Patents

Literature

384results about How to "Avoid production accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

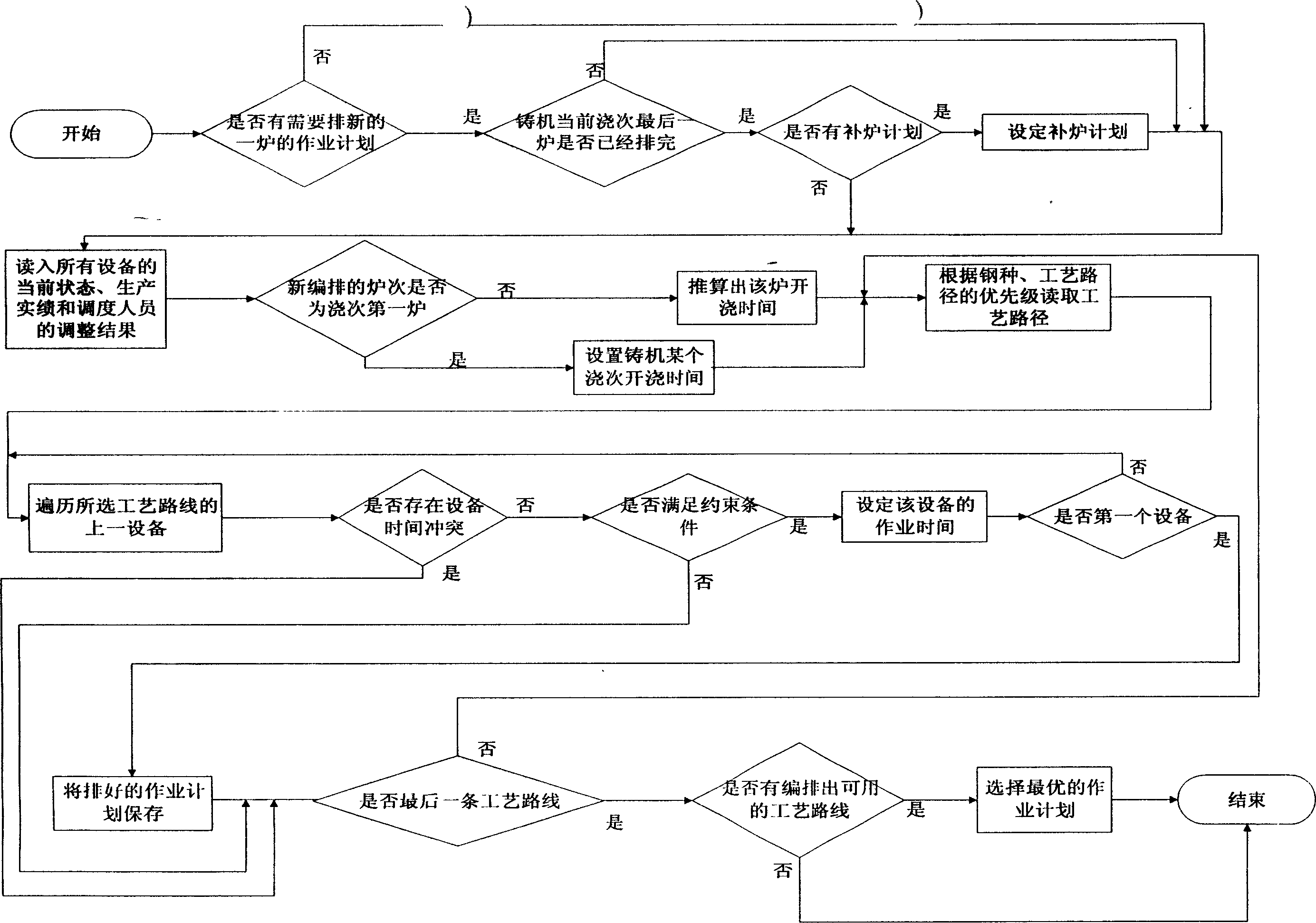

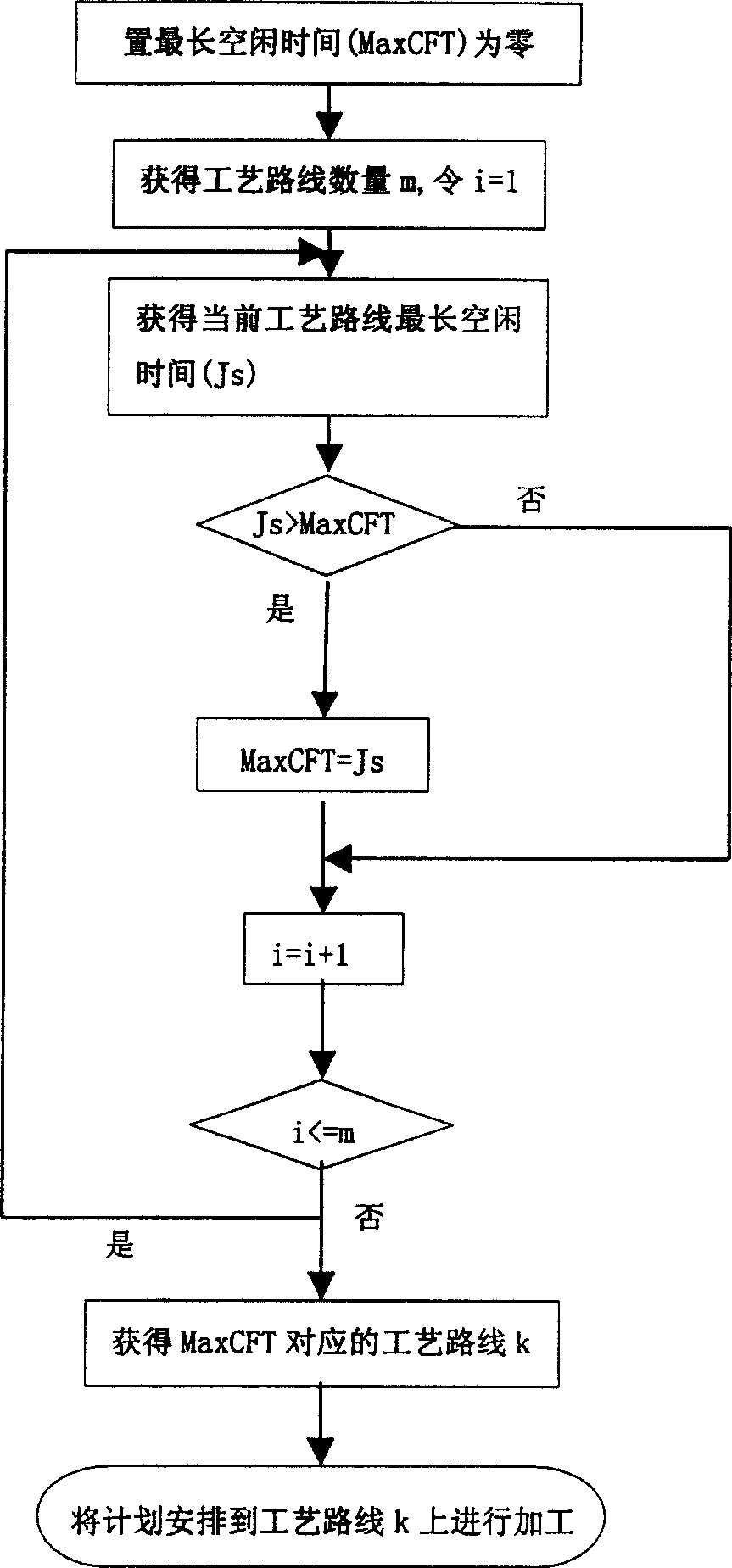

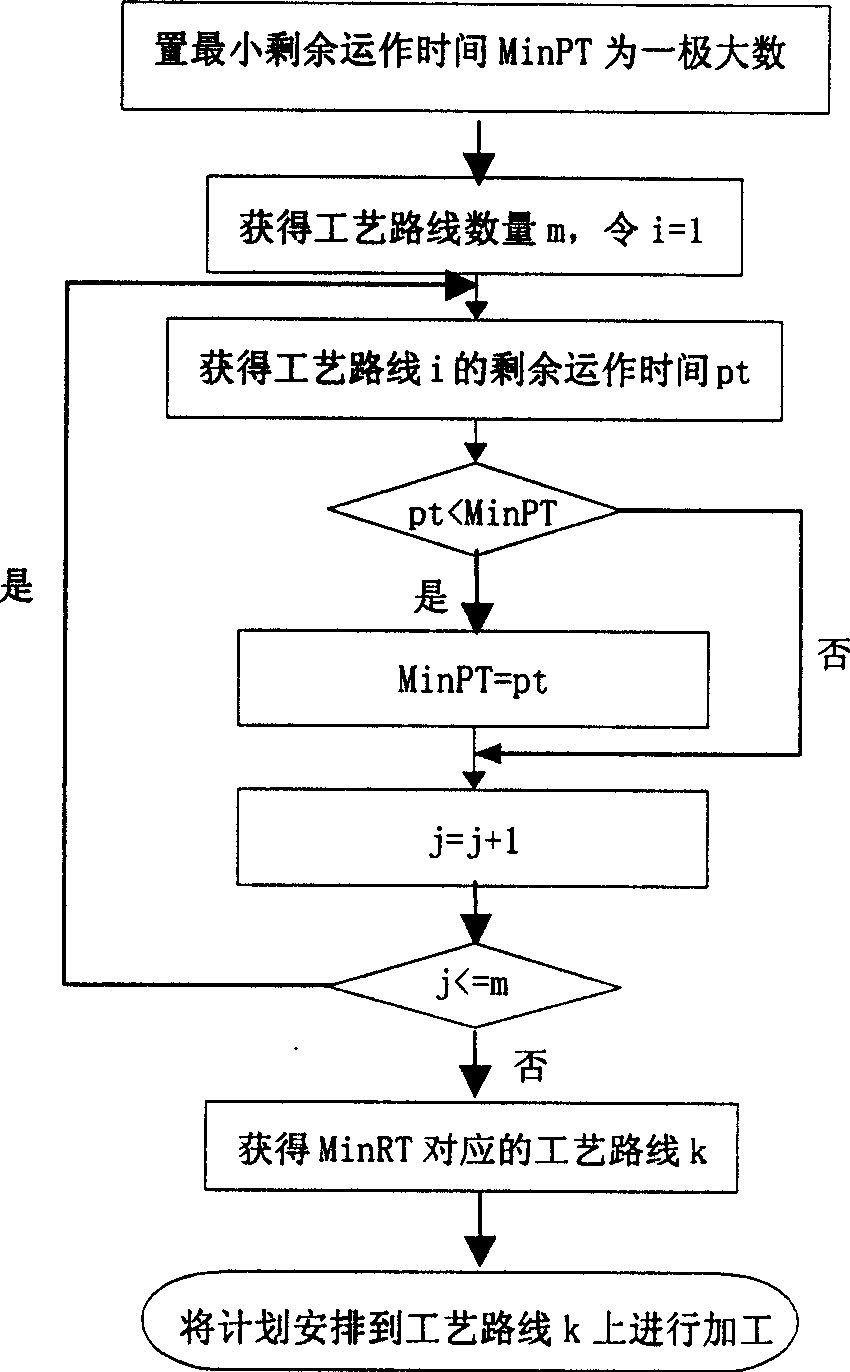

On-line dynamic dispatching method for continuous steel casting production

InactiveCN1614618AReduce cumulative time errorEasy production organizationSpecial data processing applicationsComputerized systemWorkstation

An on-line dynamic dispatching method for continuous production of steel making includes applying distributed computer system; working out a dynamic operation plan suitable for current production state by collecting data from site process and equipment, combining the set of dispatcher and using roll search mode; following the plan to carry out operation by operation station and feeding back regulation request to dispatching room for used as basis of next dispatch.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

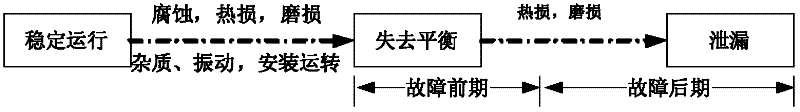

Mechanical seal online monitoring system

InactiveCN102313578AReduce lossesIncrease productivityEngine sealsMeasurement devicesCurrent sensorRadial vibration

The invention relates to a mechanical seal online monitoring system which comprises a data processing unit, a detection unit and a user terminal, wherein the detection unit is connected with the data processing unit; and the detection unit comprises an I / O (Input / Output) module, and a motor rotating speed sensor, a current sensor, a radial vibration sensor and a noise sensor which are connected with the I / O module. In the system, acquired data is subjected to the multivariable statistics process monitoring by the data processing unit, so that the indirect monitoring for the mechanical seal operation condition is realized and an early warning signal can be given in the fault early phase of the mechanical seal, and thus, a production accident is avoided, the loss of raw materials, equipment and other aspects of an enterprise is reduced and the possibility is provided for detection of the mechanical seal state and failure prediction. Meanwhile, the equipment is checked by the monitoring system without shutting down, so that compared with the prior art, a great amount of time and human resources are saved and the production efficiency of the enterprise is improved.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

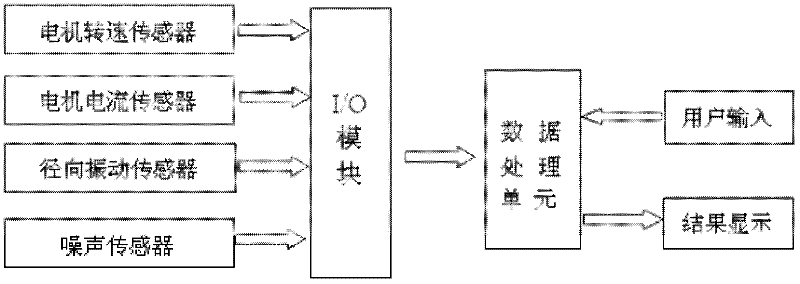

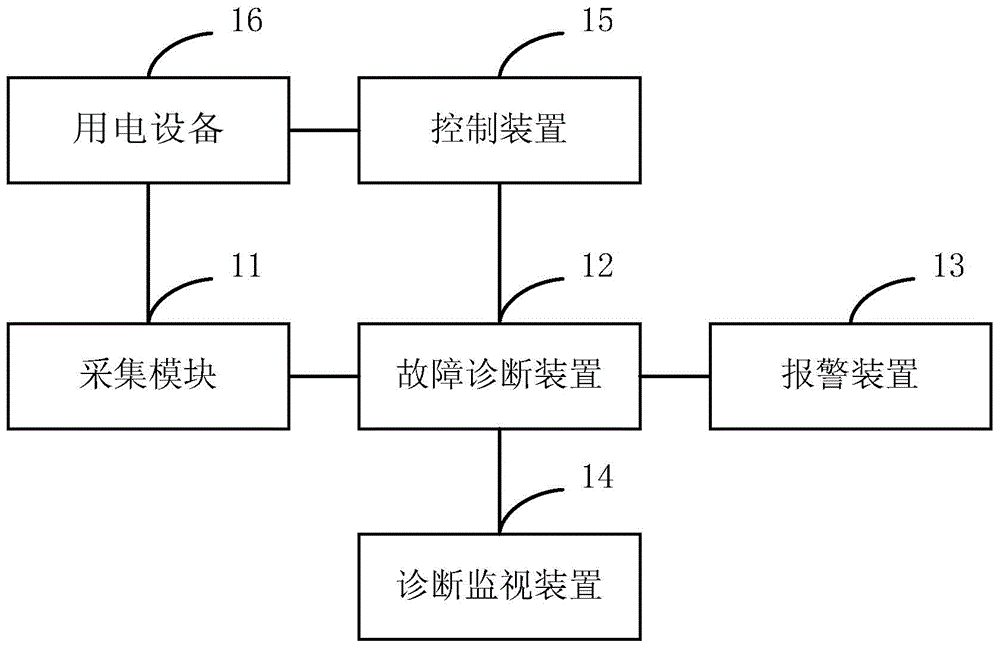

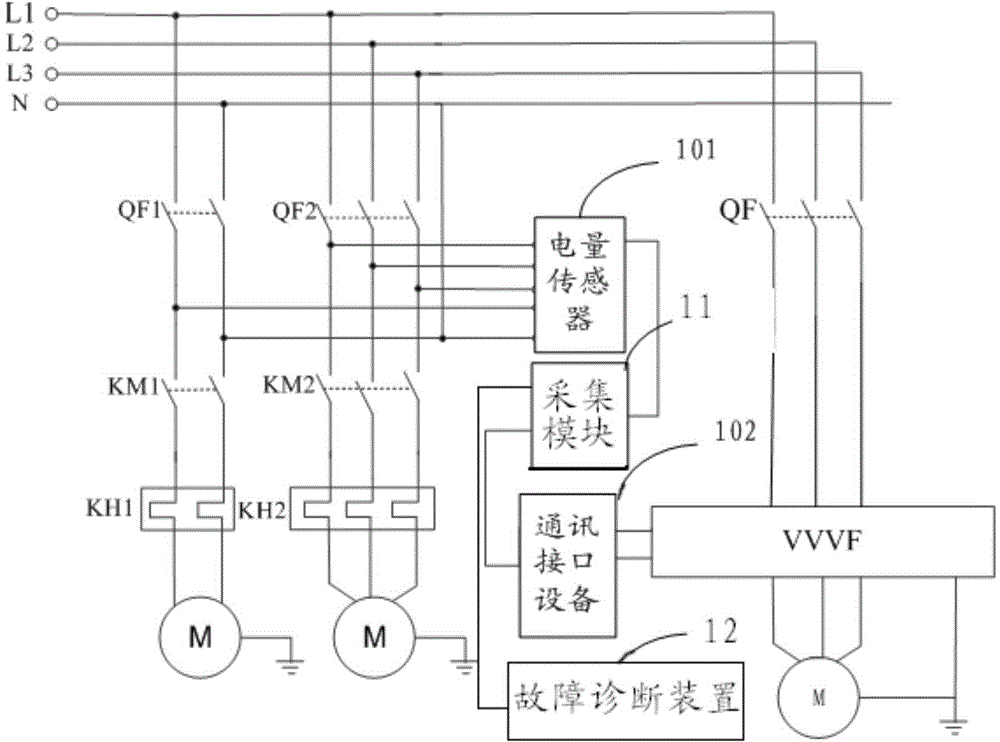

Electric device fault detecting system

ActiveCN104698321AImprove detection efficiencyAvoid production accidentsElectrical testingDiagnostic dataClosed loop

The invention provides an electric device fault detecting system which comprises an acquisition module, a fault diagnosis device, a diagnosis monitoring device and a warning device. The acquisition module is used for acquiring parameter information to be detected of an electric device. The fault diagnosis device is used for adjusting a preset range of standard parameter information and / or controlling the warning device to send prompting information to a worker according to the parameter information to be detected. The diagnosis monitoring device is used for monitoring diagnosis data, curves and a device state. The electric device fault detecting system automatically conducts real-time monitoring on the fault situation of the electric device, improves detection efficiency, avoids production accidents, uses the fault diagnosis device to automatically adjust the preset range of the standard parameter information memorized internally according to a detected result, enables the working state of the electric device to form a closed loop monitoring, can timely recognize abnormal state and faults, sends the device fault prompting information to the worker in real time, does not need to shut down the electric device and ensures normal work of other devices.

