Patents

Literature

830 results about "Bond coat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

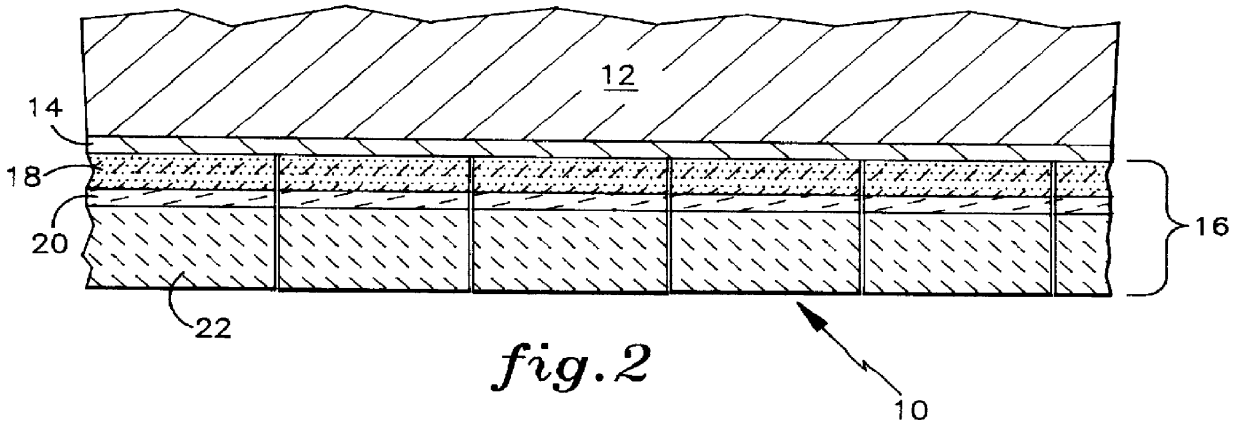

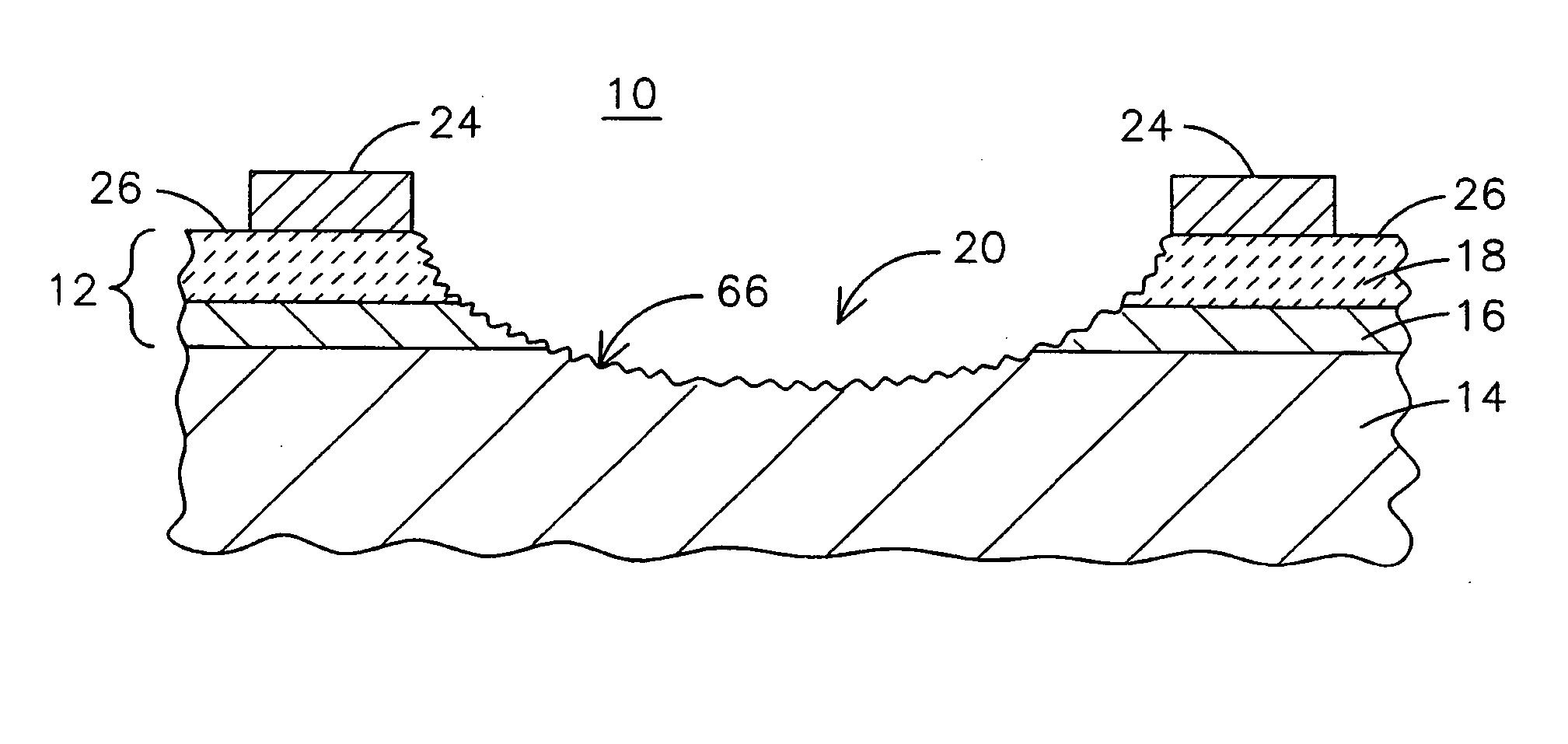

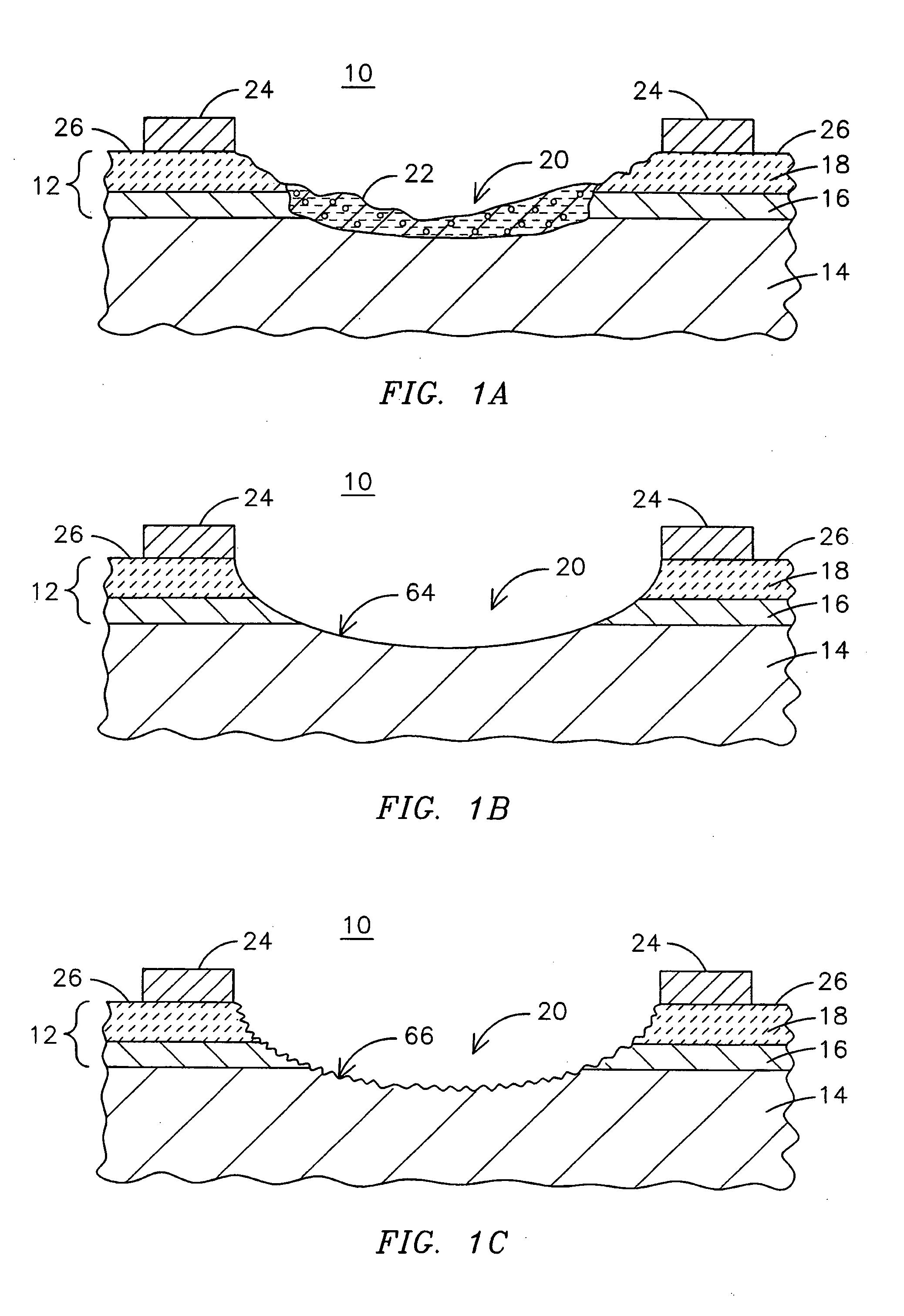

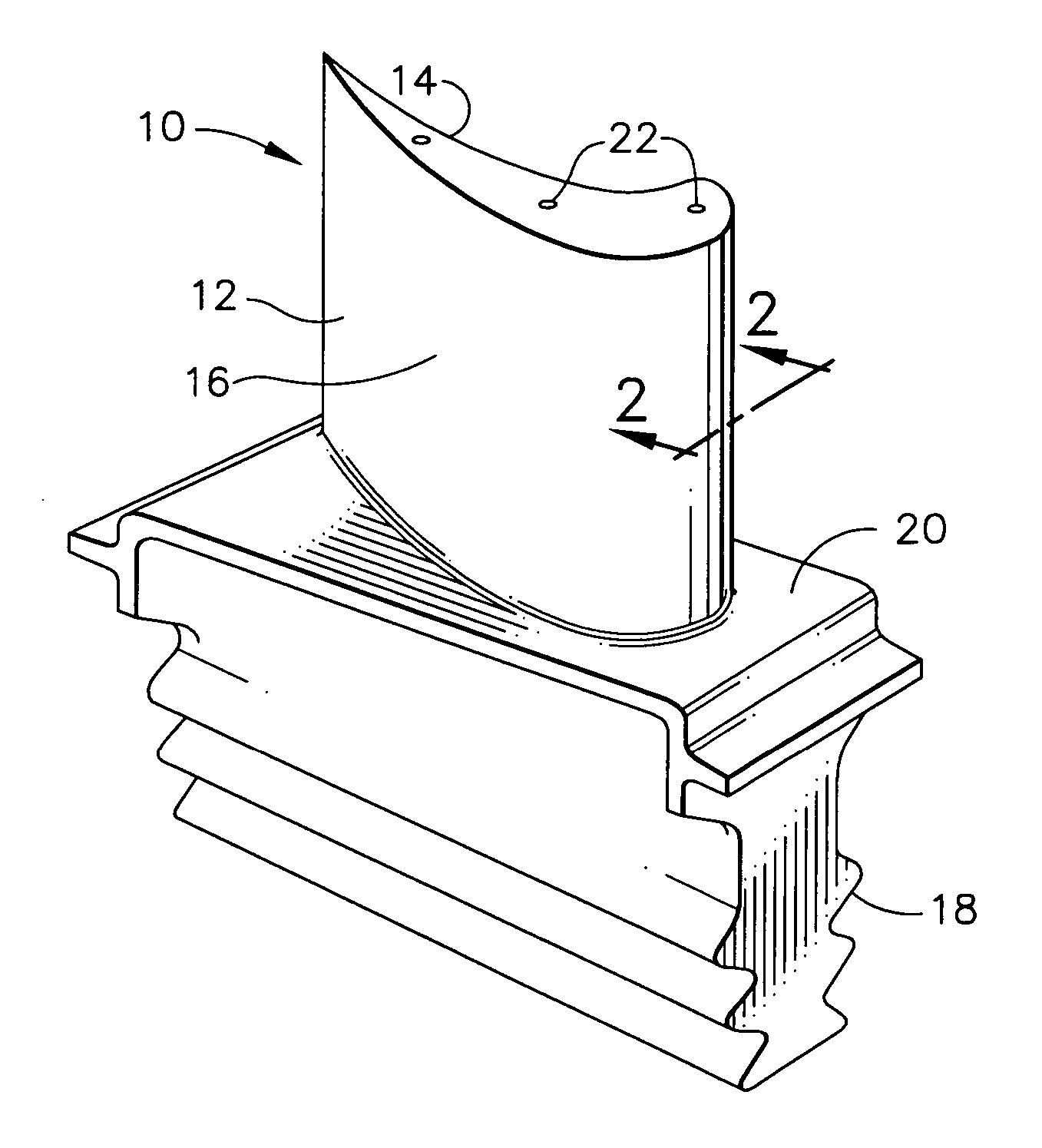

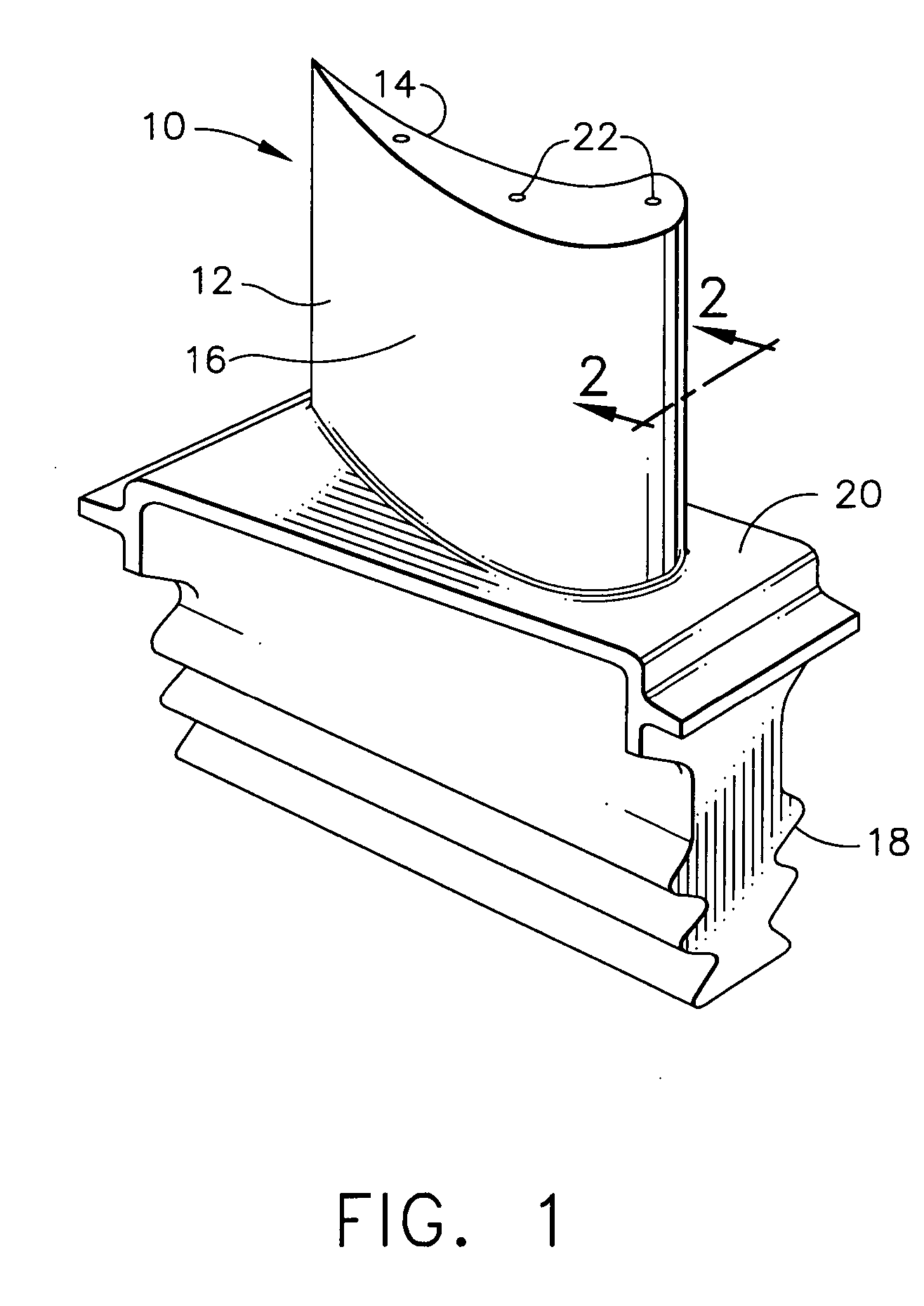

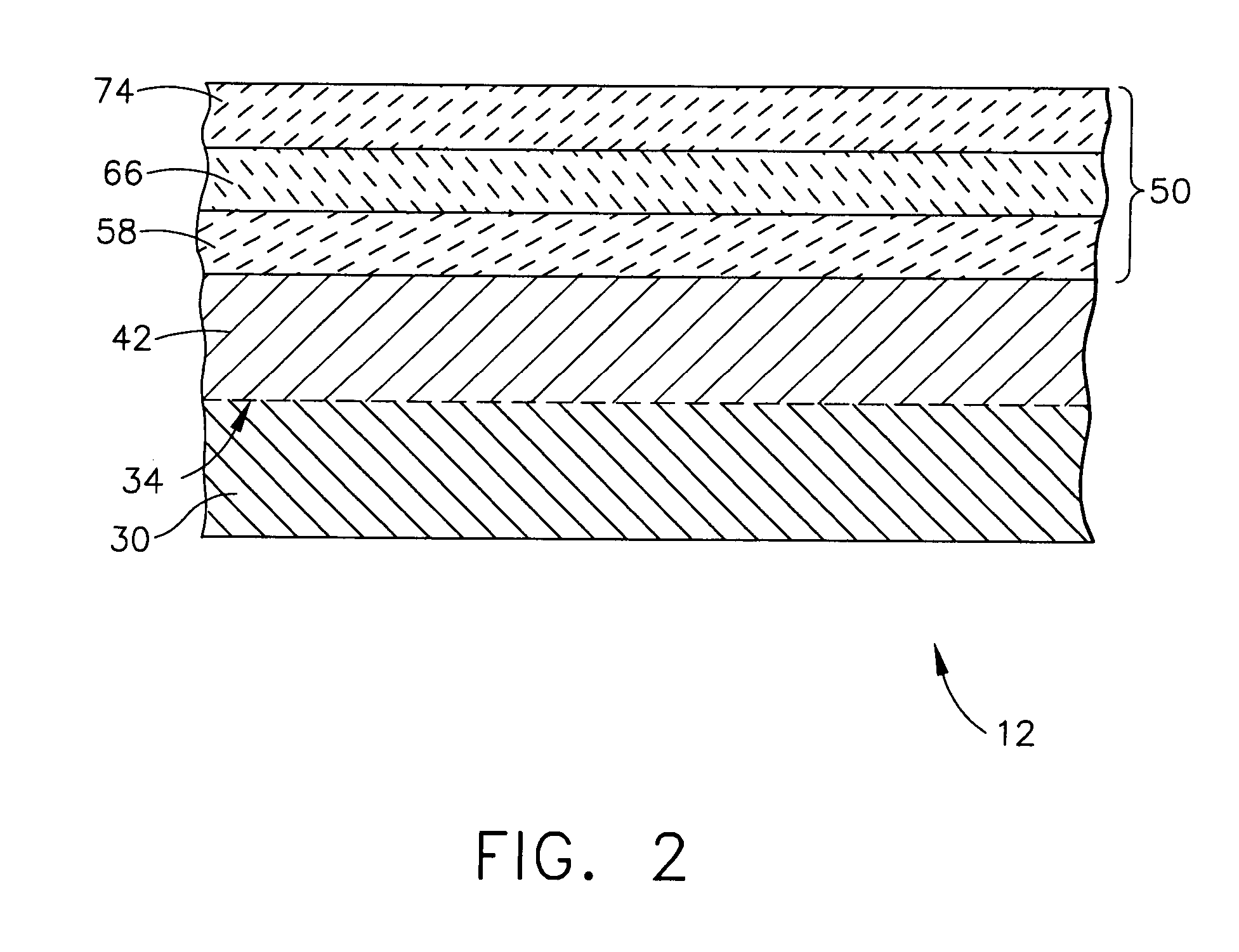

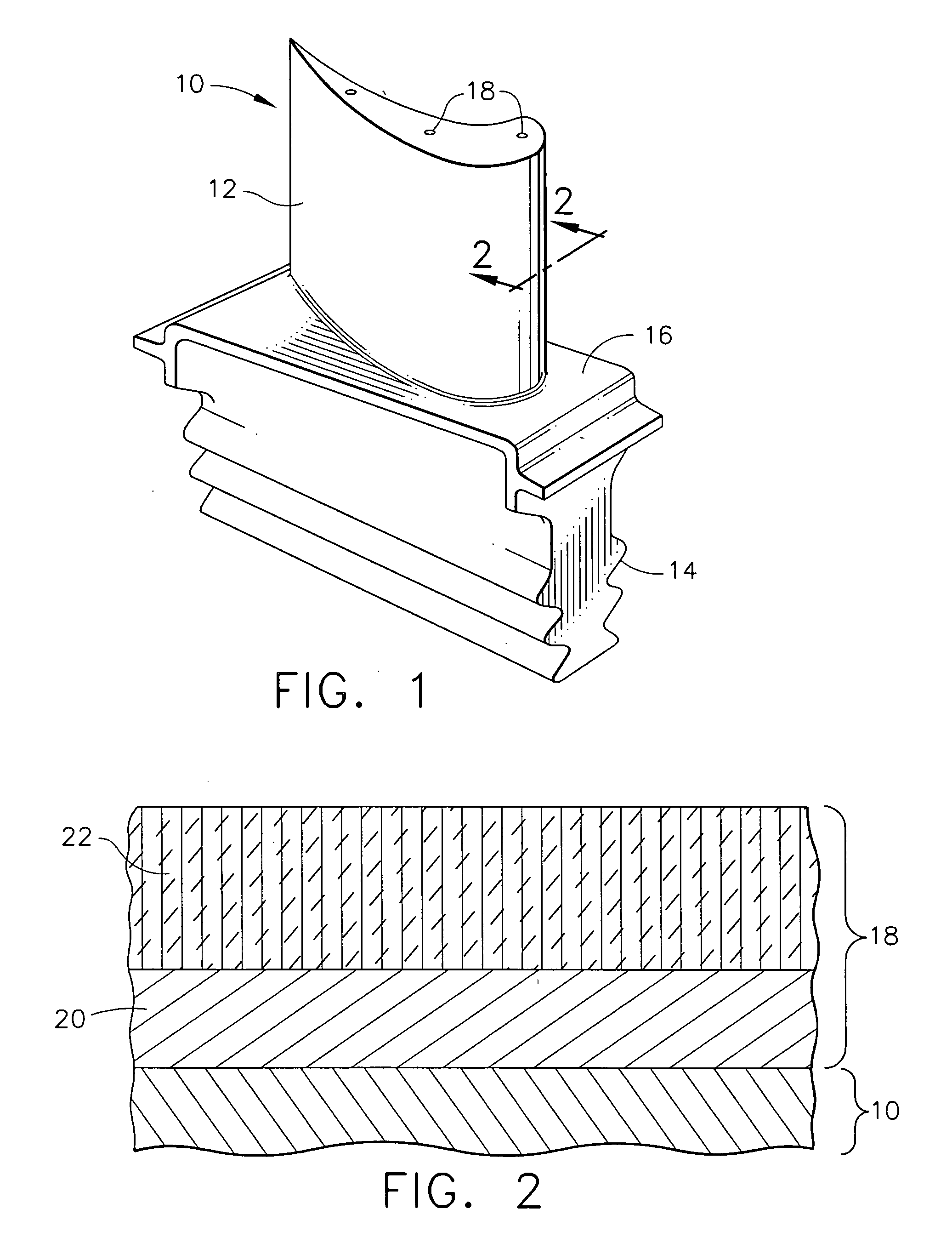

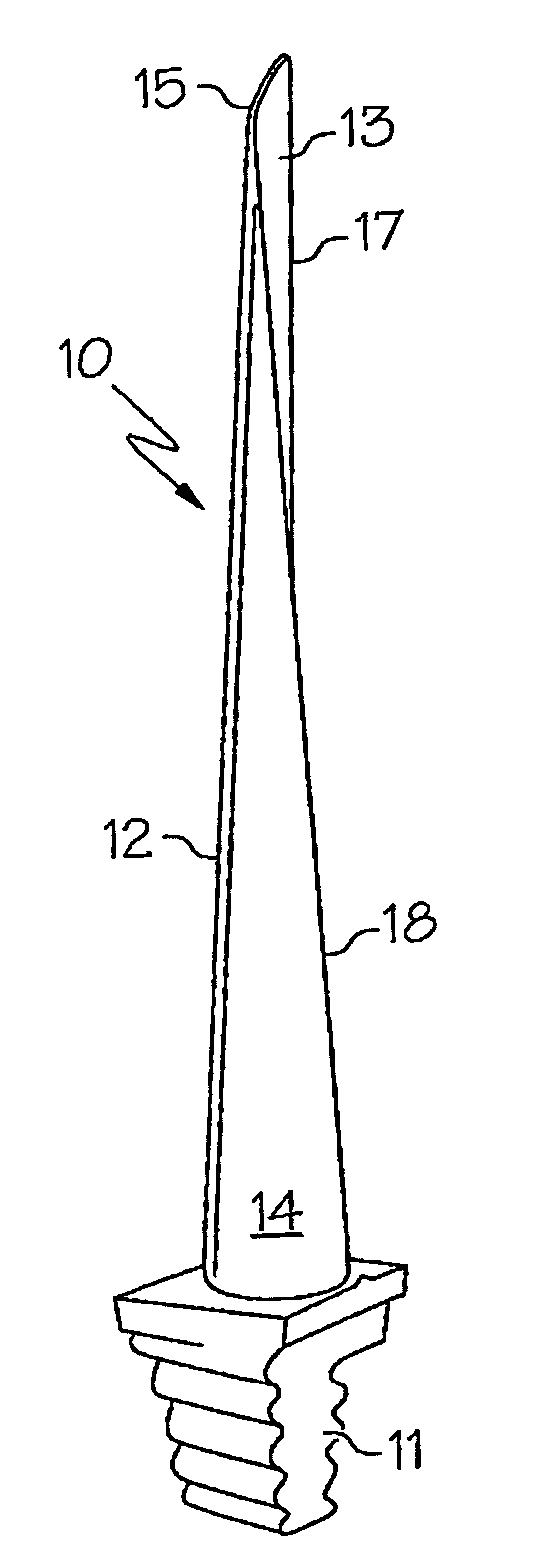

Segmented abradable ceramic coating

InactiveUS6102656AImprove wear resistanceSufficient resistanceMolten spray coatingPump componentsCeramic coatingWear resistance

