Patents

Literature

3005 results about "Aluminum substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium Substrate. Because the anodic film generated by the anodising process is transparent, any defects in the underlying aluminium substrate will remain visible after anodising.

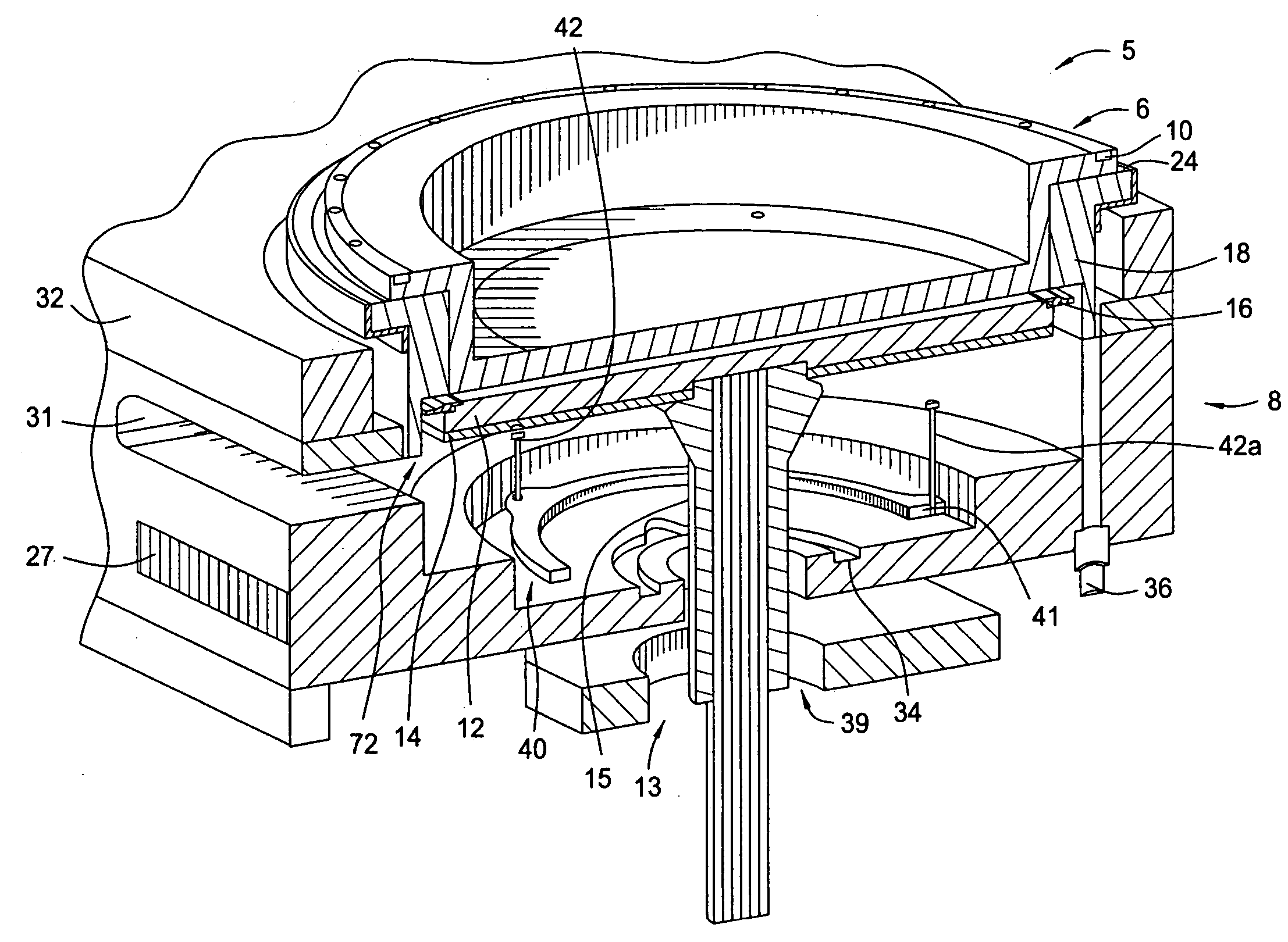

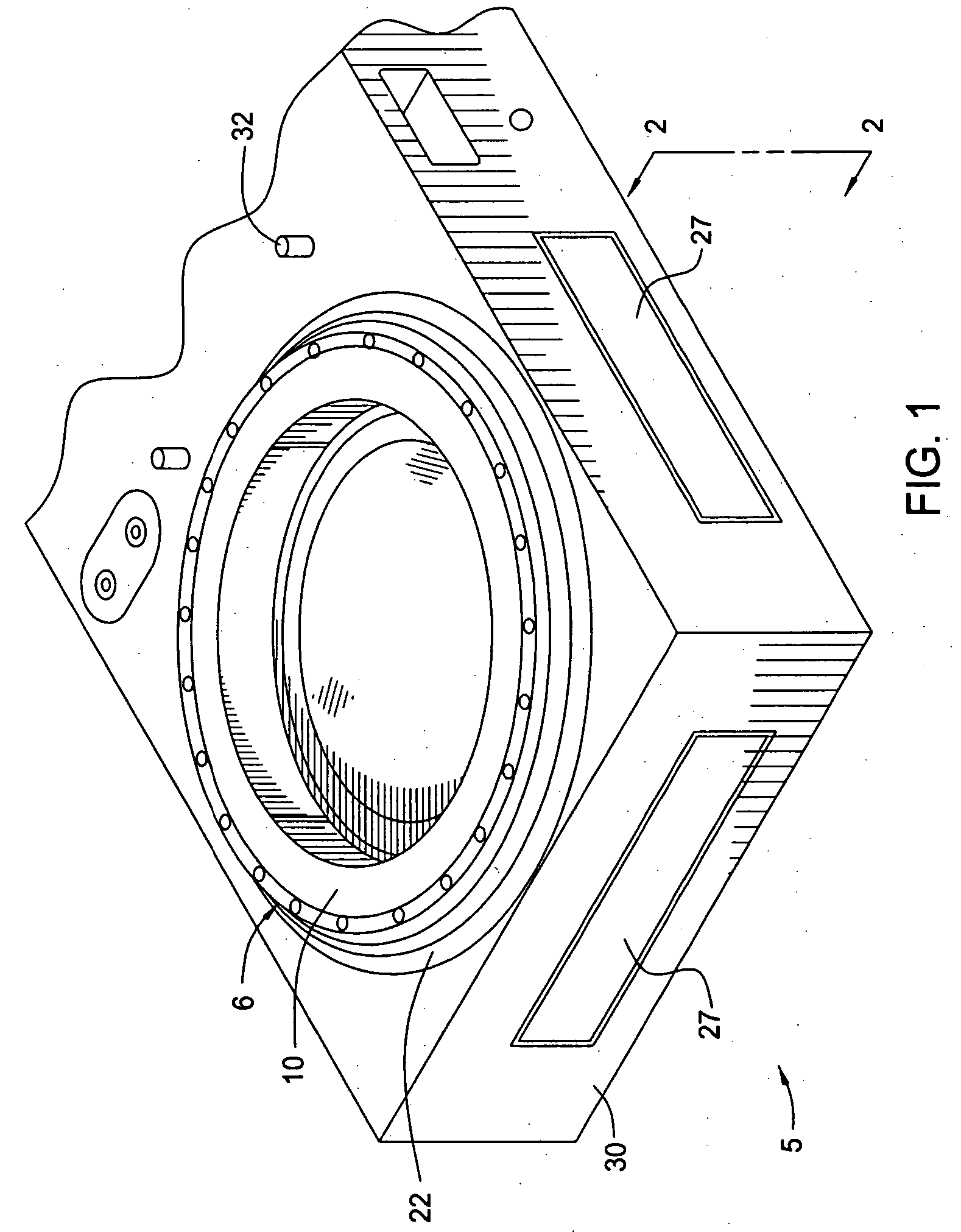

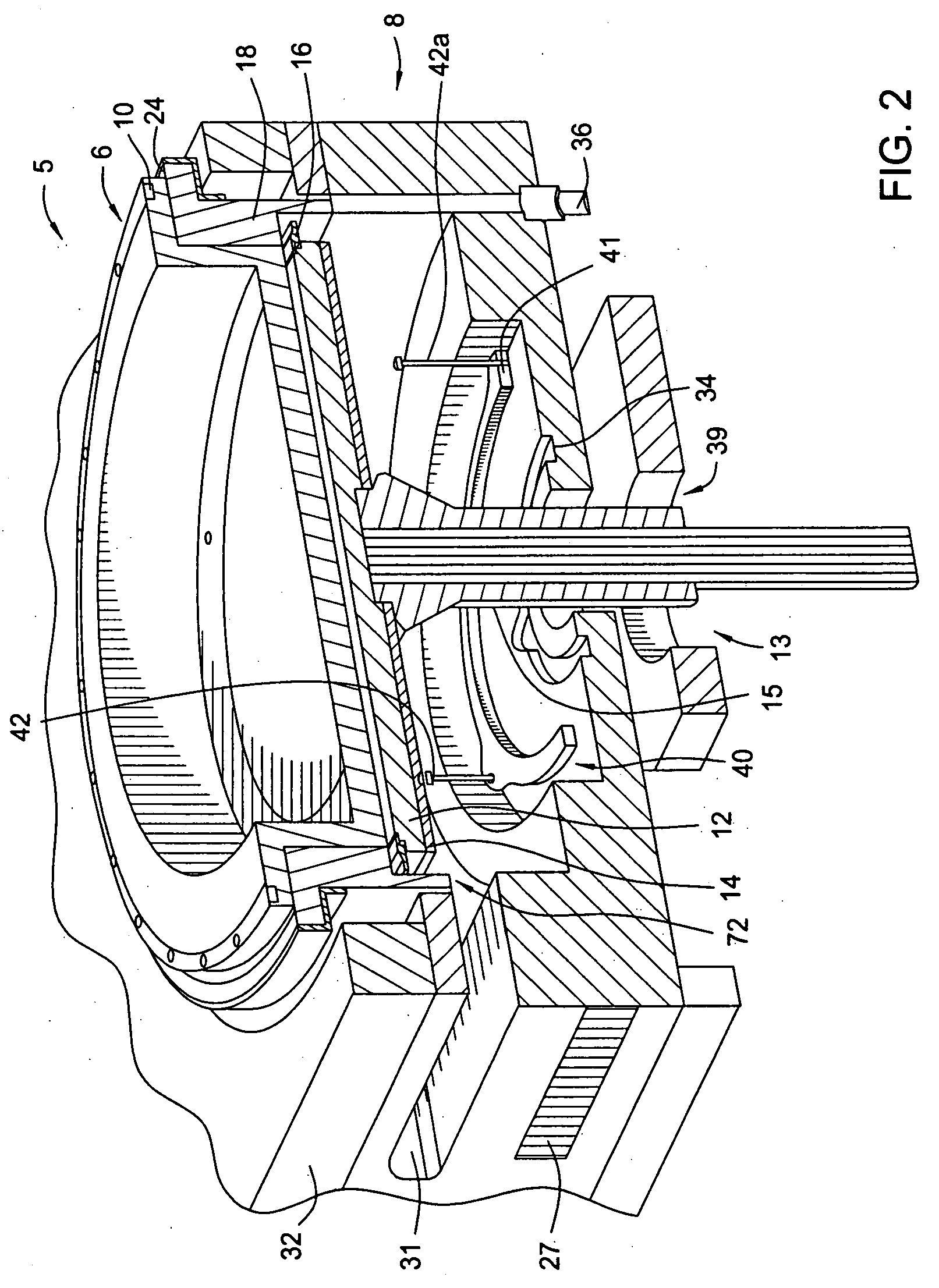

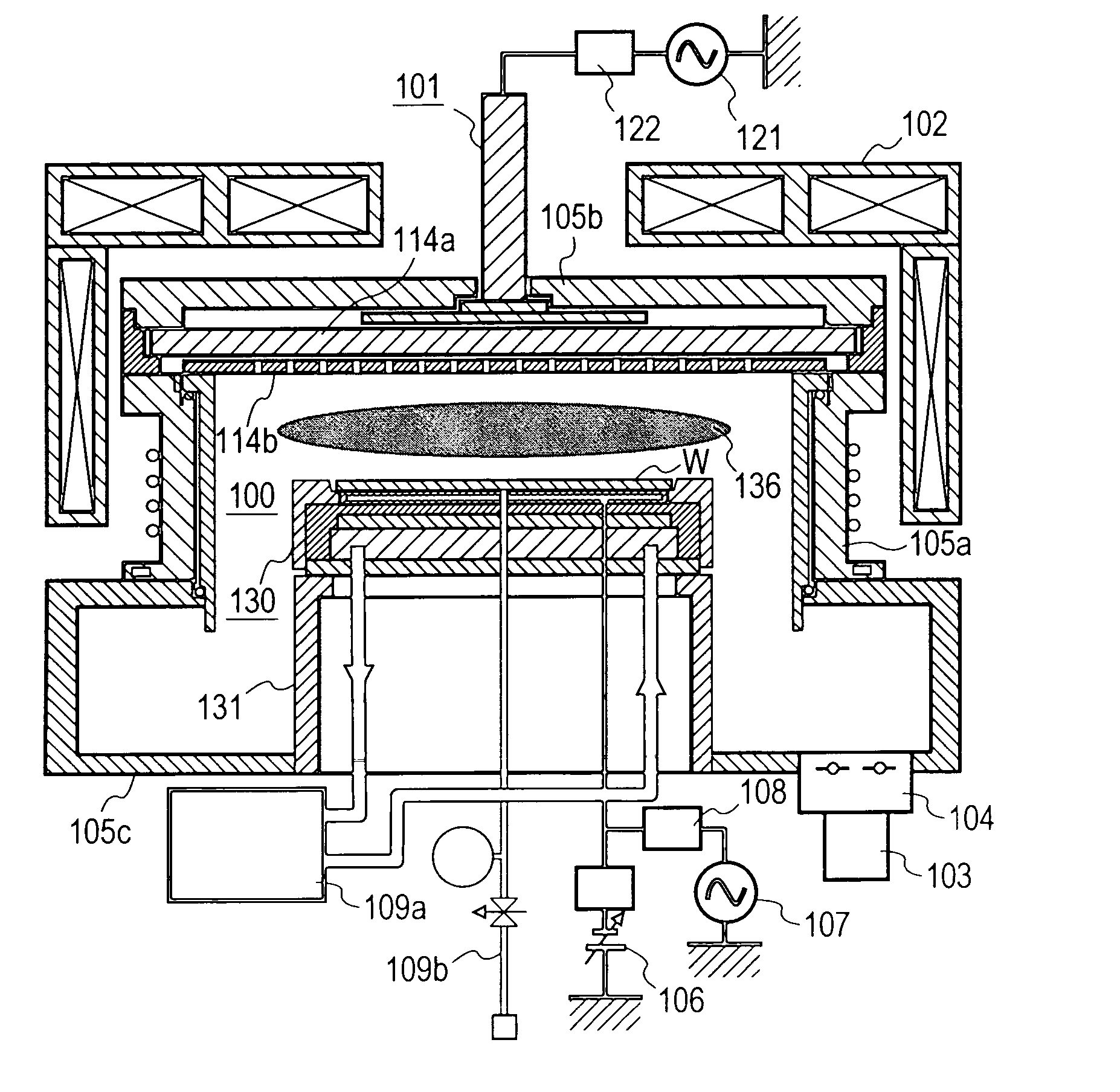

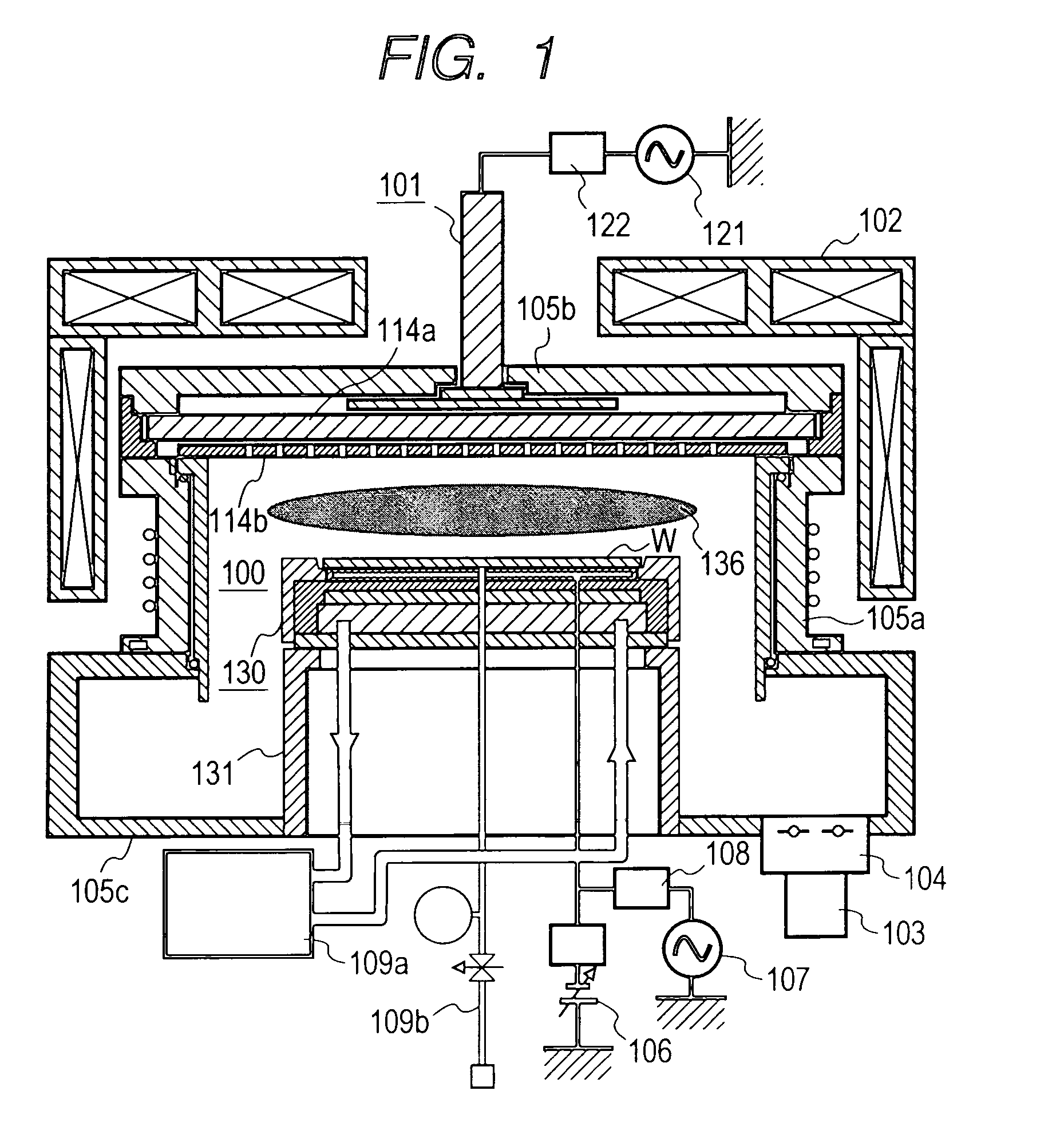

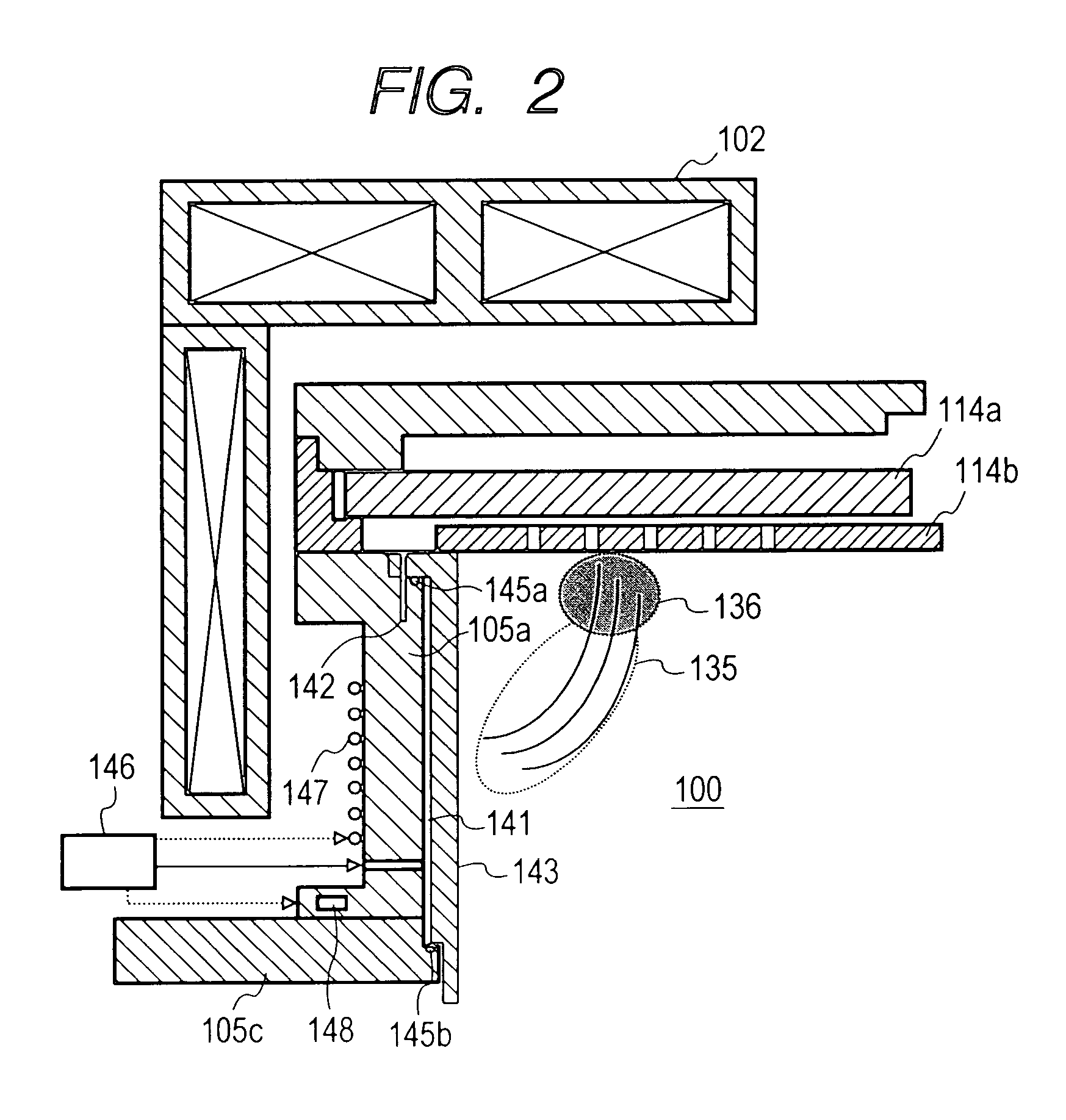

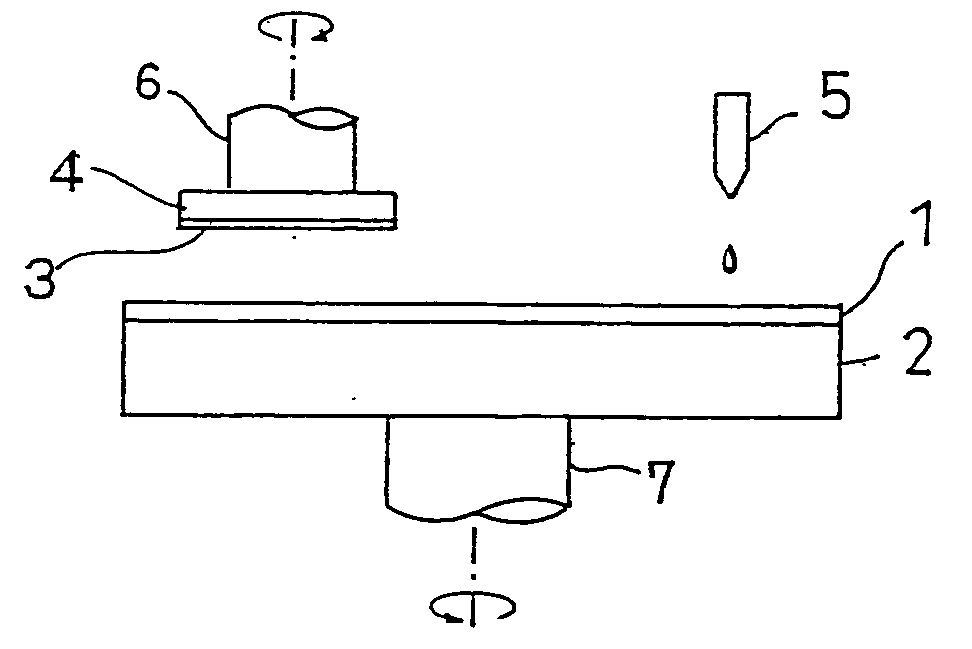

High productivity plasma processing chamber

InactiveUS20050229849A1Maximizing allowable timeReduce probabilityElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlProduction rate

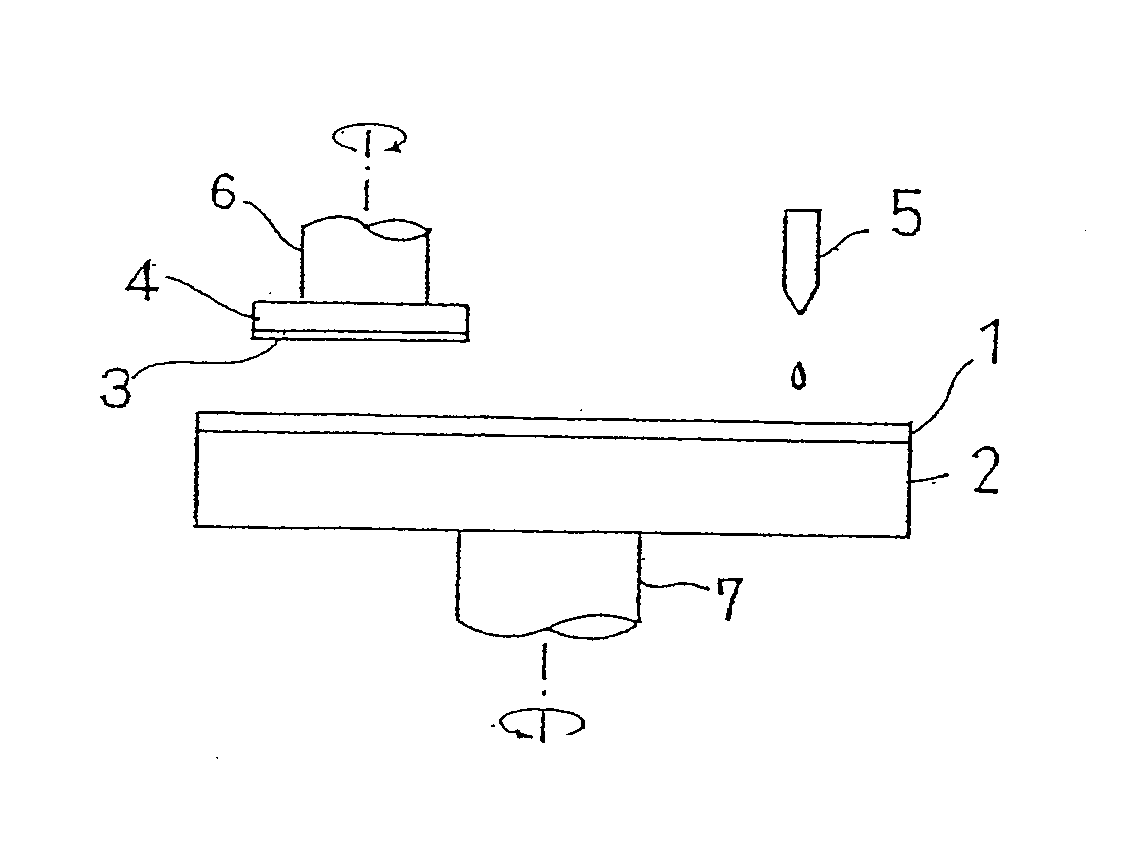

Embodiments of the present invention are generally directed to apparatus and methods for a plasma-processing chamber requiring less maintenance and downtime and possessing improved reliability over the prior art. In one embodiment, the apparatus includes a substrate support resting on a ceramic shaft, an inner shaft allowing for electrical connections to the substrate support at atmospheric pressure, an aluminum substrate support resting on but not fixed to a ceramic support structure, sapphire rest points swaged into the substrate support, and a heating element inside the substrate support arranged in an Archimedes spiral to reduce warping of the substrate support and to increase its lifetime. Methods include increasing time between in-situ cleans of the chamber by reducing particle generation from chamber surfaces. Reduced particle generation occurs via temperature control of chamber components and pressurization of non-processing regions of the chamber relative to the processing region with a purge gas.

