Patents

Literature

5226 results about "Contact layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact Layers. Contact layer dressings are thin, non-adherent sheets placed on an open wound bed to protect tissue from direct contact with other agents or dressings applied to the wound. They conform to the shape of the wound and are porous to allow exudate to pass through for absorption by an overlying, secondary dressing.

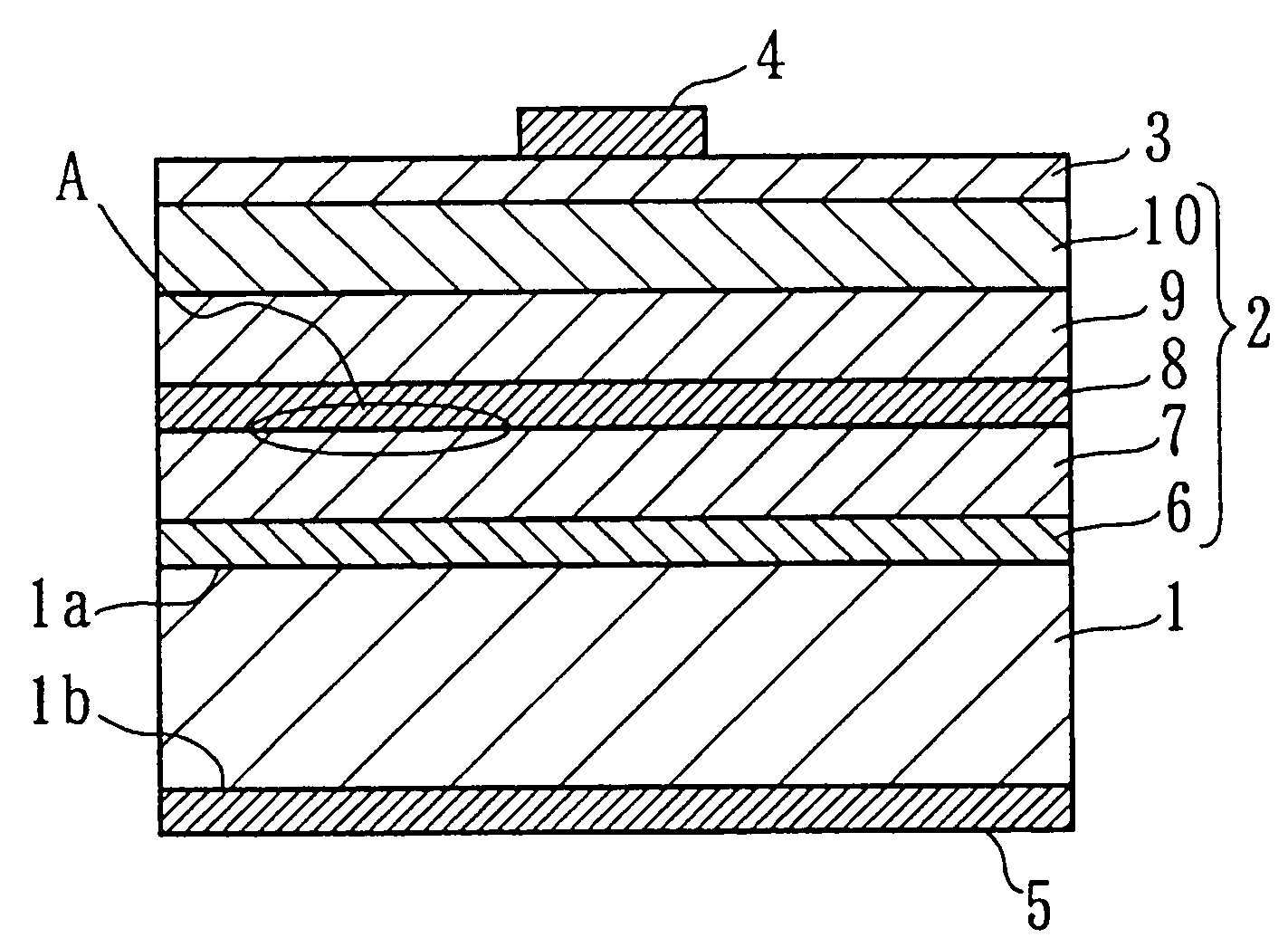

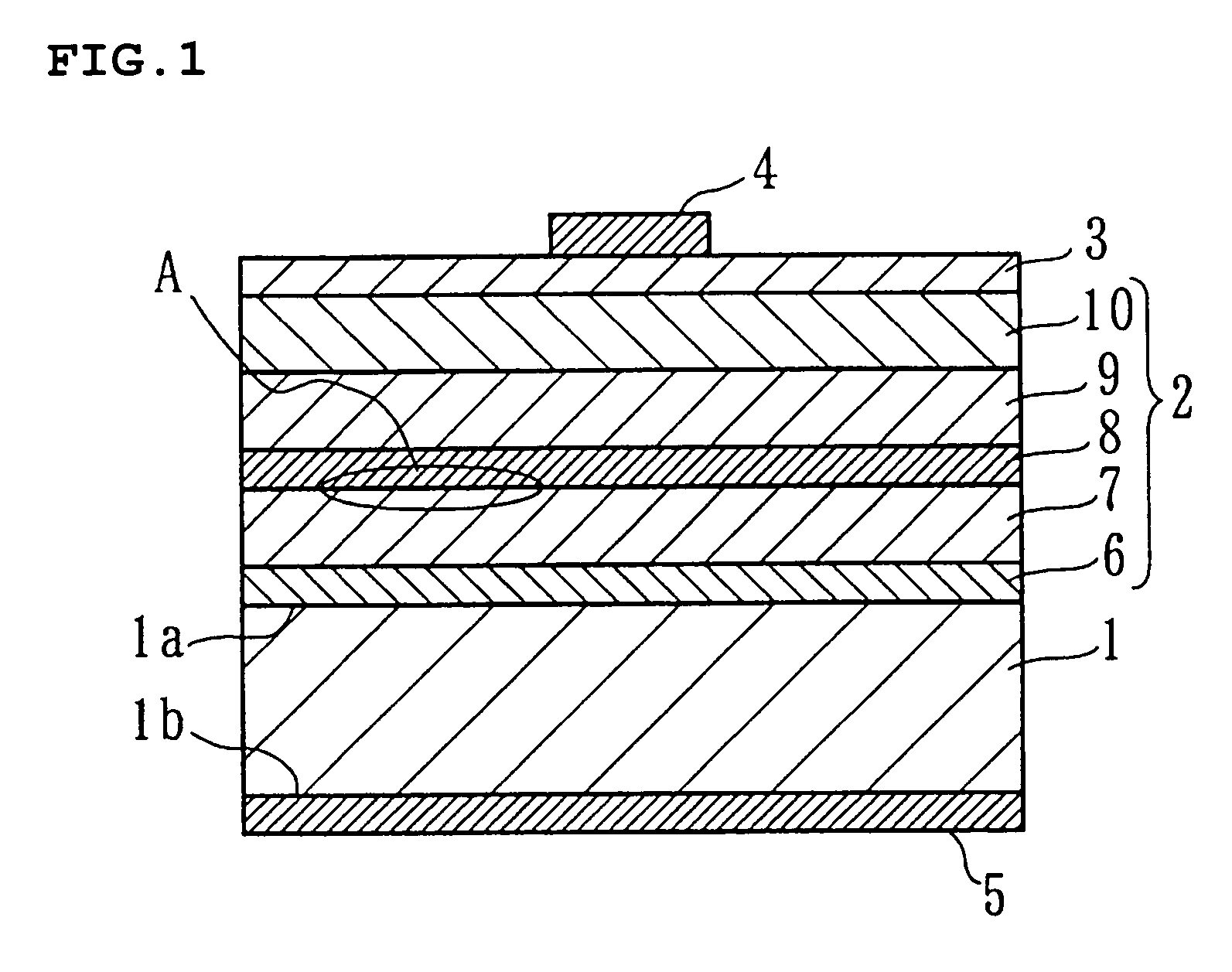

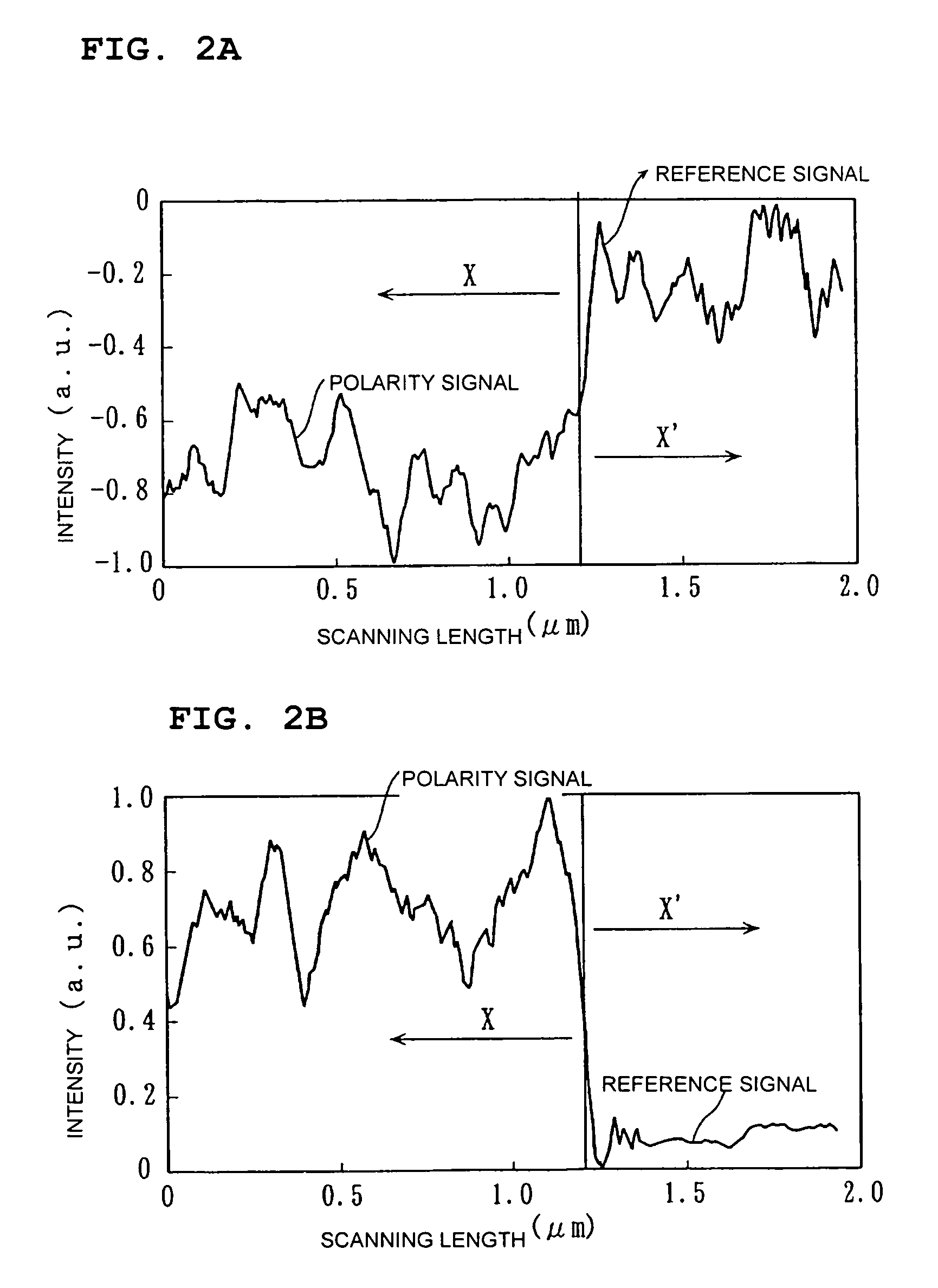

Semiconductor device in which zinc oxide is used as a semiconductor material and method for manufacturing the semiconductor device

ActiveUS7501293B2Improve surface smoothnessHigh crystallinityTransistorLaser detailsSemiconductor materialsDevice material

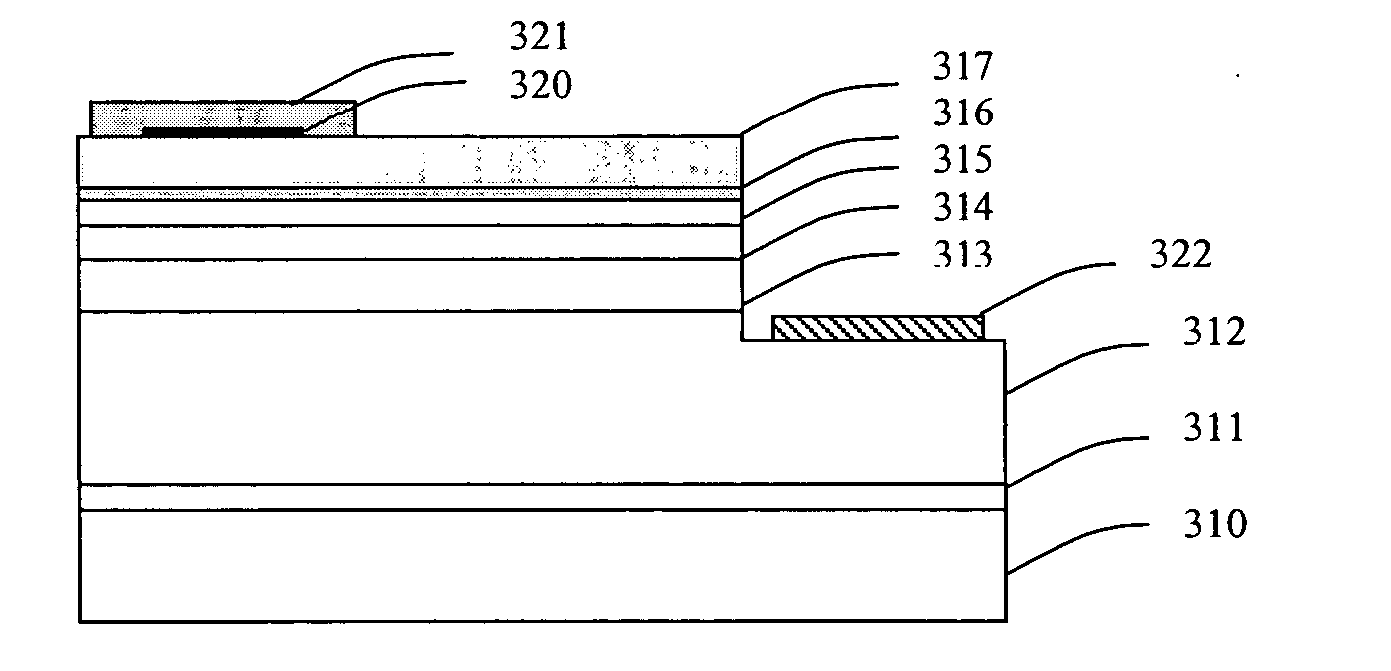

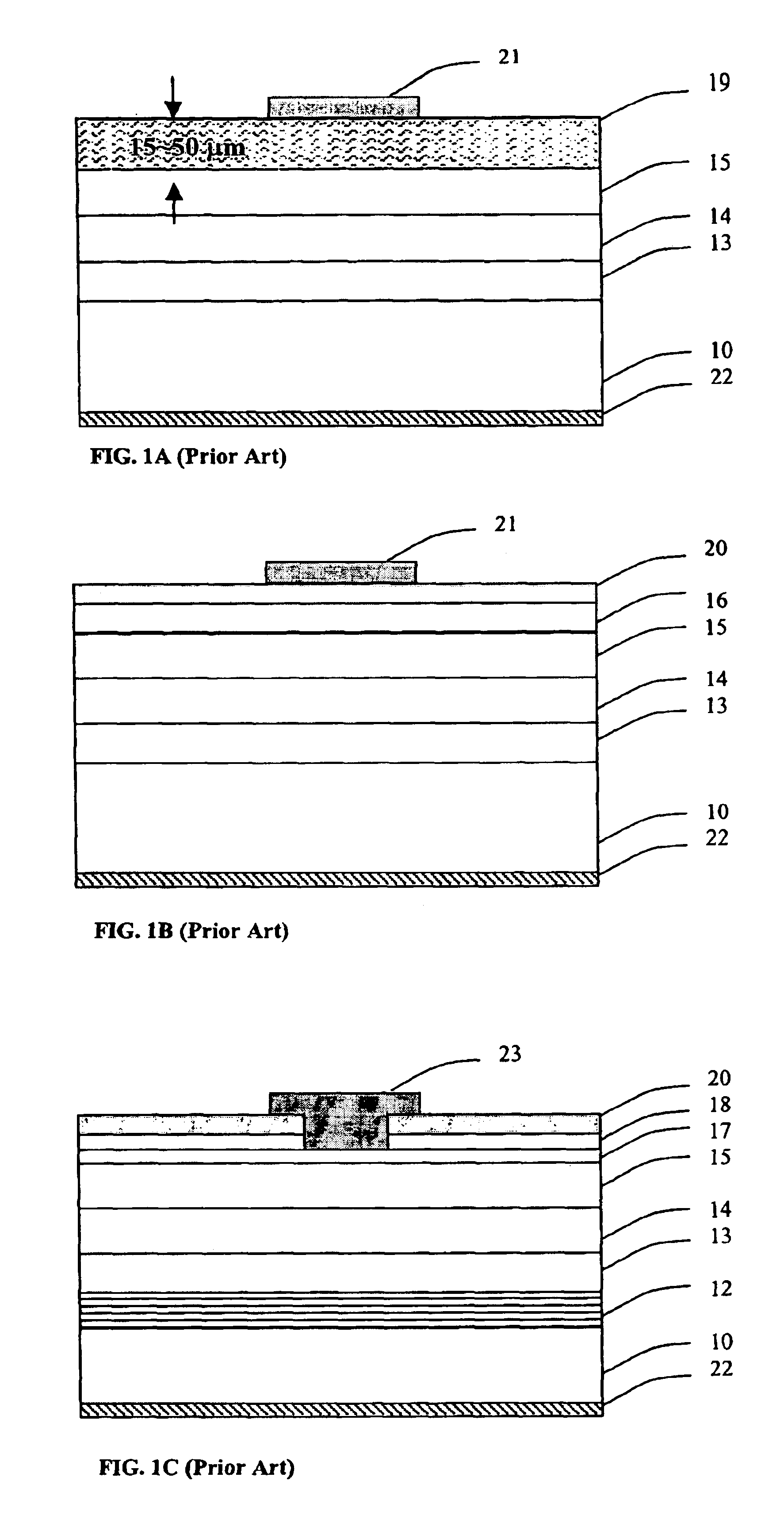

A semiconductor device having excellent crystallinity and excellent electric characteristics includes a ZnO thin film having excellent surface smoothness. ZnO-based thin films (an n-type contact layer, an n-type clad layer, an active layer, a p-type clad layer, and a p-type contact layer) primarily including ZnO are formed sequentially by an ECR sputtering method or other suitable method on a zinc-polar surface of a ZnO substrate. A transparent electrode and a p-side electrode are formed by an evaporation method or other suitable method on a surface of the p-type contact layer, and an n-side electrode is formed on an oxygen-polar surface of the ZnO substrate.

Owner:MURATA MFG CO LTD

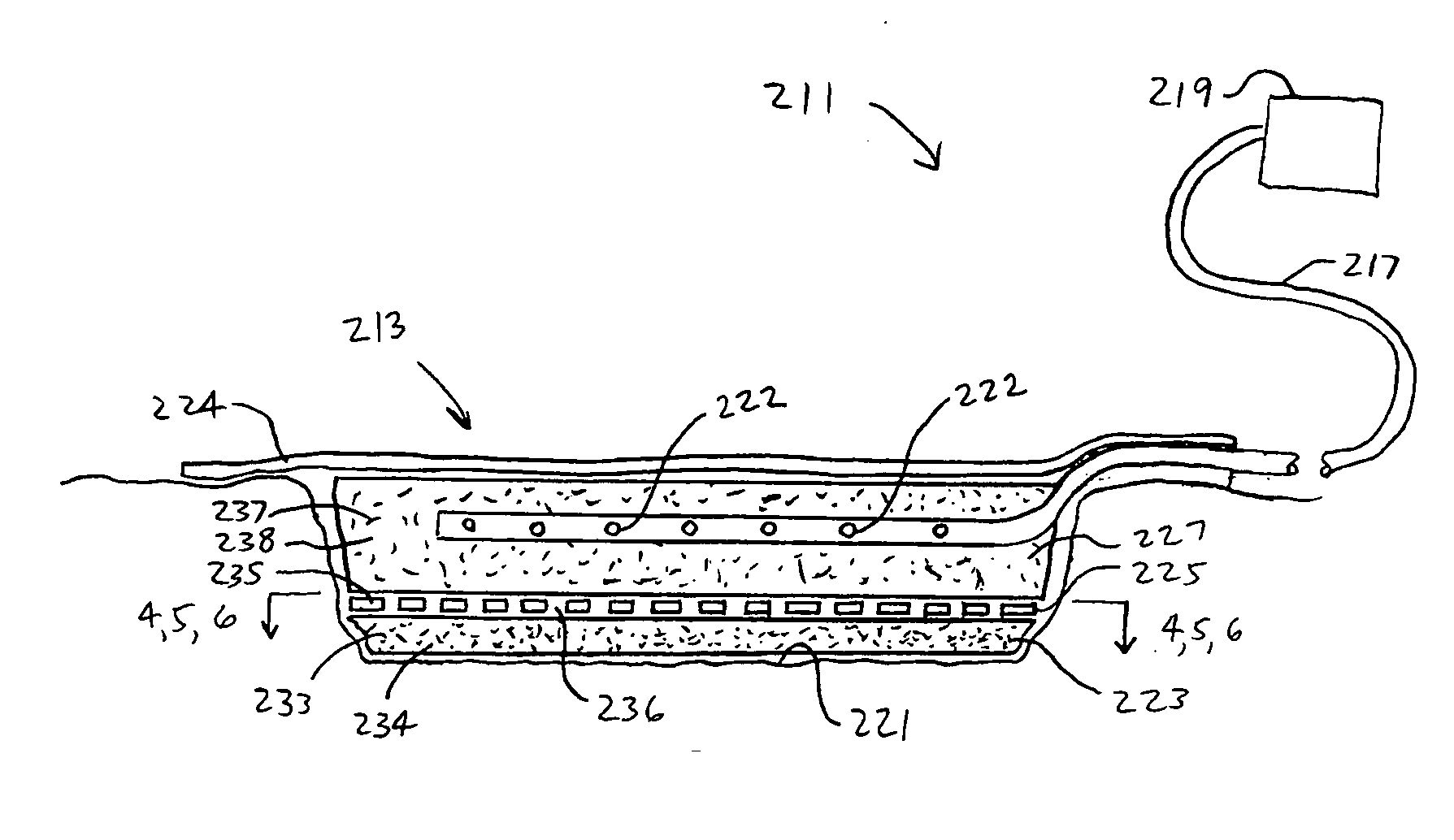

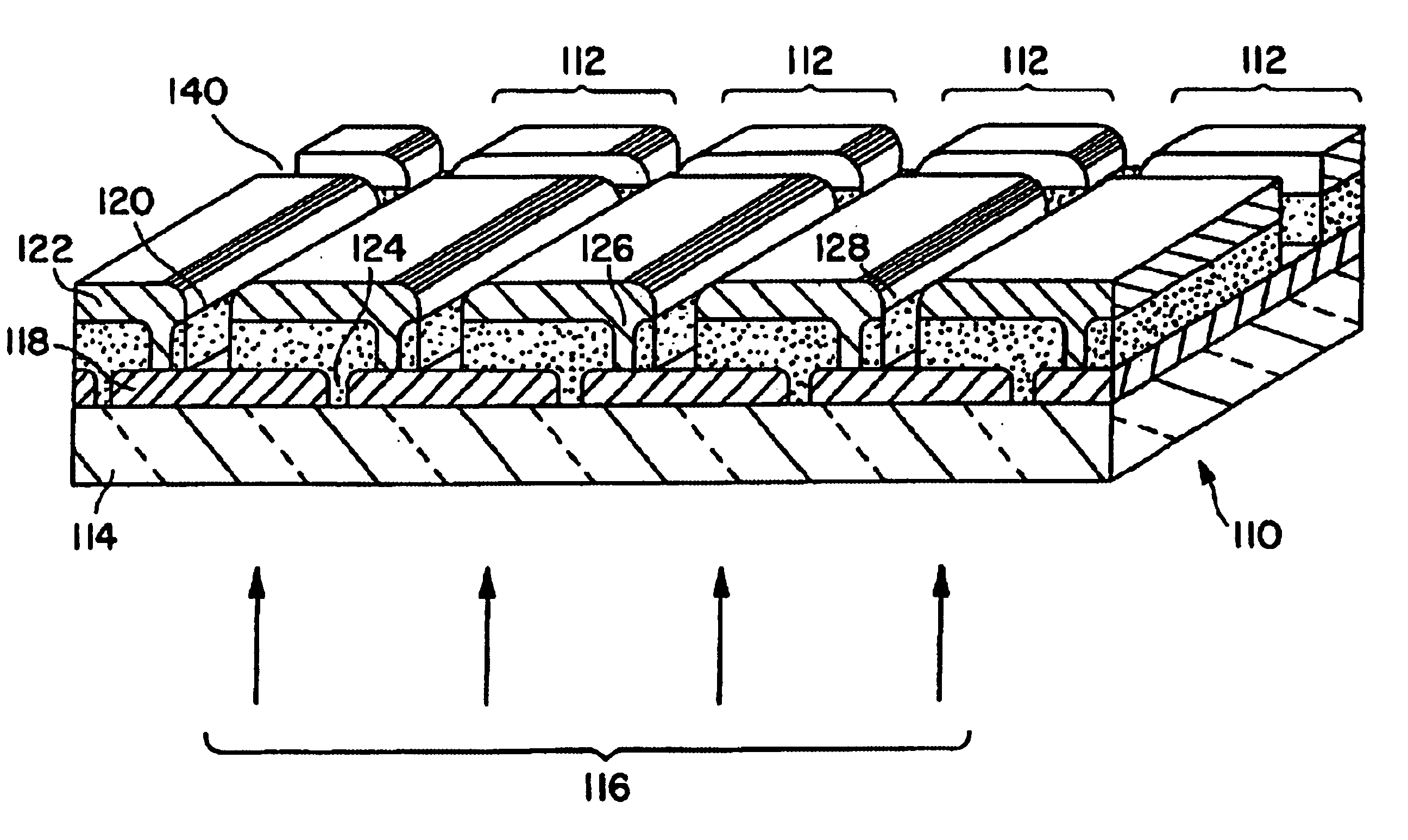

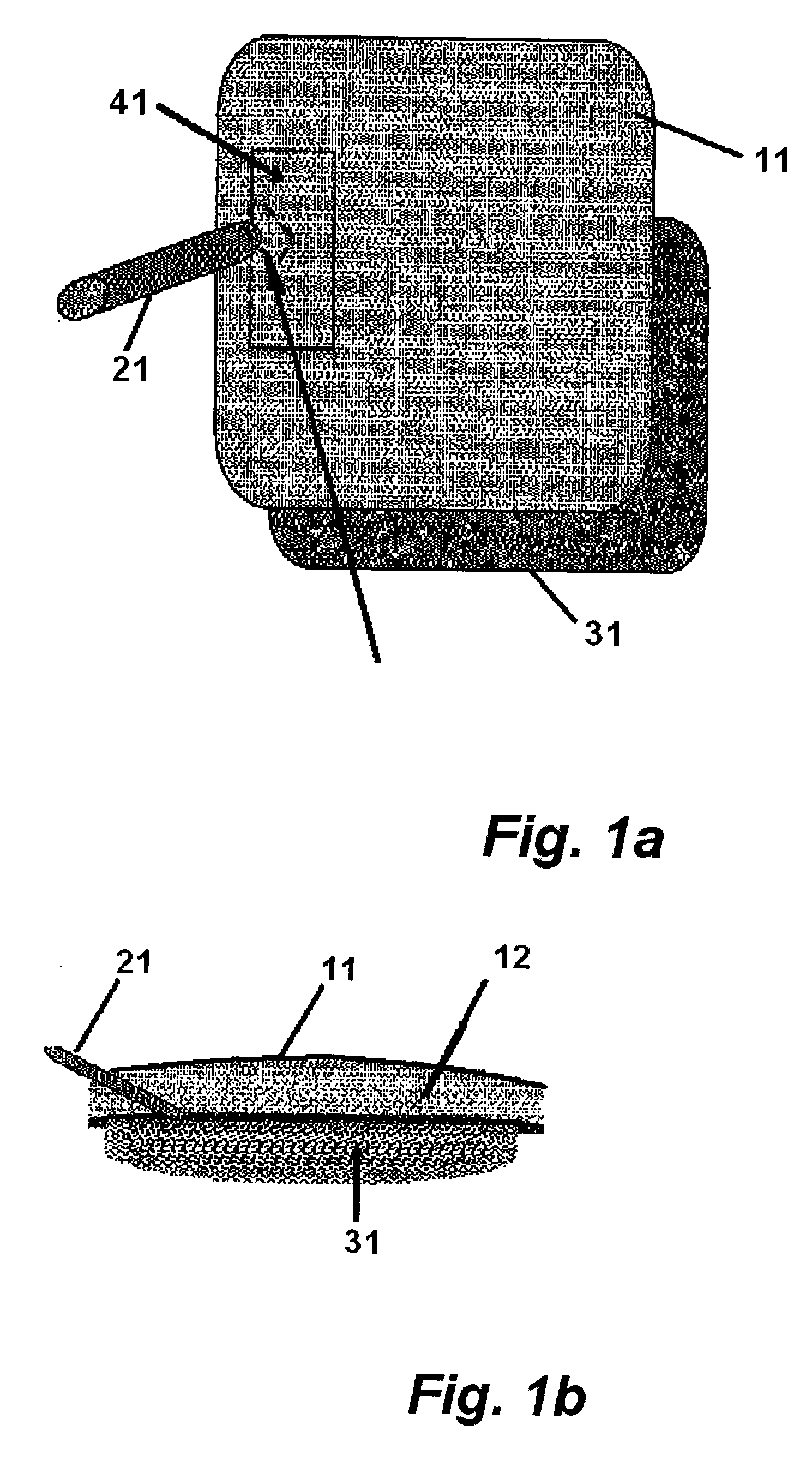

Biocompatible wound dressing

InactiveUS20070185426A1Reduce pressureReduced tissue treatmentNon-adhesive dressingsAdhesive dressingsWound dressingContact layer

