Patents

Literature

39439 results about "Manipulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

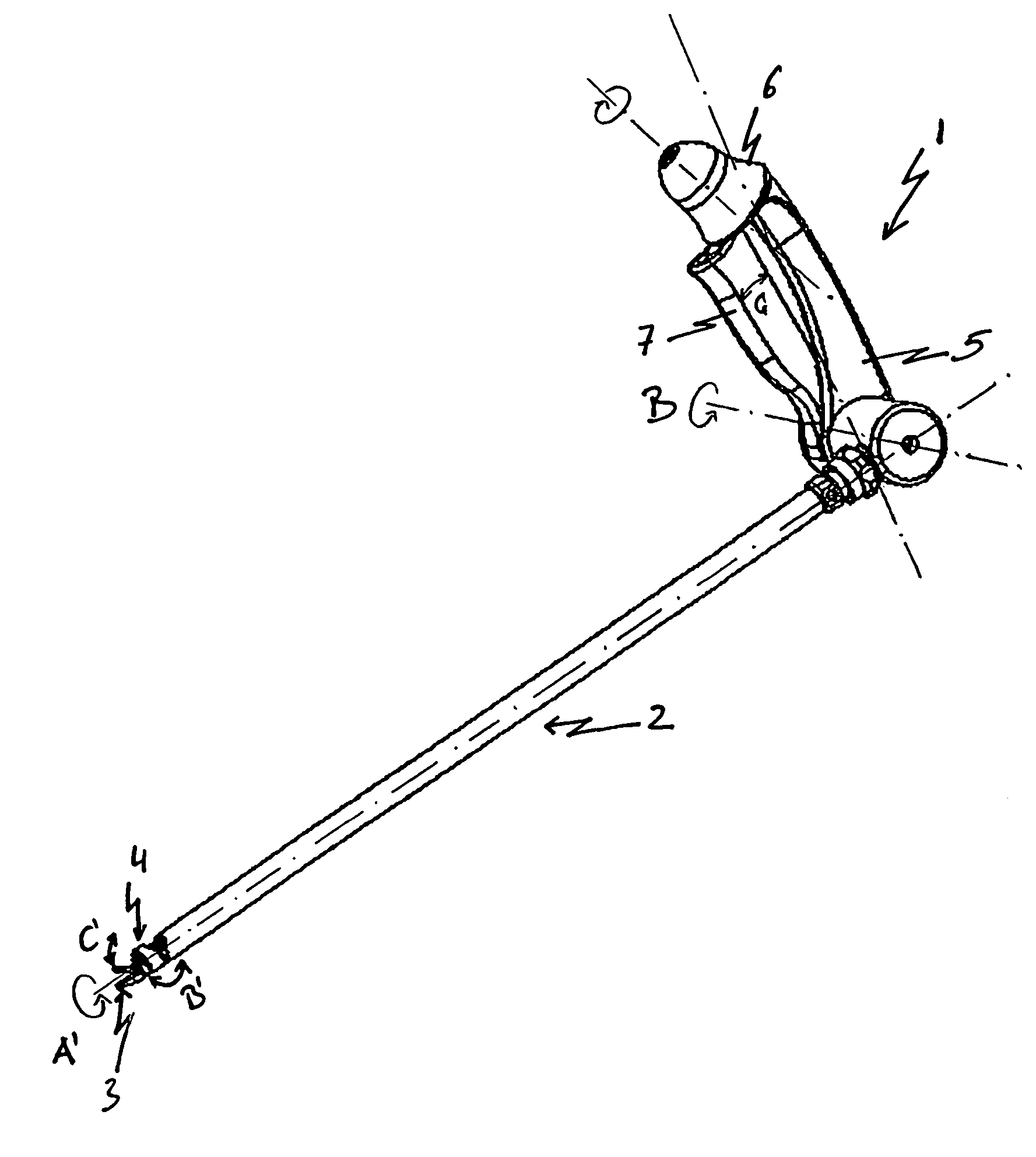

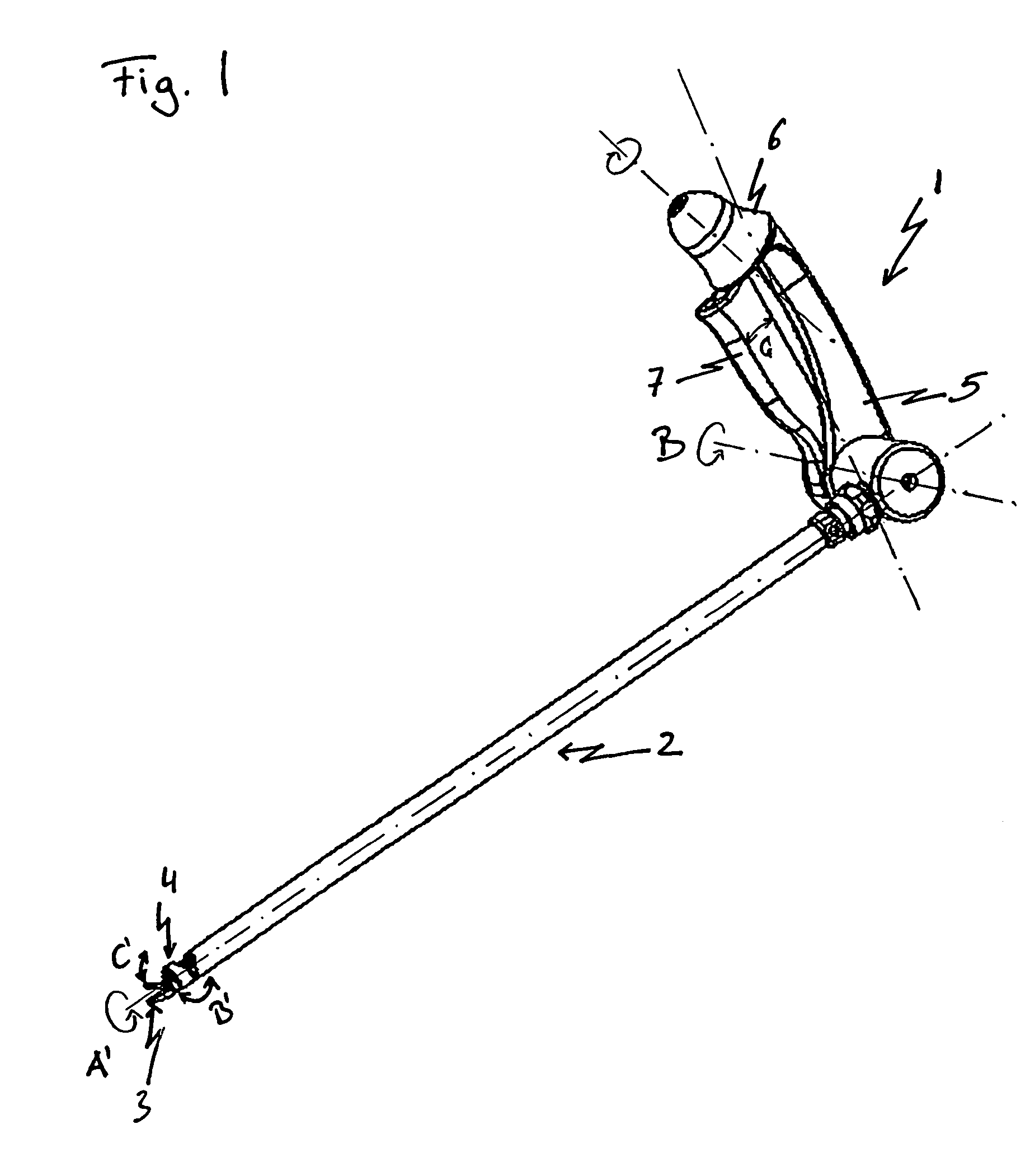

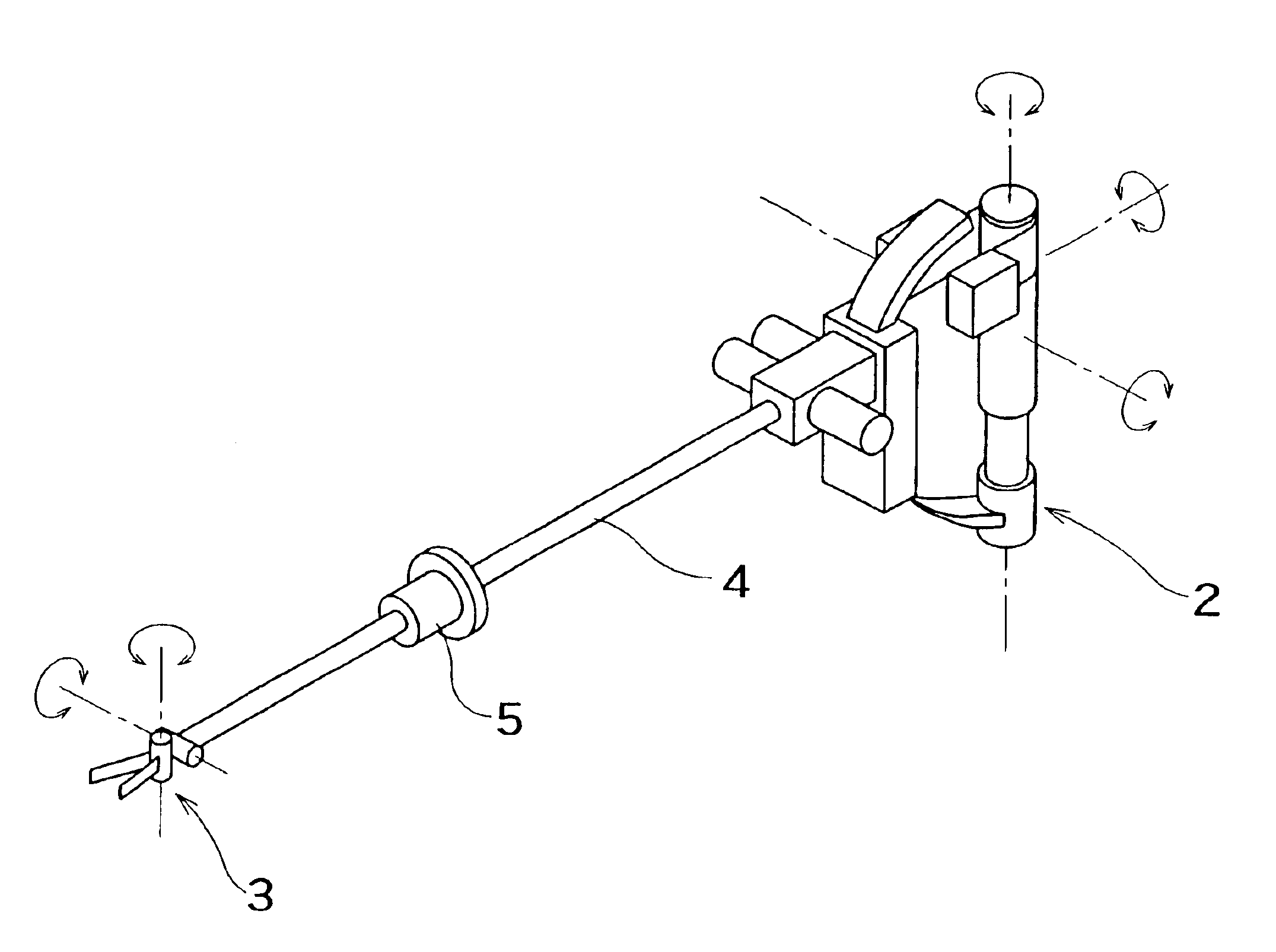

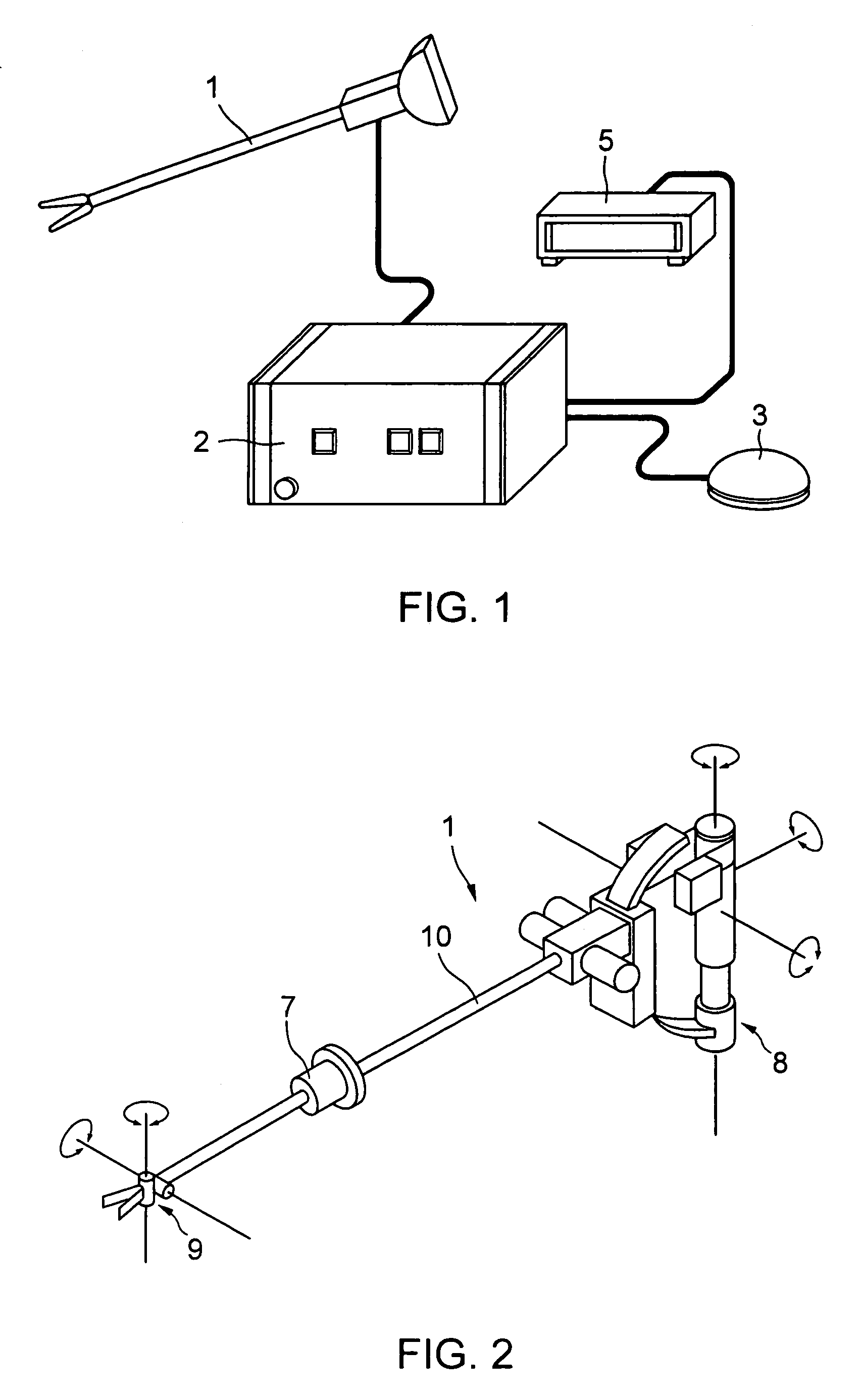

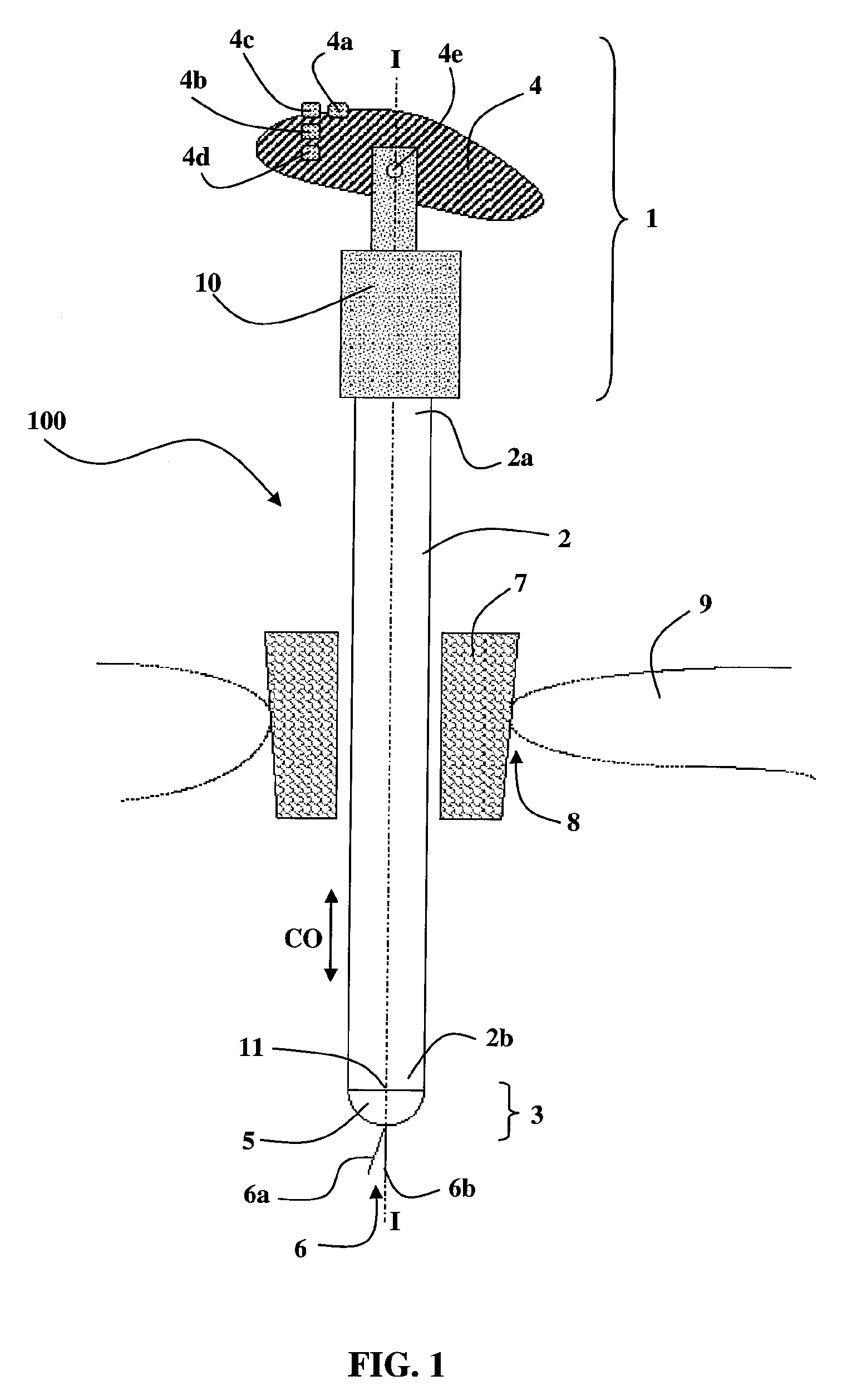

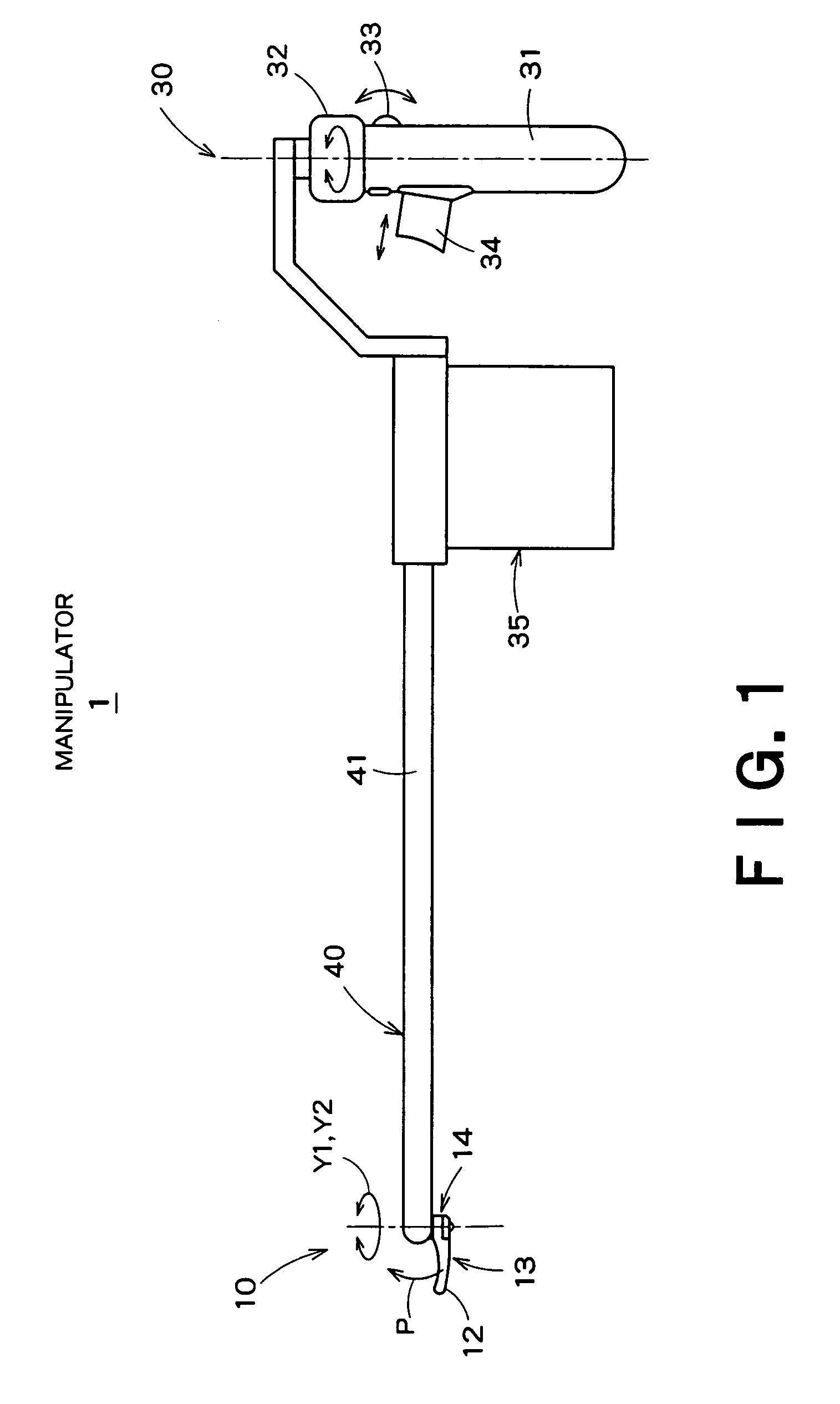

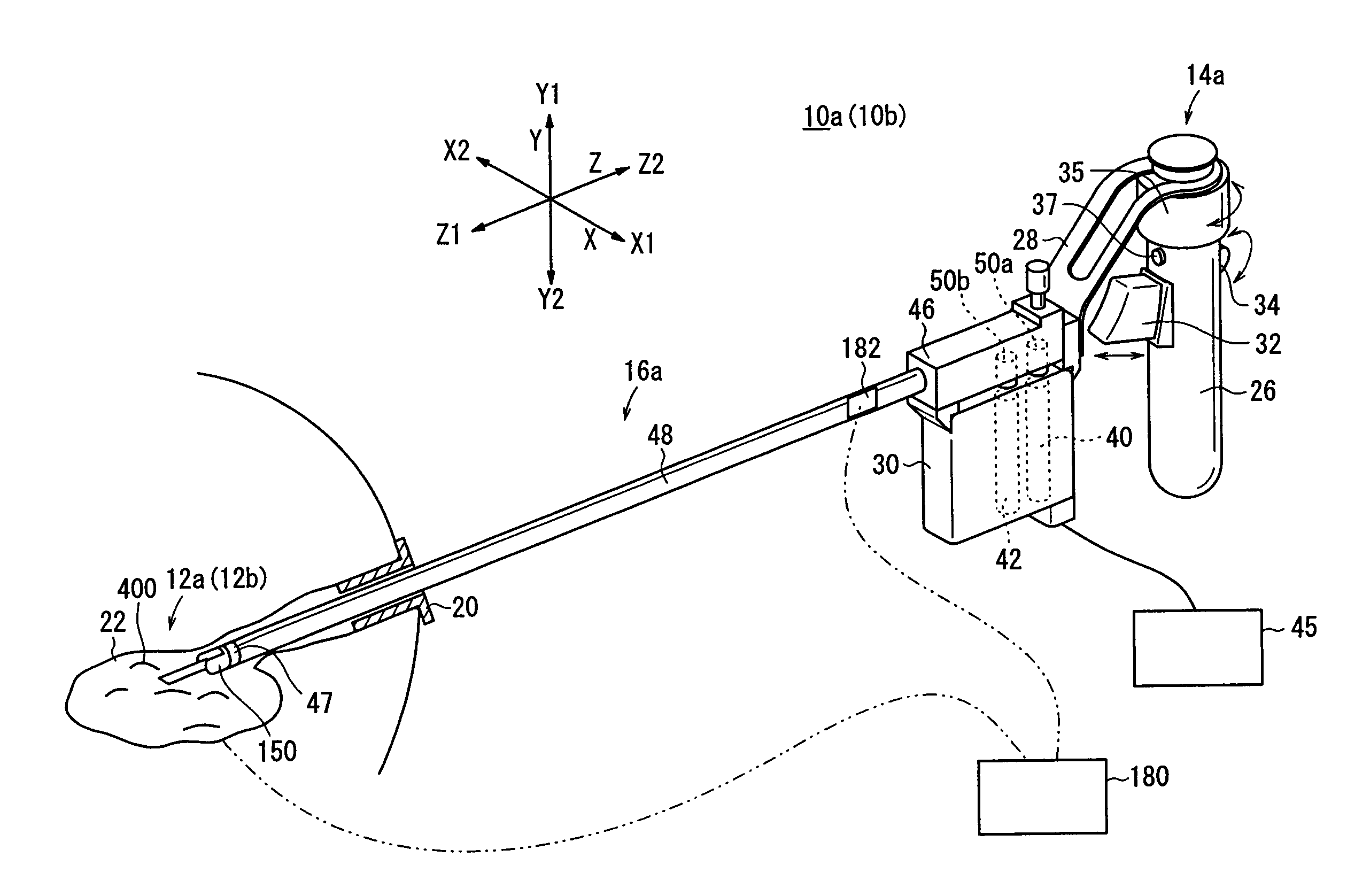

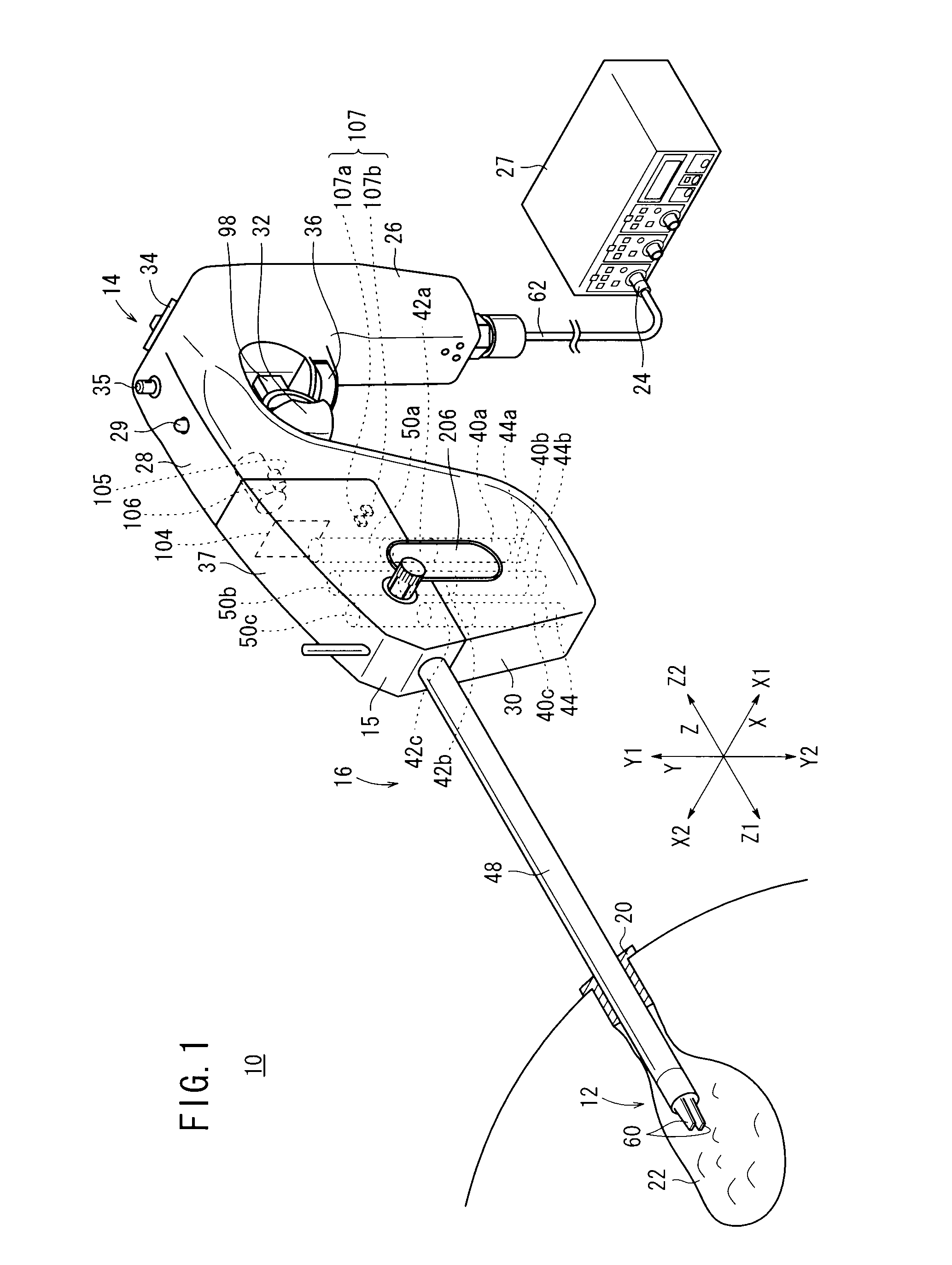

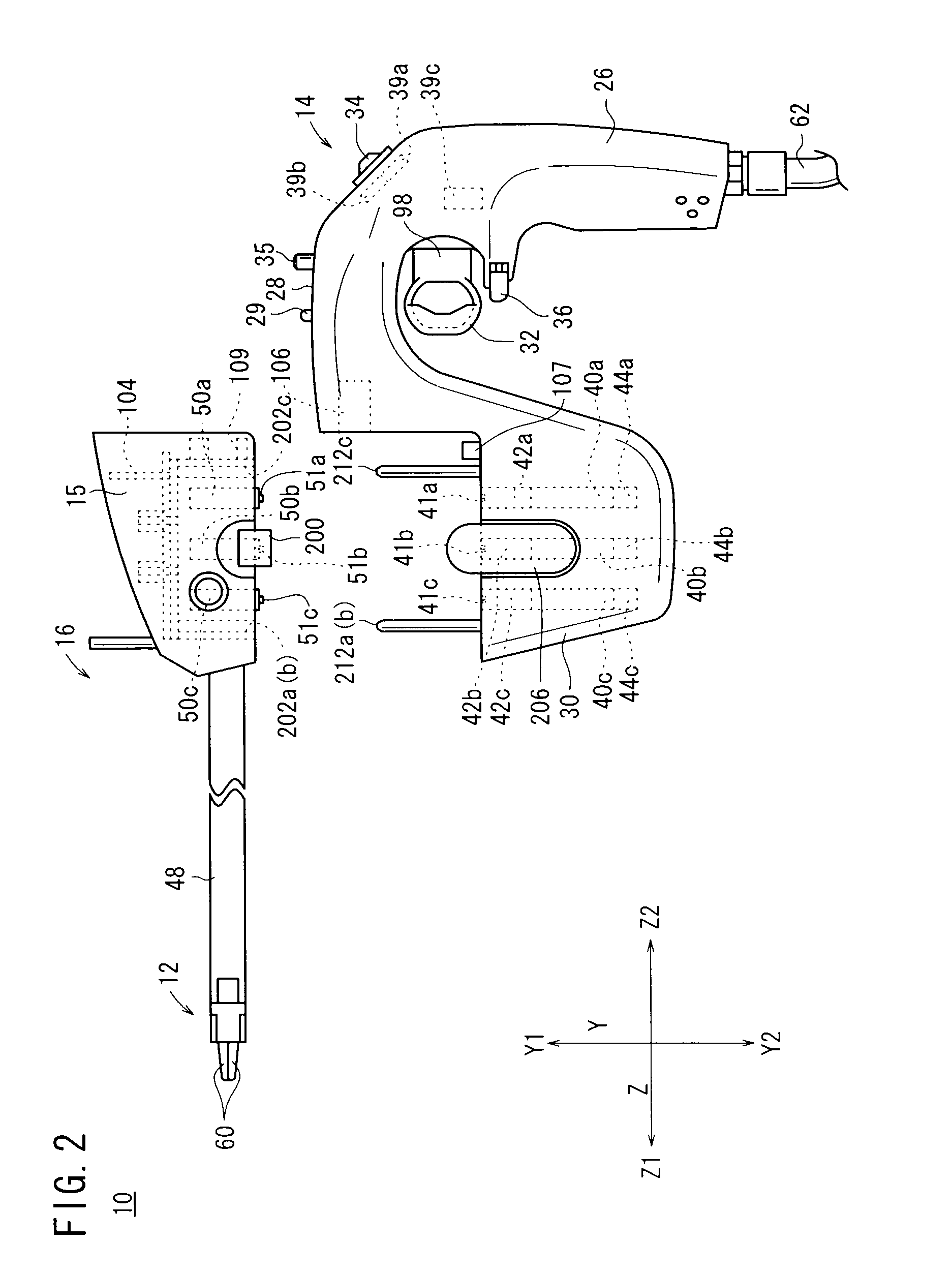

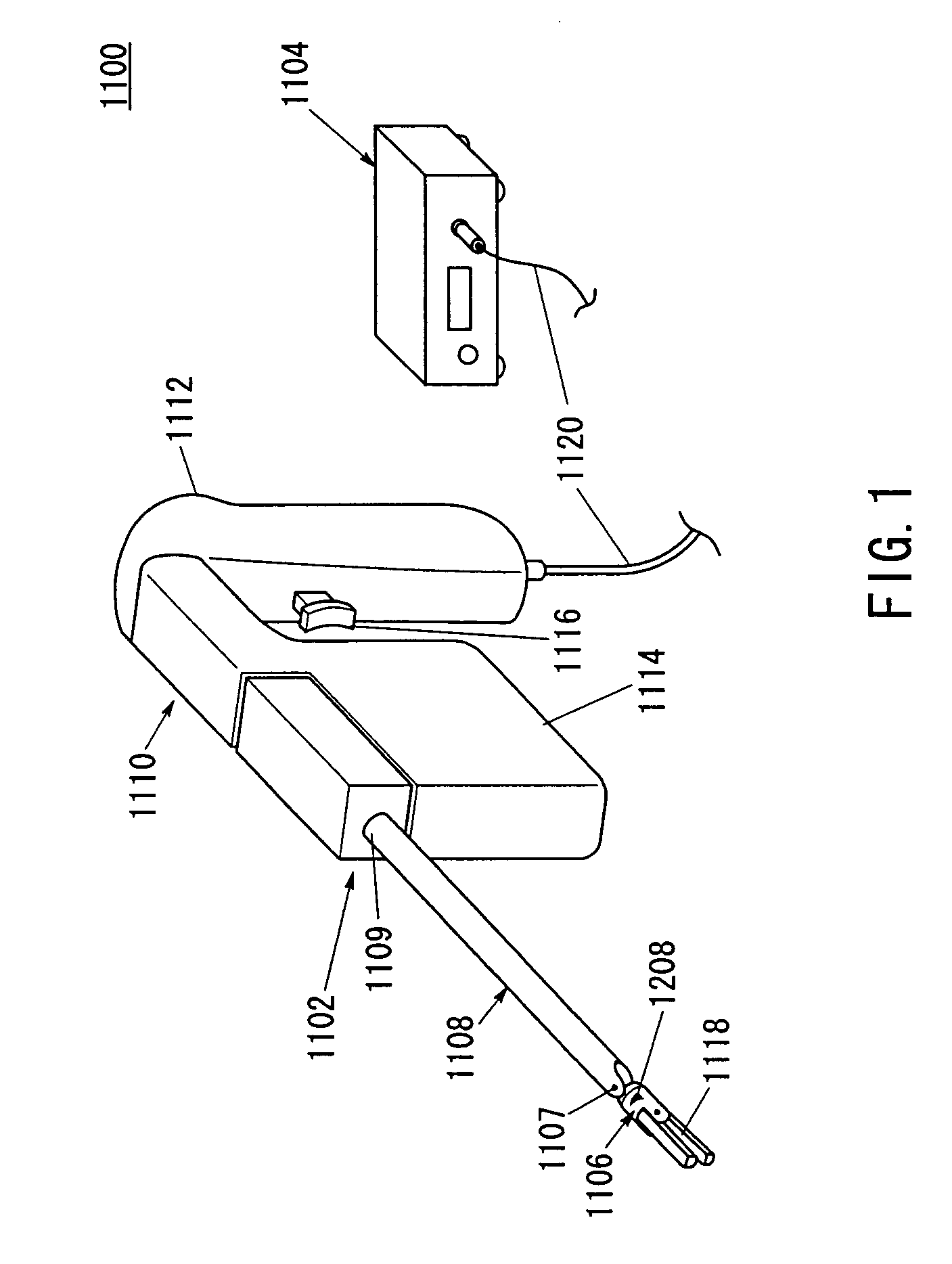

Manipulator

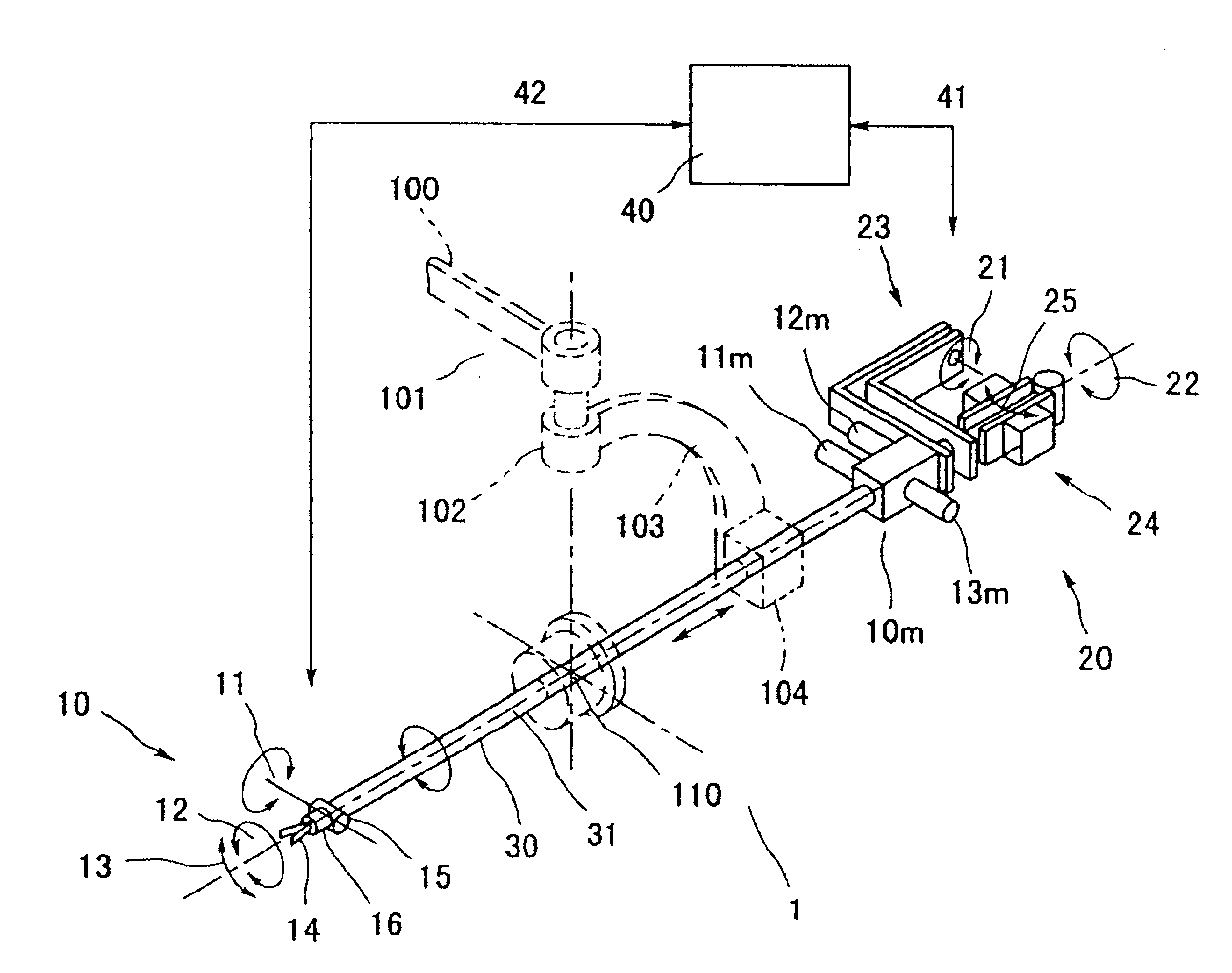

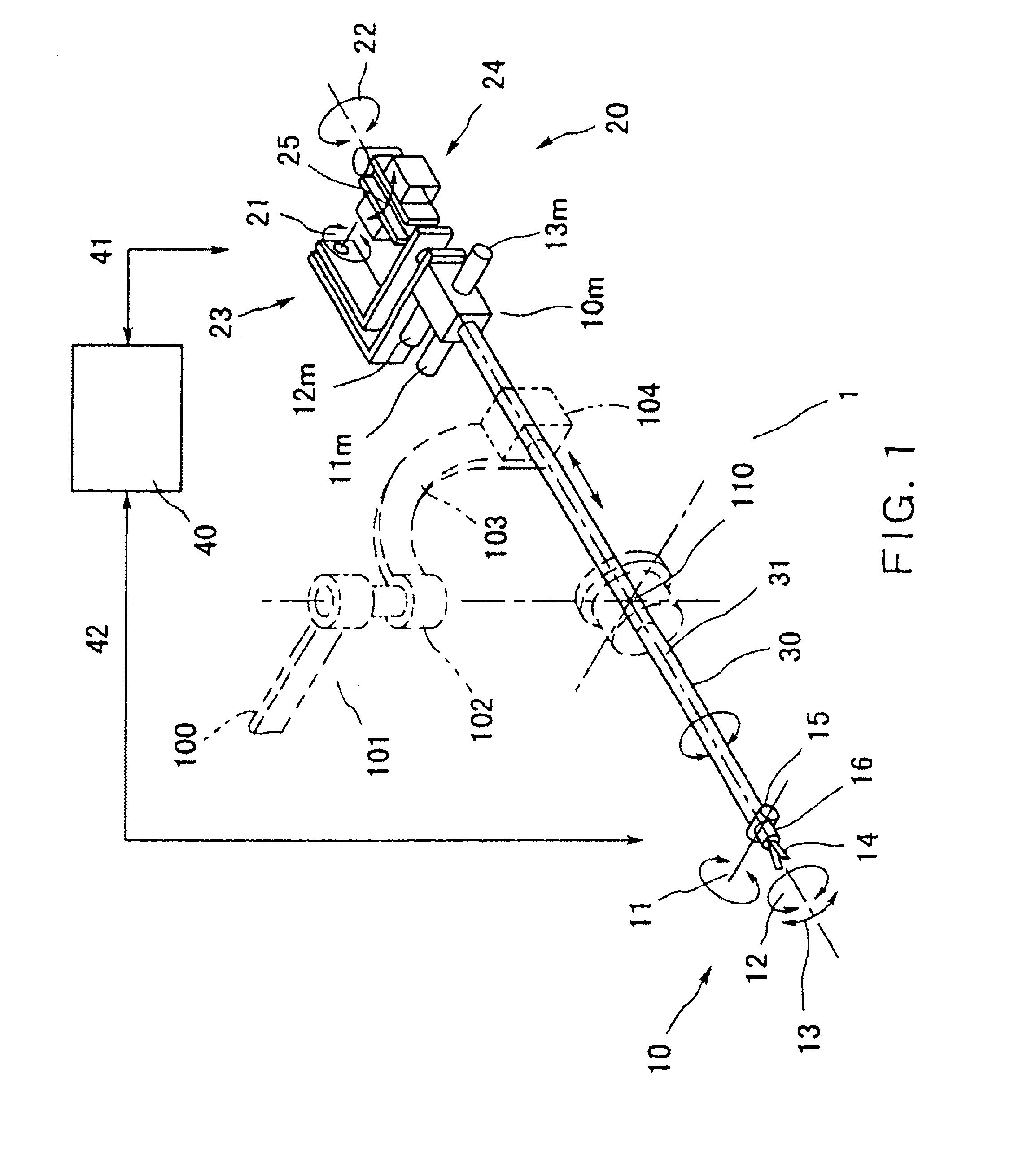

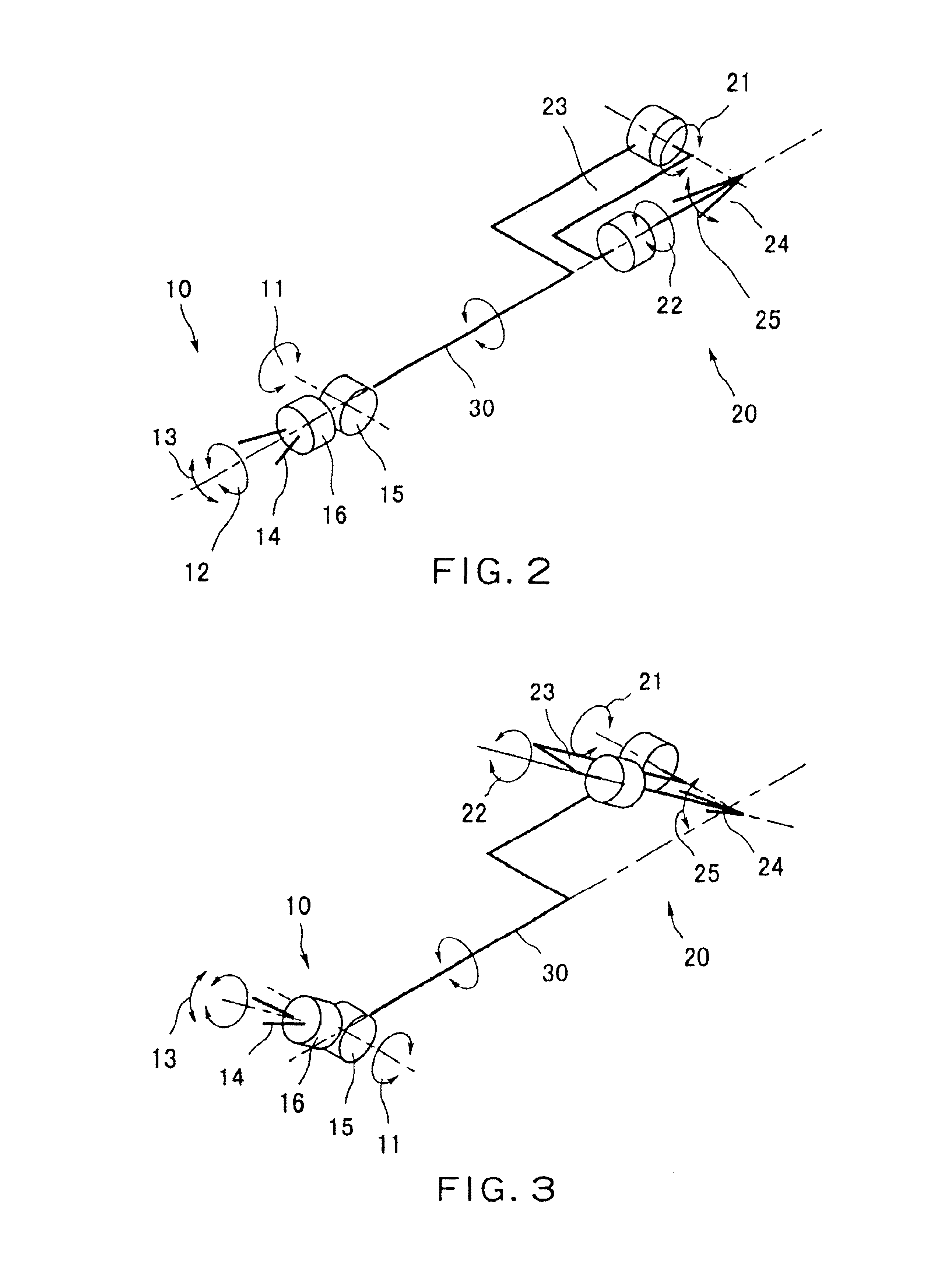

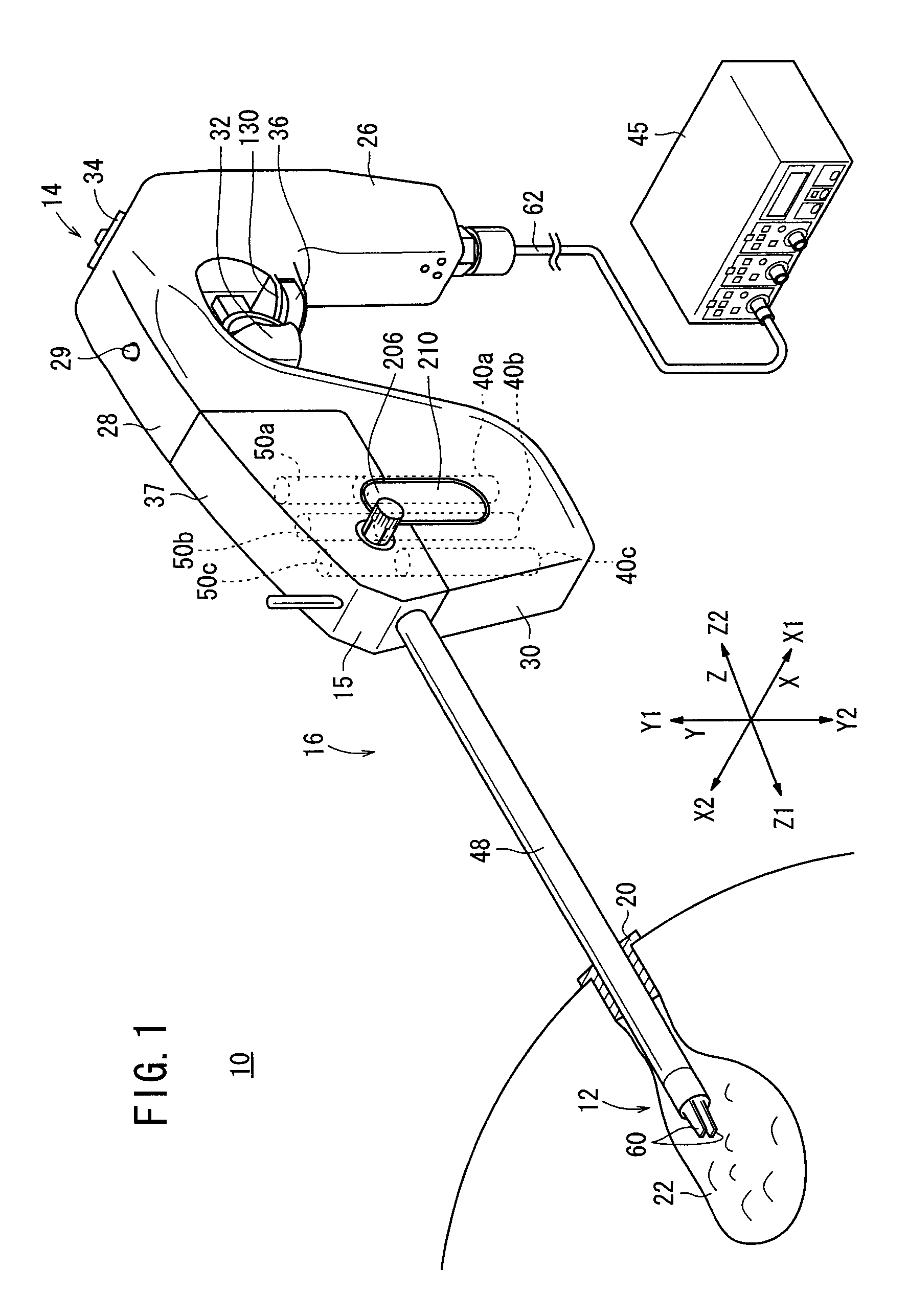

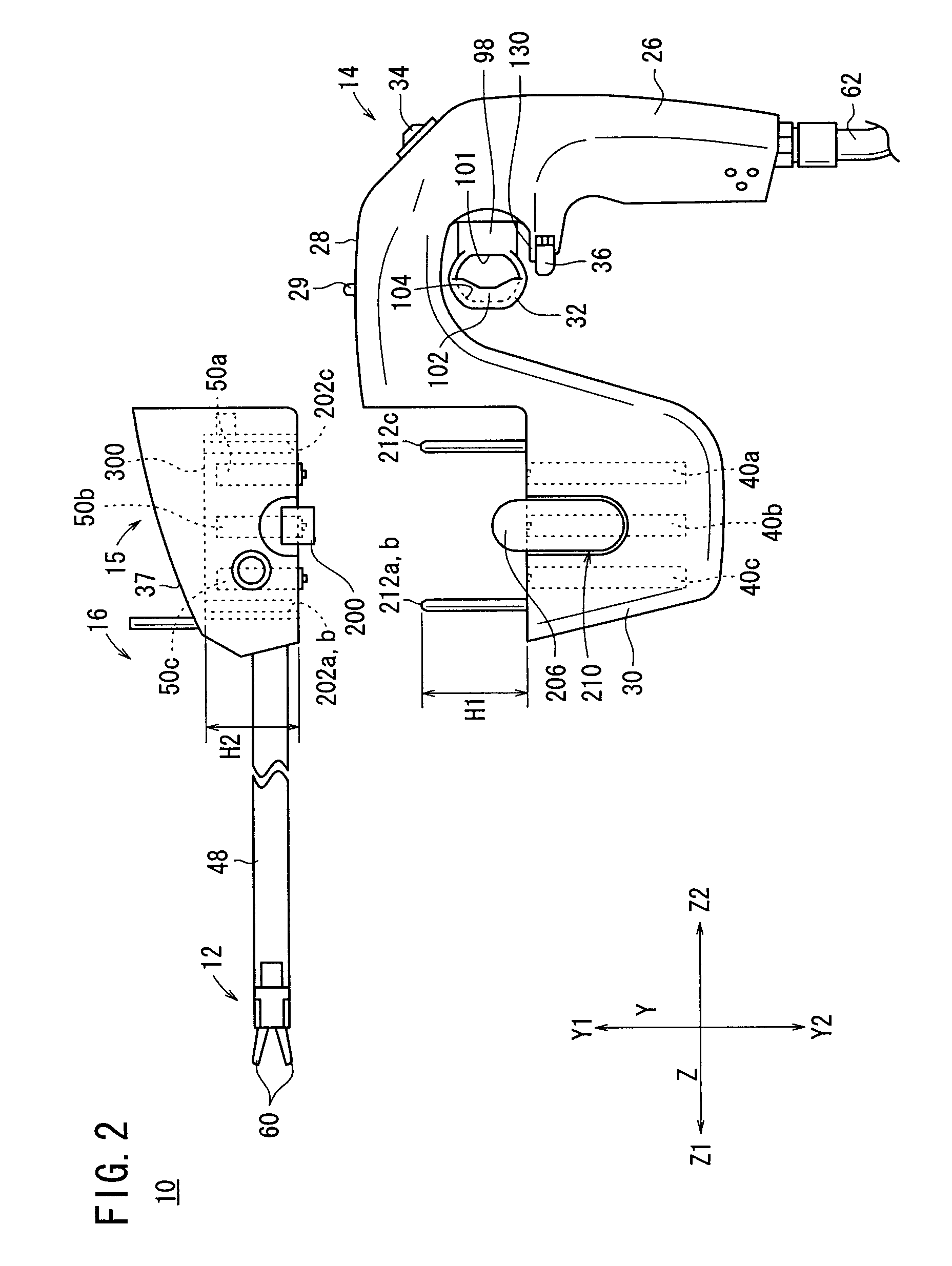

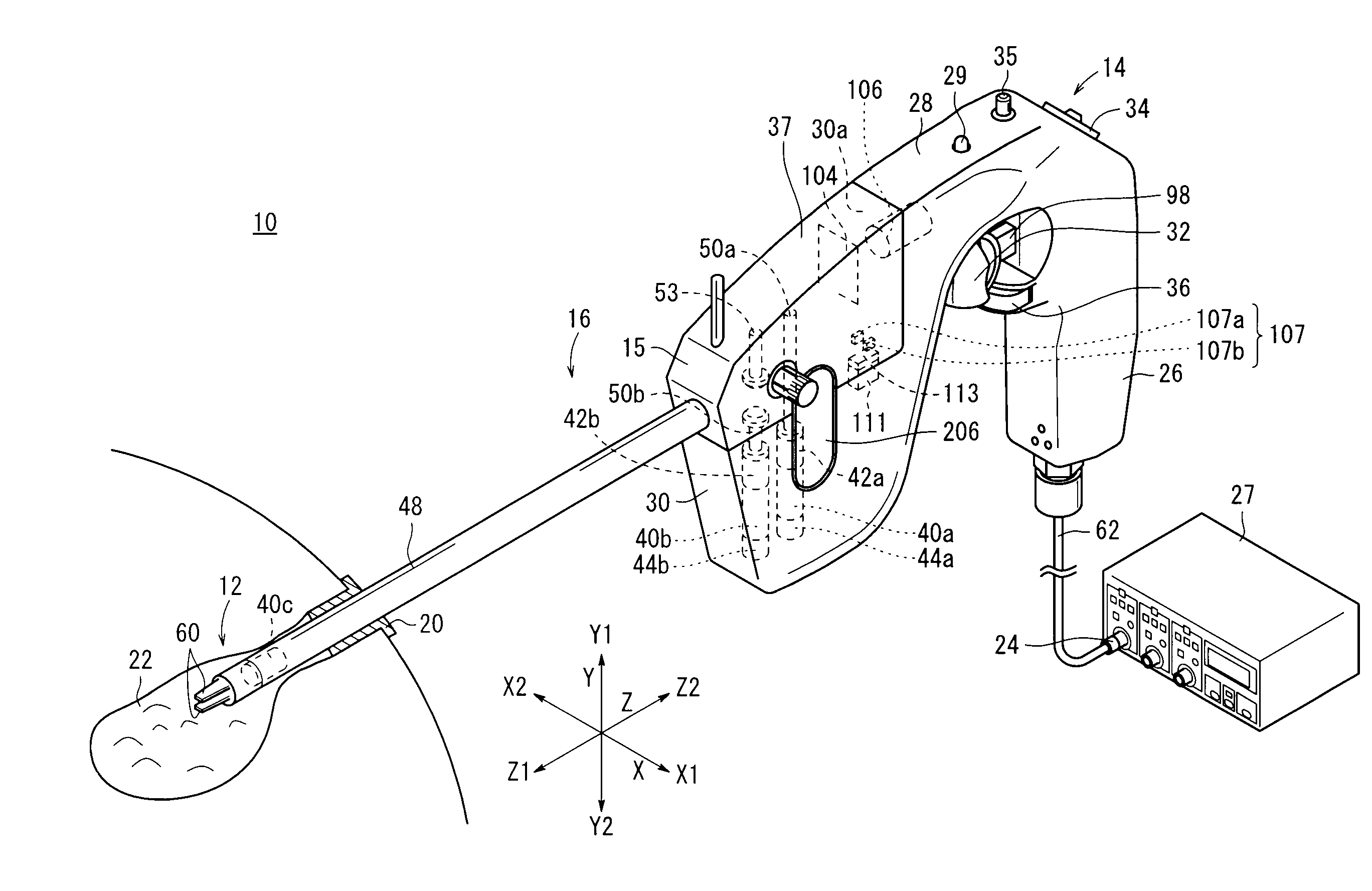

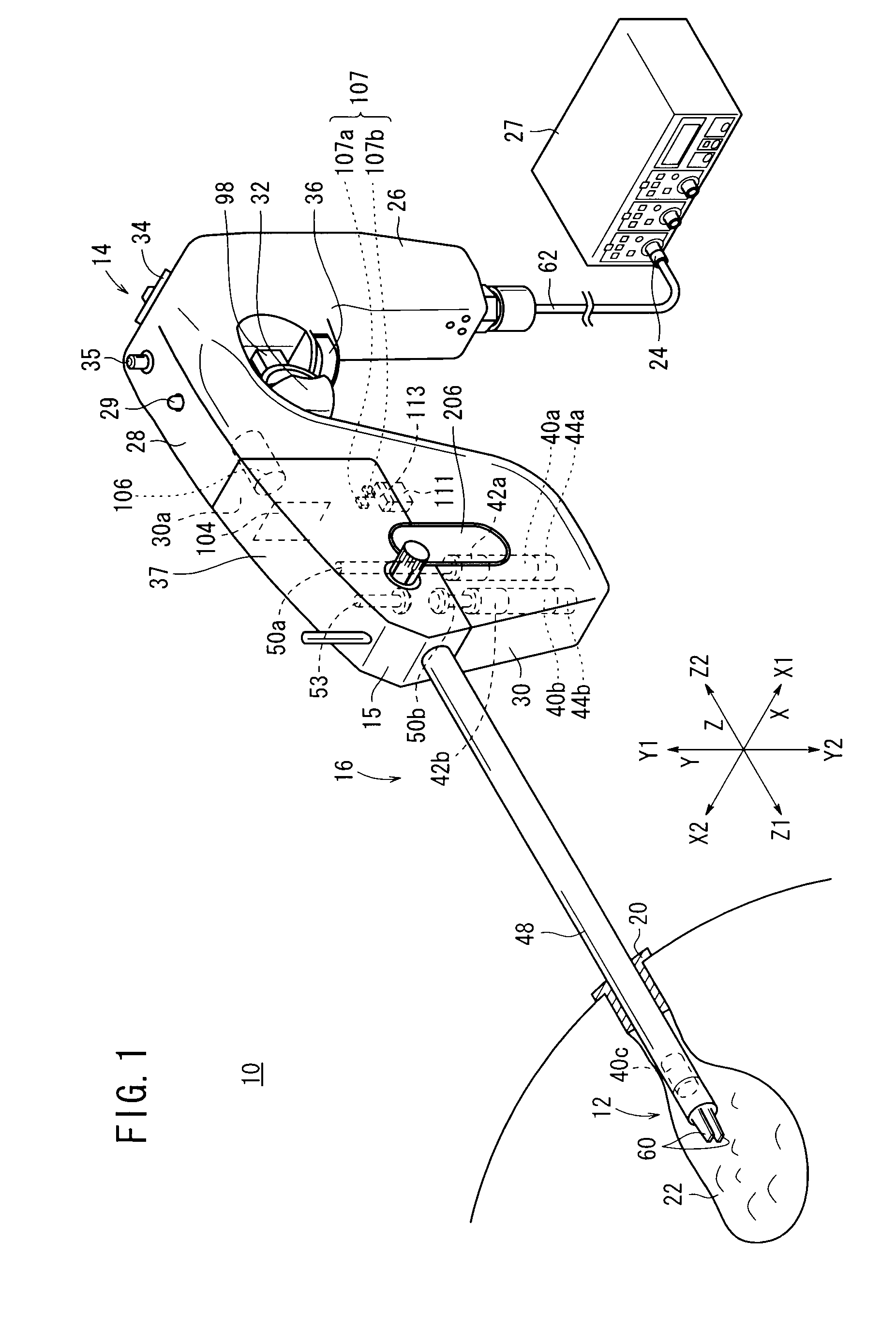

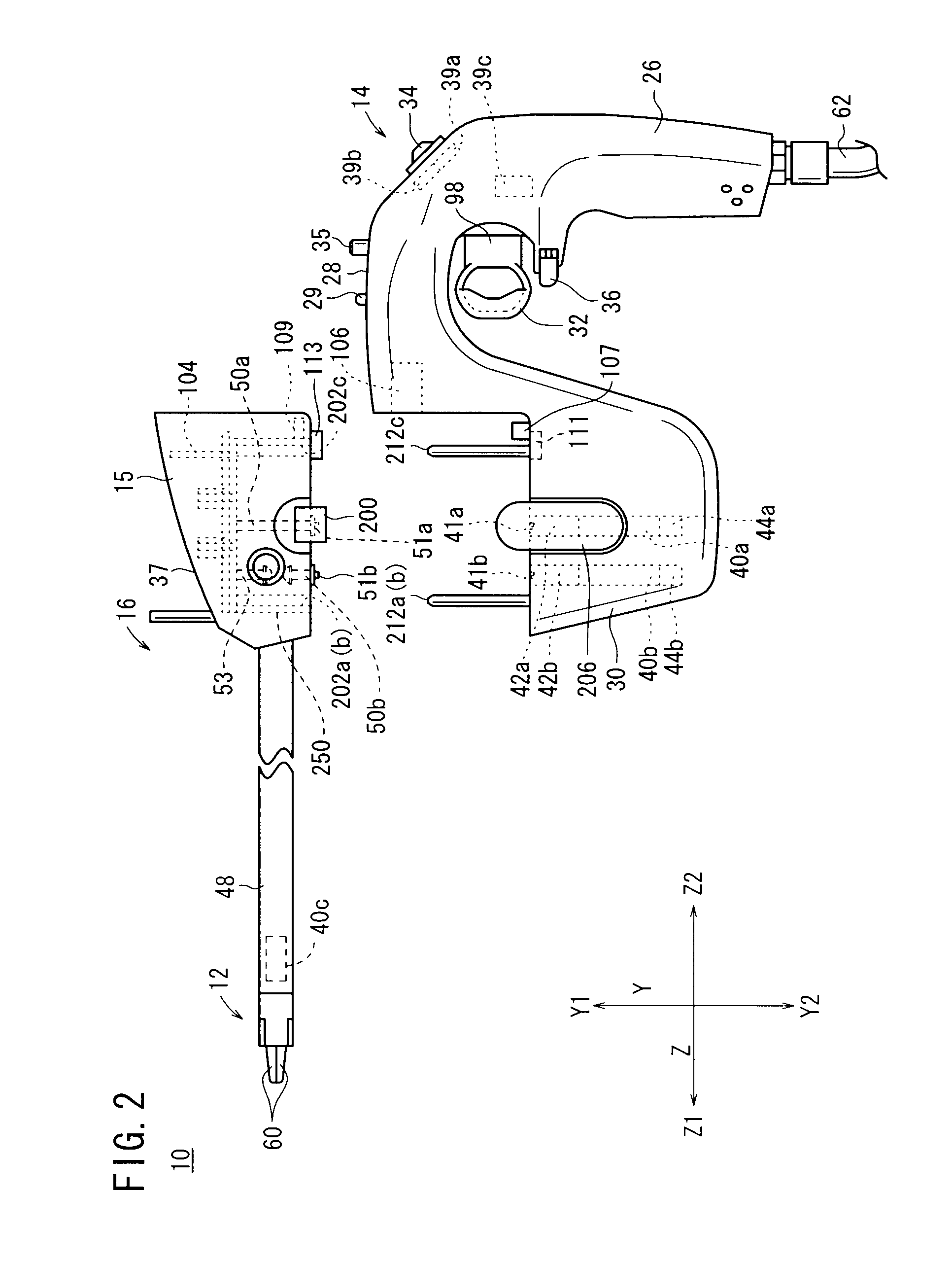

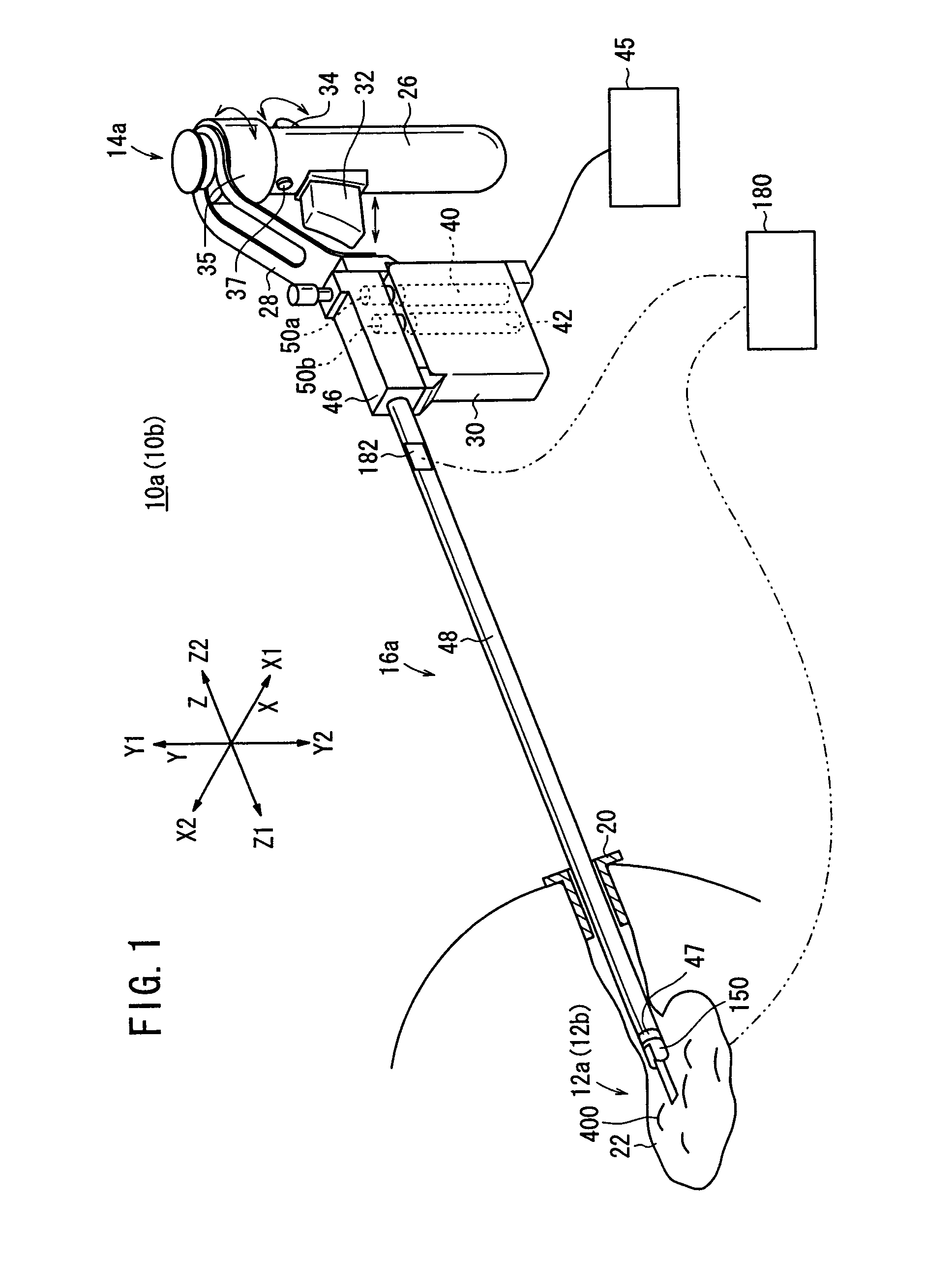

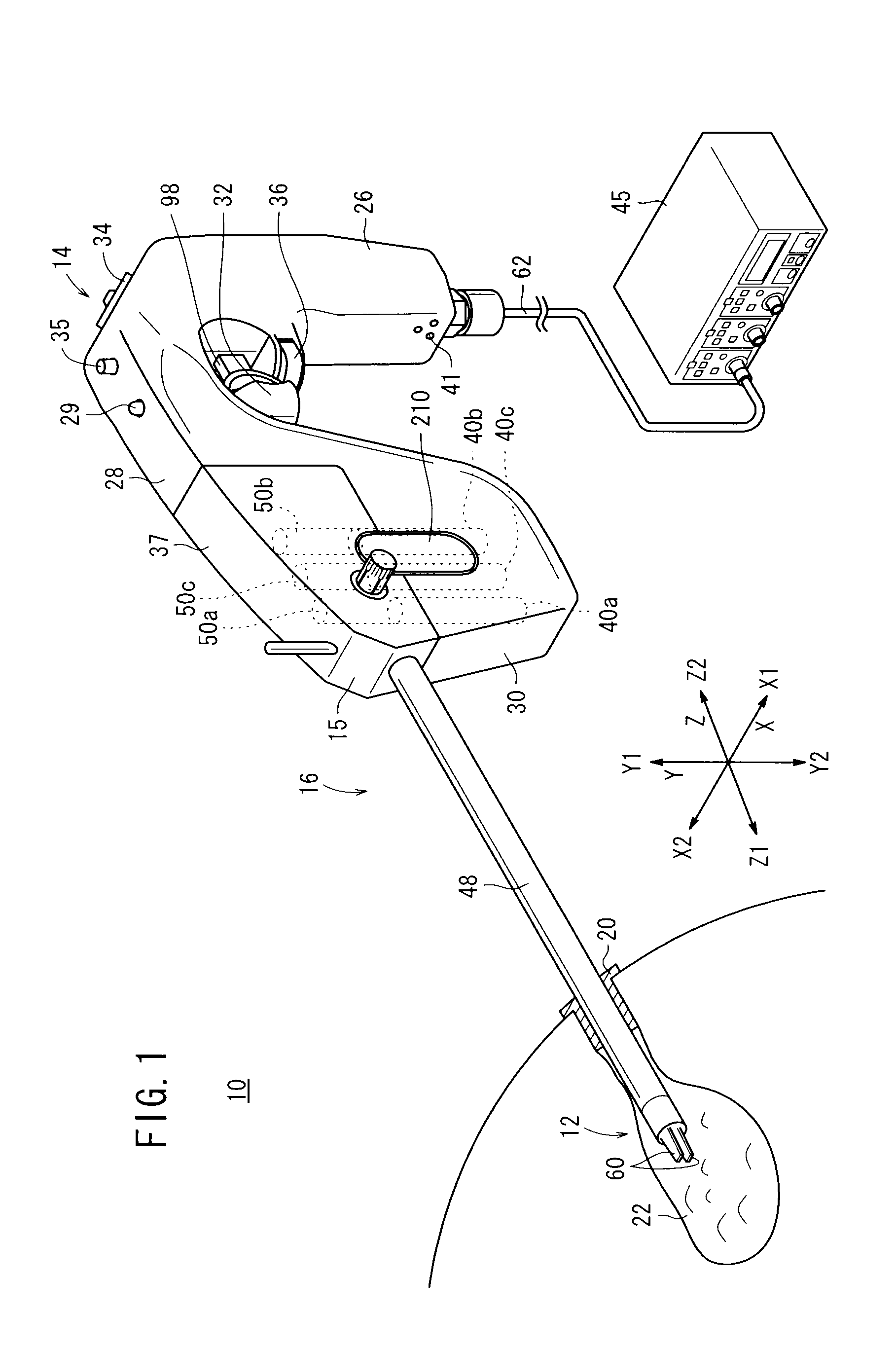

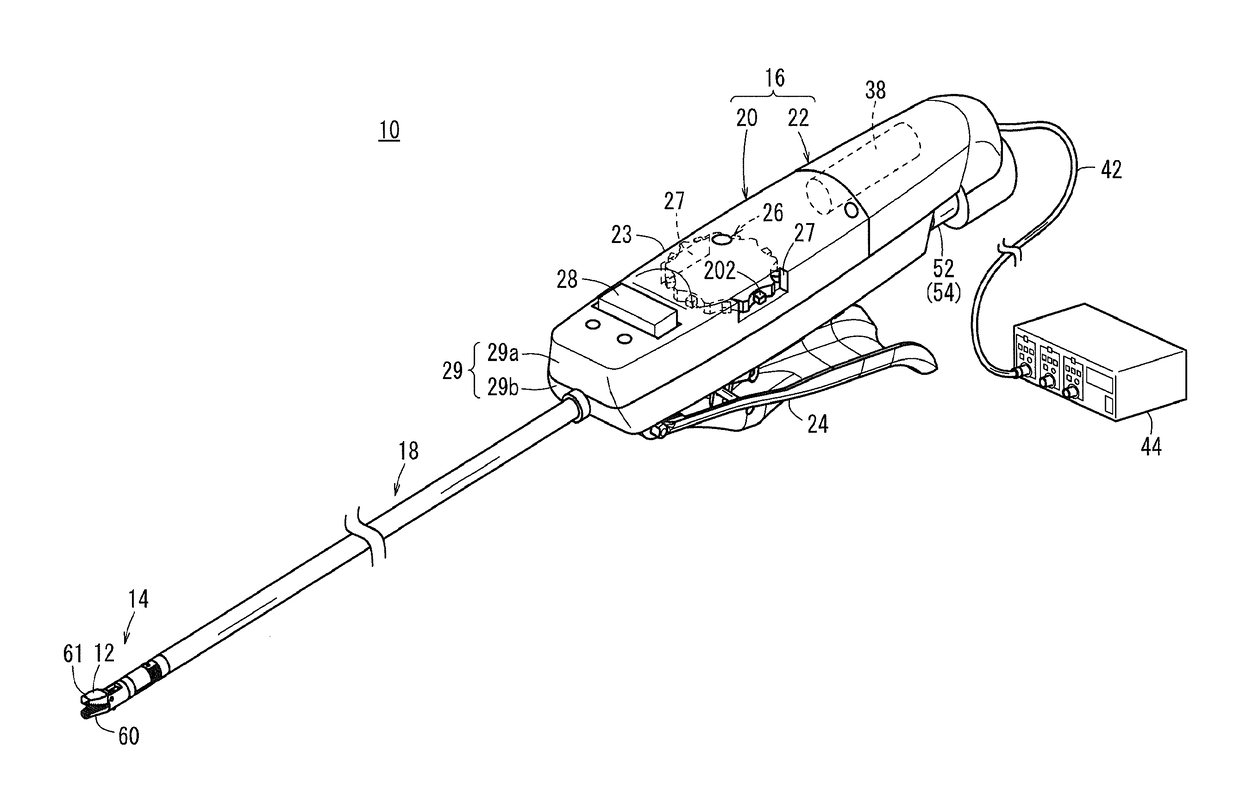

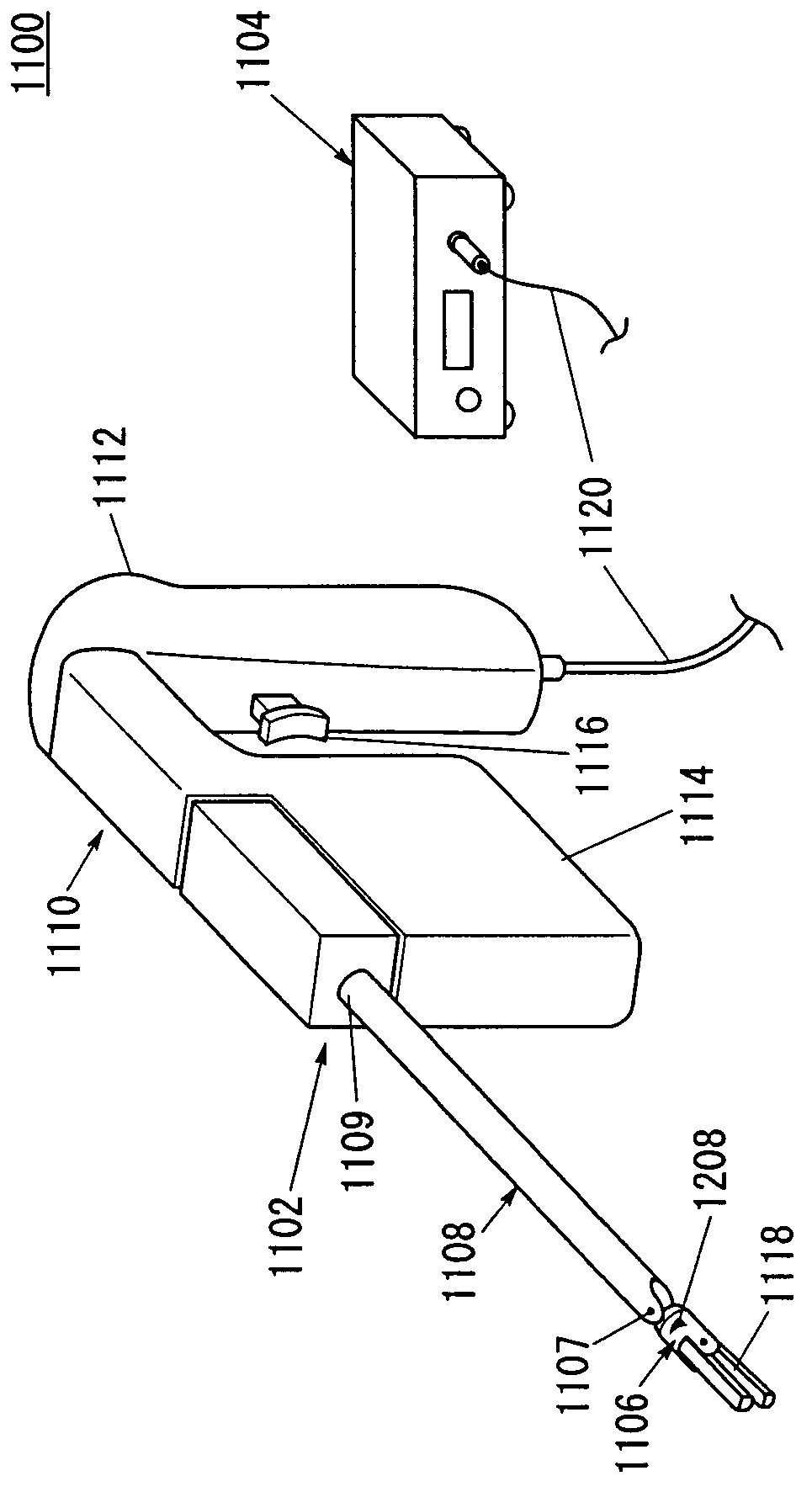

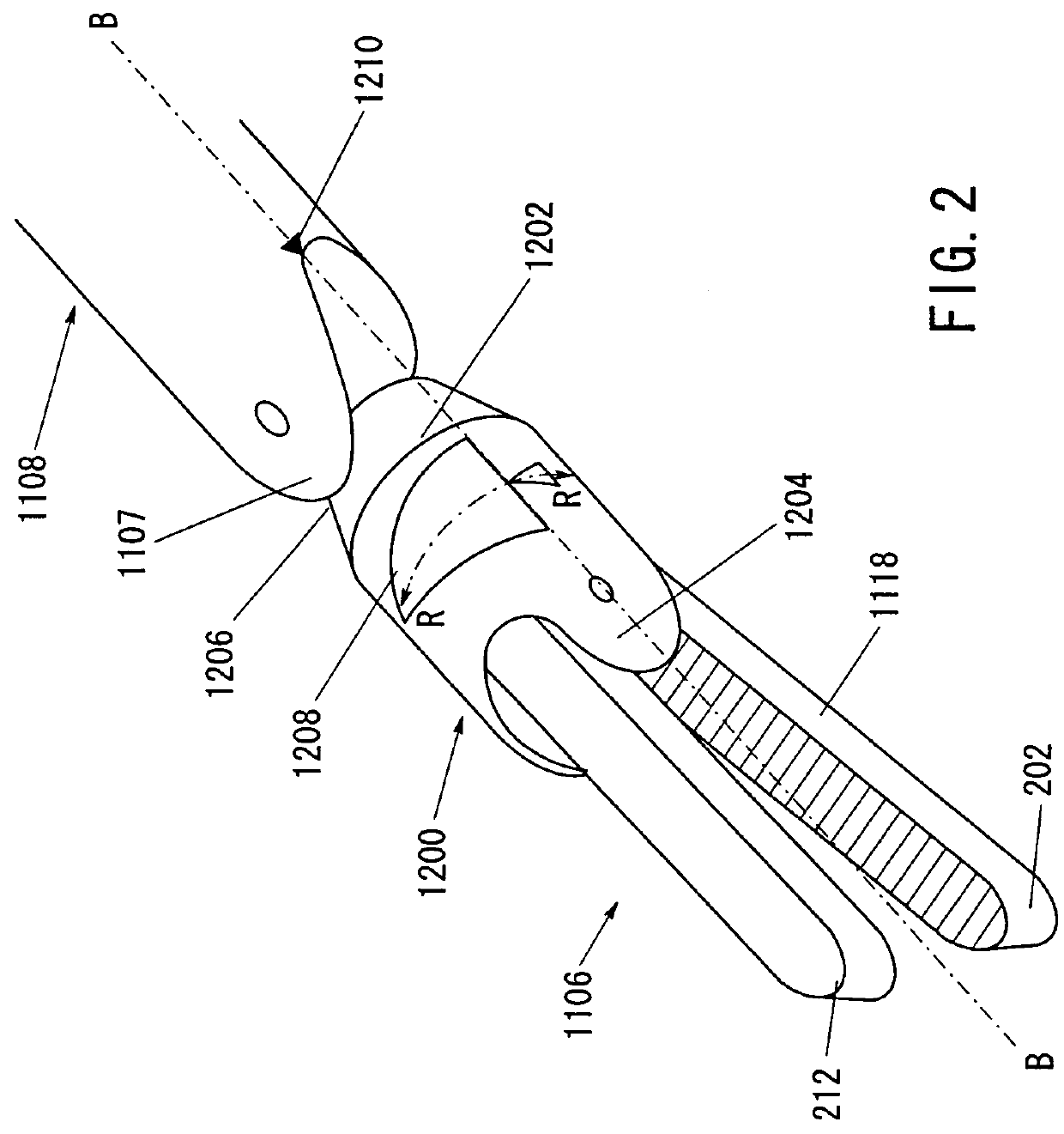

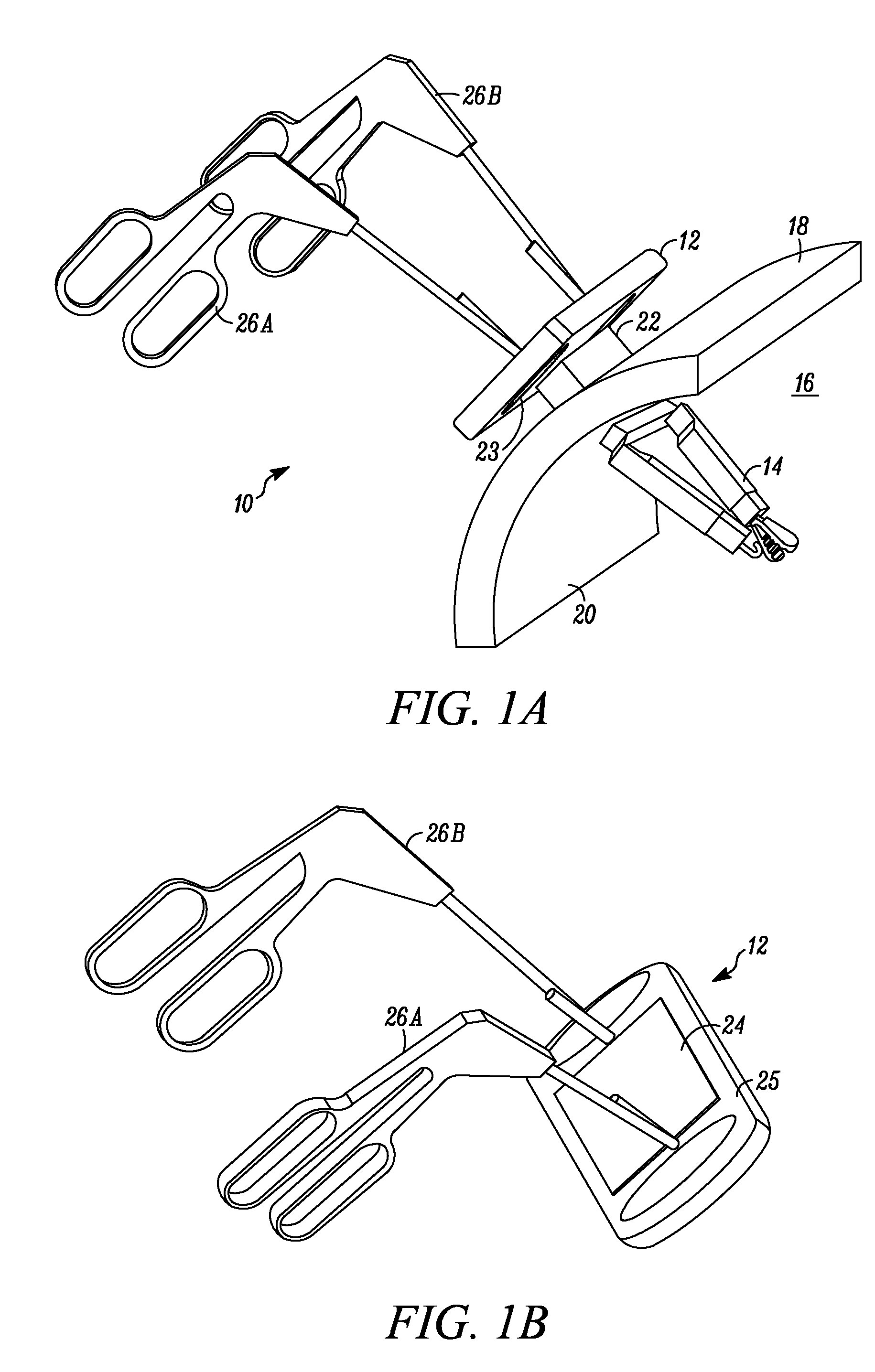

A manipulator comprises an operation command unit provided with an attitude adjusting unit and an end effector control unit, a connecting unit having one end connected to the operation command unit, a working unit connected to the other end of the connecting unit and provided with an end effector and a support unit supporting the end effector for motions, and a control unit that transmits an operation command provided by the attitude adjusting unit to the support unit to adjust the attitude of the end effector and transmits an operation command provided by the end effector control unit to the end effector to operate the end effector. The support unit includes a first joint capable of turning about a first axis perpendicular to the center axis of the connecting unit, and a second joint capable of turning about a second axis perpendicular to the first axis. The end effector can be turned for rolling about an axis substantially parallel to the second axis of the second joint. The attitude adjusting unit has a third joint having a third axis perpendicular to the center line of the connecting unit. The end effector control unit is formed such that the fingers of an operator gripping operating members included in the end effector control unit extend substantially in parallel to the fourth axis.