Owner:BEIJING YOUR WONDERFUL CONTROL SYST TECH CO LTD

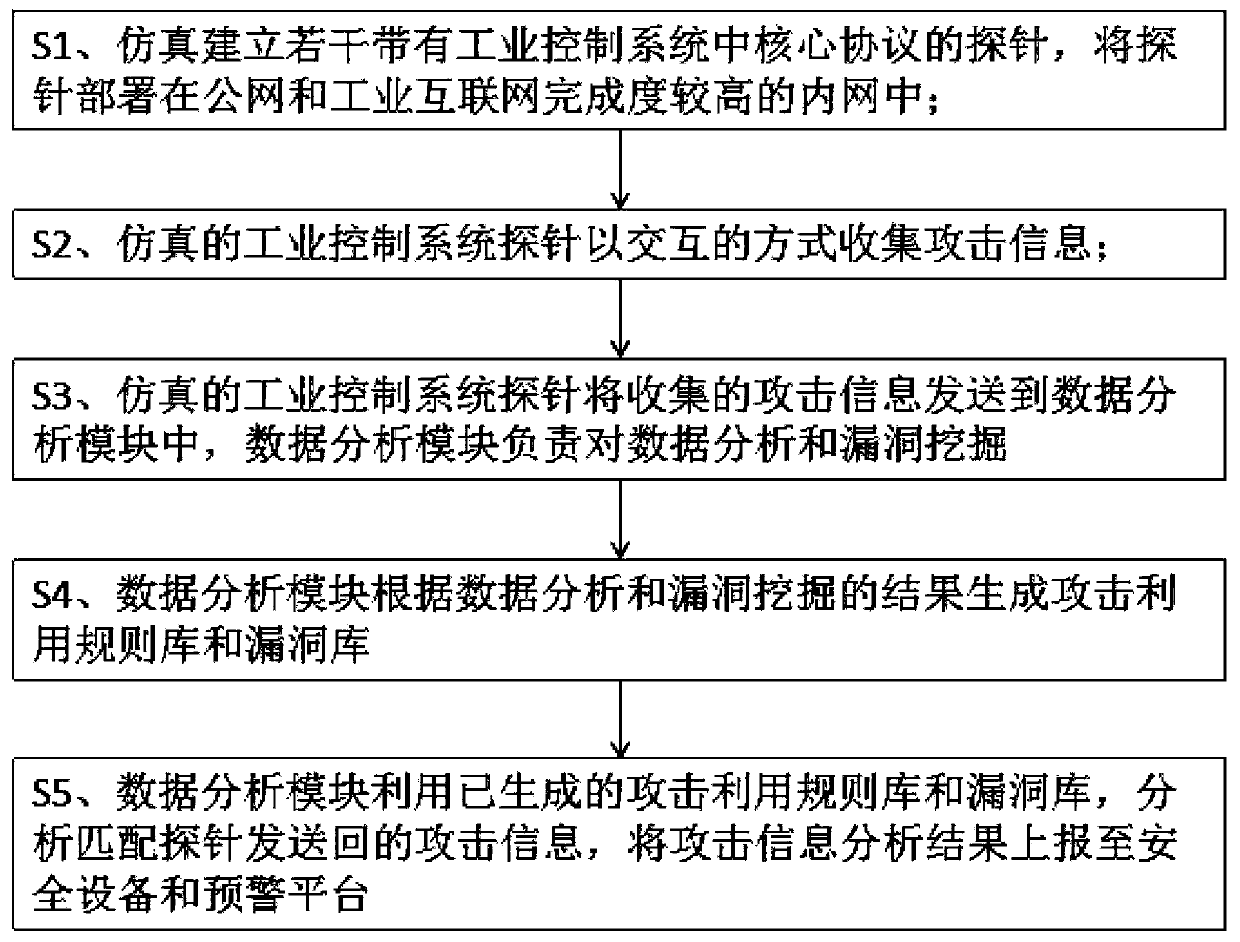

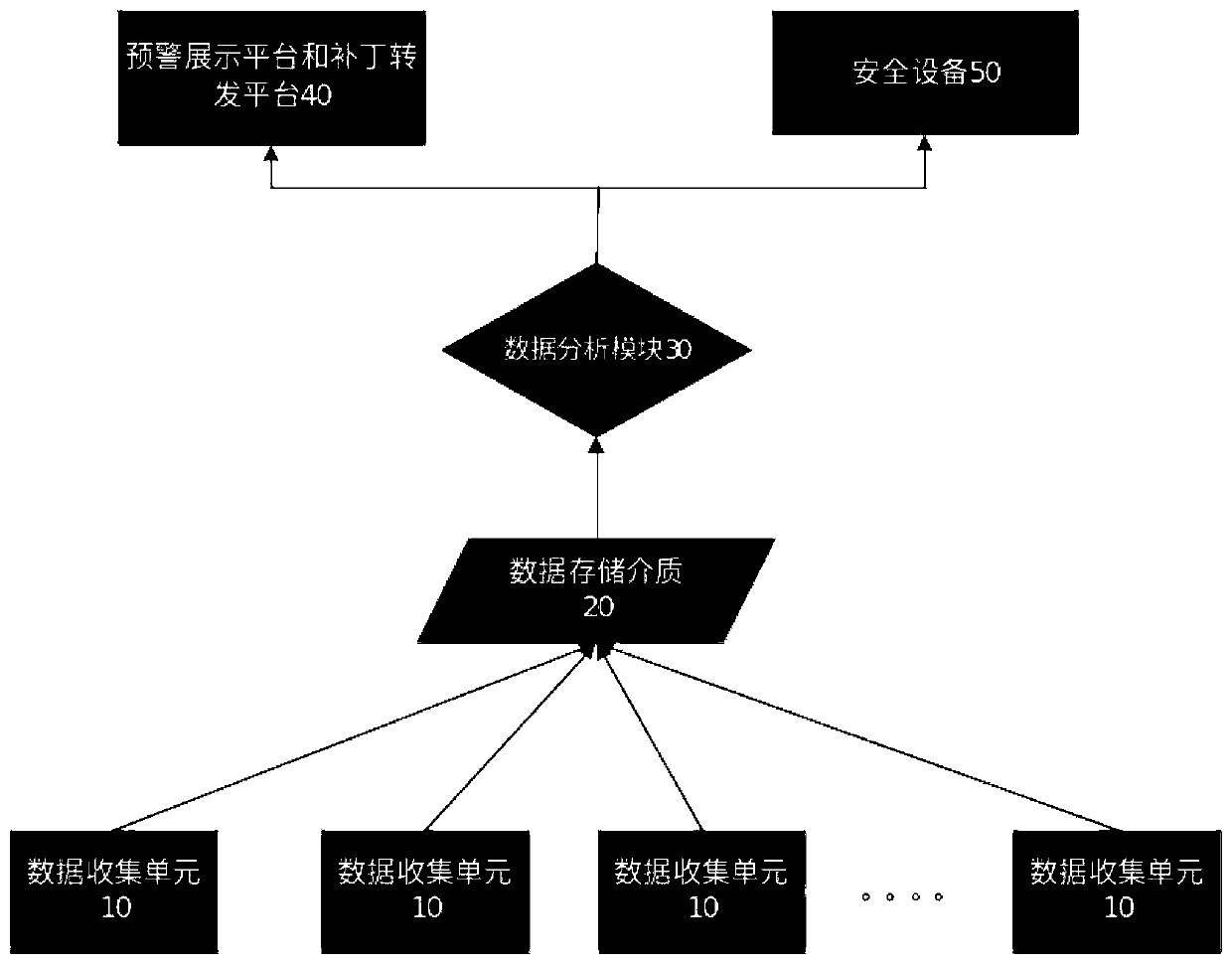

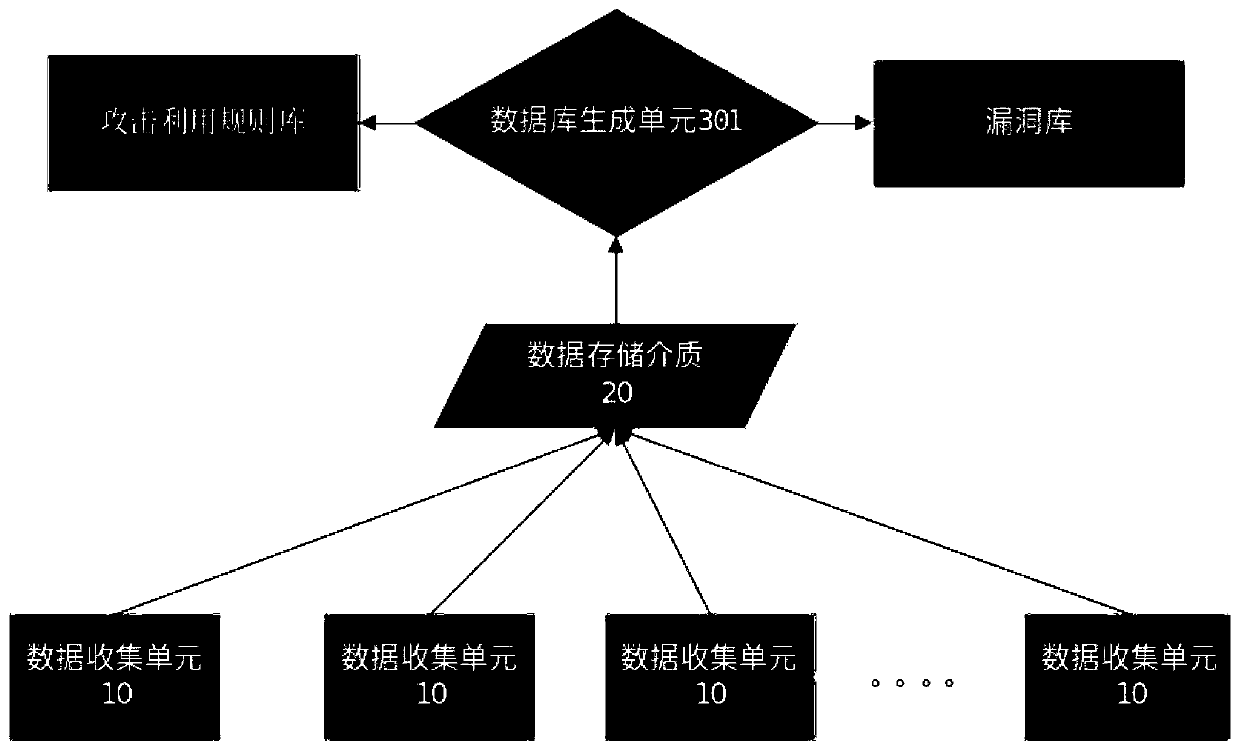

Industrial control system vulnerability trend analysis and early warning method and system

ActiveCN109818985AFix hidden vulnerabilities in a timely mannerAvoid production accidentsData switching networksInformation analysisPublic network

The invention discloses an industrial control system vulnerability trend analysis and early warning method and system, and the method comprises the steps: the simulation establishment of a plurality of probes is carried out with a core protocol in an industrial control system, and enabling the probes to be deployed in a public network and an intranet; The probe collects attack information in an interactive mode; The simulated industrial control system probe sends the collected attack information to a data analysis module, and the data analysis module is responsible for data analysis and vulnerability mining; The data analysis module generates an attack utilization rule base and a vulnerability base according to data analysis and vulnerability mining results; And the data analysis module analyzes the attack information sent back by the matching probe by using the generated attack utilization rule base and the vulnerability base, and reports the analysis result of the attack informationto the security equipment and the early warning display platform. According to the simulation industrial control system, the simulation industrial control system is induced to send an attack to the simulation industrial control system, an attack means is collected, vulnerabilities are analyzed, and serious vulnerability information existing in a production environment or to be utilized is early warned to a user.

Owner:江苏亨通工控安全研究院有限公司

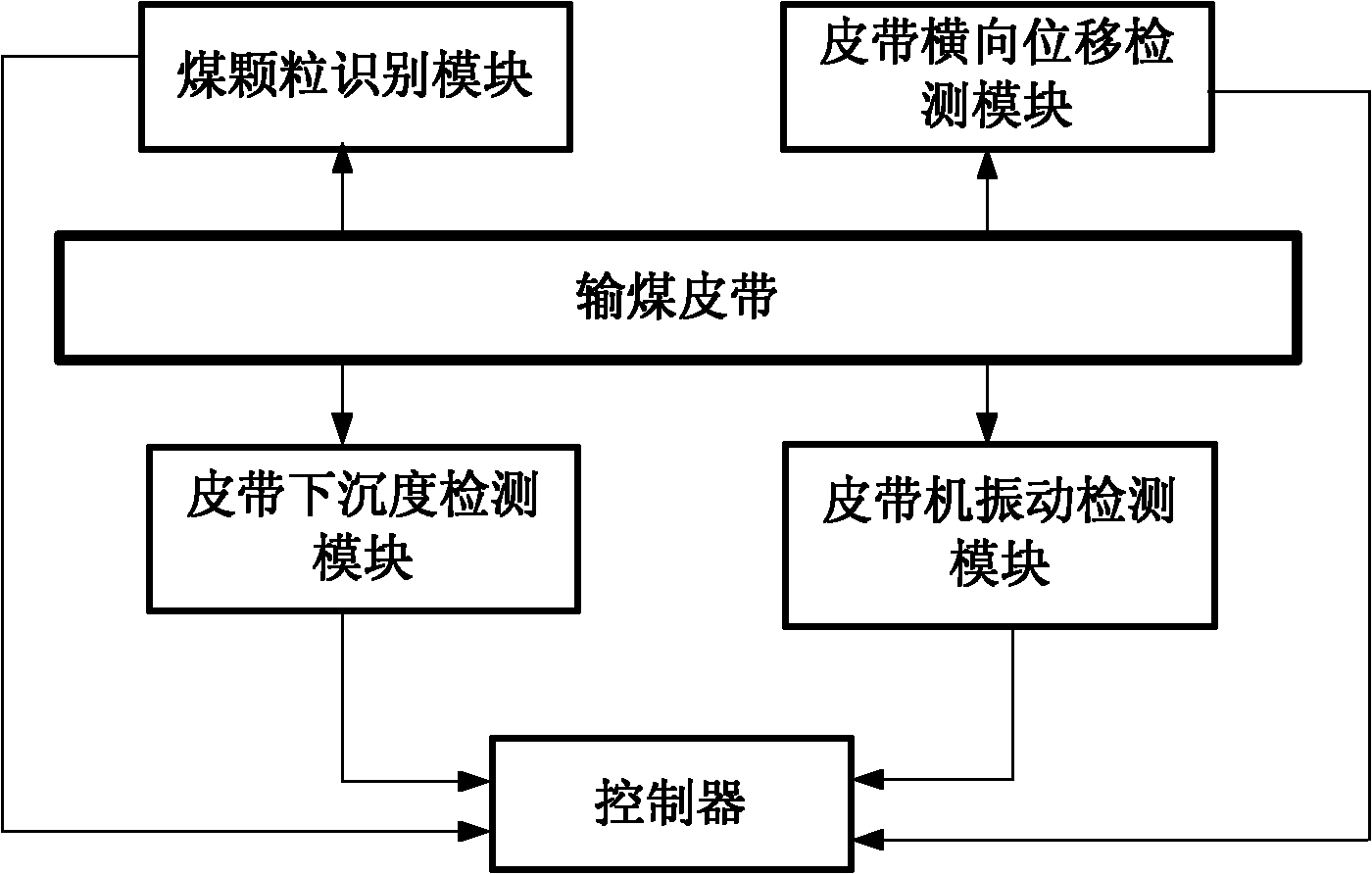

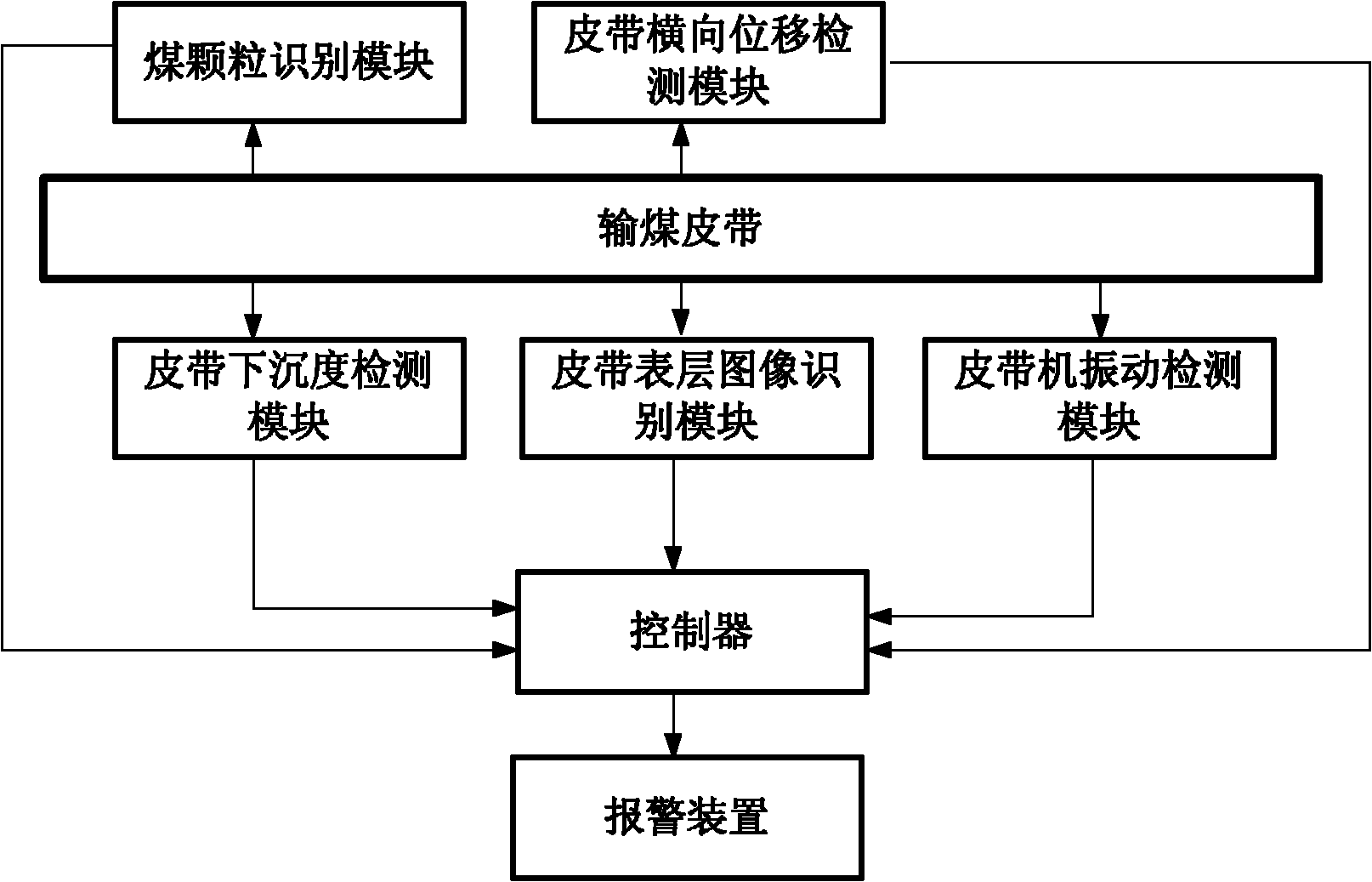

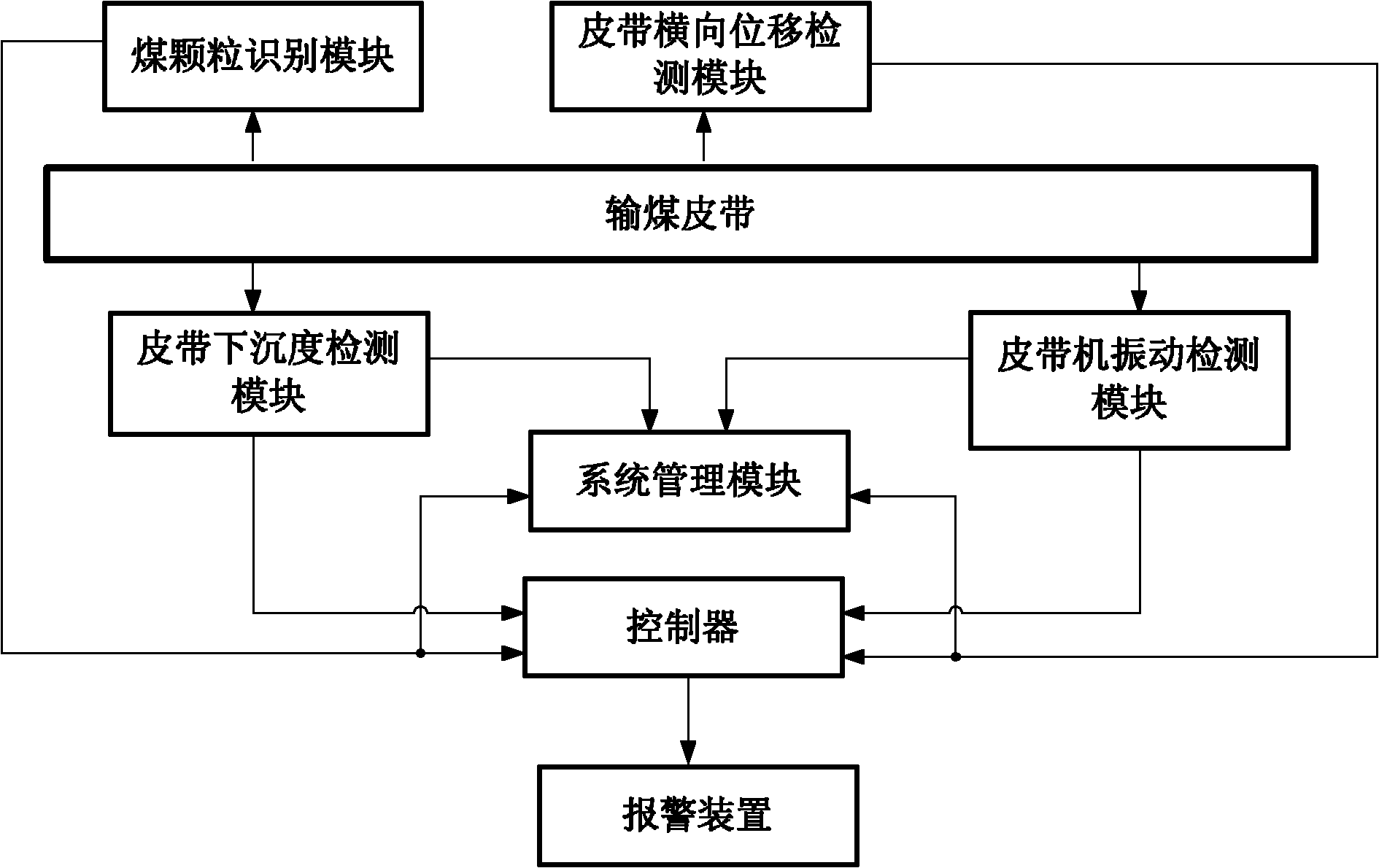

Method for monitoring coal conveying belt of coal conveying system by intelligent monitoring system

InactiveCN102424257AReduce the risk of being tornExtend your lifeControl devices for conveyorsMonitoring systemEngineering

The invention relates to a method for monitoring a coal conveying belt of a coal conveying system by an intelligent monitoring system. The intelligent monitoring system comprises a coal particles identifying module, a belt sinkage detecting module, a belt lateral displacement detecting module, a belt conveyor vibration detecting module and a controller, wherein the controller is connected with each module in a wired way or in a wireless way. The method comprises the following steps of: monitoring whether large-sized coal is existed on the coal conveying belt by the coal particles identifying module; monitoring whether the large-sized coal is existed on the coal conveying belt by the belt sinkage detecting module; monitoring the status of the coal conveying belt by the belt lateral displacement detecting module; monitoring the belt conveyor vibration condition of belt conveyor caused by the vibration of the coal conveying belt throughby the belt conveyor vibration detecting module; and braking athe belt conveyor by the controller, wherein the controller receives the instruction that the belt conveyor needs to be braked and sends out the braking instruction, so that the belt conveyor is braked.

Owner:北京纵横兴业科技发展有限公司 +3

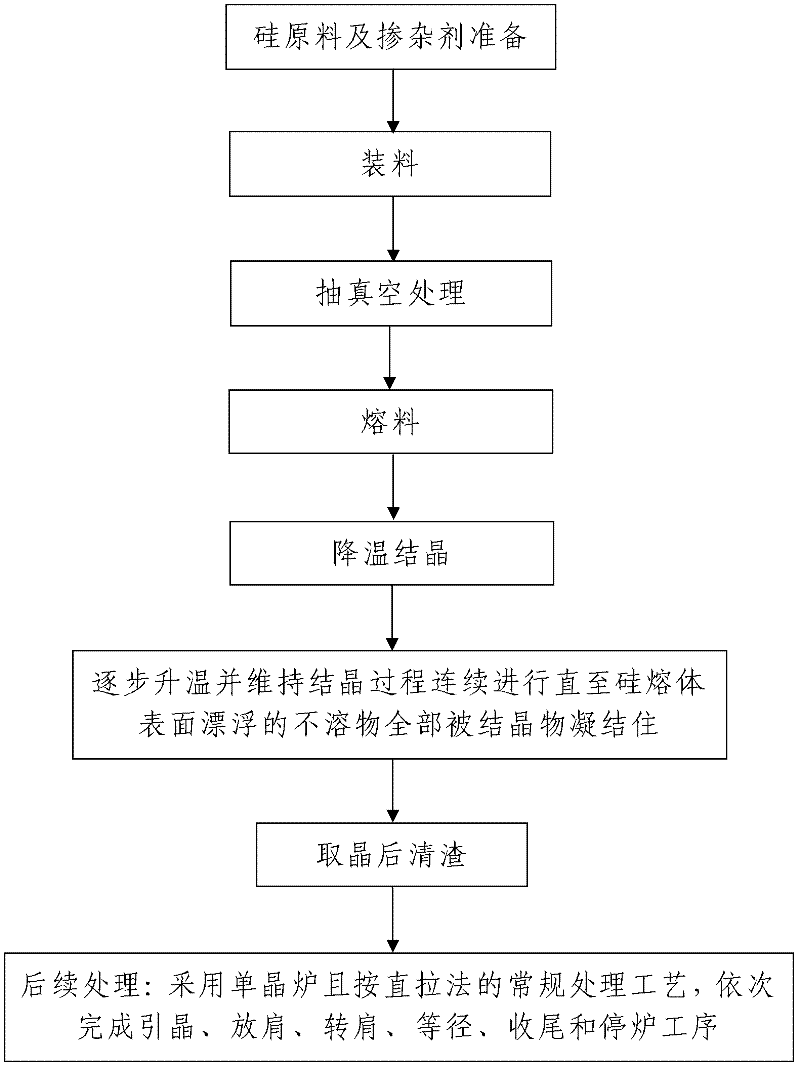

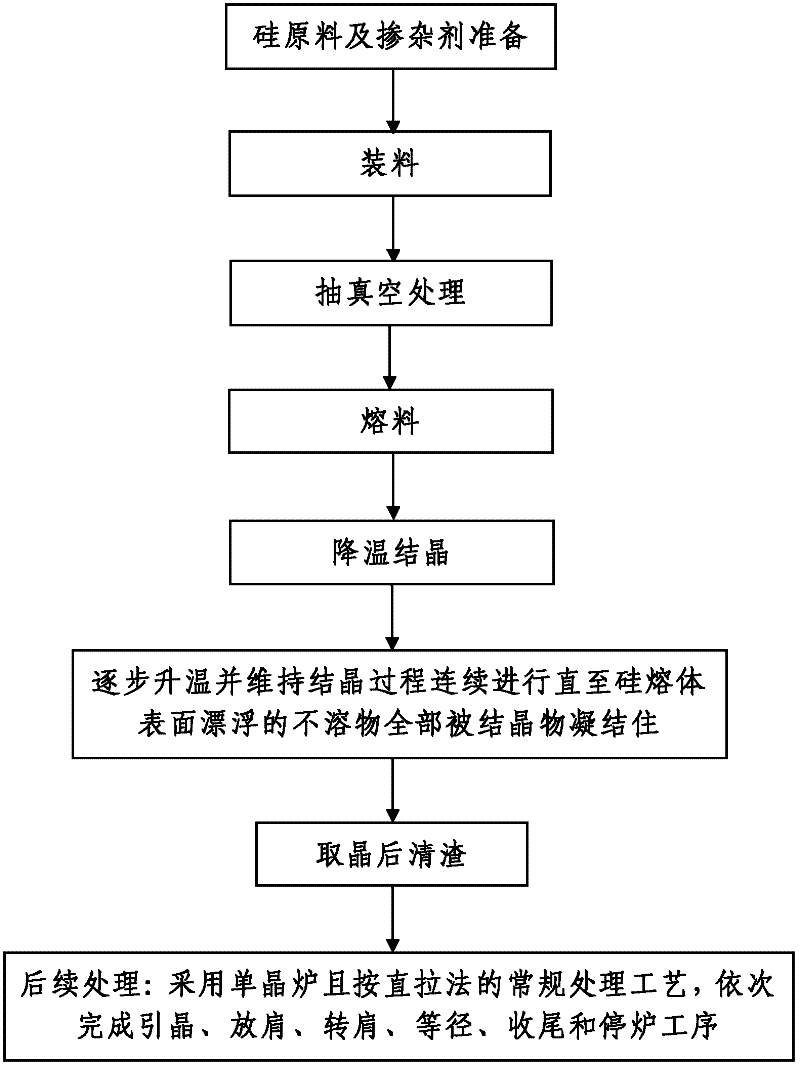

Process for producing Czochralski silicon single crystal

InactiveCN102242397AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltDopantSlag

The invention discloses a process for producing a Czochralski silicon single crystal, which comprises the following steps of: 1, preparing a silicon raw material and a doping agent; 2, charging; 3, vacuumizing; 4, melting; 5, extracting slag, namely 501, performing cooling crystallization, 502, gradually heating, and keeping the crystallization process continuously performed until insoluble substances floating on the surface of a silicon melt are completely condensed by the crystal, and 503, taking the crystal out, and removing the slag; and 6, performing subsequent treatment, namely finishing crystal leading, shoulder expanding, shoulder rotating, diameter equalizing, ending and blowing down processes in turn by using a single crystal furnace according to the conventional treatment process of a Czochralski method to obtain the finished silicon single crystal formed by pulling. The process is reasonable in design, simple in steps, convenient to implement, easy to master and good in using effect, can effectively ensure the quality of the produced silicon single crystal, and can solve the practical problems that slag removing time is difficult to master, the slag extracting effect is poor, the produced silicon single crystal has low purity, and the like.