Owner:APPLIED MATERIALS INC

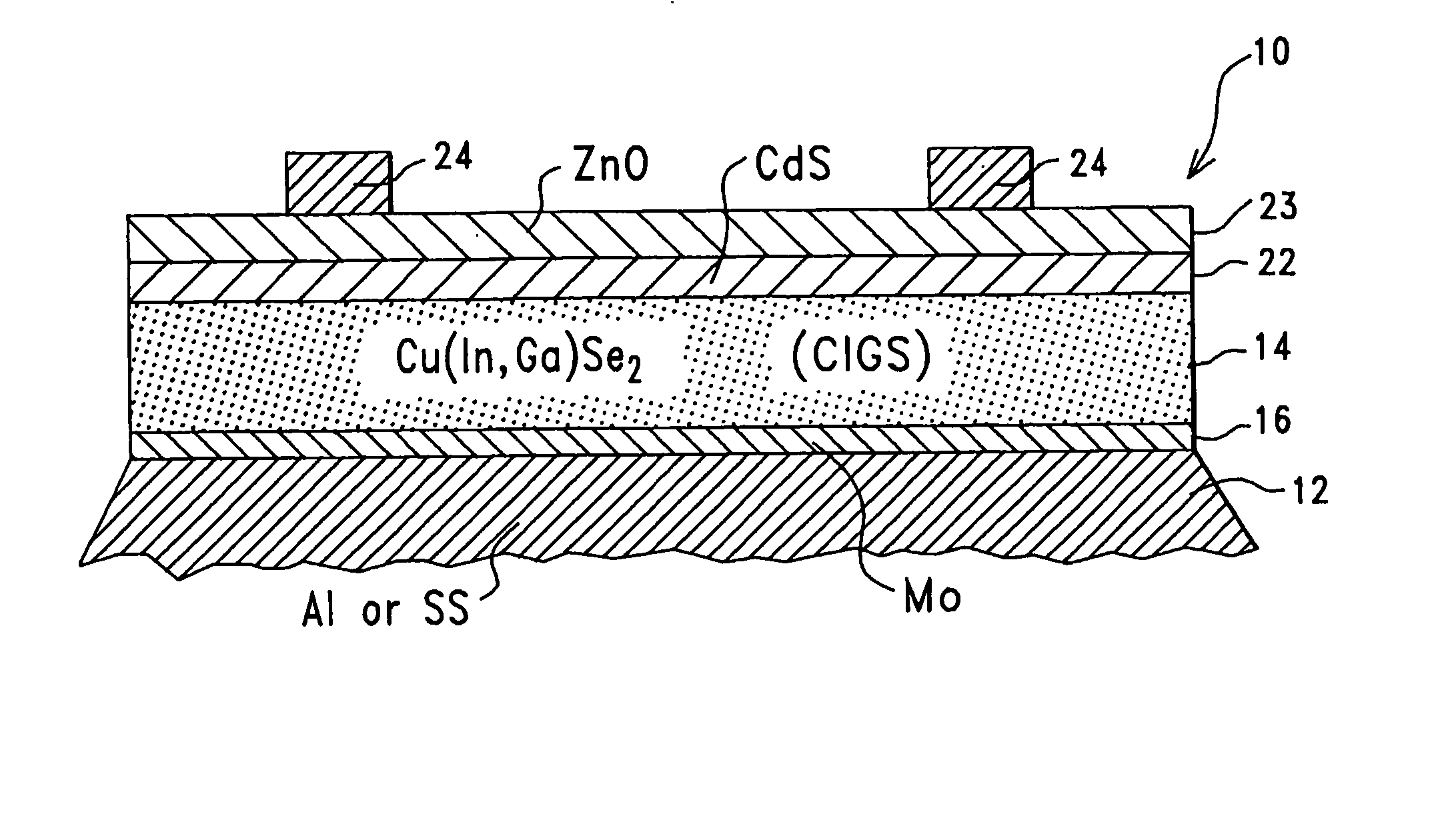

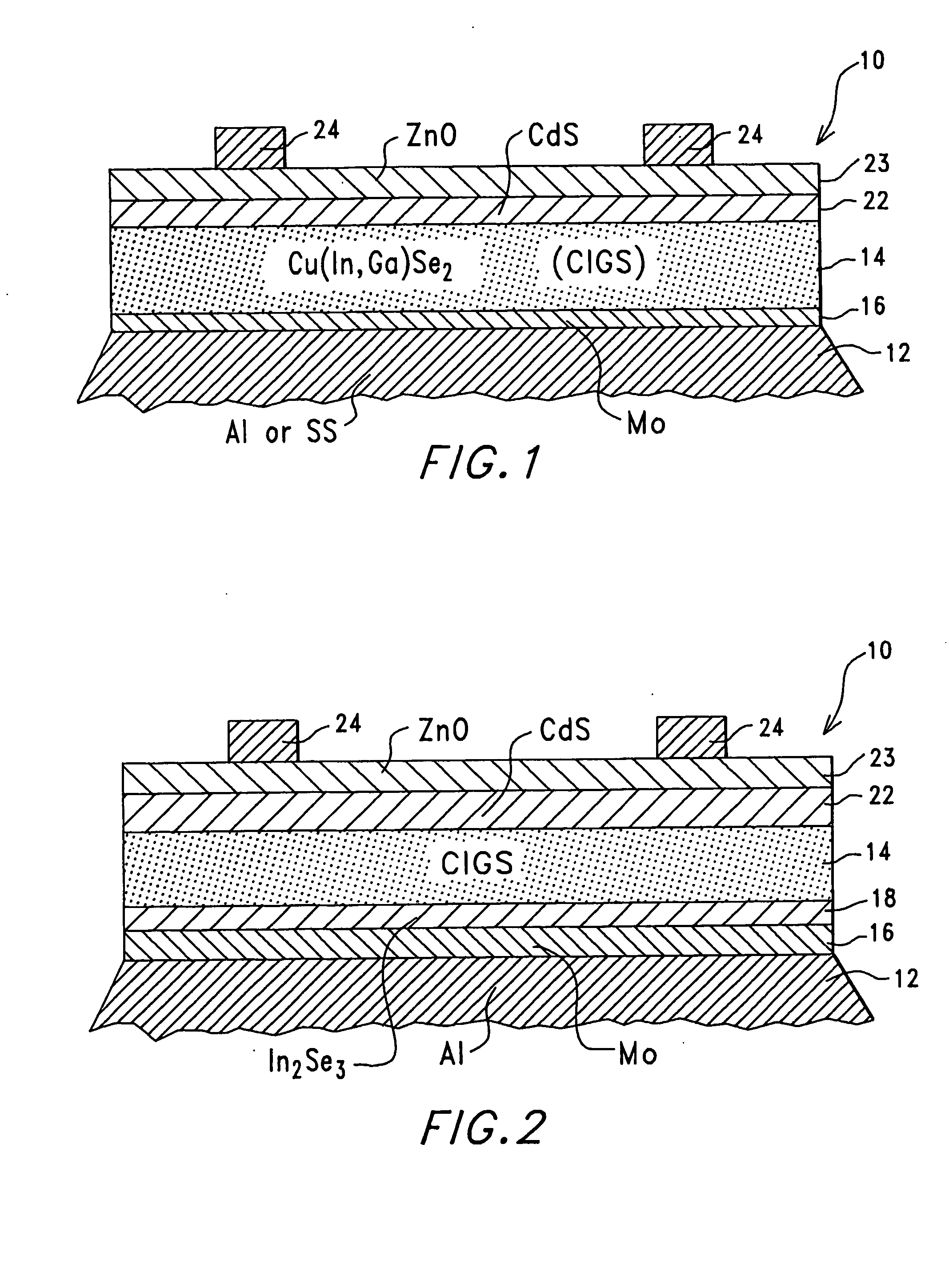

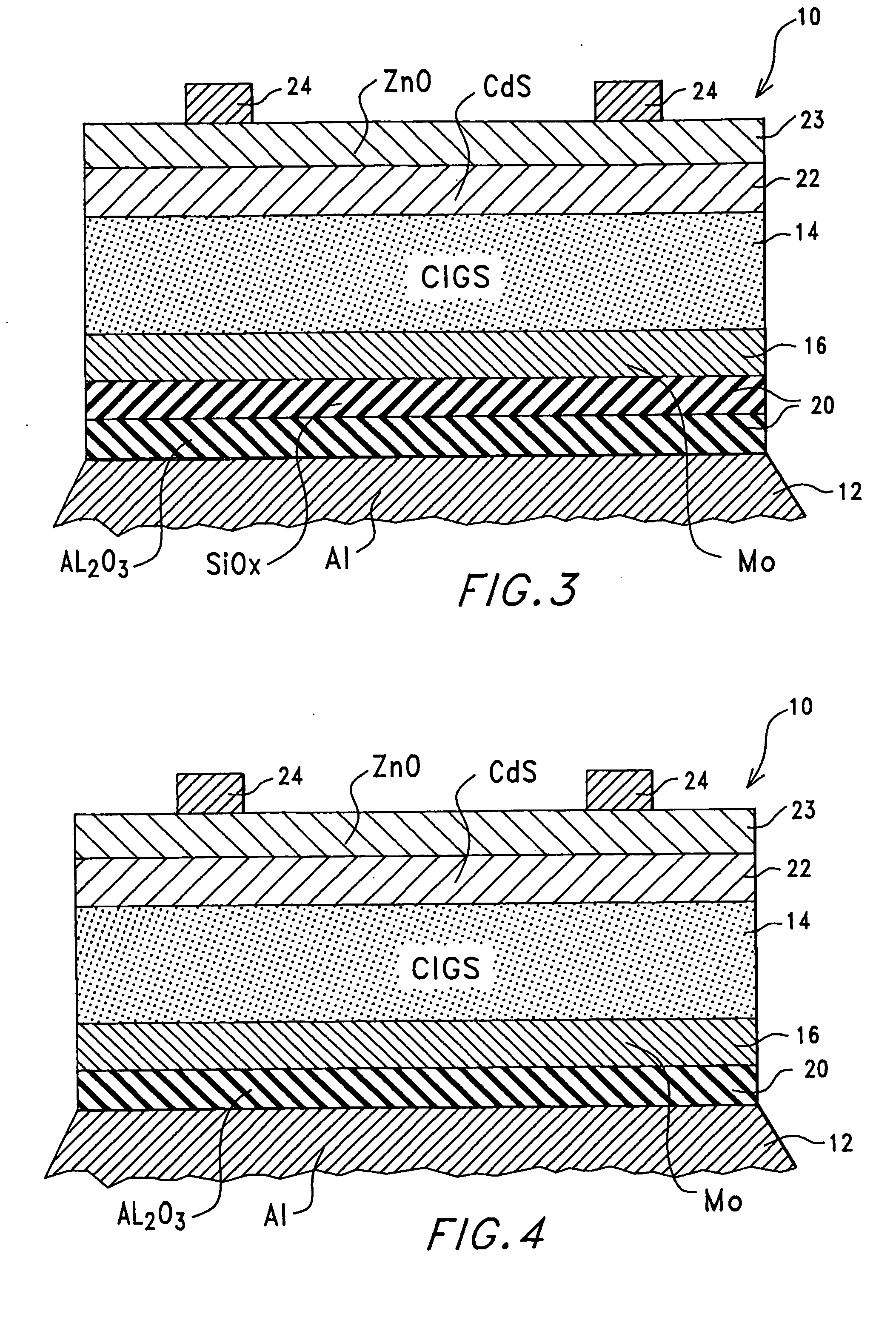

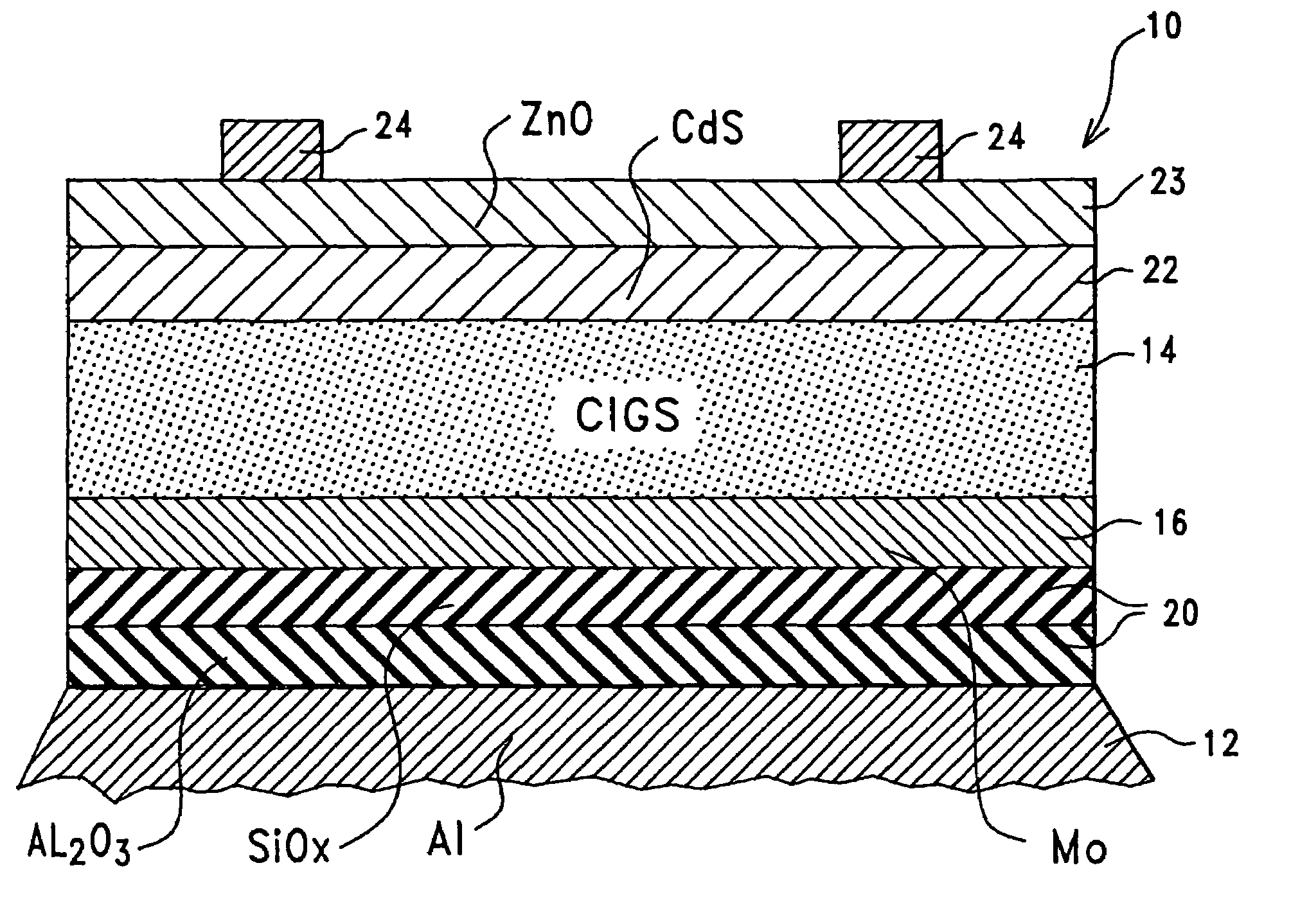

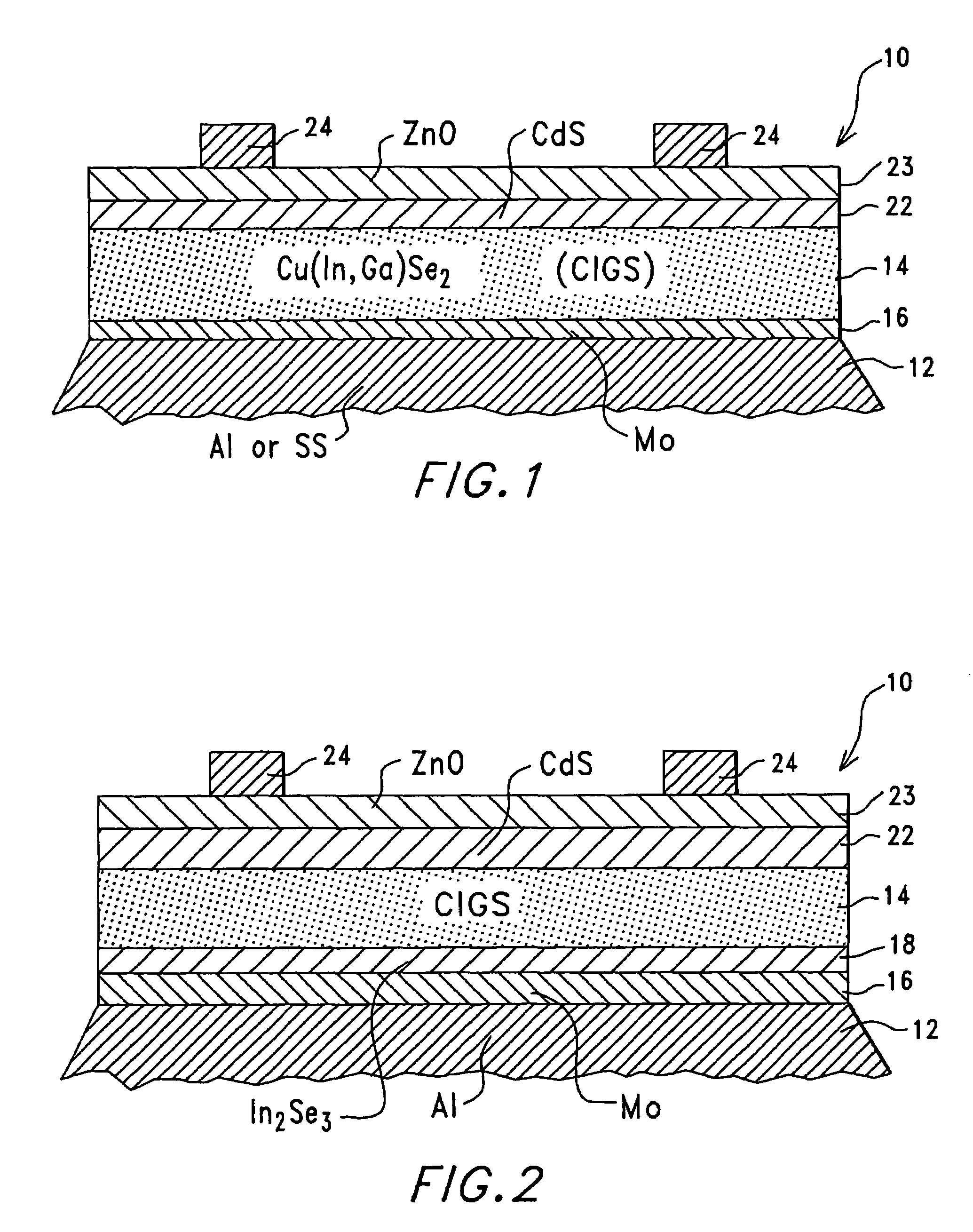

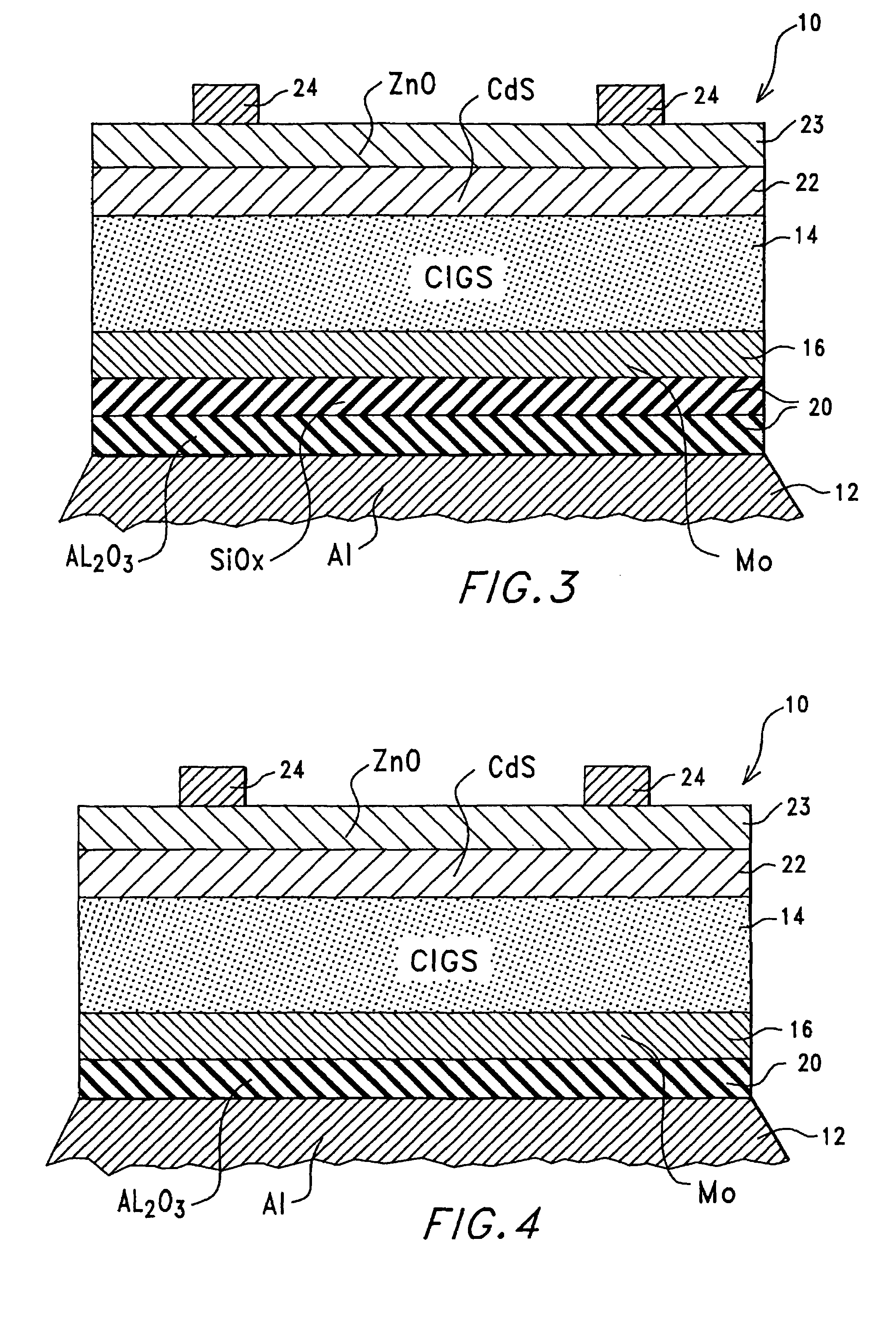

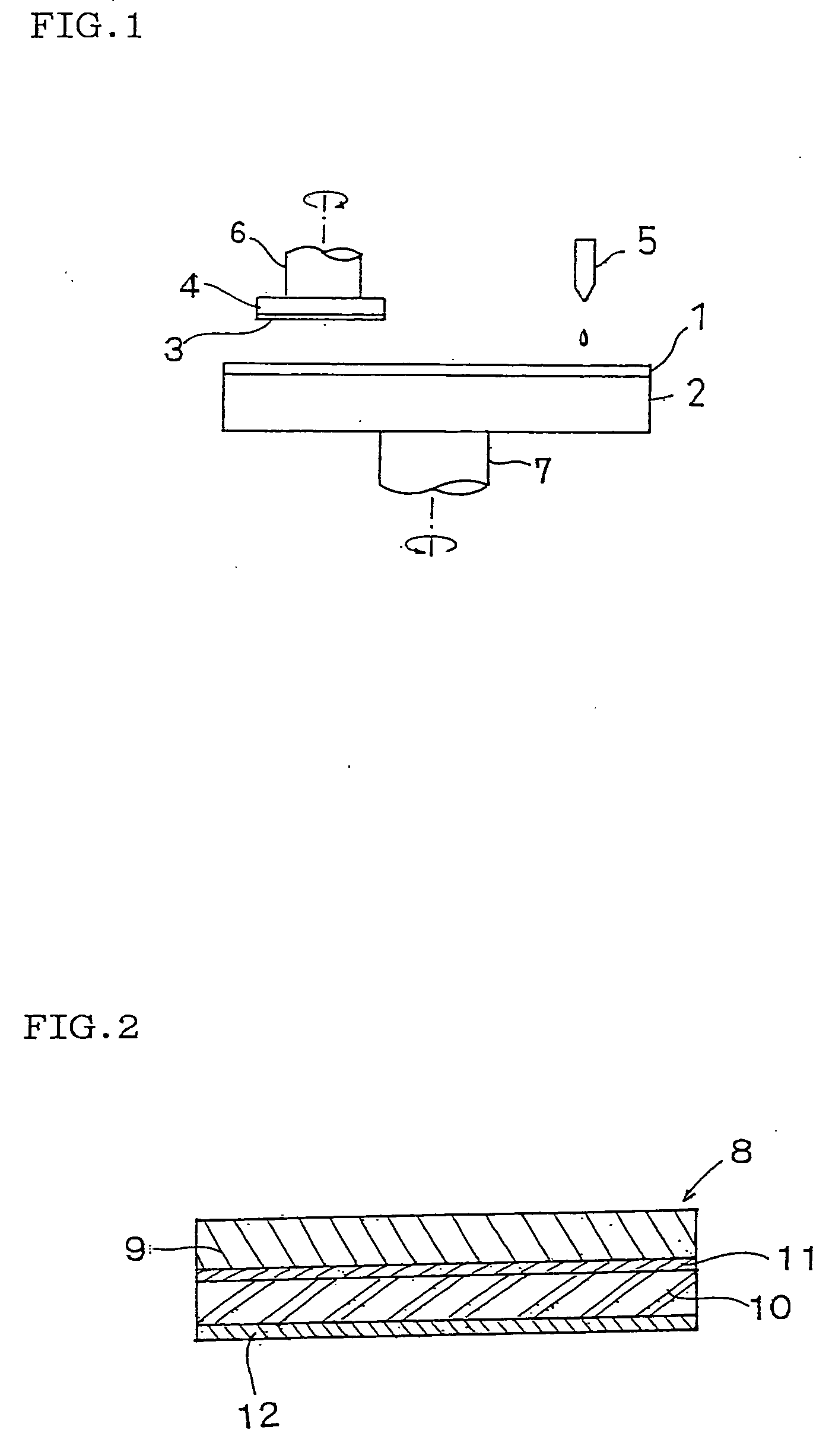

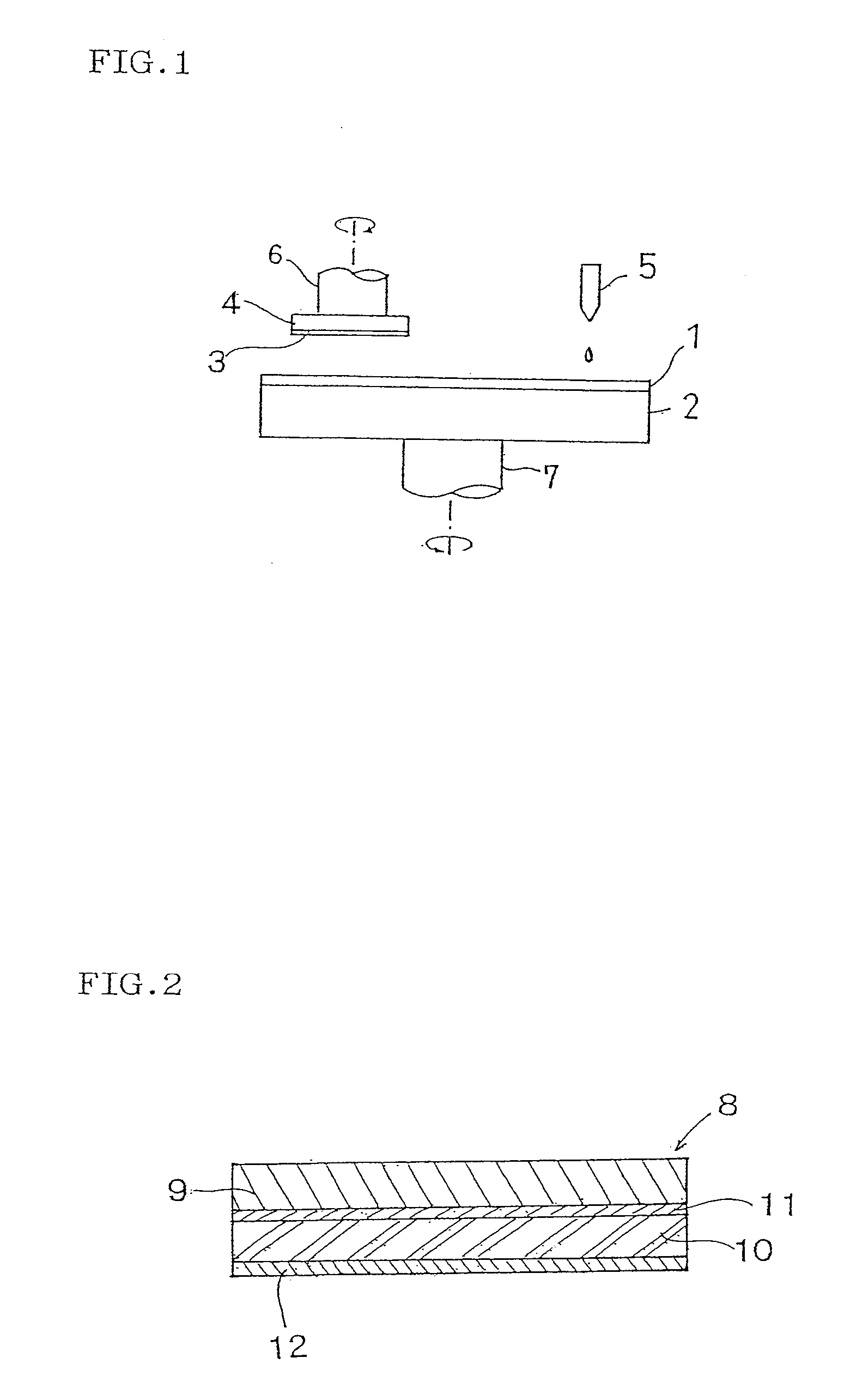

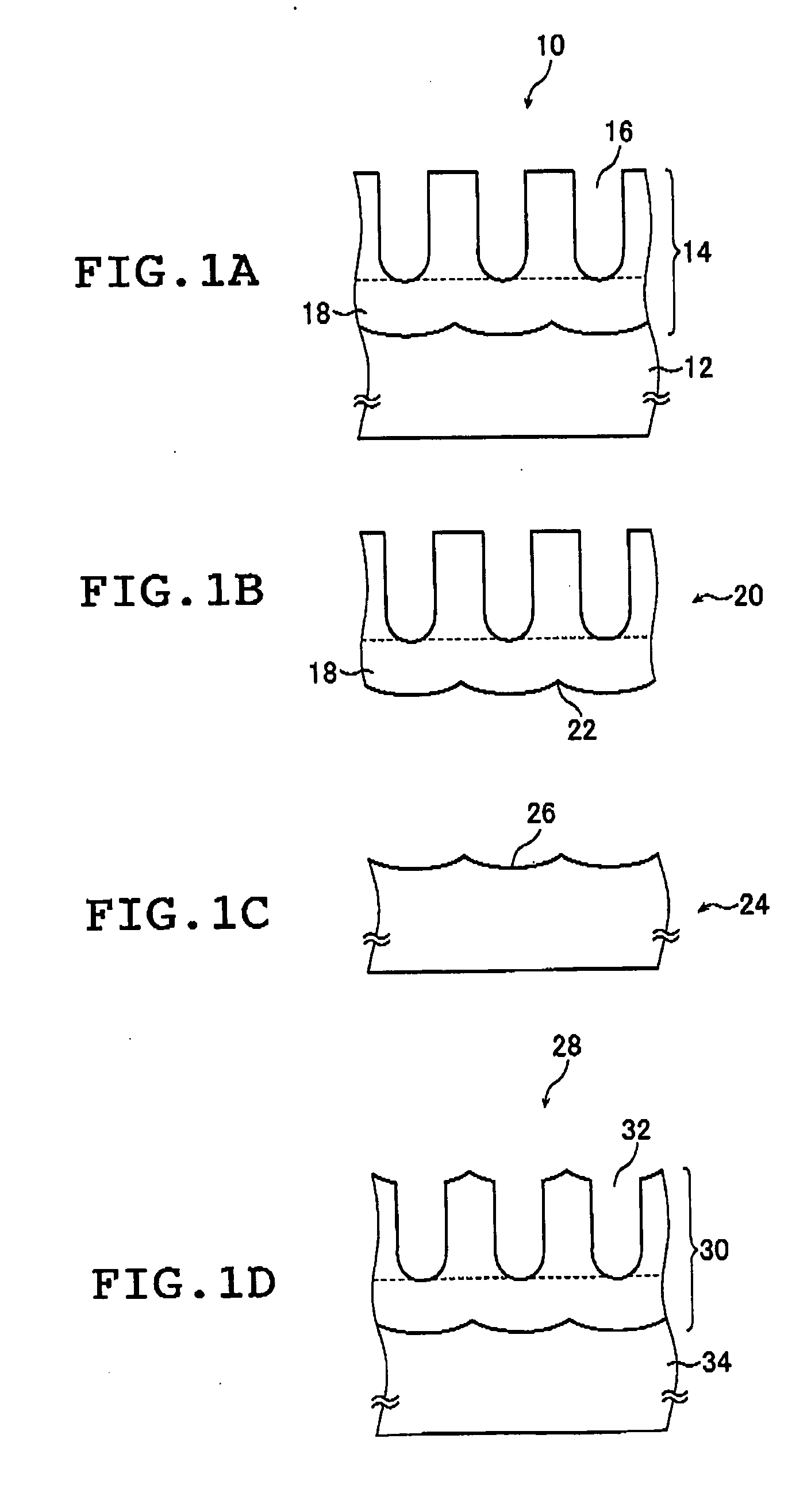

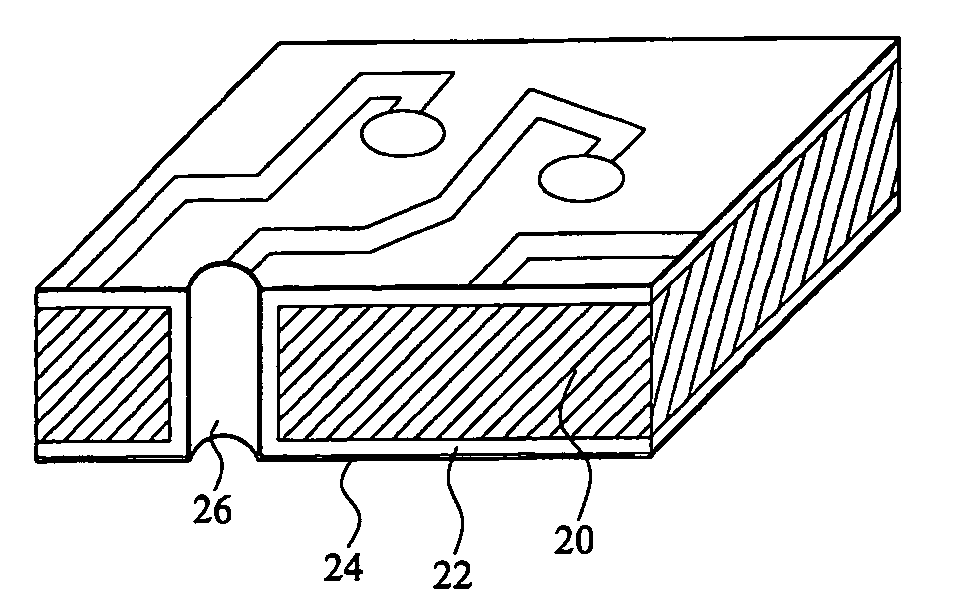

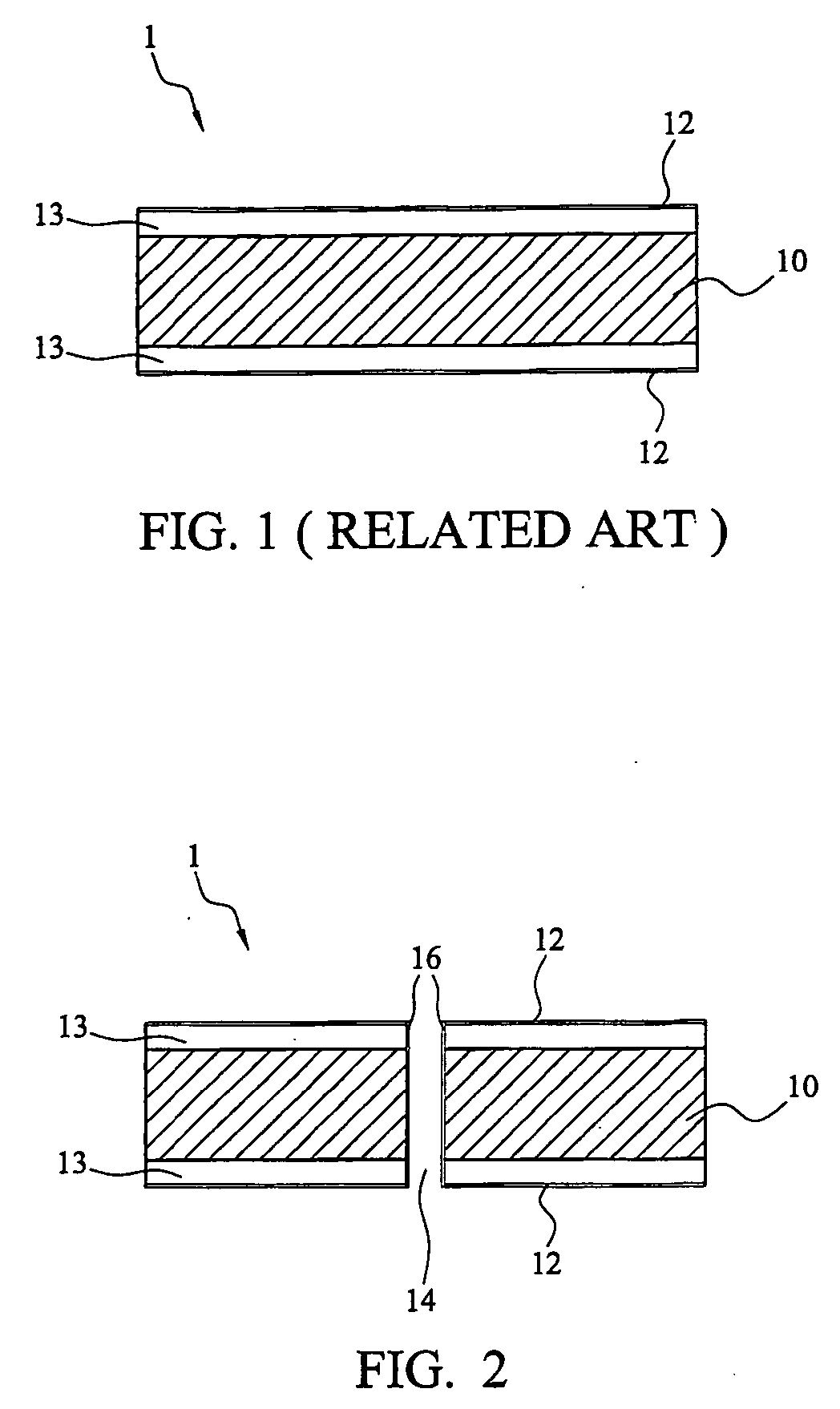

Thin-film solar cell fabricated on a flexible metallic substrate

A thin-film solar cell (10) is provided. The thin-film solar cell (10) comprises a flexible metallic substrate (12) a having a first surface and a second surface. A back metal contact layer (16) is deposited on the first surface of the flexible metallic substrate (12). A semiconductor absorber layer (14) is deposited on the back metal contact. A photoactive film deposited on the semiconductor absorber layer (14) forms a heterojunction structure and a grid contact (24) deposited on the heterjunction structure. The flexible metal substrate (12) can be constructed of either aluminium or stainless steel. Furthermore, a method of constructing a solar cell is provided. The method comprises providing an aluminum substrate (12), depositing a semiconductor absorber layer (14) on the aluminum substrate (12), and insulating the aluminum substrate (12) from the semiconductor absorber layer (14) to inhibit reaction between the aluminum substrate (12) and the semiconductor absorber layer (14).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

Thin-film solar cell fabricated on a flexible metallic substrate

A thin-film solar cell (10) is provided. The thin-film solar cell (10) comprises a flexible metallic substrate (12) having a first surface and a second surface. A back metal contact layer (16) is deposited on the first surface of the flexible metallic substrate (12). A semiconductor absorber layer (14) is deposited on the back metal contact. A photoactive film deposited on the semiconductor absorber layer (14) forms a heterojunction structure and a grid contact (24) deposited on the heterjunction structure. The flexible metal substrate (12) can be constructed of either aluminium or stainless steel. Furthermore, a method of constructing a solar cell is provided. The method comprises providing an aluminum substrate (12), depositing a semiconductor absorber layer (14) on the aluminum substrate (12), and insulating the aluminum substrate (12) from the semiconductor absorber layer (14) to inhibit reaction between the aluminum substrate (12) and the semiconductor absorber layer (14).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

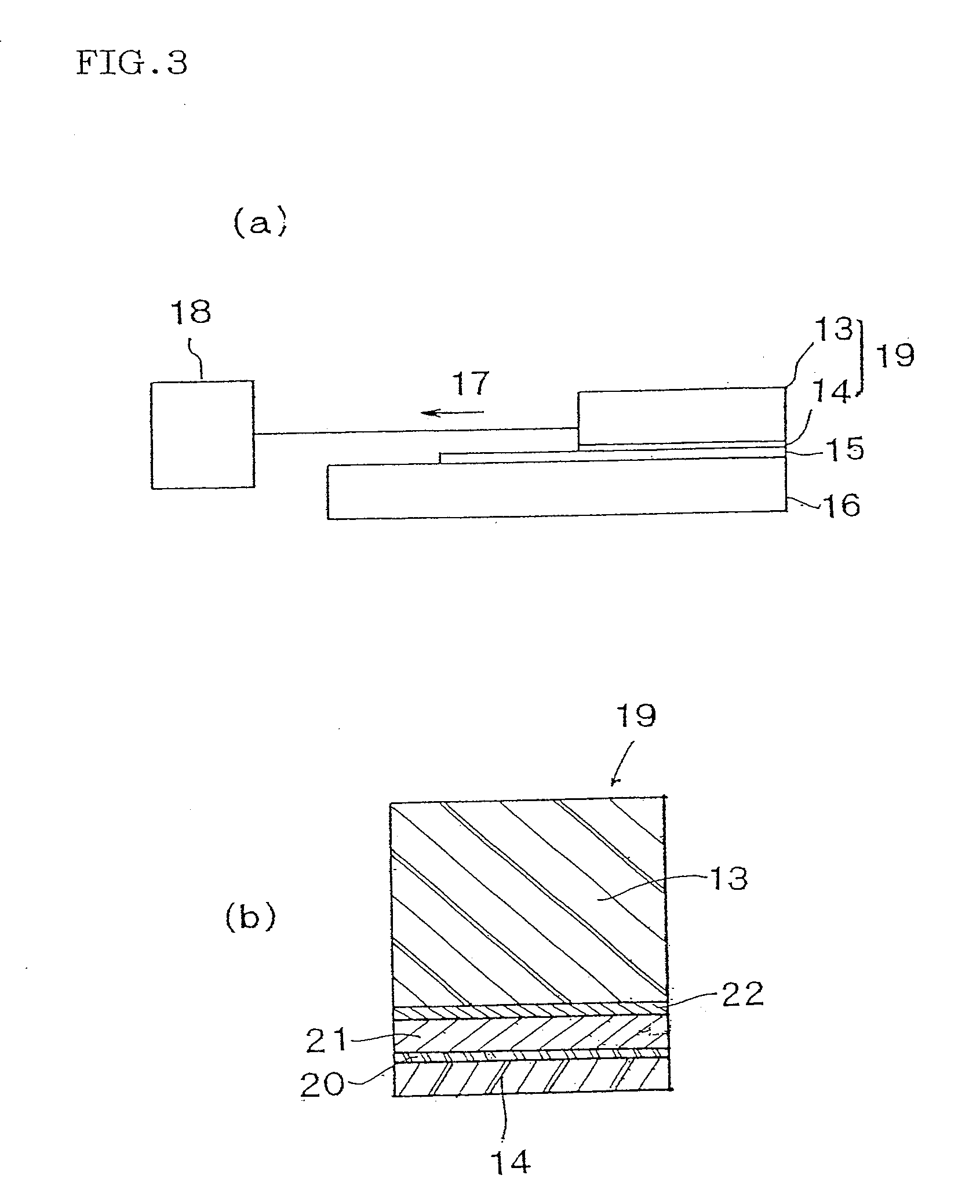

Plasma etching apparatus and method for forming inner wall of plasma processing chamber

InactiveUS20070215278A1Reduce corrosionDecreasing amountElectric discharge tubesSemiconductor/solid-state device manufacturingProduction rateHeat resistance