Owner:KARL STORZ GMBH & CO KG

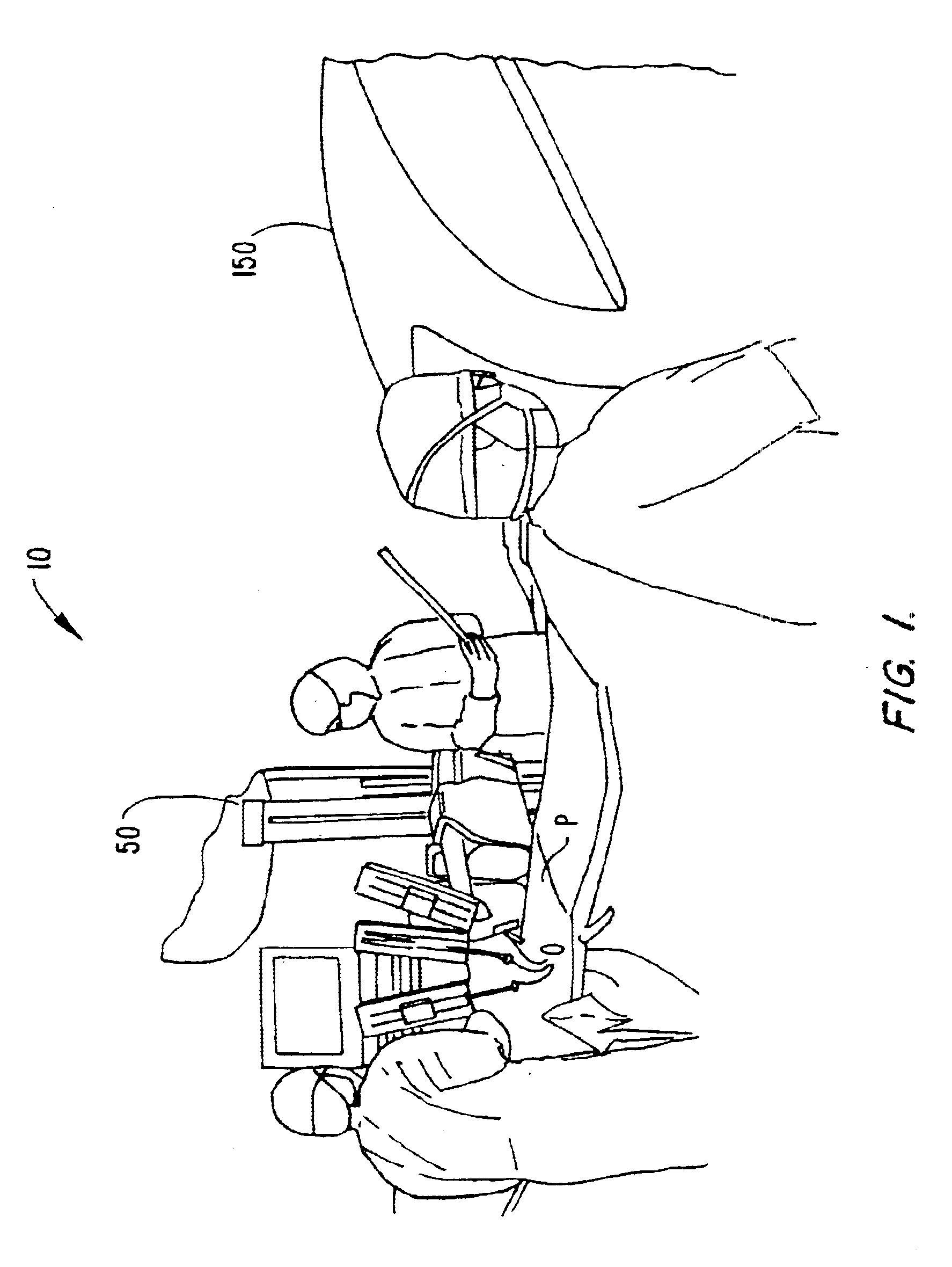

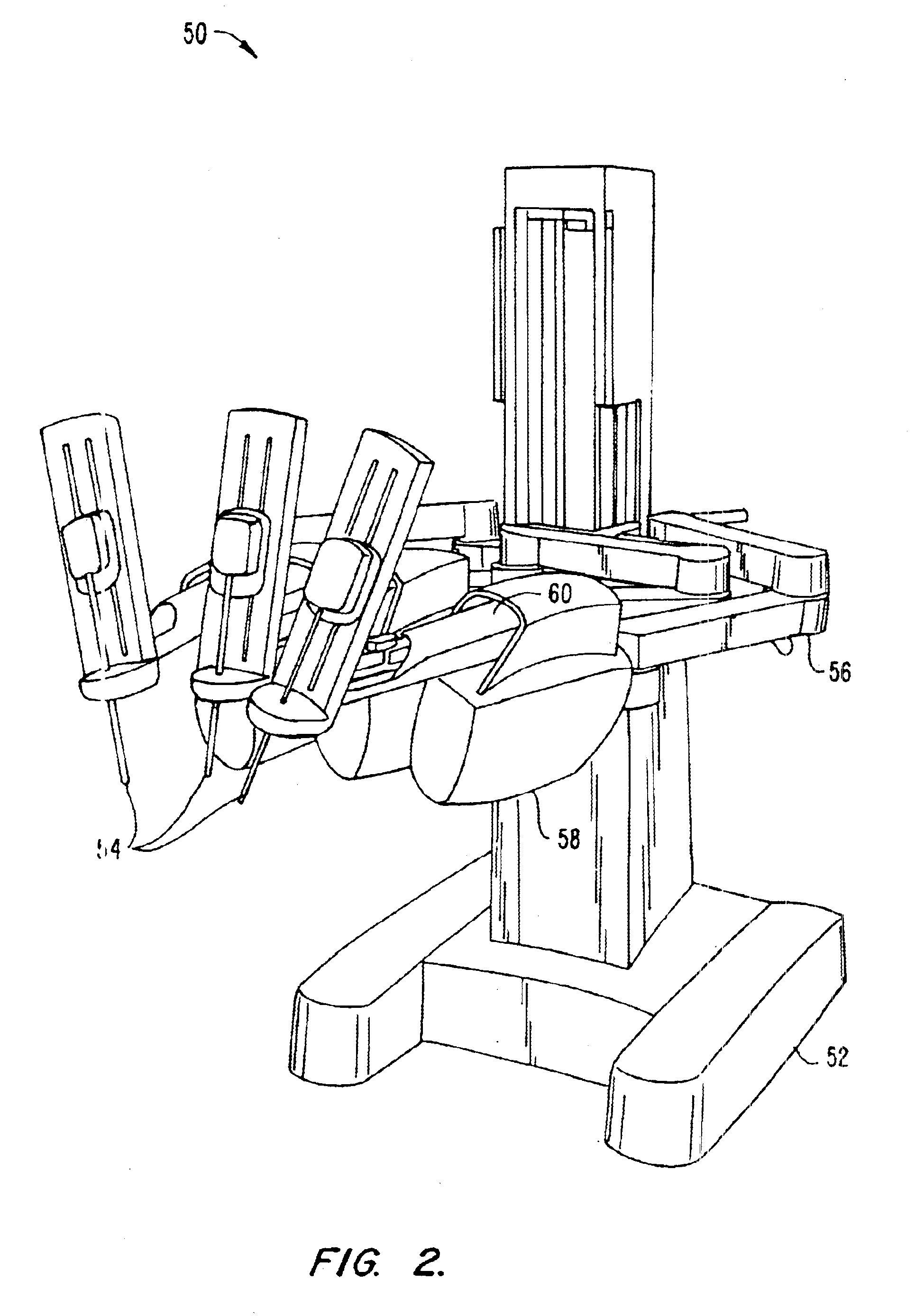

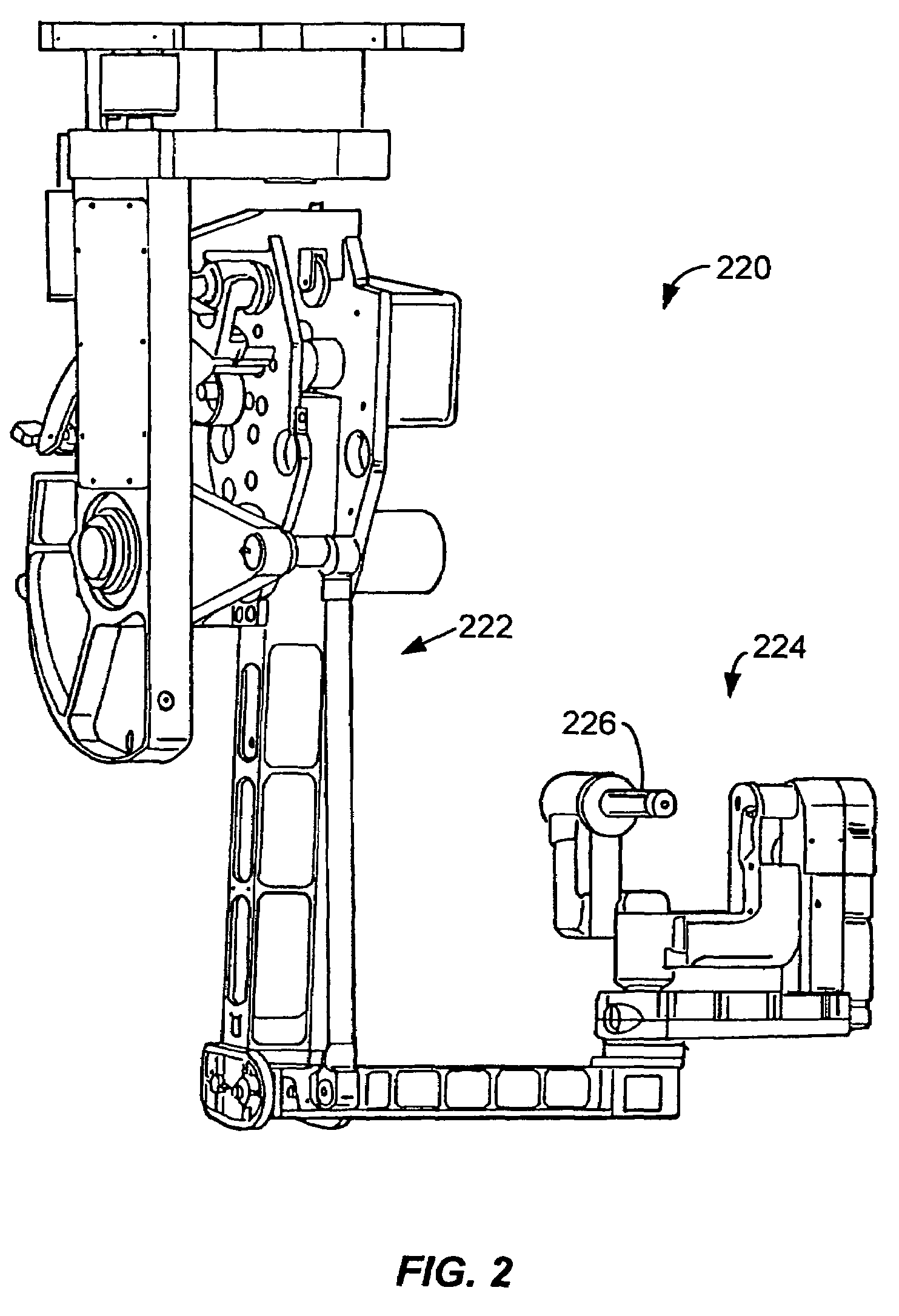

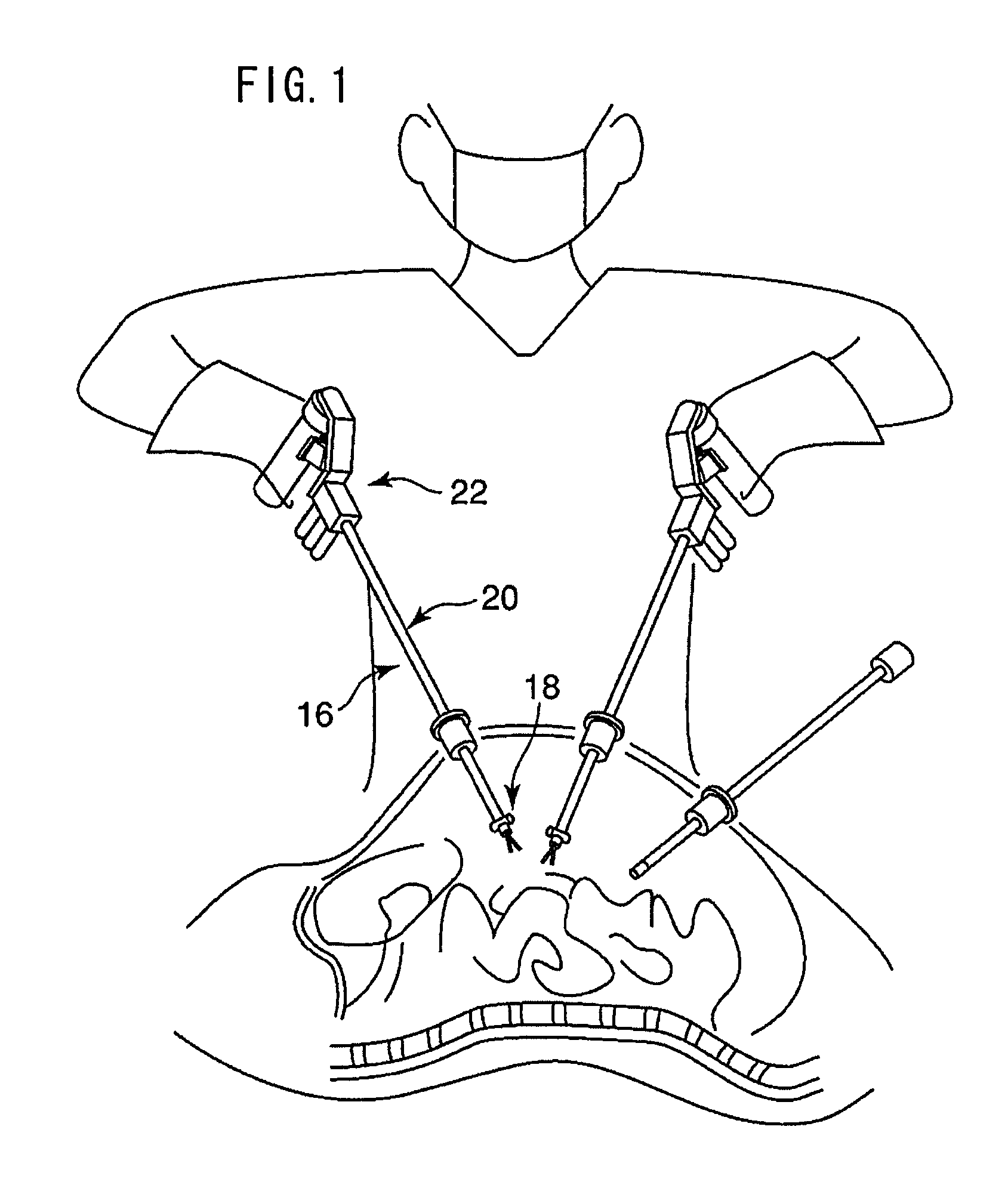

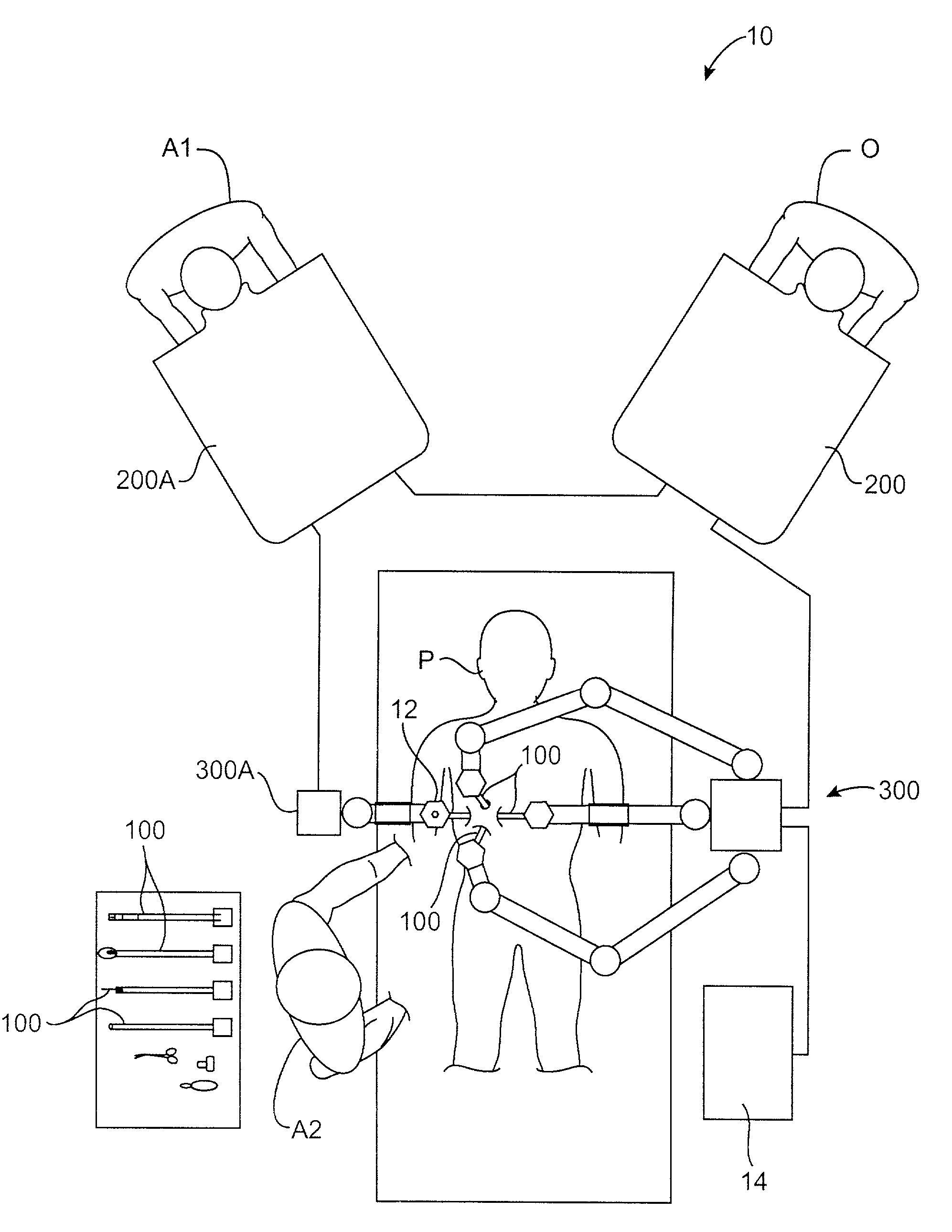

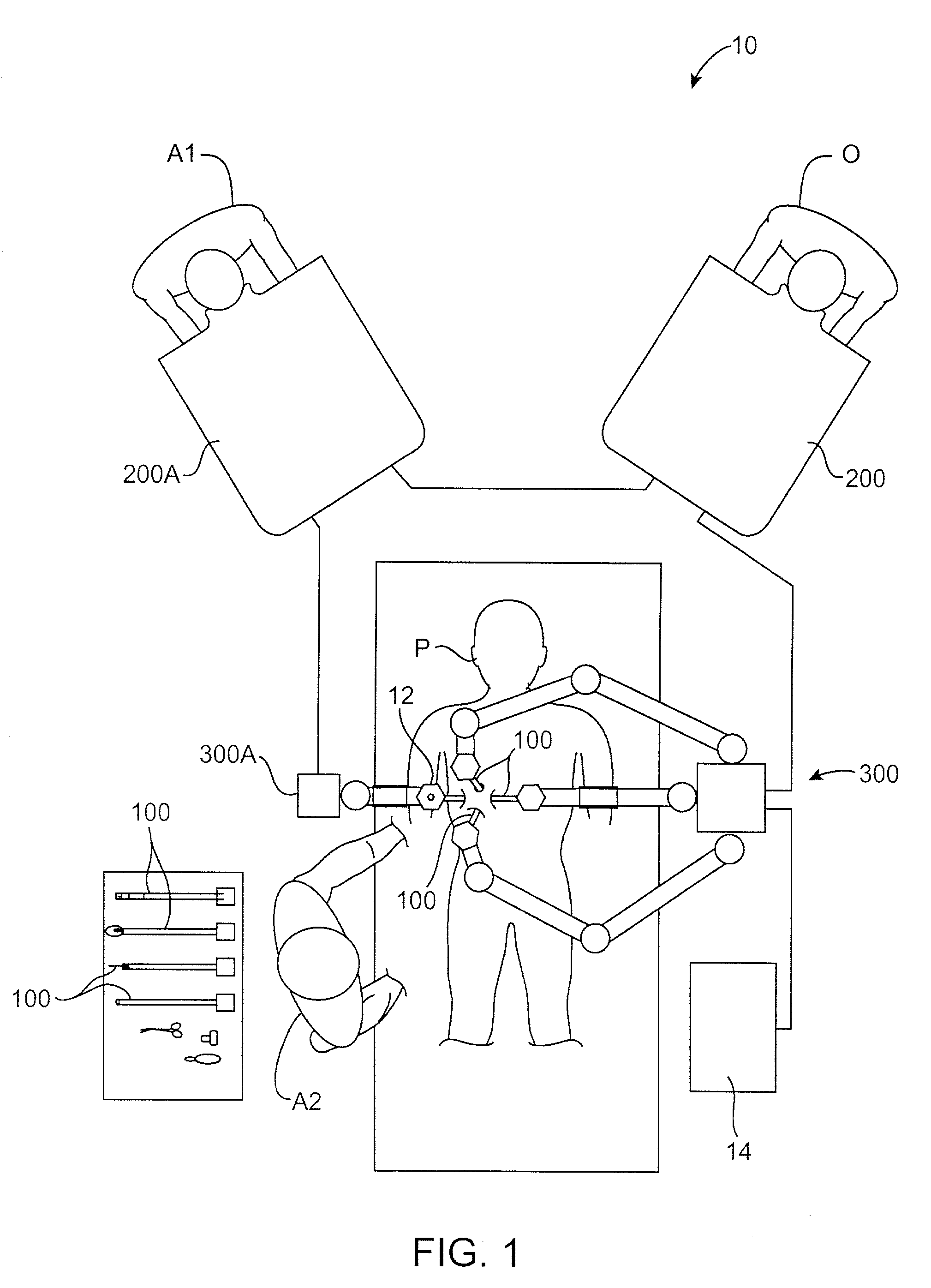

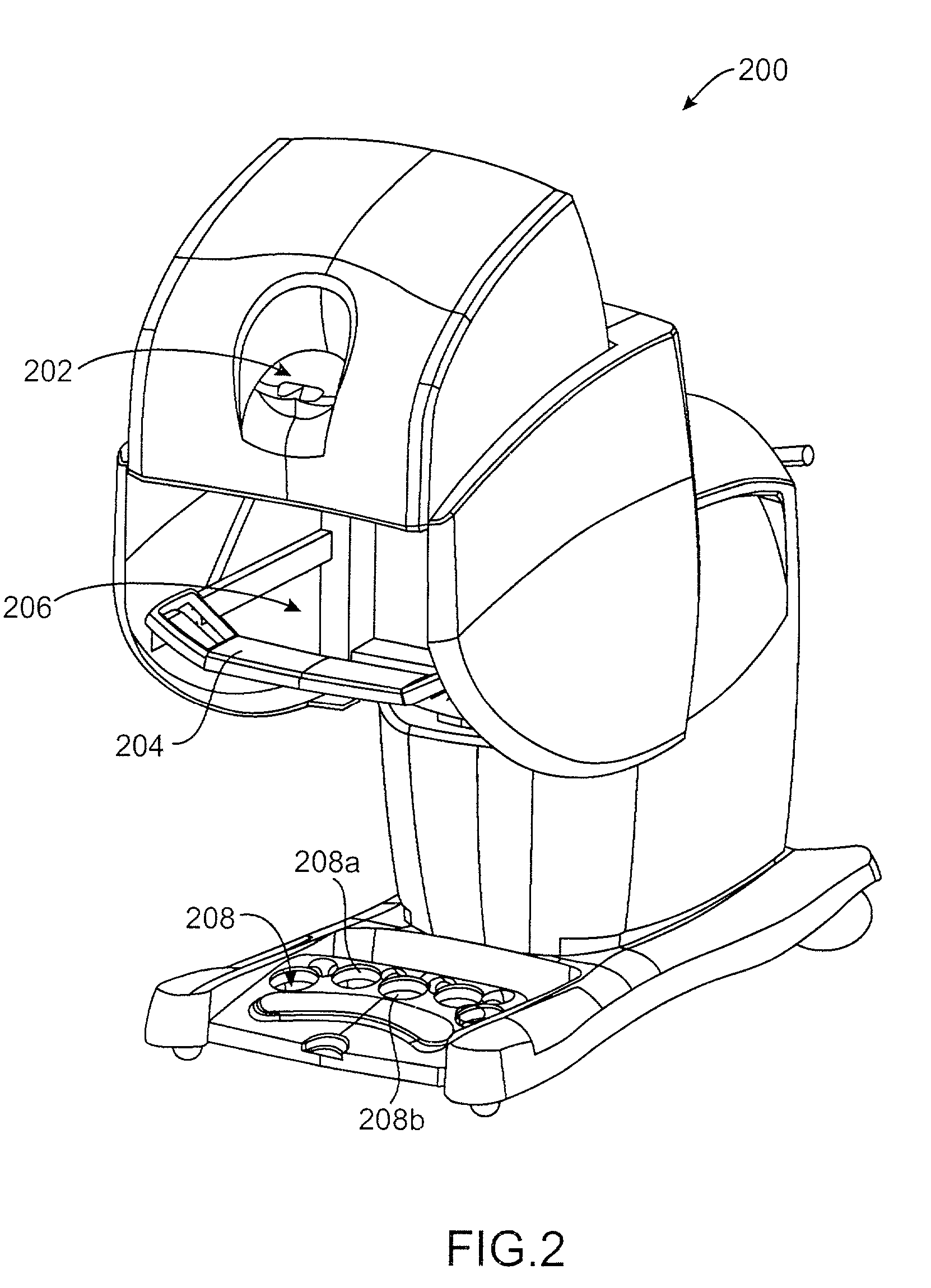

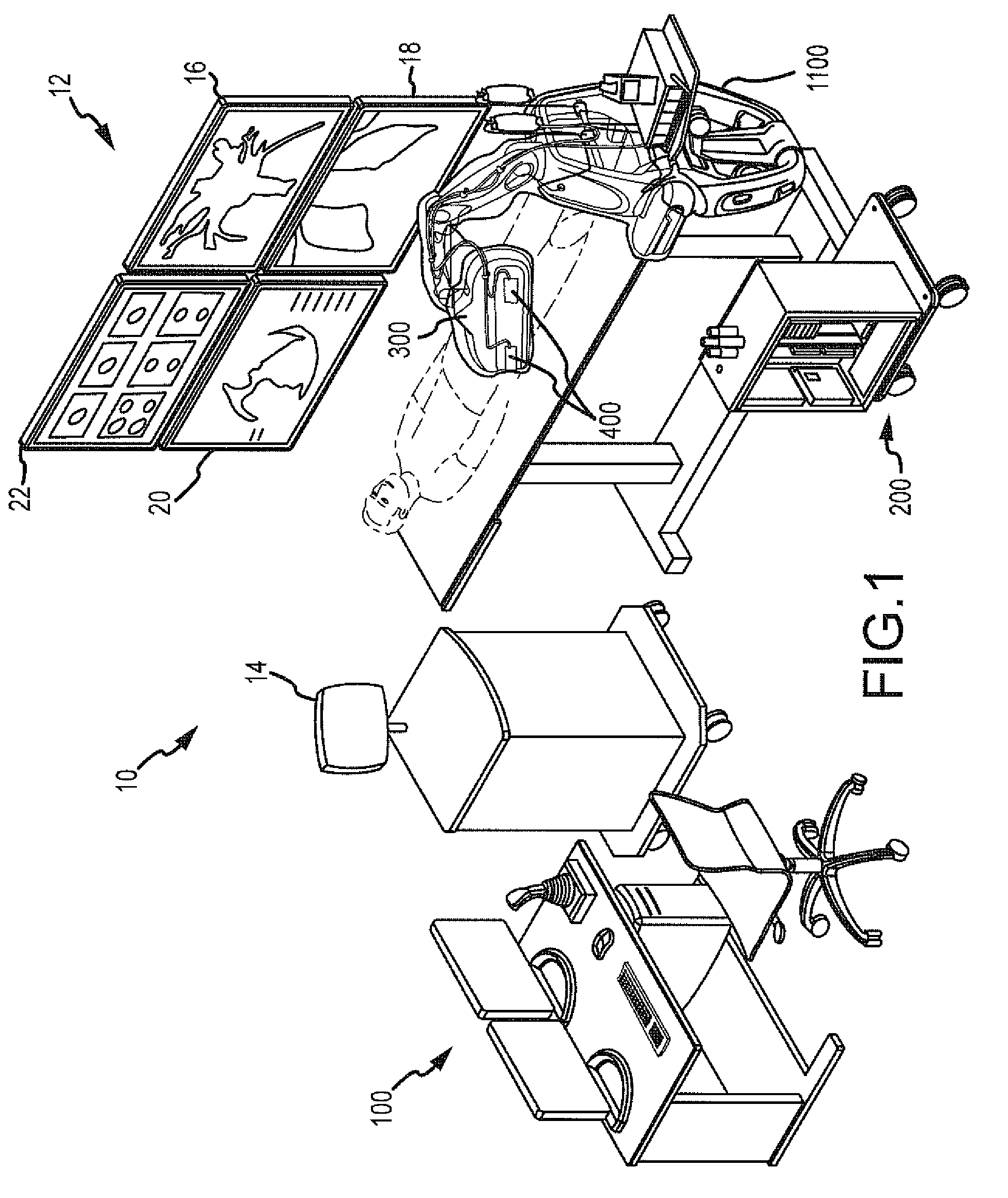

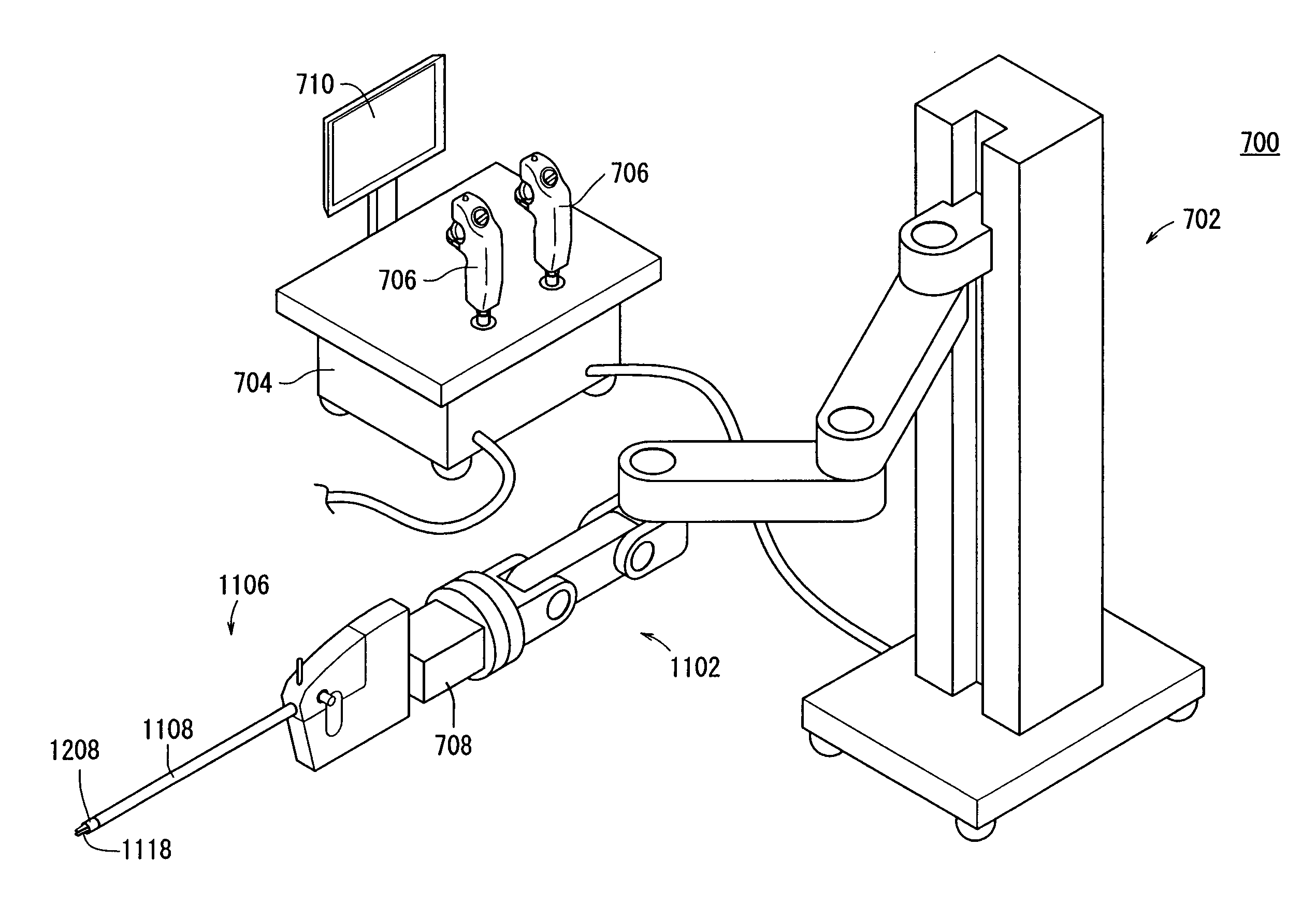

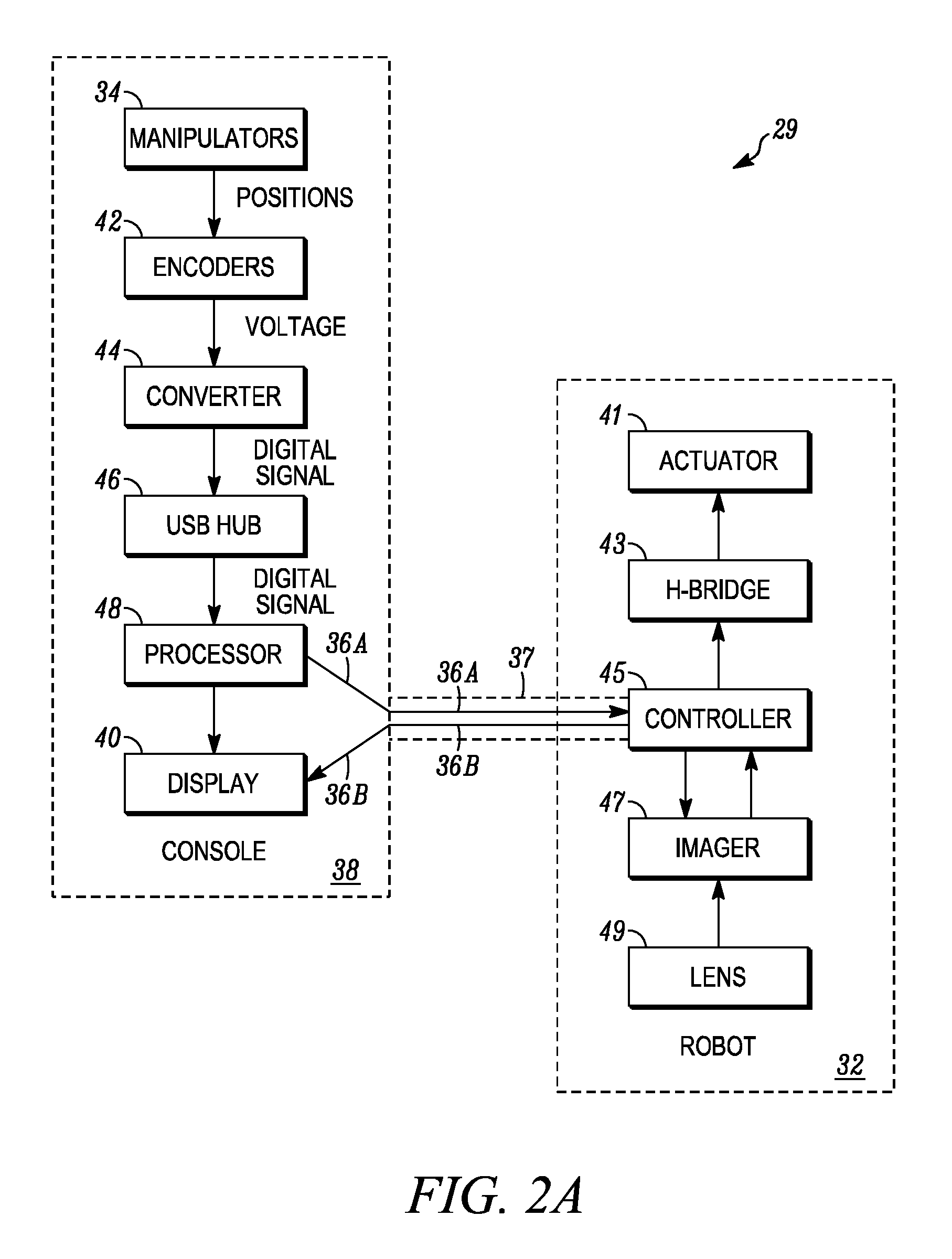

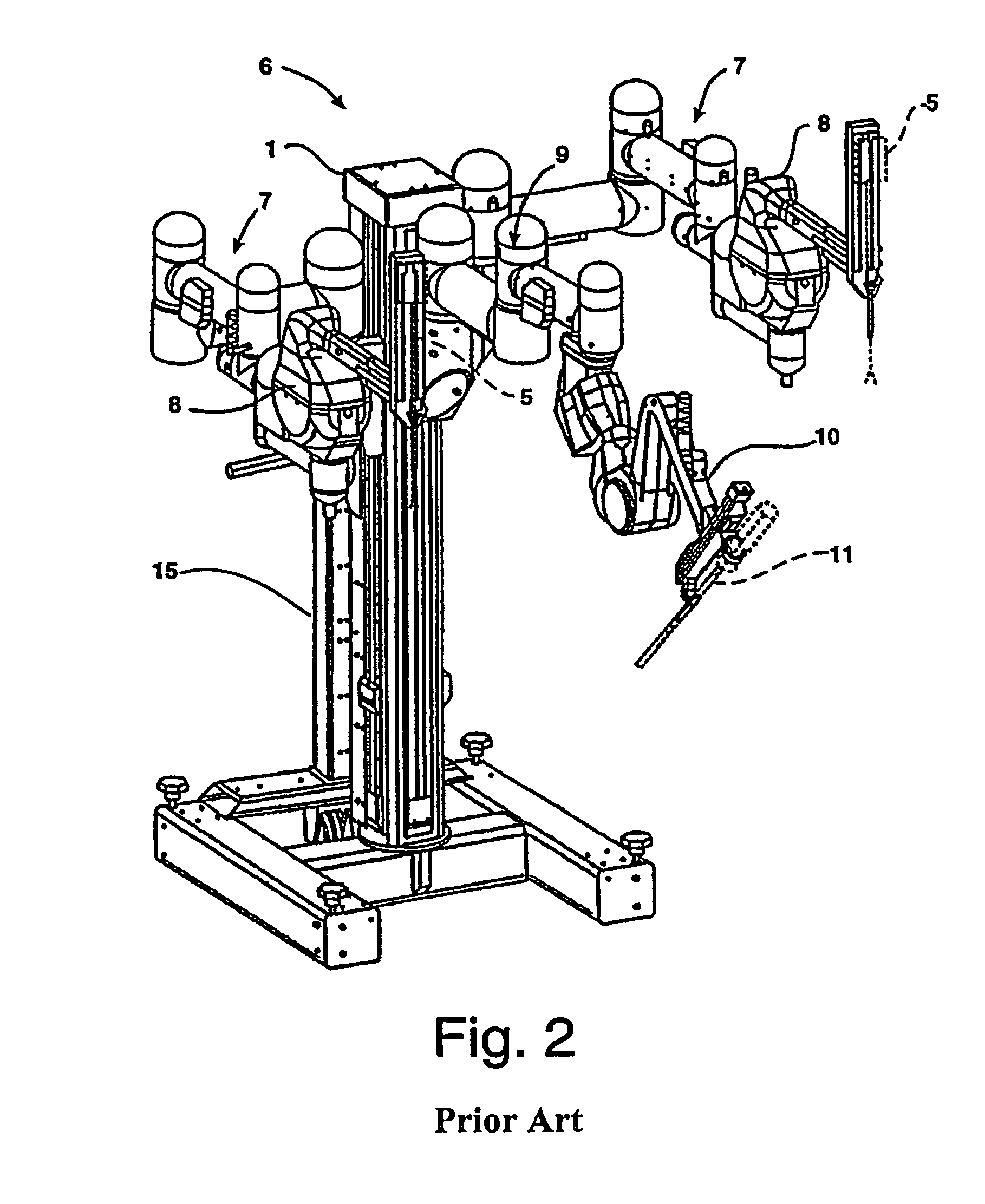

Surgical robotic tools, data architecture, and use

Robotic surgical tools, systems, and methods for preparing for and performing robotic surgery include a memory mounted on the tool. The memory can perform a number of functions when the tool is loaded on the tool manipulator: first, the memory can provide a signal verifying that the tool is compatible with that particular robotic system. Secondly, the tool memory may identify the tool-type to the robotic system so that the robotic system can reconfigure its programming. Thirdly, the memory of the tool may indicate tool-specific information, including measured calibration offsets indicating misalignment of the tool drive system, tool life data, or the like. This information may be stored in a read only memory (ROM), or in a nonvolatile memory which can be written to only a single time. The invention further provides improved engagement structures for coupling robotic surgical tools with manipulator structures.

