Patents

Literature

19162results about How to "Avoid contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

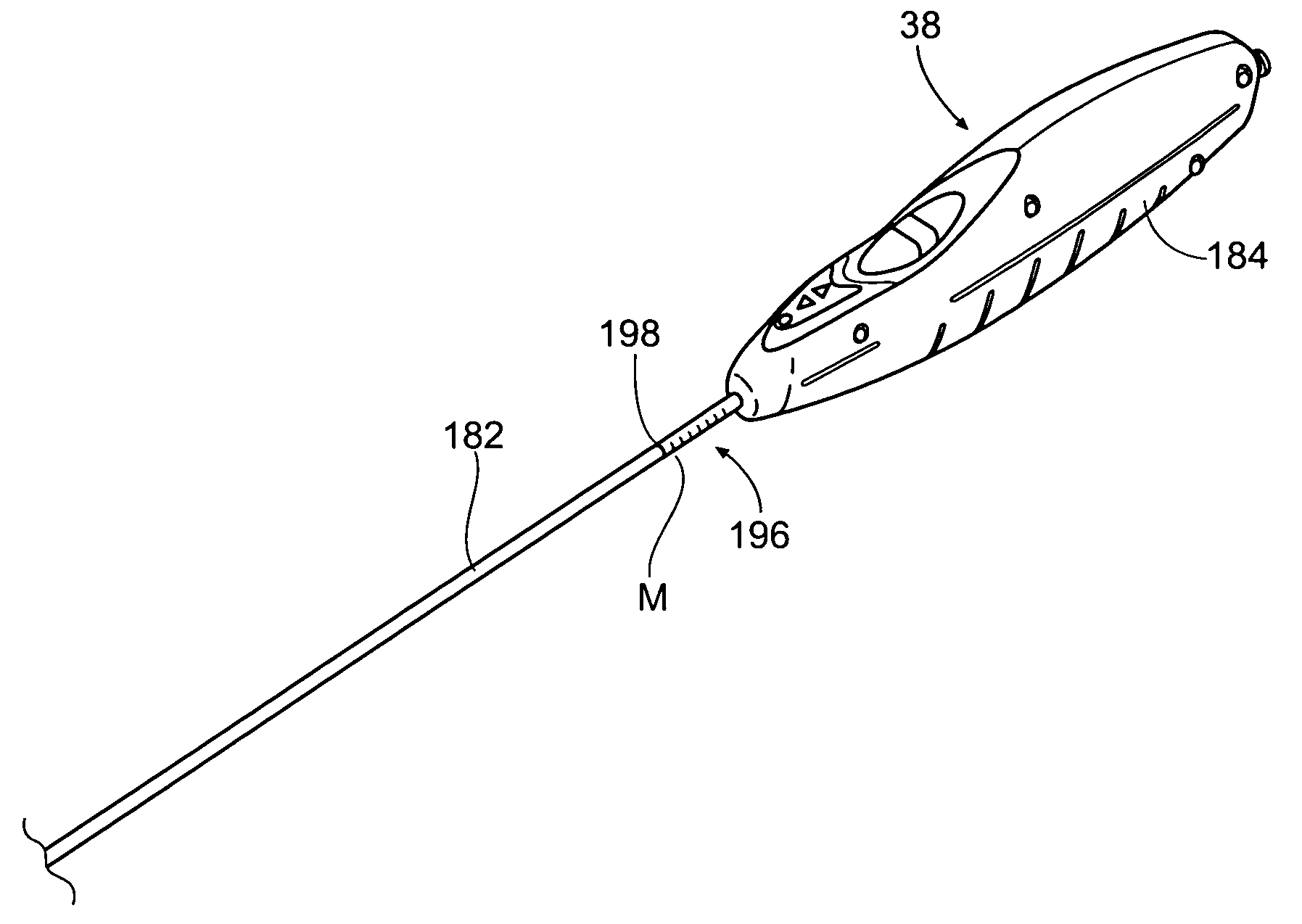

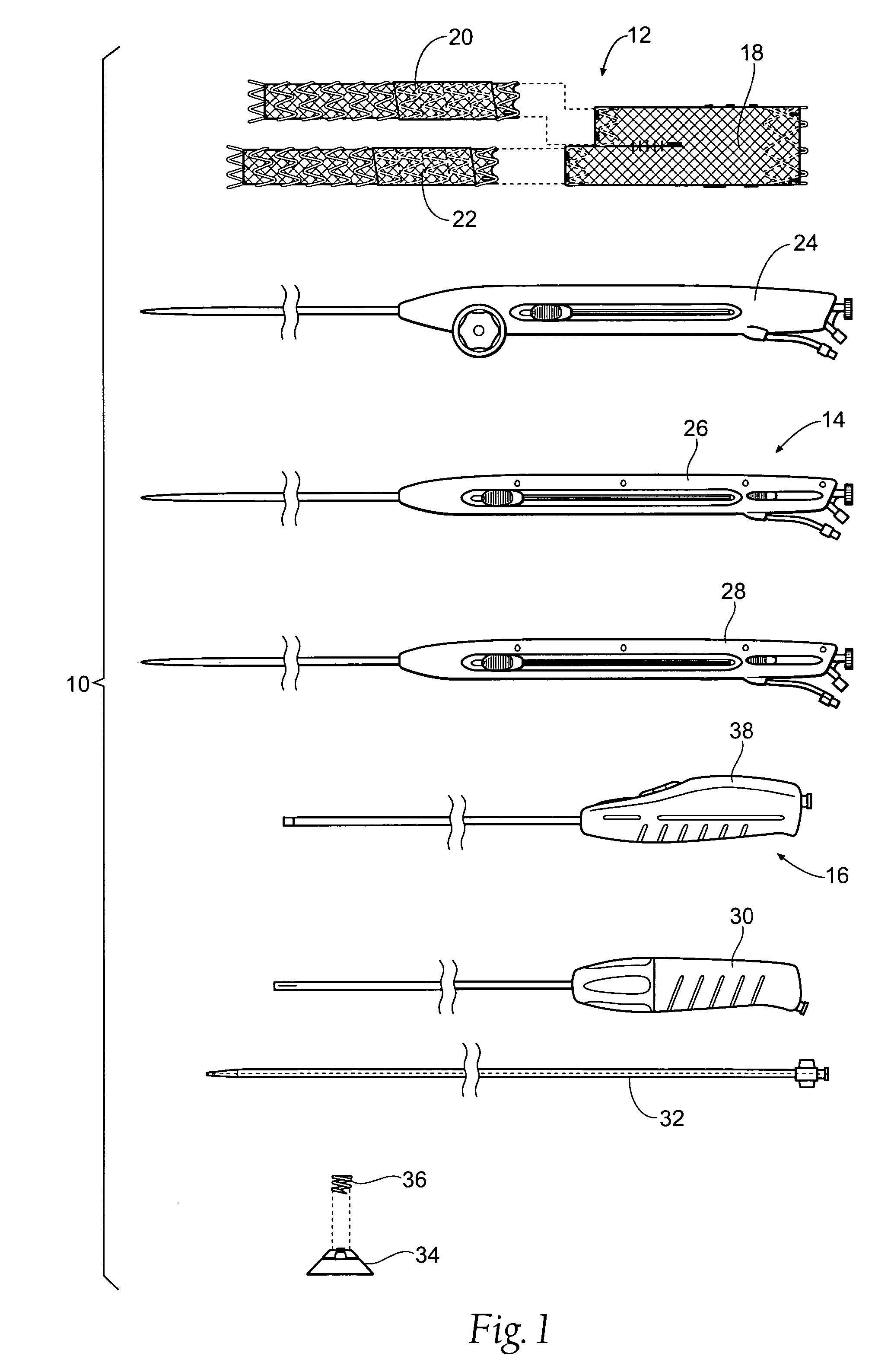

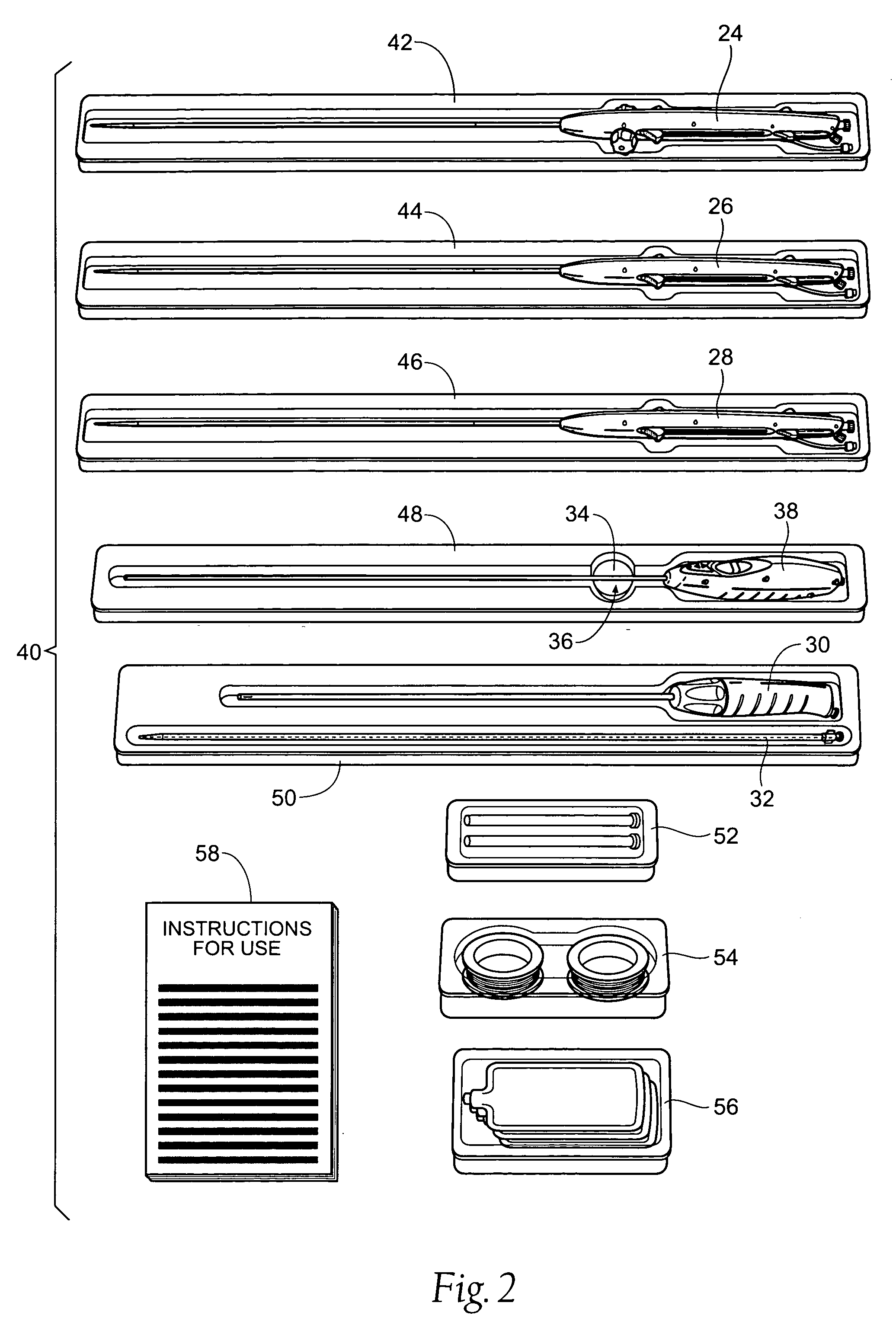

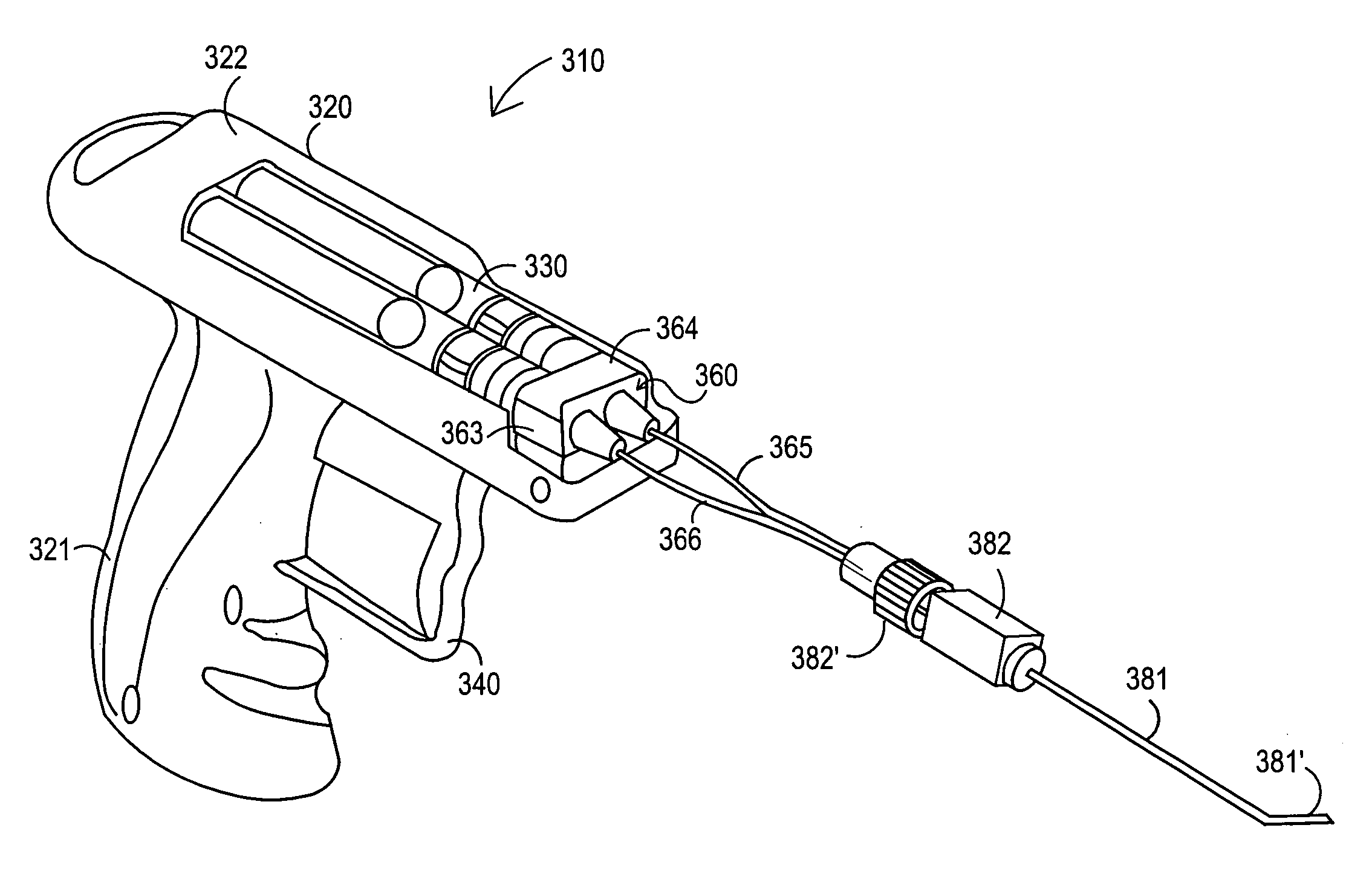

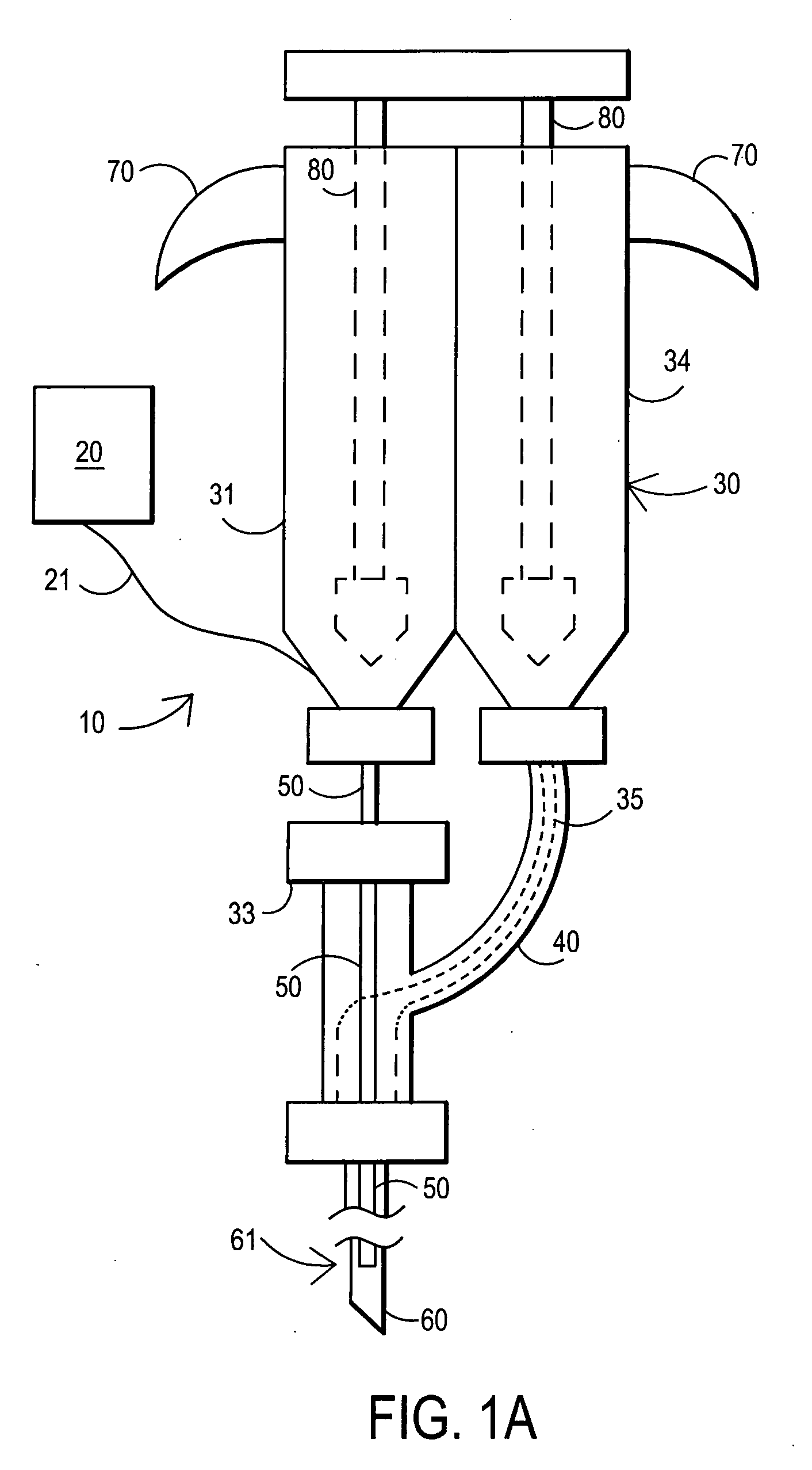

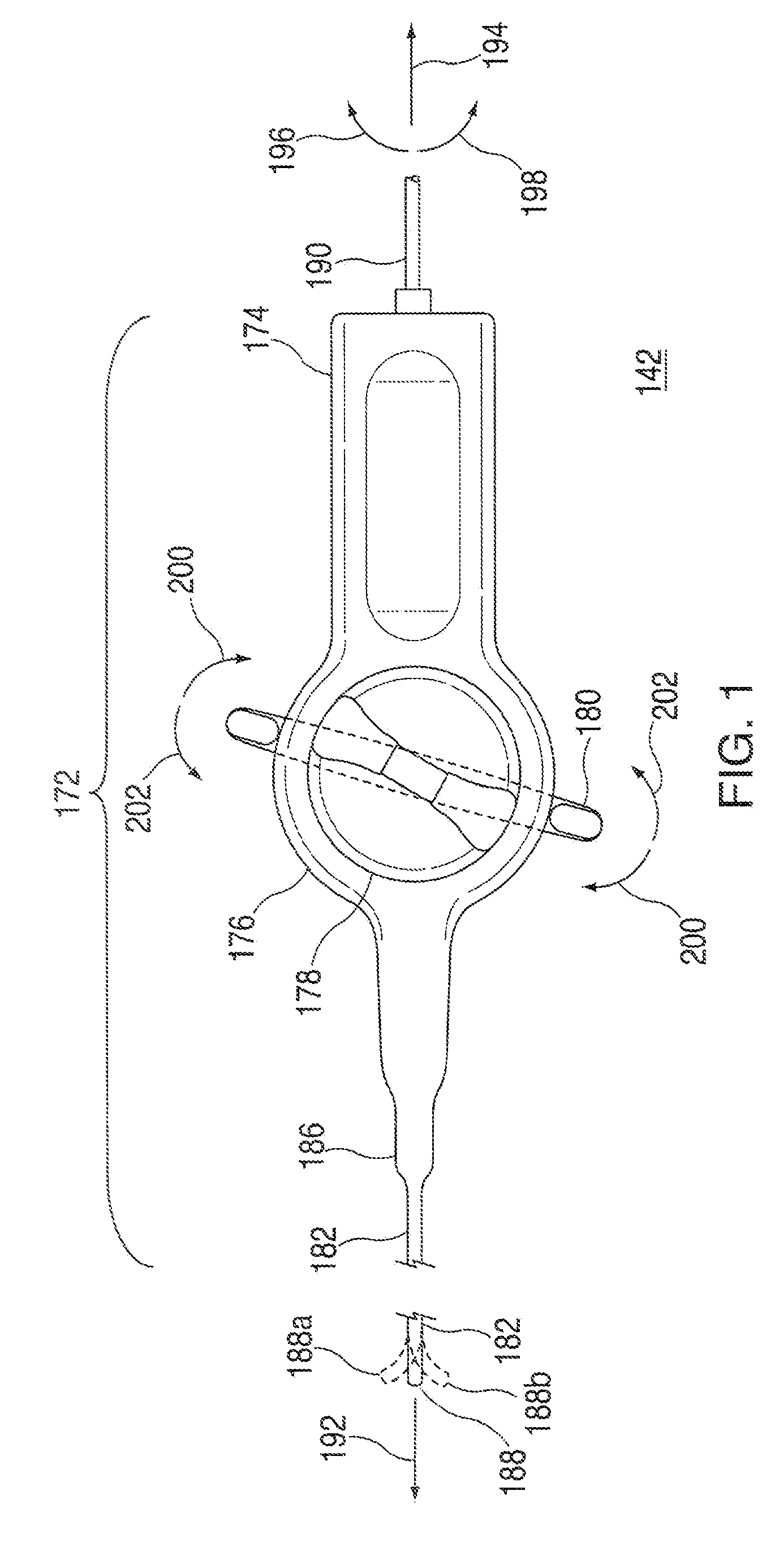

Endovascular aneurysm devices, systems, and methods

Devices, systems, and methods for implanting prostheses in the body lumens rely on tacking or anchoring the prostheses with separately introduced fasteners. After initial placement, a fastener applier system is introduced within the expanded prostheses to deploy a plurality of fasteners to at least one prosthesis end. The fasteners are usually helical fasteners which are releasably restrained on the fastener driver, and are delivered by rotation of the fastener driver. The fasteners may be applied singly, typically in circumferentially spaced-apart patterns about the interior of at least one end of the prosthesis. A lumen extension or lumens may be coupled to the prosthesis to extend the reach of the prosthesis within the implantation site. Fasteners may also be applied to the lumen extensions.

Owner:MEDTRONIC VASCULAR INC

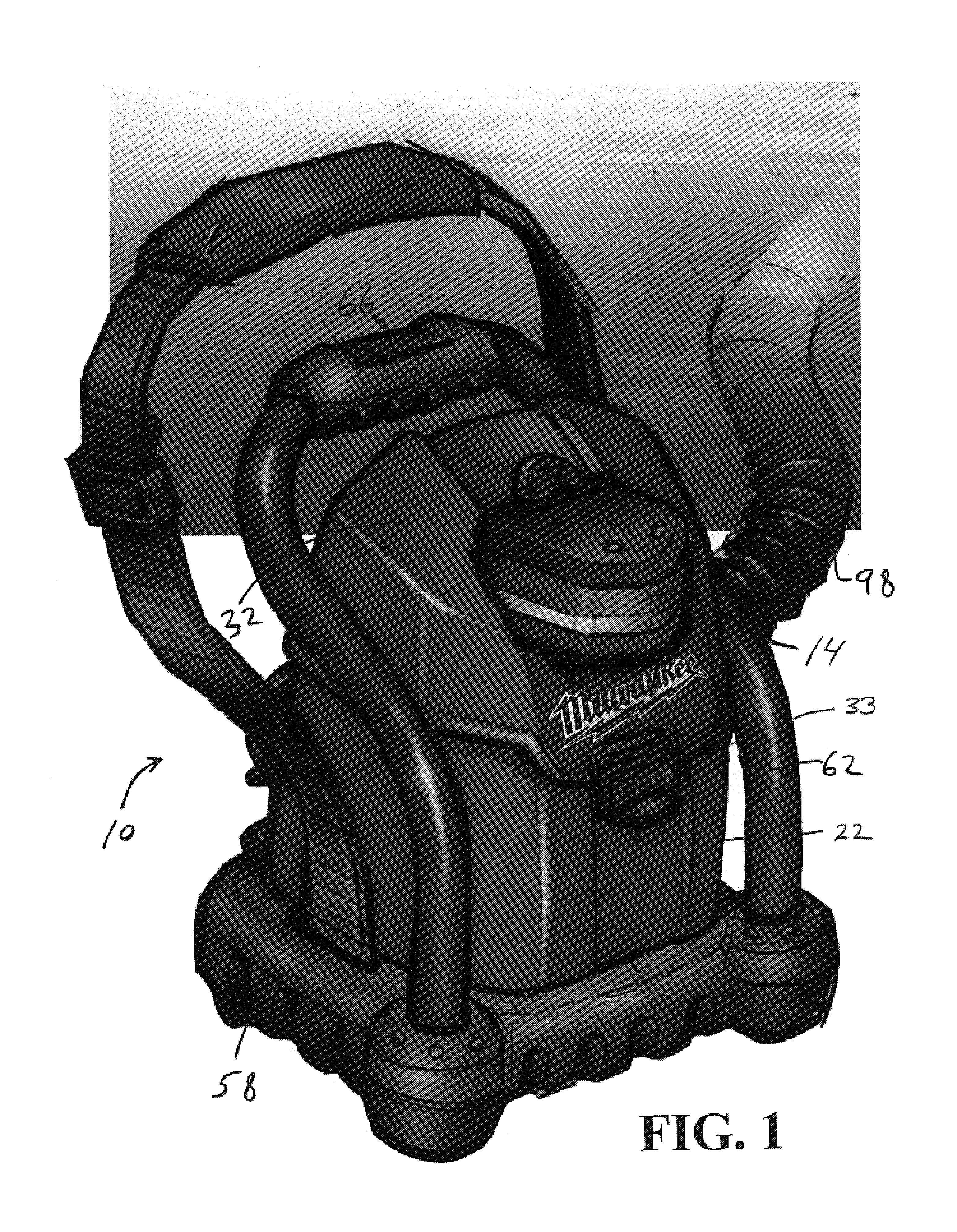

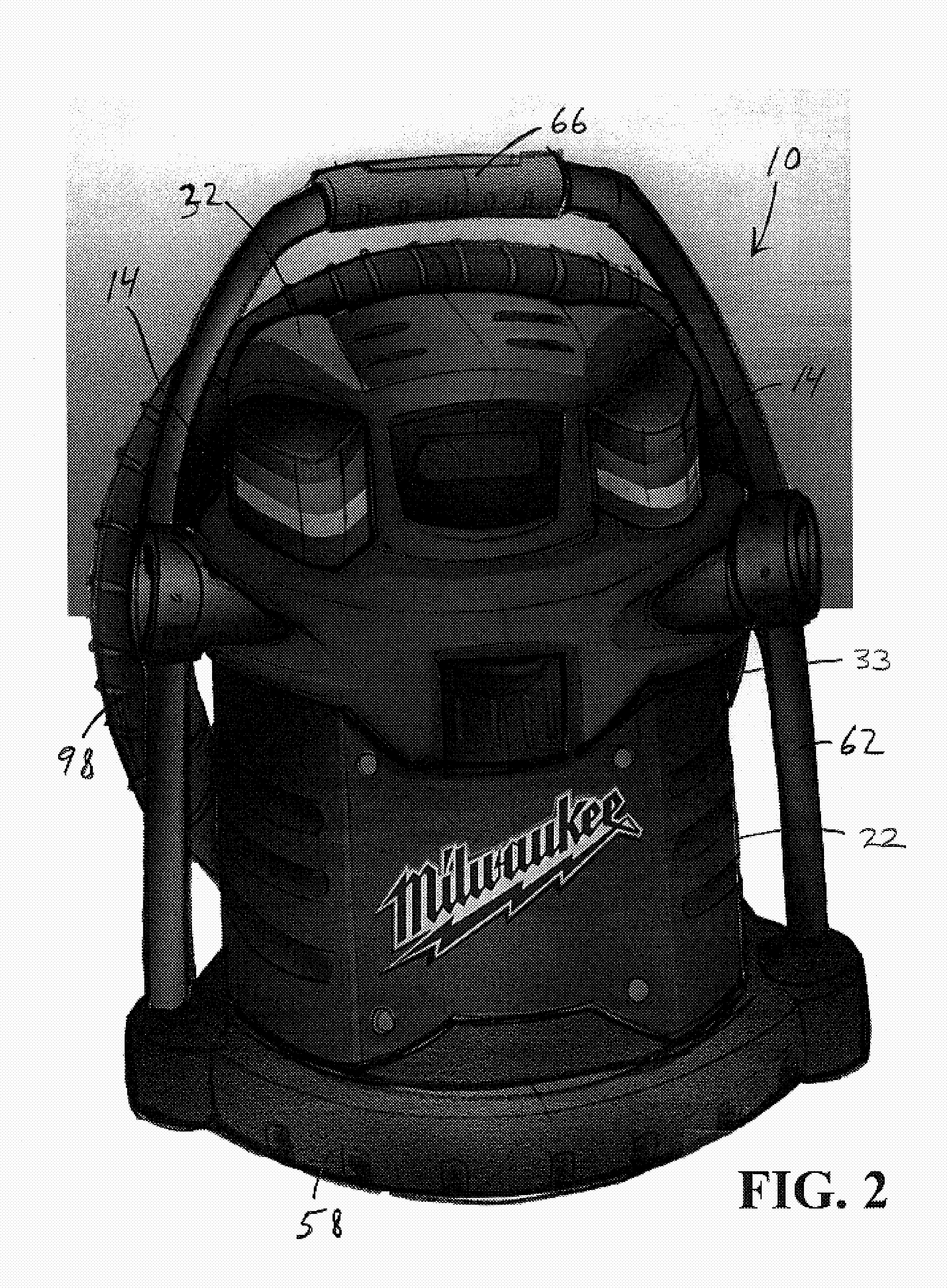

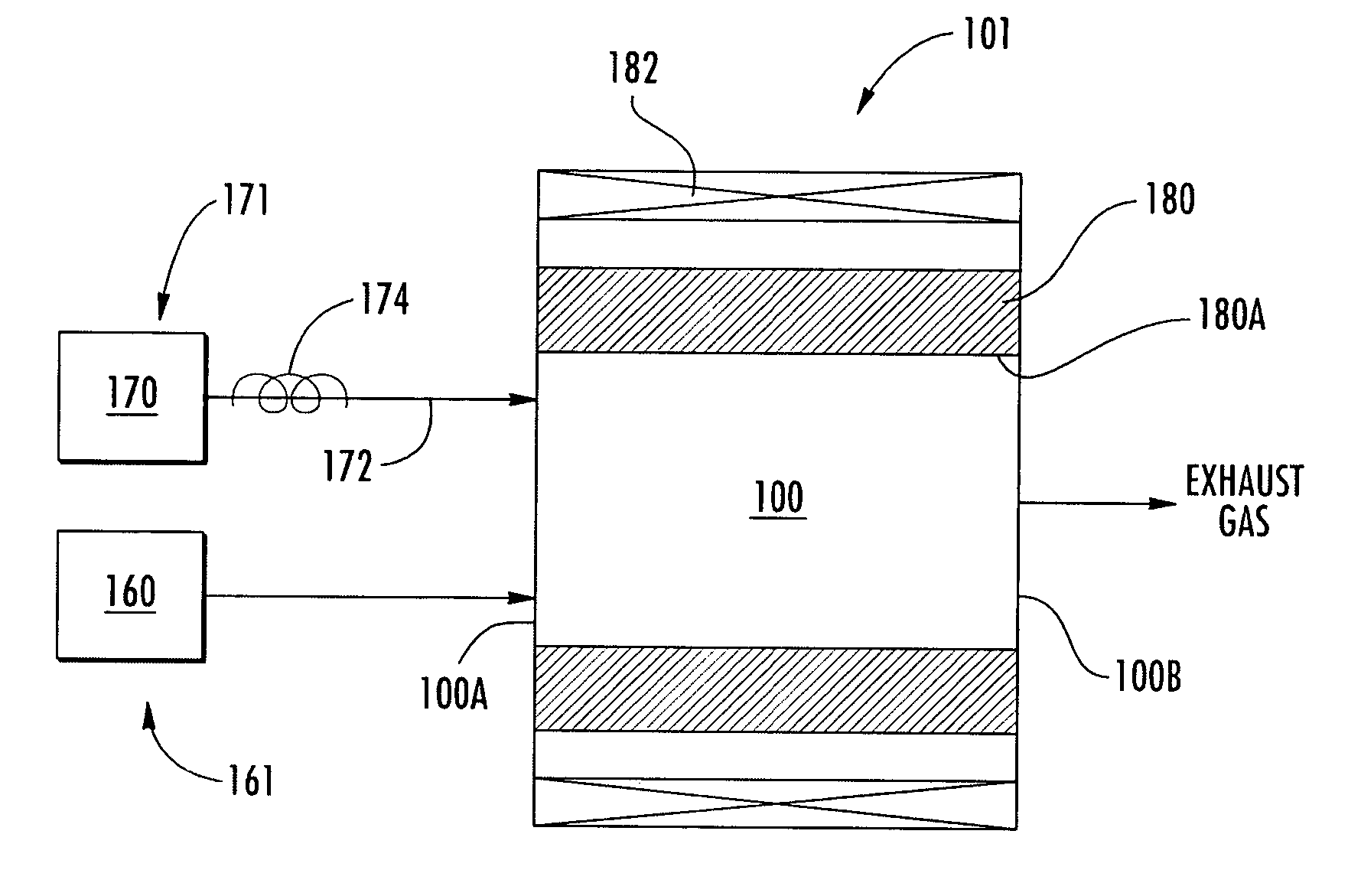

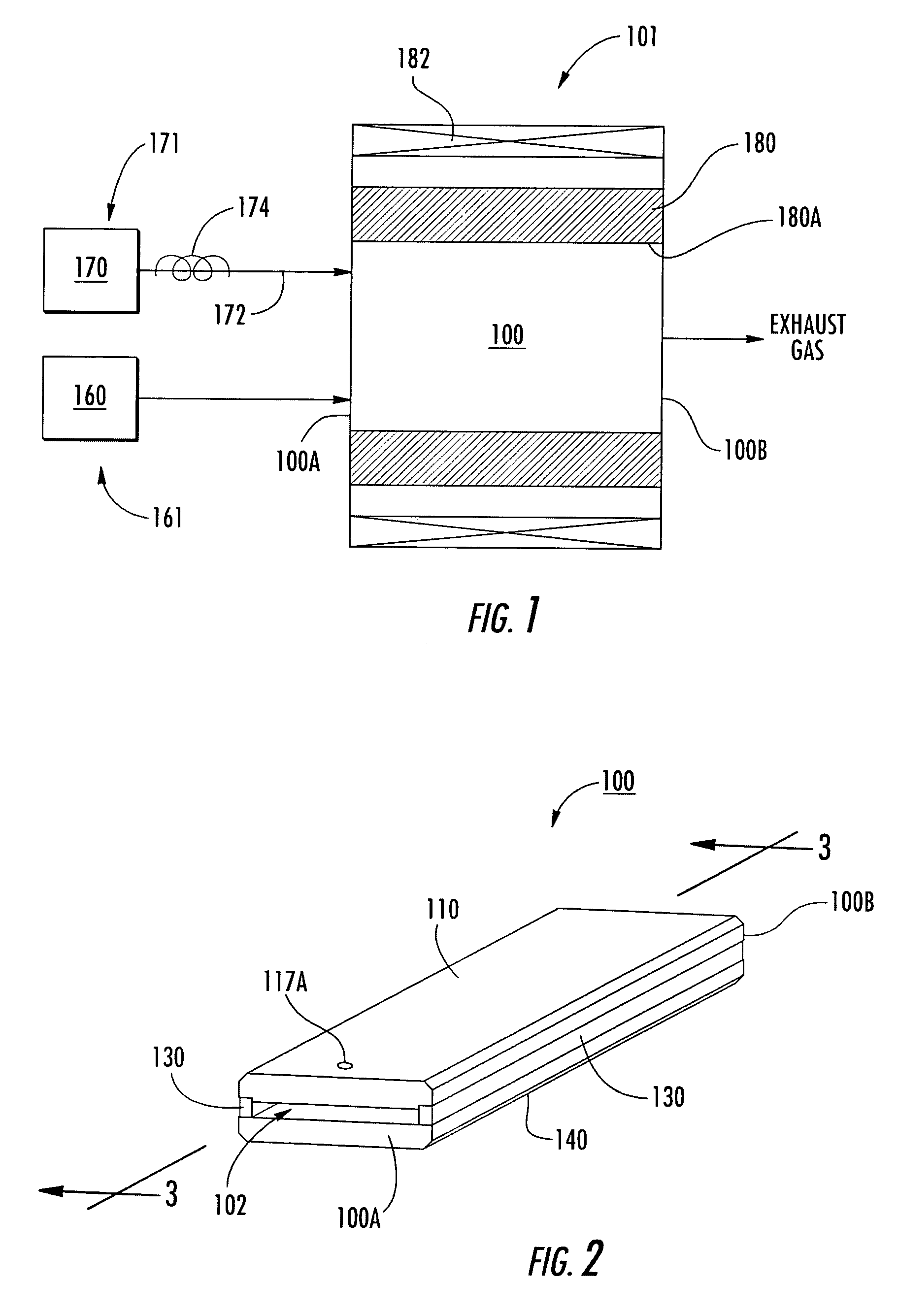

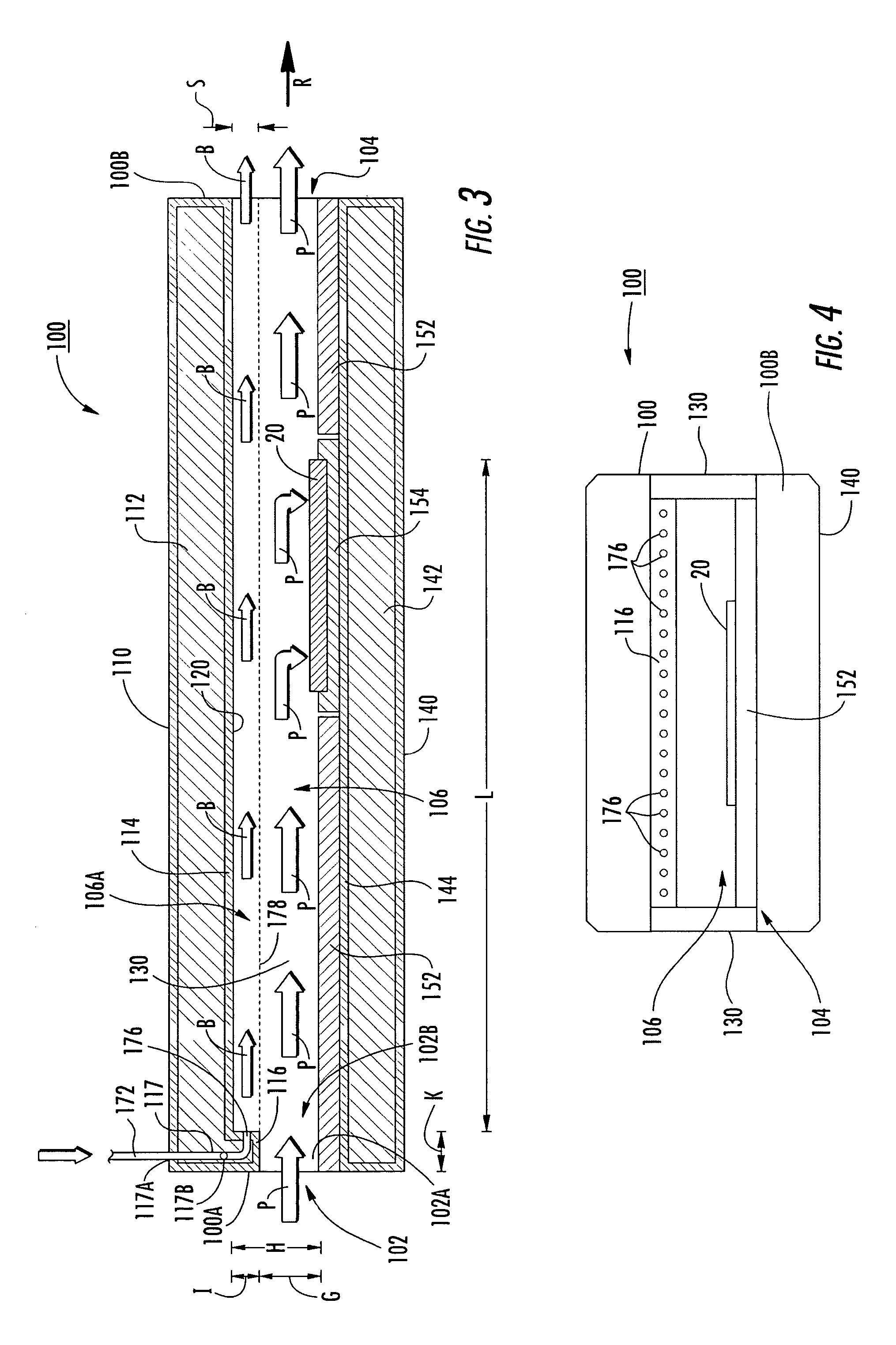

Air flow-producing device, such as a vacuum cleaner or a blower

ActiveUS7712182B2Heavy-duty constructionAvoid contactCleaning filter meansSuction filtersElectricityElectrical battery

