Patents

Literature

1947 results about "Continuous reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous reaction series The continuous change in composition of a solid solution mineral in order to maintain a state of equilibrium with a cooling magma. The mineral changes its composition by continuously exchanging cations with the cooling magma in which it floats.

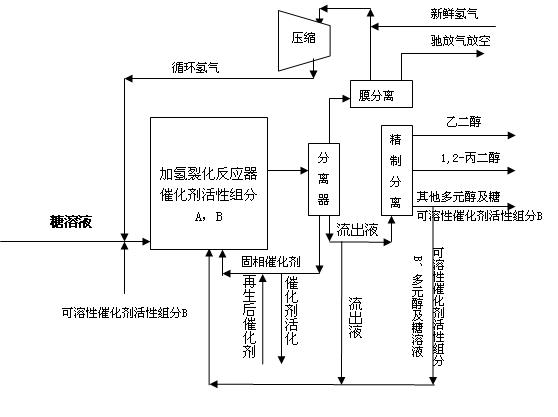

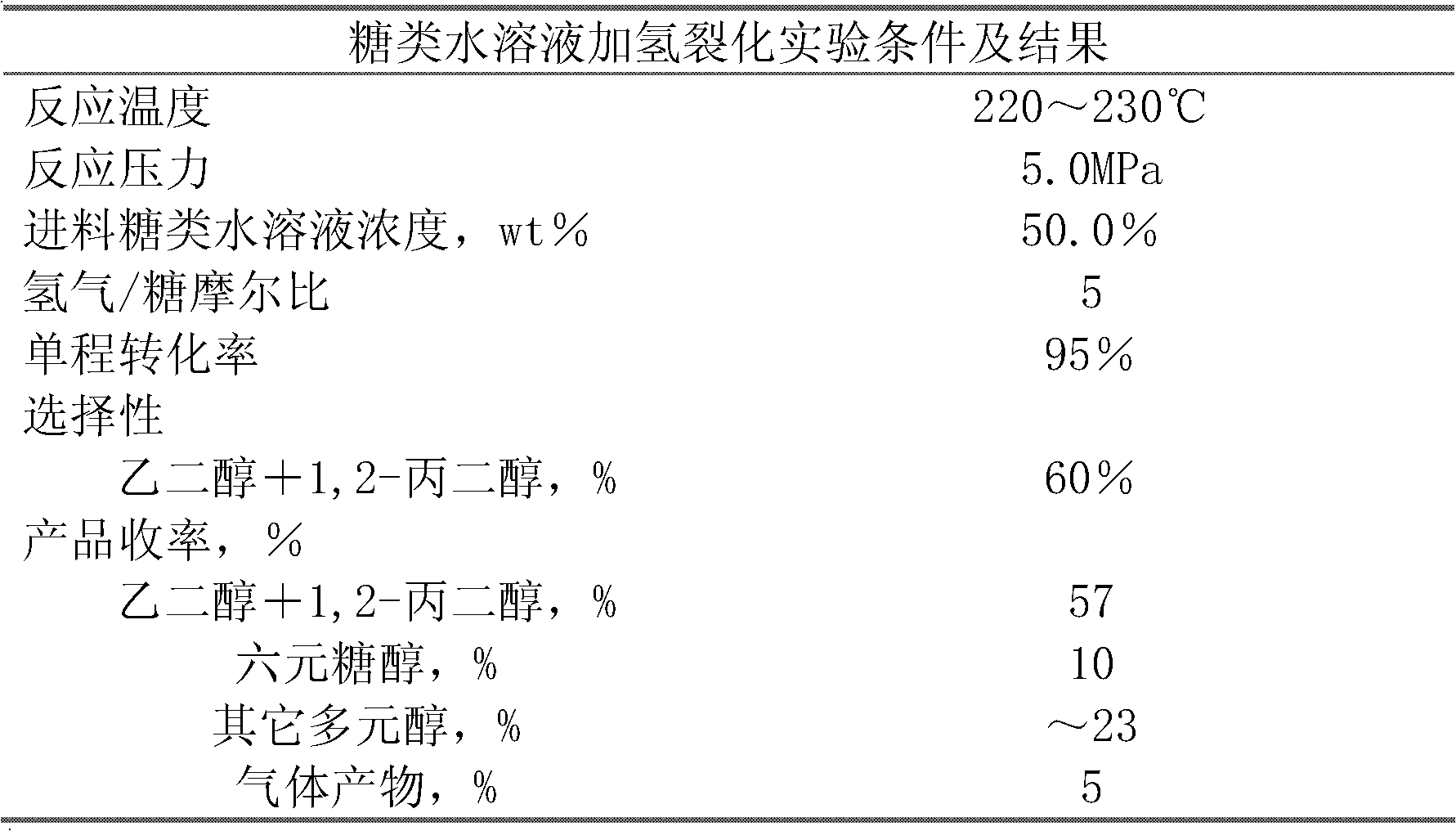

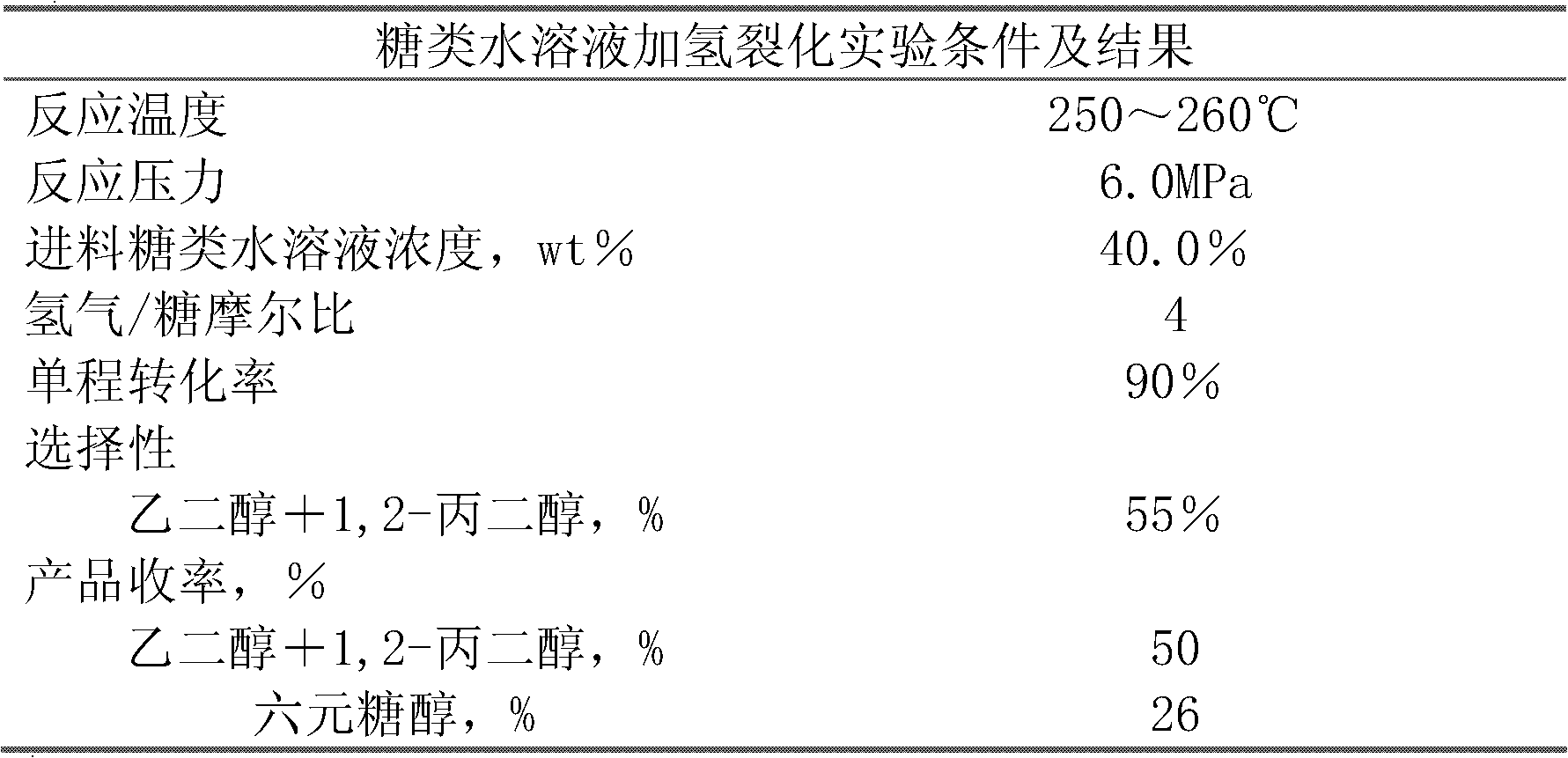

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165ARealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationGas phaseOligosaccharide

The invention relates to a continuous reaction process flow for producing ethylene glycol and 1, 2-propylene glycol through continuous hydrocrackin of sugars and provides a method for producing the ethylene glycol and the 1,2-propylene glycol through continuous hydrocrackin of sugars. In the process flow, sugars (comprising one or more than two of sugar, glucose, fructose, xylose, soluble xylo-oligosaccharide and starch) are hydrocracked in the presence of a catalyst in a reactor and the hydrocracked product enters a separating system. Hydrogen gas in a gas phase is recycled by separating and recovering; a liquid phase product partially reflows to the reactor and other liquid phase products are refined and separated to form the ethylene glycol, the propylene glycol and other polyhydric alcohols; and concentrated soluble catalyst components in the refined and separated residual component liquid phase are partially returned to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

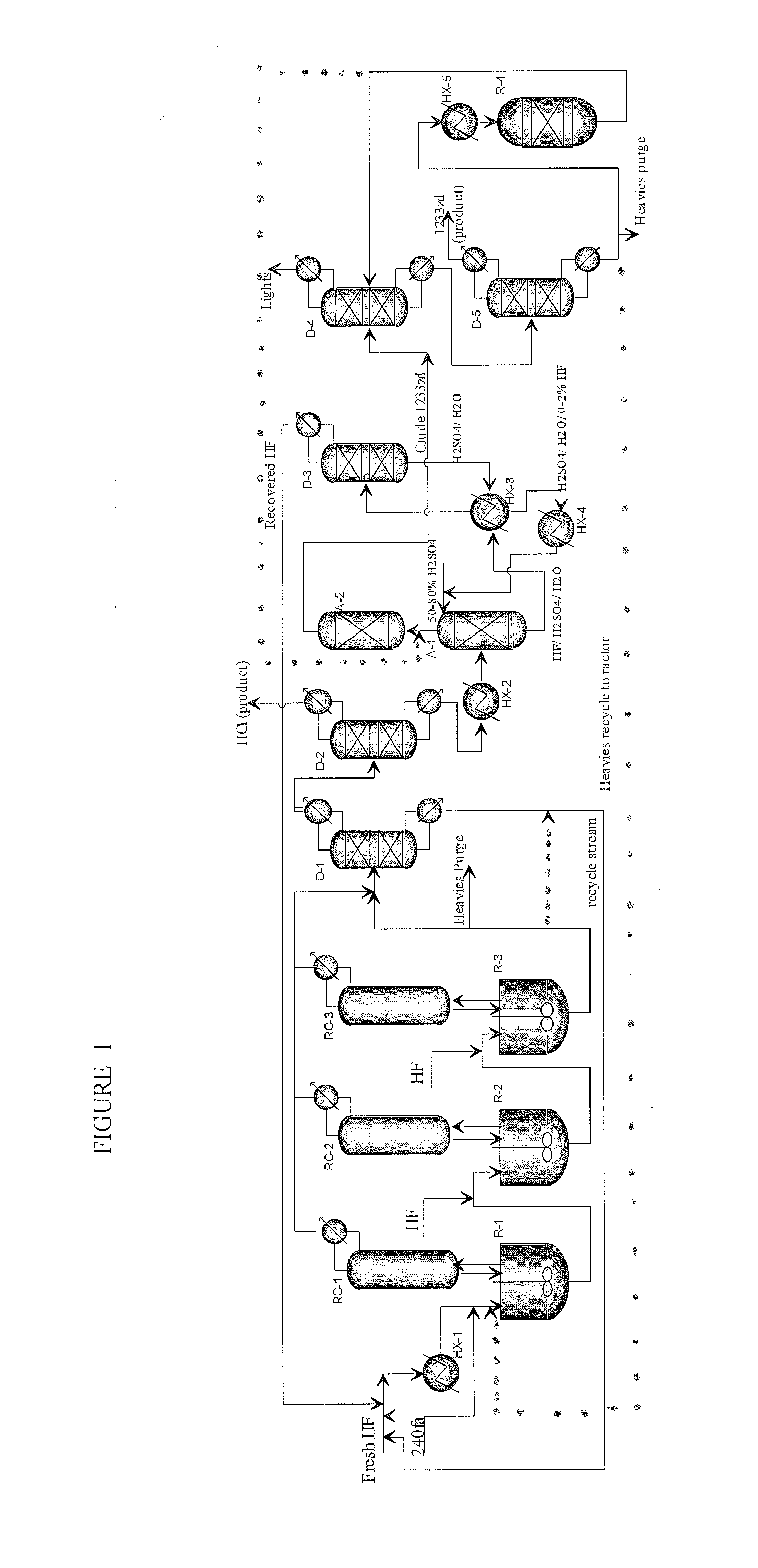

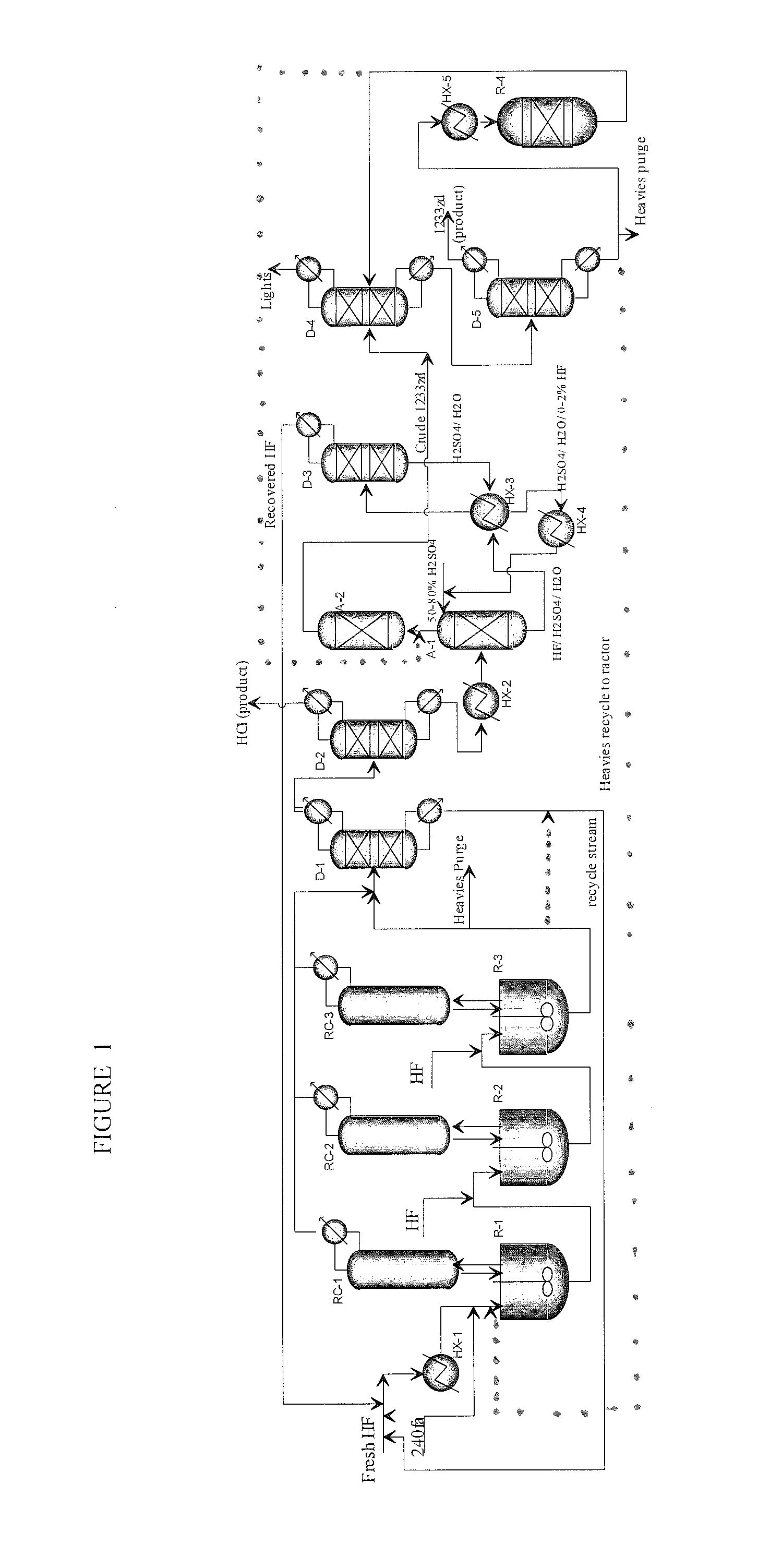

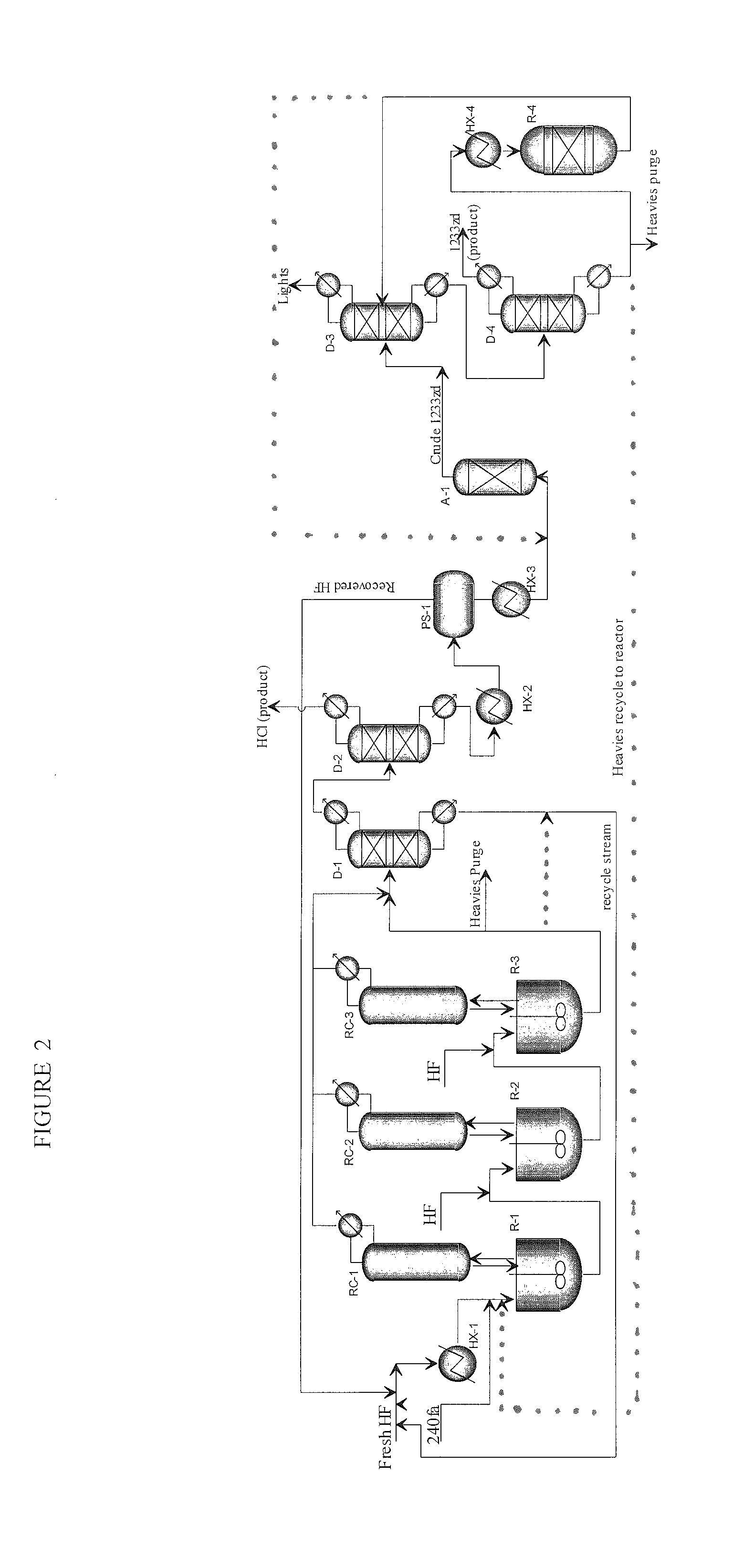

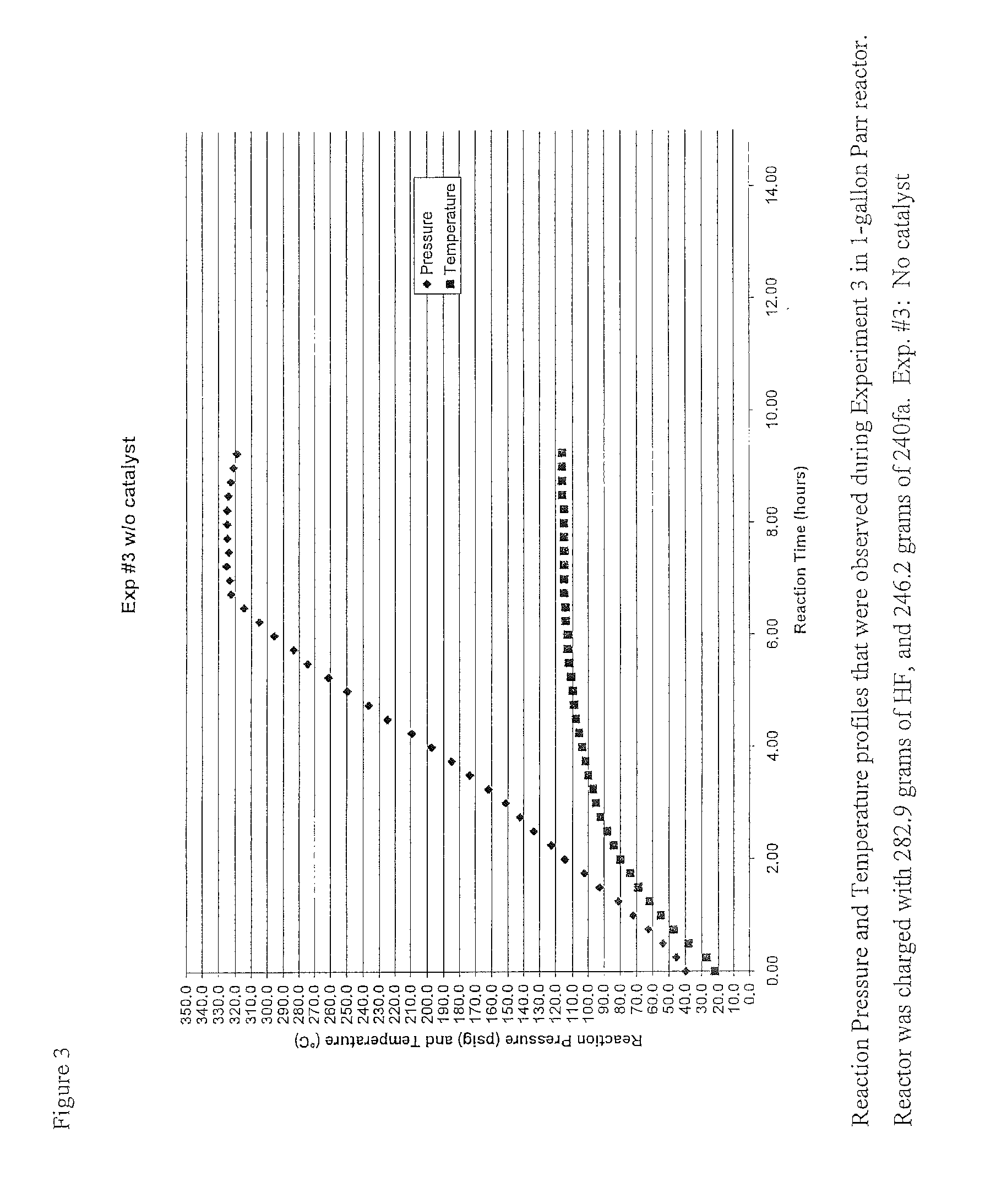

Continuous low-temperature process to produce trans-1-chloro-3,3,3-trifluoropropene