Owner:XIAN HUAJING ELECTRONICS TECH

Belt transportation system

InactiveCN106219193ASimple structureReasonable designConveyorsControl devices for conveyorsEngineeringLeather belt

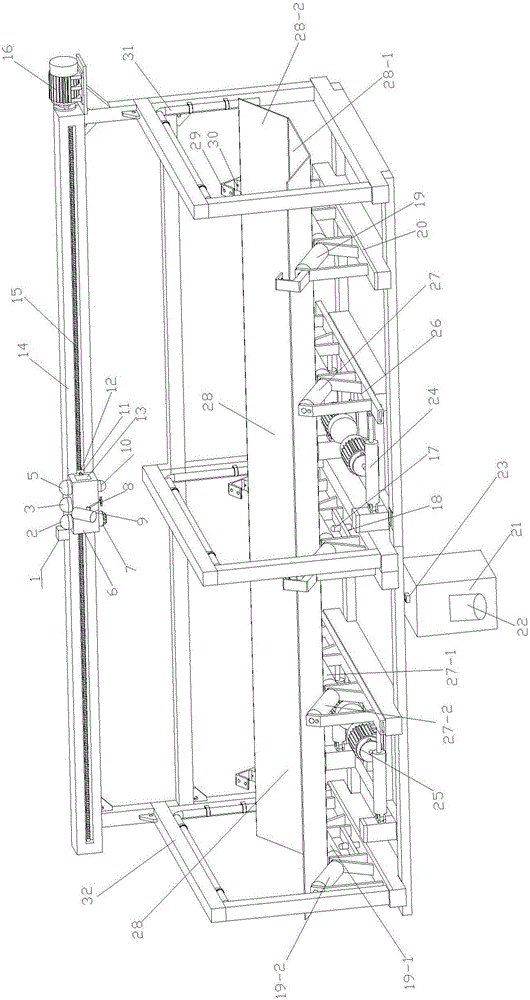

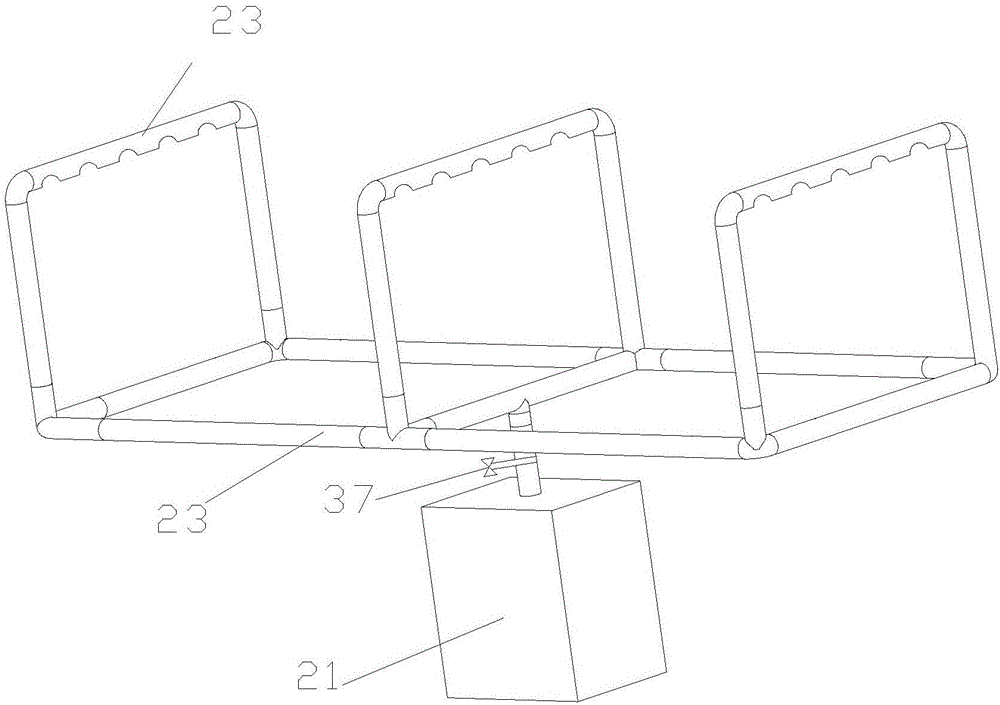

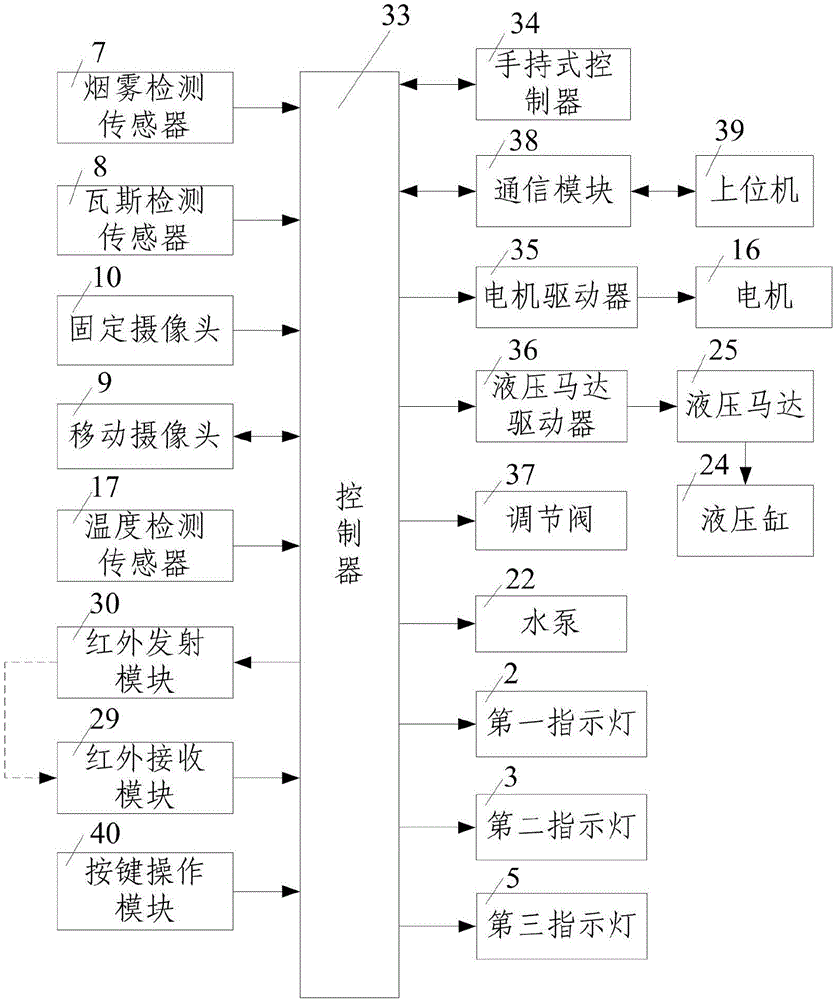

The invention discloses a belt transportation system which comprises a belt transportation mechanism, a belt detection device, a monitor device, belt deviation adjusting mechanisms and a belt cooling mechanism. The belt transportation mechanism comprises a belt and belt supporting components. The belt detection device comprises a routing inspection mechanism, temperature detection sensors and belt deviation detection modules. A routing inspection sliding mechanism and a sliding drive mechanism are arranged on a rack. The routing inspection mechanism comprises a routing inspection box, a smoke detection sensor, a gas detection sensor and a fixed camera. The monitor device comprises a control device, a wireless power supply module, a cooling control mechanism and a deviation adjusting drive mechanism. The belt transportation system is simple in structure and convenient to implement; the belt transportation work condition is detected in real time; the belt is adjusted and cooled; belt deviation or high-temperature work is prevented from bringing potential safety hazards to workers and coal mine transportation; continuous transportation of the belt is achieved; and the coal production efficiency is improved, and labor intensity is relieved.

Owner:XIAN UNIV OF SCI & TECH

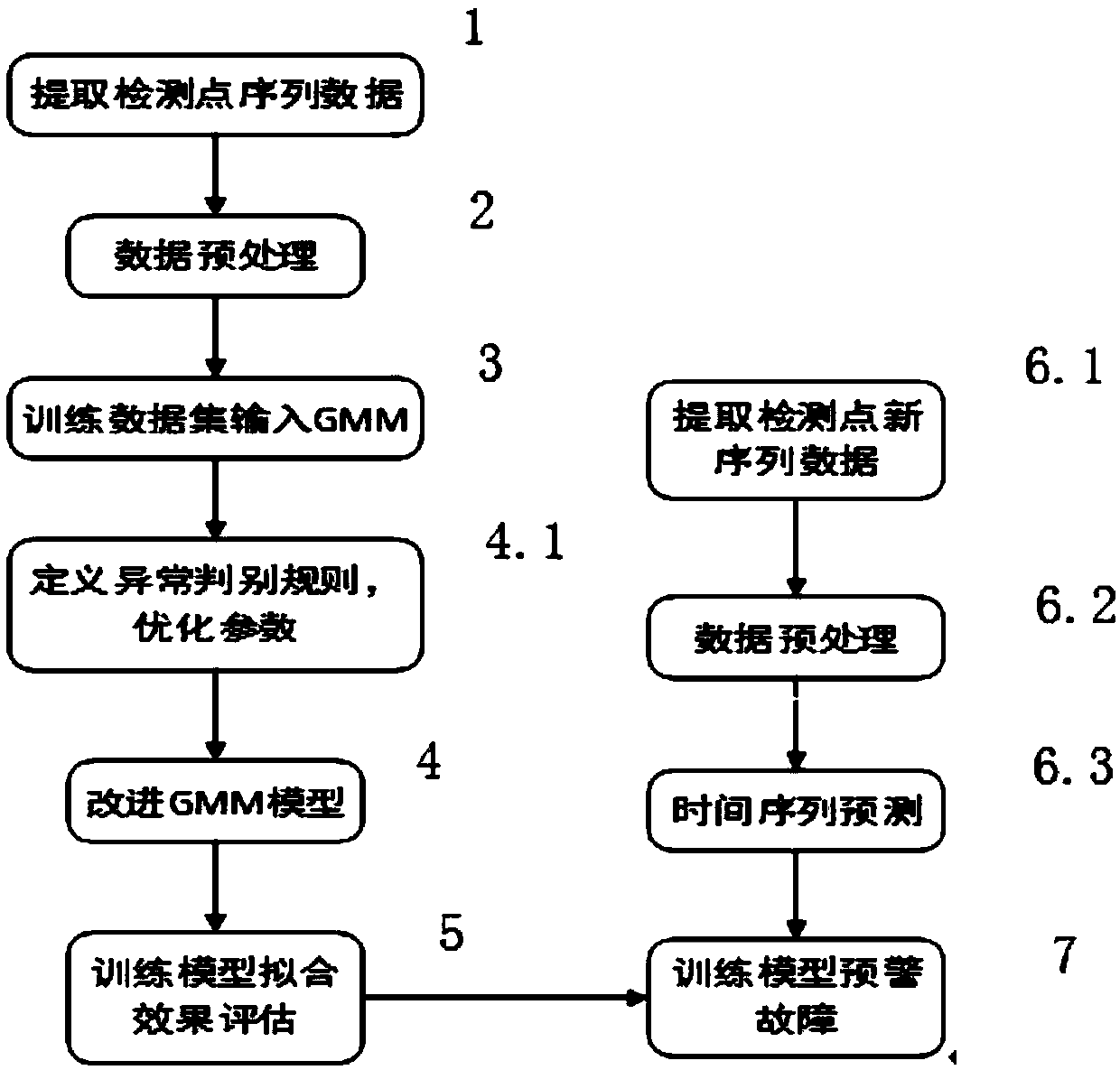

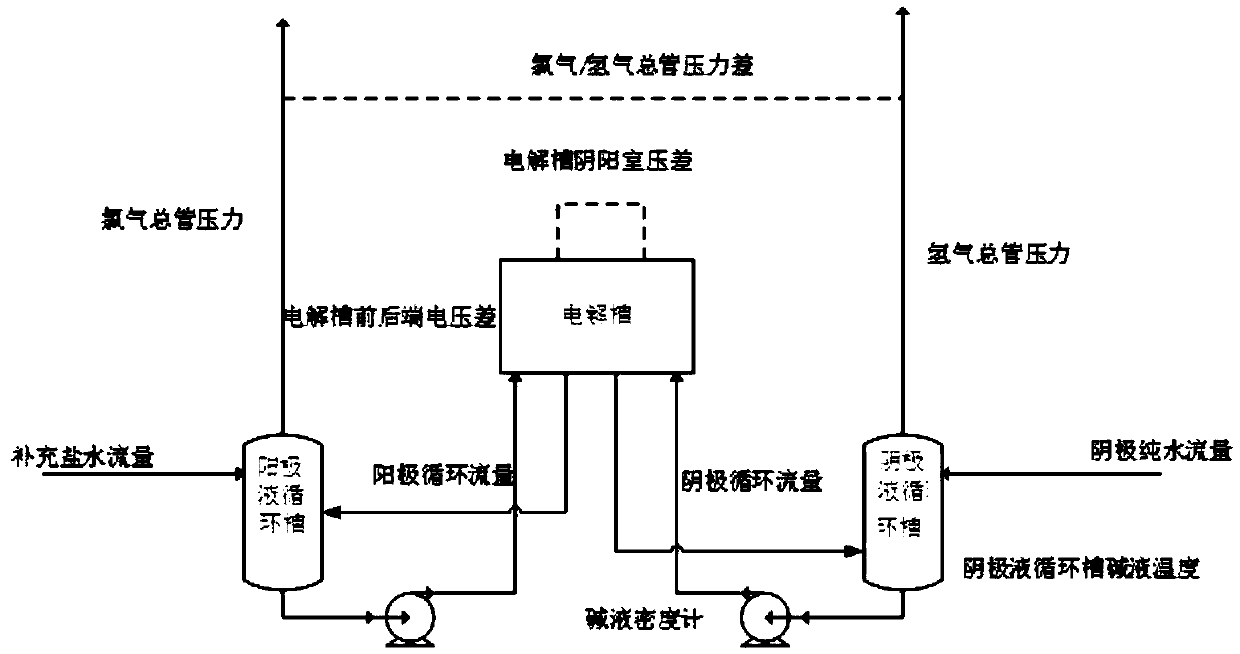

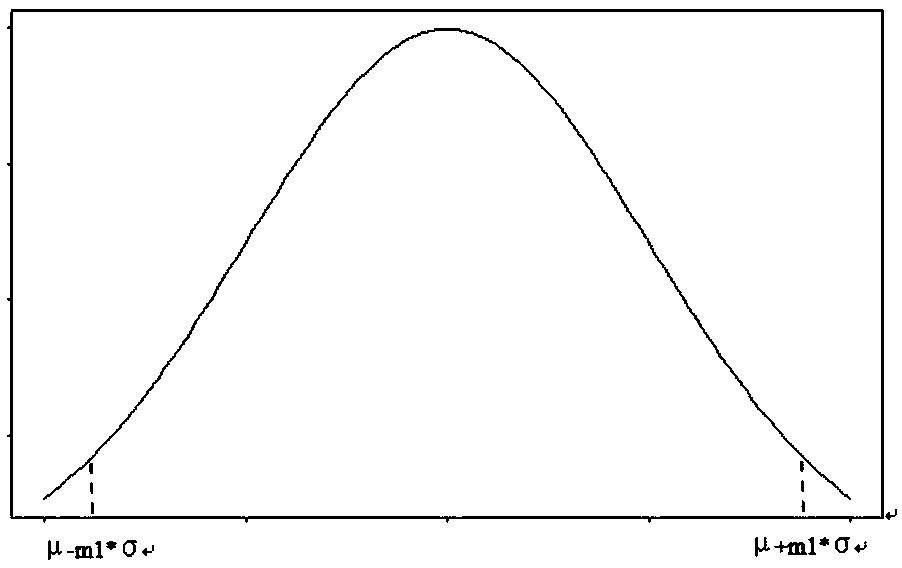

Machine learning method used for electrolytic-cell fault early-warning and application thereof

ActiveCN108805202AReduce paralysisAvoid errors of judgmentCharacter and pattern recognitionGenetic algorithmsData setPoint sequence

The invention provides a machine learning method used for electrolytic-cell fault early-warning. The method is used for establishing an anticipation model for electrolytic-cell faults. A main processof the method includes: extracting detection point sequence data; preprocessing the data; inputting a training data set to a GMM clustering model; defining abnormality discrimination rules; optimizingdiscrimination parameters; improving the GMM clustering model; and evaluating a fitting effect of the trained model. The invention also provides an application of the machine learning method used forelectrolytic-cell fault early-warning. A main process of the application includes: extracting new detection point sequence data; preprocessing the data; predicting a time sequence; and carrying out early-warning fault judgment of the trained model. According to the method and the application, benumbing of traditional conditional value alarming on operators can be effectively reduced, experiencedoperators can be replaced for judging the faults, and error judgment of human factors can be avoided.

Owner:上海新增鼎数据科技有限公司

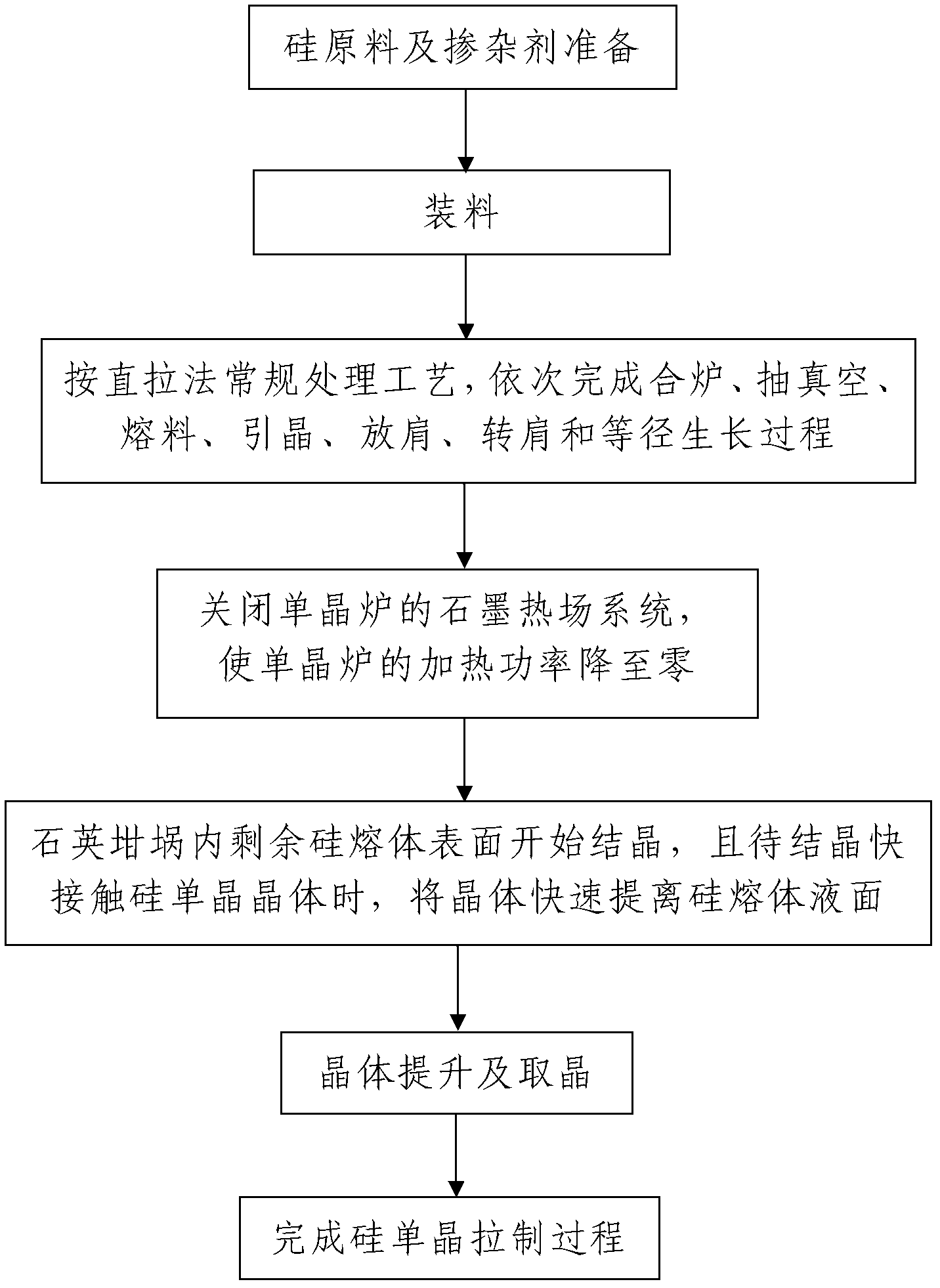

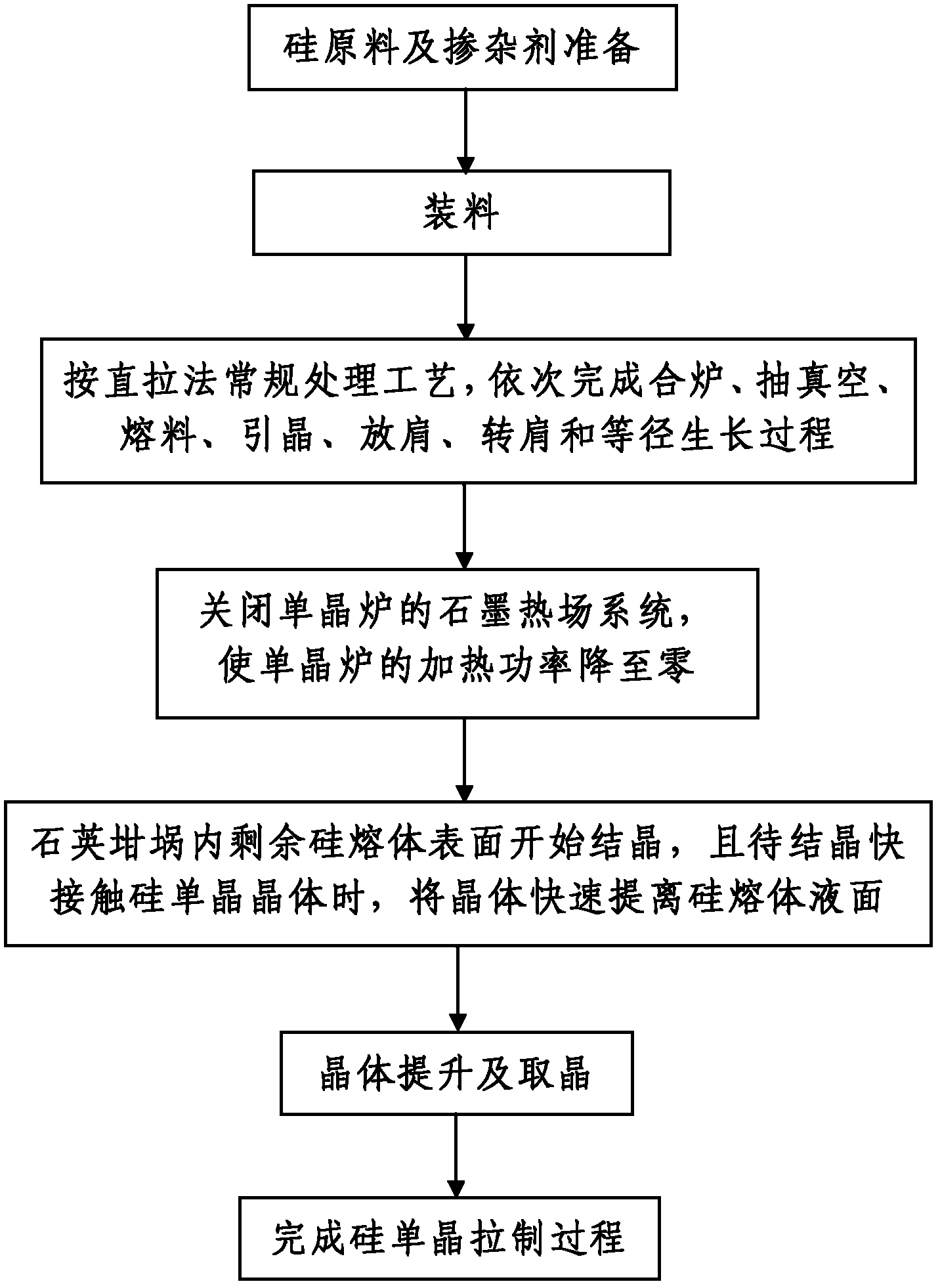

Method to raise production efficiency of czochralski silicon mono-crystal

InactiveCN102220634AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltVacuum pumpingDopant

The invention discloses a method to raise production efficiency of czochralski silicon mono-crystal. The method comprises the following steps: 1. preparation of silicon raw material and a doping agent; 2. charging; 3. processing in a mono-crystal furnace: completing processes of furnace mixing, vacuum-pumping, stock melting, seeding, diameter controlling, casting speed increase and equal diametergrowth, according to a routine processing technology of a czochralski method; 4. post processing: first, a graphite thermal field system of the mono-crystal furnace is closed to lower thermal power of the mono-crystal furnace to zero; then residual silicon melt surface in a quartz crucible begins to crystallize, and when the crystals are about to contact silicon mono-crystals, the mono-crystals are lifted from the silicon melt liquid surface rapidly; last, crystal lifting and crystal collection are carried out to obtain silicon mono-crystal finished product. The invention has the advantages of reasonable design, simple method steps, convenient realization, easy grasp, good usage effect. An ending process of crystal drawing is omitted to increase production efficiency, so as to solve the problem that czochralski silicon mono-crystal production efficiency is restricted by a demanded ending process in the silicon mono-crystal production process.

