Patents

Literature

337results about How to "Improve pyrolysis efficiency" patented technology

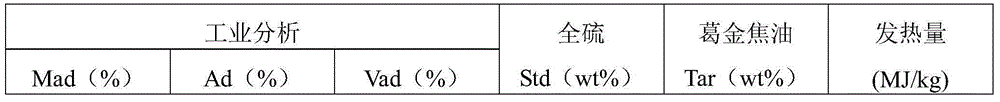

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

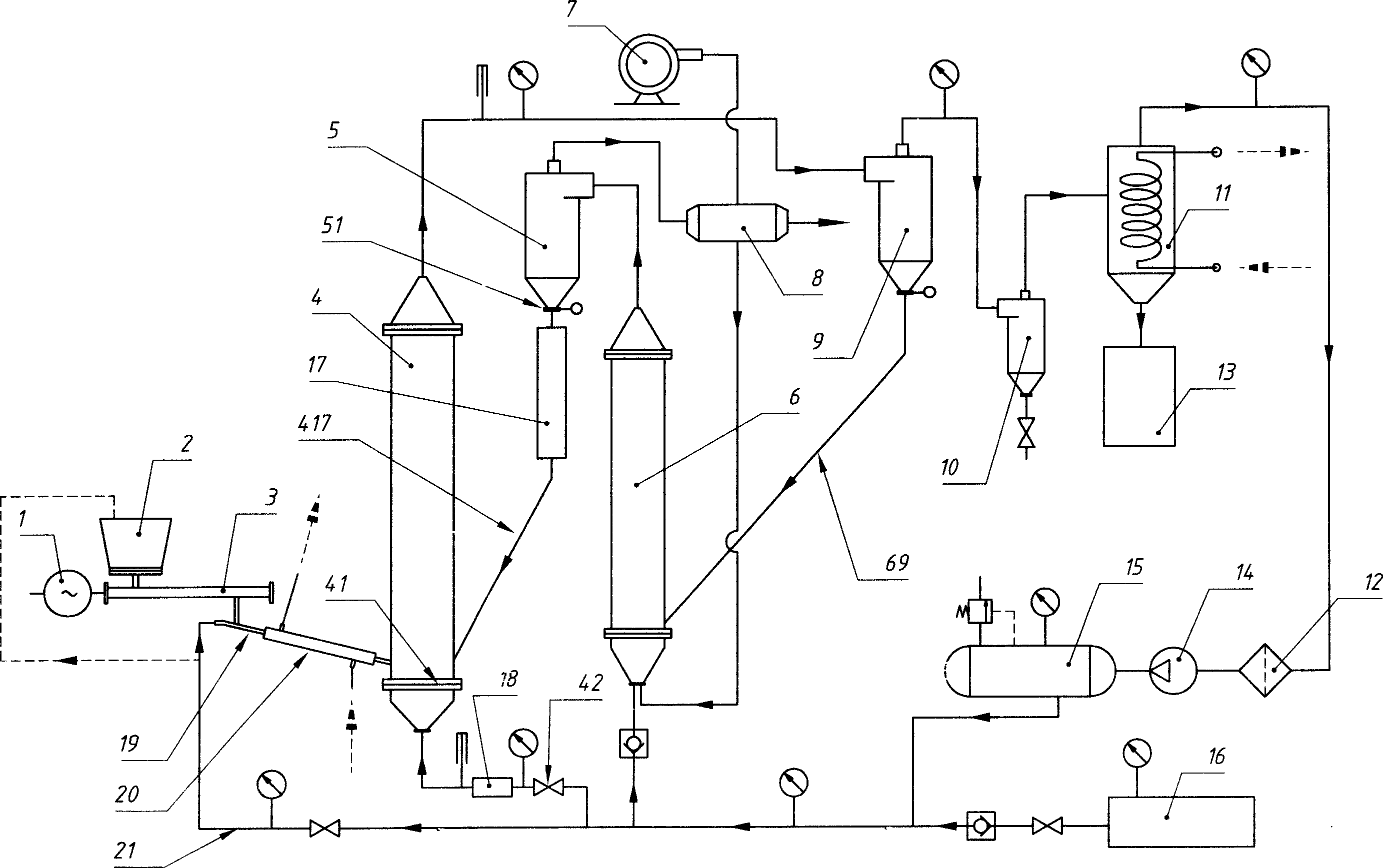

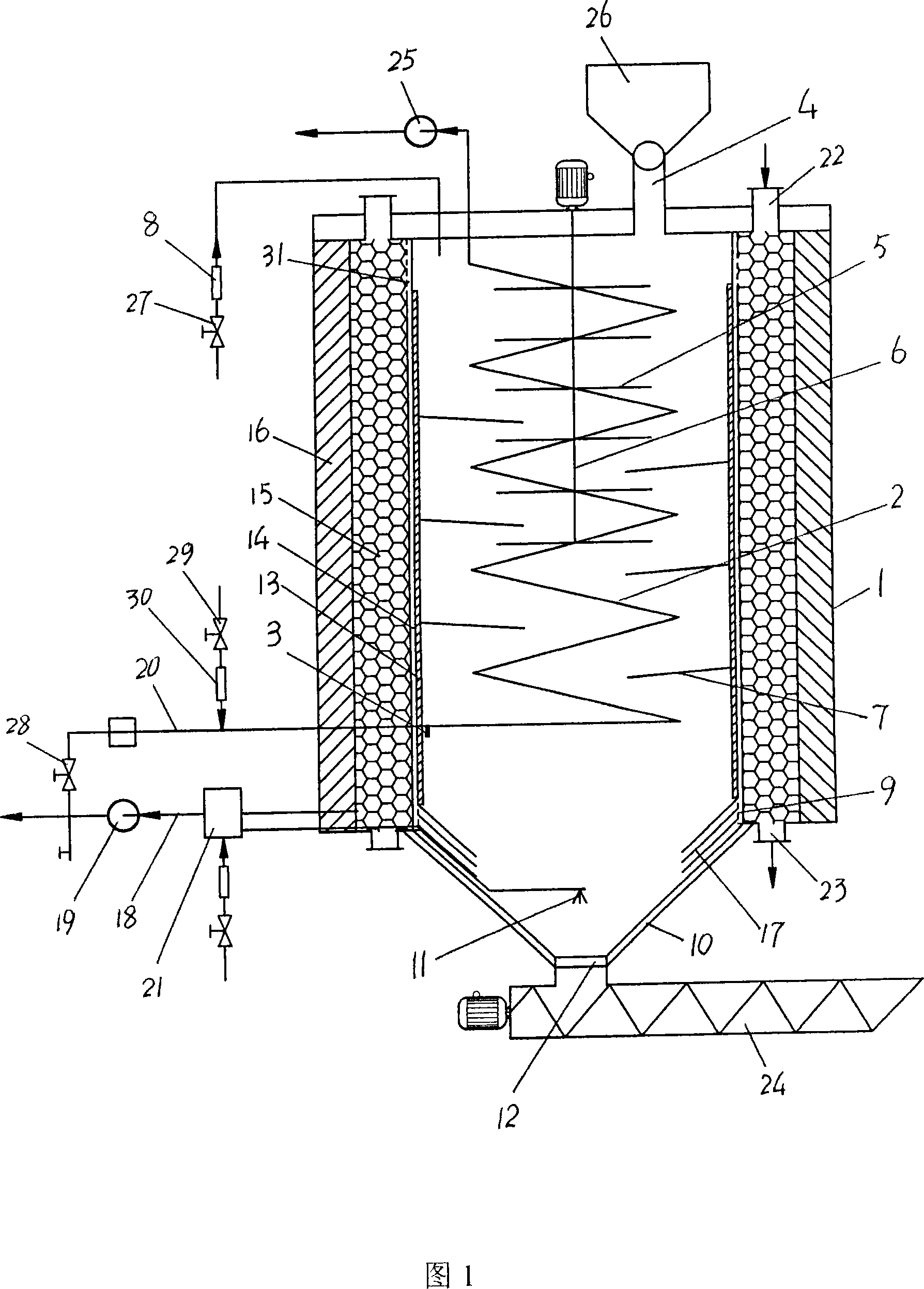

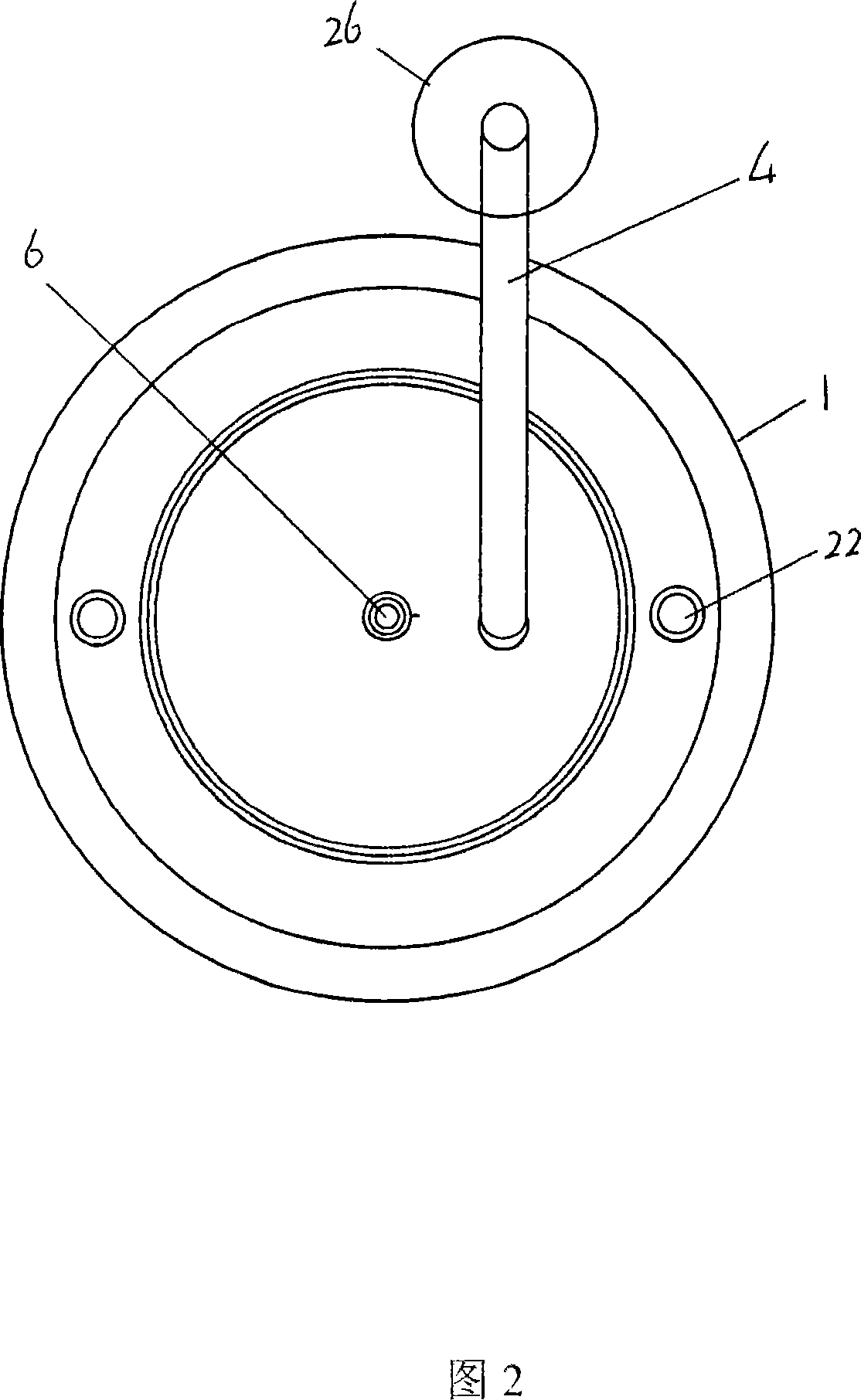

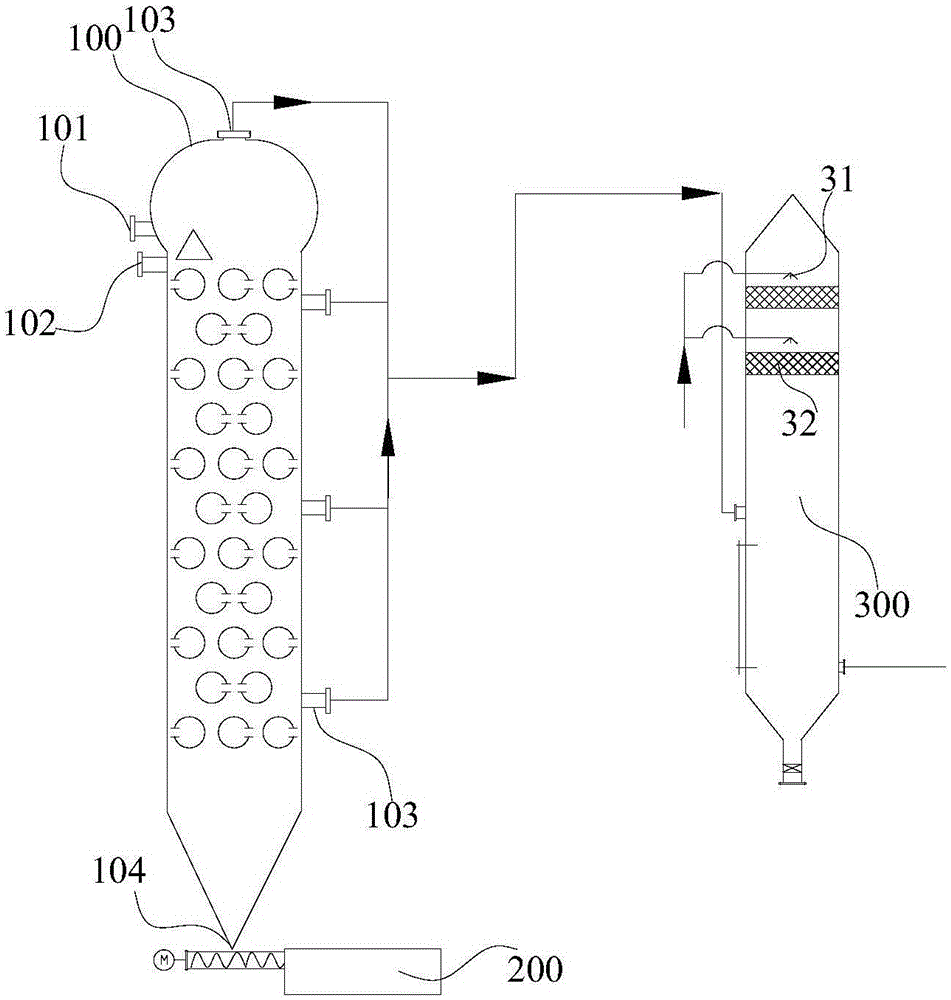

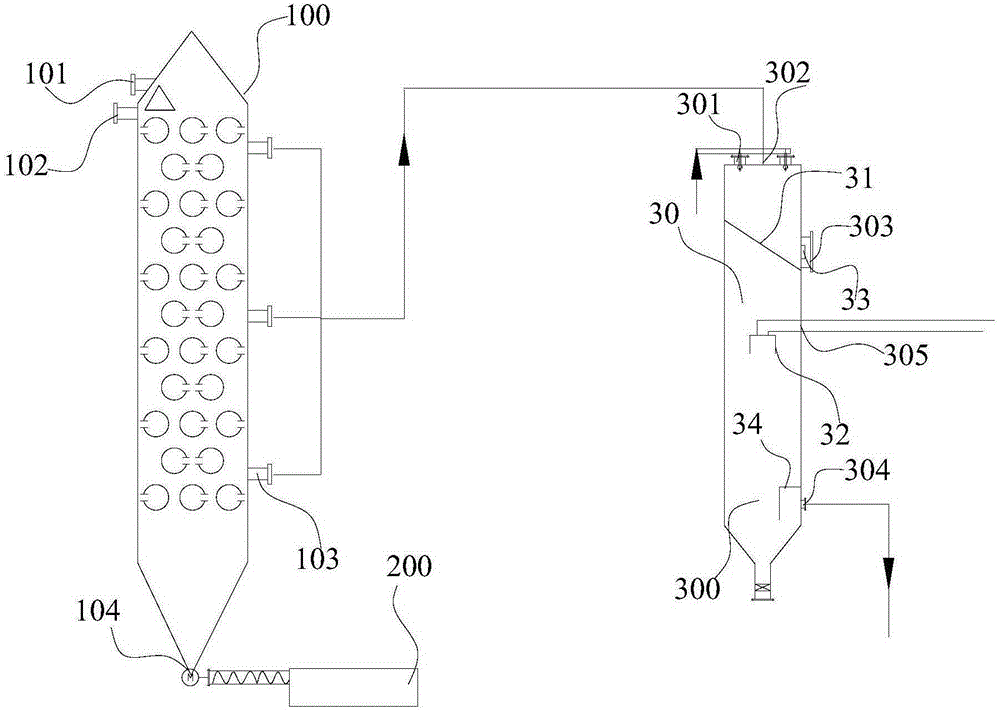

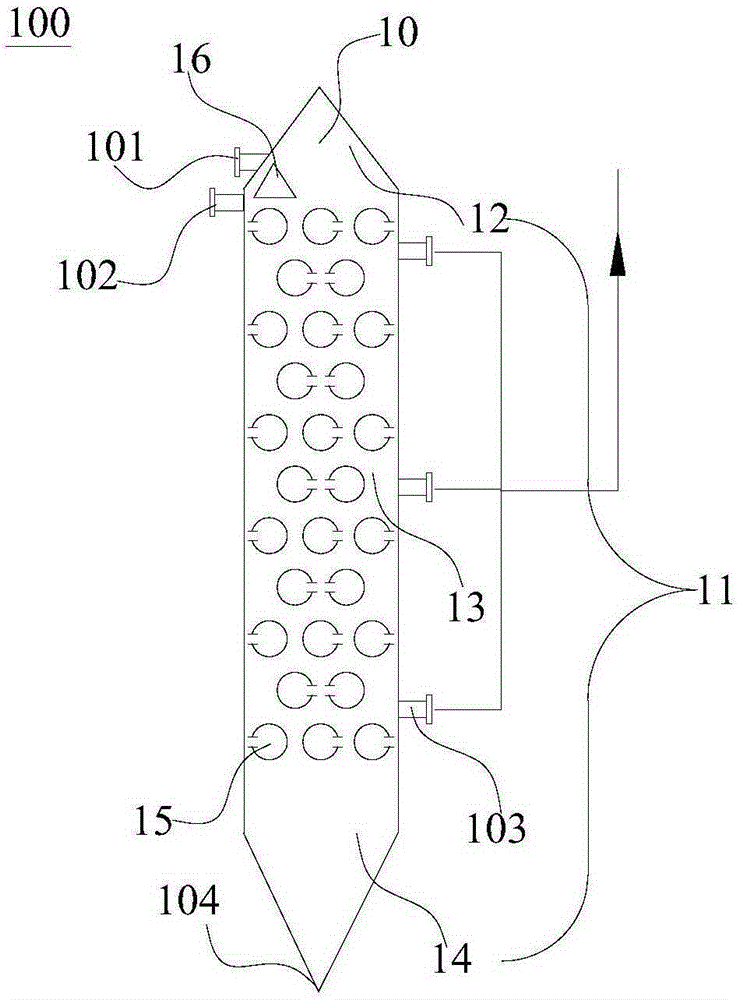

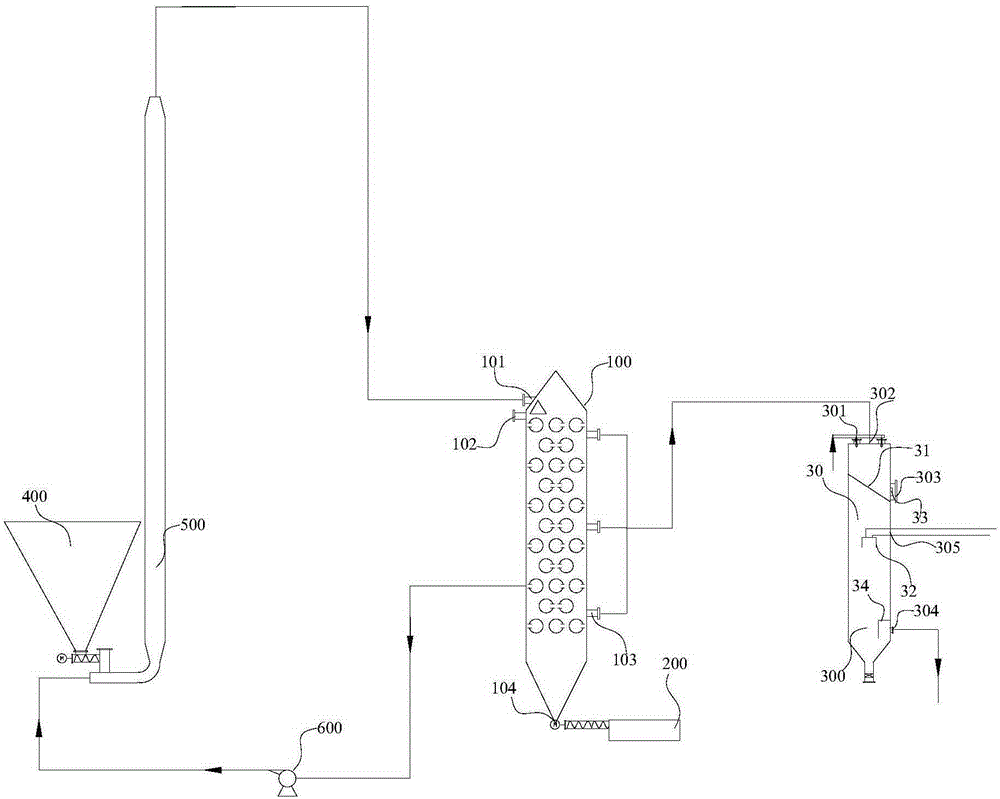

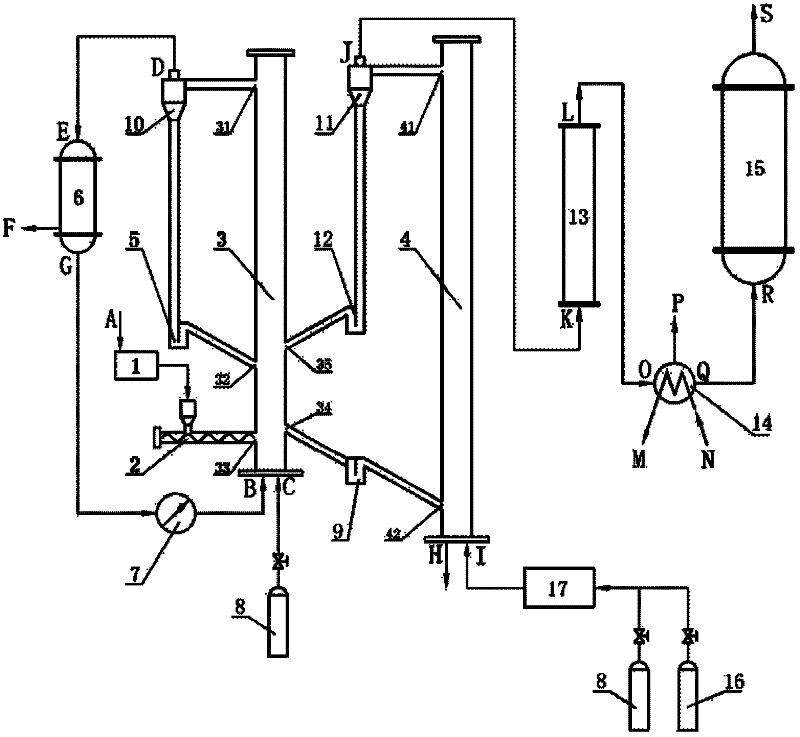

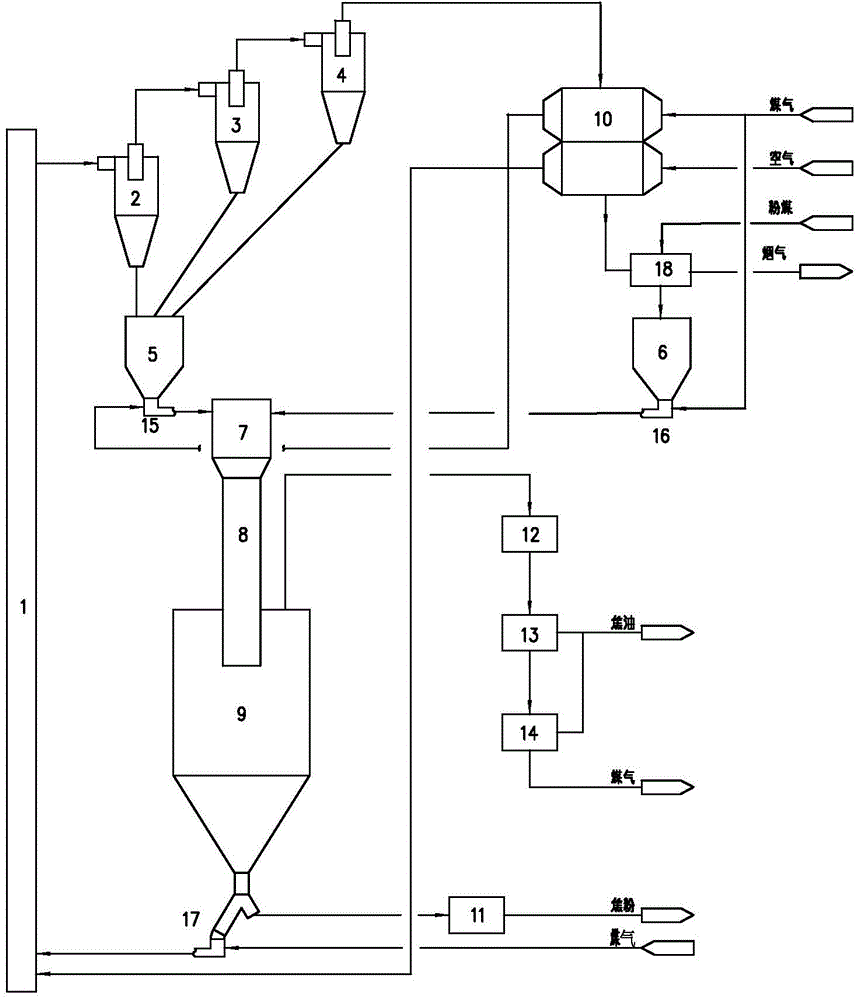

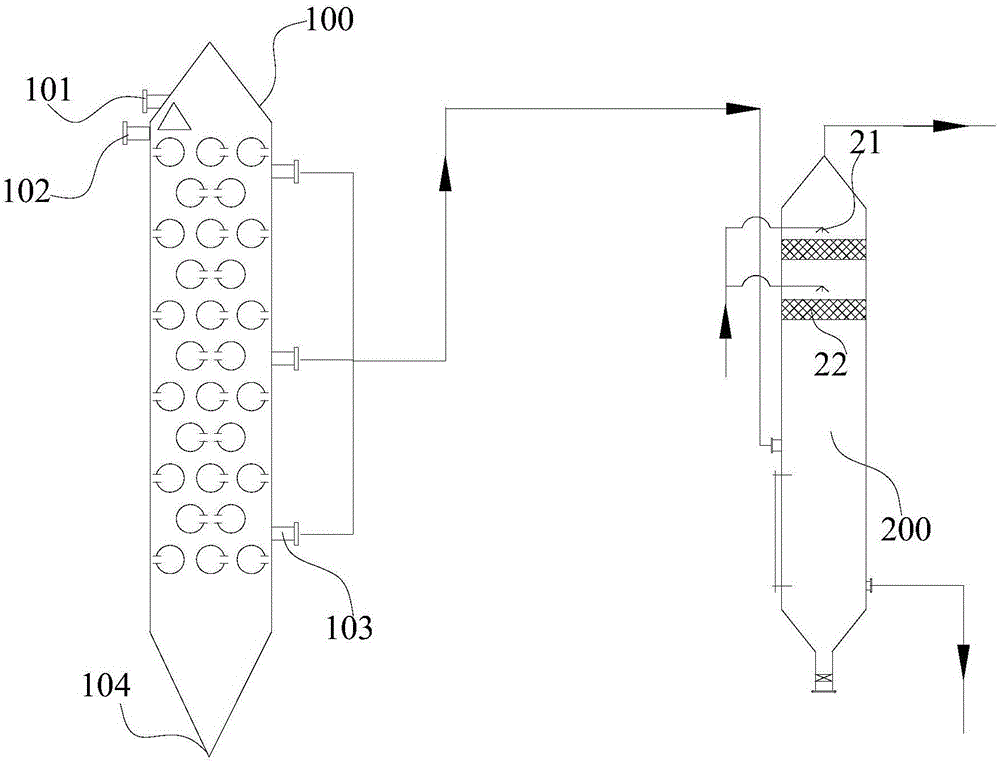

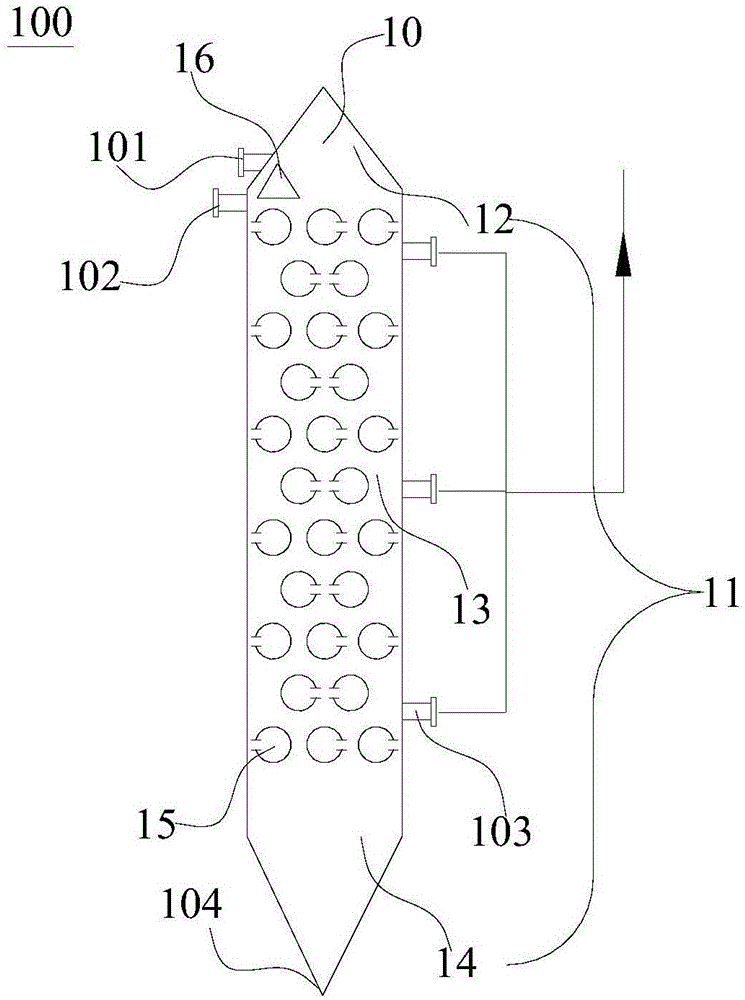

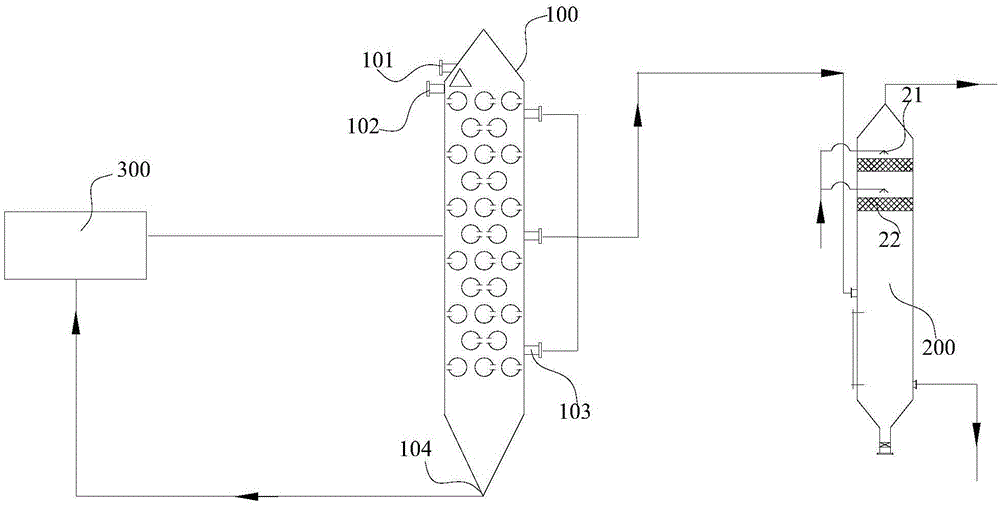

Biomass pyrolysis liquefied technique and double tower apparatus system thereof

InactiveCN1730177AImprove pyrolysis efficiencyWell mixedSolid waste disposalGas phaseProcess engineering

The invention relates to a biomass analgesic liquidation method and its twin-tower set system, the processes of which comprise the following steps: sending biomass to pyrolytic reaction tower and blending it with high-heat fluidized gas to subject biomass to pyrolytic cracking; separating thermal cracking gas with carbon residue and ash content in separator; and condensing thermal cracking gas to biological oil in condenser. In the process, heat-carrying agent is exported from pyrolytic reaction tower along with thermal cracking gas, carbon residue and so on, and carbon residue is used to preheat heat-carrying agent. The invention is special for heat-carrying agent heating tower to burn carbon residue and primary separator to separate heat-carrying agent, carbon residue and other materials. The invention can not only increase circulation rate to ensure uniform and stable temperature field in pyrolytic reaction tower, higher heating rates and shorter detention period of gas phase, but also make use of carbon residue as heat source by using existing apparatus.

Owner:CHONGQING UNIV

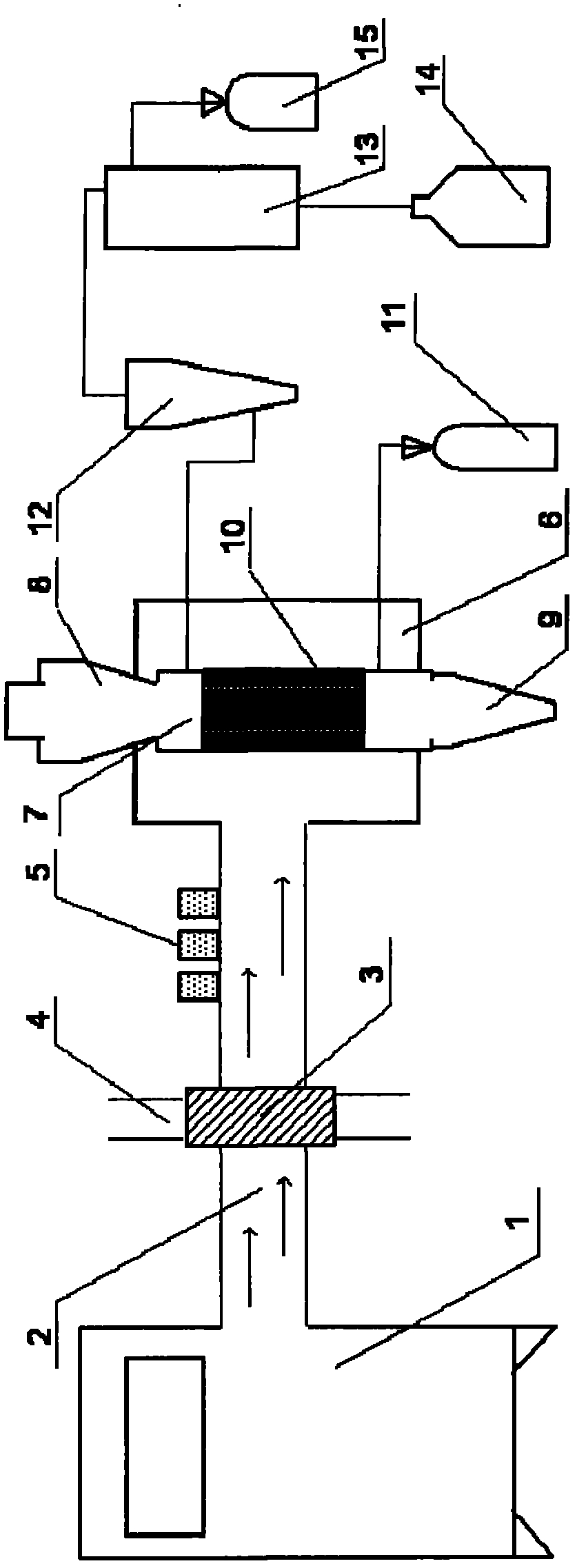

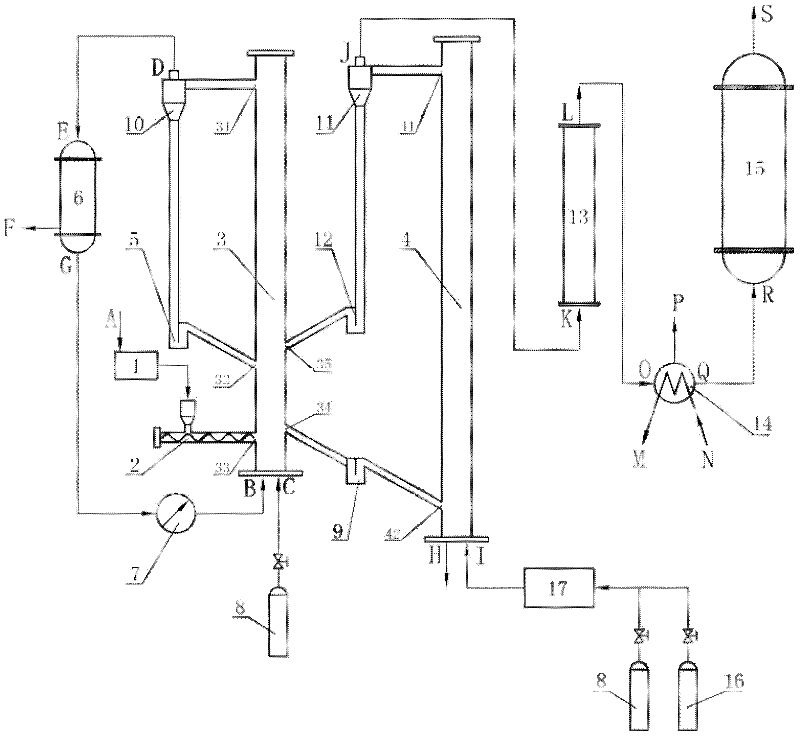

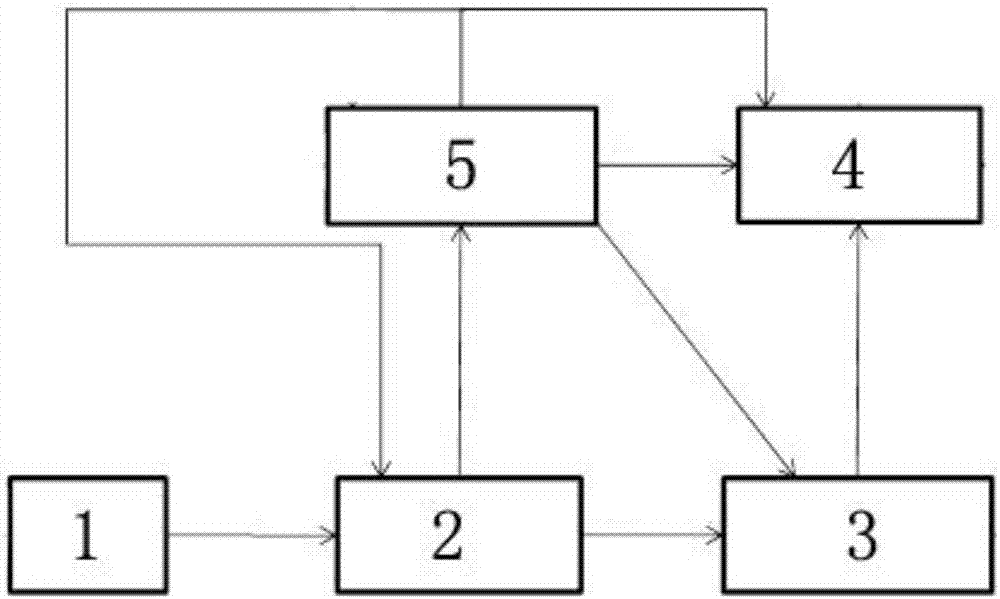

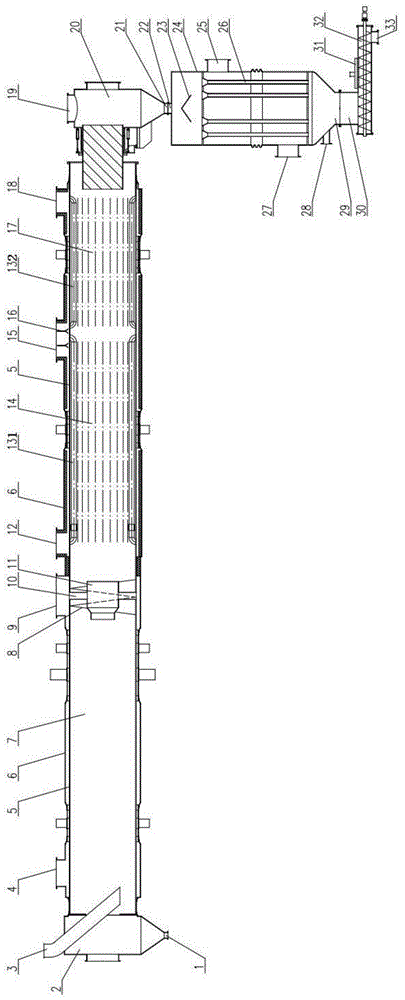

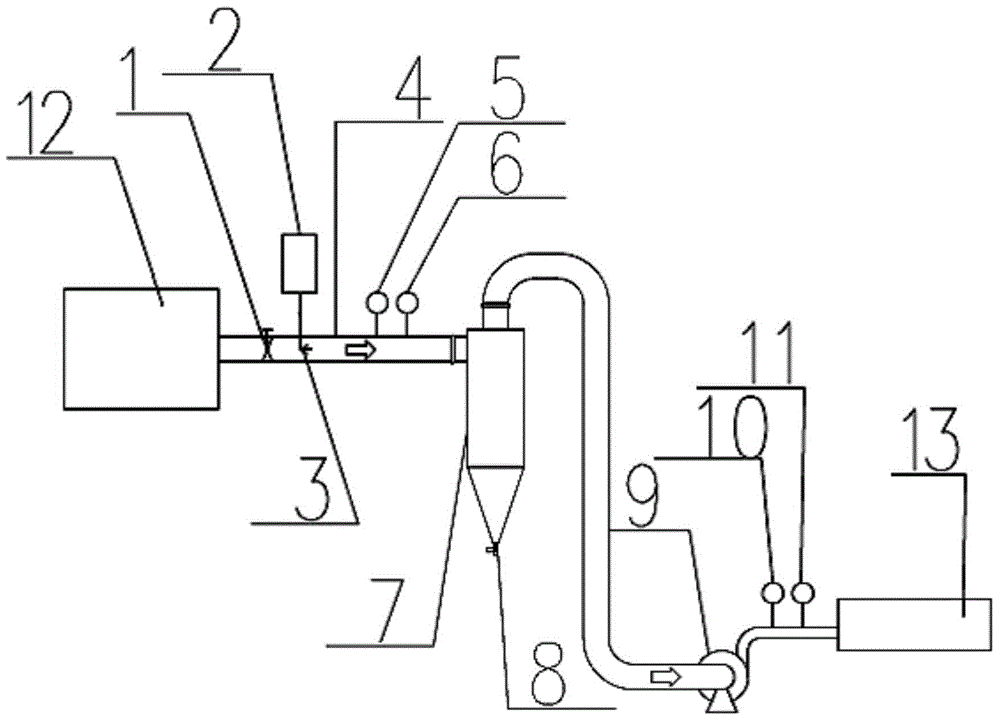

Continuous reaction device and method for microwave biomass pyrolysis

InactiveCN102580650APyrolysis continuous reaction realizedIncrease reaction rateBiofuelsLiquid hydrocarbon mixture productionMicrowaveFuel gas

The invention relates to a continuous reaction device and a method for microwave biomass pyrolysis. The continuous reaction device for the microwave biomass pyrolysis mainly comprises a microwave generator, a reactor and a resultant separating device. The continuous reaction device is a continuous operating system and can process 10-50kg of the biomass every hour. According to the continuous reaction device for the microwave biomass pyrolysis, characteristics of microwave volume heating, transient heating and selective heating are fully utilized, undried biomass is directly pyrolyzed so as toobtain three products of liquid bio-oil, bio-gas and solid coke, the pylolysis efficiency of the biomass is greatly improved, the yield and the quality of the liquid bio-oil are improved, the structure is simple, the design is reasonable, and the achievement of industrial application of the microwave biomass pyrolysis is facilitated.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