Owner:MILWAUKEE ELECTRIC TOOL CORP

Tobacco processing

InactiveUS6895974B2Lower Level RequirementsInhibition formationTobacco preparationTobacco treatmentTobacco-specific nitrosaminesEngineering

Owner:R J REYNOLDS TOBACCO COMPANY

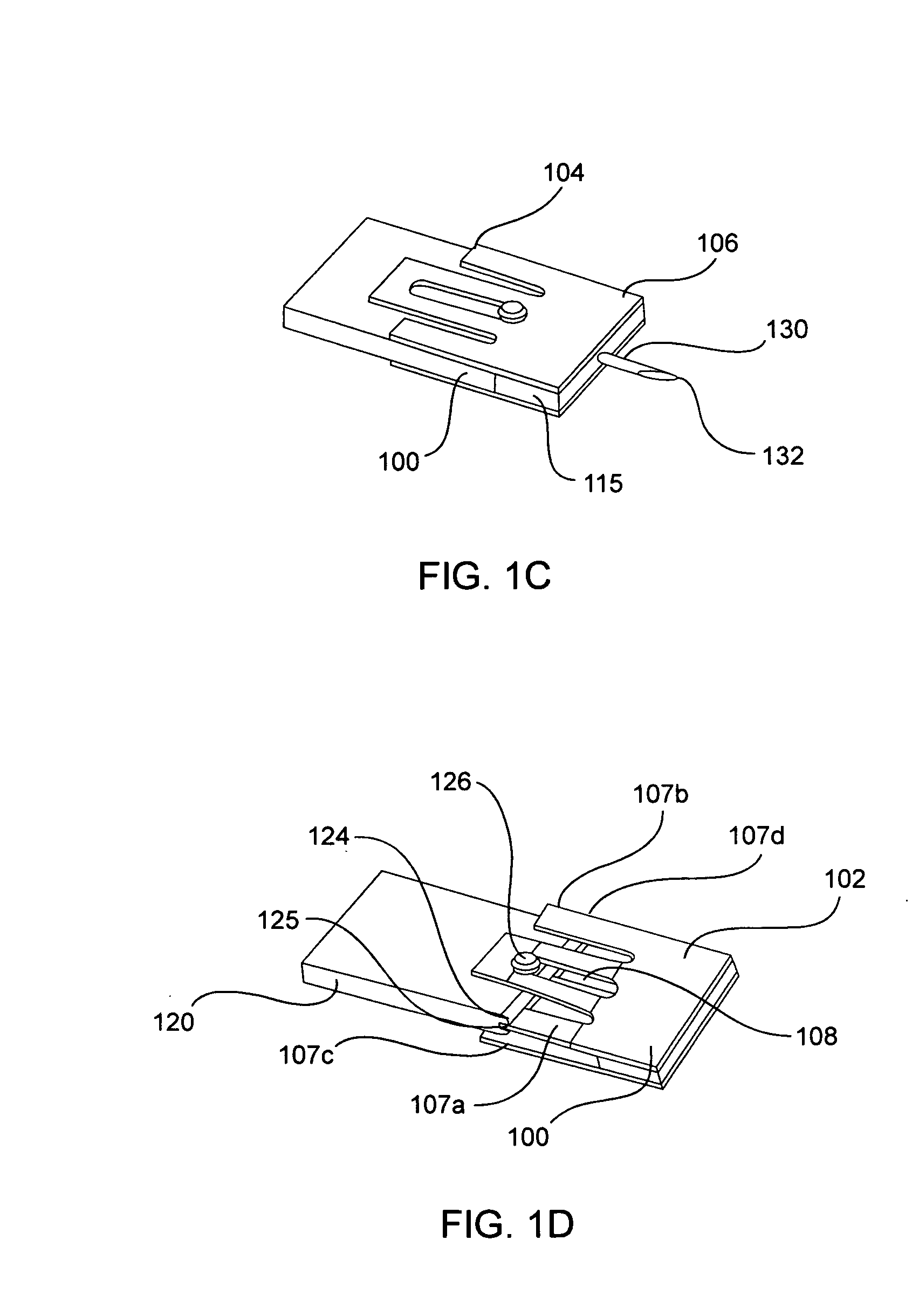

Covers for tissue engaging members

InactiveUS20070233013A1Prevent accidental contactAvoid reuseInfusion syringesDiagnostic recording/measuringBiomedical engineering

Owner:ABBOTT DIABETES CARE INC

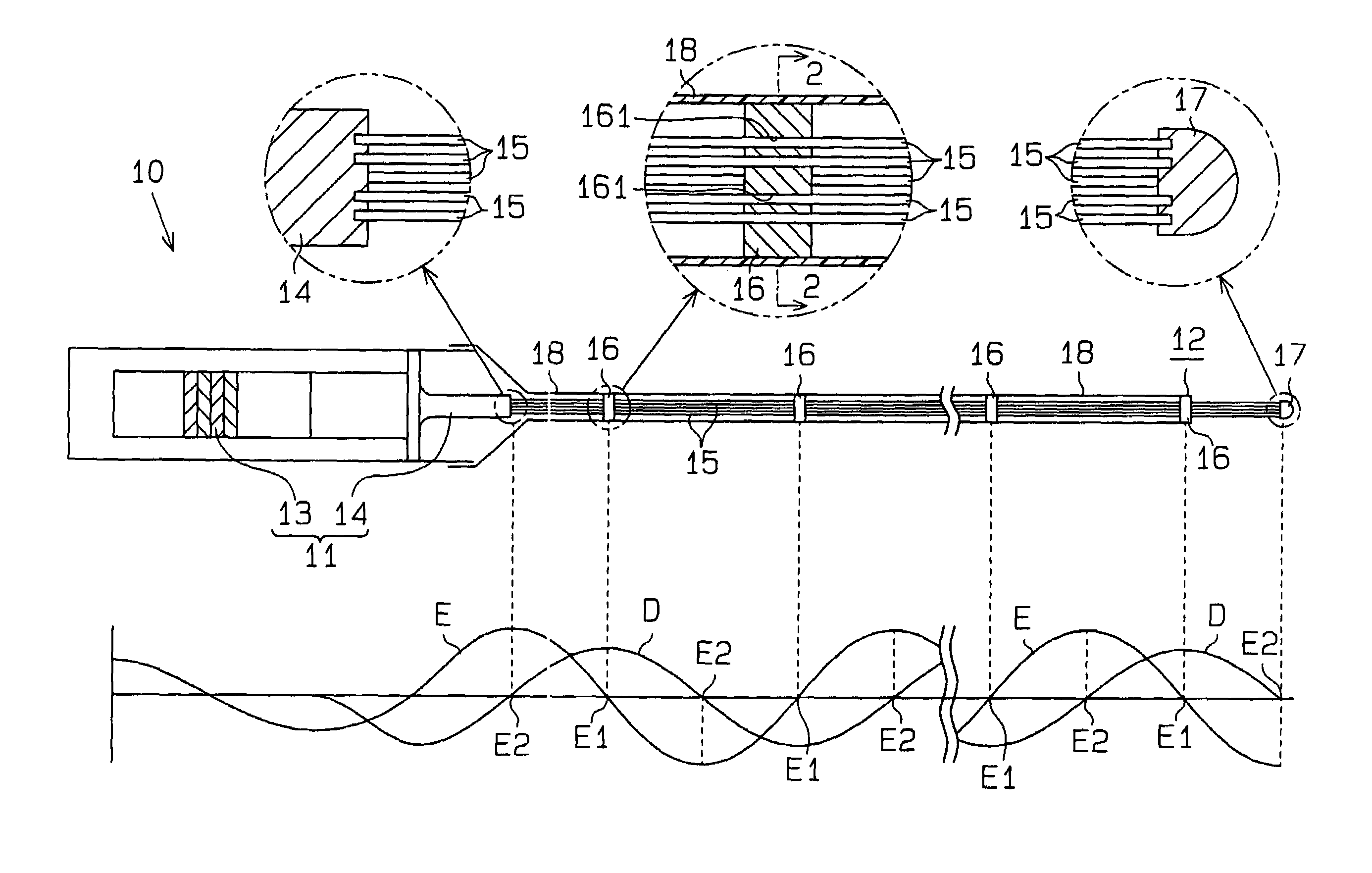

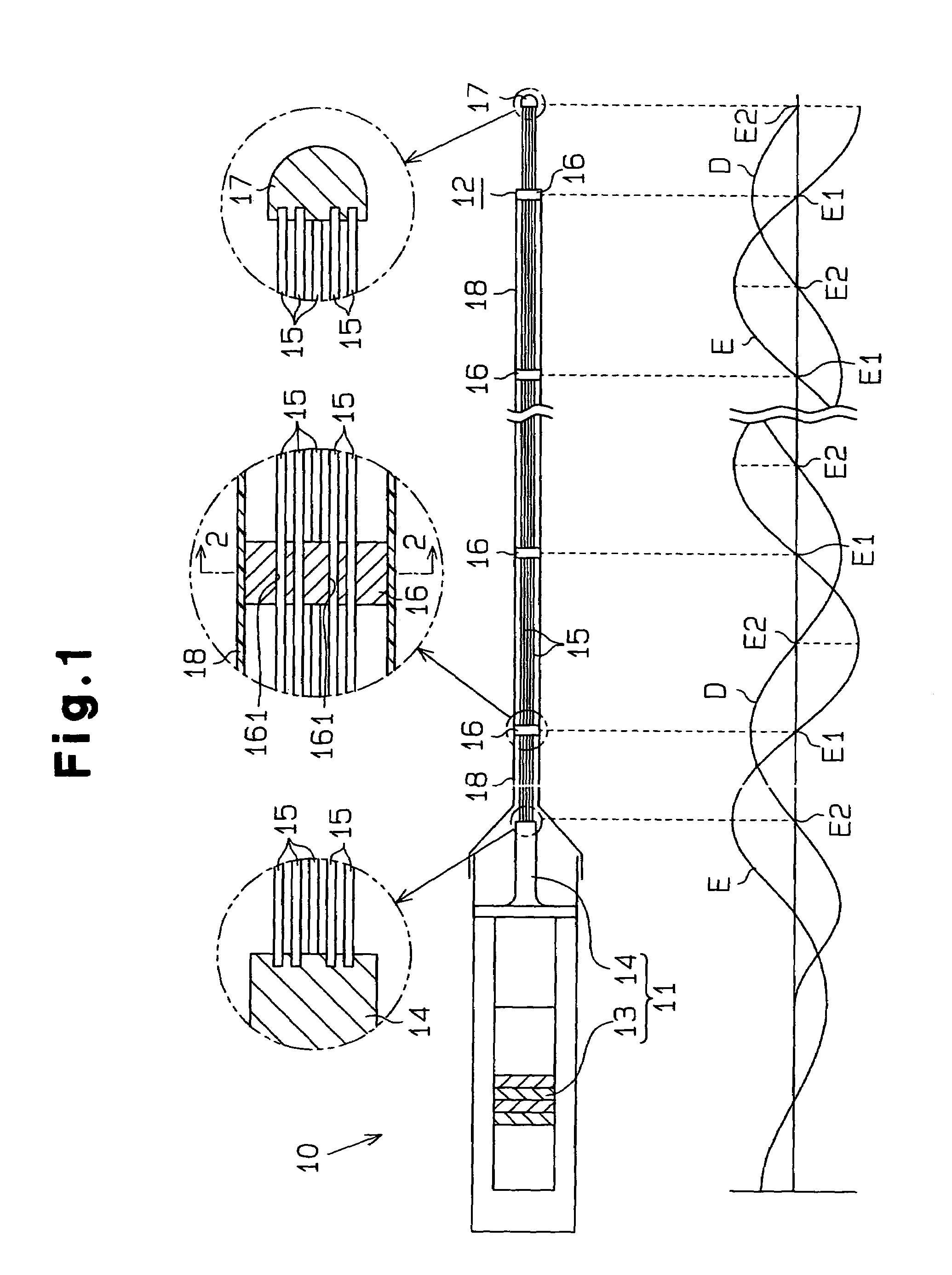

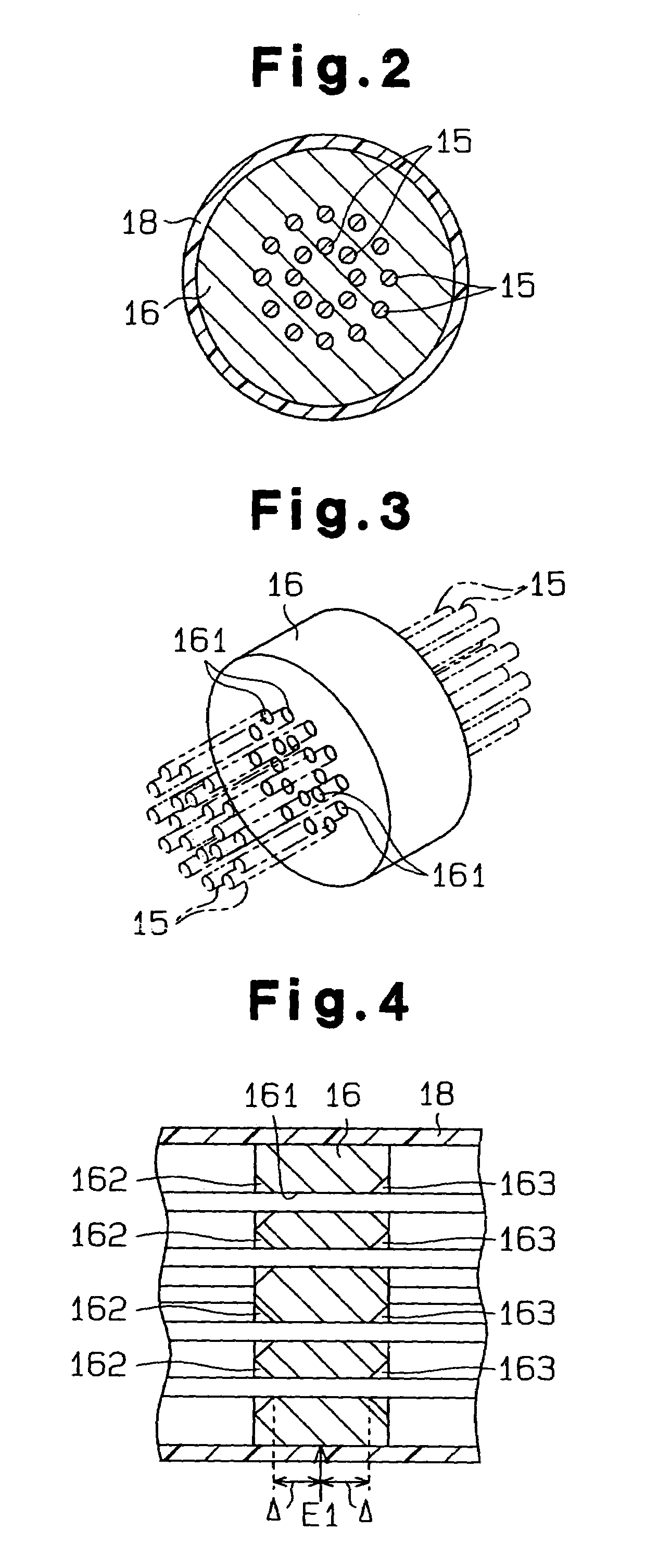

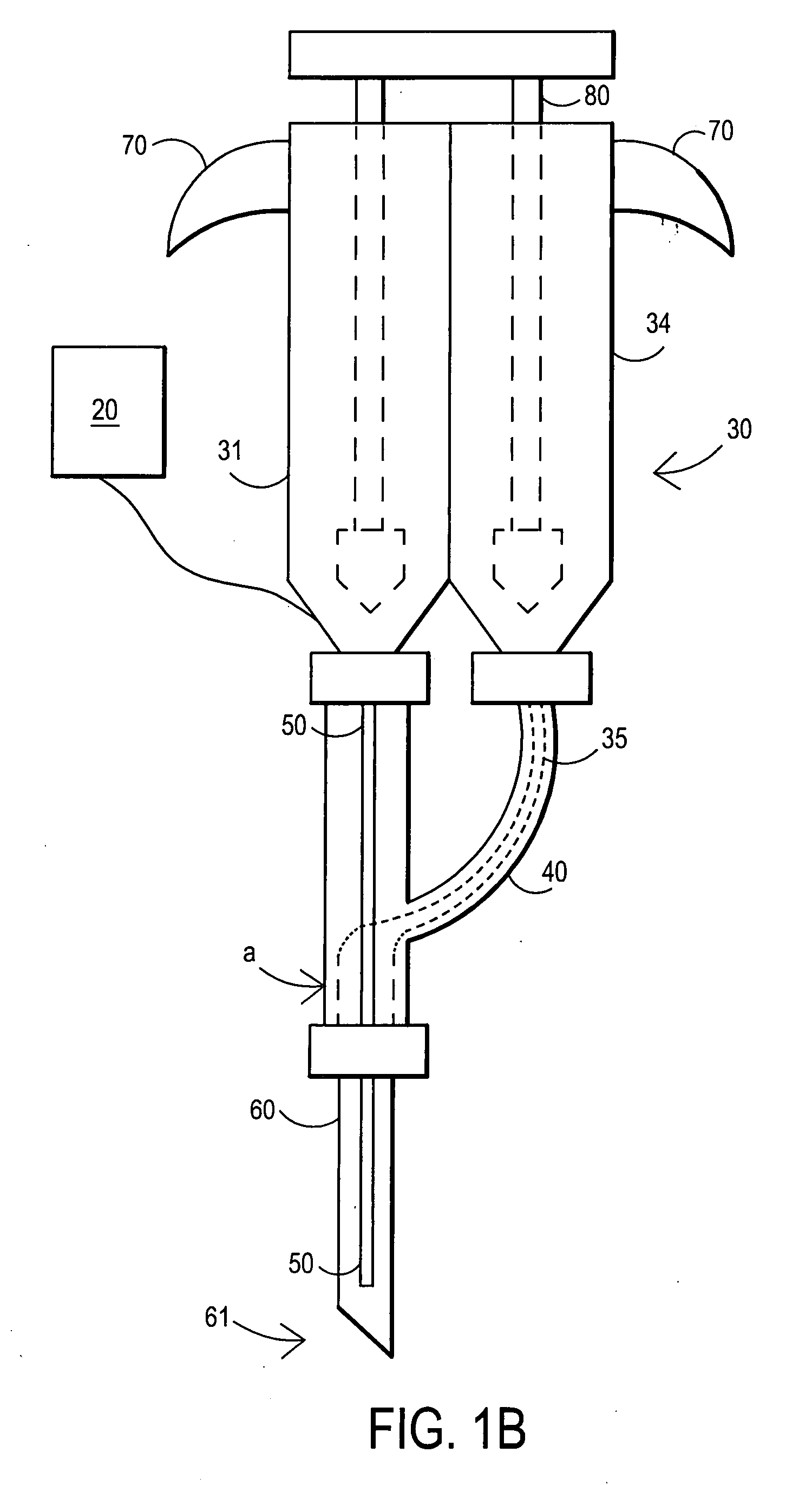

Ultrasonic wave generating/transmitting apparatus

InactiveUS7001335B2Avoid feverAvoid contactUltrasonic/sonic/infrasonic diagnosticsSurgical instrument detailsEngineeringUltrasonic vibration

Disclosed is an ultrasonic generating and transmitting apparatus equipped with a transmission section for transmitting ultrasonic vibration from a vibration section. A plurality of linear members for transmitting ultrasonic vibration and binding plates which bind the linear members in such a state as to be apart from one another are provided. The transmission section is comprised of the linear members and the binding plates.

Owner:HITACHI LTD

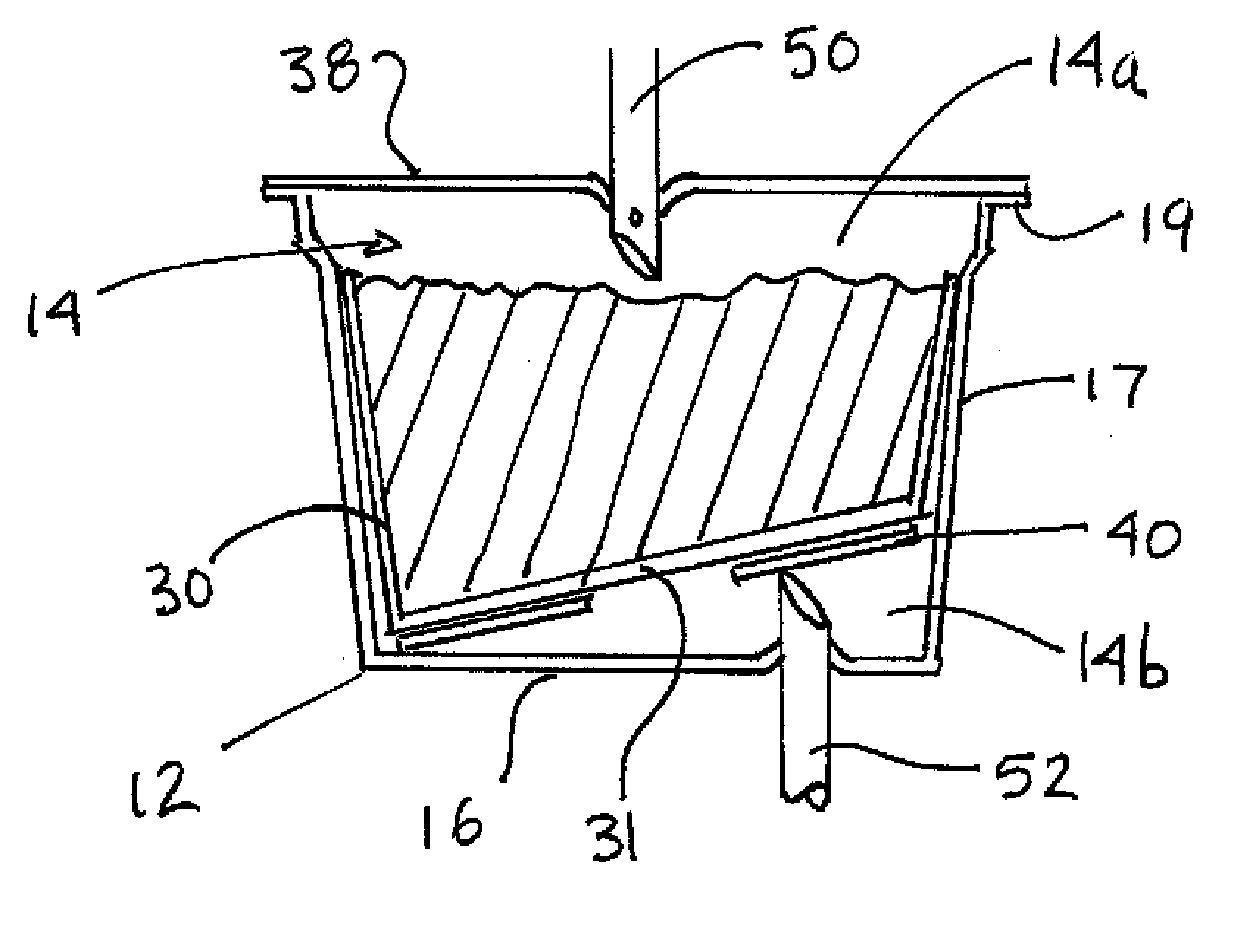

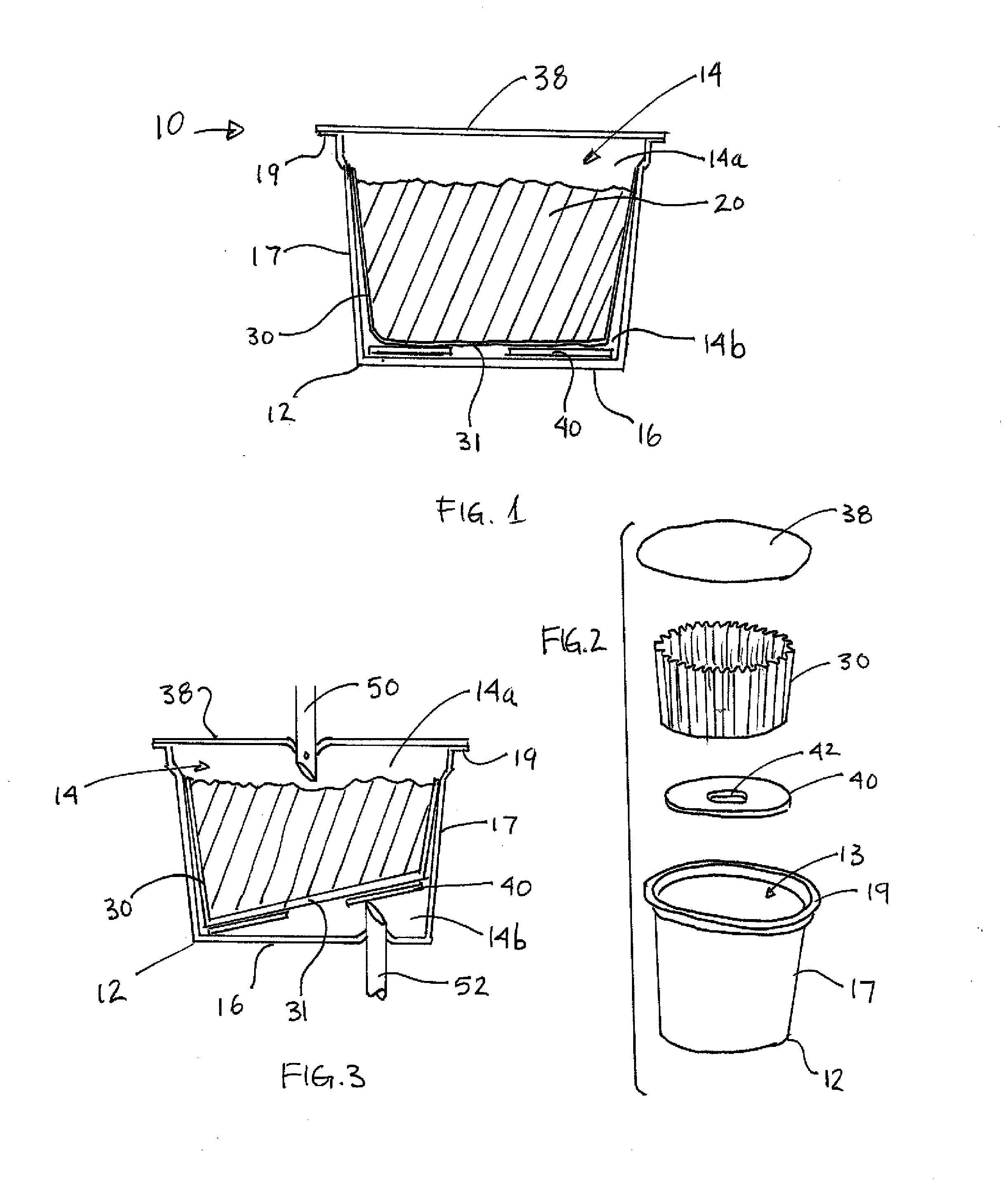

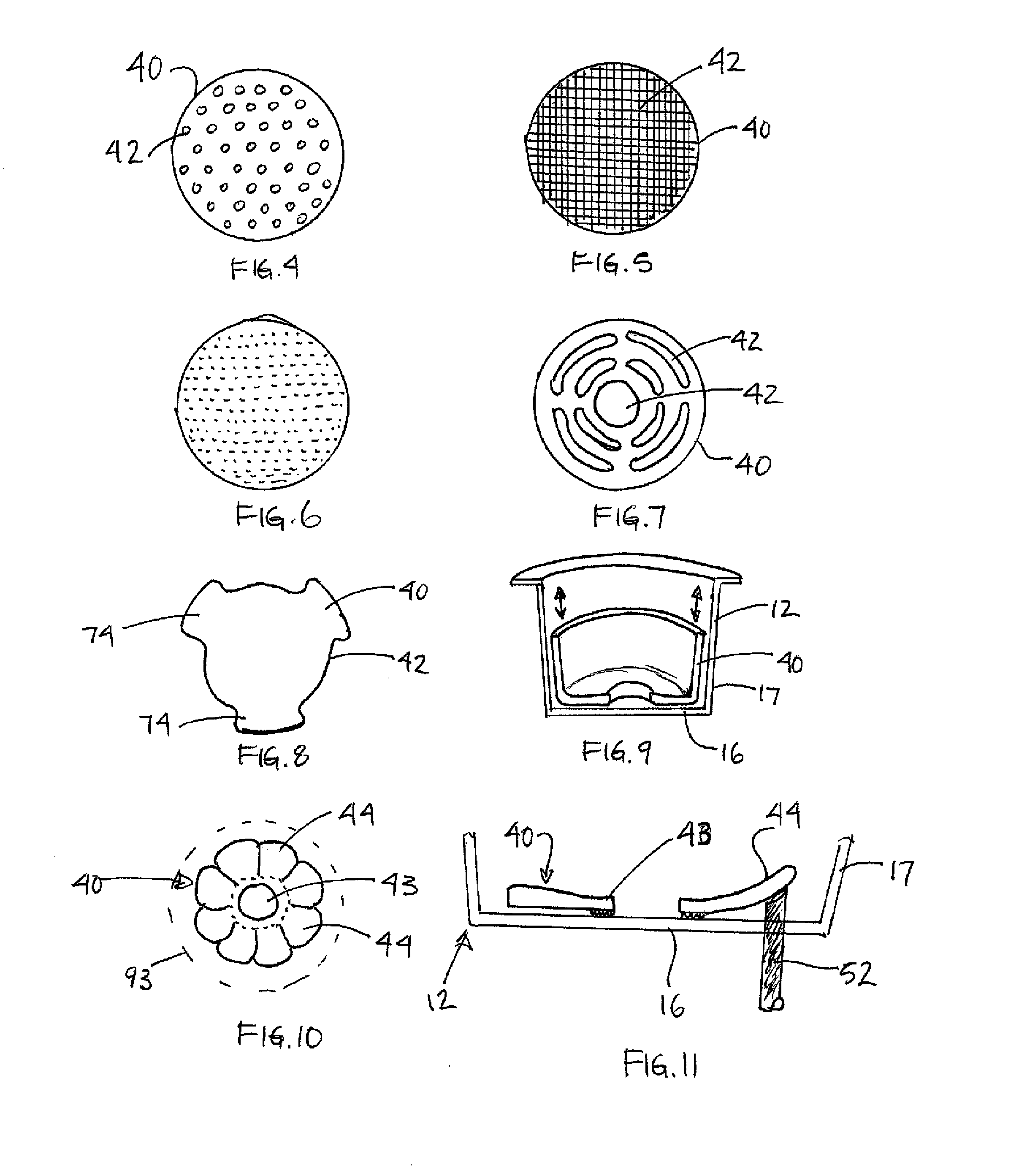

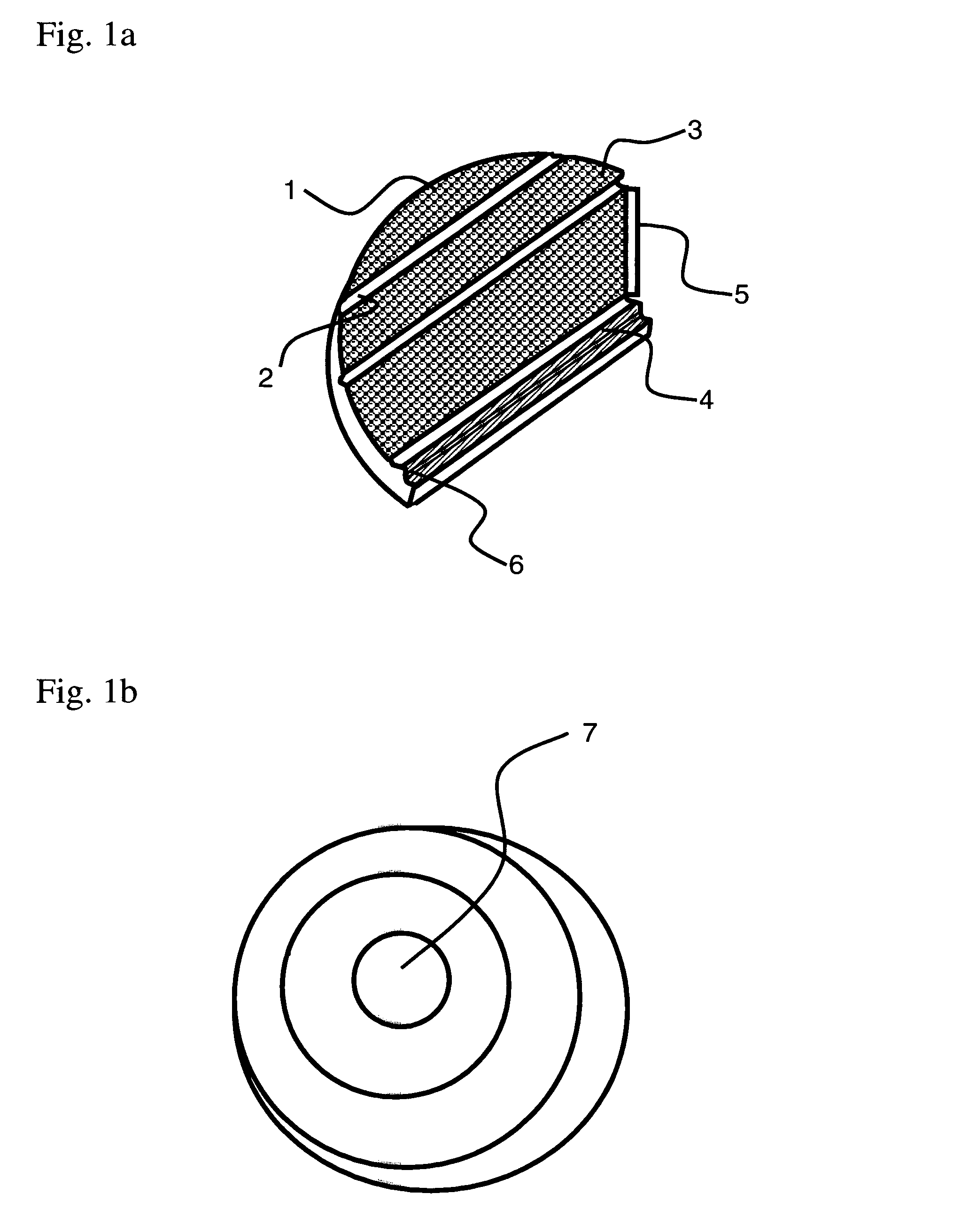

Cartridge with filter guard

ActiveUS20100303964A1Avoid damageLower the volumeTea extractionBeverage vesselsInterior spaceEngineering

A cartridge for forming a beverage includes a container defining an interior space, a filter, a beverage medium contained in the interior space, and a filter guard. The filter may be arranged so that liquid that interacts with the beverage medium flows through the filter to exit the interior space. The container may include a surface arranged to be pierced by a piercing member to permit beverage to exit the container. The filter guard may be arranged to contact the piercing member to resist damage to the filter when the container surface is pierced. In one embodiment the filter guard and filter may be in contact with the container surface that is pierced, yet damage to the filter that might be caused by the piercing element may be avoided.

