Patents

Literature

339results about How to "Reduce metal content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

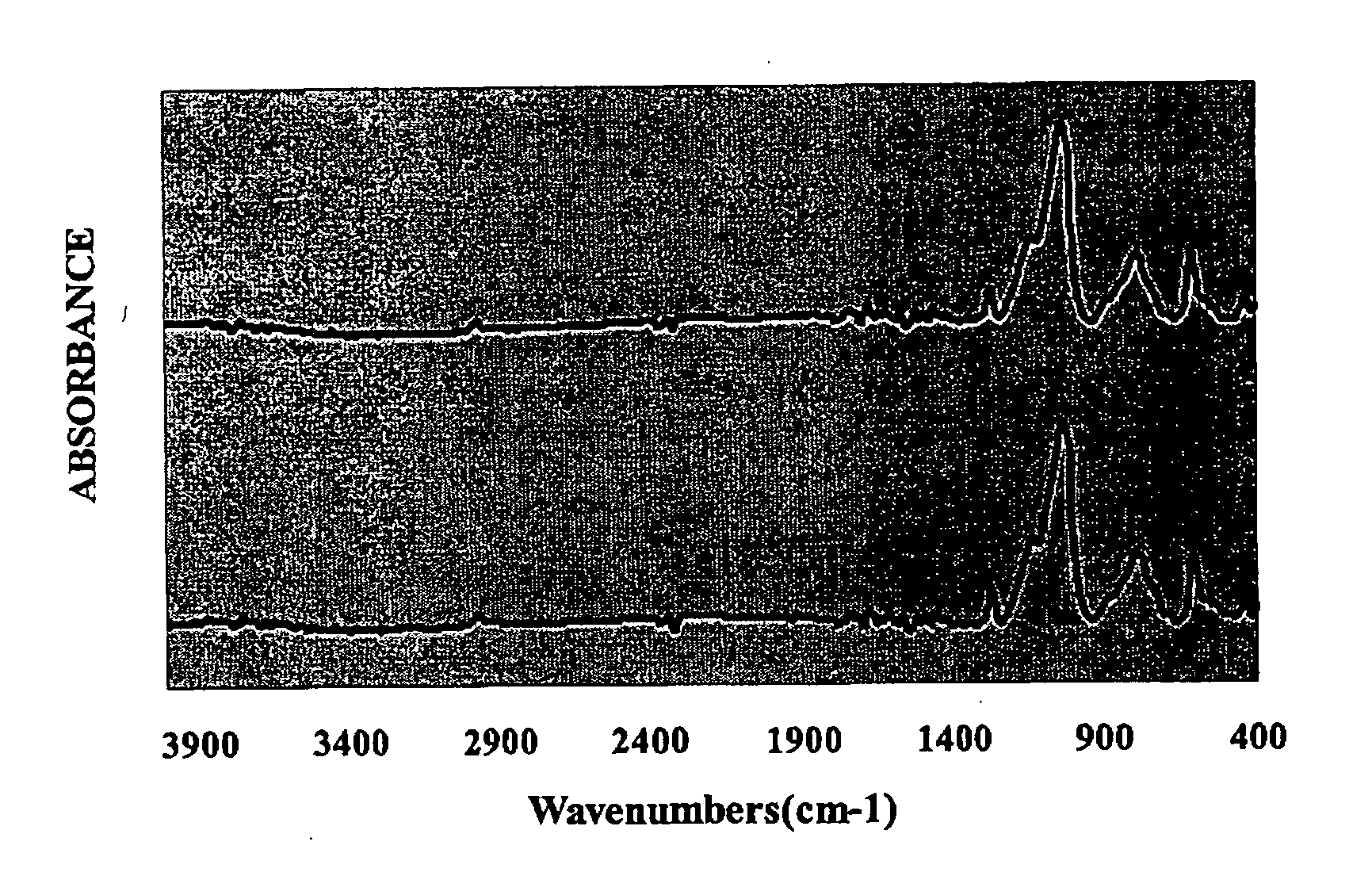

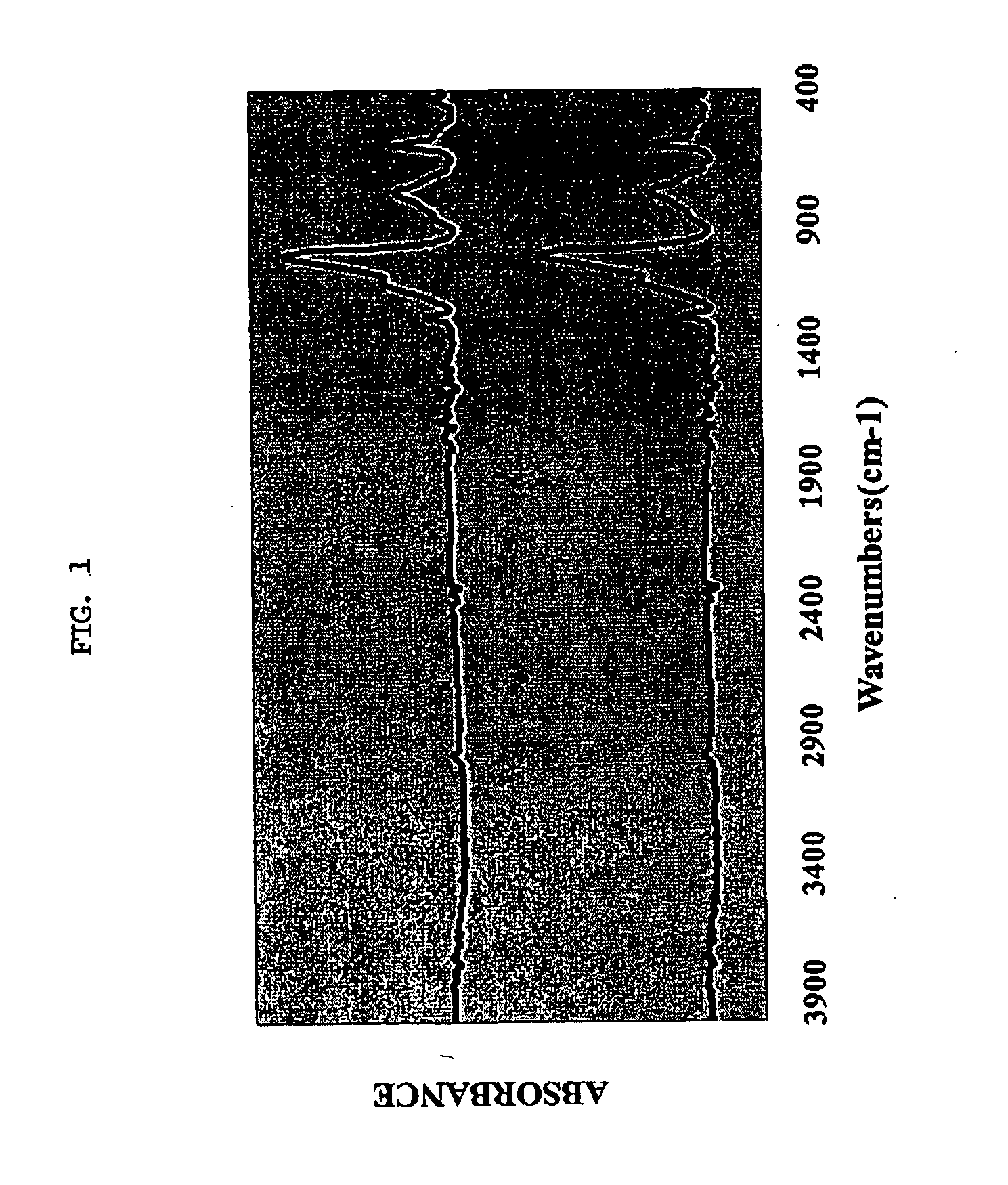

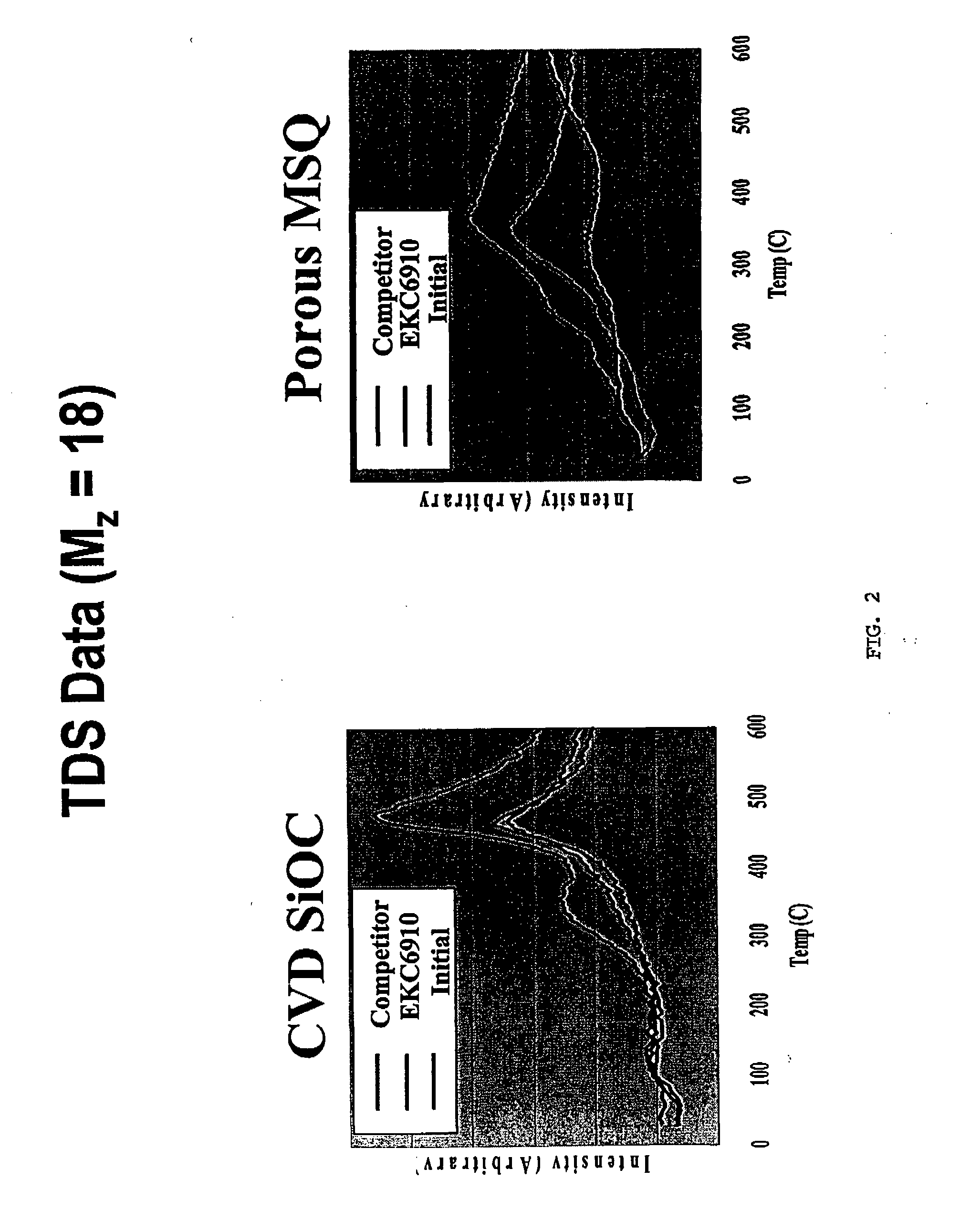

Aqueous fluoride compositions for cleaning semiconductor devices

InactiveUS20050014667A1Improve protectionReduce metal contentSurface-active detergent compositionsDetergent mixture composition preparationDevice materialNuclear chemistry

The present invention relates to dilute fluoride solutions and methods for cleaning plasma etch residue from semiconductor substrates including such dilute solutions. The compositions and methods according to the invention can advantageously provide both cleaning efficiency and material compatibility.

