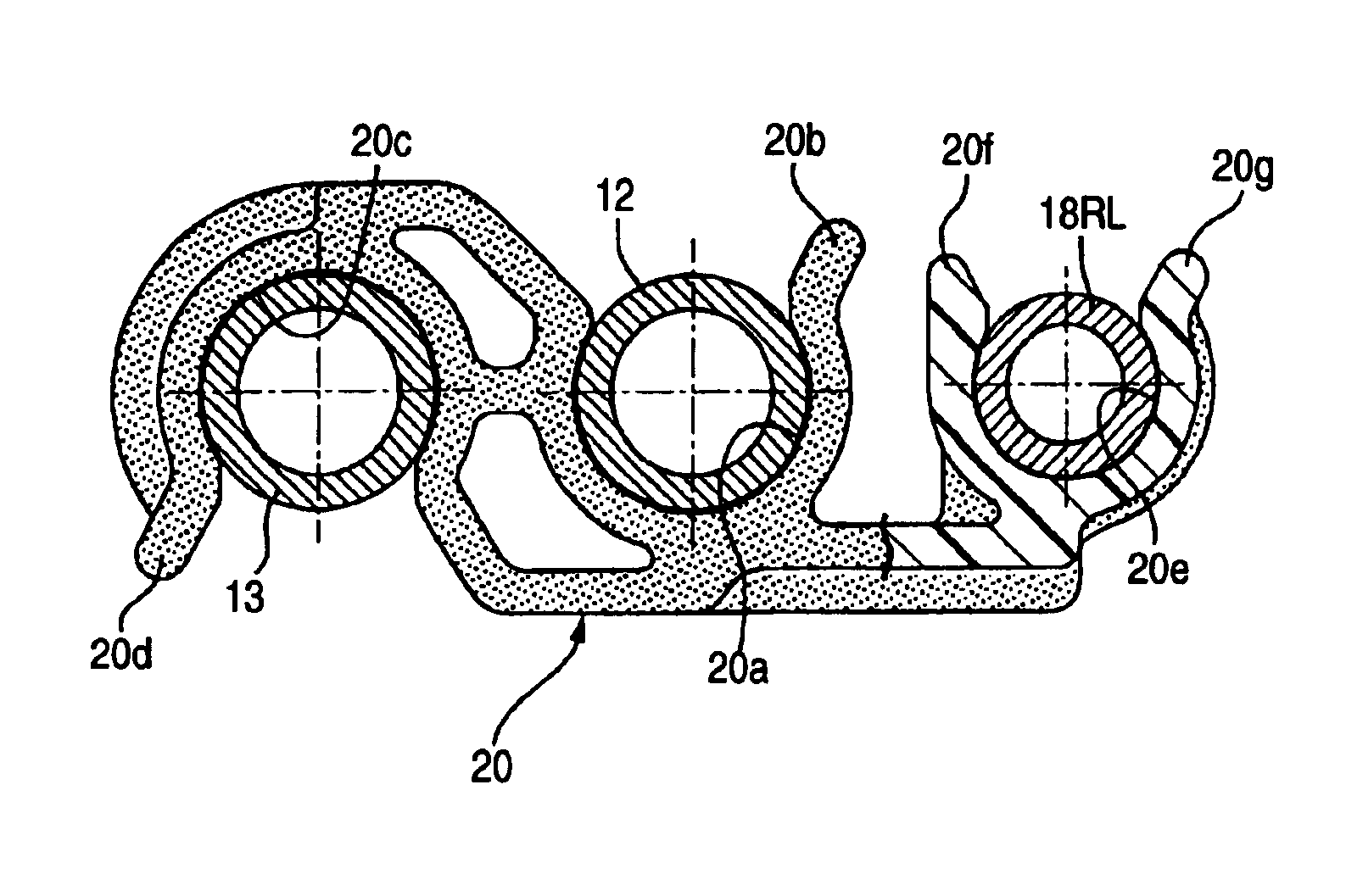

Inline pulsation damper system

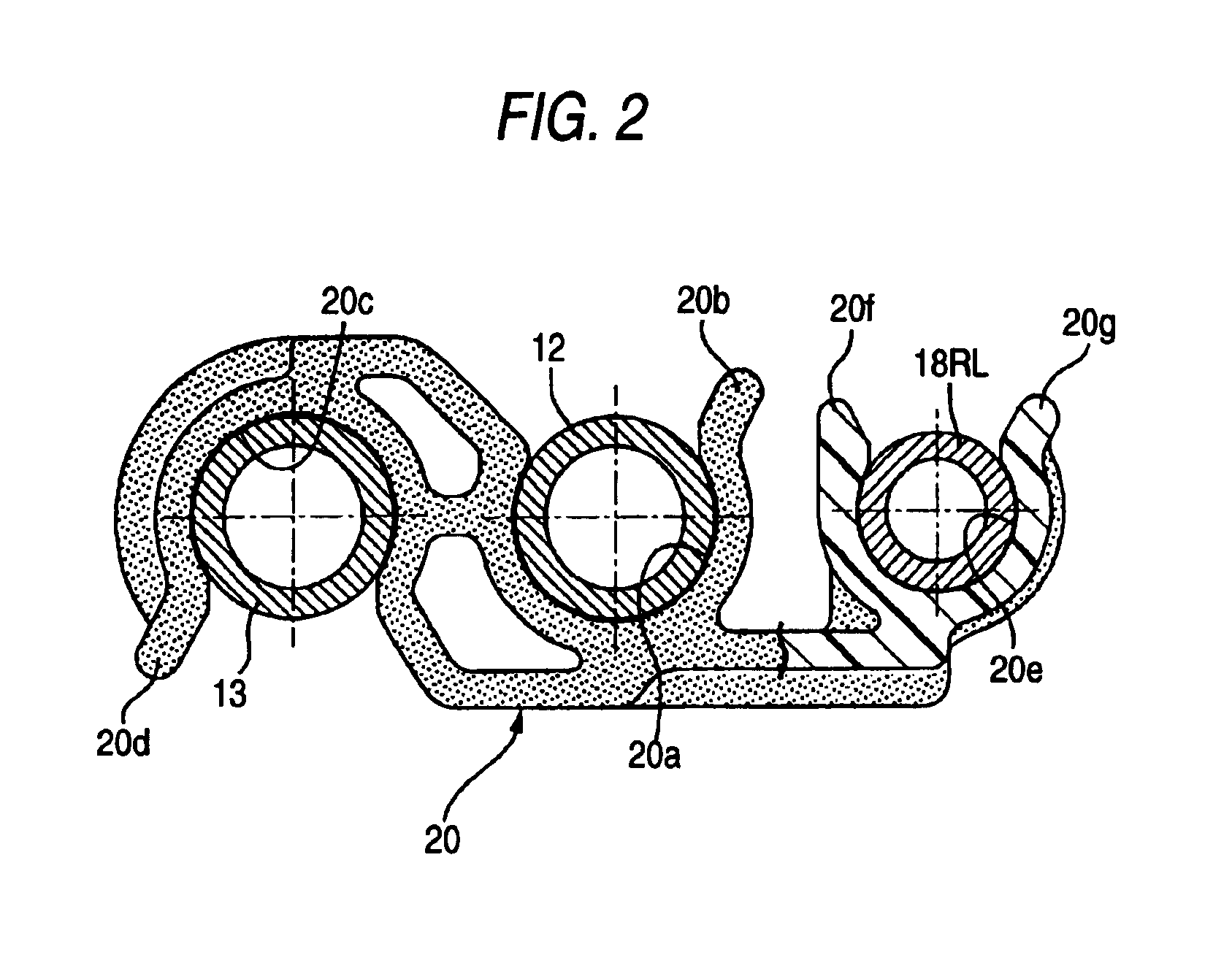

A hydraulic pulsation damper system for installation into an otherwise rigid hydraulic system to absorb and extinguish pressure pulsations being transmitted through the system by hydraulic fluid contained therein. The system is useful in suppressing pulsations in automotive fuel lines supplying fuel to fuel injection systems. The system includes fuel-conducting tubing made of flexible, non-permeable material that includes a convoluted central portion capable of expanding and contracting in response to pulsations in the fuel. Resilient foam is molded around the convoluted portion for controlling expansion of the convolutions. The foam and convoluted tubing are contained within a housing made from a larger-diameter hose having ends sealed as by swaged connectors. The damper system may be bent to accommodate installation with a fuel line in an engine and can conveniently provide a sound-deadening link in the fuel line of a vehicle between a body-mounted portion and an engine-mounted portion thereof.

Owner:DELPHI TECH INC

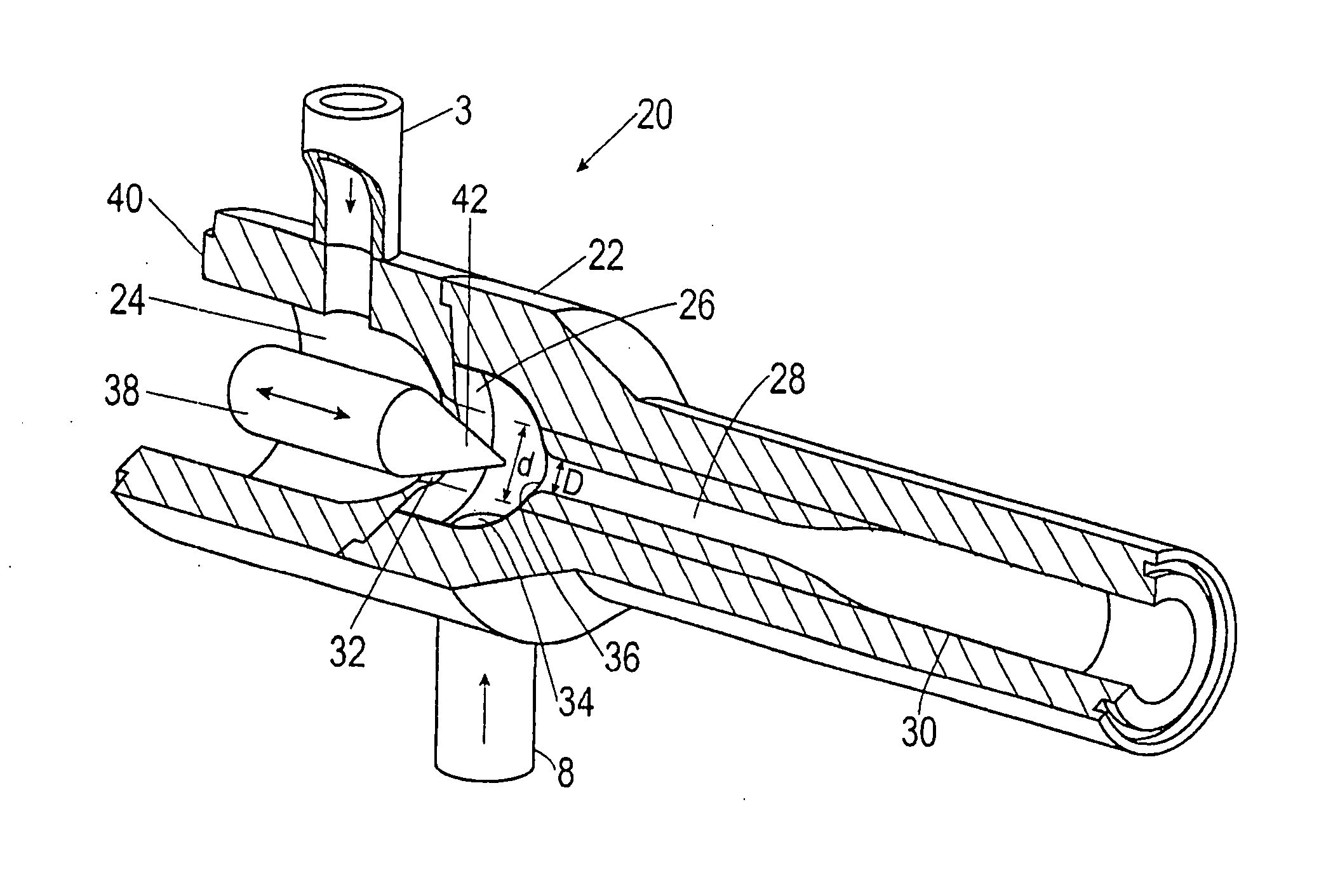

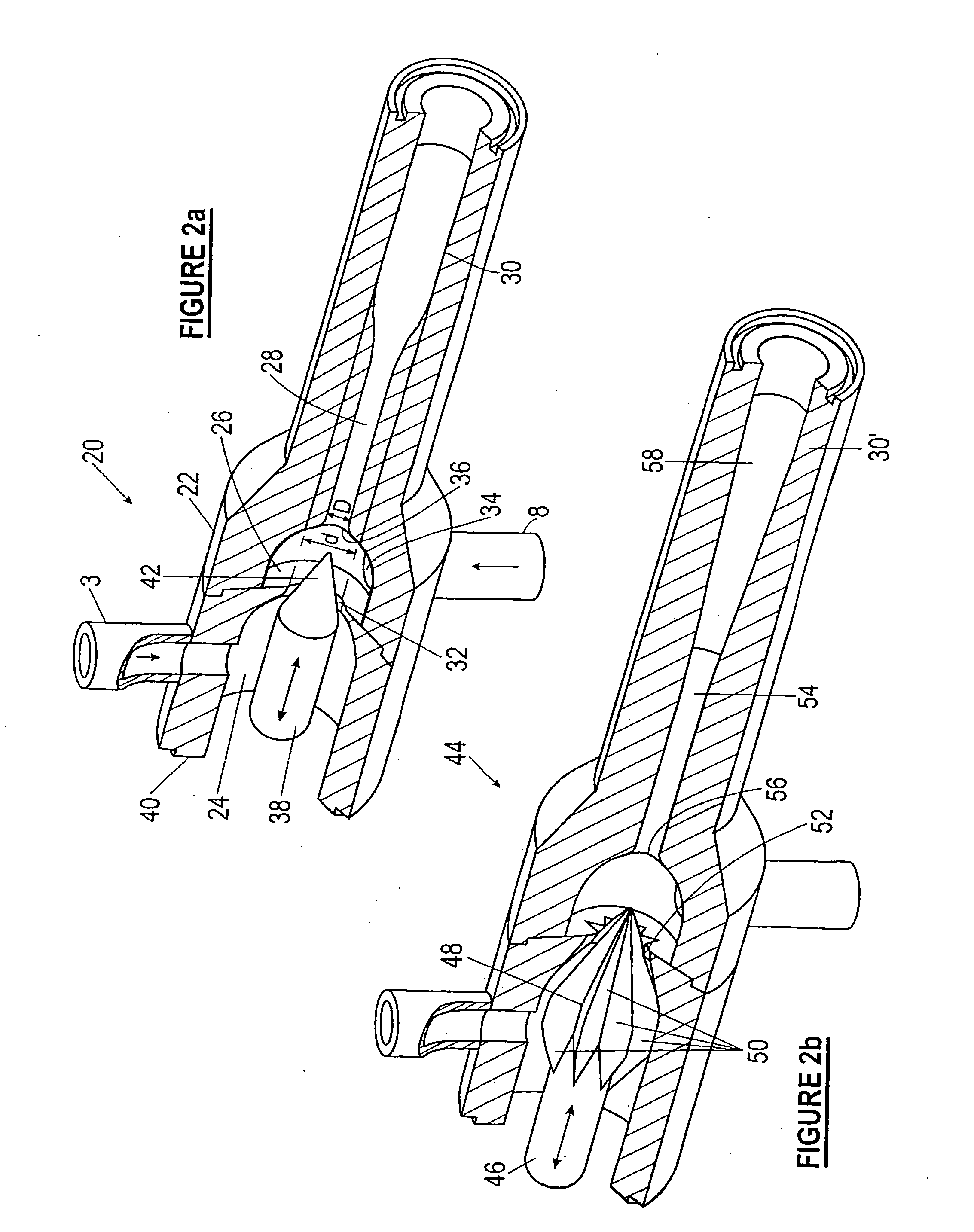

Fuel cell system and method for recycling exhaust

InactiveUS20060251935A1Increase the cross-sectional areaReduce riskFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A fuel cell system includes a primary fuel line to the fuel cell assembly, a jet pump in the primary fuel line and adapted to be driven by the flow of primary fuel, the jet pump having a nozzle, an entrainment chamber downstream of the nozzle and a mixing tube downstream of the entrainment chamber, a fuel exhaust recycle line from the fuel cell assembly opening to the entrainment chamber for supply of fuel exhaust thereto, and a mass flow control device in the primary fuel line upstream of the jet pump for controlling the primary fuel flow rate to the jet pump. The nozzle of the jet pump has an adjustable cross-sectional area to provide a variable area flow of the primary fuel so that the ratio of fuel exhaust entrained by the primary fuel in the entrainment chamber can be varied.

