Patents

Literature

587 results about "Phase composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A phase is a set of states of a macroscopic physical system that have relatively uniform chemical composition and physical properties (i.e. density, crystal structure, index of refraction, and so forth). The most familiar examples of phases are solids, liquids, and gases. Less familiar phases include: plasmas and quark-gluon plasmas;

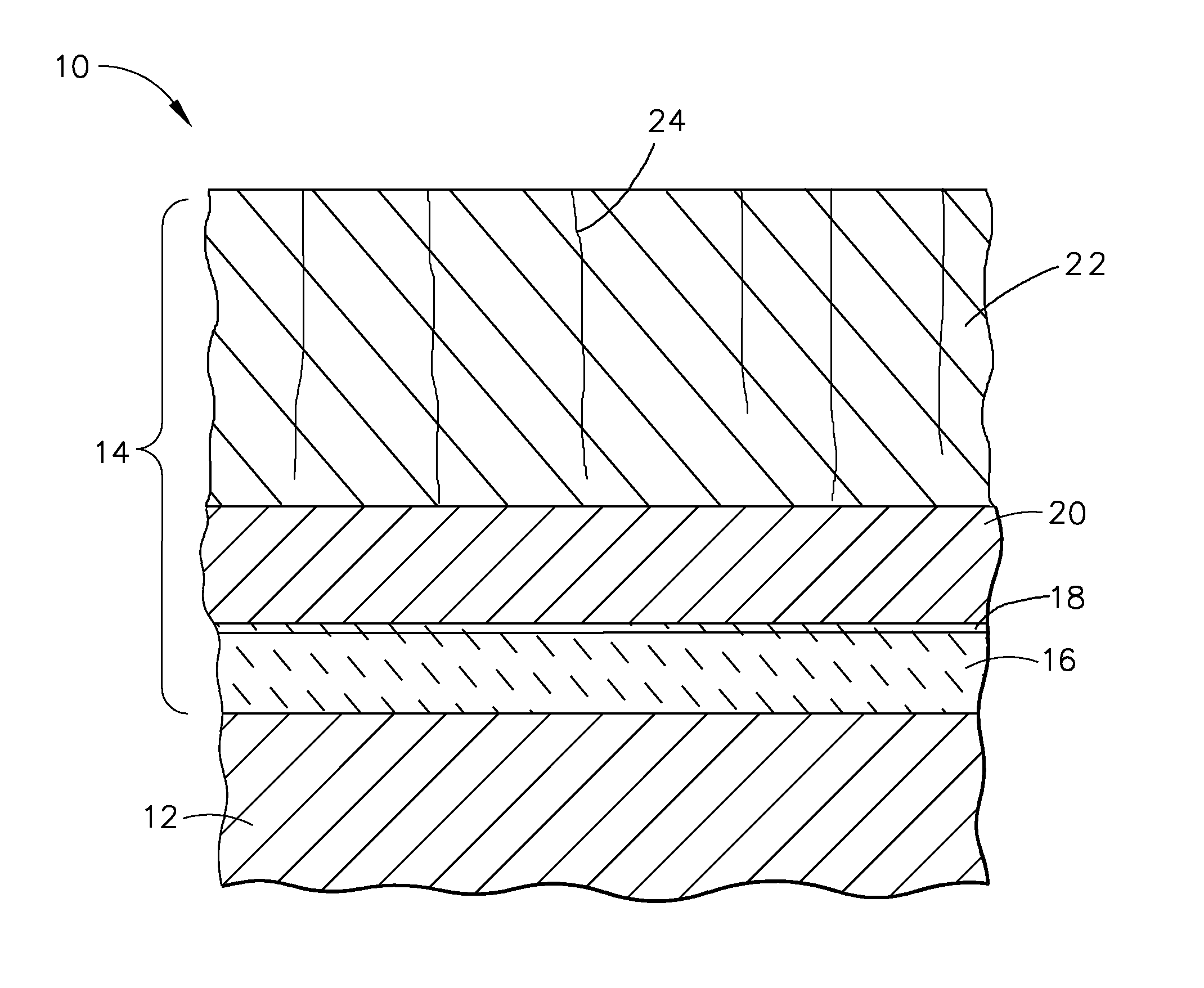

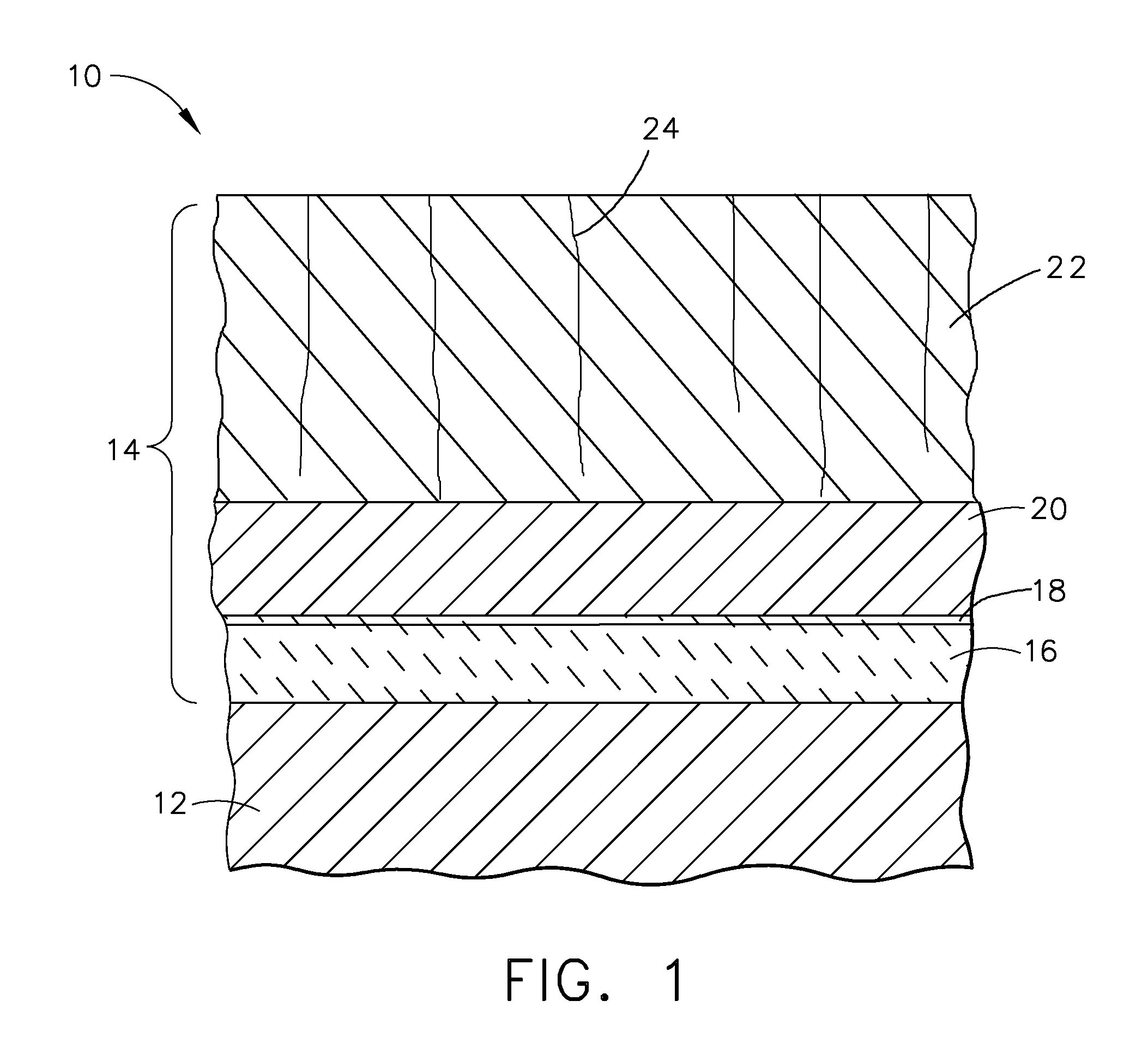

Thermal barrier coating system

ActiveUS20050170200A1Avoid low surface temperaturesInferior erosion resistancePropellersMolten spray coatingThermal sprayingMetallurgy

A TBC system suitable for protecting the surface of a substrate subjected to a hostile thermal environment. The TBC system comprises a bond coat on the substrate surface, an alumina scale on the bond coat, and a multilayer TBC comprising a thermal-sprayed first ceramic layer on the alumina scale and a thermal-sprayed second ceramic layer overlying the first ceramic layer. The first ceramic layer consists essentially of partially stabilized zirconia so as to comprise the tetragonal and cubic phases of zirconia. The second ceramic layer consists essentially of fully stabilized zirconia so as to consist essentially of the cubic phase of zirconia. The second ceramic layer is also characterized by having vertical microcracks that extend through the thickness thereof. The second ceramic layer is thicker and more erosion resistant than the first ceramic layer.

Owner:GENERAL ELECTRIC CO

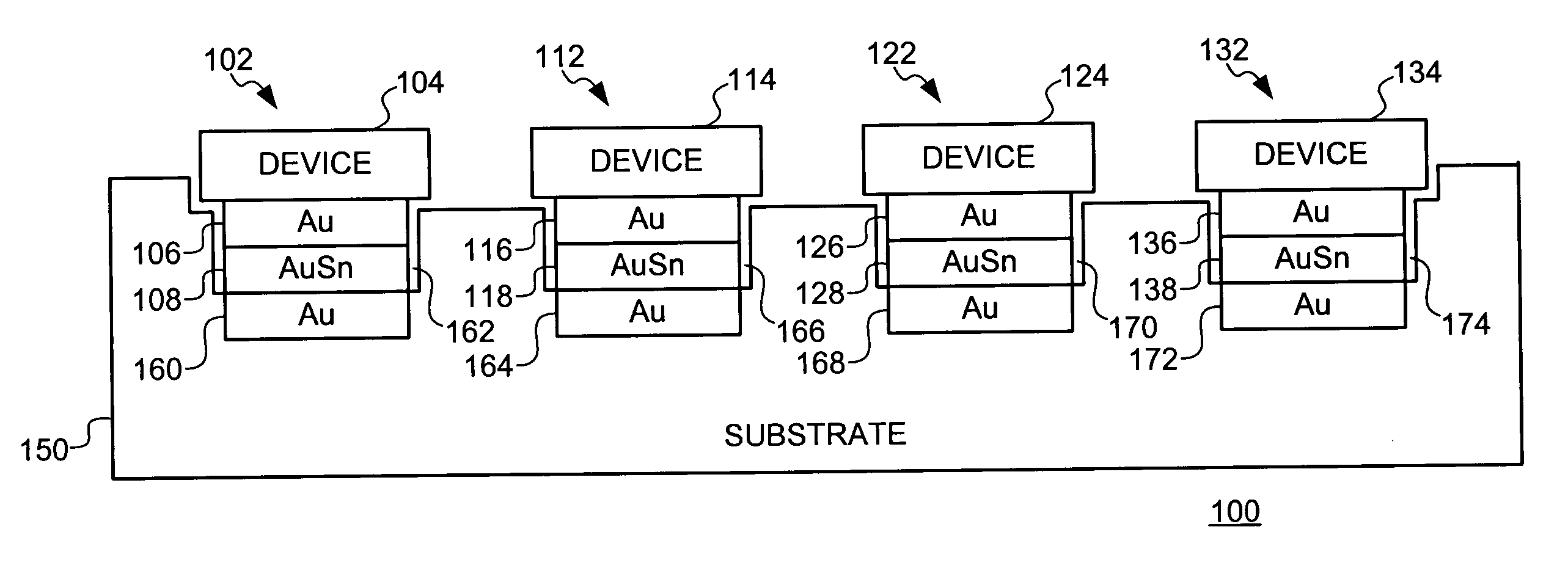

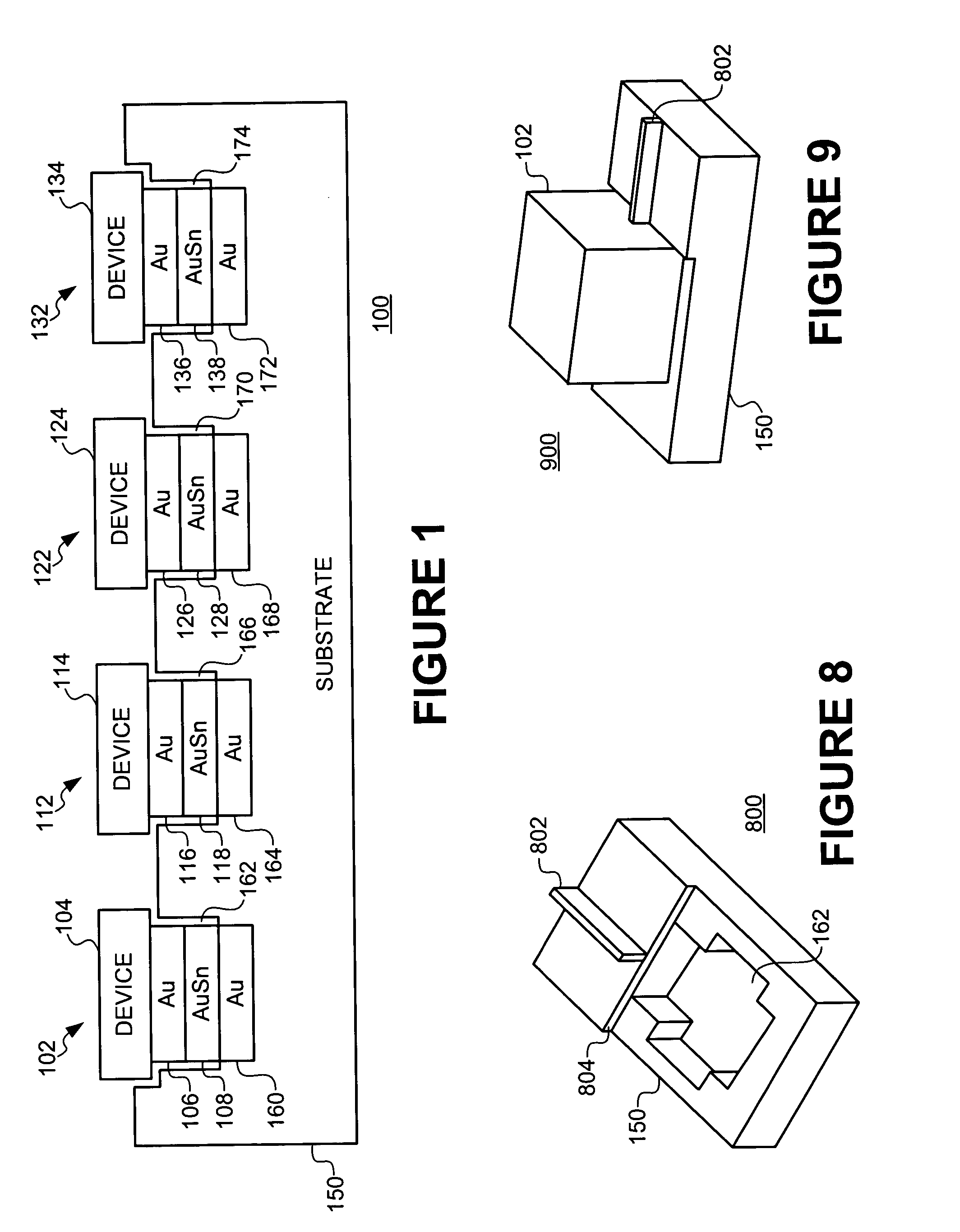

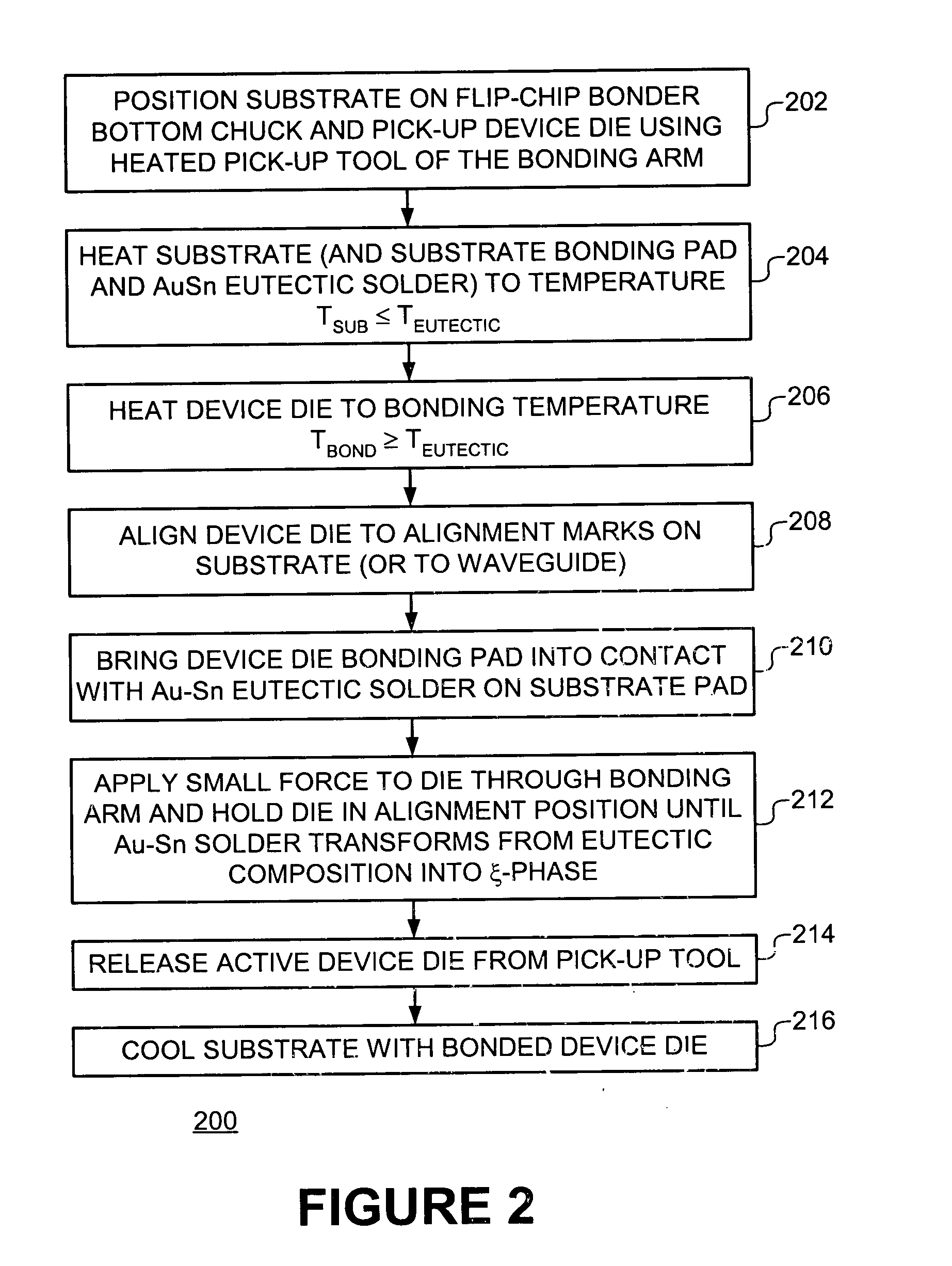

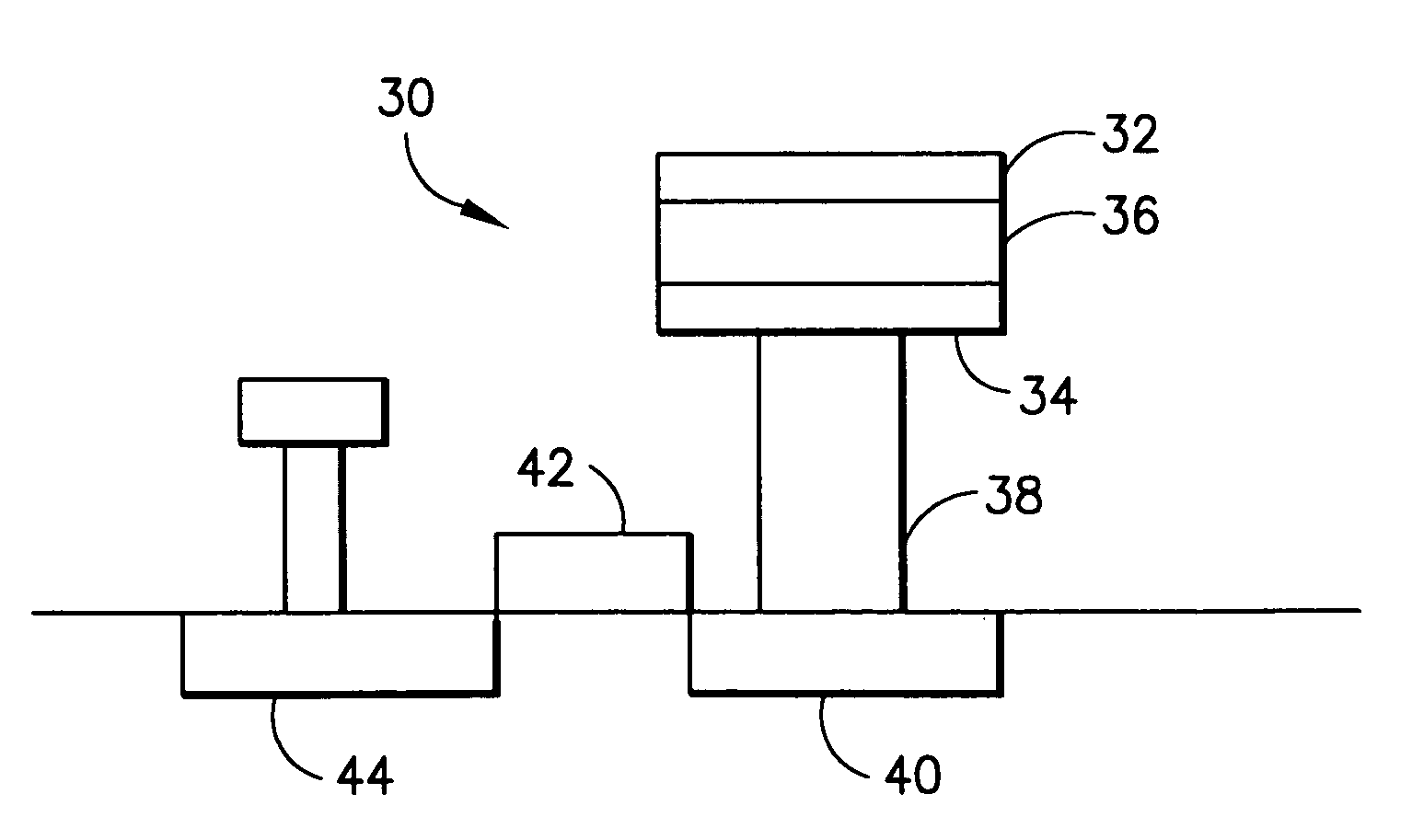

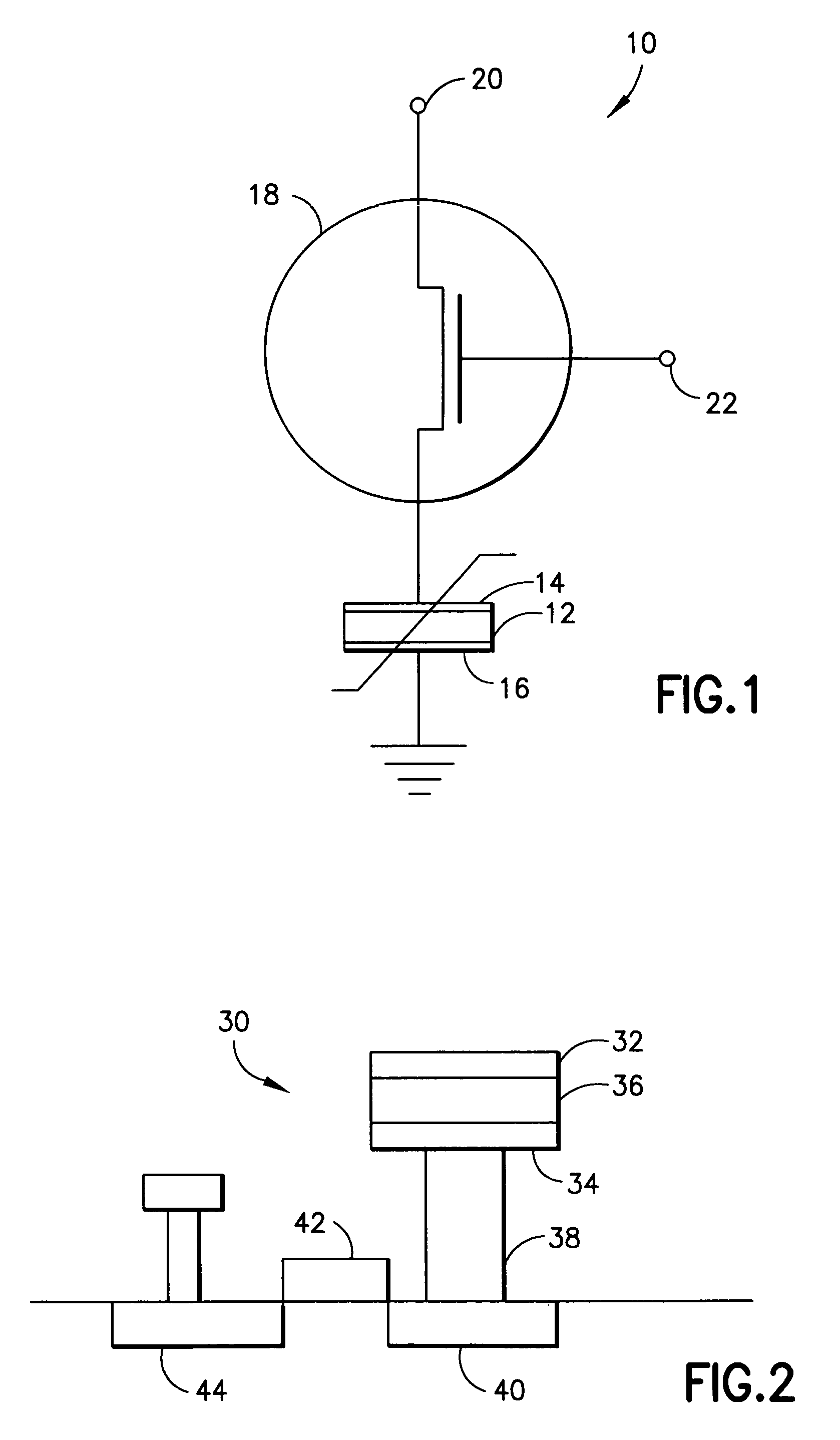

Packaging of multiple active optical devices

InactiveUS20040029304A1Printed circuit assemblingSemiconductor/solid-state device manufacturingEngineeringElectron

A cost effective method is provided for assembly of hybrid optoelectronic circuits requiring flip-chip bonding of multiple active optoelectronic devices onto common substrate or optical bench platform with fine pitch and high accuracy "after-bonding" alignment to the alignment features on substrate and / or to other elements of the hybrid circuit. A Flip-Chip Bonder equipped with high precision Bonding Arm and optical and mechanical system, heated substrate chuck and heated pick-up tool may be used both for alignment and thermal bonding of active component dies to corresponding bonding pads on the common substrate using gold-tin (Au-Sn) solder disposed between die bonding pad and the corresponding substrate bonding pad. During bonding of the first die, tin (Sn) diffuses from a eutectic composition of gold-tin (Au-Sn) solder to (gold (Au) on) the die-bonding pad and / or (gold (Au) on) the substrate bonding-pad resulting in transformation of the Au-Sn eutectic composition to a zeta-phase composition having much higher melting temperature as compared to that of a eutectic composition. As bonding of one or more subsequent dies is performed at temperatures equal to or slightly higher than the melting temperature of a eutectic composition and significantly lower than the melting temperature of a zeta-phase composition, the gold-tin (Au-Sn) solder at the bond of previously attached die does not melt and, consequently, the alignment is not compromised.