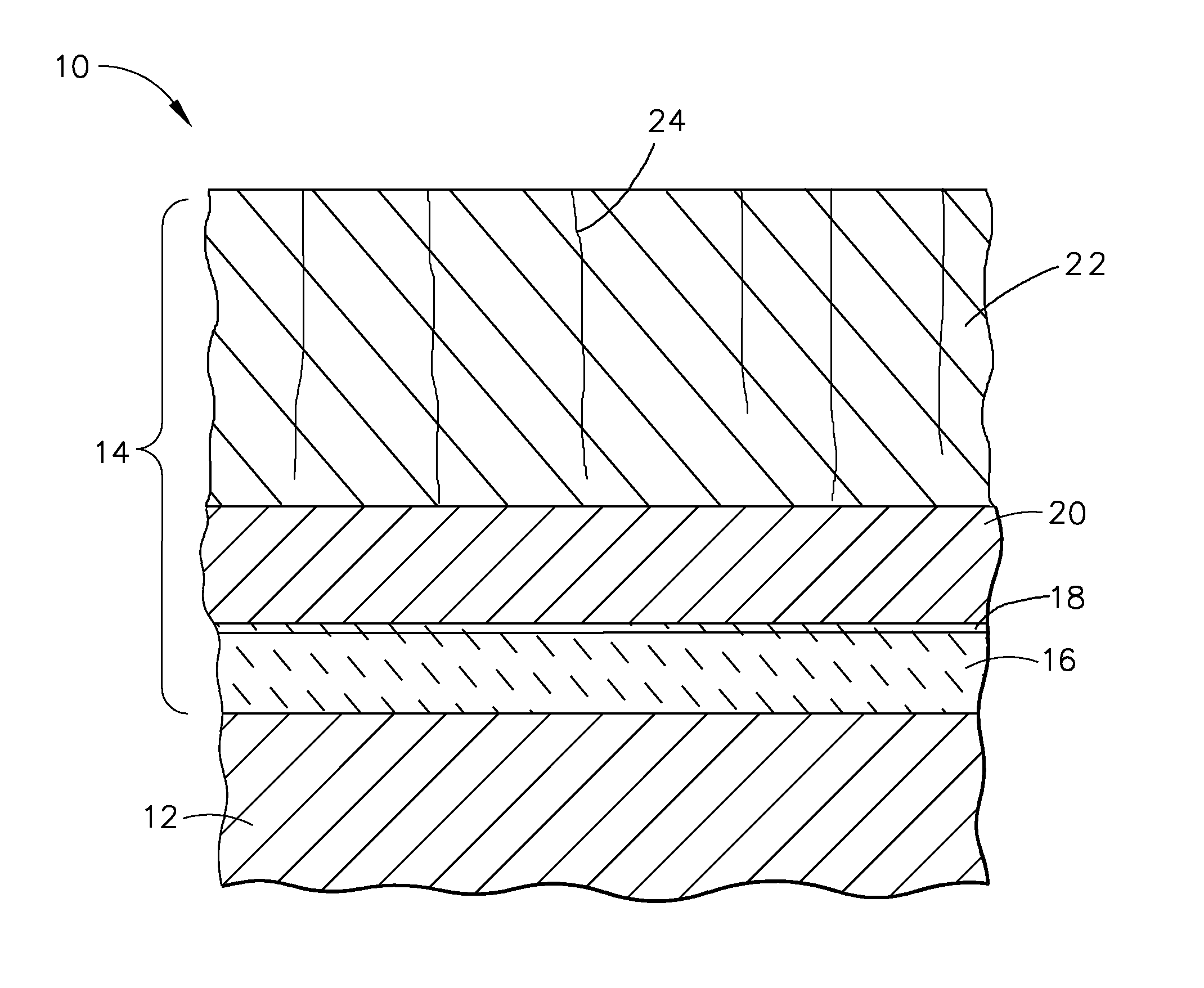

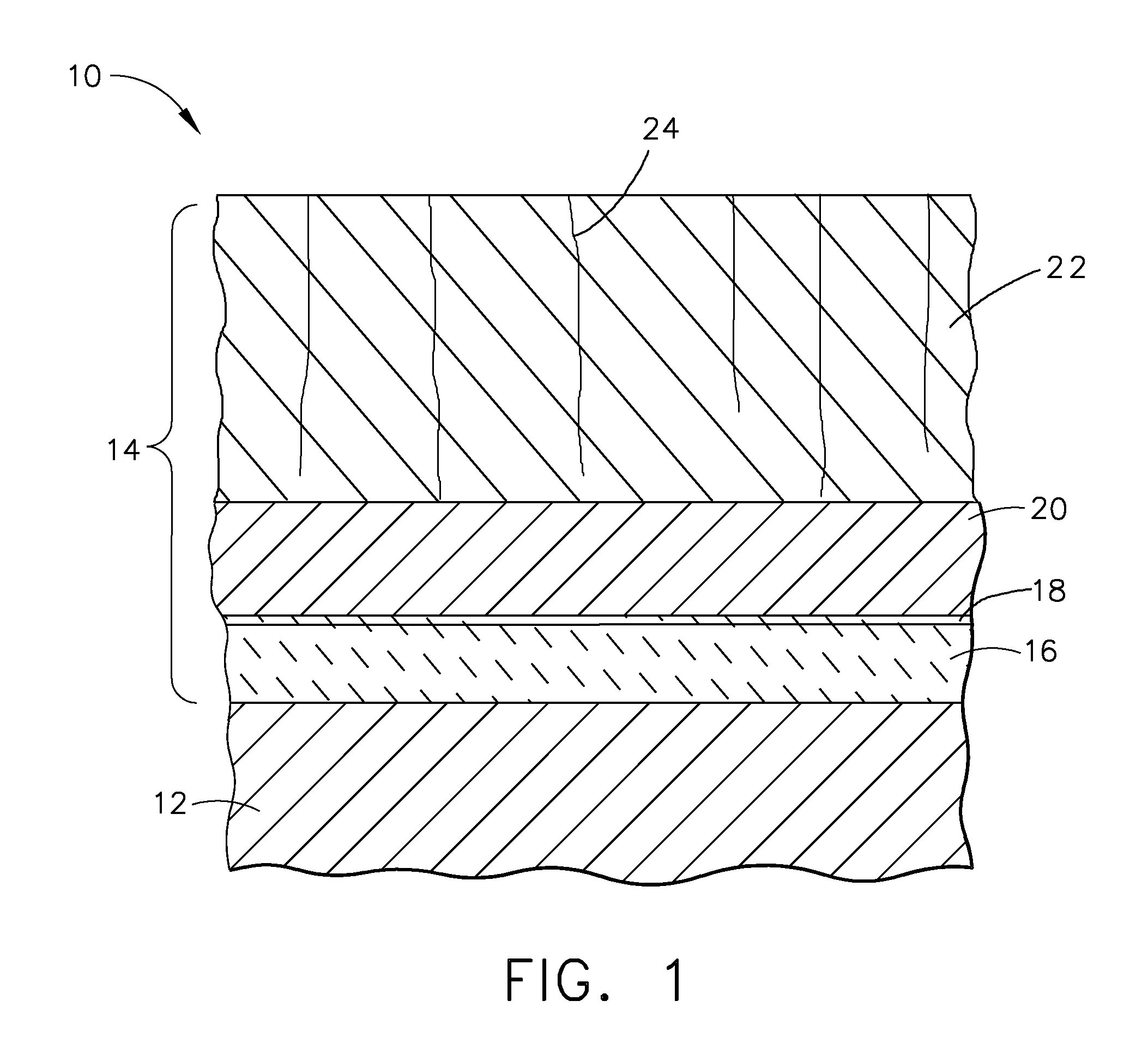

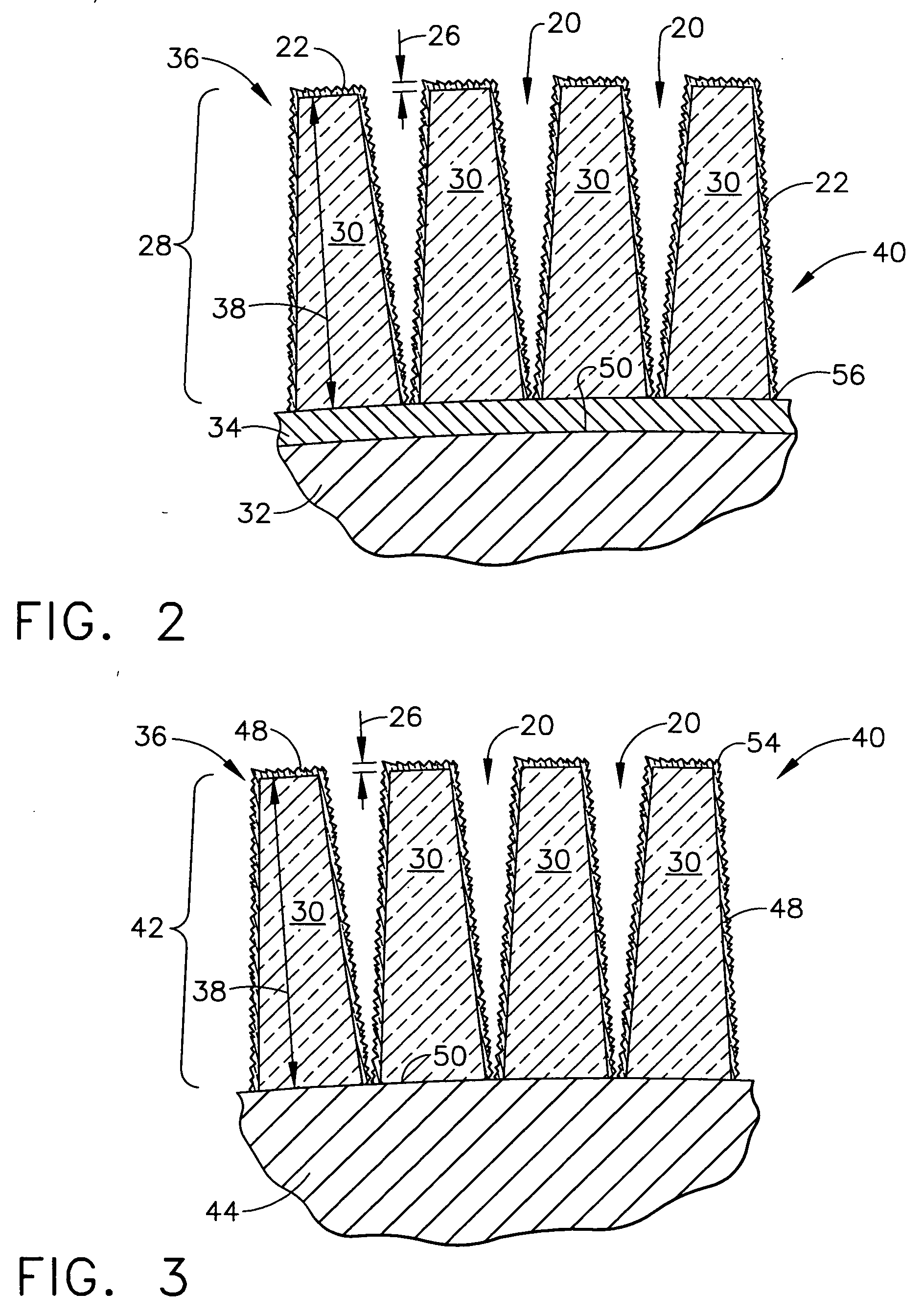

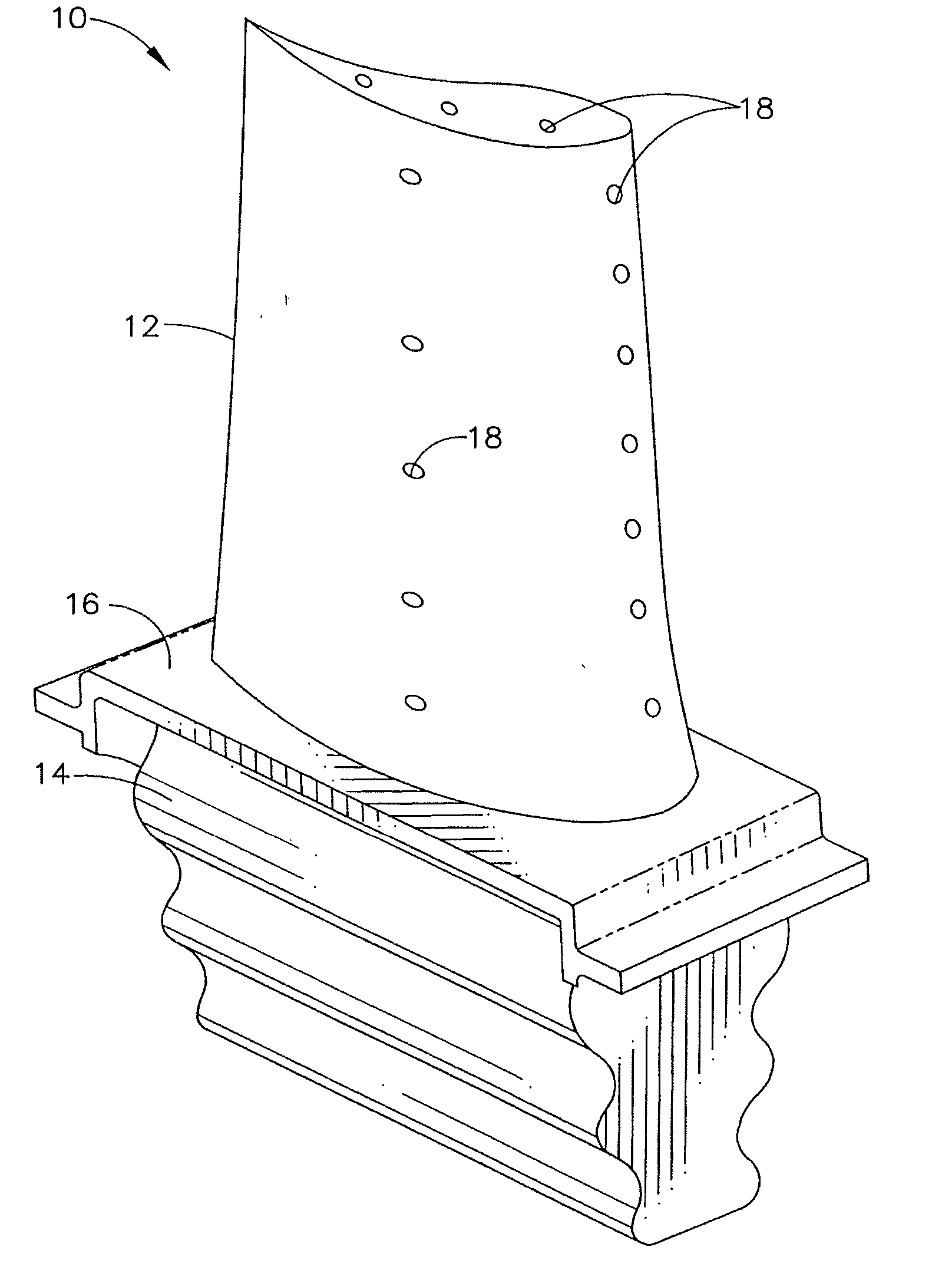

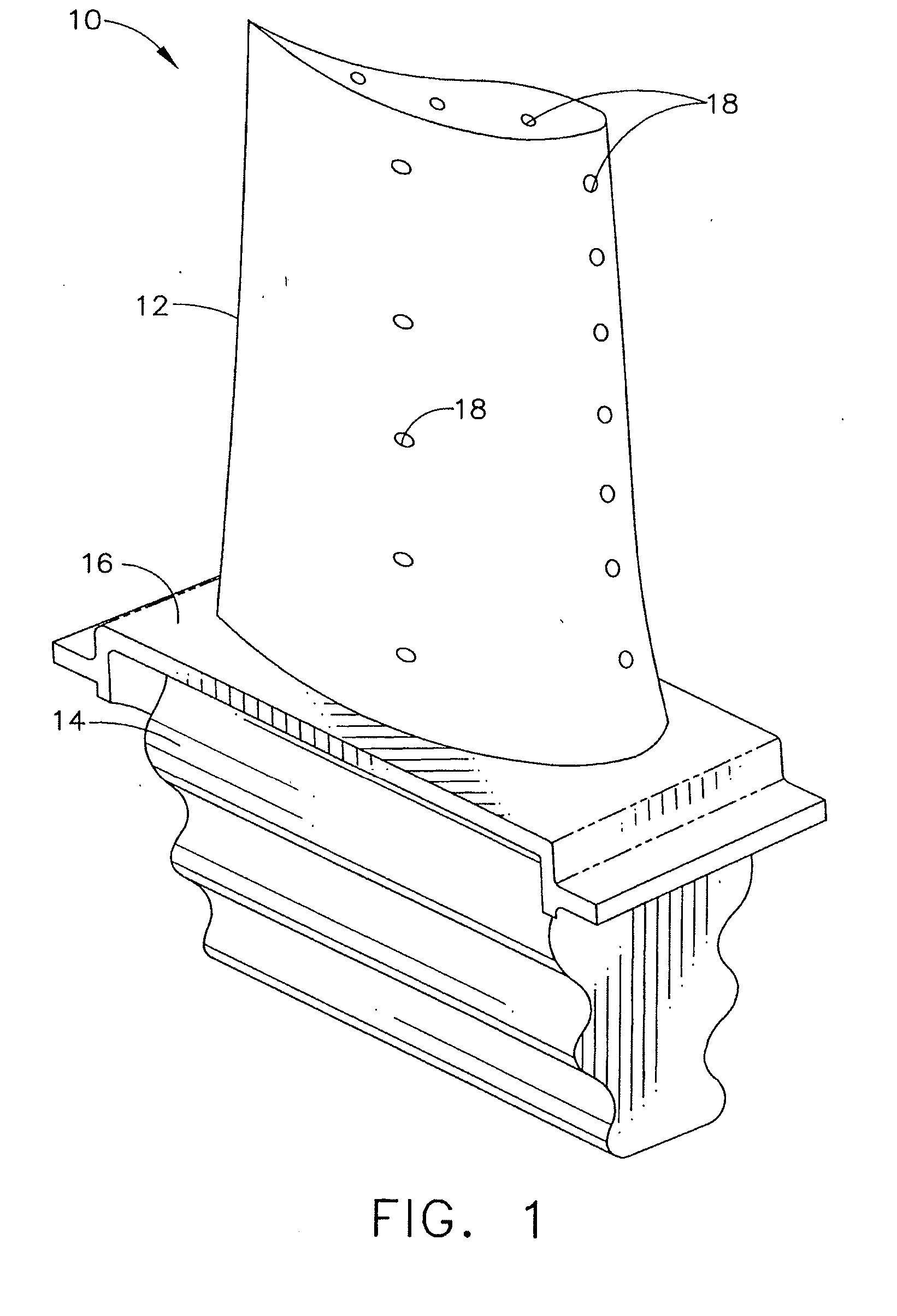

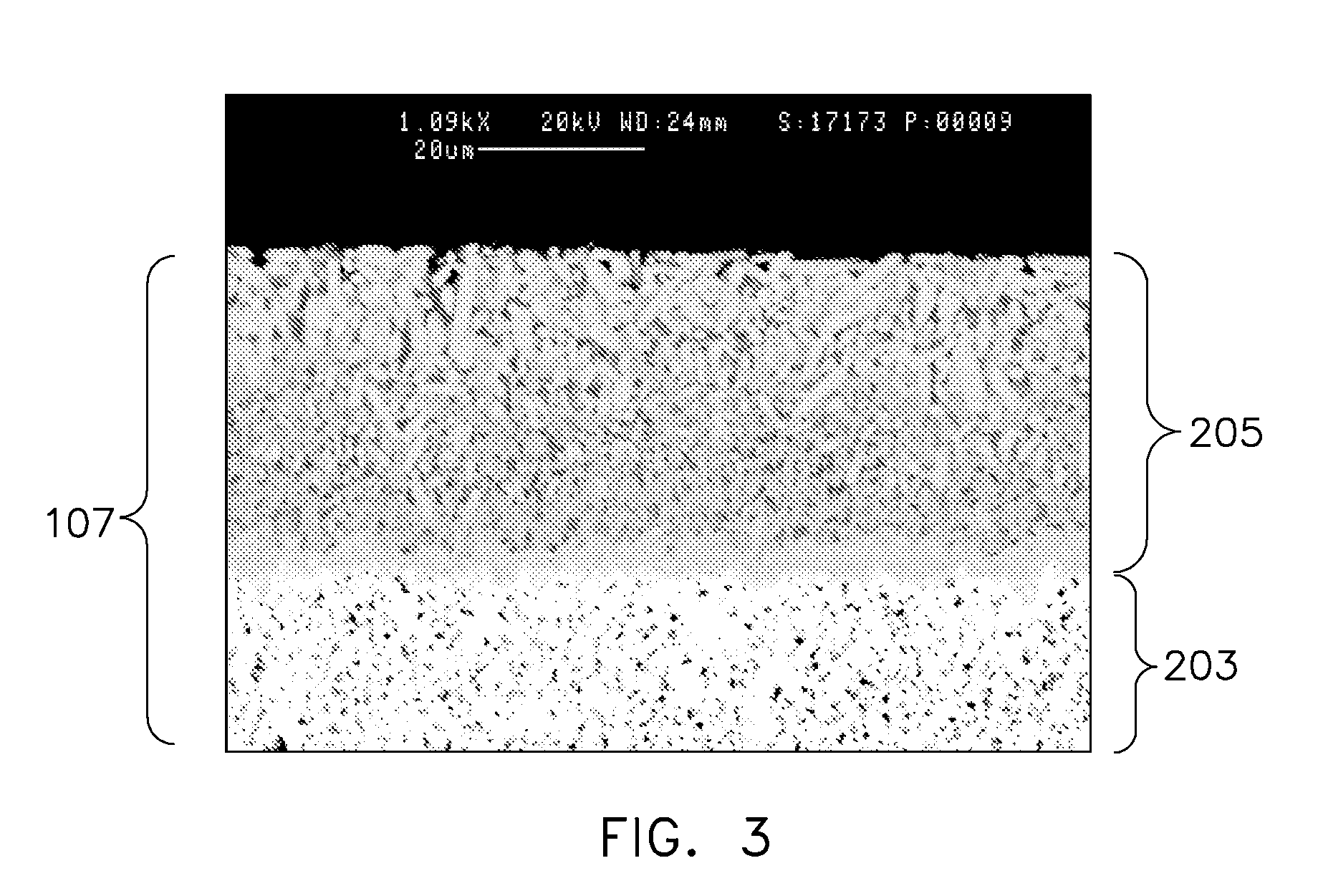

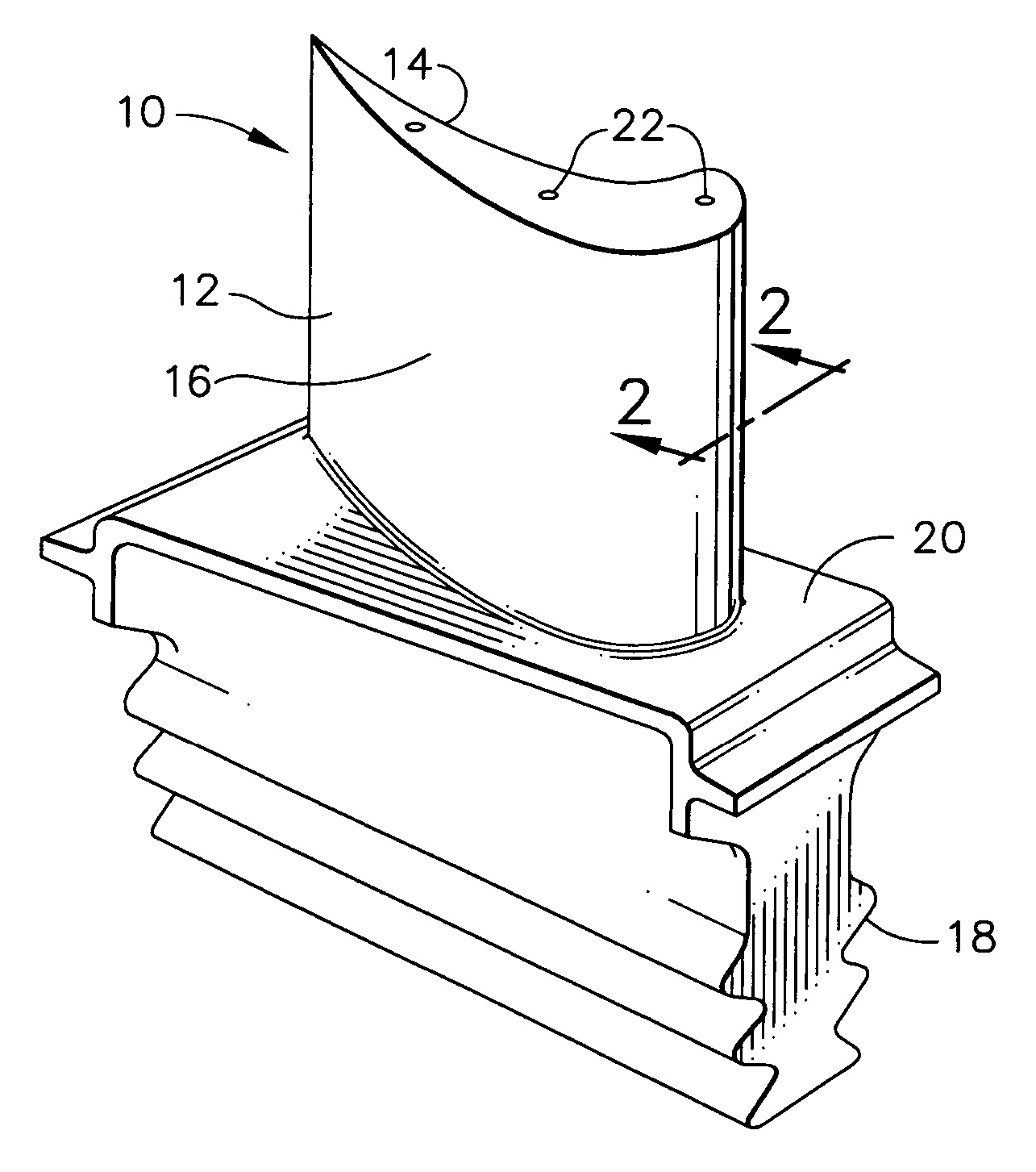

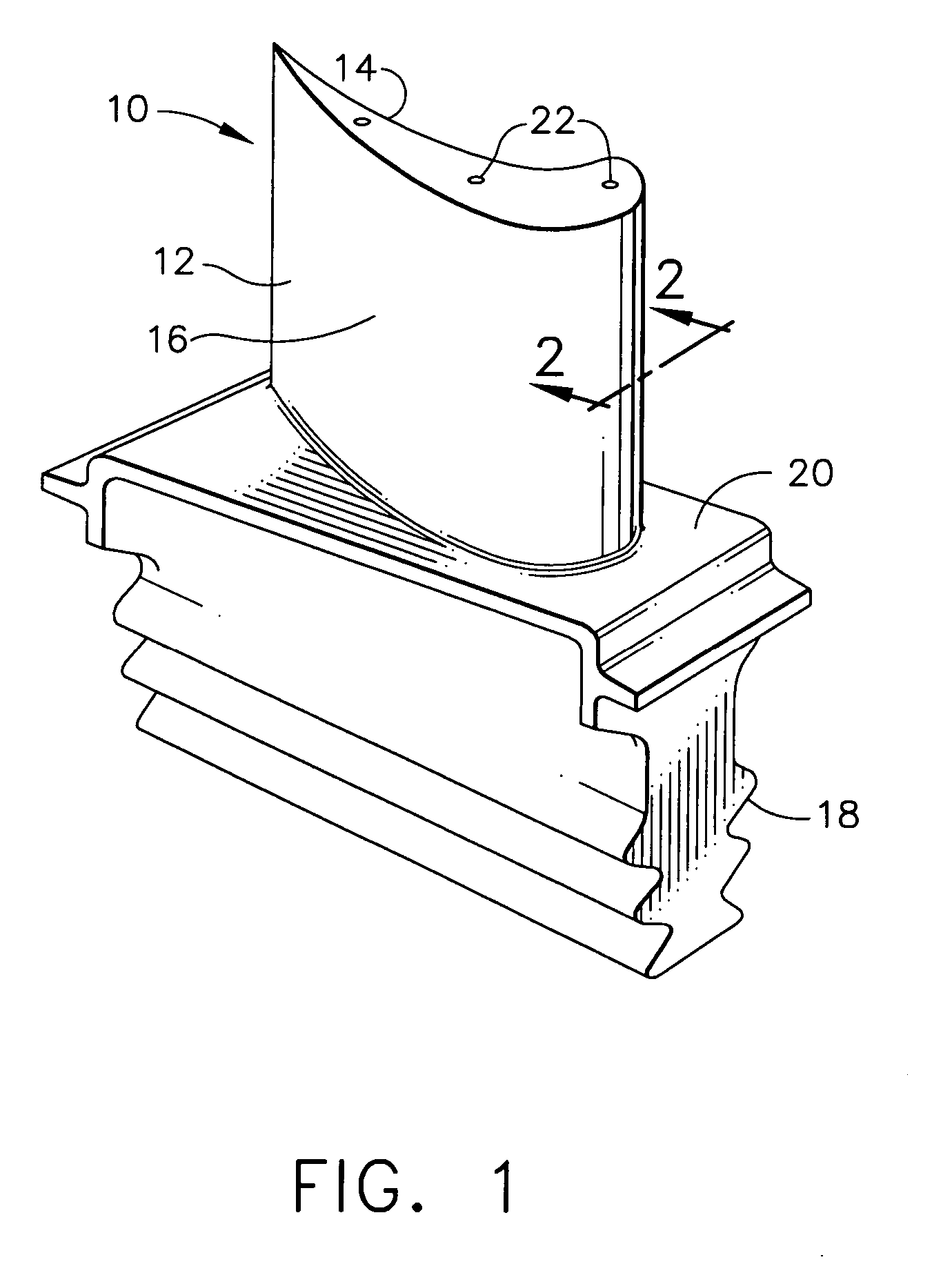

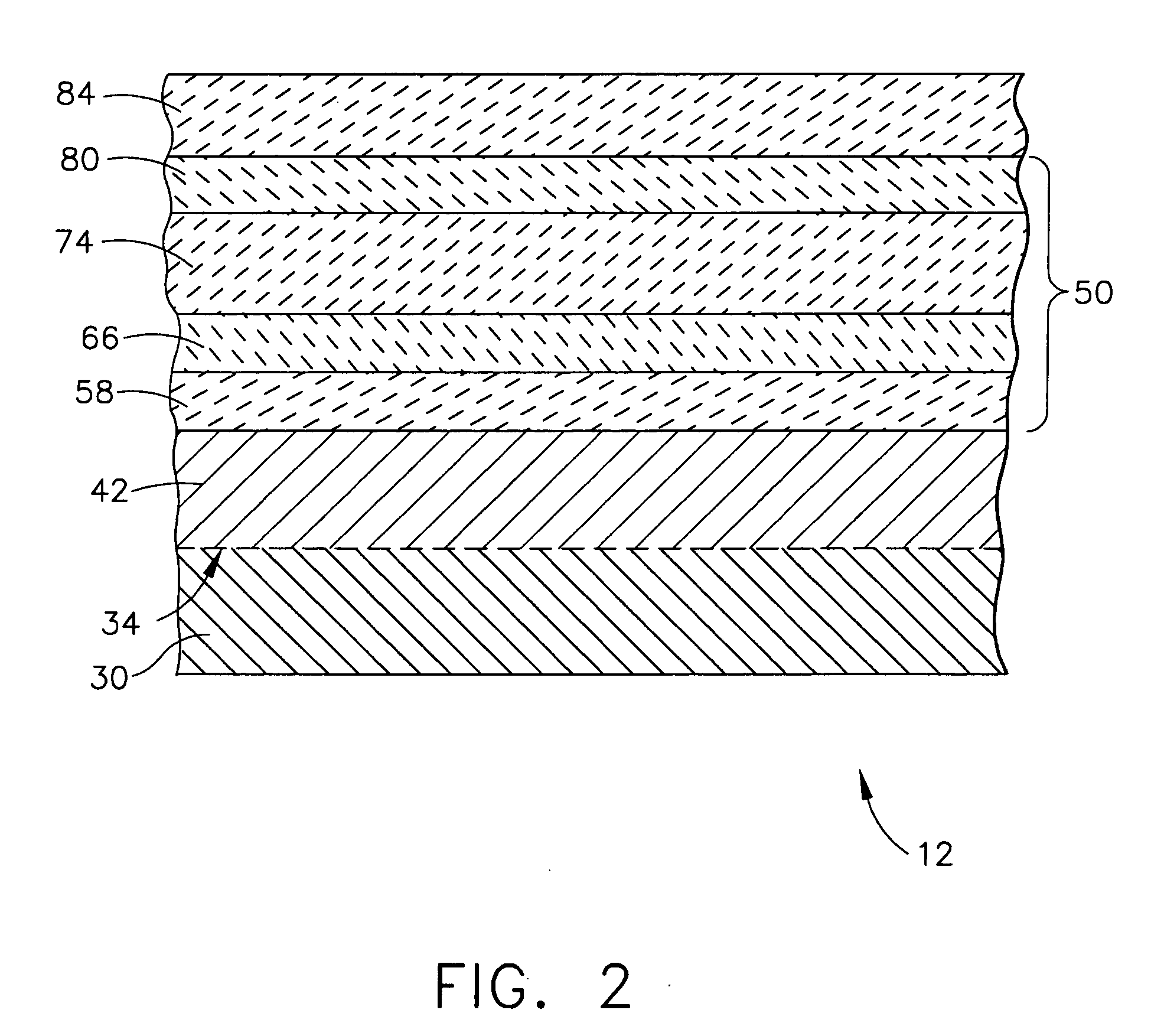

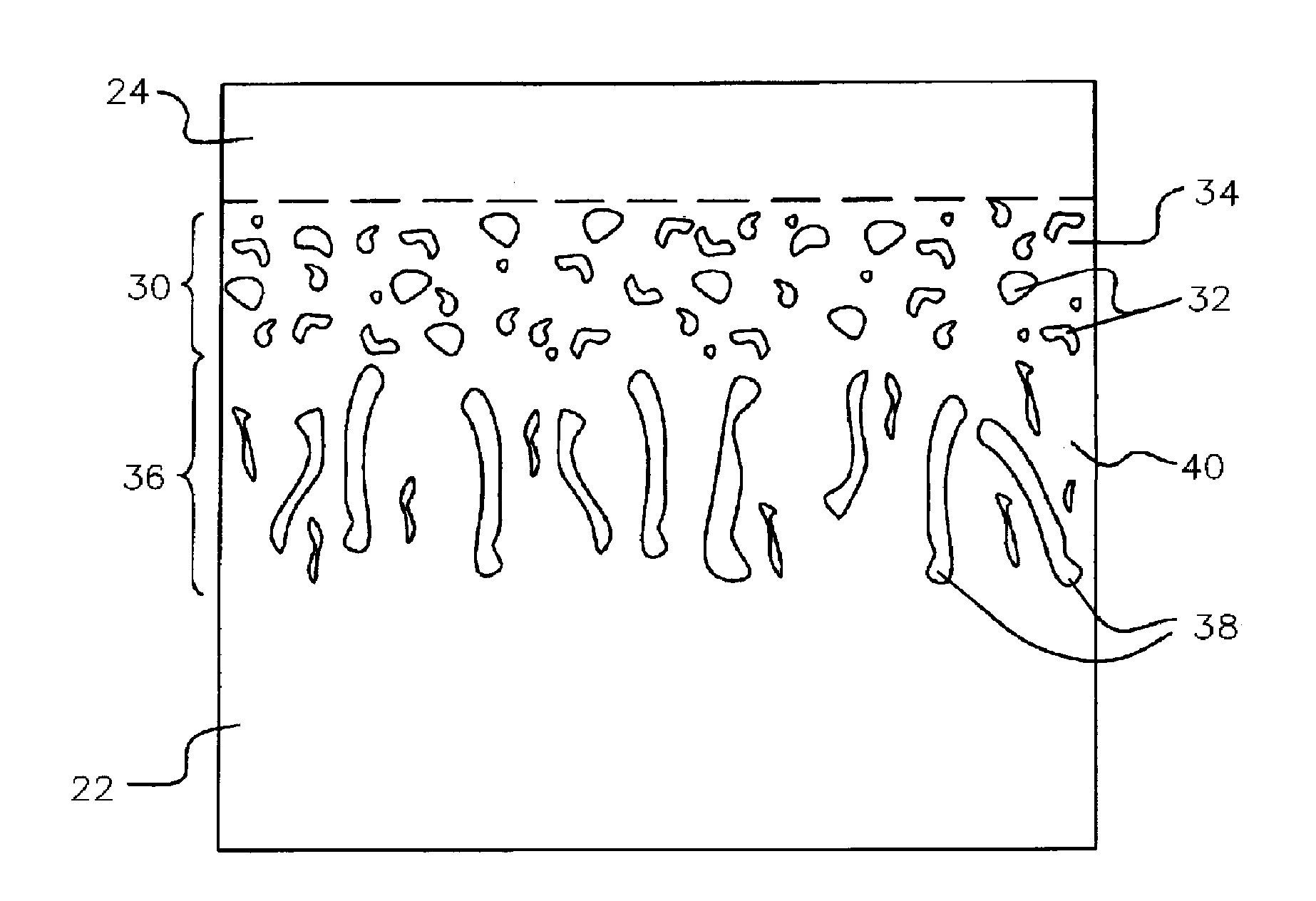

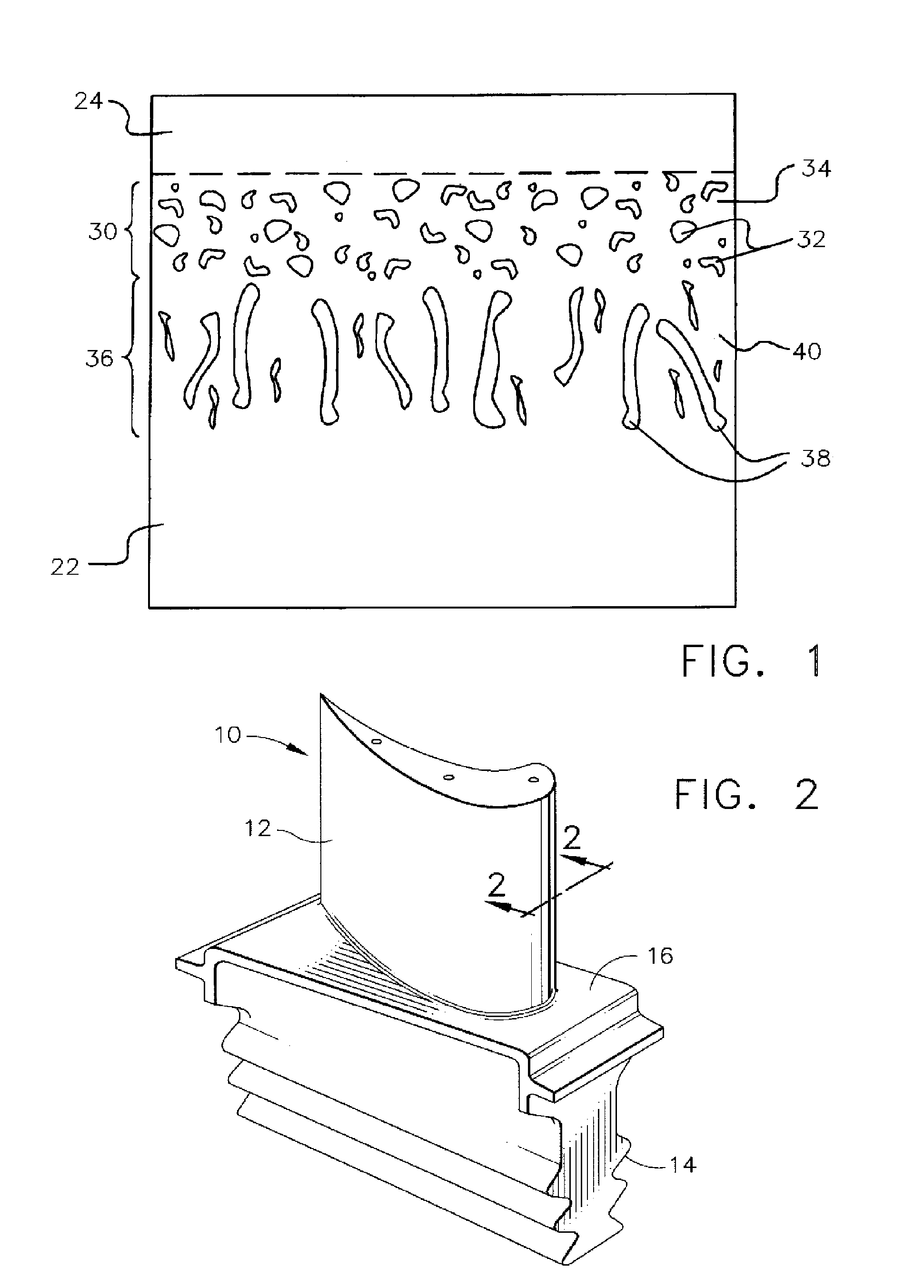

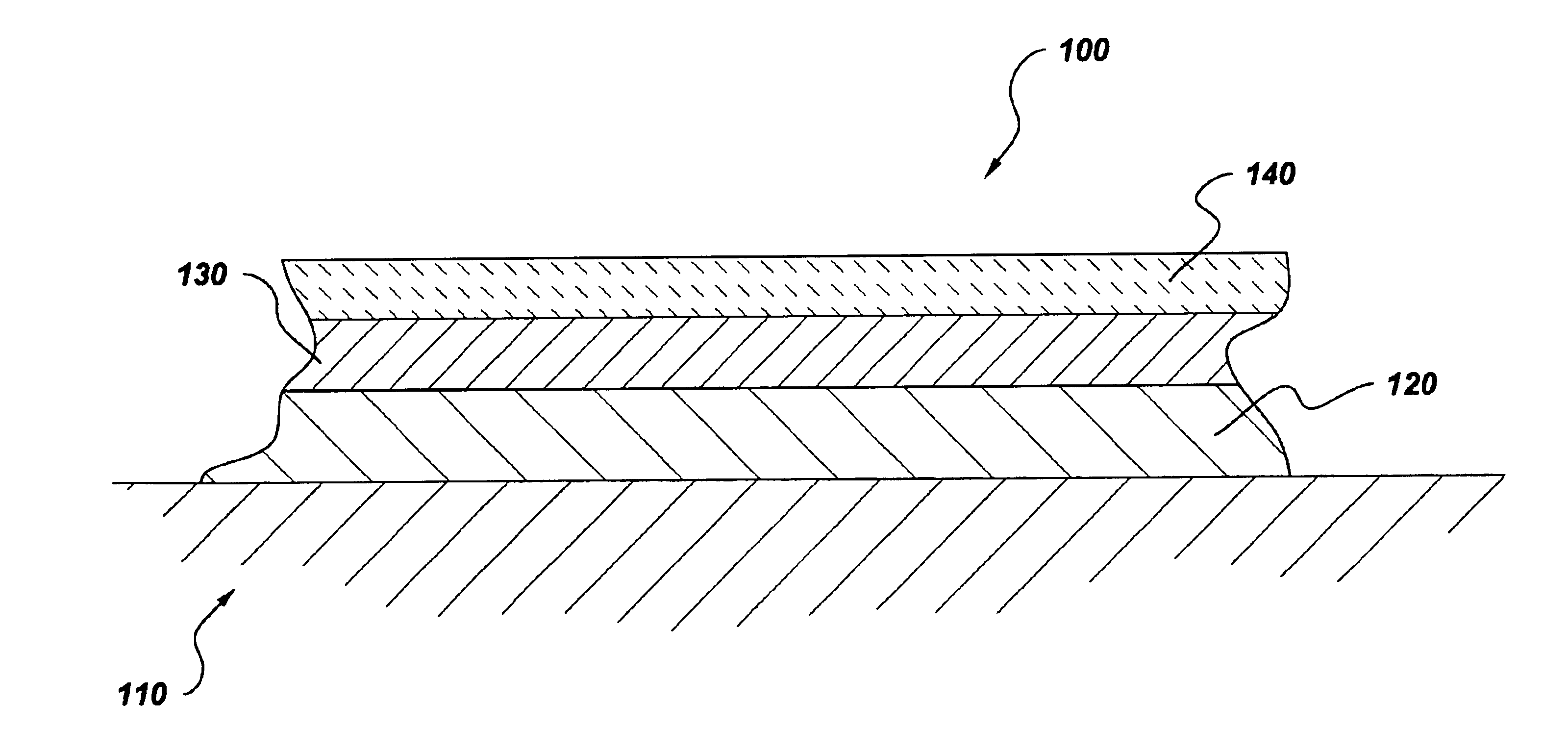

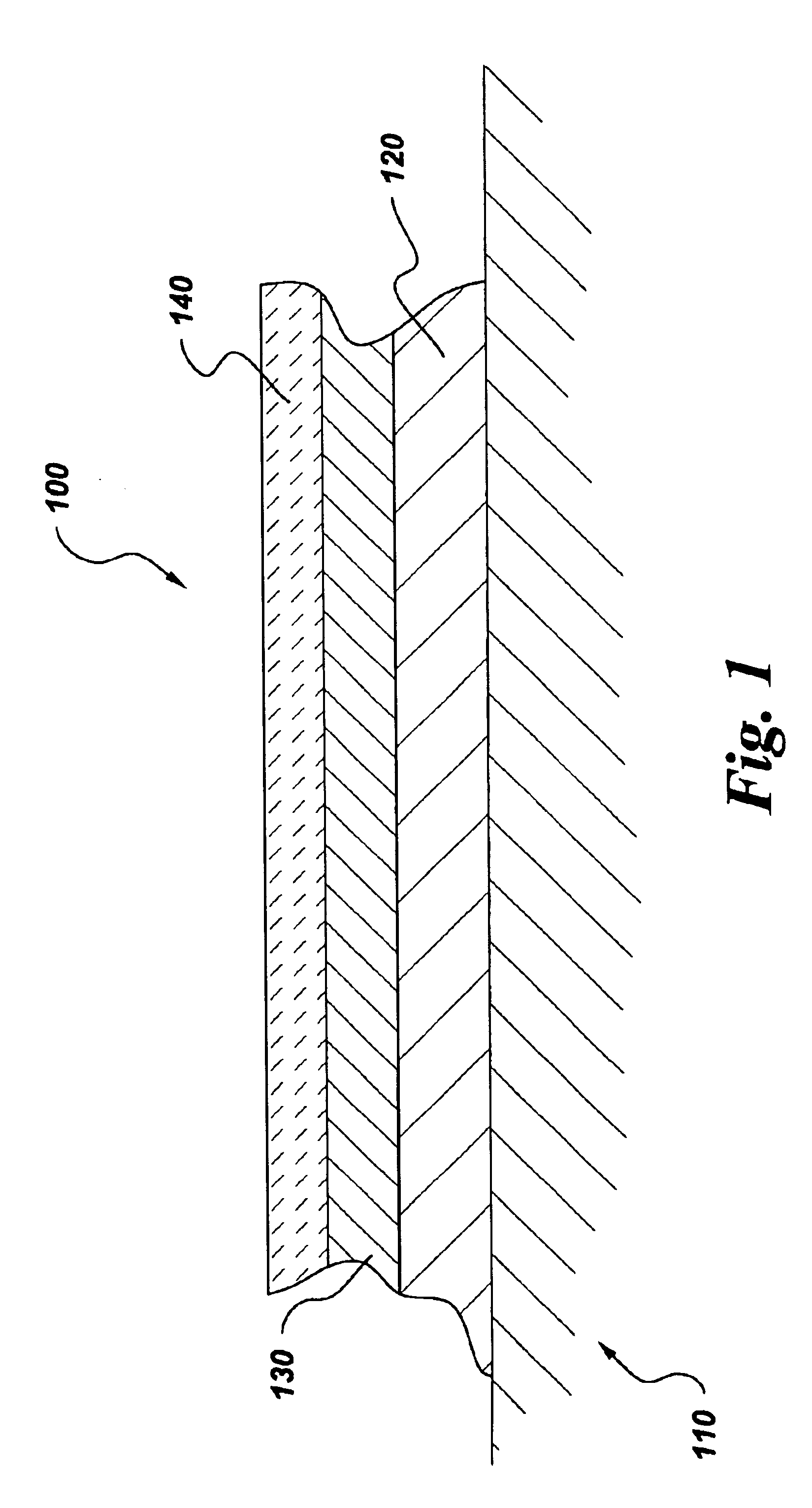

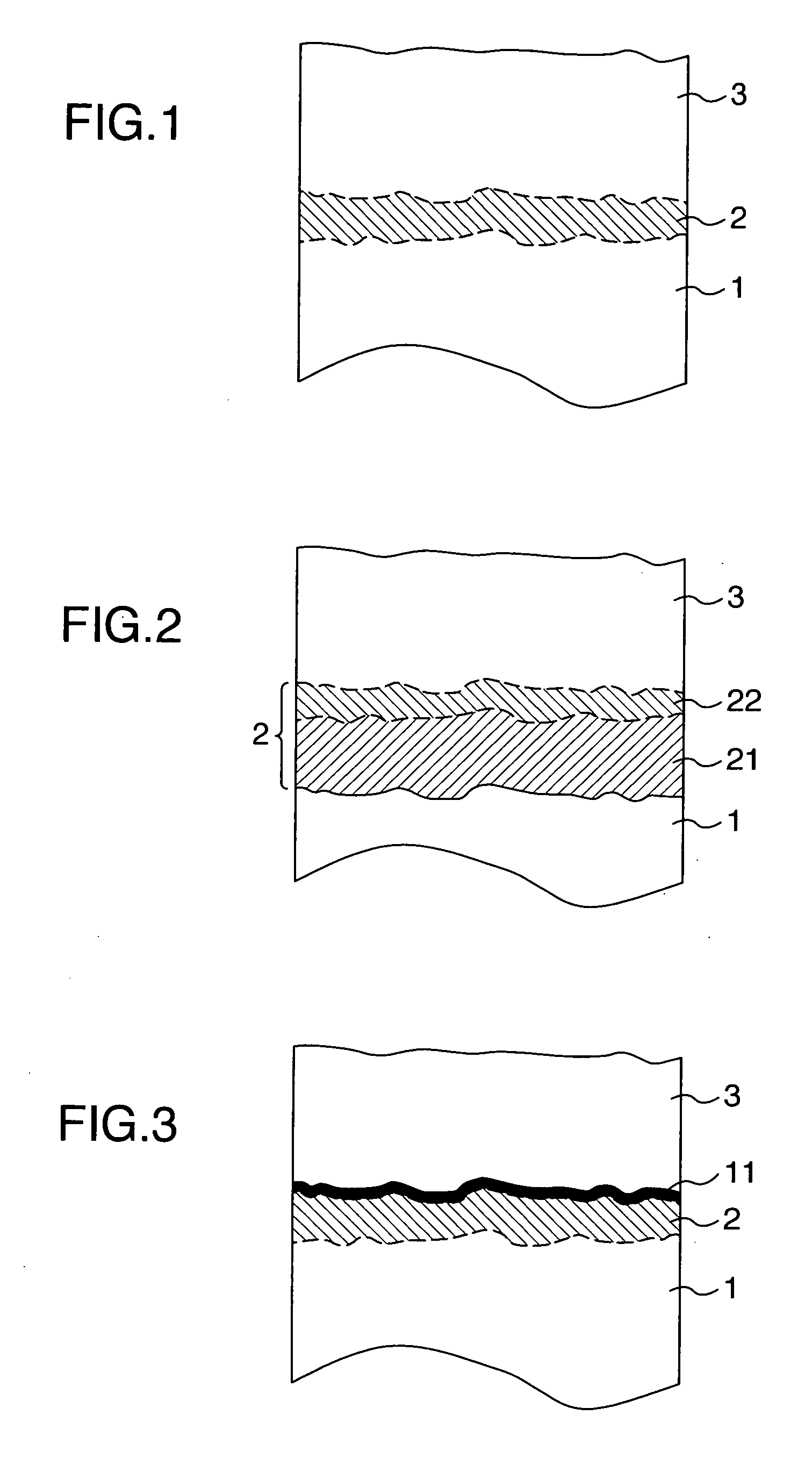

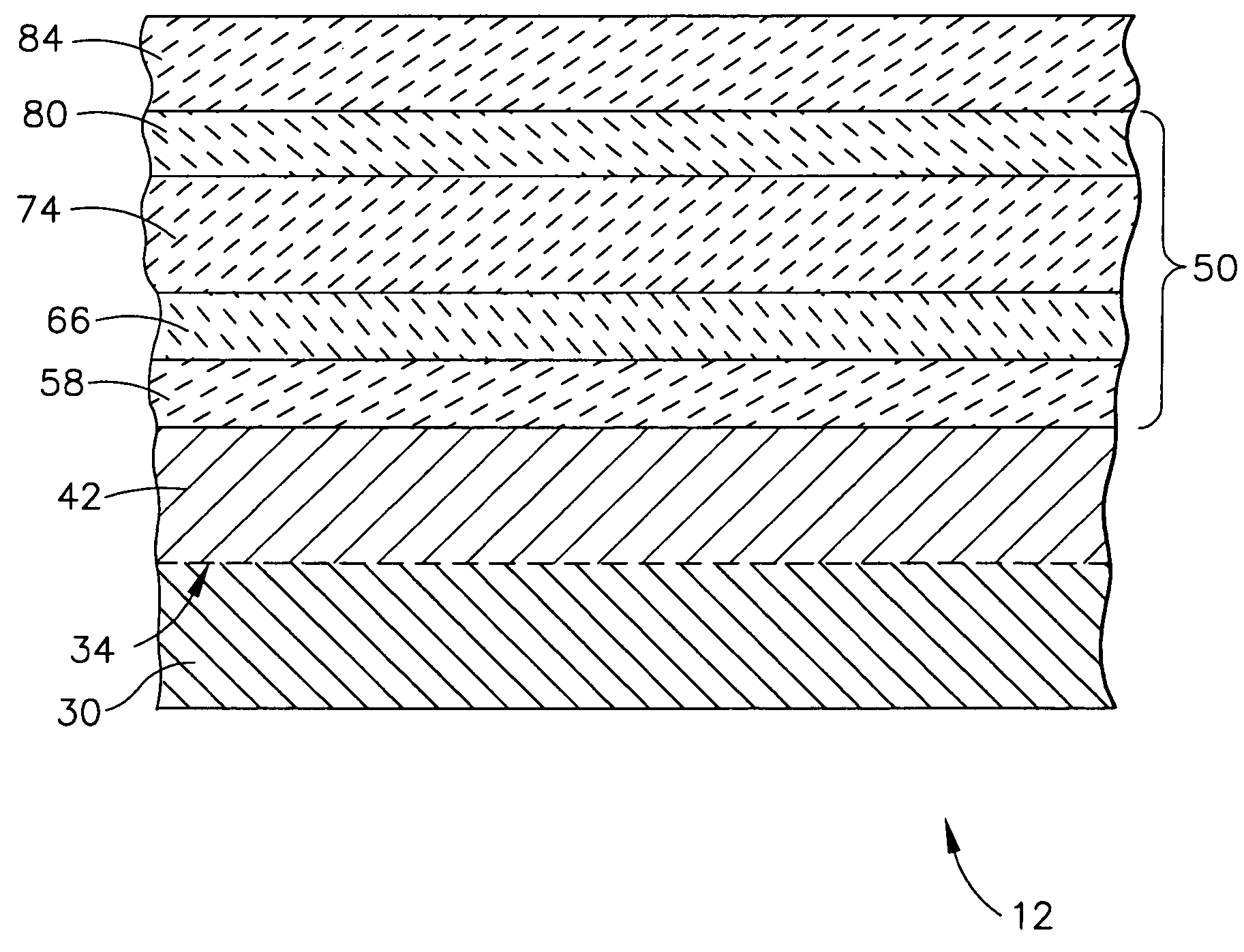

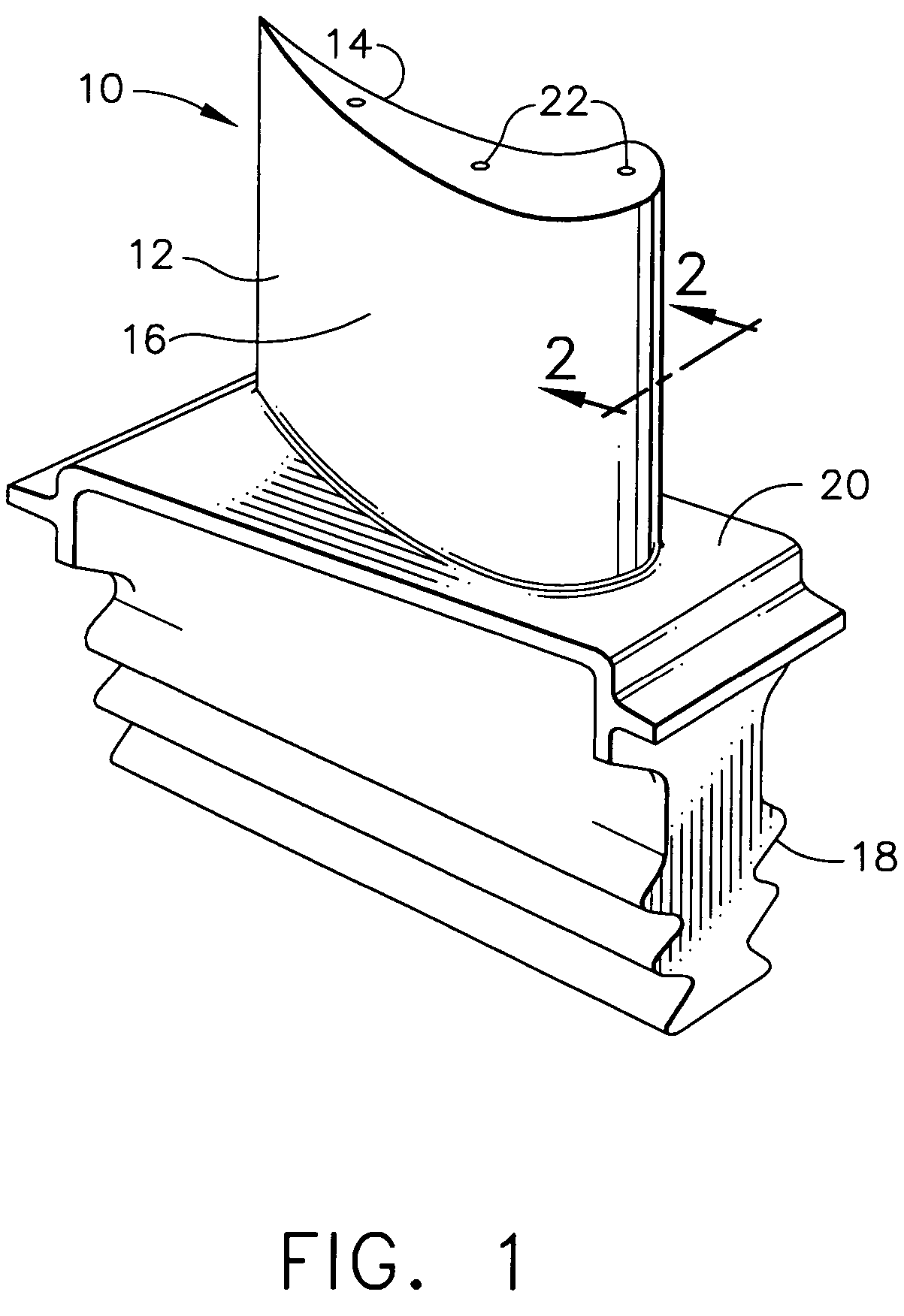

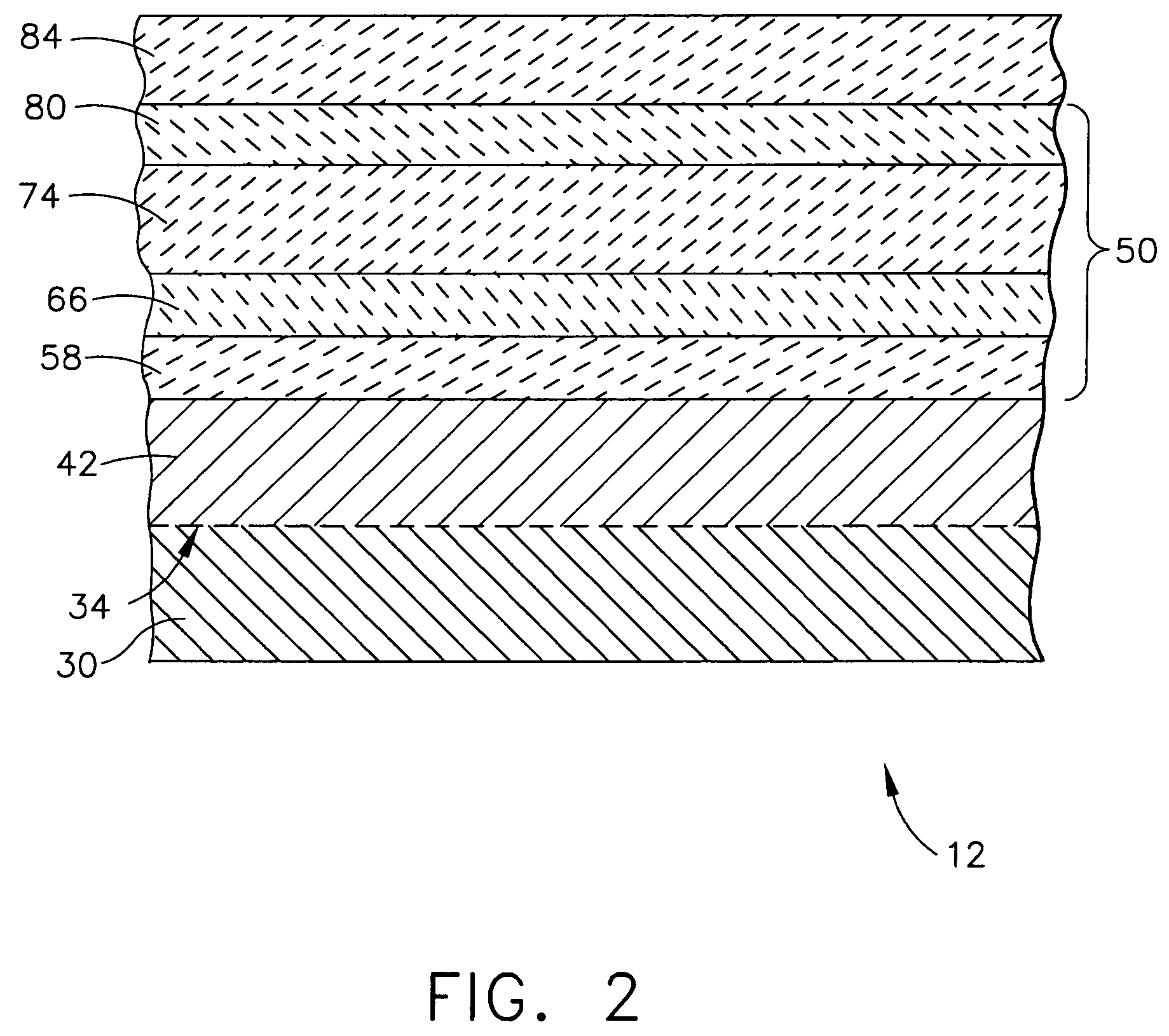

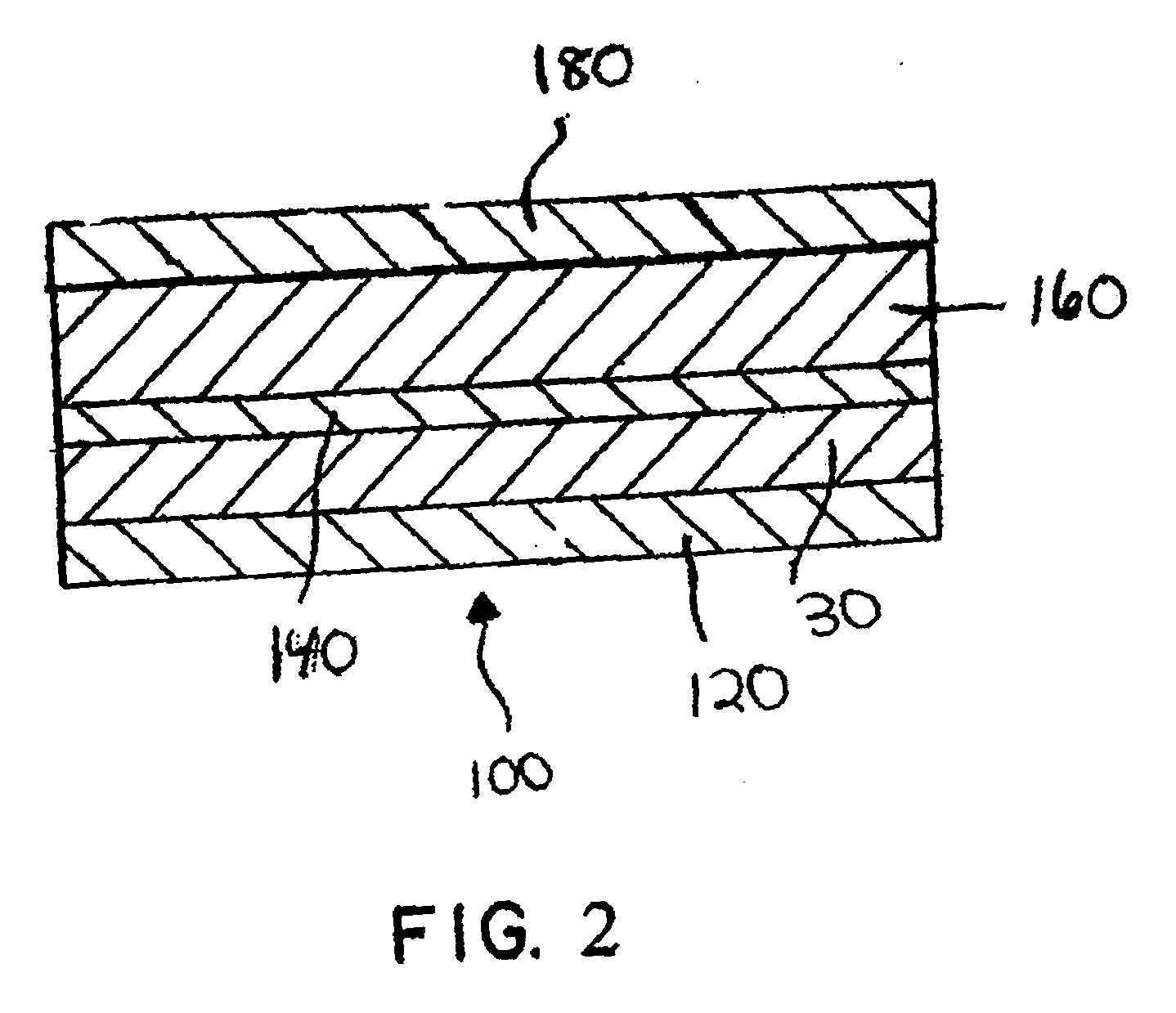

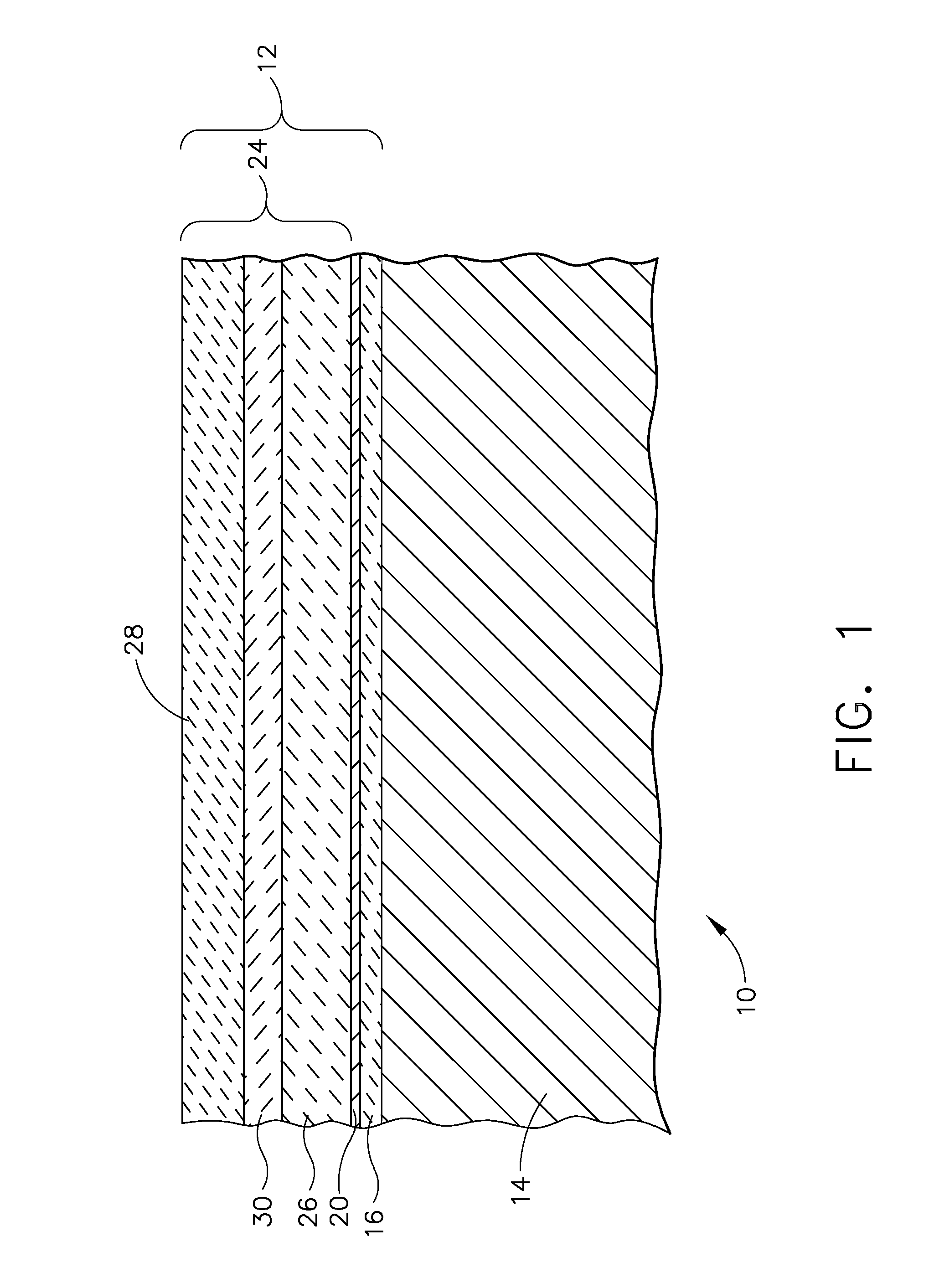