Owner:EKC TECH

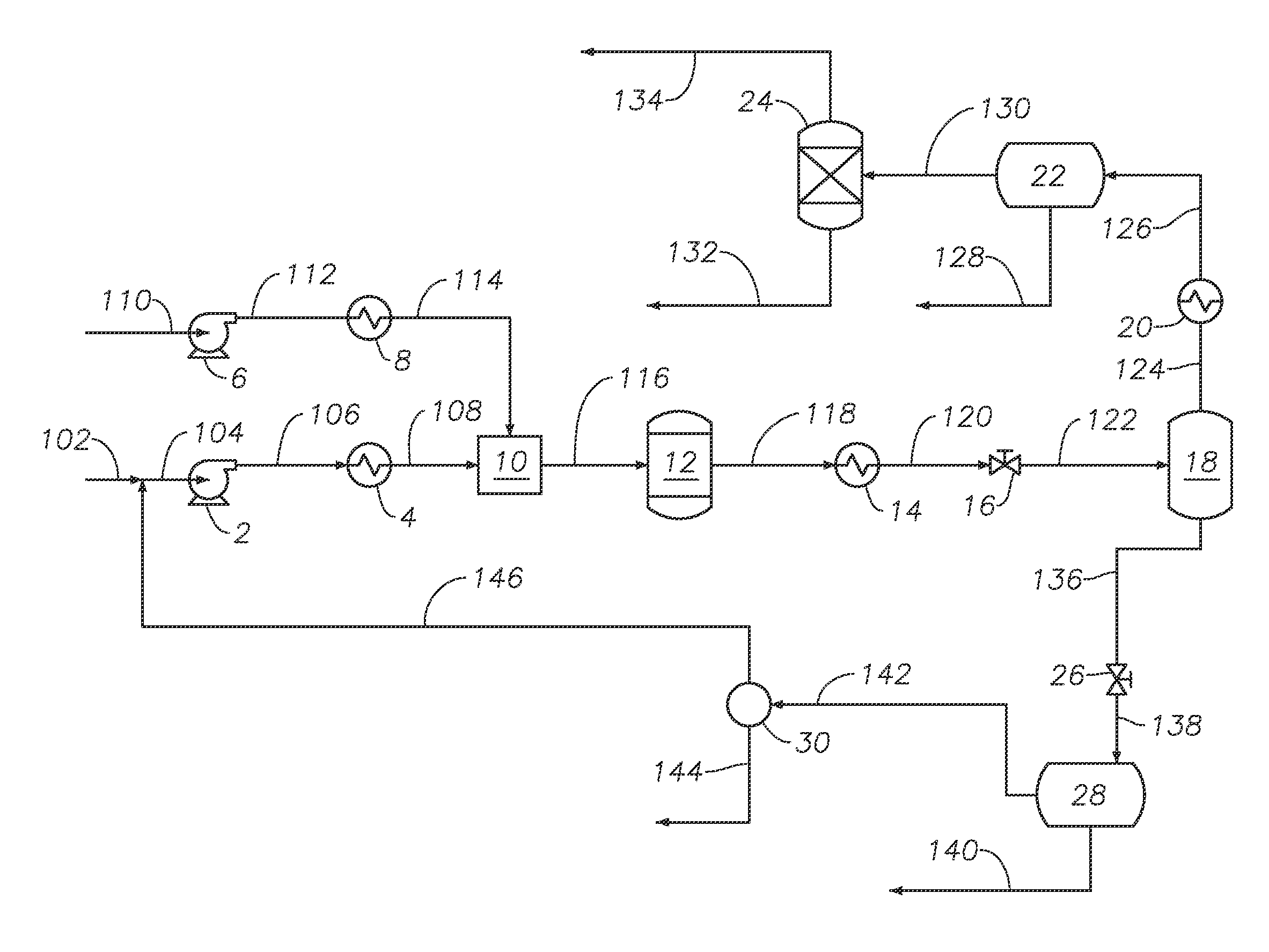

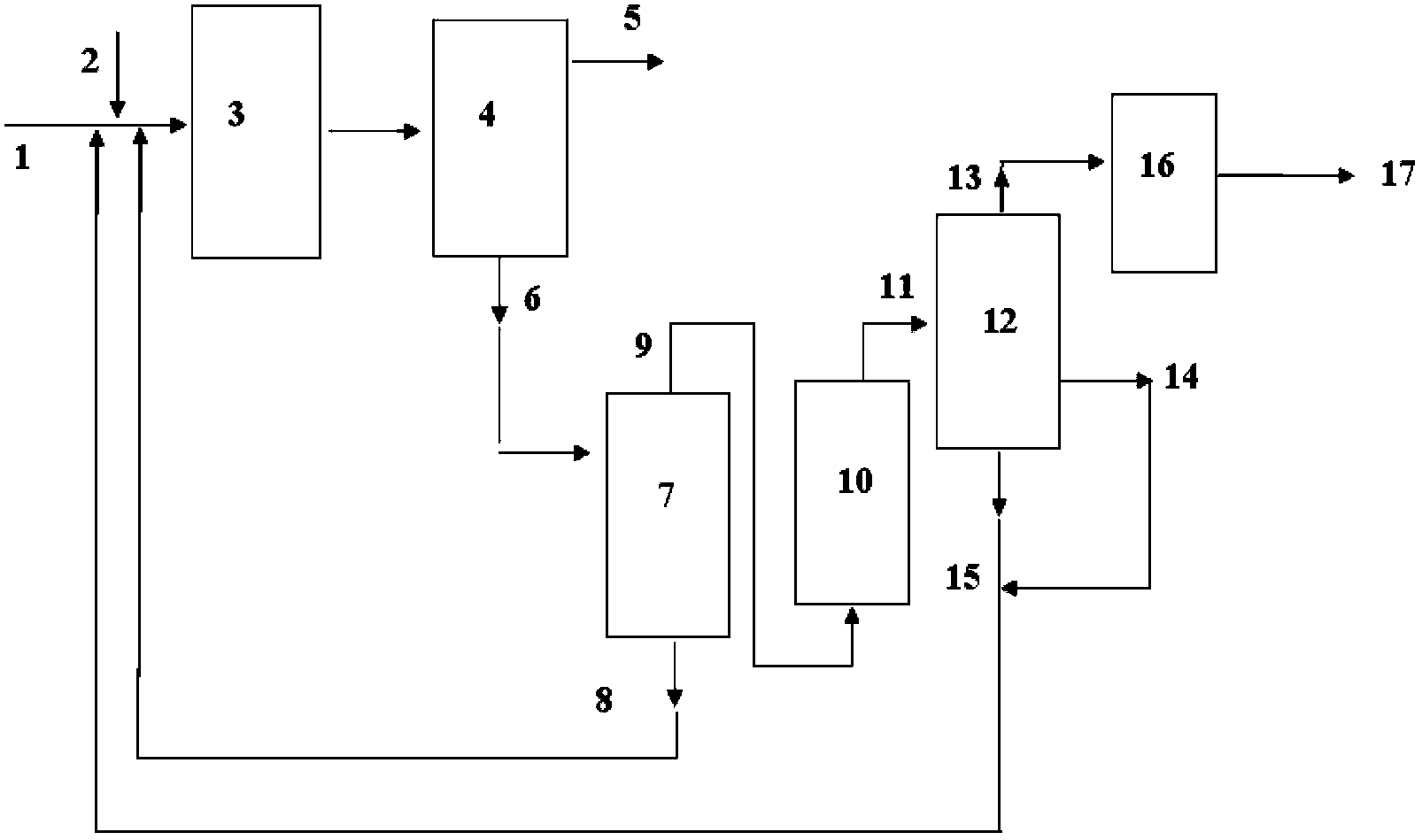

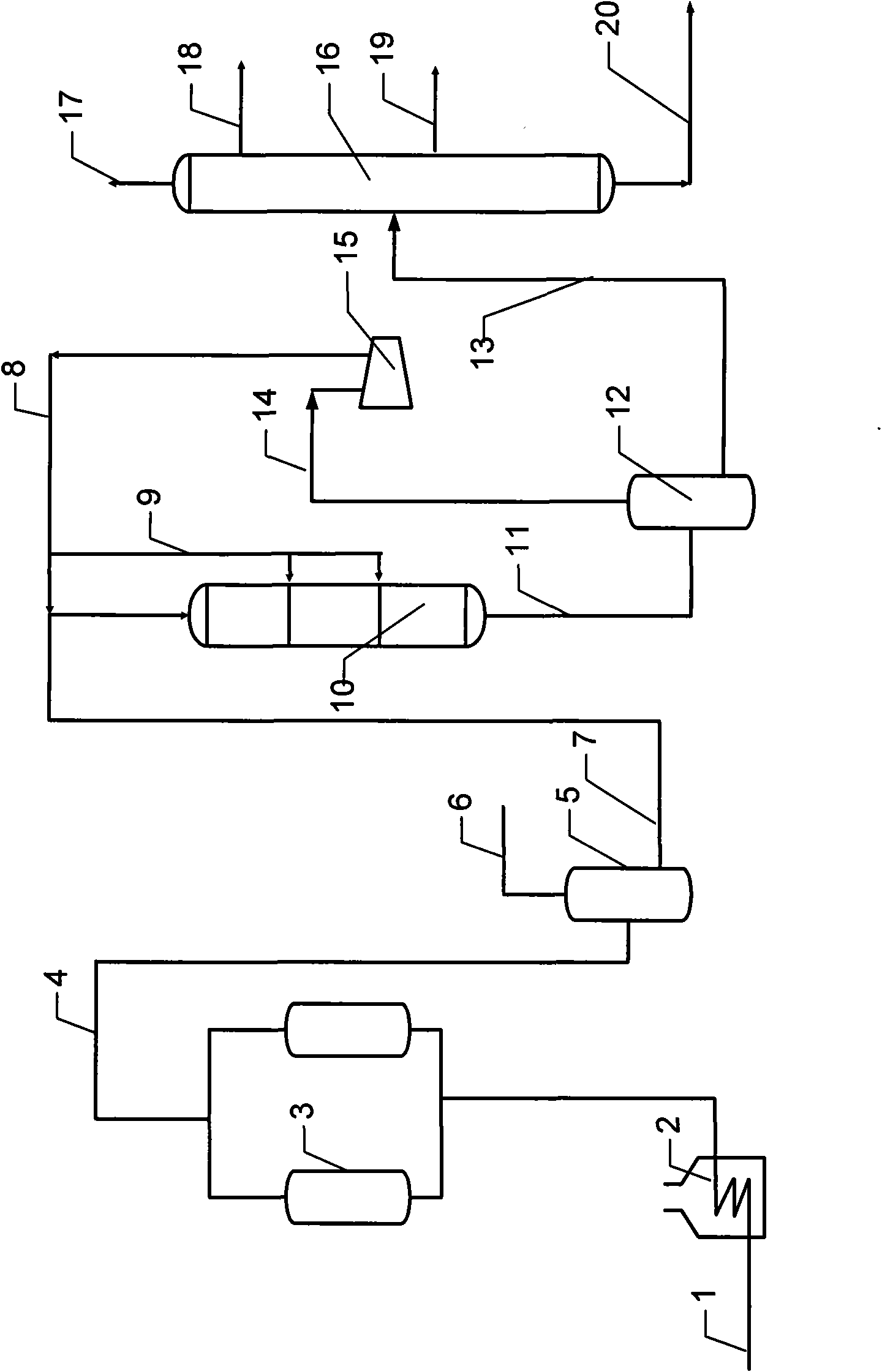

Process to produce aromatics from crude oil

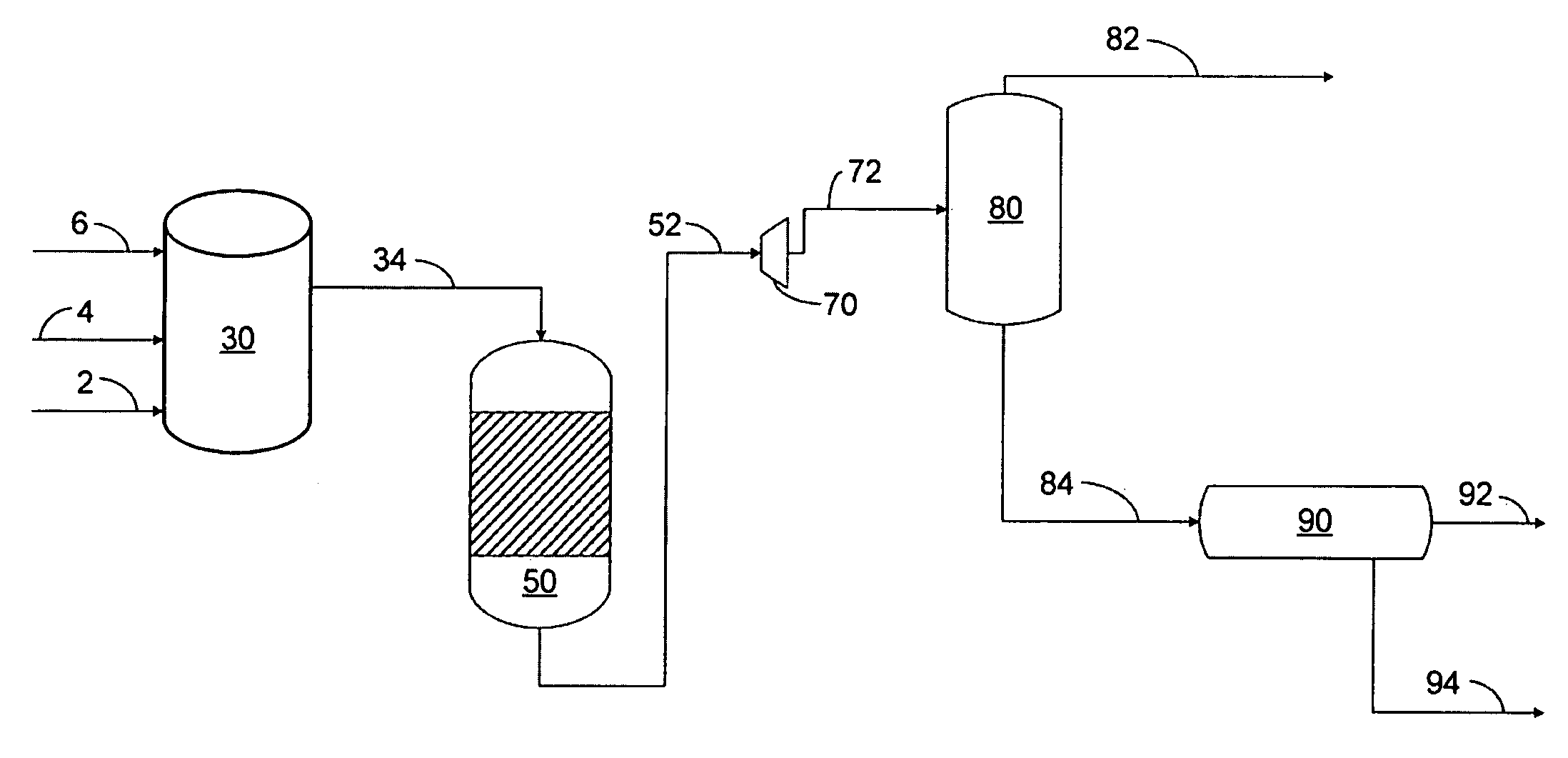

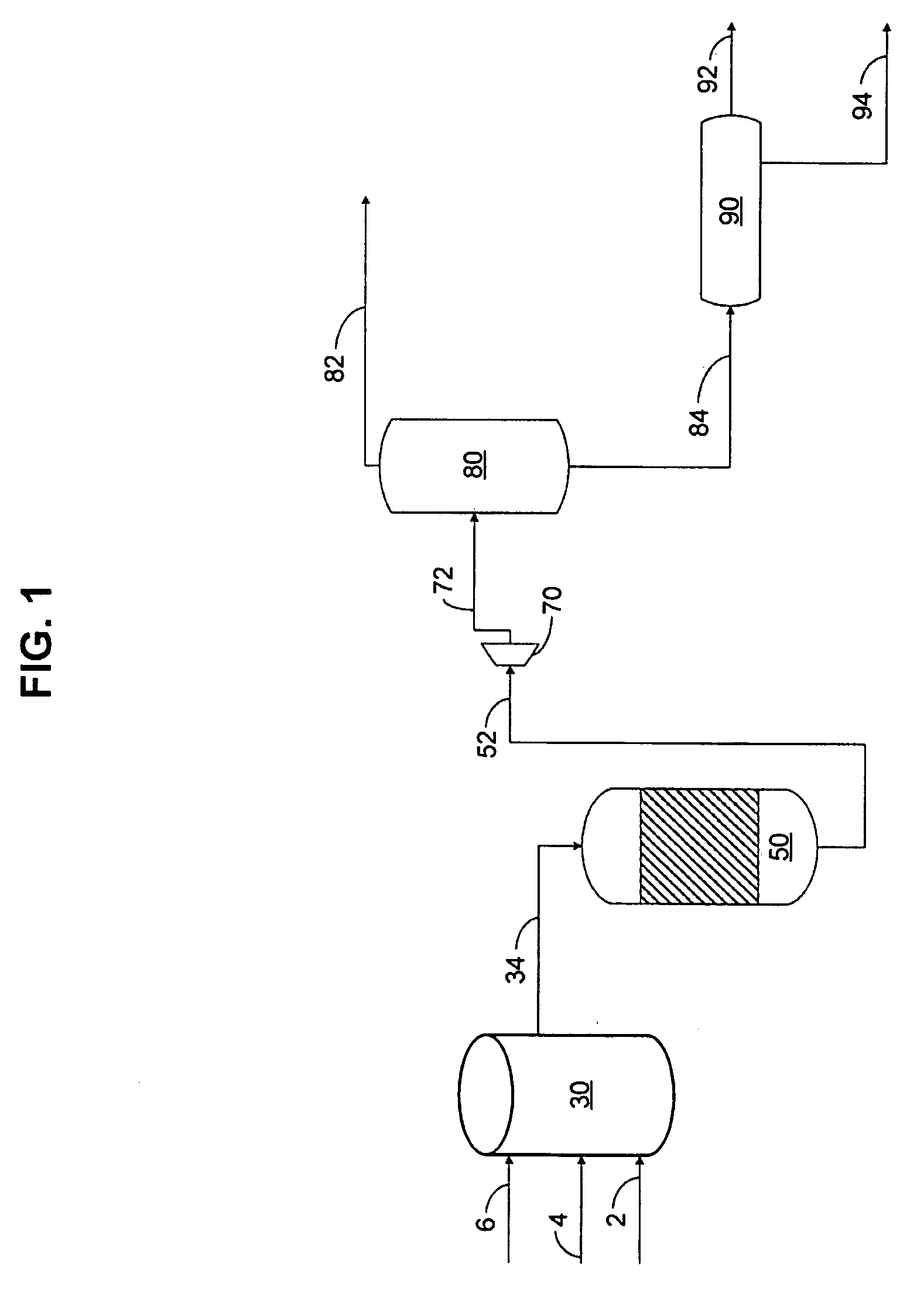

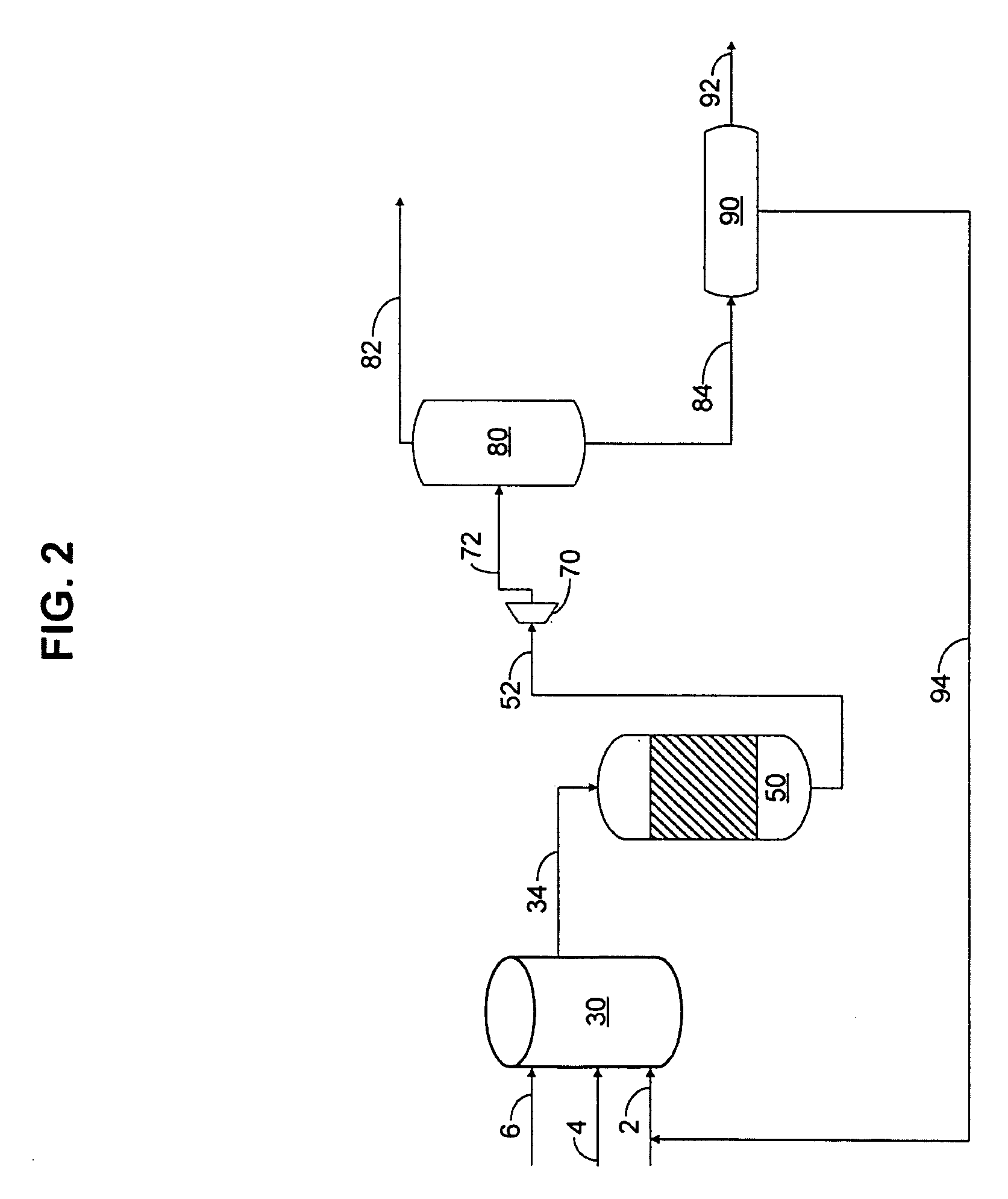

ActiveUS20150321975A1Low impurity contentHigh API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyVapor–liquid separatorWater flow

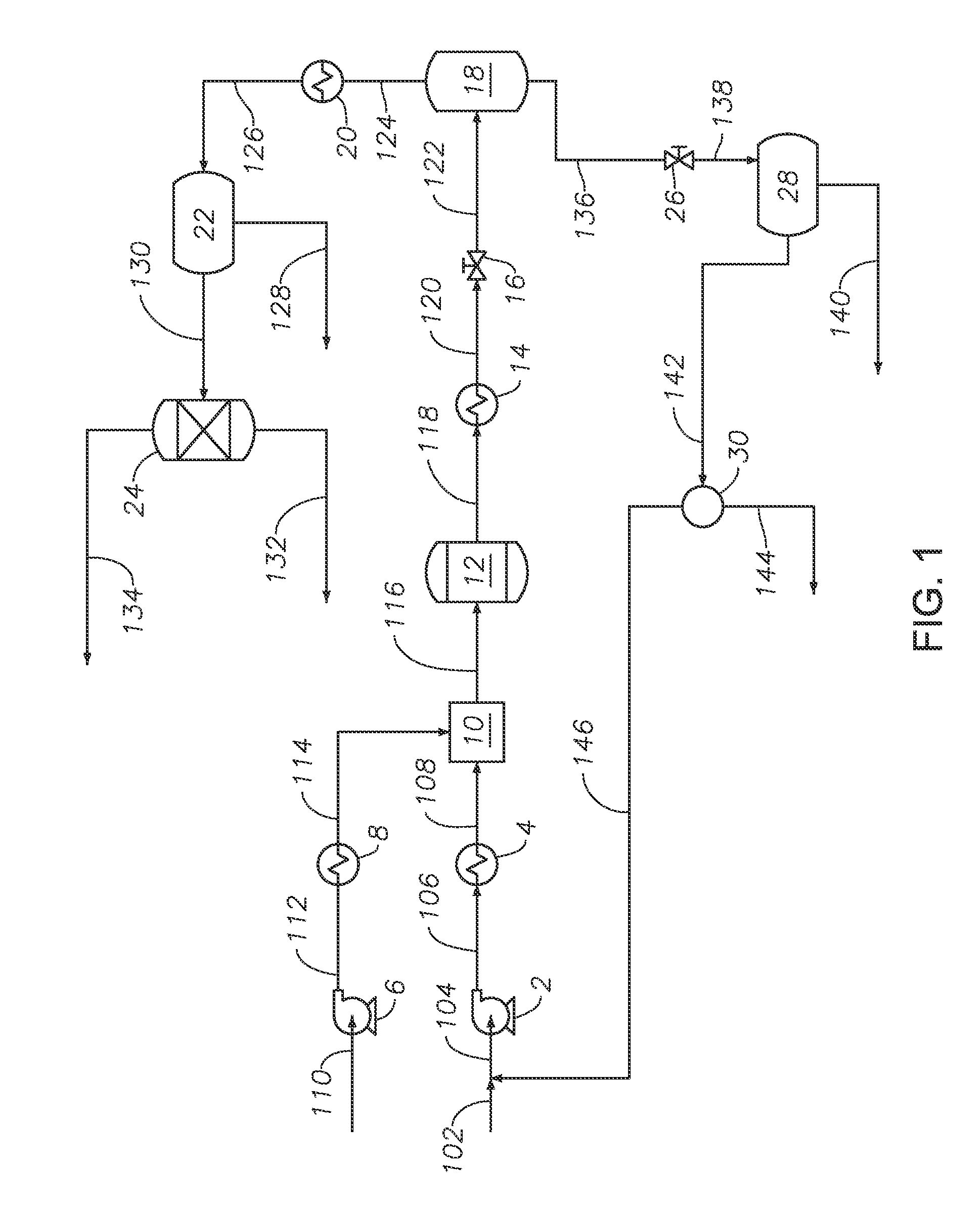

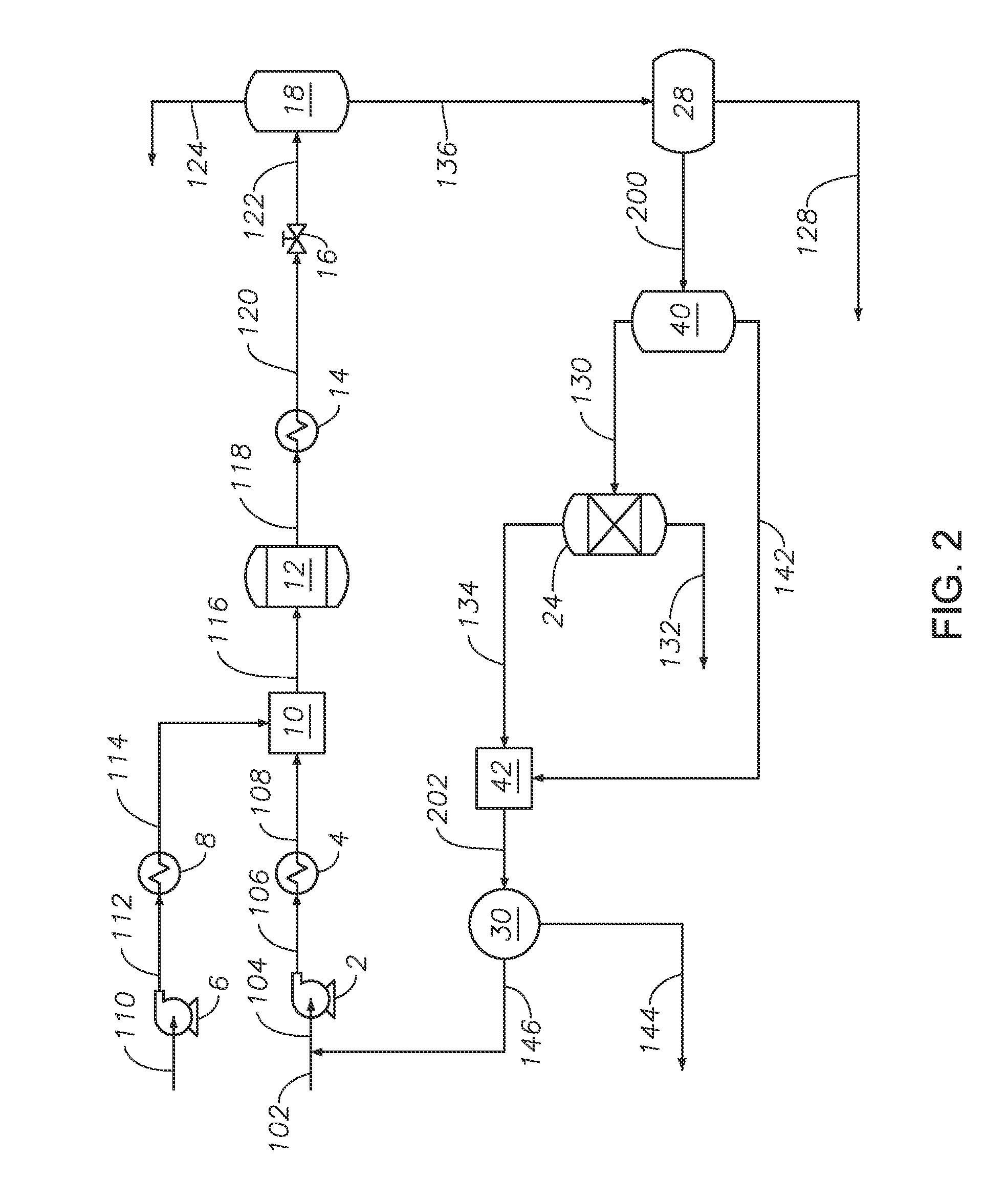

A process for producing aromatics from a hydrocarbon source in the presence of supercritical water comprising the steps of mixing a pressurized, pre-heated water stream with a pressurized, pre-heated petroleum feedstock, the pressurized, pre-heated water stream at a pressure above the critical pressure of water and a temperature above the critical temperature of water, feeding the combined stream to a supercritical water reactor to create a modified stream, cooling and depressurizing the modified stream, separating the depressurized stream in a vapor-liquid separator, condensing the vapor stream, separating the condensed stream into a water recovery stream and a light product recovery stream, extracting the aromatics from the light product recovery stream, depressurizing the liquid stream, separating the depressurized liquid stream in a heavy separator into an upgraded product stream, and recycling part of the upgraded product stream to the pressurized, pre-heated petroleum feedstock as a product recycle.

Owner:SAUDI ARABIAN OIL CO

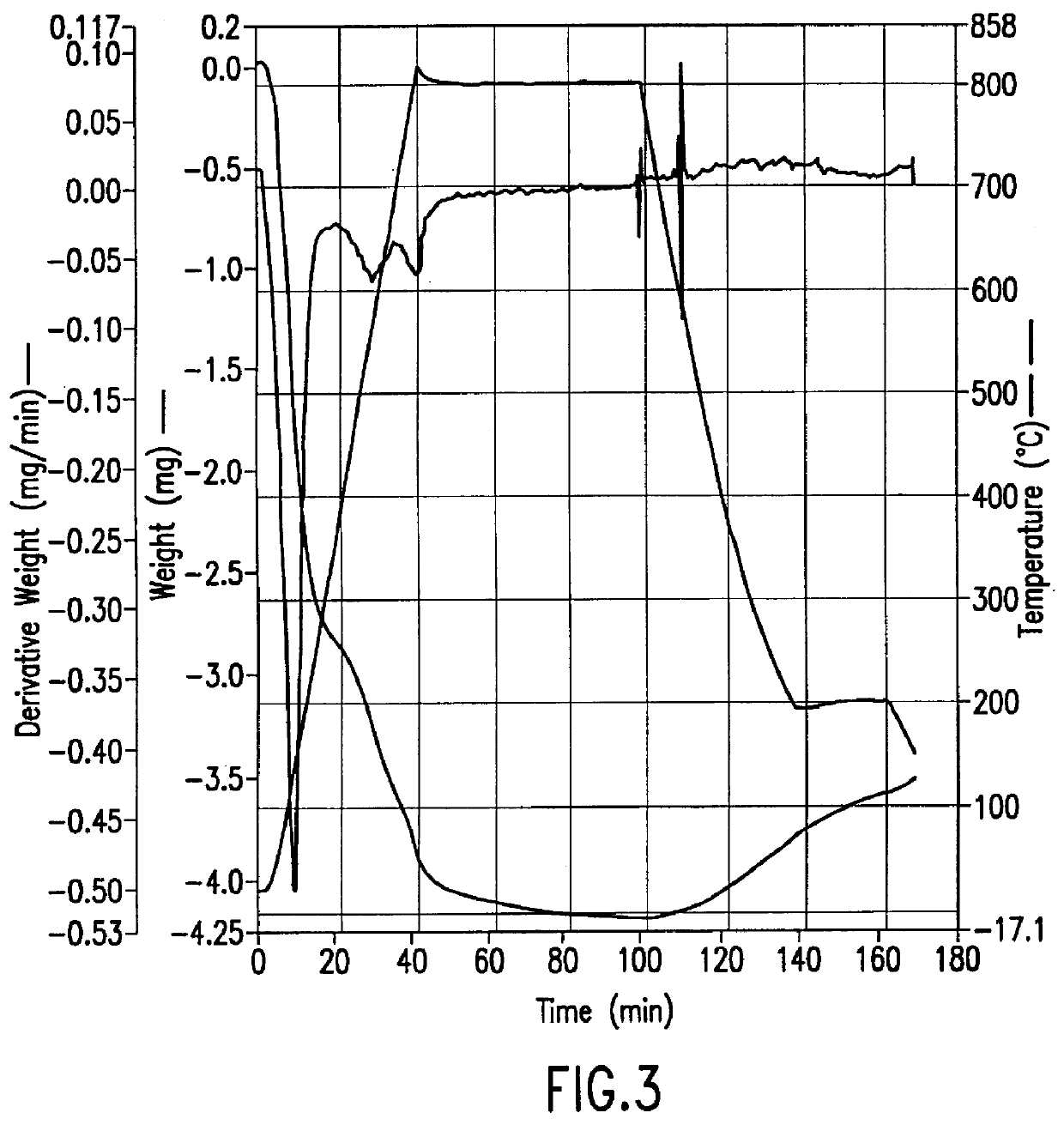

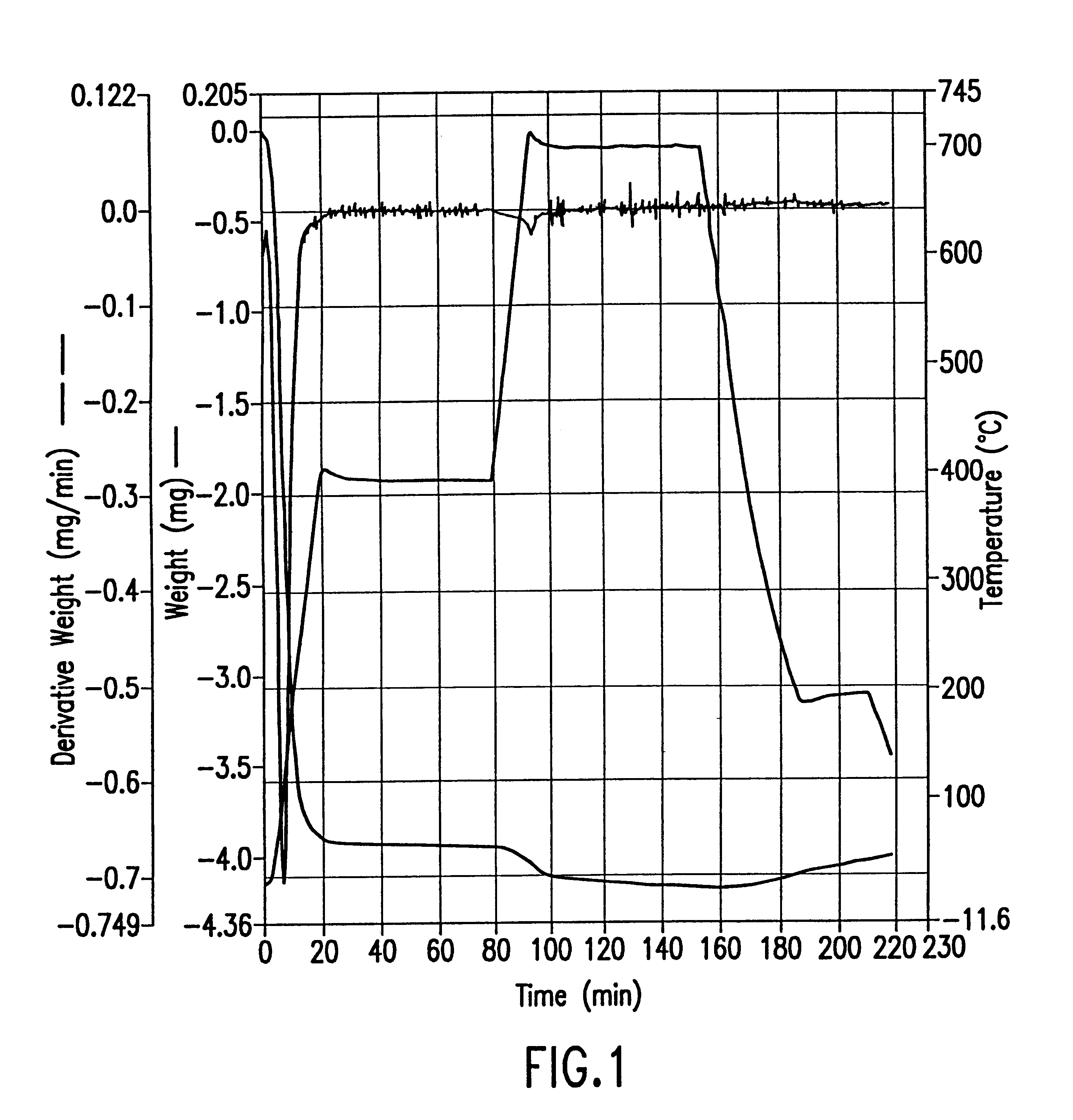

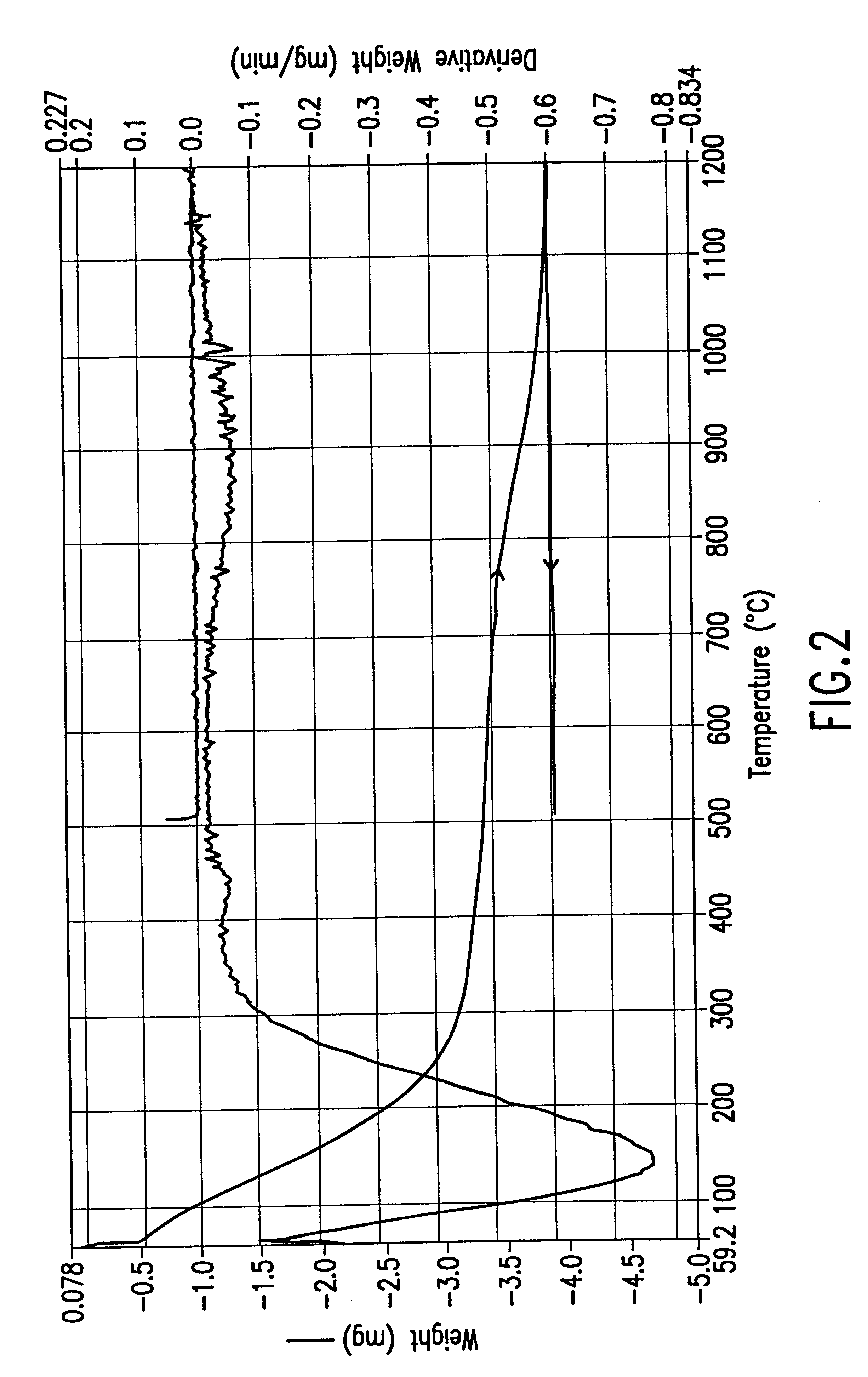

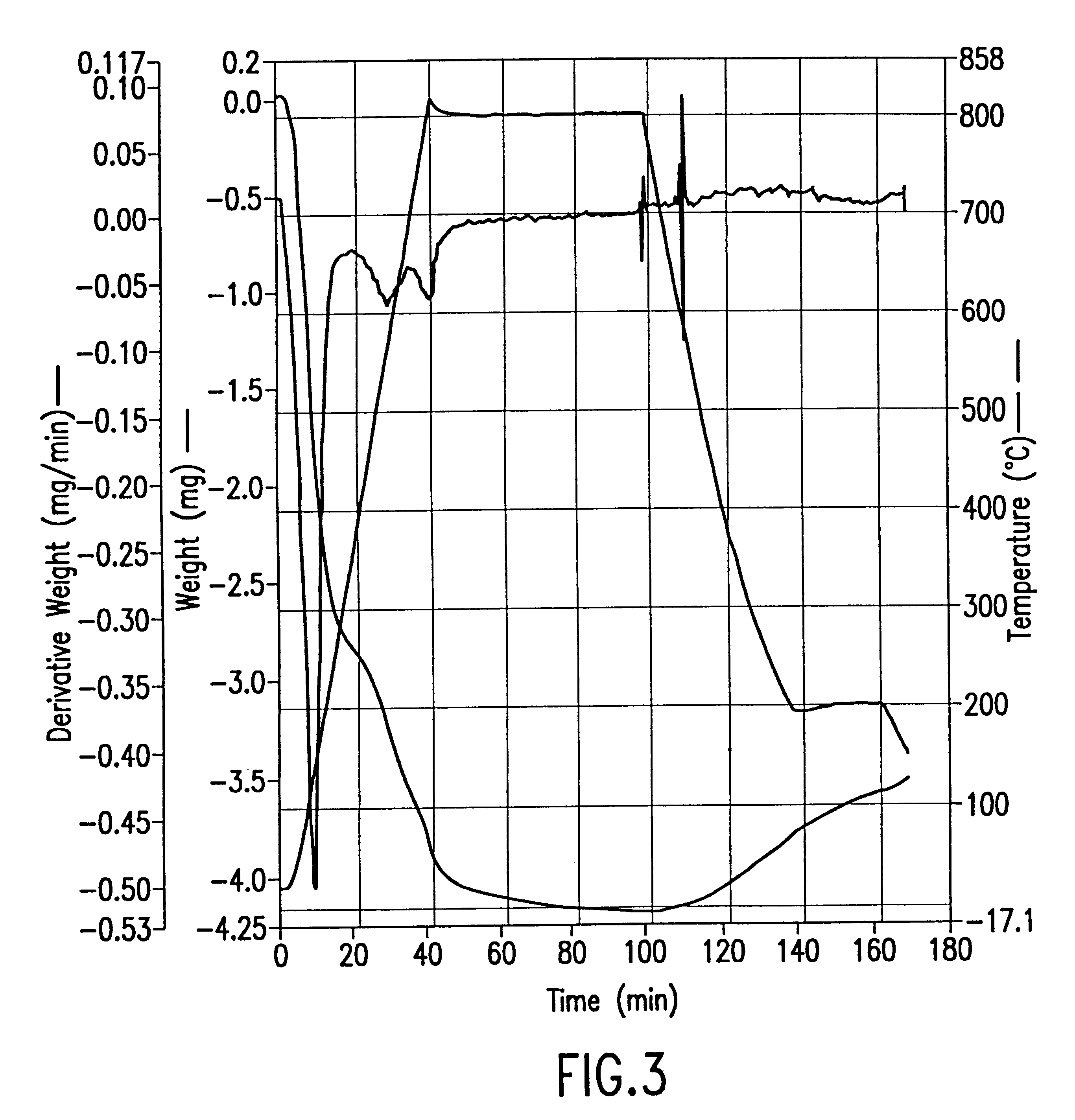

Methods for removal of water from gases using superheated zeolites

InactiveUS6110258AHigh silica-to-alumina ratioReduce metal contentGas treatmentMolecular sieve catalystsBoiling pointSilicon dioxide