Owner:INTEL CORP

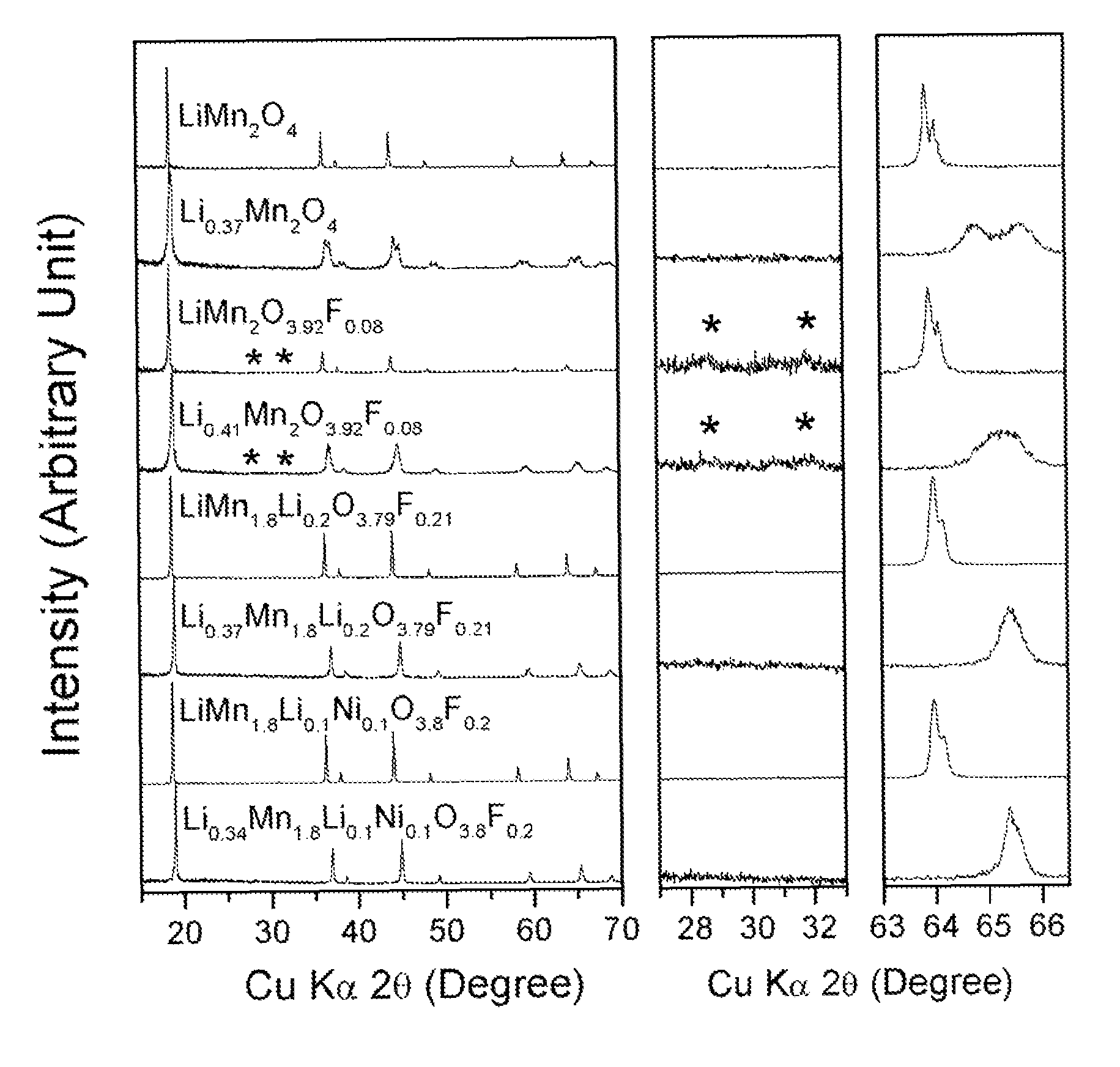

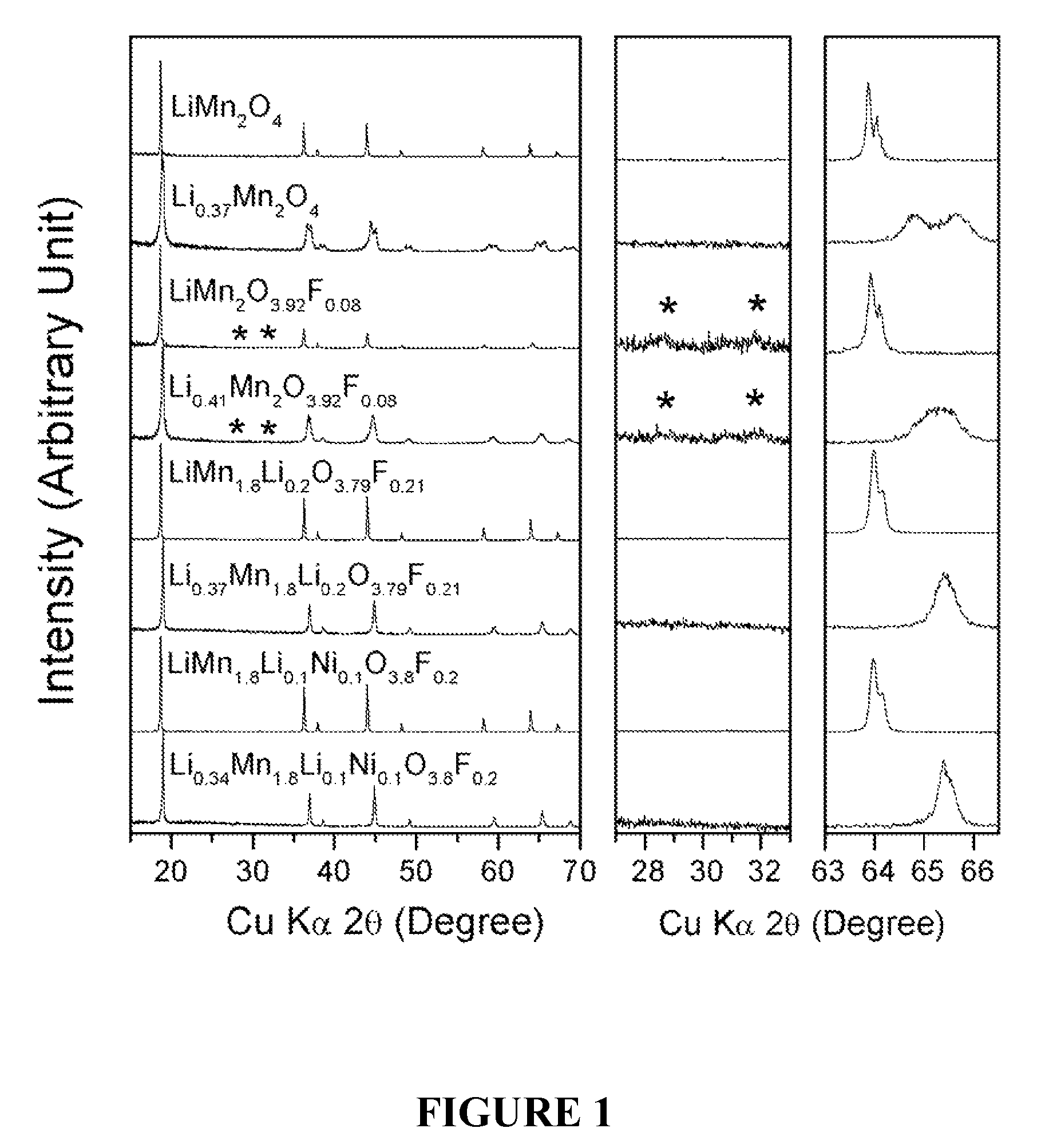

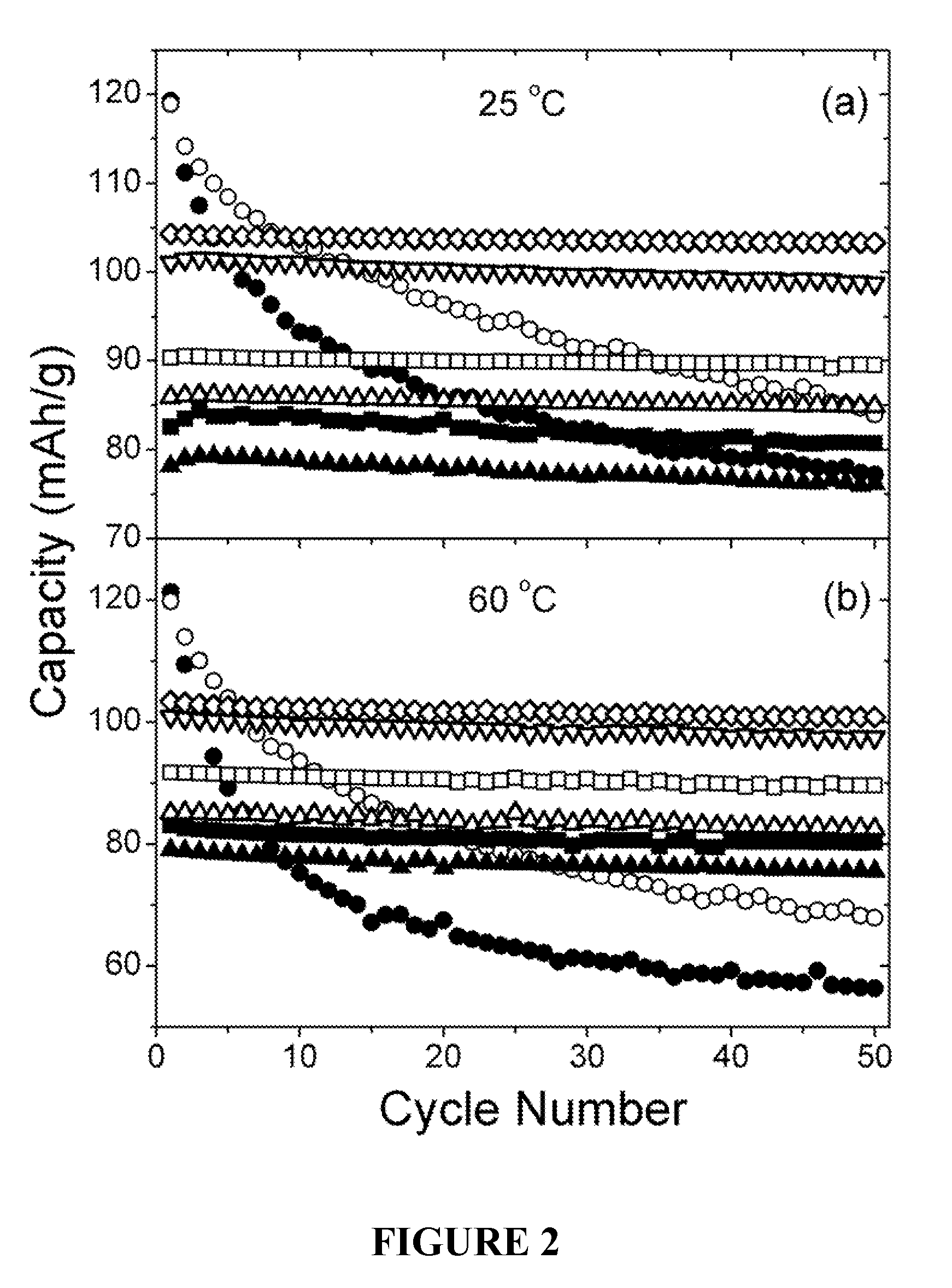

Cation-substituted spinel oxide and oxyfluoride cathodes for lithium ion batteries

InactiveUS7718319B2Cyclability at elevated temperaturesImprove rendering capabilitiesElectrode carriers/collectorsConductive materialSpinelGraphite

The present invention includes compositions and methods of making cation-substituted and fluorine-substituted spinel cathode compositions by firing a LiMn2−y−zLiyMzO4 oxide with NH4HF2 at low temperatures of between about 300 and 700° C. for 2 to 8 hours and a η of more than 0 and less than about 0.50, mixed two-phase compositions consisting of a spinel cathode and a layered oxide cathode, and coupling them with unmodified or surface modified graphite anodes in lithium ion cells.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

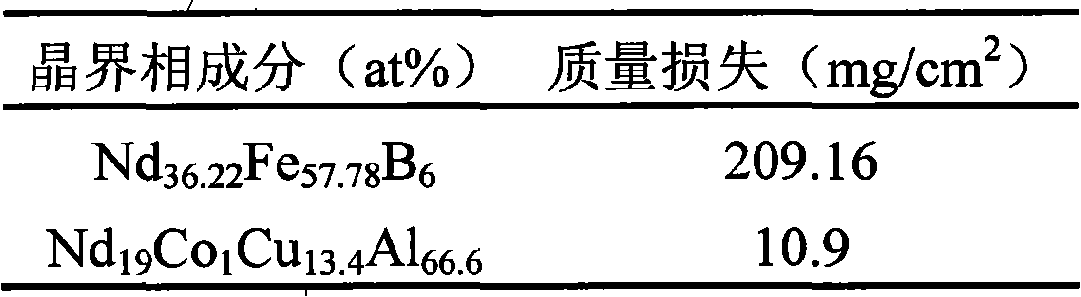

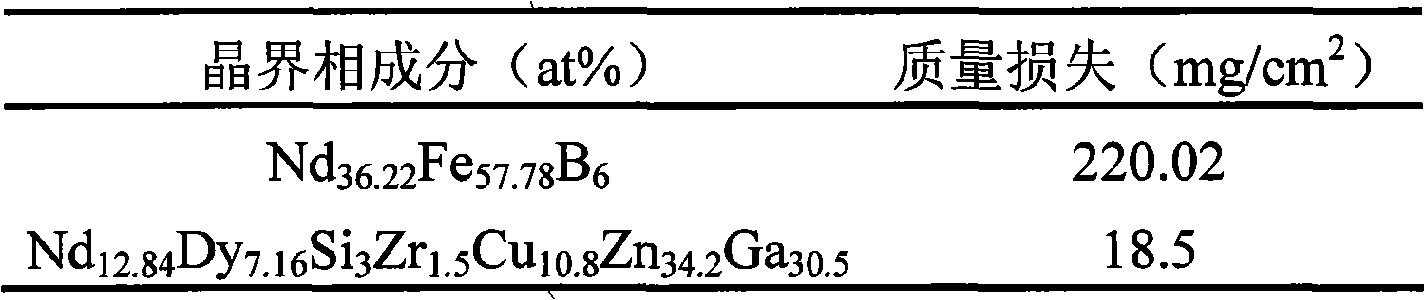

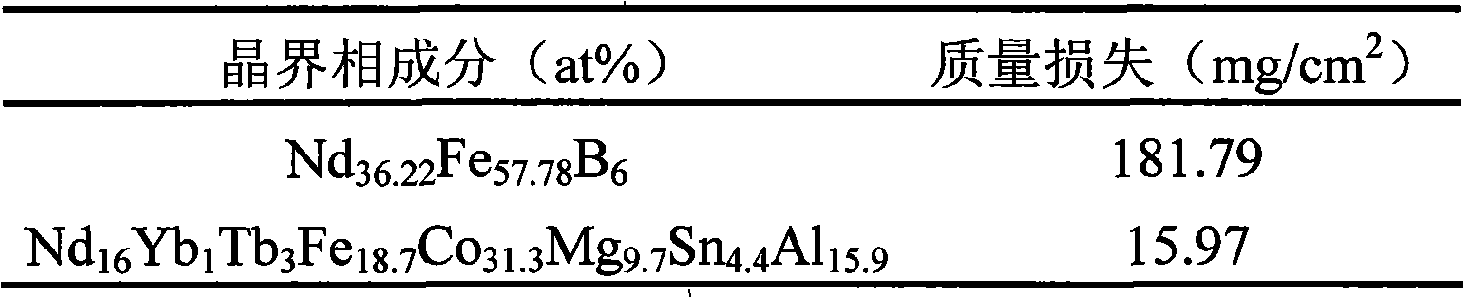

Grain boundary phase-reconstructed high-corrosion resistance Sintered NdFeB magnet and preparation method thereof

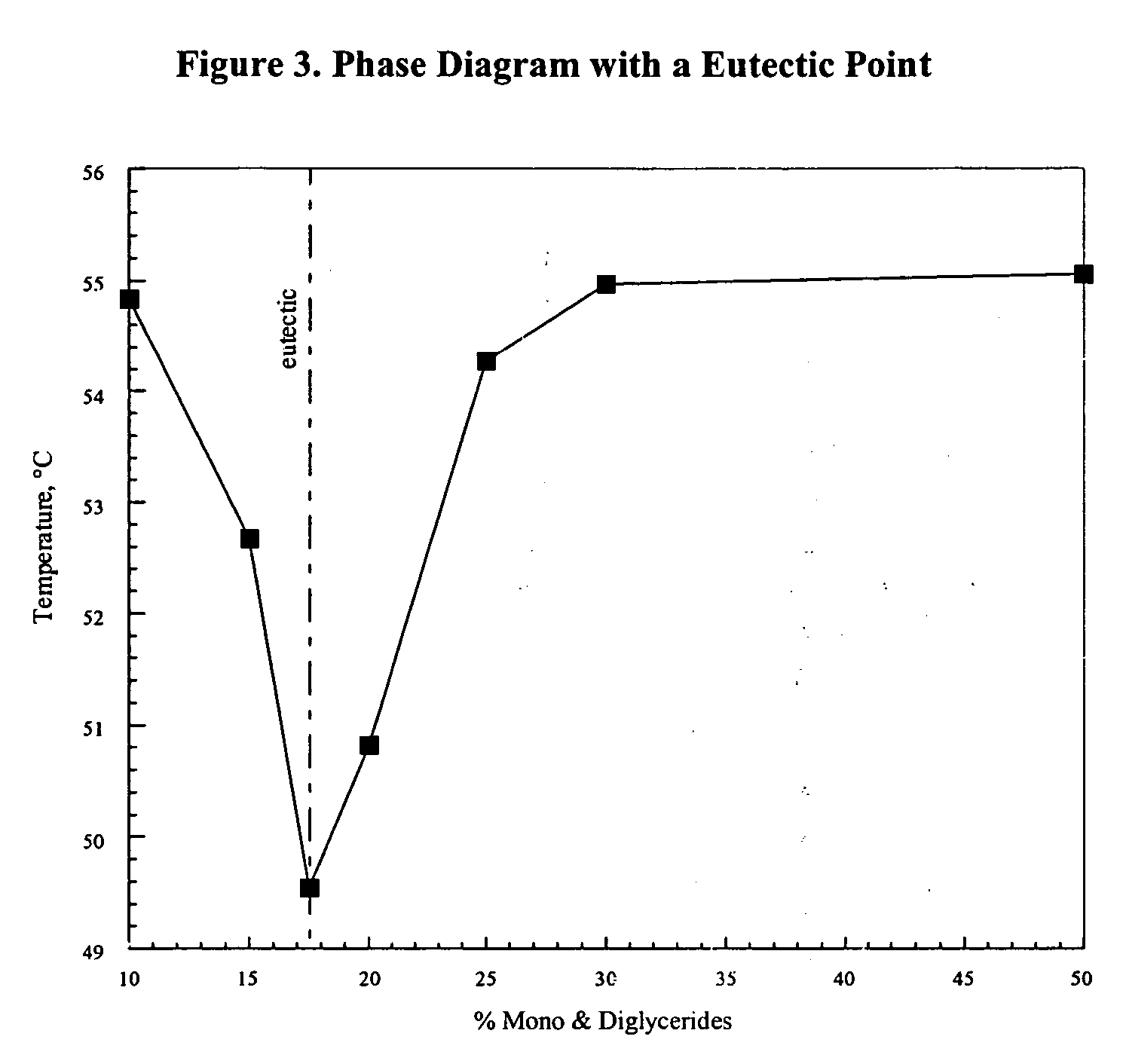

ActiveCN101320609ALow melting pointGuaranteed MagneticInorganic material magnetismInductances/transformers/magnets manufactureElectrode potentialPowder mixture

The invention discloses a sintered Nd-Fe-B magnet with high corrosion resistance and the grain boundary reconstruction and a preparation method thereof. The composition of the invention is that: NdeFe100-e-f-gBfMg, wherein, e is greater than or equal to 6 and equal to or less than 24, f is greater than or equal to 5. 6 and equal to or less than 7, g is greater than or equal to 0.03 and equal to or less than 8, M is one or some of elements Dy, Tb, Pr, Sm, Yb, La, Co, Ni, Cr, Nb, Ta, Zr, Si, Ti, Mo, W, V, Ca, Mg, Cu, Al, Zn, Ga, Bi, Sn and In; The method is that: main phrase alloy and reconstructed grain boundary phase alloy are respectively pulverized and mixed uniformly; the powder mixture is pressed to a mould in the magnetic field, and fabricated into a sintering magnet in a high vacuum sintering furnace. By the reconstruction of the grain boundary phase composition, the invention can obtain the grain boundary phase alloy with low melting point and high electrode potential, decrease the potential difference between the main phase and the grain boundary phase on the basis of ensuring the magnetic properties, promote the intrinsic corrosion resistance of magnet, and has the advantages of simple process, low cost and being suitable for the batch production. Therefore, by combining the grain boundary reconstruction and double alloy method, the sintered Nd-Fe-B magnet with high intrinsic corrosion resistance can be prepared.

Owner:ZHEJIANG UNIV

Multiple phase foaming personal cleansing products

InactiveUS20030003069A1Difference in densityEasy to separateCosmetic preparationsHair removalPersonal careCleaning product

The present invention relates to personal care foaming and cleansing products comprising multiple phases which are separate and distinct and comprise at least one surfactant solution having a density or specific gravity of approximately 1.0. In a two-phase composition, a second separated phase may comprise cosmetically acceptable oily materials as emollients / conditioners having a density greater than that of the surfactant solution. In a three phase composition, an additional phase may comprise a low density emollient / conditioning compound(s) as an upper third phase. Thus, two, three or even four phase foaming bath products, shampoos and skin cleansers can be produced that can be differentially colored to enhance the visual separation of the layers and will provide foaming, cleaning, conditioning and emolliency in a unique and attractive manner.

Owner:ALZO INTTERNAT

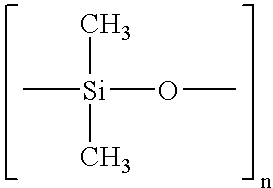

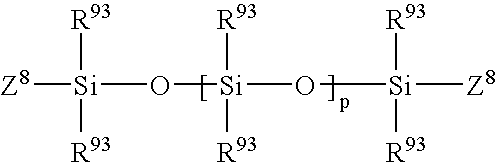

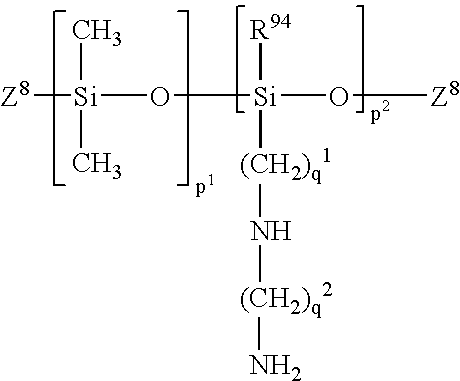

Sprayable compositions comprising pharmaceutical active agents, volatile silicones and a non-volatile oily phase

InactiveUS20060147383A1Improve permeabilityPowder deliveryOrganic active ingredientsActive agentOil phase

Compositions in the form of a spray contain a pharmaceutical active agent, at least one volatile silicone and a non-volatile oily phase, formulated into a physiologically acceptable medium, are well suited for improved transdermal administration in cosmetics and dermatology.

