Patents

Literature

1972 results about "Gadolinium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gadolinium is a chemical element with the symbol Gd and atomic number 64. Gadolinium is a silvery-white metal when oxidation is removed. It is only slightly malleable and is a ductile rare-earth element. Gadolinium reacts with atmospheric oxygen or moisture slowly to form a black coating. Gadolinium below its Curie point of 20 °C (68 °F) is ferromagnetic, with an attraction to a magnetic field higher than that of nickel. Above this temperature it is the most paramagnetic element. It is found in nature only in an oxidized form. When separated, it usually has impurities of the other rare-earths because of their similar chemical properties.

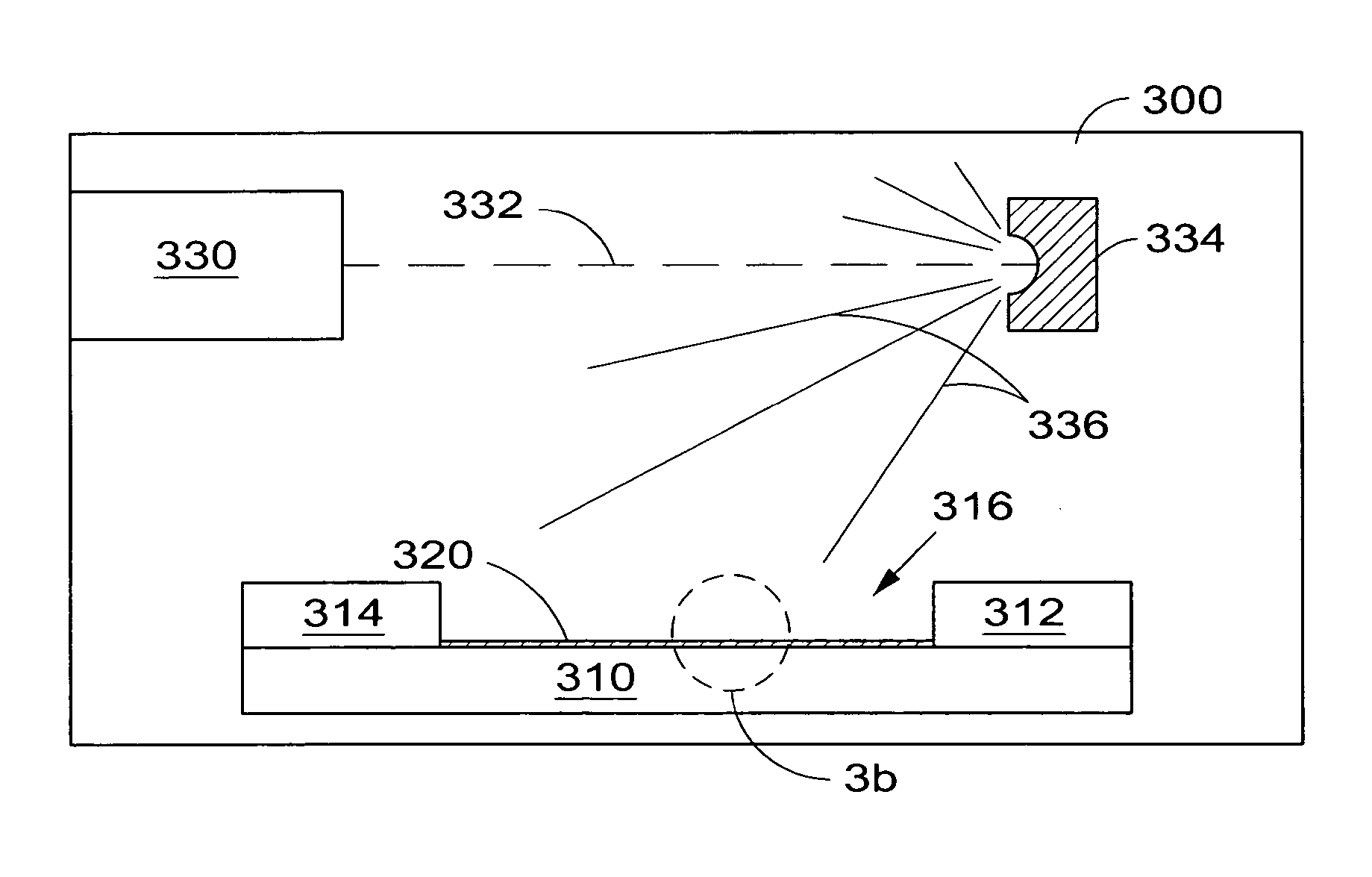

Gate oxides

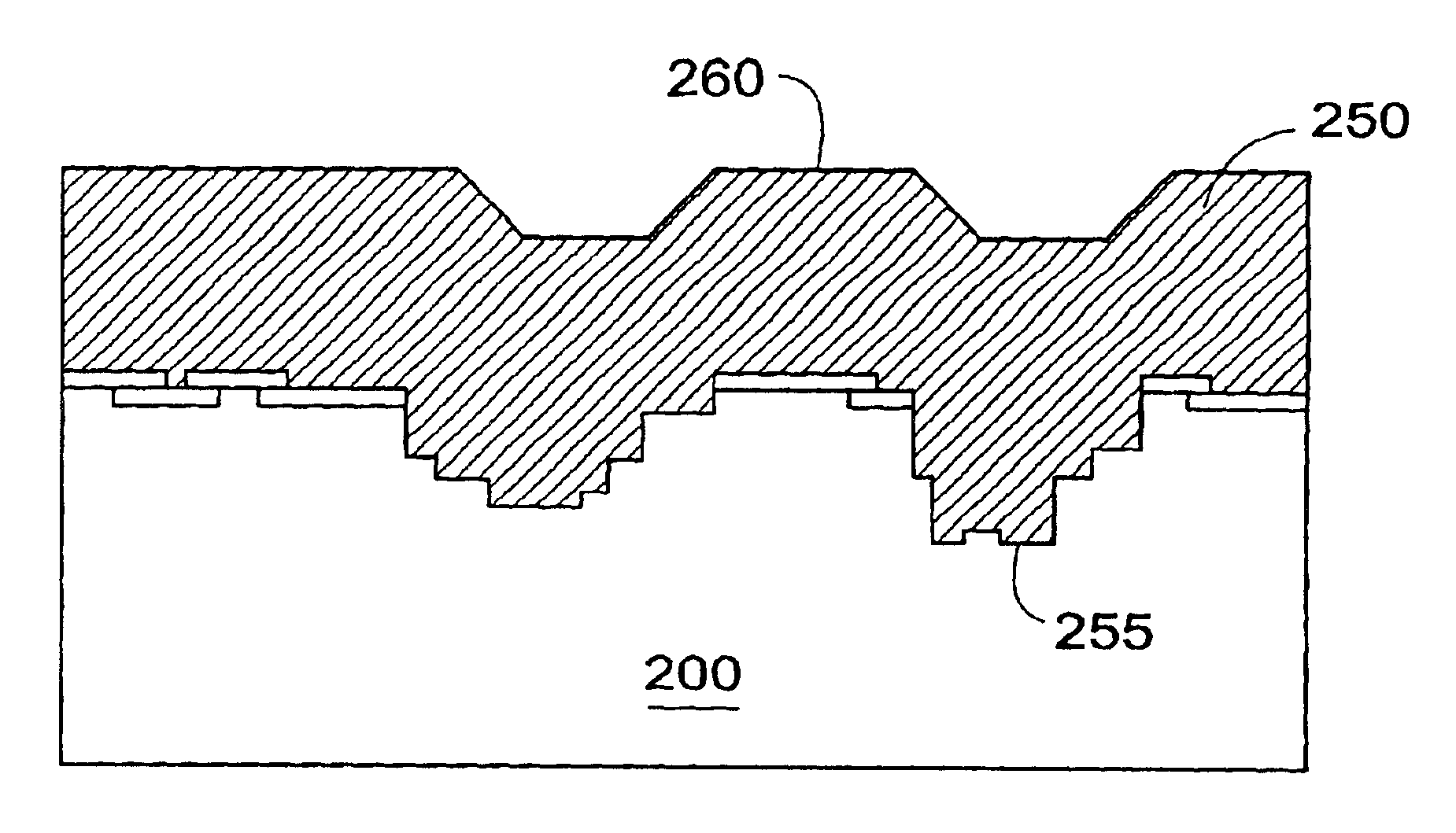

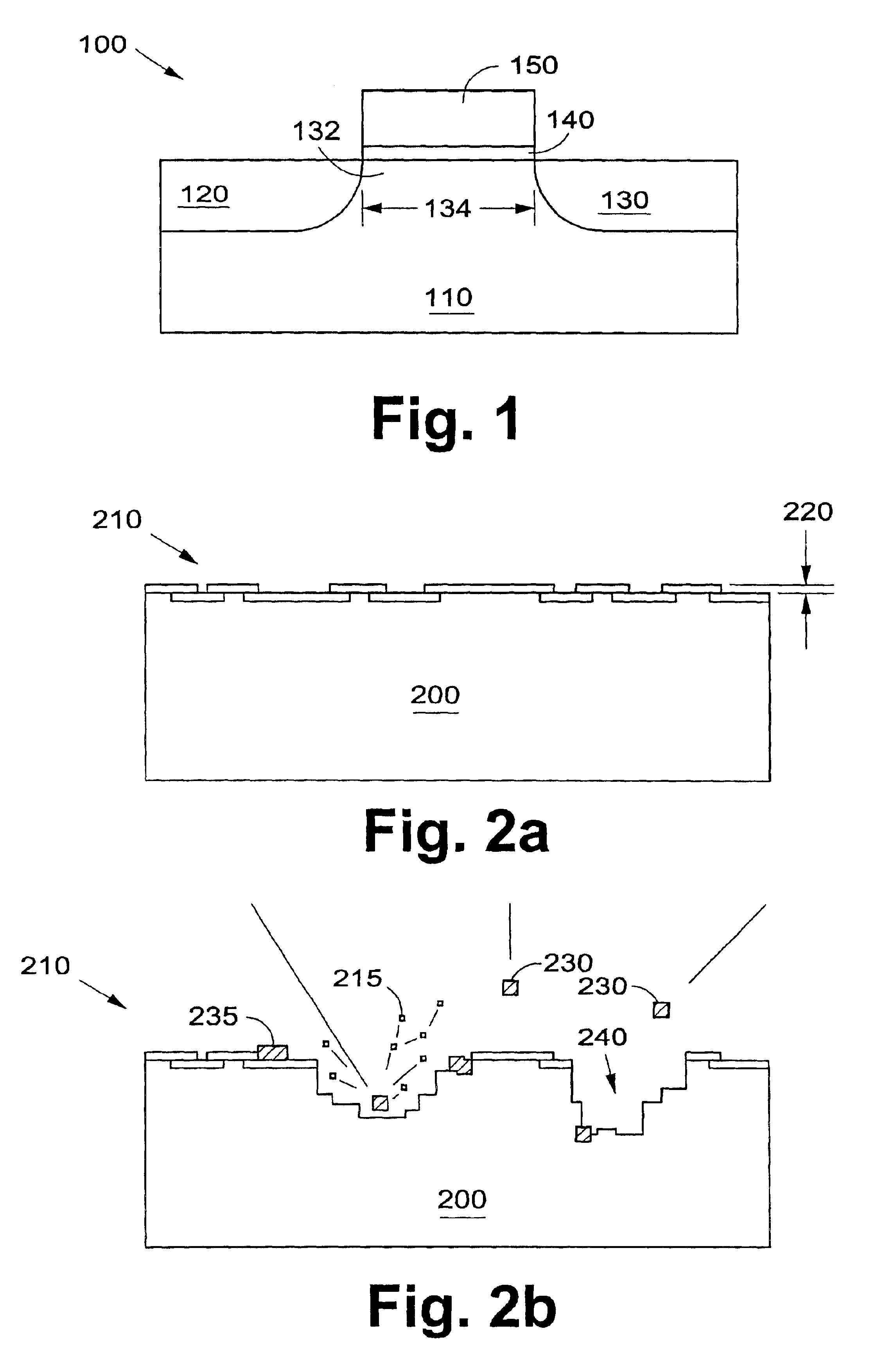

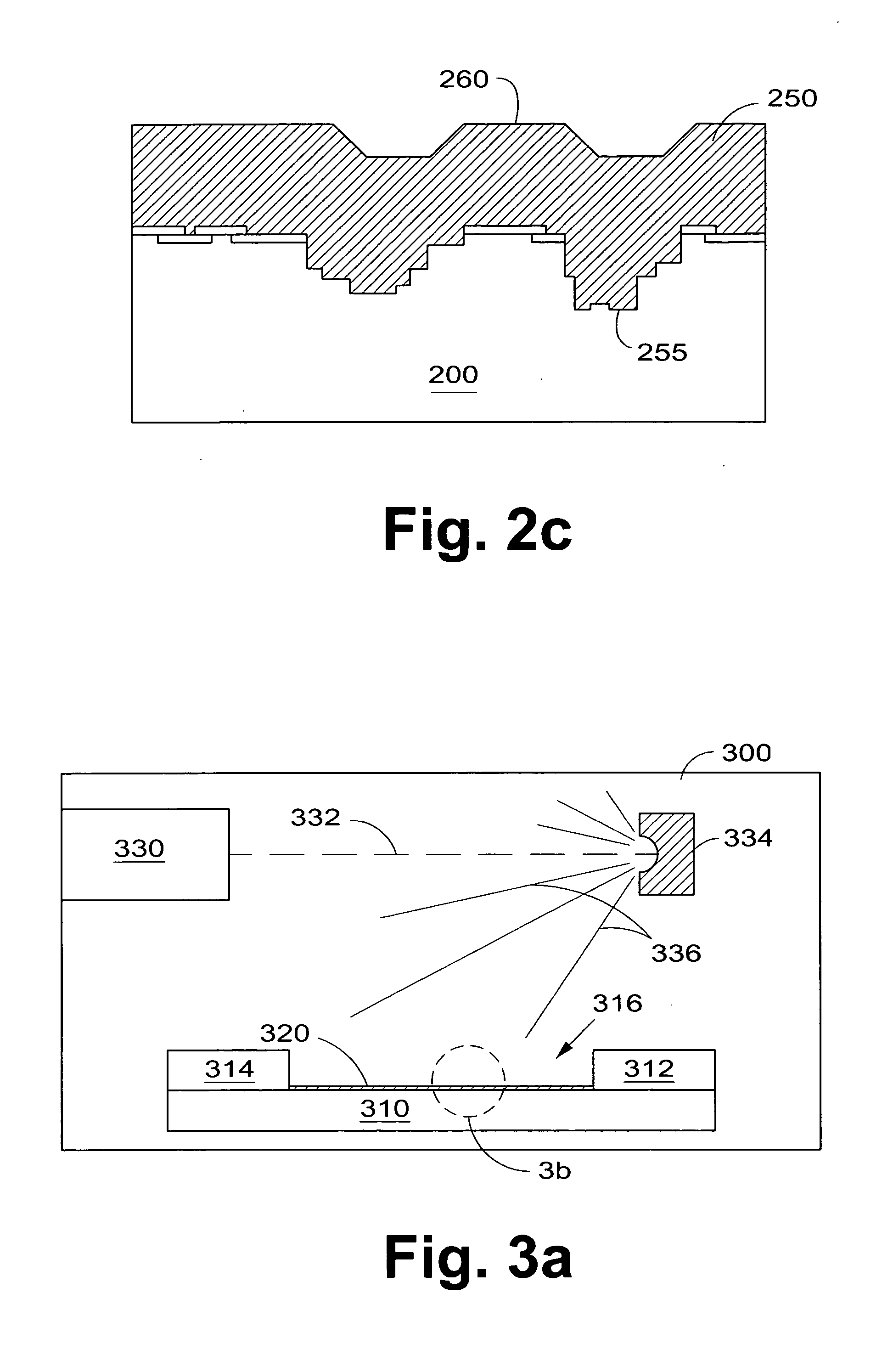

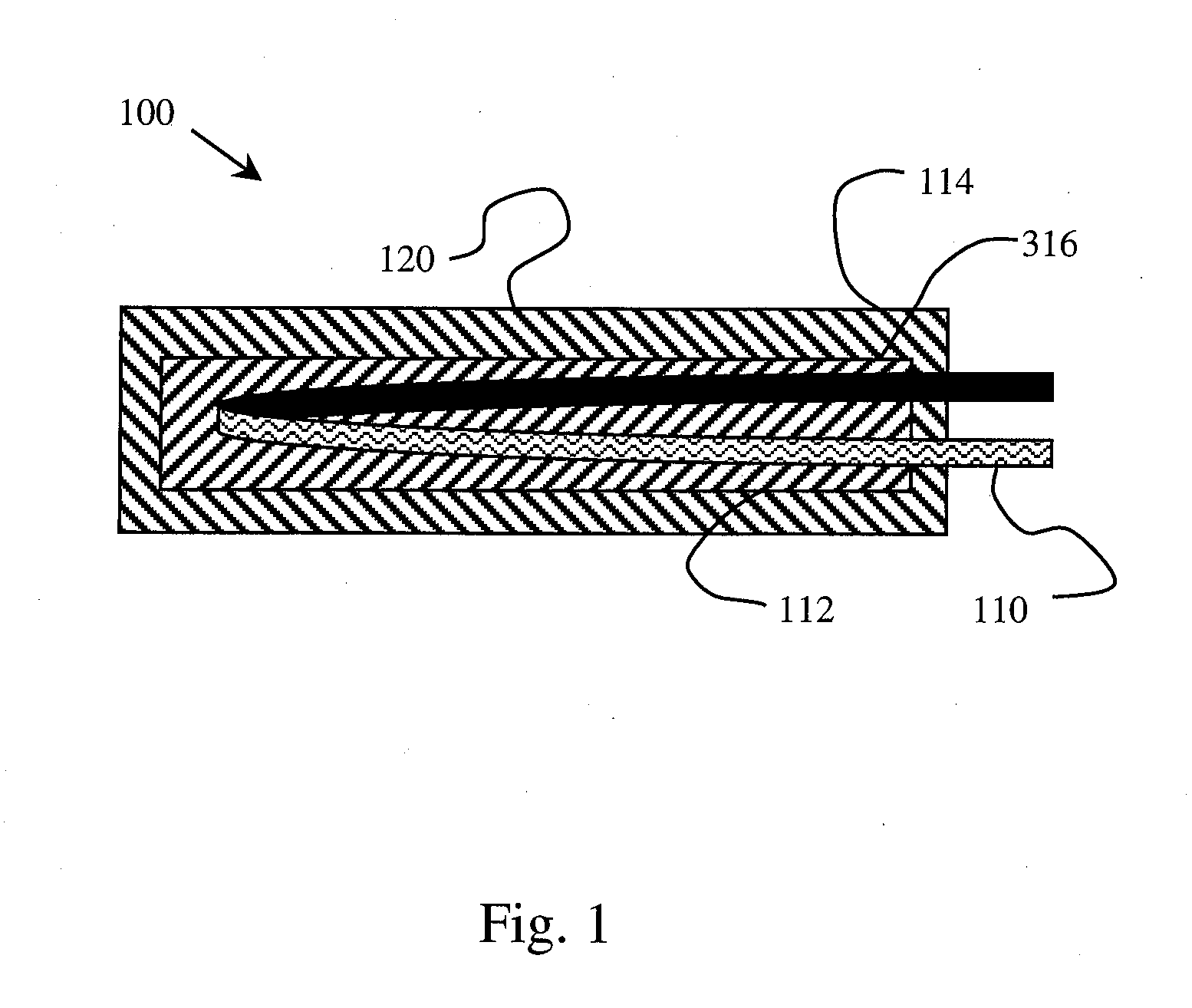

InactiveUS6844203B2Improve surface roughnessSmooth surface roughnessSemiconductor/solid-state device manufacturingSemiconductor devicesEquivalent oxide thicknessGadolinium

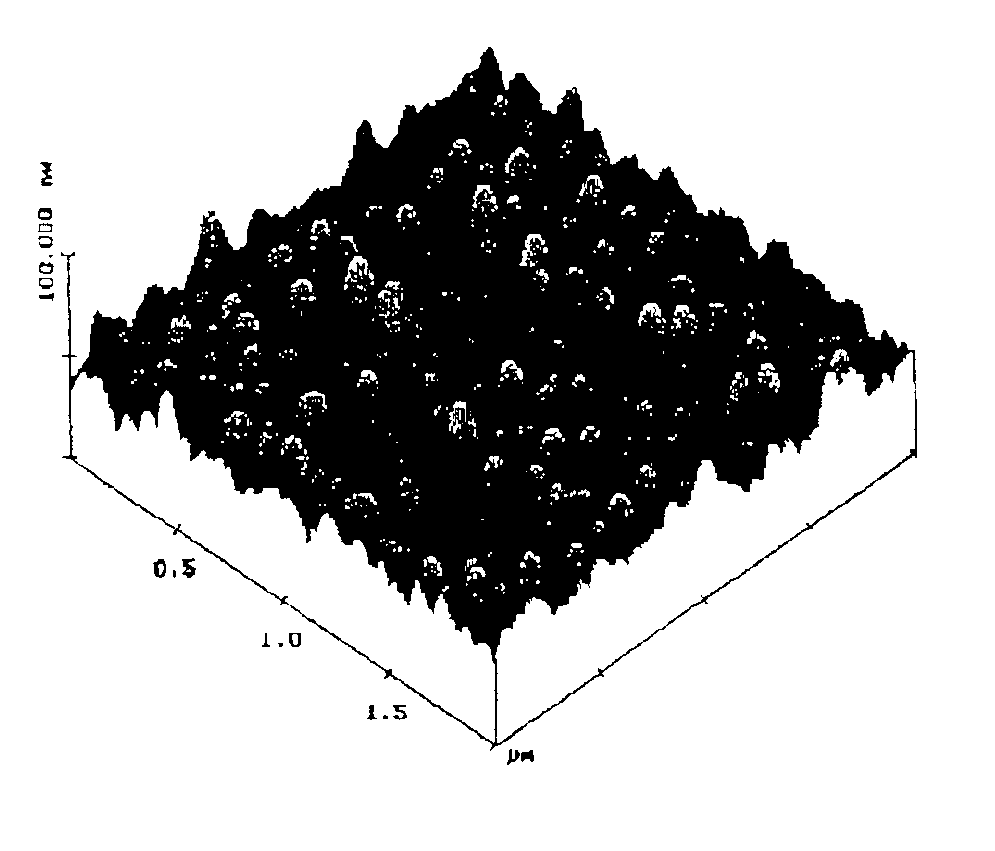

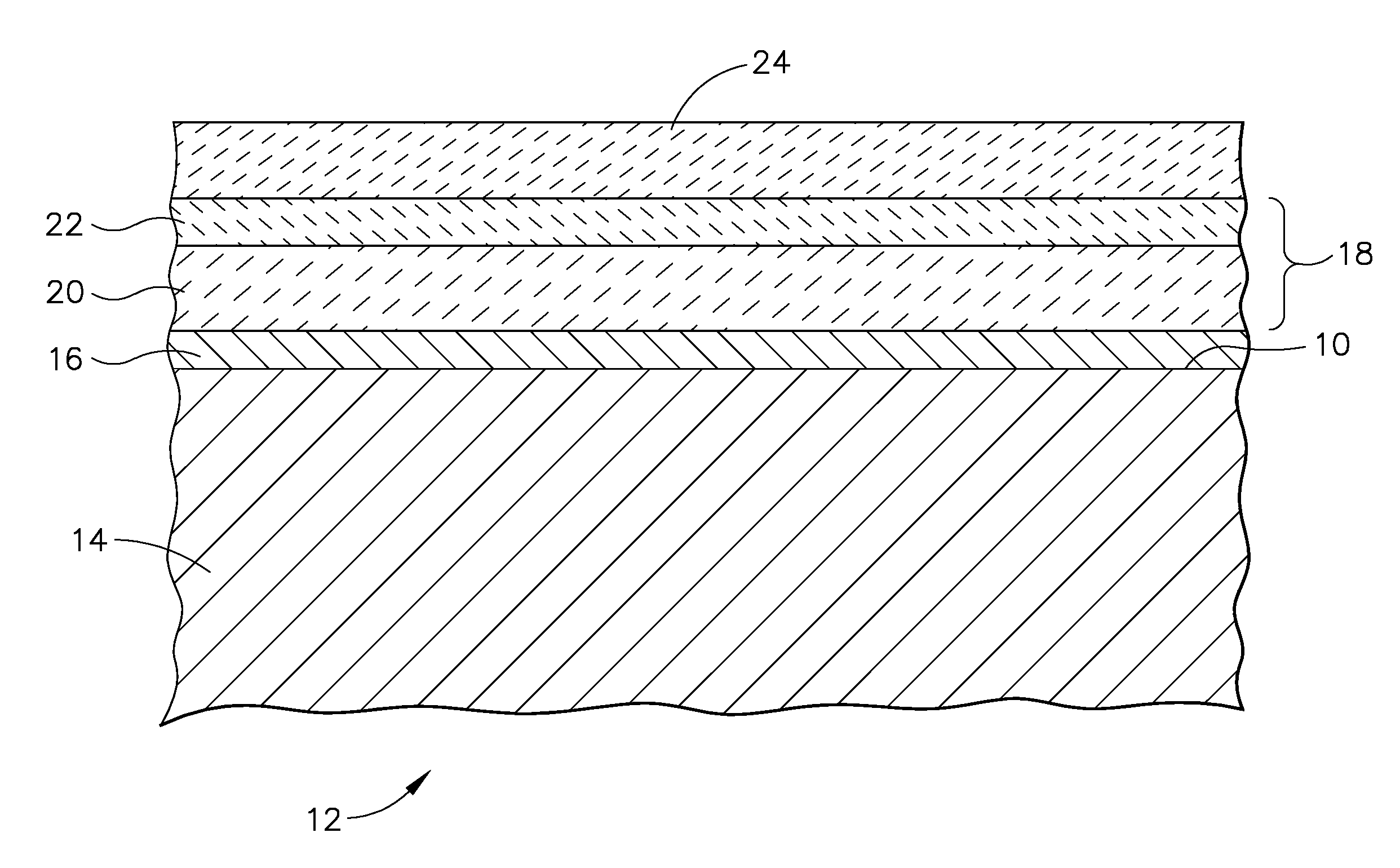

A gate oxide and method of fabricating a gate oxide that produces a more reliable and thinner equivalent oxide thickness than conventional SiO2 gate oxides are provided. Also shown is a gate oxide with a conduction band offset of 2 eV or greater. Gate oxides formed from elements such as yttrium and gadolinium are thermodynamically stable such that the gate oxides formed will have minimal reactions with a silicon substrate or other structures during any later high temperature processing stages. The process shown is performed at lower temperatures than the prior art, which further inhibits reactions with the silicon substrate or other structures. Using a thermal evaporation technique to deposit the layer to be oxidized, the underlying substrate surface smoothness is preserved, thus providing improved and more consistent electrical properties in the resulting gate oxide.