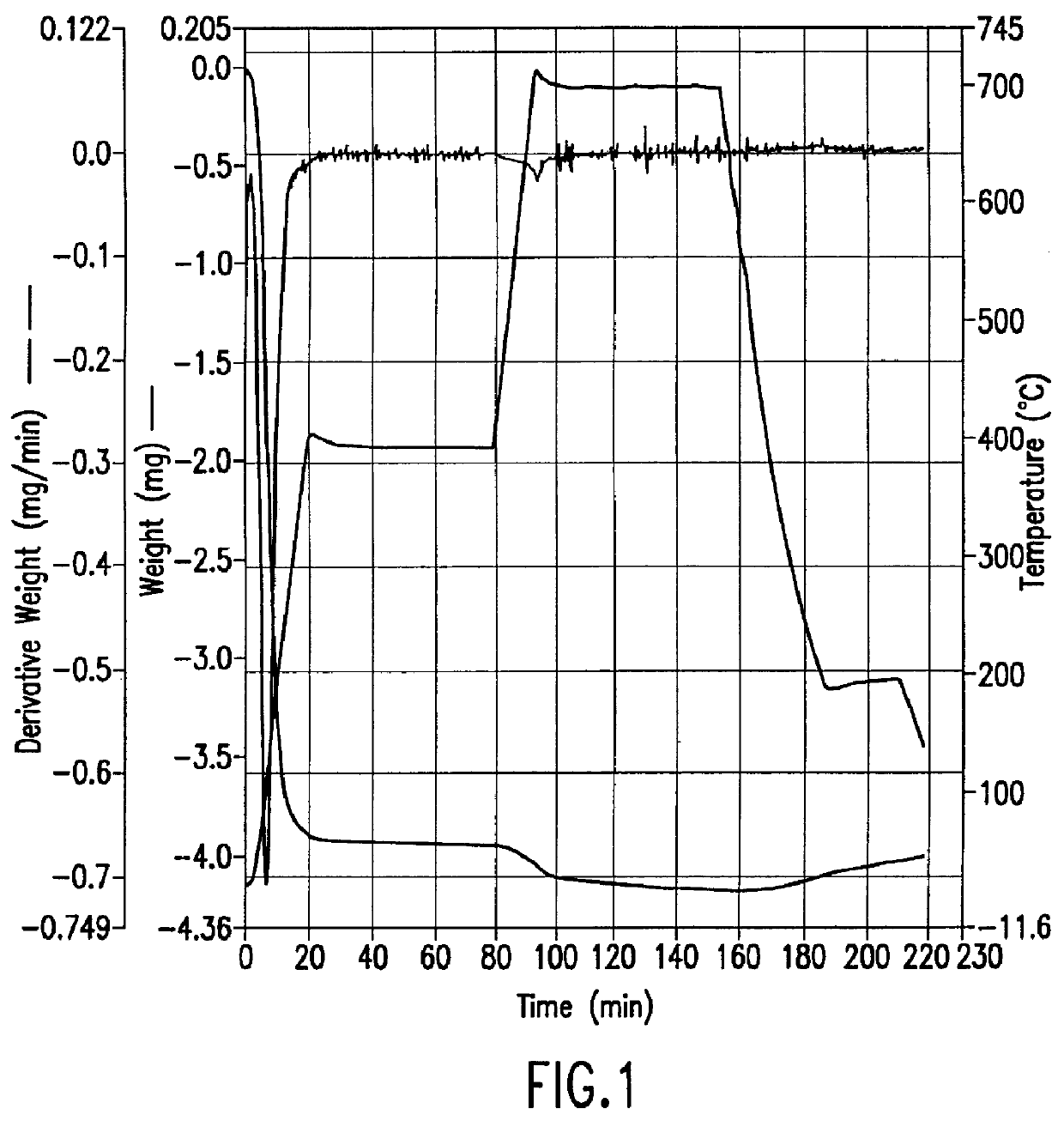

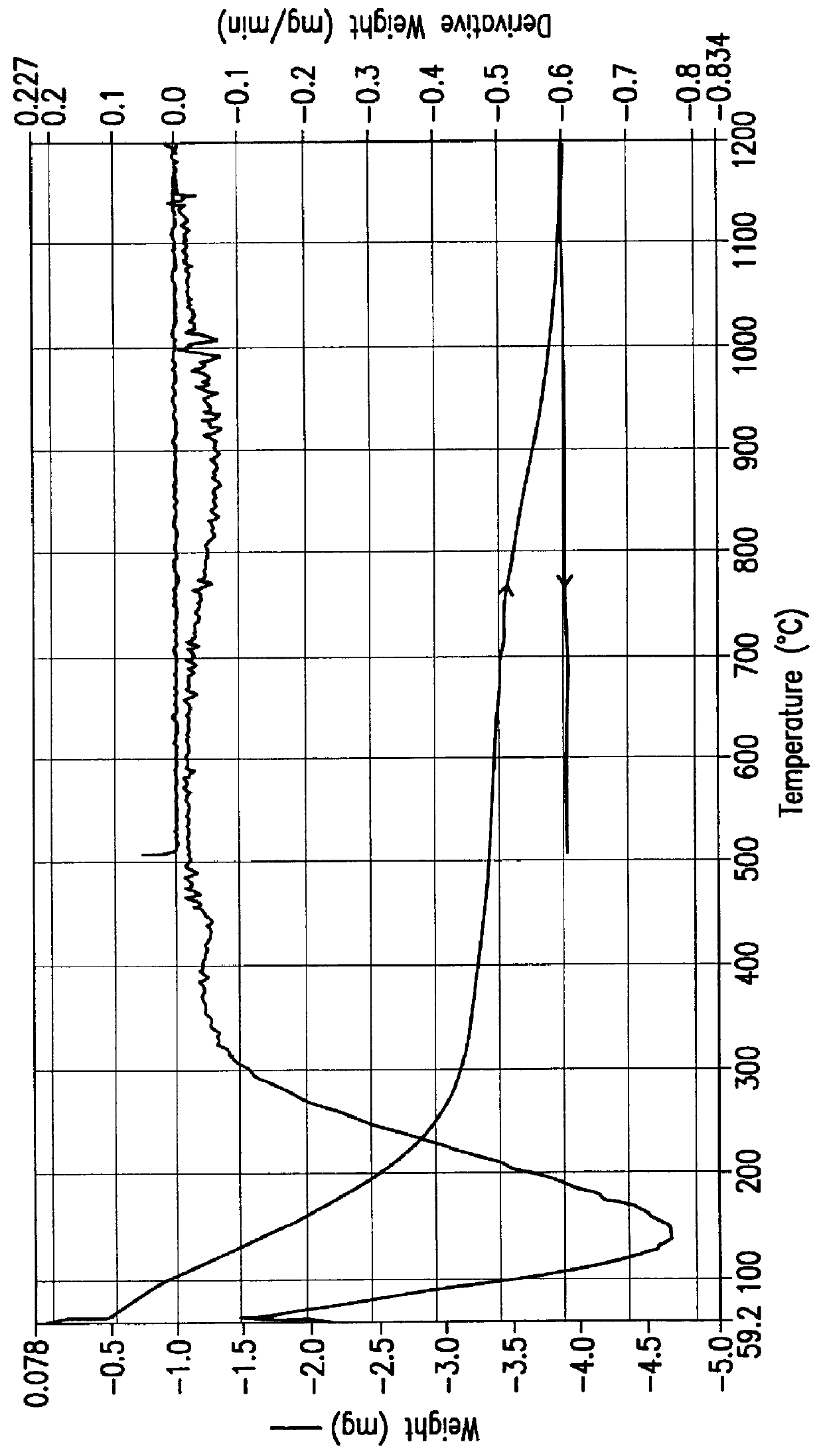

A method for removing trace moisture from a gas is disclosed. The method involves heating a zeolite having a high silica-to-alumina ratio to about 400 DEG C. to remove physically absorbed water from the zeolite, followed by heating the zeolite to a temperature in excess of 650 DEG C., to form a superheated zeolite. Heating to temperatures of 650 DEG C. or above is believed to cause dehydroxylation of the zeolite. A method for the preparation of a dehydroxylated zeolite is also disclosed. The superheated zeolite is contacted with the gas, thereby adsorbing water from the gas. A dehydroxylated zeolite for removing trace moisture from a gas wherein the zeolite has a high silica-to-alumina ratio and a low level of metallic impurities is also disclosed. The zeolite and methods of the invention are particularly useful for removing trace water from acid gases such as hydrogen chloride and hydrogen bromide.

Owner:MATHESON TRI GAS INC

Methods for removal of impurity metals from gases using low metal zeolites

InactiveUS6395070B1High silica-to-alumina ratioReduce metal contentGas treatmentMolecular sieve catalystsBoiling pointTrace metal

A method for removing trace moisture from a gas is disclosed. The method involves heating a zeolite having a high silica-to-alumina ratio to about 400° C. to remove physically adsorbed water from the zeolite, followed by heating the zeolite to a temperature in excess of 650° C., to form a superheated zeolite. The superheated zeolite is contacted with the gas, thereby adsorbing water from the gas. A dehydroxylated zeolite for removing trace moisture from a gas wherein the zeolite has a high silica-to-alumina ratio and a low level of metallic impurities is also disclosed. A method for removing metallic impurities from a gas using the low metals zeolite is also disclosed. The zeolites and methods of the invention are particularly useful for removing trace water and trace metal impurities from acid gases such as hydrogen chloride and hydrogen bromide.

Owner:MATHESON TRI GAS INC

Low metal content catalyst compositions and processes for making and using same

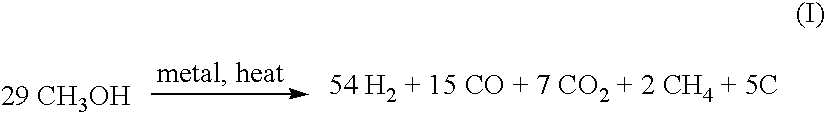

ActiveUS7125821B2Reduce metal contentReduce the amount requiredMolecular sieve catalystsMolecular sieve catalystMolecular sieveOxygenate

The invention provides low metal content molecular sieve catalyst compositions, processes for making such catalysts, and processes for using such catalysts in the conversion of an oxygenate into one or more light olefins. Preferably, the catalyst composition comprises a matrix material having a low metal content. By utilizing matrix materials having low metal contents, the amount of metal-catalyzed side reaction byproducts formed in a reaction system, particularly in an oxygenate-to-olefin reaction system, can be advantageously reduced.

Owner:EXXONMOBIL CHEM PAT INC

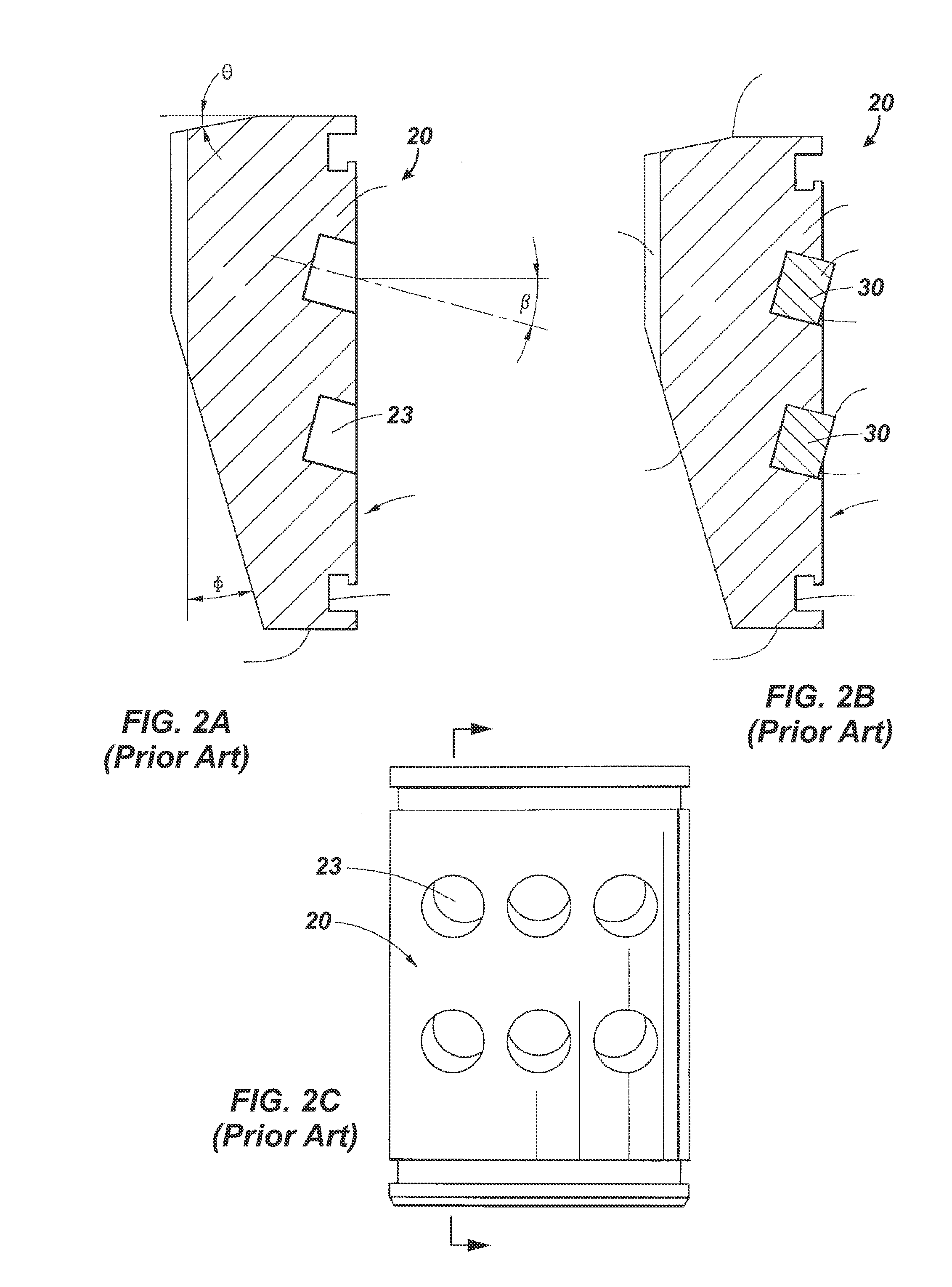

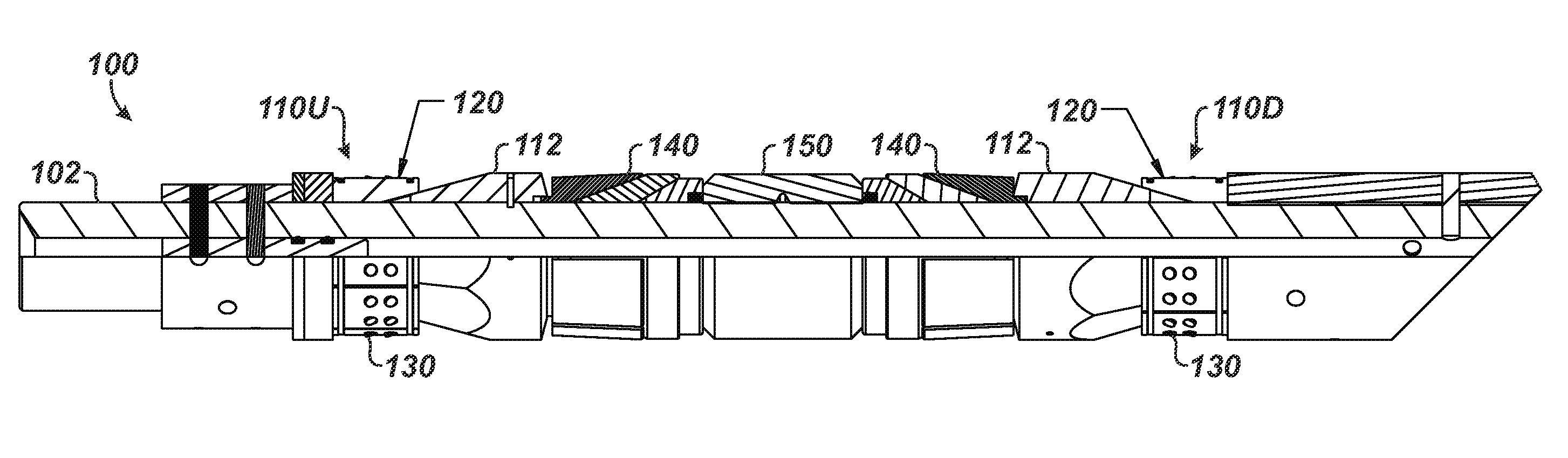

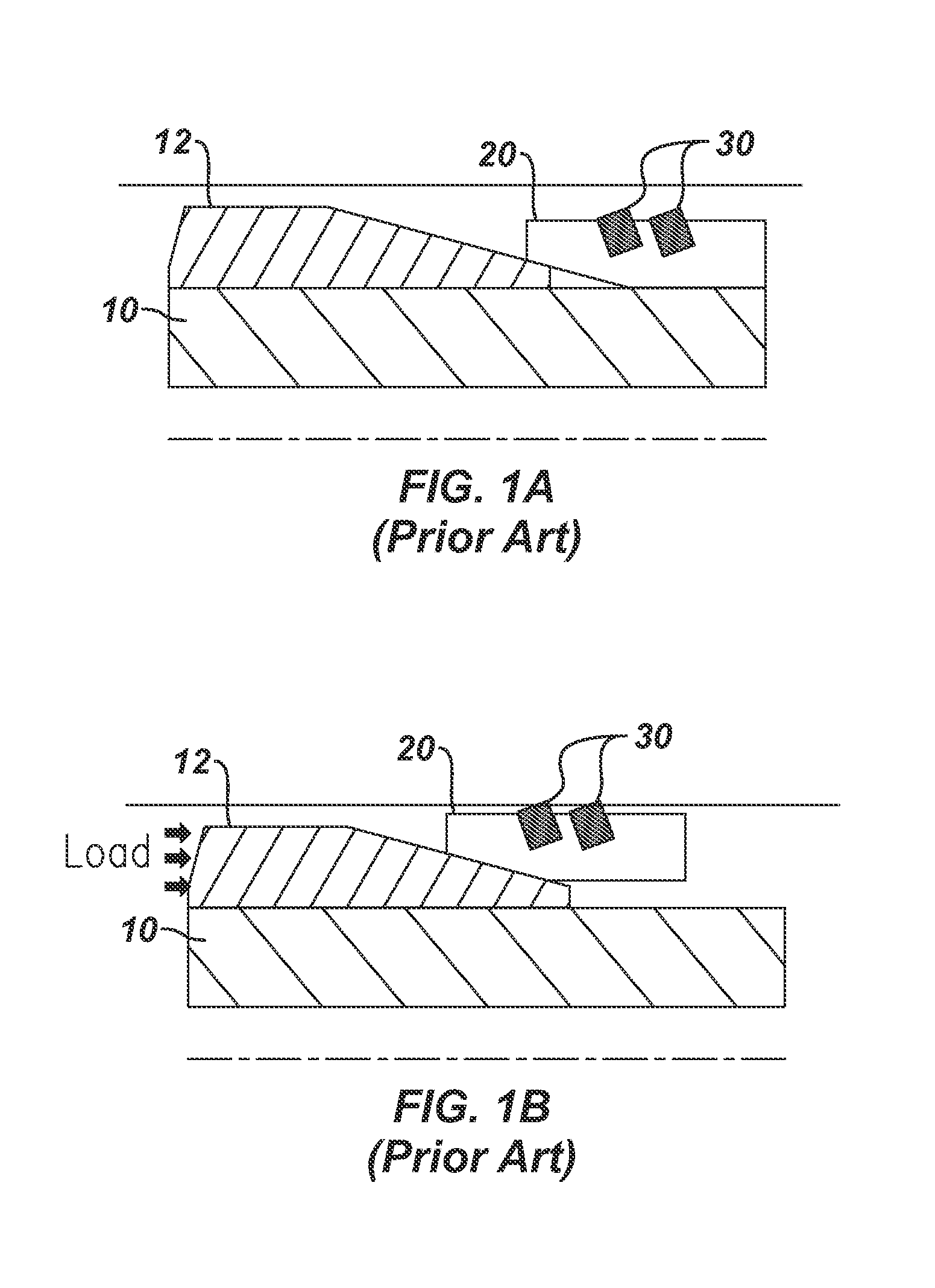

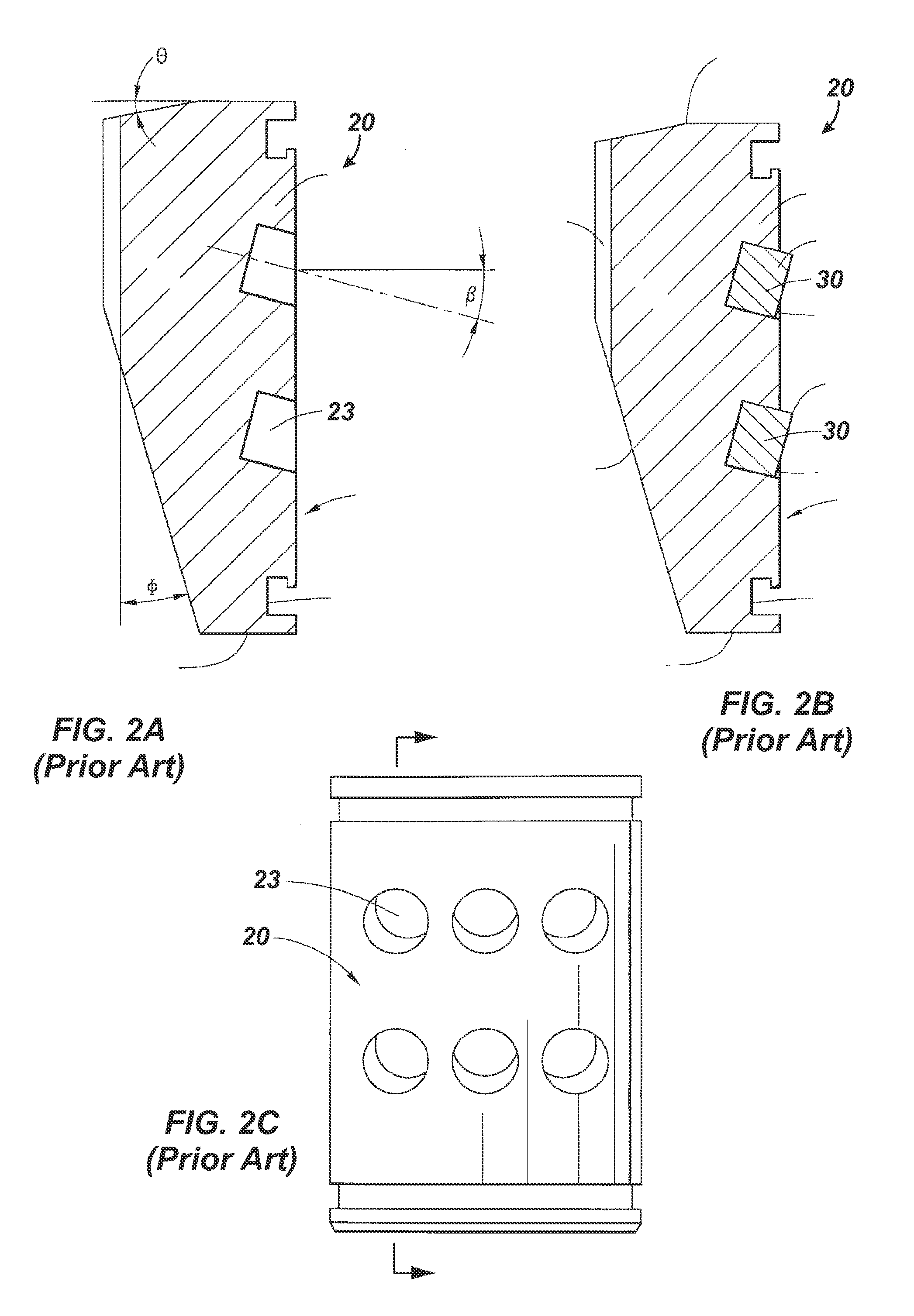

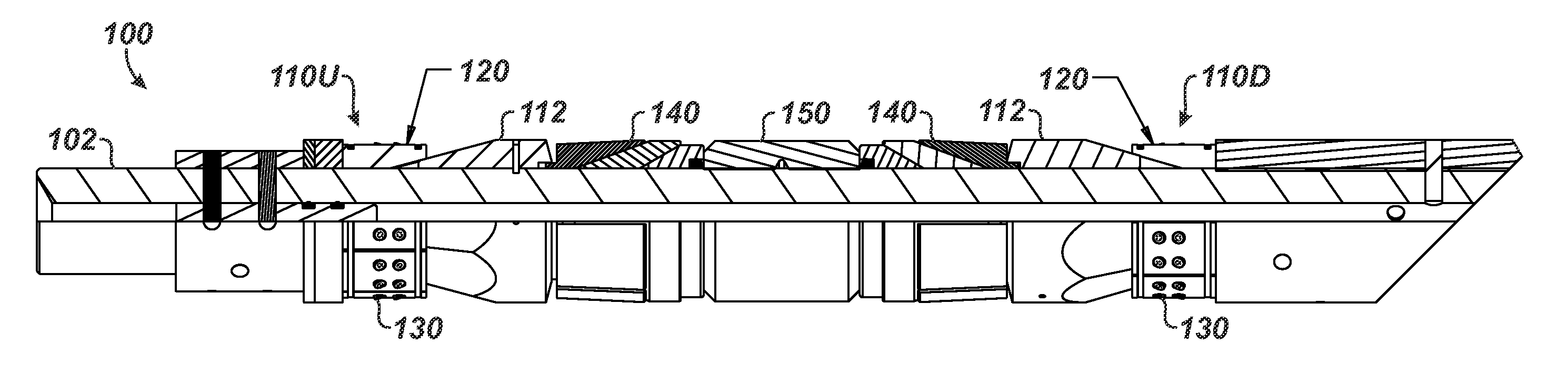

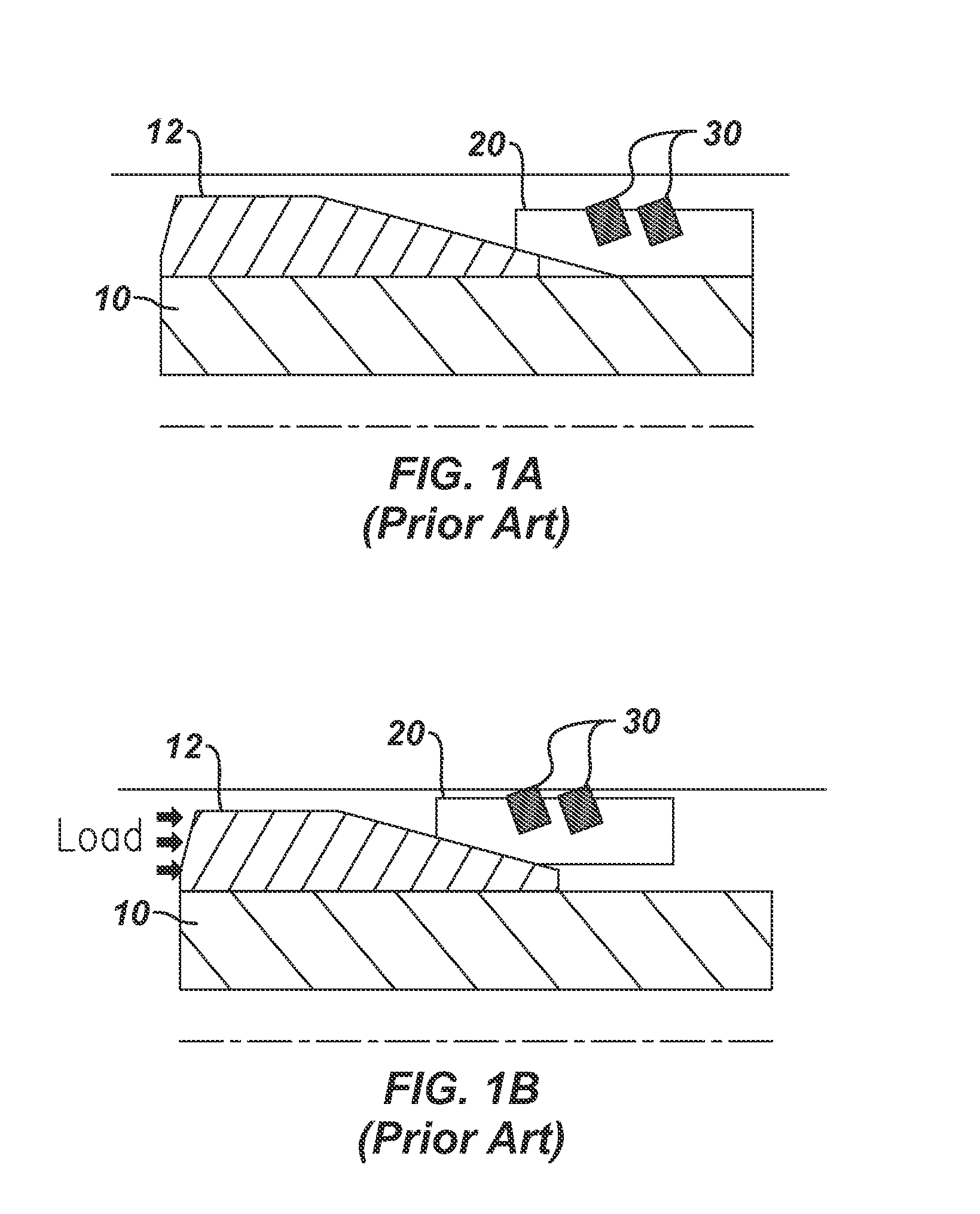

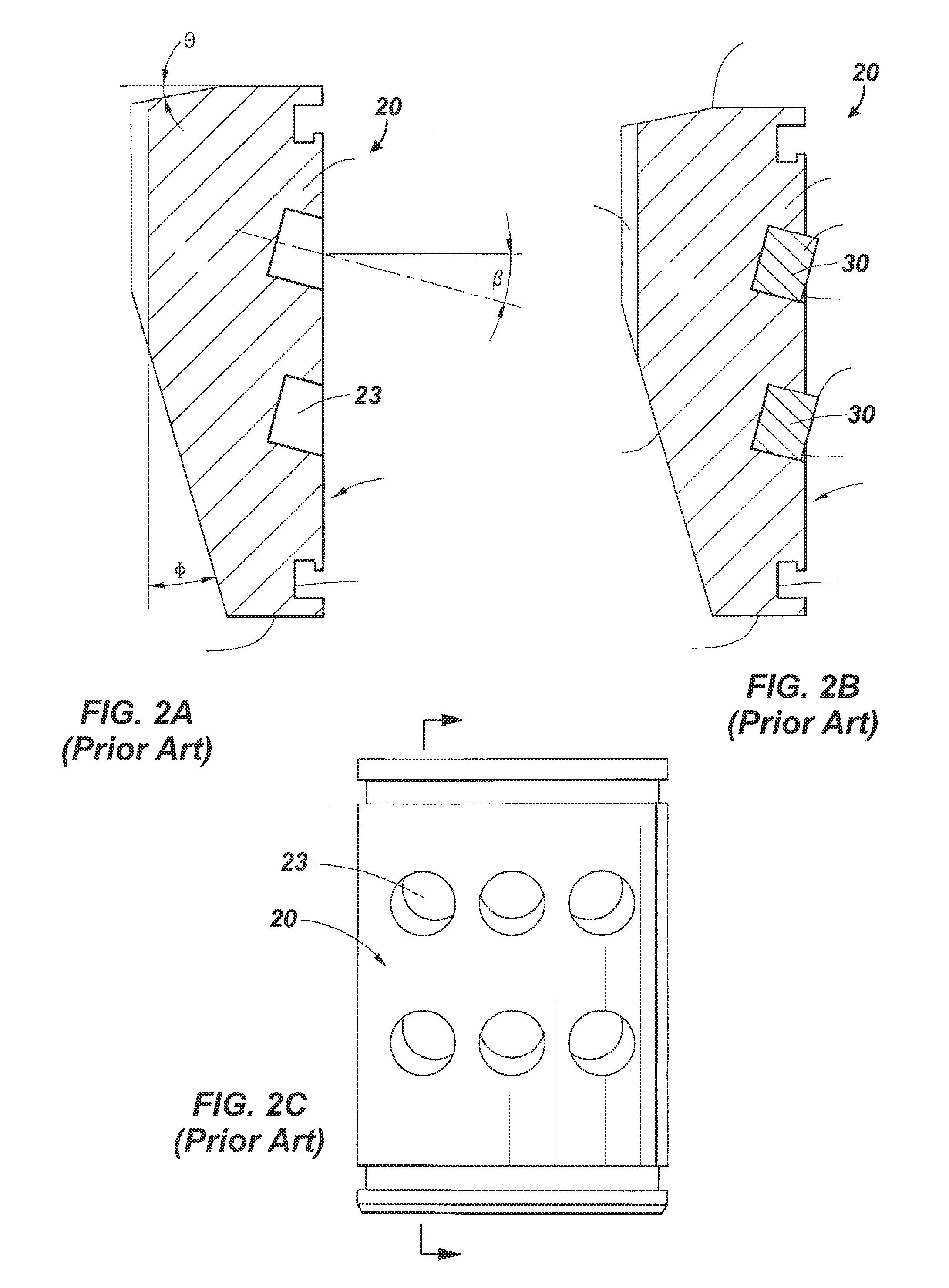

Downhole Tool Having Slip Inserts Composed of Different Materials

ActiveUS20140224477A1Reduce metal contentIncrease fluid pressureDrilling rodsFluid removalManganeseMetallic materials

A downhole tool, such as a fracture plug used during a fracture operation, installs in a downhole tubular, such as casing. The tool has a mandrel with a sealing element disposed thereon between uphole and downhole ends. Slip assemblies on the mandrel can be moved to engage the downhole tubular. The uphole assembly has inserts composed of ceramic material, and the downhole assembly has inserts composed of a metallic material. When the tool is used as a bridge plug, the uphole assembly supports the sealing element compressed, and the downhole assembly supports fluid pressure downhole of the tool. In one particular embodiment, the metallic material is a powdered metal material, such as a sintered-hardened powdered metal steel having a balance of iron, an admixture of carbon, and alloy components of molybdenum, chromium, and manganese.