Owner:XIAN HUAJING ELECTRONICS TECH

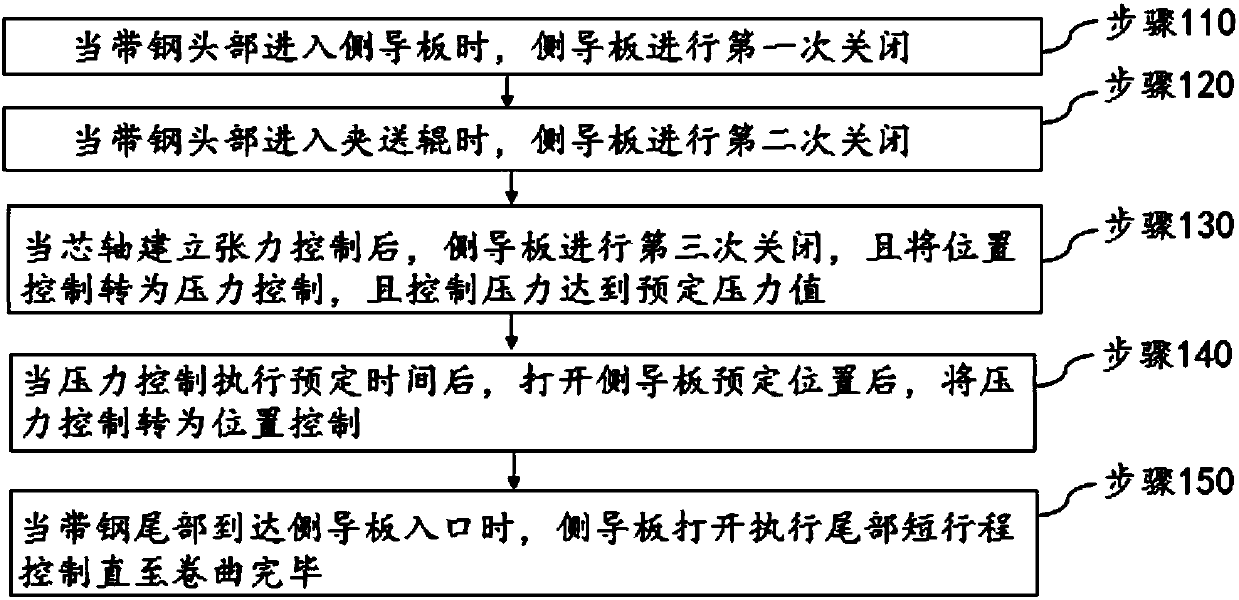

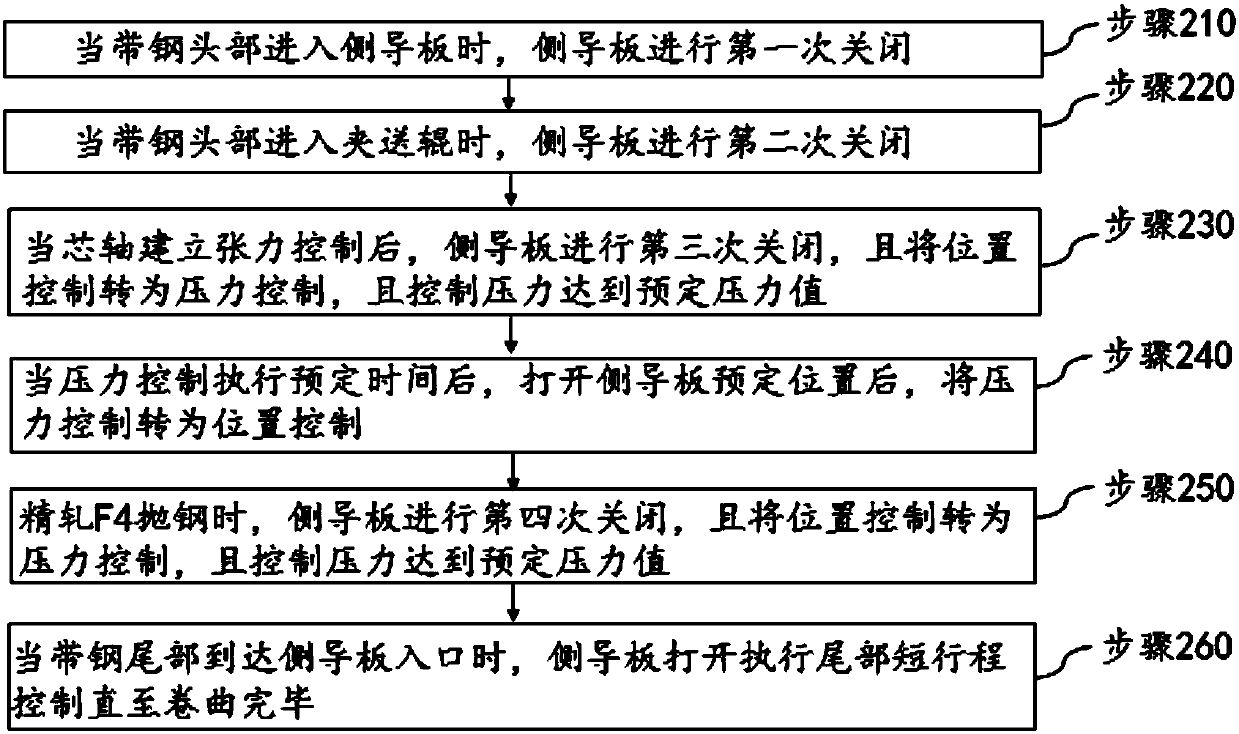

Reeling machine side guide plate control method for reducing wearing of wear-resisting plate

The invention discloses a reeling machine side guide plate control method for reducing wearing of a wear-resisting plate. The method includes the following steps that when the head of strip steel enters a side guide plate, the side guide plate is closed first time; when the head of the strip steel enters a clamping roller, the side guide plate is closed second time; when tension control over a core shaft is built, the side guide plate is closed third time, position control is changed into pressure control, and the control pressure reaches a preset pressure value; and when pressure control is executed a preset time, the side guide plate is opened to the preset position, pressure control is converted into position control. The technical problem that the quality of the edges and the surface of the strip steel are influenced by friction between the edge of the strip steel and the wear-resisting plate of the guide plate is solved, and the technical effects of being high in quality of the edges and the surface of the strip steel, the replacing efficiency of the side guide plate is reduced, and the repairing cost of the side guide plate is reduced are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

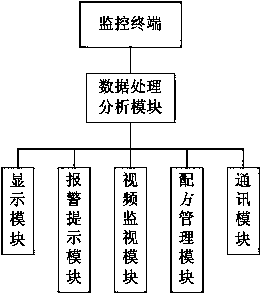

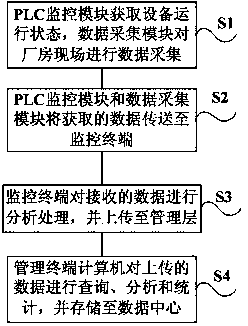

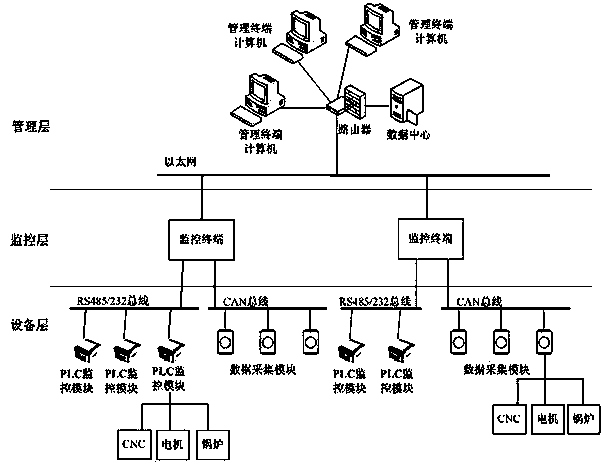

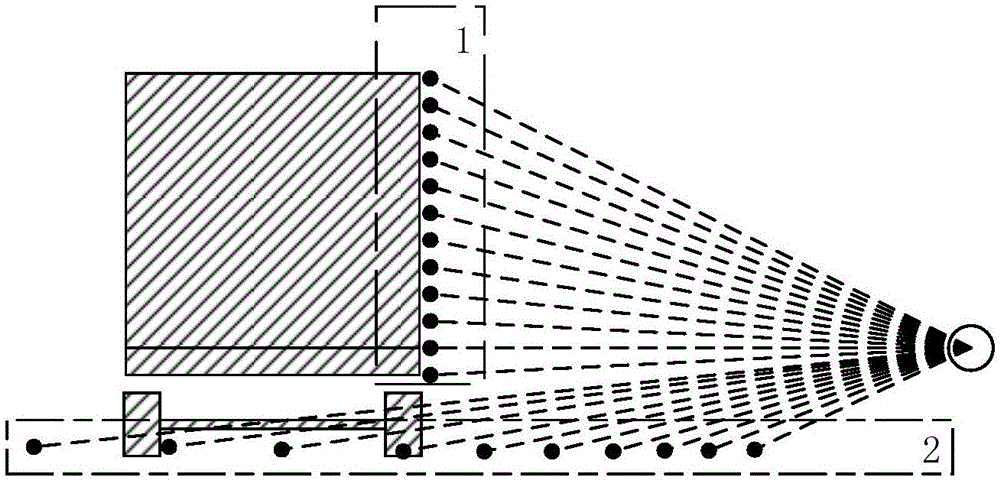

Distributed control system and distributed control method

InactiveCN103676849AAvoid production accidentsTotal factory controlProgramme total factory controlData centerProgrammable logic controller

The invention discloses a distributed control system and a distributed control method. The system comprises a device layer, a monitoring layer and a management layer. The device layer comprises PLC (programmable logic controller) monitoring modules and data acquisition modules arranged in each plant, and the PLC monitoring modules and the data acquisition modules are all connected with multiple devices in the plants. The monitoring layer comprises monitoring terminals, and the PLC monitoring modules and the data acquisition modules in each plant are all connected with the corresponding monitoring terminal. The management layer comprises multiple management terminal computers, a router and a data center, each management terminal computer and the data center are respectively connected with the router through a network, and the router is connected with each monitoring terminal through the Ethernet. Interaction between field monitoring personnel and the devices is realized by adopting a MiniHMI human-computer interface and combining with HDS configuration software, the field monitoring personnel can set working parameters, warning conditions and information inquiry, feed back important information to the management layer in real time and check device running data in real time, control of a product production method is completed through recipe management, and production accident caused by man-made misoperation is avoided.

Owner:CHENGDU SUNSHEEN TECH

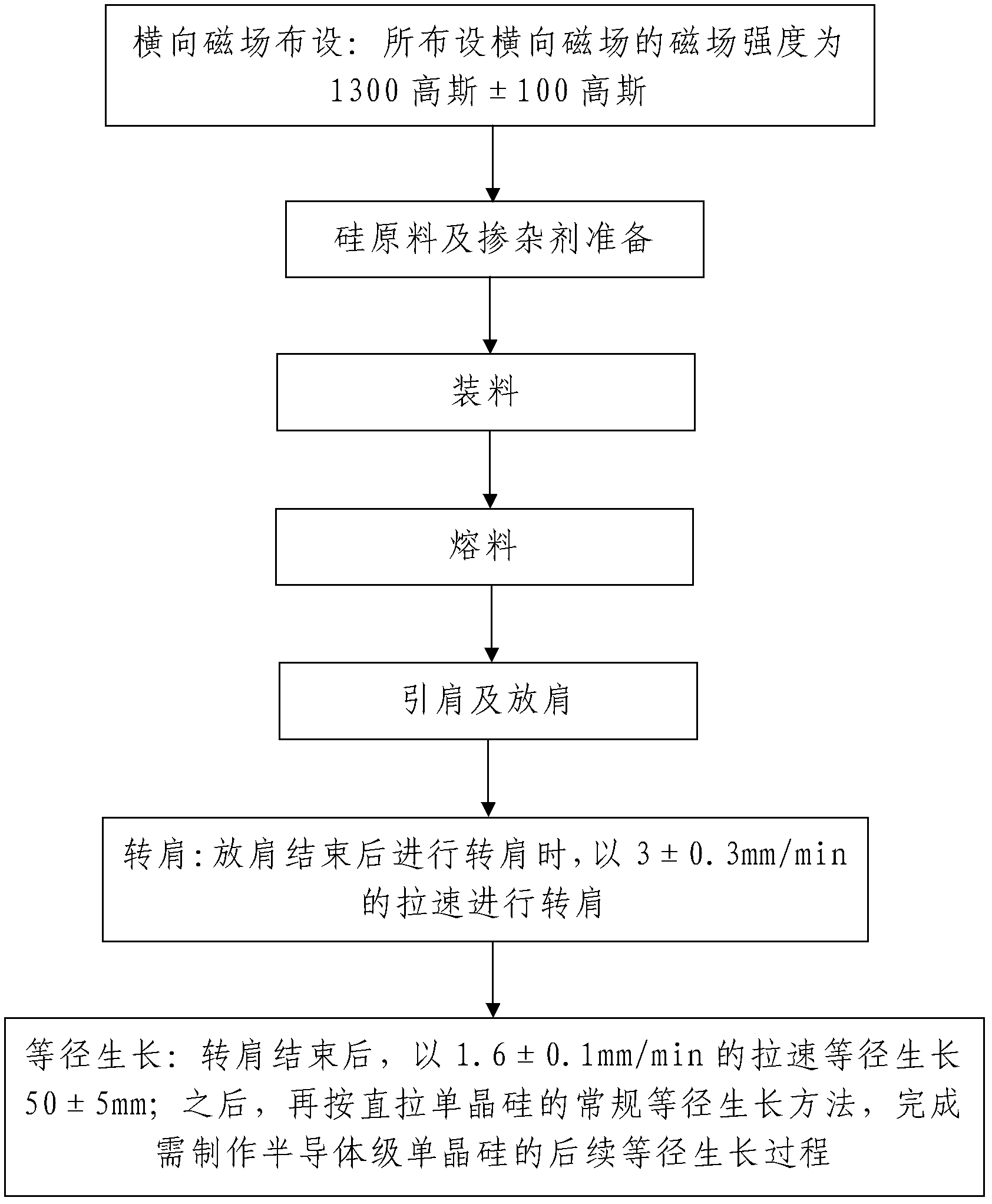

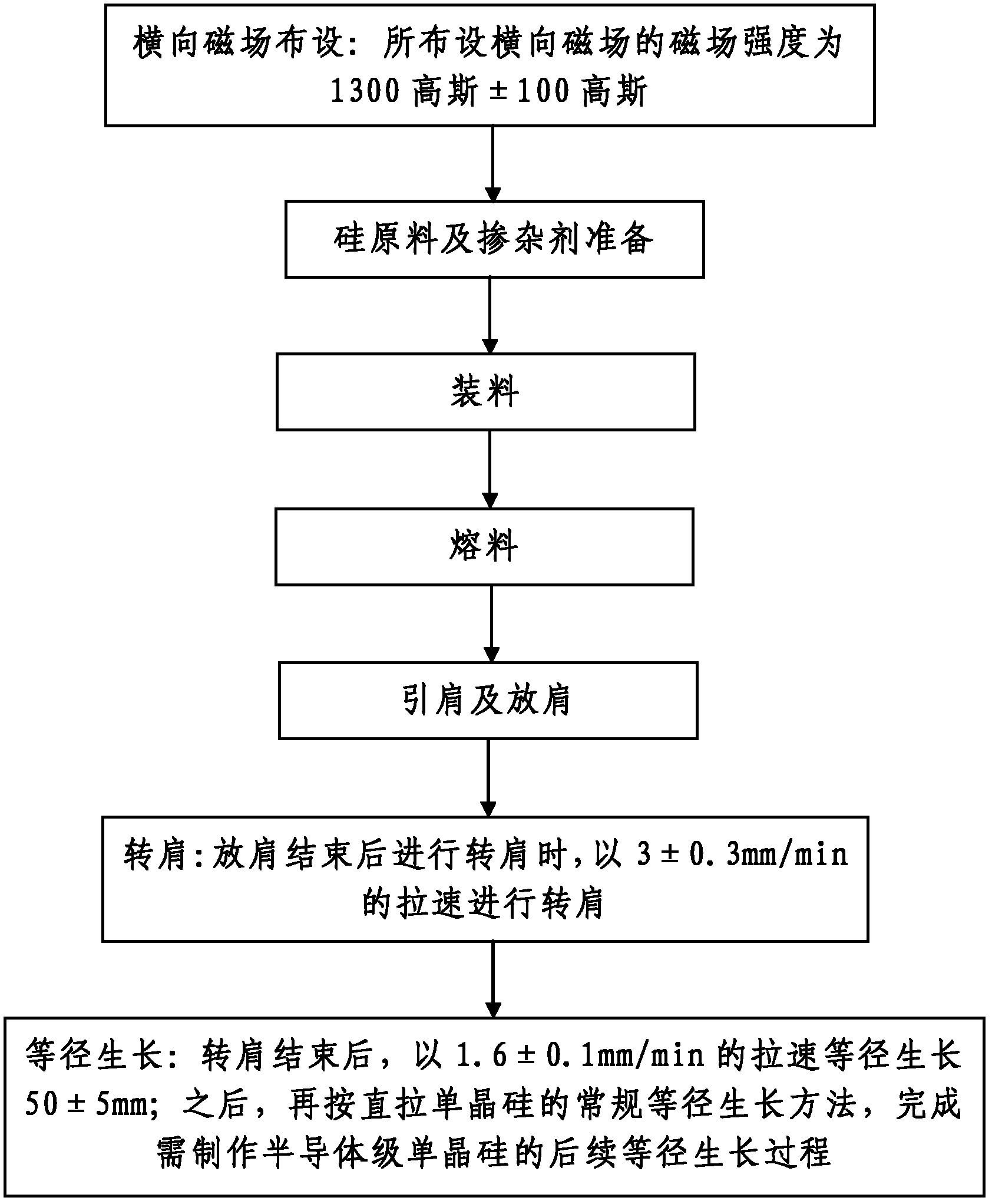

Production technology of semiconductor grade silicon single crystal

InactiveCN102220633AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltTransverse magnetic fieldSingle crystal

The invention discloses a production technology of semiconductor grade silicon single crystal, comprising the following steps: 1, arranging a transverse magnetic field: the magnetic field intensity of the transverse magnetic field is 1300 + / - 100 gausses; 2, preparing silicon material and doping agent; 3, charging; 4, melting material; 5, introducing shoulder and expanding shoulder; 6, rotating shoulder: after the step of expanding shoulder, the step of rotating shoulder is carried out with a casting speed of 3 + / - 0.3 mm / min; and 7, growing at the same diameter: after the step of rotating shoulder, the material grows up to 50 + / - 5 mm with a casting speed of 1.6 + / - 0.1 mm / min; then, a conventional method of growing at the same diameter for direct pulling silicon single crystal is used to complete the subsequent process of growing at the same diameter of the semiconductor grade silicon single crystal. The method has the advantages of reasonable design, simple steps, easiness in realization, easiness in mastering and good using effect, and is capable of effectively guaranteeing the quality of the produced semiconductor grade silicon single crystal. The produced semiconductor grade silicon single crystal has high uniformity of cross-section electric resistivity and no micro-defects such as swirl.

Owner:XIAN HUAJING ELECTRONICS TECH

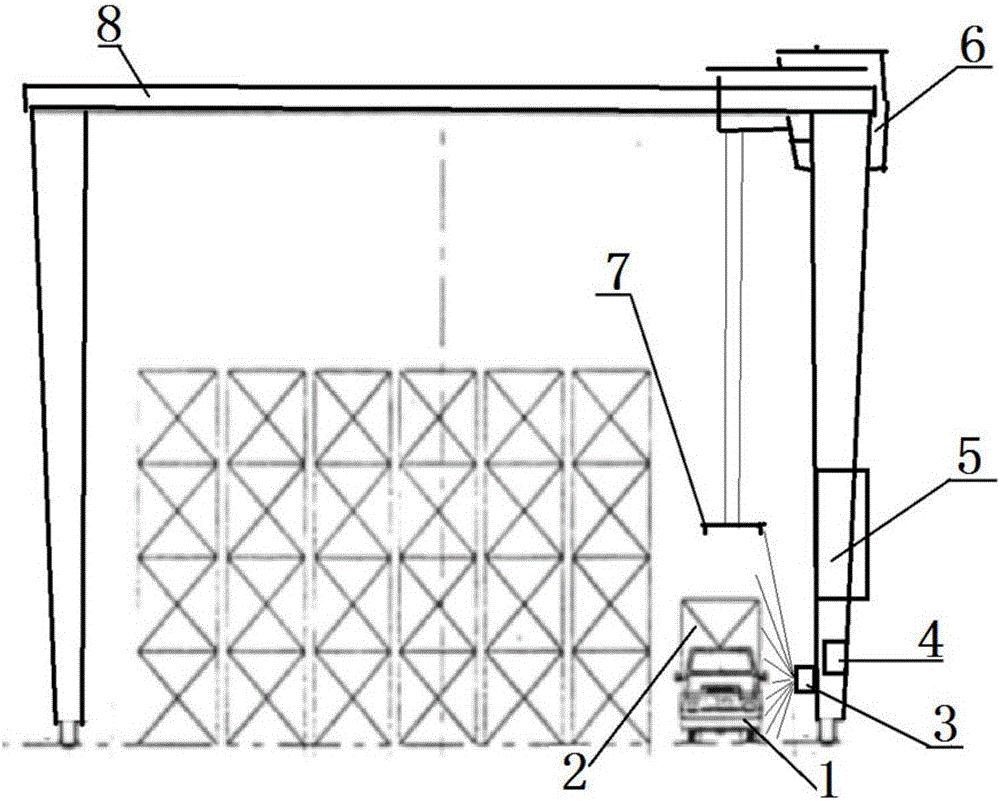

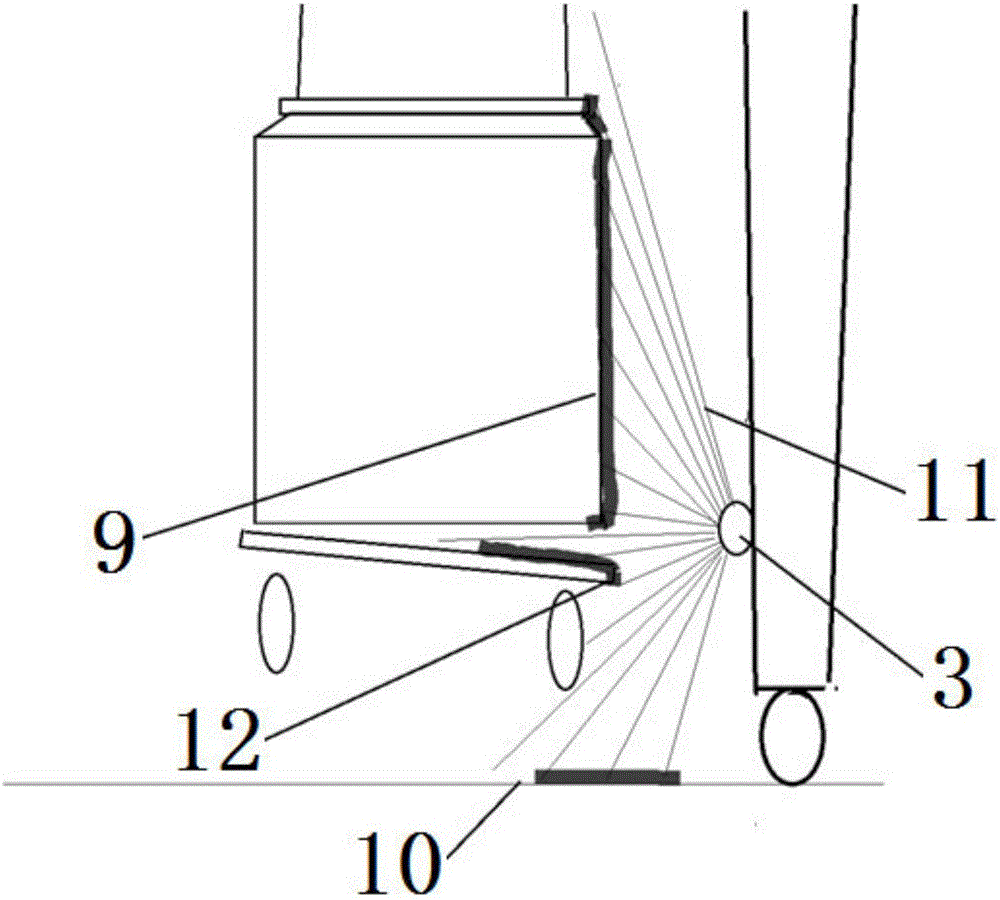

System and method for detecting hoisting prevention on basis of laser

ActiveCN106829742AEnables real-time location detectionImplement position detectionLoad-engaging elementsAutomatic controlLaser scanning

The invention discloses a system and a method for detecting hoisting prevention on the basis of laser. The system comprises a logic operation unit, a laser scanner and a PLC (programmable logic control) system. The laser scanner and the PLC system are connected with the logic operation unit. Compared with the prior art, the system and the method have the advantages that the locations of lifting appliances, containers, trucks and the like can be detected by the aid of laser scanning ranging principles and pattern recognition and automatic control technologies in real time, running of lifting mechanisms can be controlled according to safety control strategies, the system has functions of preventing the trucks from being hoisted, and accordingly production accidents can be prevented; the side contours can be continuously scanned and recognized during operation on the containers, accordingly, hoisted states of the trucks can be accurately judged, and the container loading and unloading safety can be greatly enhanced.