A plasma etching apparatus is provided which can prevent corrosion of an aluminum substrate constituting an etching processing chamber or an inside component thereof, thereby avoiding a reduction in productivity due to scattering of a sprayed coating. In the plasma etching apparatus, an anodic oxide film is disposed between a ceramic sprayed coating with excellent resistance to plasma, and the etching processing chamber and the inside component thereof made of aluminum alloy. The anodic oxide film has a thickness of 5 μm or less to have heat resistance.

Owner:HITACHI HIGH-TECH CORP

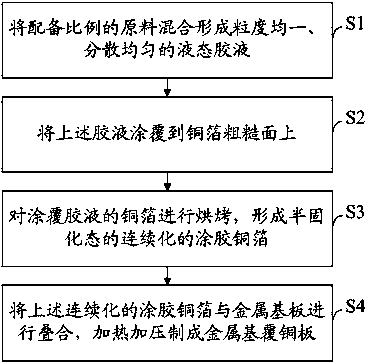

Epoxy resin composition, metal-based copper-clad plate and manufacturing method thereof

ActiveCN103694644AHigh thermal conductivityImprove thermal conductivityFilm/foil adhesivesLaminationEpoxyOrganic solvent

The invention discloses an epoxy resin composition, a metal-based copper-clad plate and a manufacturing method thereof. The epoxy resin composition comprises the following components by mass: 90-110 parts of epoxy resin, 10-50 parts of thermoplastic resin, 1-100 parts of a curing agent, 0.05-5 parts of a curing accelerant, 1-10 parts of an additive, 20-500 parts of heat conduction filler and 0-30 parts of an organic solvent. The metal-based copper-clad plate has the characteristic that 1, the heat conductivity is high; 2, the insulation property is high as the puncture-withstand voltage is higher than 6KV; 3, the anti-bending property is high, so that the metal-based copper-clad plate can be used for manufacturing a three-dimensional aluminum substrate; 4, the thickness of the insulation layer is uniform, the coating thickness tolerance can be controlled at + / - 2 microns, and the press-fit thickness tolerance can be controlled at + / - 5 microns, so that the performance of a product can be guaranteed; 5, the production efficiency is high; 6, the cost is low and is about 1 / 4-1 / 3 of the cost of an imported product.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

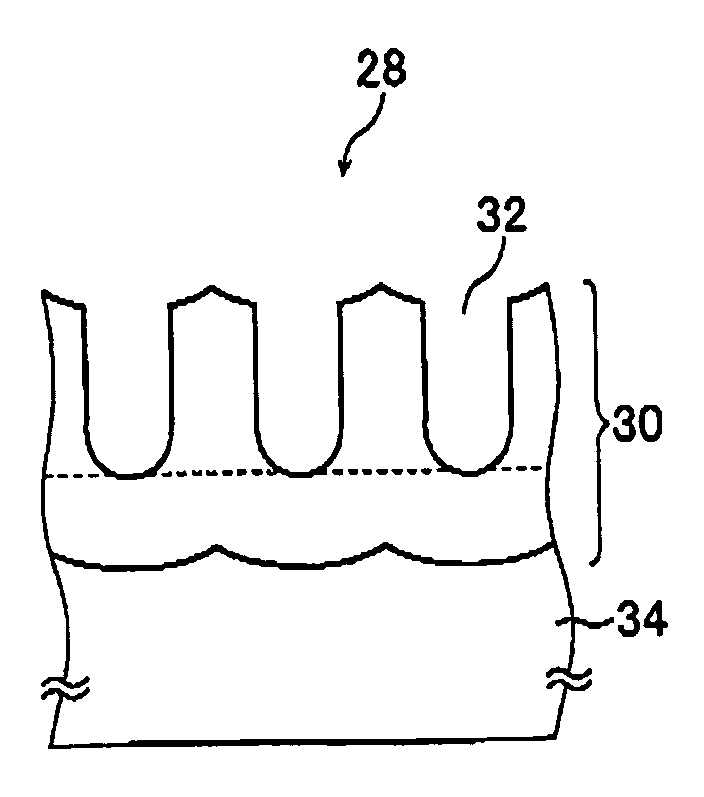

Grinding pad and method of producing the same

InactiveUS20050064709A1Reduce rateReduce hardnessLayered productsAbrasion apparatusAluminum substrateSemiconductor

The invention provides a polishing pad by which optical materials such as lenses, reflecting mirrors etc., or materials requiring a high degree of surface planarity, as in the polishing of silicone wafers, glass substrates or aluminum substrates for hard disks, or general metal polishing, can be flattened with stability and high polishing efficiency. The invention also provides a polishing pad for semiconductor wafers, which is superior in planarizing characteristic, is free from scratches and can be produced at low cost. There is provided a polishing pad which is free from dechucking error so that neither damage to wafers nor decrease in operating efficiency occurs. There is provided a polishing pad which is satisfactory in planarity, within wafer uniformity, and polishing rate and produces less change in polishing rate. There is provided a polishing pad which can make planarity improvement and scratch decrease compatible.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