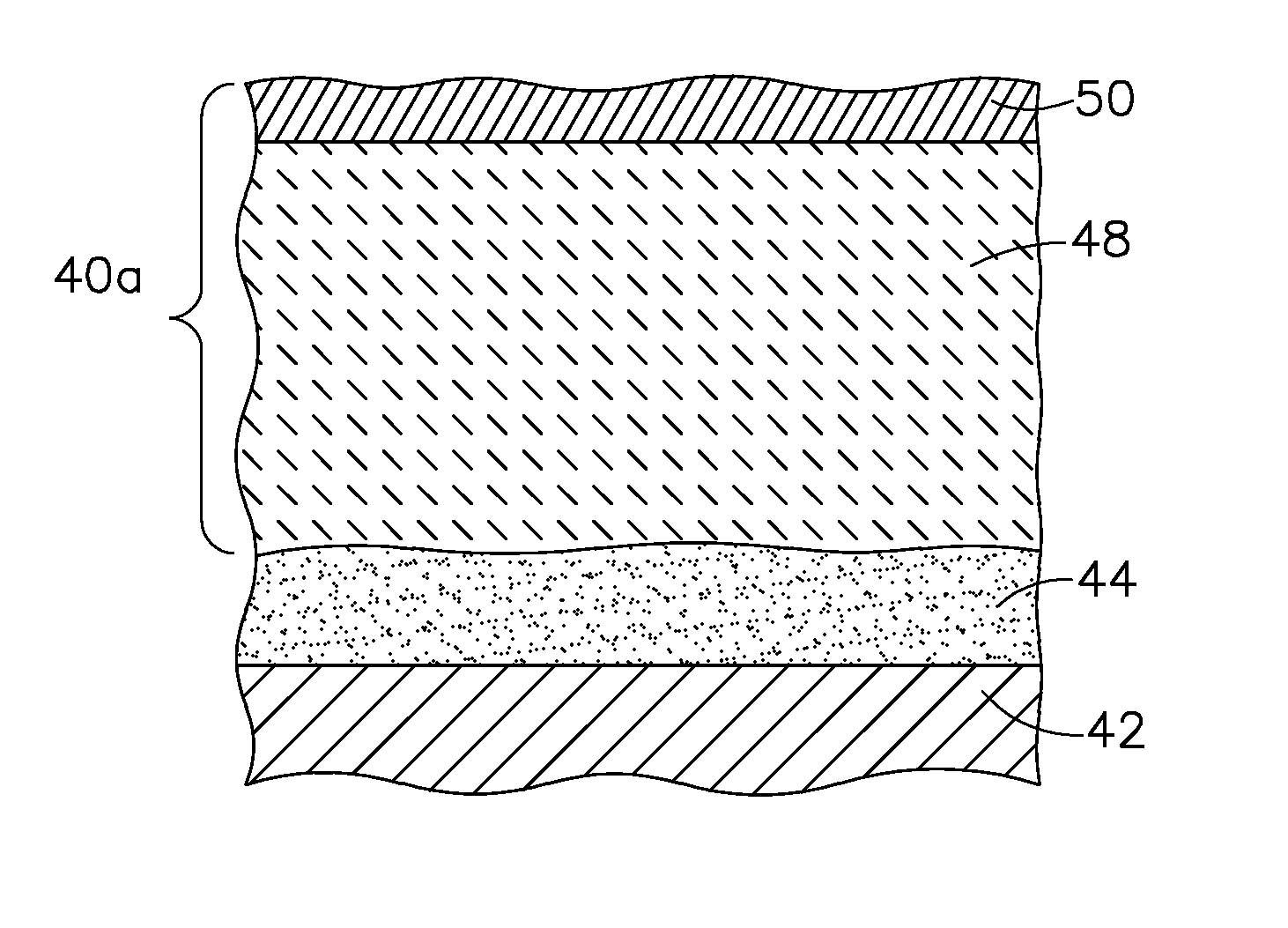

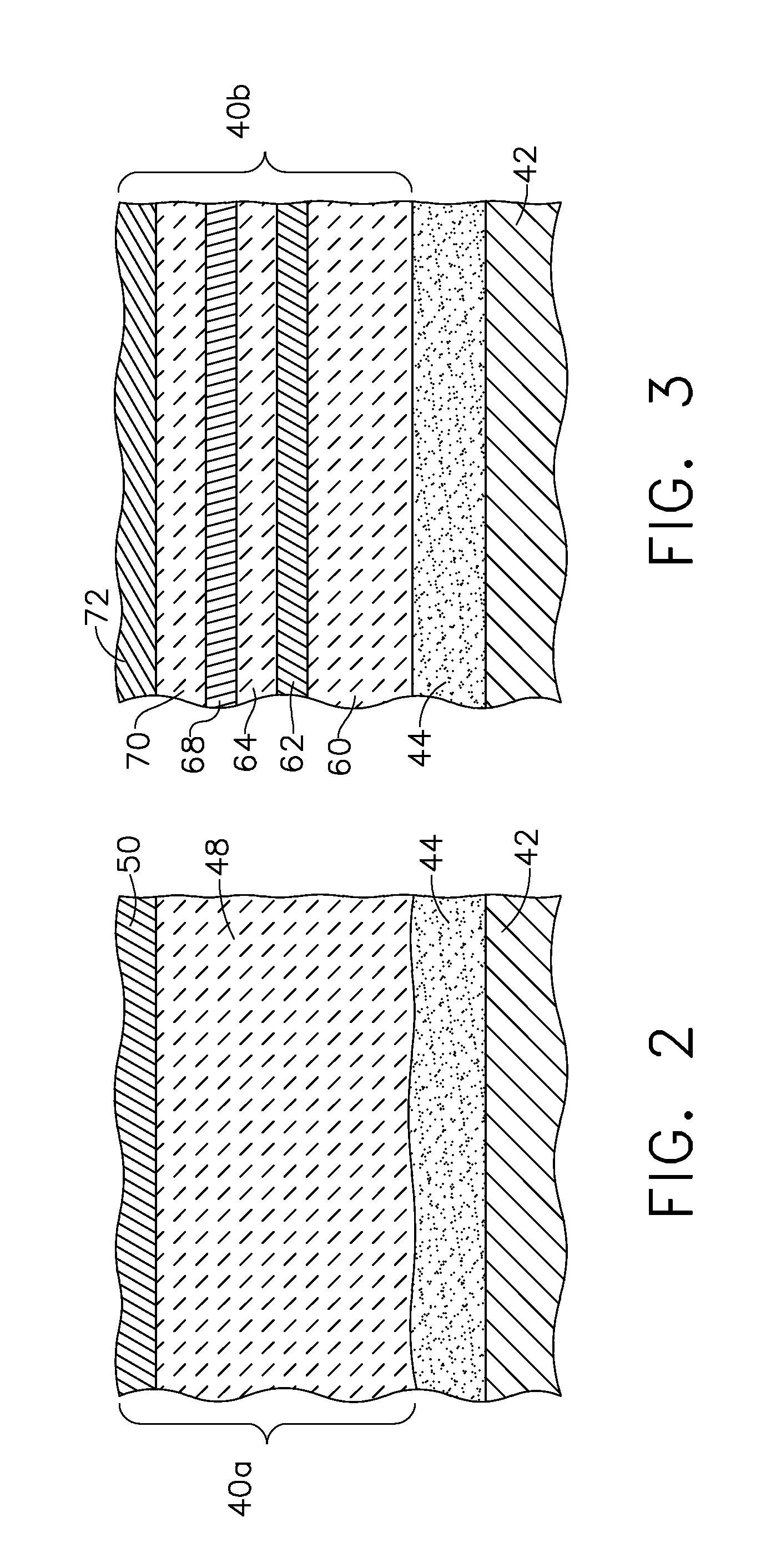

A segmented abradable ceramic coating system having superior abradability and erosion resistance is disclosed. The system includes a duct segment having a metallic substrate, a MCrAlY bond coat on the substrate and a segmented abradable ceramic coating on the bond coat. The segmented abradable ceramic coating includes a base coat foundation layer, a graded interlayer and an abradable top layer for an overall thickness of preferably about 50 mils (1.270 mm). The coating is characterized by a plurality of vertical microcracks. By precisely controlling the deposition parameters, composition of the layers and layer particle morphology, segmentation is achieved, as well as superior abradability and erosion resistance.