Owner:CERAMIC FUEL CELL LTD

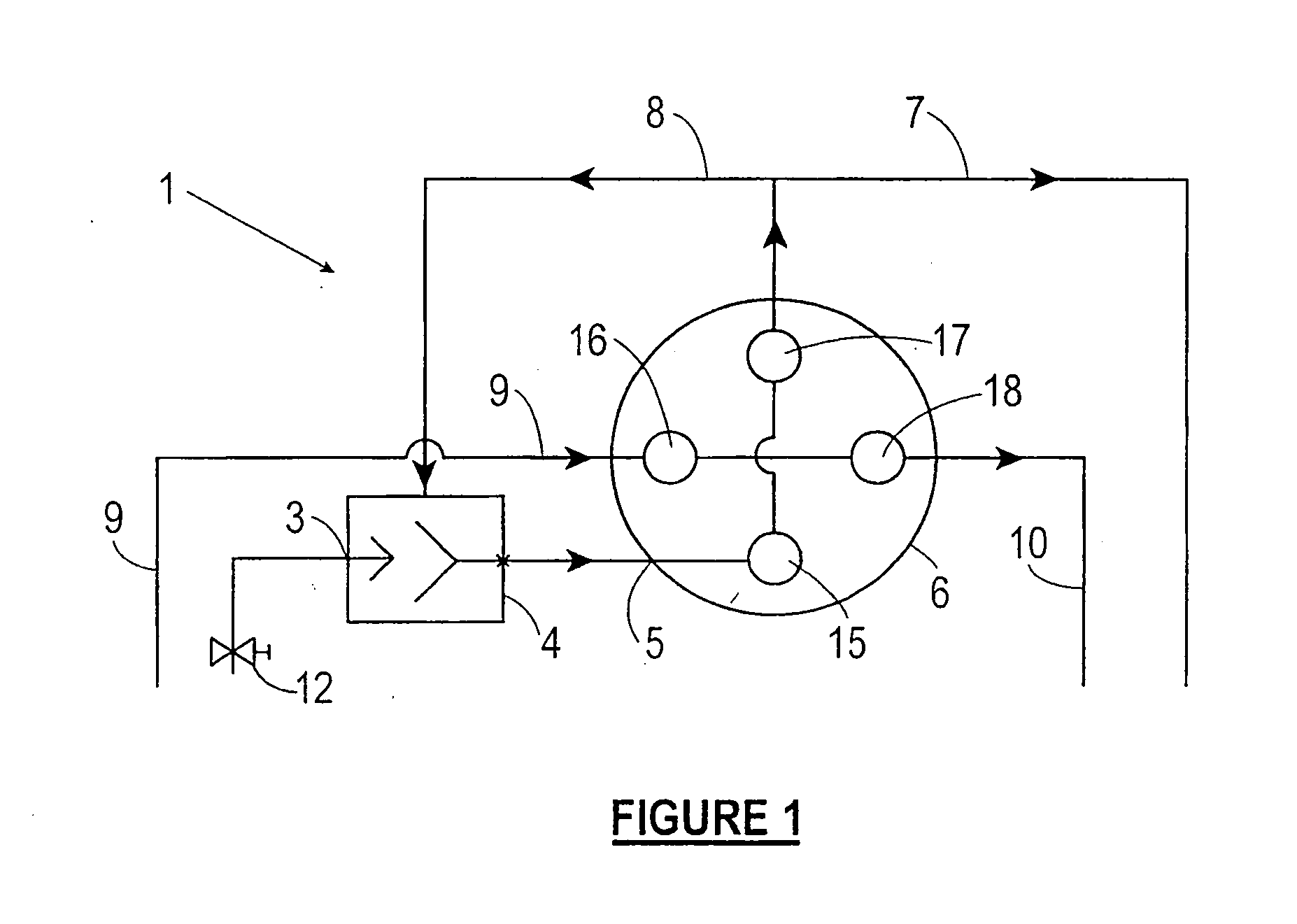

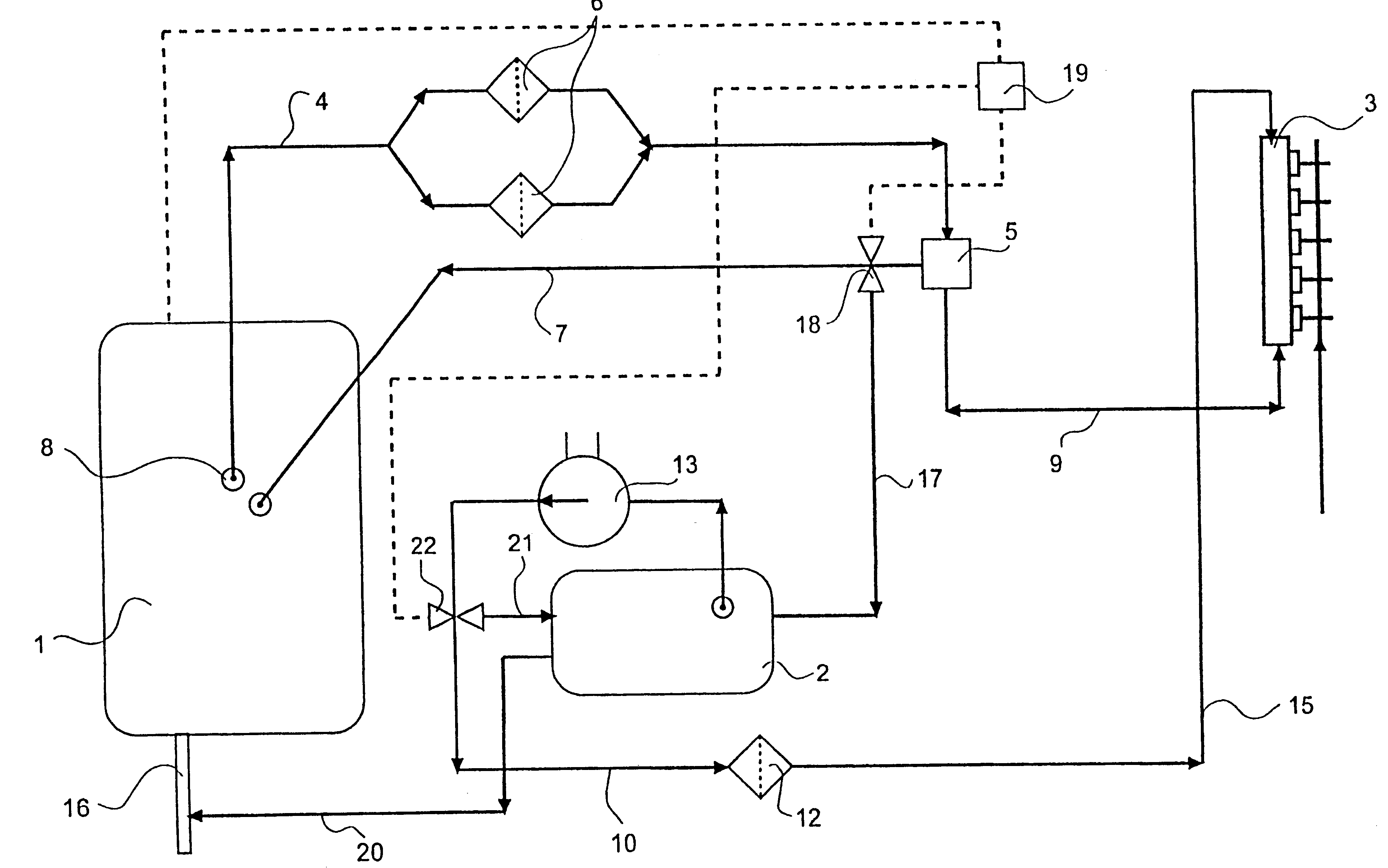

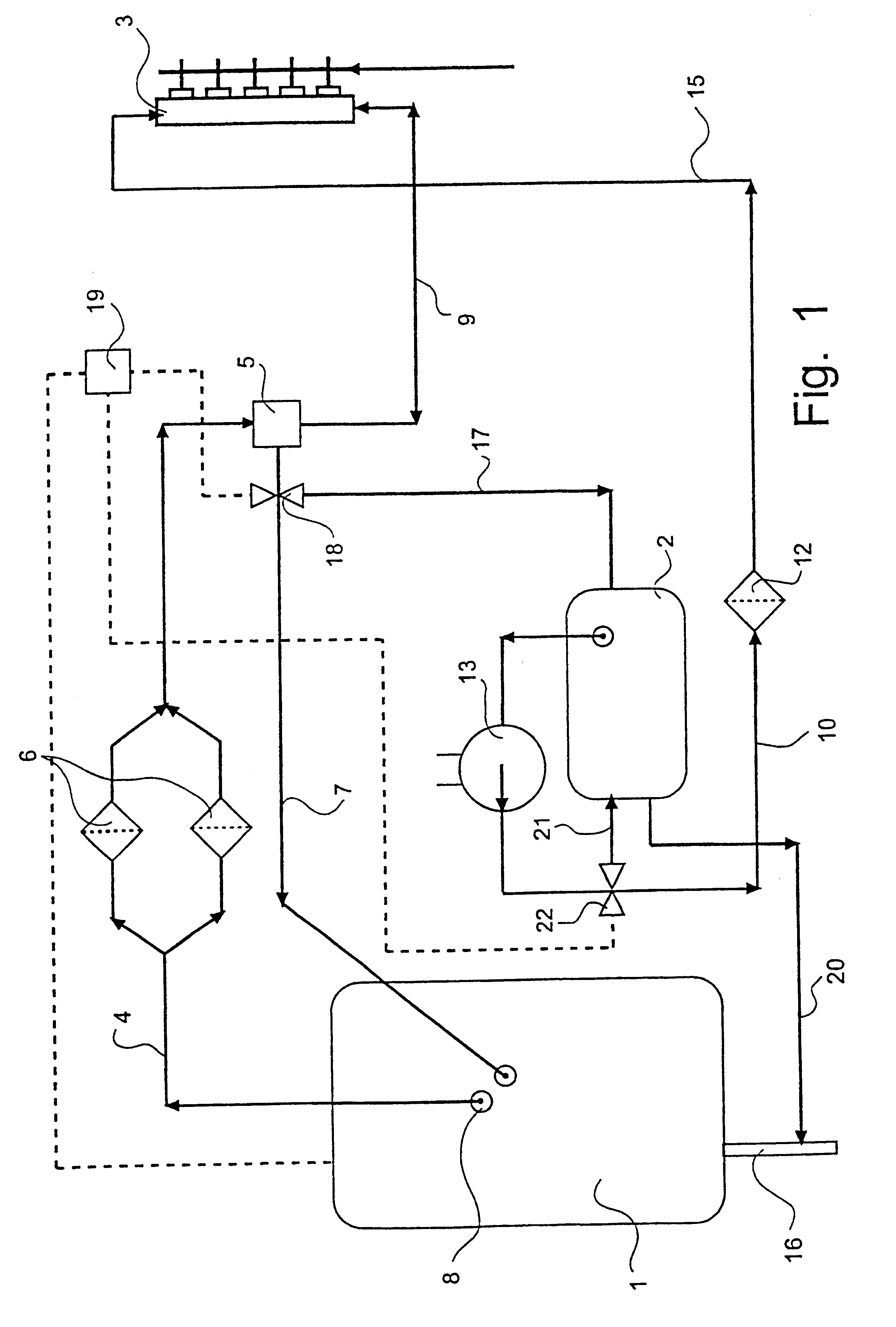

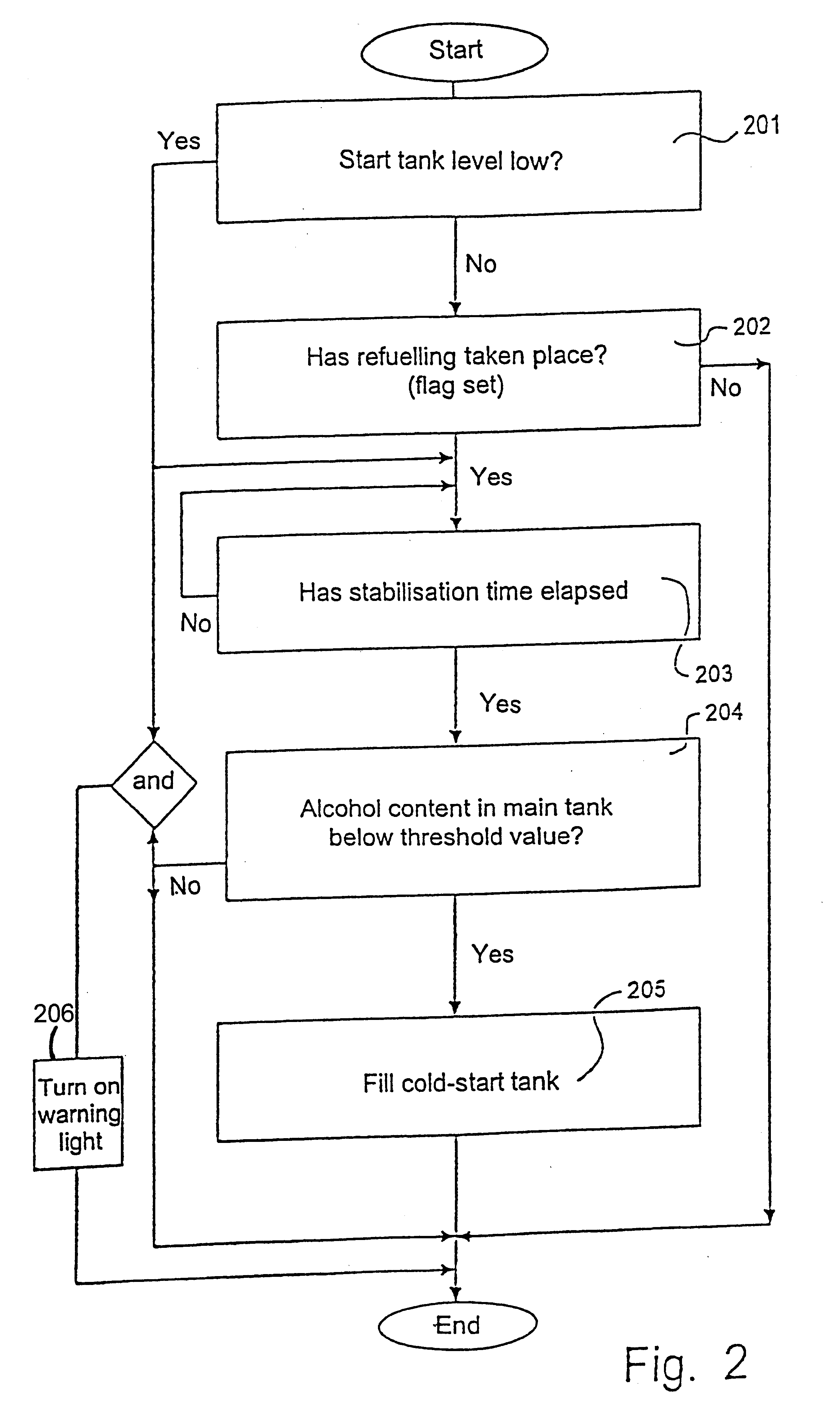

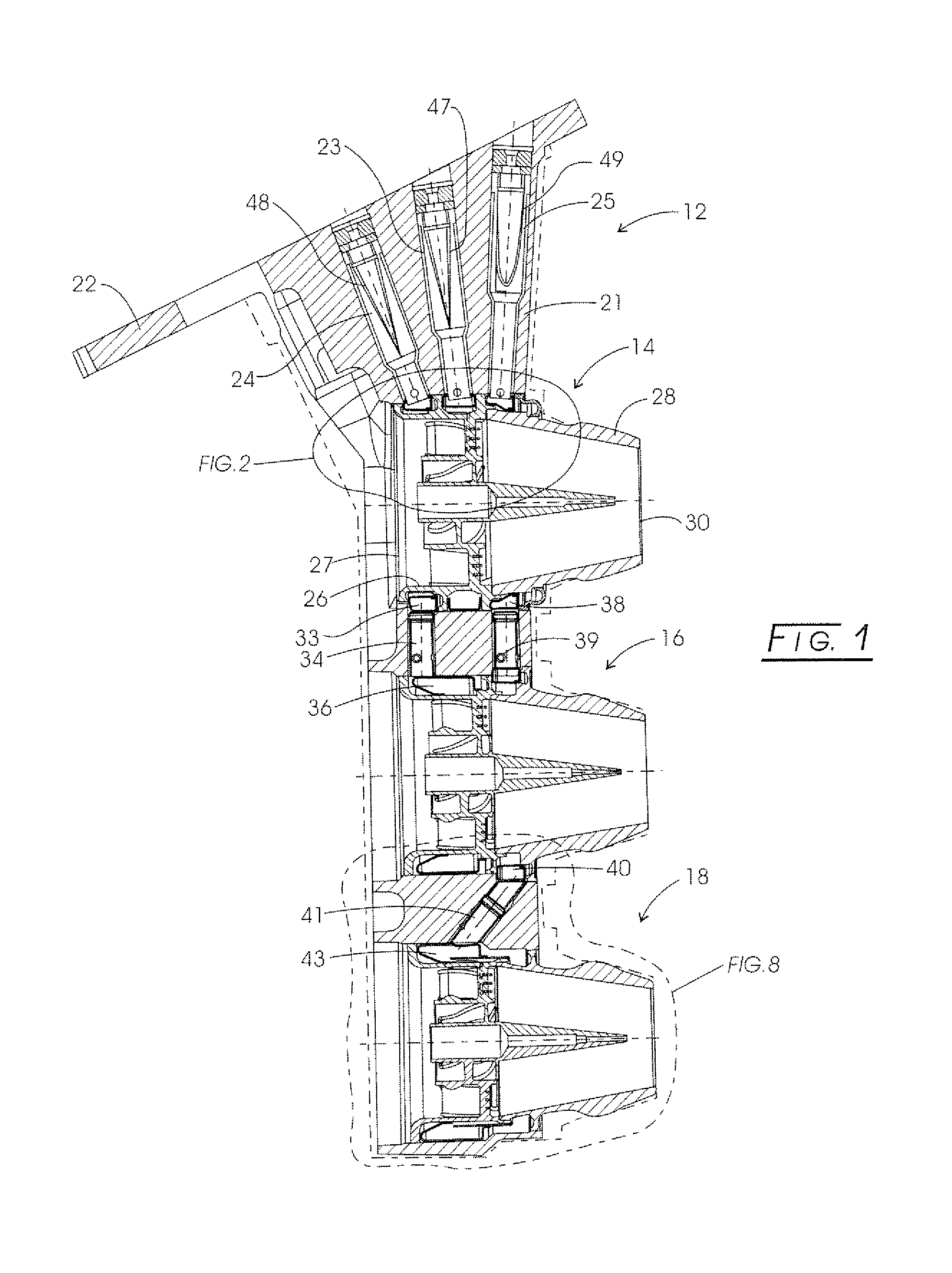

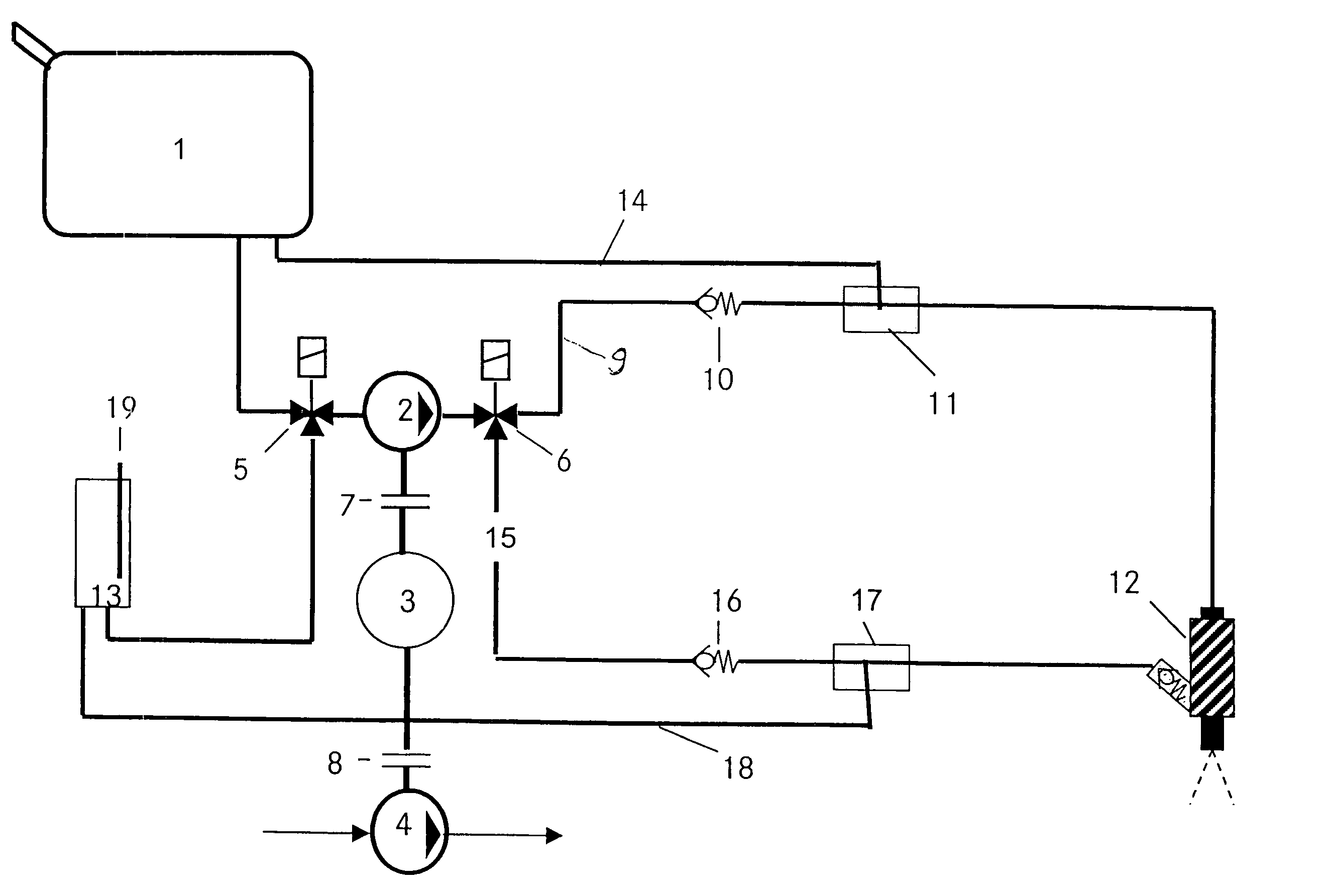

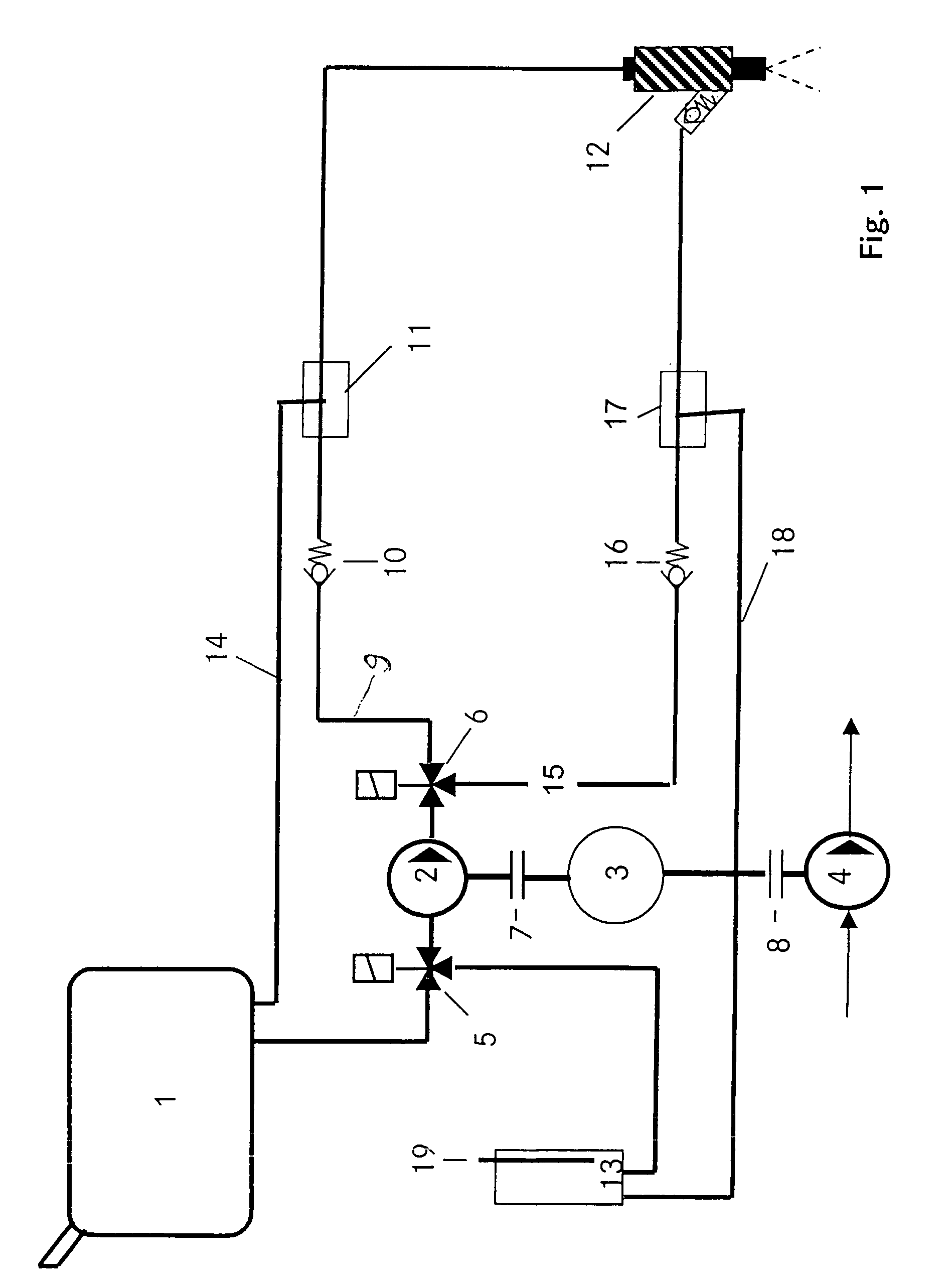

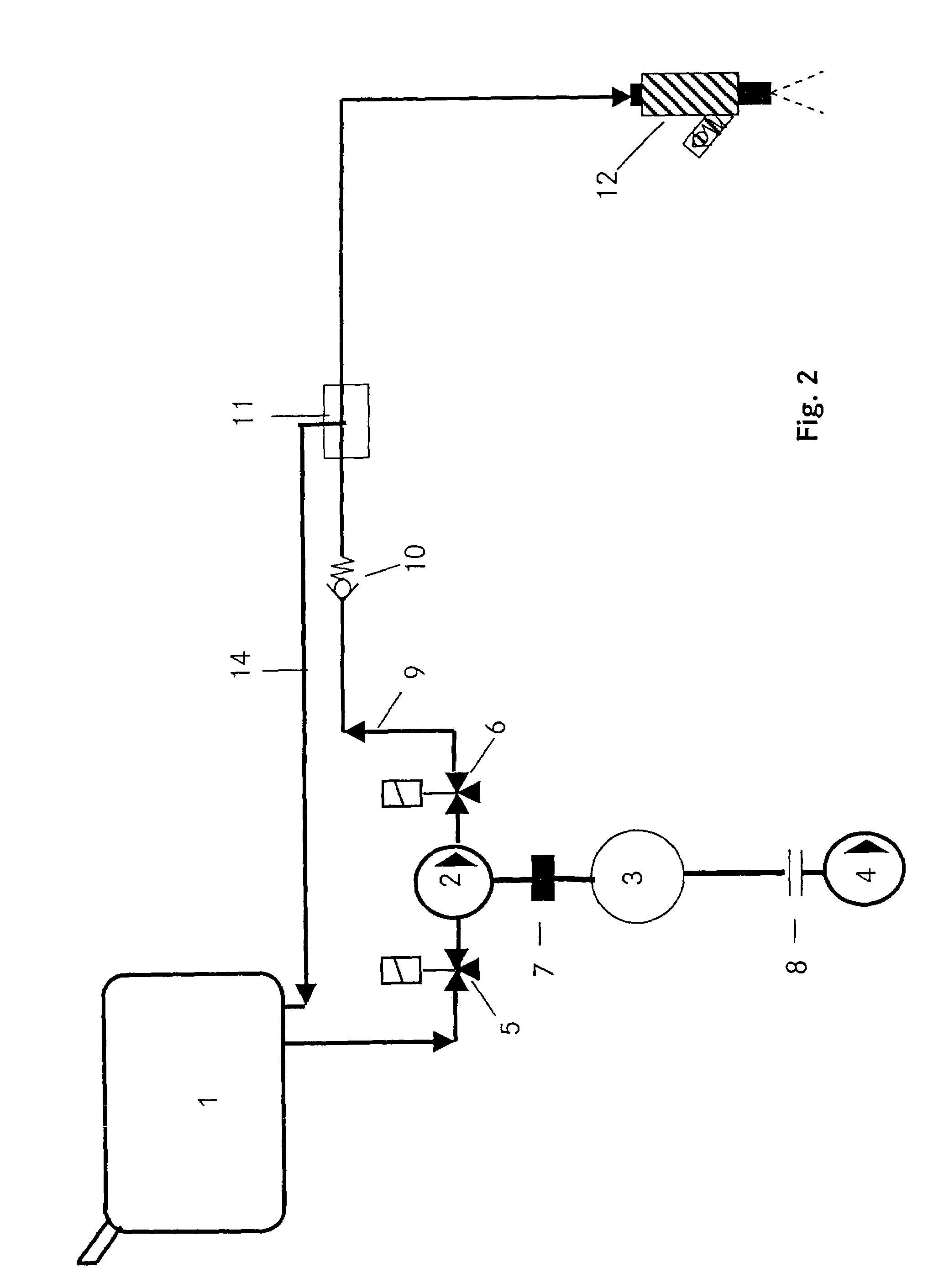

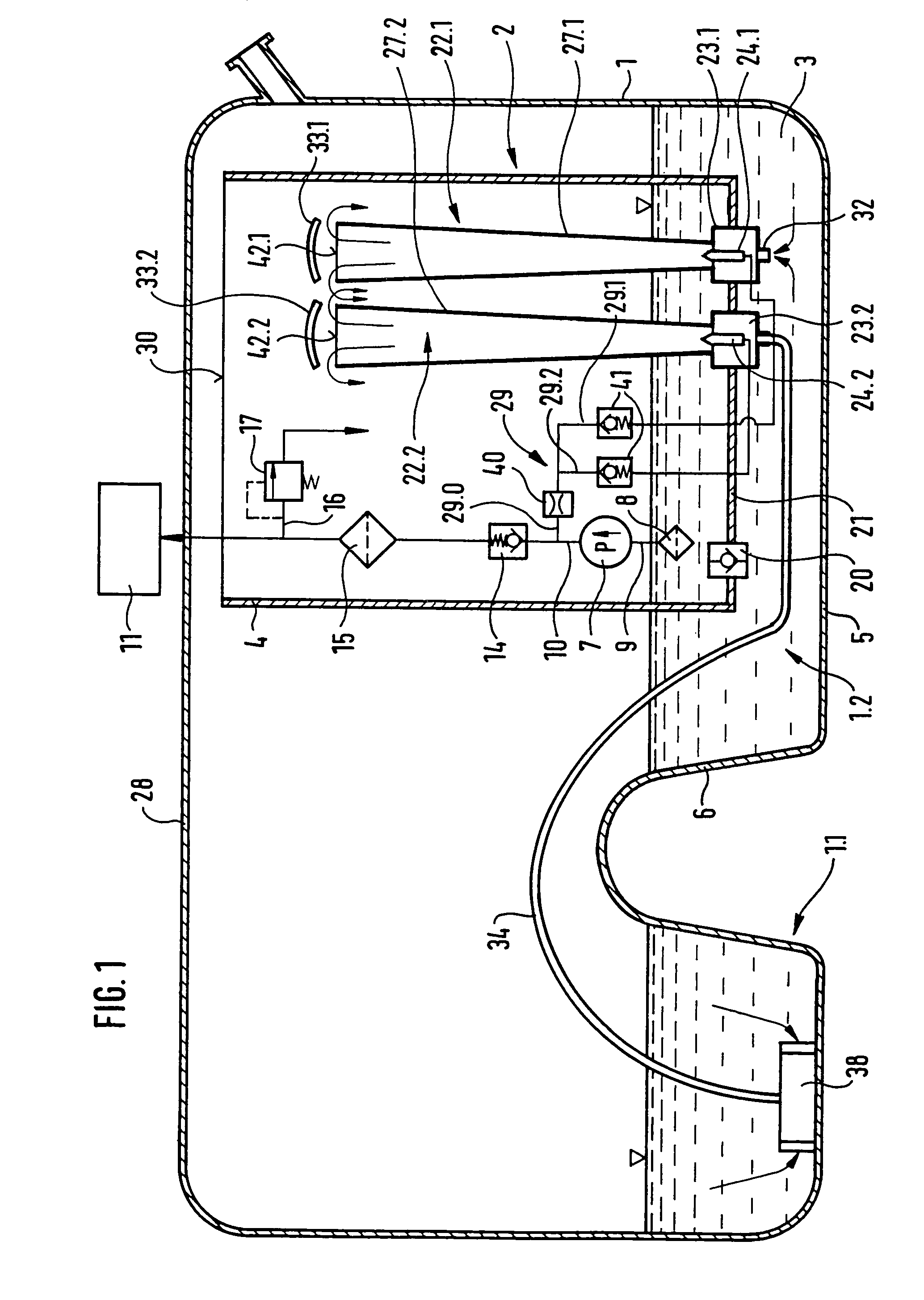

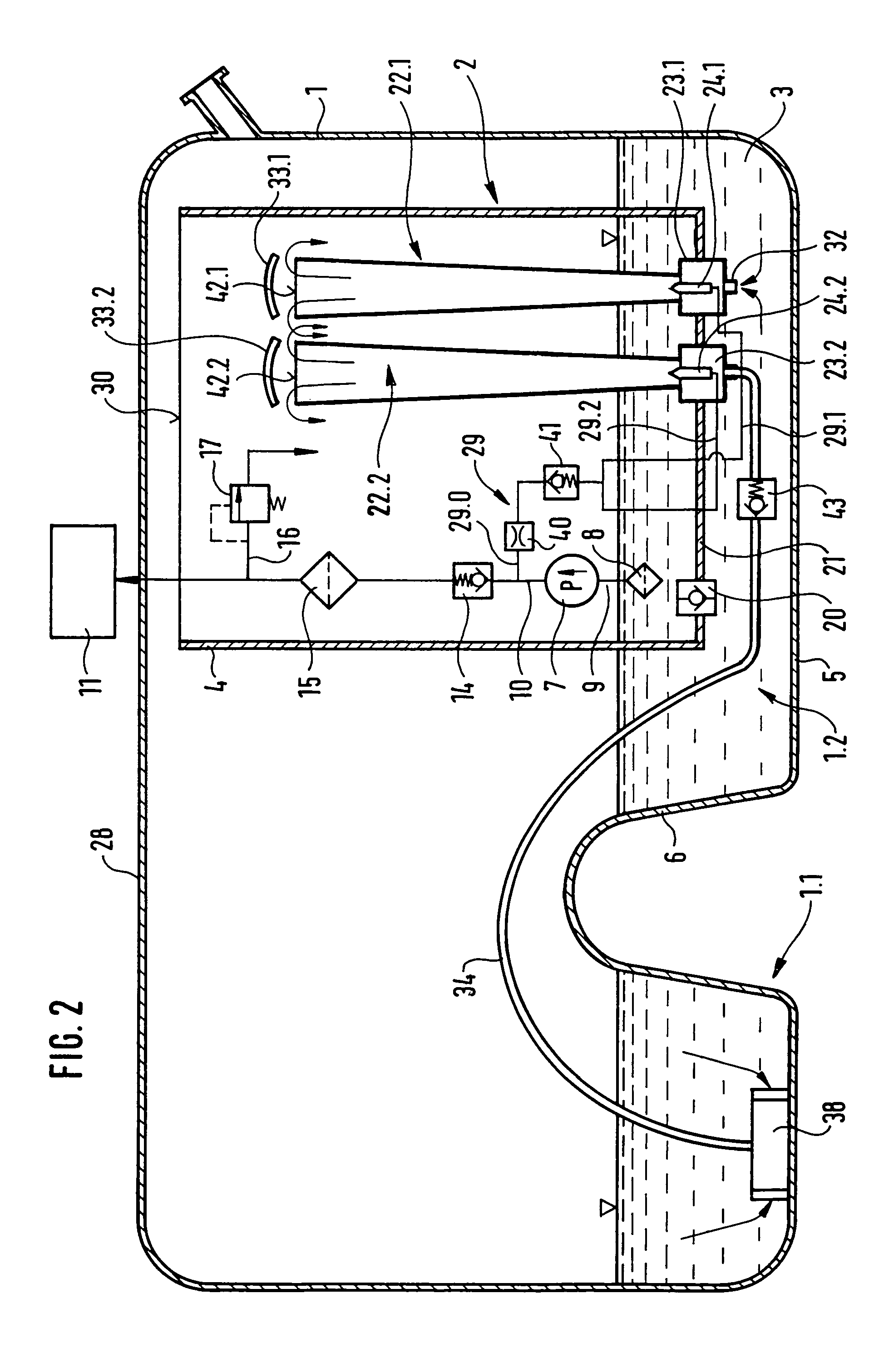

Method and system for refuelling cold-start fuel tanks

InactiveUS6467470B1Simple processImprove securityInternal combustion piston enginesLow-pressure fuel injectionAlcohol contentFuel tank

The present invention relates to a fuel system as well as a method for controlling the same. More specifically, it relates to a fuel system of motor vehicles adapted to be powered by alcohol-containing fuels, and specifically by alcohol-containing fuels and by petrol, so-called Flexible Fuel Vehicles (FFV). These vehicles can be powered by fuels with varying alcohol content, and also by pure petrol. The fuel system according to the invention comprises a main tank (1) for fuel, a cold-start tank (2) with fuel which is sufficiently inflammable to be used in connection with cold starts, as well as fuel line system connecting these tanks to each other and to injection means of the engine of the vehicle, where at least one pump (8, 13) is adapted to transfer fuel through the fuel line system. Specifically, the invention relates to a system which is controlled so that fuel is transferred from the main tank (1) to the cold-start tank (2) when the alcohol content of the fuel is below a predetermined threshold value.