Owner:INTUITIVE SURGICAL OPERATIONS INC

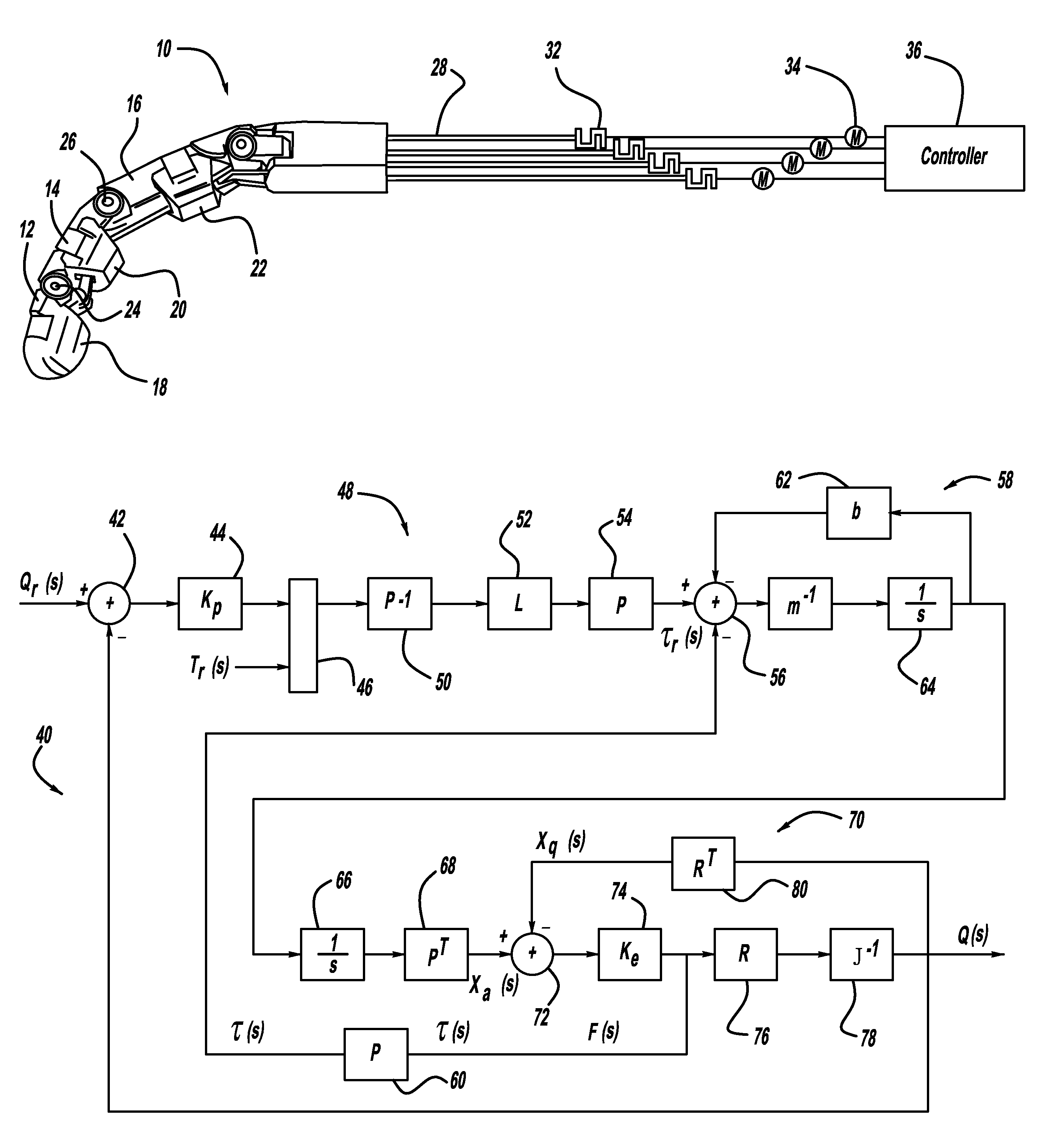

Tool grip calibration for robotic surgery

ActiveUS7386365B2Limited tool lifeStringent manufacturing toleranceProgramme-controlled manipulatorDiagnosticsEngineeringActuator

Telerobotic, telesurgical, and surgical robotic devices, systems, and methods selectively calibrate end effector jaws by bringing the jaw elements into engagement with each other. Commanded torque signals may bring the end effector elements into engagement while monitoring the resulting position of a drive system, optionally using a second derivative of the torque / position relationship so as to identify an end effector engagement position. Calibration can allow the end effector engagement position to correspond to a nominal closed position of an input handle by compensating for wear on the end effector, the end effector drive system, then manipulator, the manipulator drive system, the manipulator / end effector interfacing, and manufacturing tolerances.

Owner:INTUITIVE SURGICAL OPERATIONS INC

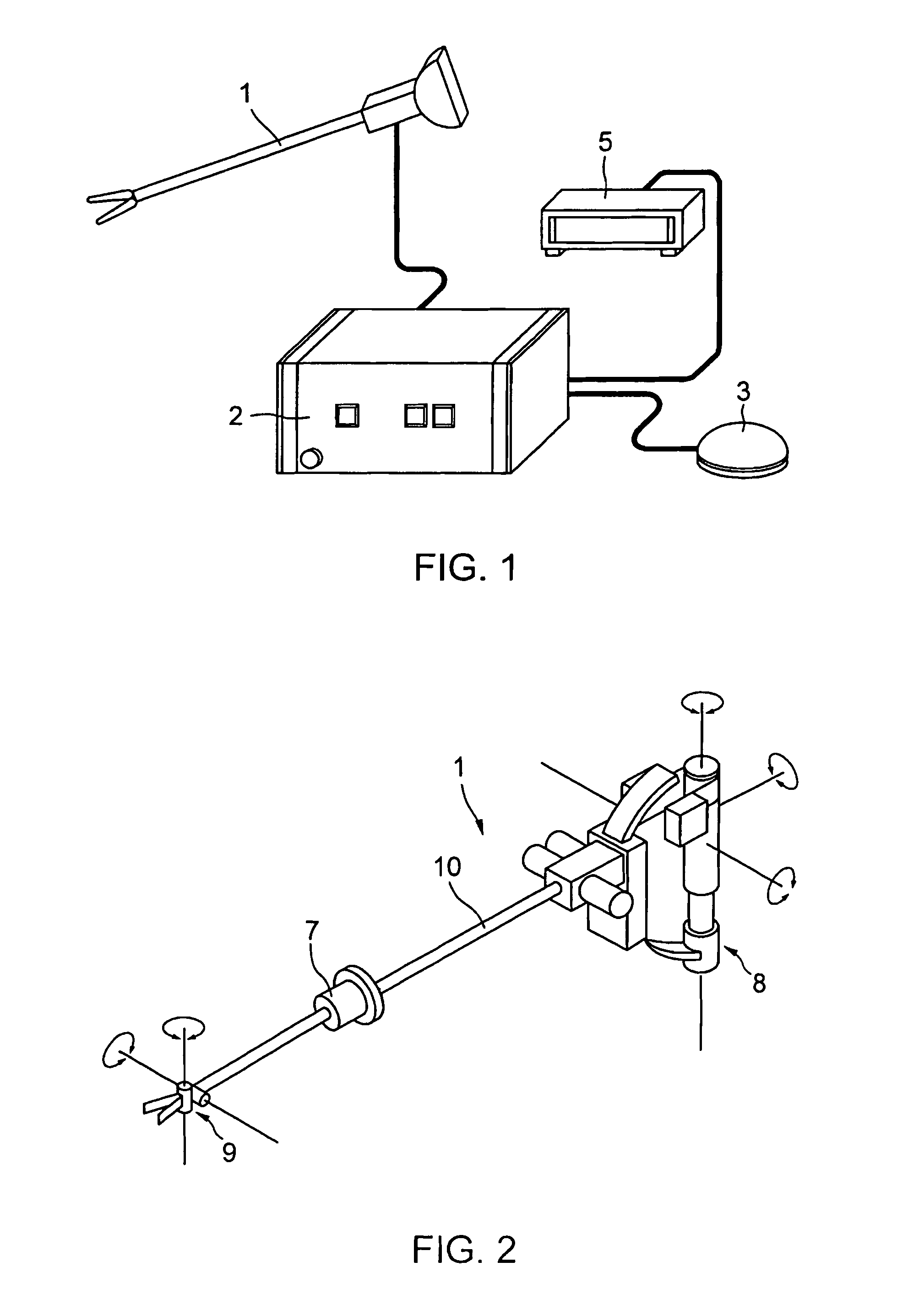

Surgical instrument

A surgical instrument comprising an instrument handle linked to a proximal end portion of a tube shaft to the distal end portion of which an instrument head is linked so as to be inclinable, in which instrument head, in turn, an effector including at least one pivotable engaging element is rotatably supported. The instrument handle comprises a number of manipulators and / or operating mechanisms designed for operating the instrument head and / or the effector. One of the manipulators consists of an operating element in the form of a rotary knob with respect to its function, the operating element being rotatably supported on the instrument handle.

Owner:TRANSENTERIX EURO SARL

Robot for surgical applications

The present invention provides a micro-robot for use inside the body during minimally-invasive surgery. The micro-robot includes an imaging devices, a manipulator, and in some embodiments a sensor.

Owner:BOARD OF RGT UNIV OF NEBRASKA

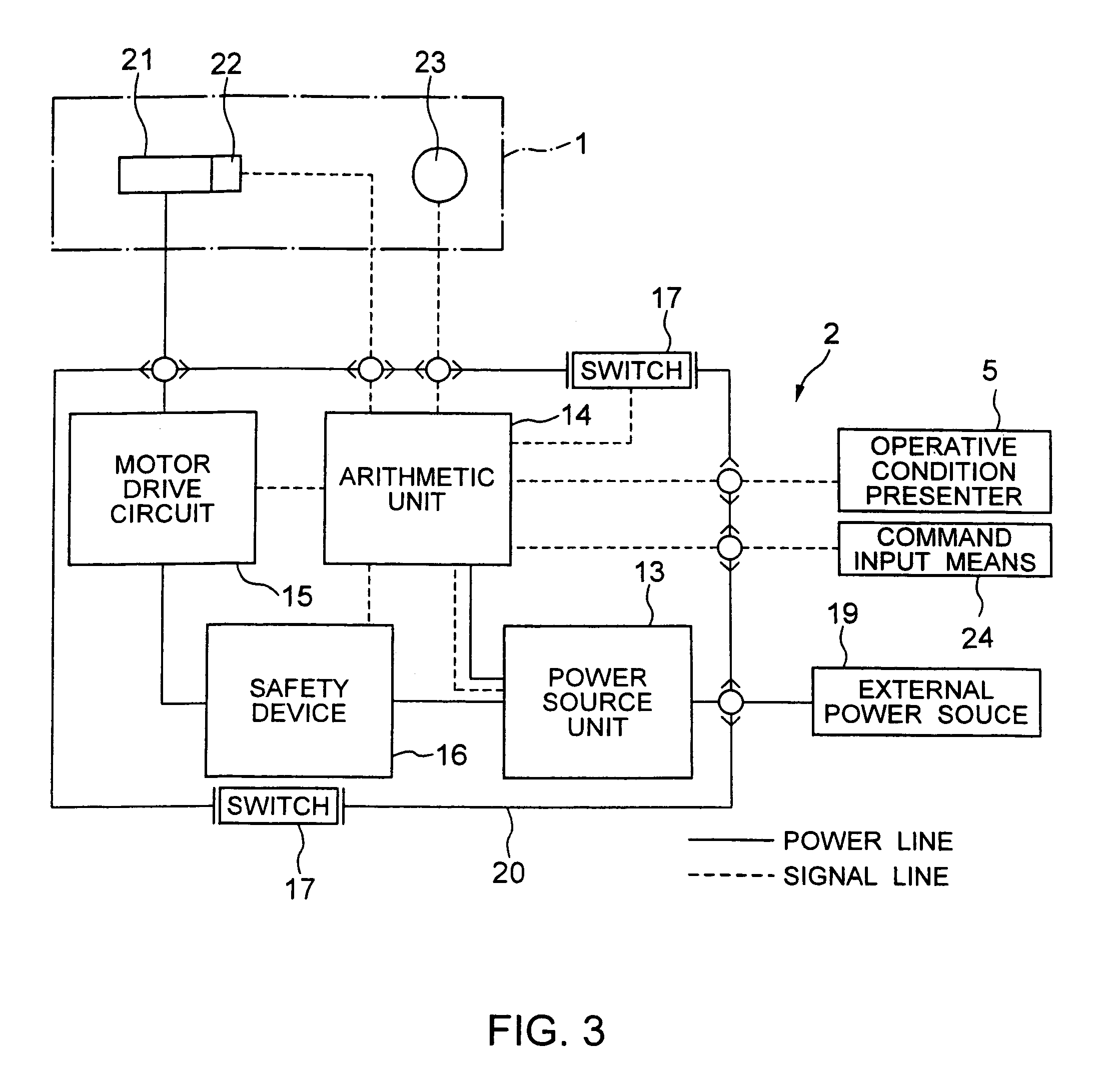

Medical manipulator and method of controlling the same

InactiveUS6853879B2Easy to operateWithout spoiling safetyProgramme-controlled manipulatorDigital data processing detailsOperabilityOperation mode

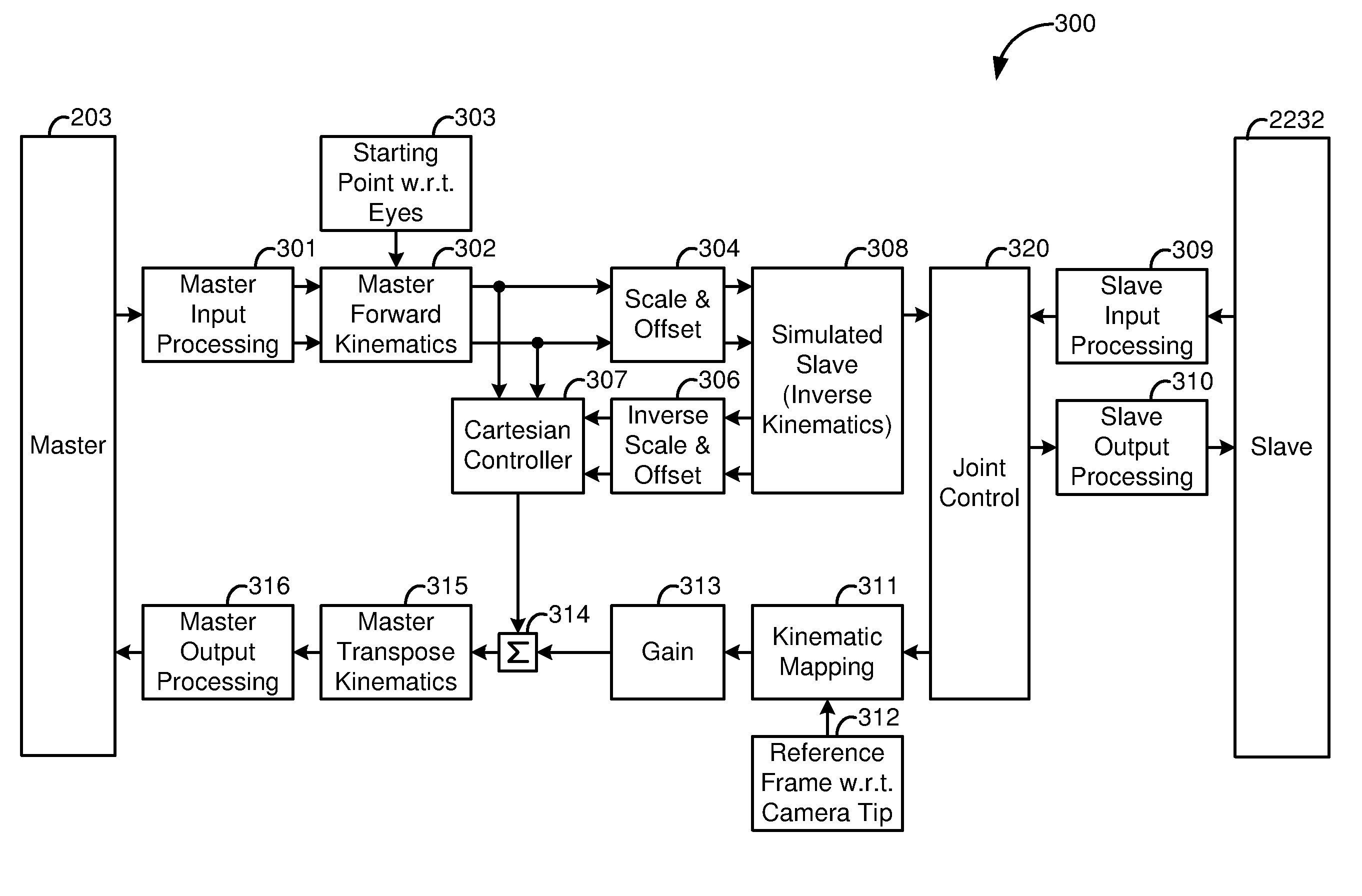

A medical master / slave manipulator is excellent in operability and capable of reducing burden on the operator. The medical master / slave manipulator includes a master unit provided with an operation control portion, a slave unit provided with a working device, an interlocking mechanism interlocking the slave unit with the master unit, an orientation difference measuring mechanism for measuring the orientation difference between the orientation of the master unit and that of the slave unit, and a control mechanism for controlling the slave unit to adjust the orientation of the slave unit to that of the master unit so that the orientation difference is reduced to zero in a transient master / slave operation mode in which an operation mode changes from an unrestricted operation mode to a master / slave operation mode.

Owner:TERUMO KK

Manipulator

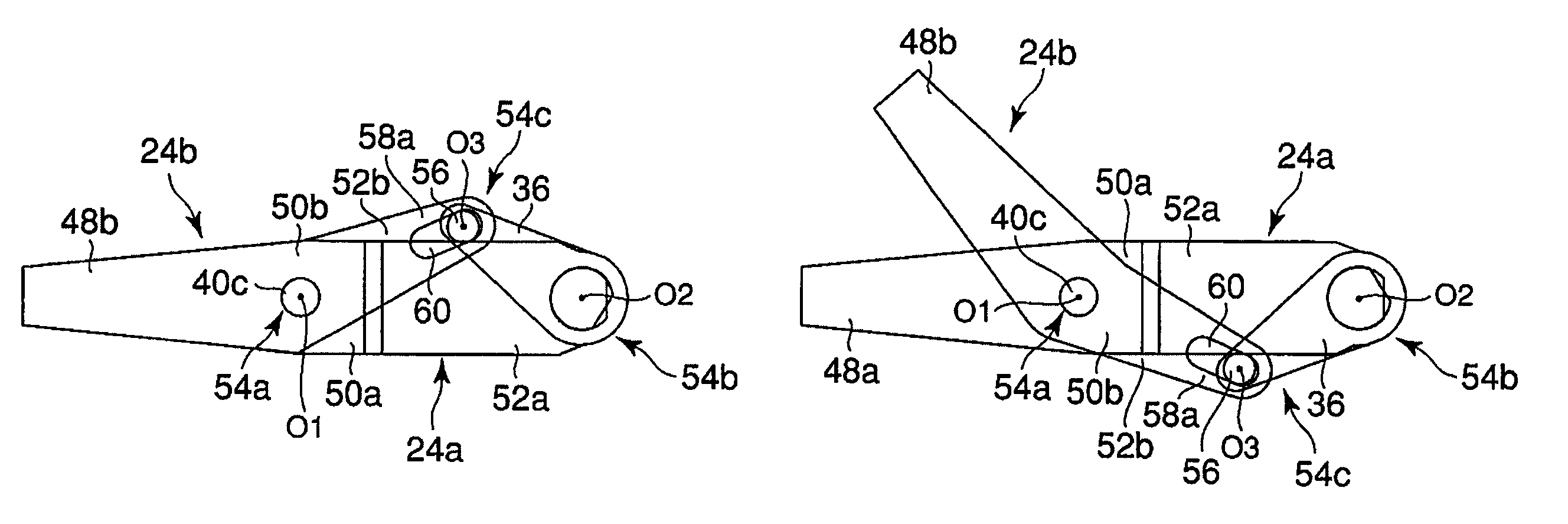

A manipulator has a working unit in which when at least a first end effector finger and a second end effector finger are maximally closed on each other, at least the distance between a third joint axis and a first joint axis is greater than the distance between the first joint axis and a distal end of the second end effector finger, or the distance between the third joint axis and the first joint axis is greater than the distance between third joint axis and a second joint axis, or the angle formed between a direction from the third joint axis to the first joint axis and a direction from the third joint axis to the second joint axis is not π.

Owner:KARL STORZ GMBH & CO KG

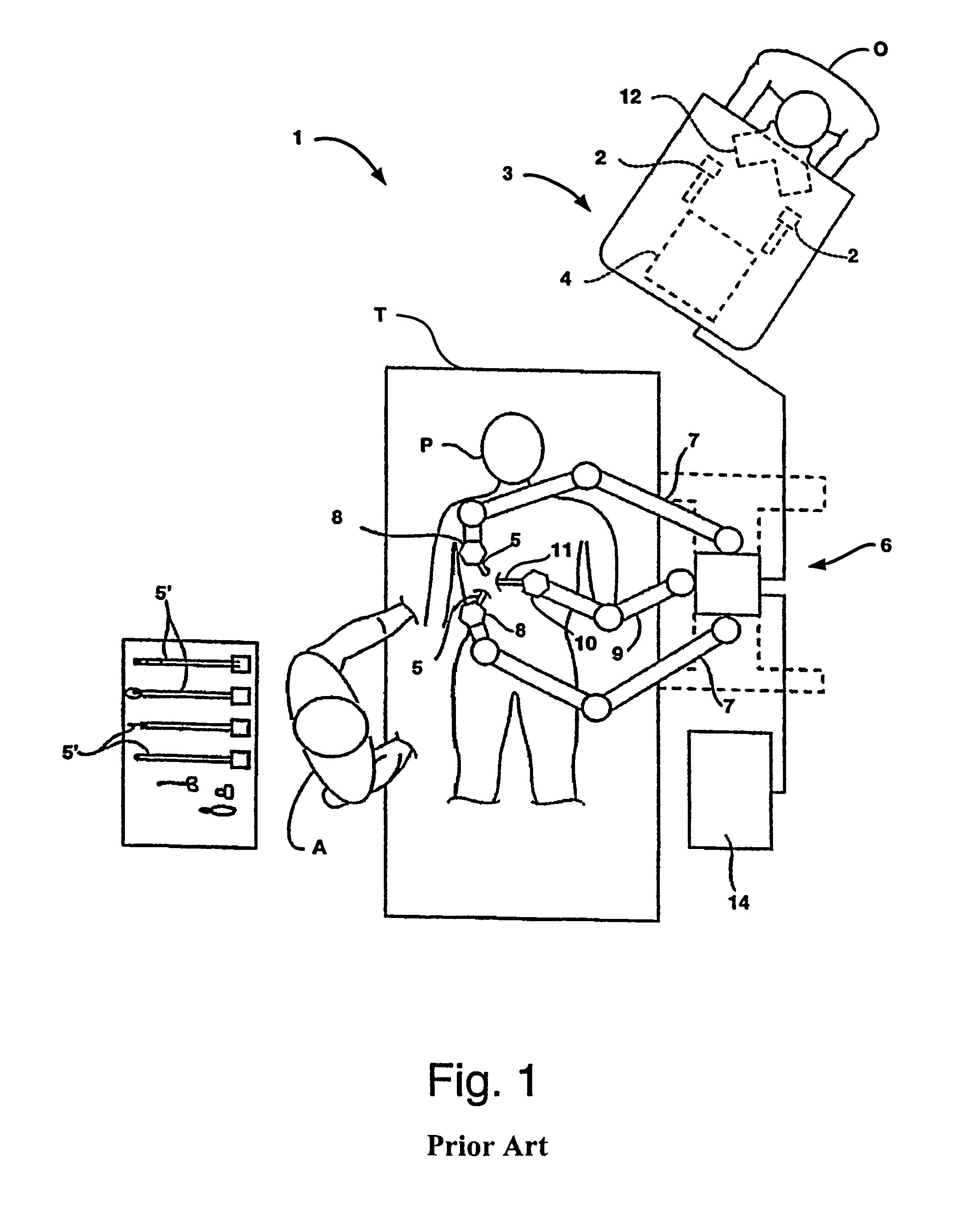

Repositioning and reorientation of master/slave relationship in minimally invasive telesurgery

InactiveUS7087049B2Easy SetupEasy to adjustDiagnostic recording/measuringSensorsEngineeringDegrees of freedom

The invention provides robotic surgical systems which allow selectable independent repositioning of an input handle of a master controller and / or a surgical end effector without corresponding movement of the other. In some embodiments, independent repositioning is limited to translational degrees of freedom. In other embodiments, the system provides an input device adjacent a manipulator supporting the surgical instrument so that an assistant can reposition the instrument at the patient's side.