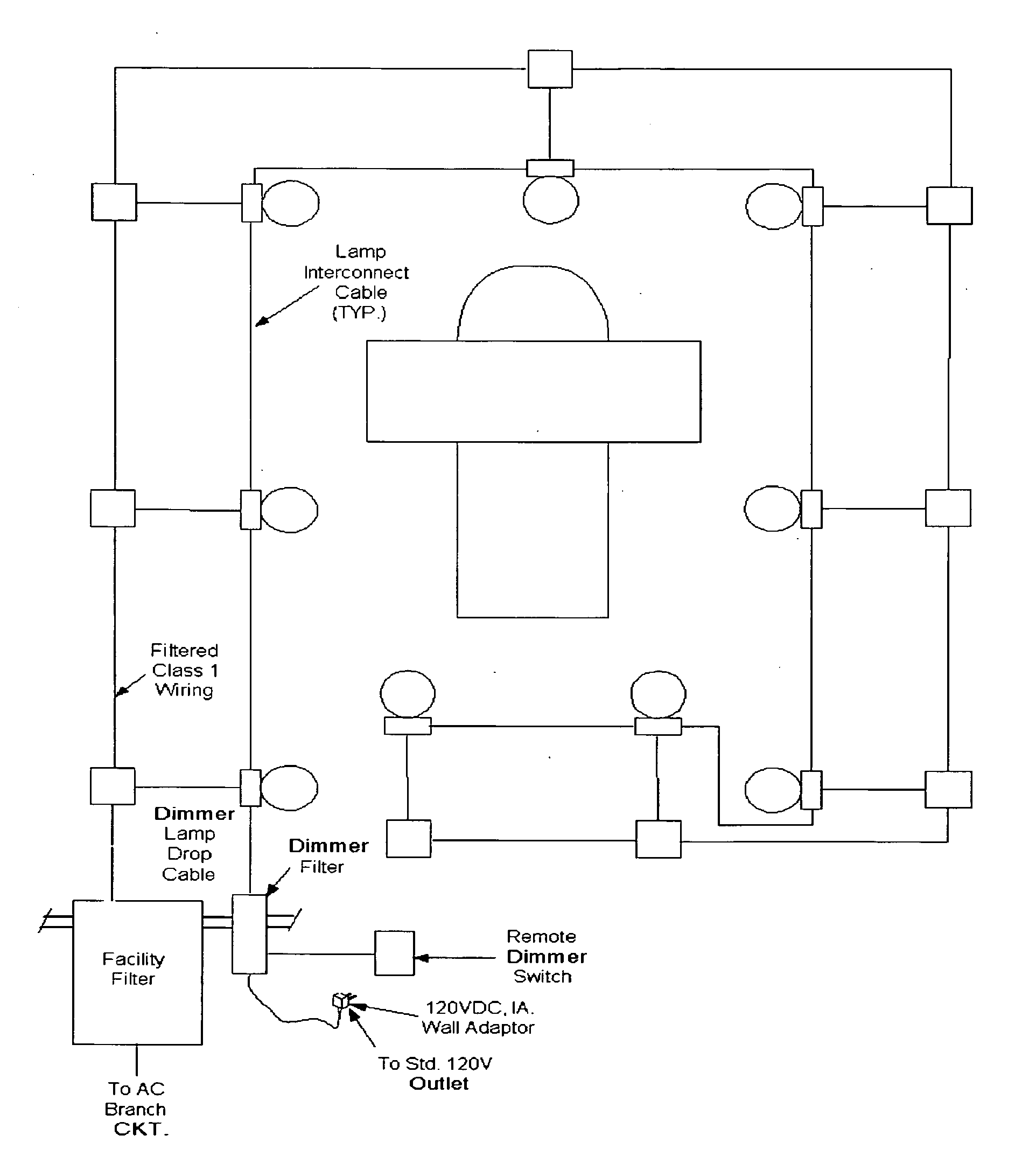

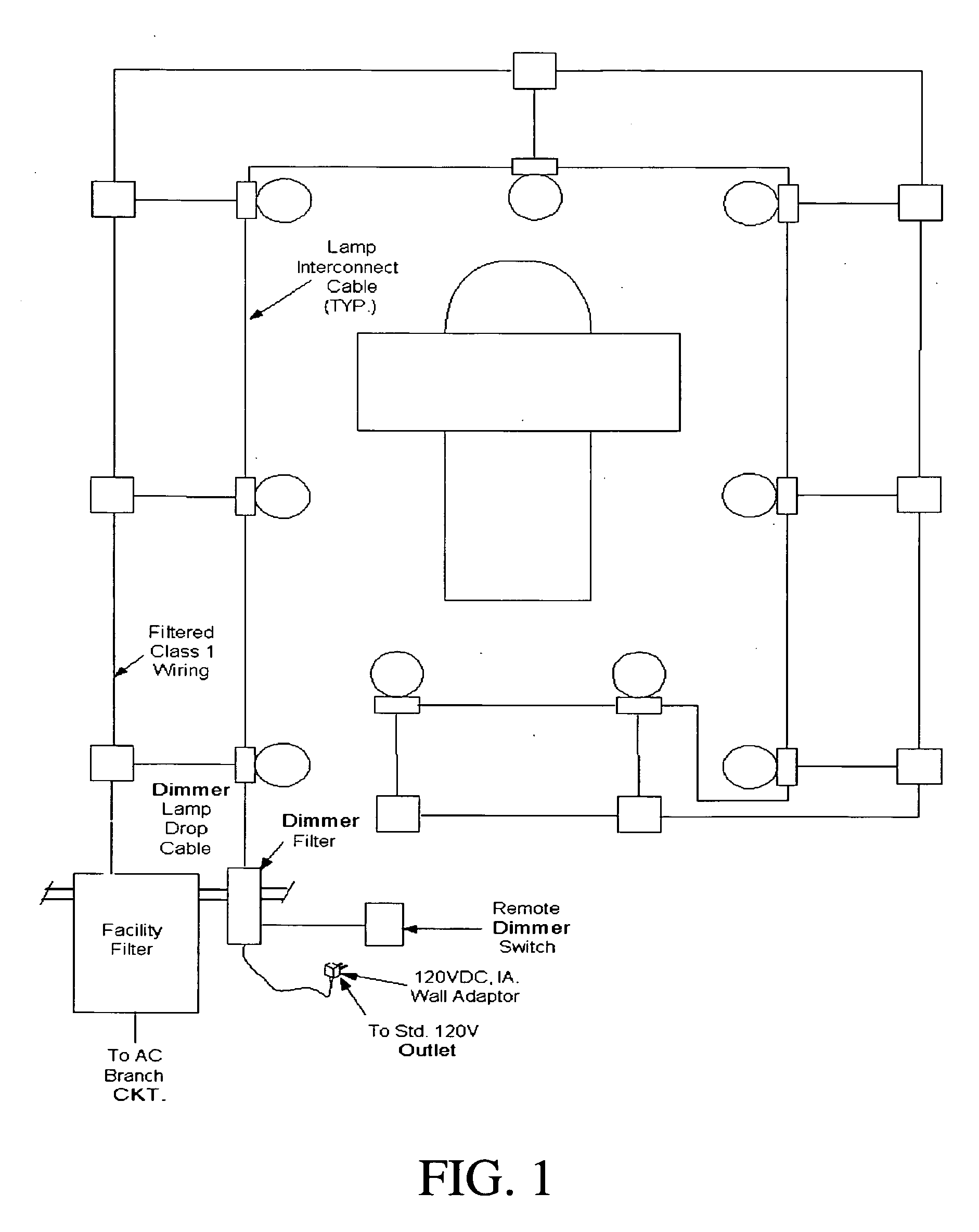

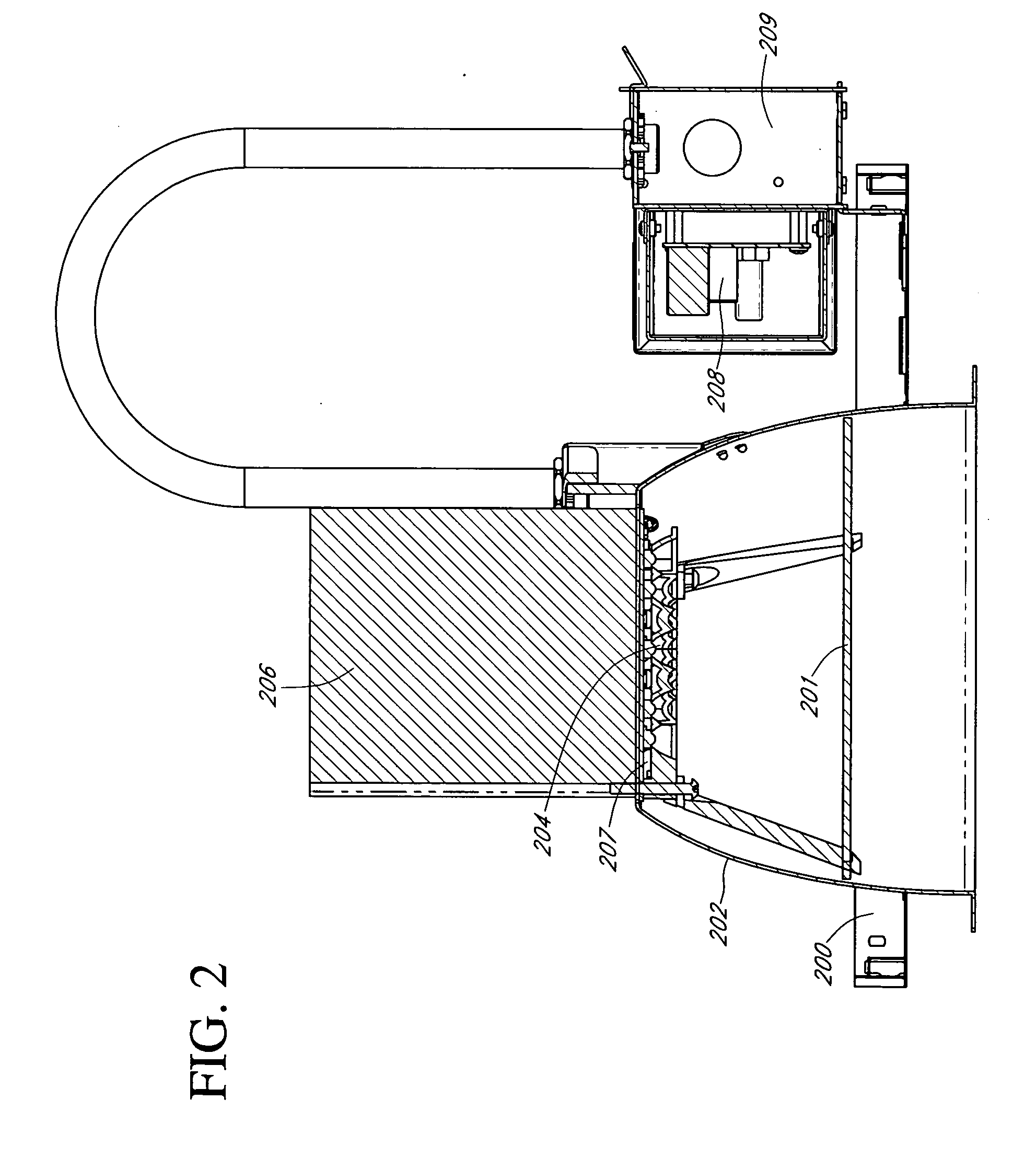

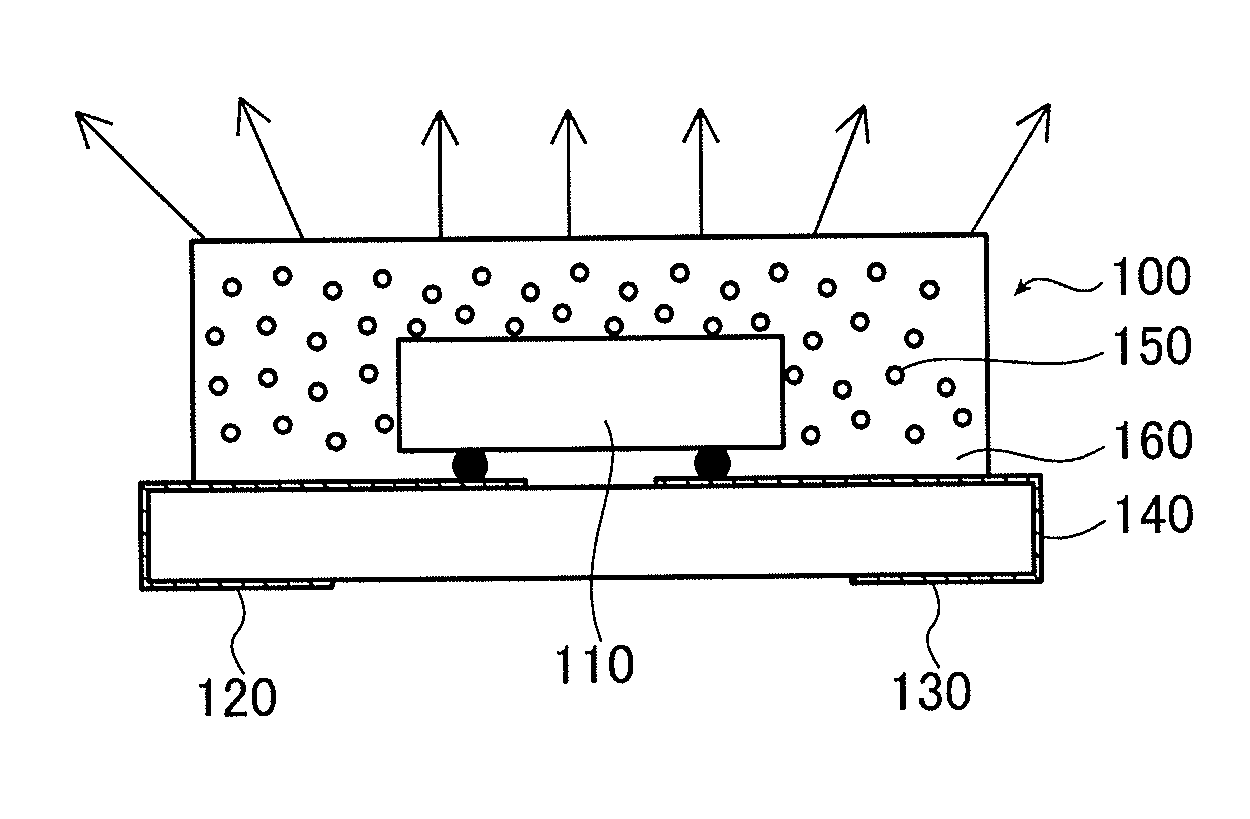

LED lighting system for use in environments with high magnetics fields or that require low EMI emissions

ActiveUS20070121328A1Highly specular reflective surfaceEliminate glarePlanar light sourcesPoint-like light sourceEffect lightEngineering

This invention is a non-ferrous lighting fixture and non-ferrous lighting system that can be used in areas with high magnetic fields or that require low EMI emissions, such as MRI operating rooms. This invention uses LED's to provide a high-intensity, quality white or other color light that is softened by reflectors and diffusers, and can be dimmed to provide flexible lighting levels. The flexible lighting levels can range from the maximum light used for patient procedures and equipment servicing / maintenance to the lowest light level used to keep a patient comfortable while facing upward on the MRI scanning table. Moreover, by using an aluminum substrate printed circuit board, this invention resolves the thermal issues associated with high-intensity lighting. Not only does this invention resolve glare and hot spot issues, it protects the user and installer from electrical hazards associated with potentially high voltages, as well. Finally, because this invention is completely non-ferrous, it does not interfere with the integrity of the MRI equipment's readings.

Owner:EVERBRITE

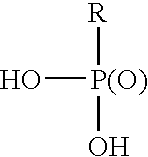

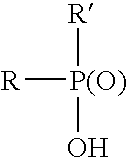

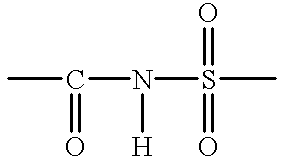

Electrodeposition coatings for use over aluminum substrates

A process for applying a coating on aluminum substrates by anionic electrodeposition of a phosphated epoxy resin made by phosphating a polyepoxide with both phosphoric acid and an organophosphonic acid and / or an organophosphinic acid. The coating has a reduced tendency to form pinholes.

Owner:PPG IND OHIO INC

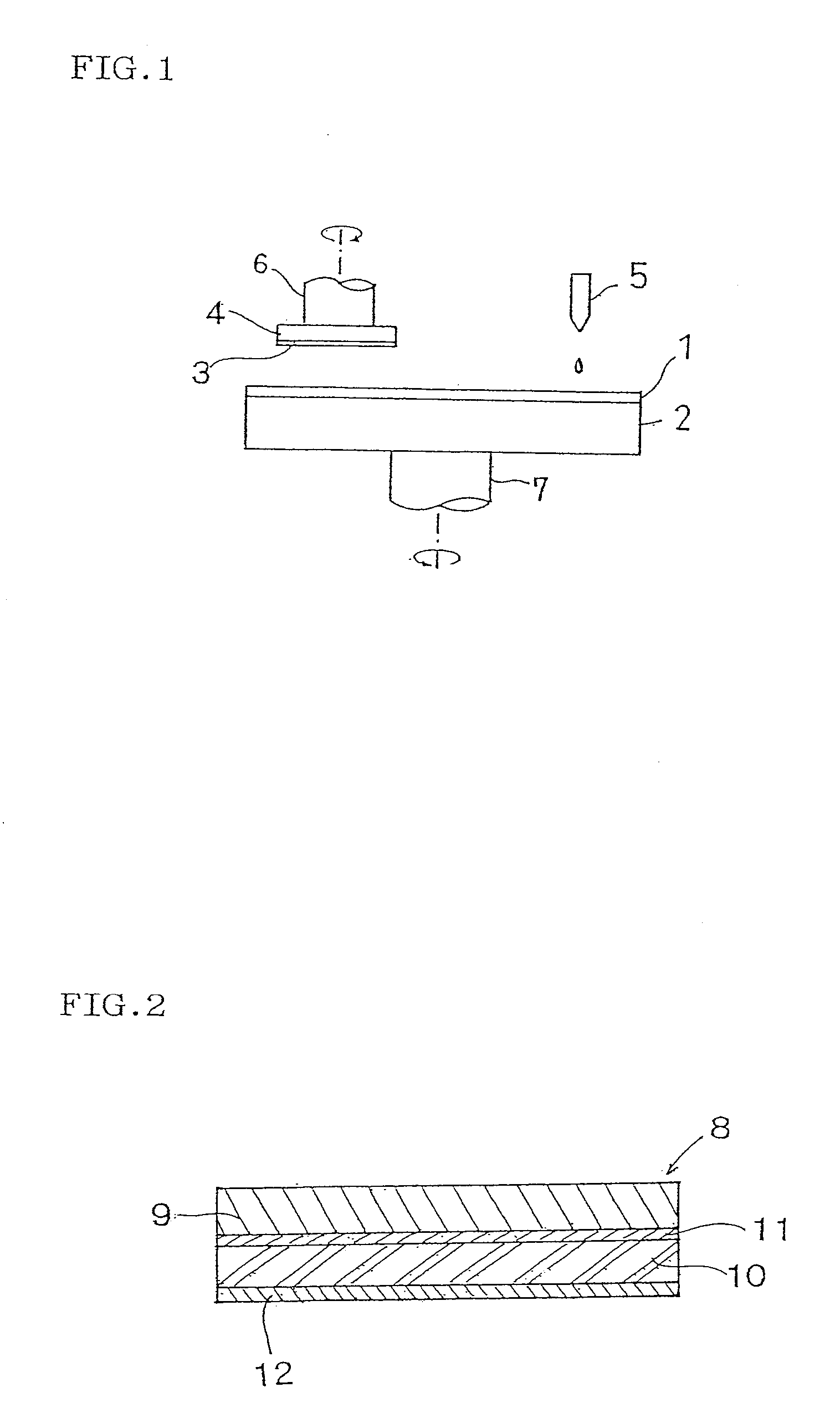

Planographic printing plate

InactiveUS20010041305A1High purityReduce surface roughnessPhotosensitive materialsRadiation applicationsAnodizingSolubility

A planographic printing plate precursor comprising: an aluminum substrate which has been subjected to a roughening treatment and an anodizing treatment; and a photosensitive layer which provided on a surface of said substrate, and which contains an infrared absorbing agent and a water-insoluble and alkali aqueous solution-soluble polymer compound, and whose solubility in an alkali developing solution varies by infrared laser exposure, wherein said substrate is obtained by electrochemically roughening an aluminum alloy plate which contains a trace amount of certain elements to an aluminum alloy of high purity.

Owner:FUJIFILM CORP

Article of manufacture and process for anodically coating an aluminum substrate with ceramic oxides prior to polytetrafluoroethylene or silicone coating

InactiveUS20050115840A1AnodisationElectrolytic inorganic material coatingCeramic coatingSilicone coating

Owner:HENKEL KGAA

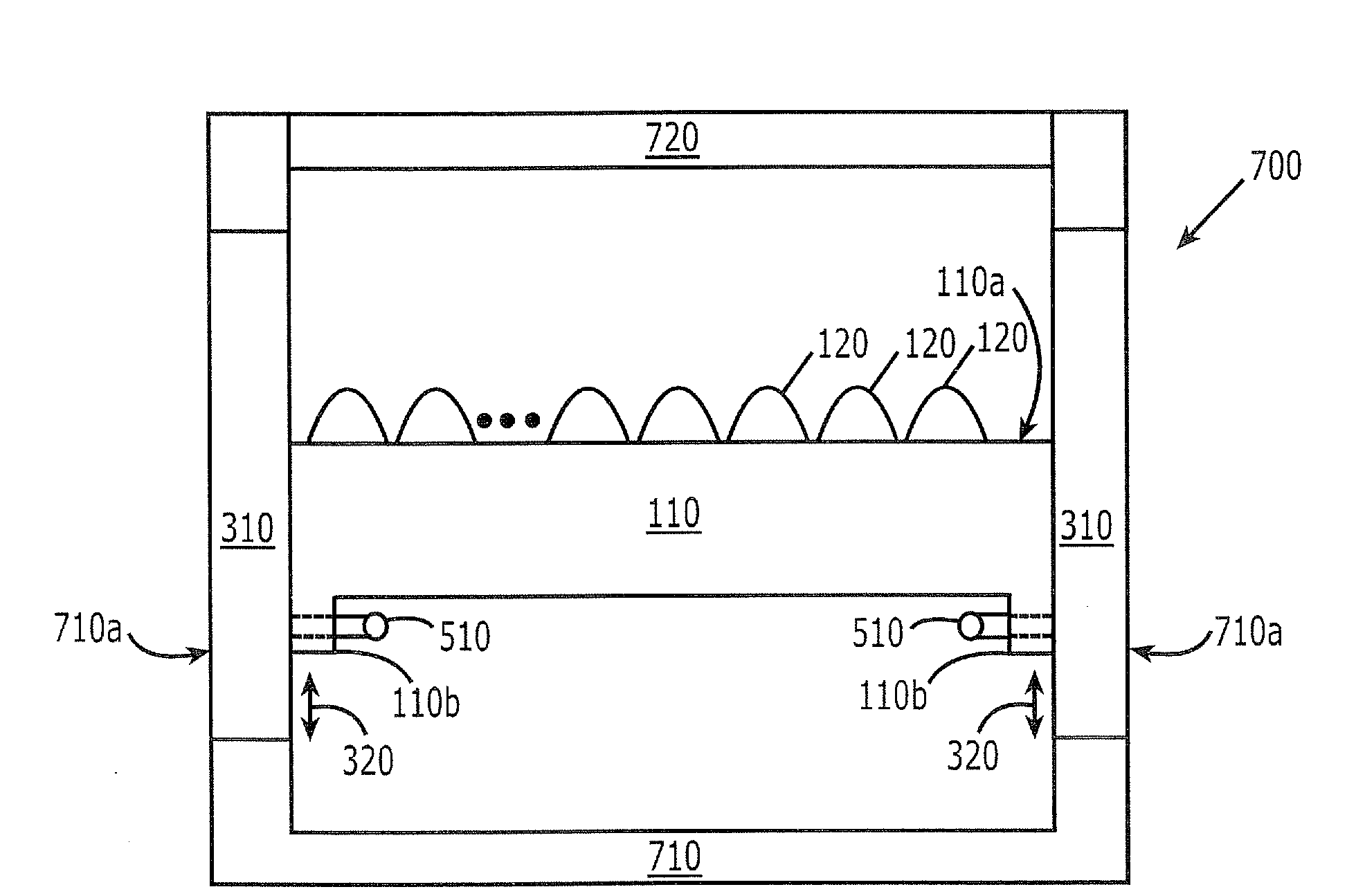

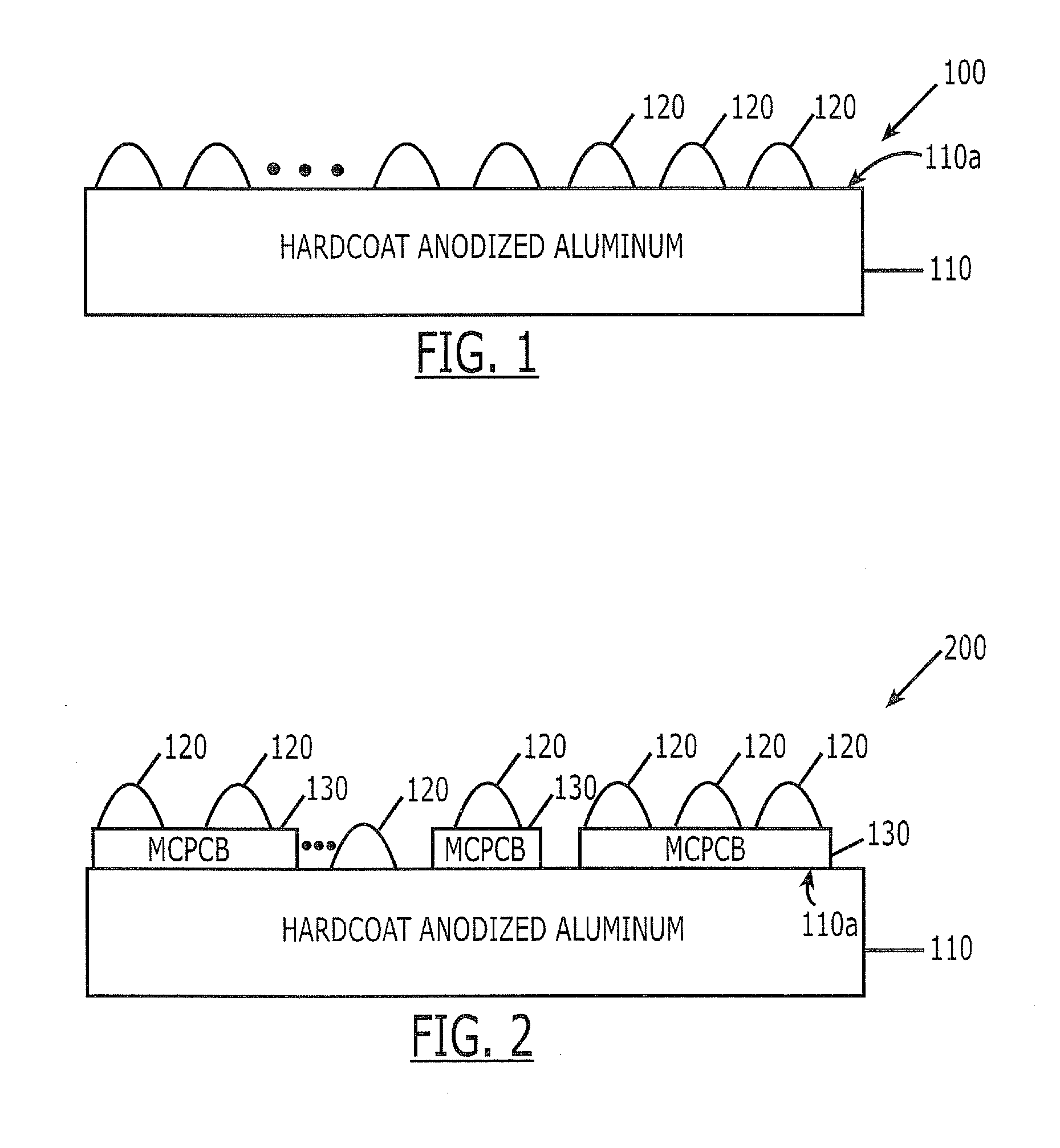

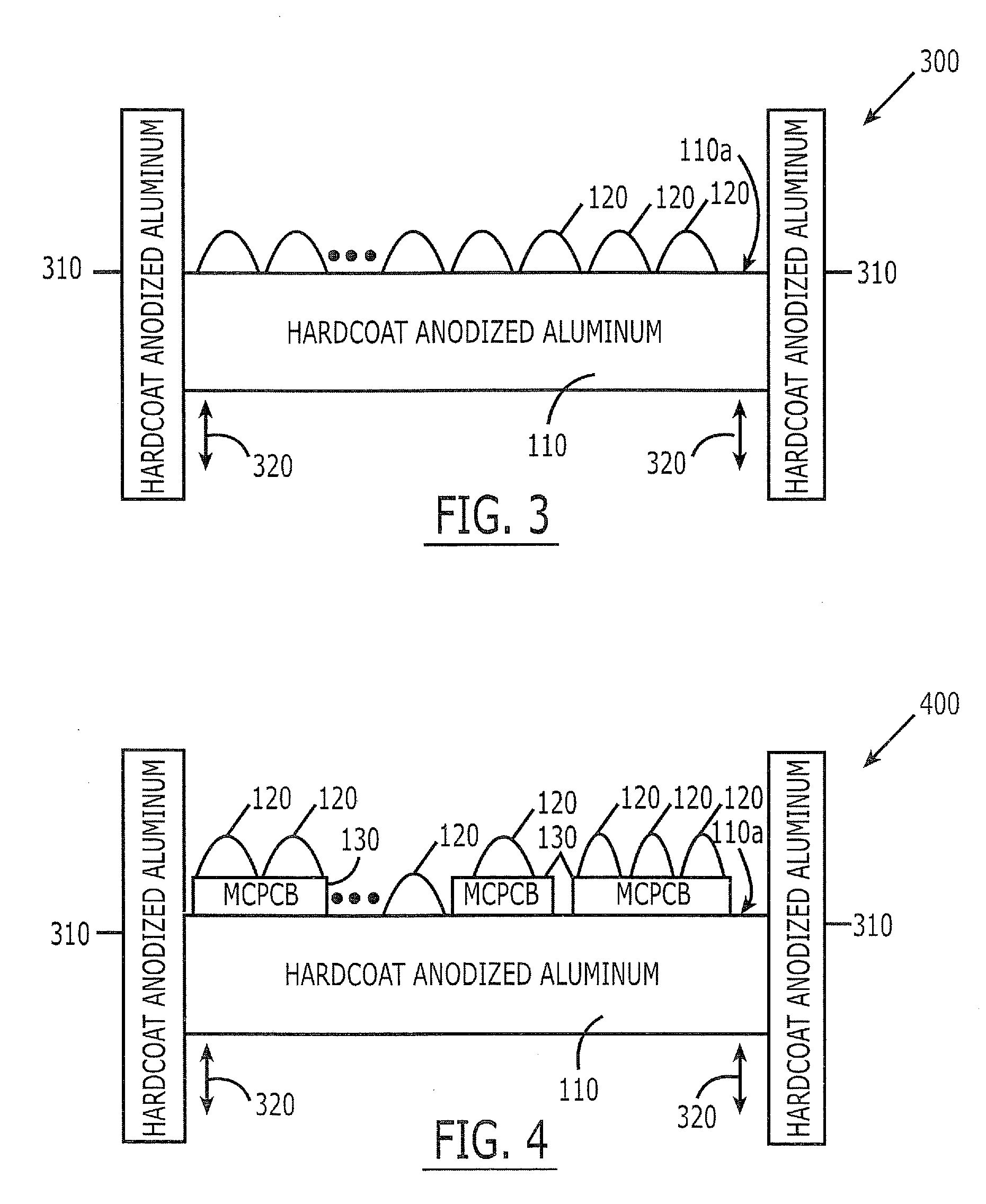

High thermal conductivity packaging for solid state light emitting apparatus and associated assembling methods

One or more solid state light emitting elements are mounted on a hardcoat anodized aluminum substrate. One or more bars also may be provided that slidably contact an edge of the hardcoat anodized aluminum substrate. The substrate and the bar(s) may be mounted in a housing with the bars mounted in apertures in the housing wall. Related assembling methods for solid state light emitting apparatus also are disclosed.