Owner:KEURIG GREEN MOUNTAIN INC

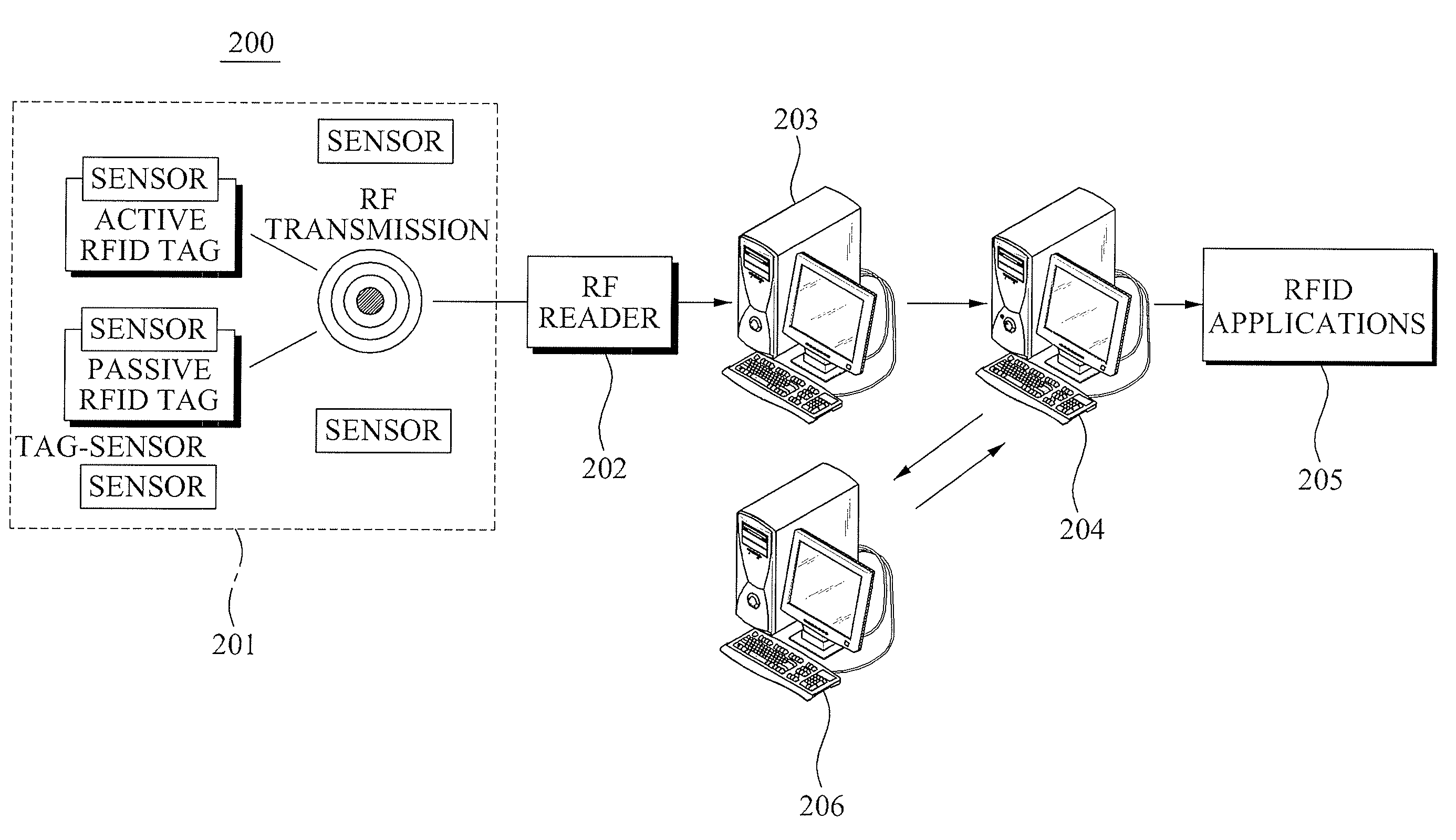

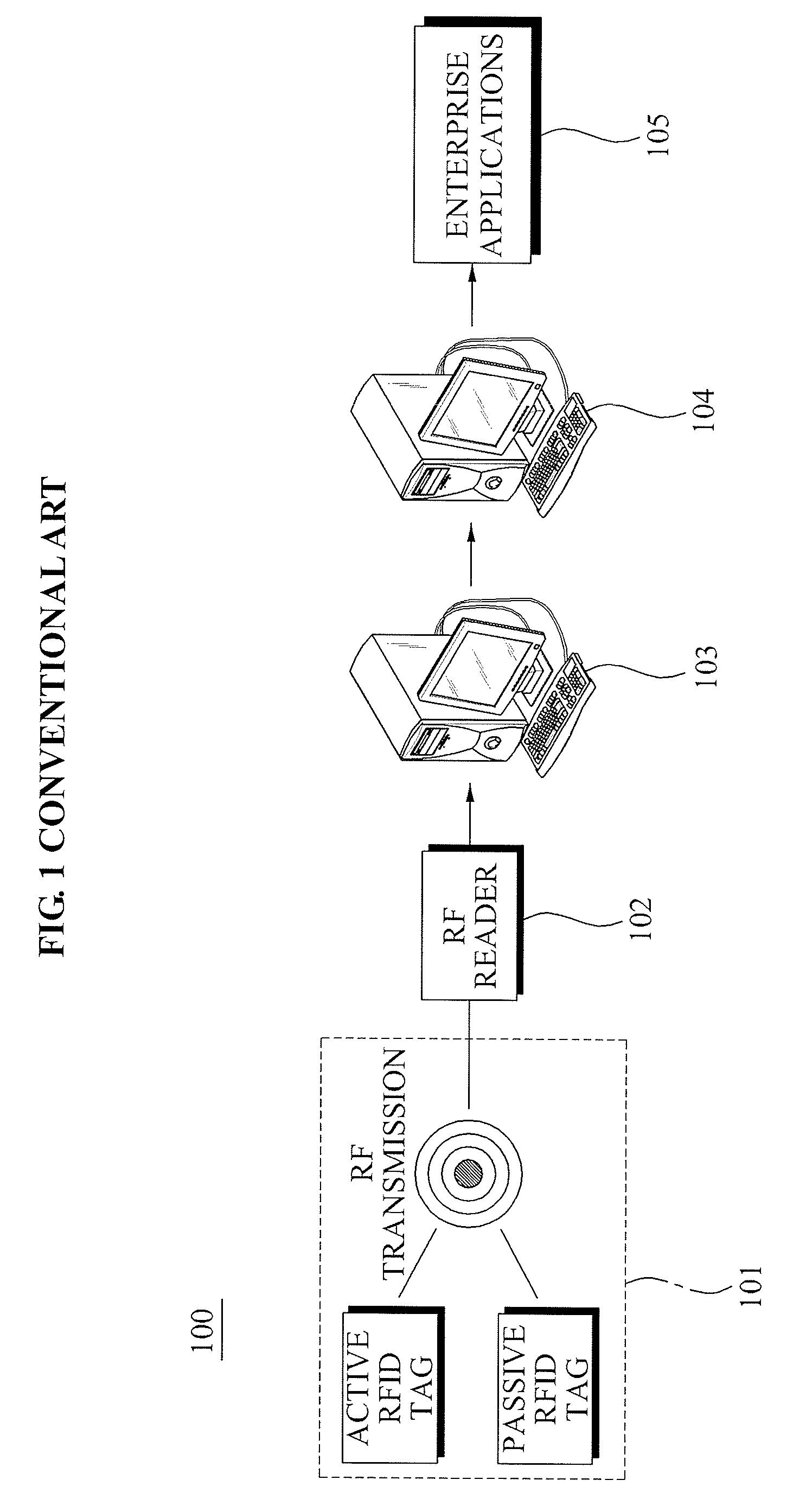

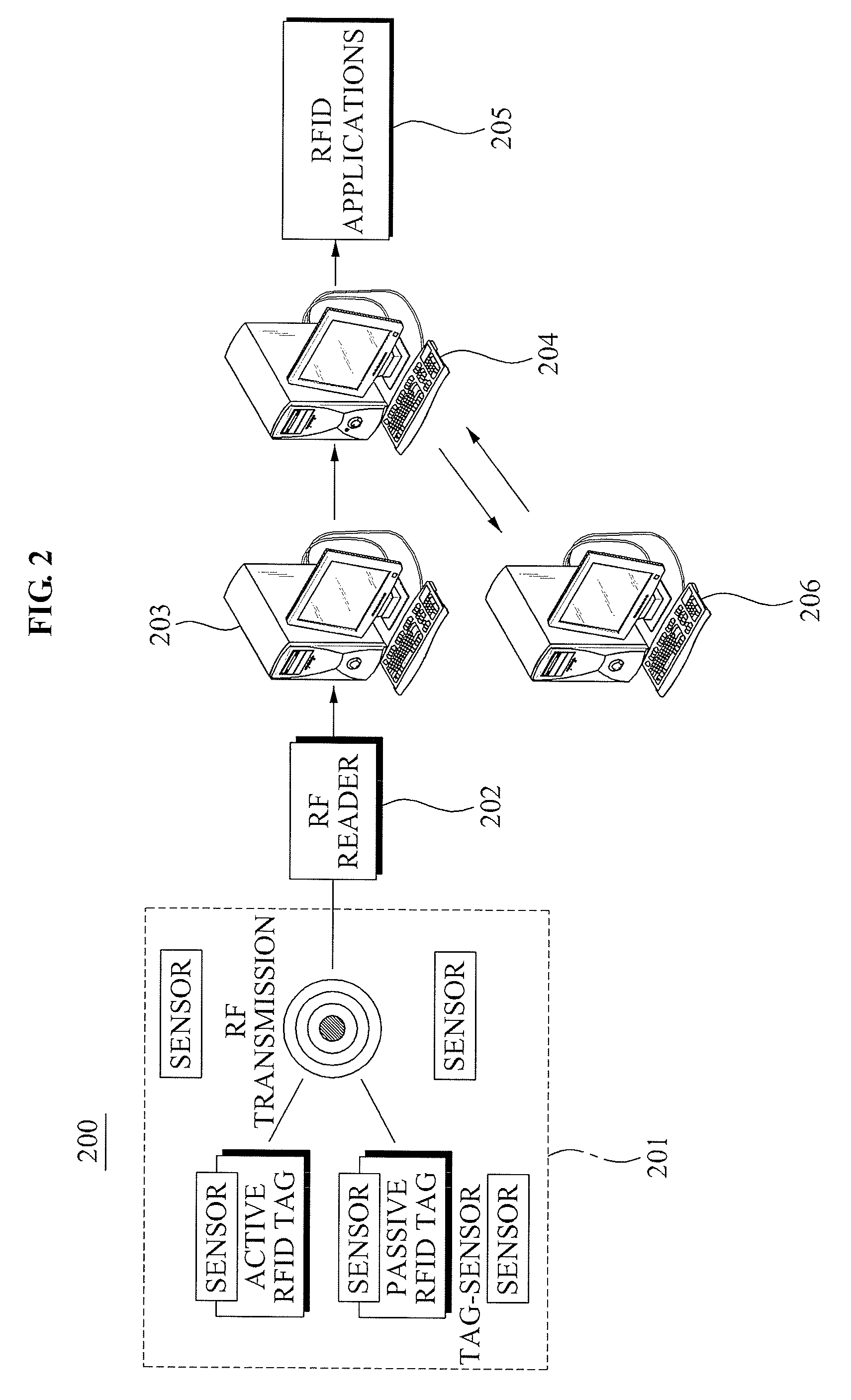

Context-aware based RFID privacy control system and personal privacy protection method using the same

InactiveUS8681984B2Avoid contactImprove securityDigital data processing detailsUnauthorized memory use protectionControl systemPrivacy protection

Owner:ELECTRONICS & TELECOMM RES INST

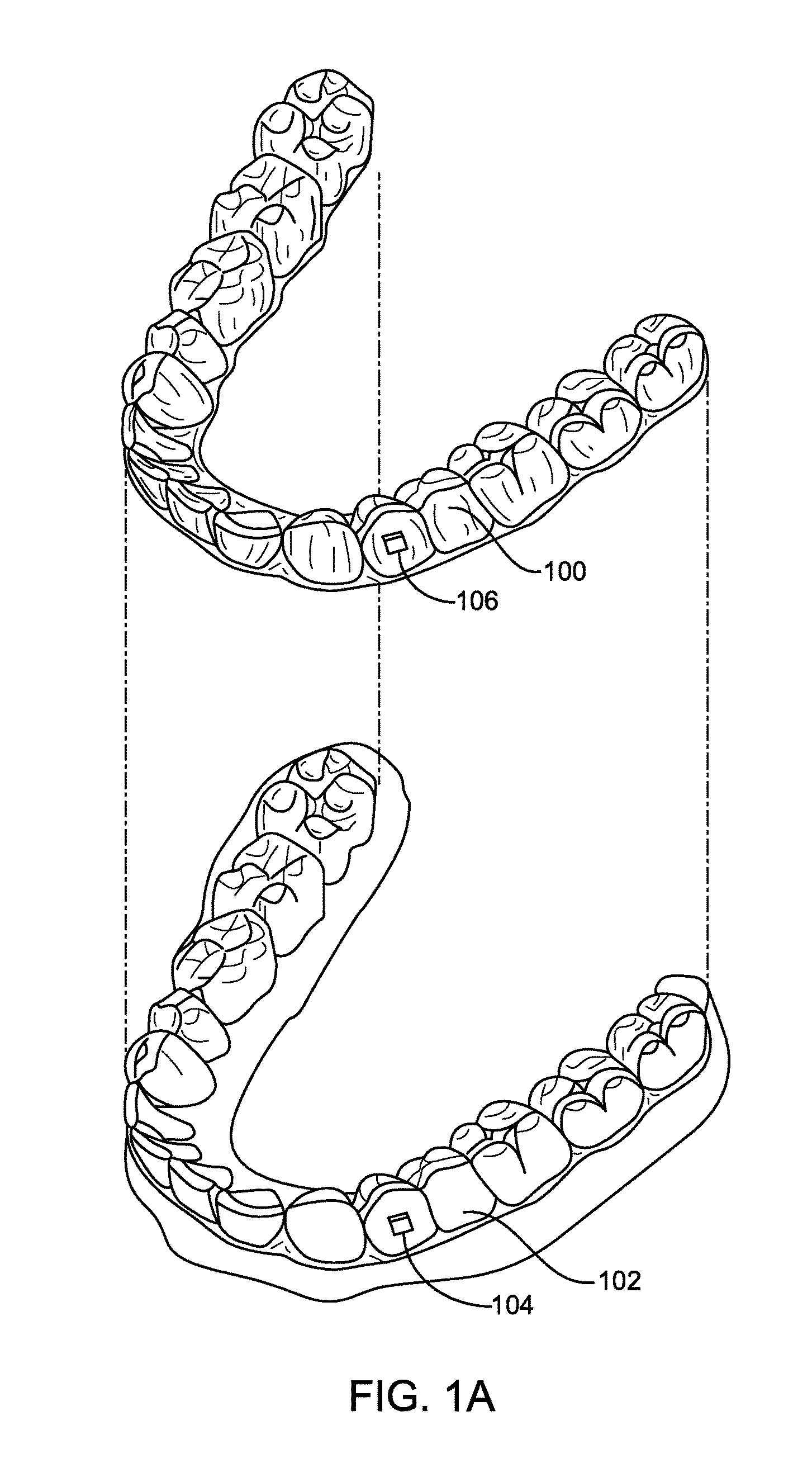

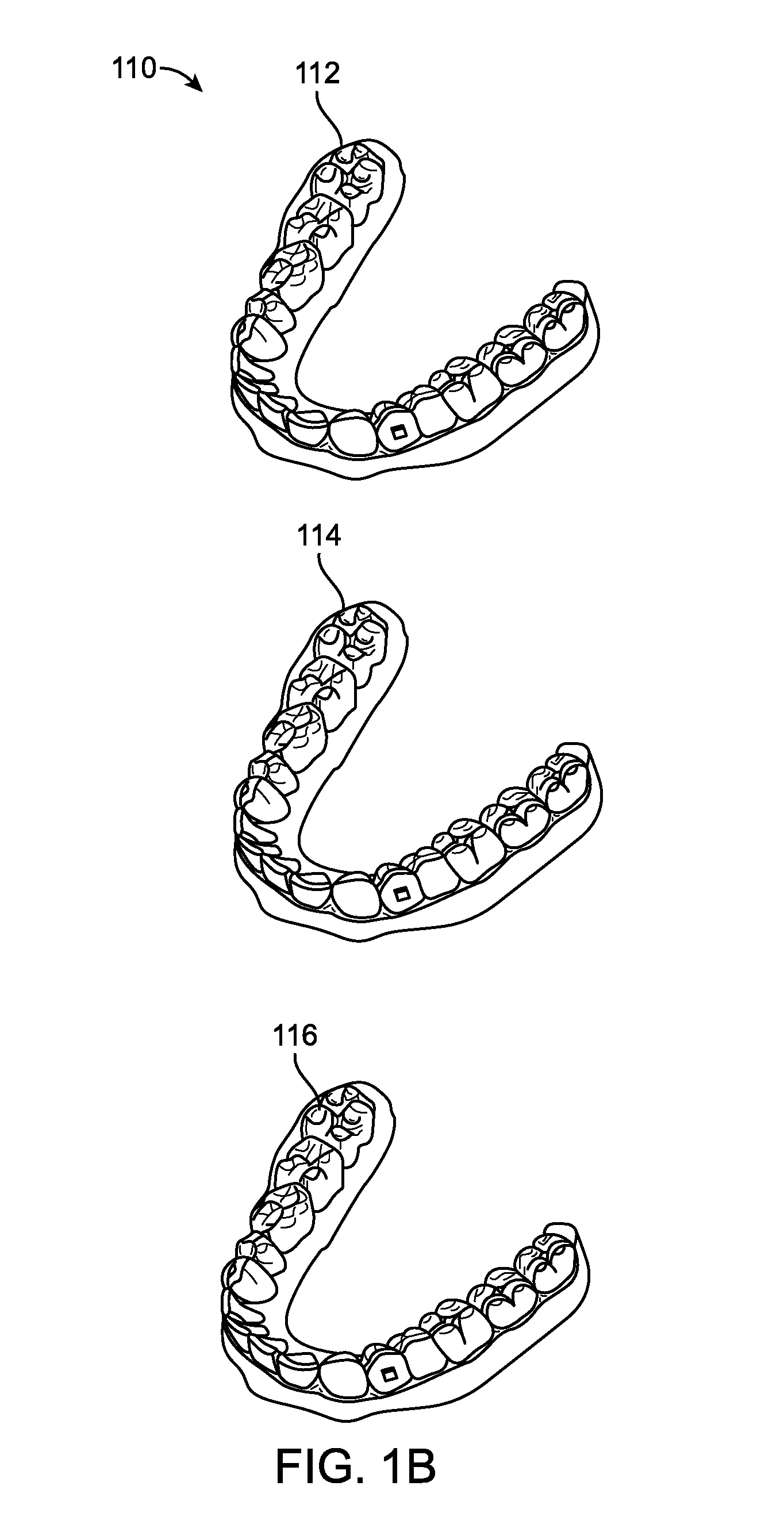

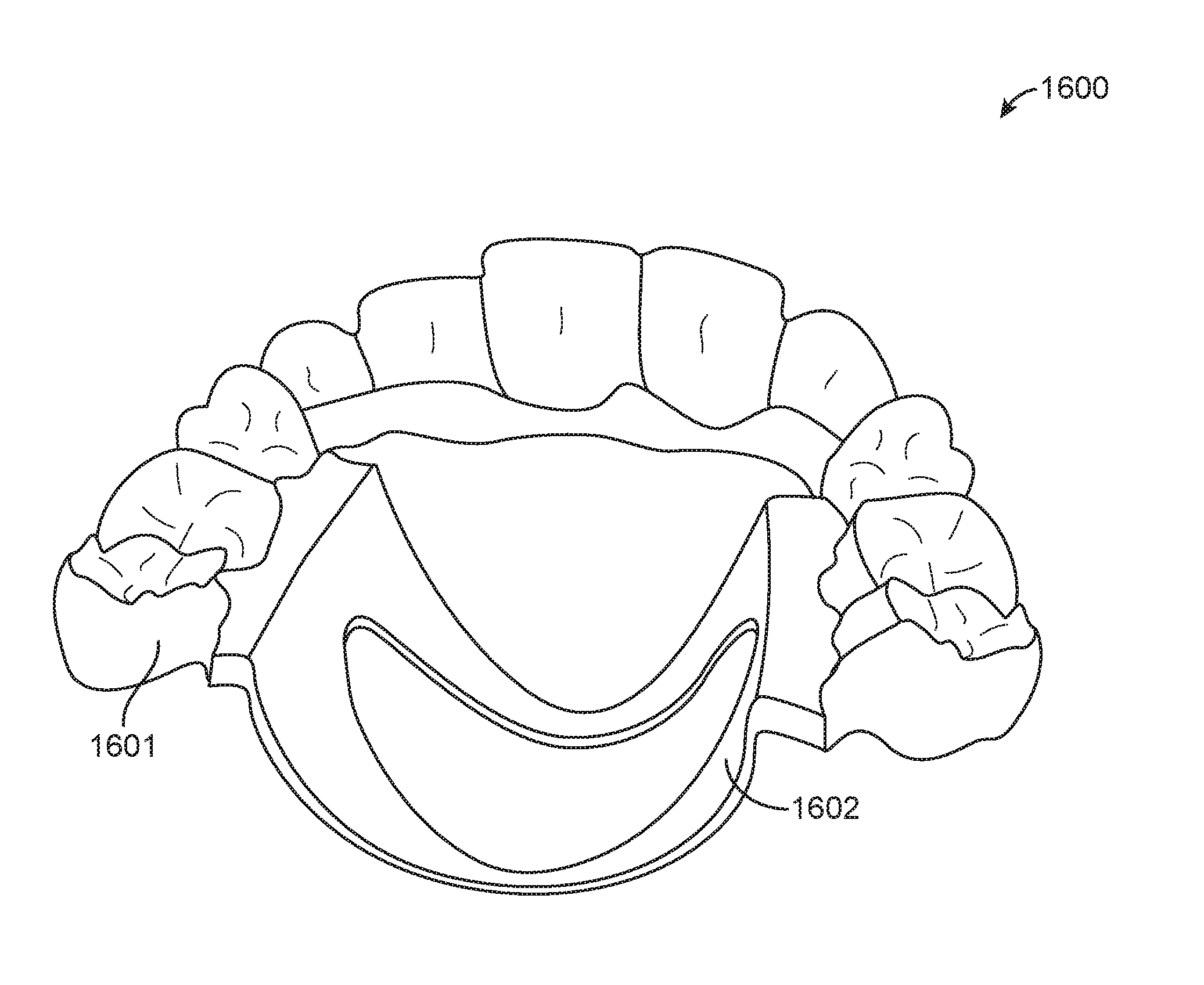

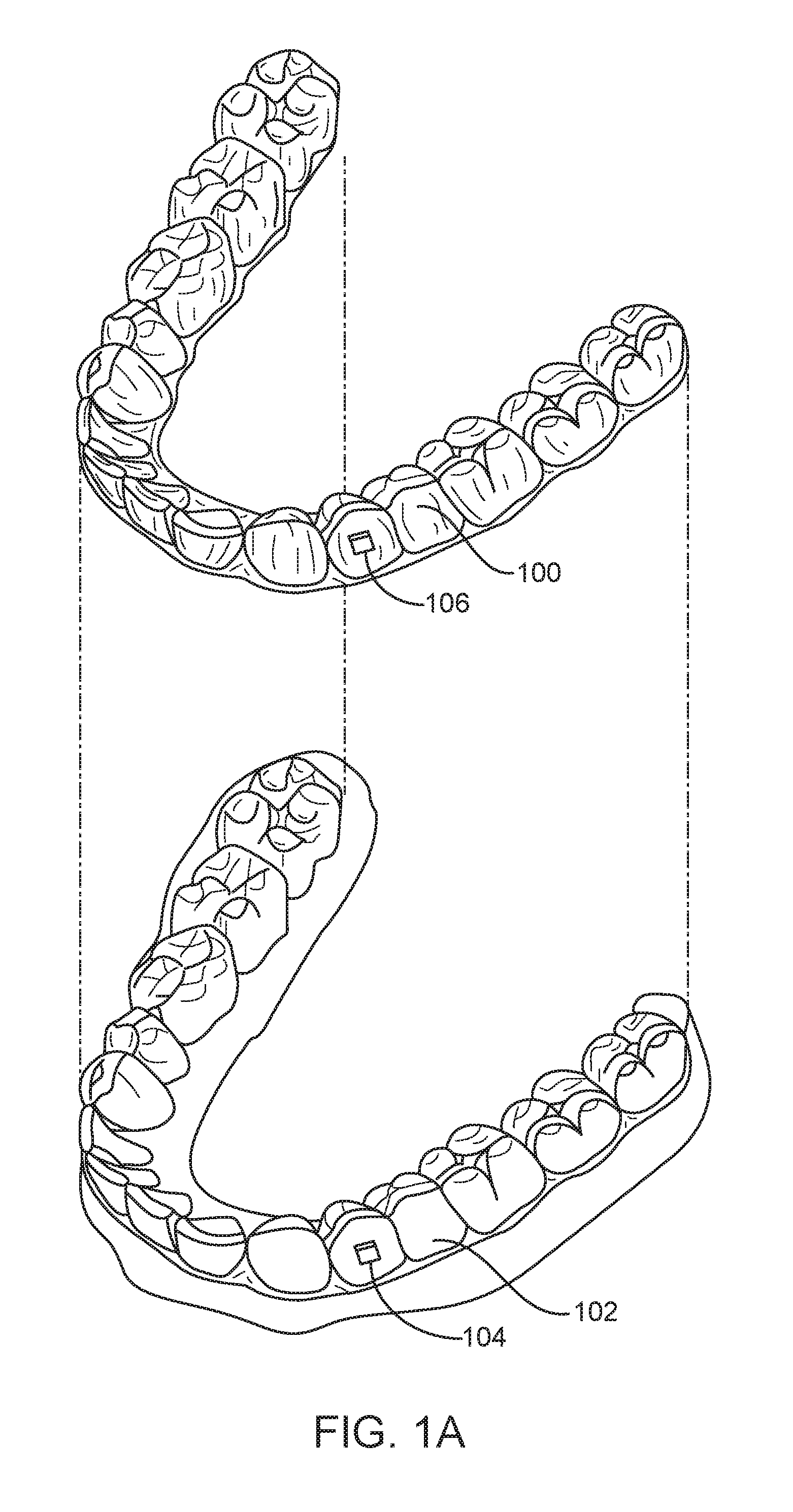

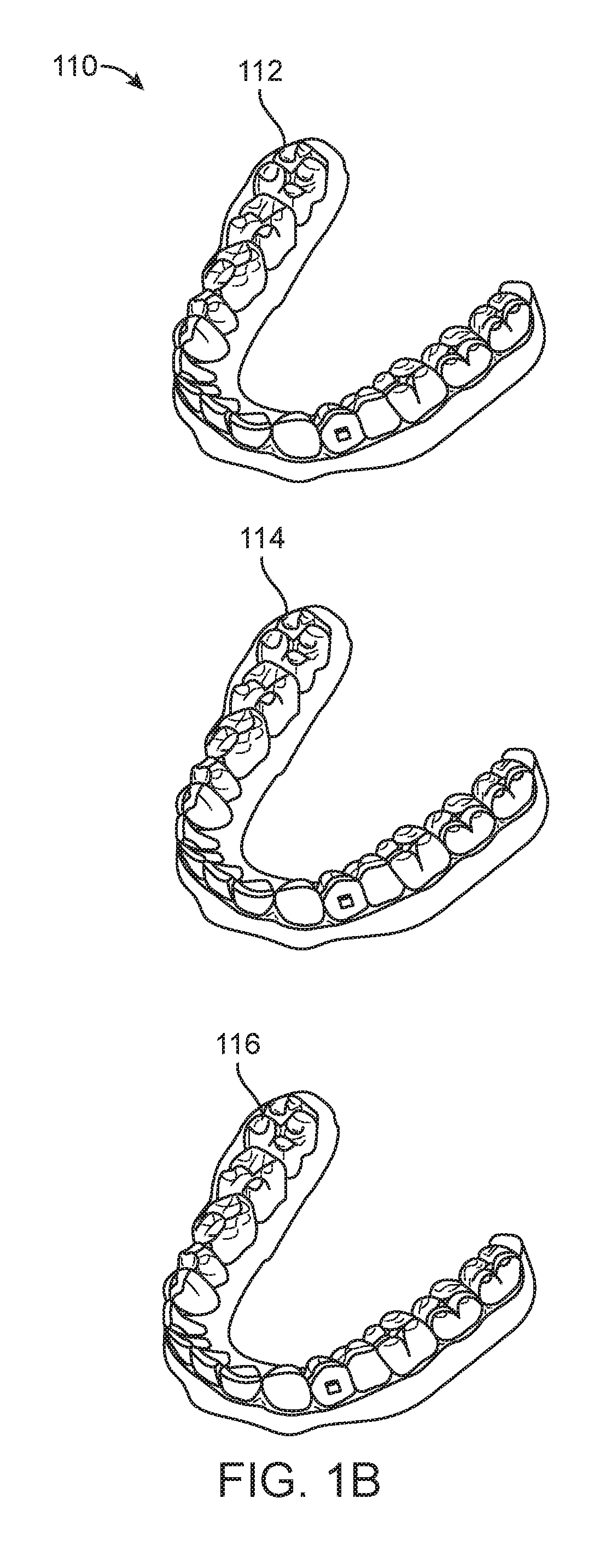

Direct fabrication of aligners for palate expansion and other applications

ActiveUS20170007367A1Improve accuracyImproved strength , accuracyAdditive manufacturing apparatusMechanical/radiation/invasive therapiesOrthodontics

Owner:ALIGN TECH

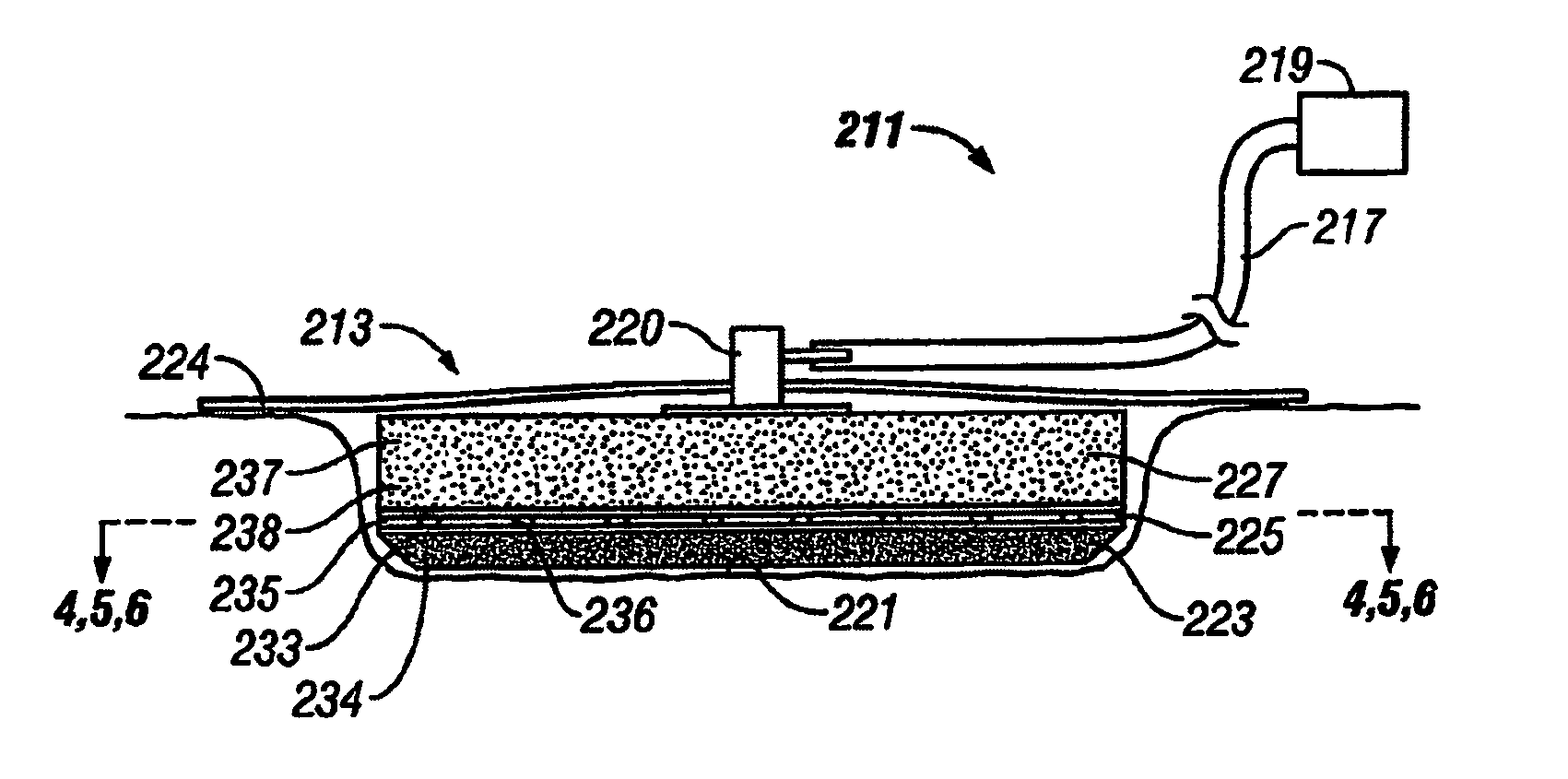

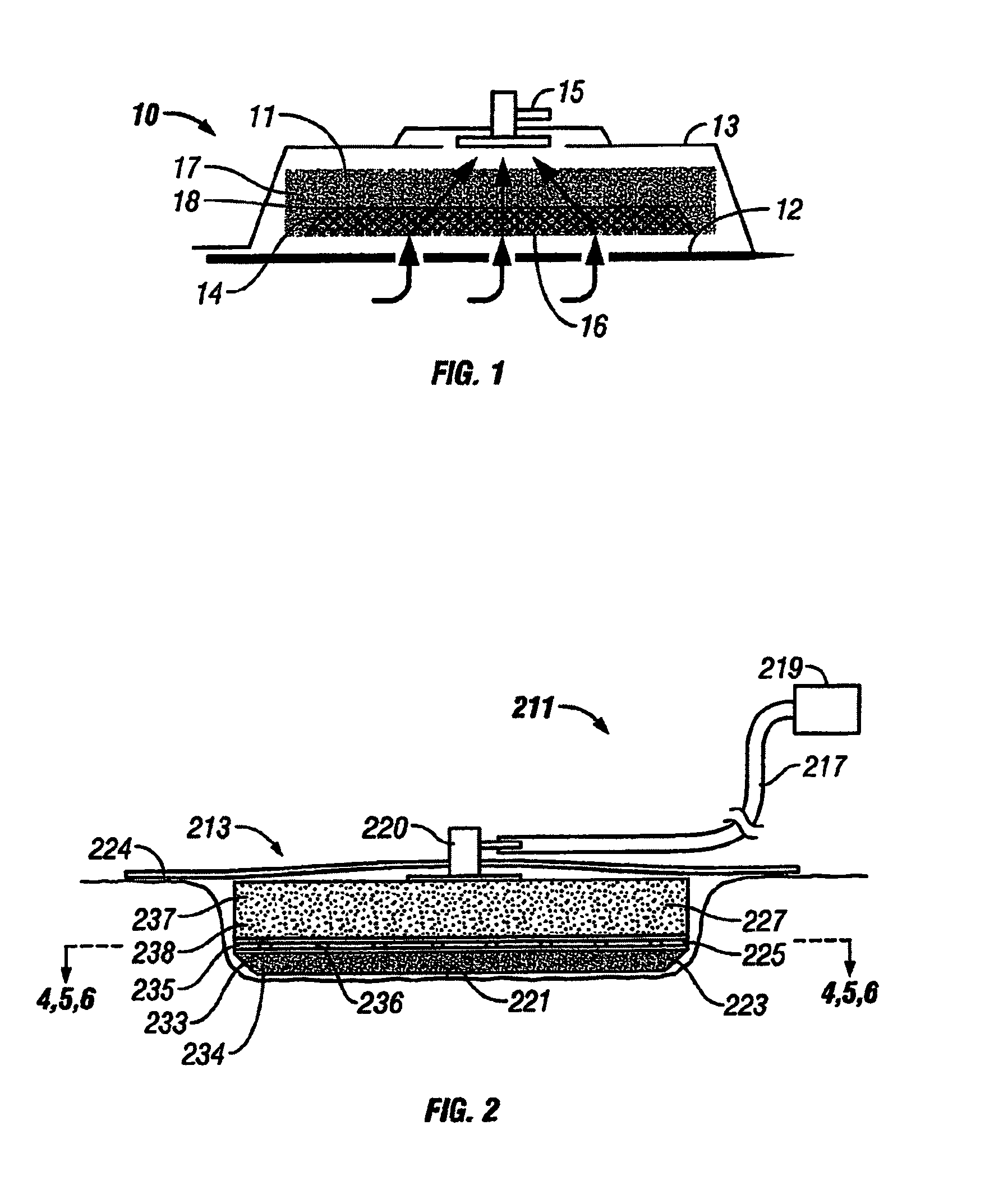

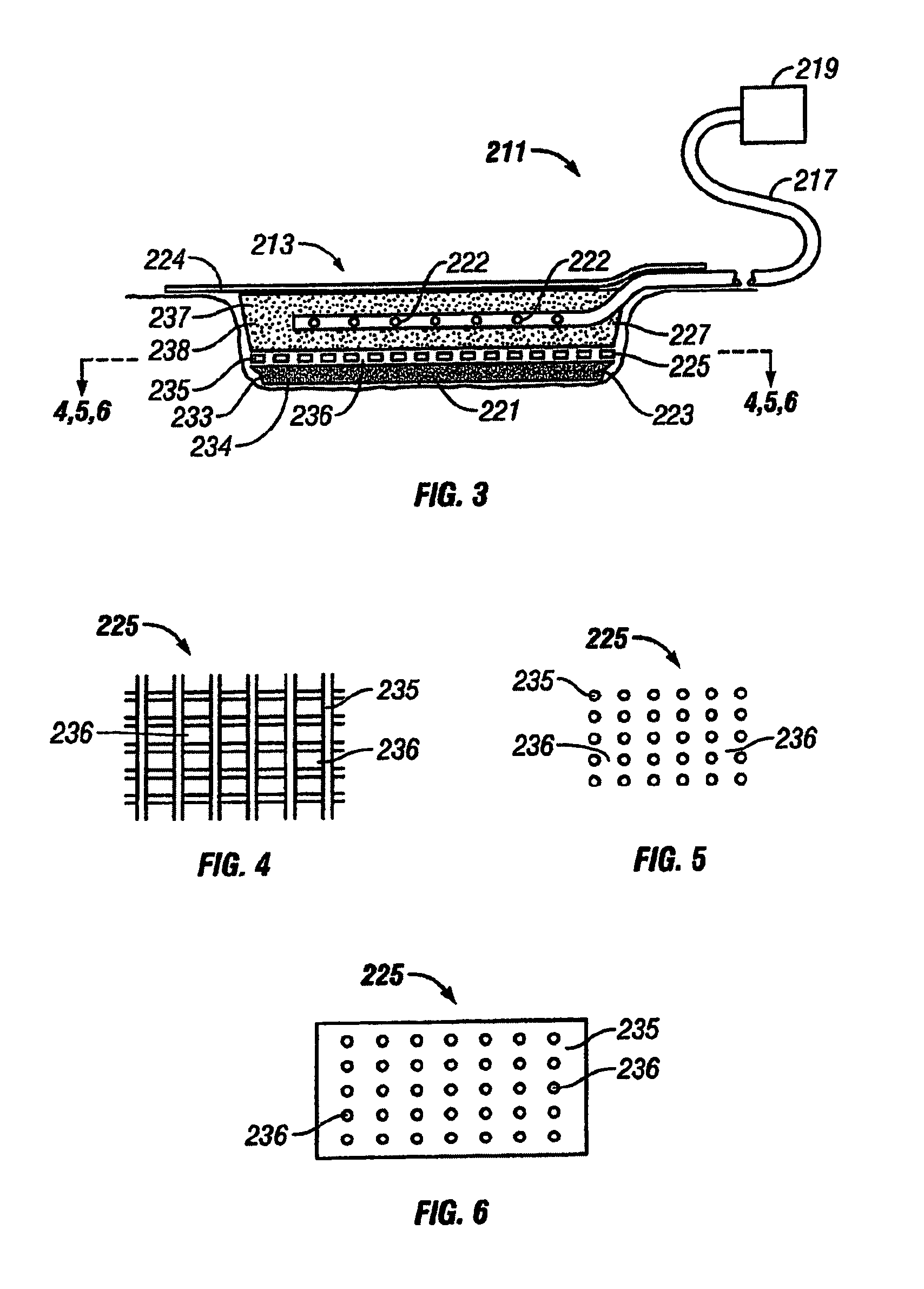

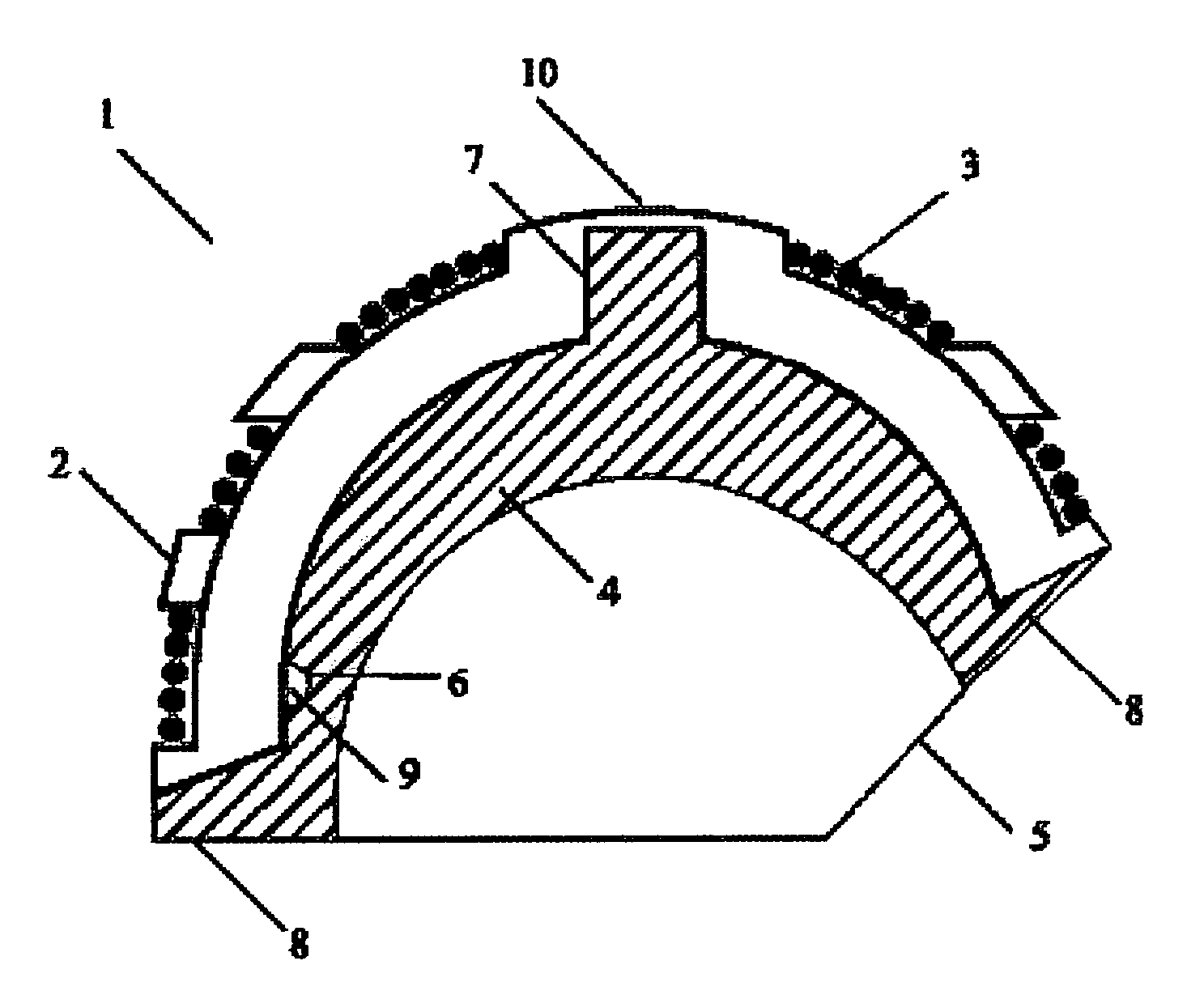

Biocompatible wound dressing

InactiveUS7700819B2Reduce pressureReduced tissue treatmentNon-adhesive dressingsAdhesive dressingsWound dressingContact layer

A multi-layer reduced pressure delivery apparatus is provided for applying reduced pressure tissue treatment to a tissue site. The multi-layer apparatus includes a tissue contact layer, a release layer, and a manifold layer. The tissue contact layer includes a scaffold adapted to contact the tissue site, the release layer includes a hydrogel-forming material and a plurality of flow channels, and the manifold layer includes a distribution manifold. The release layer is positioned between the tissue contact layer and the manifold layer to allow easy release of the manifold layer from the tissue contact layer following the administration of reduced pressure tissue treatment.

Owner:3M INNOVATIVE PROPERTIES CO

Methods for controlling formation of deposits in a deposition system and deposition methods including the same

InactiveUS20060216416A1Avoid contactChemical vapor deposition coatingProcess engineeringReaction chamber

A method for controlling parasitic deposits in a deposition system for depositing a film on a substrate, the deposition system defining a reaction chamber for receiving the substrate and including a process gas in the reaction chamber and an interior surface contiguous with the reaction chamber, includes flowing a buffer gas between the interior surface and at least a portion of the process gas to form a gas barrier layer such that the gas barrier layer inhibits contact between the interior surface and components of the process gas.