Owner:INTUITIVE SURGICAL OPERATIONS INC

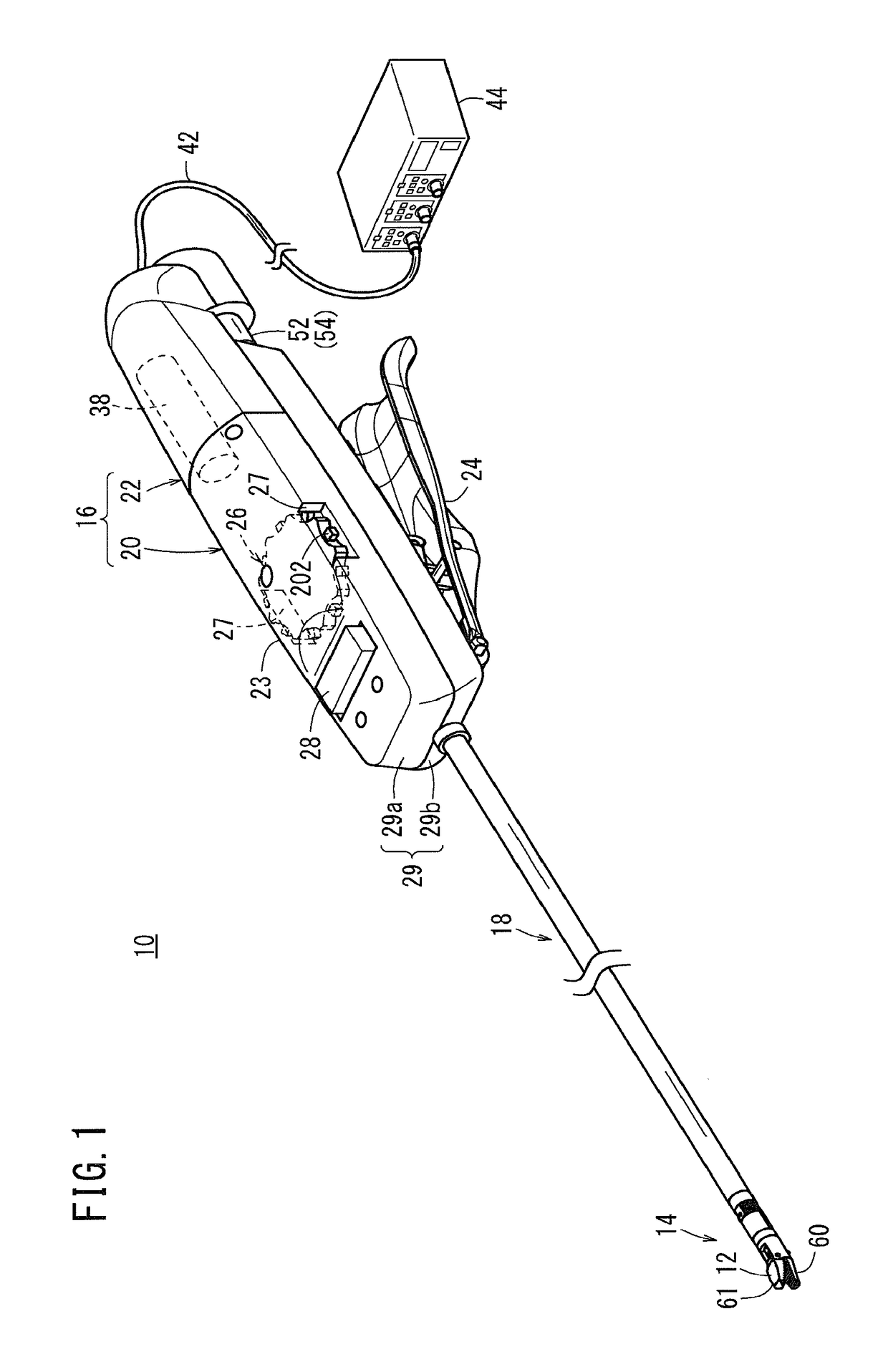

Manipulator for medical use

Owner:KARL STORZ GMBH & CO KG

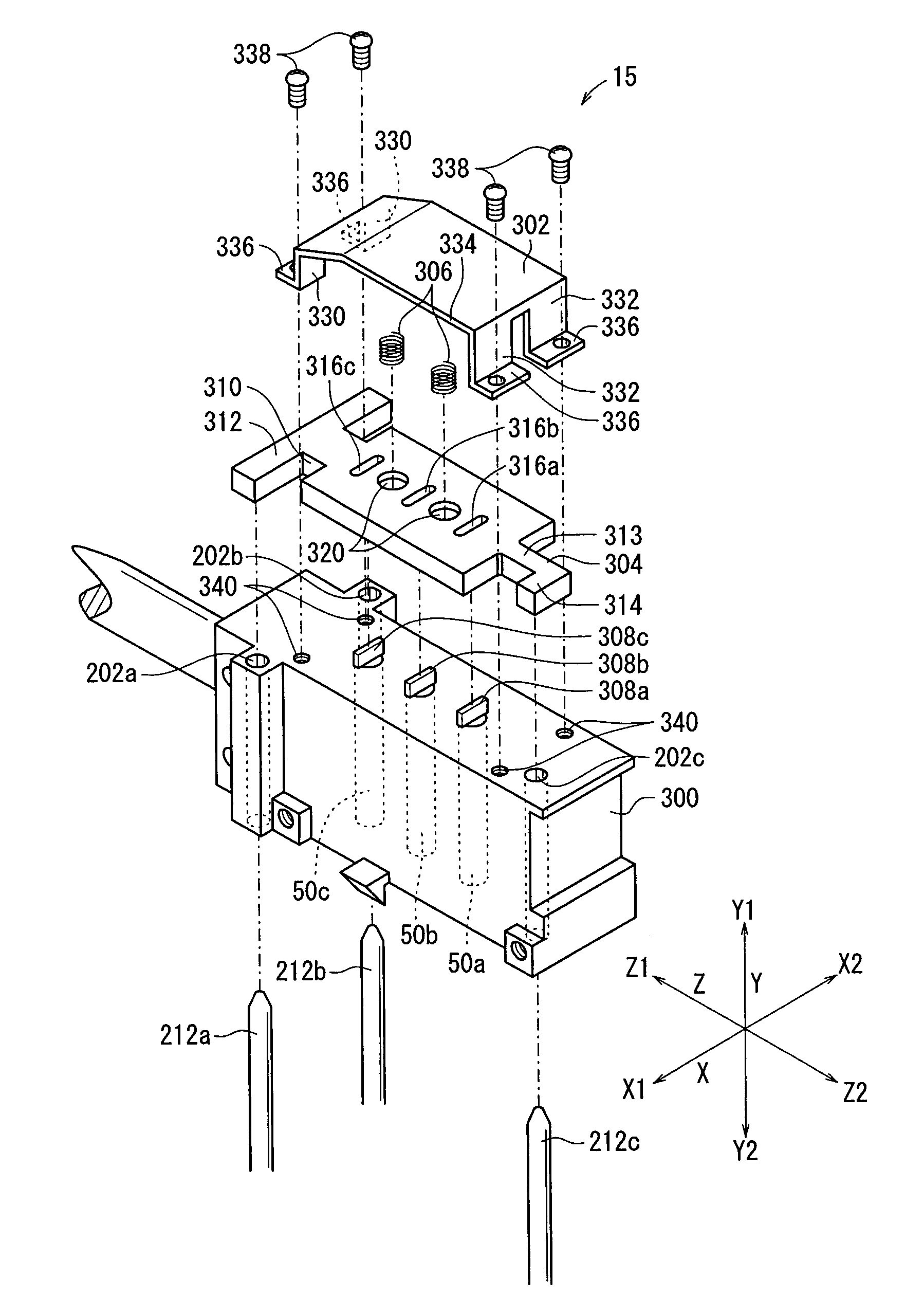

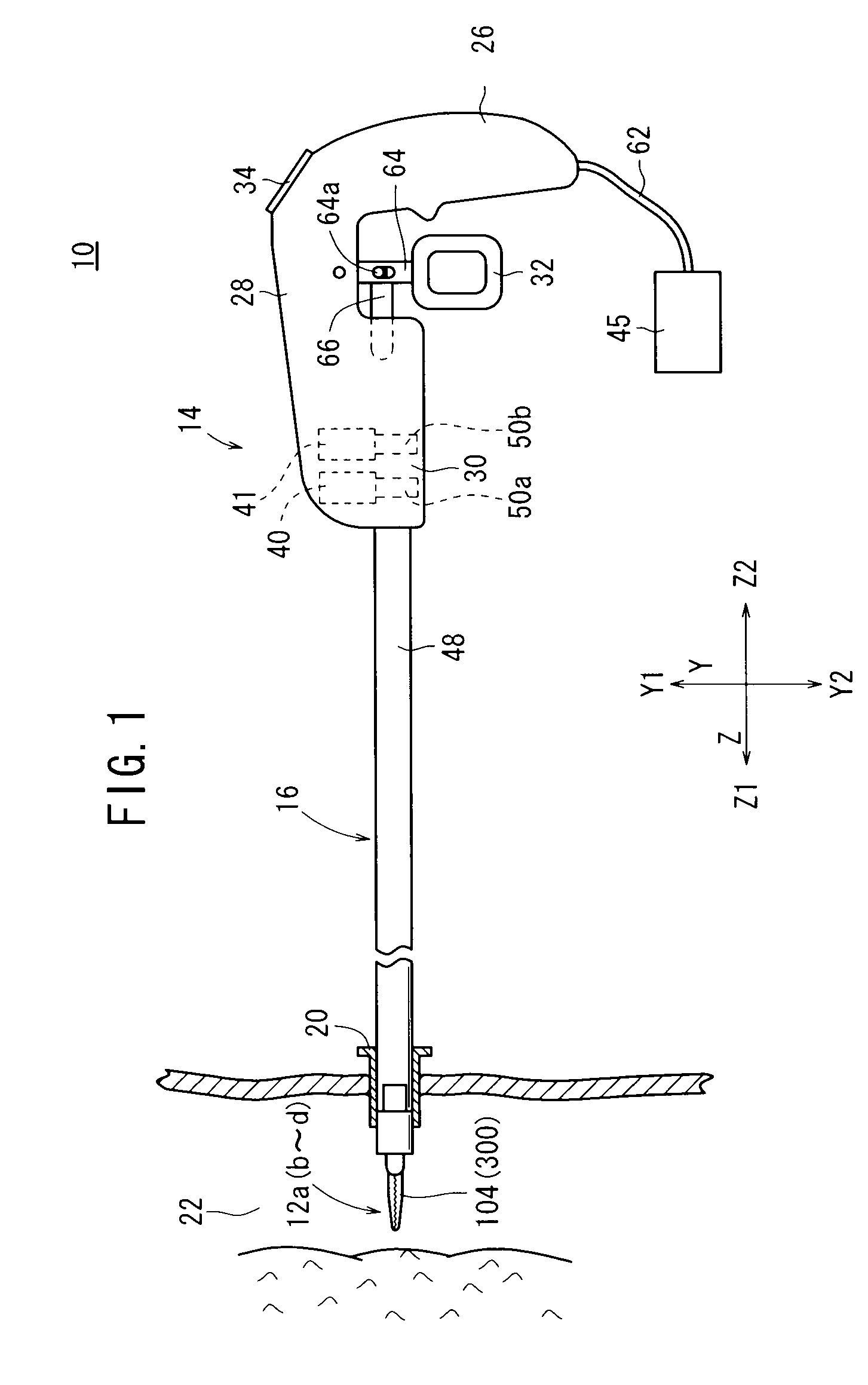

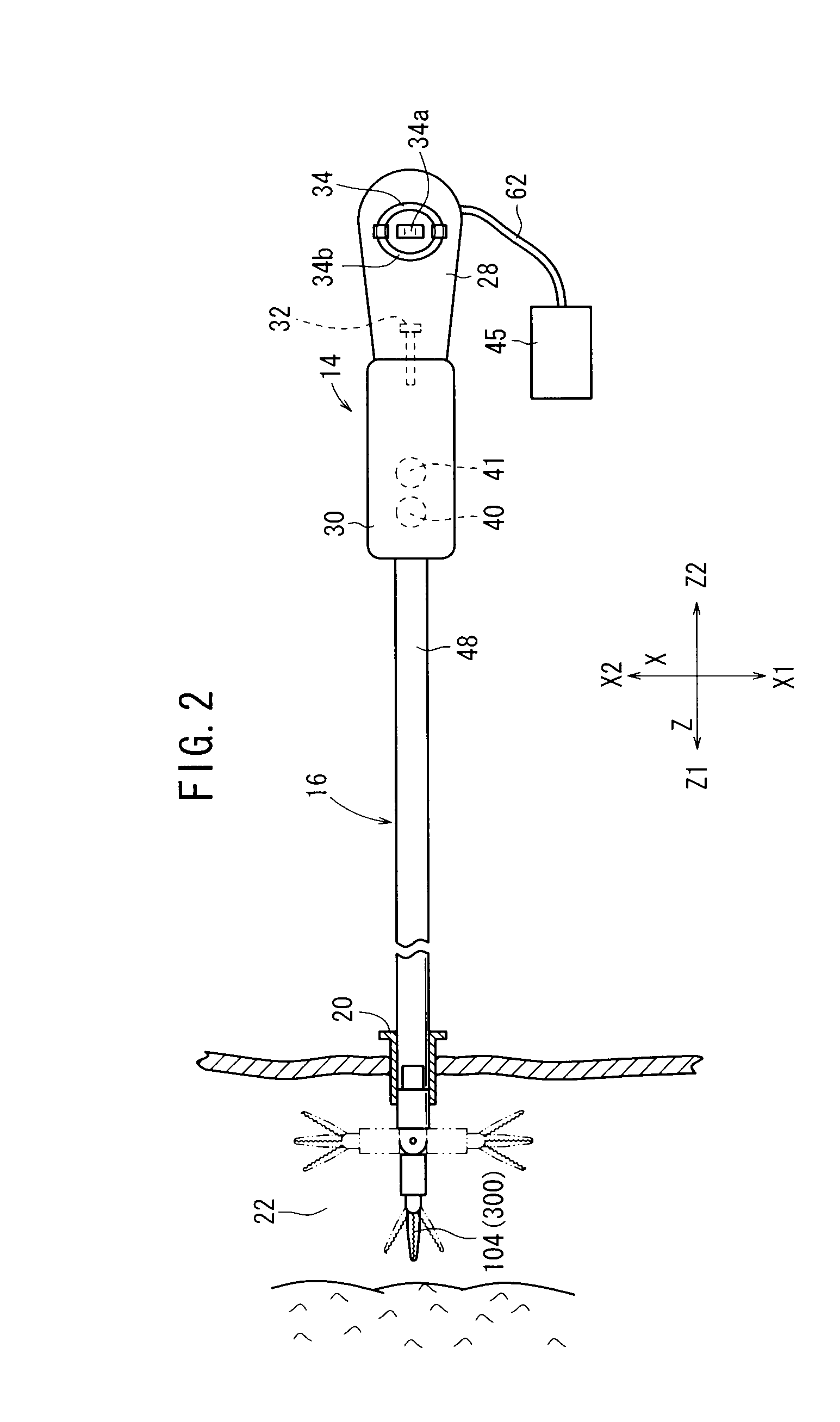

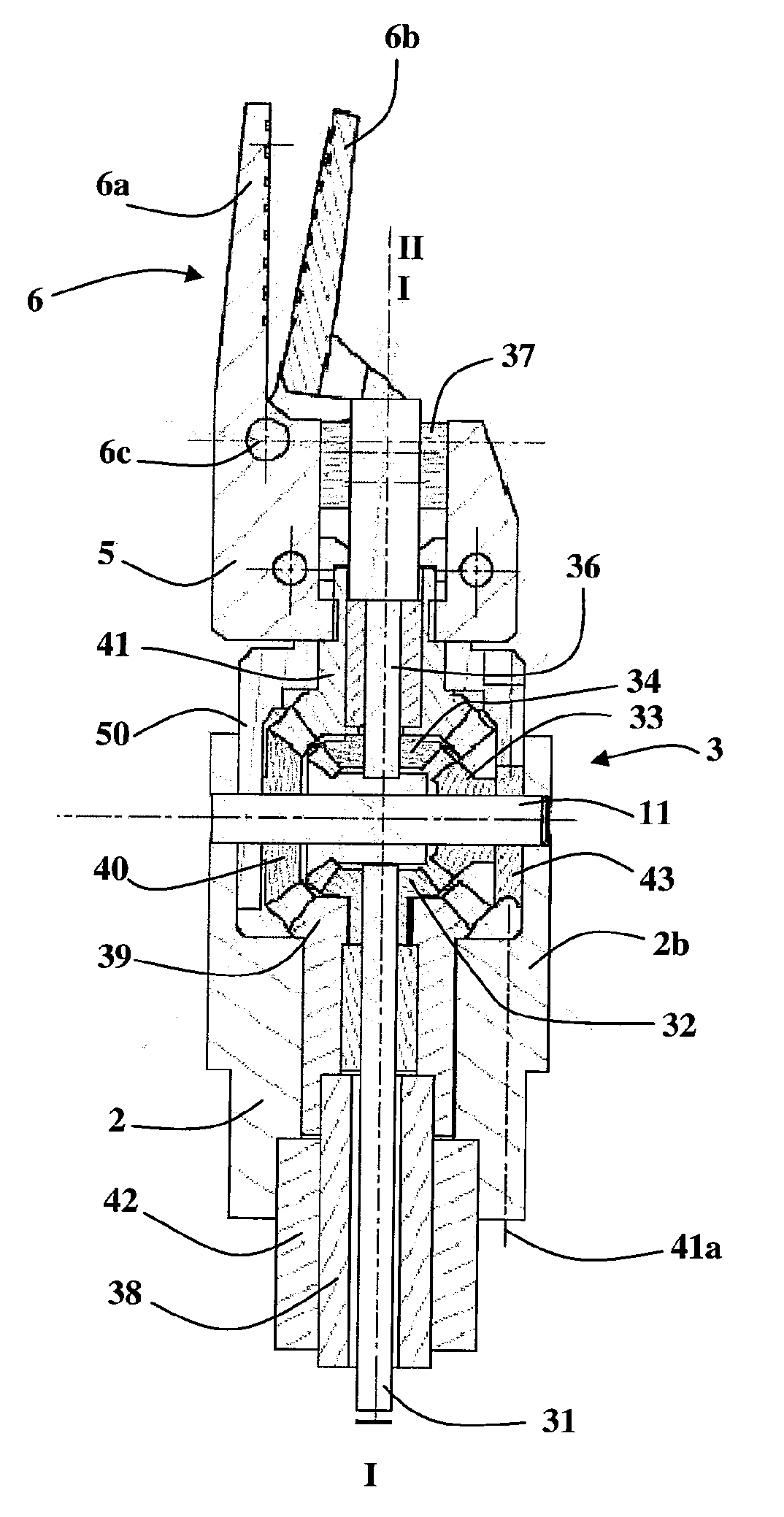

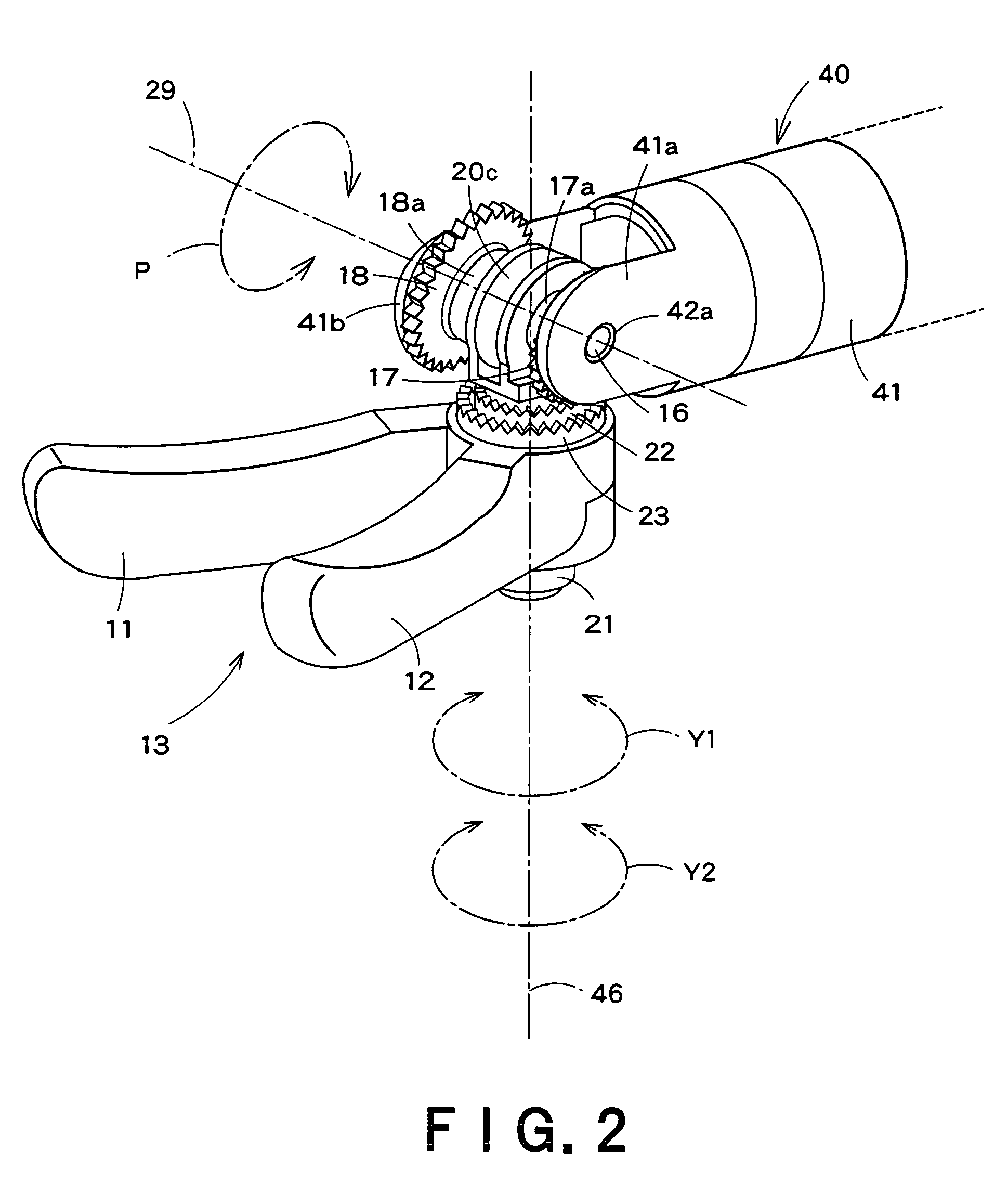

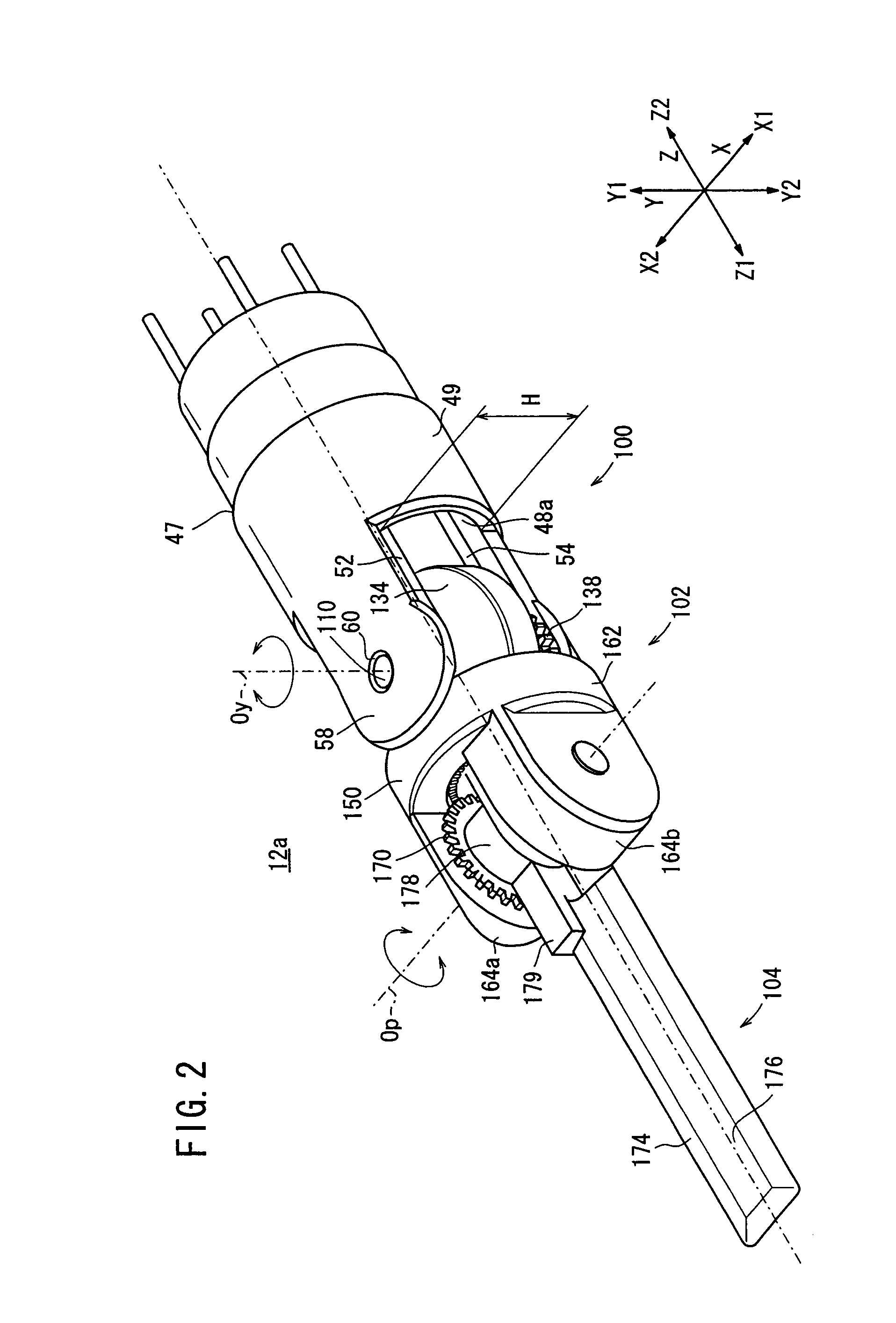

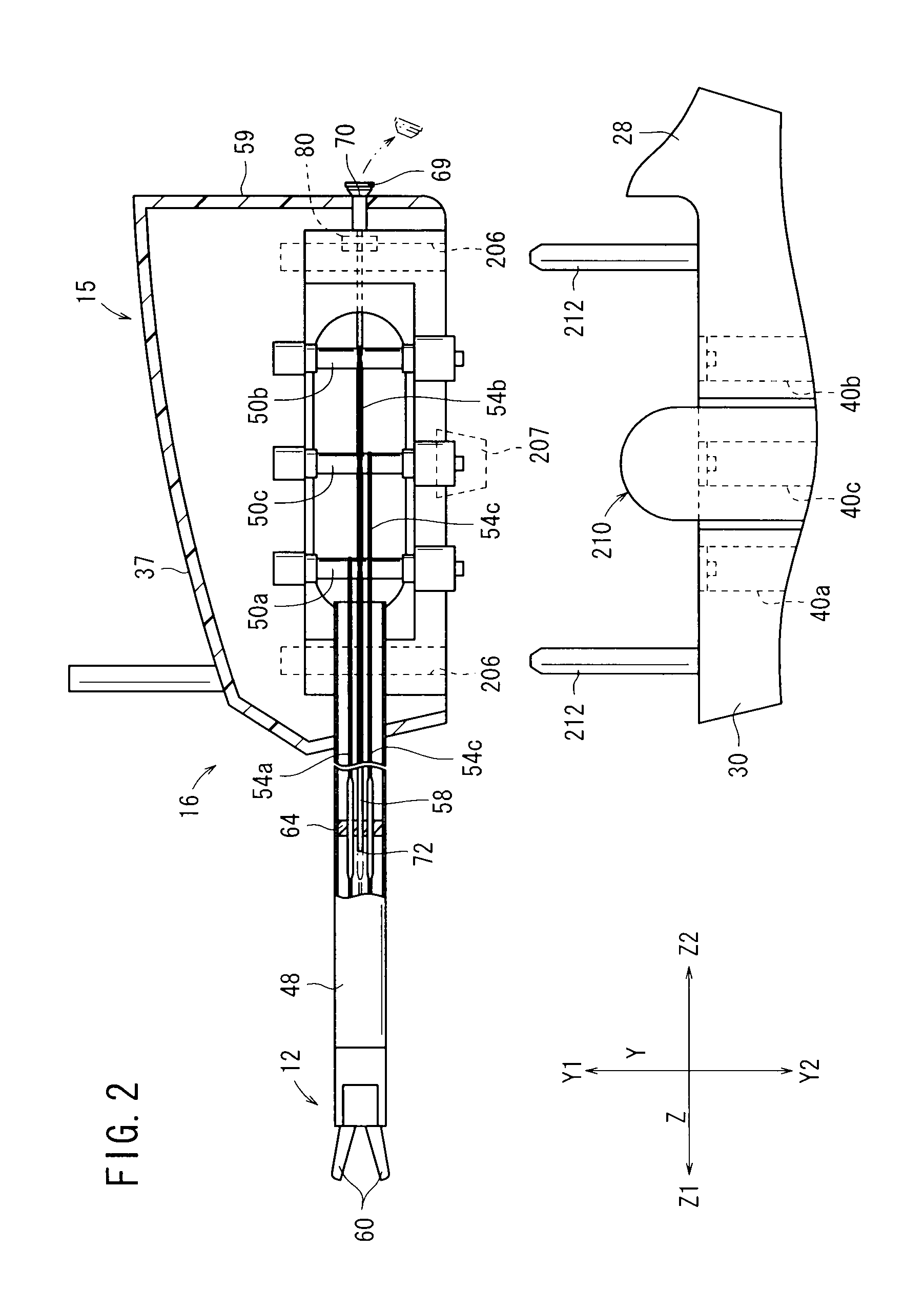

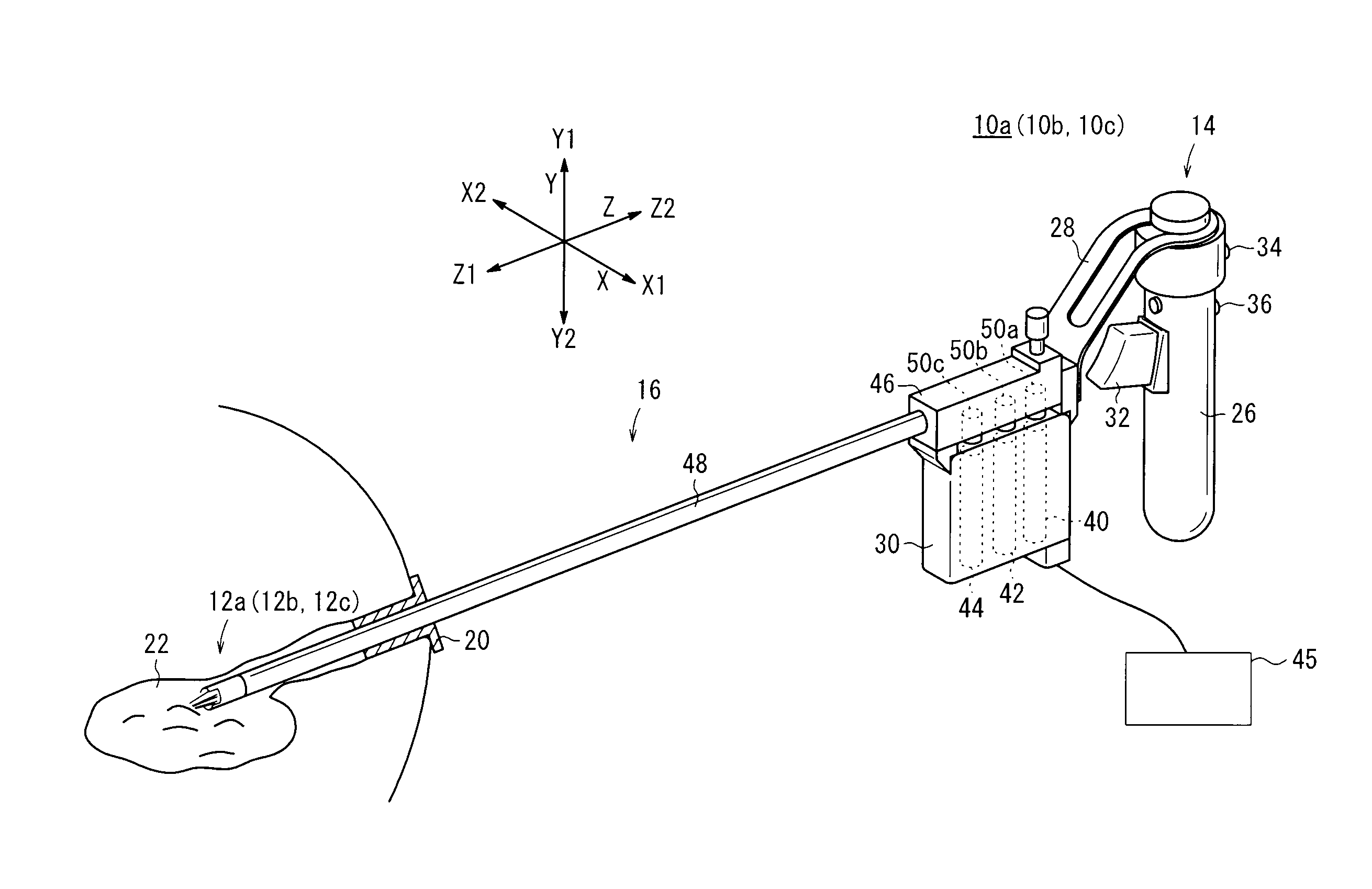

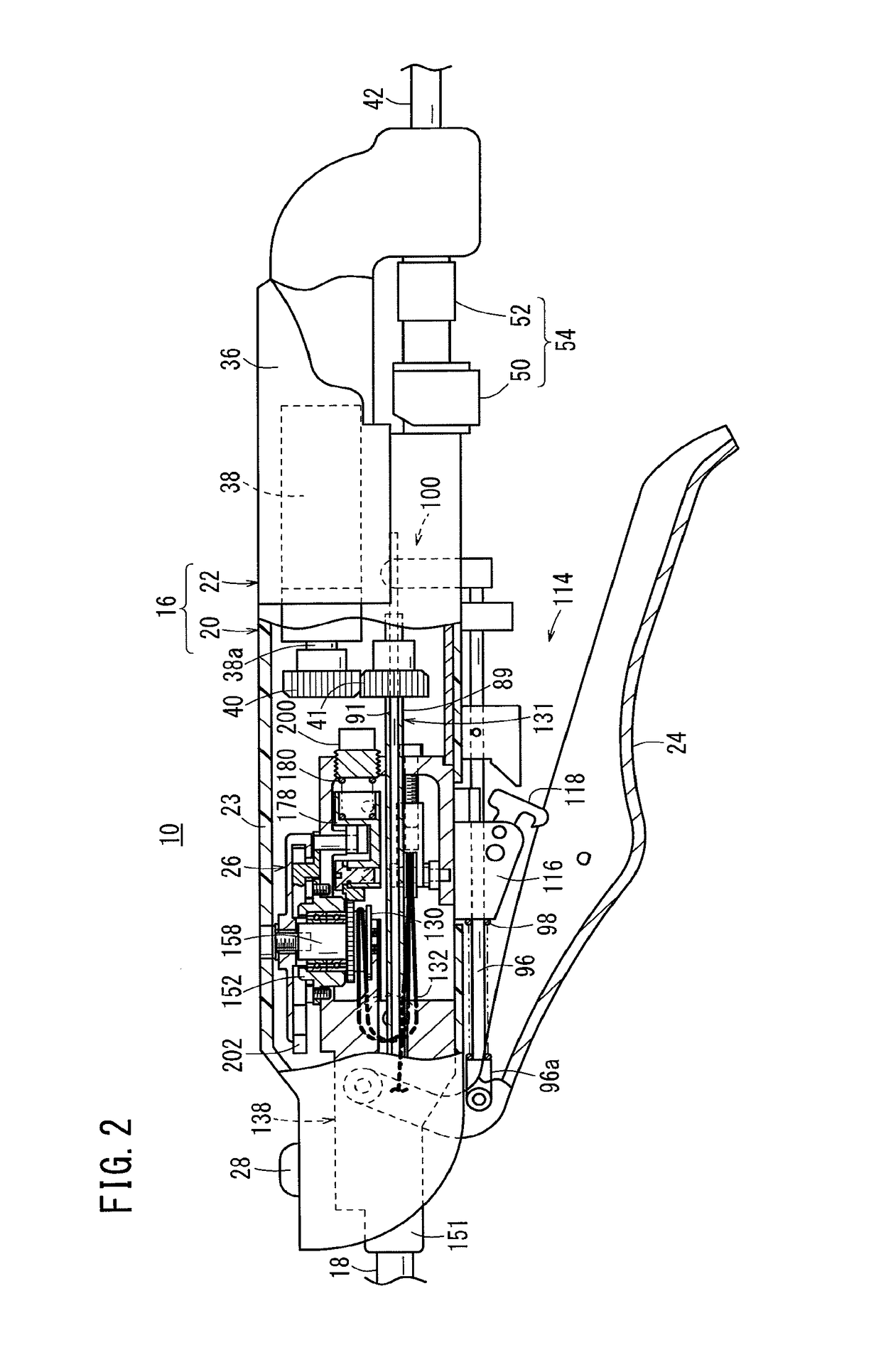

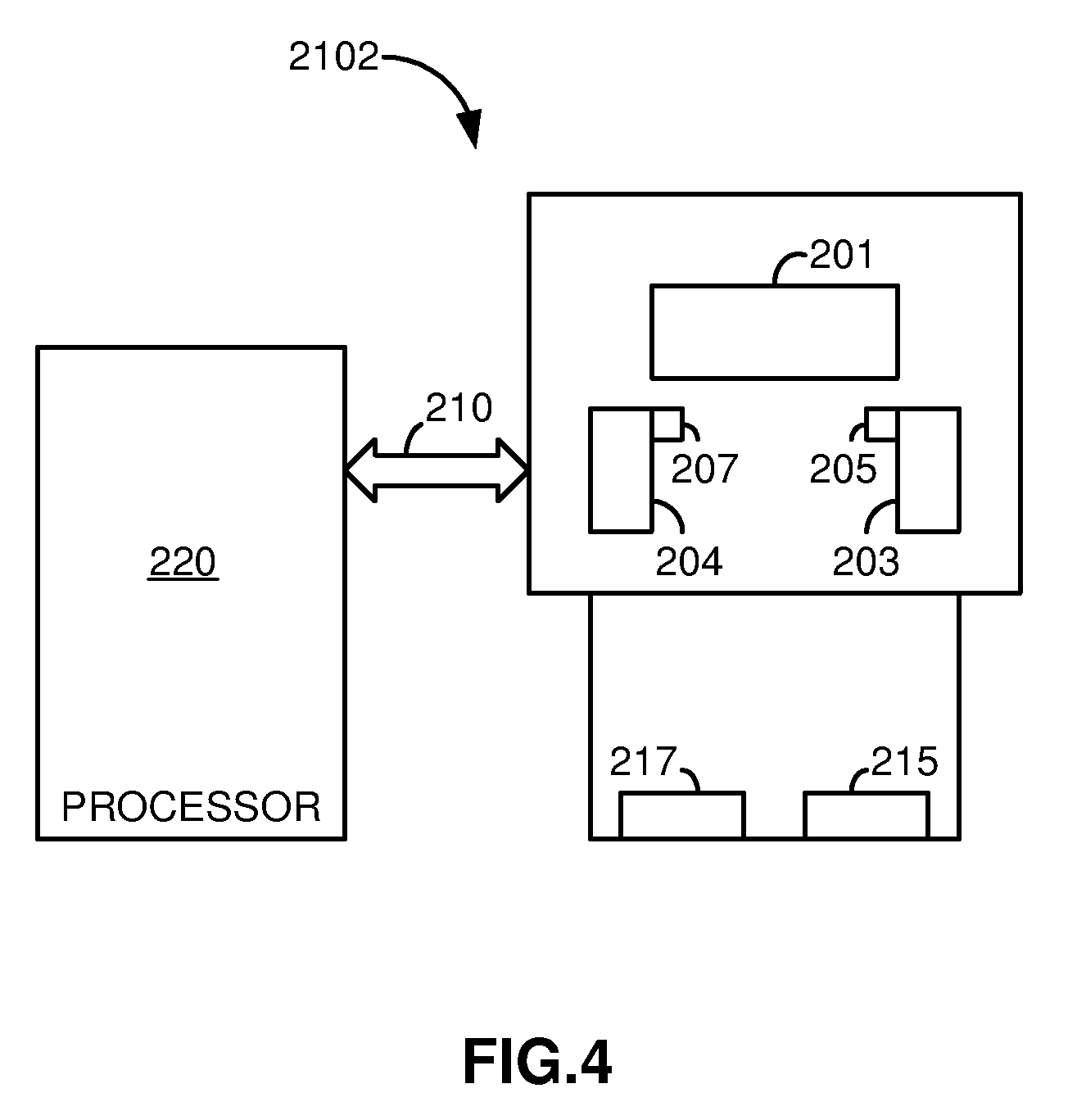

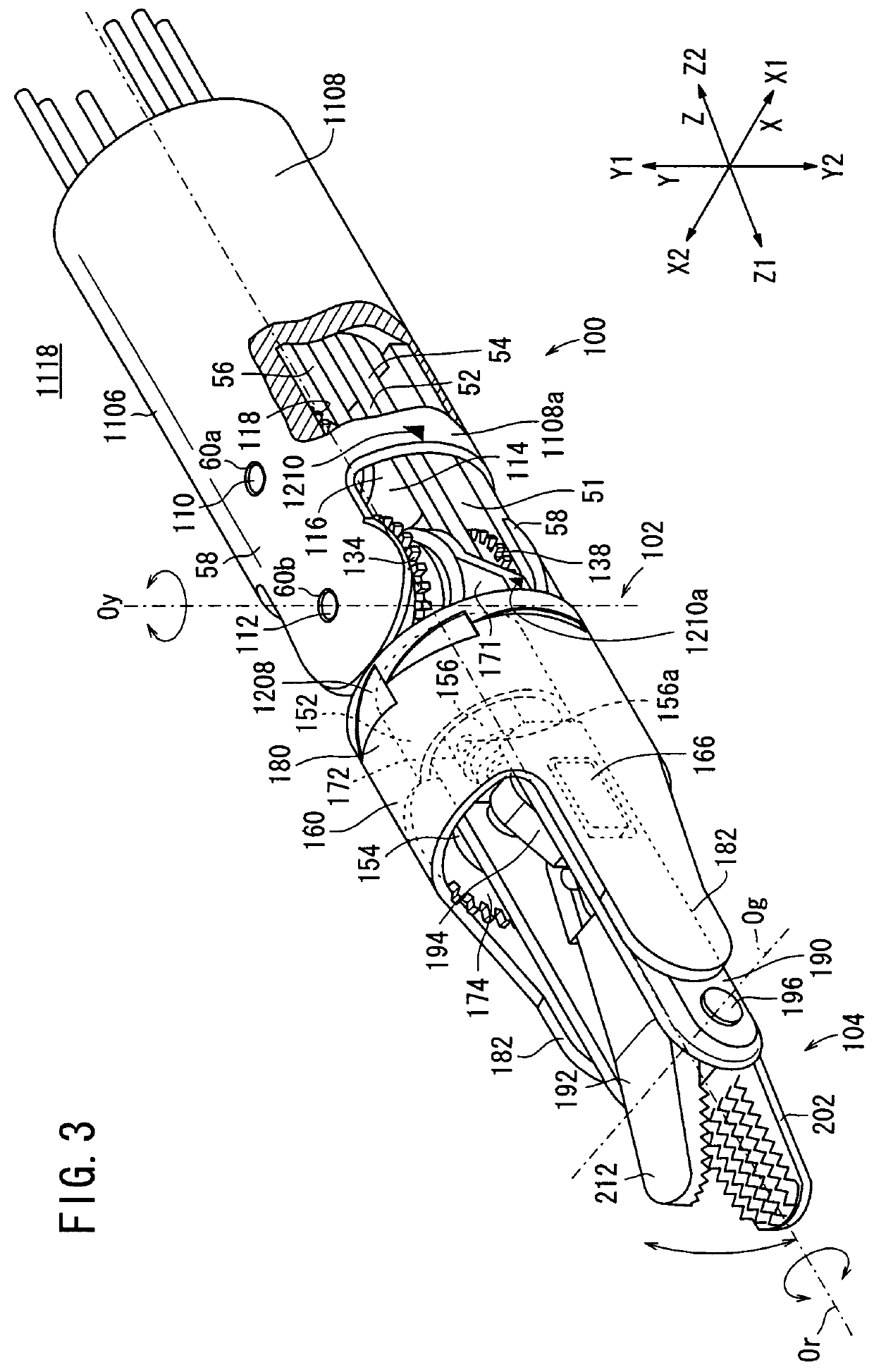

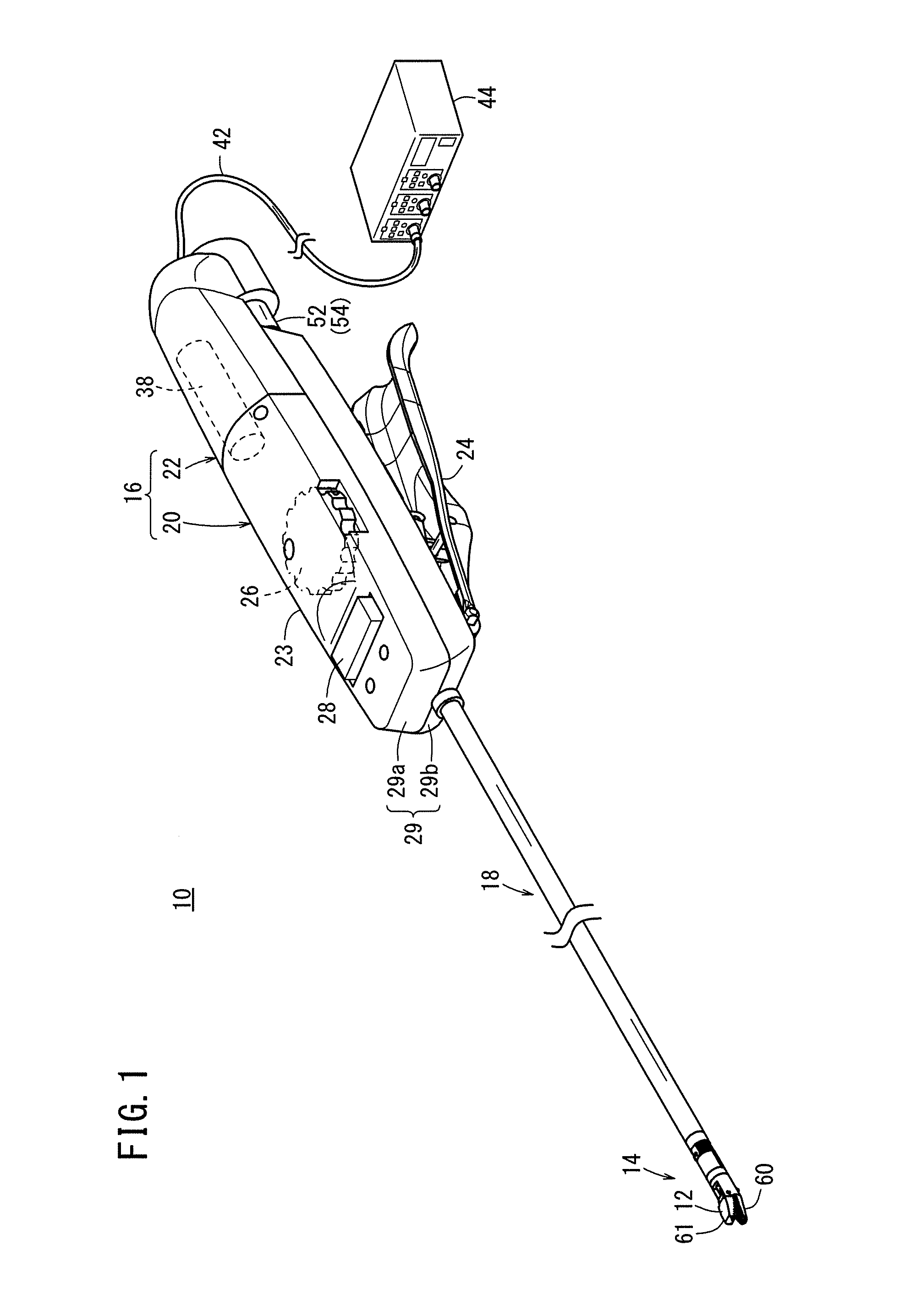

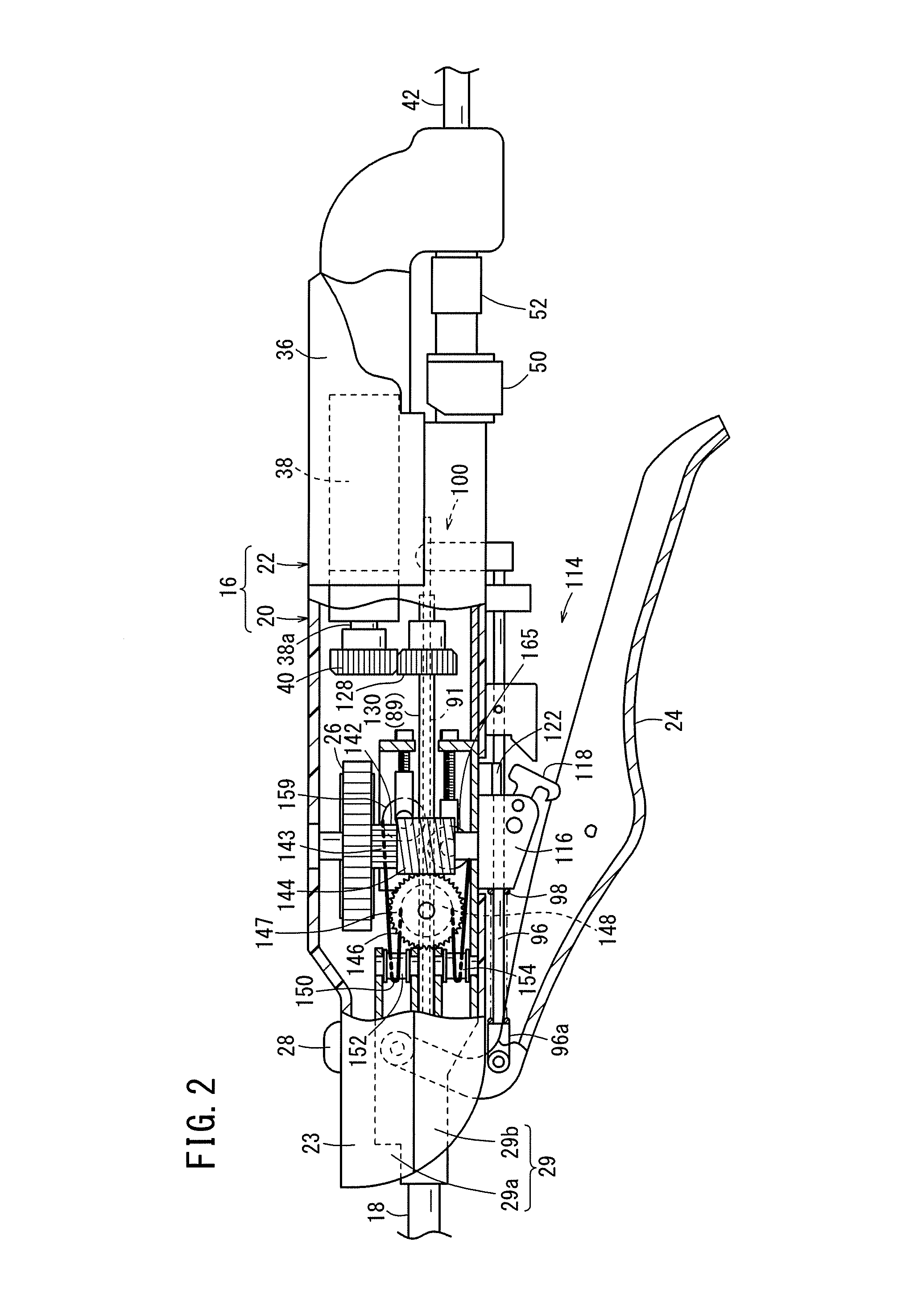

Medical manipulator

A medical manipulator includes an operating unit and a working unit. The operating unit has an actuator block with motors housed therein. The working unit is detachably mounted on the actuator block by a coupler. The working unit comprises a joint shaft that extends from the coupler, and a distal-end working unit mounted on a distal end of the joint shaft. The distal-end working unit has three axes, including a yaw axis, a roll axis about which the distal-end working unit is rotatable and which is positioned closer to a distal end of the distal-end working unit than the yaw axis, and a gripper axis about which a gripper is openable and closable and which is positioned on the distal end. The distal-end working unit can be operated about the roll axis by a motor, which is positioned closer to the distal end than the yaw axis.

Owner:TERUMO KK

Medical manipulator

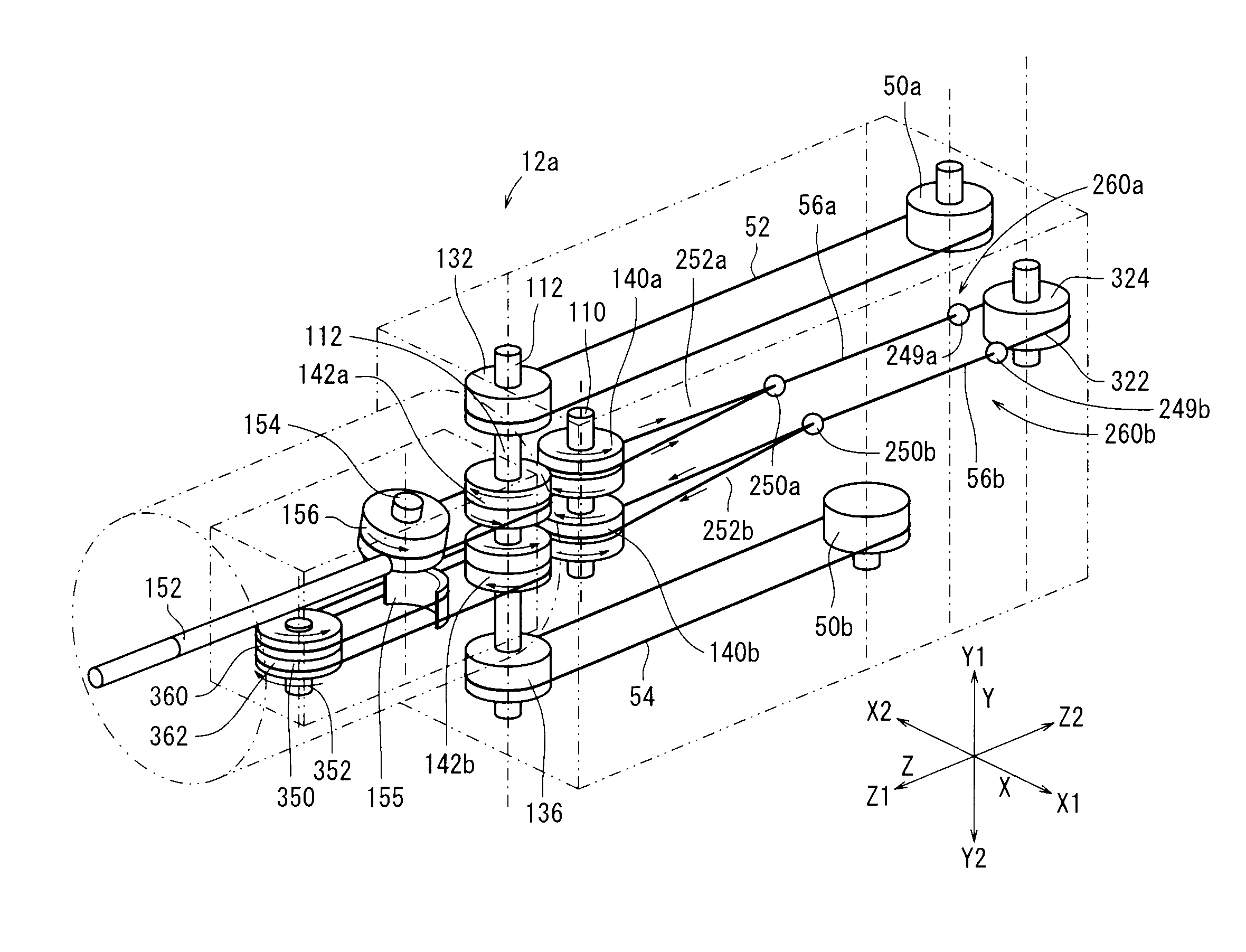

ActiveUS8523900B2Load minimizationReduce contractionDiagnosticsSurgical manipulatorsWork unitActuator

A medical manipulator includes a wire movable in opposite directions, a driven wire having both ends thereof connected to the wire, an end effector of a distal-end working unit, a transmitting member, a crescent driven member integral with the transmitting member, and a return pulley. The transmitting member, the crescent driven member, and the return pulley are successively arranged in this order from the proximal end of the medical manipulator. When the driven wire is moved in opposite directions, the transmitting member also moves in opposite directions. At this time, the crescent driven member moves toward the return pulley, and the proximal-end portion of the return pulley enters a cavity of the crescent driven member.

