Patents

Literature

12254 results about "Rare-earth element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rare-earth element (REE) or rare-earth metal (REM), as defined by the International Union of Pure and Applied Chemistry, is one of a set of seventeen chemical elements in the periodic table, specifically the fifteen lanthanides, as well as scandium and yttrium. Scandium and yttrium are considered rare-earth elements because they tend to occur in the same ore deposits as the lanthanides and exhibit similar chemical properties, but have different electronic and magnetic properties. Rarely, a broader definition that includes actinides may be used, since the actinides share some mineralogical, chemical, and physical (especially electron shell configuration) characteristics.

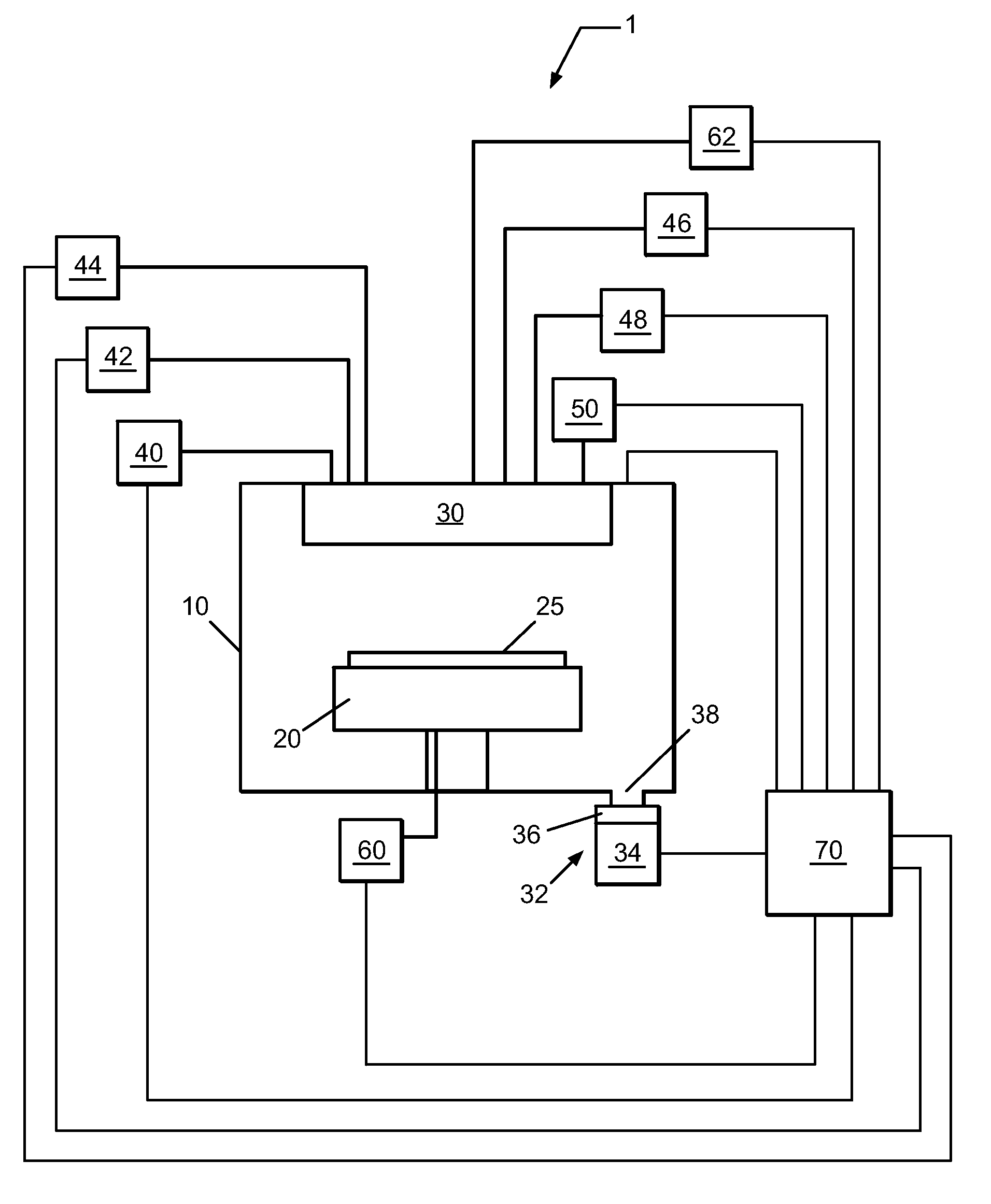

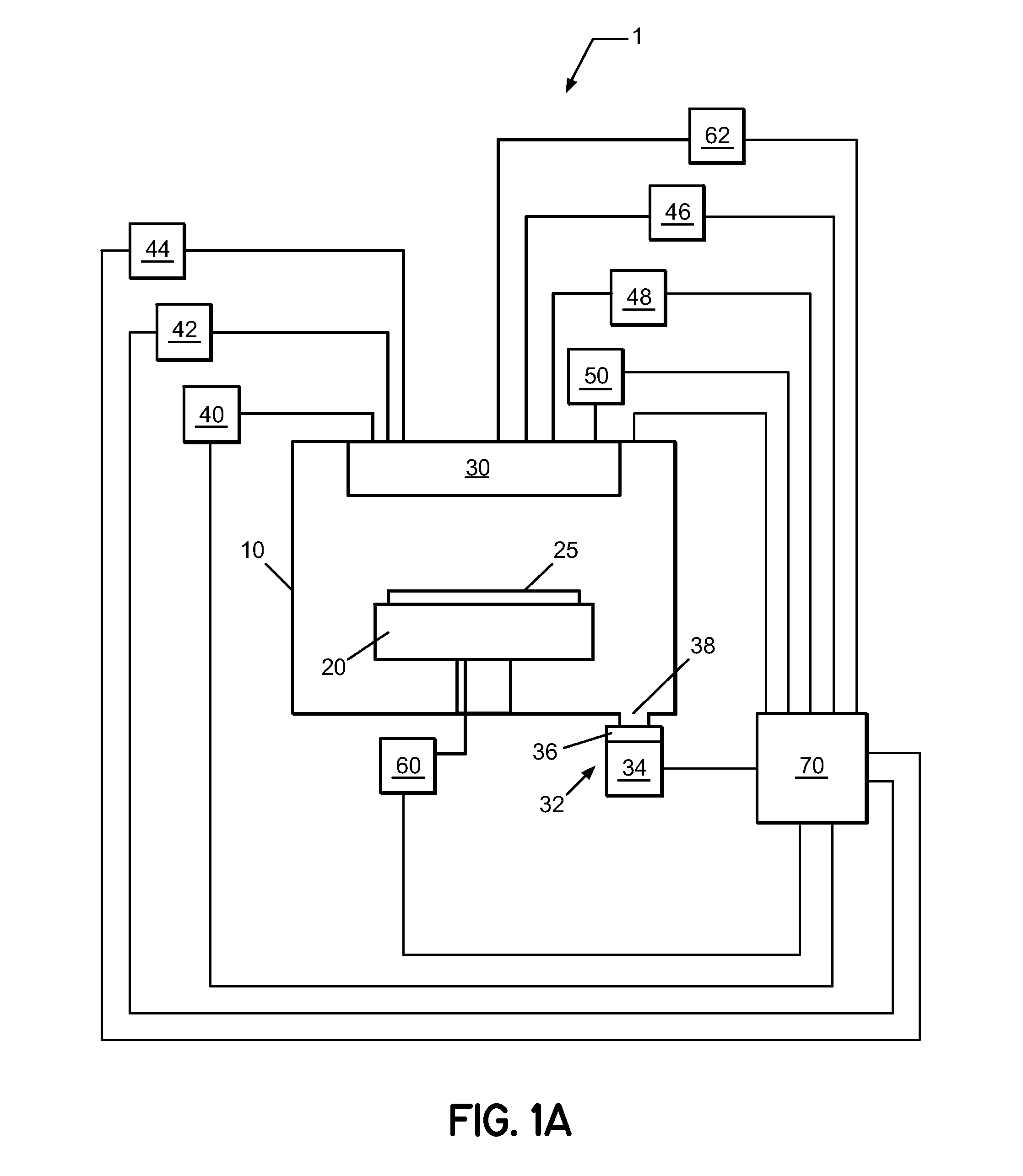

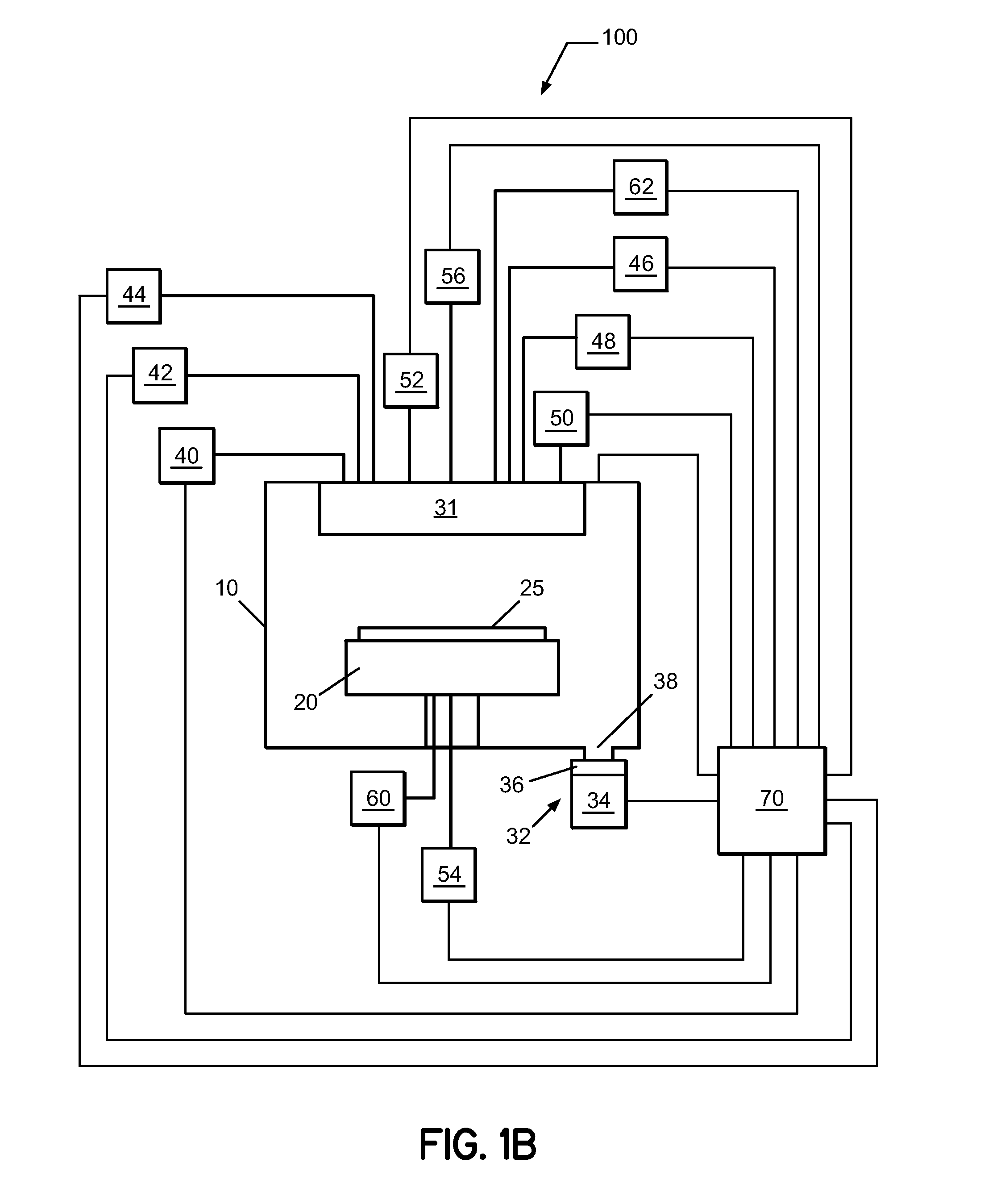

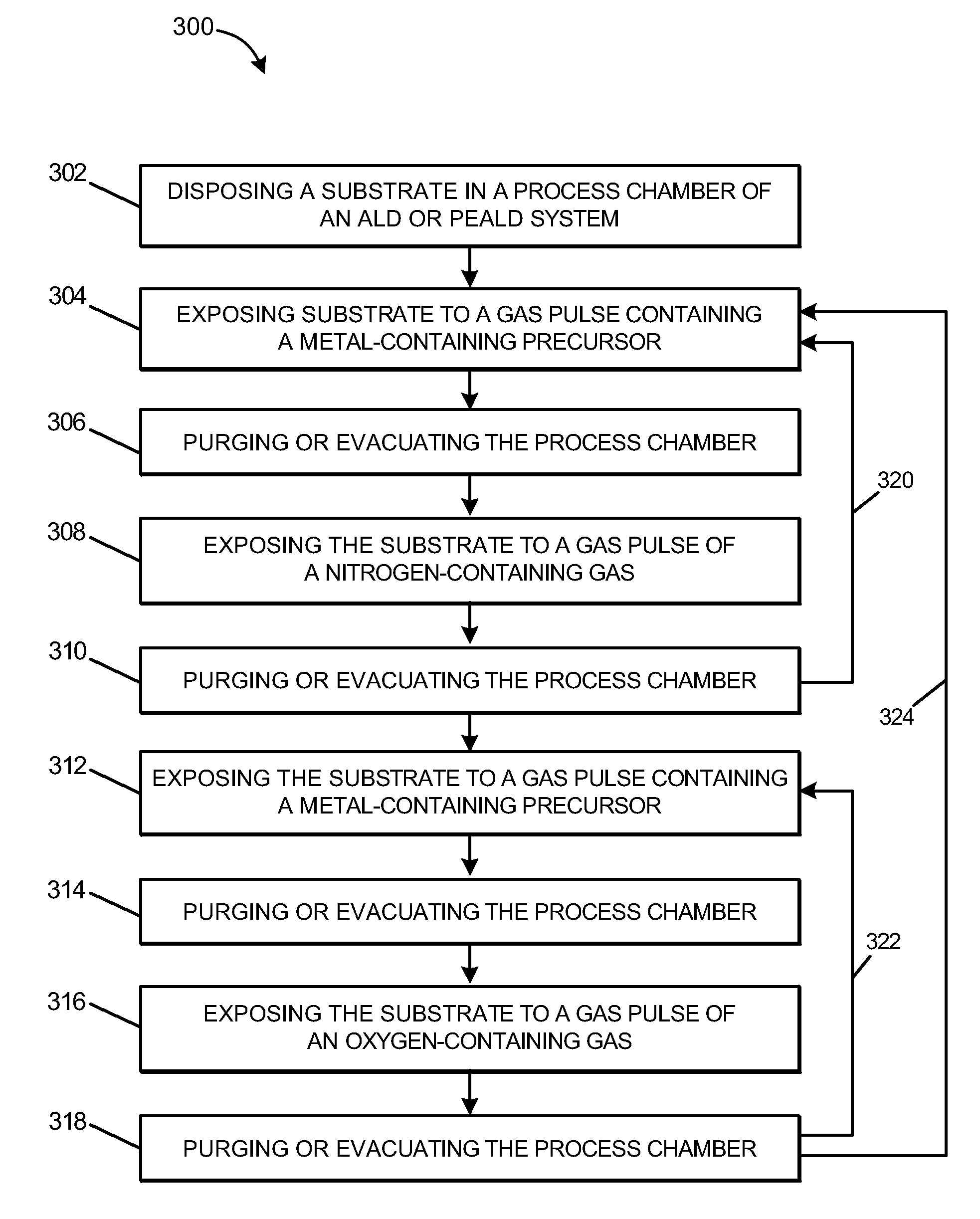

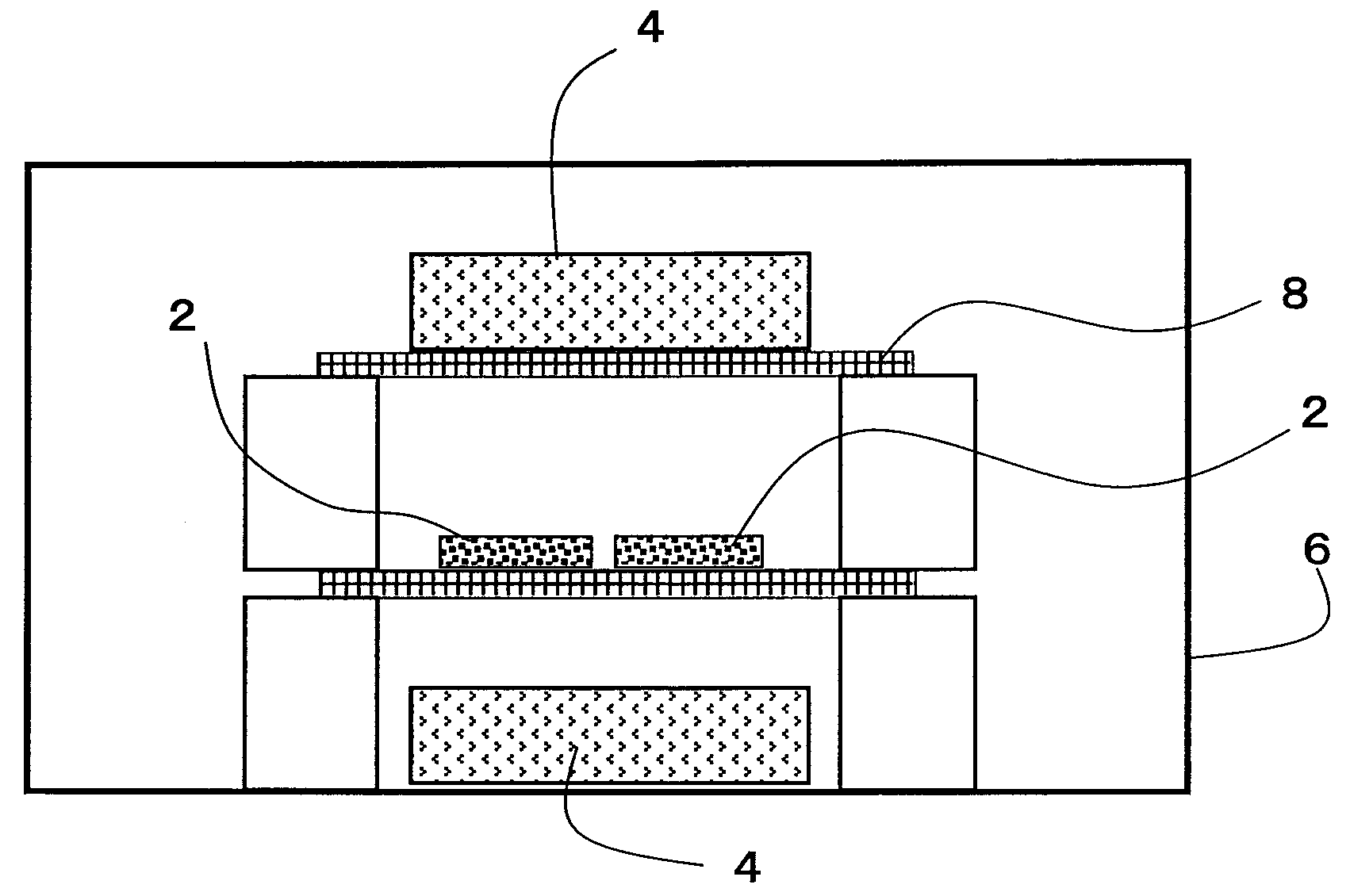

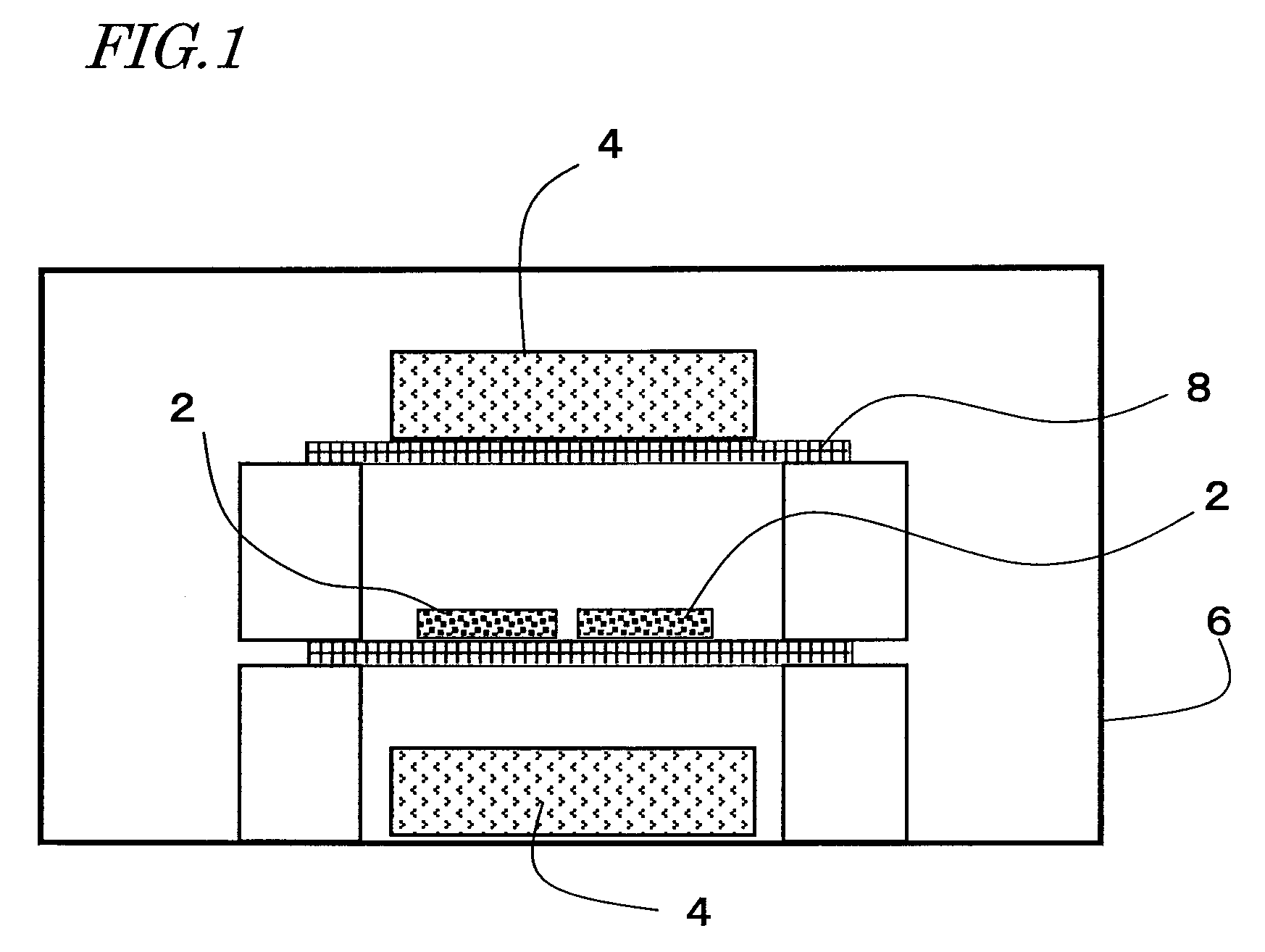

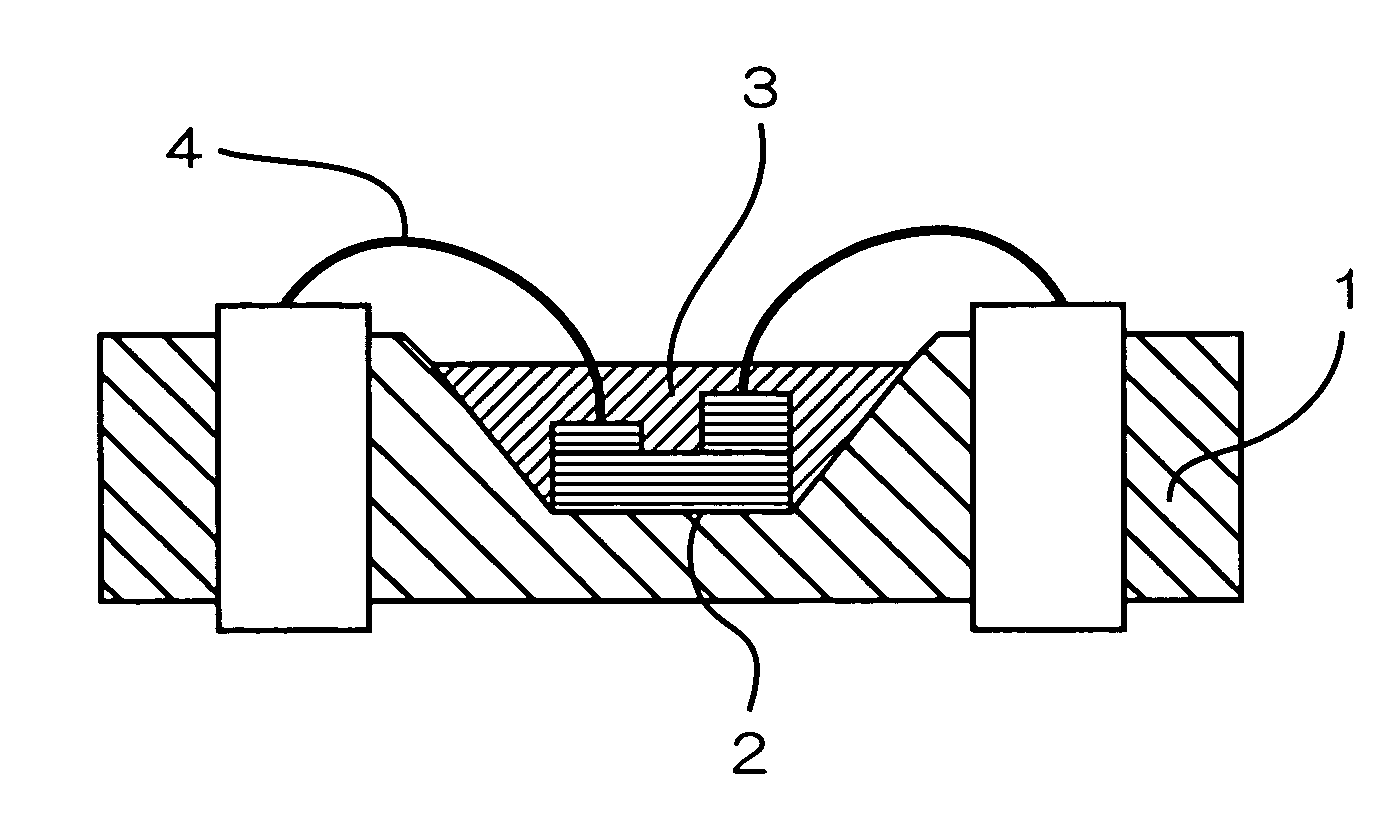

Nitrogen profile engineering in nitrided high dielectric constant films

InactiveUS7767262B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRare-earth elementNitrogen

A method of forming a nitrided high-k film by disposing a substrate in a process chamber and forming the nitrided high-k film on the substrate by a) depositing a nitrogen-containing film, and b) depositing an oxygen-containing film, wherein steps a) and b) are performed in any order, any number of times, so as to oxidize at least a portion of the thickness of the nitrogen-containing film. The oxygen-containing film and the nitrogen-containing film contain the same one or more metal elements selected from alkaline earth elements, rare earth elements, and Group IVB elements of the Periodic Table, and optionally aluminum, silicon, or aluminum and silicon. According to one embodiment, the method includes forming a nitrided hafnium based high-k film. The nitrided high-k film can be formed by atomic layer deposition (ALD) or plasma-enhanced ALD (PEALD).

Owner:TOKYO ELECTRON LTD

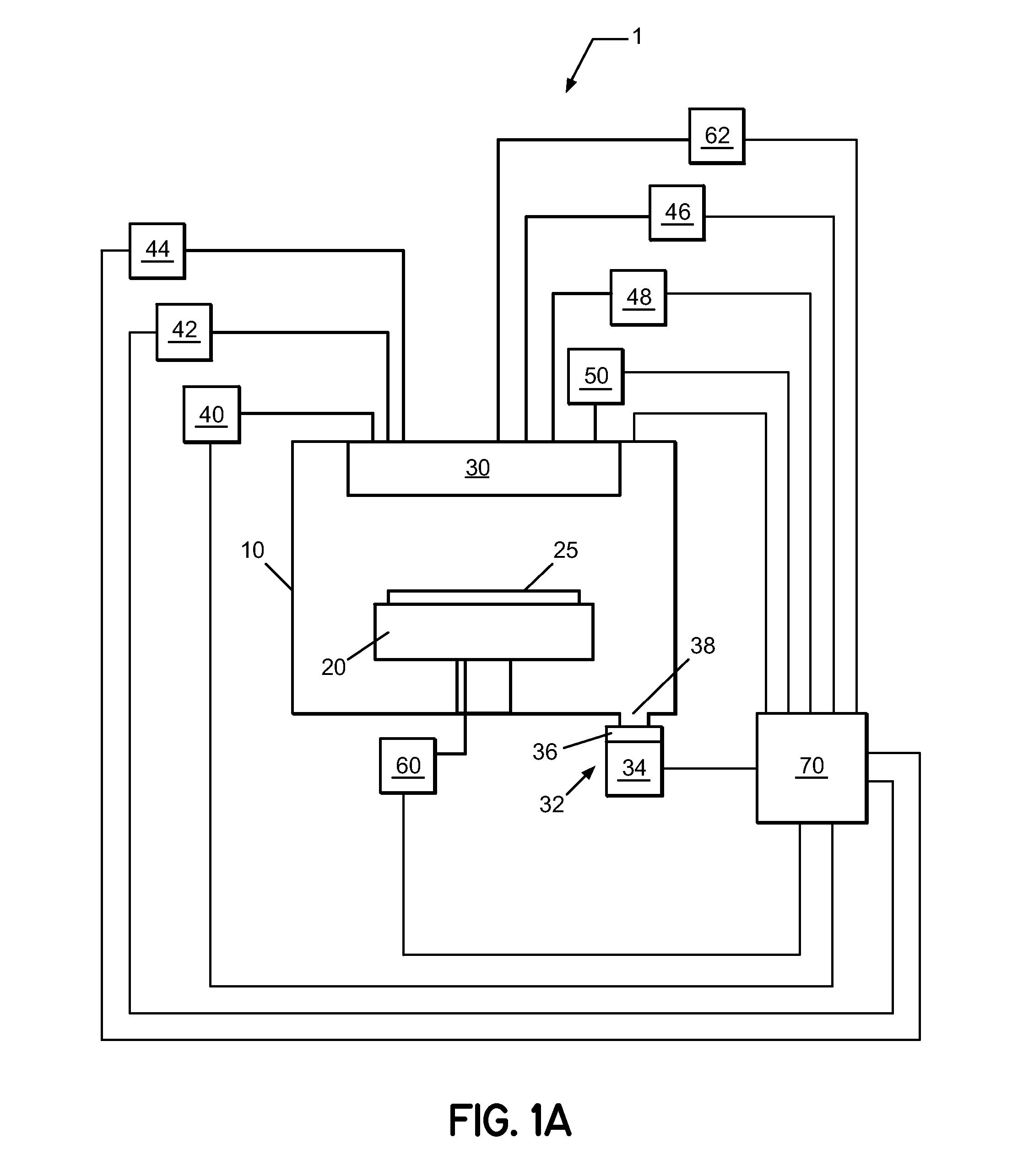

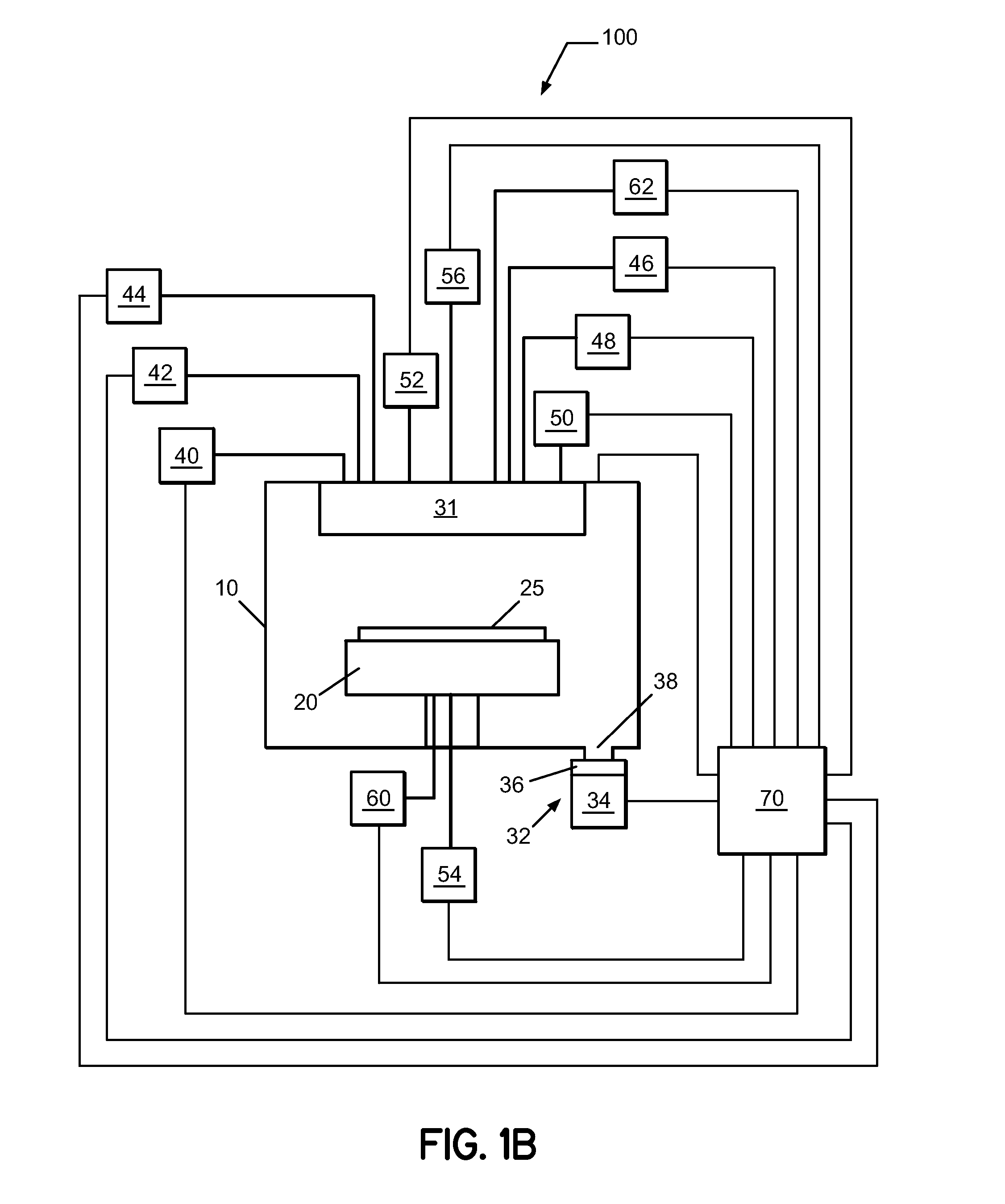

Nitrogen profile engineering in nitrided high dielectric constant films

InactiveUS20080081113A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRare-earth elementNitrogen

A method of forming a nitrided high-k film by disposing a substrate in a process chamber and forming the nitrided high-k film on the substrate by a) depositing a nitrogen-containing film, and b) depositing an oxygen-containing film, wherein steps a) and b) are performed in any order, any number of times, so as to oxidize at least a portion of the thickness of the nitrogen-containing film. The oxygen-containing film and the nitrogen-containing film contain the same one or more metal elements selected from alkaline earth elements, rare earth elements, and Group IVB elements of the Periodic Table, and optionally aluminum, silicon, or aluminum and silicon. According to one embodiment, the method includes forming a nitrided hafnium based high-k film. The nitrided high-k film can be formed by atomic layer deposition (ALD) or plasma-enhanced ALD (PEALD).