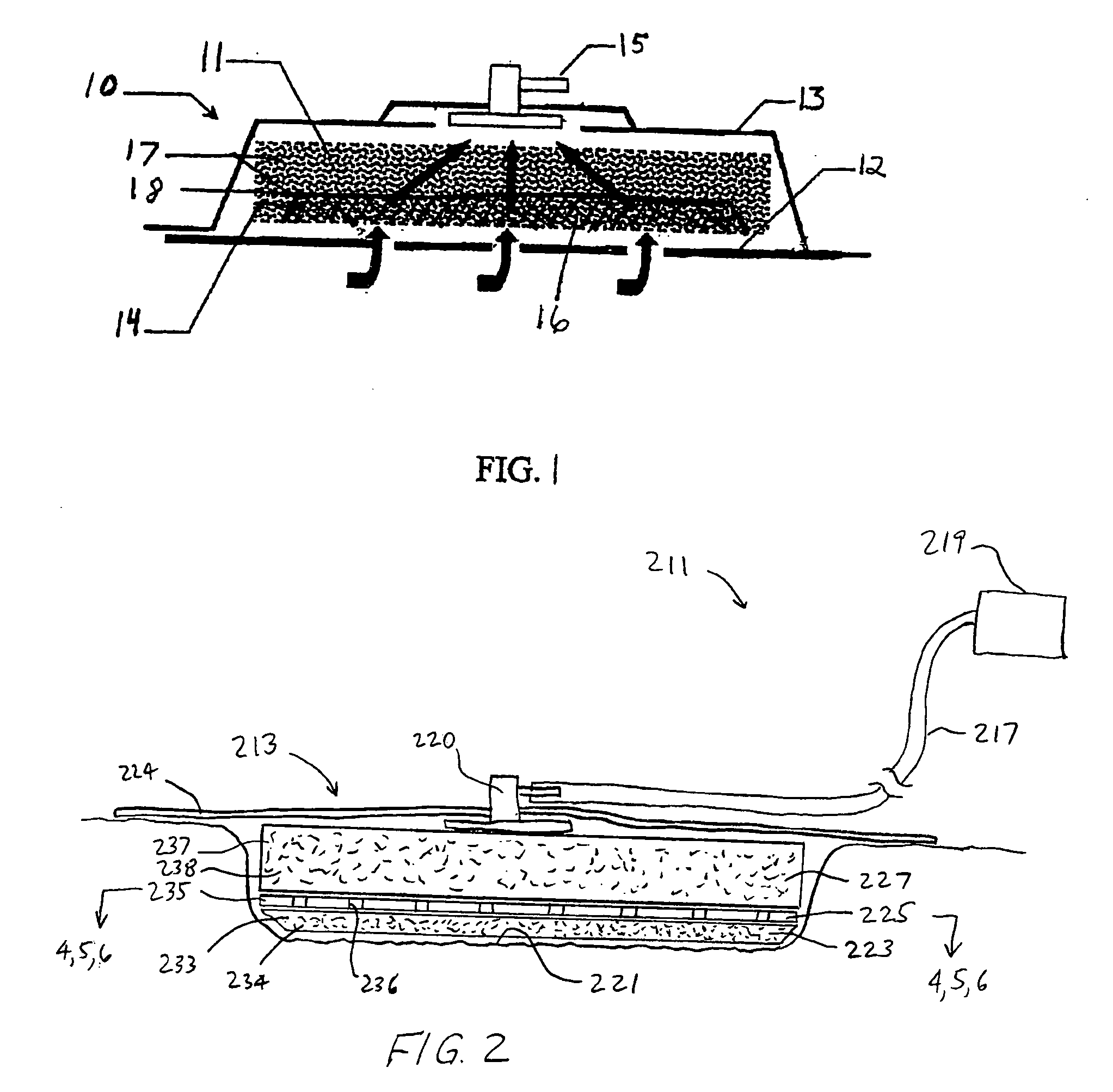

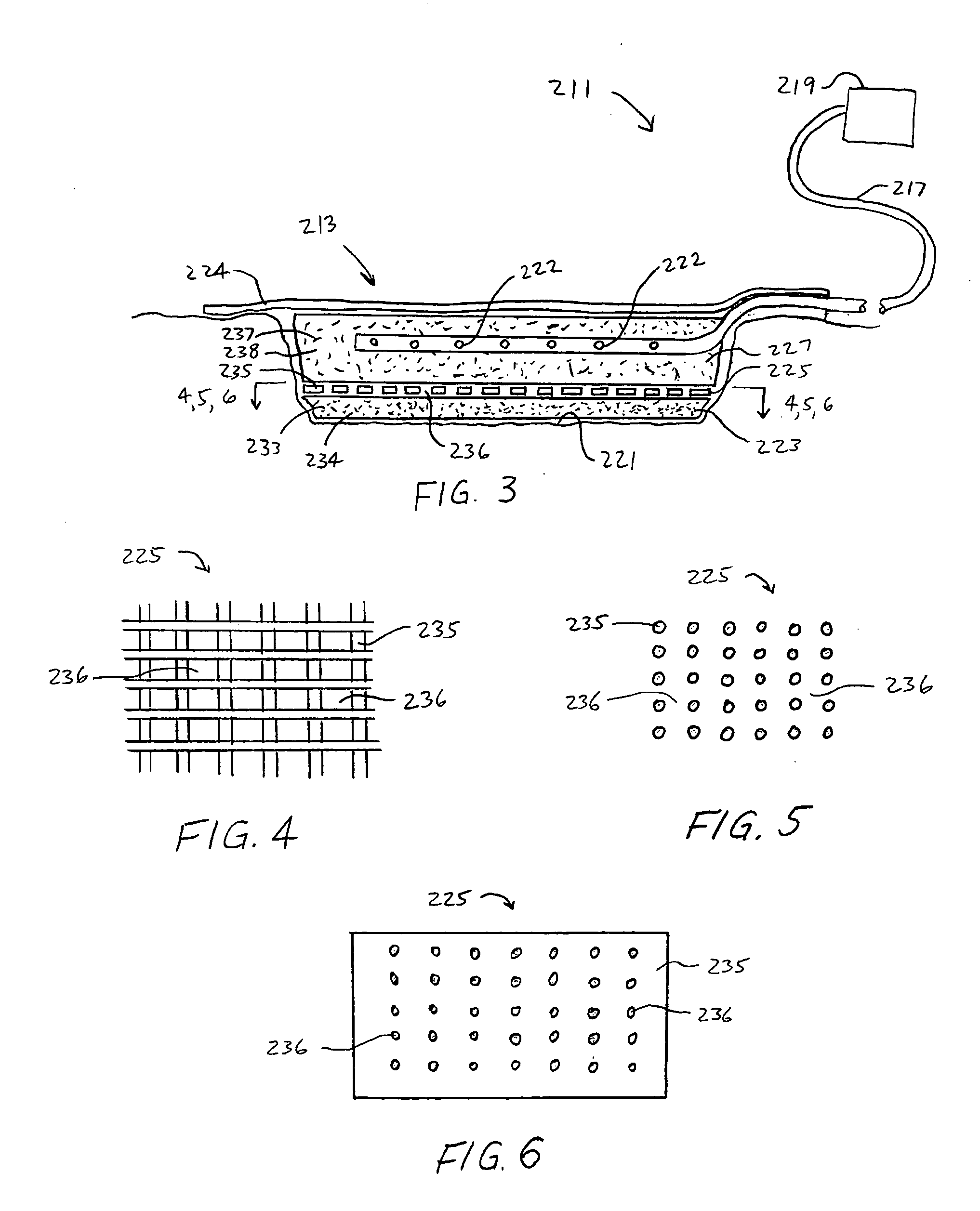

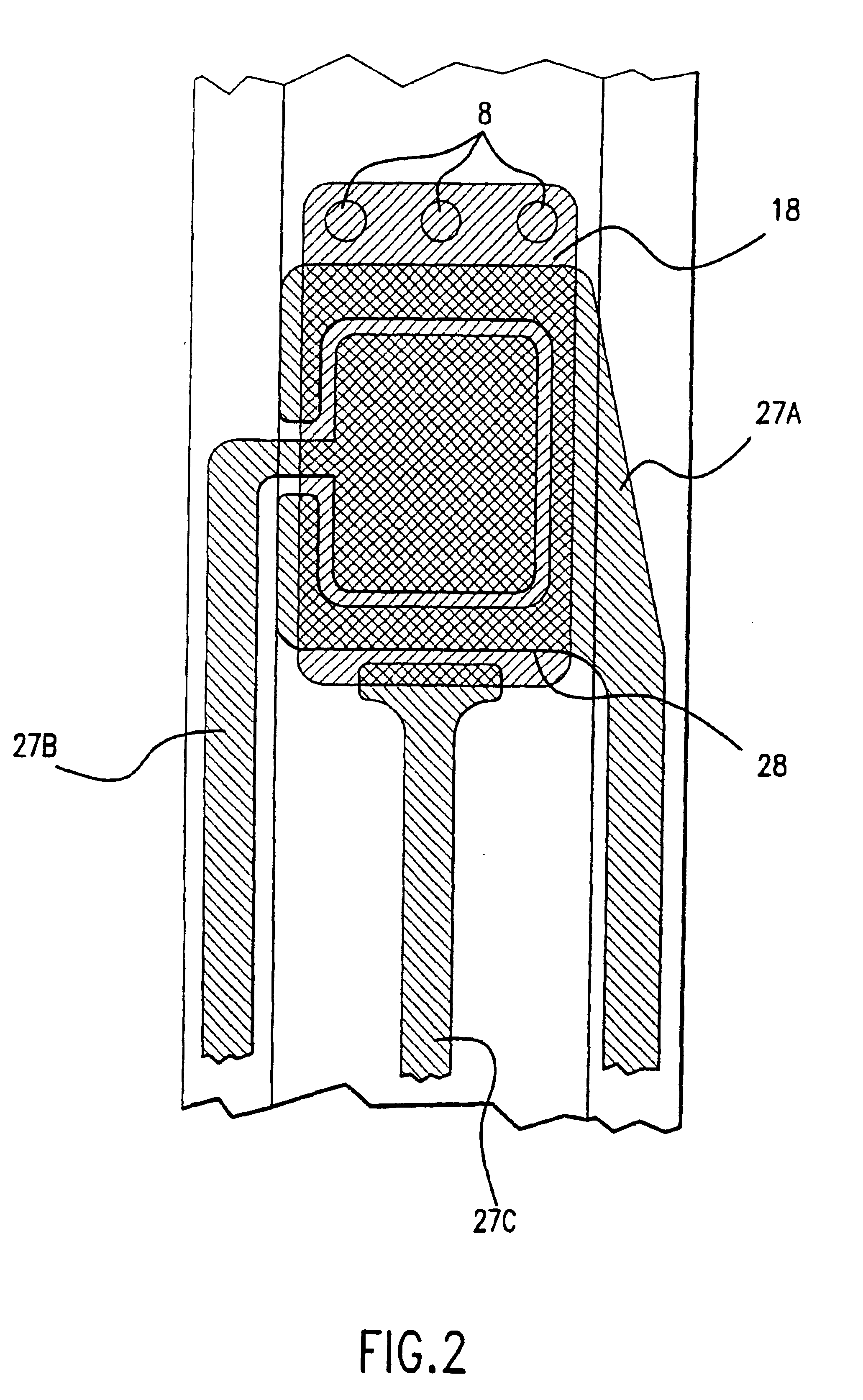

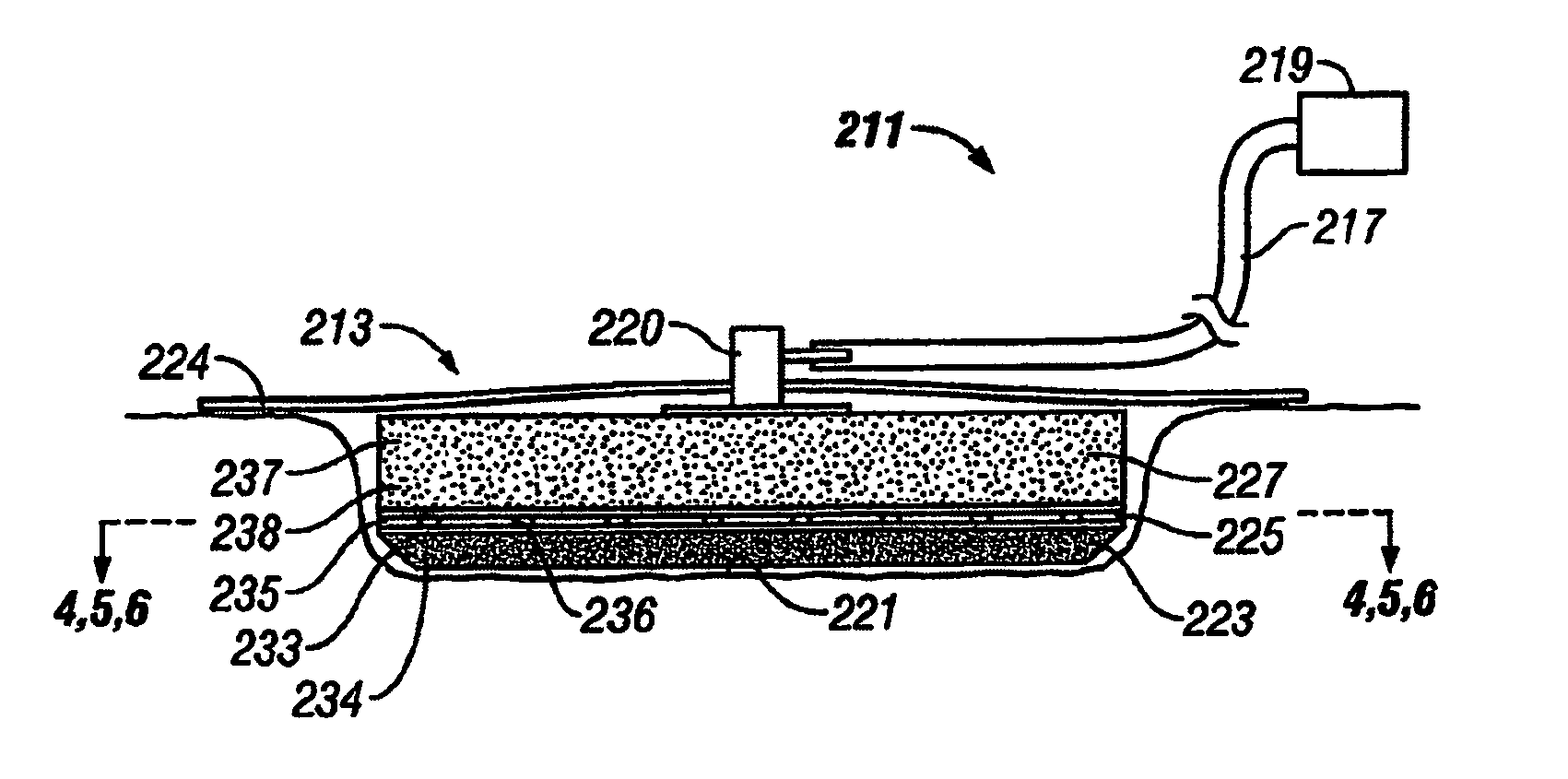

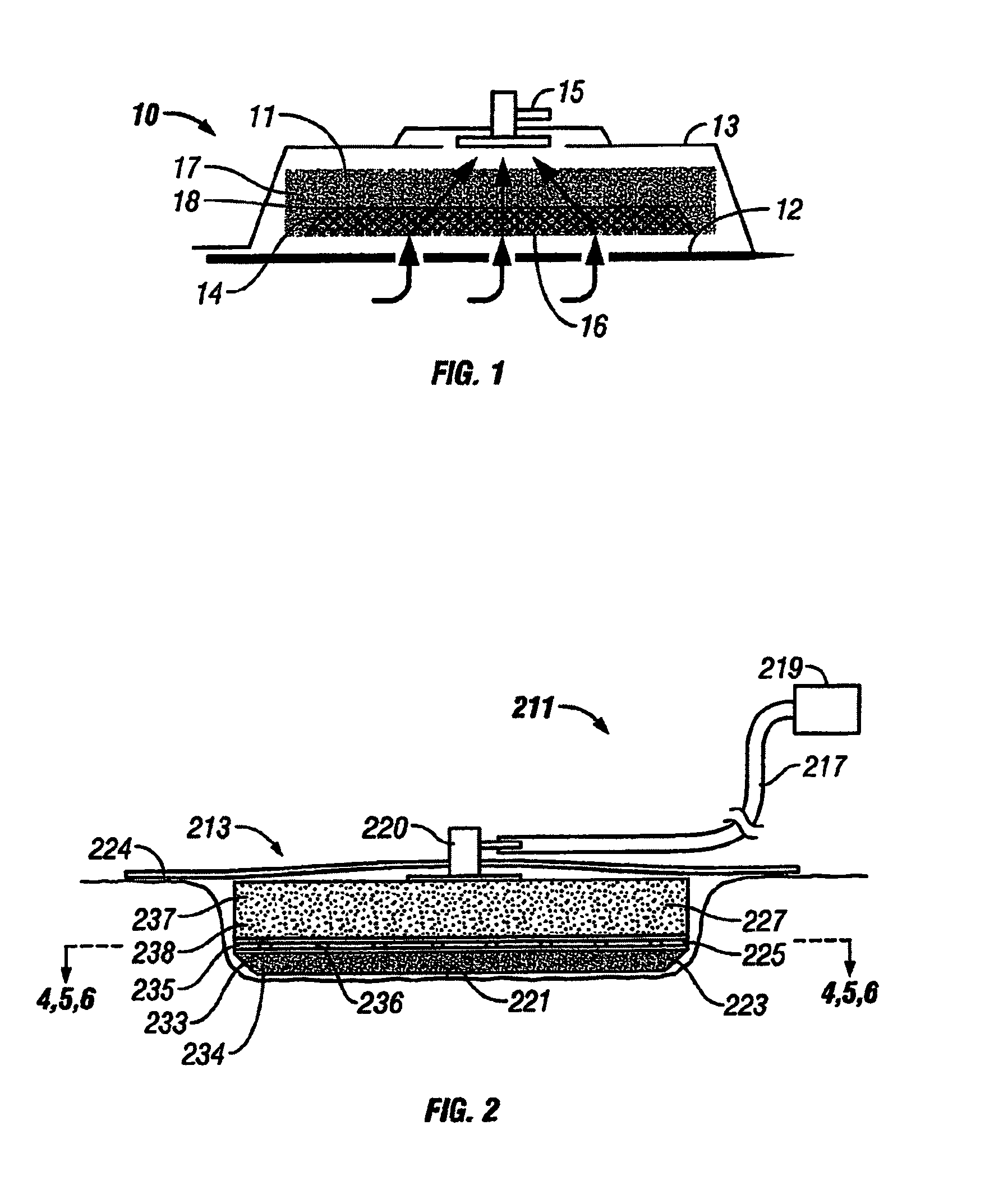

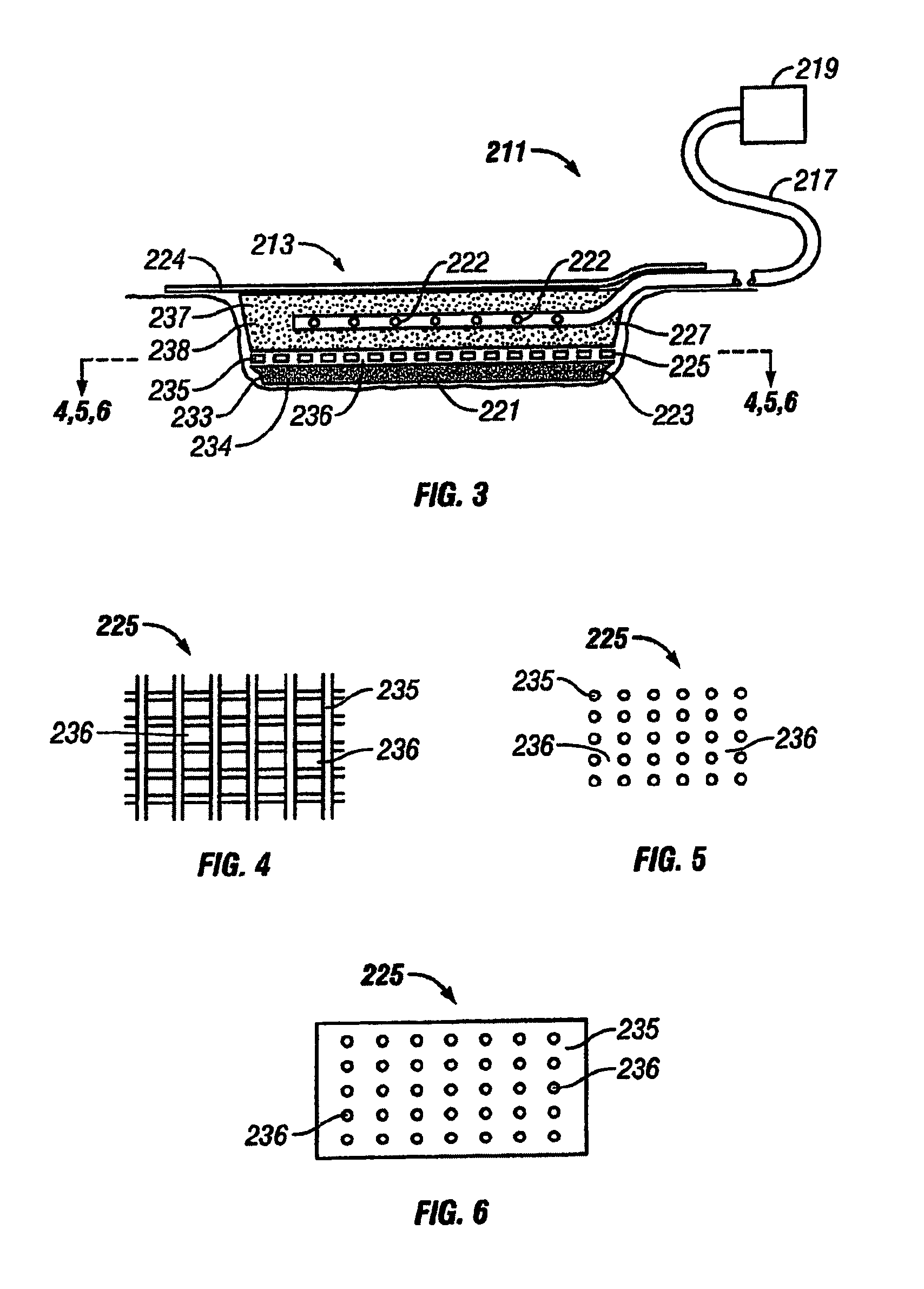

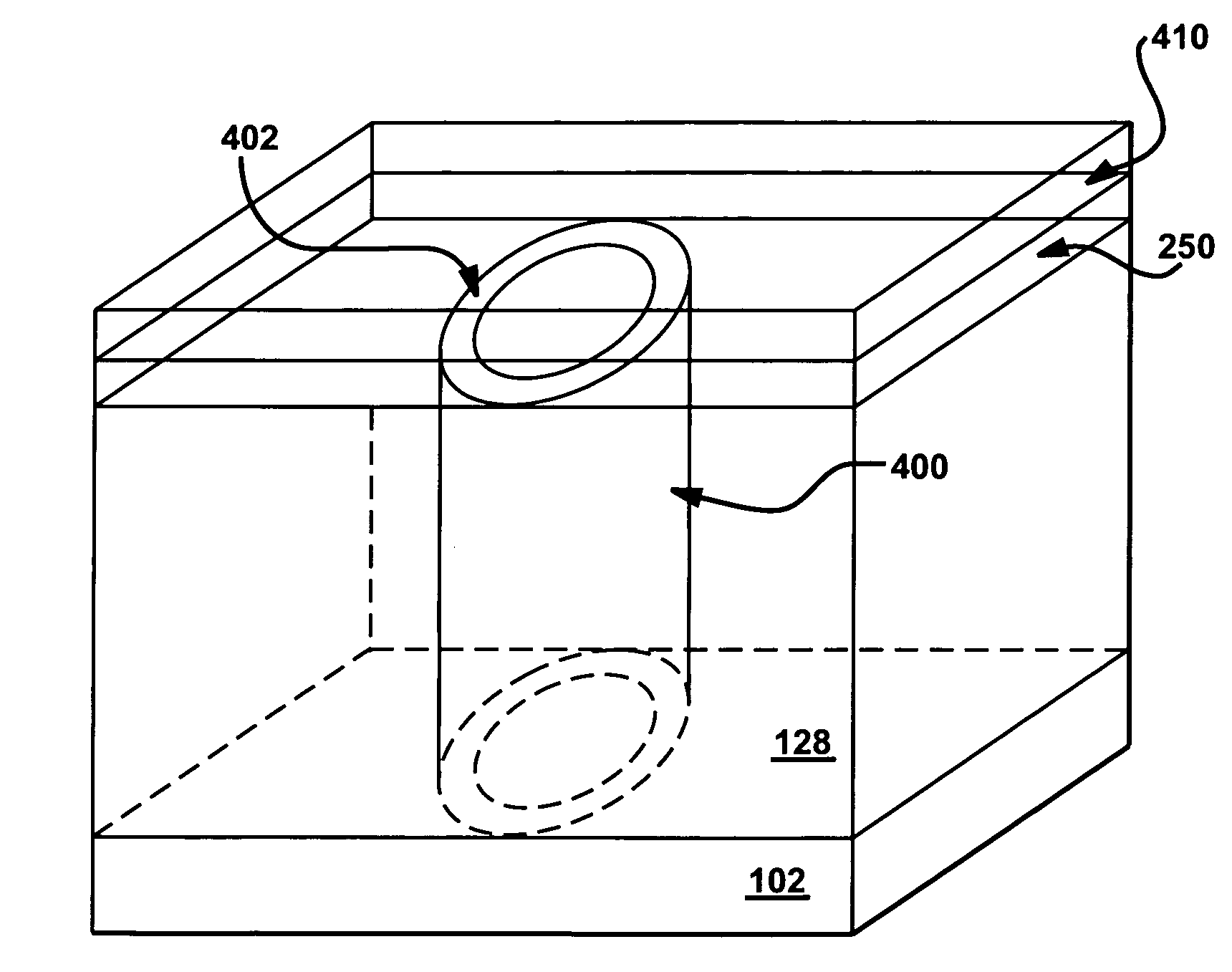

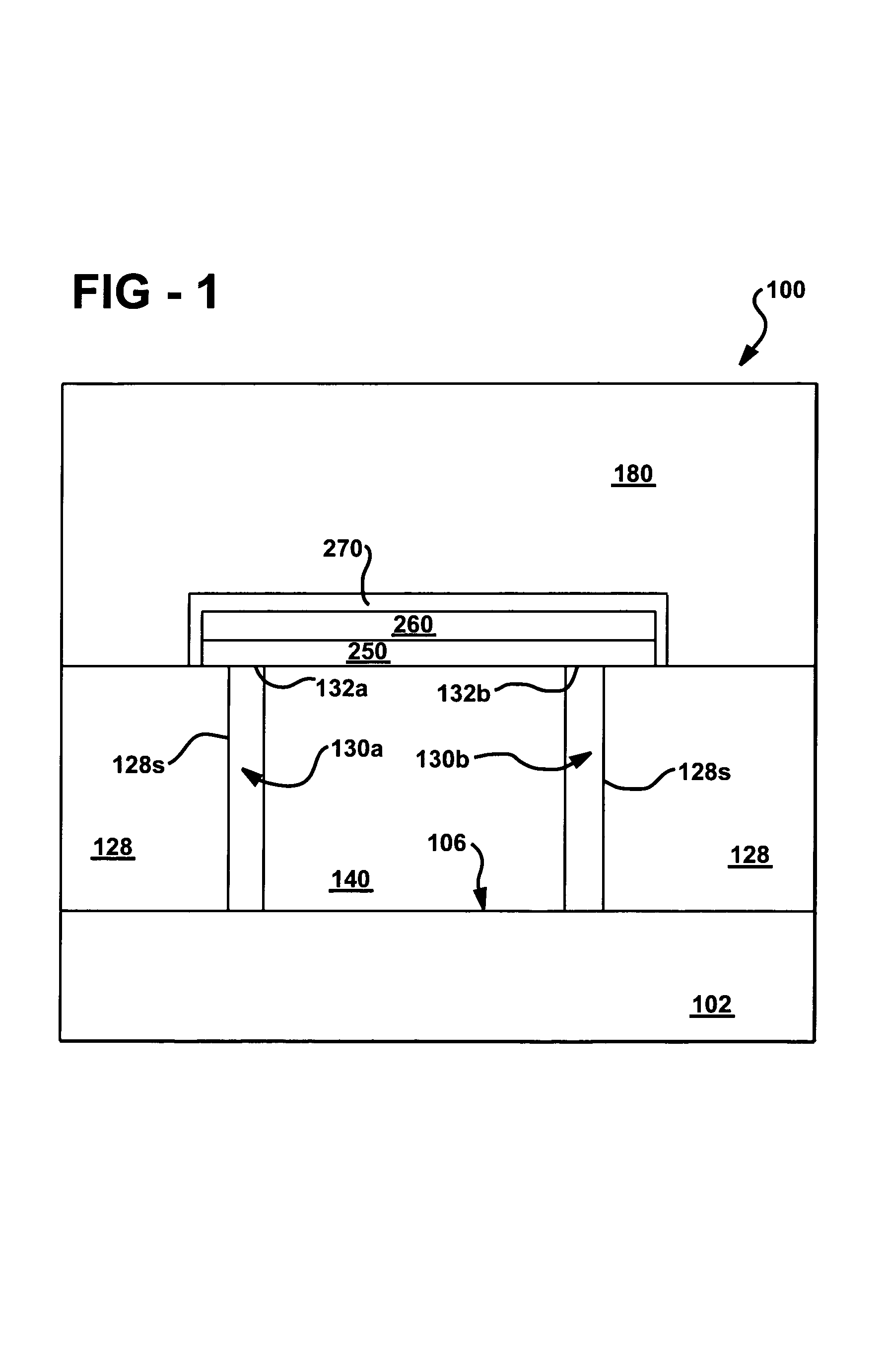

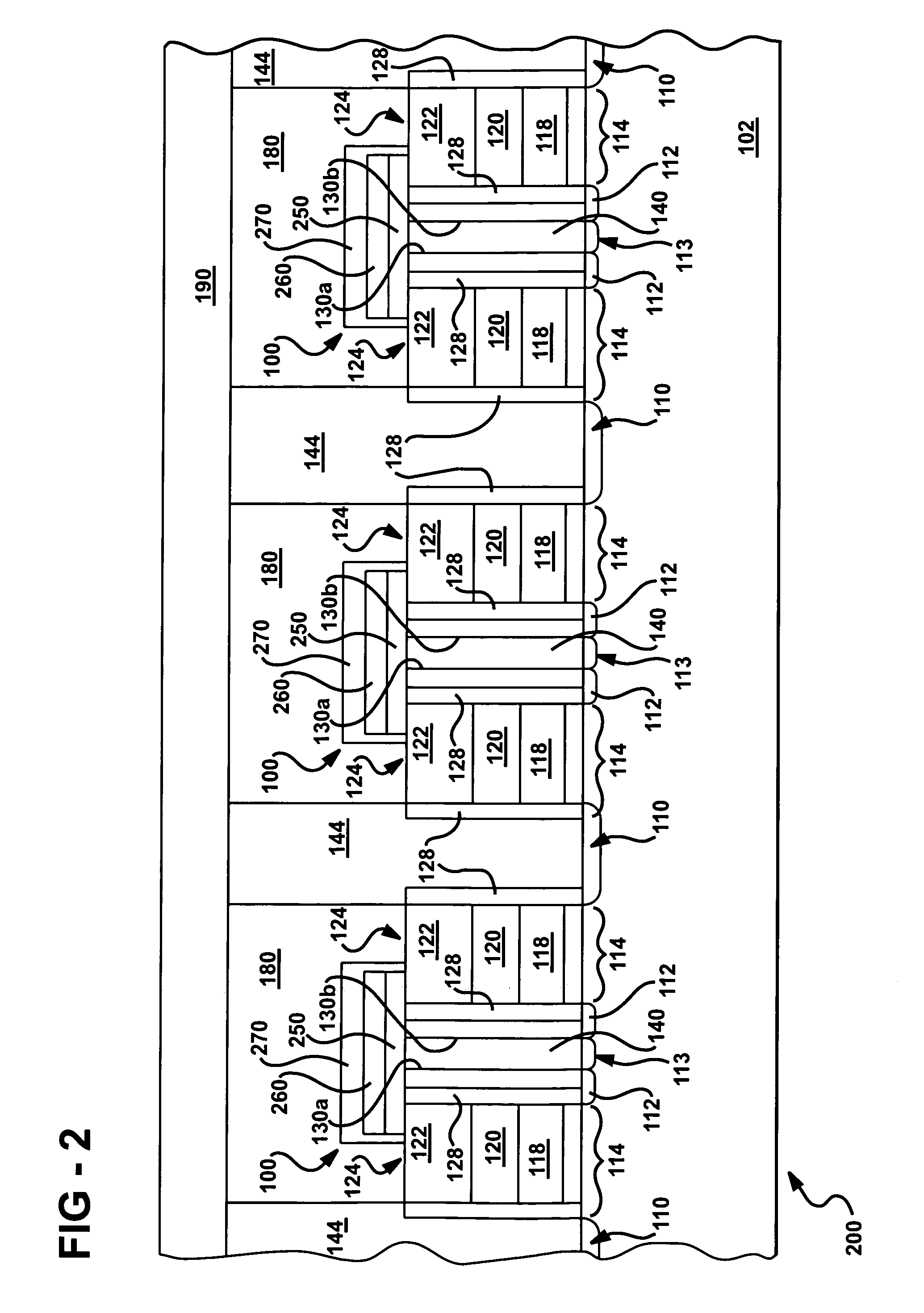

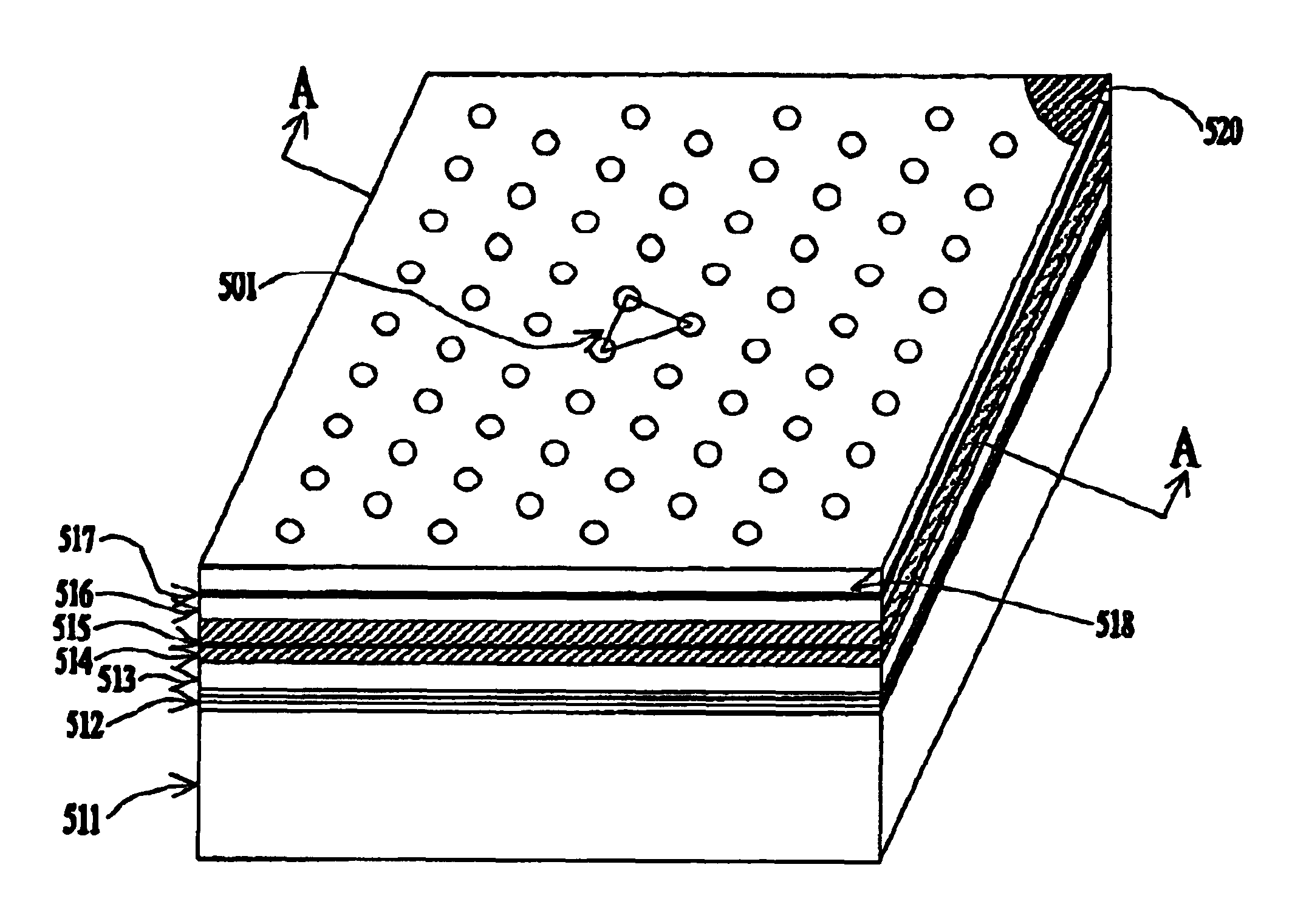

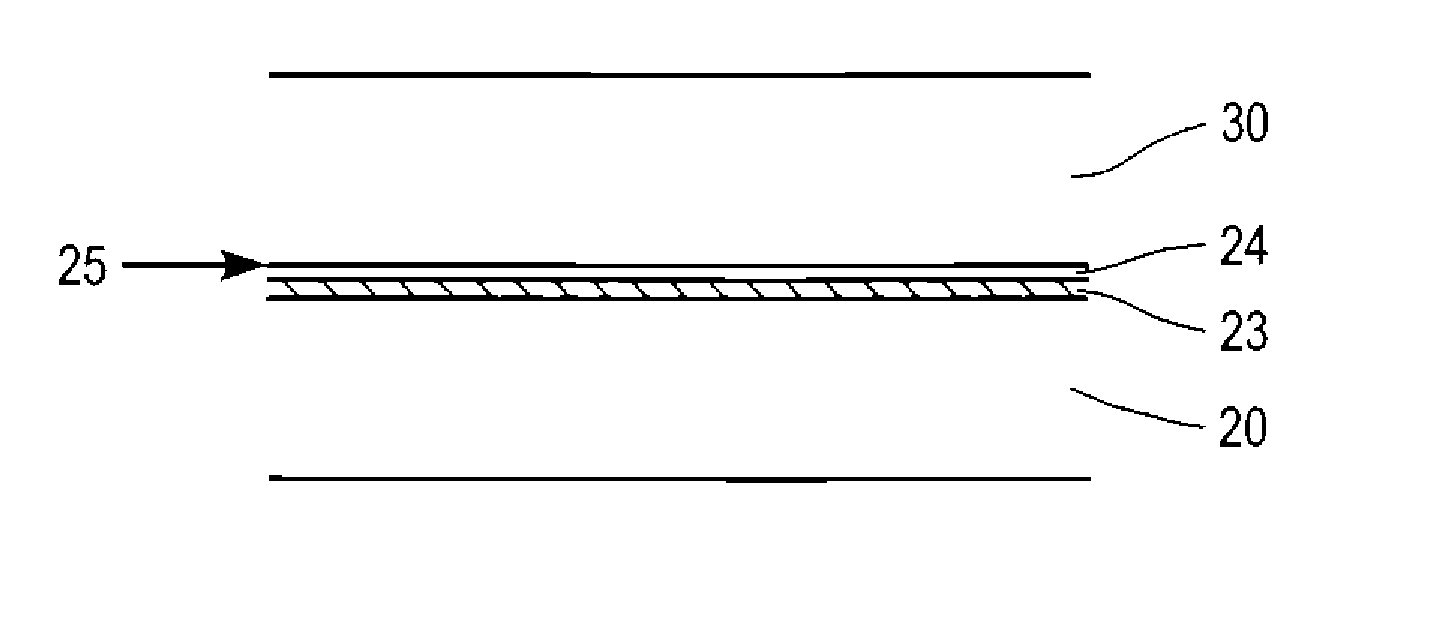

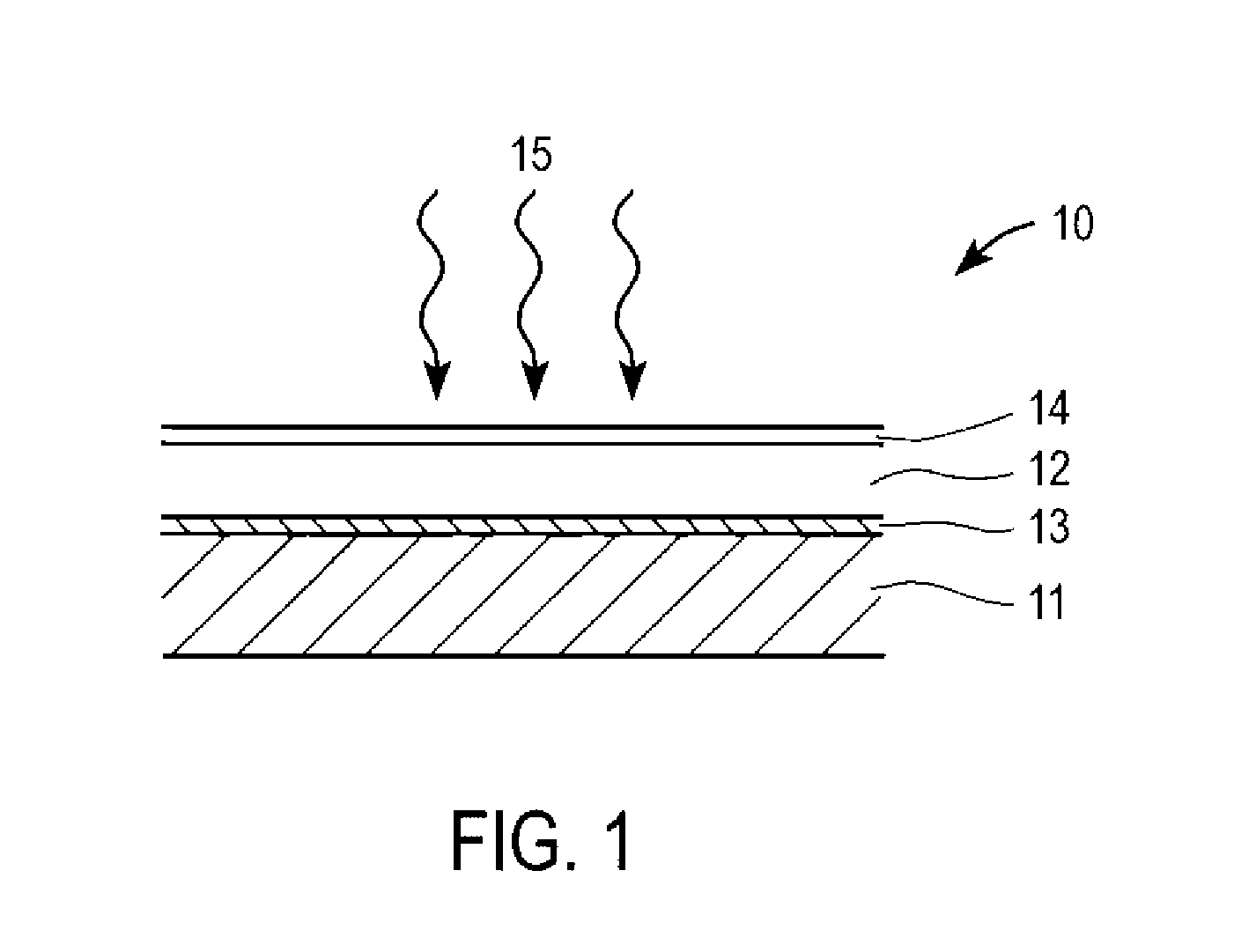

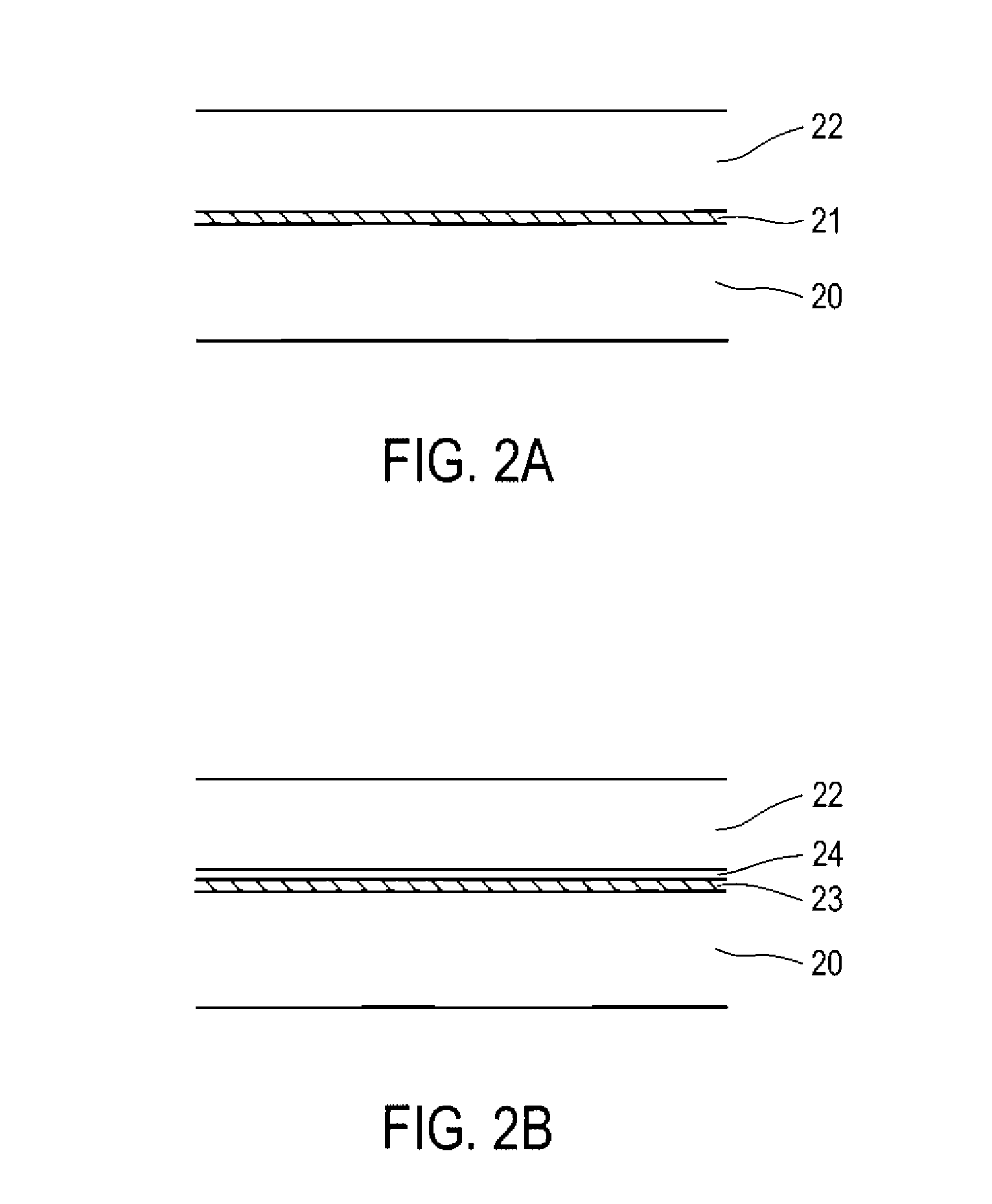

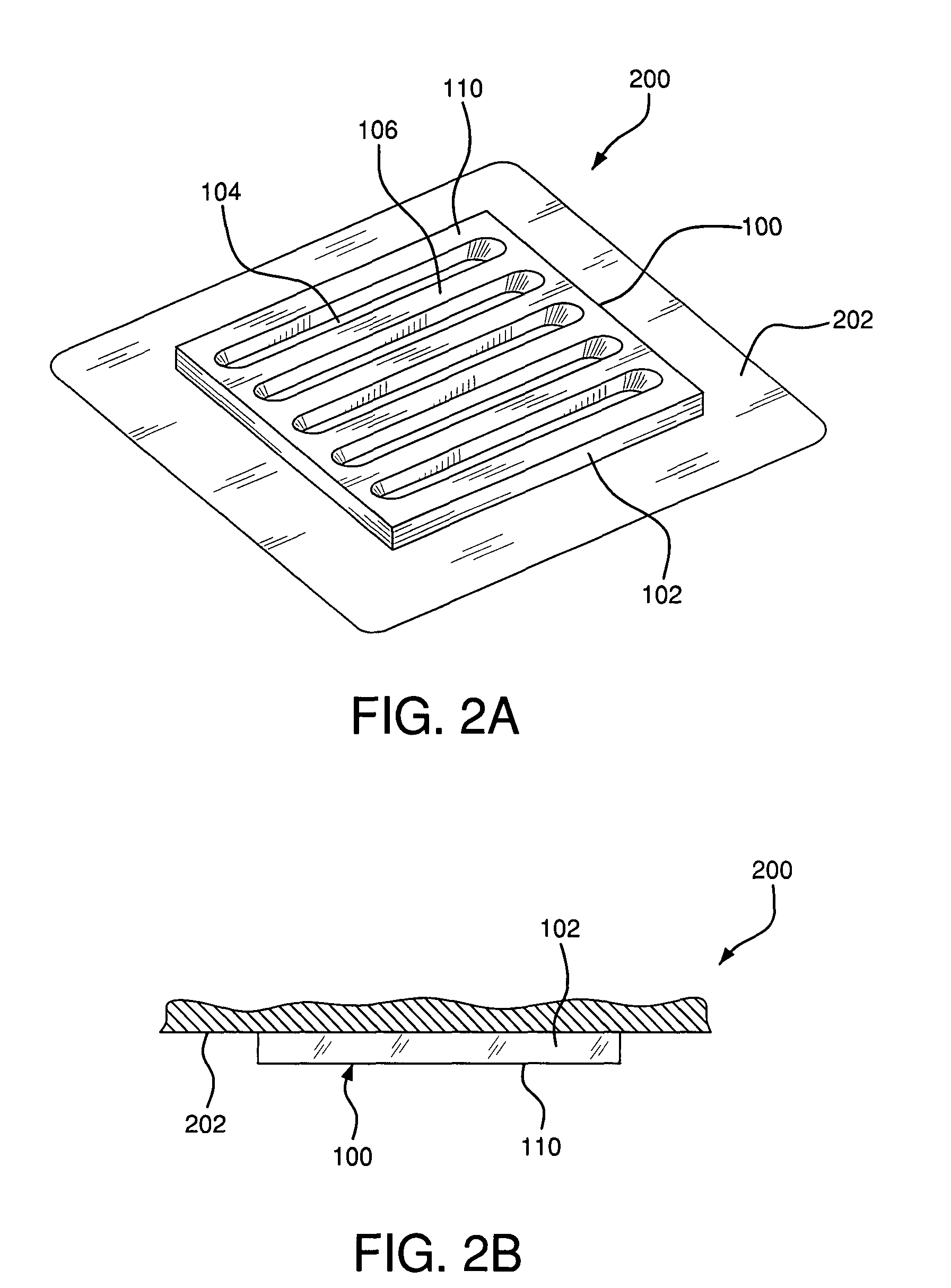

A multi-layer reduced pressure delivery apparatus is provided for applying reduced pressure tissue treatment to a tissue site. The multi-layer apparatus includes a tissue contact layer, a release layer, and a manifold layer. The tissue contact layer includes a scaffold adapted to contact the tissue site, the release layer includes a hydrogel-forming material and a plurality of flow channels, and the manifold layer includes a distribution manifold. The release layer is positioned between the tissue contact layer and the manifold layer to allow easy release of the manifold layer from the tissue contact layer following the administration of reduced pressure tissue treatment.

