Method for producing gelatine powder under normal temperature by using waste tires

A technology for waste tires and rubber powder, applied in recycling technology, removal of solid waste, recycling of mechanical materials, etc. The effect of large-scale industrial production, investment and production costs, low investment and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

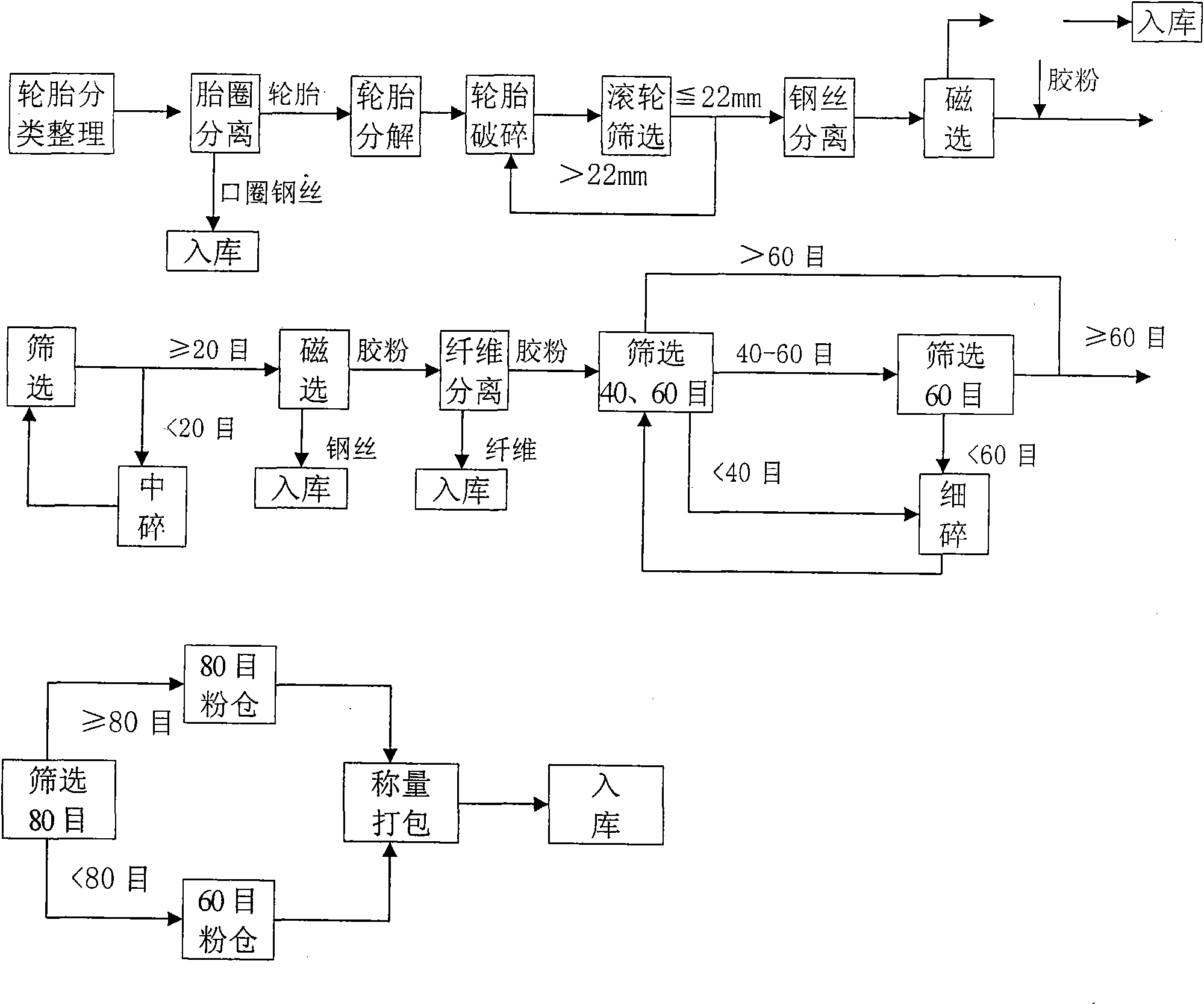

Image

Examples

Embodiment 1

[0038] The invention discloses a method for producing rubber powder using waste tires at room temperature, the steps are as follows:

[0039] a. Bead separation: use a bead separator to separate the bead ring steel wire bundle from the tire;

[0040] b. Tire crushing: Send the tires to the LP1200 tire crusher, and then to the LP800 tire crusher. After being crushed by the two-stage crusher, they are screened by the roller screening machine. Small rubber blocks with a particle size of less than or equal to 22mm are In the next process, the rubber blocks larger than 22mm are returned to the crusher for crushing and then sent to the roller screening machine, and so on;

[0041] c. Steel wire separation: Use a steel wire separator to separate the steel wire in the crushed rubber block from the rubber block to ensure that 98% of the steel wire is separated from the rubber block, and at the same time make the rubber block into rubber powder with more than 2 mesh ;

[0042] d. The ...

Embodiment 2

[0048] On the basis of embodiment 1, the more optimal technical scheme of the present invention is:

[0049] Before the bead separation step, there is also a tire sorting step: firstly remove the bias tire and semi-steel tire mixed in the all-steel radial tire, secondly take out the tire in the tire and the pad tire from the outer tire, and finally remove the accumulated tire in the tire The water is removed and the tire is allowed to dry, keeping the rim dry. There is also a tire decomposition step before the tire crushing step: the tire with the bead ring steel wire bundle removed is decomposed into more than three large rubber blocks. The steel wire after the first magnetic separation process is completely separated from the rubber particles by a steel wire separator, and the separated steel wire is directly put into storage, and a small amount of separated rubber powder is transferred to the first screening process. The fine fibers after the second magnetic separation are...

Embodiment 3

[0051] With reference to accompanying drawing 1 of specification sheet, its concrete process is as follows:

[0052] Tire sorting

[0053] 1. This production line is used to process all-steel radial tires. Among the tires purchased from outside, the mixed bias tires and semi-steel tires should be removed.

[0054] 2. Because there are tires in tires and pads among the tires purchased from outside, the tires in tires and pads should be taken out of the tires to facilitate the work of the bead separator.

[0055] 3. Remove the accumulated water in the tire, and dry the tire to ensure that the bezel is dry, which is convenient for the bead separator to work.

[0056] bead separation

[0057] The whole tire bead separator can completely separate the tire bead ring steel wire bundle from the tire, which increases the added value of the bead ring steel wire bundle. Bead ring steel wire bundles are directly put into storage, and tires without bead ring steel wire bundles enter the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com