Owner:CREE INC

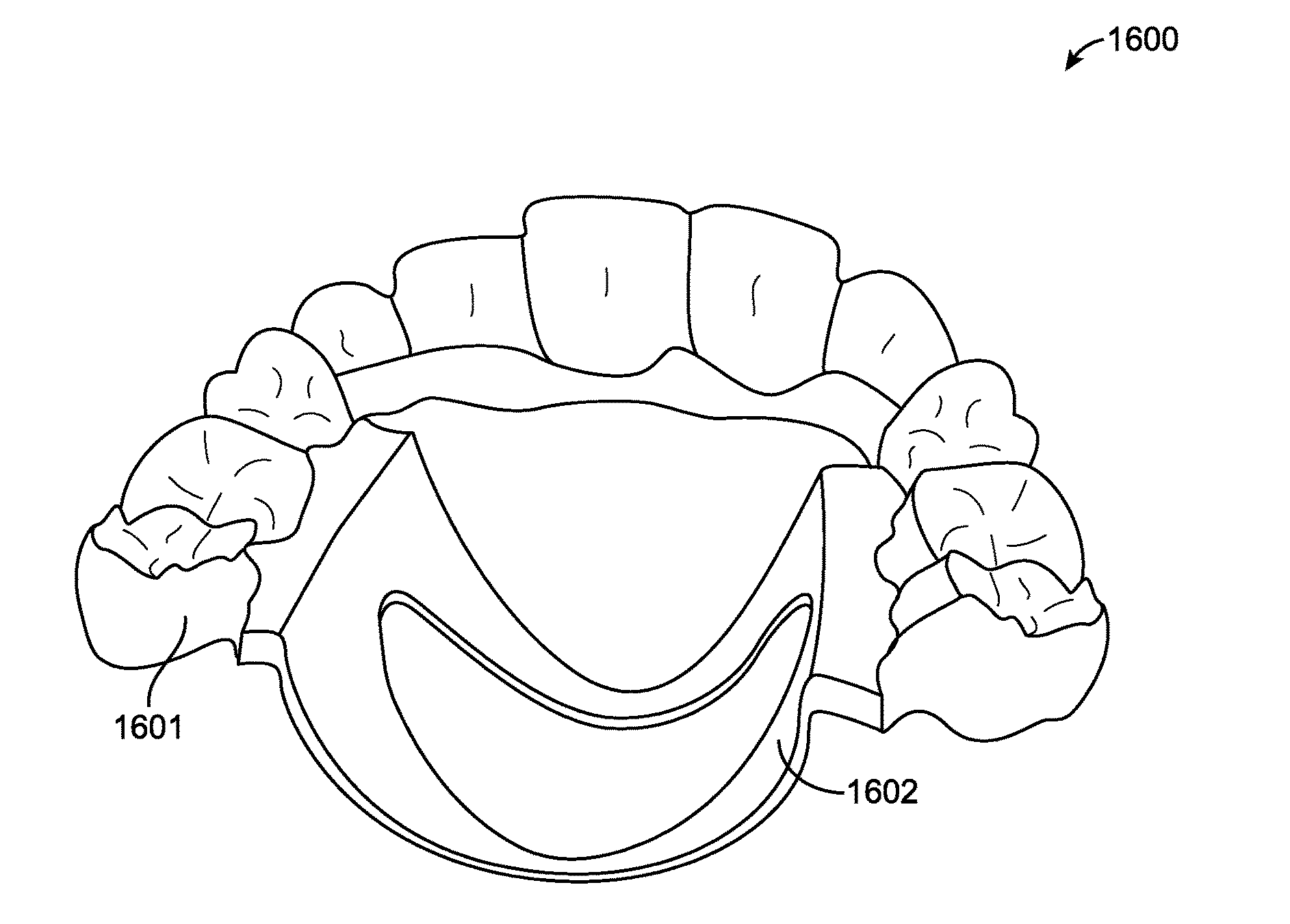

Direct fabrication of aligners for arch expansion

ActiveUS20170007366A1Improve accuracyImproved strength , accuracyAdditive manufacturing apparatusMechanical/radiation/invasive therapiesEngineering

Owner:ALIGN TECH

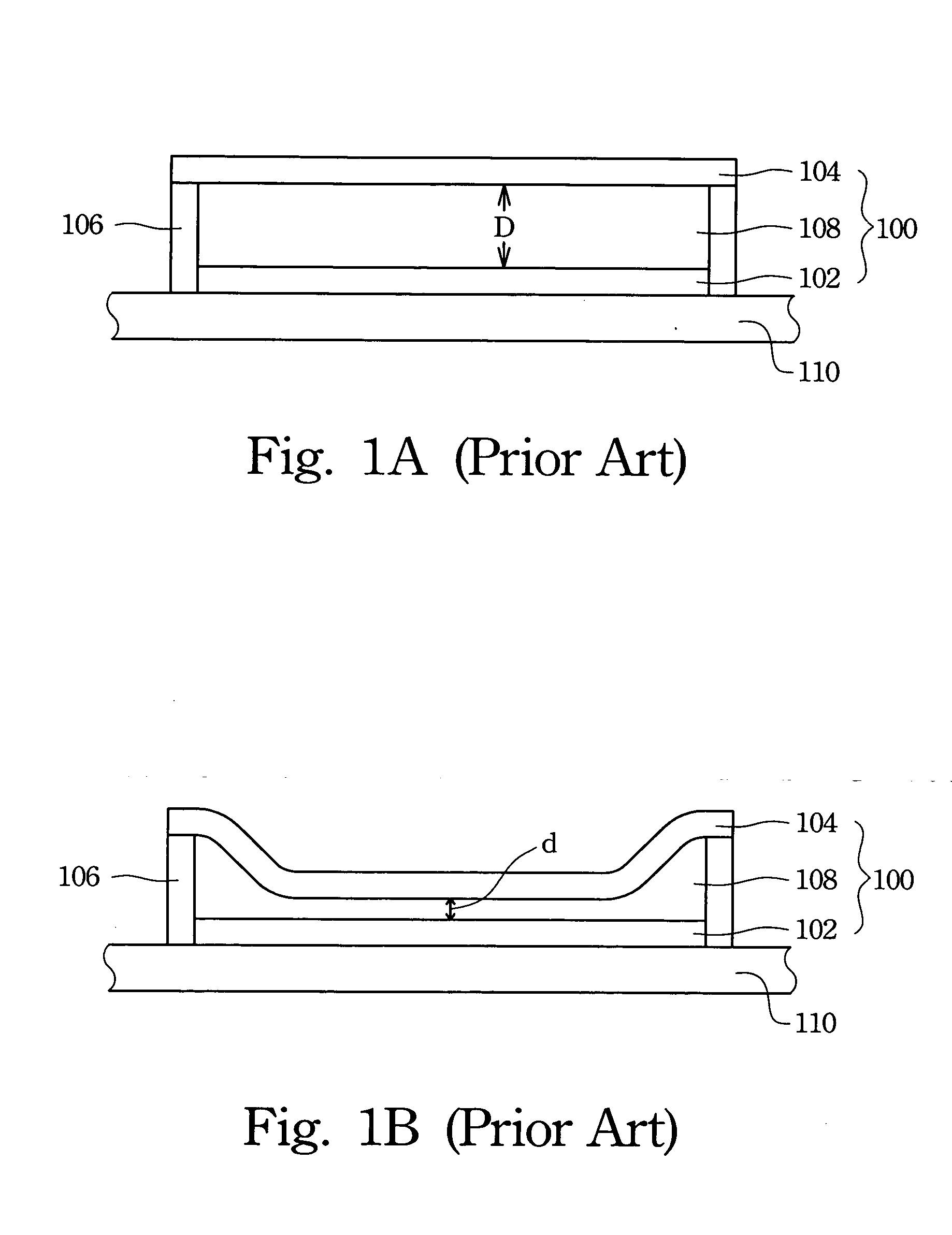

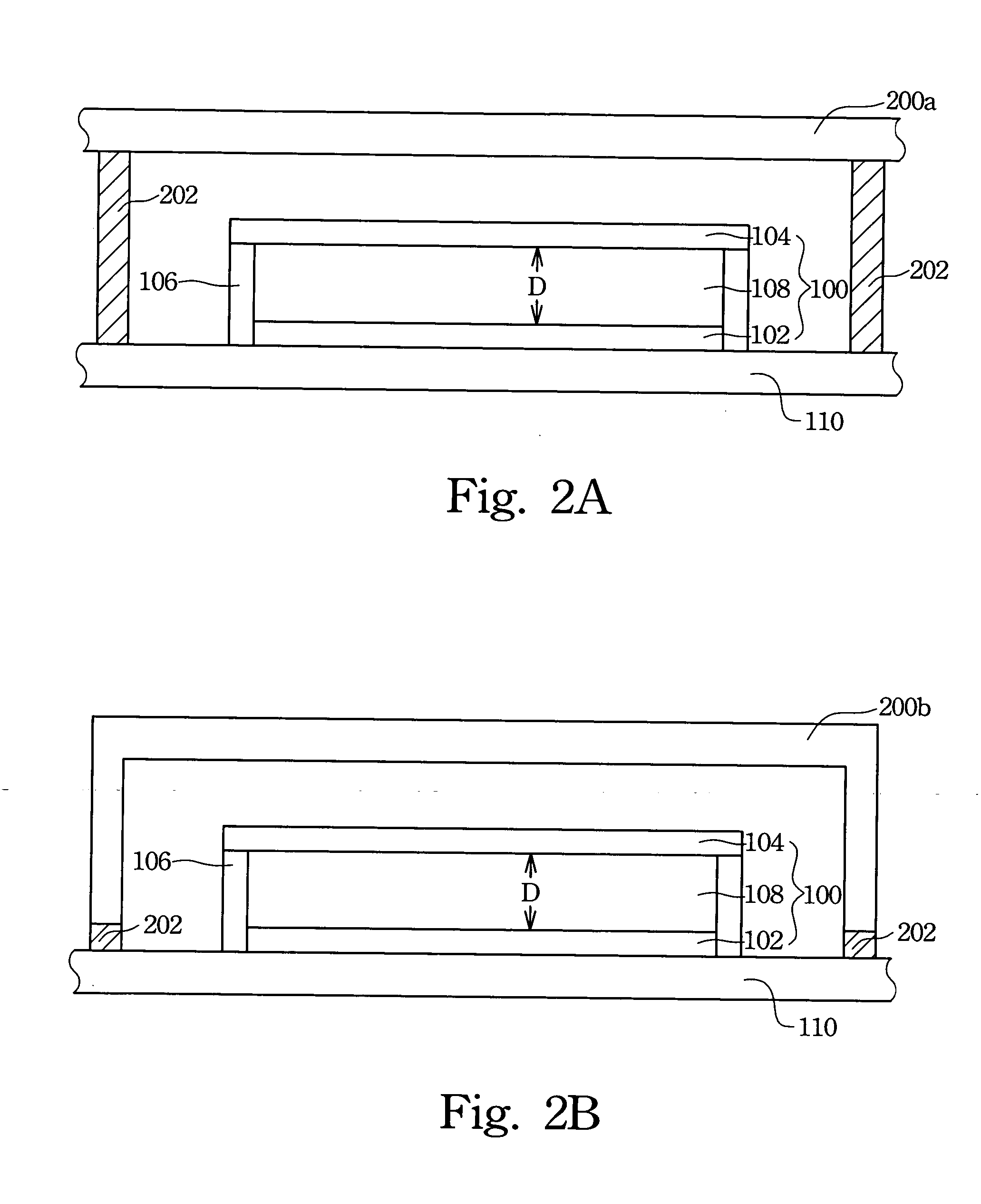

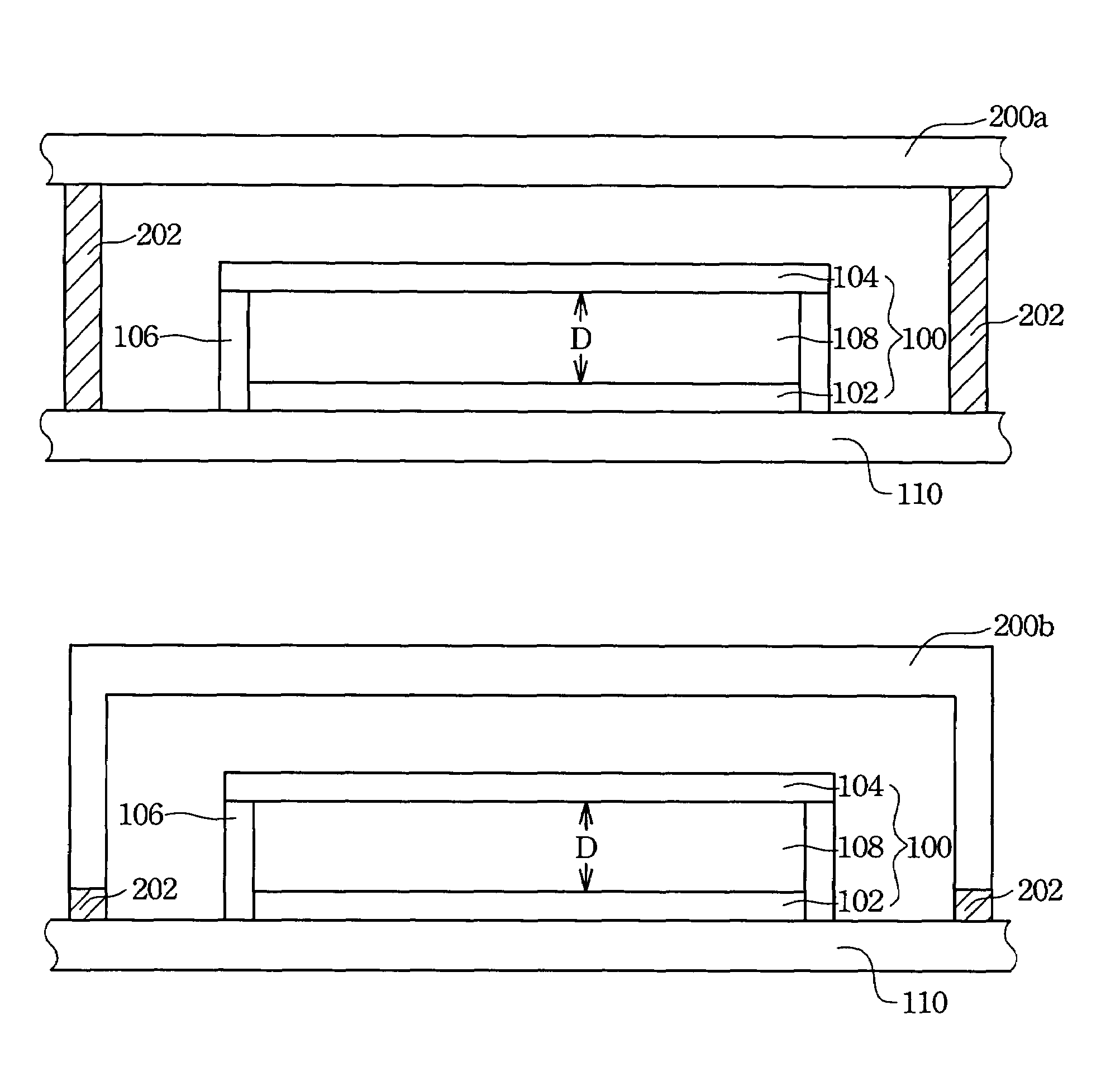

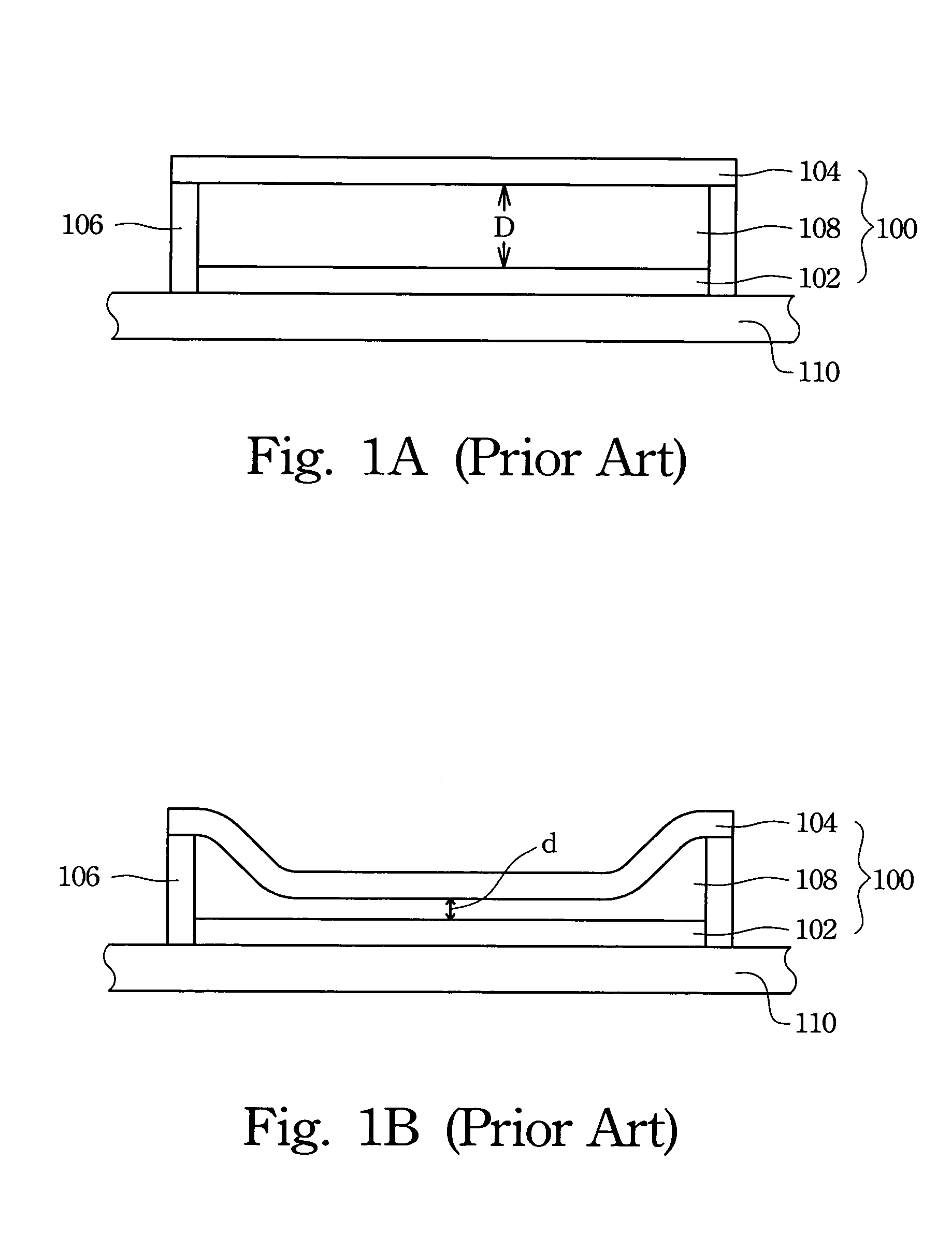

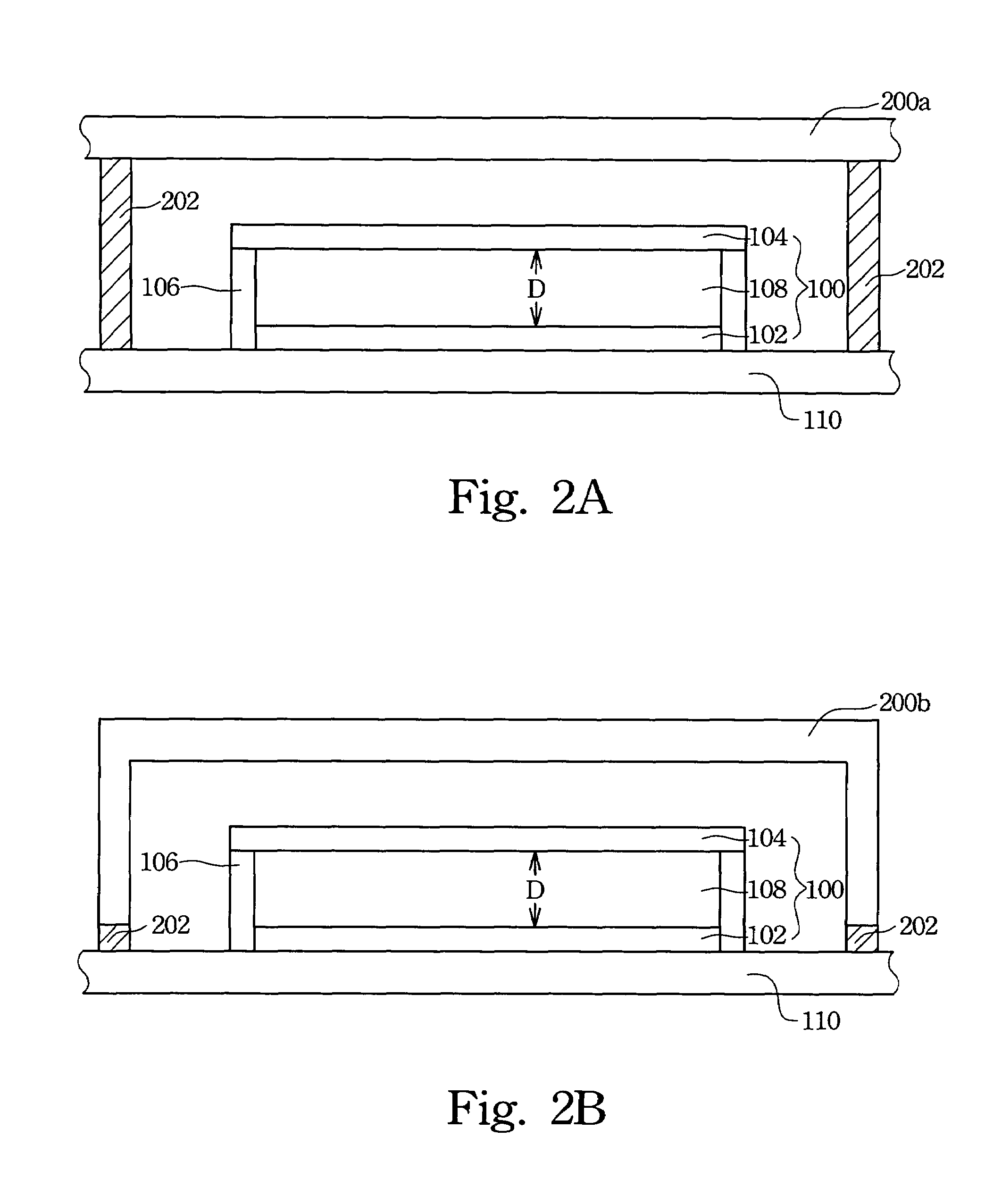

Optical interference display panel

ActiveUS20050036192A1Protection from damageReduce the possibilityMountingsNon-linear opticsAdhesiveEngineering

An optical interference display panel is disclosed that has a substrate, an optical interference reflection structure, and a protection structure. The optical interference reflection structure has many color-changeable pixels and is formed on the substrate. The protection structure is adhered to the substrate with an adhesive and encloses the optical interference reflection structure between the substrate and the protection structure. The adhesive is used to hermetically isolate the optical interference reflection structure from water, dust and oxygen in the air. Moreover, the protection structure prevents the interference reflection structure from being damaged by an external force.

Owner:SNAPTRACK

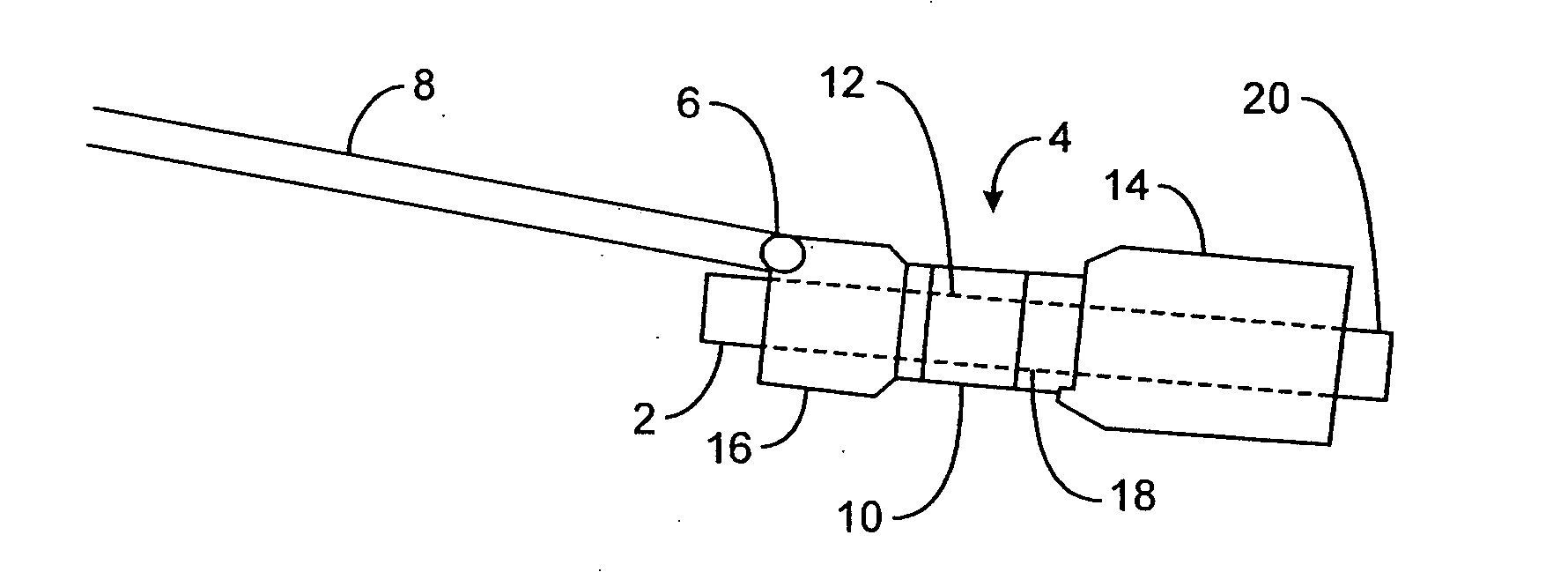

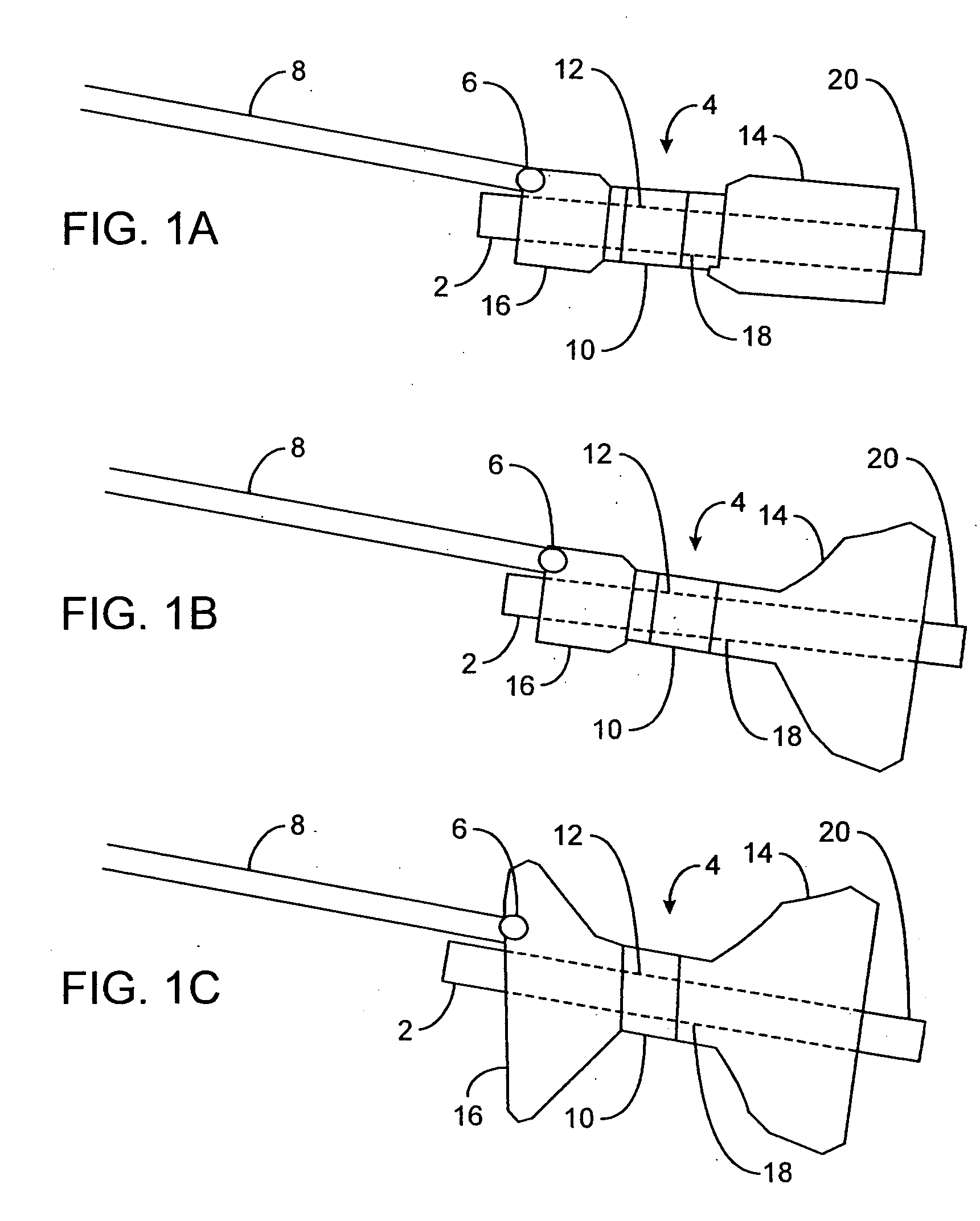

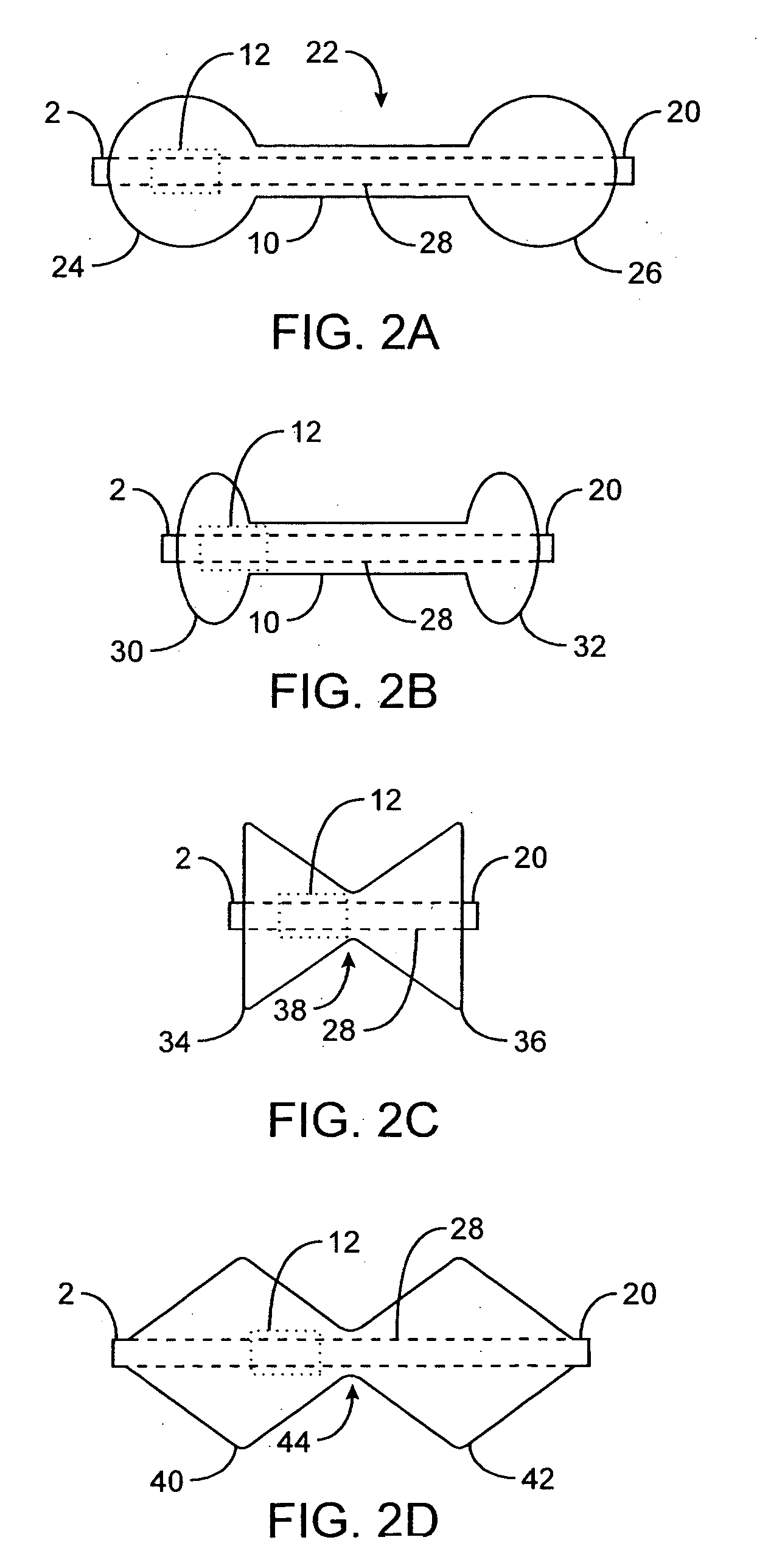

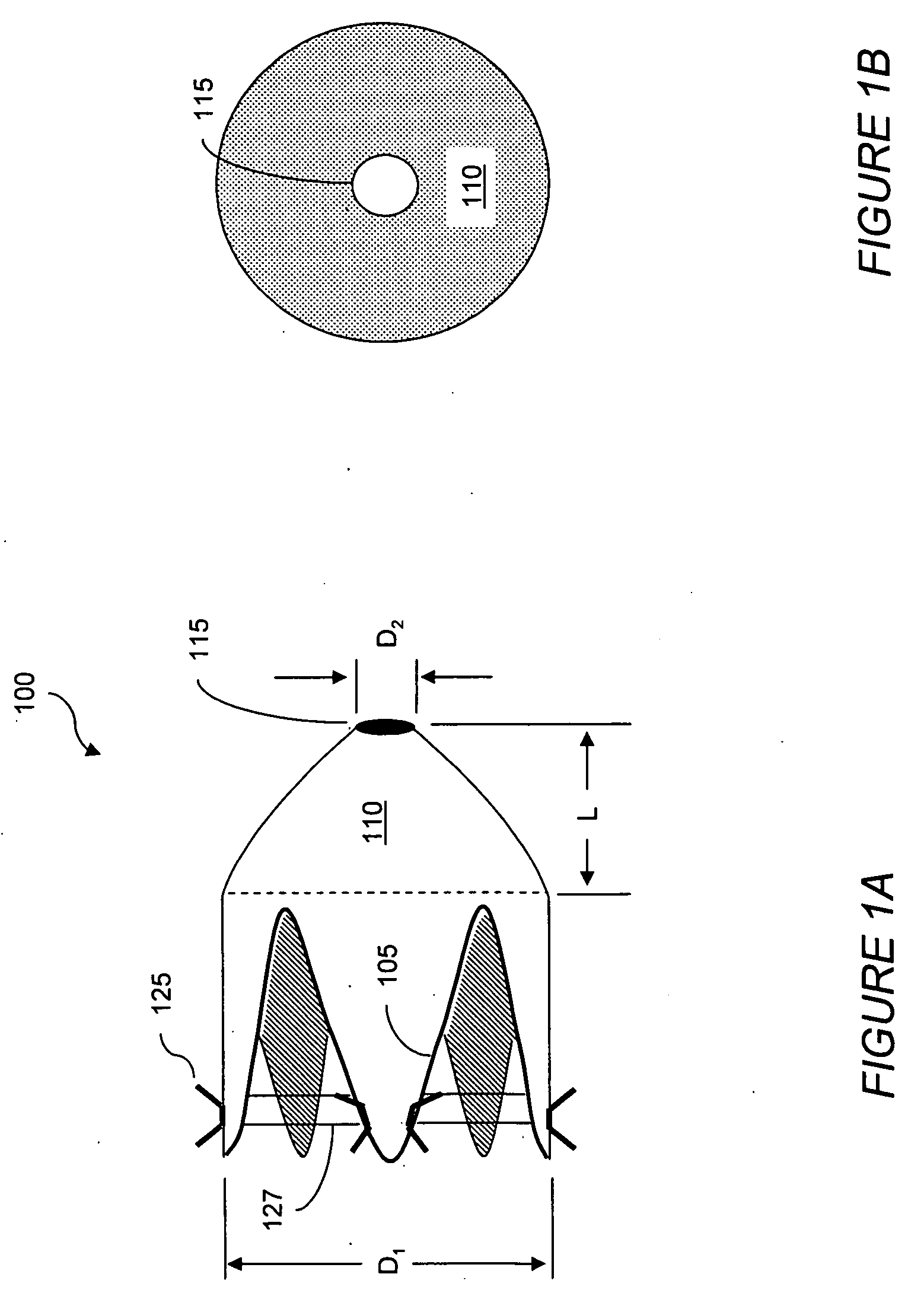

Pyloric valve obstructing devices and methods

ActiveUS20050033331A1Treat and ameliorate obesityReduced food intakeSuture equipmentsEndoradiosondesPylorusPartial obstruction

Methods, devices and systems facilitate intermittent and / or partial obstruction of a pyloric valve. Devices generally include a support portion for preventing the device from passing through the pyloric valve and a tissue engagement portion for contacting tissue adjacent the pyloric valve to obstruct the valve. Some embodiments also include a positioning member extending from the tissue engagement portion for helping position the device for obstructing the valve. A retaining member may optionally be included on the distal end of the positioning member for further maintaining a position of the device in the stomach. Some embodiments are deliverable into the stomach through the esophagus, either by swallowing or through a delivery tube or catheter. Some embodiments are fully reversible. Some embodiments self-expand within the stomach, while others are inflated or otherwise expanded.