Owner:WEATHERFORD TECH HLDG LLC

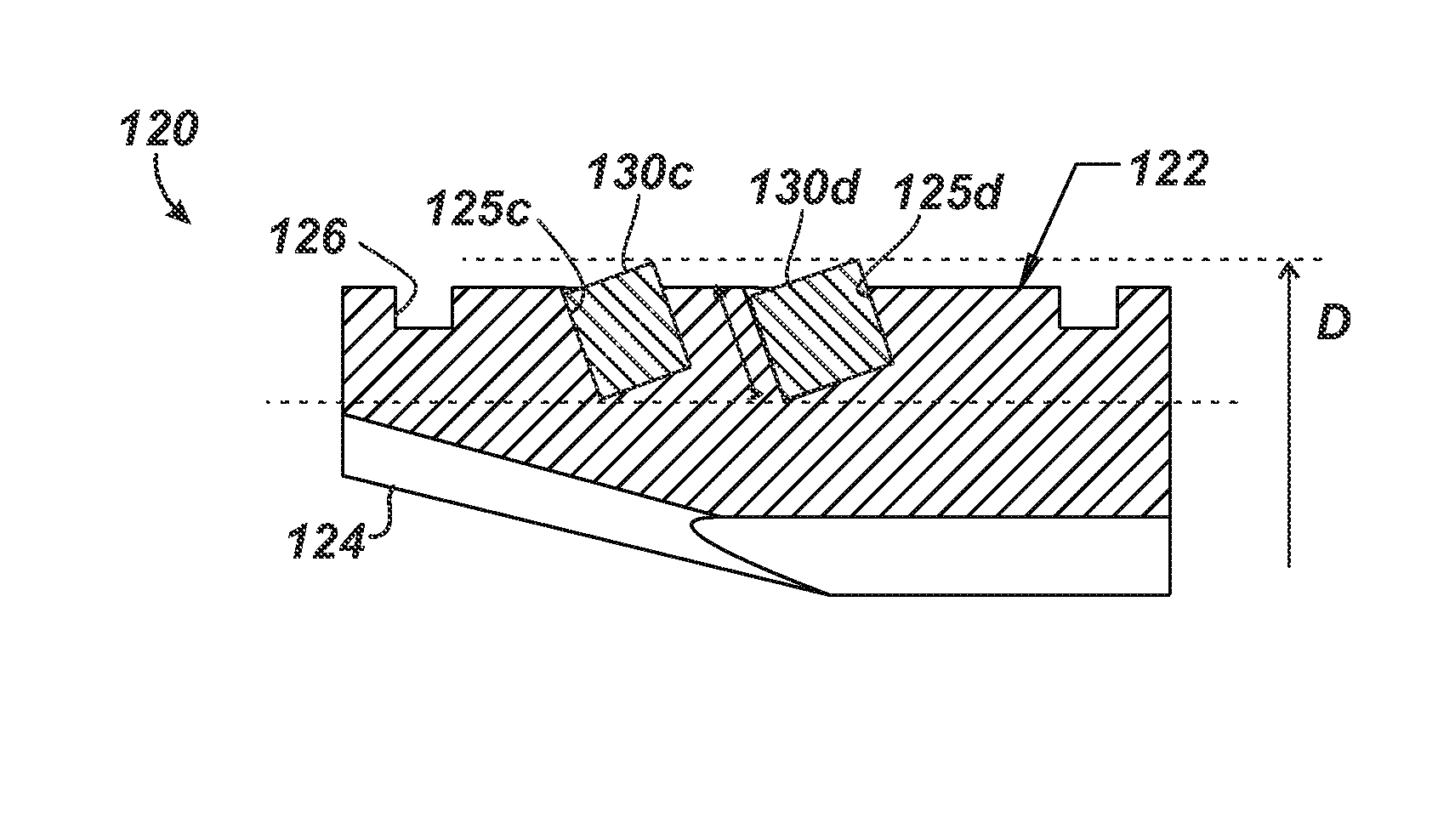

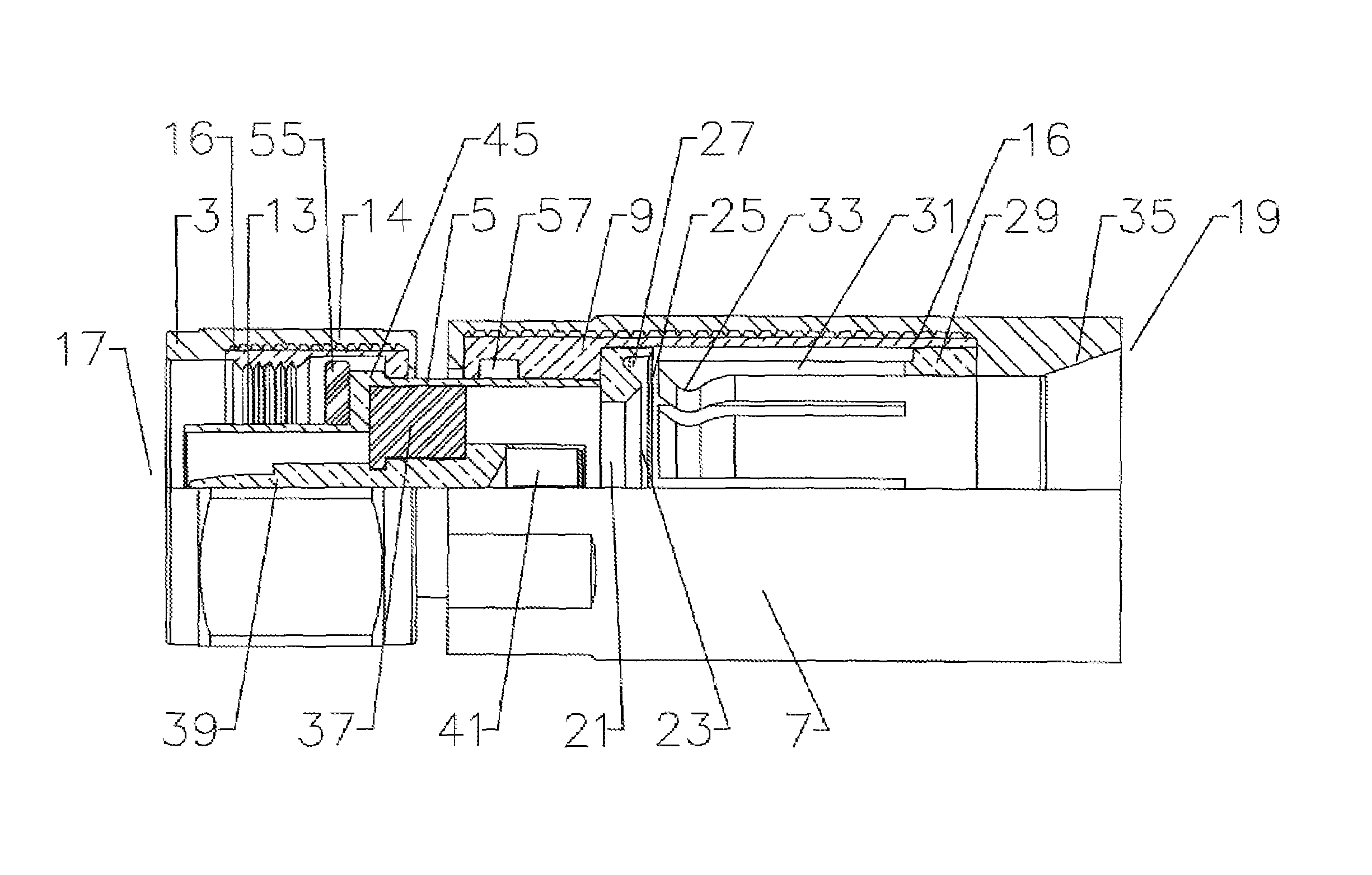

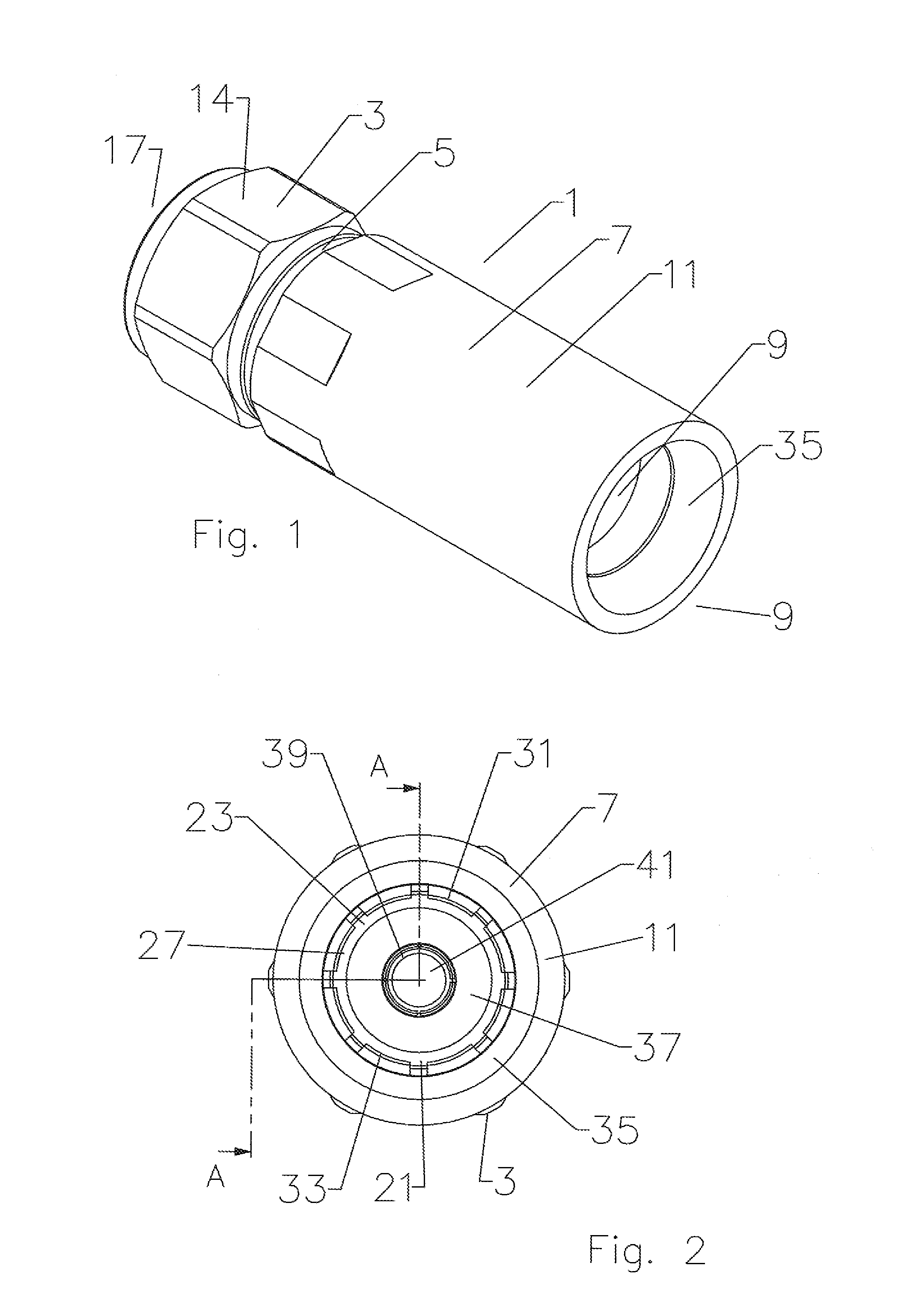

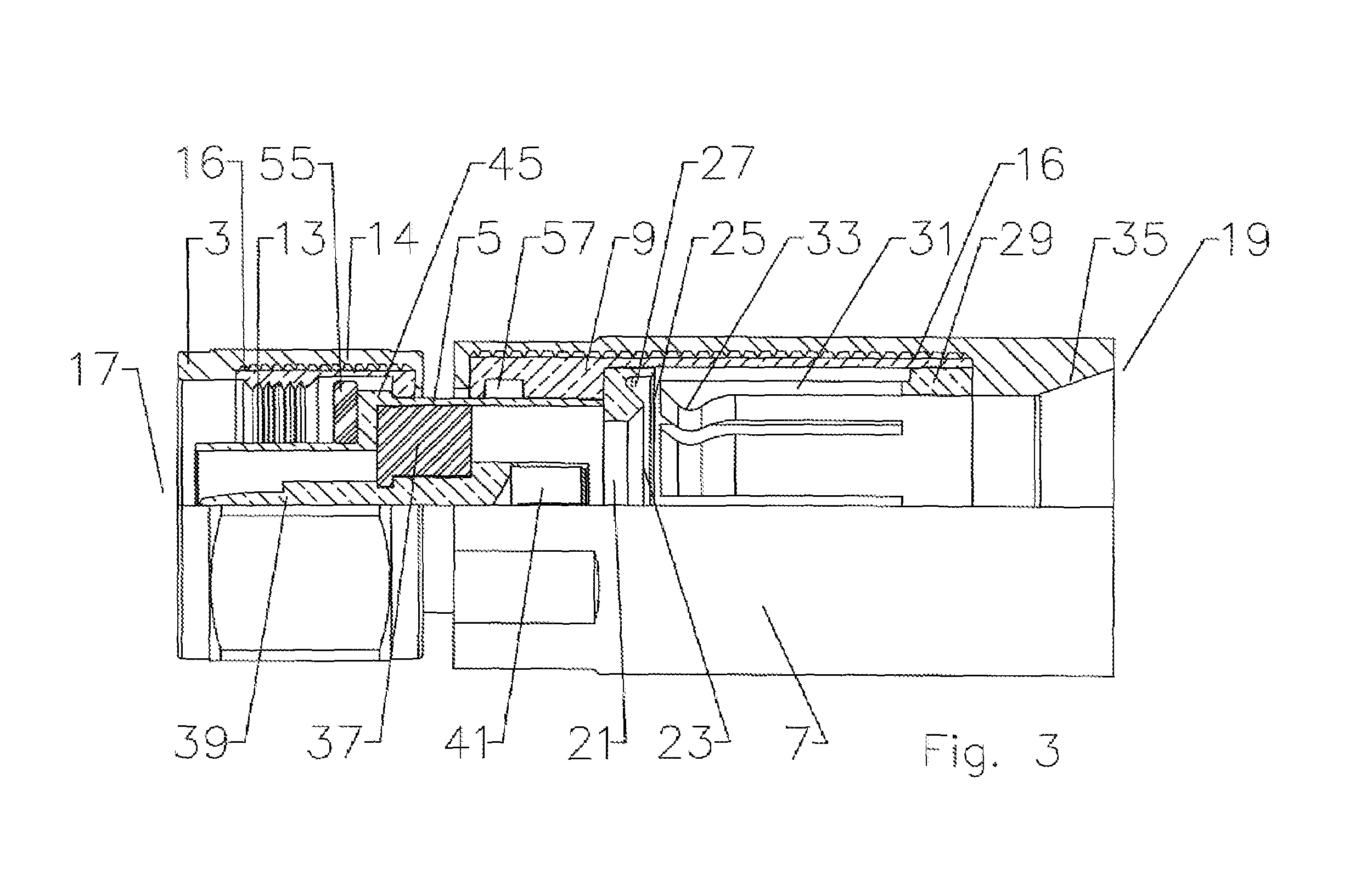

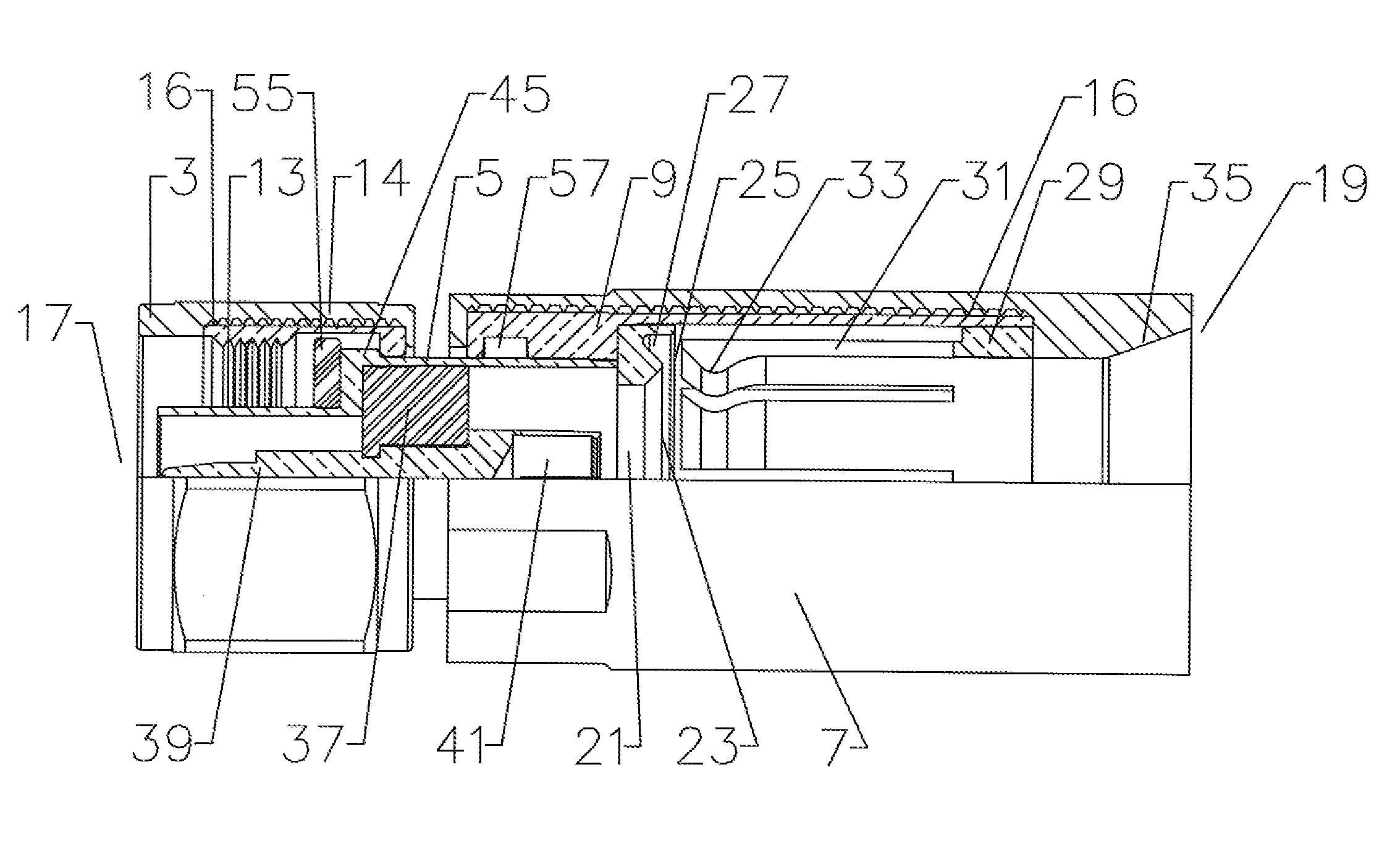

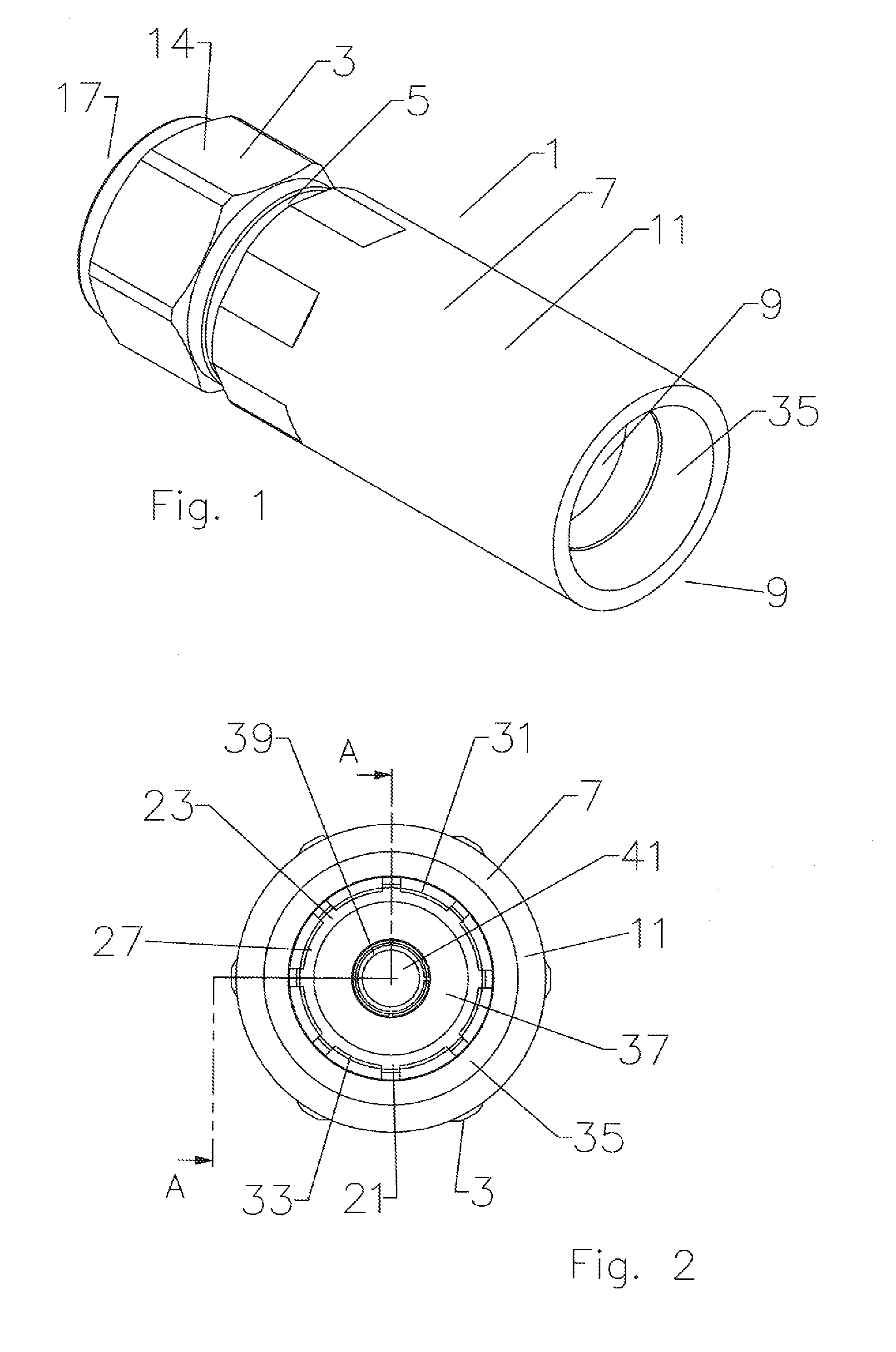

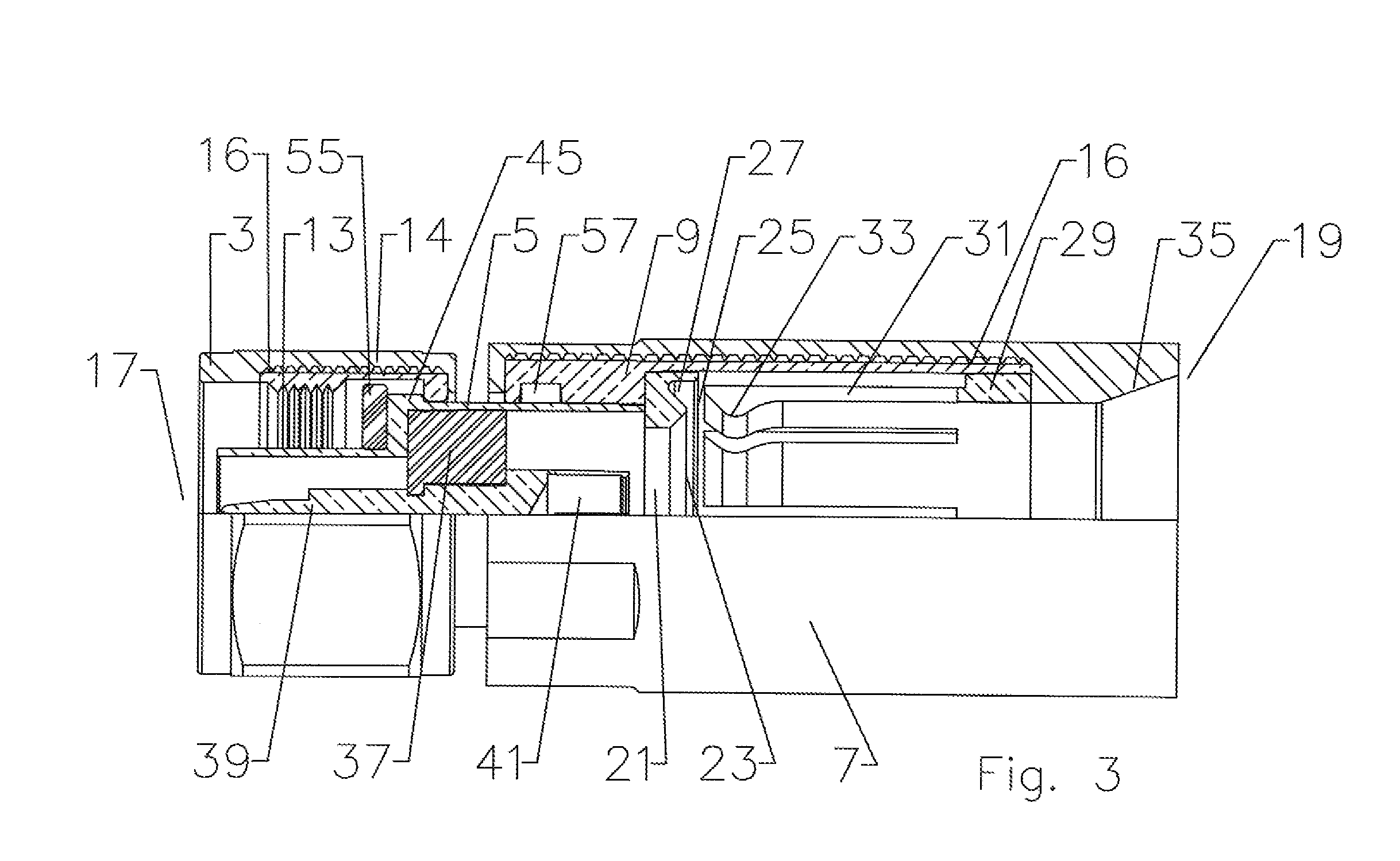

Axial compression electrical connector for annular corrugated coaxial cable

InactiveUS7275957B1Reduced material requirementsReduce weightElectrically conductive connectionsTwo pole connectionsInterference fitElectrical conductor

An electrical connector having a longitudinal axis with interface and cable ends for coaxial cable having an annular corrugated solid outer conductor. The connector having a body and an interface joined in an interference fit along the longitudinal axis of the connector. A spring finger ring within a bore of the body is rigidly connected to the body. The spring finger ring having a plurality of spring fingers extending towards an connector end; the spring fingers having an inward projecting bead at the connector end. The spring fingers positioned opposite an outer conductor groove open to the cable end, the outer conductor groove proximate the cable end of the interface.