Owner:TOKYO ELECTRON LTD

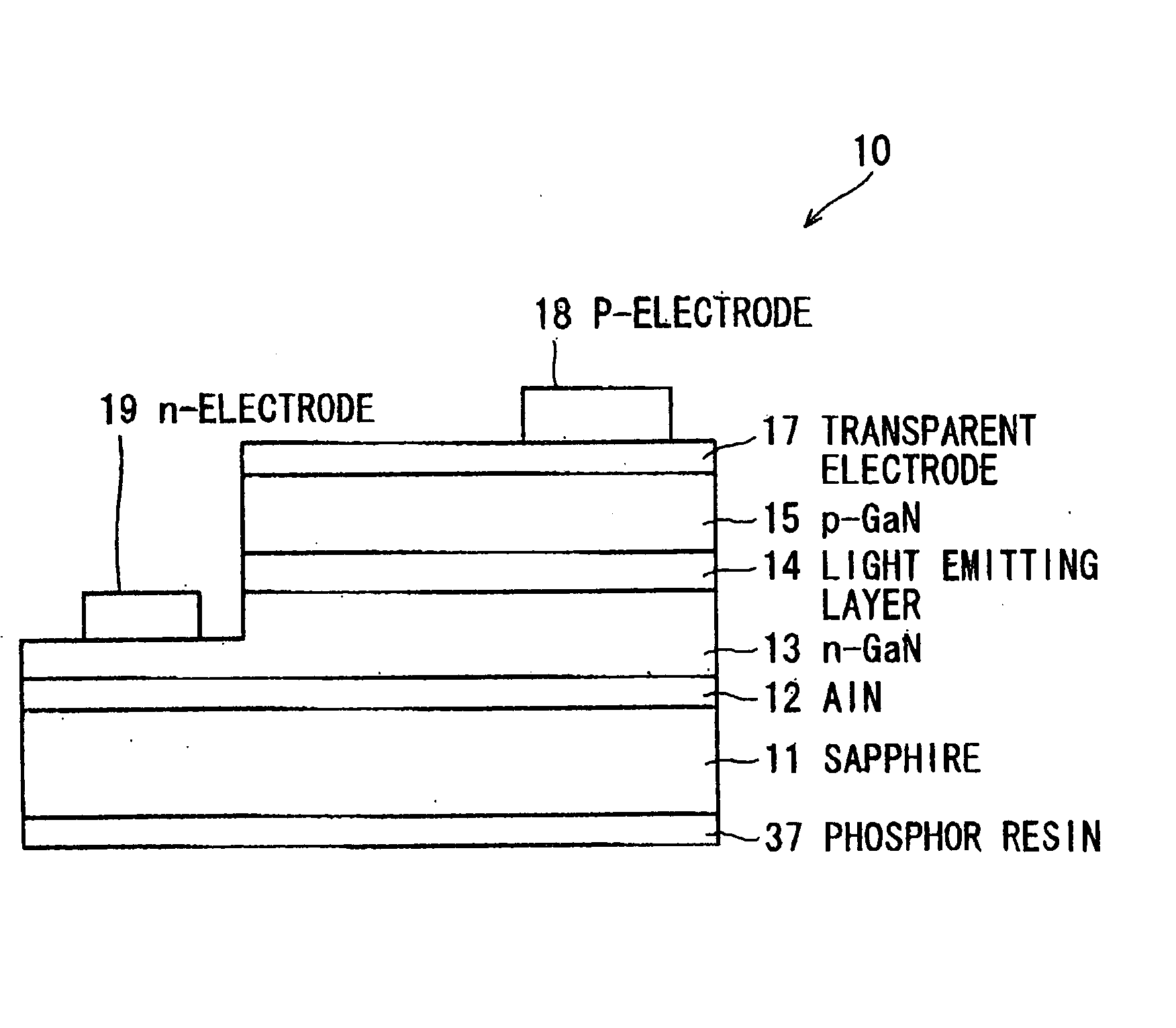

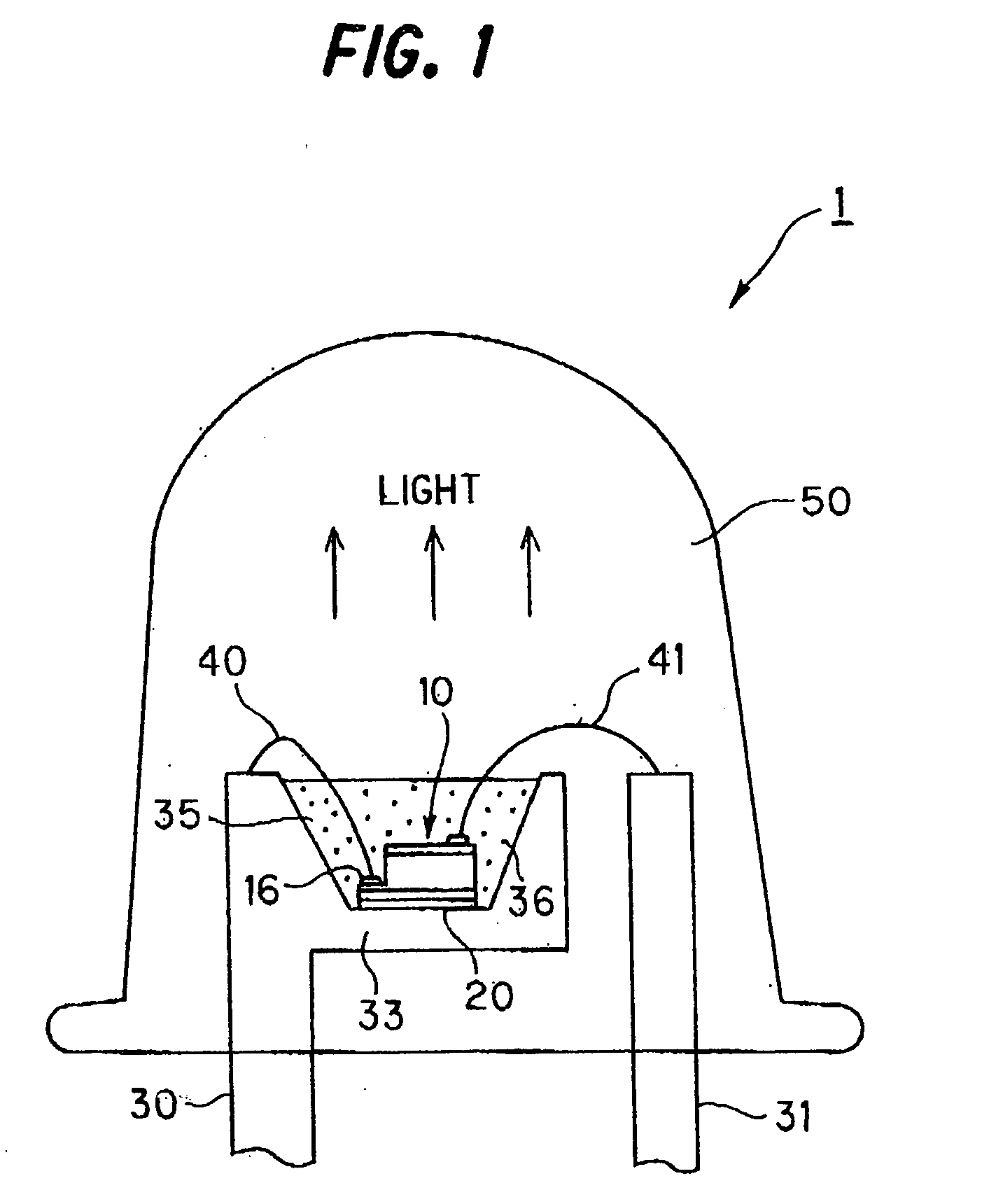

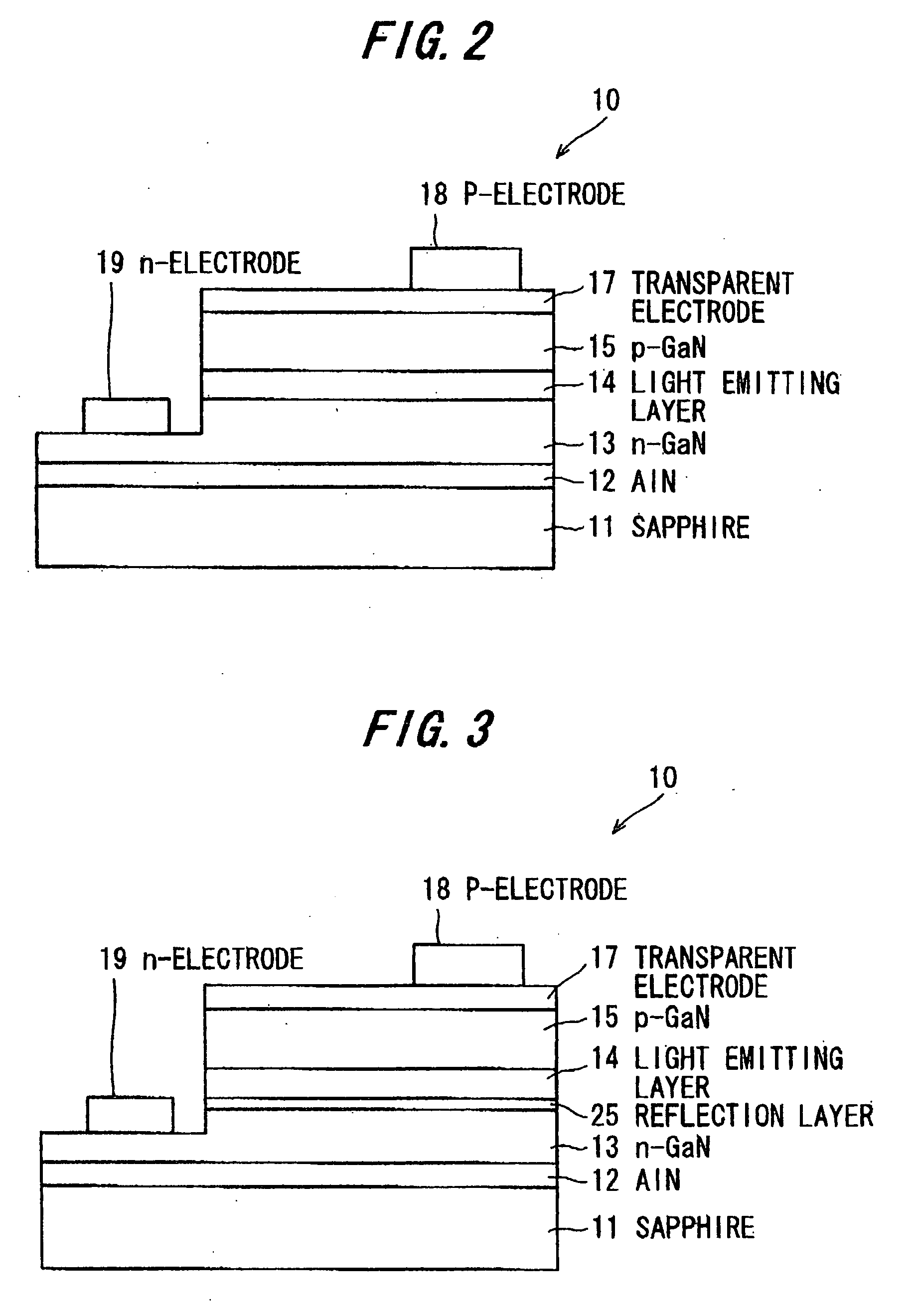

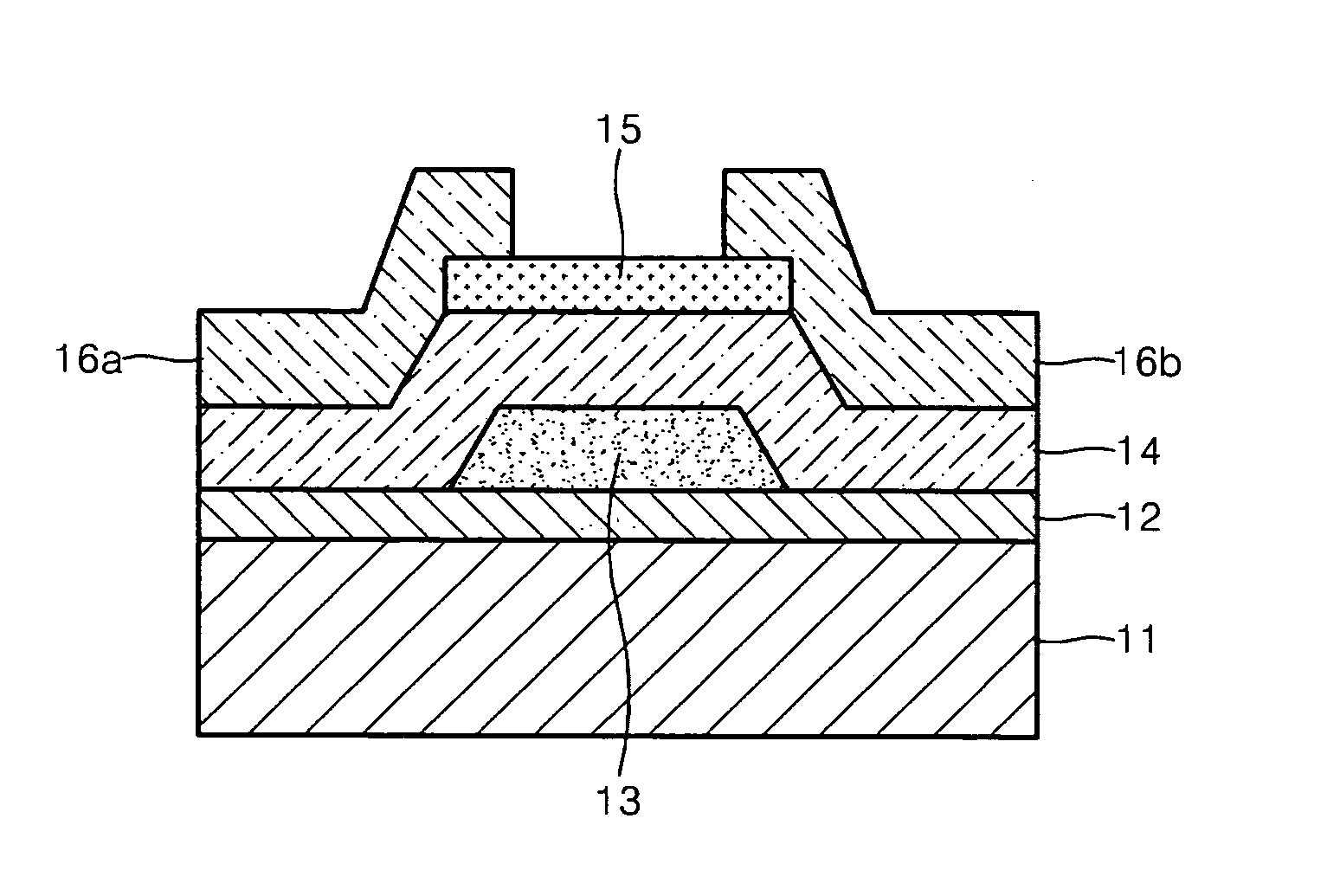

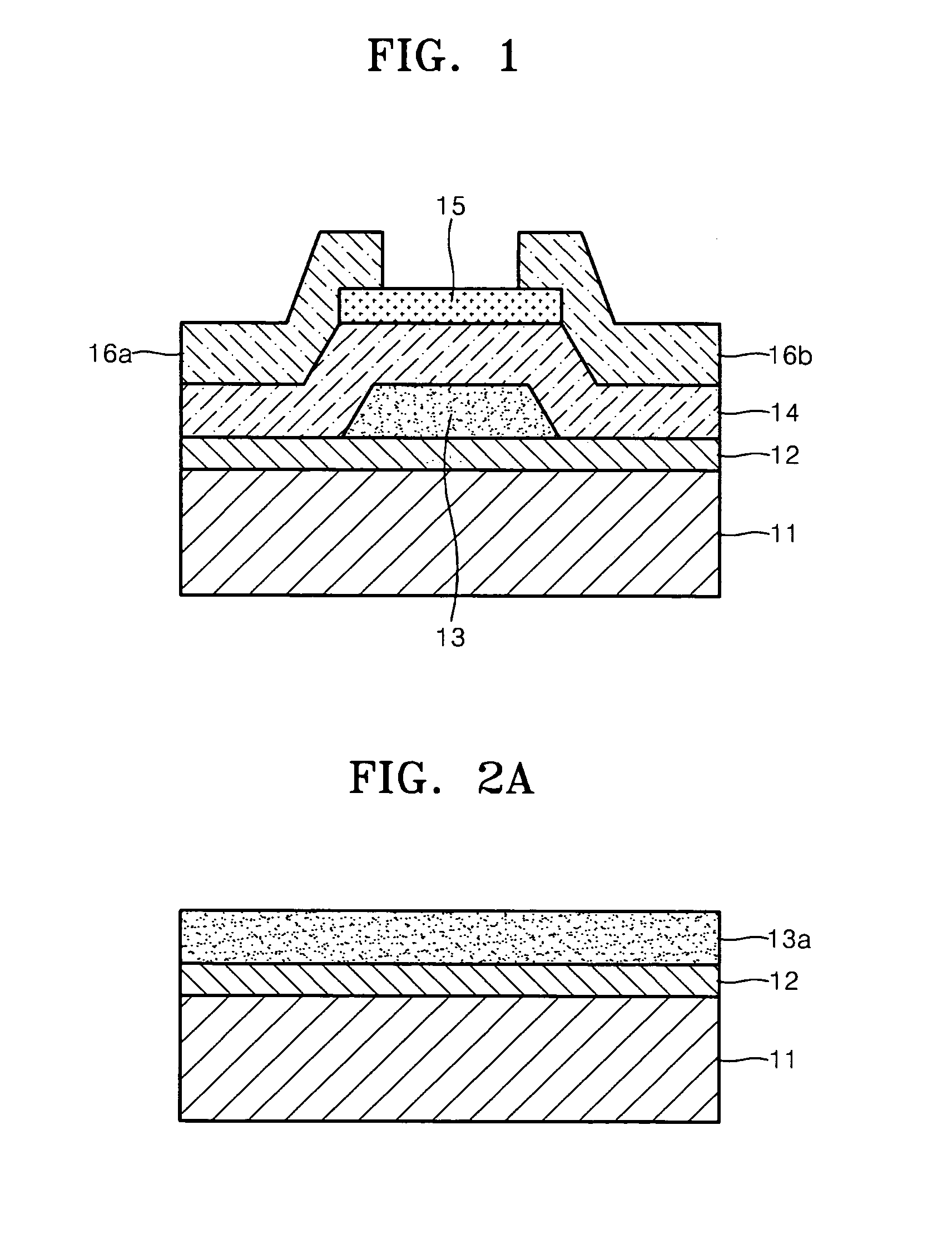

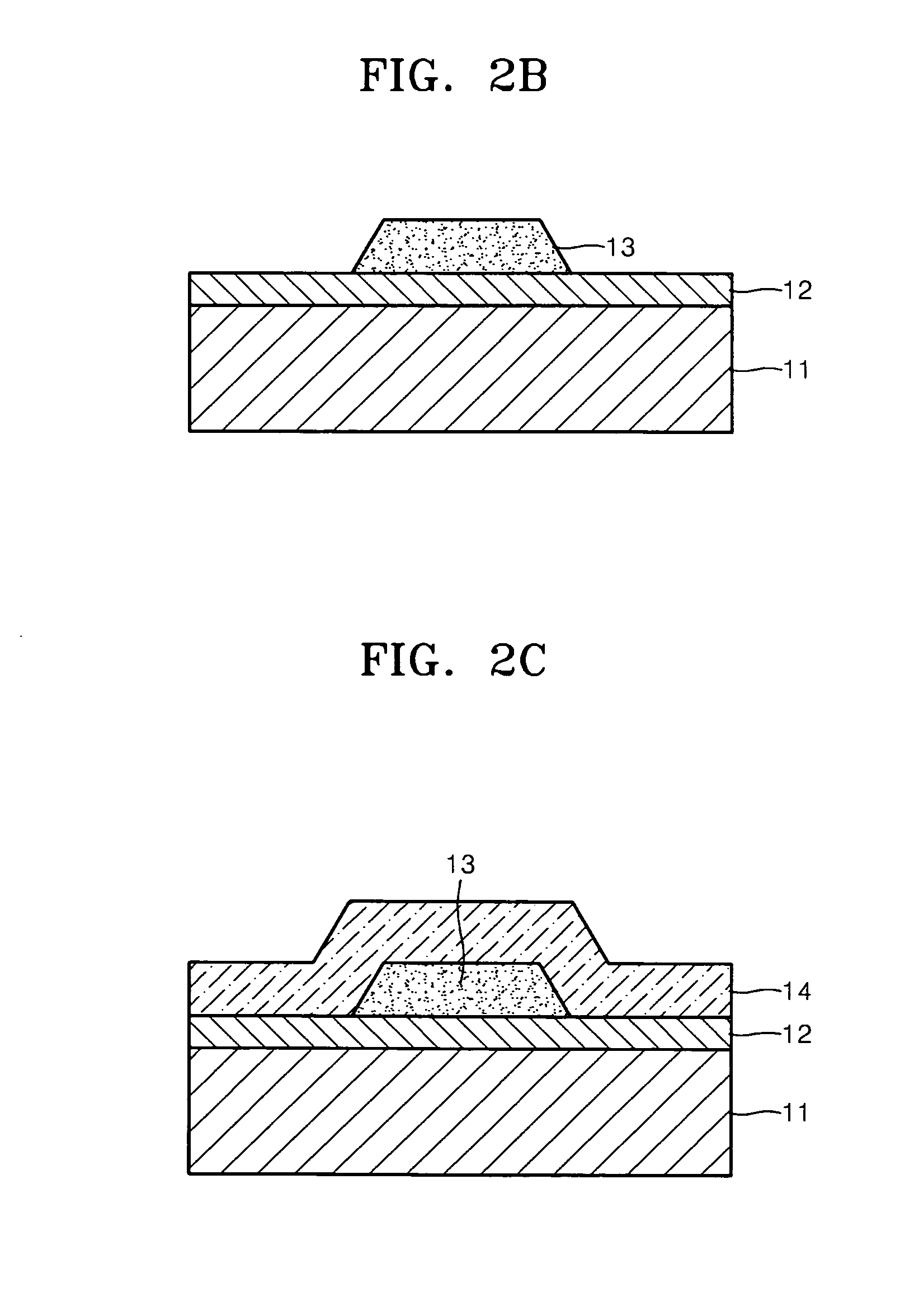

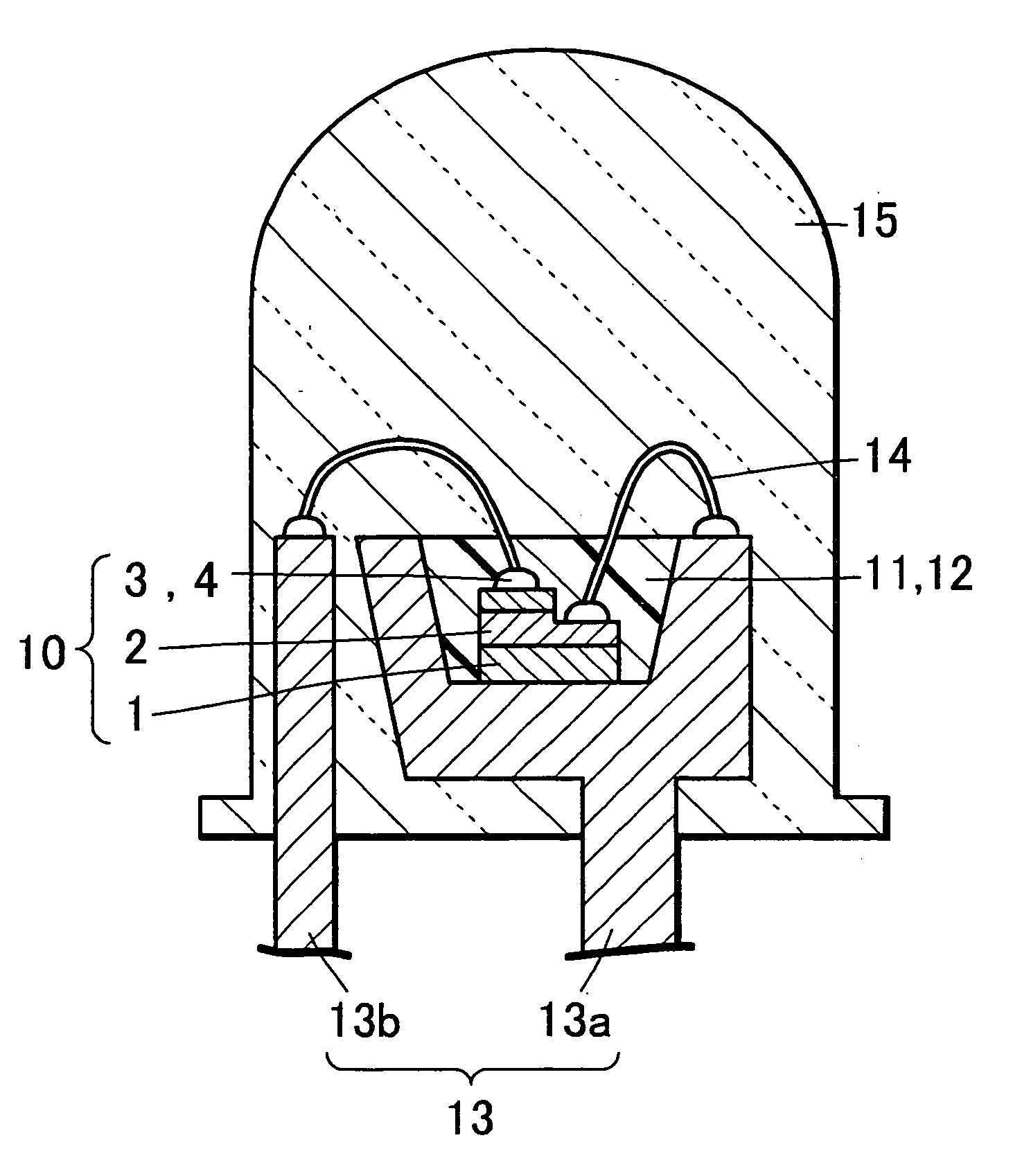

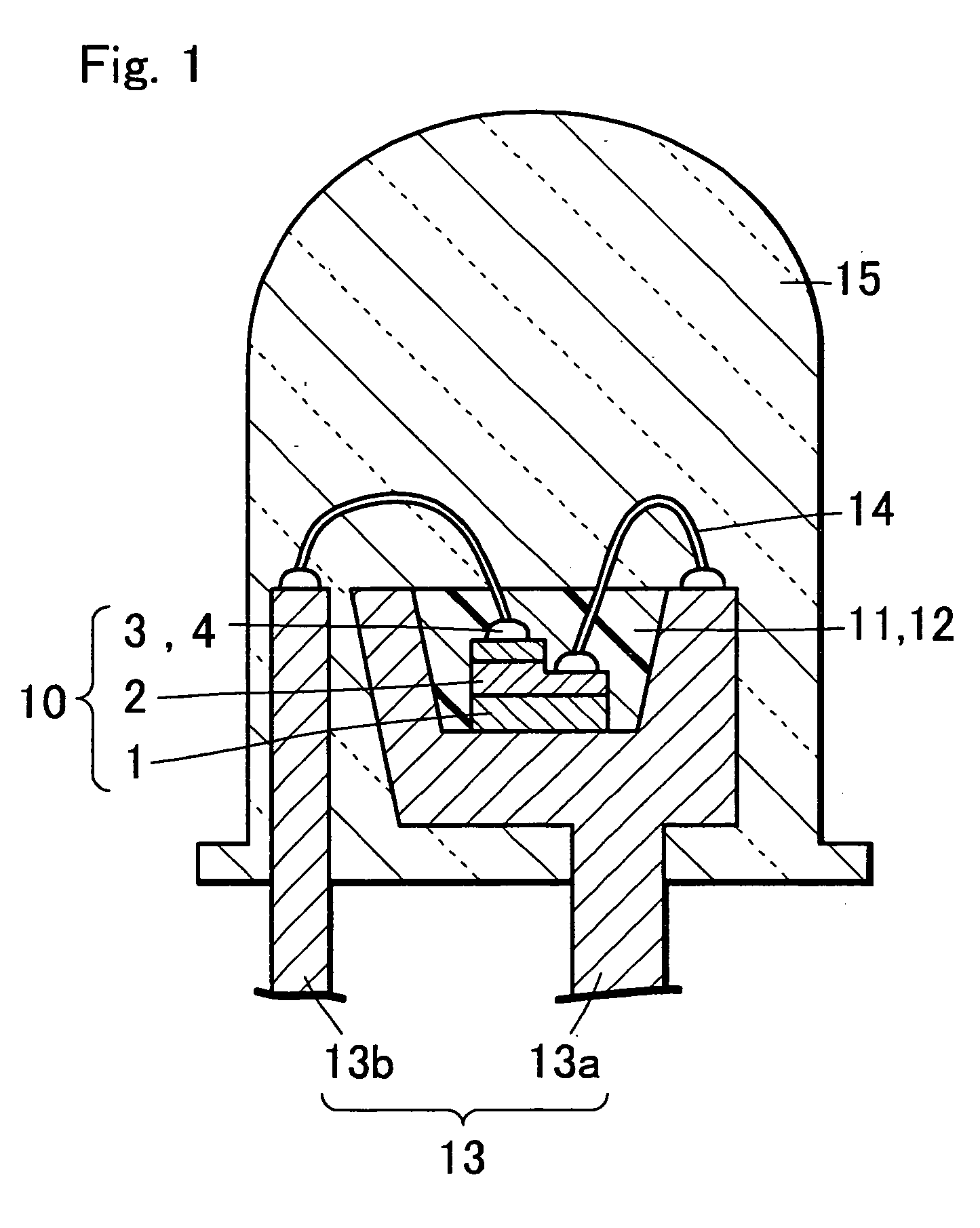

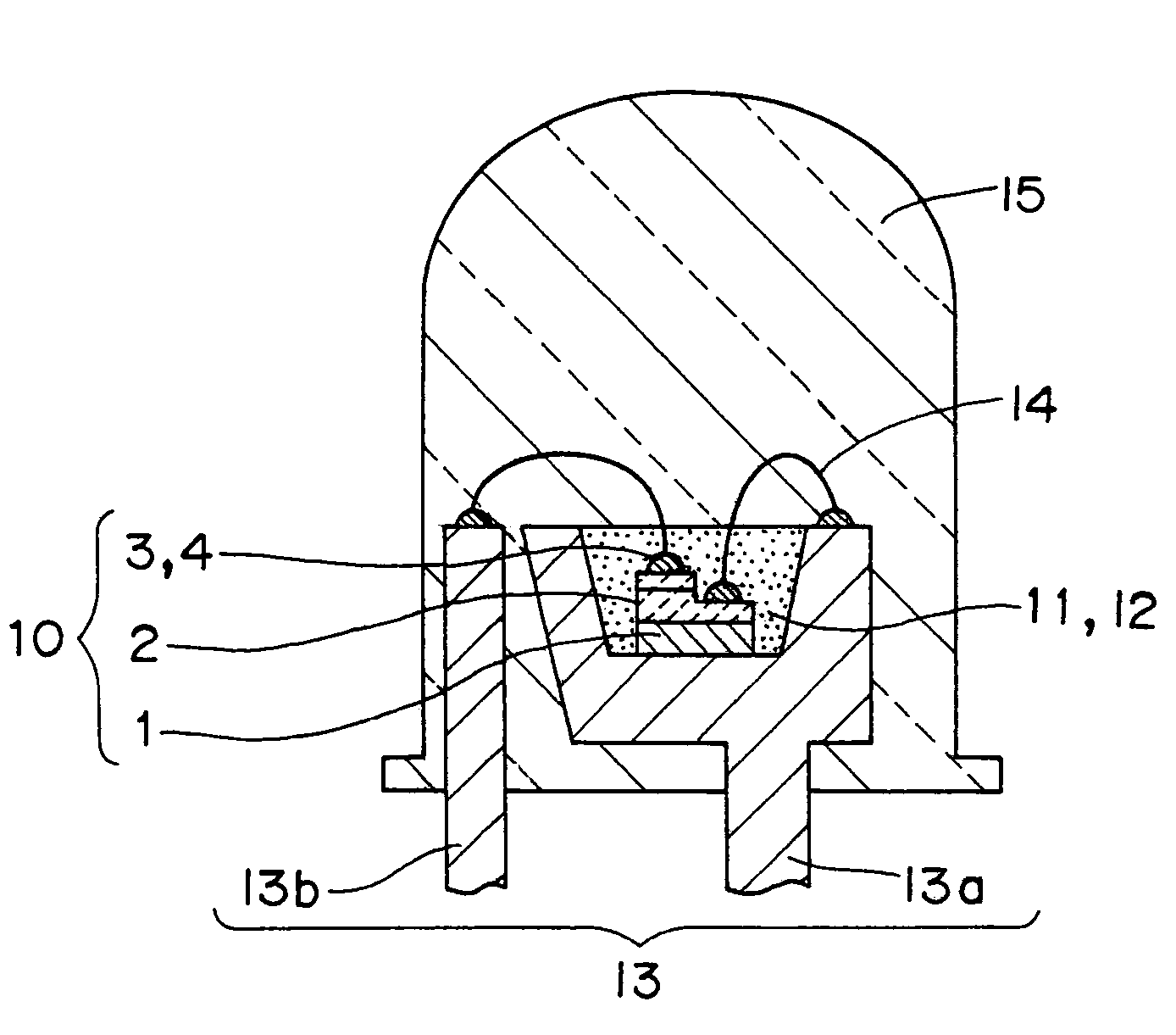

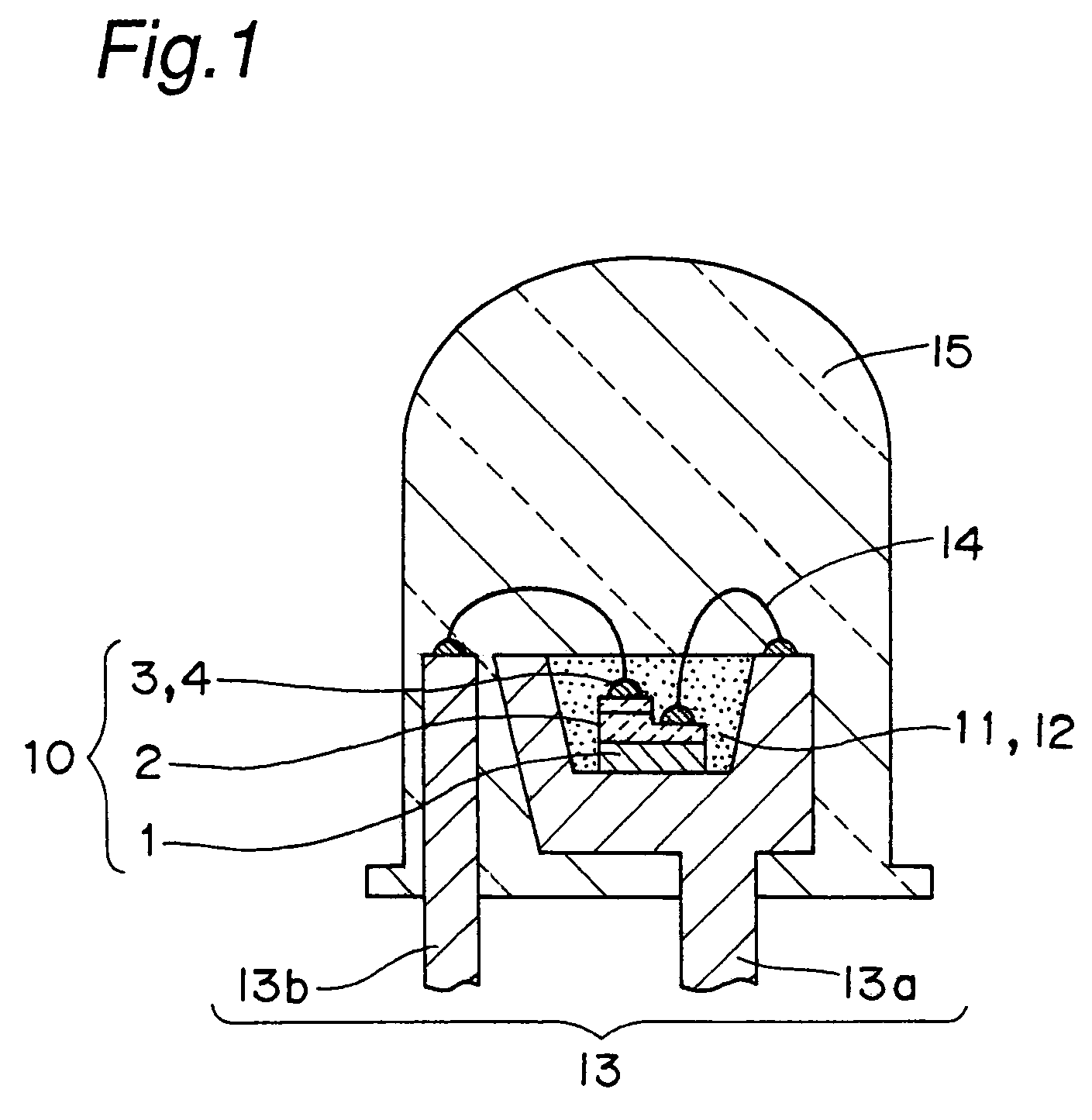

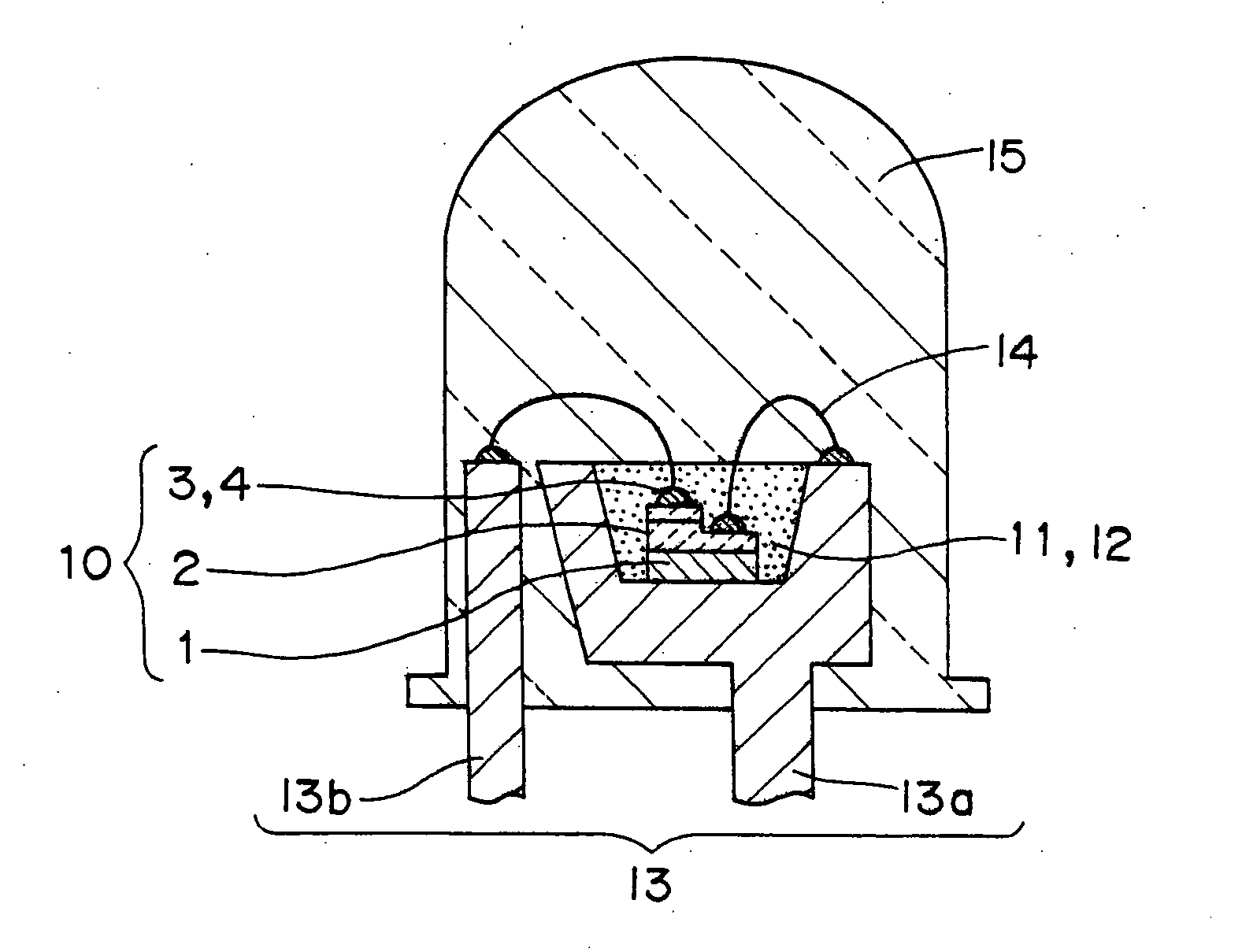

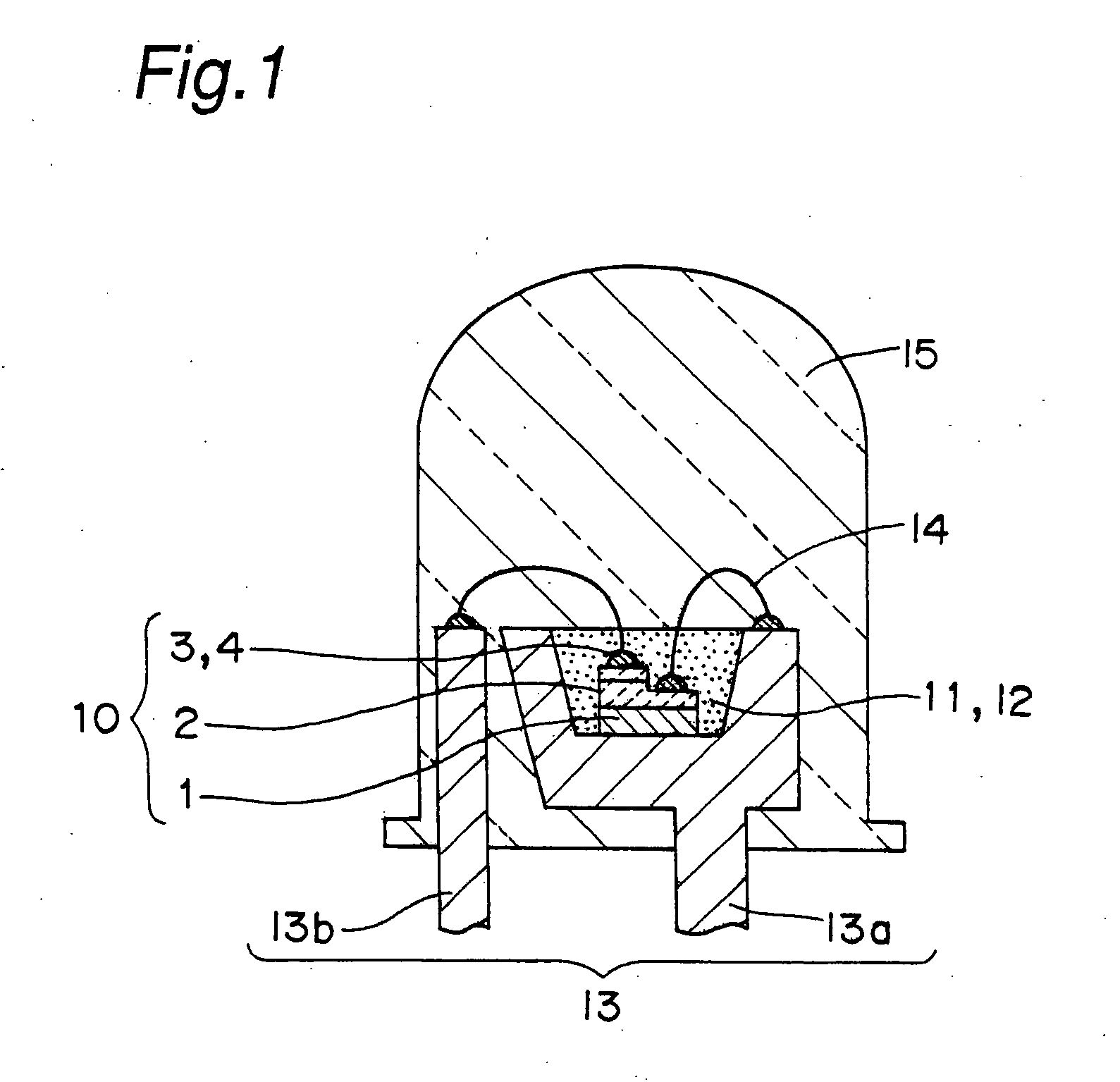

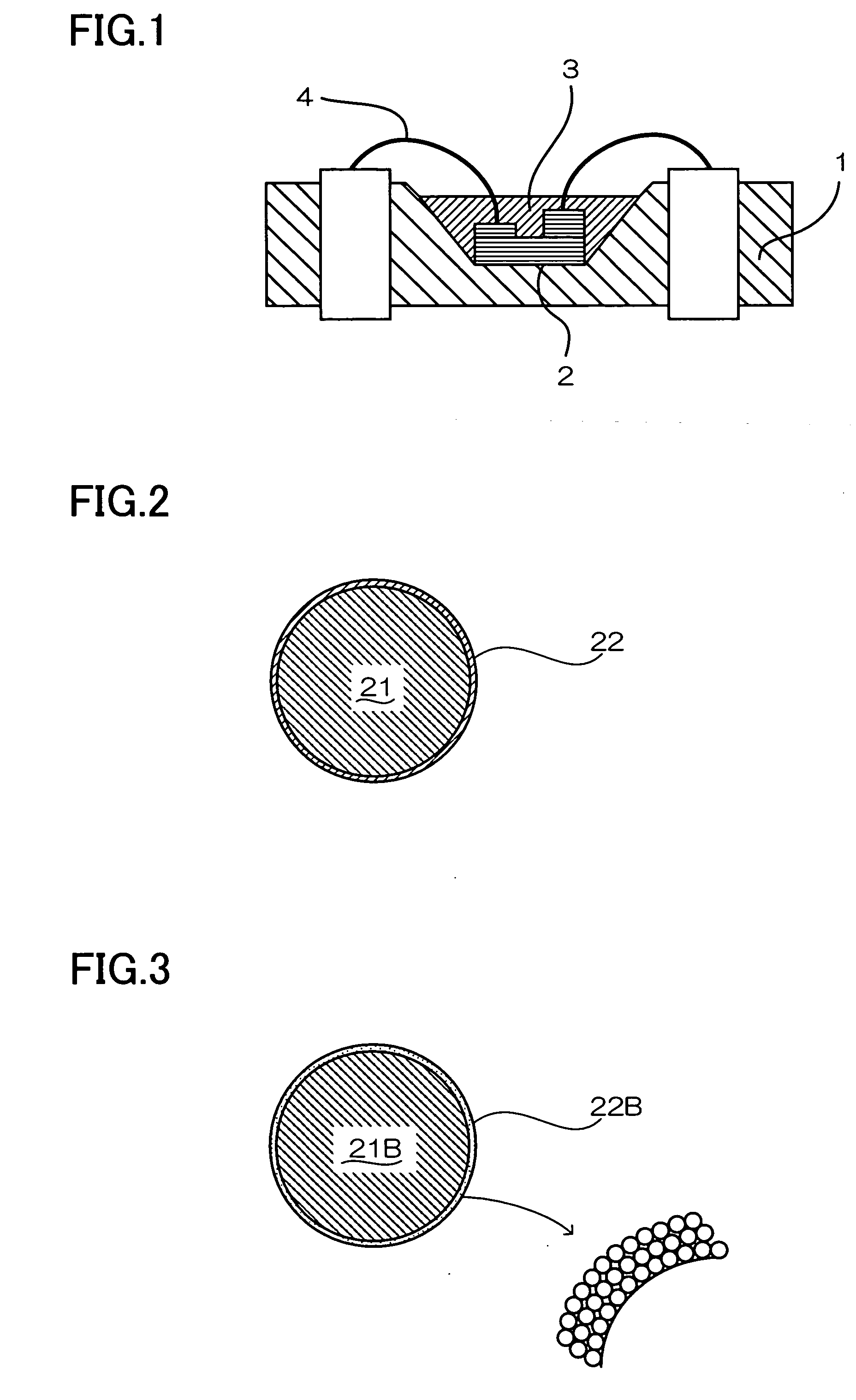

Light emitting apparatus and light emitting method

InactiveUS20050001225A1Improve propertiesIncrease brightnessSolid-state devicesBulk negative resistance effect devicesRare-earth elementSilicon nitride

A light emitting apparatus has a light emitting element with an emission wavelength in the range of 360 to 550 nm and a rare-earth element doped oxide nitride phosphor or cerium ion doped lanthanum silicon nitride phosphor. Part of light radiated from the light emitting element is wavelength-converted by the phosphor. The light emitting apparatus radiates white light generated by a mixture of the wavelength-converted light and the other part of light radiated from the light emitting element.

Owner:TOYODA GOSEI CO LTD +1

Oxide semiconductor, thin film transistor including the same and method of manufacturing a thin film transistor

InactiveUS20090008638A1Improve electrical performanceSemiconductor/solid-state device manufacturingSemiconductor devicesRare-earth elementGroup element

Example embodiments relate to an oxide semiconductor including zinc oxide (ZnO), a thin film transistor including a channel formed of the oxide semiconductor and a method of manufacturing the thin film transistor. The oxide semiconductor may include a GaxInyZnz oxide and at least one material selected from the group consisting of a 4A group element, a 4A group oxide, a rare earth element and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

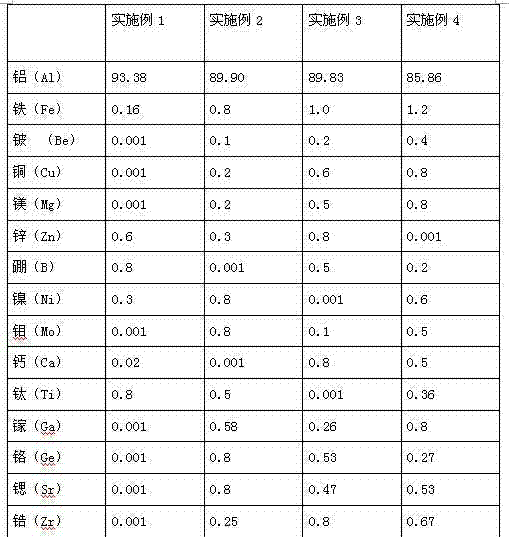

A kind of aluminum alloy material and preparation method thereof

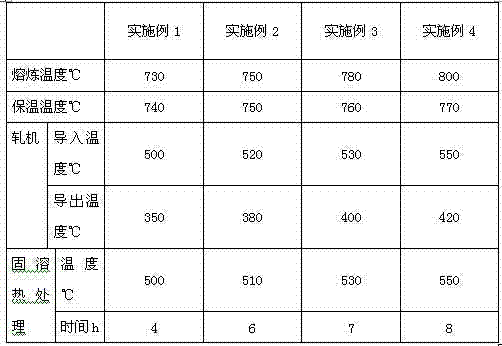

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