Owner:UNITED TECH CORP

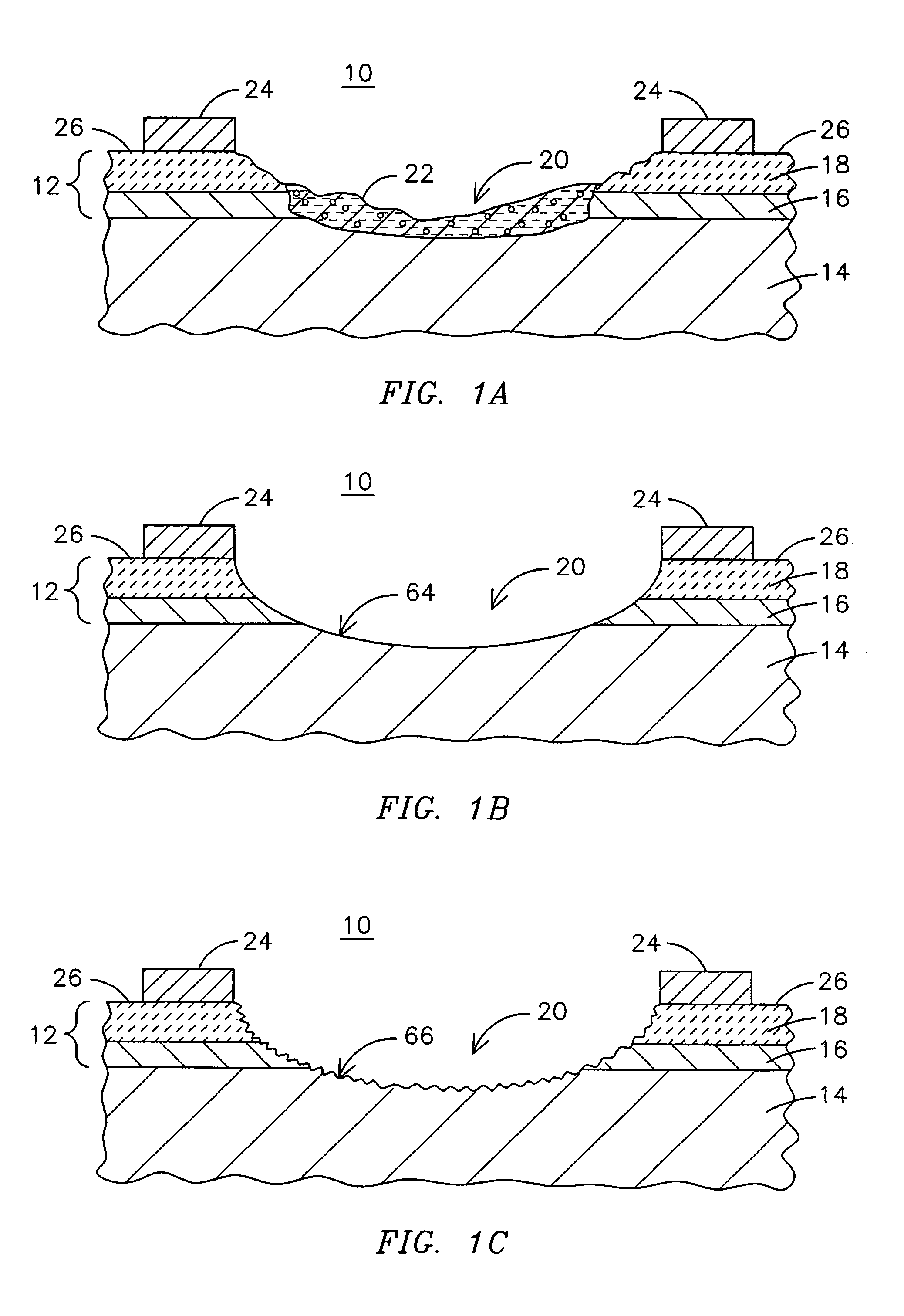

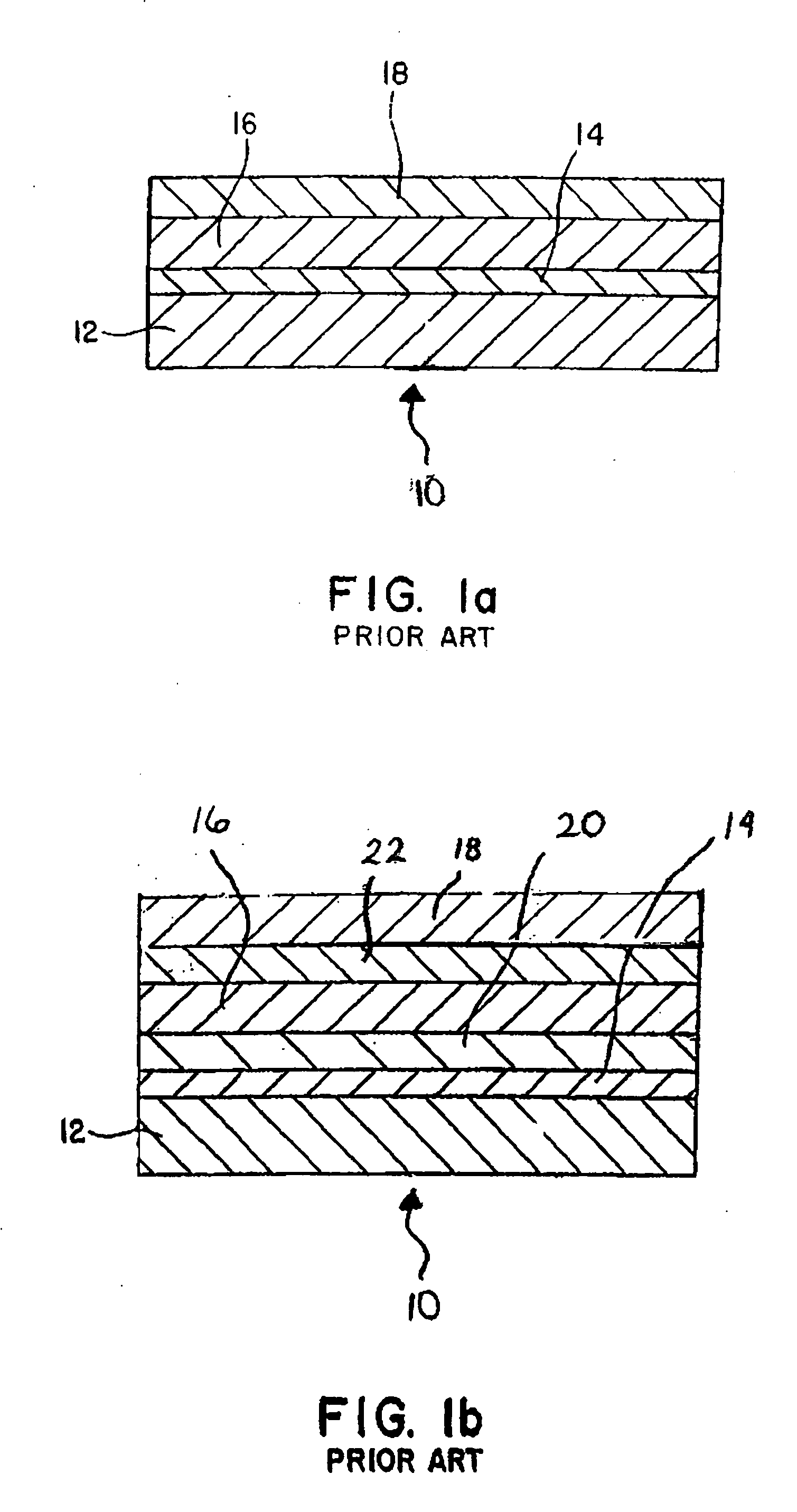

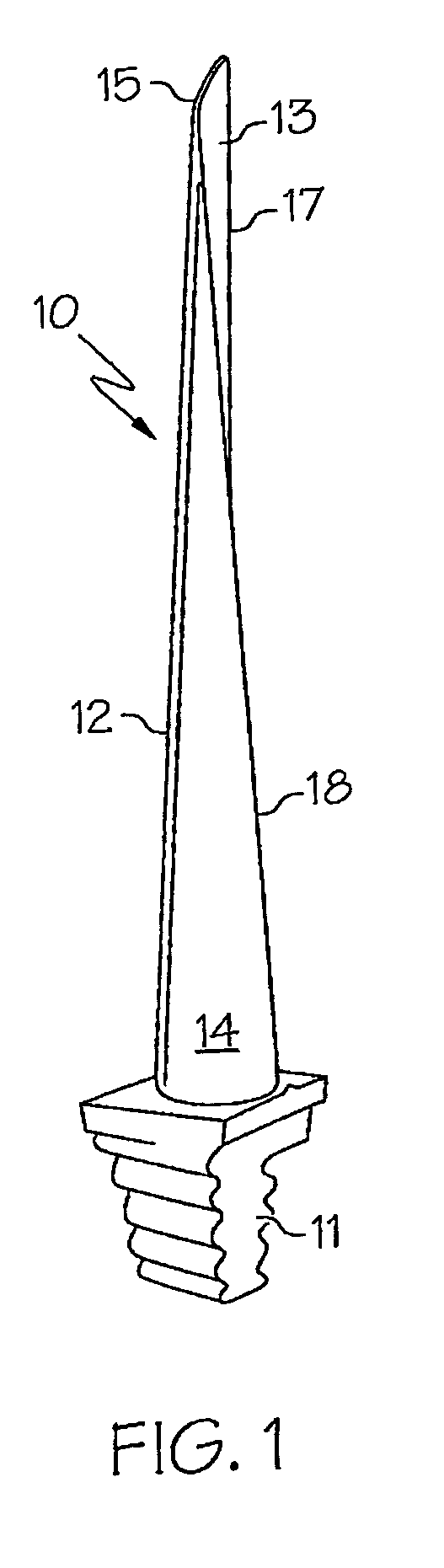

In-frame repair of gas turbine components

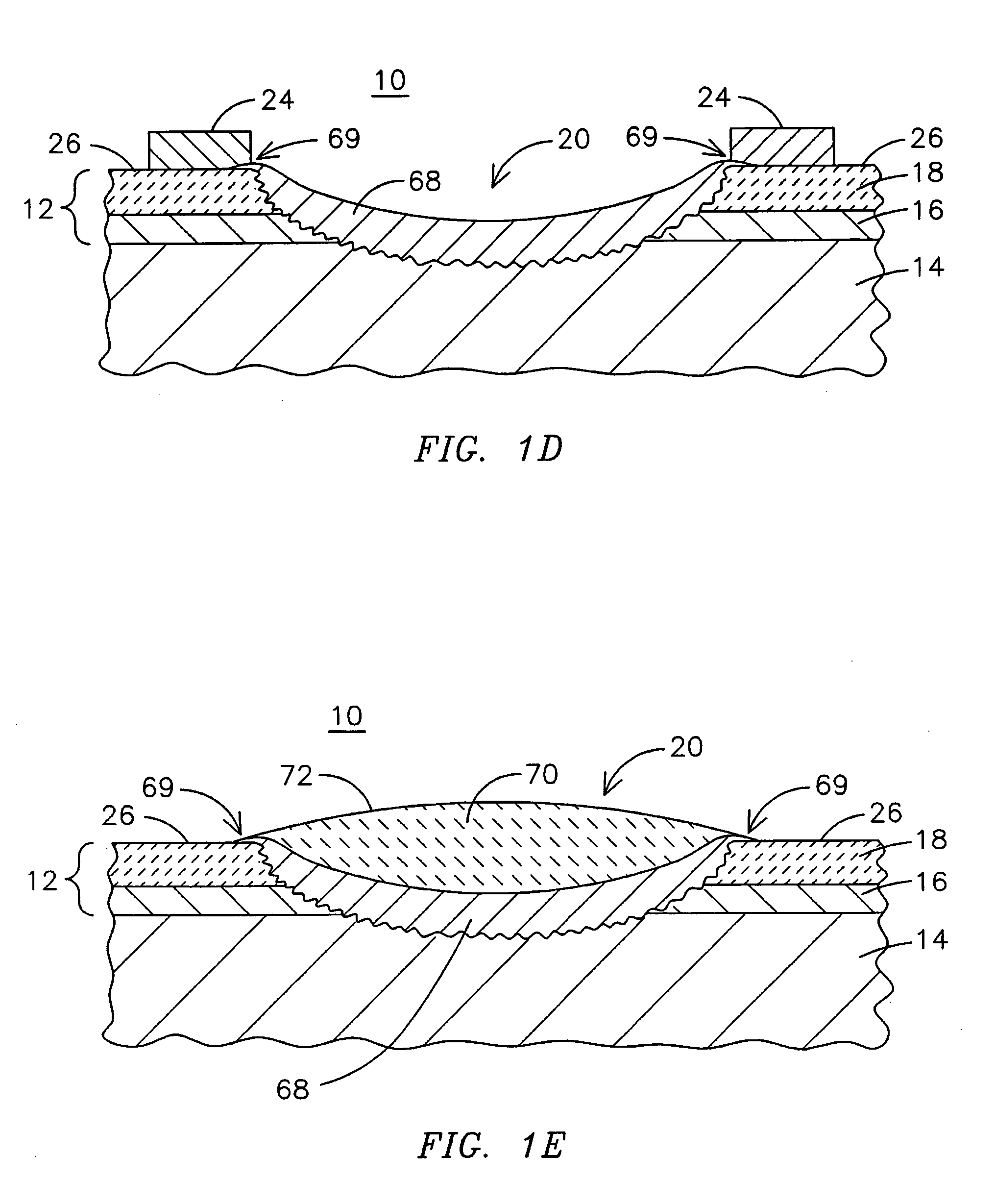

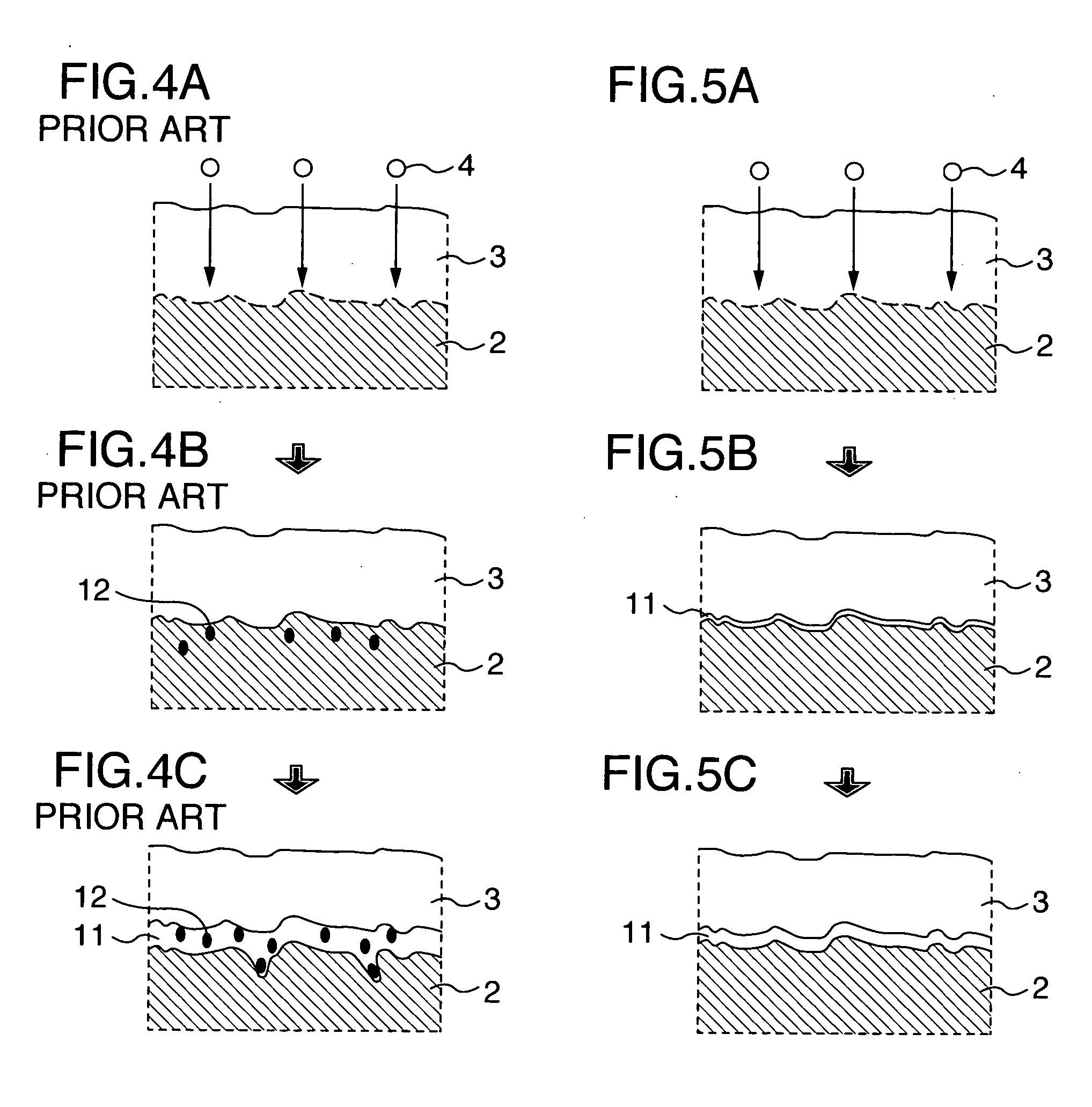

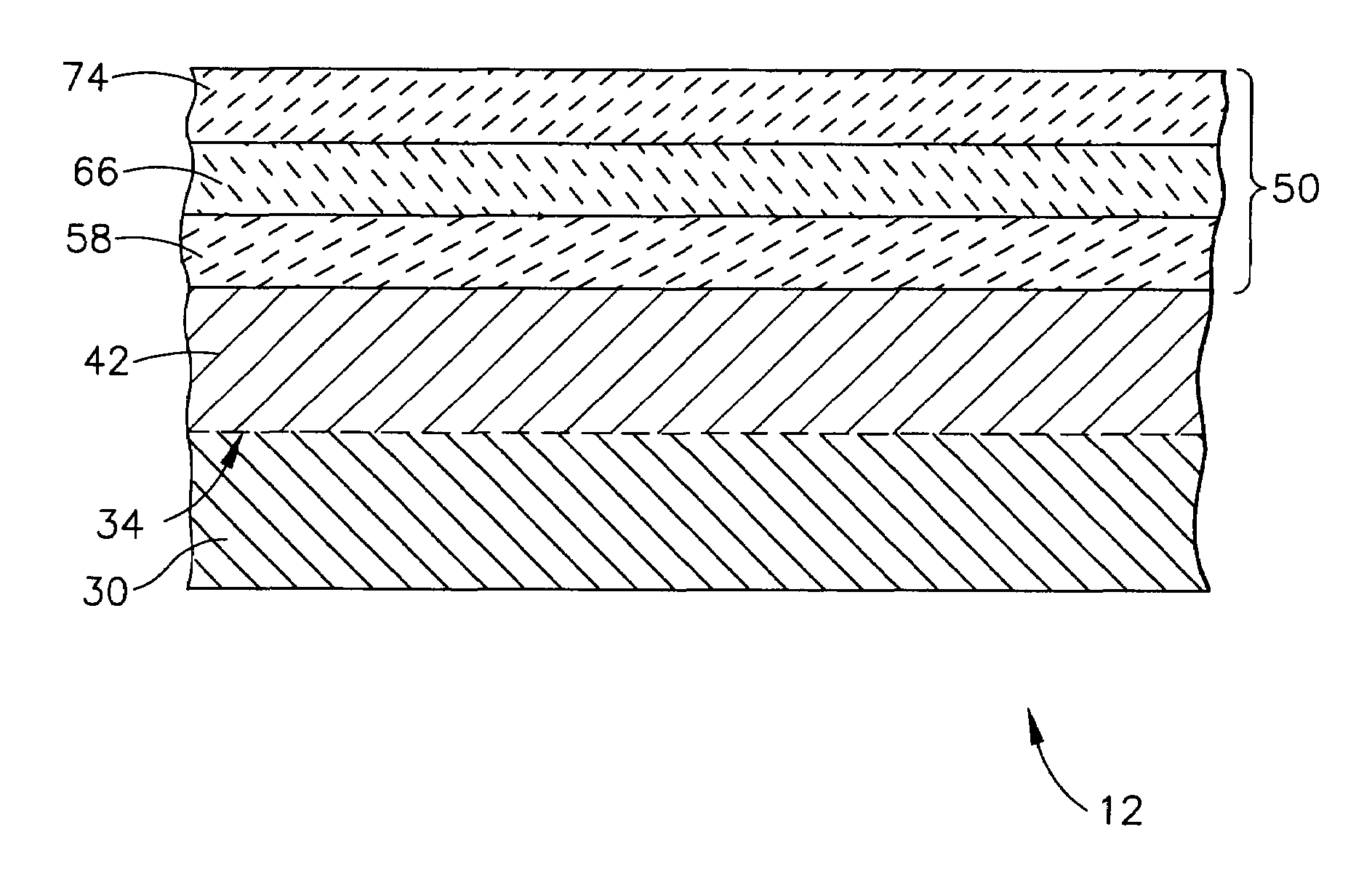

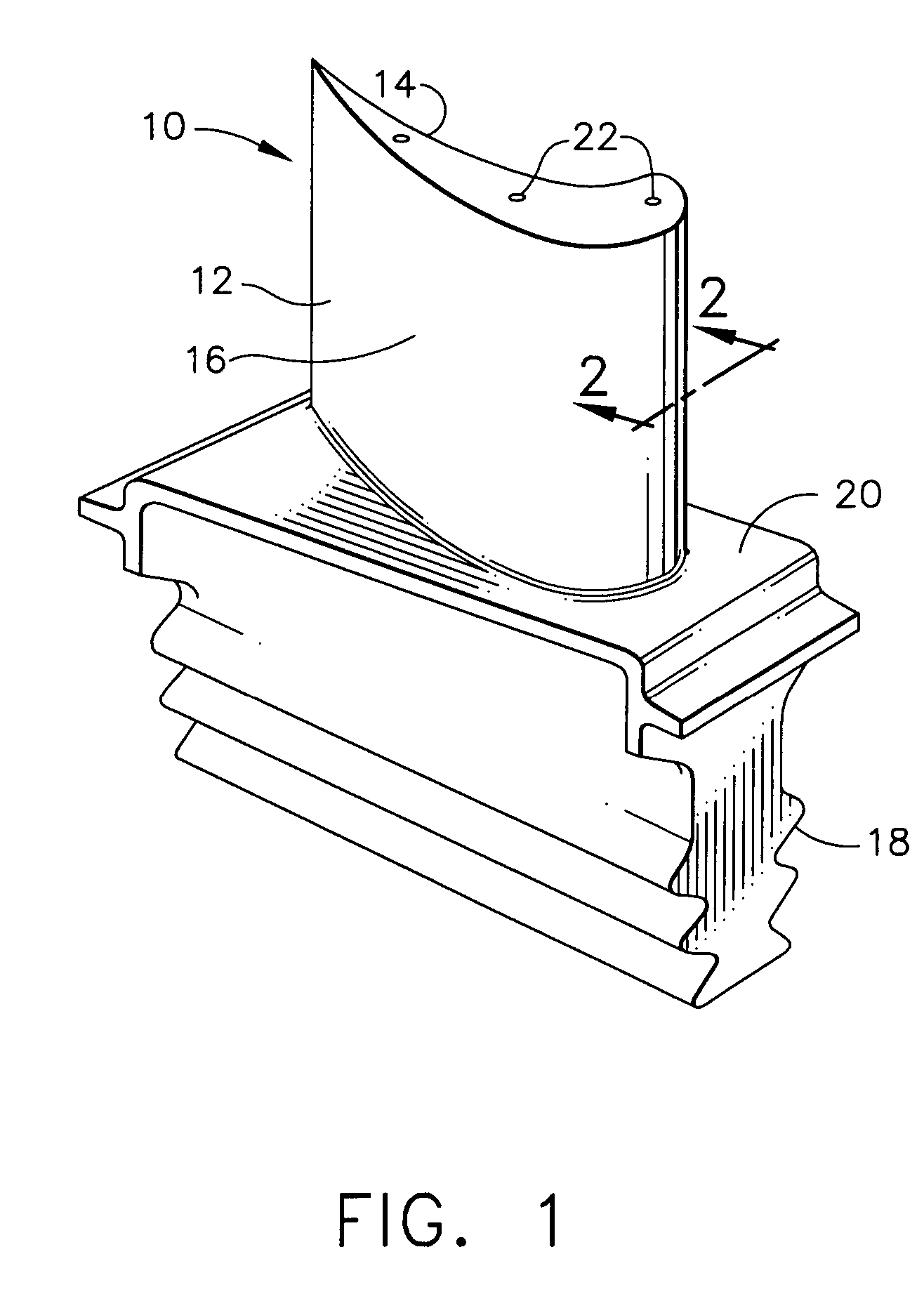

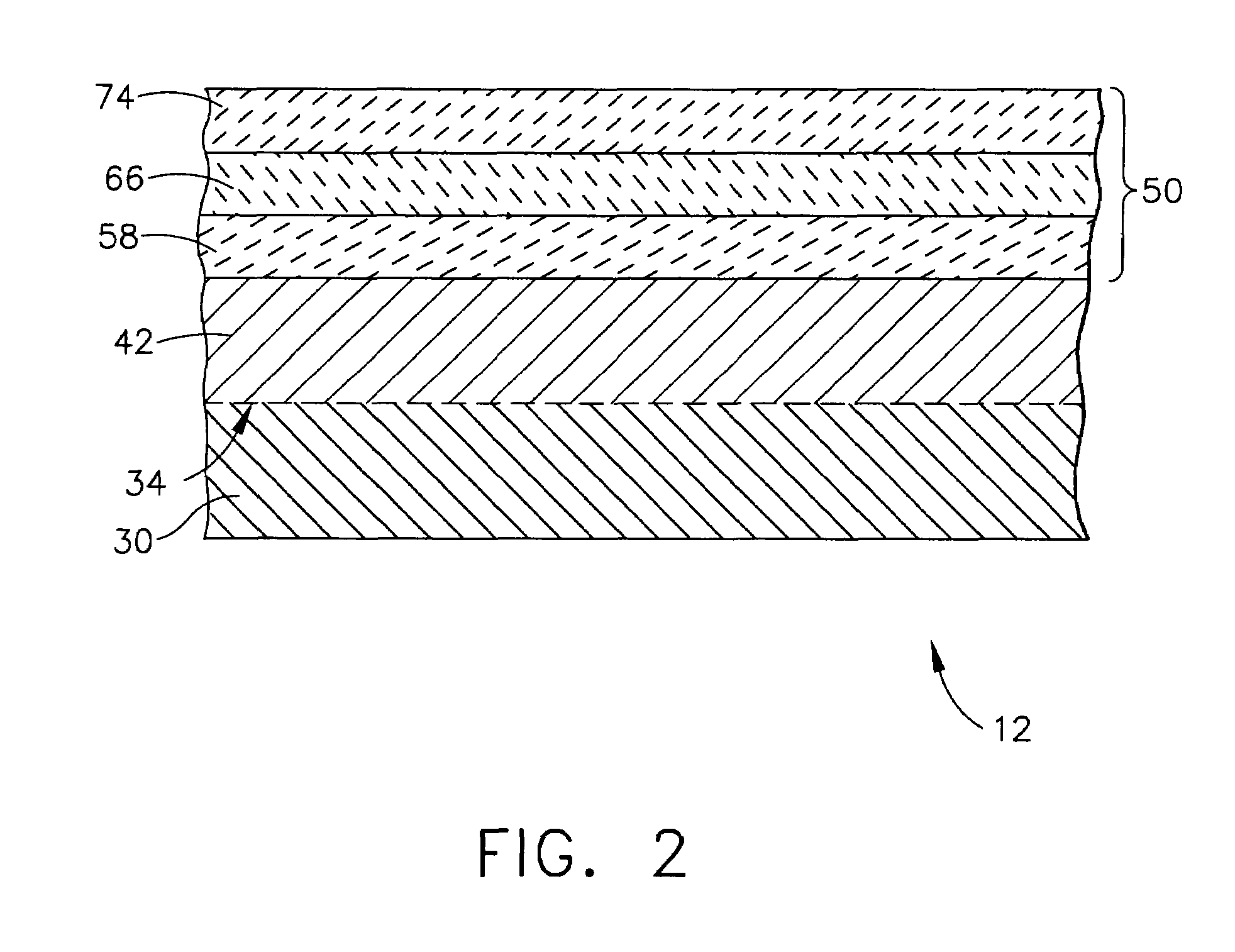

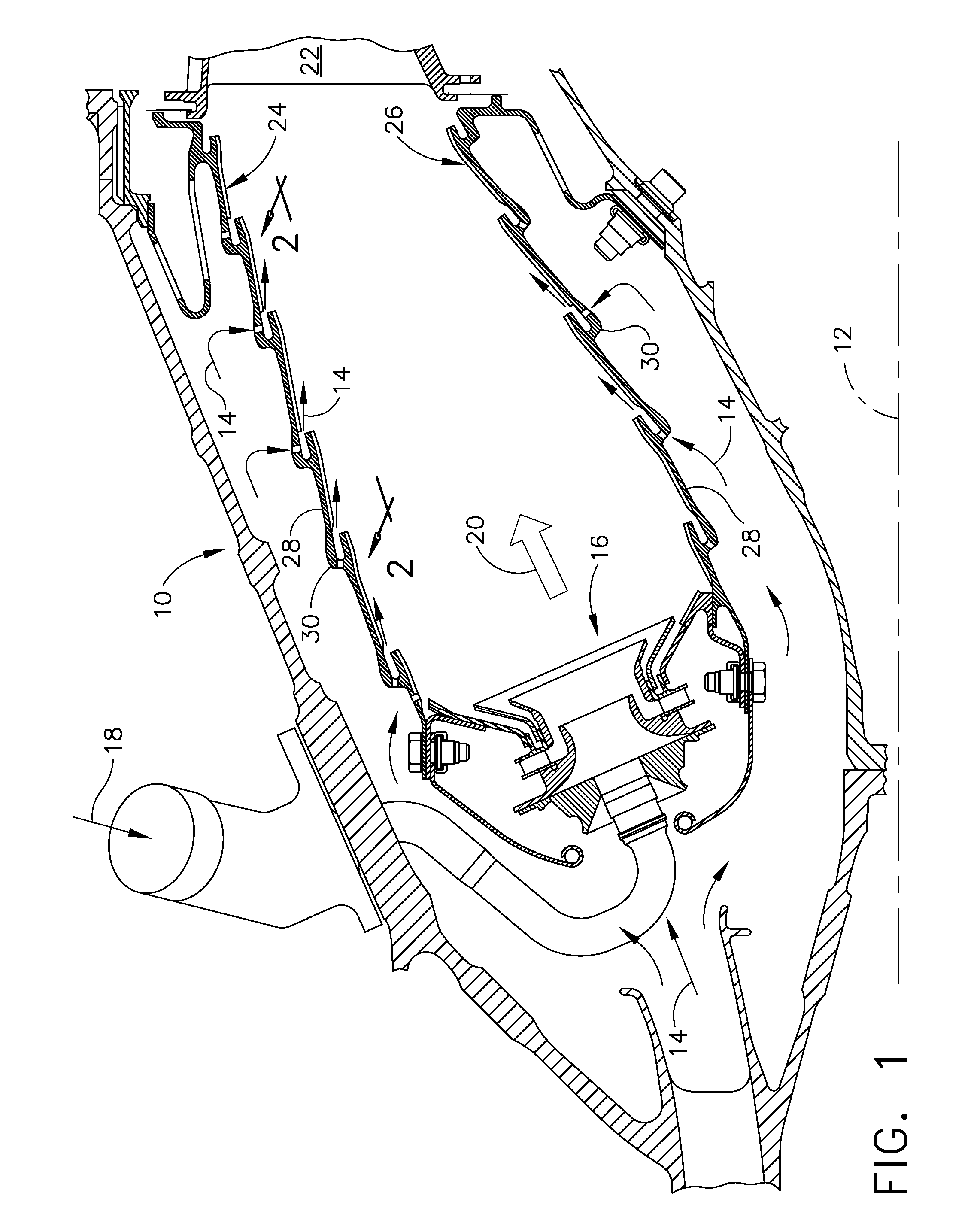

A method for in-frame repairing of a thermal barrier coating (12) on a gas turbine component includes cleaning a desired surface portion (10) of the component without removing the component from the gas turbine. The method also includes roughening the surface portion in-frame, applying a bond coat (68) to the surface portion in-frame, and applying a ceramic topcoat (70) to the bond coat, in-frame. A system (28) for cleaning the surface portion in-frame includes an abrasive media (34) having a state change characteristic occurring at a temperature lower than an operating temperature of the gas turbine so that the abrasive media changes from a solid state to another state allowing the media to exit the gas turbine during operation. The system also includes an abrasive media sprayer (36) to direct a spray of the abrasive media at the desired surface portion.

Owner:SIEMENS ENERGY INC

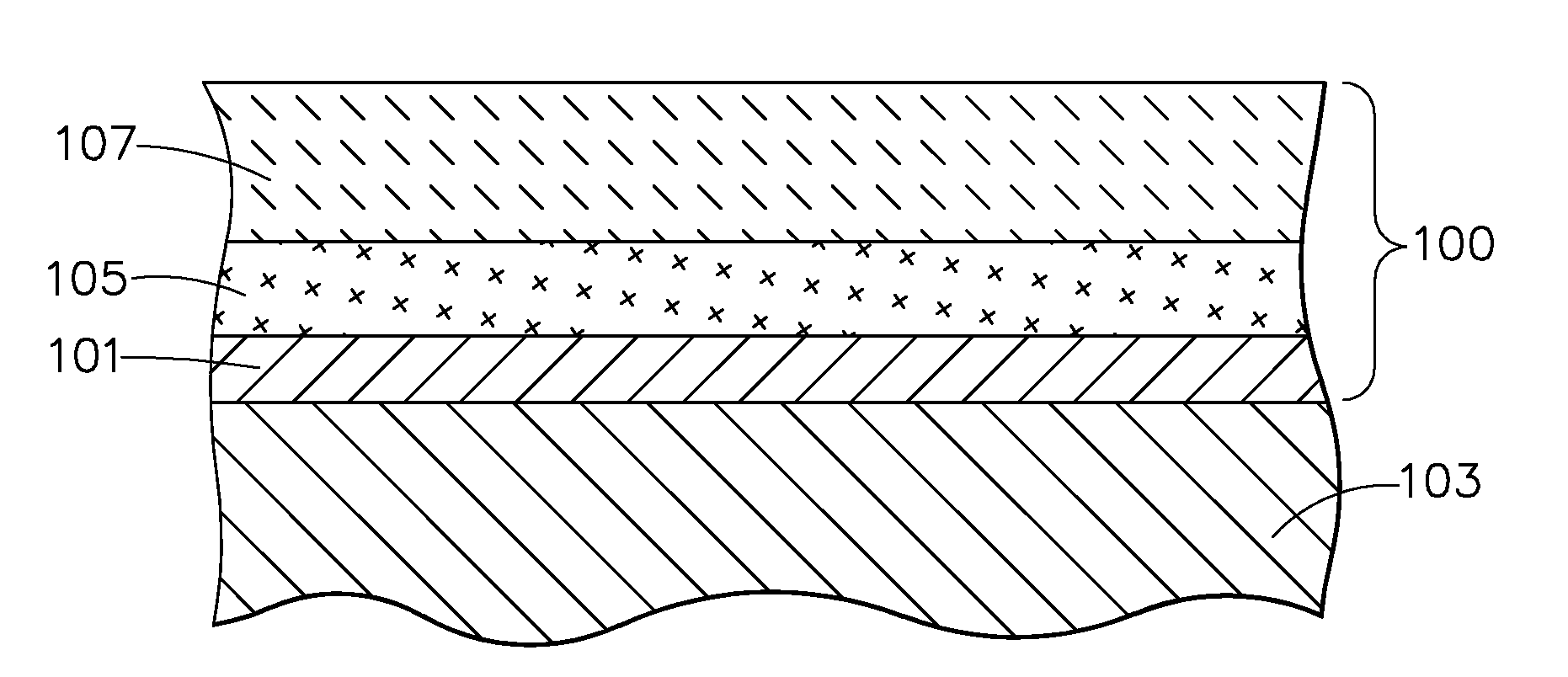

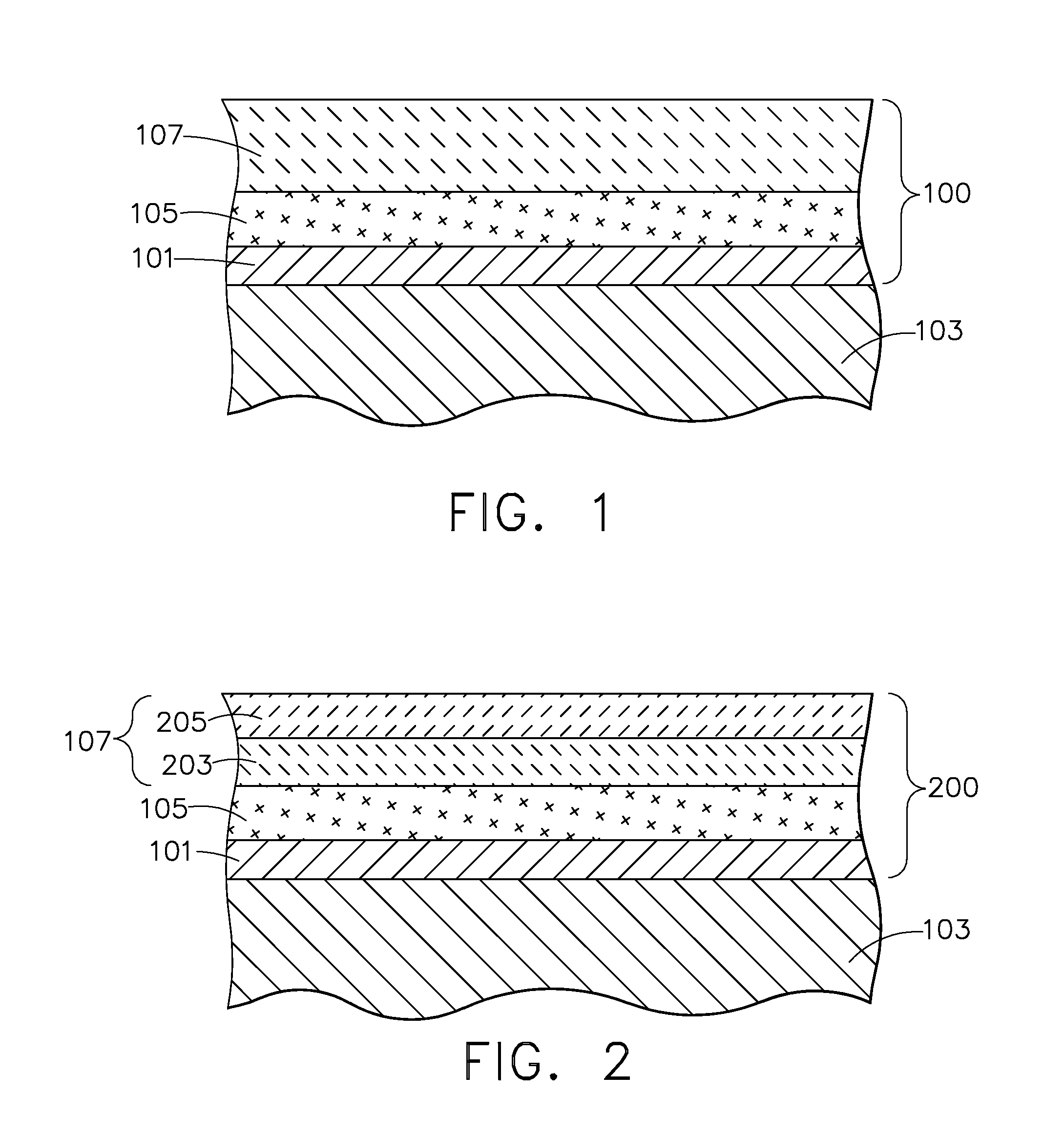

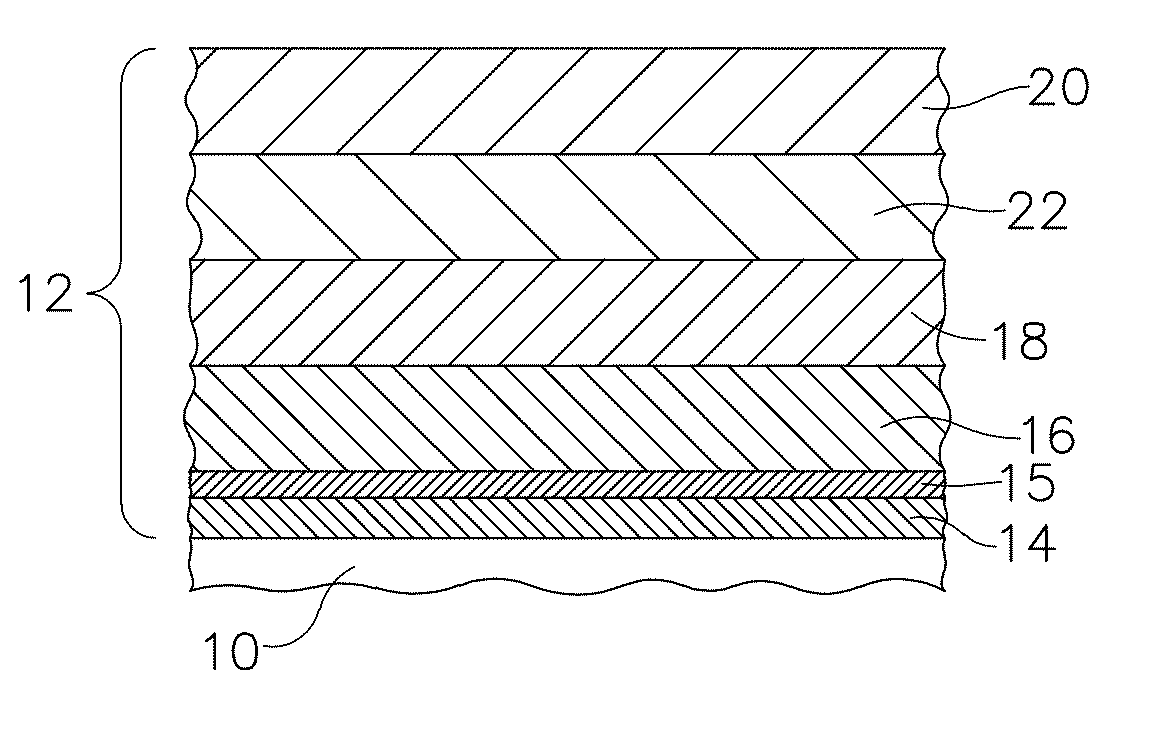

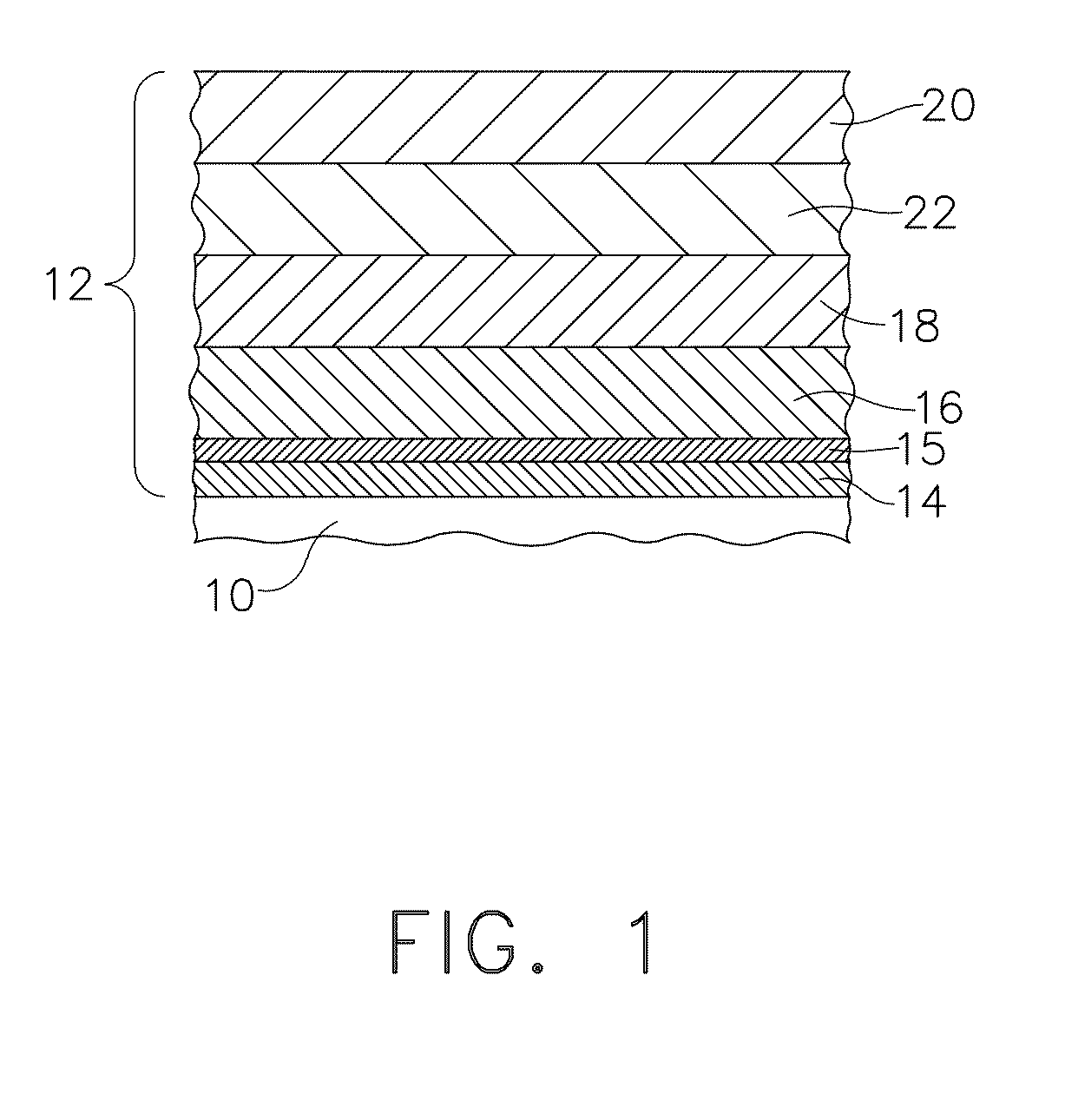

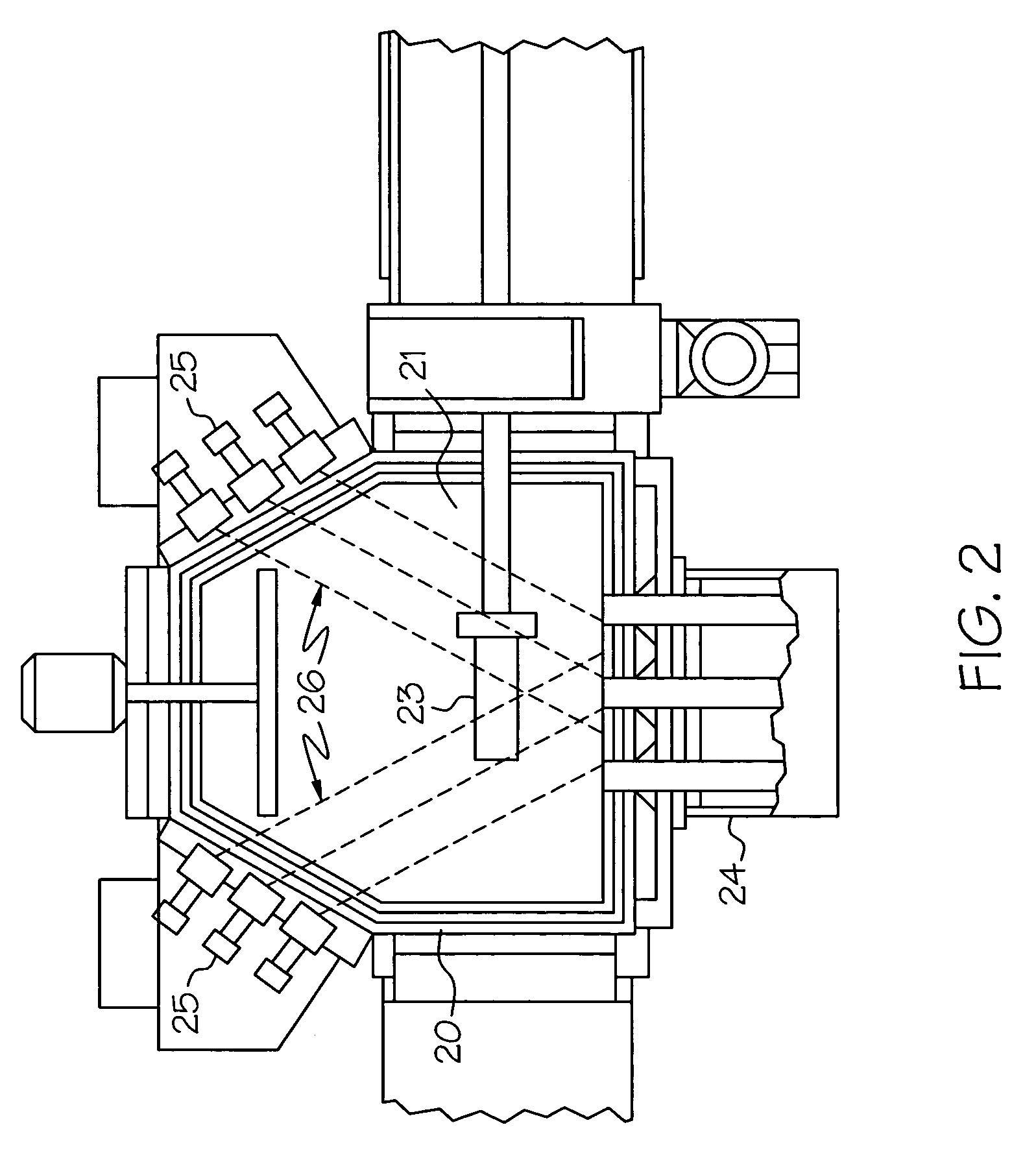

Thermal barrier coating system

ActiveUS20050170200A1Avoid low surface temperaturesInferior erosion resistancePropellersMolten spray coatingThermal sprayingMetallurgy