Owner:AB VOLVO

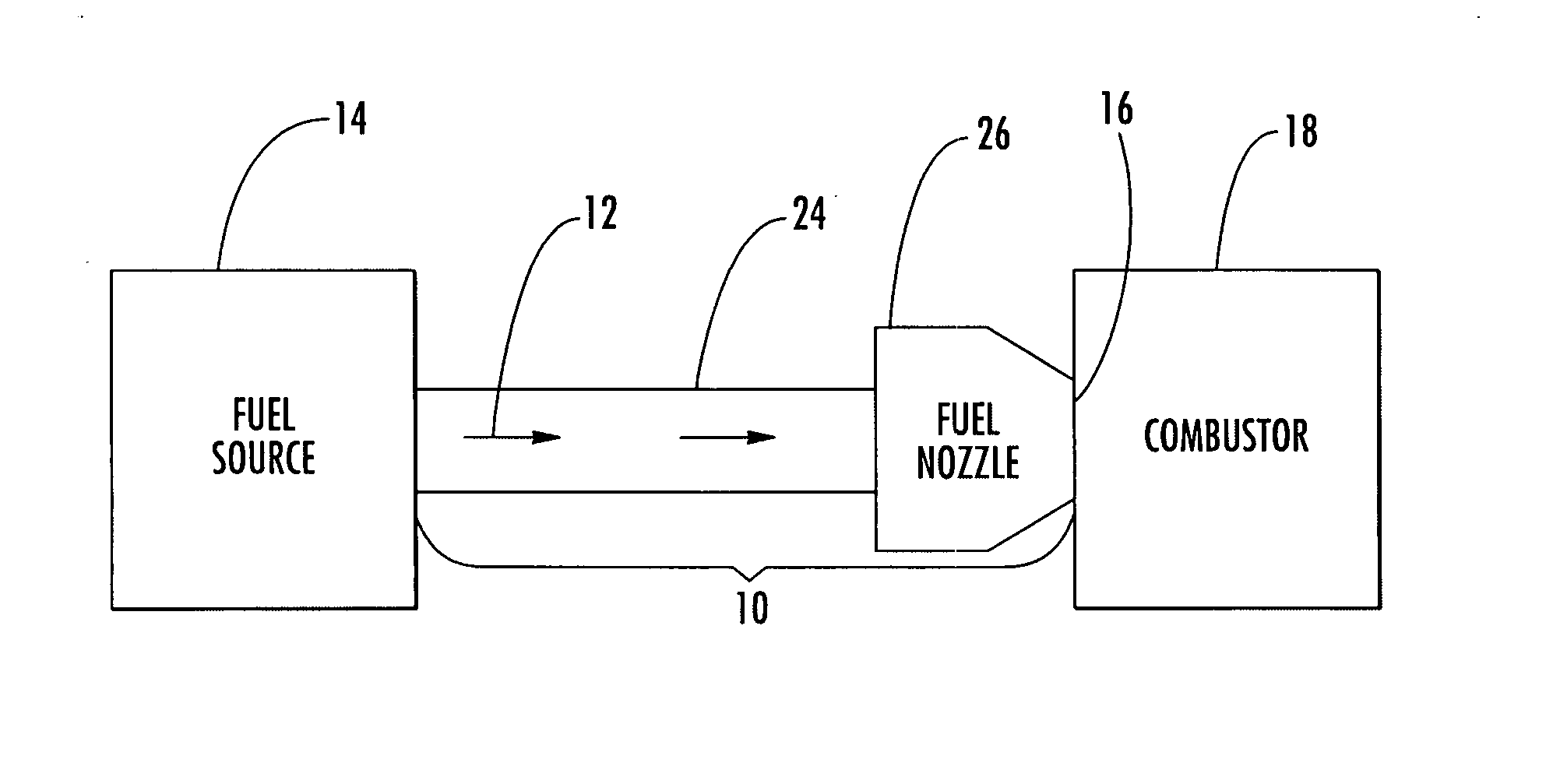

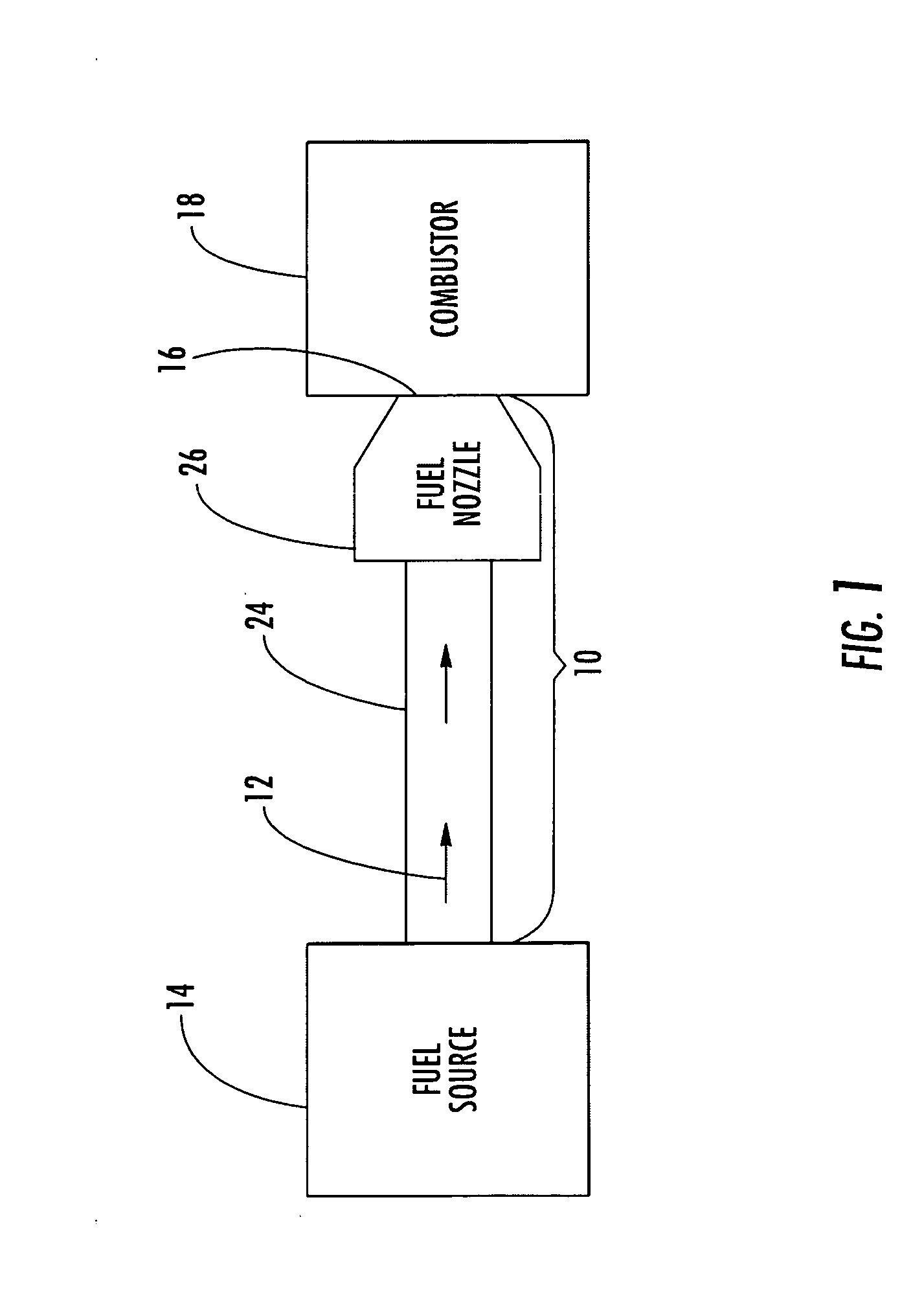

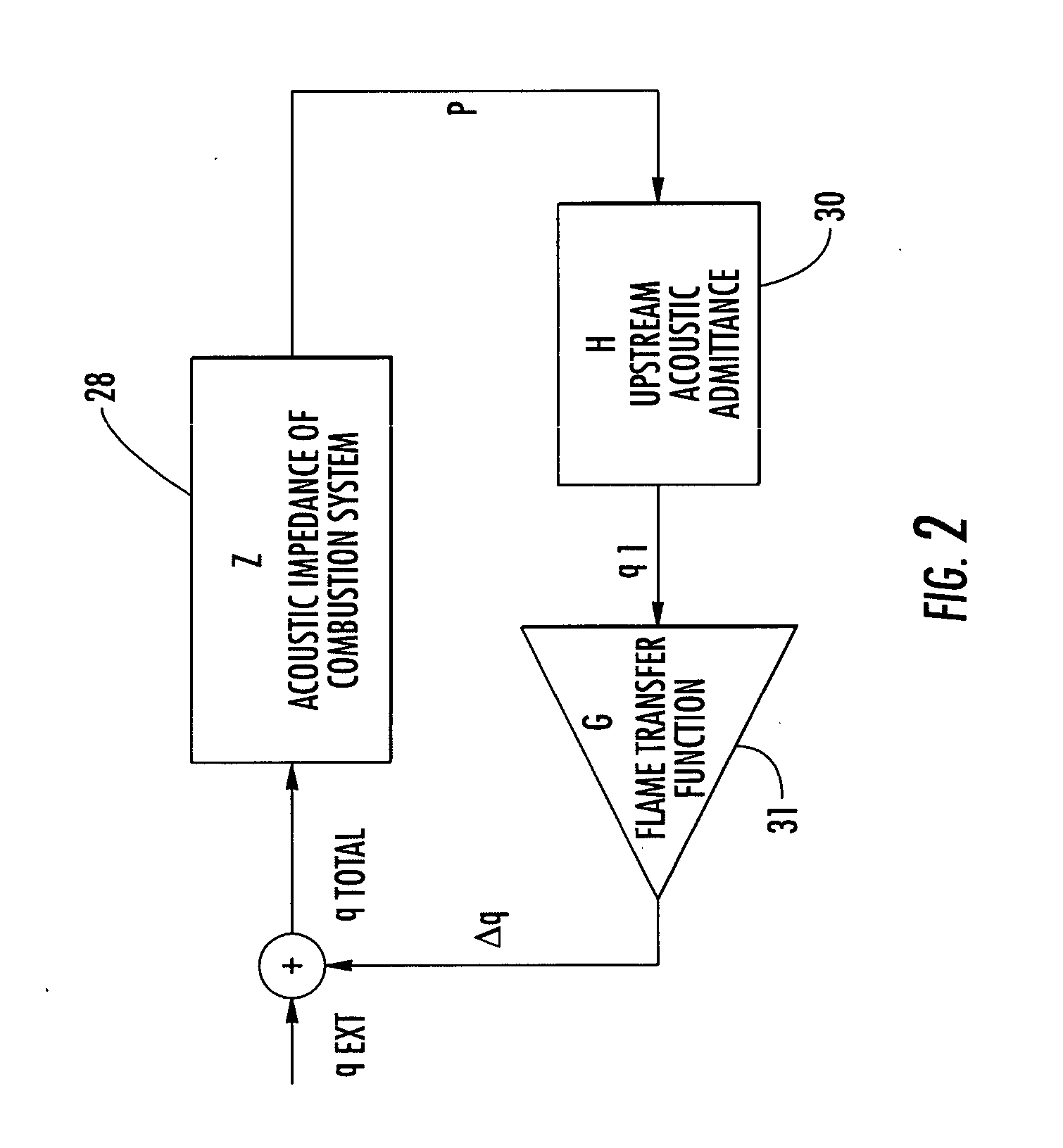

Acoustically stiffened gas-turbine fuel nozzle

InactiveUS20060000220A1Reducing combustion oscillationOscillation suppressionContinuous combustion chamberTurbine/propulsion fuel flow conduitsHelmholtz resonatorEngineering

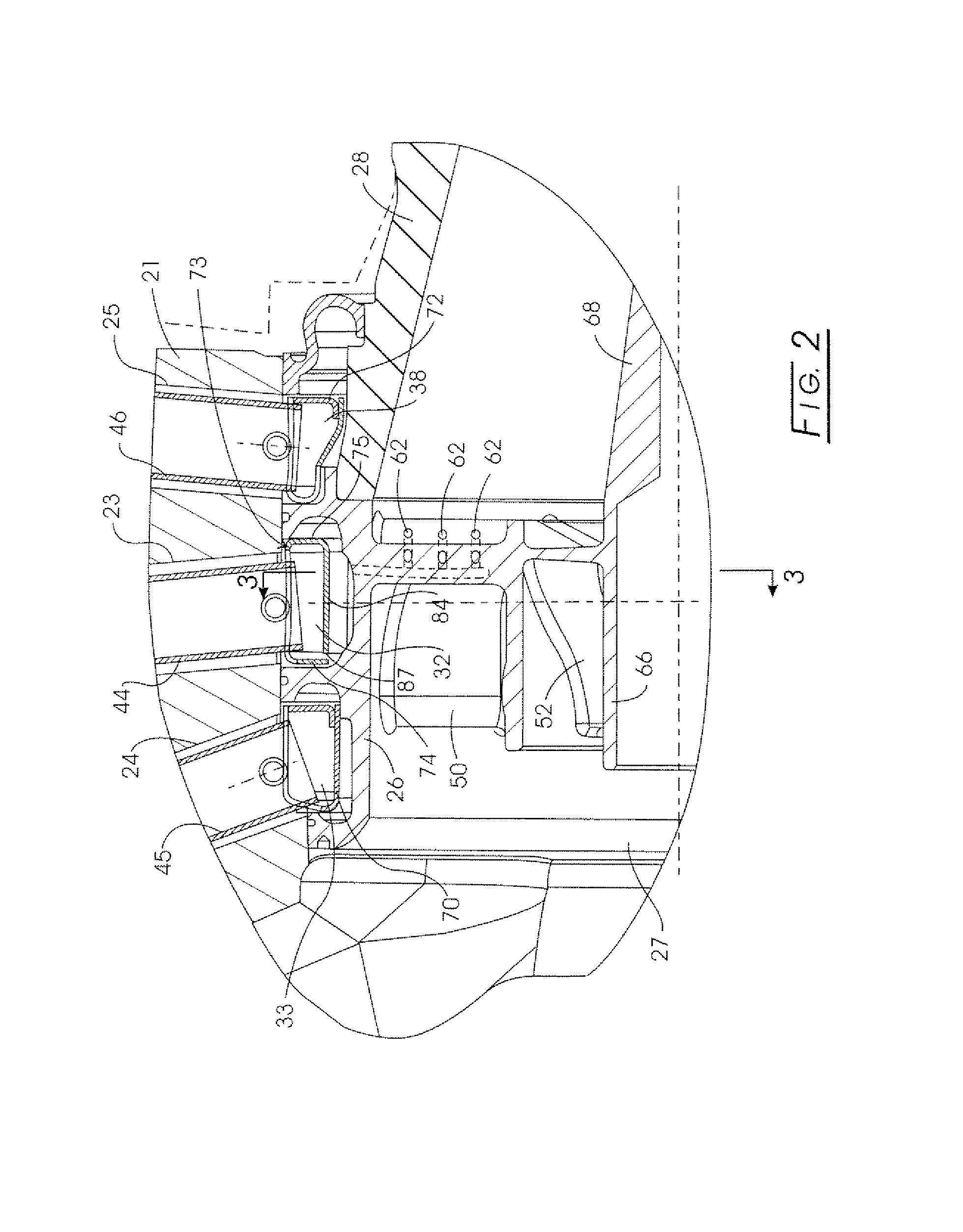

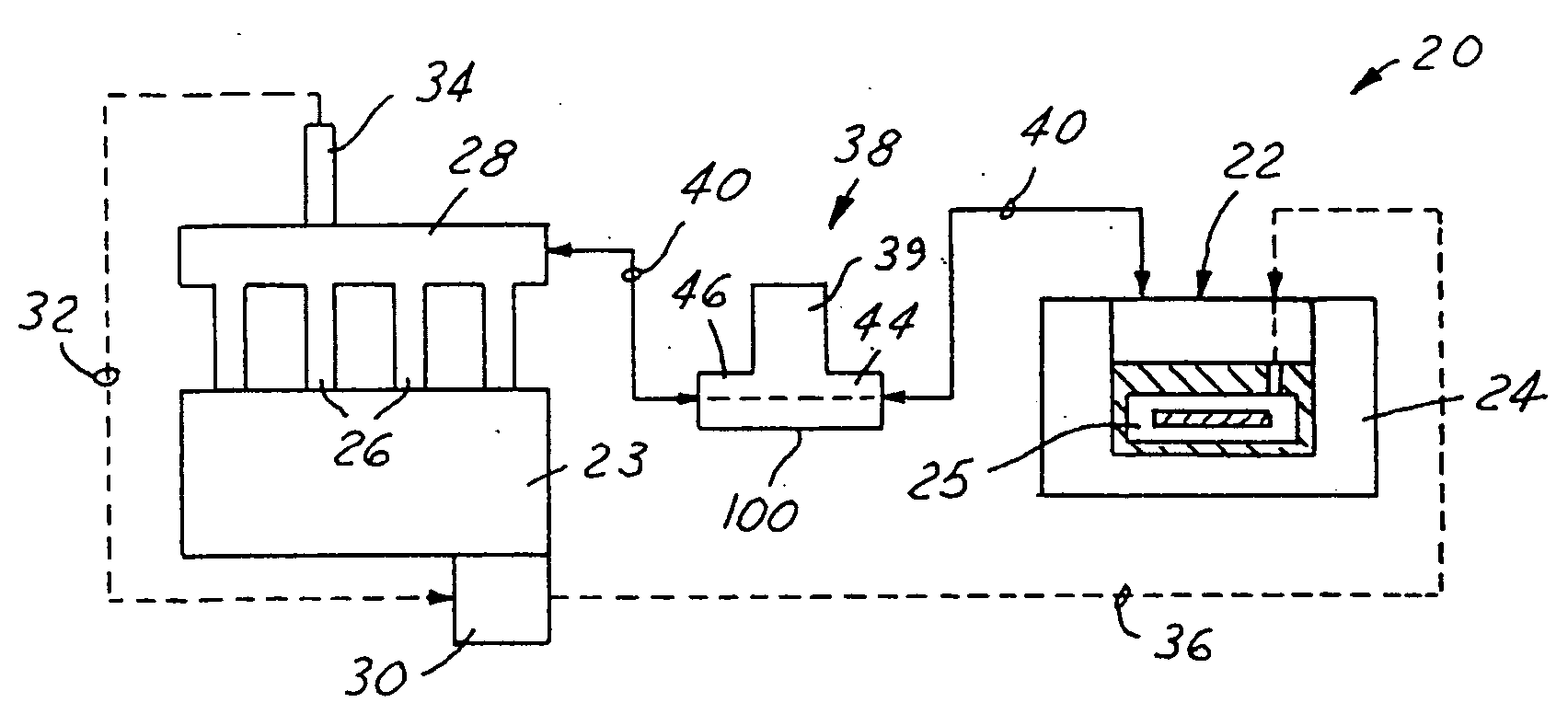

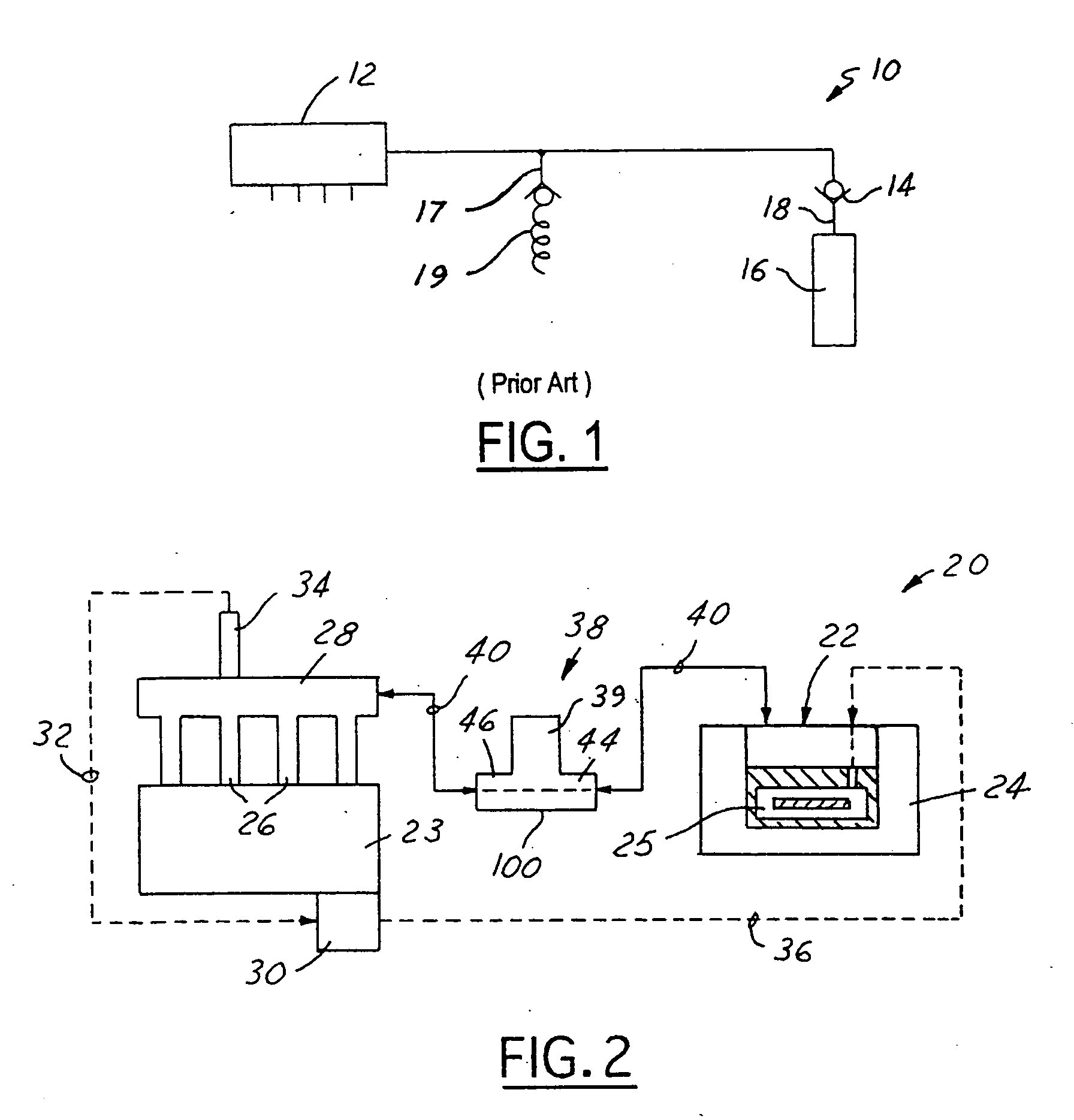

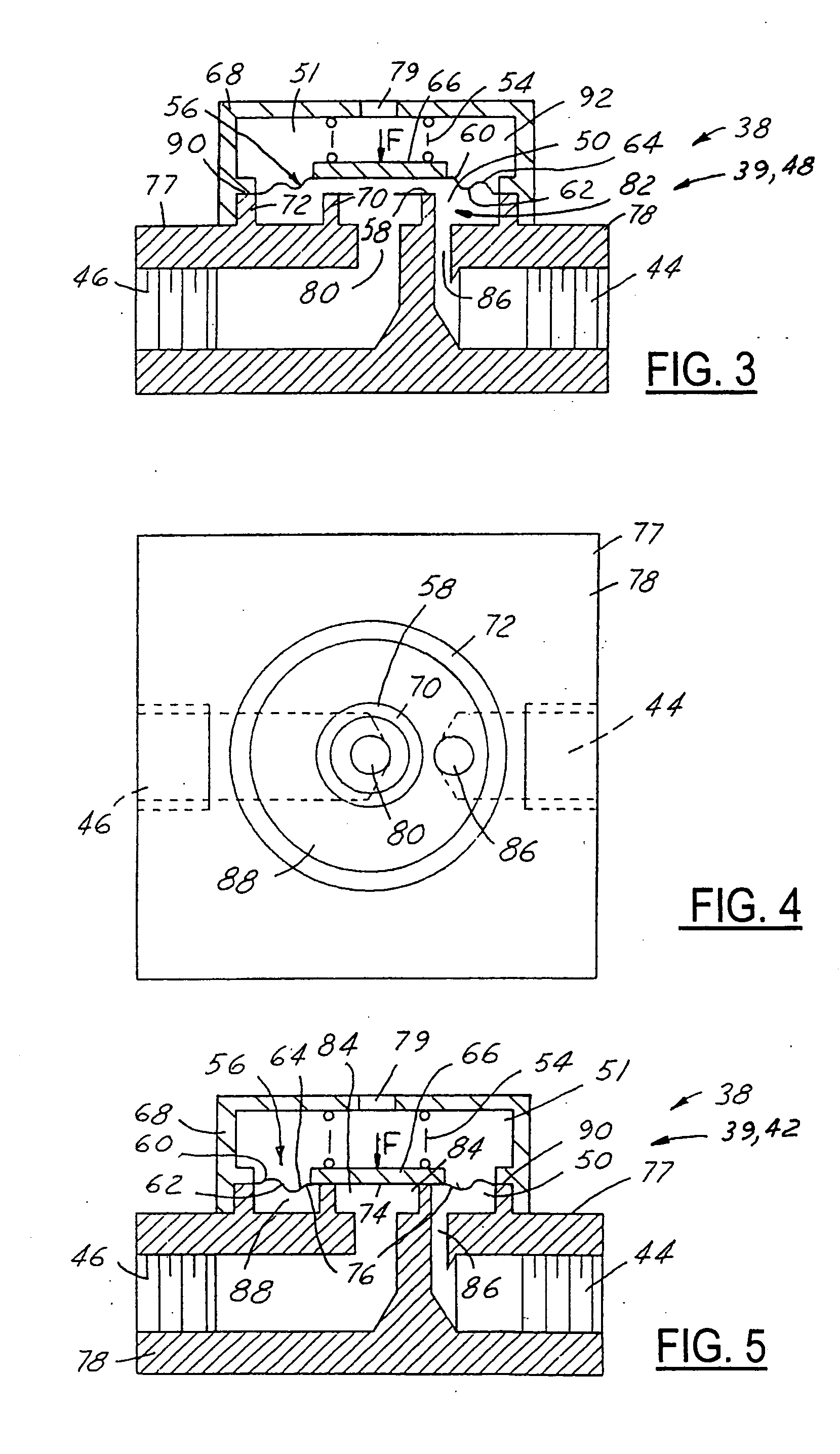

Under certain conditions, the fuel delivery system can contribute to the formation of strong dynamic pressures in the combustor of a turbine engine. Embodiments of the invention provide a system for dynamically stiffening the fuel supply passage to suppress damaging combustion dynamics. To that end, a Helmholtz resonator can be placed along and in branched relation to the fuel supply passage. The resonator can produce the effect of adding a pressure release opening at a selected location in the fuel line, causing a shift in the fuel line pressure wave pattern that blocks fuel flow fluctuations at the outlet of the fuel passage at the frequency of the oscillation. The pressure wave shift results in a shifting of the volume velocity wave pattern. Ideally, the resonator can be positioned along the flow path such that the volume velocity of the fuel at the fuel passage exit is minimized.