Owner:HEWLETT PACKARD CO +1

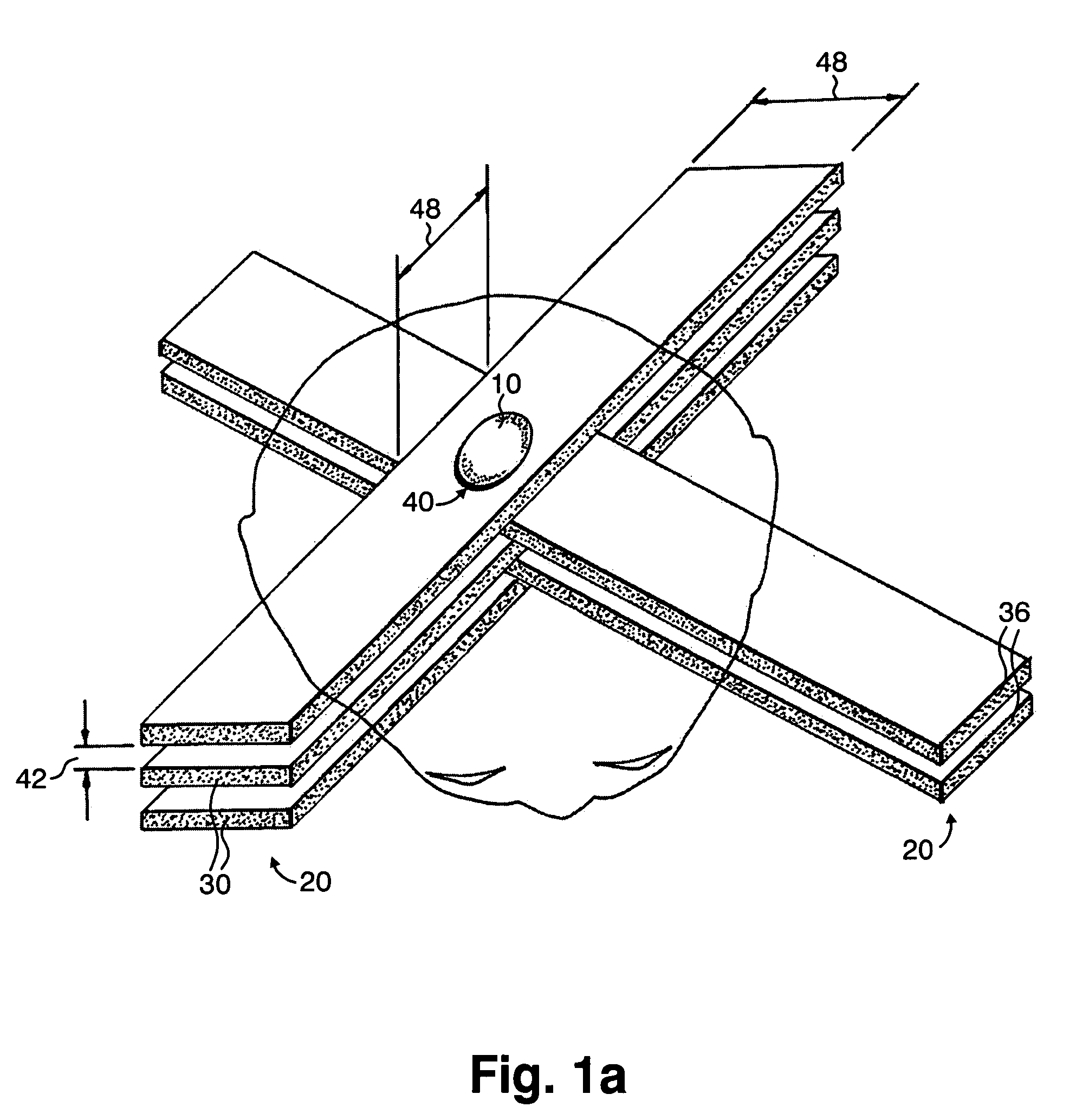

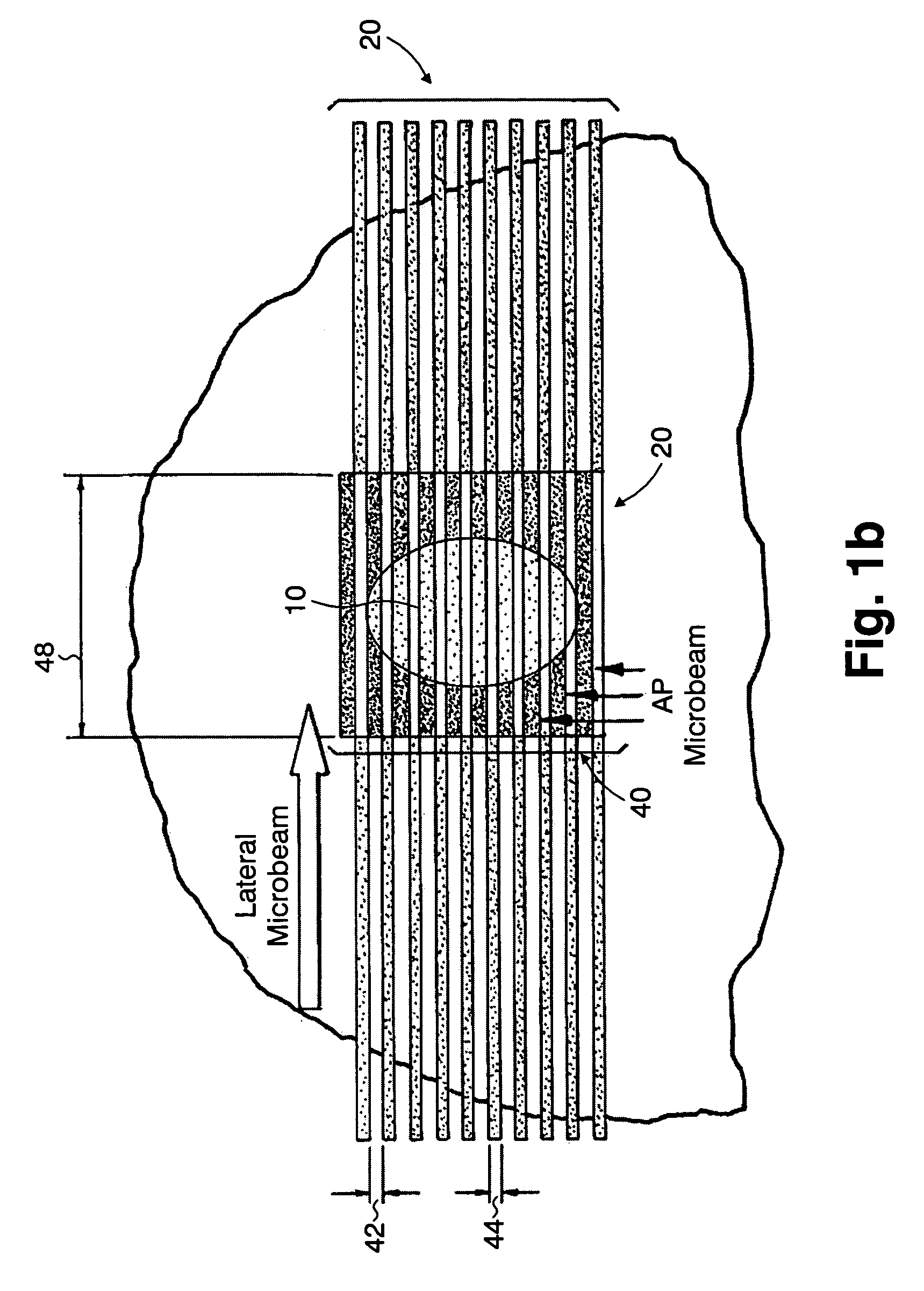

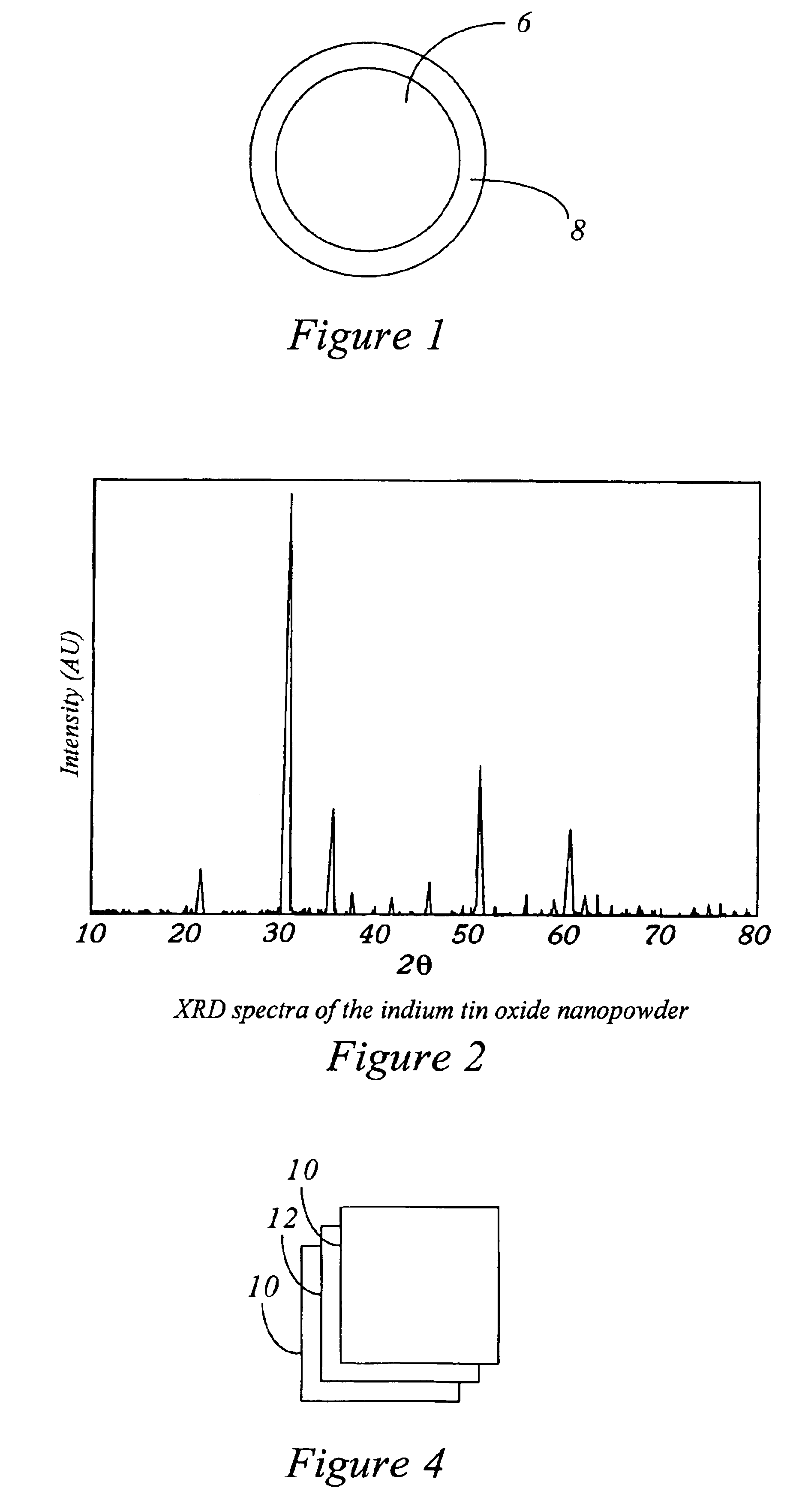

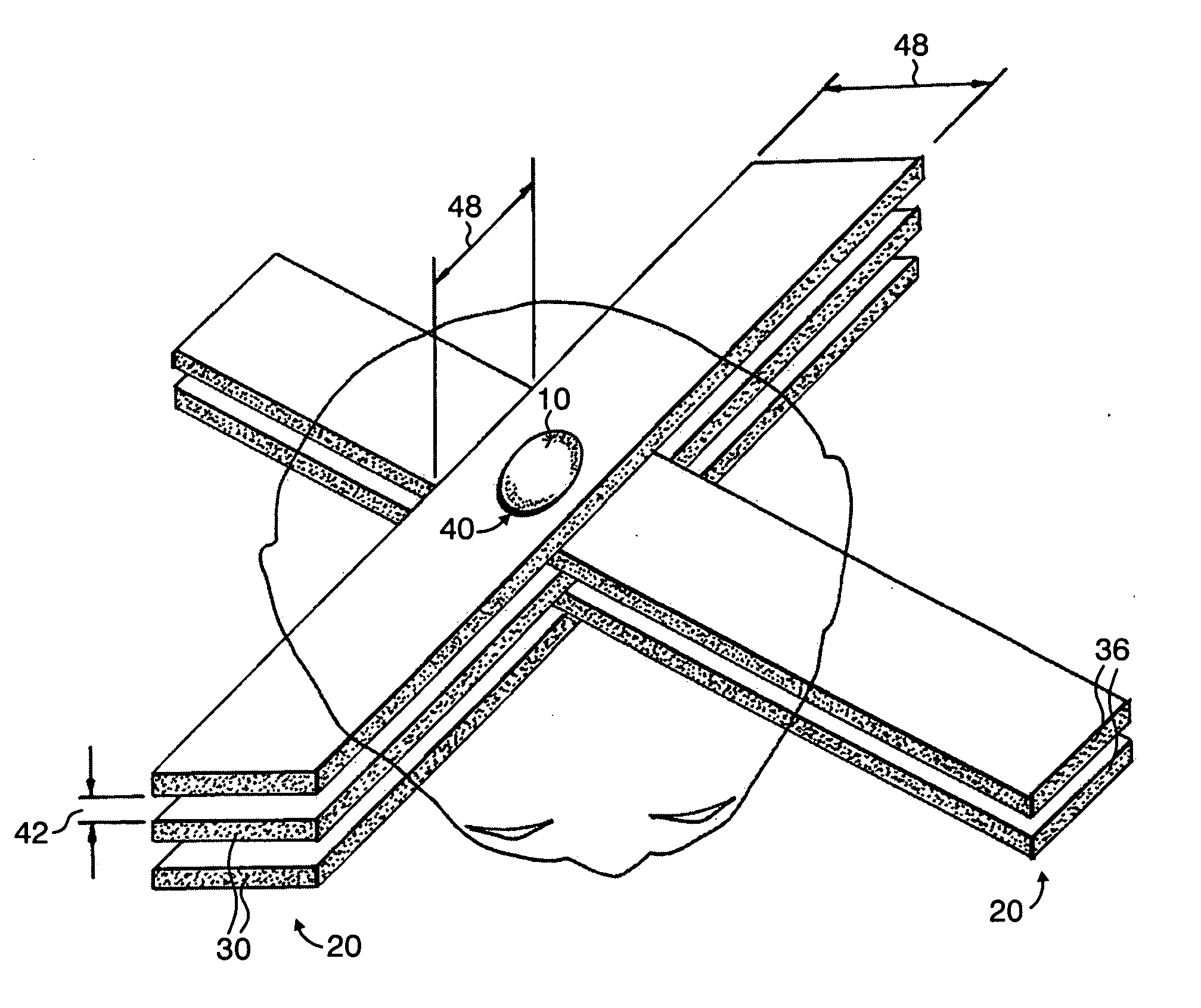

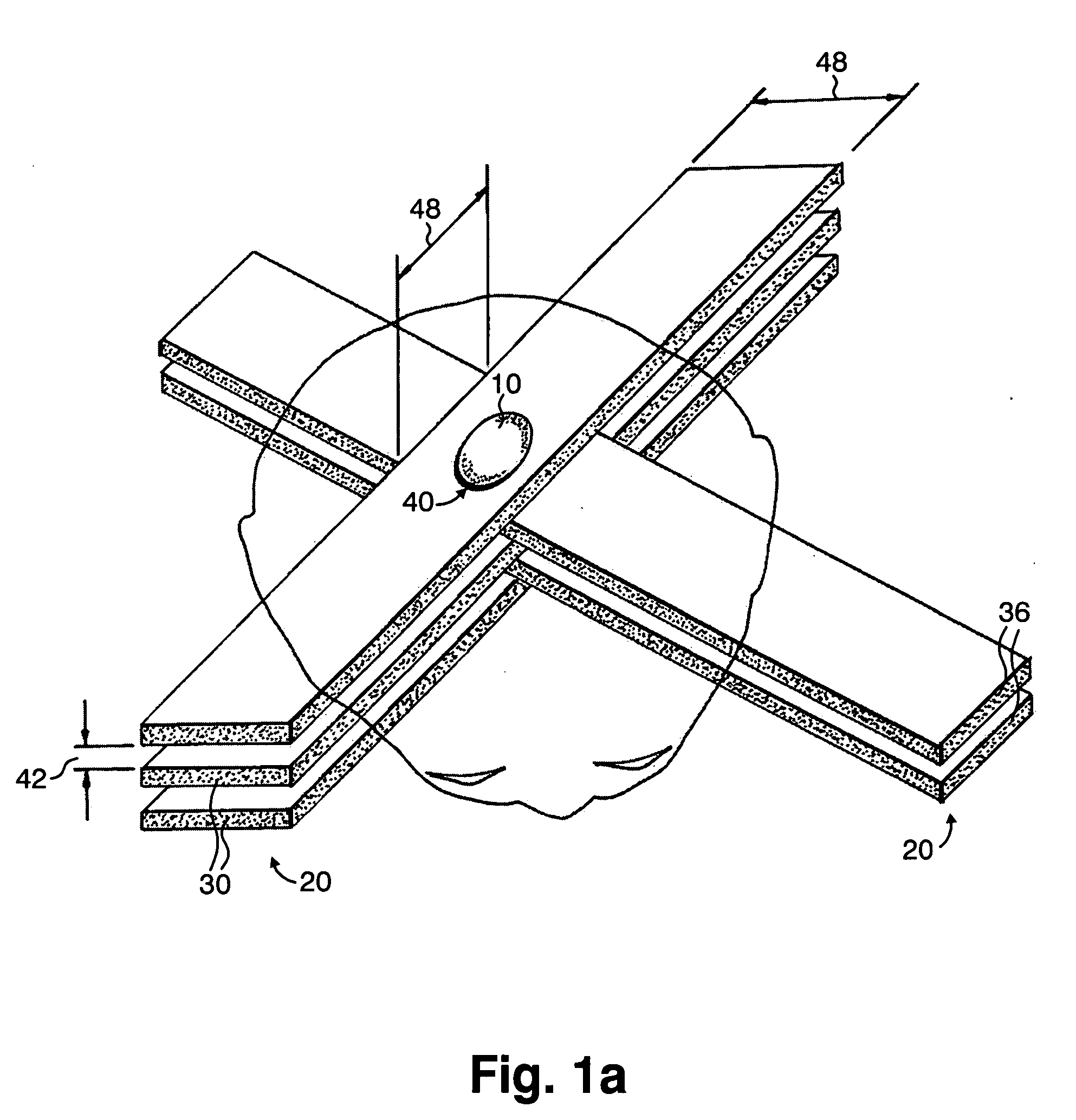

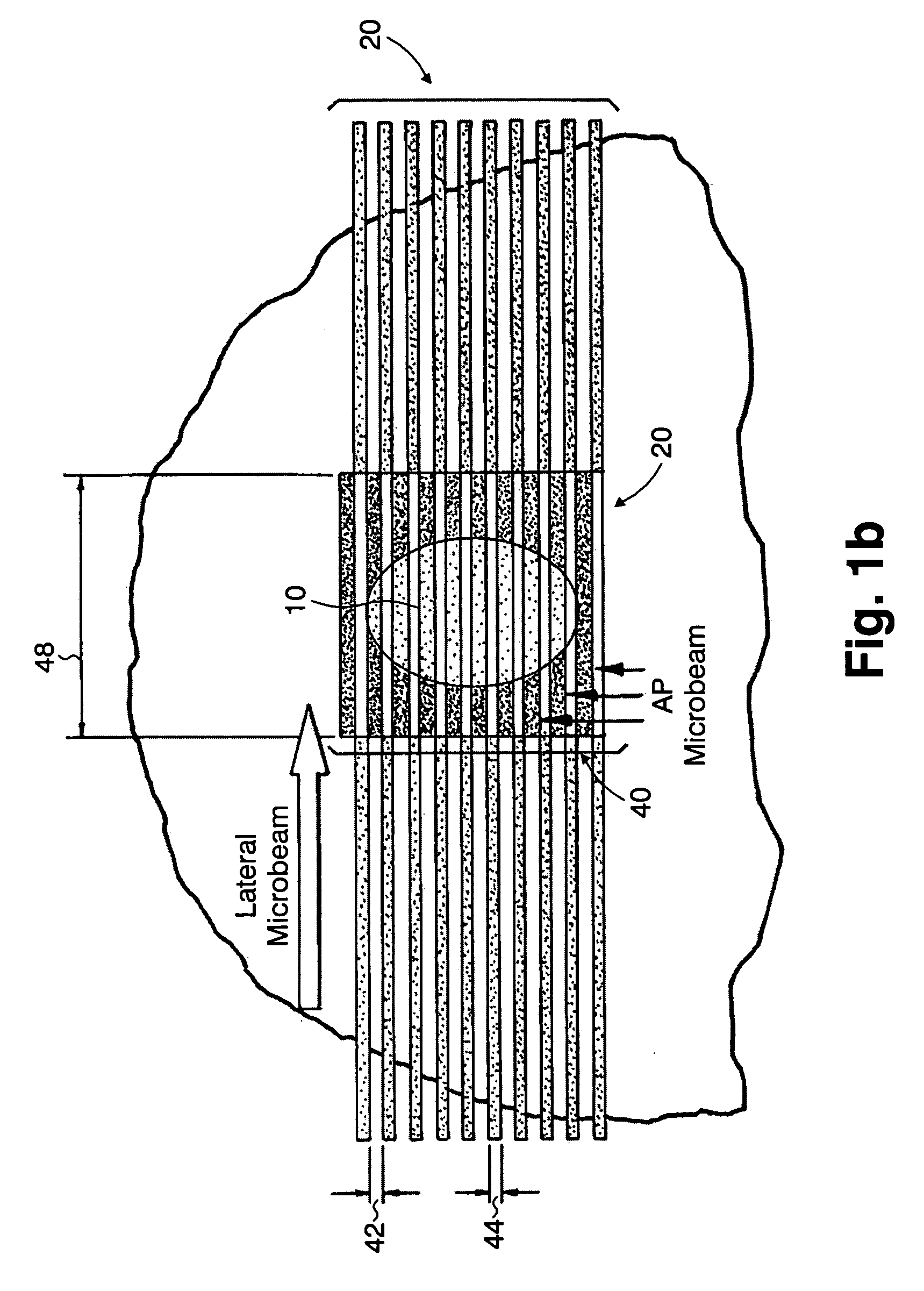

Methods for implementing microbeam radiation therapy

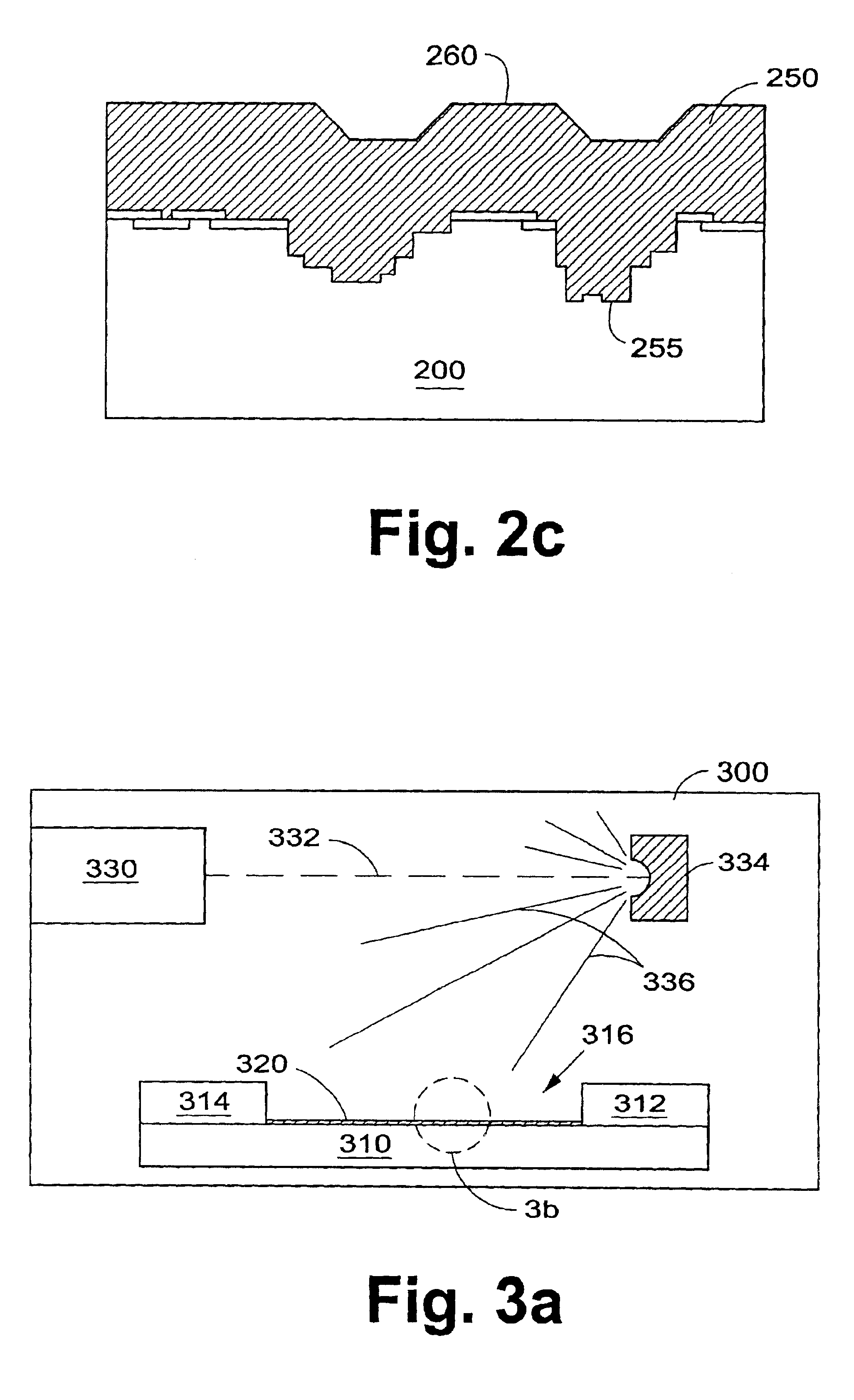

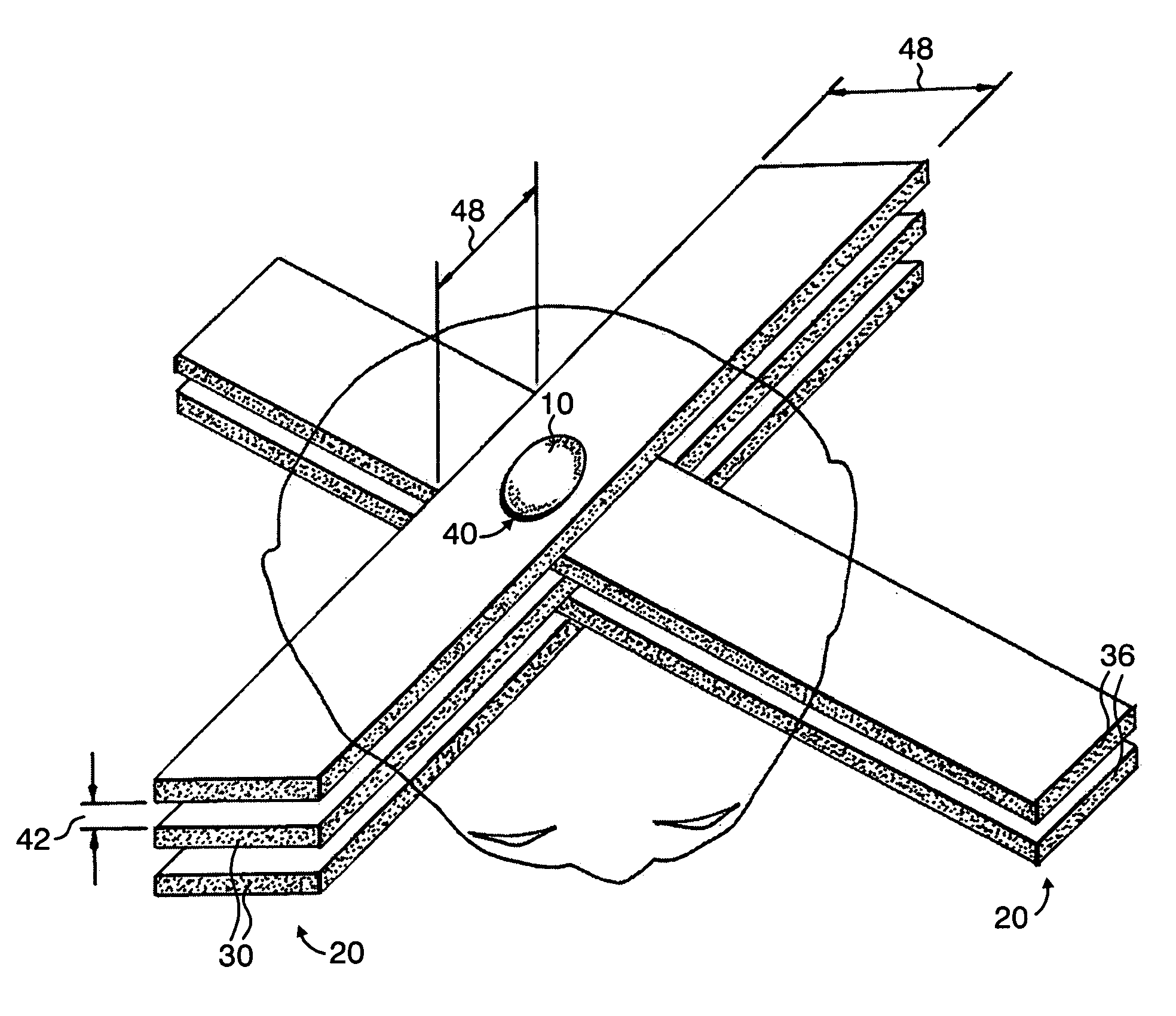

InactiveUS7194063B2Reduce harmEasily damagedIrradiation devicesX-ray/gamma-ray/particle-irradiation therapyLight beamGadolinium

A method of performing radiation therapy includes delivering a therapeutic dose such as X-ray only to a target (e.g., tumor) with continuous broad beam (or in-effect continuous) using arrays of parallel planes of radiation (microbeams / microplanar beams). Microbeams spare normal tissues, and when interlaced at a tumor, form a broad-beam for tumor ablation. Bidirectional interlaced microbeam radiation therapy (BIMRT) uses two orthogonal arrays with inter-beam spacing equal to beam thickness. Multidirectional interlaced MRT (MIMRT) includes irradiations of arrays from several angles, which interleave at the target. Contrast agents, such as tungsten and gold, are administered to preferentially increase the target dose relative to the dose in normal tissue. Lighter elements, such as iodine and gadolinium, are used as scattering agents in conjunction with non-interleaving geometries of array(s) (e.g., unidirectional or cross-fired (intersecting) to generate a broad beam effect only within the target by preferentially increasing the valley dose within the tumor.

Owner:BROOKHAVEN SCI ASSOCS

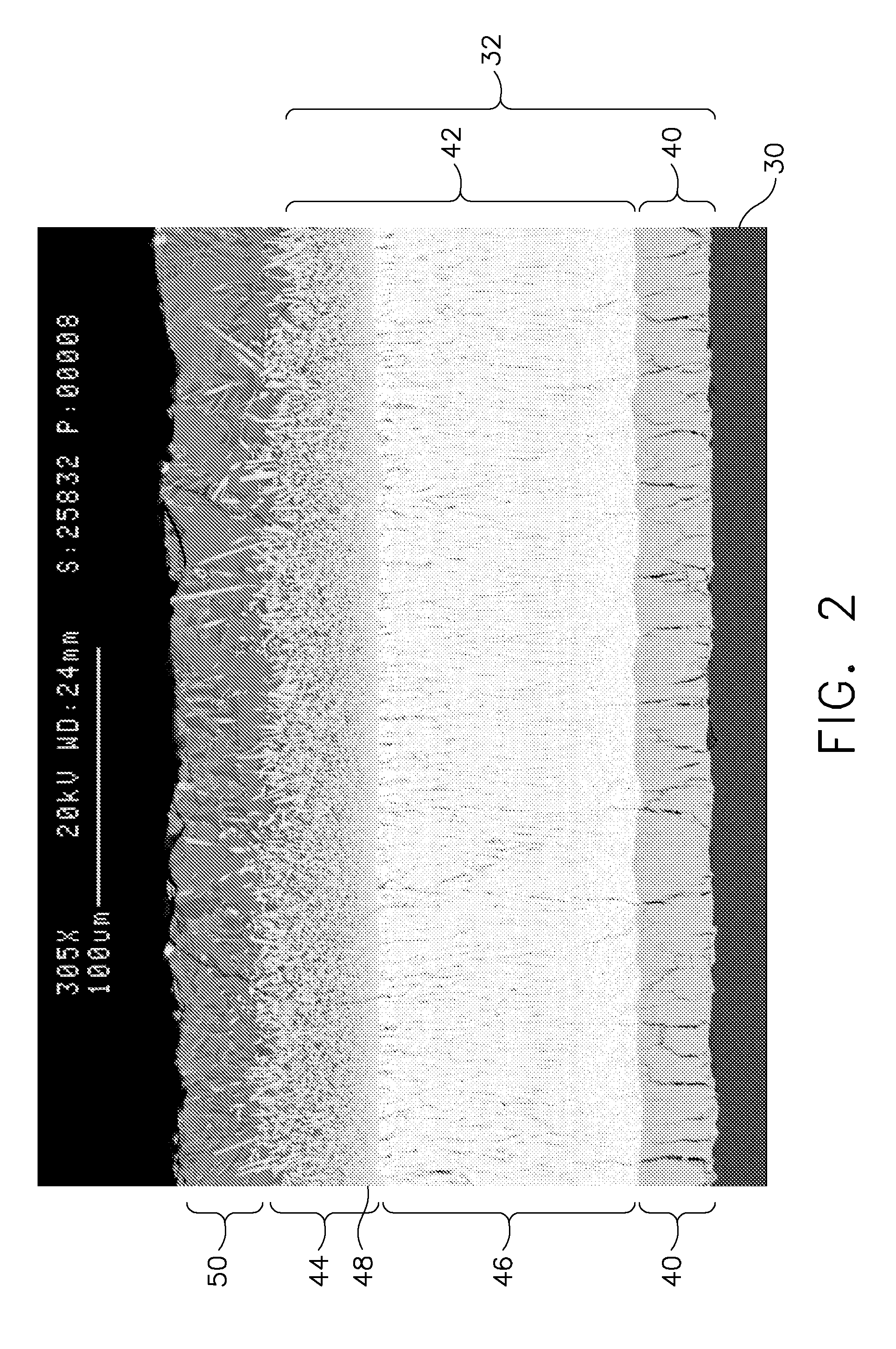

Crystalline or amorphous medium-K gate oxides, Y2O3 and Gd2O3

InactiveUS20050032292A1Semiconductor/solid-state device manufacturingSemiconductor devicesEquivalent oxide thicknessGadolinium

A gate oxide and method of fabricating a gate oxide that produces a more reliable and thinner equivalent oxide thickness than conventional SiO2 gate oxides are provided. Also shown is a gate oxide with a conduction band offset of 2 eV or greater. Gate oxides formed from elements such as yttrium and gadolinium are thermodynamically stable such that the gate oxides formed will have minimal reactions with a silicon substrate or other structures during any later high temperature processing stages. The process shown is performed at lower temperatures than the prior art, which further inhibits reactions with the silicon substrate or other structures. Using a thermal evaporation technique to deposit the layer to be oxidized, the underlying substrate surface smoothness is preserved, thus providing improved and more consistent electrical properties in the resulting gate oxide.

Owner:MICRON TECH INC

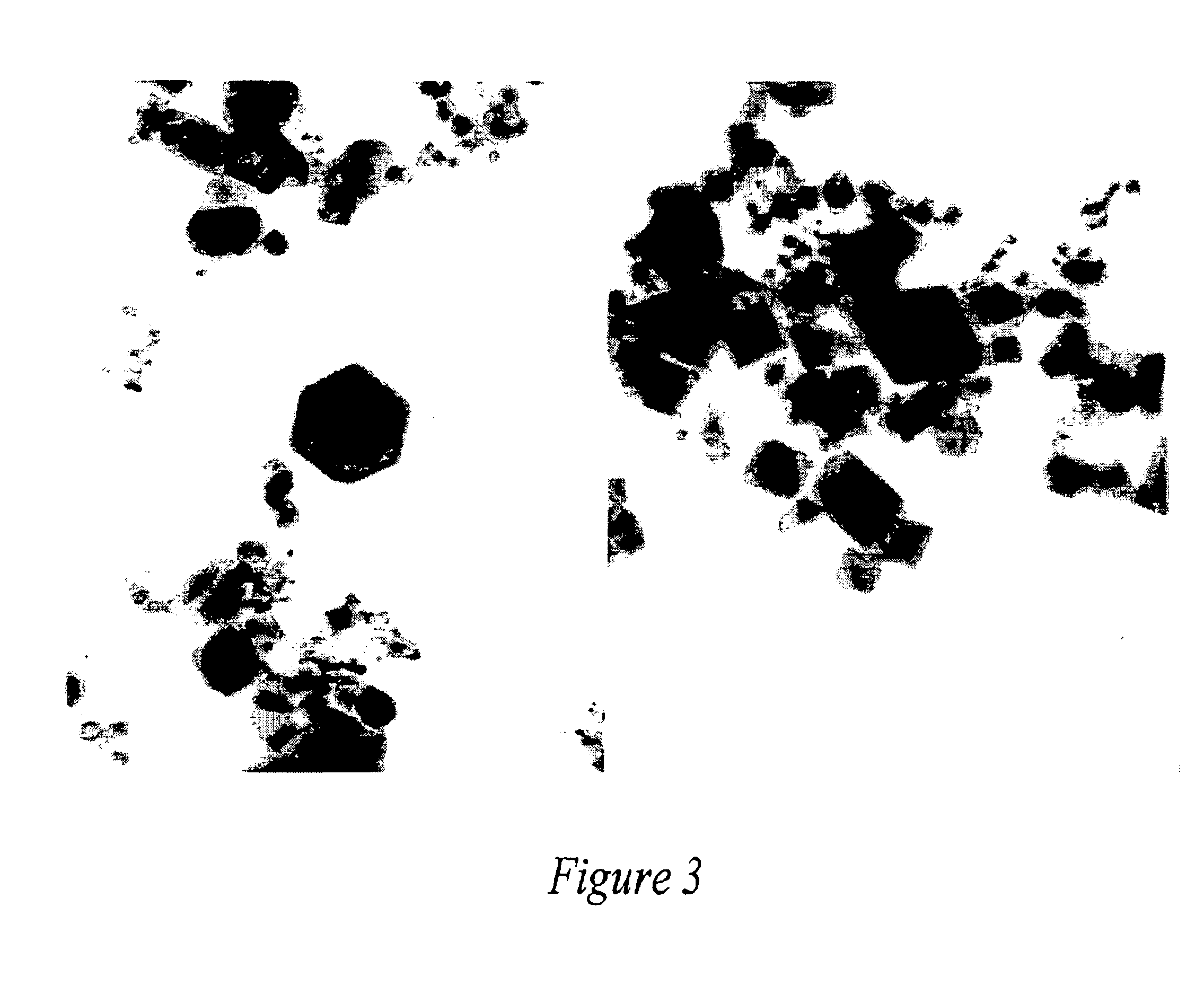

Polymer nanocomposite implants with enhanced transparency and mechanical properties for administration within humans or animals

Polymer nanocomposite implants with nanofillers and additives are described. The nanofillers described can be any composition with the preferred composition being those composing barium, bismuth, cerium, dysprosium, europium, gadolinium, hafnium, indium, lanthanum, neodymium, niobium, praseodymium, strontium, tantalum, tin, tungsten, ytterbium, yttrium, zinc, and zirconium. The additives can be of any composition with the preferred form being inorganic nanopowders comprising aluminum, calcium, gallium, iron, lithium, magnesium, silicon, sodium, strontium, titanium. Such nanocomposites are particularly useful as materials for biological use in applications such as drug delivery, biomed devices, bone or dental implants.