Oxynitide phosphor and production process thereof, and light-emitting device using oxynitride phosphor

ActiveUS20060076883A1Good colorImprove luminous performanceDischarge tube luminescnet screensLamp detailsRare-earth elementFluorescence

An oxynitride phosphor consisting of a crystal containing at least one or more of Group II elements selected from the group consisting of Be, Mg, Ca, Sr, Ba and Zn, at least one or more of Group IV elements selected from the group consisting of C, Si, Ge, Sn, Ti, Zr and Hf, and a rare earth element being an activator R, thereby providing a phosphor which is excited by an excitation light source at an ultraviolet to visible light region and which has a blue green to yellow luminescence color that is wavelength converted.

Owner:NICHIA CORP

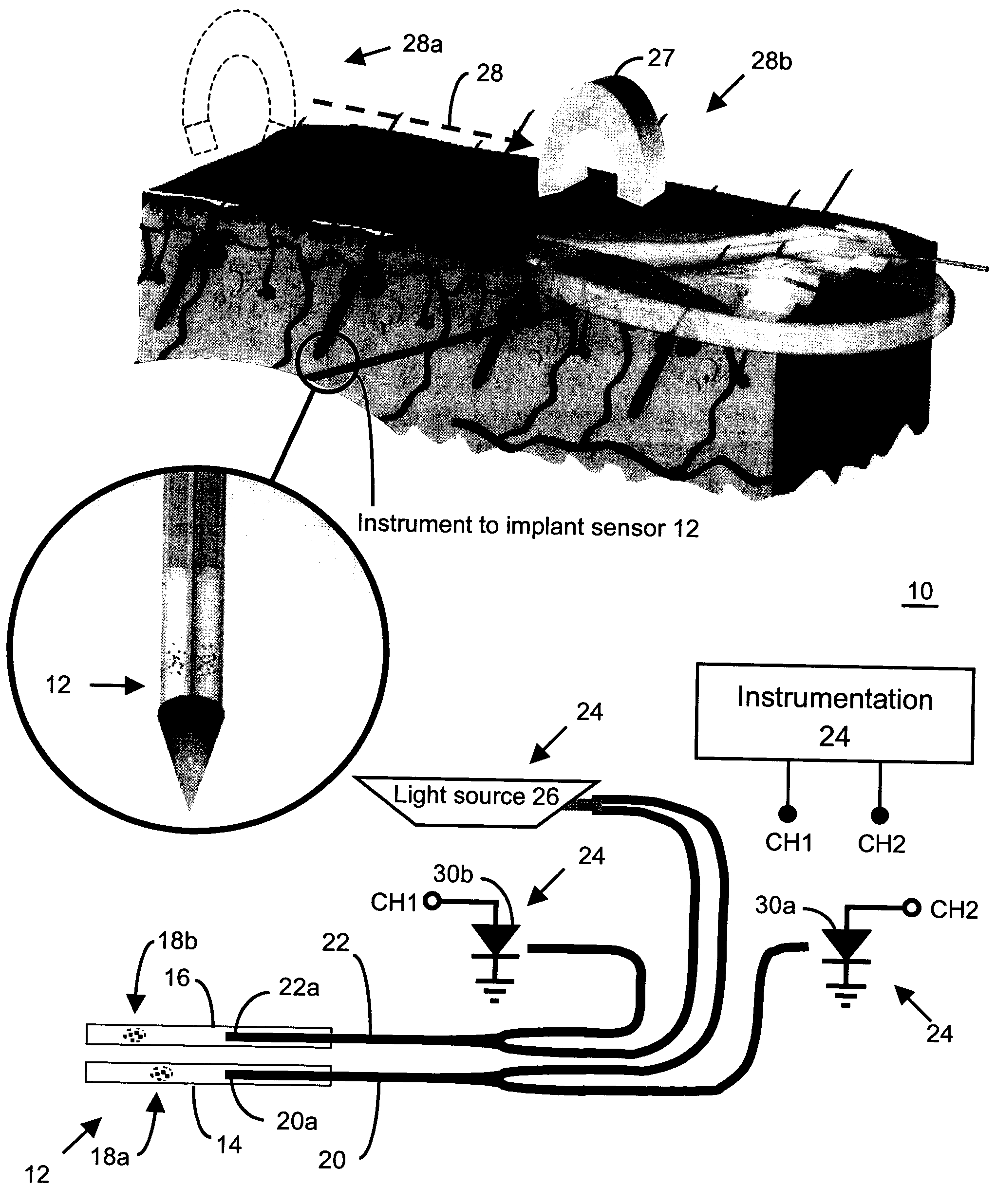

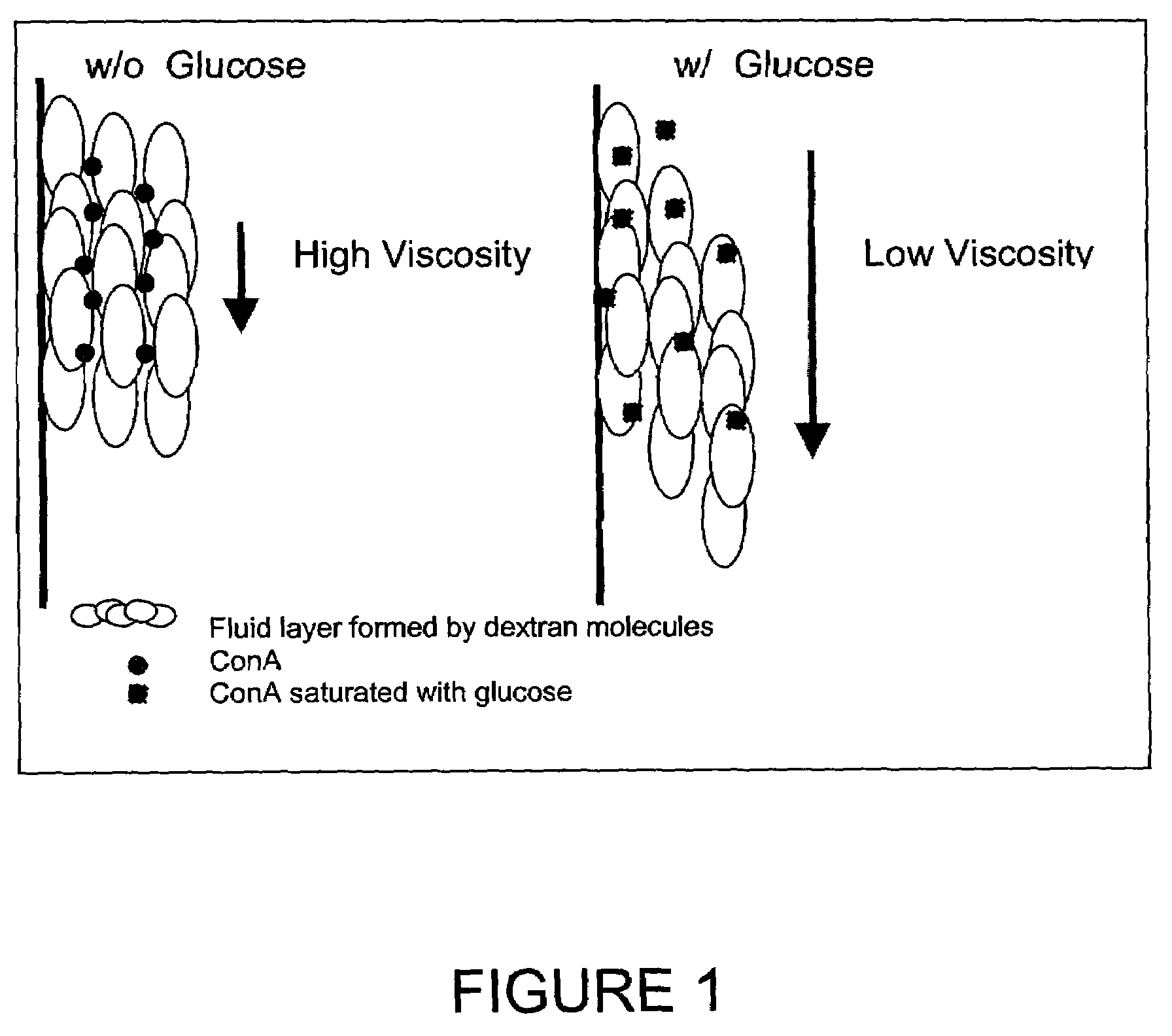

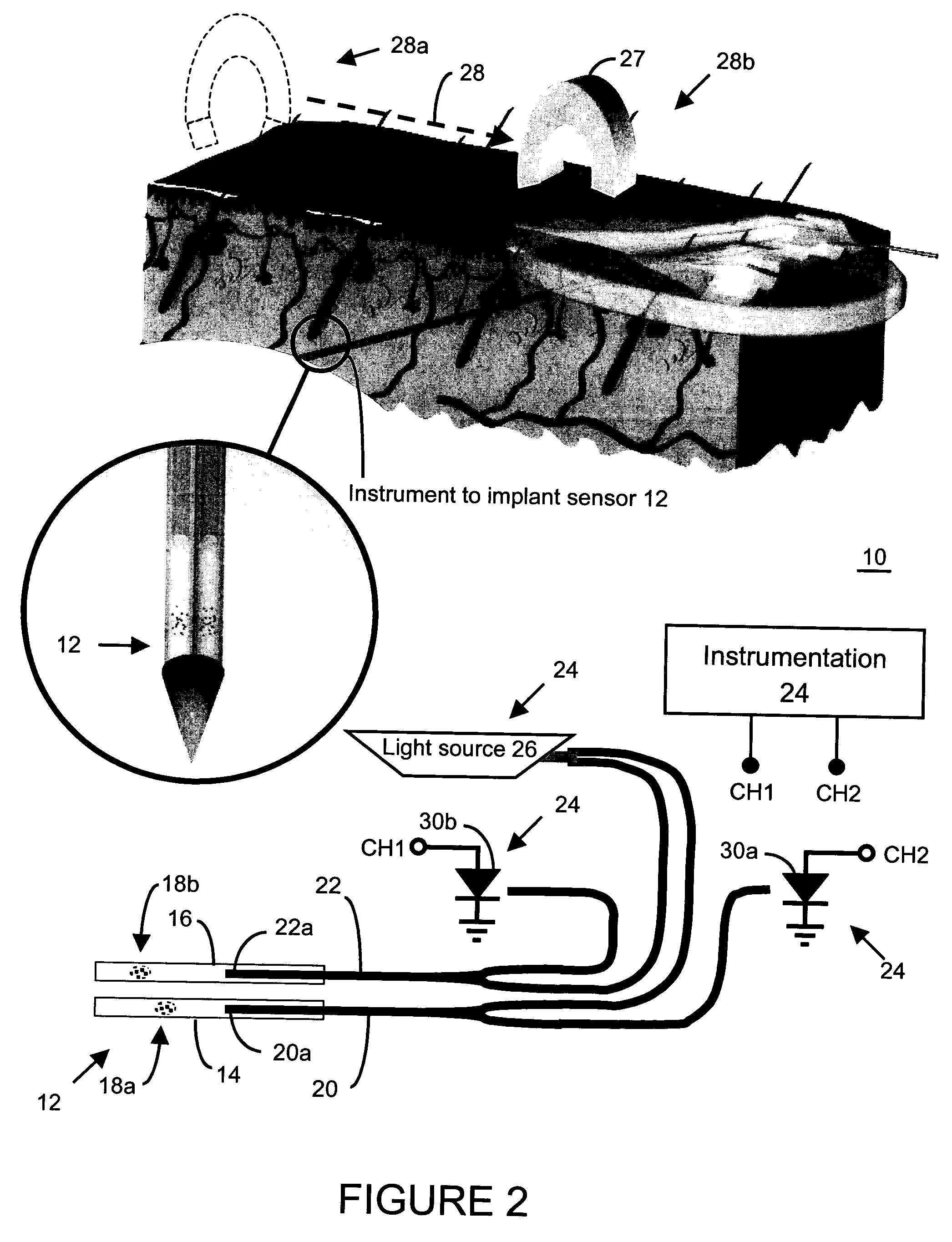

Method and apparatus for analyte sensing

InactiveUS7226414B2Reducing dispersion viscosityLow viscosityCatheterDiagnostic recording/measuringRare-earth elementEngineering

In one aspect, the present invention is directed to a glucose sensing device for implantation within subcutaneous tissue of an animal body. In one embodiment, the glucose sensing device includes a first chamber containing first magnetic particles and a hydrocolloid solution (for example, ConA-dextran hydrocolloid) wherein the first magnetic particles are dispersed in the hydrocolloid solution. In operation, glucose within the animal may enter and exit the first chamber and the hydrocolloid solution changes in response to the presence or concentration of glucose within the first chamber. The sensing device also includes a reference chamber containing second magnetic particles and a reference solution wherein the second magnetic particles are dispersed in the reference solution. The reference solution (for example, oil or alcohol compounds) includes a known or fixed viscosity. The reference solution may also be a hydrocolloid solution (for example, ConA-dextran hydrocolloid). The first and / or second magnetic particles may include amine-terminated particles, at least one rare earth element (for example, neodymium or samarium), and / or a ferromagnetic material.