Owner:BARONOVA

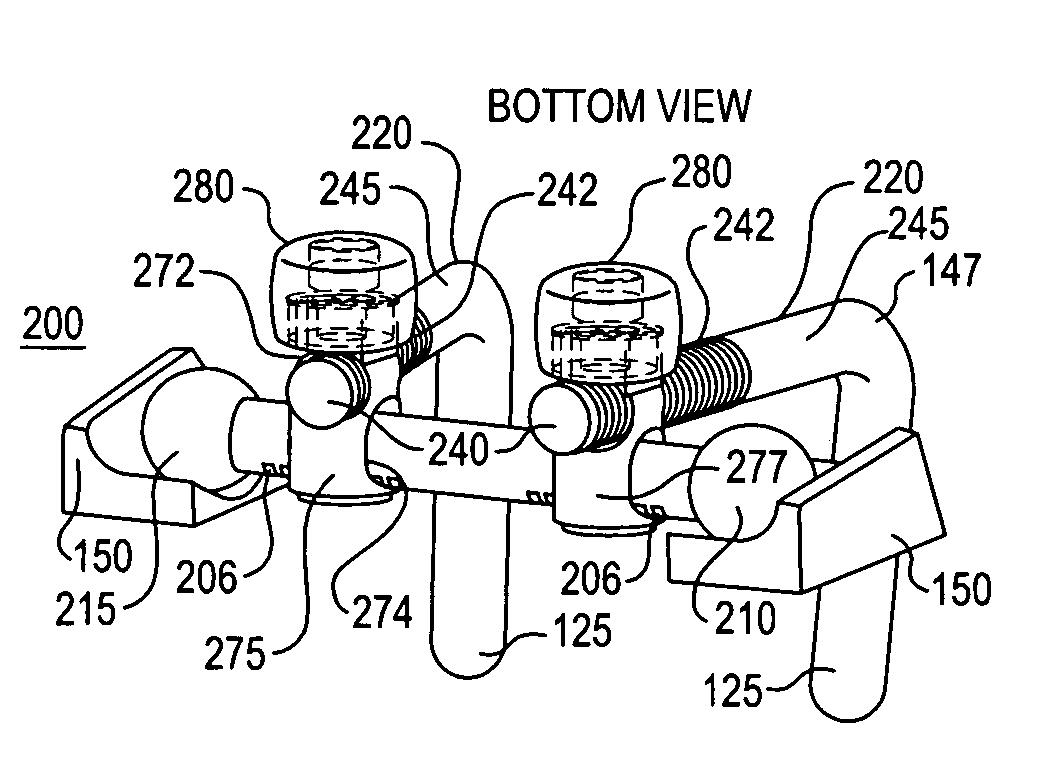

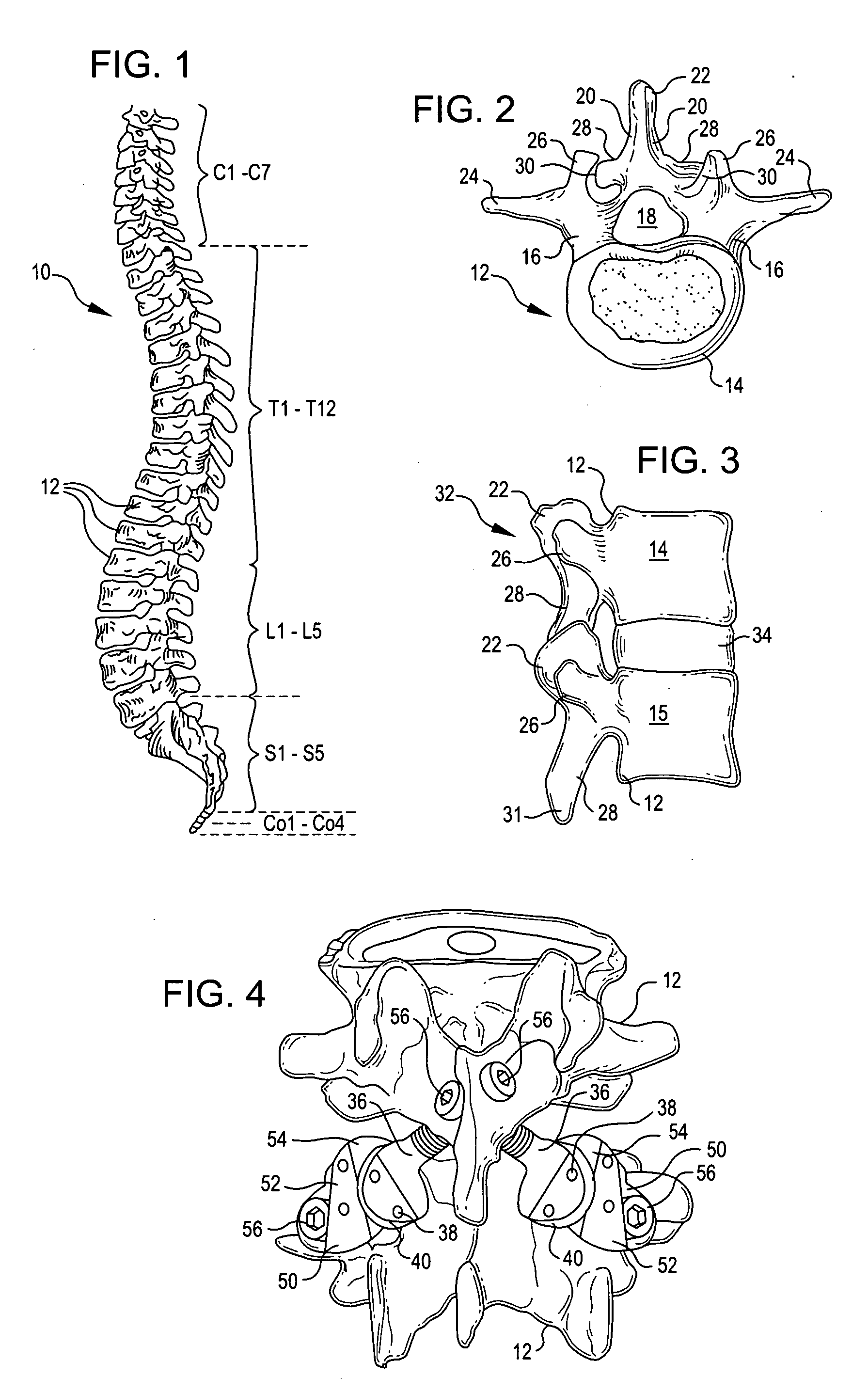

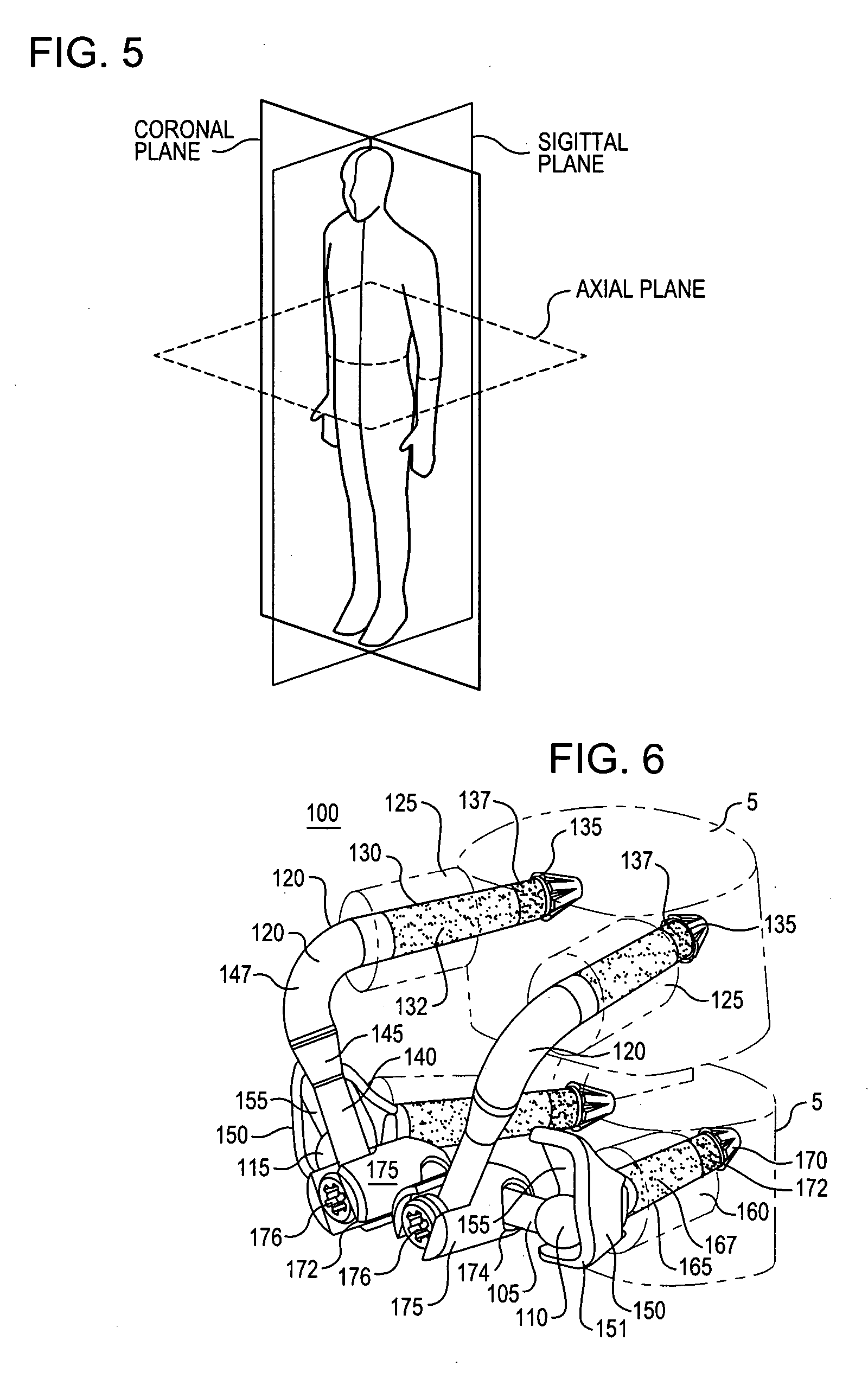

Crossbar spinal prosthesis having a modular design and related implantation methods

InactiveUS20050240265A1Reduce occurrenceShield capability be improveInternal osteosythesisJoint implantsModularityProsthesis

Modular spinal prosthesis having one of both of adaptable and configurable components are provided. The modular spinal prosthesis described herein provide an artificial articular configuration to replace damaged, worn or otherwise removed spinal facet elements.

Owner:FACET SOLUTIONS

Optical interference display panel

An optical interference display panel is disclosed that has a substrate, an optical interference reflection structure, and a protection structure. The optical interference reflection structure has many color-changeable pixels and is formed on the substrate. The protection structure is adhered to the substrate with an adhesive and encloses the optical interference reflection structure between the substrate and the protection structure. The adhesive is used to hermetically isolate the optical interference reflection structure from water, dust and oxygen in the air. Moreover, the protection structure prevents the interference reflection structure from being damaged by an external force.

Owner:SNAPTRACK

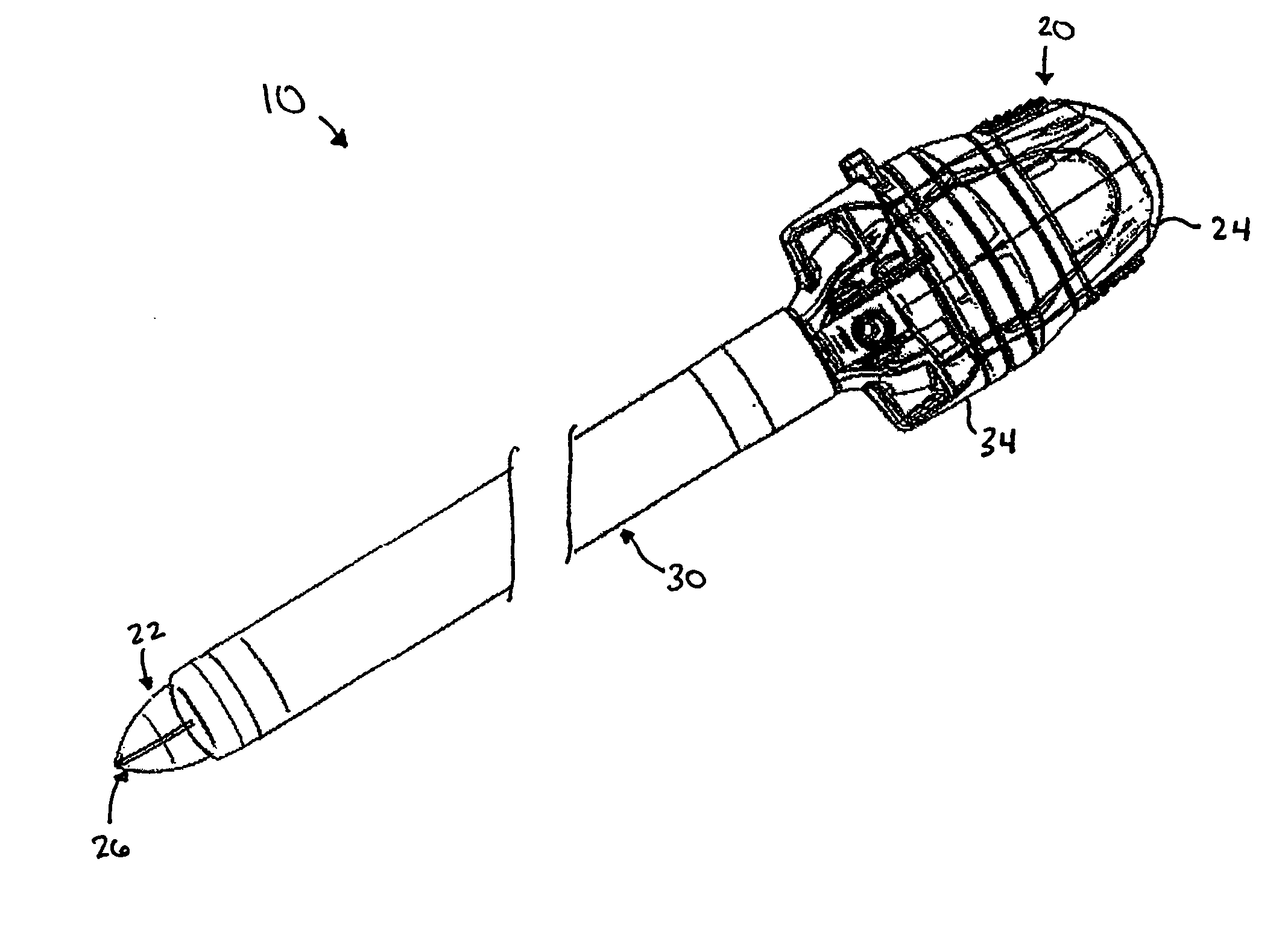

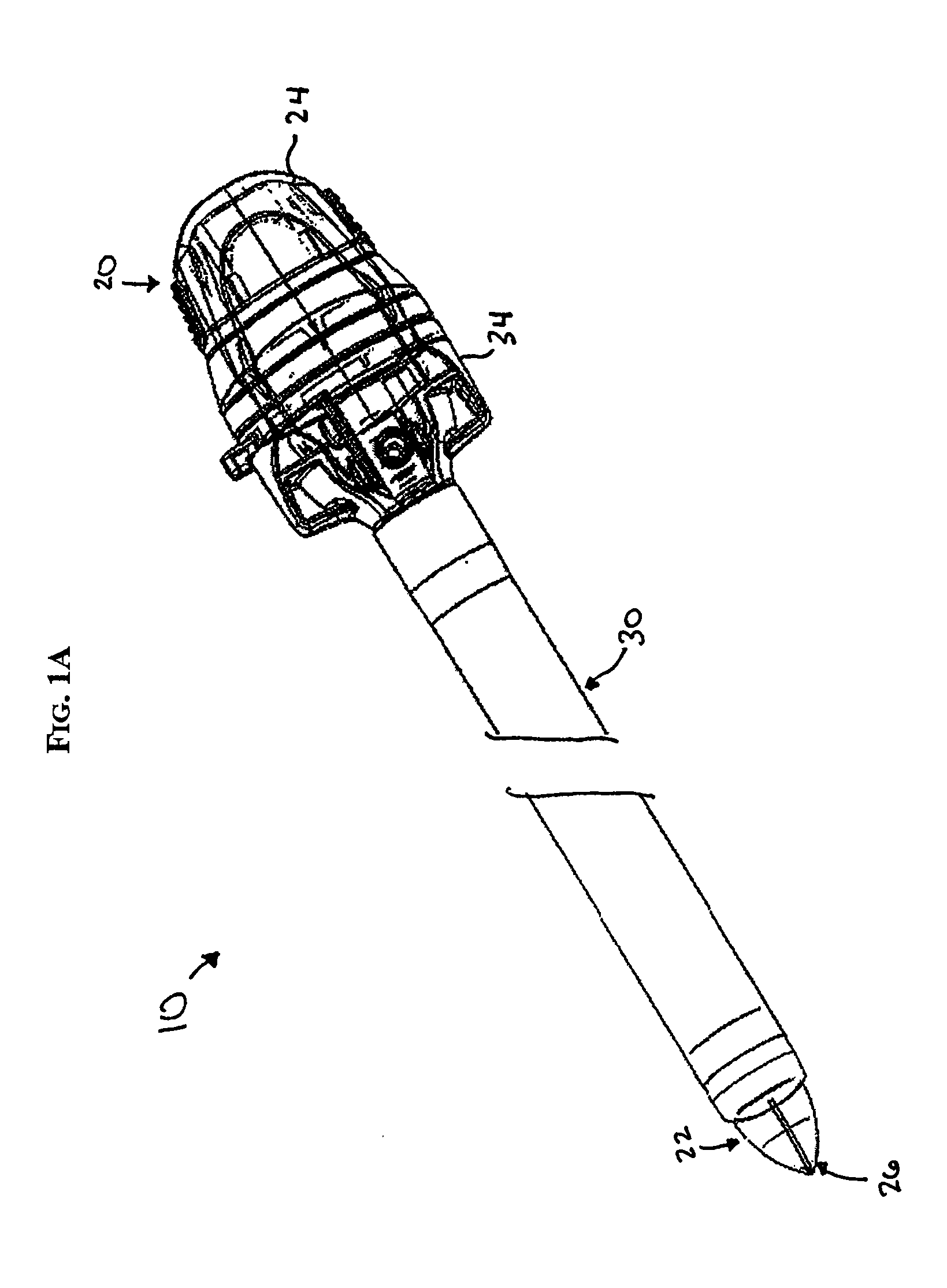

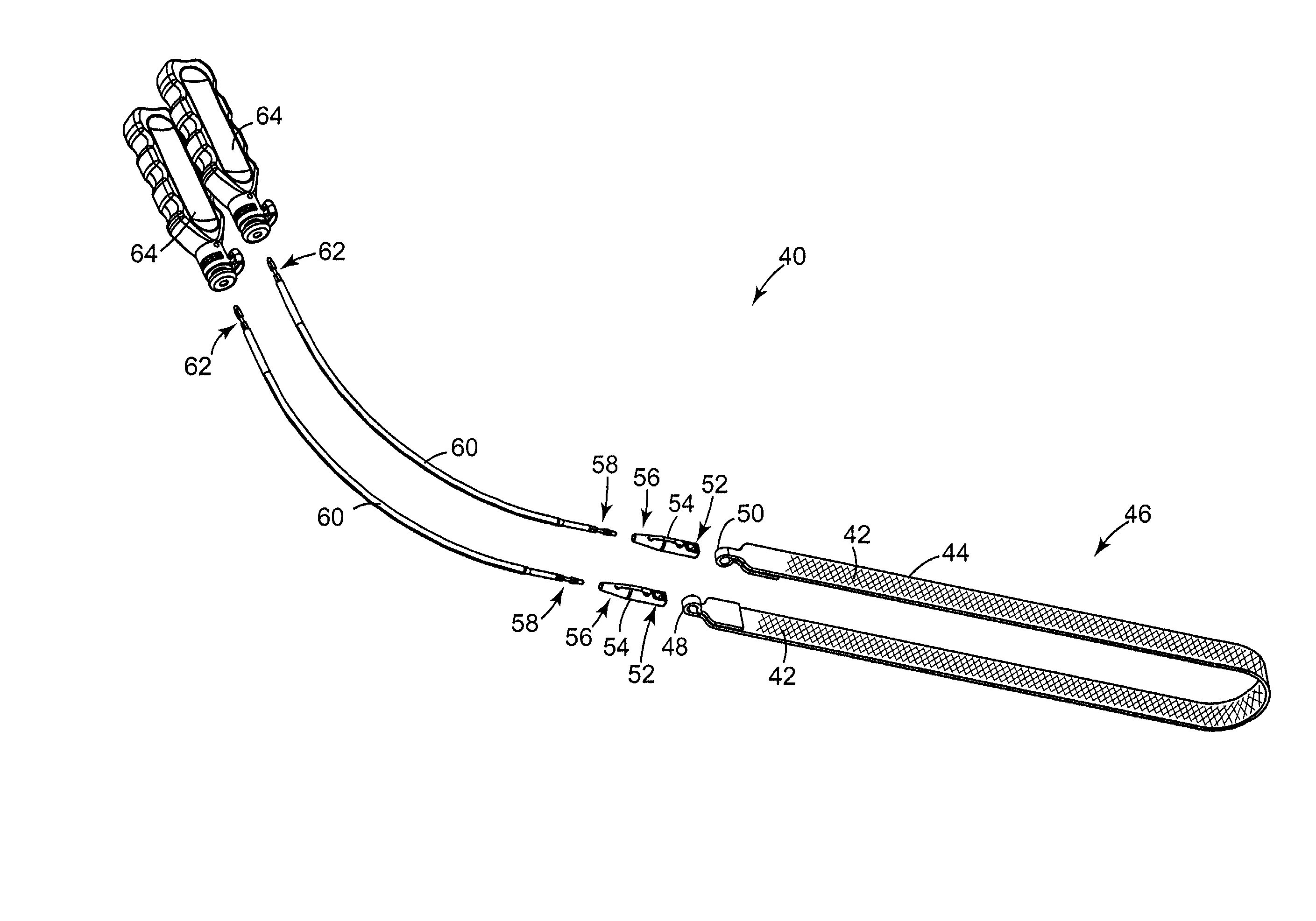

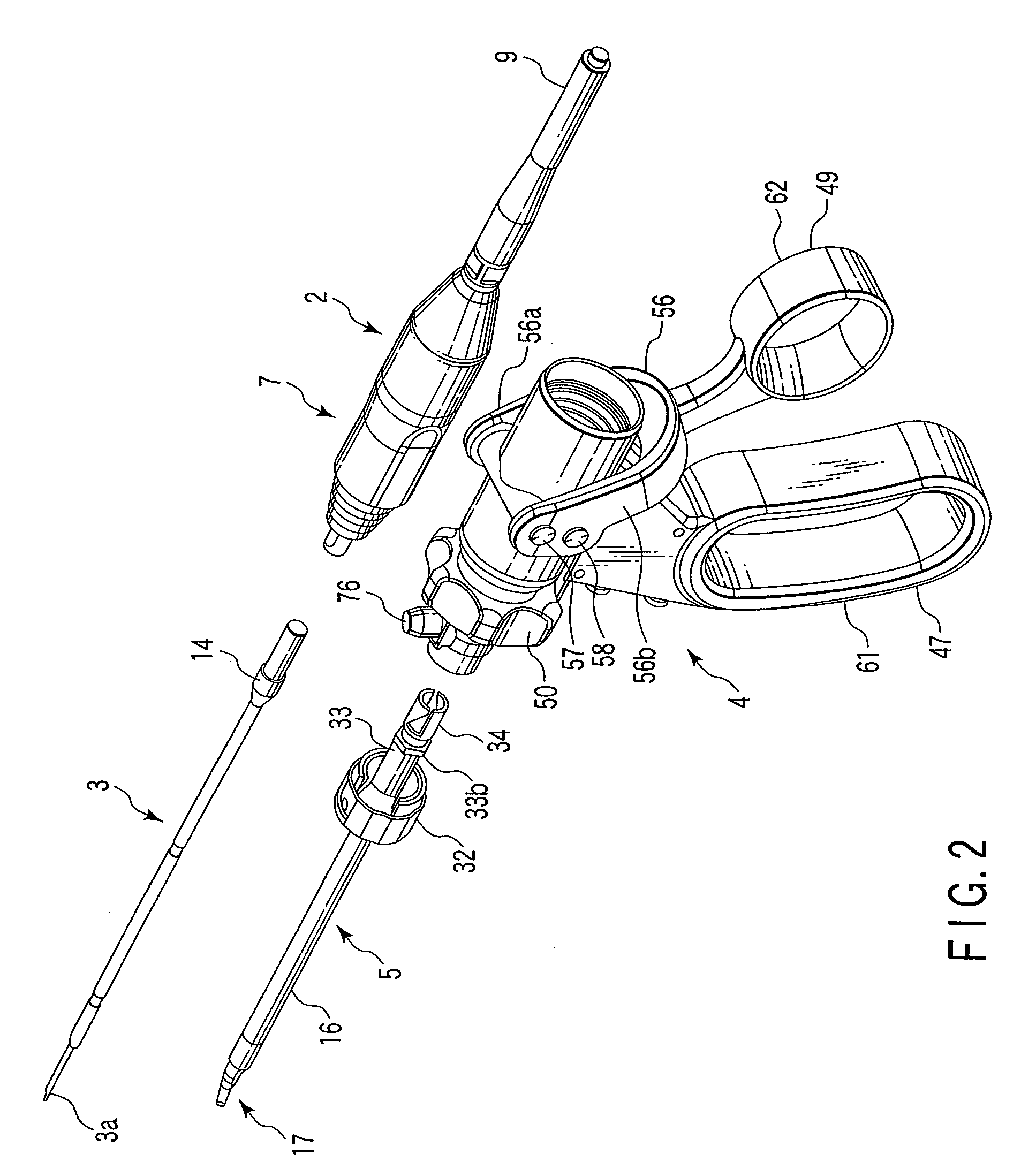

Endoscopic Translumenal Surgical Systems

InactiveUS20070260273A1Direct contact guaranteeAvoid contactCannulasGastroscopesEndoscopeAbdominal trocar

Methods and devices are provided for performing translumenal (e.g., transoral and transanal) procedures. In general, the methods and devices utilize a trocar assembly or trocar end cap that can facilitate insertion of an endoscope through tissue. In one embodiment, a flexible trocar assembly is provided and includes an obturator having an inner lumen formed therethrough for receiving an endoscope therein, and a distal end that is adapted to facilitate insertion of the endoscope through tissue and that is adapted to facilitate viewing therethrough. The trocar assembly can also include a trocar sleeve that is disposable over the obturator. In use, once the trocar assembly is inserted through tissue, the trocar sleeve can function as a placeholder, allowing the endoscope and obturator to be removed. The endoscope can then be removed from within the obturator and reinserted through the trocar sleeve for use in performing various other procedures. In other embodiments, rather than using a trocar that houses the endoscope, an end cap can be removably disposed over a distal end of the endoscope. The present invention also provides methods and devices for shielding an endoscope during insertion through a body lumen, and in particular for preventing contact between the endoscope (or trocar sleeve) and the body lumen, thus preventing bacteria from being carried into a body cavity.

Owner:ETHICON ENDO SURGERY INC

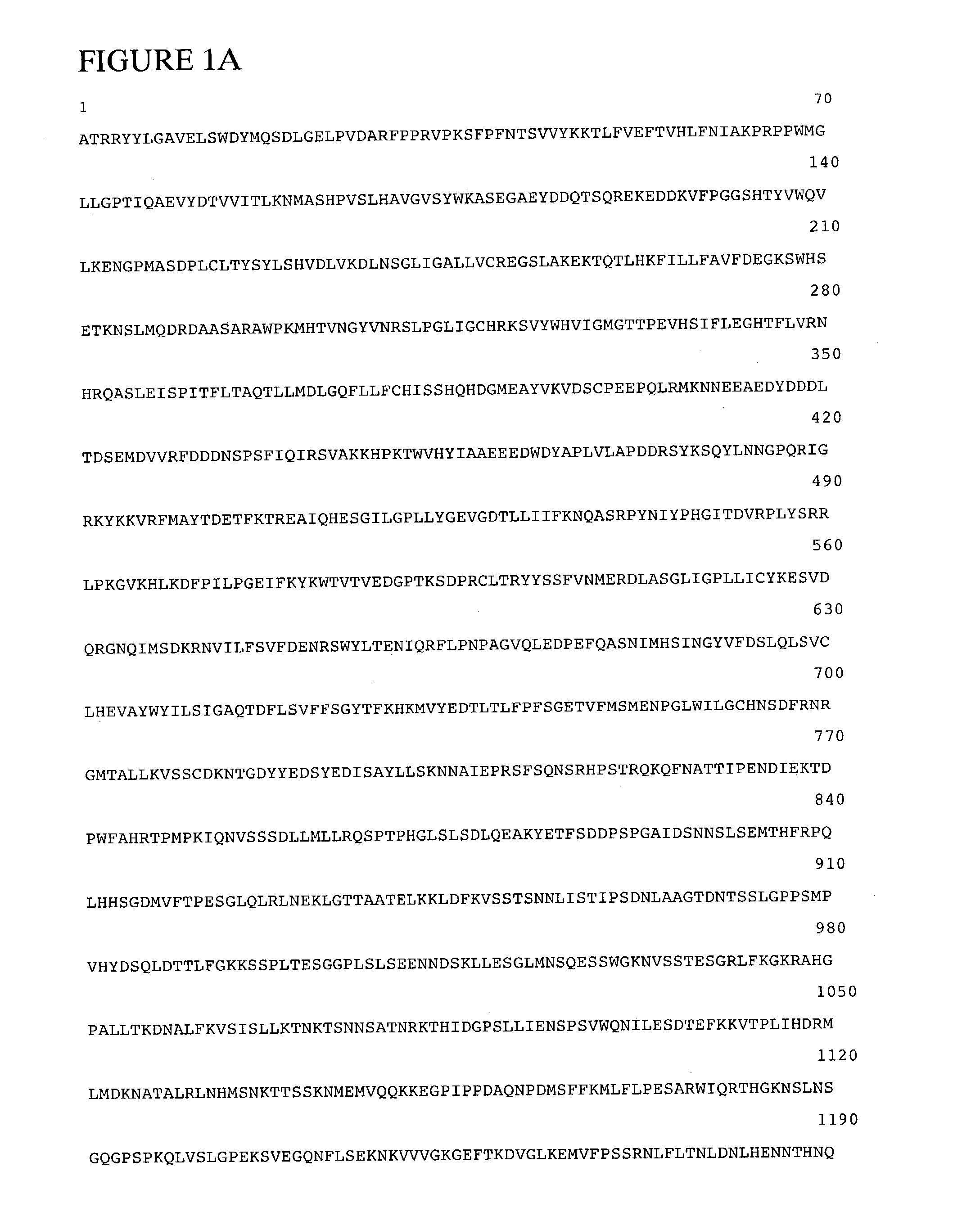

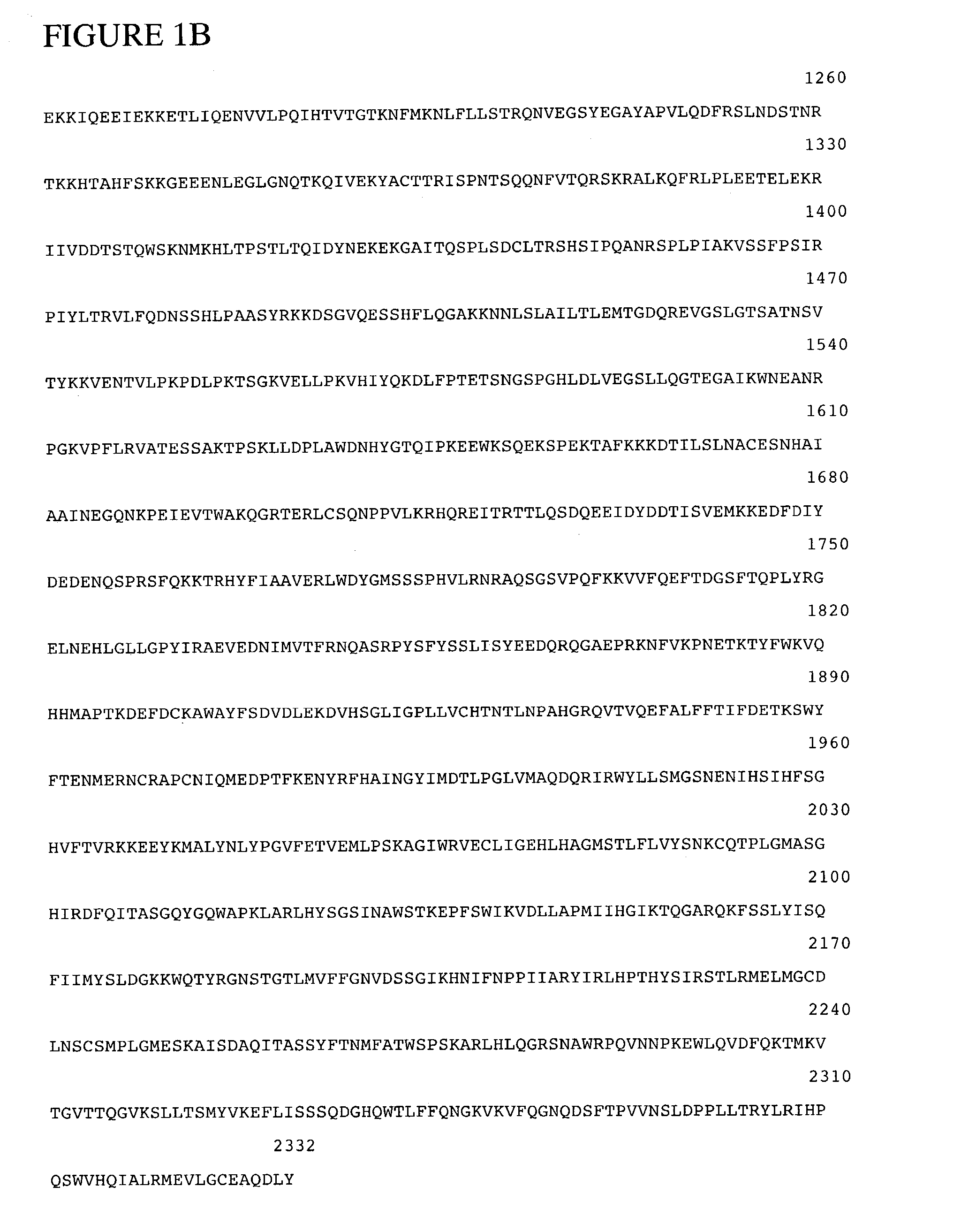

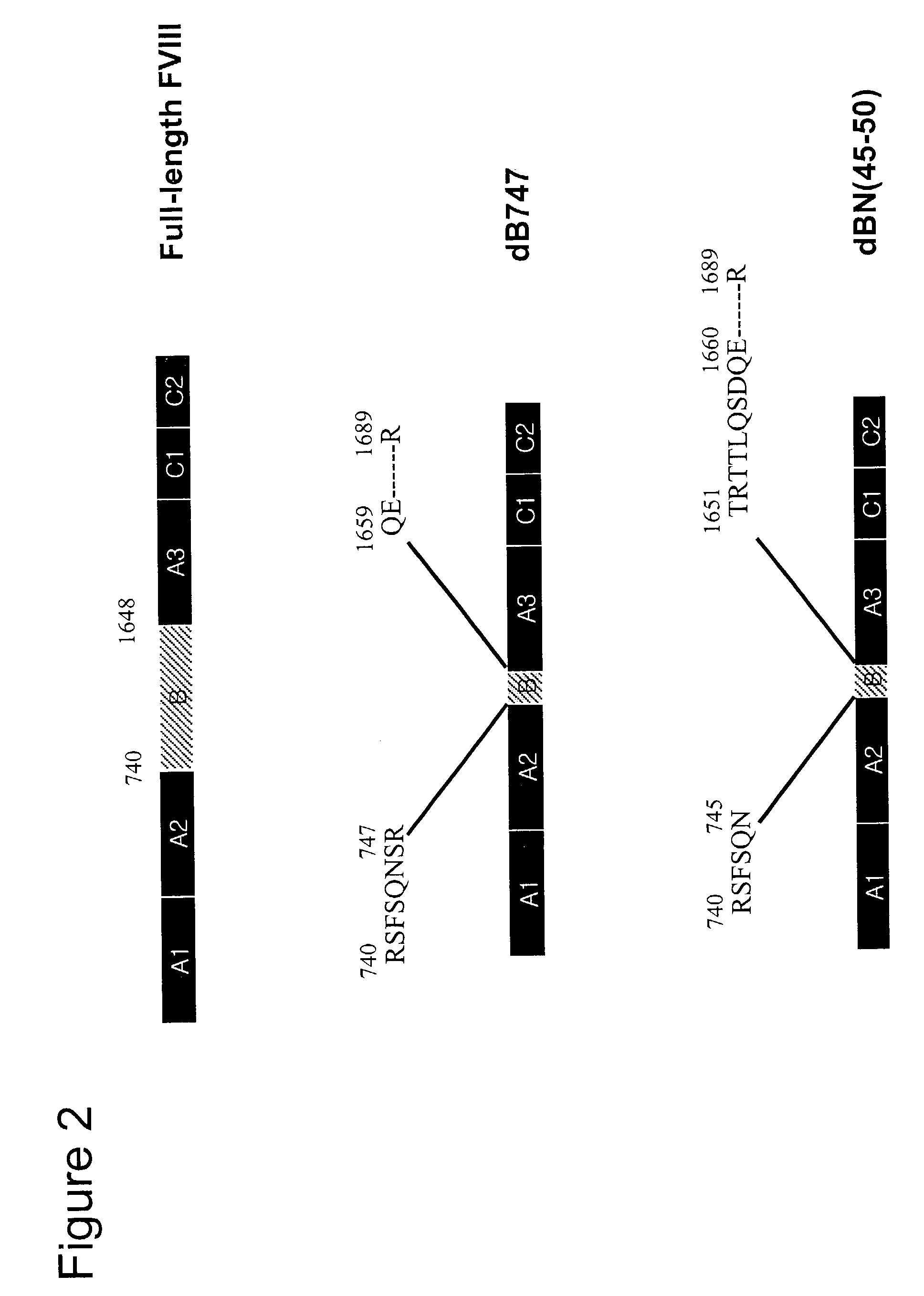

Factor VIII polypeptide

ActiveUS7041635B2Stable and efficiently expressed formFull coagulation activityFactor VIIPeptide/protein ingredientsThrombin activityAmino acid

Owner:SK BIOSCI CO LTD

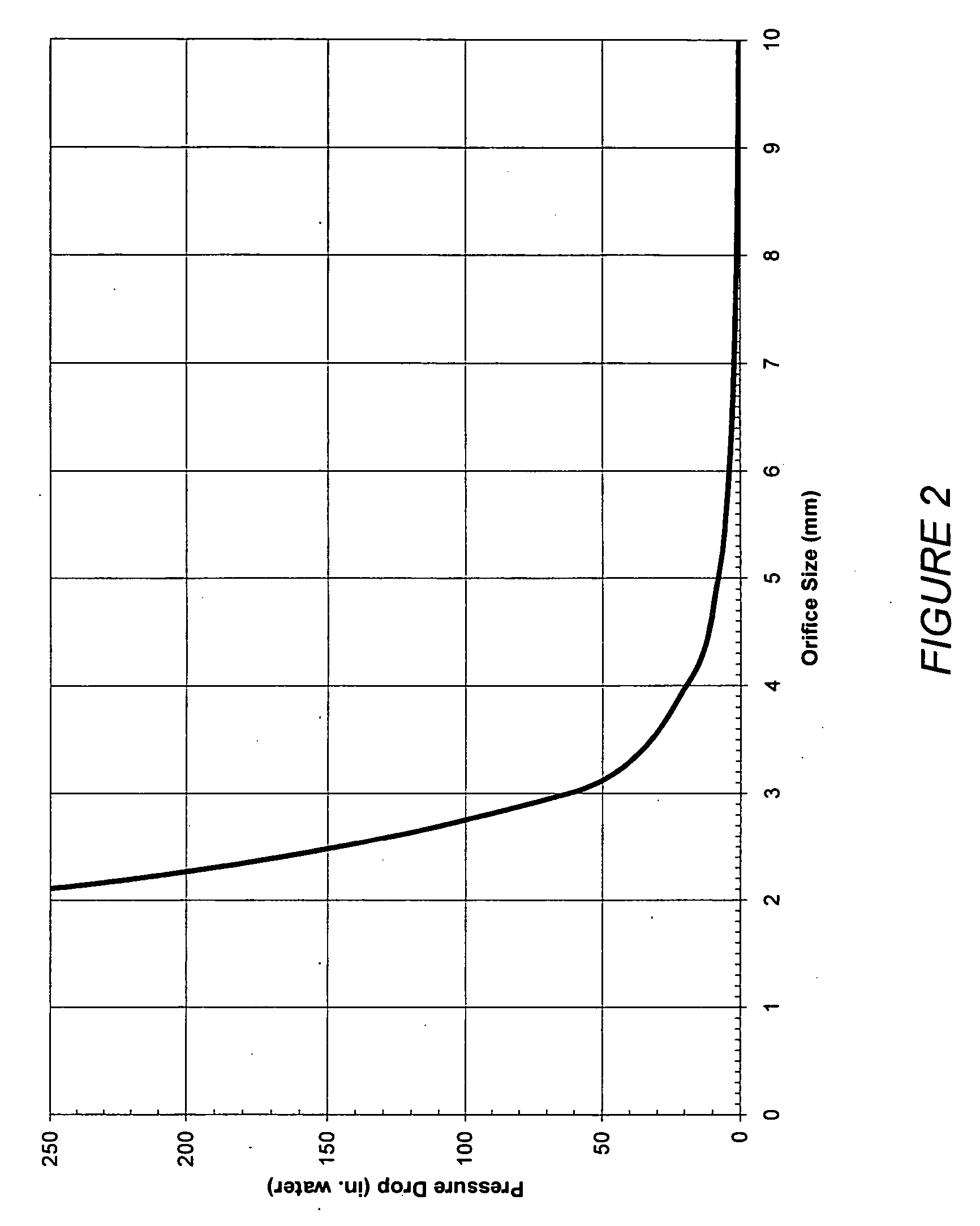

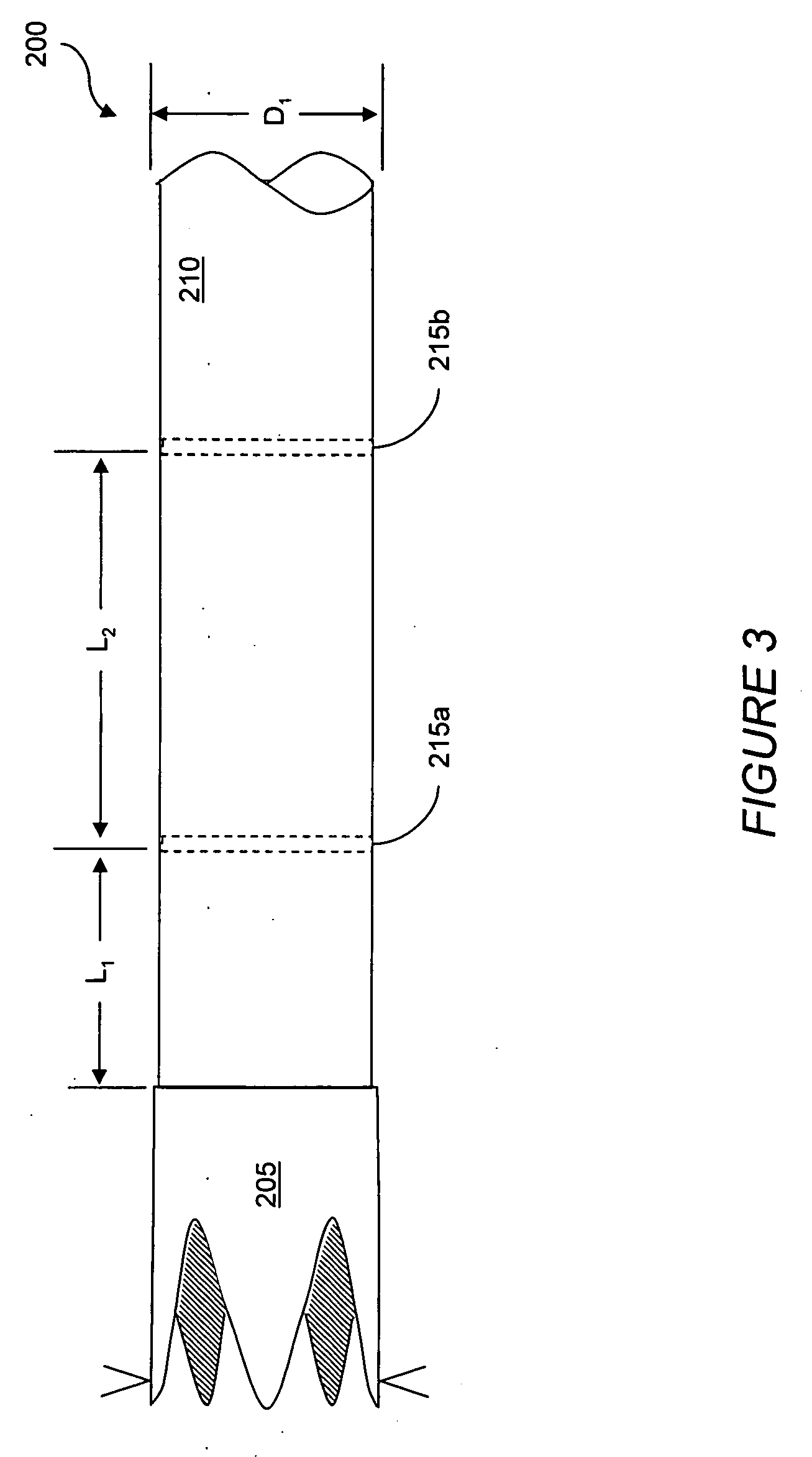

Resistive anti-obesity devices

ActiveUS20060161139A1Improve overall senseReduce food consumptionSurgeryOesophagiIntestinal structureGastric emptying

A patient is provided with an increased sense of satiety by increasing resistance to the outflow of food from the stomach and through the intestines. Stomach emptying may be slowed with devices implantable within the gastrointestinal tract below the stomach. Implants are preferably removable and can include artificial strictures that may be adjustable to vary the rate of stomach emptying. Slowing gastric emptying may induce satiety for a longer period and may therefore reduce food consumption. Many of the embodiments include intestinal liners or sleeves, but they need not. The resistor concept may be applied to a simple anchor and resistor without a long liner.