Owner:PPG IND OHIO INC

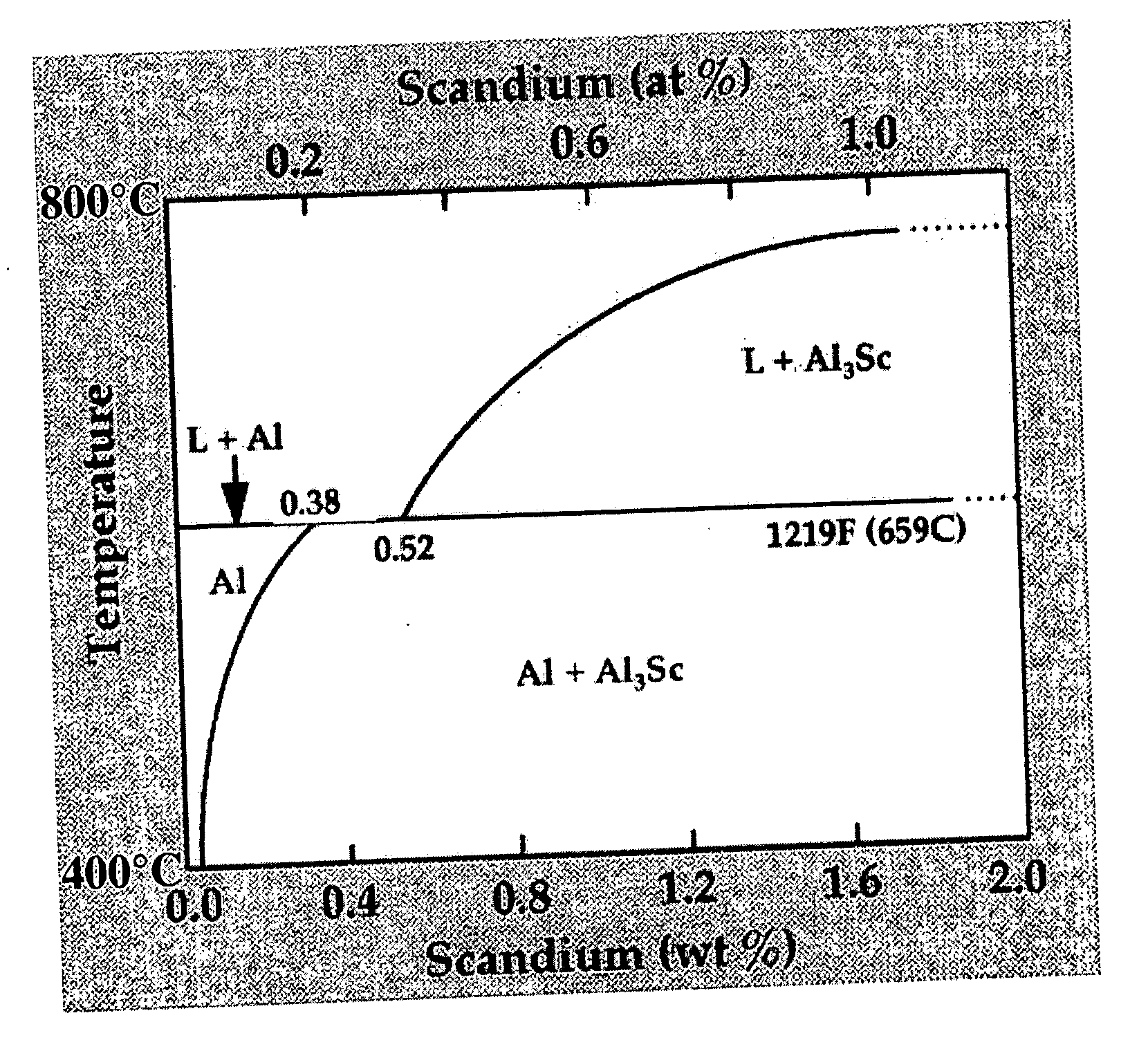

High temperature aluminum alloys

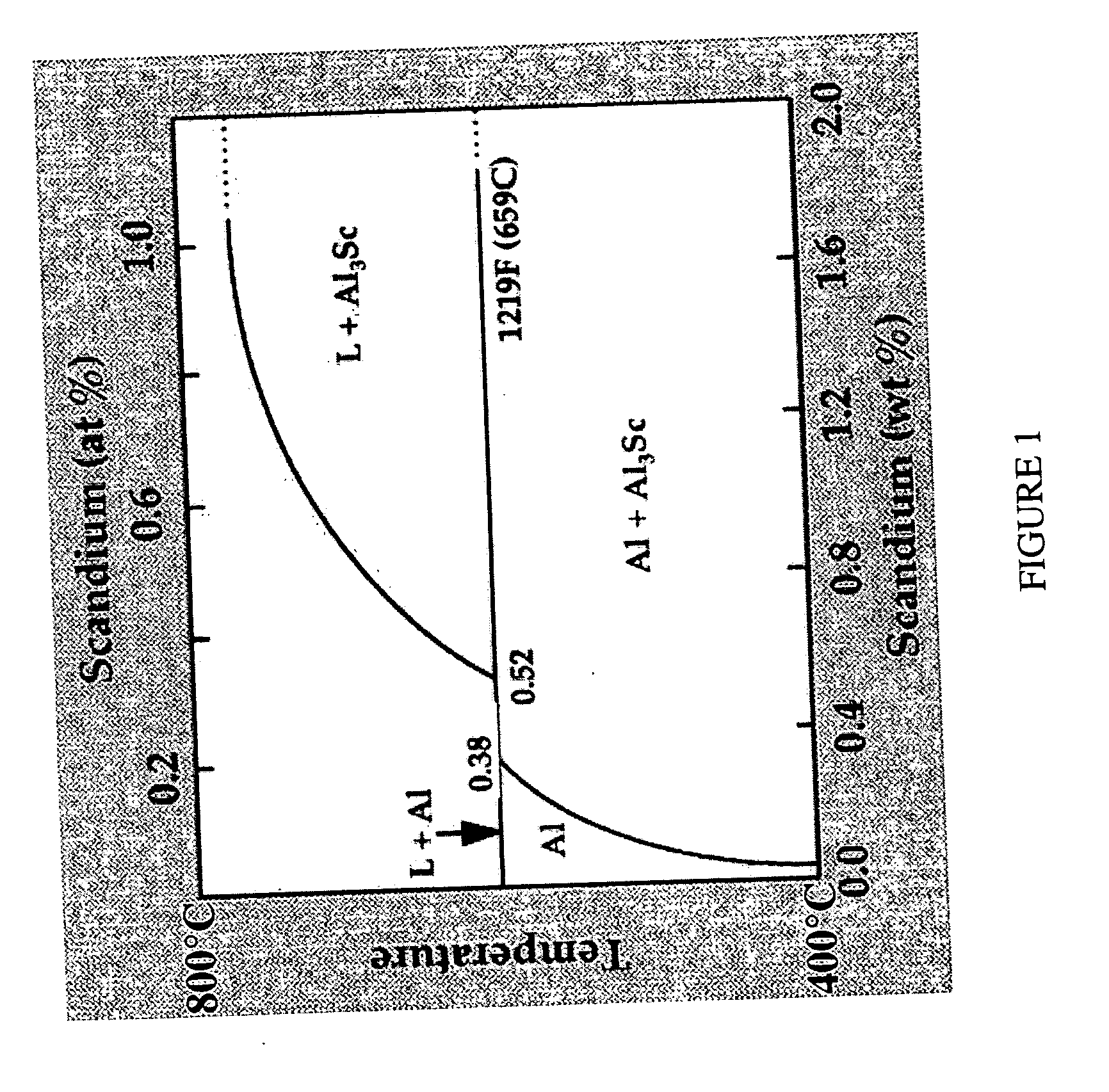

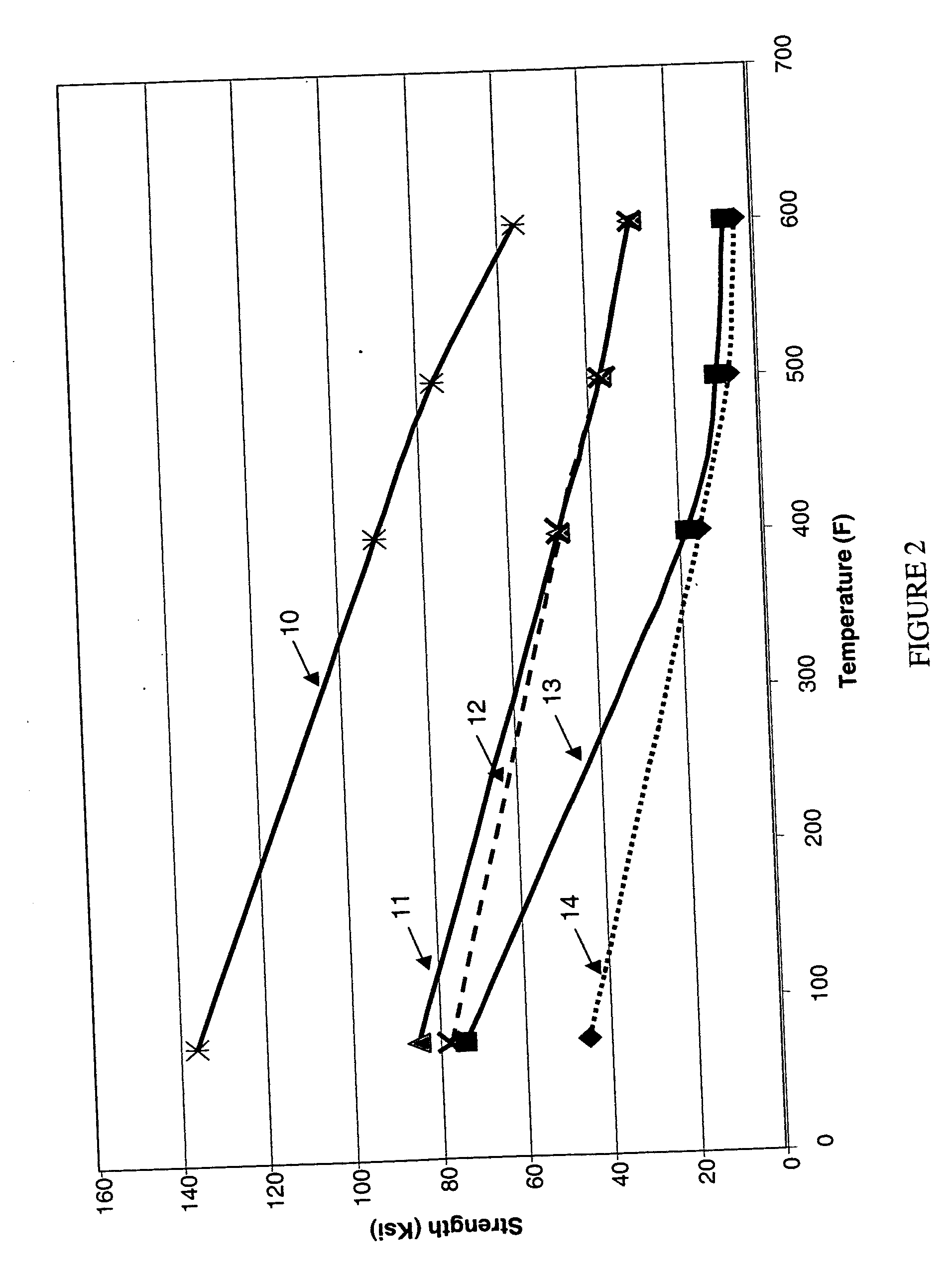

High temperature aluminum alloys that can be used at temperatures from about −420° F. (−251° C.) up to about 650° F. (343° C.) are described herein. These alloys comprise aluminum; scandium; at least one of nickel, iron, chromium, manganese and cobalt; and at least one of zirconium, gadolinium, hafnium, yttrium, niobium and vanadiuim. These alloys comprise an aluminum solid solution matrix and a mixture of various dispersoids. These alloys are substantially free of magnesium.

Owner:RTX CORP

Method of depositing rare earth oxide thin films

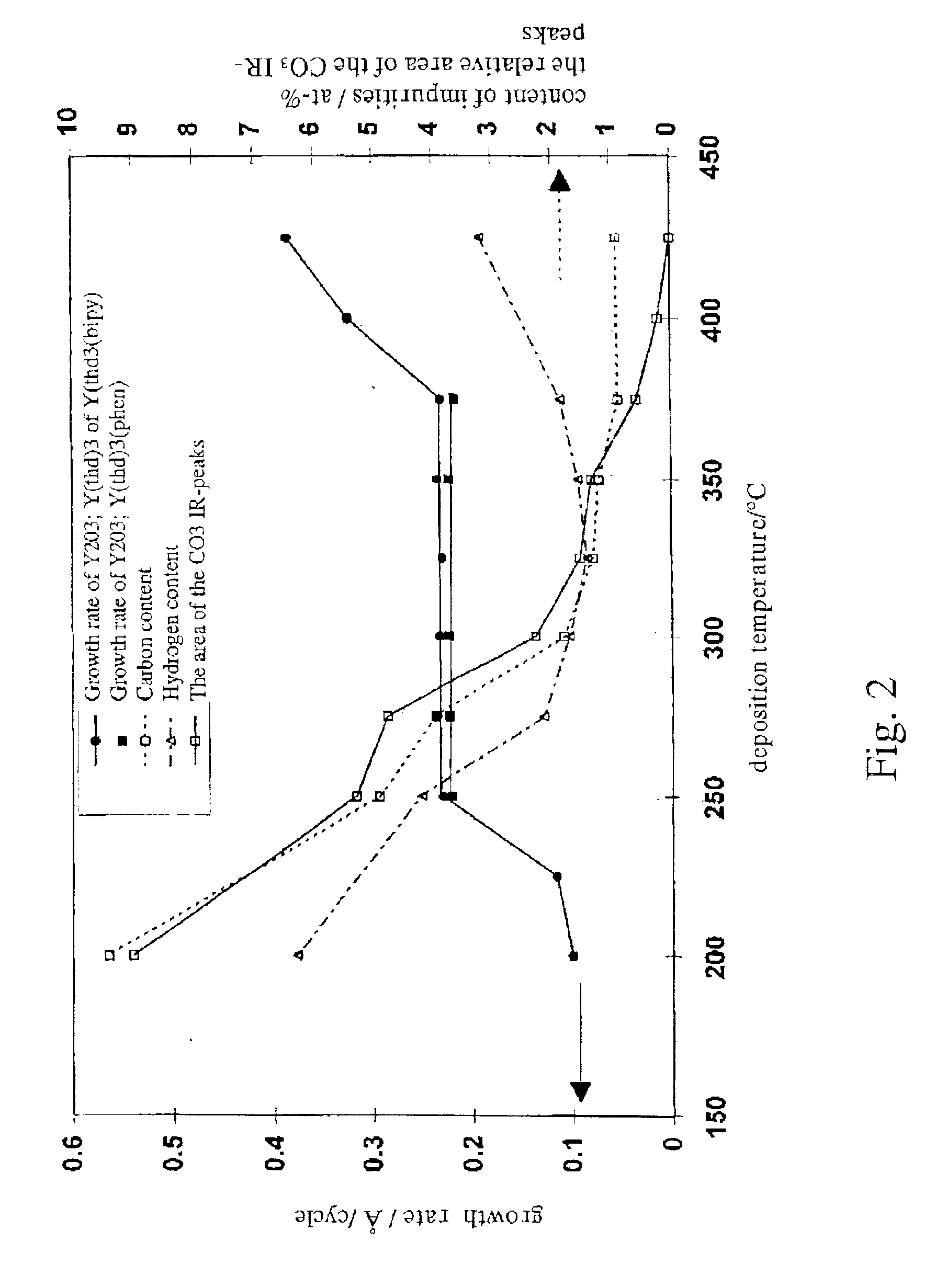

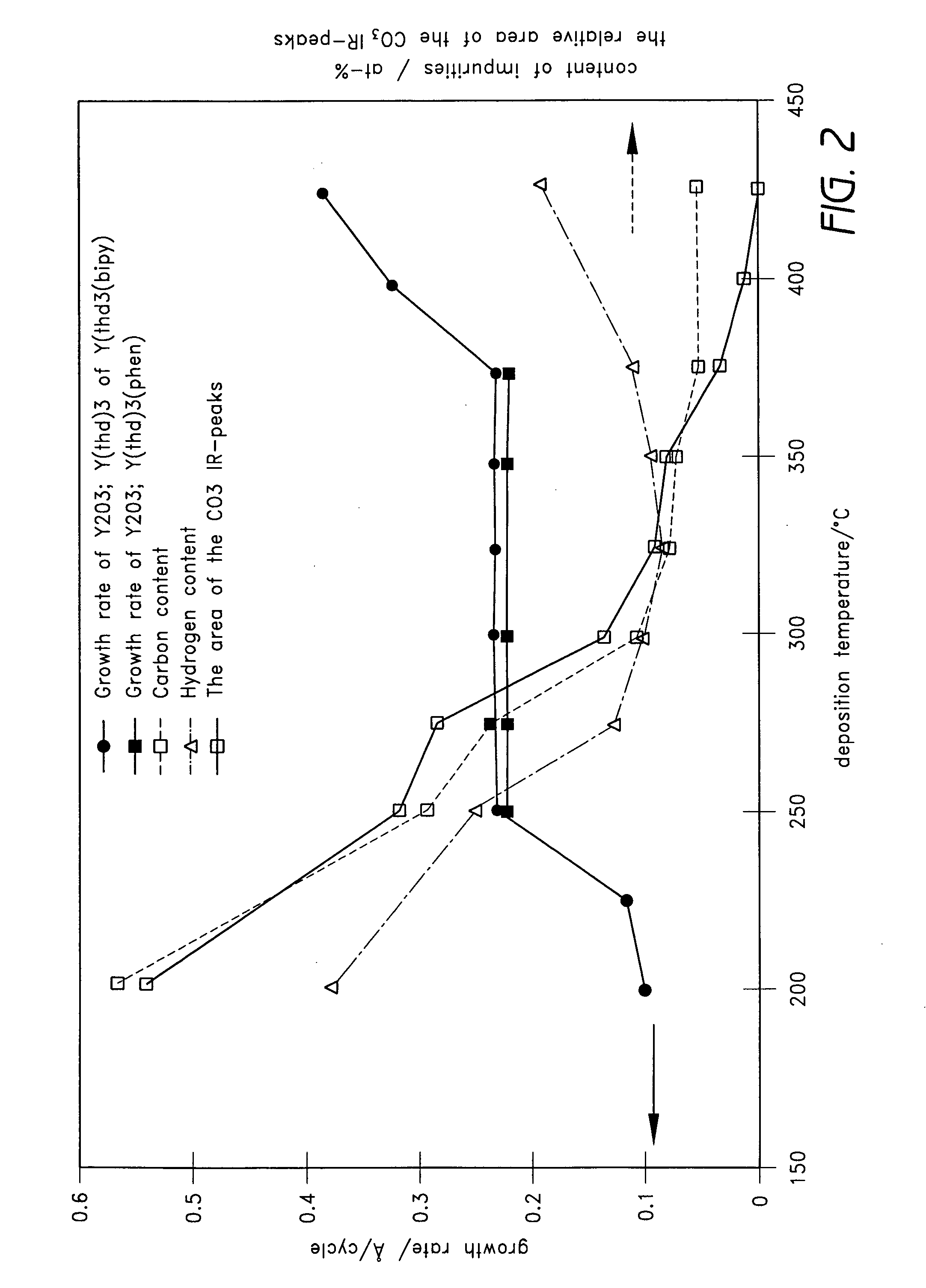

InactiveUS6858546B2Increase probabilityIncrease ratingsPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureGadolinium

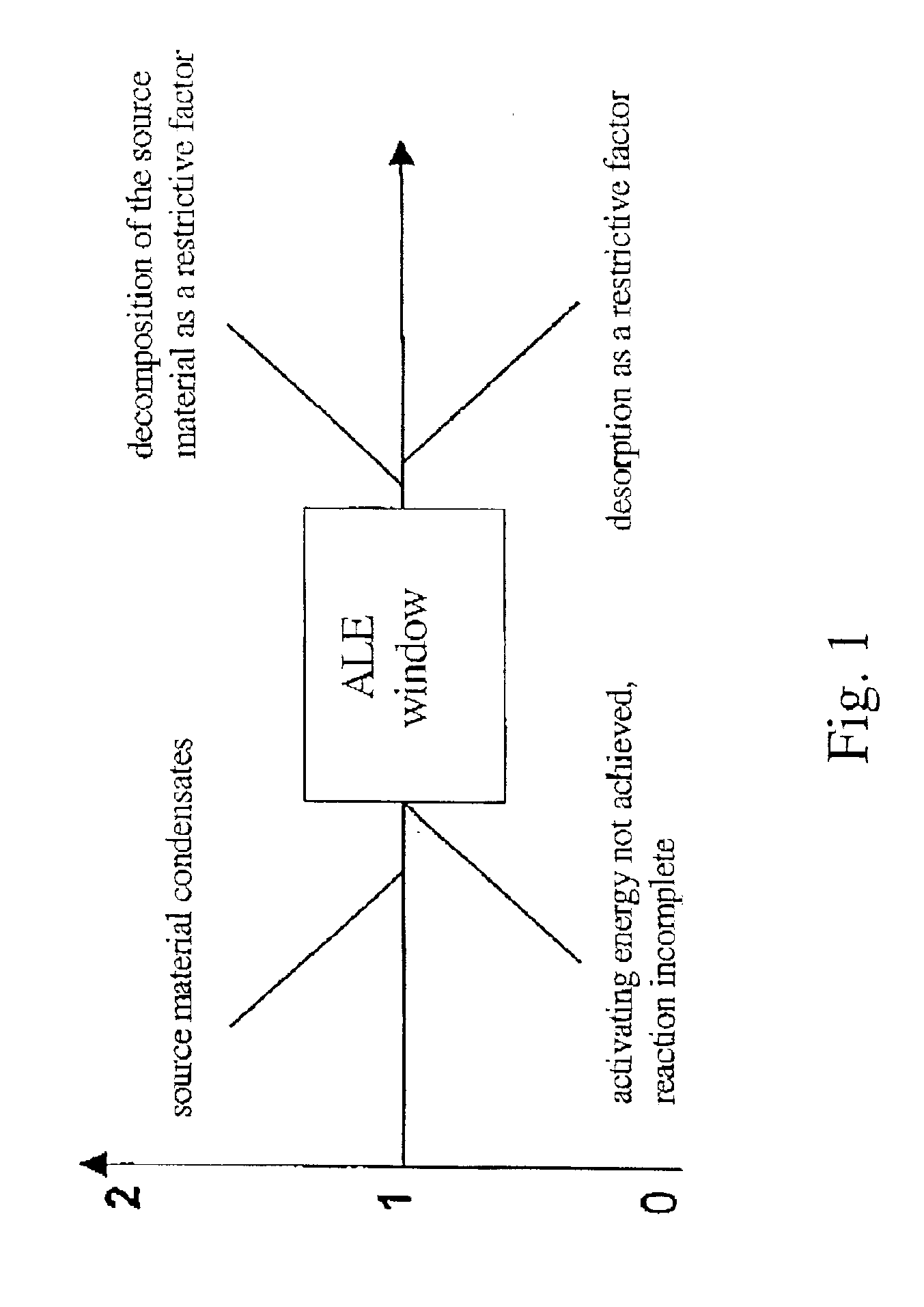

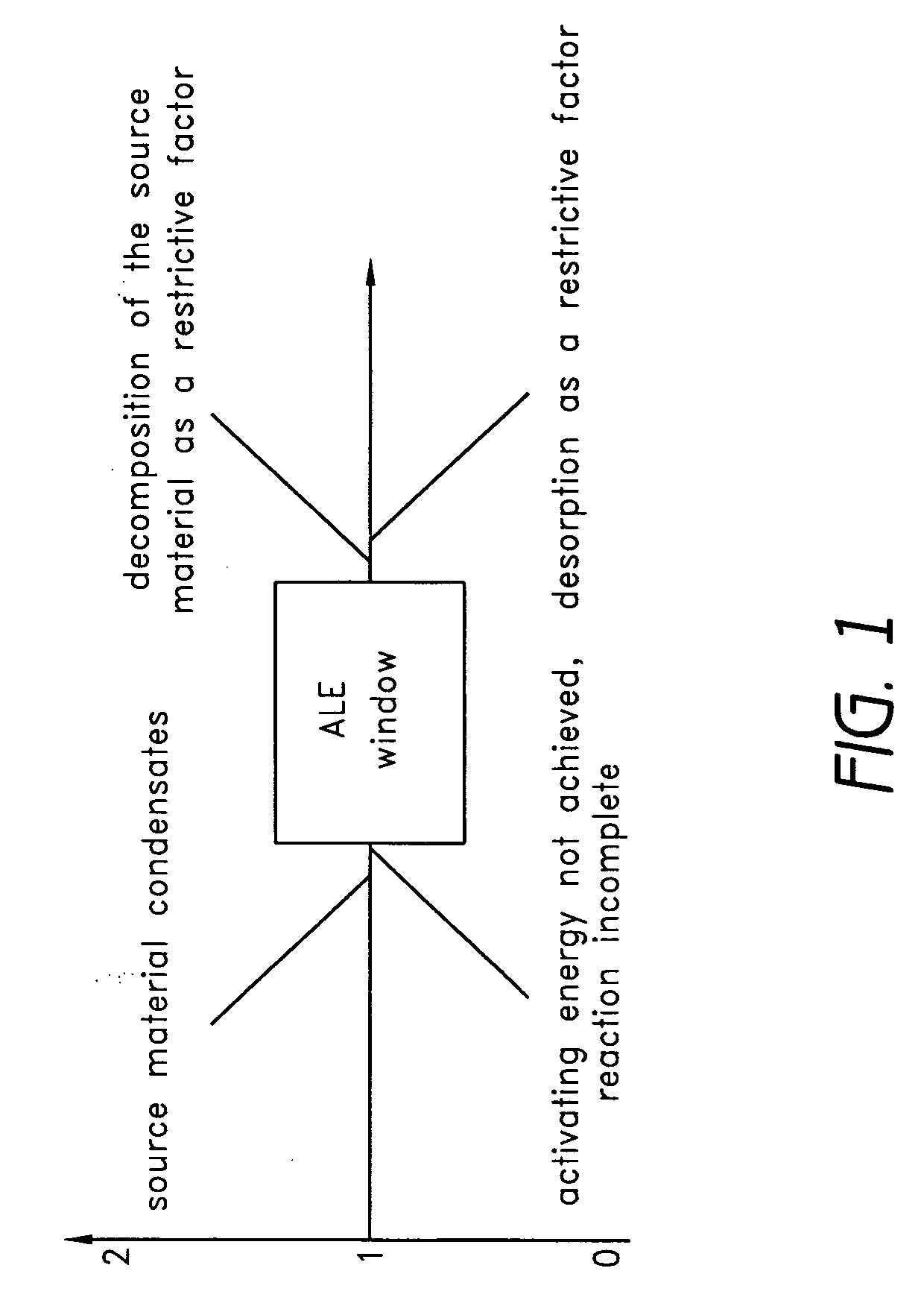

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds of rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

Methods for implementing microbeam radiation therapy

InactiveUS20060176997A1Enhance in-beam absorptionEnhance therapeutic doseX-ray/gamma-ray/particle-irradiation therapyIrradiation devicesAbnormal tissue growthOrthogonal array

A method of performing radiation therapy includes delivering a therapeutic dose such as X-ray only to a target (e.g., tumor) with continuous broad beam (or in-effect continuous) using arrays of parallel planes of radiation (microbeams / microplanar beams). Microbeams spare normal tissues, and when interlaced at a tumor, form a broad-beam for tumor ablation. Bidirectional interlaced microbeam radiation therapy (BIMRT) uses two orthogonal arrays with inter-beam spacing equal to beam thickness. Multidirectional interlaced MRT (MIMRT) includes irradiations of arrays from several angles, which interleave at the target. Contrast agents, such as tungsten and gold, are administered to preferentially increase the target dose relative to the dose in normal tissue. Lighter elements, such as iodine and gadolinium, are used as scattering agents in conjunction with non-interleaving geometries of array(s) (e.g., unidirectional or cross-fired (intersecting) to generate a broad beam effect only within the target by preferentially increasing the valley dose within the tumor.

Owner:BROOKHAVEN SCI ASSOCS

Layered thermal barrier coatings containing lanthanide series oxides for improved resistance to CMAS degradation

InactiveUS20070160859A1Avoid damageElimination of expensiveBlade accessoriesEfficient propulsion technologiesReaction layerCerium

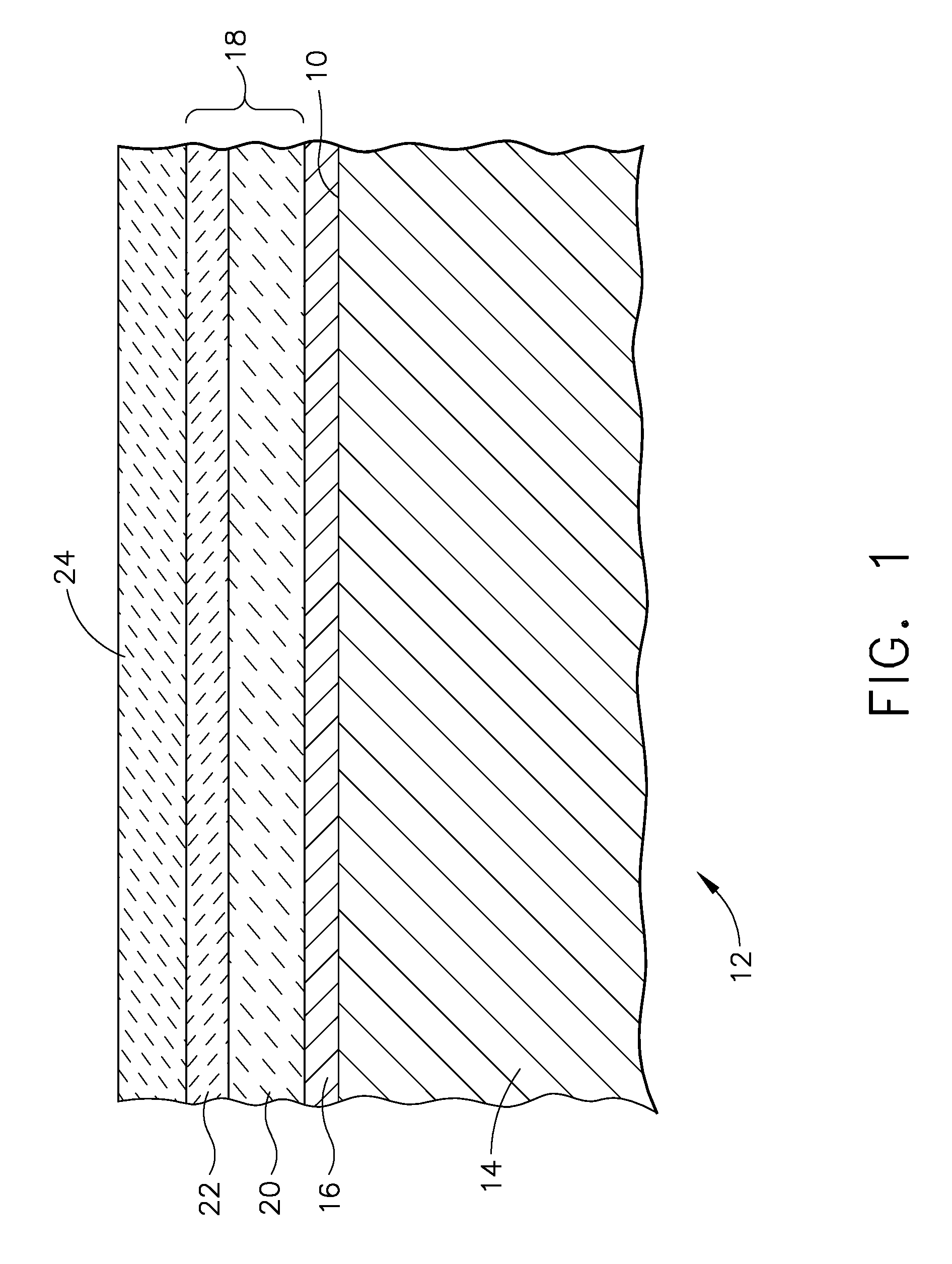

A coating applied as a two layer system. The outer layer is an oxide of a group IV metal selected from the group consisting of zirconium oxide, hafnium oxide and combinations thereof, which are doped with an effective amount of a lanthanum series oxide. These metal oxides doped with a lanthanum series addition comprises a high weight percentage of the outer coating. As used herein, lanthanum series means an element selected from the group consisting of lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), lutetium (Lu) and combinations thereof, and lanthanum series oxides are oxides of these elements. When the zirconium oxide is doped with an effective amount of a lanthanum series oxide, a dense reaction layer is formed at the interface of the outer layer of TBC and the CMAS. This dense reaction layer prevents CMAS infiltration below it. The second layer, or inner layer underlying the outer layer, comprises a layer of partially stabilized zirconium oxide.

Owner:GENERAL ELECTRIC CO

High performance lithium ion battery anode material lithium manganate and preparation method thereof

The invention provides a high performance lithium ion battery anode material lithium manganate and a preparation method of the material. The lithium manganate is a doped lithium manganate LiMn2-yXy04 which is doped with one kind or a plurality of other metal elements X, wherein X element is at least one kind selected form the group of aluminium, lithium, fluorine, silver, copper, chromium, zinc, titanium, bismuth, germanium, gallium, zirconium, stannum, silicon, cobalt, nickel, vanadium, magnesium, calcium, strontium, barium and rare earth elements lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium, and y is larger than 0 but less than or equal to 0.11. The lithium ion battery anode material lithium manganate provided in the invention has extraordinary charge and discharge cycle performance both in the environments of normal temperature and high temperature. According to the invention, the preparation method of the material is a solid phase method, the operation is simple and controllable and the cost is low so that it is easy to realize large-scale productions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