ActiveUS20120059199A1Slow reaction rateYield maximizationChlorine/hydrogen-chloridePreparation by hydrogen halide split-offIsomerizationUnit operation

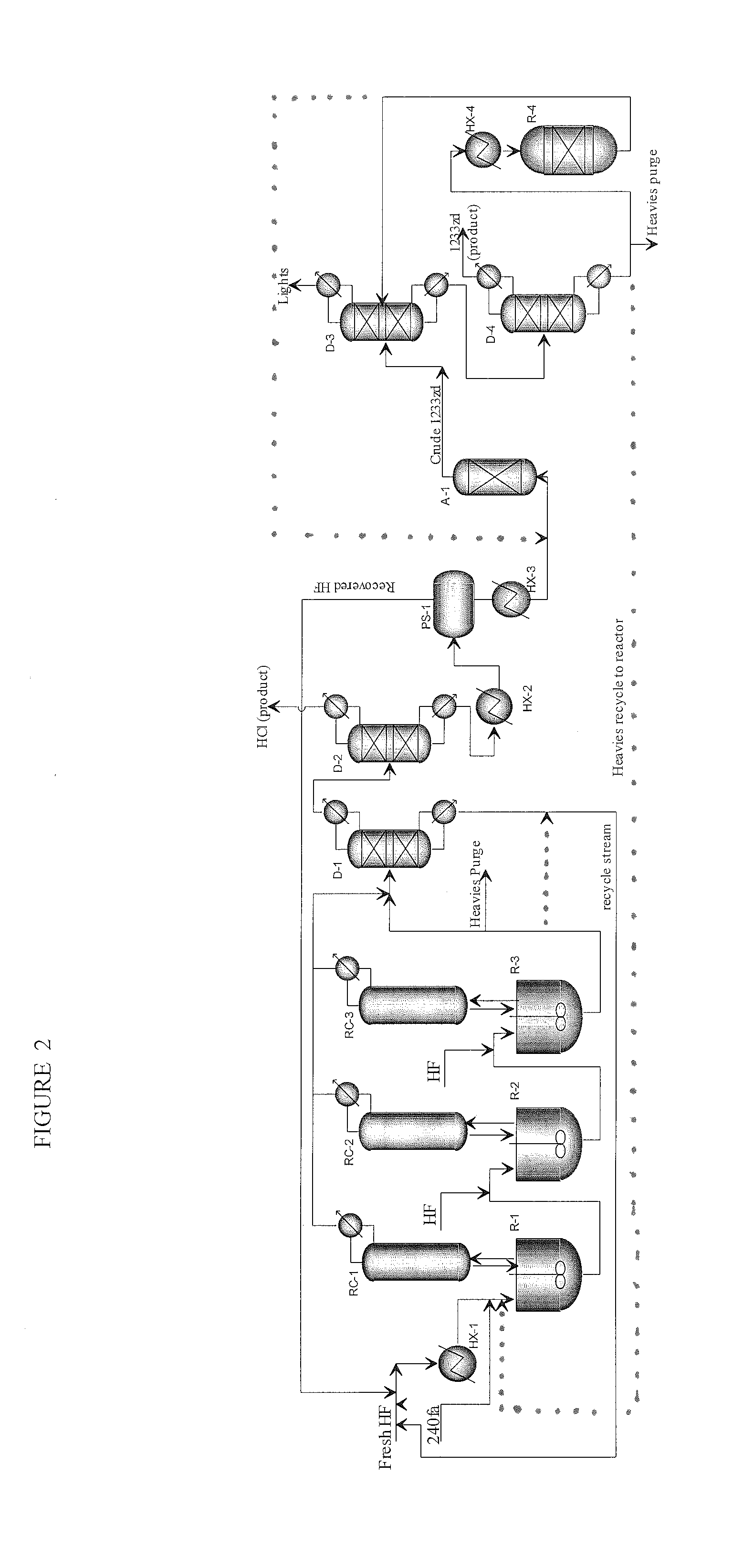

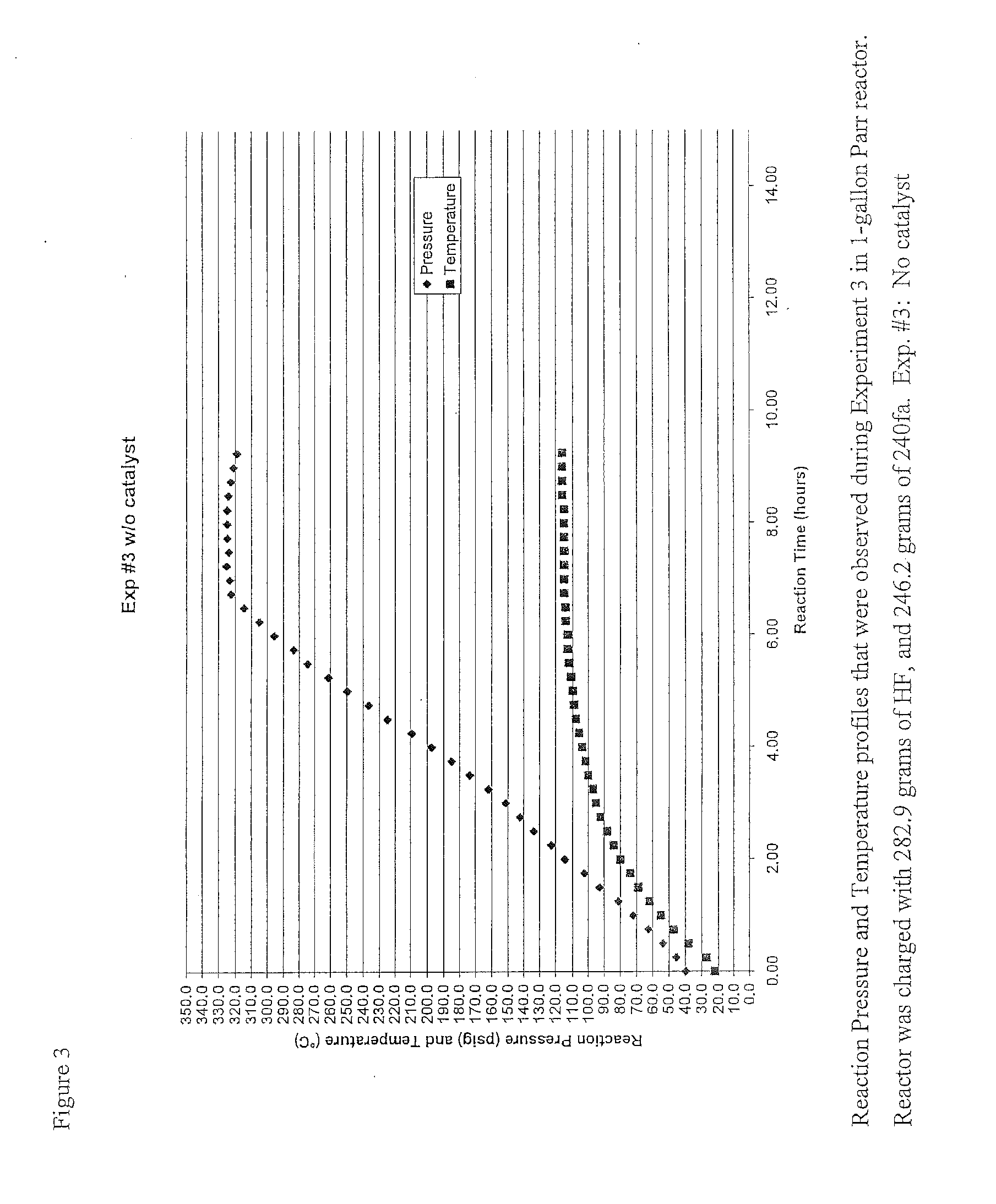

Disclosed is process for the production of (E) 1-chloro-3,3,3-trifluoropropene (HCFO-1233zd(E)) by conducting a continuous reaction without the use of a catalyst. Also disclosed is an integrated system for producing hydrofluoro olefins, particularly 1233zd(E). The manufacturing process includes six major unit operations: (1) a fluorination reaction of HCC-240fa (in continuous or semi-batch mode) using HF with simultaneous removal of by-product HCl and the product 1233zd(E); (2) recycle of unreacted HCC-240fa and HF together with under-fluorinated by-products back to (1); (3) separation and purification of by-product HCl; (4) separation of excess HF back to (1); (5) purification of final product, 1233zd(E); and (6) isomerization of by-product 1233zd(Z) to 1233zd(E) to maximize the process yield.

Owner:HONEYWELL INT INC

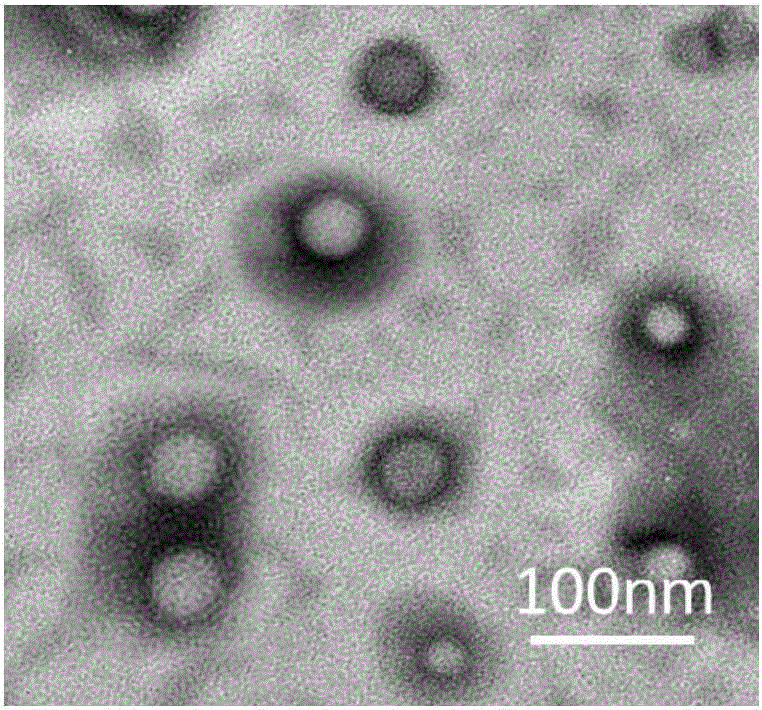

Harsh oil deposit reversed-phase microemulsion profile-control flooding system and preparation method thereof

ActiveCN104448126AImprove stabilityGood temperature and salt resistanceDrilling compositionMicrosphereOil phase

The invention relates to a harsh oil deposit reversed-phase microemulsion profile-control flooding system and a preparation method thereof. The problems in the prior art that the initial particle size of the product is improper and polymeric microspheres are poor in expansibility under high-temperature high-salt conditions are mainly solved. The harsh oil deposit reversed-phase microemulsion profile-control flooding system disclosed by the invention comprises the following components in parts by weight of microemulsion: 20-70 parts of an oil-soluble solvent, 5-20 parts of an emulsifier and a co-emulsifier, 20-70 parts of a polymer aqueous phase containing acrylamide and other temperature-resistant salt-resistant comonomers. According to the technical scheme, a semi-continuous reaction method is adopted, the aqueous phase containing acrylamide and other temperature-resistant salt-resistant comonomers is added into an oil phase containing the emulsifiers in batches, and a hydrophobic monomer is added, so that the problems are solved, the prepared polyacrylamide reversed-phase microemulsion is directly compounded or is compounded with other oil field chemicals to be applied to such field applications for improving oil recovery as depth profile control, water plugging and displacement in tertiary oil recovery of a harsh oil deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