Owner:GALDERMA RES & DEV SNC

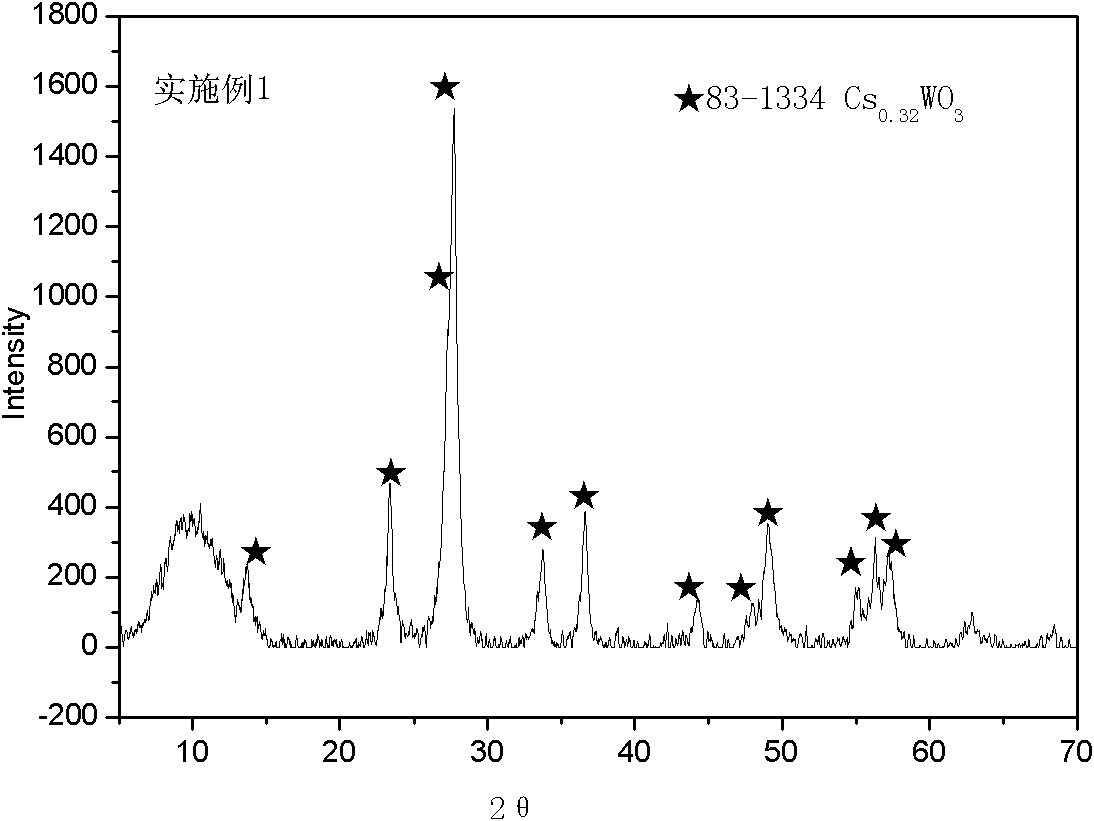

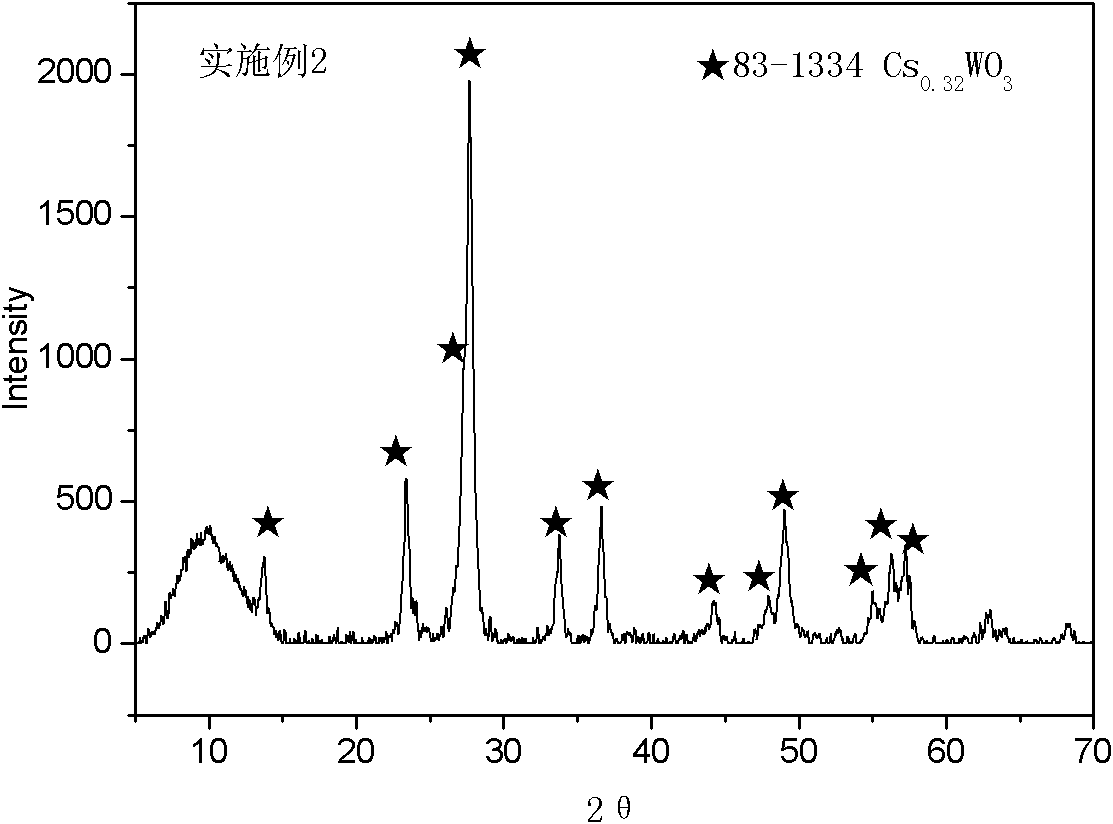

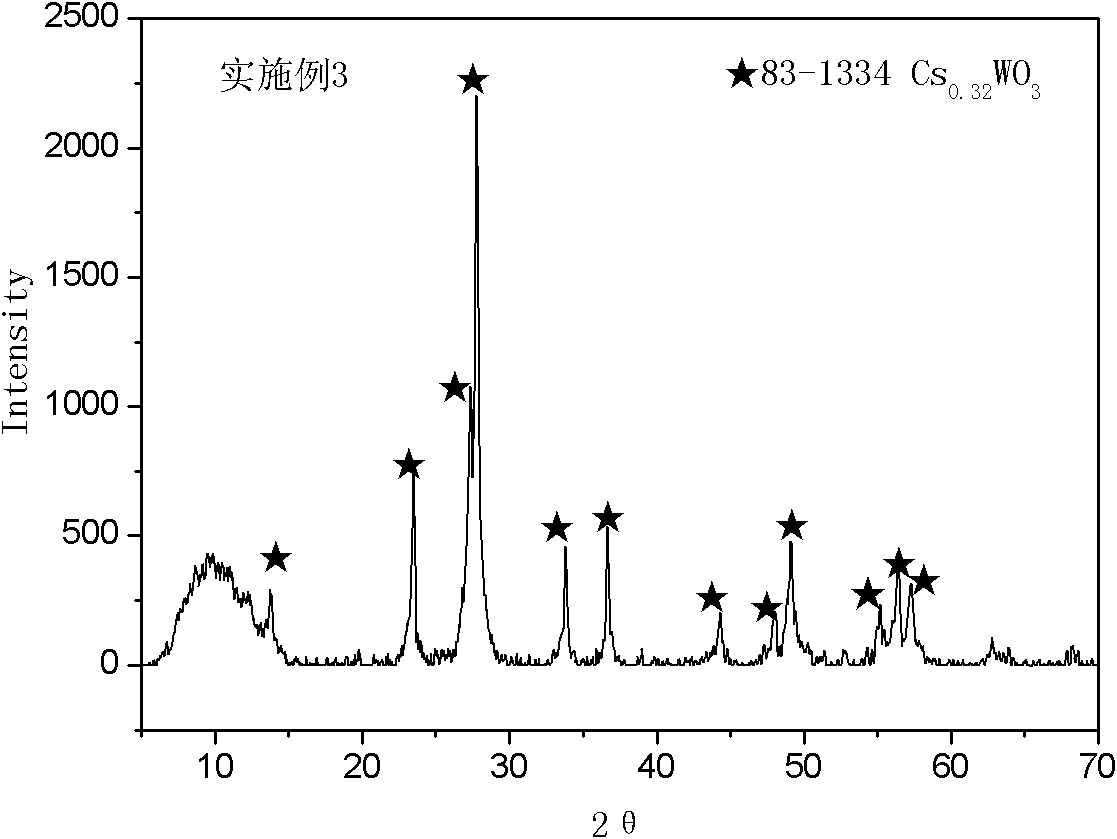

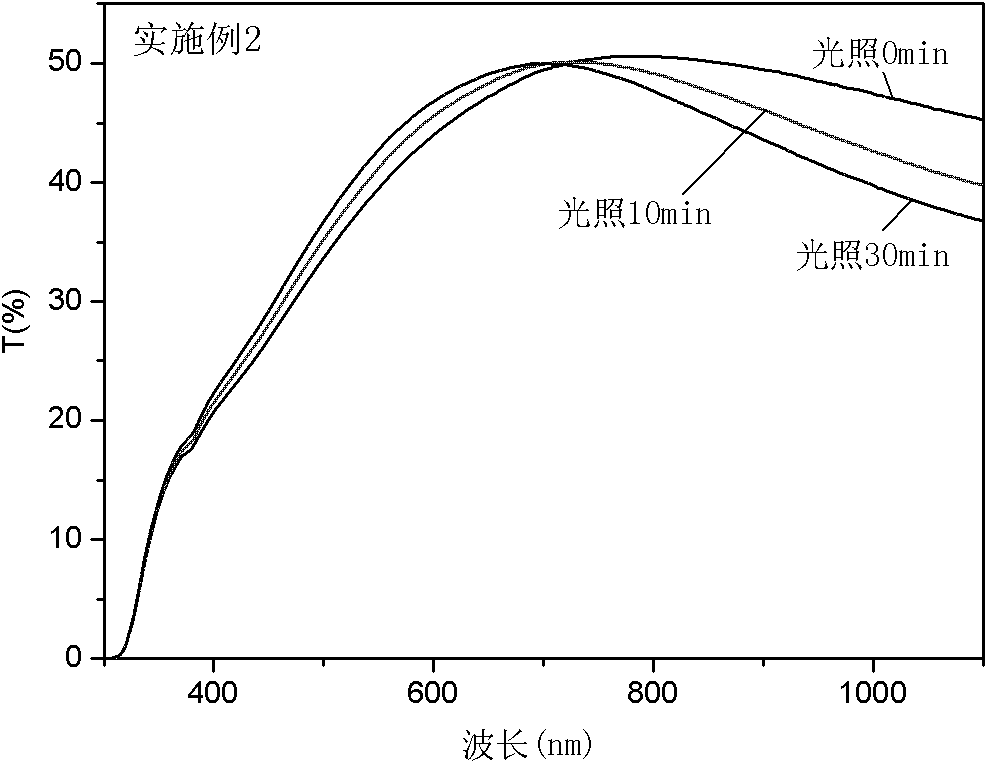

Cesium tungsten bronze powder and preparation method thereof

InactiveCN102320662AOptimal Control StructureReduce manufacturing costTungsten compoundsGranularitySolvent

The invention relates to cesium tungsten bronze powder and a preparation method thereof. The method comprises the following steps that: 1, precursor solution with tungstic acid, cesium carbonate and reducing substances is prepared according to a Cs / W mole ratio of 0.01 to 0.35 / 1, and the solvents are water or a mixture formed by ethanol and the water according to a volume ratio of 1 / 4 to 4 / 1; and 2, the precursor solution takes reaction for 1 to 3d under the condition of 180 to 200 DEG C in an autoclave, and the cesium tungsten bronze powder is obtained after the obtained precipitates are treated. The powder has the crystalline phase composition of Cs0.2WO3 or Cs0.32WO3, the size of the powder particle is 100 to 1300nm, and the specific surface area is 7 to 50m<2> / g. The synthetic process has the advantages that raw materials are cheap and mild, the operation is easy, the production cost can be reduced, in addition, the low-temperature (lower than or equal to 20 DEG C) synthesis is adopted, and the process is suitable for production and practical application. In addition, the product purposes are wide.

Owner:DALIAN POLYTECHNIC UNIVERSITY

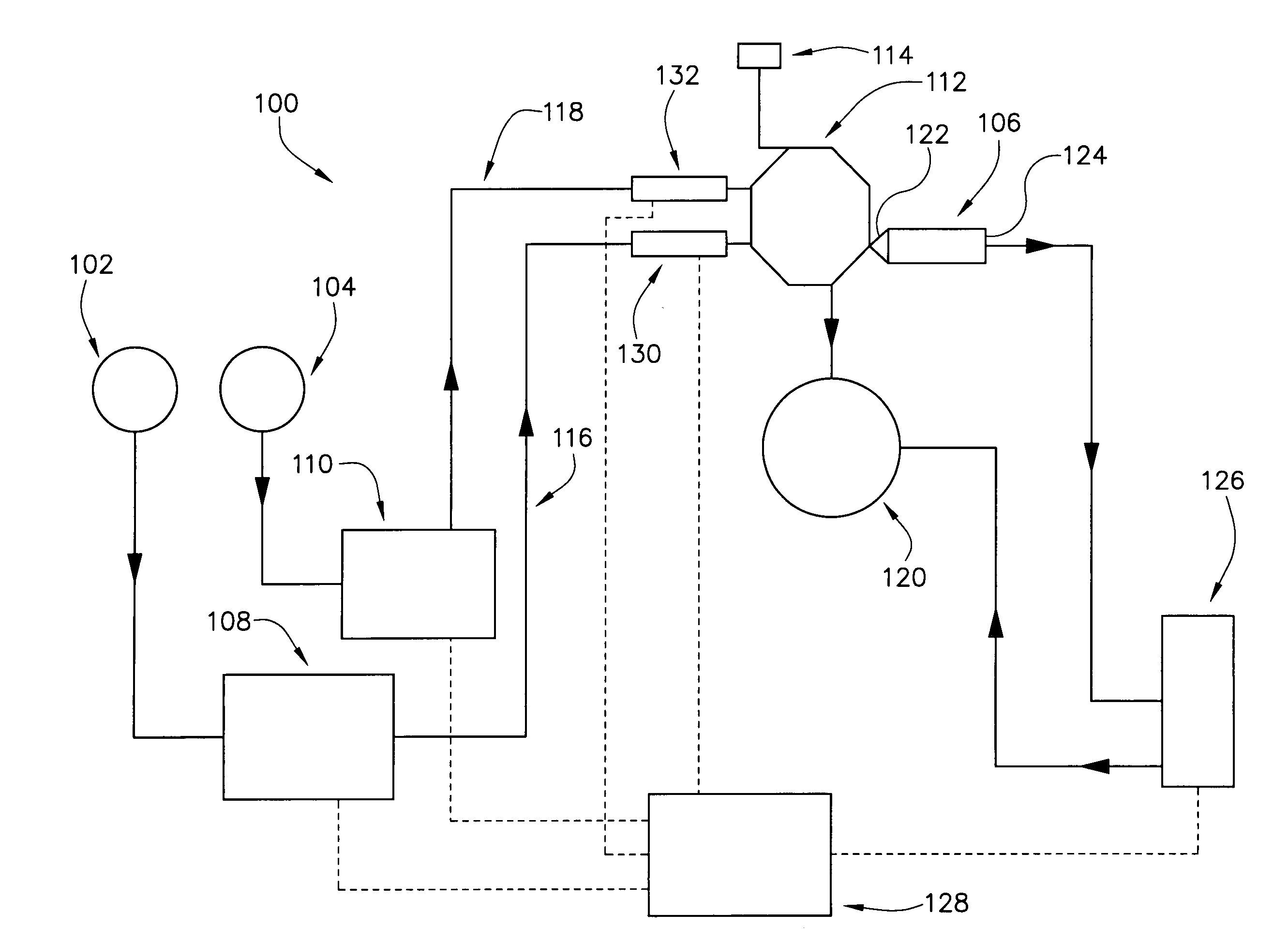

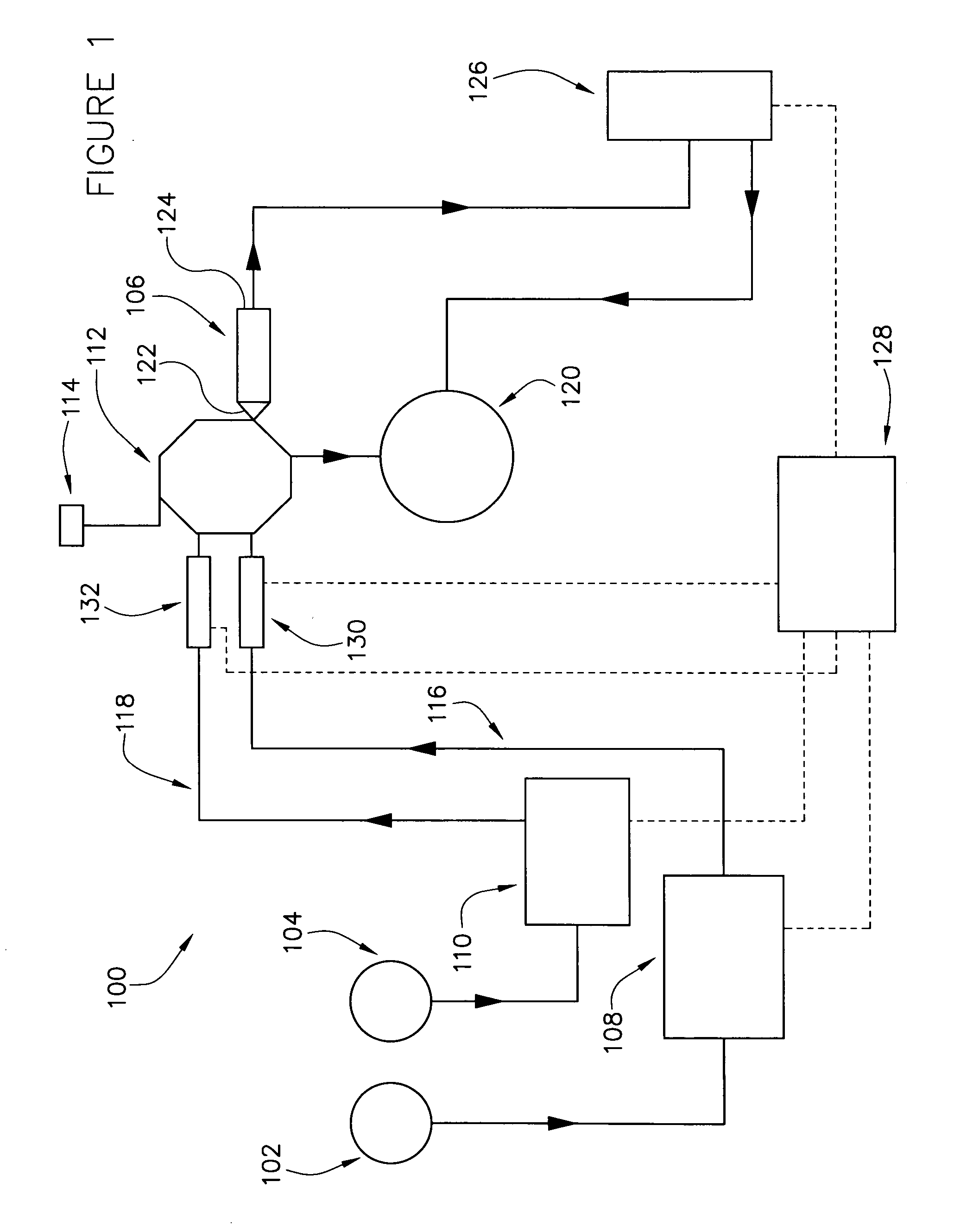

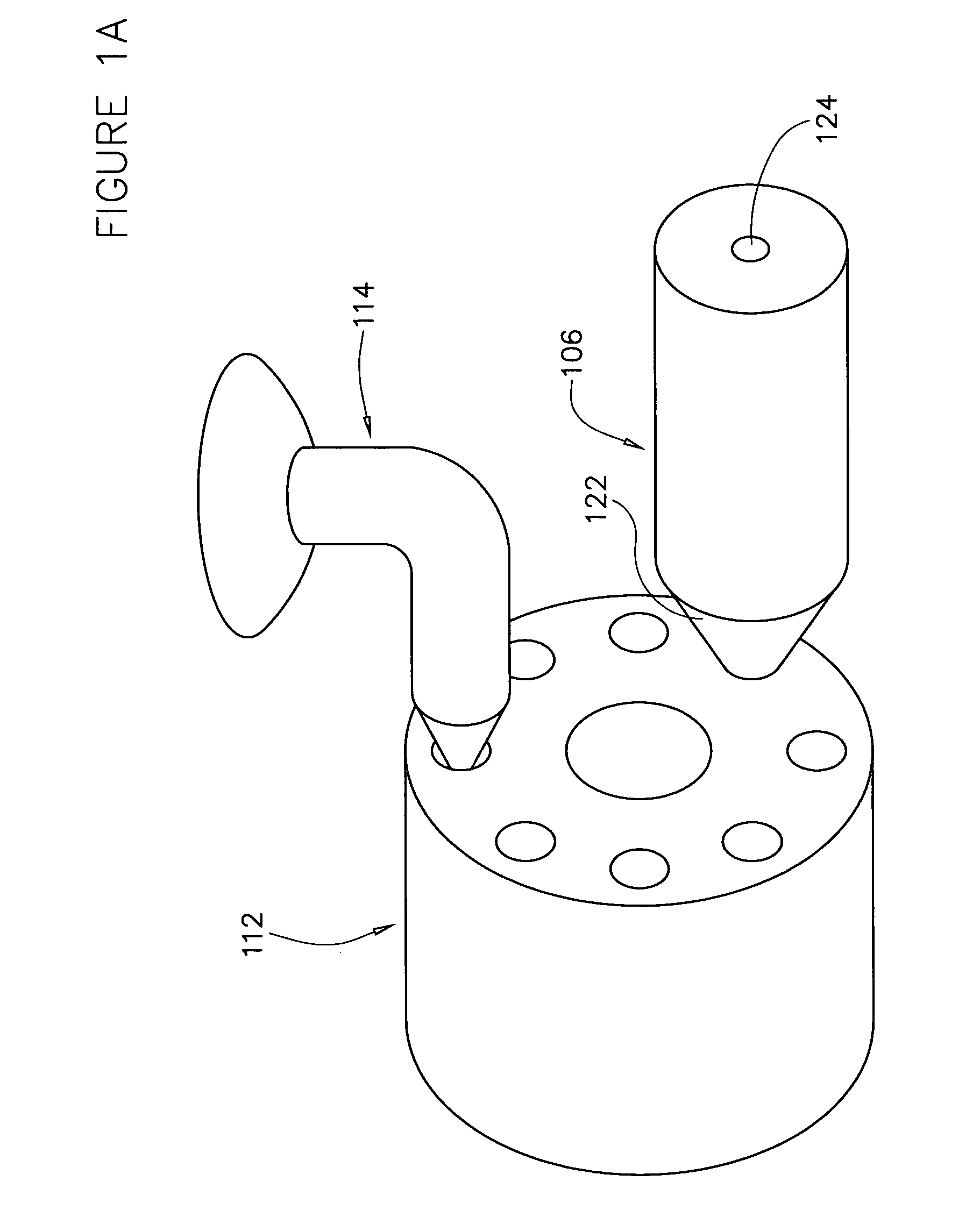

System and method for rapid chromatography with fluid temperature and mobile phase composition control

InactiveUS20060054543A1Easy to separateMinimizing temperature variationIon-exchange process apparatusComponent separationChromatographic separationFraction Collector

The invention relates to liquid chromatography techniques for rapidly characterizing samples, such as polymer solutions, emulsions and dispersions, and to devices for implementing such techniques. The system includes a design that provides the ability to perform chromatographic separations by using mobile phase composition gradients and temperature gradients during separations. The invention accomplishes this by providing mixing zones for a plurality of fluids as well as heated and chilled feeds feeding the fluids to the mixing zones. Additionally, the system provides the ability to analyze separated components with a detector and / or collect separated fractions into vessels of a fraction collector for further separation and / or analysis.

Owner:UNCHAINED LABS

Multi phase personal care composition comprising compositions having similar rheology profile in different phases

InactiveUS20070014823A1Easy to obtainEasy maintenanceCosmetic preparationsHair cosmeticsPersonal careShear stress

Multi-phase personal care compositions comprising: (a) at least one personal care composition phase; and (b) at least one another personal care composition phase; wherein the phase (a) and said the phase (b) are visually distinct phases that are packaged in physical contact, wherein the phase (a) and the phase (b) have a yield stress of from about 1 Pa to about 100 Pa, and wherein the viscosity ratio of the phase (a) to the phase (b) is from about 1:15 to about 15:1 at shear stress over the yield stress of the phases (a) and (b) up to at least 200 Pa. By matching rheology profiles of each phase compositions in such kinetic conditions, desired patterns of multi-phase personal care compositions are easily obtained and / or maintained for a longer period of time.

Owner:THE PROCTER & GAMBLE COMPANY

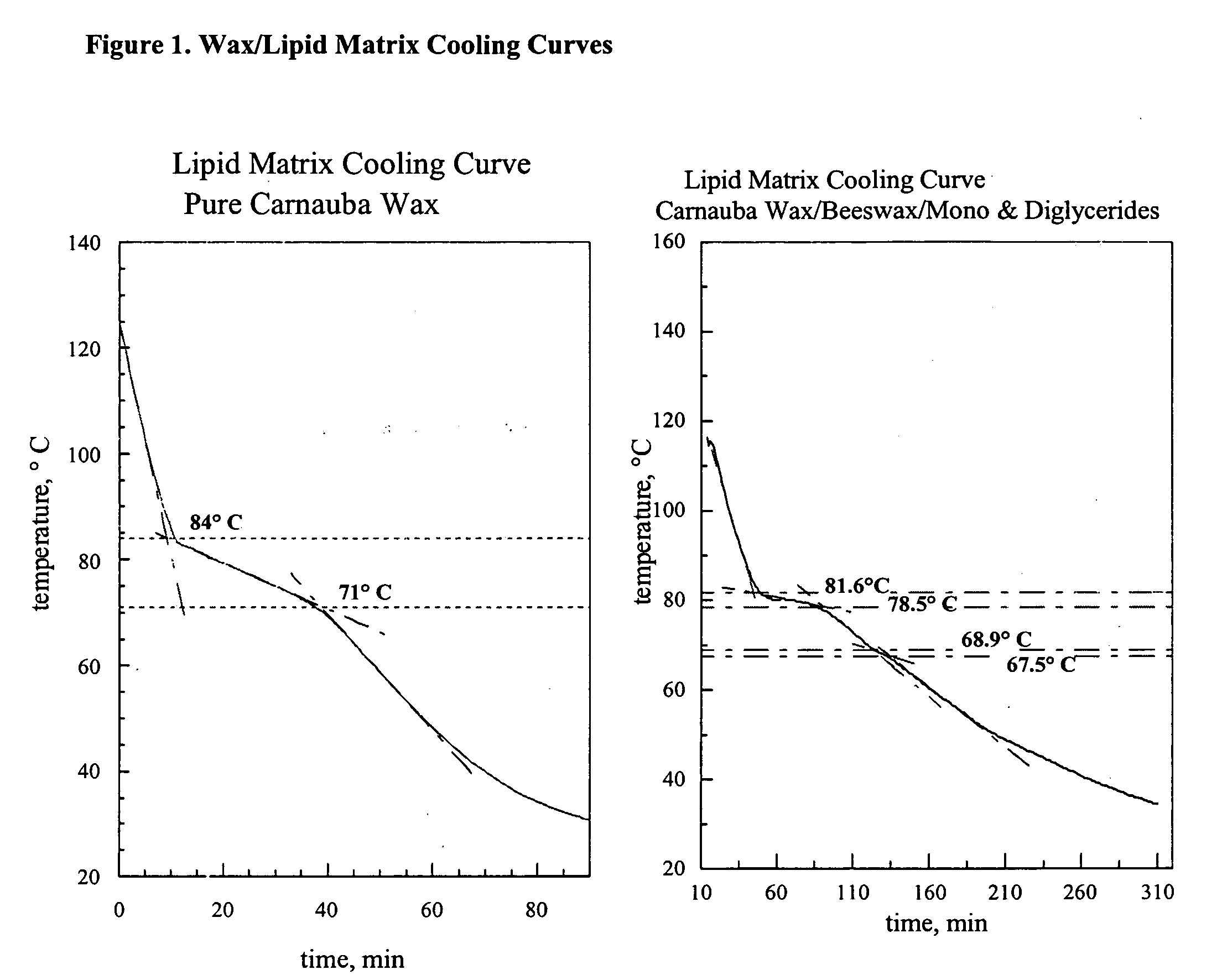

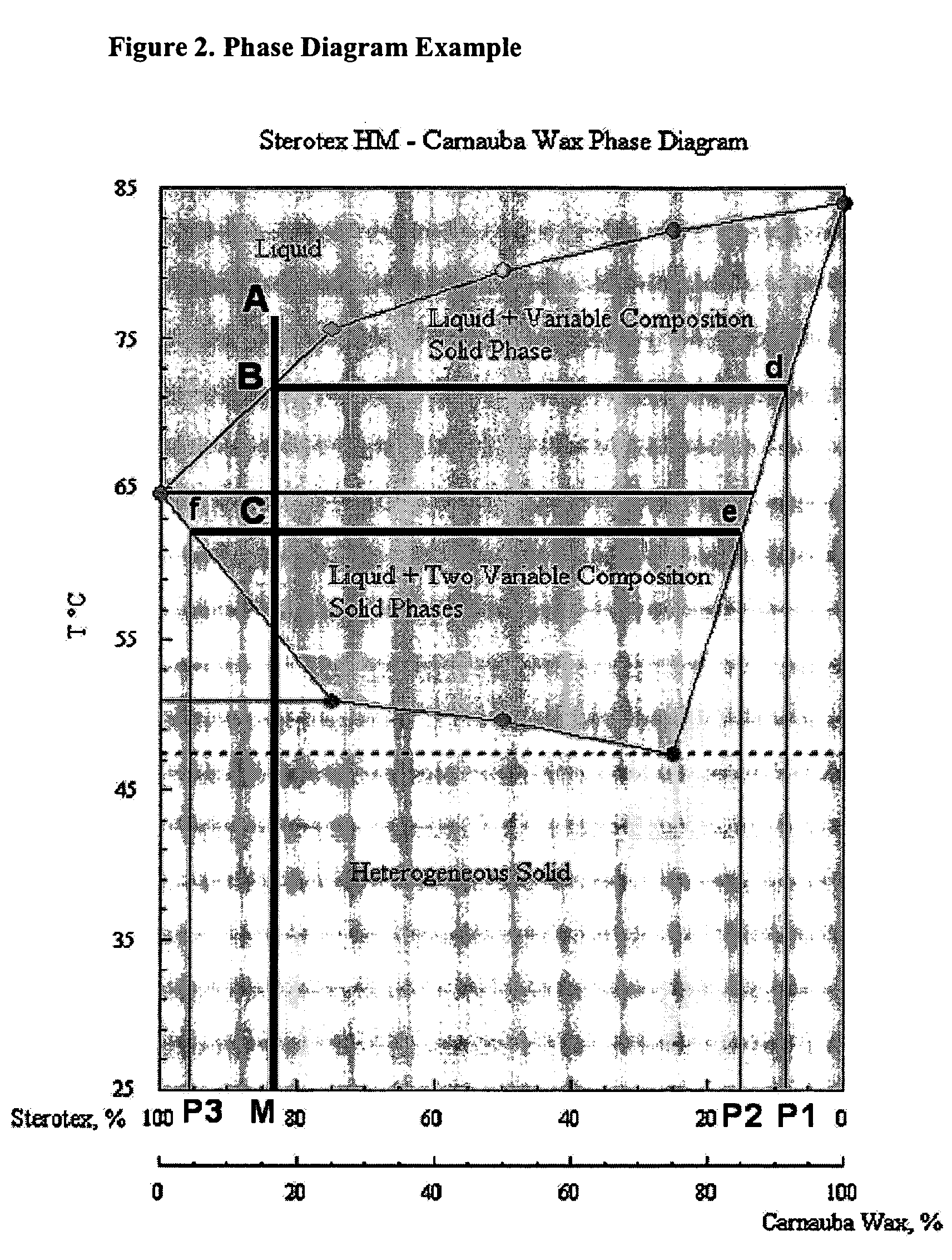

Controlled phase composition technology as an improved process for protection of drugs

InactiveUS20060008527A1Effective taste-maskingBetter conformSalicyclic acid active ingredientsPill deliveryWaxLipid formation

The present invention relates to novel processes and compositions for protecting drugs, especially water soluble drugs in aqueous environments. More specifically, this process entails coating drugs with a controlled phase composition wax / lipid middle layer for controlling migration of the drug toward the composition's surface during preparation and a polymeric outer layer.