Owner:ANDREW LLC

Insulator and high frequency connector

InactiveUS6030255ASimple processSmall in dielectric loss tangent dielectricElectrically conductive connectionsContact member cases/bases manufactureEngineeringStanding wave ratio

PCT No. PCT / JP96 / 00179 Sec. 371 Date Jul. 23, 1997 Sec. 102(e) Date Jul. 23, 1997 PCT Filed Jan. 31, 1996 PCT Pub. No. WO96 / 24177 PCT Pub. Date Aug. 8, 1996An insulator for high frequency connectors which comprises a thermoplastic norbornene resin and has a voltage and standing wave ratio of 1.89 or less even in the high frequency band of 2-3 GHz, and a high frequency connector using the insulator.

Owner:ZEON CORP

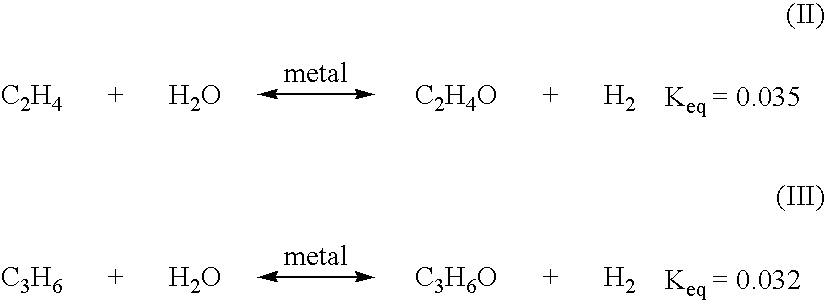

Downhole tool having slip inserts composed of different materials

ActiveUS9416617B2Reduce metal contentIncrease fluid pressureDrilling rodsSealing/packingMetallic materialsManganese

A downhole tool, such as a fracture plug used during a fracture operation, installs in a downhole tubular, such as casing. The tool has a mandrel with a sealing element disposed thereon between uphole and downhole ends. Slip assemblies on the mandrel can be moved to engage the downhole tubular. The uphole assembly has inserts composed of ceramic material, and the downhole assembly has inserts composed of a metallic material. When the tool is used as a bridge plug, the uphole assembly supports the sealing element compressed, and the downhole assembly supports fluid pressure downhole of the tool. In one particular embodiment, the metallic material is a powdered metal material, such as a sintered-hardened powdered metal steel having a balance of iron, an admixture of carbon, and alloy components of molybdenum, chromium, and manganese.

Owner:WEATHERFORD TECH HLDG LLC

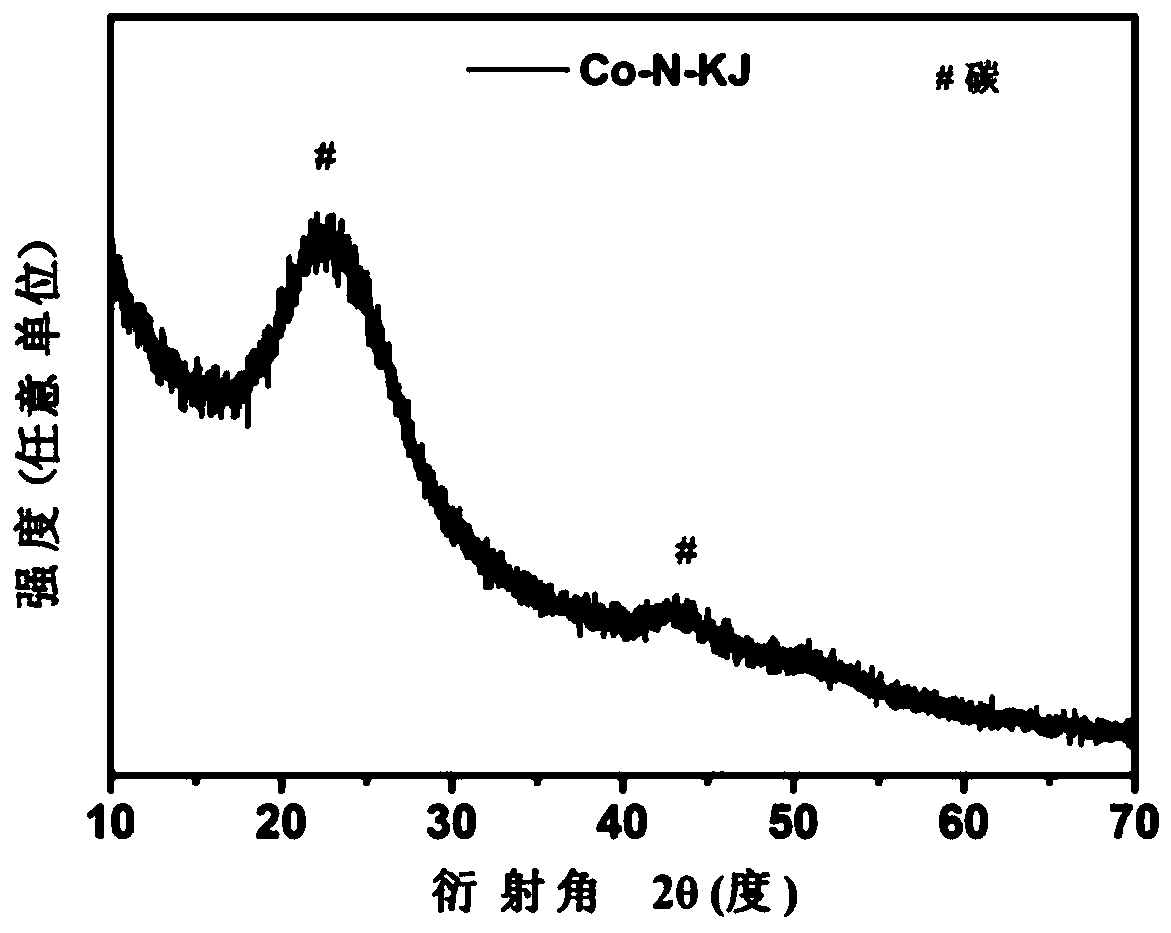

Non-noble metal catalyst used for catalytic oxygen reduction and preparation method thereof

ActiveCN108963276AImprove conductivityCapable of single-atom dispersionFuel and secondary cellsCell electrodesOxygenCalcination

The invention relates to a non-noble metal catalyst used for catalytic oxygen reduction and a preparation method thereof. The catalyst has the general formula of Me-N-C. By means of adsorption capability and range-limited calcination of the active carbon, non-noble metal atoms, Me and N which are dispersed to the atomic scale, are adsorbed and limited in the pores in the active carbon C, so that on the basis of high-electro-conductivity of the active carbon, a high-effective oxygen reduction catalyst having single-atom-dispersing capability can be obtained. The non-noble metal catalyst is lowin metal content, can be prepared at low cost and has very large specific surface area, wherein the Me and N are distributed in interior of pores in the active carbon, in a mono-atom dipsersed manner,instead of on the surface of the active carbon, so that excellent mass transfer capability and conductivity are achieved. The catalyst has excellent oxygen reduction catalytic activity, can be applied to preparation of MEA membrane electrodes and cathode catalytic reaction process of large-scale Zn-air batteries, Al-air batteries and fuel cell stacks. The invention provides the high-effective andstable catalyst for the MEA membrane electrode.