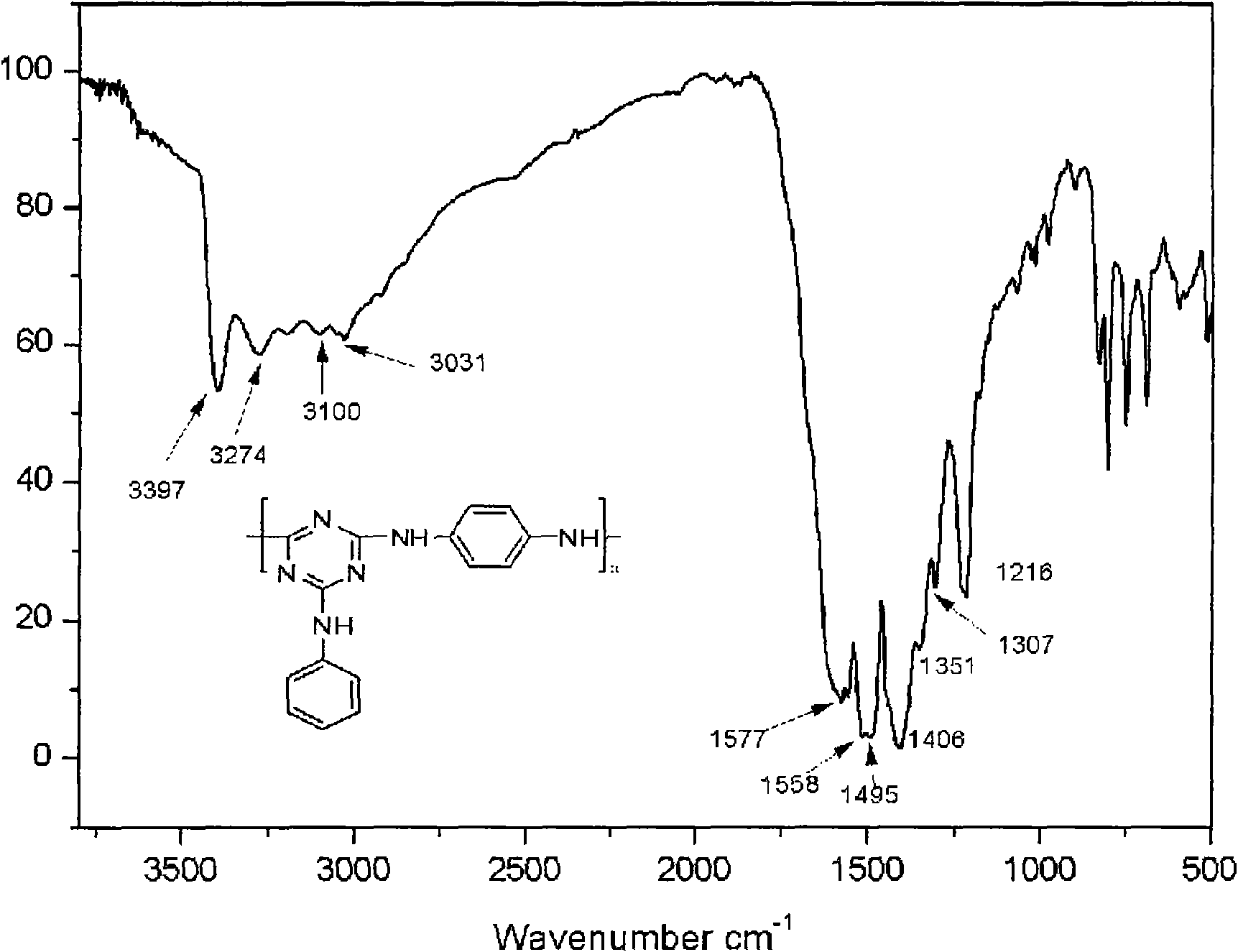

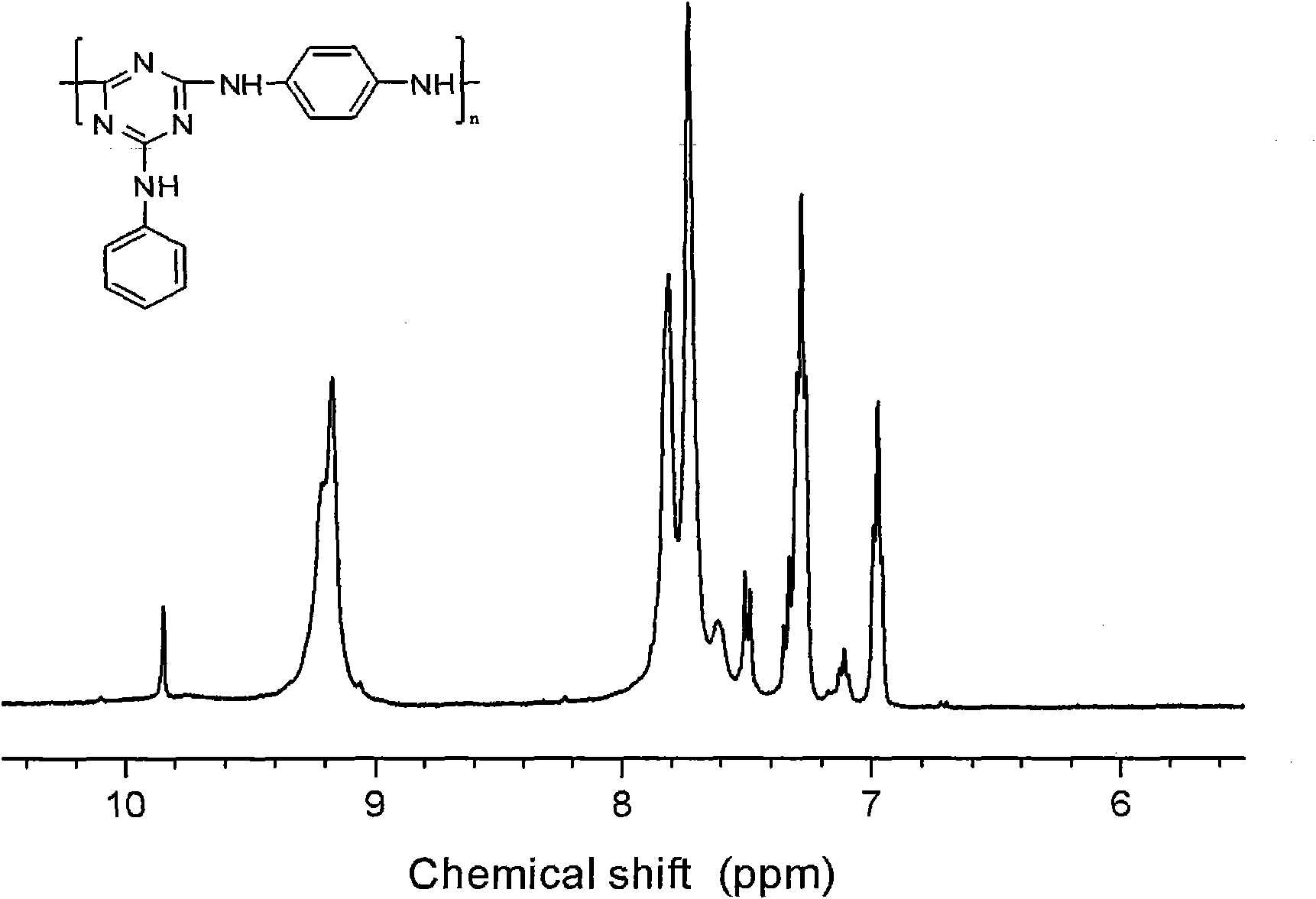

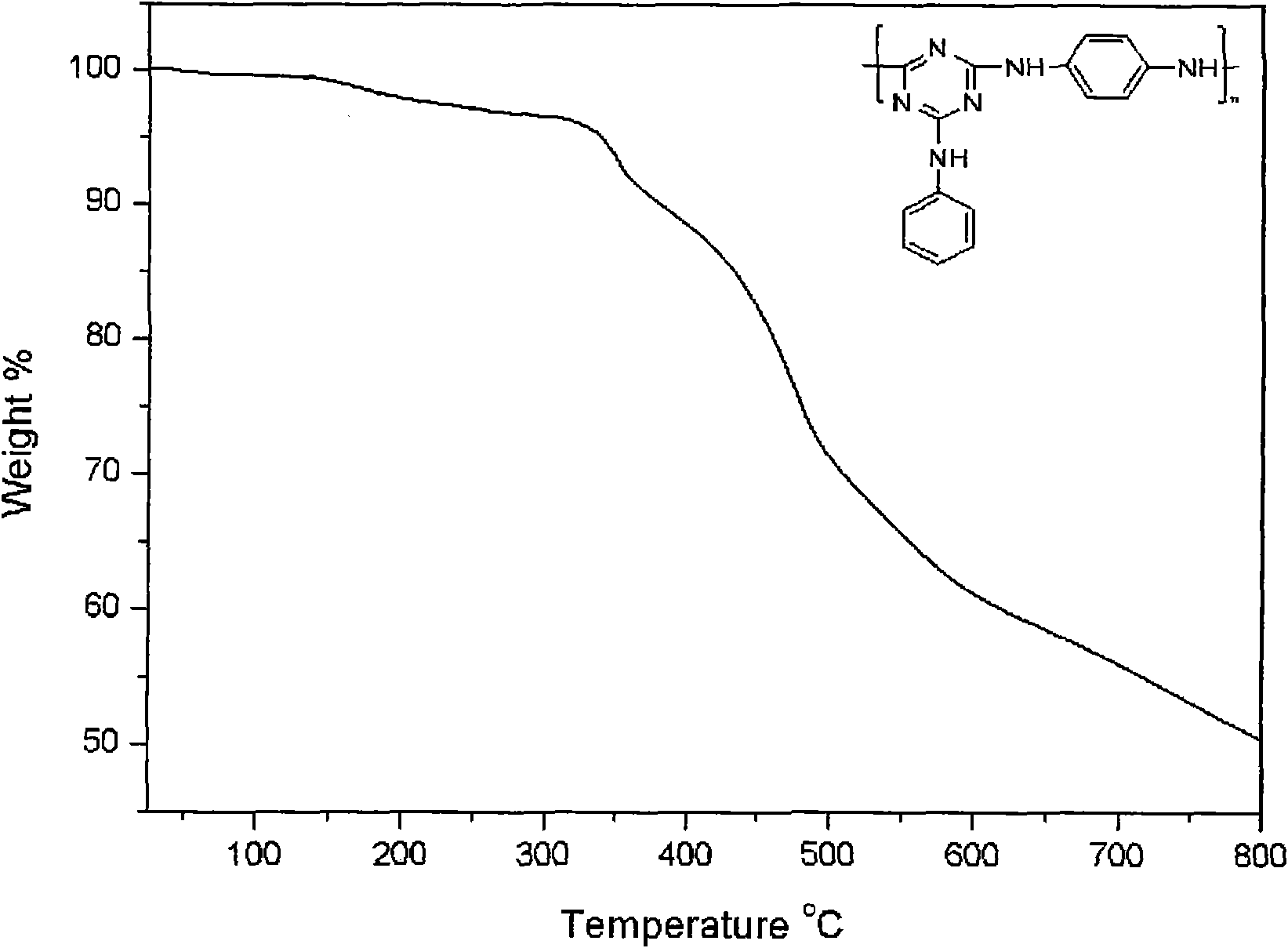

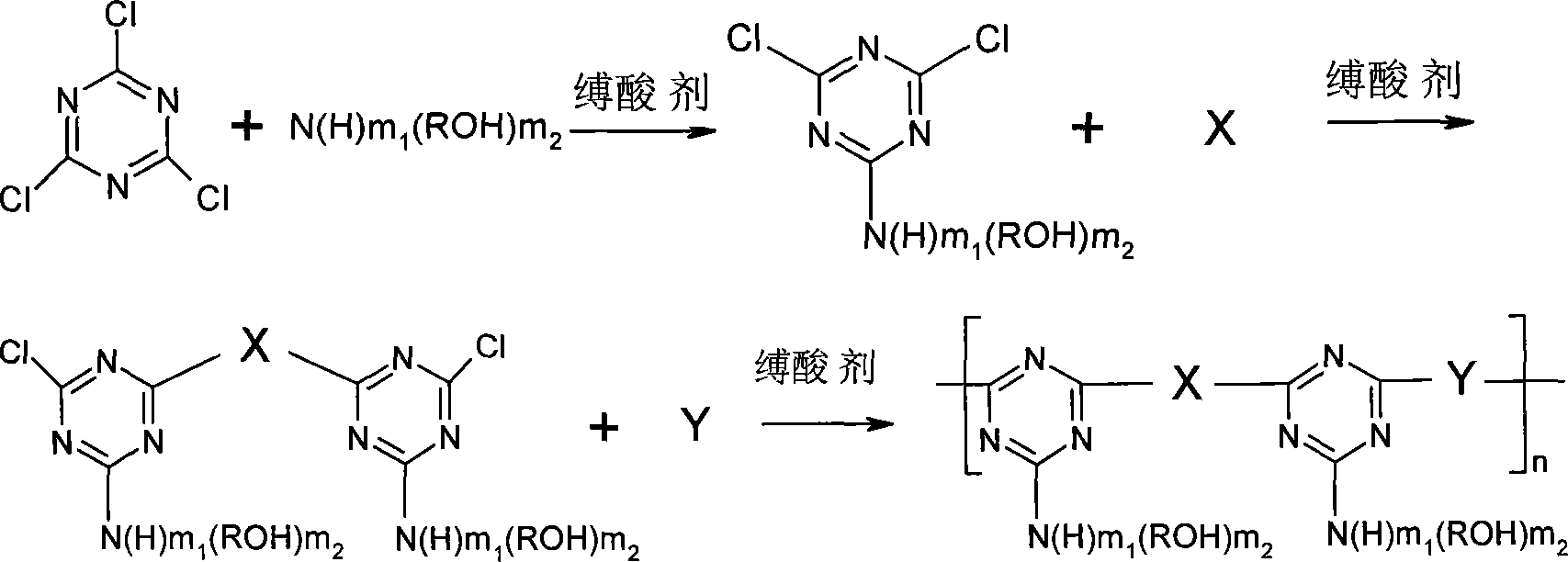

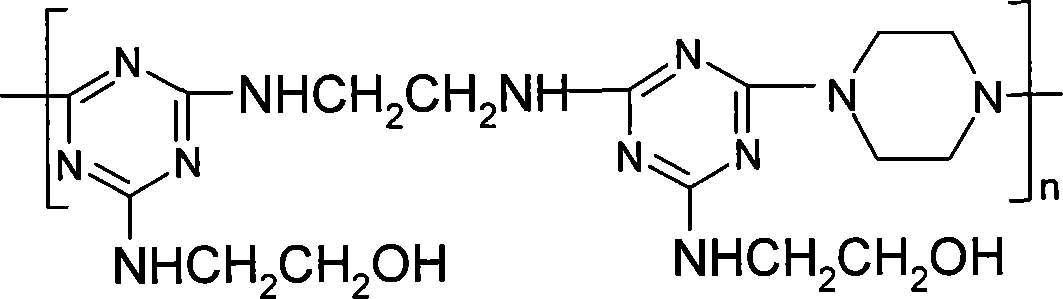

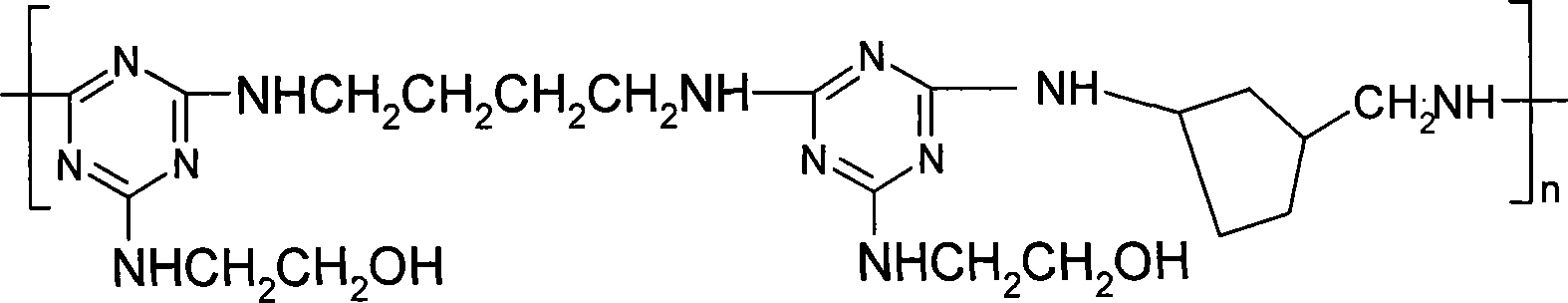

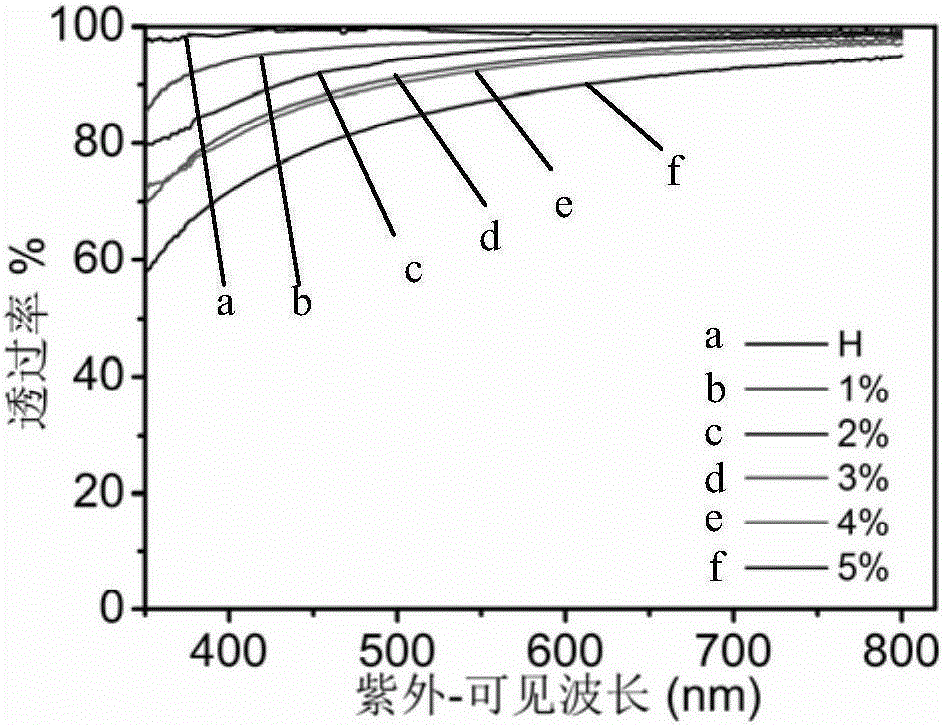

Triazine carbonific containing aromatic chain structure and preparation method

InactiveCN101586033AImprove the defects of poor mechanical behaviorGood foaming effectFireproof paintsChain structureThermal stability

A triazine carbonific containing aromatic chain structure, the carbonific is obtained by aromatic binary compound and monosubstituted cyanuric chloride with structural general formula being NH2-Ar-NH2, HO-Ar-OH or HS-Ar-SH under catalyst action. The invention further claims a method of preparing the triazine carbonific containing aromatic chain structure. Compared with the prior art, the invention has the advantages that: the triazine halogen-free flame retardant obtained by the invention has high thermal stability, high char rate under high temperature; the reaction process is one kettle way continuous reaction, and the preparation process is simple, the intermediate does not need to be processed; the post process method is simple, and the reaction time is short, the yield is high; the invention can effectively save energy consumption, improve the production efficiency and reduce the production cost.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

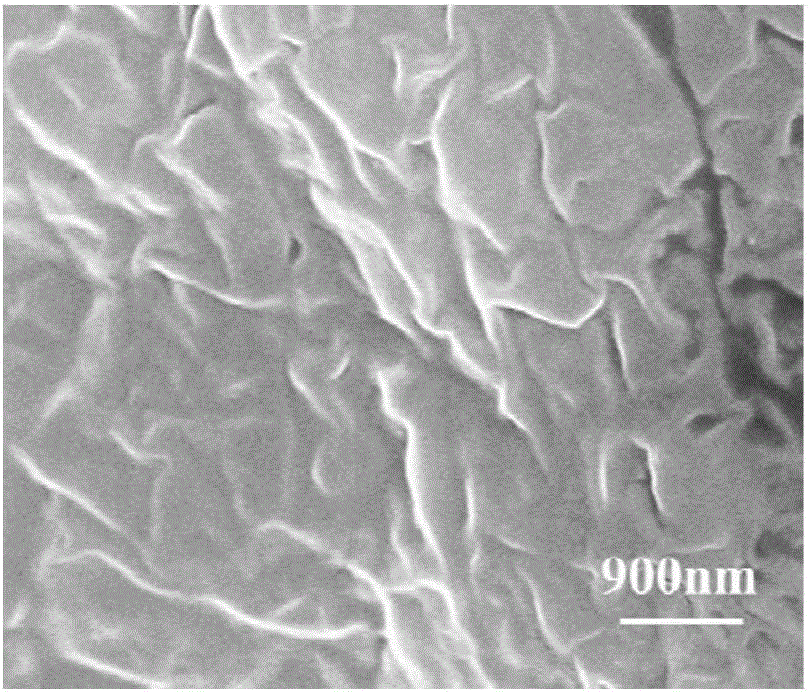

Dopamine surface modified two-dimensional nano material and preparation method thereof

InactiveCN107216689AGood dispersionGood compatibilityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsHeat conductingOrganic matter

The invention relates to a dopamine surface-modified two-dimensional nanometer material and a preparation method. A two-dimensional nanometer material wrapped with polydopamine is prepared through a one-step reaction. The invention solves the problem of poor dispersion of traditional two-dimensional nanometer materials in interstitium (water, organic matter). This characteristic preparation method provides a method for modifying the surface of two-dimensional nanomaterials with dopamine. After the surface of two-dimensional nanomaterials is modified by dopamine, functional groups (hydroxyl and amino groups) are successfully introduced. Compatibility between matter and two-dimensional nanomaterials. Therefore, this invention has great scientific significance, and has great practical application value in the production of friction-resistant composite materials, lubricating grease, and heat-conducting composite materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

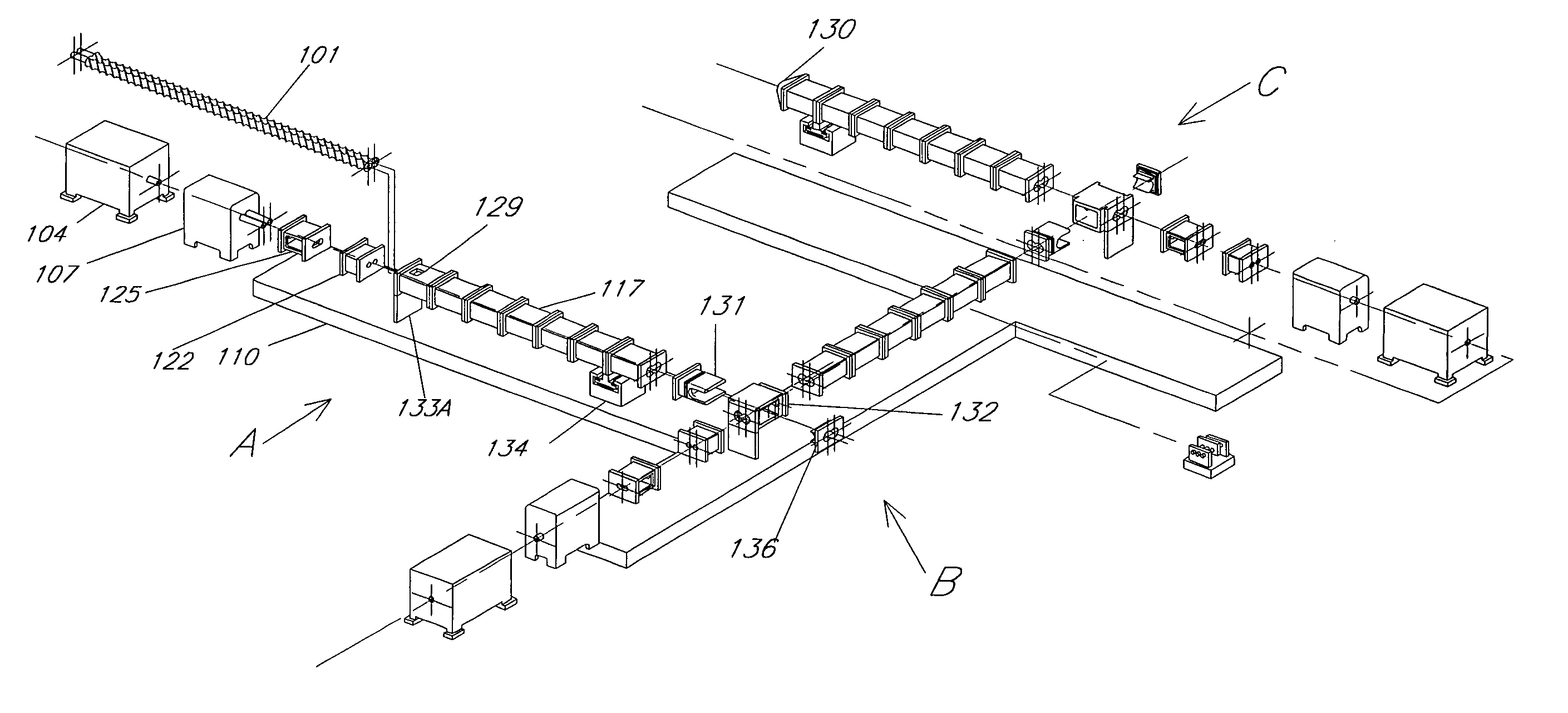

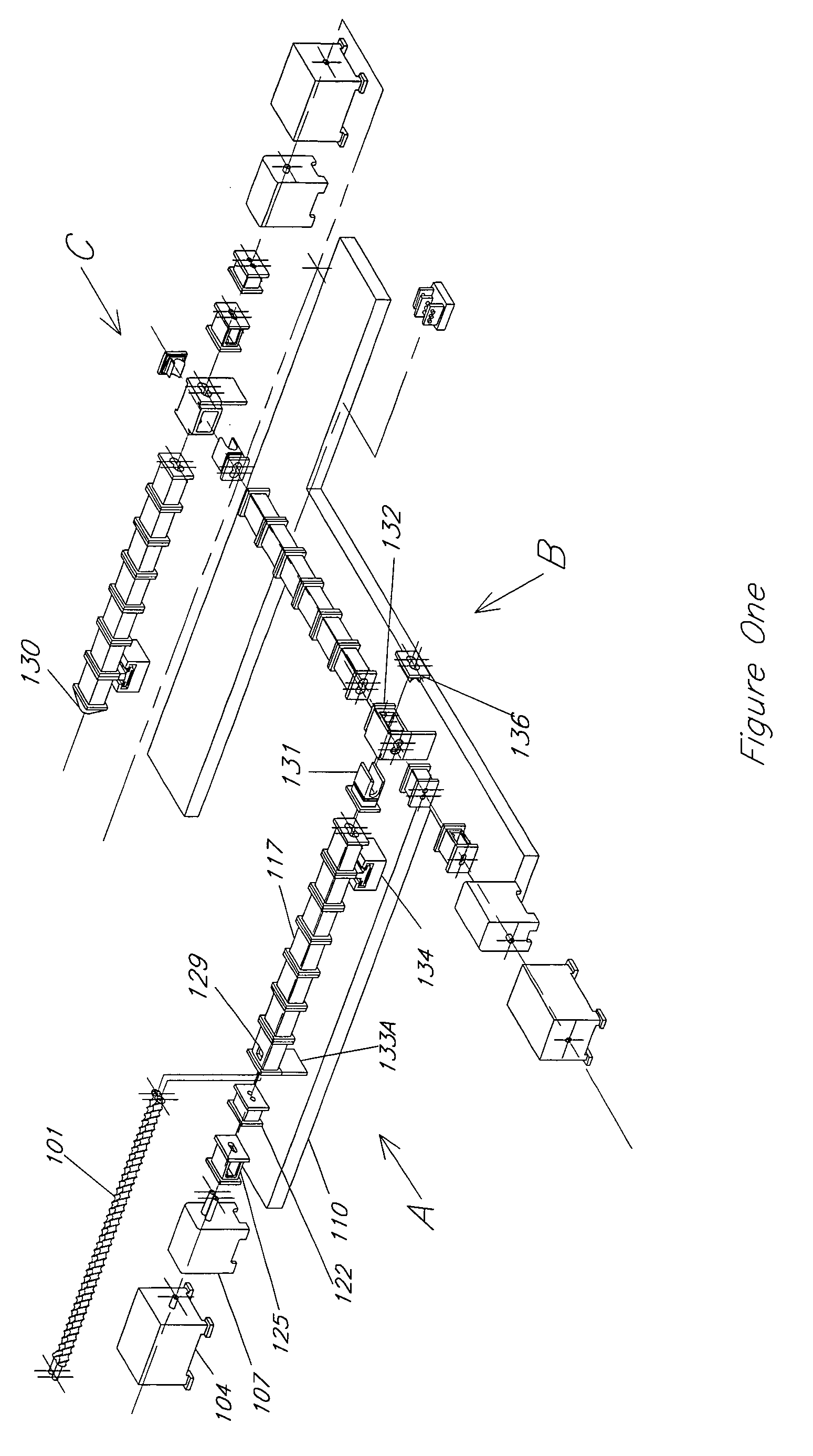

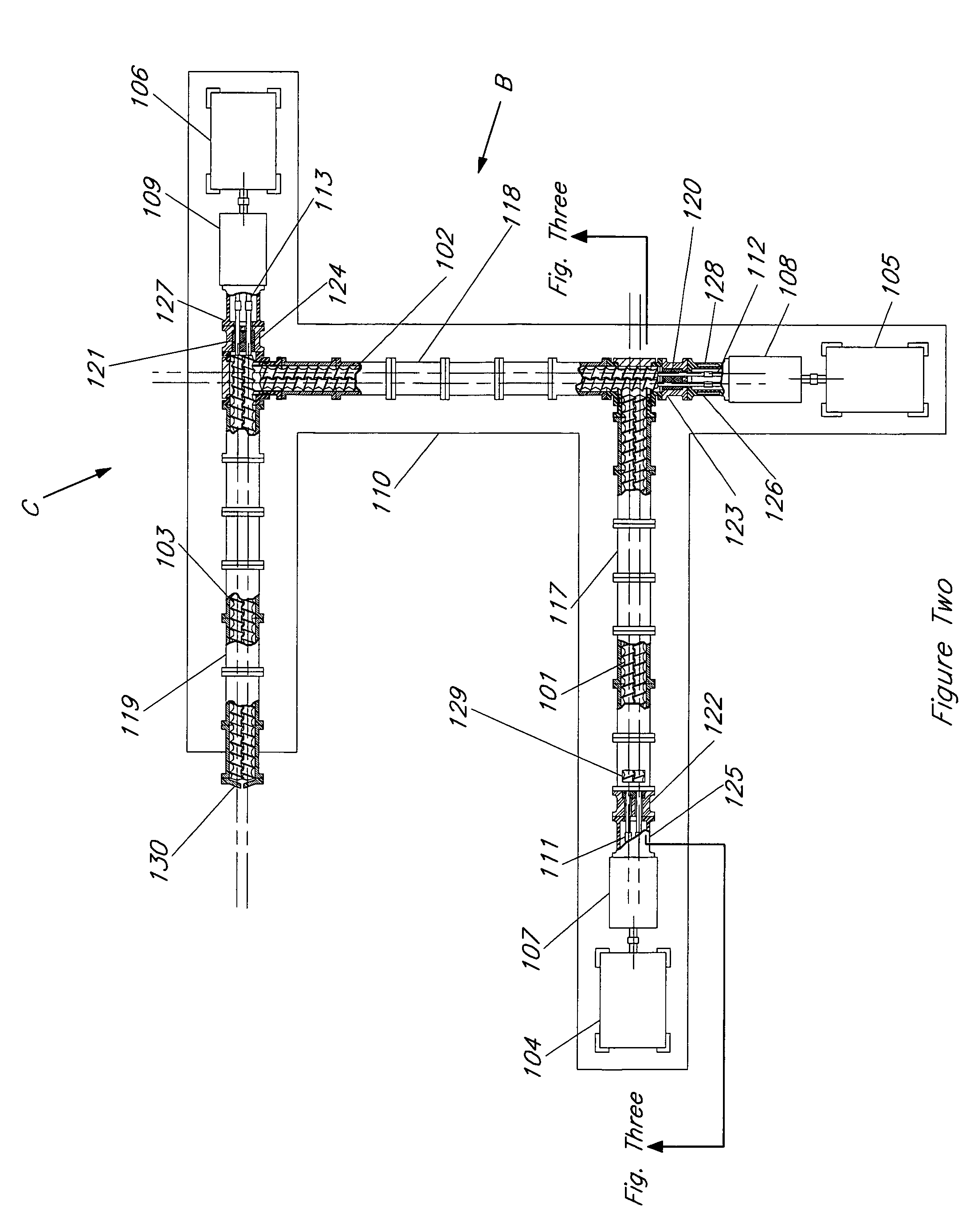

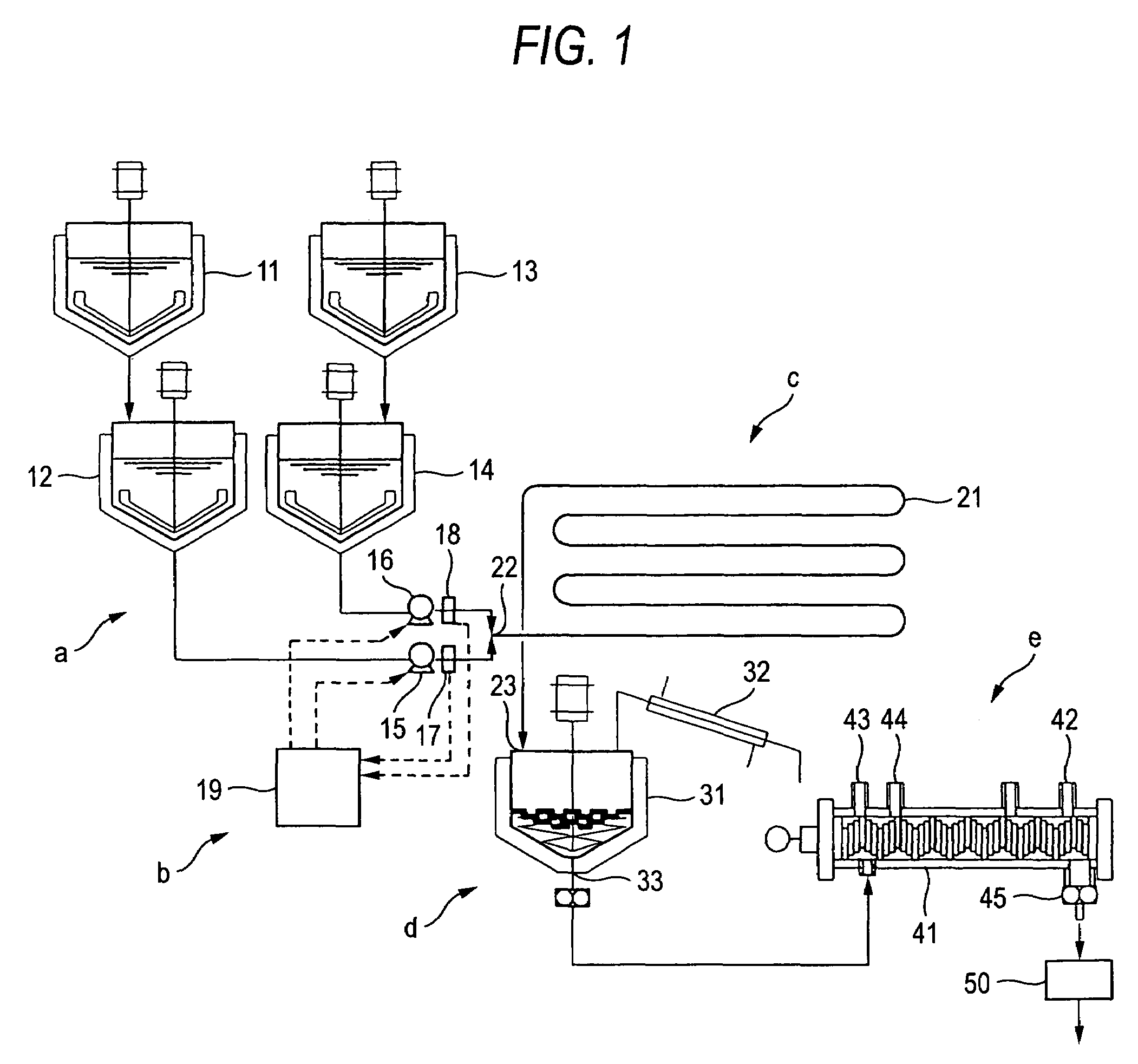

Multiple extruder assembly and process for continuous reactive extrusion

Methods are disclosed for a novel and useful single pass extrusion process for the reactive extrusion and compounding of polymers. Traditional extruders utilized in reactive processes are of length to diameter ratios ranging from 30 to 1 to as high as 56 to 1. The process disclosed uses a series of sequential, very closely-coupled, independently driven screw extruders having a total effective length to diameter ratio much greater than 70 to 1 and as high as 132 to 1 or greater, and providing greatly extended reaction times, separate and multiple introductions of reactive and non-reactive agents and mechanical connections allowing for convenient screw changes and differential thermal expansion. The assembly is employed to economically produce grafted polyolefins, produce ionomers without employing the use of strong caustic agents, remove large volumes of unwanted polymer processing solvents and produce other reacted polymer species in one continuous pass.