Owner:IDEAL IND LIGHTING LLC

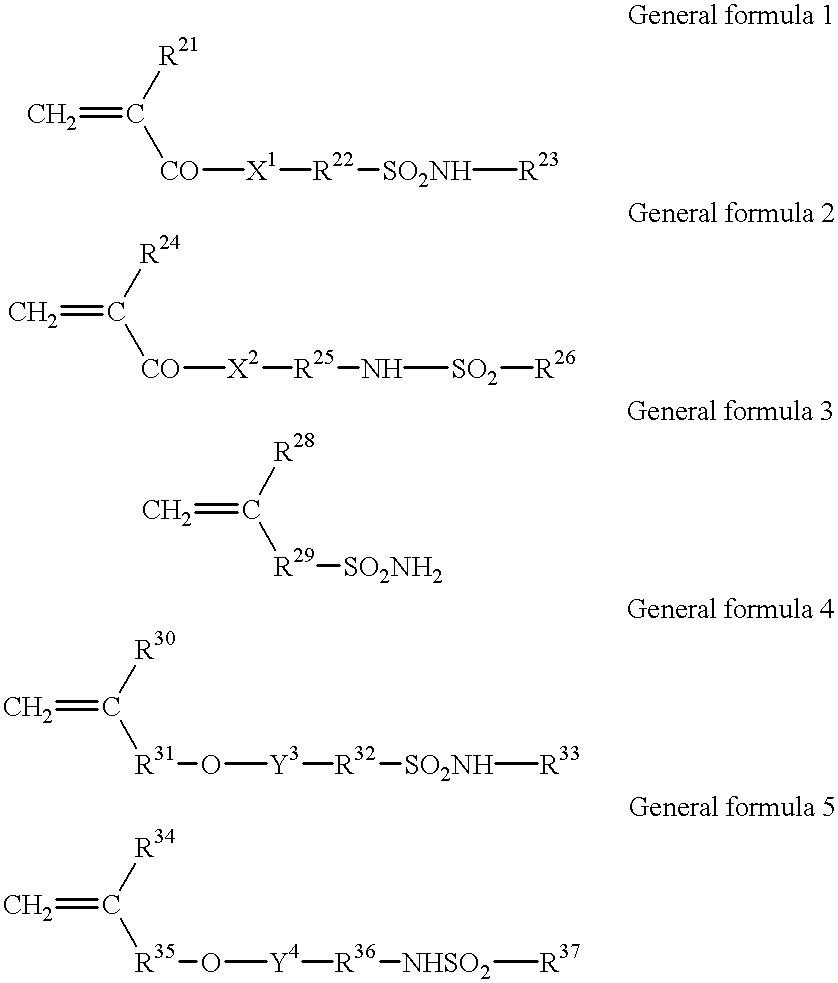

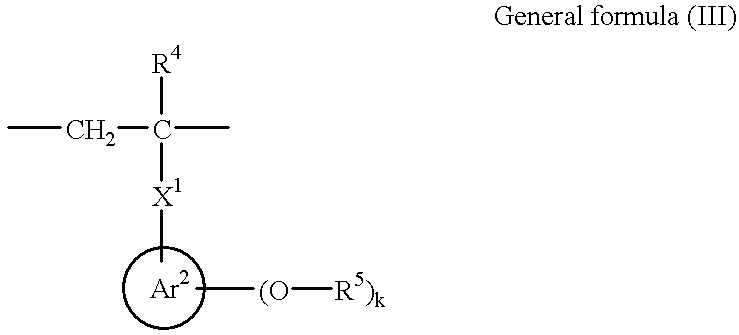

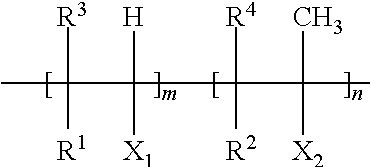

Aluminum substrates and lithographic printing plate precursors

ActiveUS20130052582A1Enhance layeringImprove adhesionPhotosensitive materialsLayered productsSide chainCarboxylic acid

An aluminum-containing substrate can be provided for use in lithographic printing plate precursors. Before radiation-sensitive layers are applied, a grained and sulfuric acid anodized aluminum-containing support is treated with an alkaline or acidic pore-widening solution to provide its outer surface with columnar pores. The diameter of the columnar pores at their outermost surface is at least 90% of the average diameter of the columnar pores. Directly on this treated surface, a hydrophilic layer is applied, which hydrophilic layer contains a non-crosslinked hydrophilic polymer having carboxylic acid side chains.

Owner:EASTMAN KODAK CO

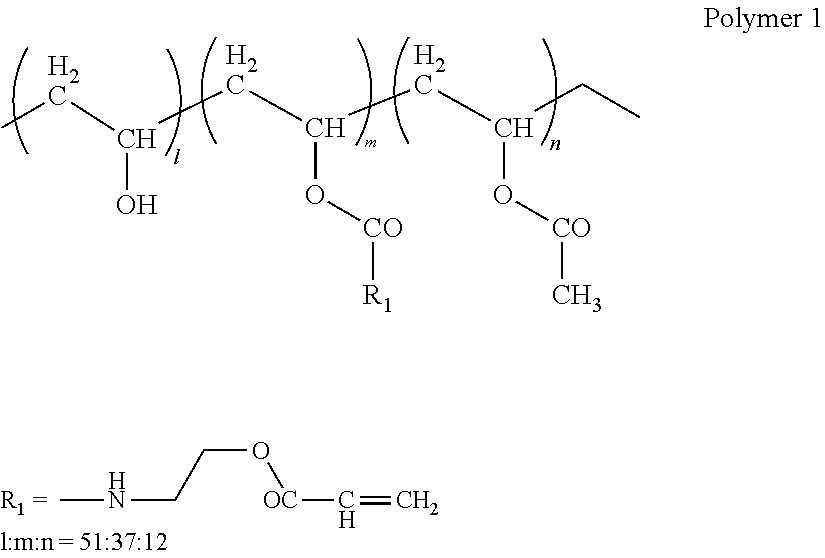

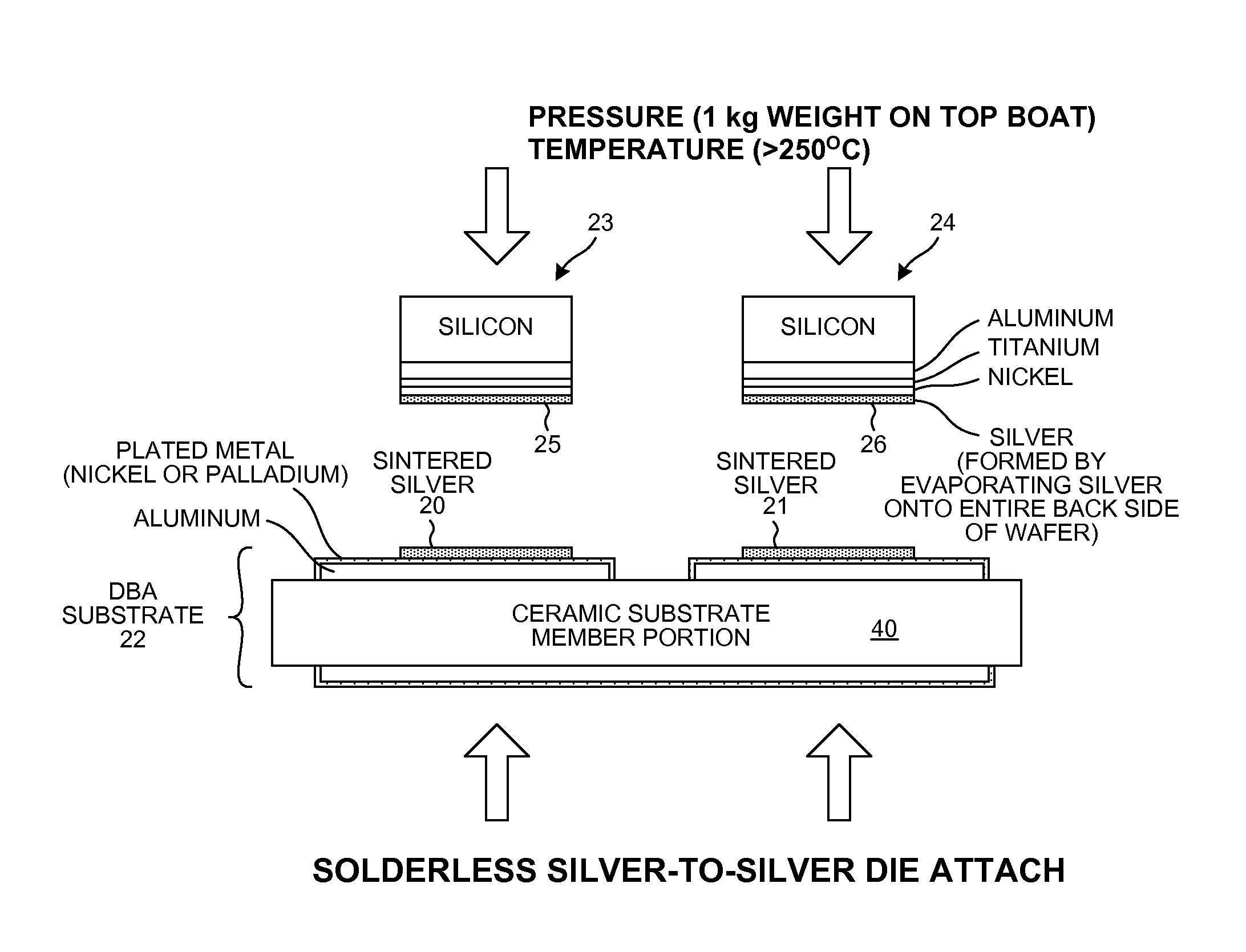

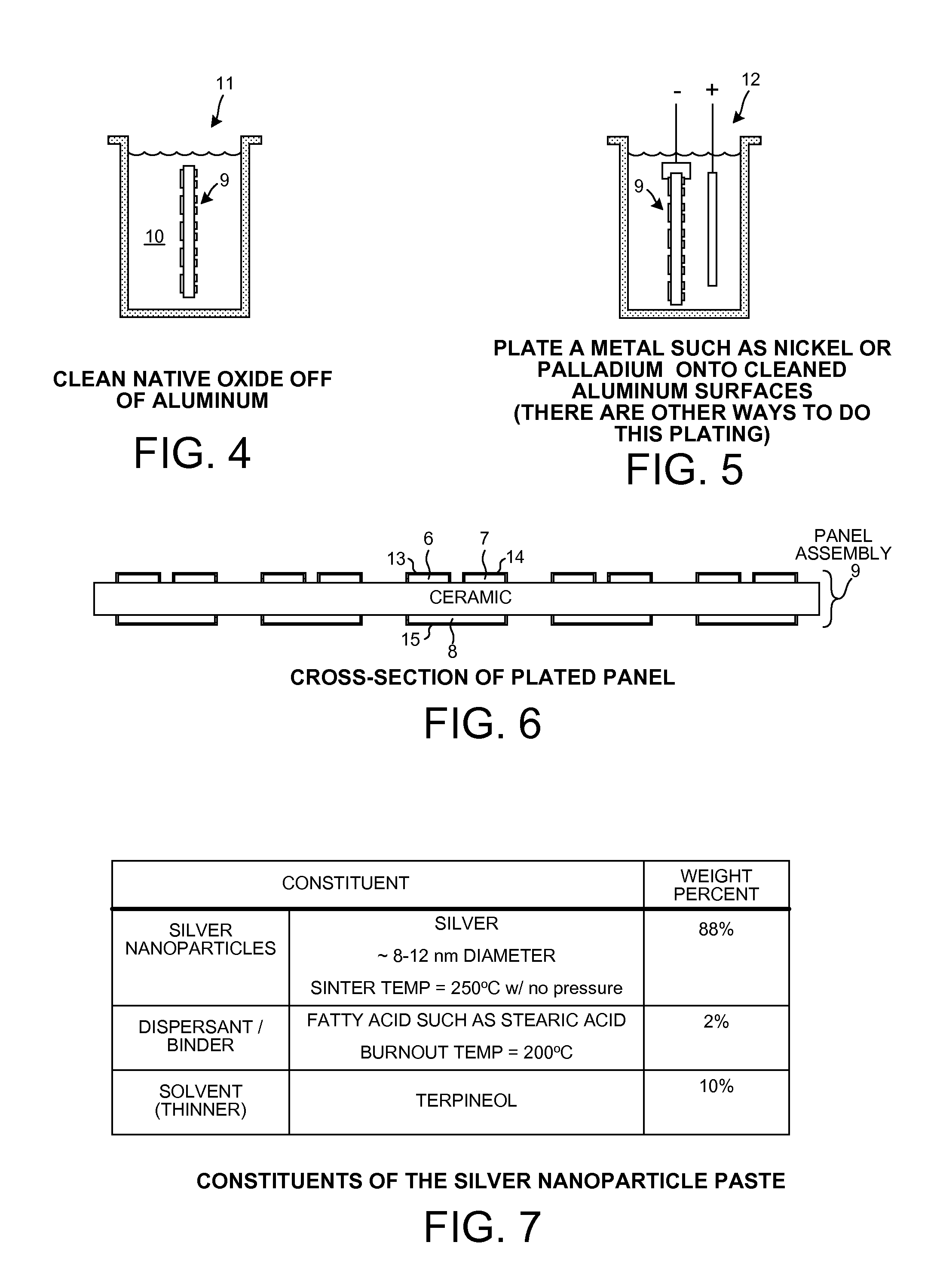

Solderless Die Attach to a Direct Bonded Aluminum Substrate

ActiveUS20130328204A1Cooking-vessel materialsSemiconductor/solid-state device detailsLead bondingLead frame

A DBA-based power device includes a DBA (Direct Bonded Aluminum) substrate. An amount of silver nanoparticle paste of a desired shape and size is deposited (for example by micro-jet deposition) onto a metal plate of the DBA. The paste is then sintered, thereby forming a sintered silver feature that is in electrical contact with an aluminum plate of the DBA. The DBA is bonded (for example, is ultrasonically welded) to a lead of a leadframe. Silver is deposited onto the wafer back side and the wafer is singulated into dice. In a solderless silver-to-silver die attach process, the silvered back side of a die is pressed down onto the sintered silver feature on the top side of the DBA. At an appropriate temperature and pressure, the silver of the die fuses to the sintered silver of the DBA. After wirebonding, encapsulation and lead trimming, the DBA-based power device is completed.

Owner:LITTELFUSE INC

Polishing pad and method of producing the same

InactiveUS20060280930A1Reduce rateReduce hardnessEdge grinding machinesLayered productsAluminum substrateSemiconductor

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Polishing pad and method of producing the same

InactiveUS20060280929A1Reduce rateReduce hardnessEdge grinding machinesLayered productsAluminum substrateSemiconductor

The invention provides a polishing pad by which optical materials such as lenses, reflecting mirrors etc., or materials requiring a high degree of surface planarity, as in the polishing of silicone wafers, glass substrates or aluminum substrates for hard disks, or general metal polishing, can be flattened with stability and high polishing efficiency. The invention also provides a polishing pad for semiconductor wafers, which is superior in planarizing characteristic, is free from scratches and can be produced at low cost. There is provided a polishing pad which is free from dechucking error so that neither damage to wafers nor decrease in operating efficiency occurs. There is provided a polishing pad which is satisfactory in planarity, within wafer uniformity, and polishing rate and produces less change in polishing rate. There is provided a polishing pad which can make planarity improvement and scratch decrease compatible.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

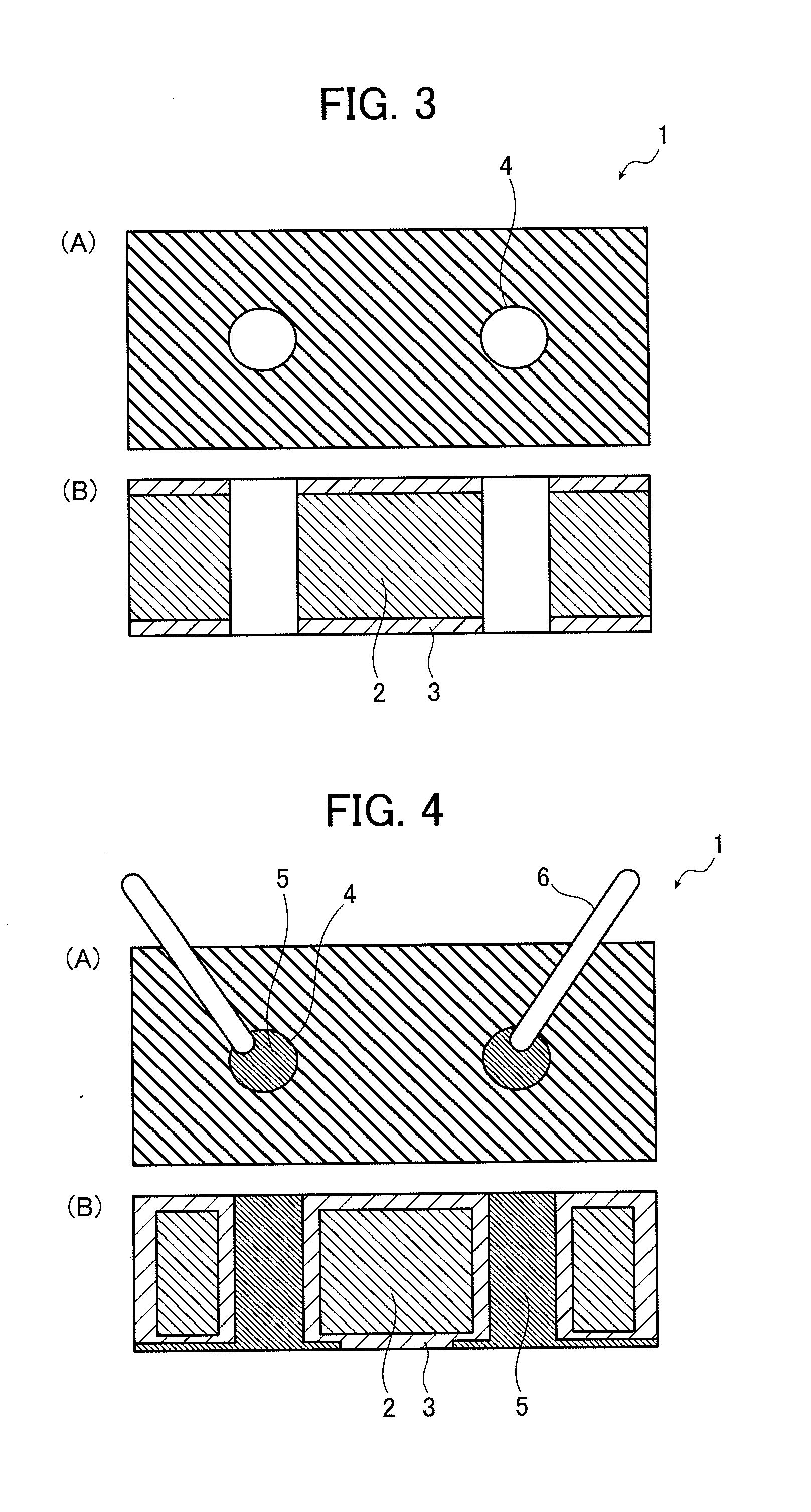

Method for producing structure

InactiveUS20060234396A1Shorten the timeReduce surface roughnessMaterial nanotechnologyNanoinformaticsPore diameterAluminum substrate

Disclosed is a method for producing a structure having: a stripping step in which an aluminum member including an aluminum substrate and an anodized layer present on the aluminum substrate, which layer contains micropores having an average pore diameter of 10 to 500 nm and a coefficient of variation in pore diameter of less than 30%, is electrolyzed in an aqueous acid solution by using the aluminum member for a cathode to thereby strip the anodized layer off the aluminum substrate so as to produce a structure composed of the anodized layer with a plurality of recesses. The method can produce a structure having regularly arranged recesses in a reduced time.

Owner:FUJIFILM CORP +1

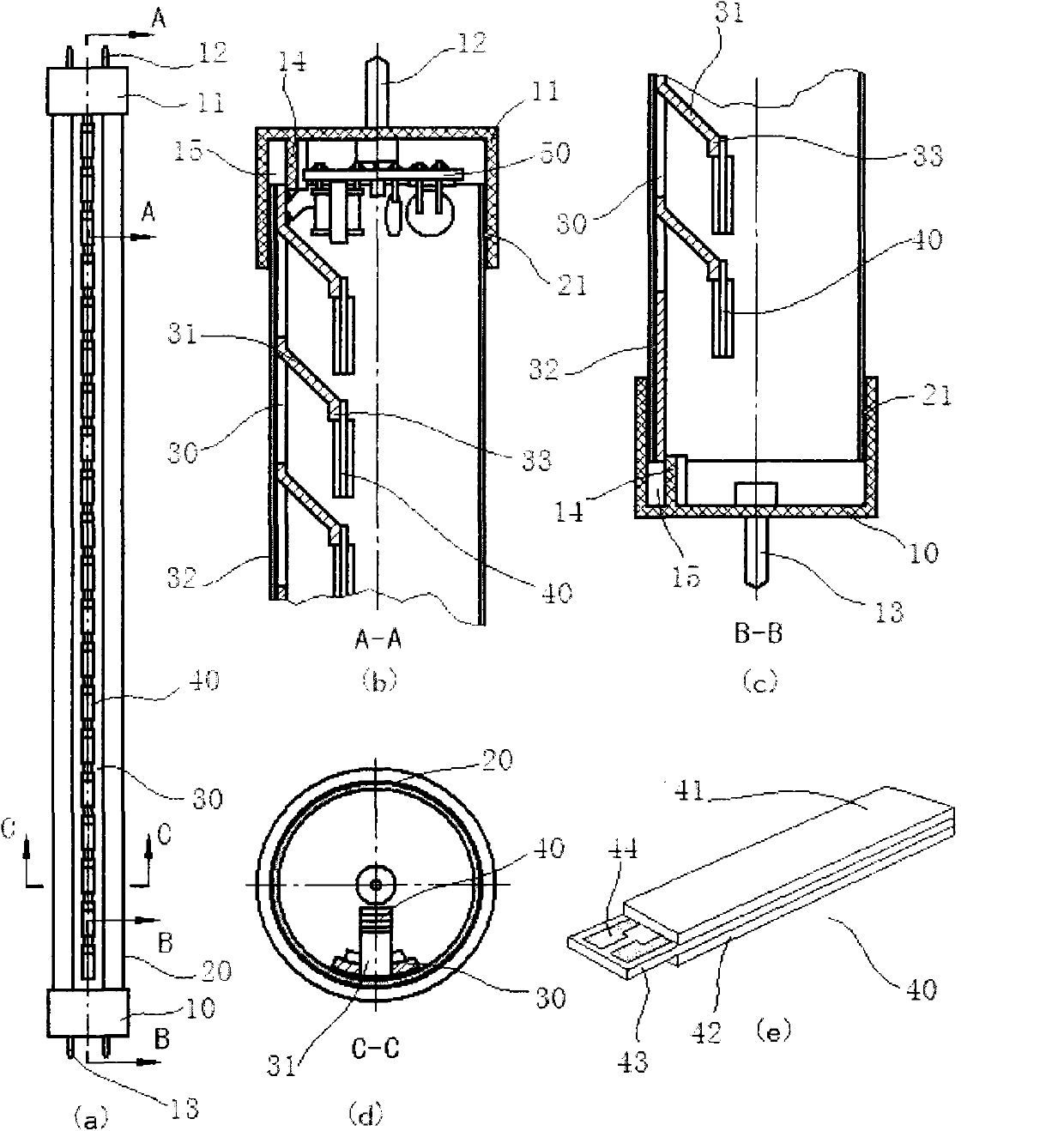

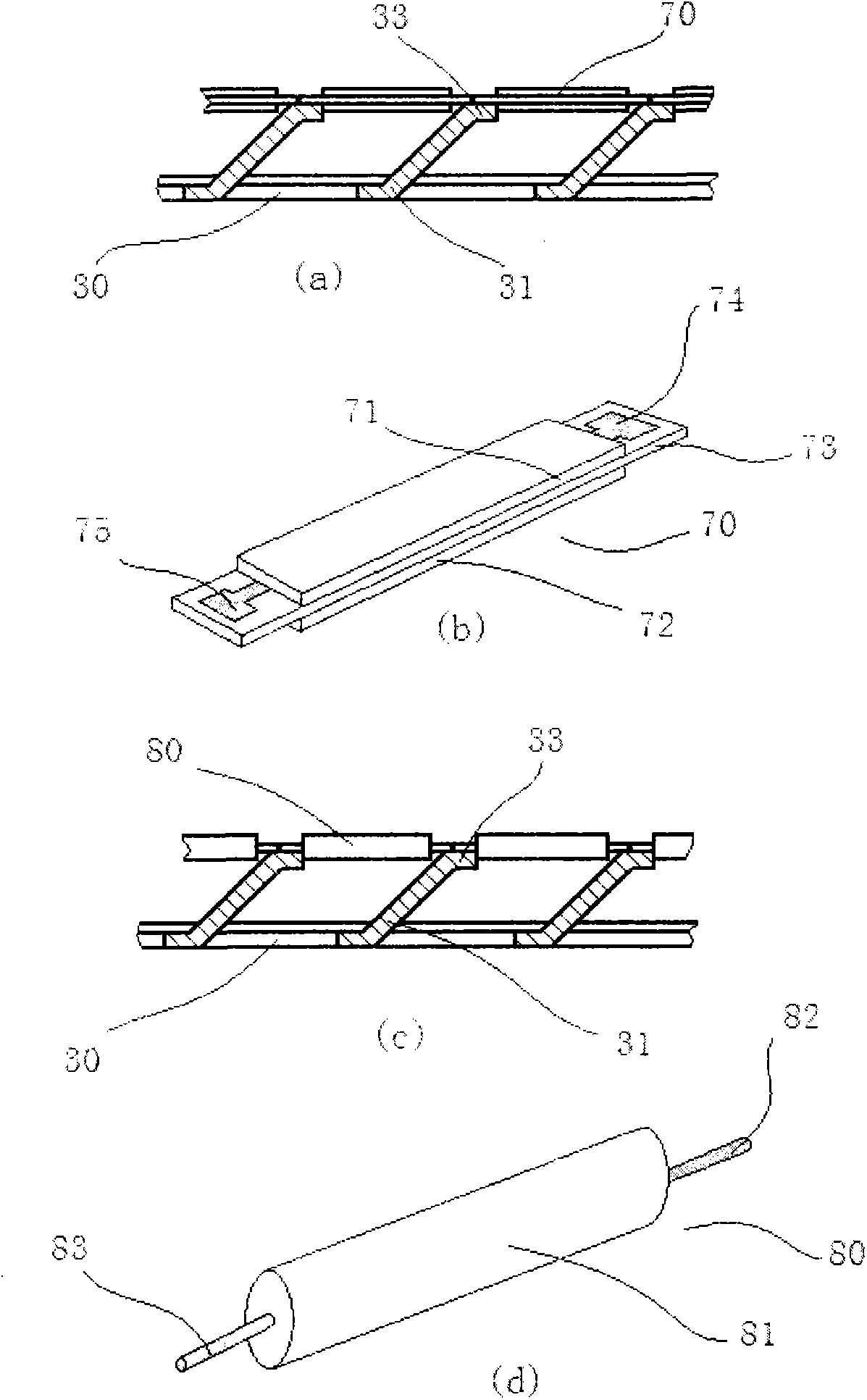

LED straight lamp made of transparent glass tube

InactiveCN103742875AReduce cooling requirementsFit tightlyPoint-like light sourceElongate light sourcesBeam angleStraight tube

The invention discloses an LED straight lamp made of a transparent glass tube. The LED straight lamp comprises a transparent glass tube body (20) and two lamp holders (10 and 11). Both the transparent glass tube body (20) and the lamp holders (10 and 11) meet the specifications of an ordinary straight tube fluorescent lamp, and the lamp holders (10 and 11) are respectively adhered to two ends of the transparent glass tube body (20). The LED straight lamp made of the transparent glass tube can also be made by the glass burn sealing technology of the ordinary straight tube fluorescent lamp. LED lamp filaments are directly welded to welding platforms (33) of LED supports (31) in the middle of an aluminum substrate (30). The outside of the bottom cross section of the aluminum substrate (30) is circular arc shaped with the curvature matching with that of the inner side of the cross section of the transparent glass tube body (20). Enough height is to be reserved between the welding platforms (33) and the aluminum substrate (30) so that light emitted from the LED lamp filaments is orthogonal to the inner wall of the transparent glass tube body (20), light consumption brought by multiple reflections is reduced, and the beam angle of the LED straight lamp made of the transparent glass tube can reach more than 300 degrees.