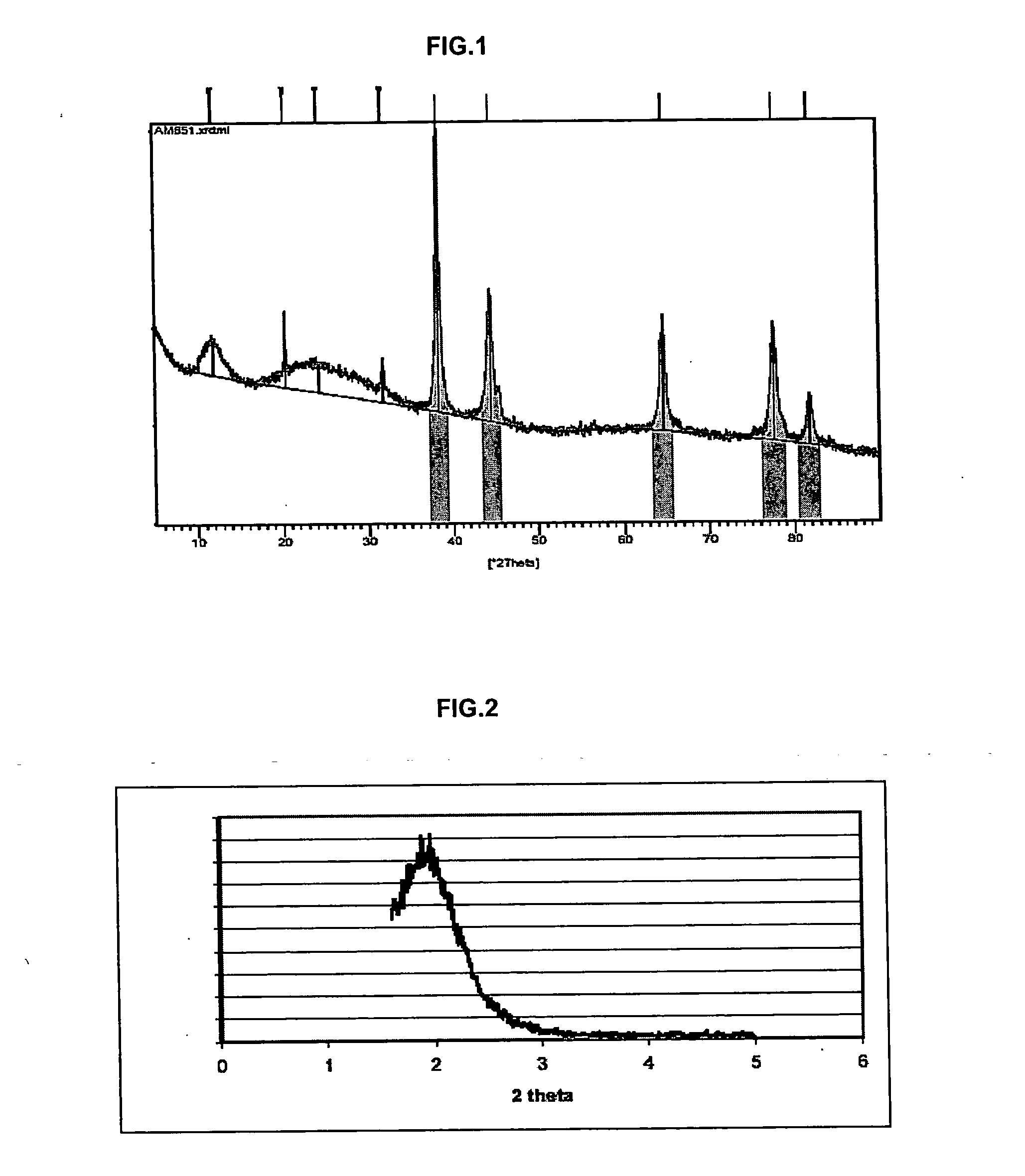

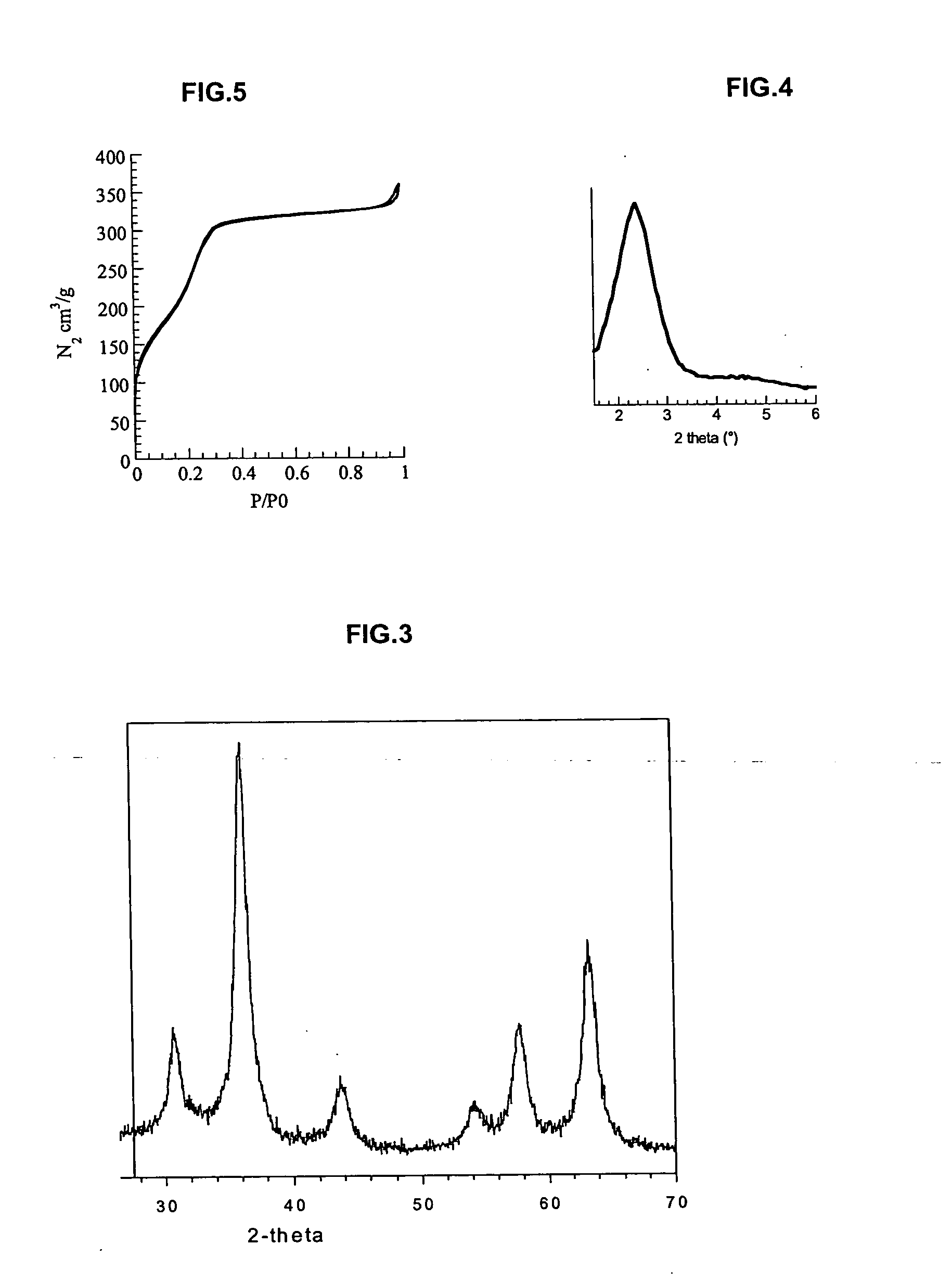

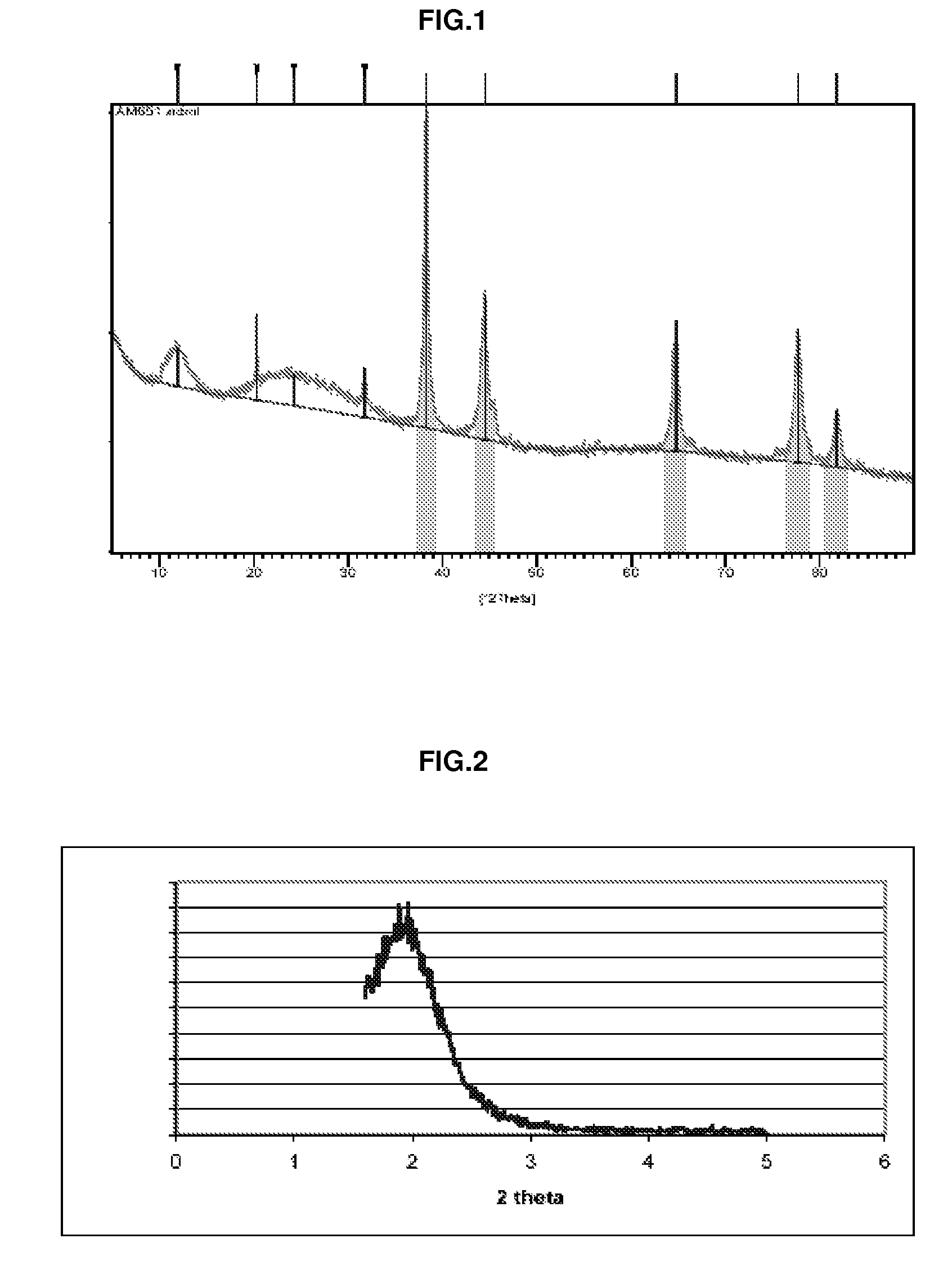

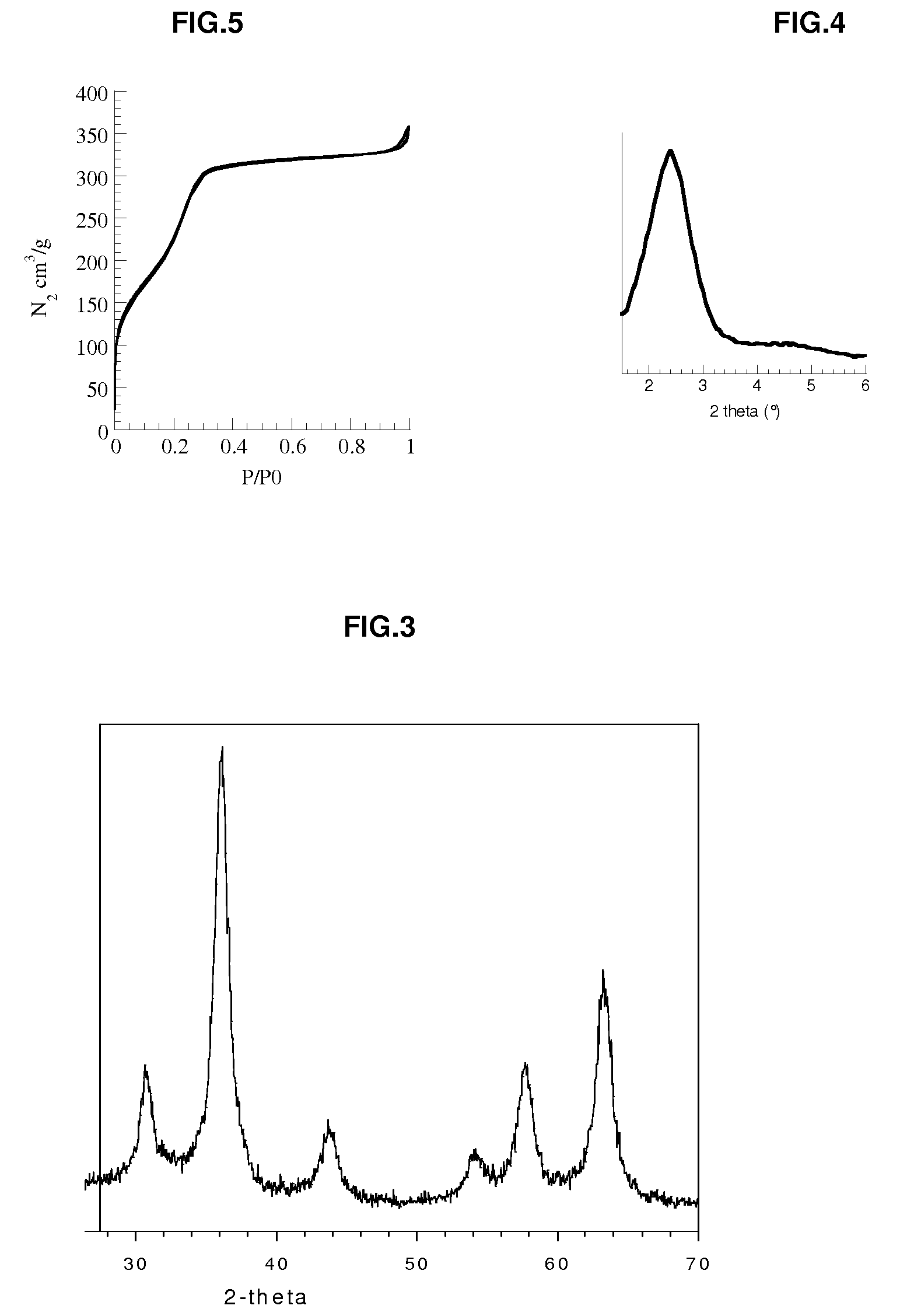

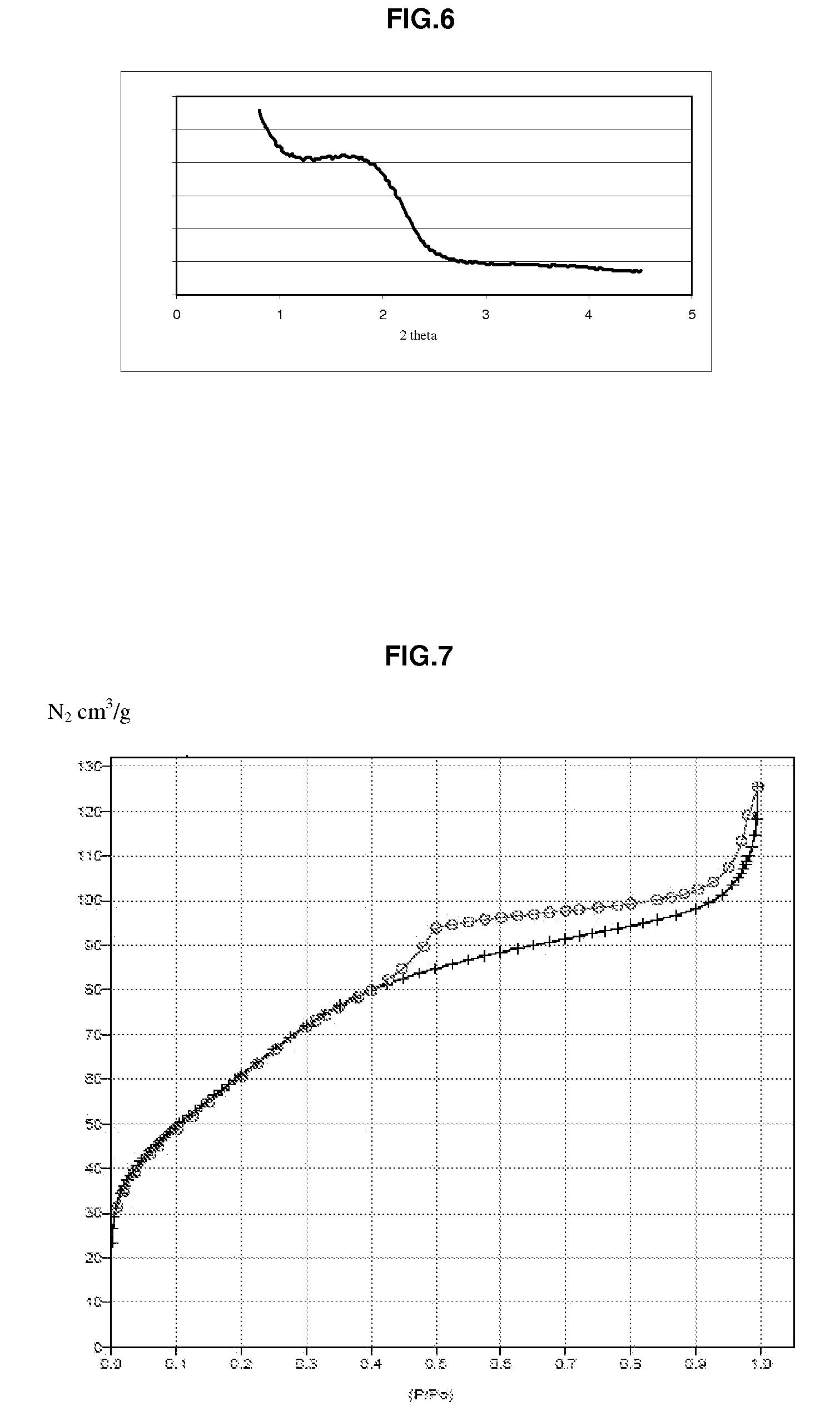

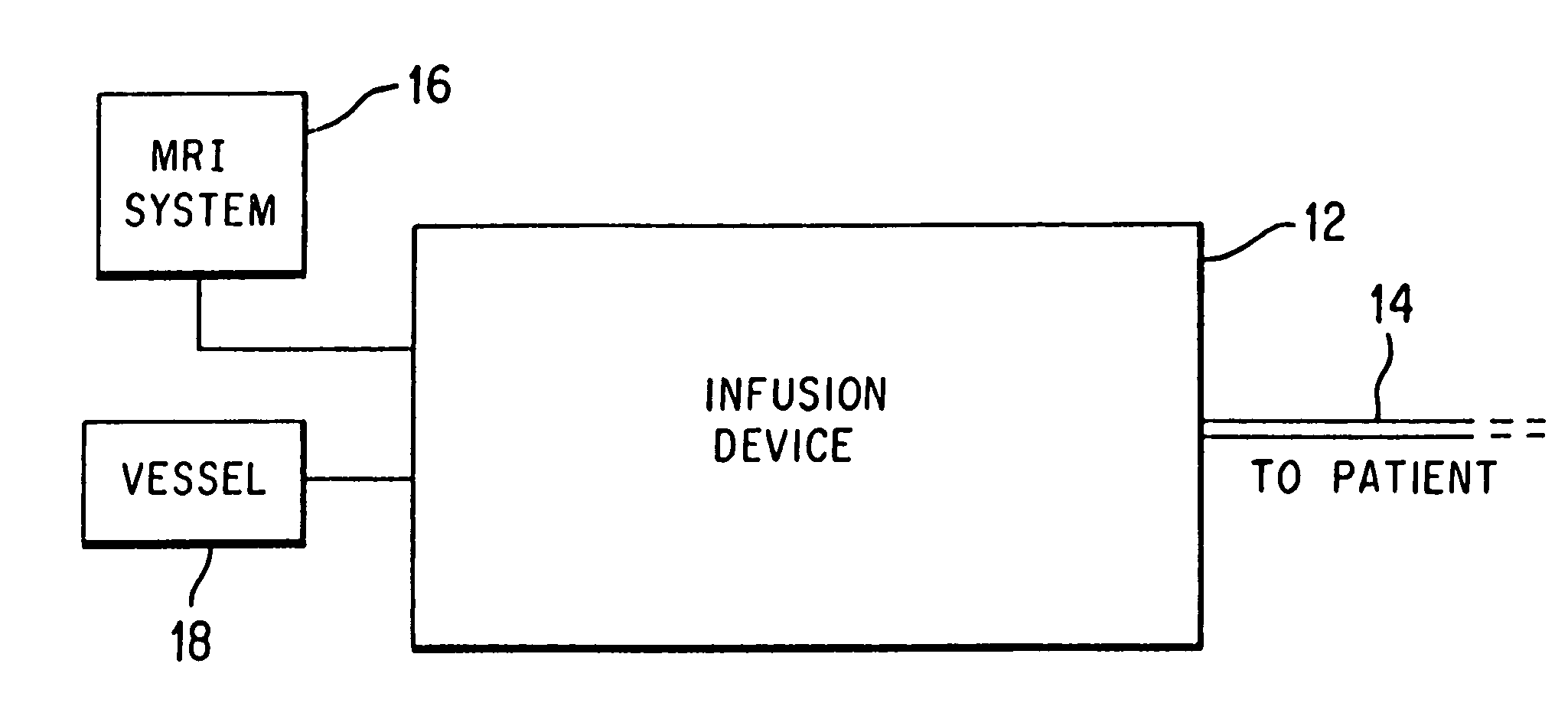

Inorganic material that has metal nanoparticles that are trapped in a mesostructured matrix

An inorganic material that consists of at least two elementary spherical particles, each of said spherical particles comprising metal nanoparticles that are between 1 and 300 nm in size and a mesostructured matrix with an oxide base of at least one element X that is selected from the group that consists of aluminum, titanium, tungsten, zirconium, gallium, germanium, tin, antimony, lead, vanadium, iron, manganese, hafnium, niobium, tantalum, yttrium, cerium, gadolinium, europium and neodymium is described, whereby said matrix has a pore size of between 1.5 and 30 nm and has amorphous walls with a thickness of between 1 and 30 nm, said elementary spherical particles having a maximum diameter of 10 μm. Said material can also contain zeolitic nanocrystals that are trapped within said mesostructured matrix.

Owner:INST FR DU PETROLE

Inorganic material that has metal nanoparticles that are trapped in a mesostructured matrix

An inorganic material that consists of at least two elementary spherical particles, each of said spherical particles comprising metal nanoparticles that are between 1 and 300 nm in size and a mesostructured matrix with an oxide base of at least one element X that is selected from the group that consists of aluminum, titanium, tungsten, zirconium, gallium, germanium, tin, antimony, lead, vanadium, iron, manganese, hafnium, niobium, tantalum, yttrium, cerium, gadolinium, europium and neodymium is described, whereby said matrix has a pore size of between 1.5 and 30 nm and has amorphous walls with a thickness of between 1 and 30 nm, said elementary spherical particles having a maximum diameter of 10 μm. Said material can also contain zeolitic nanocrystals that are trapped within said mesostructured matrix.

Owner:INST FR DU PETROLE

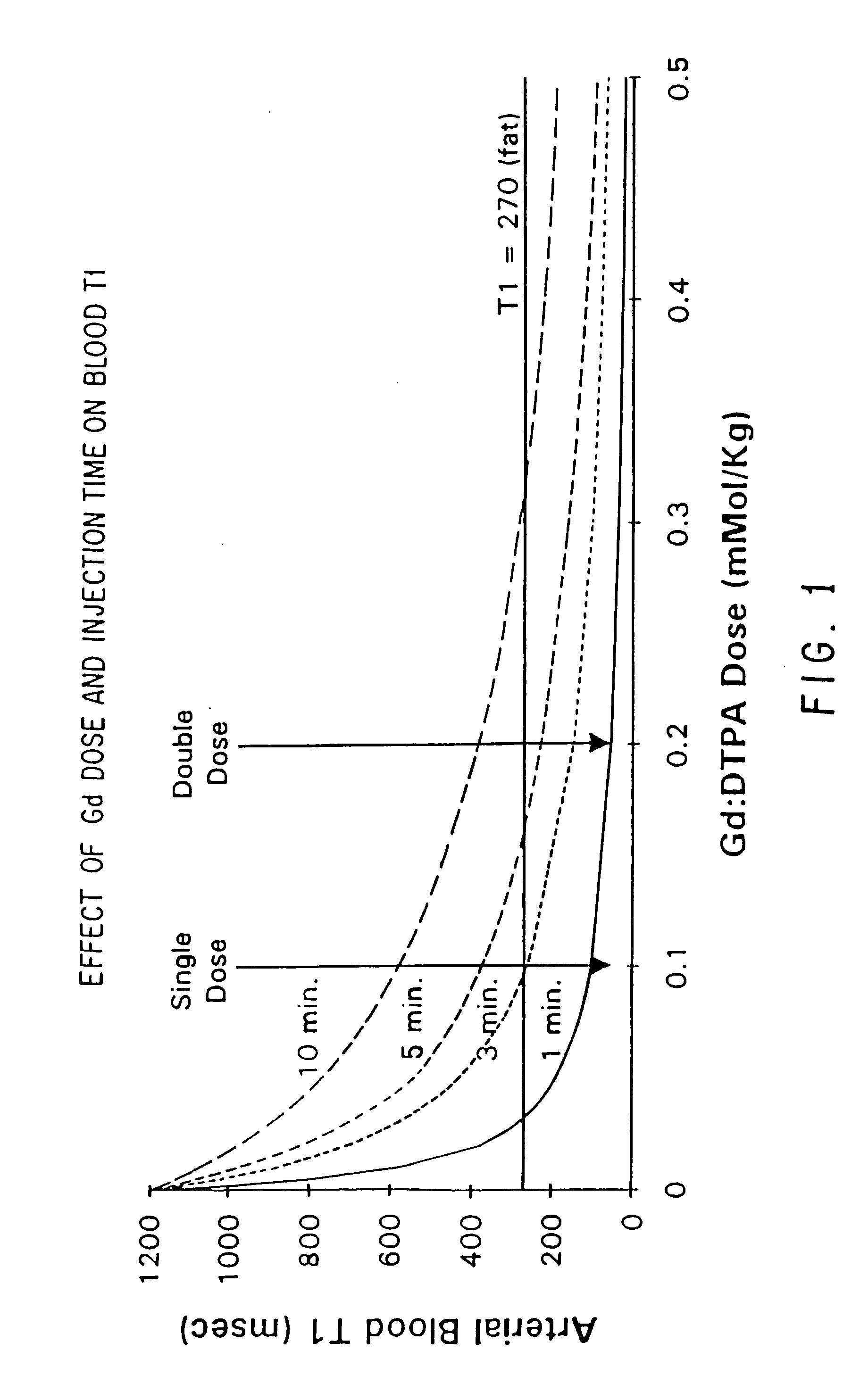

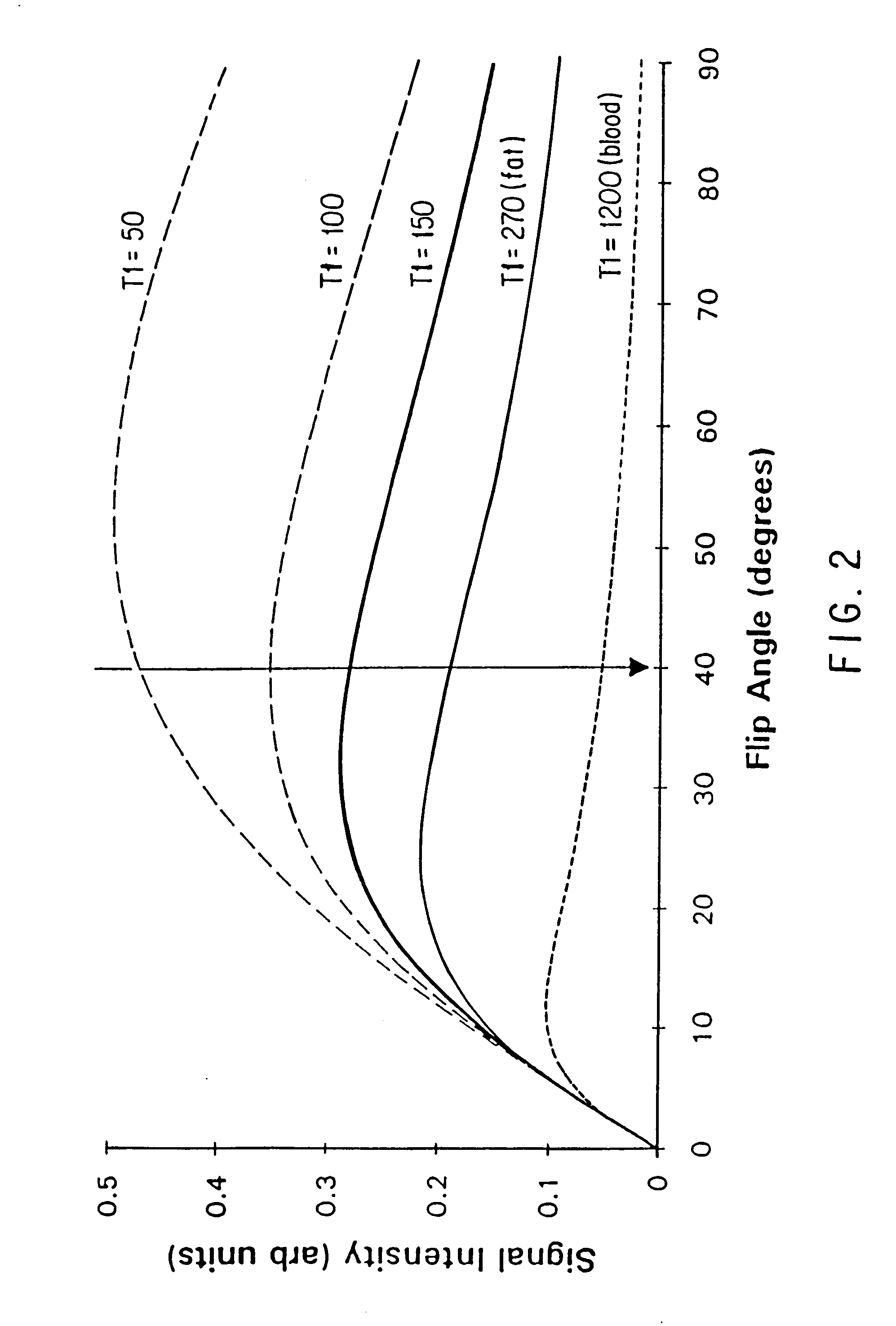

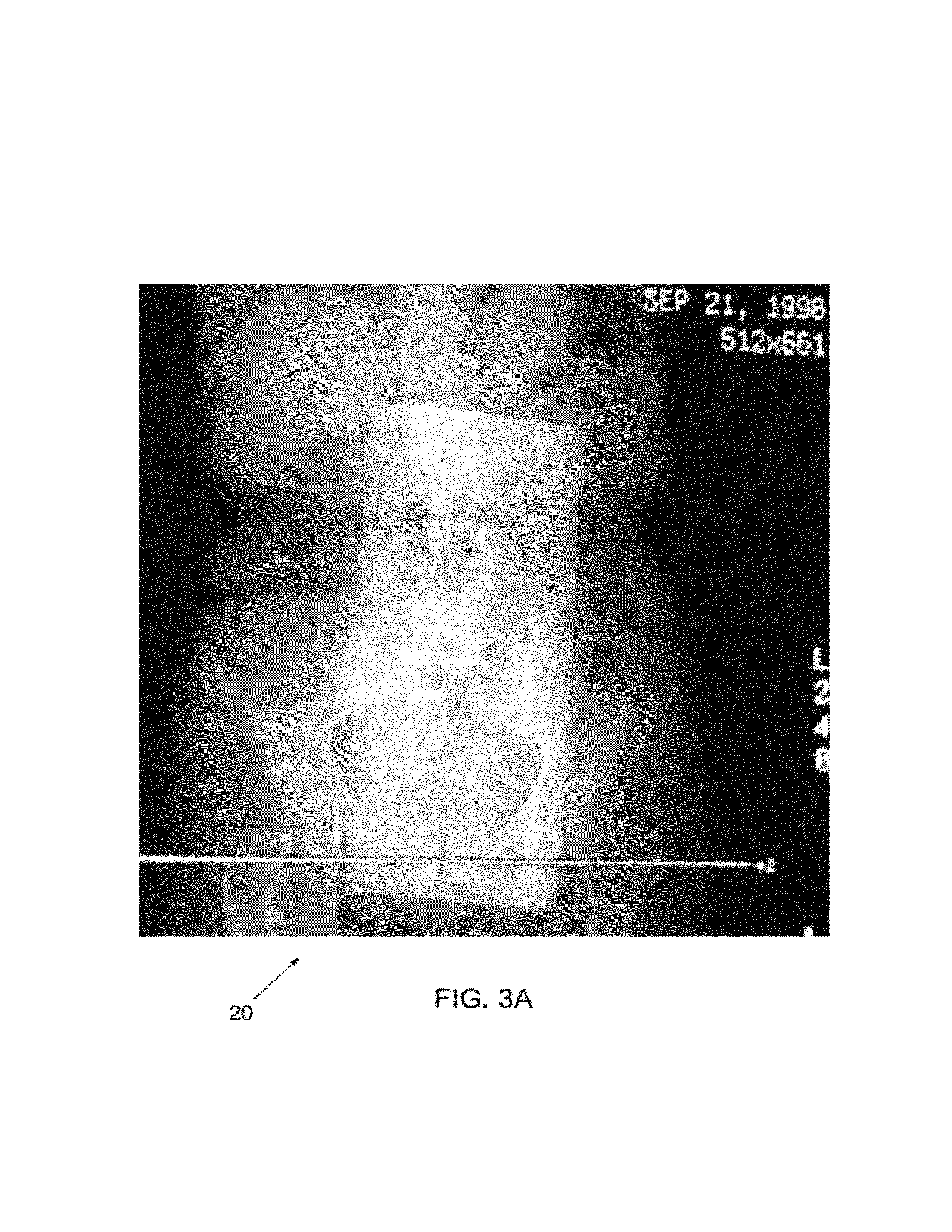

Method and apparatus for imaging abdominal aorta and aortic aneurysms

InactiveUS20060264741A1Eliminate riskIncrease contrastDiagnostic recording/measuringSensorsPre operativePathology diagnosis

The present invention is a technique and apparatus for acquiring anatomic information used in diagnosing and characterizing abdominal aortic aneurismal disease and the like. This technique provides anatomic information, in the form of images, using a combination of a plurality of magnetic resonance angiography sequences, including a spin-echo and four contrast enhanced (e.g., gadolinium) magnetic resonance angiography sequences. The anatomic images may be used in, for example, pre-operative, operative and post-operative evaluation of aortic pathology, including aneurysms, atherosclerosis, and occlusive disease of branch vessels such as the renal arteries. The gadolinium-enhanced magnetic resonance angiography provides sufficient anatomic detail to detect aneurysms and all relevant major branch vessel abnormalities seen at angiography operation. This technique and apparatus allows for imaging the aorta at a fraction of the cost of conventional aortography and without the risks of arterial catheterization or iodinated contrast.