Owner:SIEMENS ENERGY INC

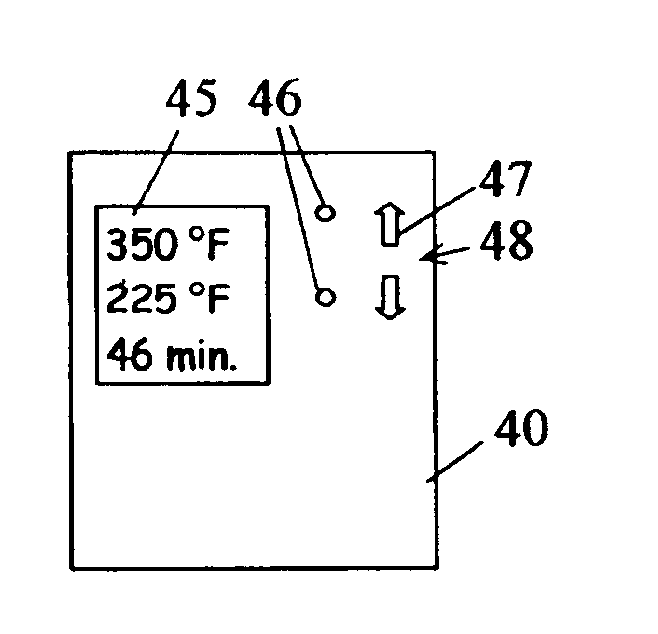

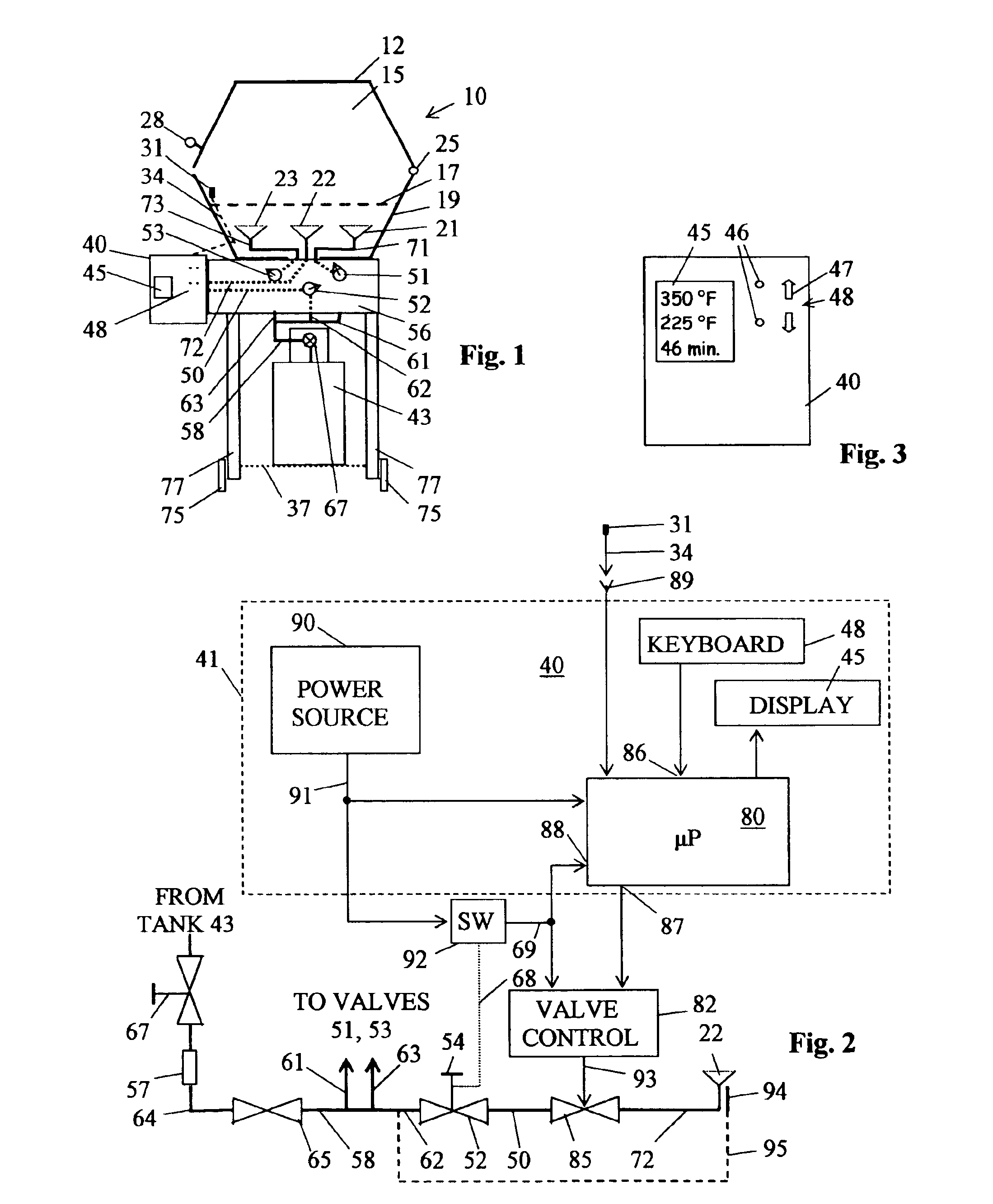

Temperature controlled burner apparatus

InactiveUS6881055B2Easy to controlMore powerTemperature control without auxillary powerSelf-cleaning stoves/rangesTemperature controlCombustor

A system for controlling temperature in an enclosure operates in a low heat or a high heat mode with flame always present. The presently intended use is for providing a cooking grill with a controlled temperature cooking space. An electrically controlled valve having high flow rate and low flow rate settings is interposed in the fuel line for at least one of the burners in the grill. A temperature sensor signals cooking space temperature to a controller that may be a microprocessor. The system includes a keyboard allowing the user to communicate a selected set point to the microprocessor and the microprocessor communicates status to a display. The microprocessor selects the setting of the electrically controlled valve. In a preferred embodiment, the electrically controlled valve is placed in series fuel flow with one of the manually adjustable valves commonly found on cooking grills.

Owner:ADEMCO INC

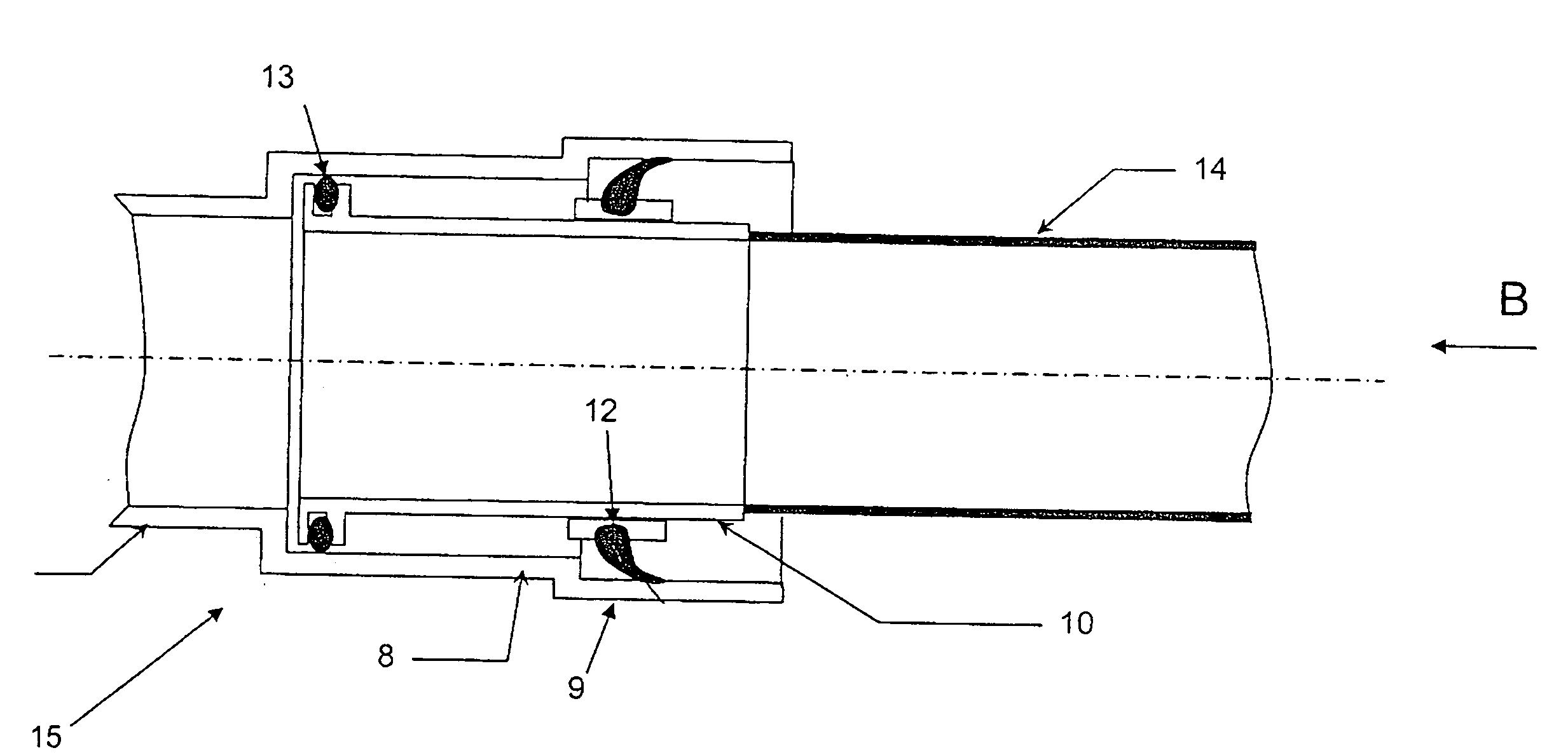

Fuel line check valve

ActiveUS7444990B1Reduce fuel leakageReduce evaporative emissionsCheck valvesLow pressure fuel injectionWorking pressureFuel line

A check valve includes a body defining a passageway through which fuel flows in a first fuel-flow direction during pump operation. The check valve also includes a seat, a seal member, and a biasing member biasing the seal member toward the seat. The seal member is movable between a first seated position in which the seal member is engaged with the seat and the pressure in the fuel rail is substantially equal to the operating pressure, and a second seated position in which the seal member is engaged with the seat and a residual pressure in the fuel rail is substantially less than the operating pressure. The seal member and the seat define a leak path between the fuel pump and the fuel rail permitting fuel to flow in a second fuel-flow direction opposite the first fuel-flow direction when the seal member is in the second seated position.

Owner:ROBERT BOSCH CORP +1

Semiaromatic moulding compositions and uses of these

ActiveUS20110123749A1Low process temperatureSufficient compatibilityNon-metal conductorsEnvelopes/bags making machineryLaurolactamPolymer science

A polyamide moulding composition with the following constitution is described:(a) from 40 to 90% by weight of a copolyamide, where this is composed of(a1) 1,6-hexanediamine and 1,10-decanediamine and also(a2) terephthalic acid and at least one other polyamide-forming monomer selected from the group of: dicarboxylic acid having from 8 to 18 carbon atoms, laurolactam, aminolauric acid, and / or mixtures thereof;(b) from 10 to 40% by weight of macromolecular plasticizers, with the proviso that these can have been replaced to some extent by low-molecular-weight plasticizers;(c) from 0 to 20% by weight of additives and / or added substances.Uses of this type of moulding composition are also described, in particular for the production of a fuel line, cooling line, oil line or urea line for the automobile sector, as also are production processes to give mouldings.

Owner:EMS PATENT AG

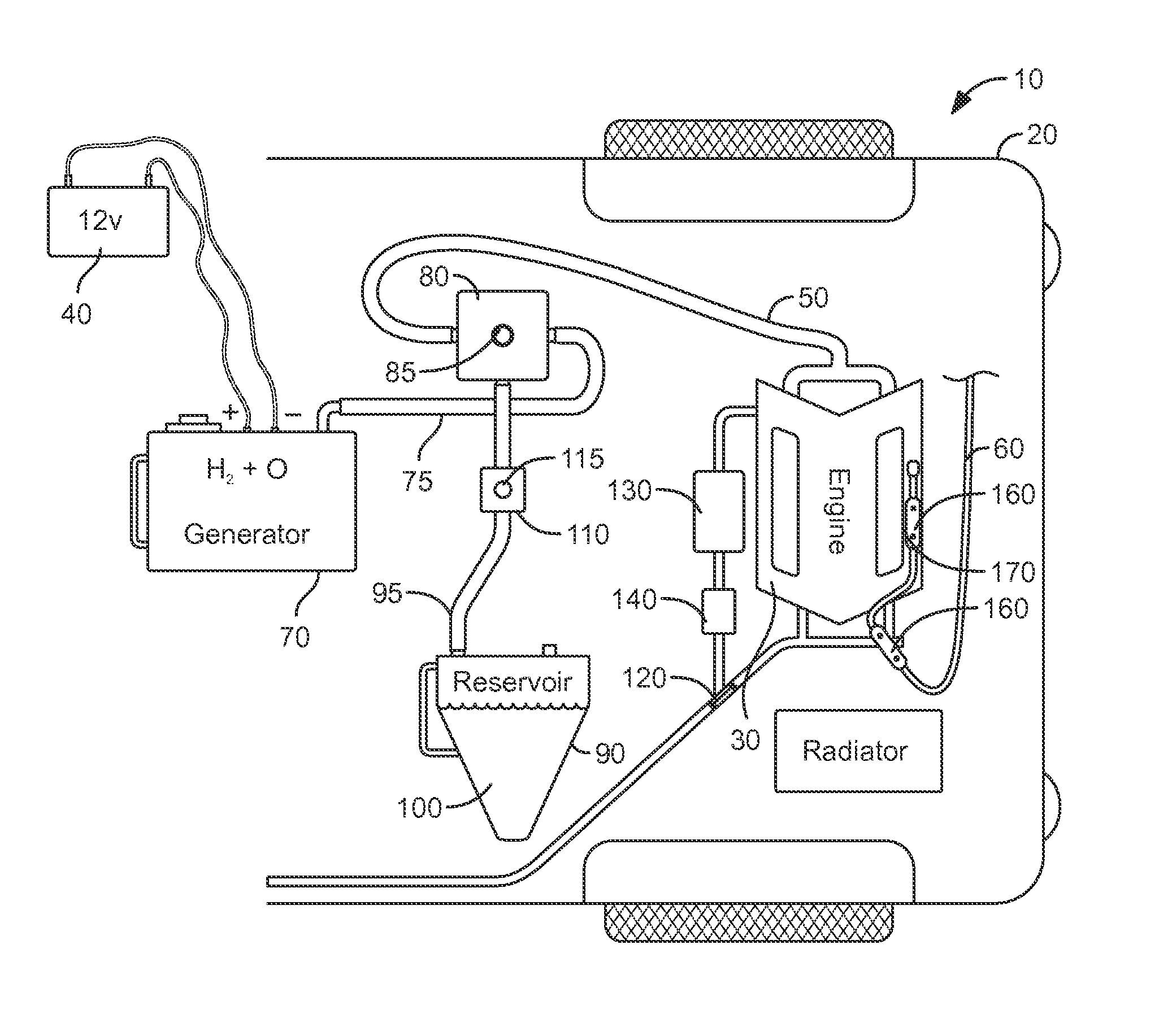

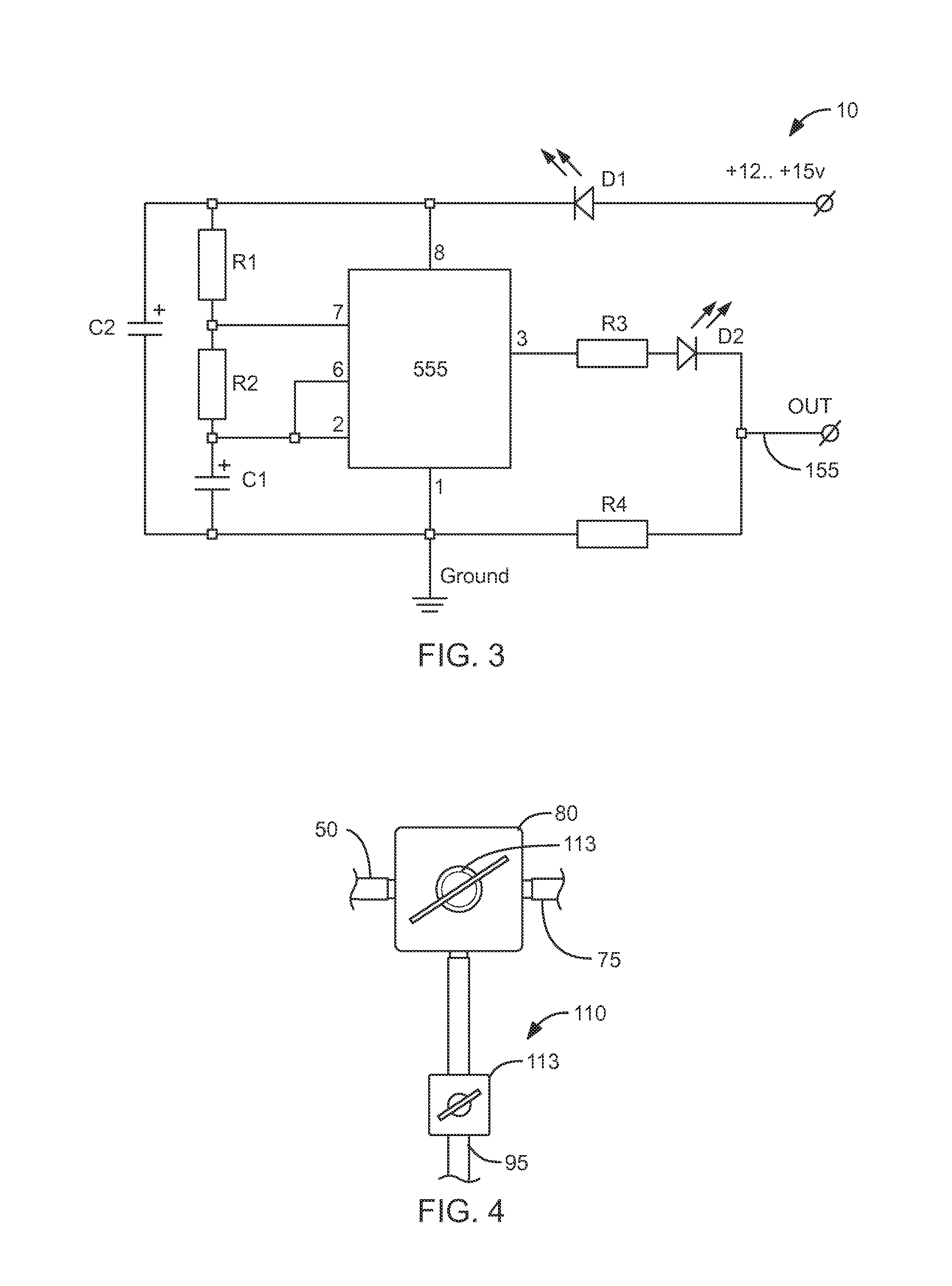

Engine fuel efficiency improvements

InactiveUS7458368B1Good fuel atomizationEfficient combustionPhotography auxillary processesNon-fuel substance addition to fuelFuel efficiencyInternal combustion engine

The present invention is a system for increasing the fuel efficiency of a vehicle of the type having an internal combustion engine, a battery, a vacuum line, and a fuel line that feeds fuel to the engine. The system comprises a hydrogen gas generator and a vacuum regulator. A vacuum regulator is in fluid communication with the vacuum line of the vehicle and an output line of the gas generator. The vacuum regulator includes a vacuum pressure adjustment means for controlling the amount of hydrogen gas that is introduced into the vacuum line of the vehicle. In use, hydrogen gas is introduced into the vehicle vacuum line and then into the engine where it is mixed with the fuel from the fuel line and ambient air. The hydrogen gas increases the atomization of the fuel for more efficient burning thereof in the engine. A fuel additive including an acetone-based compound, a xylene-based compound, and an upper cylinder lubricant may be mixed with the hydrogen gas to further atomize the fuel. An oxygen sensor signal generator that generates a bypass signal replicates the output of a vehicle oxygen sensor under normal operating conductions to keep the air mixture of the engine unaffected. The system may additional include at least one fuel heating means fixed to a high-temperature portion of the engine, such that the fuel is heated before being introduced into the engine so as to further increase atomization of the fuel for more efficient burning thereof in the engine.

Owner:HUFFMAN DANIEL

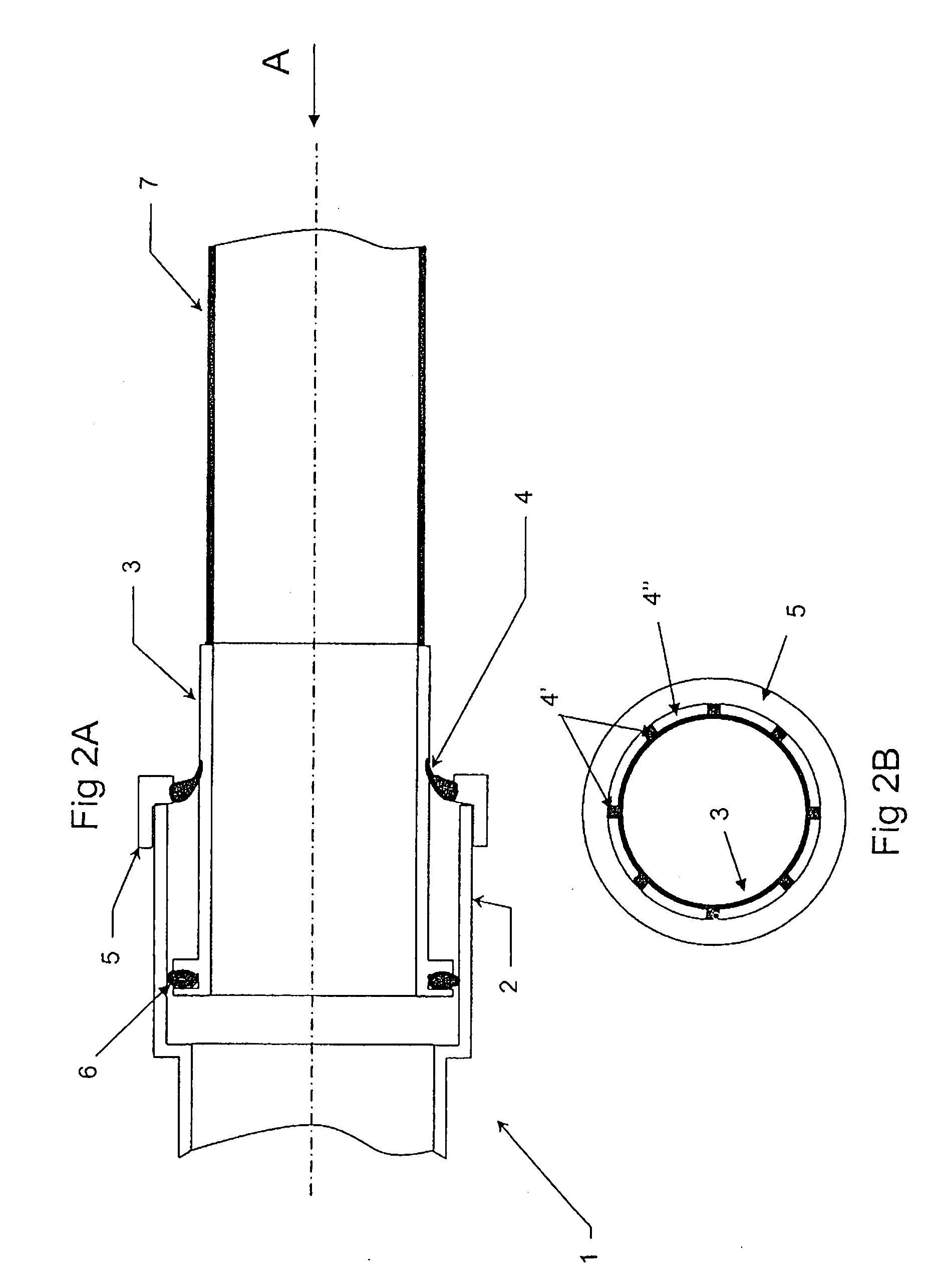

Aircraft fuel pipe coupling

InactiveUS20080078880A1Reduce harmEasy to assembleSleeve/socket jointsPower plant fuel tanksElectricityCoupling

A coupling for connecting fuel pipes in an aircraft is provided. At least one of the fuel pipes is capable of movement with respect to the coupling. The coupling comprises a pipe end fitting and a socket arrangement. The pipe end fitting is located within the socket arrangement. At least one resiliently flexible electrical contact is located between the pipe end fitting and the socket arrangement. The coupling may thus form a flexible coupling electrically connecting two pipes to prevent static electricity build-up whilst permitting movement between the pipes.

Owner:AIRBUS OPERATIONS LTD

Nozzle assembly with fuel tube deflector

ActiveUS7140560B2Prevents orReduce thermal stressLiquid surface applicatorsContinuous combustion chamberEngineeringFuel line

A deflector at the downstream end of a fuel tube deflects incoming fuel into an annular fuel channel in a fuel swirler of an injector. The deflector prevents direct impact of the cooler fuel on the exposed walls of the swirler body. The deflector can be formed by a tab or other integral portion of the heatshield, or as a separate piece fixed to the heatshield or swirler body. The deflector minimizes disruption of flow through any flow slots that are covered by the deflector, and may have i) a relatively small circumferential extent, such that the deflector covers only a few flow slots, ii) flow openings or slots that allow a portion of the fuel to flow inwardly of the deflector into the otherwise covered flow slot(s), or iii) a space or gap between the side(s) of the deflector and the inner walls of the annular channel.

Owner:PARKER INTANGIBLES LLC

No-return loop fuel system

InactiveUS20050034710A1Emission reductionReduce the number of partsDiaphragm valvesOperating means/releasing devices for valvesFuel tankEngineering