Owner:BIOTEX

Method of producing conjugated diene polymers with narrow molecular weight distribution and polymer produced

Conjugated diene polymers having good wear resistance, mechanical properties, storage stability, processability and a reduced cold flow are produced by polymerizing a conjugated diene compound with a catalyst of rare earth element compound, a compound containing at least one halogen atom, an aluminoxane, and an organoaluminum compound in an organic solvent and reacting the resulting polymer just after the polymerization with at least one compound selected from the group consisting of a halogenated organometallic compound, a halogenated metal compound, an organometallic compound, a heterocumulene compound, a hetero three-membered-ring containing compound, a halogenated isocyano compound, a carboxylic acid, an acid halide, an ester compound, a carbonic ester compound, an acid anhydride and a metal salt of a carboxylic acid as a modifying agent.

Owner:JSR CORPORATIOON

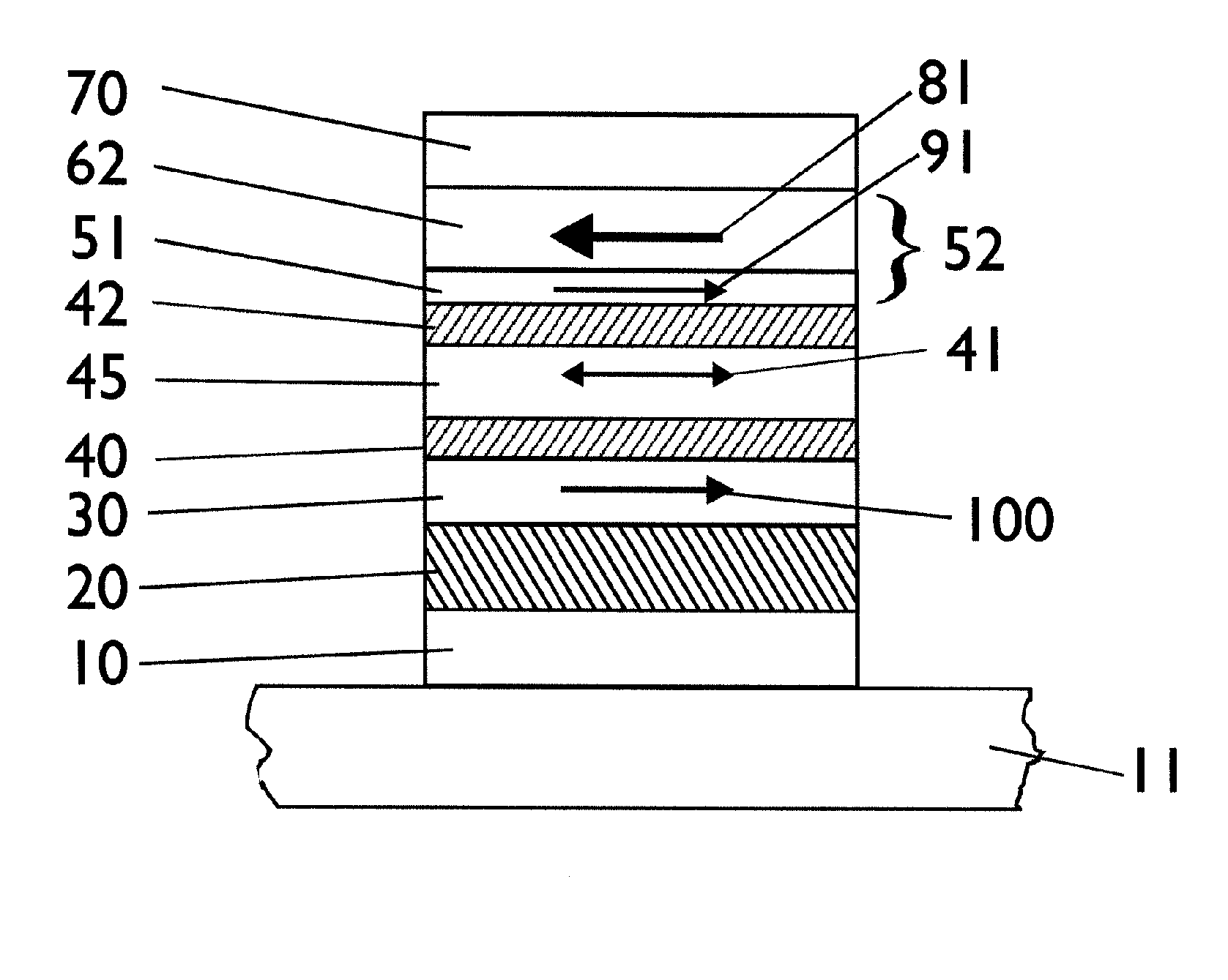

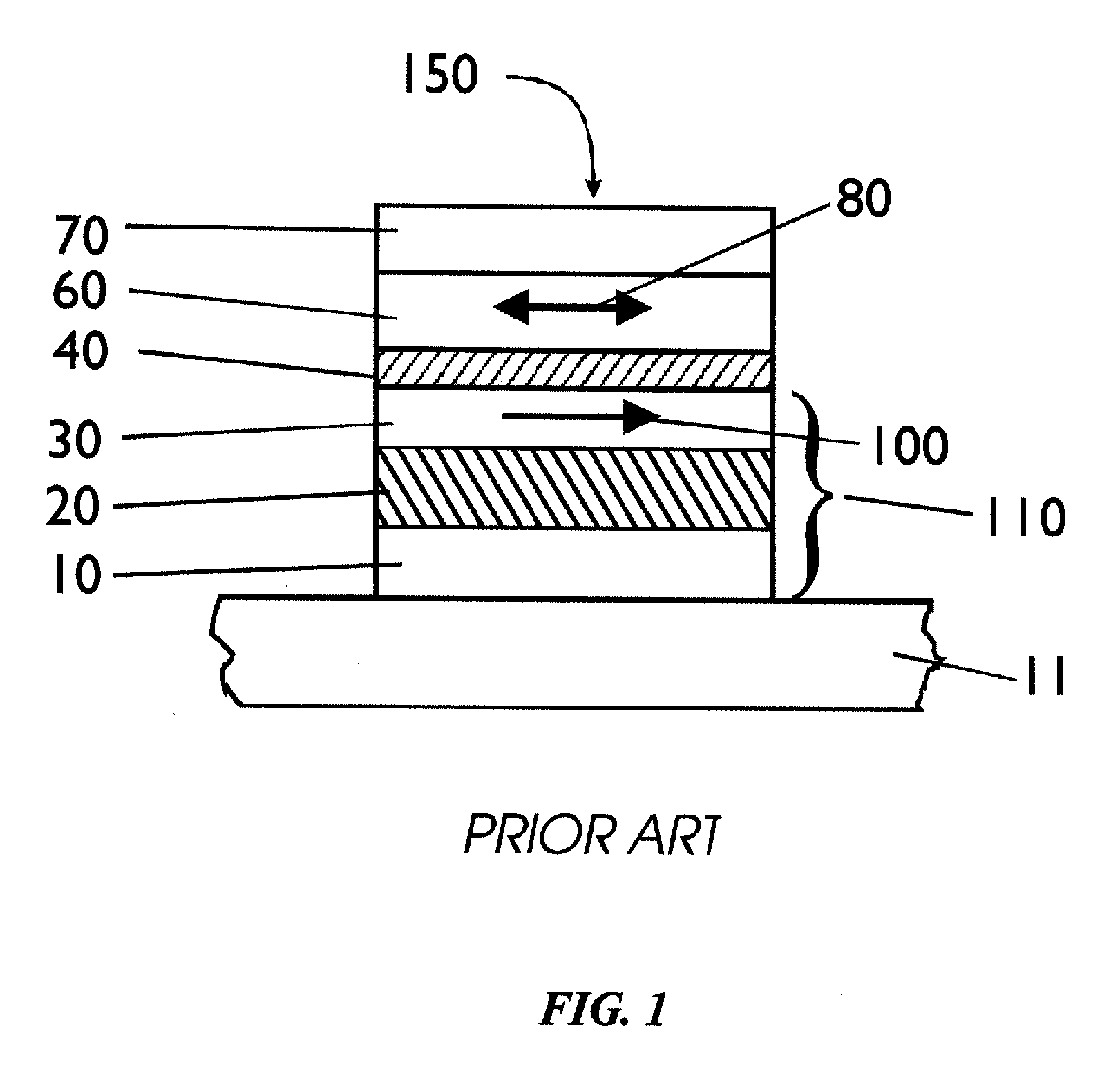

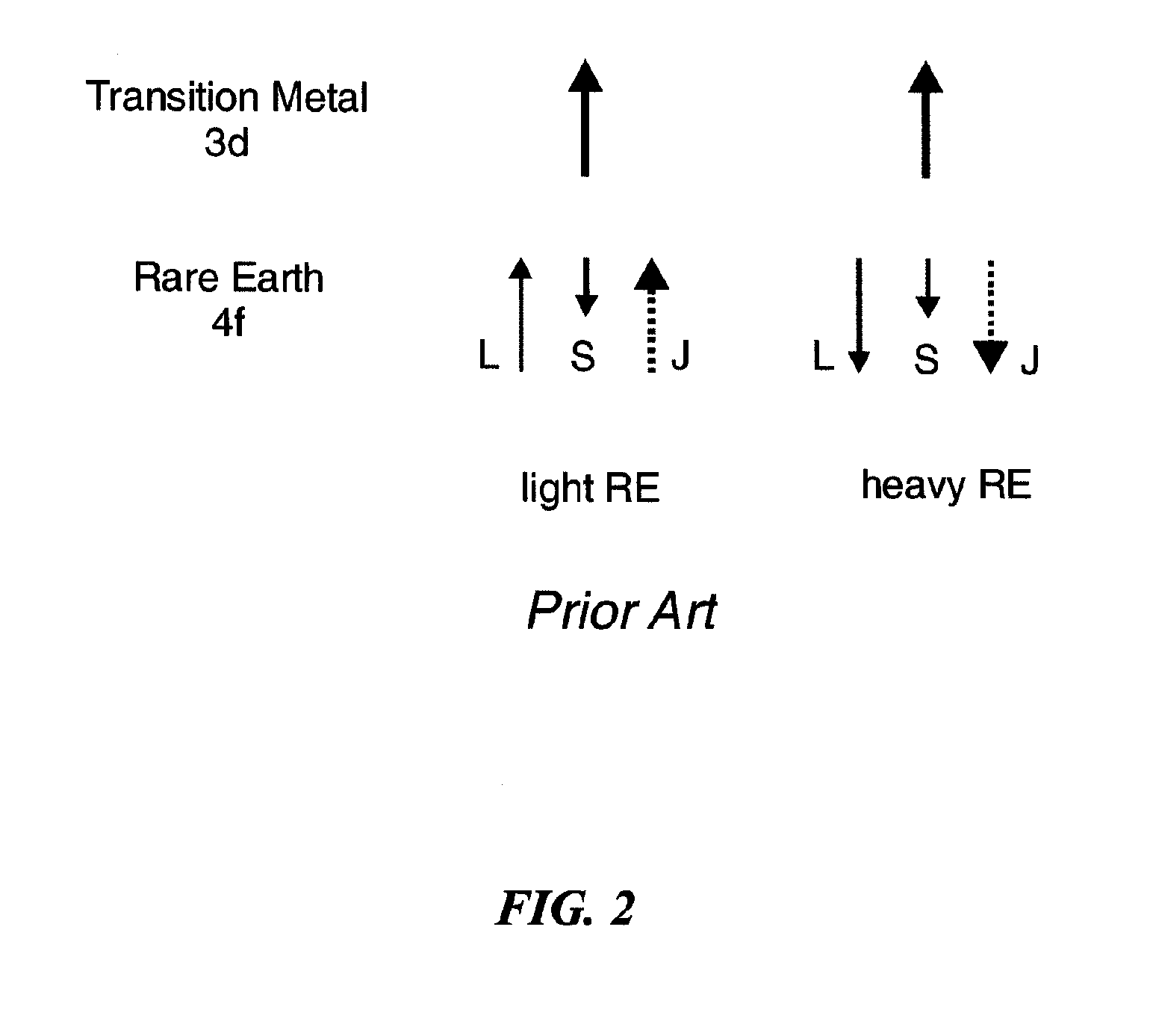

Spin-polarization devices using rare earth-transition metal alloys

ActiveUS7230265B2Magnetic-field-controlled resistorsGalvano-magnetic material selectionRare-earth elementMetal alloy

A tunnel barrier in proximity with a layer of a rare earth element-transition metal (RE—TM) alloy forms a device that passes negatively spin-polarized current. The rare earth element includes at least one element selected from the group consisting of Gd, Tb, Dy, Ho, Er, Tm, and Yb. The RE and TM have respective sub-network moments such that the absolute magnitude of the RE sub-network moment is greater than the absolute magnitude of the TM sub-network moment. An additional layer of magnetic material may be used in combination with the tunnel barrier and the RE—TM alloy layer to form a magnetic tunnel junction. Still other layers of tunnel barrier and magnetic material may be used in combination with the foregoing to form a flux-closed double tunnel junction device.

Owner:IBM CORP

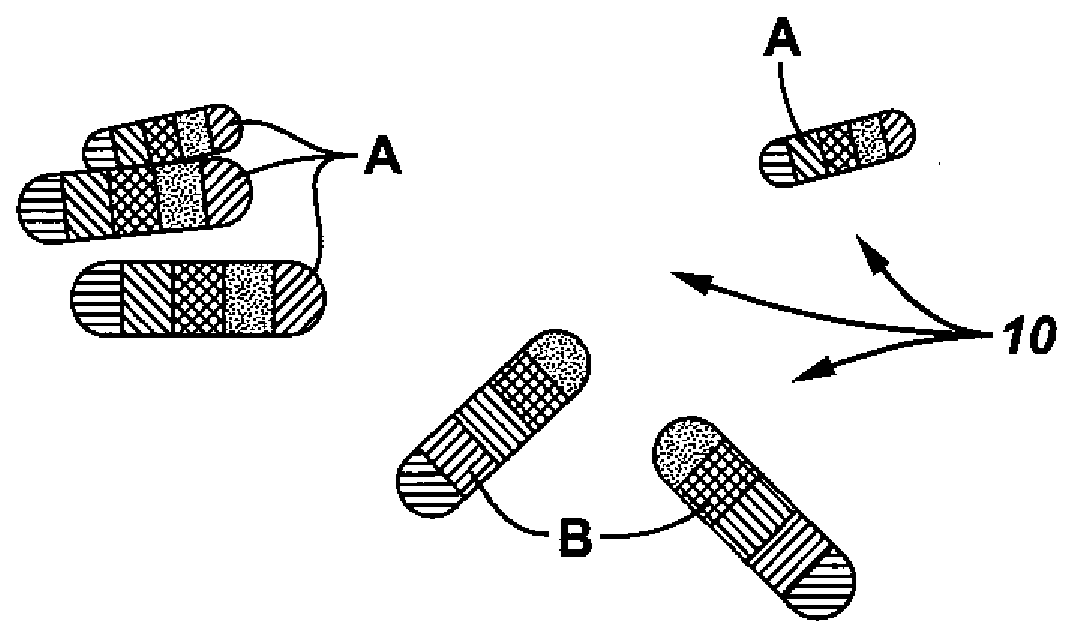

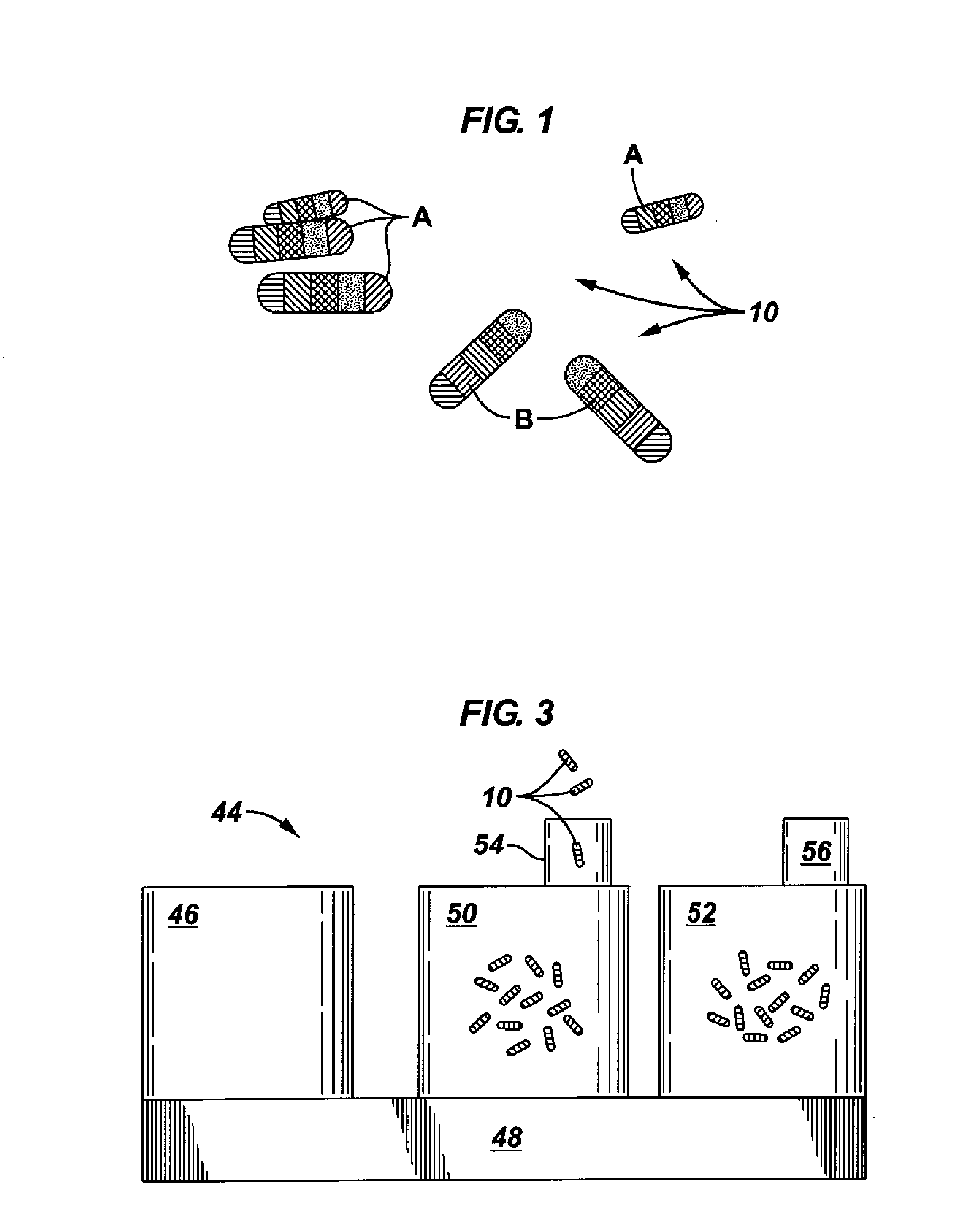

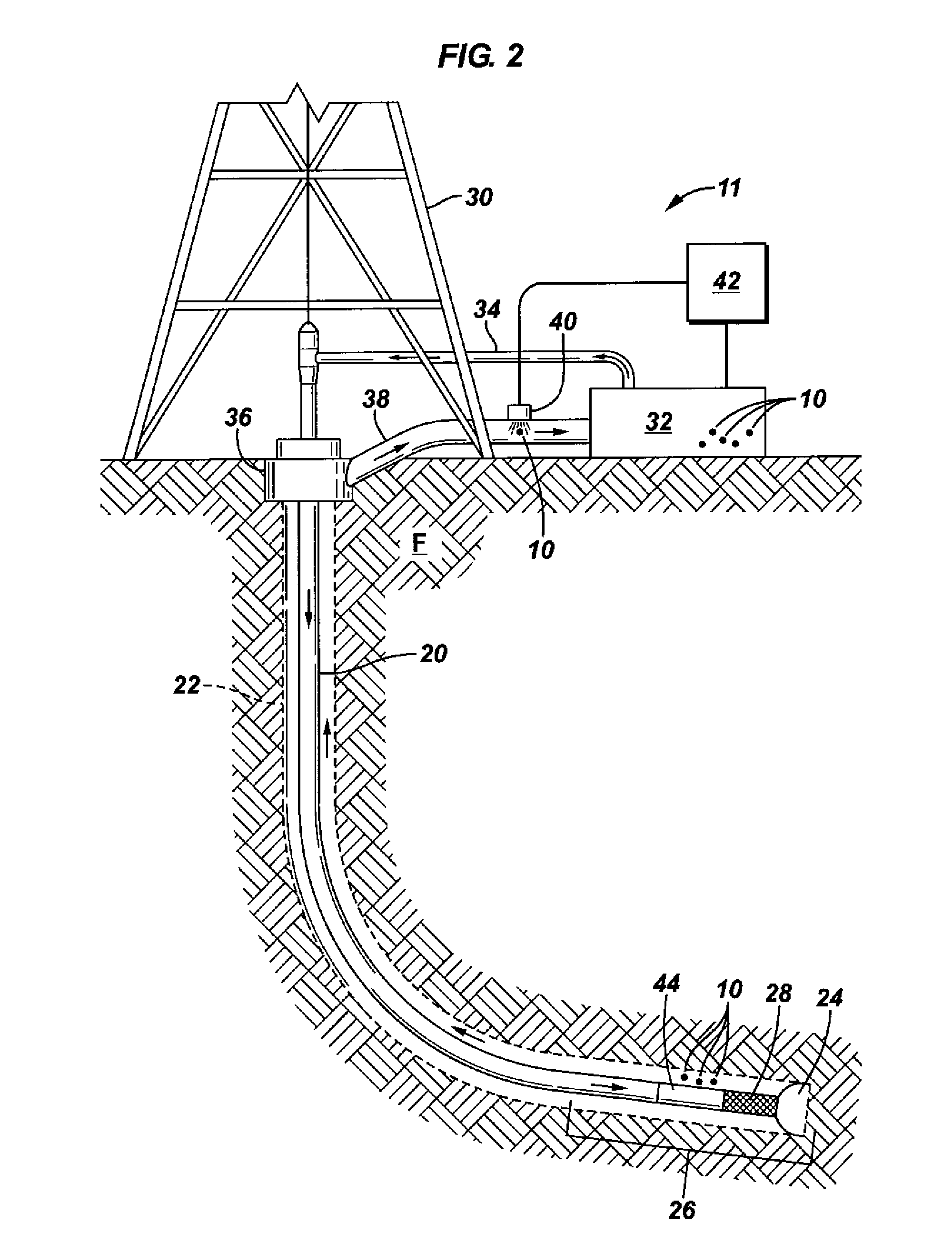

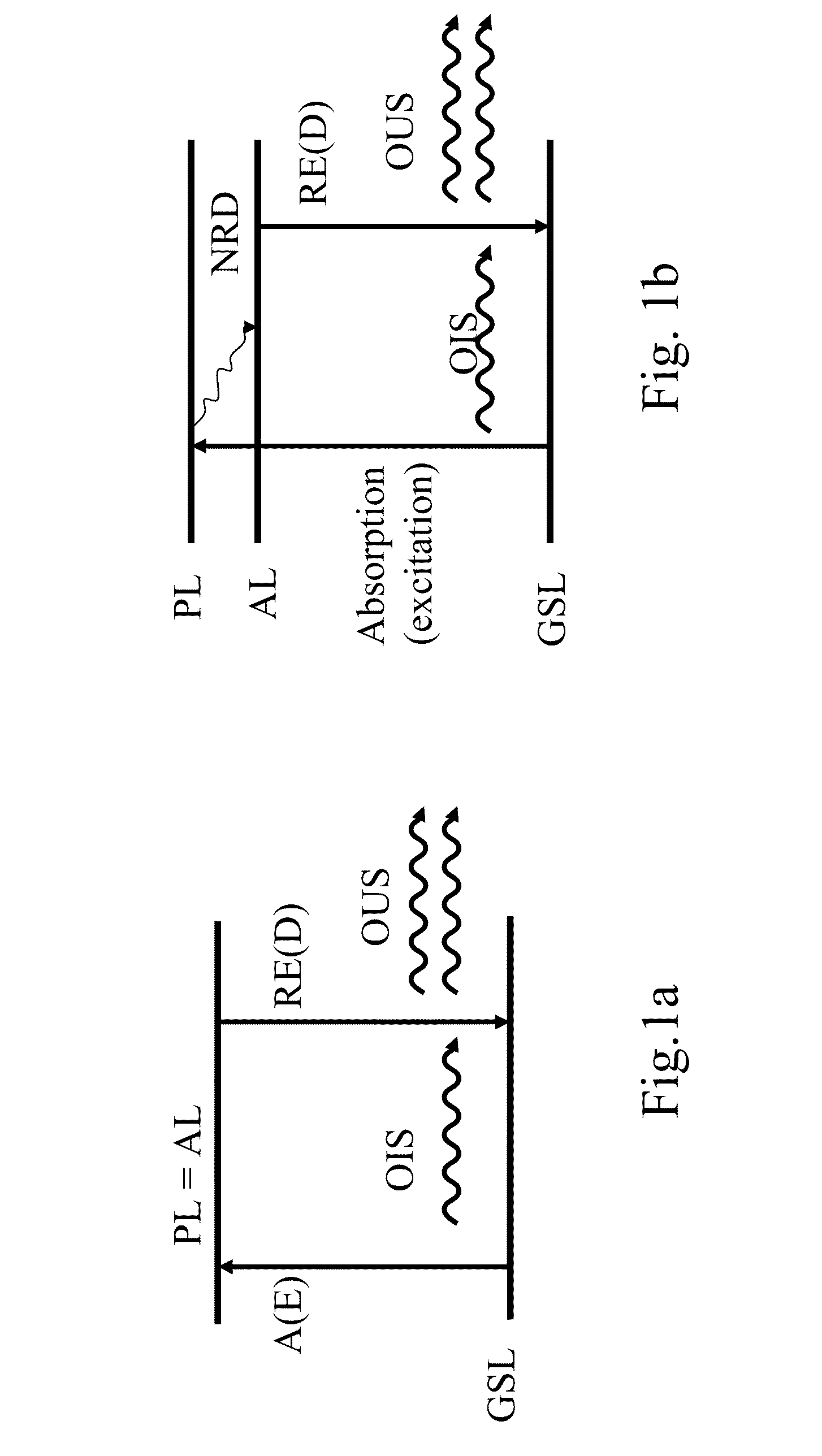

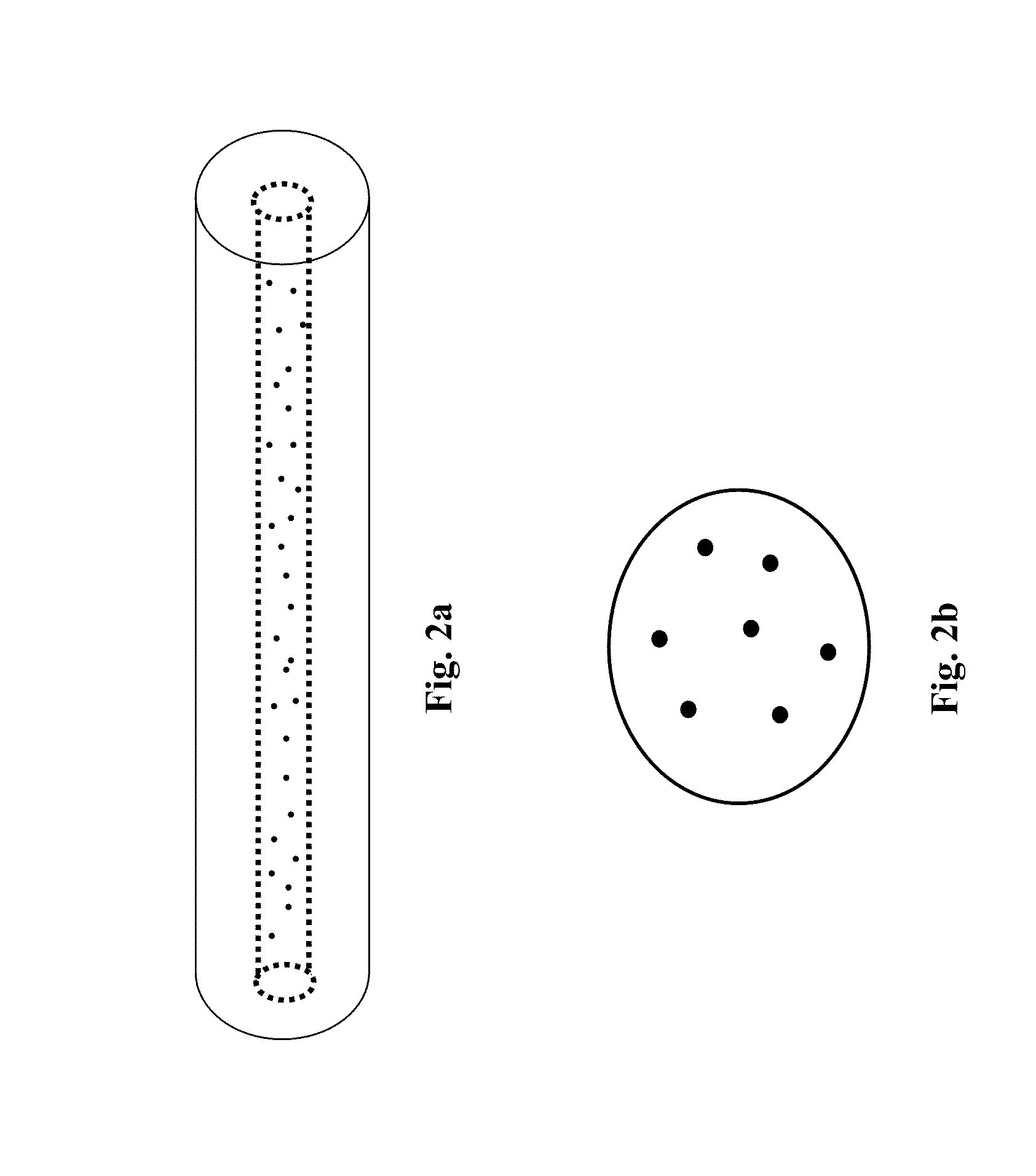

Tagged particles for downhole application

A tagged object includes a main body and a plurality of coded particles. Each coded particle may have a miniature body and be configured to provide a resolvable optical emission pattern when illuminate. The plurality of coded particles may be immobilized to the main body. A method for performing oilfield monitoring may include disposing of different types of tagged objects at different locations, wherein the different types of tagged objects each comprise a plurality of coded particles. Each of the coded particles may have a miniature body containing rare earth elements configured to produce a unique optical emission pattern when illuminated. The method may include allowing an event to trigger the release of one of the different types of tagged objects from one of the different locations. In addition, the method may include identifying the released tagged objects by unique optical emission patterns, in some cases in order to determining an occurrence location of the event.