Owner:PRINCE MARTIN R

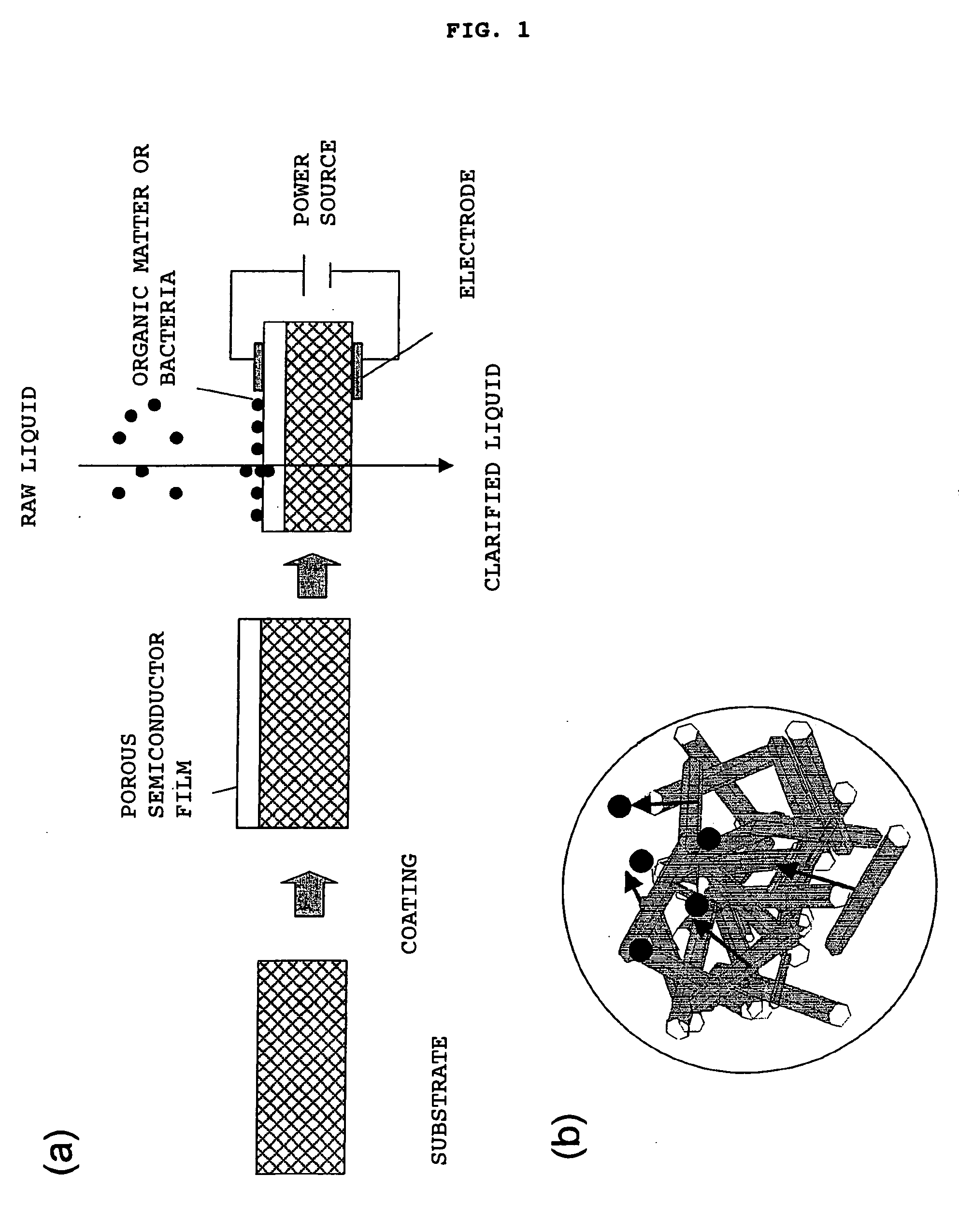

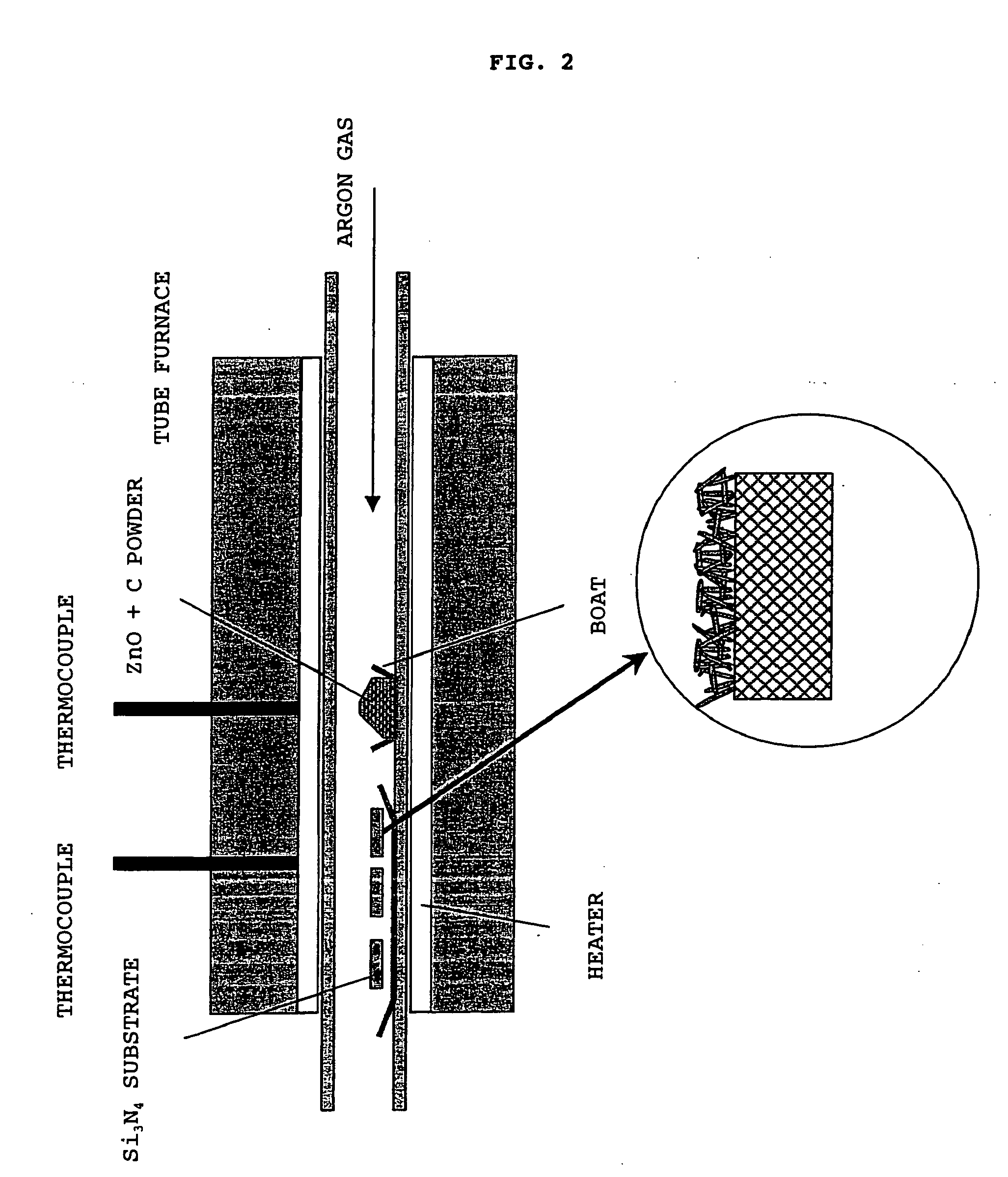

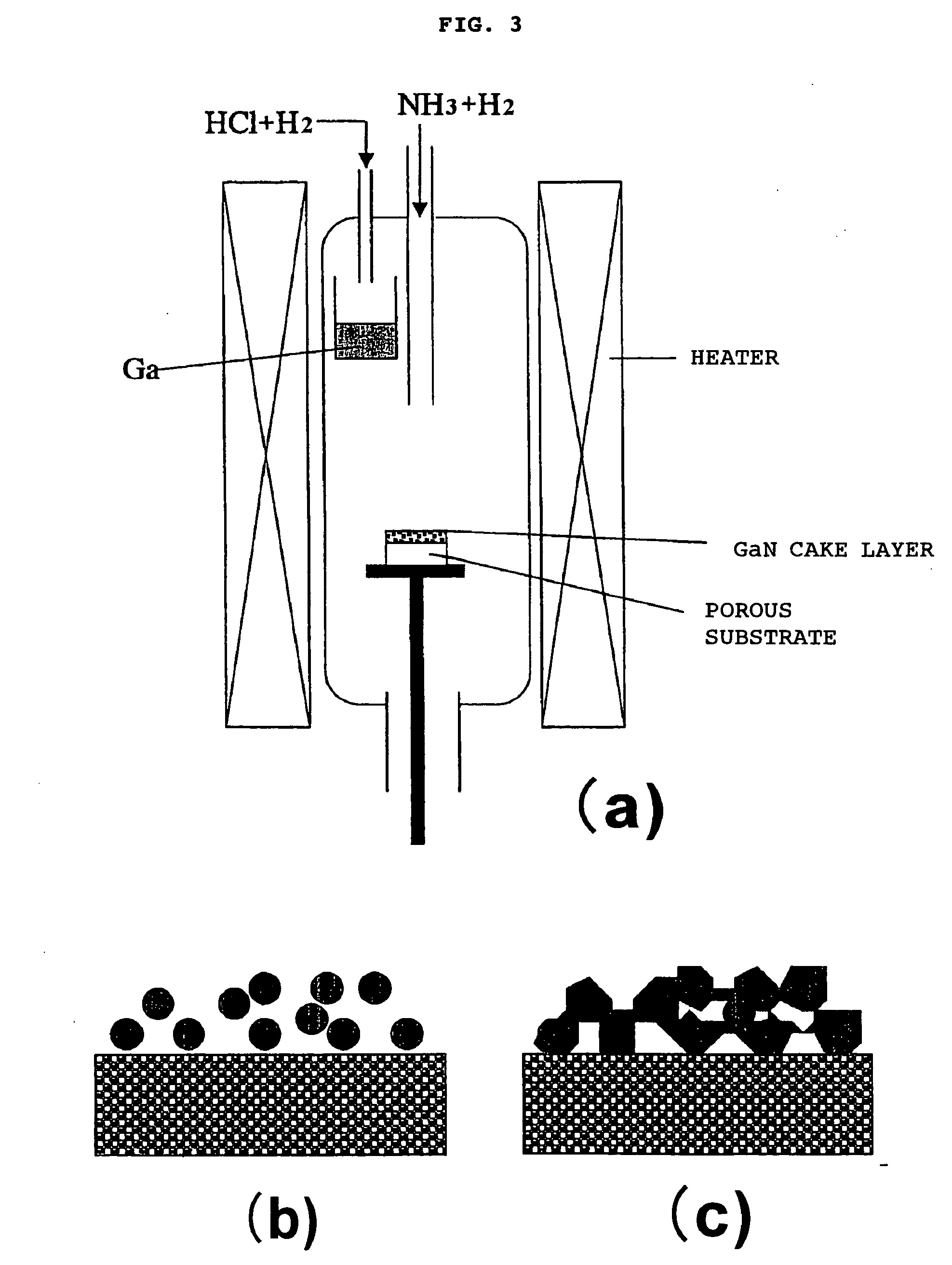

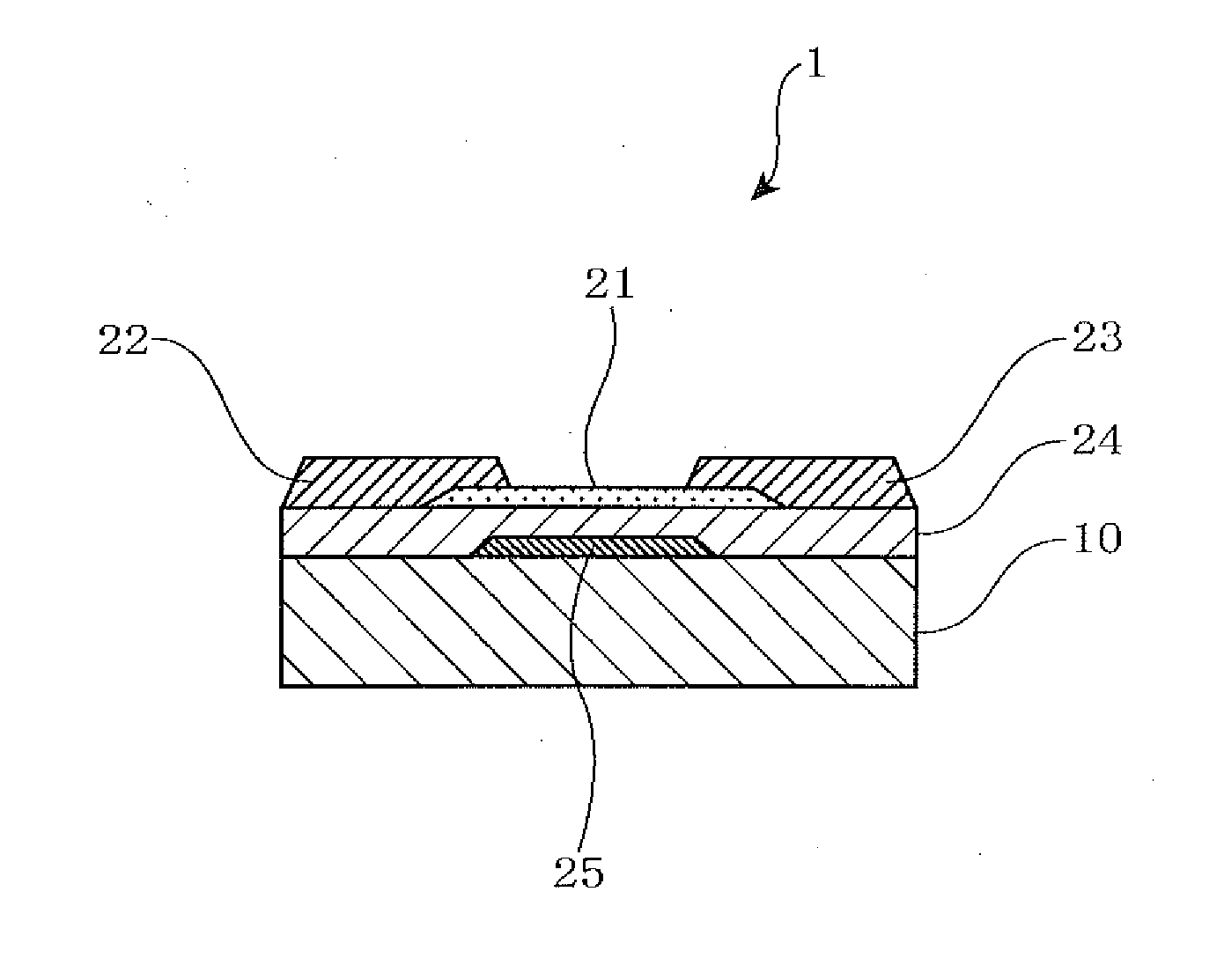

Porous semiconductor and process for producing the same

InactiveUS20050042743A1Increase brightnessLow costBioreactor/fermenter combinationsBiological substance pretreatmentsPorous substrateRare-earth element

The present invention provides a filter with which organic matter, bacteria, viruses, and other harmful substances can be trapped, and the trapped material can be sterilized and decomposed, at low cost and extremely high efficiency. A porous ceramic or metal is used as a substrate, and a porous semiconductor composed of a semiconductor material having a light emitting function is formed in the interior or on the surface of this substrate. An electrode is provided to this product to serve as a filter, voltage is applied so that ultraviolet light is emitted while a fluid is being filtered, and any harmful substances are filtered and simultaneously sterilized and decomposed. The porous semiconductor layer is preferably composed of columns grown perpendicular to the substrate plane, and has the function of emitting ultraviolet light with a wavelength of 400 nm or less. The pores in the porous substrate column are through-holes perpendicular to the substrate plane, and the average size of these pores is preferably from 0.1 to 100 μm. The distal ends of the columns preferably have a pointed shape. To manufacture, a suspension of semiconductor particles having a light emitting function is filtered through the porous substrate serving as a filter medium so as to form a deposited layer of semiconductor particles on the porous substrate surface. A deposited layer of p-type semiconductor particles and a deposited layer of n-type semiconductor particles may also be formed so that these form a pn junction. Further, the present invention is characterized in that an insulating layer is formed on the top and bottom surfaces of the porous semiconductor layer, and semiconductor particles are dispersed in the insulating layer, with the bandgap of the semiconductor particles in the porous light emitting layer or the porous semiconductor layer being at least 3.2 eV, and being doped with gadolinium, which is the light emitting center. In addition, the porous semiconductor layer may be made of porous silicon nitride composed of columnar Si3N4 particles with an average aspect ratio of at least 3 and an oxide-based binder phase containing at least one of rare earth element, and emit visible light or ultraviolet light.

Owner:SUMITOMO ELECTRIC IND LTD

Method of depositing rare earth oxide thin films

InactiveUS20090035949A1Eliminate the problemIncrease probabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureMischmetal

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds or rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

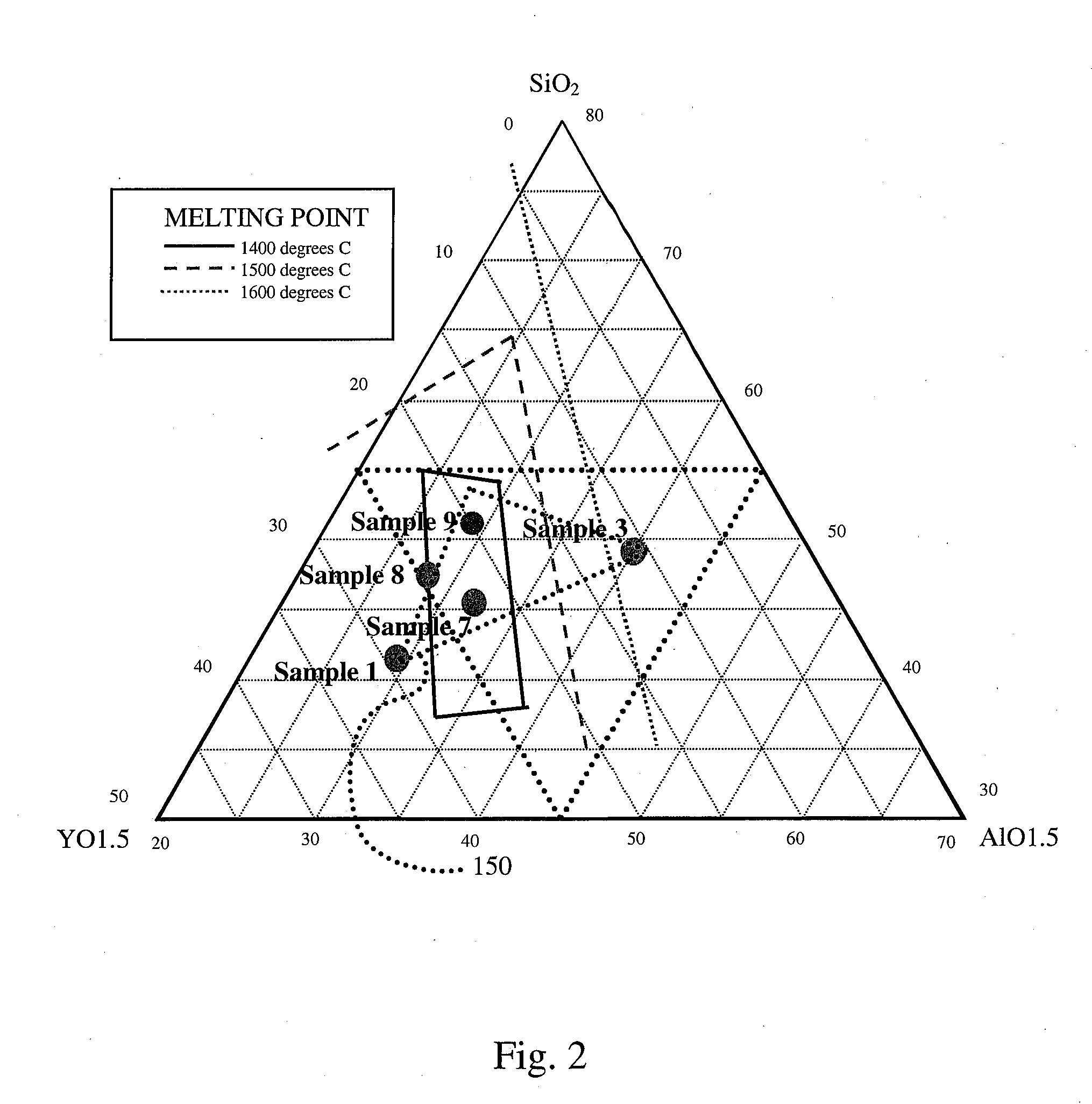

Ceramic bonding composition, method of making, and article of manufacture incorporating the same

A ceramic bonding composition comprises a first oxide and at least a second oxide having a formula of Me2O3; wherein the first oxide is selected from the group consisting of aluminum oxide, scandium oxide, and combinations thereof; Me is selected from the group consisting of yttrium, lanthanum, cerium, praseodymium, neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, and combinations thereof. The ceramic bonding composition can further comprise silica. An article of manufacture comprising at least two members attached together with the ceramic bonding composition.

Owner:GENERAL ELECTRIC CO

Paramagnetic liquid interface

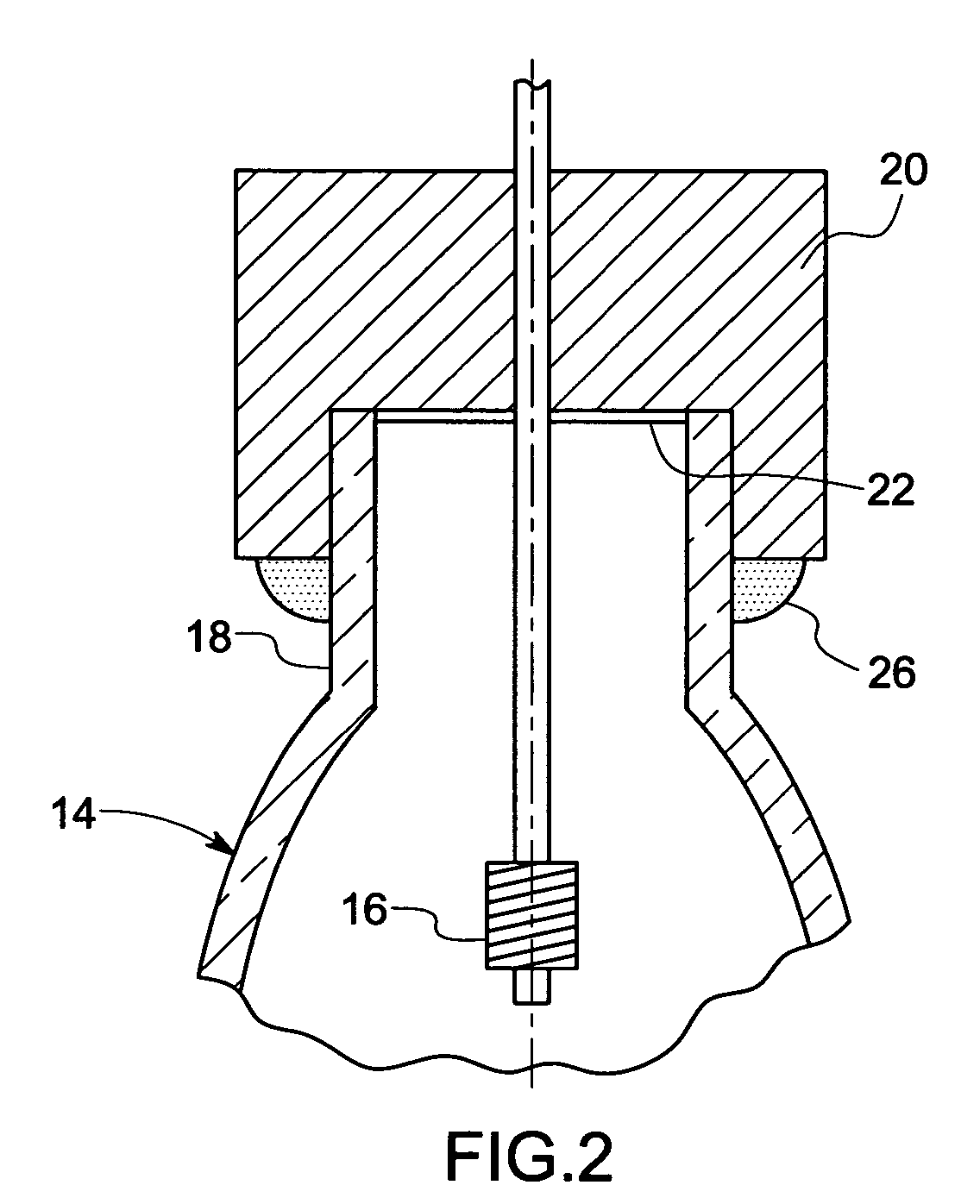

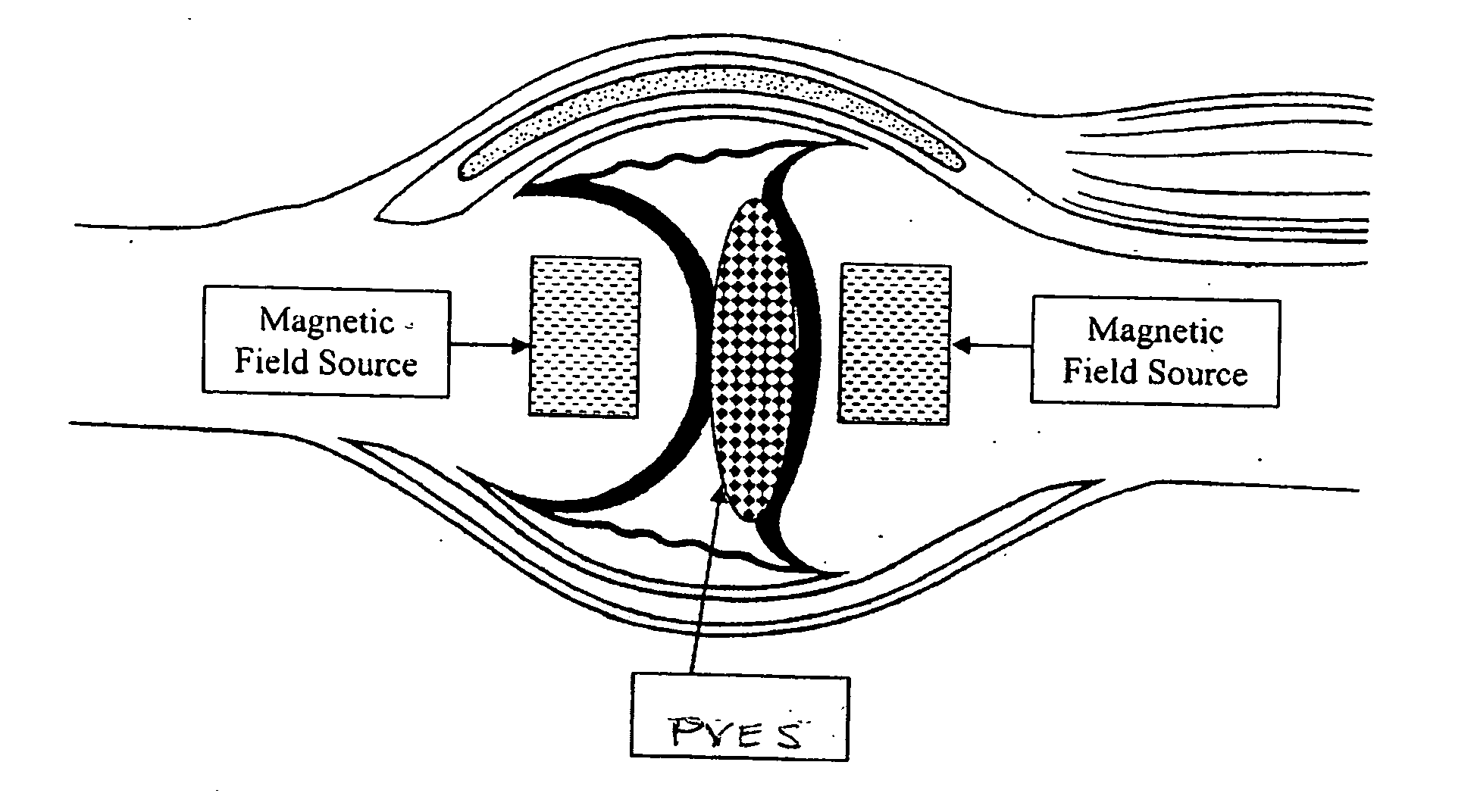

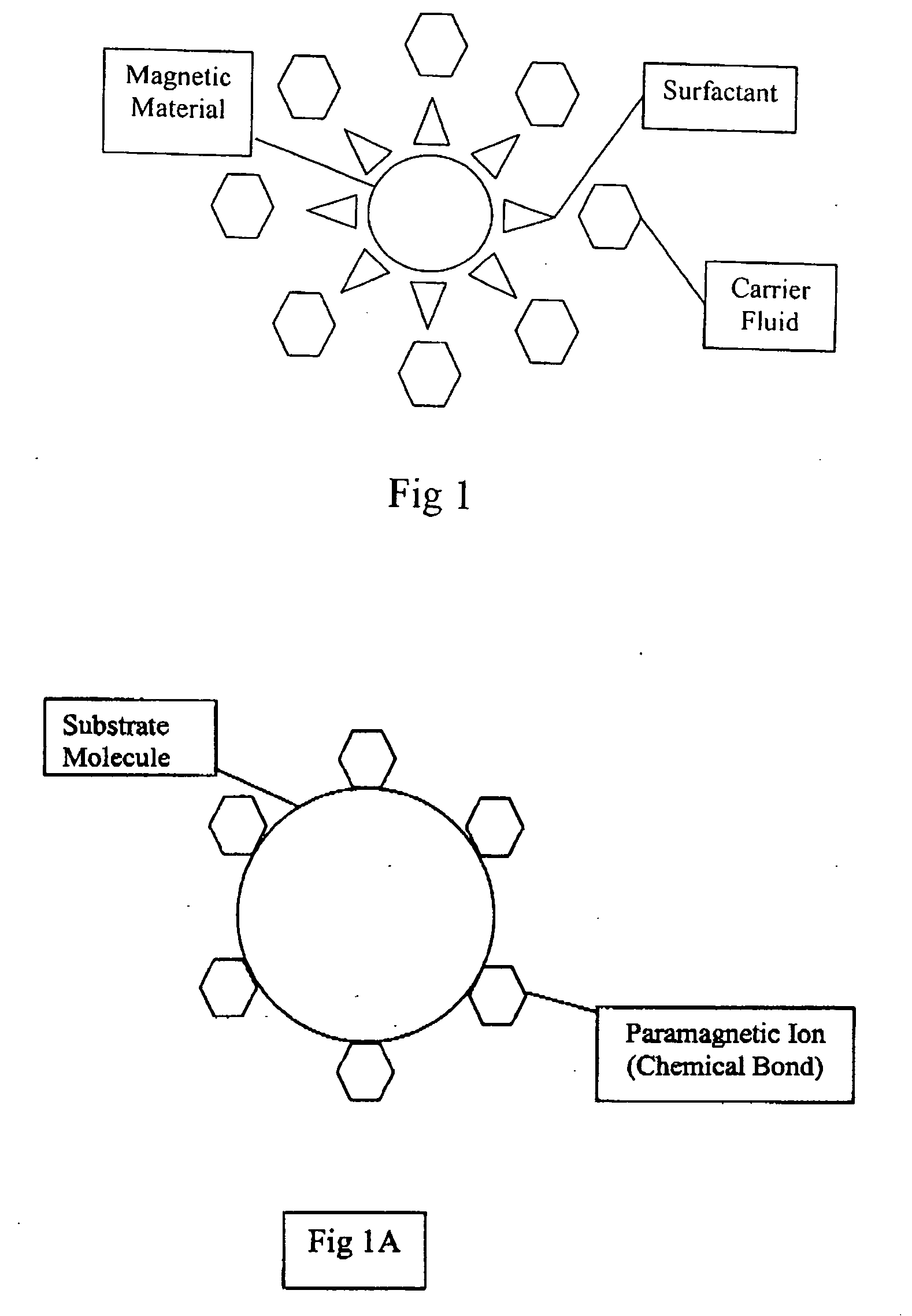

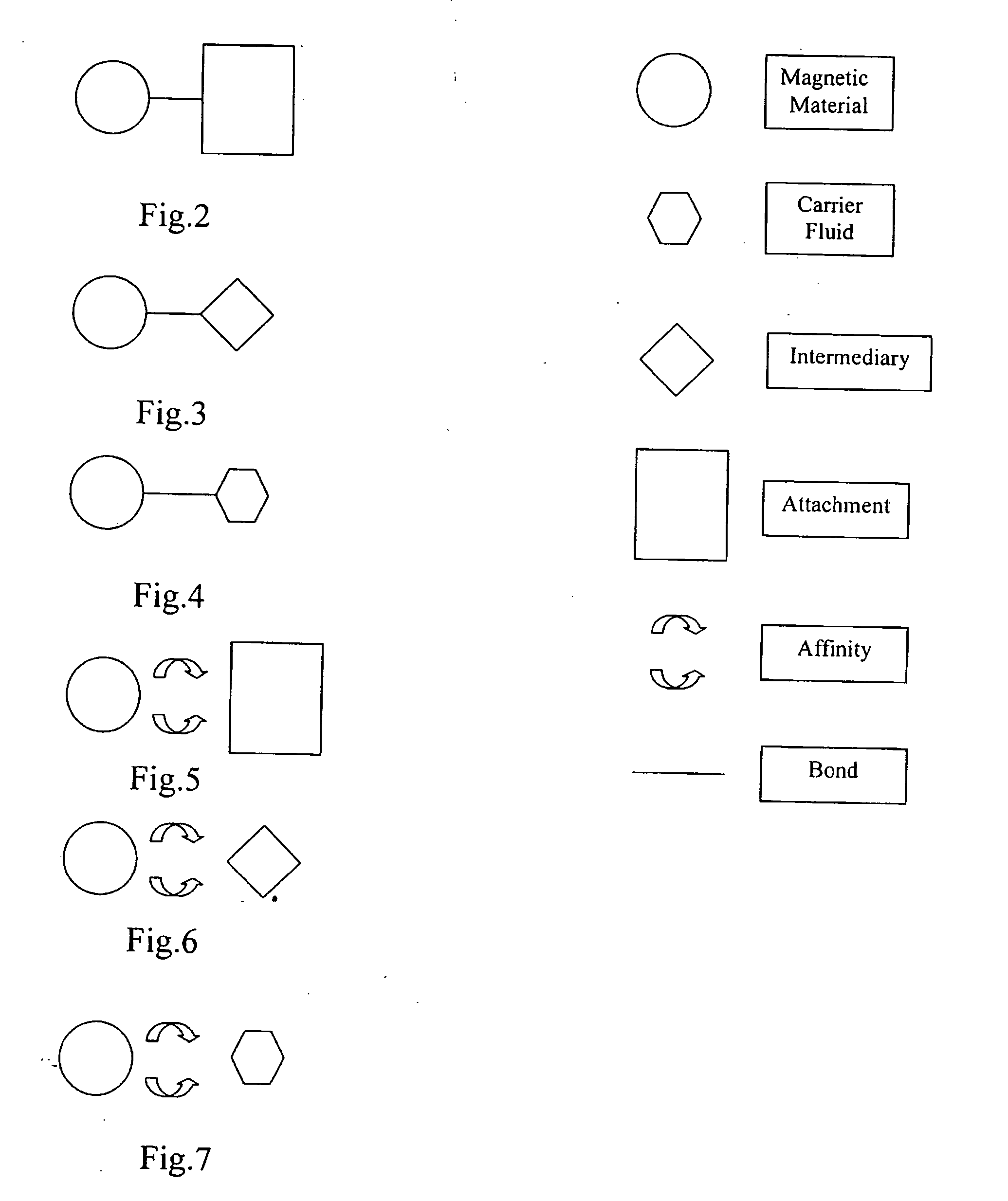

InactiveUS20070100457A1Improve rheologyExtended durationFinger jointsWrist jointsArticular surfacesEngineering

Natural joint interfaces wear out and / or are damaged causing pain and disability. They can be currently replaced by artificial surfaces made of materials or in the near future by magnetic fields. They would benefit from a PVES (paramagnetic visco-viscoelastic supplement) that can replace or augment natural joint interfaces or augment total joint replacements. Joint replacement components can be modular and would benefit from a PVES to decrease wear and damp impact between modular parts of a single component. The PVES is a dynamic interface allowing components to be less rigid. Energy transmission is reduced. PVES can act as an interface between natural damaged joint surfaces obviating the need for classic total joint replacement or between the surfaces of artificial joint components to improve or supplement their function. These PVES can be controlled by magnetic fields with respect to their location, physical properties, loads, etc. PVES are typically made of paramagnetic ions and a substrate molecule. One such PVES can be made of gadolinium ions and hyaluronic acid to form gadolinium hyaluronate.