Owner:KARL STORZ GMBH & CO KG

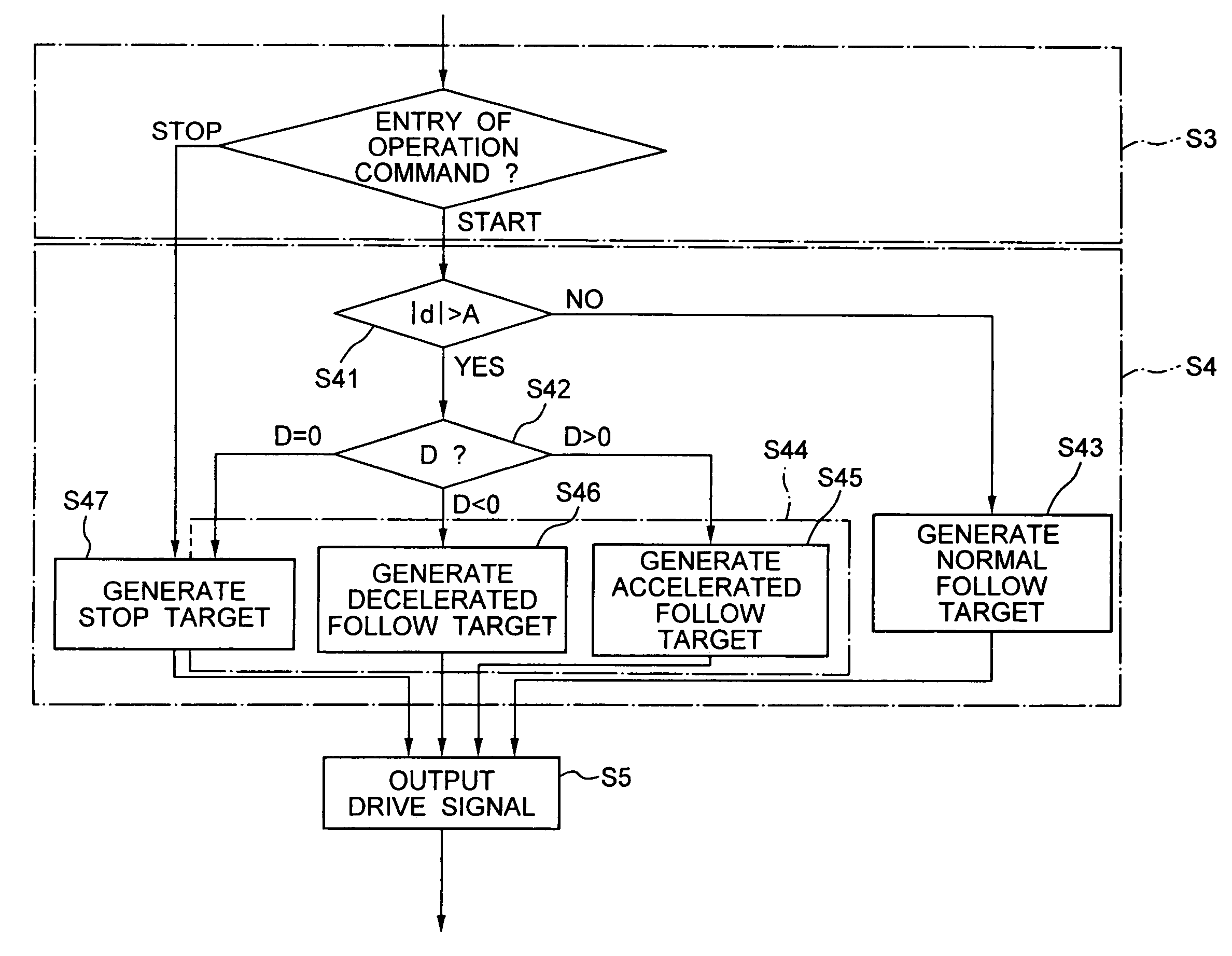

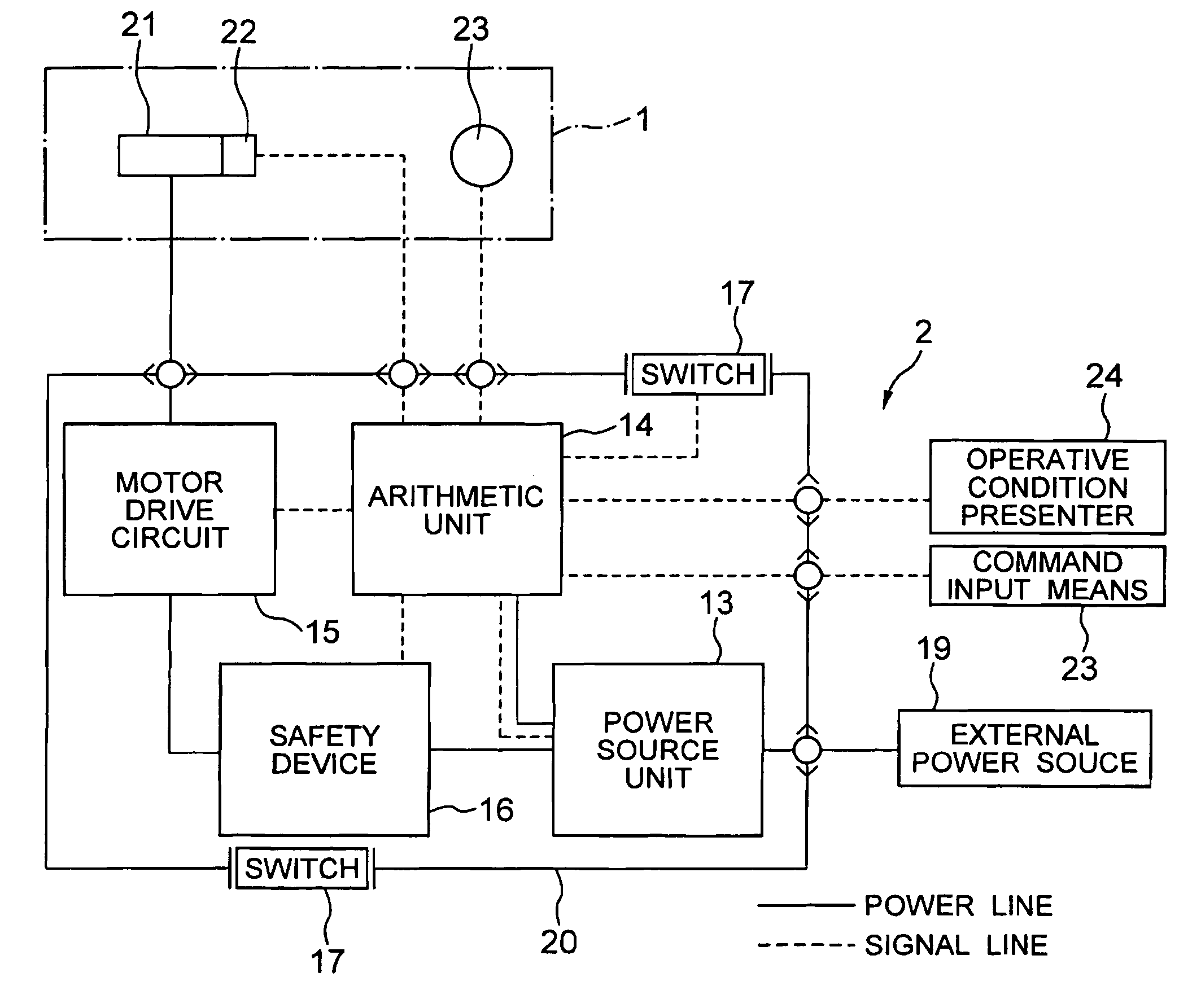

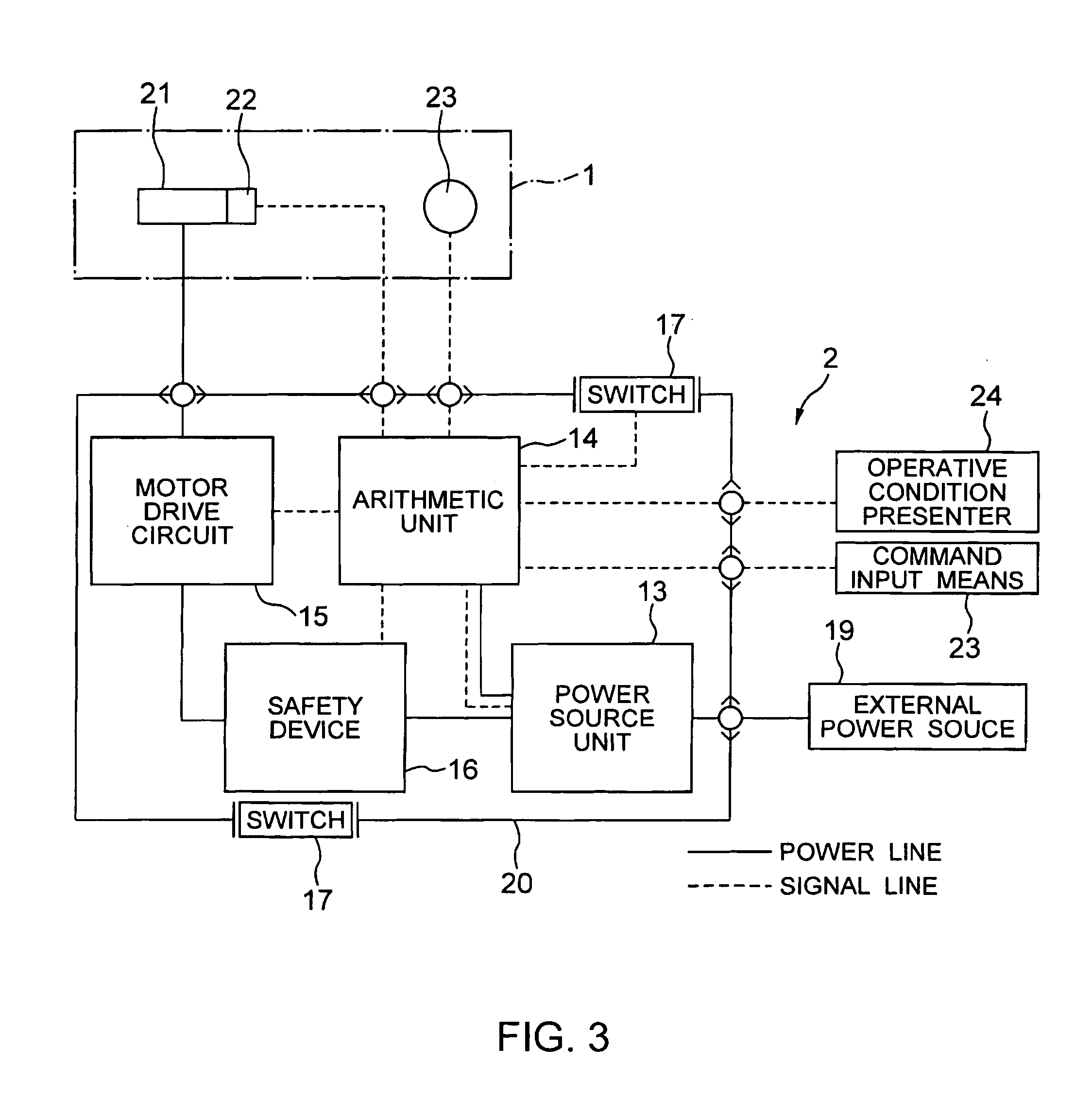

Manipulator and its control apparatus and method

ActiveUS6993413B2Improve controllabilityImprove securityProgramme-controlled manipulatorGripping headsWork unitManipulator

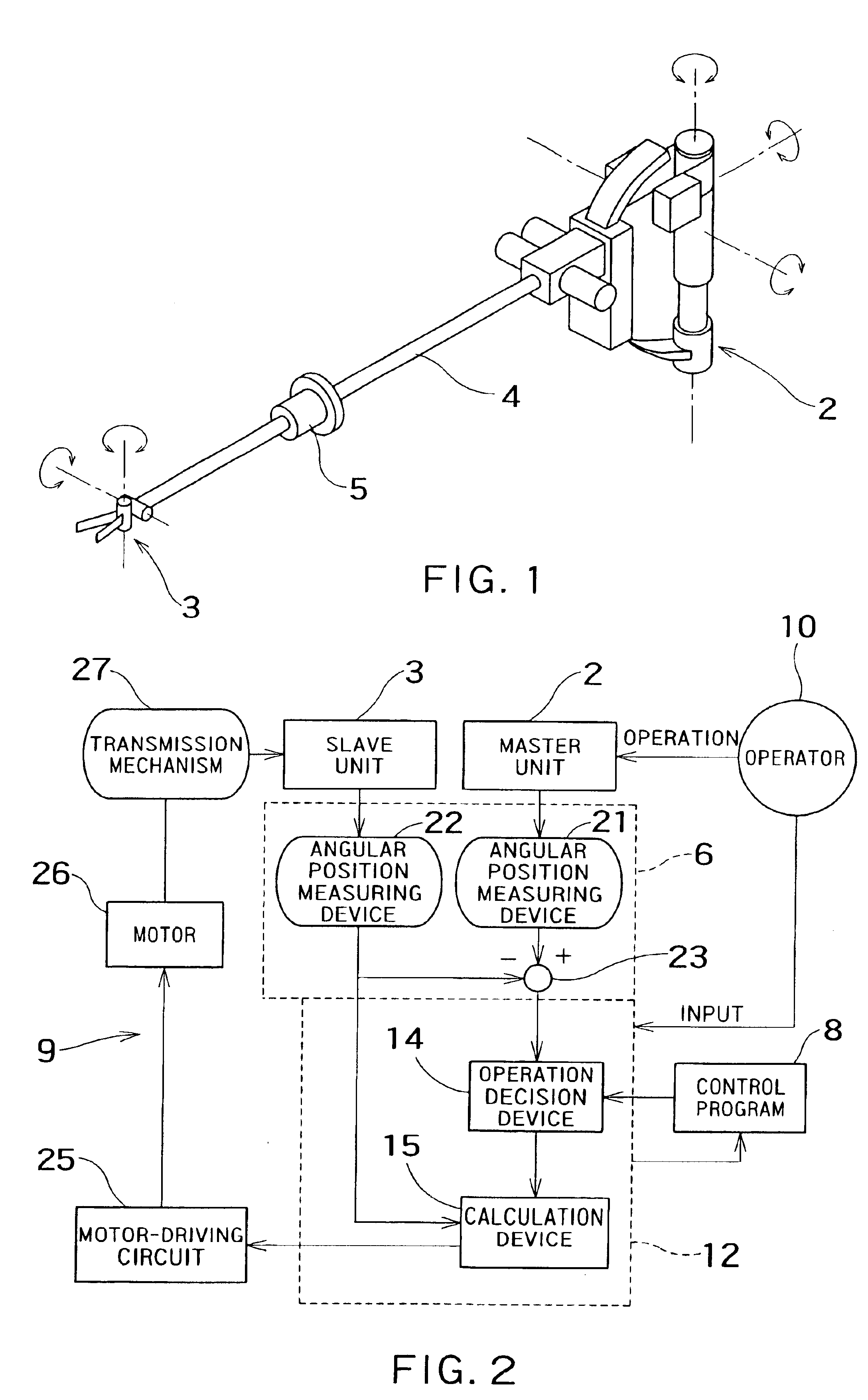

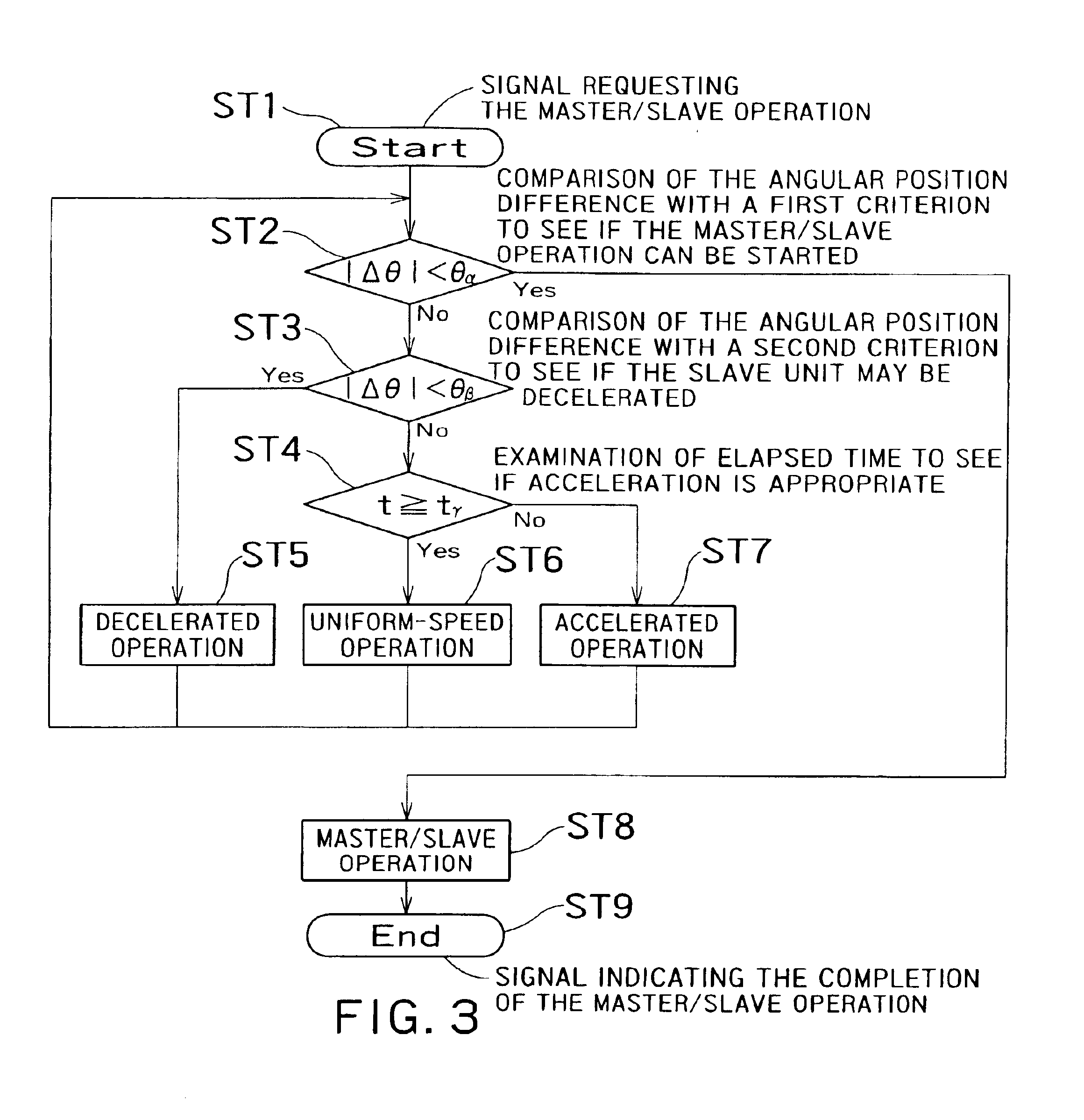

A manipulator operative in a master / slave operative mode, comprising: a master unit commanding an operation; a slave unit having a work unit; a detector detecting the orientation of the master unit and the orientation of the slave unit; and a control device controlling the slave unit in response to the command from the master unit, wherein the control device includes: a function of determining a non-mater / slave operative mode or a master / slave operative mode; a function of calculating a difference between the orientation of the master unit and the orientationof the slave unit; and a function of comparing the absolute value of the difference with a preset reference value; and depending upon the result of the comparison, determining a normal master / slave operative mode or a transitional master / slave operative mode, in the master / slave operative mode, the transitional master / slave operative mode is a transitional mode from the non-master / slave operative mode to the master / slave operative mode.

Owner:TERUMO KK

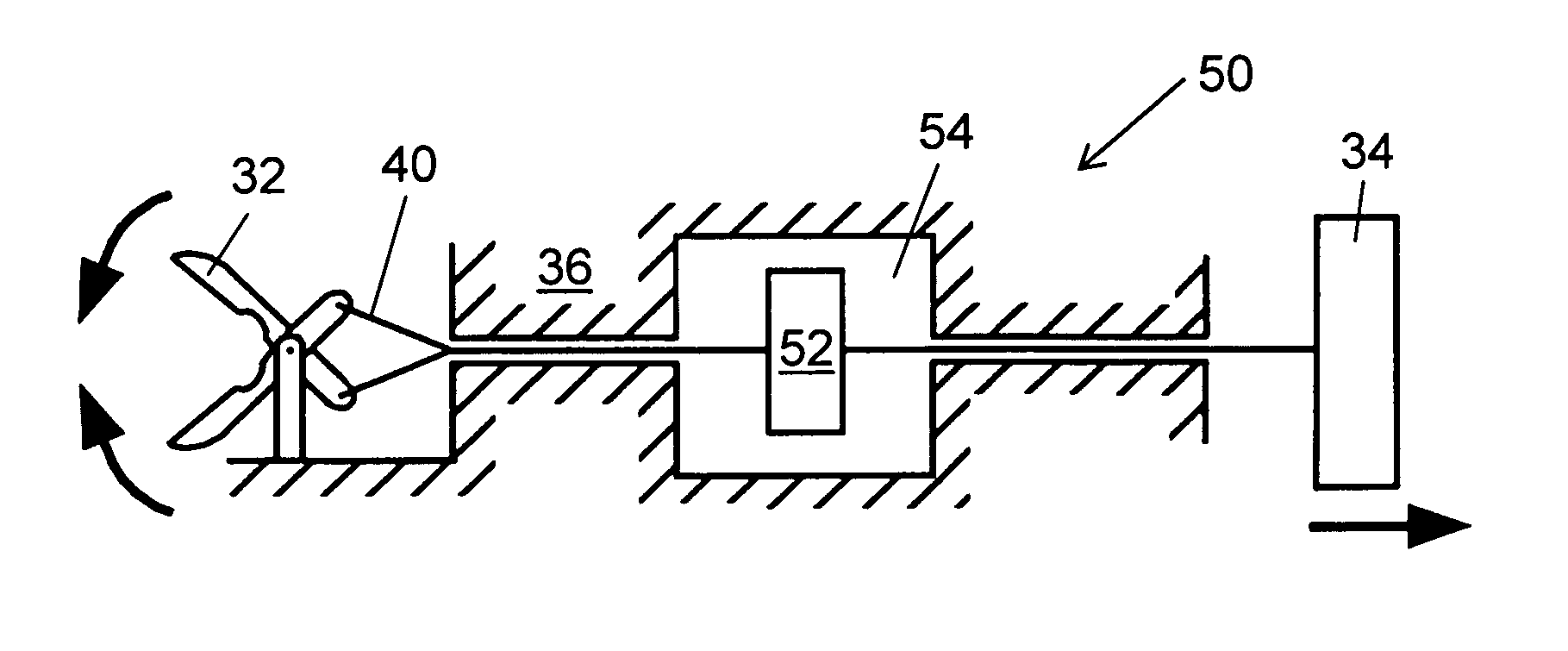

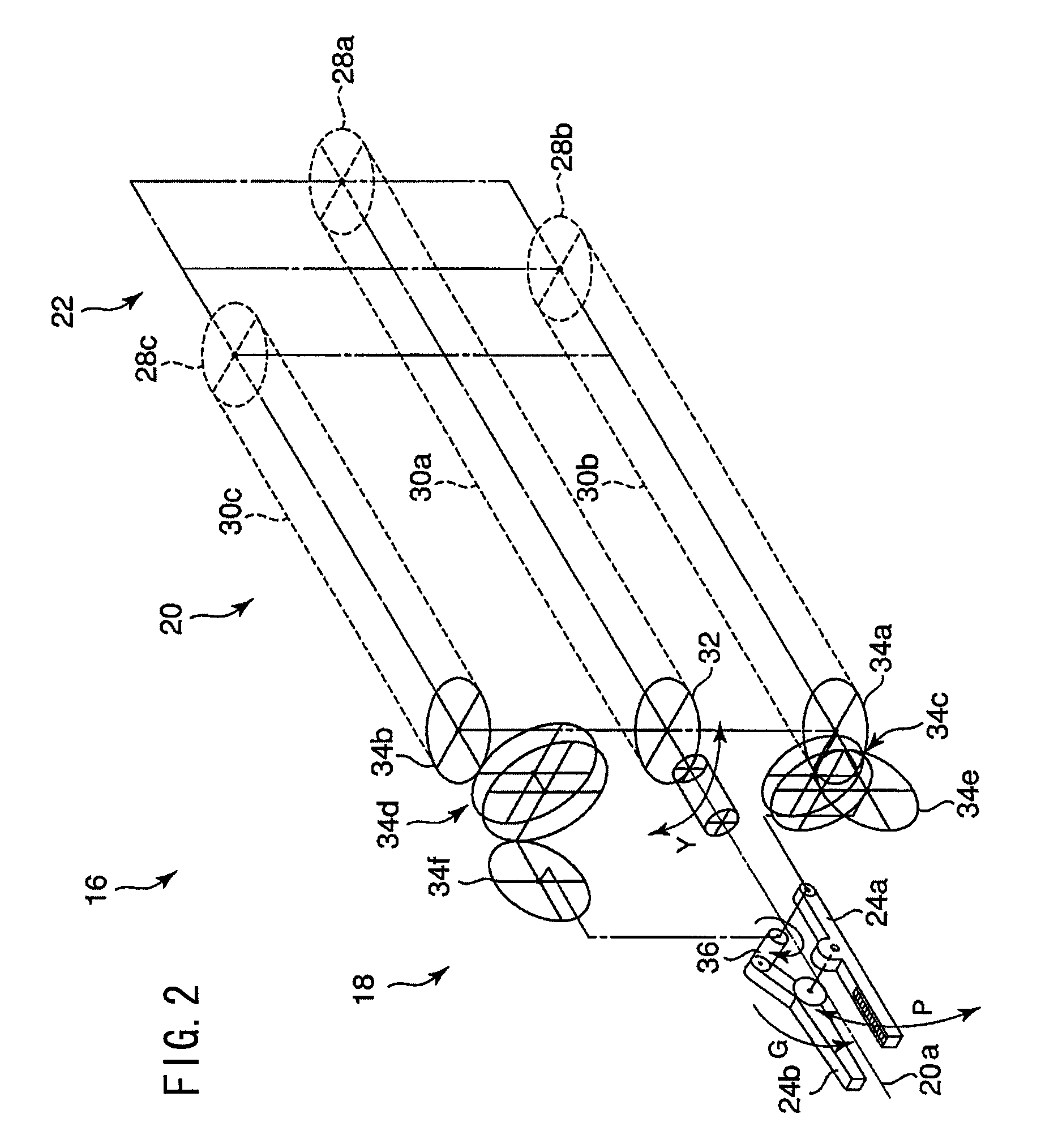

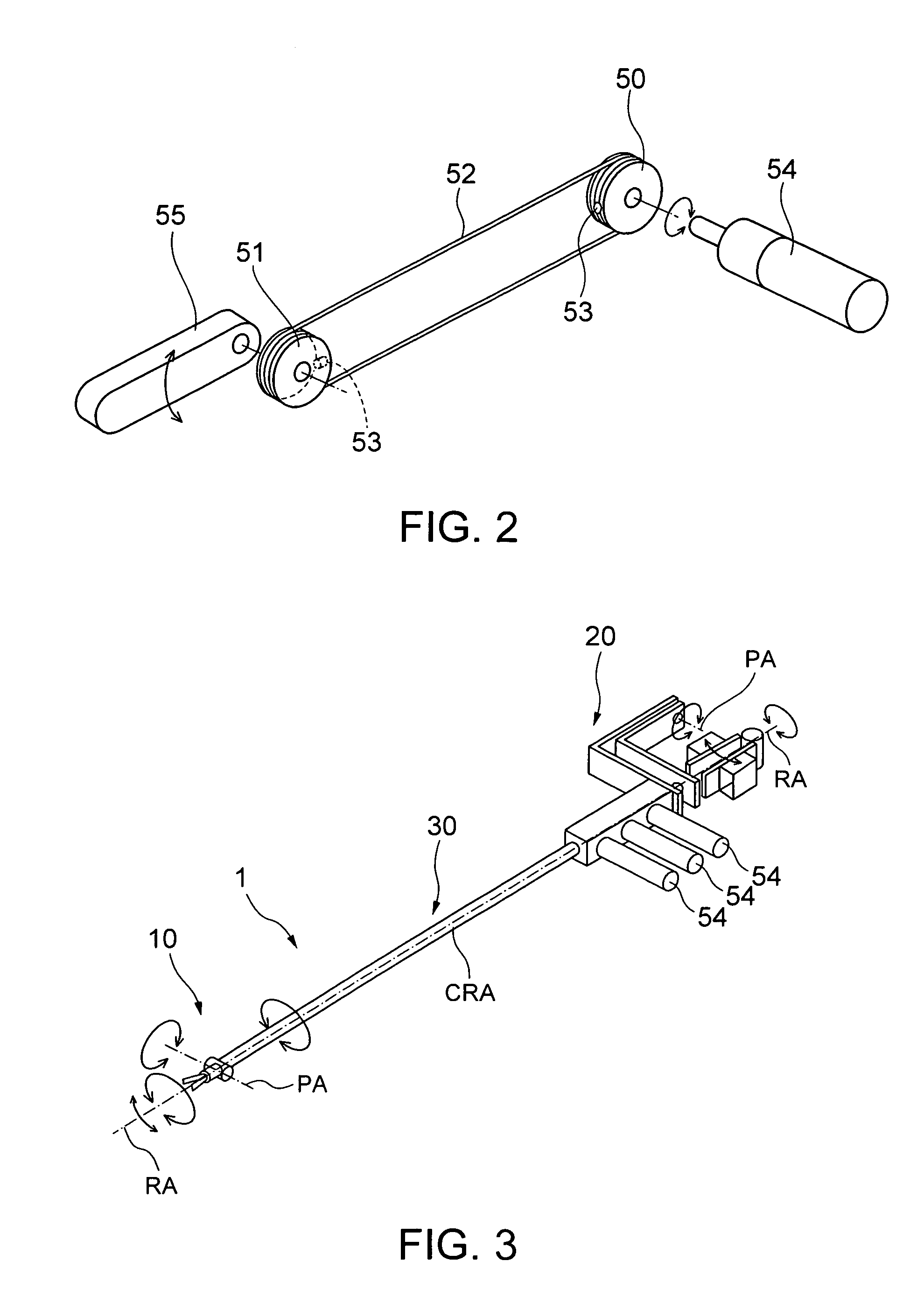

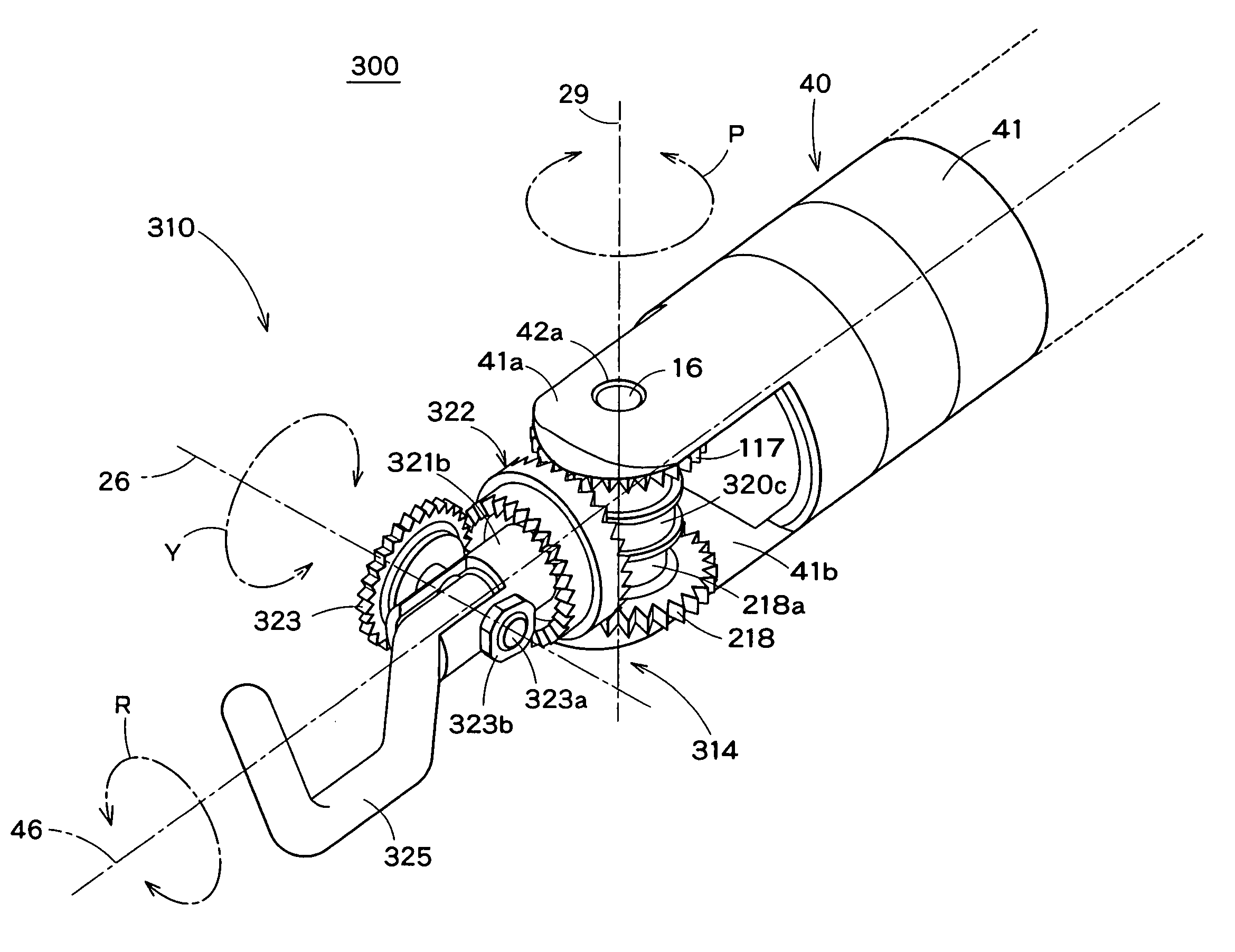

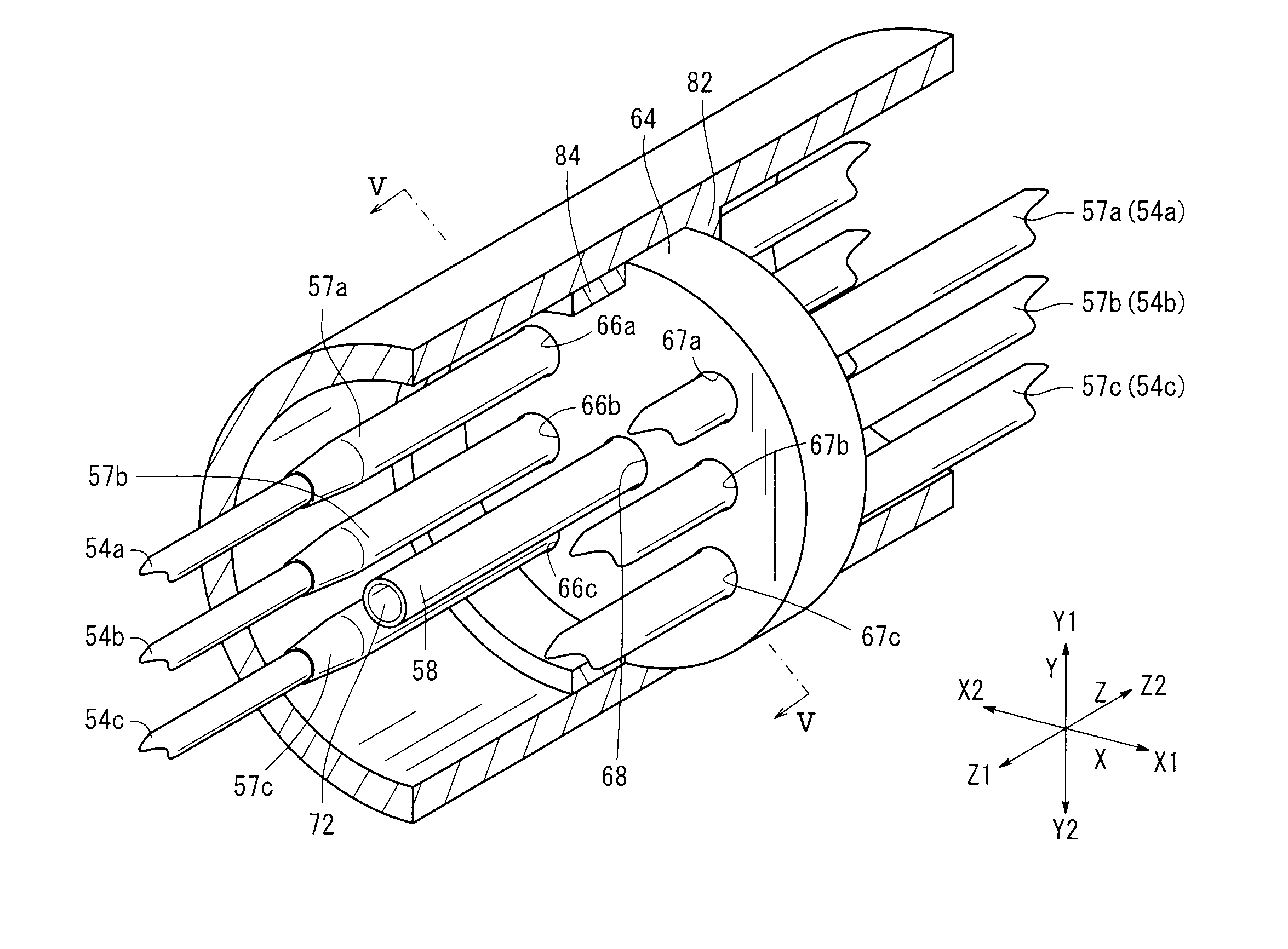

Power transmission mechanism and manipulator

ActiveUS7300373B2Small sizeEnhance reliability and rigidity and controllabilitySuture equipmentsProgramme-controlled manipulatorElectric power transmissionEngineering

A power transmission mechanism comprising: a flexible power transmission element; a pair of a drive pulley and a driven pulley on which the flexible power transmission element is wound, each the pulley having a pin-embedding hole formed to extend from the outer circumferential thereof toward the center thereof, and a slit elongated in the circumferential direction of the pulley to extend to opposite sides of the embedding hole and communicating with the embedding hole; and a pair of columnar or tapered anchor pins each having a path hole penetrating the anchor pin across the lengthwise direction thereof to receive the flexible power transmission element inserted therein, wherein each the anchor pin receiving the flexible power transmission element in the path hole thereof is embedded in the embedding hole of the associated pulley under pressure, and the flexible power transmission element is thereby held on the pulley.