Owner:GI DYNAMICS

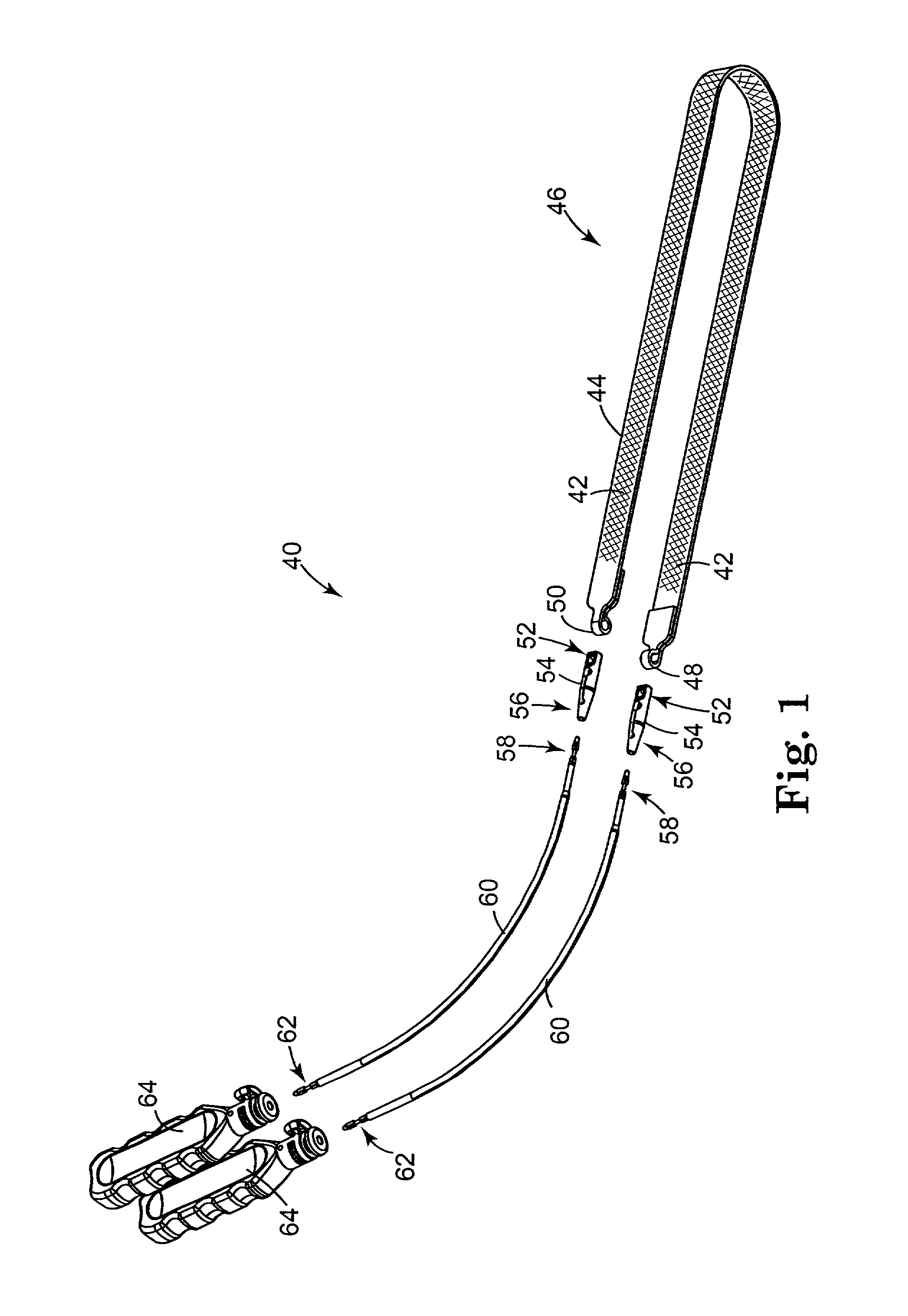

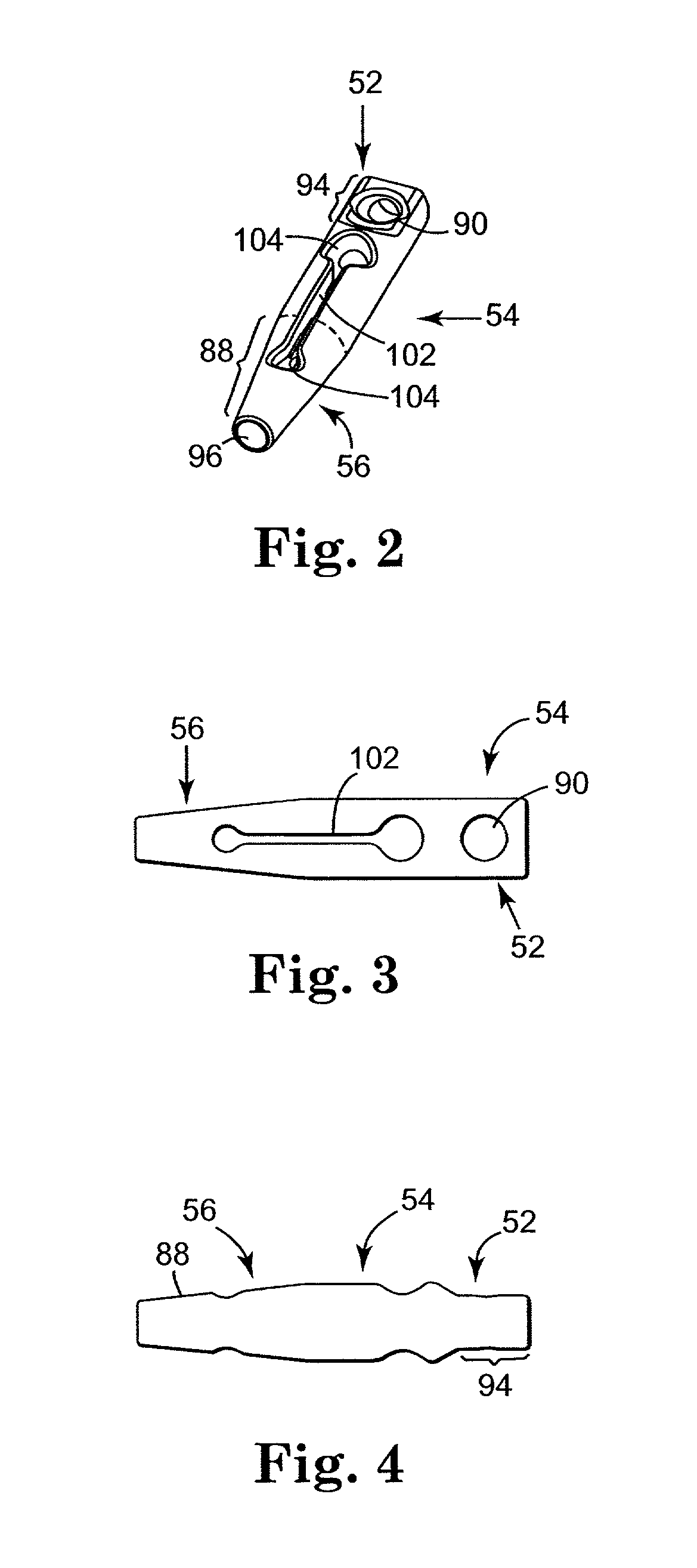

Sling assembly with secure and convenient attachment

InactiveUS20020151762A1Decrease rigidity and resistanceReduce amountSuture equipmentsSurgical furnitureSurgical departmentSurgical procedures

Surgical articles that are conveniently and securely coupled are disclosed. Improved surgical procedures are also disclosed.

Owner:STASKIN DAVID MD DR

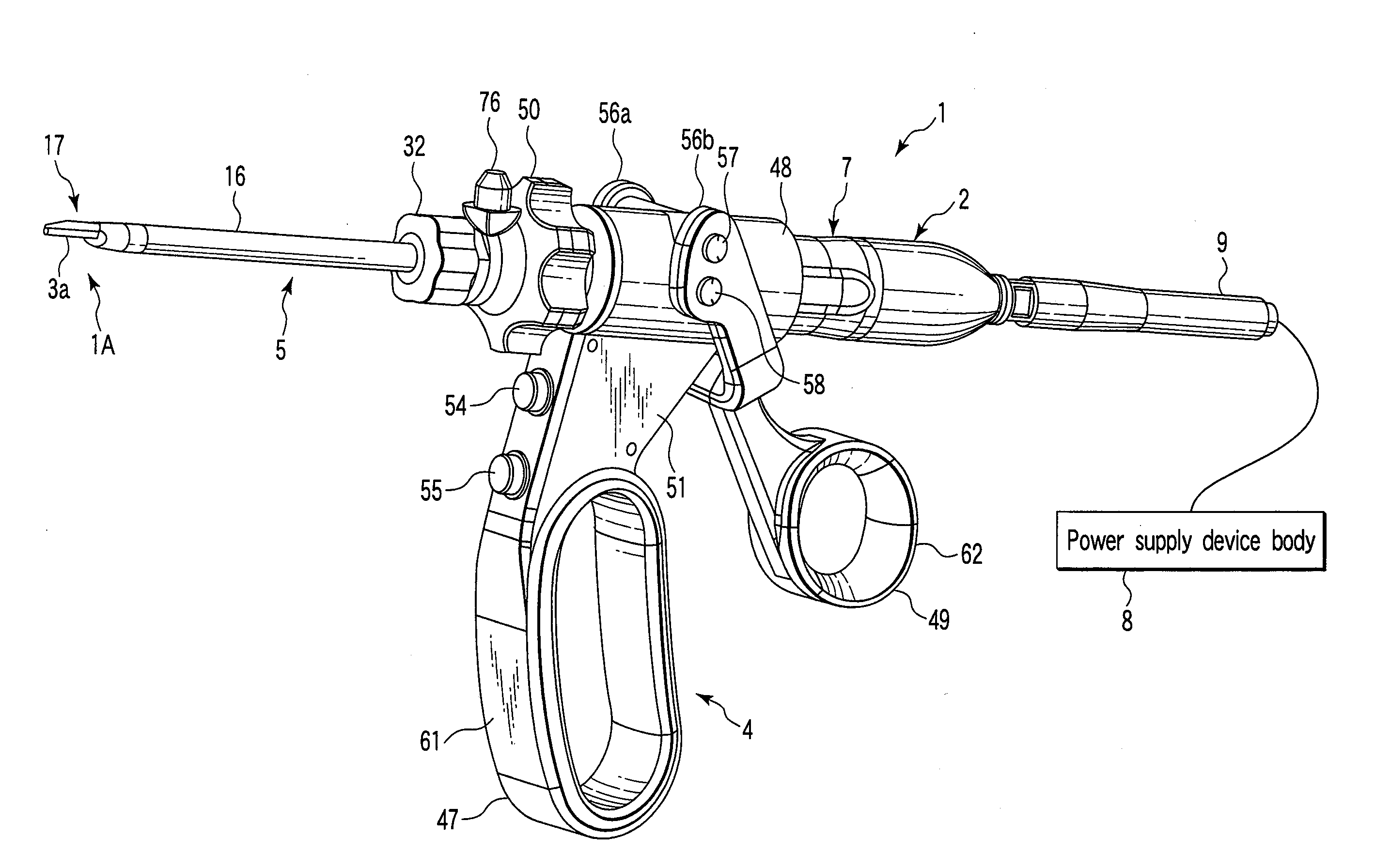

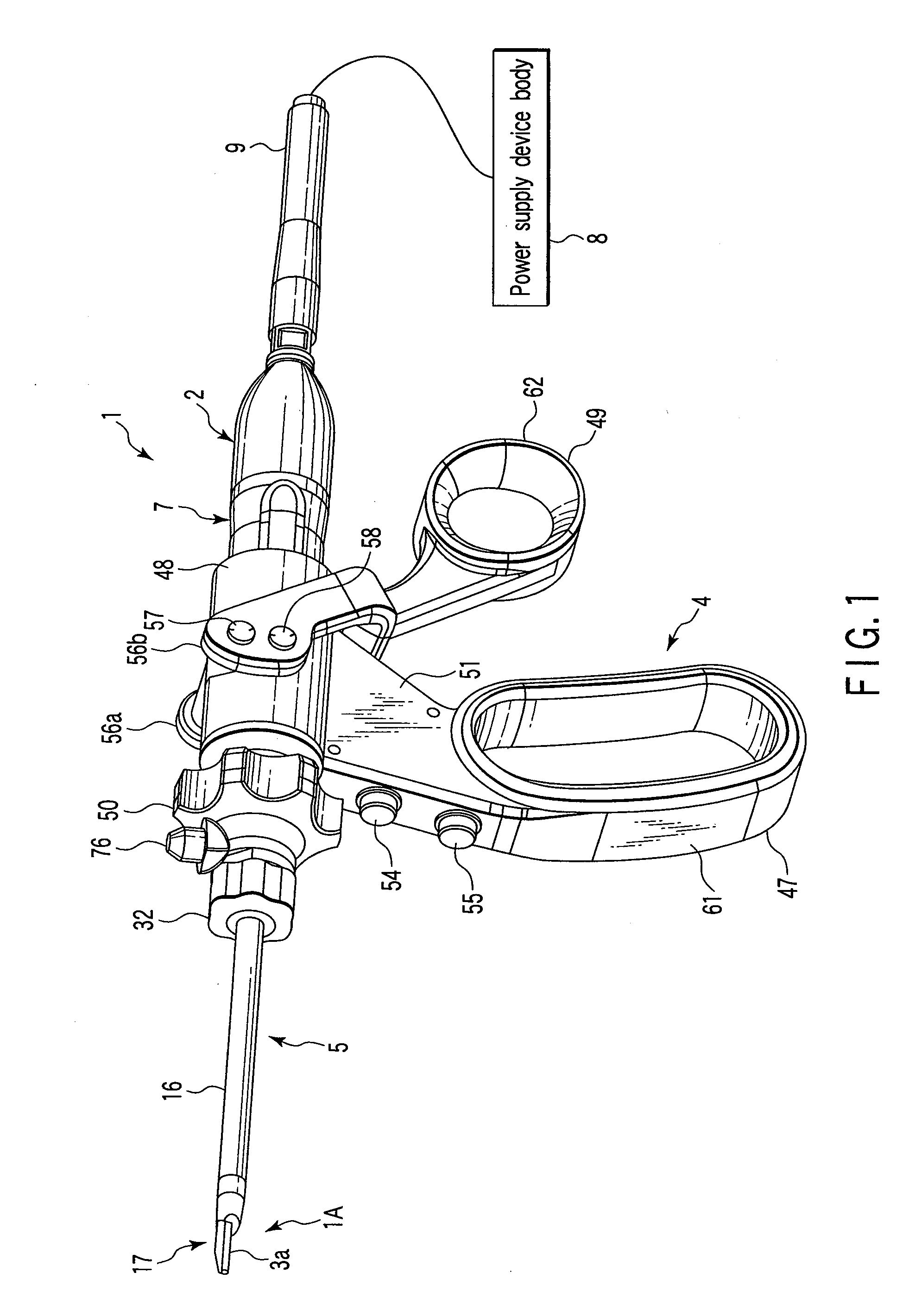

Surgical operating apparatus

InactiveUS20090088785A1Increase rangeReduce manufacturing costUltrasound therapySurgical instruments for heatingSurgical operationDistal portion

A surgical operating apparatus includes a sheath having a distal end portion and a proximal end portion; a shaft-shaped probe body which is inserted in the sheath and has a distal end portion and a proximal end portion, and in which ultrasonic vibration is transmitted; a jaw which is rotatably supported on the distal end portion of the sheath and has a first electrode section which is one of bipolar electrodes; a probe distal end portion which is provided at the distal end portion of the probe body, is engaged with the jaw, and constitutes a second electrode section which is the other of the bipolar electrodes; and a driving member including a tubular body section, which is inserted in the sheath slidably in an axial direction of the sheath, and an operation section which is provided on a distal end side of the body section and has a connection section for connection to the jaw, the driving member rotating the jaw by a sliding operation of the body section, wherein a tube body of the body section has, on an inner peripheral surface side thereof, an insulation tube which effects electrical insulation between the probe body and the body section, and the insulation tube has a projection portion which projects forward of the body section.

Owner:OLYMPUS MEDICAL SYST CORP

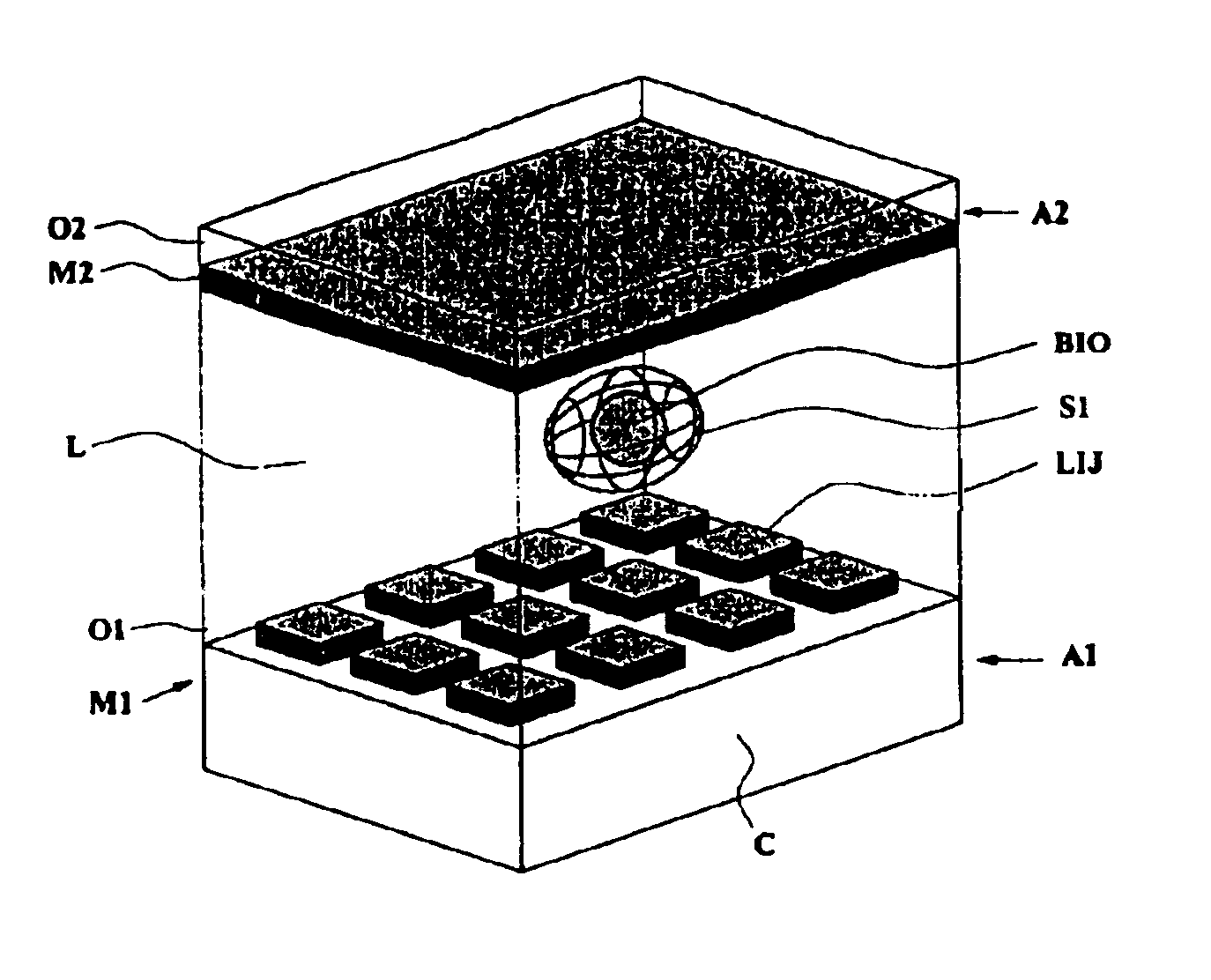

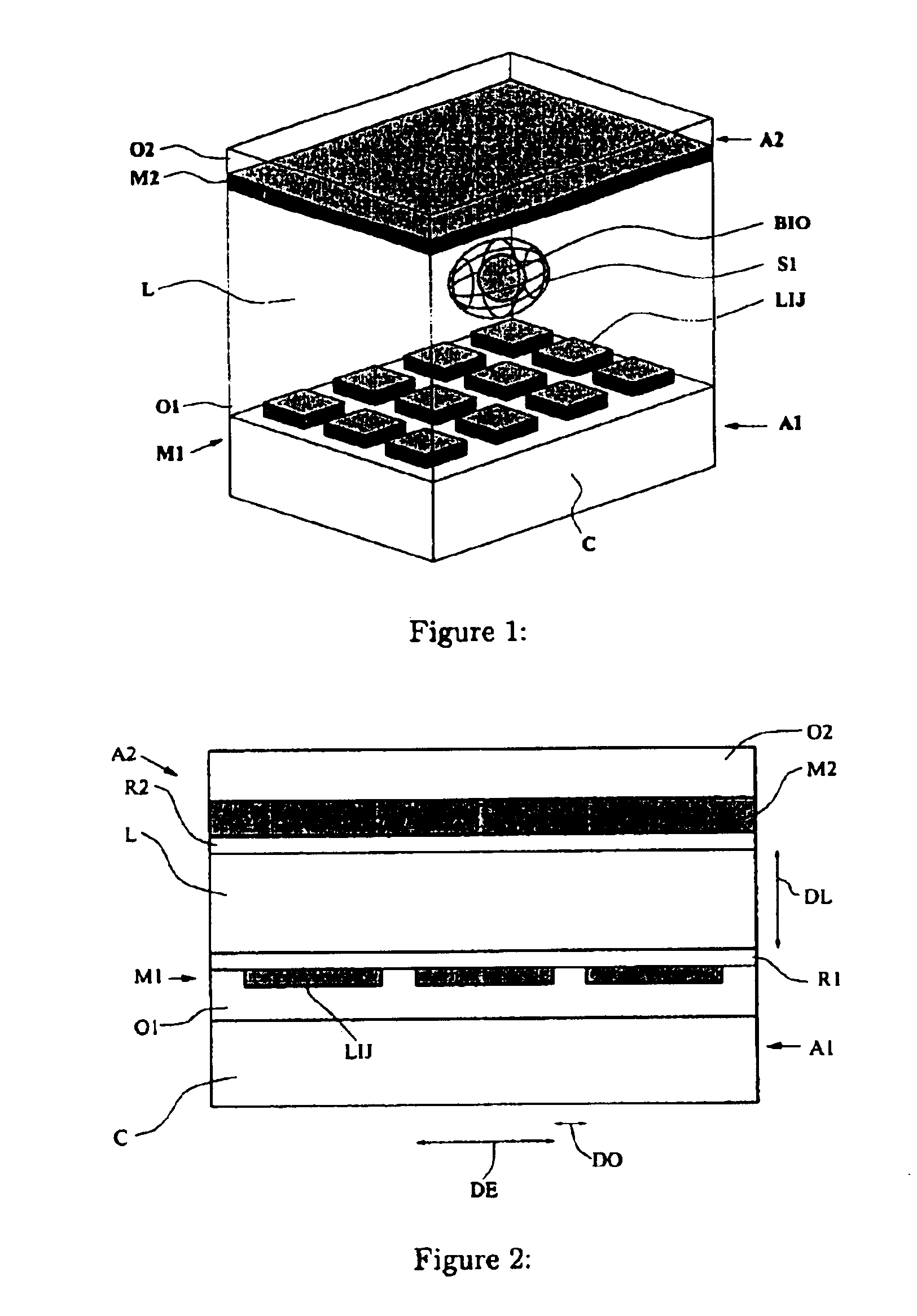

Method and apparatus for the manipulation of particles by means of dielectrophoresis

InactiveUS6942776B2Increase rangeAvoid the needElectrostatic separatorsSludge treatmentPlanar substrateEngineering

An apparatus and method for establishing closed dielectrophoretic potential cages and precise displacement thereof comprising a first array of selectively addressable electrodes, lying on a substantially planar substrate and facing toward a second array comprising one electrode. The arrays define the upper and lower bounds of a micro-chamber where particles are placed in liquid suspension. By applying in-phase and counter-phase periodic signals to electrodes, one or more independent potential cages are established which cause particles to be attracted to or repelled from cages according to signal frequency and the dielectric characteristics of the particles and suspending medium. By properly applying voltage signal patterns into arrays, cages may trap one or more particles, thus permitting them to levitate steadily and / or move. In the preferred embodiment, where one array is integrated on a semiconductor substrate, displacement of particles can be monitored by embedded sensors.

Owner:SILICON BIOSYSTEMS SPA +1

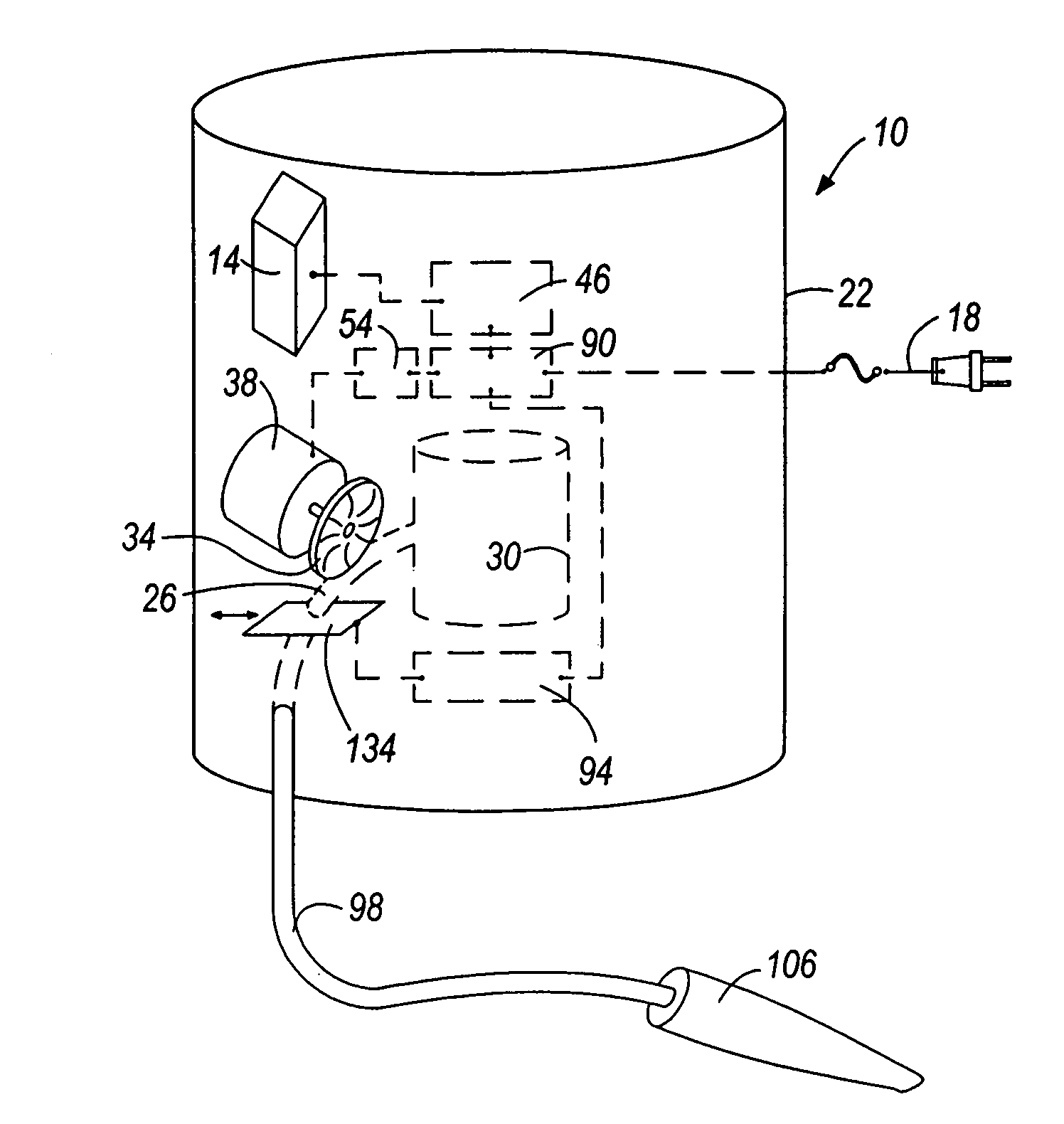

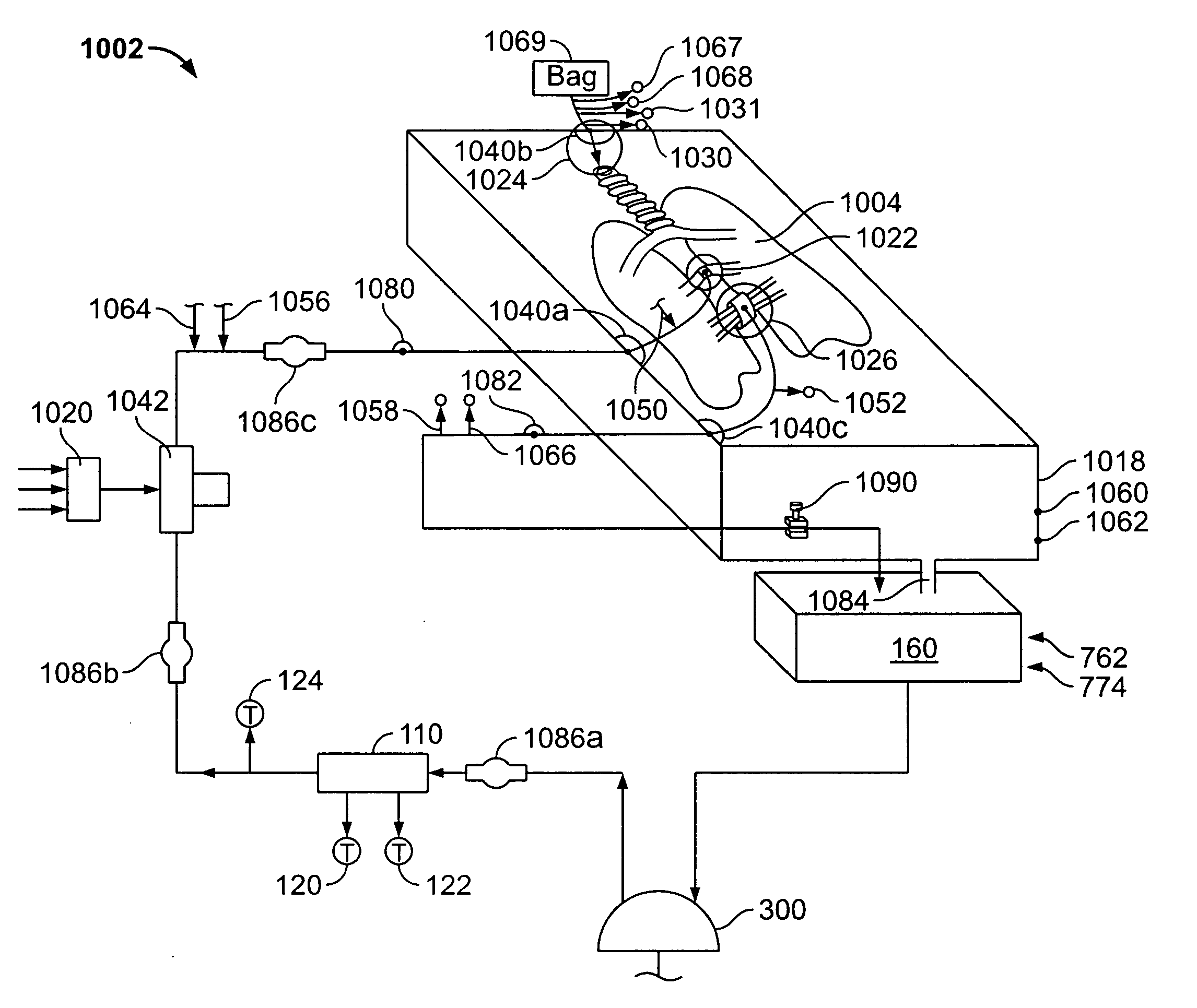

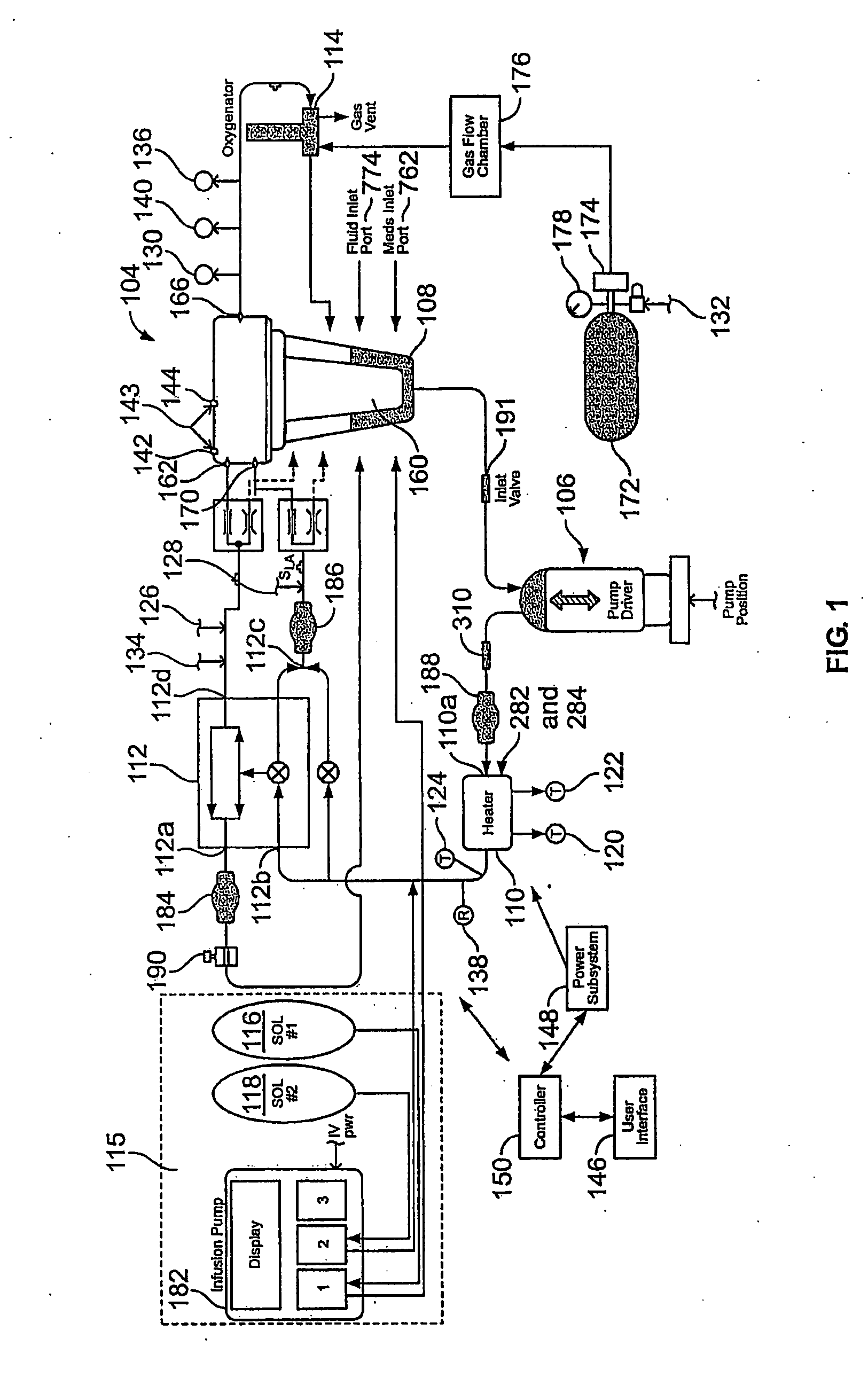

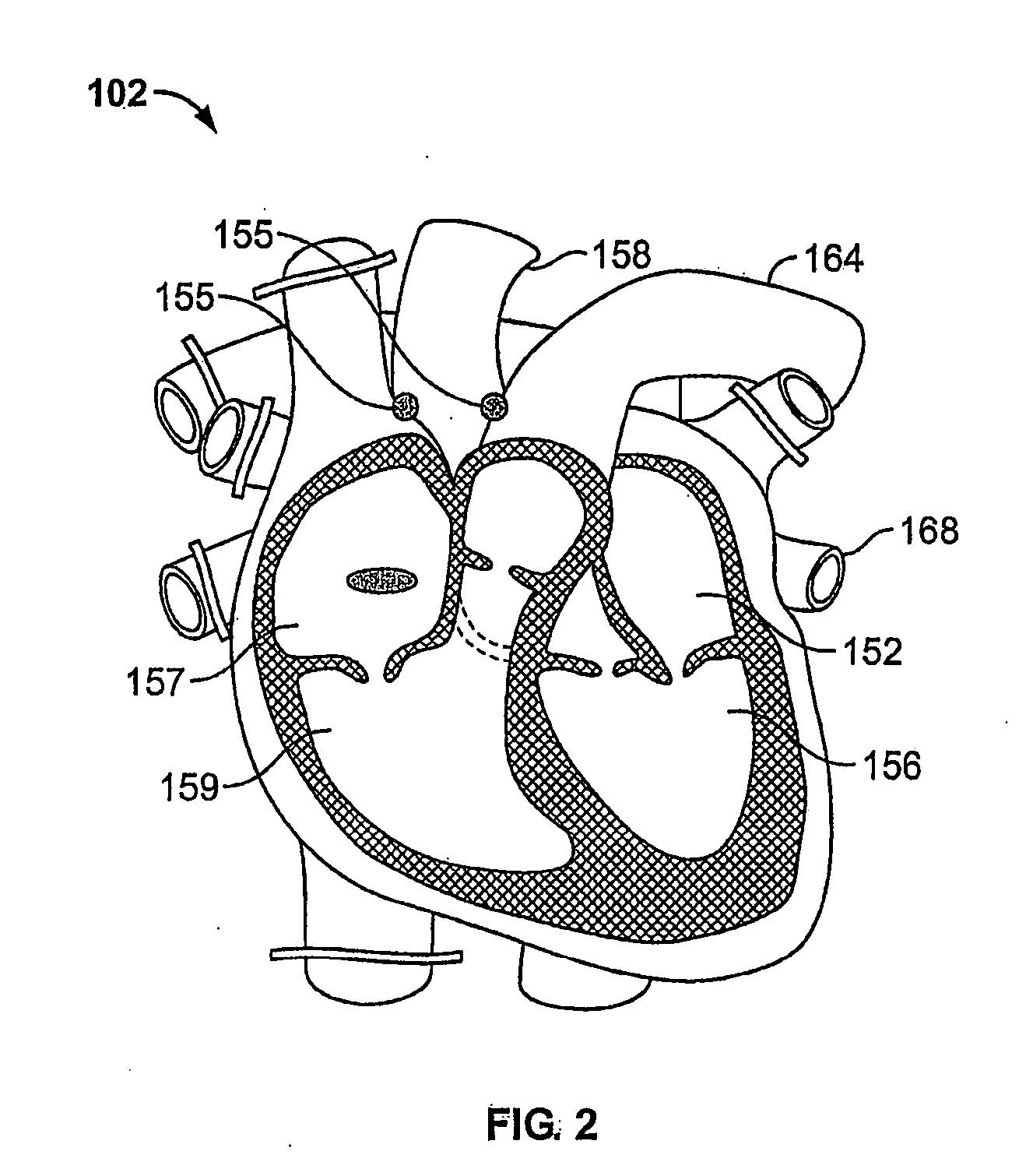

Systems and methods for ex vivo organ care

The invention, in various embodiments, provides systems, methods and solutions using an organ ex vivo.

Owner:TRANSMEDICS

Method for repairing intervertebral discs

ActiveUS20080103564A1Increase pressureHalt leakageDiagnosticsPharmaceutical delivery mechanismIntervertebral discBiomedical engineering

A method of repairing a defect in an annulus fibrosus of an intervertebral disc, without excising the entire nucleus pulposus of the disc. The method includes inserting an introducer needle through the annulus fibrosus by puncturing the annulus fibrosus with the introducer needle, injecting an in situ curable, bio-compatible polymerizable or polymeric material composition into the disc through the introducer needle directly or indirectly so that the in situ curable composition contacts a defect in the annulus fibrosus; and curing said material in situ.