Owner:KCI LICENSING INC

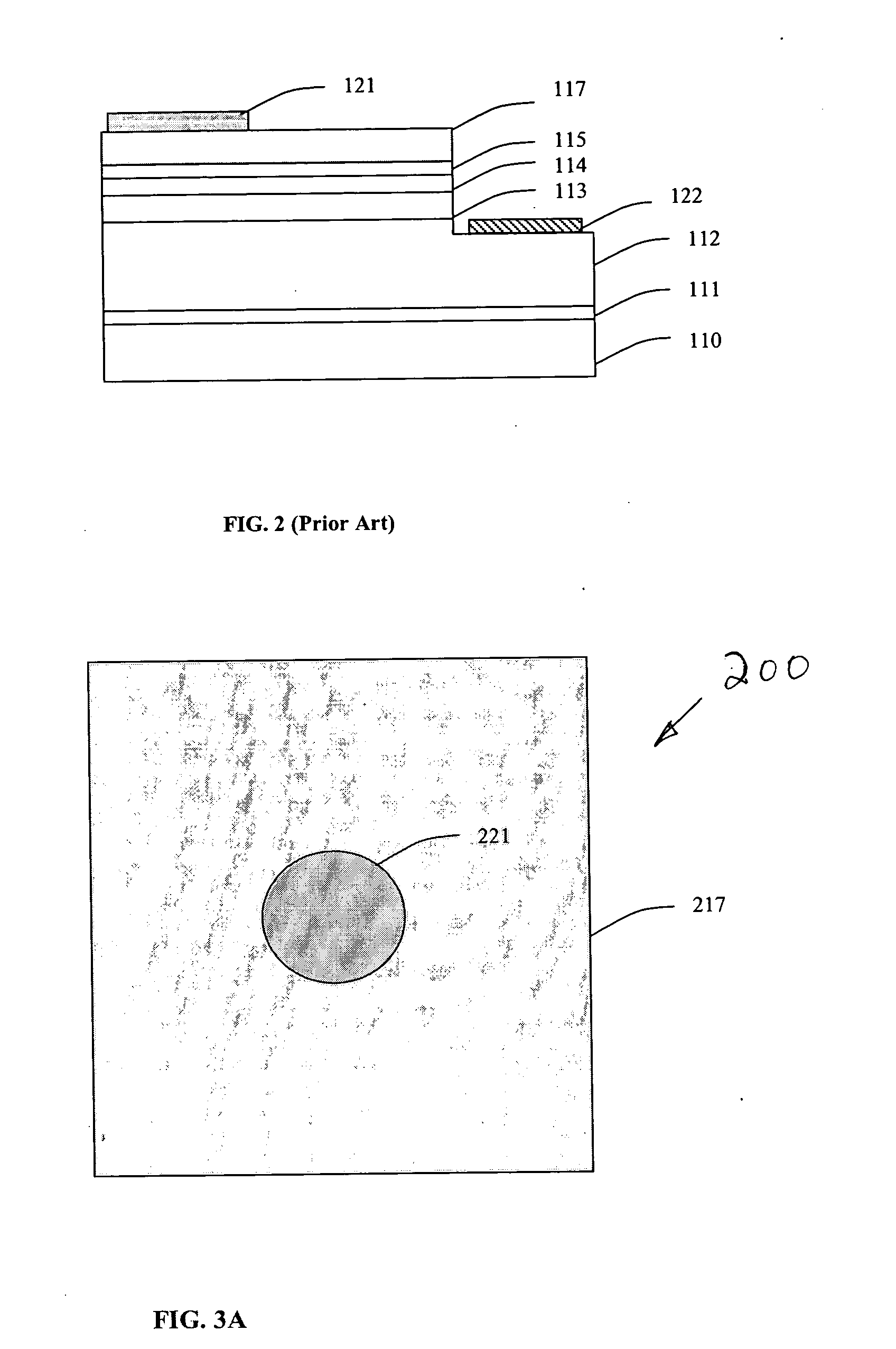

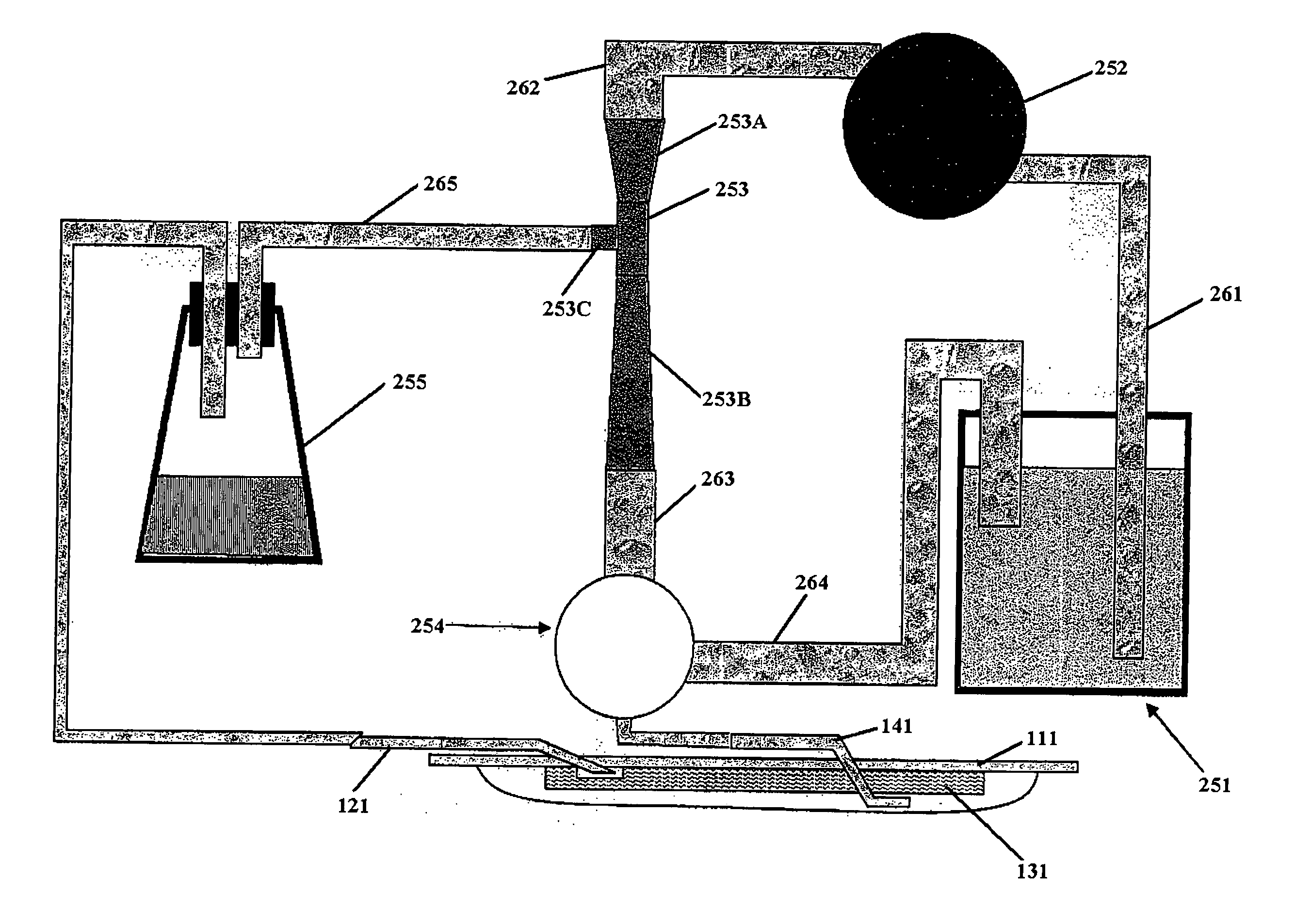

Integrated poration, harvesting and analysis device, and method therefor

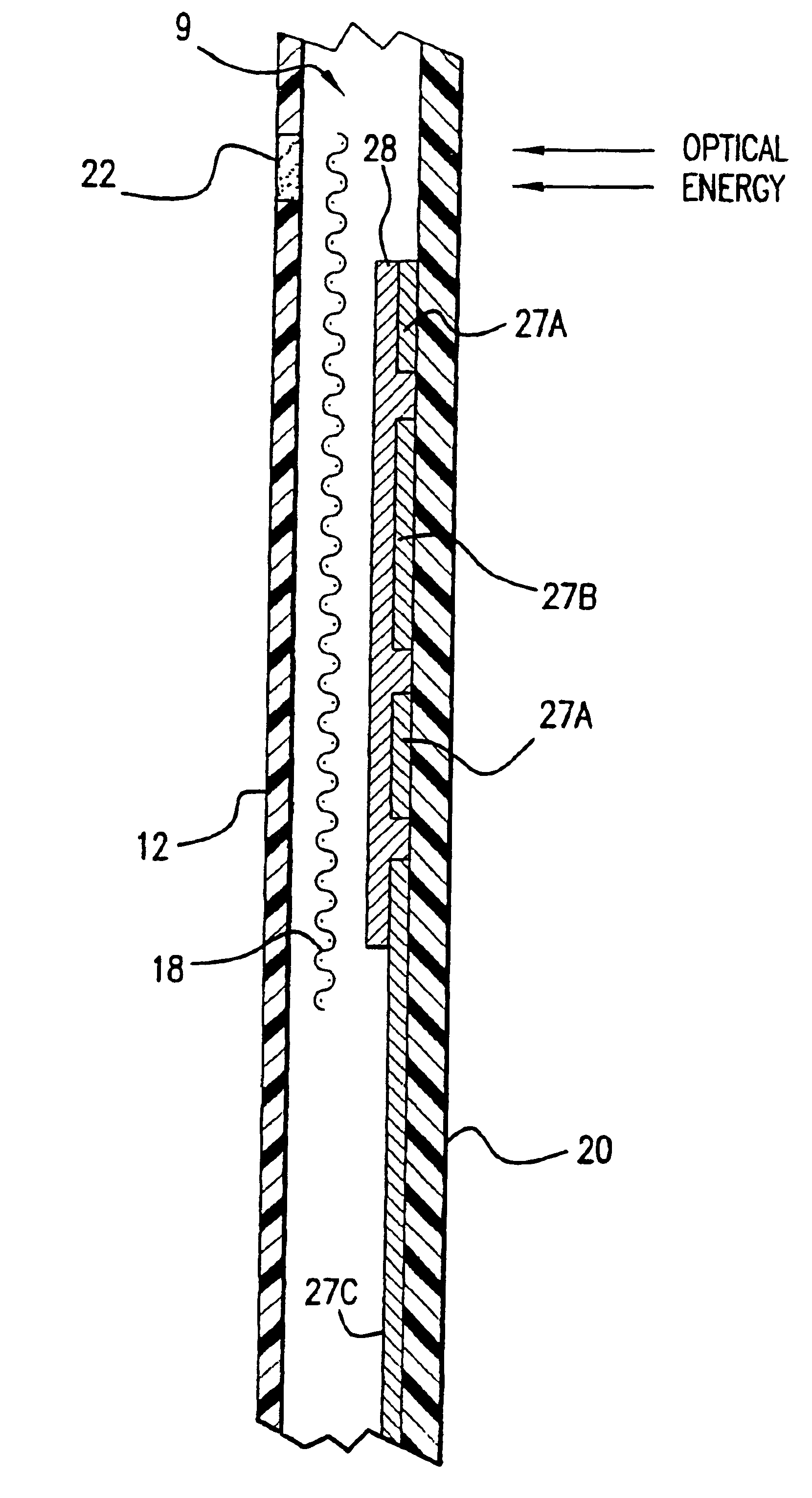

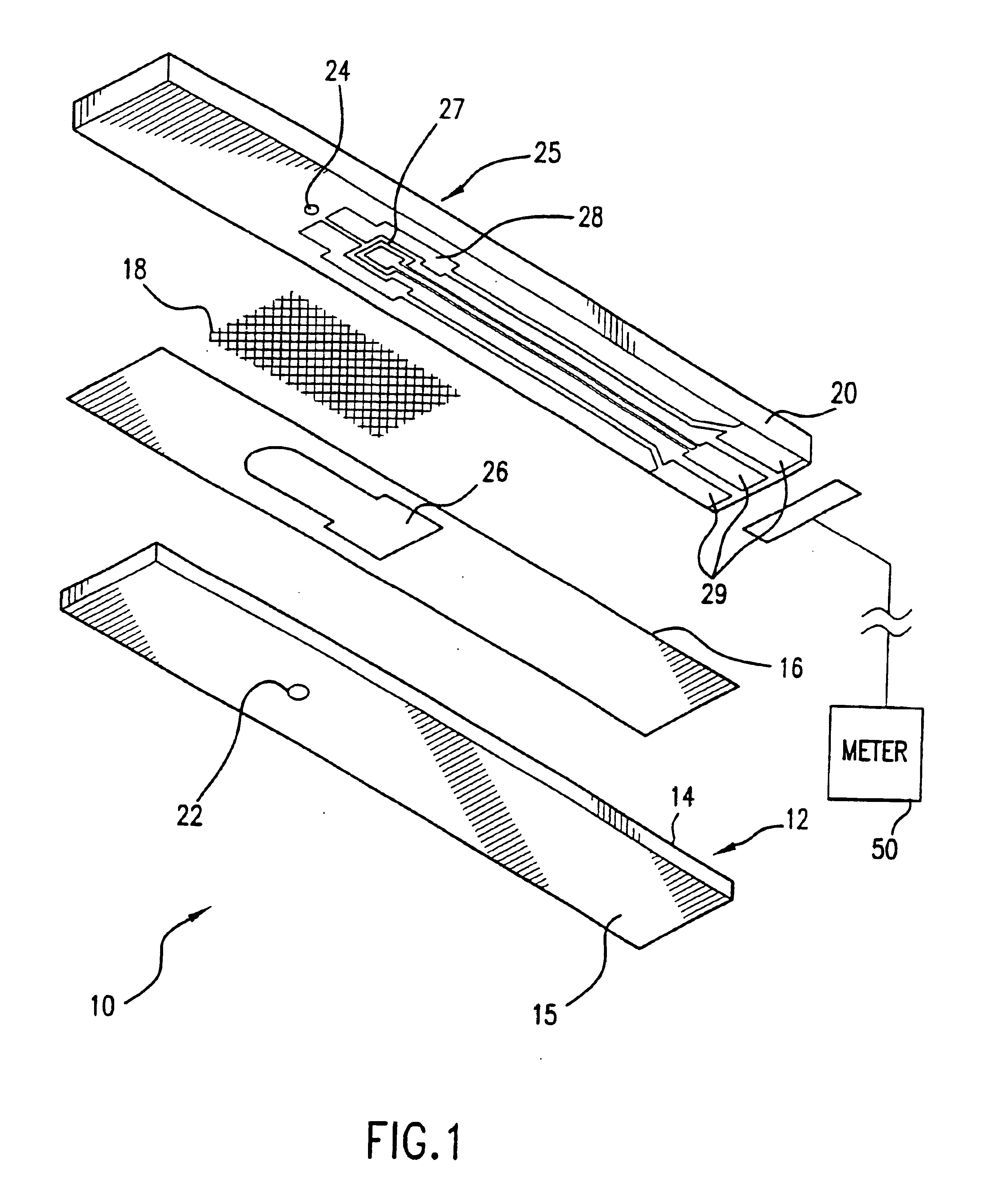

An integrated device for poration of biological tissue, harvesting a biological fluid from the tissue, and analysis of the biological fluid. The device comprises a tissue-contacting layer having an electrically or optically heated probe to heat and conduct heat to the tissue to form at least one opening, such as a micropore to collect biological fluid from the opening, and a detecting layer responsive to the biological fluid to provide an indication of a characteristic of the biological fluid, such as the concentration of an analyte in interstitial fluid. In the embodiment in which, the probe comprises a photosensitizing assembly designed for the uniform application of a photosensitizing material, such as, for example, a dye or a pigment, to a tissue, e.g., the stratum comeum. In one embodiment, the photosensitizing assembly comprises photosensitizing material combined with a carrier, such as, for example, an adhesive or an ink, and the resulting combination is applied to a substrate, such as, for example, an inert polymeric substrate to form a photosensitizing assembly. In another embodiment, the photosensitizing assembly comprises photosensitizing material incorporated into a film-forming polymeric material.

Owner:NITTO DENKO CORP +1

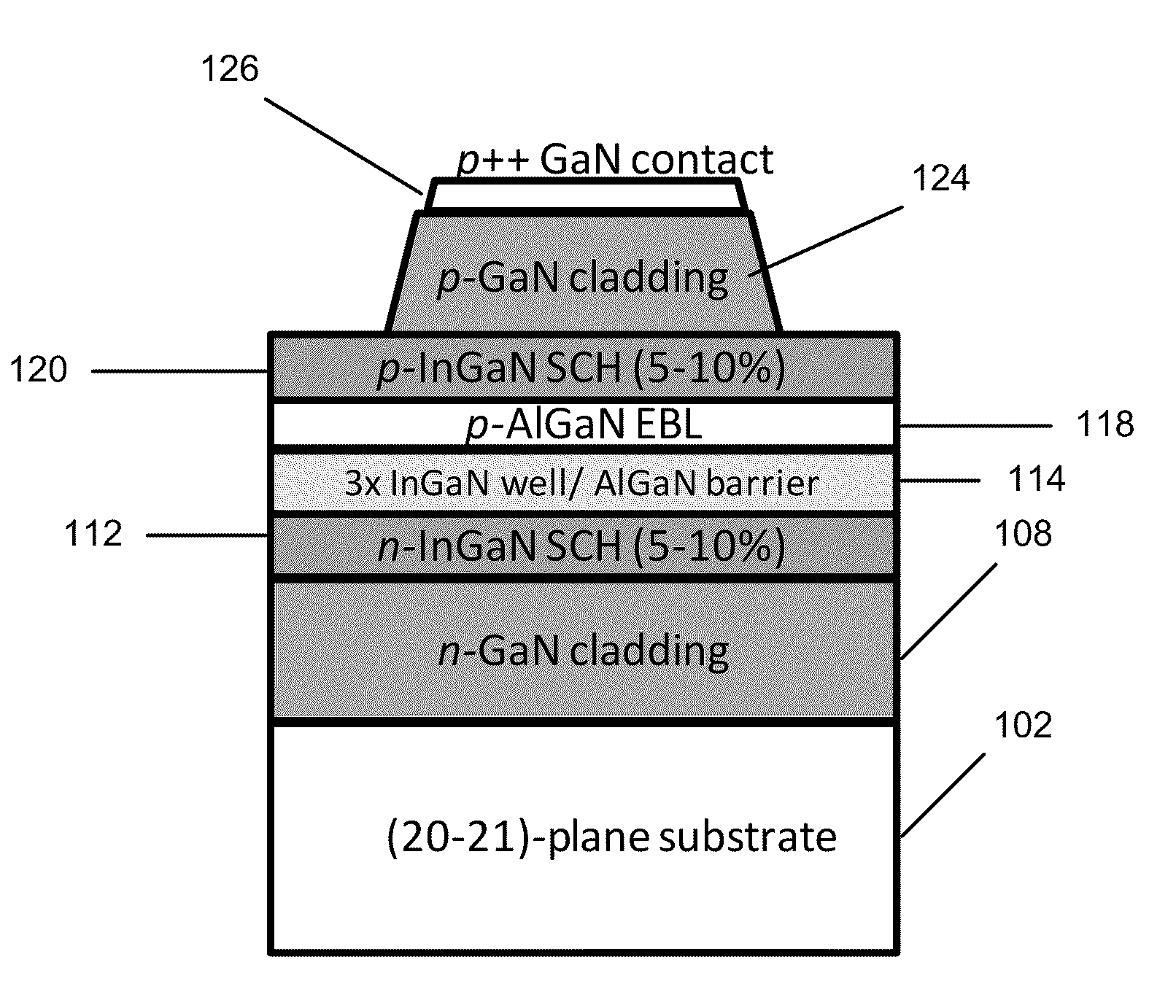

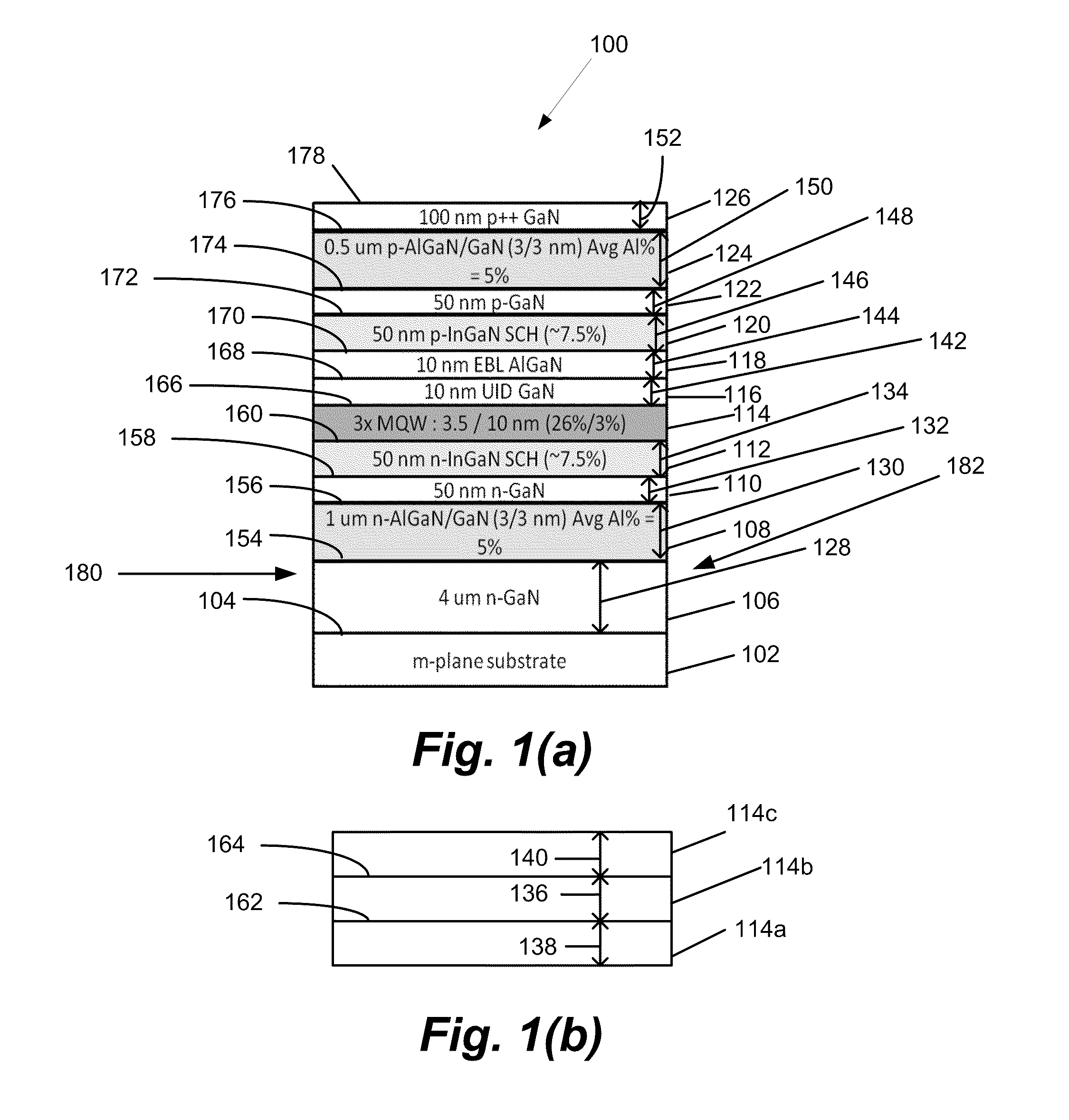

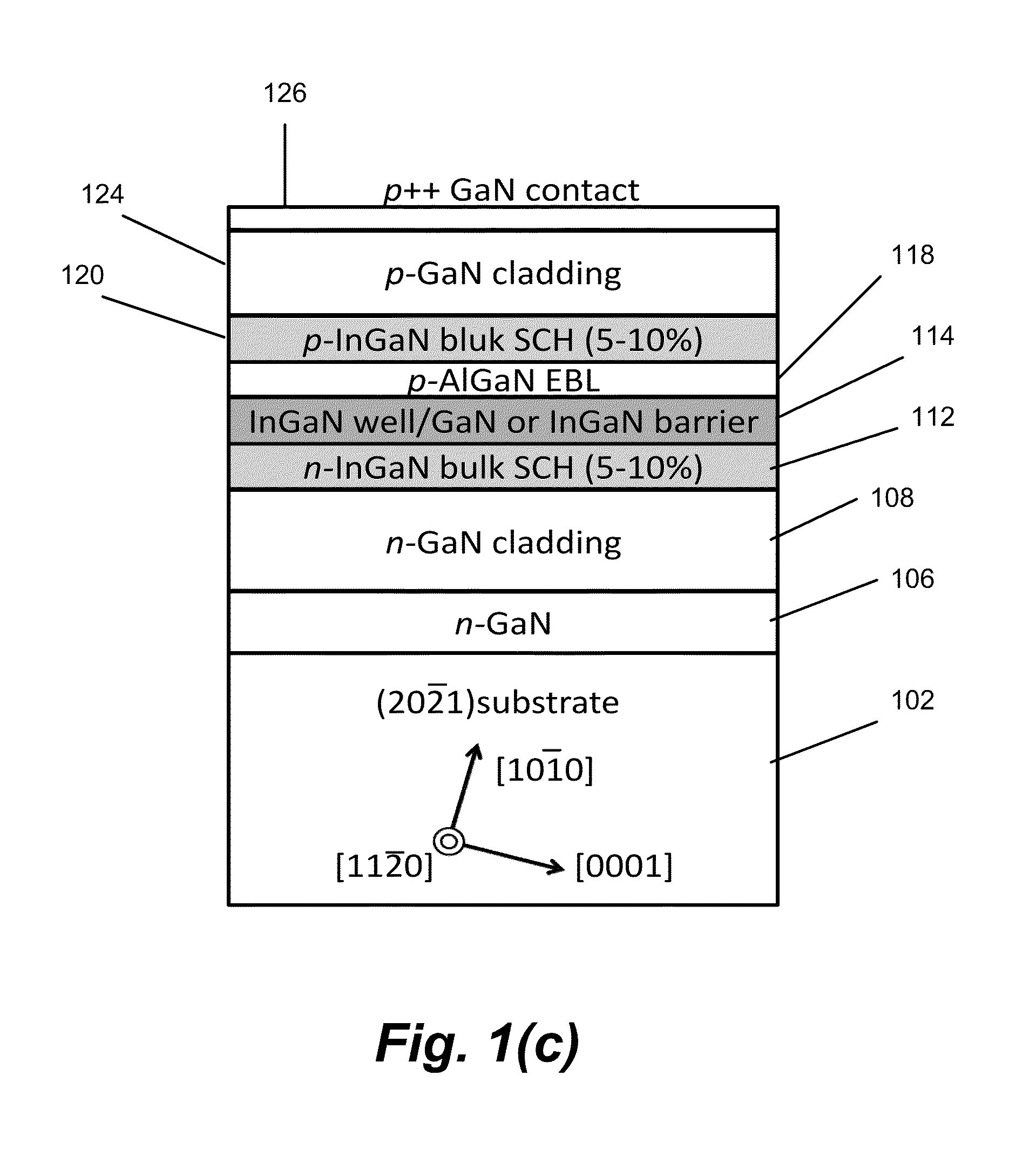

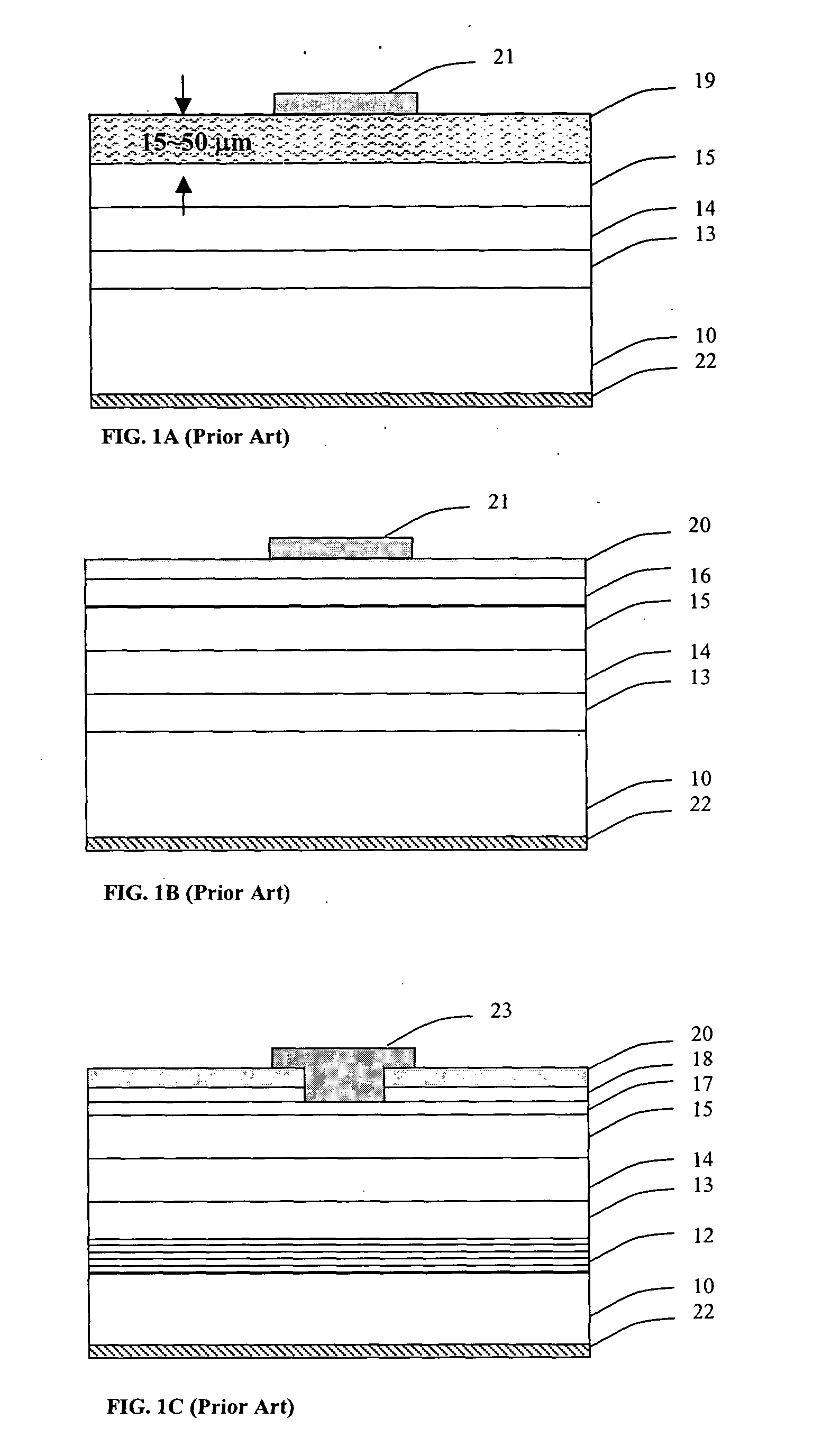

LONG WAVELENGTH NONPOLAR AND SEMIPOLAR (Al,Ga,In)N BASED LASER DIODES

InactiveUS20100309943A1Simple structureImprove electricityOptical wave guidanceLaser detailsContact layerStimulated emission

A laser diode, grown on a miscut nonpolar or semipolar substrate, with lower threshold current density and longer stimulated emission wavelength, compared to conventional laser diode structures, wherein the laser diode's (1) n-type layers are grown in a nitrogen carrier gas, (2) quantum well layers and barrier layers are grown at a slower growth rate as compared to other device layers (enabling growth of the p-type layers at higher temperature), (3) high Al content electron blocking layer enables growth of layers above the active region at a higher temperature, and (4) asymmetric AlGaN SPSLS allowed growth of high Al containing p-AlGaN layers. Various other techniques were used to improve the conductivity of the p-type layers and minimize the contact resistance of the contact layer.

Owner:RGT UNIV OF CALIFORNIA

Biocompatible wound dressing

InactiveUS7700819B2Reduce pressureReduced tissue treatmentNon-adhesive dressingsAdhesive dressingsWound dressingContact layer

A multi-layer reduced pressure delivery apparatus is provided for applying reduced pressure tissue treatment to a tissue site. The multi-layer apparatus includes a tissue contact layer, a release layer, and a manifold layer. The tissue contact layer includes a scaffold adapted to contact the tissue site, the release layer includes a hydrogel-forming material and a plurality of flow channels, and the manifold layer includes a distribution manifold. The release layer is positioned between the tissue contact layer and the manifold layer to allow easy release of the manifold layer from the tissue contact layer following the administration of reduced pressure tissue treatment.

Owner:3M INNOVATIVE PROPERTIES CO

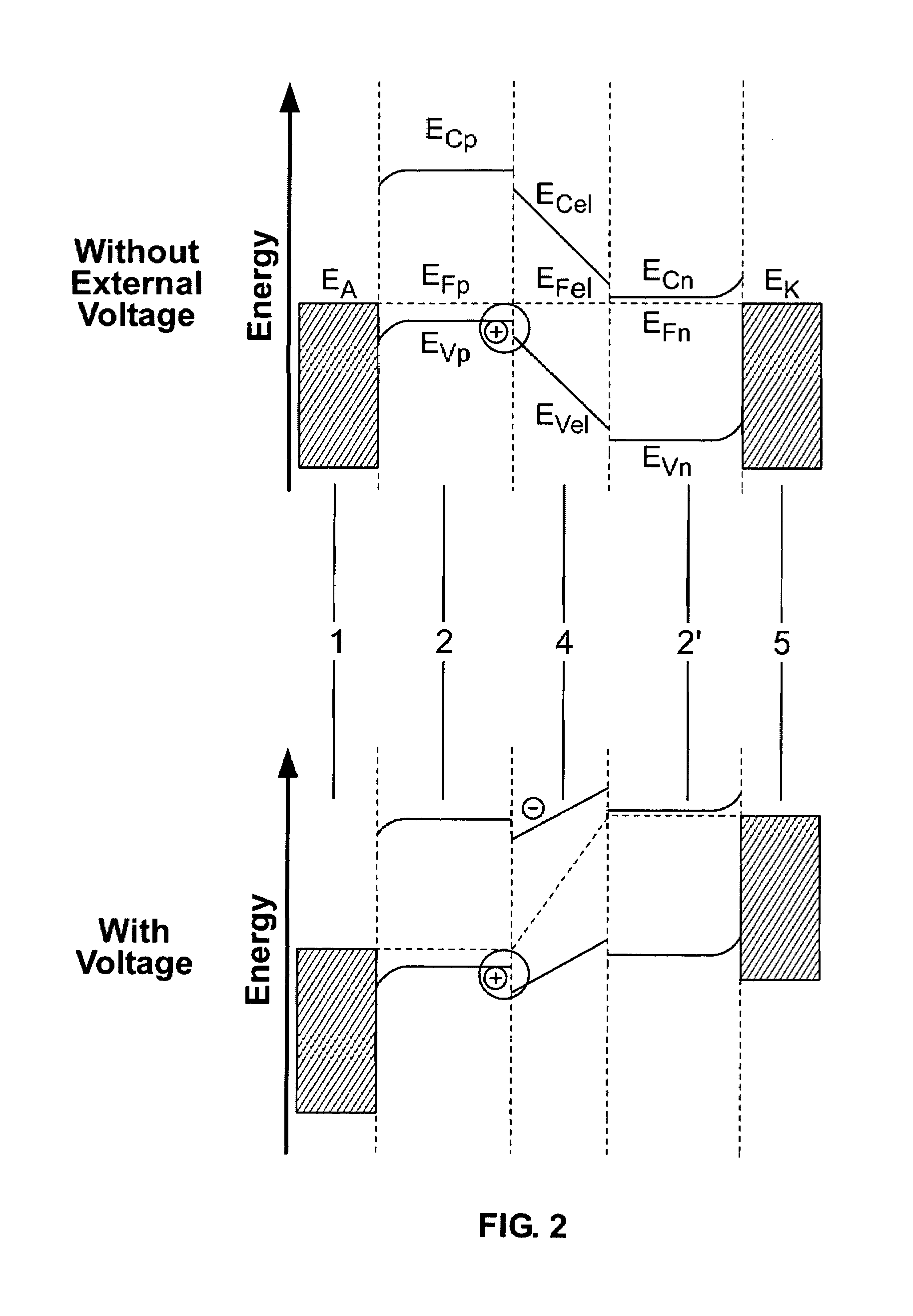

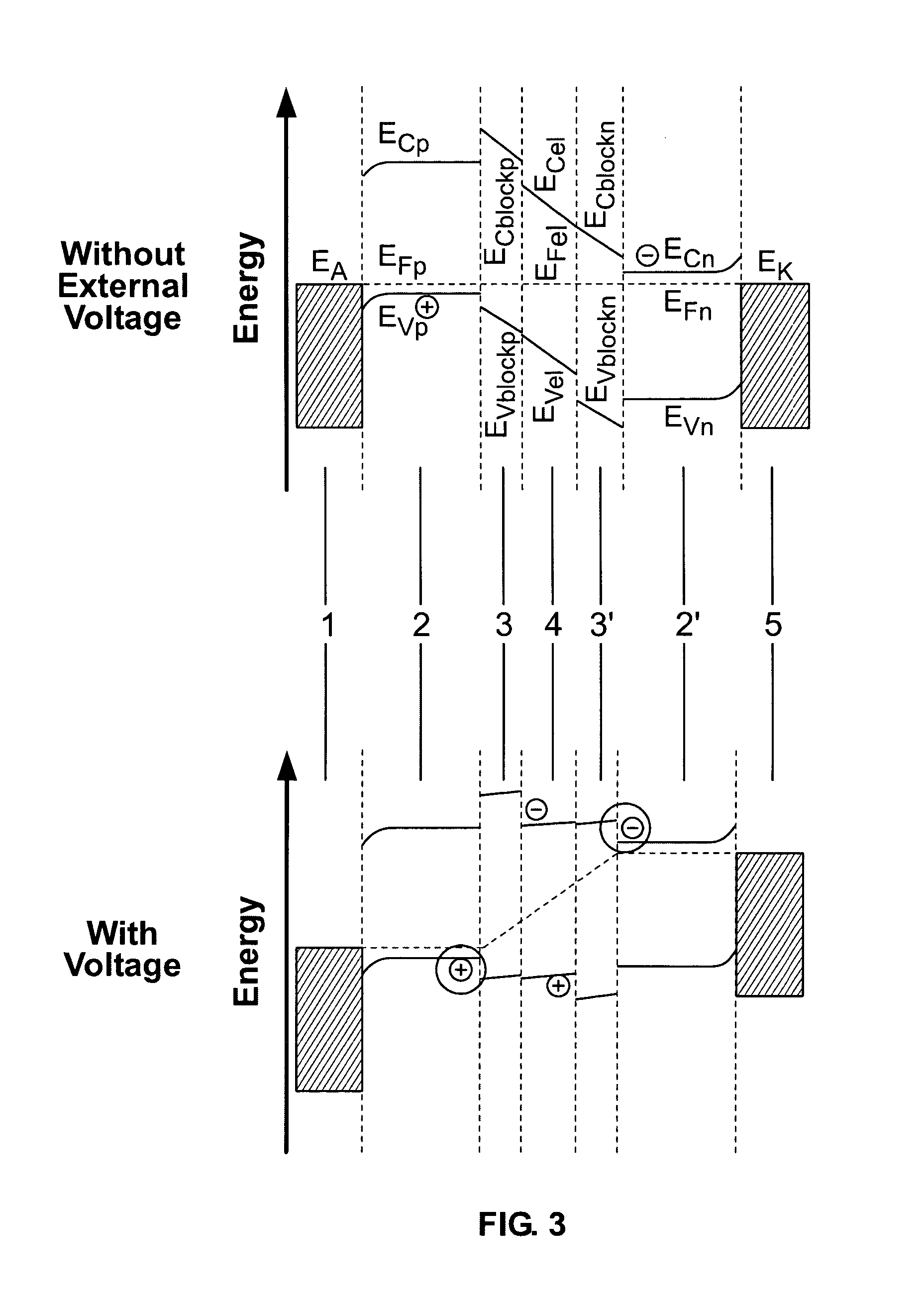

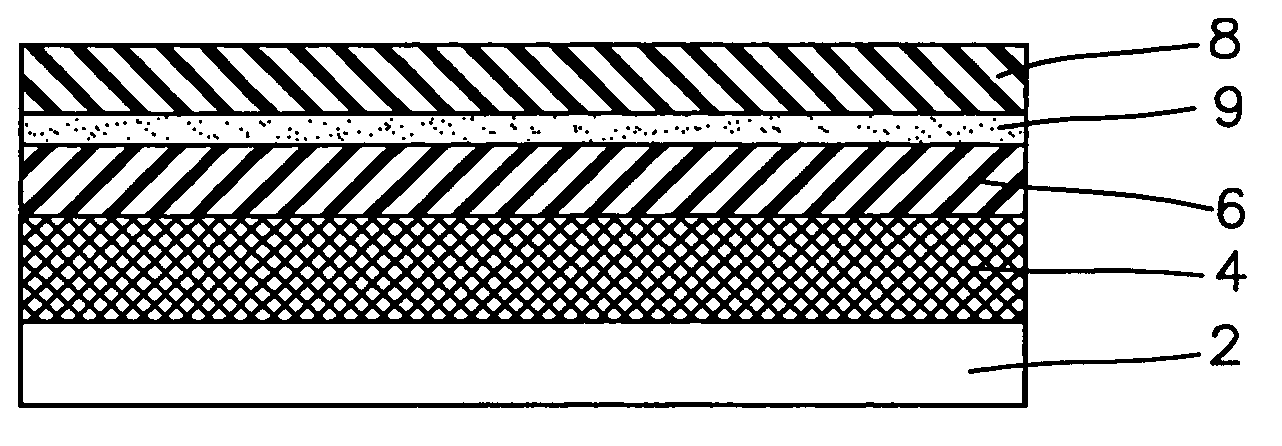

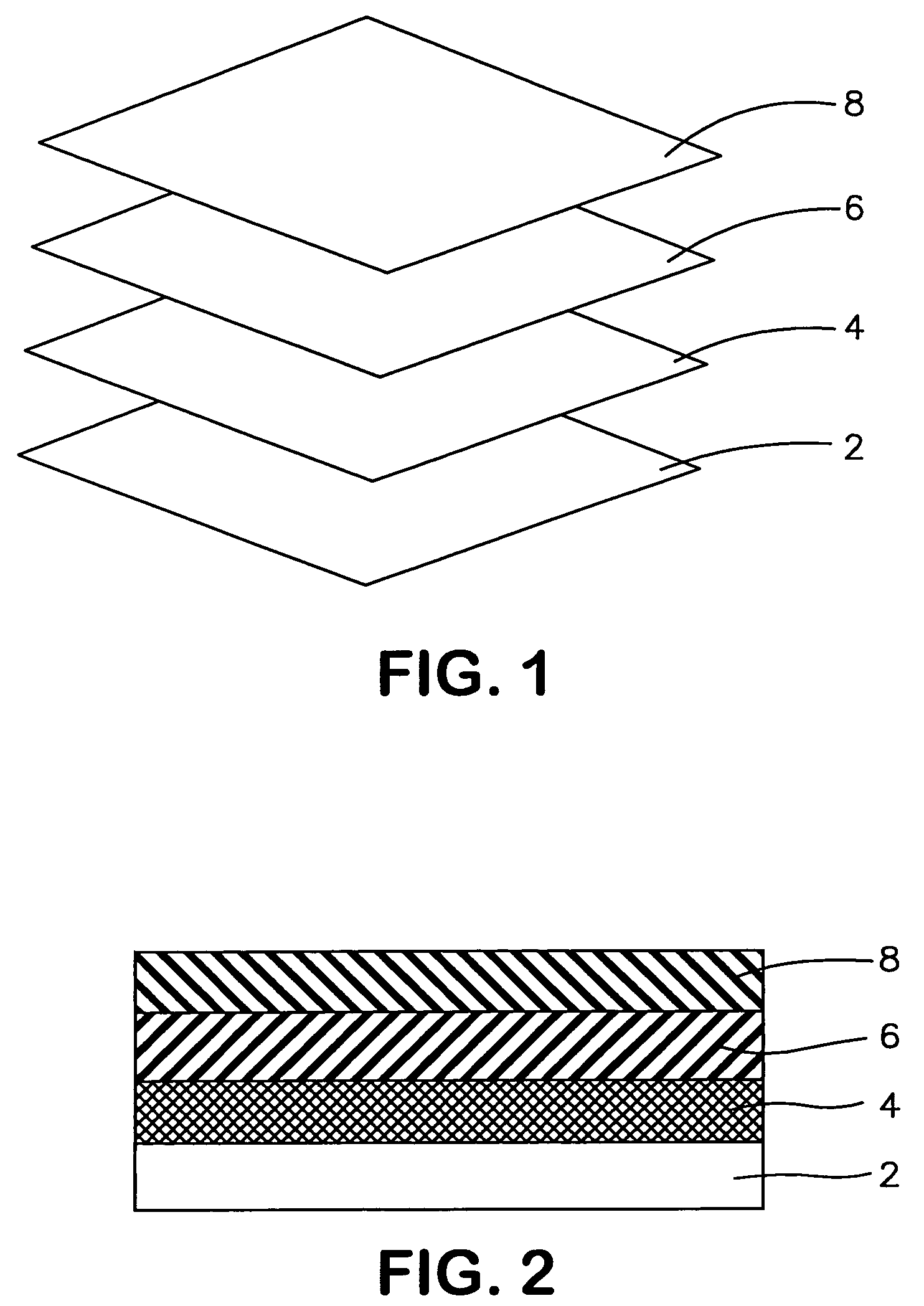

Light emitting component comprising organic layers

InactiveUS7074500B2Inhibit injectionDischarge tube luminescnet screensElectroluminescent light sourcesTransport layerCharge carrier

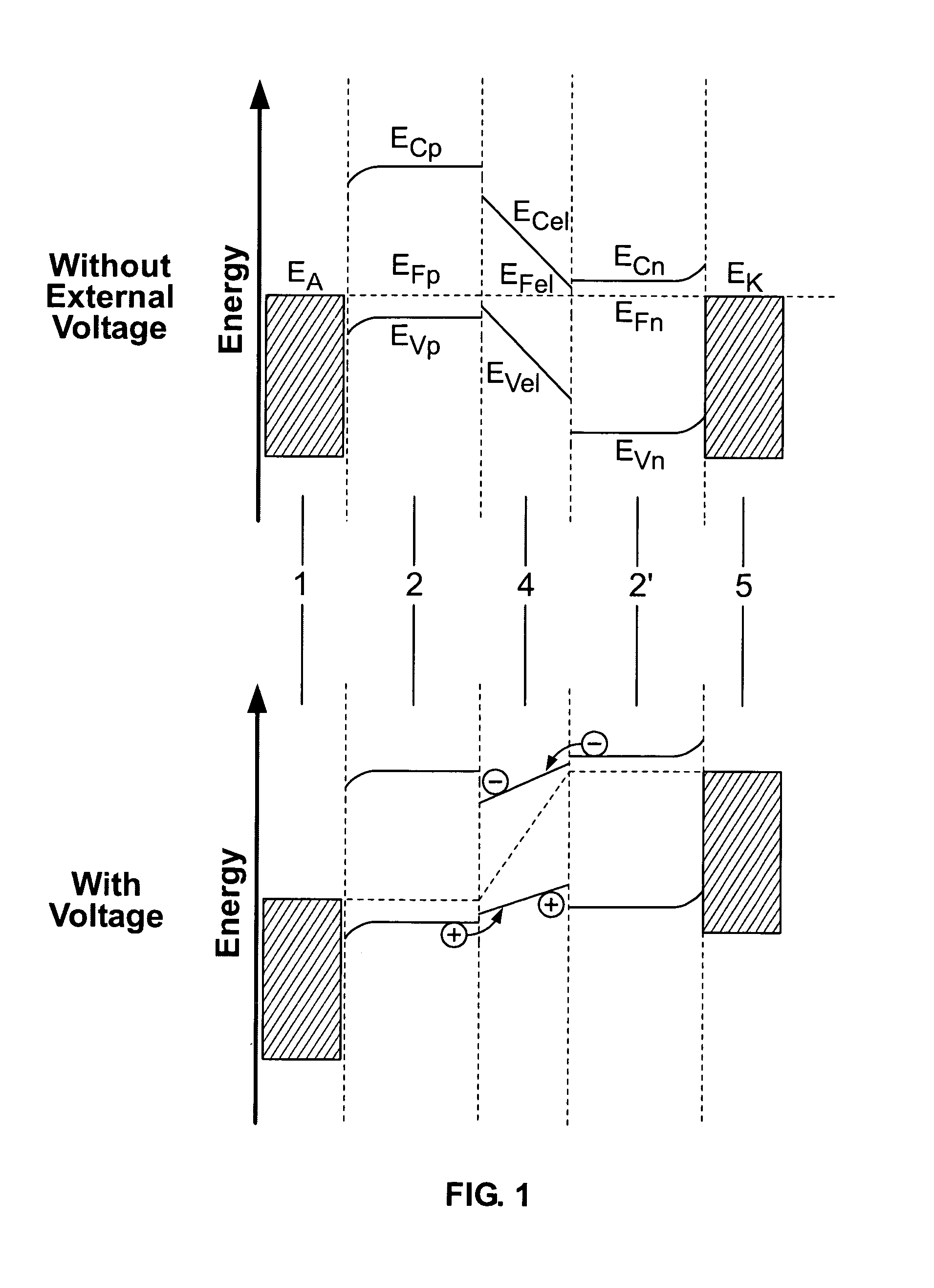

The invention relates to a light-emmiting component having organic layers, in particular to an organic light-emmiting diode. The component has at least one doped charge carrier transport layer (2), a light-emmiting layer (4) and contact layers (1, 5) and also has a blocking layer (3; 3′) wherein an organic material is provided between the charge carrier transport layer (2, 2′) and the light-emmiting layer (4). The energy levels of the charge carried transport layer are chosen in such a way that efficient doping is possible and the blocking layer nevertheless ensures that non-radiating recombination processes on the interface with the emitting layer are prevented.