Owner:ORREX PLASTICS CO LLC

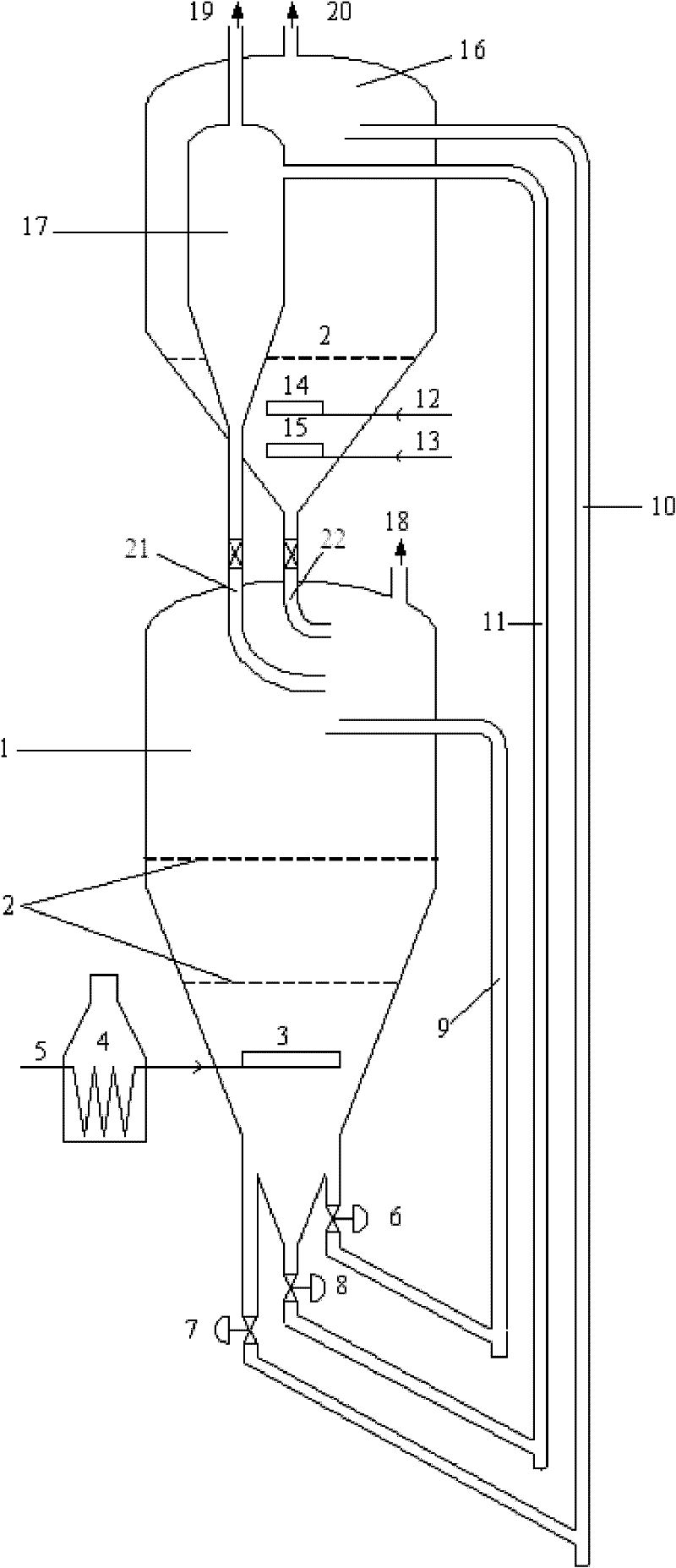

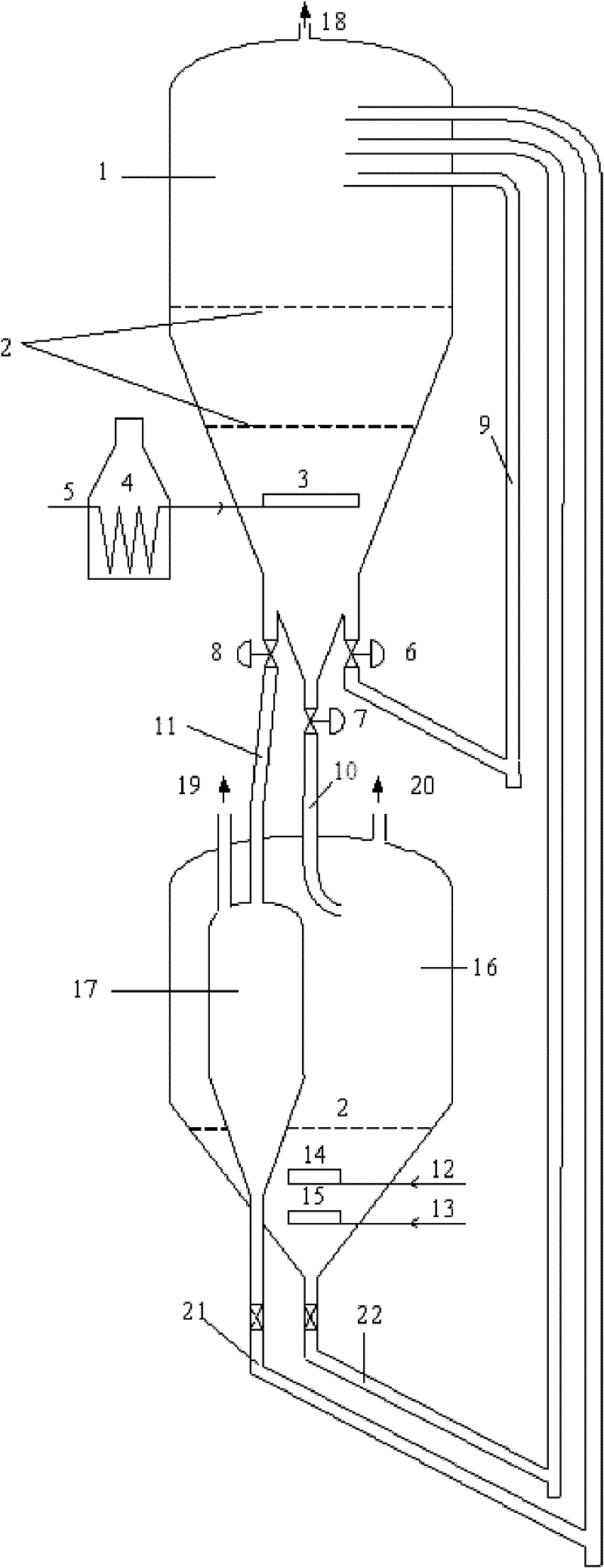

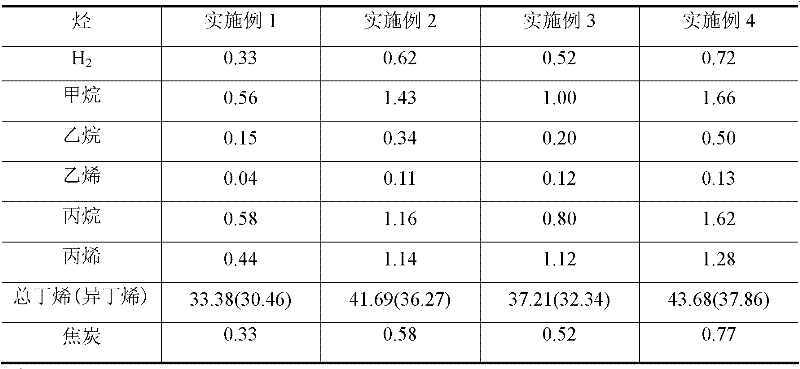

Catalyst for alkane dehydrogenation and device

ActiveCN102451677AHigh catalytic activityHigh selectivityHydrocarbonsChemical recyclingAlkaneAlkali metal oxide

The invention provides a catalyst for alkane dehydrogenation as well as a continuous reaction regeneration device and method using the catalyst for catalytic dehydrogenation. The catalyst comprises four ingredients, the ingredient A is oxides of one kind of element or several kinds of elements from Ti, Nb, Ta, Mo, W, Re, In or Ga, the ingredient B is one kind or several kinds of materials in MgO, P2O5, ZrO2, Al2O3 or SiO2, the ingredient C is oxides of one kind of material or several kinds of materials from Zn, Cd and Sn, and the ingredient D is one kind of material or a mixture of several kinds of materials from alkali oxides or alkaline earth metal oxides. The catalyst does not contain noble metal such as Pt and the like, does not contain toxic ingredients such as Cr and the like and cannot pollute the environment. The activity of the catalyst is high, the selectivity of olefin generated by alkane dehydrogenation is high, the stability of the catalyst is good, the mechanical intensity is high, the continuous reaction regeneration device is used for alkane dehydrogenation, the reaction and the catalyst regeneration are continuously carried out, the efficiency is high, and the safety is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing 4-nitrodiphenylamine and 4-nitrosodiphenylamine from carbanilide

InactiveUS6137010AHigh yieldImprove responseOrganic compound preparationAmino preparation by hydrogen substitutionAniline4-aminodiphenylamine

This invention relates to a process for preparing 4-nitrodiphenylamine and 4-nitrosodiphenylamine to be used for 4-aminodiphenylamine as an intermediate of antiozonant, wherein carbanilide is reacted with nitrobenzene in the presence of an appropriate base, while simultaneously adding aniline to the mixture so as to regenerate some amounts of carbanilide as a starting material. According to this invention, 4-nitrodiphenylamine and 4-nitrosodiphenylamine can be prepared in a higher selectivity and conversion rate via a continuous reaction by recycling carbanilide, a starting material, while adding a certain amount of aniline during the process. Further, the amount of waste water can be significantly reduced compared to the conventional method without any corrosive materials harmful to the environment.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

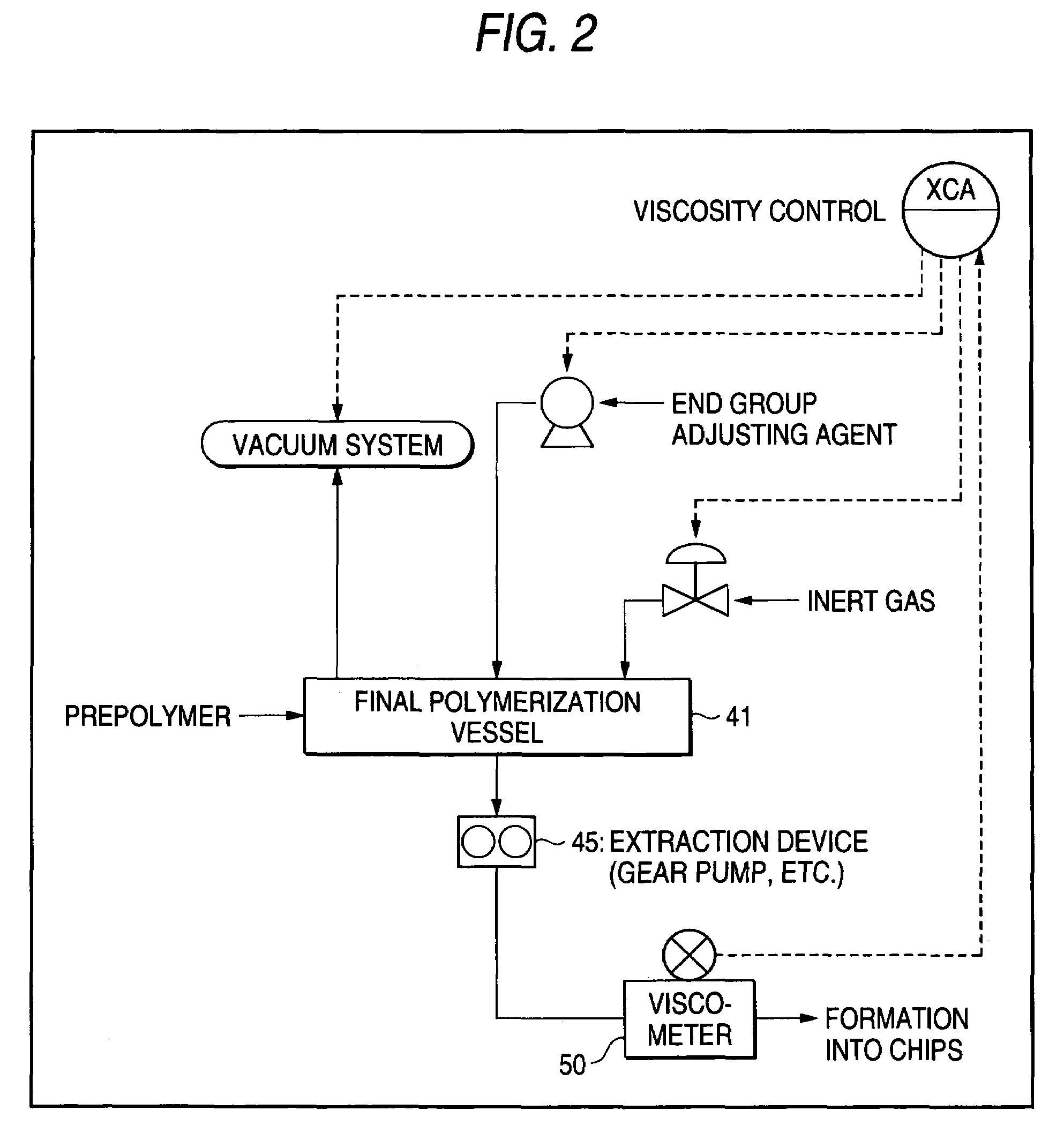

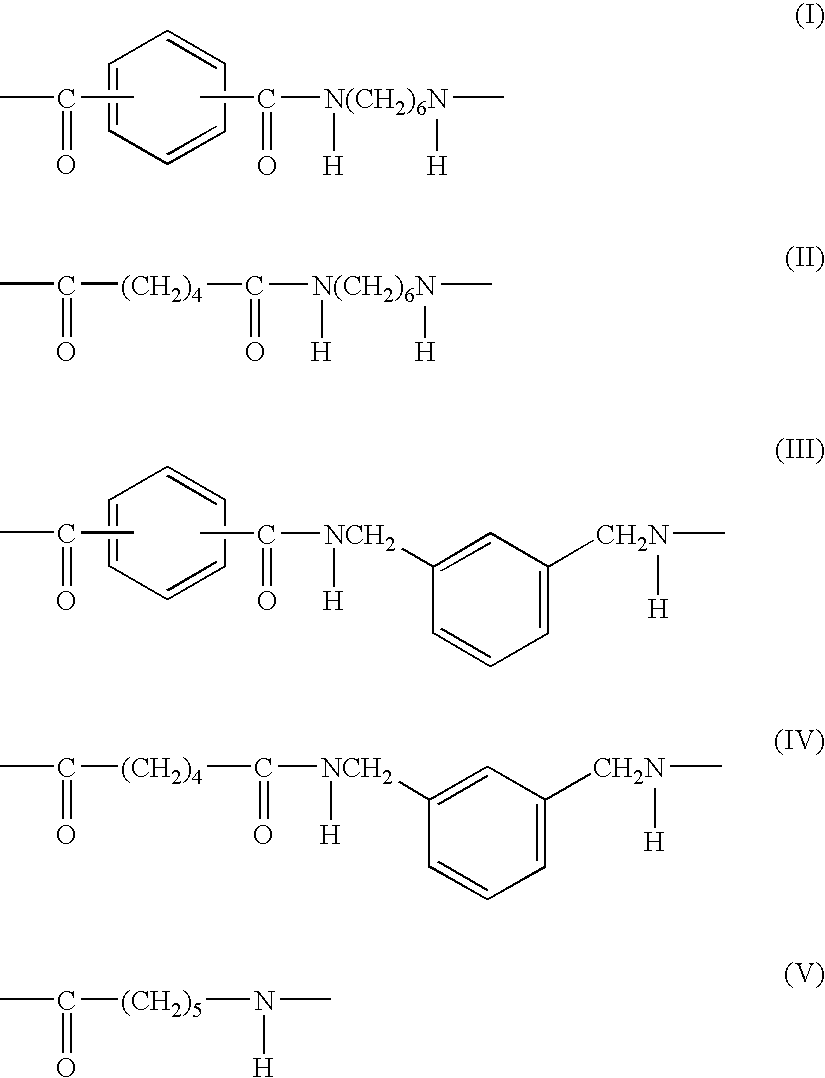

Method for continuous production of polyamide

InactiveUS7381788B2Quality improvementThe degree of polymerization is controllableCeramic shaping apparatusChemical/physical/physico-chemical stationary reactorsPolyamideCarboxylic acid

Provided is a continuous production method of a polyamide with stabilized polymerization degree and good quality, particularly an aromatic-containing polyamide. A continuous production method of a polyamide, comprising (a) a raw material preparation step of individually melting a diamine and a dicarboxylic acid, or producing a salt of amine and carboxylic acid in water, (b) a raw material introduction step of continuously introducing the prepared raw materials into a tubular reaction apparatus, (c) an amidation step of passing the introduced raw materials through the tubular reaction apparatus, thereby effecting amidation to obtain a reaction mixture containing an amidated product and a condensed water, (d) an initial polymerization step of introducing the reaction mixture into a continuous reaction apparatus capable of separation and removal of water, and elevating the polymerization degree while separating and removing water at a temperature higher than the melting point of the finally obtained polyamide to obtain a polyamide prepolymer, and (e) a final polymerization step of introducing the polyamide prepolymer into a continuous reaction apparatus capable of separation and removal of water, and further elevating the polymerization degree at a temperature higher than the melting point of the finally obtained polyamide to obtain a polyamide adjusted to a desired relative viscosity [RV].

Owner:TOYOBO CO LTD

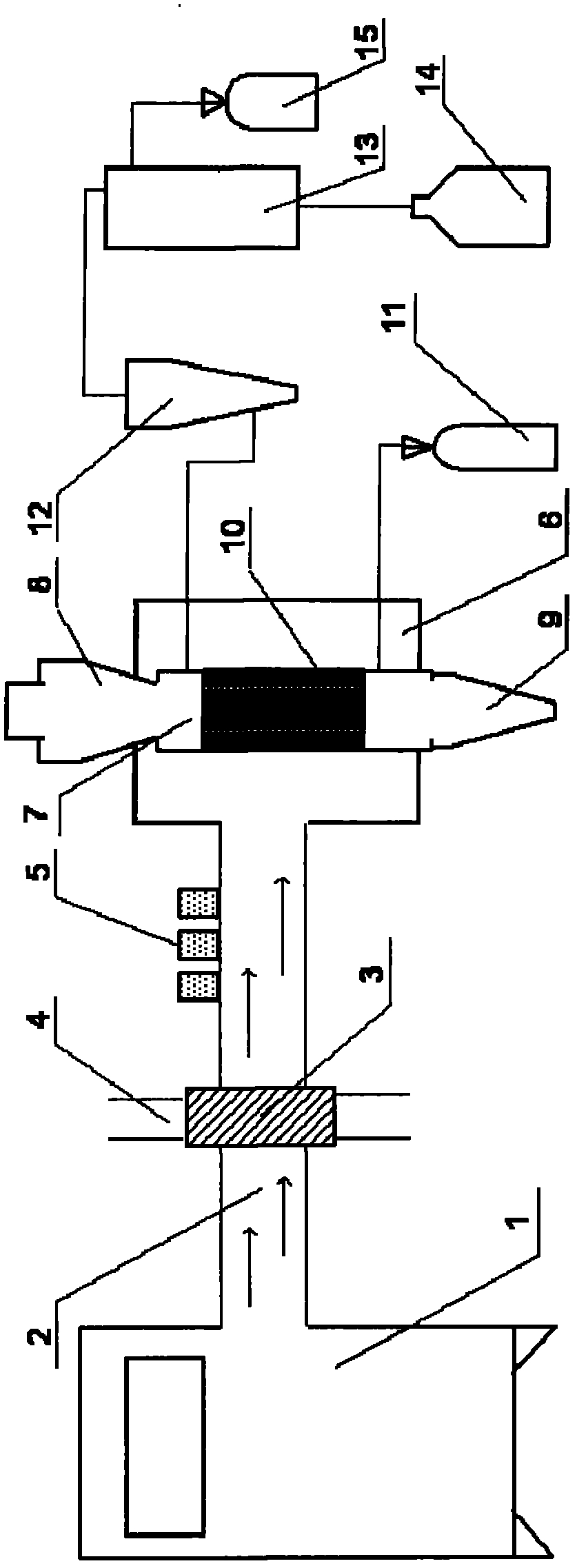

Continuous reaction device and method for microwave biomass pyrolysis

InactiveCN102580650APyrolysis continuous reaction realizedIncrease reaction rateBiofuelsLiquid hydrocarbon mixture productionMicrowaveFuel gas

The invention relates to a continuous reaction device and a method for microwave biomass pyrolysis. The continuous reaction device for the microwave biomass pyrolysis mainly comprises a microwave generator, a reactor and a resultant separating device. The continuous reaction device is a continuous operating system and can process 10-50kg of the biomass every hour. According to the continuous reaction device for the microwave biomass pyrolysis, characteristics of microwave volume heating, transient heating and selective heating are fully utilized, undried biomass is directly pyrolyzed so as toobtain three products of liquid bio-oil, bio-gas and solid coke, the pylolysis efficiency of the biomass is greatly improved, the yield and the quality of the liquid bio-oil are improved, the structure is simple, the design is reasonable, and the achievement of industrial application of the microwave biomass pyrolysis is facilitated.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of photo-moisture dual cured hot melt polyurethane sealant

InactiveCN105255435AImprove the shortcomings of low initial strengthRapid positioningNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to a preparation method of a photo-moisture dual cured hot melt polyurethane sealant. The preparation method comprises following steps: firstly, an HDI (hexamethylene diisocyanate) trimer reacts with a hydroxyl acrylate monomer, after the reaction, polyether polyol is added for continuous reaction, and a prepolymer A is obtained; bifunctional isocyanate reacts with crystalline polyester polyol and non-crystalline polyester polyol, and a prepolymer B is obtained; the prepolymer A and the prepolymer B are mixed in a certain ratio, then a photoinitiator, a catalyst, a coupling agent and the like are added, and the photo-moisture dual cured hot melt polyurethane sealant is obtained. The preparation method improves the defects of failure in rapid positioning of UV glue, low initial strength of the hot melt polyurethane sealant and the like, rapid positioning can be realized, the hot melt polyurethane sealant can achieve higher strength in a short time, and the hot melt polyurethane sealant can be used for bonding of appliances, furniture, electronic components and the like.