Owner:PAUZA KEVIN

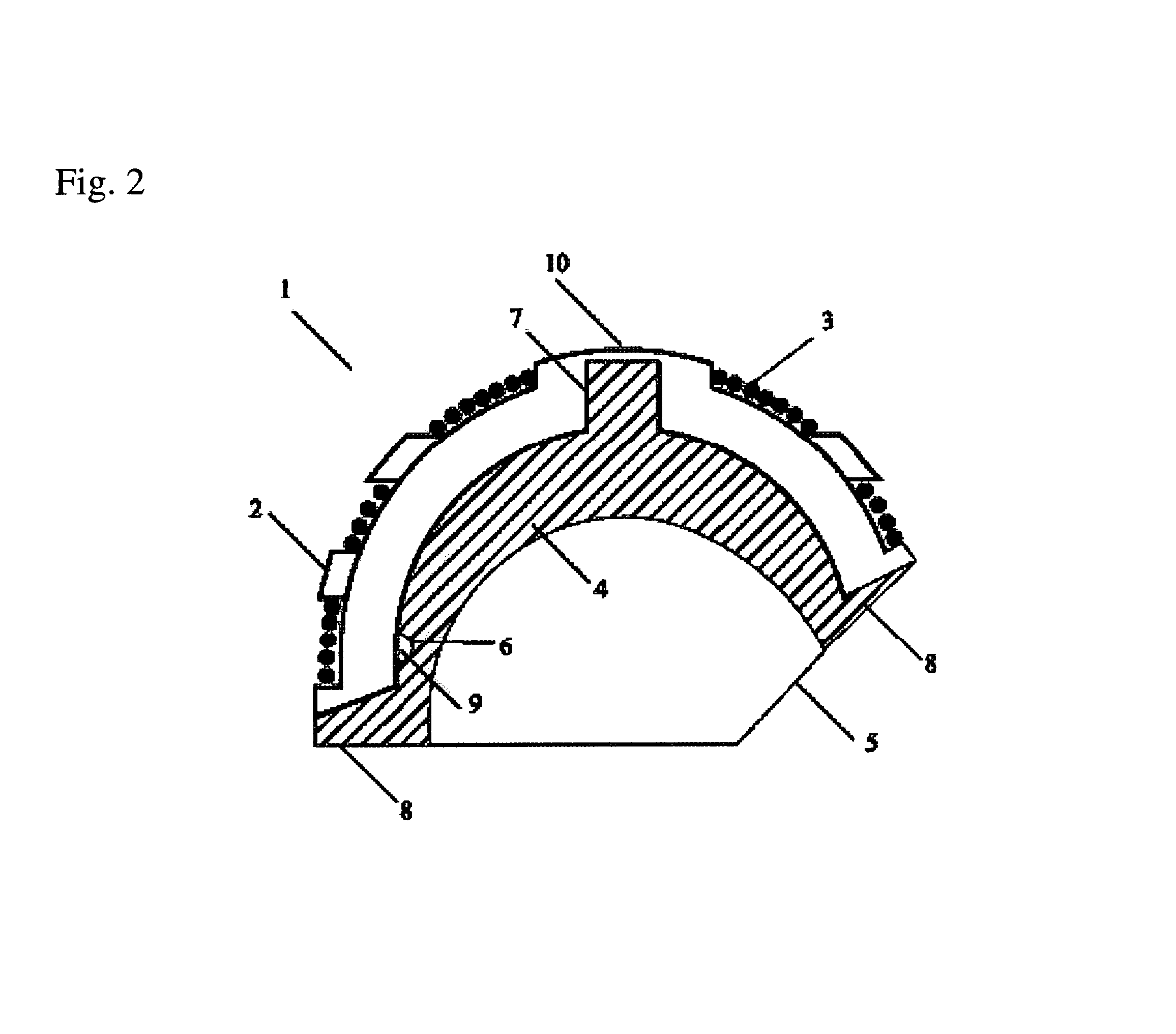

Canine acetabular cup

ActiveUS7169185B2Increase flexibilityLife maximizationSurgeryJoint implantsPorous coatingRight femoral head

Owner:IMPACT SCI & TECH

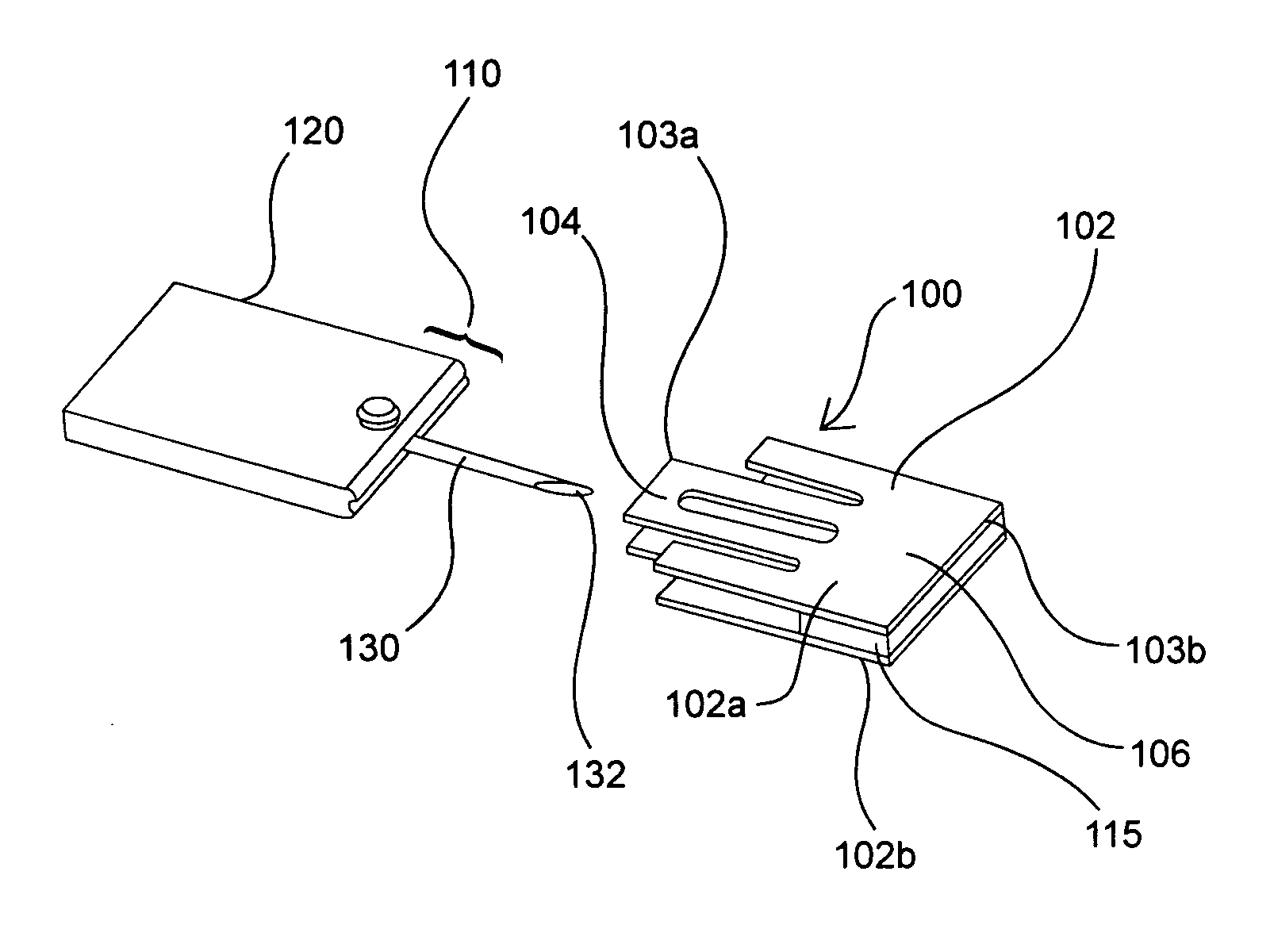

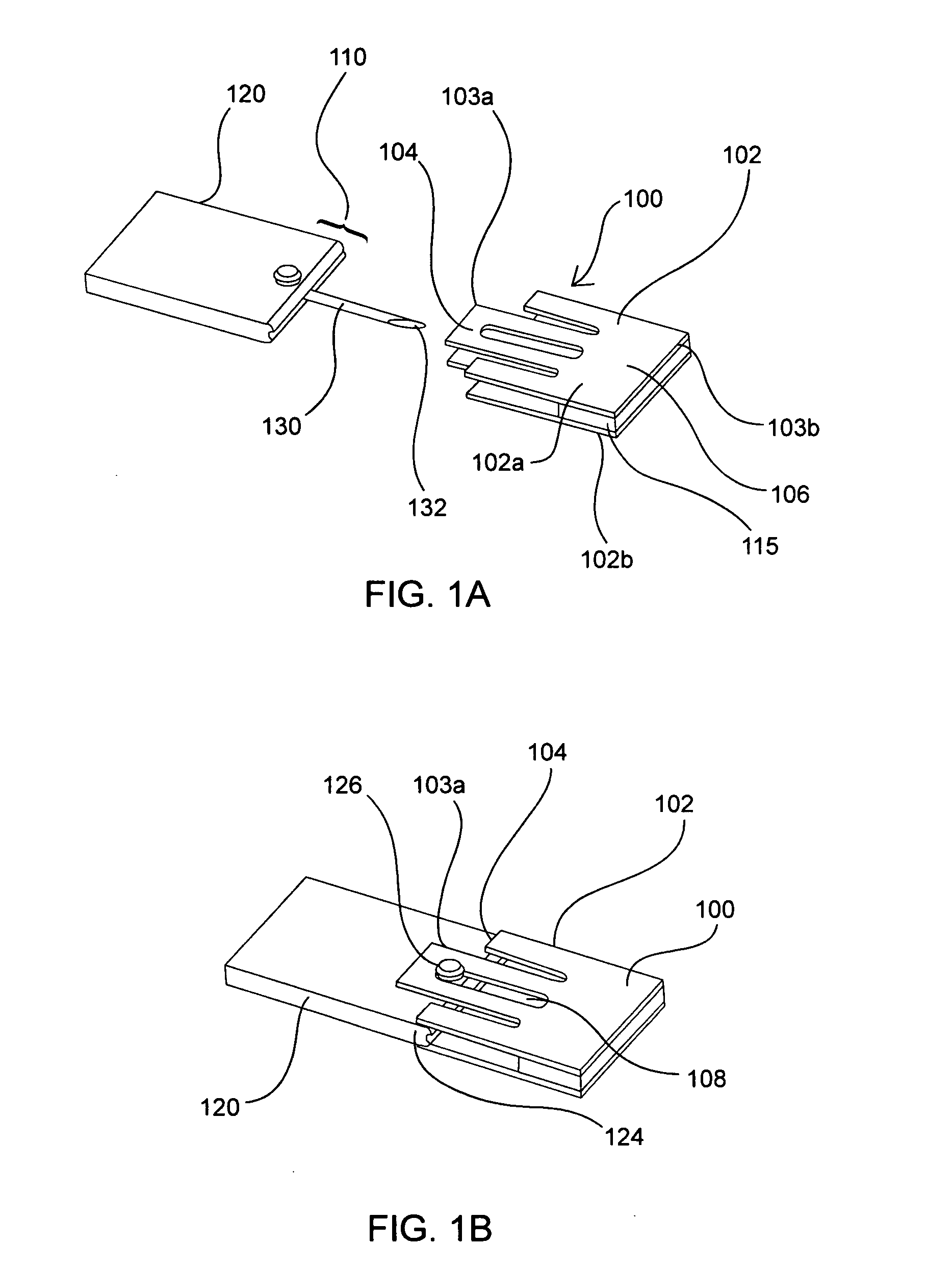

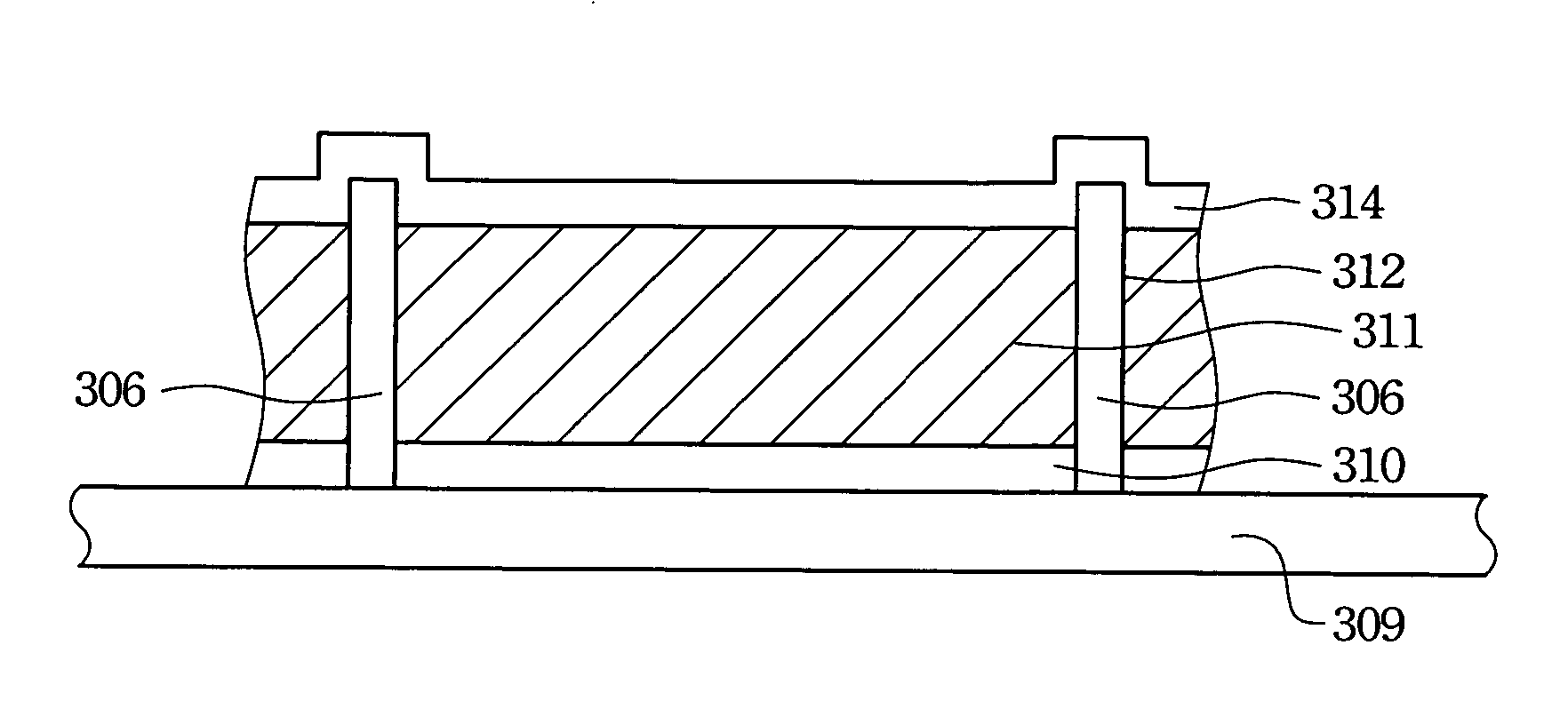

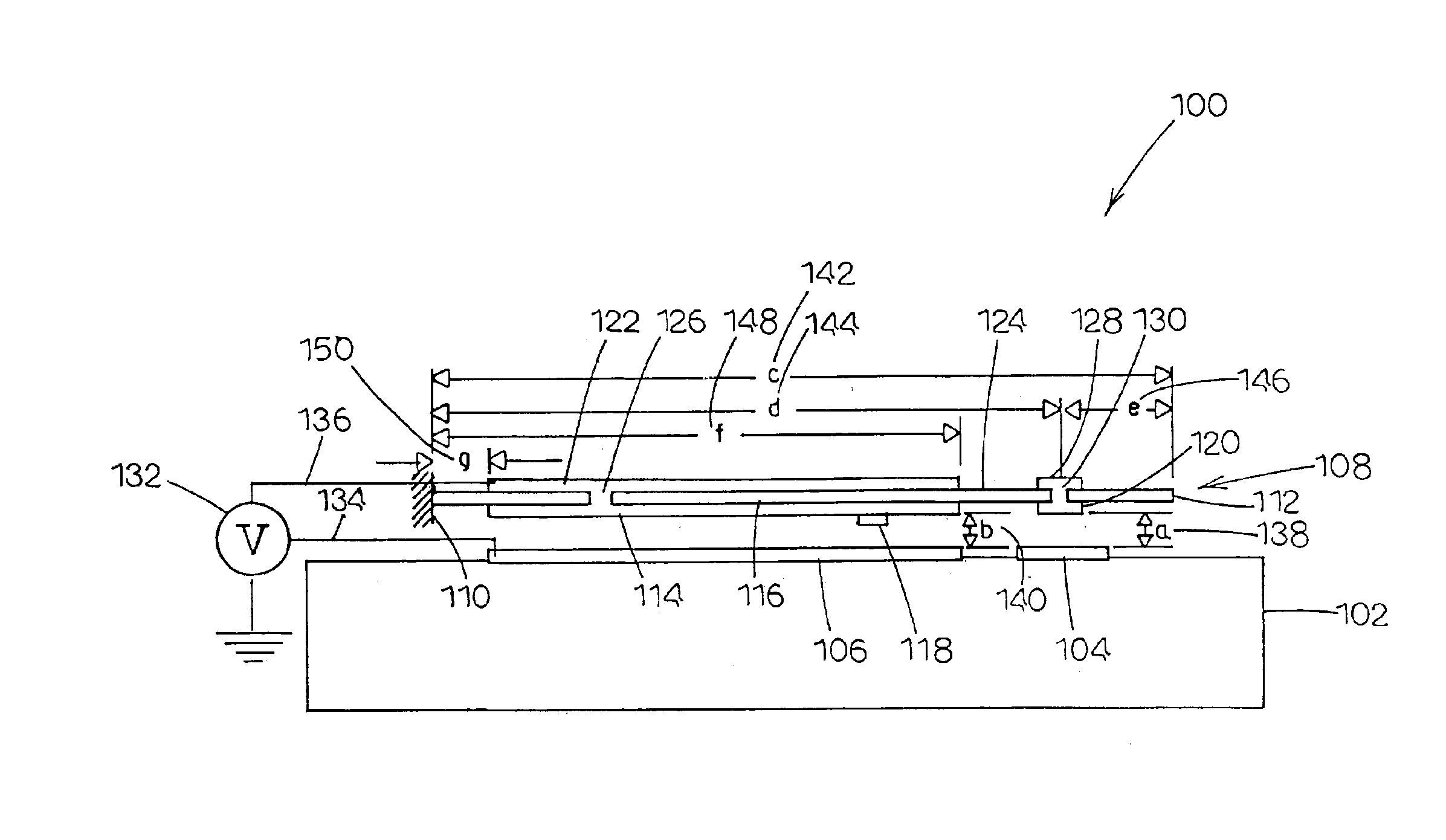

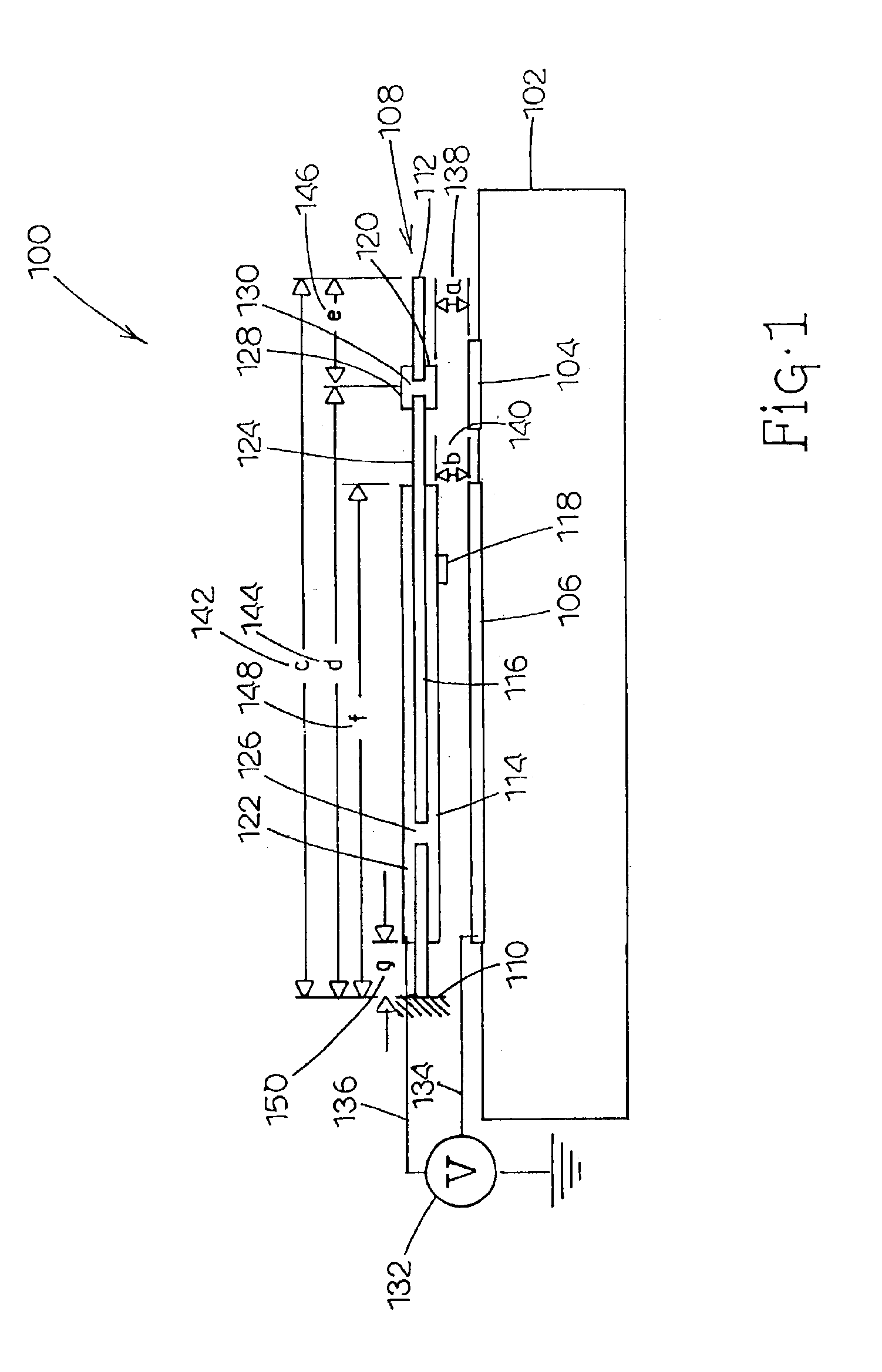

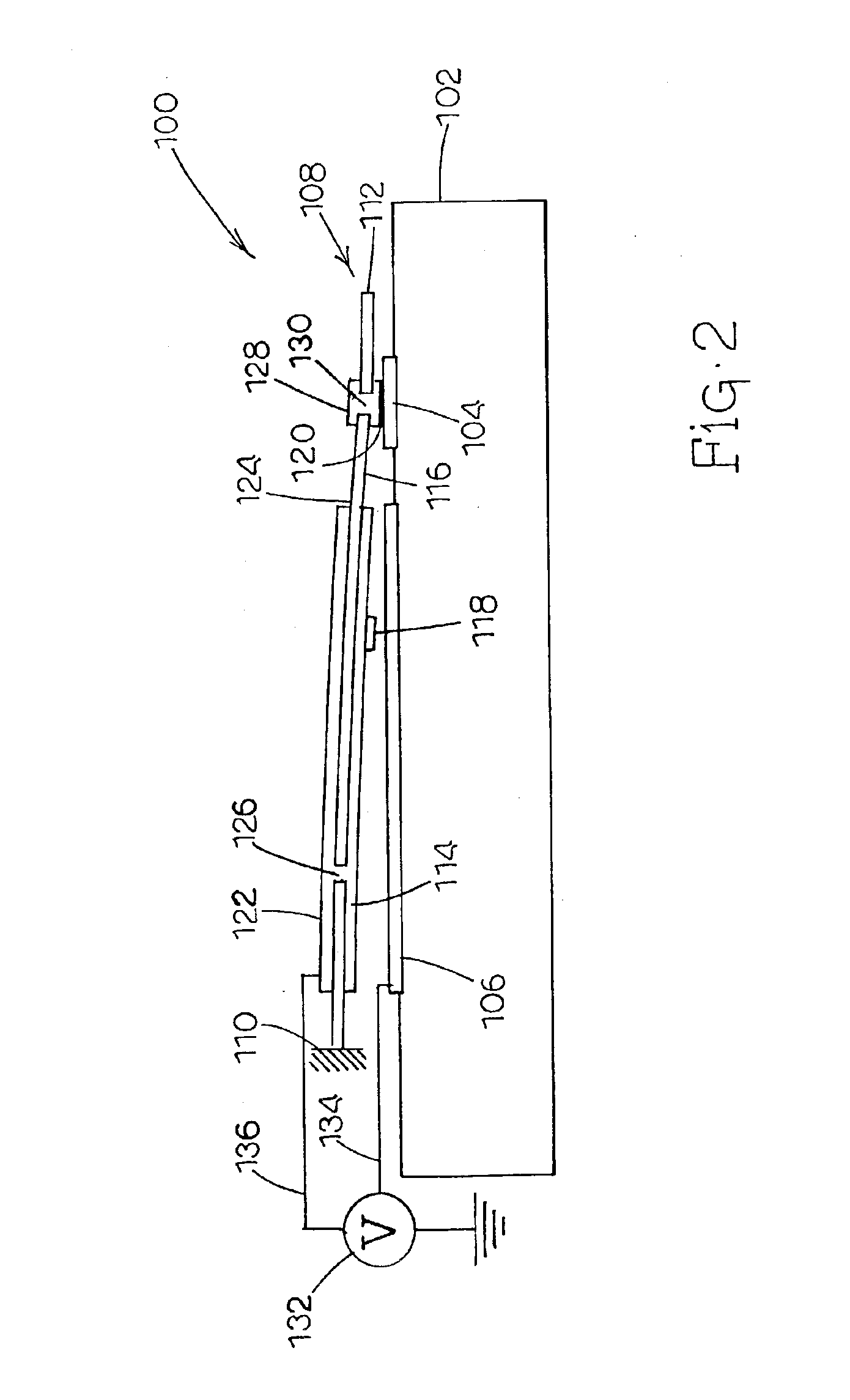

MEMS device having contact and standoff bumps and related methods

InactiveUS6876482B2Avoid contactOptical radiation measurementSolid-state devicesConductive materialsElectrical and Electronics engineering

MEMS Device Having Contact and Standoff Bumps and Related Methods. According to one embodiment, a movable MEMS component suspended over a substrate is provided. The component can include a structural layer having a movable electrode separated from a substrate by a gap. The component can also include at least one standoff bump attached to the structural layer and extending into the gap for preventing contact of the movable electrode with conductive material when the component moves.

Owner:AAC TECH PTE LTD

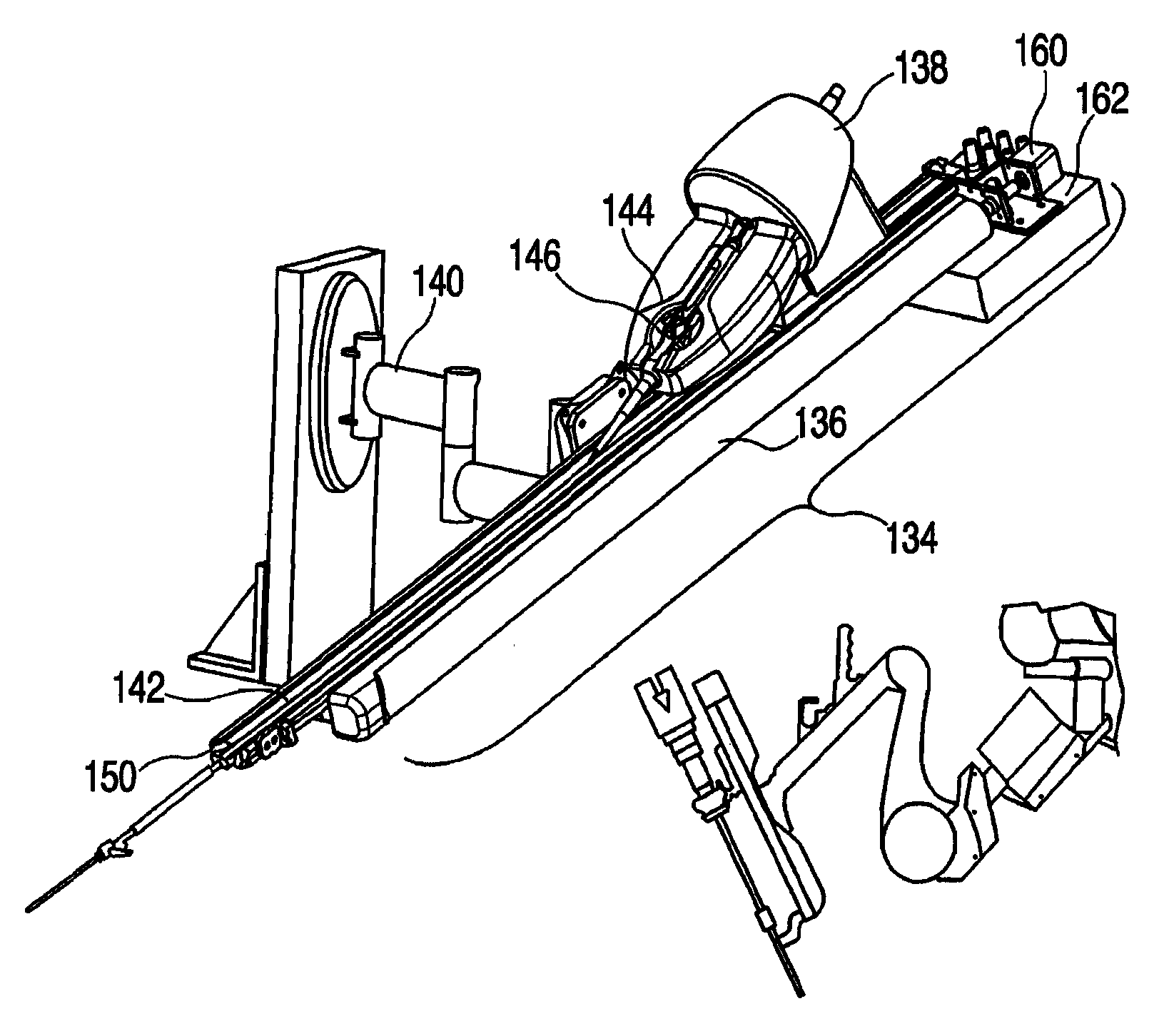

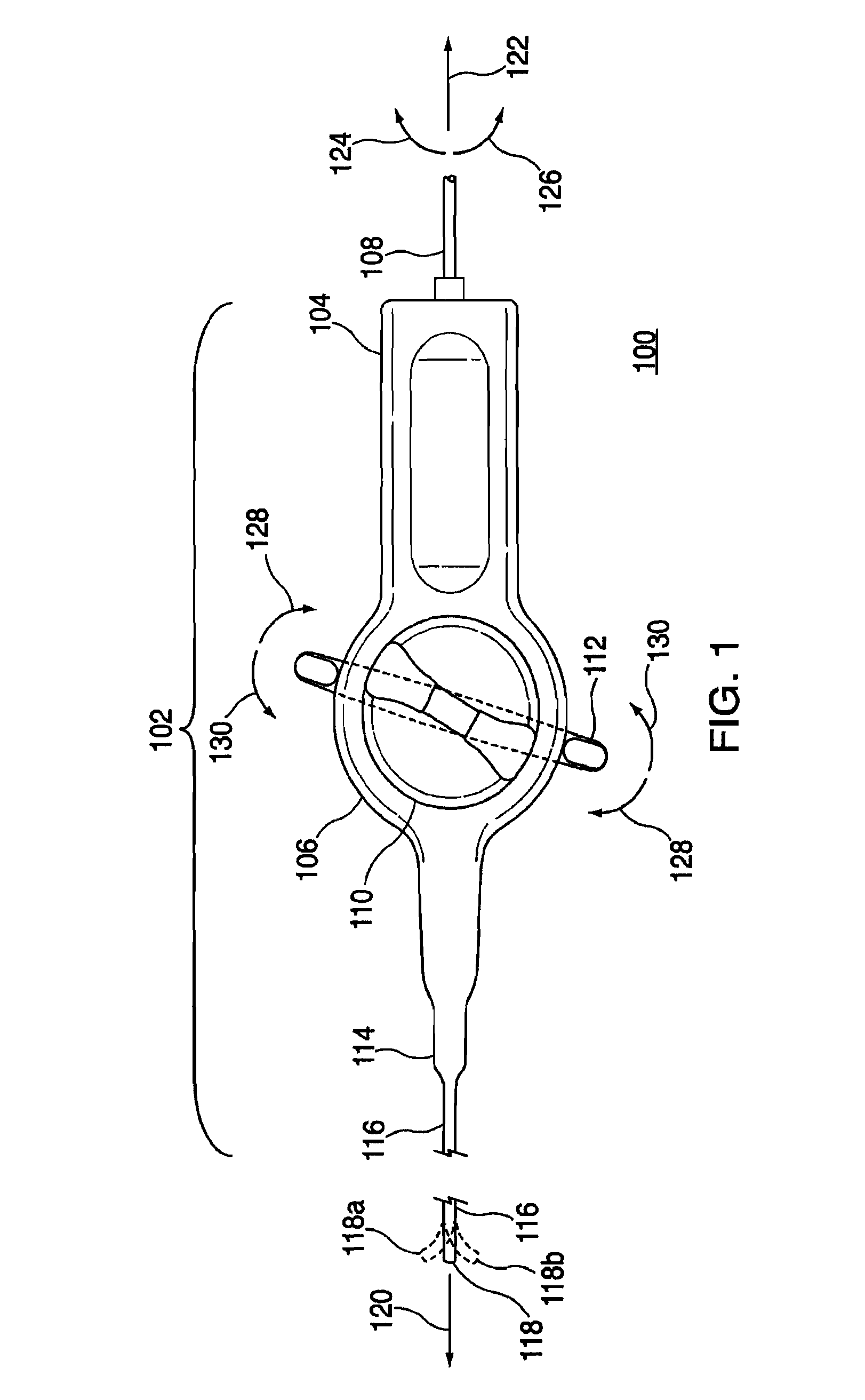

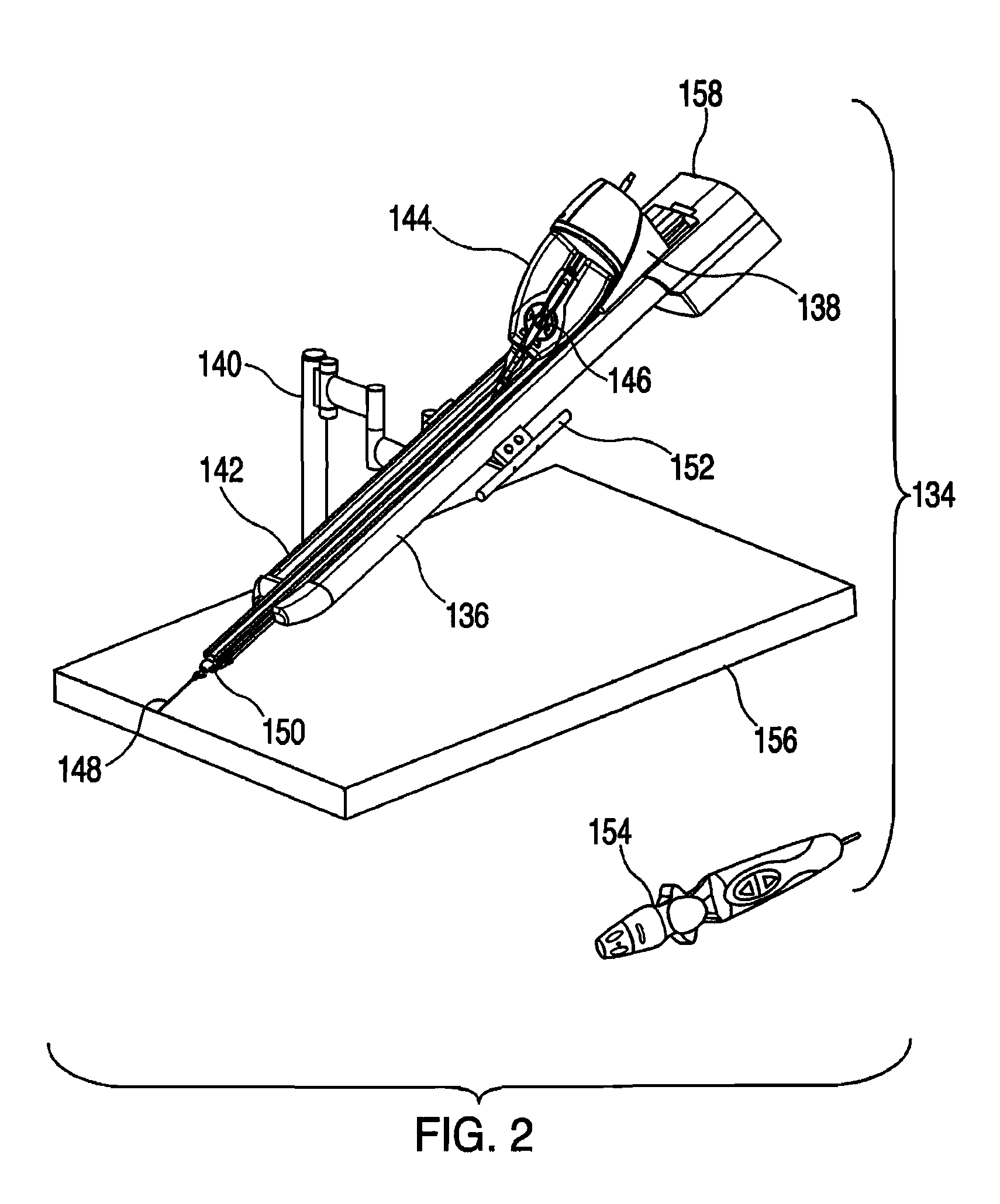

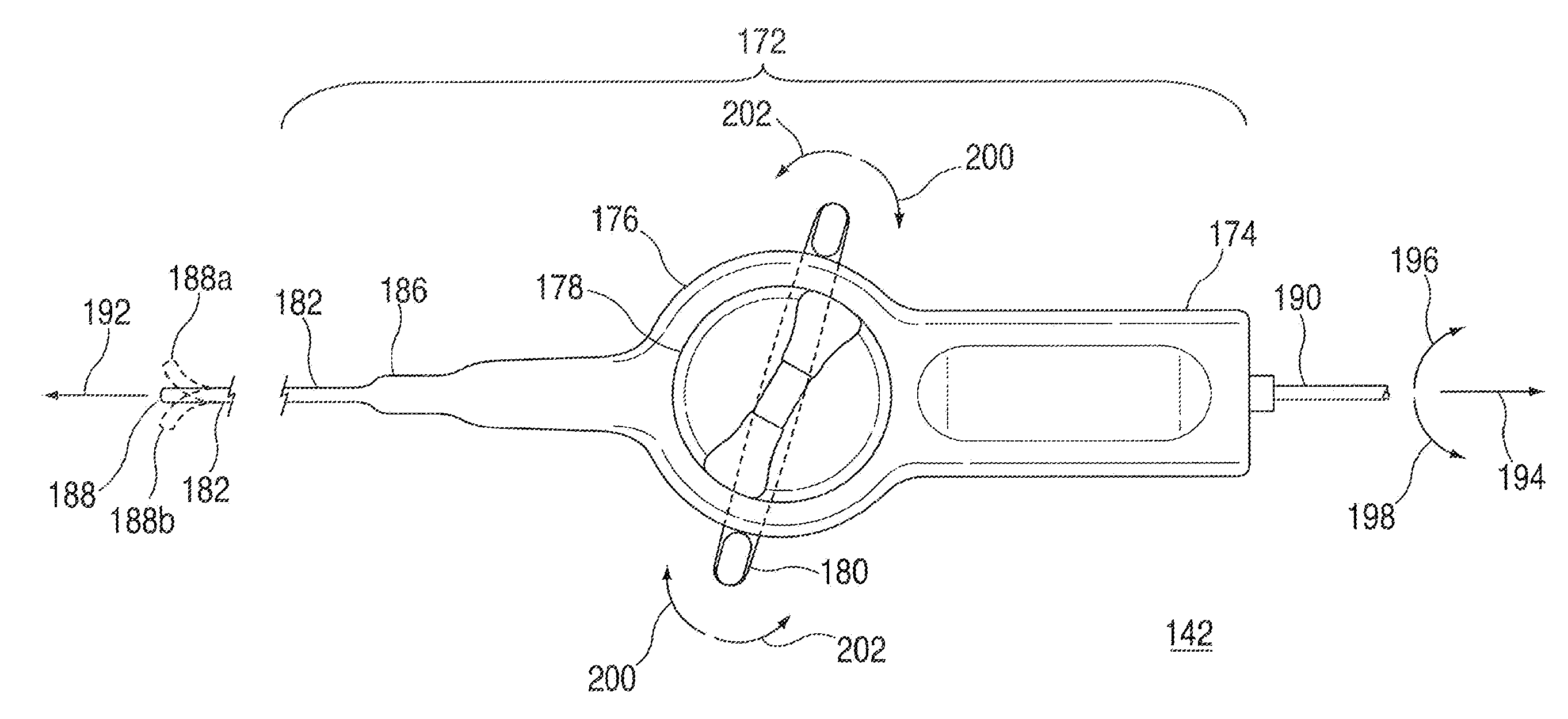

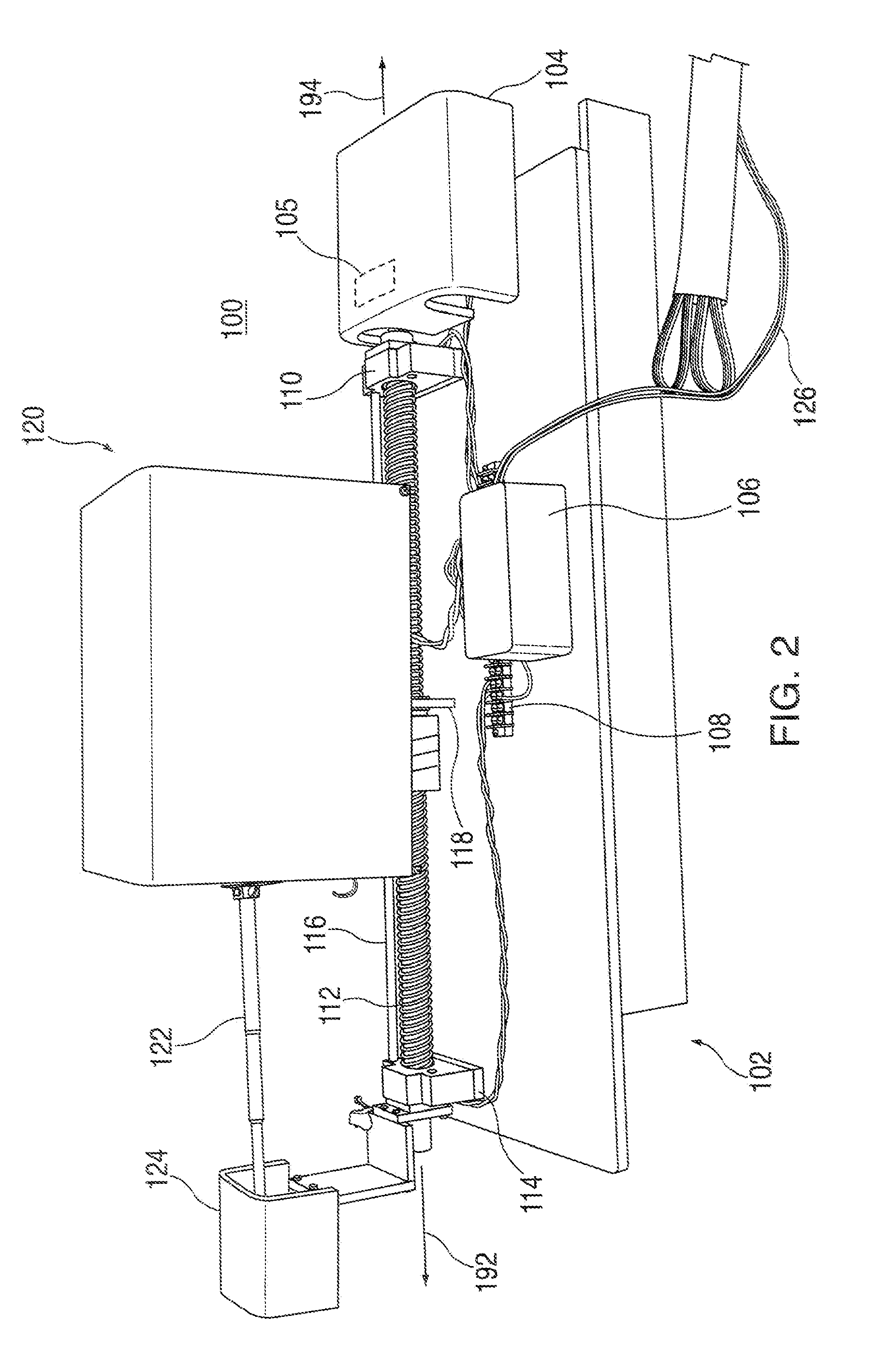

Remotely controlled catheter insertion system

A system for remotely controlling the positioning within the body of a patient of an elongated medical device optionally having a control handle, comprises a robotic system and a remote controller configured to control the robotic device. The robotic system comprises a handle controller; a sled member coupled to the handle controller, the sled member being configured to position the medical device within the body of the patient; and a sled base configured to advance the sled member towards the body of a patient, the sled bed being coupled to a sterile barrier effective to maintain sterility inside the sled base. A medical device introducer is effective to guide the elongated medical device into a patient's body.