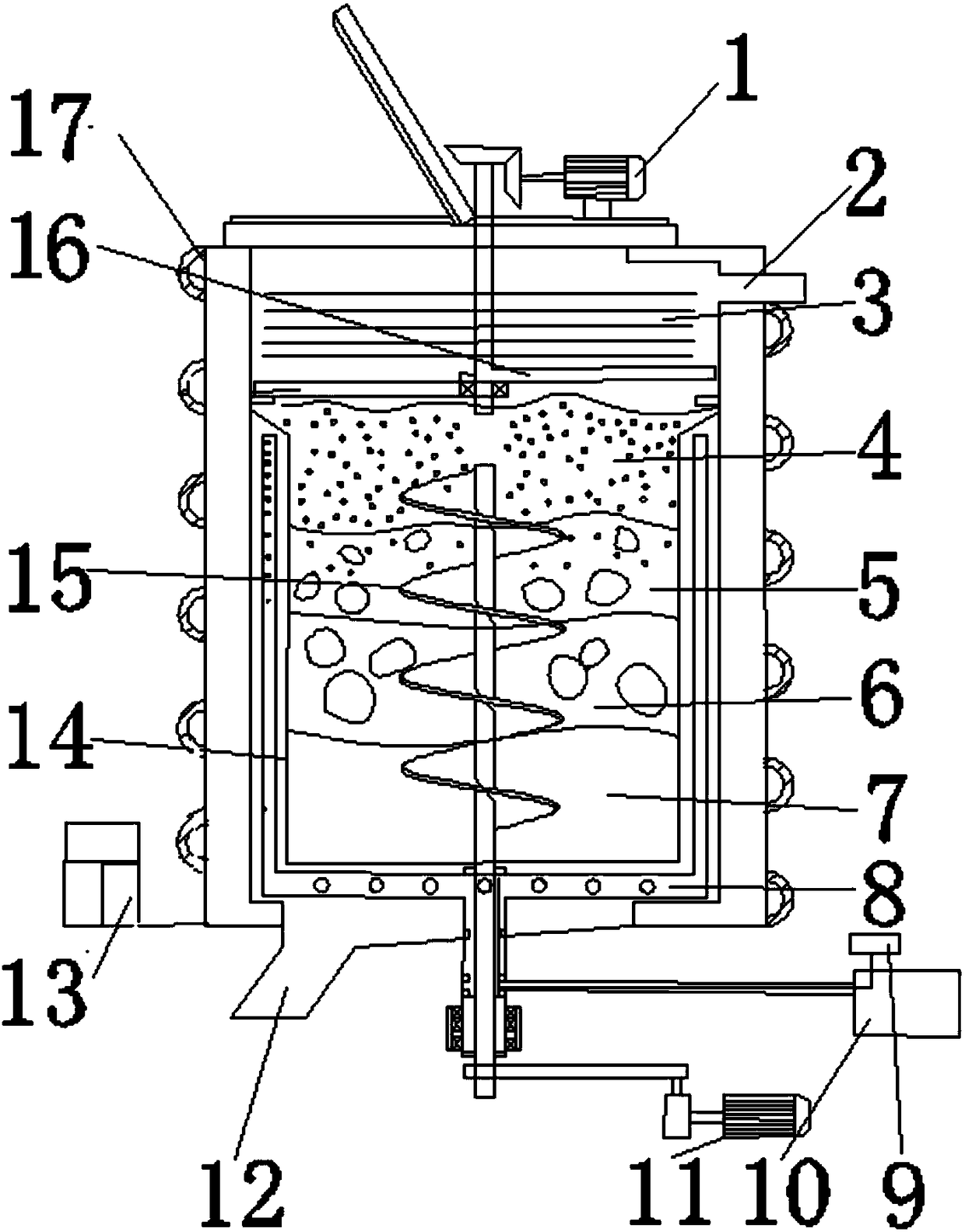

Internal-combustion heating type biomass gasification furnace

ActiveCN101021334AImprove biomass gasification rate and gas calorific valueImprove gasification efficiencyDomestic stoves or rangesLighting and heating apparatusNitrogen gasEngineering

The present invention relates to an internal combustion heated biomass gasification furnace. Its structure is characterized by that it adopts a cylindrical furnace body, in the furnace body interior a coiled internal combustion pipe is set, the internal combustion pipe inlet is positioned in the lower portion of said cylindrical furnace body, and its outlet is extended to the exterior of furnace body from the top portion of cylindrical furnace body, its igniter is positioned in the internal combustion pipe inlet; over the cylindrical furnace body a helical feeding mechanism is set, its helical feeding hole is positioned on the eccentric position of cylindrical furnace body top portion, on the centre axis position of said cylindrical furnace body a stirring shaft with stirring blades is set, on the inside wall of cylindrical furnace body several layers of baffle plates are set, the combustion-supporting air inlet is set in the top portion of said cylindrical furnace body, and the gas outlet in the furnace body is positioned in the lower portion of said furnace body.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

Pyrolysis reactor

PendingCN105400527AImprove pyrolysis efficiencyReduce energy consumptionIndirect heating destructive distillationCoke ovens heatingSlagEngineering

The invention provides a pyrolysis reactor, which includes: regenerative type radiant tubes, a stirring device, a catalyst adding component, an air pumping umbrella and a distributor. The regenerative type radiant tubes are arranged in multiple layers along the height direction of the pyrolysis reactor, and a plurality of regenerative type radiant tubes parallel to each other are disposed in each layer in the horizontal direction; the stirring device consists of a stirring shaft and a plurality of stirring rods connected to the stirring shaft, and the stirring shaft rotatably extends from a slag discharge port into the pyrolysis reactor; the catalyst adding component includes a catalyst main tube; a plurality of catalyst branch tubes, one or more catalyst jet members and a carrier gas delivery member; the air pumping umbrella is disposed on the top wall of the pyrolysis reactor and is connected to oil gas outlets; and the distributor is arranged on the top wall of the pyrolysis reactor and is connected to a feed port through a flange. The pyrolysis reactor provided by the invention can significantly improve the pyrolysis efficiency.