Owner:NOVALED GMBH

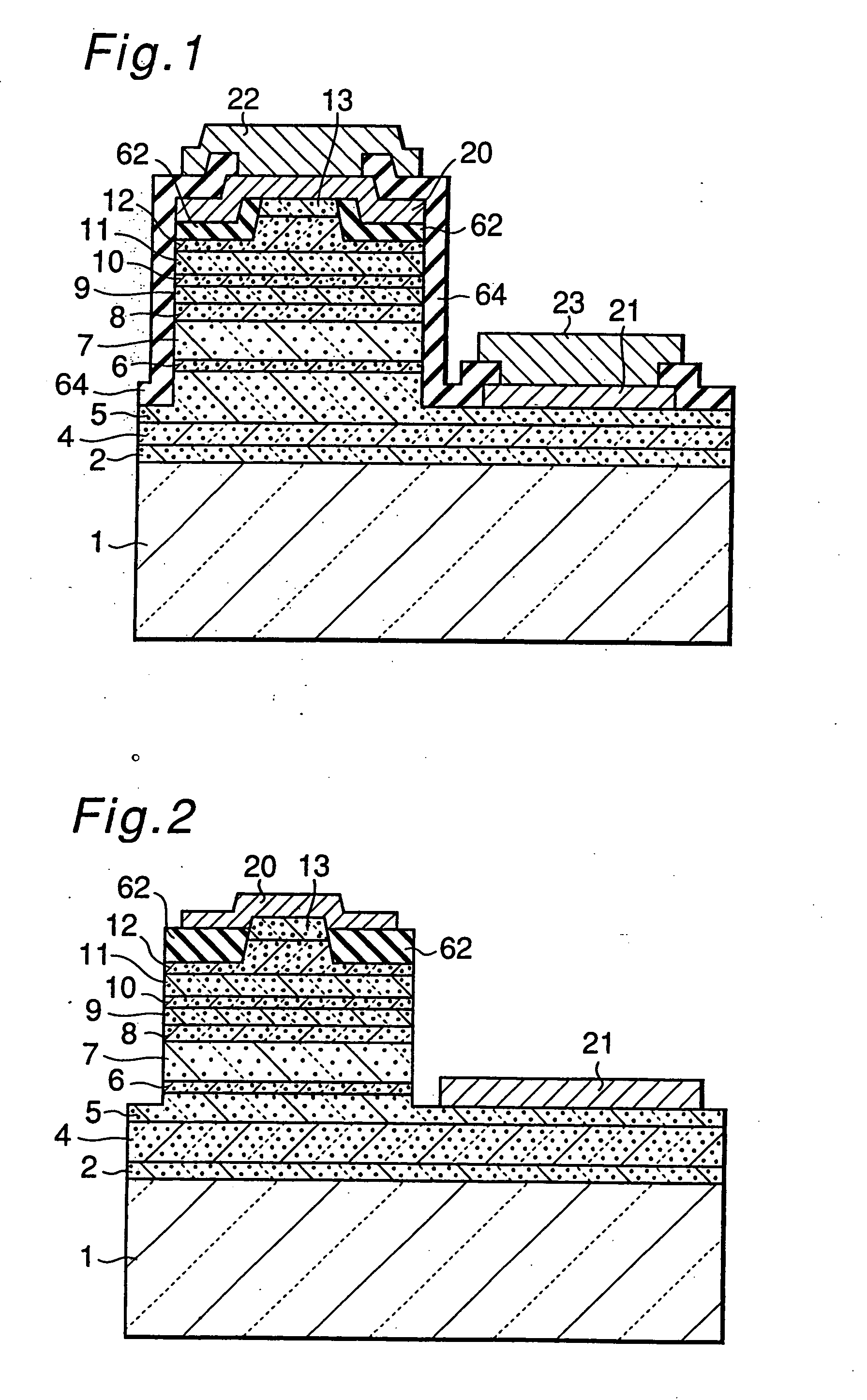

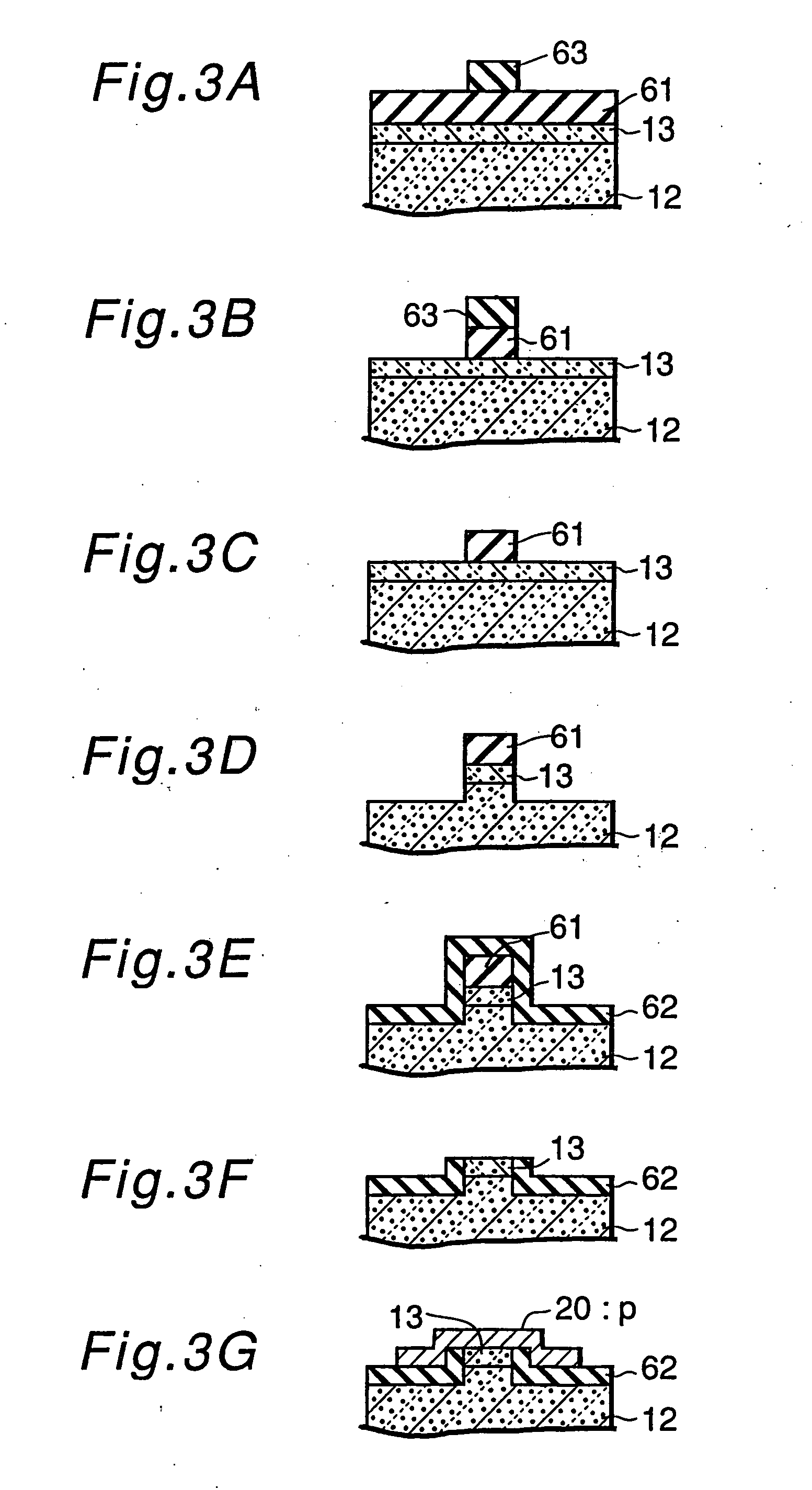

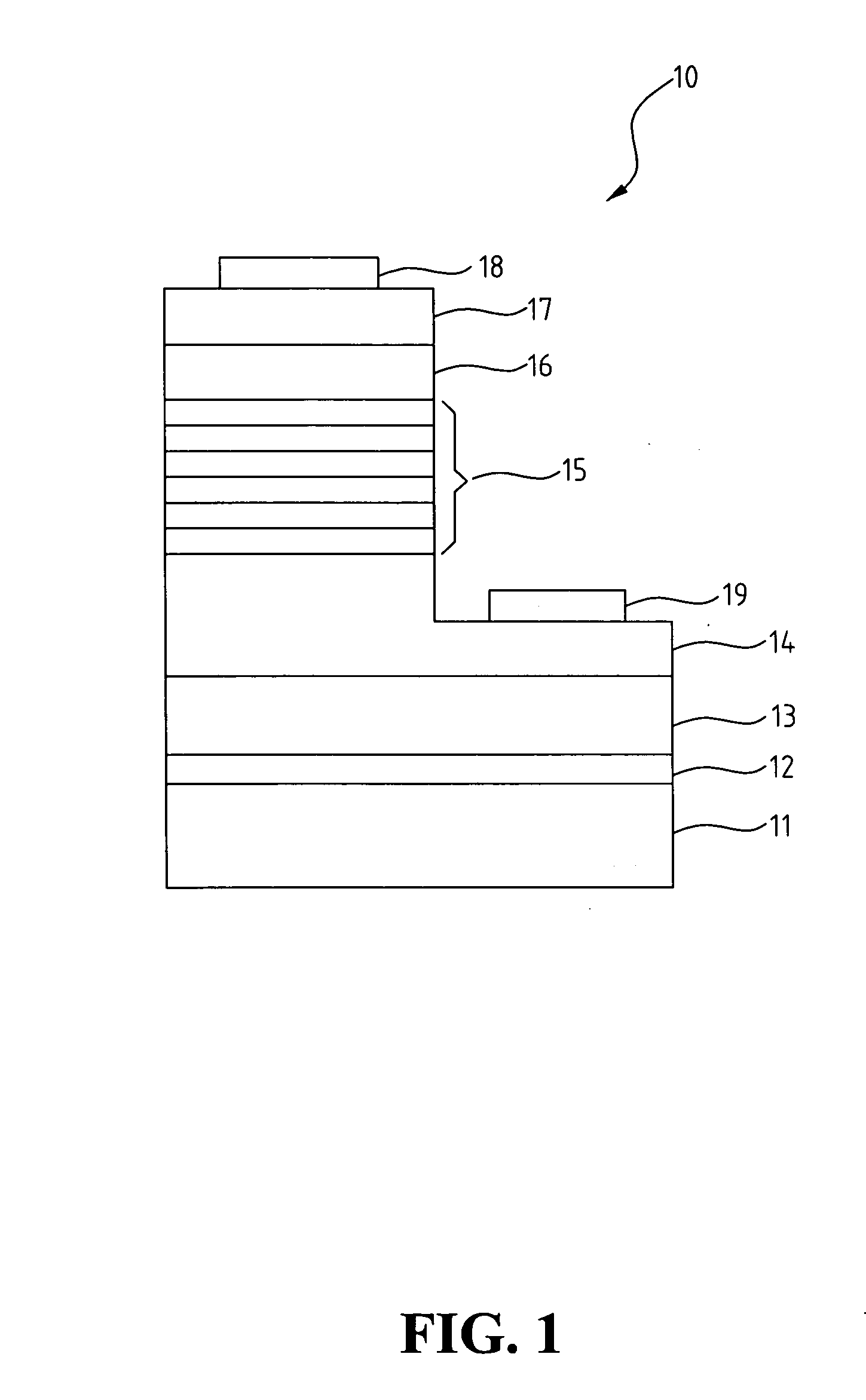

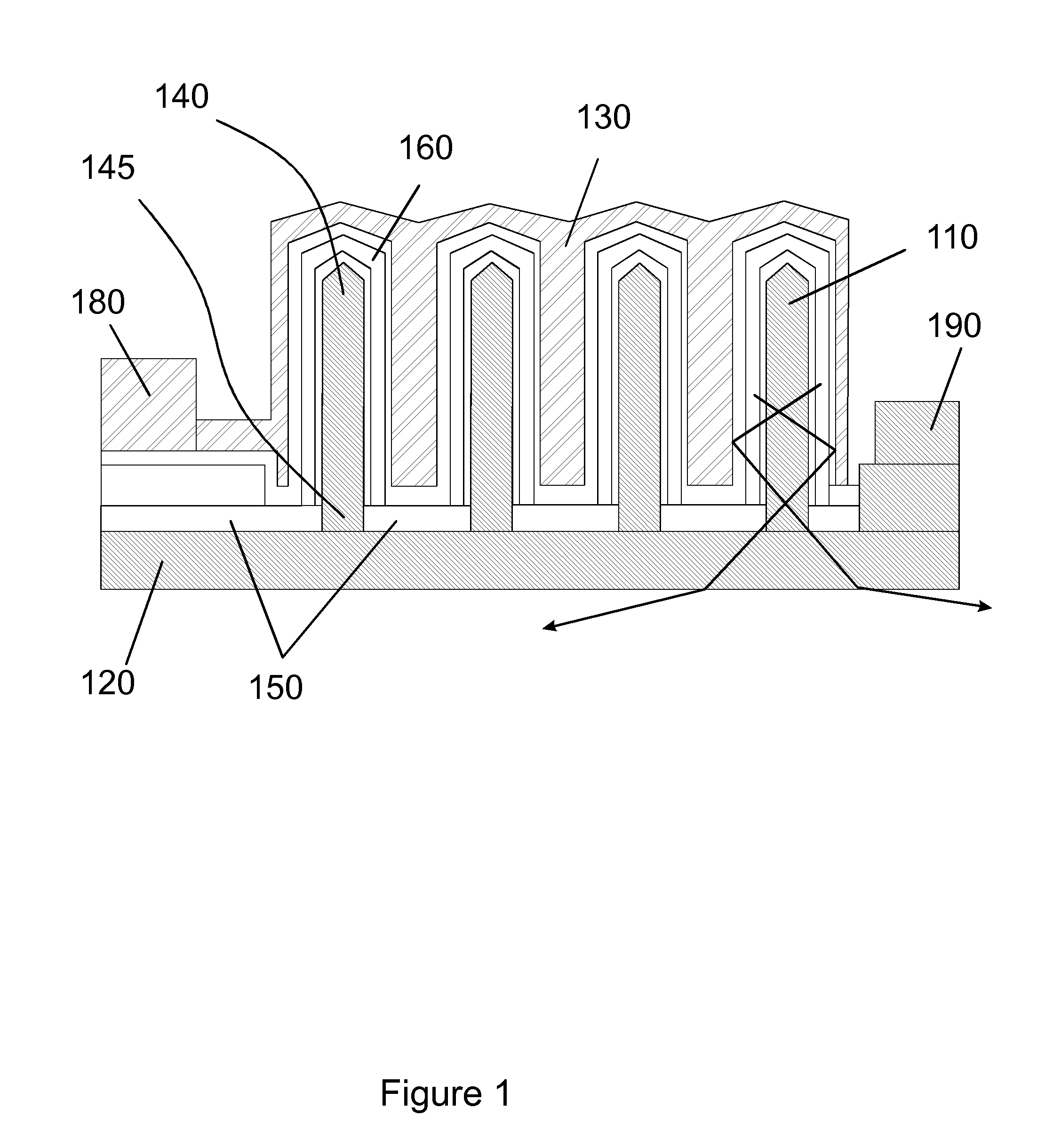

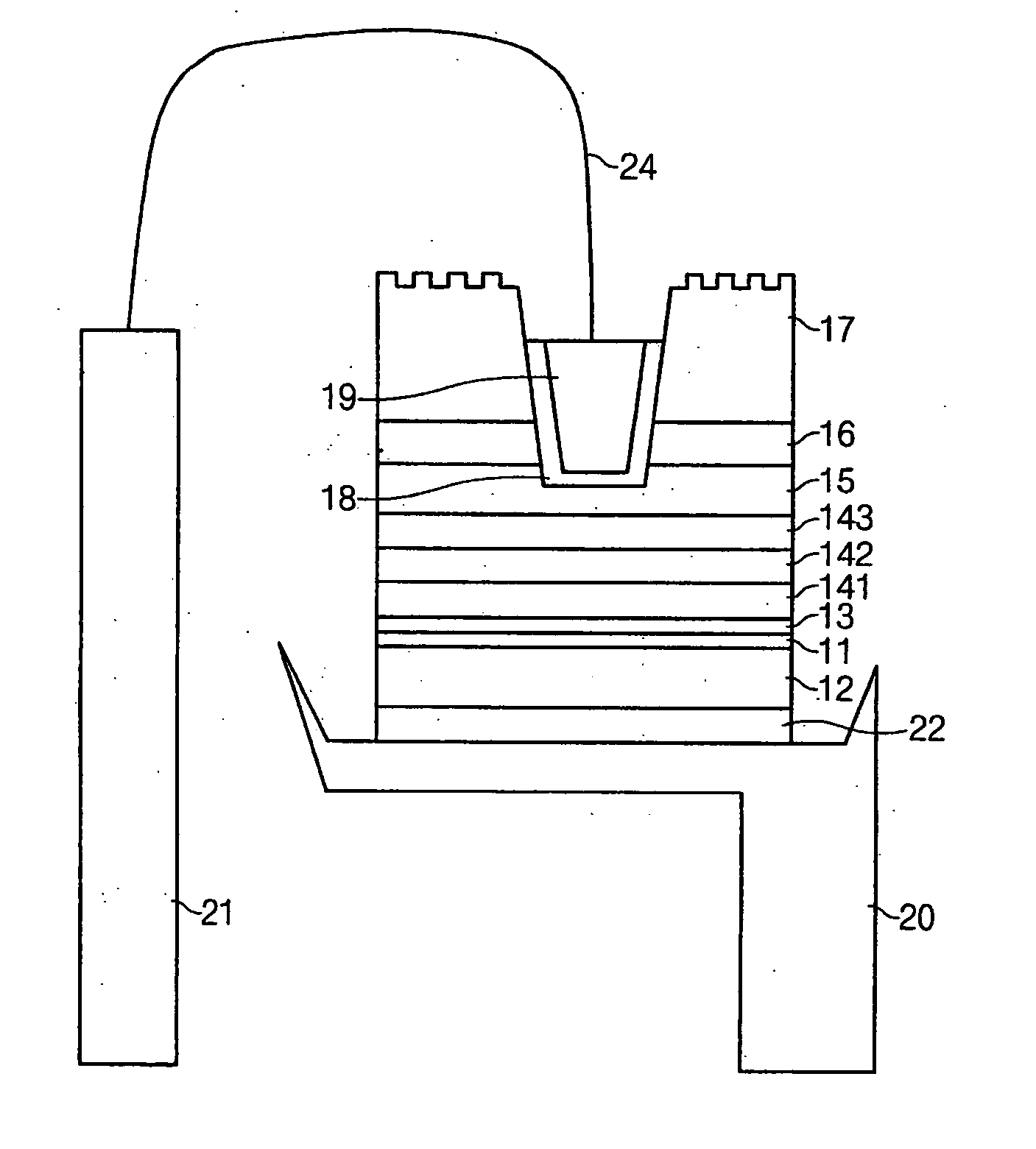

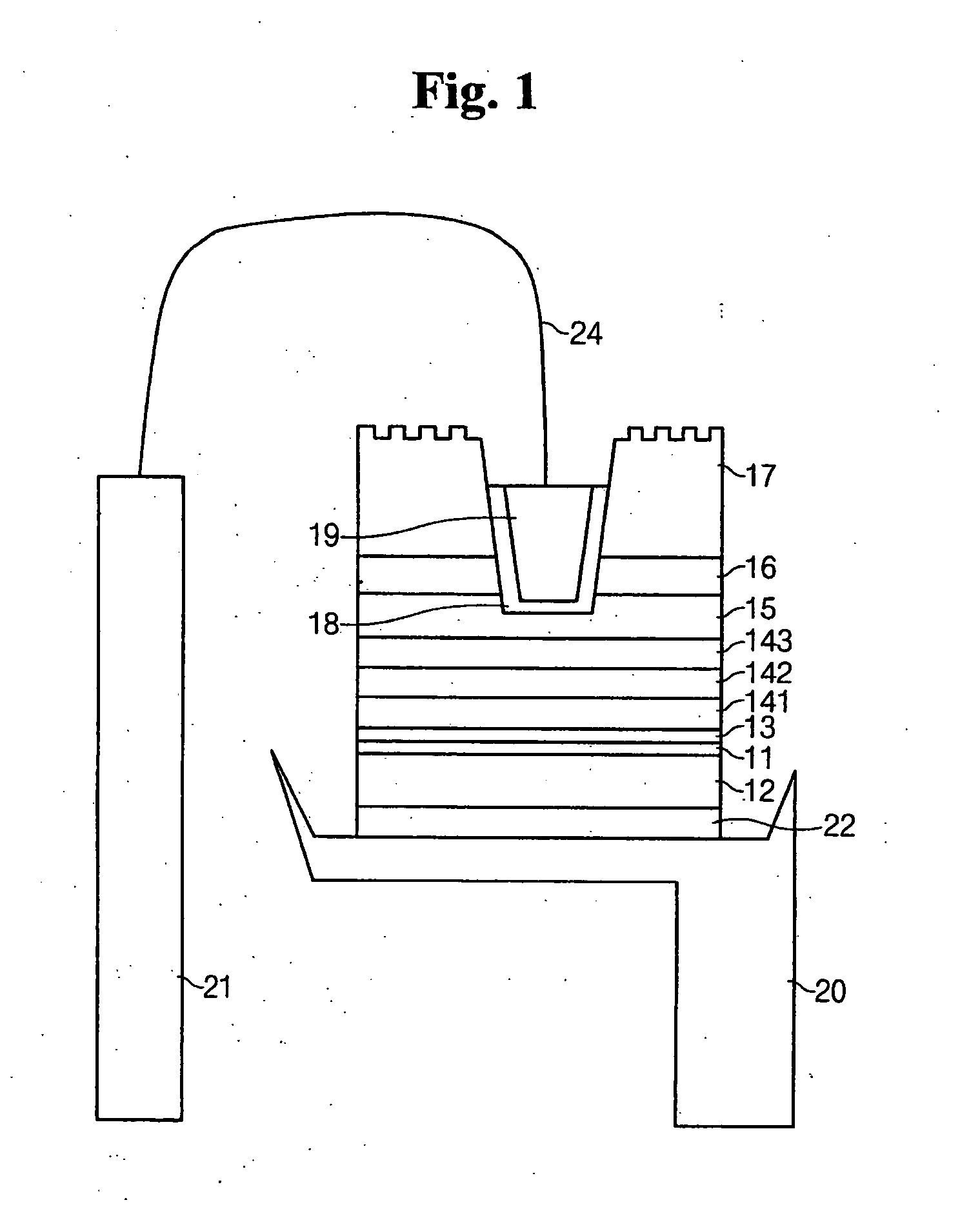

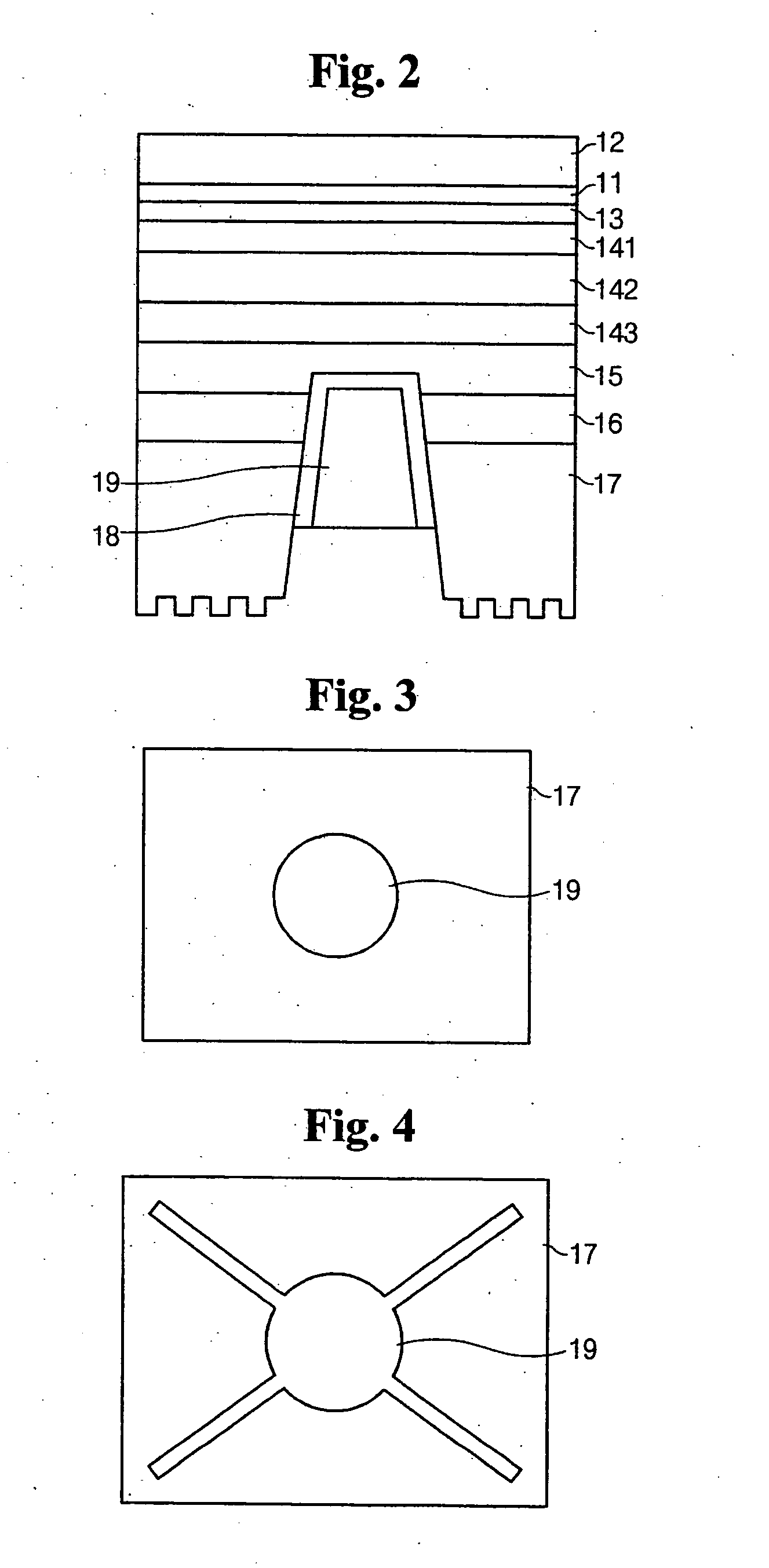

Nitride semiconductor laser device

InactiveUS20060078022A1Long lastingStable lateral modeOptical wave guidanceLaser active region structureContact layerTransverse mode

A nitride semiconductor laser device has an improved stability of the lateral mode under high output power and a longer lifetime, so that the device can be applied to write and read light sources for recording media with high capacity. The nitride semiconductor laser device includes an active layer, a p-side cladding layer, and a p-side contact layer laminated in turn. The device further includes a waveguide region of a stripe structure formed by etching from the p-side contact layer. The stripe width provided by etching is within the stripe range of 1 to 3 μm and the etching depth is below the thickness of the p-side cladding layer of 0.1 μm and above the active layer. Particularly, when a p-side optical waveguide layer includes a projection part of the stripe structure and a p-type nitride semiconductor layer on the projection part and the projection part of the p-side optical waveguide layer has a thickness of not more than 1 μm, an aspect ratio is improved in far field image. Moreover, the thickness of the p-side optical waveguide layer is greater than that of an n-side optical waveguide layer.

Owner:NICHIA CORP

Multi layered wound dressing

ActiveUS7759537B2Allowing versatilityReduce usagePlastersAdhesive dressingsWound dressingContact layer

A multi layered wound dressing for use on wounds producing high levels of exudate, the dressing comprising a transmission layer having a high MVTR; an absorbent core capable of absorbing and retaining exudates; and a wound contacting layer which transmits exudate to the absorbent core, the absorbent core and wound contacting layer limiting the lateral spread of exudate in the dressing to the region of the wound.

Owner:CONVATEC TECH INC

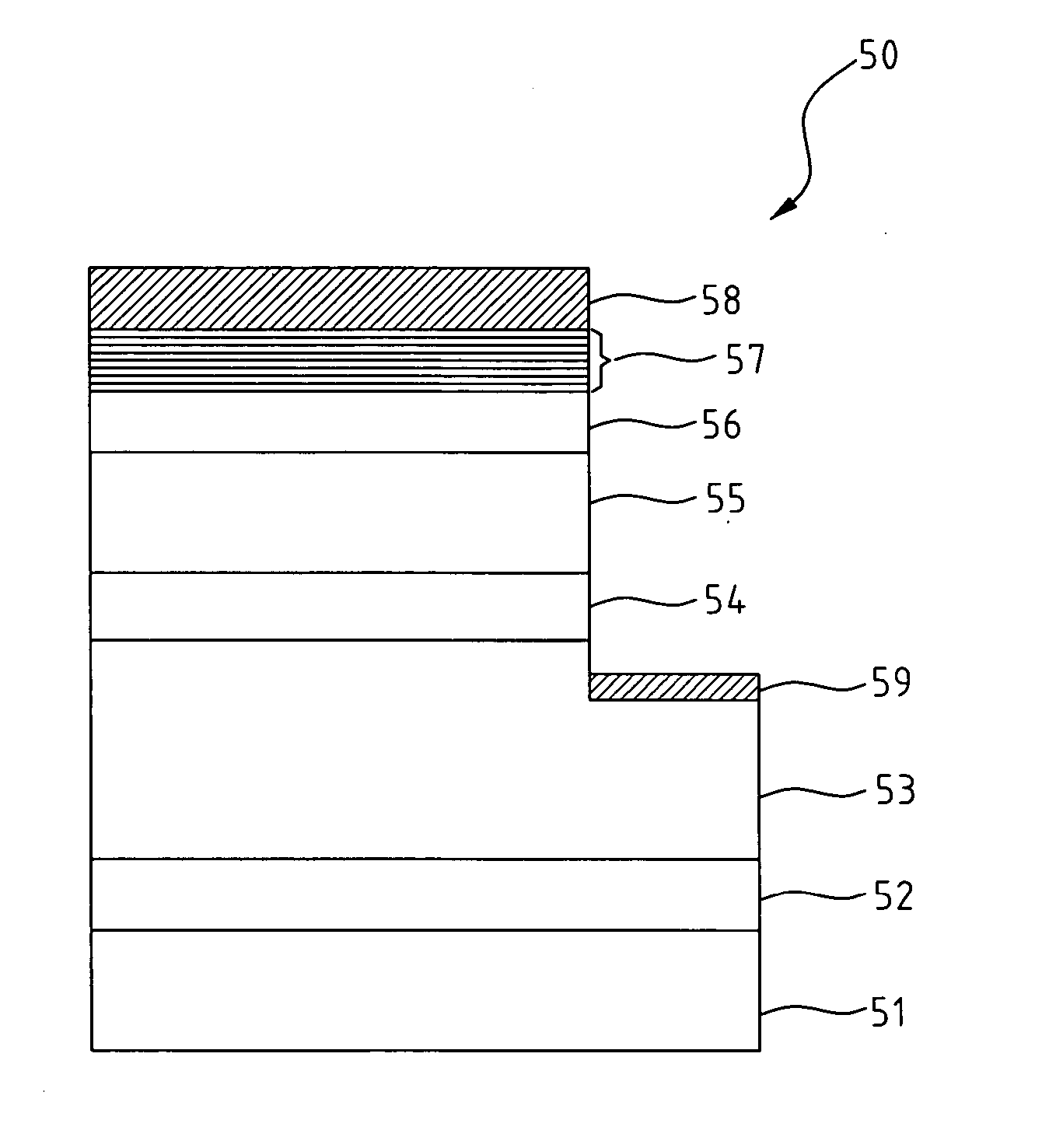

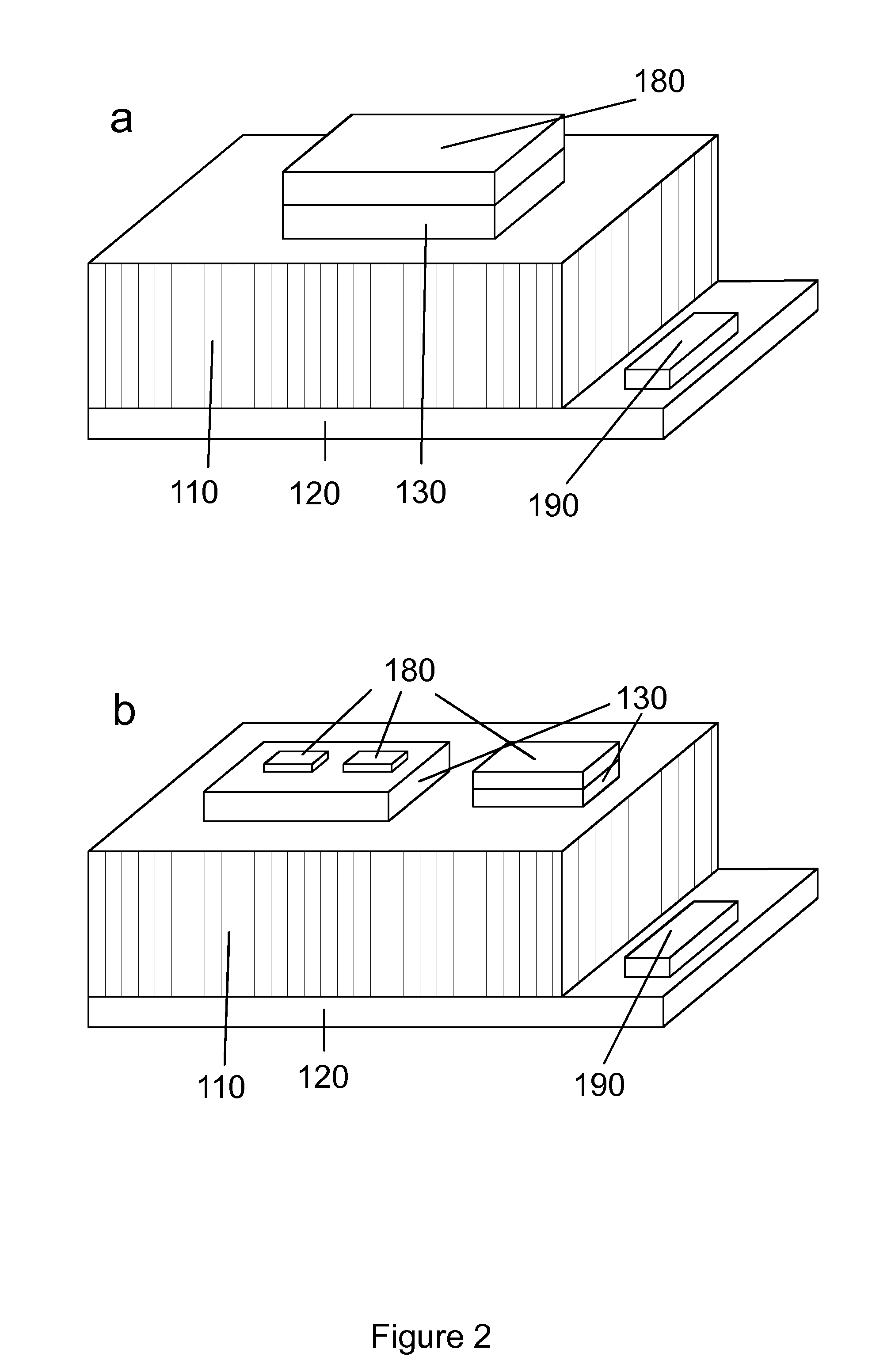

Gallium-nitride based light emitting diode structure with enhanced light illuminance

InactiveUS20060038193A1High light transmittanceConvenient lightingSemiconductor devicesIlluminanceQuantum well

Disclosed is a multi-quantum-well light emitting diode, which makes enormous adjustments and improvements over the conventional light emitting diode, and further utilizes a transparent contact layer of better transmittance efficiency, so as to significantly raise the illuminance of this light emitting diode and its light emission efficiency. The multi-quantum-well light emitting diode has a structure including: substrate, buffer layer, n-type gallium-nitride layer, active light-emitting-layer, p-type cladding layer, p-type contact layer, barrier buffer layer, transparent contact layer, and the n-type electrode layer.