Owner:SCHLUMBERGER TECH CORP

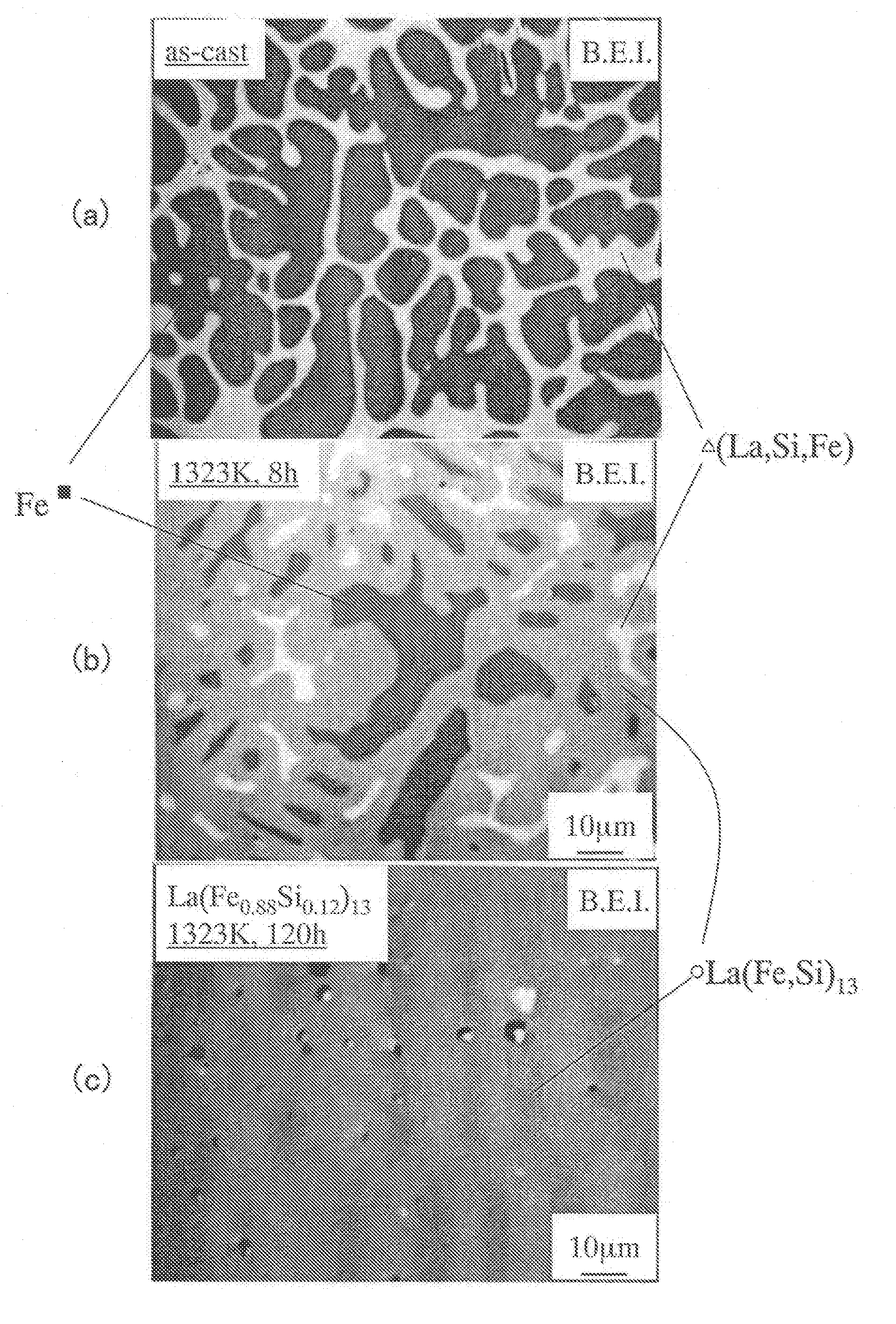

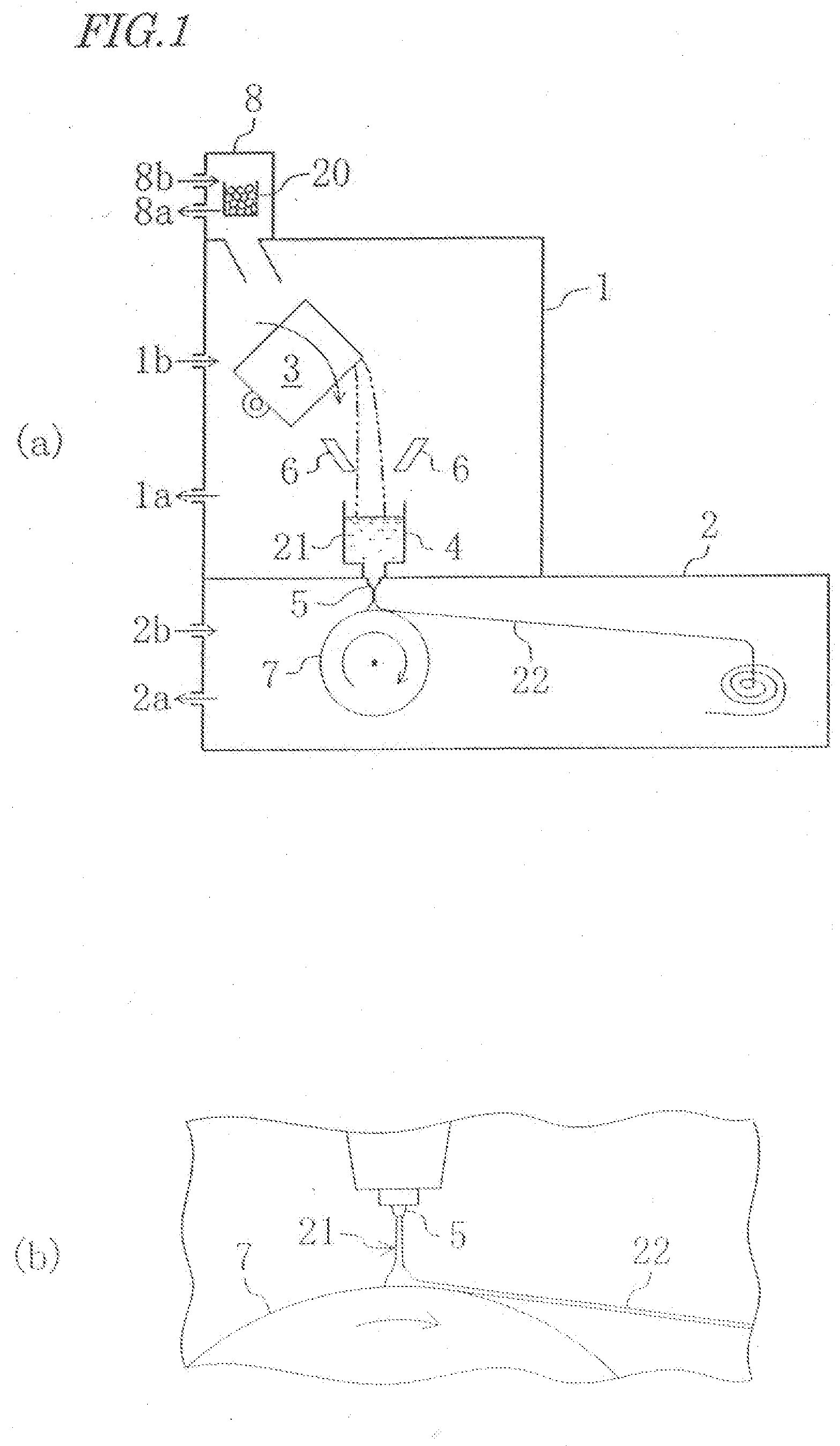

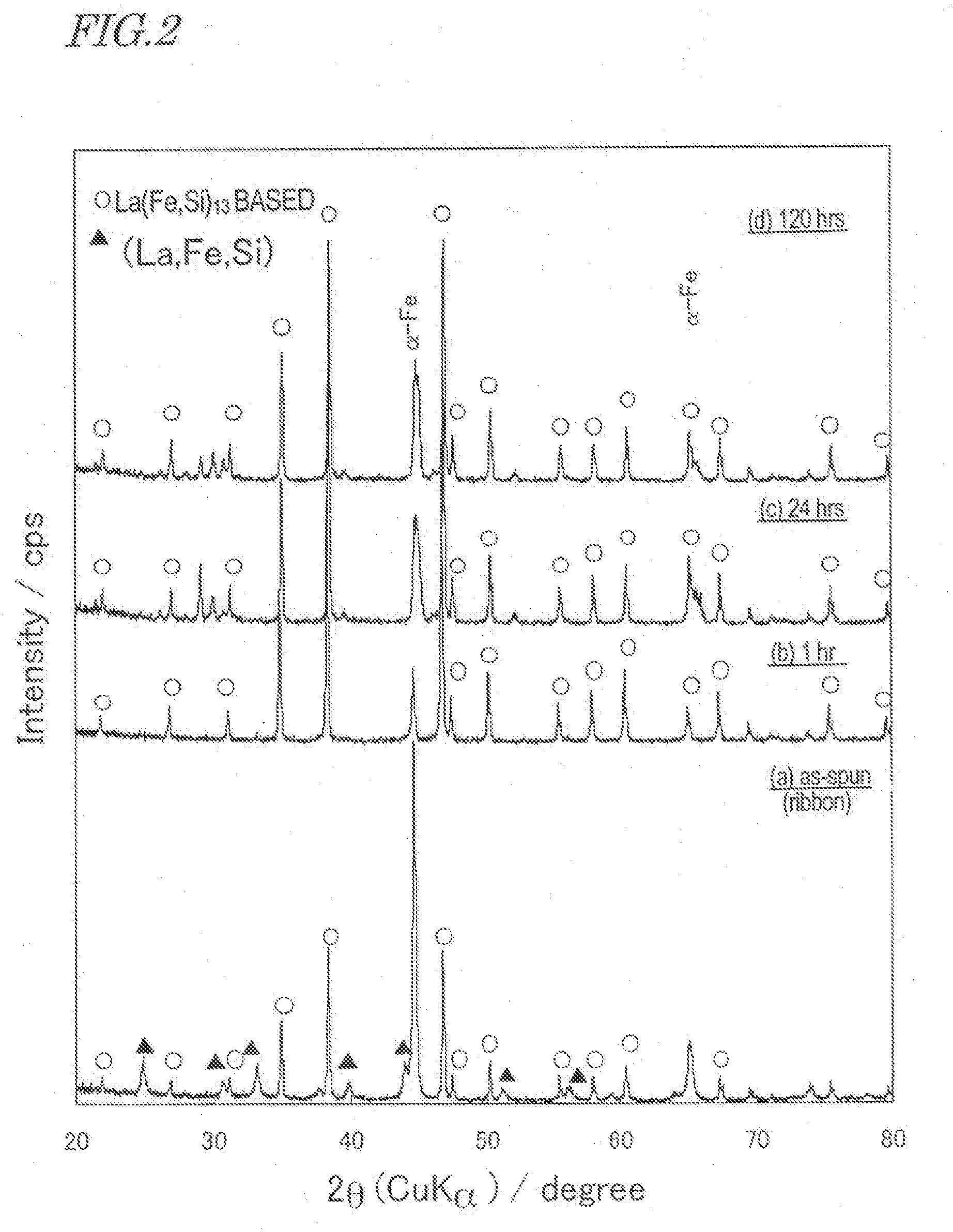

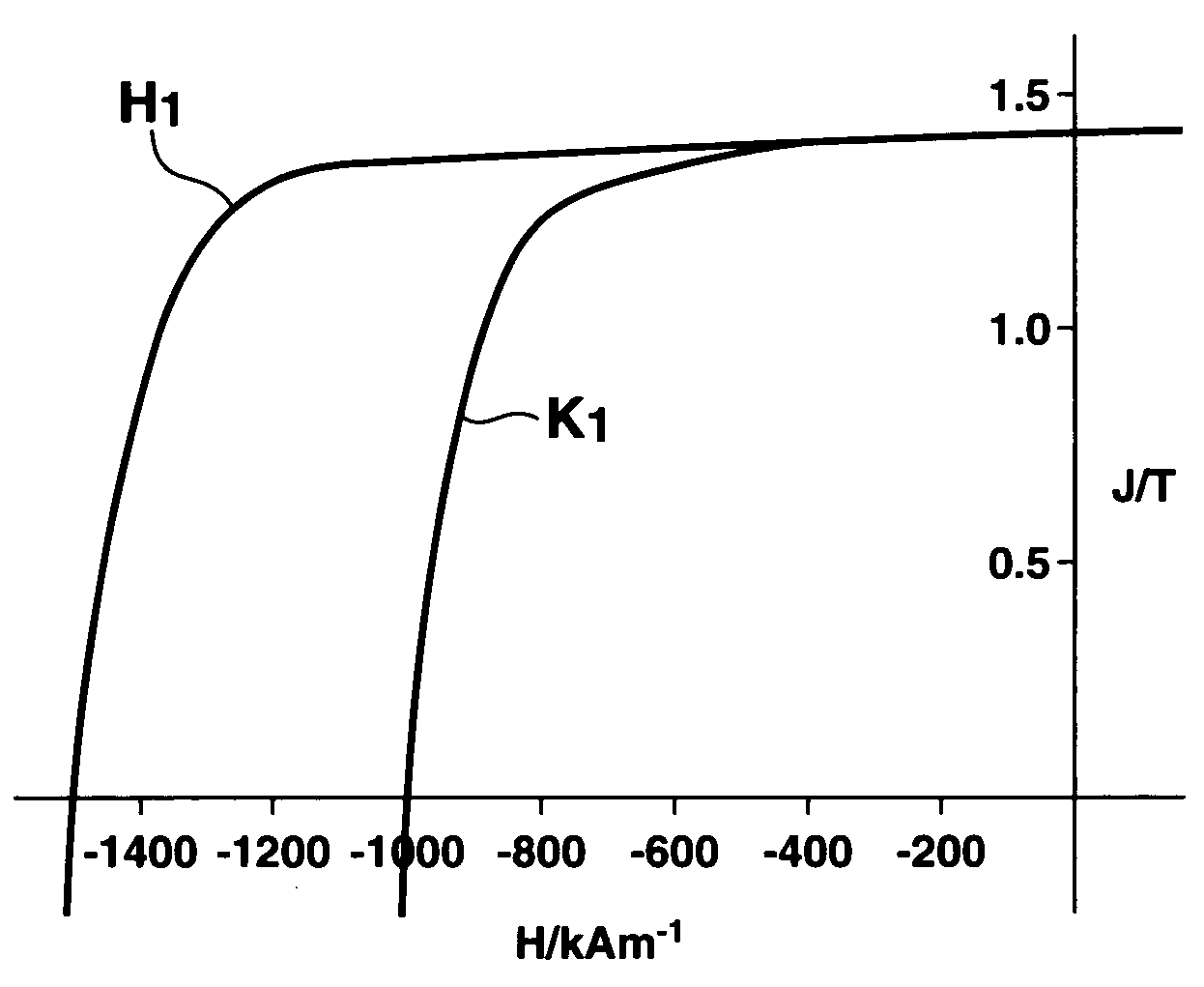

Magnetic alloy material and method of making the magnetic alloy material

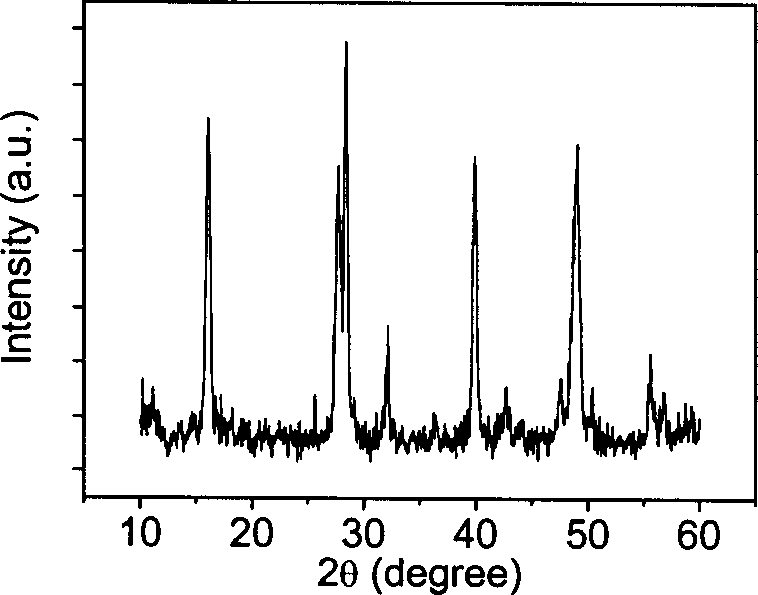

InactiveUS20060231163A1Short timeEasy to crushInorganic material magnetismRare-earth elementCrystal structure

A magnetic alloy material according to the present invention has a composition represented by Fe100-a-b-cREaAbCoc, where RE is a rare-earth element always including La, A is either Si or Al, 6 at %≦a≦11 at %, 8 at %≦b≦18 at %, and 0 at %≦c≦9 at %, and has either a two phase structure consisting essentially of an α-Fe phase and an (RE, Fe, A) phase including 30 at % to 90 at % of RE or a three phase structure consisting essentially of the α-Fe phase, the (RE, Fe, A) phase including 30 at % to 90 at % of RE and an RE(Fe, A)13 compound phase with an NaZn13-type crystal structure. The respective phases have an average minor-axis size of 40 nm to 2 μm.

Owner:HITACHI METALS LTD

Nitride phosphor and method for preparation thereof, and light emitting device

InactiveUS7258816B2High luminous efficiencyDifficult to generateDischarge tube luminescnet screensNitrogen compoundsRare-earth elementNitride phosphor

Owner:NICHIA CORP

Oxide films with nanodot flux pinning centers

InactiveUS20050159298A1Increasing critical current densitySimple and versatileMaterial nanotechnologyMolecular sieve catalystsNanodotRare-earth element

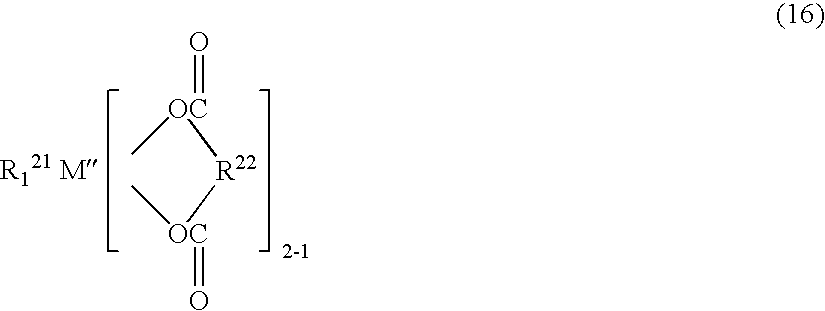

A method for producing a thin film includes disposing a precursor solution onto a substrate to form a precursor film. The precursor solution contains precursor components to a rare-earth / alkaline-earth-metal / transition-metal oxide including a salt of a rare earth element, a salt of an alkaline earth metal, and a salt of a transition metal in one or more solvents, wherein at least one of the salts is a fluoride-containing salt. The precursor solution also contains an additive component comprising one or more metal compounds capable of forming a second phase nanoparticle, either alone or in combination with one or more of the precursor components of the precursor solution or a dopant component comprising one or more metal compounds capable of substituting for an element of the rare-earth / alkaline-earth-metal / transition-metal oxide, and treating the precursor film to form an intermediate metal oxyfluoride including the rare earth, the alkaline earth metal, the transition metal and the additive metal or dopant metal of the precursor solution.

Owner:AMERICAN SUPERCONDUCTOR

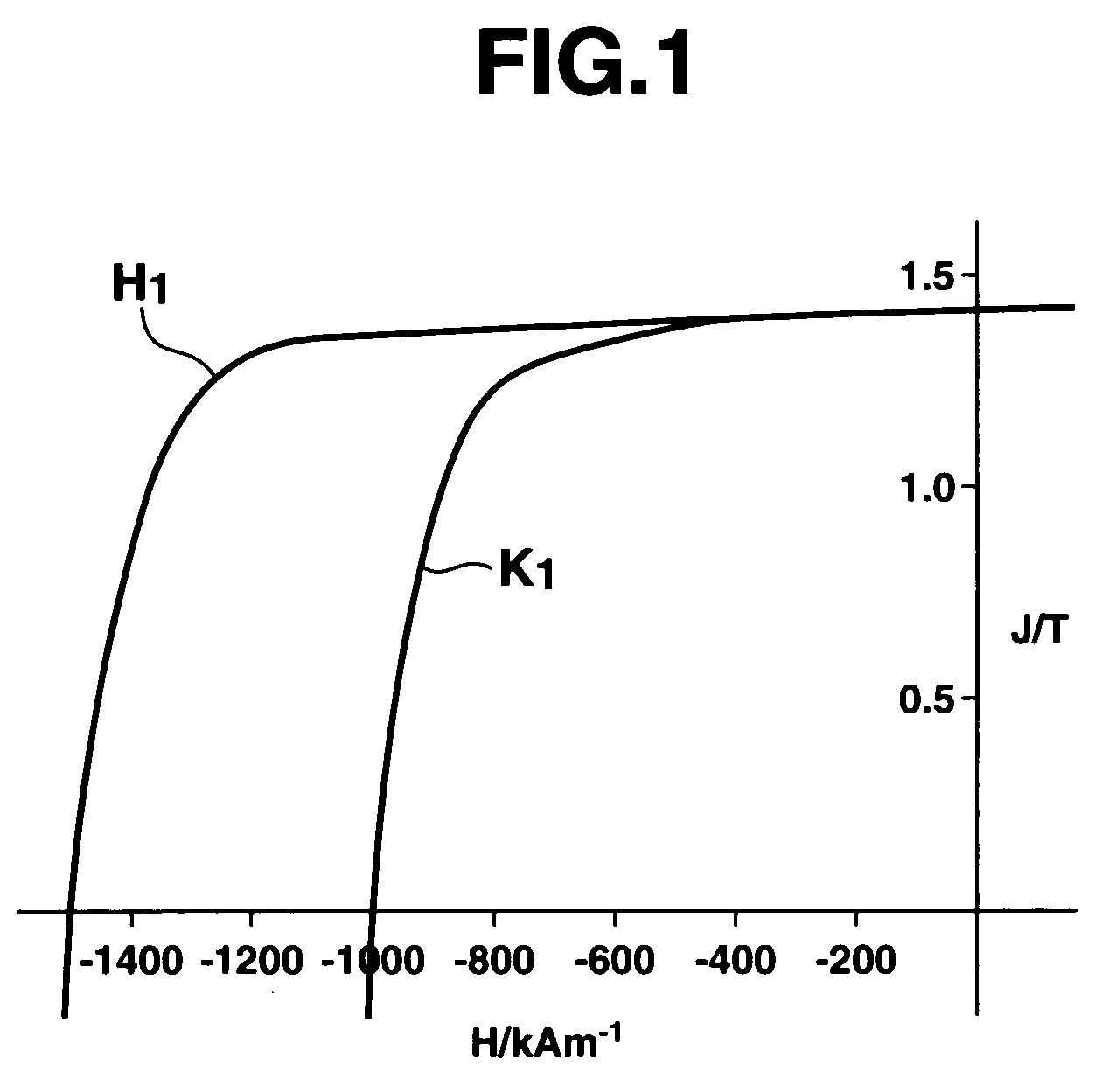

Preparation of Rare Earth Permanent Magnet Material

ActiveUS20080245442A1Improve remanenceImprove coercive forceElectric discharge tubesPermanent magnetsRare-earth elementRemanence

A method for preparing a rare earth permanent magnet material comprising the steps of:disposing a powder comprising one or more members selected from an oxide of R2, a fluoride of R3, and an oxyfluoride of R4 wherein R2, R3 and R4 each are one or more elements selected from among rare earth elements inclusive of Y and Sc on a sintered magnet form of a R1—Fe—B composition wherein R1 is one or more elements selected from among rare earth elements inclusive of Y and Sc, andheat treating the magnet form and the powder at a temperature equal to or below the sintering temperature of the magnet in vacuum or in an inert gas.The invention offers a high performance, compact or thin permanent magnet having a high remanence and coercivity at a high productivity.

Owner:SHIN ETSU CHEM IND CO LTD

Amplifying Optical Fiber and Method of Manufacturing

InactiveUS20100118388A1Improve efficiencyIncrease output powerGlass optical fibreMaterial nanotechnologyRare-earth elementNanoparticle

Disclosed is an amplifying optical fiber having a central core and an optical cladding surrounding the central core. The central core is based on a silica matrix that includes nanoparticles, which are composed of a matrix material that includes doping ions of at least one rare earth element. The amplifying optical fiber can be employed, for example, in an optical amplifier and an optical laser.

Owner:DRAKA COMTEQ BV

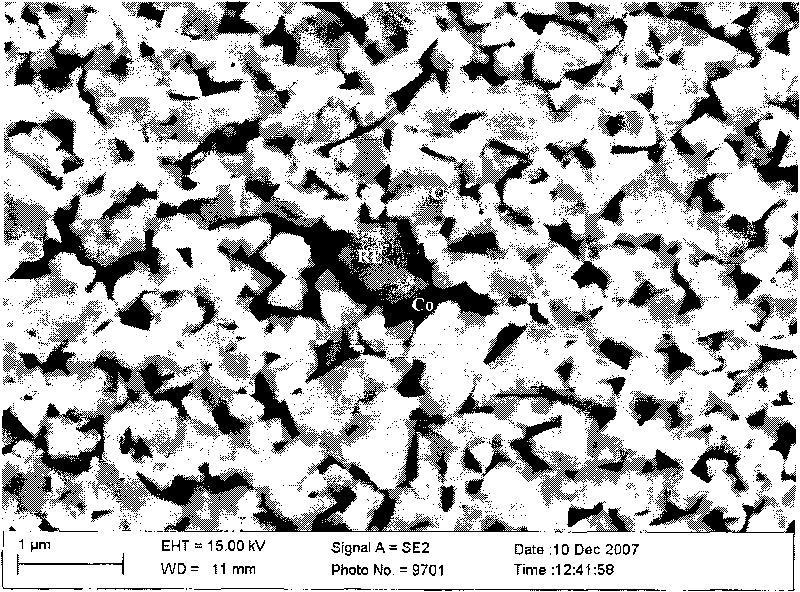

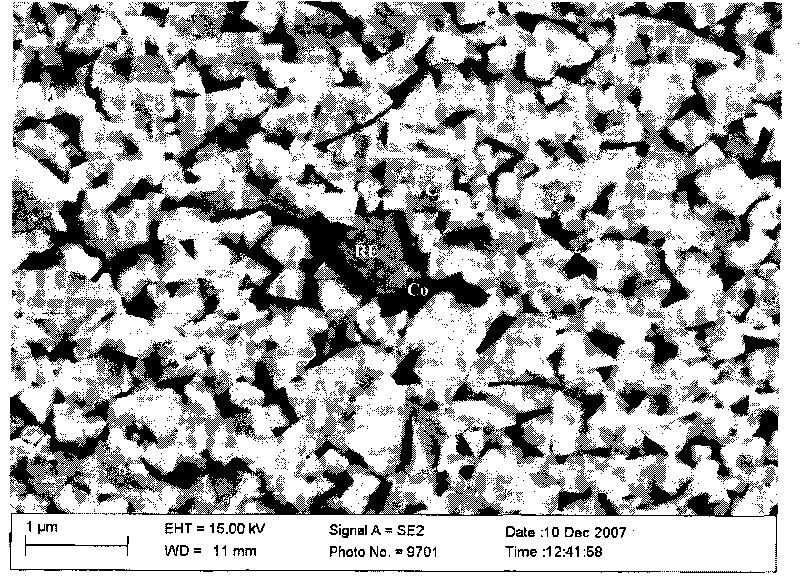

Superfine WC-Co cemented carbide containing rare-earth elements and preparation method thereof

ActiveCN101760685AChange processSteady improvement in overall performanceRare-earth elementChemical reaction

The invention discloses a superfine WC-Co cemented carbide containing rare-earth elements and a preparation method thereof, belonging to the technical field of cemented carbide. In the cemented carbide, the weight of WC rigid phase accounts for 85-94% of that of the cemented carbide, the weight of Co binder phase accounts for 5-14% of that of the cemented carbide, the weight of grain growth inhibitor accounts for 0.3-2.0% of that of the cemented carbide, and the weight of the thulium in the rare earth addition accounts for 0.2-1.2% of that of the Co binder phase. The method comprises the following steps: weighing various powder stocks, ball-milling, drying and pelletizing to form a compound; and suppressing and shaping the compound, sintering and cooling to obtain the cemented carbide. The adding mode of nano rare earth oxide or Co-RE composite powder can be implemented easily and conveniently, and the rare earth is diffusely and evenly distributed, thereby facilitating to perform physo-chemical reactions; and the cemented carbide has the advantages of low production cost, stable and enhanced performance and easy implementation, production and application.