Owner:UNIV OF SCI & TECH OF CHINA

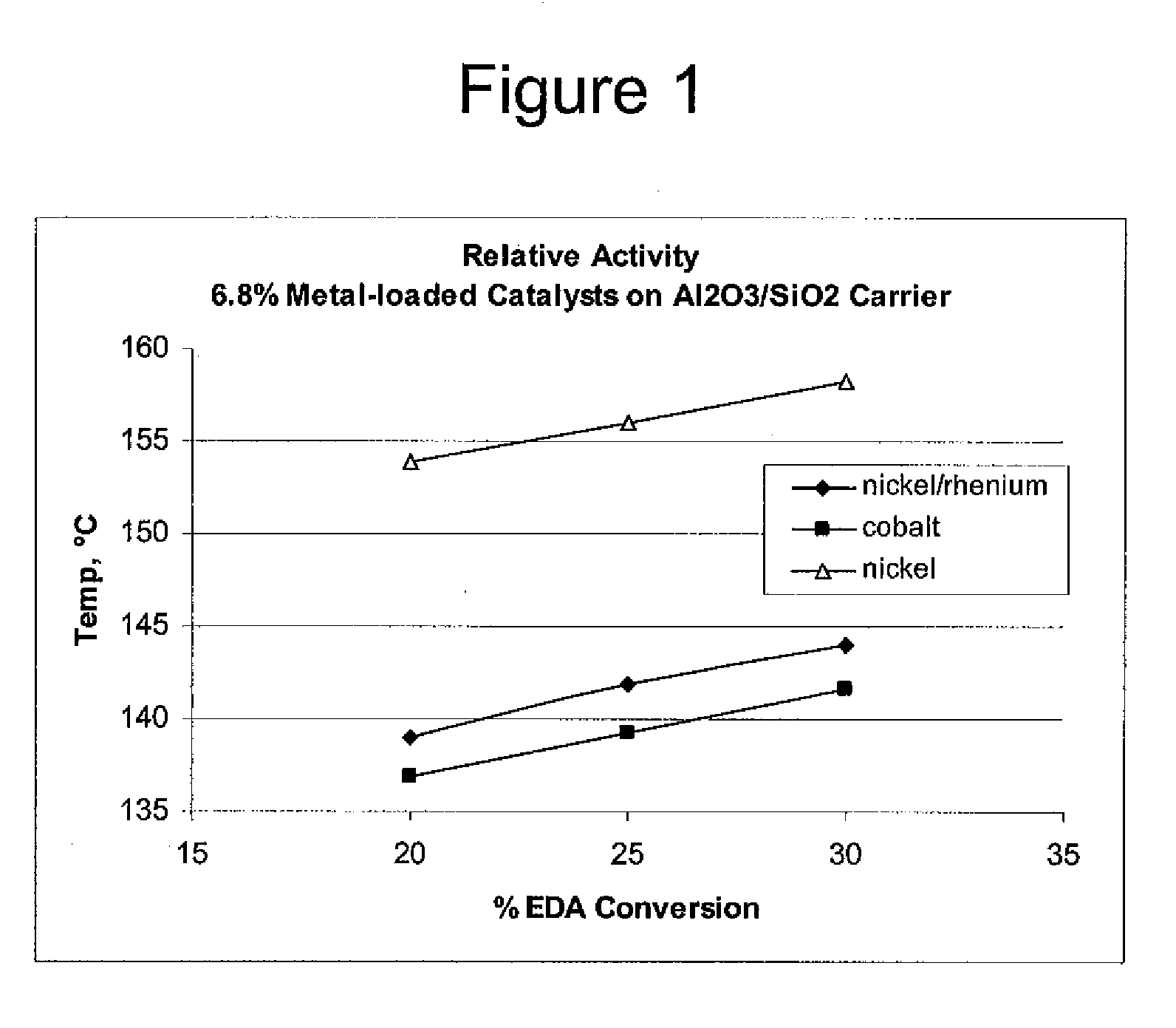

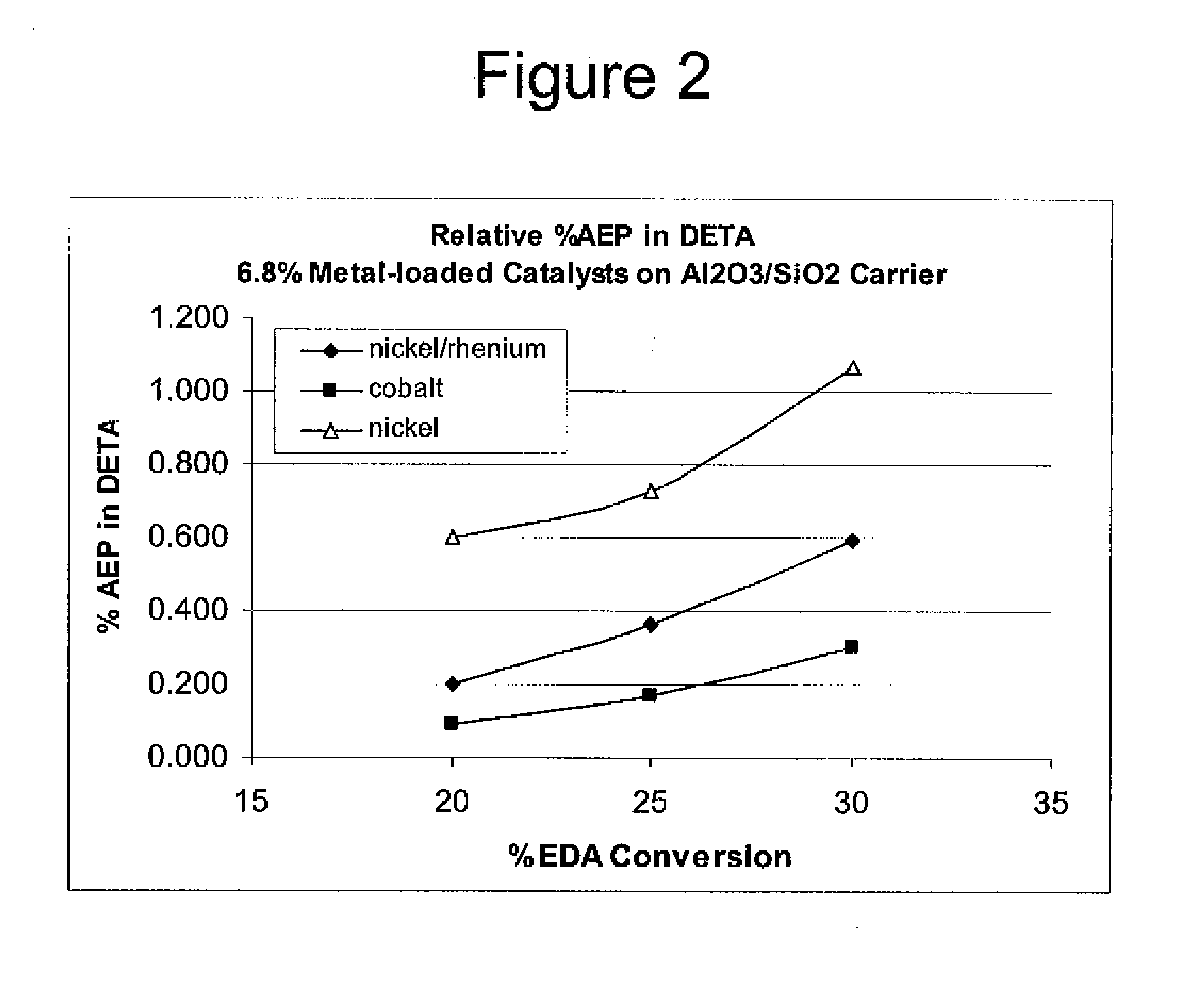

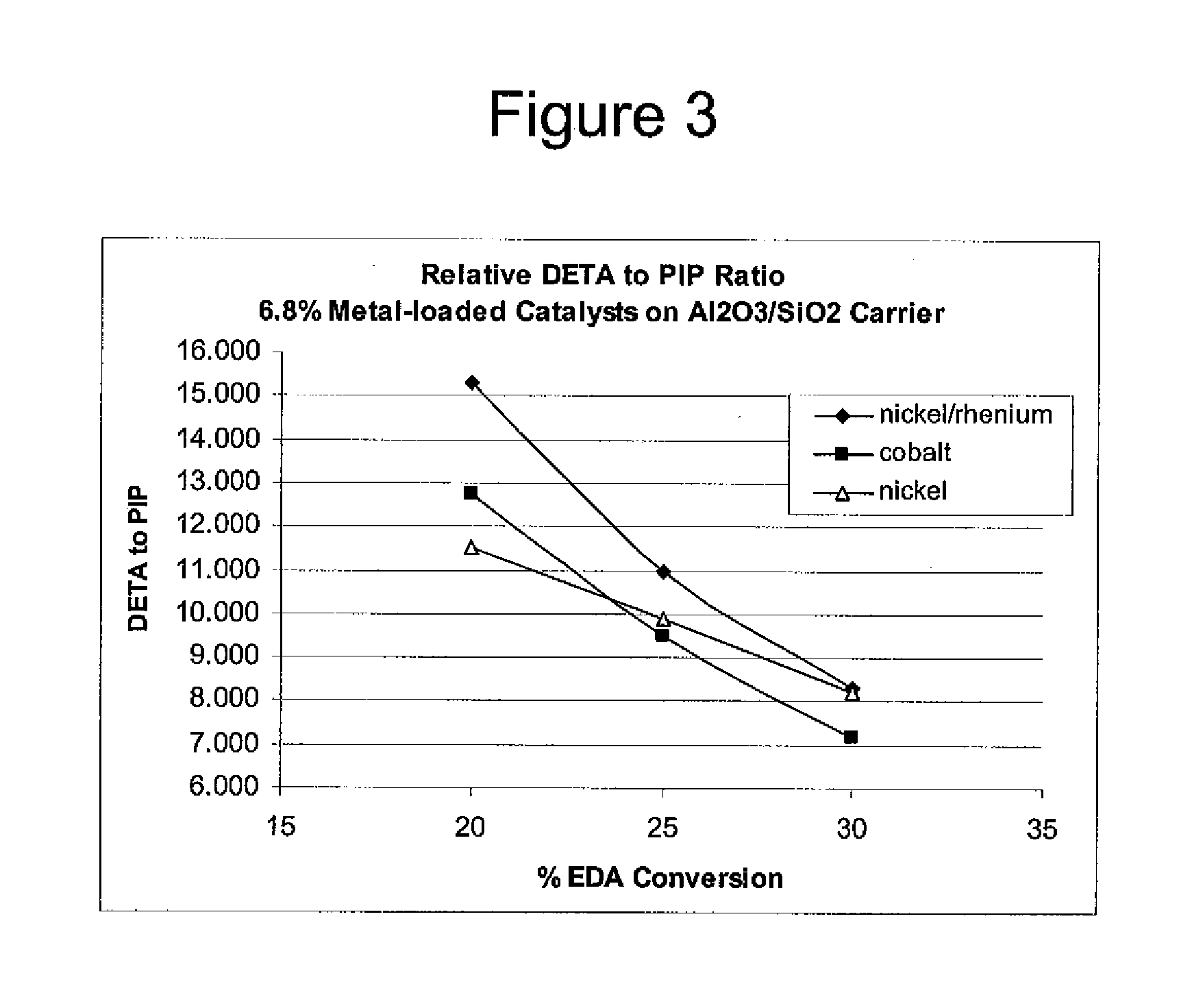

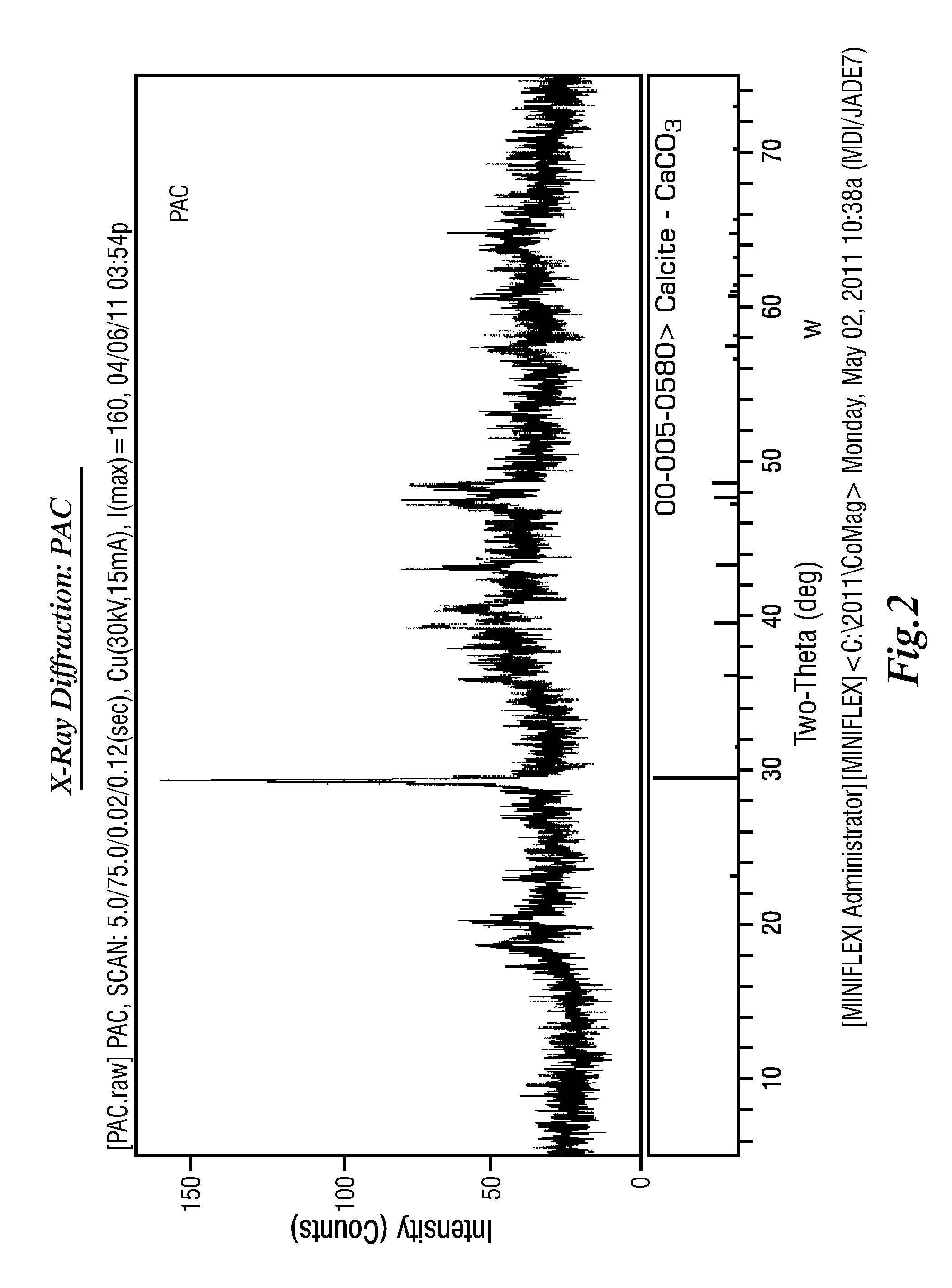

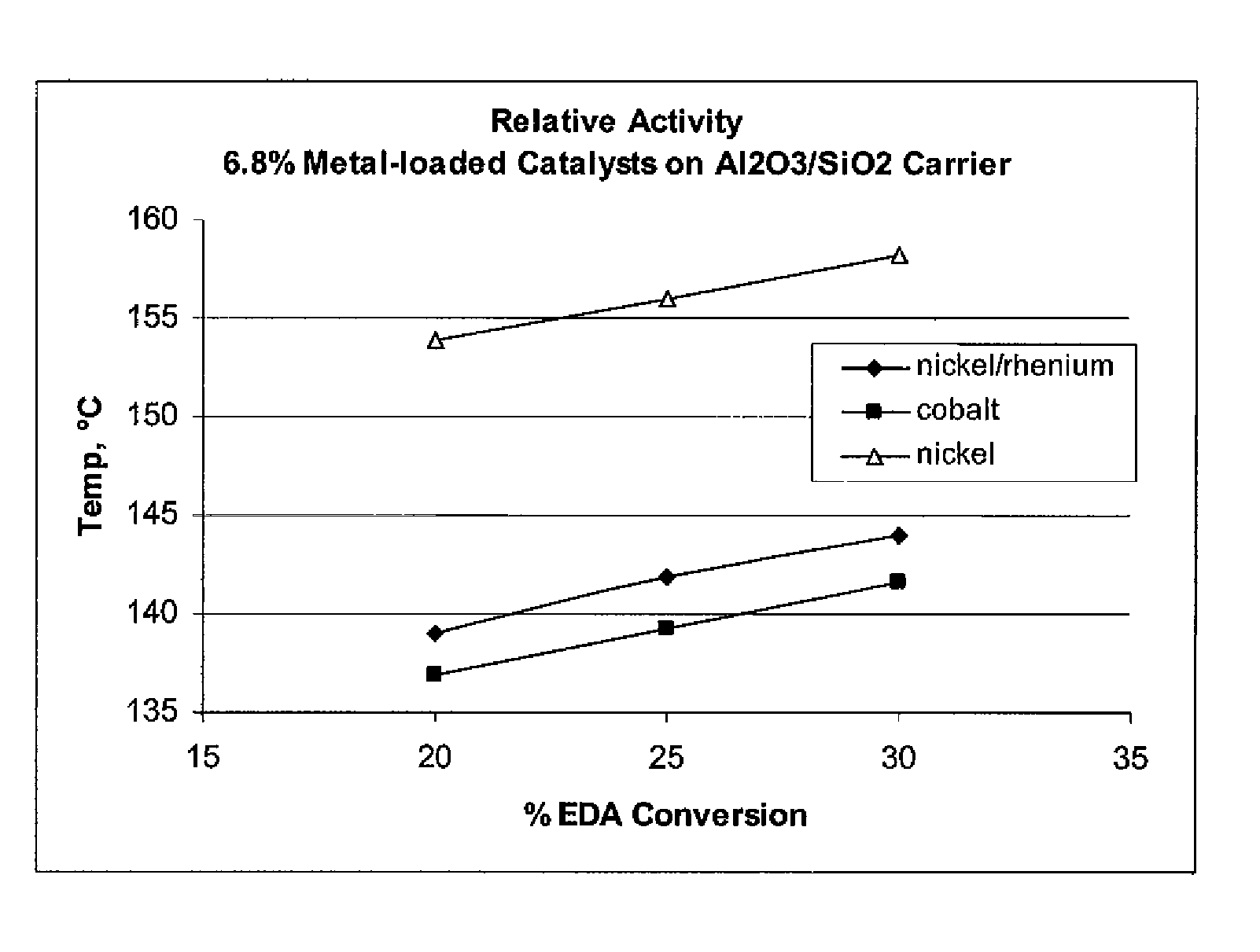

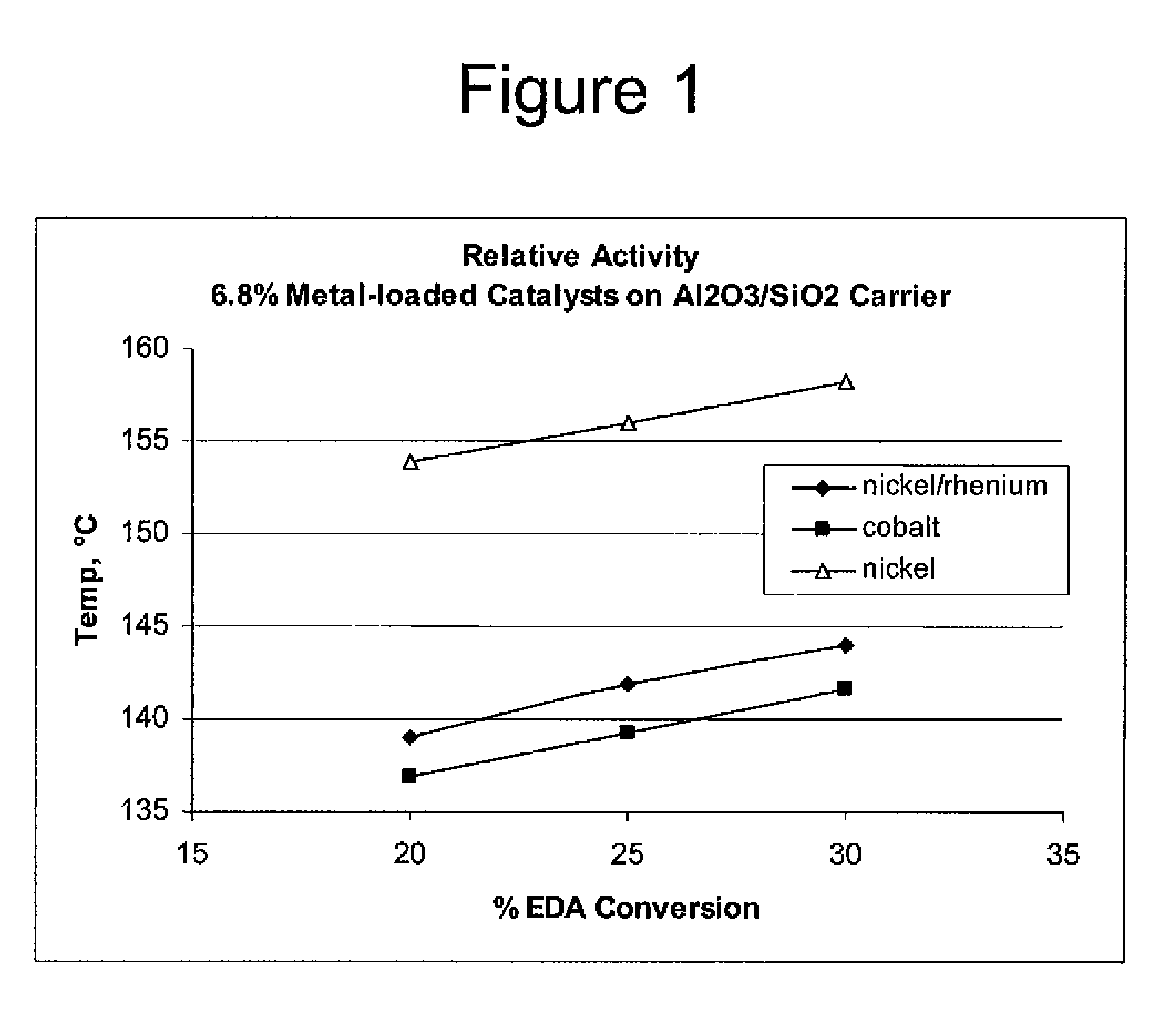

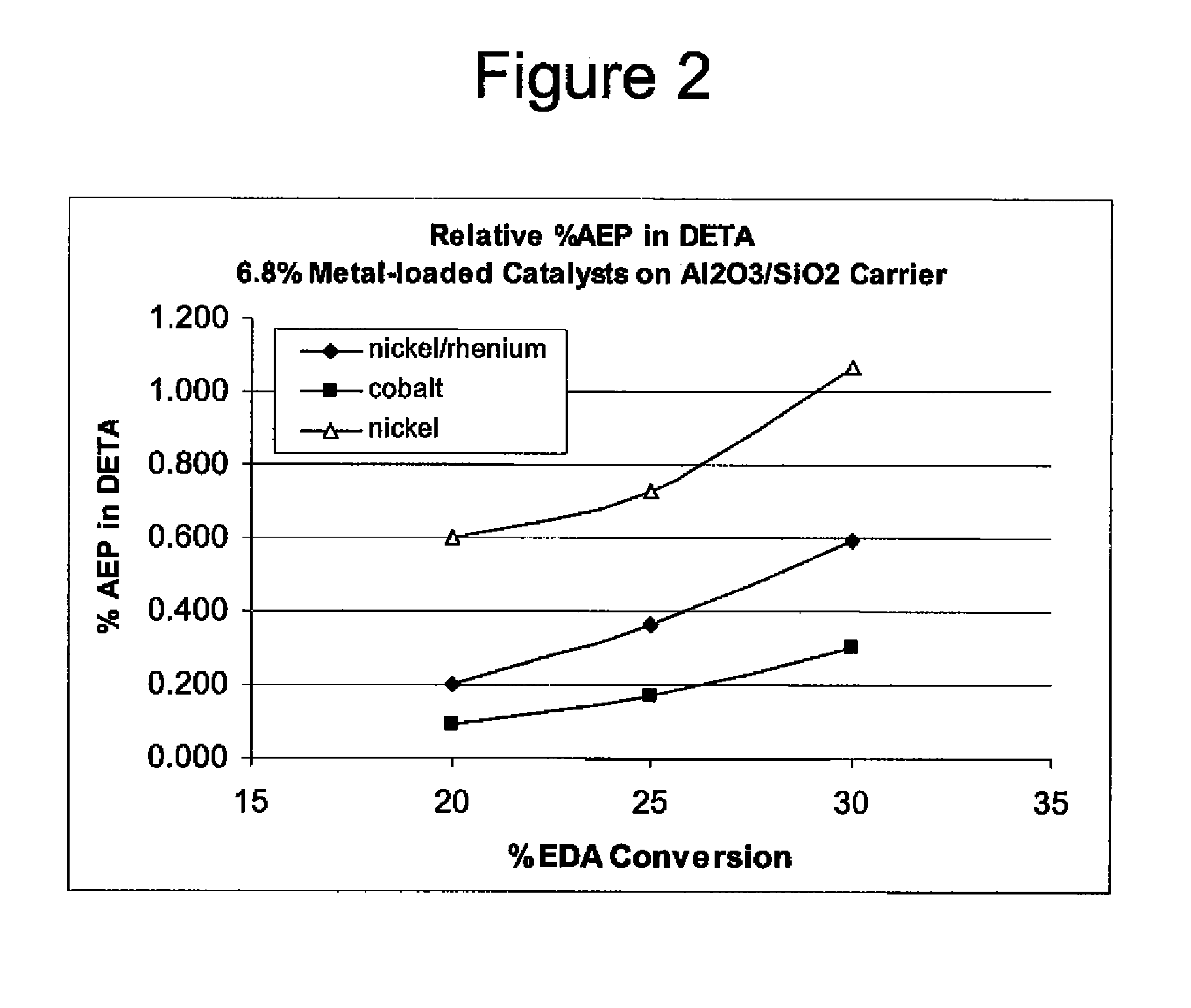

Low metal loaded, alumina supported, catalyst compositions and amination process

ActiveUS20100137642A1Good choiceMinimizingOther chemical processesOrganic compound preparationRheniumAmination

The present invention provides catalyst compositions useful for transamination reactions. The catalyst compositions have a catalyst support that includes transitional alumina, use a low metal loading (for example, less than 25 wt. %), and do not require the presence of rhenium. The catalyst compositions are able to advantageously promote transamination of a reactant product (such as the transamination of EDA to DETA) with excellent activity and selectivity, and similar to transaminations promoted using a precious metal-containing catalyst.

Owner:UNION CARBIDE CORP

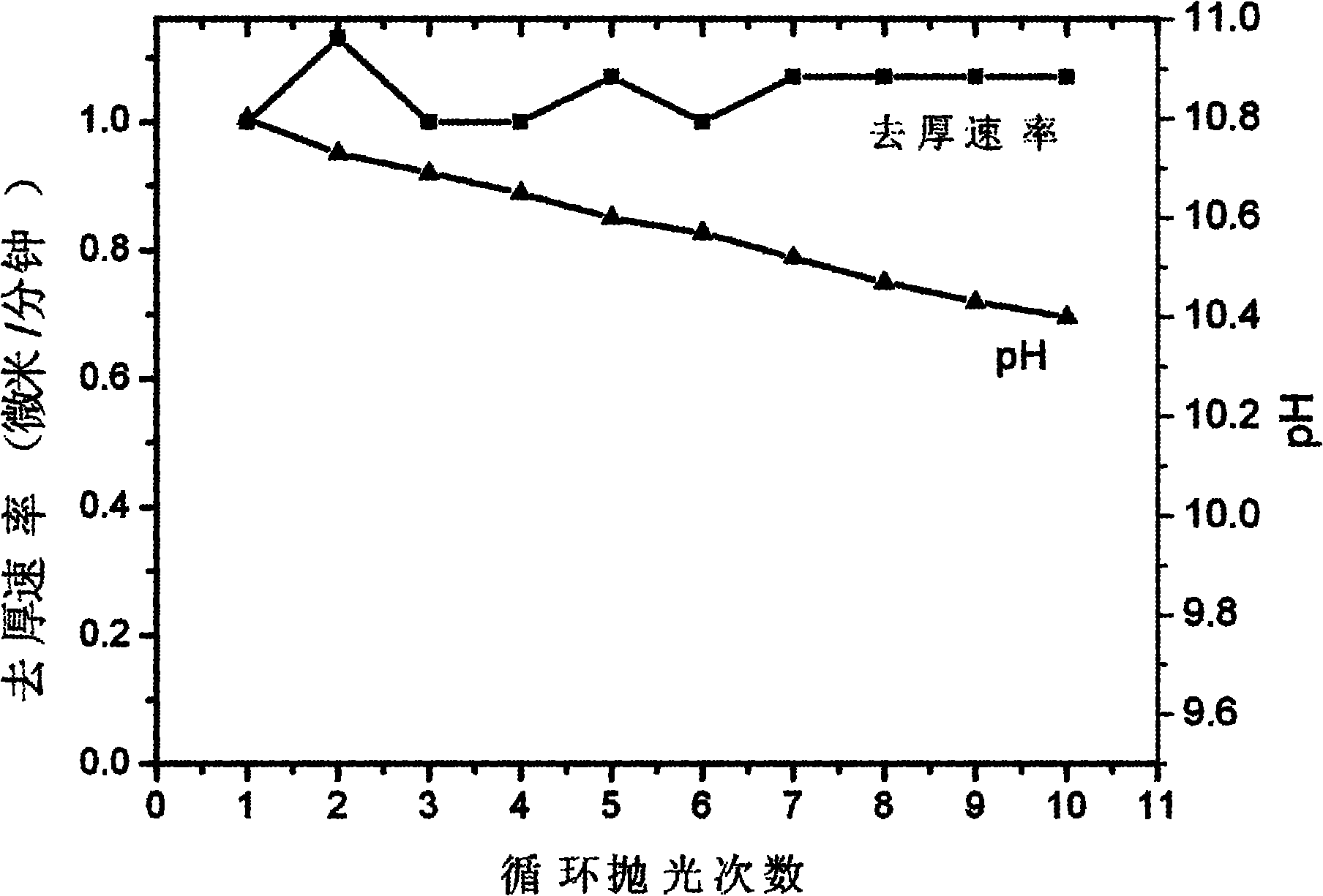

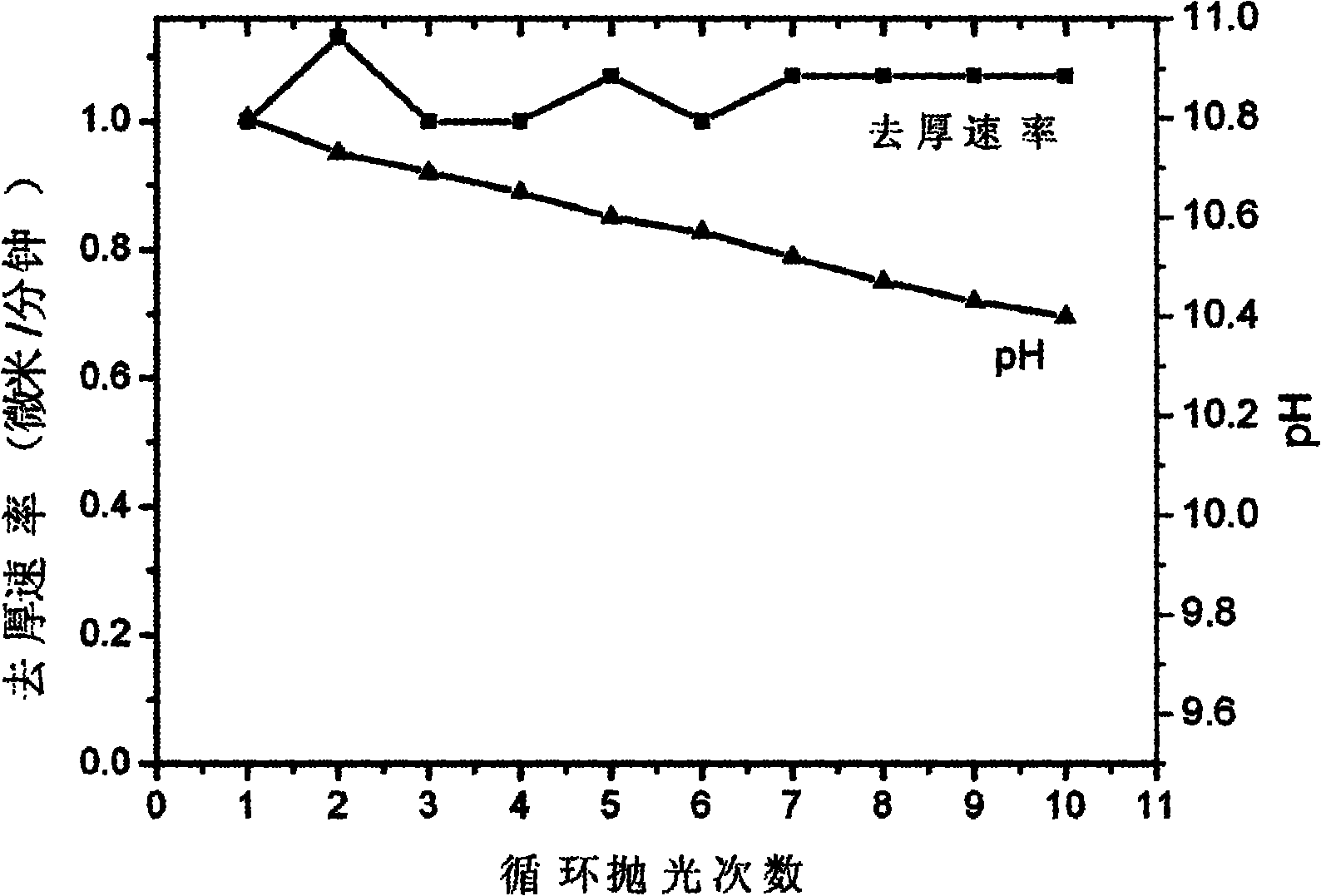

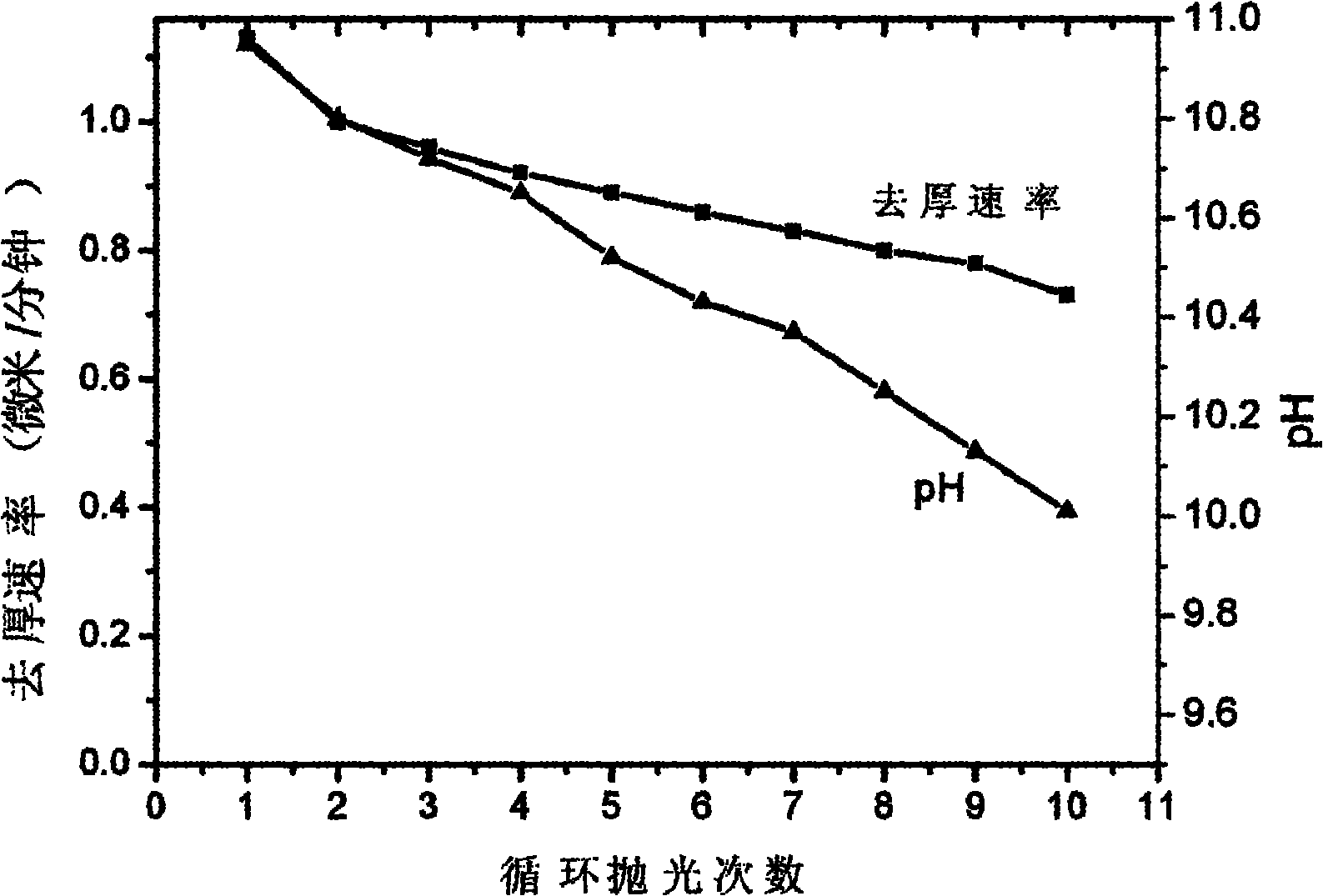

Silicon wafer chemical and mechanical polishing composition with high stability

InactiveCN102093820AWide applicabilityPracticalOther chemical processesPolishing compositions with abrasivesOrganic acidCompound (substance)

The invention discloses a silicon wafer chemical and mechanical polishing composition with high stability, belonging to the technical field of polishing compositions for roughlly polishing a semiconductor silicon substrate material. The polishing composition comprises the following components in percentage by weight: 0.5-50 percent of silicon dioxide abrasive particles, 0.01-10 percent of silicon-containing stabilizer, 0.01-20 percent of organic alkali corrosive, 0.01 -10 percent of organic acid chelating agent, 0.01-5.0 percent of other functional auxiliaries and the balance of deionized water. The polishing solution has a stabilization period of over 2 years, can perform repeated polishing or cyclic polishing, and has stable pH value and removal speed, wherein the number of cyclic polishing times can be up to 10. Meanwhile, the polishing composition has high silicon wafer removal rate up to over 1.0 mum / min, and the cyclic polishing removal rate in multiple times can be stable. The polishing solution is convenient to prepare and easy to use, has low cost, and is suitable for the rough polishing of silicon wafers of various types and sizes in the semiconductor industry.

Owner:TSINGHUA UNIV +2

Axial Compression Electrical Connector for Annular Corrugated Coaxial Cable

InactiveUS20070224880A1Reduced material requirementsReduce weightElectrically conductive connectionsTwo pole connectionsInterference fitCoaxial cable

An electrical connector having a longitudinal axis with interface and cable ends for coaxial cable having an annular corrugated solid outer conductor. The connector having a body and an interface joined in an interference fit along the longitudinal axis of the connector. A spring finger ring within a bore of the body is rigidly connected to the body. The spring finger ring having a plurality of spring fingers extending towards an connector end; the spring fingers having an inward projecting bead at the connector end. The spring fingers positioned opposite an outer conductor groove open to the cable end, the outer conductor groove proximate the cable end of the interface.