Owner:FORMOSA EPITAXY INCORPORATION +1

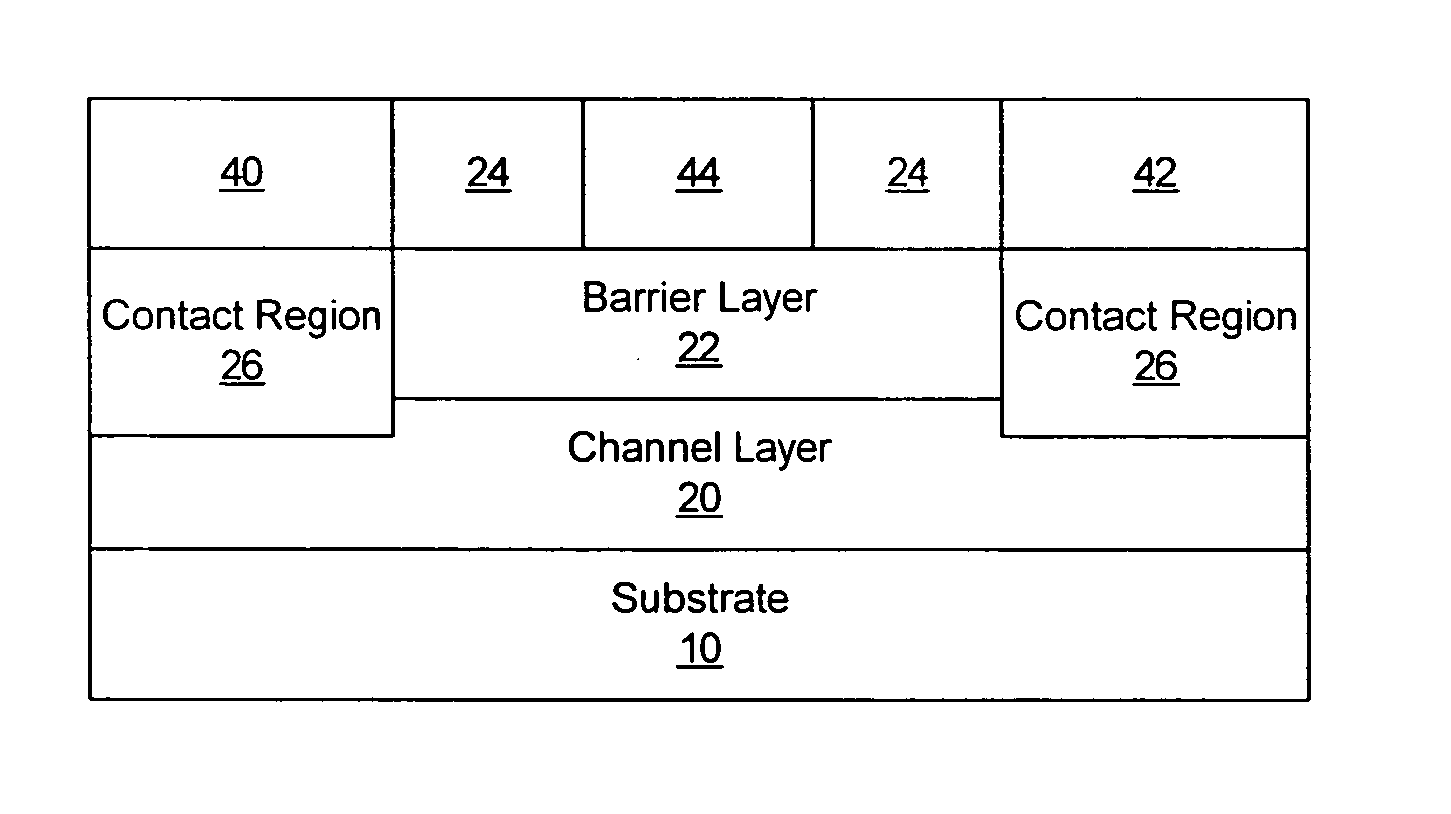

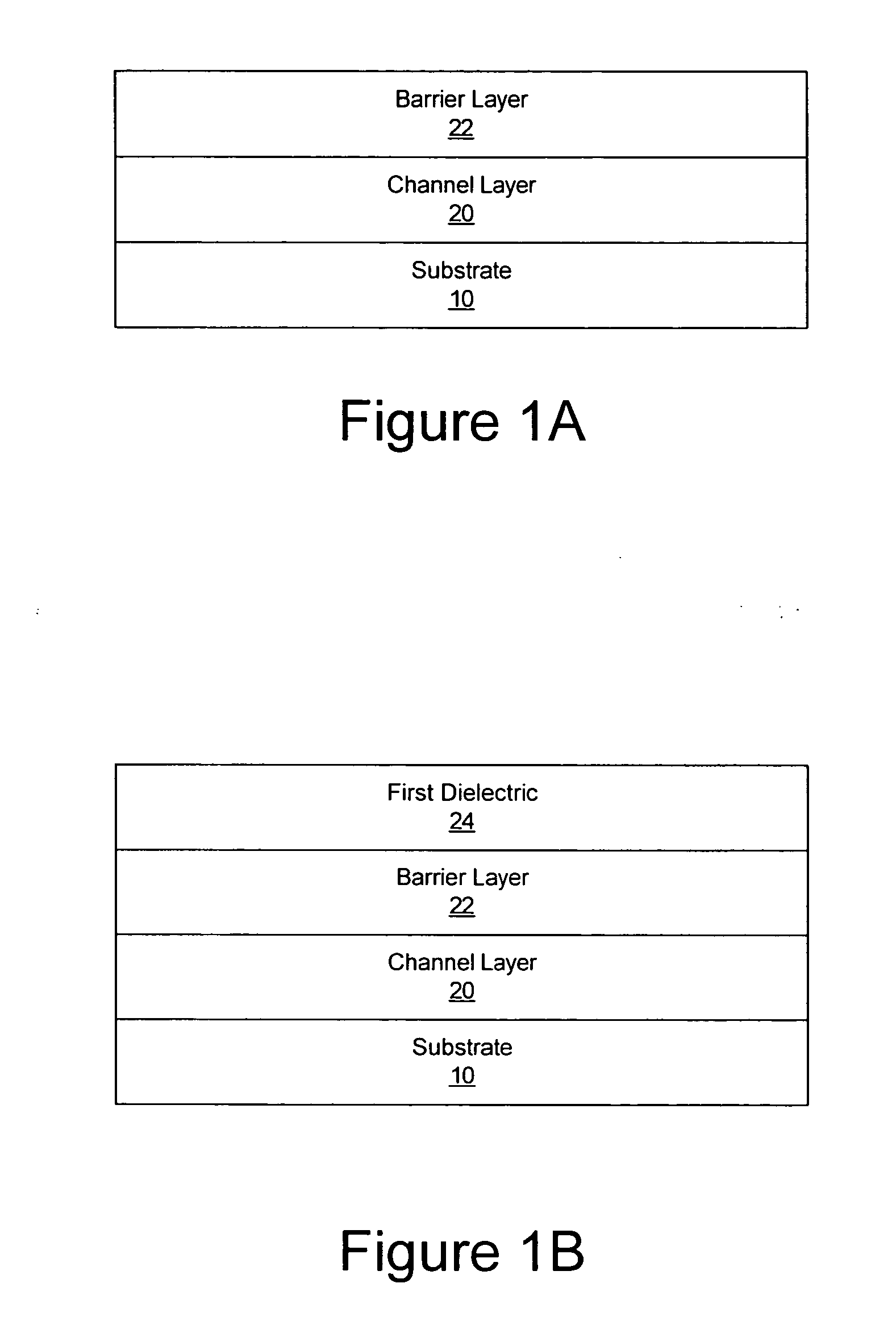

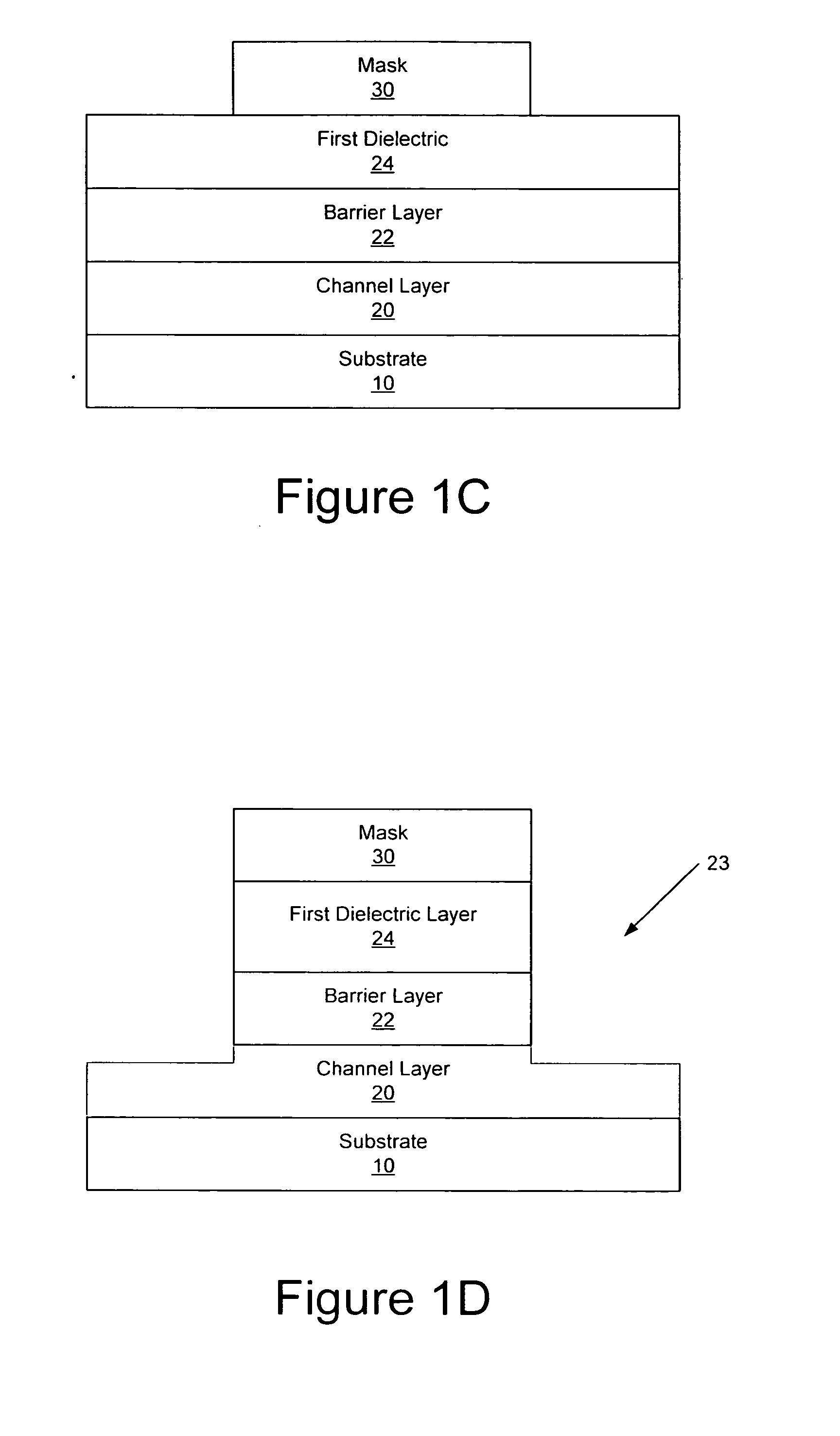

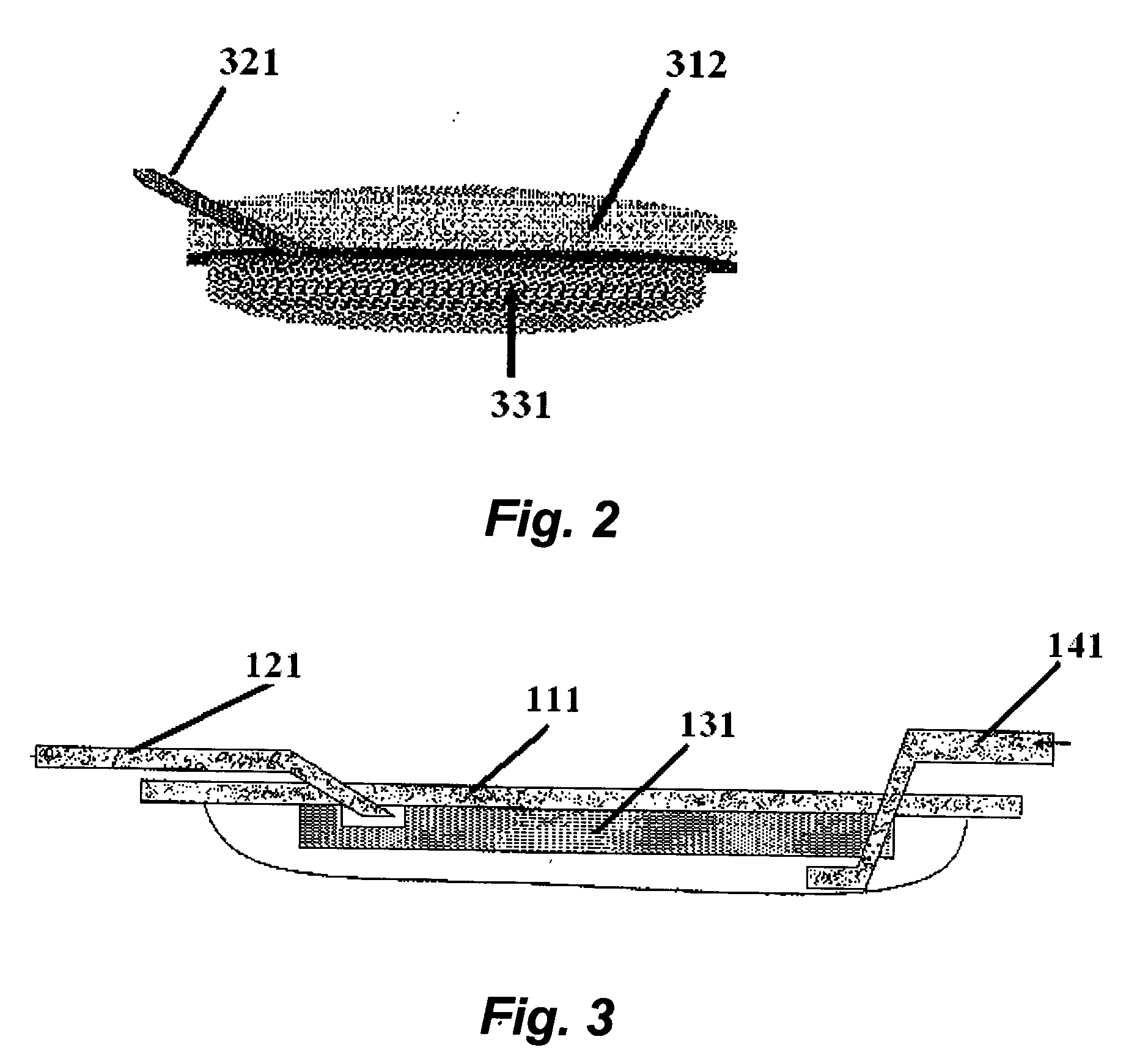

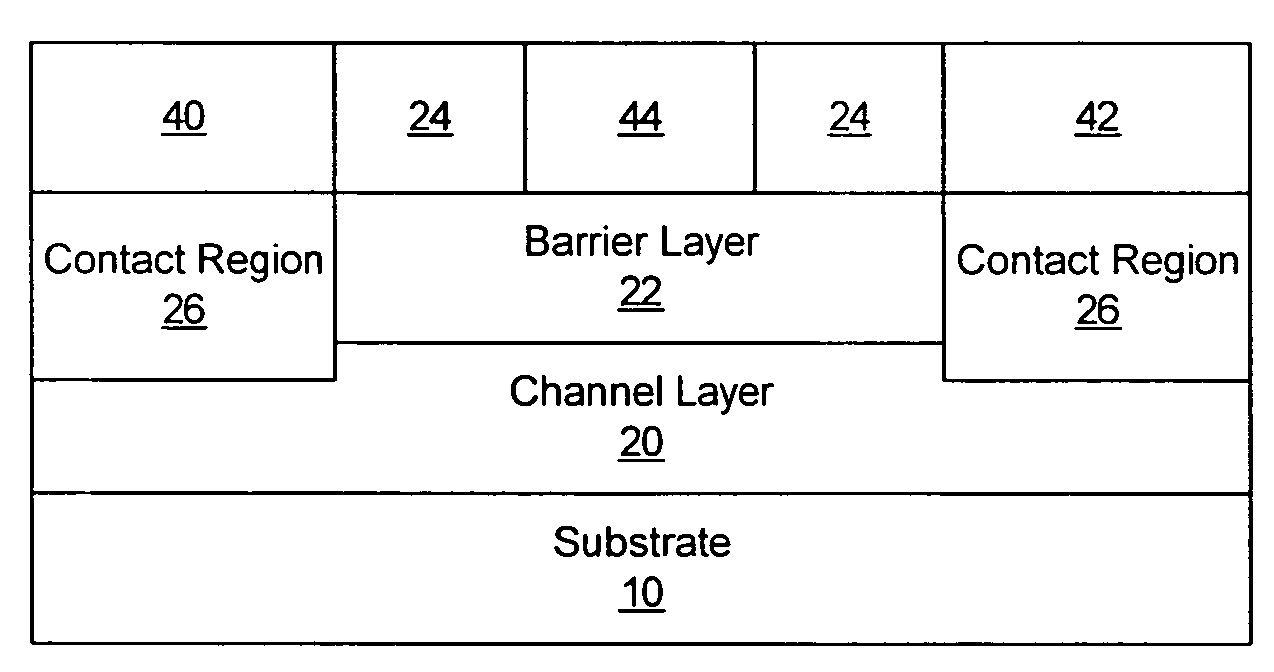

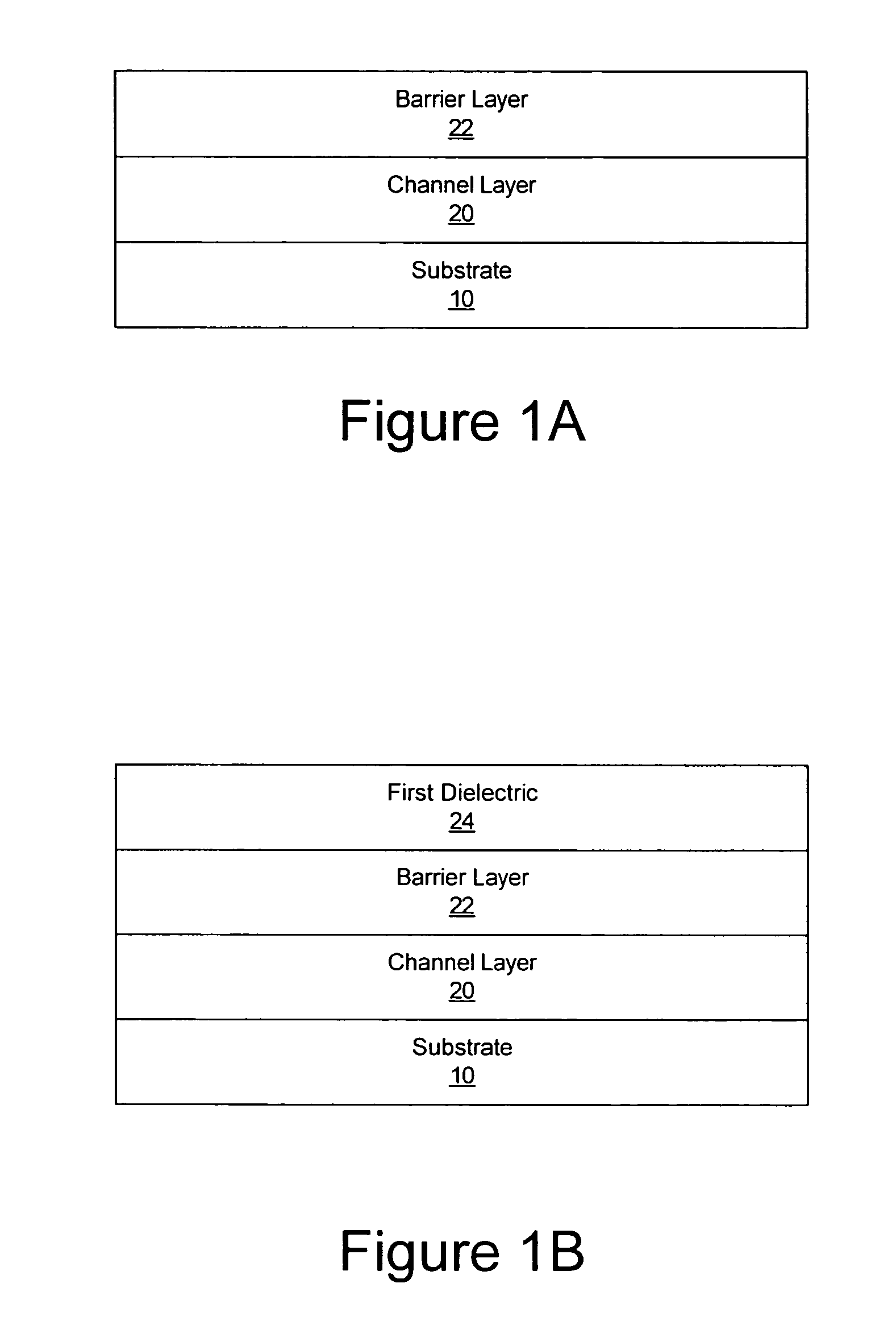

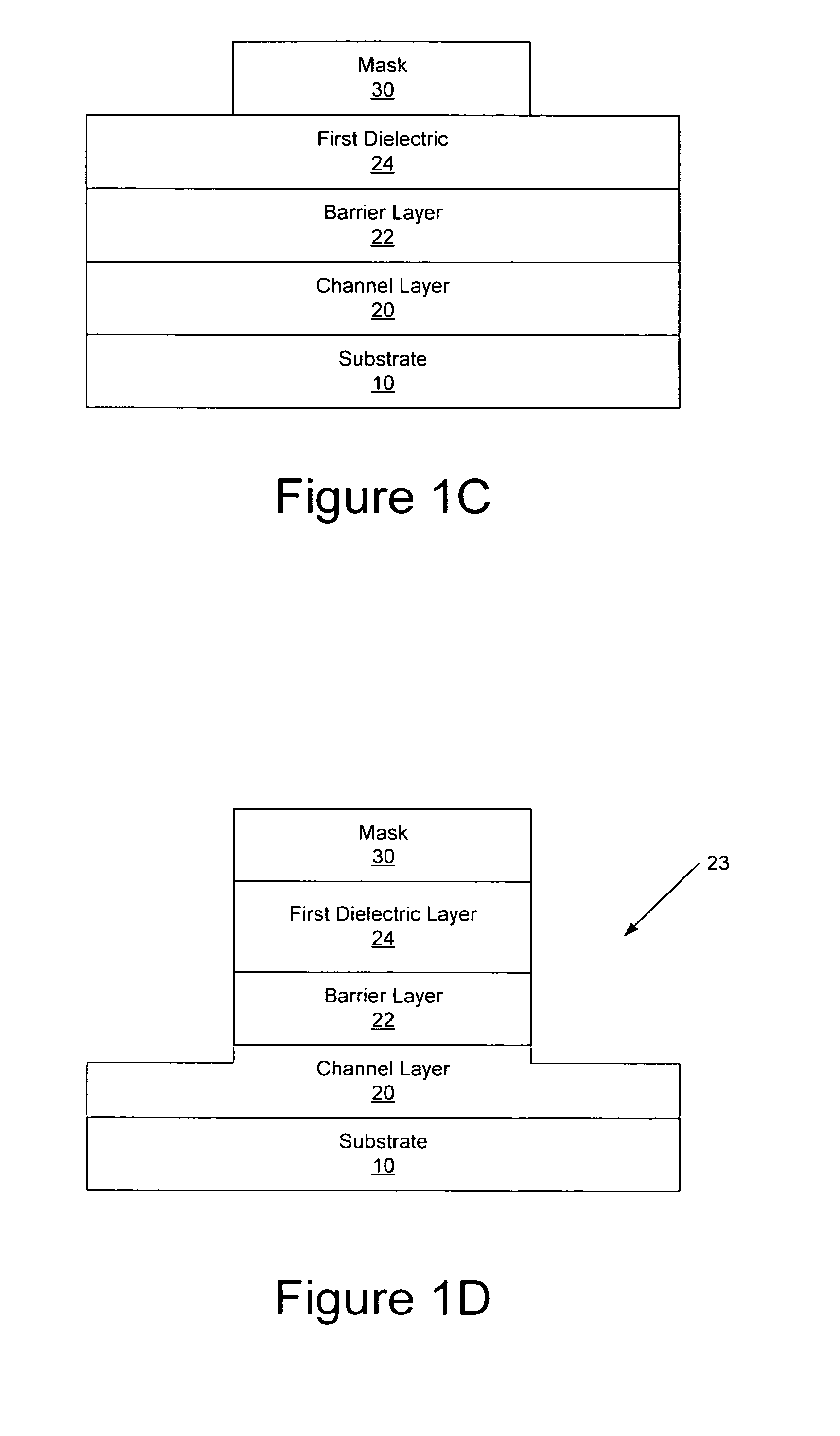

Methods of fabricating nitride-based transistors having regrown ohmic contact regions and nitride-based transistors having regrown ohmic contact regions

ActiveUS20050258451A1High electron mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesLow temperature depositionSemiconductor materials

Transistor fabrication includes forming a nitride-based channel layer on a substrate, forming a barrier layer on the nitride-based channel layer, forming a contact recess in the barrier layer to expose a contact region of the nitride-based channel layer, forming a contact layer on the exposed contact region of the nitride-based channel layer, for example, using a low temperature deposition process, forming an ohmic contact on the contact layer and forming a gate contact disposed on the barrier layer adjacent the ohmic contact. A high electron mobility transistor (HEMT) and methods of fabricating a HEMT are also provided. The HEMT includes a nitride-based channel layer on a substrate, a barrier layer on the nitride-based channel layer, a contact recess in the barrier layer that extends into the channel layer, an n-type nitride-based semiconductor material contact region on the nitride-based channel layer in the contact recess, an ohmic contact on the nitride-based contact region and a gate contact disposed on the barrier layer adjacent the ohmic contact. The n-type nitride-based semiconductor material contact region and the nitride-based channel layer include a surface area enlargement structure.

Owner:CREE INC

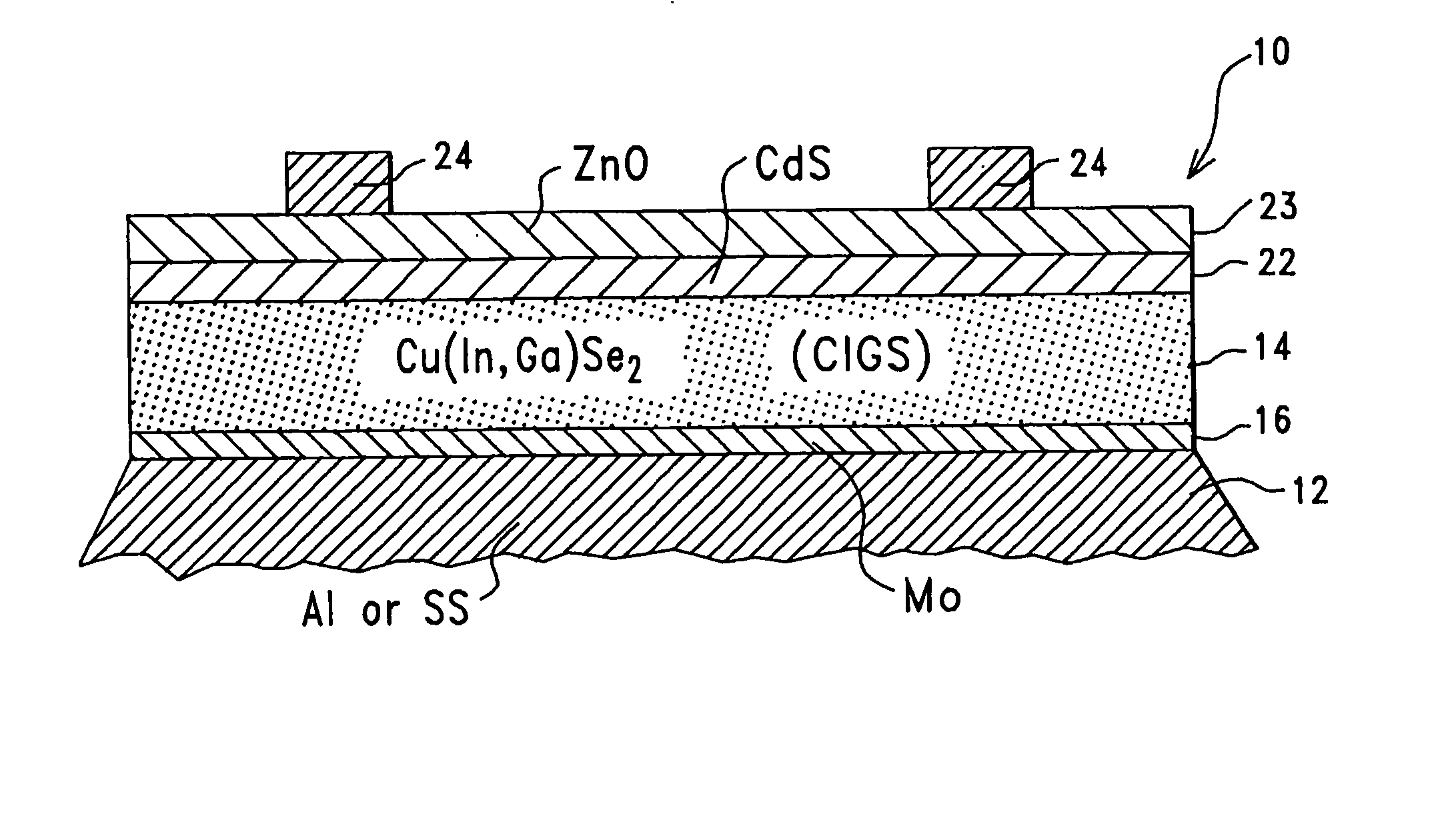

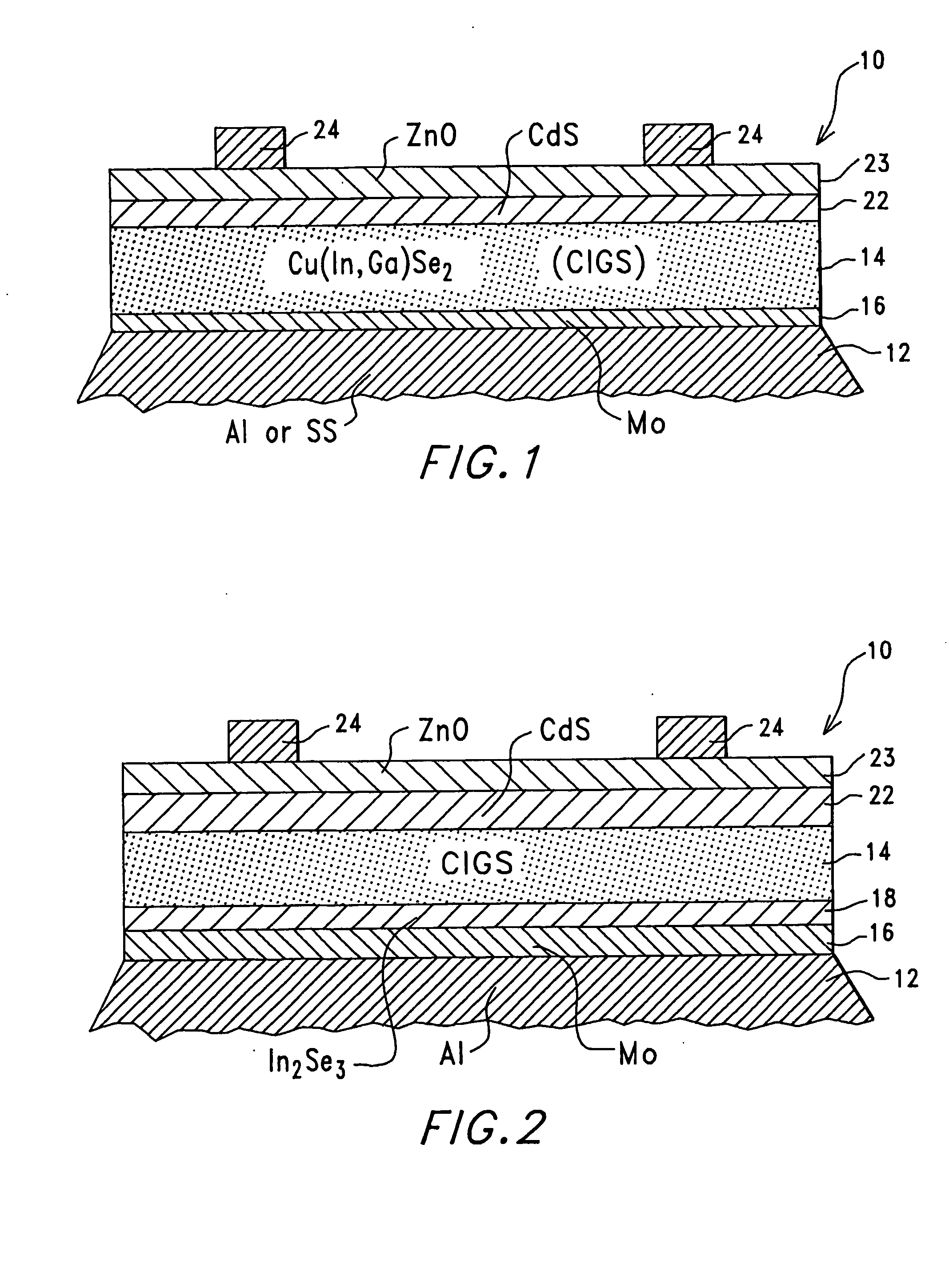

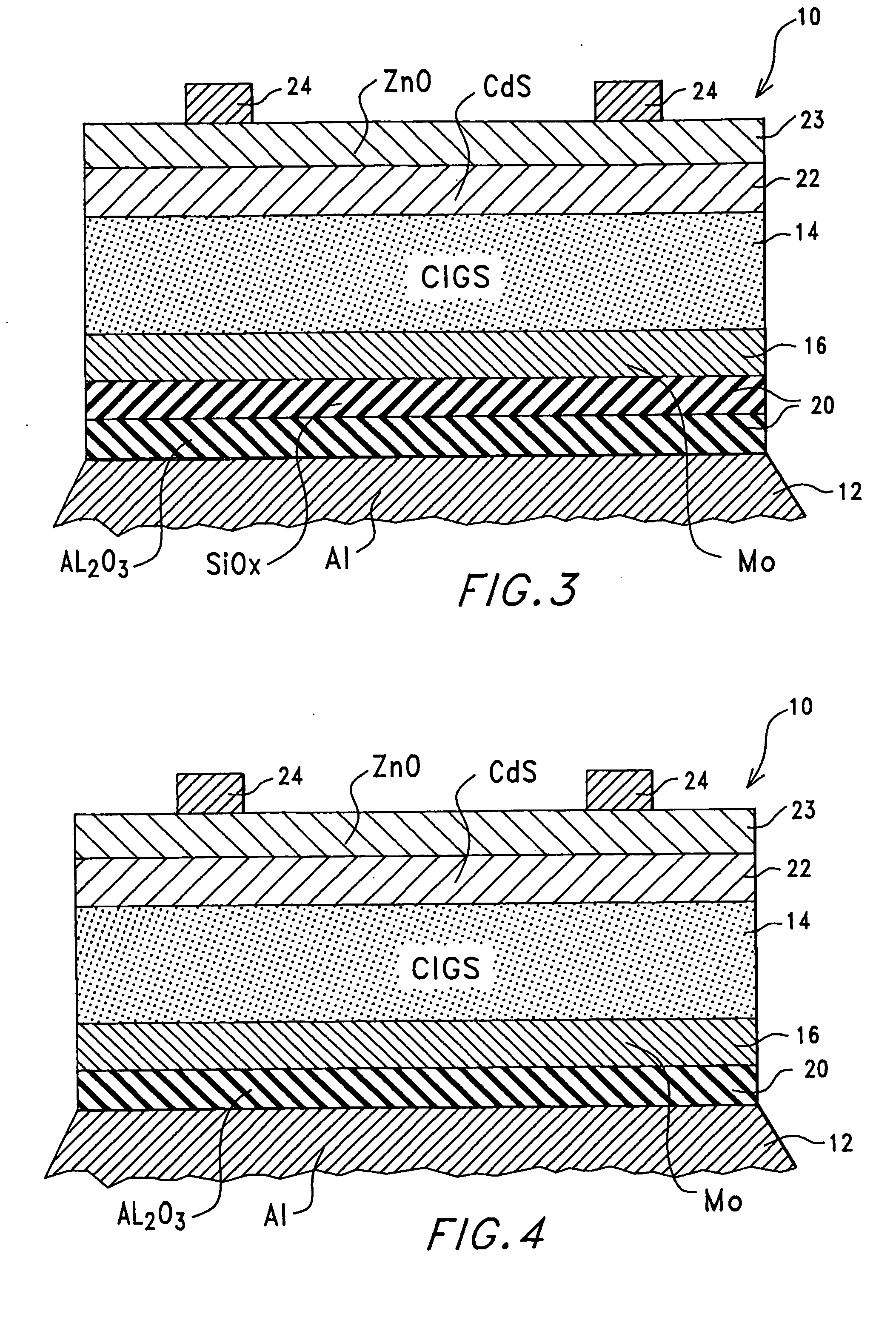

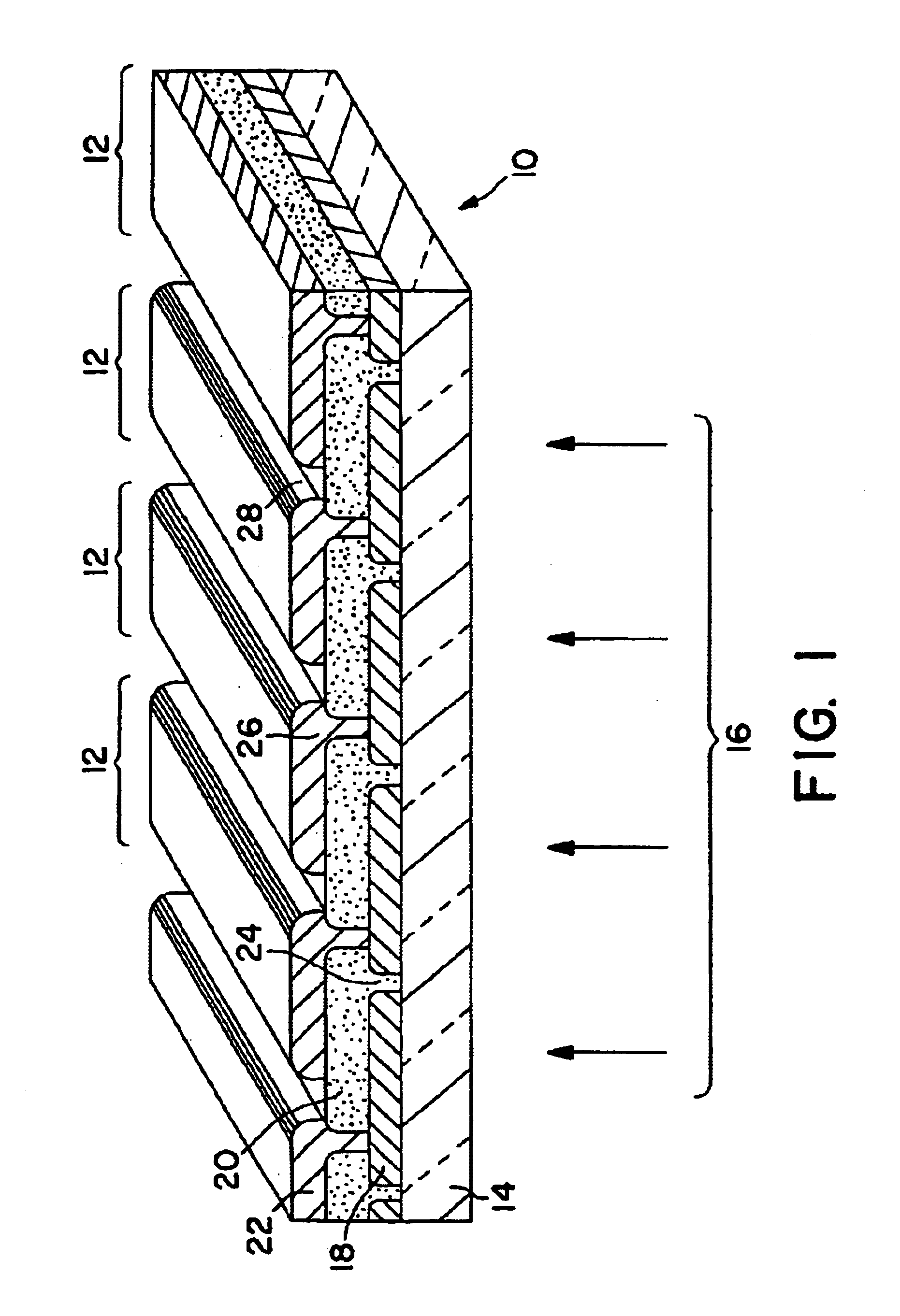

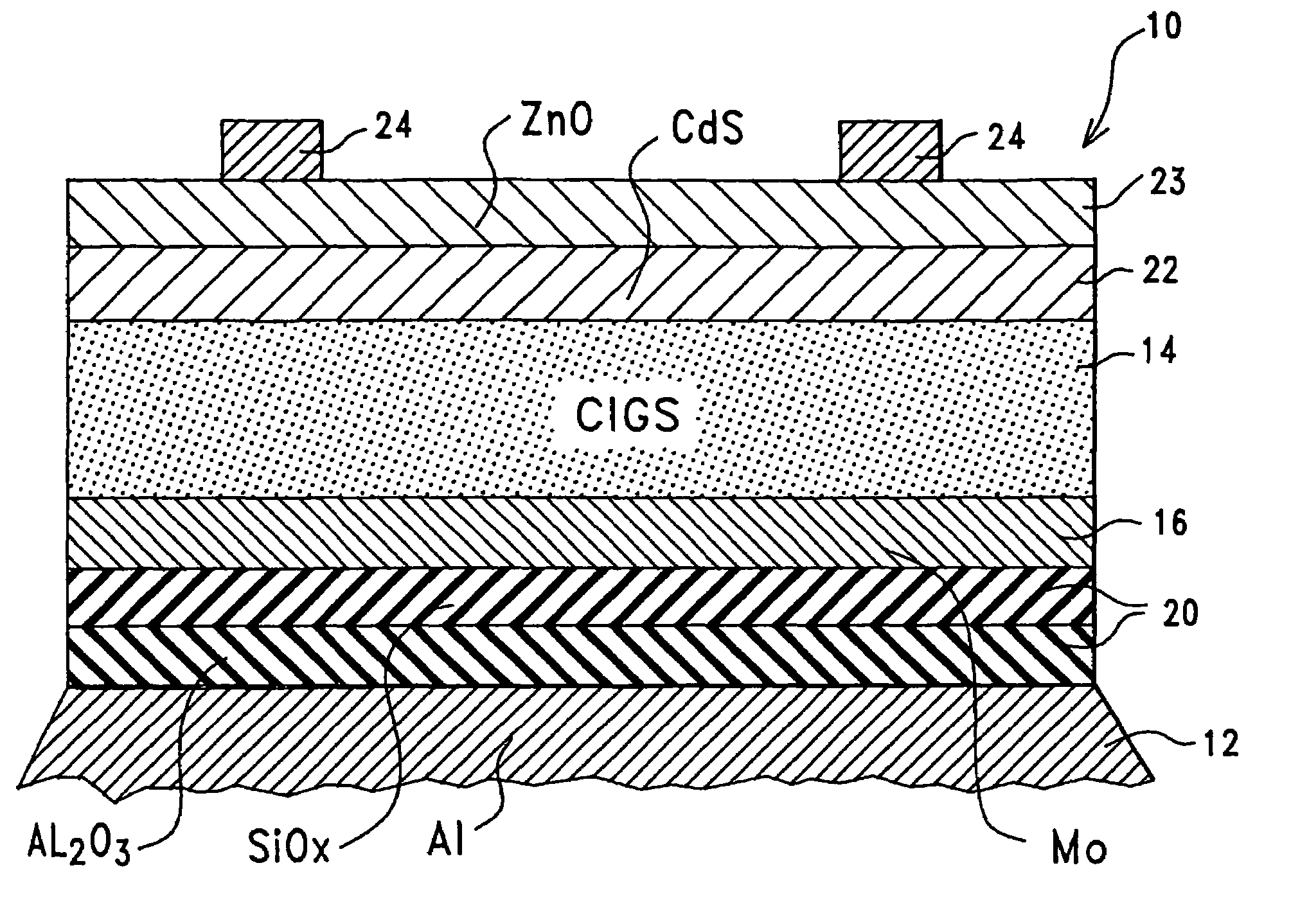

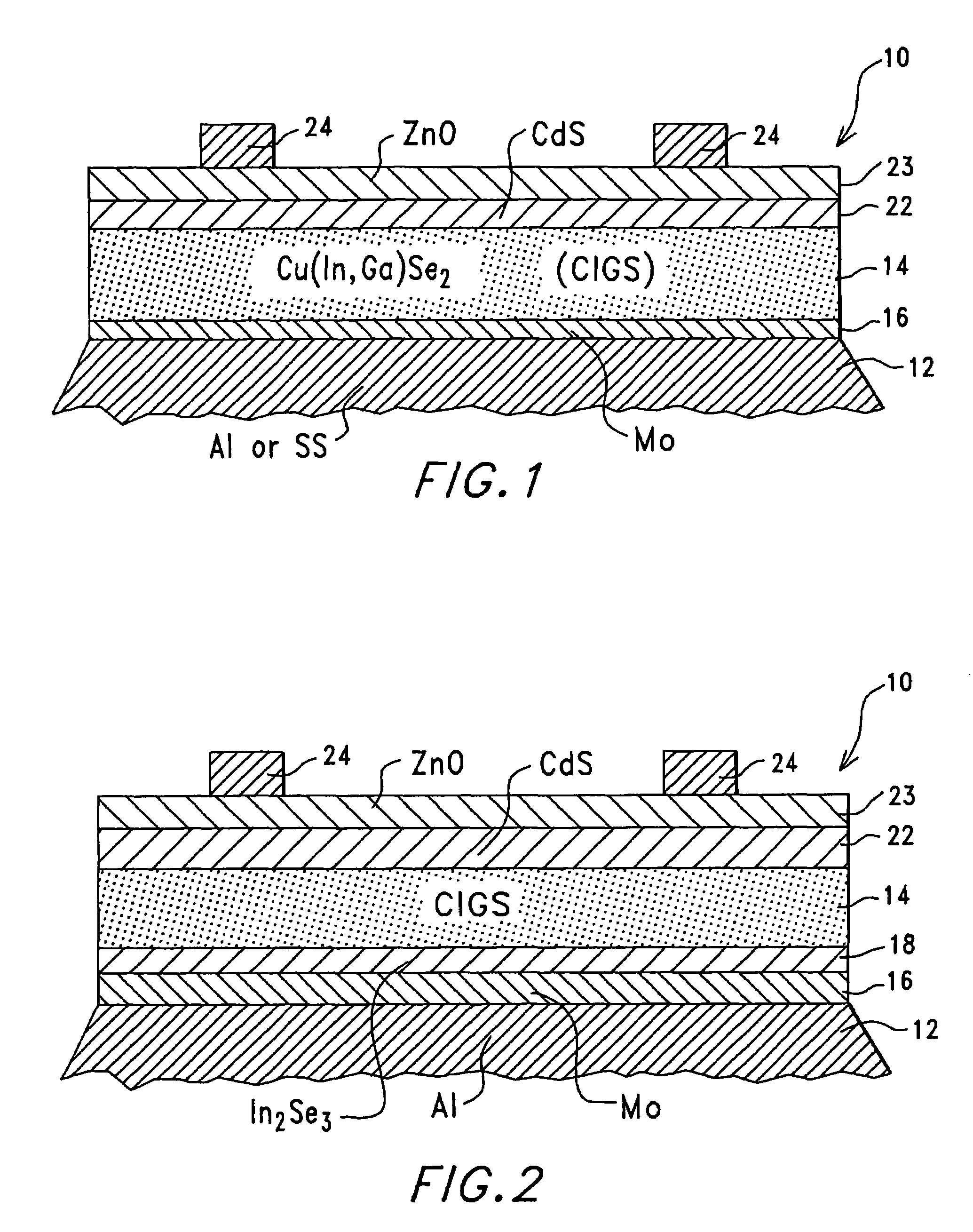

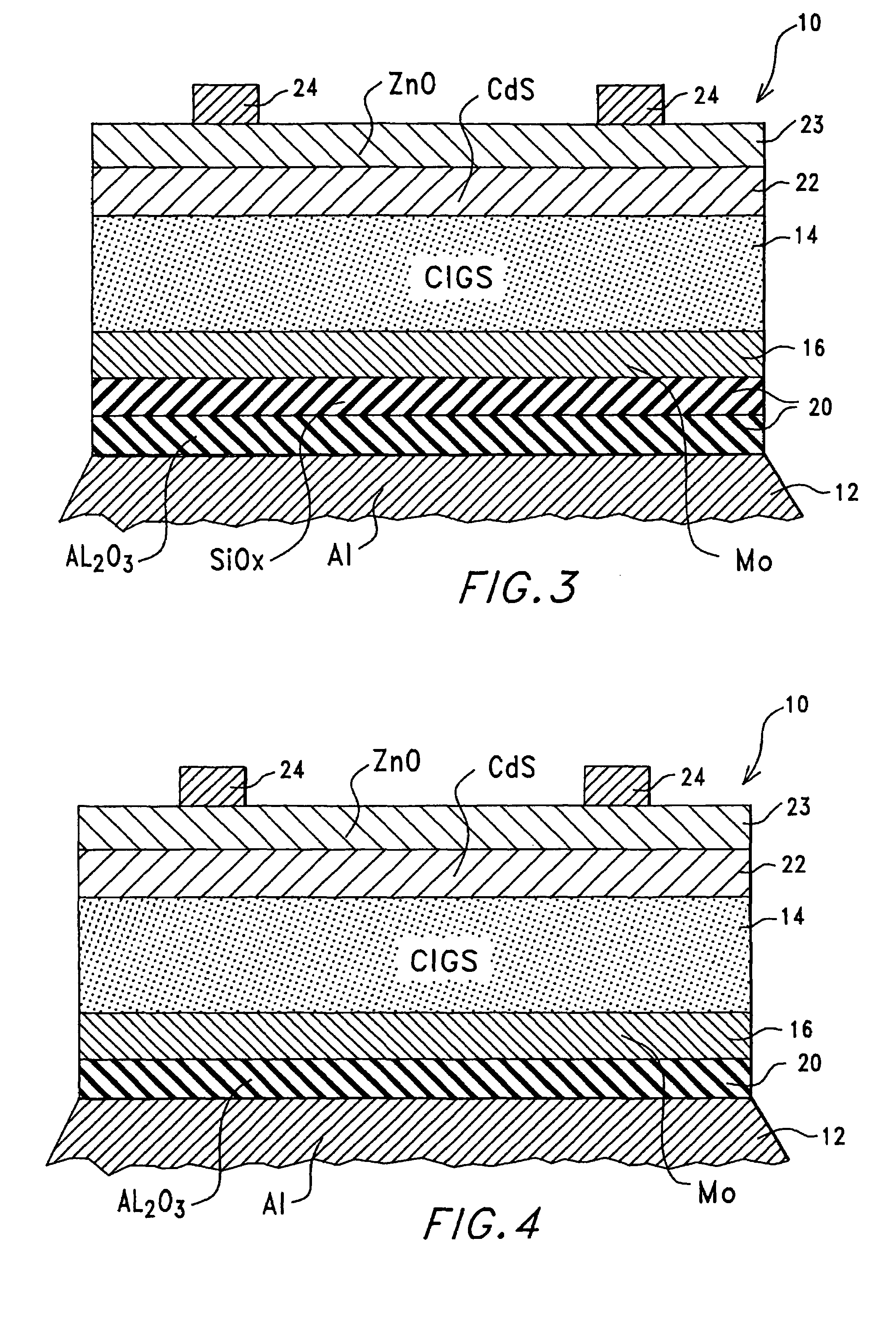

Thin-film solar cell fabricated on a flexible metallic substrate

A thin-film solar cell (10) is provided. The thin-film solar cell (10) comprises a flexible metallic substrate (12) a having a first surface and a second surface. A back metal contact layer (16) is deposited on the first surface of the flexible metallic substrate (12). A semiconductor absorber layer (14) is deposited on the back metal contact. A photoactive film deposited on the semiconductor absorber layer (14) forms a heterojunction structure and a grid contact (24) deposited on the heterjunction structure. The flexible metal substrate (12) can be constructed of either aluminium or stainless steel. Furthermore, a method of constructing a solar cell is provided. The method comprises providing an aluminum substrate (12), depositing a semiconductor absorber layer (14) on the aluminum substrate (12), and insulating the aluminum substrate (12) from the semiconductor absorber layer (14) to inhibit reaction between the aluminum substrate (12) and the semiconductor absorber layer (14).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