Owner:匡正芳

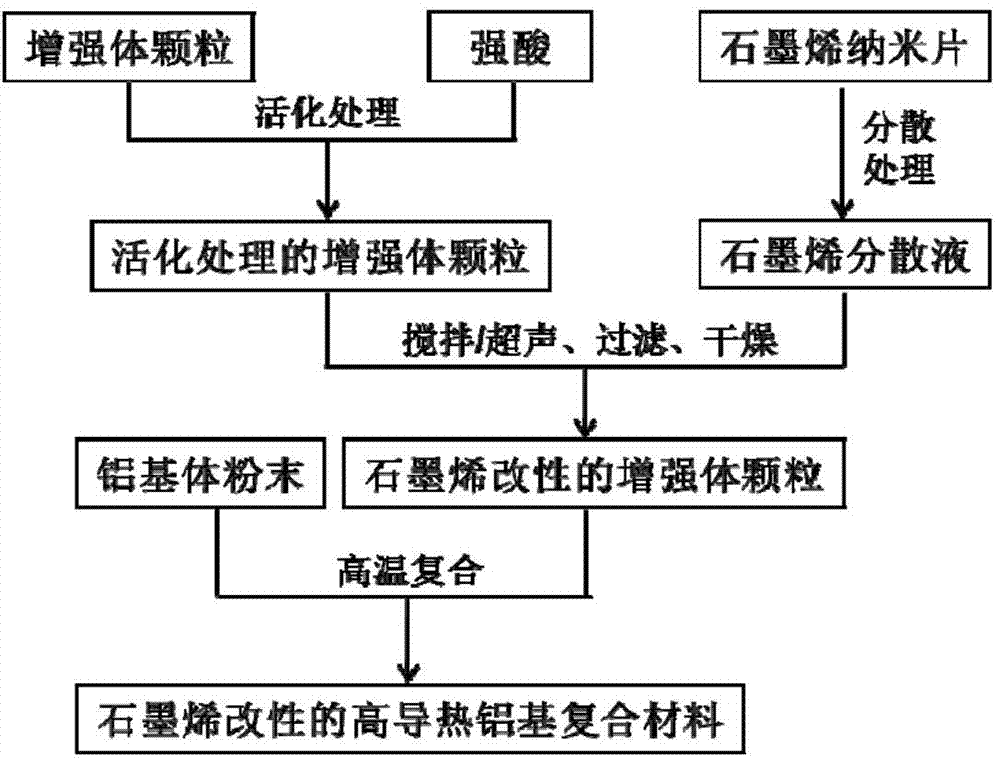

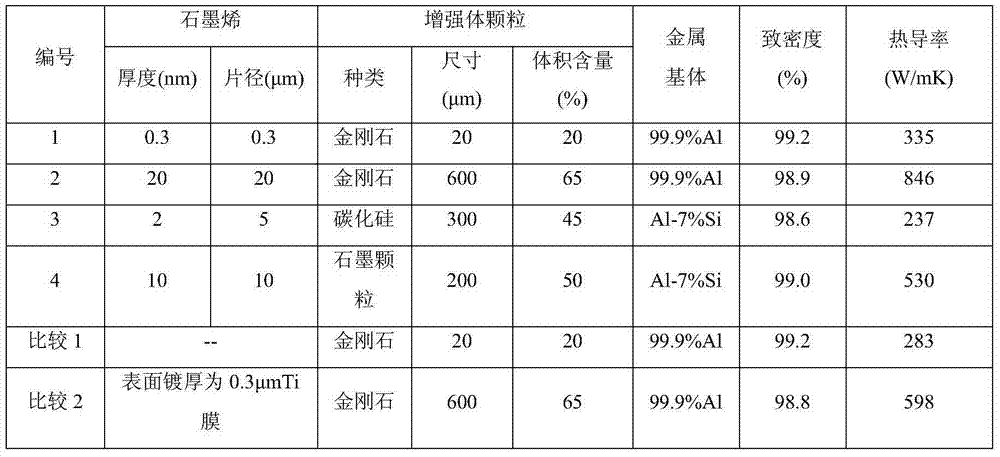

Graphene modified high-heat-conductivity aluminum-based composite material and powder metallurgy preparation method

ActiveCN104264000AReduce thermal resistanceHigh thermal conductivityMaterial nanotechnologyStrong acidsAluminum substrate

The invention provides a graphene modified high-heat-conductivity aluminum-based composite material and a powder metallurgy preparation method thereof. The material comprises reinforced grains and an aluminum substrate, wherein the composite boundary of the reinforced grains and the aluminum substrate contains high-heat-conductivity graphene nanosheets. The method comprises the following steps: (1) soaking the reinforced grains with a strong acid solution, subsequently washing with deionized water till being neutral, drying, and removing the surface impurities, thereby obtaining activated reinforced grains; (2) adding the activated reinforced grains into a graphene dispersion liquid, mechanically stirring or performing ultrasonic dispersion, and wrapping the graphene nanosheets on the surface, thereby preparing the graphene modified reinforced grains; and (3) mixing the graphene modified reinforced grains with the aluminum substrate powder, pressing into blanks, and sintering, thereby preparing the graphene modified high-heat-conductivity aluminum-based composite material. The composite material provided by the invention is good in chemical stability, high in thermal conductivity and can be used as a heat management material of a large-power semiconductor device.

Owner:SHANGHAI JIAO TONG UNIV

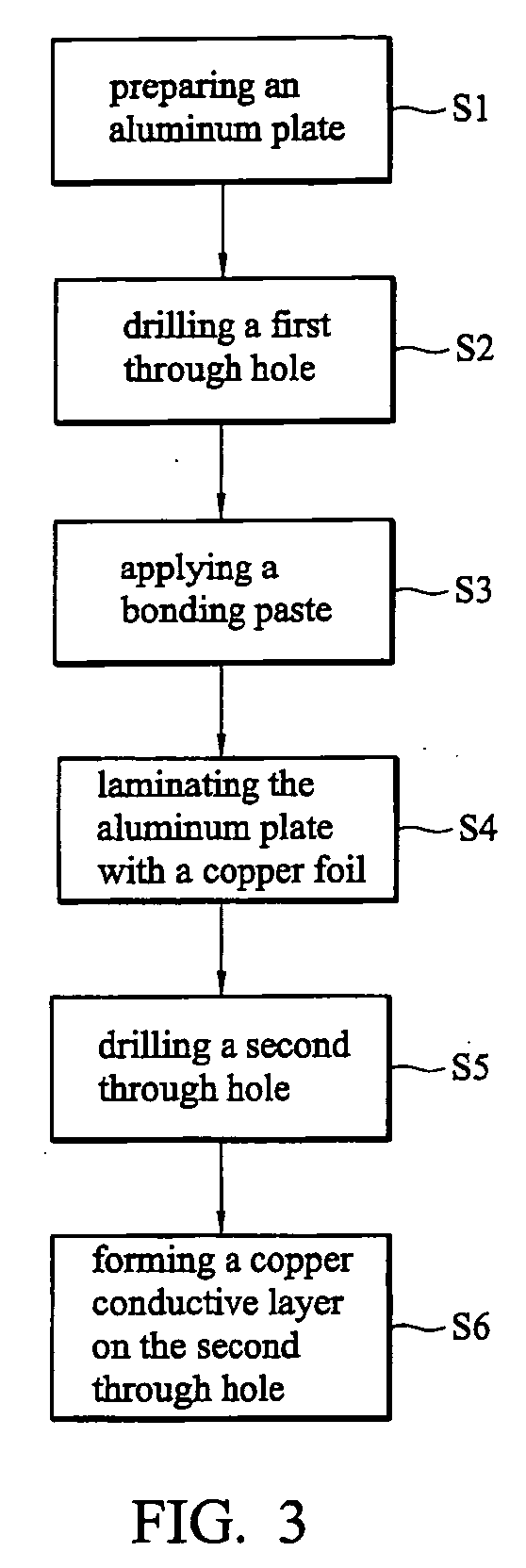

Circuit board with a through hole wire and manufacturing method thereof

InactiveUS20070010086A1Improve thermal conductivityImprove cooling effectPrinted circuit aspectsSemiconductor/solid-state device manufacturingIsolation effectCopper foil

An aluminum substrate is drilled to form a first through hole, and is then laminated with copper foils on upper and lower surfaces of the aluminum substrate via a binder. Due to the pressure of the lamination, the binder is partially forced to flow into and fill the first through hole, and the binder is then solidified. Concentric with the first through hole, a second through hole having a smaller aperture than the first through hole is drilled. By a non-electrical and electrical plating method, a copper conductive layer is formed on the side wall of the second through hole to complete the through hole wire. Because of the isolation effect of the binder, the aluminum substrate is not electrically connected to the copper foils and the copper conductive layer.

Owner:DELTA ELECTRONICS INC

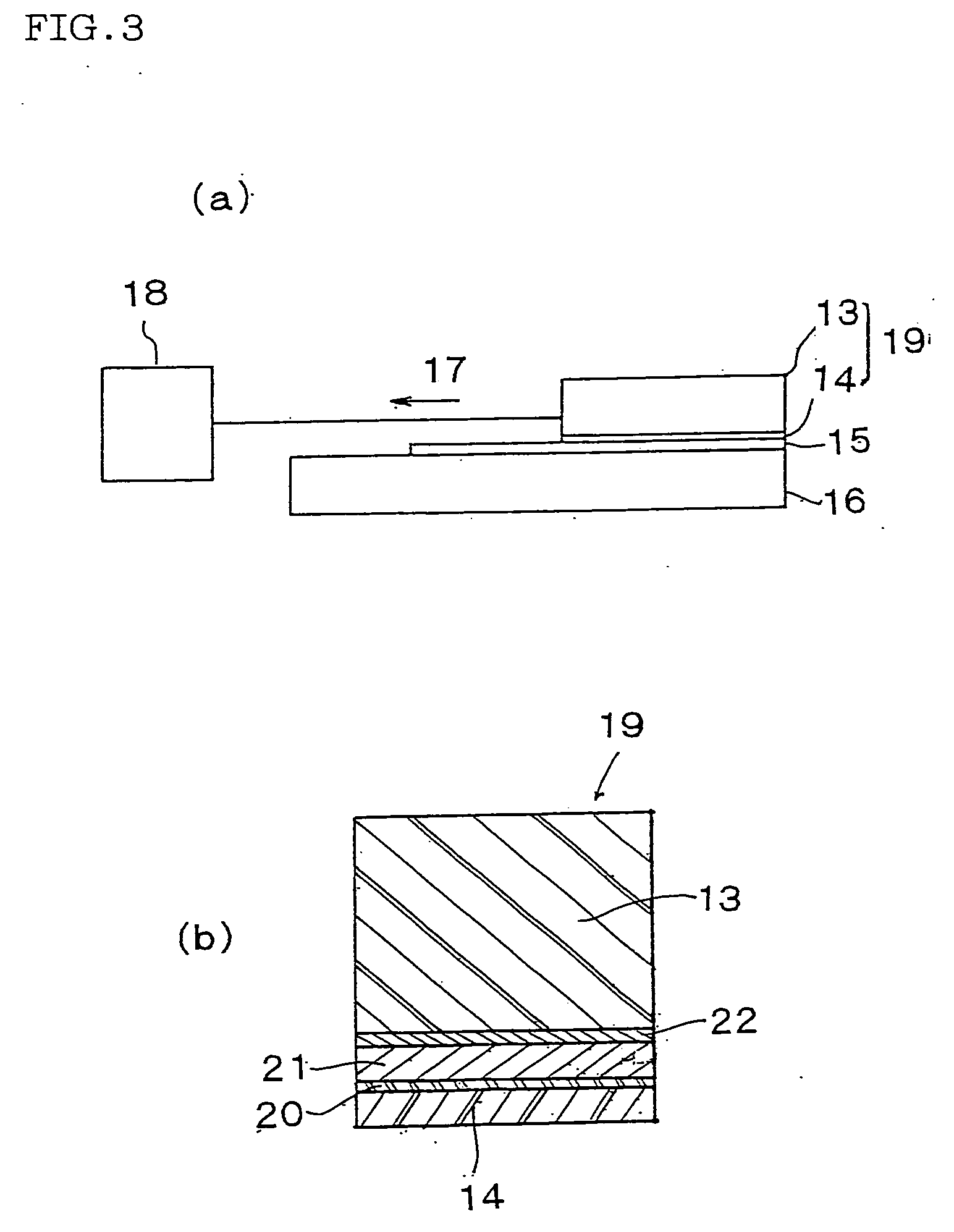

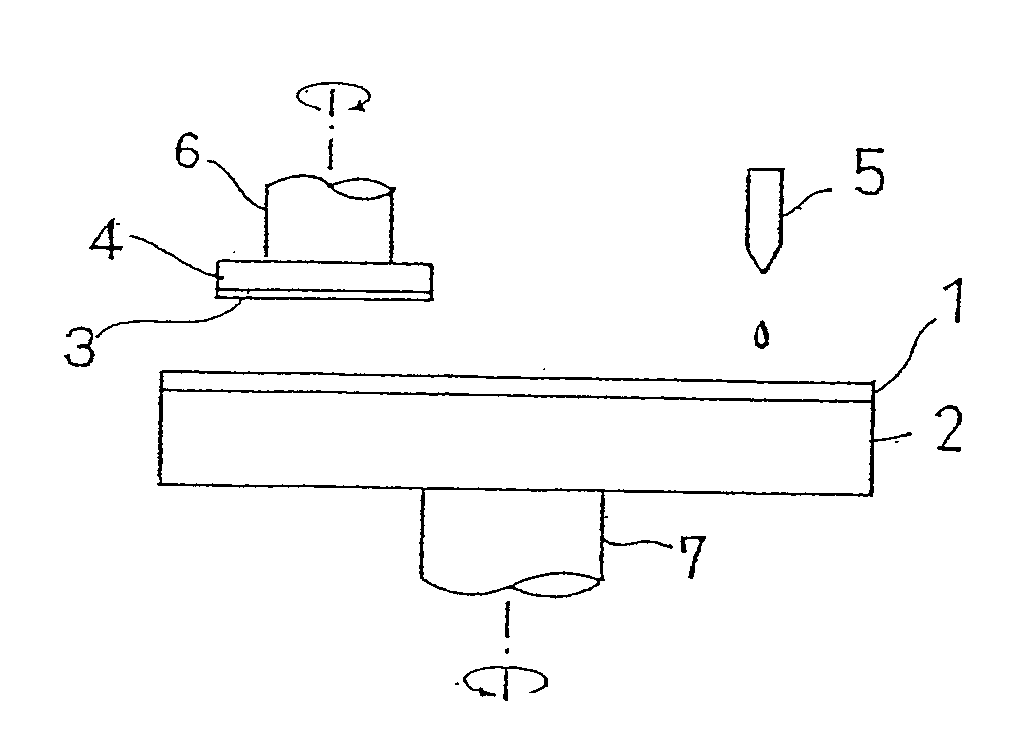

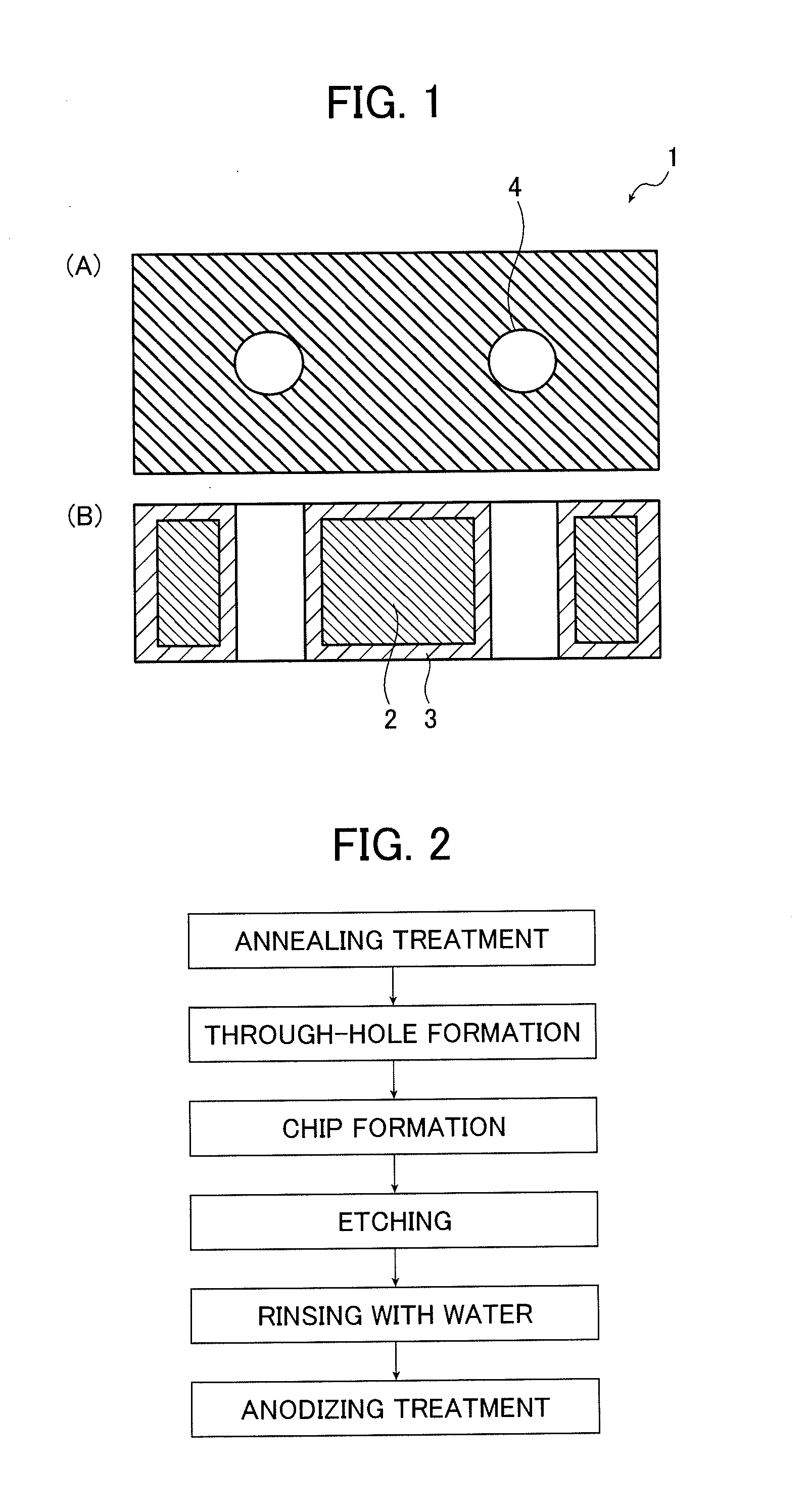

Insulated substrate, process for production of insulated substrate, process for formation of wiring line, wiring substrate, and light-emitting element

InactiveUS20120256224A1Improve insulation performanceImprove cooling effectAnodisationDuplicating/marking methodsOptoelectronicsAluminum substrate

Provided is an insulating substrate which includes an aluminum substrate and an anodized film covering a whole surface of the aluminum substrate and in which the anodized film contains intermetallic compound particles with a circle equivalent diameter of 1 μm or more in an amount of up to 2,000 pcs / mm3. Also provided is a method for manufacturing the insulating substrate which includes an anodizing treatment step for anodizing the aluminum substrate. The anodized film of the insulating substrate covering the whole surface of the aluminum substrate contains intermetallic compound particles with a circle equivalent diameter of 1 μm or more in an amount of up to 2,000 pcs / mm3.

Owner:FUJIFILM CORP

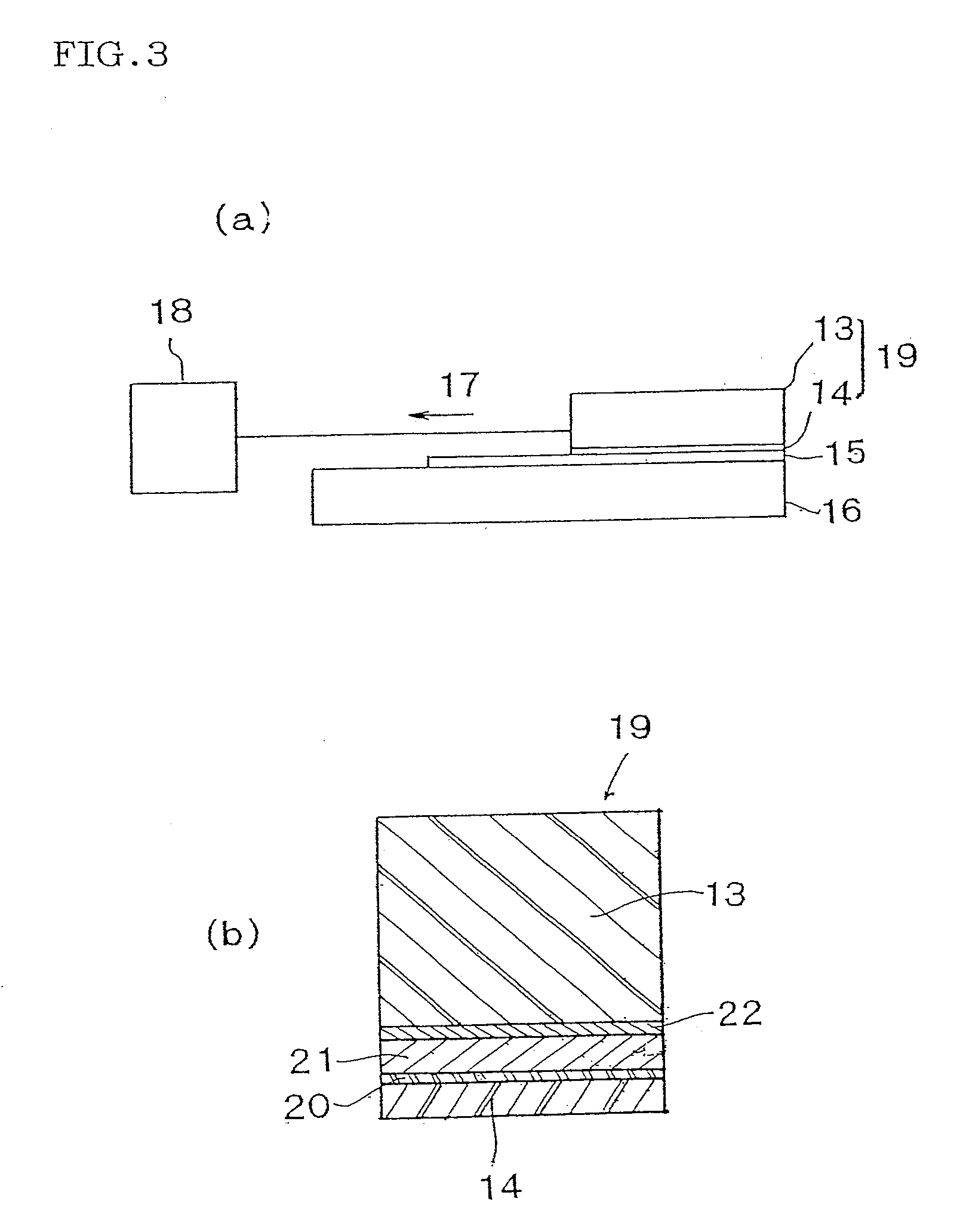

Method for providing surface texturing of aluminum sheet, substrate for lithographic plate and lithographic plate

InactiveUS20050258136A1Layered productsSurface reaction electrolytic coatingEngineeringAluminum substrate