Owner:PARTICLE DYNAMICS INT

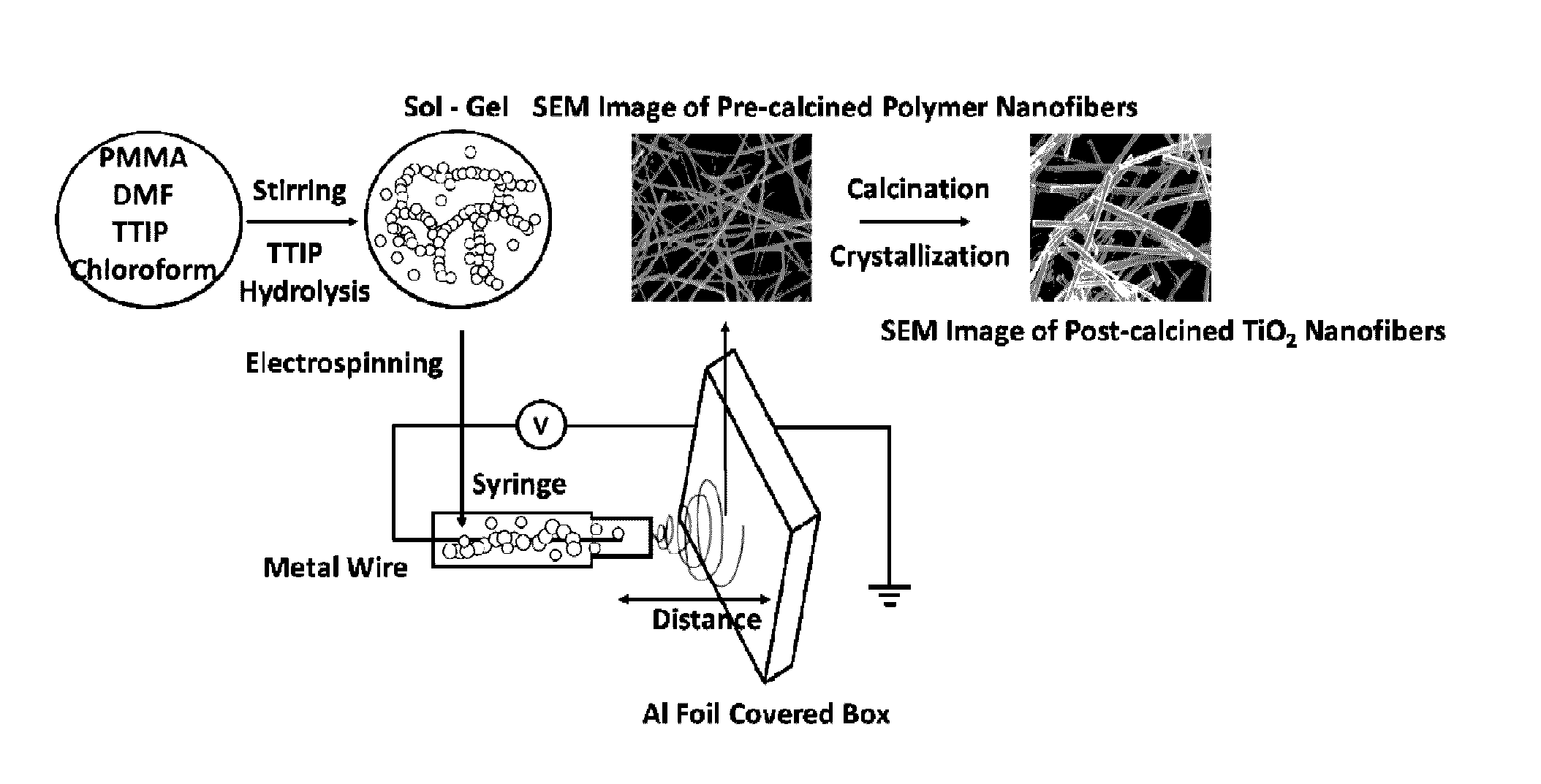

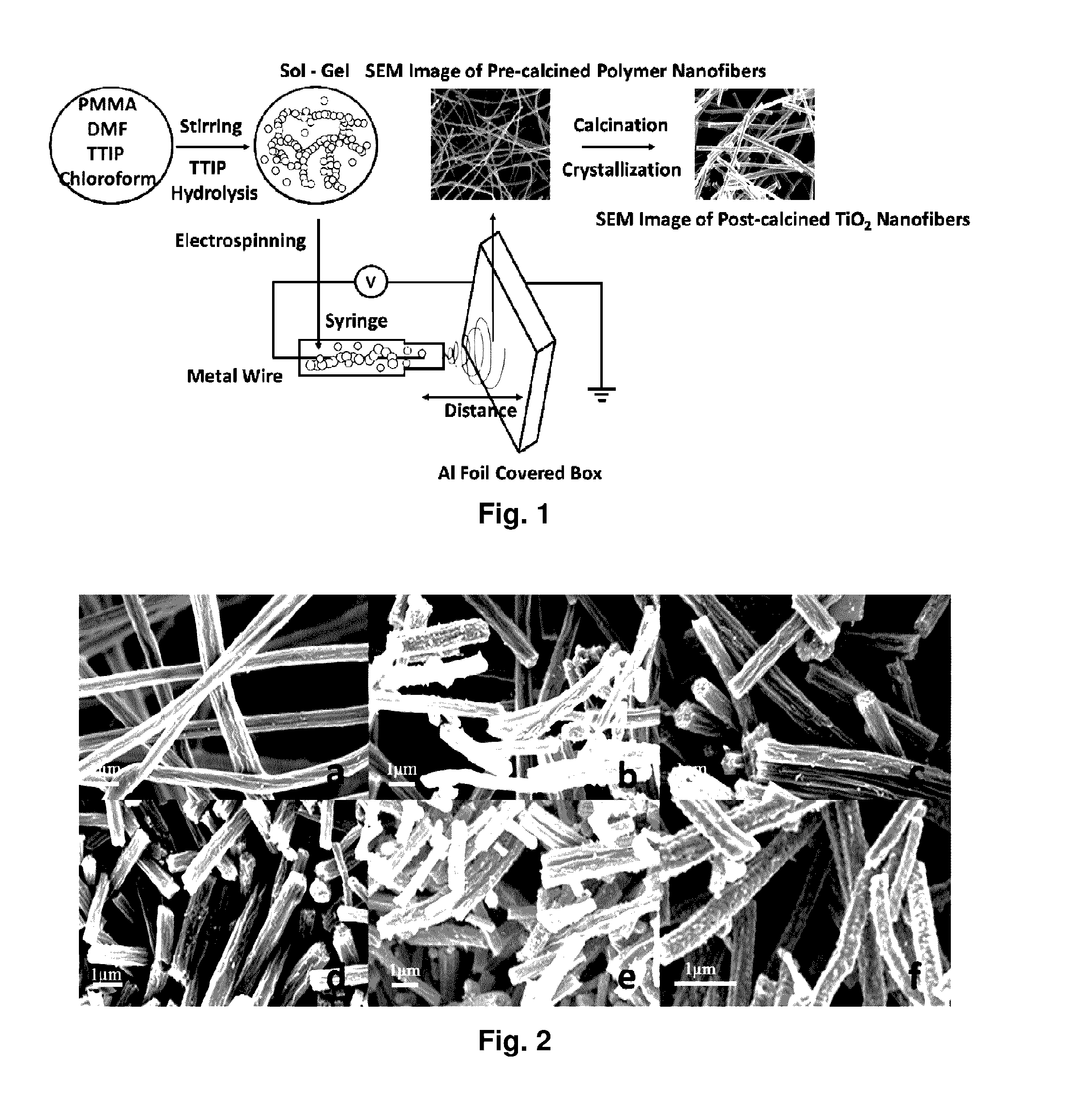

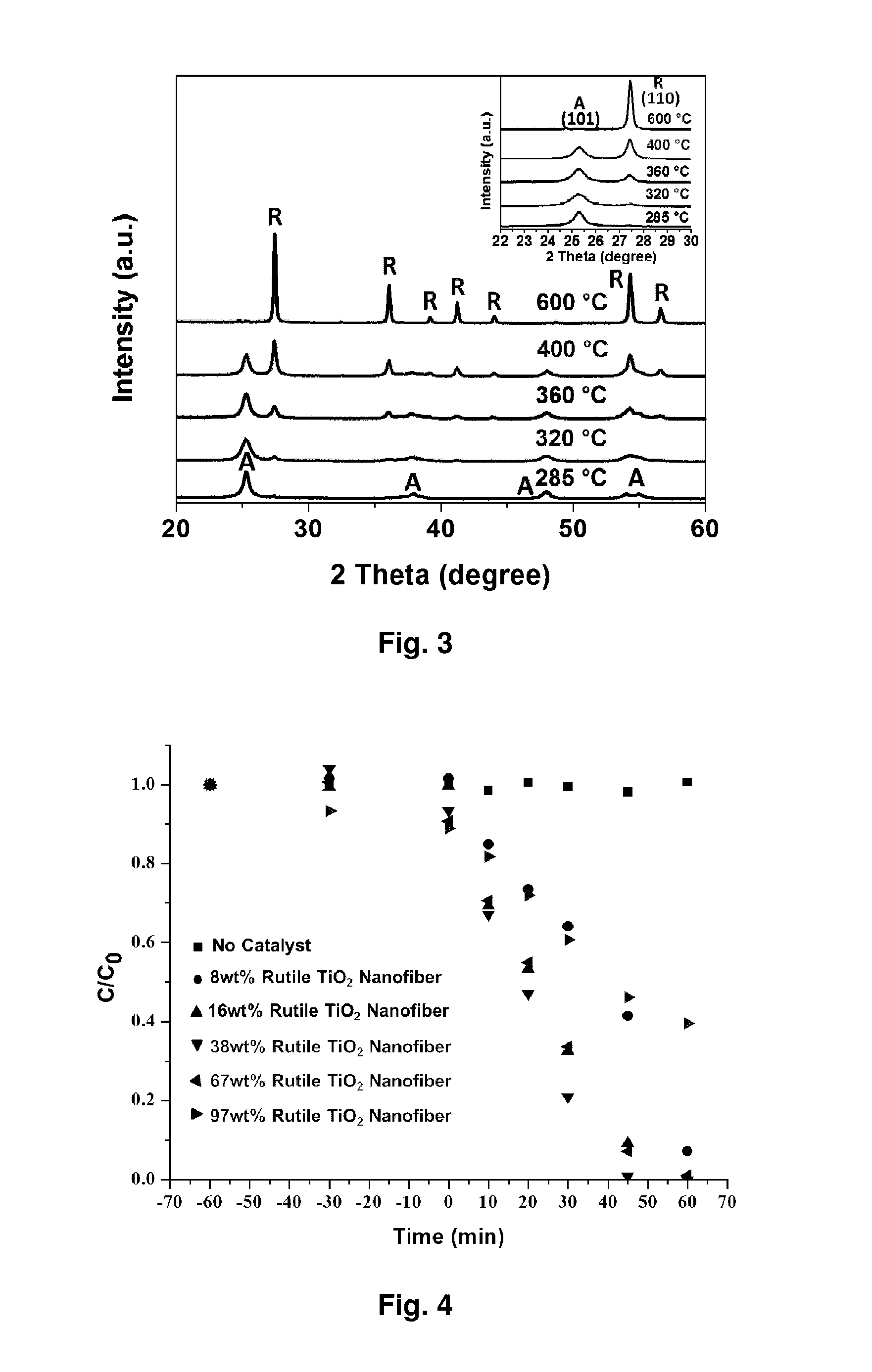

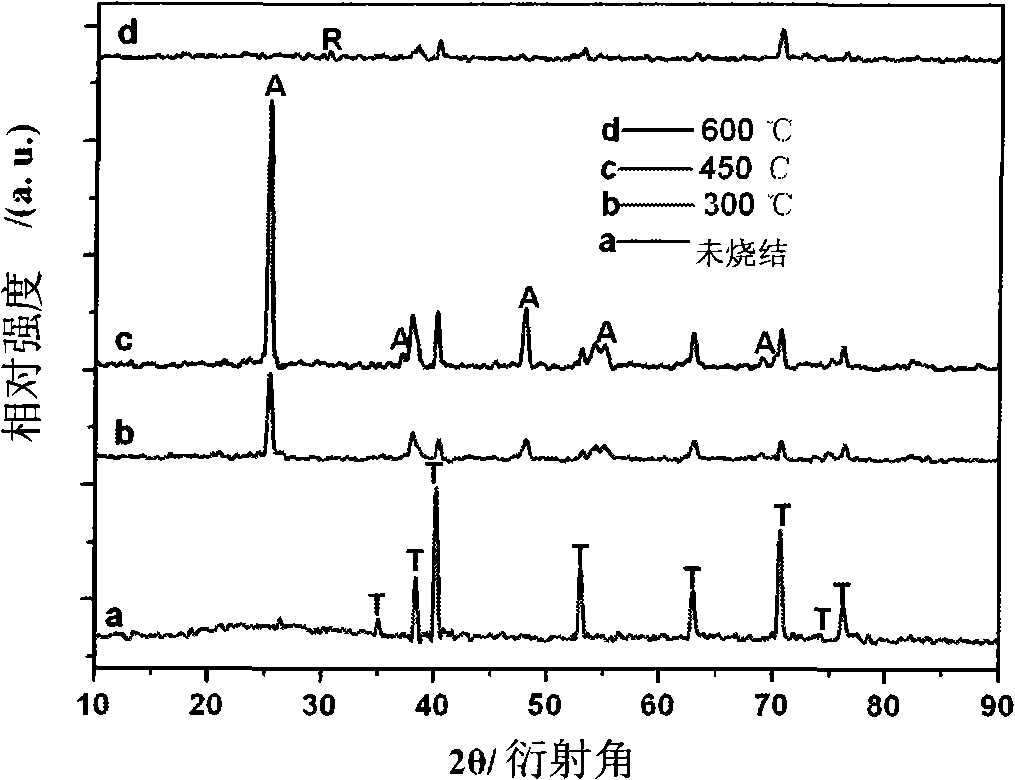

Metal oxide nanofibrous materials for photodegradation of environmental toxins

ActiveUS20170056873A1Rapid and inexpensiveAccelerated photodegradationWater/sewage treatment by irradiationWater treatment compoundsFiberRutile

Mixed-phase TiO2 nanofibers prepared via a sol-gel technique followed by electrospinning and calcination are provided as photocatalysts. The calcination temperature is adjusted to control the rutile phase fraction in TiO2 nanofibers relative to the anatase phase. Post-calcined TiO2 nanofibers composed of 38 wt % rutile and 62 wt % anatase exhibited the highest initial rate constant of UV photocatalysis. This can be attributed to the combined influences of the fibers' specific surface areas and their phase compositions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Porous article of sintered calclium phosphate, process for producing the same and artificial bone and histomorphological scaffold using the same

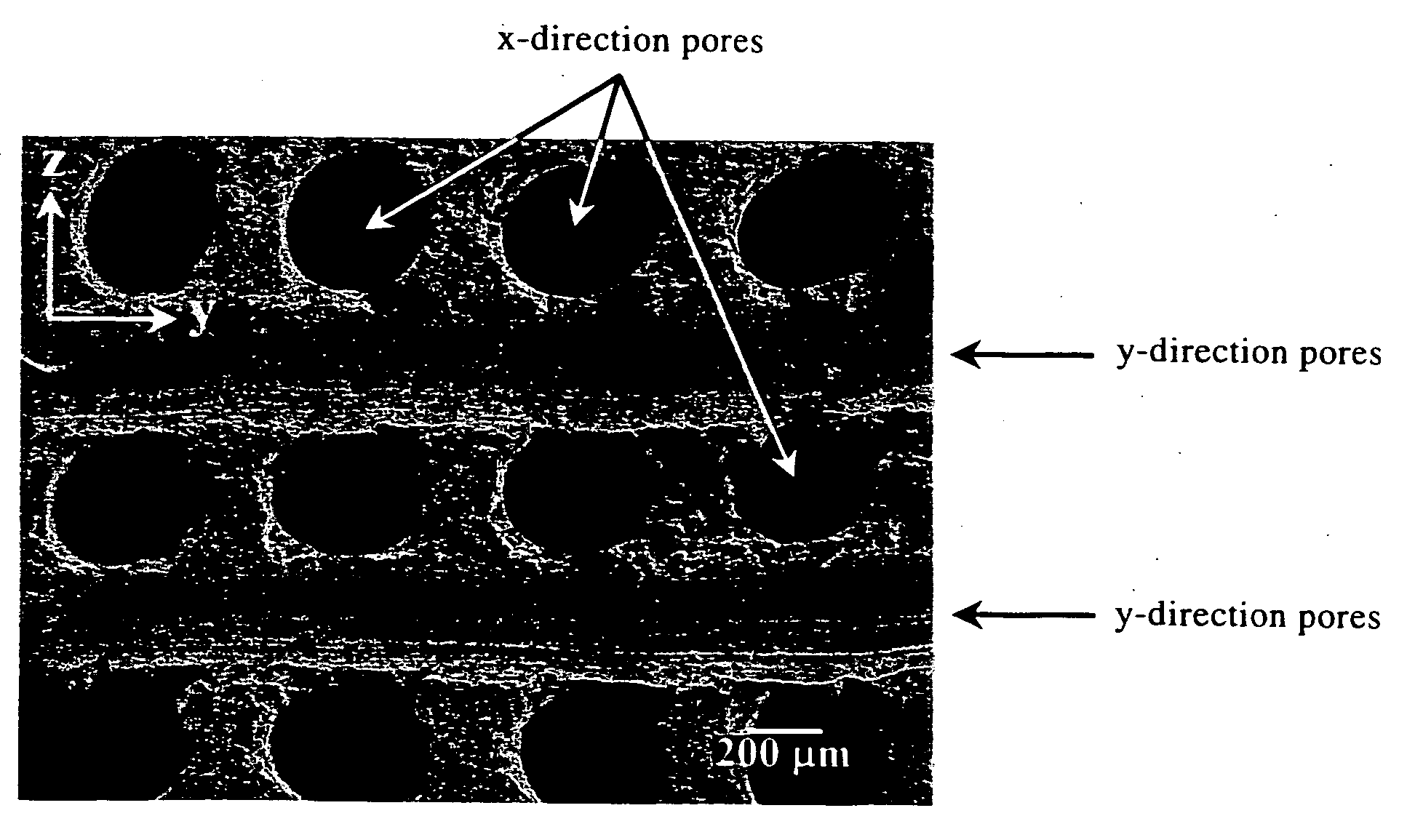

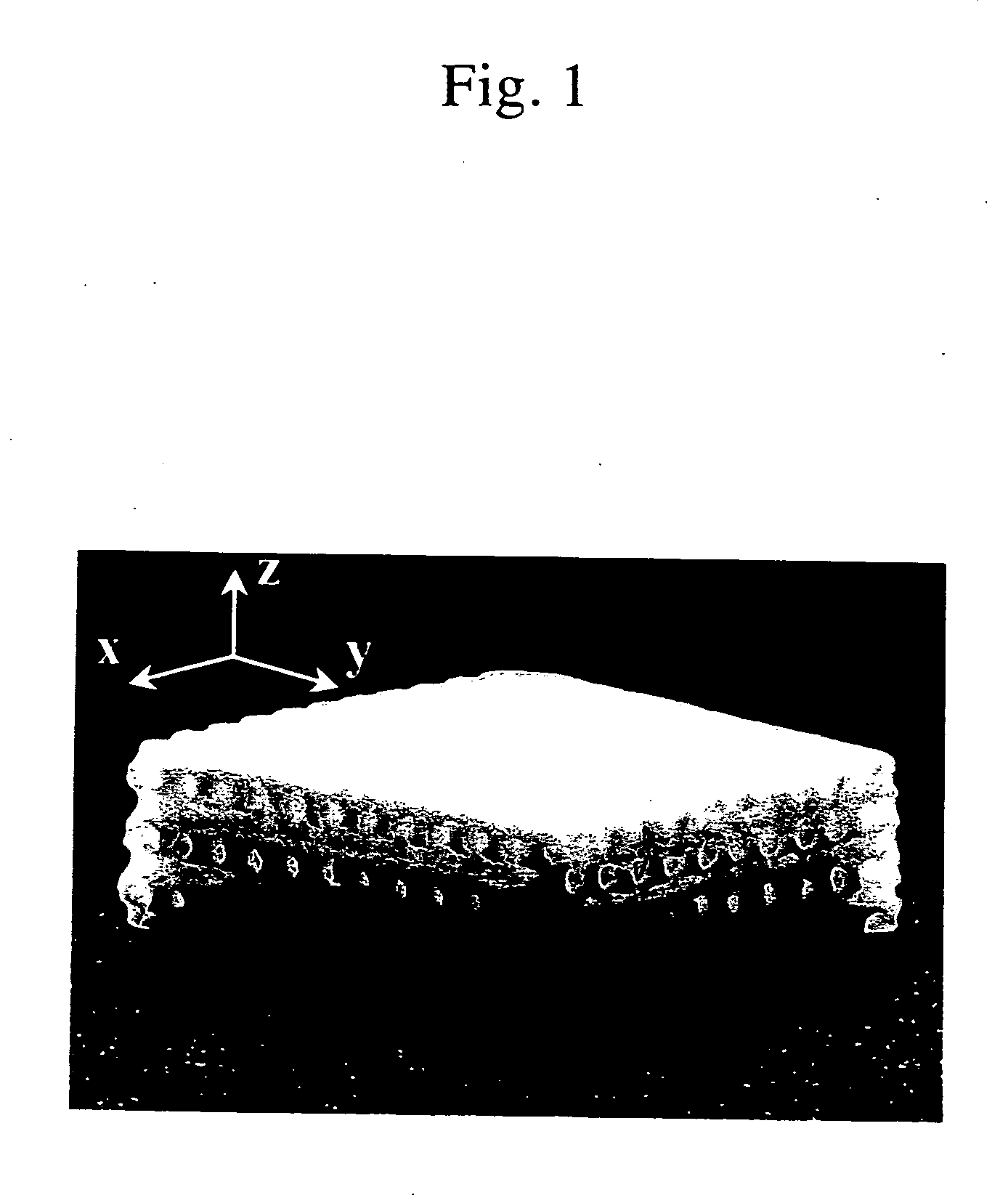

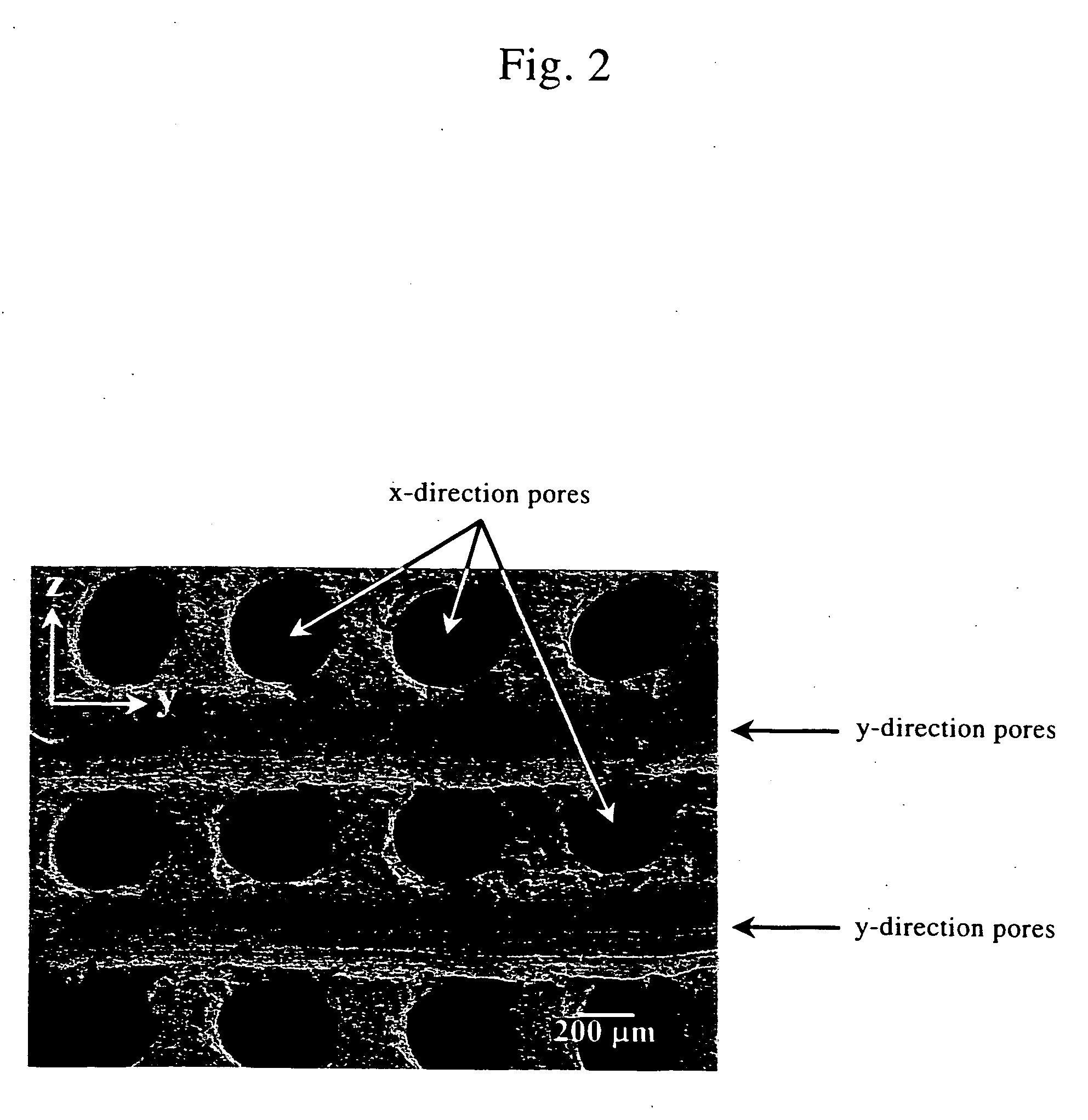

InactiveUS20050049715A1Good fluidity of powderPoor adhesionBone implantJoint implantsPorosityCalcium biphosphate

The present invention provides porous material of calcium phosphate of high strength whose open pores penetrate the porous body and have a size of 70 μm or more, preferably 100 μm or more, and are arranged in a three-dimensional network, whose porosity is sufficiently high for blood vessels to invade and perforate itself or for cells to infiltrate itself, whose chemical composition, in particular, Ca / P molar ratio can be freely changed within the range of 0.75 to 2.1, to which elements important for facilitating osteogenesis and producing resorbable effect can be added, and whose phase composition can be relatively easily changed. The invention is porous sintered compact of calcium phosphate which has artificially formed, penetrated open pores 70 μm to 4 mm in diameter, whose porosity is from 20% to 80%, and whose chief ingredient is calcium phosphate having a Ca / P molar ratio of from 0.75 to 2.1.

