Patents

Literature

115results about How to "Chemical composition is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High density ultrafine composite ferric lithium phosphate anode material and preparation method

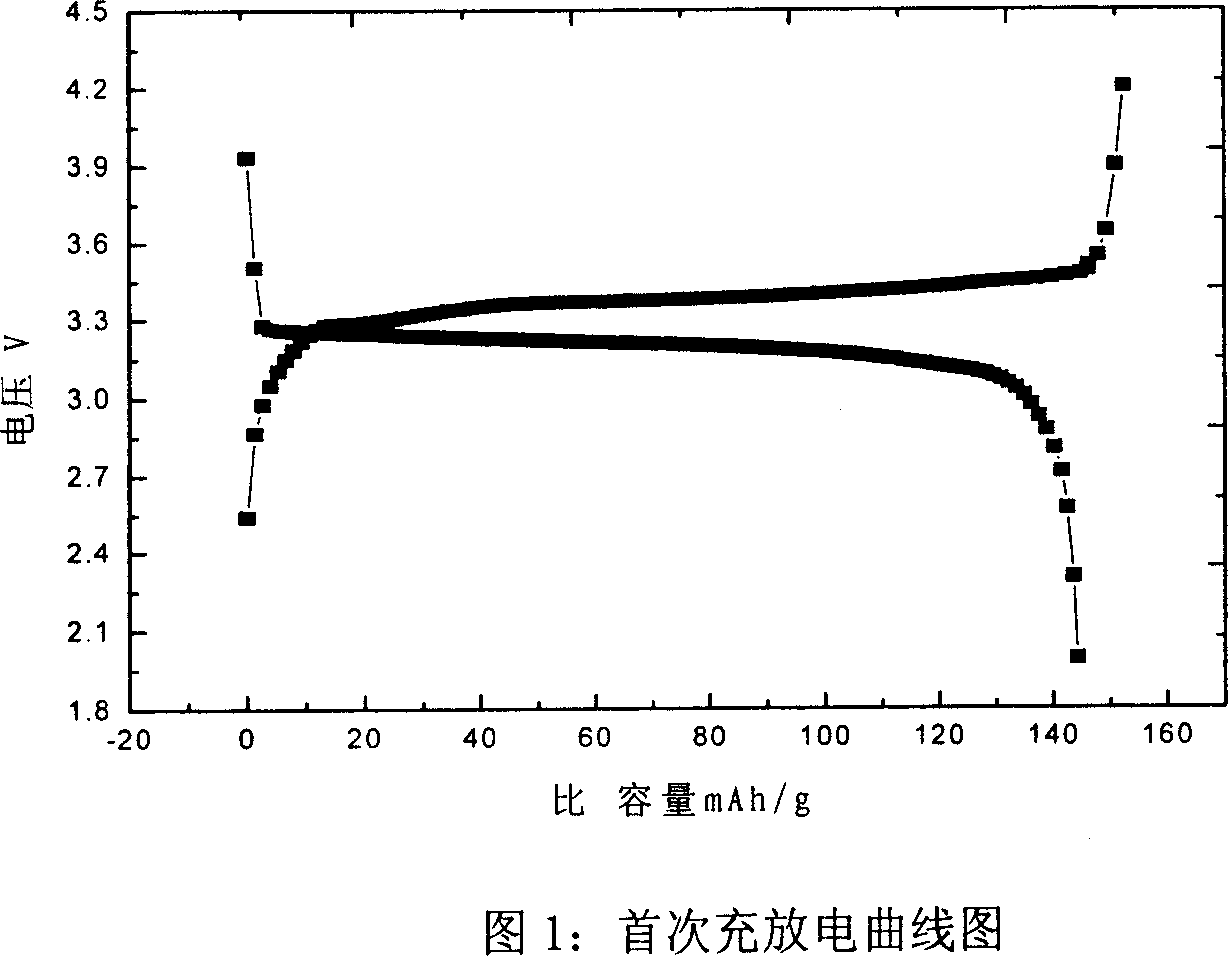

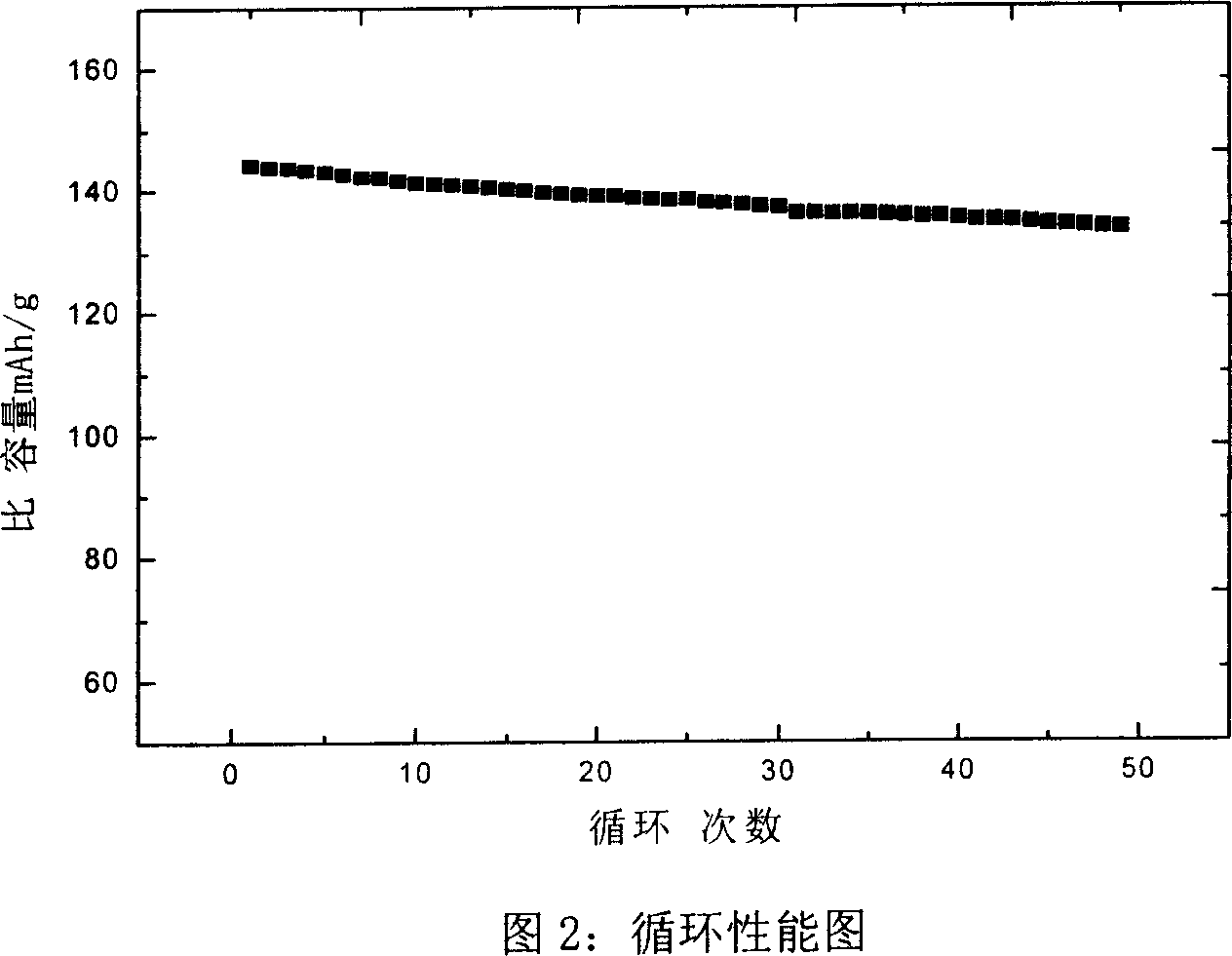

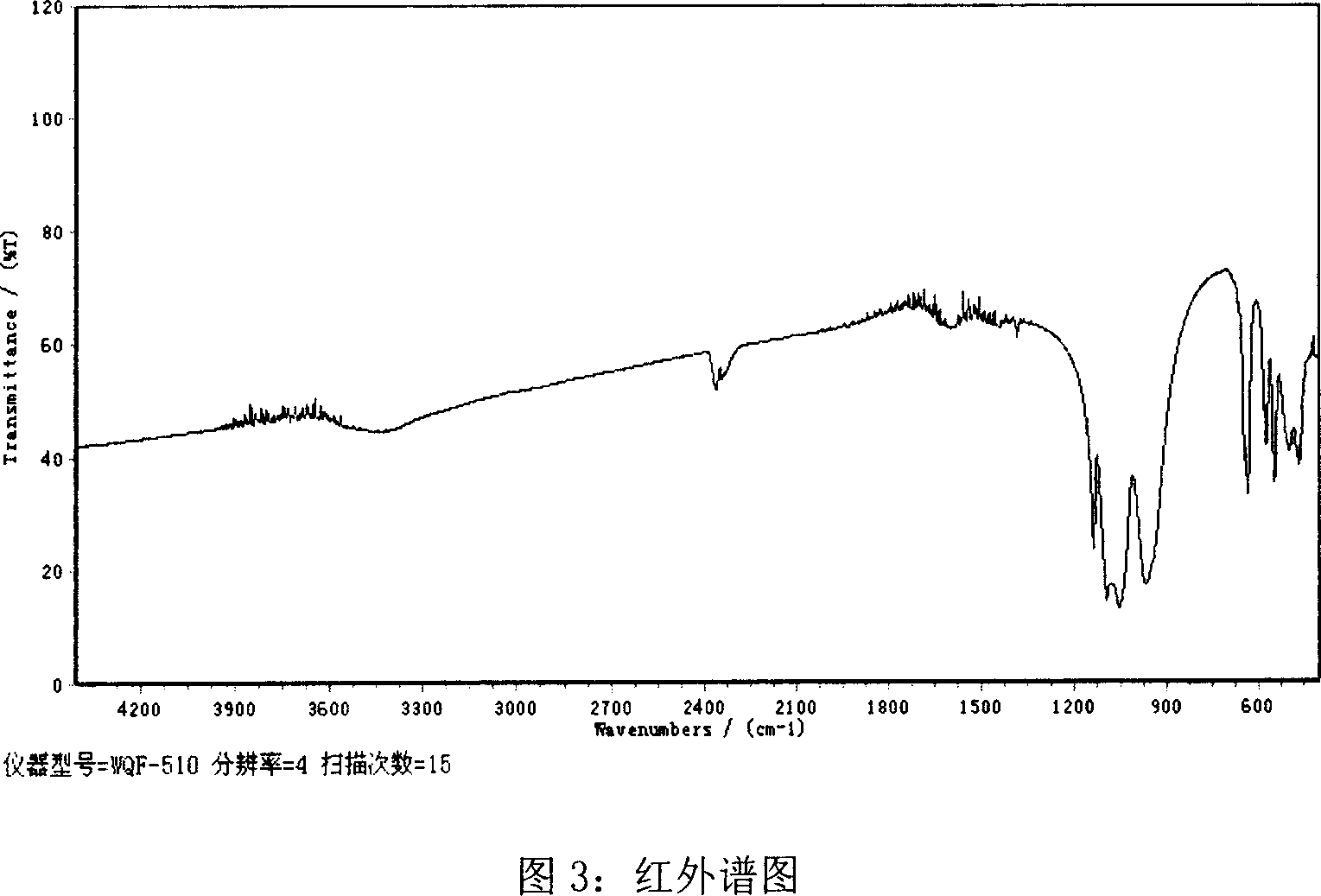

ActiveCN1907844AChemical composition is easy to controlEasy to dopeCell electrodesPhosphorus compoundsIron saltsOrganic compound