Owner:ANDREW LLC

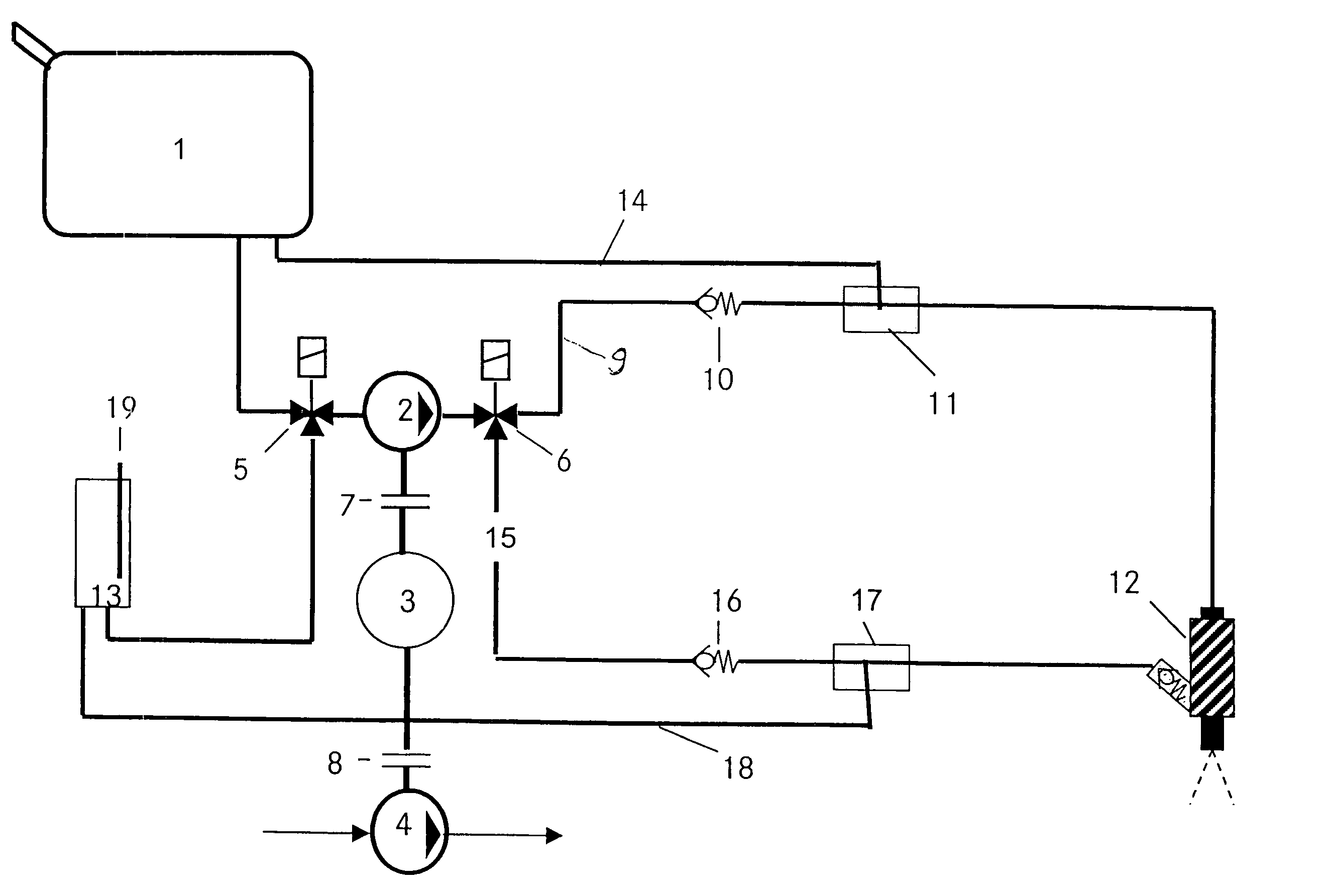

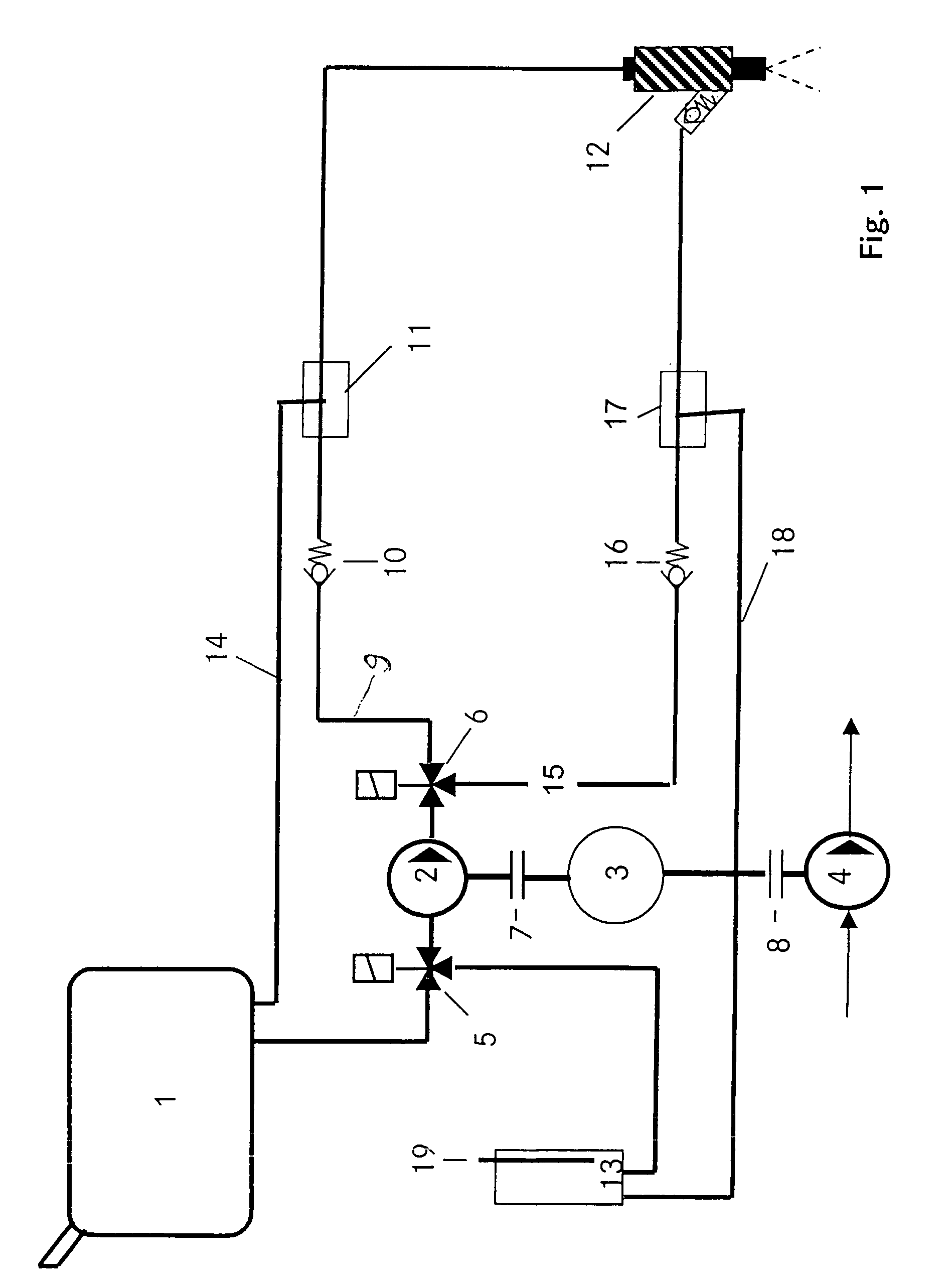

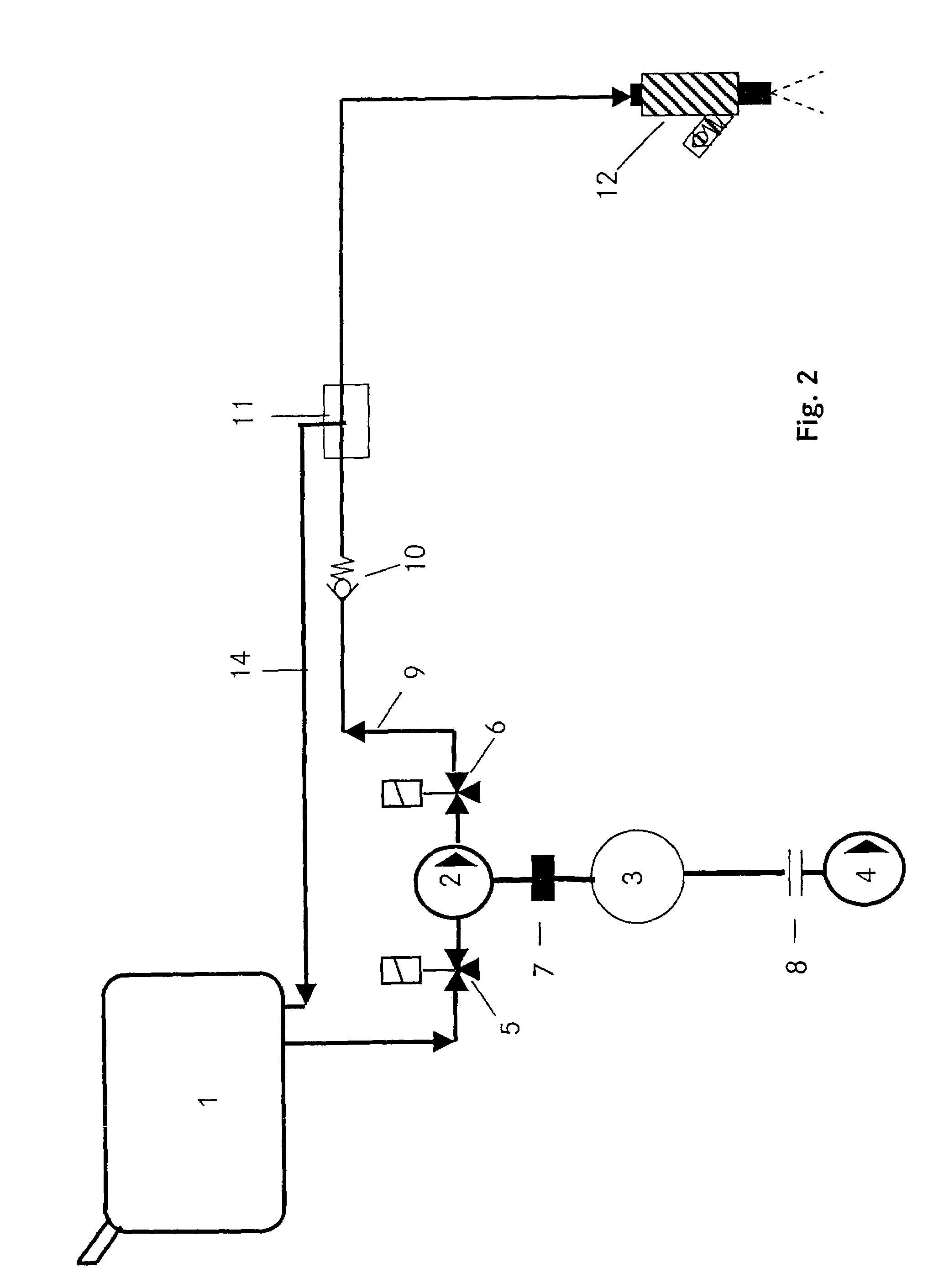

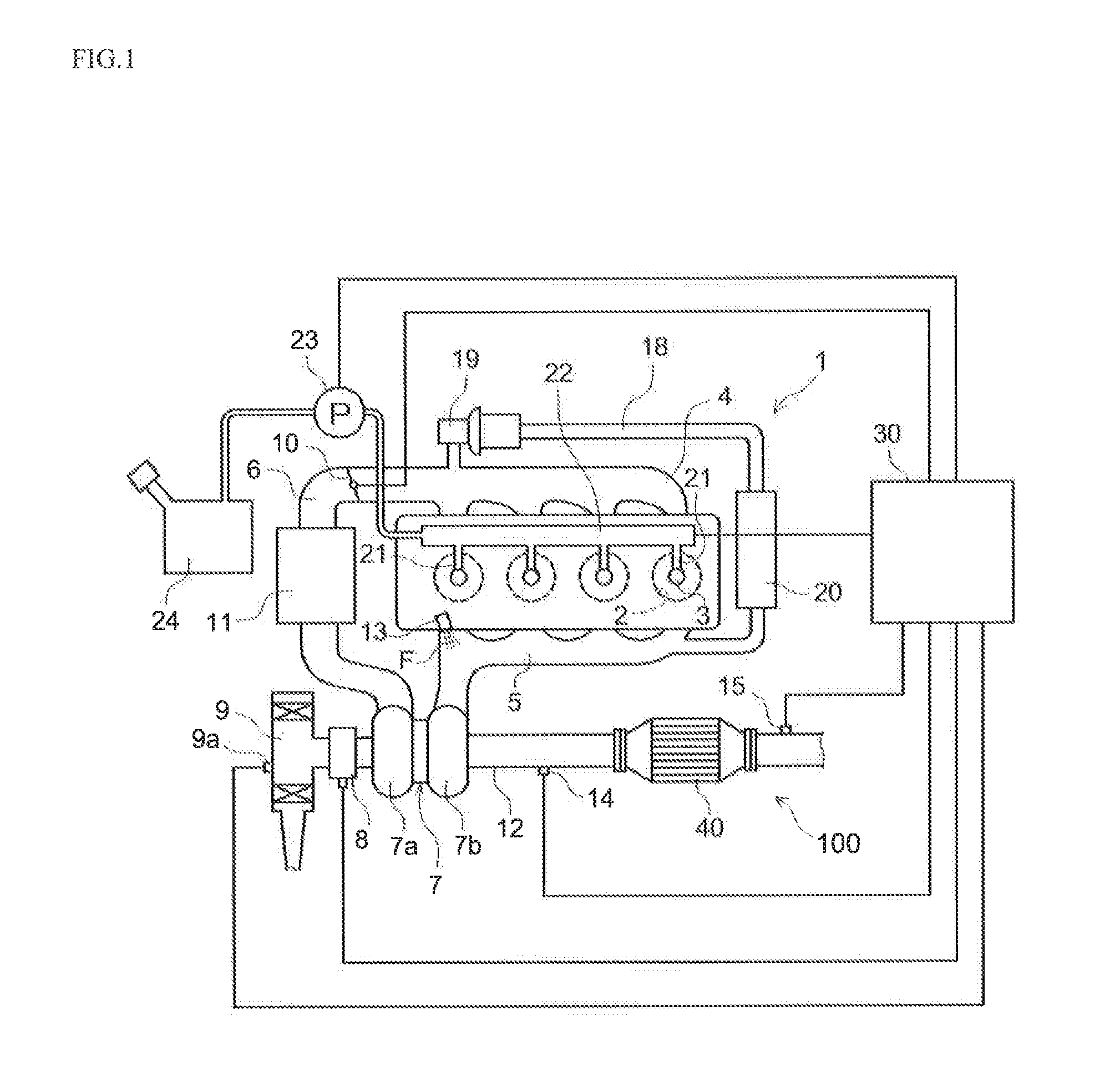

Fuel supply system for an internal combustion engine

InactiveUS7028672B2Reduce gas emissionsReduce metal contentInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringLiquid fuel

In a fuel supply system for an internal combustion engine having two separate storage containers for liquid fuels, both connected to a first controllable valve which is connected, via a connecting line including a fuel pump to an inlet of a second controllable valve having two outlets in communication by separate fuel lines with a fuel injection nozzle of the internal combustion engine, each of the two separate fuel lines includes a fuel pressure regulator, one being in communication with one and the other with the other of the two separate fuel storage containers for returning exess fuel to the fuel storage container from which fuel is being supplied to the fuel injection nozzle.

Owner:DAIMLER AG

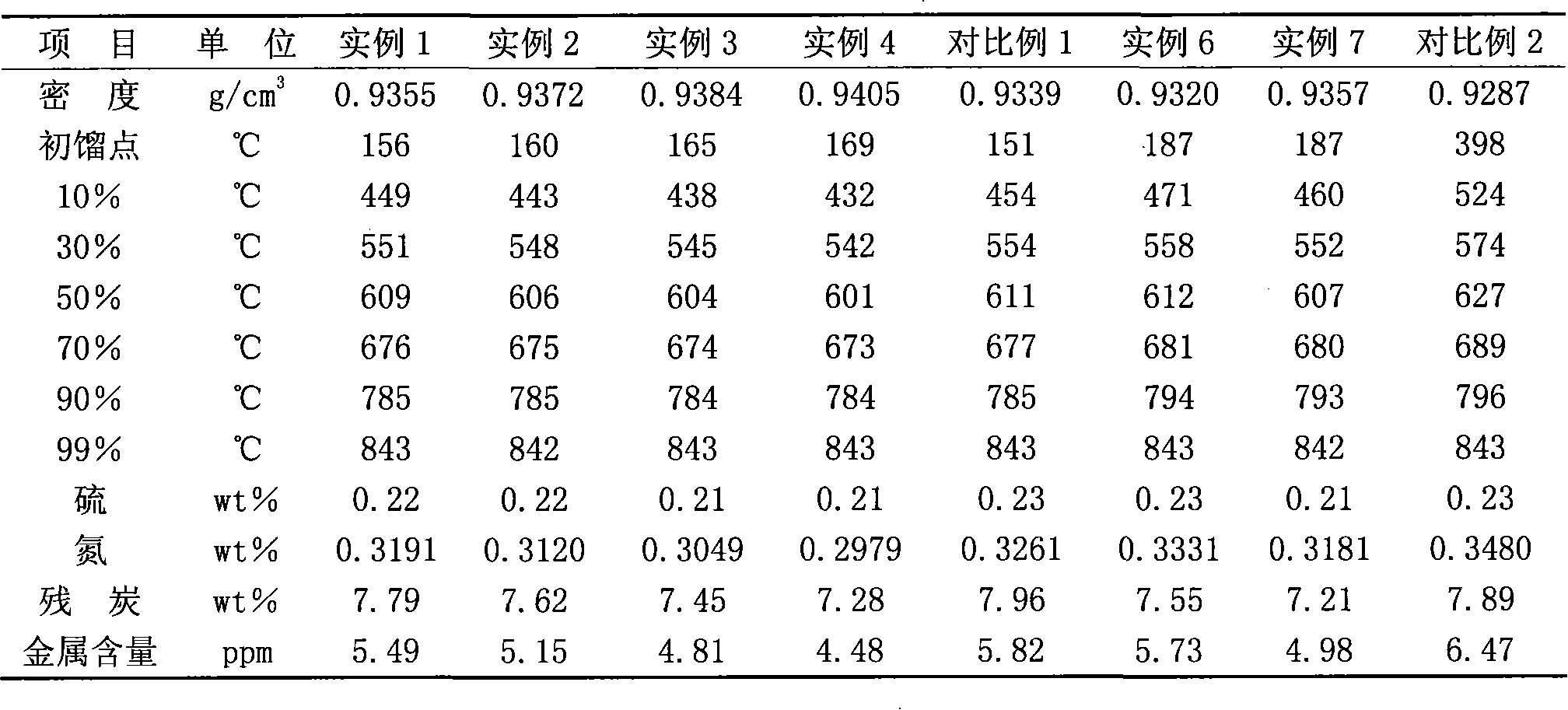

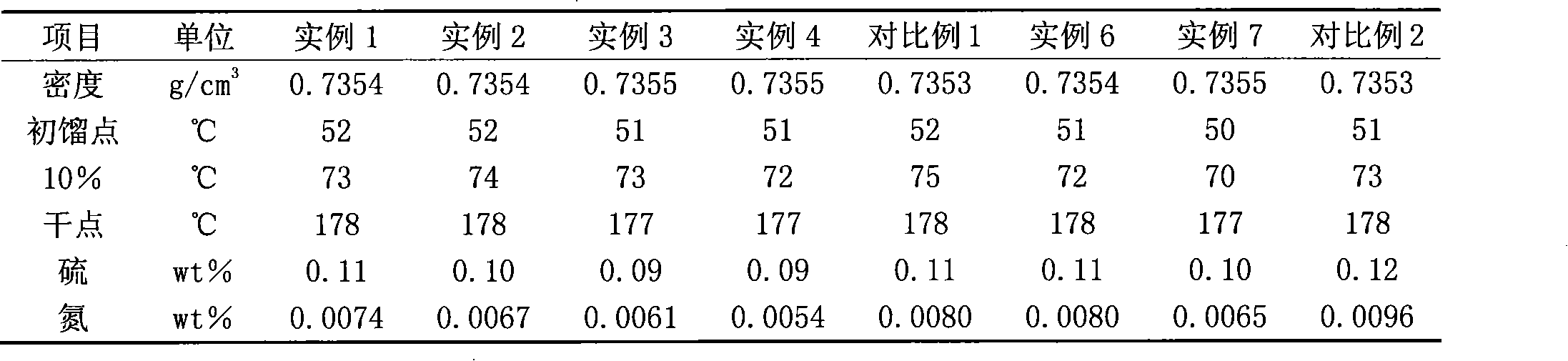

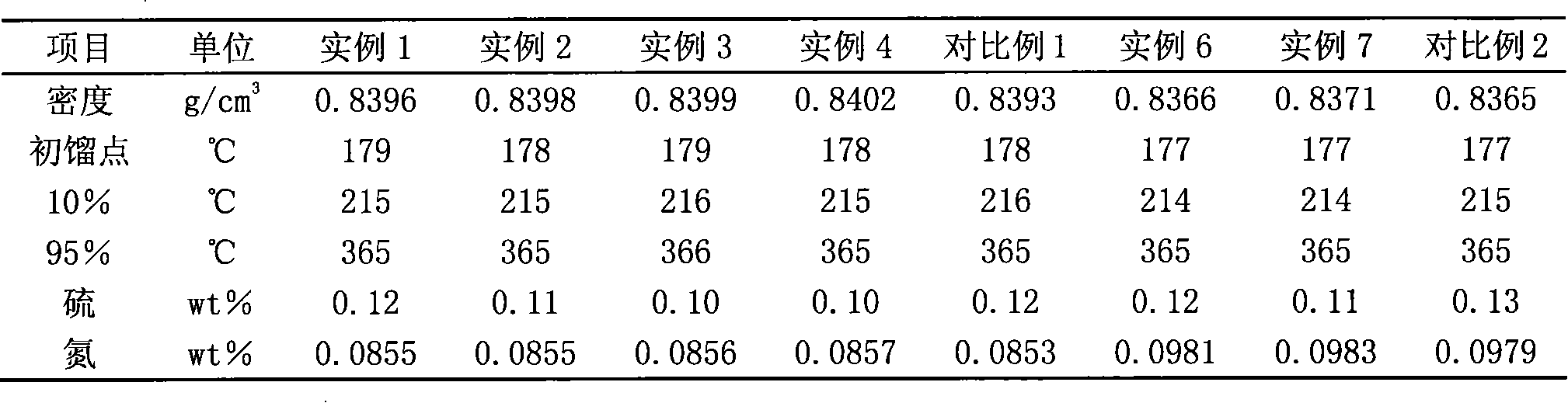

Delayed coking production method utilizing ethylene cracking tar as raw material

InactiveCN101608132AIncrease profitProcess operation impactThermal non-catalytic crackingKeroseneReaction temperature

The invention relates to a delayed coking production method utilizing ethylene cracking tar as a raw material. A delayed coking mixed raw material is formed by the ethylene cracking tar, vacuum residue and catalytic oil slurry according to the weight proportion of 1:1-100:0-10; a defoaming agent which accounts for 10 to 100 ppm of feeding weight is injected into the top of a coking tower; the feeding rate of a delayed coking device is between 1 and 10 kg / h; the temperature of a preheating section is between 360 and 380 DEG C; the reaction pressure of the top of the coking tower is between 0.1 and 0.3 MPa (meter); the reaction temperature is between 490 and 510 DEG C; and the recycle ratio is between 0.15 and 0.55. The method extends the source and variety of raw materials of delayed coking, ensures that the sulfur content and the nitrogen content of gasoline and kerosene produced by the delayed coking device are reduced, the sulfur content and the metal content of wax oil and coke are reduced, the yield is not affected, the yield of the coke is increased, and any adverse effect on the process operation of the delayed coking device cannot be produced.

Owner:PETROCHINA CO LTD

Dual zone aromatic alkylation process

ActiveUS20080171900A1High selectivityLow molar ratioMolecular sieve catalystsMolecular sieve catalystAlkyl transferAlkylation

A process for the catalytic alkylation of an aromatic substrate with an alkylating agent is disclosed that comprises contacting the aromatic substrate and the alkylating agent in sequential alkylation zones to obtain an alkylaromatic. The first catalyst comprises UZM-8 zeolite and the second catalyst comprises beta zeolite. The process is particularly well suited for the alkylation of benzene with propylene to produce cumene.

Owner:UOP LLC

Precious Metal Oxide Catalyst for Water Electrolysis

ActiveUS20070292744A1Low oxygen overvoltageReduce energy consumptionMachining electrodesCellsOvervoltageSolubility

The invention is directed to iridium oxide based catalysts for use as anode catalysts in PEM water electrolysis. The claimed composite catalyst materials comprise iridium oxide (IrO2) and optionally ruthenium oxide (RuO2) in combination with a high surface area inorganic oxide (for example TiO2, Al2O3, ZrO2 and mixtures thereof). The inorganic oxide has a BET surface area in the range of 50 to 400 m2 / g, a water solubility of lower than 0.15 g / l and is present in a quantity of less than 20 wt. % based on the total weight of the catalyst. The claimed catalyst materials are characterised by a low oxygen overvoltage and long lifetime in water electrolysis. The catalysts are used in electrodes, catalyst-coated membranes and membrane-electrode-assemblies for PEM electrolyzers as well as in regenerative fuel cells (RFC), sensors, and other electrochemical devices.

Owner:UMICORE AG & CO KG

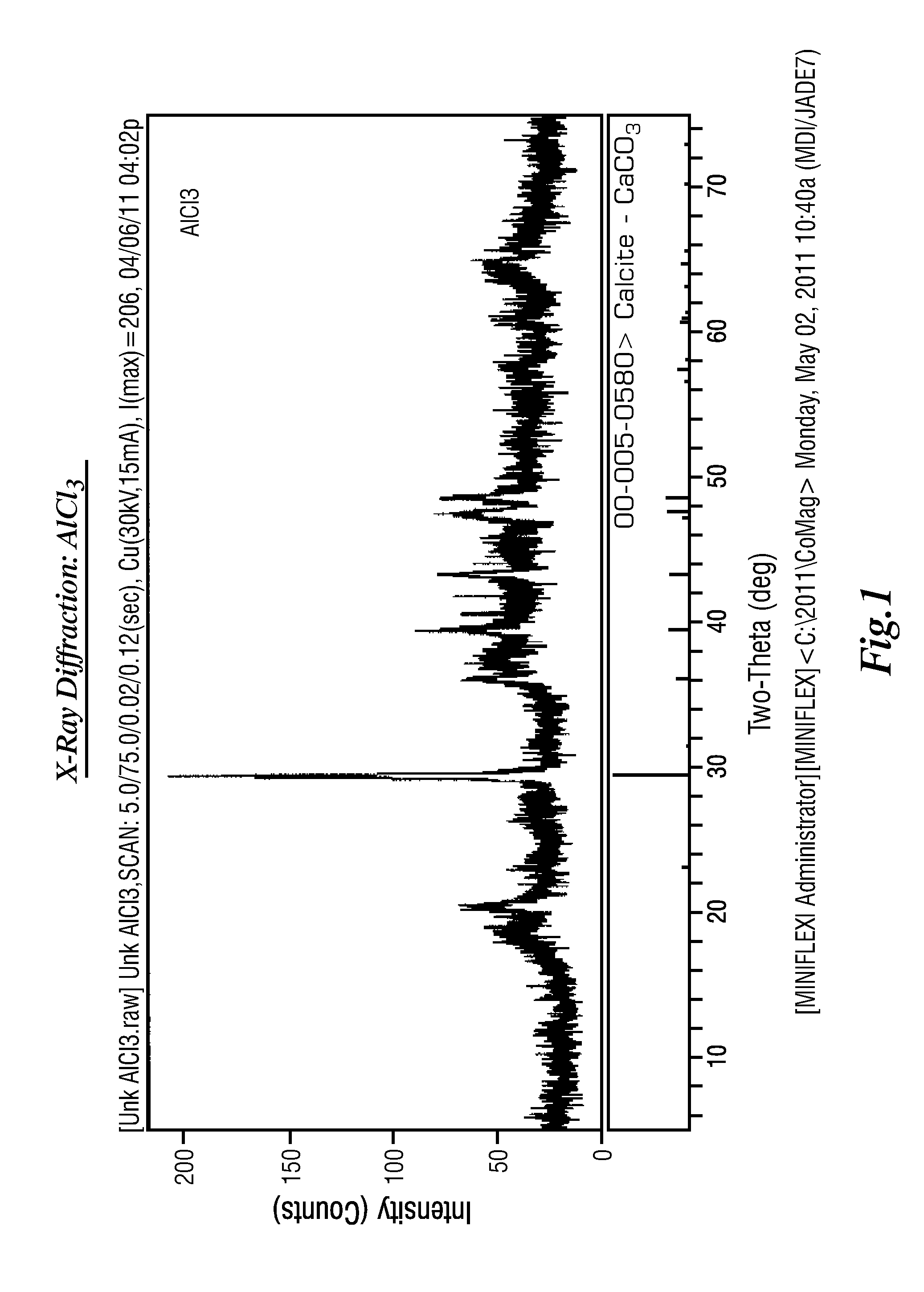

Extraction of Sulfate from Water

InactiveUS20120031850A1Reduce metal contentLess soluble in waterSedimentation separationRadioactive contaminantsAluminium chlorideAluminite

Sulfate anions and divalent metal ions, such as magnesium, strontium and barium, in water are removed by treating the water with polyaluminum chloride, usually together with lime, to form ettringite and similar crystalline species which are readily removable by settling, filtration and the like. Iron is also removed by oxidation in a variation of the process. The process is particularly useful for treating aqueous solutions used in well treatment, where flowback fluids can provide some of the divalent metal ions necessary to form the ettringite-like materials, thus reducing the amount of lime otherwise necessary and further facilitating recycling of the fluid.

Owner:SMART CHEM SERVICES LP

Low metal loaded, alumina supported, catalyst compositions and amination process

ActiveUS8293676B2Reduce metal contentRemarkable activityOrganic compound preparationOther chemical processesRheniumAmination

The present invention provides catalyst compositions useful for transamination reactions. The catalyst compositions have a catalyst support that includes transitional alumina, use a low metal loading (for example, less than 25 wt. %), and do not require the presence of rhenium. The catalyst compositions are able to advantageously promote transamination of a reactant product (such as the transamination of EDA to DETA) with excellent activity and selectivity, and similar to transaminations promoted using a precious metal-containing catalyst.

Owner:UNION CARBIDE CORP

Preparation method and application of chitosan and/or metal composite of chitosan derivative

InactiveCN101654529ASmall toxicityReduce metal contentOrganic active ingredientsAntimycoticsPolymer scienceRare earth metal compounds

The invention discloses a solid phase synthesis method and a liquid phase synthesis method of chitosan and / or zinc, silver, bismuth and rare earth metal composite of chitosan derivative. The solid phase synthesis comprises the following steps: (1) grinding chitosan and / or chitosan derivative to fine powder; (2) grinding the oxides of zinc and / or silver and / or bismuth and rare earth metal to fine powder of which content is 0.0005-2wt% of the weight of chitosan and / or chitosan derivative; (3) mixing the fine powders obtained in step (1) and step (2) and fully grinding for 1-6h to obtain the chitosan and / or metal composite of chitosan derivative. The product of the preparation method can be used to cure diseases such as female vaginitis, cervicitis, cervical erosion, bedsore, skin ulcer, fireburn, empyrosis, trauma, other dermatitis disease, tinea of feet and hands and the like and can be used to prepare various surgical dressings such as film, sponge, gynecological suppository, adhesivefilm and the like.

Owner:LIAOCHENG UNIV

Reformed oil olefine saturation hydrogenation method

InactiveCN1394937AHigh low temperature activityReduce metal contentRefining by selective hydrogenationChemistryNickel oxides

The reformate olefine saturation hydrogenation method includes the following steps: in the presence of one kind of catalyst making the reformate contact with hydrogen gas, its contact temp. is 200-320 deg.C, contact pressure is not less than 0.7 MPa, liquid hourly space velocity is 1-8 hr (-1), and volume ratio of hydrogen and oil is not less than 30. The described catalyst contains tungsten oxide and / or molybdenum oxide, nickel oxide and cobaltous oxide loaded on the alumina, the catalyst is used as reference, the content of the described tungsten oxide and / or molybdenum oxide is 4 wt% to less than 10 wt%, the content is nickel oxide is 1-5 wt%, the content of cobaltous oxide is 0.01-1 wt% and the ratio of total atomicity of nickel and cobalt and total atomicity of nickel, cobalt, tungsten and / or molybdenum is 0.3-0.9.

Owner:CHINA PETROLEUM & CHEM CORP +1

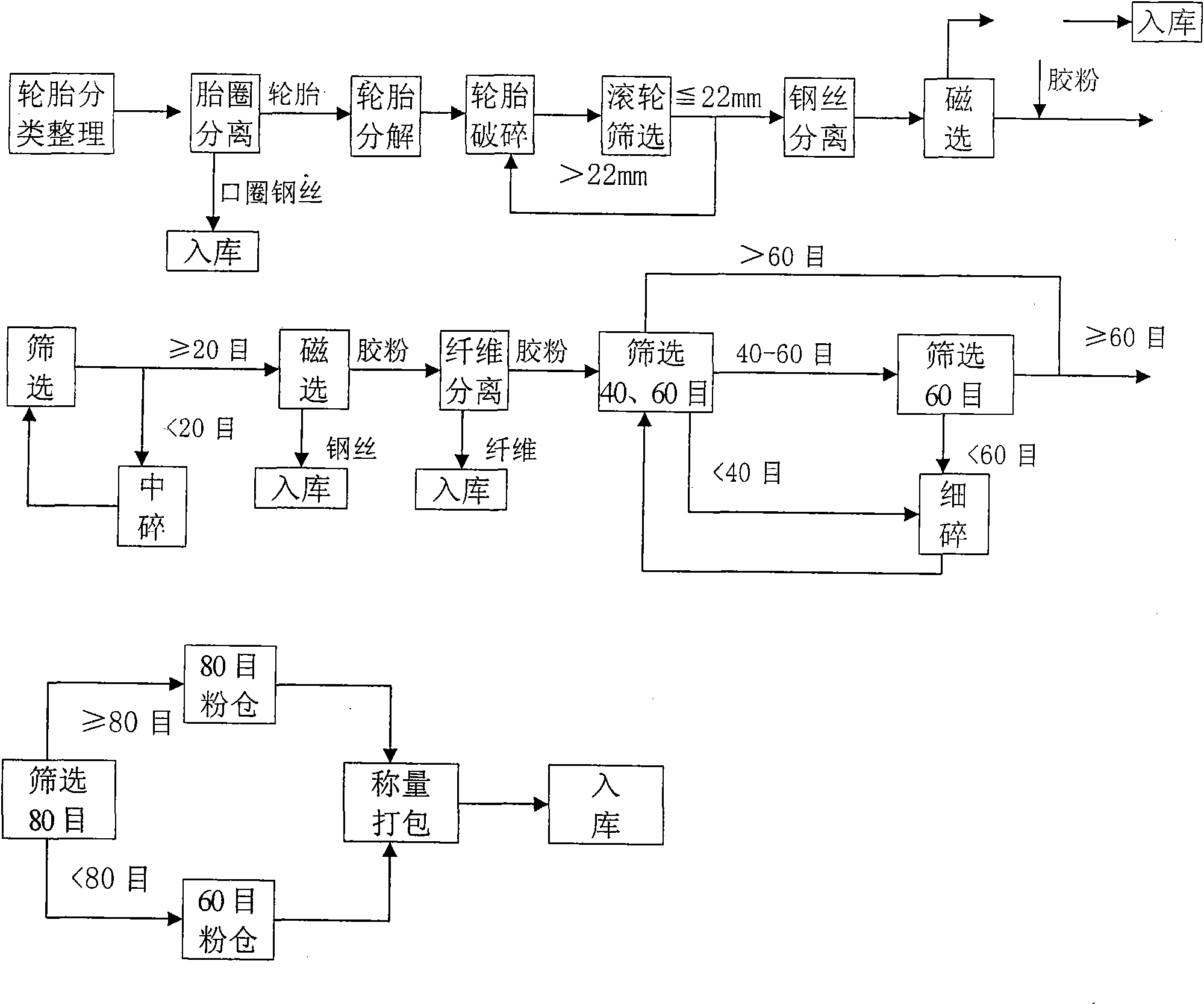

Method for producing gelatine powder under normal temperature by using waste tires

InactiveCN101670625ALow investment costLow production costSolid waste disposalPlastic recyclingTire beadRoom temperature

The invention discloses a method for producing gelatine powder under normal temperature by using waste tires, which relates to the technical field of producing gelatine powder under normal temperatureby using waste rubber products, and comprises the detailed steps of: a. separating a tire bead; b. crashing the tire; c. separating steel wires; d. magnetically separating for the first time; e. screening for the first time; f. magnetically separating for the second time; g. screening for the second time; and h. screening for the third time. The method has simple technique, is convenient for large-scale industrial production, and has lower investment and production cost; the grain diameter quality of the produced gelatine powder is stable; moreover, the method can produce the gelatine powderwith different grain diameter specifications, thus meeting the demands of different users.

Owner:SICHUAN LESHAN YALIAN MACHINE

Process for upgrading heavy and highly waxy crude oil without supply of hydrogen

ActiveUS20090145805A1Increase gravityReduce the amount requiredThermal non-catalytic crackingRefining by heating/coolingAlkaneHydrogen

A continuous process to upgrade heavy crude oil for producing more valuable crude feedstock having high API gravity, low asphaltene content, and high middle distillate yield, low sulfur content, low nitrogen content, and low metal co teat without external supply of hydrogen and / or catalyst. Heavy crude oil having substantial amount of asphaltene and heavy components is mixed with highly waxy crude oil having large amount of paraffinic components and water to decompose asphaltene compounds and remove sulfur, nitrogen, and metal containing substances under supercritical conditions. Product has higher API gravity, lower asphaltene content, high middle distillate yield, lower sulfur content, lower nitrogen content, and lower metal content to be suitable for conventional petroleum refining process.