Owner:NAT INST OF ADVANCED IND SCI & TECH

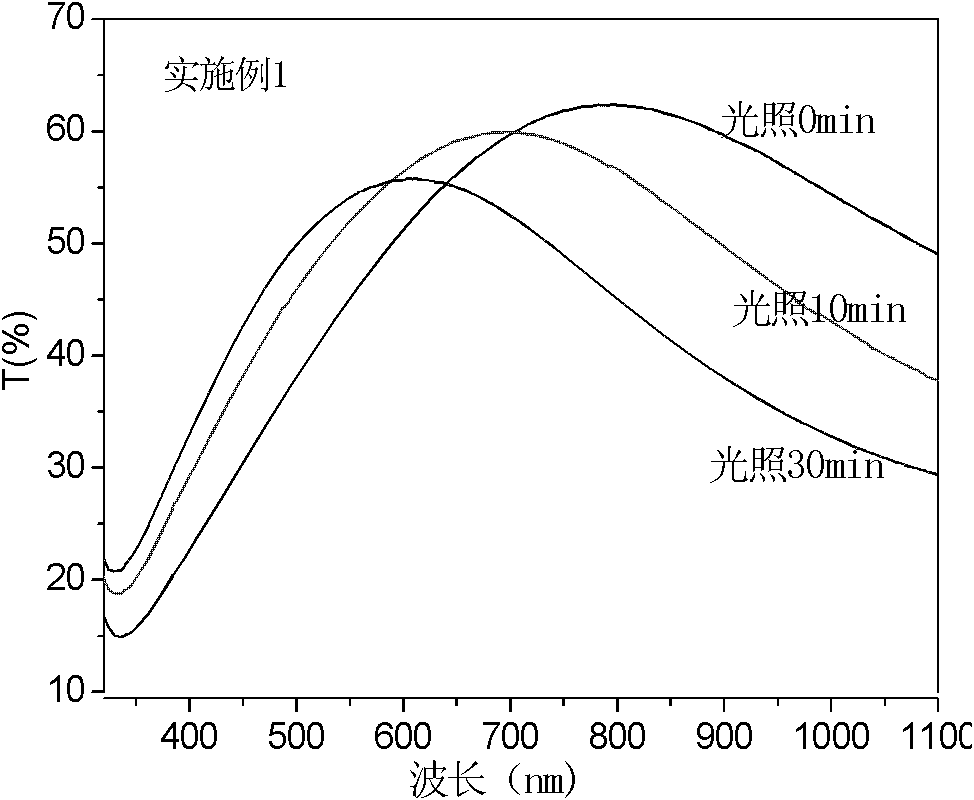

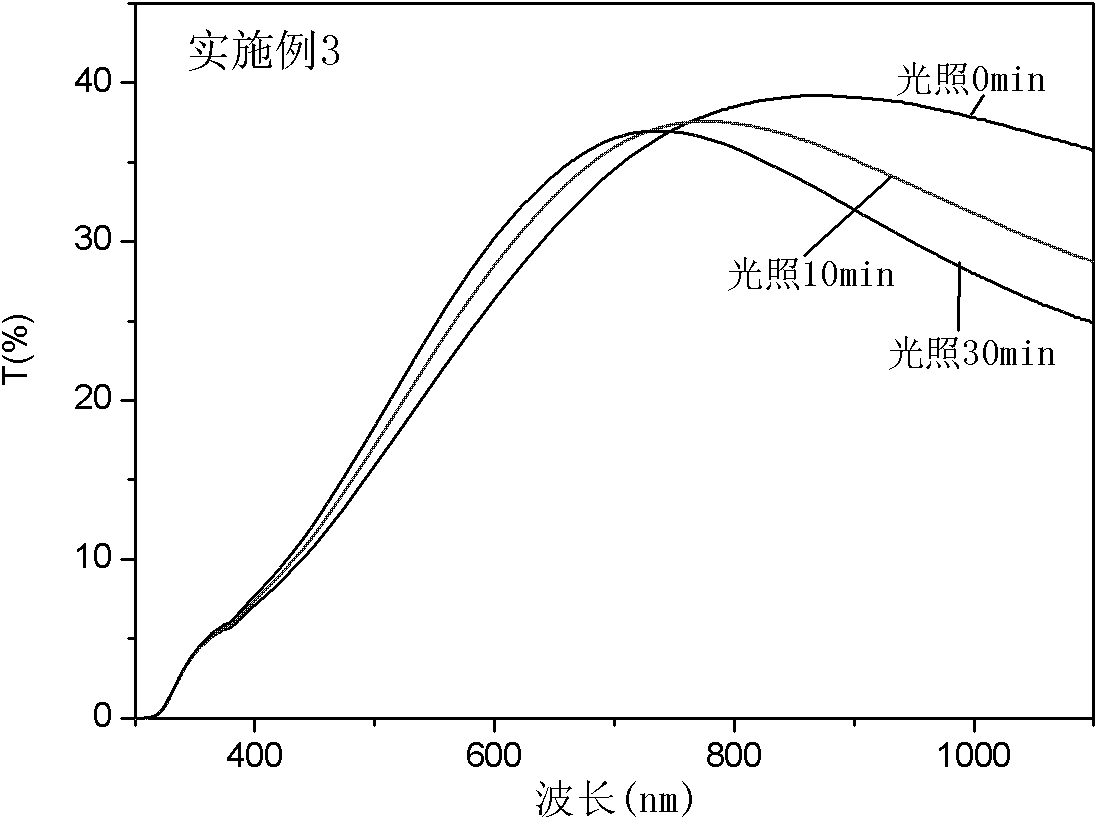

A kind of glass transparent thermal insulation coating and preparation method thereof

A glass transparent heat-insulating coating and its preparation method, the coating contains cesium tungsten bronze powder with a general formula of Cs0.1-3.5WO3, the crystal phase composition of the powder is Cs0.2WO3 or Cs0.32WO3, the powder The particle size is 100-1300nm, and the specific surface area is 7-50m2 / g. The glass transparent heat-insulating coating of the present invention has the functions of visible light transmission and near-infrared shielding, and has the function of light self-regulation, that is, with the extension of light intensity and light time, the effects of visible light transmission and near-infrared shielding will be further enhanced , so it is especially suitable for preparing transparent thermal insulation film on the surface of glass. It is an intelligent transparent thermal insulation coating for glass and has broad application prospects in the fields of thermal insulation of architectural window glass and automotive glass. The coating has simple components and is suitable for large-scale industrial production and practical application.

Owner:DALIAN POLYTECHNIC UNIVERSITY

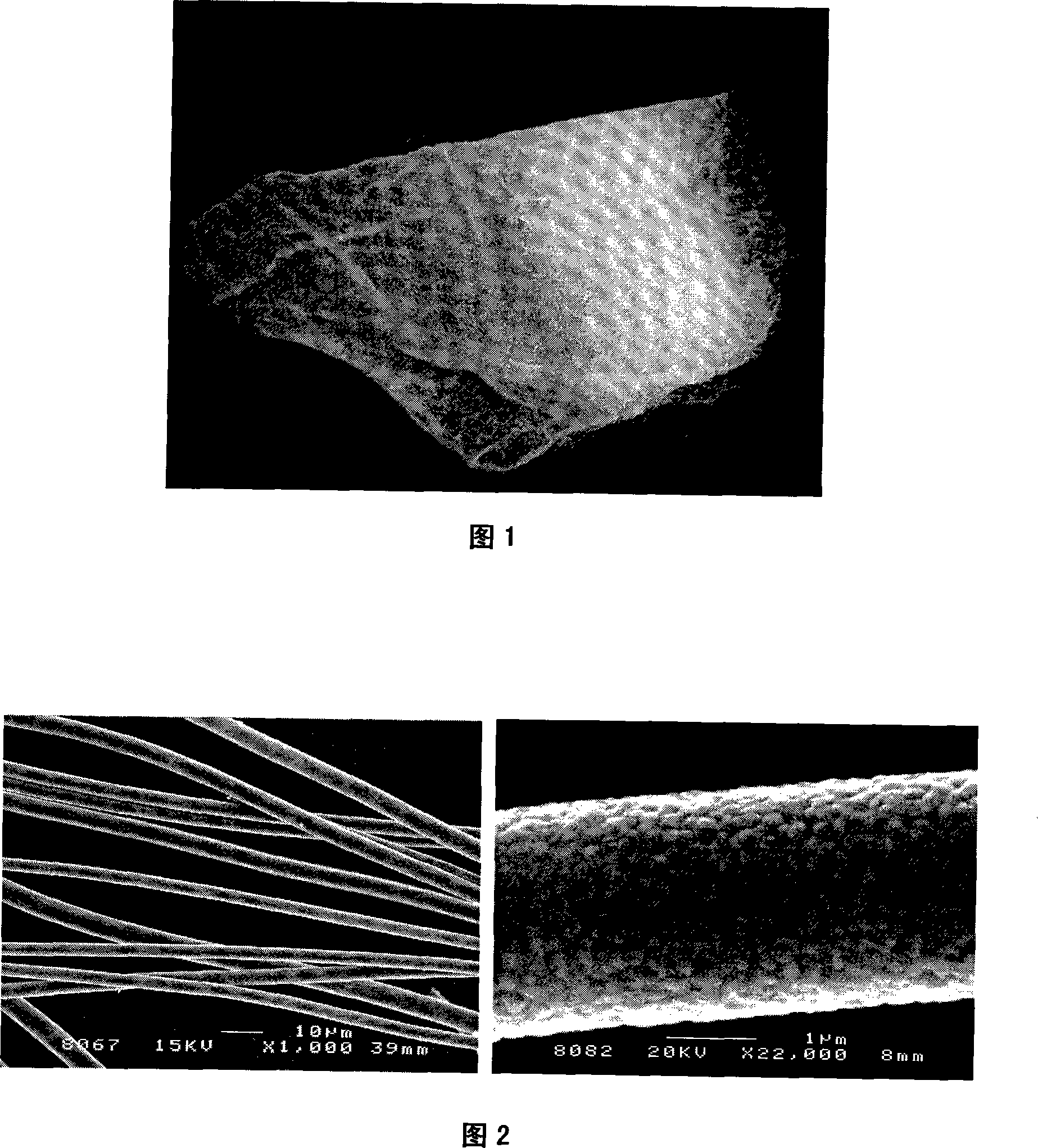

Method for preparing zirconium oxide refractory fibre

The present invention provides a method for preparing a zirconium oxide refractory fiber. The method adopts zirconium oxychloride, aqueous hydrogen peroxide solution, yttrium chloride or yttrium nitrate as raw material, the inorganic zirconium spinnable glue solution is made by reaction and compression, the gelatinous fiber can be obtained by centrifugal fiber forming, and after heat treating sintering the zirconium oxide refractory fiber which has the following advantages can be obtained: crystal phase composition with square phase and / or cubic phase zirconium oxide, purity up to 99.5% above, diameter around 5 mu m, length approximate continuous, soft and flexible property and without slag including sphere. The using temperature of the fiber is above 1600 DEG C, the material can be used as extreme temperature refractory, heat insulation material, protecting material, ablative material, satellite battery separator material and the like, used for the fields of aerospace, war industry and national defense, atomic energy and the like; the fiber can also be used as the flame-proof heat-insulating material of the extraordinary high-temperature electric furnace with temperature 1600 DEG C to 2200 DEG C, the oil or gas burning furnace and other extraordinary high-temperature heating mechanism, and is used for the fields of ceramic sintering, crystal growth, metal smelting, petroleum cracking, scientific researching and the like. The invention totally adopts the inorganic raw material, has the advantages of low cost, no pollution, simple technique and excellent effect.

Owner:山东红阳高温节能材料股份有限公司

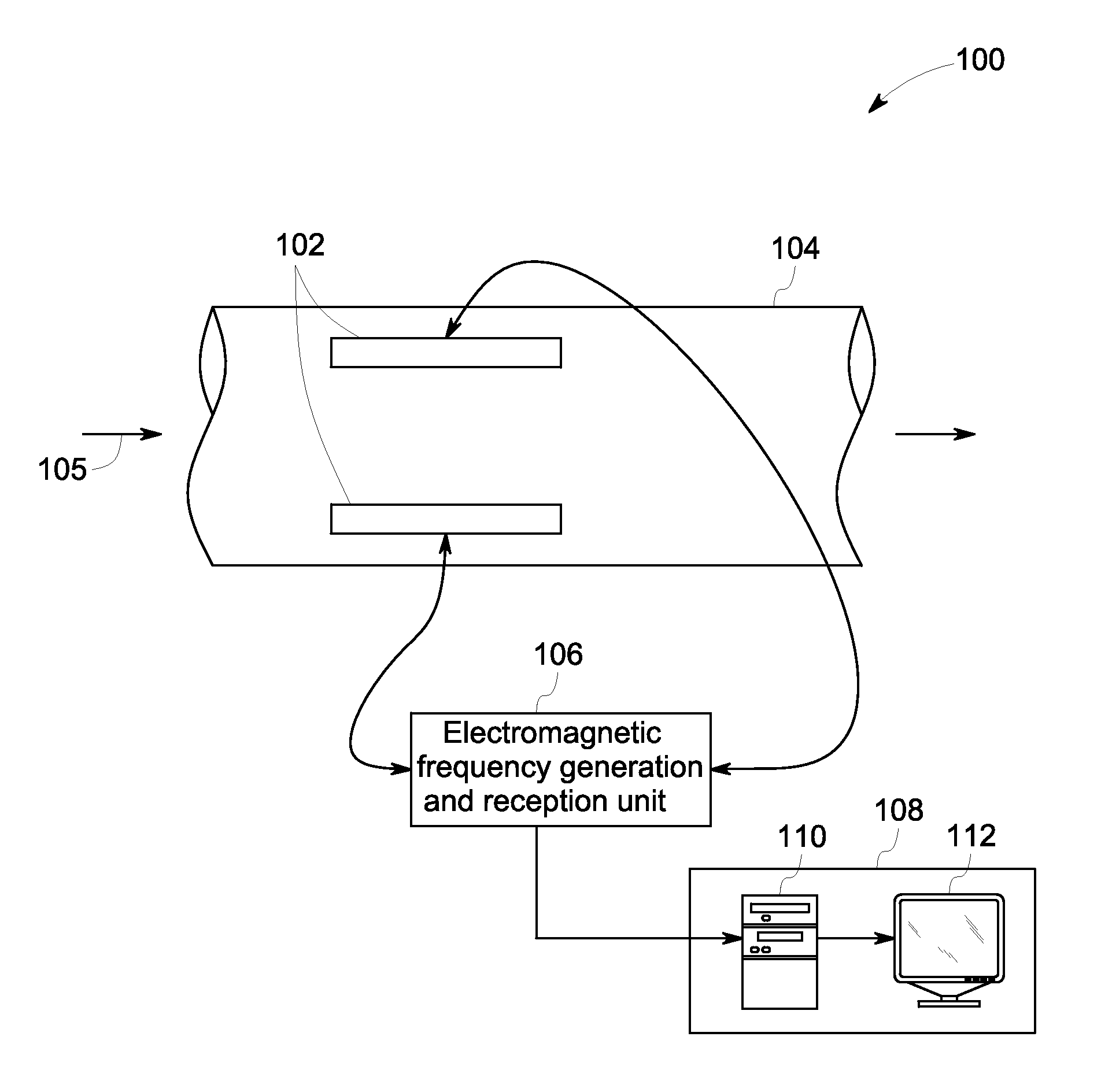

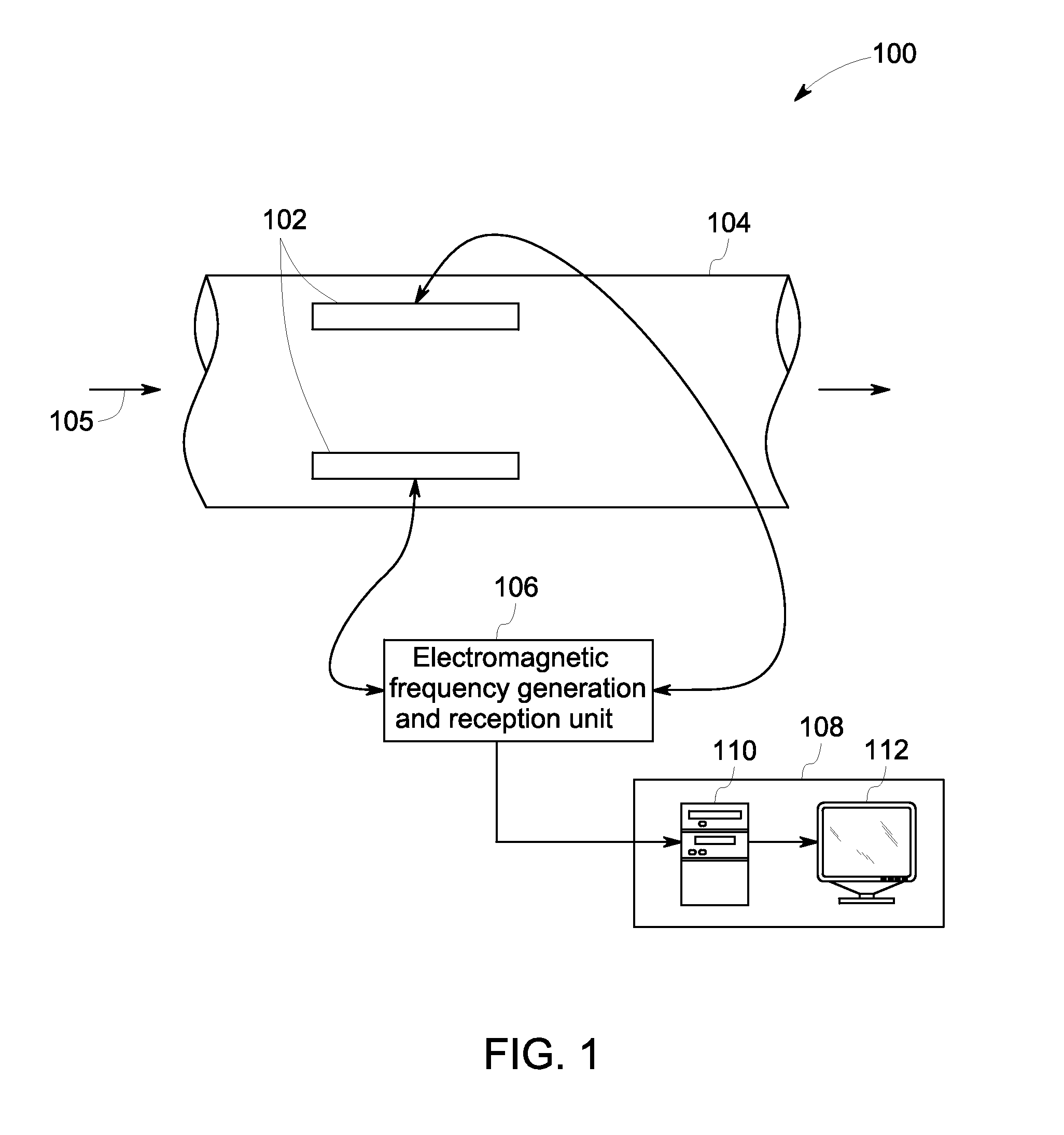

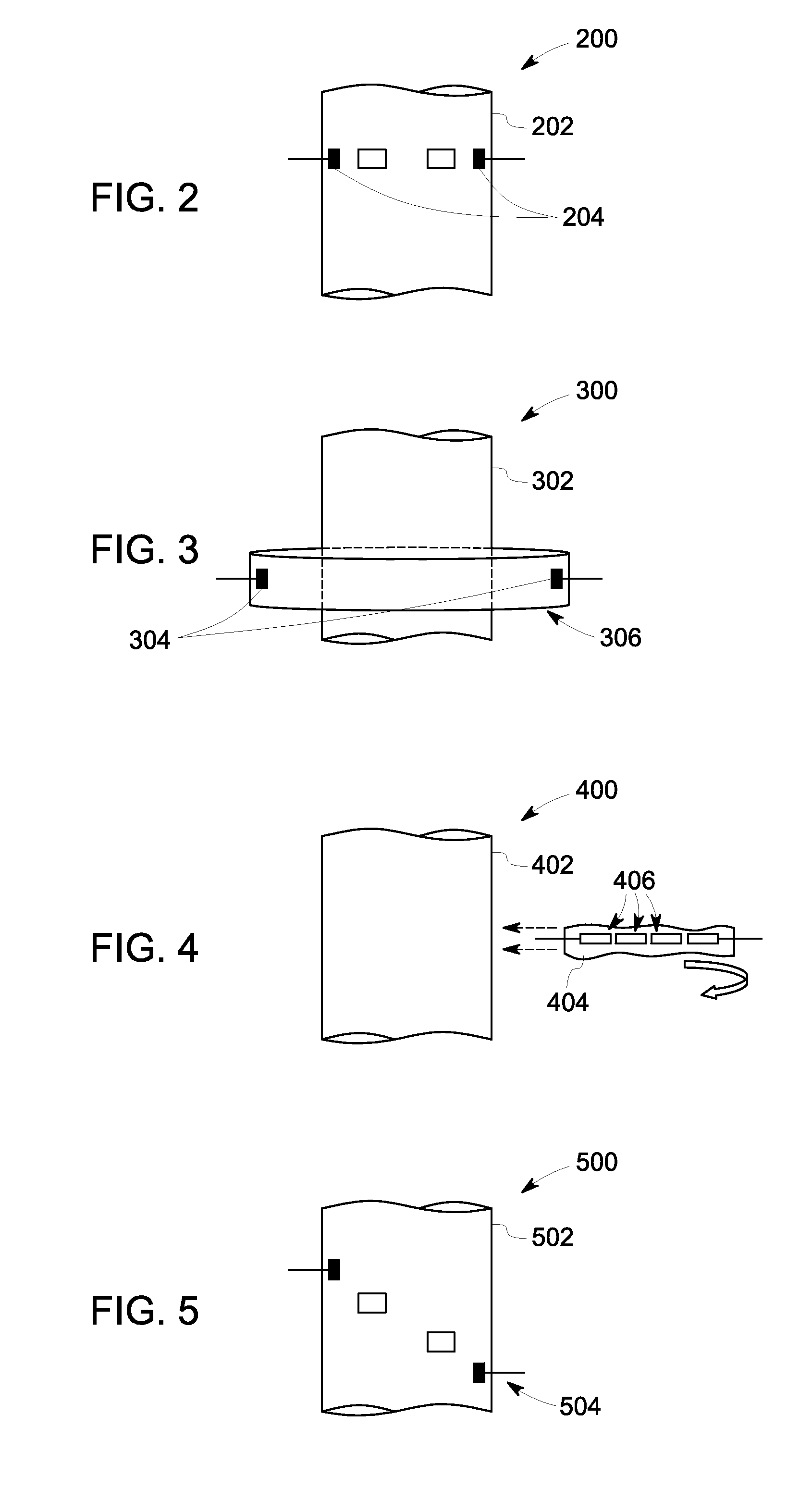

Multiphase flow measurement using electromagnetic sensors

Owner:BAKER HUGHES INC

Regeneration method of catalyst for dehydrogenation of low-carbon alkanes

ActiveCN101940959AExtend the life cycleExtended service lifeCatalyst regeneration/reactivationHydrocarbonsAir atmosphereAlkane

The invention discloses a regeneration method of a catalyst for dehydrogenation of low-carbon alkanes, which comprises the following steps: firstly regenerating the catalyst in the air atmosphere at a lower temperature, burning out carbon deposits on the surface of the catalyst and most of carbon deposits in holes, and then preferably regenerating the catalyst further in a vapor-air mixed atmosphere at a temperature of 400-500 DEG C, so that the carbon deposits on the surface of the catalyst and in the holes can be completely removed, and simultaneously, the acid value and the acid distribution of the catalyst can be modulated so as to restore the crystal form and crystal phase composition of the deactivated catalyst to the original state of the fresh catalyst. Thus, the catalyst can be regenerated, and simultaneously, the physicochemical properties and the dehydrogenation activity of the regenerated catalyst are similar to those of the fresh catalyst, thereby prolonging the service cycle and life of the catalyst. The method has the advantages of moderate regeneration conditions and short regeneration time, and further lowers the production cost of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