This invention belongs to battery field, which relates to ultra-micro compound lithium iron phosphate cathode material with high density and its fabrication method. Said cathode material is prepared by mixing iron salt, lithium salt and phosphates at a P / Li / Fe ratio of 1-1.1:1-1.1:1-1.1, adding conductive additives containing dopant element and carbon-bearing organic compound, adding organic acid as carrier, adjusting pH, controlling solution temperature in reactor to form sol, separating the sol to obtain nano-precursor and placing it into micorwave oven under protection of inert gas, and obtaining the final product. It is easy to control the chemical component, phase composition and particle size distribution. The conductive additive can be well-distributed. The method also has the advantages of short reaction time, low energy consumption during synthesis process and low cost. The obtained composite has high purity and good compatibility with electrolyte, excellent conductive property and charge and discharge property with large current, and good structure stability,thermal stability and cycle performance.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

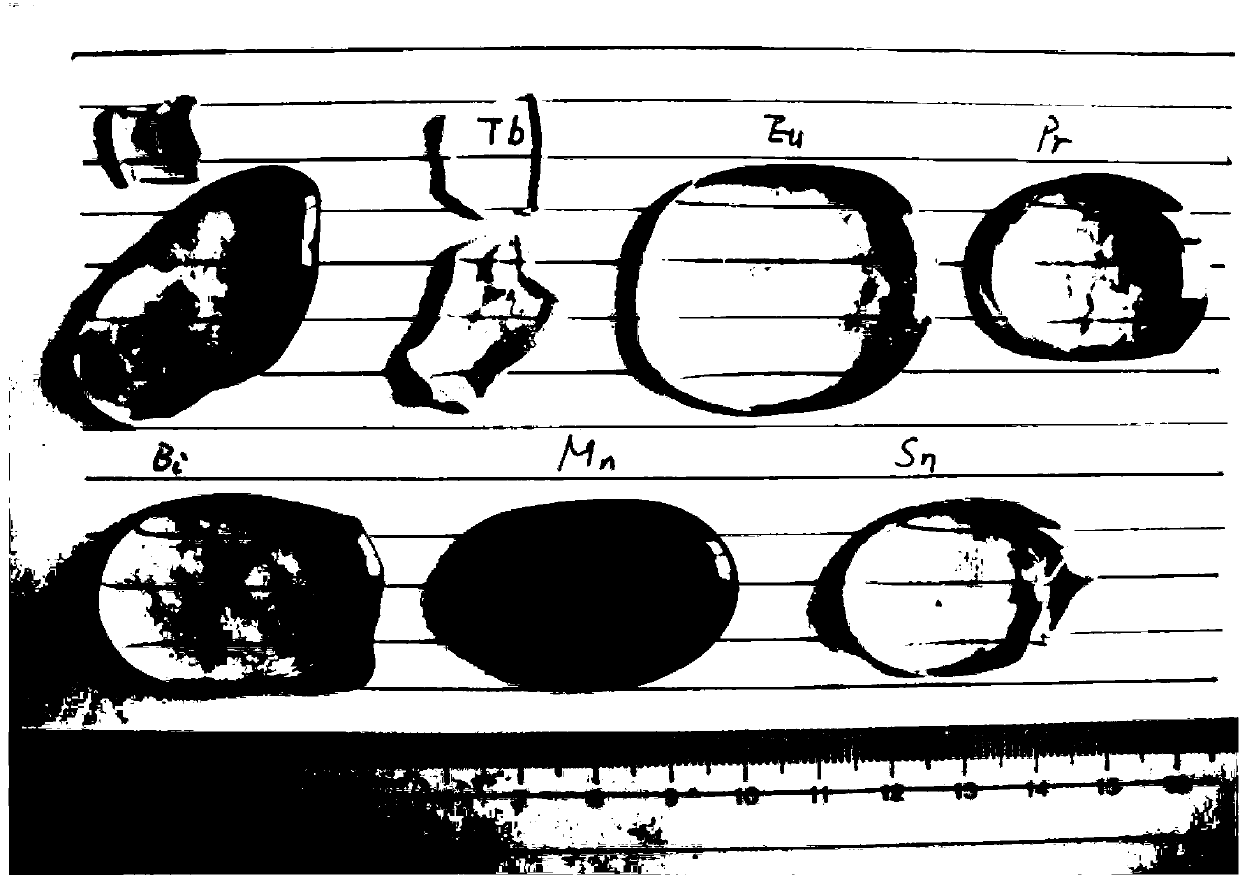

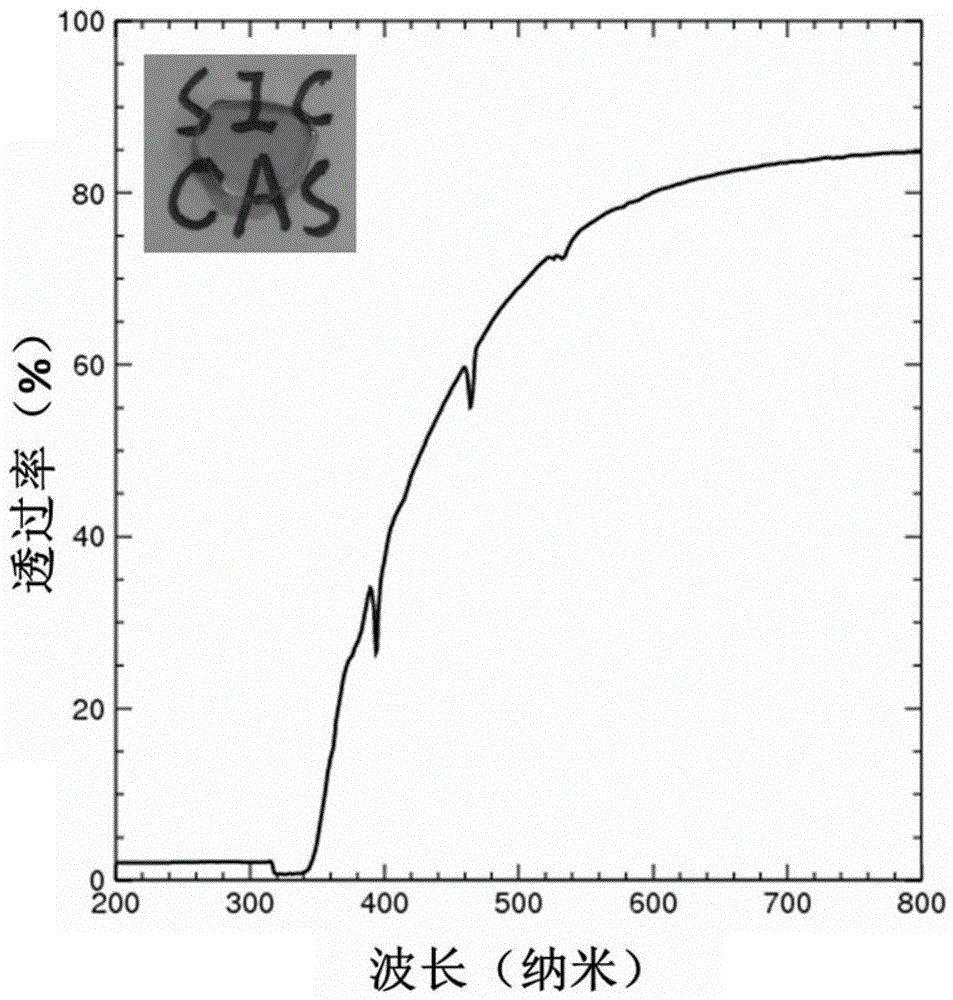

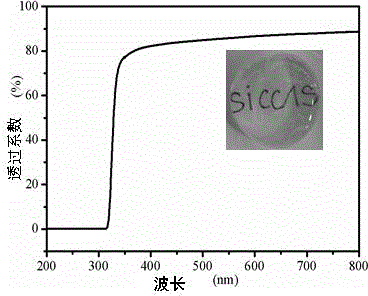

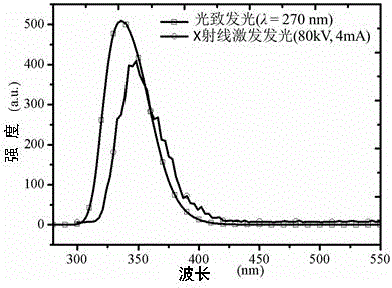

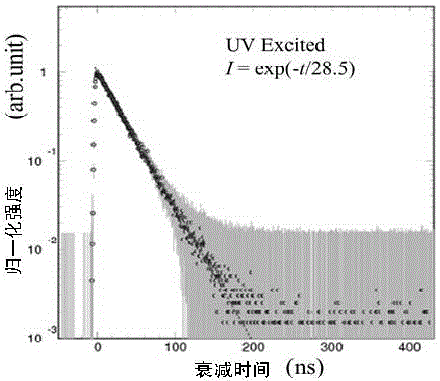

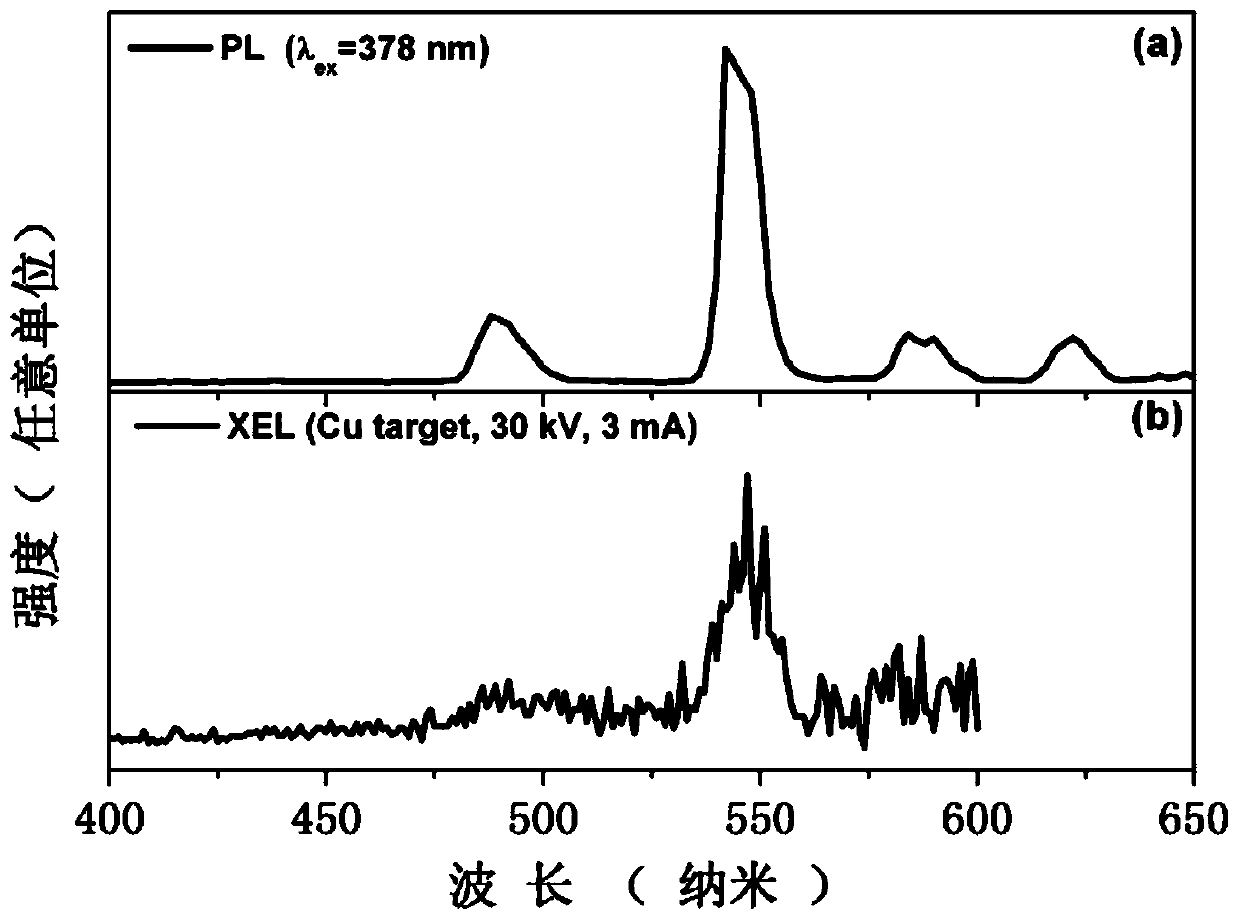

Gd2O3-rich borogermanate scintillation glass, and preparation method and application thereof