Owner:SHENWU TECH GRP CO LTD

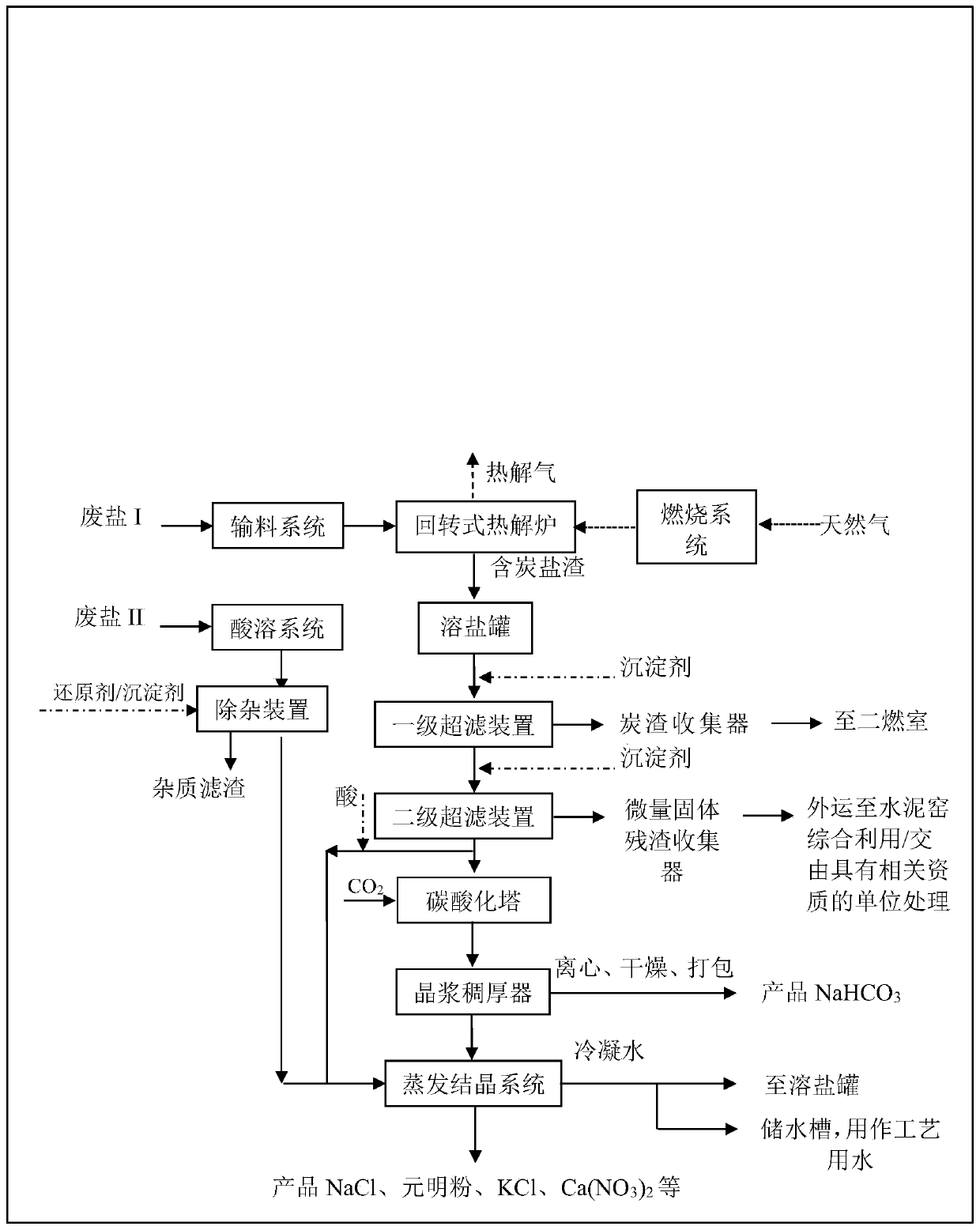

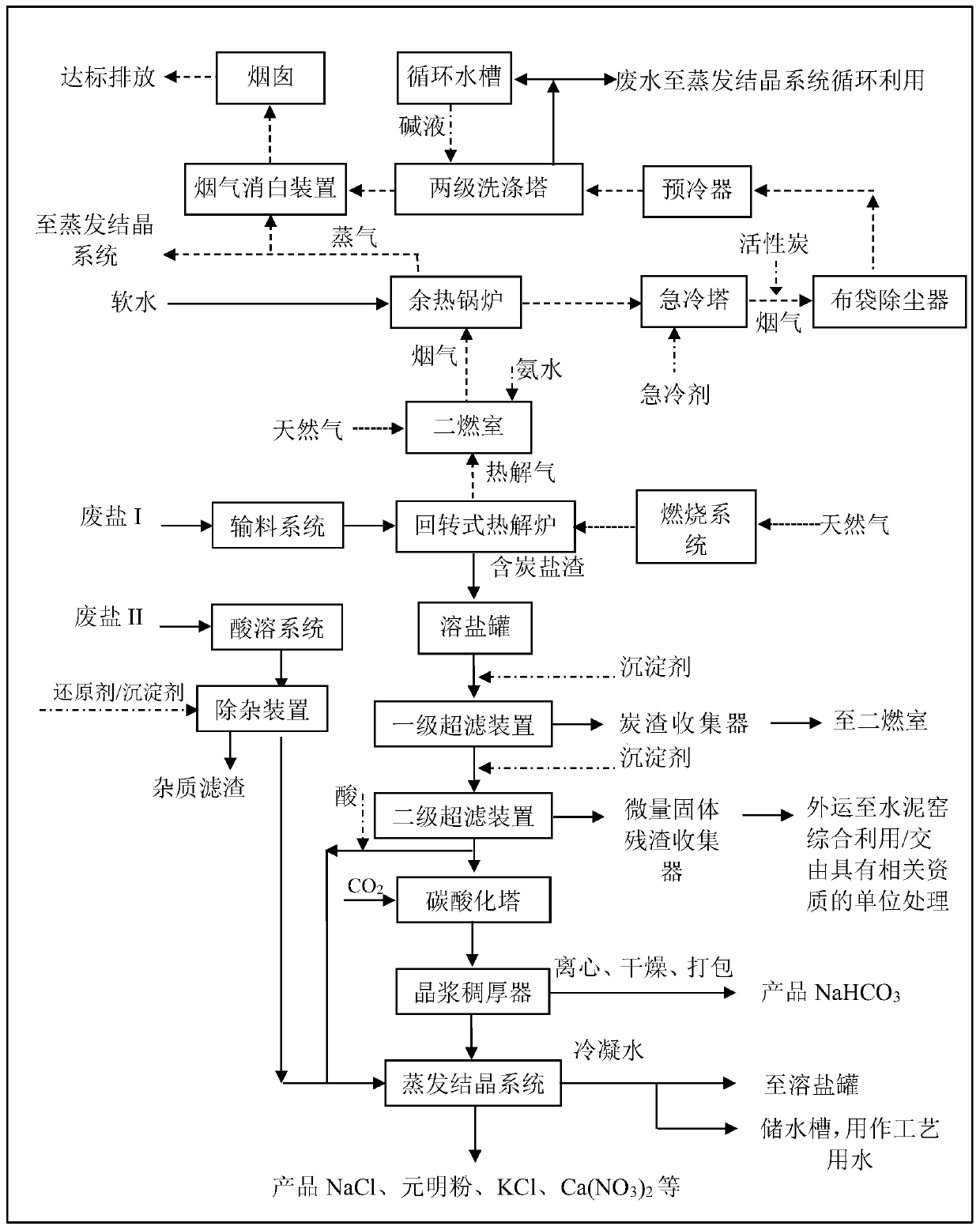

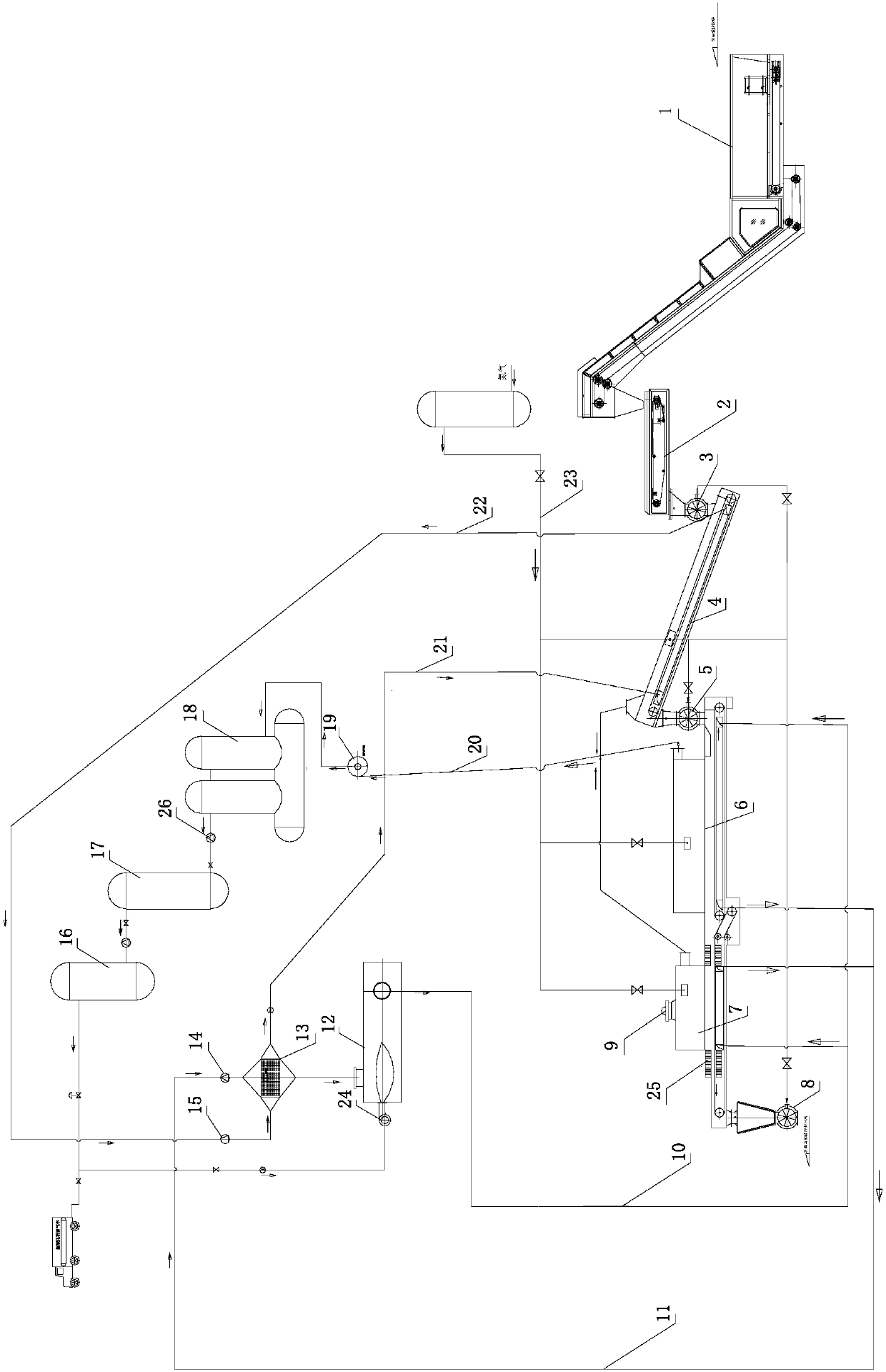

Waste salt resourceful treatment system and application

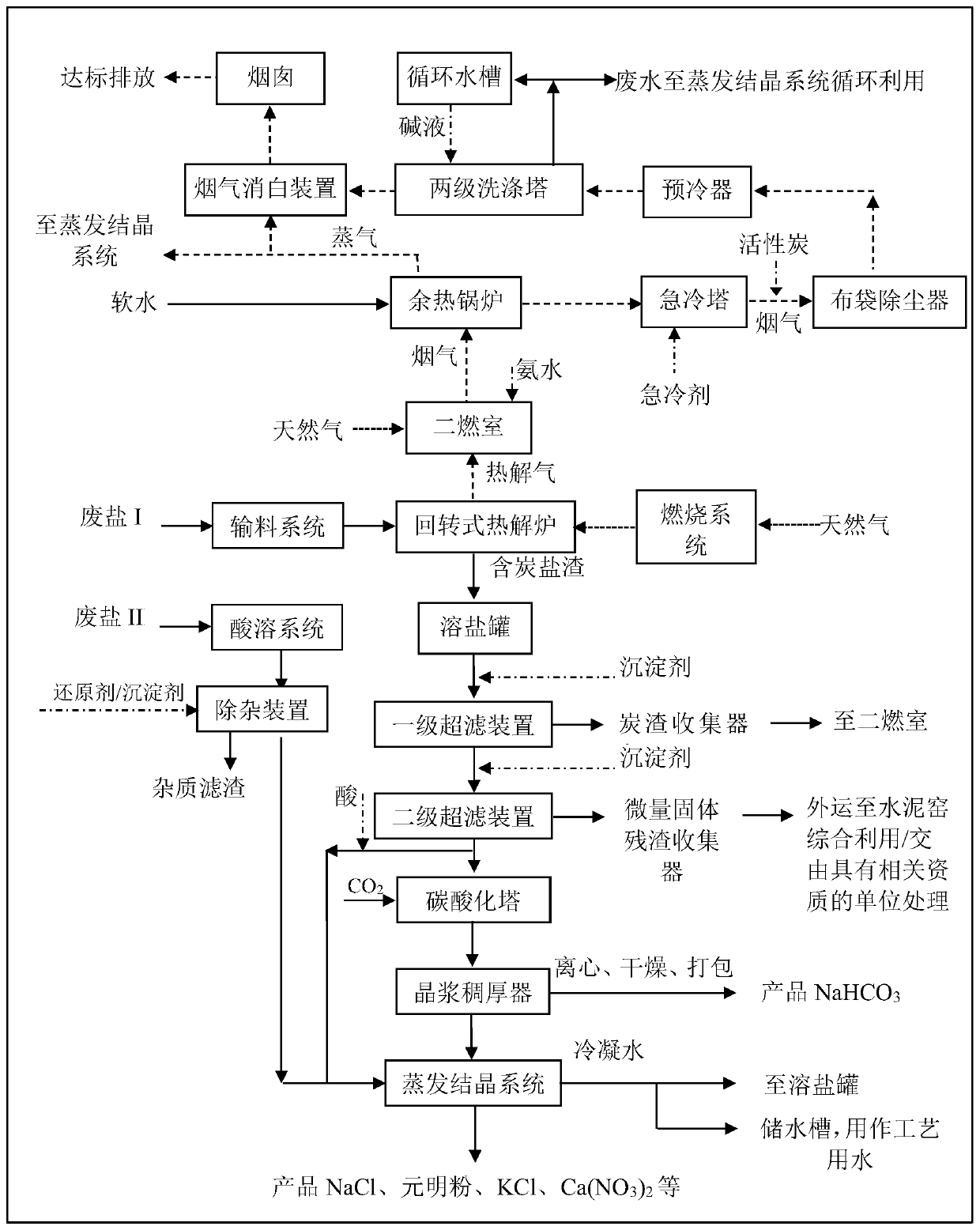

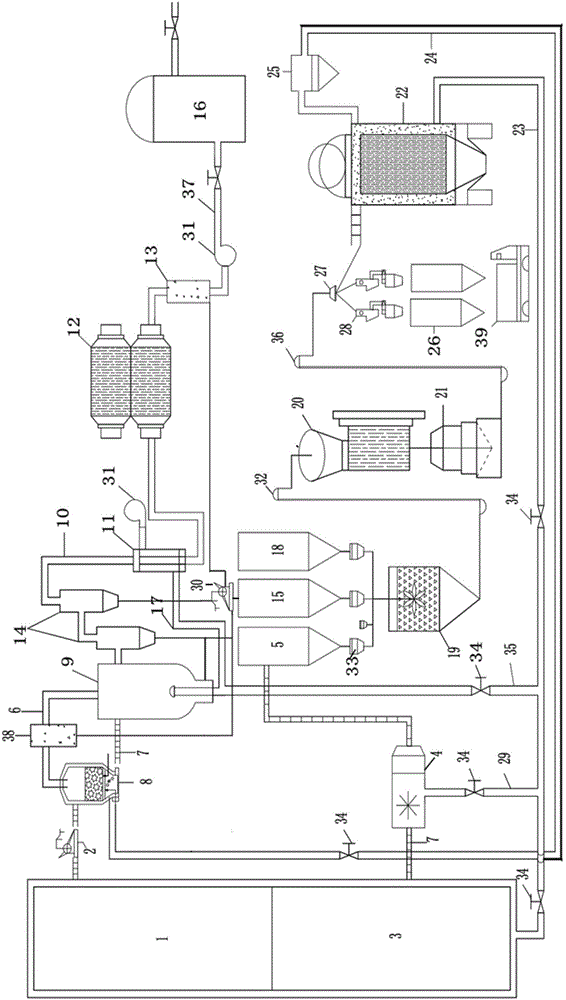

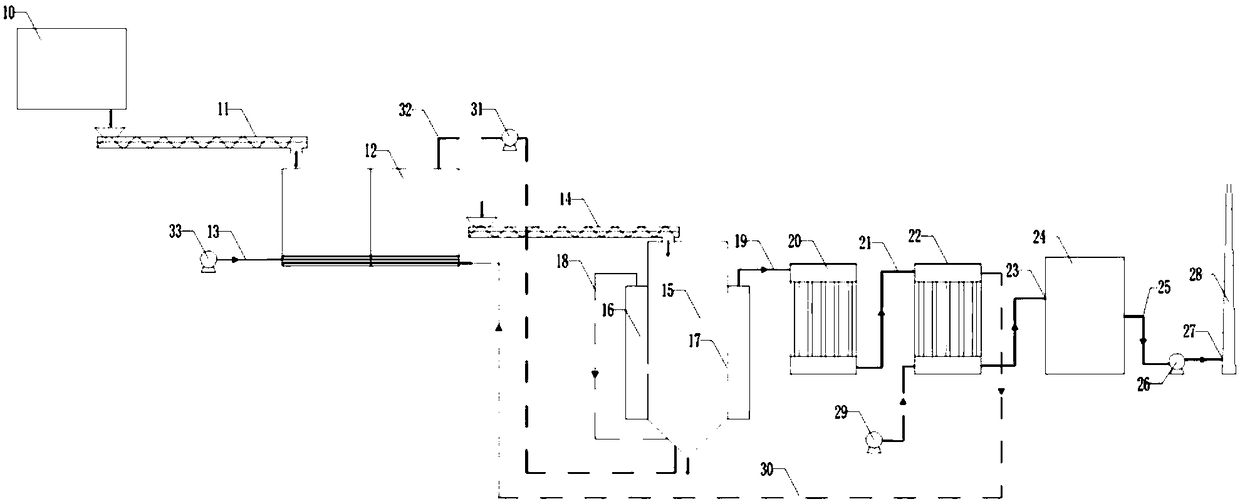

PendingCN110201975ARealize resourcesAchieve emission standardsSolid waste disposalTransportation and packagingSlagEvaporation

The invention relates to a waste salt resourceful treatment system which comprises a waste salt carbonization and pyrolysis system, a carbon-containing salt slag dissolving and filtering system and anevaporating and salt separating system in sequential connection, wherein the waste salt carbonization and pyrolysis system can carry out carbonization and pyrolysis treatment on waste salt I composedof sodium chloride, and sodium sulfate monomer salt or mixed waste salt and also can treat tail gas; the carbon-containing salt slag dissolving and filtering system can dissolve and filter the carbon-containing salt slag treated by the waste salt carbonization and pyrolysis system; and the evaporating and salt separating system can carry out evaporation and concentration, fractional crystallization and drying treatment on the strong brine treated by the carbon-containing salt slag dissolving and filtering system to obtain product salt. The waste salt resourceful treatment system takes industrial waste salt as the raw material, removes organic pollutant from waste salt and separates mixed inorganic salt to finally obtain an industrial second-grade salt product, so that recycling of waste salt is realized, and the flue gas generated during the production process is discharged after reaching the standard.

Owner:北京航天环境工程有限公司

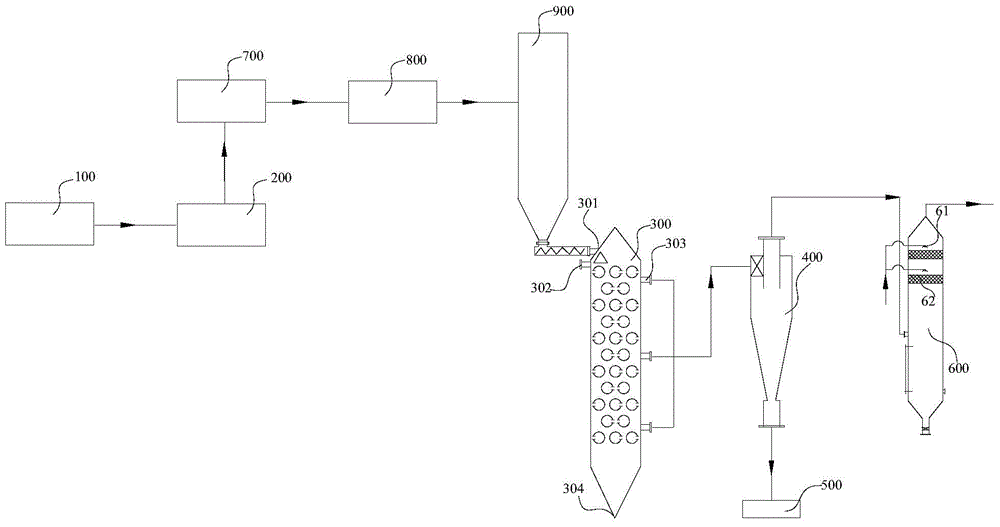

Preparation system and preparation method for biomass molding fuel

ActiveCN104560216AImprove pyrolysis efficiencyNo pollution in the processBiofuelsSolid fuelsPre treatmentProcess engineering

The invention discloses a preparation system and a preparation method for a biomass molding fuel. The preparation system comprises a raw material pretreatment system, a low-temperature pyrolysis system, a high-temperature gasification system, a densification molding system and a boiler system. The preparation method comprises the following steps: performing low-temperature pyrolysis and high-temperature gasification on a dried and crushed biomass; mixing the obtained residues with dried and crushed sludge and an auxiliary raw material, and performing extrusion molding to obtain the biomass molding fuel. According to the preparation system disclosed by the invention, biomass gasification and biomass molding technologies are integrated, the whole system is in close connection to complement each other, the operating and maintenance costs are low, the obtained molding fuel is good in performance, the biomass is subjected to two-stage gasification by virtue of the preparation method, the gasification quality and efficiency are high, and the gasification residues are comprehensively utilized, so that the stabilization, quantity reduction, harmlessness and resource utilization of the sludge can be realized to the maximum extent.

Owner:岳阳红普科技发展有限公司

Treatment system for waste salt recycling treatment and application thereof

PendingCN110201976ARealize resourcesReduce dosageSolid waste disposalTransportation and packagingSodium bicarbonateSlag

The invention relates to a treatment system for waste salt recycling treatment. The treatment system comprises a waste salt carbonization pyrolysis system, a coke-containing salt slag dissolving and filtering system and an evaporation and desalination system which are sequentially connected with one another, wherein the waste salt carbonization pyrolysis system can be used for carrying out carbonization pyrolysis treatment on waste salt I composed of sodium chloride monomer salt, sodium sulfate monomer salt or the mixed waste salt; the coke-containing salt slag dissolving and filtering systemcan be used for carrying out the dissolution and filtration operation on the coke-containing salt slag obtained after the treatment by the waste salt carbonization pyrolysis system; and the evaporation and desalination system can be used for carrying out the evaporation and concentration, fractional crystallization and drying treatment on strong brine obtained after the treatment by the coke-containing salt slag dissolving and filtering system, so that salt products are obtained. According to the treatment system, with the industrial waste salt as a raw material, organic pollutants are removedfrom the waste salt, desalination treatment is carried out on mixed inorganic salt, and finally the industrial secondary salt products are produced, such as anhydrous sodium sulfates, sodium chlorides, sodium bicarbonate and other finished salt, so that the recycling of the waste salt can be realized; and the system can be applied to the waste salt recycling treatment.