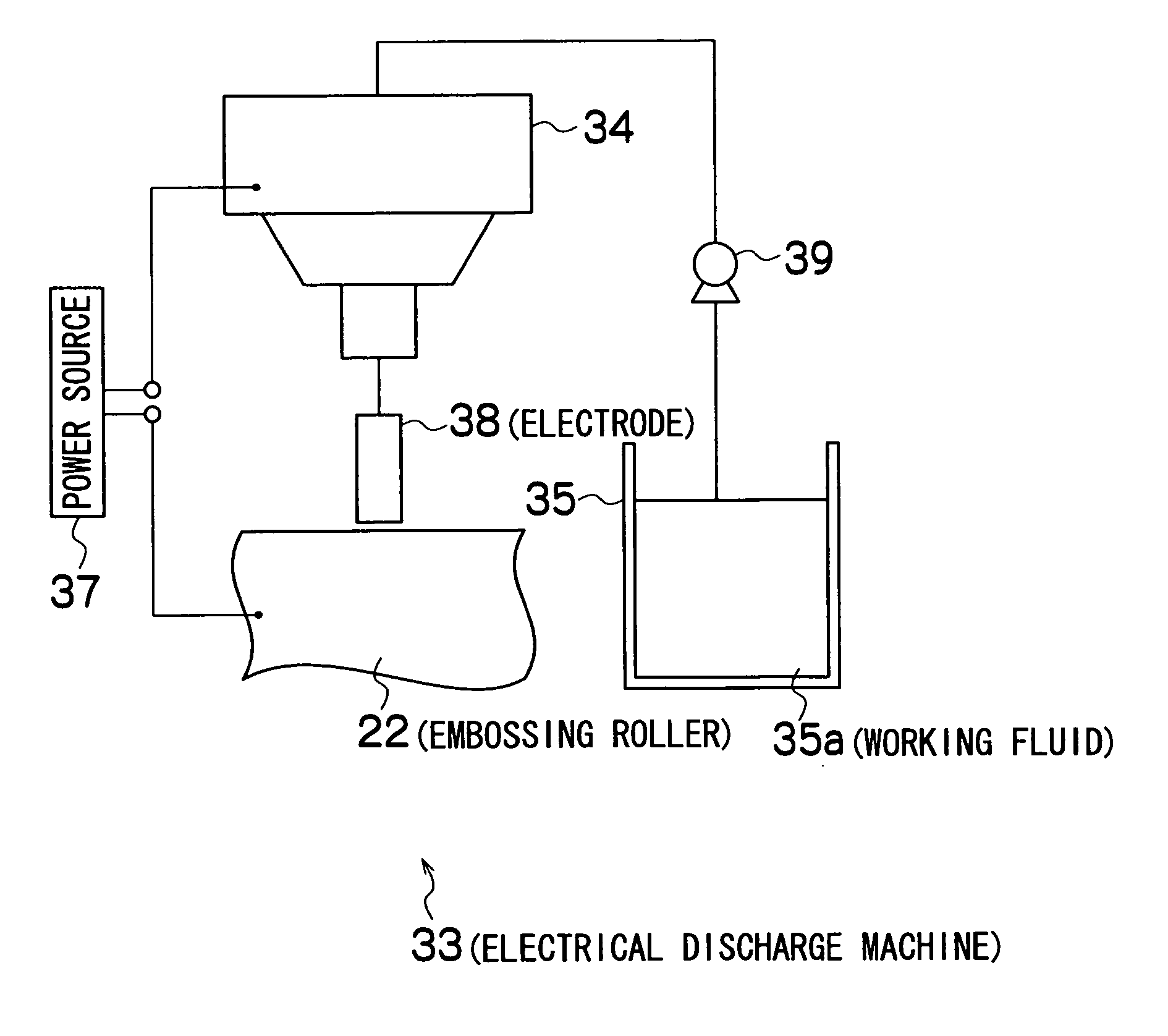

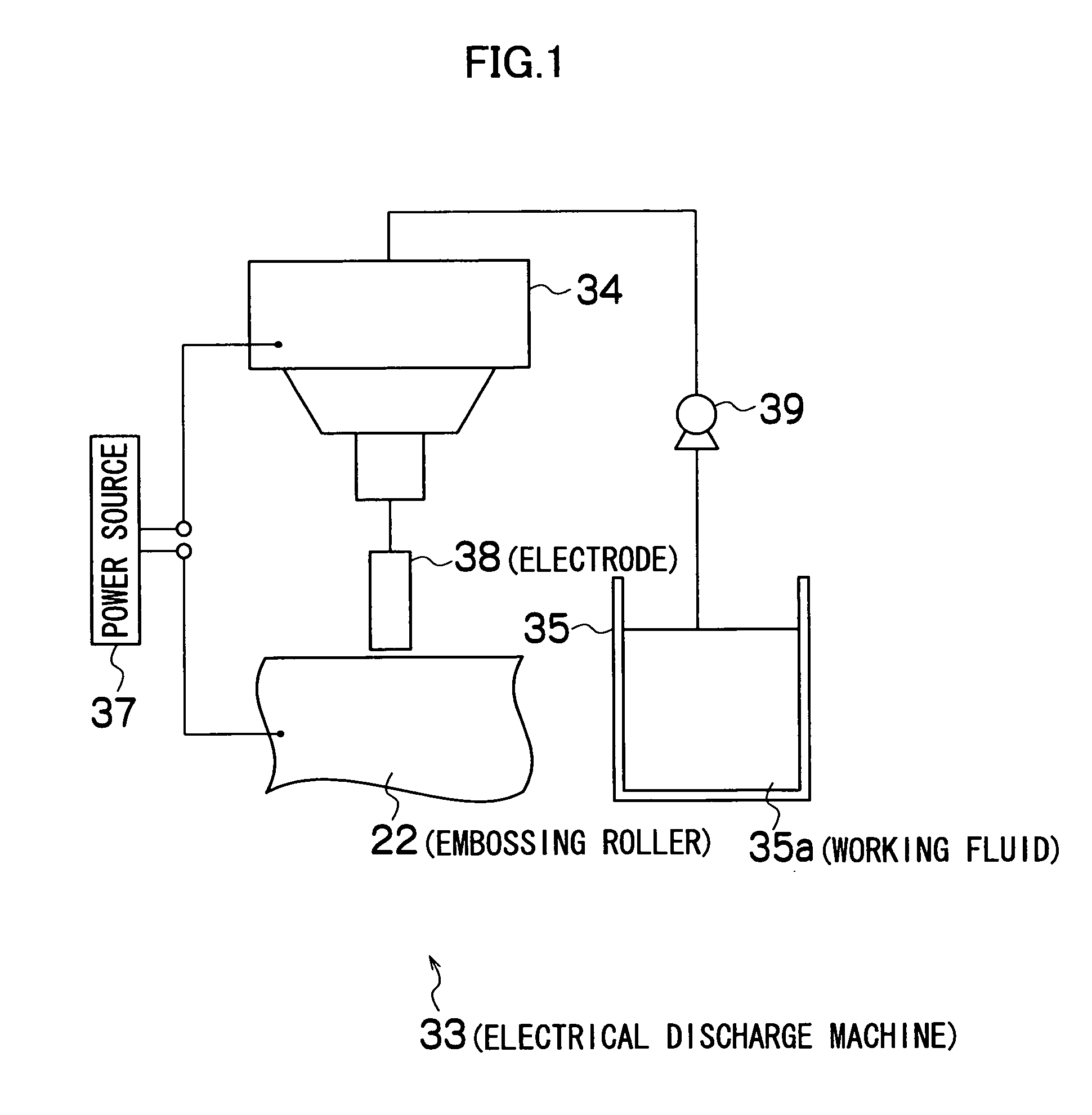

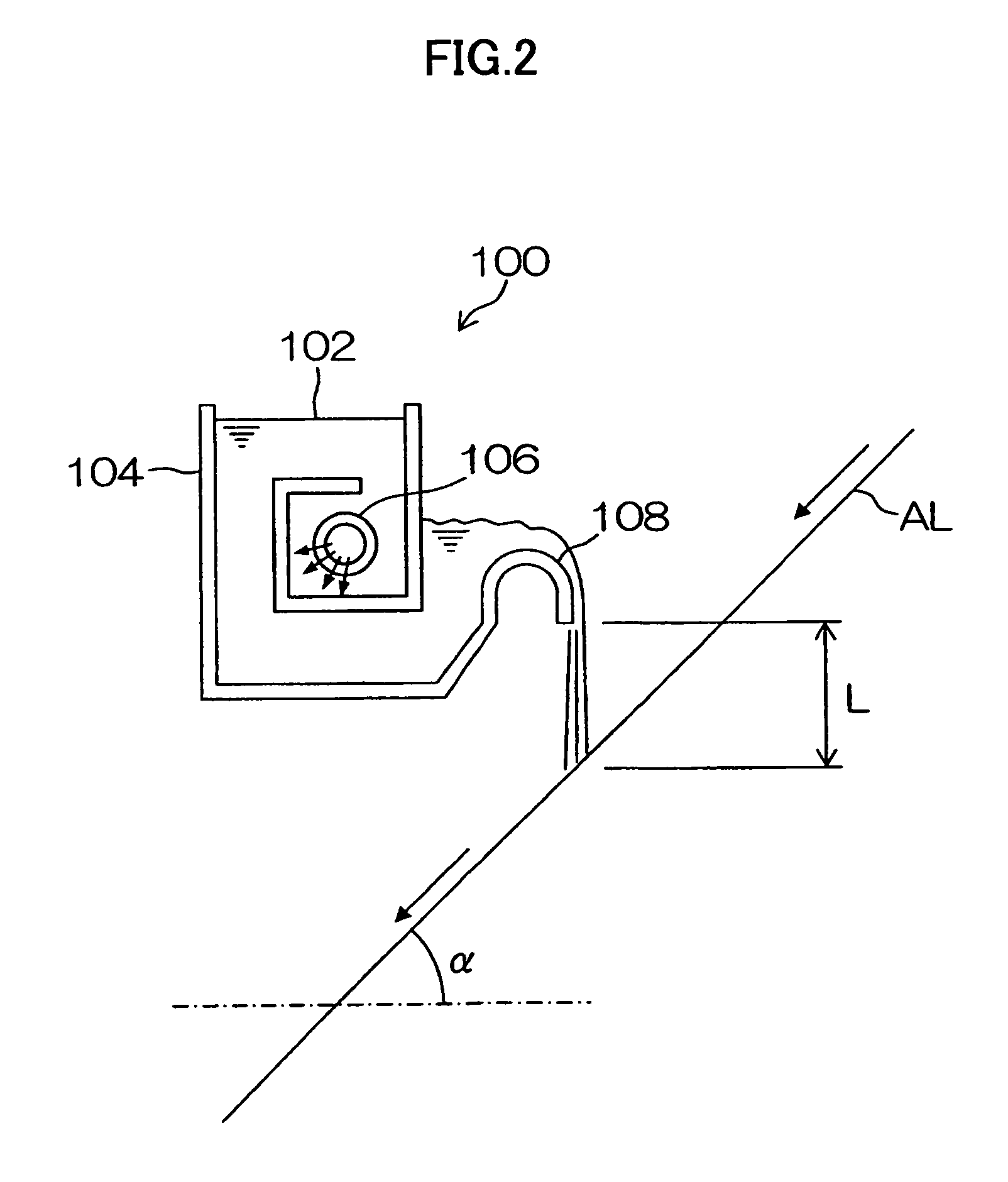

According to the present invention, since the concavo-convex pattern of the embossing form is formed by electrical discharge machining, the peaks on the surface of the resultant embossing form are all of the same level or height, which enables the enhancement of the service life of the embossing form. Further, since the concavo-convex pattern of the embossing form is formed by electrical discharge machining, even a complicated and minute concavo-convex pattern can be formed. Accordingly, when applying the method of the present invention to, for example, the production of a substrate for a lithographic plate, an aluminum substrate for a lithographic plate which excels in plate wear, sensitivity and resistance to stains can be produced. And when applying the same to the production of an aluminum decorative laminate, an aluminum decorative laminate which excel in glossiness and paint adhesion can be produced.

Owner:FUJIFILM HLDG CORP +1

Method for preparing radiating coating of light-emitting diode (LED) lamp

InactiveCN102807817AHigh radiation coolingEasy to usePoint-like light sourceLighting heating/cooling arrangementsRare-earth elementWater based

Owner:ANHUI SHILIN LIGHTING

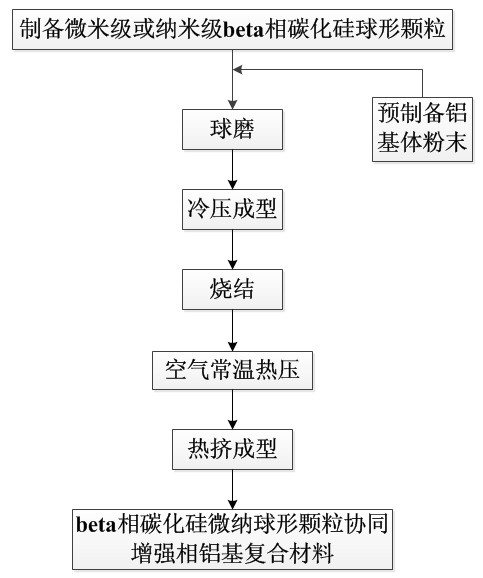

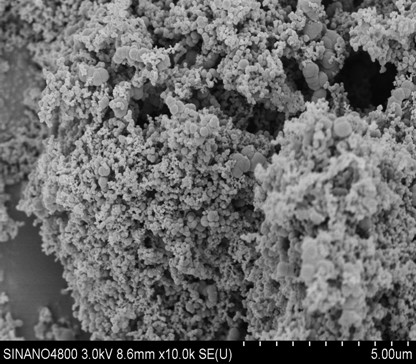

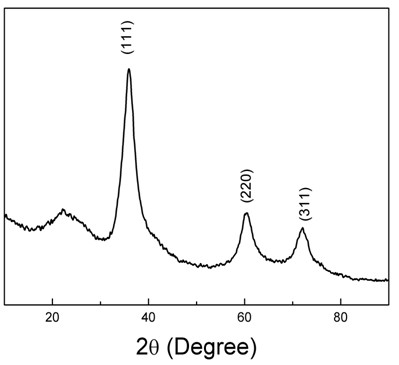

Silicon carbide reinforced aluminum-based composite material and its preparation method

The invention relates to a silicon carbide reinforced aluminum-based composite material and its preparation method. The composite material is characterized by being composited by micron-scale and nano-scale beta-phase silicon carbide spherical particles and an aluminum substrate, with the beta-phase silicon carbide spherical particles distributed in the aluminum substrate to form a synergistic reinforced phase. The preparation method is summarized to be mainly composed of: pre-preparing beta-phase silicon carbide spherical particles, adding aluminum substrate powder and the beta-phase silicon carbide spherical particles accounting for 0-25wt% of the composite material into a ball mill for ball milling treatment, and conducting cold press molding, sintering, as well as air hot pressing sequentially, and finally carrying out hot extrusion molding to obtain a molded product of the composite material. Specifically, the particle size of the aluminum substrate powder is 1micrometer to 100micrometers. The technical scheme of the invention innovatively uses spherical particulate beta-phase silicon carbide and makes use of the synergistic reinforcement effect of the micron and nano-silicon carbide particles, substantially improves the strength, toughness, abrasion resistance and others of the aluminum-based composite material. The preparation process is simple, and the cost input is effectively reduced.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

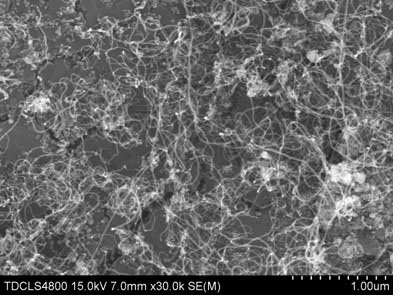

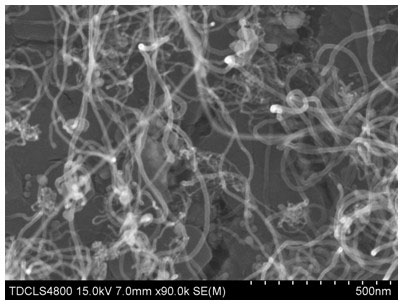

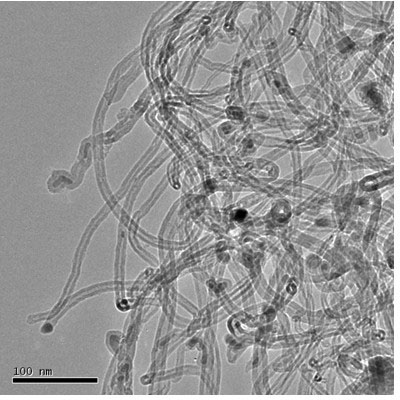

Method for preparing carbon nanotube reinforced aluminum-based composite material

InactiveCN102424919AImprove mechanical propertiesEnhanced interface bindingCarbon nanotubeAluminum substrate

The invention relates to a method for preparing a carbon nanotube reinforced aluminum-based composite material and belongs to a technique for preparing aluminum-based composite materials. The method comprises: preparing composite powder in which carbon nanotubes are uniformly distributed on the surface of aluminum powder by using cobalt as a catalyst and by using a chemical vapor deposition process; allowing the carbon nanotubes to reach deep parts of the aluminum powder substrate by using a ball milling process; densifying the composite powder by a pressing and sintering process or hot pressing process to obtain a blocky material; and obtaining the carbon nanotube reinforced aluminum-based composite material through hot extrusion forming. The method has the advantages that: the aluminum particle bridging function of carbon nanotubes is fully played, and the interface combination between carbon nanotubes and the aluminum substrate is strengthened; and the ball milling time is relatively short, so the damage to the structure of carbon nanotubes in a ball milling process is avoided. The composite material prepared by the method has a much higher mechanical property than that of pure aluminum substrate and thus, has a bright industrial application prospect.

Owner:TIANJIN UNIV

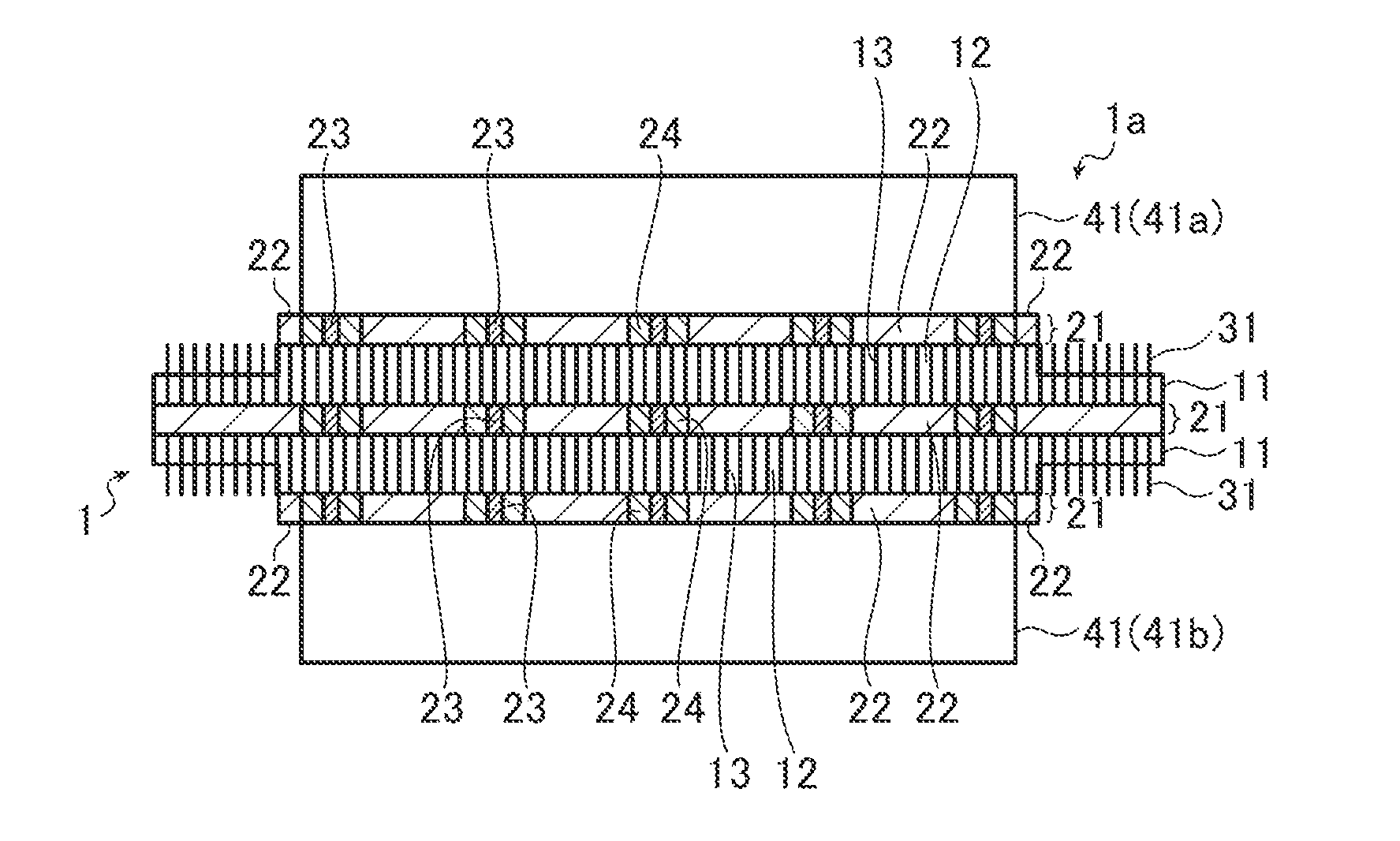

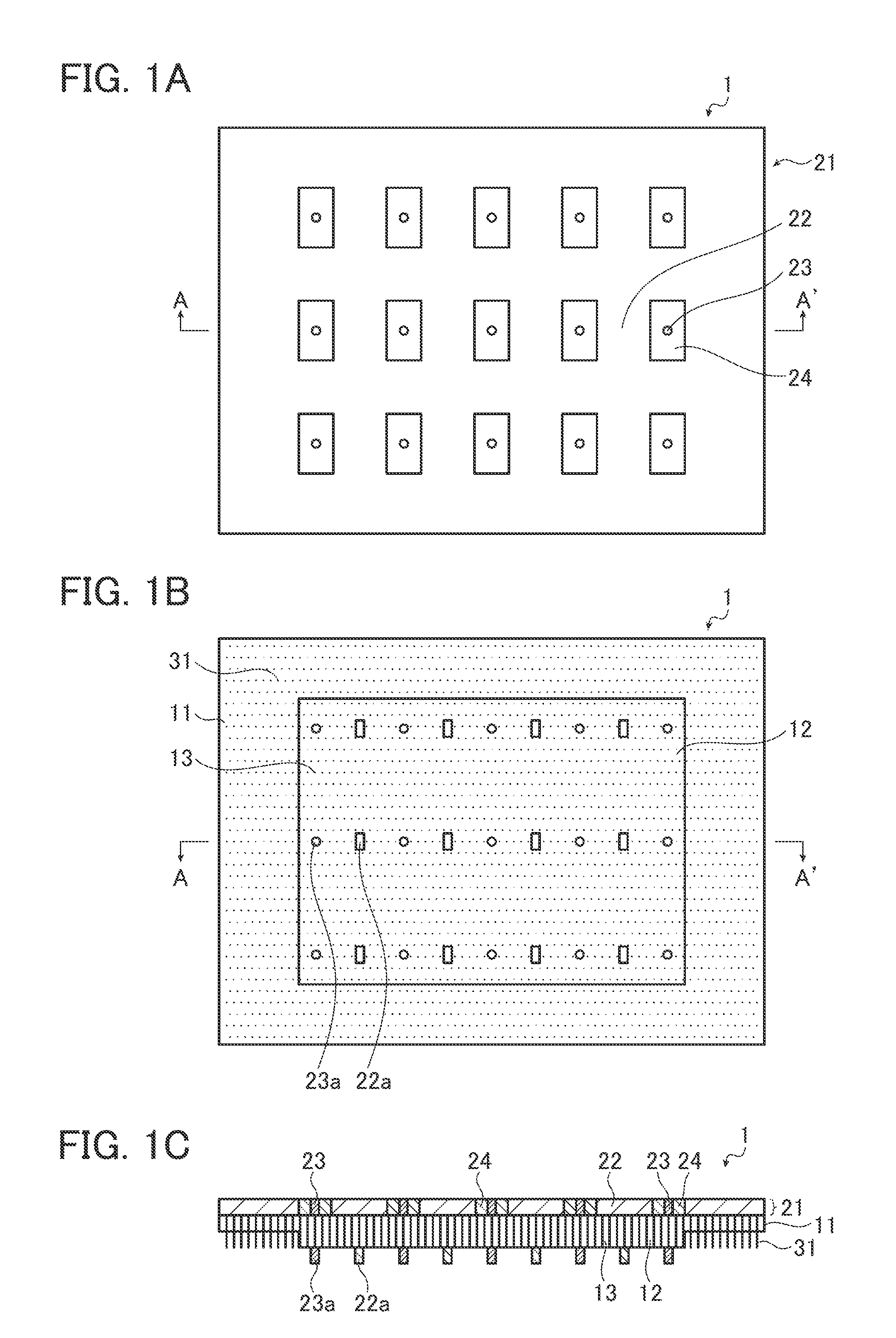

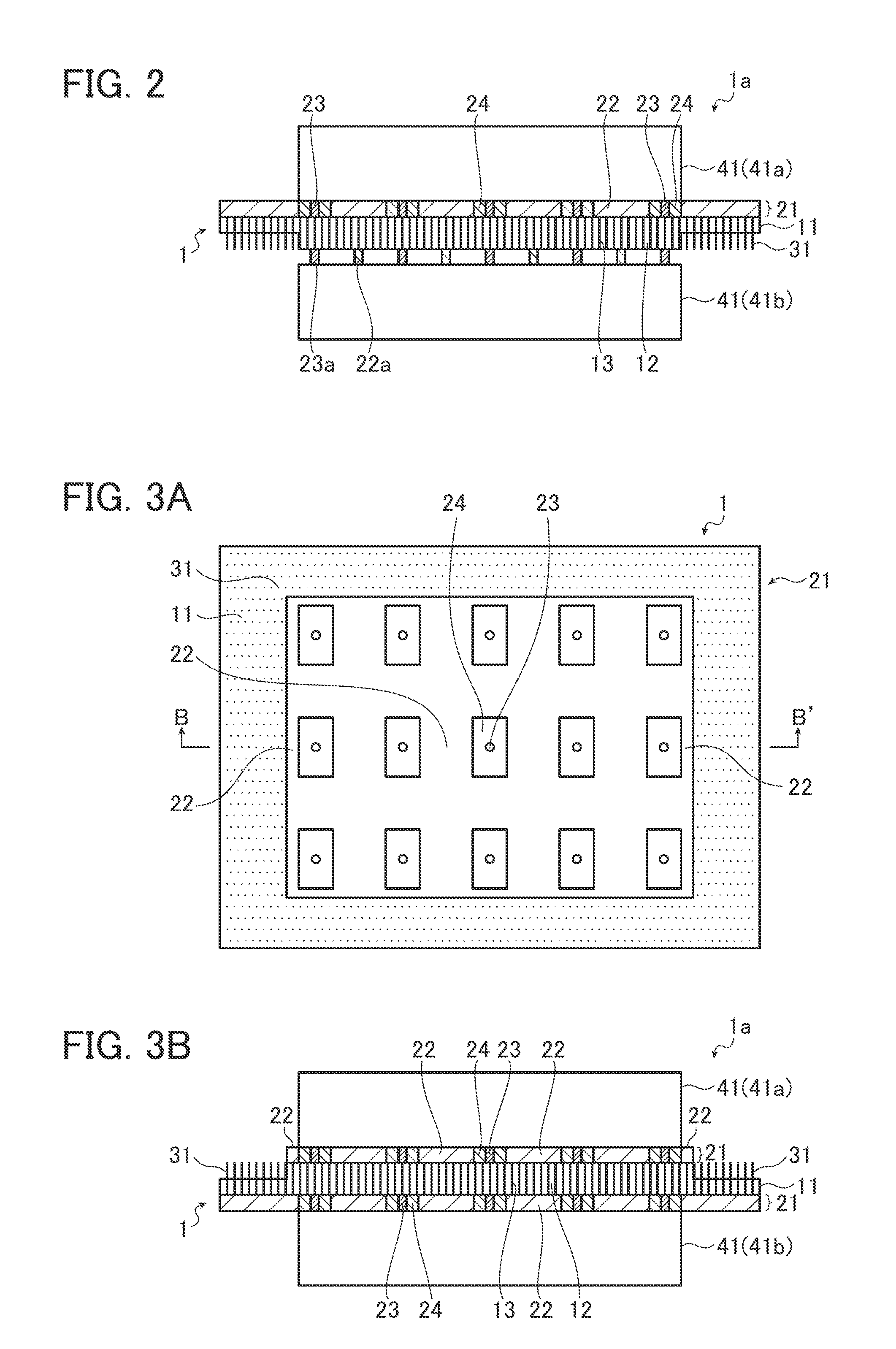

Multi-layered board and semiconductor package

InactiveUS20140085829A1Improve cooling effectImprove performanceSemiconductor/solid-state device detailsSolid-state devicesHeat conductingSemiconductor package

The invention provides a multi-layered board and a semiconductor package including the multi-layered board with improved heat dissipation performance of the semiconductor package. A multi-layered board includes an anisotropically-conductive member that includes an insulating base which is an anodized film of an aluminum substrate and in which through-holes are formed in a thickness direction and a plurality of conduction passages which are formed of a conductive material filled in the through-holes and which extend through the insulating base in the thickness direction with the conduction passages insulated from each other, a heat conducting layer that includes heat conducting portions and is disposed on at least one surface of the anisotropically-conductive member, and heat dissipating portions formed of the conductive material and protruding from the insulating base.