Owner:SAUDI ARABIAN OIL CO

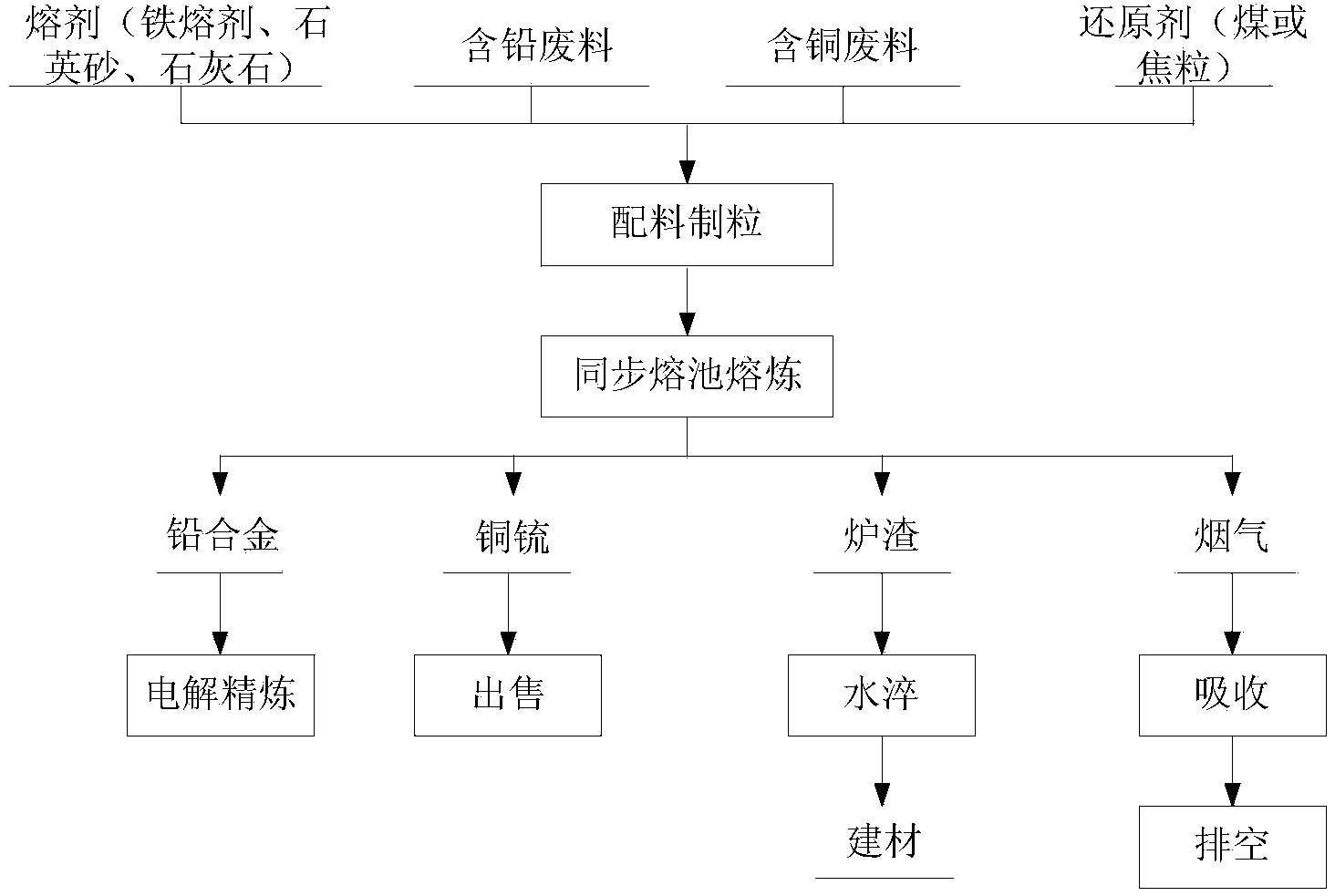

Method for smelting lead-containing waste and copper-containing waste synchronously in molten pool

ActiveCN103667712ASimple and efficient processLow metal content in slagProcess efficiency improvementScrapCopper

This invention provides a method for smelting lead-containing waste and copper-containing waste synchronously in a molten pool. The method comprises the following steps: (1) mixing the lead-containing waste, the copper-containing waste, one or more fluxes and carbon-containing reducing agents and then pelletizing, wherein the ratio of the lead-containing waste and copper-containing waste is controlled to achieve the effect that the mass ratio of (Cu+Fe):S is (1.75-4):1; (2) adding the mixture to the smelting equipment (i.e. the molten pool), wherein the mass ratio of water-quenched slag to the furnace burden (i.e. the mixture) is (0.7-5):1, and the smelting temperature is 1050-1250 DEG C; (3) keeping the smelting temperature for 30-180 min for separating and clarifying lead alloy, copper matte and smelting slag. According to the invention, the method can be used for treating the lead-containing waste and the copper-containing waste synchronously; the process is efficient and simple; the direct recovery rates of lead and copper can reach above 75% respectively; the metal content of the generated slag is low, and the slag can be used as a building raw material; the extraction and separation of lead, copper and other elements in the wastes can be realized through one step; the lead is concentrated in the lead alloy, and the copper is concentrated in the copper matte; the product additional value is high; the subsequent processing is simple.

Owner:CENT SOUTH UNIV

Inserts Having Geometrically Separate Materials for Slips on Downhole Tool

ActiveUS20150368994A1Reduce metal contentEasy millingFluid removalSealing/packingEngineeringFluid pressure

A downhole tool, such as a fracture plug used during a fracture operation, installs in a downhole tubular, such as casing. The tool has a mandrel with a sealing element disposed thereon between uphole and downhole ends. Slip assemblies on the mandrel can be moved to engage the downhole tubular. When the tool is used as a bridge plug, the uphole assembly supports the sealing element compressed, and the downhole assembly supports fluid pressure downhole of the tool. The slip assemblies have inserts composed of at least two materials that are different from one another and are geometrically separate from one another. In addition or as an alternative, the slip assemblies can be composed of at least two different materials that are geometrically separate from one another.

Owner:WEATHERFORD TECH HLDG LLC

Method for synthesizing decalin

InactiveCN101602644AReduce metal contentImprove conversion rateHydrocarbon by hydrogenationCatalyst activation/preparationReaction temperatureActive phase

The invention provides a method for synthesizing decalin, and relates to a method for synthesizing a compound. The invention provides the method for synthesizing the decalin from naphthalene in one step by using a load type catalyst taking nano metal with low content and small size as an active phase and under the conditions of low reaction temperature and pressure. The method comprises the following steps of: mixing the naphthalene and cyclohexane, and placing the mixture in a high pressure autoclave; adding a catalyst in the high pressure autoclave; and discharging air in the high pressure autoclave, stabilizing the pressure of hydrogen gas in the high pressure autoclave to between 2 and 5MPa for reaction, and obtaining the decalin. The conversion rate of the naphthalene is 100 percent, and the maximum yield of the decalin is 99 percent. The method for preparing the catalyst of Ni / gamma-Al2O3 comprises the following steps of: dissolving metallic salt of nickel in water, adding gamma-Al2O3 in the mixed solution, pouring clear solution out, and drying the clear solution to obtain a precursor of the catalyst; and reducing the precursor of the catalyst.

Owner:XIAMEN UNIV

Combination processing method of inferior heavy oil

ActiveCN103789036AHigh yieldHigh residual carbon valueTreatment with hydrotreatment processesHydrogenGasoline

A combination processing method of inferior heavy oil comprises the following steps that: A, a heavy oil feedstock enters into a liquid flow bed reactor for hydrocracking in the effects of hydrogen and a dispersible hydrocracking catalyst; B, the obtained hydrogenation product is fractionally distilled to obtain light oil and heavy oil, the cutting point is 320-380 DEG C, and the light oil is led out of the device; C, the heavy oil obtained by fractional distillation is extracted by a solvent to obtain deasphalted oil and deoiled asphalt; D, the deoiled asphalt is contacted with a catalytic cracking catalyst for cracking reaction in catalytic cracking conditions, and light oil, heavy cycle oil and slurry oil are obtained by fractional distillation; E, the deoiled asphalt obtained by the step C is recycled into the liquid flow bed reactor in the step A. According to the combination processing method provided by the invention, a variety of processes are integrated for processing of the inferior heavy oil, full transformation of the heavy oil can be realized, and more gasoline and diesel oil which are excellent in performances can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

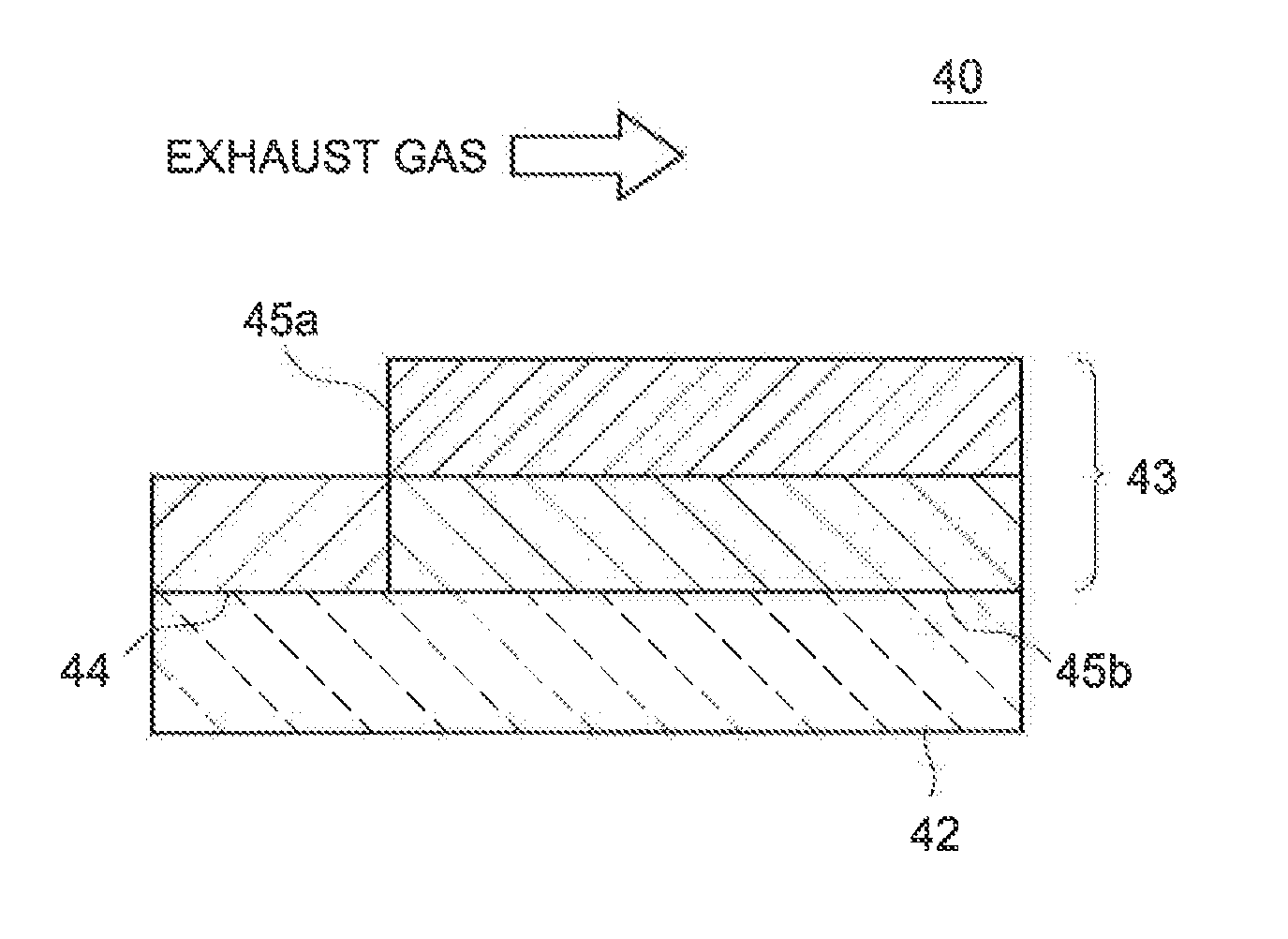

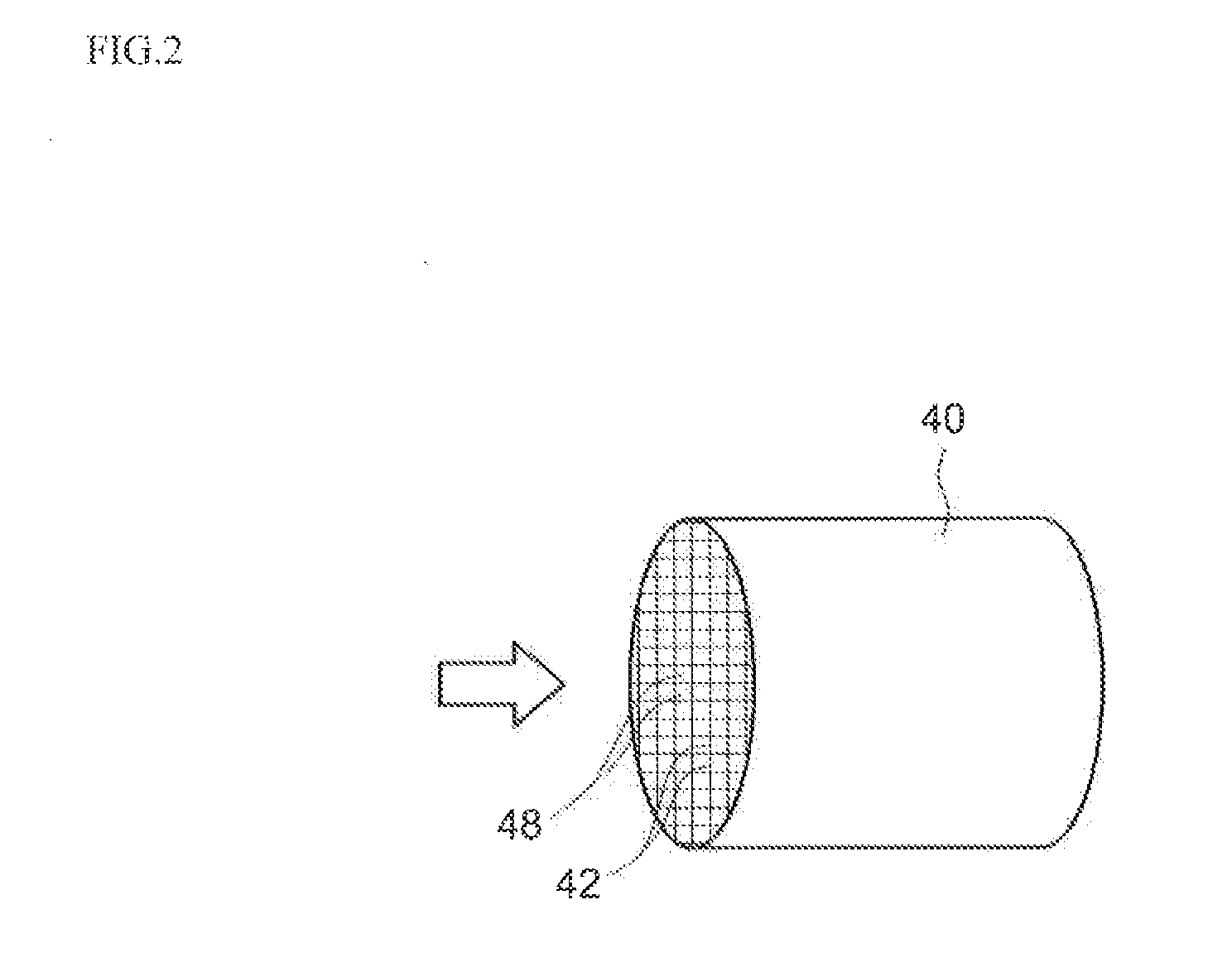

Exhaust gas purification catalyst

InactiveUS20130150236A1Reduce in quantityLower performance requirementsInternal combustion piston enginesDispersed particle separationComposite oxideExhaust gas

Disclosed is an exhaust gas purification catalyst that is provided with a base material and a catalyst later, which is formed on the base material and has an upstream side catalyst section and a downstream side catalyst section. Ba is added to the upstream side catalyst section and the downstream side catalyst section, the quantity of Ba added to the upstream side catalyst section is a quantity corresponding to 8 to 22 mass % relative to the total mass of a ceria-zirconia composite oxide contained in the upstream side catalyst section, and the quantity of Ba added to the downstream side catalyst section is a quantity corresponding to 3 to 7 mass % relative to the total mass of a ceria-zirconia composite oxide contained in the downstream side catalyst section 45b.

Owner:TOYOTA JIDOSHA KK

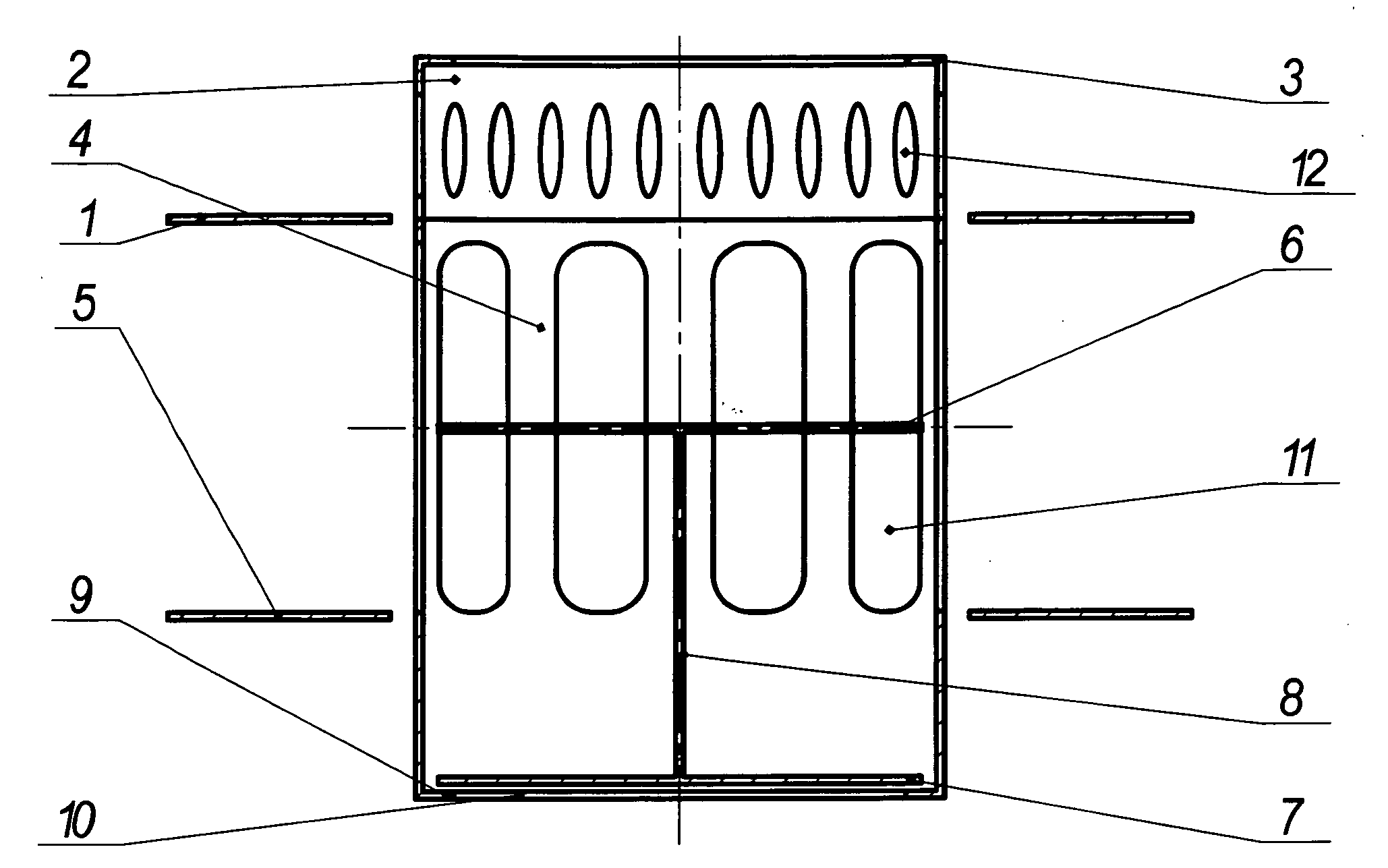

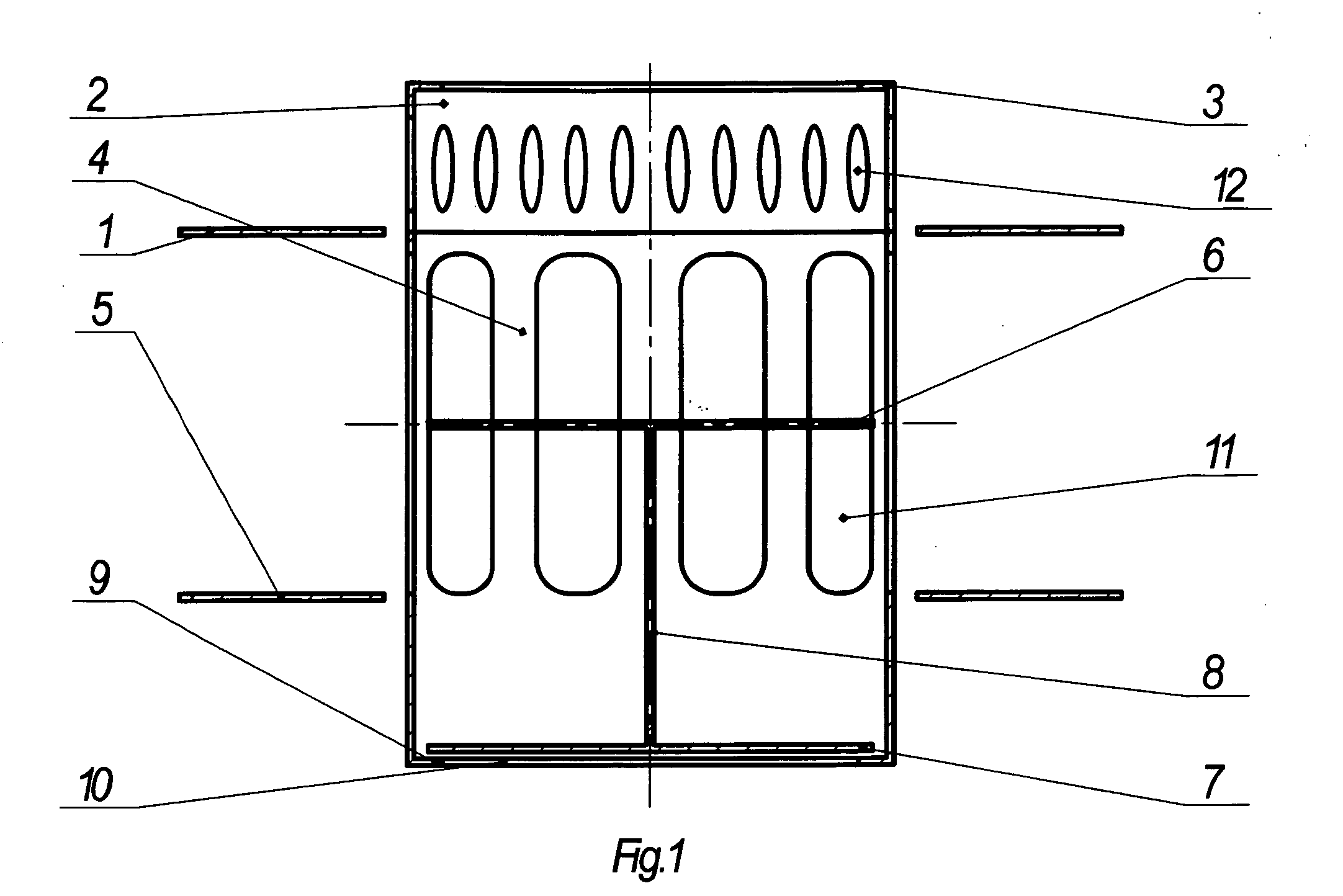

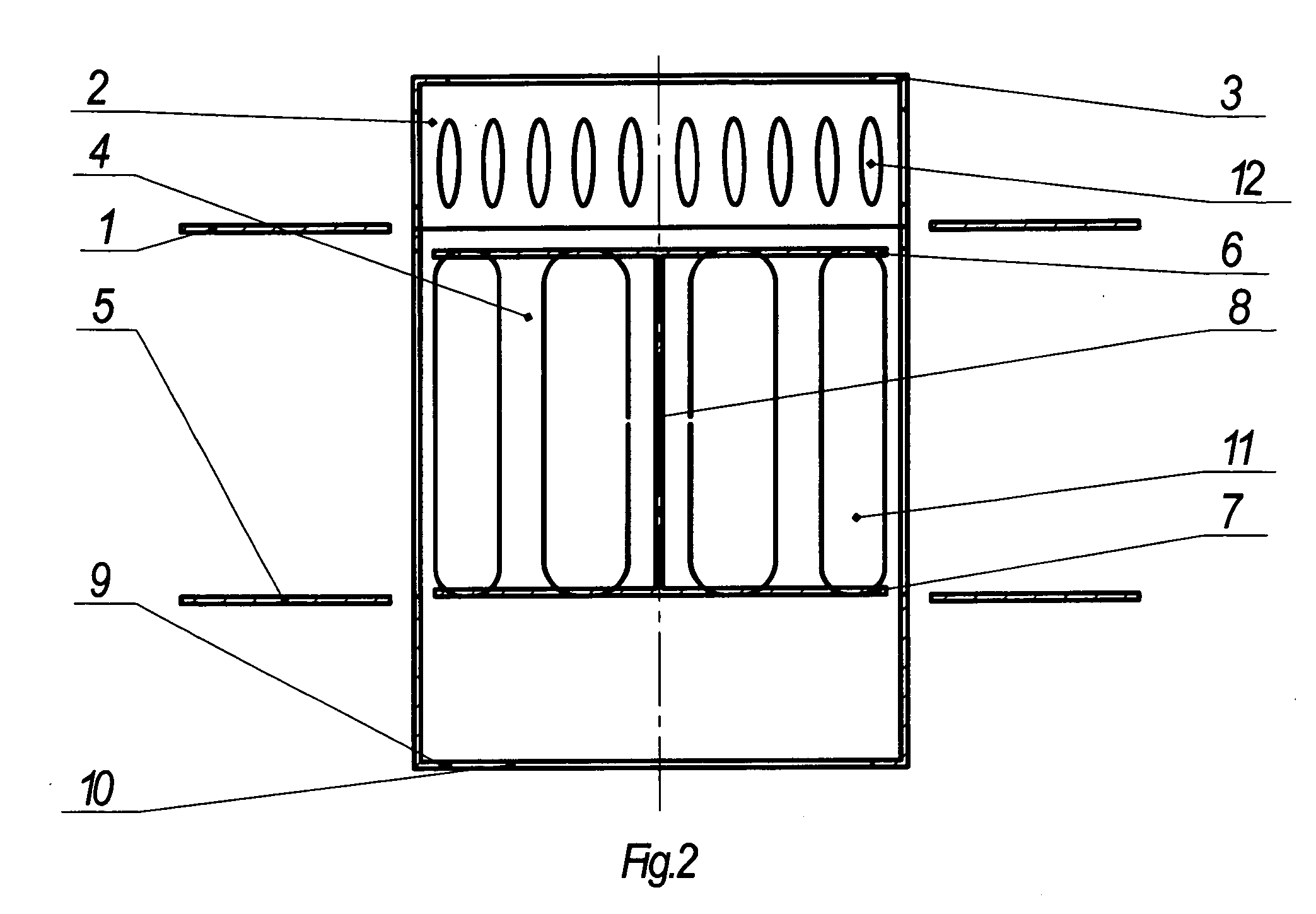

Mass Transfer Device

InactiveUS20090200690A1Reduce free cross sectionDecrease expenditureFuel re-atomisation/homogenisationMachines/enginesEngineeringLimiter

A mass-exchange contact device is proposed, comprising: upper and lower flat ring-shaped trays outwardly attached to a column, a sleeve including sidewalls attached to the trays and having windows made therein with bottom edges in the plane of the lower tray, a barbotage unit connected to the top of sleeve and having orifices in its sidewalls, a movable double-acting valve including two upper and lower plates attached to a rod axially disposed therebetween. The top of barbotage unit includes an ascending limiter of valve's movement, the bottom of sleeve includes a descending limiter of the valve's movement. In some embodiments, the barbotage unit is made as a portion of the sleeve. The height of windows preferably is equal to the height of valve. The proposed design significantly improves device operation for a cyclic mode, reliability, durability, reduces its weight and cost, extends its operational range for steam and liquid loads.

Owner:MALETA BOGDAN VLADIMIROVICH +1

Combined process for delayed coking and hydrotreating

ActiveCN101638588AOptimize processLess investmentTreatment with hydrotreatment processesWaxChemistry

The invention discloses a combined process for delayed coking and hydrotreating, which comprises the following steps that: a coking raw material is heated to enter a coking tower to react, oil gas escapes from the top of the coking tower, gas components and liquid components are separated, and the cycle ratio in a coking process is 0; and the liquid components are mixed with hydrogen to react in ahydrogenation reactor, then the obtained hydrogenated reaction effluent is distilled to obtain hydrogenated naphtha, hydrogenated diesel oil and hydrogenated wax oil, and the hydrogenated wax oil used as a high-quality raw material is fed into a catalytic cracking device or a hydrocracking device. By adopting the process flow of zero circulation of a coking device, the method provided by the invention furthest improves the yield of a liquid product, improves the processing depth of heavy oil, saves a coking fractionating tower, and achieves the aims of optimizing the flow and reducing the investment; and by adopting reasonable graduation of a hydrogenation catalyst, the method can furthest take account of the running period and the refining depth of each coking product fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com