Owner:YANTAI DARBOND TECH

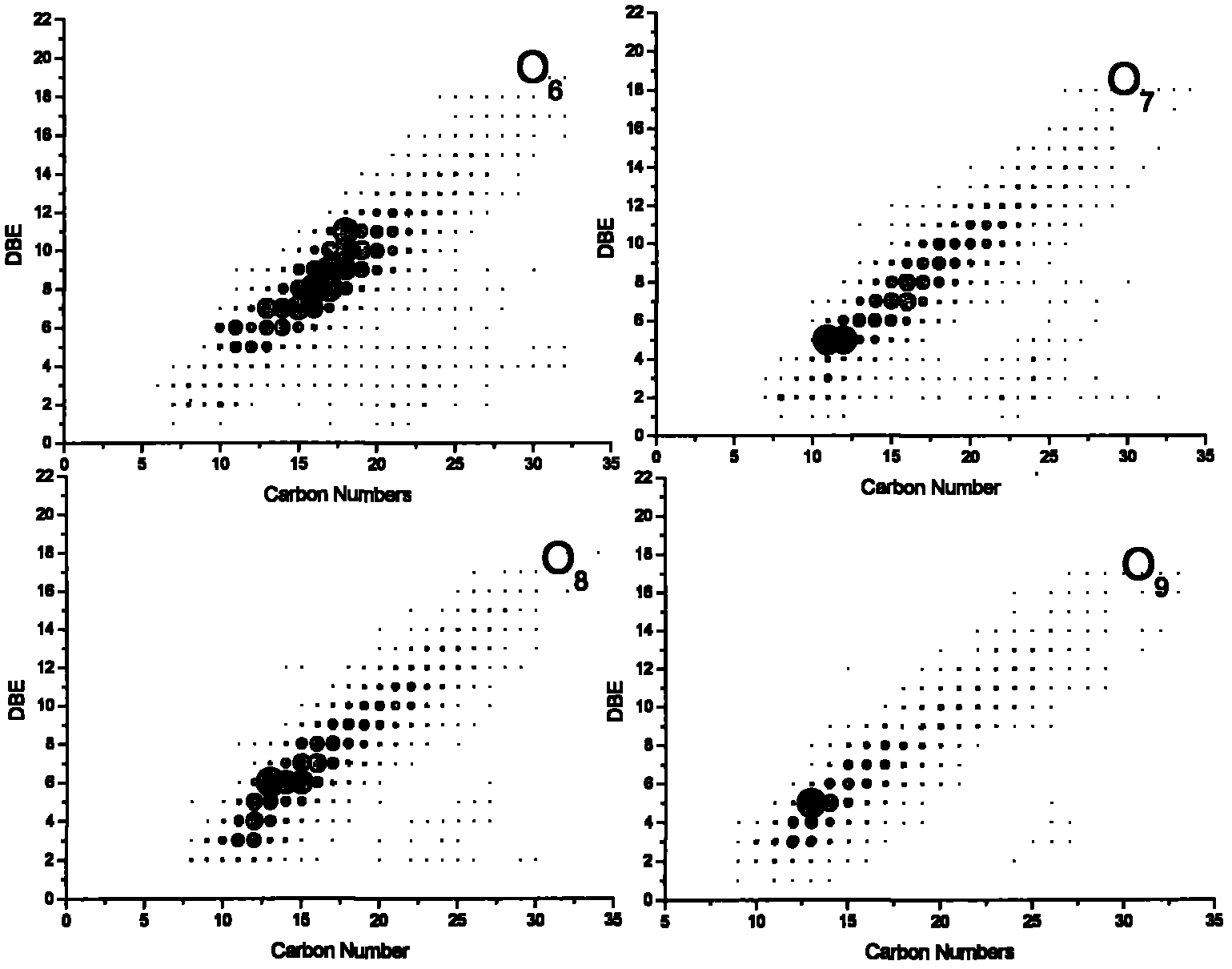

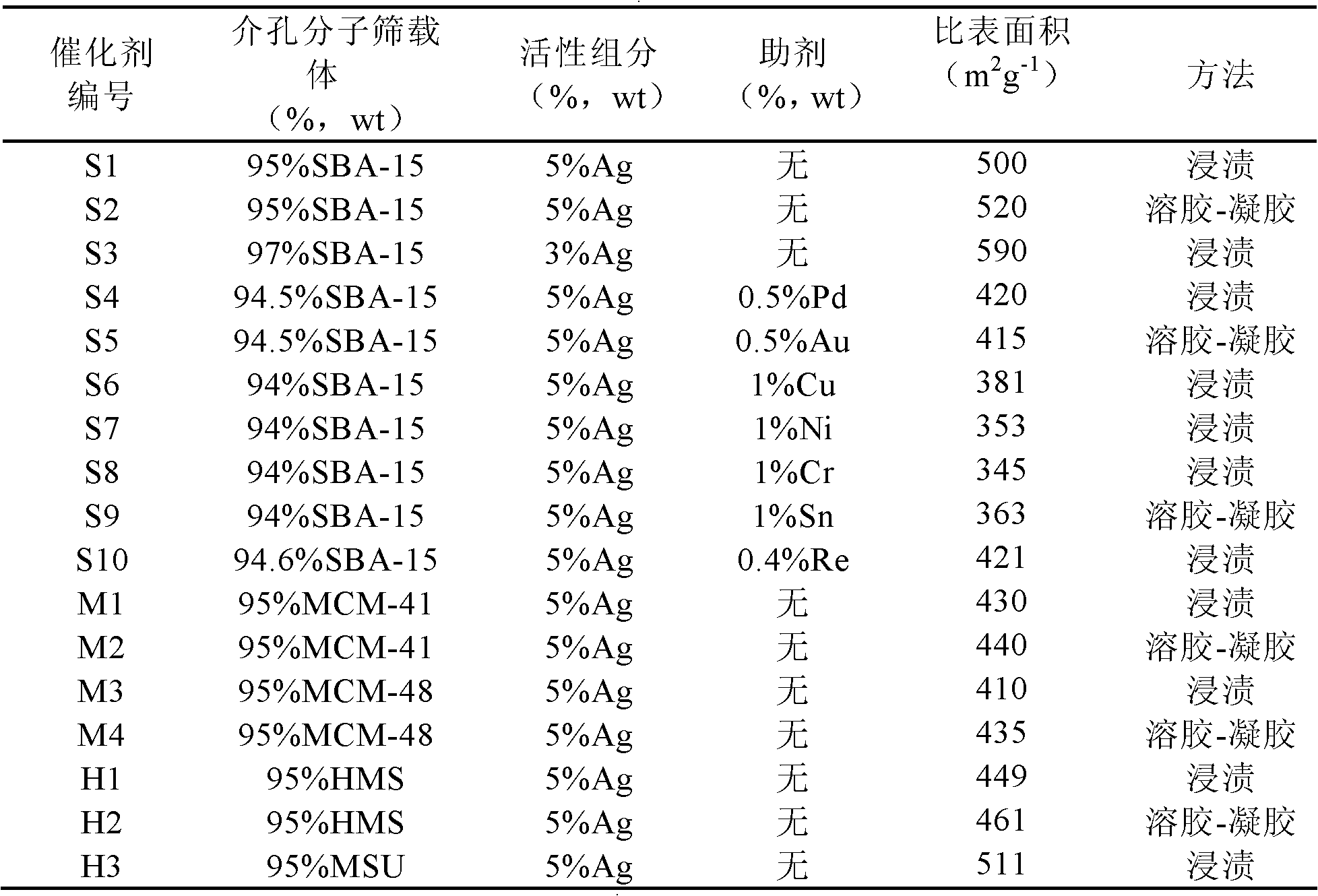

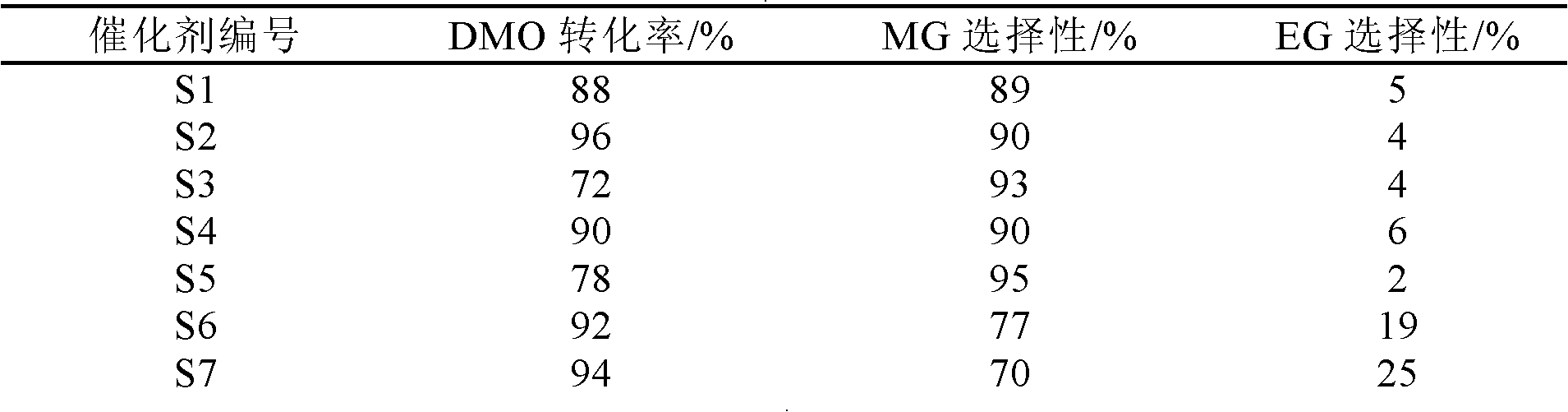

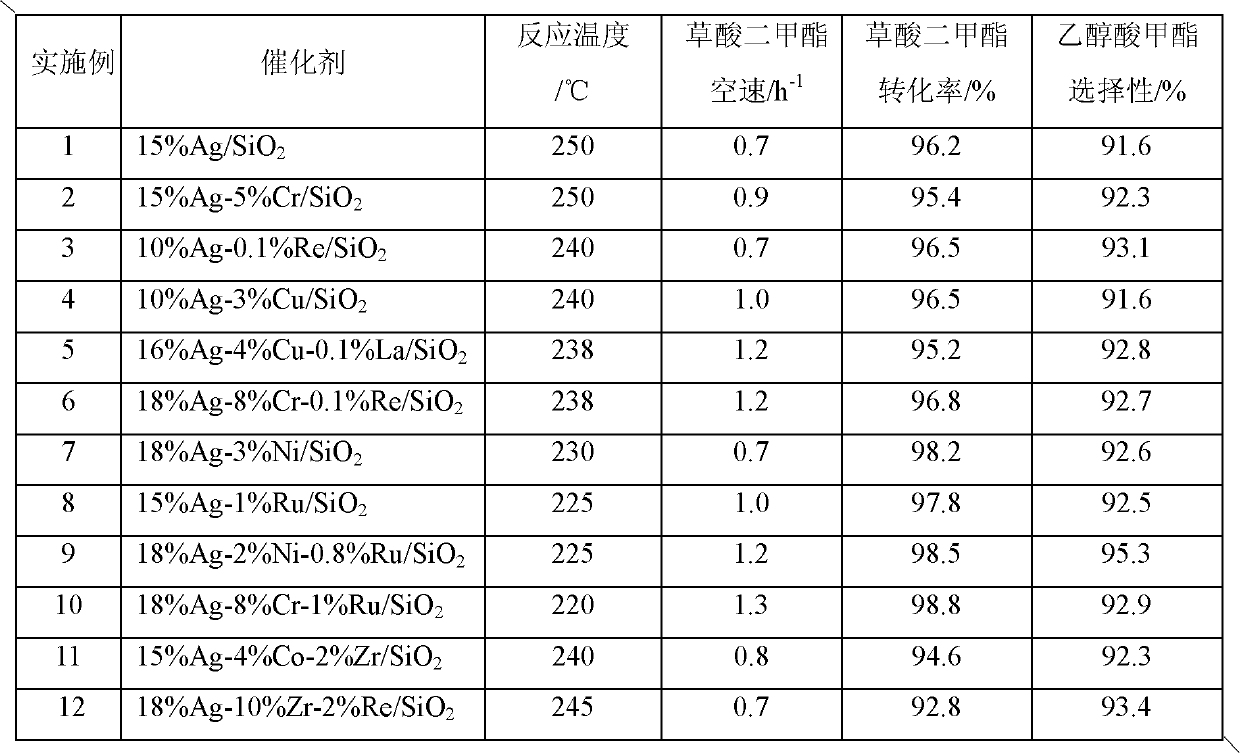

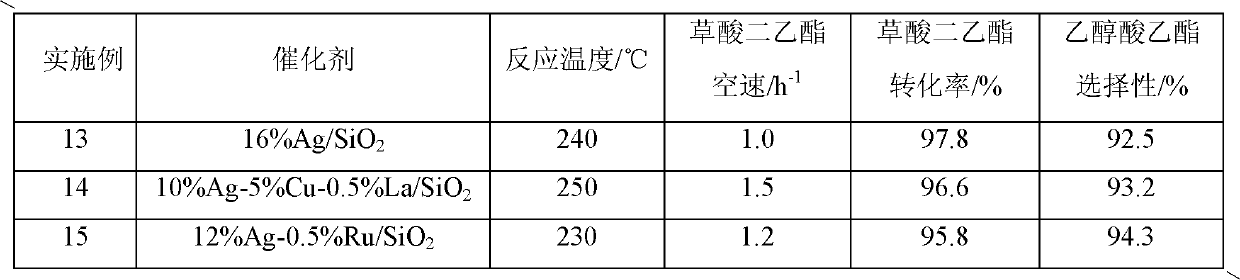

Method for synthesizing methyl glycollate and ethylene glycol by dimethyl oxalate hydrogenation

ActiveCN102336666AEasy to makeImprove performanceMolecular sieve catalystsOrganic compound preparationHydrogen pressureHydrogenation reaction

The invention discloses a method for synthesizing methyl glycollate and ethylene glycol by dimethyl oxalate hydrogenation. The method comprises the following steps of: performing hydrogenation reaction on dimethyl oxalate serving as a raw material under the action of a catalyst at the temperature of between 120 and 300 DEG C under the hydrogen pressure of 0.2 to 10.0MPa, performing fixed bed continuous reaction, and thus obtaining target products, namely the methyl glycollate and the ethylene glycol. The method is mild in reaction conditions and environmentally-friendly, the conversion rate of the dimethyl oxalate reaches over 99 percent, the total selectivity of the methyl glycollate and the ethylene glycol reaches over 98 percent, the selectivity of the methyl glycollate serving as a main product reaches 95 percent, and a new effective path is provided for preparing the methyl glycollate and the ethylene glycol by dimethyl oxalate hydrogenation.

Owner:SHANGHAI HUAYI GRP CO

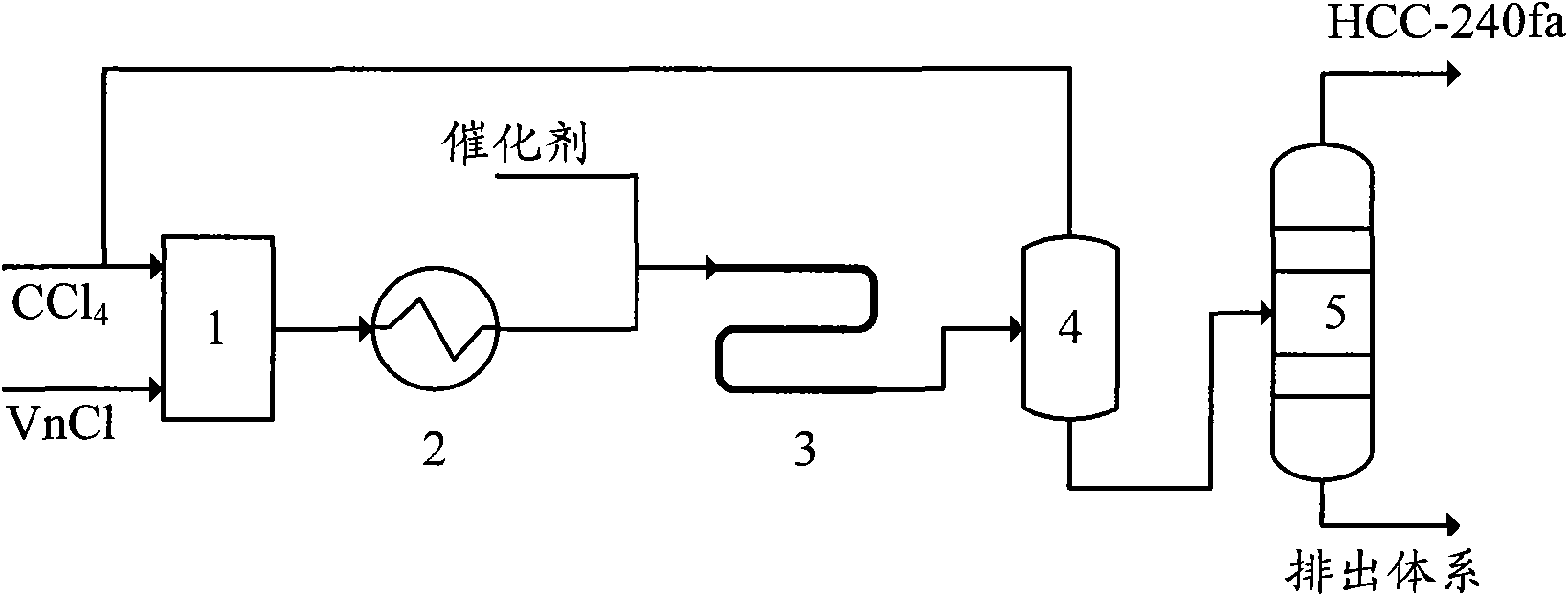

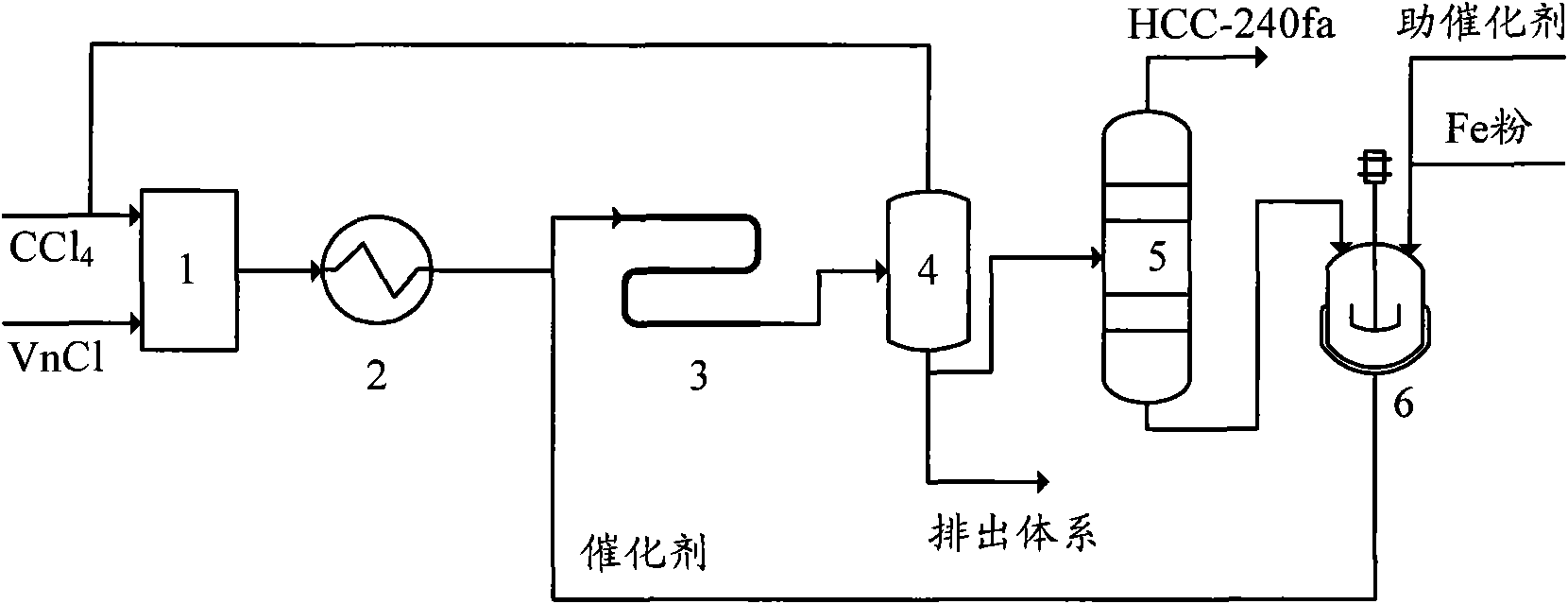

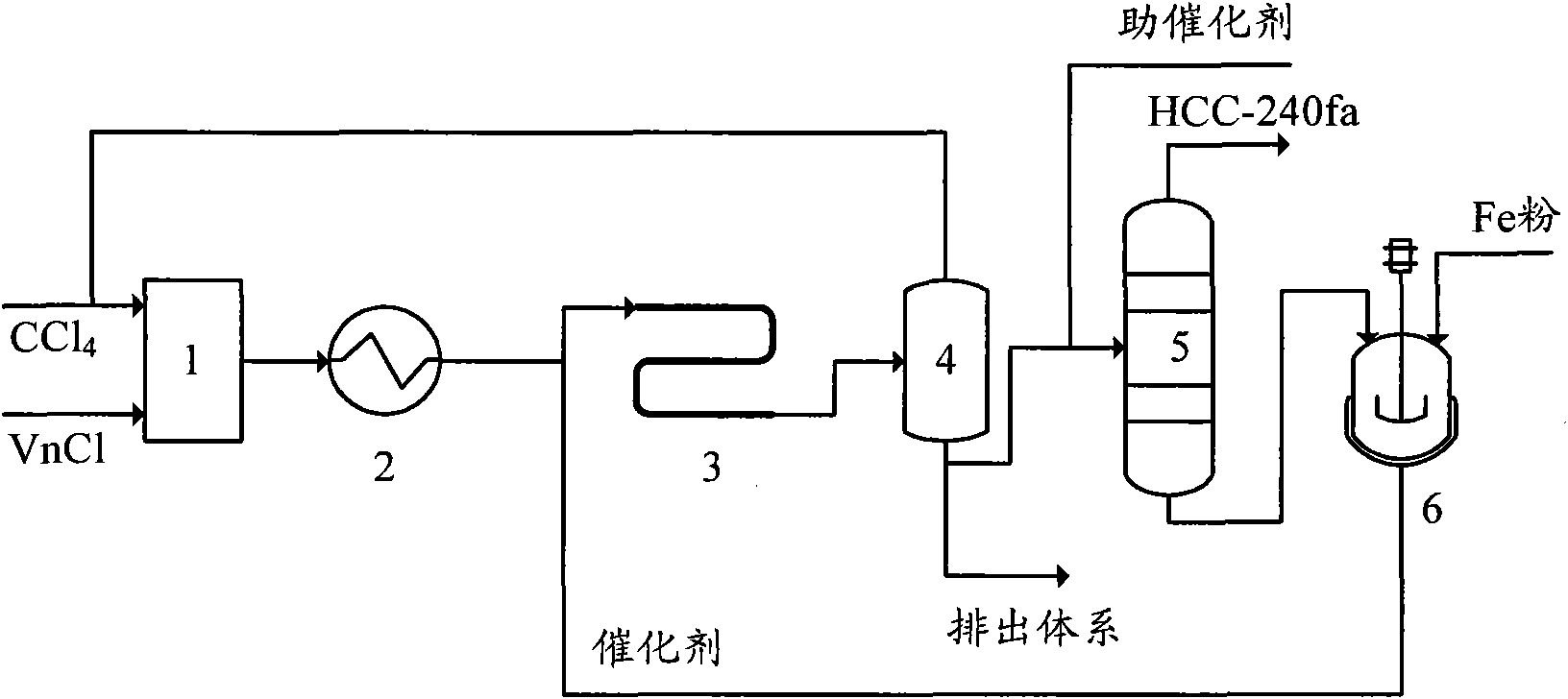

Production method of 1,1,1,3,3-pentachloropropane

InactiveCN101913980AEasy to transportAccurate measurementOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingReaction temperatureSilicon tetrachloride

The invention provides a production method of 1,1,1,3,3-pentachloropropane (HCC-240fa). The 1,1,1,3,3-pentachloropropane is synthesized by continuously reacting the materials of carbon tetrachloride and chloroethylene in a tubular reactor. The method comprises the steps of firstly mixing the carbon tetrachloride with the chloroethylene and preheating the mixture to a reaction temperature, then introducing the mixture together with a catalyst into the tubular reactor for telomeric reaction, removing the unreacted carbon tetrachloride and chloroethylene through flash evaporation, and then further distilling to obtain the HCC-240fa, wherein the unreacted carbon tetrachloride and chloroethylene are recycled and the catalyst is recycled after being subjected to the activating treatment. The invention adopts the liquid as the activated system and uses the tubular reactor for reaction, thereby ensuring simple and convenient operation as well as continuous production.