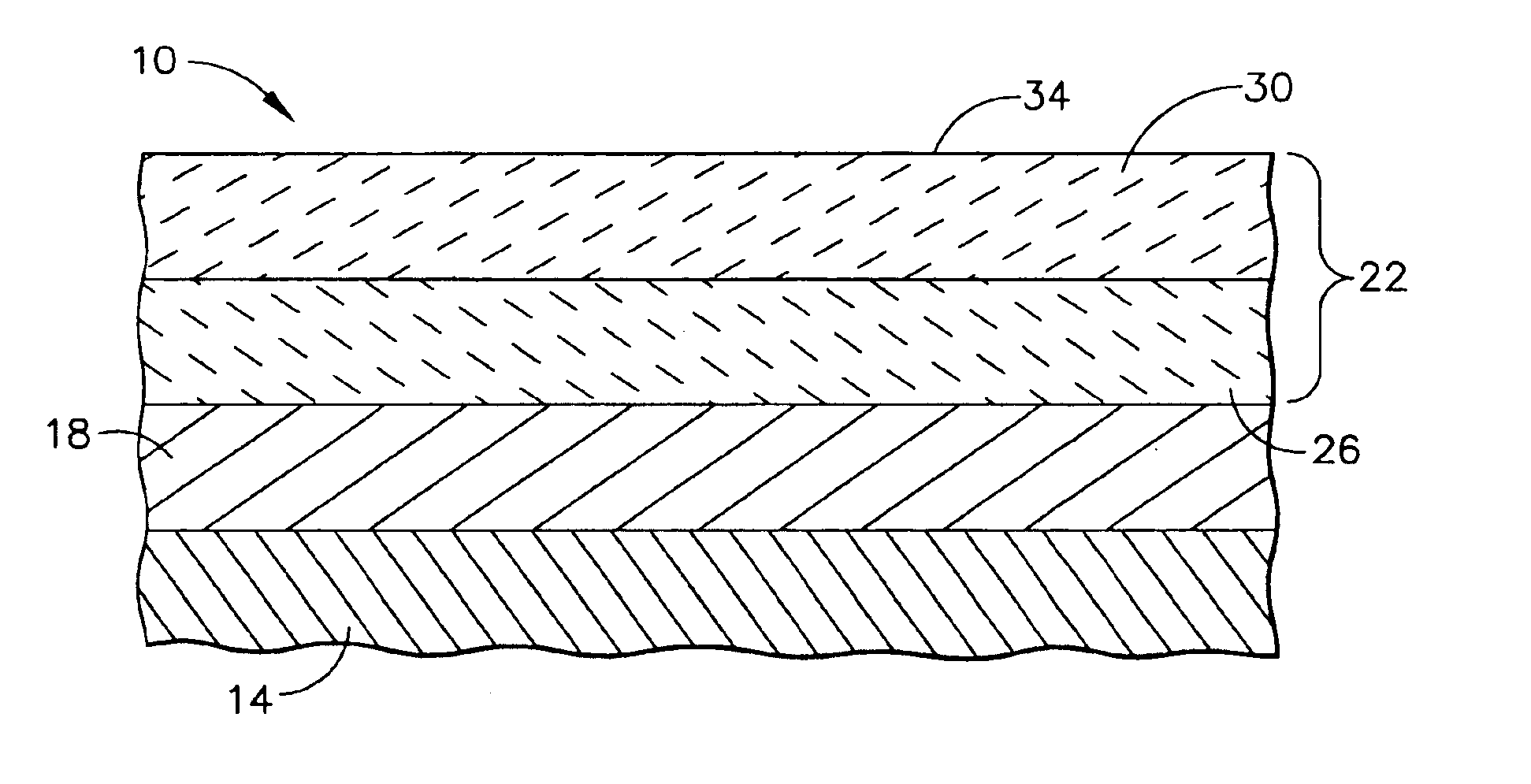

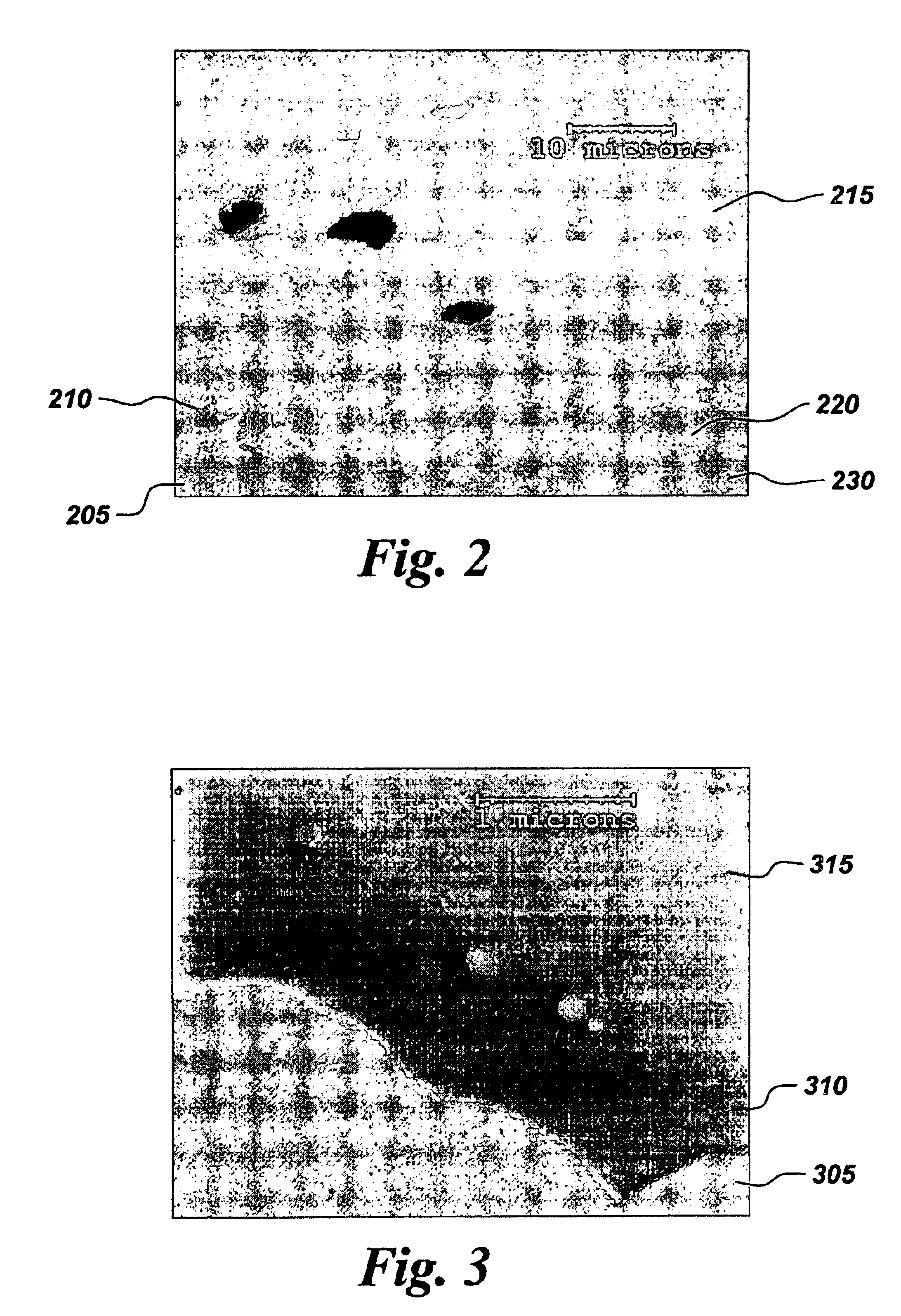

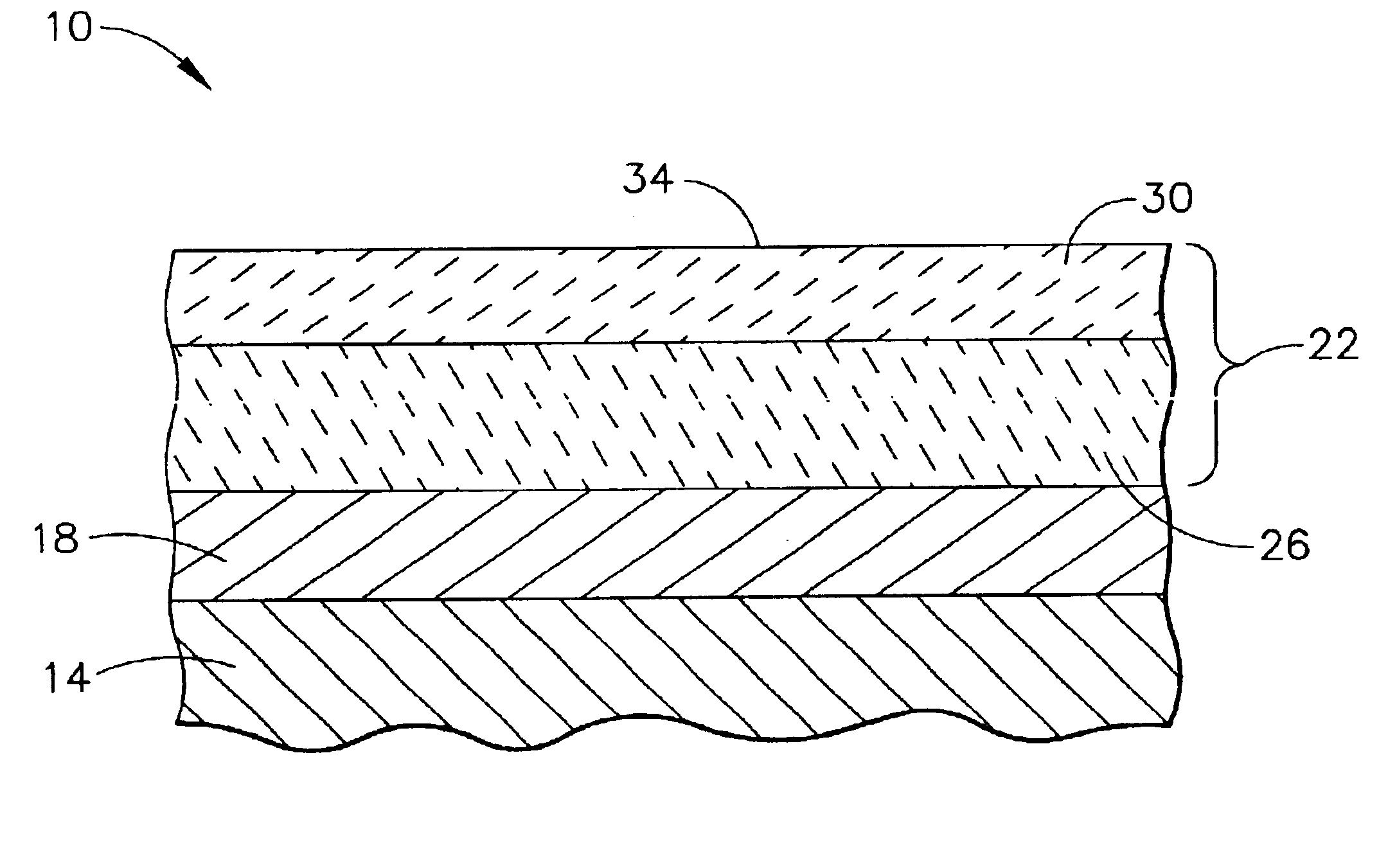

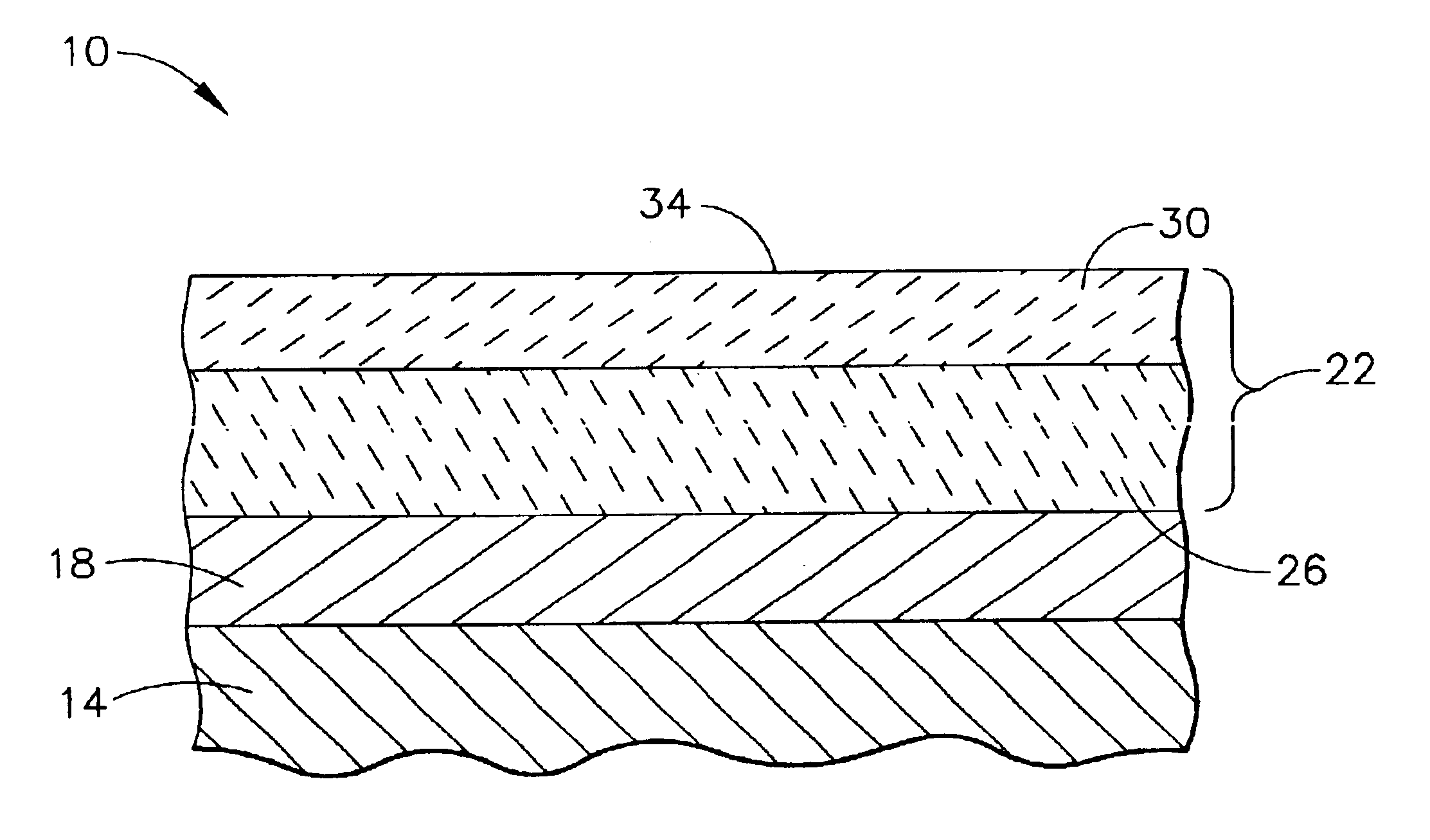

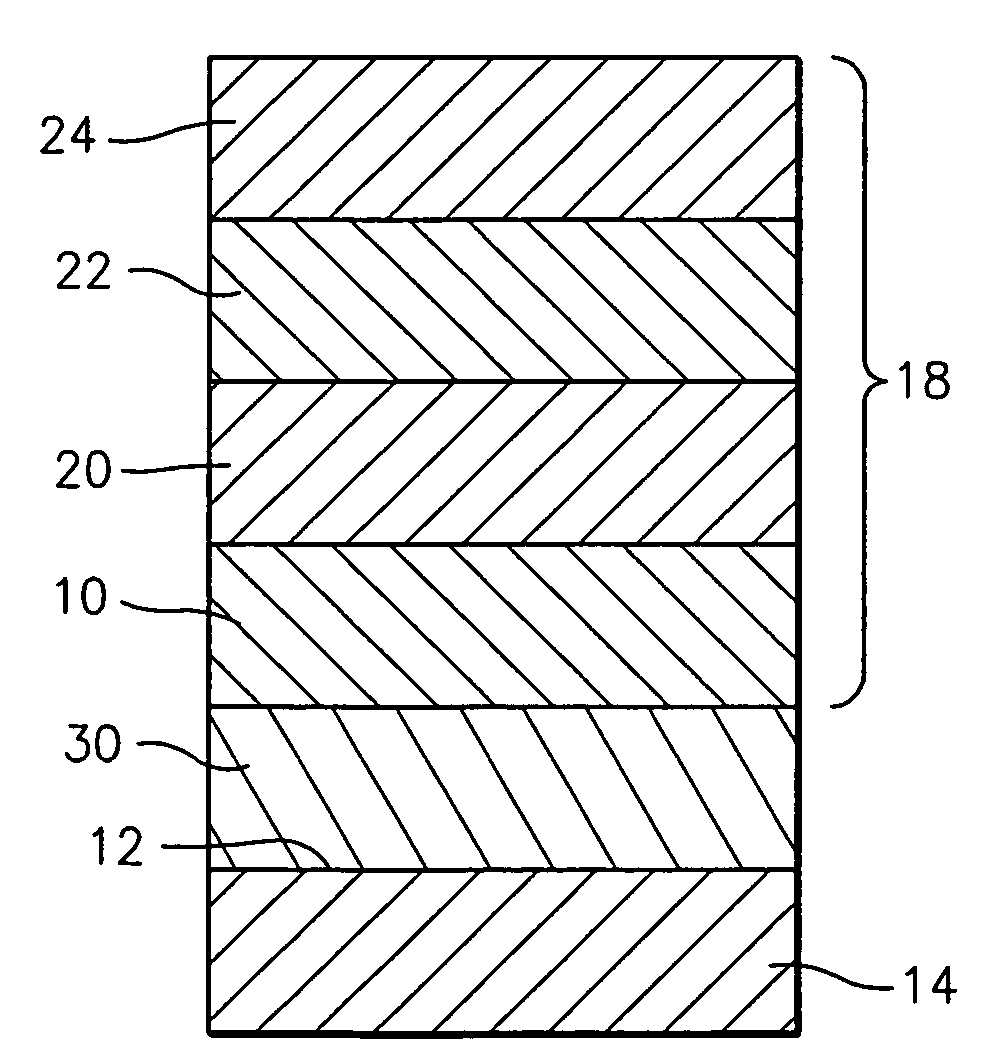

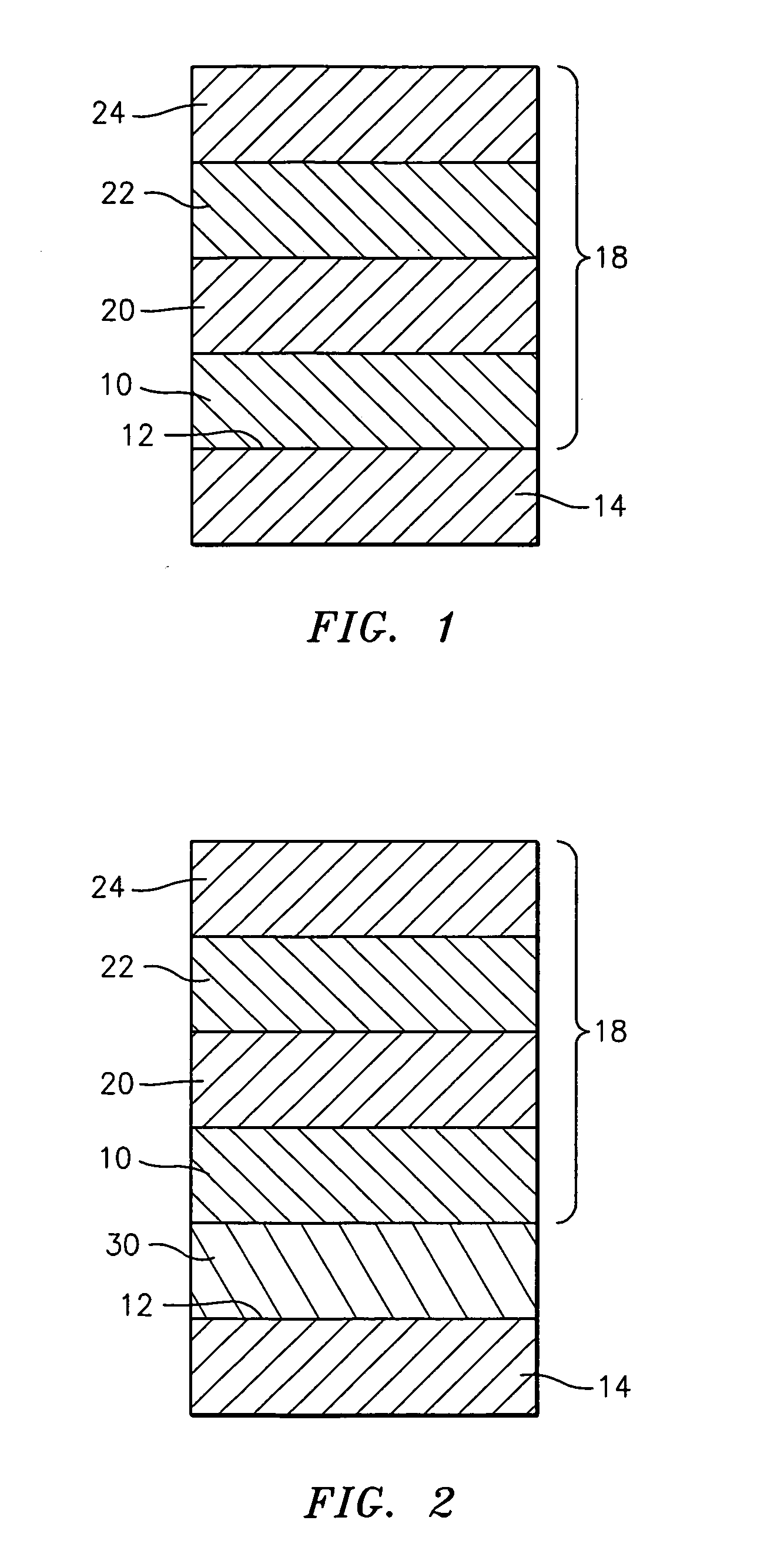

A TBC system suitable for protecting the surface of a substrate subjected to a hostile thermal environment. The TBC system comprises a bond coat on the substrate surface, an alumina scale on the bond coat, and a multilayer TBC comprising a thermal-sprayed first ceramic layer on the alumina scale and a thermal-sprayed second ceramic layer overlying the first ceramic layer. The first ceramic layer consists essentially of partially stabilized zirconia so as to comprise the tetragonal and cubic phases of zirconia. The second ceramic layer consists essentially of fully stabilized zirconia so as to consist essentially of the cubic phase of zirconia. The second ceramic layer is also characterized by having vertical microcracks that extend through the thickness thereof. The second ceramic layer is thicker and more erosion resistant than the first ceramic layer.

Owner:GENERAL ELECTRIC CO

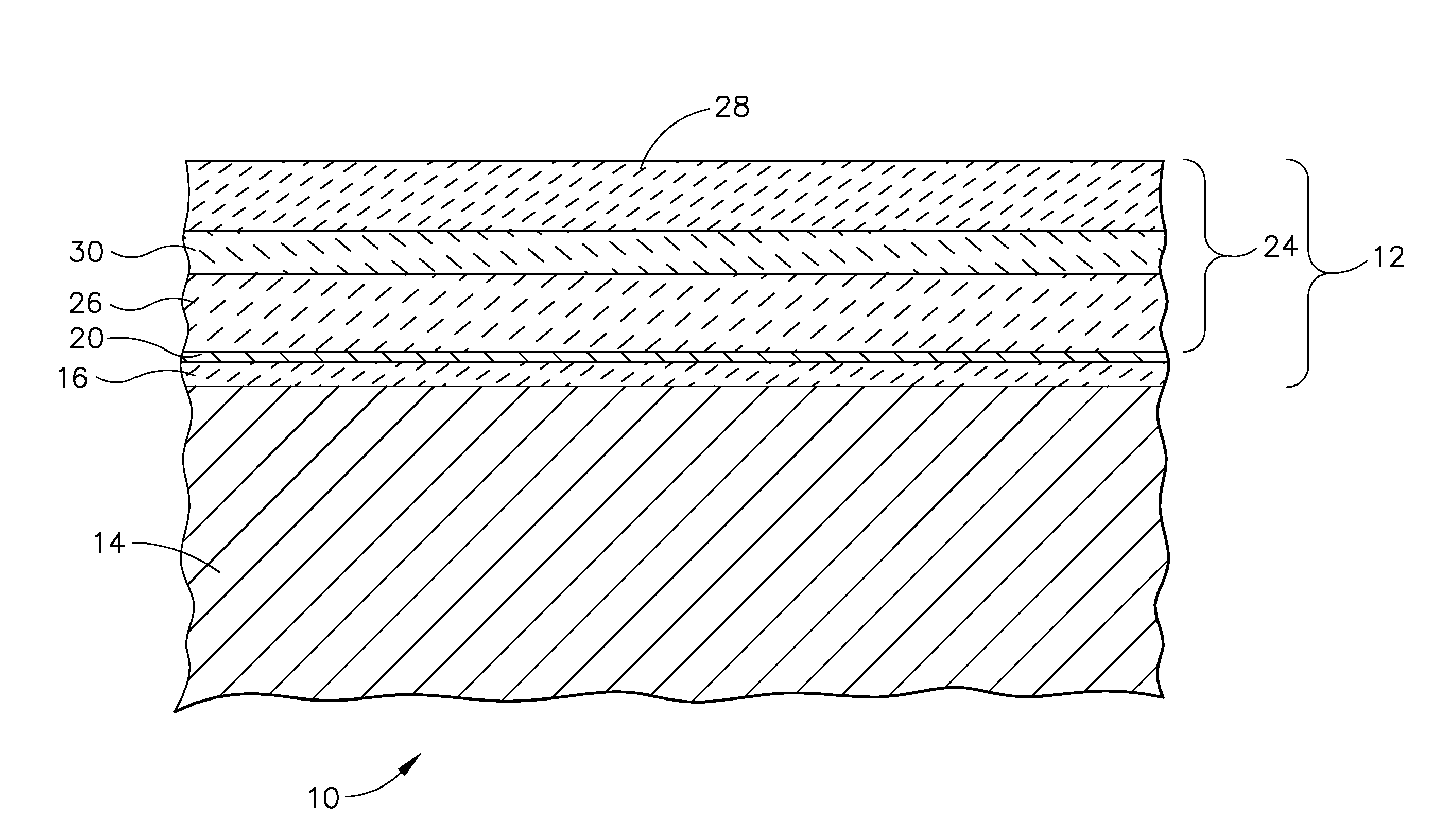

Thermal barrier coatings with protective outer layer for improved impact and erosion resistance