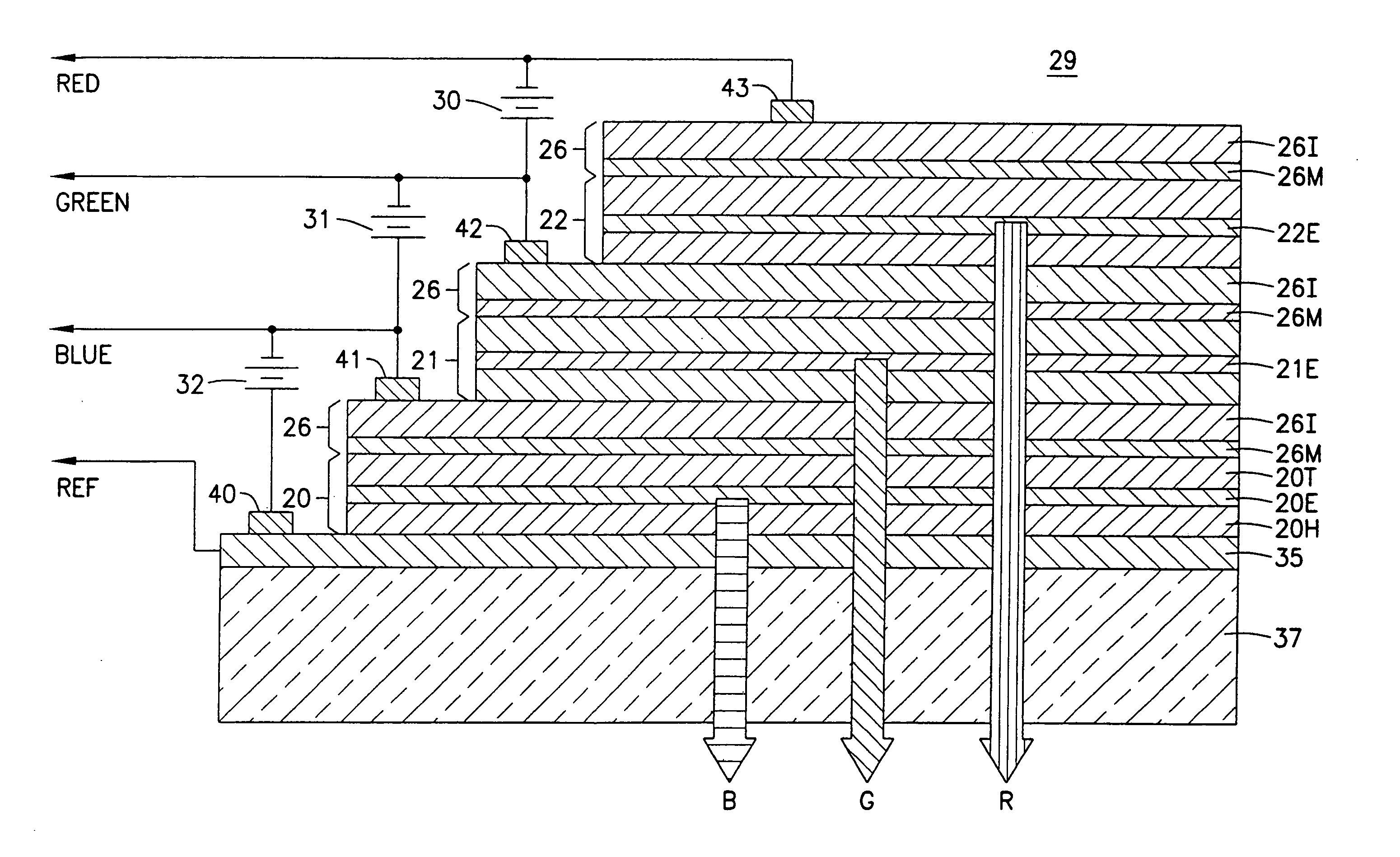

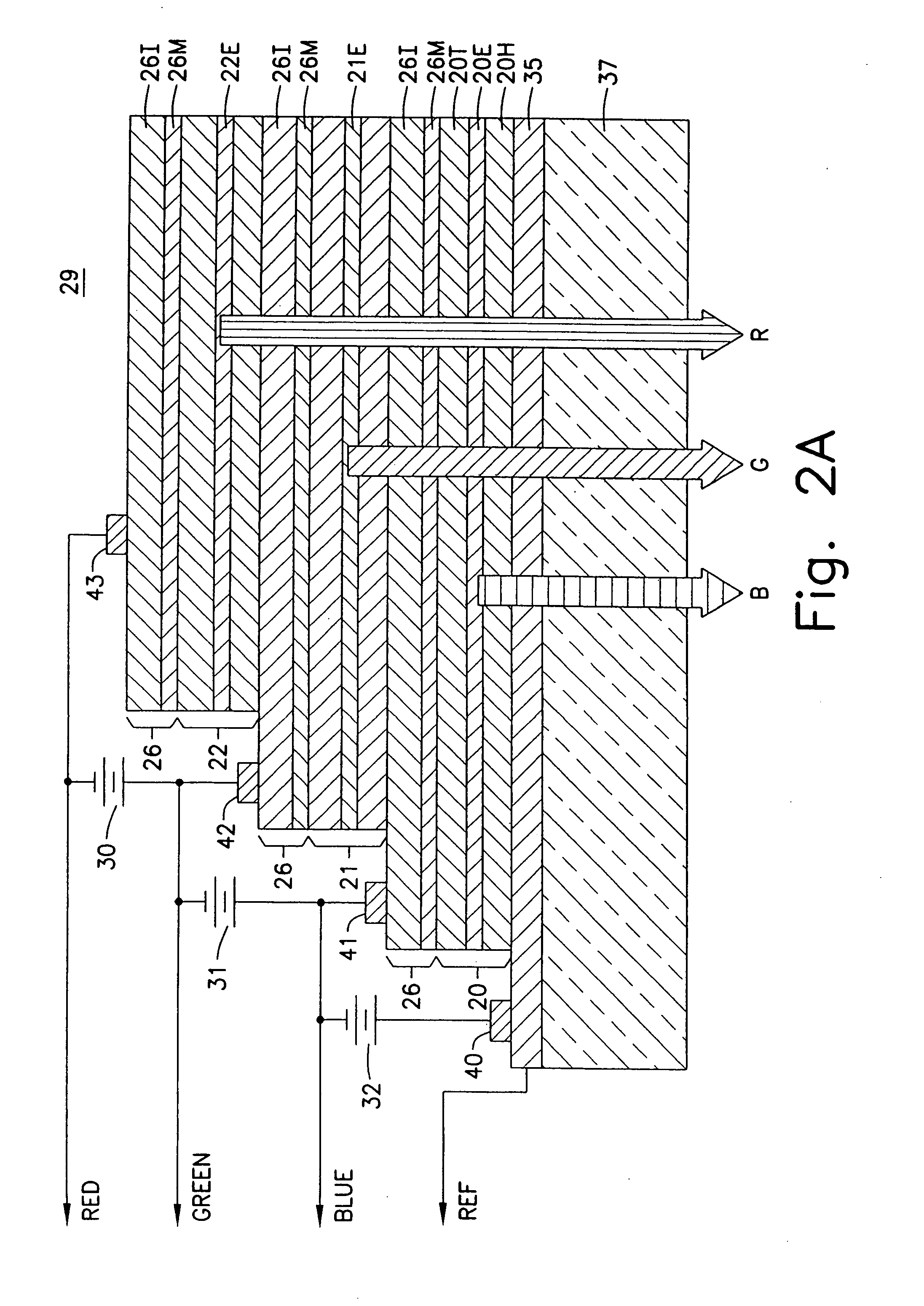

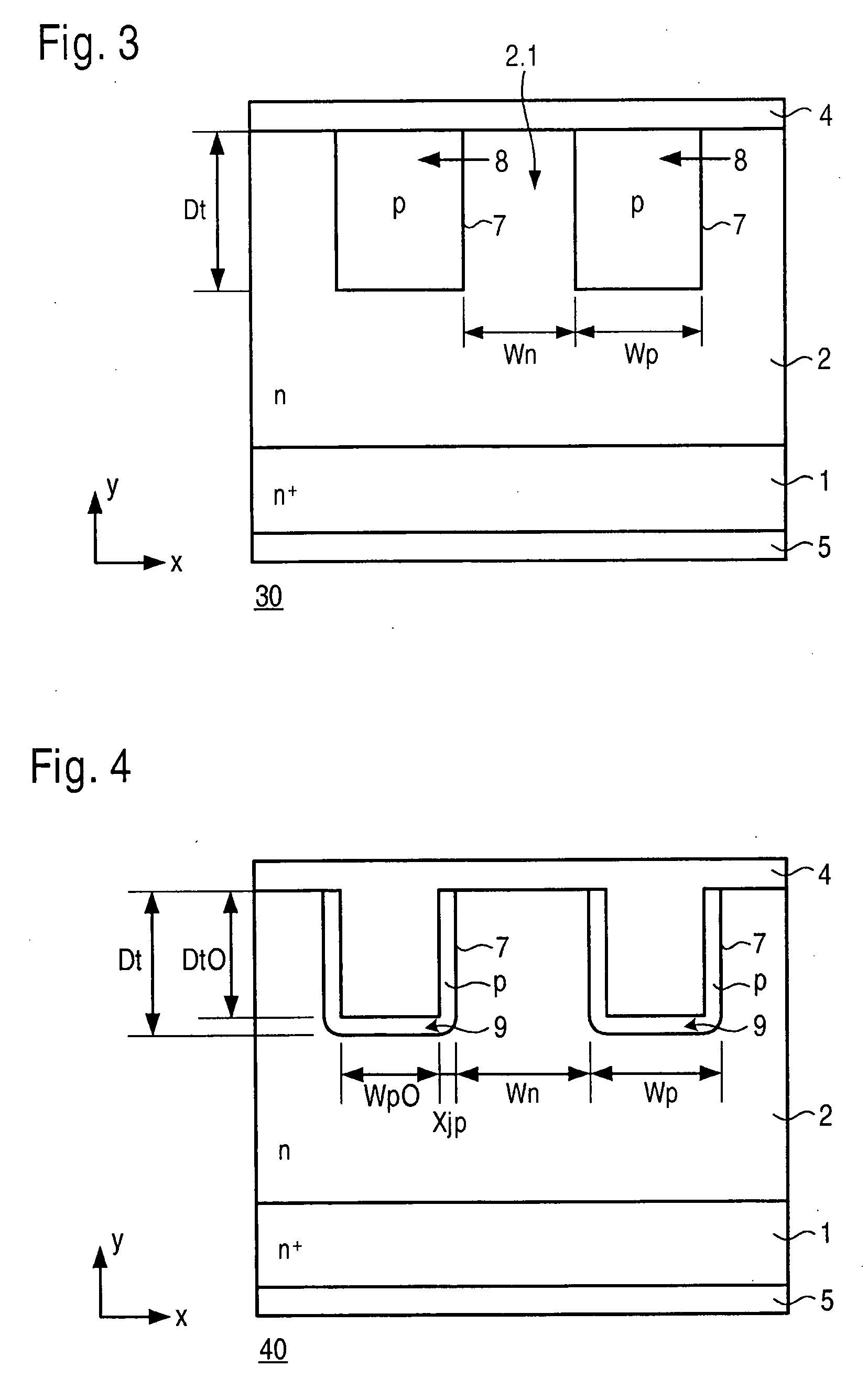

Transparent contacts for organic devices

InactiveUS20070132369A1Low production costSubstantially transparentStatic indicating devicesSolid-state devicesHead-up displayEngineering

A multicolor organic light emitting device employs vertically stacked layers of double heterostructure devices which are fabricated from organic compounds. The vertical stacked structure is formed on a glass base having a transparent coating of ITO or similar metal to provide a substrate. Deposited on the substrate is the vertical stacked arrangement of three double heterostructure devices, each fabricated from a suitable organic material. Stacking is implemented such that the double heterostructure with the longest wavelength is on the top of the stack. This constitutes the device emitting red light on the top with the device having the shortest wavelength, namely, the device emitting blue light, on the bottom of the stack. Located between the red and blue device structures is the green device structure. The devices are configured as stacked to provide a staircase profile whereby each device is separated from the other by a thin transparent conductive contact layer to enable light emanating from each of the devices to pass through the semitransparent contacts and through the lower device structures while further enabling each of the devices to receive a selective bias. The devices are substantially transparent when de-energized, making them useful for heads-up display applications.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Electrically programmable memory element with improved contacts

InactiveUS6969866B1Reduced programming energyReduce cell areaSemiconductor/solid-state device detailsSolid-state devicesPhase-change memoryEngineering

A memory element comprising a volume of phase change memory material; and first and second contact for supplying an electrical signal to the memory material, wherein the first contact comprises a conductive sidewall spacer. Alternately, the first contact may comprise a contact layer having an edge adjacent to the memory material.

Owner:OVONYX MEMORY TECH LLC

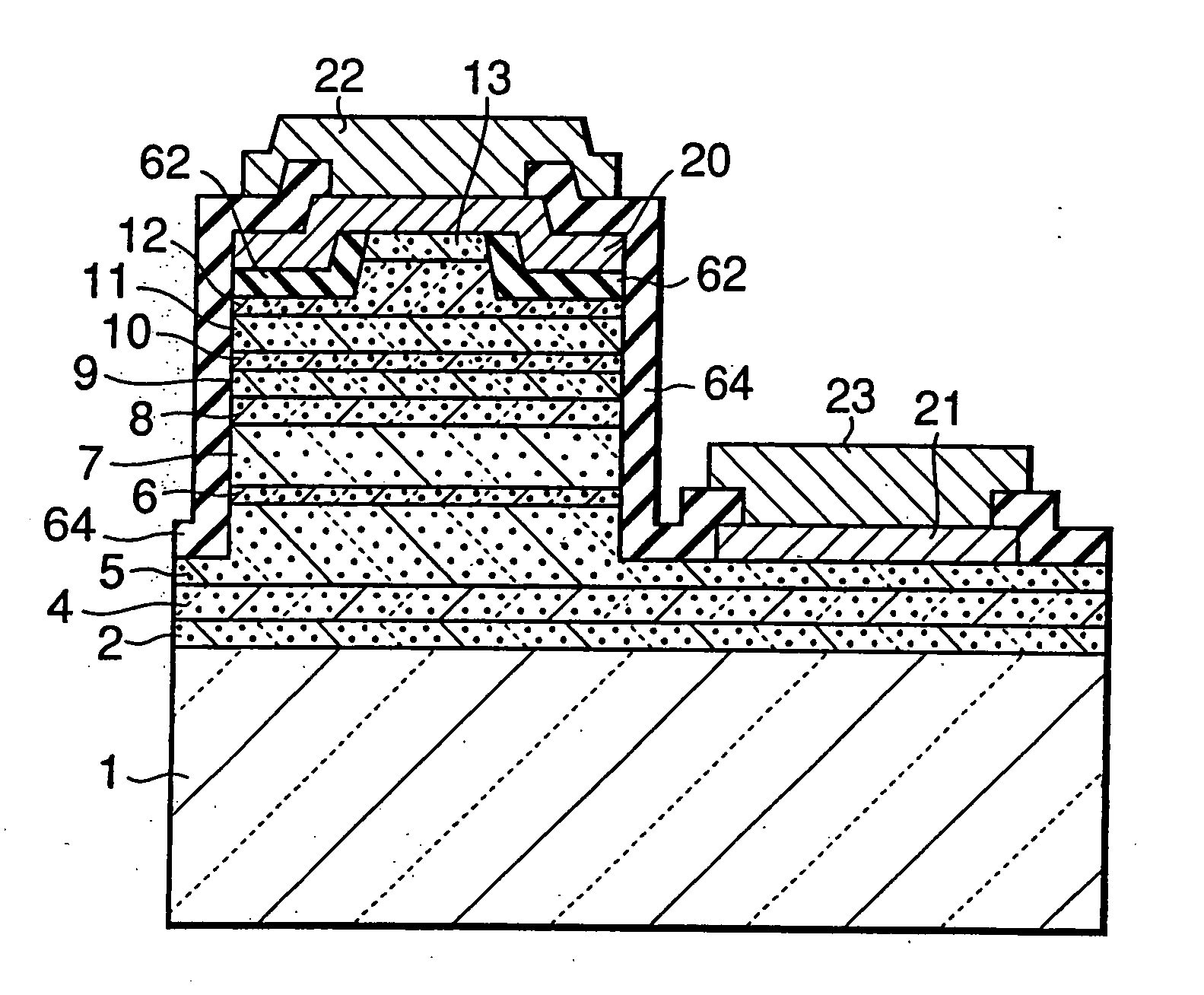

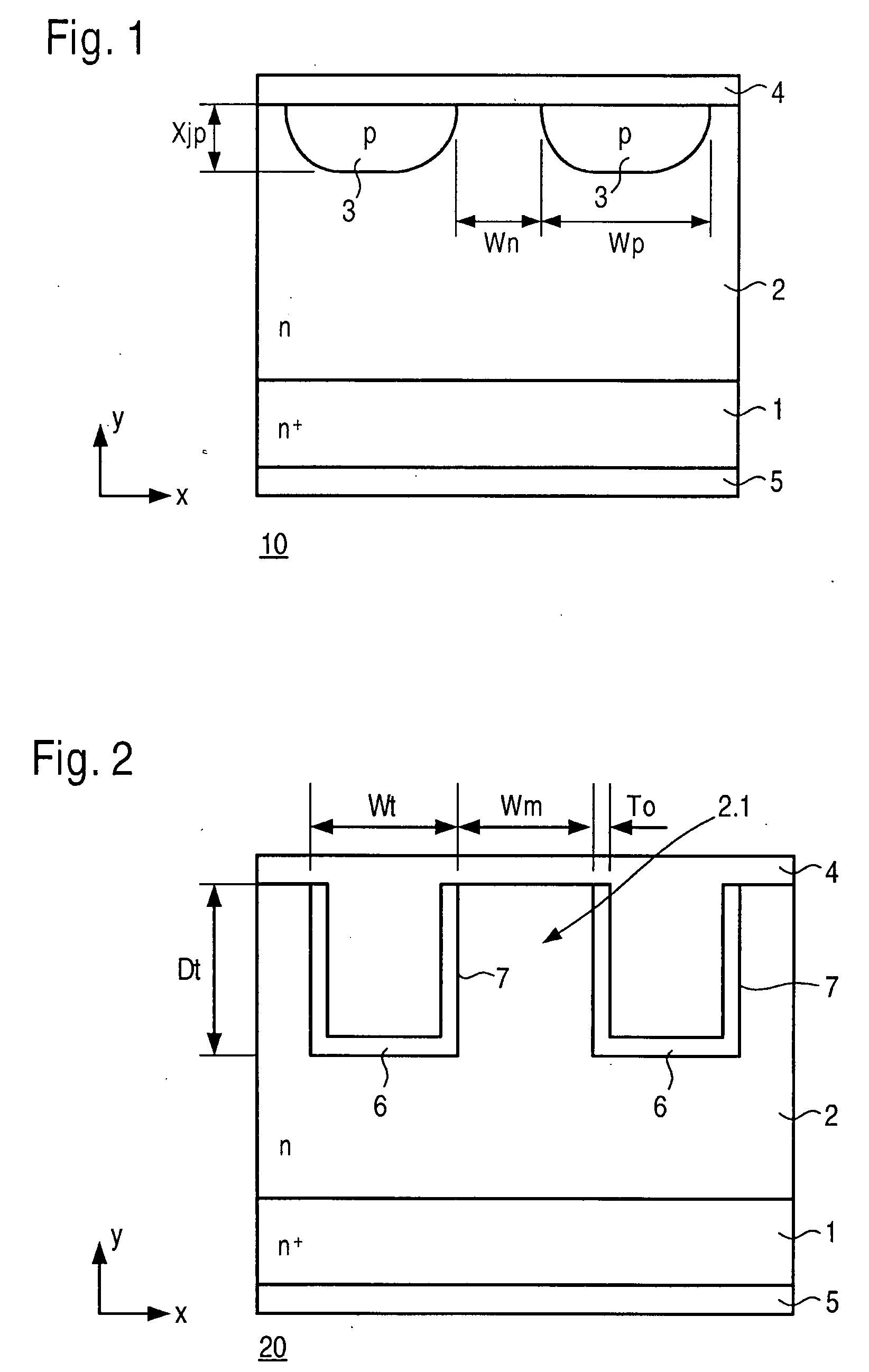

Semiconductor Device And Method For Manufacturing Same

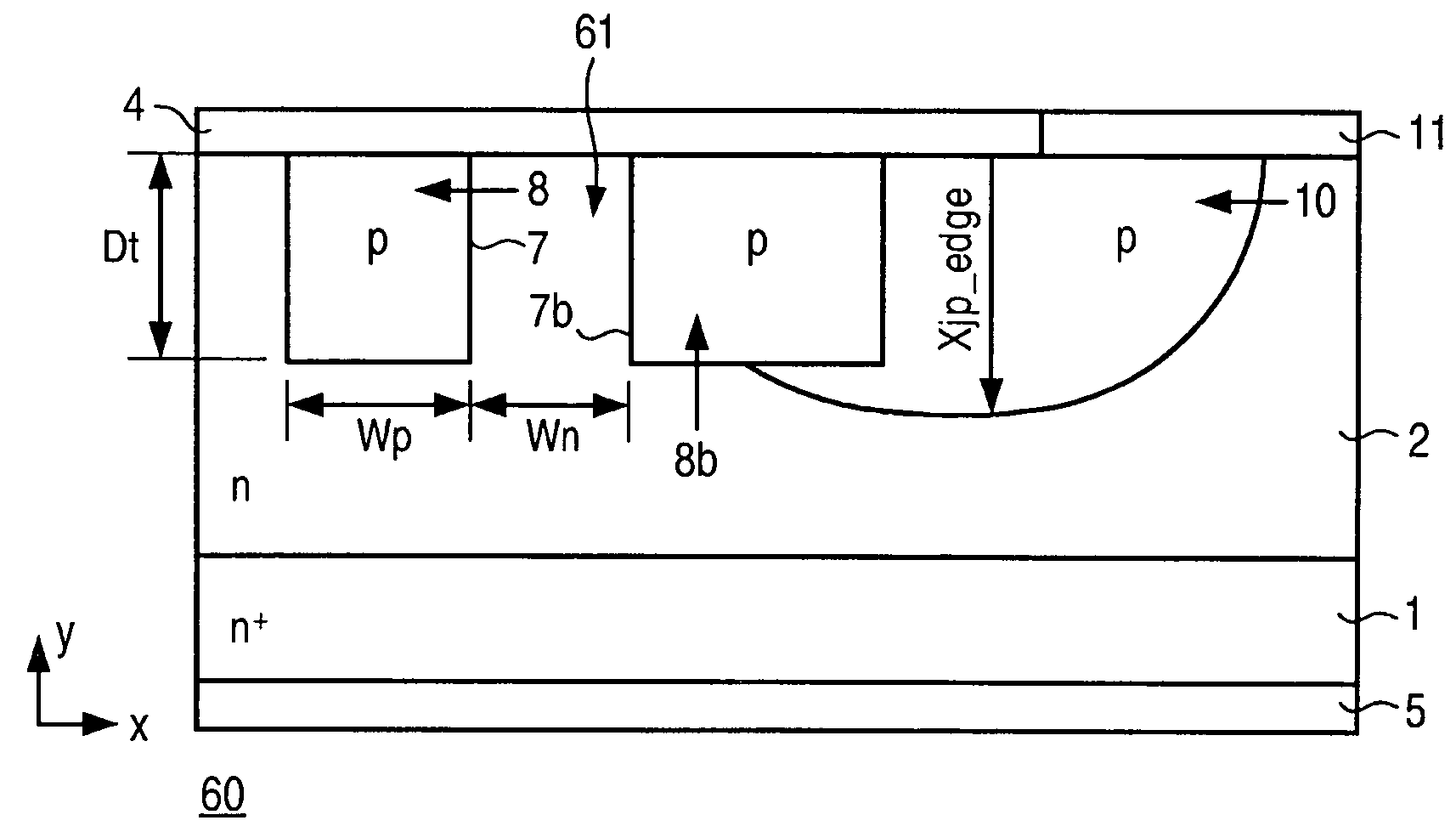

ActiveUS20080197439A1Lower forward voltageImprove sturdinessSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringContact layer

A semiconductor device including a Schottky diode of the trench-junction-barrier type having an integrated PN diode, and a corresponding method for manufacturing the device, are provided. An n layer is provided on an nt substrate, and trenches are provided in the n layer. The trenches are provided with p-doped regions. The nt substrate and the n layer carry a contact layer.

Owner:ROBERT BOSCH GMBH

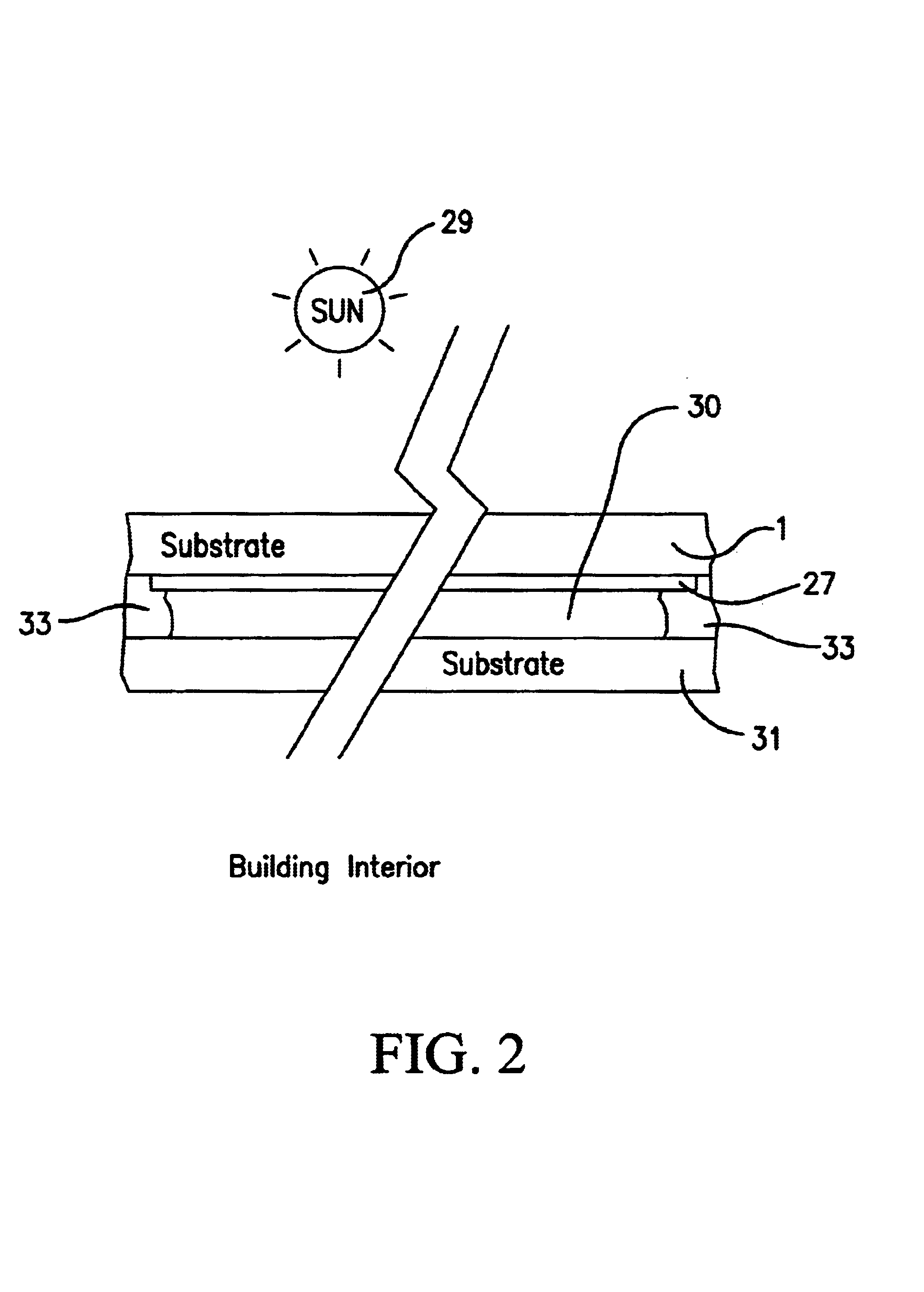

Partially transparent photovoltaic modules

InactiveUS6858461B2Least amount of loss of photovoltaicDegree of transparencyPhotovoltaic supportsSemiconductor/solid-state device manufacturingSemiconductor materialsElectrical battery

A photovoltaic cell comprising a supporting substrate, a front contact layer on the substrate, a layer or layers of semiconductor material and a back contact layer comprising a metal, the back contact having areas without metal thereby permitting the passage of light through the cell.

Owner:BP CORP NORTH AMERICA INC

Thin-film solar cell fabricated on a flexible metallic substrate

A thin-film solar cell (10) is provided. The thin-film solar cell (10) comprises a flexible metallic substrate (12) having a first surface and a second surface. A back metal contact layer (16) is deposited on the first surface of the flexible metallic substrate (12). A semiconductor absorber layer (14) is deposited on the back metal contact. A photoactive film deposited on the semiconductor absorber layer (14) forms a heterojunction structure and a grid contact (24) deposited on the heterjunction structure. The flexible metal substrate (12) can be constructed of either aluminium or stainless steel. Furthermore, a method of constructing a solar cell is provided. The method comprises providing an aluminum substrate (12), depositing a semiconductor absorber layer (14) on the aluminum substrate (12), and insulating the aluminum substrate (12) from the semiconductor absorber layer (14) to inhibit reaction between the aluminum substrate (12) and the semiconductor absorber layer (14).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

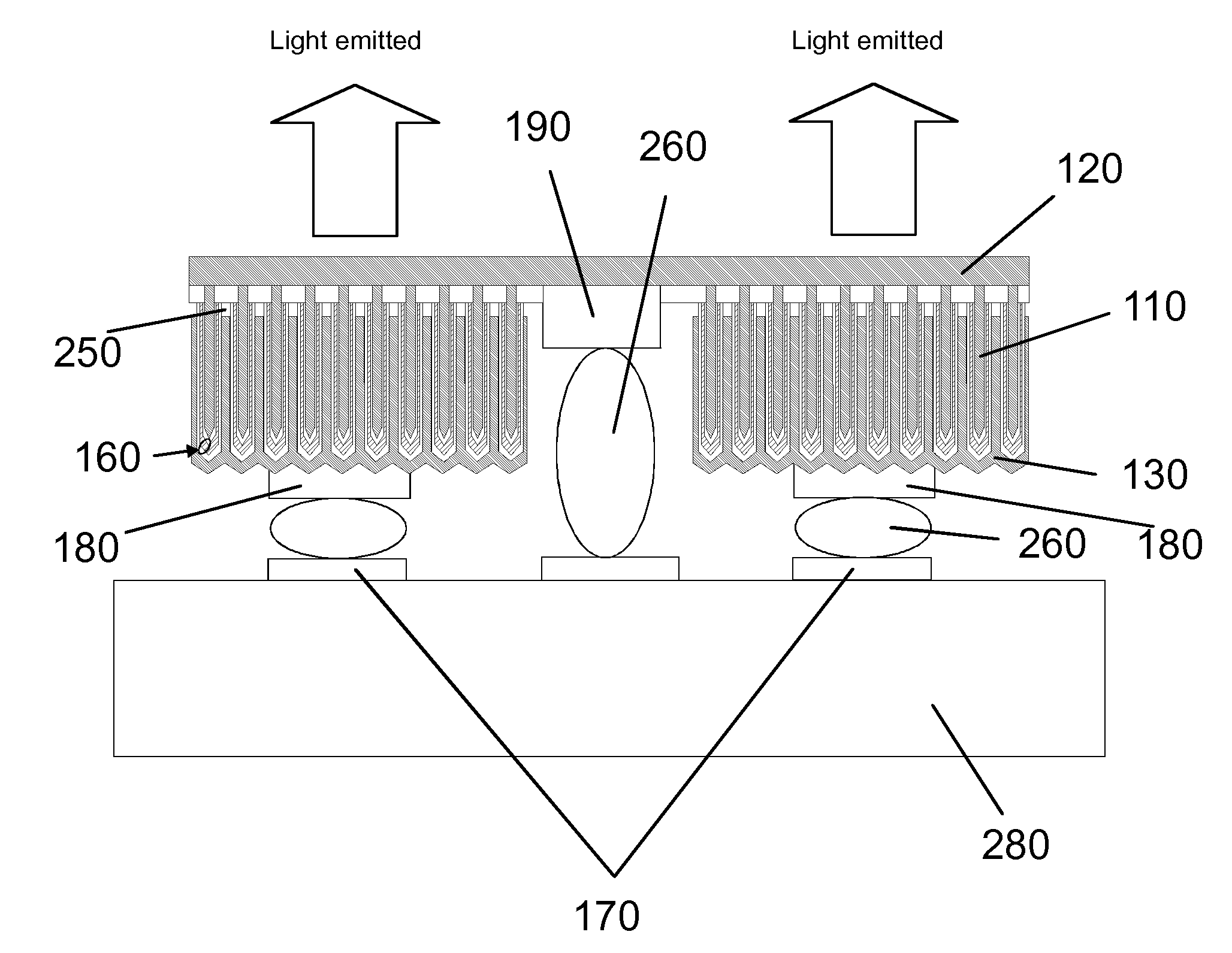

Nanostructured LED

ActiveUS20110254034A1Reduce lossesImprove efficiencyPlanar light sourcesVehicle headlampsElectrical resistance and conductanceNanowire

The device according to the invention comprises a nanostructured LED with a first group of nanowires protruding from a first area of a substrate and a contacting means in a second area of the substrate. Each nanowire of the first group of nanowires comprises a p-i-n junction and a top portion of each nanowire or at least one selection of nanowires is covered with a light-reflecting contact layer. The contacting means of the second area is in electrical contact with the bottom of the nanowires, the light-reflecting contact layer being in electrical contact with the contacting means of the second area via the p-i-n junction. Thus when a voltage is applied between the contacting means of the second area and the light-reflecting contact layer, light is generated within the nanowire. On top of the light-reflecting contact layer, a first group of contact pads for flip-chip bonding can be provided, distributed and separated to equalize the voltage across the layer to reduce the average serial resistance.