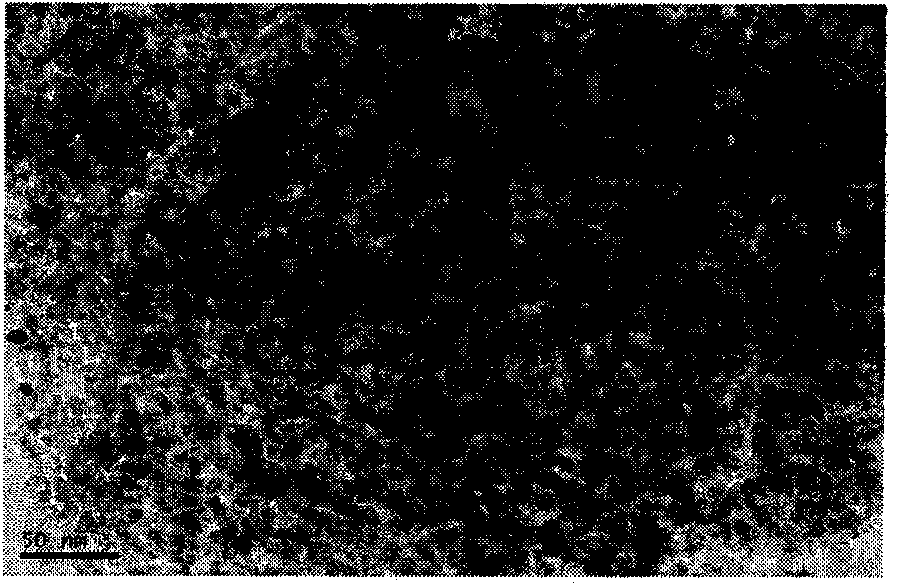

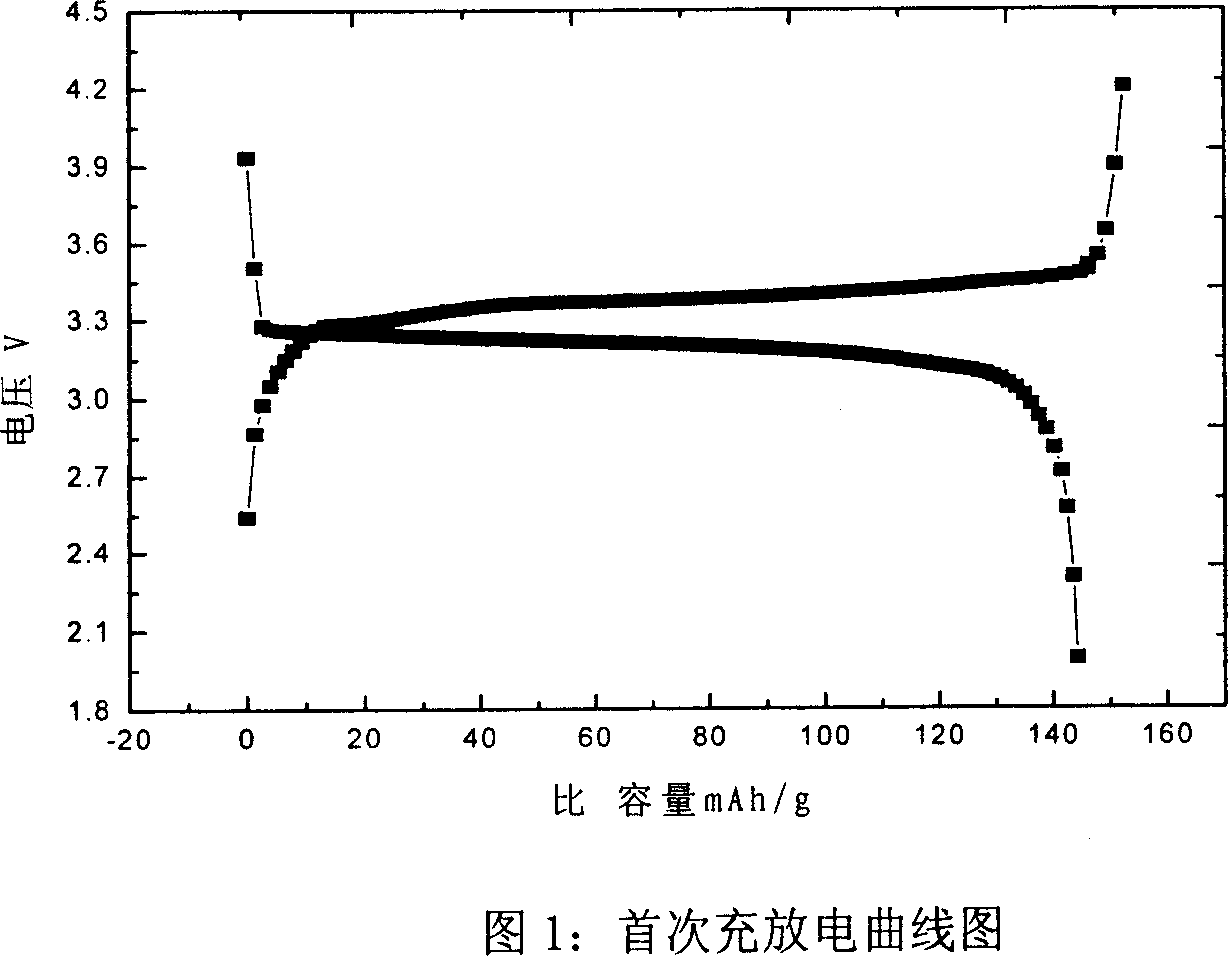

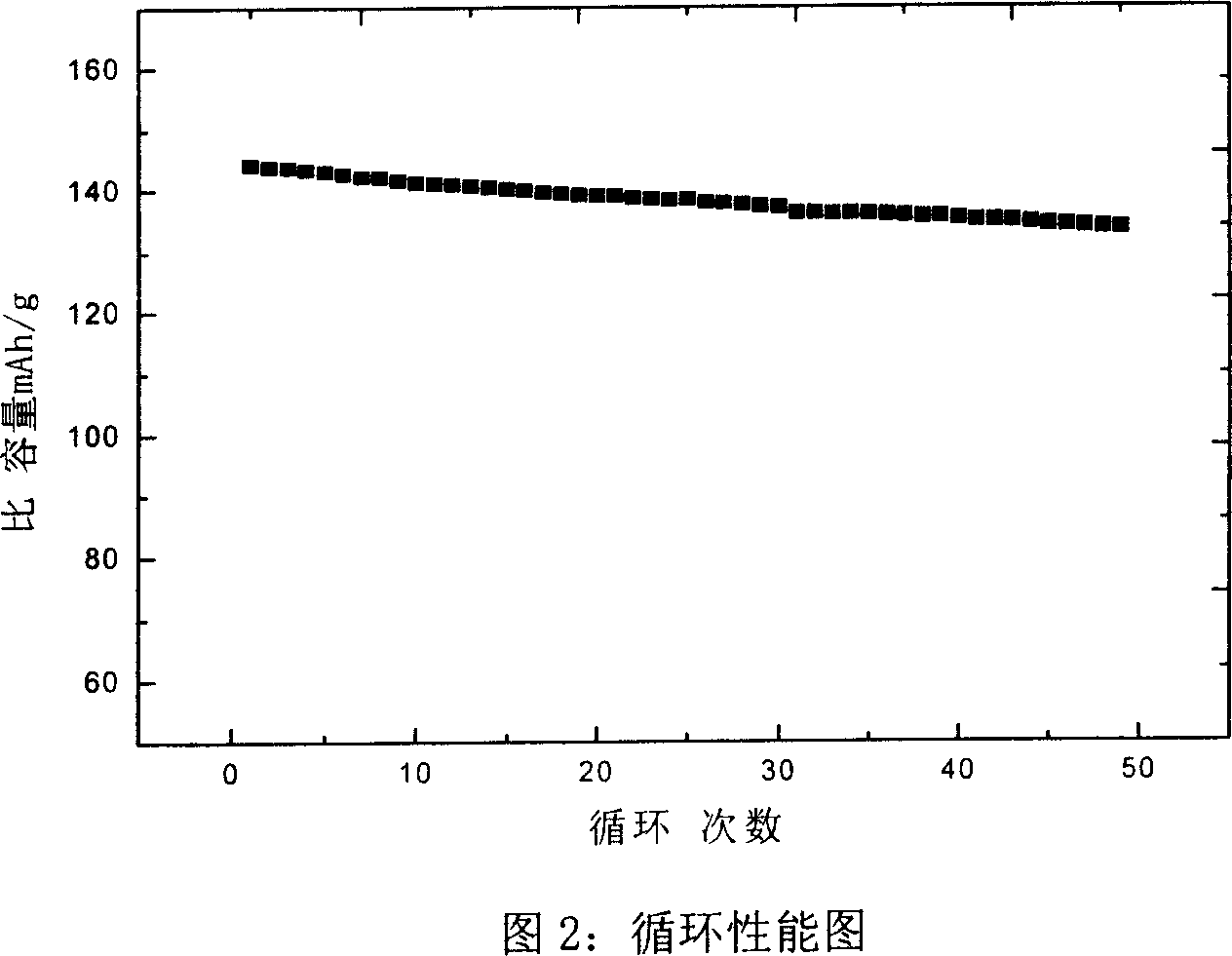

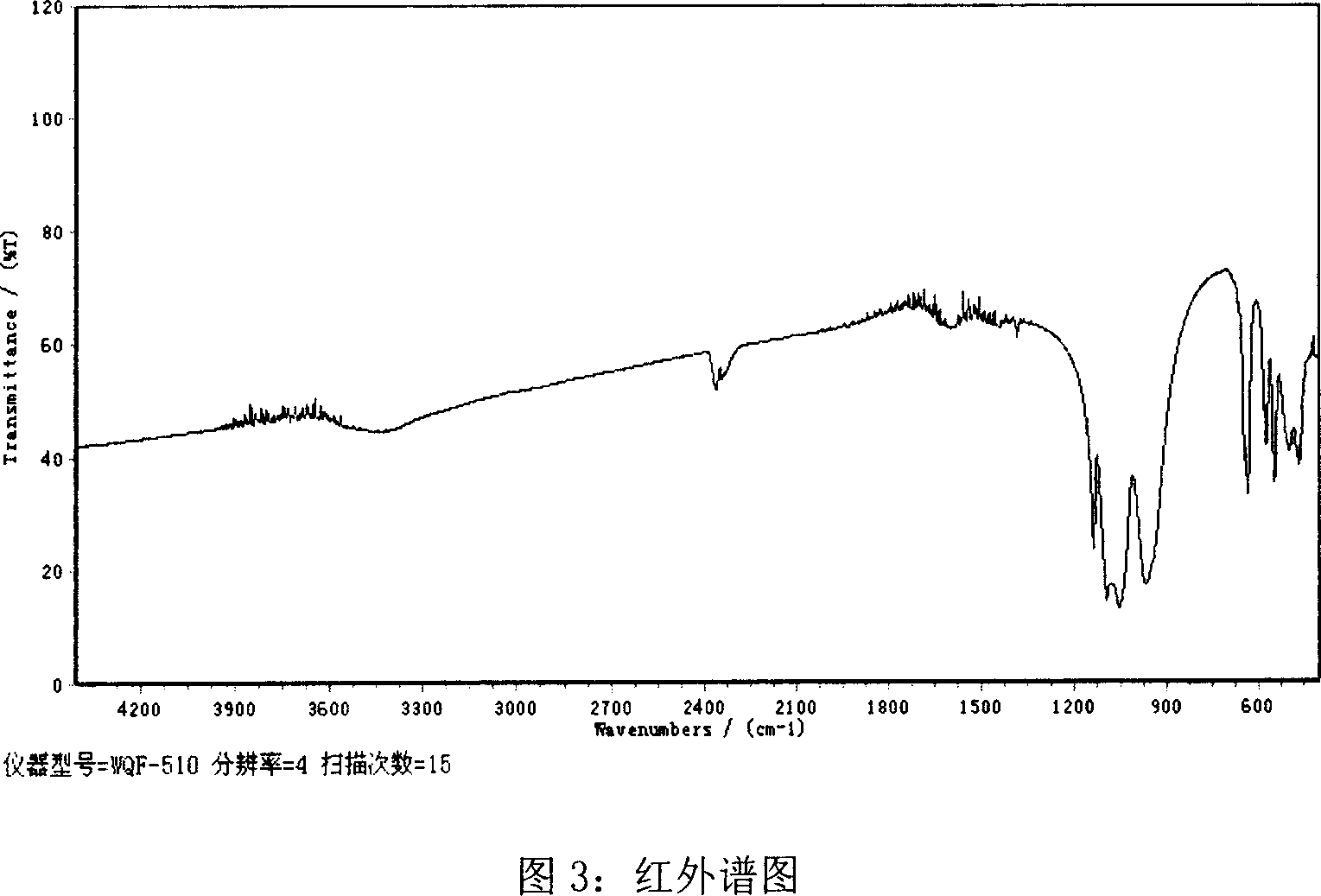

High density ultrafine composite ferric lithium phosphate anode material and preparation method

ActiveCN1907844AChemical composition is easy to controlEasy to dopeCell electrodesPhosphorus compoundsIron saltsOrganic compound

This invention belongs to battery field, which relates to ultra-micro compound lithium iron phosphate cathode material with high density and its fabrication method. Said cathode material is prepared by mixing iron salt, lithium salt and phosphates at a P / Li / Fe ratio of 1-1.1:1-1.1:1-1.1, adding conductive additives containing dopant element and carbon-bearing organic compound, adding organic acid as carrier, adjusting pH, controlling solution temperature in reactor to form sol, separating the sol to obtain nano-precursor and placing it into micorwave oven under protection of inert gas, and obtaining the final product. It is easy to control the chemical component, phase composition and particle size distribution. The conductive additive can be well-distributed. The method also has the advantages of short reaction time, low energy consumption during synthesis process and low cost. The obtained composite has high purity and good compatibility with electrolyte, excellent conductive property and charge and discharge property with large current, and good structure stability,thermal stability and cycle performance.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

Stannous oral compositions

InactiveUS20050112070A1Minor side effectsEfficient deliveryCosmetic preparationsToilet preparationsSide effectStaining

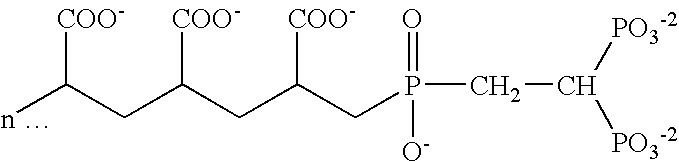

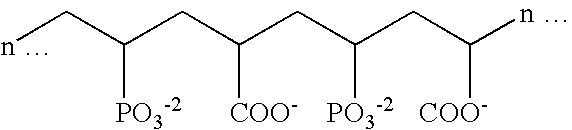

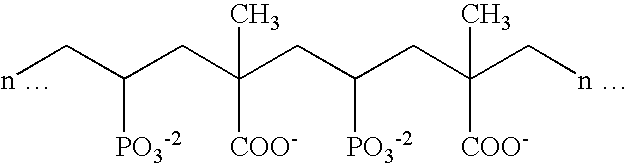

Disclosed are oral compositions comprising a stannous ion source, a fluoride ion source, and a polymeric mineral surface active agent that binds stannous, said compositions providing adequate therapeutic efficacy with minimal side effects of tooth staining and astringency. The composition simultaneously provides reduction and control of supragingival calculus. The present oral care compositions may be formulated as single phase or dual phase compositions. The present invention also provides a method for effective delivery of stannous-containing compositions with minimal side effects of tooth staining or astringency and with effective tartar control by administering to a subject a stable dentifrice composition comprising a clinically effective amount of stannous fluoride and / or other stannous salts in combination with a fluoride ion source and a polymeric mineral surface active agent, preferably a phosphate- or phosphonate-containing polymer.

Owner:THE PROCTER & GAMBLE COMPANY

Nanometer ferrous silicate lithium material and preparation method thereof

ActiveCN101546828AHigh purityHigh charge and discharge capacityElectrode manufacturing processesPhosphorus compoundsCarbon nanotubeReaction temperature

The invention relates to a nano ferrous silicate lithium material and a preparation method thereof. The preparation method comprises the following steps: a lithium source, an iron source, a silicate source and a doping element compound are dissolved into a water solution which contains a complexing agent according to a certain stoichiometric ratio, a high-conductivity carbon nano tube dispersed by an auxiliary agent is added into the water solution and used as a wrapping material, an obtained solution is heated under the temperature of 100-200 DEG C for 1-3 hours to obtain gelatin, the obtained gelatin is sintered in an inert atmosphere furnace, the reaction temperature is 600-900 DEG C, and the reaction time is 3-16 hours. The invention effectively controls the chemical composition, the phase composition and the grain diameter of ferrous silicate lithium, and the obtained ferrous silicate lithium is nano ferrous silicate lithium wrapped by the carbon nano tube and has small and uniform grains with high purity quotient, higher charge-discharge capacity and good multiplying power property and circulation property, thus the ferrous silicate lithium is an ideal material for producing lithium ion batteries.

Owner:SHENZHEN DYNANONIC

Pumpable multiple phase compositions for controlled release applications downhole

Pumpable multiple phase vesicle compositions carry agents and components downhole or through a conduit, and controllably releasing them at a different place and time by breaking the compositions. In one non-limiting embodiment the pumpable multiple phase vesicles have a third phase containing a first phase which bears the agent to be controllably released. The first and third phases of the vesicles are separated by a surface active material bilayer that forms the second phase. The pumpable multiple phase vesicles may have internal and external phases that are both oil miscible, both aqueous miscible, or both alcohol miscible. The surface active material bilayer may be composed of compounds such as phospholipids, alkyl polyglycosides, gemini surfactants, sorbitan monooleate, sorbitan trioleate, and many others. The agent may be released by one or more of a variety of mechanisms.

Owner:BAKER HUGHES INC

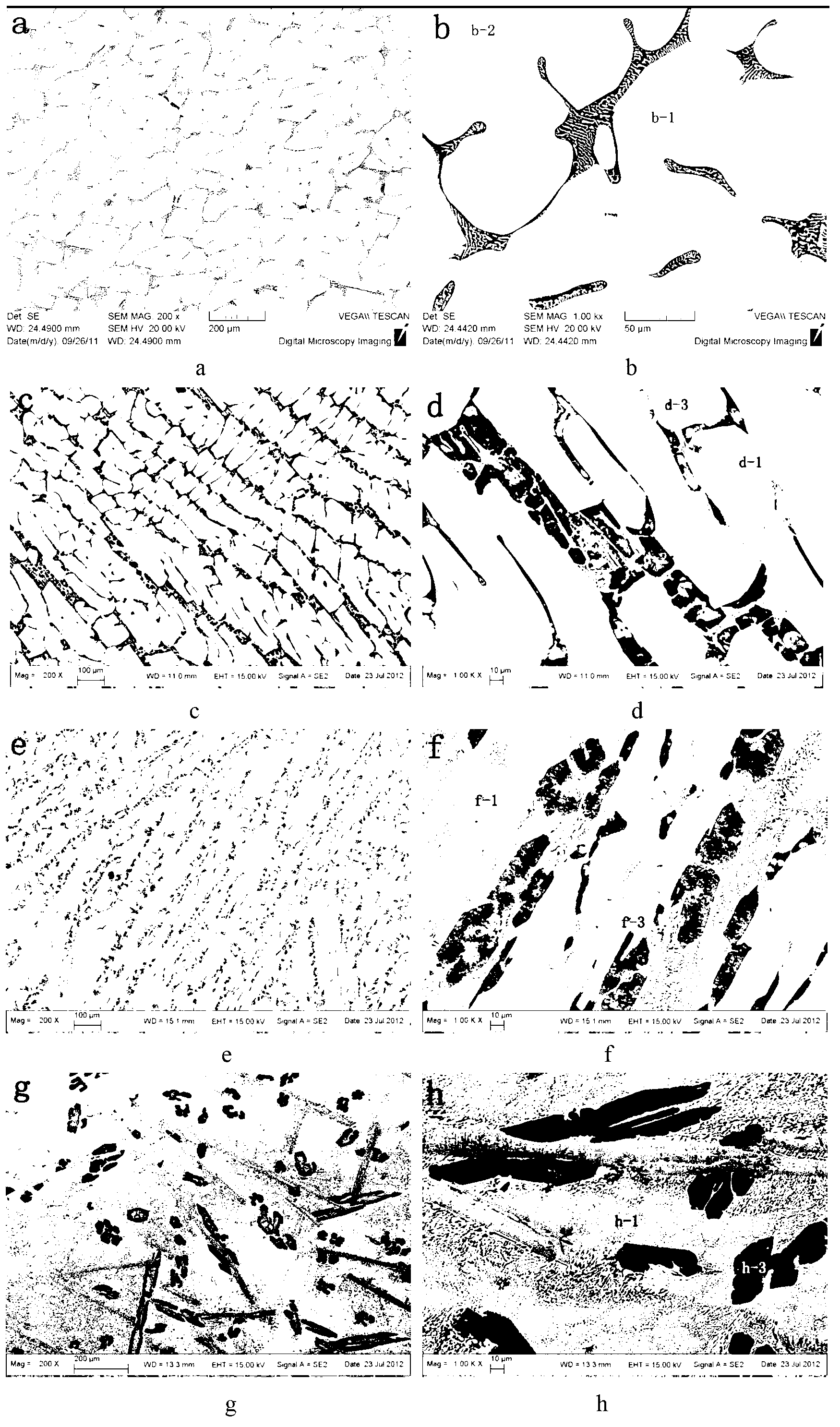

Method of representing microstructure of scale on section of hot-rolled steel plate by adoption of EBSD

ActiveCN103837557AIntuitive Microscopic MorphologyIntuitive display of microscopic topographyMaterial analysis using wave/particle radiationMetallic materialsStressed state

The invention relates to a method of representing a microstructure of scale on a section of a hot-rolled steel plate by adoption of EBSD, and belongs to the technical field of physical property examination of metal materials. The phase, the orientation, the stress state, and other data of a sample, which are obtained by back scattering diffraction information formed by irradiating electron beams onto the surface of the sample, are utilized to analyze a crystalline-state material. The back scattering signals are very sensitive to the surface of the sample, and therefore the sample used for EBSD observation needs high flatness and the least stress layers as possible. The method is advantageous in that: problems of scale sample preparation difficulties, namely, easy breakage and poor conductive performance, are solved; a scale section representing problem of the hot-rolled steel plate is solved; scale crystallographic parameters are selected in subsequent EBSD surface scanning; each phase is indentified by utilization of structural information; and the microcosmic conformation, the phase composition and the crystal grain size of the scale are represented accurately, thus achieving accurate qualitative / quantitative representation of the scale on the section of the hot-rolled steel plate.

Owner:SHOUGANG CORPORATION

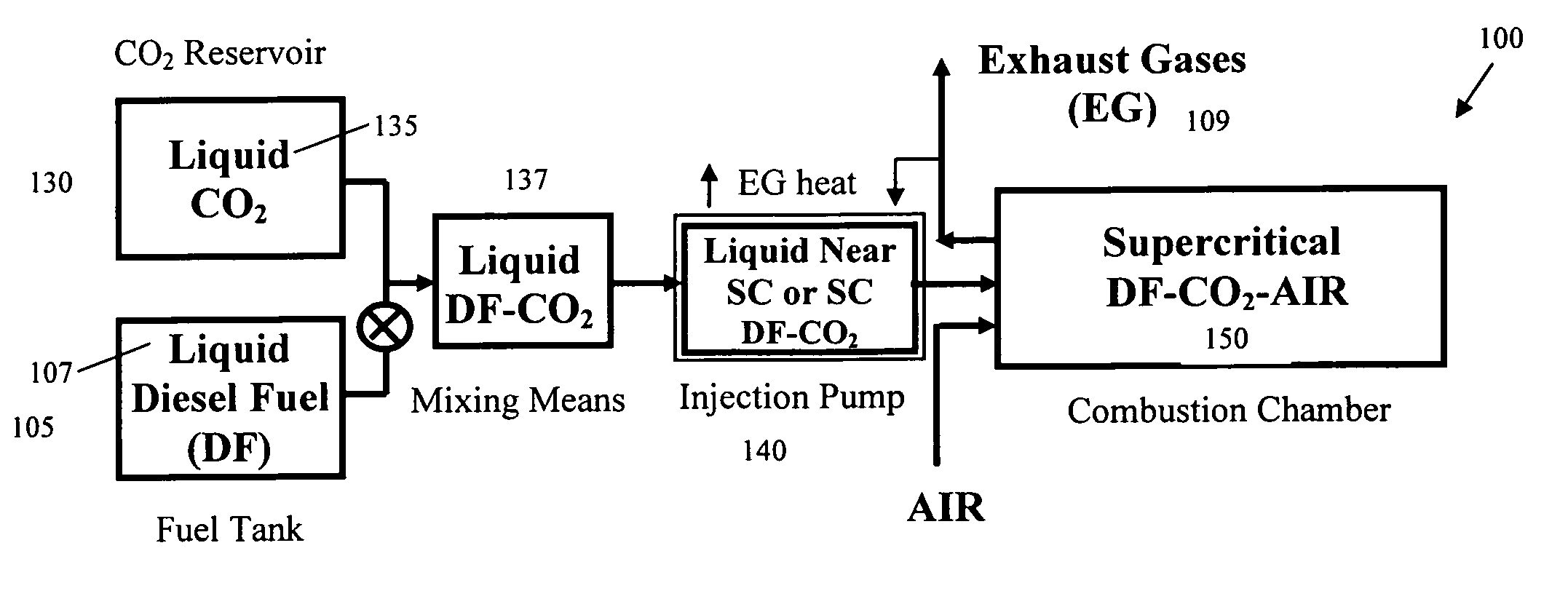

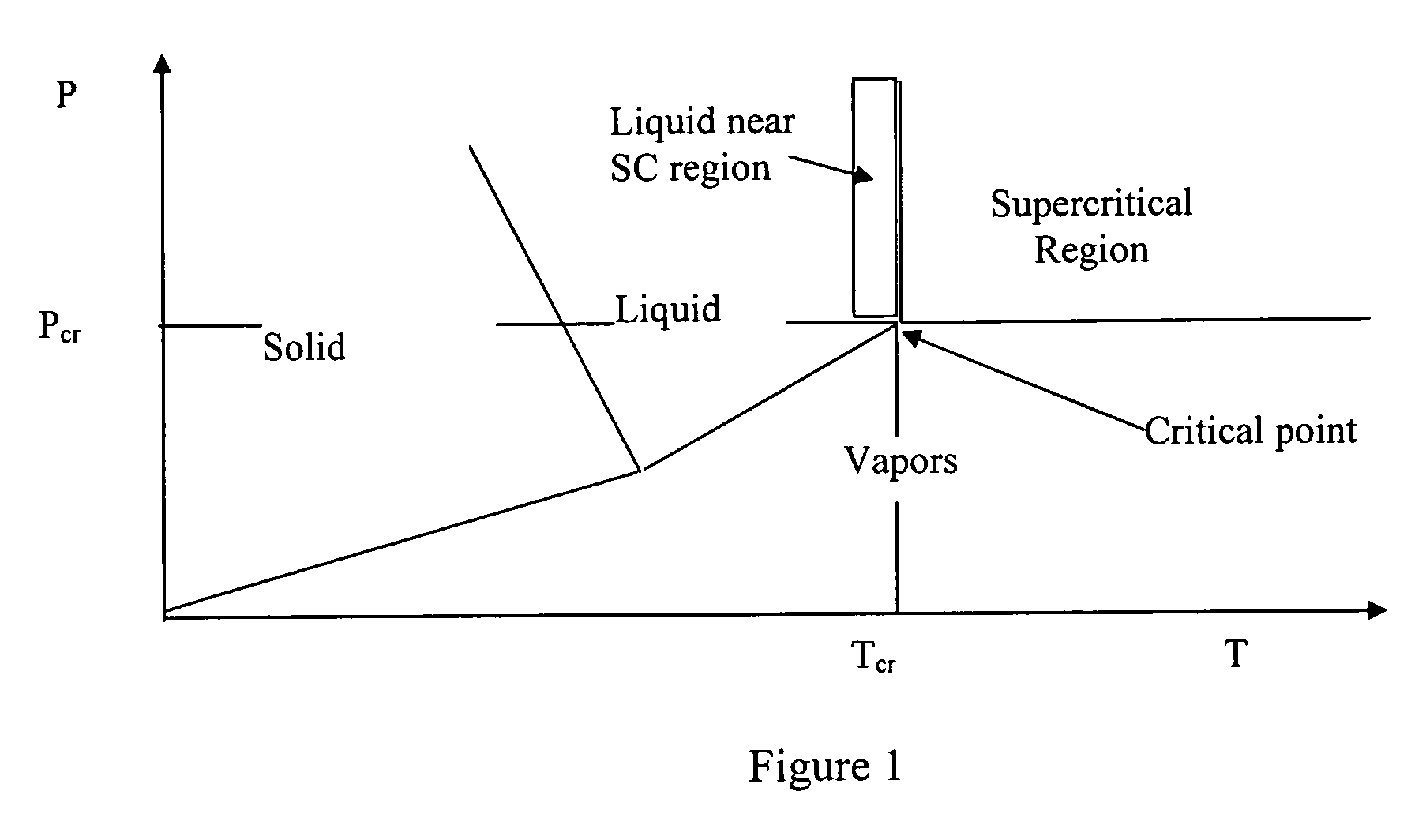

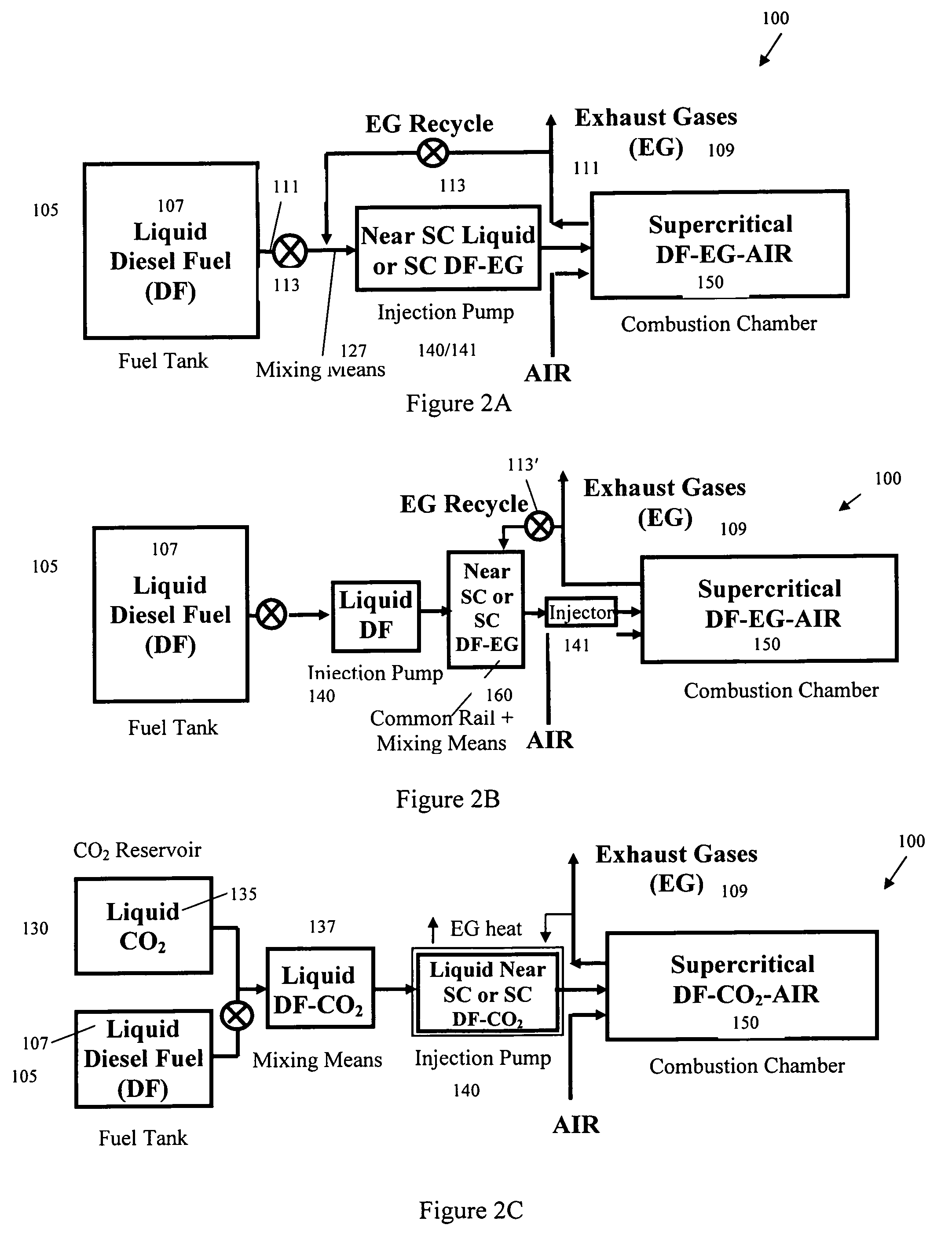

Supercritical diesel fuel composition, combustion process and fuel system

ActiveUS7488357B2Internal combustion piston enginesNon-fuel substance addition to fuelParticulatesBiodiesel