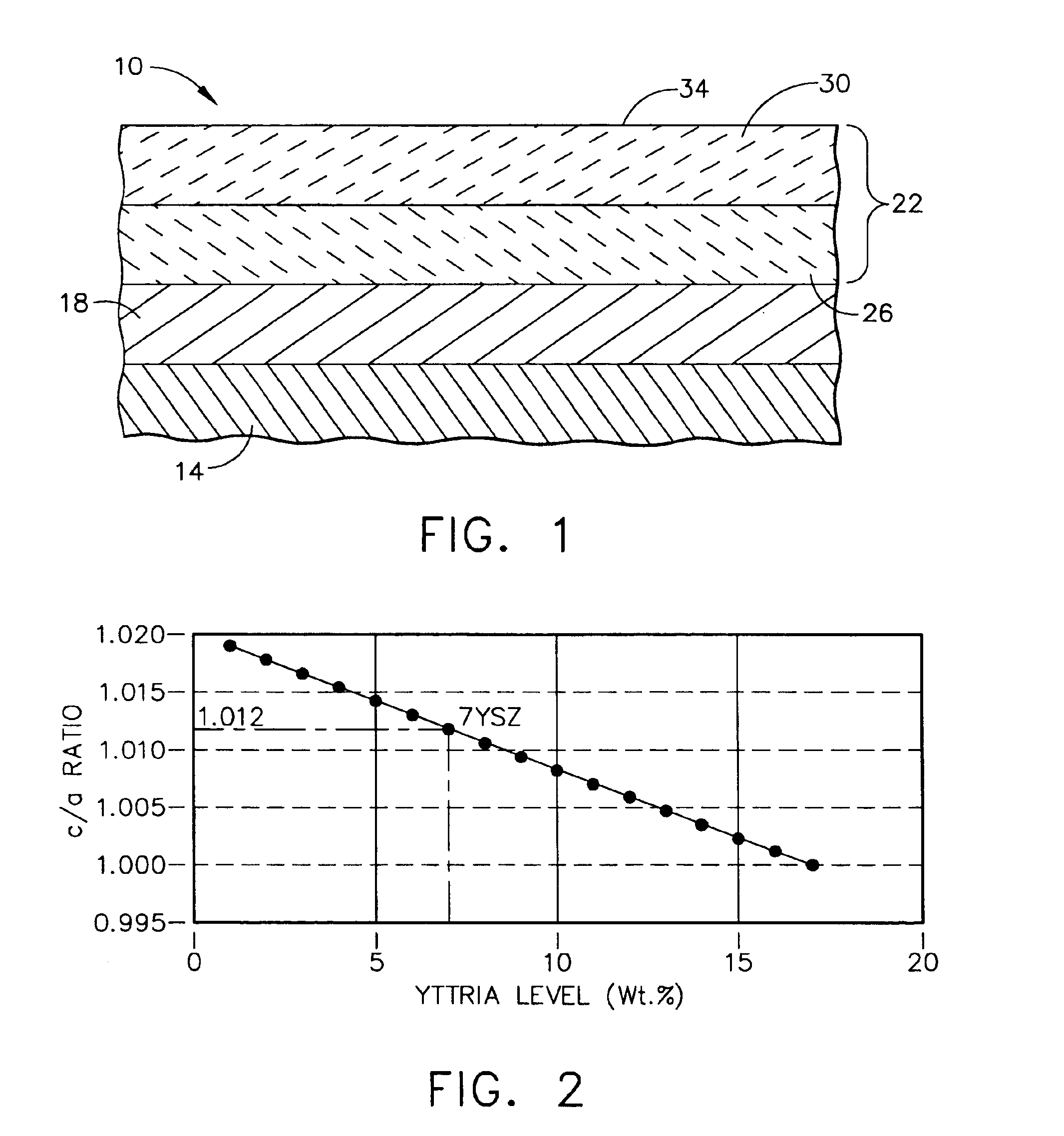

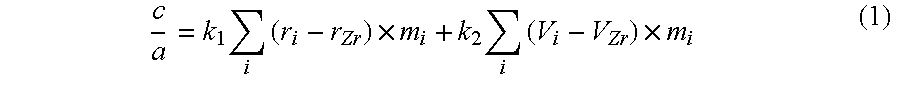

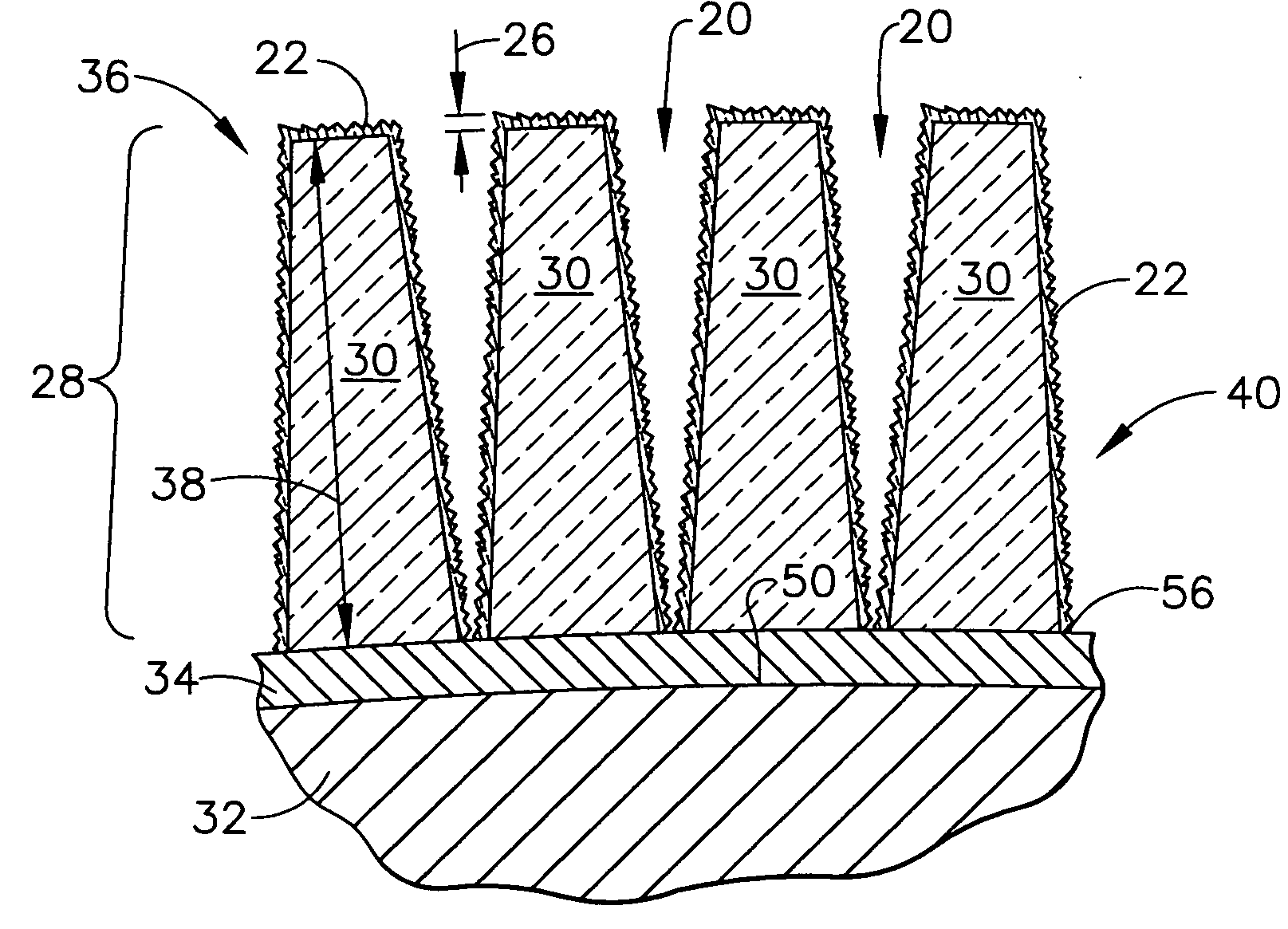

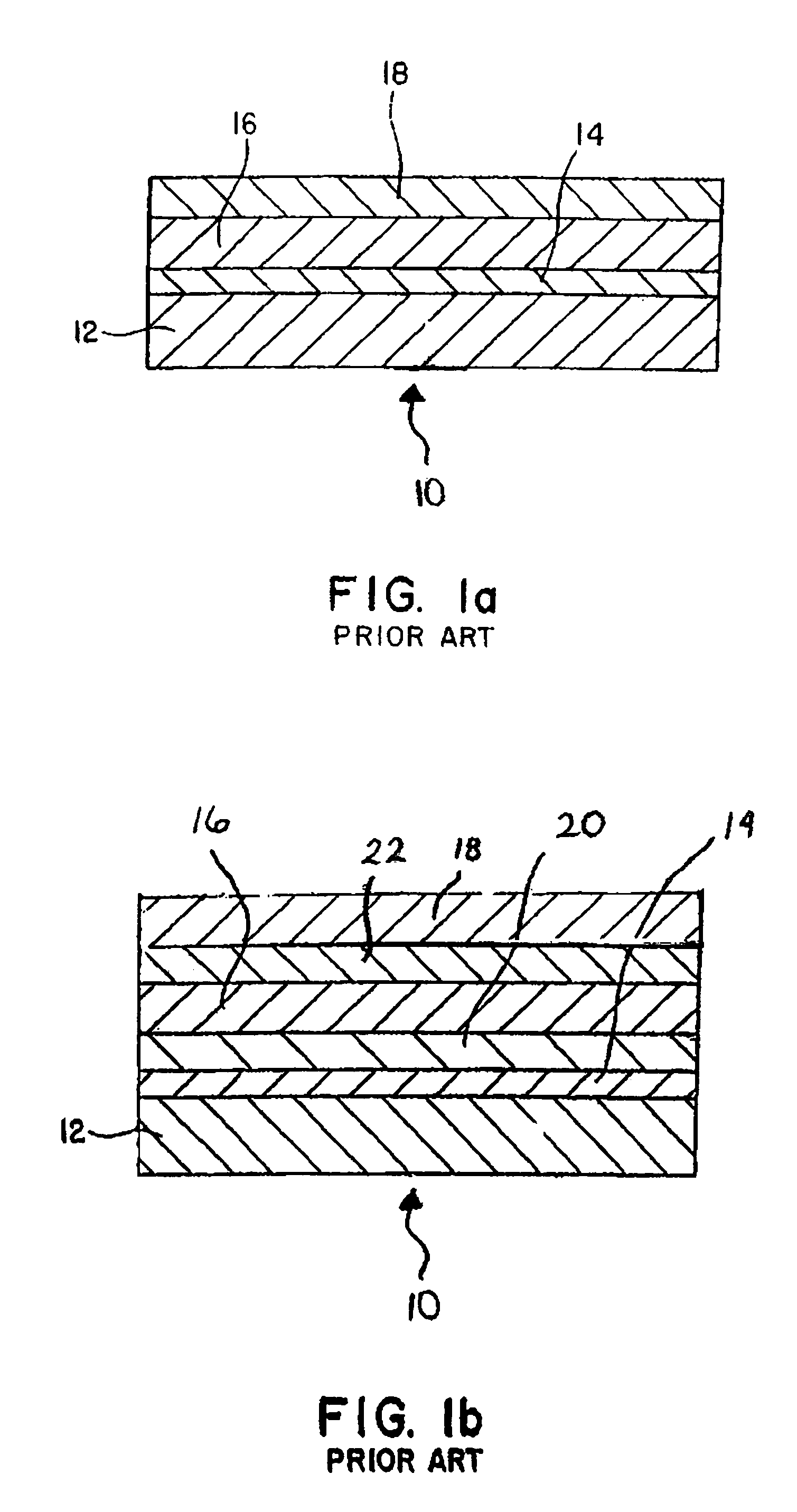

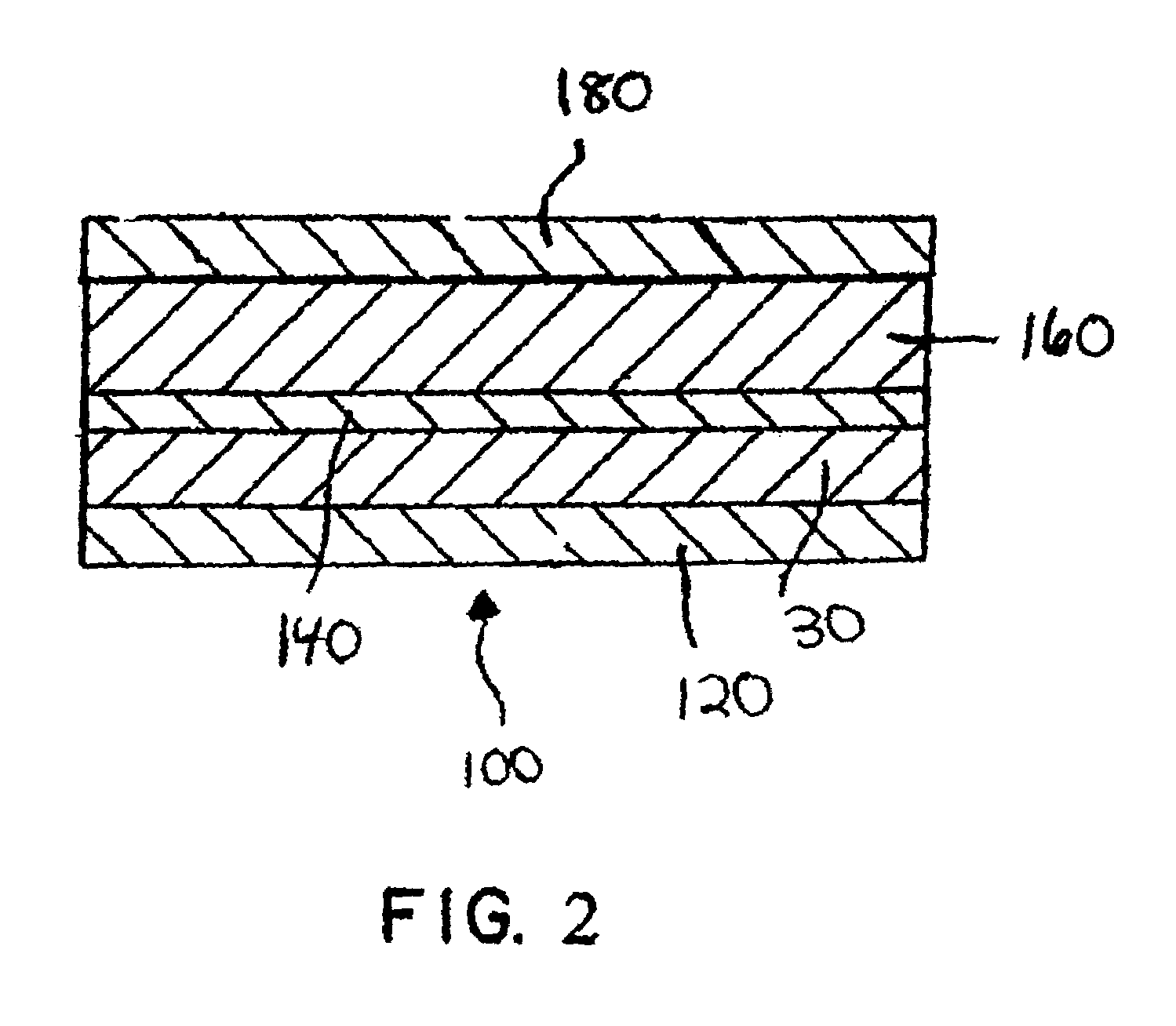

InactiveUS6875529B1Improve erosion resistanceImprove impact resistanceMolten spray coatingVacuum evaporation coatingBond coatMetallic substrate

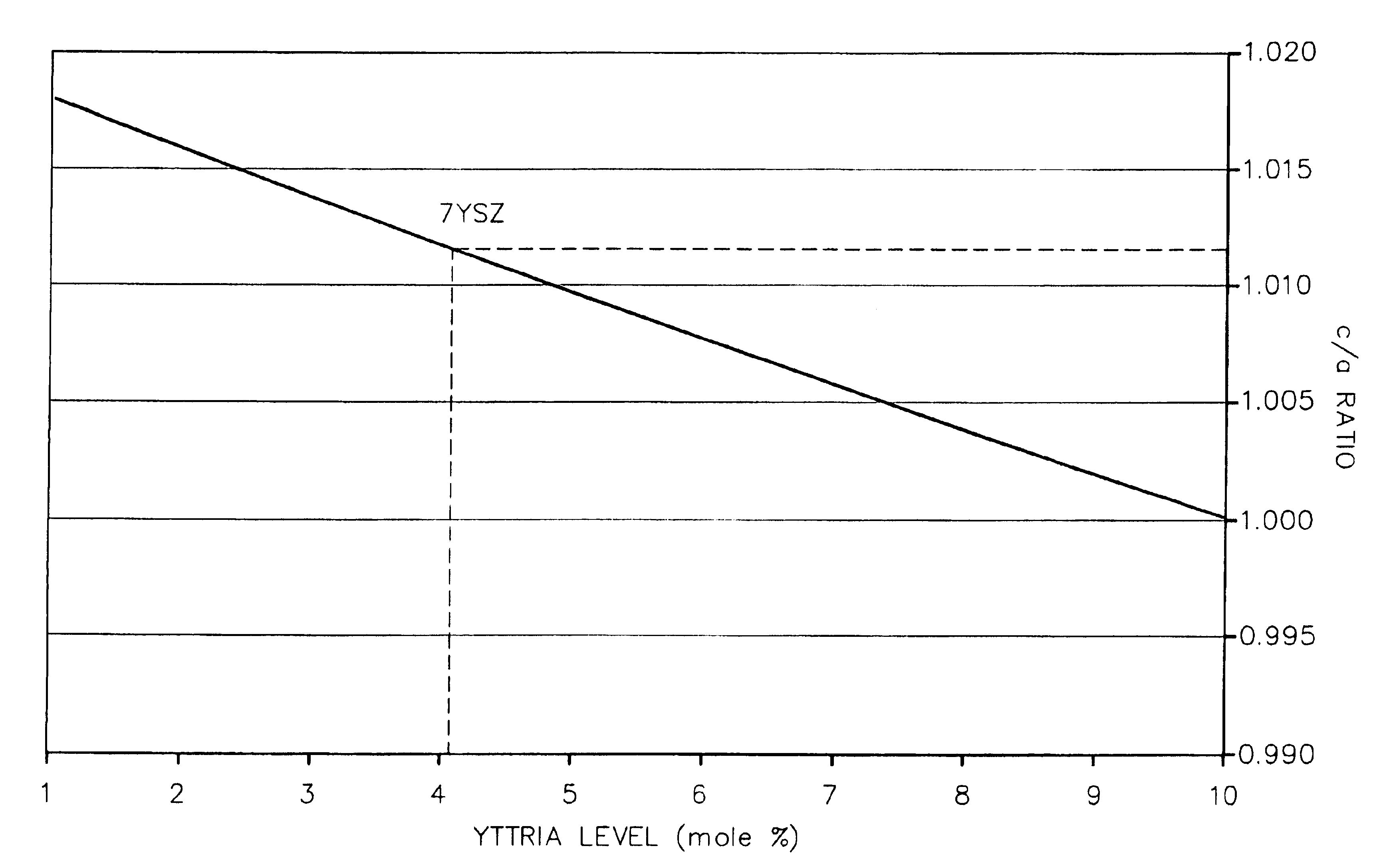

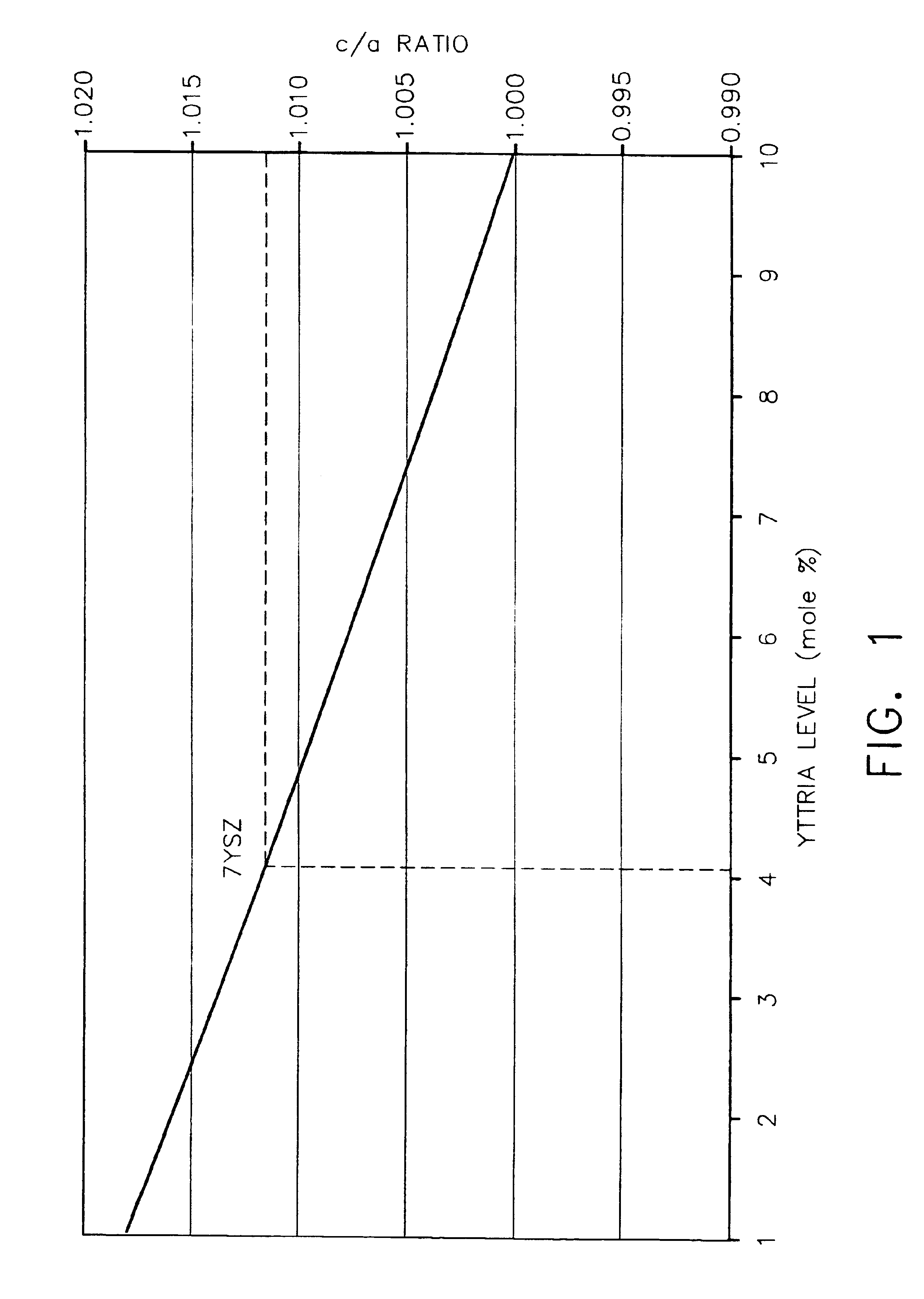

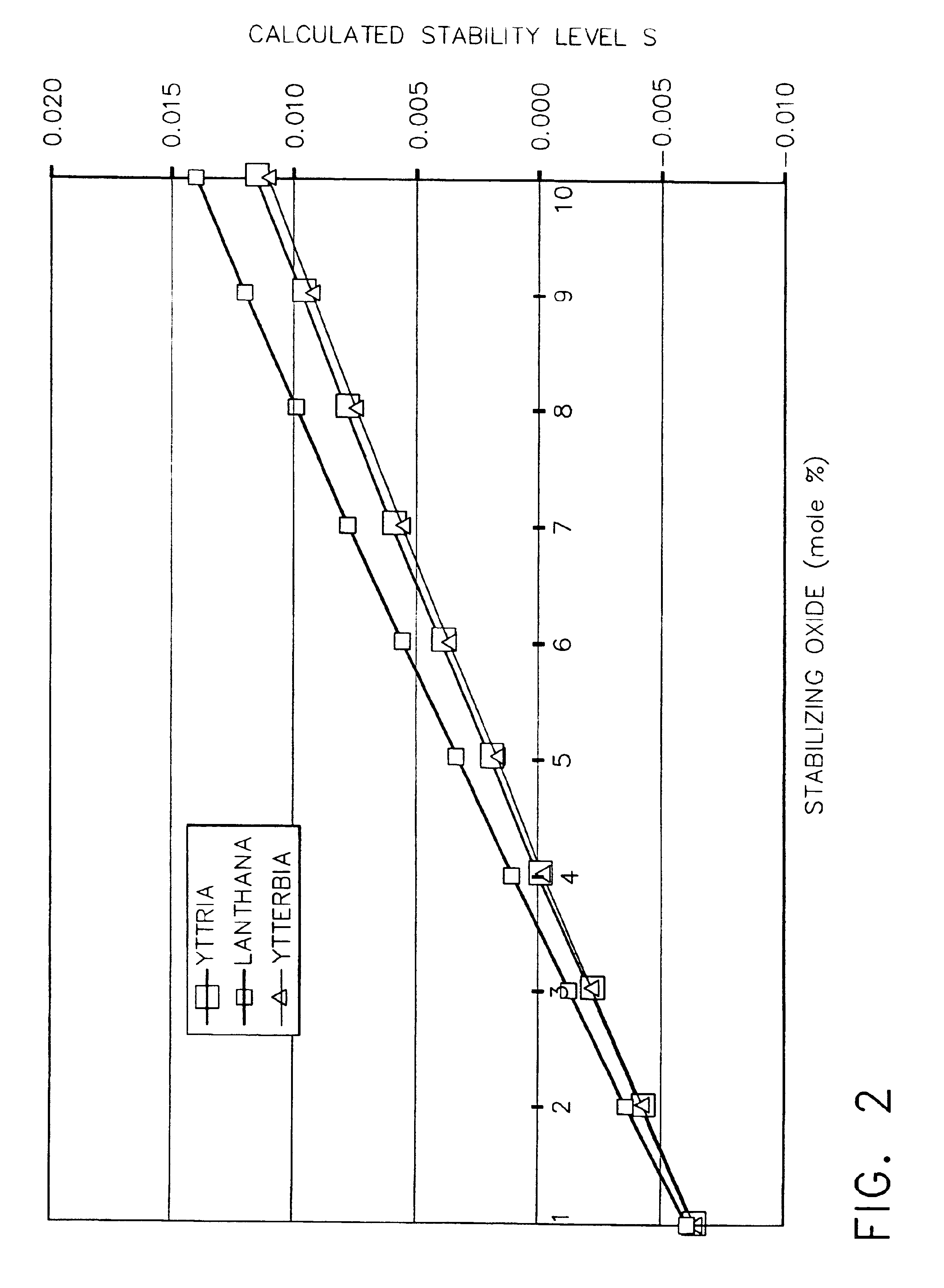

A reduced thermal conductivity thermal barrier coating having improved impact and erosion resistance for an underlying metal substrate of articles that operate at, or are exposed to, high temperatures. This coating comprises an inner layer nearest to the underlying metal substrate comprising a ceramic thermal barrier coating material, as well as a protective outer layer adjacent to and overlaying the inner layer and having an exposed surface. The outer layer has a thickness up to about 5 mils (127 microns) sufficient to impart impact and erosion resistance to the thermal barrier coating, and comprises a zirconia-containing ceramic composition having a c / a ratio of the zirconia lattice in the range of from about 1.011 to about 1.016 and stabilized in the tetragonal phase by a stabilizing amount of a stabilizing metal oxide selected from the group consisting of yttria, calcia, ceria, scandia, magnesia, india, ytterbia and mixtures thereof. This coating can be used to provide a thermally protected article having a metal substrate and optionally a bond coated layer adjacent to and overlaying the metal substrate. The thermal barrier coating can be prepared by forming the inner layer comprising the ceramic thermal barrier coating material, followed by forming on the inner layer the protective outer layer.

Owner:GENERAL ELECTRIC CO

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

Bond coat for corrosion resistant EBC for silicon-containing substrate and processes for preparing same

ActiveUS20060280952A1Improve adhesionHigh melting pointMolten spray coatingBlade accessoriesBond coatMaterials science

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and an environmental barrier coating (EBC) overlying the bond coat layer, wherein the EBC comprises a corrosion resistant outer layer comprising a corrosion resistant metal silicate. A process is also provided for forming the corrosion resistant outer layer over the silicide-containing bond coat layer.

Owner:GENERAL ELECTRIC CO

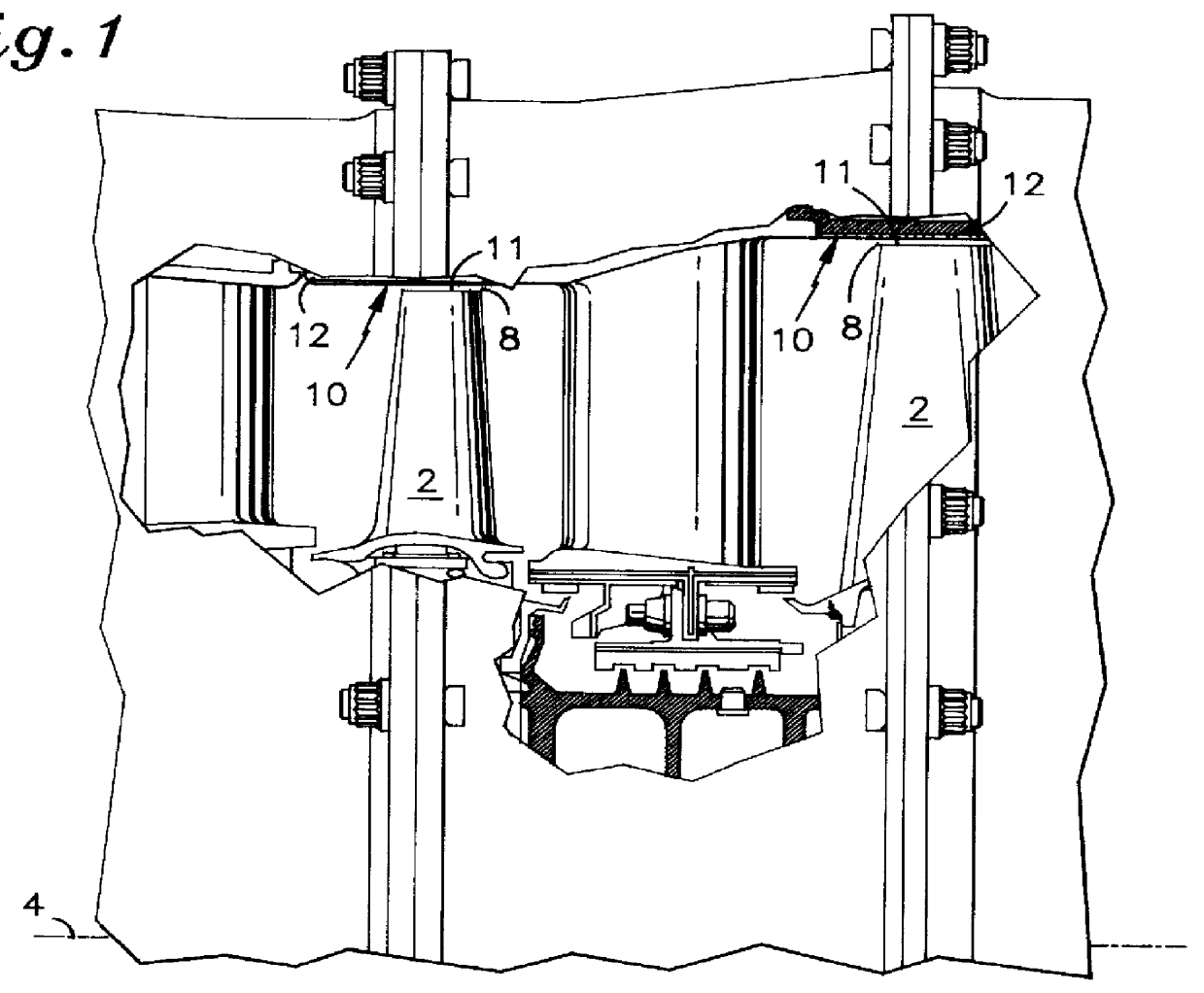

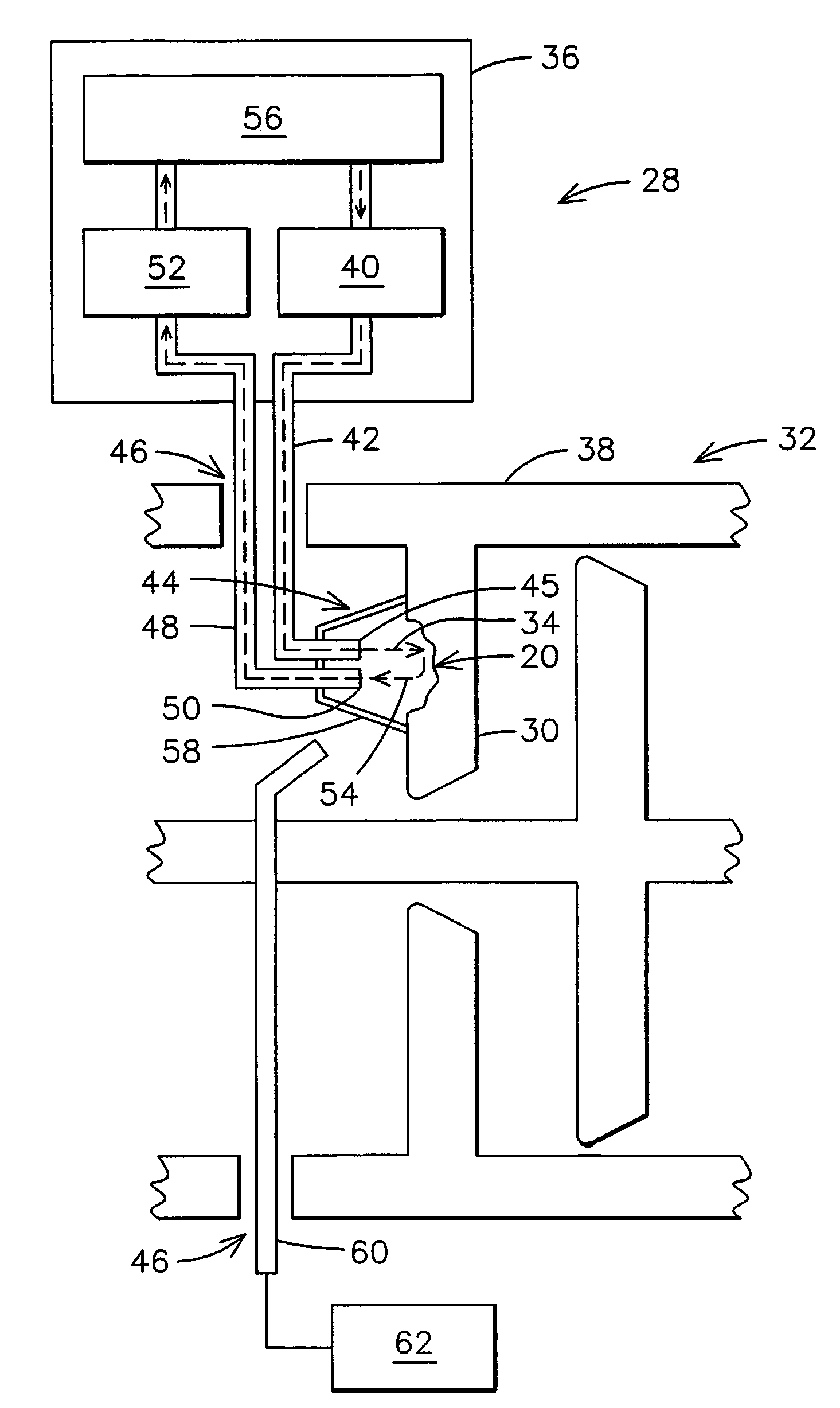

In-frame repairing system of gas turbine components

A method for in-frame repairing of a thermal barrier coating (12) on a gas turbine component includes cleaning a desired surface portion (10) of the component without removing the component from the gas turbine. The method also includes roughening the surface portion in-frame, applying a bond coat (68) to the surface portion in-frame, and applying a ceramic topcoat (70) to the bond coat, in-frame. A system (28) for cleaning the surface portion in-frame includes an abrasive media (34) having a state change characteristic occurring at a temperature lower than an operating temperature of the gas turbine so that the abrasive media changes from a solid state to another state allowing the media to exit the gas turbine during operation. The system also includes an abrasive media sprayer (36) to direct a spray of the abrasive media at the desired surface portion.

Owner:SIEMENS ENERGY INC

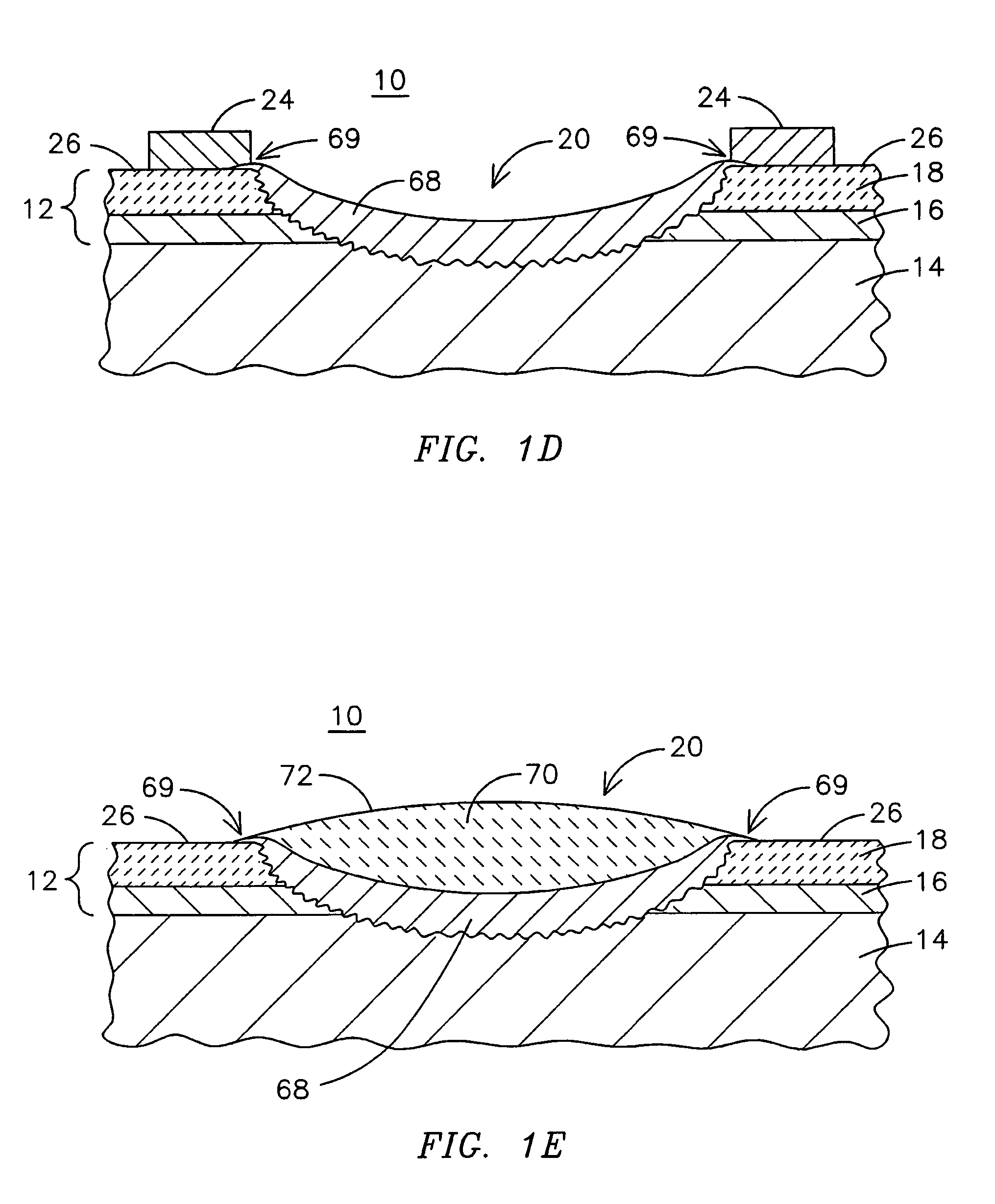

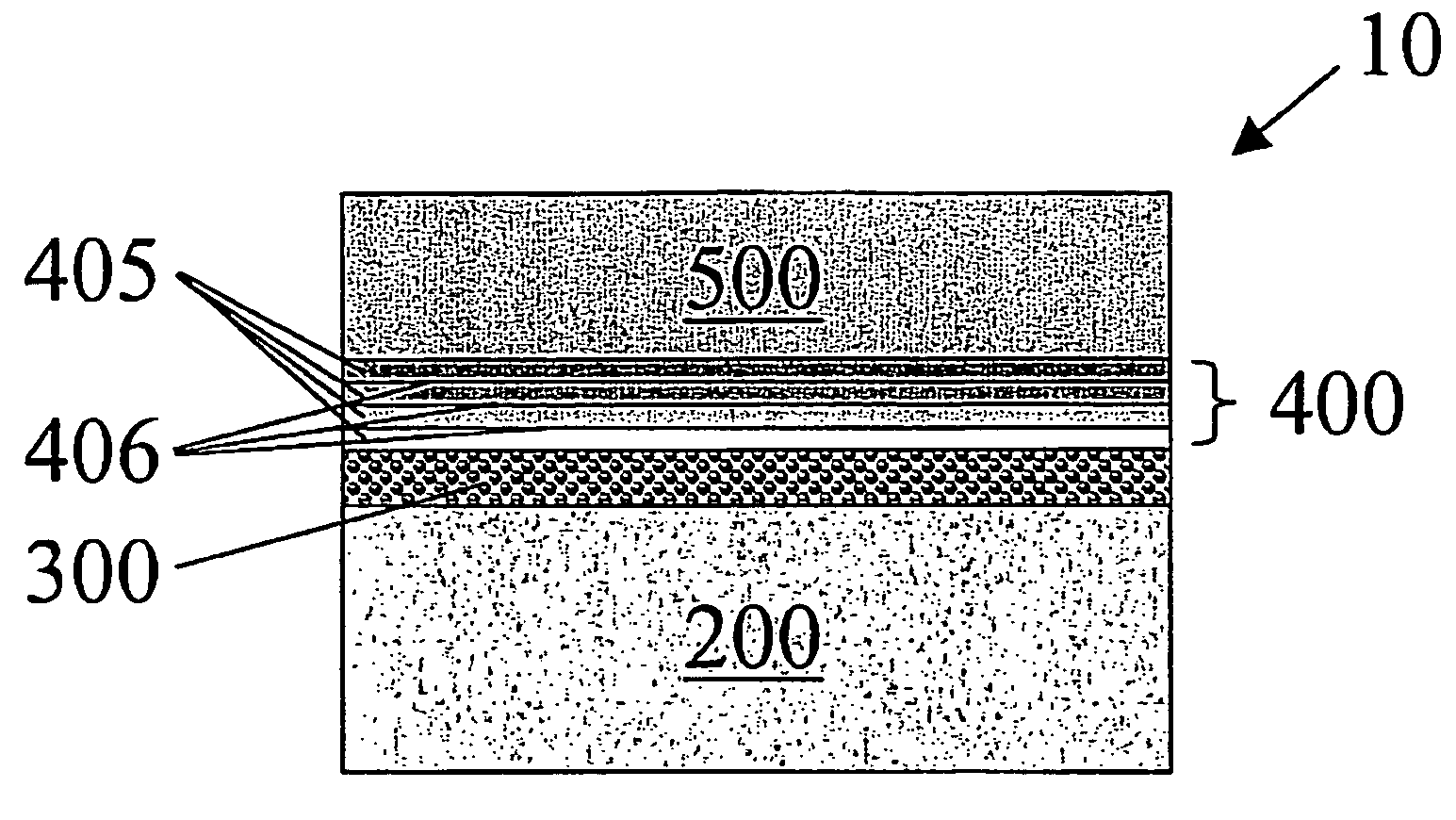

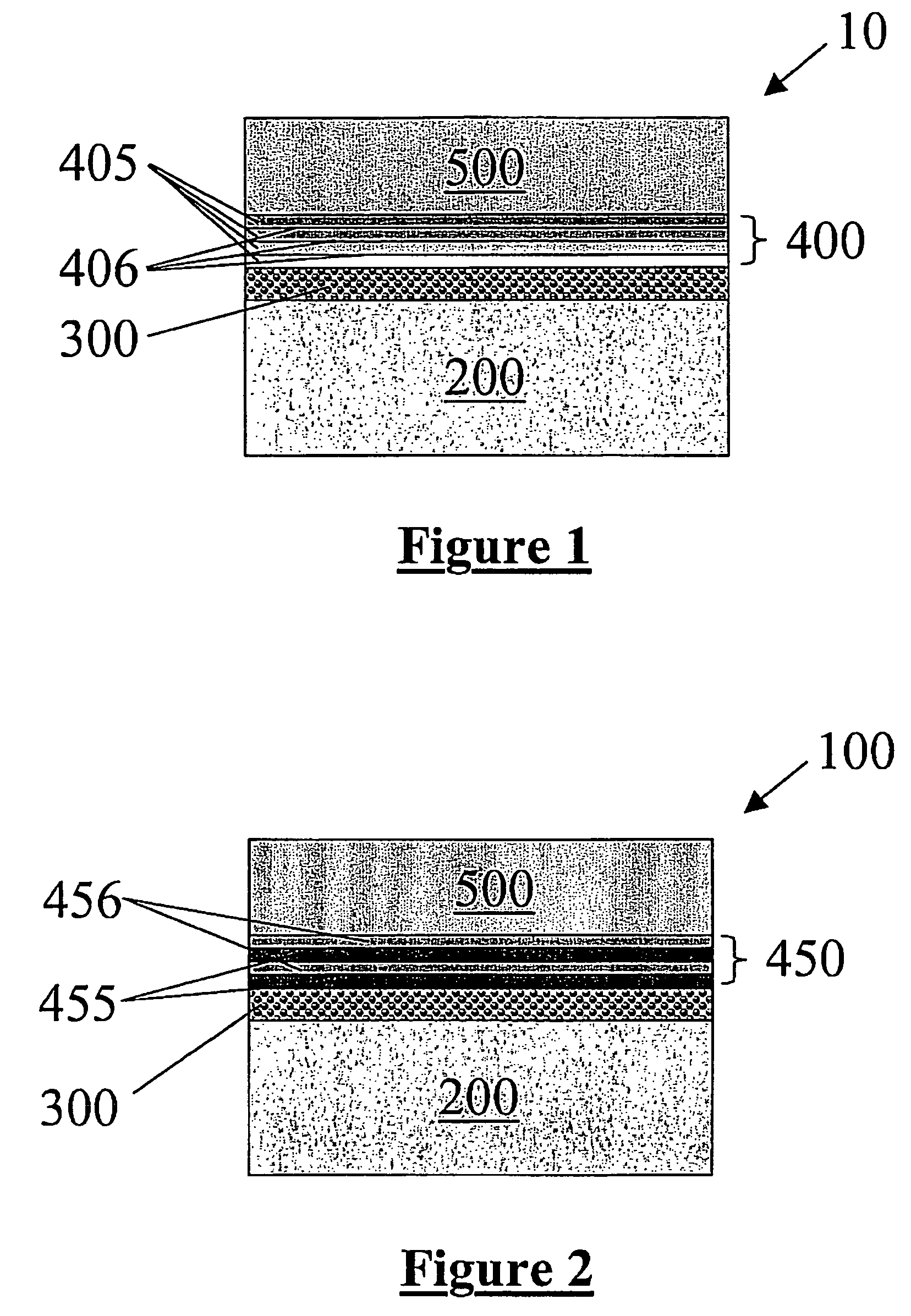

Multifunctionally graded environmental barrier coatings for silicon-base ceramic components