Owner:北京航天环境工程有限公司

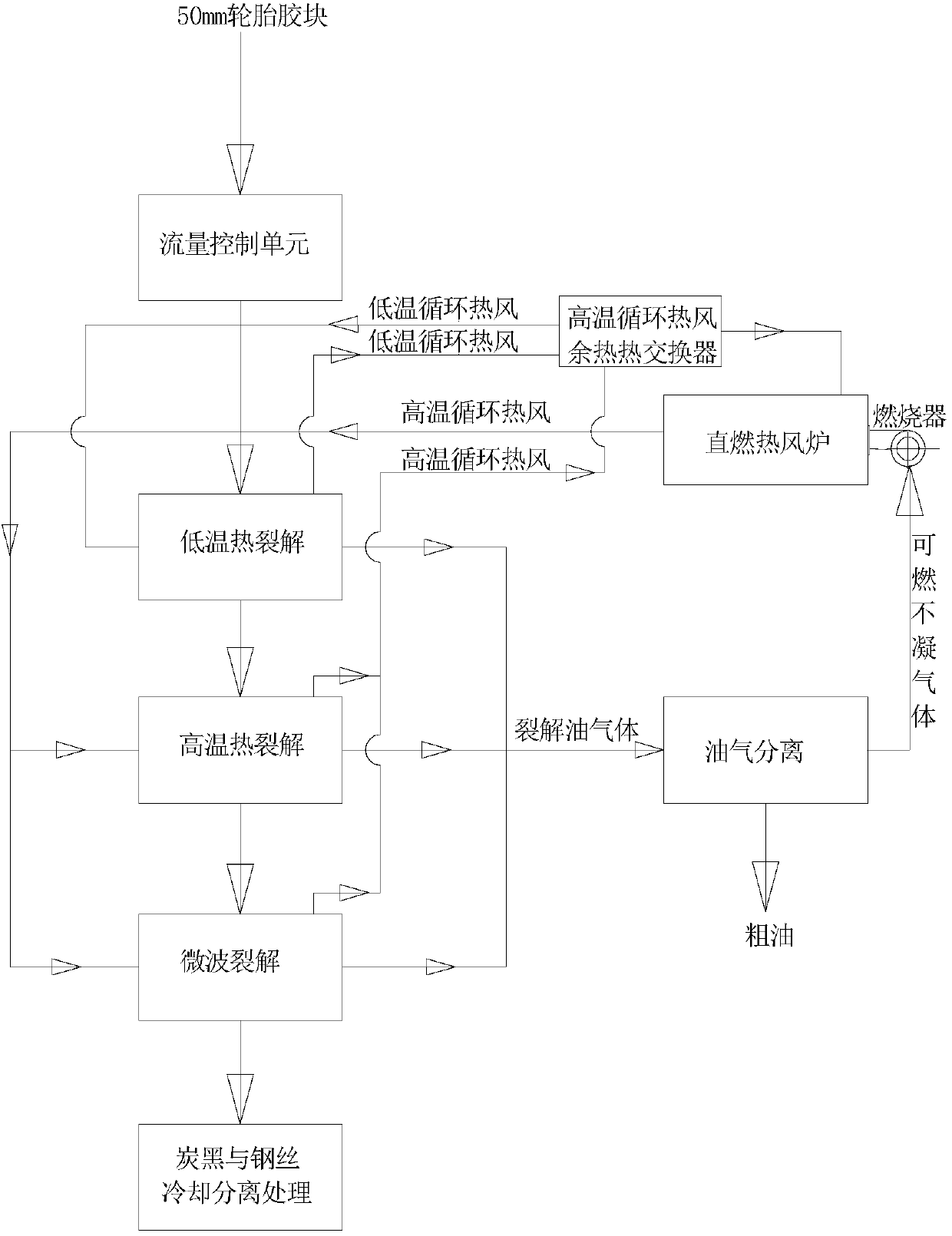

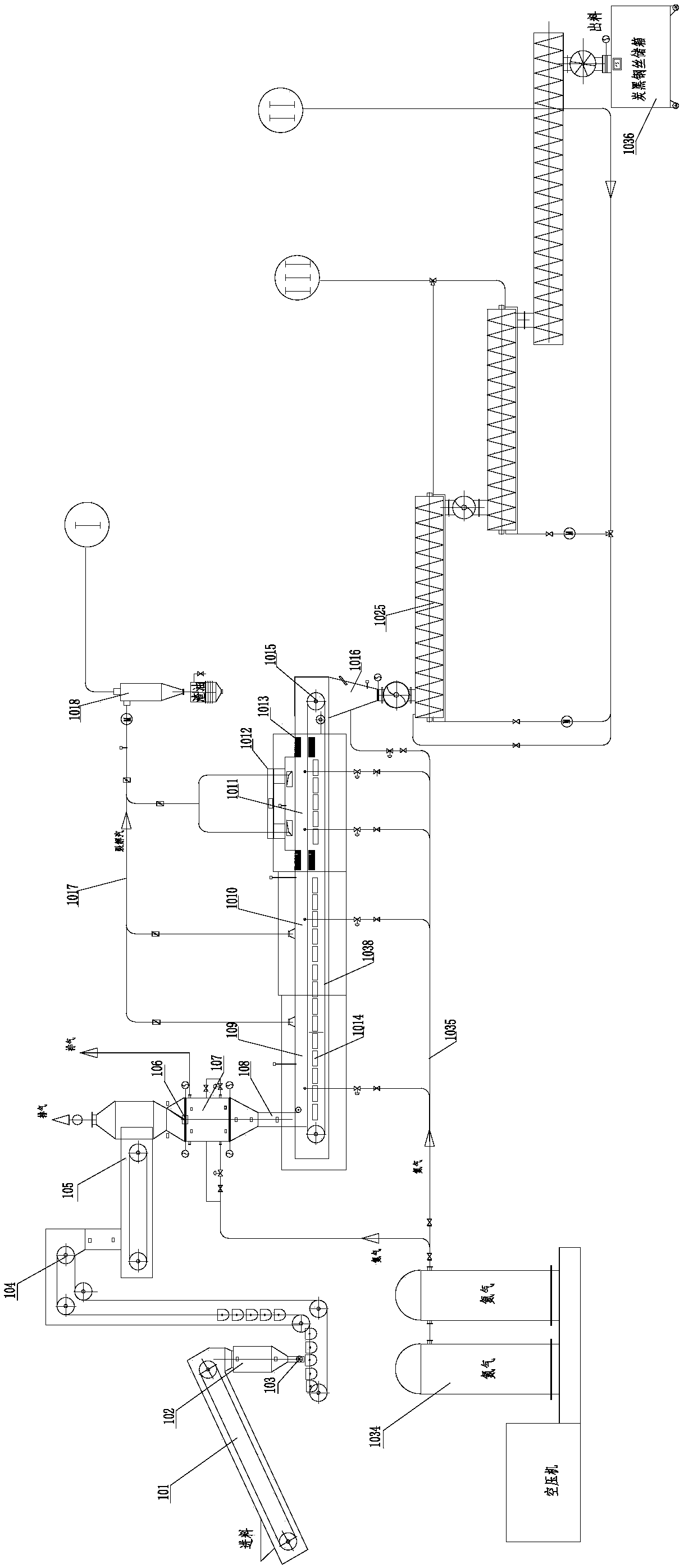

Method and system for cracking waste rubber

PendingCN108018062ARapid lysisReduce energy consumptionPigmenting treatmentTransportation and packagingMicrowaveWaste rubber

The invention provides a method and a system for cracking waste rubber. The waste rubber is sequentially sent to a low-temperature thermal cracking chamber, a high-temperature thermal cracking chamberand a microwave cracking chamber which respectively have an oxygen-free or oxygen-deficient environment, wherein thermal cracking of the waste rubber in the low-temperature thermal cracking chamber is carried out in a 200-400 DEG C environment, thermal cracking in the high-temperature thermal cracking chamber is carried out in a 500-800 DEG C environment, and microwave cracking in the microwave cracking chamber is carried out in a 500-800 DEG C environment; a cracking oil gas generated in the cracking process is continuously discharged from the low-temperature thermal cracking chamber, the high-temperature thermal cracking chamber and the microwave cracking chamber; and solids generated in the cracking process are recovered. The method and the system can effectively reduce the energy consumption in the cracking process and improve the cracking efficiency of the waste tire and the quality of cracked carbon black.

Owner:江苏林达智思环保科技有限公司

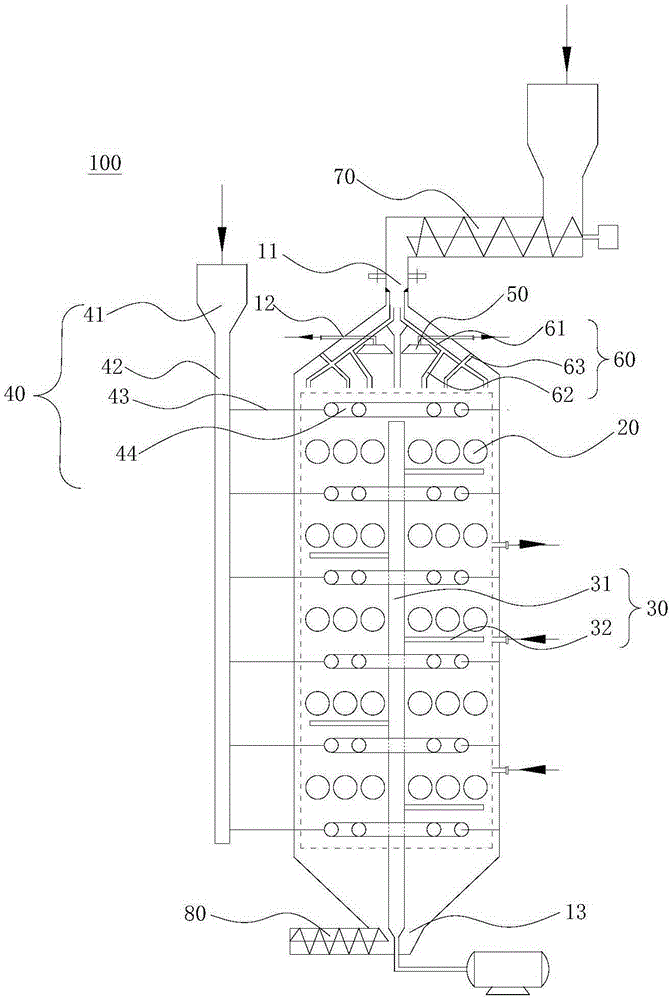

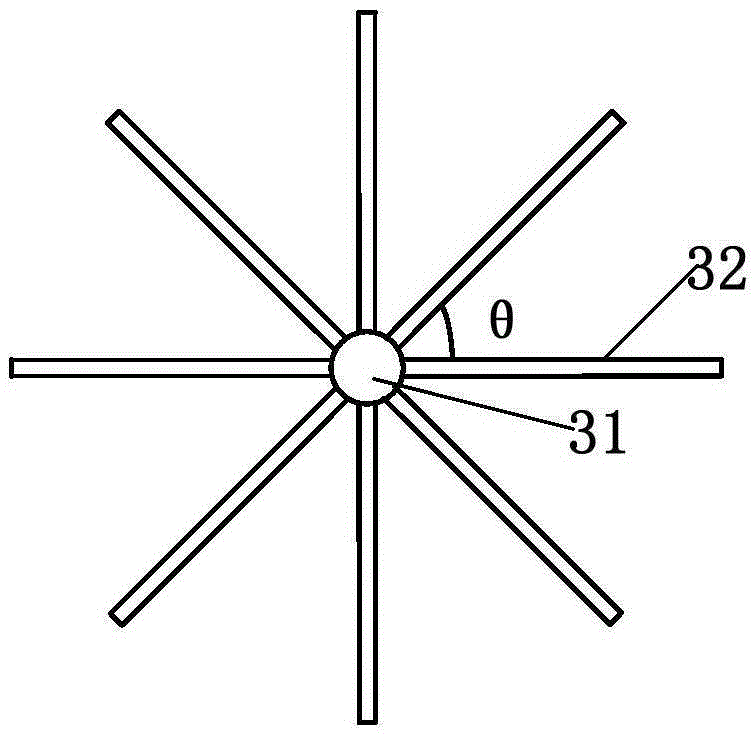

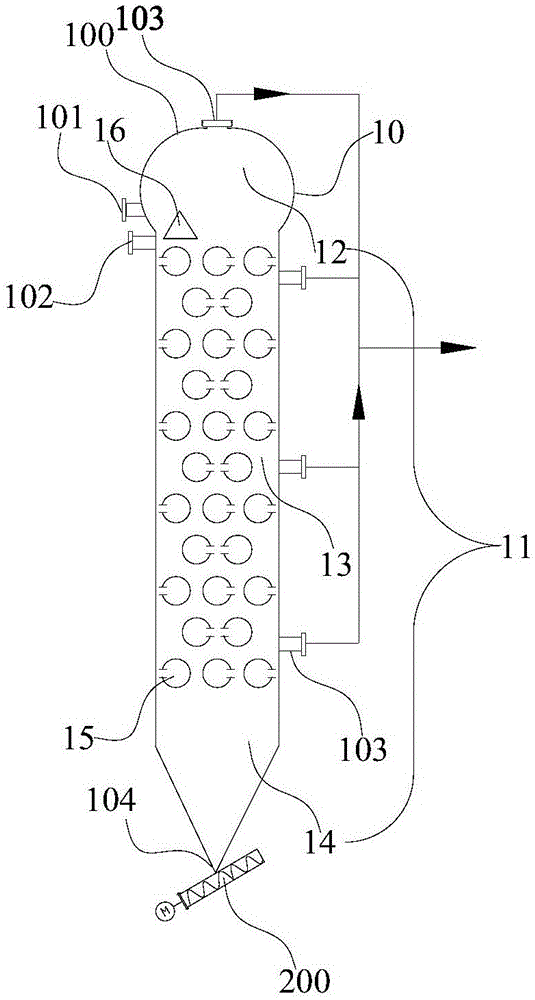

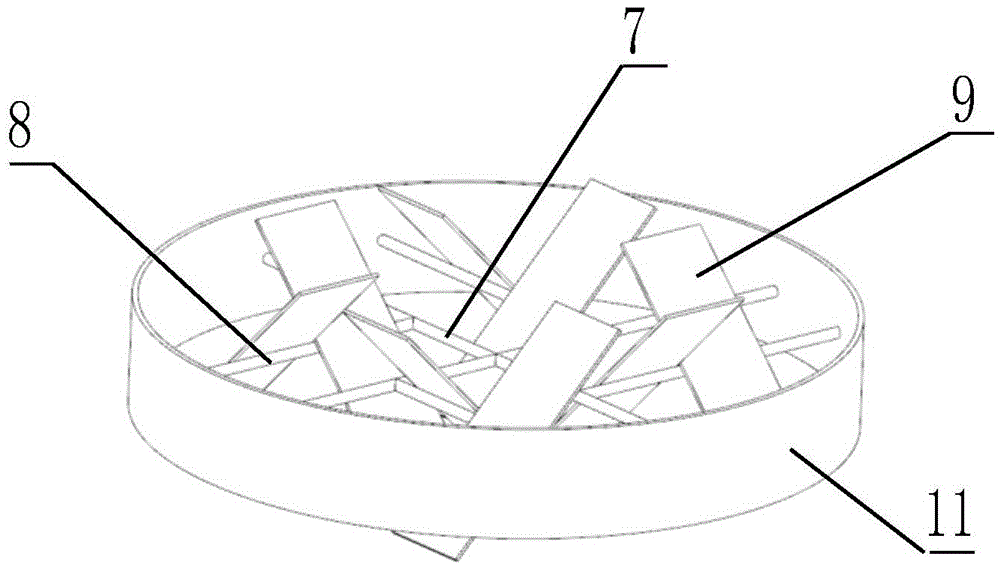

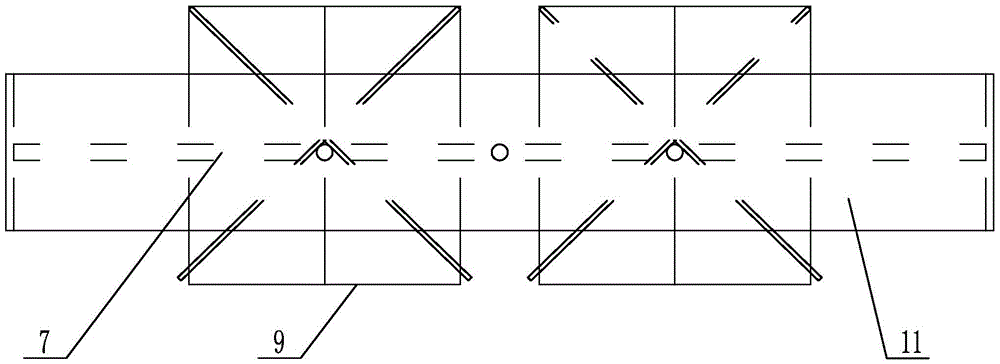

Coal flash pyrolysis system and method

ActiveCN105154120AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationSlagTar

The invention discloses a coal flash pyrolysis system and method. The coal flash pyrolysis system comprises a flash pyrolysis reactor, a slag cooler and a cooling device. The flash pyrolysis reactor comprises a reactor body, multiple layers of heat storage type radiant tubes, a coal inlet, a distributor, a distribution gas inlet, multiple pyrolysis gas outlets and a semicoke outlet. The slag cooler is connected with the semicoke outlet and is suitable for cooling semicoke. The cooling device is connected with the pyrolysis gas outlets and is suitable for cooling pyrolysis gas so that tar and fuel gas can be obtained. The system can significantly increase the tar yield and greatly simplify the flash pyrolysis reaction technological process.

Owner:SHENWU TECH GRP CO LTD

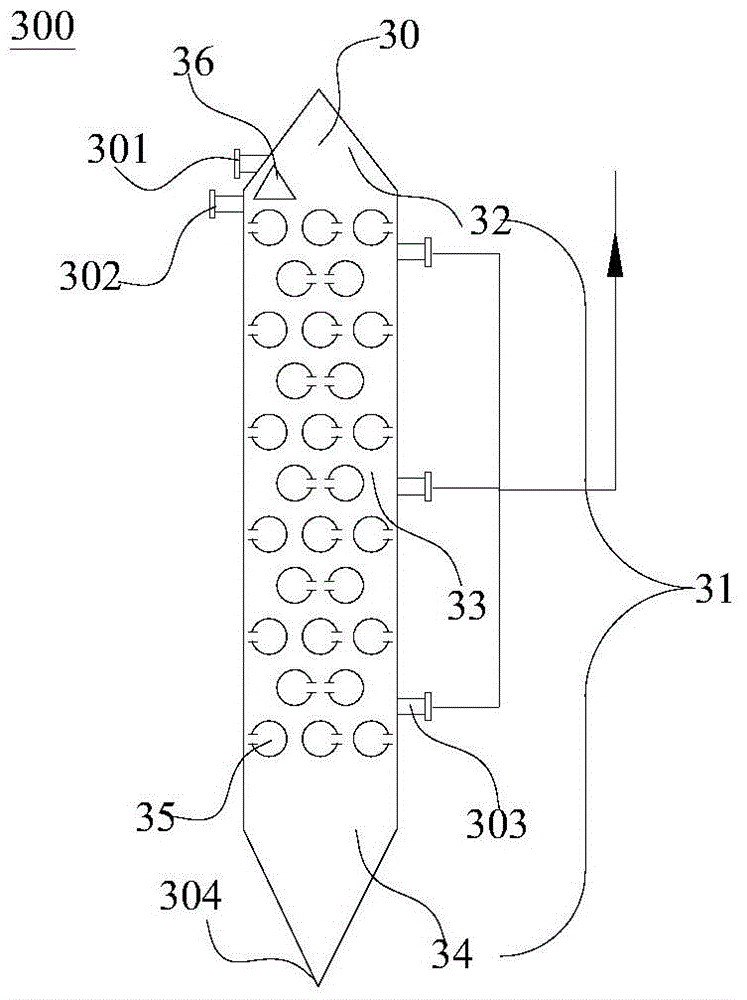

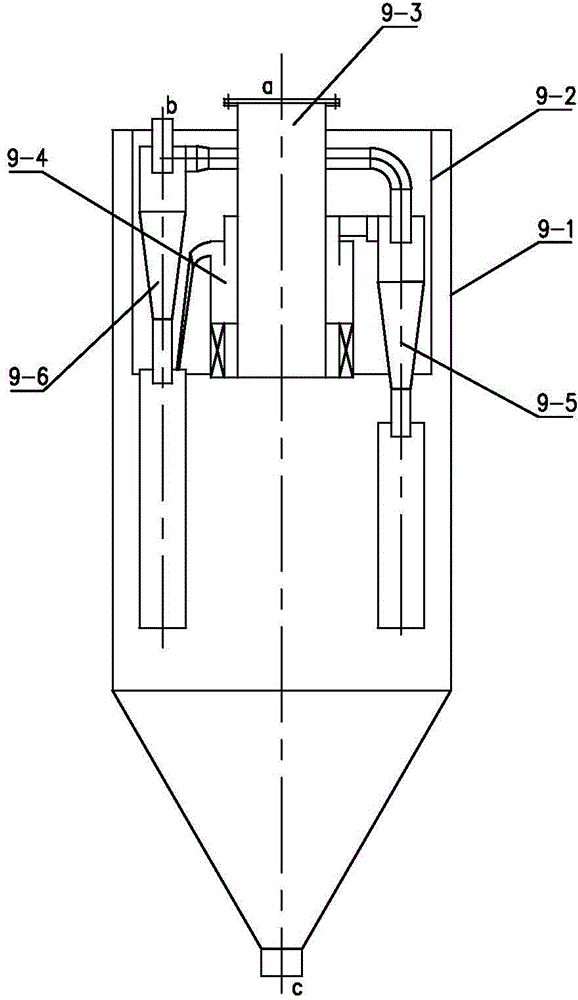

Rapid biomass pyrogenation system and method

ActiveCN105176563AEvenly dispersedImprove running stabilityBiofuelsLiquid hydrocarbon mixture productionSpray towerProcess engineering

The invention discloses a rapid biomass pyrogenation system and method. The system comprises a rapid pyrogenation reactor, a residue cooling machine and a spraying tower. The rapid pyrogenation reactor comprises a reactor body, a multi-layer heat storage type radiation pipe, a biomass inlet, a material distributor, a distribution gas inlet, a plurality of pyrogenation gas outlets and a semicoke outlet. The residue cooling machine is connected with the semicoke outlet and suitable for cooling semicoke. The spraying tower is connected with the pyrogenation gas outlet and suitable for spraying pyrogenation gas through cooling liquid so that bio-oil and fuel gas can be obtained. The system can convert biomass into bio-oil with high value-added, and therefore efficient and clean utilization of biomass is achieved, and the rapid pyrogenation reaction technological process is greatly simplified.