Owner:CATHETER PRECISION INC

Remotely controlled catheter insertion system

A remotely controlled insertion system for a medical device is described. The system comprises a robotic device and a remote control mechanism. The robotic device has a handle controller to receive and hold the control handle or proximal end of a medical device. The medical device is capable of moving in up to six ranges of motion. In ione embodiment a first motor is connected through a drive screw to a handle controller to move the medical device forward and backward. A second motor is connected to drive wheels effective to rotate the medical device clockwise and counter-clockwise. A third motor drives a series of gears that are connected to one or more control members on the medical device, this being effective to deflect a tip of the medical device so that movement of the third motor causes such deflection. A control unit is connected to all three motors.

Owner:CATHETER PRECISION INC

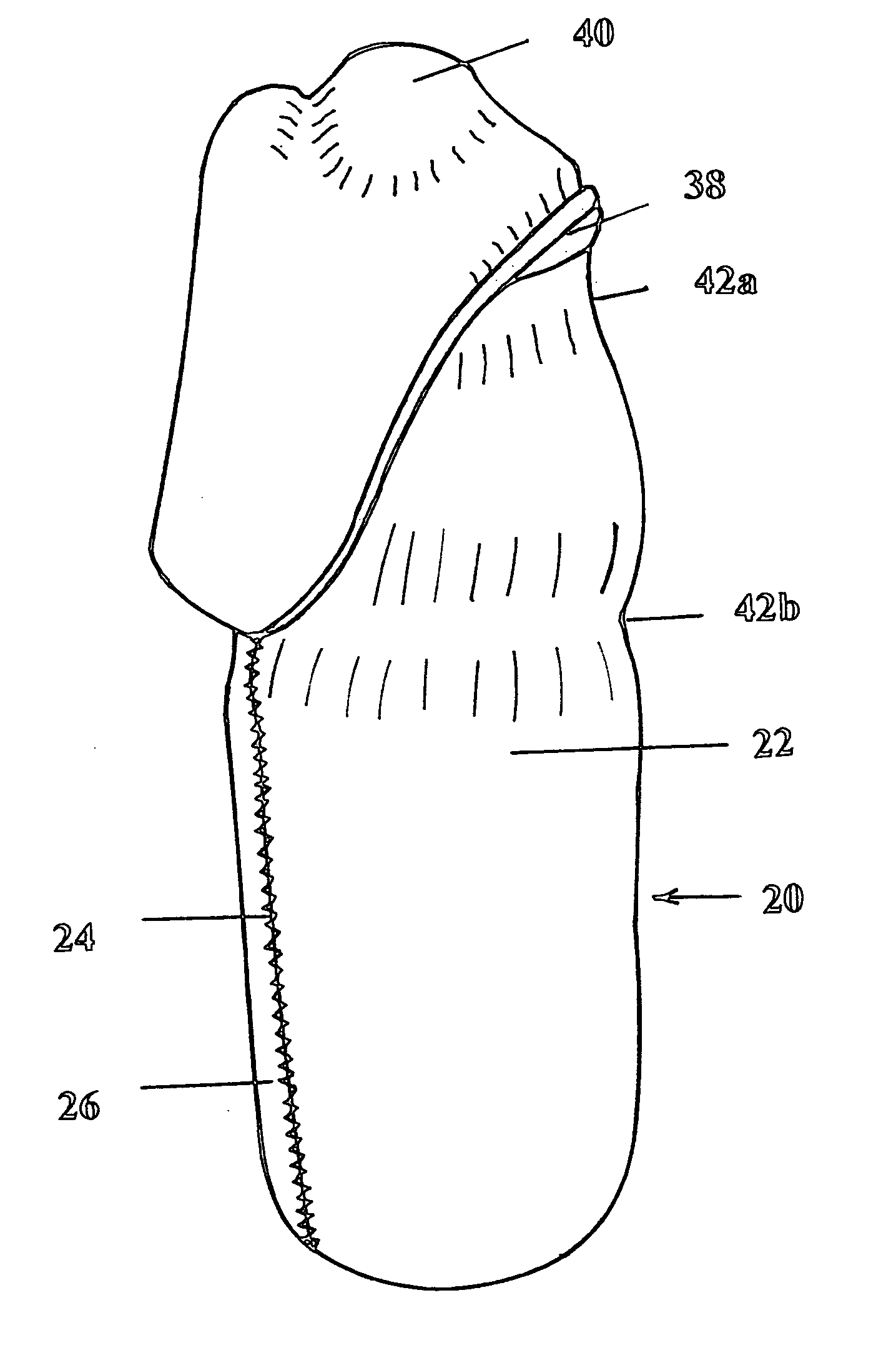

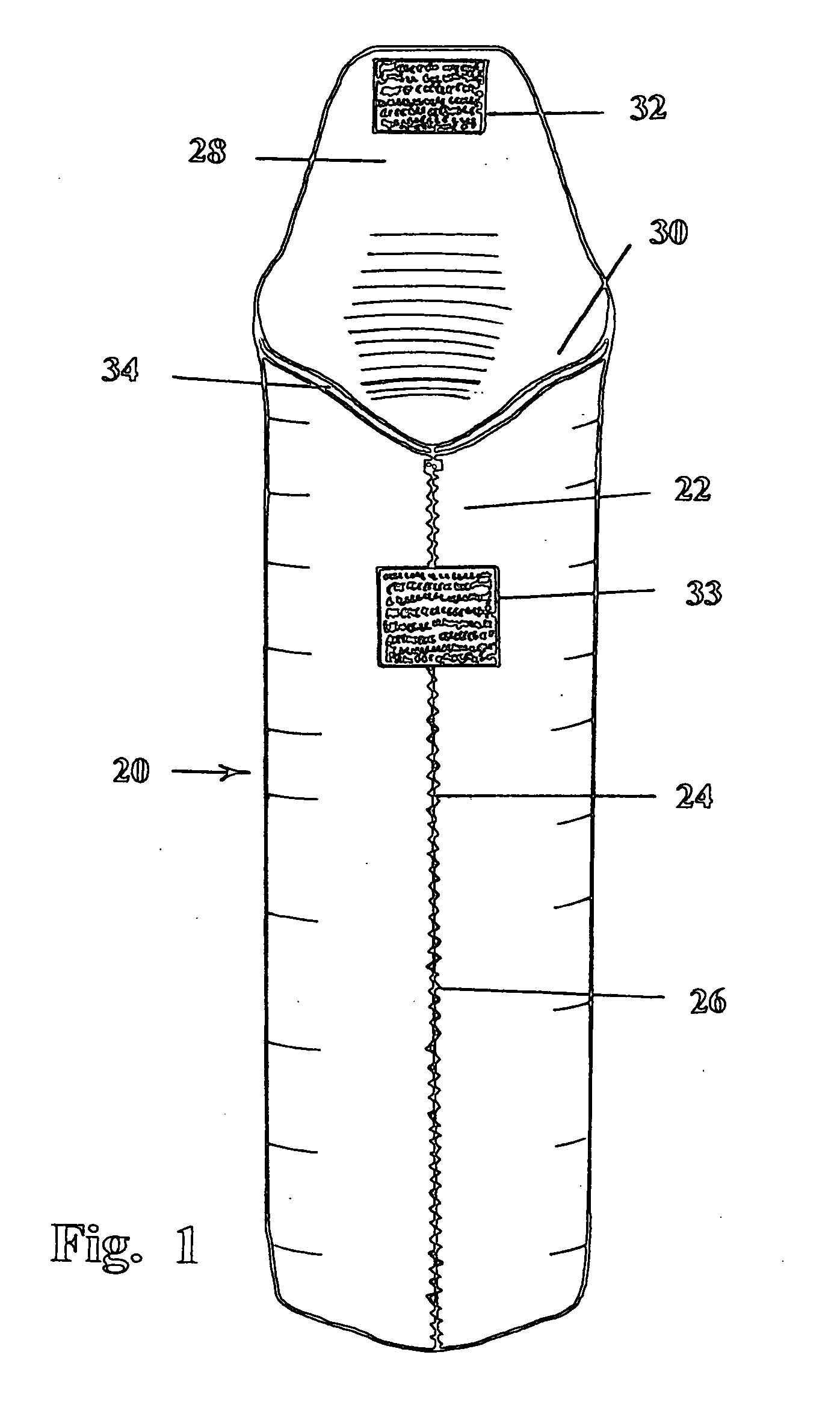

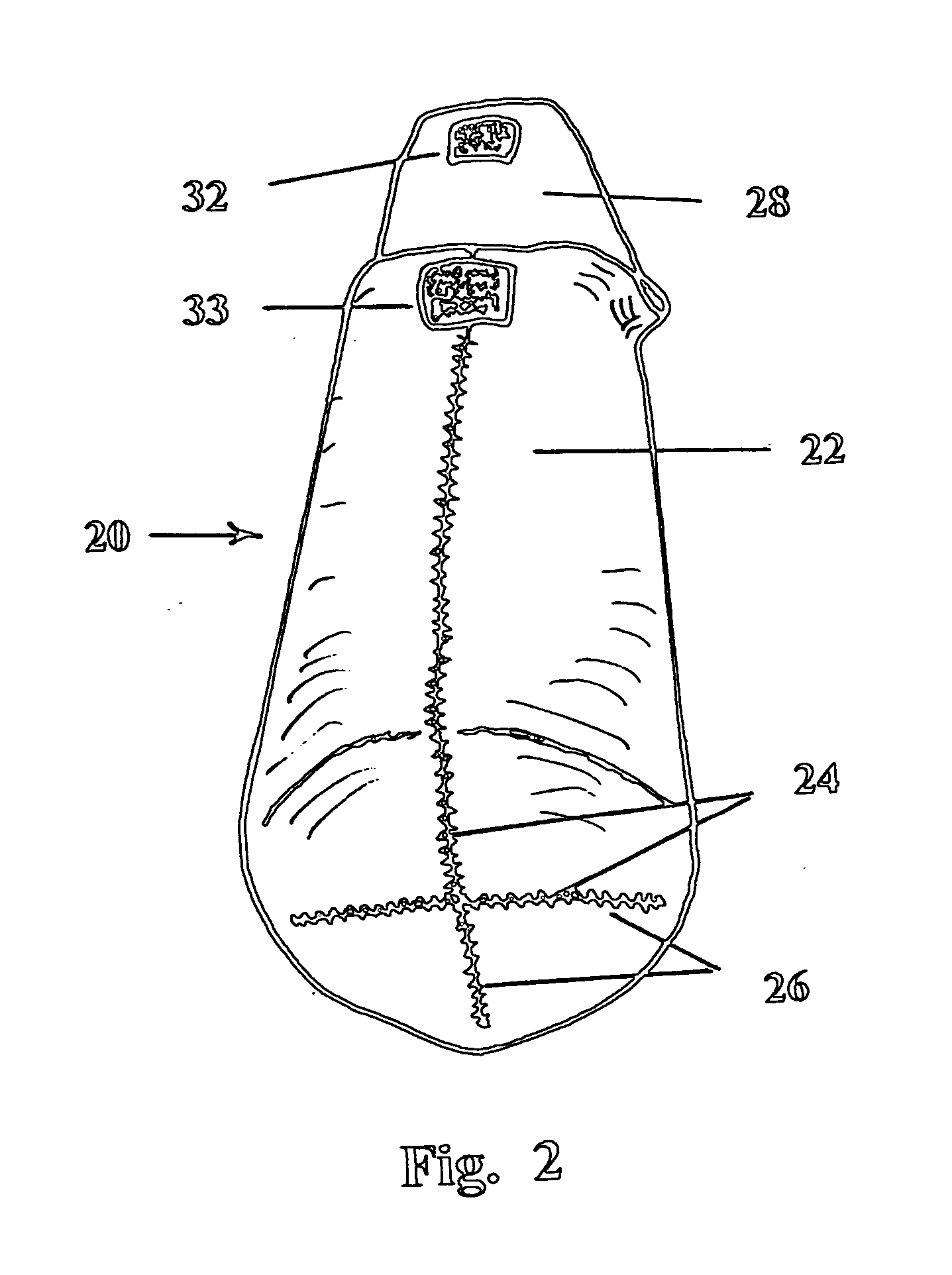

Multi-purpose insulating and protective cover for containers

InactiveUS20070221693A1Easy to modifyHazardous materialTravelling sacksTravelling carriersEngineeringBaby bottle

A unique one piece container cover (20) made from a single blank of flexible insulating material (36) and constructed so the tubular container cover (20) is closed at the bottom and open at the top with a flap (28) that when pulled over the enclosed container (39), integrally forms a complete seal (38) with the cover body (22) thus encapsulating the container (39) providing insulation to keep the container (39) contents either hot or cold while also protecting container (39) from outside contamination. The container cover (20) works with various sizes and shapes of bottles, containers or cans. The multipurpose cover (20) can be used without attachments for use in a bike cage, diaper bag, travel bag or the like. The cover (20) can also be fitted with various attachments for hiking, running, backpacking, golf, carrying baby bottles or the like. The cover (20) is efficient, cost effective, lightweight, durable, easy to use and clean, and can be produced in many colors with graphics.

Owner:MOORE HOWARD LEE

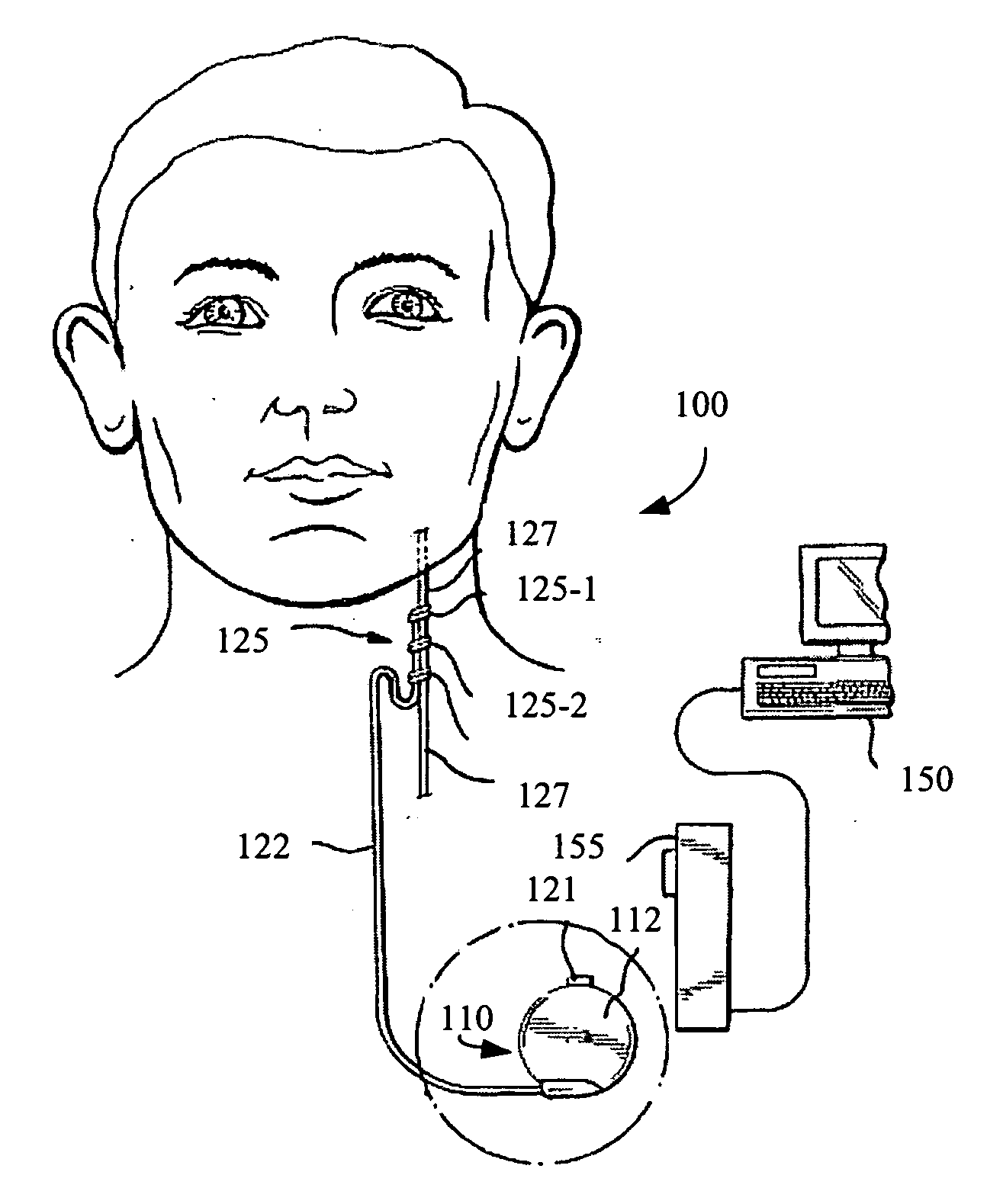

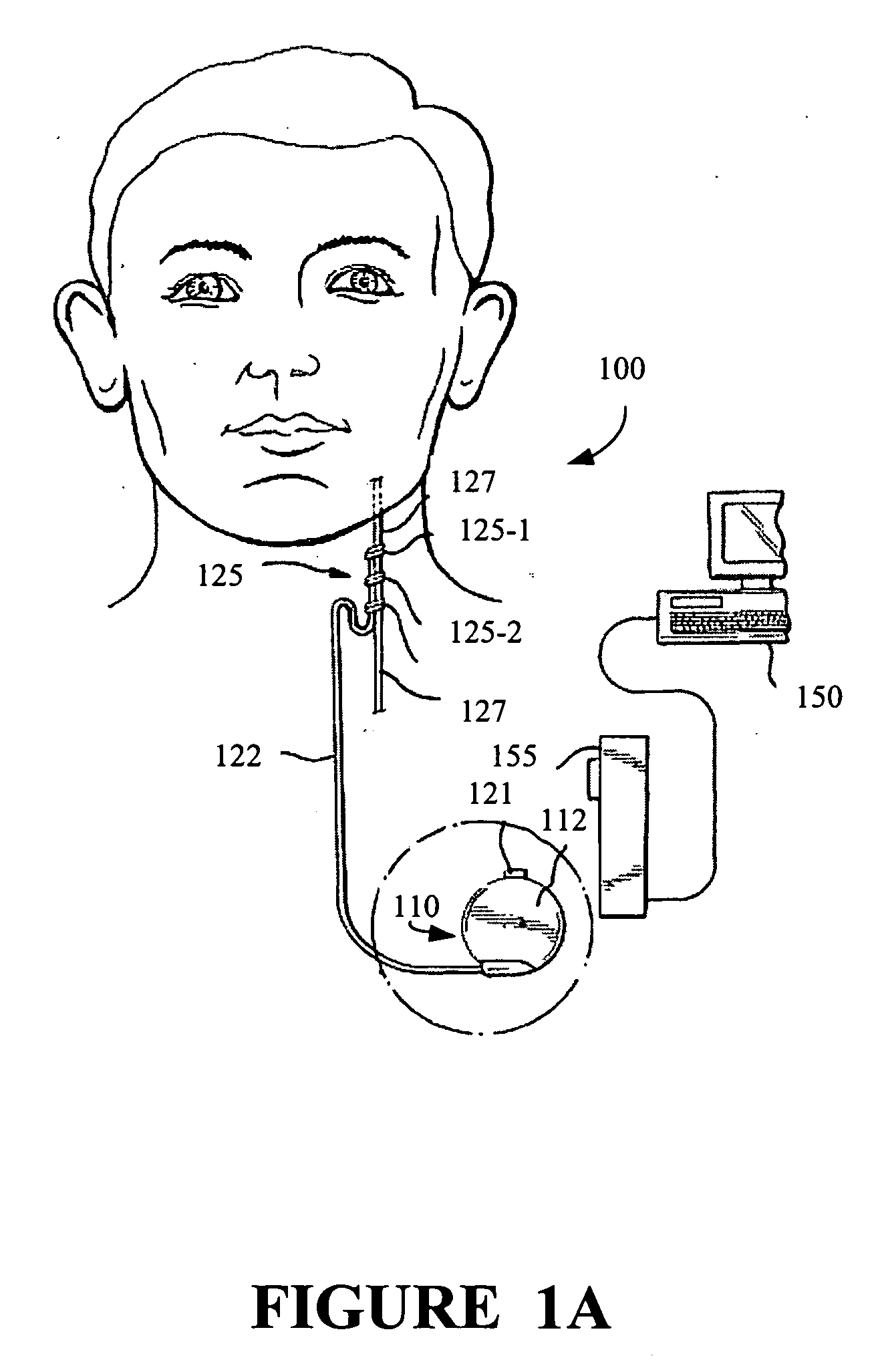

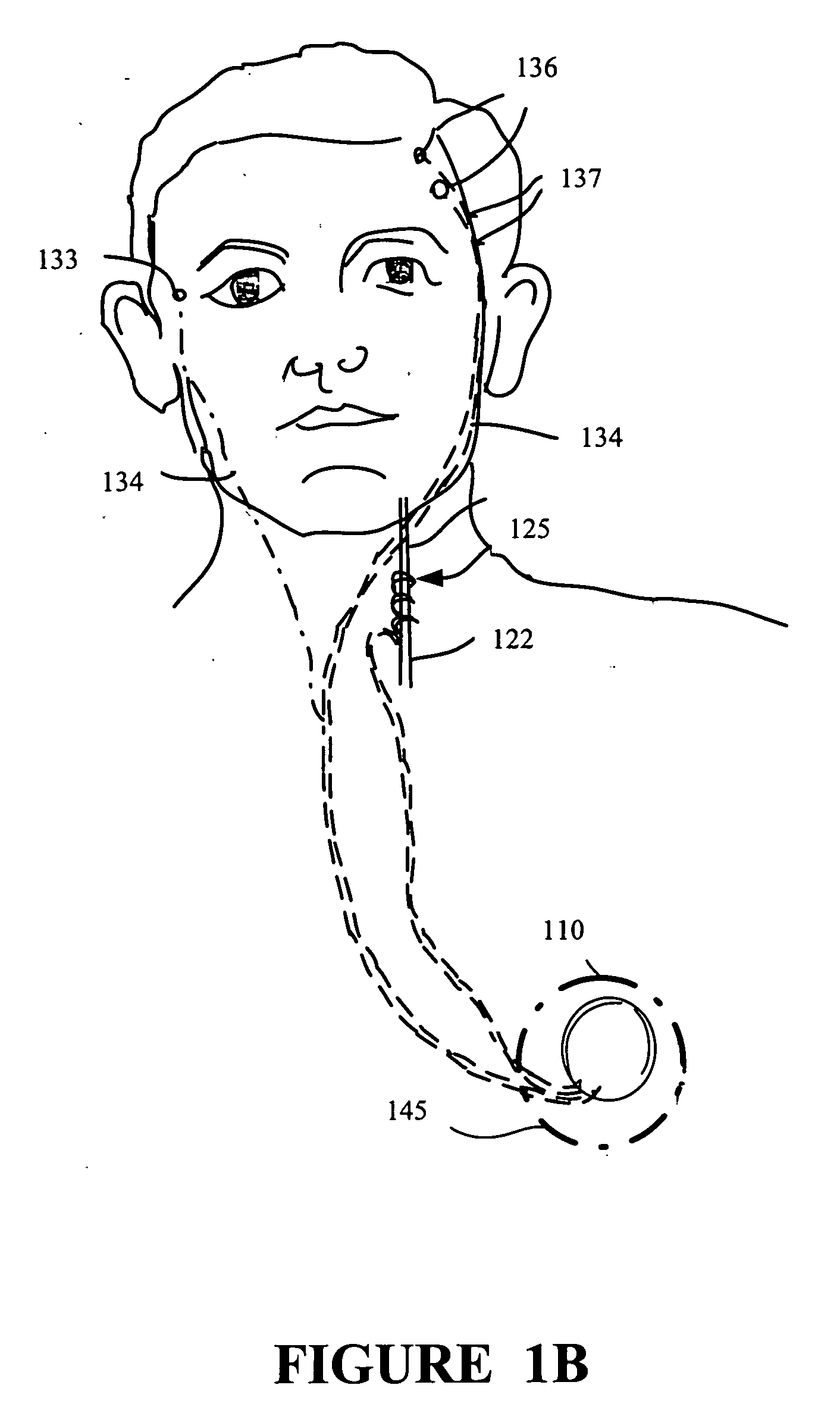

Method and apparatus for forming insulated implantable electrodes

A method, system, and an apparatus are provided for insulating an electrode implanted in a body of a patient. The method comprises surgically exposing a nerve of the patient, implanting at least one electrode in the body of the patient, wherein the implanting comprises coupling theat least one electrode to the nerve of the patient, providing a mold form, disposing the mold form around at least a portion of the at least one electrode and the nerve, introducing into the mold form a curable liquid insulant, allowing the curable liquid insulant to cure, removing the mold form from around the at least one electrode and from the patient's body, and surgically closing the exposure of the nerve.

Owner:LIVANOVA USA INC

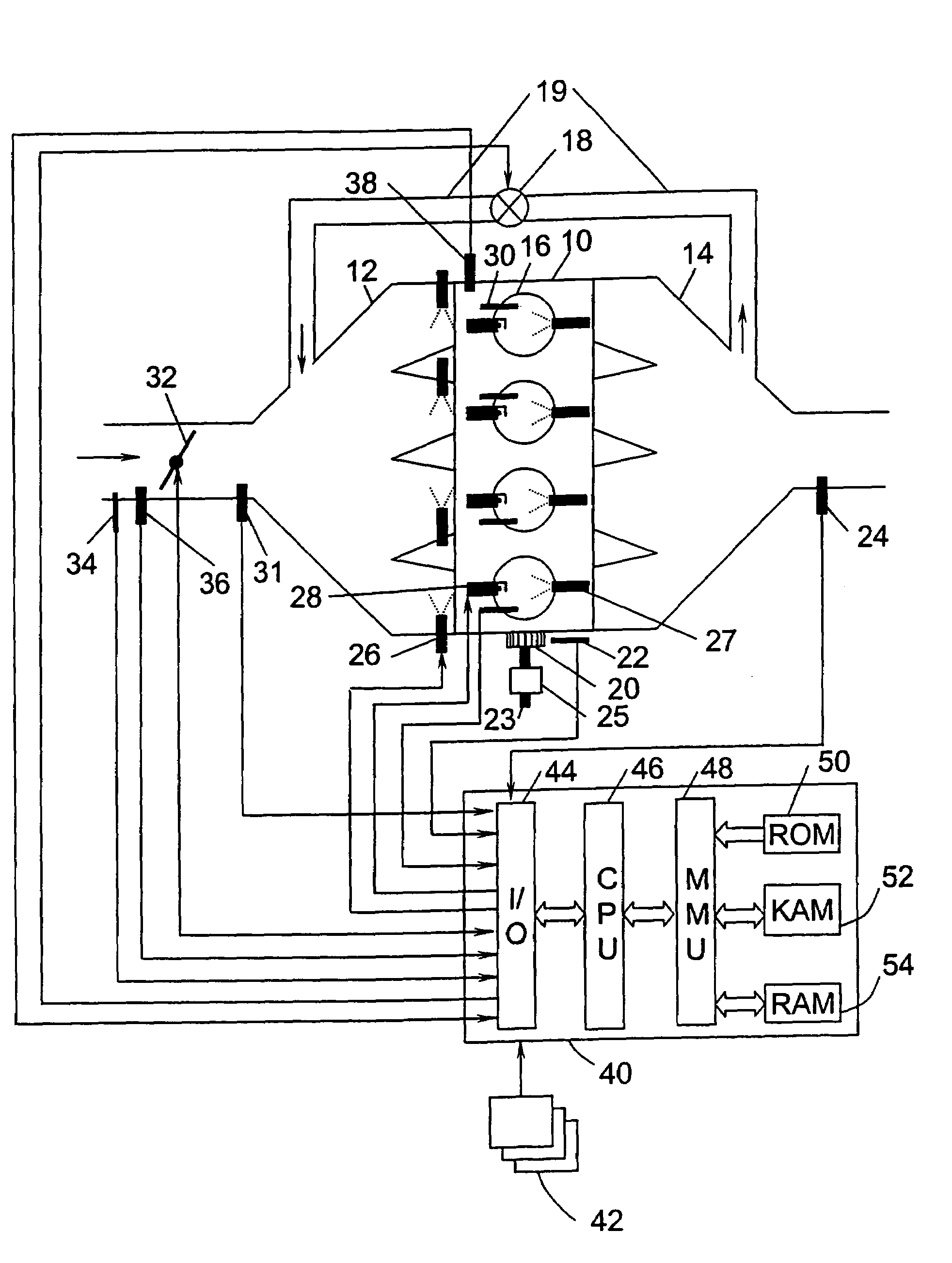

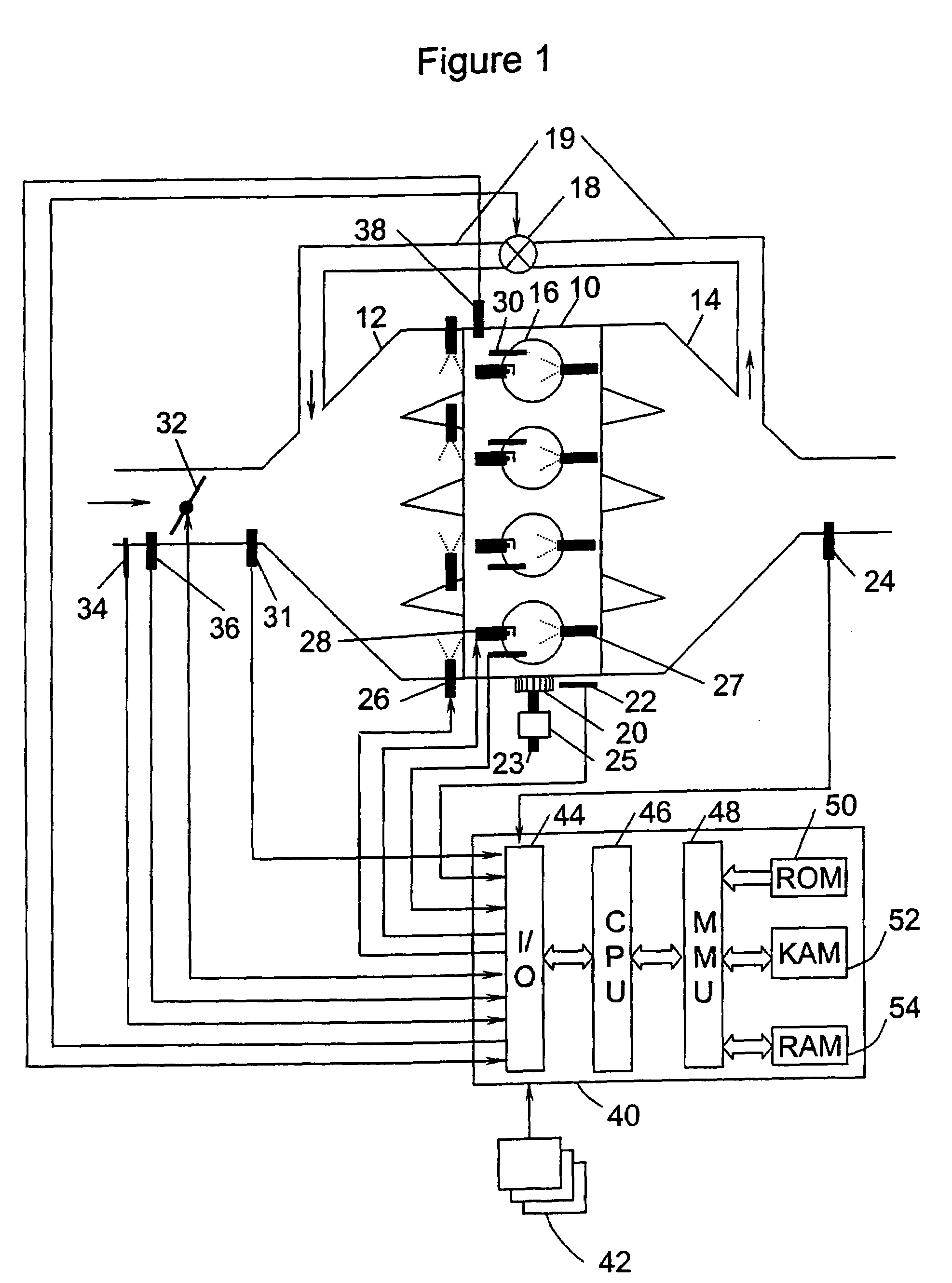

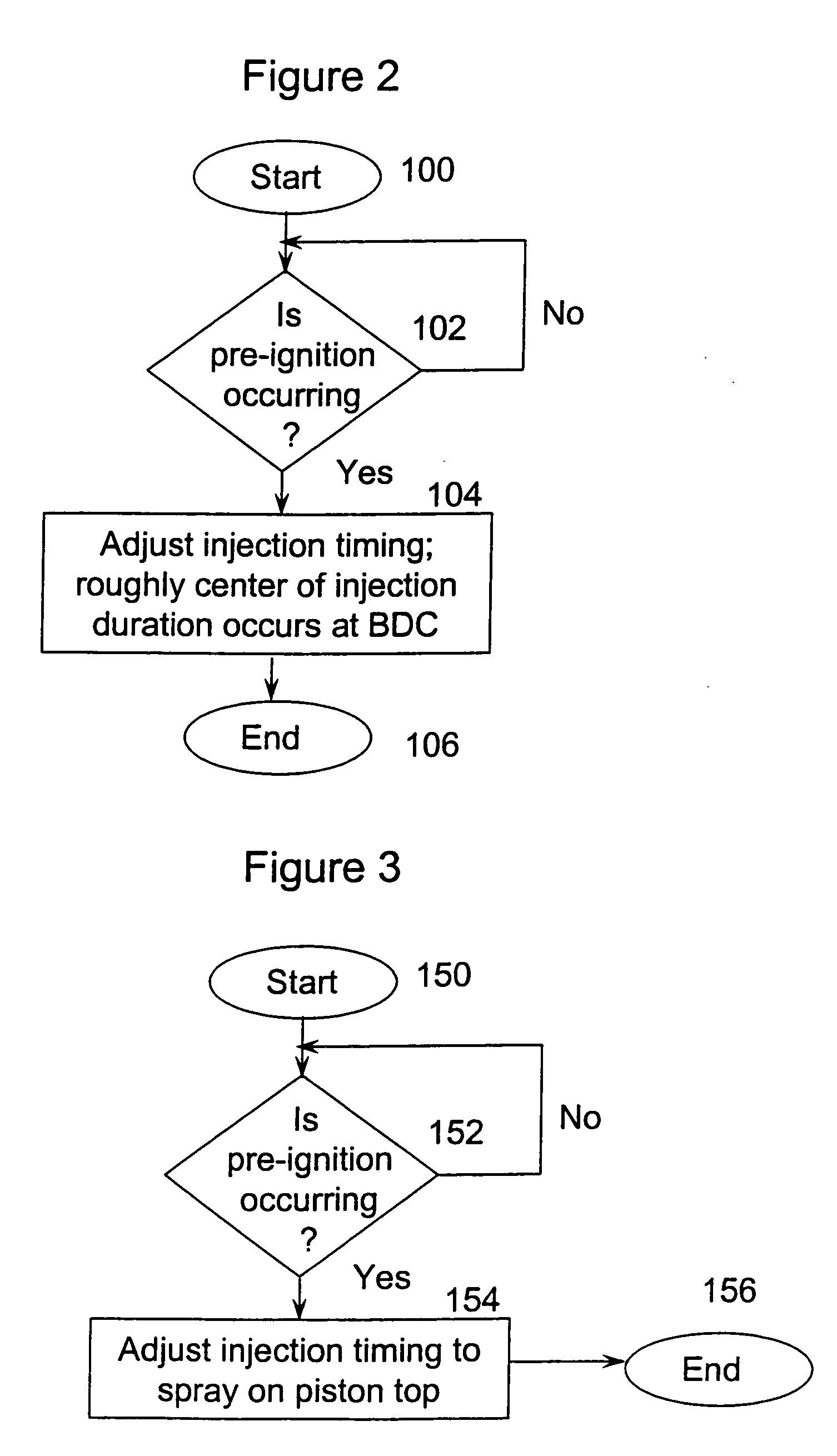

System and method to pre-ignition in an internal combustion engine

ActiveUS7178503B1Mitigate pre-ignitionReduce air densityAnalogue computers for vehiclesElectrical controlCombustion chamberAlcohol fuel

An engine system and method are disclosed for controlling pre-ignition of an alcohol fuel. In one embodiment, the fuel injection timing is adjusted to cause the fuel to avoid combustion chamber surfaces. In another embodiment, the fuel injection timing is adjusted to spray the fuel directly onto the piston surface to cool the piston. Also disclosed is a cylinder cleaning cycle in which engine knock is purposely caused for one to hundreds of engine cycles by adjusting the fuel content away from alcohol toward gasoline. Further measures to cause knock which are disclosed: adjusting spark timing, intake boost, exhaust gas fraction in the cylinder, cam timing, and transmission gear ratio.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com