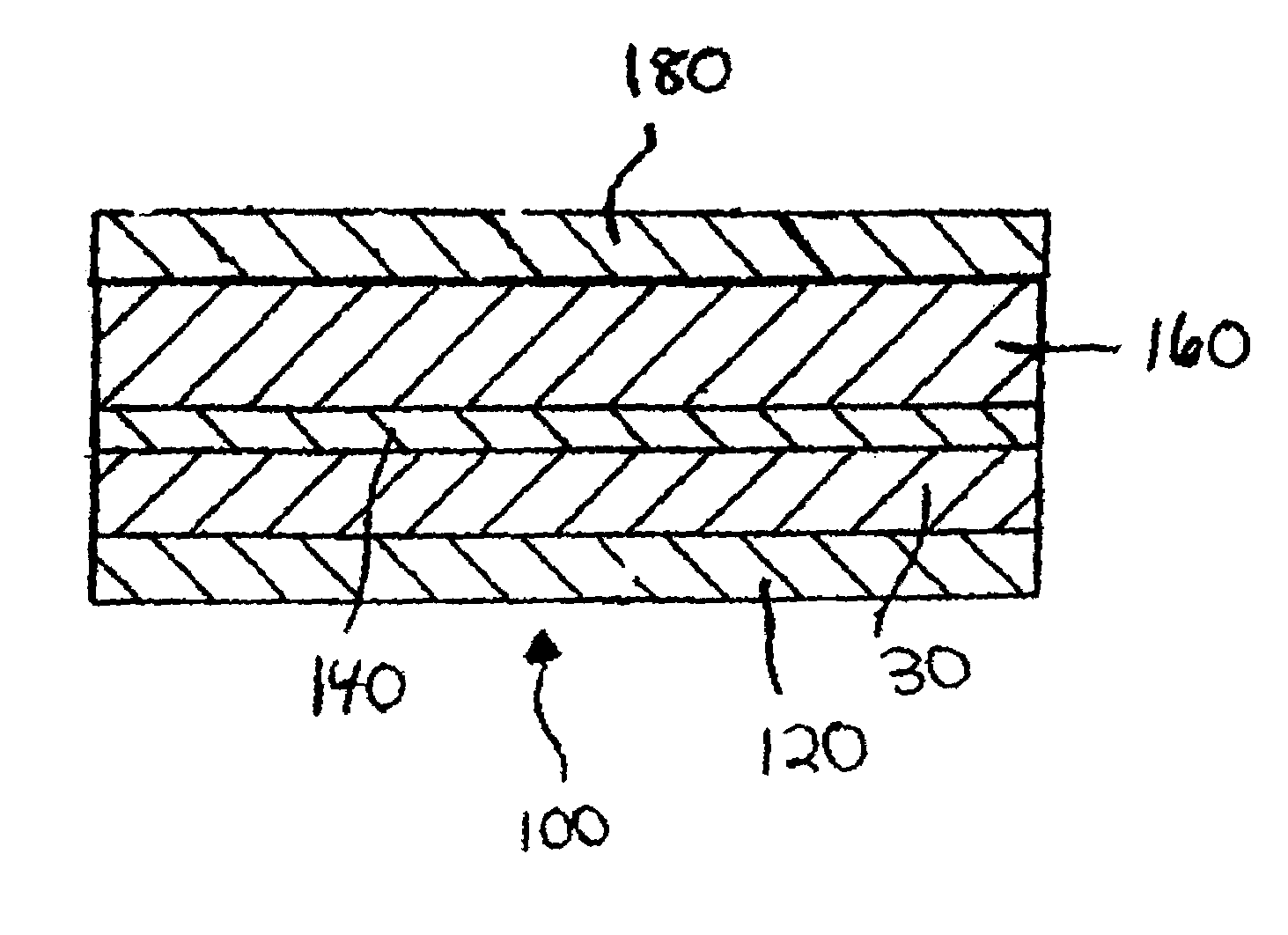

InactiveUS7740960B1Low thermal conductivityIncrease flow ratePropellersReaction enginesCombustionWater vapor

A multilayered coating system consisting of a multicomponent zirconia-base or hafnia-base oxide top layer, an interlayer comprised of a plurality of sublayers and a bond coat layer is provided. The multilayered coating system of the present invention, with an interlayer comprised of a plurality of sublayers, provides a protective coating solution for silicon-base ceramic components exposed to very high temperatures and / or high gas flow velocity water vapor combustion environments. The plurality of sublayers affords for a multitude of interfaces that aid in phonon scattering within the coating system and thereby reduces its thermal conductivity. Furthermore, the plurality of interlayer sublayers afford a strain tolerant buffer between the top layer and substrate and thereby accommodate the thermal expansion mismatch between the oxide top layer (coefficient of thermal expansion (CTE) up to ˜8-10×10−6 m / m-C) and the silicon-base ceramic substrate (CTE≈4-5×10−6 m / m-C).

Owner:ARMY US SEC THE

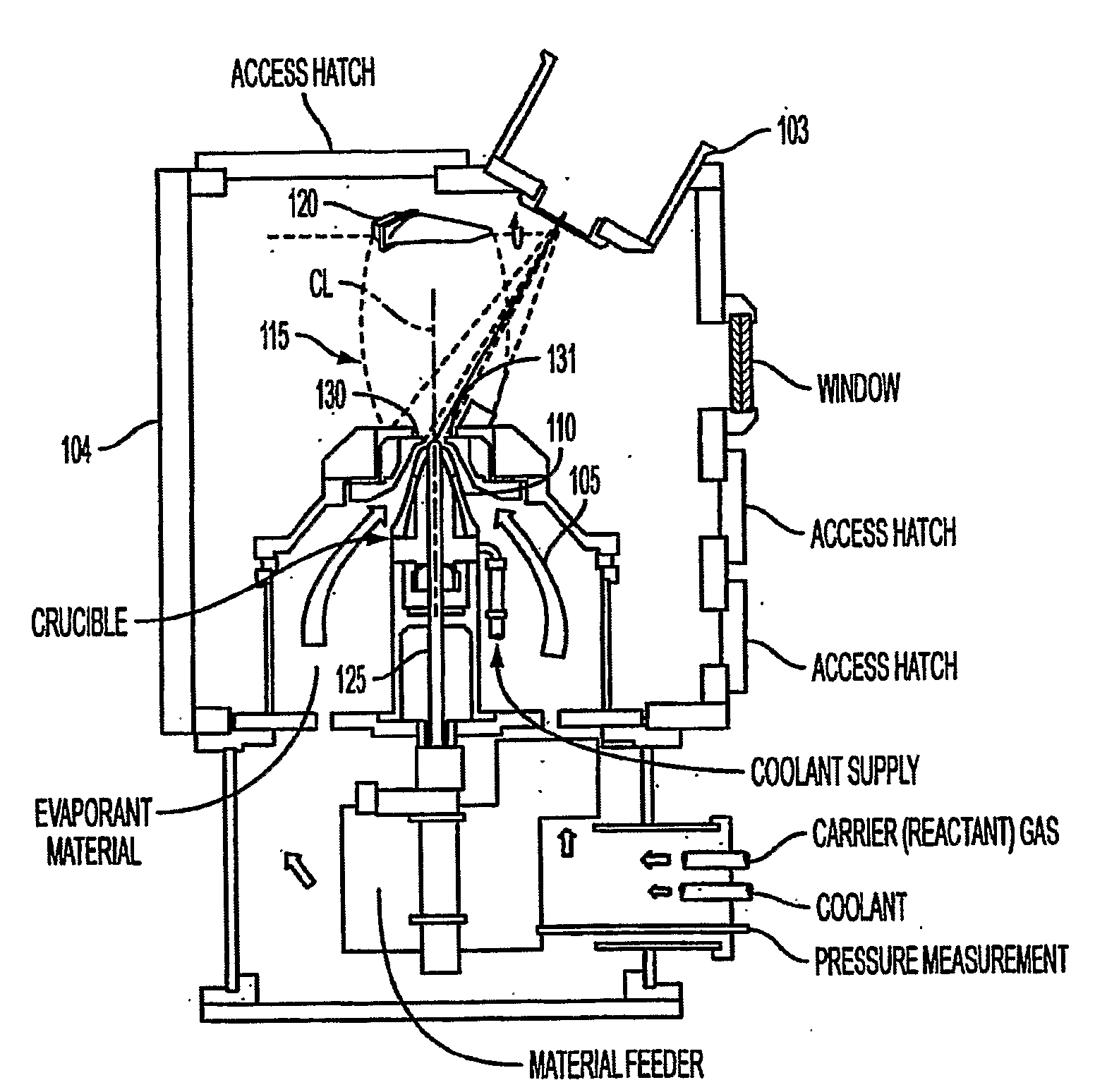

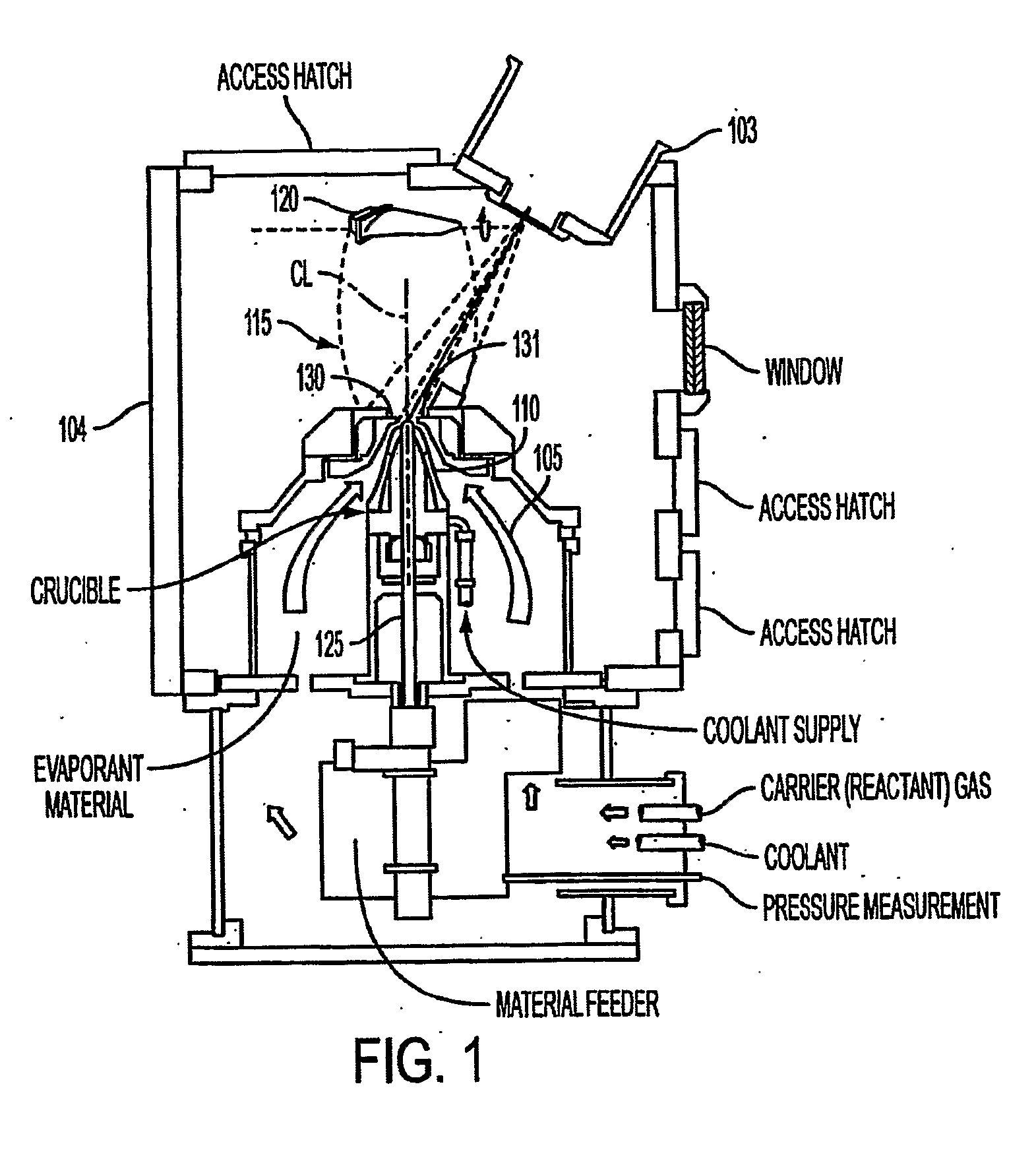

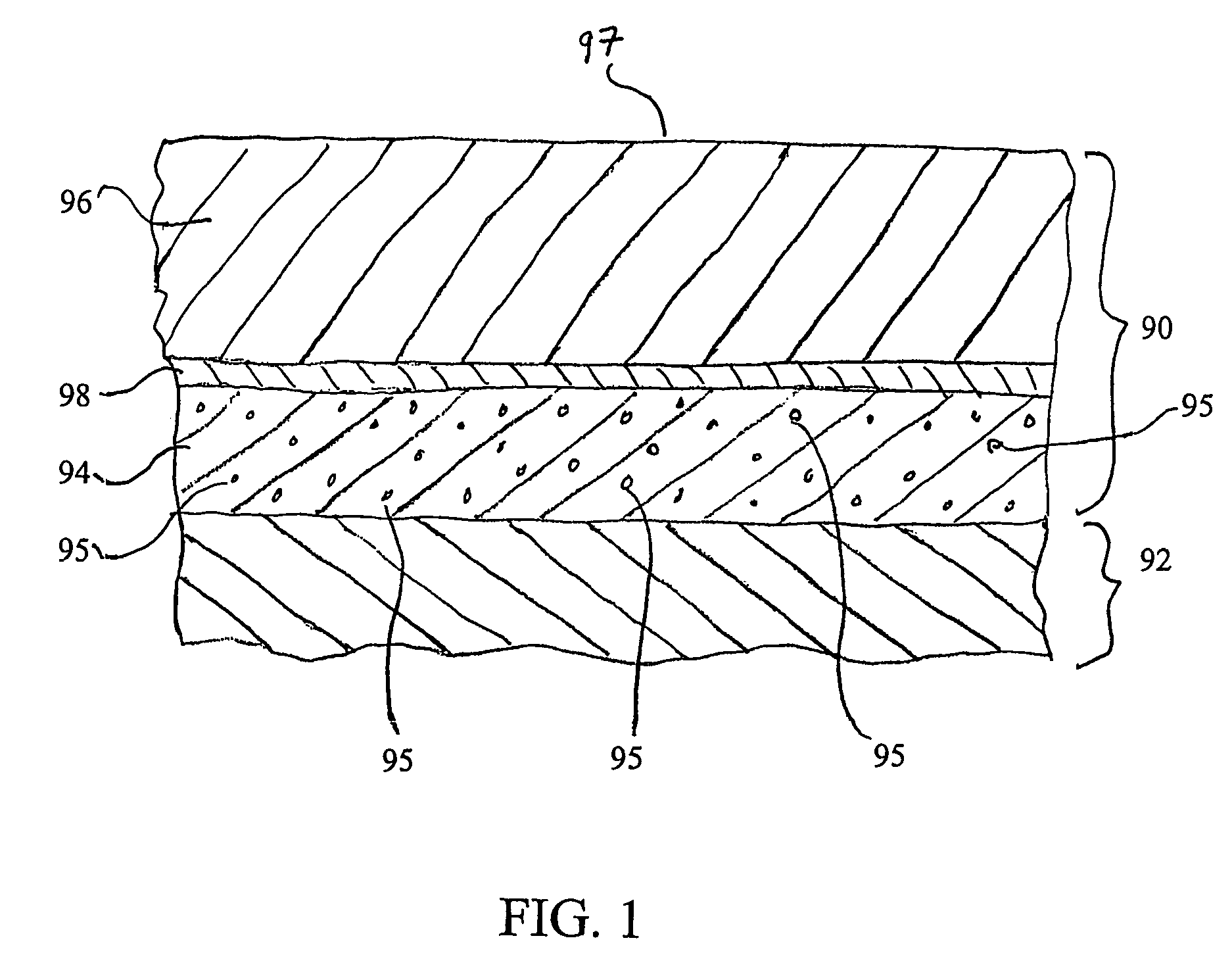

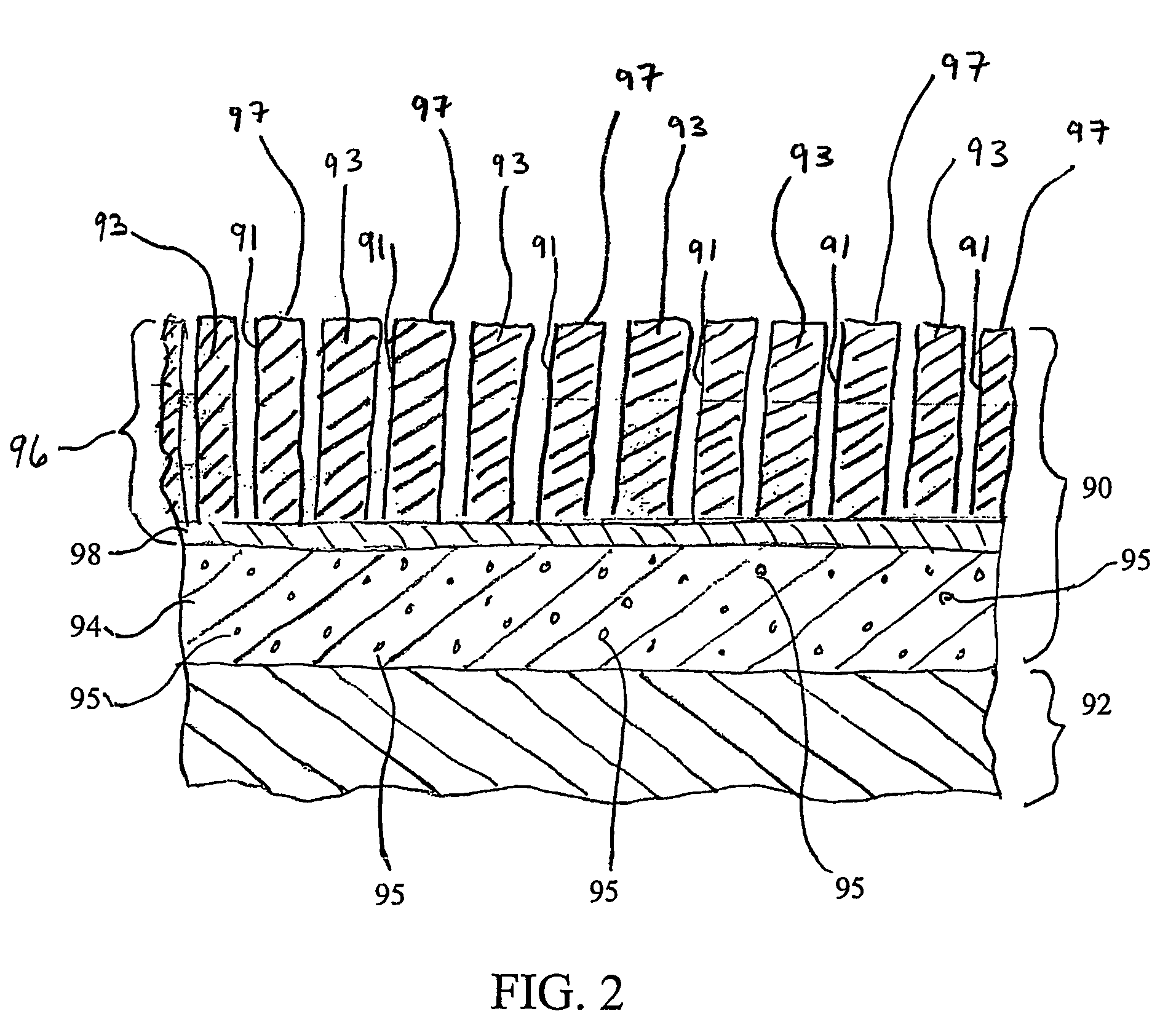

Reliant Thermal Barrier Coating System and Related Methods and Apparatus of Making the Same

ActiveUS20080220177A1Improve performanceLower cost of capitalMolten spray coatingElectric discharge heatingBond coatMaterials science

A method and apparatus for forming a thermal barrier coating system (90) in communication with at least a portion of at least one substrate (92). The method includes: depositing a first bond coat (94) on at least a portion of at least one substrate (92); depositing a first thermal barrier coat (96) disposed on the bond coat (94); whereby the deposition occurs in one or more chambers to form the thermal barrier coating system (90); and wherein the deposition of the first bond coat (94) (or subsequent bond coats) and the deposition of the first thermal barrier coat (96) (or subsequent thermal barrier coats) is performed without out-of-chamber handling of the thermal barrier coating system (90).

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

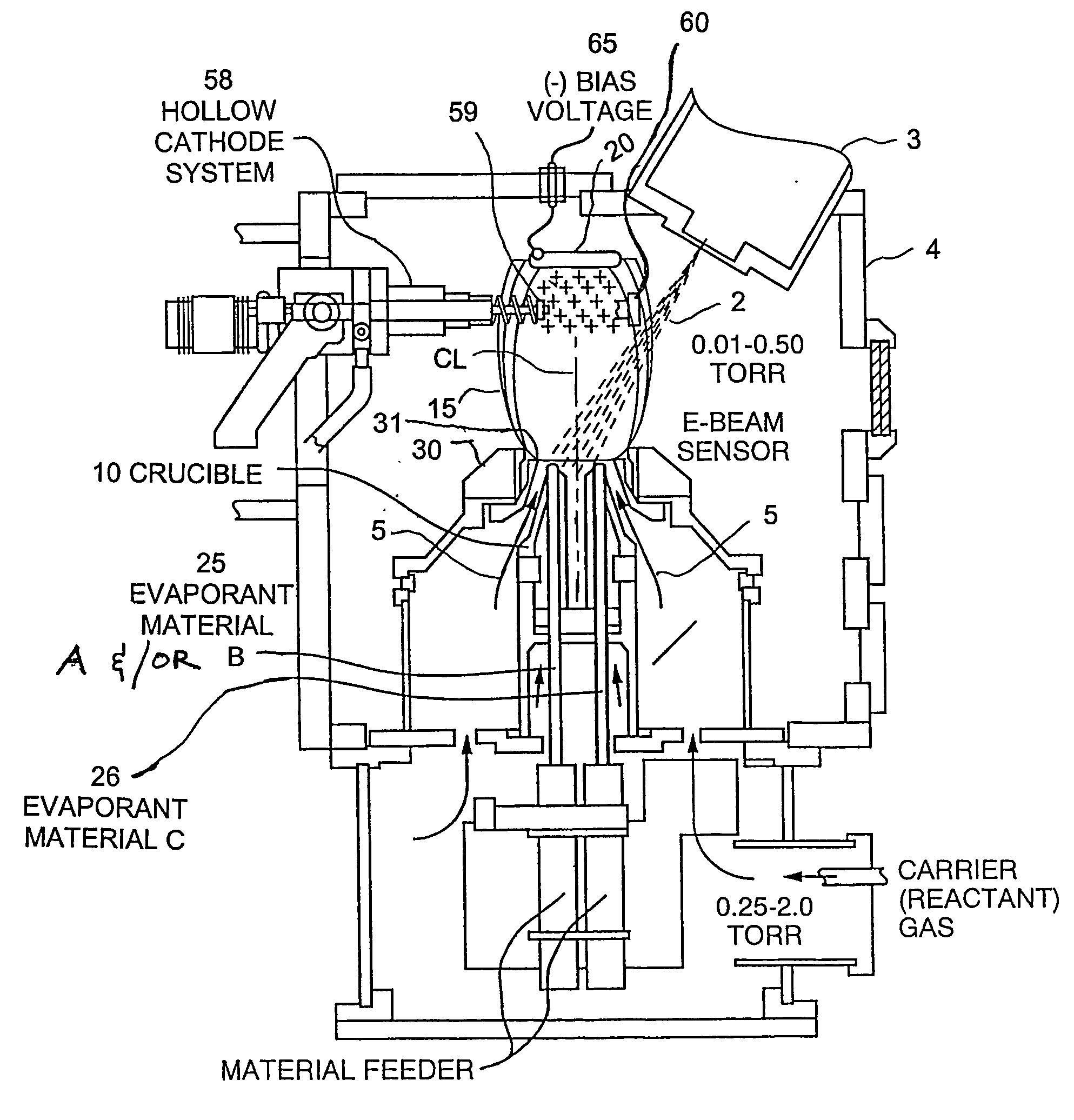

Extremely strain tolerant thermal protection coating and related method and apparatus thereof

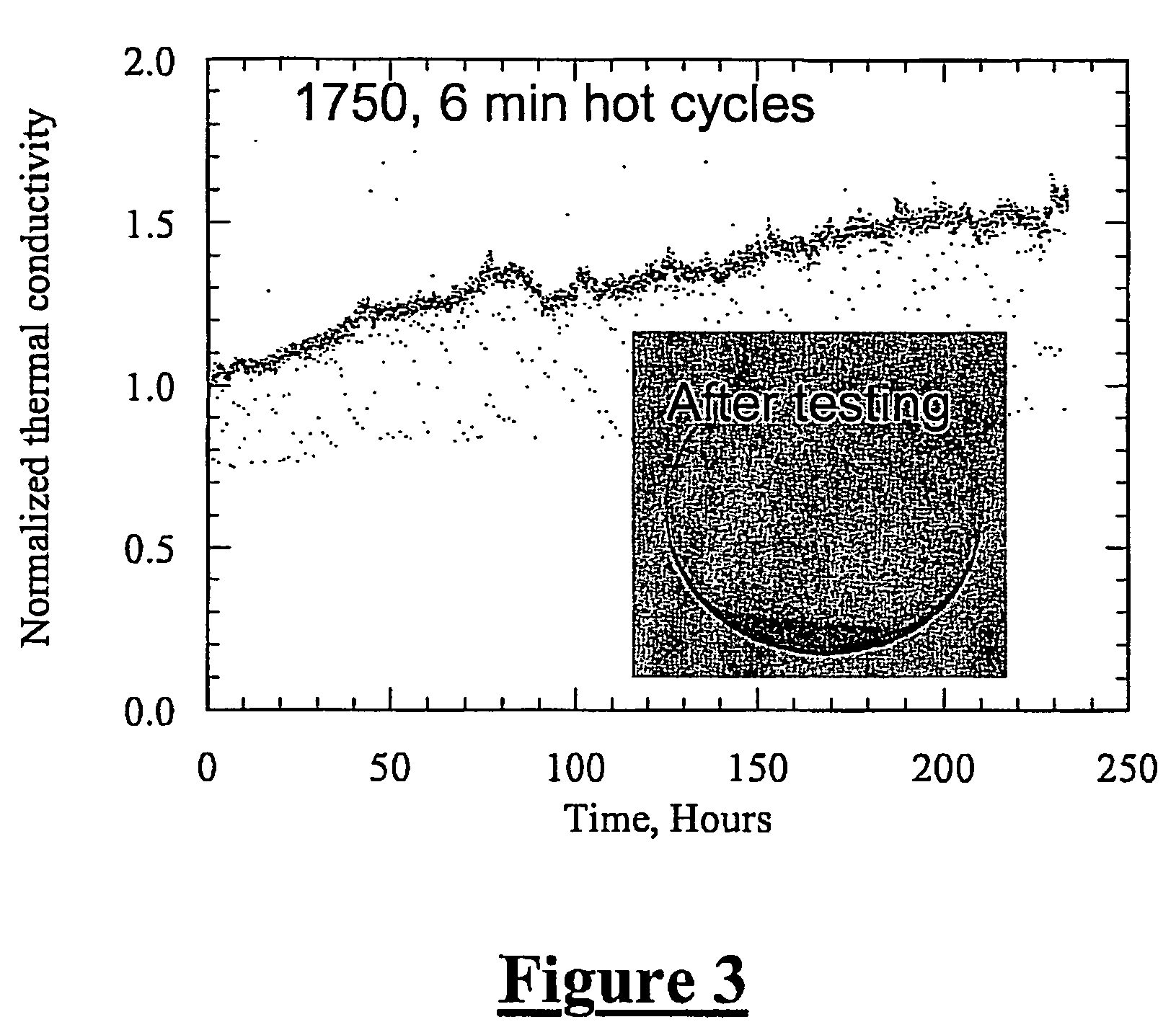

InactiveUS20050266163A1Effective applicationHigh strain toleranceLiquid surface applicatorsMolten spray coatingPorosityHigh rate

Method and Apparatus for efficiently applying coating systems to a surface that can survive the thermal gradient that is encountered in high temperature, high heat flux environments such as a rocket engine or like using vapor or cluster deposition process such as a directed vapor deposition (DVD) approach. Method and Apparatus provides electron or other energetic beam technique to evaporate and deposit compositionally and morphologically controlled bond coats at high rate while providing a highly strain tolerant thermal barrier coating that has an improved porosity morphology between columnar grains.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

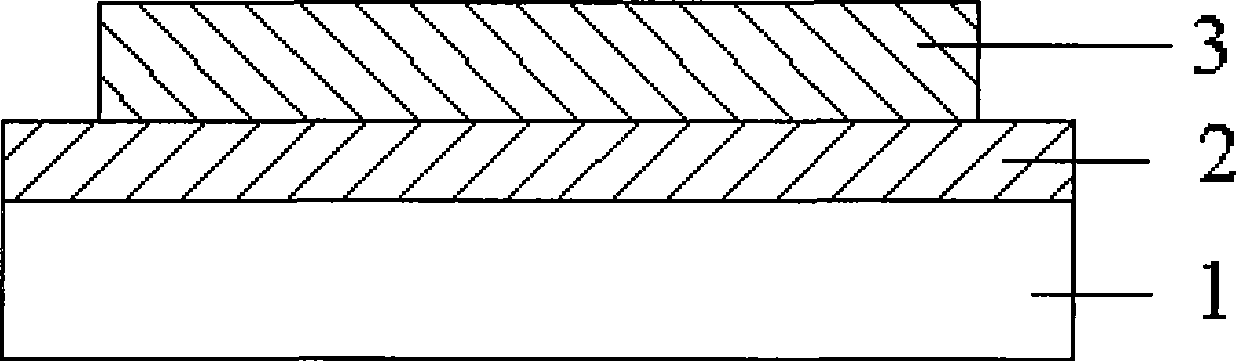

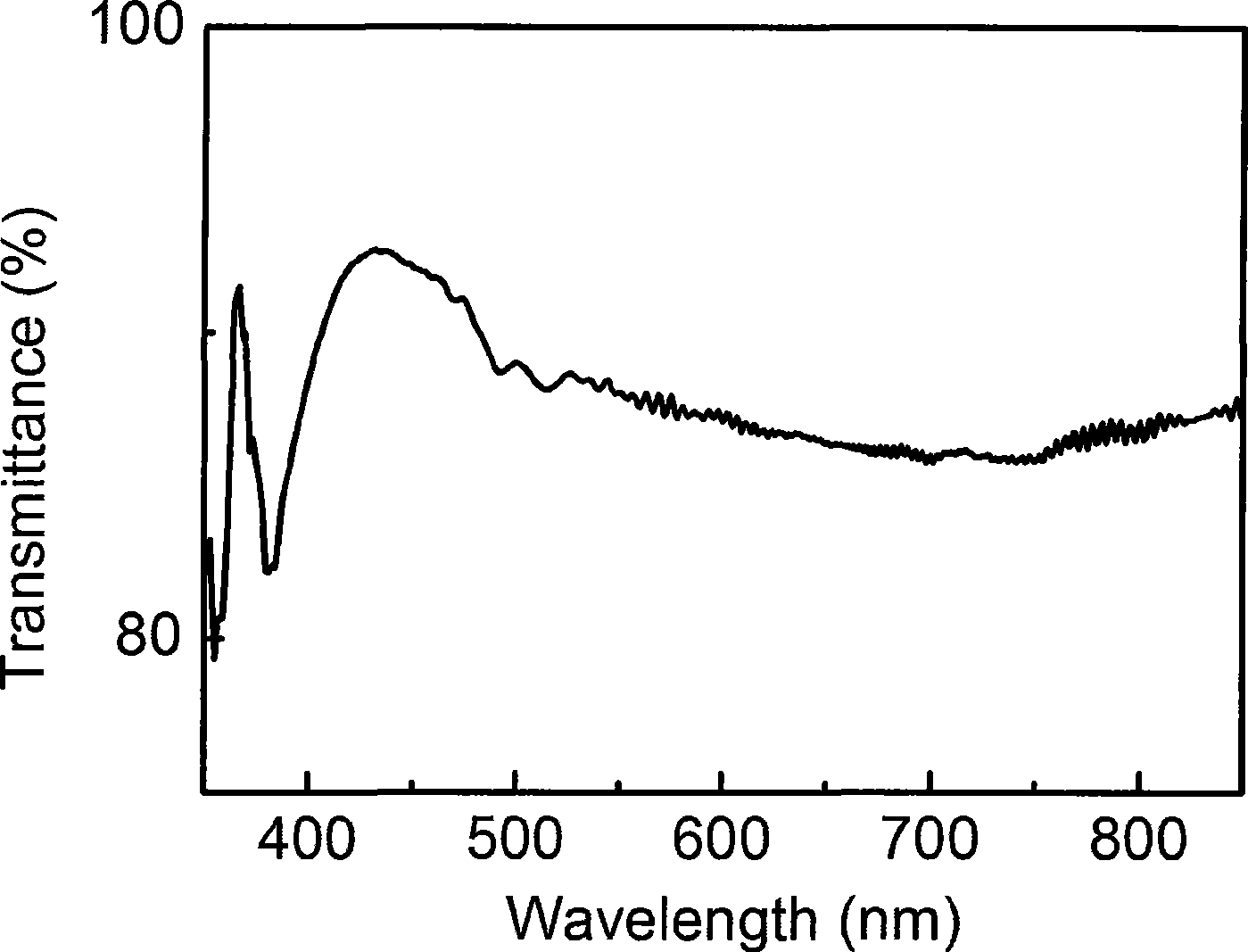

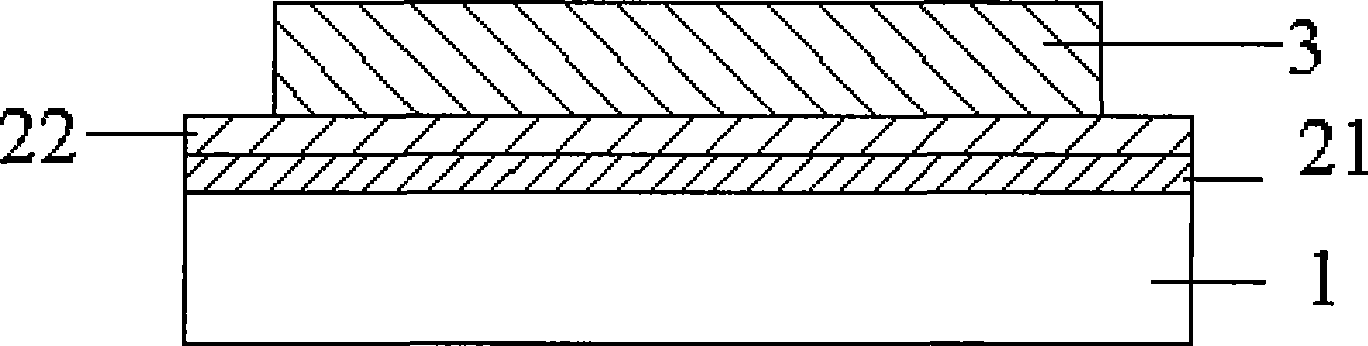

Substrate for flexible organic optoelectronic device and preparation method thereof

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Yttria containing thermal barrier coating topcoat layer and method for applying the coating layer

ActiveUS20080145674A1Reduced and eliminated infiltrationIncrease gas turbine engine component lifePropellersReaction enginesCoating systemBond coating

A gas turbine engine component and coating system including a superalloy substrate having a coating system disposed thereon. A bond coating may be applied to the substrate. An adherent layer of ceramic material forming a thermal barrier coating is present on the bond coat layer. A topcoat layer overlies the thermal barrier coating. The topcoat layer includes greater than about 20 wt % yttria.

