Wellhead lifting-clamping device

An elevator and jaw technology, applied in the field of wellhead elevator devices, can solve problems such as unfavorable safety production, and achieve the effects of simple structure, automatic lifting and lowering, and high production safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

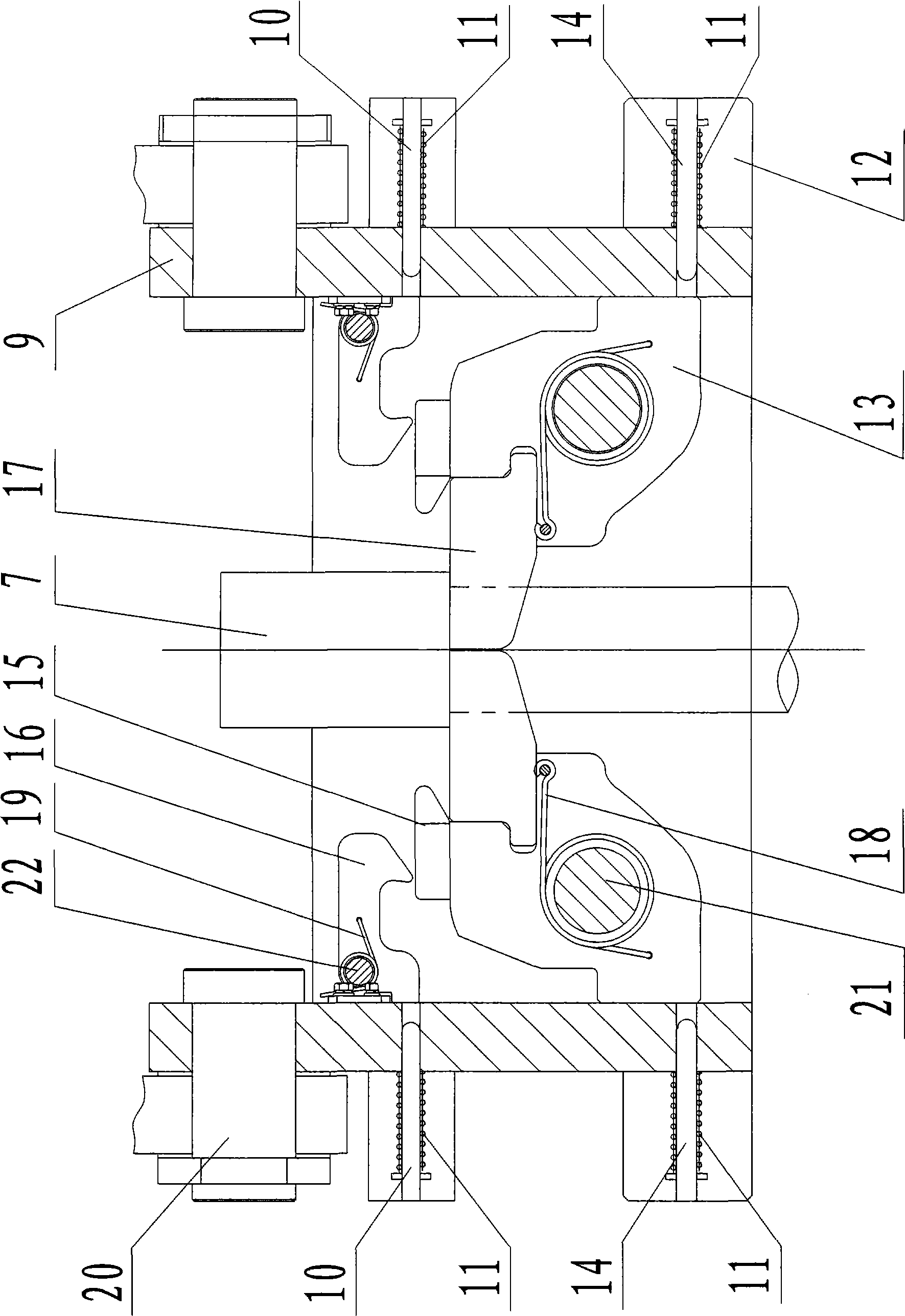

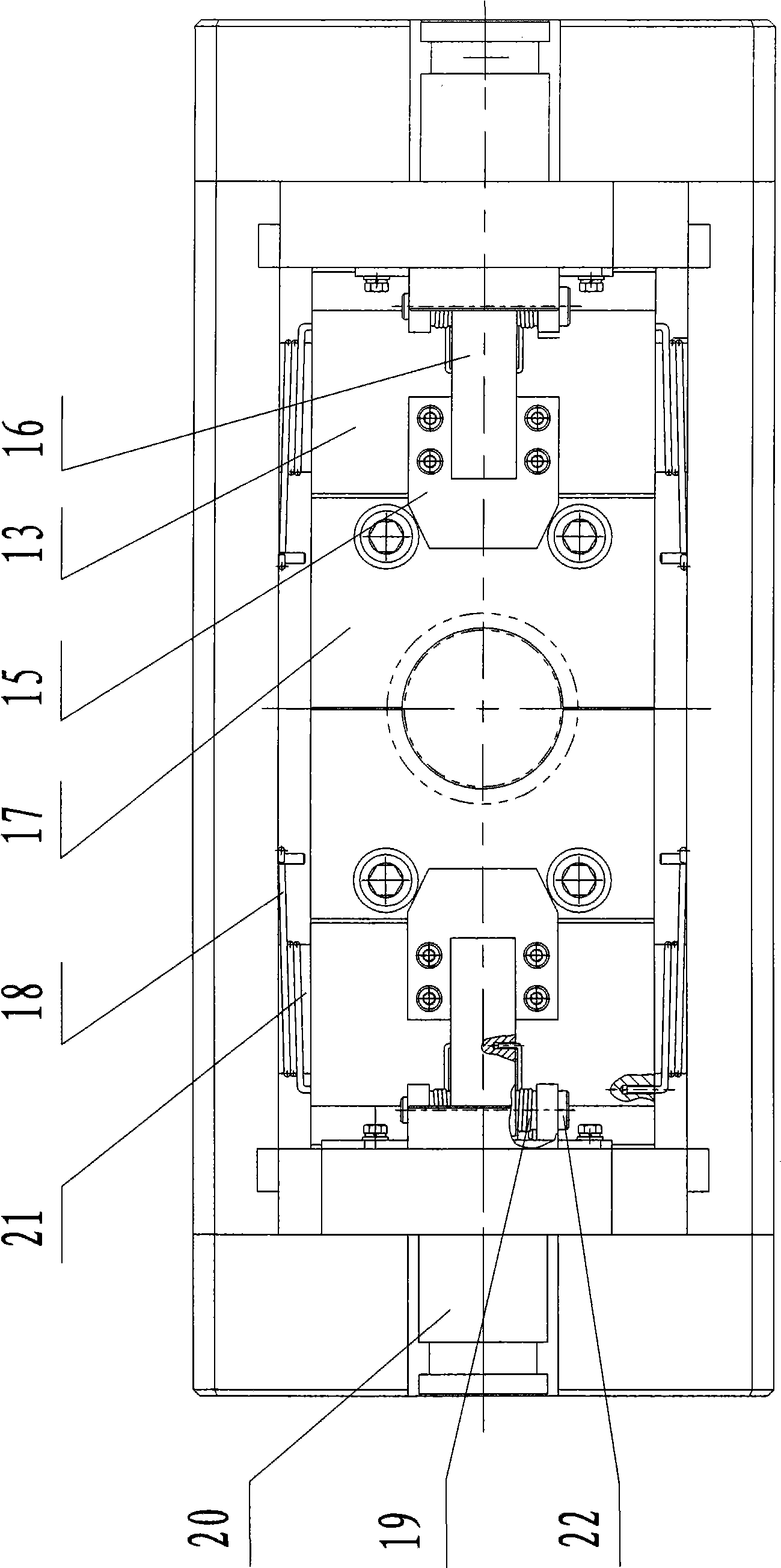

[0024] like figure 2 , image 3 As shown, the present invention includes housing 9, two groups of push rods, claws 13 and positioning hooks 16, wherein two groups of push rods are four in total, two are one group, that is, two first push rods 10 are one group, Two second push rods 14 form a group; there are two claws 13, which are arranged symmetrically with the axis of the housing 9. The claws 13 are installed in the housing 9 through the first shaft 21, and the claws 13 can rotate around the first axis. 21 rotation, both ends of the first shaft 21 are provided with claw torsion spring 18, provide the initial position for the claw 13 and reset the claw 13 after rotation; each claw 13 is fixed with a claw slide Block 15, the claw slide block 15 is located at the middle part of the claw 13 near the upper side of the oil pipe (sucker rod) 7, one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com