Owner:TERUMO KK

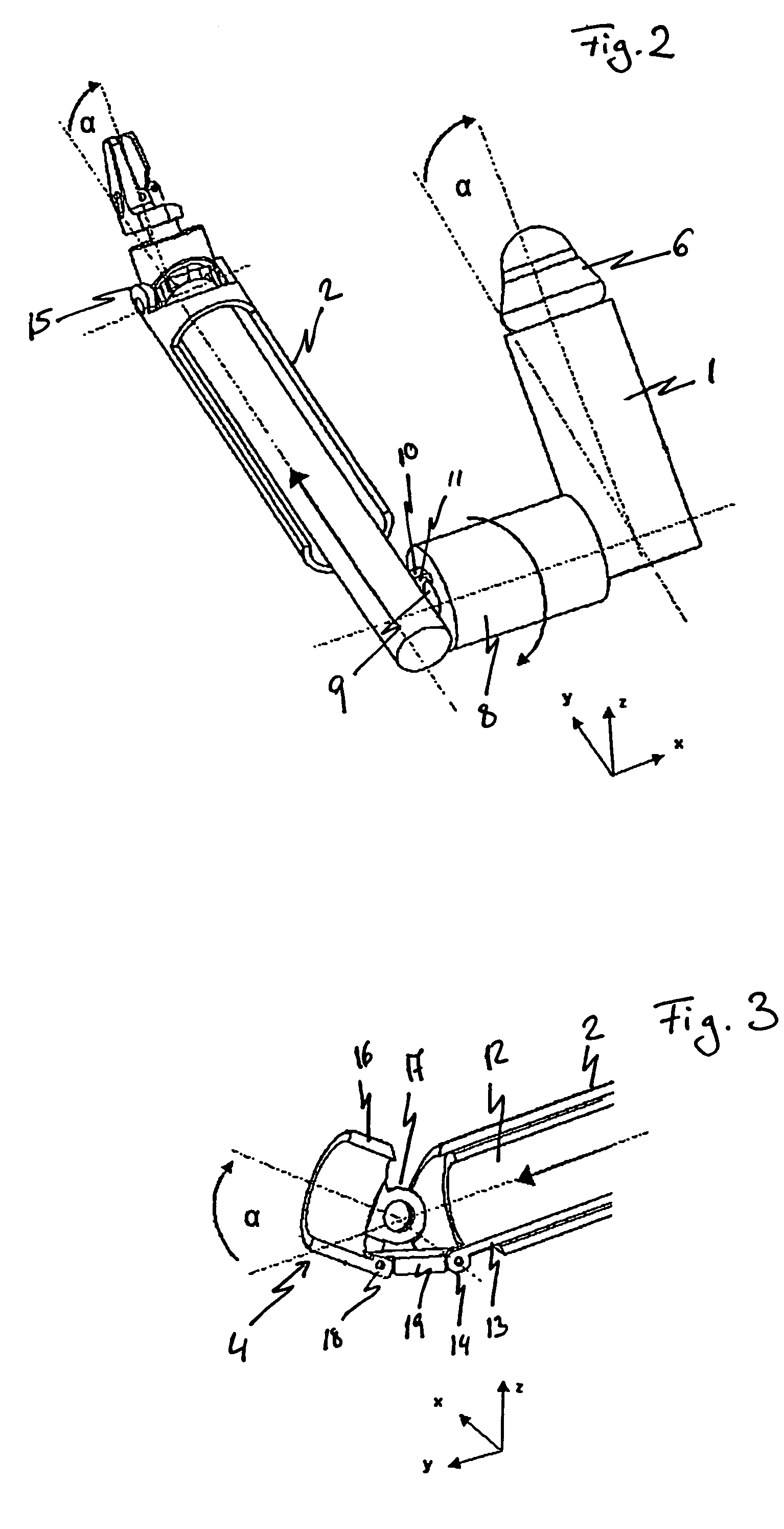

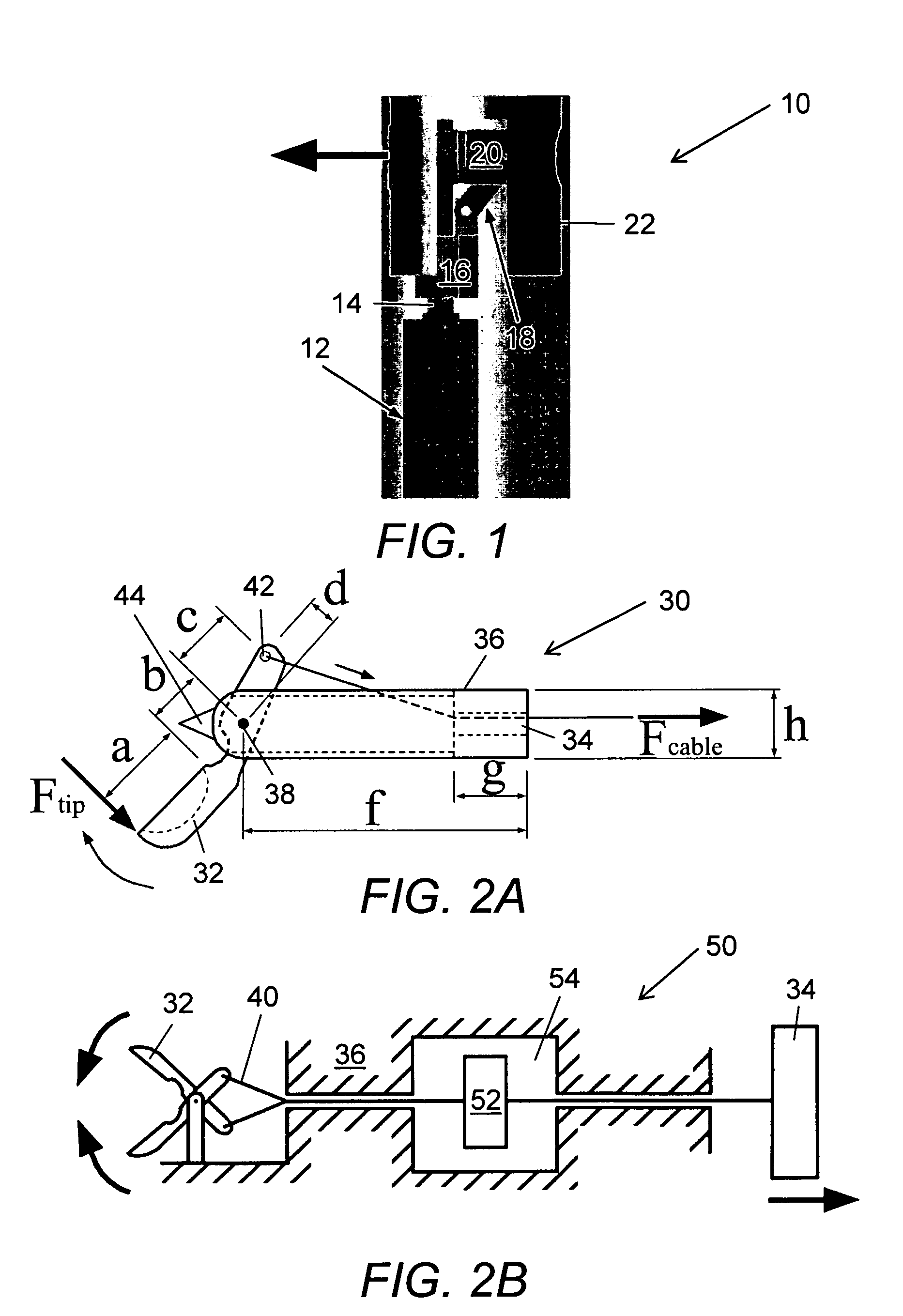

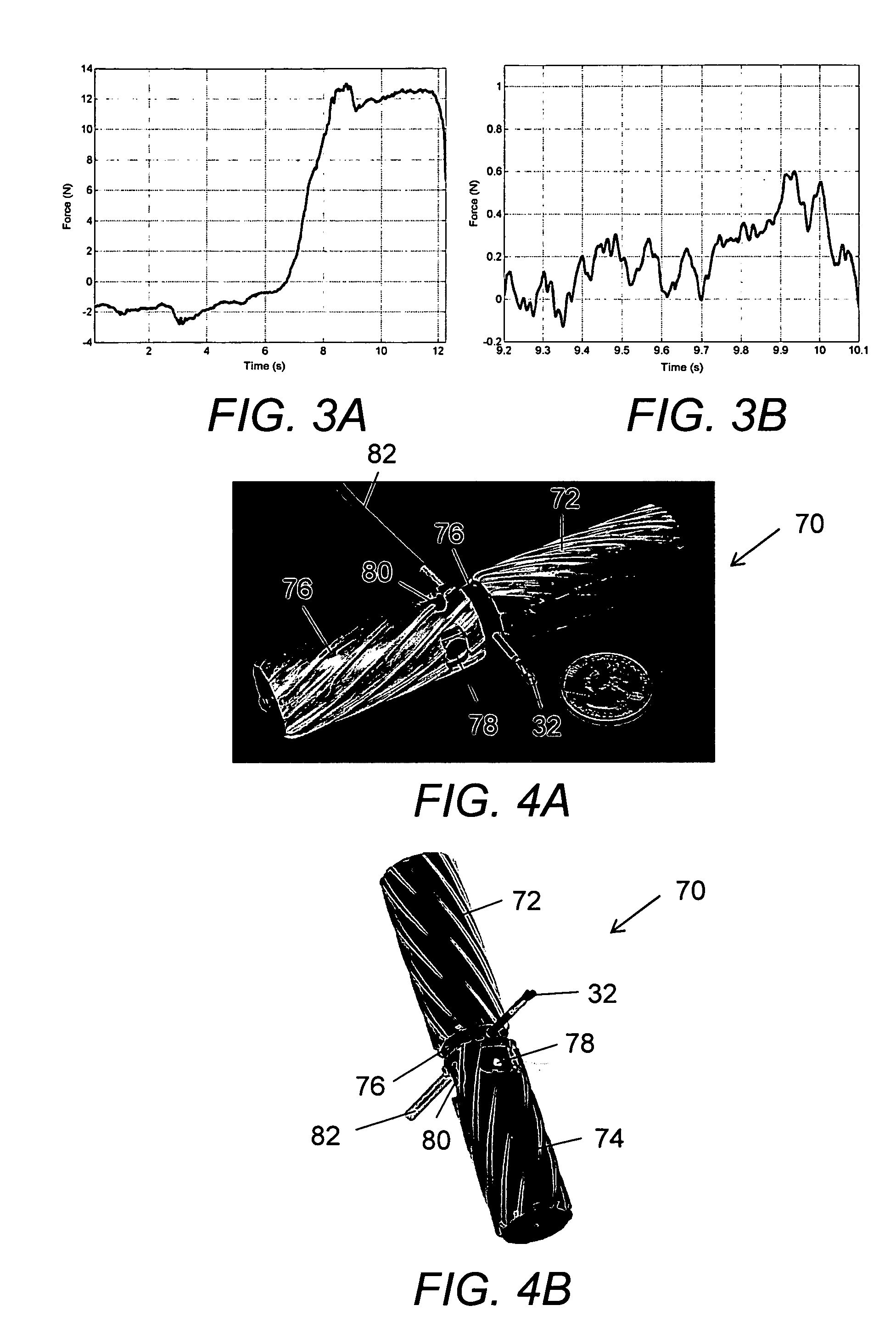

Ergonomic and semi-automatic manipulator, and applications to instruments for minimally invasive surgery

Owner:DEXTERITE SURGICAL

Manipulator

ActiveUS7540867B2Increase freedomSimple structureMechanical apparatusDiagnosticsEngineeringManipulator

A manipulator has a treating portion, a driving portion which are connected by a connecting portion, a first pulley on which a first wire which passes through inside of the connecting portion and is driven by the driving portion is hung for rotation, and a main shaft portion which rotatably supports the treating portion around a main shaft along a direction different from a first rotor axis that the first pulley rotates, one end portion of which is fixed to the first pulley.

Owner:TERUMO KK

Manipulator and its control apparatus and method

ActiveUS7295893B2Improve safety and controllabilityProgramme-controlled manipulatorComputer controlEngineeringWork unit

A manipulator operative in a master / slave operative mode includes a master unit commanding an operation; a slave unit having a work unit; a detector detecting the orientation of the master unit and the orientation of the slave unit; and a control device controlling the slave unit in response to a command from the master unit. The control device determines a non-master / slave operative mode or a master / slave operative mode, and calculates a difference between the orientation of the master unit and the orientation of the slave unit. The absolute value of the calculated difference is compared with a preset reference value, and depending upon the result of the comparison, a normal master / slave operative mode or a transitional master / slave operative mode is determined, wherein in the master / slave operative mode, the transitional master / slave operative mode is a transitional mode from the non-master / slave operative mode to the master / slave operative mode.

Owner:TERUMO KK

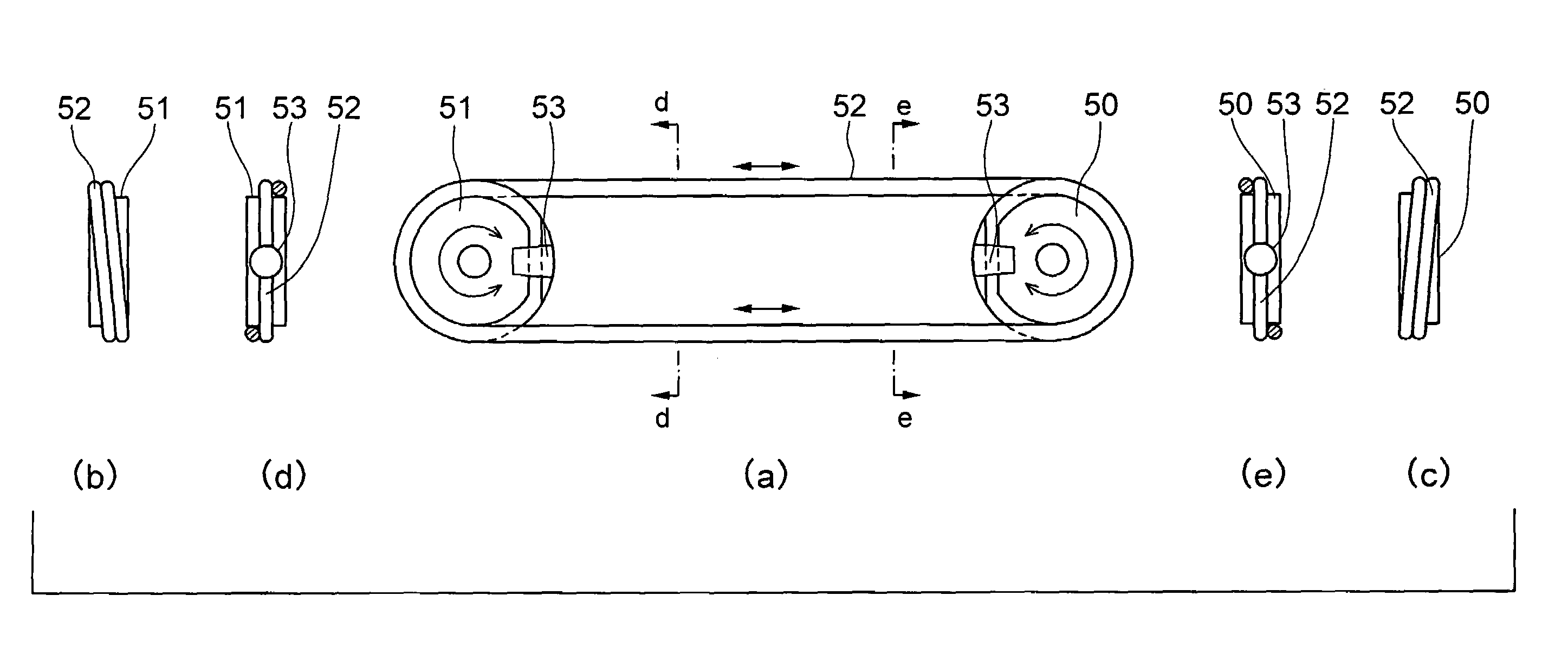

Manipulator

A manipulator includes a working unit comprising an operation command unit, horizontal roller and vertical rollers mounted thereon, drive pulleys rotatable in response to operation of the horizontal roller and the vertical roller, a connector, a first rotational axis disposed on a distal end of the connector, a second rotational axis extending perpendicularly to the first rotational axis, tubular members rotatably supported on a shaft providing the first rotational axis, and wires having rear and front portions trained around the drive pulleys and the tubular members, respectively. A drive mechanism operates about the first rotational axis in response to rotation of the tubular member, and an end effector operates about the second rotational axis in response to rotation of the tubular member.

Owner:TERUMO KK +1

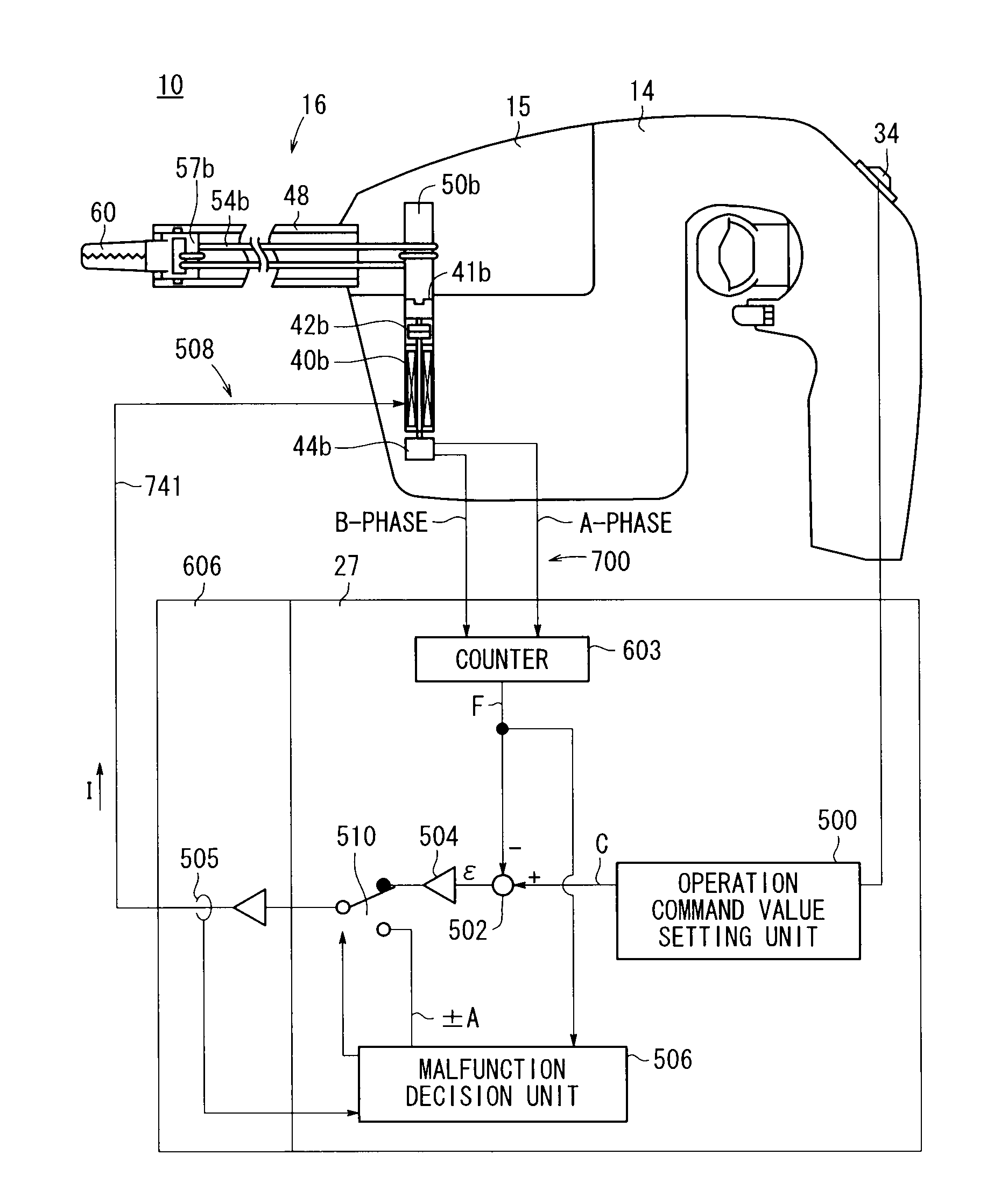

Medical manipulator

ActiveUS8154239B2Improve reliabilityAccurately respondProgramme-controlled manipulatorComputer controlEngineeringActuator

A medical manipulator includes an actuator block having a motor, a coupler detachably mounted on the actuator block and having a rotor connected to a rotatable shaft of the motor, a distal-end working unit mounted on a distal end of a joint shaft, which extends from the coupler and is operatively connected to the rotor by a wire, an encoder for detecting an angular displacement of the motor, and a controller for reading a signal from the encoder and comparing the read signal with an operation command value for energizing the motor through a feedback loop. The controller outputs a signal having a level greater than the resolution of the encoder and a lower operation limit of the motor within a range in which the distal-end working unit remains still, and monitors the angular displacement of the motor for thereby determining whether the feedback loop is malfunctioning or not.

Owner:KARL STORZ GMBH & CO KG

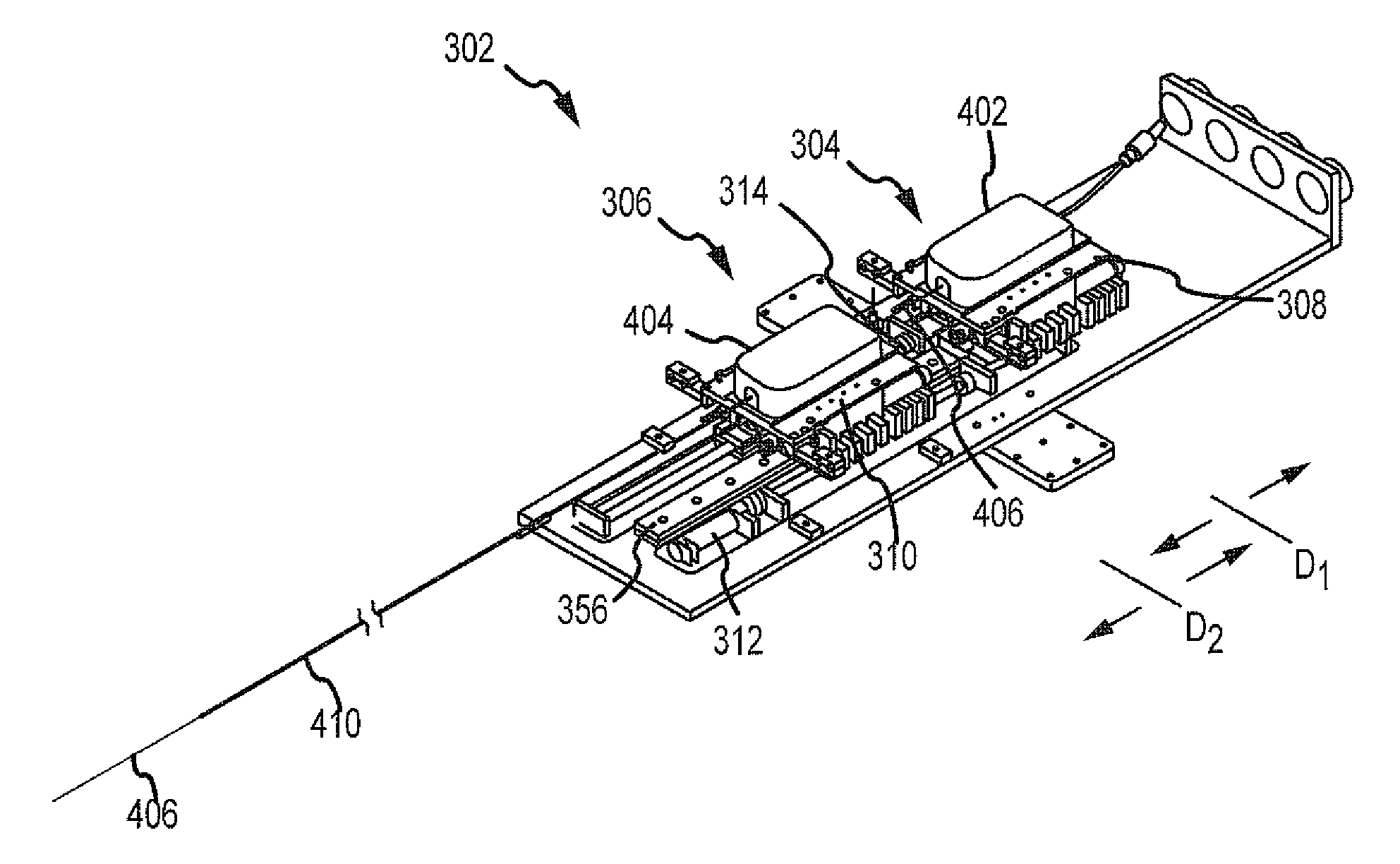

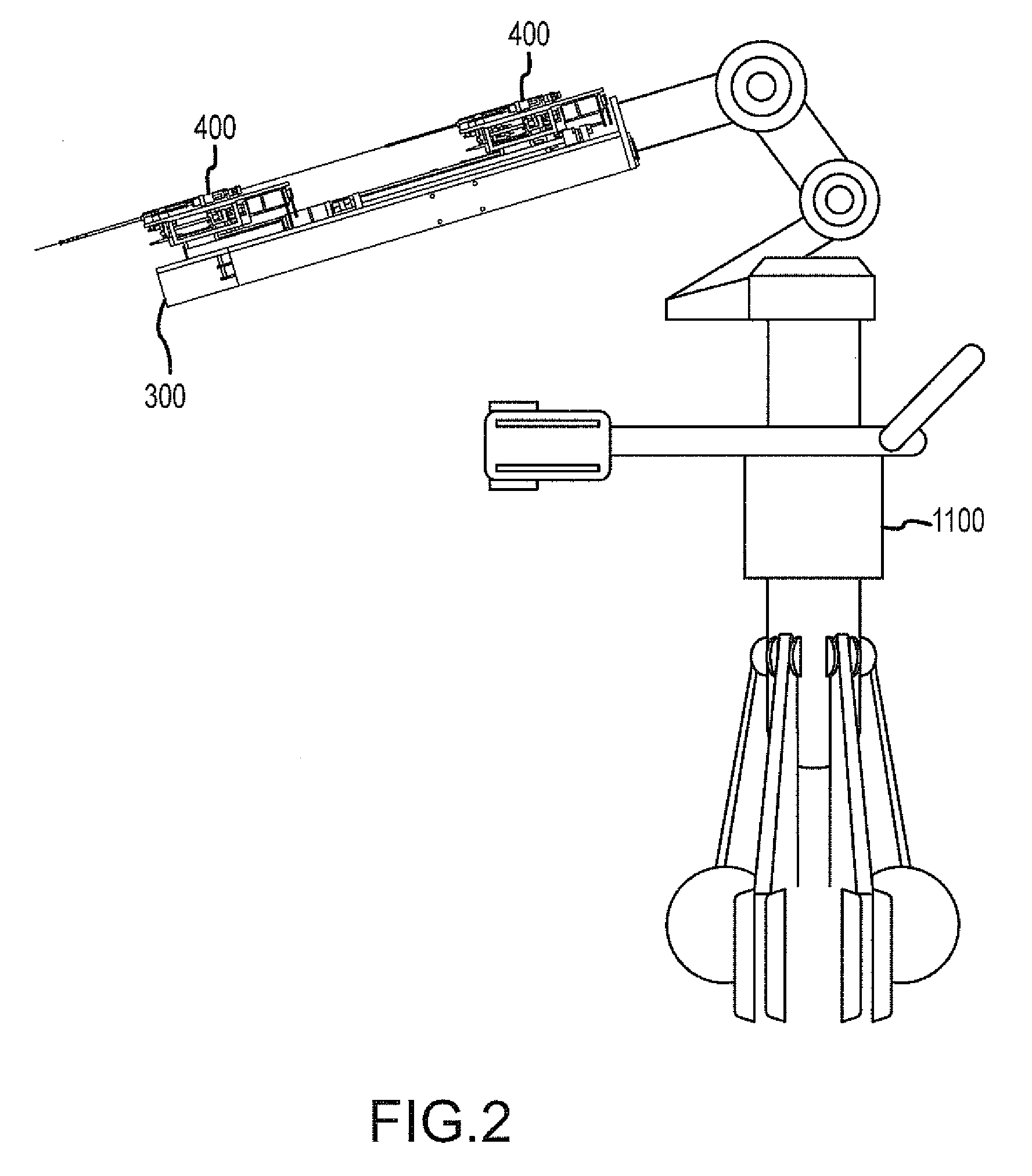

Robotic catheter manipulator assembly

ActiveUS8317744B2Minimize and eliminate procedural variabilityMinimize and eliminate exposureDiagnosticsMedical devicesEngineeringManipulator

A robotic catheter manipulator assembly may include a support member including a catheter manipulation base and a sheath manipulation base movable relative to each other and to the support member. Each respective manipulation base may be releasably connectable to a catheter cartridge and a sheath cartridge. A drive mechanism may be provided for moving the catheter and sheath manipulation bases relative to each other and to the support member. The manipulation base or the cartridge may include a first element engageable with a complementary second element slidably engaged with the other one of the manipulation base or the cartridge for controlling movement of a component connected to the cartridge. The cartridge, for example, may be a transseptal cartridge, a catheter cartridge or a sheath cartridge, and the component may respectively be a surgically insertable device such as a transseptal needle, a catheter or a sheath.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Manipulator

ActiveUS8382790B2Easy to cleanAvoid flowDiagnosticsSurgical instrument detailsEngineeringManipulator

Owner:KARL STORZ GMBH & CO KG

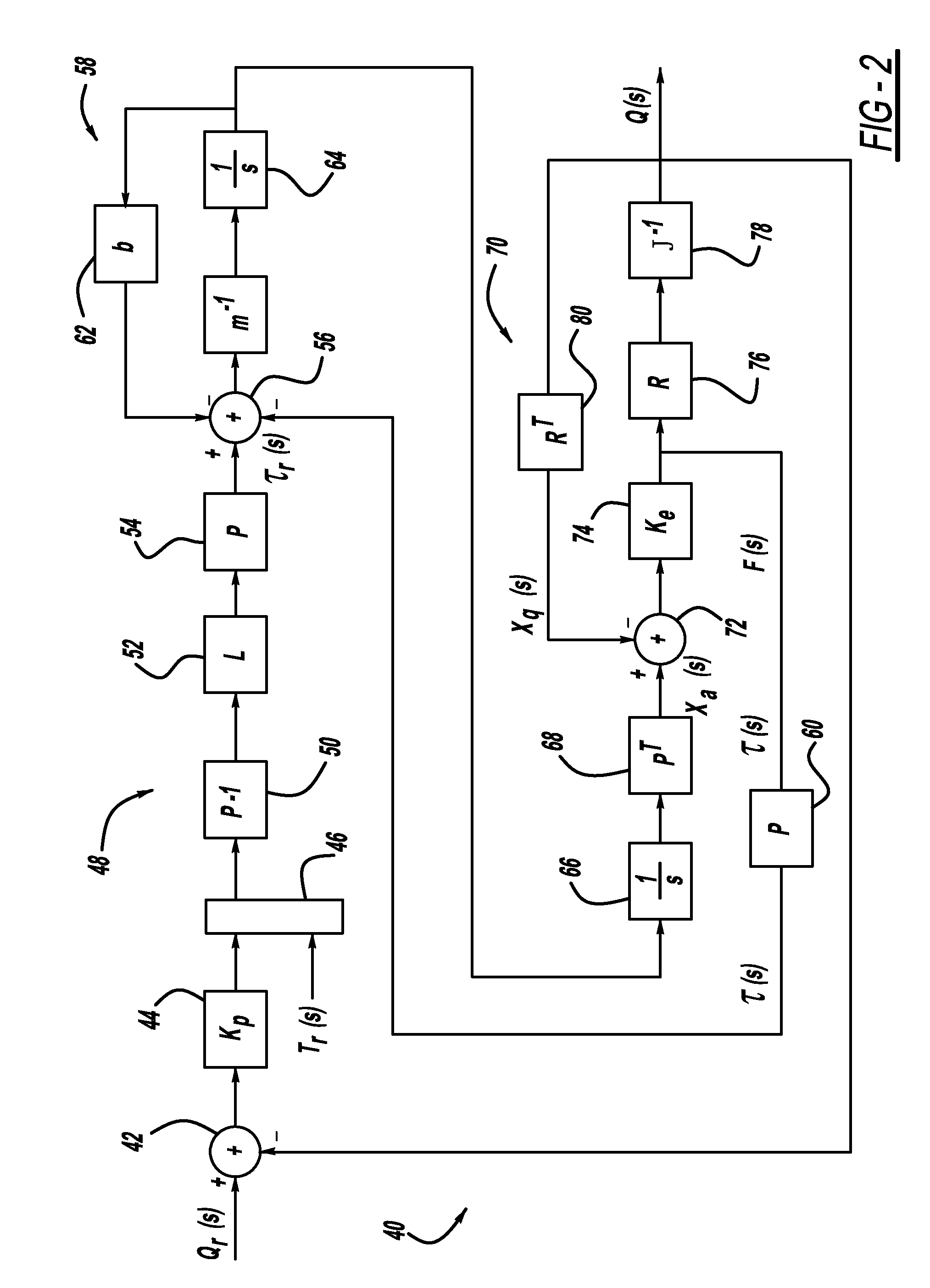

Manipulator and control method therefor

ActiveUS8237388B2Improve the level ofProgramme controlProgramme-controlled manipulatorWork unitActuator

A manipulator has a working unit including an end effector and a posture axis for changing the orientation of the manipulator, a compound mechanism provided on the working unit, and a controller for actuating a gripper axis, a yaw axis, and a roll axis by respectively controlling movement positions of three motors. The controller includes a torque generation detector for detecting a timing at which torque is generated on the gripper axis. When the controller detects the timing at which a torque τg′ is generated on the gripper axis under operation of a given motor, the movement positions of the plural motors are shifted and set, corresponding to the directions at which interference torques are generated with respect to the yaw axis and the roll axis, and to predetermined positions of the same directions.

Owner:KARL STORZ GMBH & CO KG

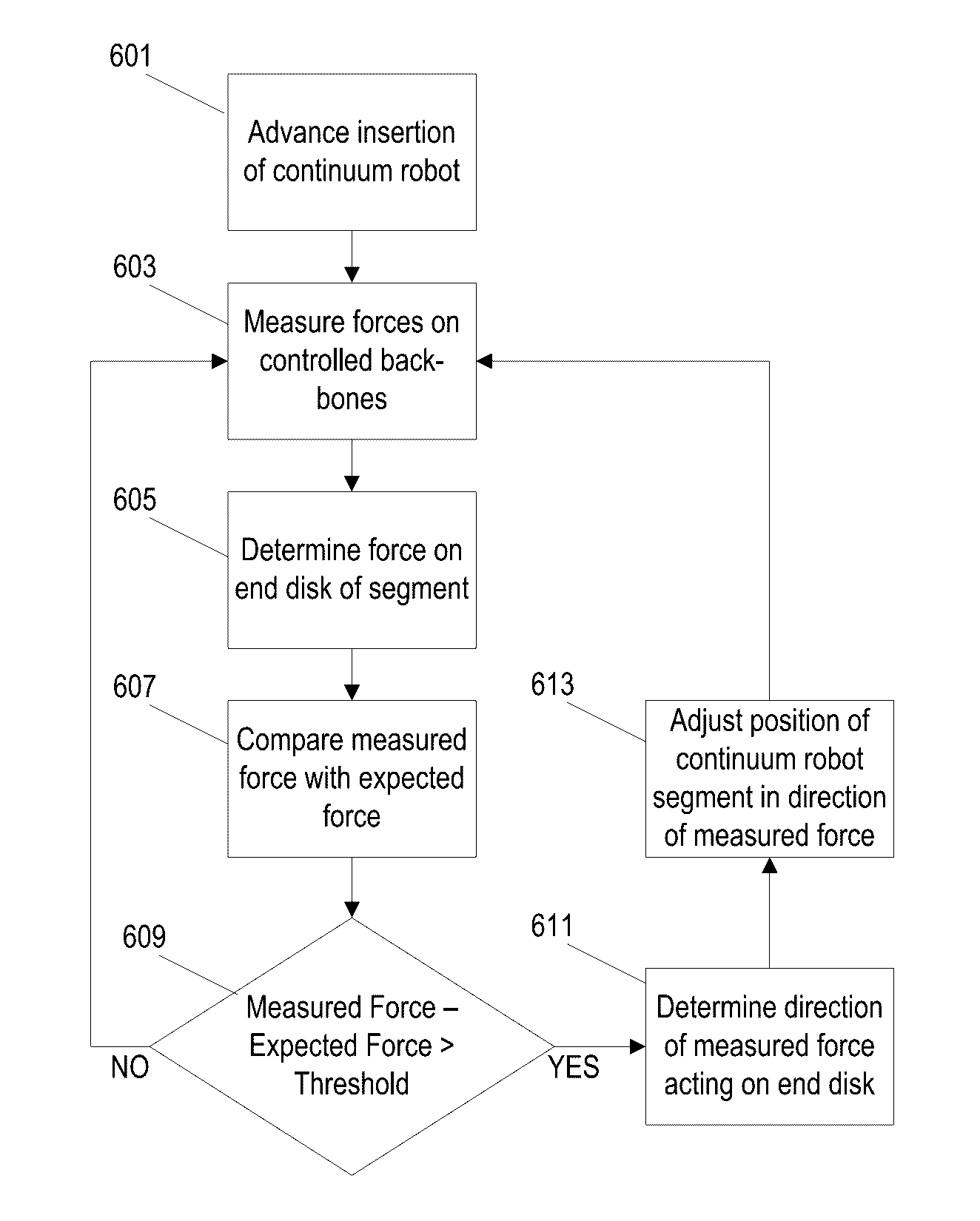

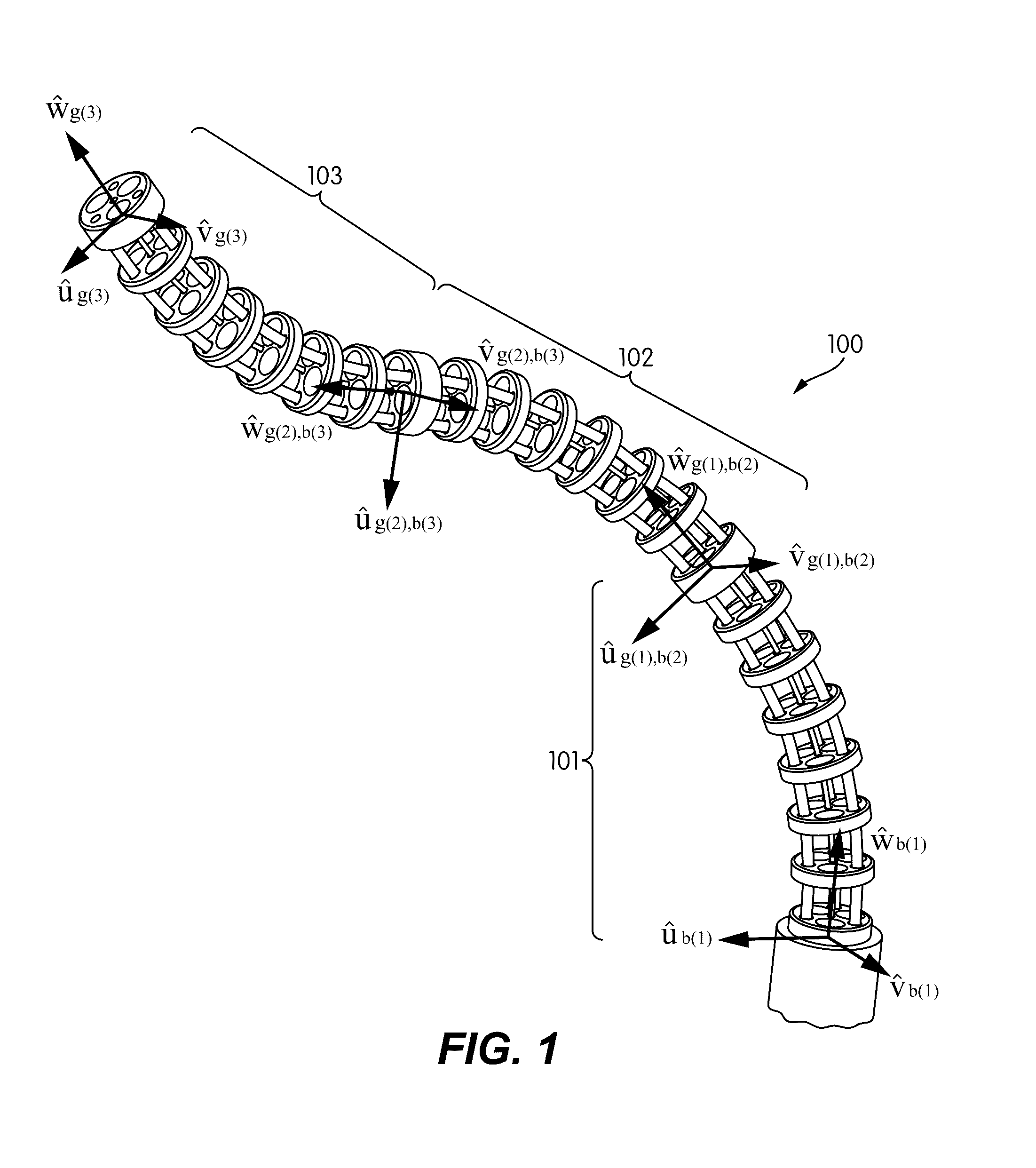

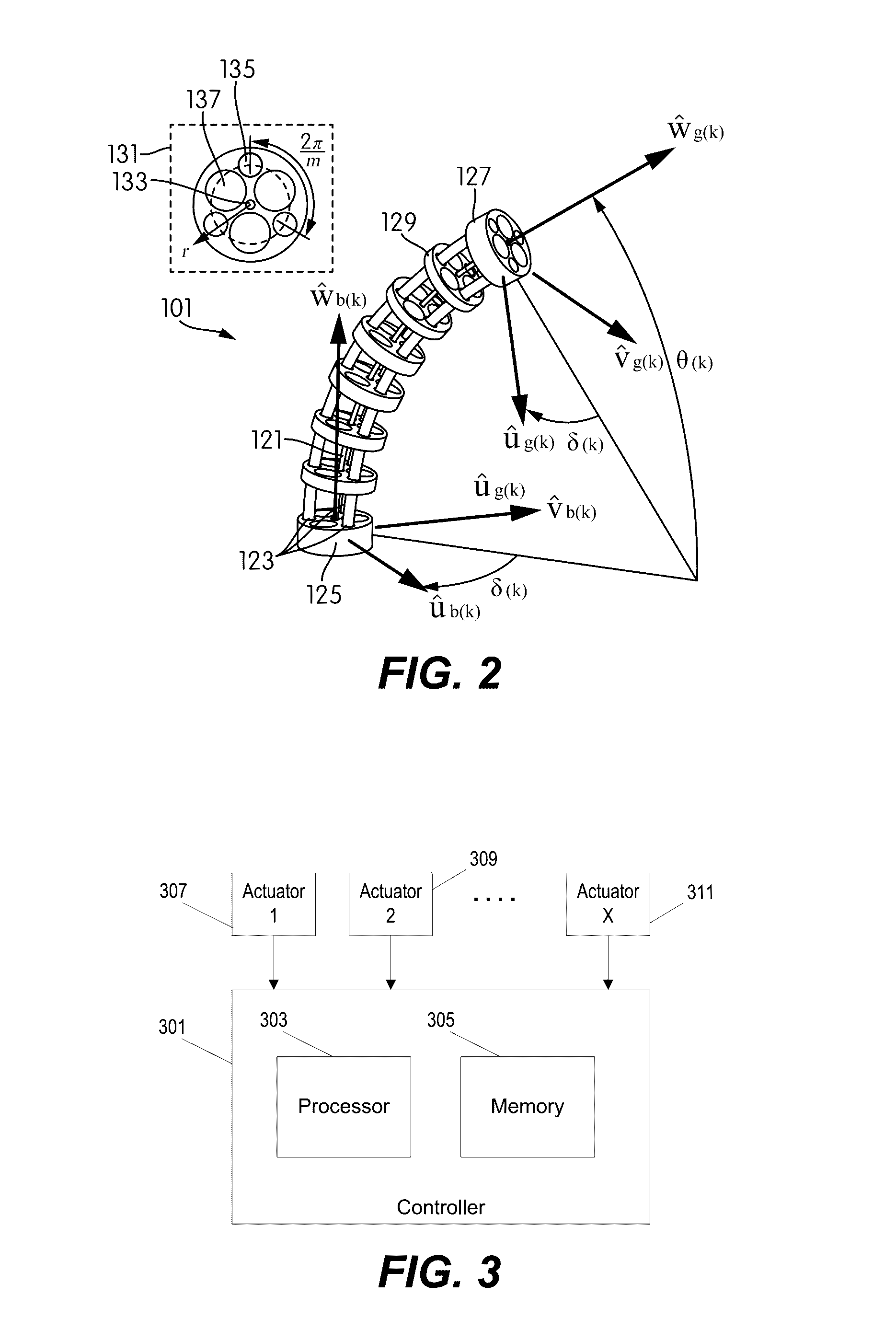

Systems and methods for safe compliant insertion and hybrid force/motion telemanipulation of continuum robots

ActiveUS9539726B2Easy to operateImprove stabilityProgramme-controlled manipulatorDiagnosticsEngineeringManipulator

Methods and systems are described for controlling movement of a continuum robot that includes a plurality of independently controlled segments along the length of the continuum robot. The continuum robot is inserted into a cavity of unknown dimensions or shape. A plurality of forces acting upon the continuum robot by the surrounding cavity are estimated. A positioning command indicating a desired movement of the distal end of the continuum robot is received from a manipulator control. The desired movement is augmented based, at least in part, on the estimated plurality of forces acting on the continuum robot such that movement is restricted to within safe boundaries of the surrounding cavity. The positioning of the continuum robot is then adjusted based on the augmented desired movement.

Owner:VANDERBILT UNIV

Brake release mechanism and medical manipulator provided with same

ActiveUS10064639B2Easily and swiftly releasingFacilitated releaseSurgical needlesDrum brakesEngineeringManipulator

A medical manipulator is provided with a brake release mechanism. The brake release mechanism is provided with a release button which is provided on a tilt wheel, and a lever mechanism which has at least one portion arranged on the inside of the tilt wheel and which is pressed when the release button moves inwards. By the action of the lever mechanism when the release button is operated, braking by a brake mechanism is released.