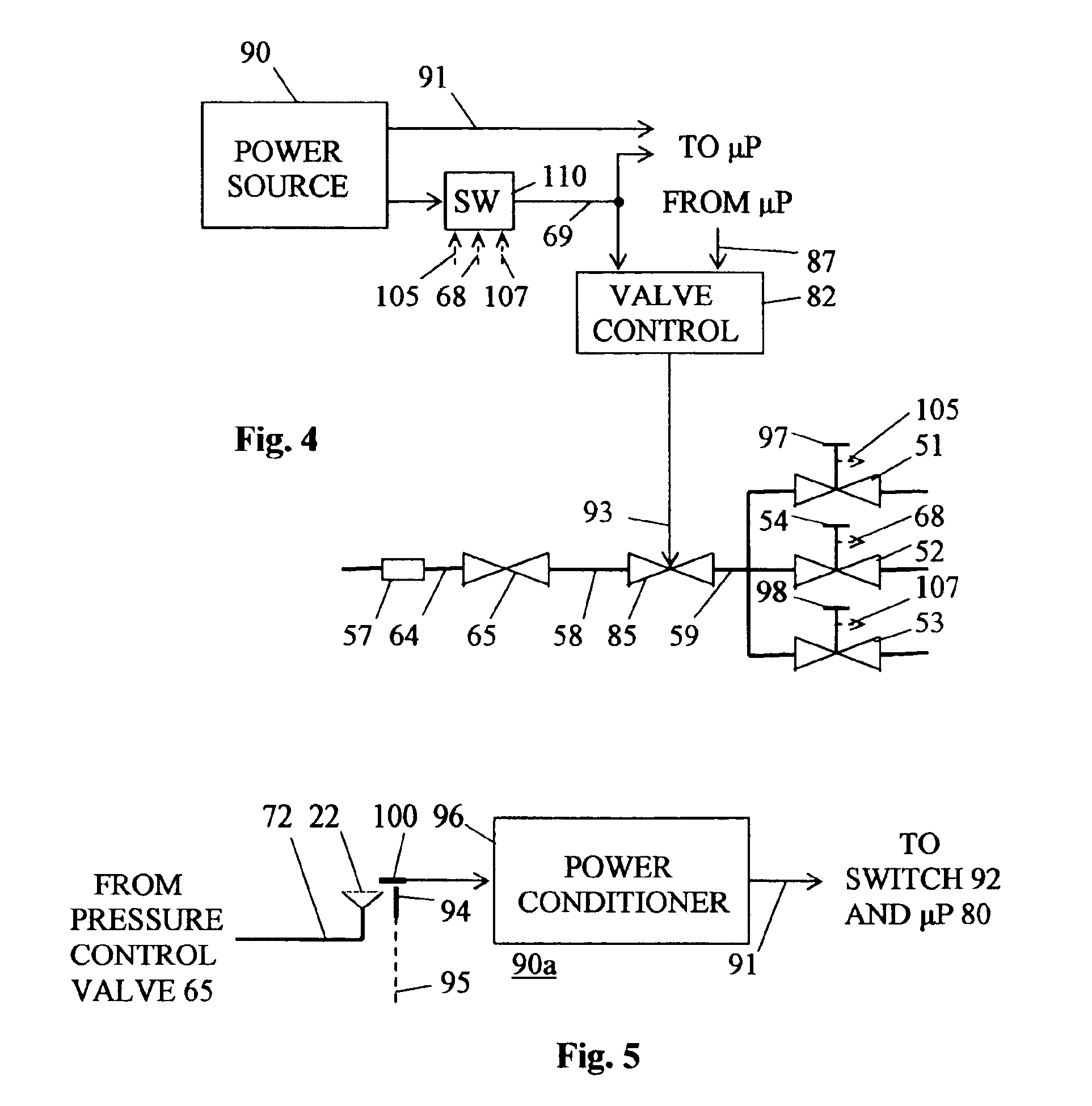

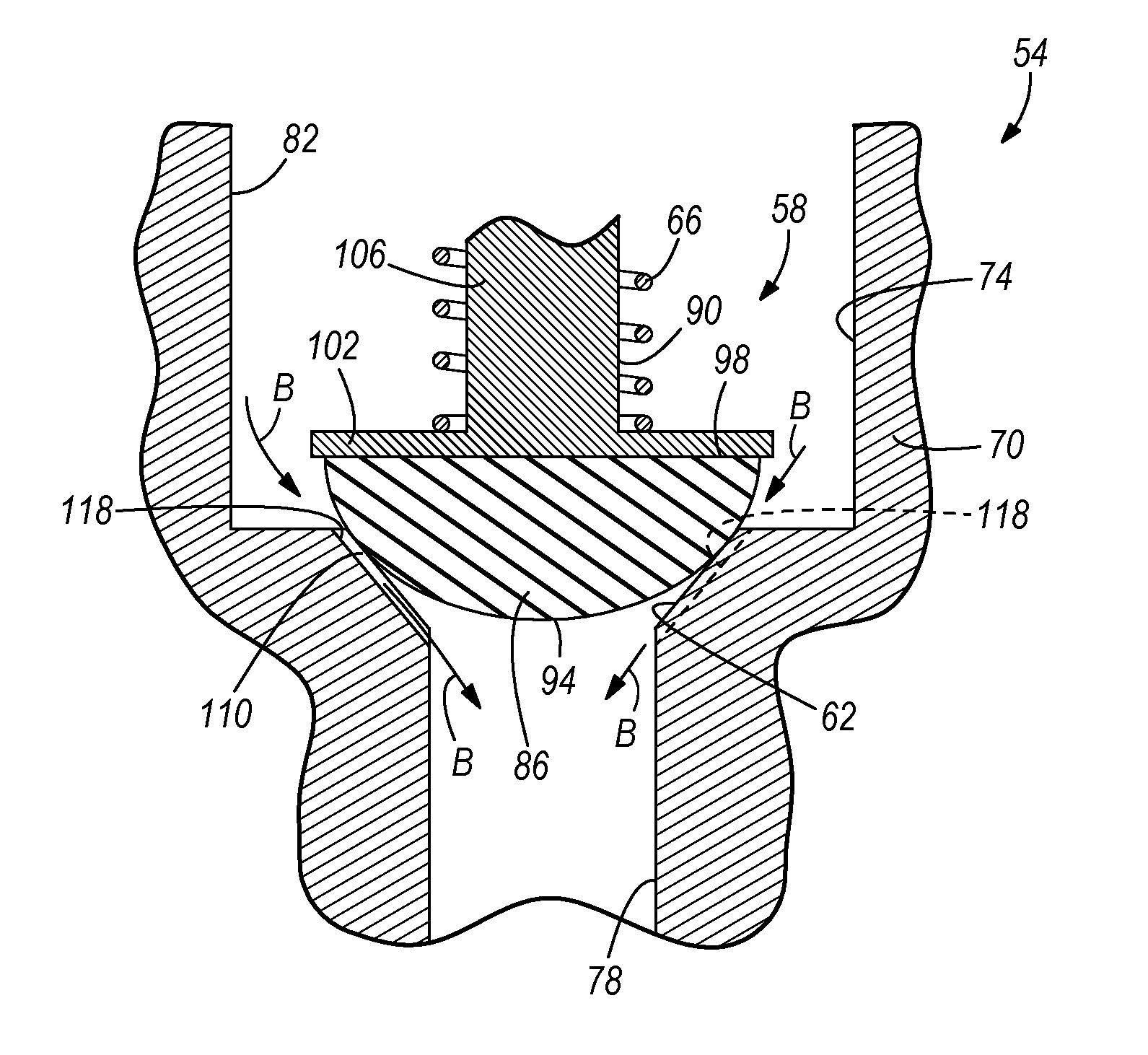

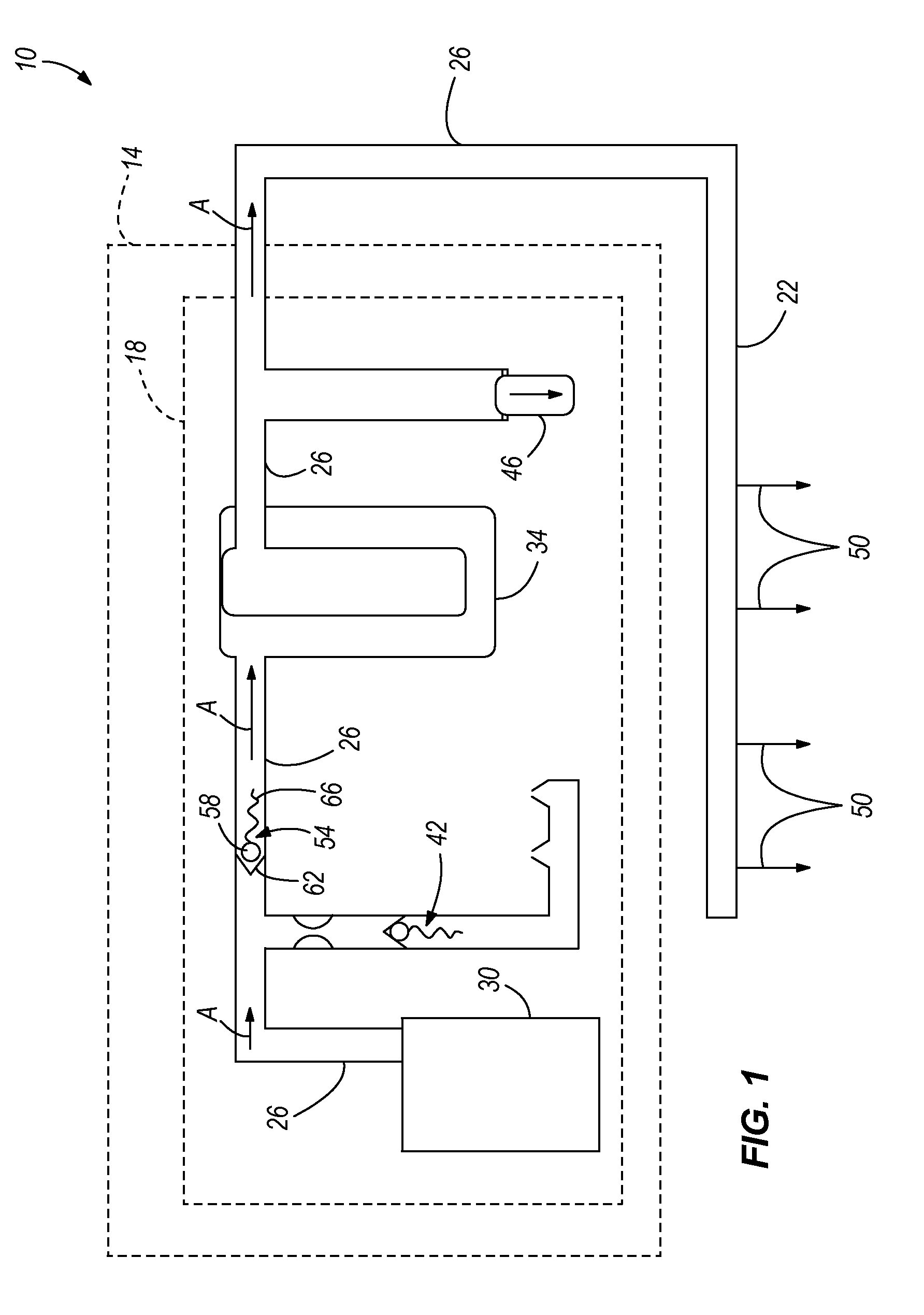

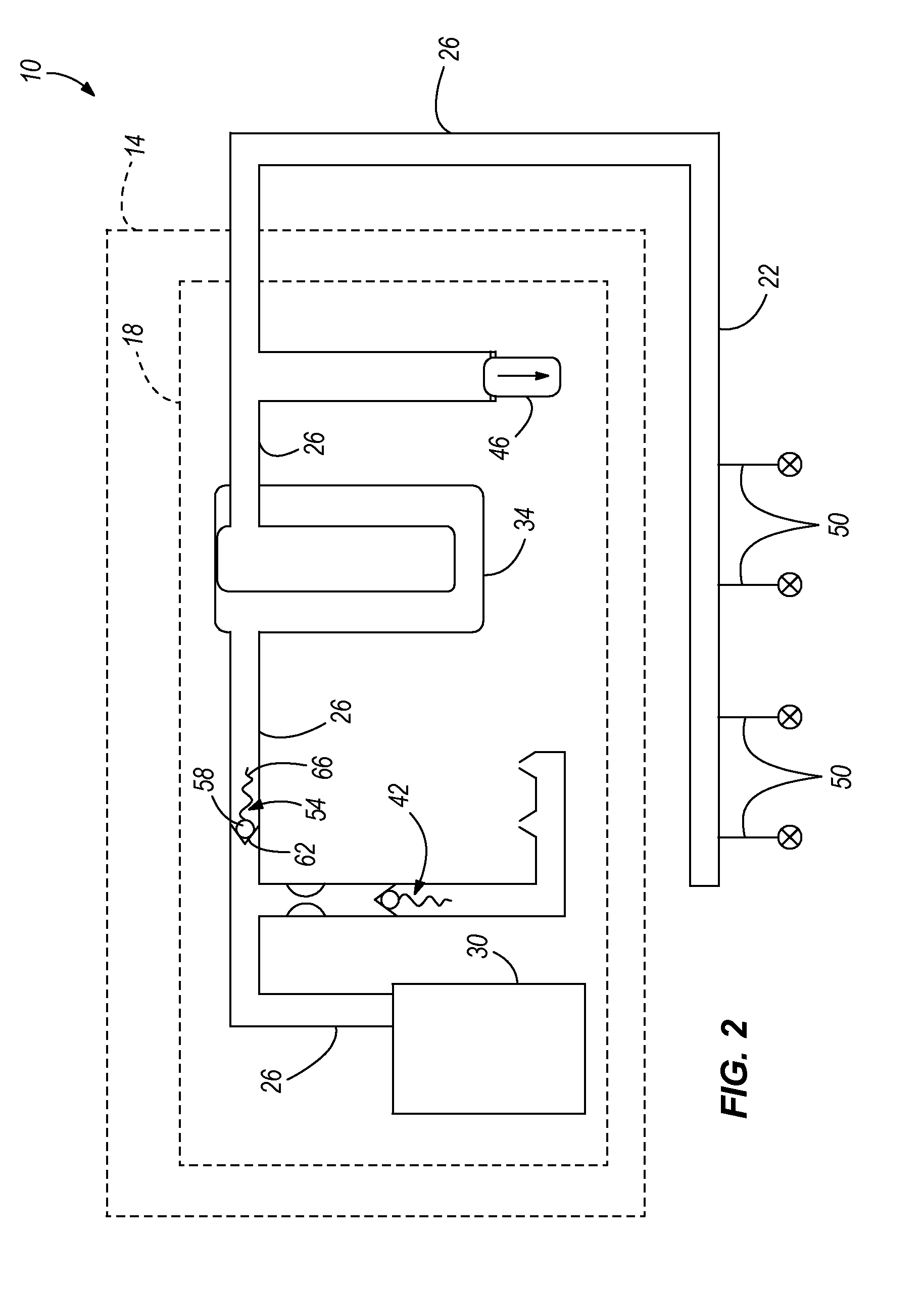

A no-return loop fuel injection system supplies fuel from a fuel pump to an injector fuel rail, through a fuel line. A biased closed pressure control valve communicates with the fuel line and has a valve head preferably of a diaphragm type carrying a fuel side having first and second areas which are segregated and defined by a valve seat when the pressure control valve is closed. An opposite second side of the pressure control valve is exposed to a reference pressure and a closure biasing force. The pressure control valve opens when a hydraulic opening force induced by a fuel pressure exerted upon the first area, plus a fuel pressure exerted upon the second area, is greater than the net reference pressure and closure biasing forces. Preferably, the first area is smaller than the second area, thus manipulating the effects of the fuel pressures exerted upon the first and second areas with respect to opening the valve. When the pressure control valve is open, the system operating pressure exposed to both the first and second areas is sufficient to produce the hydraulic force necessary to keep the valve open. Preferably, the pressure control valve is part of a pressure valve assembly of a fuel pump module located inside a fuel tank. The pressure valve assembly preferably has a flow check valve orientated in a parallel flow configuration to the pressure control valve when the fuel pump is of a variable speed type, or, for systems utilizing constant speed pumps the check valve is replaced with a flow bypass orifice.

Owner:TI GRP AUTOMOTIVE SYST LLC

Fuel filter

ActiveUS8173013B2High filtration precisionLow priceWater/sewage treatmentMembrane filtersFuel tankFuel filter

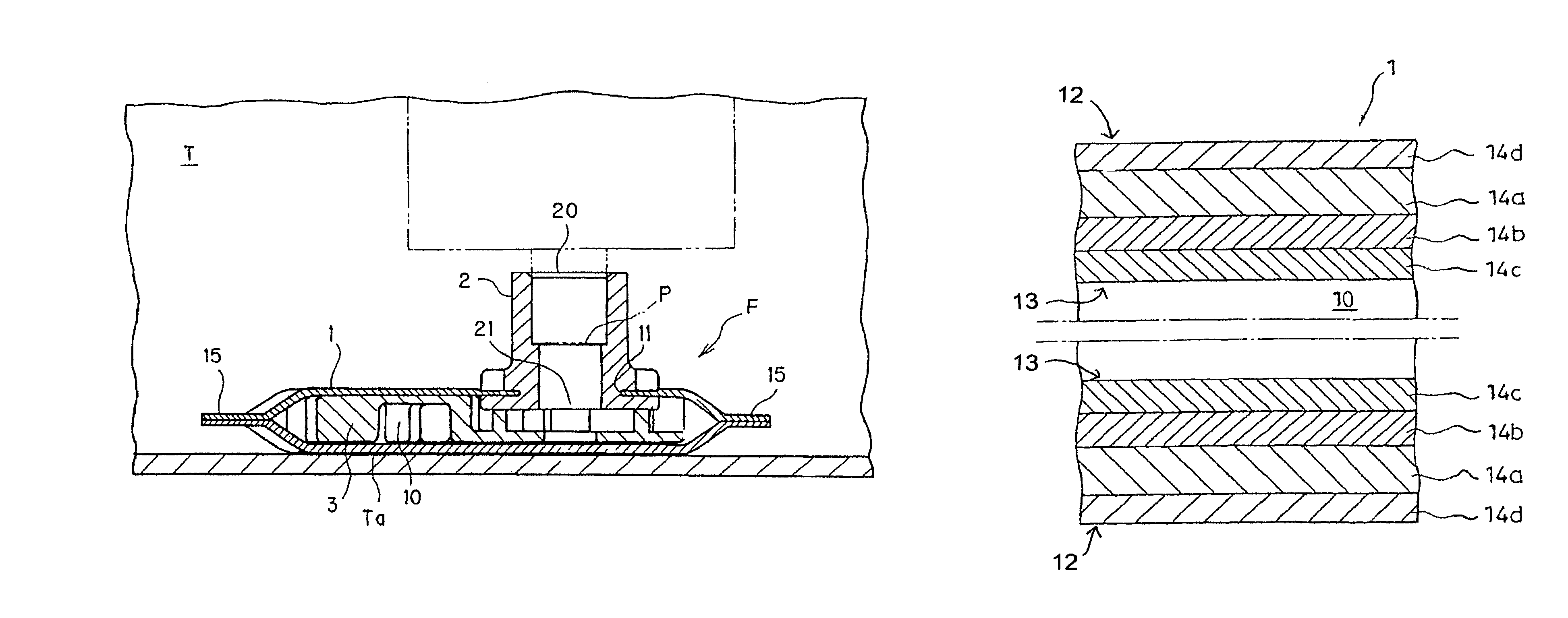

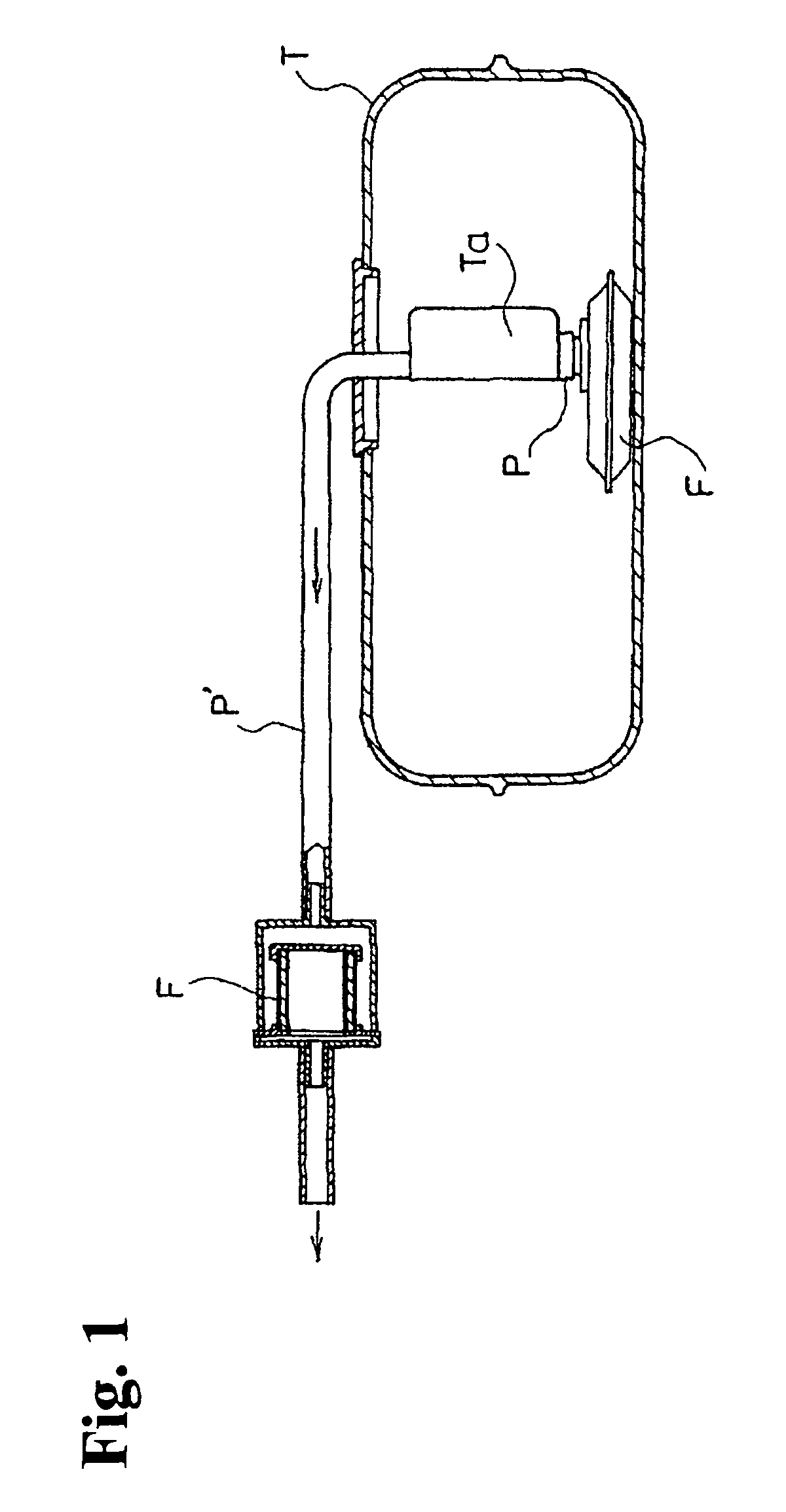

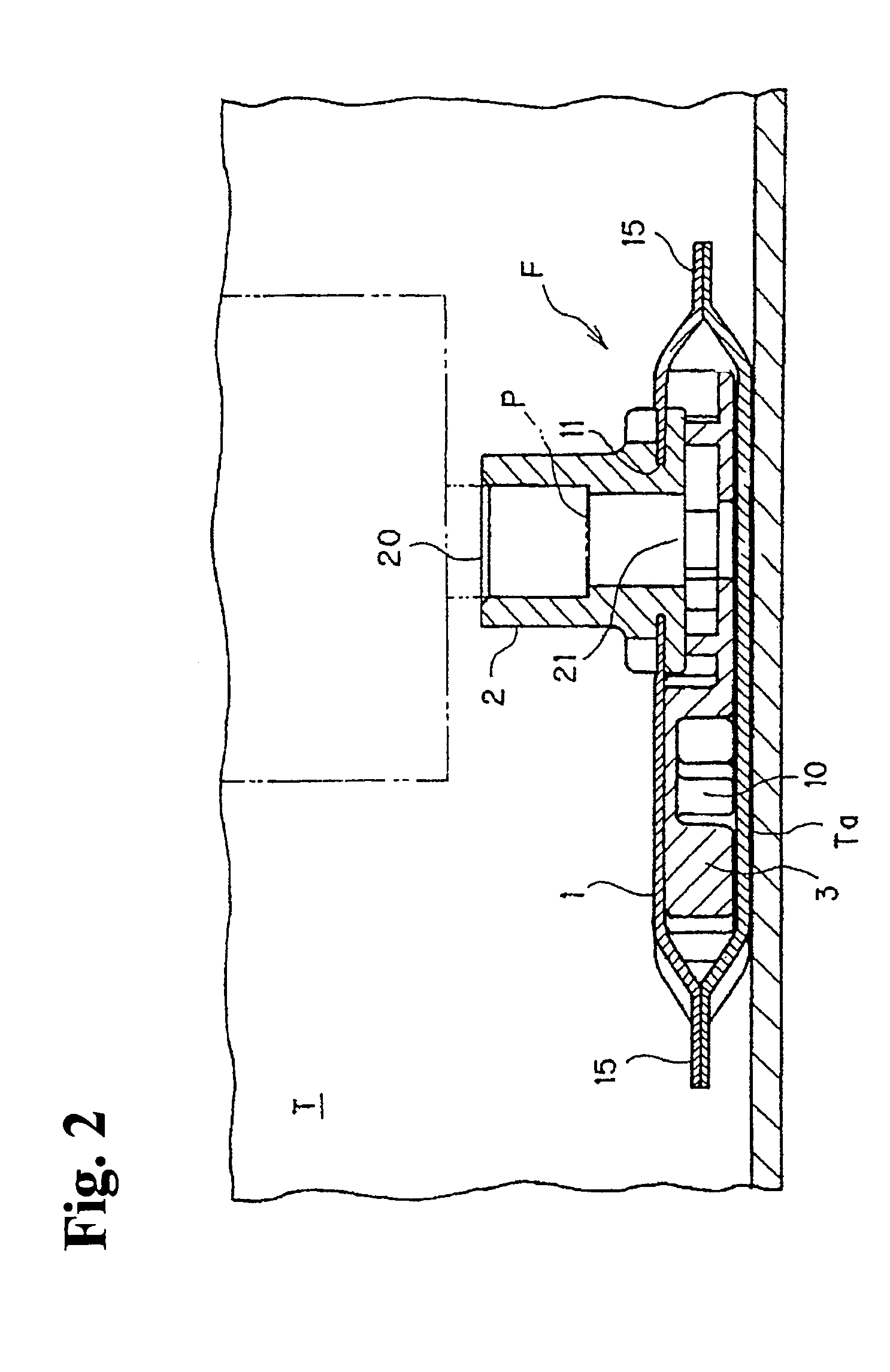

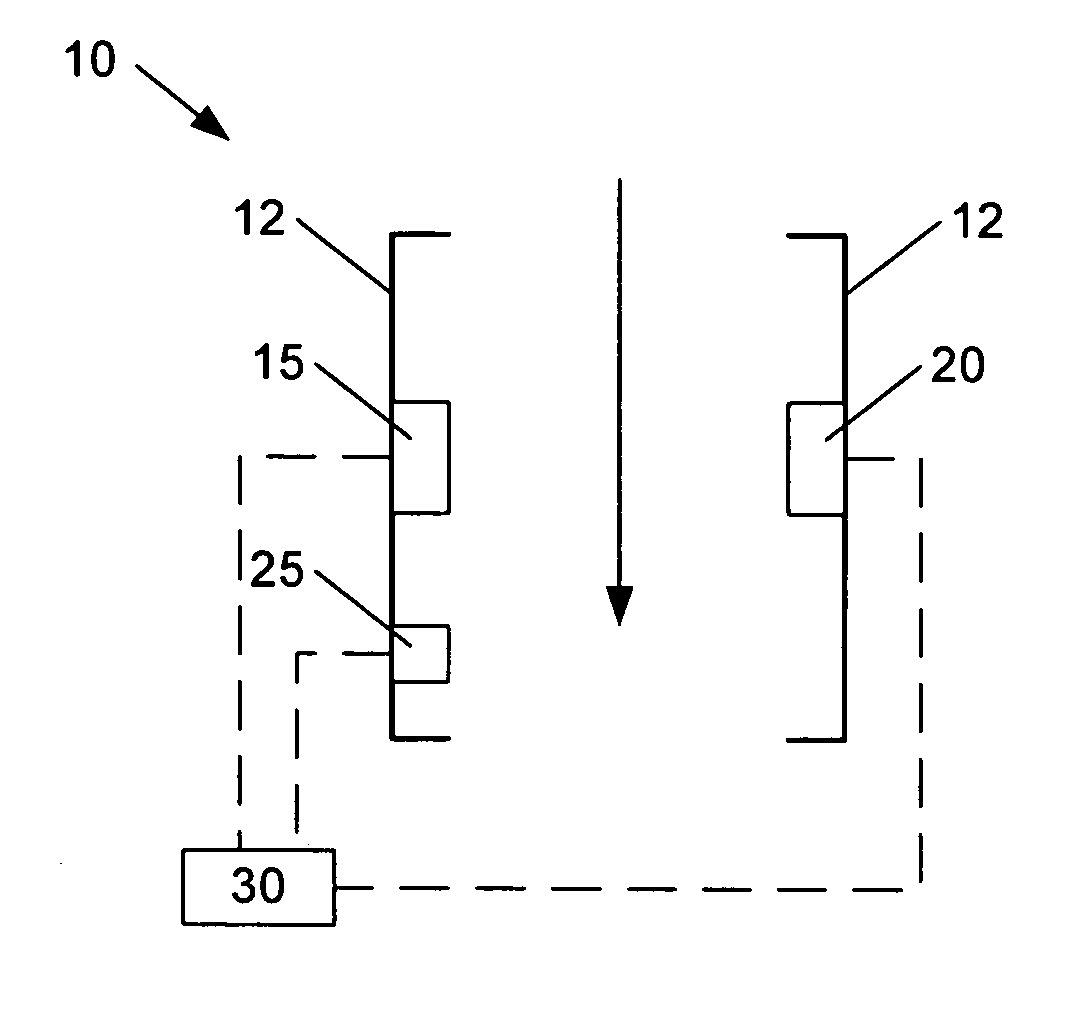

Disclosed is a fuel filter in which is disposed in a fuel suction port of a fuel tank or in a fuel line and used to filter the fuel. At least one of filter materials constituting the fuel filter is made into a multifunctional filter material having a function of trapping dust of different particle diameters in stages, by differing the diameter of the pores in the filter material from the primary side to the secondary side of the filter material so that the size of the pores decreases toward the secondary side.

Owner:NIFCO INC

Hydrogen concentration sensor for an electrochemical fuel cell

ActiveUS20050214603A1Analysing fluids using sonic/ultrasonic/infrasonic wavesFuel cell auxillariesHydrogen concentrationFuel cells

In a hydrogen gas line where the composition of the gas is primarily hydrogen, impurities present in the gas line will typically reduce the speed of sound. Accordingly, an acoustic sensor can be used in such a hydrogen gas line to indicate when impurities have accumulated in the gas line. In particular, the hydrogen gas line may be in a fuel line for an electrochemical fuel cell system. The sensor may comprise transducers, more particularly piezoelectric transducers, as both sound detectors and / or sound generators. Further, the sensor can measure either the speed or frequency of sound to determine the hydrogen concentration. If the fuel is recirculated back to the anode inlet, such a hydrogen sensor in the anode exhaust may be used to determine when it is beneficial to purge the anode exhaust to the external atmosphere.