Owner:GRIMAT ENG INST CO LTD

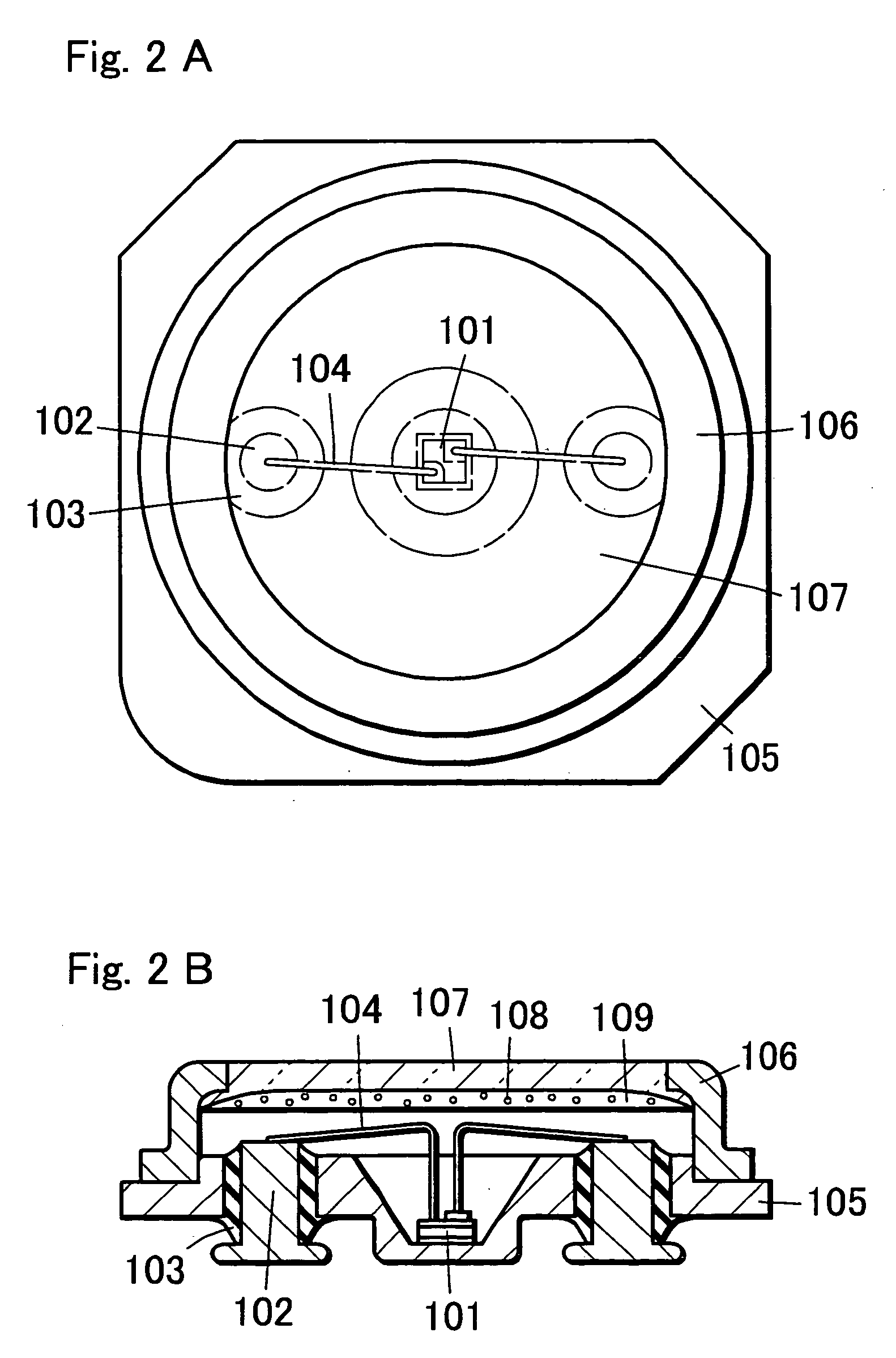

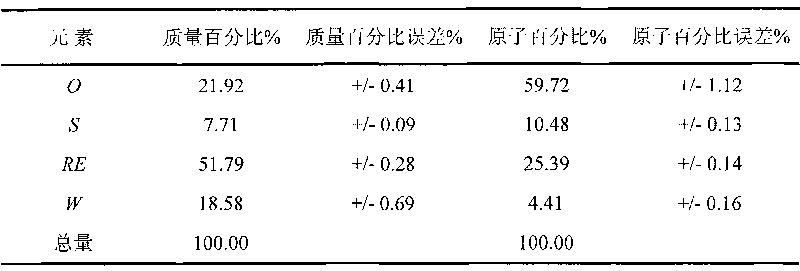

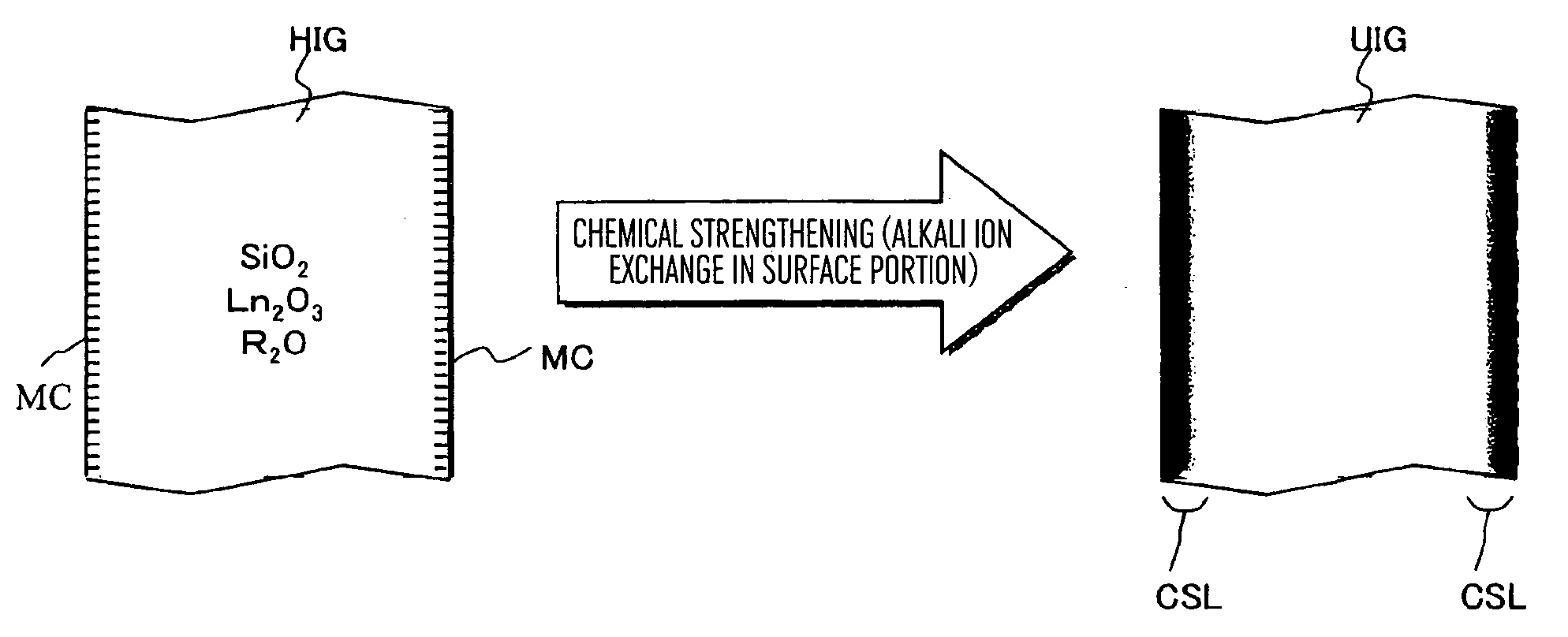

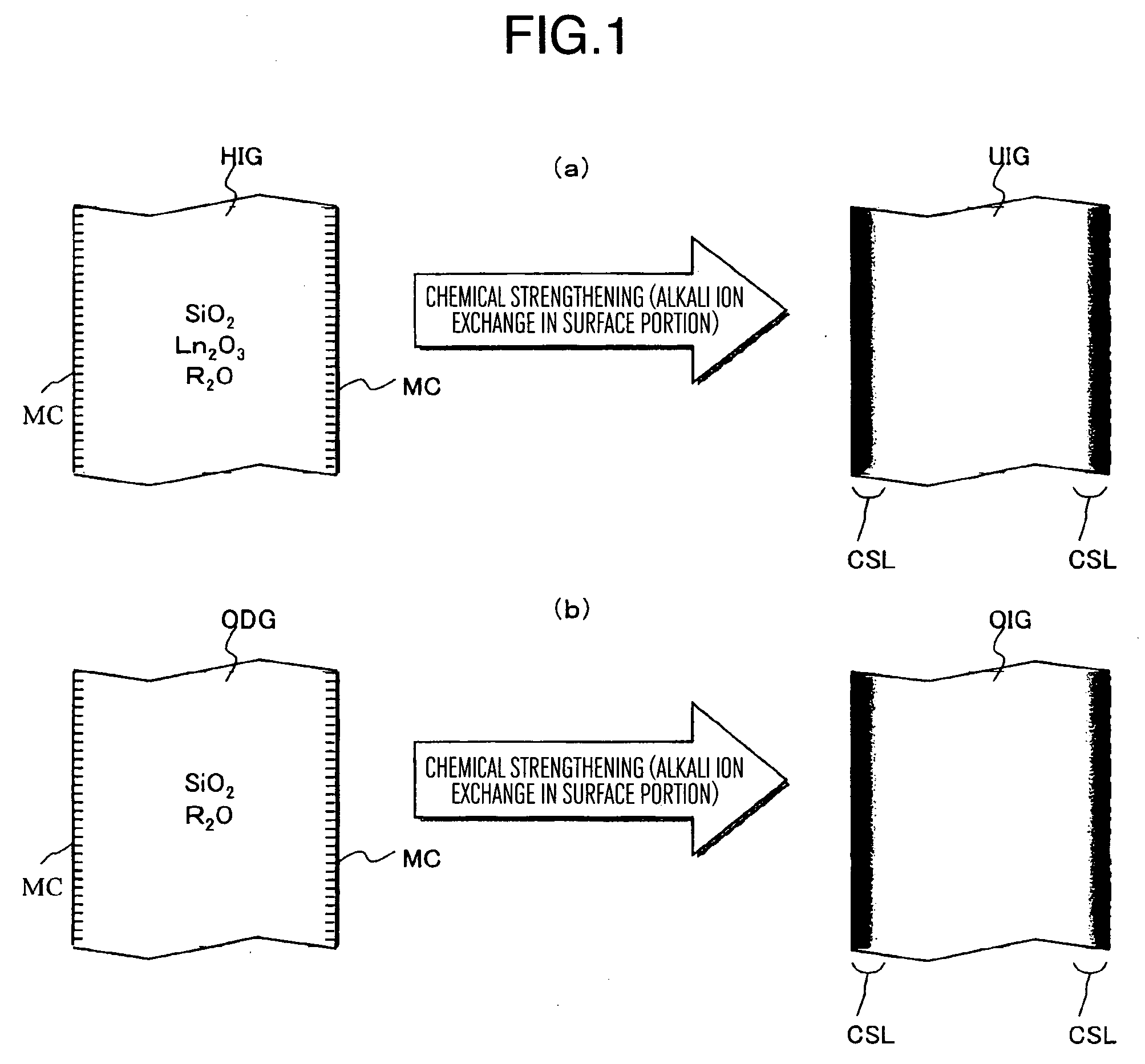

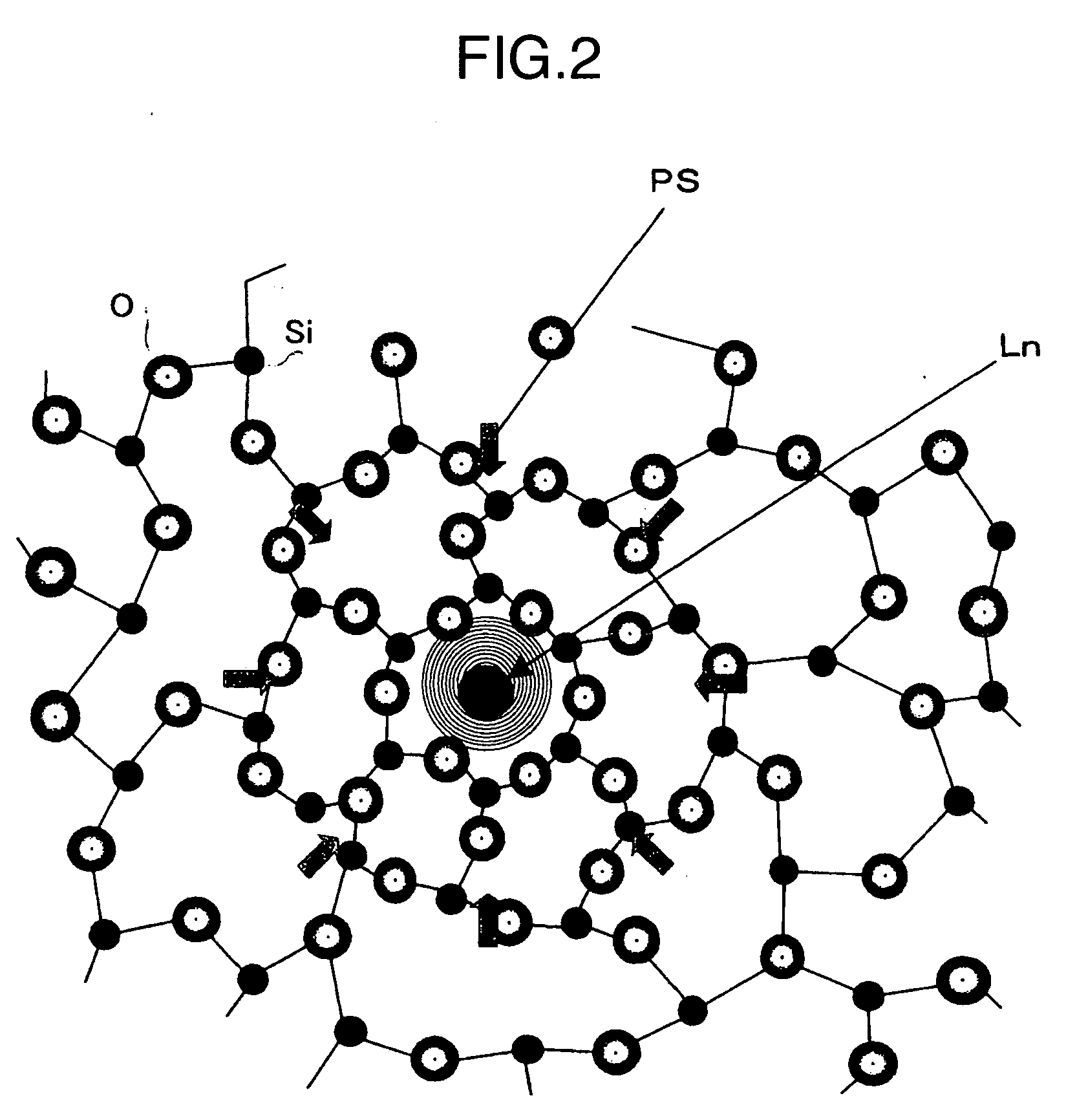

Glass member

InactiveUS20060063009A1Low heat resistanceHigh strengthCathode ray tubes/electron beam tubesGlass/slag layered productsRare-earth elementHigh intensity

The present invention is envisioned to provide a high-strength glass which is applicable to the objective of size and weight reduction. A compression stress layer is formed in a surface portion of an oxide-based glass containing at least one rare earth element selected from the group consisting of Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu and further containing at least Si element and an alkali metal element.

Owner:HITACHI LTD

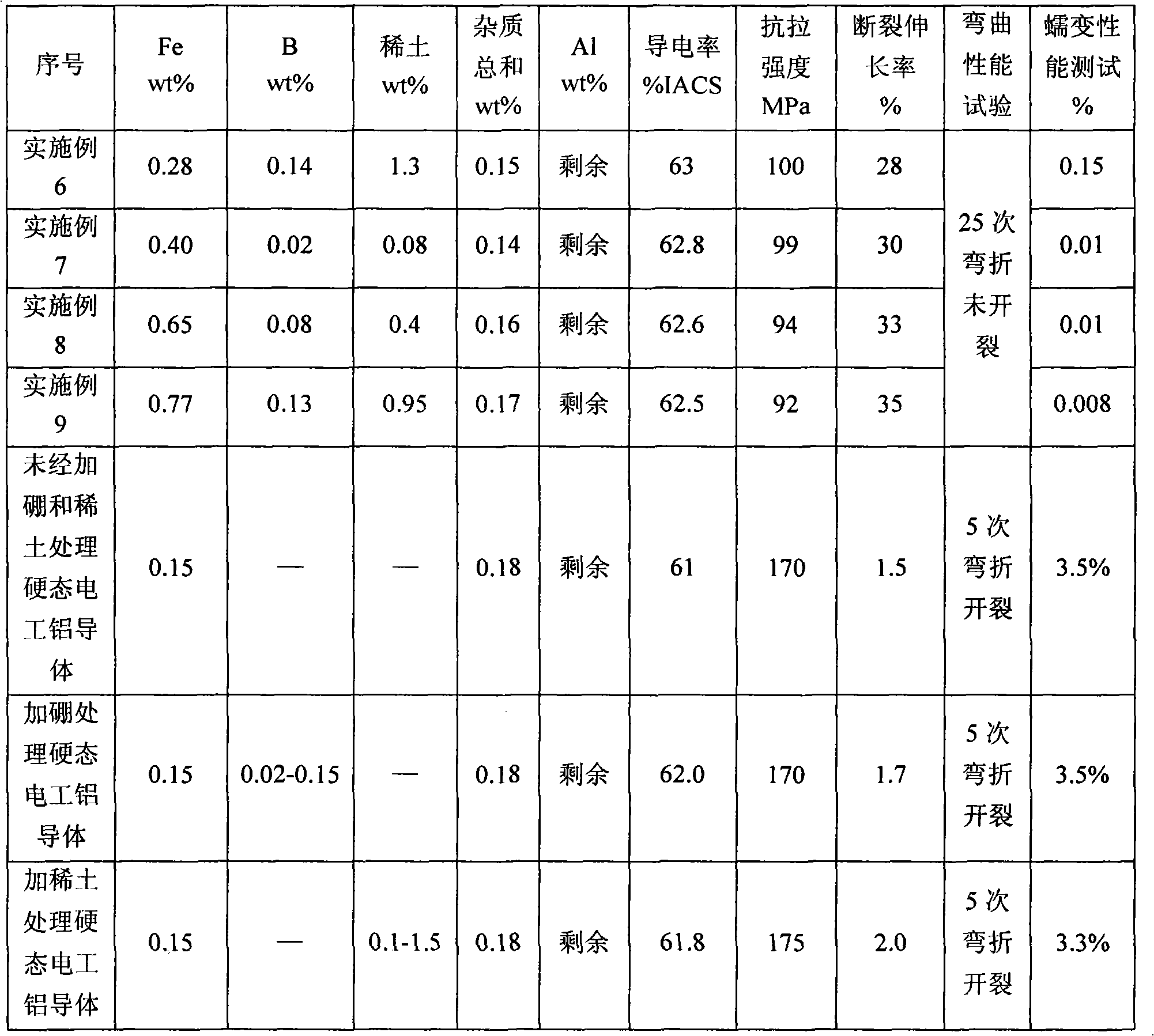

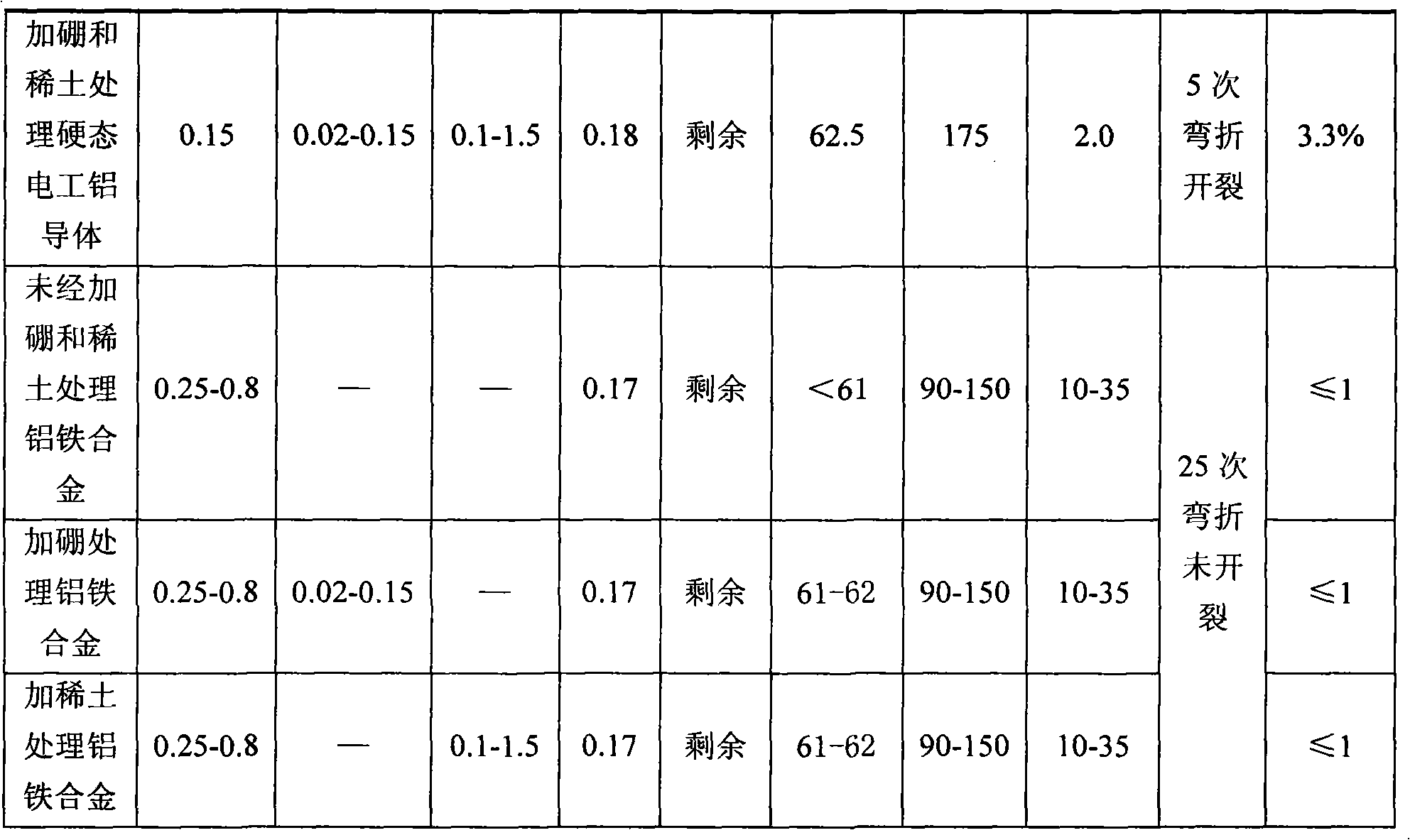

High-conductivity aluminum alloy material for cable and preparation method thereof

InactiveCN101886198ALittle impact on electrical performanceEasy to stretchMetal/alloy conductorsRare-earth elementPliability

The invention relates to a high-conductivity aluminum alloy material for a cable and a preparation method thereof. The aluminum alloy material comprises the following components in percentage by weight: 0.25-0.80 percent of iron element, 0.02-0.15 percent of boron element, 0.1-1.5 percent of rare earth element and the balance of aluminum and inevitable impurities. The aluminum alloy is formed by adding an aluminum alloy intermediate alloy, an aluminum-boron alloy and an aluminum-rare earth intermediate alloy into an aluminum ingot of which the purity is more than 99.80 percent by weight and carrying out a casting process and annealing treatment on the mixture. Compared with a common electric aluminum conductor, the prepared aluminum alloy conductor has more excellent conductive performance and the conductivity reaching or exceeding 62.5 percent IACS (International Annealed Copper Standard); the aluminum alloy conductor treated by using a special process has excellent flexibility and creep resistance; and compared with a common electric aluminum conductor, the prepared aluminum alloy material used as a cable extrusion insulating lead core is more energy-saving and safer.

Owner:ANHUI JOY SENSE CABLE

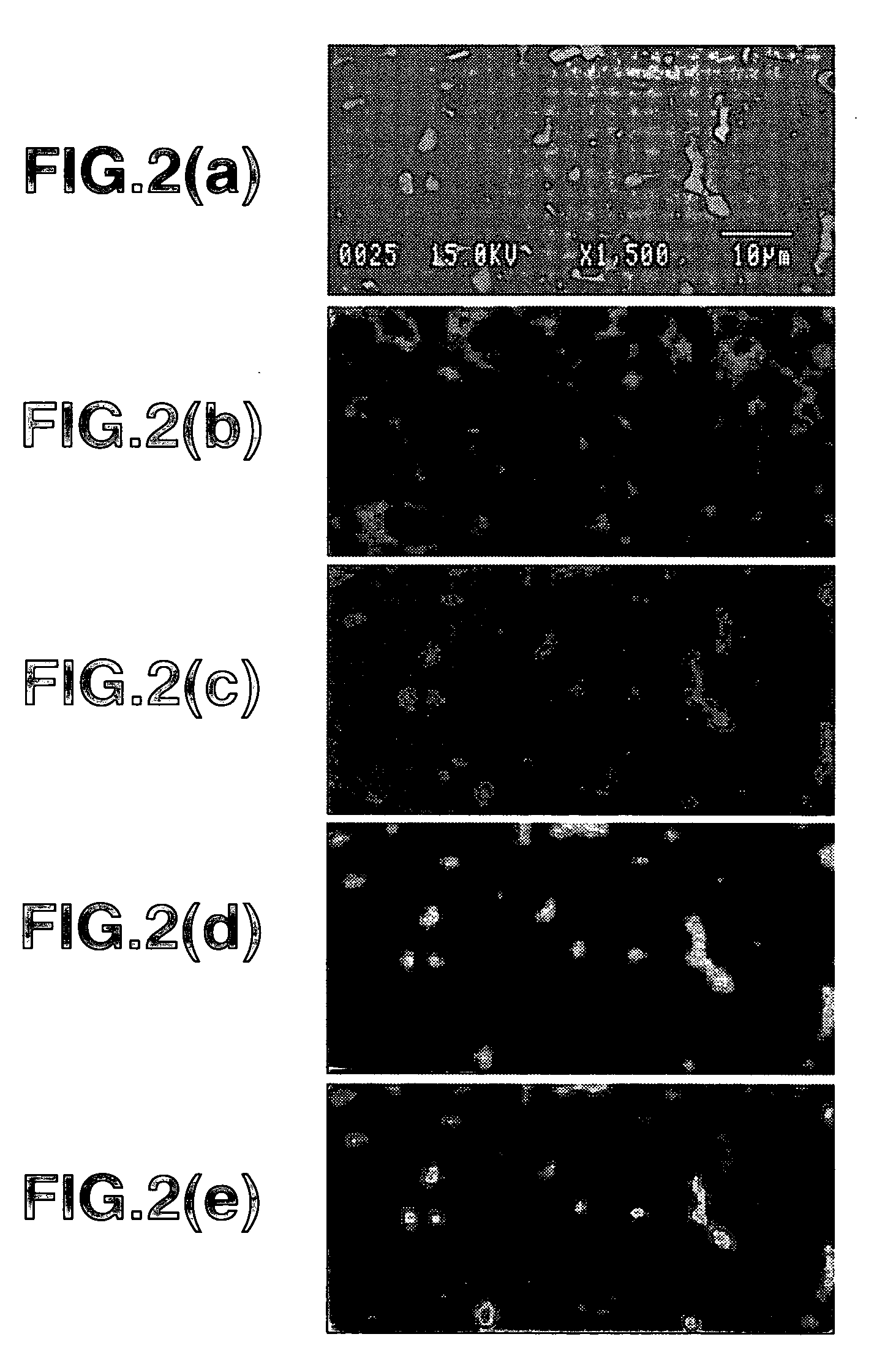

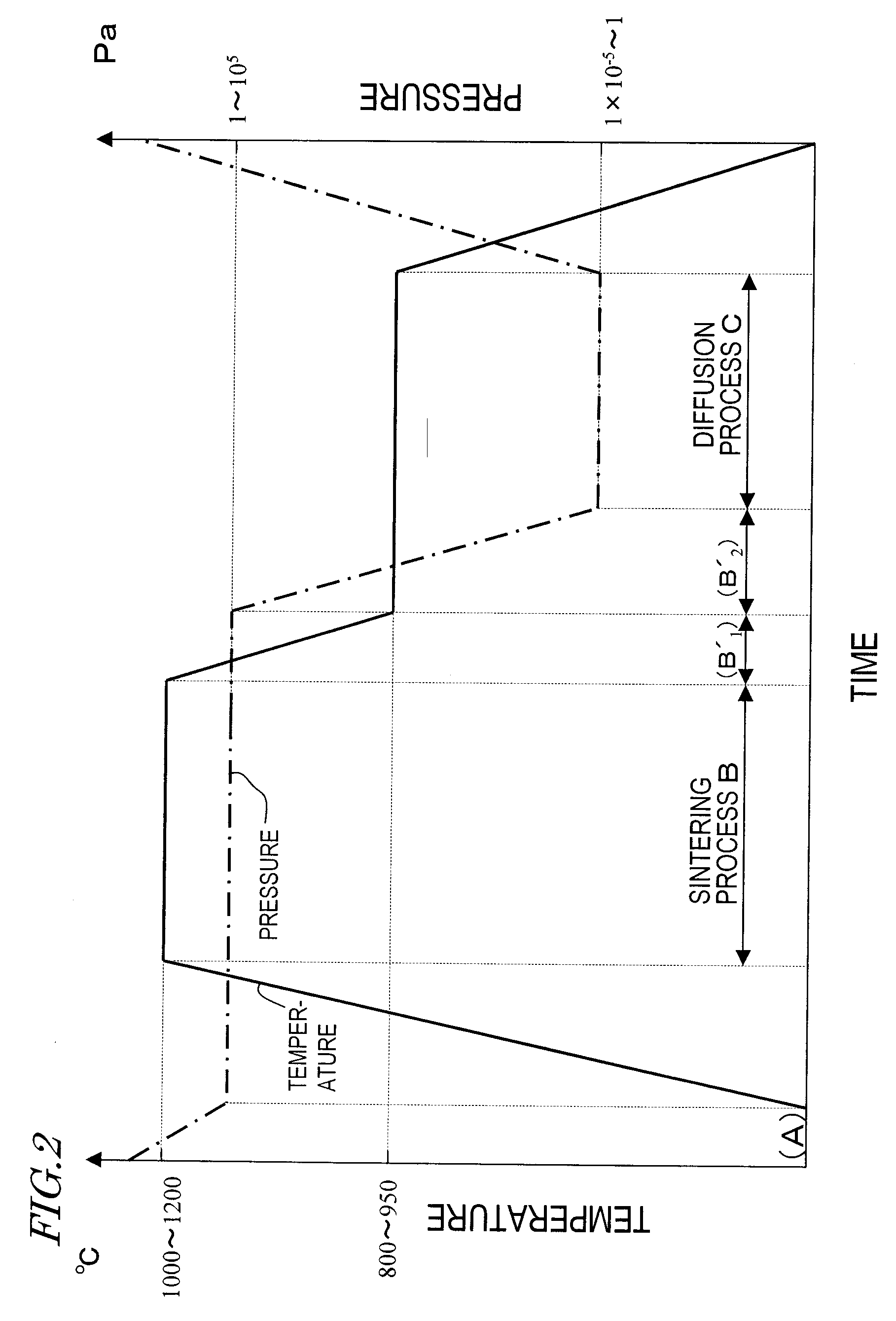

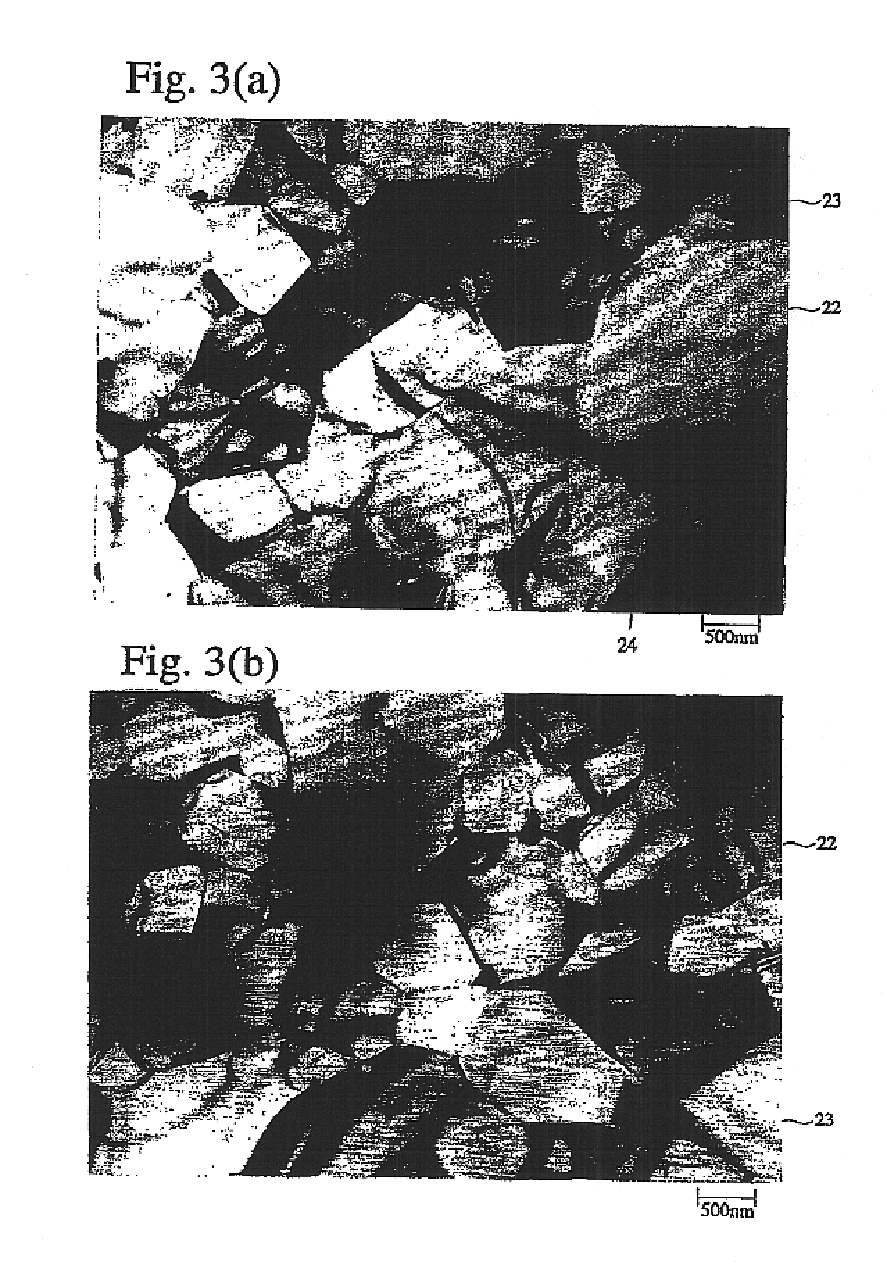

R-Fe-B Rare Earth Sintered Magnet and Method for Producing Same

ActiveUS20080286595A1Decrease in remanence Br minimizedCoercivity HcJ can be increasedInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementMetallurgy

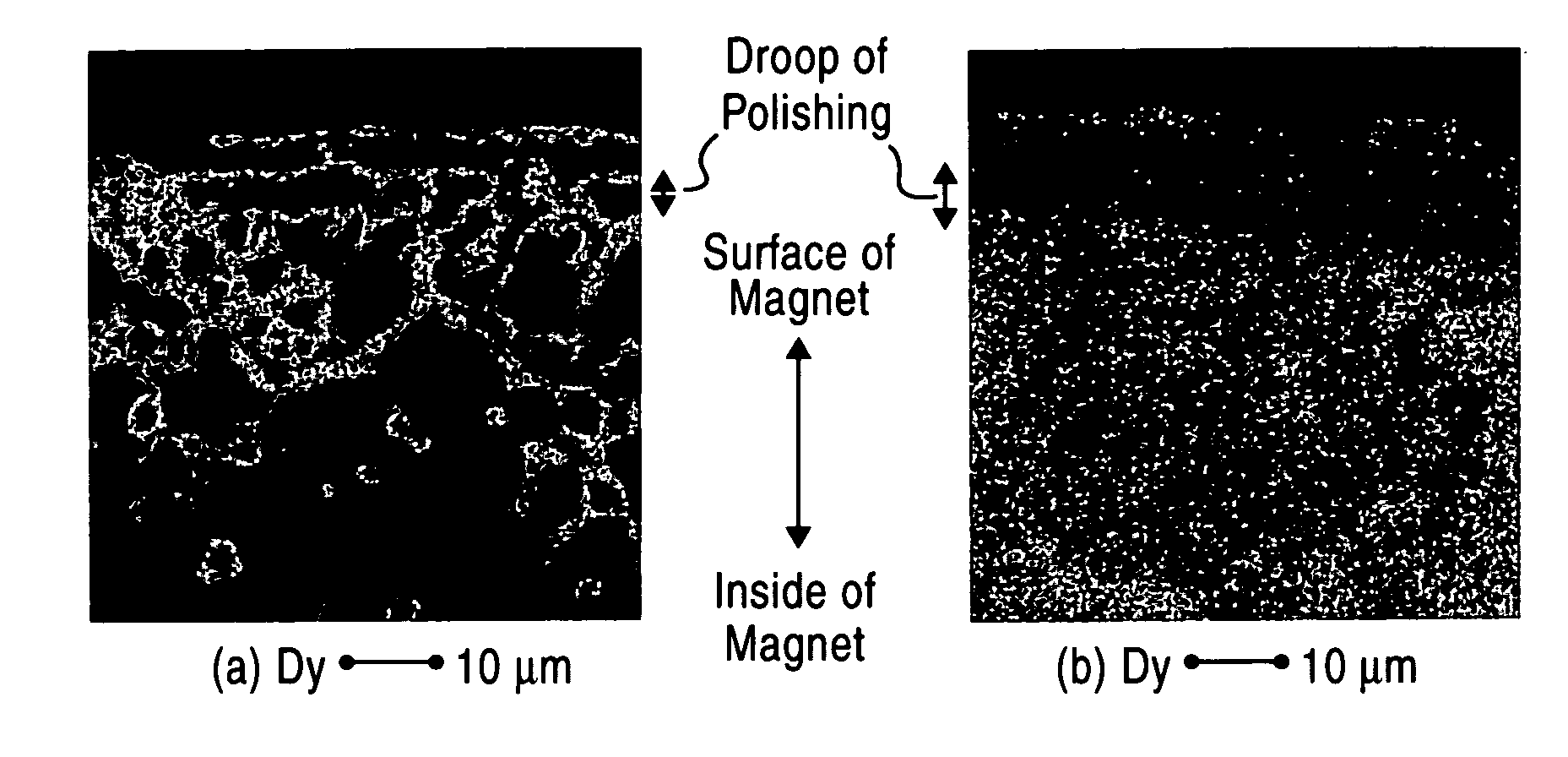

In a method for producing an R—Fe—B based rare-earth sintered magnet according to the present invention, first, provided is an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R. Thereafter, the sintered magnet body is heated while a heavy rare-earth element RH, which is at least one element selected from the group consisting of Dy, Ho and Tb, is supplied to the surface of the sintered magnet body, thereby diffusing the heavy rare-earth element RH into the rare-earth sintered magnet body.