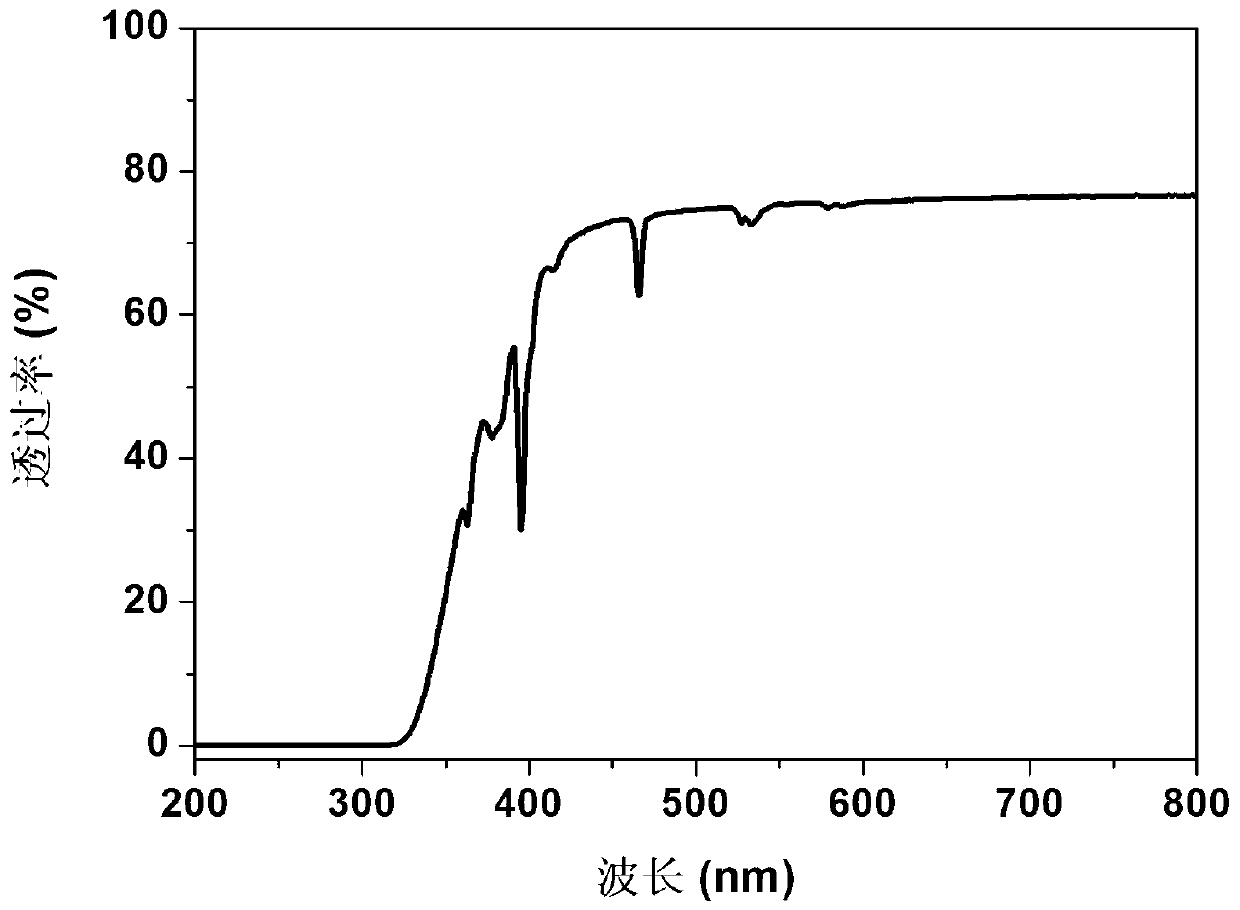

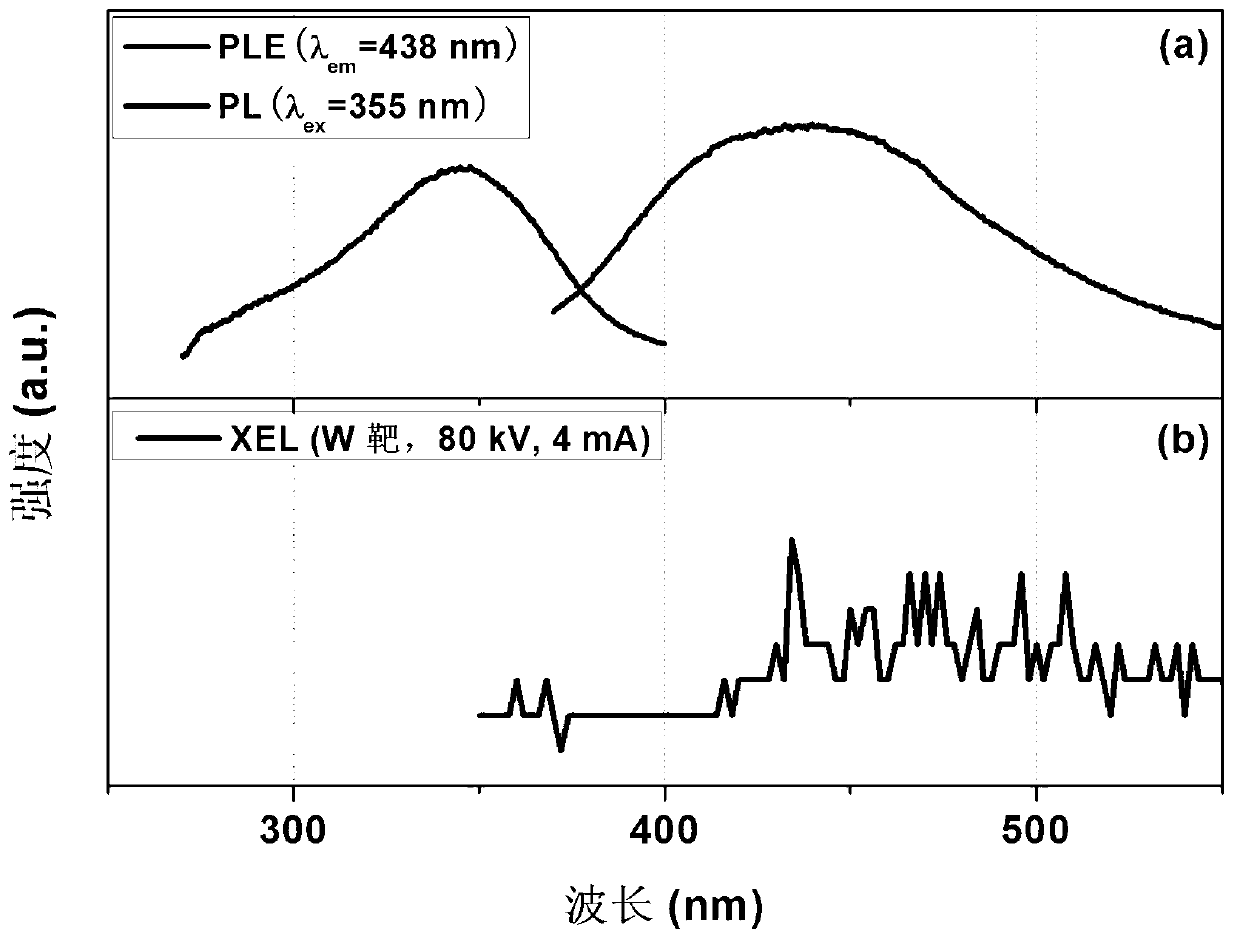

InactiveCN102826753ASimple preparation processChemical composition is easy to controlRare earth ionsAnalytical chemistry

The invention relates to a Gd2O3-rich borogermanate scintillation glass, and a preparation method and application thereof. The invention provides a Gd2O3-rich borogermanate scintillation glass which is characterized by comprising the following components in percentage by mol: 20-60 mol% of B2O3, 20-60 mol% of GeO2, 15-40 mol% of Gd2O3 and 0.01-10 mol% of compound containing rare earth or transition metal ions. The rare earth ions comprise Y<3+>, La<3+>, Ce<3+>, Pr<3+>, Nd<3+>, Pm<3+>, Sm<3+>, Eu<3+> (Eu<2+>), Gd<3+>, Tb<3+>, Dy<3+>, Ho<3+>, Er<3+>, Tm<3+>, Yb<3+> and Lu<3+>; and the transition metal ions comprise Mn<2+> (Mn<4+>), Sn<2+>, Zn<2+>, Bi<3+>, Cr<3+>, Ti<4+> and Zr<4+>. The invention also provides a method for preparing the Gd2O3-rich borogermanate scintillation glass, and application of the Gd2O3-rich borogermanate scintillation glass.