Owner:FUJIFILM CORP

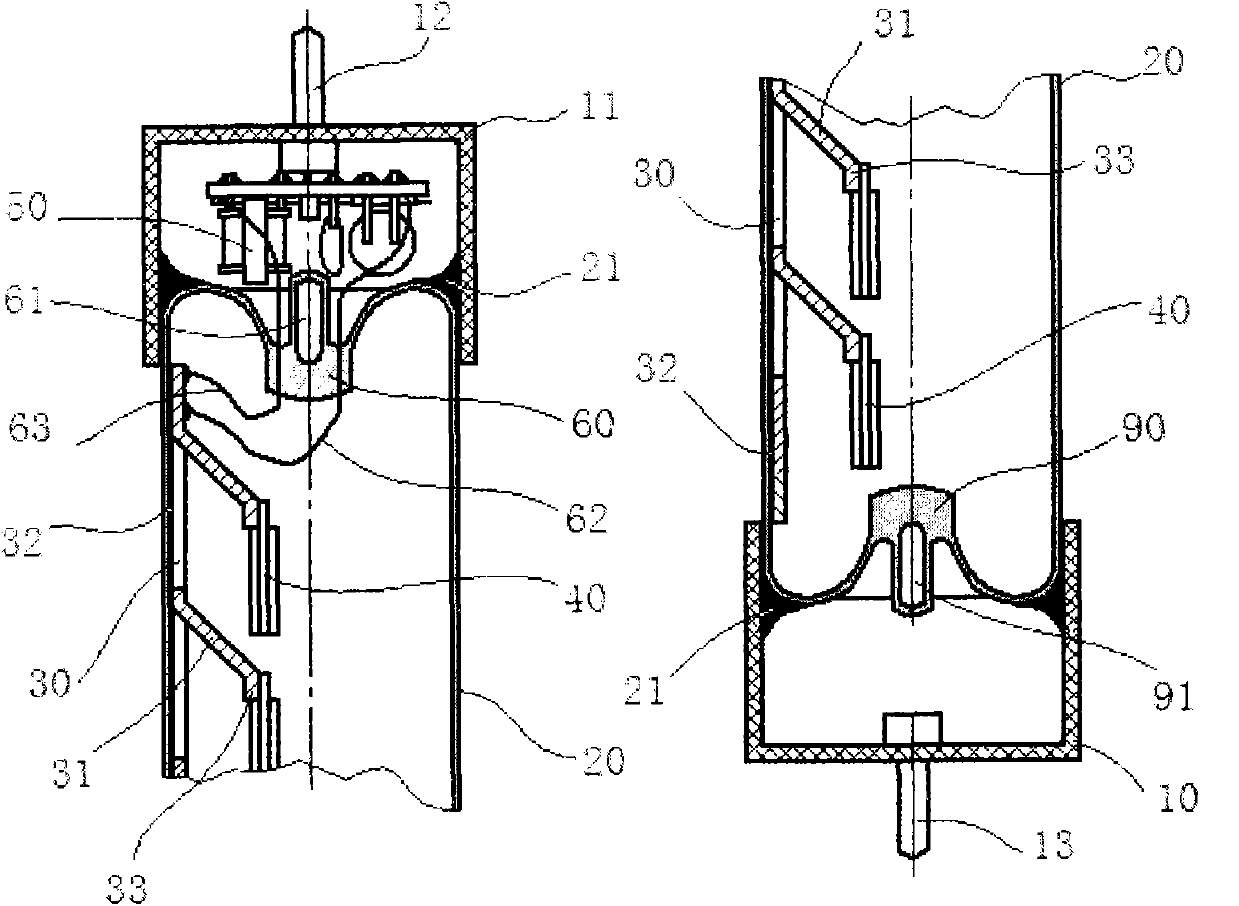

LED daylight lamp tube

InactiveUS8408742B2Improve cooling effectEasy to usePoint-like light sourceLighting support devicesHeat conductingEngineering

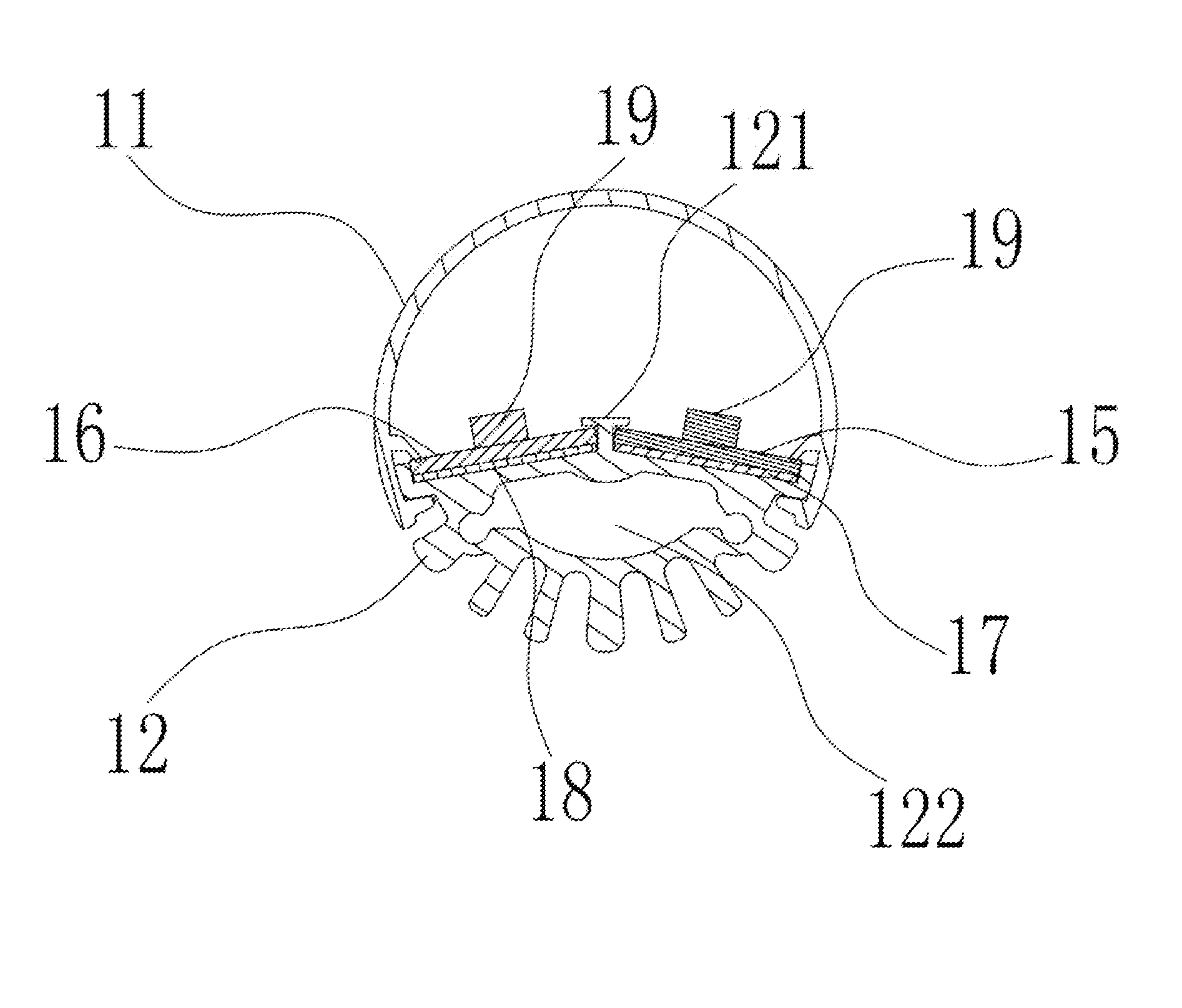

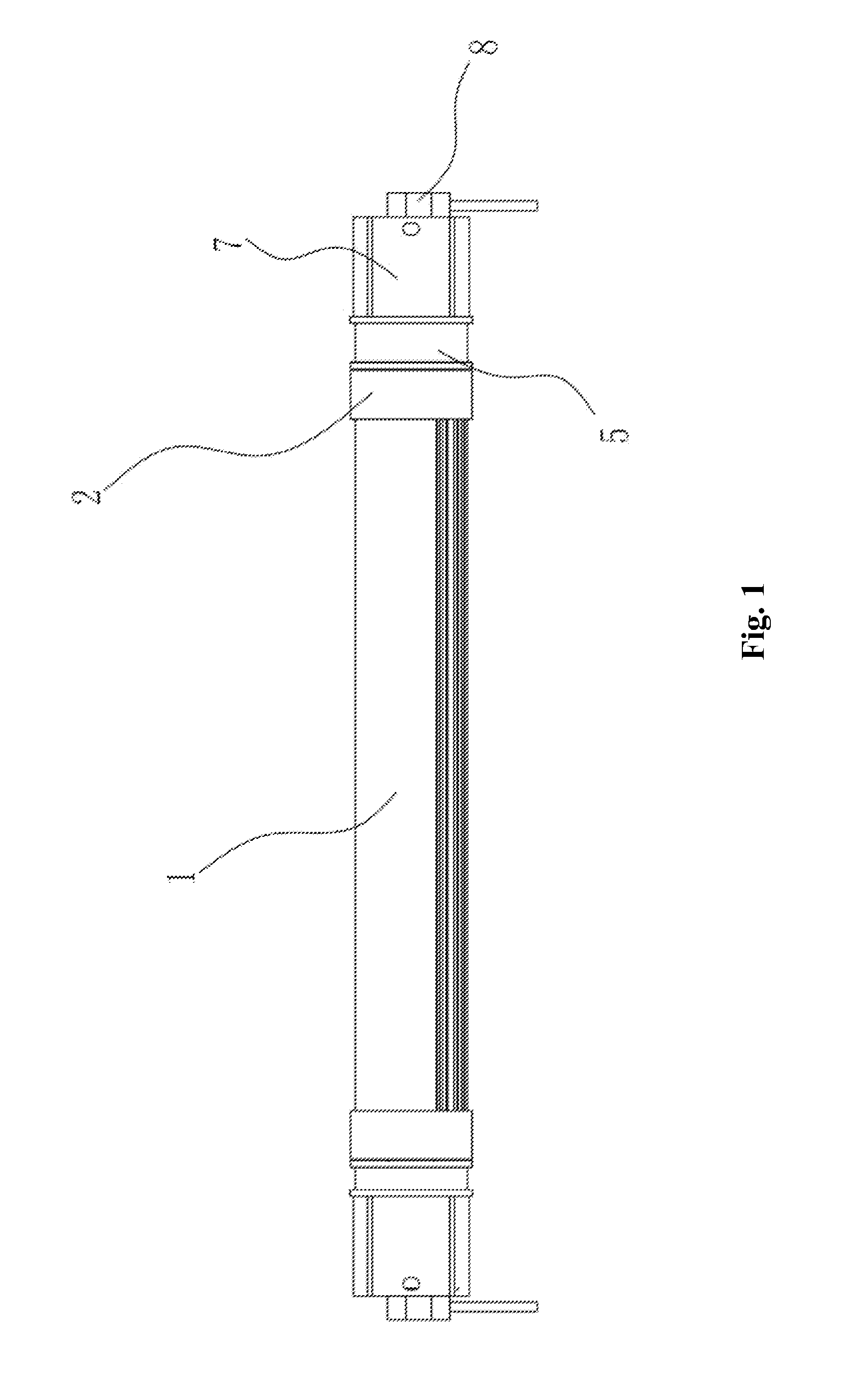

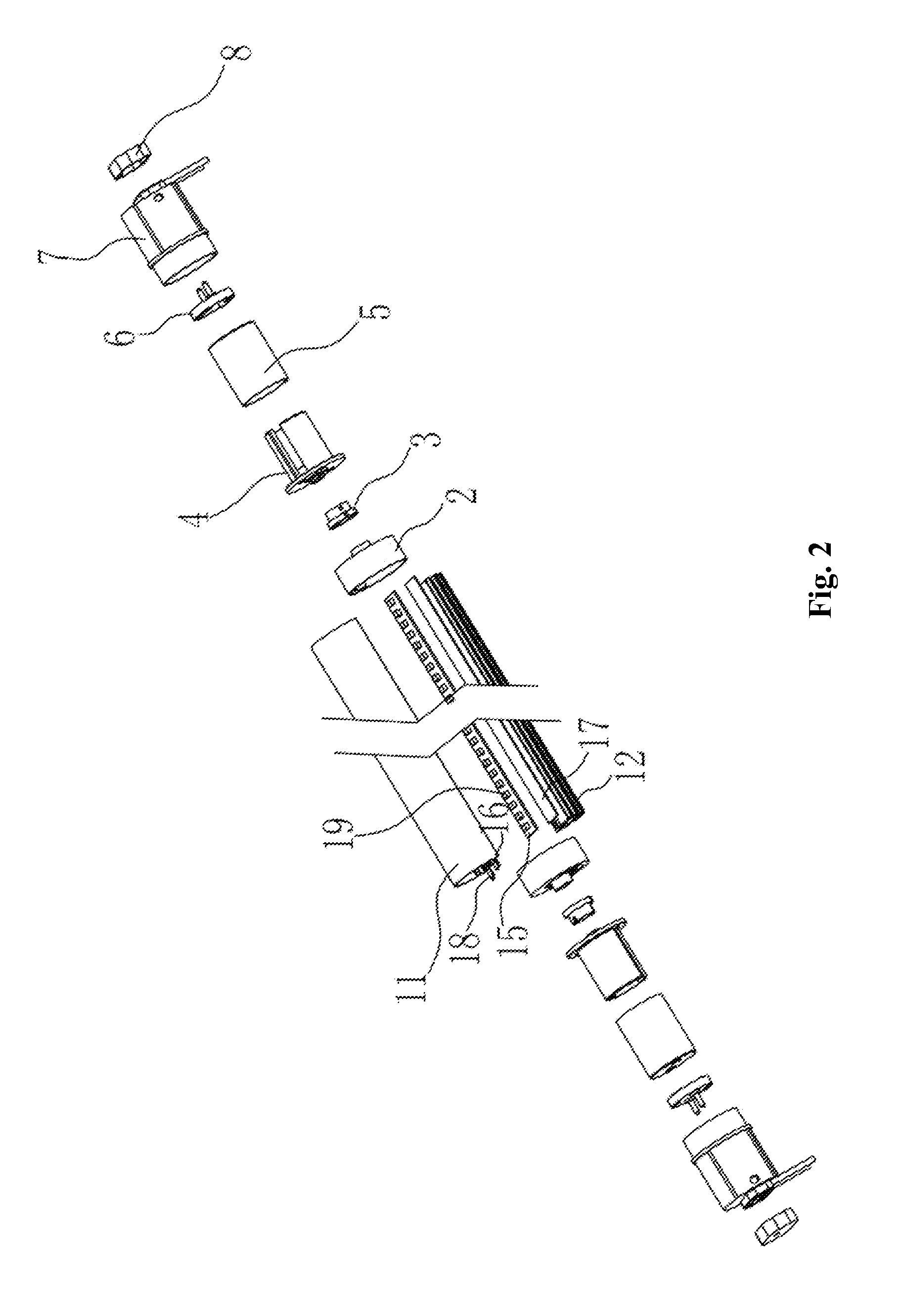

The invention discloses an LED daylight lamp tube, comprising a tube body and caps fixedly connected to two ends of the tube body, wherein the tube body comprises: an axial bar-shaped radiator, a radiating face of which is fan-shaped and a heat conducting face of which is provided with at least two axial bar-shaped slots forming included angle; an illuminant, which comprises PCB aluminum substrates corresponding in amount to the bar-shaped slots of the radiator, wherein the front face of each of the PCB aluminum substrates is equipped with a plurality of LED illuminants and the PCB aluminum substrates are clamped in the bar-shaped slots of the radiator; a bar-shaped heat conducting gasket, which is adhered to the back face of the PCB aluminum substrate in a fitting manner and clamped between the PCB aluminum substrate and a heat conducting face of the bar-shaped slot; and a circular arc lampshade, which is in clamped connection with two sides of the radiator and forms the cylindrical tube body with the radiator together. According to the LED daylight lamp tube of the invention, the PCB aluminum substrates of the LED illuminants are installed on the fan-shaped radiator at an included angle of 210 degrees, and wide-angle illumination of the LED daylight lamp tube is realized through the two movable caps arranged at two ends of the tube, in addition, the LED daylight lamp tube has better radiating effect and longer service life.

Owner:SHENZHEN EVITEO IMP&EXP

Halogen-free high heat-resistant and heat-conducting resin film and manufacturing method thereof

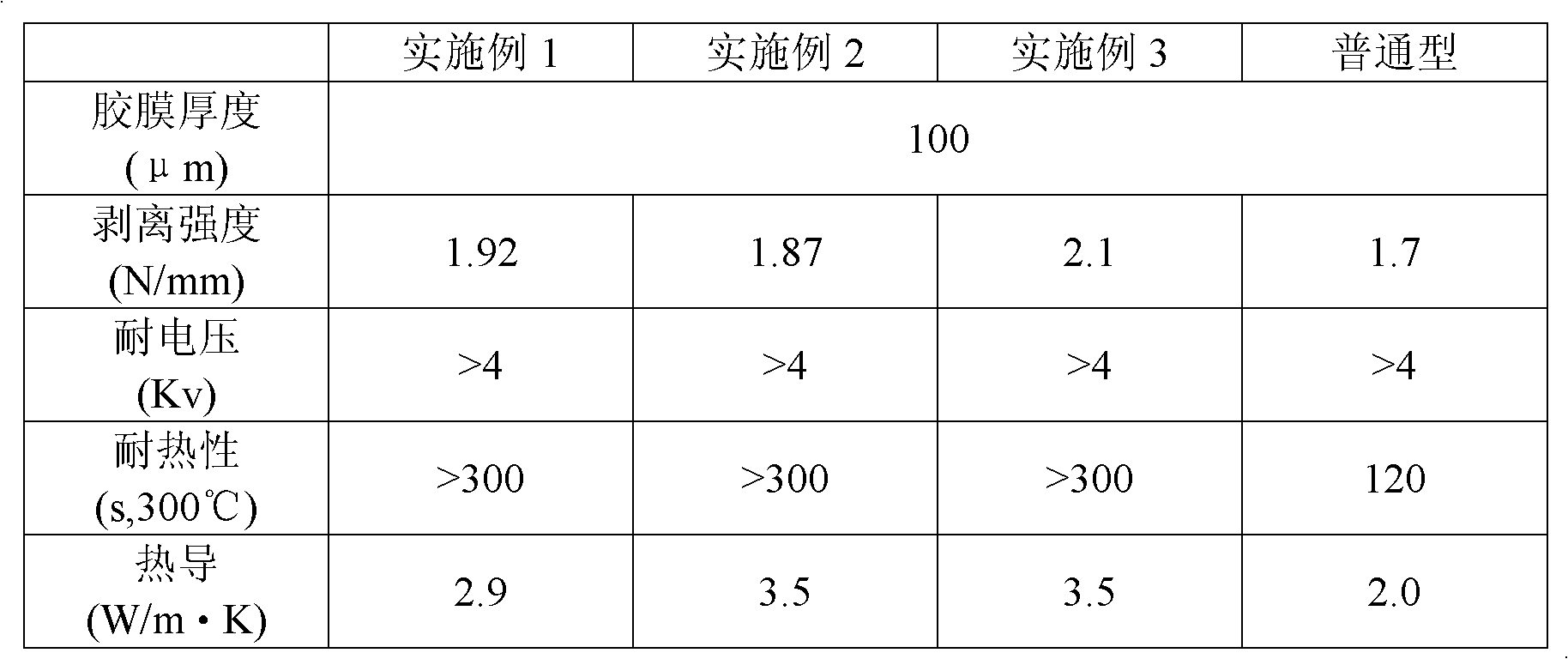

ActiveCN102660210ASolve the brittleness problemImprove cooling effectNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyHeat conducting

The invention discloses a halogen-free high heat-resistant and heat-conducting resin film and a manufacturing method thereof. The halogen-free high heat-resistant and heat-conducting resin film is prepared by semi-curing of a heat-conducting resin liquid, wherein the heat-conducting resin liquid is prepared from 70 to 100 parts of a halogen-free epoxy resin, 0 to 30 parts of one or more flexibilizers, 80 to 120 parts of one or more solvents, 1 to 20 parts of one or more curing agents, 0.01 to 1 part of one or more promoters, 0.5 to 5.0 parts of a coupling agent and 80 to 600 parts of one or more high heat-conducting filling materials. The halogen-free high heat-resistant and heat-conducting resin film has a thermal conductivity great than or equal to 2.5W / m.K and heat resistance (at a temperature of 300 DEG C) great than or equal to 300s. The halogen-free high heat-resistant and heat-conducting resin film has flexibility so that the problem of brittleness of the traditional heat-conducting materials is solved. An aluminum substrate prepared from the halogen-free high heat-resistant and heat-conducting resin film is suitable for electronic products such as LED, vehicle systems and variable-frequency power sources needing good heat conductivity, can greatly improve the thermal diffusivity of the electronic products, and has high reliability and energy-saving and environmental-protection effects.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

Catalyst and process for hydrocracking hydrocarbon-containing feedstocks

ActiveUS20040138059A1Improve spatial resolutionCatalyst carriersOther chemical processesNitrogenPore diameter

This invention relates to silico-aluminum substrates, catalysts, and the hydrocracking and hydrotreatment processes that use them. The catalyst comprises at least one hydro-dehydrogenating element that is selected from the group that is formed by elements of group VIB and group VIII of the periodic table and a non-zeolitic silica-alumina-based substrate that contains an amount of more than 5% by weight and less than or equal to 95% by weight of silica (SiO2) and has the following characteristics: A mean pore diameter, measured by mercury porosimetry, encompassed between 20 and 140 Å, a total pore volume, measured by mercury porosimetry, encompassed between 0.1 ml / g and 0.6 ml / g, a total pore volume, measured by nitrogen porosimetry, encompassed between 0.1 ml / g and 0.6 ml / g, a BET specific surface area encompassed between 100 and 550 m<2> / g, a pore volume, measured by mercury porosimetry, encompassed in the pores with diameters of more than 140 Å, of less than 0.1 ml / g, a pore volume, measured by mercury porosimetry, encompassed in the pores with diameters of more than 160 Å, of less than 0.1 ml / g, a pore volume, measured by mercury porosimetry, encompassed in the pores with diameters of more than 200 Å, of less than 0.1 ml / g, a pore volume, measured by mercury porosimetry, encompassed in the pores with diameters of more than 500 Å, of less than 0.01 ml / g, an X diffraction diagram contains at least the main lines that are characteristic of at least one of the transition aluminas contained in the group that consists of the alpha, rho, chi, eta, gamma, kappa, theta and delta aluminas.

Owner:INST FR DU PETROLE

Coating of aluminum substrate for direct plate making of ink-jet printing, production method and use

ActiveCN101397438AWith roughnessAvoid pollutionPrinting pre-treatmentProtein coatingsSolventAluminum substrate

The invention relates to a coating for aluminum lithographic supports applied to direct ink jet stencil making, a preparation process and application thereof. The coating is prepared by mixing 0.5-15wt percent of hydrophilic high molecular polymer, 0.5-15wt percent of nanometer or micrometer-sized oxide particles, 0-1wt percent of additive and 80-98wt percent of solvent with agitating at room temperature. The coating can avoid the problem that acid or alkaline waste liquid produced after anodic oxidation treatment of aluminum lithographic supports can cause great pollution to the environment. After thermocuring of the coating, aluminum lithographic supports can absorb ink and can be directly printed after ink jet CTP stencil making, thus reducing the post-treatment process. The coating has good adhesion to aluminum lithographic supports; after the coating is applied to aluminum lithographic supports, due to presence of the nanometer or micrometer-sized oxide particles, the aluminum lithographic supports can have high specific surface energy and satisfy requirements on ink absorbance and environment protection; in addition, surfaces of the aluminum lithographic supports have high wear resistance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing pore diameter controllable through hole anodized aluminum oxide film

The invention relates to technology for preparing an anodized aluminum oxide film, in particular to a method for preparing a pore diameter controllable through hole anodized aluminum oxide film. The method comprises the following steps of: performing anode electrolysis treatment on an anodized aluminum oxide film with an aluminum substrate in mixed solution of perchloric acid and acetone to obtain a pore diameter controllable anodized aluminum oxide film with two open ends in short time (2-300 seconds), wherein the pore diameters at the top end and the bottom end fo the anodized aluminum oxide film are accurately controllable in ranges of between 10 and 100nm and between 5 and 25nm; and putting the aluminum oxide film with the aluminum substrate subjected to stage depressurization-method oxidation into acetone solution of perchloric acid, and applying voltage 5-15V higher than film forming voltage for anode electrolysis treatment to obtain the pore diameter controllable through hole anodized aluminum oxide film. In the method, the pore diameters at the top end and the bottom end of the anodized aluminum oxide film can be respectively controlled, holing and removal of the aluminum substrate are completed by one step, and a plurality of problems of complicated process, time consumption, difficult control of pore diameters and the like in the conventional process for preparing the through hole anodized aluminum oxide film.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com