Owner:CATHAY NEBULA SCI & TECH CO LTD

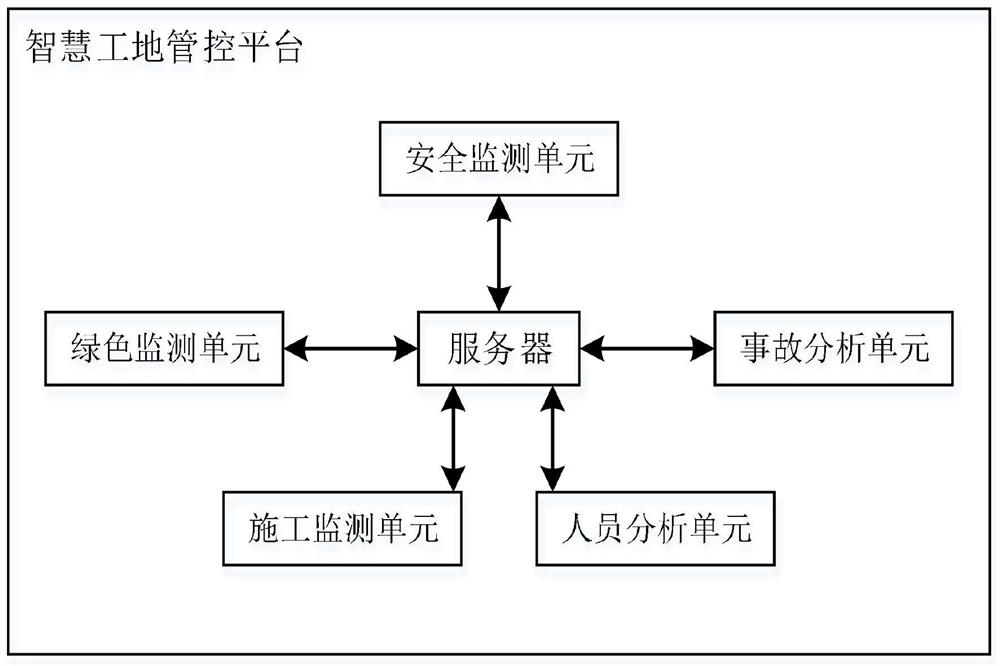

Intelligent construction site management and control system based on data analysis

InactiveCN113919726APrevent disputesPrevent slow construction progressMeasurement devicesResourcesControl systemElectric power equipment

The invention discloses an intelligent construction site management and control system based on data analysis, relates to the technical field of intelligent construction site management and control, solves the technical problem that in the prior art, a construction site cannot be reasonably managed and controlled, verifies the identity of a worker, accurately analyzes the ability of the worker, reasonably matches a proper post, the situation that the construction progress is slow due to improper posts of workers is prevented, and the safety risk of the workers is indirectly reduced; the construction environment of a factory is monitored, the situation that the surrounding environment is affected due to the fact that the construction environment of a project is abnormal is prevented, meanwhile, the environment improvement cost is increased, the construction progress of the construction site is slowed down, meanwhile, the benefits of the construction site are reduced, and the project feasibility is reduced; the operation of the power equipment in the construction site is monitored, so that production accidents caused by electric injury of workers due to misoperation of the power equipment are prevented, the safety of the construction environment of the workers is reduced, and the risk of slowing down the project progress is increased.

Owner:格瑞利(江苏)智能科技有限公司

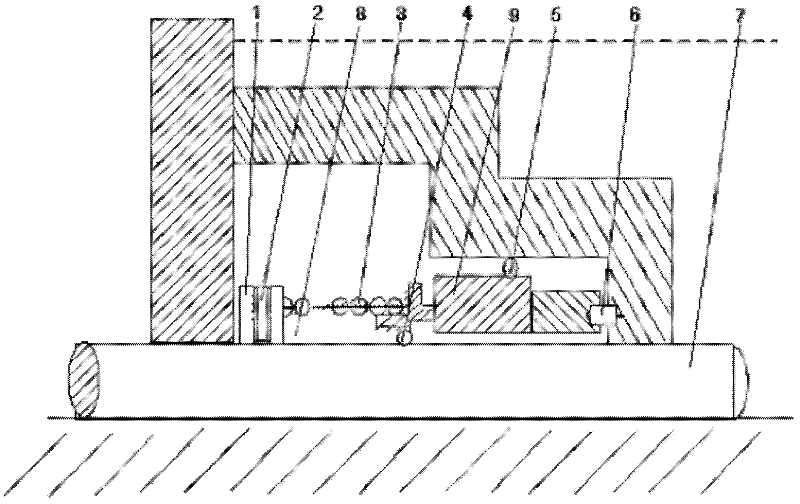

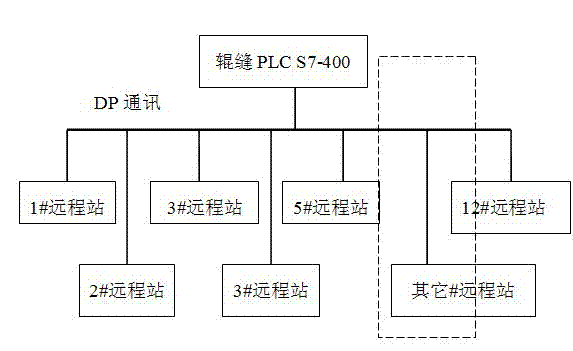

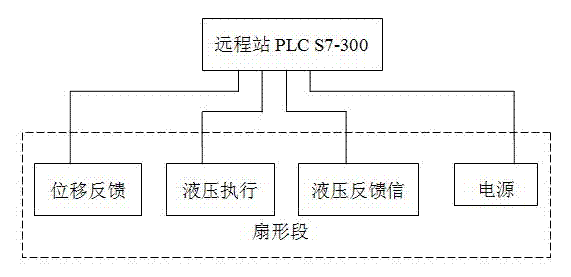

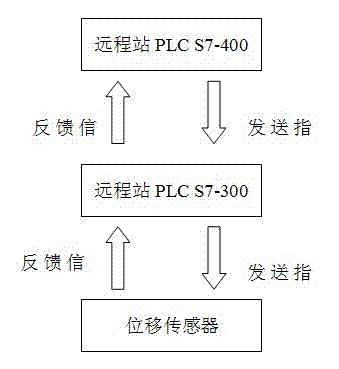

Dynamic slight press fan-shaped section hydraulic system leakage fault on-line judging and early warning method

InactiveCN102310179AAvoid production accidentsAvoid getting out of controlControl systemControl engineering

The invention relates to a dynamic slight press fan-shaped section hydraulic system leakage fault on-line judging and early warning method, which belongs to the technical field of continuous casting equipment maintenance in the metallurgical industry. The method has the technical scheme that (1) a roll gap control system PLCS7-300 sends a 'fan-shaped section hydraulic system locking' order to a remote station PLCS7-300; (2) the pressure value of the fan-shaped section hydraulic system is fed back; (3) the value of a fan-shaped section displacement sensor is fed back; (4) the roll gap control system PLCS7-400 judges the feedback pressure value of the hydraulic system and the value of the fan-shaped section displacement sensor combinedly; and further the results are output to a continuous casting master control system. With the method disclosed by the invention, roll gap control loss caused by the leakage fault of the hydraulic system can be prevented, the actual roll gap is controlledto meet the scope designed by the technology, the contraction taper of the roller gap is ensured to guarantee casting blank quality, an early warning function is played to protect fan-shaped section equipment, key equipment is monitored comprehensively and managed automatically in the whole continuous casting production process, the continuous casting production is stabilized, the technical control level is improved, the product quality is improved, and economic benefits are created.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

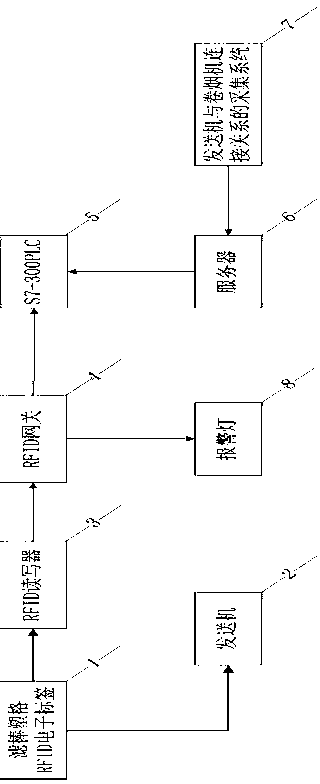

Method for preventing conveying errors of filter rods for filter rod conveying machine

ActiveCN103211299AAvoid slow recognitionQuick noteCigarette manufactureSpecial data processing applicationsIndustrial EthernetProgrammable logic controller

The invention relates to a method for preventing conveying errors of filter rods for a filter rod conveying machine. A device adopted by the method comprises an RFID (Radio Frequency Identification) electronic tag, an RFID reader-writer, an RFID gateway, an S7-300PLC (Programmable Logic Controller), an alarm lamp, a conveyer, an acquisition system and a server, wherein the acquisition system and the server are connected with cigarette making machines; the server acquires a production task which is executed currently by each cigarette making machine in real time, extracts material codes of required filter rods from a material list of the production tasks, and stores the material codes; the server writes a storage region of the S7-300PLC through an industrial Ethernet through an acquired current connection relationship between the conveyer and the cigarette making machines and the acquired material codes of the filter rods used by the cigarette making machine currently; and the S7-300PLC is used for checking the material codes of the filter rods in information of the RFID electronic tag, read by the RFID reader-writer, and the material codes of the filter rods required by the corresponding cigarette making machines. According to the method, quality accidents can be effectively avoided.

Owner:CHINA TOBACCO ZHEJIANG IND

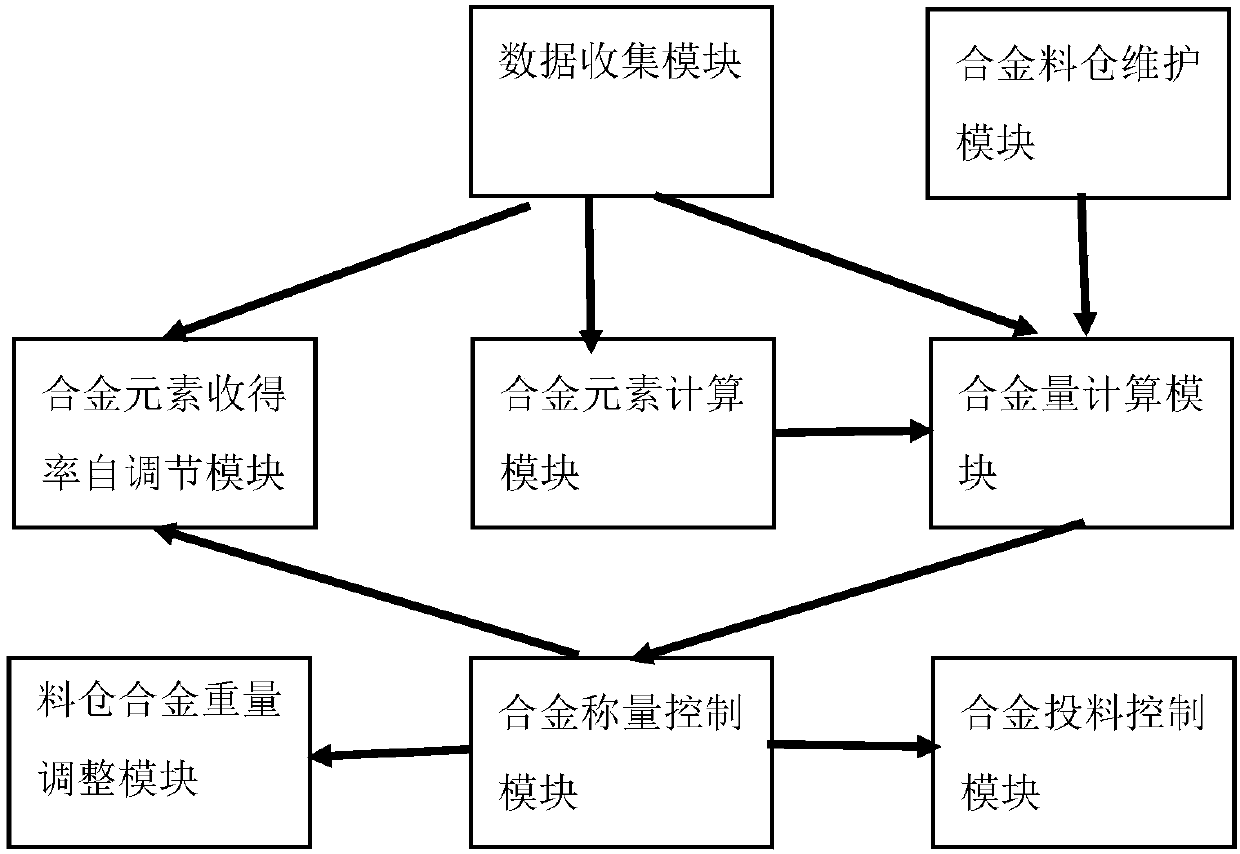

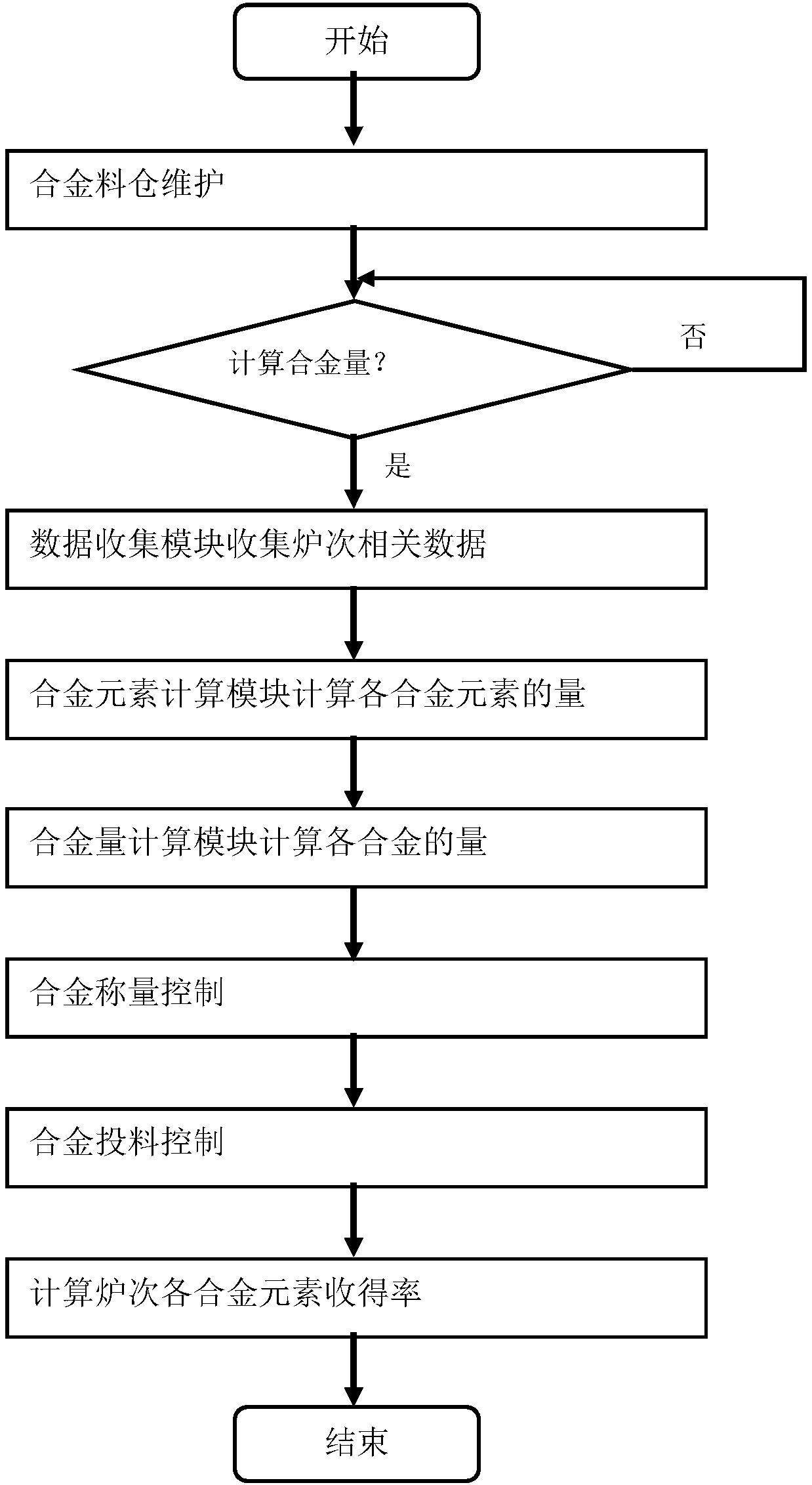

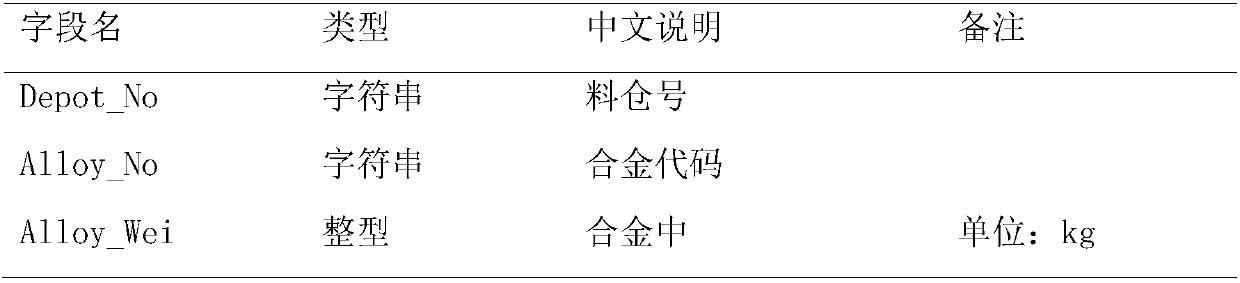

Steel ladle refining furnace molten steel silicon manganese component control device and method

The invention relates to a steel ladle refining furnace molten steel silicon manganese component control device. The control device comprises following control modules including an alloy material binmaintaining module, a data collecting module, an alloy element calculating module, an alloy amount calculating module, an alloy weighing control module, an alloy charging control module, a material bin alloy weight adjusting module and an alloy element yield self-adjusting module. The alloy material bin maintaining module is used for storing the alloy storage situation of various alloy material bins and providing the maintaining function. The data collecting module is used for collecting and tidying various parameters needed for calculation. The alloy element calculating module is used for calculating the weight of elements Si, Mn and C thrown into an alloy. The alloy amount calculating module is used for calculating the weight of silicon iron, a silicon manganese alloy, ferromanganese iron, high carbon ferromanganese, mid-carbon ferromanganese, low-carbon ferromanganese and other alloys needing to be thrown. The alloy weighing control module is used for controlling weighing of the alloy needing to be thrown. The alloy charging control module is used for weighed alloy throwing control. The material bin alloy weight adjusting module is used for adjusting the weight of the alloy in the alloy material bins. The alloy element yield self-adjusting module is used for calculating the yield of various alloy elements of the furnace time.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

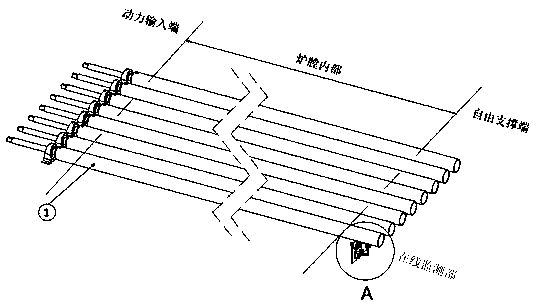

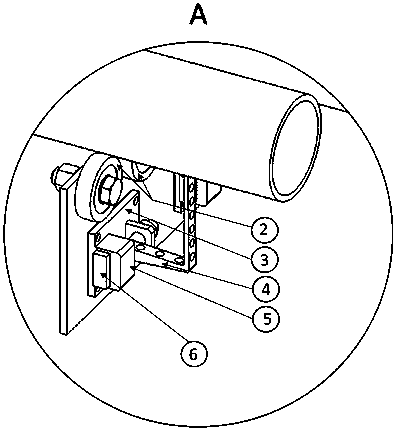

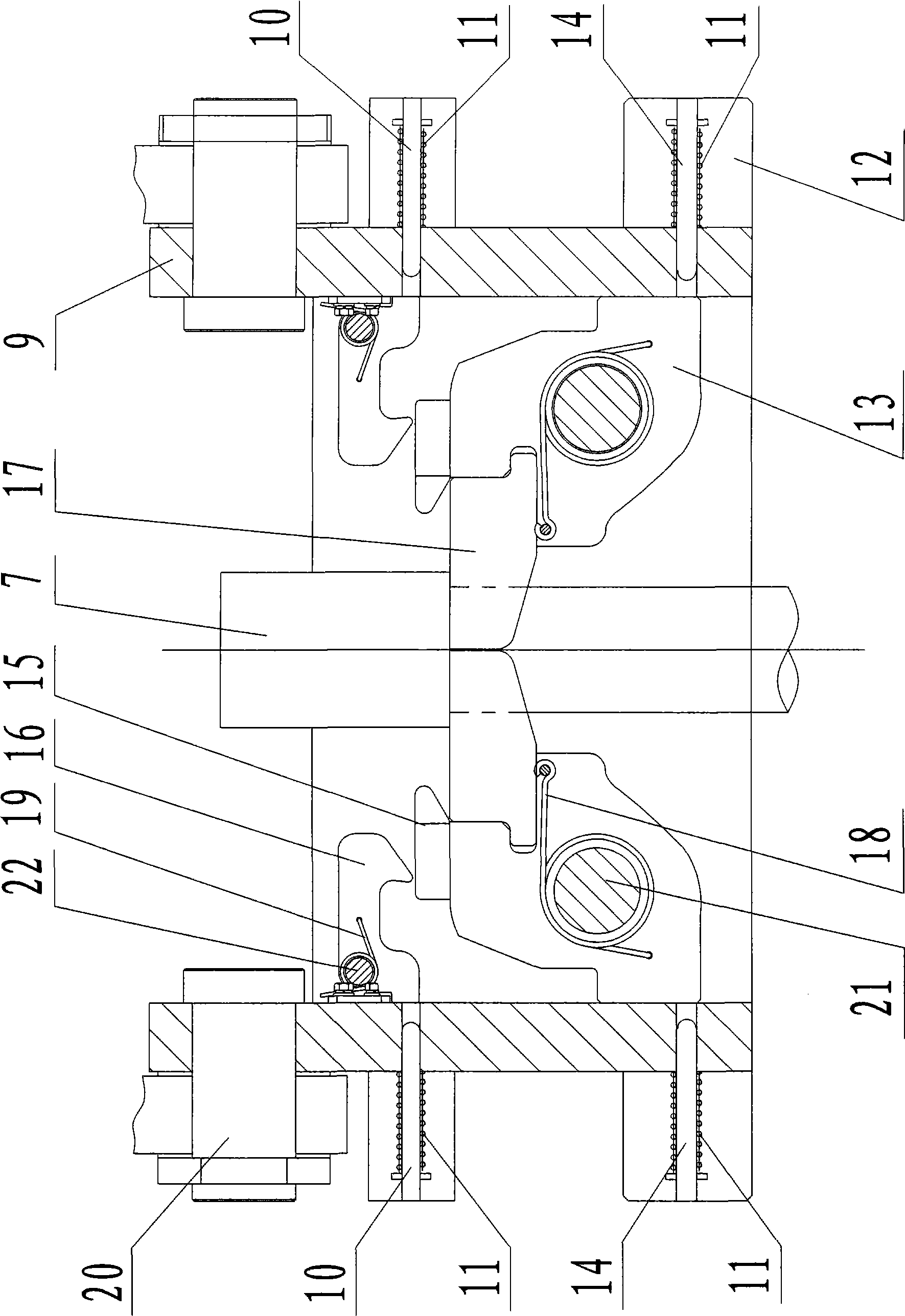

Real-time monitoring device for rollers of high-temperature roller kiln

ActiveCN109405538AReal-time monitoring of running conditionsAvoid production accidentsFurnace typesCapacitanceCoil spring

The invention discloses a real-time monitoring device for rollers of a high-temperature roller kiln. The real-time monitoring device comprises a transmission roller part and an online monitoring part.The transmission roller part comprises multiple roller kiln rollers which are arranged in parallel, and the free ends of the roller kiln rollers are arranged on a free end installation frame. The online monitoring part comprises swing arms, angular displacement capacitance sensors, spiral leaf springs, wireless signal transmitting devices and a computer. The upper sides of the swing arms are attached to the exact lower sides of the rollers, and the lower sides of the swing arms are connected with rotating shafts. The spiral leaf springs are arranged at one ends of the rotating shafts, and theangular displacement capacitance sensors and the wireless signal transmitting devices are arranged at the other ends of the rotating shafts. When the roller kiln rollers rotate, radial jumping of thefree ends of the rollers is collected by a monitoring device, electric signals are generated and are converted into digital signals, and the digital signals are conveyed to the computer for analyzingand judging of the running conditions of the rollers. By means of the real-time monitoring device, the running conditions of the rollers in the kiln can be monitored in real time, the production accidents that the rollers lose efficacy and kiln blockage happens are avoided, and the production efficiency is improved.