Owner:SHENWU TECH GRP CO LTD

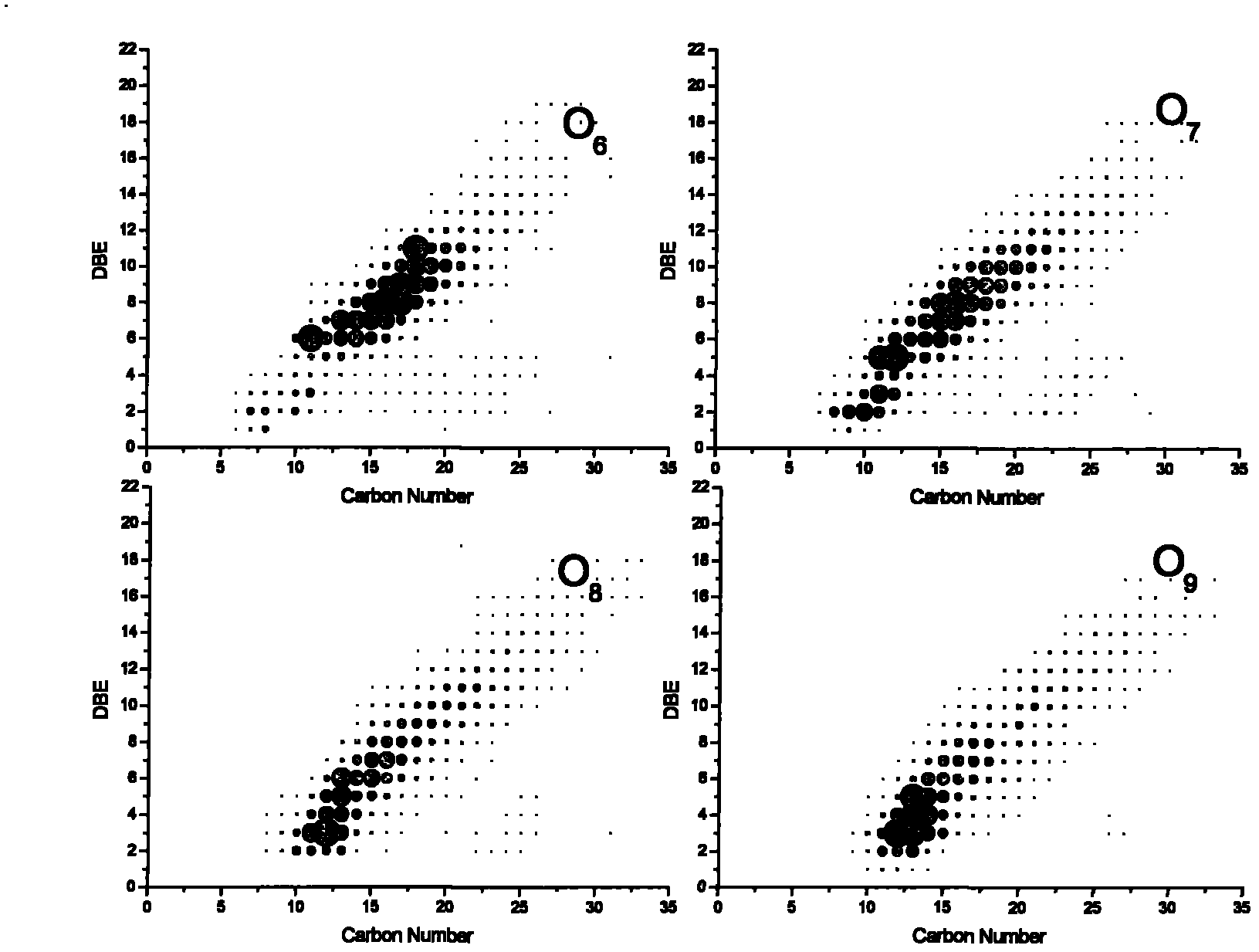

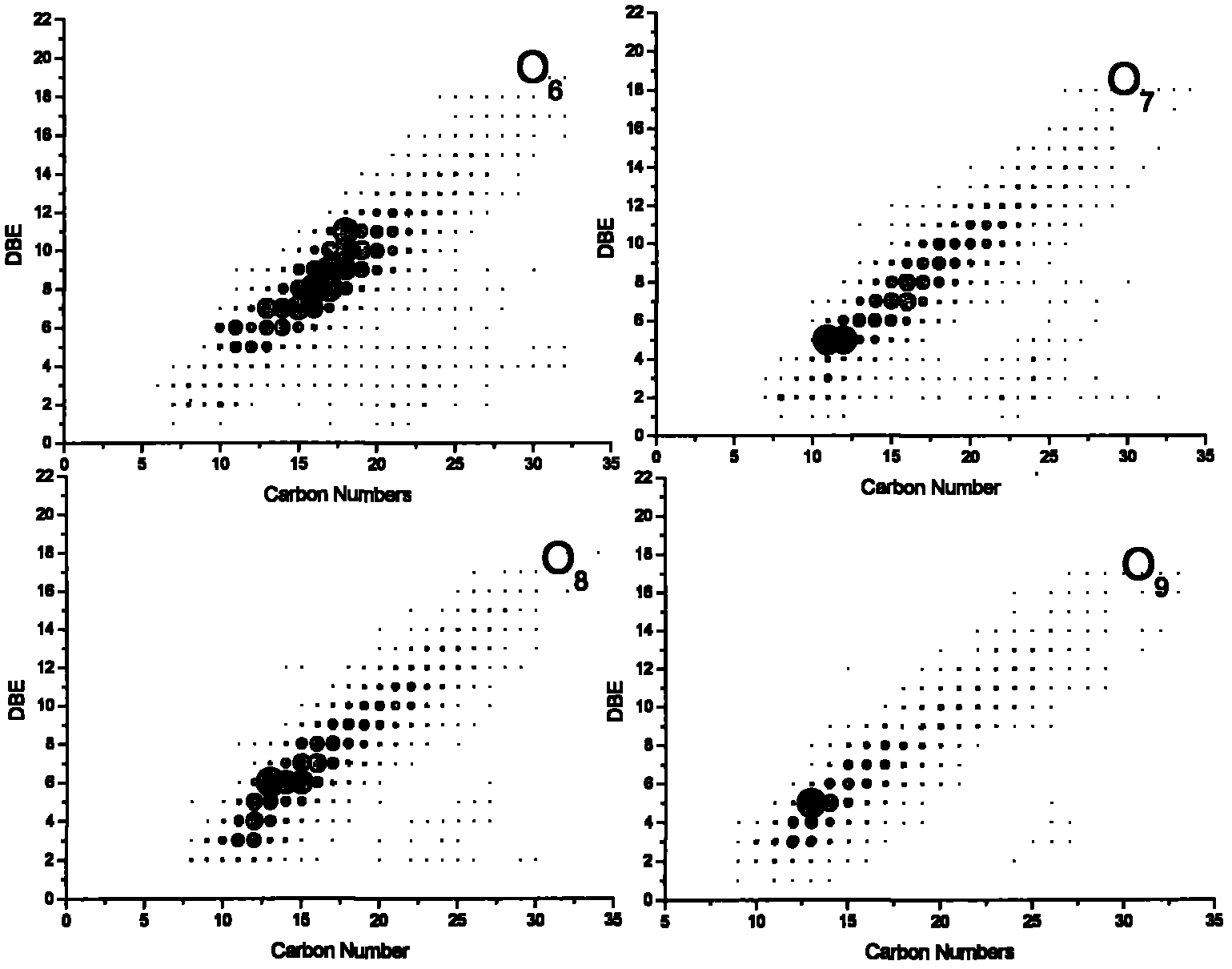

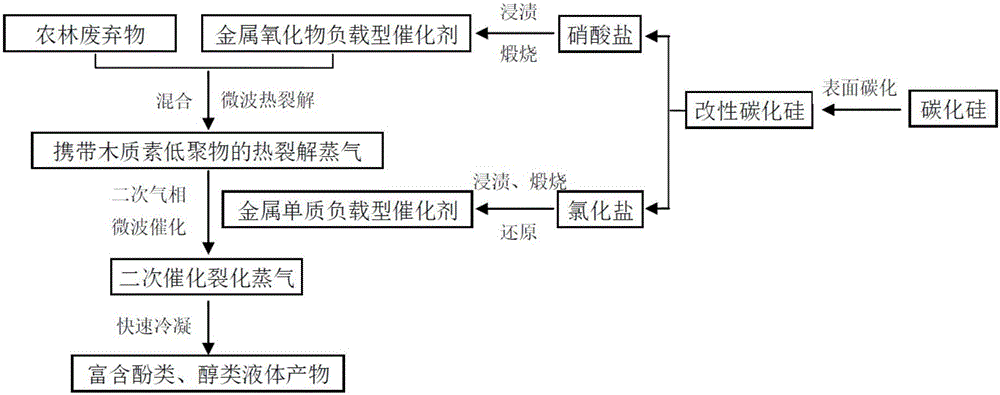

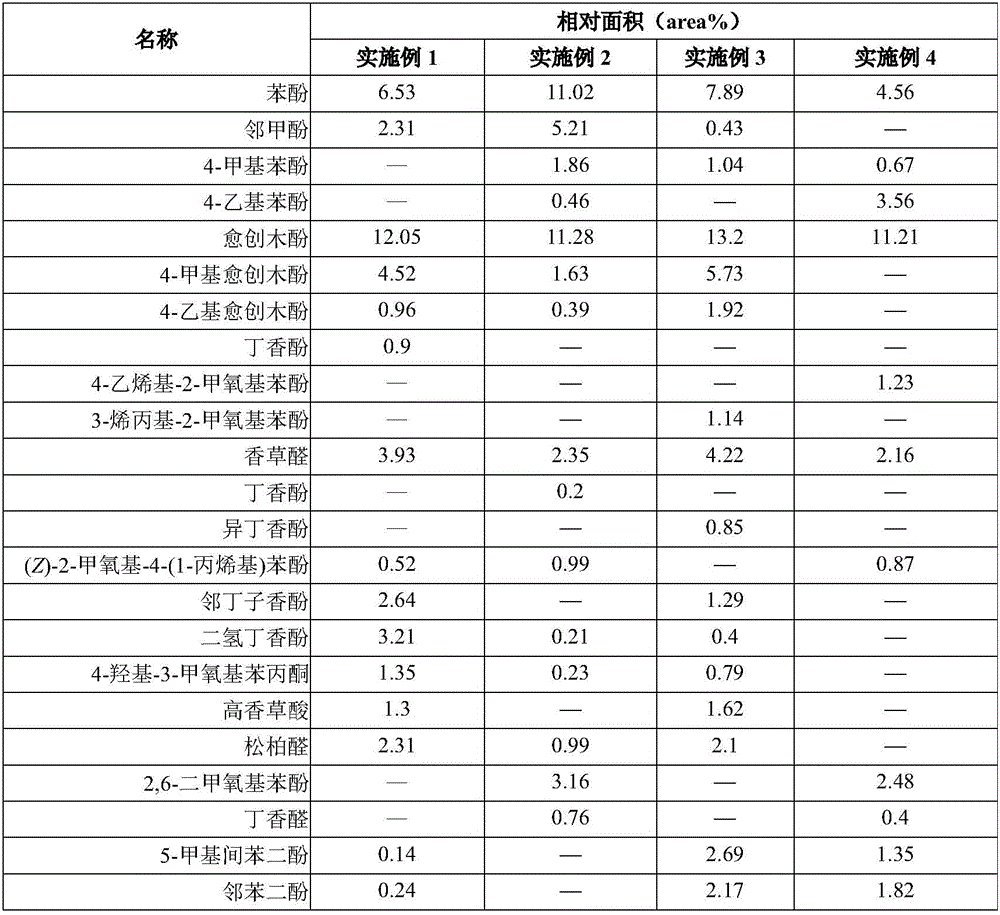

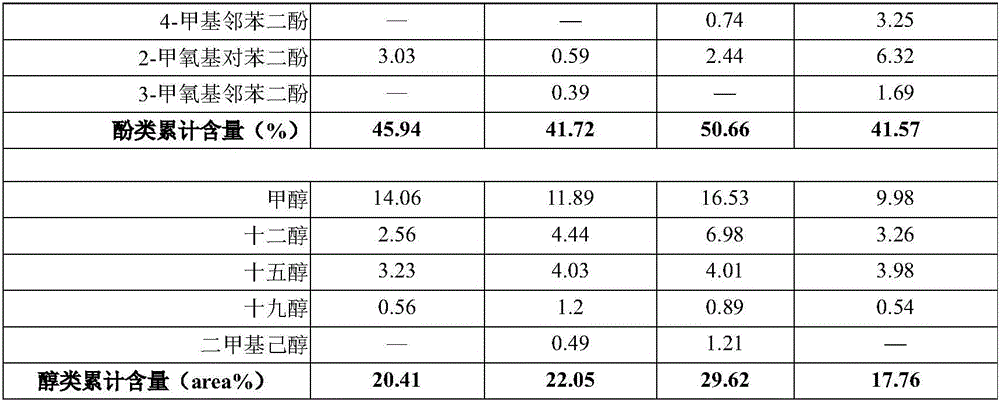

Method for preparing liquid product containing rich phenols and alcohols through microwave catalytic thermal cracking of forestry and agricultural residues

ActiveCN106635110AReserved functionImprove absorbing performancePhysical/chemical process catalystsLiquid hydrocarbon mixture productionLiquid productAlcohol

The invention discloses a method for preparing a liquid product containing rich phenols and alcohols through microwave catalytic thermal cracking of forestry and agricultural residues and belongs to the technical field of biomass energy. The method is a new method for obtaining the liquid product containing rich phenols and alcohols by organically combining microwave absorbent silicon carbide with a catalytic active metal component and through primary solid-phase microwave catalytic thermal cracking and secondary gas-phase cracking reaction, and resourceful conversion and high-value utilization of the forestry and agricultural residues are promoted.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing hydrocarbon type oil and hydrochloric acid through pyrolytic-catalytic plastic and device

InactiveCN102517062AIncreased pyrolysisShort cycleLiquid hydrocarbon mixture productionPreparation from chloridesFractionationMixed gas

The invention discloses a method for preparing hydrocarbon type oil and hydrochloric acid through pyrolytic-catalytic plastic and a device. The method comprises the following steps of: crushing waste plastic containing chlorine, feeding into a low-temperature fluidized bed through a spiral feeder, leading the plastic to generate low-temperature pyrolysis under the atmosphere of N2 in the bed, separating out the chlorine in the plastic in a form of HCI (Hydrogen Chloride) gas, entering a washing tower after the HCI gas is separated by a cyclone separator and being absorbed in the washing tower to prepare the hydrochloric acid; and leading solid residues generated by the low-temperature pyrolysis into a high-temperature fluidized bed through a reefed line, introducing mixed gas of N2 / O2 into the high-temperature fluidized bed, carrying out combustion and heat release on a part of hydrocarbon residues and O2, pyrolyzing the unreacted solid residues under the high-temperature anoxic atmosphere to generate macromolecule gaseous hydrocarbons, entering a catalyst bed after the macromolecule gaseous hydrocarbons are subjected to gas-solid separation, generating micromolecule hydrocarbons under the action of a catalyst and obtaining the various hydrocarbon type oil after condensation and fractionation.

Owner:SOUTHEAST UNIV

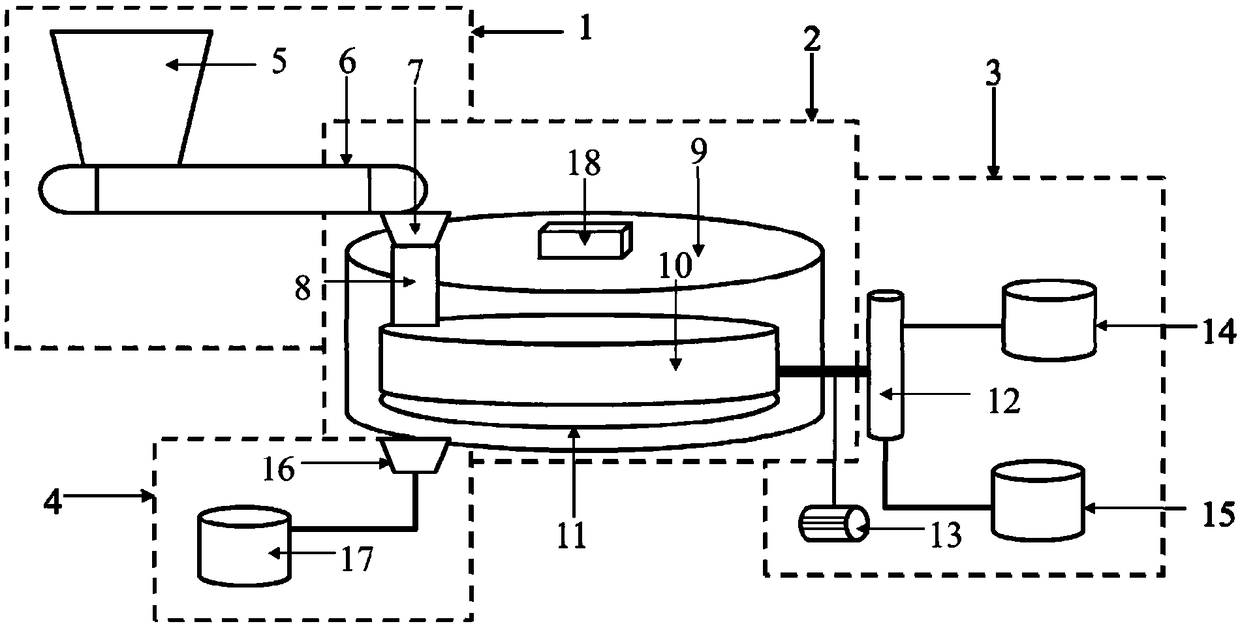

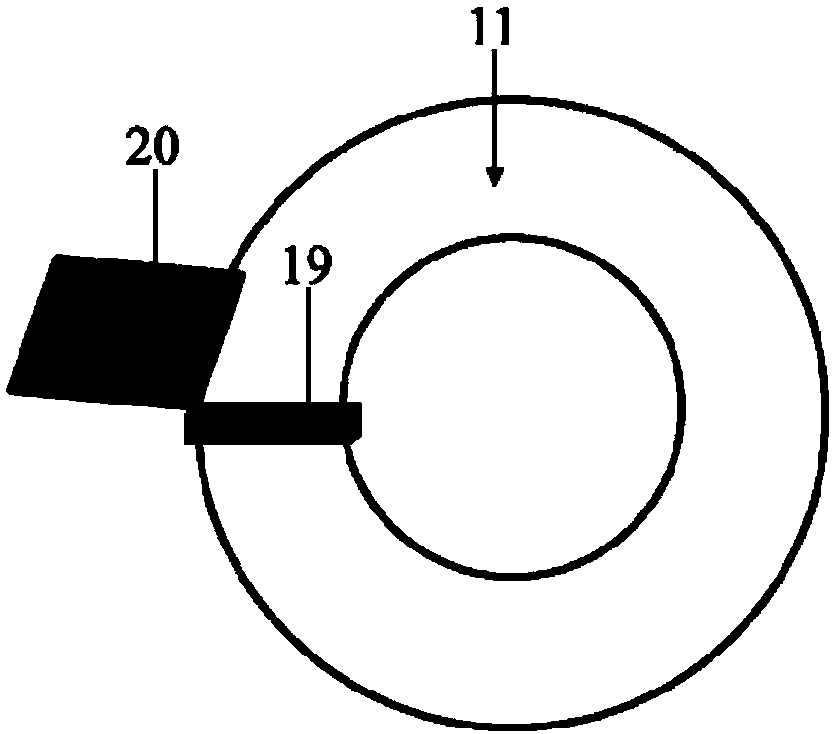

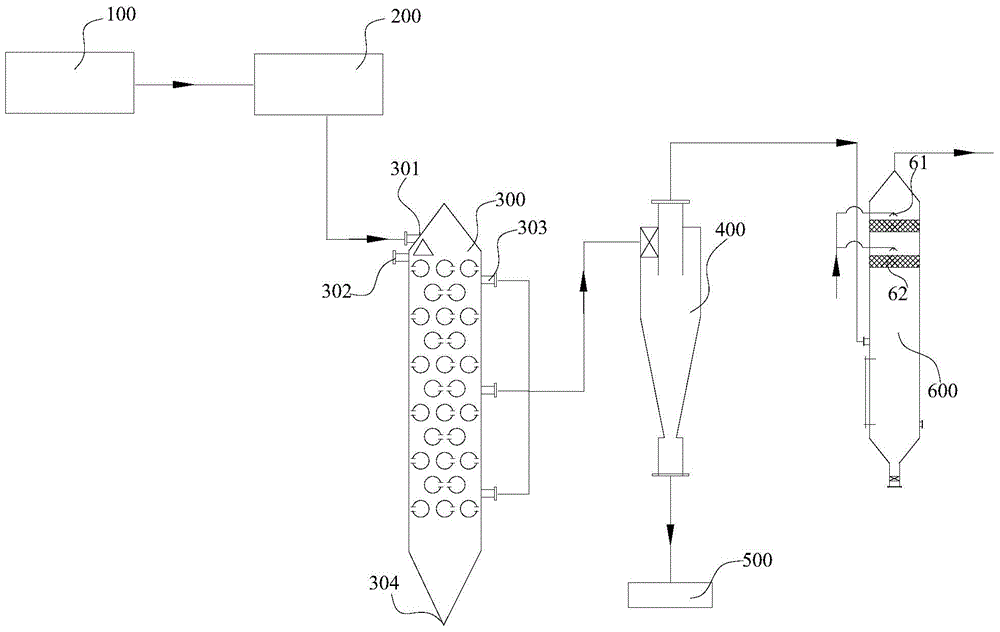

Oil-based drill cutting continuous microwave pyrolysis device and process

ActiveCN108203217APrevent leakageAvoid contactSludge treatment by pyrolysisByproduct vaporizationThermodynamicsMicrowave pyrolysis

The invention discloses an oil-based drill cutting continuous microwave pyrolysis device. The device comprises a feeding device, a microwave reaction device, an oil and gas cooling recovery device anda pyrolysis residue cooling device. The feeding device comprises a feeding bin and a belt conveyor. The microwave reaction device comprises a microwave reaction chamber, a waveguide feed port is arranged at the top end of the microwave reaction chamber, and a quartz chamber is arranged inside the microwave reaction chamber. The quartz chamber is composed of a fixed ring wall and a rotating tray,and the top end of the quartz chamber is open. A feeding buffer bin is disposed below the end of the belt conveyor and communicated with the quartz chamber through a chute. A discharging port is arranged on the fixed ring wall at the position above the corresponding discharge buffer bin. The discharging port is provided with a scraper plate, and the scraper plate is connected to the discharge buffer bin through a chute. The device can achieve continuous uniform feeding and continuous discharging without blockage in the closed environment, prevents leakage of microwaves, and prolongs service life.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

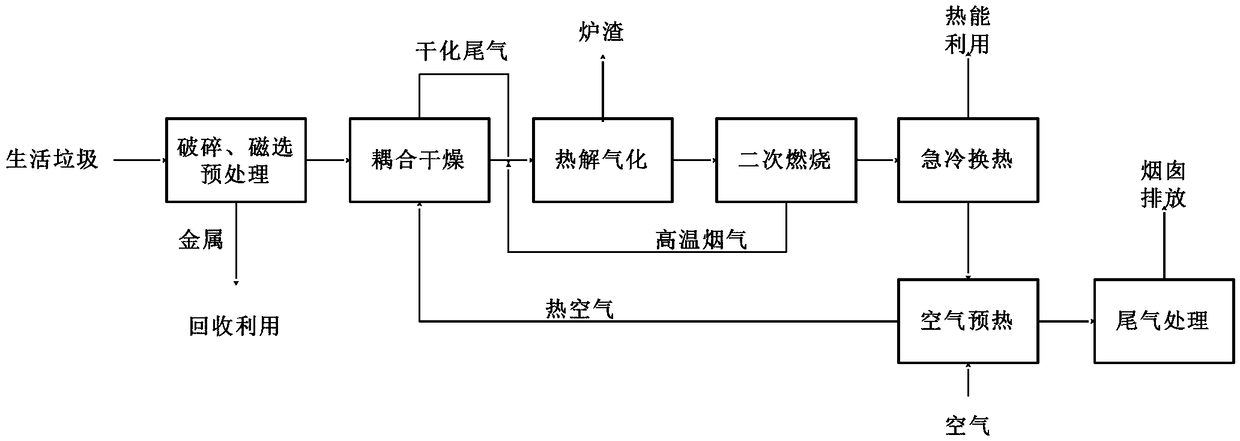

Treatment process and system for coupling, drying and pyrolyzing household garbage

InactiveCN109185887AControl moisture contentImprove pyrolysis efficiencyIncinerator apparatusCombined combustion mitigationAir preheaterCombustion chamber

The invention discloses a treatment process and system for coupling, drying and pyrolyzing household garbage. The treatment process includes the steps that (1) the household garbage is subjected to crushing and magnetic separation pretreatment; (2) the household garbage is subjected to biothermal air coupling and drying treatment; (3) the household garbage is subjected to pyrolysis gasification through a pyrolysis gasification furnace; (4) pyrolysis produces combustible gas into a secondary combustion chamber for secondary combustion; (5) secondary combustion produces high temperature flue gasto pass through a quenching heat exchanger; (6) after the heat exchange, the flue gas is exchanged with the air through an air preheater; and (7) the flue gas is finally discharged through an exhaustgas treatment system. The treatment system includes a crushing magnetic separation device, a biothermal air coupling and drying treatment device, the pyrolysis gasification furnace, the secondary combustion chamber, the quenching heat exchanger, the air preheater, the exhaust gas treatment system, and a chimney. The system has the advantages of high pyrolysis treatment efficiency of the householdgarbage, high stability of garbage pyrolysis and gasification, high controllability of the process, and low difficulty in treatment of exhaust gas, and can be widely applied to the technical field ofhousehold garbage pyrolysis treatment.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

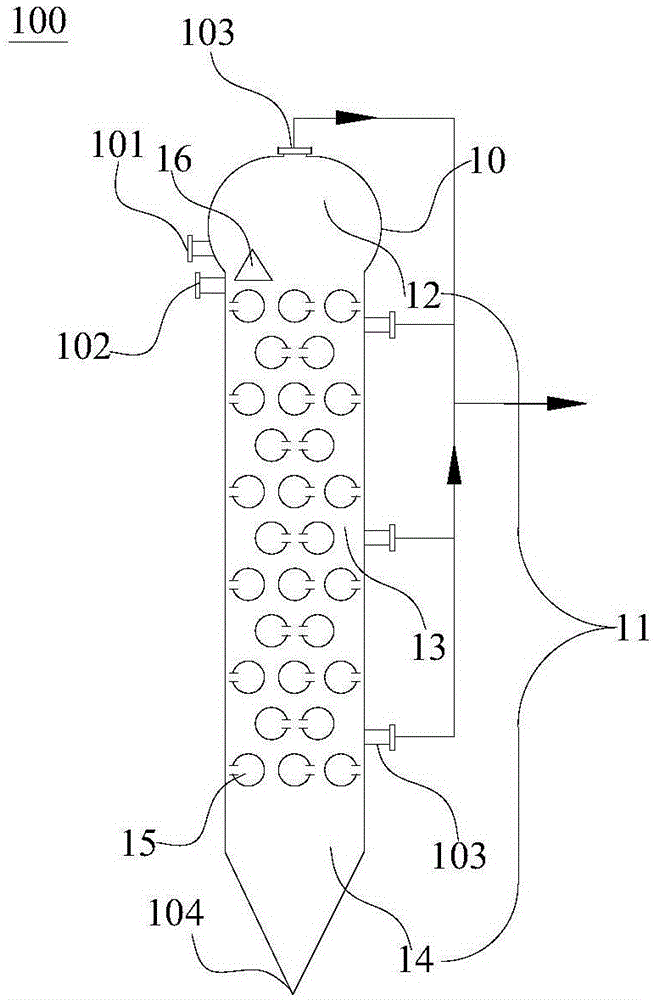

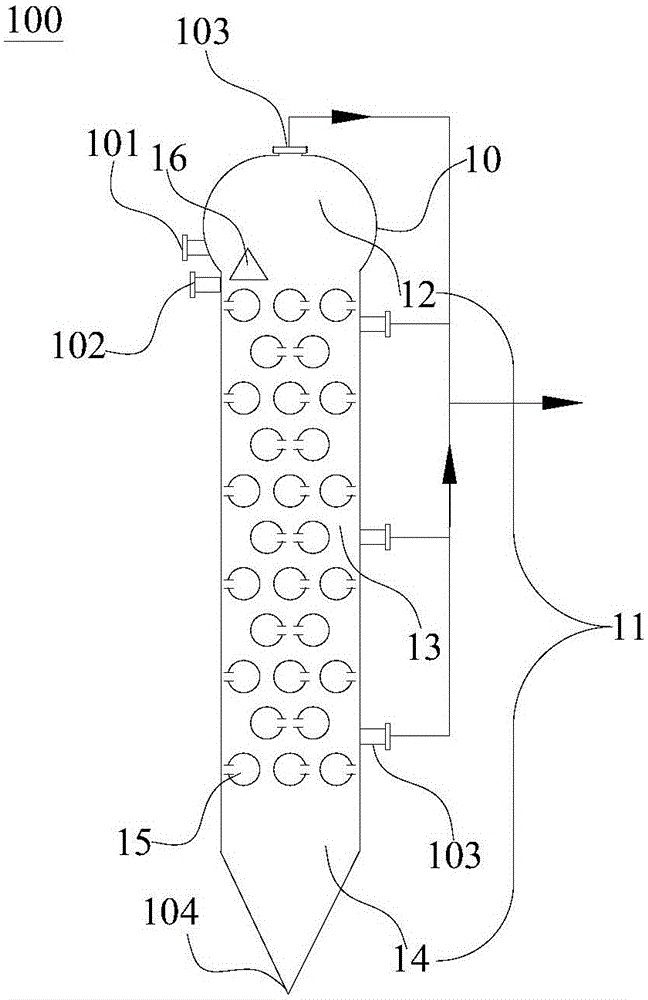

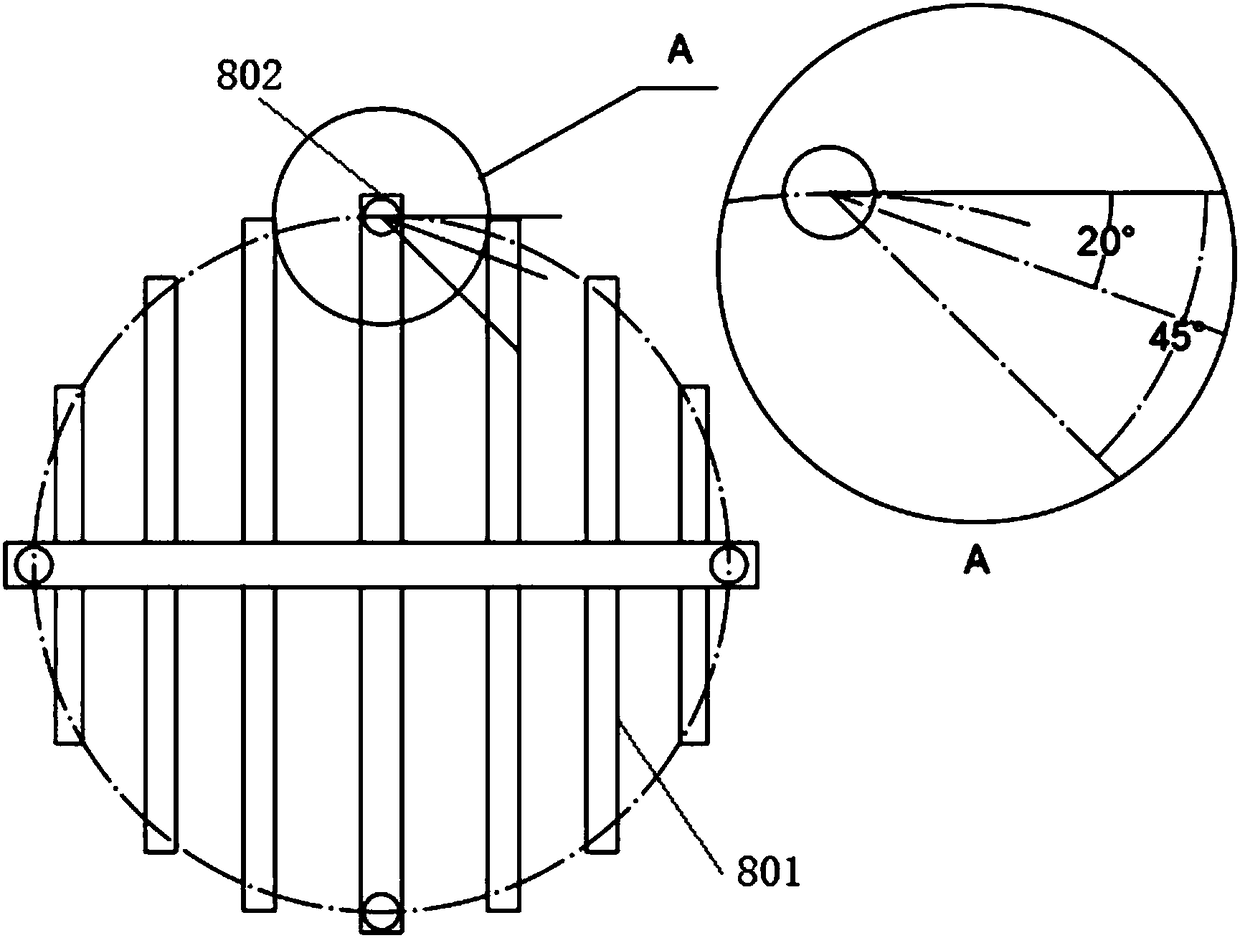

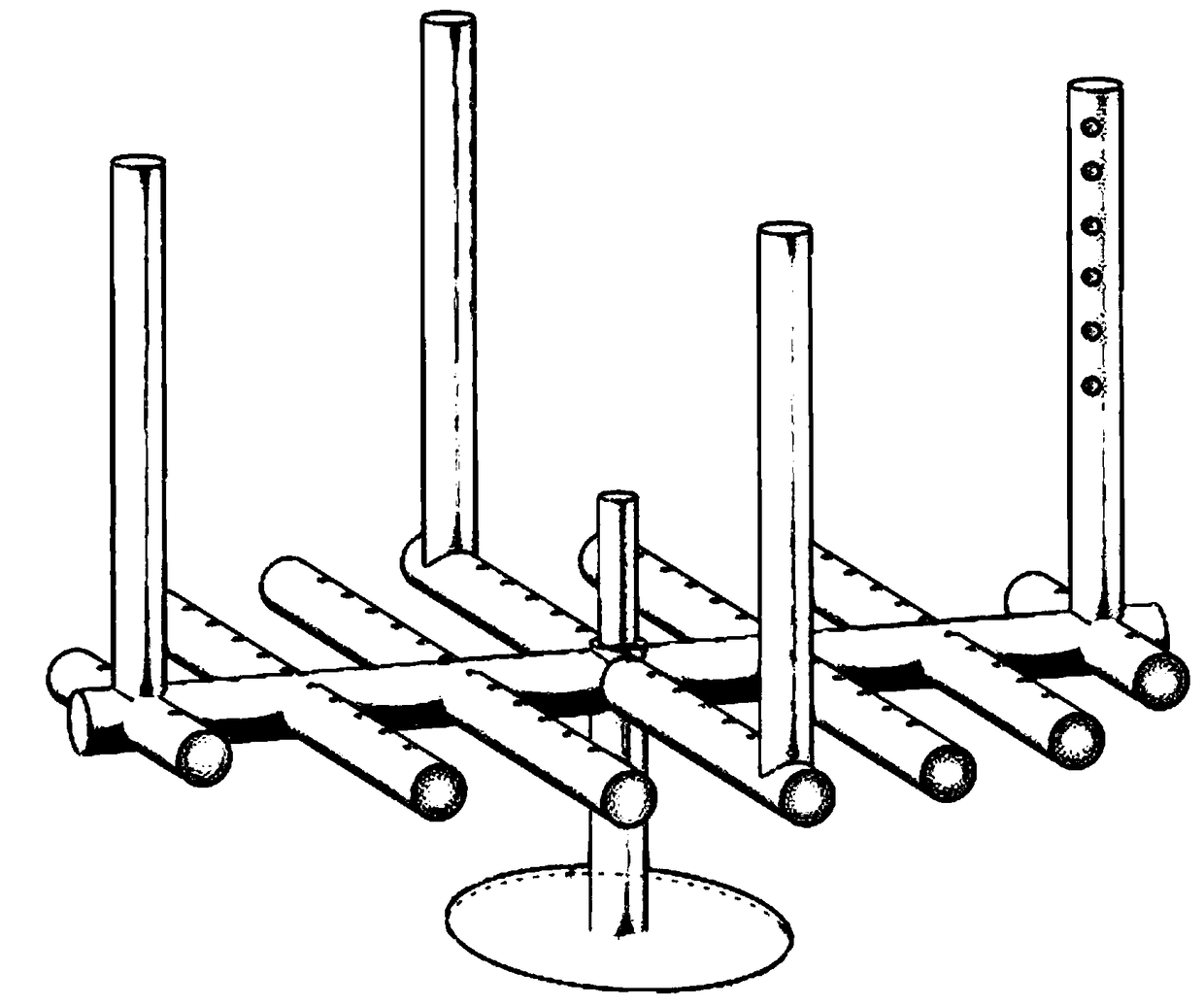

Flash pyrolysis reaction device

ActiveCN105154119AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationDistributorStorage type