Owner:NANOSYS INC

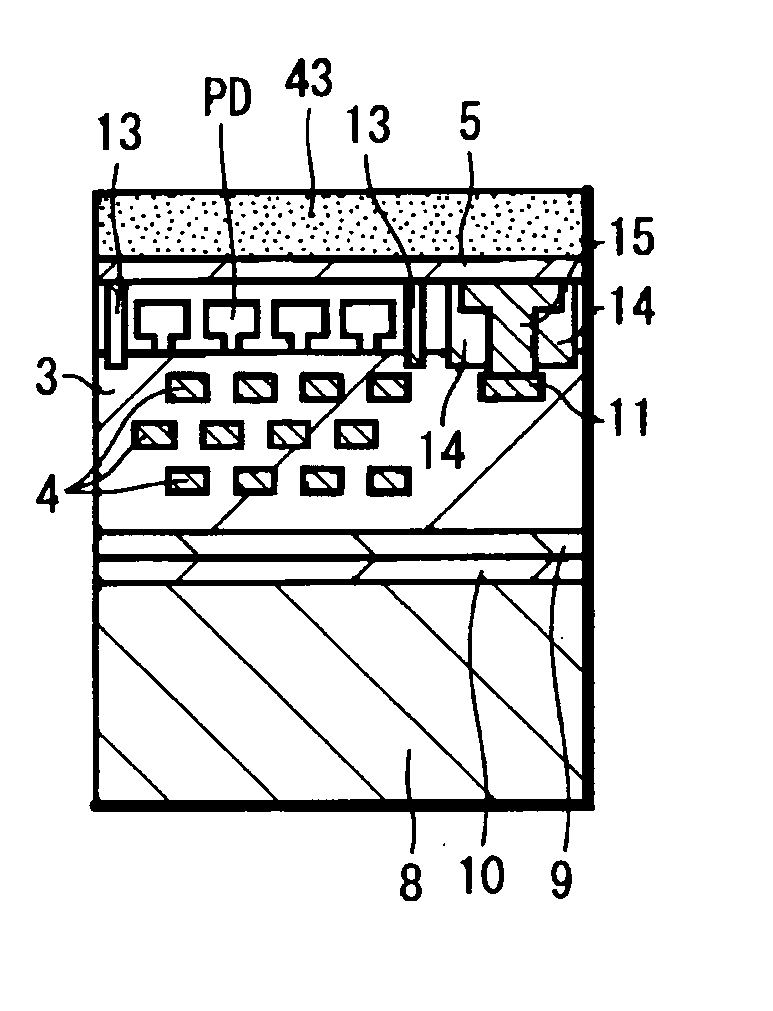

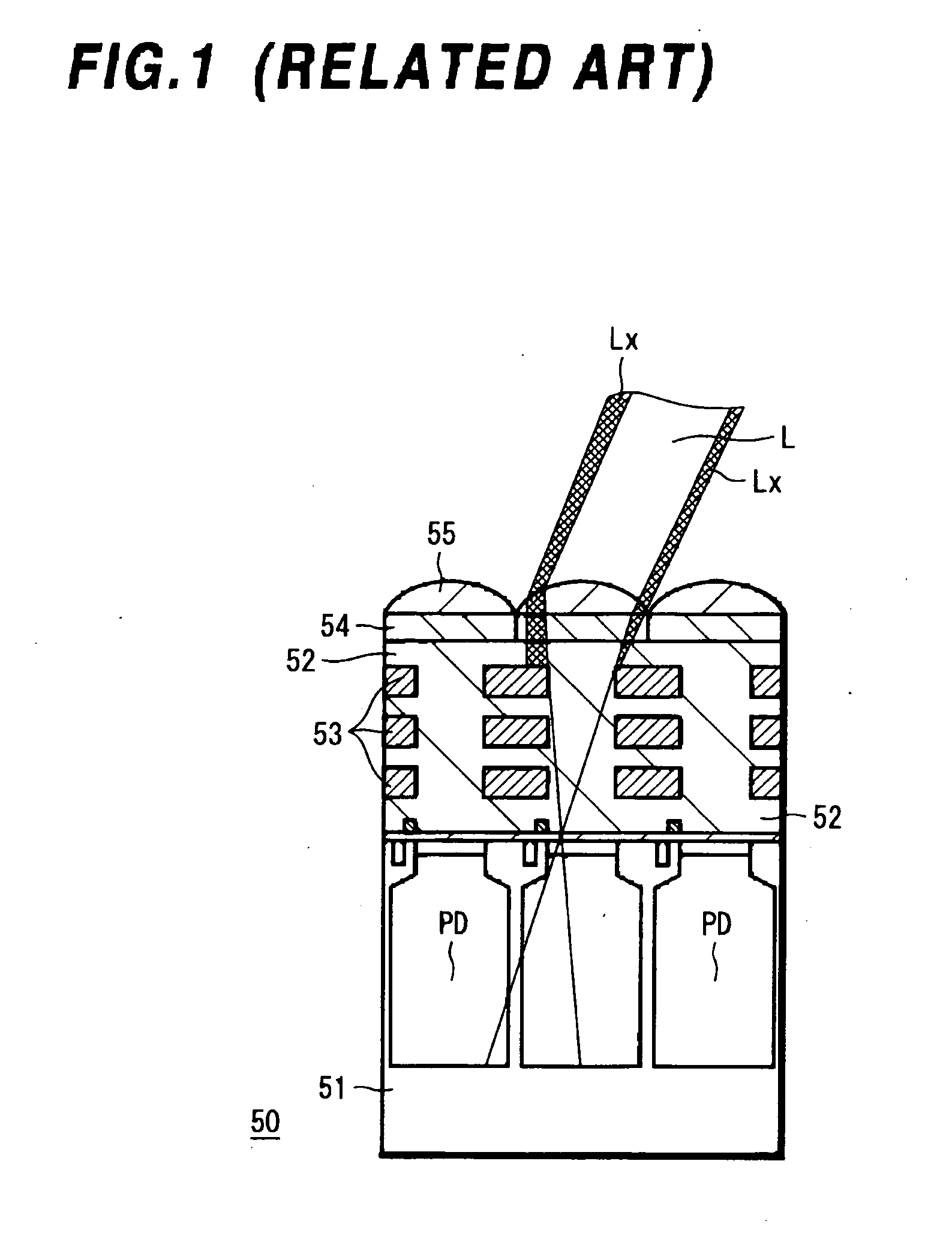

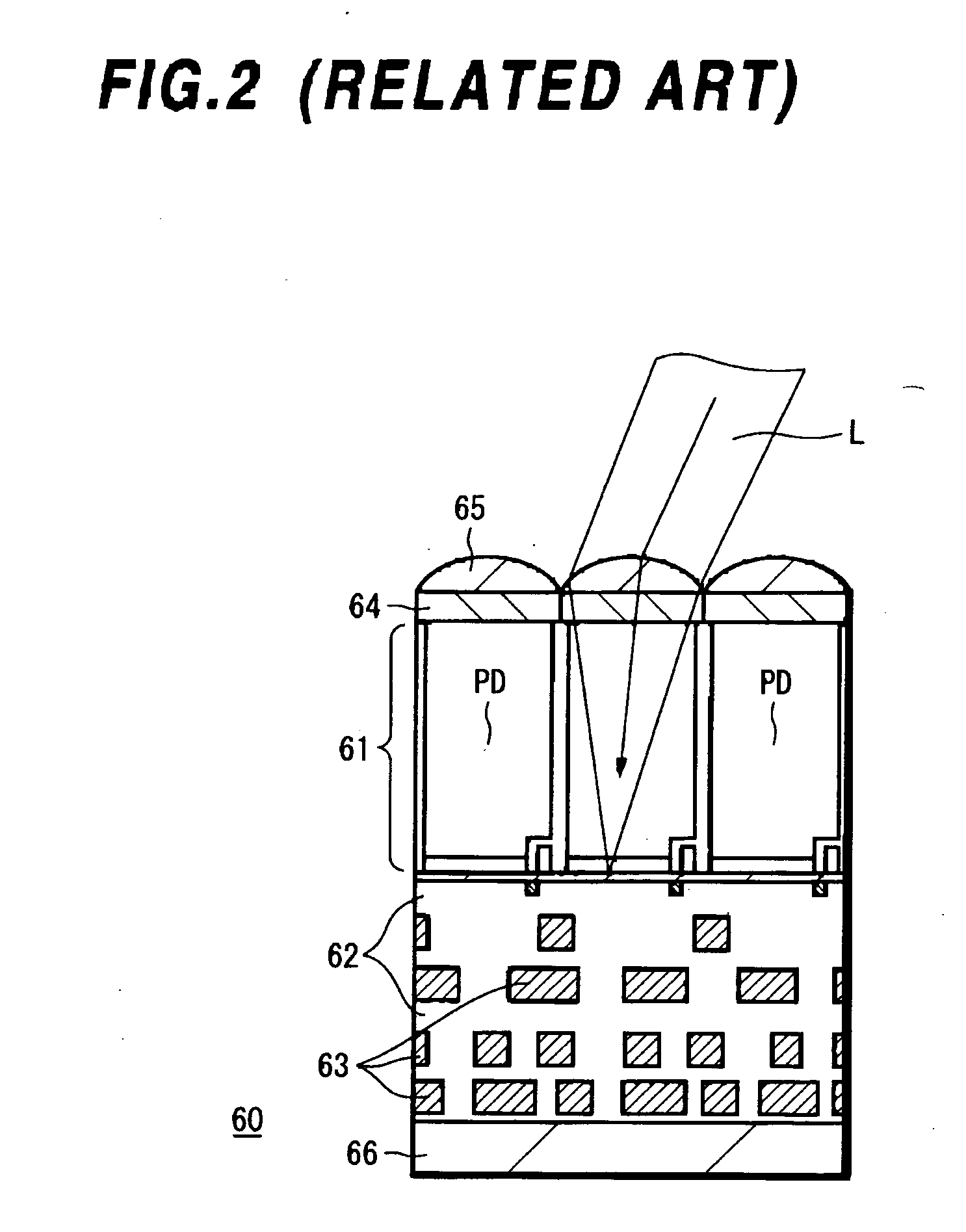

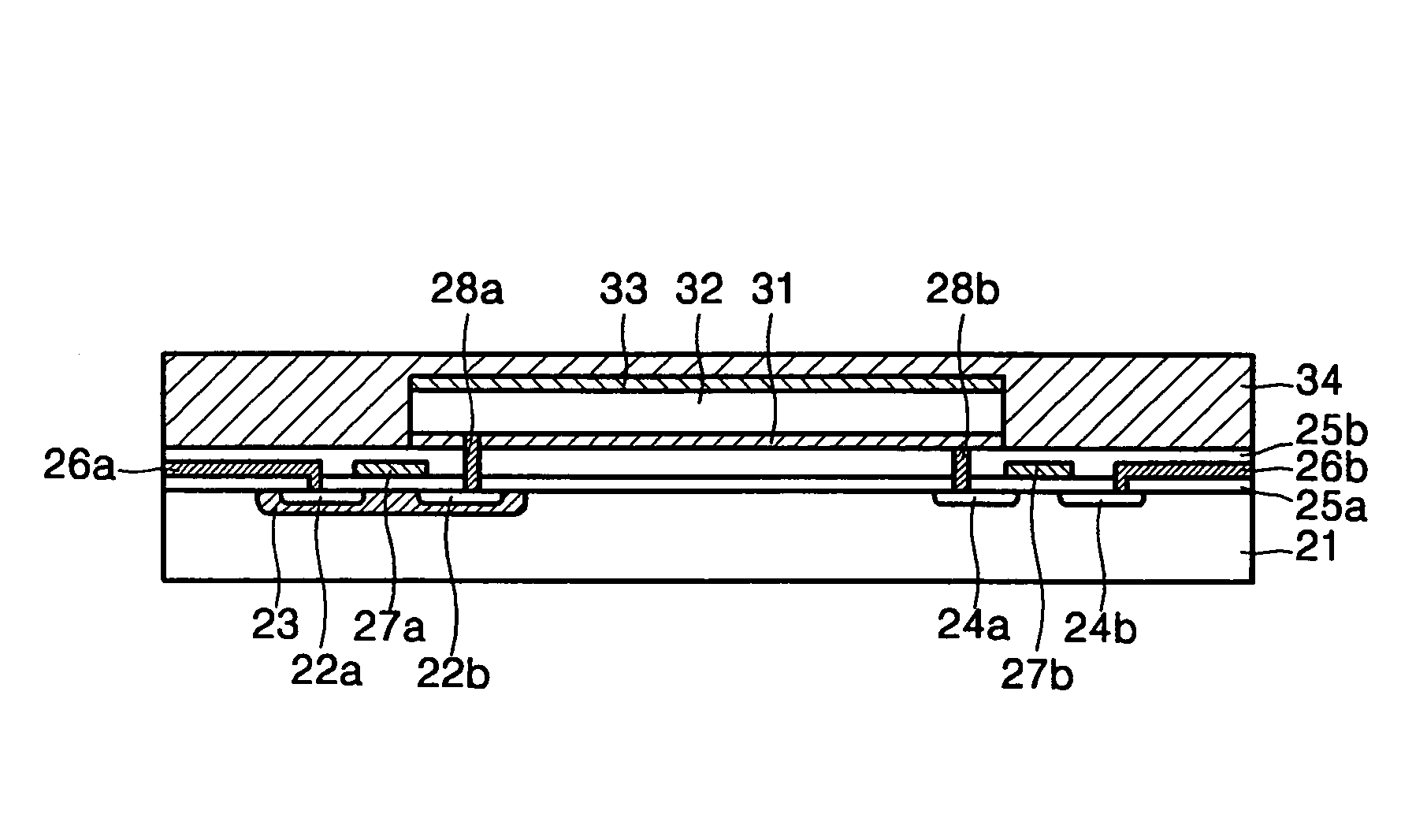

Solid-state imaging device and method of manufacturing solid-state imaging device background of the invention

InactiveUS20050104148A1Precise alignmentSemiconductor/solid-state device detailsSolid-state devicesContact layerEngineering

A solid state imaging device having a back-illuminated type structure in which a lens is formed on the back side of a silicon layer with a light-receiving sensor portion being formed thereon. Insulating layers are buried into the silicon layer around an image pickup region, with the insulating layer being buried around a contact layer that connects an electrode layer of a pad portion and an interconnection layer of the surface side. A method of manufacturing such a solid-state imaging device is also provided.

Owner:SONY CORP

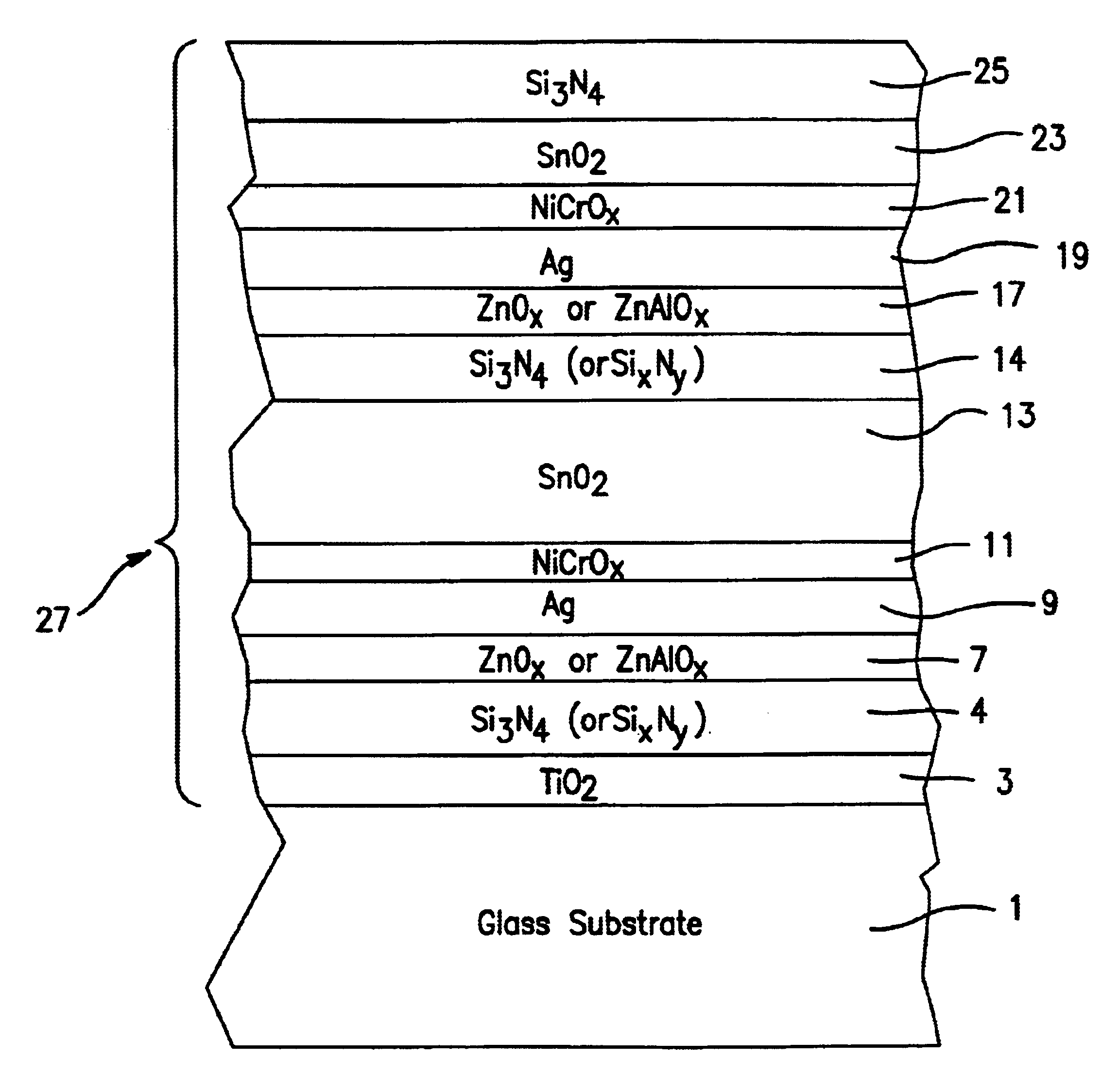

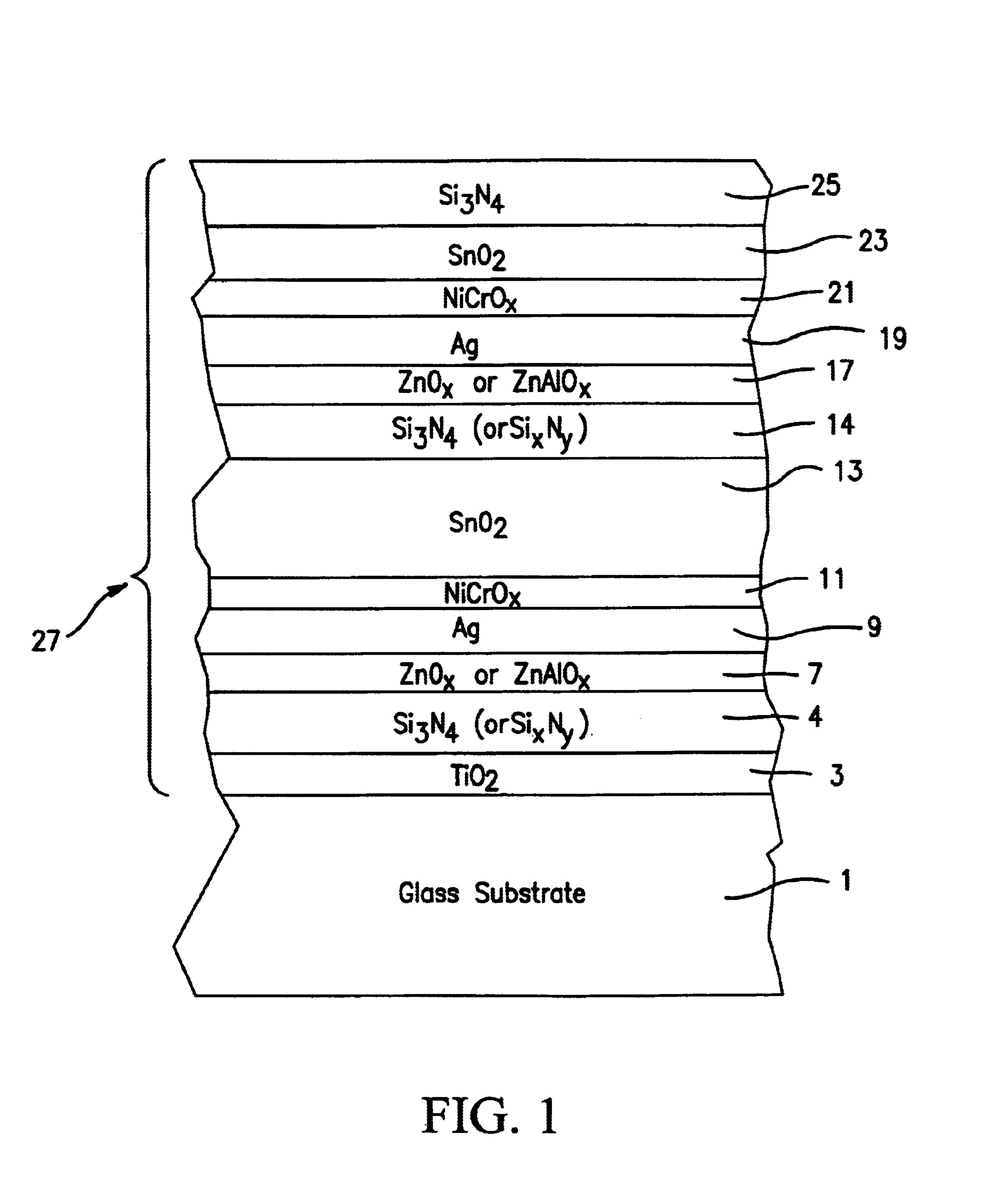

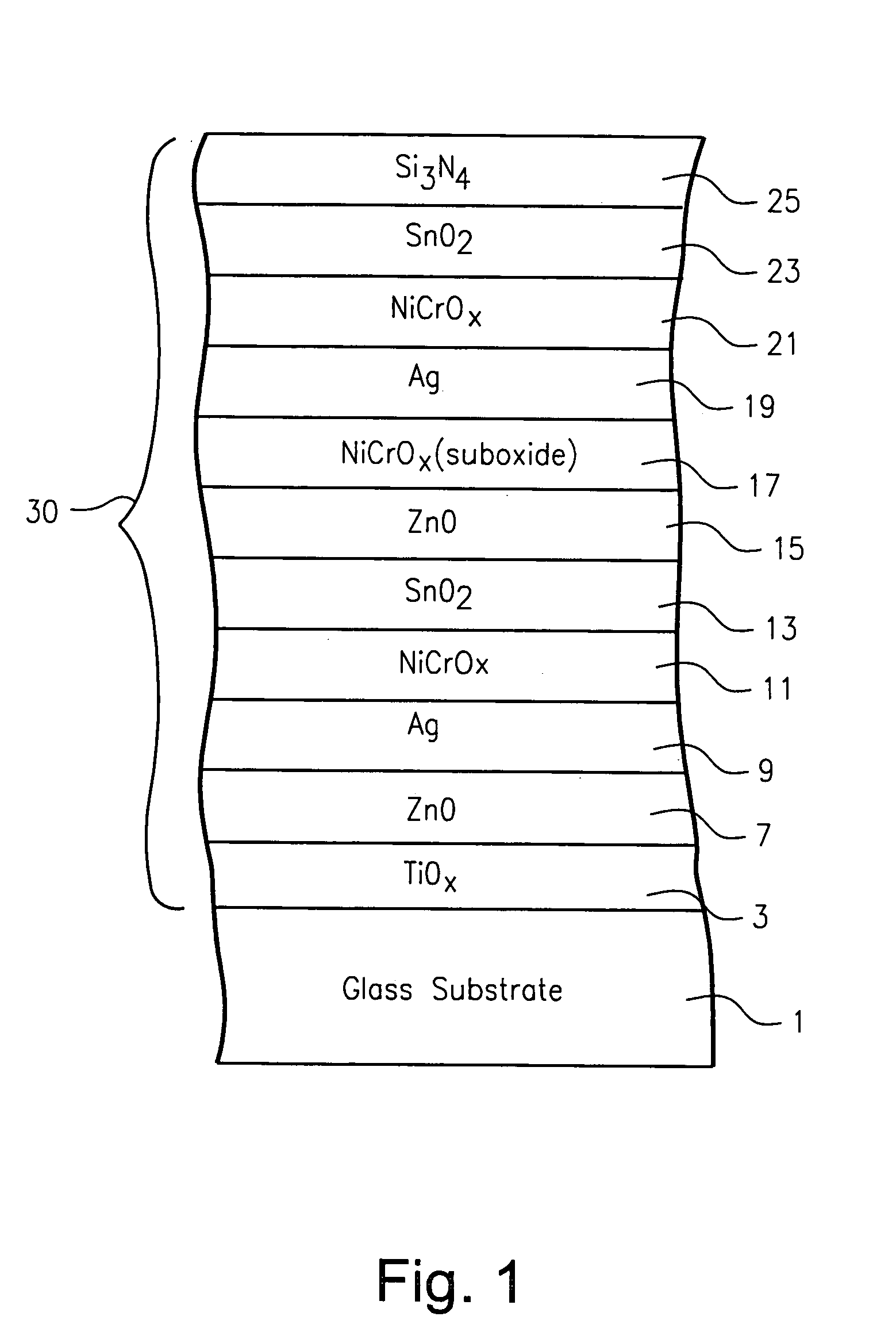

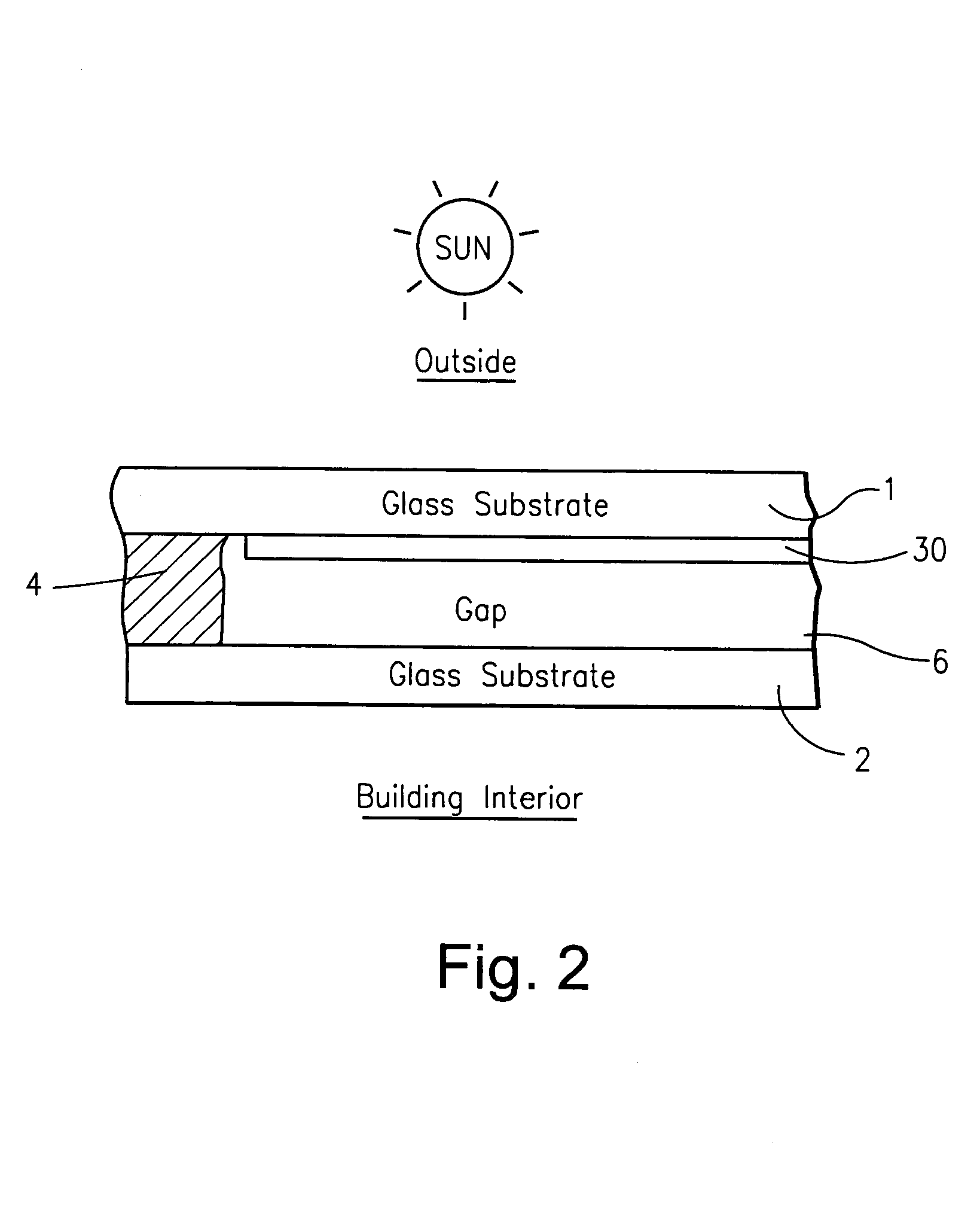

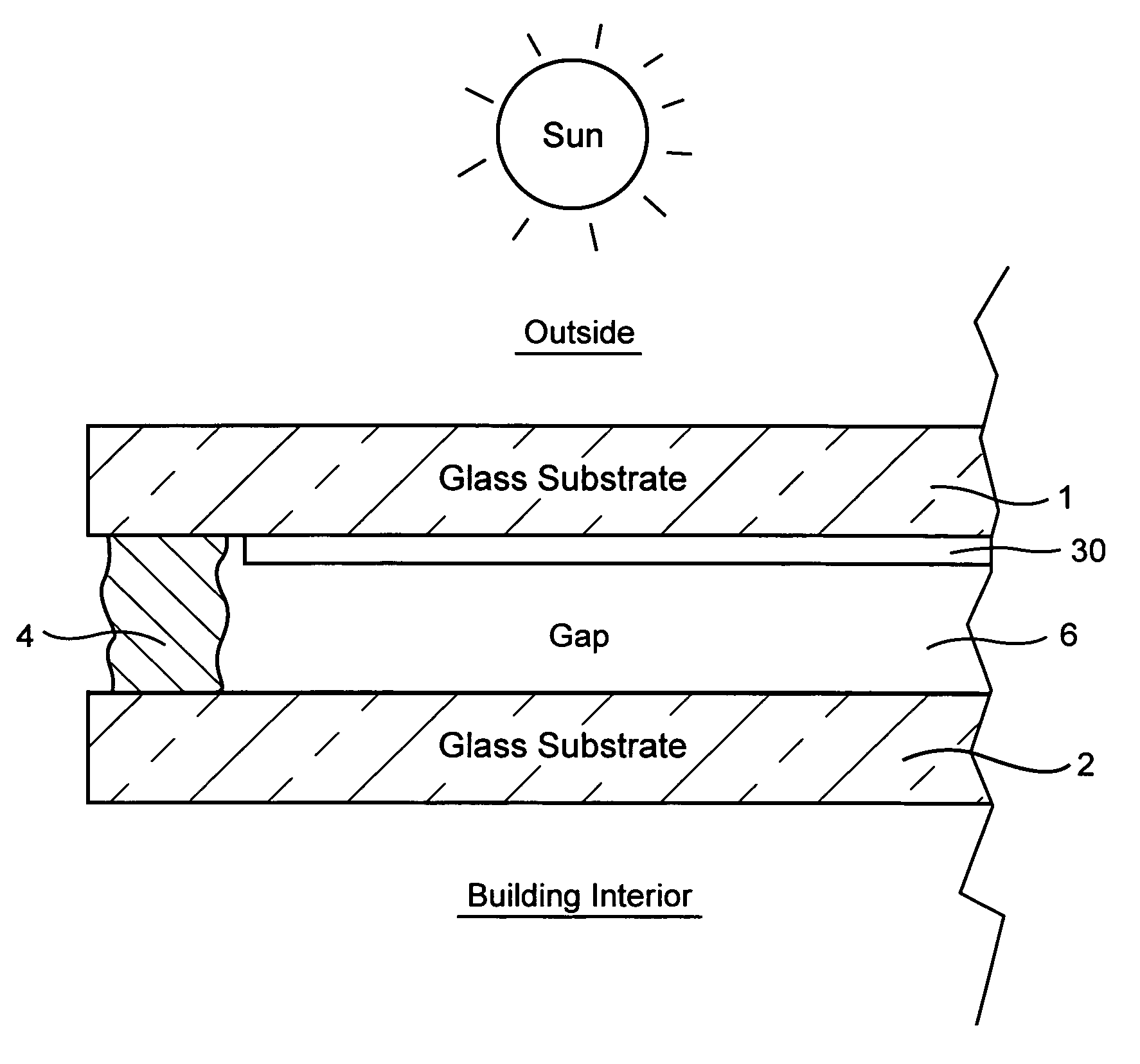

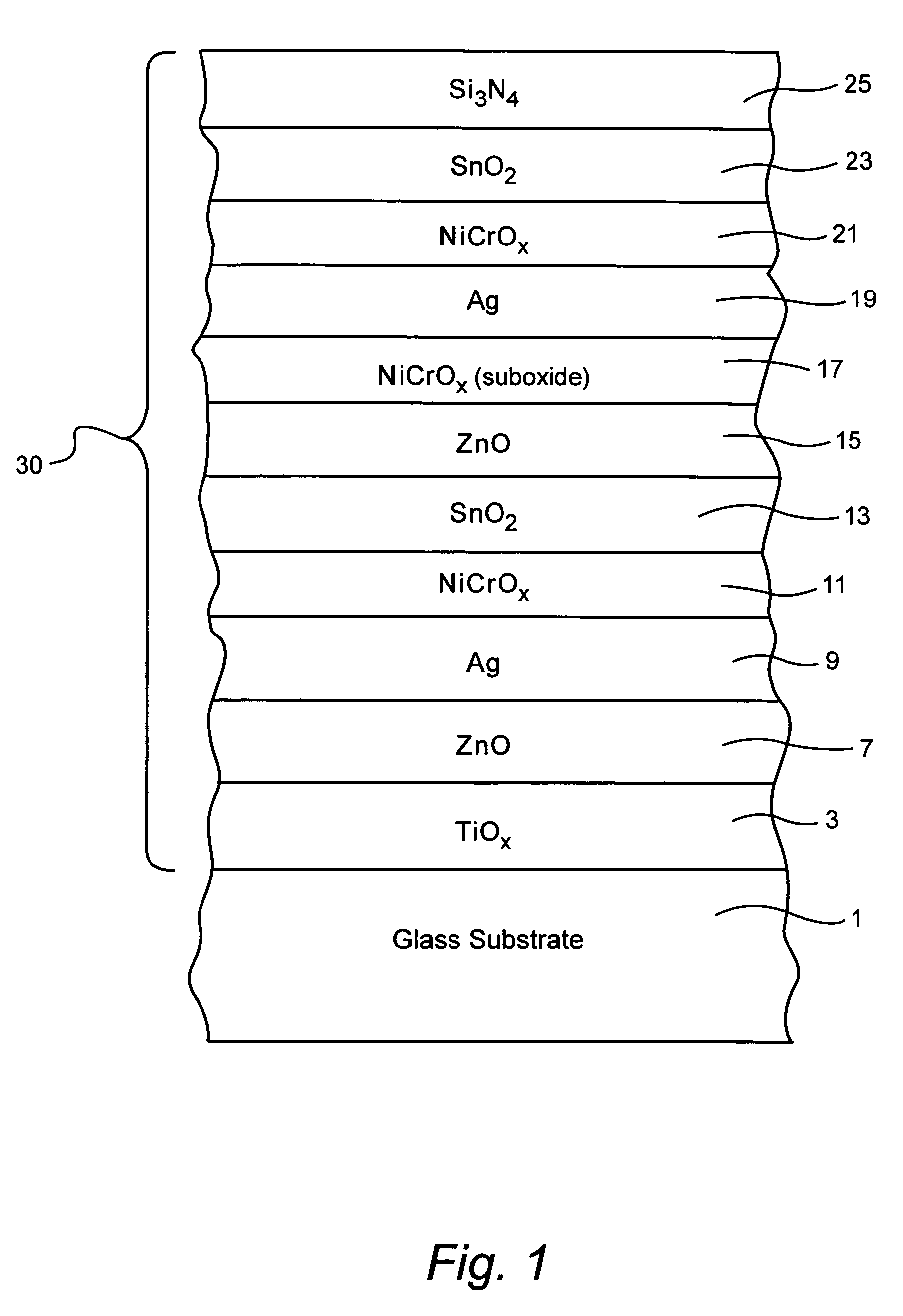

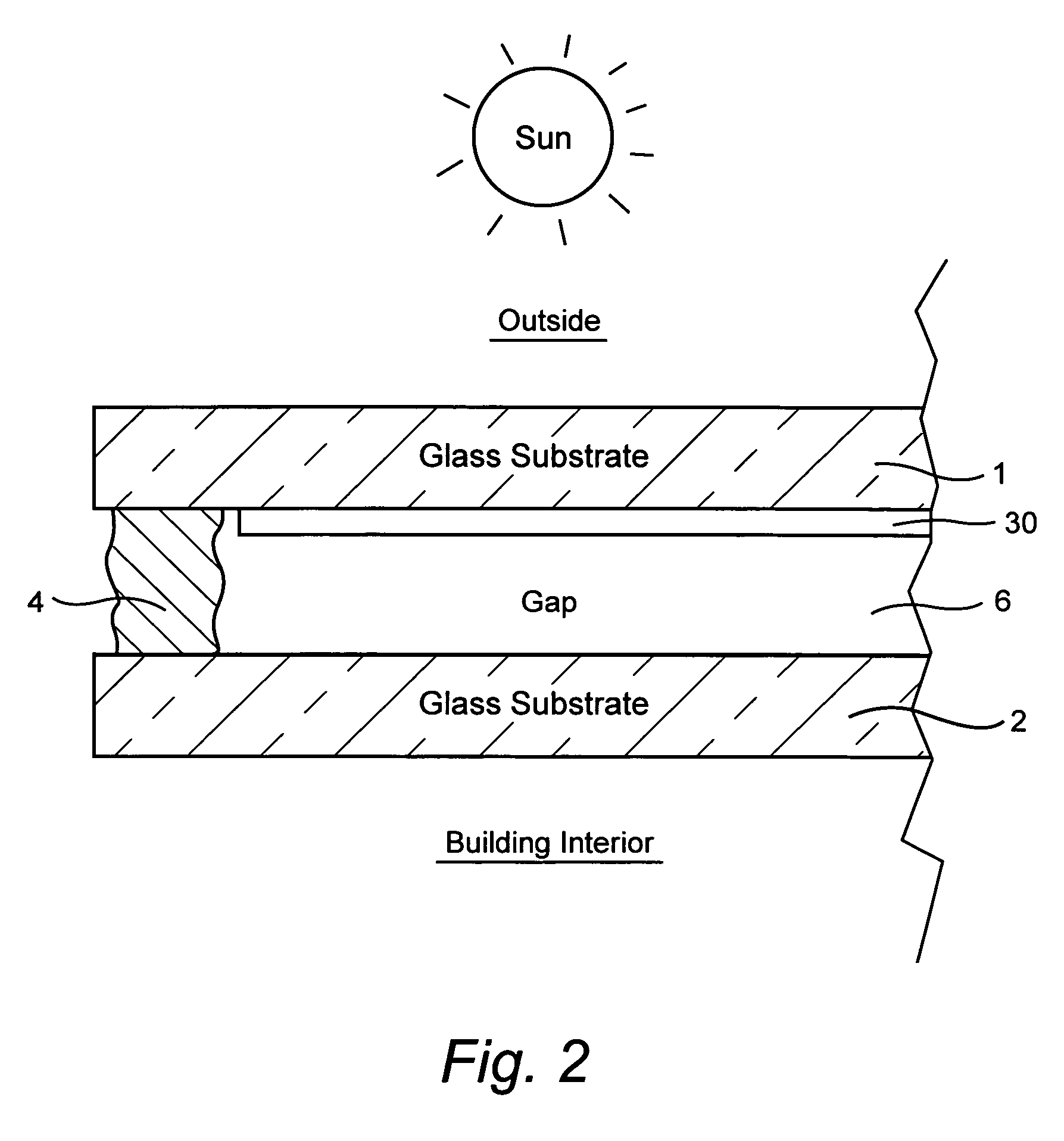

Heat treatable coated article with zinc oxide inclusive contact layer(s)

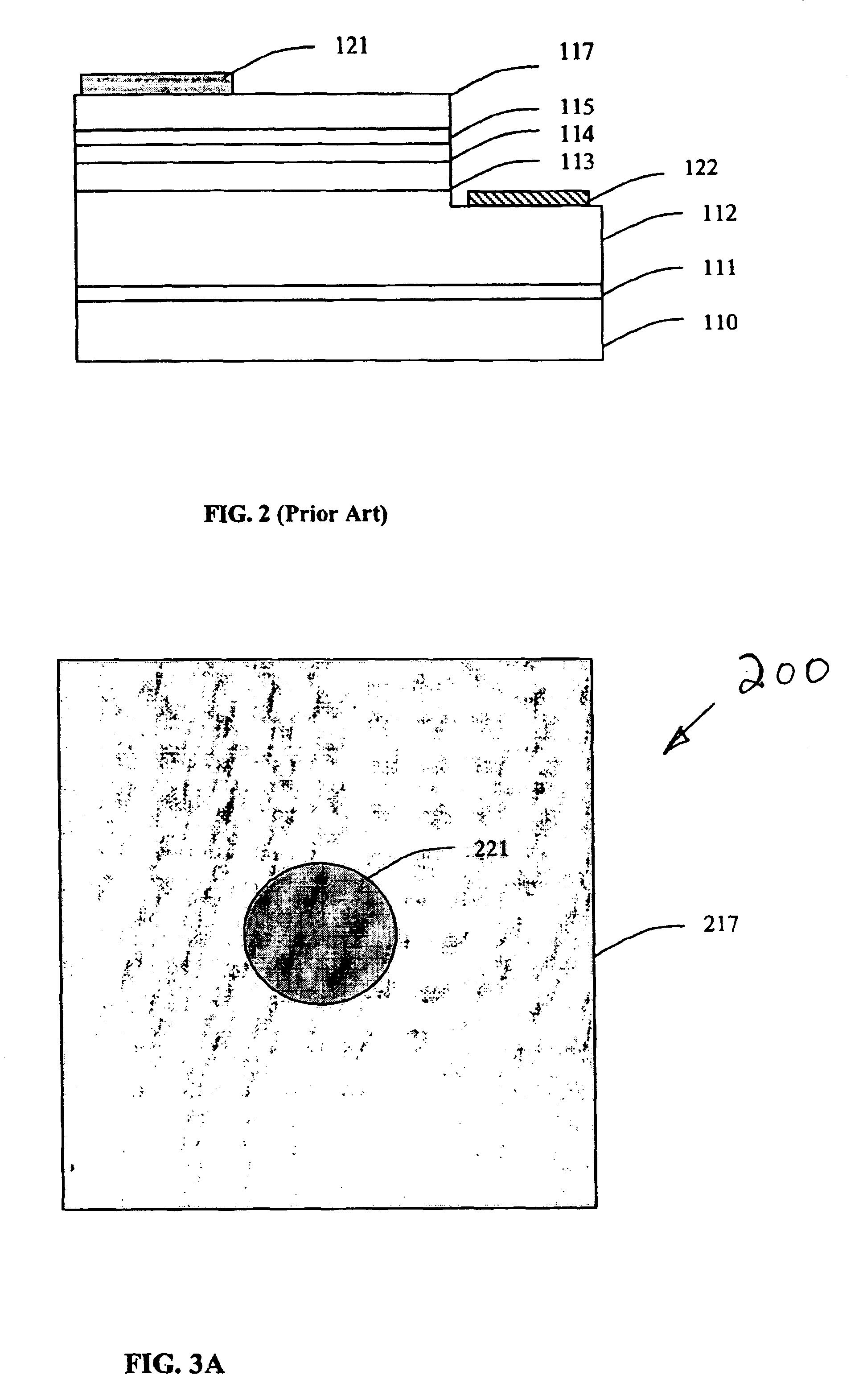

InactiveUS6887575B2Reduce sheet resistanceImprove performanceVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceContact layer

A coated article is provided so as to have a fairly high visible transmission (TY or Tvis) to sheet resistance (Rs) ratio (i.e., a ratio Tvis / Rs). The higher this ratio, the better the coated article's combined functionality of providing for both good solar performance (e.g., ability to reflect and / or absorb IR radiation) and high visible transmission. In certain example embodiments, coated articles herein may be heat treatable. Coated articles herein may be used in the context of insulating glass (IG) window units, architectural or residential monolithic window units, vehicle window units, and / or the like.

Owner:GUARDIAN GLASS LLC

Semiconductor light emitting diode and method for manufacturing the same

InactiveUS20050104081A1Simple processSolid-state devicesSemiconductor devicesContact layerLight-emitting diode

Provided is a light emitting diode including a base substrate having a via hole, a buffer layer having a via hole which is partially overlapped with the via hole of the base substrate, a first conductive contact layer formed on the buffer layer, a first clad layer formed on the second conductive contact layer, a light emitting layer formed on the first clad layer, a second clad layer formed on the light emitting layer, a second conductive contact layer formed on the second conductive clad layer, a first electrode formed on the second conductive contact layer, and a second electrode connected with the first conductive contact layer through the via hole.