Owner:SOUTHEAST UNIV

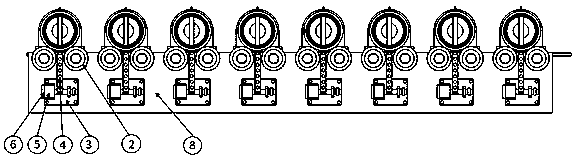

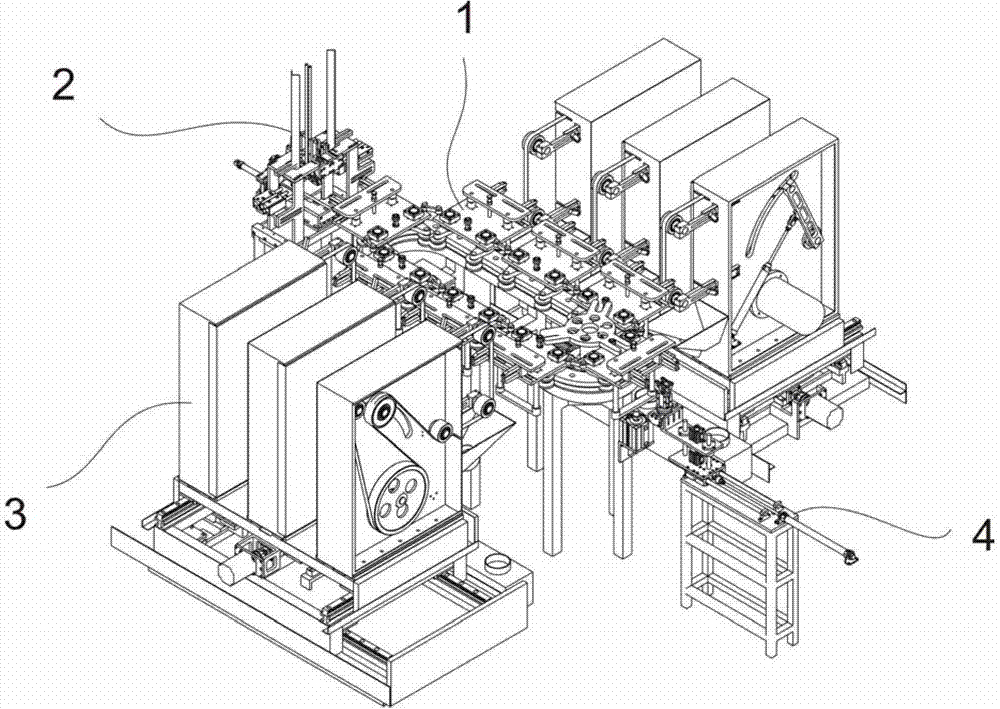

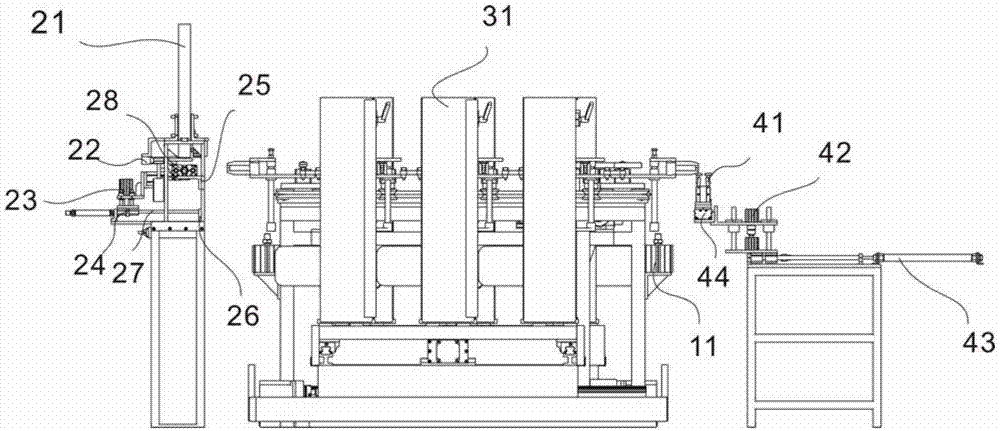

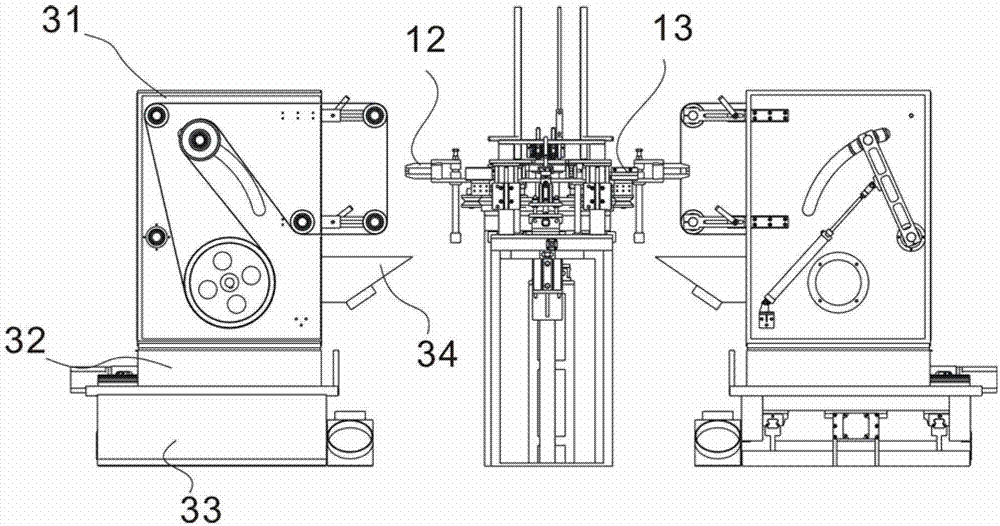

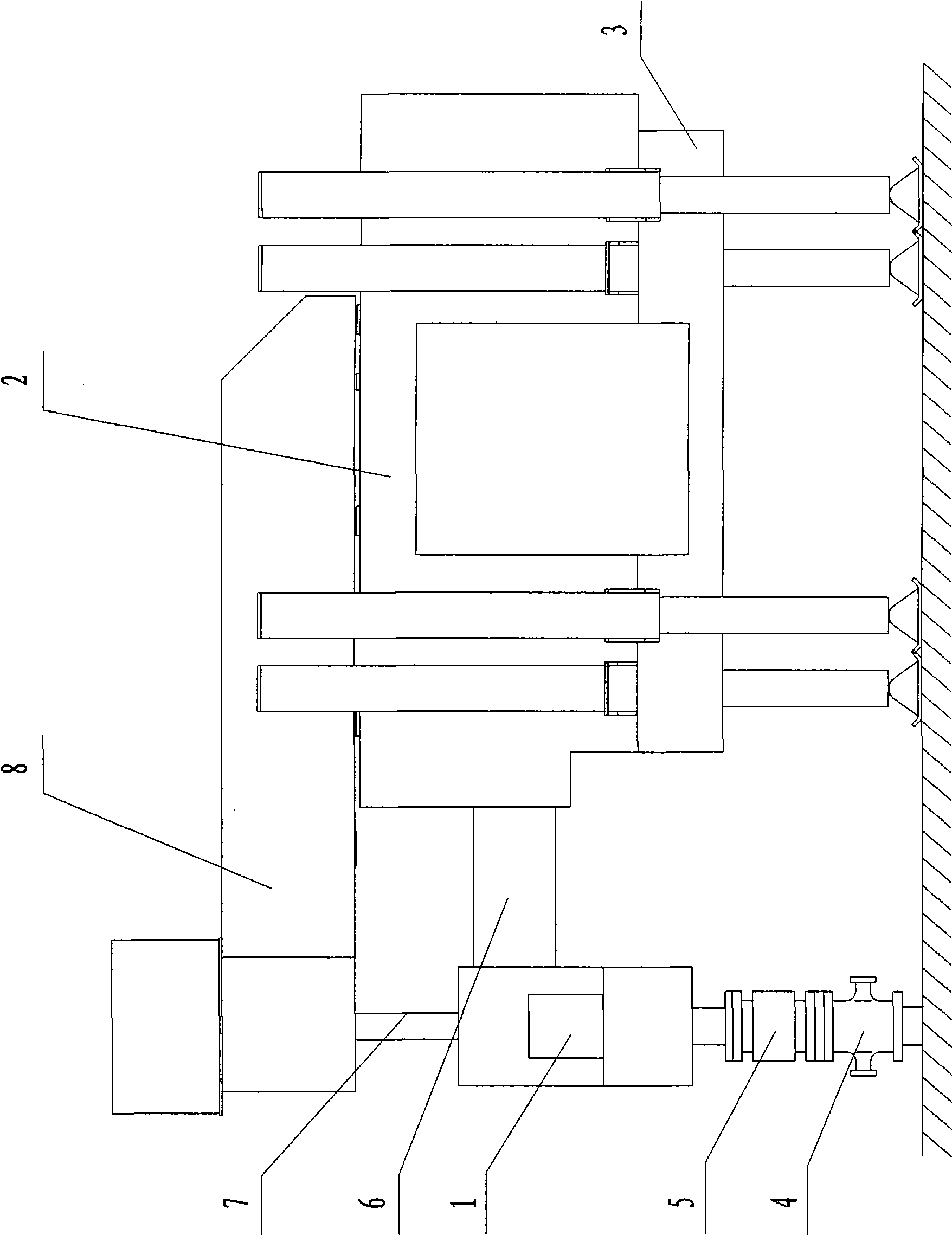

Vertical-surface grinding system for tableware machining

ActiveCN102825525AImprove machining accuracyIncrease productivityKitchenware cleanersBelt grinding machinesMachining processSurface grinding

The invention relates to the field of machining tableware, and in particular relates to a vertical-surface grinding system for tableware machining. The vertical-surface grinding system comprises an elliptical rotary material flow device, wherein two parallel positive and reverse grinding stations are arranged on two sides of the rotary material flow device, and another two relative semicircular stations of two ends are respectively a feeding station and an overturning station. Through the vertical-surface grinding system disclosed by the invention, the vertical-surface grinding machining of different side surfaces is carried out on different stations, and the whole vertical-face grinding machining process is subdivided, so that the machining precision is improved, and the integral grinding degree is excellent; in addition, when the vertical-surface grinding machine unit, a feeding machine and a secondary lifting overturning machine are arranged at the different stations, the whole process flow is operated without manpower, not only is the machining precision effectively improved, the integral grinding is complete, the production efficiency is improved and production accidents are avoided.

Owner:TIANJIN TTX GROUP

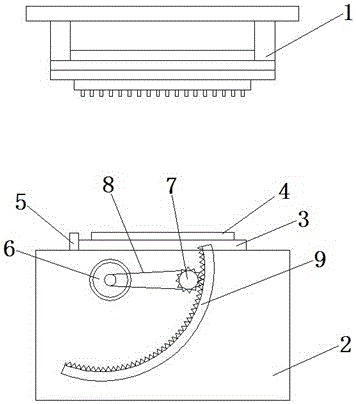

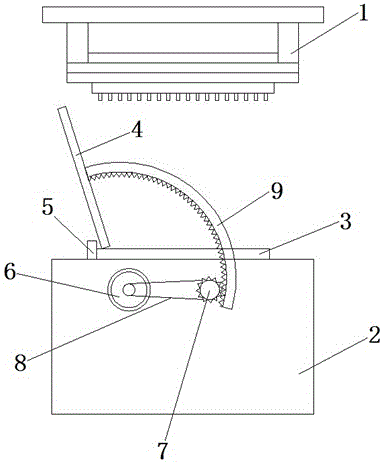

Lower mold stripping mechanism for automobile

ActiveCN106216510APrevent slippingGuarantee the safety of lifeShaping toolsEjection devicesEngineeringStamping process

The invention discloses a lower mold stripping mechanism for an automobile. The lower mold stripping mechanism comprises an upper mold assembly and a lower mold assembly which correspond to each other. The lower mold assembly is composed of a lower mold box and a lower mold base arranged on the lower mold box. A stripping mechanism is arranged in the lower mold box and comprises a motor, a transmission gear and an arc-shaped rack which are arranged in the lower mold box. The transmission gear is in transmission connection with the arc-shaped rack. A center shaft is arranged on the transmission gear. The center shaft of the transmission gear is in transmission connection with an output shaft of the motor through a belt. The portion, in contact with the lower mold base, of the top of the lower mold box is provided with an opening out of which the arc-shaped rack can extend. One side of the lower mold base is provided with an arc-shaped through hole the same as the arc-shaped rack in radian. A check block is arranged at the position, on the other side of the lower mold base, of the lower mold box. By the adoption of the lower mold stripping mechanism for the automobile, no manual operation is needed in the whole stamping process of automobile workpieces, and the lower mold stripping mechanism is safe and efficient.

Owner:GUANGDONG JINGRONG TECH HLDG CO LTD

Wellhead lifting-clamping device

InactiveCN101545360ASimple structureImprove production safetyDrilling rodsDrilling casingsEngineeringManipulator

The invention relates to oilfield workover equipment, in particular to a wellhead lifting-clamping device used on an oilfield workover manipulator. The device comprises a shell, two sets of push rods, a claw and a positioning hook, wherein the claw which can be reset is hinged on the shell; a claw slider is arranged on the claw; the positioning hook which can be reset is hinged on the shell and is positioned above the claw slider; and the two sets of push rods are arranged on the shell outside the claw and the positioning hook respectively. The self of the device carries no power source and needs to be turned on and off through the cooperation of an elevator-unlocking device and an elevator-locking device outside, thereby greatly simplifying the structure of the lifting-clamping device, canceling a long gas pipe which is arranged on a pneumatic elevator and moves together with the elevator, reducing accident potential and helping to the safe production of oilfield. As the two sets of push rods are arranged on two sides, the elevator can be automatically unlocked and locked under the push of the elevator-unlocking device and the elevator-locking device outside. Through the fast replacement of claw clamp-heads with different specifications, the wellhead lifting-clamping device can lift up and put down oil pipes different in pipe diameter and oil-pumping rods different in size.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION +1

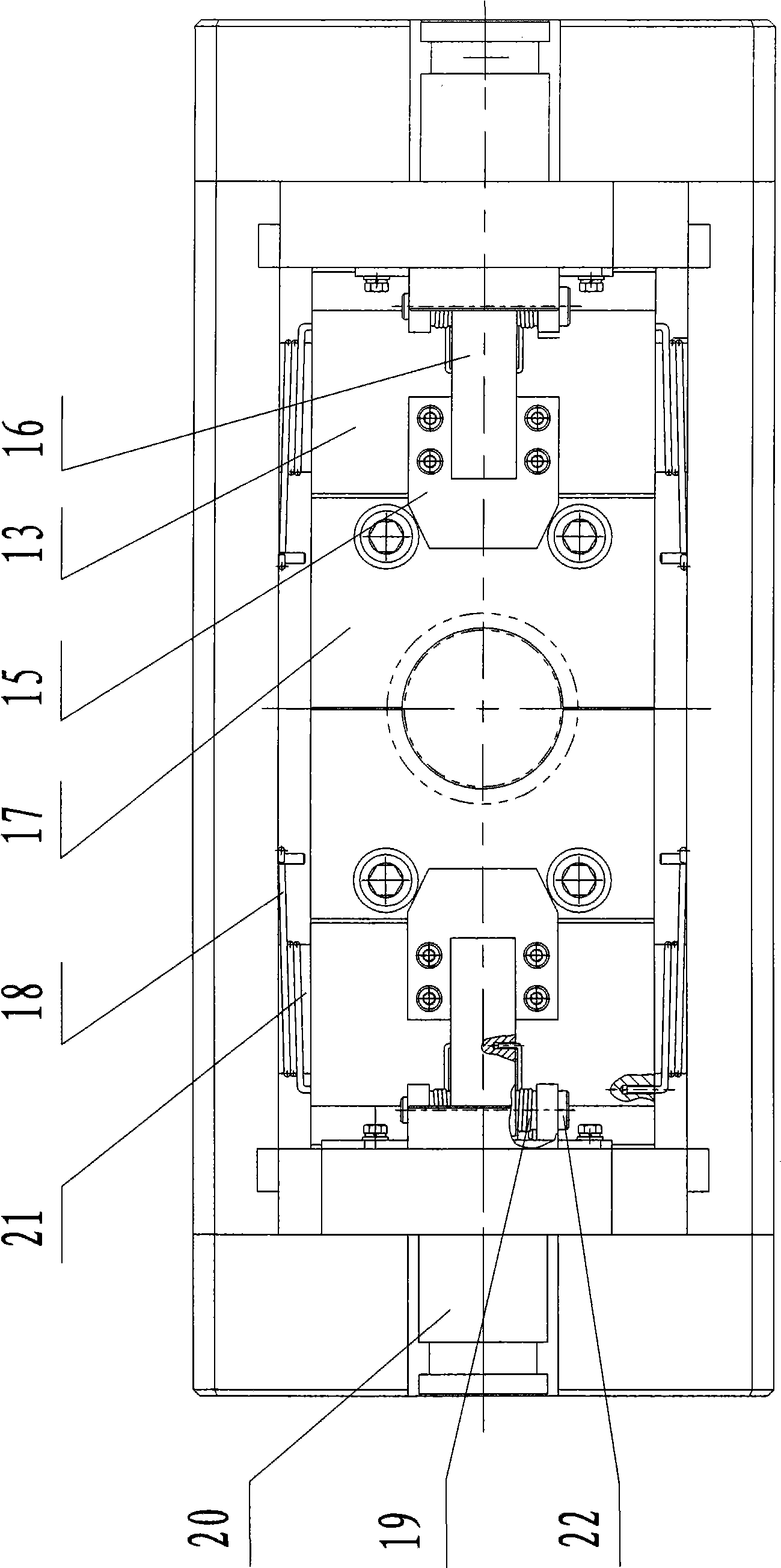

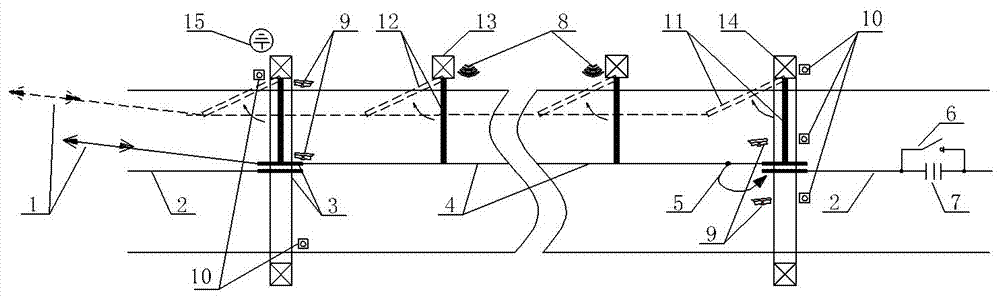

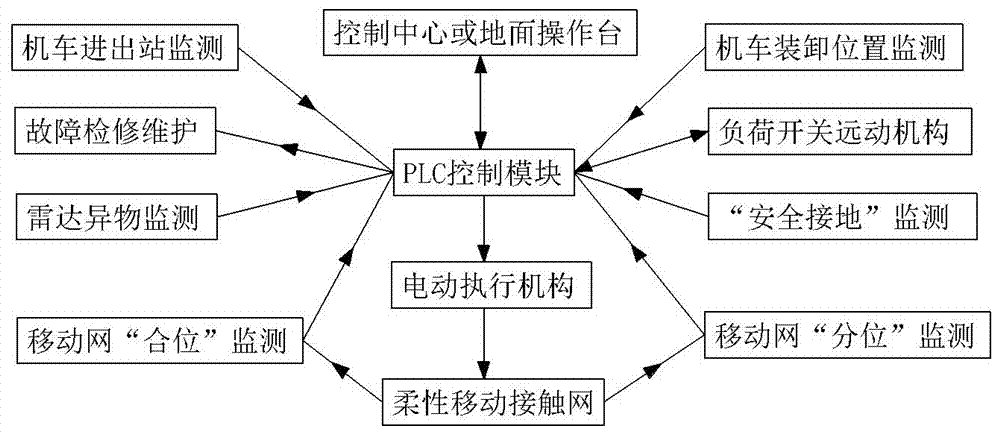

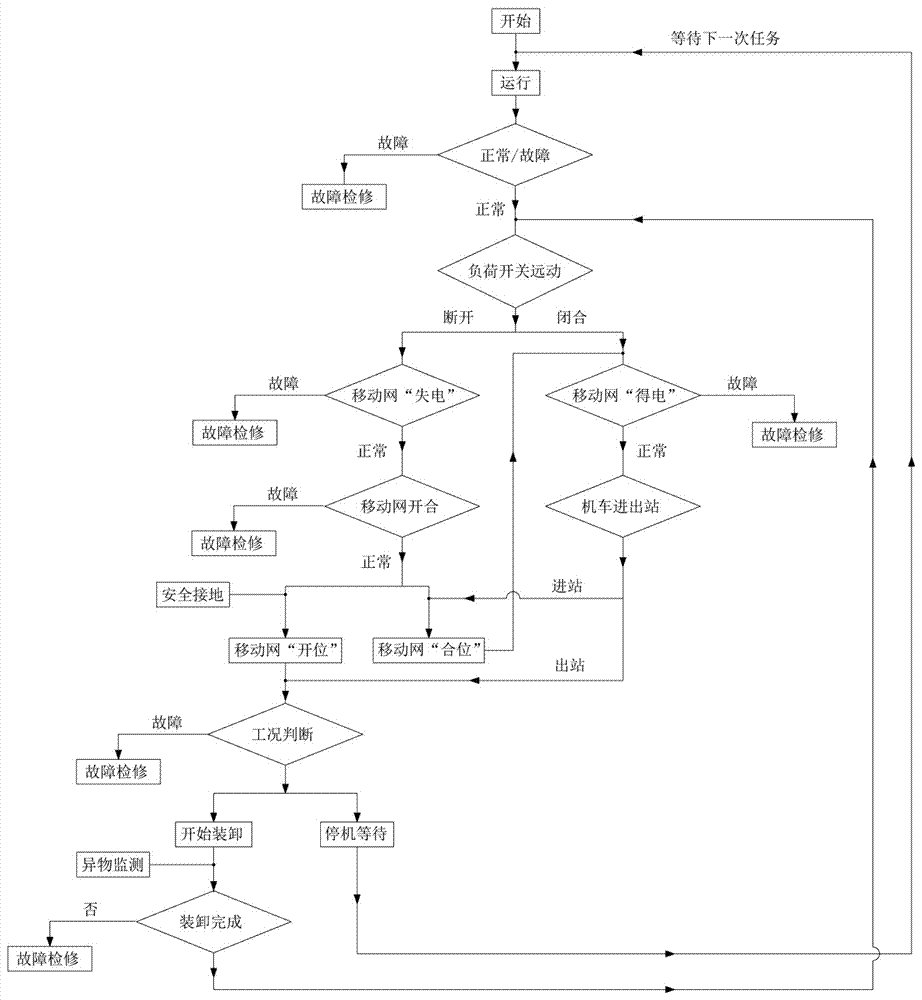

Horizontal rotation and flexible movement contact network control system and method thereof

ActiveCN107082031AMake sure the tension is constantGood followabilityTrolley linesVideo monitoringContact network

The invention relates to a horizontal rotation and flexible movement contact network control system and a method thereof. At a terminal, a mobile flexible contact network adopts an unilateral constant-tension compensation balance weight for carrying out tension compensation; at an initial end, a motor serves as a power mechanism to drive a power rotating cantilever to horizontally rotate so as to drive the mobile flexible contact network to be opened or closed; and at a middle end and a transition end, the horizontally rotated cantilever serves as a rotating assist so as to realize horizontal lateral displacement of the mobile flexible contact network. Automatic safety interlocking control of the whole processes is completed by virtue of a PLC (Programmable Logic Controller) as well as middle end and transition end radars, initial end and transition end video monitors, an initial end position sensor, a transition end grounding detection sensor, a load switch for fixing the flexible contact network and an initial end motor which are communicated with the PLC, thereby solving the problems that the cantilever structure suffers large lifting force, the flexible hanging mobile contact network has no tension compensation in the movement process, a following mechanism is uneven in stress and the synchronism is poor.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

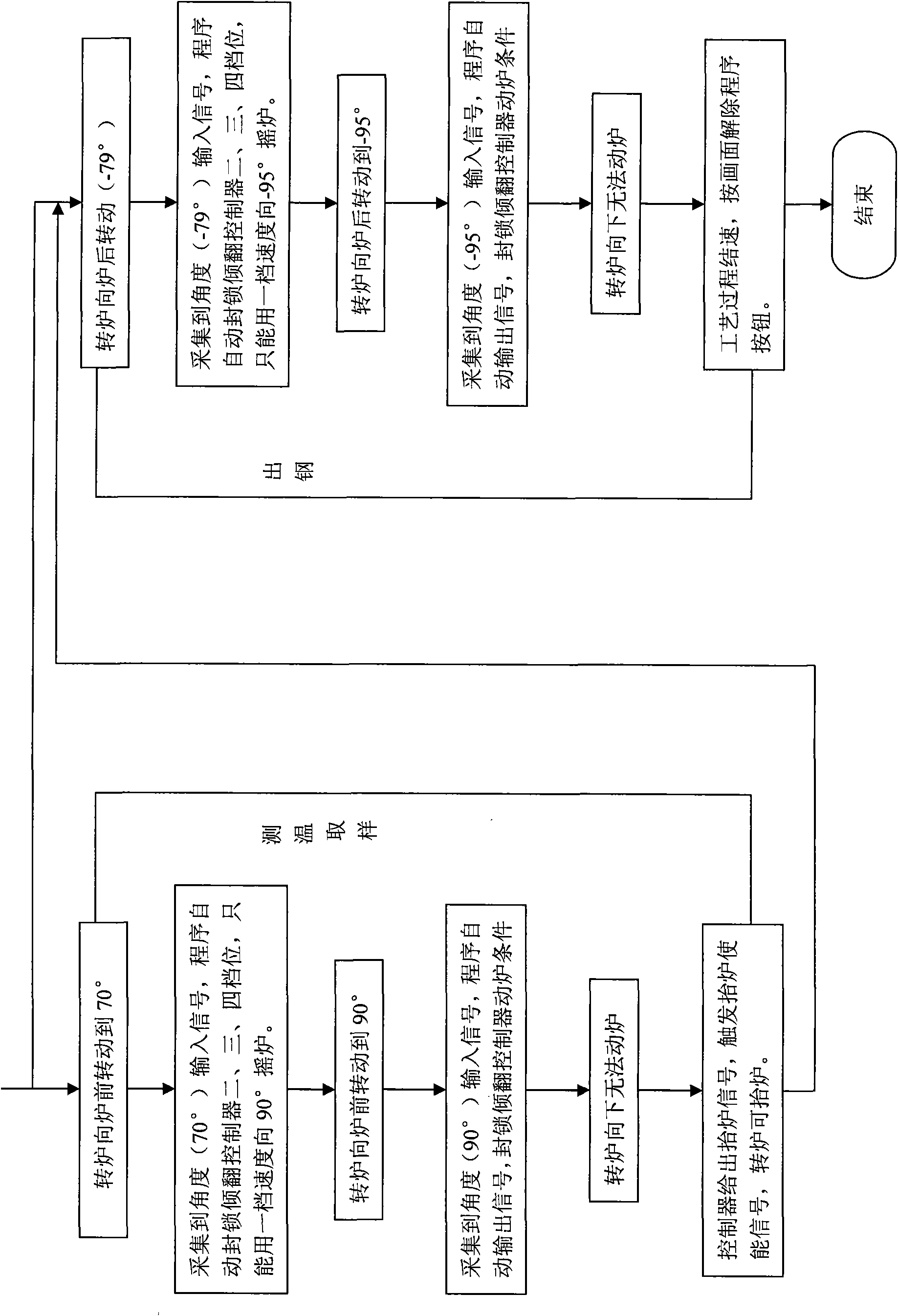

Method for preventing converter from dumping steel

ActiveCN101684509AAvoid production accidentsFull Control of Steelmaking OperationsManufacturing convertersEngineeringAutomation

The invention relates to the technical field of steel-making automation, in particular to a method for preventing a converter from doumping steel. Through the control of a PLC, the steel dumping prevention is realized by carrying out corresponding blocking on the gear positions of second, third and fourth gears of a dumping controller of the converter, a numerical controller enabling and switching-off ports; when a system carries out the sampling and slagging of a rocking furnace in front of the converter or when an angle goes to steel tapping area behind the converter, the enabling signals ofthe dumping second, third and fourth gears are blocked from transmitting to the numerical controller, so that the converters in the two areas only can work at first-gear speed, no matter which gearsthe controller is set at; during sampling in front of the converter or tapping steel behind the converter, when reaching a certain angle point in a heavy state, the converter is prevented form turningdown. The invention has the advantages that the technology can control steel making operation completely, automatically realize safe linkage of converter rotating, turning down and tapping, achieve asafe and effective automatic operation, and avoid production accidents caused by steel-making disoperation, instead of equipment faults.