An embodiment of the invention is a composition of diesel, biodiesel or blended fuel (DF) with exhaust gas (EG) mixtures or with liquid CO2. The composition is in a liquid state near the supercritical region or a supercritical fluid mixture such that it quasi-instantaneously diffuses into the compressed and hot air as a single and homogeneous supercritical phase upon injection in a combustion chamber. Suitable temperatures and pressures are greater than about 300° C. and 100 bar, and the mole fraction of EG or CO2 (XEG or XCO2) in DF is in the range of 0.0-0.9. In a combustion process embodiment, composition embodiments are injected into a combustion chamber under supercritical conditions. The content of EG or CO2 in DF can be controlled as a function of engine operating parameters such as rpm and load. The thermodynamic and transport properties of supercritical DF-EG or DF-CO2 compositions can be more easily tuned and controlled than subcritical two-phase compositions. Delivery of the DF-EG or DF-CO2 composition into the combustion chamber as a homogeneous isotropic single-phase composition provides a significant increase in engine efficiency. Combustion process and fuel system embodiments of the invention provide an improved composition process with reduced formation of particulate matter (PM), aldehydes, polyaromatic hydrocarbons (PAHs), CO, NOx, and SOx.

Owner:SYRACUSE UNIVERSITY

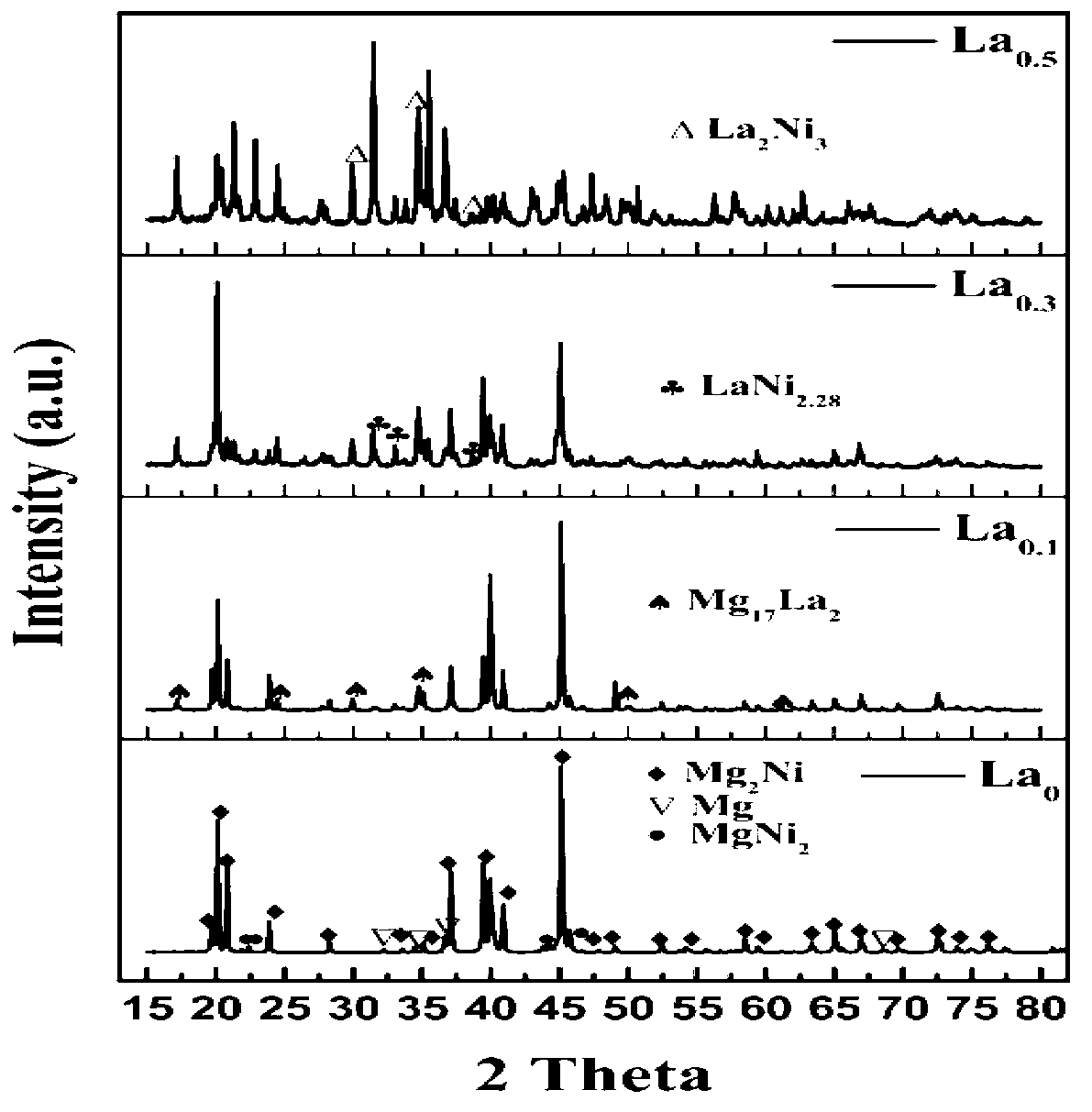

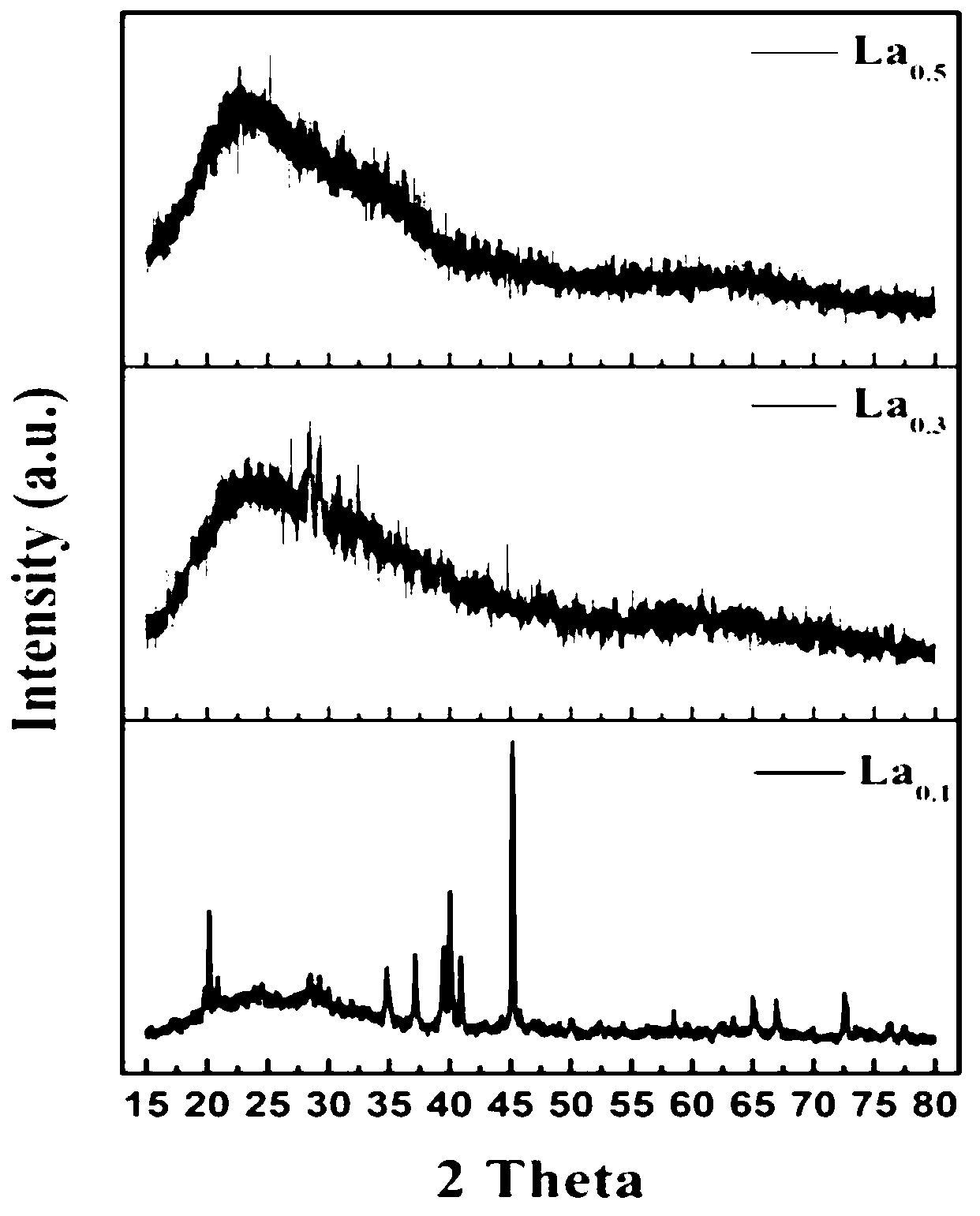

Mg-Ni-La based composite hydrogen-storage alloy powder and preparation process thereof

The invention discloses Mg-Ni-La based composite hydrogen-storage alloy powder and a preparation process thereof. The Mg-Ni-La based composite hydrogen-storage alloy powder is composed of Mg-Ni-La alloy strips and multi-walled carbon nanotubes (MWCNTs) and TiF3 catalysts. According to the Mg-Ni-La based composite hydrogen-storage alloy powder and the preparation process thereof, a melt rapid-quenching technology is used, a melt is ejected by the aid of the argon gas pressure and sprayed on surfaces of rotating smooth copper rods, by the aid of the quenching effect produced by the rotating copper rods, alloy structures are refined, and channels such as grain boundaries / phase boundaries, which are beneficial to diffusion of H atoms, are increased, so that amorphous / nano crystalline alloys are prepared. According to the Mg-Ni-La based composite hydrogen-storage alloy powder, the MWCNTs and the TiF3 catalysts are added simultaneously, rare earth La is added to improve the phase composition of Mg-Ni alloys, the formation of a new phase is beneficial to decomposition of H2 molecules on material surfaces and diffusion of the H atoms in materials, and the hydrogen absorption and desorption dynamic performance of Mg2Ni alloys is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

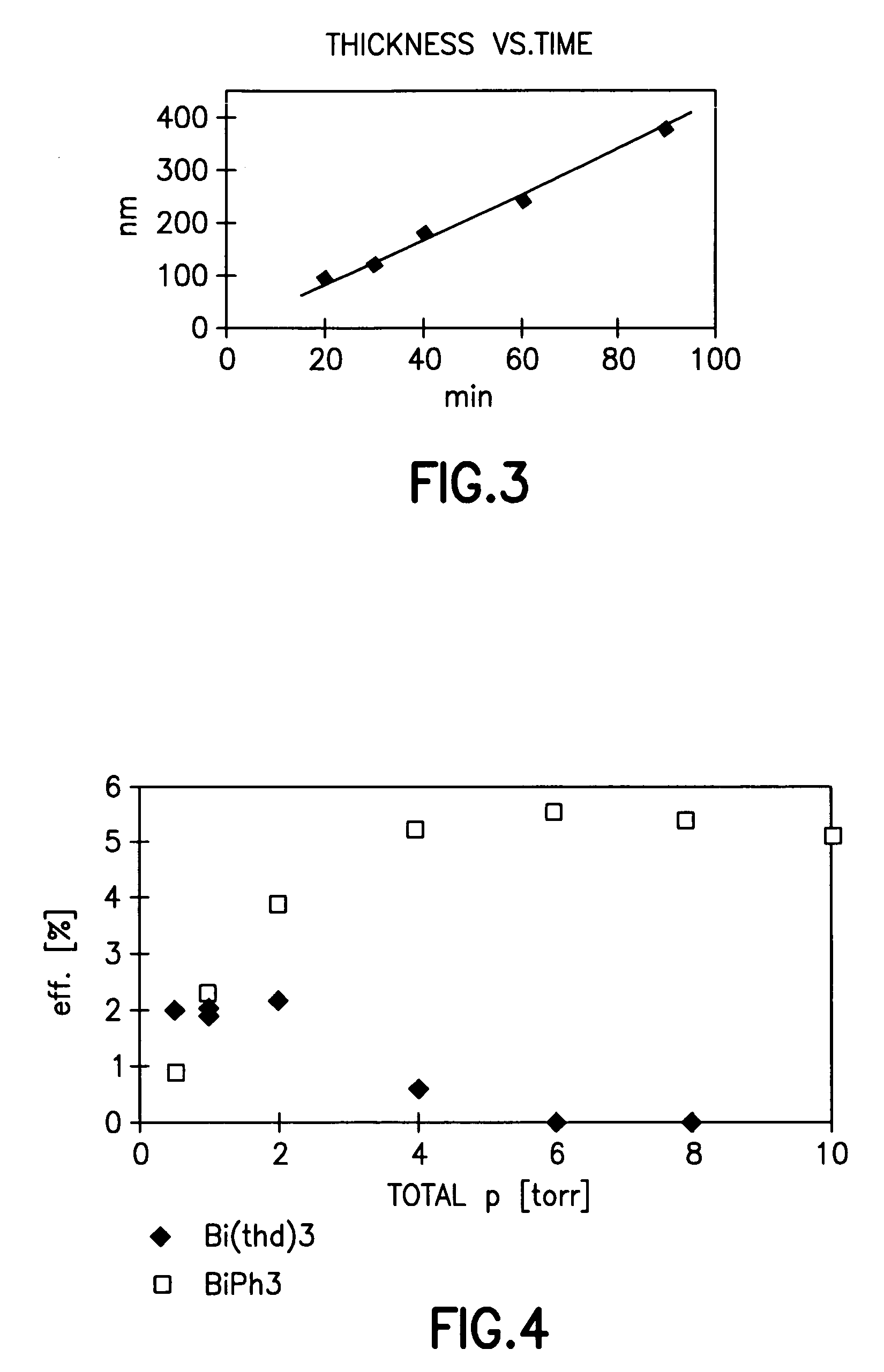

Low temperature chemical vapor deposition process for forming bismuth-containing ceramic thin films useful in ferroelectric memory devices

InactiveUS7005303B2Easy to transportImproved stoichiometry, morphology and ferroelectric characterSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densityGas phase

A low temperature CVD process for deposition of bismuth-containing ceramic thin films suitable for integration to fabricate ferroelectric memory devices. The bismuth-containing film can be formed using a tris(β-diketonate) bismuth precursor. Films of amorphous SBT can be formed by CVD and then ferroannealed to produce films with Aurivillius phase composition having superior ferroelectric properties suitable for manufacturing high density FRAMs.

Owner:ENTEGRIS INC

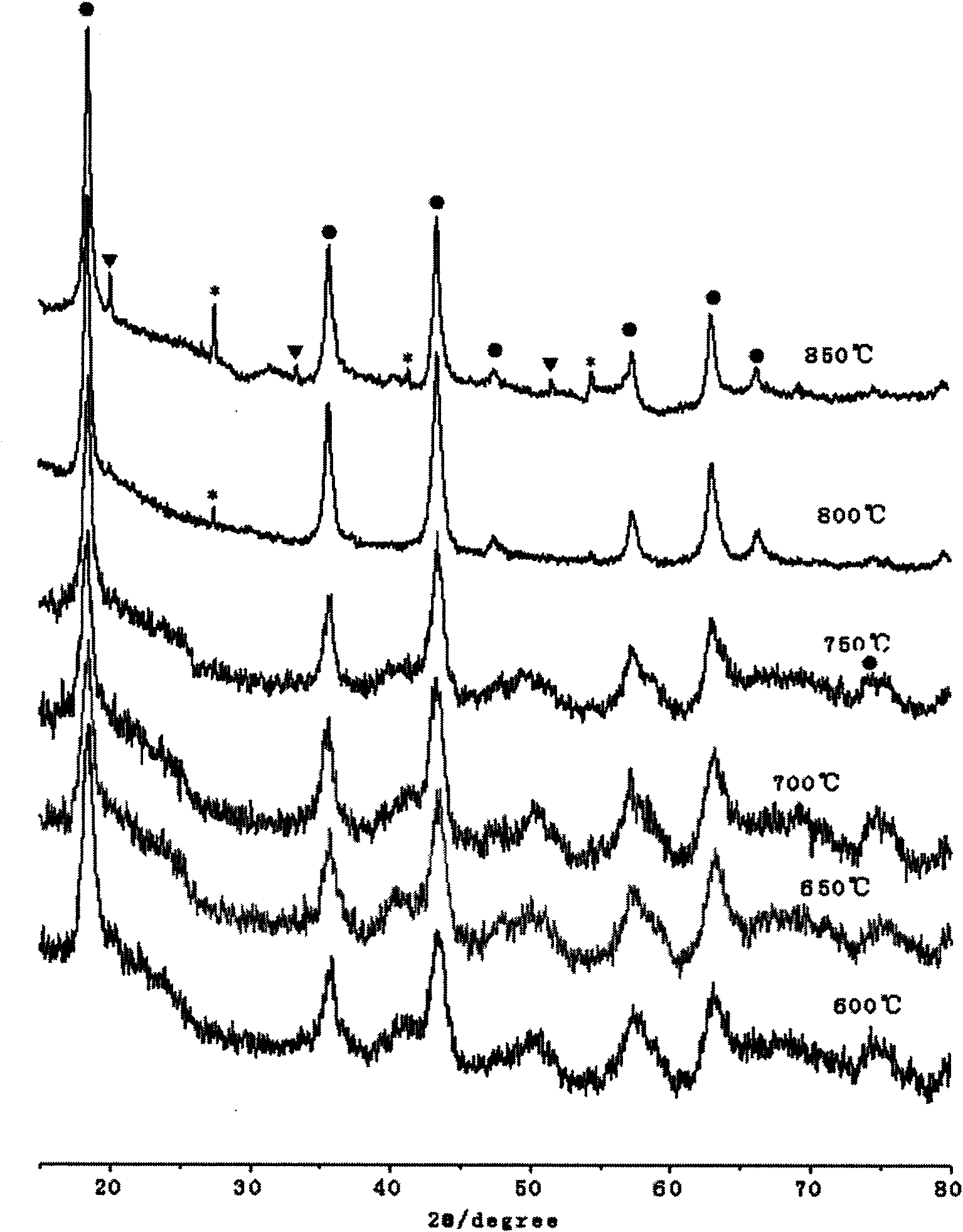

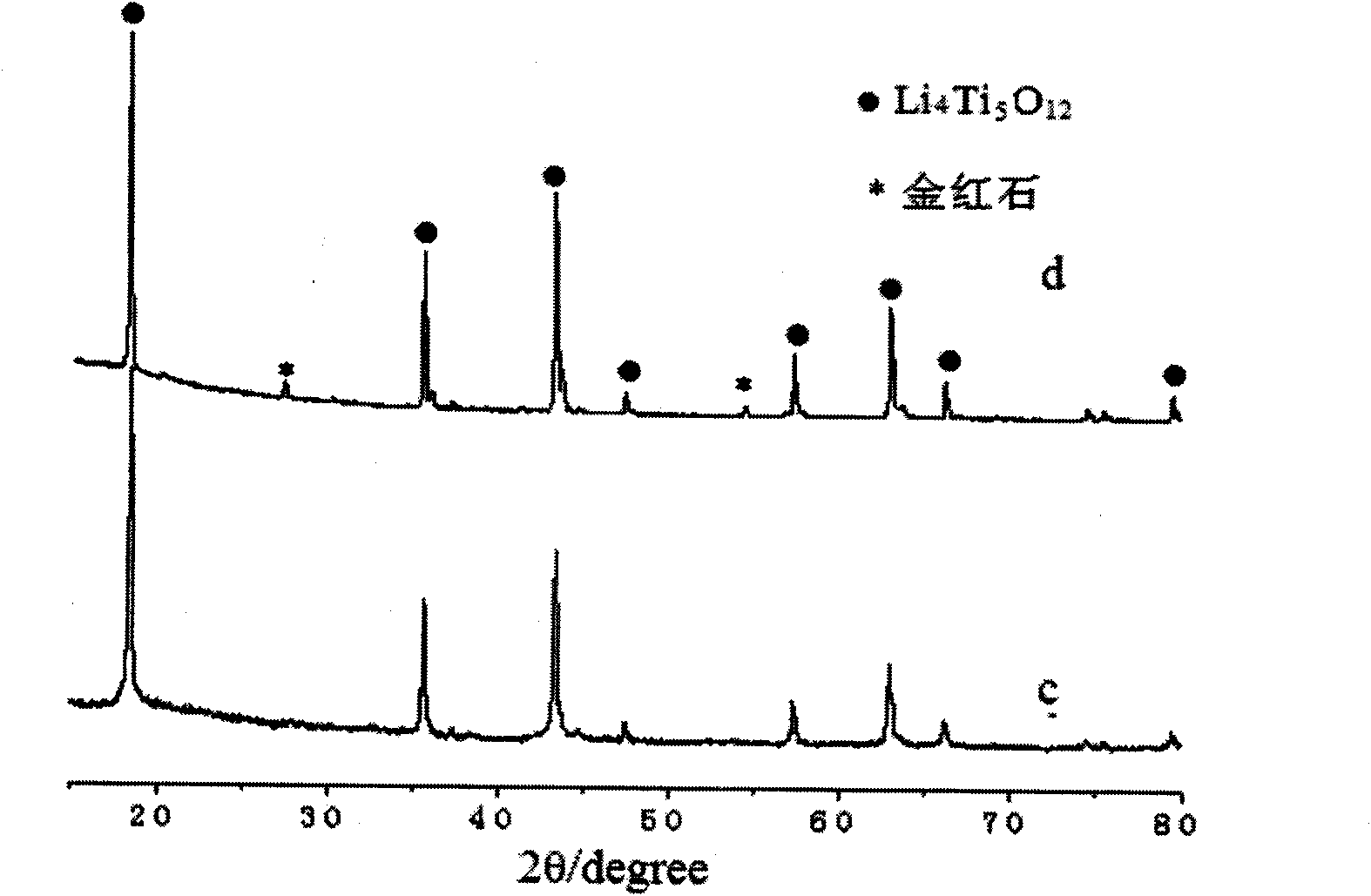

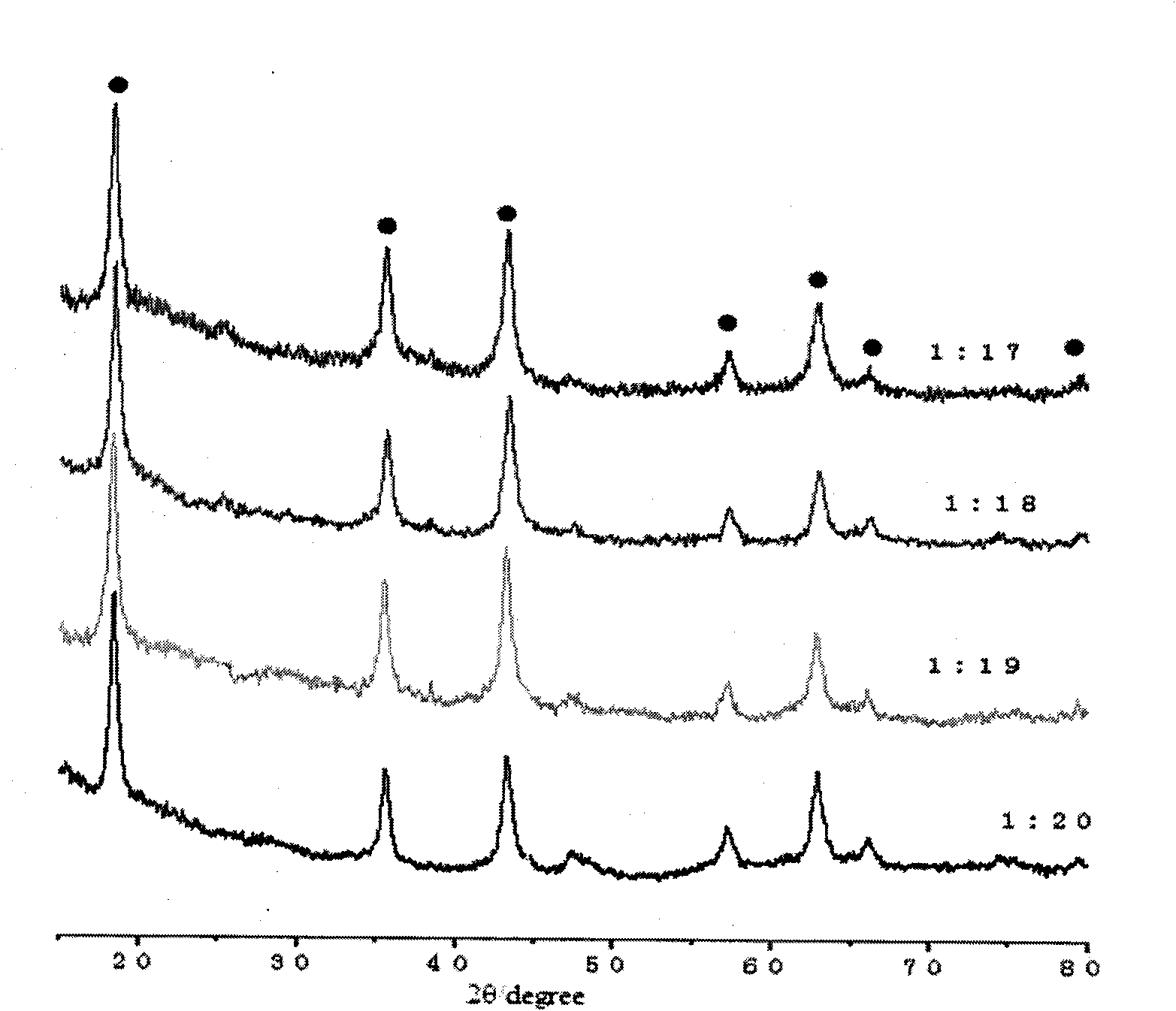

Method for preparing spinel lithium titanate of cathode material of lithium ion battery

InactiveCN101593830ALow costReduce energy consumptionElectrode manufacturing processesCombined methodMicroparticle

The invention relates to a method for preparing a cathode material Li4Ti5O12 of a high-performance lithium ion battery. The method comprises the following steps of: adopting the combined method of sol-gel and microwave treatment to prepare micro powder of nano-class Li4Ti5O12, and simultaneously modifying Li4Ti5O12 by carbon doping and metallic doping. The method utilizes the sol-gel method to effectively control chemical composition, phase composition and powder size of the Li4Ti5O12, thereby improving the uniformity and the electric conductivity of the Li4Ti5O12; simultaneously by utilizing the characteristics of the microwave technique of quick temperature rise, even heating and conglobation resistance, the high-power industrial microwave oven is used for treatment, so that the treatment time of the Li4Ti5O12 is greatly shortened, the yield is greatly improved, and the cost and the energy consumption of the material are reduced, the process is simplified, the efficiency on the industrialized production of the lithium ion battery is improved, and the industrialized application is easily achieved; and by doping carbon and metallic elements, the electric conductivity of lithium iron phosphate is greatly improved, and the charging and discharging capacities and the cycle index of the lithium iron phosphate are simultaneously and effectively increased.