Owner:JINGGANGSHAN UNIVERSITY +1

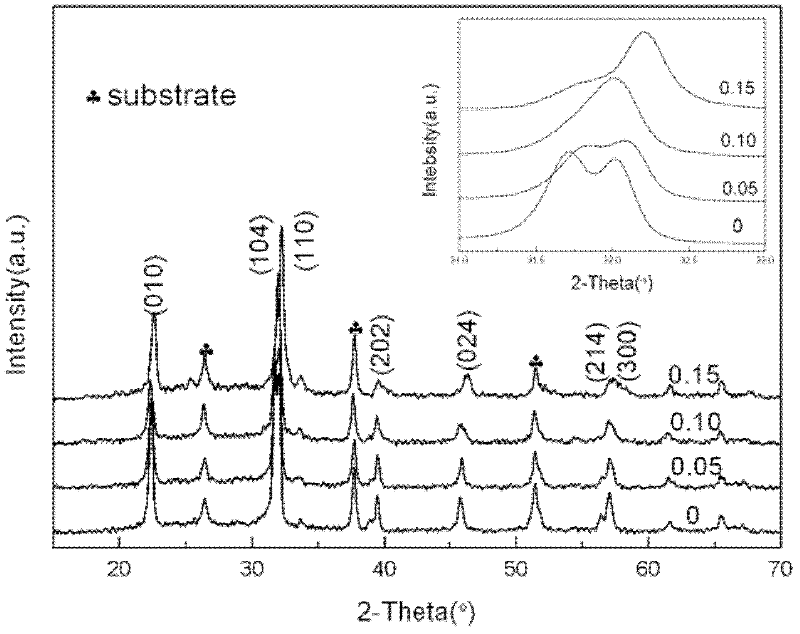

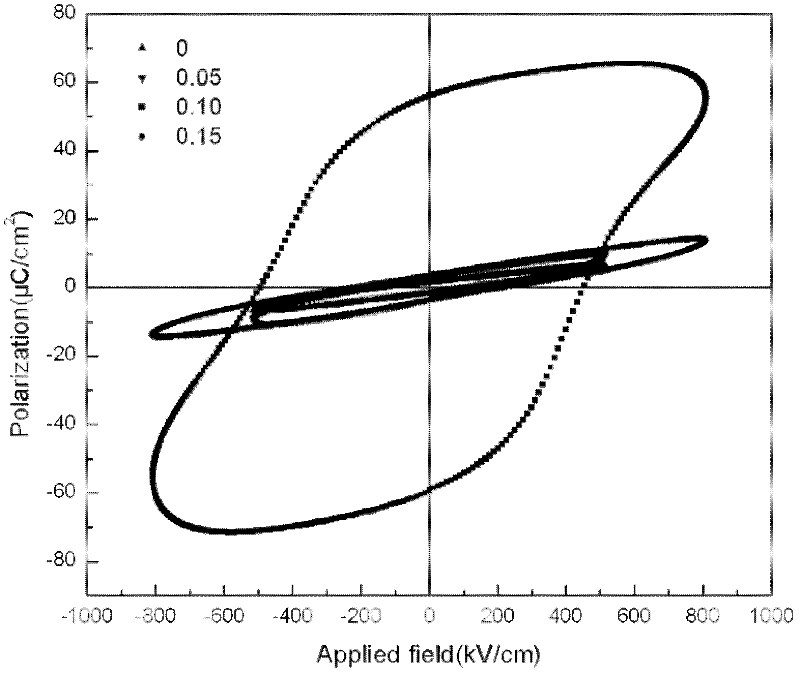

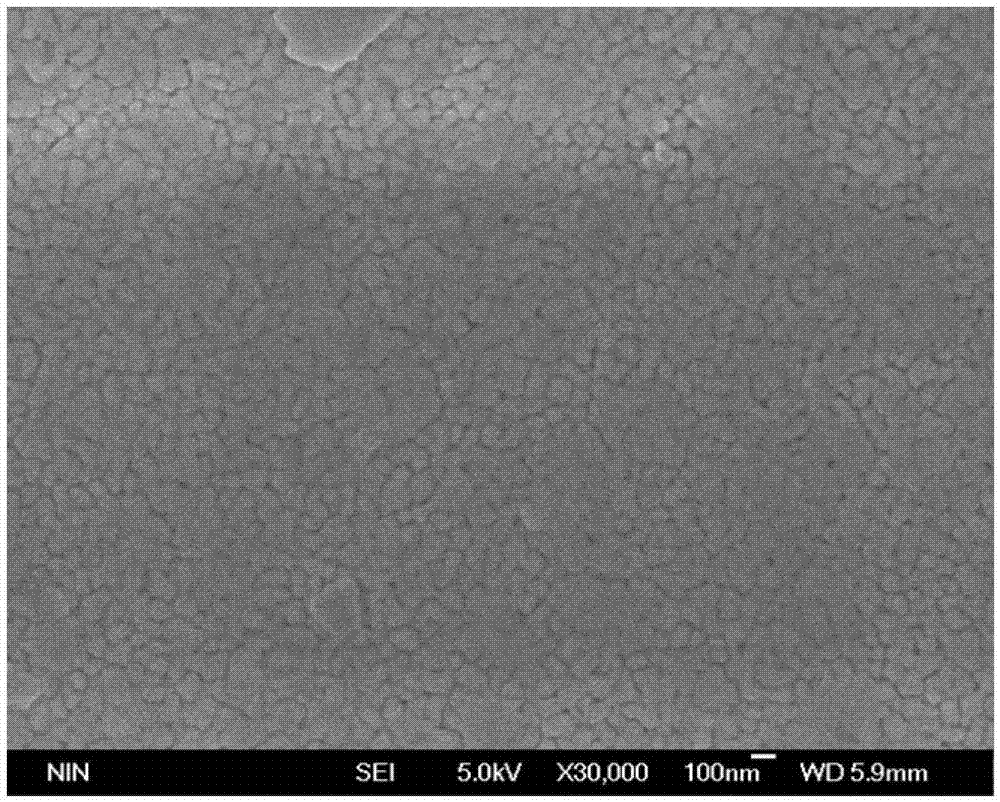

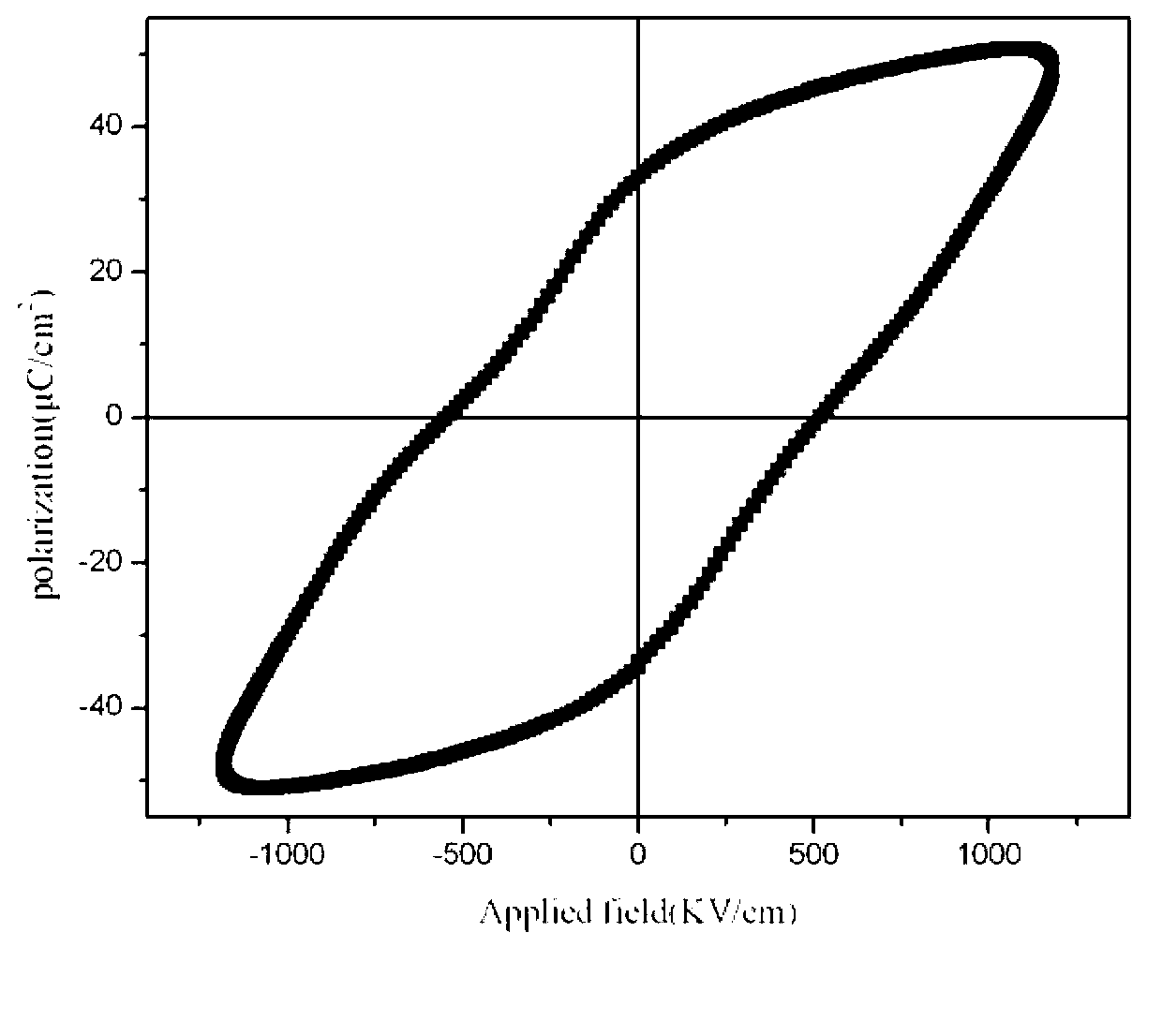

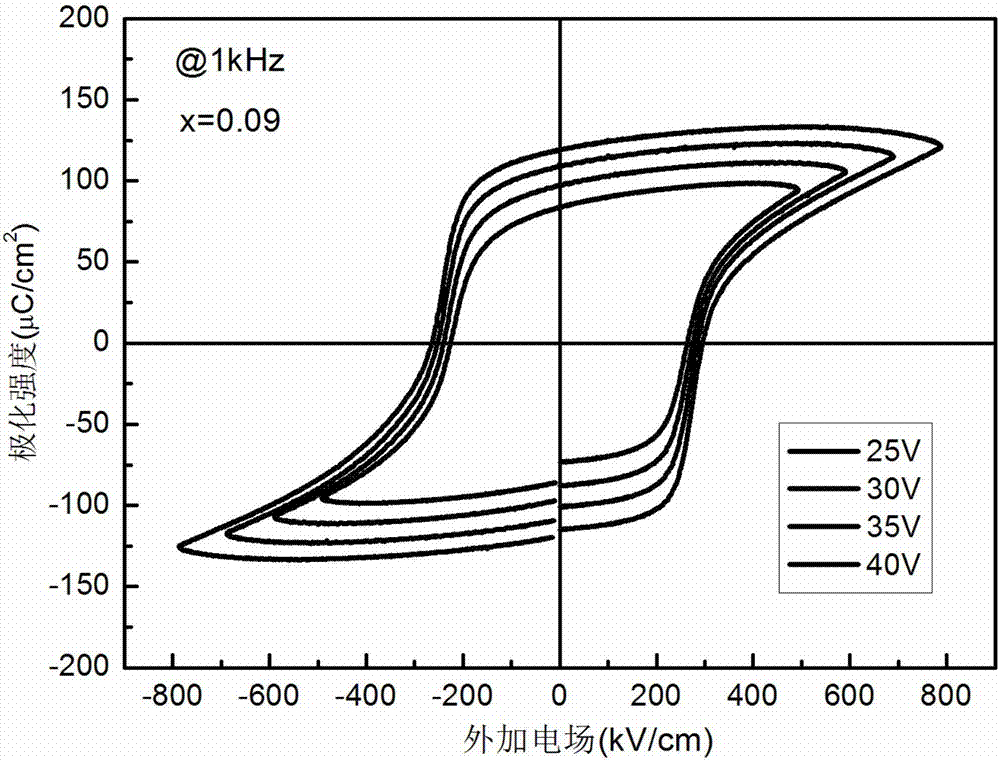

Method for preparing Tb-doped BiFeO3 ferroelectric film on surface of conductive glass substrate

InactiveCN102633443AInhibit volatilizationIncrease the remanent polarization valueChemistryEthylene glycol monomethyl ether

The invention discloses a method for preparing a Tb-doped BiFeO3 ferroelectric film on the surface of a conductive glass substrate. The method comprises the following steps of: 1, cleaning the substrate; 2, irradiating the substrate by using ultraviolet so that the surface of the substrate reaches atomic cleanliness; 3, dissolving Fe(NO3)3.9H2O, Bi(NO3)3.5H2O and Tb(NO3)3.5H2O in a molar ratio of 1: (1-x): x (x=0-0.15) into a mixed solution of ethylene glycol monomethyl