Owner:ANGANG STEEL CO LTD

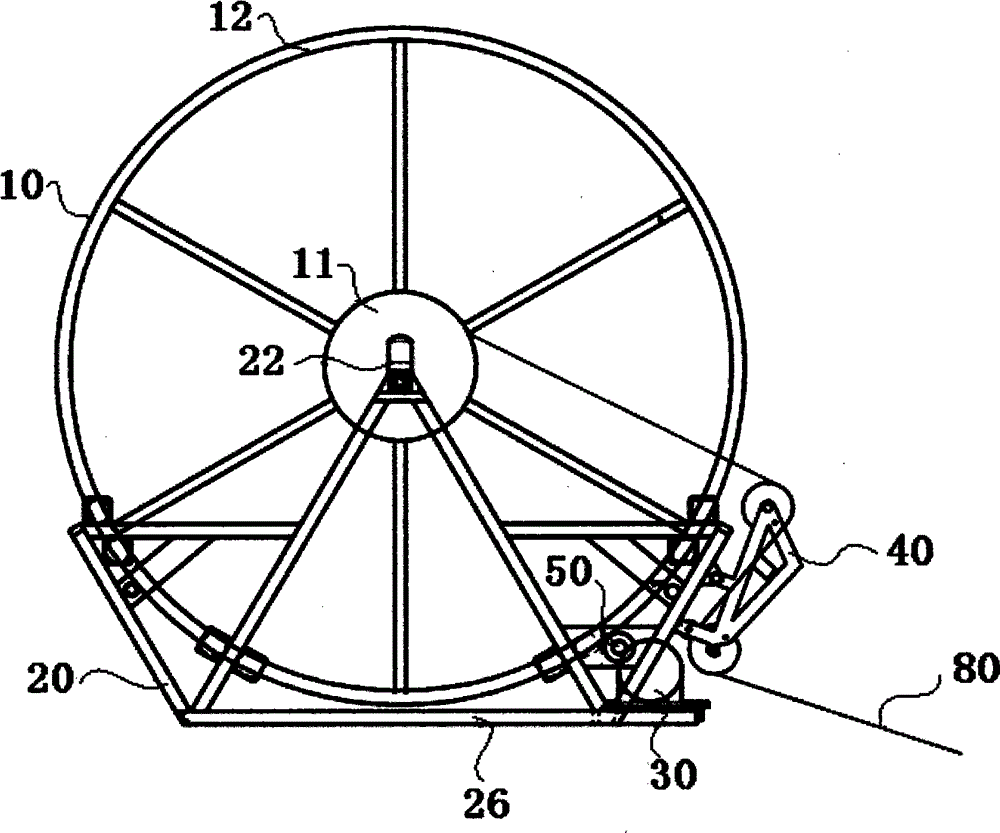

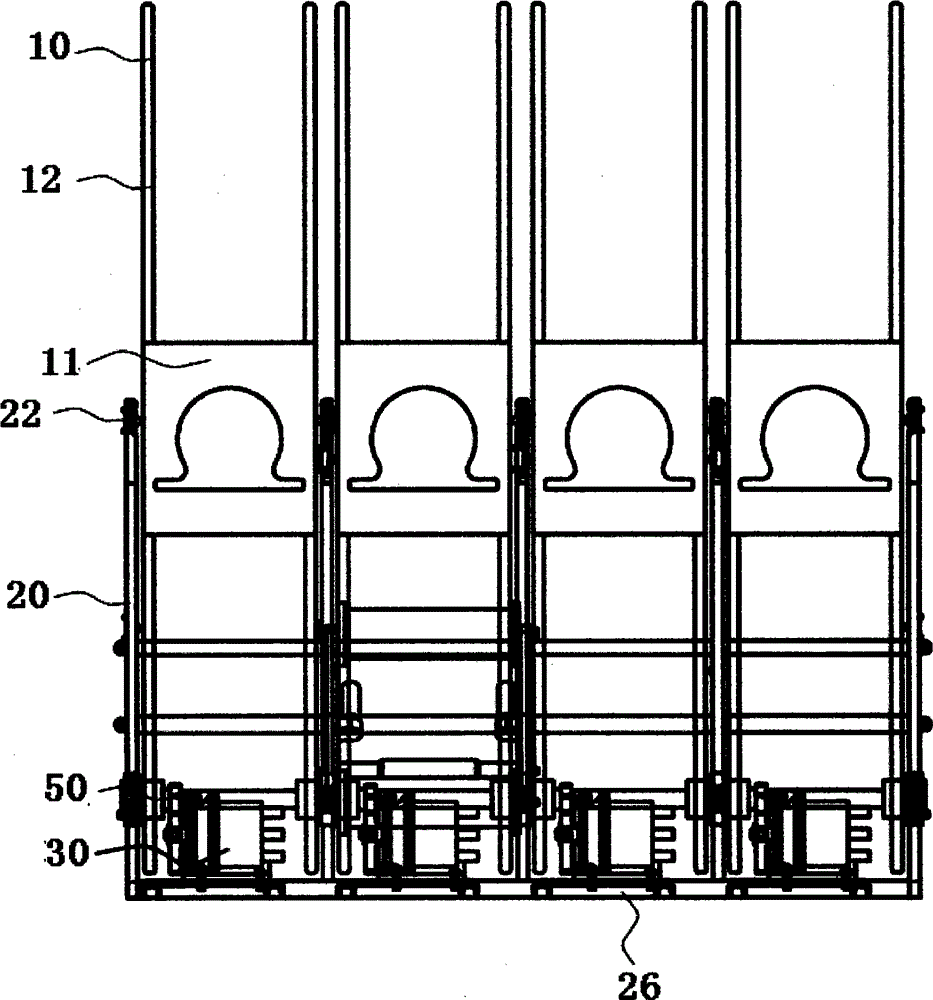

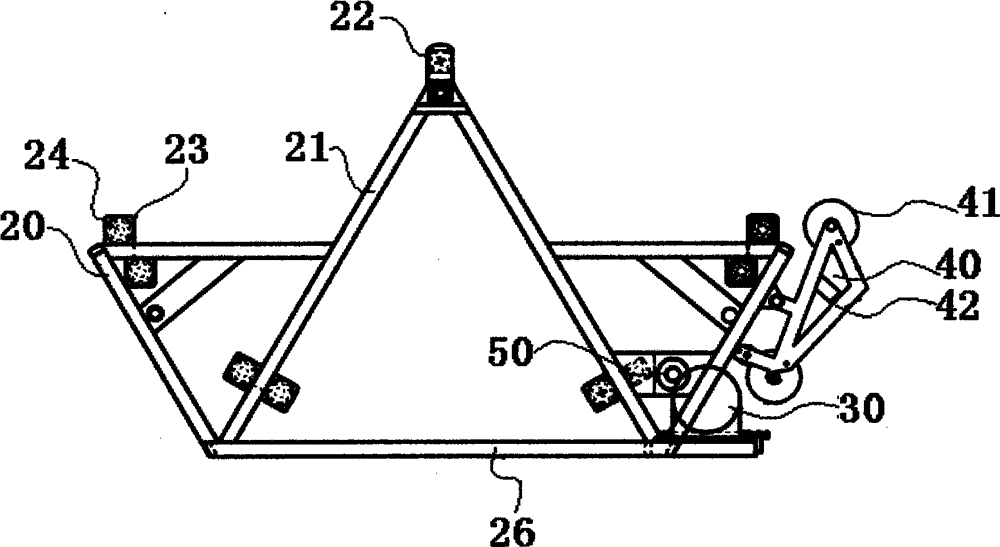

Automatic large-diameter pipe deploying and retracting system and transport cart

The invention provides an automatic large-diameter pipe deploying and retracting system and a transport cart. The automatic large-diameter pipe deploying and retracting system comprises coiling blocks used for winding pipes and each composed of two rims and a wheel shaft connected with the two rims, a storage rack providing containing positions for the multiple coiling blocks, a driving source used for driving each rotary mechanism, and a power source used for providing power for the driving source and separated from the storage rack, wherein the storage rack comprises multiple containing spaces separated by multiple interval frameworks; the interval frameworks are provided with clamping bases for fixing the coiling blocks in the containing spaces in a suspending mode by clamping the two ends of the wheel shafts of the coiling blocks; the storage rack is provided with the rotary mechanisms used for driving the coiling blocks suspended in the containing spaces. As the storage rack is provided with the multiple coiling blocks capable of being operated independently, the deploying and retracting operation of multiple pipes can be achieved. The power element and the execution element are separated on a large span, so that an oil-gas source and the power element are separated, and production accidents are avoided.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

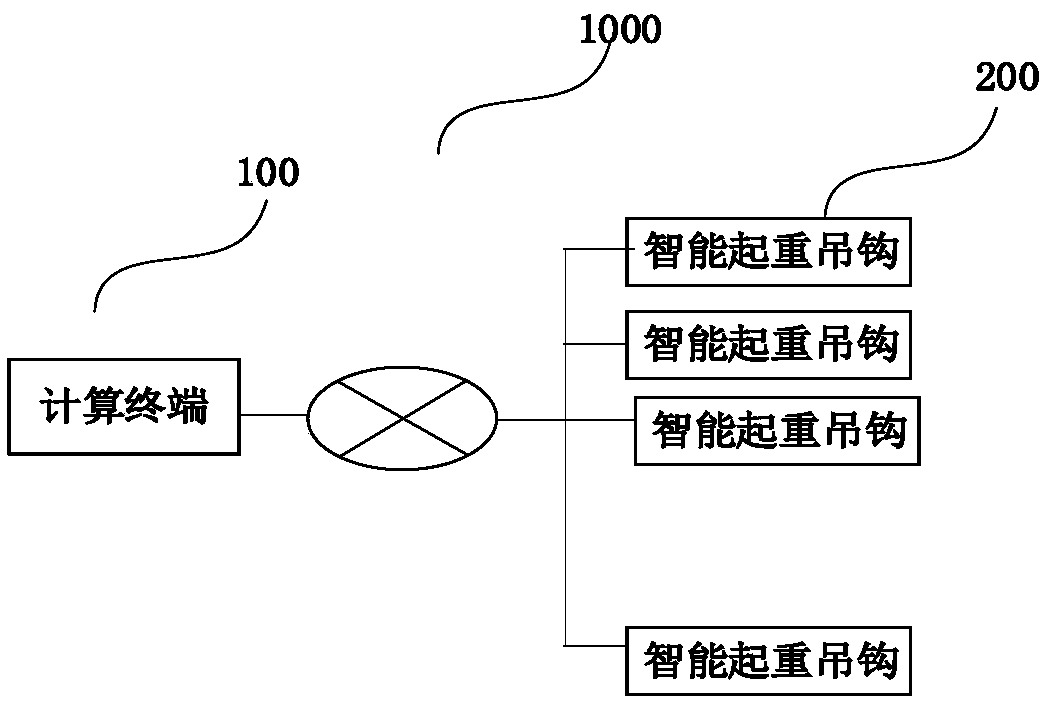

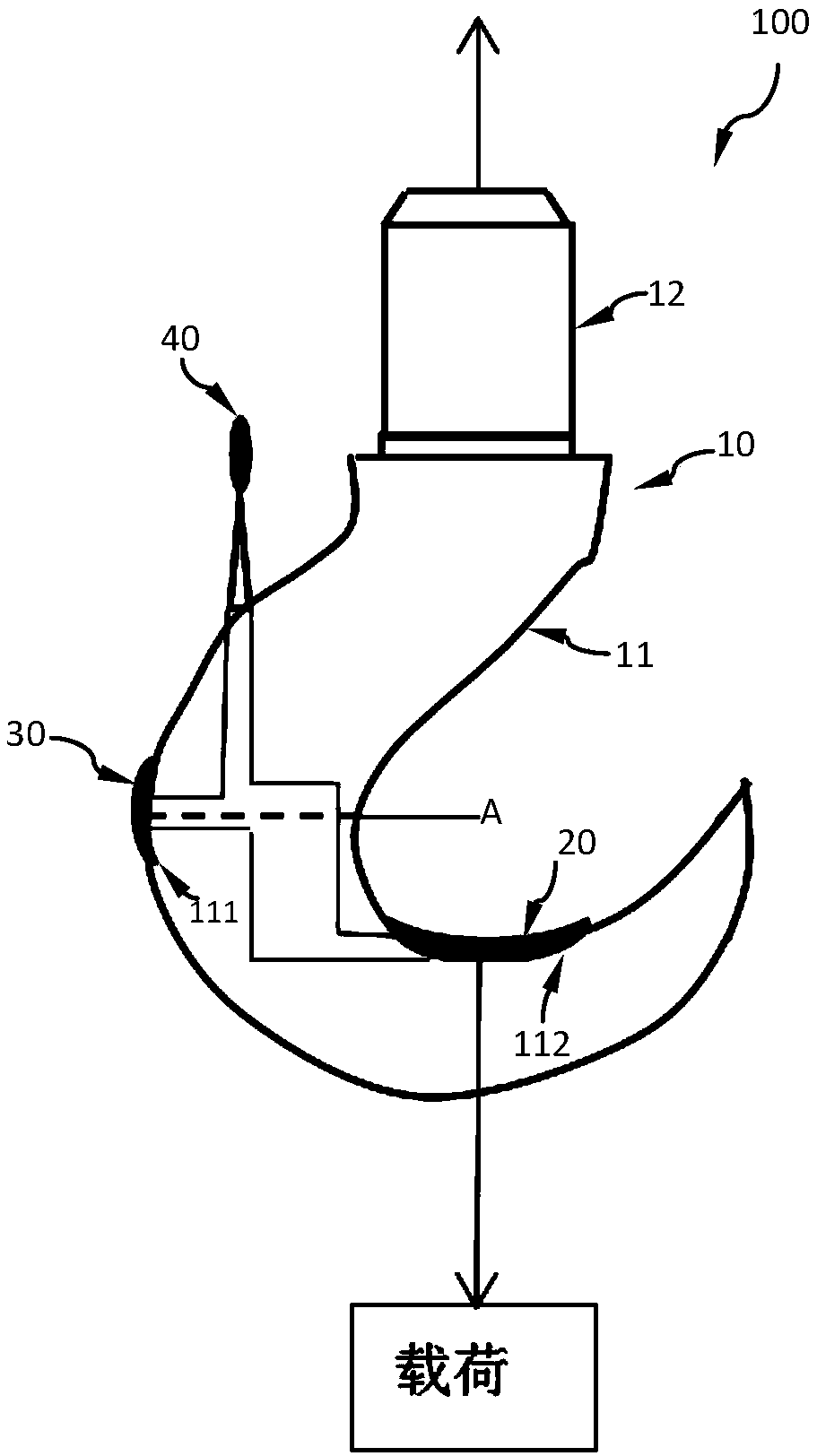

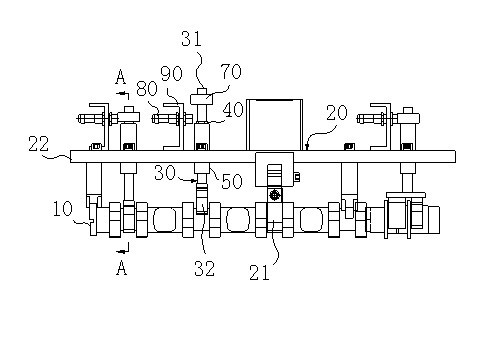

Intelligent lifting hook, monitoring system and using method of intelligent lifting hook

PendingCN108750926AAvoid production accidentsRealize intelligenceBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesMonitoring systemComputer terminal

An intelligent lifting hook comprises a lifting hook body, a power supply unit, a strain measurement unit and a data transmission unit, wherein the lifting hook body is provided with a bent hook partfor hooking and lifting loads, and the outer side wall of the bent hook part is provided with an installation sunken part; the power supply unit is arranged on the lifting hook body and used for supplying power; the strain measurement unit is fixedly installed on the installation sunken part, connected with a power supply unit circuit and used for measuring the strain borne by the bent hook part;and the input end of the data transmission unit is connected with a strain measurement unit circuit so that a strain signal can be received, and the output end of the strain measurement unit is in communication connection with an external computing terminal so that the stain signal can be transmitted to the computing terminal. The intelligent lifting hook is connected with the external computing terminal so that whether the lifting hook is overloaded, and whether the stress of the lifting hook is within the safety range or not can be controlled and monitored, production accidents caused by damage to the lifting hook or overload are prevented, and through strain changing, compared with the actual workload of a certain external intelligent lifting hook, intelligentization of a common liftinghook is achieved. Meanwhile, the invention further provides a monitoring system and a using method of the intelligent lifting hook.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Device for detecting qualifying diameter dimensions of shafts

ActiveCN102032851AAvoid production accidentsImprove stabilityMechanical diameter measurementsEngineeringElectrical and Electronics engineering

The invention belongs to the field of machining lines of shafts and in particular to a device for detecting and qualifying diameter dimensions of shafts. The device provided by the invention comprises a positioning mechanism, a measuring component and a limiting mechanism, wherein the positioning mechanism is used for being positioned with a measured shaft; the measuring component can move linearly; the measuring component moves horizontally along a guide mechanism; a reference part is arranged on the measuring component; the distance between the reference part and the shaft line of the measured shaft is matched with the standard value of the radius of the measured part of the measured shaft; and the limiting mechanism is used for limiting the nearest position of the measuring component. Because in the invention, the error correction is realized by depending on the physical measurement in a form similar to a go / no-go gauge, the device has the advantages of good stability and high error correction efficiency and can effectively avoid the occurrence of production accidents.

Owner:CHERY AUTOMOBILE CO LTD

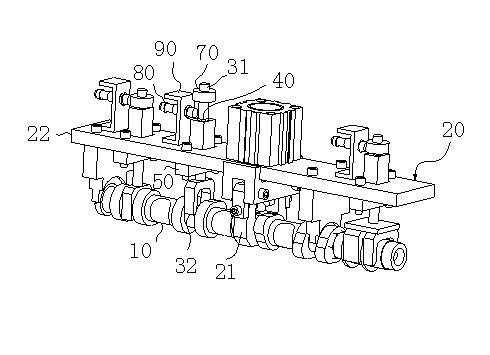

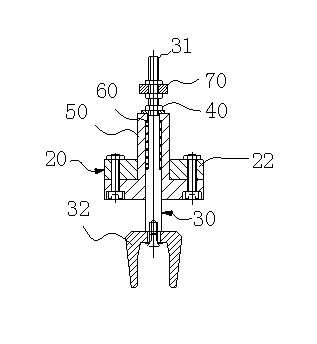

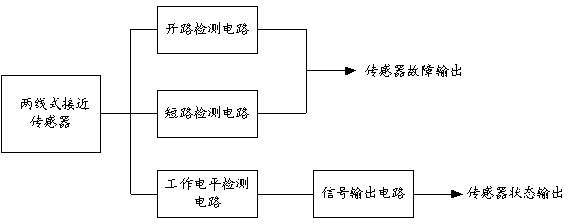

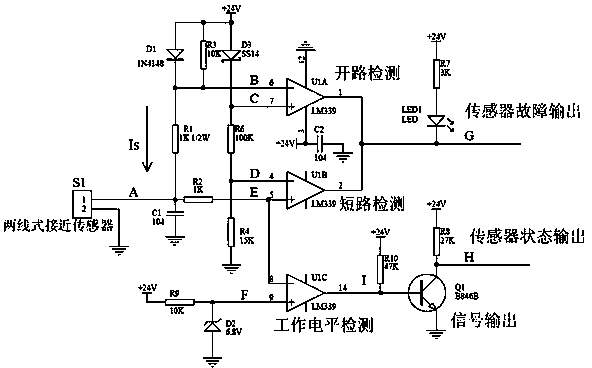

Direct-current two-wire type proximity sensor fault detection circuit

ActiveCN104266672ASolve the failure of judging the sensorAvoid production accidentsInstrumentsProximity sensorEngineering

The invention provides a direct-current two-wire type proximity sensor fault detection circuit. By detecting working currents of a two-wire type proximity switch sensor, the working condition and open and short circuit faults of the sensor are judged, corresponding signals are output, and therefore the problems that sensor faults cannot be judged by detection equipment, leakage currents exist in direct-current two-wire type proximity sensor output, residual voltage of signals causes unstable levels, and the detection equipment cannot identify the situation that the residual voltage of the signals causes the unstable levels are effectively solved. The direct-current two-wire type proximity sensor fault detection circuit can be arranged between the sensor and control equipment such as a PLC and used for outputting fault output signals to the PLC or an alarm system or other devices, actions of giving an alarm or conducting emergency shutdown are carried out on the sensor faults, and therefore production accidents caused by the sensor faults can be effectively avoided. Compared with the prior art, no residual voltage or leakage current exists in sensor signals processed by the direct-current two-wire type proximity sensor fault detection circuit, and compatibility is better.