Owner:GENERAL ELECTRIC CO

Bond coat for silicon-containing substrate for EBC and processes for preparing same

ActiveUS20060280953A1Improve adhesionHigh melting pointLiquid surface applicatorsMolten spray coatingCalcium silicateAlkaline earth metal

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and typically an environmental barrier coating overlaying the bond coat layer. An article is also provided wherein the environmental barrier coating comprises: (1) an optional inner silica scale layer overlaying the bond coat layer; (2) intermediate layer overlaying the inner silica scale layer, or the bond coat layer in the absence of the inner silica scale layer, and comprising mullite, or a combination of mullite with a barium strontium aluminosilicate, a yttrium silicate, or a calcium aluminosilicate; and (3) an outer steam-resistant barrier layer overlaying the intermediate layer and consisting essentially of an alkaline earth silicate / aluminosilicate. Processes are also provided for forming the silicide-containing bond coat layer over the substrate, followed by forming the environmental barrier coating over the bond coat layer.

Owner:GENERAL ELECTRIC CO

Thermal barrier coatings with improved impact and erosion resistance

InactiveUS6869703B1Increase impactIncrease resistanceMolten spray coatingVacuum evaporation coatingPorosityBond coat

A reduced thermal conductivity thermal barrier coating having improved impact and erosion resistance for an underlying metal substrate of articles that operate at, or are exposed to, high temperatures. This coating comprises a zirconia-containing ceramic composition having a c / a ratio in the range of from about 1.0117 to about 1.0148 and stabilized in the tetragonal phase by a stabilizing amount of a stabilizer metal oxide. The coating has a fraction of porosity of from about 0.10 to about 0.25, and an impact and erosion resistance property defined by at least one of the following formulas: (a) I=exp.[5.85−(144×s)−(3.68×p)]; and / or; (b) E=[187−(261×p)−(9989×s)], wherein s=1.0117−c / a ratio; p is the fraction of porosity; I is least about 140 g / mil; and E is least about 130 g / mil. This coating can be used to provide a thermally protected article having a metal substrate and optionally a bond coat layer adjacent to and overlaying the metal substrate. The thermal barrier coating can be prepared by depositing the zirconia-containing ceramic composition on the bond coat layer, or the metal substrate in the absence of the bond coat layer.

Owner:GENERAL ELECTRIC CO

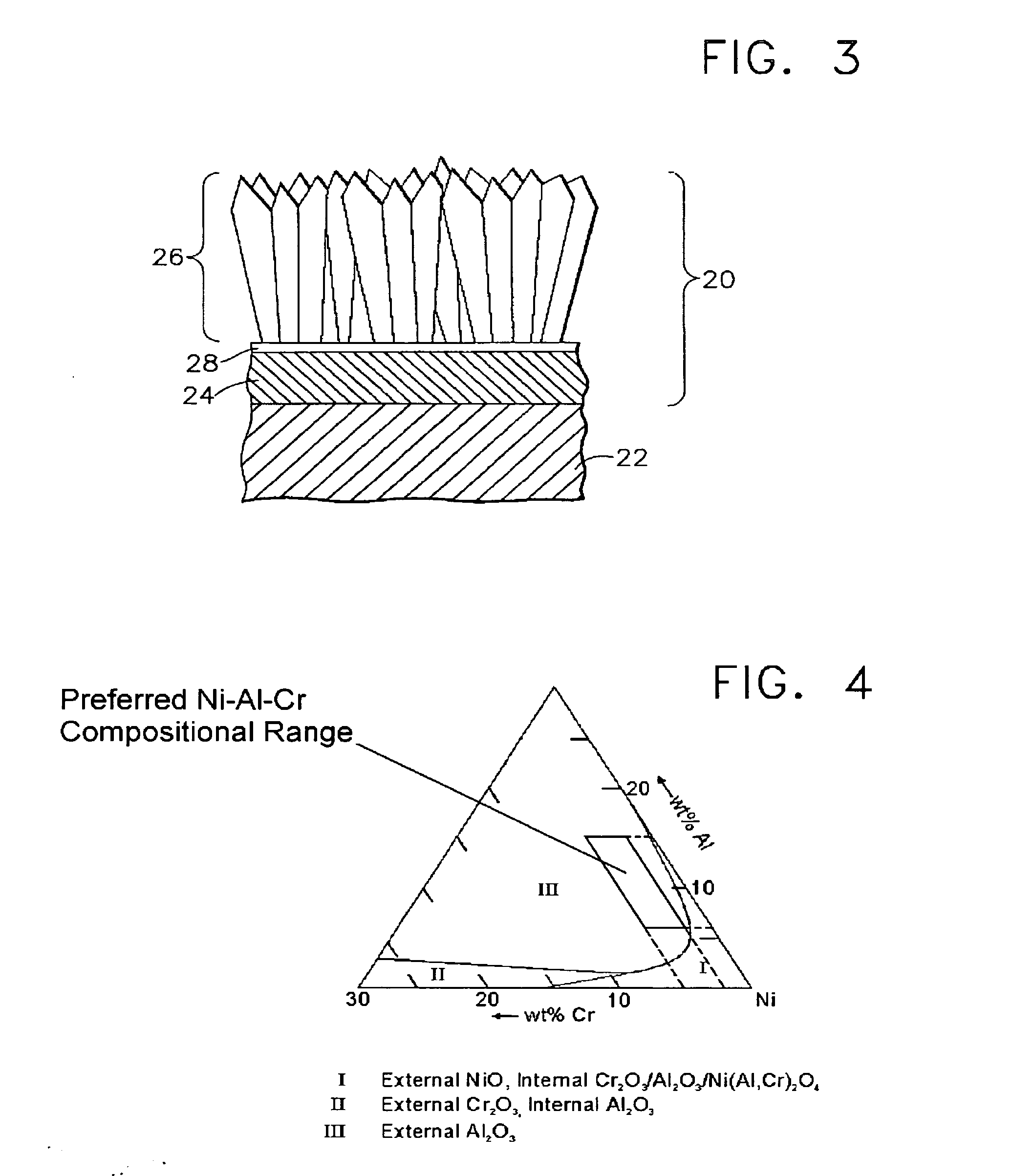

Superalloy article having a gamma-prime nickel aluminide coating

ActiveUS20060093851A1Reduce morbidityInhibited DiffusionPropellersRotary propellersReaction zoneBond coat

An article for use in hostile thermal environments, such as a component of a gas turbine engine. The article includes a nickel-base superalloy substrate that is prone to formation of a deleterious secondary reaction zone (SRZ), and an overlay coating having a predominantly gamma prime-phase nickel aluminide (Ni3Al) composition suitable for use as an environmental coating, including a bond coat for a thermal barrier coating. The coating comprises a chromium-containing nickel aluminide intermetallic overlay coating of predominantly the gamma prime phase, in which aluminum is present in the coating in an amount approximately equal to the aluminum content of the superalloy substrate so as to inhibit diffusion of aluminum from the overlay coating into the superalloy substrate.

Owner:GENERAL ELECTRIC CO

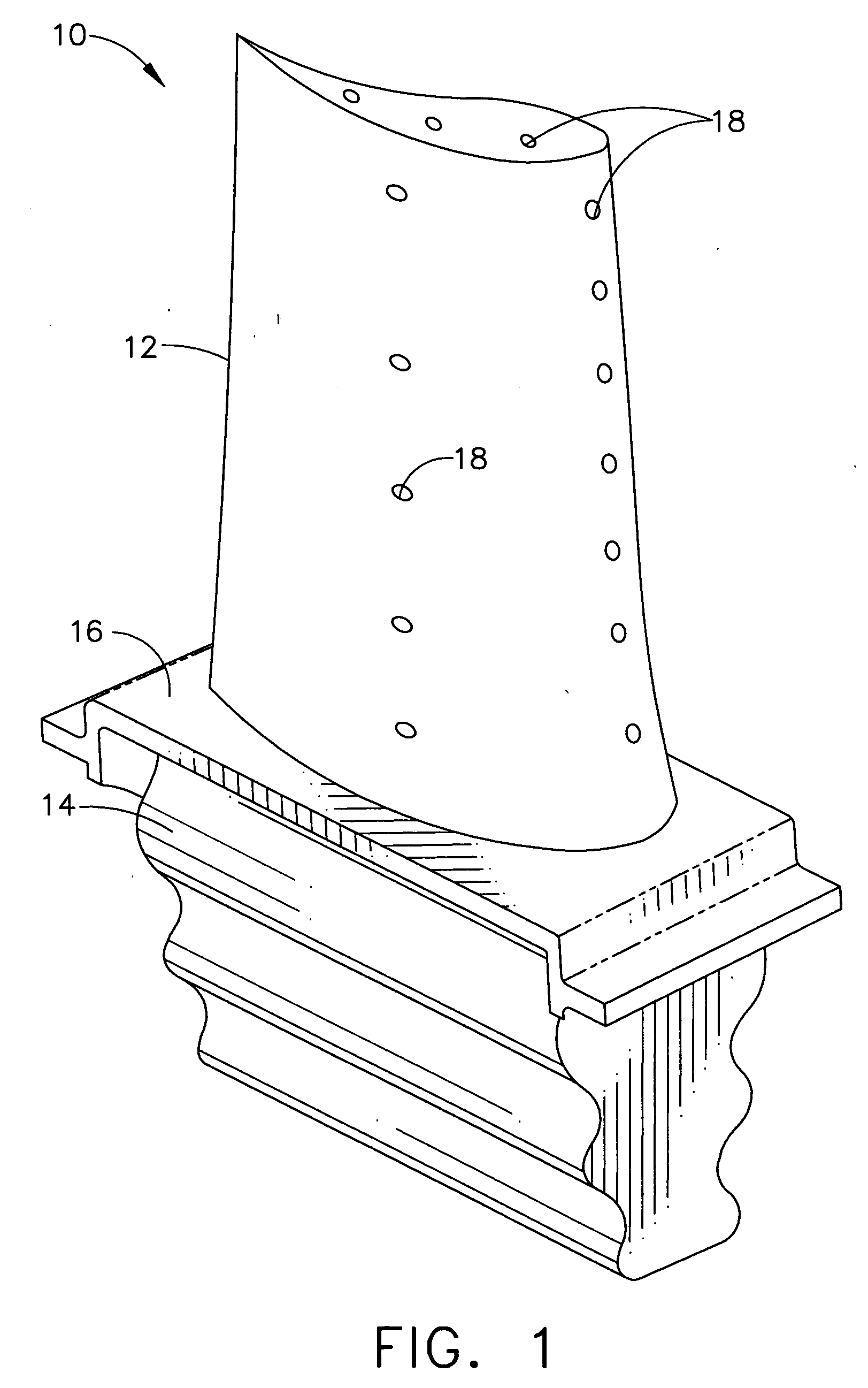

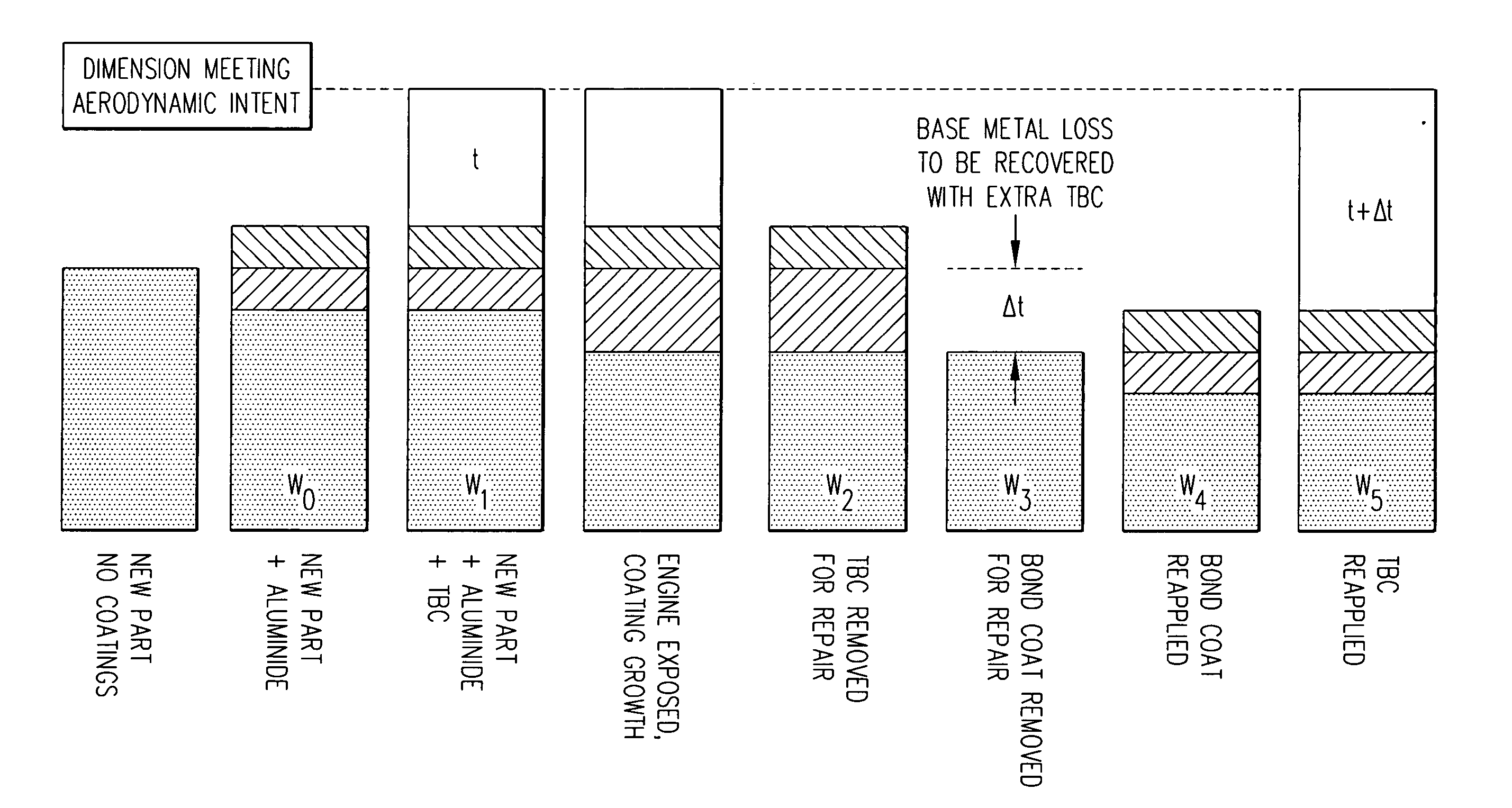

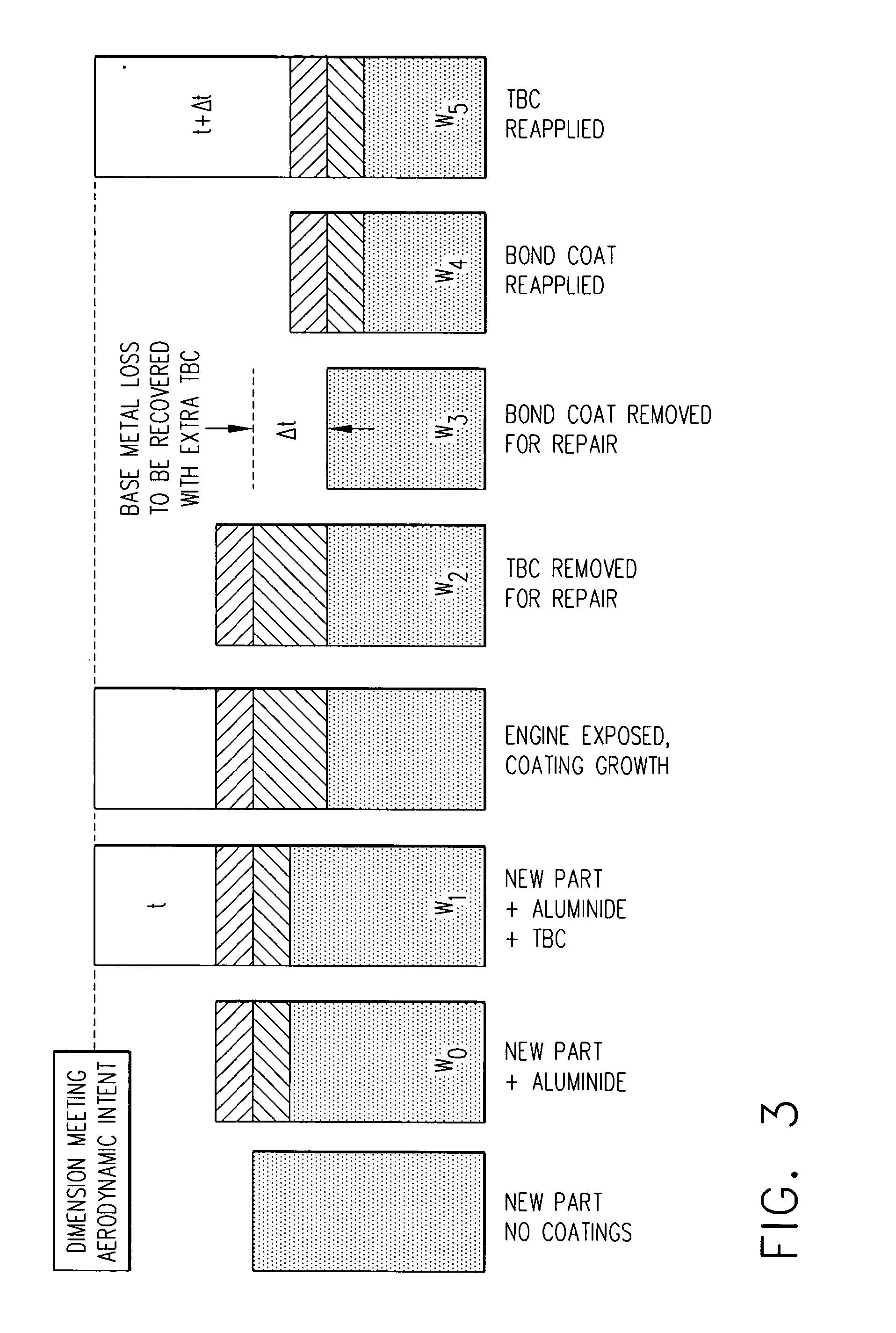

Method for repairing coated components

ActiveUS20050106316A1Increase ceramic spallation lifeReduce coatingMolten spray coatingLayered productsTurbine bladeAlloy

According to an embodiment of the invention, a method for repairing a coated high pressure turbine blade, which has been exposed to engine operation, to restore coated airfoil contour dimensions of the blade, is disclosed. The method comprises providing an engine run high pressure turbine blade including a base metal substrate made of a nickel-based alloy and having thereon a thermal barrier coating system. The thermal barrier coating system comprises a diffusion bond coat on the base metal substrate and a top ceramic thermal barrier coating comprising a yttria stabilized zirconia material. The top ceramic thermal barrier coating has a nominal thickness t. The method further comprises removing the thermal barrier coating system, wherein a portion of the base metal substrate also is removed, and determining the thickness of the base metal substrate removed. The portion of the base metal substrate removed has a thickness, Δt. The method also comprises reapplying the diffusion bond coat to the substrate, wherein the bond coat is reapplied to a thickness, which is about the same as applied prior to the engine operation; and reapplying the top ceramic thermal barrier coating to a nominal thickness of t+Δt, wherein Δt compensates for the portion of removed base metal substrate. Advantageously, the coated airfoil contour dimensions of the high pressure turbine blade are restored to about the coated dimensions preceding the engine run.

Owner:GENERAL ELECTRIC CO

Water based environmental barrier coatings for high temperature ceramic components

Environmental barrier coatings for high temperature ceramic components including: a bond coat layer; an optional silica layer; and at least one transition layer including: from about 85% to about 100% by volume of the transition layer of a primary transition material selected from a rare earth disilicate, or a doped rare earth disilicate; and from 0% to about 15% by volume of the transition layer of a secondary material selected from Fe2O3, iron silicates, rare earth iron oxides, Al2O3, mullite, rare earth aluminates, rare earth aluminosilicates, TiO2, rare earth titanates, Ga2O3, rare earth gallates, NiO, nickel silicates, rare earth nickel oxides, Lnb metals, Lnb2O3, Lnb2Si2O7, Lnb2SiO5, borosilicate glass, alkaline earth silicates, alkaline earth rare earth oxides, alkaline earth rare earth silicates, and mixtures thereof; where the transition layer is applied to the component as a slurry including at least water, the primary transition material and at least one slurry sintering aid, and where a reaction between the slurry sintering aid and the primary transition material results in the transition layer having a porosity of from 0% to about 15% by volume of the transition layer.

Owner:GENERAL ELECTRIC CO

Environmental barrier coating

A coating for a silicon based material such as those used in high temperature environments. An aspect of the invention is directed to an environmental barrier coating including a silicon bond coat, and intermediate coat, and a top coat. The intermediate coat may comprise tantalum aluminate, niobium aluminate, or a mixture of the two. The intermediate coat is resistant to solid-state suburface reactions with the bond coat and the top coat and is substantially inert to reactions with silica at high temperatures.

Owner:GENERAL ELECTRIC CO

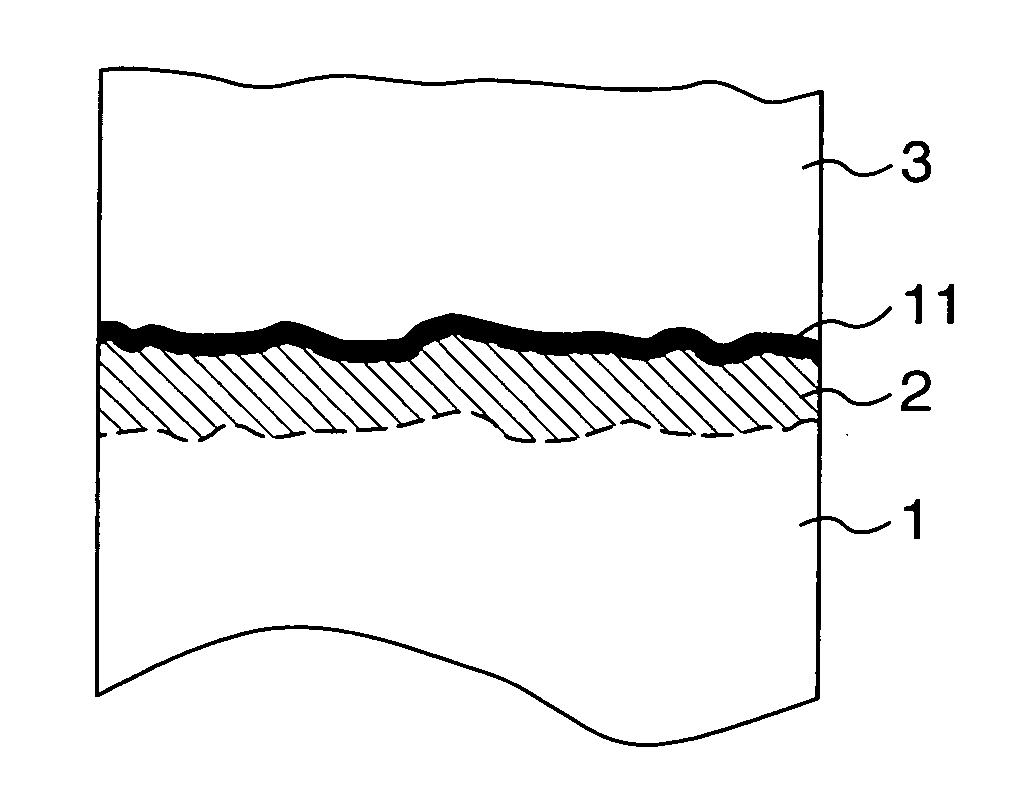

High temperature component with thermal barrier coating and gas turbine using the same

There is provided a high temperature component with a thermal barrier coating, which can be used as a high temperature component for a gas turbine, an aircraft gas turbine engine, or the like. A top coat is formed of a ceramic on a bond coat, the bond coat being formed on a heat resistant alloy substrate composed mainly of at least one element of nickel and cobalt, wherein the bond coat contains at least one of nickel and cobalt, chromium and aluminum, and further contains at least one selected from a group consisting of tantalum, cesium, tungsten, silicon, platinum, manganese and boron in a range of 0 to 20 wt %. The high temperature component according to the present invention has very high durability of a thermal-insulating ceramic layer, and is less susceptible to spalling damage.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY +1

Thermal barrier coating protected by thermally glazed layer and method for preparing same

A thermal barrier coating for an underlying metal substrate of articles that operate at, or are exposed to, high temperatures, as well as being exposed to environmental contaminant compositions. This coating comprises an inner layer nearest to the underlying metal substrate comprising a ceramic thermal barrier coating material having a melting point of at least about 2000° F. (1093° C.), as well as a thermally glazed outer layer having an exposed surface and a thickness up to 0.4 mils (about 10 microns) and sufficient to at least partially protect the thermal barrier coating against environmental contaminants that become deposited on the exposed surface, and comprising a thermally glazeable coating material having a melting point of at least about 2000° F. (1093° C.) in an amount up to 100%. This coating can be used to provide a thermally protected article having a metal substrate and optionally a bond coated layer adjacent to and overlaying the metal substrate. The thermal barrier coating can be prepared by forming the inner layer comprising the ceramic thermal barrier coating material, followed by depositing the thermally glazeable coating material on the inner layer, and then thermally melting the thermally glazeable coating material to form the thermally glazed outer layer.

Owner:GENERAL ELECTRIC CO

Bond coat for silicon-containing substrate for EBC and processes for preparing same

ActiveUS7442444B2Improve adhesionHigh melting pointMolten spray coatingVacuum evaporation coatingCalcium silicateAlkaline earth metal

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and typically an environmental barrier coating overlaying the bond coat layer. An article is also provided wherein the environmental barrier coating comprises: (1) an optional inner silica scale layer overlaying the bond coat layer; (2) intermediate layer overlaying the inner silica scale layer, or the bond coat layer in the absence of the inner silica scale layer, and comprising mullite, or a combination of mullite with a barium strontium aluminosilicate, a yttrium silicate, or a calcium aluminosilicate; and (3) an outer steam-resistant barrier layer overlaying the intermediate layer and consisting essentially of an alkaline earth silicate / aluminosilicate. Processes are also provided for forming the silicide-containing bond coat layer over the substrate, followed by forming the environmental barrier coating over the bond coat layer.

Owner:GENERAL ELECTRIC CO

Chromium nitride aluminum-titanium composite coating, cutter deposited with same, and preparation method

InactiveCN102166849AHigh hardnessStrong adhesionVacuum evaporation coatingSputtering coatingOxidation resistantHigh surface

The invention discloses a chromium nitride aluminum-titanium composite coating, a cutter deposited with the same, and a preparation method. A Cr bonding layer, a CrN supporting layer and a main wear-resistant layer are sequentially deposited on a cutter substrate, wherein the main wear-resistant layer is a multi-layer composite coating composed of a TiAlN layer in a nanocrystalline structure and a CrTiAlN layer in a superlattice structure in an alternate mode, thereby obtaining the cutter with the chromium nitride aluminum-titanium composite coating. The chromium nitride aluminum-titanium composite coating provided by the invention combines the advantages of high hardness, low friction coefficient, strong adhesive force and high oxidation resistance temperature of the superlattice structure and nanocrystalline structure. The obtained cutter has high surface hardness, relatively strong film-base adhesive force, good wear resistance and good high temperature resistance.

Owner:YICHANG HOUHUANG VACUUM TECH

Coating system for silicon based substrates

ActiveUS20070014996A1Reduction in substrate strengthReduces stored elastic strain energyLiquid surface applicatorsMolten spray coatingCoating systemOxygen

Owner:RAYTHEON TECH CORP

Bond coat for corrosion resistant EBC for silicon-containing substrate and processes for preparing same

ActiveUS7354651B2Improve adhesionHigh melting pointMolten spray coatingPropellersBond coatCorrosion resistant

Owner:GENERAL ELECTRIC CO

Chromium and active elements modified platinum aluminide coatings

ActiveUS7229701B2Promote oxidationIncrease resistanceVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionGas phase

The present invention provides a chromium and active elements modified platinum aluminide coating that may be used on a surface of a gas turbine engine component such as a turbine blade. The coating may be used as a protective coating that impedes the progress of corrosion, oxidation, and sulfidation in superalloy materials that comprise the substrate of the turbine blade. Additionally, the coating may be used as a bond coat onto which a thermal barrier coating is deposited. The presence of active elements as well as chromium and platinum provides improved corrosion, oxidation, and sulfidation resistance. The coating is applied using an electron beam physical vapor deposition. The coating is applied alternatively using selected sequential diffusion processing steps involving chromium, platinum and aluminum.

Owner:HONEYWELL INT INC

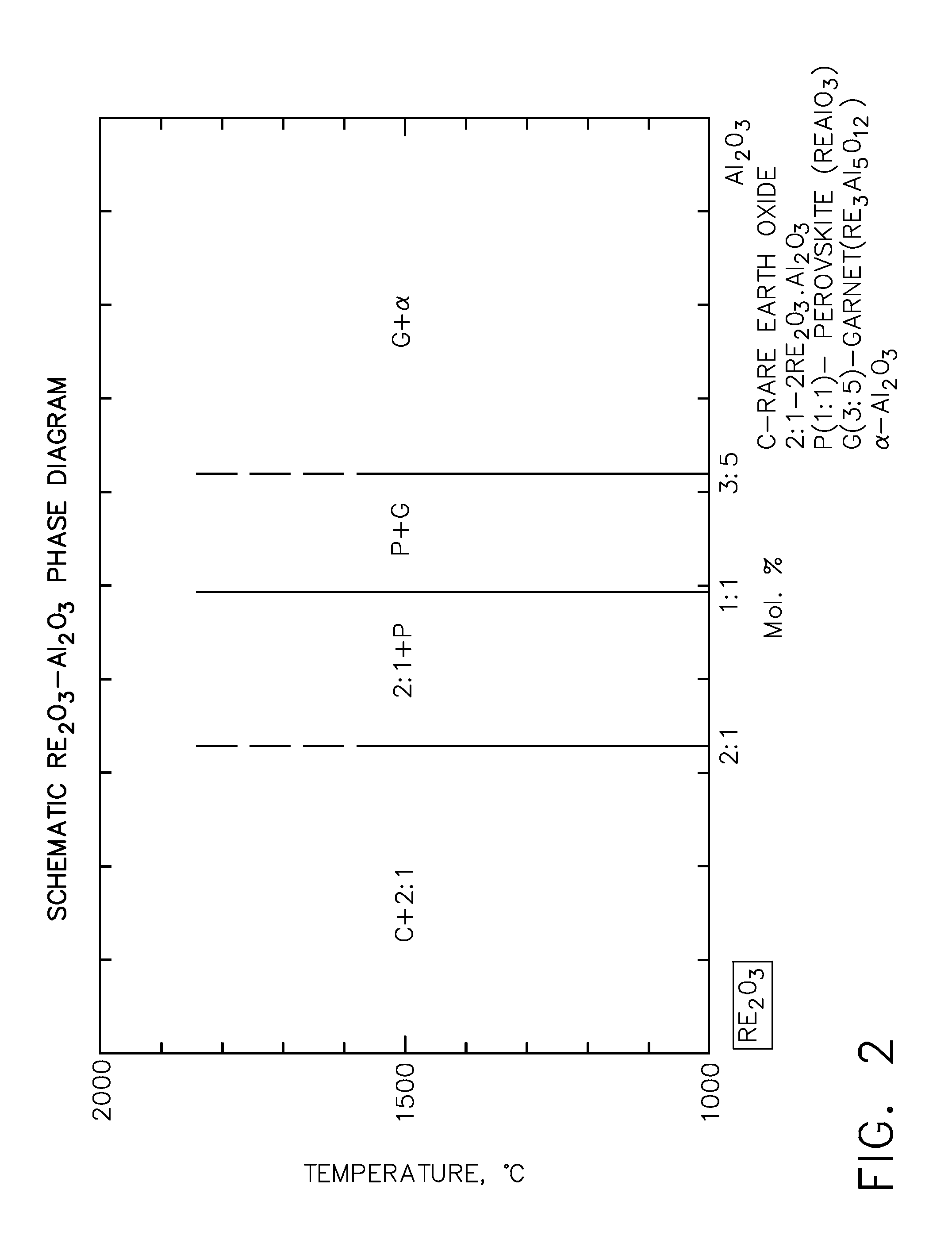

Thermal Barrier Coating Systems Including a Rare Earth Aluminate Layer for Improved Resistance to CMAS Infiltration and Coated Articles

ActiveUS20090169914A1Efficient propulsion technologiesNatural mineral layered productsRare earthBond coat

Thermal barrier coating systems for use with hot section components of a gas turbine engine include an inner layer overlying a bond coated substrate and a top layer overlying at least a portion of the inner layer. The inner layer includes a thermal barrier material such as yttria-stabilized zirconia. The top layer includes a rare earth aluminate. The thicknesses and microstructures of the layers may be varied depending on the type of component to be coated. Articles incorporating the thermal barrier coating system exhibit improved resistance to CMAS infiltration

Owner:GENERAL ELECTRIC CO

CMAS resistant thermal barrier coating

ActiveUS20070172703A1Reduce componentsReduces sand related distressMolten spray coatingBlade accessoriesIndiumCerium

A turbine engine component is provided which has a substrate and a thermal barrier coating applied over the substrate. The thermal barrier coating comprises alternating layers of yttria-stabilized zirconia and a molten silicate resistant material. The molten silicate resistant outer layer may be formed from at least one oxide of a material selected from the group consisting of lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, scandium, indium, zirconium, hafnium, and titanium or may be formed from a gadolinia-stabilized zirconia. If desired, a metallic bond coat may be present between the substrate and the thermal barrier coating system. A method for forming the thermal barrier coating system of the present invention is described.

Owner:RTX CORP

Coating Systems for Protection of Substrates Exposed to Hot and Harsh Environments and Coated Articles

InactiveUS20110151219A1Reduce the effectUsed in environmentContinuous combustion chamberMolten spray coatingCoating systemOxygen

Coating system for reducing CMAS infiltration of substrates includes at least an inner ceramic layer and an outer alumina-containing layer. The outer layer includes up to 50 percent by weight titania. Additional ceramic layers and alumina-containing layers may be provided. The coating may be used for gas turbine engine components. Deposition techniques for the coating layers may depend on the end use of the component. Coated articles include a substrate, an optional bond coat on the substrate and a coating over the bond coat or on at least a portion of the substrate in the absence of a bond coat. The inner ceramic layer(s) exhibit a microstructure indicative of a deposition technique selected from thermal spray, physical vapor deposition, and suspension plasma spray, whereas the outer alumina-containing layer exhibits a microstructure indicative of suspension plasma spray, solution plasma spray, and a high velocity oxygen fuel spray.

Owner:GENERAL ELECTRIC CO

Coating system for silicon based substrates

ActiveUS7374818B2Reduced strengthReduces stored elastic strain energyLiquid surface applicatorsElectric shock equipmentsCoating systemOxygen

Owner:RTX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com