Owner:XIAN MODERN CHEM RES INST

Triazine series oligomer and its synthesizing method

The invention relates to a triazine series oligomer and the compound method. The method has the following steps: adding solvent into cyanuric chloride, dropping alkylol amine and acid roping agent to gain substitute of cyanuric chloride; heating, dropping diamidogen and acid roping agent to gain the substitute of cyanuric chloride; adding diamidogen and acid roping agent into reaction solution, heating, pumping, washing, and drying to gain triazine series oligomer. The invention has strong charring and expanding ability, and good thermal stability. It has advantages of continuously reaction process, short reaction time, simple compounding technology, little organic solvent, and easy to recycle organic solvent.

Owner:NORTHEAST FORESTRY UNIVERSITY

One-component transparent waterborne polyurethane emulsion waterproof paint and preparation method thereof

InactiveCN105255348AImprove solubilityIncrease the amount of participationPolyurea/polyurethane coatingsSilicon dioxideTin

The invention discloses one-component transparent waterborne polyurethane emulsion waterproof paint and a preparation method thereof and relates to polyurethane waterproof paint. The waterproof paint comprises a resin phase and a nano-material phase. The preparation method comprises the following steps: diol and a hydrophilic chain extender are dried, and other prepolymerization monomers are dried; diol, diisocyanate, fluorine-containing acrylate monomers and hydroxyl-terminated siloxane after a dehydration process are added to a four-neck flask, the mixture is heated and added with an organic tin initiator for a reaction under the protection of nitrogen, and the mixture is heated and added with dimethylolpropionic acid for continuous reaction; after a reaction system is cooled, the chain extender and acrylate monomers are added for a reaction; after a prepolymer is cooled to the temperature lower than the room temperature, a neutralizer and a cross-linking agent are added; then deionized water is added for emulsification, and mixed liquor A is obtained; a silane coupling agent is dissolved in absolute ethyl alcohol, silica microspheres are added to absolute ethyl alcohol, and mixed liquor B is obtained; the mixed liquor B is added to the mixed liquor A, the mixture is heated, and a radical initiator is added for a reaction; an organic solvent is removed, and the one-component transparent waterborne polyurethane emulsion waterproof paint is obtained.

Owner:XIAMEN UNIV

Continuous low-temperature process to produce trans-1-chloro-3,3,3-trifluoropropene

ActiveUS8704017B2Yield maximizationChlorine/hydrogen-chlorideHydrocarbon from carbon oxidesIsomerizationUnit operation

Disclosed is process for the production of (E) 1-chloro-3,3,3-trifluoropropene (HCFO-1233zd(E)) by conducting a continuous reaction without the use of a catalyst. Also disclosed is an integrated system for producing hydrofluoro olefins, particularly 1233zd(E). The manufacturing process includes six major unit operations: (1) a fluorination reaction of HCC-240fa (in continuous or semi-batch mode) using HF with simultaneous removal of by-product HCl and the product 1233zd(E); (2) recycle of unreacted HCC-240fa and HF together with under-fluorinated by-products back to (1); (3) separation and purification of by-product HCl; (4) separation of excess HF back to (1); (5) purification of final product, 1233zd(E); and (6) isomerization of by-product 1233zd(Z) to 1233zd(E) to maximize the process yield.

Owner:HONEYWELL INT INC

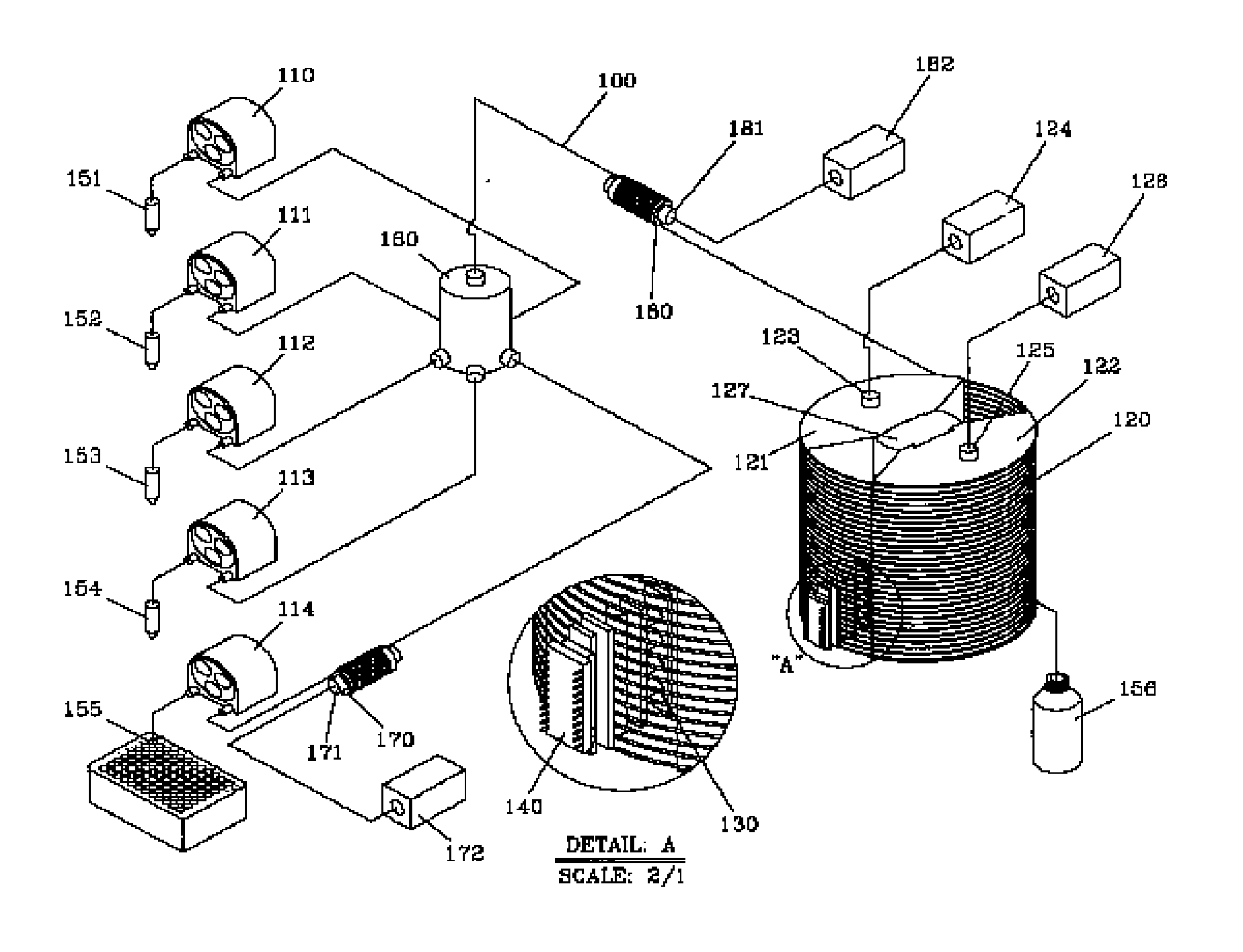

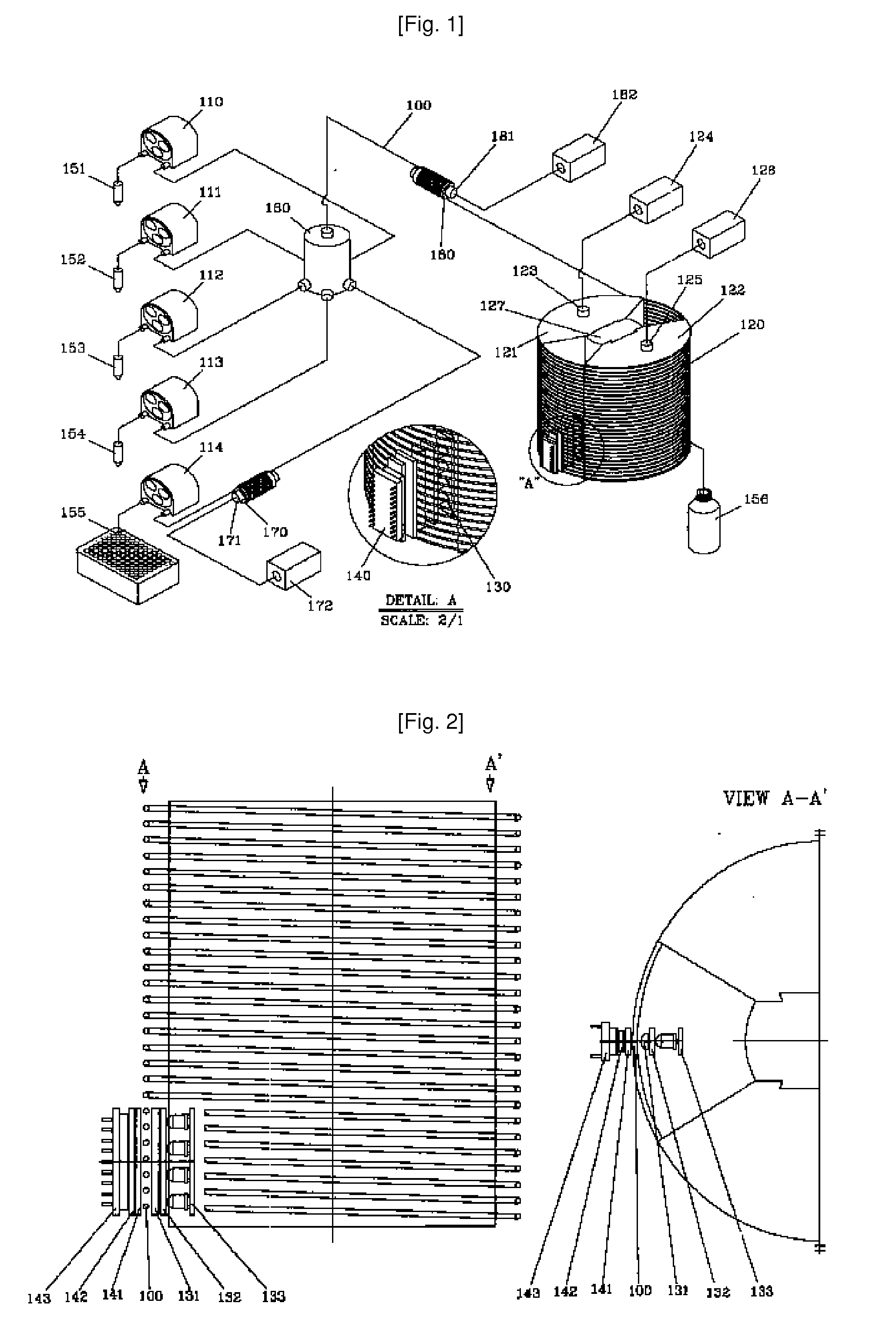

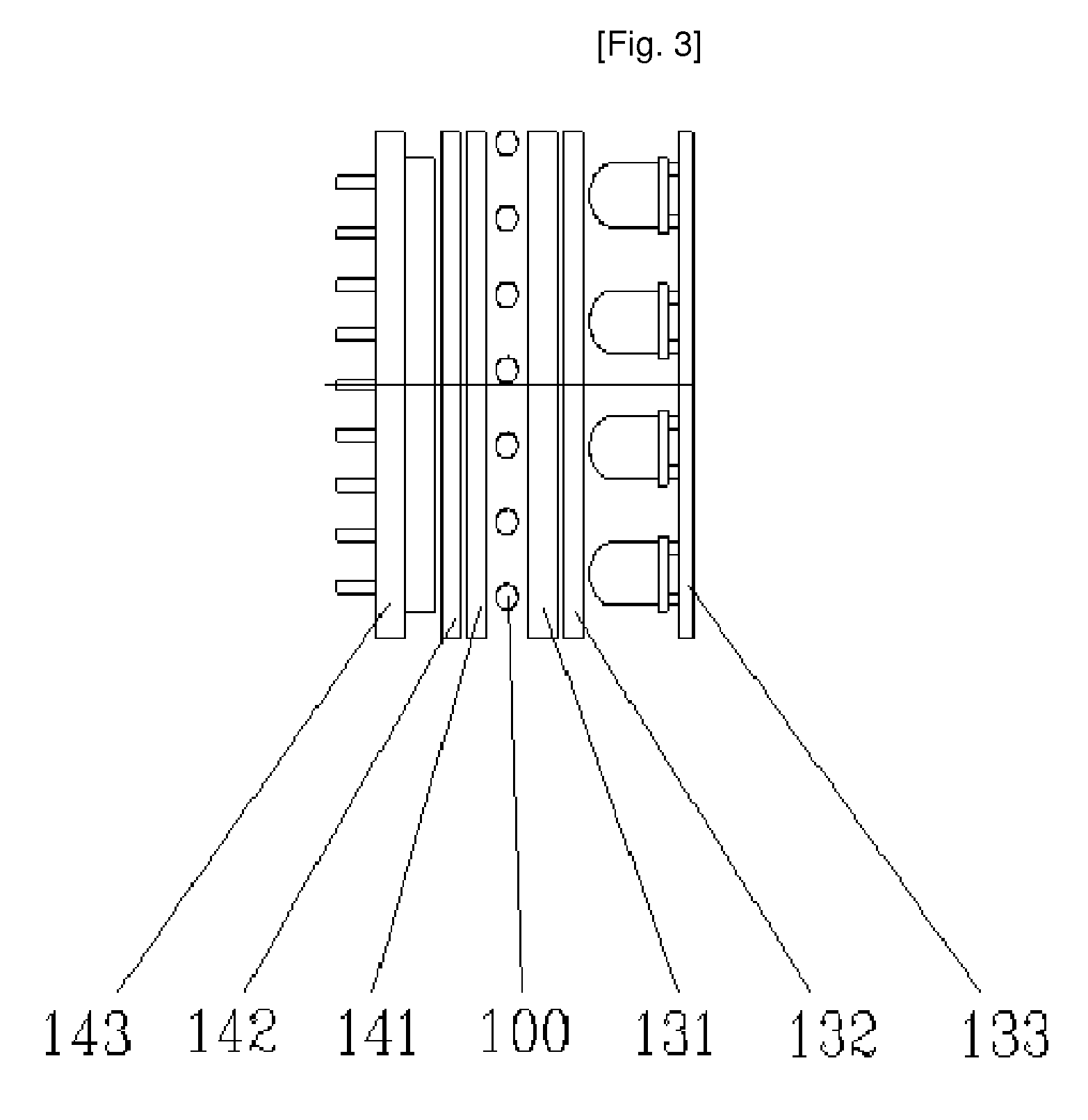

Miniaturized Apparatus For Real-Time Monitoring

InactiveUS20080032416A1Easy to useMinimize timeHeating or cooling apparatusChemiluminescene/bioluminescenceTemperature controlMiniaturization

The present invention relates to a apparatus for quantitative continuous real-time monitoring to monitor a continuous reaction of biochemical reagent and the reaction, such as DNA. More particularly, the present invention is directed to a miniaturized apparatus for real-time monitoring of biochemical reaction, which comprises capillary tubes (100) wherein biochemical reaction mixture flow; a thermal conduction block (120) which is coiled with capillary tube several rounds in order and composed of several blocks for temperature control of which temperatures are different from each other for heating or cooling the biochemical reaction mixture which flow in capillary tube, and a temperature controller which controls the temperature of above temperature control block; a radiation part (130) to radiate the reaction mixture flowing through the capillary tube and a light receiving section (140) which receives and measures the intensity of the fluorescence generated from the capillary tubes.

Owner:BIONEER

Method for producing oxalic ester with CO coupling

ActiveCN101492370AHigh selectivityImprove conversion ratePreparation by carbon monoxide or formate reactionNitrogen oxidesAlcohol

The invention relates to a method for producing oxalic ester by CO coupling, which mainly solves the problems of the prior art such as low selectivity and low CO single pass conversion in producing the oxalic ester by CO coupling. In the invention, firstly CO and nitrite ester are put into a coupling reactor and then contacted with a catalyst containing Pd; liquid phase reaction effluent II and gas phase reaction effluent III are obtained from effluent I through gas-liquid separation; the gas phase reaction effluent III, O2 and monohydric alcohol of C1-C4 are taken as raw material and put into a regeneration reactor for reaction to generate gas effluent IV containing nitrite ester; the gas effluent IV returns to the coupling reactor for continuous reaction and the mol ratio of nitrogen oxide:O2:monohydric alcohol of C1-C4 is 1:0.3-0.5:1-1.5. The technical proposal of obtaining the oxalic ester product by separating the liquid phase reaction effluent II better solves the problem and can be applicable to the industrial production of oxalic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