Owner:HYDE EDWARD R JR

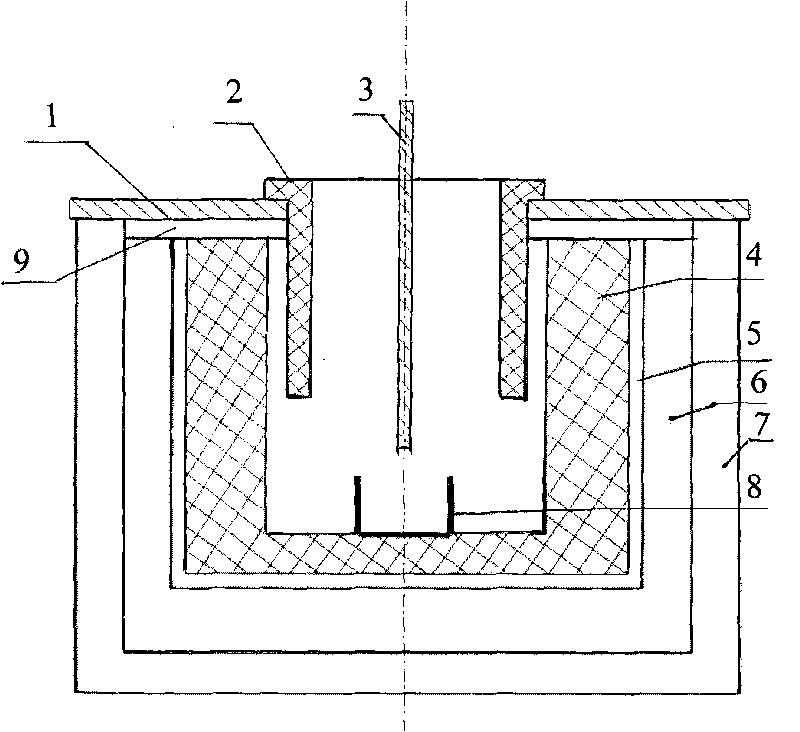

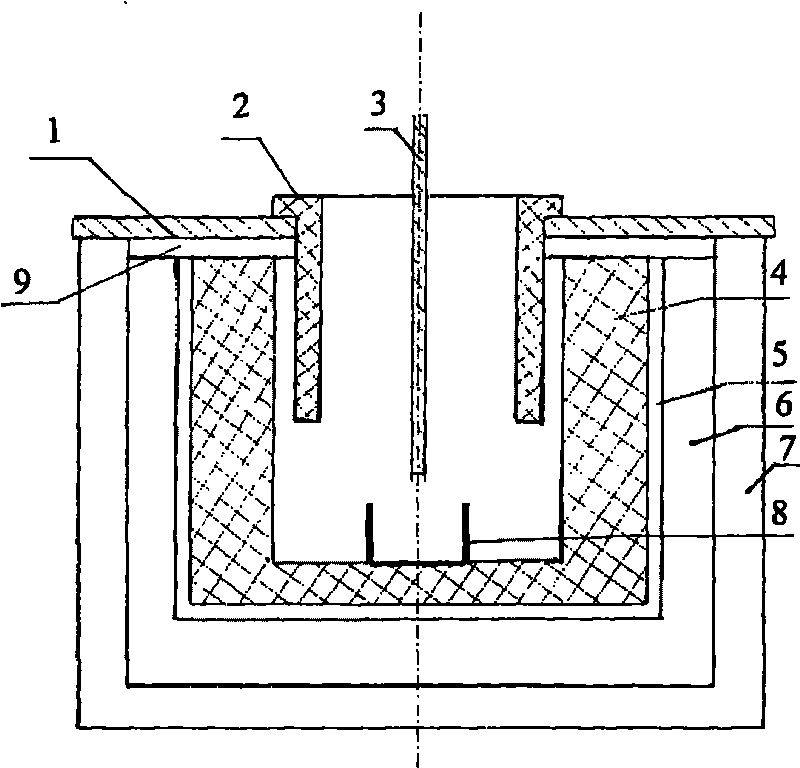

Rare earth aluminum alloy, and method and device for preparing same

The invention discloses a rare earth aluminum alloy, and a method and a device for preparing the same. The alloy contains at least one rare earth metal of lanthanum, cerium, praseodymium, neodymium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, lutetium, scandium and yttrium, the content of raw earth is 5 to 98 weight percent, and the balance is aluminum and inevitable impurities. The device for preparing the rare earth aluminum alloy is characterized in that: a) graphite serves as an electrolysis bath, a graphite plate is an anode, a tungsten bar is a cathode and a molybdenum crucible serves as a rare earth aluminum alloy receiver; b) the diameter of the tungsten bar is 30 to 55 mm; and c) the anode of the graphite consists of a plurality of graphite plates. The rare earth aluminum alloy, and the method and the device for preparing the same have the advantages that: the alloy has uniform components, little segregation and low impurity content; technology for preparing the rare earth aluminum alloy through fusion electrolysis can maximally replace a process for preparing single medium-heavy metal through metallothermic reduction, greatly reduce energy consumption and the emission of fluorine-containing tail gas and solid waste residue, improve current efficiency and metal yield and reduce the consumption of auxiliary materials and the energy consumption; and the rare earth aluminum alloys with different rare earth contents can be obtained by controlling different electrolytic temperatures and different cathode current densities.

Owner:GRIREM ADVANCED MATERIALS CO LTD

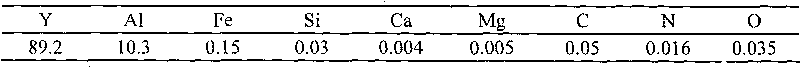

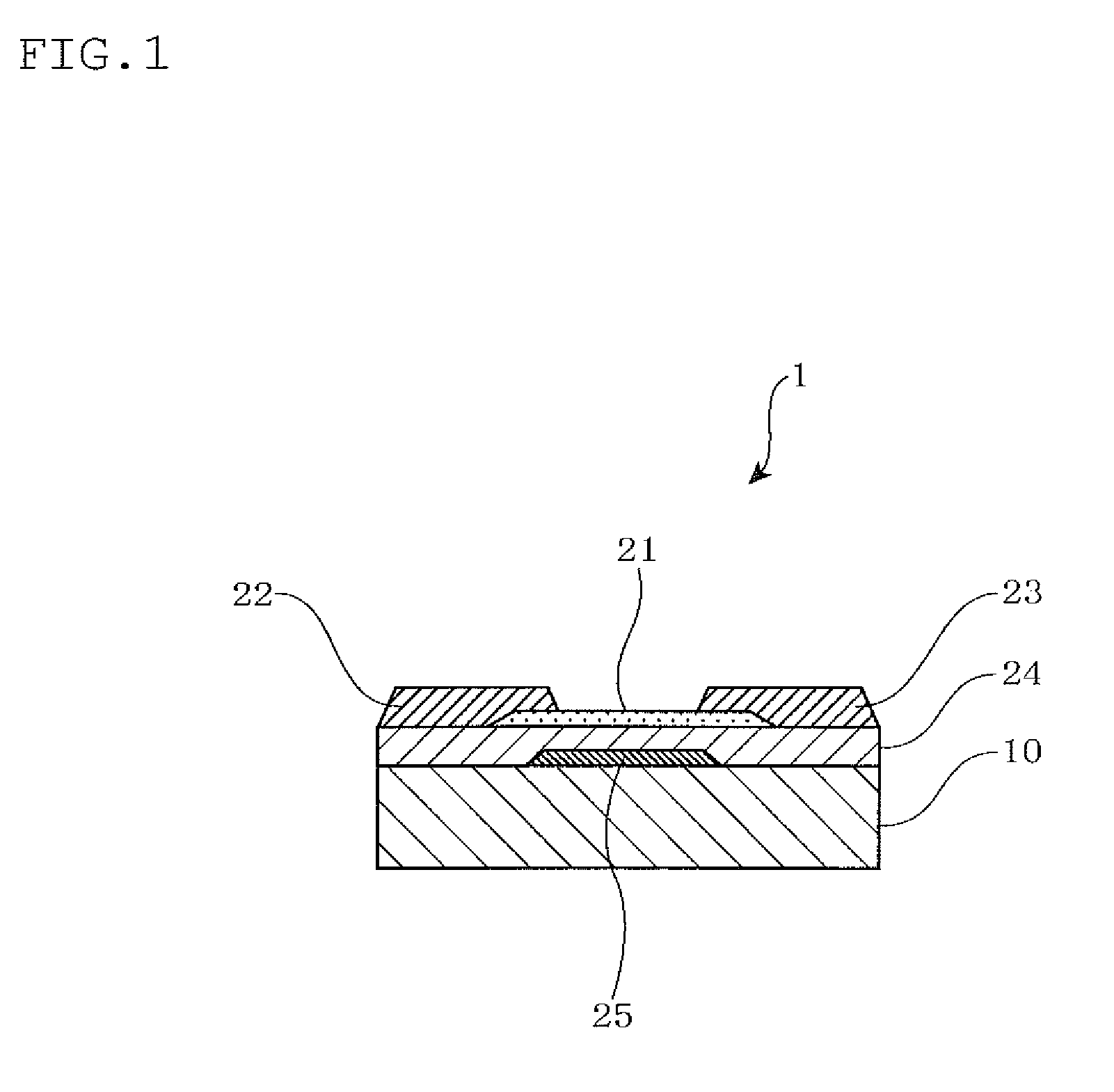

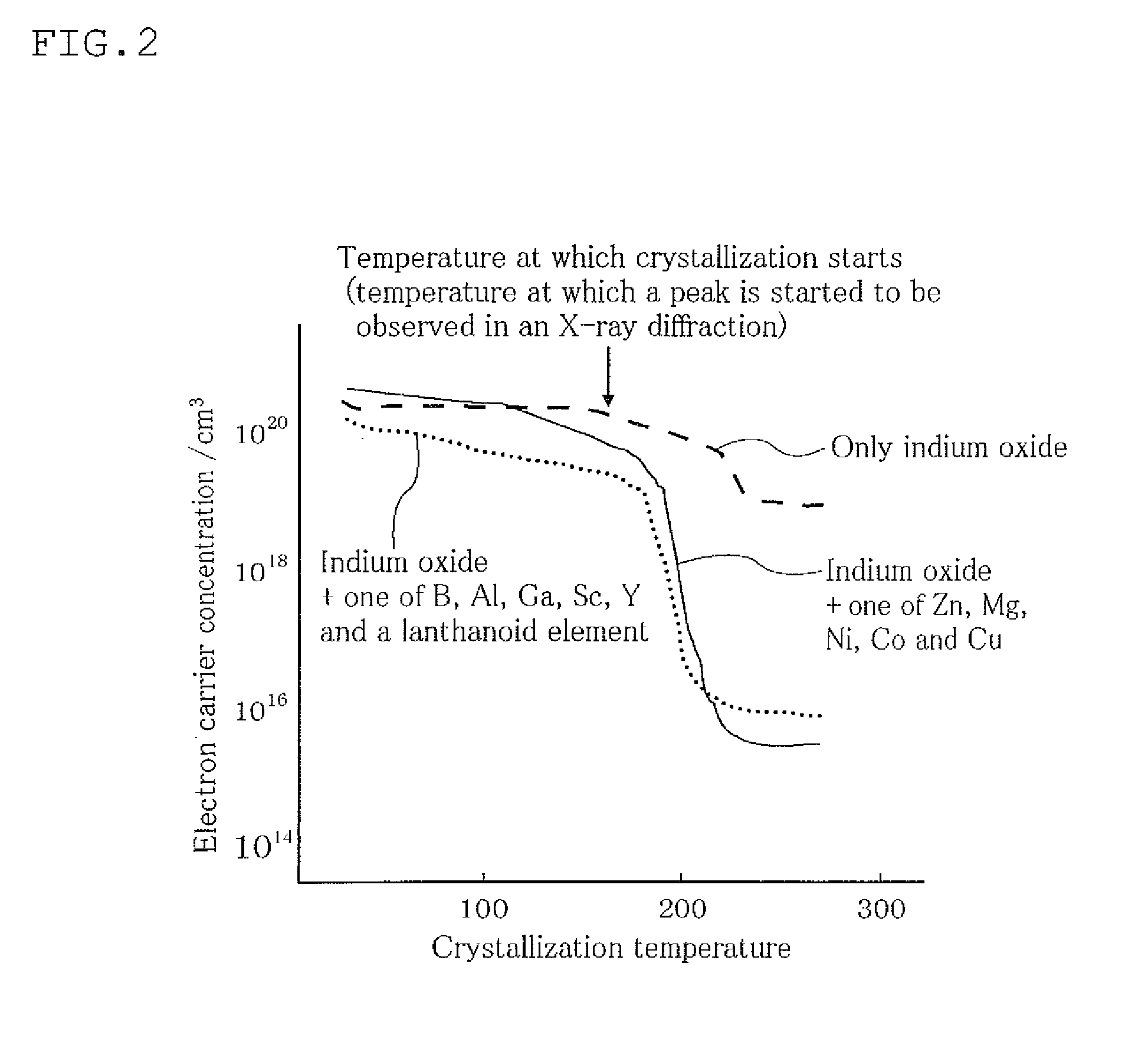

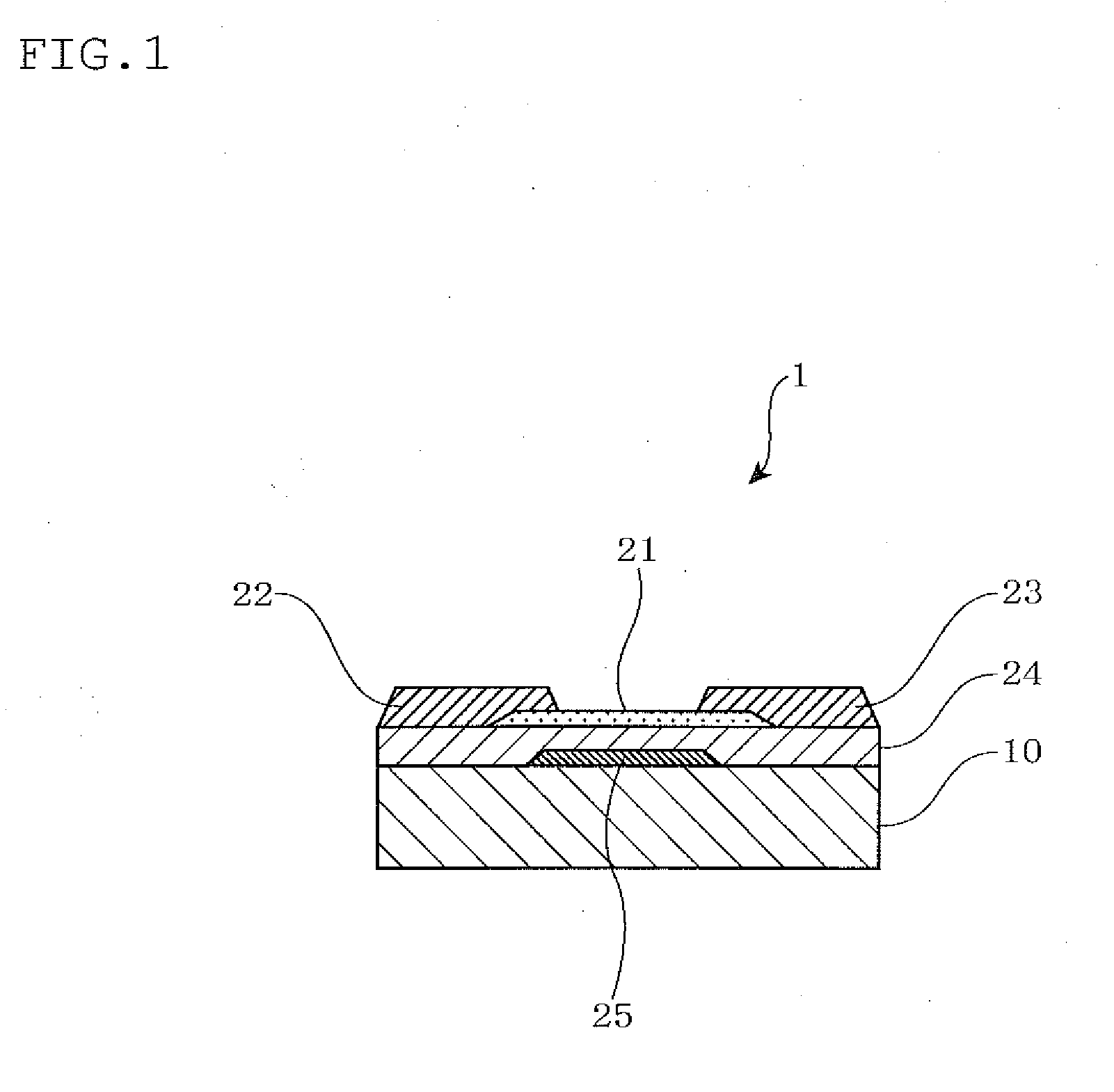

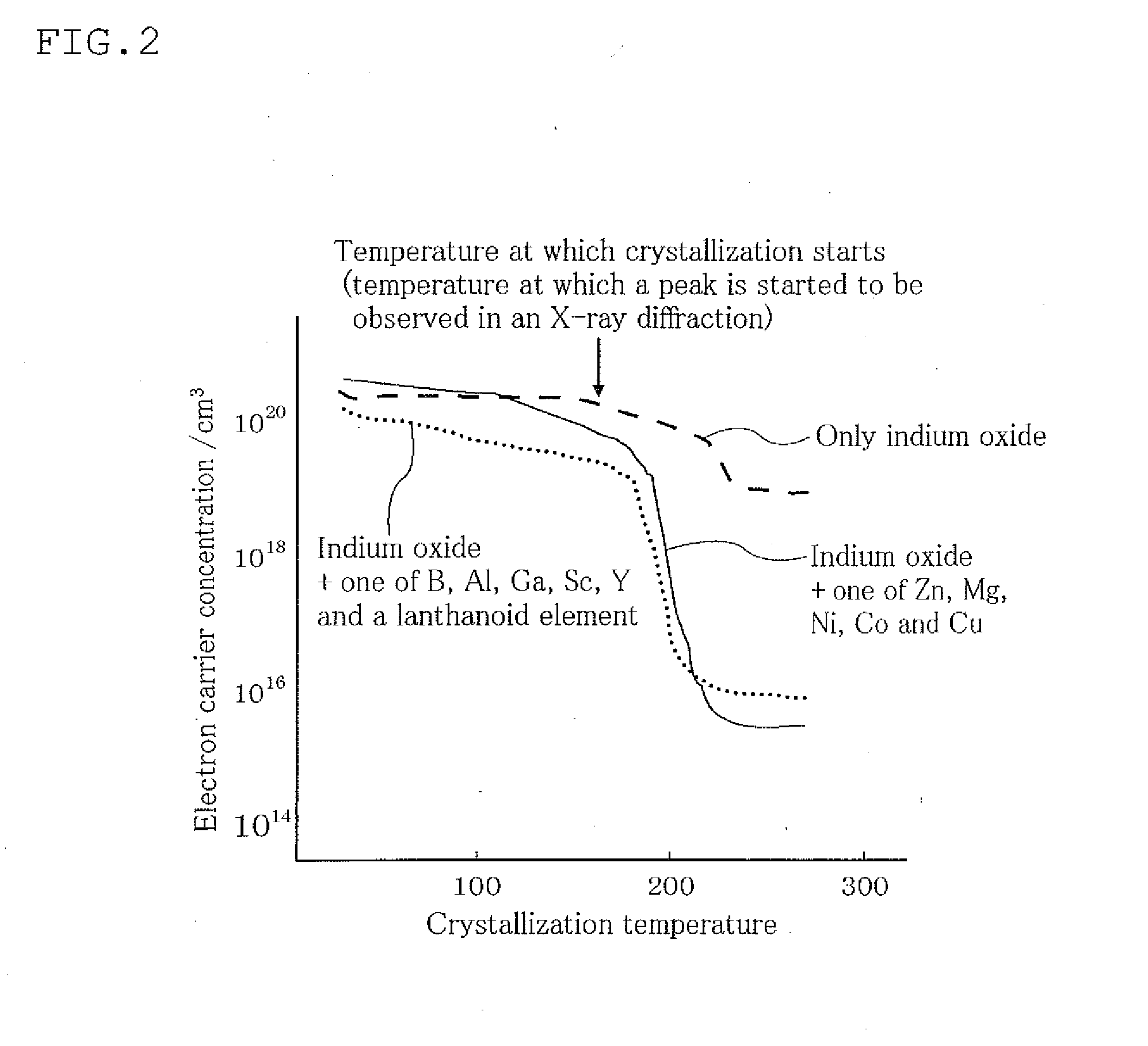

Sputtering target, oxide semiconductor film and semiconductor device

A sputtering target including an oxide sintered body, the oxide sintered body containing indium (In) and at least one element selected from gadolinium (Gd), dysprosium (Dy), holmium (Ho), erbium (Er) and ytterbium (Yb), and the oxide sintered body substantially being of a bixbyite structure.

Owner:IDEMITSU KOSAN CO LTD

Secured documents indentified with anti-stokes fluorescent compositions

The present invention provides a secured document including a composition capable of anti-Stokes fluorescence containing an ion capable of absorption of electromagnetic radiation, an ion capable of emitting electromagnetic radiation, and a matrix composition comprising gadolinium, yttrium, lanthanum, and luetium, wherein the wavelength of the emitted electromagnetic radiation is shorter than the wavelength of the absorbed electromagnetic radiation, and wherein the concentrations of the absorbing and emitting ions are adjusted to achieve concentration quenching of anti-Stokes luminescence.

Owner:BUNDESDRUCKEREI GMBH

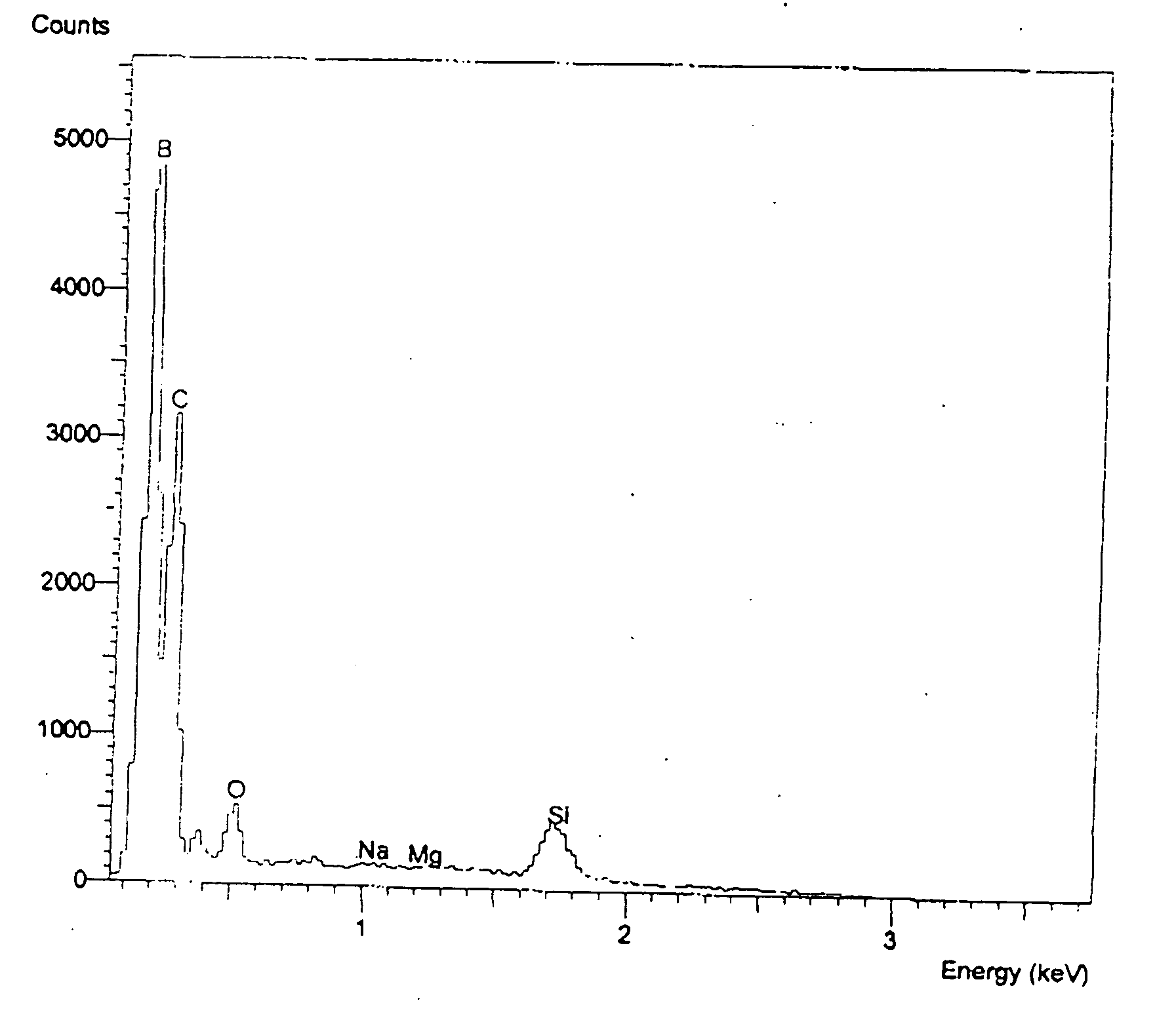

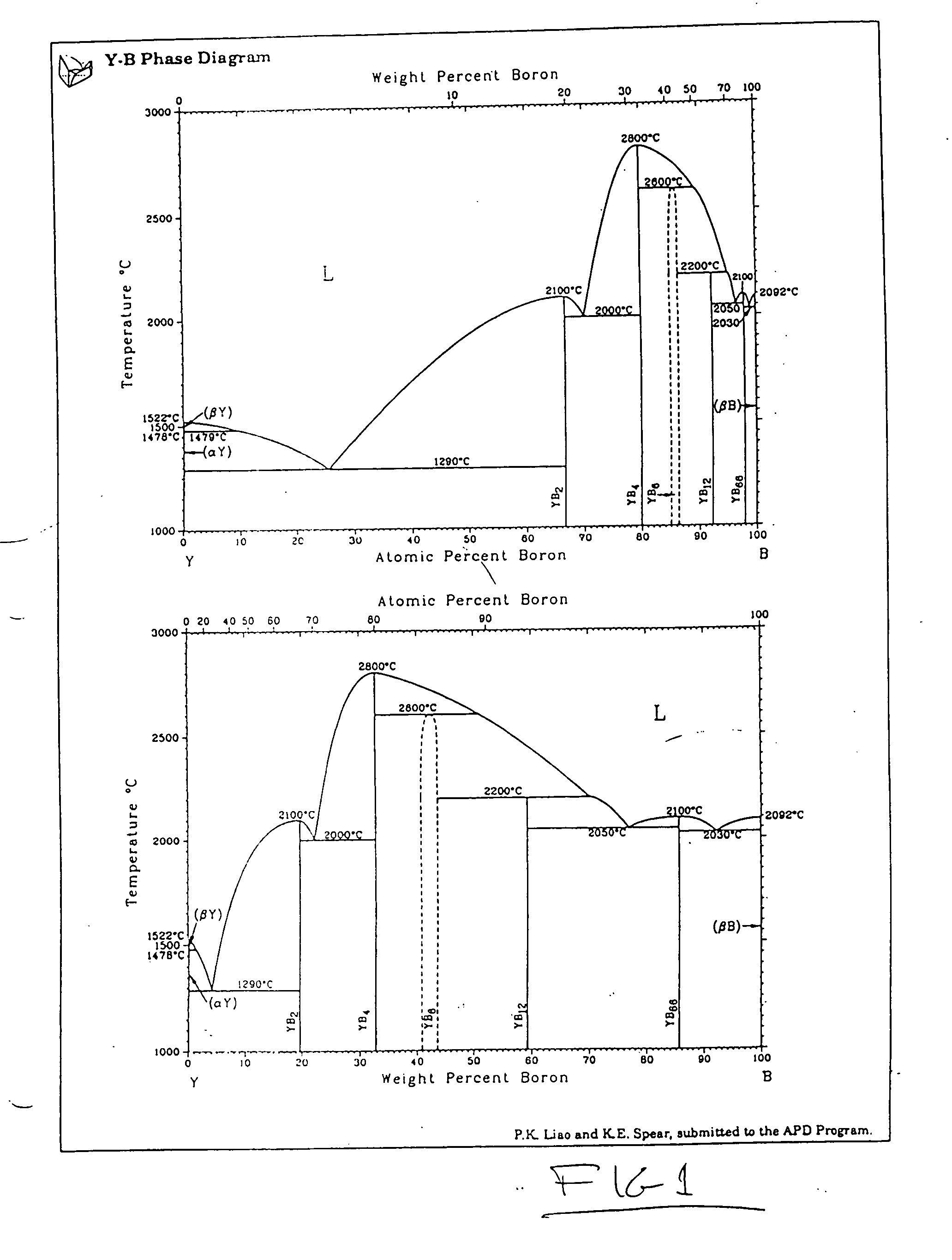

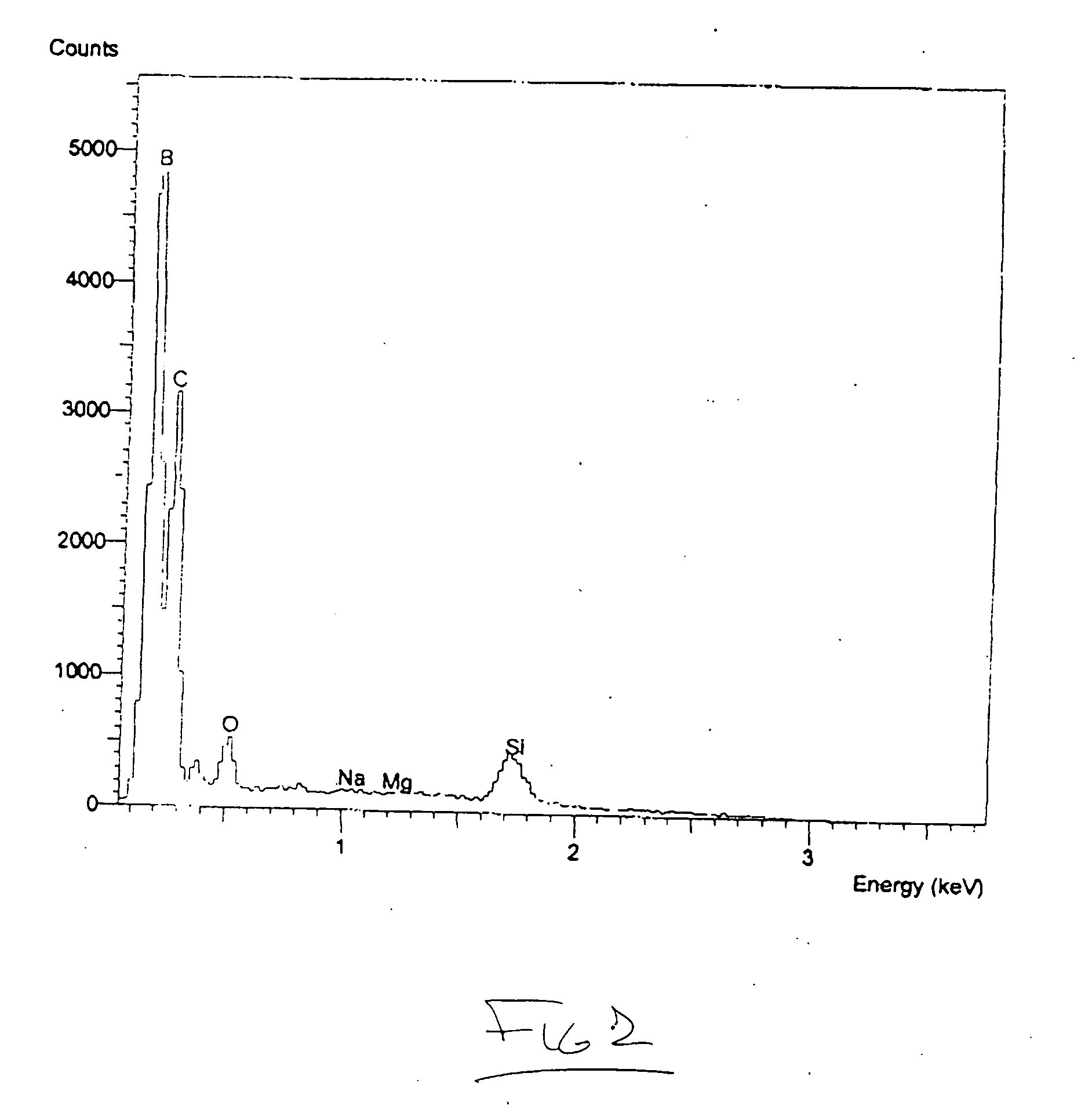

Method for depositing boron-rich coatings

InactiveUS20050208218A1Not readyReduce usageSpark gapsLiquid surface applicatorsLutetiumControl manner

A method is disclosed for coating substantially pure boron or highly boron-rich borides in a controlled manner. Such a method of coating of boron has a variety of applications, including surface chemical and wear protection, neutron absorption, prevention of impurity emission from heated filaments and ion beams, elimination of metal dust from vacuum systems, boridizing, boron cluster emission, and reactive chemistry. Borides with a boron-to-metal ratio of 20 or more are known to exist and may be used as a feedstock for substantially pure boron coatings for deposition processes requiring feedstock electrical conductivity, and / or enhanced reactivity. While most metal borides coincidentally produce significant metal vapor as a by-product, certain borides of yttrium, holmium, erbium, thulium, terbium, gadolinium, and lutetium have been identified as capable of producing substantially pure boron vapor.