Owner:BALLARD POWER SYSTEMS

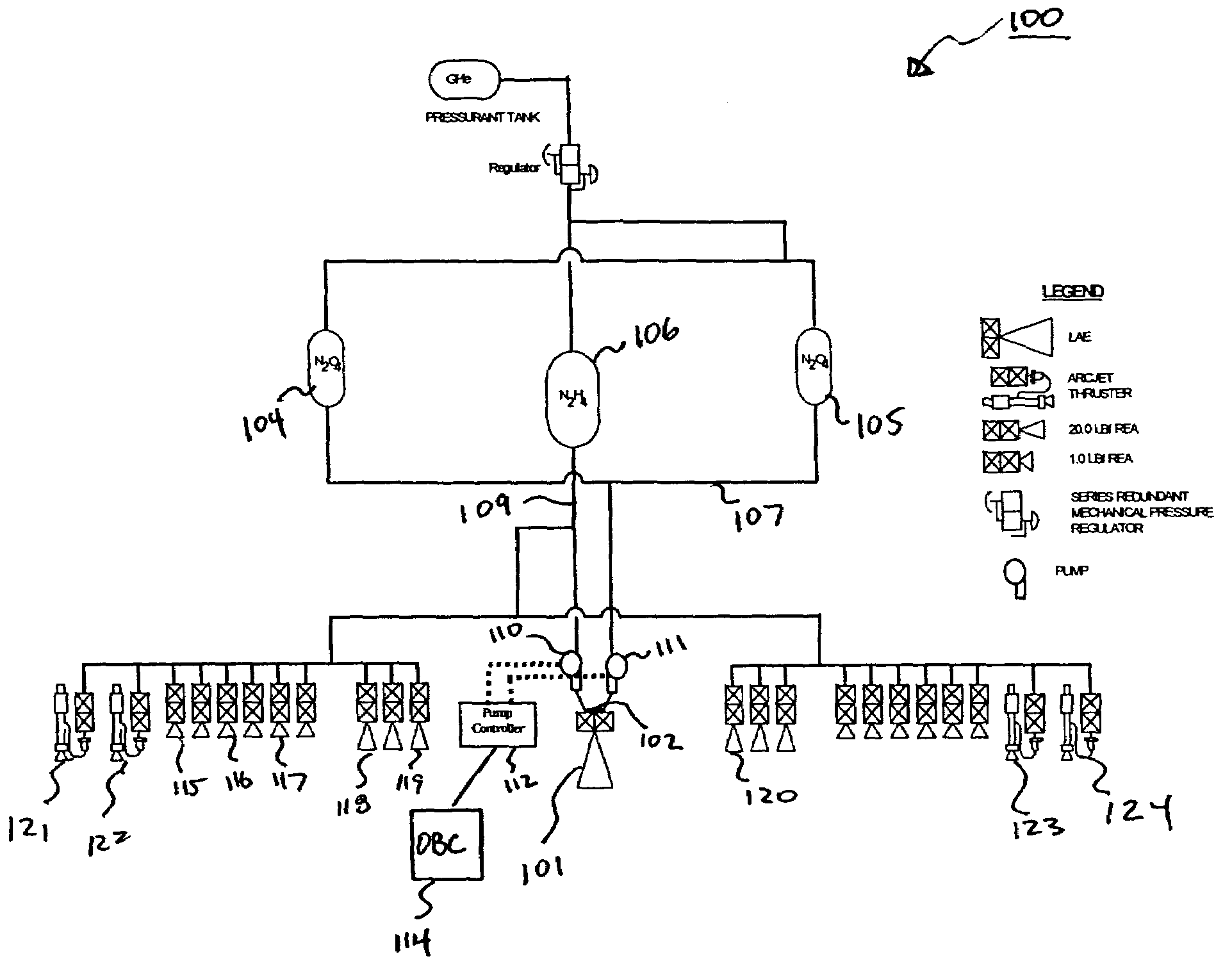

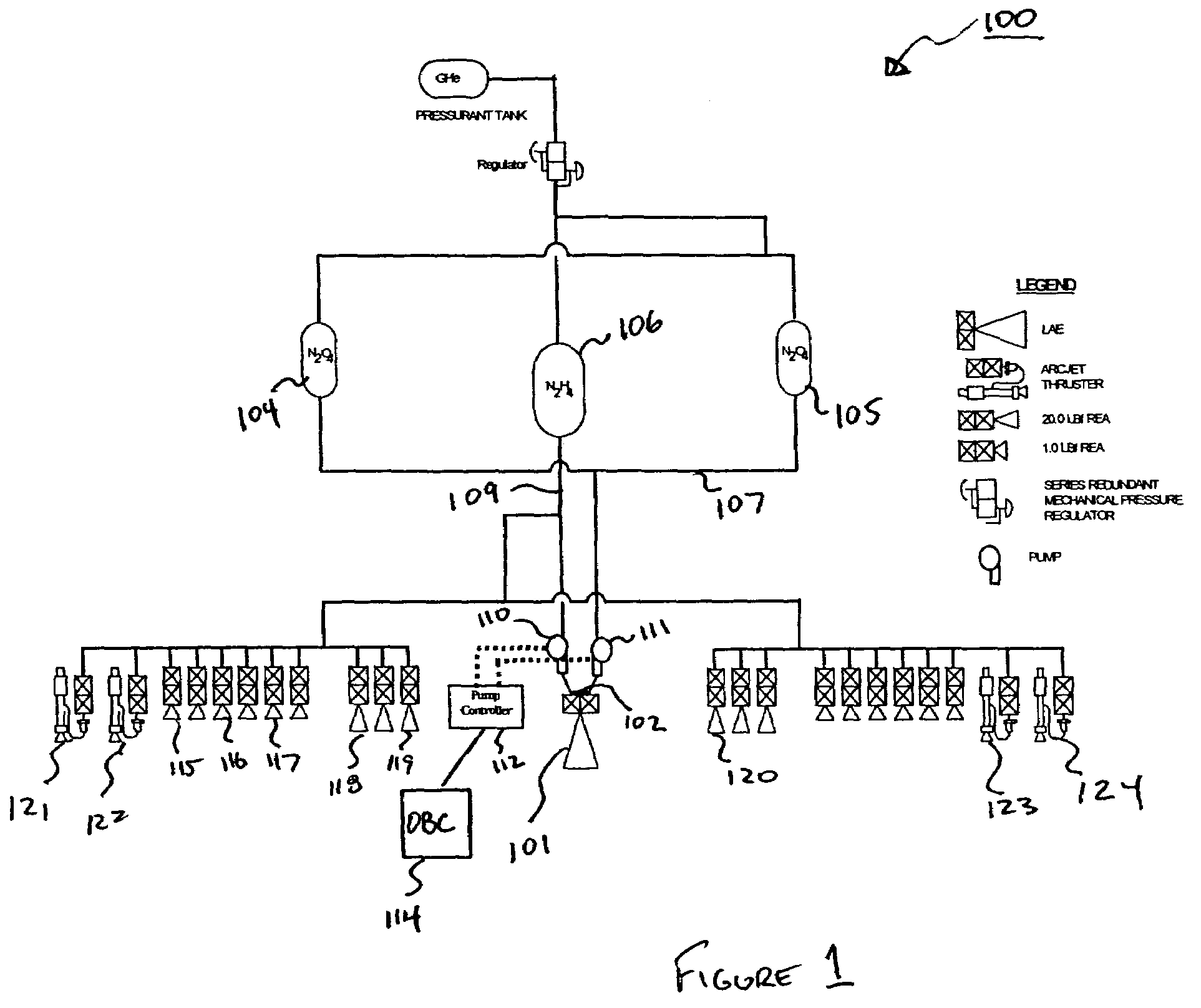

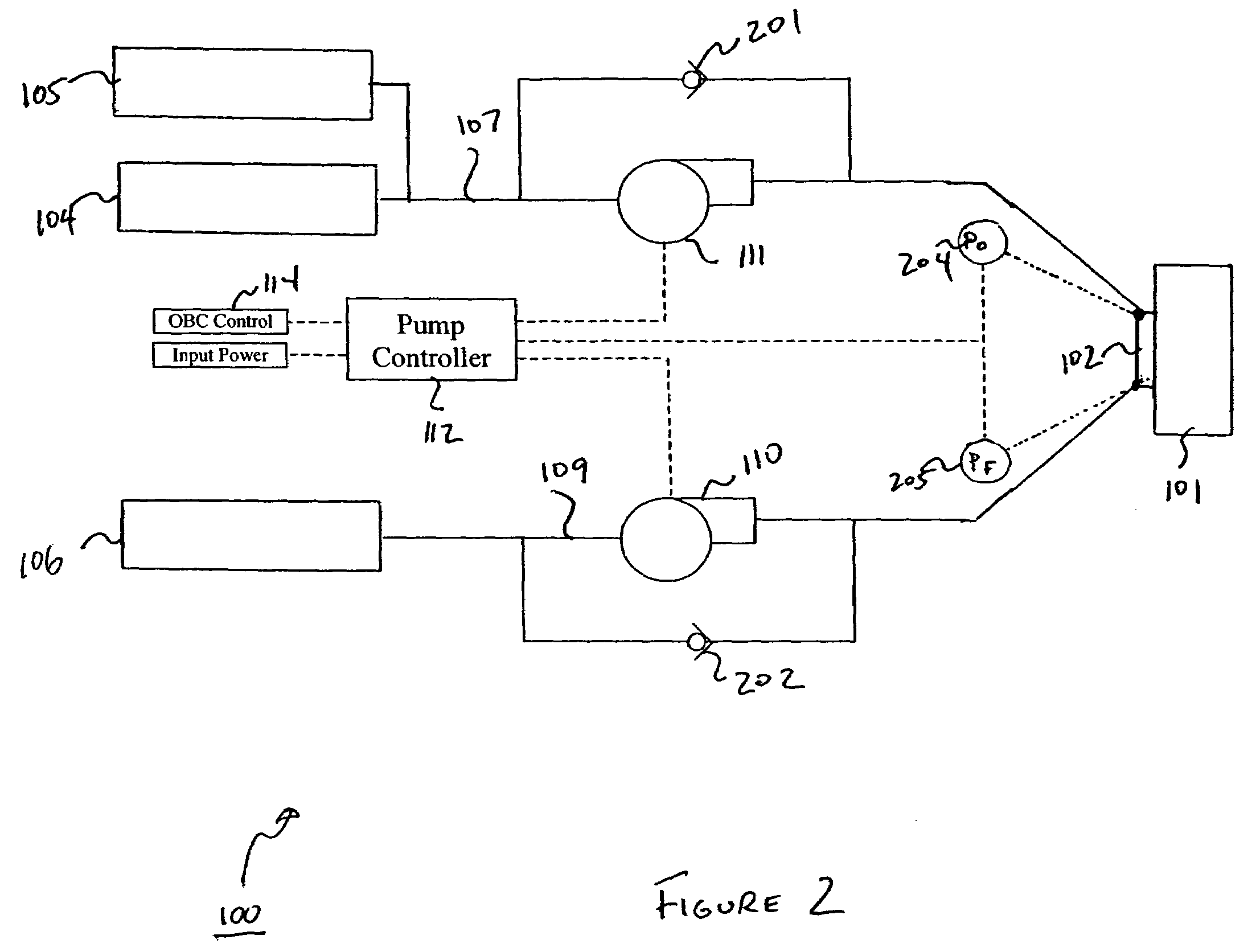

Enhanced high-efficiency spacecraft propulsion system

InactiveUS7762498B1Improving seal materialImproving geometry selectionLaunch systemsCosmonautic propulsion system apparatusSpacecraft propulsionOn board

A high-efficiency spacecraft propulsion system, including includes electric pumps inserted in the oxidizer and fuel lines that increase liquid apogee engine (“LAE”) operating pressure and reduce tank-operating pressure. An on-board computer generates pump drive signals, in response to measured oxidizer and fuel line pressures, that are input to the pump controller electronics. The controller electronics provides current drives to the pump motors. The system uses an LAE that can operate at higher thrust chamber pressures (e.g., 500 psia) than standard LAEs, where pump-fed rocket motors have integrated turbopumps that are fuel operated. The turbopump increases LAE complexity and cost, reduces fuel efficiency, and is not compatible with active thrust and mixture ratio control.

Owner:LOCKHEED MARTIN CORP

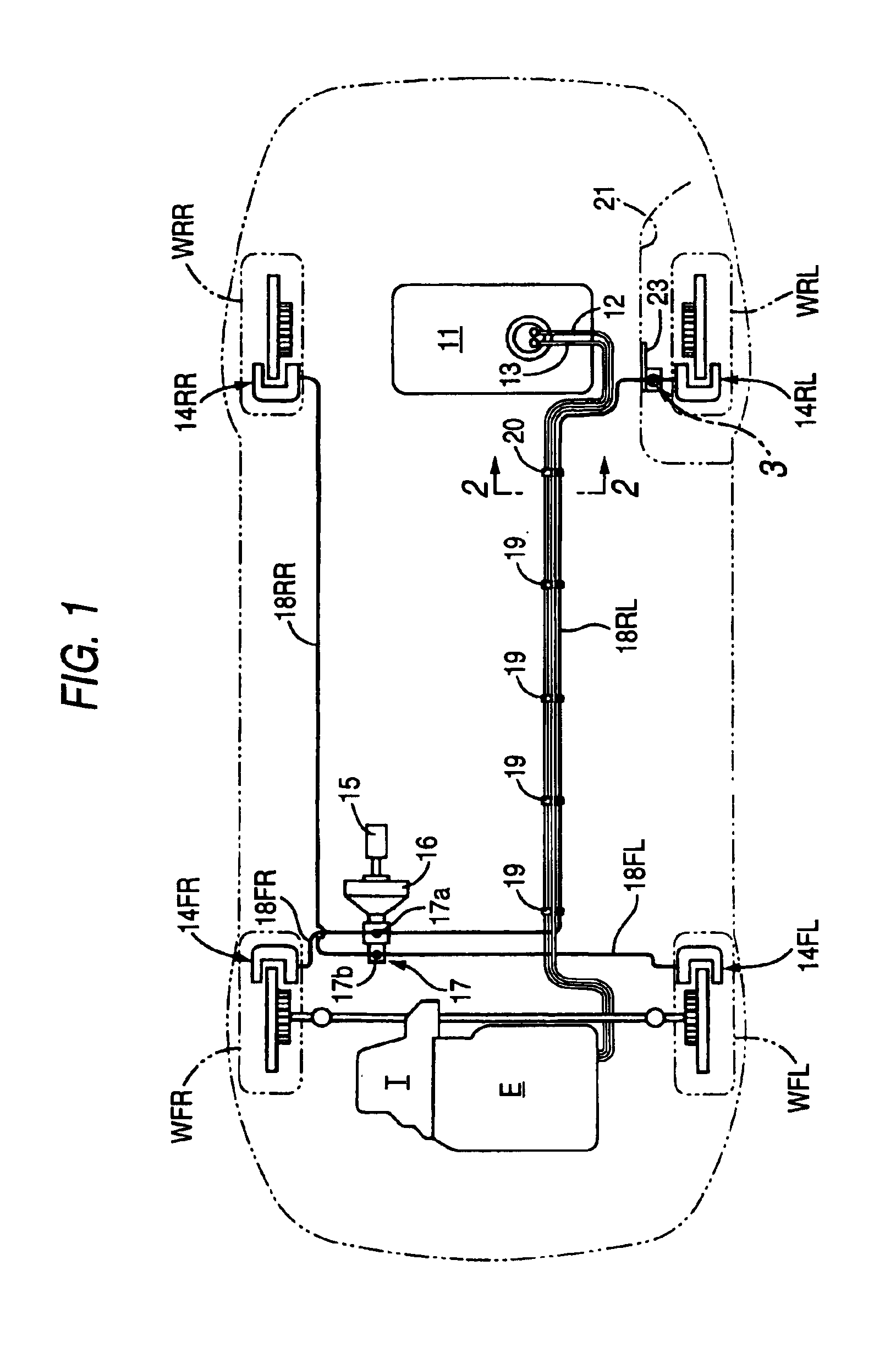

Fuel supply system for an internal combustion engine

InactiveUS7028672B2Reduce gas emissionsReduce metal contentInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringLiquid fuel

In a fuel supply system for an internal combustion engine having two separate storage containers for liquid fuels, both connected to a first controllable valve which is connected, via a connecting line including a fuel pump to an inlet of a second controllable valve having two outlets in communication by separate fuel lines with a fuel injection nozzle of the internal combustion engine, each of the two separate fuel lines includes a fuel pressure regulator, one being in communication with one and the other with the other of the two separate fuel storage containers for returning exess fuel to the fuel storage container from which fuel is being supplied to the fuel injection nozzle.

Owner:DAIMLER AG

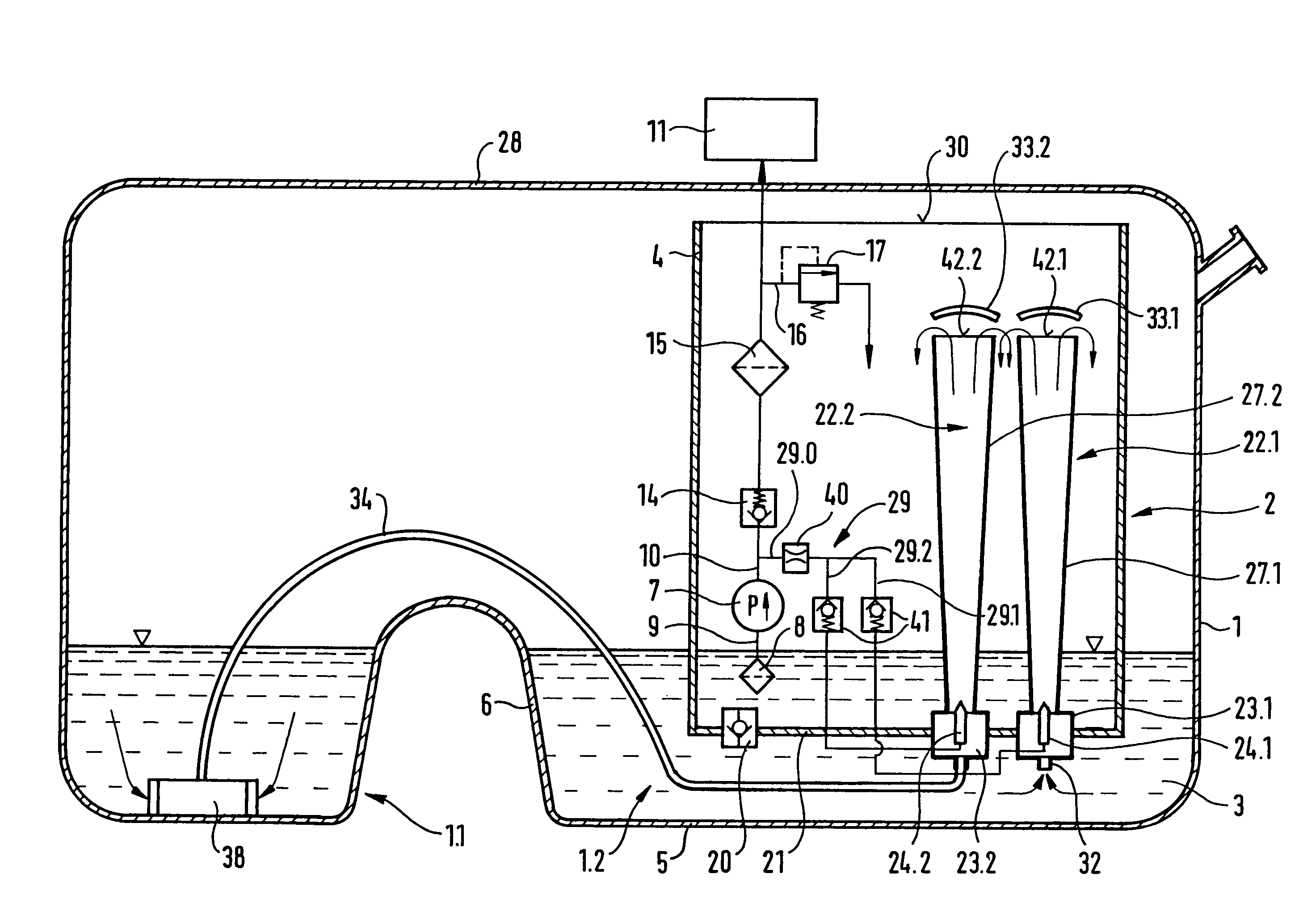

Apparatus for delivering fuel from a tank to an internal combustion engine

ActiveUS7303378B2Eliminate needAvoid flowLiquid fuel feedersPump installationsSiphonExternal combustion engine

The fuel supply apparatus according to the invention is improved in a simple manner in that it is provided with short fuel lines. According to the invention, the drive line of the suction jet pumps is connected to a pressure line downstream of the fuel supply pump and has at least one check valve or a siphon.

Owner:ROBERT BOSCH GMBH

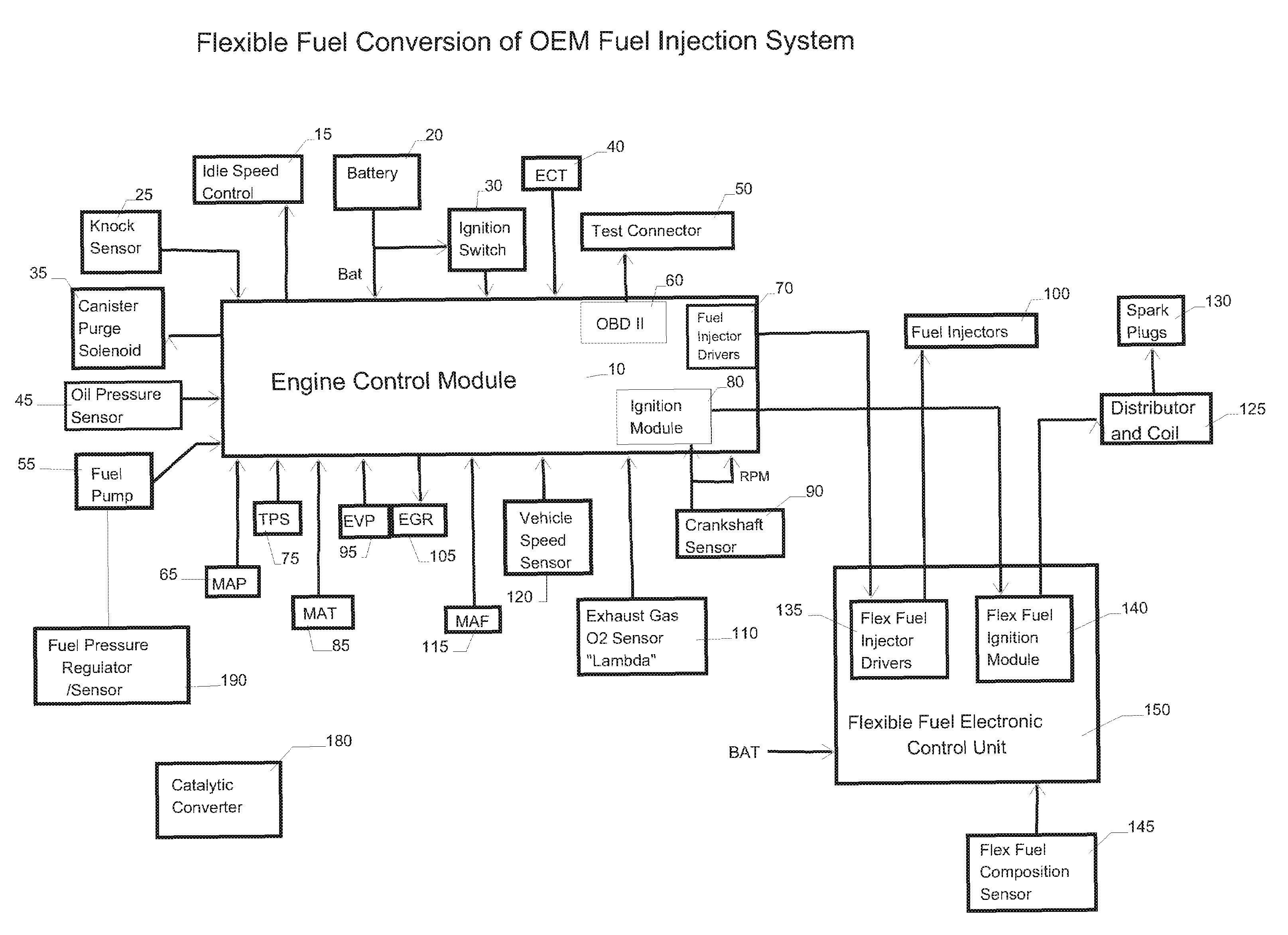

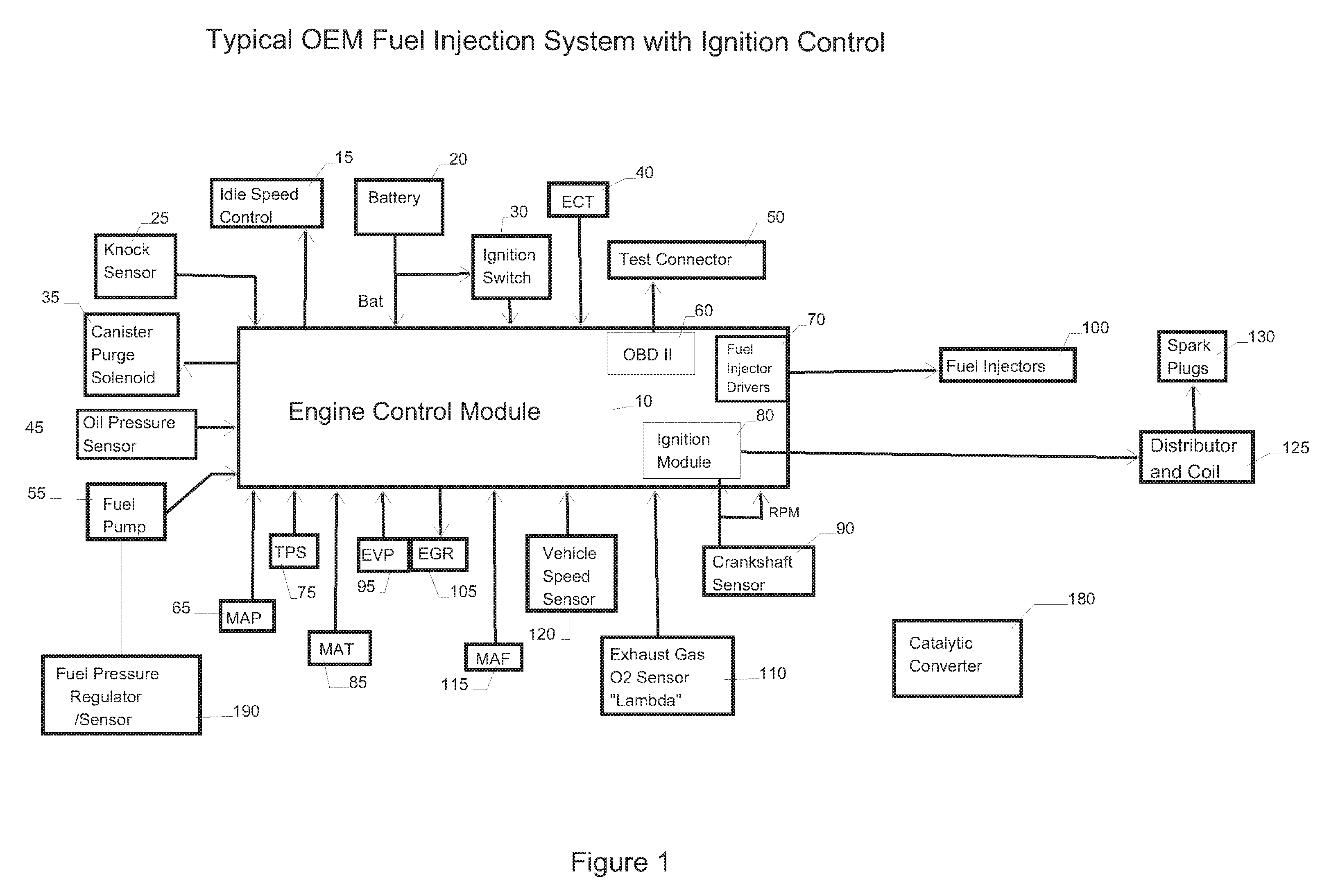

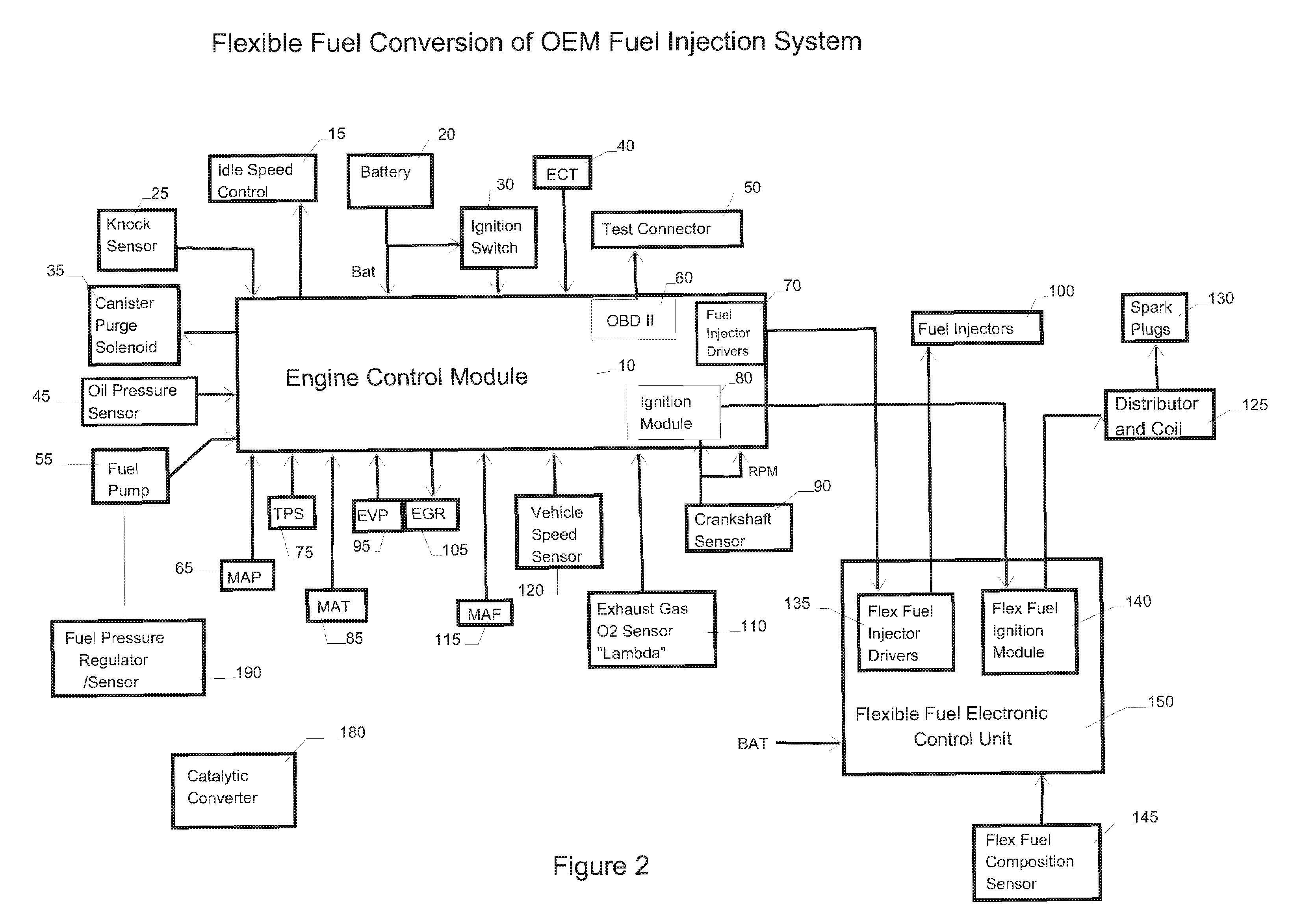

Addition of flexible fuel engine control system

InactiveUS7305939B2Reduce dependenceInexpensively convertElectrical controlInternal combustion piston enginesDriver circuitAlternative fuels

The apparatus and method convert the fuel system of an internal combustion engine in a pre-existing (used) vehicle to operate on a mixture of fuels (like ethanol and gasoline) from a single fuel tank. The apparatus includes a fuel composition sensor installed in the fuel line and an electronic control unit with at least one fuel injector driver circuit for controlling an output signal to at least one fuel injector for controlling the air to fuel ratio of the engine. The electronic control unit controls both ignition timing and the air to fuel ratio of the engine based upon the percentage or ratio of the alternative fuel to gasoline from the fuel composition sensor. The electronic control unit receives both timing signals and fuel injector control signals from the engine's original Engine Control Module and the original emission control devices are not modified or replaced.