Owner:深圳市伊爱高新技术开发有限公司

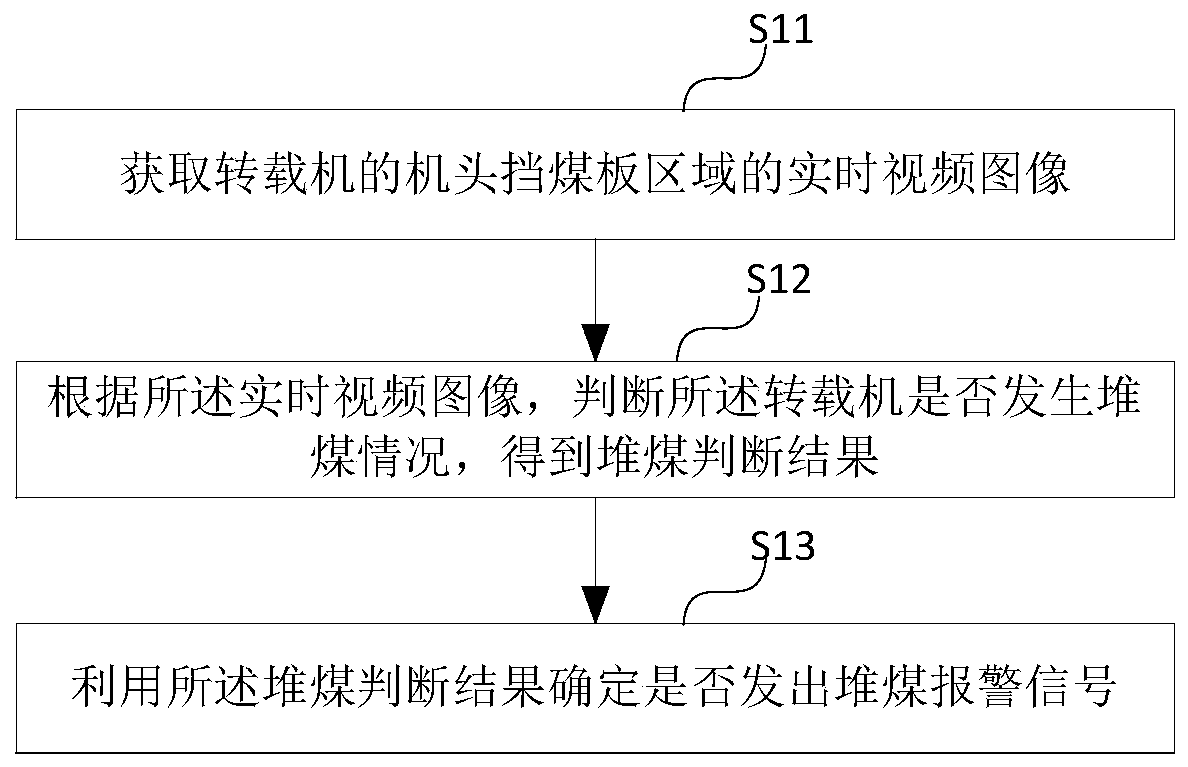

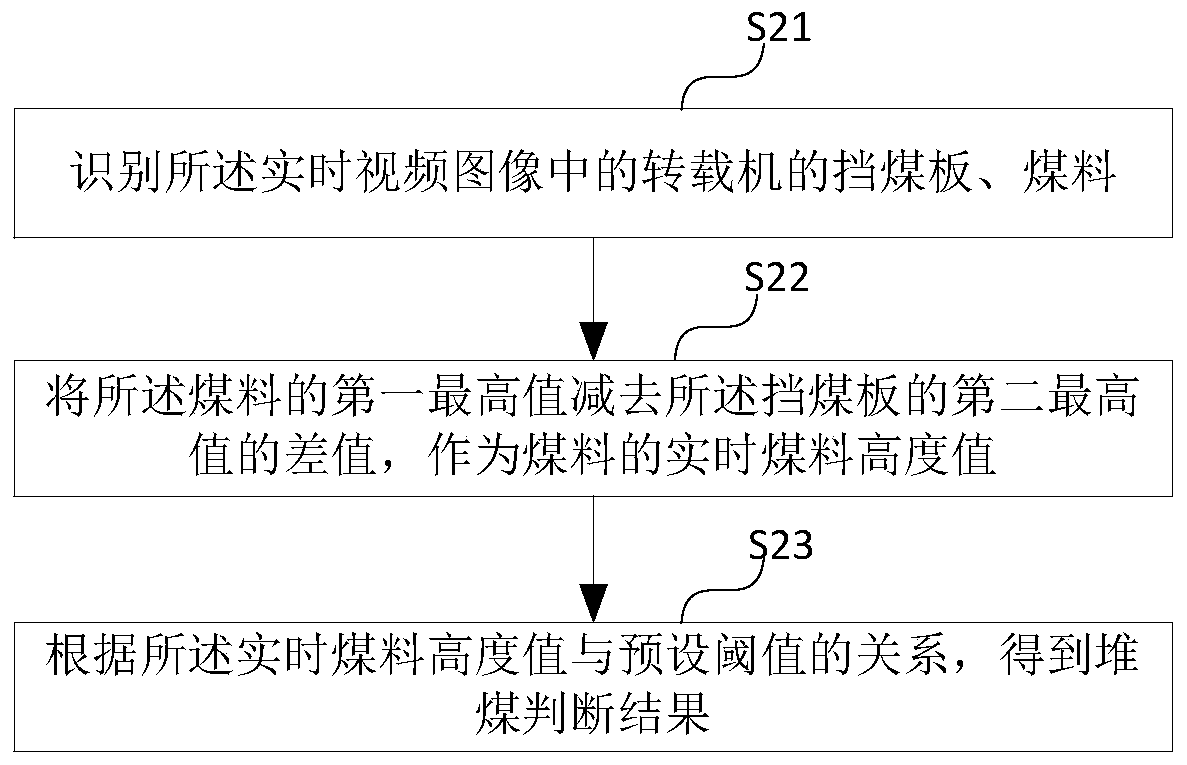

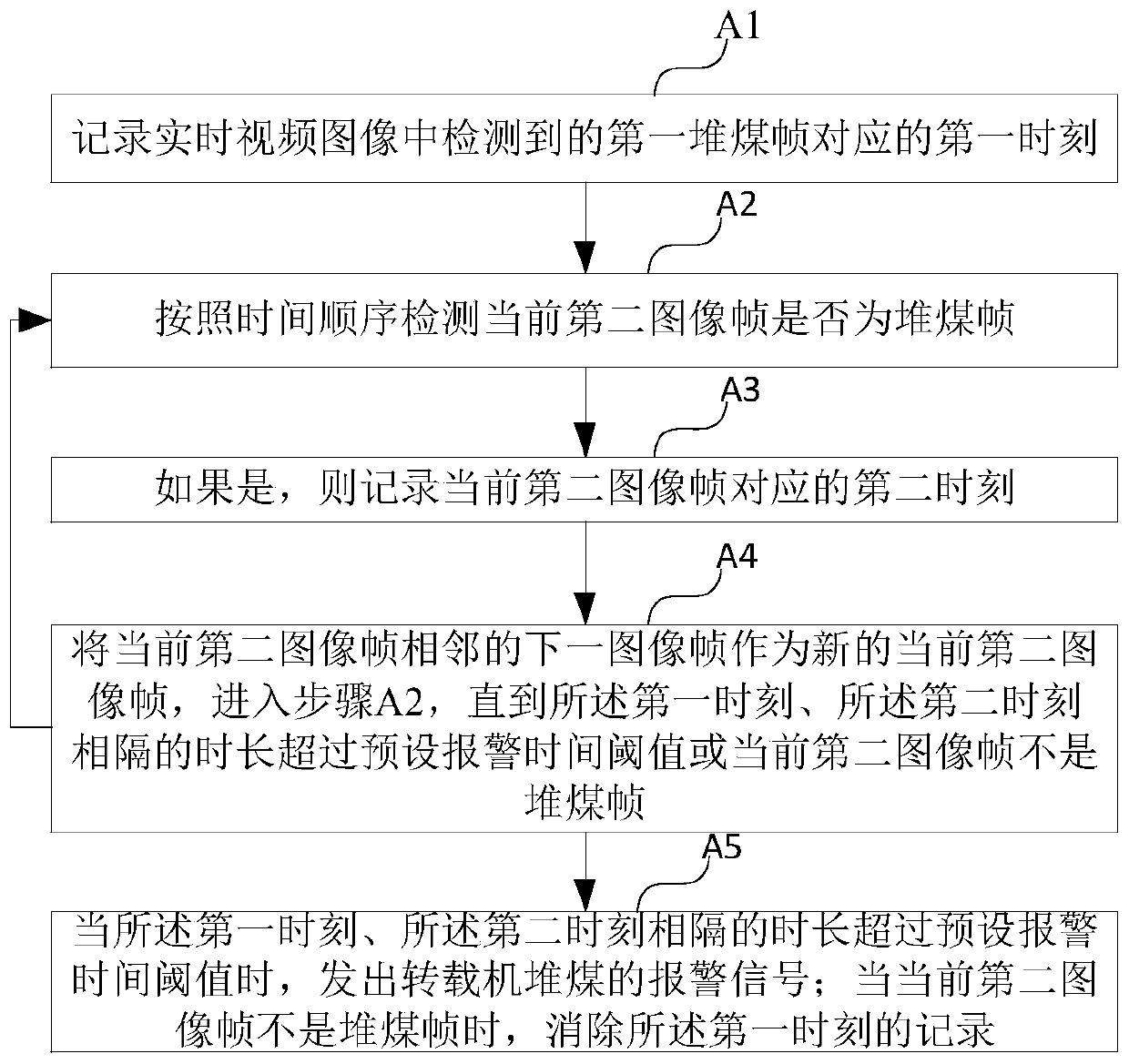

Coal piling safety alarm method, device and equipment for coal mine reversed loader and medium

ActiveCN110422589AAccurate identificationAccurate processingConveyorsControl devices for conveyorsComputer scienceCoal

The embodiment of the invention provides a coal pilling safety alarm method and device for a coal mine reversed loader, coal pilling safety alarm equipment for the coal mine reversed loader and a medium. The method comprises the following steps of acquiring a real-time video image of a coal blocking plate area of a machine head of the reversed loader; judging whether a coal piling condition occursin the reversed loader or not according to the real-time video image to obtain a coal pilling judgment result; and determining whether a coal pilling alarm signal is sent or not by utilizing the coalpilling judgment result. According to the coal piling safety alarm method for the coal mine reversed loader provided by the embodiment, the height of a coal pile is indentified according to the obtained video so that whether an alarm is given or not can be further judged. Compared with a mode that a special person is arranged at a feeding port of the reversed loader to monitor the feeding port state at all shifts and timely performs stopping treatment during coal pilling in the prior art, the coal piling condition of the coal mine reversed loader can be accurately identified, moreover, working personnel can be reminded to treat the coal piling condition, and the production accident is avoided.

Owner:JINGYING SHUZHI TECH HLDG CO LTD

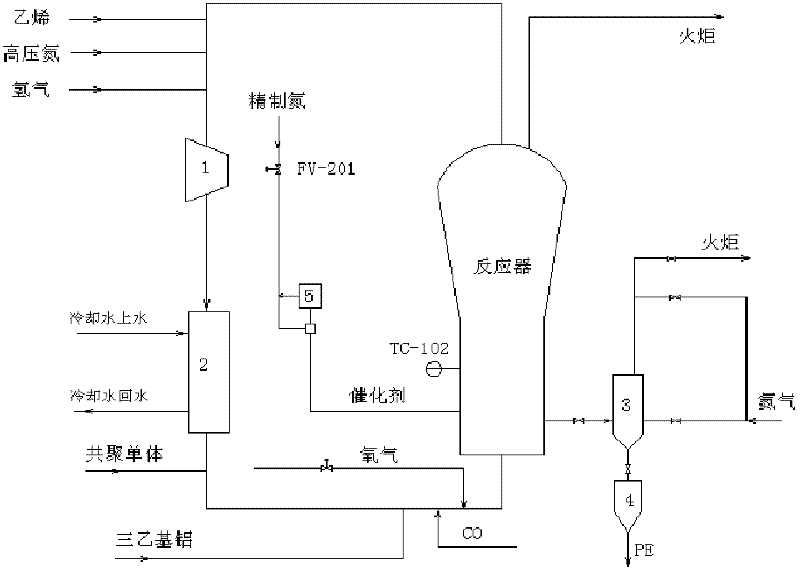

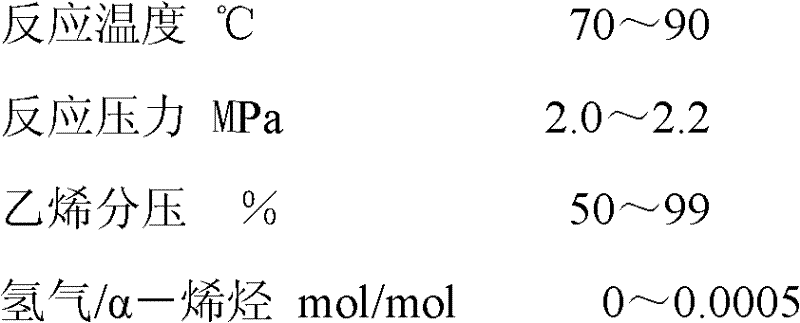

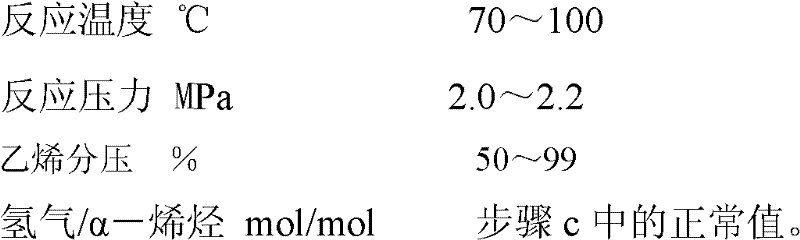

Method for quickly starting polymerization reaction in alpha-olefin gas-phase fluidized bed reactor

The invention relates to a method for quickly starting polymerization reaction in an alpha-olefin gas-phase fluidized bed reactor, belongs to a method for preparing alpha-olefin homopolymer or copolymer, and in particular relates to a method for preparing corresponding polymer by ethylene polymerization or copolymerization of ethylene and other alpha-olefins. The method is characterized by comprising the following steps of: displacing trace water in the gas-phase fluidized bed reactor by using nitrogen and ethylene, initiating to start alpha-olefin polymerization reaction or alpha-olefin copolymerization reaction by using a metallocene catalyst, switching to the conventional chromium catalyst alpha-olefin polymerization or alpha-olefin copolymerization reaction system, stopping adding the metallocene catalyst, and switching to the conventional alpha-olefin gas-phase fluidized bed reactor for polymerization reaction. By the method for quickly starting continuous polymerization reaction in the alpha-olefin gas-phase fluidized bed reactor, the trace water is quickly removed, time for establishing continuous and stable polymerization reaction is short, and the consumption of the ethylene for displacement is low; and production accidents are avoided, the consumption of the ethylene is reduced, and the production period is shortened.

Owner:CHINA PETROLEUM & CHEM CORP

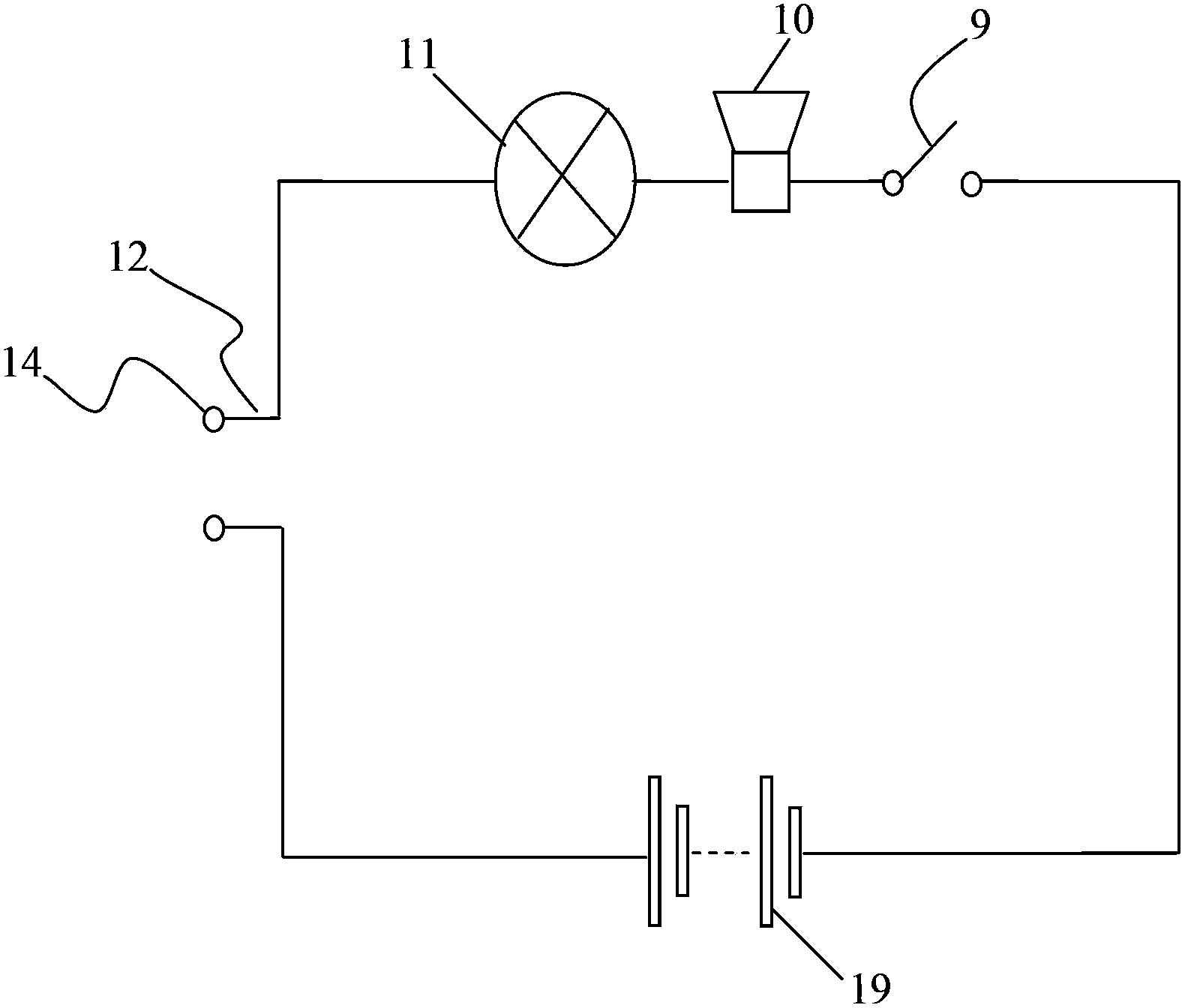

Tracking device for forecasting of slag discharge of continuous casting crystallizer and measuring of tonnage of tundish molten steel

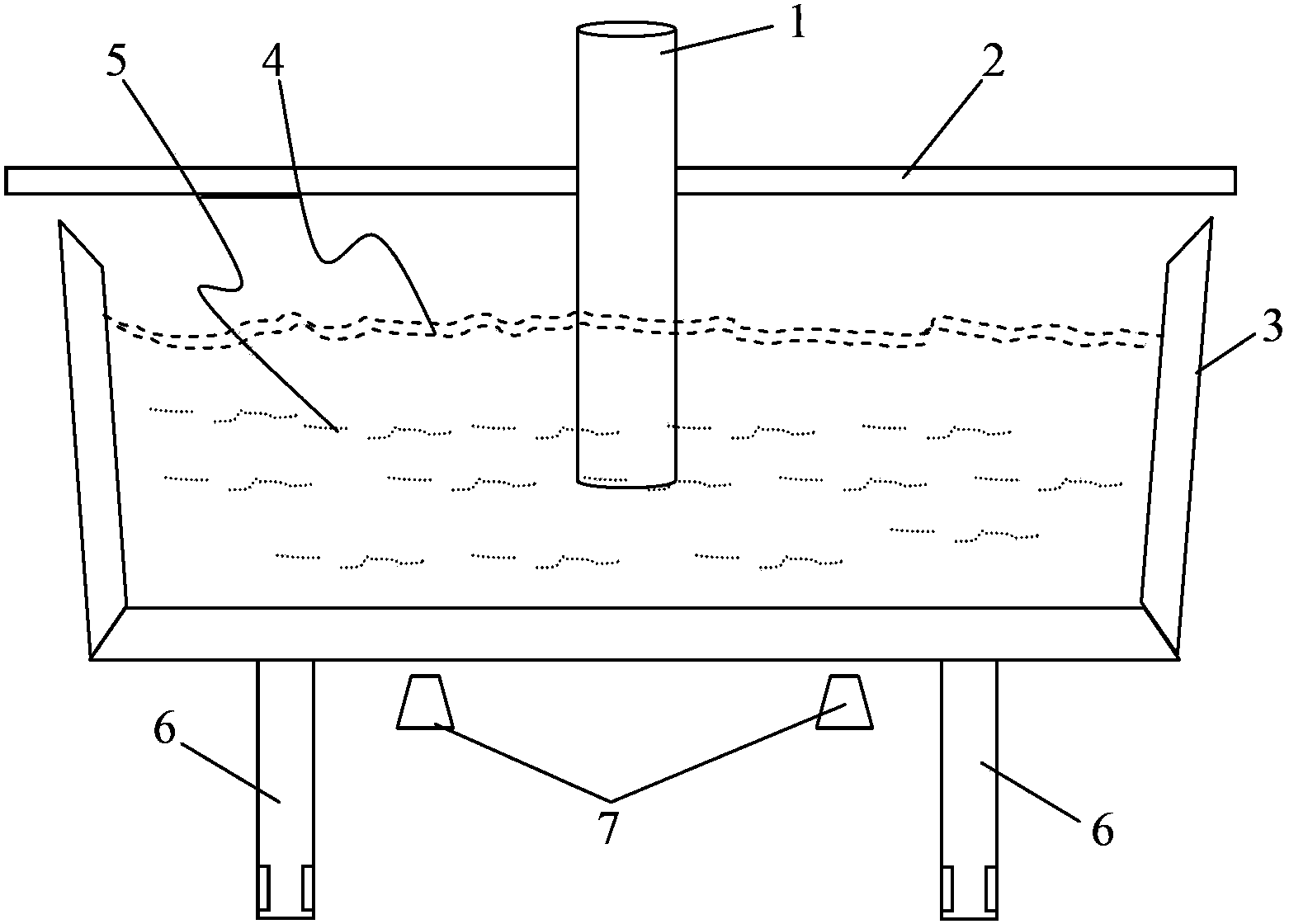

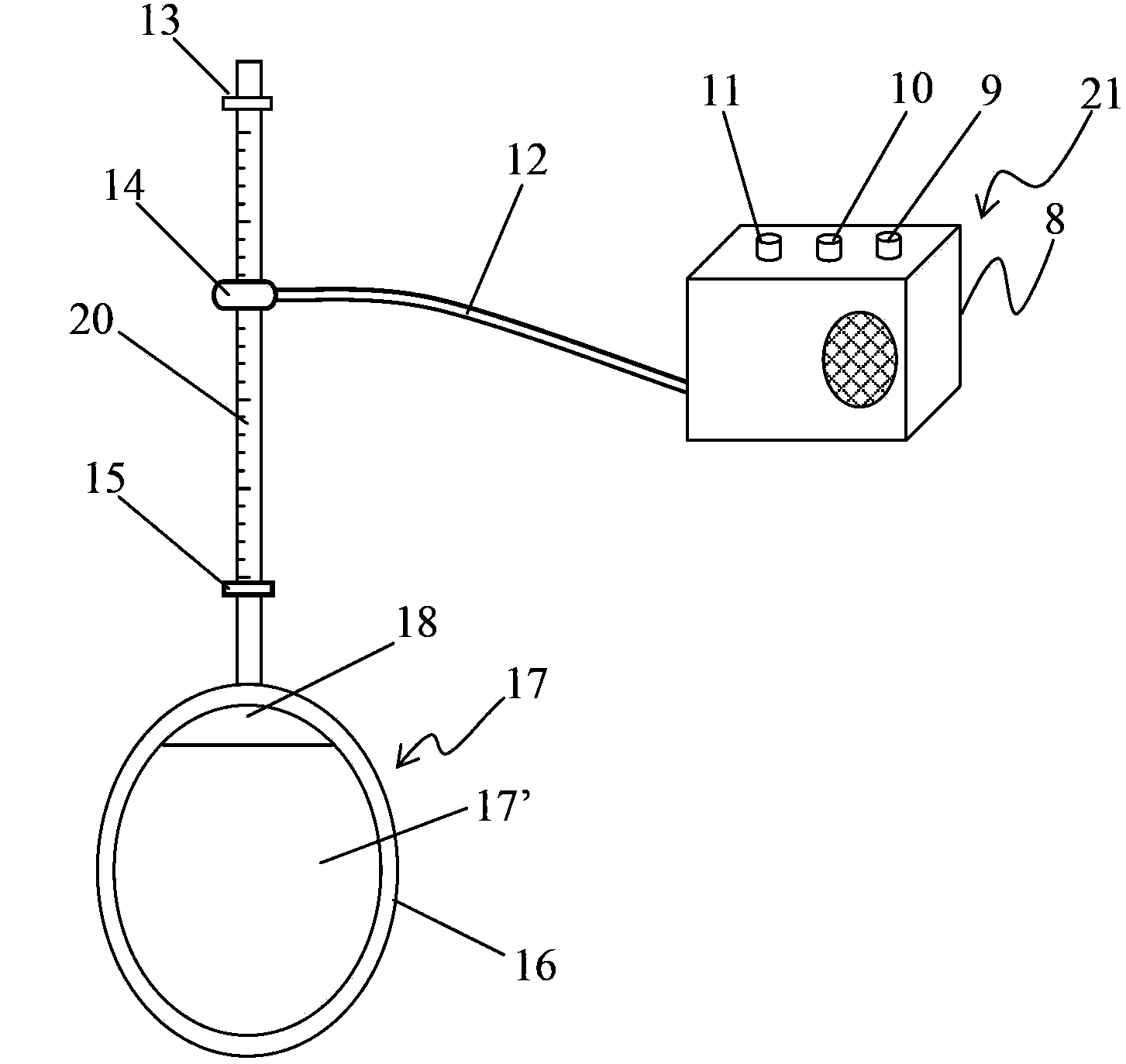

ActiveCN104043800AImprove accuracyAvoid interferenceCasting parameters measurement/indication devicesSlagTundish

The invention relates to a tracking device for forecasting of slag discharge of a continuous casting crystallizer and measuring of tonnage of tundish molten steel. The device comprises a scale, a steel ball and an alarming system, wherein the steel ball floats on the liquid level of molten steel, the lower end of the scale is connected with the steel ball, the scale is movably sheathed with a contact sheet, the upper and lower parts of the scale are respectively provided with an upper conductive metal sheet and a lower conductive metal sheet, the alarming system is electrically connected with the touch sheets via conducting wires, the alarming system comprises an alarming box, an alarming lamp, an alarming buzzer and an alarming switch, the alarming lamp, the alarming buzzer and the alarming switch are arranged on the alarming box, the contact sheets and the alarming lamp are connected by the conducting wires, the alarming lamp, the alarming buzzer and the alarming switch are sequentially and serially connected, and the switch is connected with a power source. The device has the advantages that the interference on the weight of molten steel by the steel slag and covering agent in a tundish is effectively avoided; the production accidents caused by the slag in the tundish flowing into the crystallizer is effectively prevented; the defect of high error of weighing numbers due to accumulation of garbage, dust and the like on a weighing press head is effectively overcome.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com