Owner:ZHENGZHOU UNIV +1

Method for preparing lithium iron phosphate serving as cathode material of nano-level lithium ion battery

ActiveCN102522546ASmall particle sizeLow costMaterial nanotechnologyCell electrodesCarbon compositesSlurry

The invention discloses a method for preparing lithium iron phosphate serving as a cathode material of a nano-level lithium ion battery. The method is characterized by comprising the following steps of: adding a composite carbon source into a solvent, and uniformly dispersing; mixing a lithium source, iron source and phosphorus source compound and the composite carbon source, putting the mixture into a ball grinder for grinding to obtain slurry; drying and smashing the slurry to obtain a precursor; calcining the precursor under a protective atmosphere; and along with the thermal cracking of the carbon source compound, coating a layer of carbon source on a crystal to form a carbon-coated film with relatively high graphitized crystallinity at high temperature, and thus obtaining the lithium iron phosphate with a carbon composite olivine structure. According to the lithium iron phosphate cathode material prepared by using the method, the chemical constituent, the phase composition and the particle size of the LiFePO4 can be controlled effectively; the primary particle size of the LiFePO4 is 20 to 600 nanometers; and the LiFePO4 has relatively high electronic conductivity and relatively high specific capacity.

Owner:连云港华海诚科电子材料有限公司

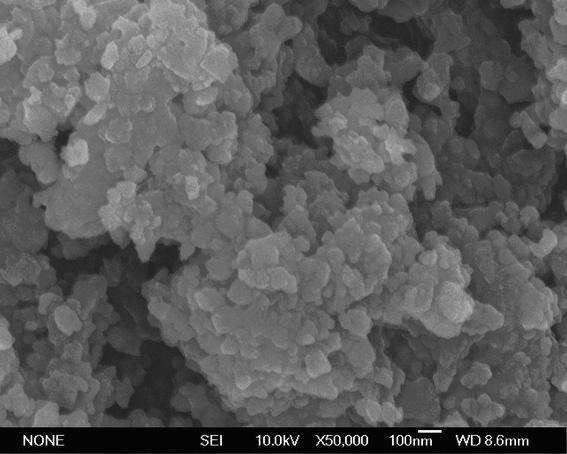

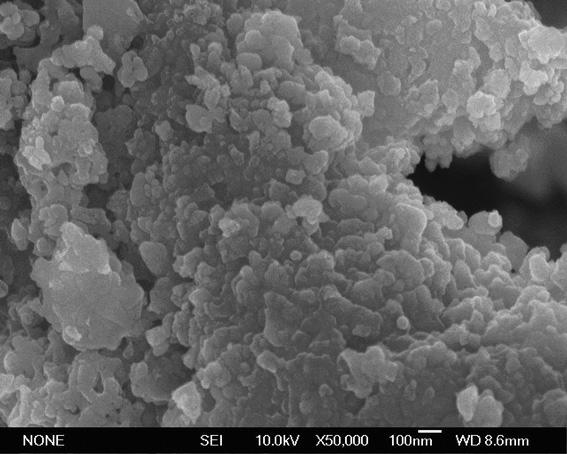

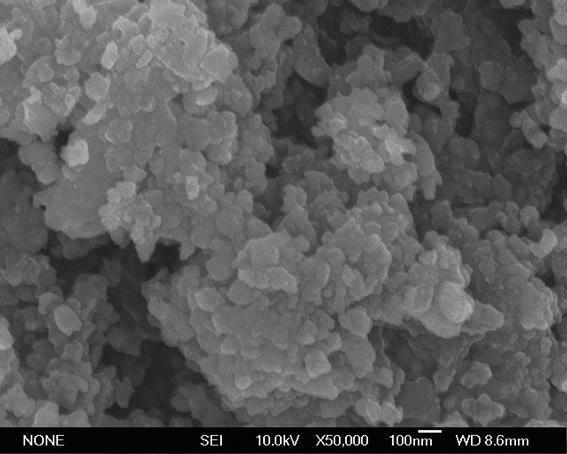

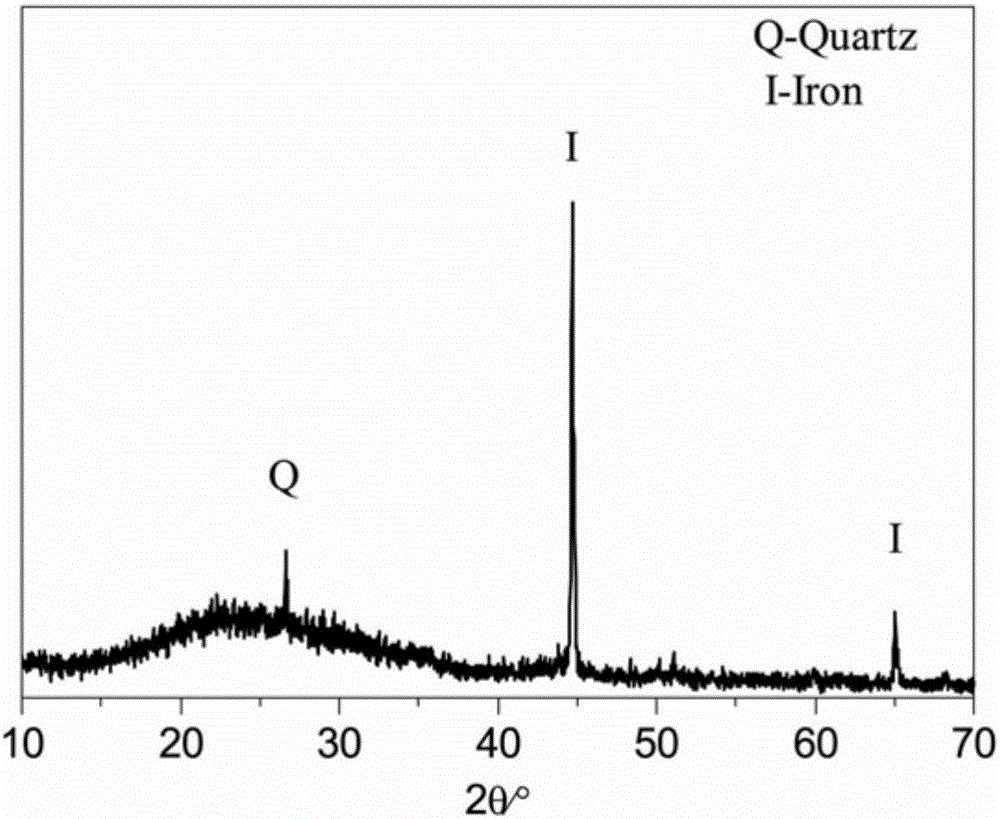

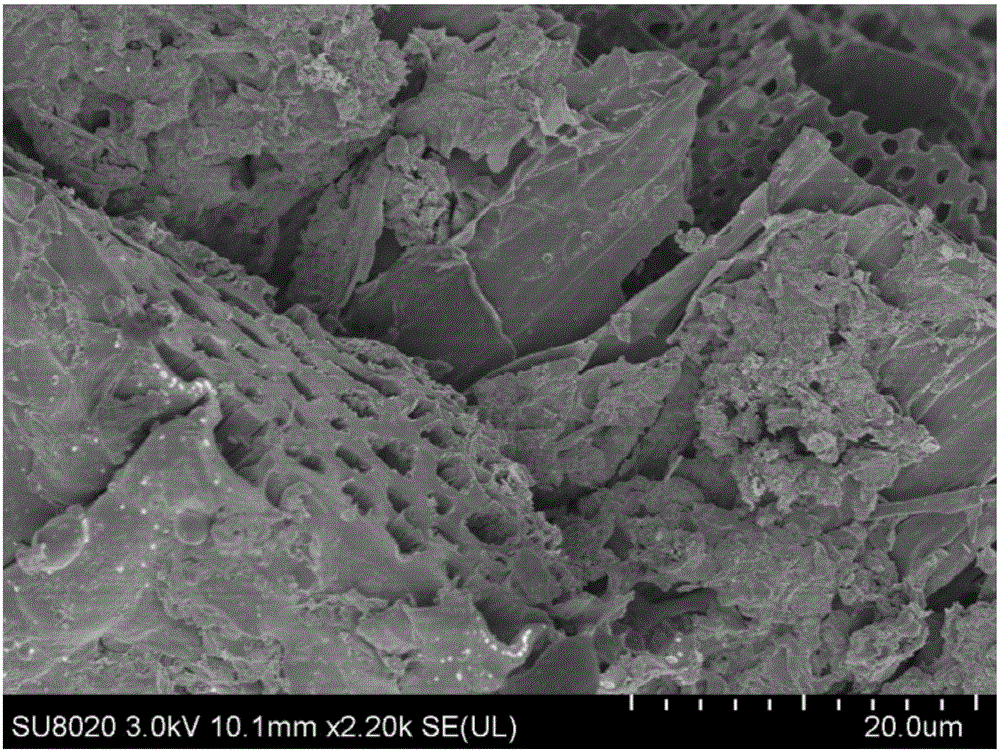

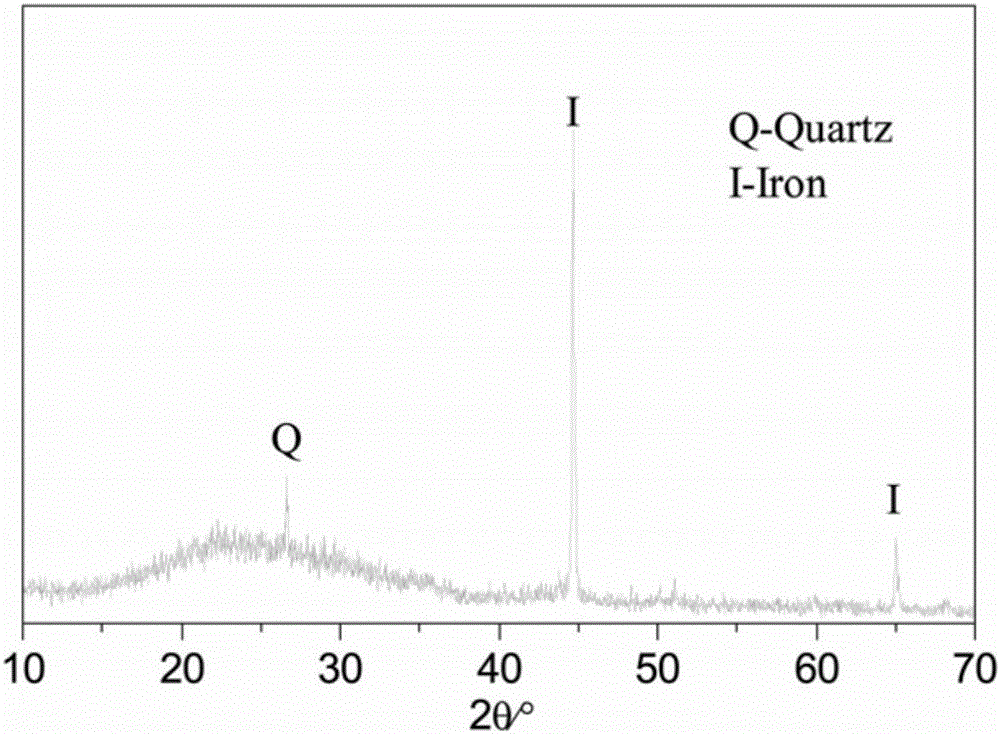

Fe/C composite porous structure material as well as preparation method and application thereof

ActiveCN105776506AHigh particle strengthHas a bonding effectTreatment using aerobic processesContaminated soil reclamationPorosityMagnetic susceptibility

The invention discloses a Fe / C composite porous structure material as well as a preparation method and application thereof. The Fe / C composite porous structure material is characterized by being prepared from low-grade sedimentary iron ore and biomass as raw materials in manners of crushing, mixing, extrusion molding and pyrolysis and reduction reaction in the presence of hydrogen atmosphere at 650-900 DEG C, wherein the main phase composition comprises biomass carbon and zero-valent iron. The Fe / C composite porous structure material disclosed by the invention is high in opening porosity, magnetic susceptibility, adsorbability and biological chemical activity, can be used for treating eutrophicated river water, living sewage and landscape water bodies, or can be used for mediation of underground water pollution and polluted soil.

Owner:HEFEI UNIV OF TECH

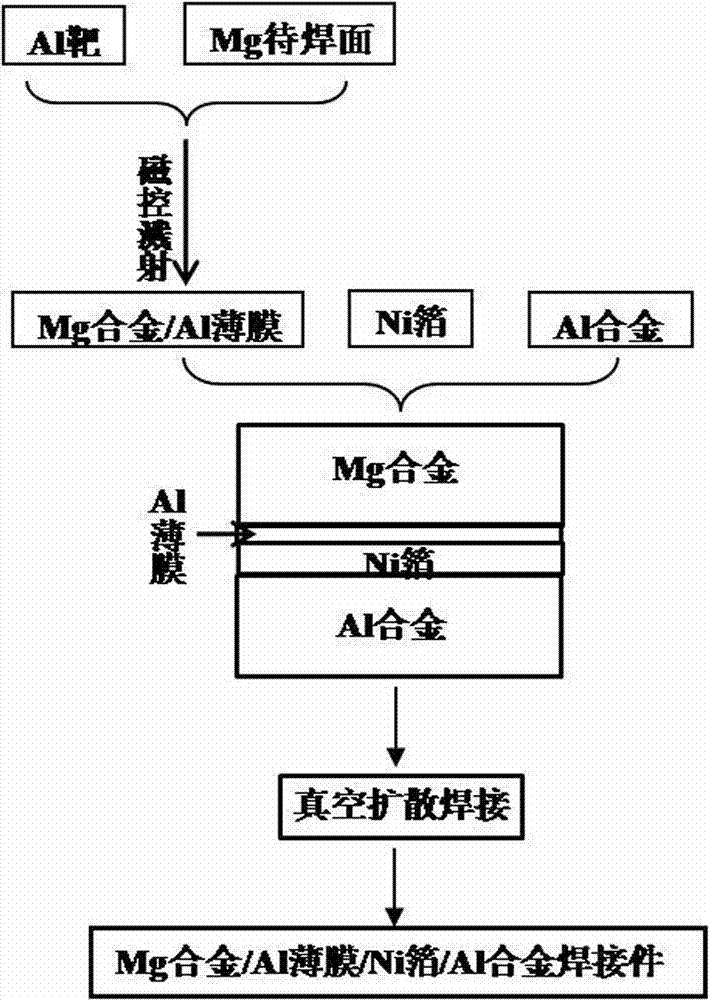

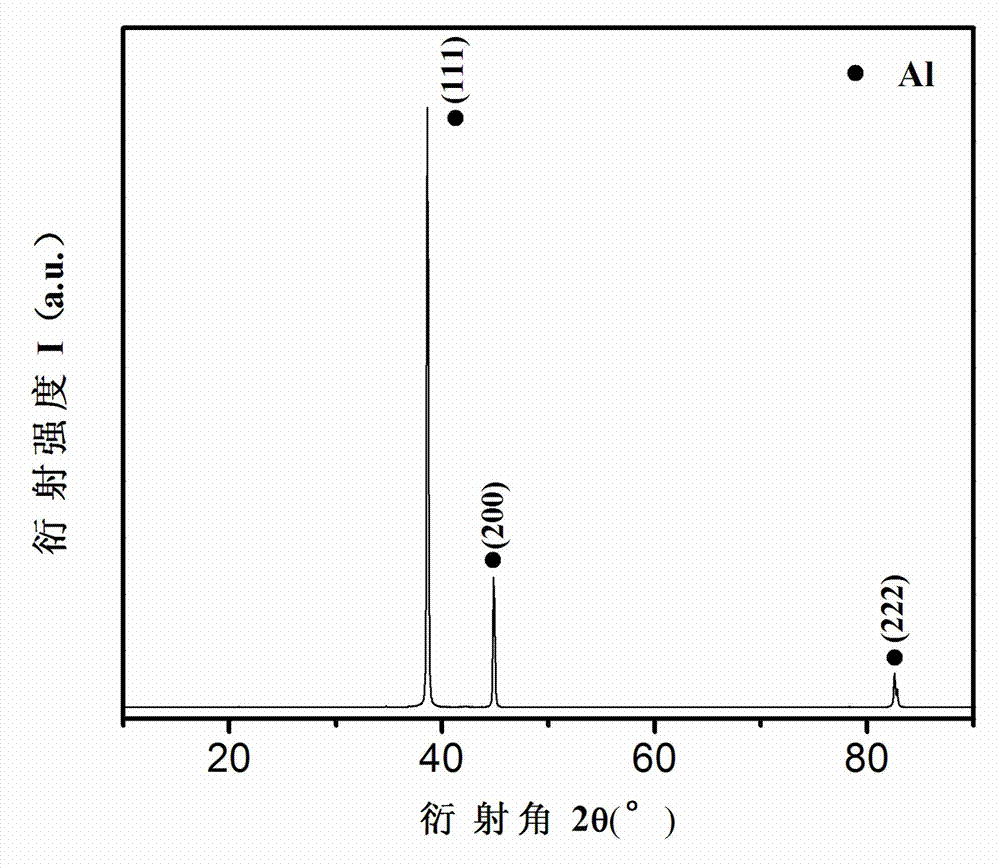

Spreading welding method of magnesium alloy and aluminum alloy containing composite middle layer

InactiveCN102861986AAchieve high-strength weldingSimple processNon-electric welding apparatusPhase compositionShear strength

The invention relates to a low temperature high intensity welding method of magnesium alloy and aluminum alloy containing a composite middle layer. The method includes utilizing an aluminum film and a nickel foil to serve as a composite middle layer. The aluminum film is precipitated on the face of magnesium alloy to be welded by magnetron sputtering. The method further includes adopting vacuum spreading welding with the welding temperature as 400-460 DEG C, keeping the temperature for 10-120min and enabling the welding pressure to be 0.1-3MPa. The method has the advantage of utilizing a composite middle layer of the aluminum film and the nickel foil to achieve spreading welding of the magnesium alloy and the aluminum alloy. Addition of the aluminum film layer and the nickel foil changes magnesium / aluminum interface phase composition and microstructure, and avoids generation of compounds between high-hardness fragile magnesium and aluminum at the interface. The shearing strength reaches 26MPa, and the magnetron sputtering aluminum coated film on the face of the magnesium alloy to be welded improves inoxidizability of the face of the oxydic magnesium alloy to be welded and improves structure and performance of products between Mg and Ni. The method is suitable for reliable welding of magnesium alloy and aluminum alloy in different kinds, and is simple in process, high in parallel accuracy and small in welding piece transformation.

Owner:WUHAN UNIV OF TECH

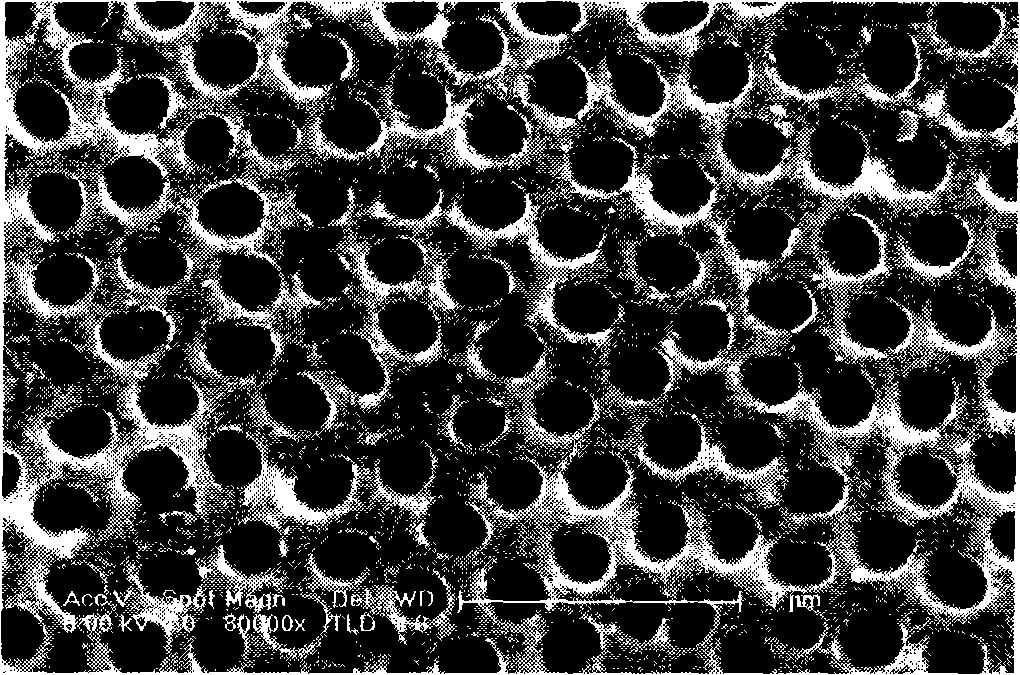

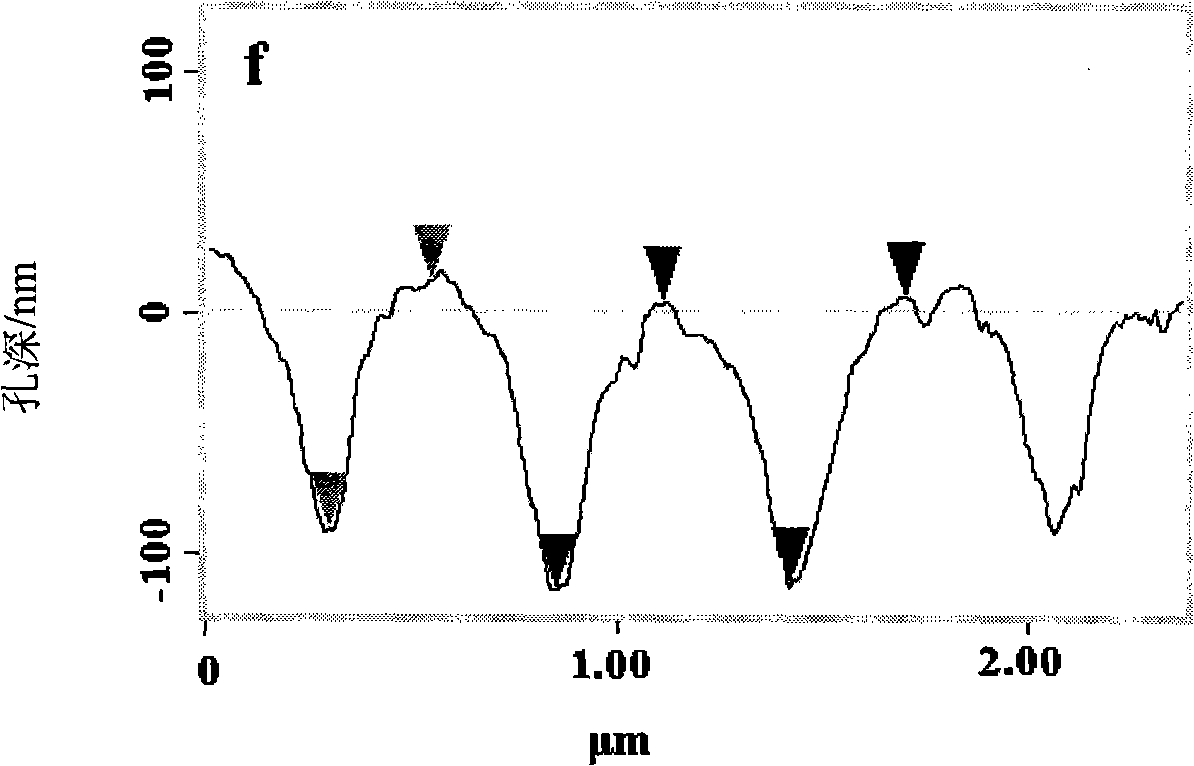

TiO2 nanometer pore array material preparation method and uses thereof

InactiveCN101307479AImprove bindingShorten the migration pathPolycrystalline material growthSurface reaction electrolytic coatingChemical oxygen demandTitanium oxide

Owner:SHANGHAI JIAO TONG UNIV

Method of preparing block polyurethane microcapsule composite finishing agent

InactiveCN101109151ARealize functionRealize the temperature adjustment functionFibre treatmentOil emulsionMoisture permeability

A preparing method for a compound finishing agent for micro capsule of blocking polyurethane is provided, which comprises the following procedures: a) preparing the pre-polymer of the blocking polyurethane; adjusting the content of hard blocks with the composition and content of fixing soft blocks not changed, so that the inversible phase composes rich soft blocks and short hard blocks, and fixing phase composes rich hard blocks; b) adding the pre-polymer of the blocking polyurethane and the phase-transformation material in certain proportion into some water solution containing emulsifier to form a water-wrapped-oil emulsion system; when the emulsification goes to such stage as the diameter of micro capsule meets requirement, some chain extender and cross-linking agent are added, they are mixed for certain time under thermostatic condition, now emulsion of compound finishing agent for micro capsule of blocking polyurethane taking blocking polyurethane as wall of the micro capsule and phase-transformation material as the core of the micro capsule is obtained. The invention uses the same chemical substrate-polyurethane, so the requirement from the compound finishing agent on assistant, the formula of the finishing liquid and the finishing process are basically equivalent, thereby the synergy between air permeability, moisture permeability and temperature adjusting can be achieved well.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com