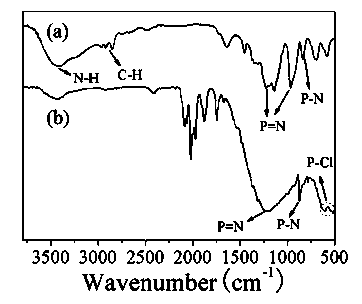

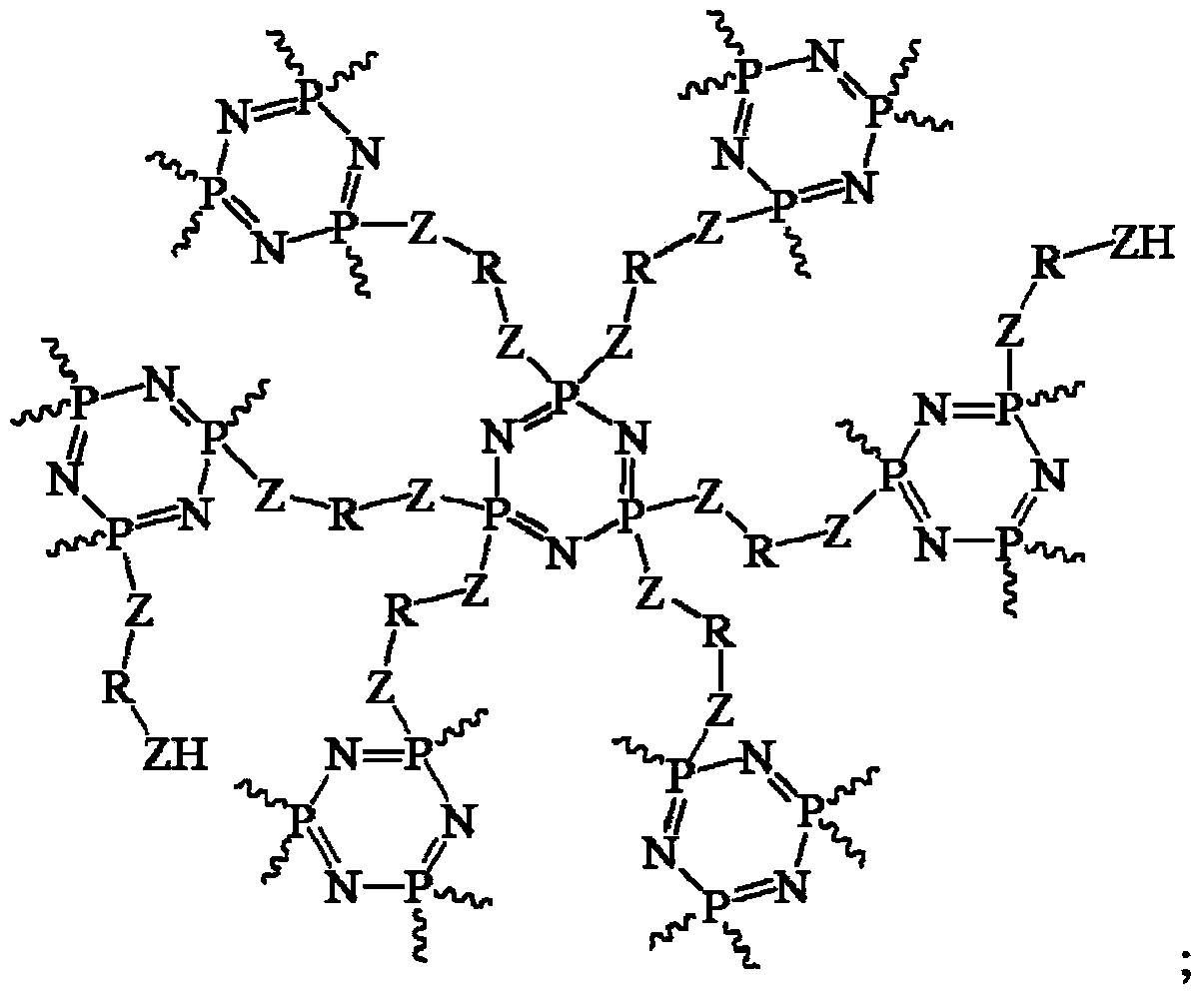

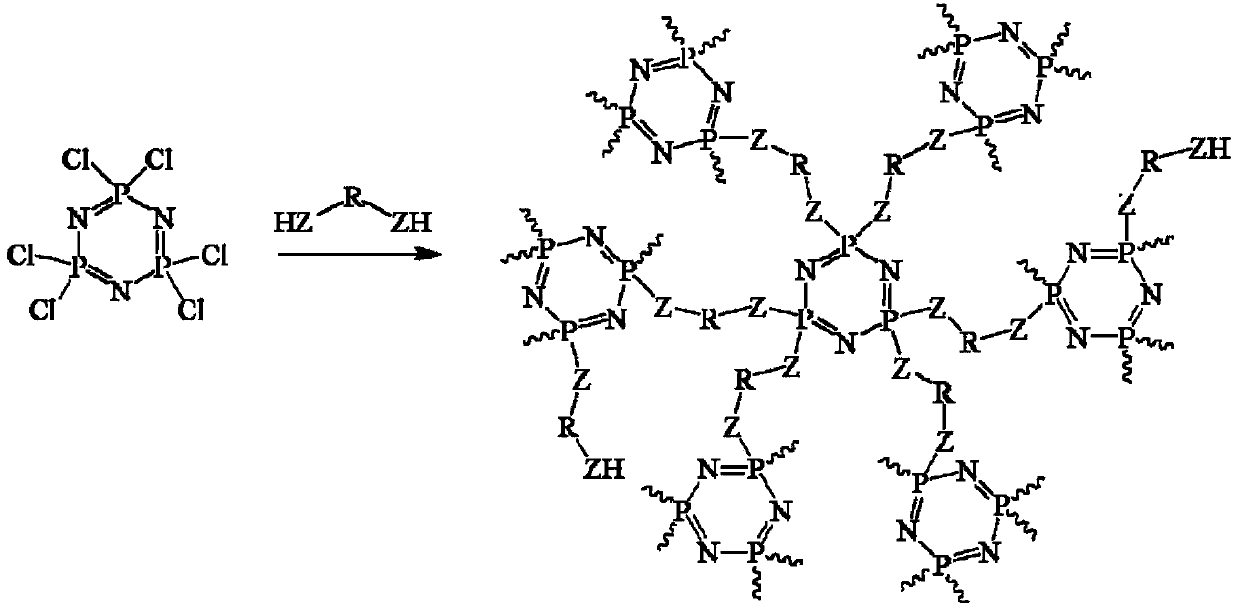

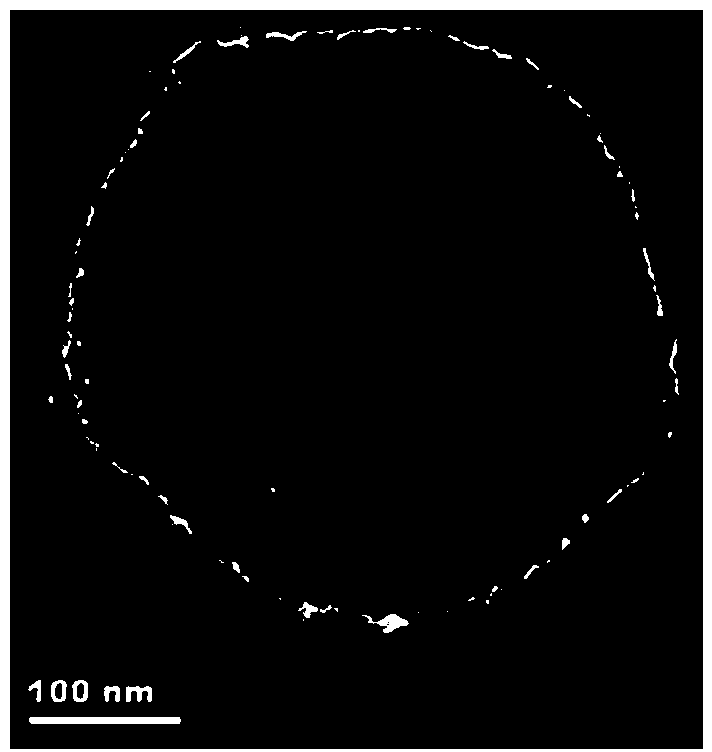

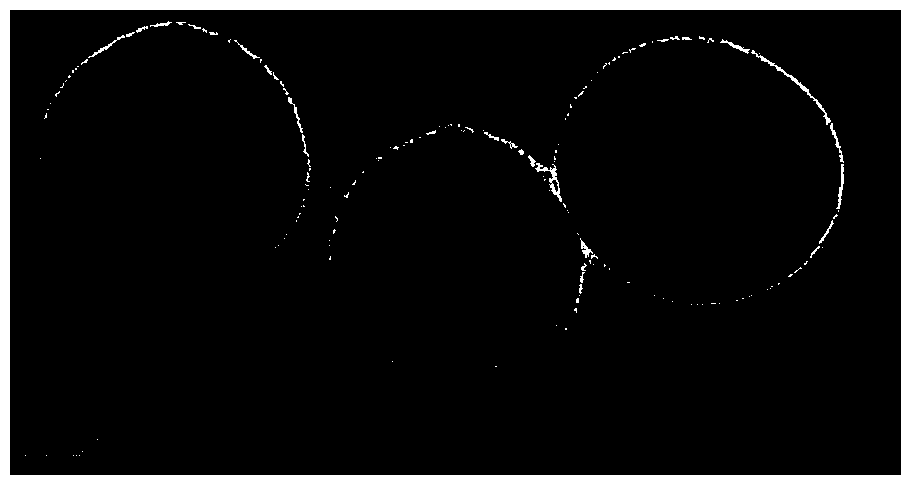

Hyperbranched polyphosphazene flame retardant charring agent and preparing method thereof

An efficient hyperbranched polyphosphazene flame retardant charring agent is prepared by reacting hexachlorocyclotriphosphazene with a binary compound containing two active groups. The charring agent has characteristics of good foaming charring performance, excellent flame retardant effects and good processing performance, and can be widely used in plastics, rubber, coating, adhesives, and other polymer materials. A preparing method adopts a one-pot method, and has characteristics of continuous reaction process, short reaction time and high production efficiency. By controlling the mole ratio of the hexachlorocyclotriphosphazene to the binary compound, no end-capping agent is added in the reaction process. When compared with the addition of end-capping agents in synthesis processes in triazine type charring agent patents, the synthetic process of the charring agent is simplified.

Owner:苏州安鸿泰新材料有限公司

Yolk-eggshell-structured zeolite molecular sieve-mesoporous titanium oxide composite material and preparation method thereof

ActiveCN103894223APreparation highEasy to prepareCatalyst carriersMolecular sieve catalystsYolkPtru catalyst

The invention belongs to the technical fields of inorganic porous materials and catalysts and patricianly relates to a yolk-eggshell-structured zeolite molecular sieve-mesoporous titanium oxide composite material and a preparation method thereof. The composite material is characterized in that a yolk is made of zeolite molecular sieve materials, an eggshell is made of a mesoporous titanium oxide nanocrystal aggregate, and a size-adjustable cavity is formed between a zeolite molecular sieve and the mesoporous titanium oxide. The preparation method comprises the steps of wrapping a phenolic resin macromolecule layer or amorphous silicon dioxide on the outer surface of the zeolite molecular sieve, then wrapping a layer of amorphous silicon dioxide, forging to transform the titanium dioxide into crystallized titanium dioxide nanocrystals, and finally removing the phenolic resin macromolecule layer or the amorphous silicon dioxide, so as to obtain the targeted composite material. The method is simple and is easy to control. The composite material has a hierarchical pore structure and can be taken as a catalyst or a catalyst carrier for continuous reaction as well as an adsorption-catalysis composite material.

Owner:元颉新材料科技(浙江)有限公司

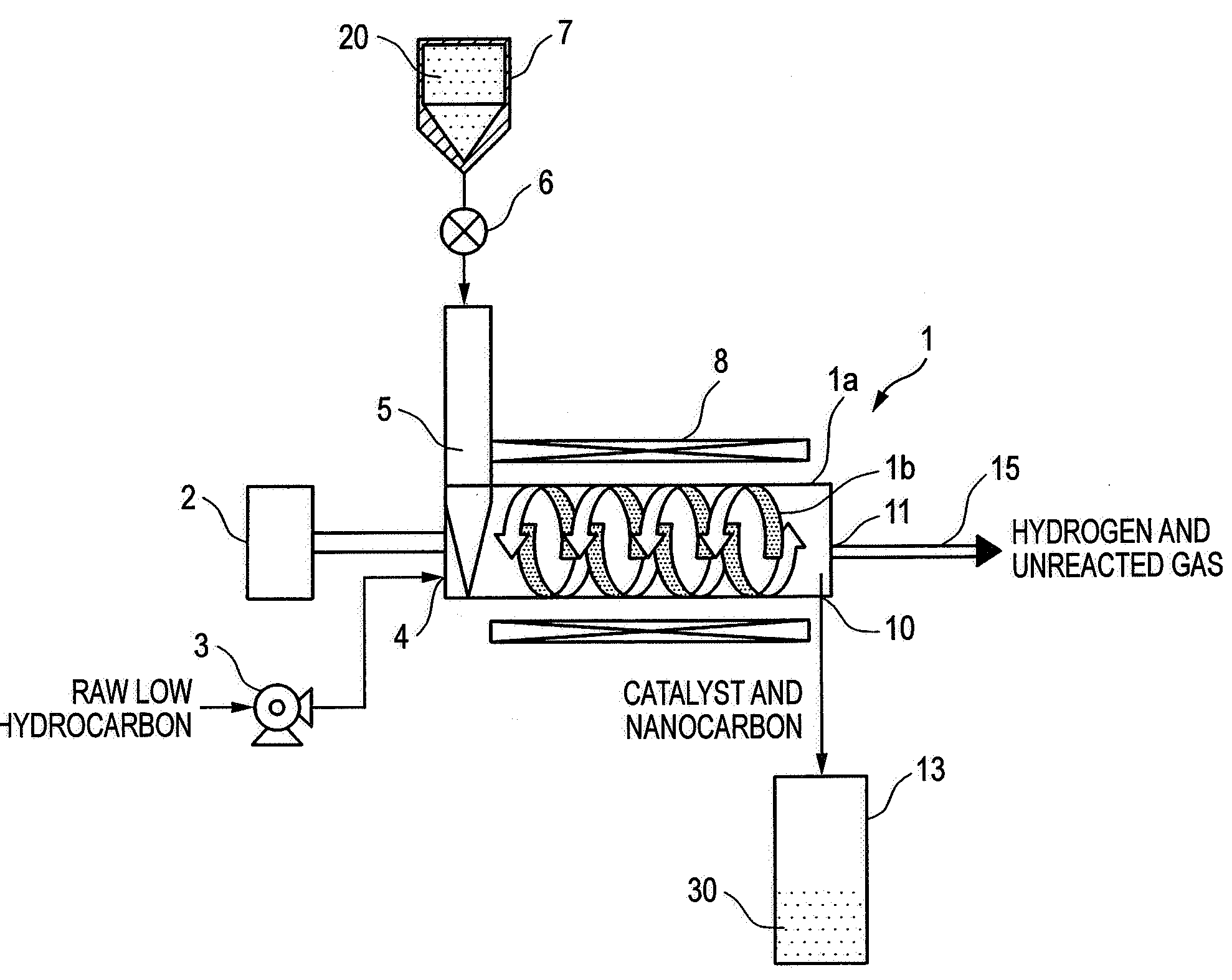

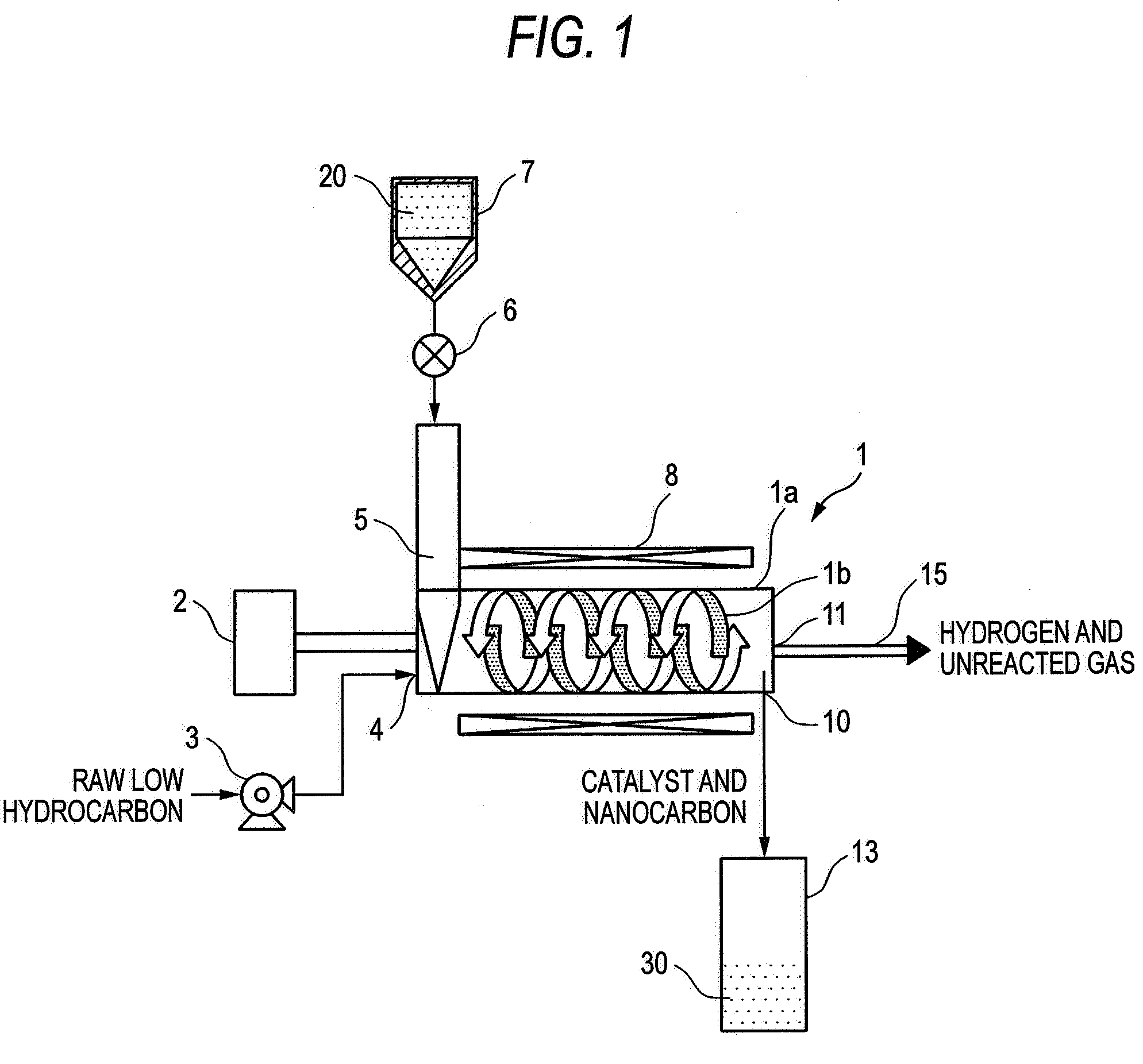

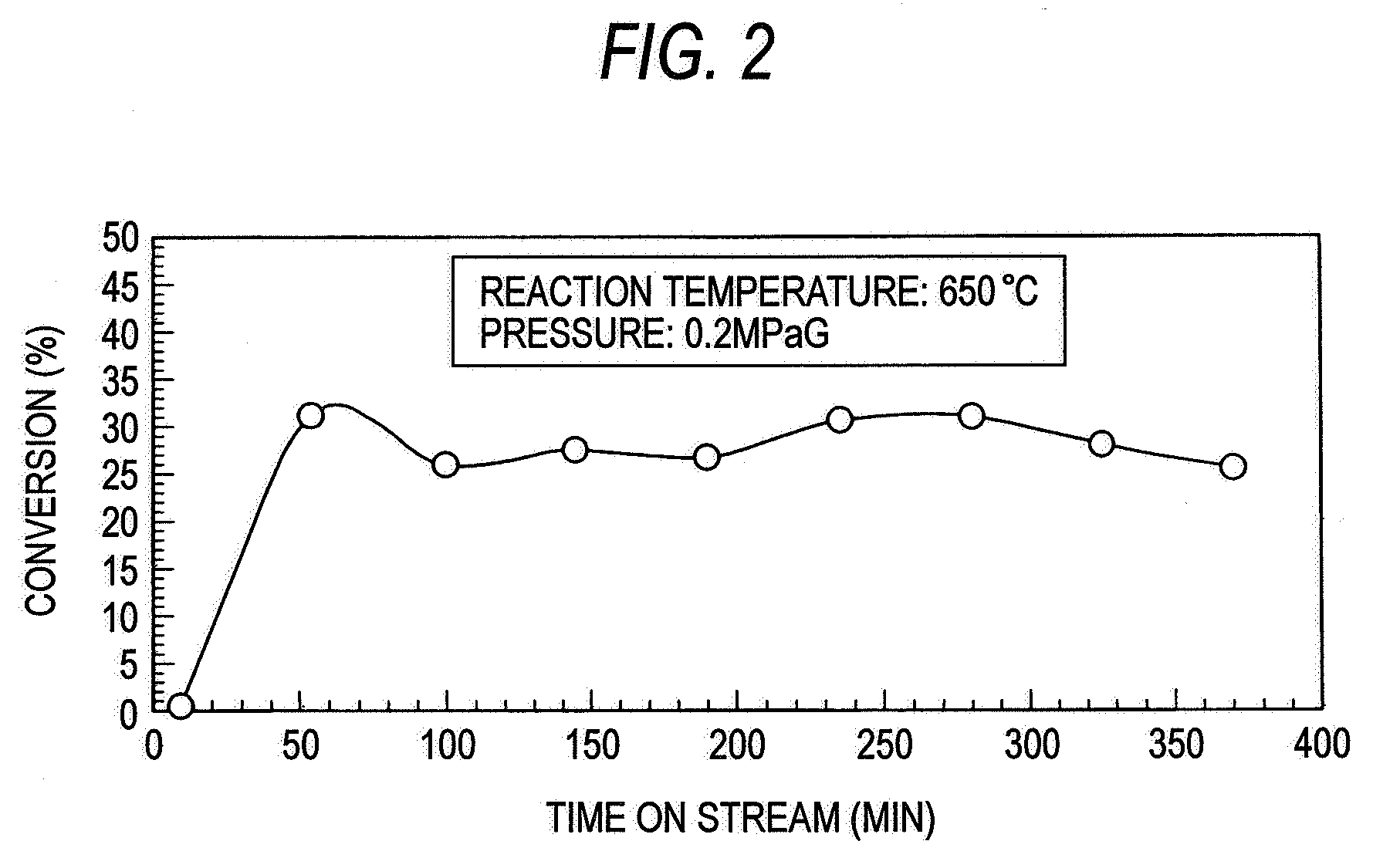

Method for producing nanocarbon and catalytic reaction device for producing nanocarbon

A cylindrical screw feeder main body, catalyst feeding portions for introducing a catalyst into the screw feeder main body, low hydrocarbon feeding portions for introducing a low hydrocarbon into the screw feeder main body as a raw material, a screw for conveying the catalyst and nanocarbon produced by pyrolysis of the low hydrocarbon in the feeder main body, a solid matter discharging portion for discharging the catalyst and the nanocarbon conveyed by the screw out of the screw feeder main body and a gas discharging portion for discharging the unreacted low hydrocarbon and hydrogen produced by the pyrolysis of the low hydrocarbon out of the screw feeder main body are provided. Nanocarbon grown with the catalyst as top with time is continuously discharged out of the screw feeder main body while unused catalyst is being fed thereto at the same amount as that of nanocarbon, allowing efficient continuous reaction.

Owner:KITAMI INST OF TECH +2

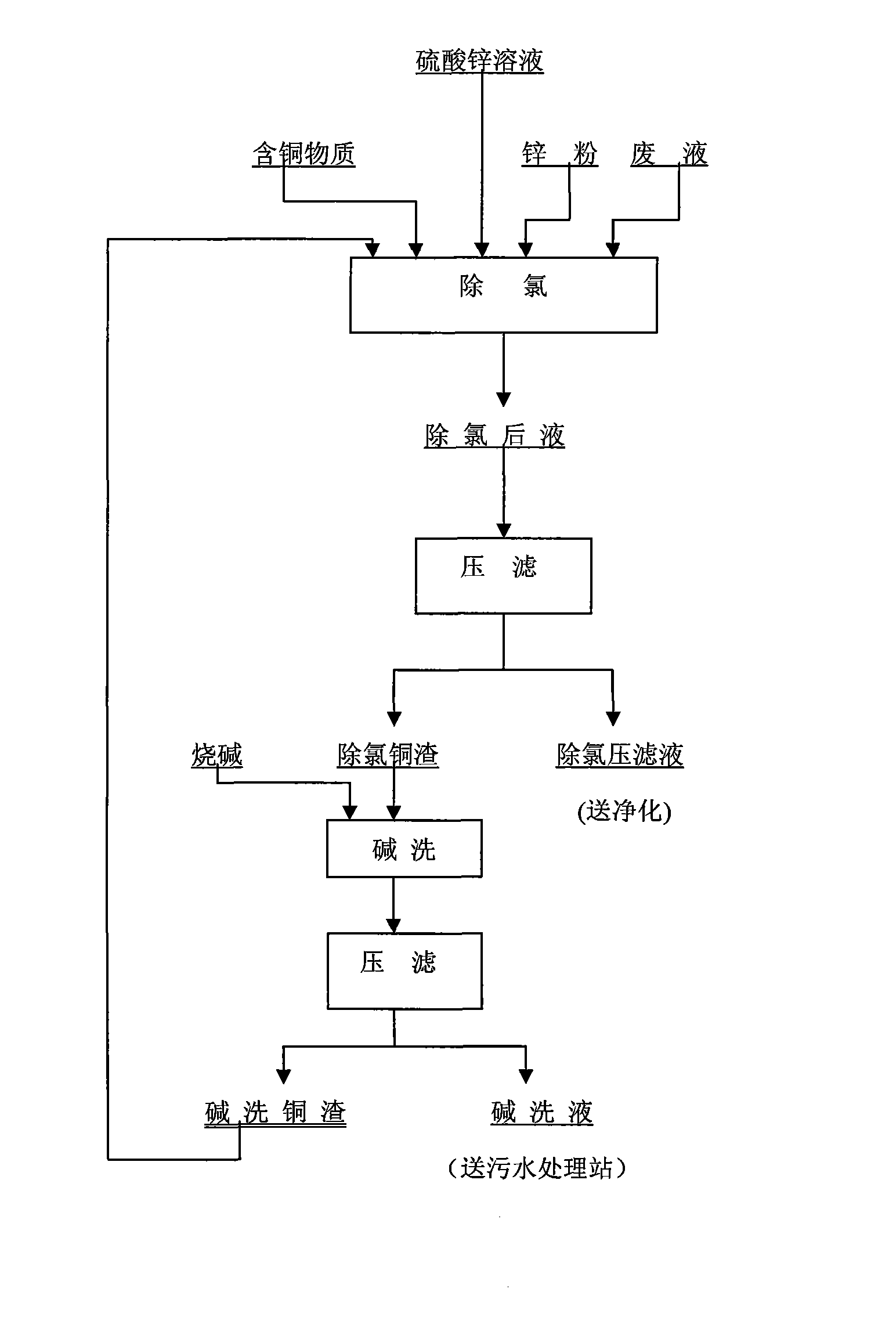

Method for circularly removing chlorine in zinc sulphate solution by copper slag

InactiveCN101633982ATake advantage ofReduce consumptionProcess efficiency improvementZincCopper sulfate

The invention relates to a method for circularly removing chlorine in a zinc sulphate solution by copper slag. The method comprises the following steps: copper ions, zinc powders and a zinc sulphate solution are added into a continuous reaction groove and react in a stirring state to obtain the zinc sulphate solution containing Cl<-> equal to or less than0.3g / l, and a CuCl precipitate generated in the reaction enters slag; a mixture of the zinc sulphate solution and the slag are treated by liquid-solid separation to obtain a dechlorinated zinc sulphate solution and copper slag; the separated copper slag is washed with alkali to remove chlorine ions; the copper slag after being washed with the alkali is returned to the continuous reaction groove for carrying out a circular reaction; and when the copper ions are deficient, a certain copper sulfate is added at proper time for replenishment. The invention utilizes the zinc powders as a reducer for reacting with the copper ions in the zinc sulphate solution to generate a CuCl copper slag precipitate, Cl<-> is eluted with the alkali, Cu2O is also obtained and is returned to react with the Cl<-> in the solution for circular dechlorination, copper sulfate does not need to be added or a little copper sulfate is only added in the dechlorination process, the consumption of raw materials is little, and the cost is low; compared with a method that the copper slag which can be changed is added continuously, the interference of external factors to a dechlorination technique is little, the process is easy to control, and the dechlorination effect is stable and reliable.