Owner:ROCHESTER PROD

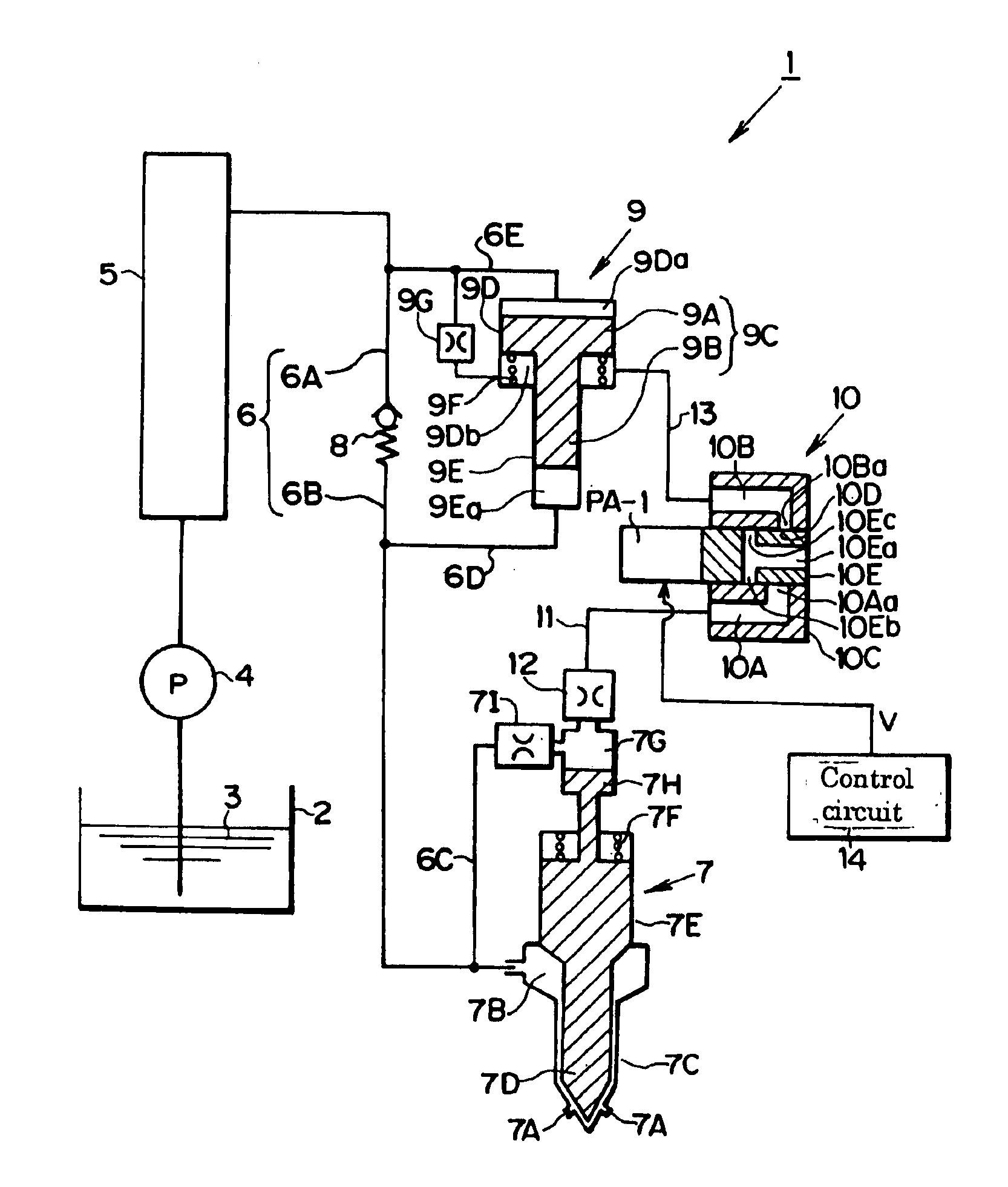

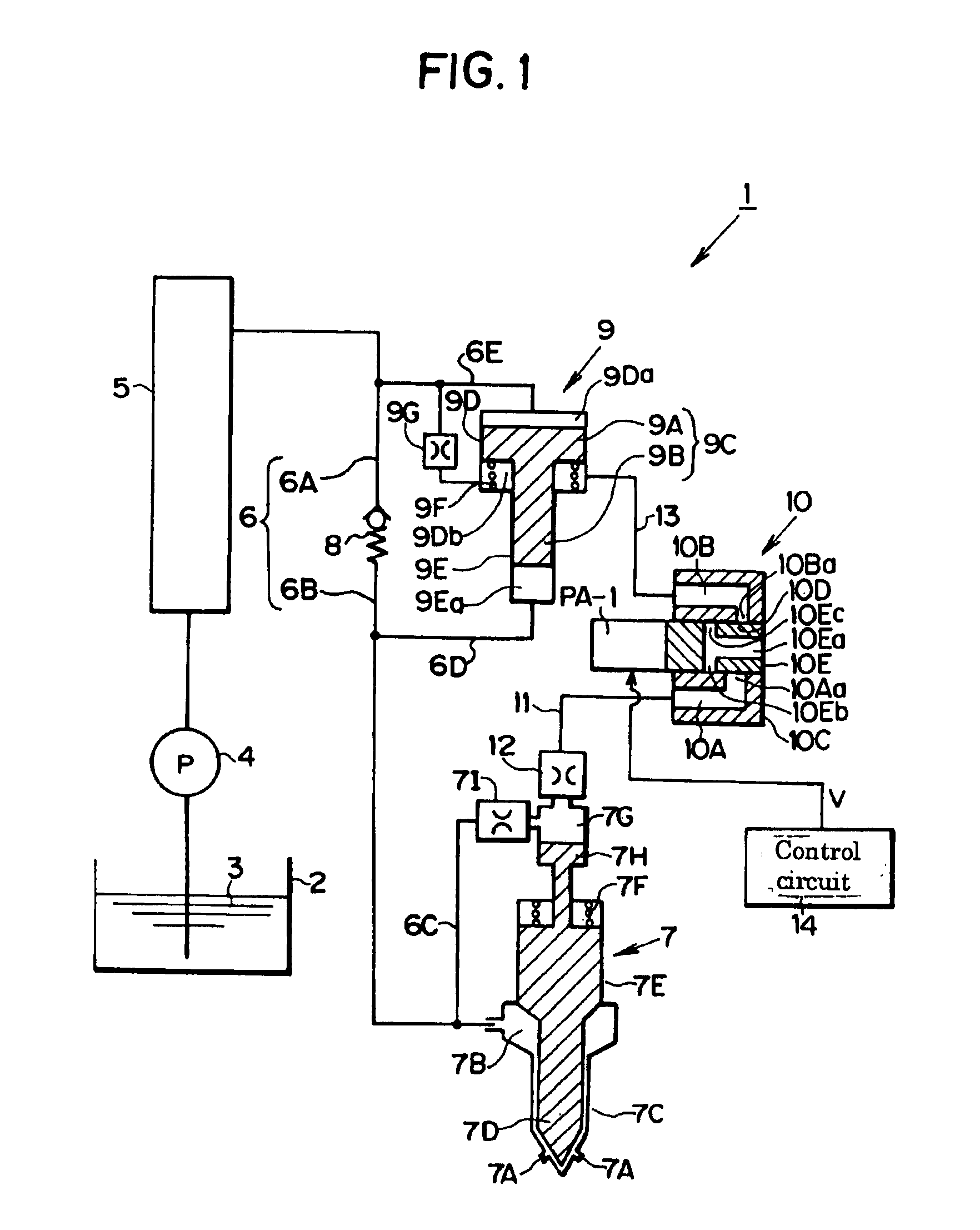

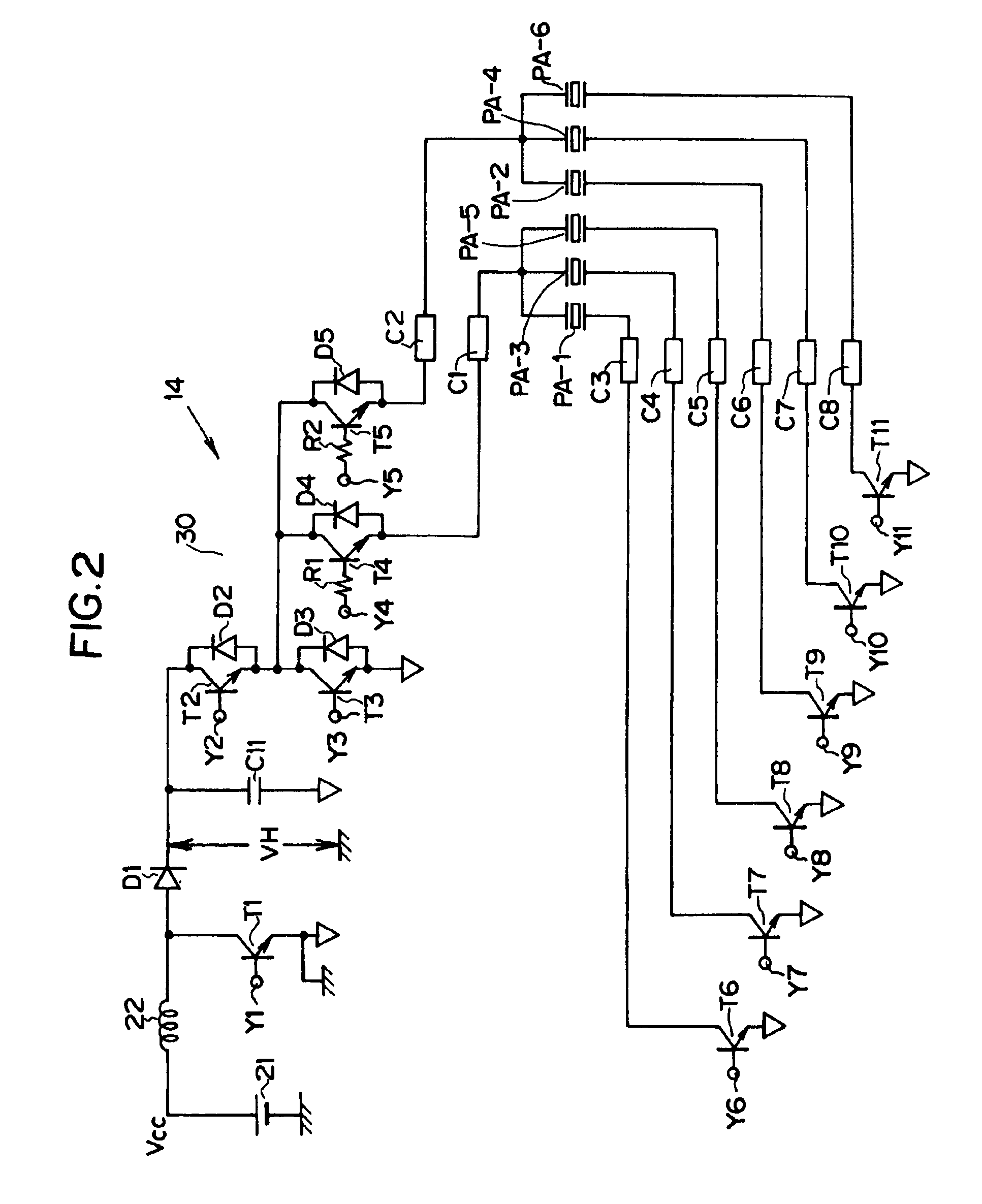

Fuel injection device

InactiveUS6910463B2Reducing unnecessary radiationSimple configurationElectrical controlMachines/enginesCommon railPiezoelectric actuators

A check valve (8) and a booster (9) are inserted in parallel in a supplied fuel line (6) connecting a common rail (5) and an injection valve (7), a piston (10E) of a hydraulic circuit (10) is driven for positioning by a piezoelectric actuator (PA-1), the pressures in a chamber (9Db) of the booster (9) and the pressure in a fuel chamber (7G) of the injection valve (7) are selectively lowered by controlling the alignment state between ports (10Eb), (10Ec) provided in the piston (10E) to communicate with a low-pressure portion and an opening 10Aa of a first chamber 10A and an opening (10Ba) of a second chamber (10B) of cylinder (10C), whereby the pressure of the fuel supplied to the fuel reservoir (7B) of the injection valve (7) is rapidly switched to one or the other of high-pressure fuel from the common rail (5) and pressure-boosted high-pressure fuel from the booster (9).

Owner:DIESEL KIKI CO LTD

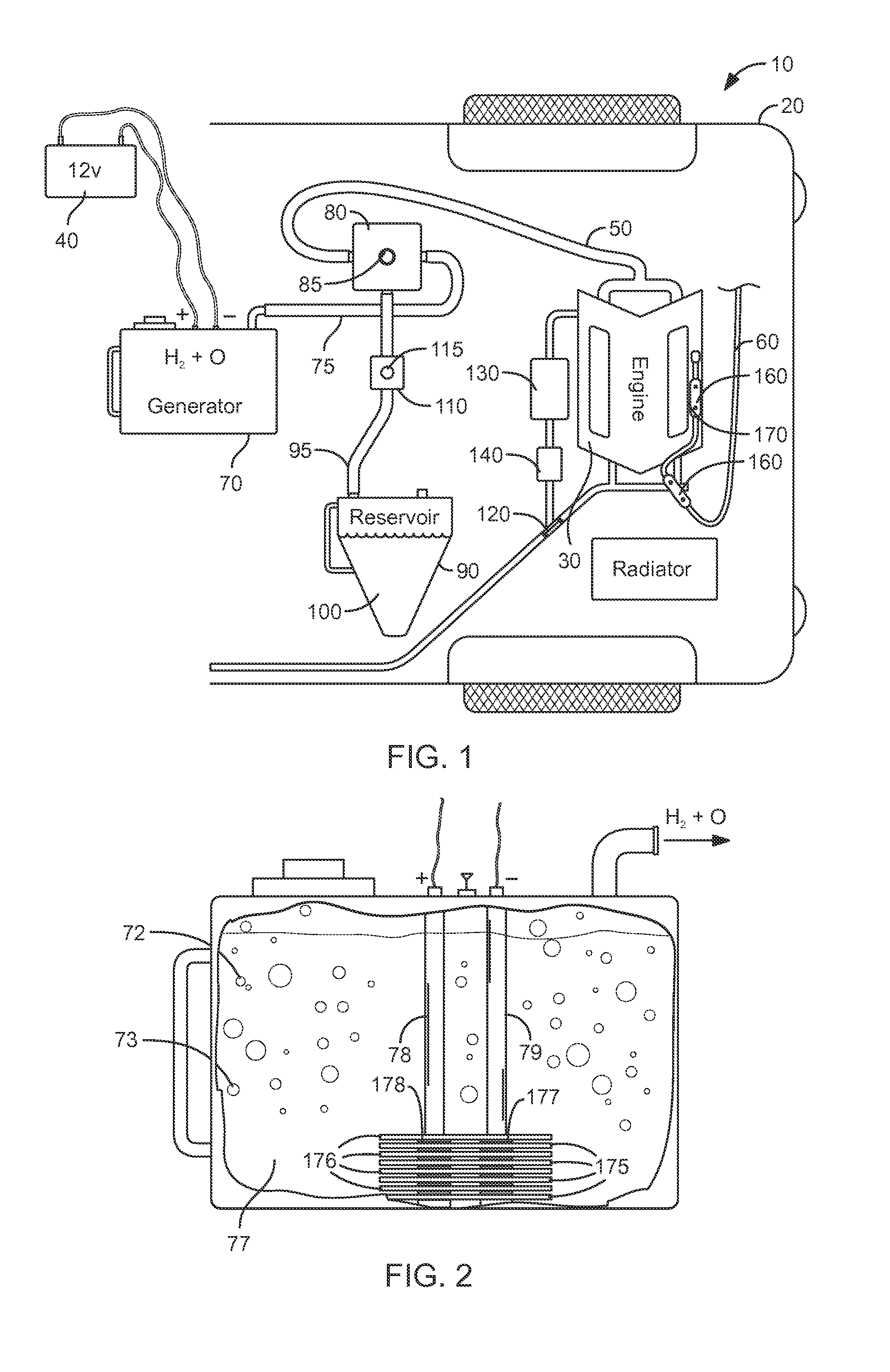

Hydrolysis system to produce hydrogen-oxygen gas as a fuel additive for internal combustion engines

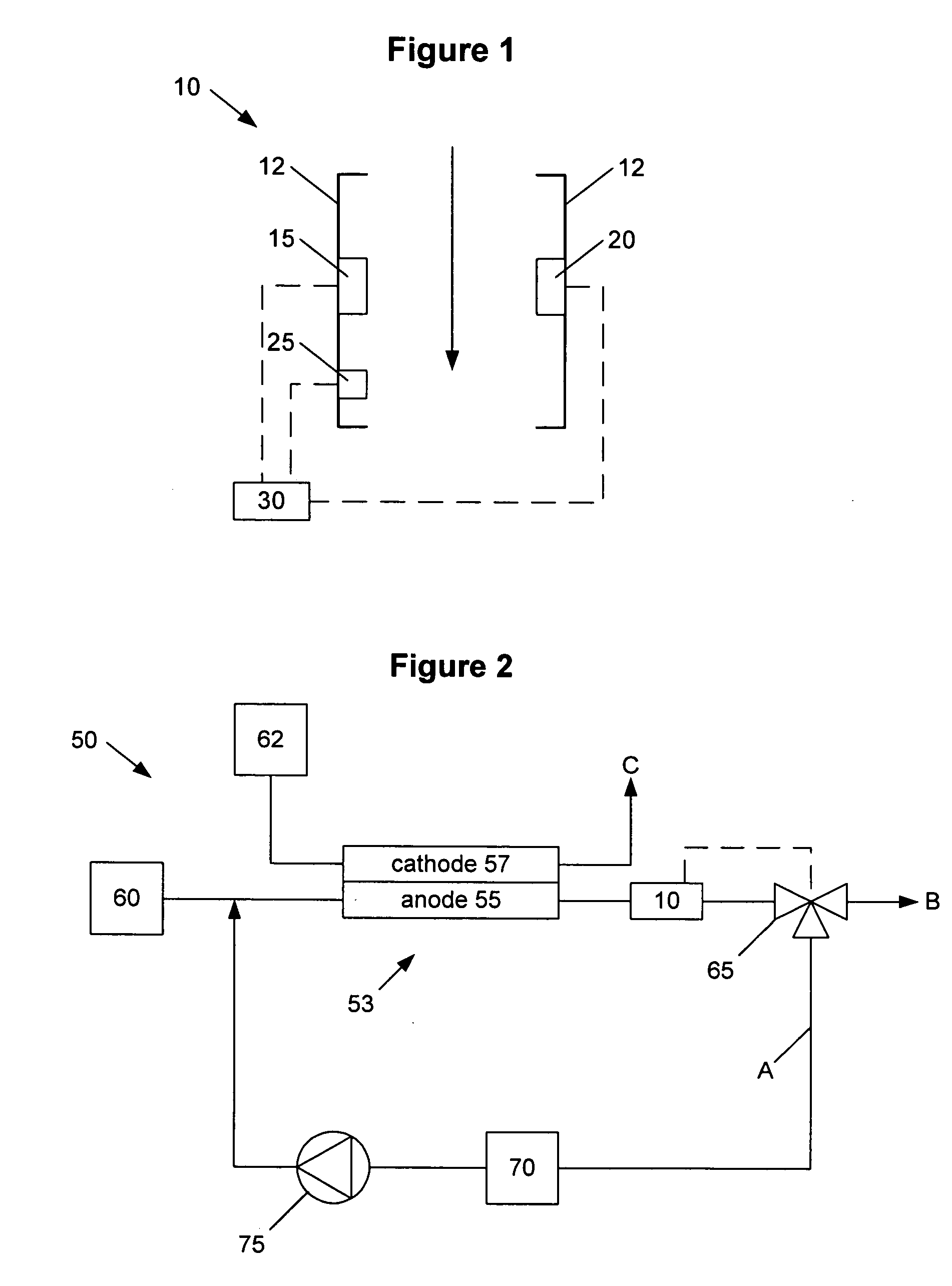

InactiveUS20110220039A1Overcome problemsImprove combustion efficiencyCellsInternal combustion piston enginesElectrolysisHydrogen

Internal combustion engines operate by igniting a mixture of liquid fuel and air inside its combustion chamber. The energy from the ignition is converted to mechanical energy that is used to power a vehicle. Research indicates that adding hydrogen gas into the combustion chamber improves the efficiency of the engine. The present invention is an electrolysis system that produces hydrogen and oxygen gases and injects them into the fuel line of the engine to create a mixture of the gases and the liquid fuel that is subsequently introduced into the combustion chamber for ignition. The operating temperature of the engine is lower if the gases are injected into the fuel line rather than directly into the combustion chamber.