Owner:ITSWELL

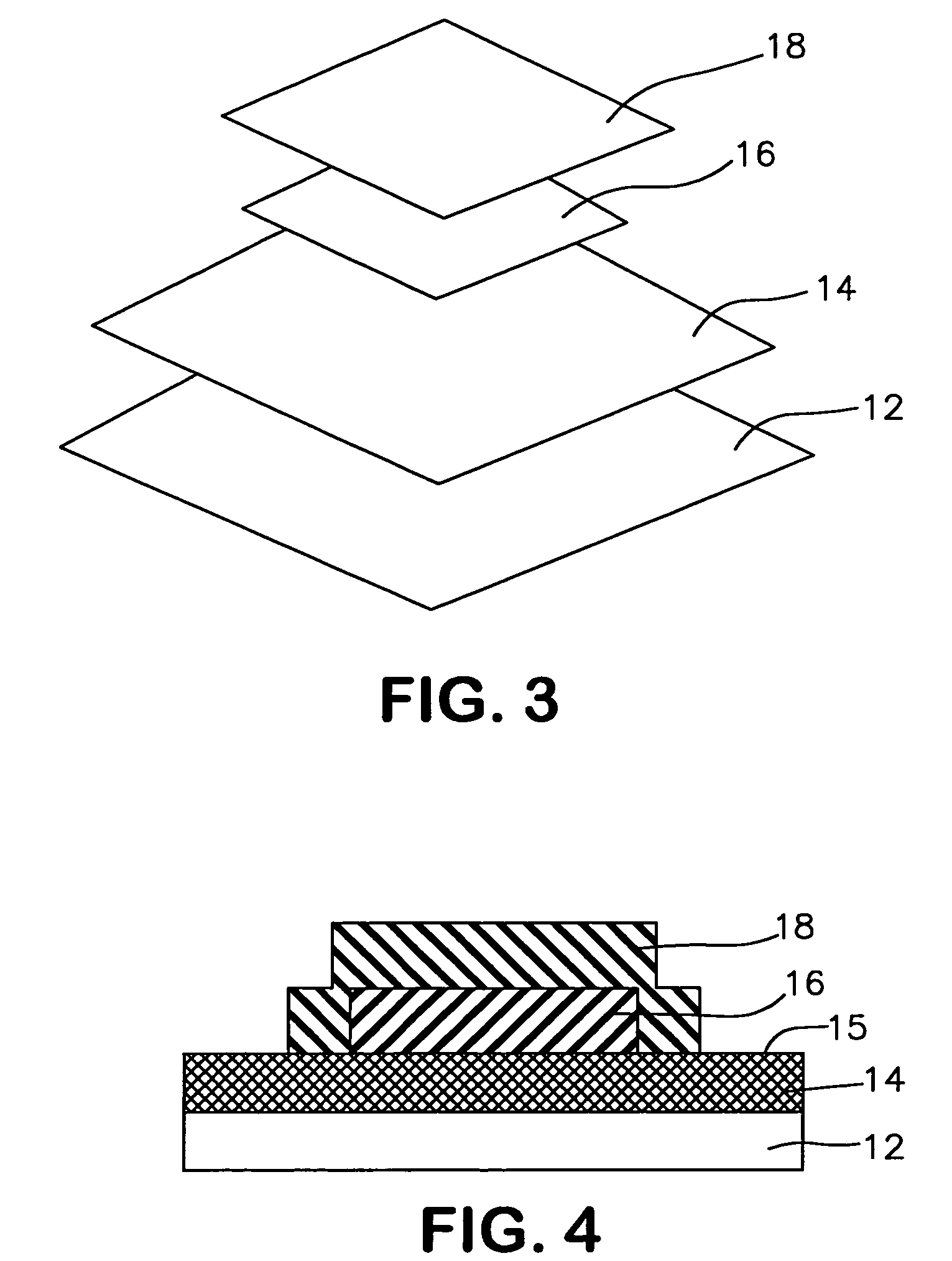

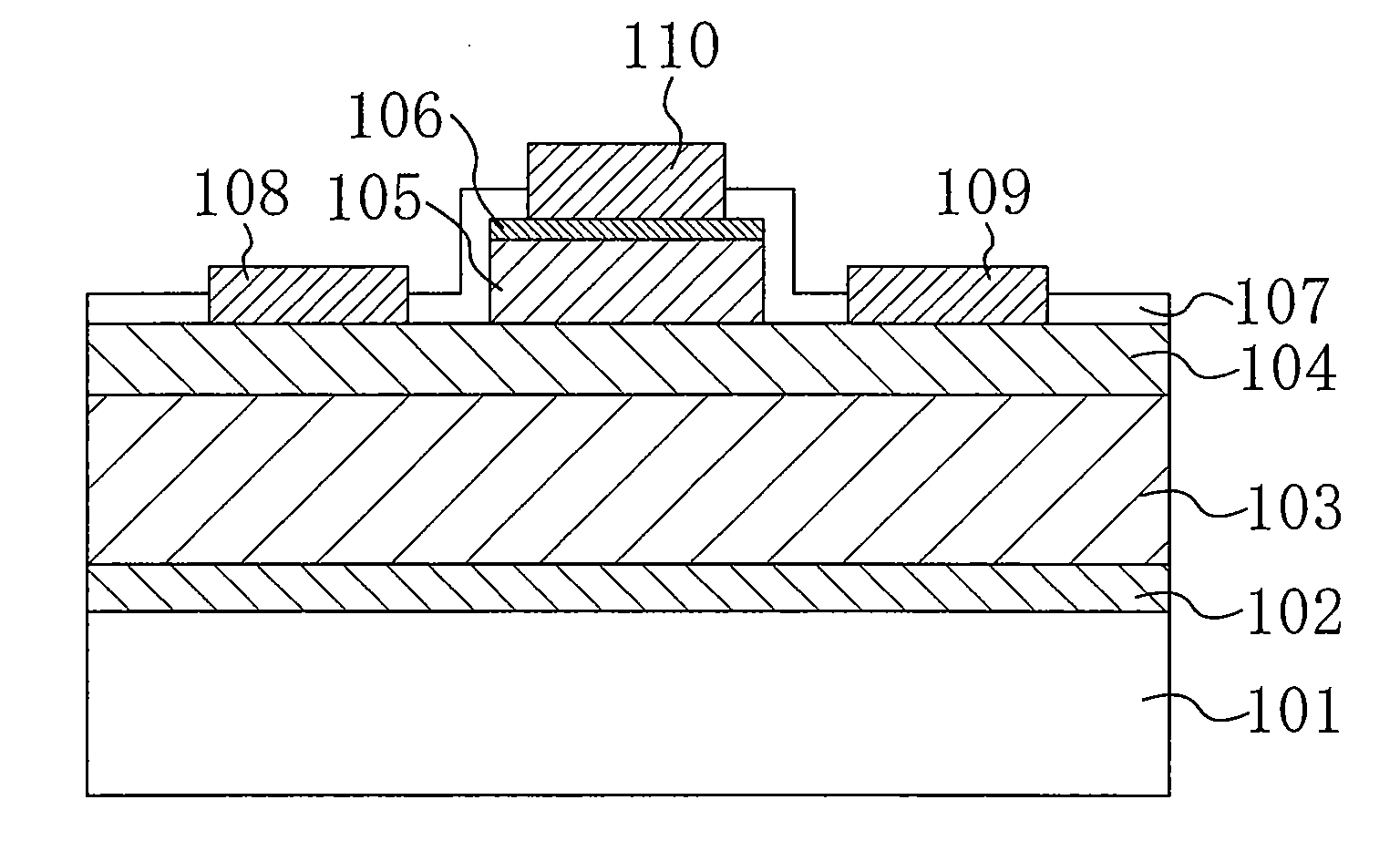

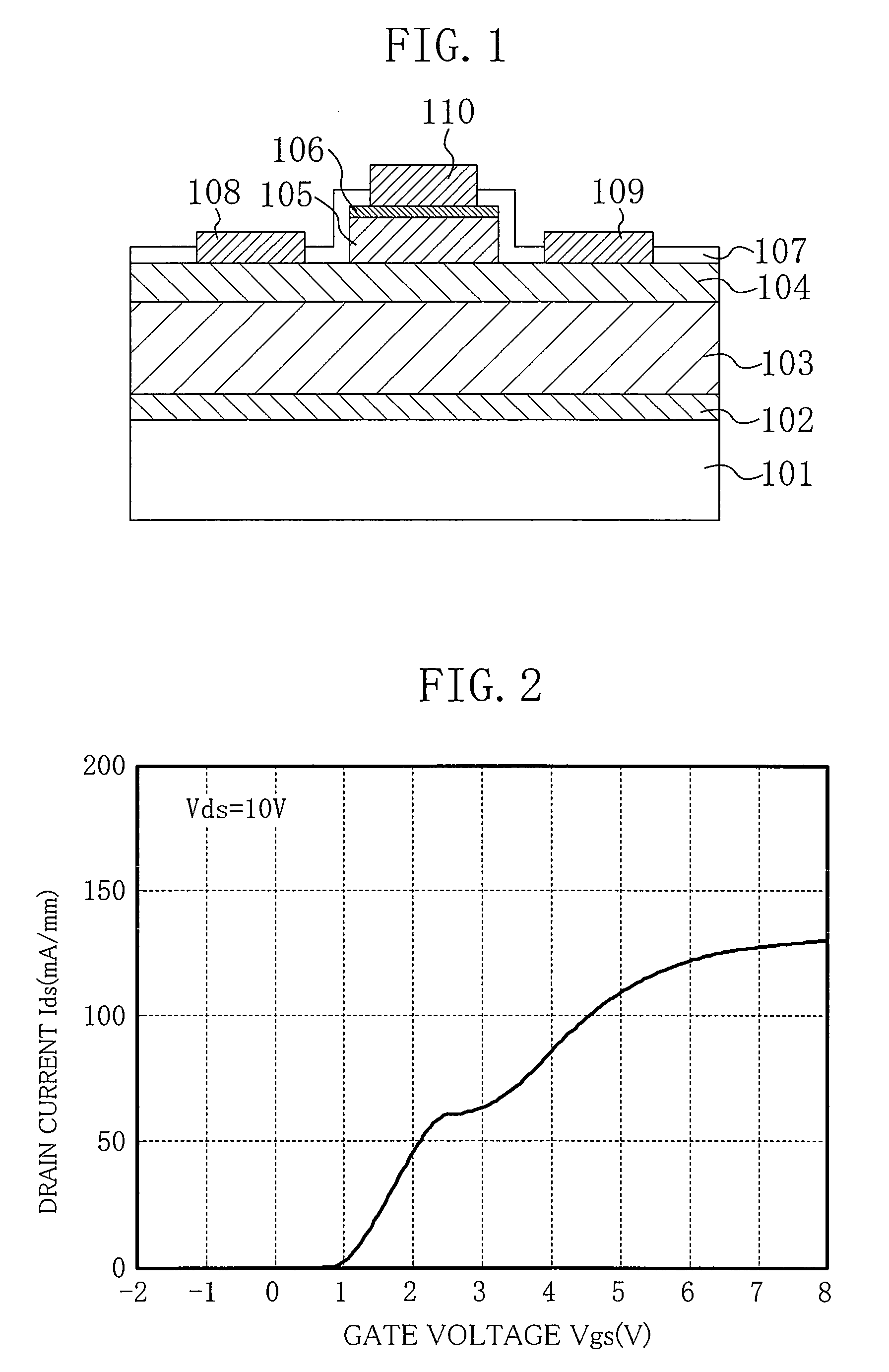

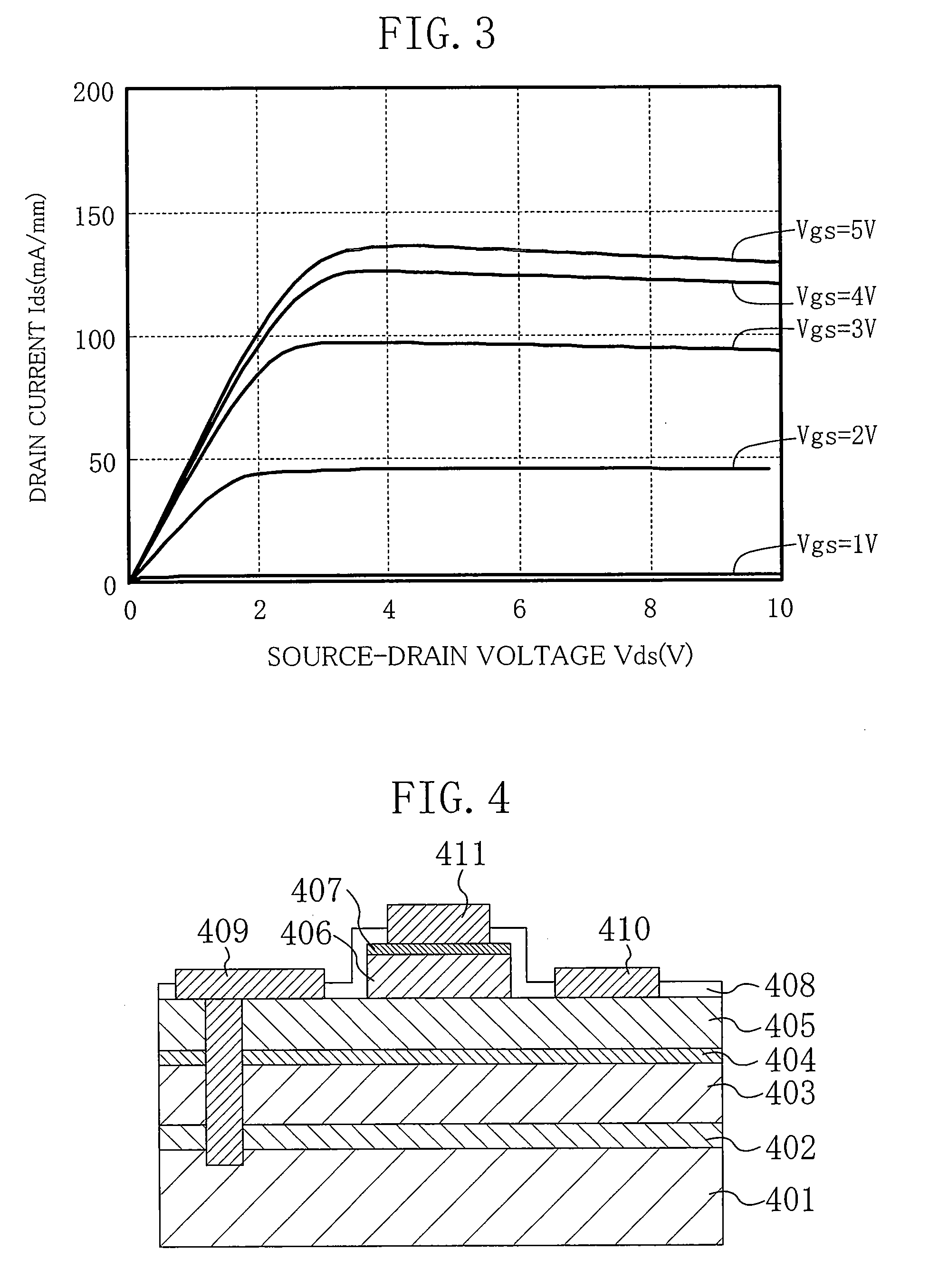

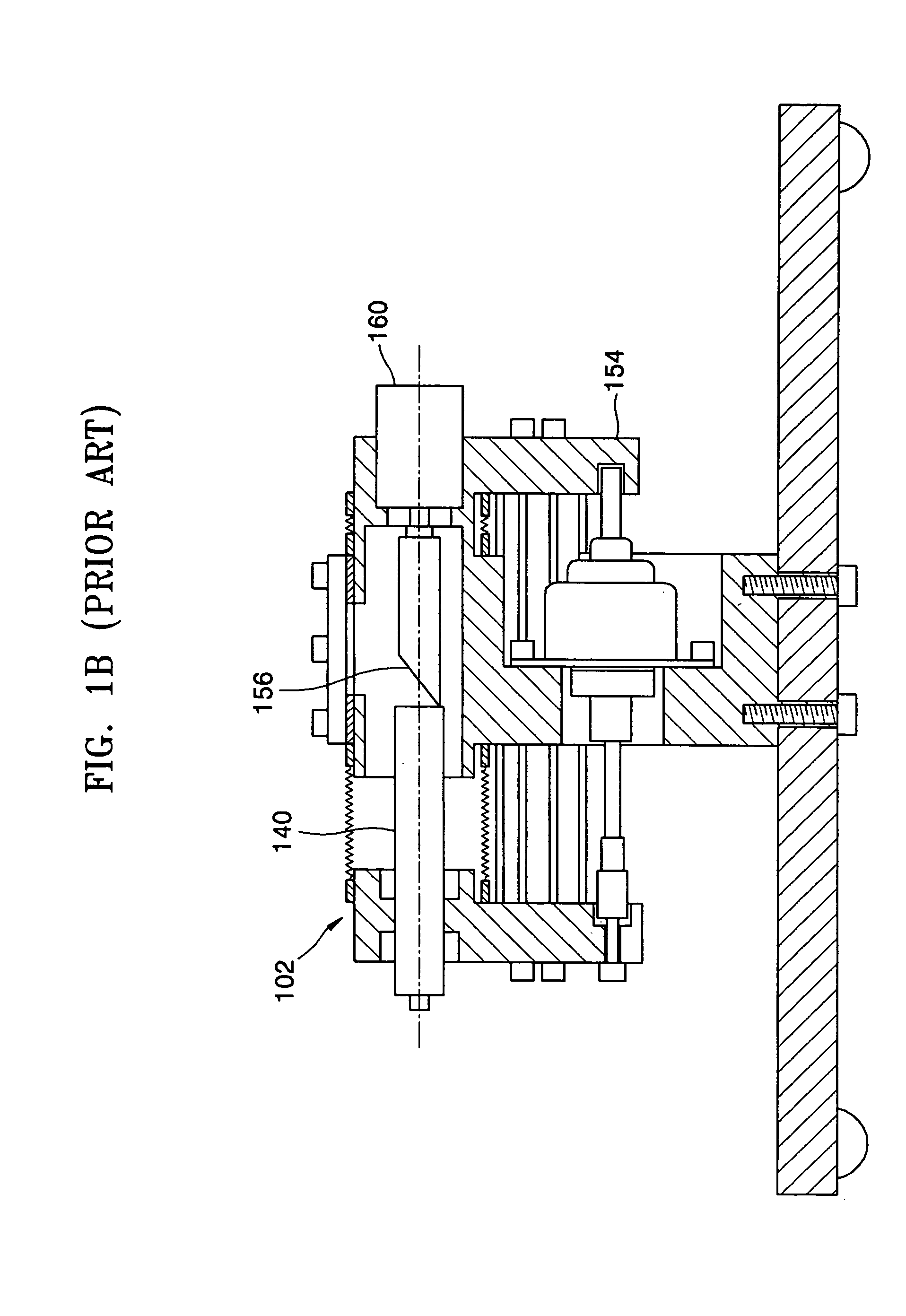

Transistor and method for operating the same

ActiveUS20090121775A1Promote generationIncrease current channelElectronic switchingSemiconductor devicesControl layerOhmic contact

In a transistor, an AlN buffer layer 102, an undoped GaN layer 103, an undoped AlGaN layer 104, a p-type control layer 105, and a p-type contact layer 106 are formed in this order on a sapphire substrate 101. The transistor further includes a gate electrode 110 in ohmic contact with the p-type contact layer 106, and a source electrode 108 and a drain electrode 109 provided on the undoped AlGaN layer 104. By applying a positive voltage to the p-type control layer 105, holes are injected into a channel to increase a current flowing in the channel.

Owner:PANASONIC CORP

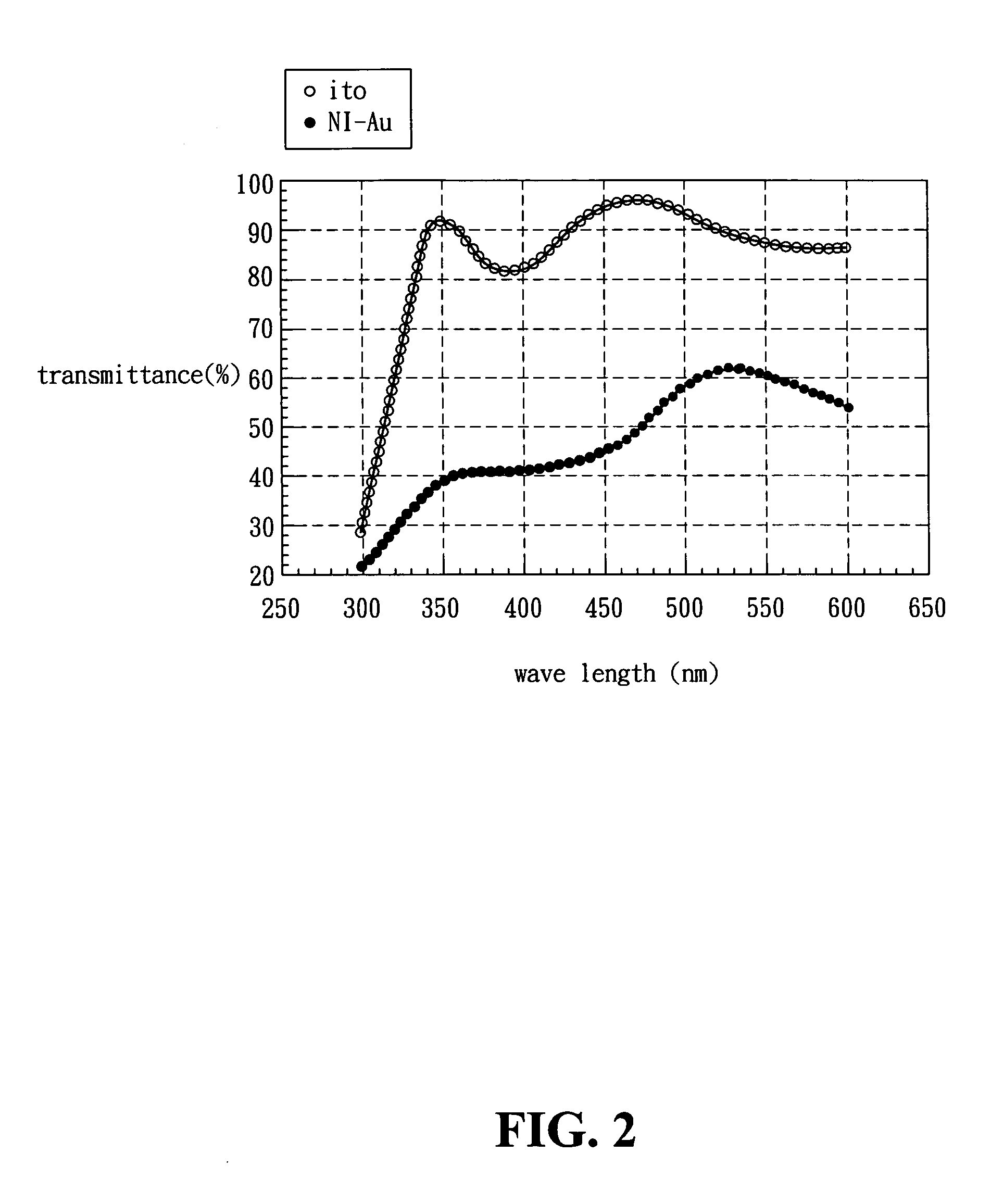

Light emiting diodes with current spreading layer

A light-emitting diode (LED) for both AlGaInP- and GaN-based materials needs a good transparent current spreading layer to disseminate electrons or holes from the electrode to the active layer. The present invention utilizes a conductive and transparent ITO (Indium Tin Oxide) thin film with an ultra-thin (to minimize the absorption) composite metallic layer to serve as a good ohmic contact and current spreading layer. The present invention avoids the Schottky contact due to direct deposition of ITO on the semiconductor. For AlGaInP materials, a thick GaP current spreading layer is omitted by the present invention. For GaN-based LEDs with the present invention, semi-transparent Ni / Au contact layer is avoided. Therefore, the light extraction of LED can be dramatically improved by the present invention. Holes may be etched into the semiconductor cladding layer forming a Photonic Band Gap structure to improve LED light extraction.

Owner:DICON FIBEROPTICS

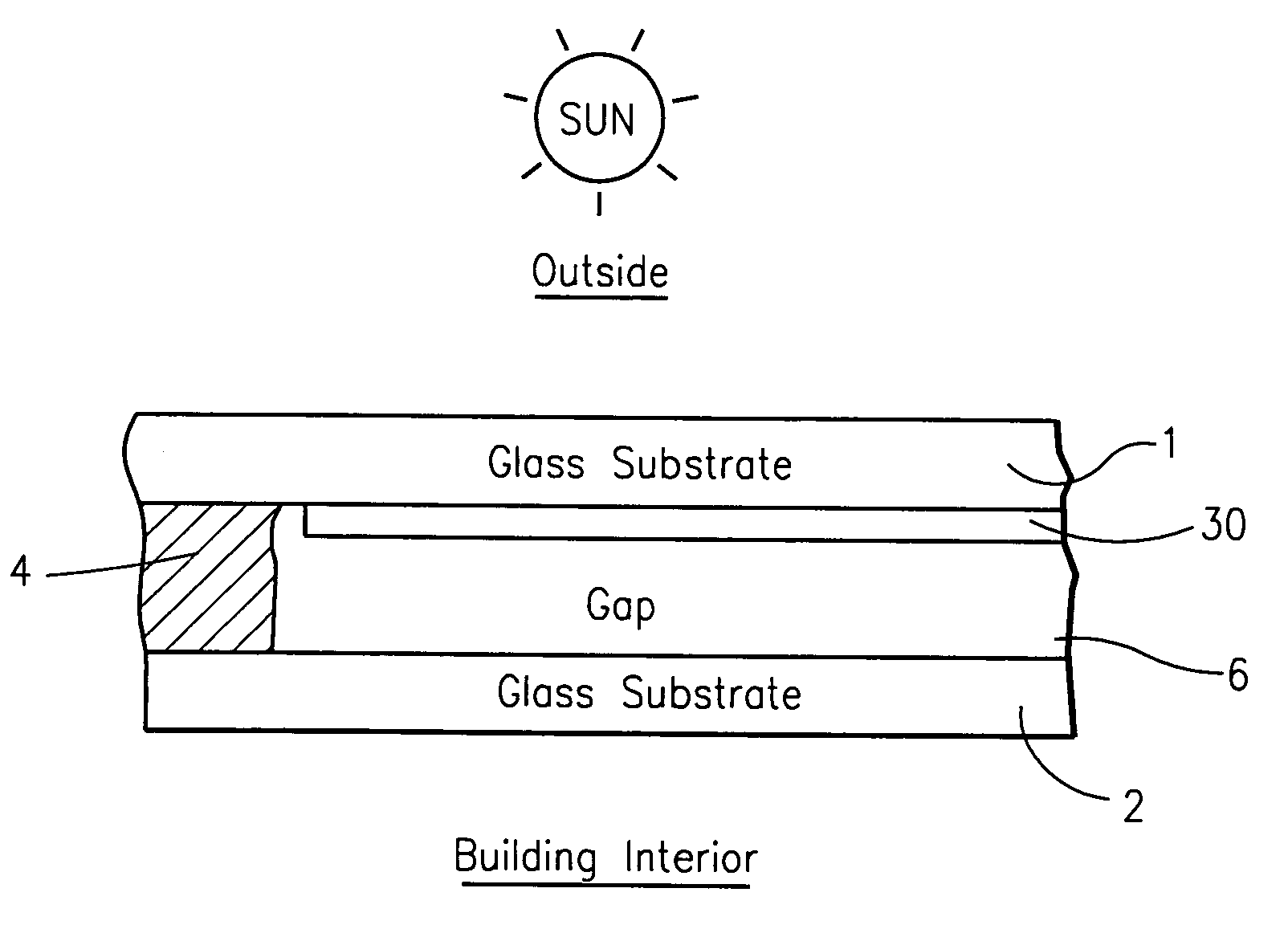

Coated article with low-E coating including IR reflecting layer(s) and corresponding method

ActiveUS7189458B2High selectivitySolution value is not highGlass/slag layered productsCoatingsLow emissivityRadiance

A coated article is provided with a low-emissivity (low-E) layer stack for use in a window unit or the like. The layer stack, or coating, may permit the coated article to achieve one or more of a fairly low solar factor (SF) value, a high selectivity (Tvis / SF) value, substantially neutral color at normal and / or off-axis viewing angles, and / or low emissivity. When high selectivity values are achieved, there is provided a high ratio of visible transmission to SF, which is a desirable feature in certain example instances. In certain example embodiments, a sub-oxide layer (e.g., NiCrOx) may be used as a contact layer under an infrared (IR) reflecting layer in order to permit low SF values, high selectivity, and good coloration to be achieved.

Owner:GUARDIAN GLASS LLC +1

Coated article with low-E coating including IR reflecting layer(s) and corresponding method

InactiveUS7198851B2High selectivityIncrease valueGlass/slag layered productsCoatingsLow emissivityRadiance

A coated article is provided with a low-emissivity (low-E) layer stack for use in a window unit or the like. The layer stack, or coating, may permit the coated article to achieve one or more of a low solar factor (SF) value, a high selectivity (Tvis / SF) value, substantially neutral color at normal and / or off-axis viewing angles, and / or low emissivity. When high selectivity values are achieved, there is provided a high ratio of visible transmission to SF, which is a desirable feature in certain example instances. In certain example embodiments, a sub-oxide layer may be used as a contact layer under an infrared (IR) reflecting layer in order to permit low SF values, high selectivity, and good coloration to be achieved.

Owner:GUARDIAN GLASS LLC +1

Light emitting diodes with current spreading layer

A light-emitting diode (LED) for both AlGaInP- and GaN-based materials needs a good transparent current spreading layer to disseminate electrons or holes from the electrode to the active layer. The present invention utilizes a conductive and transparent ITO (Indium Tin Oxide) thin film with an ultra-thin (to minimize the absorption) composite metallic layer to serve as a good ohmic contact and current spreading layer. The present invention avoids the Schottky contact due to direct deposition of ITO on the semiconductor. For AlGaInP materials, a thick GaP current spreading layer is omitted by the present invention. For GaN-based LEDs with the present invention, semi-transparent Ni / Au contact layer is avoided. Therefore, the light extraction of LED can be dramatically improved by the present invention. Holes may be etched into the semiconductor cladding layer forming a Photonic Band Gap structure to improve LED light extraction.

Owner:DICON FIBEROPTICS

Vacuum wound dressing

Provided, in one embodiment, is a vacuum wound dressing for covering a wound bed comprising: a wound contact layer comprising a fibrous blend or fibrous material that forms a cohesive gel when wetted by wound exudate; a source of vacuum situated to be separated from the wound bed by the wound contact layer; and a vacuum sealing layer covering the wound contact layer and adapted to retain relative vacuum in the wound contact layer, wherein (i) the dressing is essentially missing a non-gelling, foam layer in which the source of vacuum is situated or (ii) the vacuum sealing layer comprises as an outer layer a foam layer.

Owner:CONVATEC TECH INC

Methods of fabricating nitride-based transistors having regrown ohmic contact regions

ActiveUS7432142B2Semiconductor/solid-state device manufacturingSemiconductor devicesLow temperature depositionSemiconductor materials

Transistor fabrication includes forming a nitride-based channel layer on a substrate, forming a barrier layer on the nitride-based channel layer, forming a contact recess in the barrier layer to expose a contact region of the nitride-based channel layer, forming a contact layer on the exposed contact region of the nitride-based channel layer, for example, using a low temperature deposition process, forming an ohmic contact on the contact layer and forming a gate contact disposed on the barrier layer adjacent the ohmic contact. A high electron mobility transistor (HEMT) and methods of fabricating a HEMT are also provided. The HEMT includes a nitride-based channel layer on a substrate, a barrier layer on the nitride-based channel layer, a contact recess in the barrier layer that extends into the channel layer, an n-type nitride-based semiconductor material contact region on the nitride-based channel layer in the contact recess, an ohmic contact on the nitride-based contact region and a gate contact disposed on the barrier layer adjacent the ohmic contact. The n-type nitride-based semiconductor material contact region and the nitride-based channel layer include a surface area enlargement structure.

Owner:CREE INC

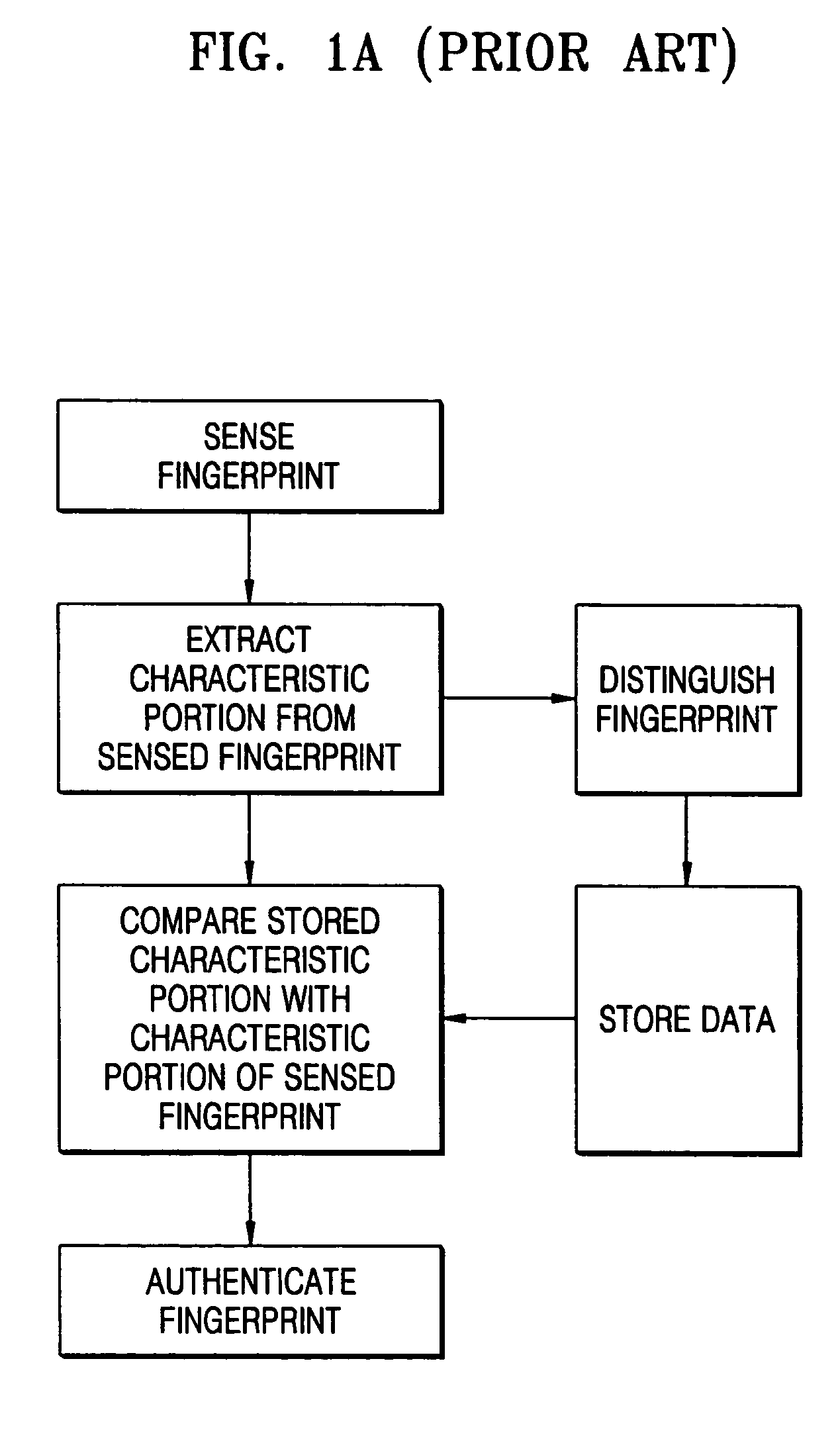

Fingerprint sensor and fabrication method thereof

InactiveUS7400750B2Improve authentication speedTransistorPiezoelectric/electrostrictive device manufacture/assemblyDopantEngineering

Provided are a fingerprint sensor and a fabrication method thereof. The fingerprint sensor includes: a complementary metal-oxide semiconductor structure which is formed on a substrate that is doped with a first type dopant; an insulating layer which is formed on the complementary metal-oxide semiconductor structure; a lower electrode which is formed in a central portion of the insulating layer; a piezoelectric region which is formed on the lower electrode; an upper electrode which is formed on the piezoelectric layer; and a fingerprint contact layer which is formed to cover a portion of an upper surface of the insulating layer on which the lower electrode has not been formed, the lower electrode, the piezoelectric region, and the upper electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

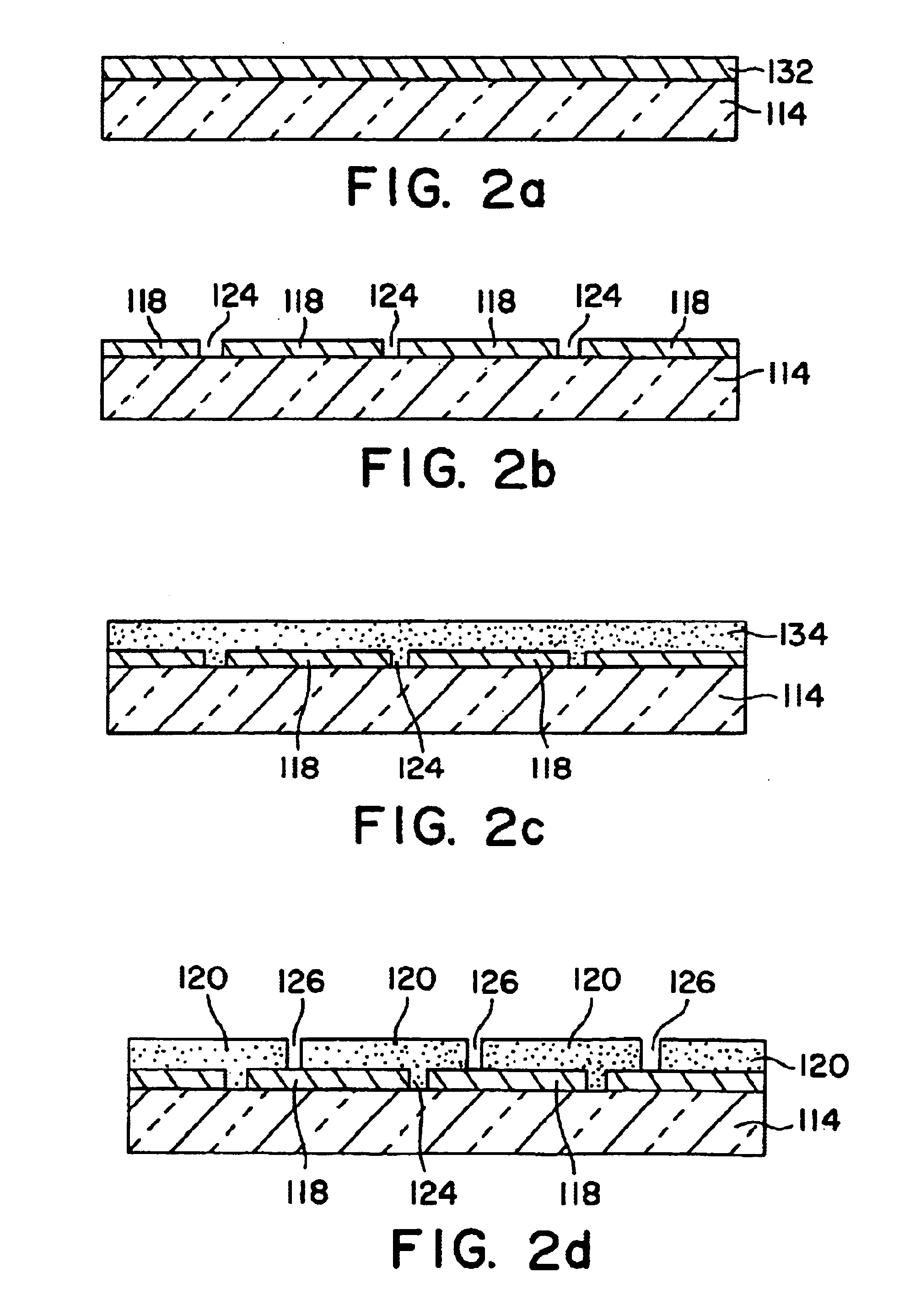

Technique For Preparing Precursor Films And Compound Layers For Thin Film Solar Cell Fabrication And Apparatus Corresponding Thereto

InactiveUS20070093006A1Final product manufactureSolid-state devicesCompound (substance)Degrees of freedom

The present invention advantageously provides for, in different embodiments, improved contact layers or nucleation layers over which precursors and Group IBIIIAVIA compound thin films adhere well and form high quality layers with excellent micro-scale compositional uniformity. It also provides methods to form precursor stack layers, by wet deposition techniques such as electroplating, with large degree of freedom in terms of deposition sequence of different layers forming the stack.

Owner:SOLOPOWER

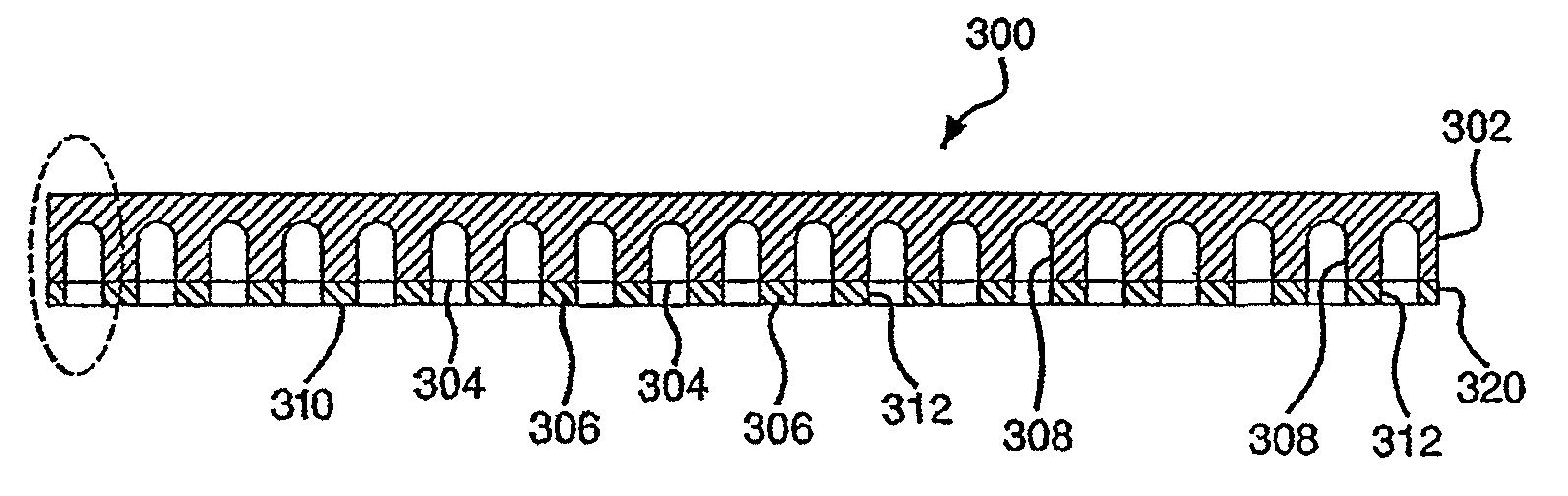

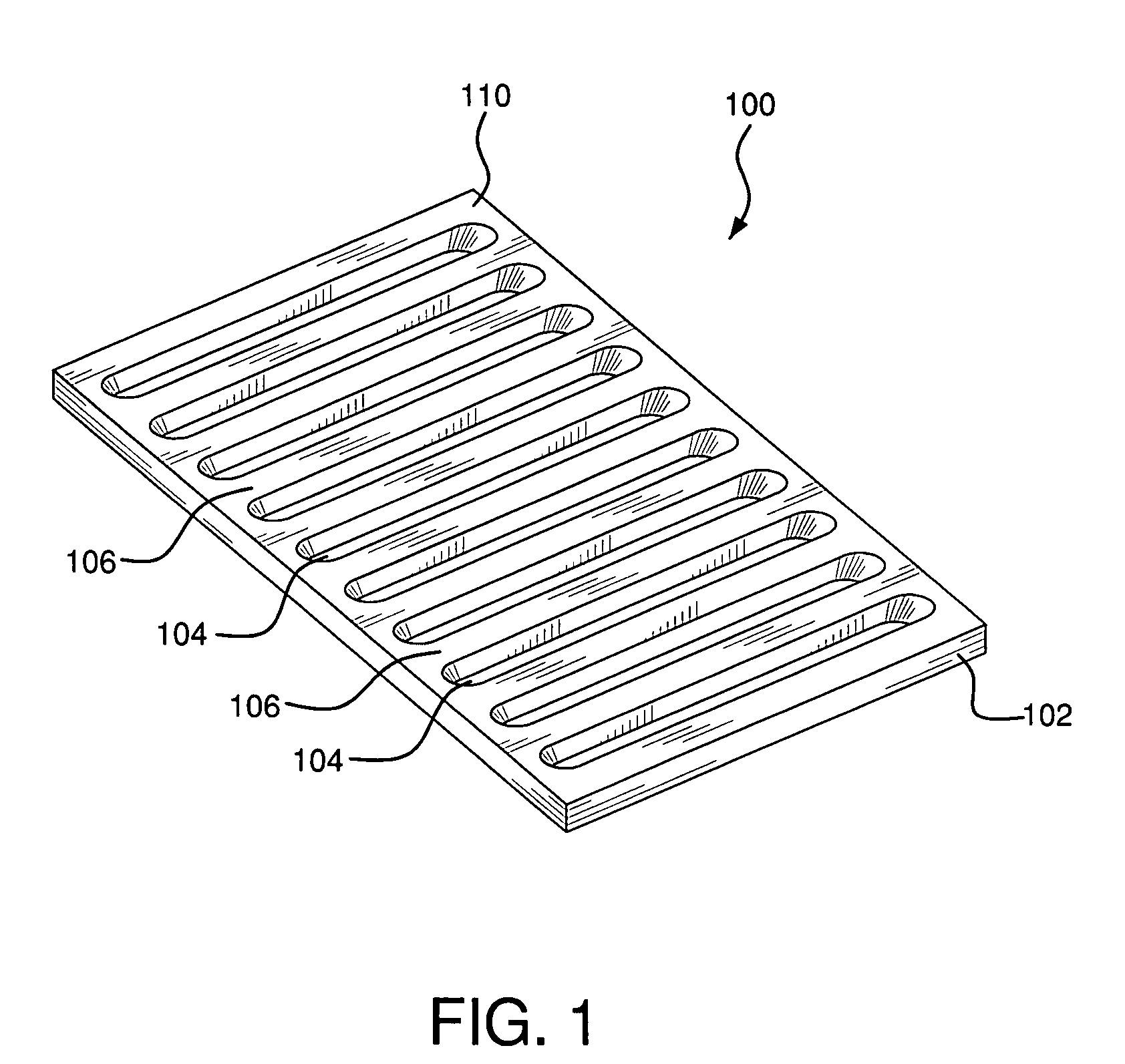

Growth stimulating wound dressing with improved contact surfaces

A wound contact device comprising a permeable material and a wound contact layer having voids extending through the contact layer to a depth in the permeable material. The wound contact layer can comprise a thin sheet or film forming a generally flat and smooth wound contact surface having essentially no discontinuities or gaps. The wound contact layer can comprise a thin sheet of highly calendered fabric forming a wound contact surface having a mean surface roughness in the range of about 0 microns to about 200 microns. In progressive wound healing, an embodiment of the wound contact device having the fabric contact surface is used in earlier healing stages and an embodiment of the wound contact device with film contact surface is used in later healing stages. The wound contact device is particularly useful in wound dressings for use in suction-assisted wound therapy.

Owner:BOEHRINGER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com