Owner:IBADEX

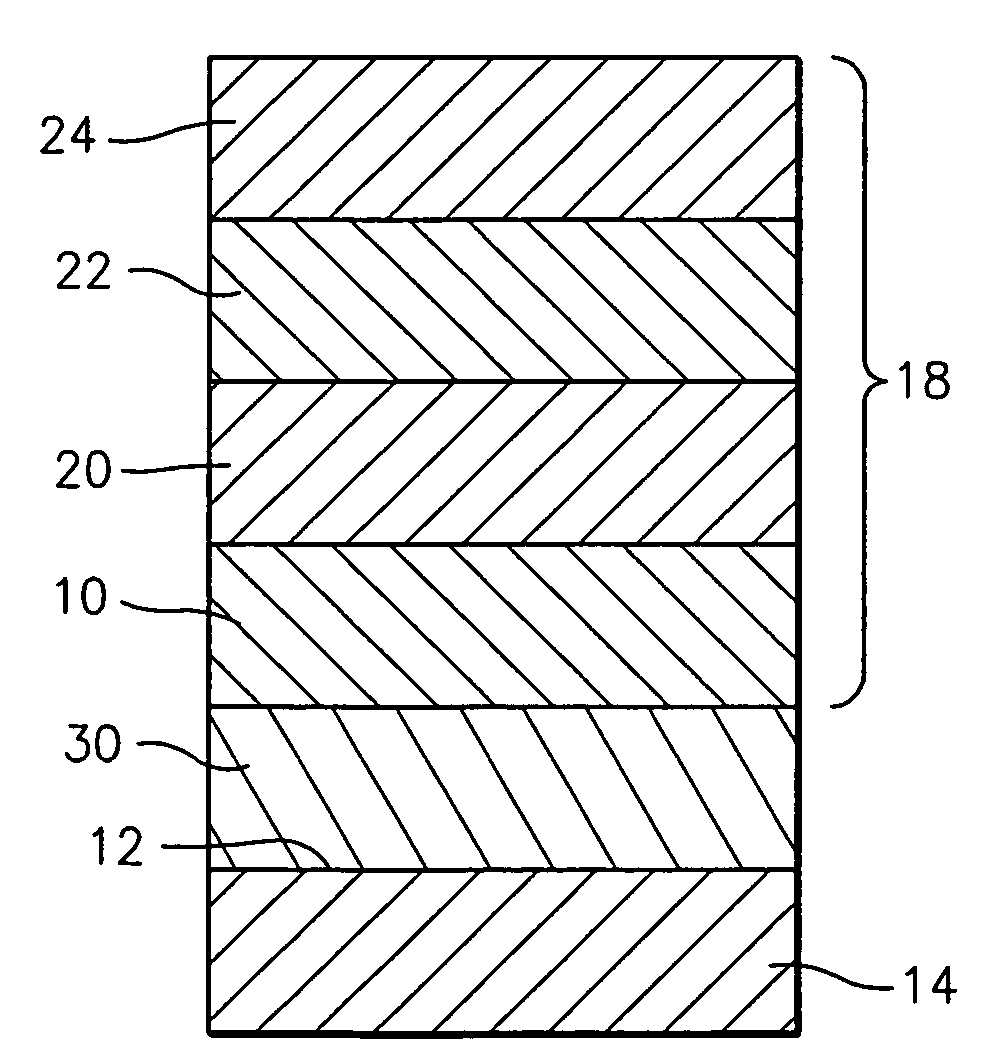

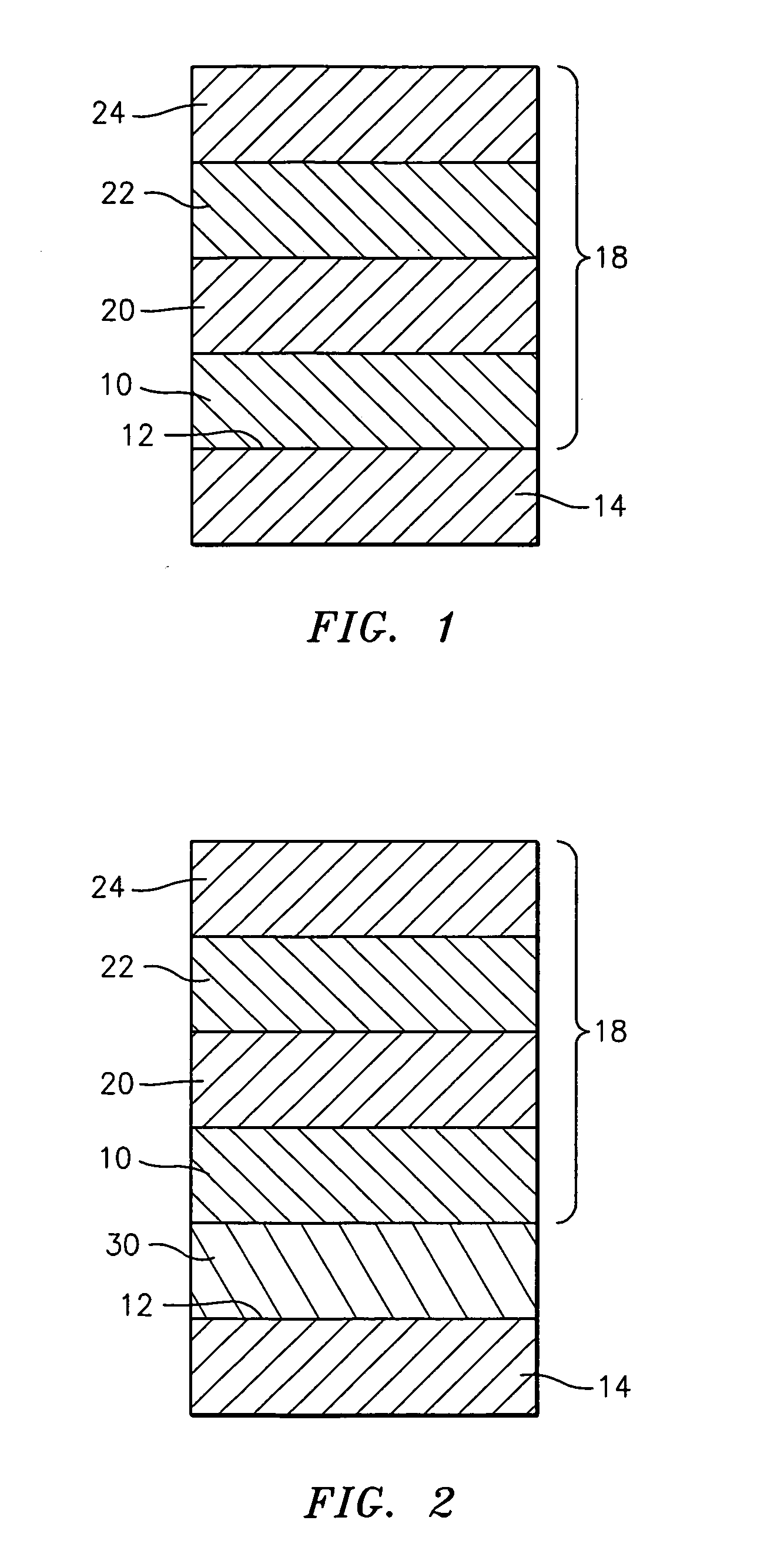

CMAS resistant thermal barrier coating

ActiveUS20070172703A1Reduce componentsReduces sand related distressMolten spray coatingBlade accessoriesIndiumCerium

A turbine engine component is provided which has a substrate and a thermal barrier coating applied over the substrate. The thermal barrier coating comprises alternating layers of yttria-stabilized zirconia and a molten silicate resistant material. The molten silicate resistant outer layer may be formed from at least one oxide of a material selected from the group consisting of lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, scandium, indium, zirconium, hafnium, and titanium or may be formed from a gadolinia-stabilized zirconia. If desired, a metallic bond coat may be present between the substrate and the thermal barrier coating system. A method for forming the thermal barrier coating system of the present invention is described.

Owner:RTX CORP

Sputtering target, oxide semiconductor film and semiconductor device

A sputtering target including an oxide sintered body, the oxide sintered body containing indium (In) and at least one element selected from gadolinium (Gd), dysprosium (Dy), holmium (Ho), erbium (Er) and ytterbium (Yb), and the oxide sintered body substantially being of a bixbyite structure.

Owner:IDEMITSU KOSAN CO LTD

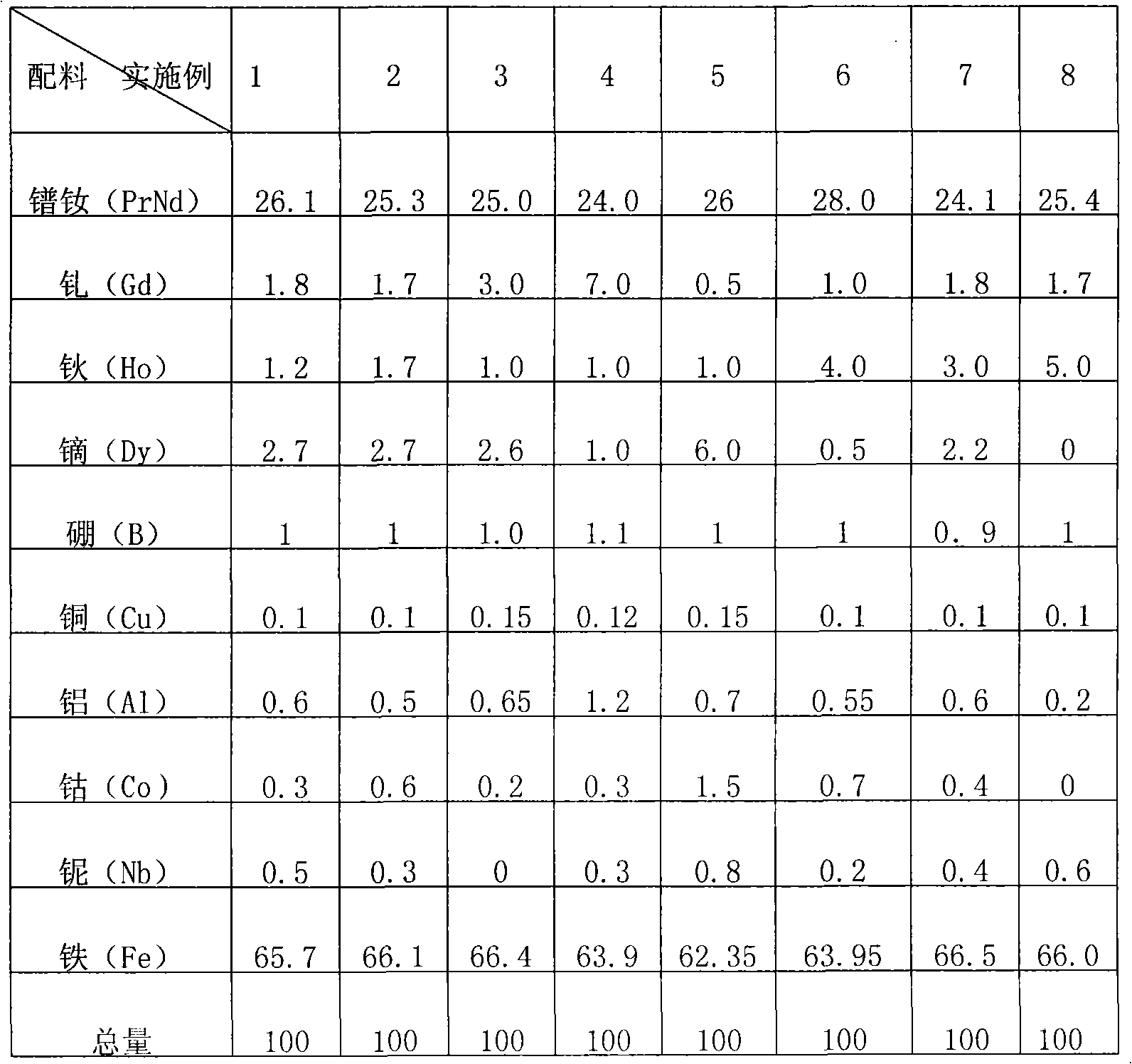

Neodymium iron boron permanent magnet for motor and manufacturing method thereof

ActiveCN101409121AReduce manufacturing costLow costInductances/transformers/magnets manufactureMagnetic materialsNiobiumMaterials science

The invention discloses an NdFeB permanent magnet used for NdFe motors and a manufacture method thereof. The magnet comprises the following components by weight: 24-28 percent of PrNd, 0.5-7 percent of Gd, 1-5 percent of Ho, 0-6 percent of Dy, 0.9-1.1 percent of B, 0.1-0.15 percent of Cu, 0.2-1.2 percent of Al, 62.35-66.5 percent of Fe, 0.2-1.5 percent of Co and 0.2-0.8 percent of Nb. The magnet is manufactured through the procedures of mixing, melting, milling, forming, sintering and grinding processing. Through the use of cheap gadolinium and holmium instead of expensive praseodymium, neodymium, dysprosium and terbium for the production of high-performance NdFeB permanent magnet, the invention can greatly reduce production cost and the product has high magnetic property and strong market competitiveness.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

Lead-free mixture as a radiation protection additive

The present invention provides a mixture containing a) at least 26 wt. % of gadolinium and b) one or more elements, alloys and / or compounds from the group consisting of barium, indium, tin, lanthanum, molybdenum, niobium, tantalum, zirconium and tungsten, a process for the preparation of this mixture, use of the mixture as radiation protection, use of the mixture to prepare polymeric radiation protection substances, a process for preparing radiation screening rubbers, thermoplastic materials and polyurethanes, a process for preparing products from the polymeric radiation protection substances and products made from these polymeric radiation protection substances.

Owner:LANXESS DEUTDCHLAND GMBH

Coating composition, article, and associated method

InactiveUS20080009417A1Semiconductor/solid-state device manufacturingSuperconductor device manufacture/treatmentGadoliniumCerium

A processing apparatus for use in a corrosive operating environment at a temperature range of 25-1500° C. is provided. The apparatus has protective coating structure that includes a glassy material. The glassy material includes at least one of yttrium, cerium, or gadolinium; and aluminum and silicon. The coating composition resists etching by a harsh environment.

Owner:GENERAL ELECTRIC CO

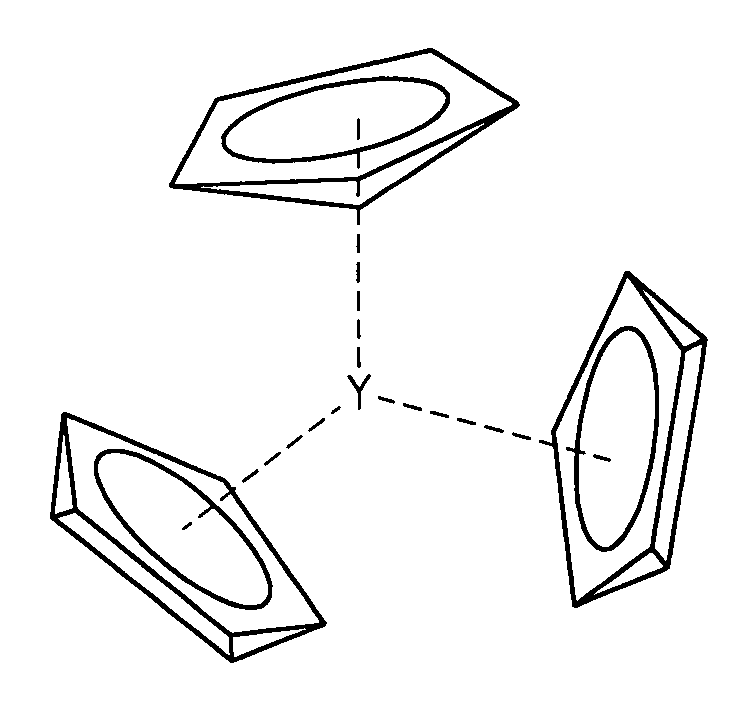

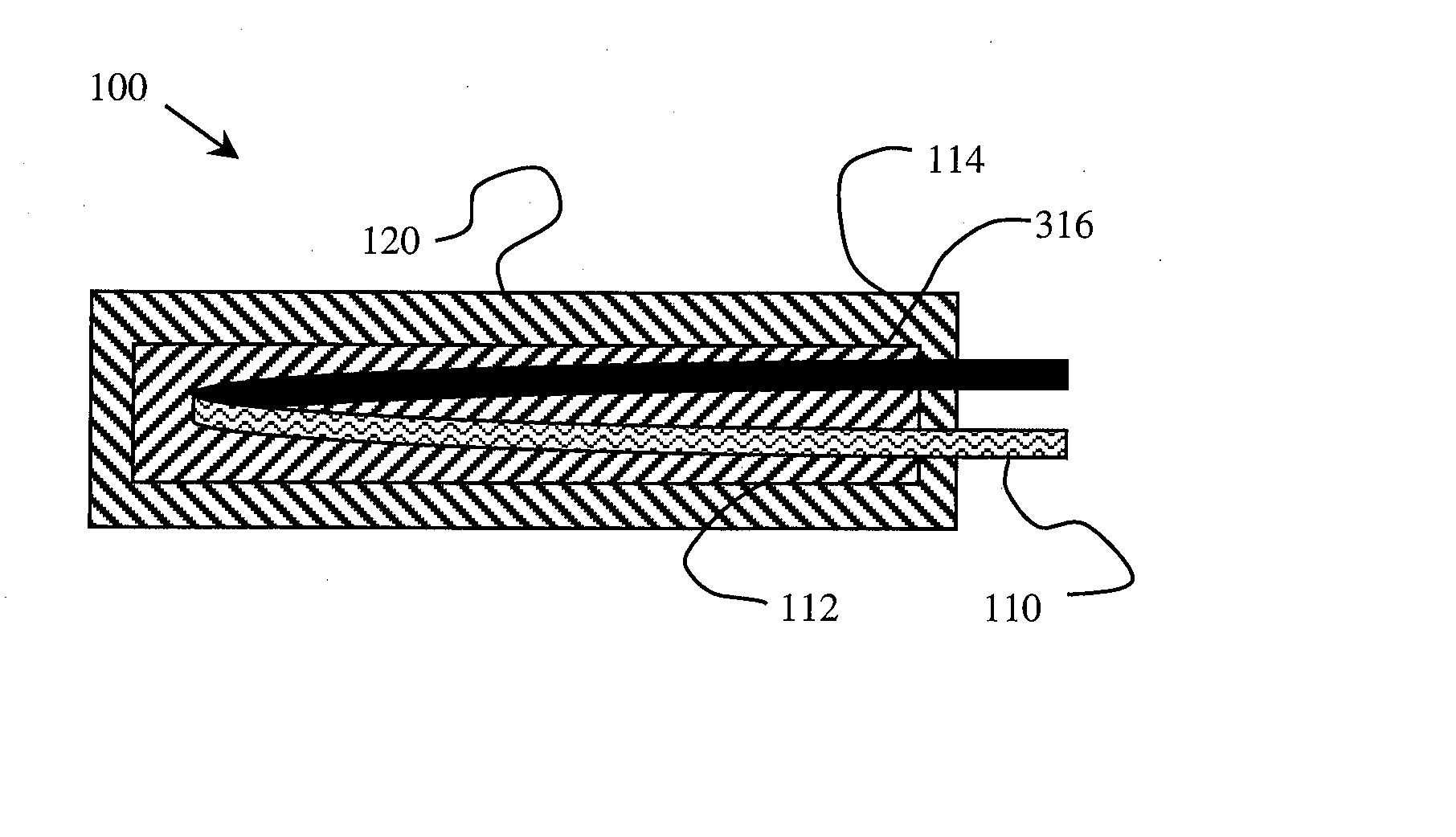

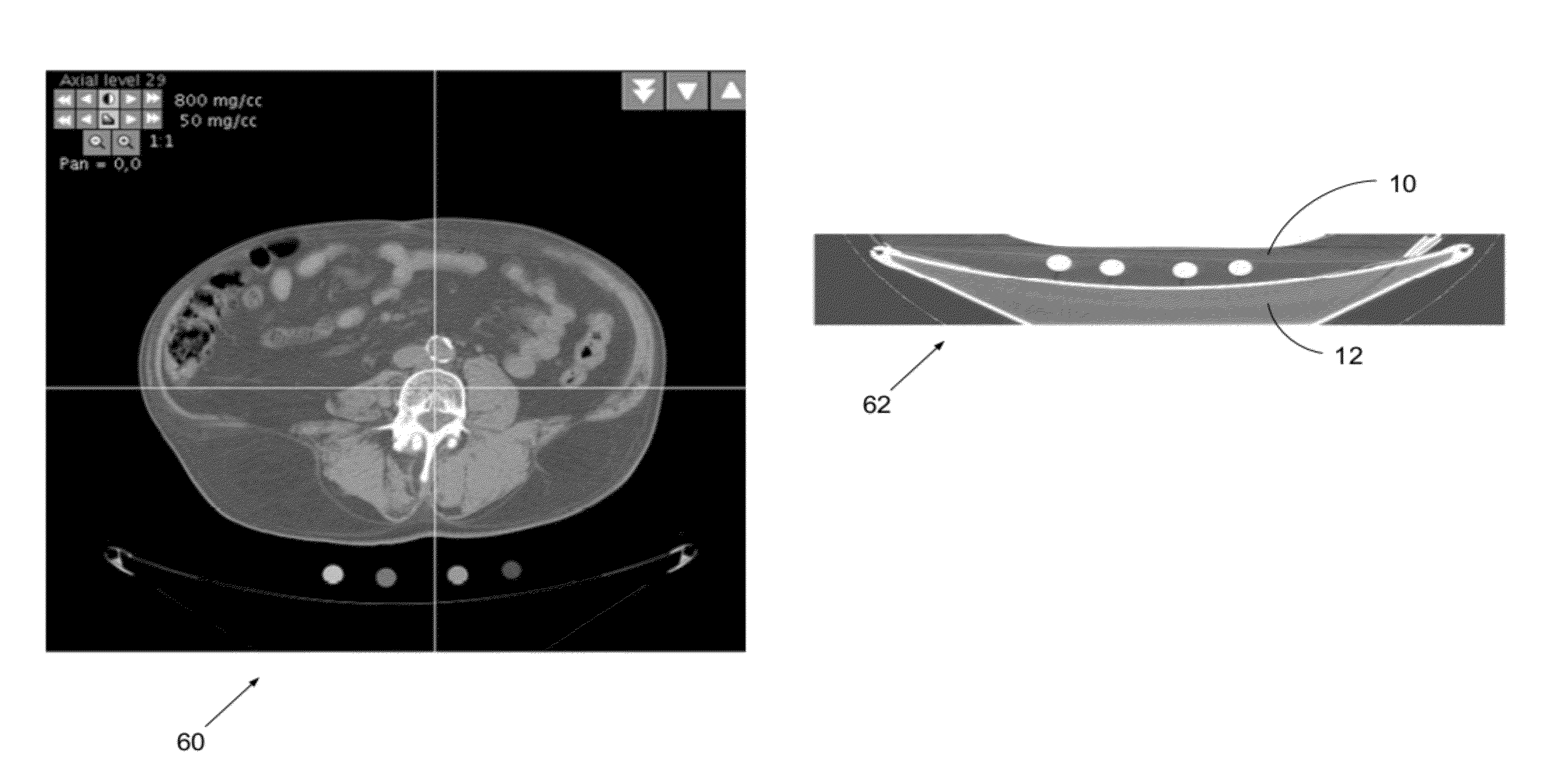

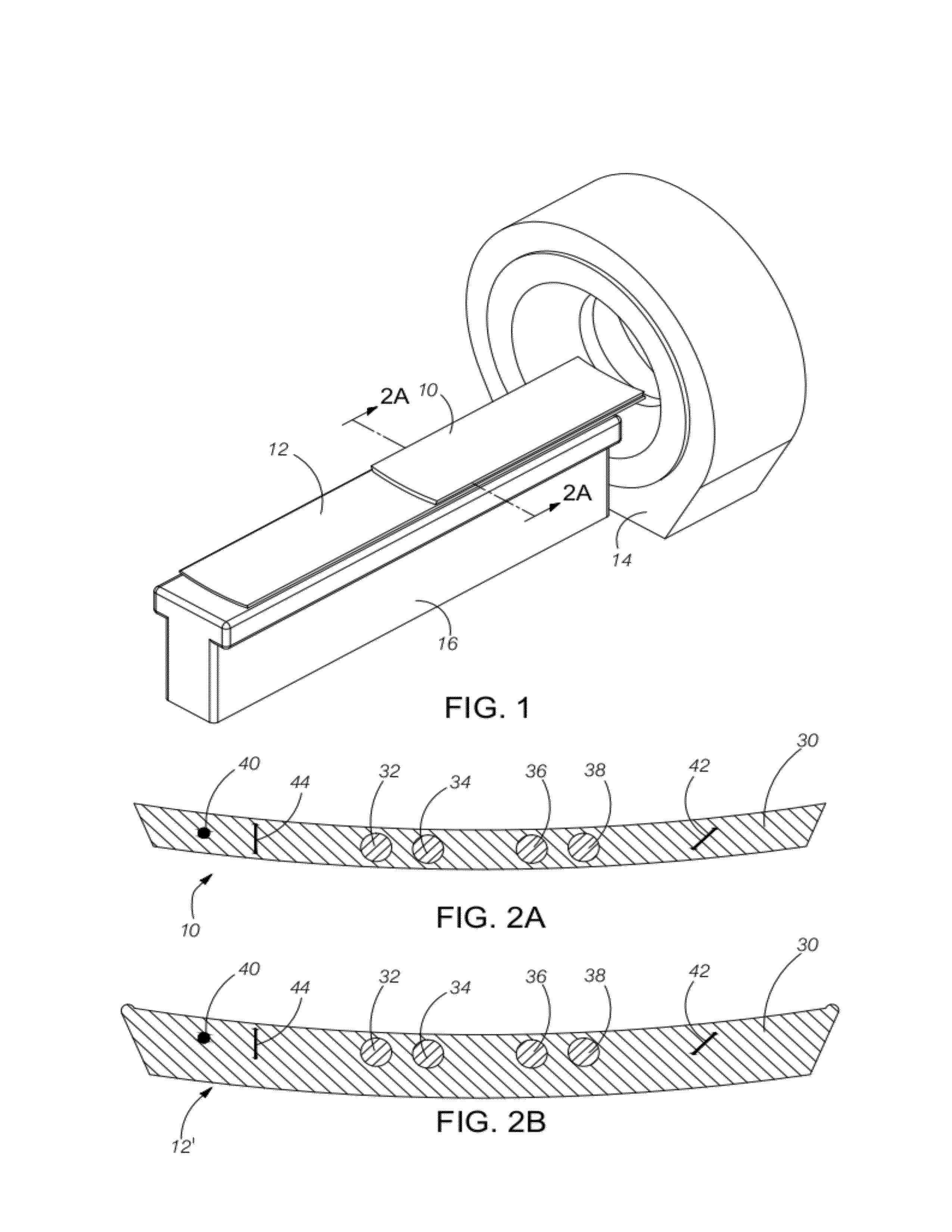

Extended and fixed INTable simultaneously imaged calibration and correction methods and references for 3-D imaging devices

ActiveUS8186880B1Small cross-sectional sizeMinimizes patient movementMaterial analysis using wave/particle radiationRadiation/particle handlingReference sampleImage calibration

Calibration and reference samples with reduced cross-sectional areas encased within imaging tables or couch pads have low attenuation properties and provide patient comfort. The samples are stable and provide reproducible images without artifacts. The torso-length samples avoid positioning errors and misalignment. Sample density or mass calibration materials include calcium compounds representative of bone and calcifications, iodine compounds for contrast angiography, gadolinium compounds for MRI, and fat and tissue equivalent materials. Density corrections for variable patient scatter and imperfect image reconstructions improve quantitative measurement. Automated computer methods detect the samples and record readings on all images over the extent of the scans without operator interaction. Spatial references function as location references and enable spatial correction of device imperfections such as point spread function (PSF) or motion for improved images. Comparative analysis of backward and forward projections corrects images based on simultaneous imaging of the references of known properties.

Owner:ARNOLD BEN A

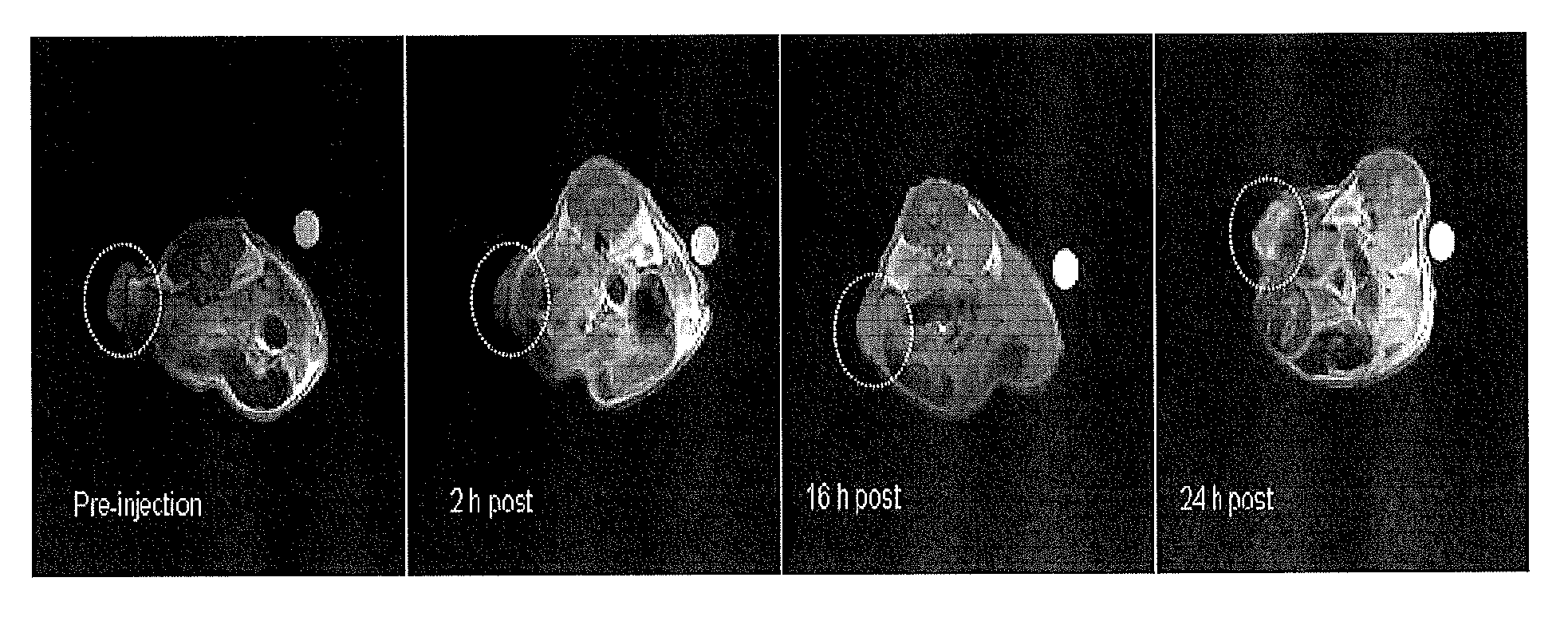

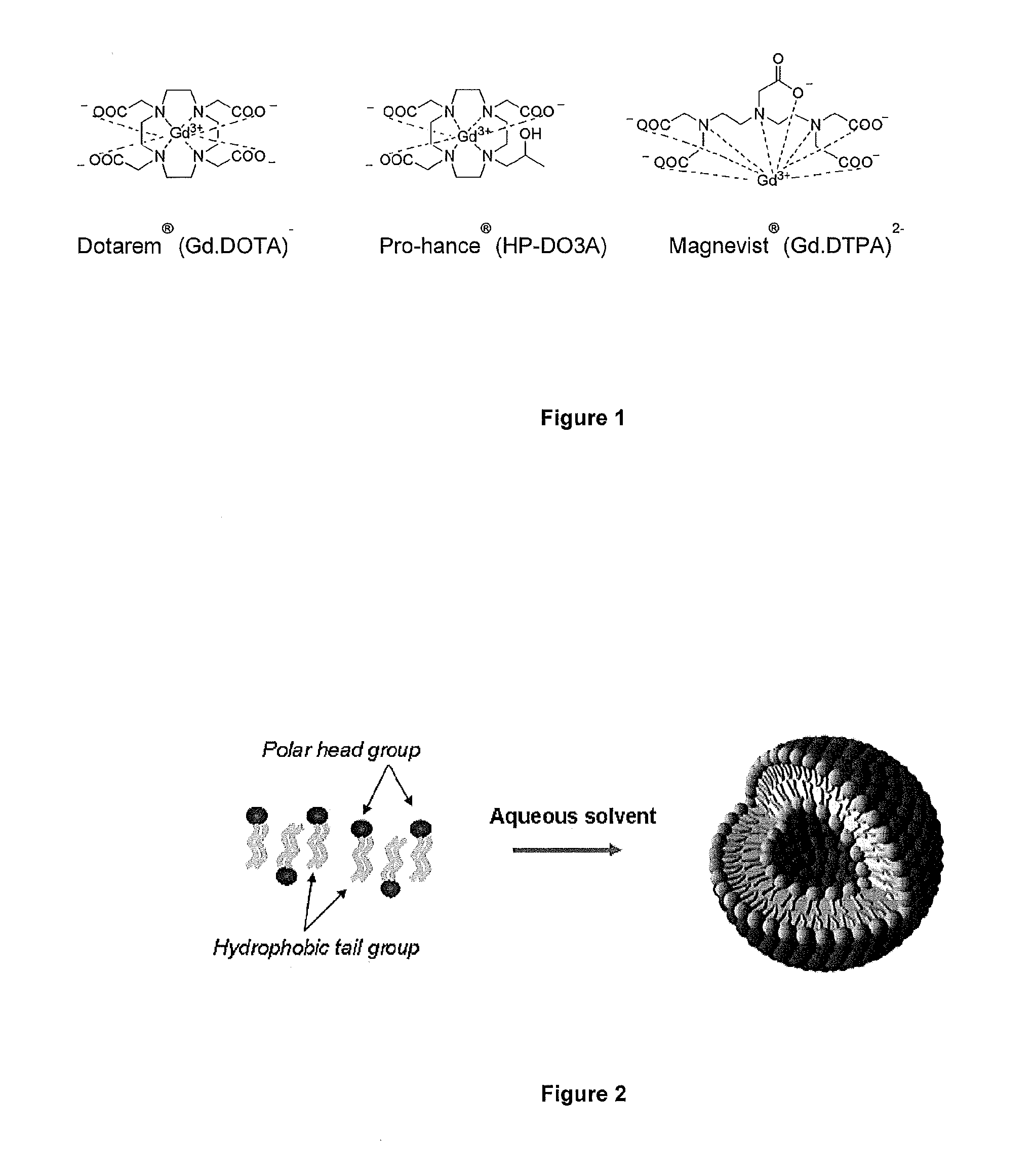

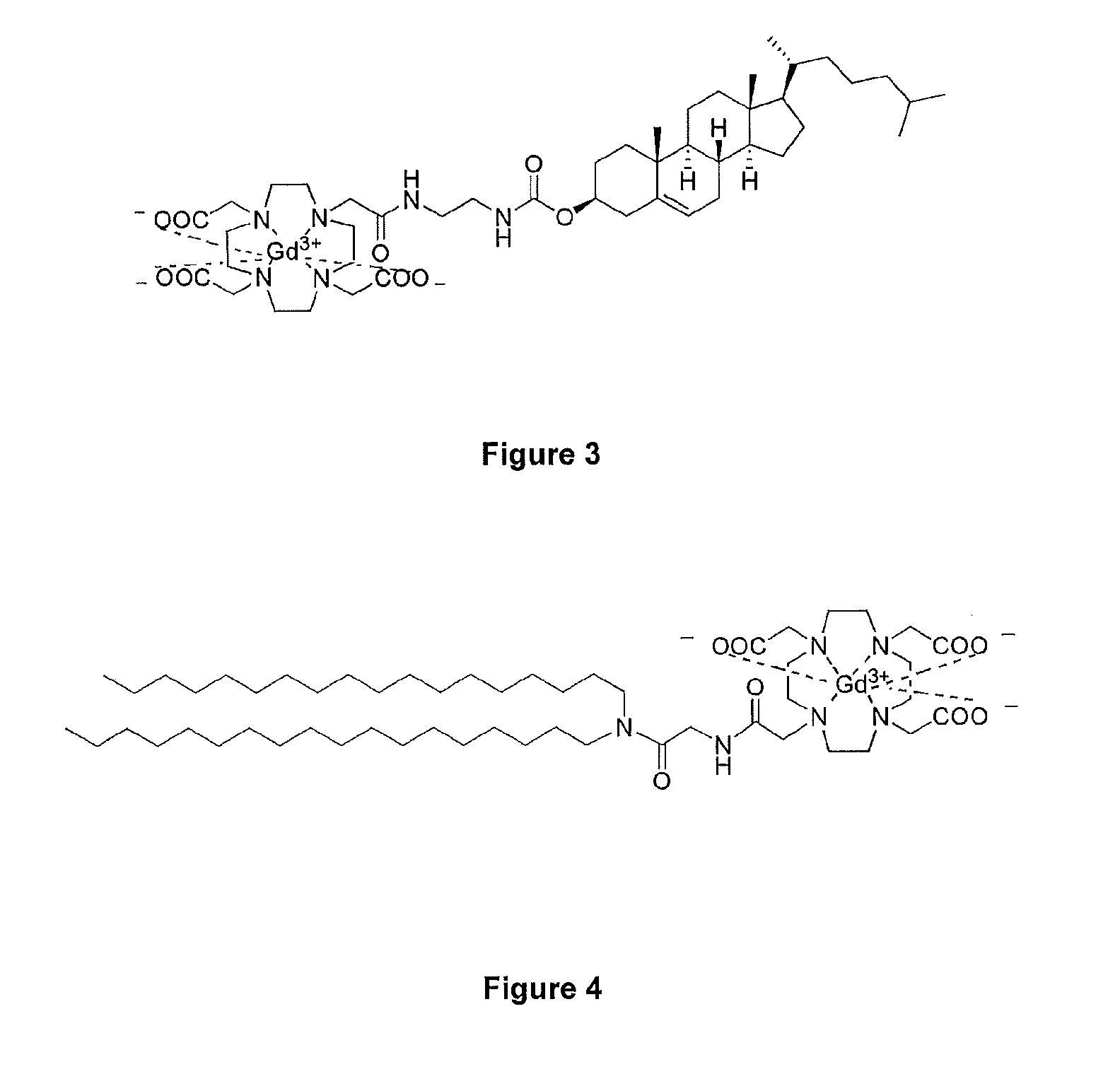

Novel Liposome Nanoparticles for Tumor Magnetic Resonance Imaging

The present invention provides novel liposomes comprising Gd.DOTA.DSA (gadolinium(III)2-{4,7-bis-carboxymethyl-10-[(N,N-distearylamidomethyl-N′-amido-methyl]-1,4,7,10-tetra-azacyclododec-1-yl}-acetic acid), characterised in that said liposome further comprises a neutral, fully saturated phospholipid component (e.g. DSPC (1,2-distearoyl-sn-glycero-3-phosphocholine]), which are of particular use in the preparation of magnetic resonance contrast agents for enhancing a magnetic resonance image of tumours in a mammal.