Owner:蒙自矿冶有限责任公司

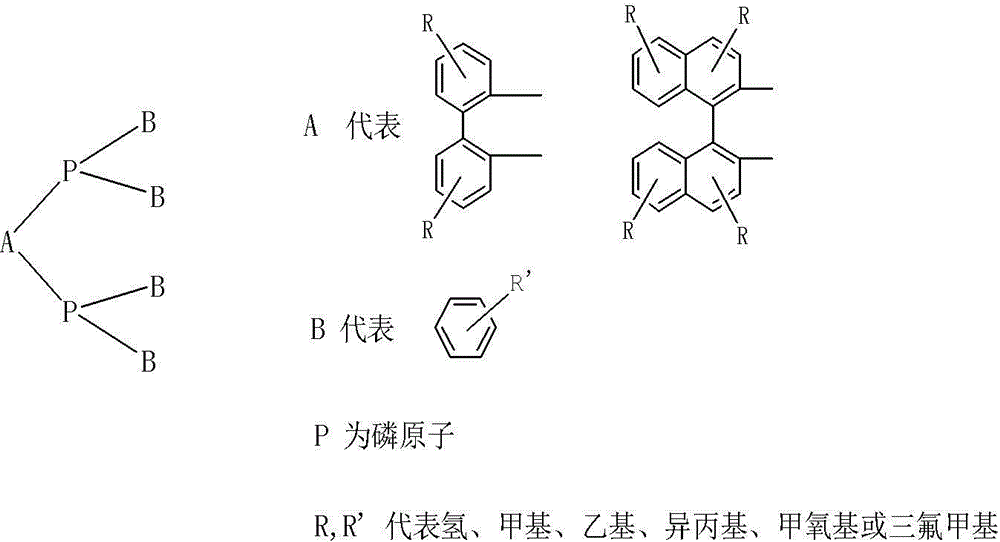

Method for preparing aldehyde through linear chain olefin hydroformylation

InactiveCN102911021AReduce dosageGuaranteed uptimeOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionDiphosphines

The invention relates to a method for preparing aldehyde through linear chain olefin hydroformylation. According to the method, a continuous reaction mode is used for performing olefin hydroformylation reaction in a homogeneous catalyst system; a catalyst is a composite catalysis system composed of a rhodium complex, a biphenyl backbone or biphenyl backbone diphosphine ligands and triphenylphosphine or triphenyl phosphate monophosphorous ligands; a reaction solvent comprises butyraldehyde, valeraldehyde, toluene or isodecanol; when the catalyst system uses propylene or butene-1 as raw materials under the condition of a low molar ratio of the diphosphine ligands to the rhodium complex, contents of the aldehyde generated by hydroformylation of the propylene and the butene-1 is larger than 97% and 95% respectively; and when the catalyst system uses a mixture of the butene-1 and butene-2 as raw materials, and the content of n-valeraldehyde in hydroformylation reaction products can reach above 85%.

Owner:QINGDAO SANLI BENNUO CHEM IND +1

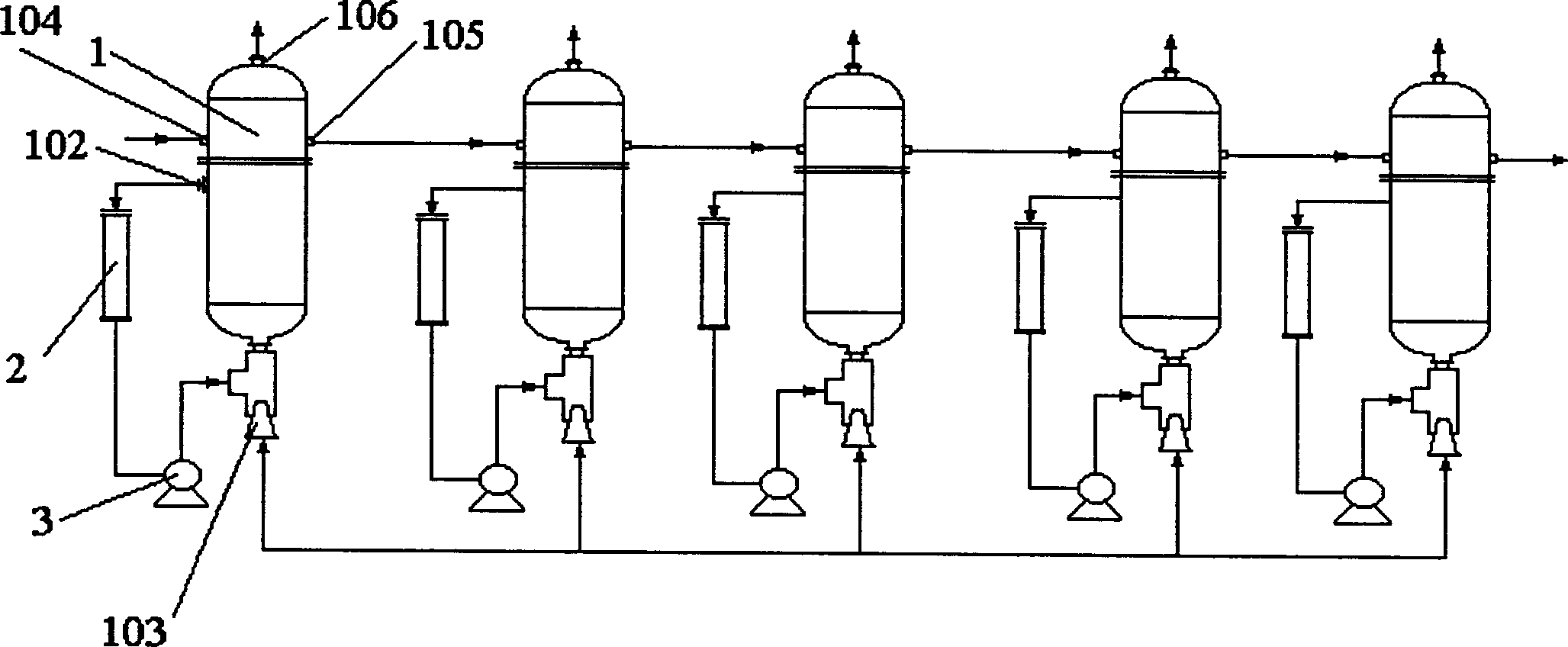

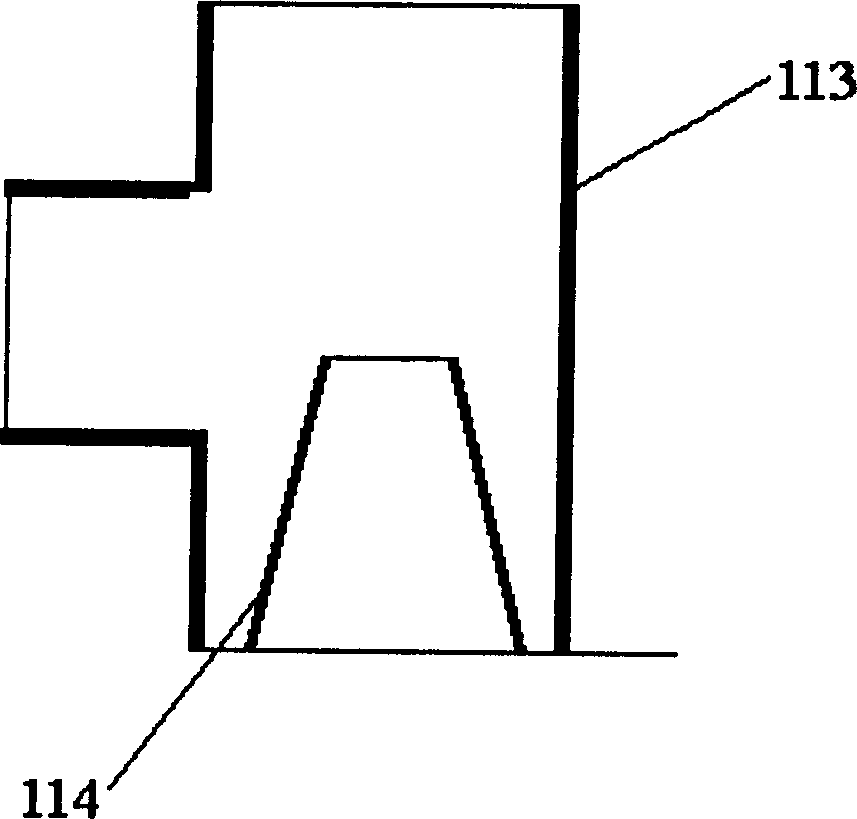

Continuous production method of chlorinated paraffin

InactiveCN1824737APrevent burning phenomenonAvoid production accidentsPetroleum chemical modificationParaffin oilsChlorinated paraffins

The present invention discloses a method for continuously producing chloroparaffine. Said method includes the following steps: making paraffin oil be passed through paraffin oil inlet and continuously fed into reactor; making chlorine gas be passed through circulation material and chlorine gas feeding device and fed into reactor from bottom portion of said reactor; under the catalysis of UV light making them implement chlorination reaction; making reaction product of the prior-stage be fed into reactor of next-stage to make continuous reaction, making the reaction product of the last reactor be fed into subsequent work-shop section to make refinement; making the reaction product overflowed from upper portion of reactor be fed into inlet of external cooling device, cooled, then passed through circulating pump, conveyed and premixed with chlorine gas, then fed into reactor.

Owner:SHANGHAI CHLOR ALKALI CHEM

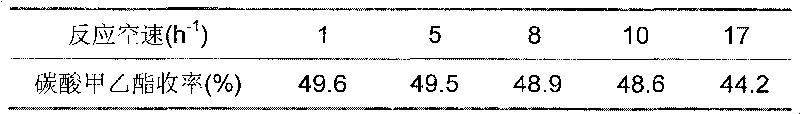

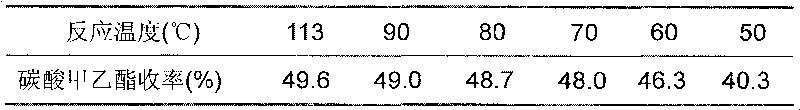

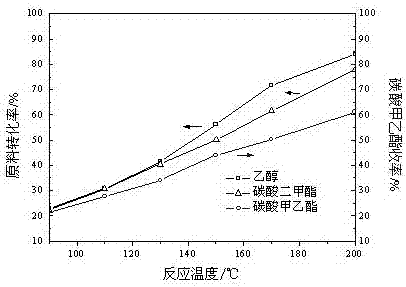

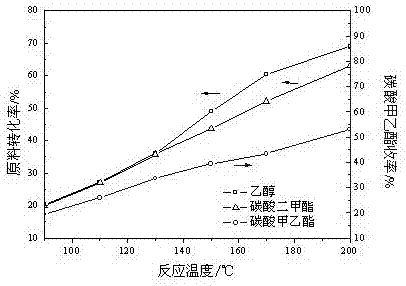

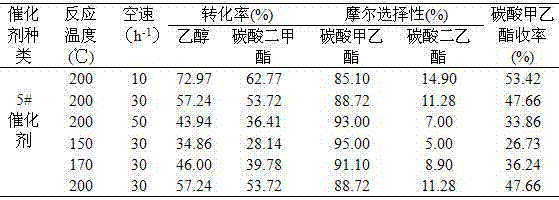

Synthesis method of methyl ethyl carbonate

InactiveCN101704751AStable in natureHigh yieldPreparation from organic carbonatesSynthesis methodsFixed bed

The synthesis method of methyl ethyl carbonate belongs to the technical field of organic compounds synthesized by ester exchange. Dimethyl carbonate and diethyl carbonate, or dimethyl carbonate and ethanol are used as raw materials to perform ester exchange in the presence of catalyst. The reaction mode comprises two kinds of fixed bed continuous reaction and kettle-type reaction. The catalyst issolid alkali catalyst in which the carrier is active carbon, carbon molecular sieve or mesoporous carbon and the active component is Na2O, K2O, MgO, CaO, SrO or BaO. In the process of fixed bed continuous synthesis, the catalyst is stable without inactivation after long-term use, thereby retaining the high yield of the methyl ethyl carbonate, simplifying the production process, and achieving environmental friendliness and energy conservation. In the kettle-type reaction, the catalytic efficiency is high, the catalyst can be recovered by simple filtering and re-sintering, and the target product can be obtained in short time with high yield.

Owner:JILIN UNIV

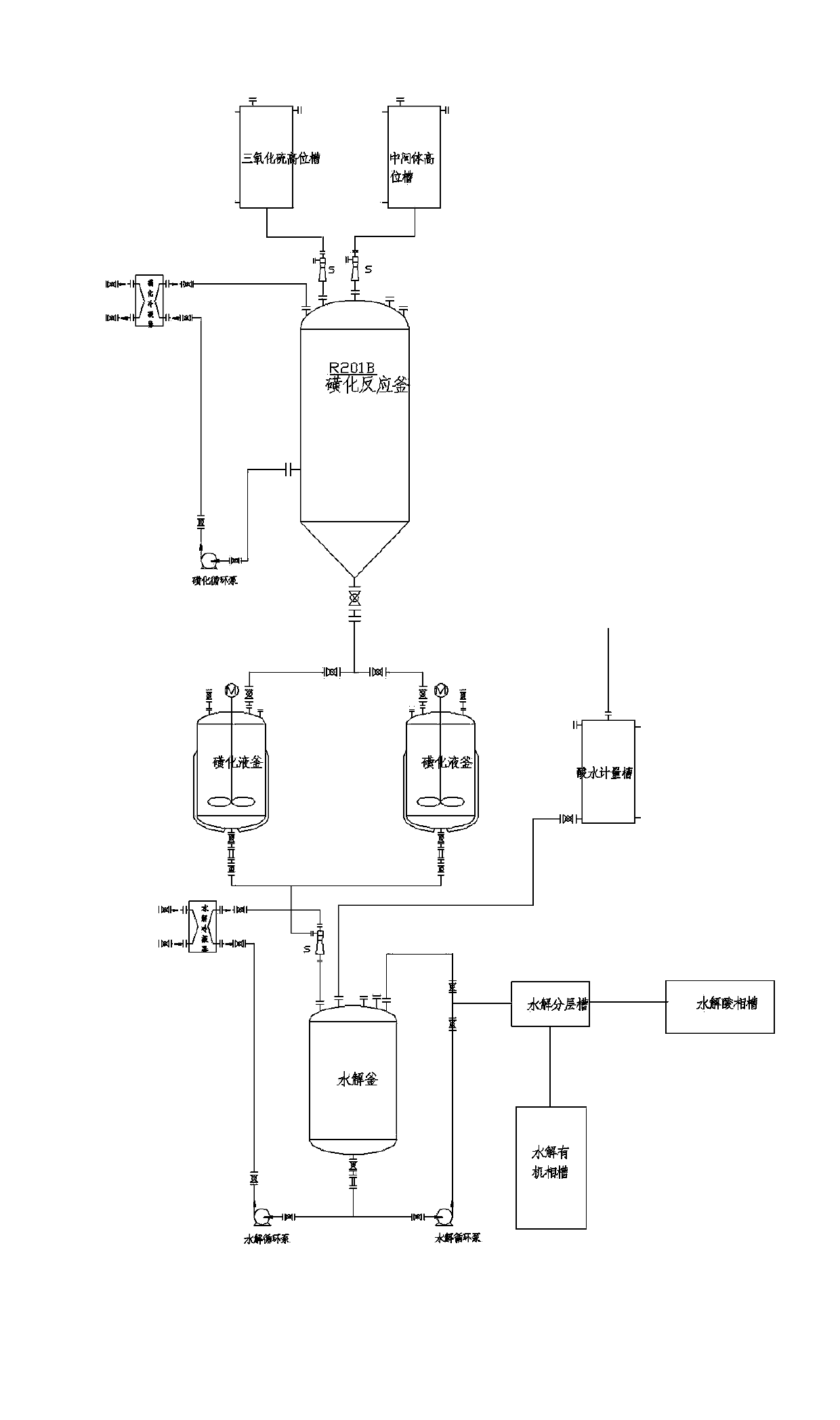

Acesulfame cyclization continuous production method

ActiveCN103130743AImprove continuityReduce labor intensityOrganic chemistryBiochemical engineeringSulfur trioxide

The invention relates to an acesulfame cyclization continuous production method. The acesulfame cyclization continuous production method is characterized in that sulfonation reaction and hydrolysis reaction comprise the following steps: respectively dripping intermediates and sulfur trioxide generated in synthesis reaction into a sulfonation reaction kettle by a certain flow rate, conducting cooling in the sulfonation reaction kettle, and conducting primary reaction; reactants in the sulfonation reaction kettle automatically overflowing into a sulfonation liquid kettle after reaching a certain amount, and conducting spontaneous reaction; putting sulfonation liquid into a hydrolysis kettle after the spontaneous reaction, and meanwhile dripping acid water to conduct hydrolysis reaction. The acesulfame cyclization continuous production method has the advantages that cyclization continuous reaction process is adopted, continuity of production operation is achieved, and labor intensity of workers is reduced, besides, compared with traditional batch production process, stability of cyclization continuous reaction is high, service life of the reaction kettles is prolonged, cryogenic load is lightened, and production efficiency is greatly improved.

Owner:ANHUI JINGHE IND

Method for preparing glycolate by catalyzing oxalate under action of hydrogenation

ActiveCN102001944AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationOxalateGlycolates

The invention relates to a method for preparing glycolate by catalyzing oxalate under the action of hydrogenation. The oxalate is used as the raw material, has hydrogenation under the action of catalyst at 120 to 300 DEG C under 0.2 to 10.0 MPa, and continuously reacts in a fixed bed tube type reactor so as to acquire the target product glycolate. The conversion ratio of the oxalate is more than or equal to 90% and the selectivity of the glycolate is more than or equal to 90%. Compared with the prior art, the method of the invention has high catalyst activity and selectivity and mild reaction condition, so the conversion ratio of the raw materials and the selectivity of the target product are both greatly increased.

Owner:SHANGHAI HUAYI GRP CO

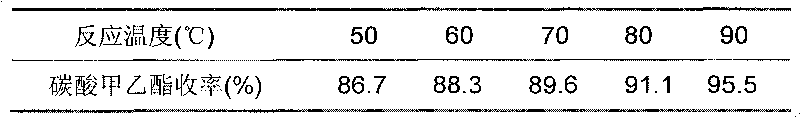

Method for preparing ethyl methyl carbonate through ester exchange method

InactiveCN107473968AGood dispersionImprove mass transfer effectPhysical/chemical process catalystsPreparation from organic carbonatesDispersityMethyl carbonate

The invention provides a method for preparing ethyl methyl carbonate through an ester exchange method, and relates to a method for preparing a chemical raw material. A first catalyst prepared by the method simultaneously has macropore and micropore structures, wherein the macropores can obviously improve the mass transfer effect; and the micropores can obviously improve the specific surface area of a carrier and simultaneously improve the dispersity of active centers. Meanwhile, the prepared first catalyst simultaneously has an alkali active center and a Lewis acid catalytic active center. The prepared 15%MgO-5%MgCl2-2%La2O3 / Al2O3-SiO2 is used in a dimethyl carbonate and ethanol ester exchange fixed bed continuous reaction; when the reaction temperature is 200 DEG C and the space velocity is 30h<-1>, the catalyst is not inactivated after 5000h of continuous reaction, the dimethyl carbonate conversion rate can be kept at 70%, the ethanol conversion rate can be kept at 80%, and the yield of the product ethyl methyl carbonate is 56%; and after the reaction, the catalyst can be reused through simple filtration treatment, and the activity of the catalyst can still be kept unchanged after the catalyst is reused for multiple times.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for producing o-chloroaniline

InactiveCN101333169AHigh yieldLow costOrganic compound preparationAmino compound preparationEthylenediamineO-nitrochlorobenzene

An o-chloroaniline production method takes o-nitrochlorobenzene as raw material and is characterized in that the o-nitrochlorobenzene is dissolved in alcohol solvent in the presence of catalyst and additive and reacted with hydrogen at 10-120 DEG C and under 0.3-4.0 MPa; the reaction process is continuous reaction; after the completion of the reaction, the o-chloroaniline is obtained through treatment, wherein, the catalyst can be selected from one of the following: Ni / Al2O3, Raney Ni, Pt / C and Pd / C; while the additive can be selected from one, or two, or three of the following compounds: cyclohexylamine, ethylenediamine, ethanolamine, diethanolamine, triethanolamine, pyridine, liquid ammonia, ammonium bicarbonate, ammonium carbonate, sodium carbonate, sodium bicarbonate, potassium bicarbonate, potassium carbonate, potassium hydrogen phosphate, potassium dihydrogen phosphate, sodium hydrogen phosphate and sodium dihydrogen phosphate; the dosage of the catalyst takes up 0.05% to 20% of the mass of the o-nitrochlorobenzene; the dosage of the additive takes up 0. 5% to 20% of the mass of the o-nitrochlorobenzene; the alcohol can be methanol or ethanol; the dosage of alcohol takes up 30% to 150% of the dosage of the o-nitrochlorobenzene; the continuous reaction is realized through 1 to 6 tank reactors which are connected in series.

Owner:淮安嘉诚高新化工股份有限公司

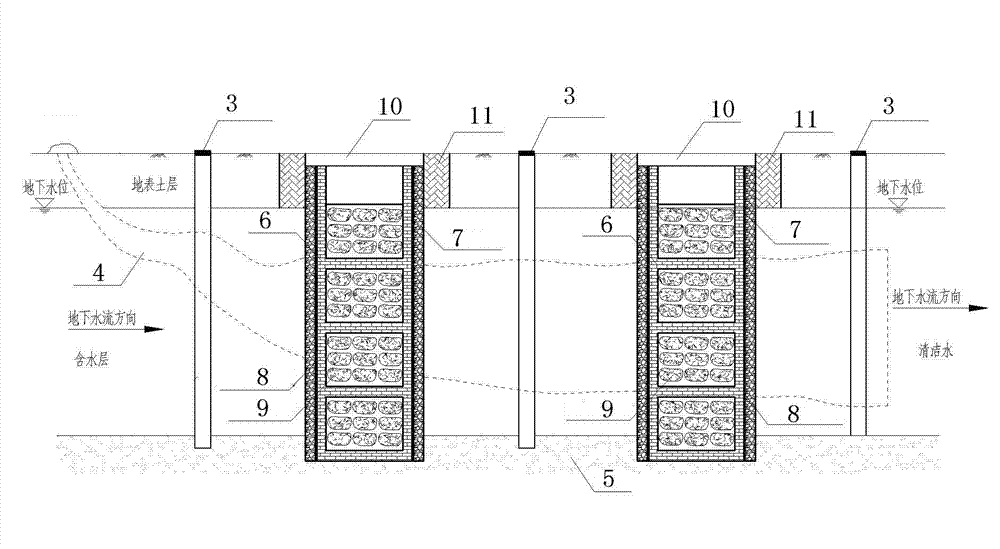

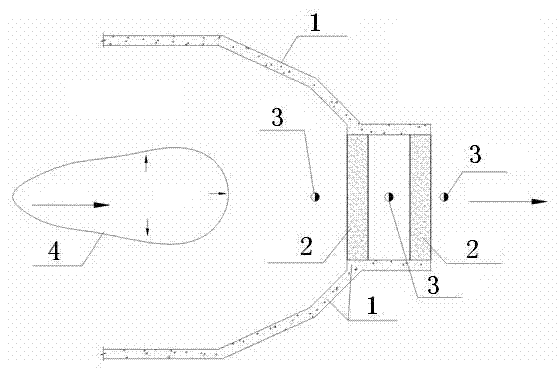

Underground water pollution restoration system and construction method thereof

ActiveCN104261505AAvoid rangeAvoid easy cloggingWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentGroundwater remediationWater quality

The invention relates to an underground water in-situ restoration system which is characterized by comprising a vertical impermeable wall arranged along the periphery of the polluted zone, wherein the vertical impermeable wall is in a semi-closed structure; the opening of the vertical impermeable wall is provided with a multi-treatment-unit reaction grid; the multi-treatment-unit reaction grid is arranged on the front edge downstream the underground water pollution stream and is perpendicular to the underground water flow; and the upstream and downstream of the multi-treatment-unit reaction grid are respectively provided with an underground water monitoring well for determining the change conditions of water level and water quality before and after underground water restoration. The system can overcome the defects of narrow restoration range, high clogging tendency, single treated pollution component and the like of the traditional continuous reaction wall in engineering application, can effectively restore underground water pollution streams with multiple pollutant components and complicated underground flow field, and can monitor the dynamic changes of water level and water quality of underground water in real time, thereby periodically cleaning and replacing the reaction medium in the treatment unit reaction grid.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com