Owner:HITACHI METALS LTD

Nitride phosphor and production process thereof, and light emitting device

InactiveUS20060038477A1High luminous brightnessImprove luminous performanceDischarge tube luminescnet screensNitrogen compoundsRare-earth elementNitride phosphor

To provide a phosphor containing a comparatively much red component and having high light emitting efficiency, high brightness and further high durability, the nitride phosphor is represented by the general formula LXMYN((2 / 3)X+(4 / 3)Y):R or LXMYOZN((2 / 3)X+(4 / 3)Y−(2 / 3)Z):R (wherein L is at least one or more selected from the Group II Elements consisting of Mg, Ca, Sr, Ba and Zn, M is at least one or more selected from the Group IV Elements in which Si is essential among C, Si and Ge, and R is at least one or more selected from the rare earth elements in which Eu is essential among Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er and Lu.); contains the another elements.

Owner:NICHIA CORP

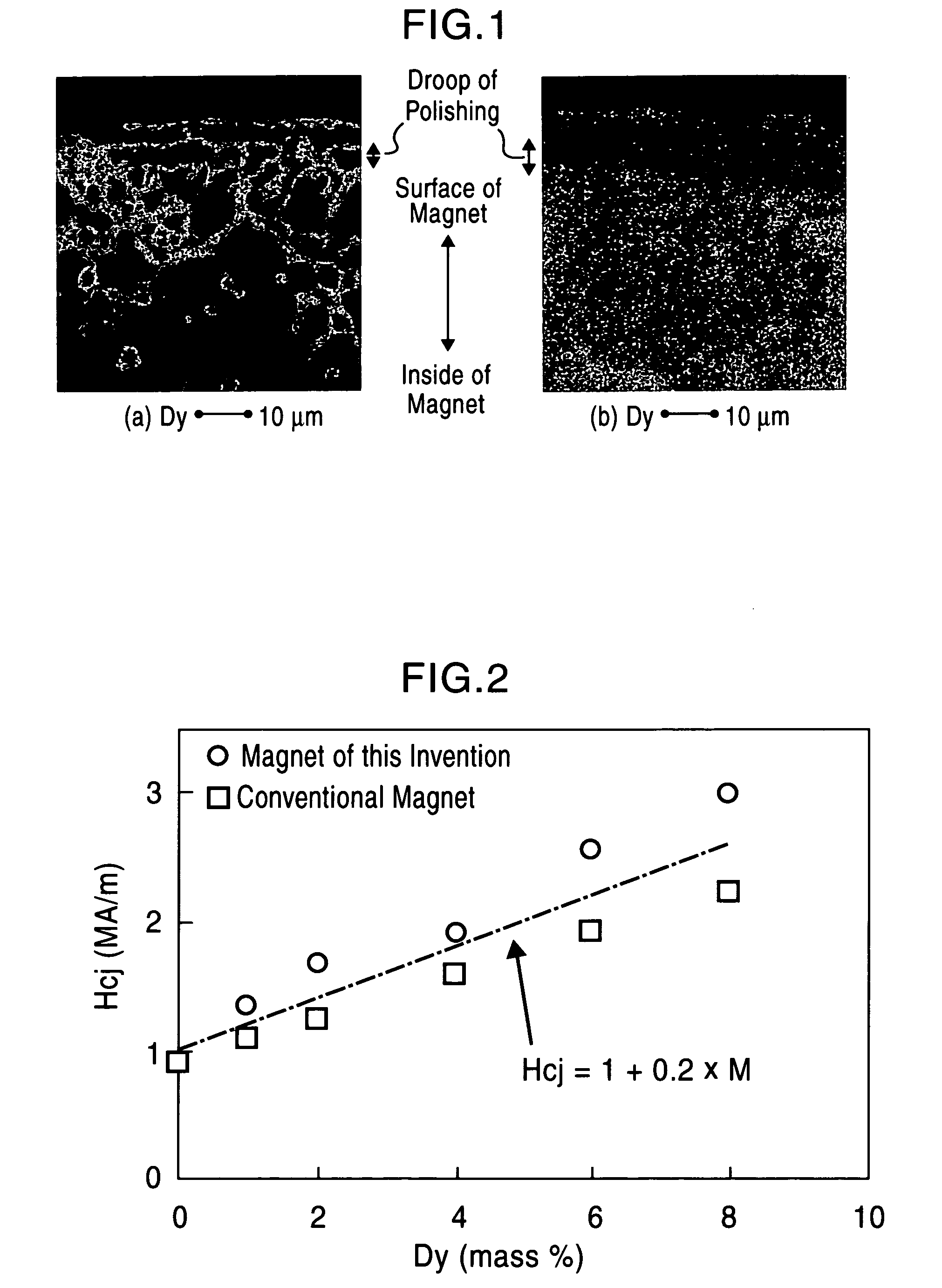

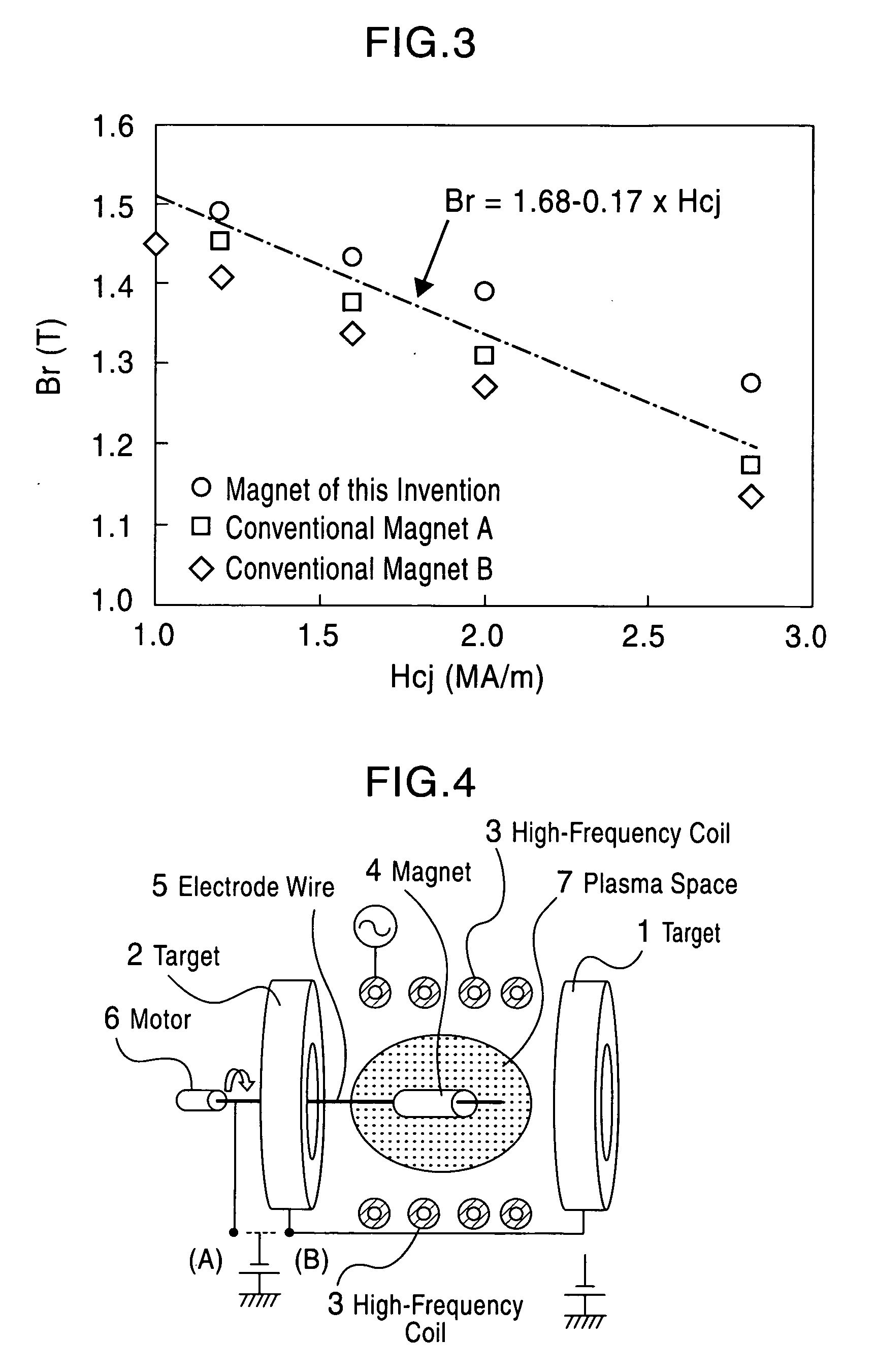

Rare earth - iron - bron based magnet and method for production thereof

InactiveUS20070034299A1High energyImprove resolutionInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementTrace element

[Object] To provide a high-performance rare earth-based magnet exhibiting a high coercive force or a high residual magnetic flux density even when the content of a rare earth element such as Dy or the like which is scarce is reduced. [Construction] A rare earth-iron-boron based magnet includes a crystal grain boundary layer enriched in element M (M is at least one rare earth element selected from Pr, Dy, Tb, and Ho) by diffusion of the element M from the surface of the magnet, wherein the relation between the coercive force Hcj and the content of the element M in the whole of the magnet is represented by the following expression: Hcj≧1+0.2×M (wherein 0.05≦M≦10) wherein Hcj is the coercive force (unit: MA / m), and M is the content of the element M in the whole of the magnet (% by mass). Furthermore, the magnet satisfies the following expression: Br≧1.68−0.17×Hcj wherein Br is the residual magnetic flux density (unit: T).

Owner:JAPAN SCI & TECH CORP +1

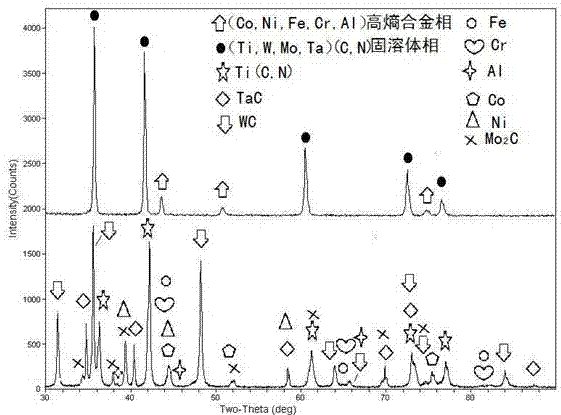

Titanium carbonitride based metal ceramic based on high-entropy alloy binder phase and preparation method of metal ceramic

InactiveCN102787266AImprove corrosion resistanceImprove wear resistanceRare-earth elementHigh entropy alloys

Disclosed is a titanium carbonitride based metal ceramic material based on a high-entropy alloy binder phase. The binder phase of the titanium carbonitride based metal ceramic material is high-entropy alloy, the hard phase of the titanium carbonitride based metal ceramic material is carbonitride solid solution, the high-entropy alloy binder phase includes at least four of ferrum, cobalt, nickel, chromium, aluminum, vanadium, titanium, copper, zirconium, molybdenum, manganese and rare earth elements, and the molar content ratio of each element ranges from 5% to 35%. In a preparation method, the titanium carbonitride based metal ceramic material based on the high-entropy alloy binder phase comprises raw materials including, in weight percent, 3-30% of the high-entropy alloy binder phase, 0-30% of second carbide powder and the balance carbonitride solid solution powder, the carbonitride solid solution powder includes at least one of Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x), the M1 component of the (Ti, M1...) and (Cx, N1-x) includes at least one of W, Mo, Ta, Nb, V, Cr, Zr, Hf, Y and lanthanide, and 0<x<1 in the Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x). The preparation method includes the process steps of (1) ball-milling mixing, (2) forming and (3) low-pressure sintering.

Owner:SICHUAN UNIV

Cast aluminum alloys

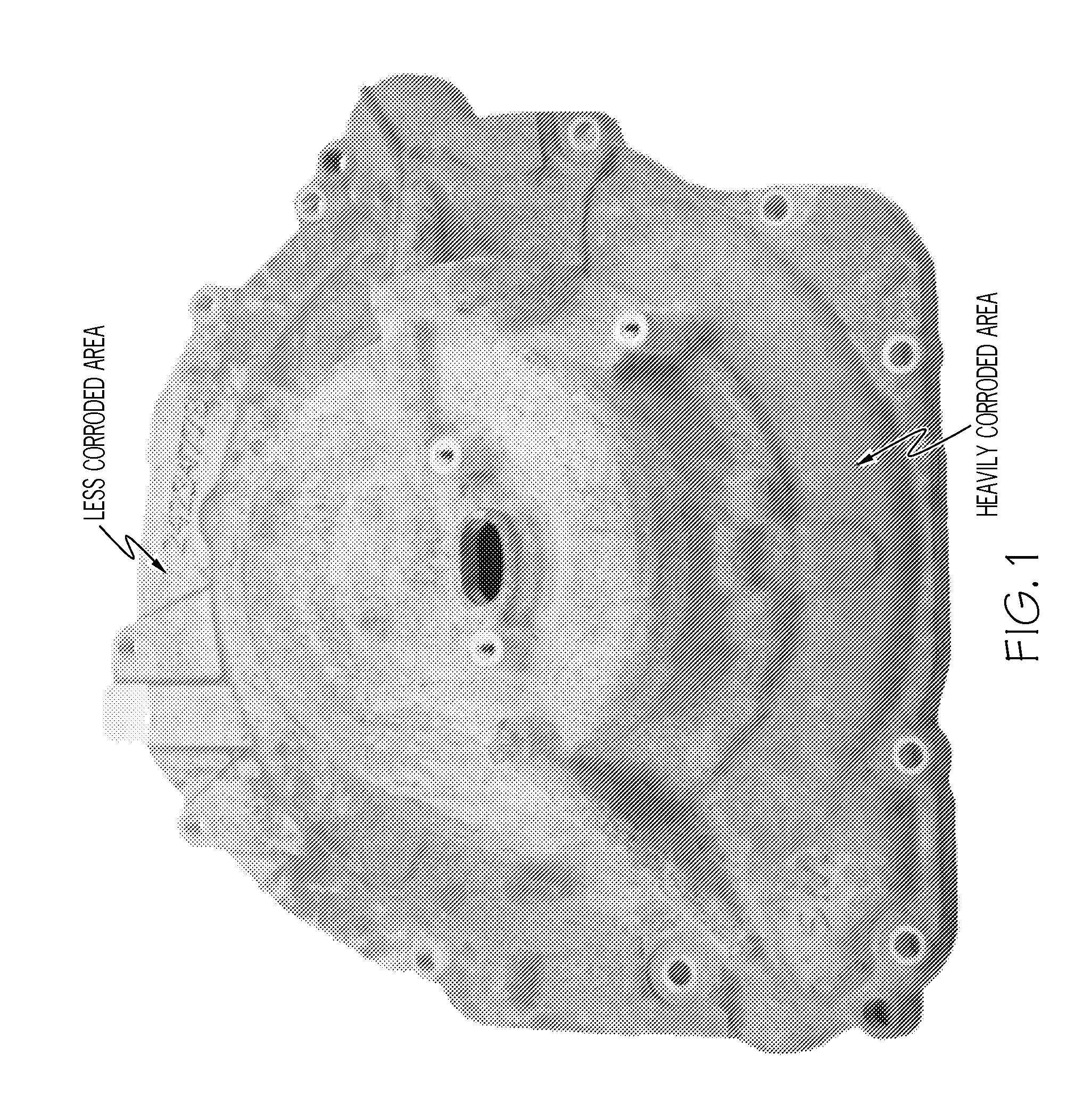

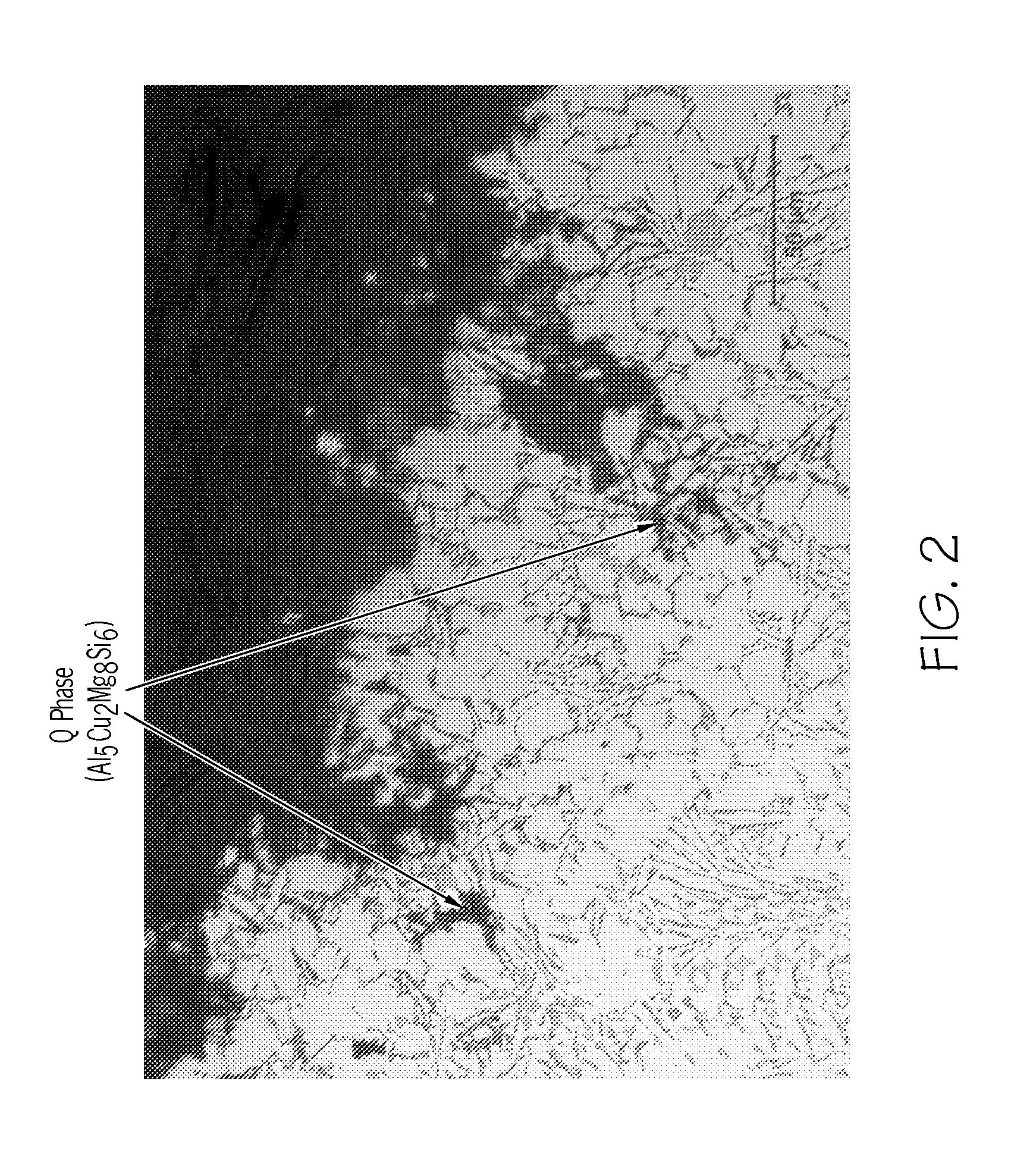

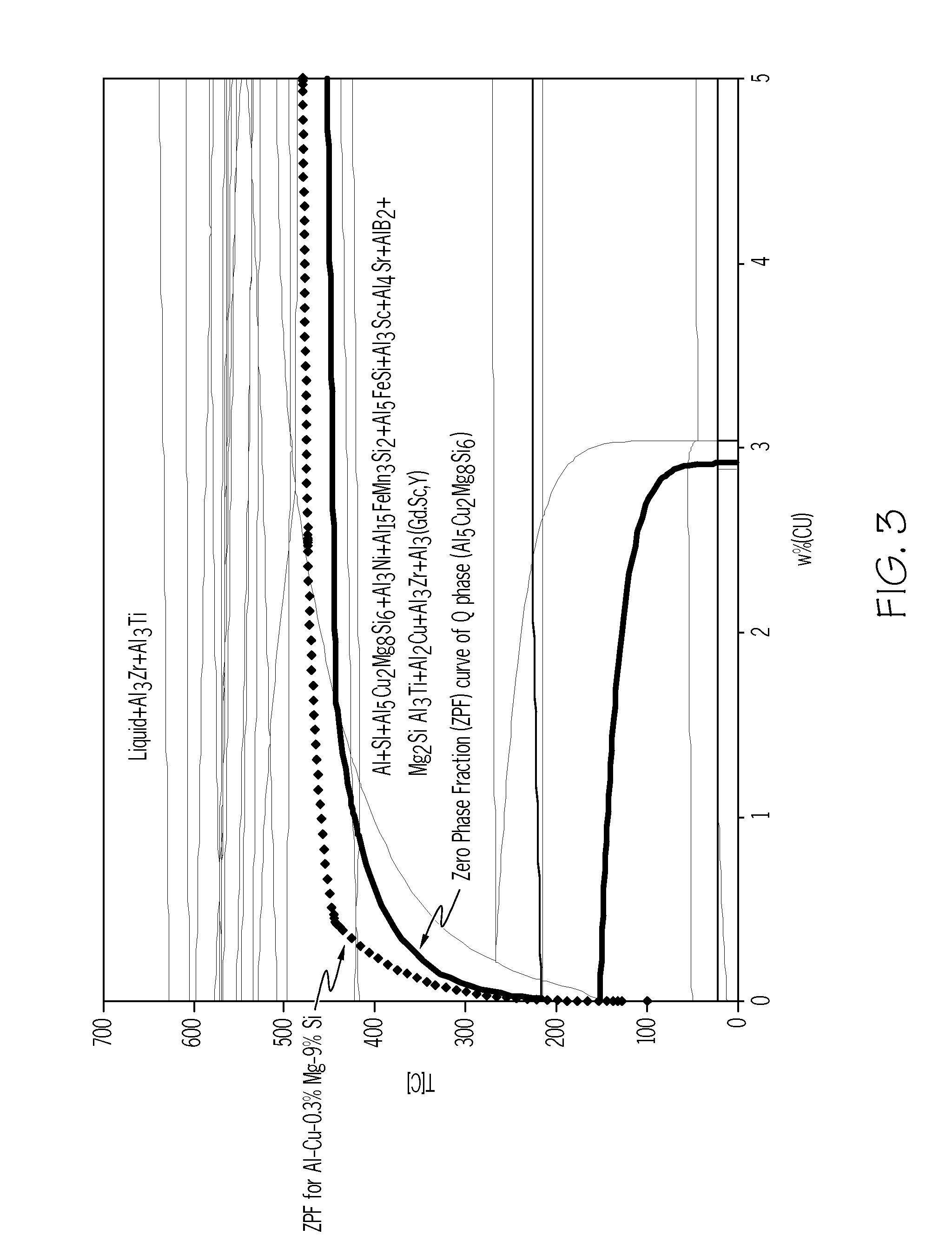

ActiveUS20120000578A1Improve mechanical propertiesImprove corrosion resistanceAngiosperms/flowering plantsRare-earth elementIndium

Aluminum alloys having improved properties are provided. The alloy includes about 0 to 2 wt % rare earth elements, about 0.5 to about 14 wt % silicon, about 0.25 to about 2.0 wt % copper, about 0.1 to about 3.0 wt % nickel, approximately 0.1 to 1.0% iron, about 0.1 to about 2.0 wt % zinc, about 0.1 to about 1.0 wt % magnesium, 0 to about 1.0 wt % silver, about 0.01 to about 0.2 wt % strontium, 0 to about 1.0 wt % scandium, 0 to about 1.0 wt % manganese, 0 to about 0.5 wt % calcium, 0 to about 0.5 wt % germanium, 0 to about 0.5 wt % tin, 0 to about 0.5 wt % cobalt, 0 to about 0.2 wt % titanium, 0 to about 0.1 wt % boron, 0 to about 0.2 wt % zirconium, 0 to 0.5% yttrium, 0 to about 0.3 wt % cadmium, 0 to about 0.3 wt % chromium, 0 to about 0.5 wt % indium, and the balance aluminum. Methods of making cast aluminum parts are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

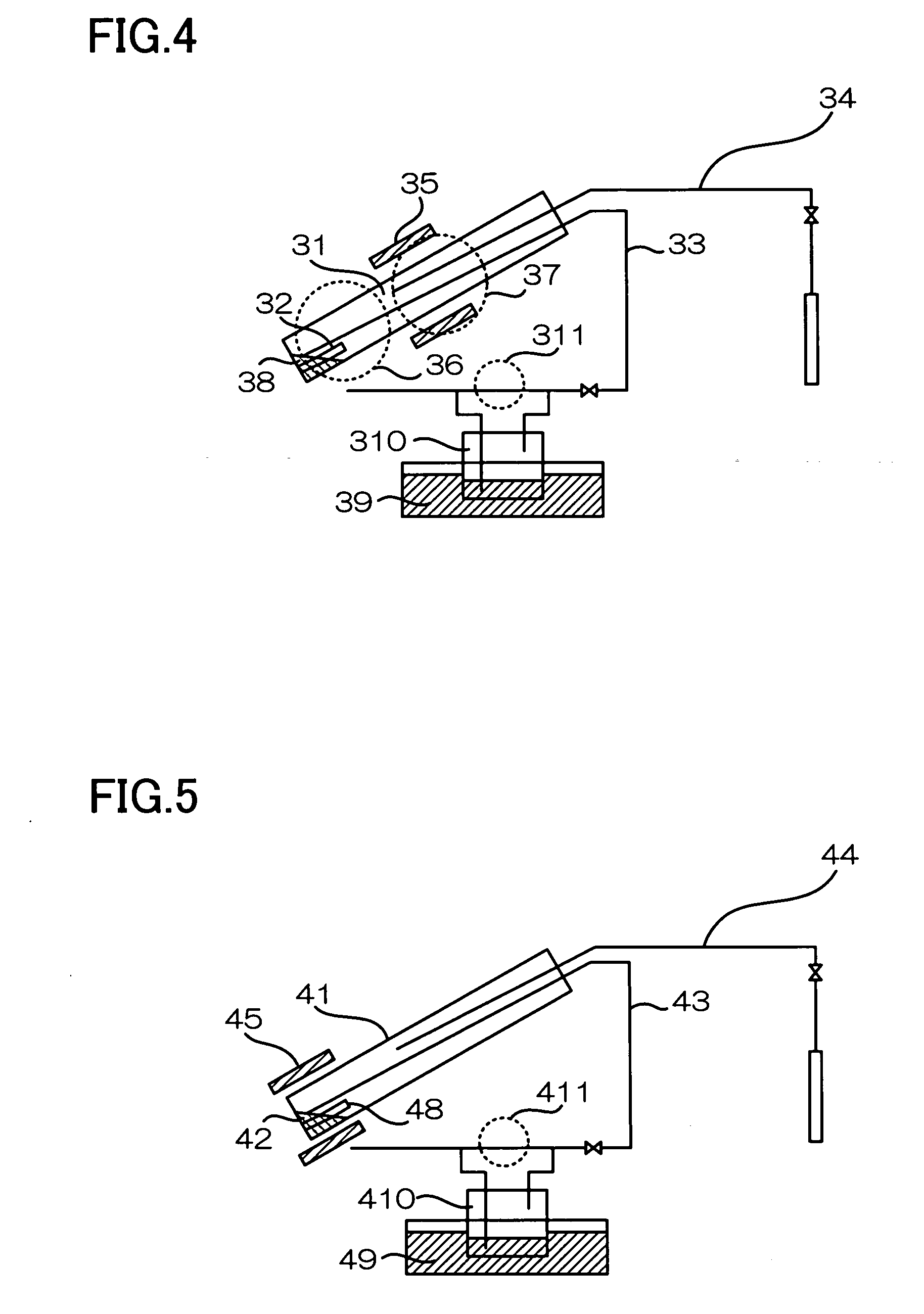

Light emitting device, phosphor, and method for preparing phosphor

ActiveUS20060001352A1Solve the lack of lifeIncrease thermal resistanceGas-filled discharge tubesDischarge tube luminescnet screensRare-earth elementOxygen

The surface of a phosphor is coated with a coating member made of a material different from the phosphor in chemical vapor-phase reaction. The coating member is made of any of metal oxide, metal nitride and metal oxynitride. The coating member coats the surface of the phosphor whereby having a substantially smooth film, or is formed such that a large number of fine particles relatively smaller than the phosphor aggregate to coat the whole surface of the phosphor. The coating member contains at least one metallic element selected from the group consisting of Al, Si, and rare earth elements. In addition, the phosphor is a transparent water-soluble phosphor and is an alkaline-earth silicon-nitride phosphor, an alkaline-earth silicon oxynitride phosphor, or the like. The BET value of the coated phosphor is 1.0 to 10 times the BET value before coating. The average thickness of the coating is 10 nm to 500 nm.