Owner:KARL STORZ GMBH & CO KG

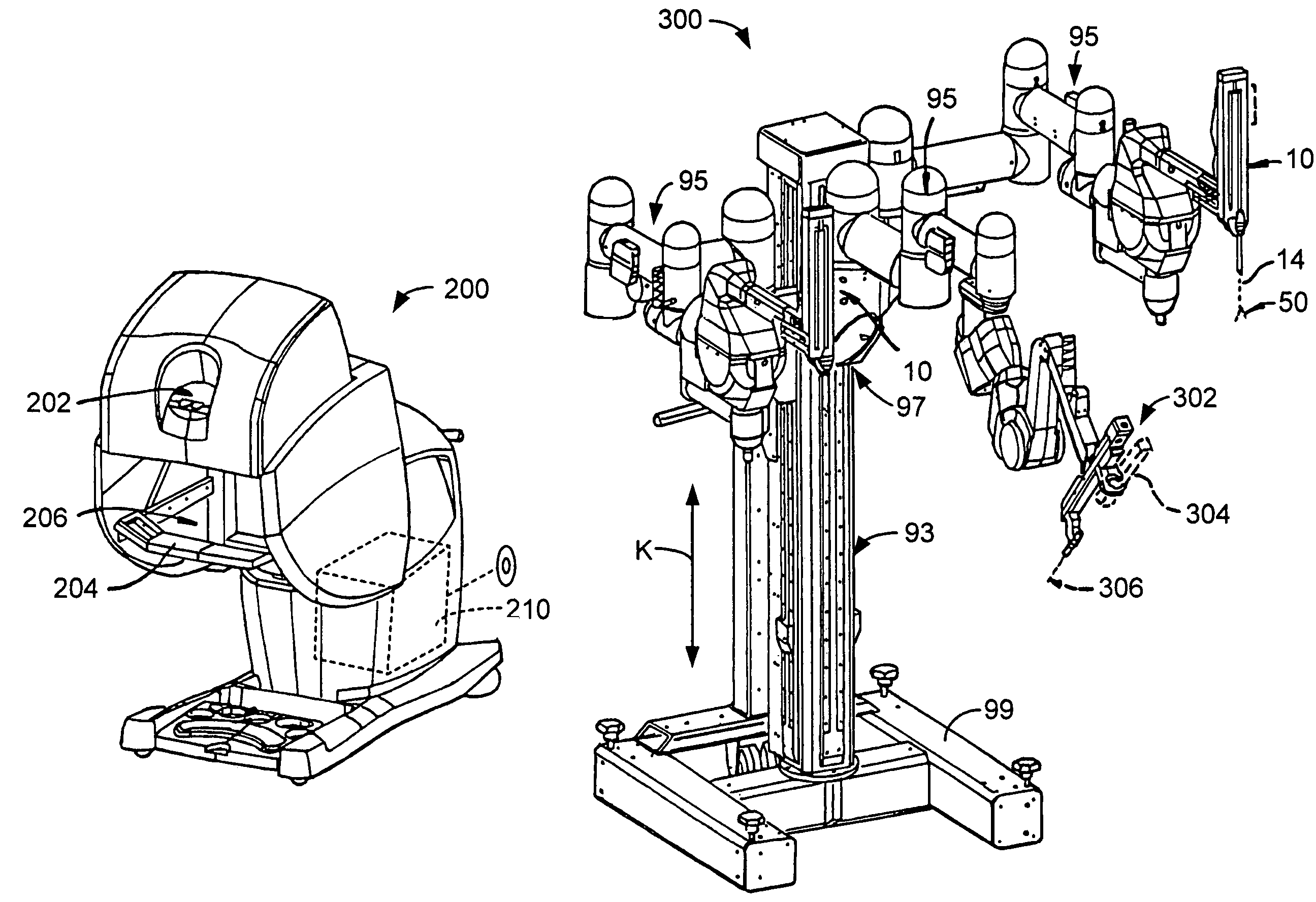

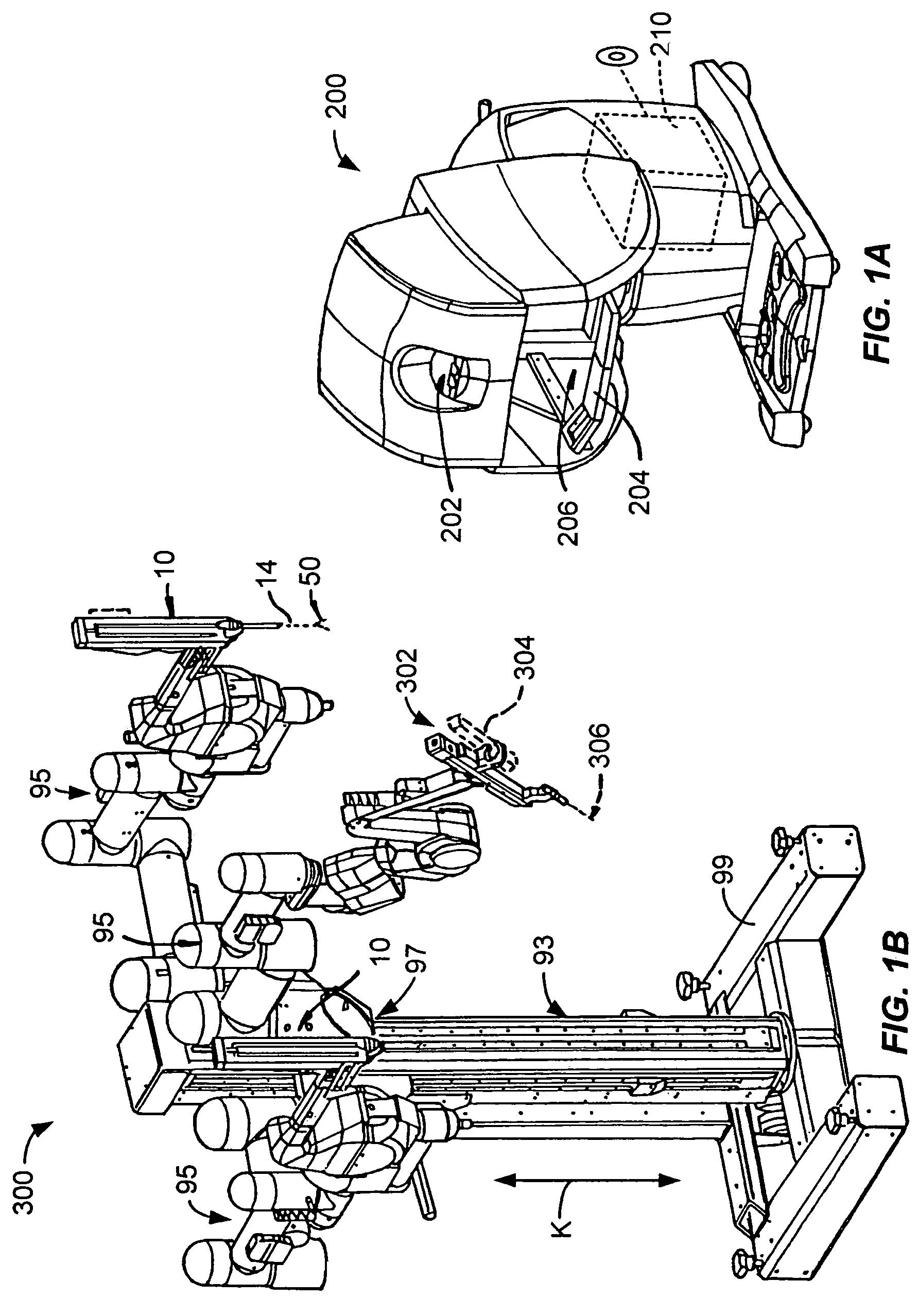

Medical robotic system with coupled control modes

In a coupled control mode, the surgeon directly controls movement of an associated slave manipulator with an input device while indirectly controlling movement of one or more non-associated slave manipulators, in response to commanded motion of the directly controlled slave manipulator, to achieve a secondary objective. By automatically performing secondary tasks through coupled control modes, the system's usability is enhanced by reducing the surgeon's need to switch to another direct mode to manually achieve the desired secondary objective. Thus, coupled control modes allow the surgeon to better focus on performing medical procedures and to pay less attention to managing the system.

Owner:INTUITIVE SURGICAL OPERATIONS INC

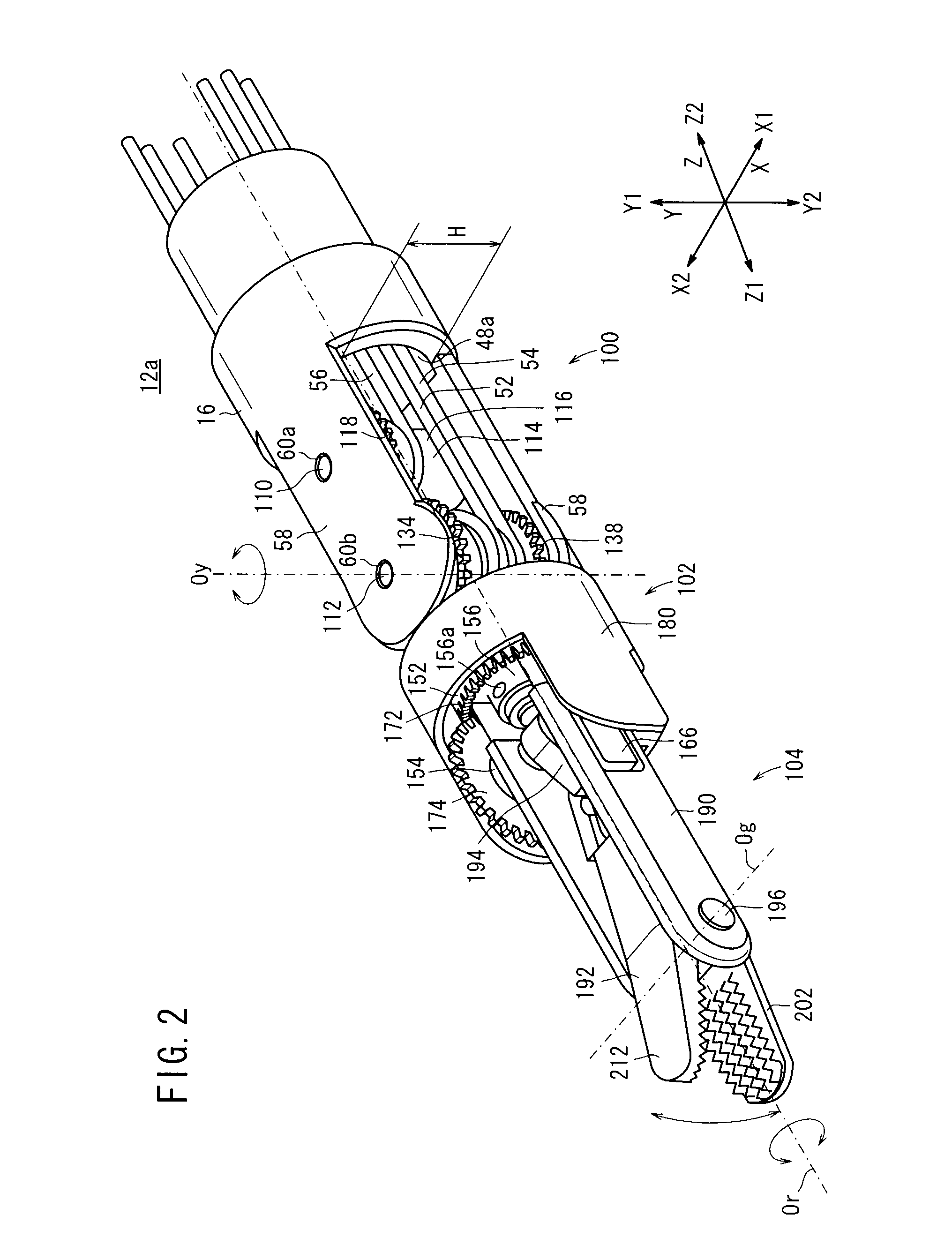

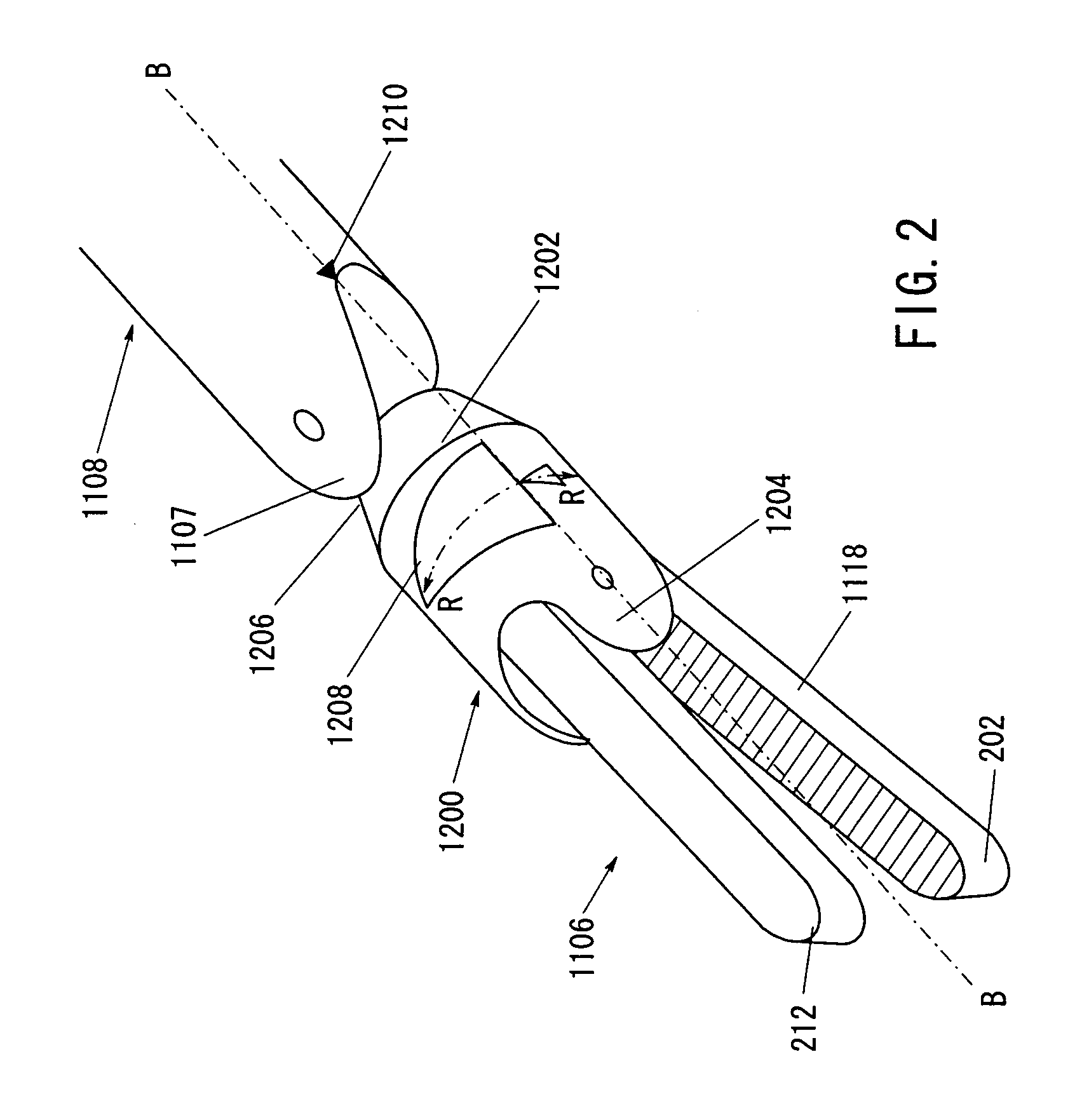

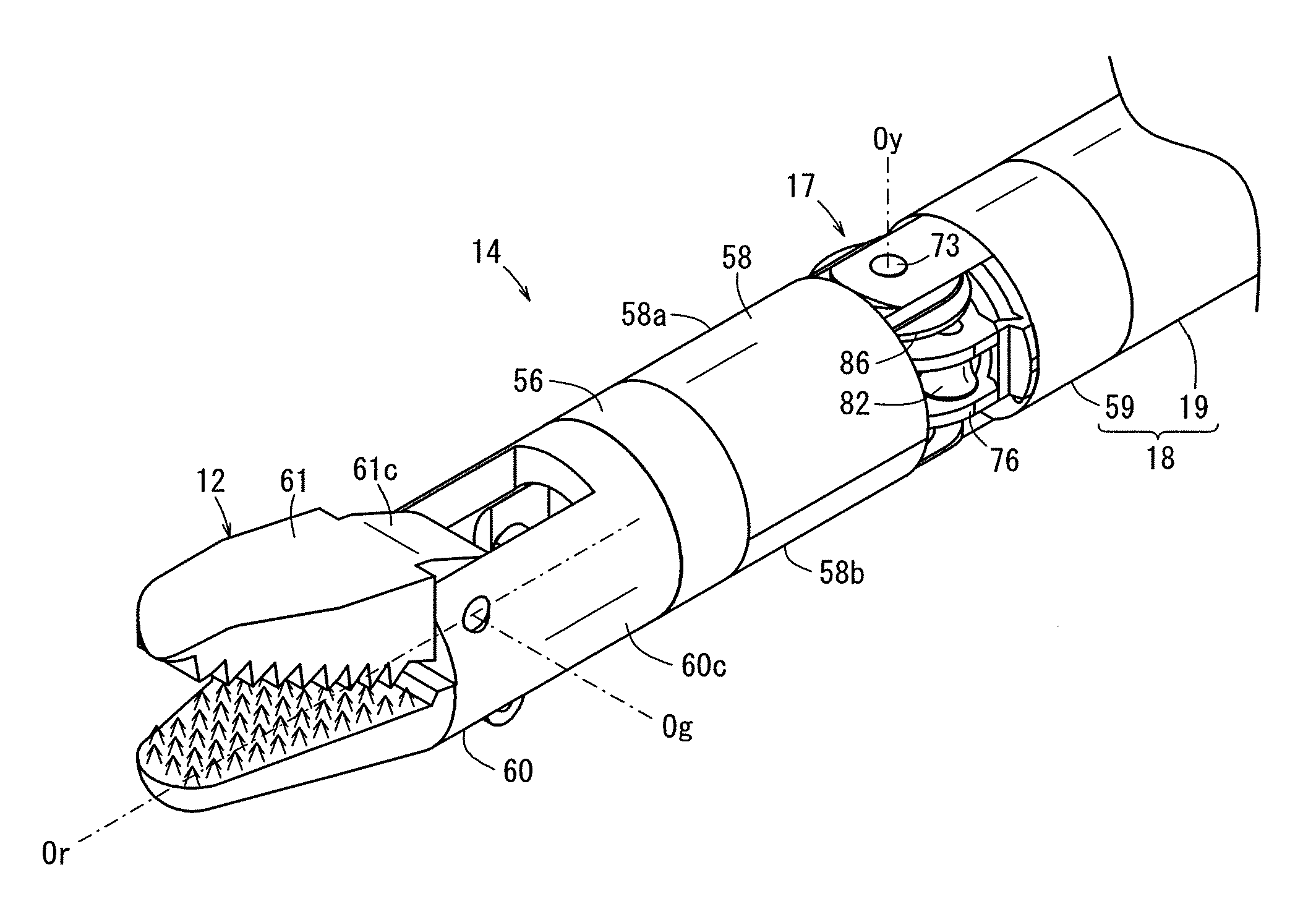

Manipulator for medical use

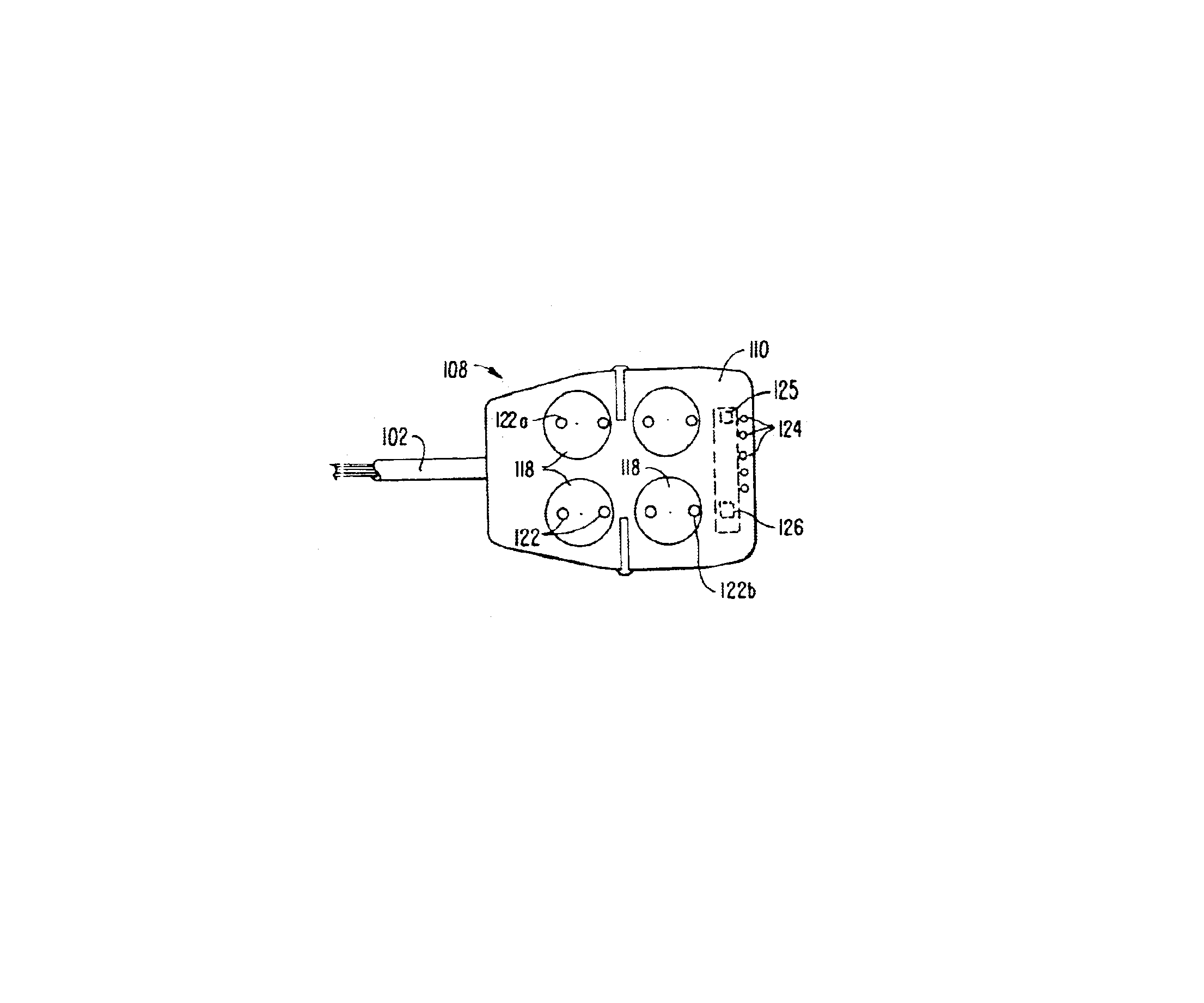

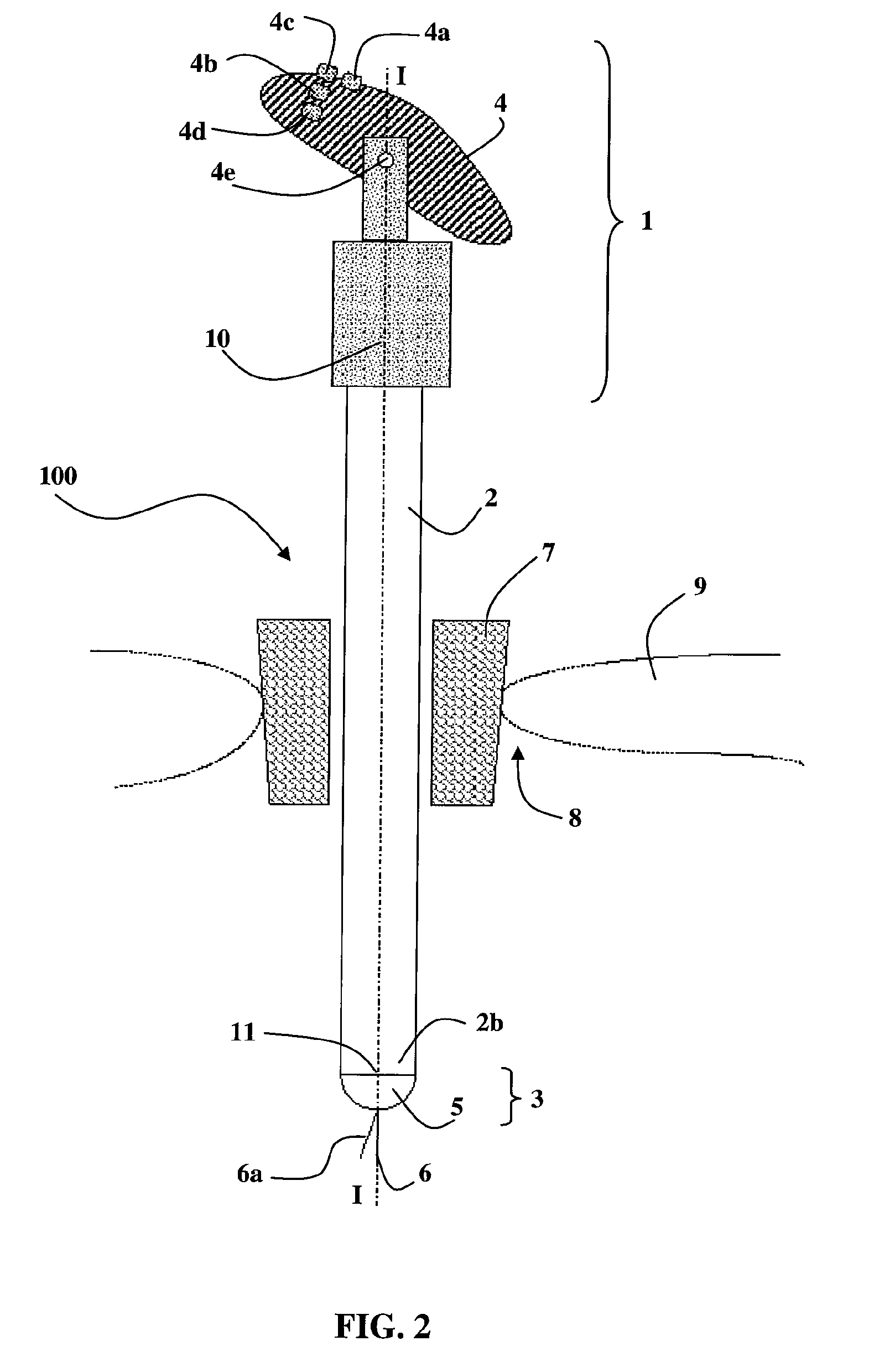

ActiveUS20080183193A1Easily confirm rotational angleEasy to confirmDiagnosticsSurgical manipulatorsWork unitManipulator

A manipulator comprises a hollow shaft, wires provided on the shaft and a working unit disposed on one end of the shaft and being driven by at least one wire of the wires, the working unit having a tip tool including a rolling mechanism which rotates about an axis Or directed to a distal end thereof. A tip side surface of a proximal end member and a cover of a distal end member are relatively rotated by the rolling mechanism. The cover has a rotation identifier for indicating a degree of relative rotation of the tip side surface. The tip side surface has an alignment indicator for indicating an initial position of the cover.

Owner:KARL STORZ GMBH & CO KG

Manipulator for medical use

ActiveUS10245058B2Easily confirm rotational angleEasy to confirmDiagnosticsSurgical manipulatorsWork unitEngineering

Owner:KARL STORZ GMBH & CO KG

Methods, systems, and devices for surgical visualization and device manipulation

Owner:BOARD OF RGT UNIV OF NEBRASKA

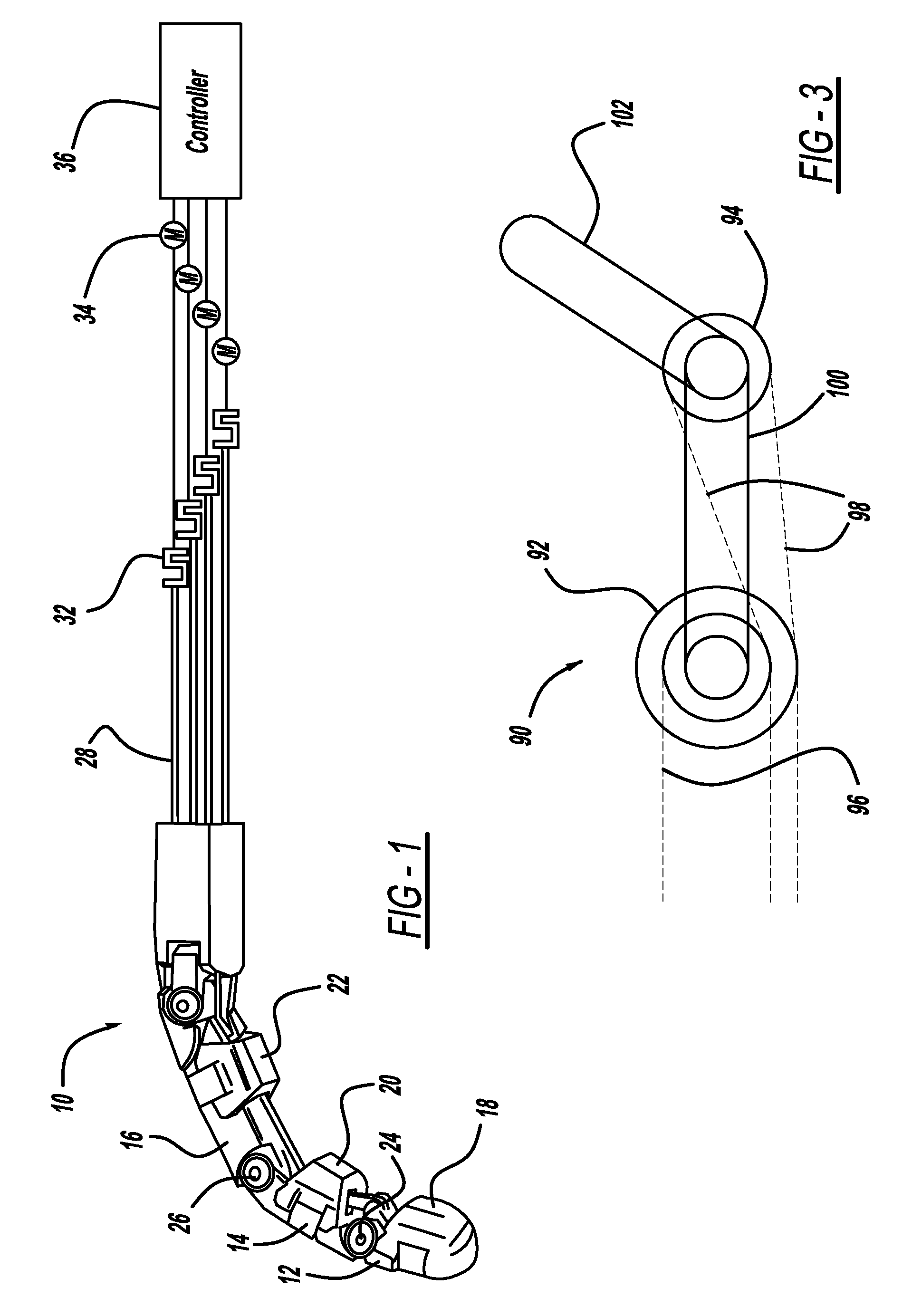

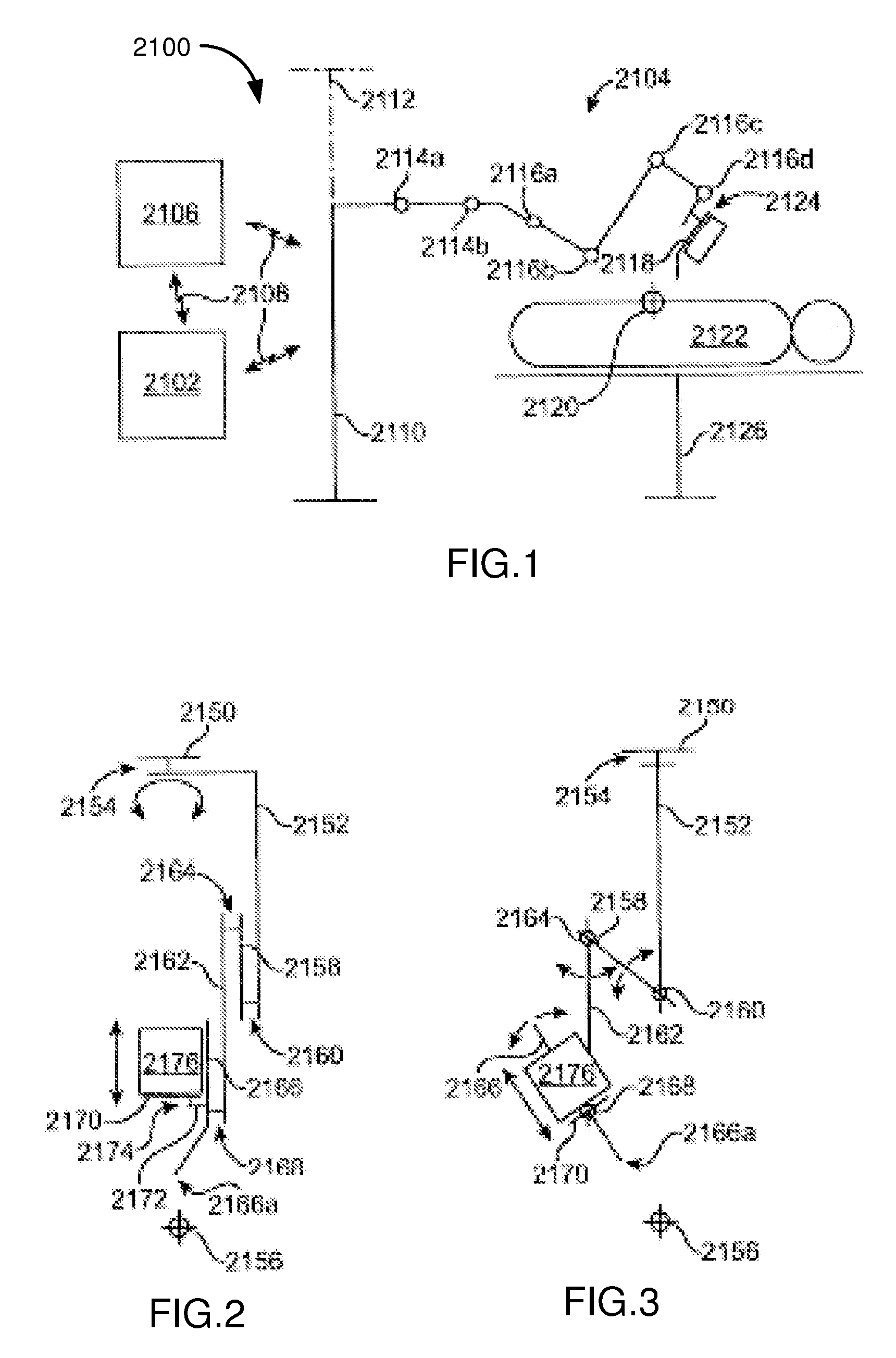

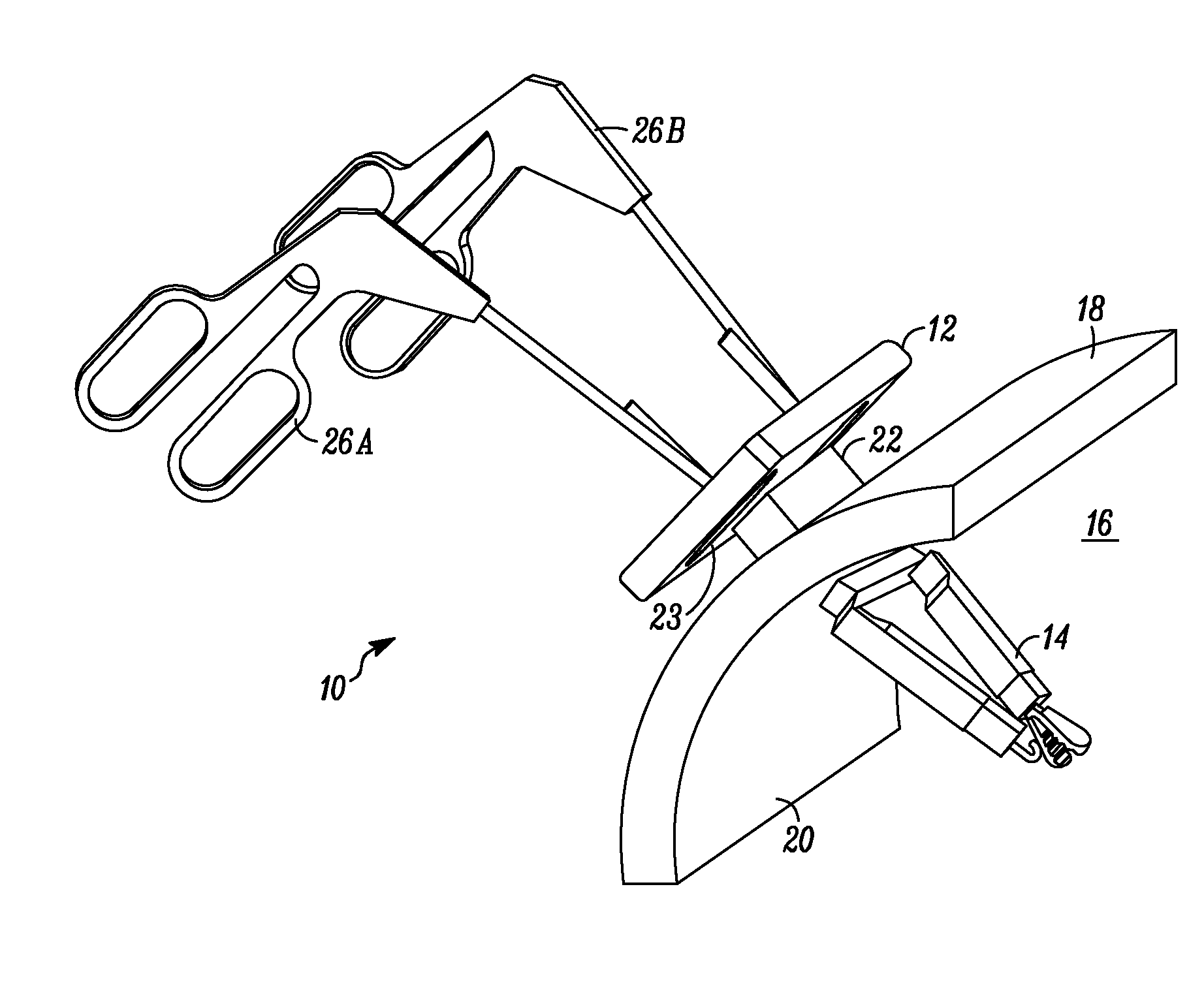

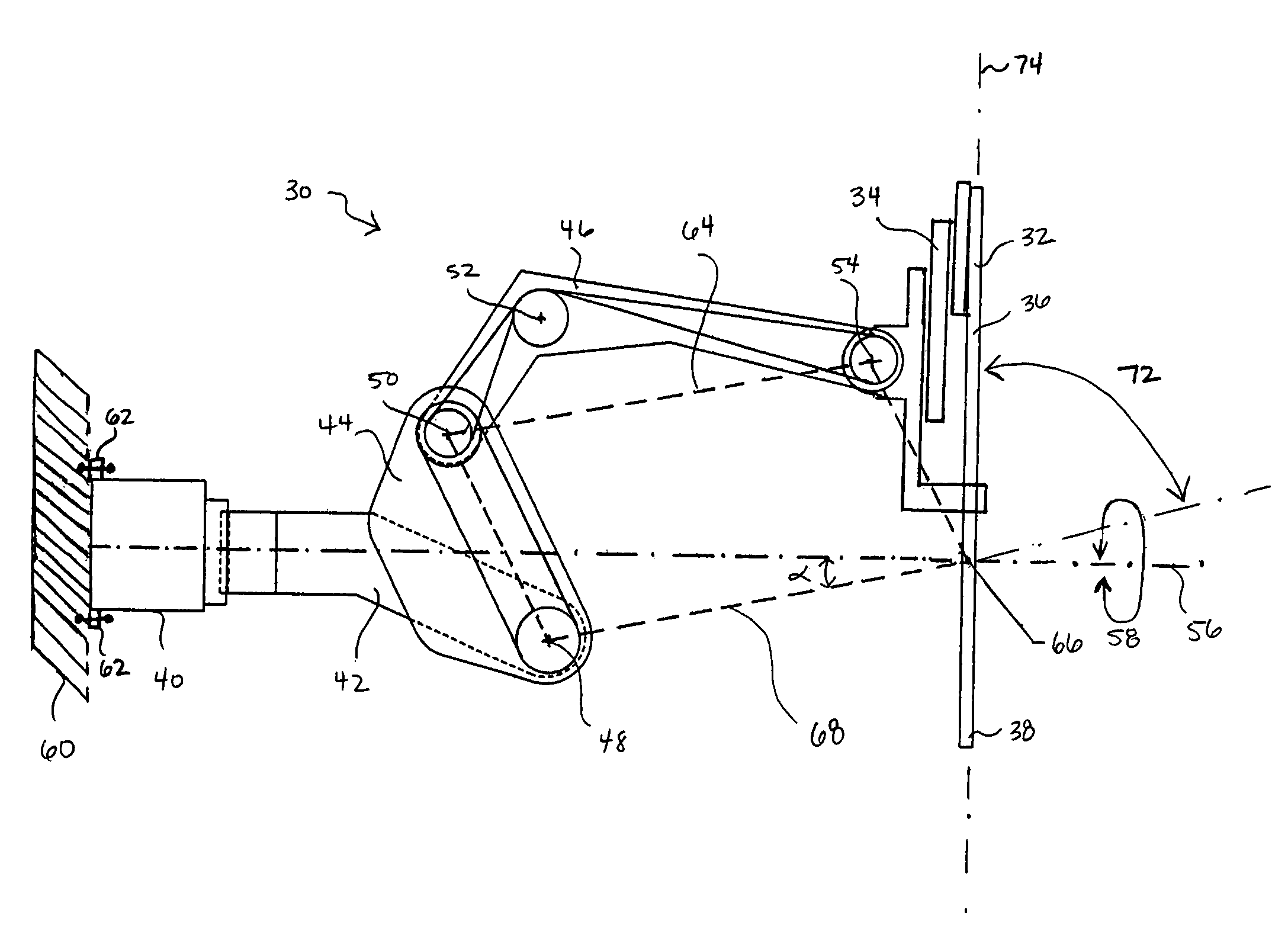

Offset remote center manipulator for robotic surgery

ActiveUS7594912B2Increase rangeReduces overall complexity and size and physical weightMechanical apparatusDiagnosticsEngineeringManipulator

Medical, surgical, and / or robotic devices and systems often including offset remote center parallelogram manipulator linkage assemblies which constrains a position of a surgical instrument during minimally invasive robotic surgery are disclosed. The improved remote center manipulator linkage assembly advantageously enhances the range of instrument motion while at the same time reduces the overall complexity, size, and physical weight of the robotic surgical system.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Medical manipulator

ActiveUS9345503B2Increased number of degree of freedomSmoother techniqueDiagnosticsSurgical robotsActuatorManipulator

A medical manipulator has a distal-end working unit including an end effector. The distal-end working unit has a rotor having a hollow tube rotatable in unison with the end effector and a rotational support tube having a posture variable with respect to the shaft. The rotor is rotatably supported by an inner circumferential surface of the rotational support tube. Engaging members that are disposed in side holes formed in the rotational support tube have inner ends inserted in an annular groove.

Owner:KARL STORZ GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com