Owner:NOWICKI RICHARD +3

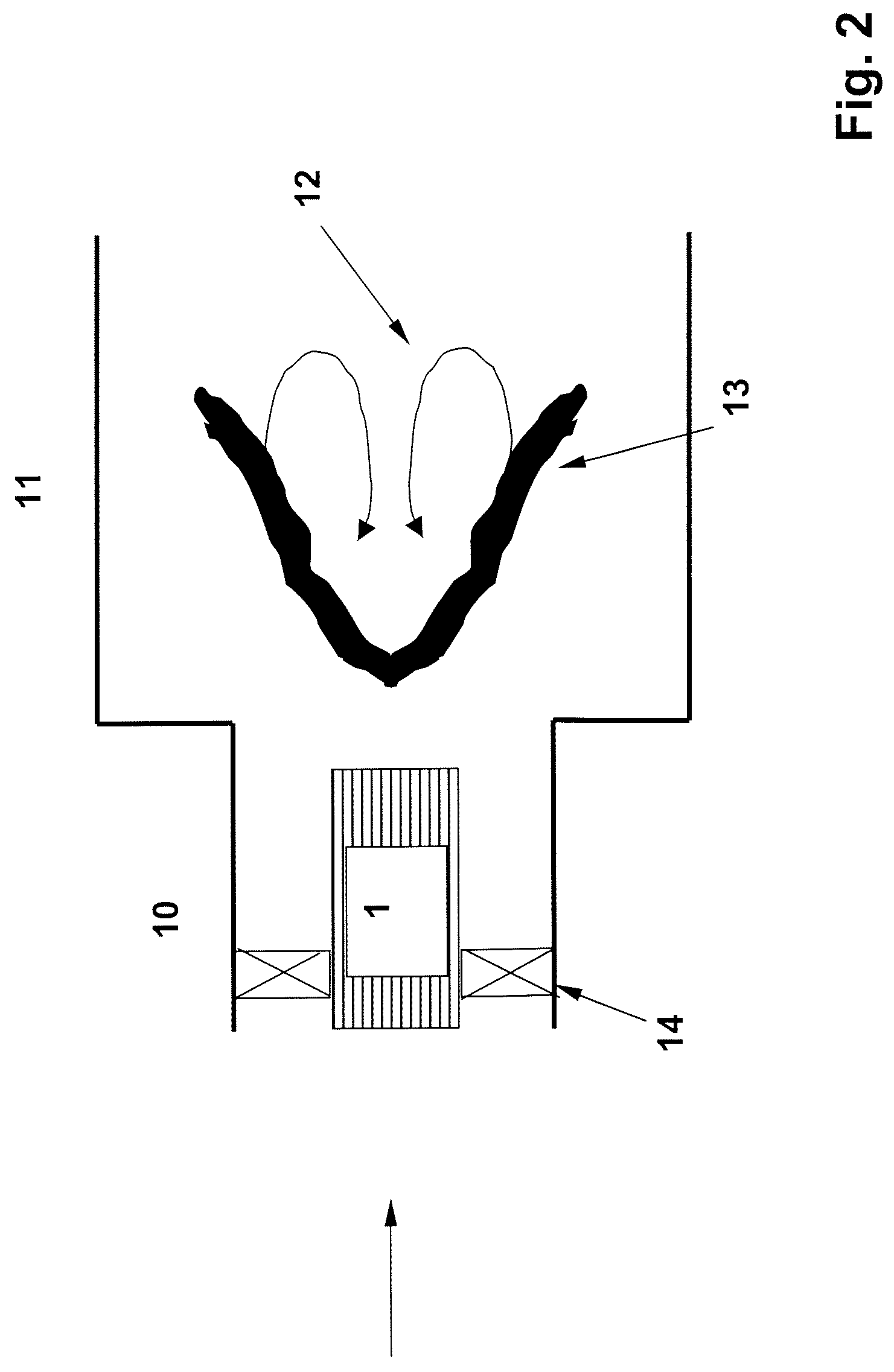

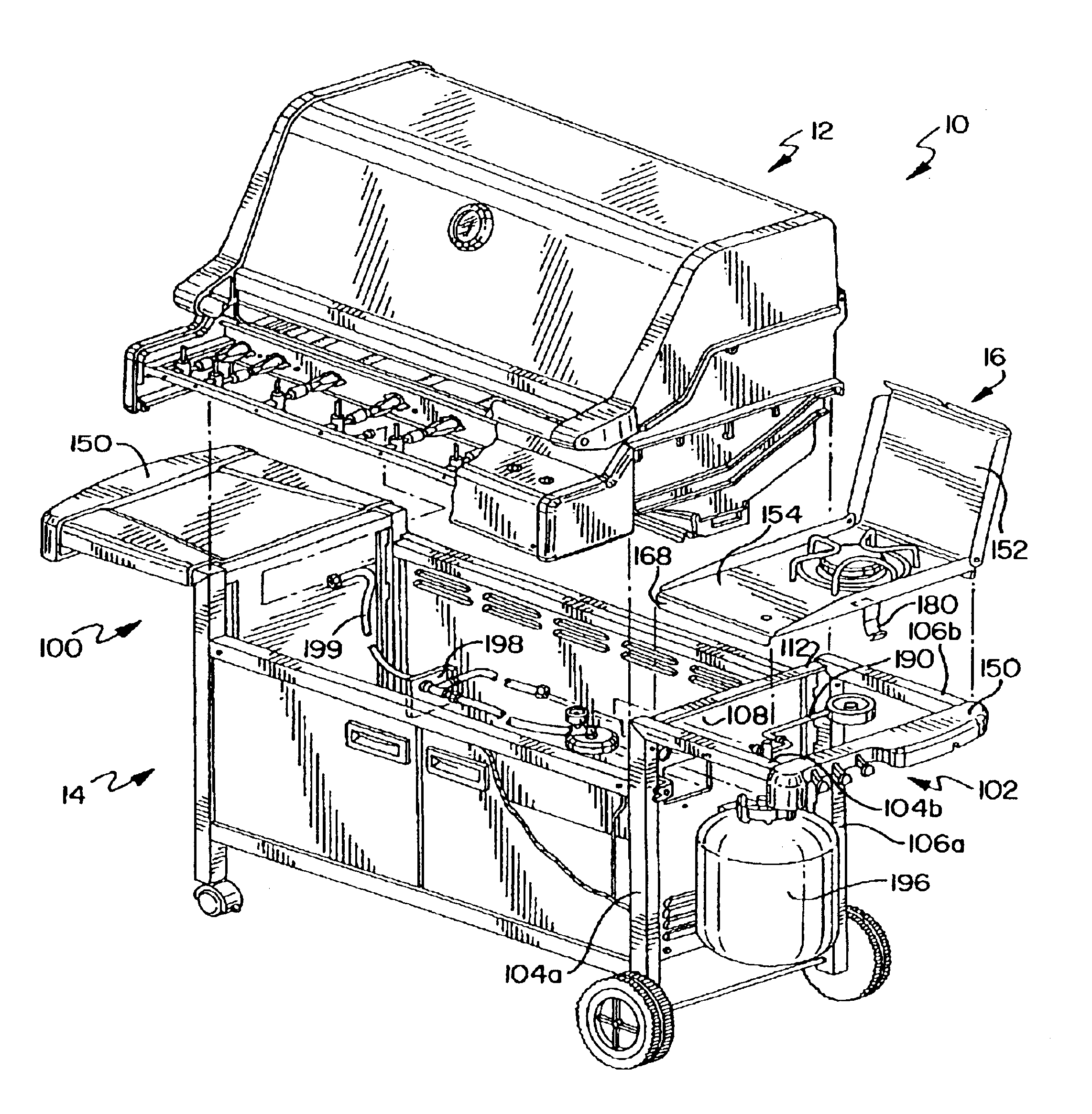

Barbecue grill assembly

The present invention provides a barbecue grill assembly with a support frame assembly including a left and right frame assembly. These frame assemblies are formed from a front frame member, a rear frame member, and a side member that connects the front and rear frame members. The grill assembly can have a first and a second horizontal member to connect the frame members of the left and right frame assemblies. The barbecue grill assembly further comprises a cooking chamber with a cover hingeably connected to a firebox. The firebox has a pair of opposed end walls with a mounting assembly that engages a limited extent of the front and rear frame members when the cooking chamber is connected to the support frame assembly. The end wall also have extending rails that define a channel configured to house conduit and fuel lines. Preferably, the left and right frame assemblies are pre-welded to facilitate assembly of the barbecue grill assembly.

Owner:WEBER-STEPHEN PRODUCTS

Multi-layer compositions comprising a fluoropolymer

InactiveUS6156400ADecorative surface effectsDuplicating/marking methodsComposite constructionPolymer science

This invention provides a method of bonding substantially non-fluorinated polymeric material to dissimilar polymers, particularly fluoropolymer materials, utilizing a bonding composition comprising base-treated amide group-containing substantially non-fluorinated polymer. Multi-layer articles and composite constructions, including retroreflective sheeting, fuel line hoses, and adhesive articles made of a fluoropolymer layer and a substantially non-fluorinated layer are also provided.

Owner:3M INNOVATIVE PROPERTIES CO

Systems and methods for thermal management in a gas turbine powerplant

InactiveUS7984606B2Easy to manageAnalogue computers for vehiclesTurbine/propulsion engine coolingWorking fluidThermal management system

A thermal management system for a gas turbine powerplant with an engine oil line and an engine fuel line incorporates a heat transfer control module that includes a reversible heat pump with a heat pump compressor for circulating working fluid in forward and reverse directions through a working fluid line of the heat pump. The heat control module also includes a first heat exchanger having a heat exchange path for the working fluid between the compressor and a heat pump expansion valve and another heat exchange path for the engine oil. A second heat exchanger has a heat exchange path for the working fluid between the compressor and the expansion valve and another heat exchange path for the engine fuel. The heat pump can be operated in forward or reverse directions depending on whether heat is to be transferred from the engine oil or the fuel to the heat pump working fluid. In another embodiment an engine oil reservoir located between the first heat exchanger and the engine collects the oil before it is introduced to the engine and thus acts as a heat capacitor for the system.

Owner:PROPULSION GAS TURBINE & ENERGY EVALUATIONS

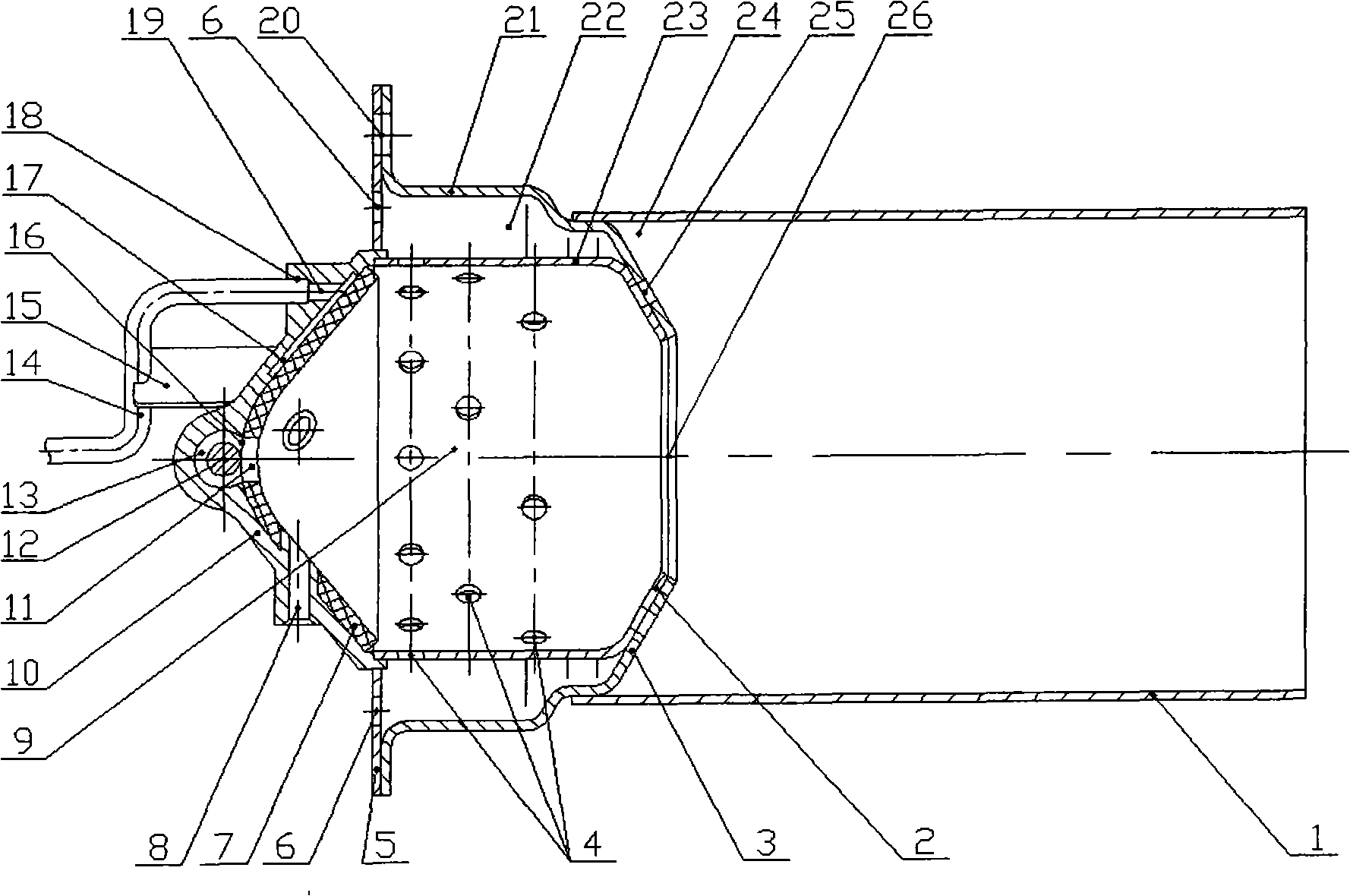

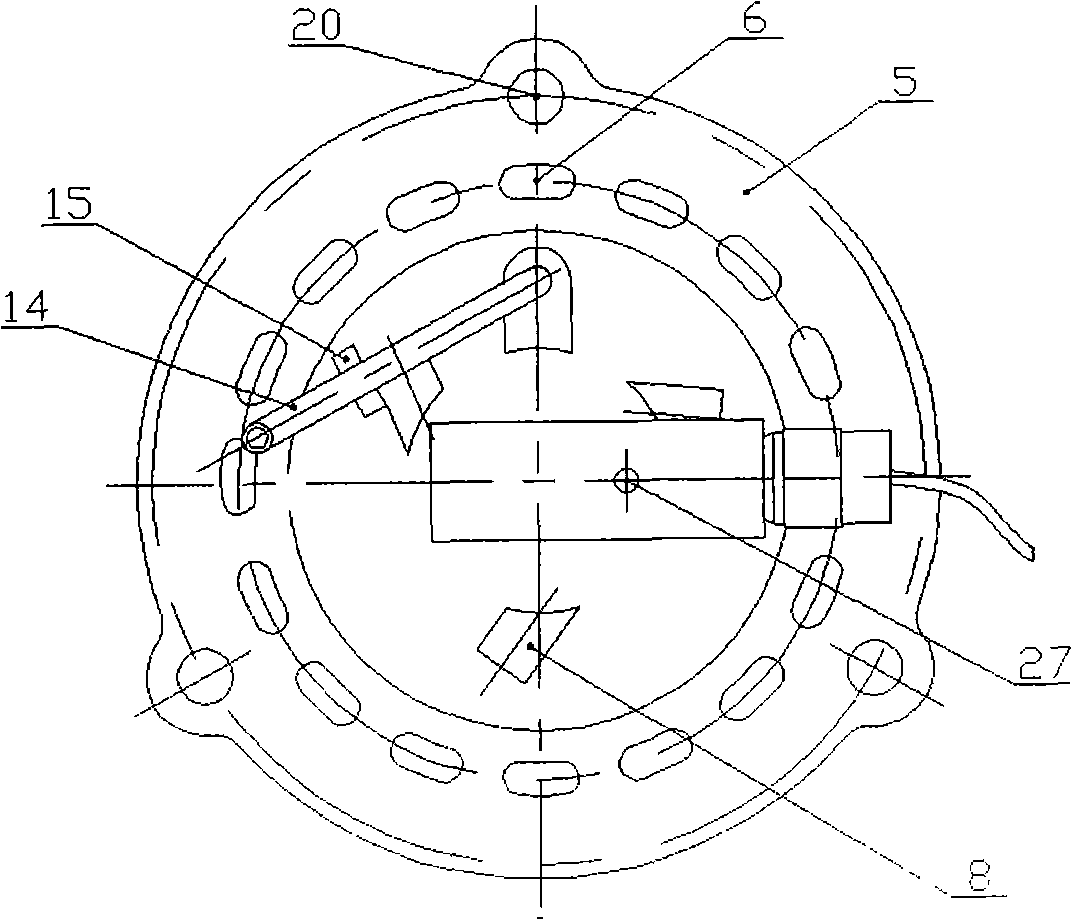

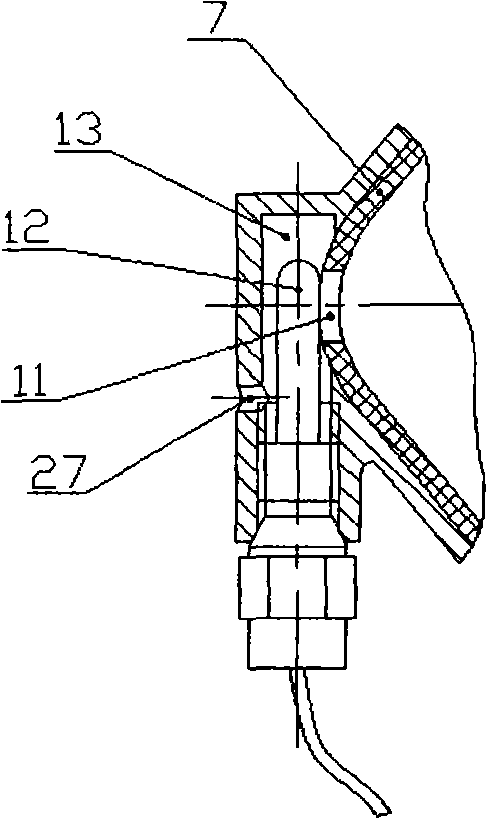

Wimble cap-shaped combusting device of oil heater

InactiveCN101280922AEasy to moveReduce flowLiquid fuel evaporation burnersCombustorCombustion chamber

The present invention provides a wimble cover shaped combustor of fuel heater comprising a combustion chamber cover, a oil suction wimble liner, a primary combustion barrel, a secondary combustion barrel, an air inlet guide barrel, an air inlet split stream slice, a fuel oil tube and a glow plug; the oil suction wimble liner is applied on the combustion chamber cover internal surface, an oil groove is arranged between the both; the primary combustion barrel is connected to the combustion chamber cover, and the air inlet guide barrel is arranged at outer portion of the primary combustion barrel, and air inlet holes are arranged circumferentially on the barrel wall of the primary combustion barrel; the primary combustion barrel is connected to the back end of the air inlet guide barrel to form a conical contraction hole; the front end of the air inlet guide barrel connects to the air inlet split stream slice which is provided with air split stream holes; the secondary combustion barrel connect is connected to the back end of the air inlet guide barrel; the combustion chamber cover has a conical shape, a fuel oil tube connected onto, a glow plug arranged on top, and tangential air holes are arranged circumferentially on the combustion chamber cover. The invention provides credible, rapid ignition start, uneasily generates carbon deposition, has high combustion efficiency and economical efficiency improved by more than 6%.

Owner:河北宏业永盛汽车加热器股份有限公司 +1

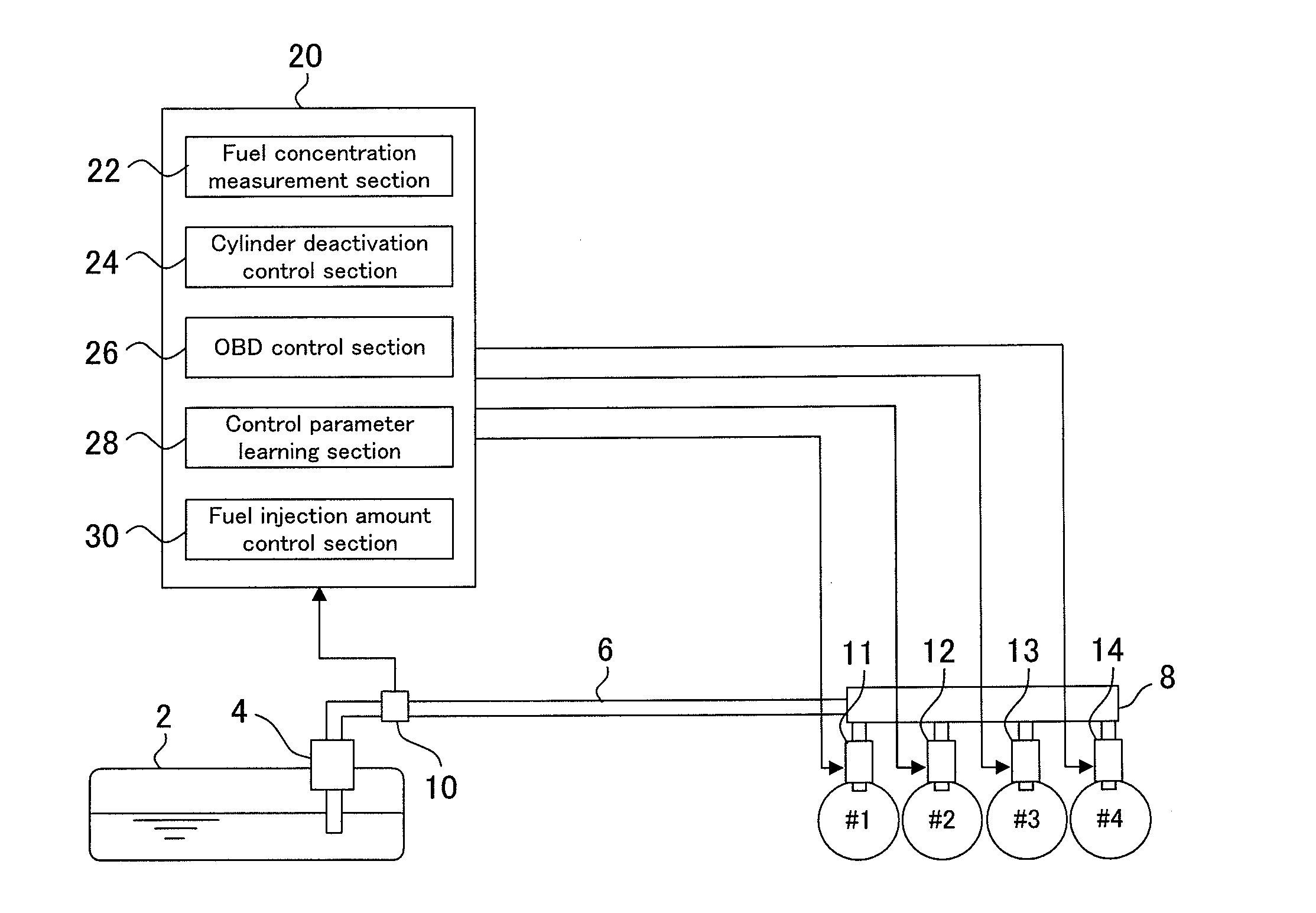

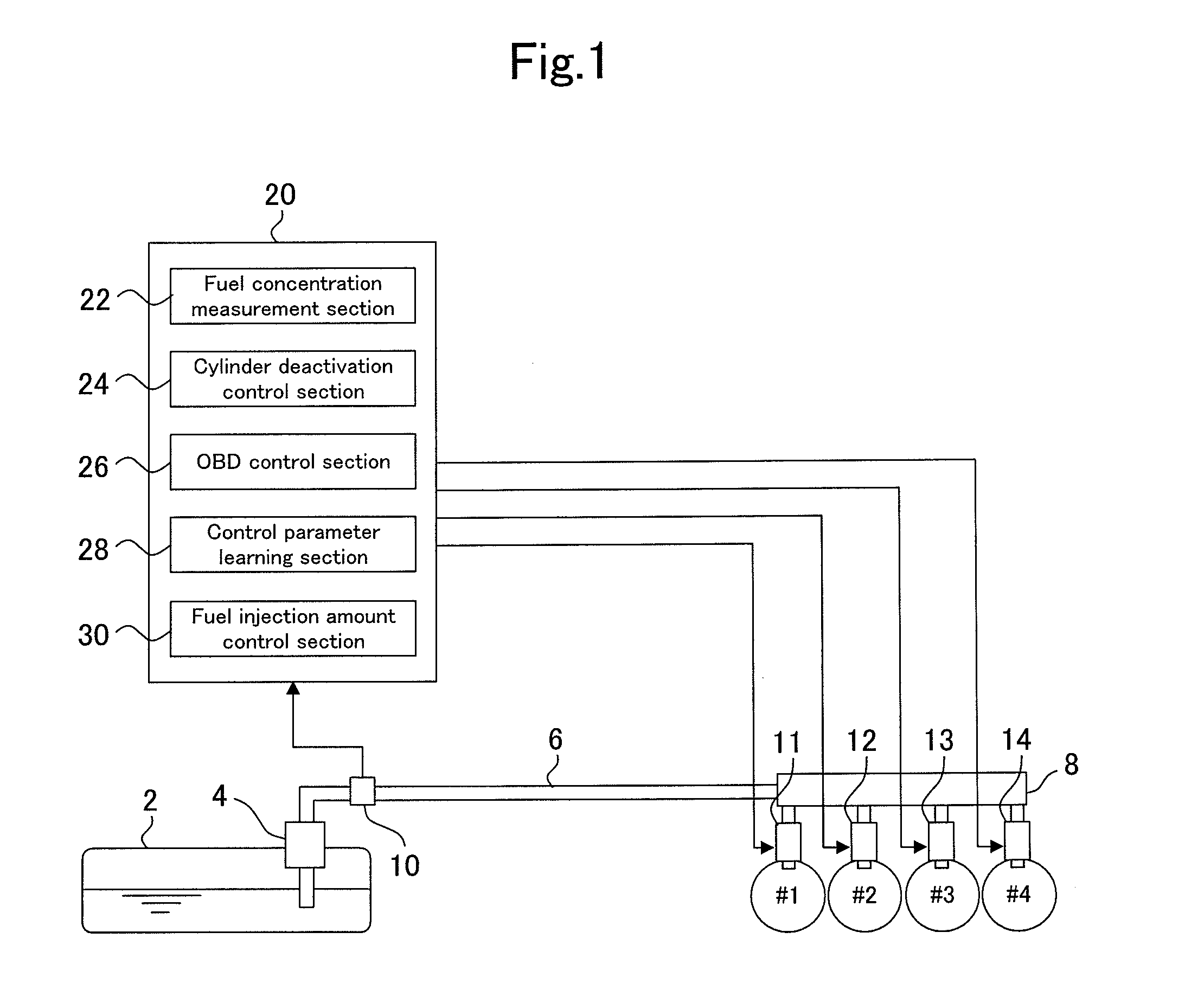

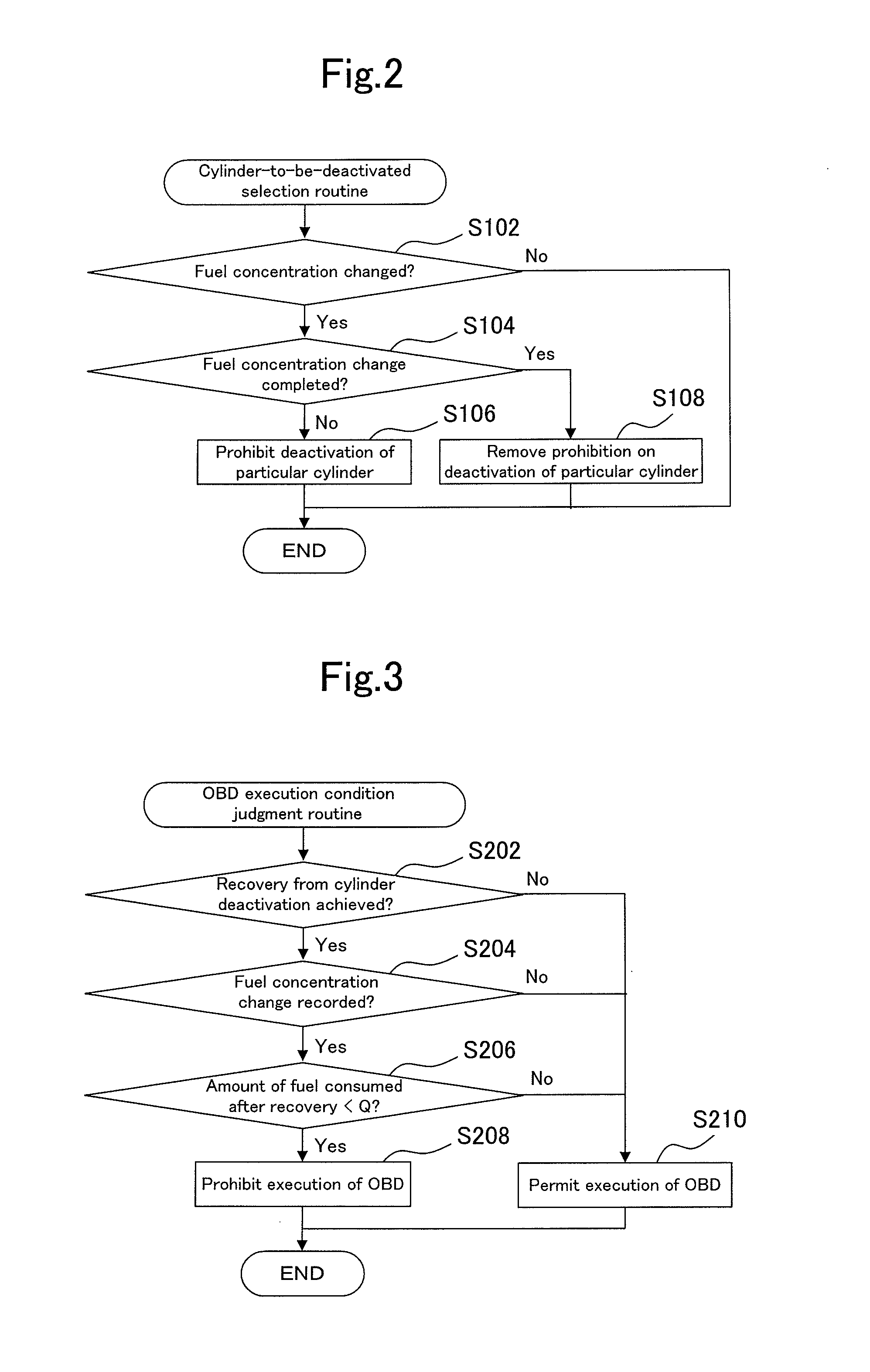

Control device for internal combustion engine

InactiveUS20120103312A1Avoid disagreementReduce the differenceElectrical controlInternal combustion piston enginesMultifuelExternal combustion engine

An object of the present invention is to avoid an air-fuel ratio difference between cylinders upon recovery from a cylinder deactivation in a situation where some of a plurality of cylinders of an internal combustion engine capable of using a plurality of types of fuels having different properties are to be deactivated upon the halt of fuel injection from an injector.To accomplish the object, a control device to which the present invention is applied includes a fuel property sensor that is installed in a fuel line between a fuel tank and a delivery pipe, and detects a fuel property change from a change in a signal of the fuel property sensor. Upon detection of a fuel property change, the control device prohibits the deactivation of a cylinder before the completion of a fuel property change in the delivery pipe.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com