The invention discloses a flash pyrolysis reaction device. The flash pyrolysis reaction device comprises a reactor, multiple layers of heat storage type radiant tubes, a distributor, a material inlet, a distribution gas inlet, multiple pyrolysis gas outlets and a semicoke outlet. The reactor comprises a reactor body, and a reaction space is defined in the reactor body and forms a dispersion zone, a pyrolysis zone and a discharge zone from top to bottom. The multiple layers of heat storage type radiant tubes are distributed at intervals in the pyrolysis zone in the height direction of the reactor body, and each layer of heat storage type radiant tubes comprises multiple heat storage type radiant tubes distributed at intervals in the horizontal direction. The material inlet is located in the position, above the distributor, in the dispersion area. The distribution gas inlet is located in the dispersion zone and communicated with the distributor so that materials in the distributor can be conveniently blown out through distribution gas to enter the dispersion zone and then evenly fall into the pyrolysis zone. The multiple pyrolysis gas outlets are formed in the dispersion zone and / or the pyrolysis zone. The semicoke outlet is formed in the discharge zone. The device can significantly increase the tar yield and greatly simplify the flash pyrolysis reaction technological process.

Owner:SHENWU TECH GRP CO LTD

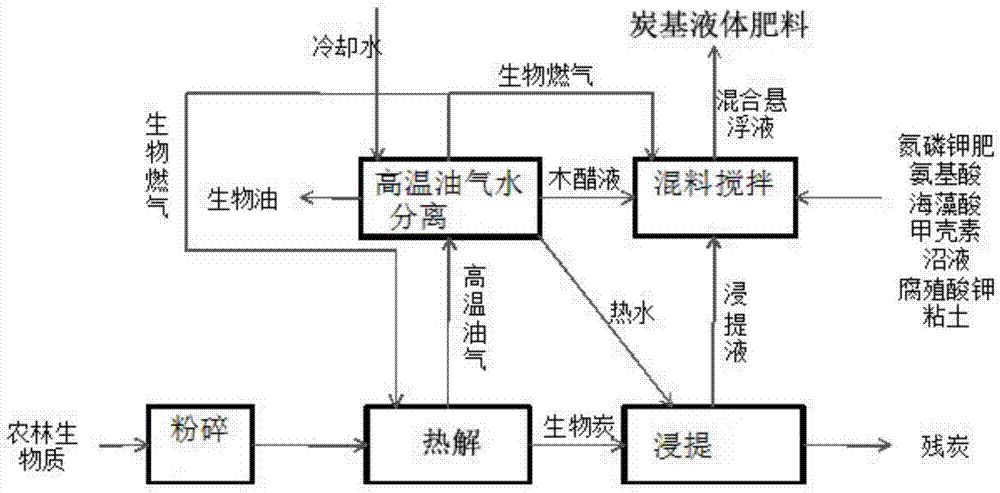

Carbon-based liquid fertilizer, and system and method for production of the same

InactiveCN108002895AIncrease productionReduce the amount neededGaseous fuelsWaste based fuelChitin formationSlurry

The invention relates to a carbon-based liquid fertilizer. The carbon-based liquid fertilizer is prepared from the following components in parts by weight: 1 to 3 parts of wood vinegar, 2 to 6 parts of a biomass charcoal extract, 1 to 2 parts of biogas slurry, 0.5 to 3 parts of a suspending concentrate, 3 to 8 parts of a nitrogen-phosphorus-potassium fertilizer, 1 to 3 parts of potassium humate, 0.5 to 2 parts of alginic acid, 0.5 to 2 parts of chitin and 0.5 to 2 parts of amino acid. The invention also relates to a system and a method for production of the carbon-based liquid fertilizer. Through application of the carbon-based liquid fertilizer, the yield of a crop is more obviously improved, and the usage amount of a chemical fertilizer can be effectively reduced.

Owner:北京源农炭肥技术有限公司

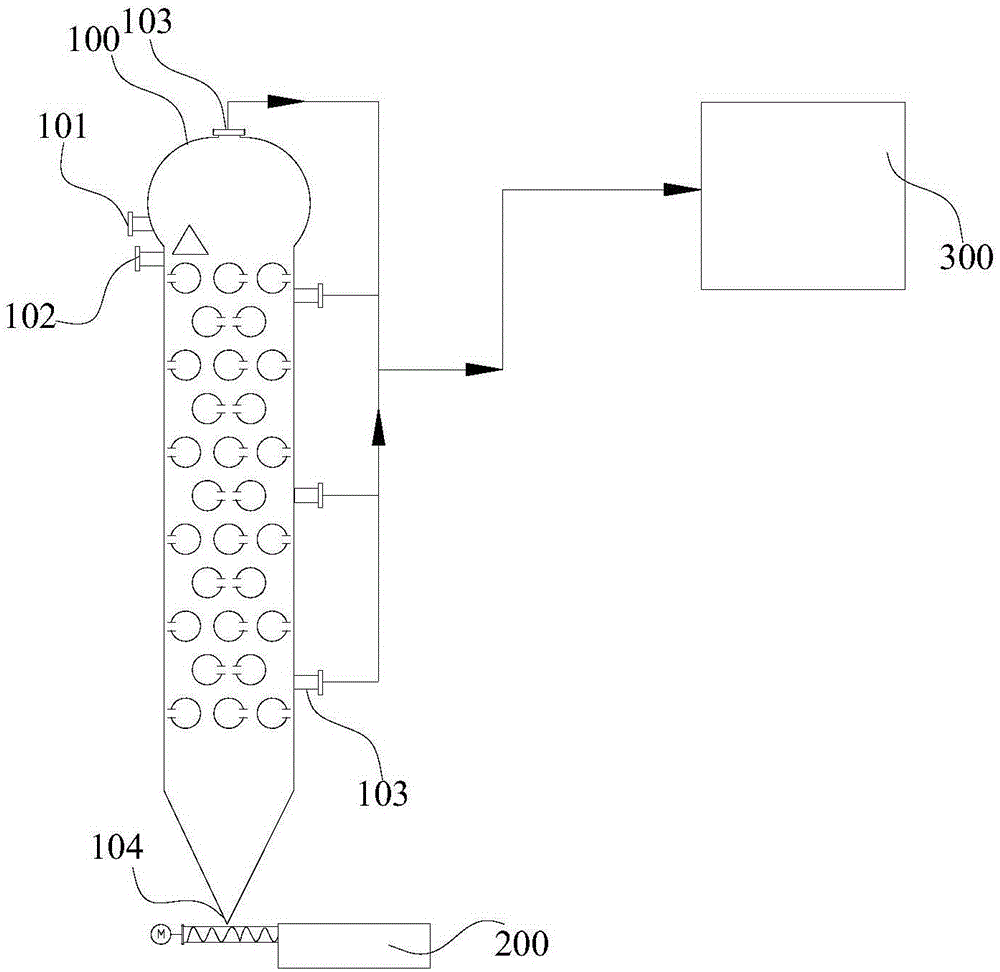

Rapid tire pyrolysis system and method

The invention discloses a rapid tire pyrolysis system and a rapid tire pyrolysis method. The system comprises a steel wire drawing machine, a grinder, a rapid pyrolysis reactor, a cyclone separator, a slag cooler and a spray tower, wherein the rapid pyrolysis reactor comprises a reactor body, a multi-layer heat storage type radiating tube, a rubber particle inlet, a distributor, a distribution gas inlet, a plurality of pyrolysis gas outlets and a carbon black outlet; the steel wire drawing machine is suitable for drawing a steel wire in a tire; the grinder is connected with the steel wire drawing machine; the cyclone separator is connected with the pyrolysis gas outlets; the slag cooler is connected with the cyclone separator; the spray tower is connected with the cyclone separator and is suitable for spraying purified pyrolysis gas by using cooling liquid in order to obtain pyrolysis oil and fuel gas. According to the system, the utilization value of a waste tire can be maximized, the particle size of an obtained carbon black product is smaller, and subsequent grinding is not needed.

Owner:SHENWU TECH GRP CO LTD

Integrated complete system and process for coal pyrolysis and upgrading

ActiveCN104927889ALess investment in equipmentIncreased process reliabilityCoke quenchingIndirect heating destructive distillationCoal pyrolysisScrew conveyor

The invention relates to an integrated complete system and process for coal pyrolysis and upgrading. A drying pyrolysis unit, an upgraded coal cooling unit and a humidifying discharge unit are sequentially arranged along a process route in a connecting manner; by arranging the drying pyrolysis unit, coal drying and coal pyrolysis reaction are completed in the same rotary cylinder, so that equipment investment is effectively reduced and the process reliability is improved; by arranging the upgraded coal cooling unit, cold air is adopted for indirect cooling of materials in material distribution tube nests, the equipment is simple, the safety is high, yields of waste water and waste gas are low, and heat is recycled from hot air obtained after heat exchange; by arranging the humidifying discharge unit, a sprayer is adopted to spray water on the upgraded coal for humidifying in the process of the conveying the upgraded coal by a screw conveyer, so that the operation is simple and reliable, the water spraying amount can be adjusted according to the process demands, the product quality is good and the process is environment-friendly.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

Wind power blade waste pyrolysis incinerator and control method thereof

The invention discloses a wind power blade waste pyrolysis incinerator and a control method thereof. The wind power blade waste pyrolysis incinerator comprises an incinerator body; a cooling pipe is arranged at the exterior of the incinerator body; an opening is formed in the top of the incinerator body; a smoke vent communicating with the outside is formed in the upper end of the incinerator body; an ash discharge chute furnace is arranged at the bottom of the incinerator body; a working cavity is formed in the incinerator body; an electric control feed door, a spiral agitator, a gas supply and distributing device and an isolation hood are arranged in the incinerator body; the electric control feed door and the spiral agitator are driven by motors correspondingly; the electric control feed door is arranged between a drying zone and a pyrolysis zone; a plurality of through holes are formed in the electric control feed door; the spiral agitator is located in the pyrolysis zone and the combustion zone; the gas supply and distributing device is arranged at the bottom of a combustion zone, is connected with a spiral bearing and can rotate in the incinerator body; and the isolation hoodis arranged on the inner side of the gas supply device and is used for isolating the gas supply device and a wind power blade material. Wind power blade waste can be pyrolyzed and burnt fully, and pollution is reduced.

Owner:上海博士高环保成套工程有限公司

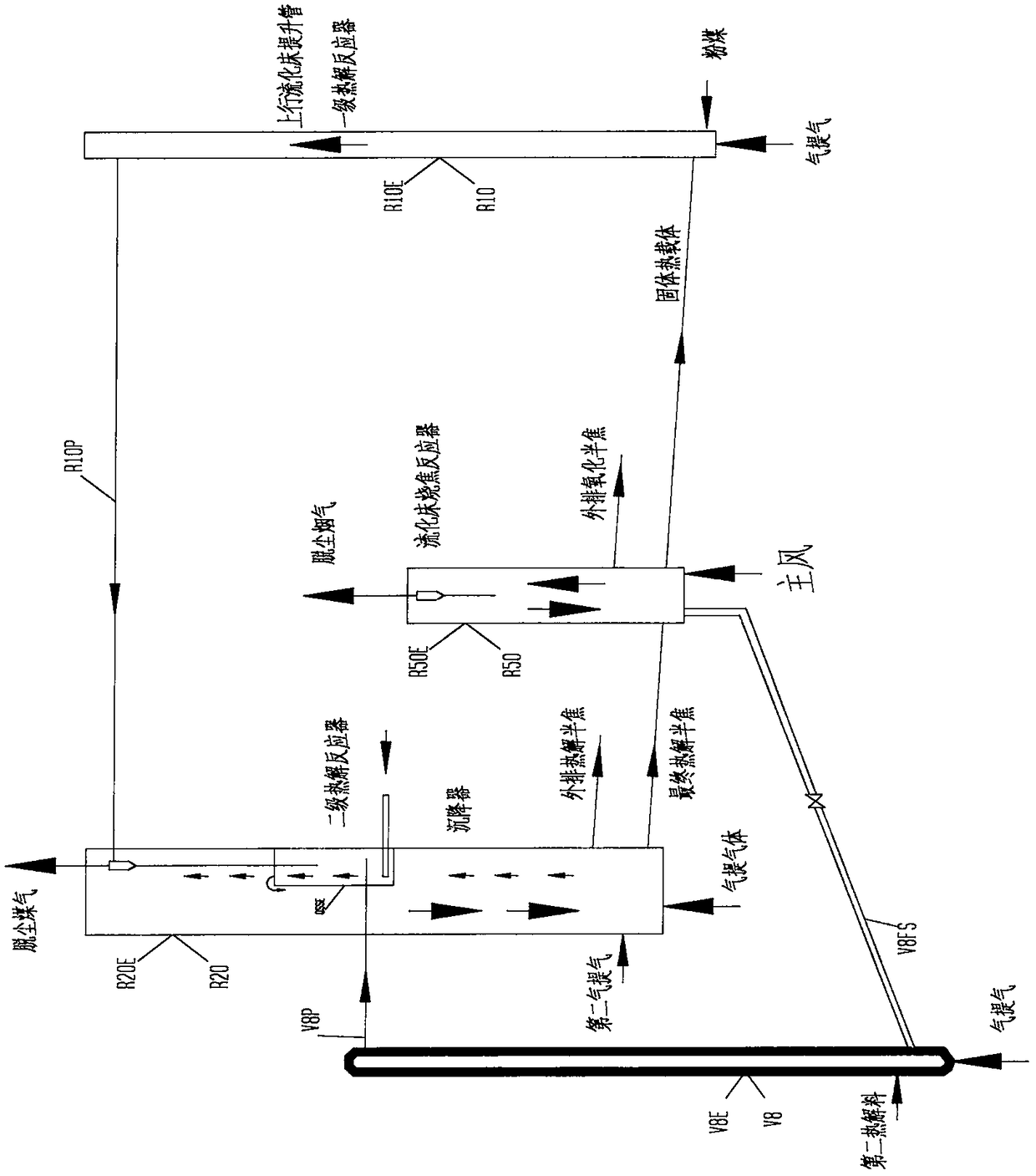

Down-flow gas semi-coke activated pulverized coal pyrolysis system and method

ActiveCN104449774AImprove pyrolysis efficiencyImprove dust removal efficiencyDirect heating destructive distillationGasification processes detailsCycloneFlue gas

The invention relates to a down-flow gas semi-coke activated pulverized coal pyrolysis system and method. The system is characterized in that a high-temperature flue gas heat exchanger is communicated with a second L-shaped valve, a first L-shaped valve, a vertical mill and an upward heating riser; the vertical mill is communicated with a dry pulverized coal surge bin; a cyclone mixer is communicated with a high-temperature semi-coke surge bin, the high-temperature flue gas heat exchanger, the dry pulverized coal surge bin and a downer reaction pipe; the downer reaction pipe is communicated with an oil-gas cyclone dust collector; the oil-gas cyclone dust collector is communicated with a semi-coke cooler and the upward heating riser; the upward heating riser is communicated with a primary cyclone dust collector; the primary cyclone dust collector is communicated with a secondary cyclone dust collector; the secondary cyclone dust collector is communicated with a ternary cyclone dust collector; the ternary cyclone dust collector is communicated with the high-temperature flue gas heat exchanger; and the primary cyclone dust collector, the secondary cyclone dust collector and the ternary cyclone dust collector are communicated with the high-temperature semi-coke surge bin. The system and the method can be used for improving the yield of coal tar and reducing the consumption of energy, the dust collectors discharge materials smoothly, and subsequent fine dust removal is carried out stably.