Owner:IMPERIAL INNOVATIONS LTD +1

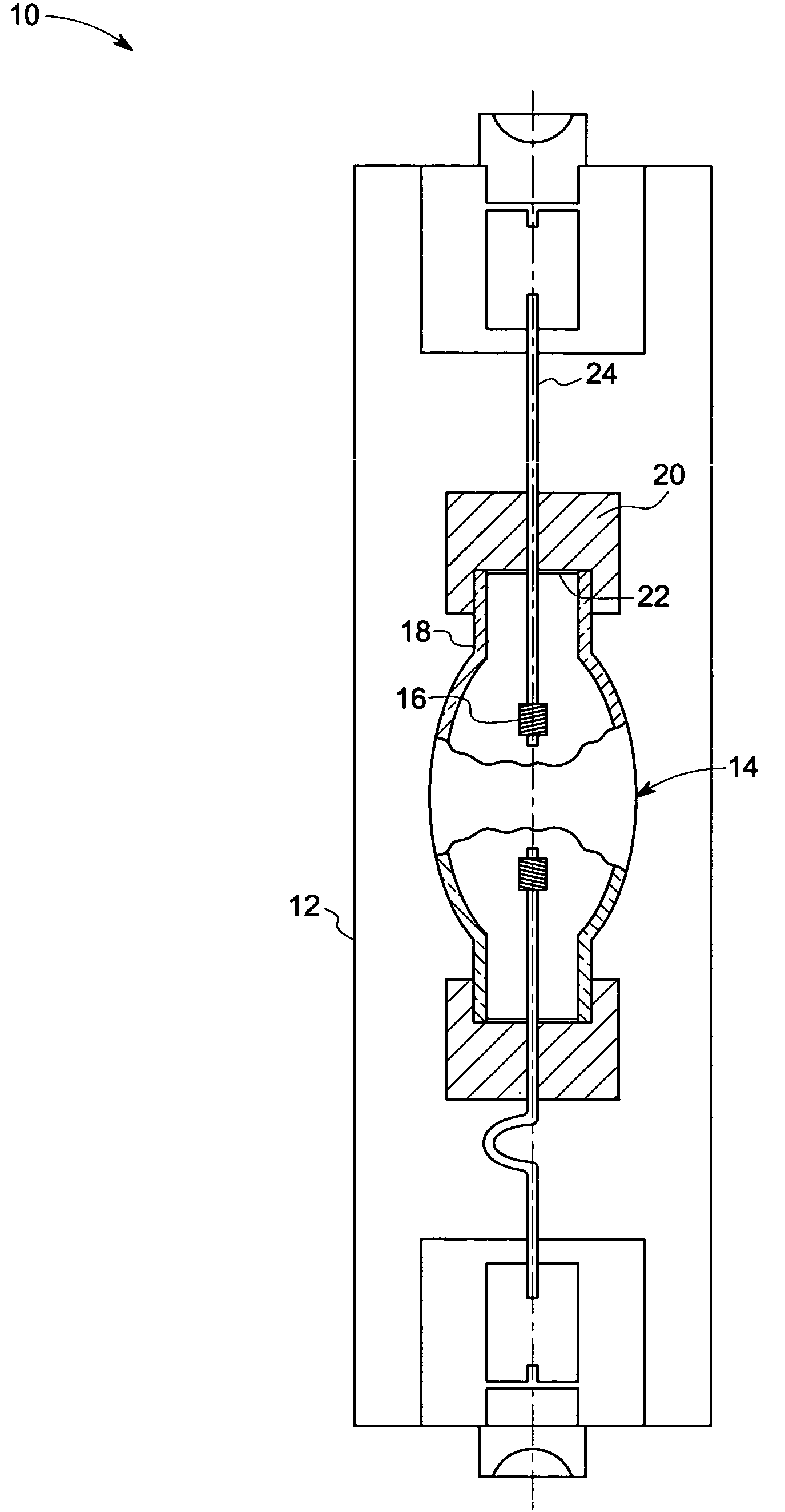

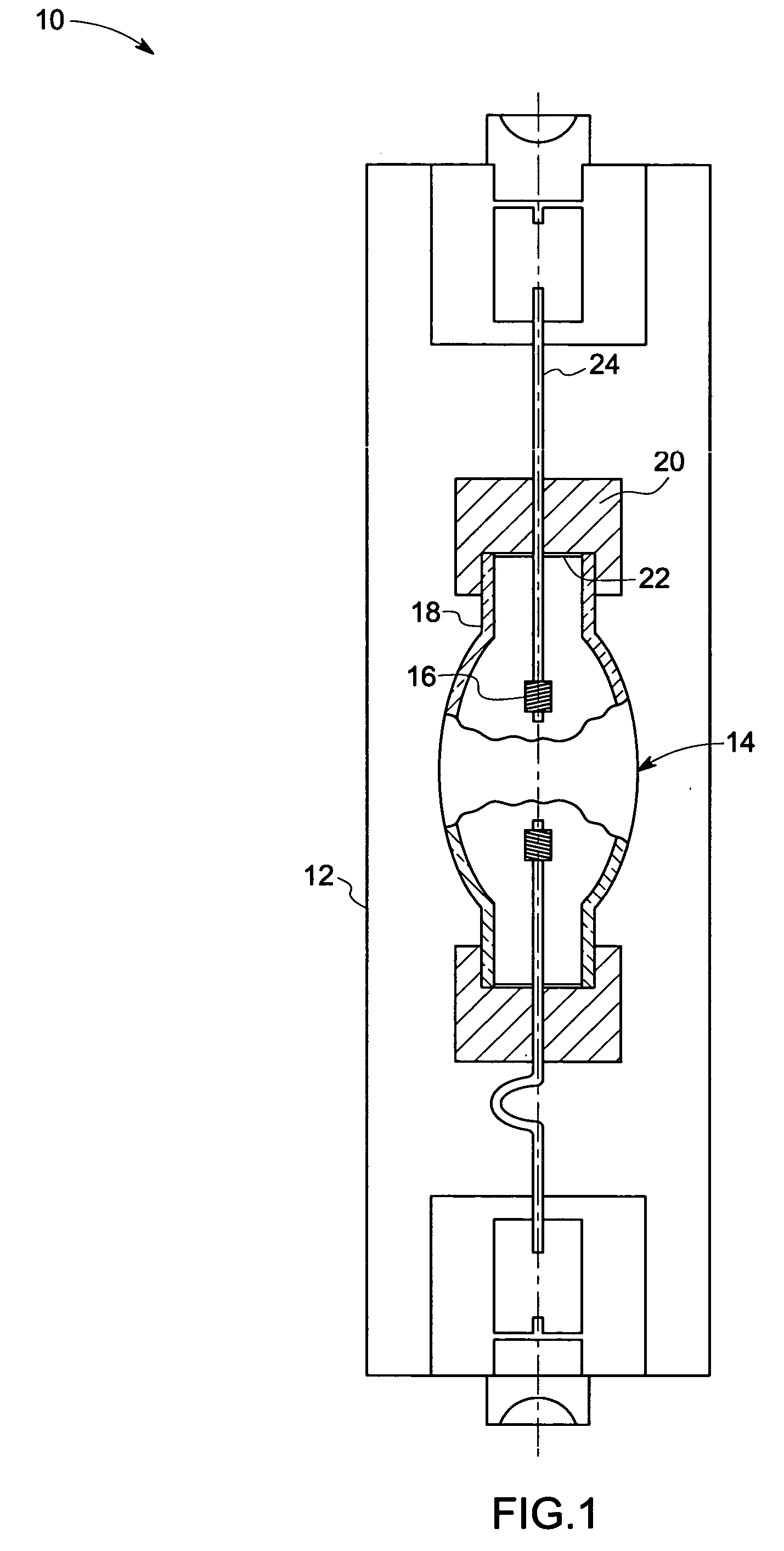

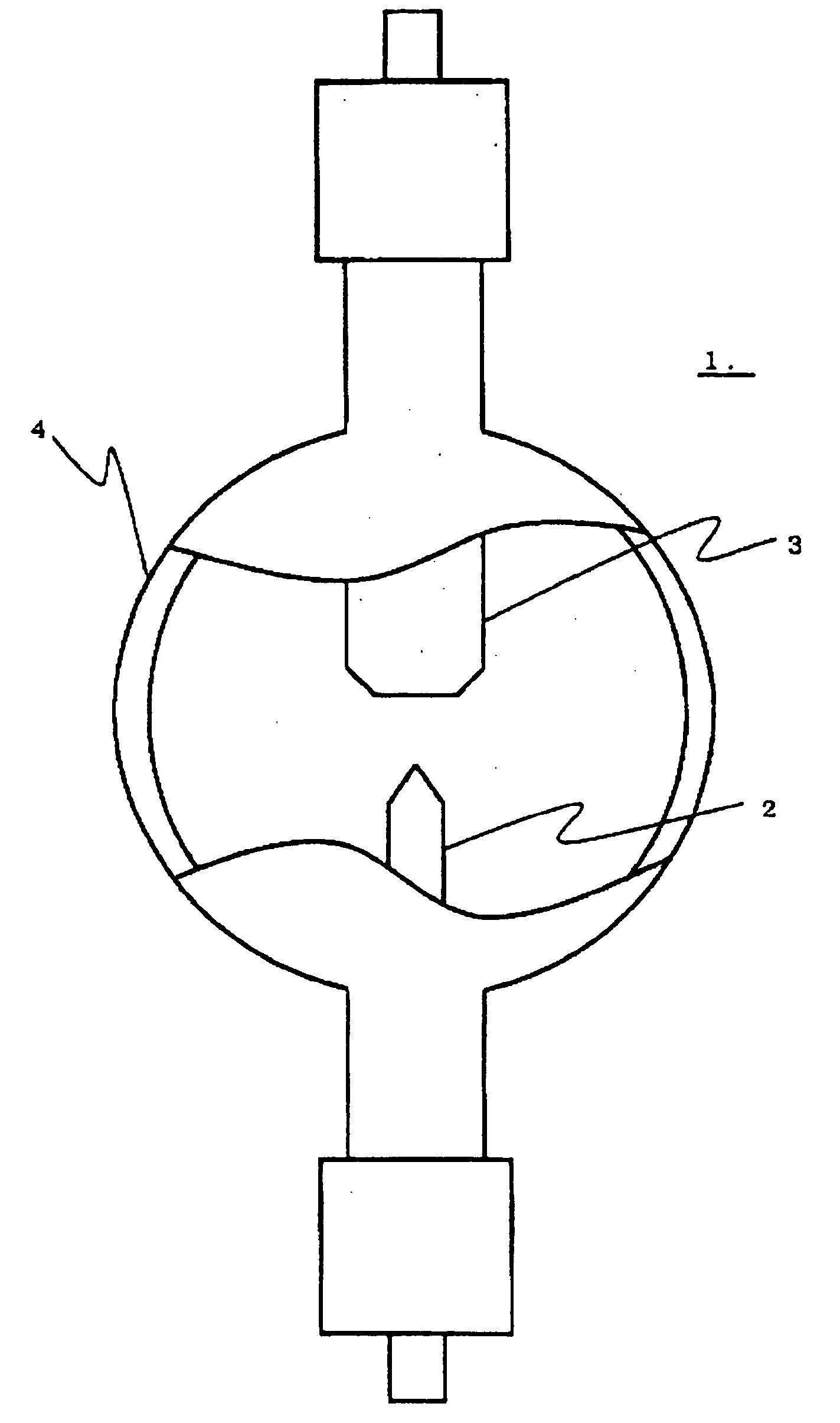

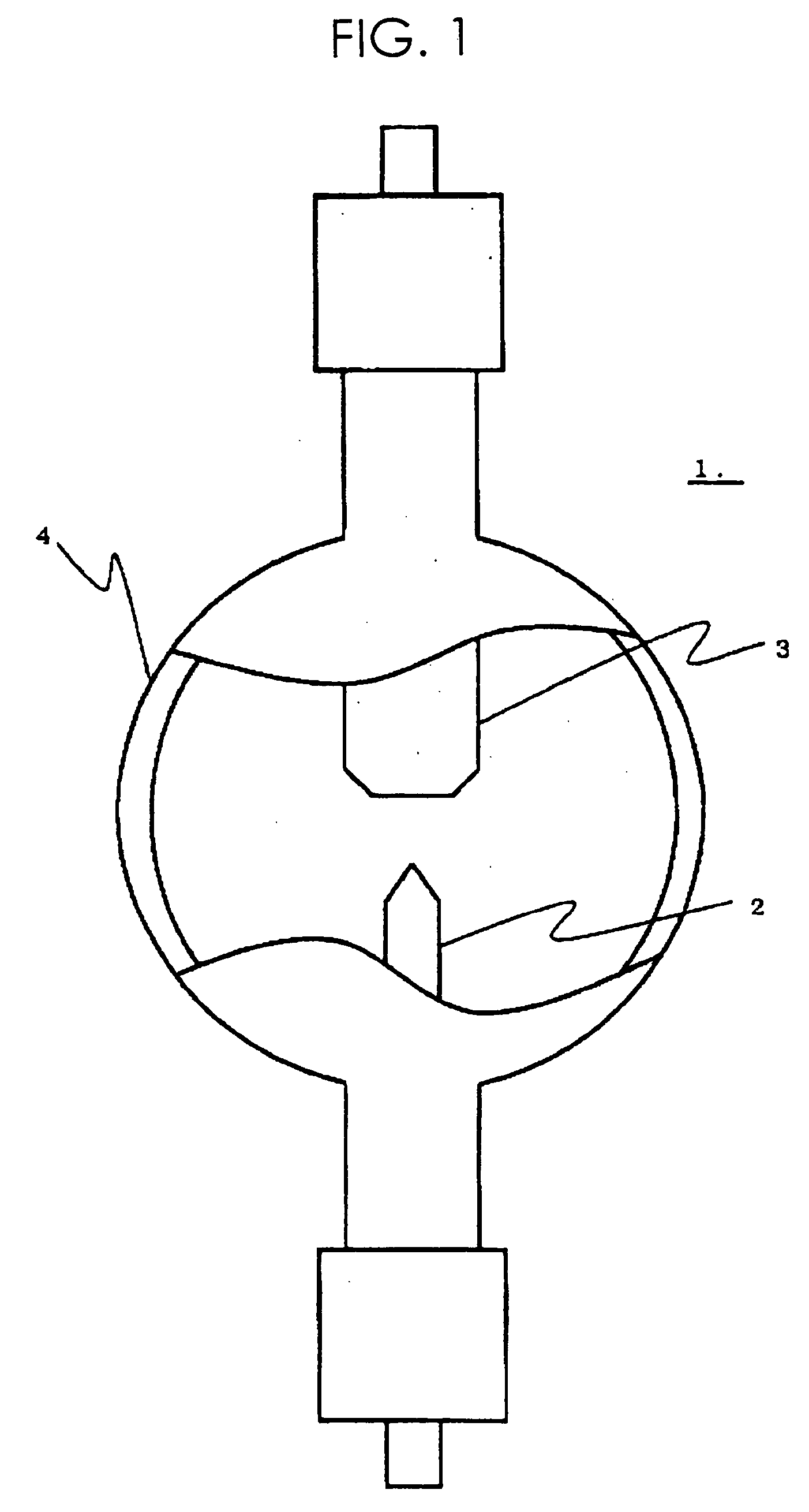

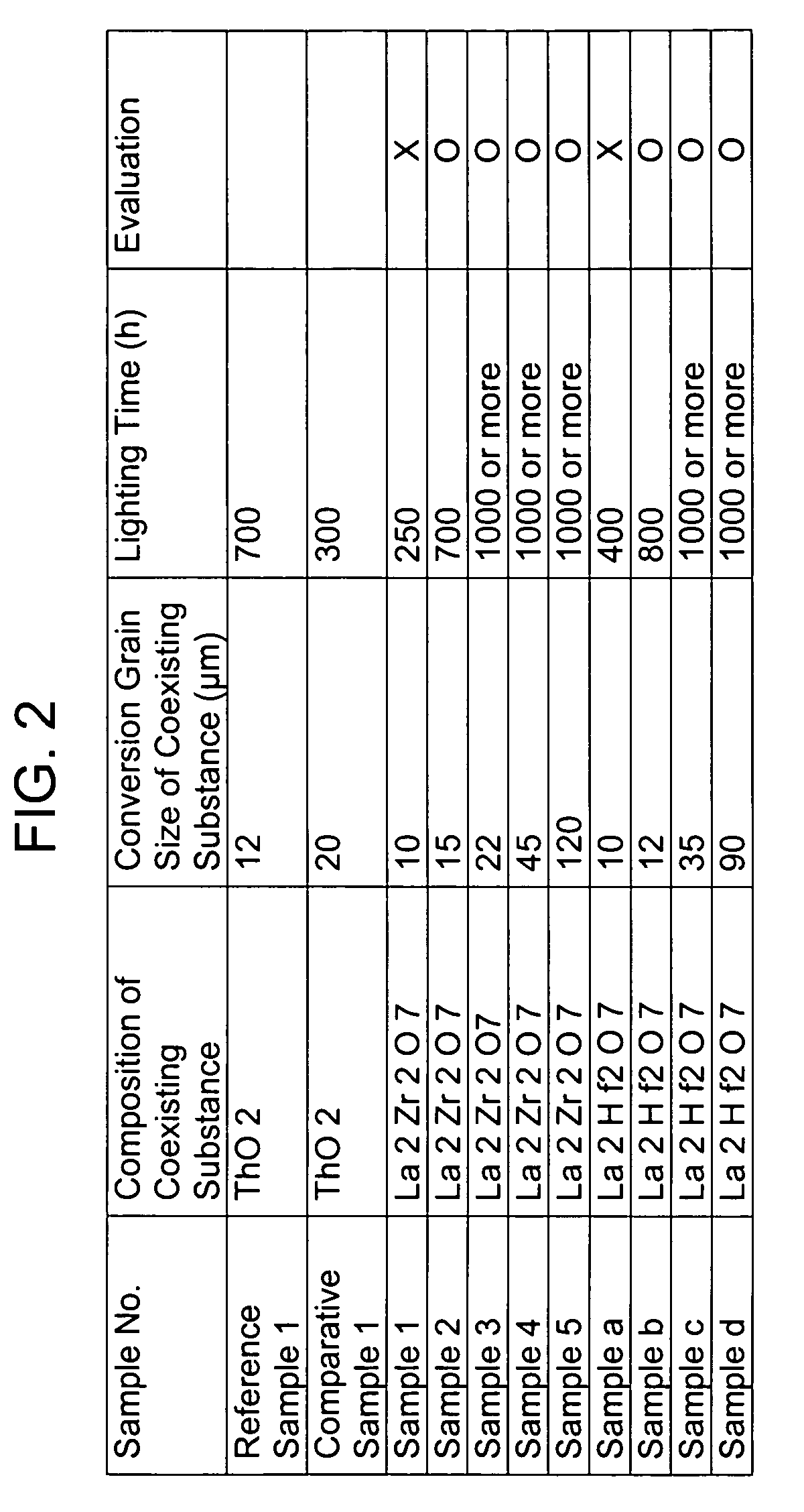

High-load and high-intensity discharge lamp

ActiveUS20060220559A1Long life-timeImprove stabilityWork-feeding meansSolid cathode detailsNiobiumCerium

The present high-load and high-intensity discharge lamp includes a cathode made of a material which does not (substantially) include thorium but can be used as a cathode material of high heat load, so that a long lifetime and high stability corresponding to those of thoriated-tungsten can be realized. Specifically, the cathode is made of a metal base having a high melting point which mainly consists of tungsten and includes a coexisting substance in which an oxide of at least one kind of metal selected from lanthanum, cerium, yttrium, scandium, and gadolinium and an oxide of at least one kind of metal selected from titanium, zirconium, hafnium, niobium, and tantalum are coexistent. The conversion grain size of the coexisting substance is 15 μm or greater, and the plurality of coexisting substances are present in the metal base with a high melting point.

Owner:USHIO DENKI KK

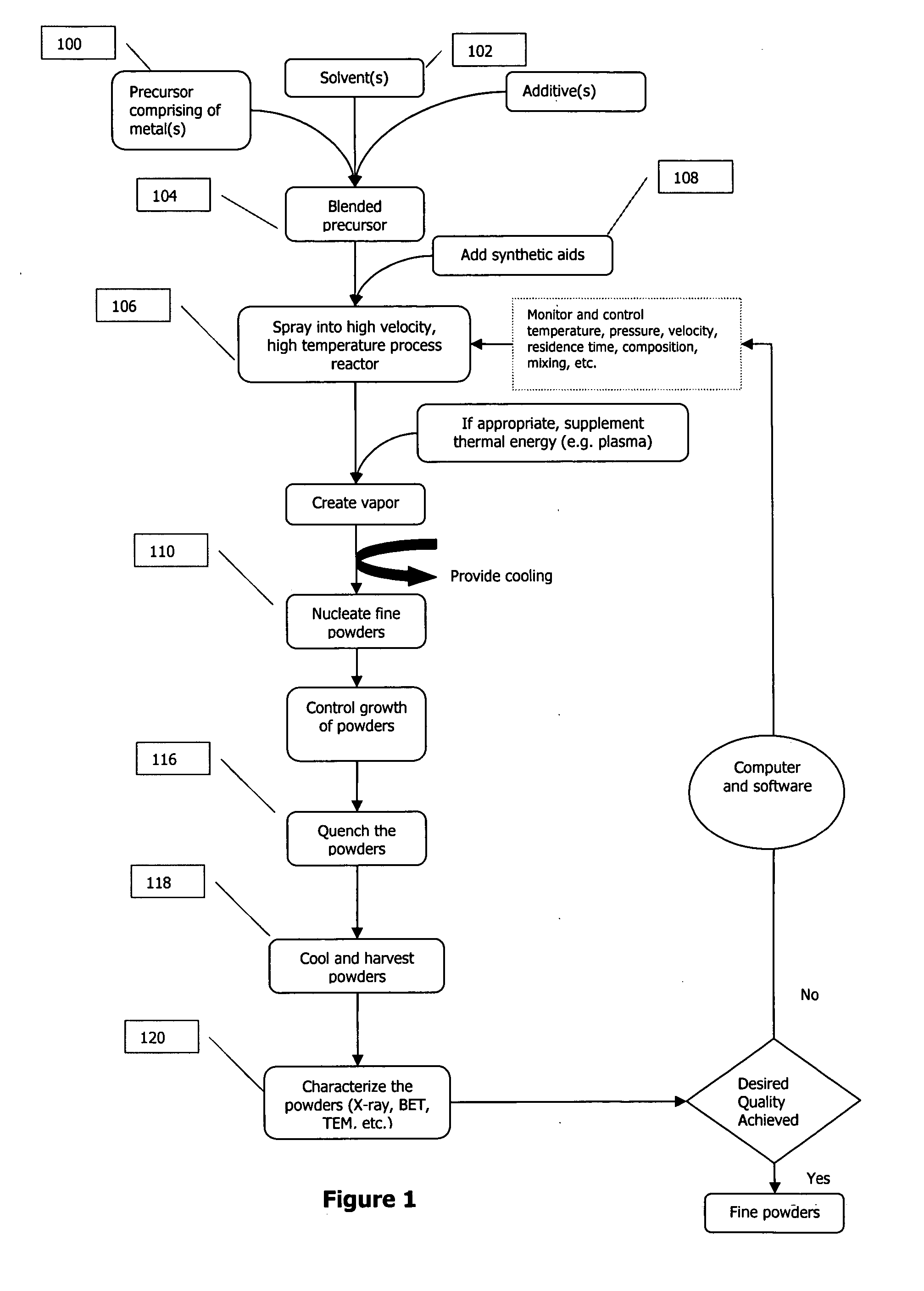

Nanoparticles of rare earth oxides

ActiveUS20070104629A1Increase volumeLow cost productionMaterial nanotechnologyLanthanum oxide/hydroxidesCeriumScandium

Rare earth compositions comprising nanoparticles, methods of making nanoparticles, and methods of using nanoparticles are described. The compositions of the nanomaterials discussed may include scandium (Sc), yttrium (Y), lanthanum(La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium(Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), and lutetium (Lu). The nanoparticles can be used to make organometallics, nitrates, and hydroxides. The nanoparticles can be used in a variety of applications, such as pigments, catalysts, polishing agents, coatings, electroceramics, catalysts, optics, phosphors, and detectors.

Owner:PPG IND OHIO INC

Gadolinium-containing sintered rare earth permanent magnet alloy and preparation method thereof

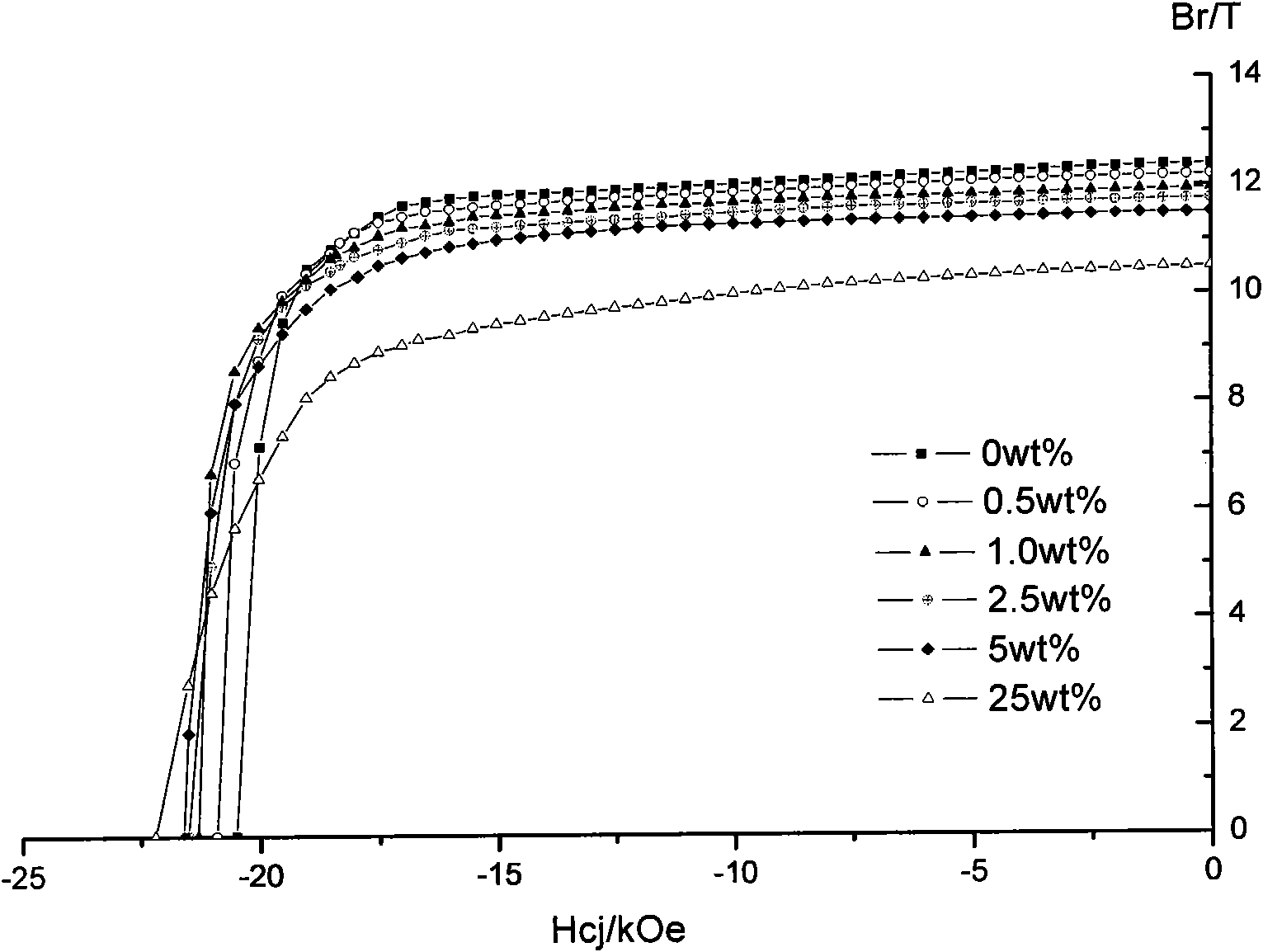

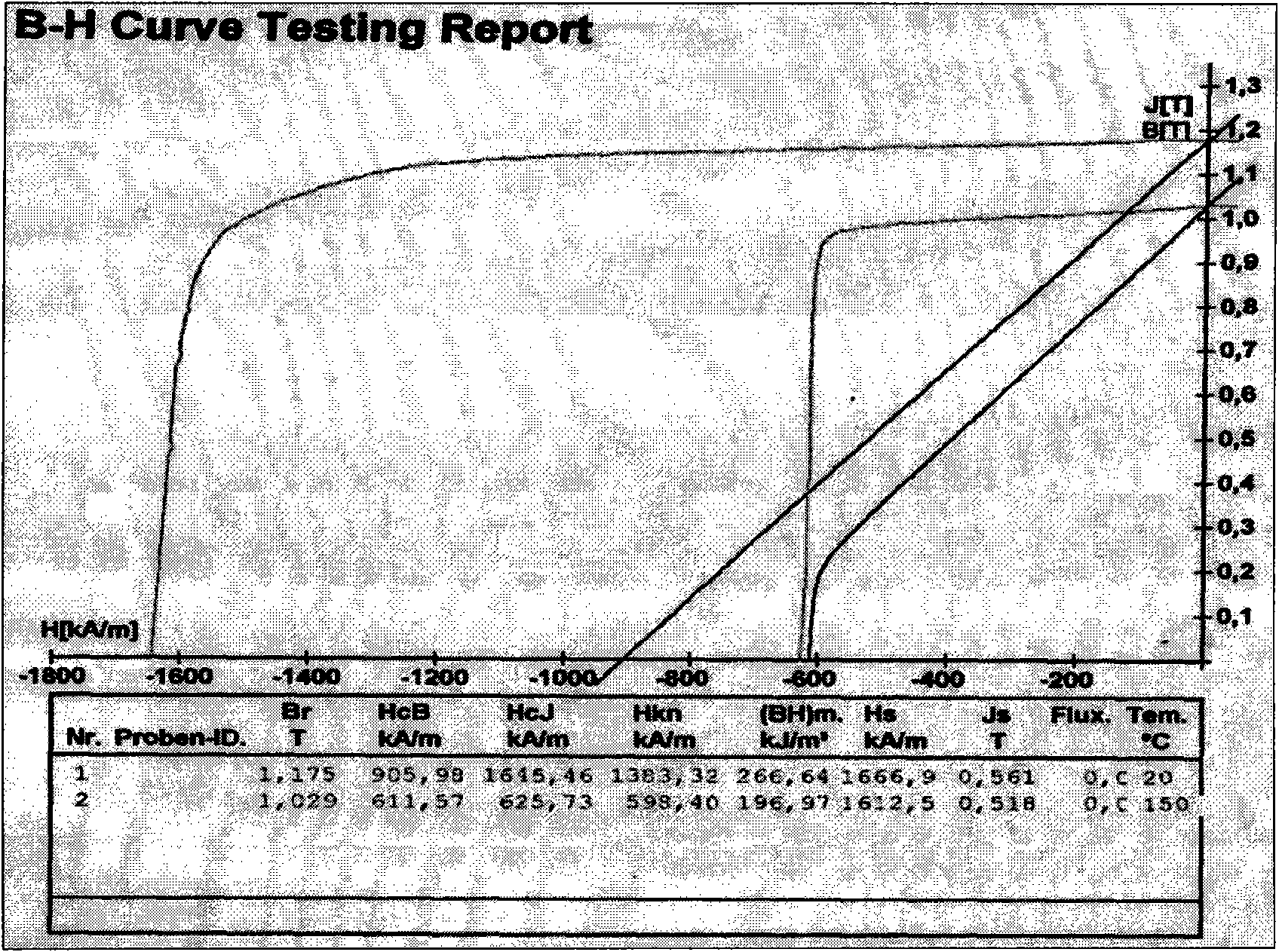

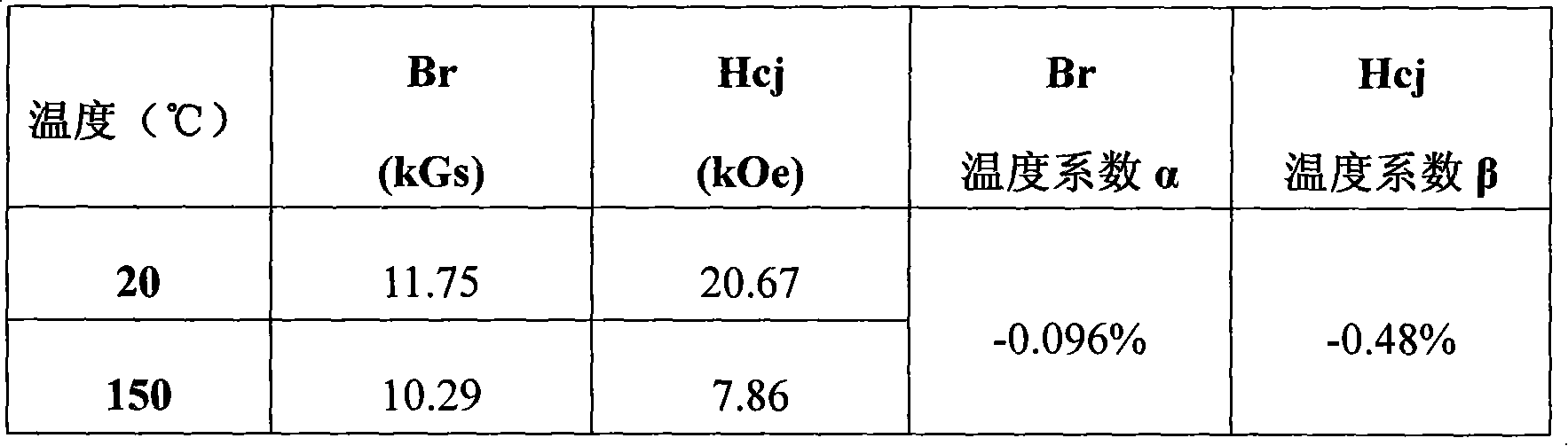

InactiveCN101630557AThe temperature coefficient of coercive force decreasesCoercive force temperature coefficient β decreasesMagnetic materialsGadoliniumRare earth

The invention relates to a gadolinium-containing sintered neodymium-iron-boron rare earth permanent magnet alloy and a preparation method thereof. The permanent magnet alloy comprises components in the following formula: Re[alpha]Gd[beta]B[gamma]MxNyFe[100-alpha-beta-gamma-x-y], wherein the weight percentage beta of the gadolinium element is more than 0.50 and less than or equal to 25. Through the method for adding the Gd element into a sintered Nd-Fe-B magnet, a sintered Nd-Fe-B permanent magnet with high coercive force and high temperature resistance is prepared. The coercive force temperature coefficient beta of the prepared magnet is reduced, so the coercive force of the magnet at high temperature is improved and the magnet has the high temperature resistance.

Owner:NINGBO KONIT IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com