Owner:NICHIA CORP

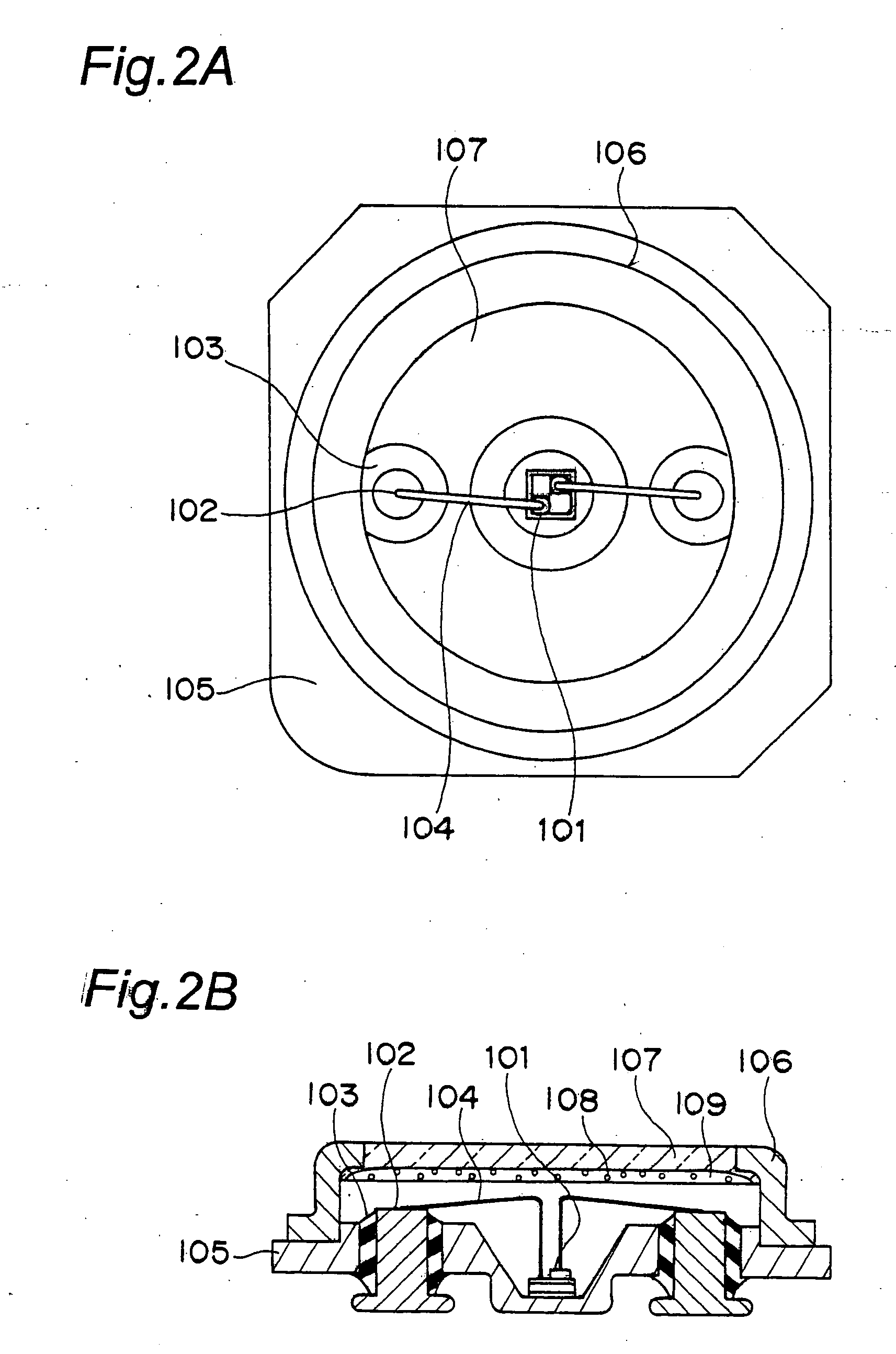

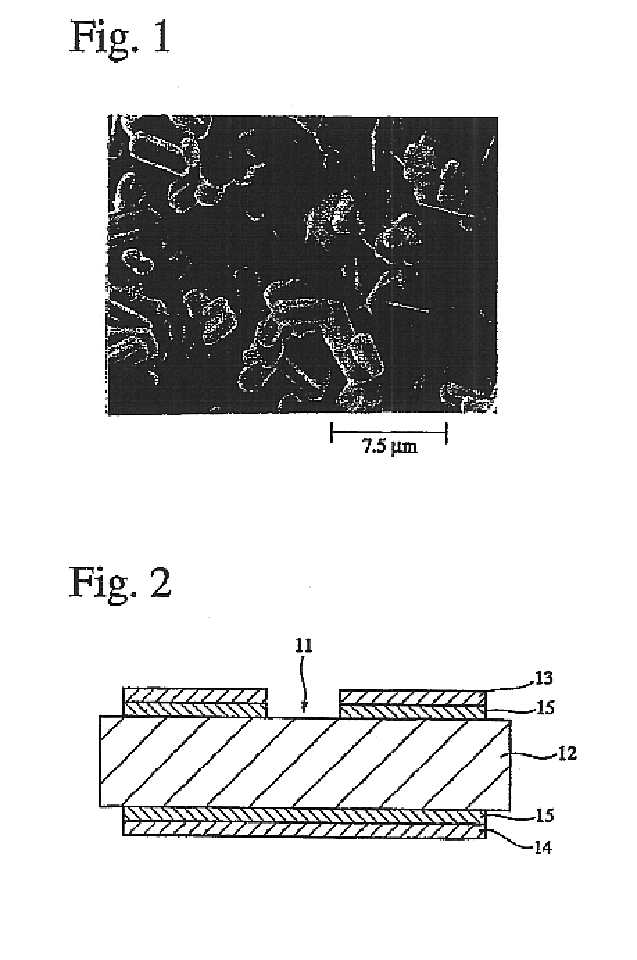

Silicon nitride powder, silicon nitride sintered body, sintered silicon nitride substrate, and circuit board and thermoelectric module comprising such sintered silicon nitride substrate

InactiveUS6846765B2High mechanical strengthImprove thermal conductivityNitrogen compoundsSemiconductor/solid-state device detailsRare-earth elementNitrogen atmosphere

A silicon nitride sintered body comprising Mg and at least one rare earth element selected from the group consisting of La, Y, Gd and Yb, the total oxide-converted content of the above elements being 0.6-7 weight %, with Mg converted to MgO and rare earth elements converted to rare earth oxides RExOy. The silicon nitride sintered body is produced by mixing 1-50 parts by weight of a first silicon nitride powder having a particle ratio of 30-100%, an oxygen content of 0.5 weight % or less, an average particle size of 0.2-10 μm, and an aspect ratio of 10 or less, with 99−50 parts by weight of α-silicon nitride powder having an average particle size of 0.2-4 μm; and sintering the resultant mixture at a temperature of 1,800° C. or higher and pressure of 5 atm or more in a nitrogen atmosphere.

Owner:HITACHI METALS LTD

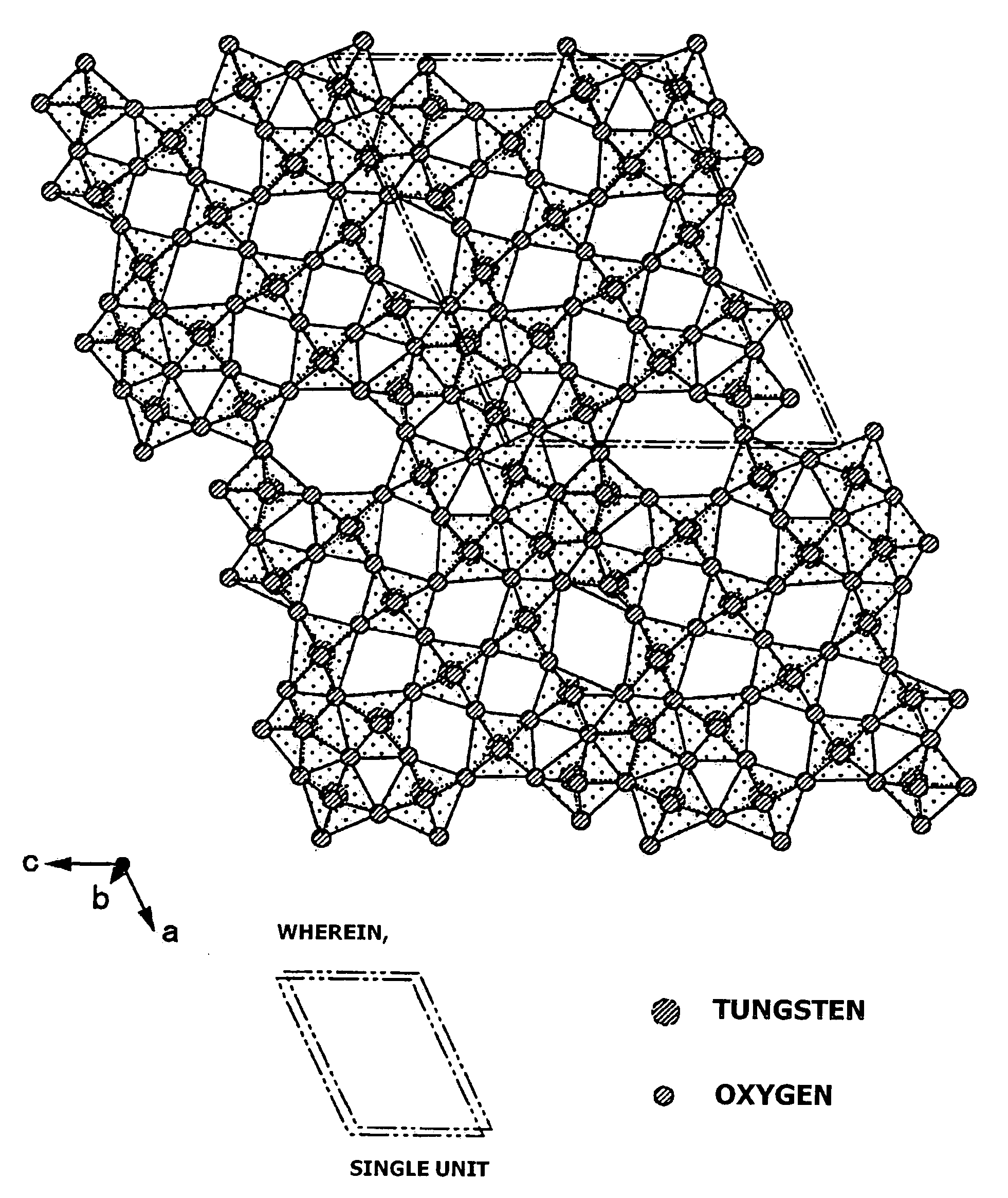

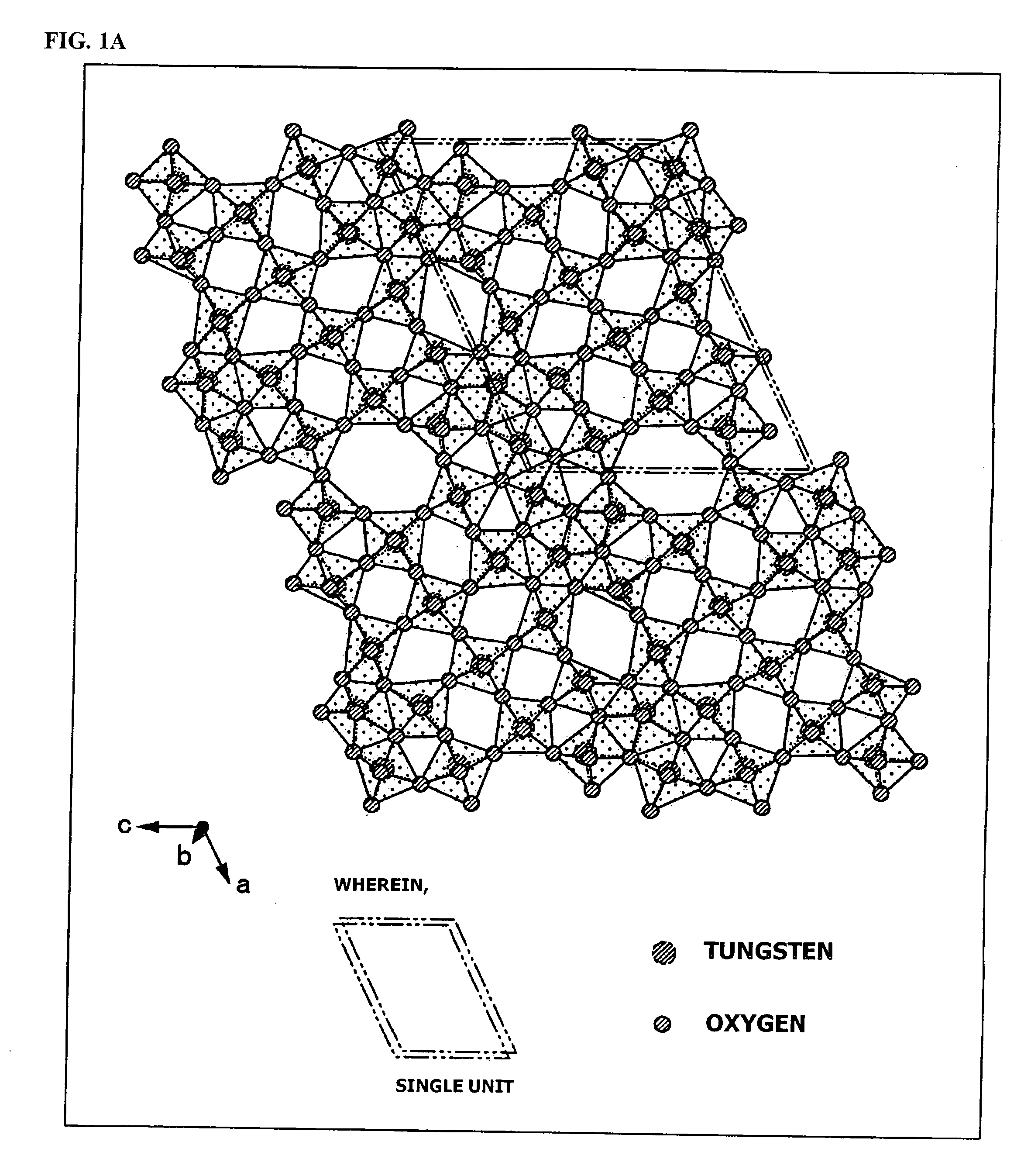

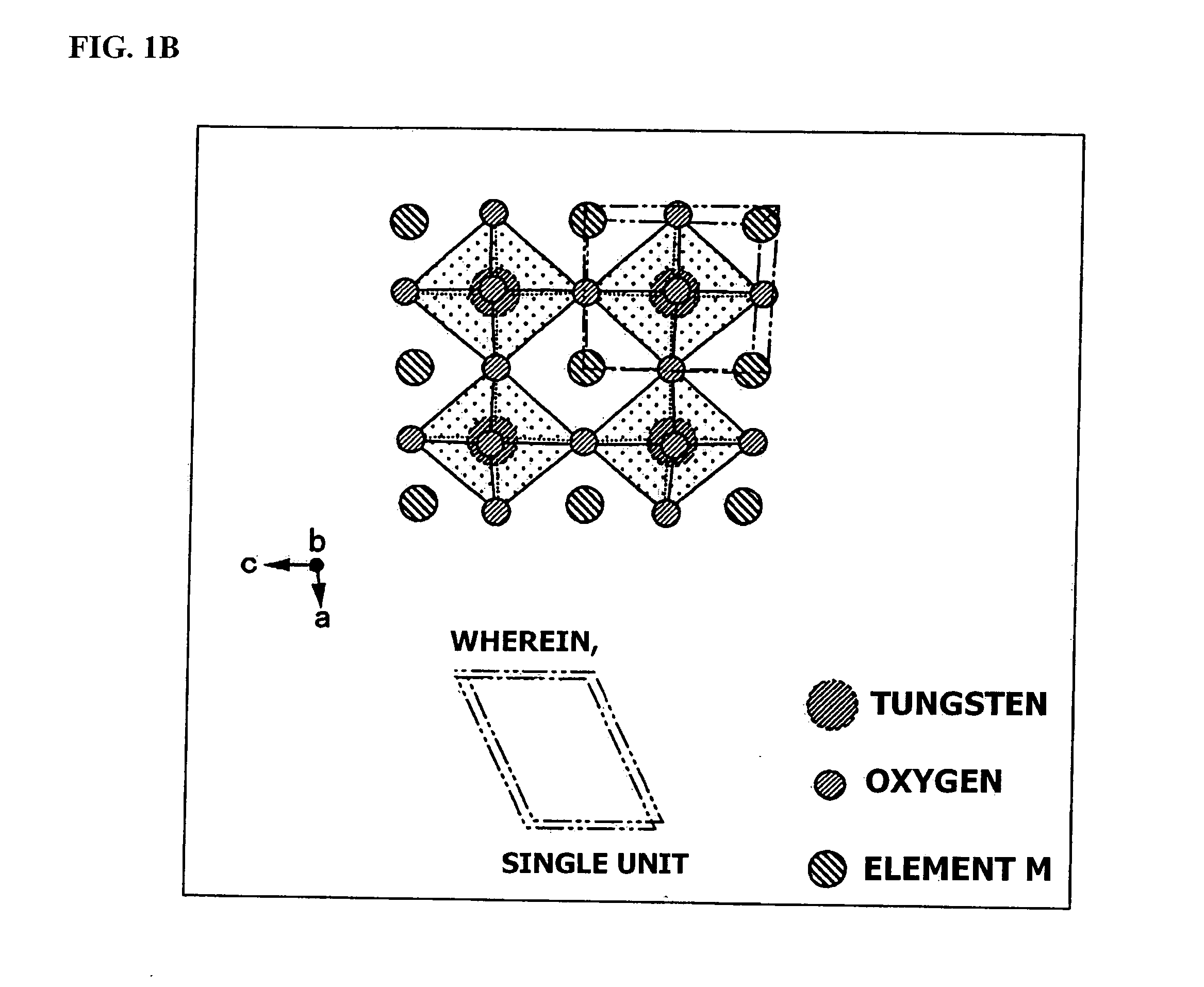

Conductive particle, visible light transmissive particle dispersed conductor, method for producing same, transparent conductive thin film, method for producing same, transparent conductive article using same, and infrared shielding article

ActiveUS20070187653A1Improve conductivityGood visible light transmittanceMaterial nanotechnologyConductive materialInfraredRare-earth element

An object of the present invention is to provide an infrared-shielding nanoparticle dispersion that has a property whereby visible light is adequately transmitted, and light in the near-infrared region is adequately shielded; an infrared-shielding body manufactured using the infrared-shielding nanoparticle dispersion; a method for manufacturing infrared-shielding nanoparticles that are used in the infrared-shielding nanoparticle dispersion; and infrared-shielding nanoparticles manufactured using the method for manufacturing infrared-shielding nanoparticles. The present invention is a method for manufacturing infrared-shielding nanoparticle dispersion obtained by dispersing infrared-shielding nanoparticles in a medium, an infrared-shielding body manufactured by using the infrared-shielding nanoparticle dispersion, and infrared-shielding nanoparticles used in the infrared-shielding nanoparticle dispersion, wherein the infrared-shielding nanoparticles include a substance expressed by the general formula MXAYW(1-Y)O3 (where M is one or more elements selected from H, He, alkali metals, alkaline-earth metals, rare earth elements, Mg, Zr, Cr, Mn, Fe, Ru, Co, Rh, Ir, Ni, Pd, Pt, Cu, Ag, Au, Zn, Cd, Al, Ga, In, Tl, Si, Ge, Sn, Pb, Sb, B, F, P, S, Se, Br, Te, Ti, Nb, V, Mo, Ta, Re, Be, Hf, Os, Bi, and I; A is one or more elements selected from Mo, Nb, Ta, Mn, V, Re, Pt, Pd, and Ti; W is tungsten; O is oxygen; 0<X≦1.2; 0<Y≦1).

Owner:SUMITOMO METAL MINING CO LTD

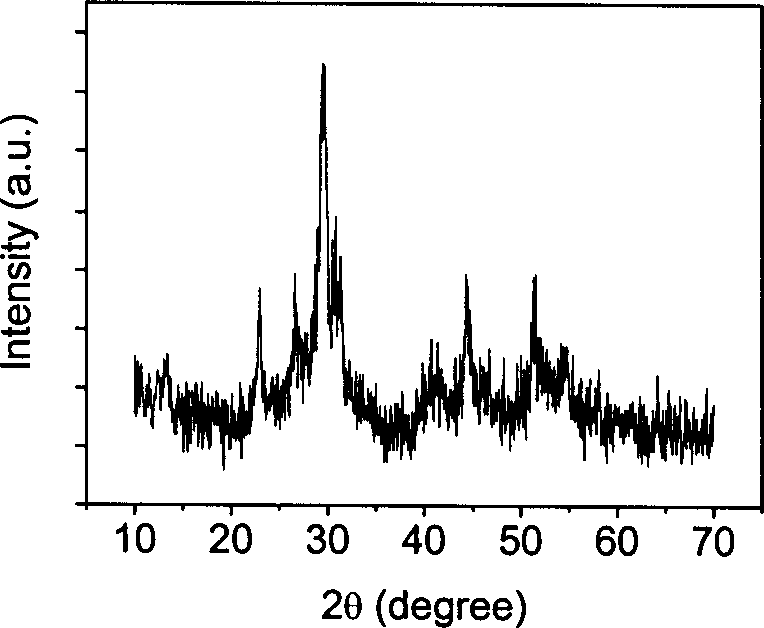

High performance lithium ion battery anode material lithium manganate and preparation method thereof

The invention provides a high performance lithium ion battery anode material lithium manganate and a preparation method of the material. The lithium manganate is a doped lithium manganate LiMn2-yXy04 which is doped with one kind or a plurality of other metal elements X, wherein X element is at least one kind selected form the group of aluminium, lithium, fluorine, silver, copper, chromium, zinc, titanium, bismuth, germanium, gallium, zirconium, stannum, silicon, cobalt, nickel, vanadium, magnesium, calcium, strontium, barium and rare earth elements lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium, and y is larger than 0 but less than or equal to 0.11. The lithium ion battery anode material lithium manganate provided in the invention has extraordinary charge and discharge cycle performance both in the environments of normal temperature and high temperature. According to the invention, the preparation method of the material is a solid phase method, the operation is simple and controllable and the cost is low so that it is easy to realize large-scale productions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

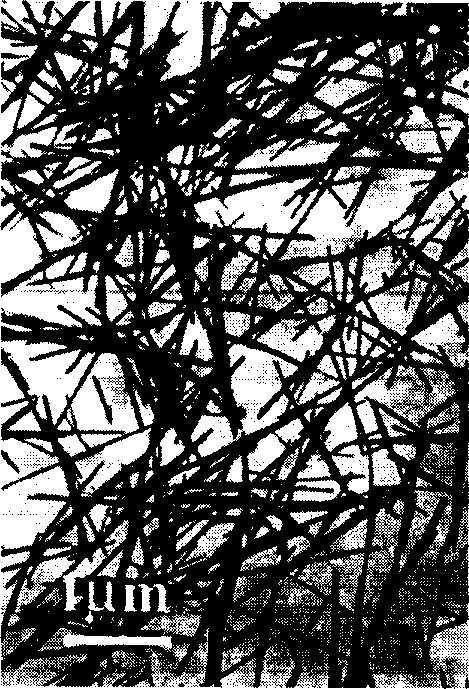

Synthesis process of nanostring and nanopowder of RE hydroxide or oxide

InactiveCN1403375ALarge specific surface areaSimple processRare earth metal compoundsRare-earth elementNanowire

Owner:TSINGHUA UNIV

Method for preparing positive active material for rechargeable lithium battery and positive active material prepared by same

ActiveUS7326498B2Inhibiting high-temperature swellingElectrode manufacturing processesNon-aqueous electrolyte accumulatorsRare-earth elementAlkaline earth metal

Disclosed is a method of preparing a positive active material for a rechargeable lithium battery including adding first and second compounds to a solvent to prepare an acidic solution with a pH from 0.01 to 3, the first compound including an element that is capable of forming a double bond with an oxygen of a lithium metal oxide, and the second compound including at least one element selected from the group consisting of alkali metals, alkali earth metals, group 13 elements, group 14 elements, transition metals and rare-earth elements; adding a lithium-containing compound to the acidic coating solution to coat the lithium-containing compound; and heat-treating the coated lithium-containing compound to form a surface-treatment layer comprising a compound represented by the formula MXOk where M is an element selected from the group consisting of alkali metals, alkali earth metals, group 13 elements, group 14 elements, transition metals, rare-earth elements and combinations thereof; X is an element that is capable of forming a double bond with oxygen; and k is an integer from 2 to 4.

Owner:SAMSUNG SDI CO LTD

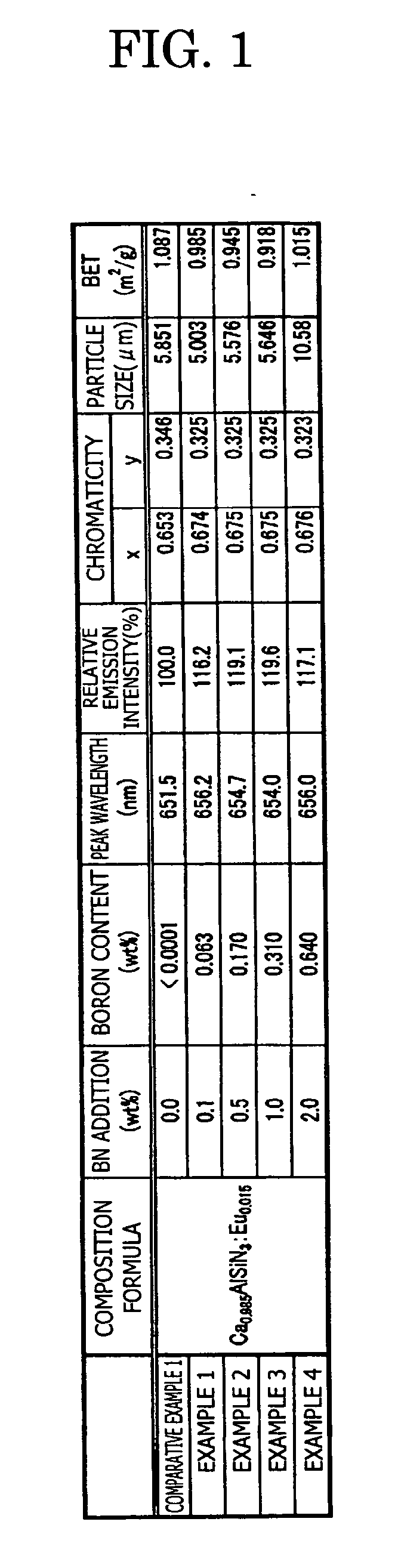

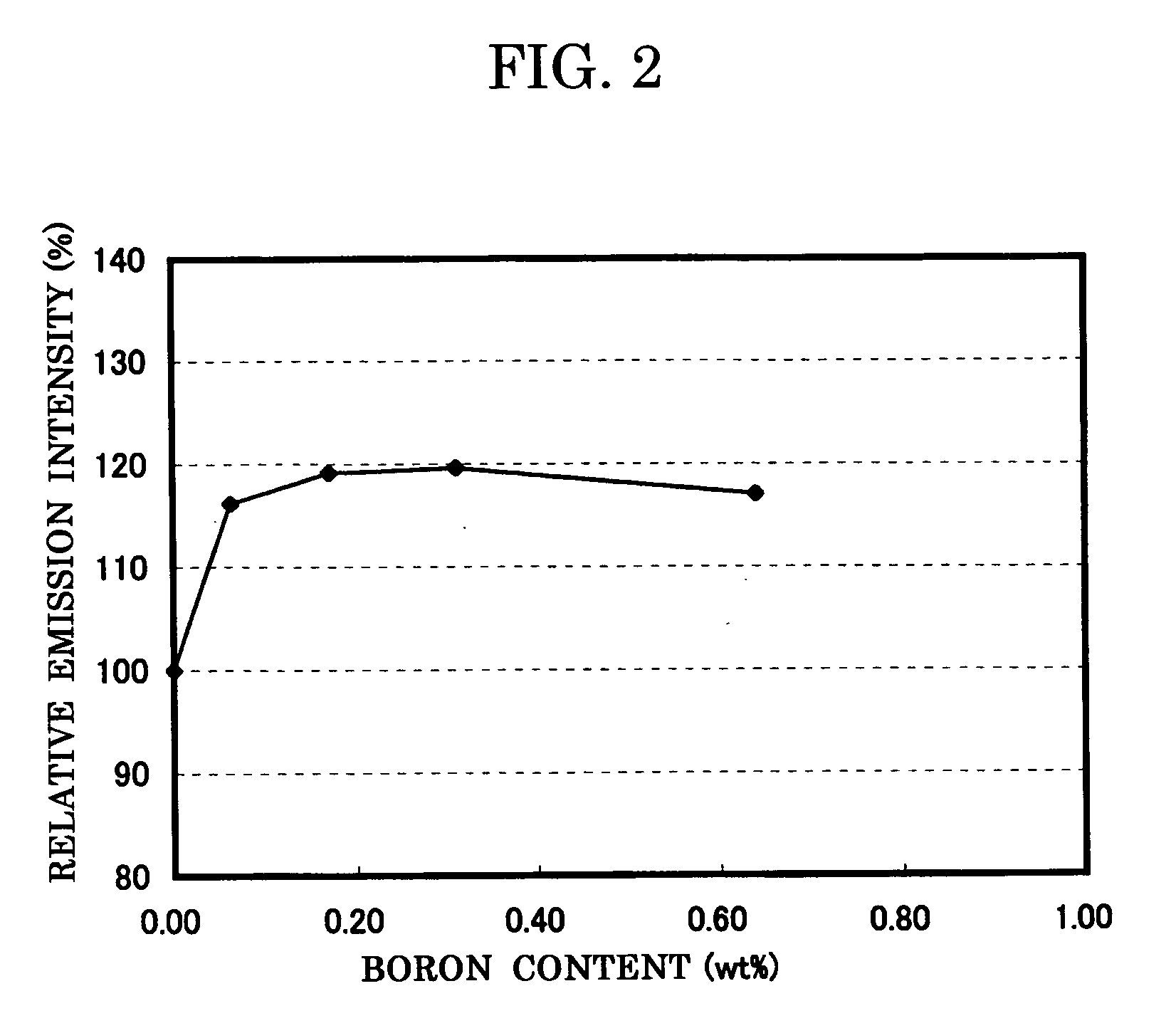

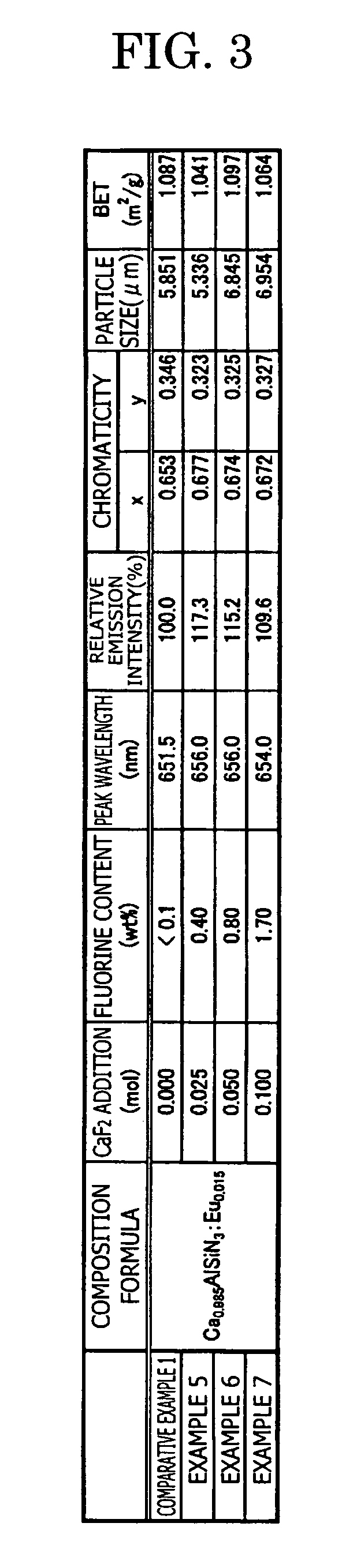

Phosphor and manufacturing method for the same, and light source

ActiveUS20060065878A1Improve emission efficiencyImprove efficiencySynthetic resin layered productsCellulosic plastic layered productsRare-earth elementUltraviolet

To provide a phosphor having an emission spectrum with a broad peak in a range from yellow color to red color (580 nm to 680 nm) and an excellent excitation band on the longer wavelength side from near ultraviolet / ultraviolet of excitation light to visible light (250 nm to 550 nm), and having an improved emission intensity. The phosphor is provided, which is given by a general composition formula expressed by MmAaBbOoNn:Z, (wherein element M is more than one kind of element having bivalent valency, element A is more than one kind of element having tervalent valency selected from the group consisting of Al, Ga, In, Tl, Y, Sc, P, As, Sb, and Bi, element B is more than one kind of element having tetravalent valency, O is oxygen, N is nitrogen, and element Z is more than one kind of element selected from rare earth elements or transitional metal elements, satisfying m>0, a>0, b>0 o≧0, and n=2 / 3m+a+4 / 3b−2 / 3o), and further containing boron and / or fluorine.

Owner:CITIZEN ELECTRONICS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com