Owner:王树宽

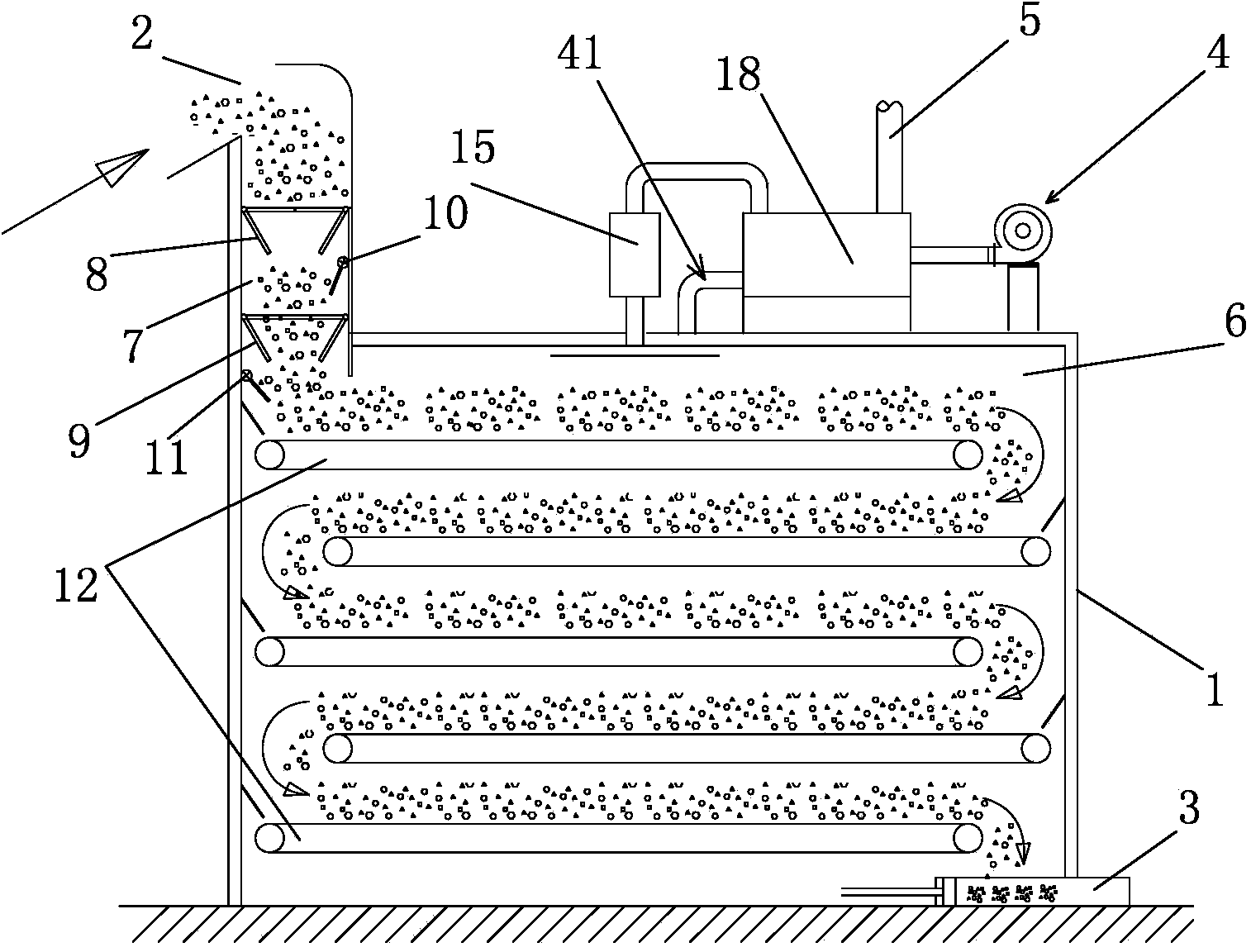

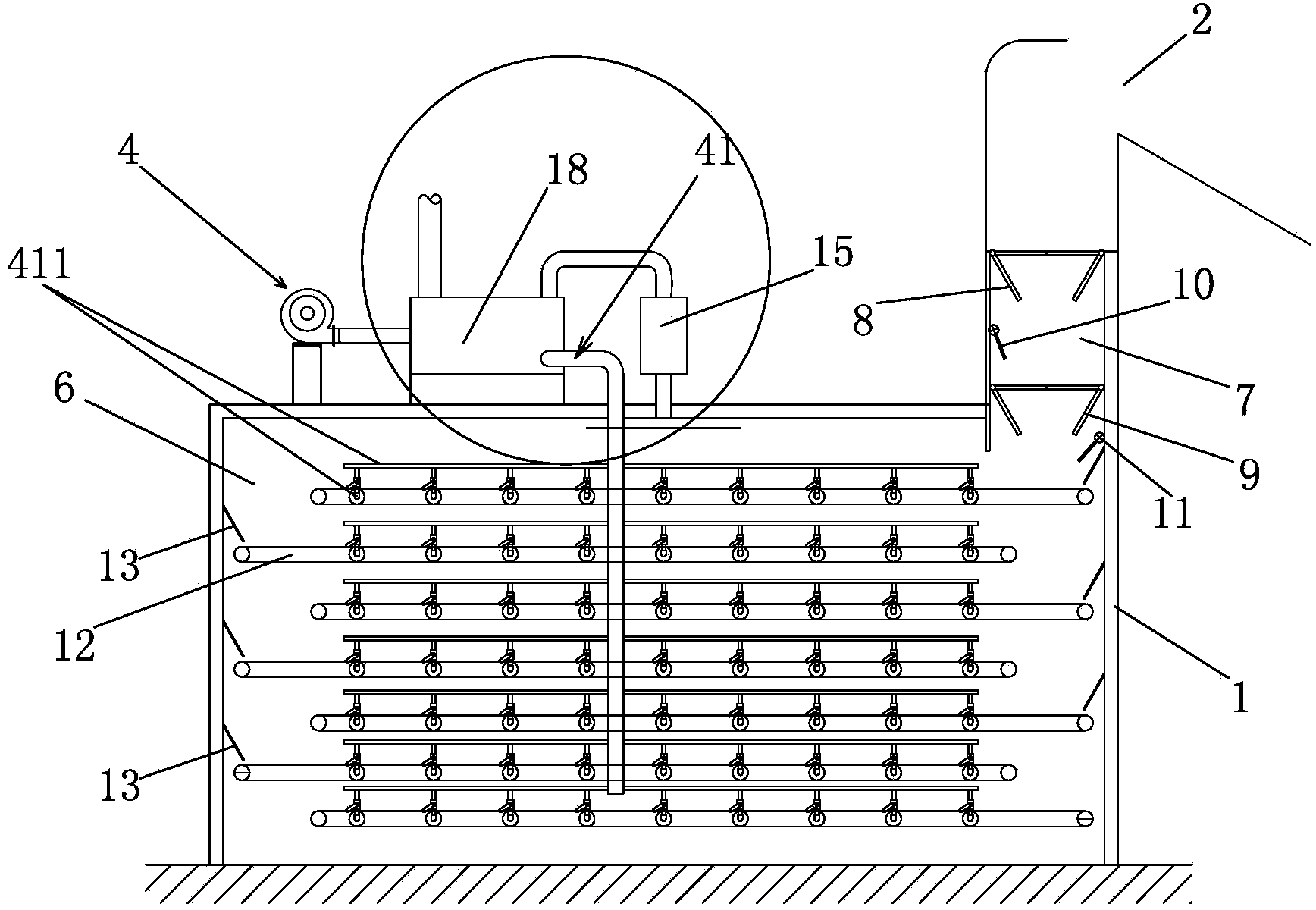

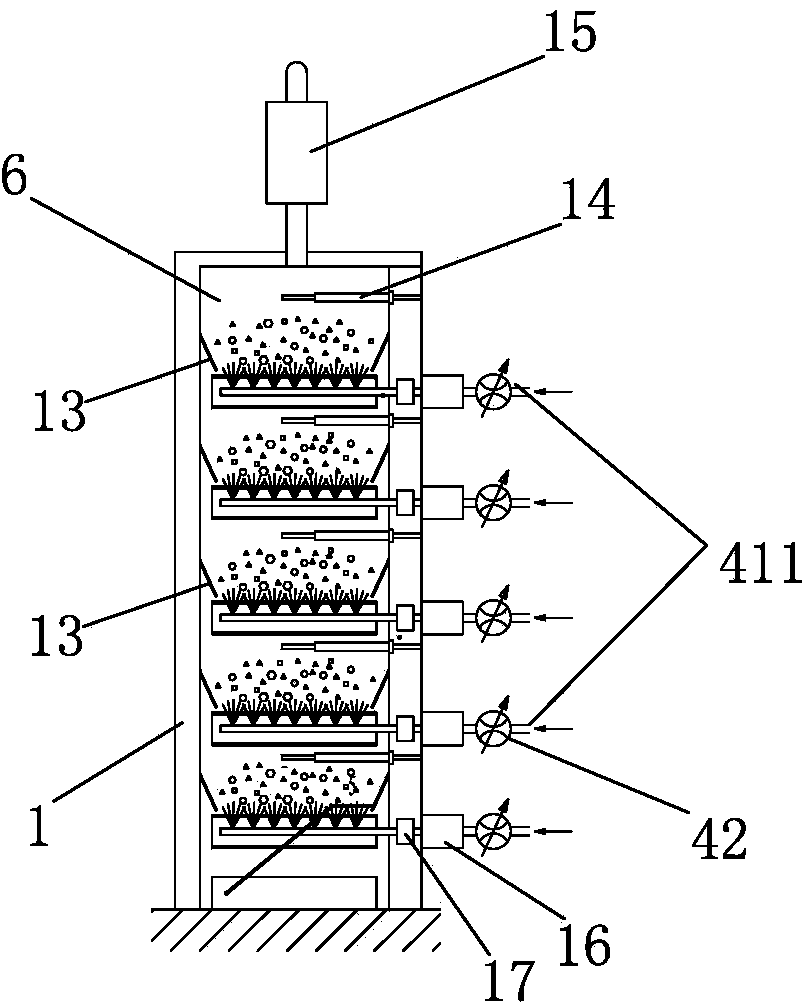

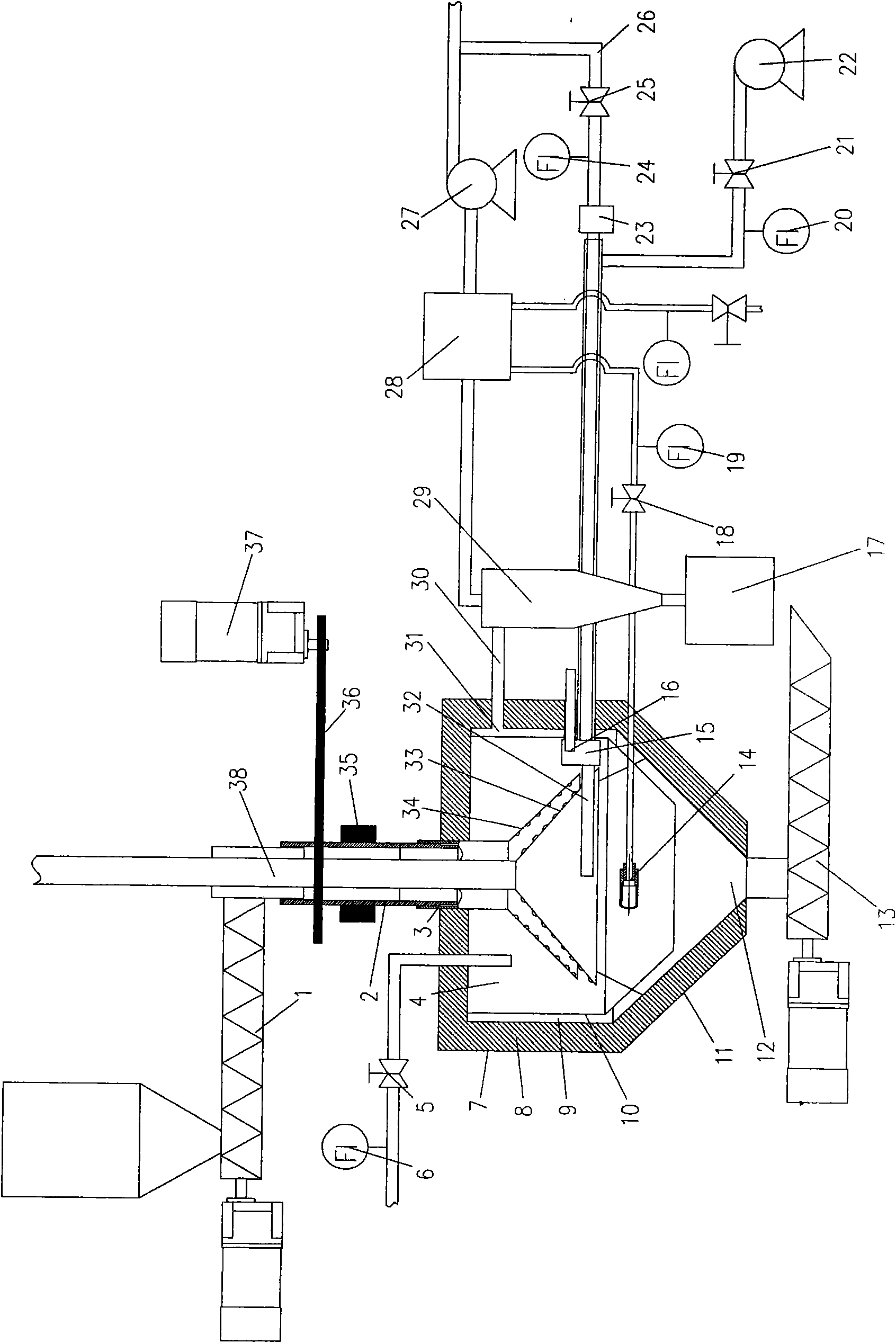

Large air pyrolysis treatment device of urban domestic garbage

InactiveCN103639177AImprove uniformityPyrolysis reaction is sufficientSolid waste disposalWorking environmentMaterial transport

The invention discloses a large air pyrolysis treatment device of urban domestic garbage. The large air pyrolysis treatment device is provided with a treatment chamber main cabin and an isolating cabin, wherein the treatment chamber main cabin is internally provided with a transporting channel which is formed by a plurality of layers of transporting belts and realizes zigzag reciprocating circulation; the treatment chamber main cabin is internally provided with a thermoelectric couple; a waste gas exhausting hole at the top part of the treatment chamber main cabin is provided with a waste gas purifying device which is used for purifying waste gas from a treatment chamber and then the purified waste gas is exhausted outwards; an air inlet device comprises a fan and an air inlet pipeline; the air inlet pipeline is provided with an air inlet flow valve. The large air pyrolysis treatment device disclosed by the invention has the advantages that the placement of garbage materials can be finished under the condition of relative isolation of the working environment of the treatment chamber main cabin by virtue of the isolating cabin, and thus outward leakage of odor and heat is prevented when the garbage enters; due to the garbage material transporting channel which is formed by the plurality of layers of transporting belts and realizes zigzag reciprocating circulation, full pyrolytic reaction can be carried out on the garbage materials in the treatment chamber; energy is greatly saved and the pyrolytic efficiency is greatly improved.

Owner:沈志远 +1

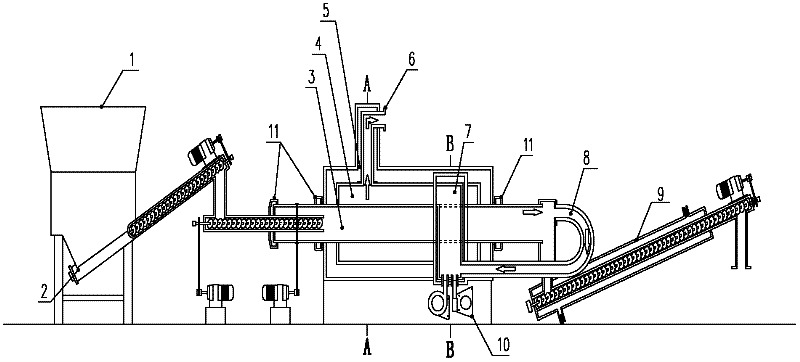

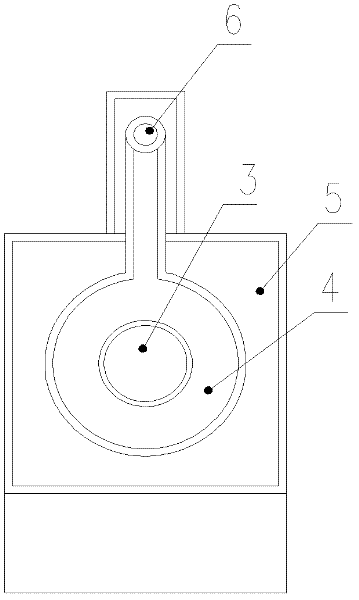

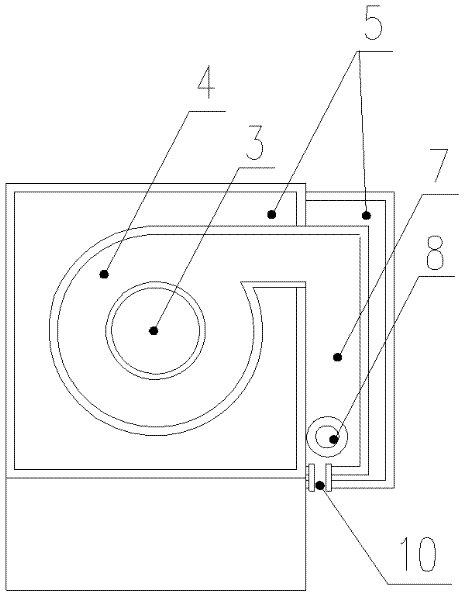

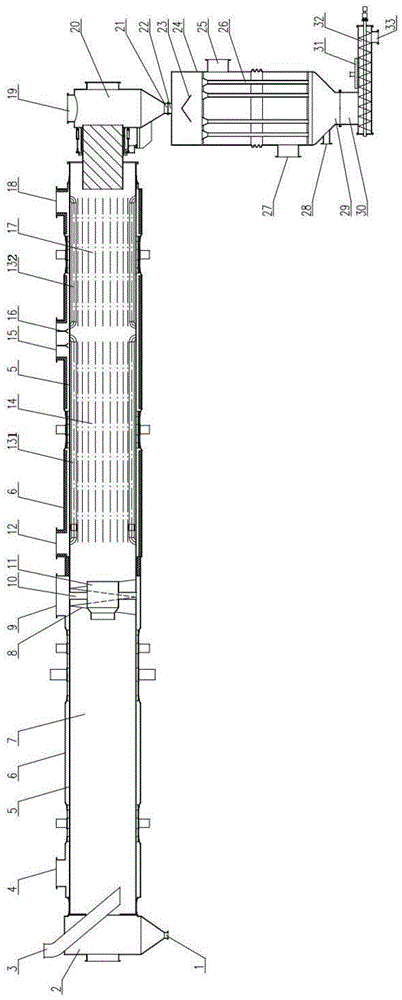

External-heating type integrated biomass pyrolysis equipment

InactiveCN102492443AEasy to controlImprove processing efficiencyBiofuelsEnergy inputAutomatic controlBiomass

The invention discloses external-heating type integrated biomass pyrolysis equipment, which belongs to the field of biomass treatment equipment and comprises a framework, a feed hopper, a conveying device, a pyrolysis device, a heating device and a discharge device, wherein the feed hopper, the conveying device, the pyrolysis device, the heating device and the discharge device are arranged on the framework. The feed hopper is connected with the pyrolysis device through the conveying device, the heating device is wrapped outside the pyrolysis device, heat insulation layers are wrapped outside the pyrolysis device and the heating device, a discharge outlet and a pyrolysis gas outlet are arranged at the tail end of the pyrolysis device, the discharge outlet is connected with the discharge device, and the pyrolysis gas outlet is connected with the heating device. The pyrolysis equipment utilizes continuous feeding, compensates energy requirements by gas produced during pyrolysis and produce biomass charcoal, waste heat can be used for drying pyrolysis raw materials, and automatic control of full process can be realized. The external-heating type integrated biomass pyrolysis equipment has the advantages of high treatment efficiency, low energy consumption, no secondary pollution, simplicity and convenience in operation and the like.

Owner:王凯军 +2

Device for producing ammonia gas through pyrolysis of urea by using high-temperature flue gas as heat source

InactiveCN104548931AReduce electricity consumption costsLow running costChemical industryDispersed particle separationSuperheaterRotational flow

The invention relates to the field of processes for producing ammonia gas through urea, and aims to provide a device for producing ammonia gas through pyrolysis of urea by using high-temperature flue gas as a heat source. The device for producing ammonia gas through pyrolysis of urea by using high-temperature flue gas as the heat source comprises a rotational flow pyrolysis furnace, a bypass flue duct, a flue gas baffle, a mechanical atomizing spraying gun, a flue gas flow sensor, a flue gas temperature sensor, a booster fan, an ash discharging bucket, a pressure sensor and a temperature sensor. The device adopts a small amount of high-temperature flue gas close to a high-temperature superheater as the heat source for urea pyrolysis, adopts a cheap low-grade energy source to replace a high-grade energy source, and reduces the consumption of power required by urea pyrolysis and running cost; the device adopts the rotational flow pyrolysis furnace, so that the content of dust in flue gas is effectively reduced, the abrasion of dust against the booster fan is reduced, the work environment of the booster fan is improved, the service life of the booster fan is prolonged, meanwhile, uniform mixing of the urea and the high-temperature flue gas is ensured, and the pyrolysis efficiency of the urea is improved.

Owner:浙江百能科技有限公司

System and method of fast pyrolysis of oil shale

ActiveCN105131992AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationSpray towerShale oil and gas

The invention discloses a system and a method of fast pyrolysis of oil shale. The system comprises a fast pyrolysis reactor and a spray tower, wherein the fast pyrolysis reactor comprises a reactor body, a multilayer regenerative radiant tube, an oil shale inlet, a distributing device, a distributing gas inlet, a plurality of pyrolysis gas outlets and a carbocoal outlet, the fast pyrolysis reactor is suitable for performing fast pyrolysis treatment on the oil shale by adopting the regenerative radiant tube, so as to obtain carbocoal and pyrolysis gas, and the spray tower is connected with the plurality of pyrolysis gas outlets and is suitable for performing spray treatment on the pyrolysis gas by adopting cooling liquid, so as to obtain shale oil and gas. According to the system, fast pyrolysis of the oil shale can be realized, and the yield of the obtained shale oil is high.

Owner:SHENWU TECH GRP CO LTD

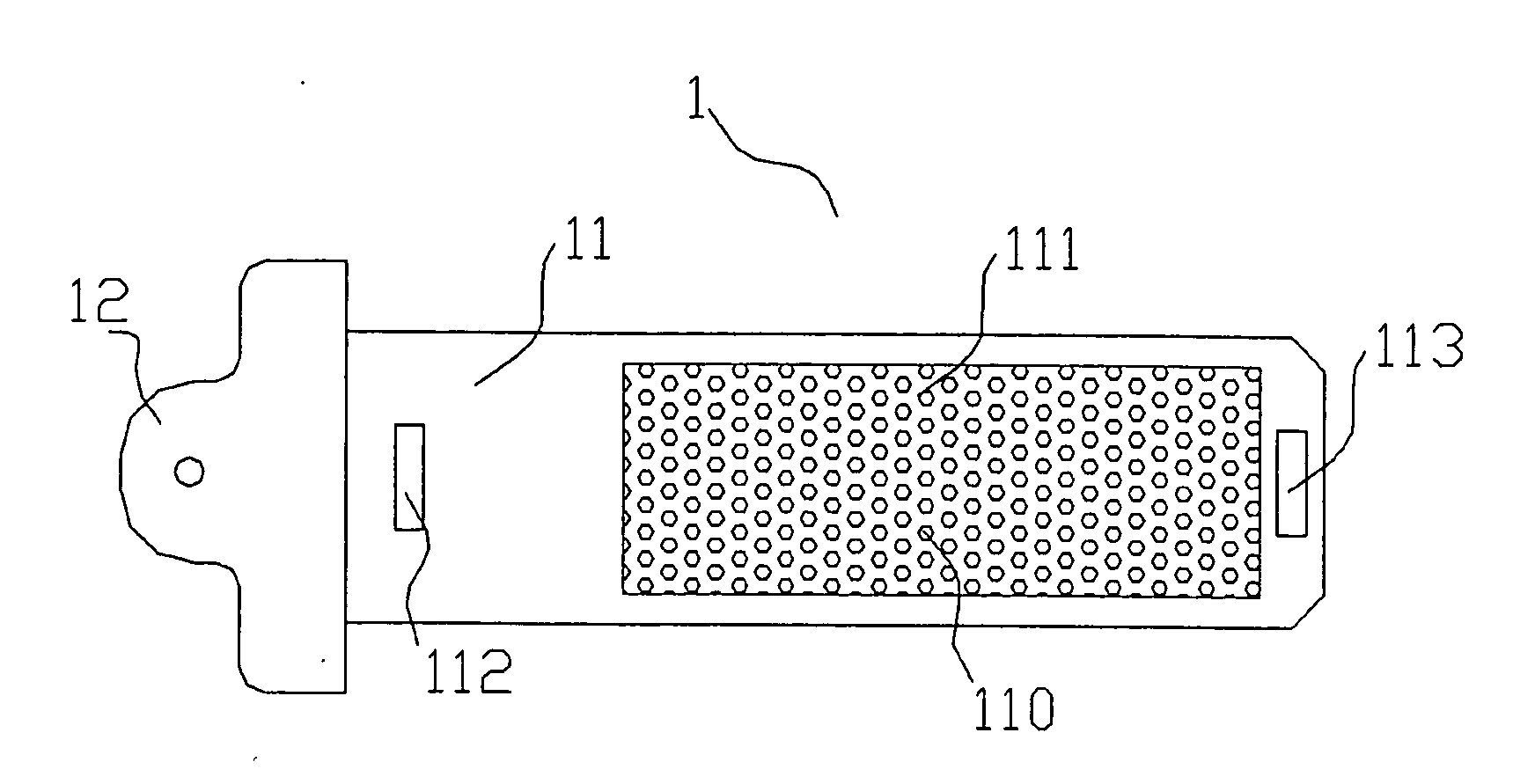

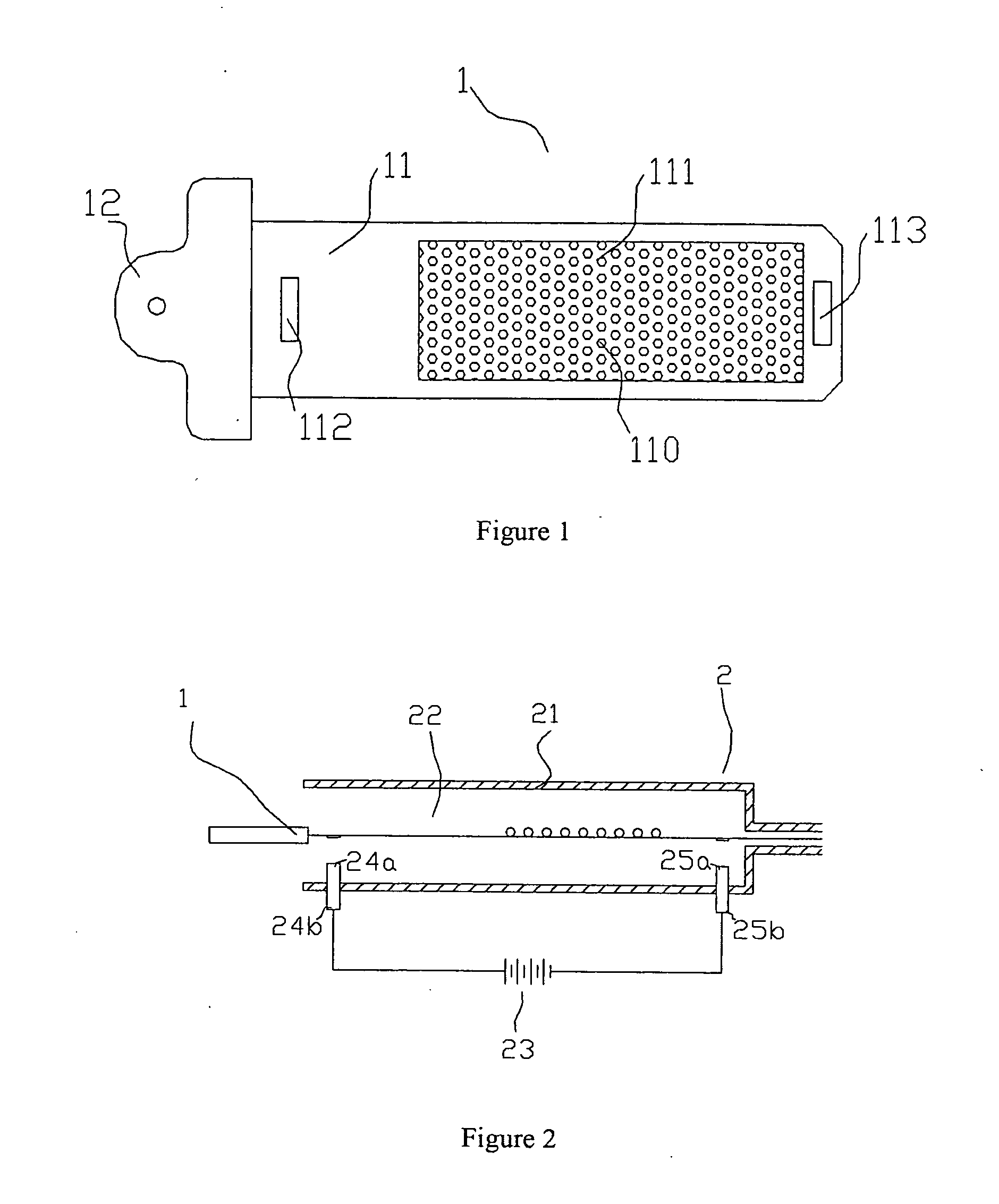

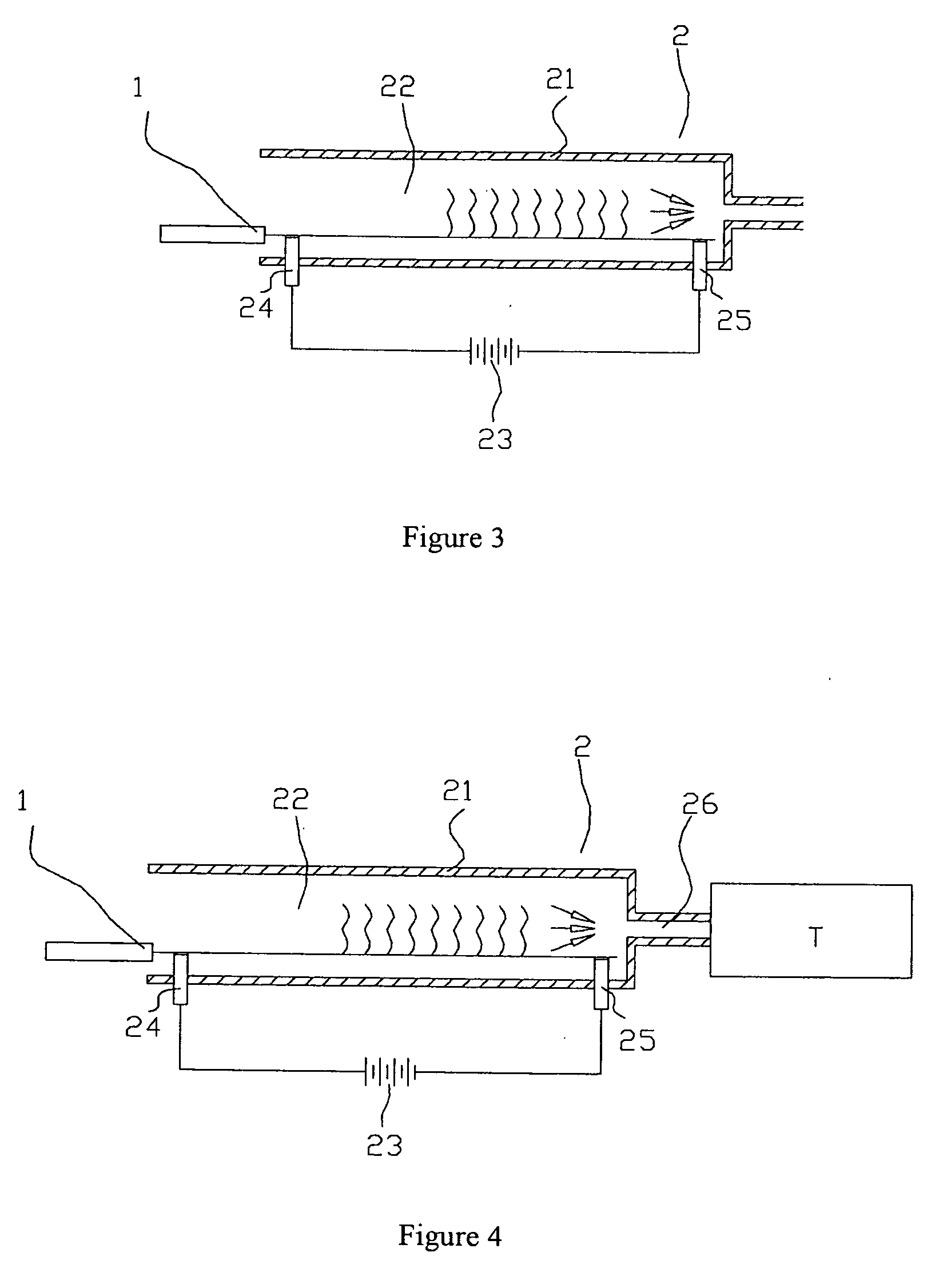

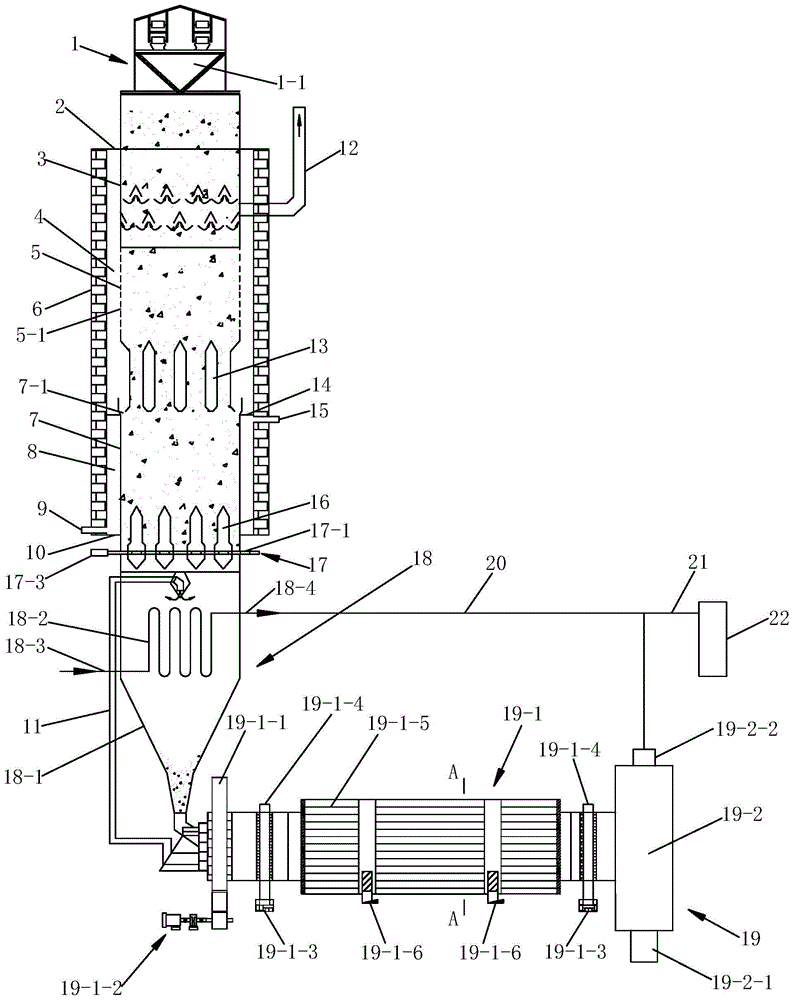

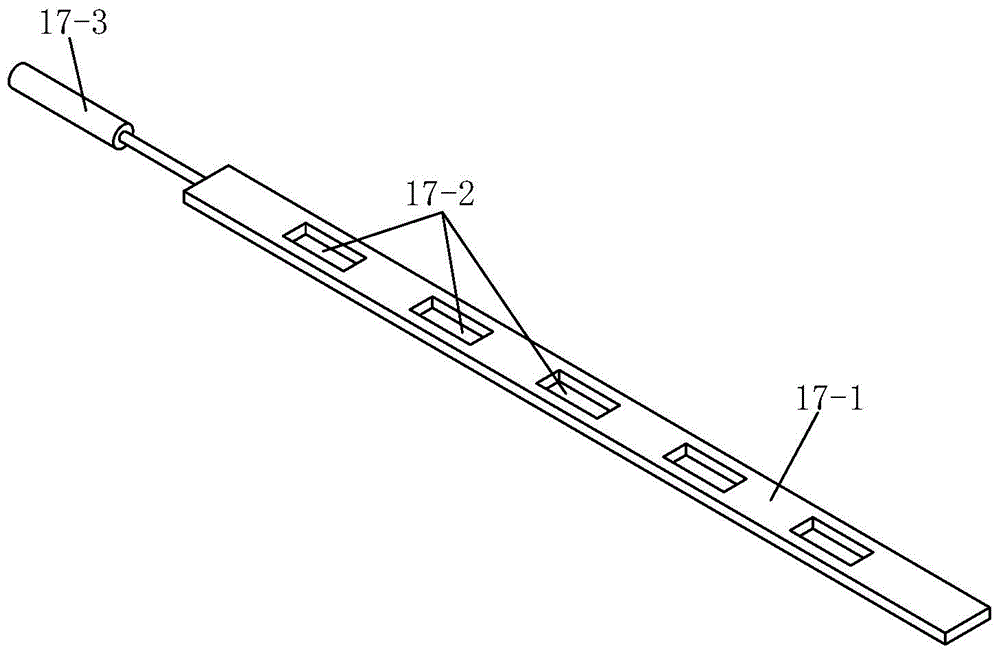

Sampling component, sampling device and ion mobility Spectrometer

InactiveUS20110290041A1Improve efficiencyReduce power consumptionWithdrawing sample devicesPreparing sample for investigationElectricityWipe sampling

The present invention discloses a sampling component comprising a sampling body that can be electrically heated and the outer surface of which has a wiping sampling area; and an insulated handle that is connected with one longitudinal end of the sampling body. The sampling component according to the present invention contacts directly the contacts of an external power supply after being disposed in a analysis chamber, the power supply is turned on to heat the sampling body so as to realize sample pyrolysis, and the power is turned off immediately after the sampling component is taken away. Thus, the power supply of the sampler can work discontinuously so that the power consumption of the system is reduced, meanwhile, the system malfunction caused by a long-term work of the sampling device under a high temperature can be avoided. The present invention further discloses a sampling device having said sampling component and an ion mobility spectrometer having the sampling device.

Owner:NUCTECH CO LTD

Coal pyrolysis and activated carbon production integrated device

The invention discloses a coal pyrolysis and activated carbon production integrated device. The integrated device comprises a thermal insulation jacket, a preheating furnace, a pyrolysis furnace used for performing pyrolysis on preheated coal, an activating furnace used for activating semi-coke generated after pyrolysis, and an activating agent conveying pipe used for inputting gas activating agents into the activating furnace. The preheating furnace, the pyrolysis furnace and the activating furnace are sequentially communicated from top to bottom. An activating furnace heating cavity is formed between the activating furnace and the thermal insulation jacket. A gas conveying channel is formed between the thermal insulation jacket and the pyrolysis furnace. The activating furnace is provided with an associated gas outlet for associated gas produced through activation of the semi-coke to enter the gas conveying channel. A gas heat carrier inlet for the associated gas to enter the pyrolysis furnace from the gas conveying channel is formed in the side wall of the pyrolysis furnace. The integrated device can effectively improve the pyrolysis and activation efficiency, the tar yield is effectively increased, high-quality coal gas, tar and activated carbon can be produced at the same time, and the additional value for quality-divided processing and utilizing of the coal is improved.

Owner:XIAN UNIV OF SCI & TECH

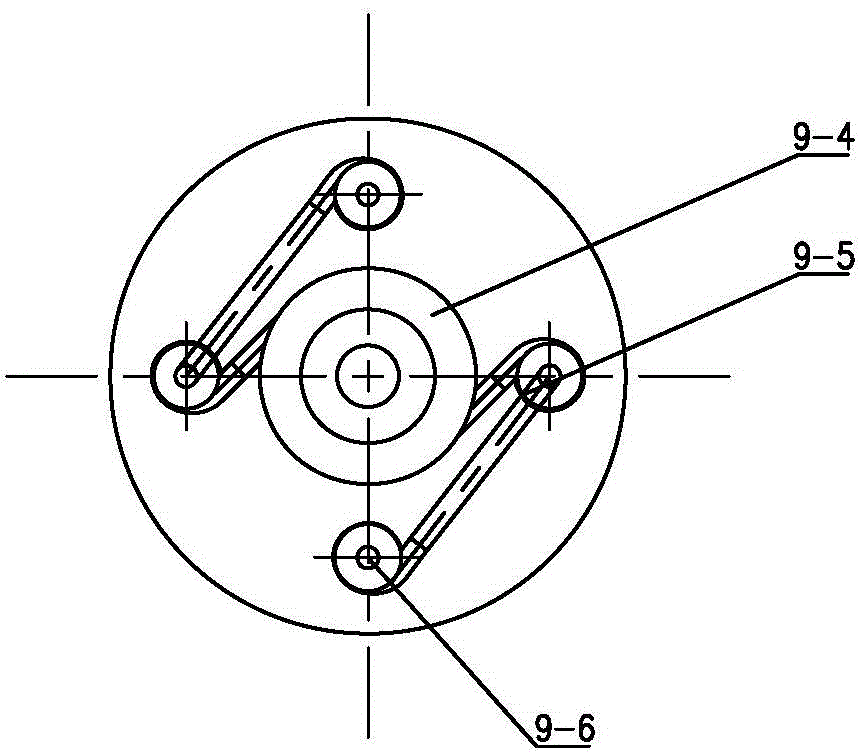

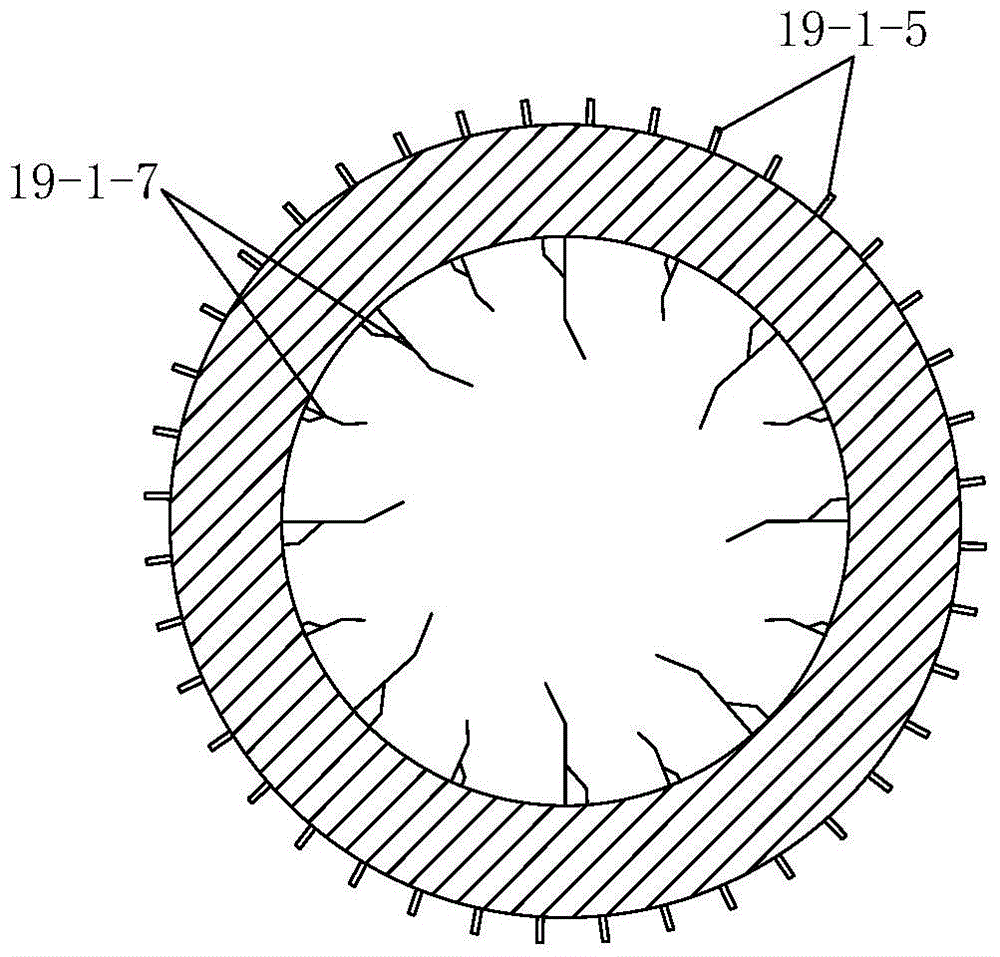

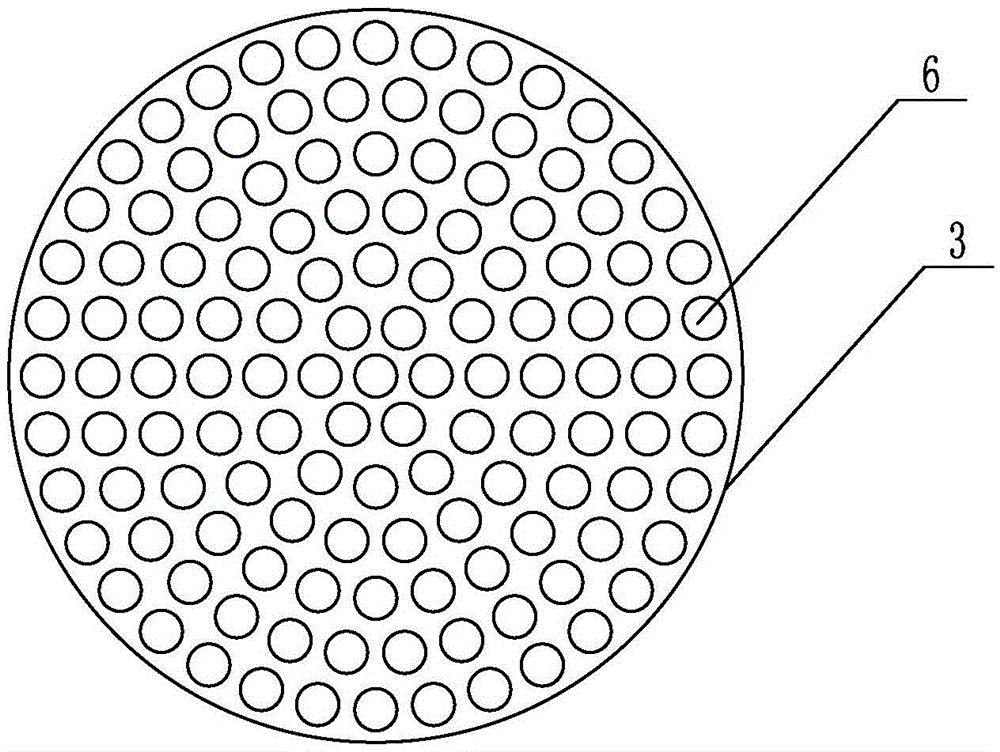

Urea powerful mixing device for SCR system of small and medium-sized ship

ActiveCN105464763AImprove pyrolysis efficiencyEfficient mixingExhaust apparatusSilencing apparatusFlue gasConcentration ratio

The invention relates to the field of ship flue gas denitrification equipment, in particular to a urea powerful mixing device for an SCR system of a small and medium-sized ship. The urea powerful mixing device for the SCR system of the small and medium-sized ship comprises a tube body, a porous plate, a urea nozzle and a mixing device, wherein the porous plate, the urea nozzle and the mixing device are arranged in the tube body from bottom to top; a flow rectifying device is the porous plate where a plurality of round holes are distributed, and a flow disturbing device is the mixing device; and the device has the beneficial effects that the flow rectifying device (porous plate) is arranged at the upstream position of the urea nozzle, the flow disturbing device is arranged at the downstream position of the urea nozzle, and due to the structure, smoke and sprayed urea mist can be more sufficiently mixed in the limited space, the urea nozzle can absorb more smoke gas waste heat in a short time so as to improve the decomposition speed, and therefore it can be ensured that the concentration ratio of NH3 / NOX meets the reaction requirement when mixed smoke gas enters an SCR reactor inlet.

Owner:ZHEJIANG UNIV

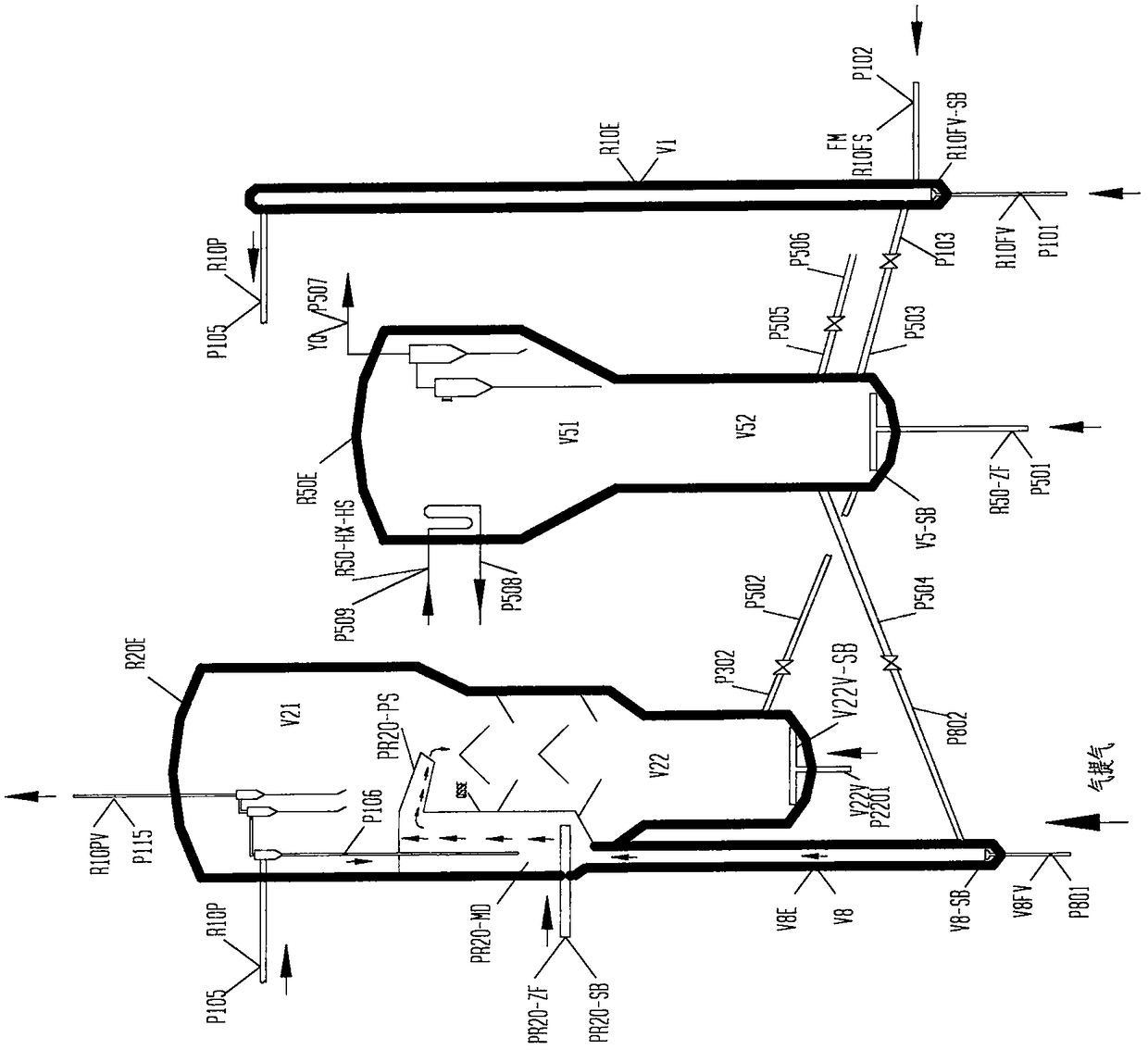

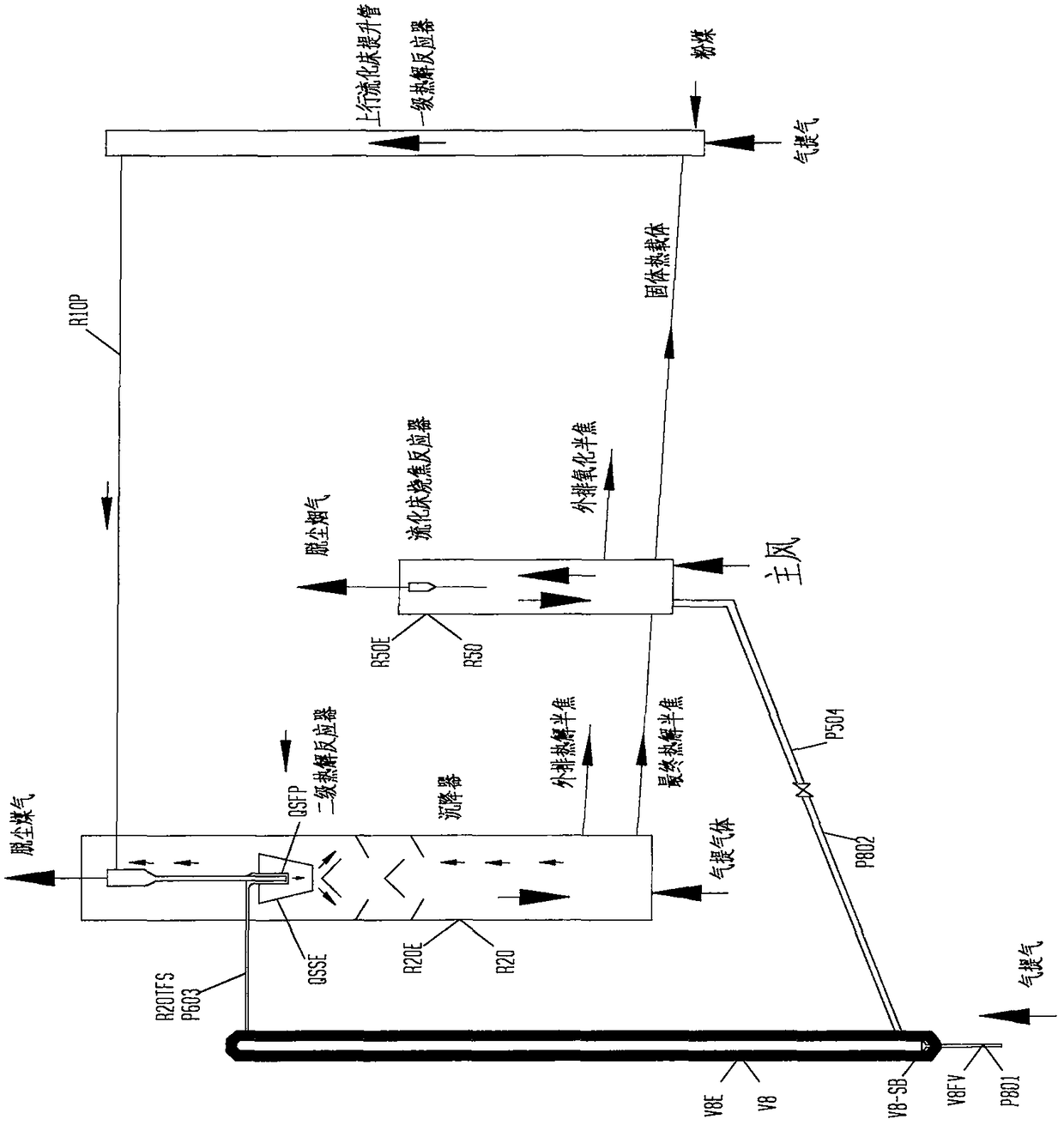

Method and device for pyrolysis of carbon and hydrogen-containing powder in forced mixing secondary pyrolysis pre-reaction zone

InactiveCN108085034ASimple structureReduce volumeEnergy inputSpecial form destructive distillationHeat carrierHydrogen

The invention relates to a method and a device for pyrolysis of carbon and hydrogen-containing powder in a forced mixing secondary pyrolysis pre-reaction zone, the method and the device are suitable for the processing of pulverized coal, forced pre-mixing of solid R10PSX obtained by separation of primary pyrolysis reaction product R10P and second solid heat carrier R20KS is completed in the forcedmixing secondary pyrolysis pre-reaction zone PR20, and a highly-mixed mixed solid phase raw material is provided for a secondary pyrolysis reaction process.

Owner:洛阳瑞华新能源技术发展有限公司

Internal combustion heating rotation conical biomass gasification furnace

InactiveCN101538484AIncrease temperatureImprove efficiencyCombined combustion mitigationCombustible gas productionProcess engineeringBiomass gasifier

The invention provides an internal combustion heating rotation conical biomass gasification furnace which is characterized in that the furnace body is internally provided with two concentric cones, wherein the external cone is a rotation cone and the internal cone is a fixed cone; the top of the rotation cone is connected with a material cylinder at the lower section; the top of the fixed cone is communicated with a smoke gas pipeline; the bottom end surface of the fixed cone is closed and the lower part thereof is tangentially connected with a combustion pipeline; the side wall of the furnace body is arranged as jacket structure; the jacket comprises a high-temperature resistance furnace wall, a combustion gas pipeline, a heat preservation layer and an external wall of the gasification furnace sequentially from inside to outside; the airflow passage in which the combustion gas is led out from the gasification furnace is that the combustion gas is led to the bottom port of the combustion gas pipeline from the bottom of the gasification furnace along the inclined surface of the conical furnace bottom; the delivery outlet of the combustion gas is arranged at the upper part of the combustion gas passage; and a gas transmission pipeline connected on the delivery outlet of the combustion gas outside the gasification furnace is connected with a gas storage cabinet by an induced draft fan. The gasification furnace greatly improves the biomass gasification rate and the heat value of the combustion gas.

Owner:HEFEI UNIV OF TECH

Integrated system for pyrolysis and upgrading of coal

ActiveCN104877695AGuaranteed uptimeSolve the blockageIndirect heating destructive distillationSpecial form destructive distillationCold airSprayer

The invention relates to an integrated system for pyrolysis and upgrading of coal. The integrated system is provided with a drying and pyrolysis unit, an upgraded-coal cooling unit and a humidifying and discharging unit in sequence along the process route in a connection manner. The integrated system has the advantages that coal drying and coal pyrolysis reactions are finished in a same rotary drum by the drying and pyrolysis unit, so that the equipment investment is effectively reduced and the process reliability is improved; cold air in the upgraded-coal cooling unit is utilized for indirectly cooling materials in material-distributing tube nest, the equipment is simple and good in safety, the yield of waste water and waste gas is low, hot air obtained after heat exchange is utilized for heat recovery and reutilization of heat; in the process of utilizing a spiral conveyor in the humidifying and discharging unit to carry out conveying on upgraded coal, a sprayer is adopted for carrying out water spraying and humidification on the upgraded coal, the operation is simple and reliable, the water spraying amount can be adjusted according to the process need, the quality of a product is good and the process is environmental-friendly.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com