ether and glacial acetic acid; and 4, preparing the film by adopting a spin coating method, then pre-annealing, annealing, crystallizing, and thus obtaining the crystalline Tb-doped BiFeO3 ferroelectric film. By the method, the residual polarization value of the film can be greatly improved; and after Tb is doped, the residual polarization value can be improved to 55mu C / cm<2>.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing SiC particle reinforced foamed aluminium radical composite material

The invention relates to a preparing method for a SiC particle reinforced foam aluminum based composite, which comprises the following procedures: taking by mass among the total alloy amount 1-3% Mg, 6-8% Si and remainder Al, heating 10-20% SiC particles to melt into molten aluminum alloy, carrying out electromagnetic agitating evenly; adding 1-3% foaming agent by mass, after agitating evenly the foaming agent, keeping temperature and foaming 3-5 minutes; cooling after the molten aluminum grows steadily so as to cool and solidify the molten aluminum alloy foam, then getting SiC particle reinforced foam aluminum based composite with even hole structure and high porosity. The method adds molten aluminum alloy SiCp, which on one hand increases the viscosity of the molten alloy so as to prevent the bubbles dissolved from the foaming agent from floating upward and prolong the lives of the bubbles, on another hand, SiCp can also improve the strength of the foam aluminum. These bubbles take SiCp as a core and grow, then are cooled concurrently in all directions, this can overcome any shortcoming in solidifying and get foam aluminum of high porosity and even hole structure. By using electromagnetic agitating, the burning loss in the agitating blade can be avoided, this is useful for controlling the chemical components of the alloy.

Owner:SHANGHAI UNIV

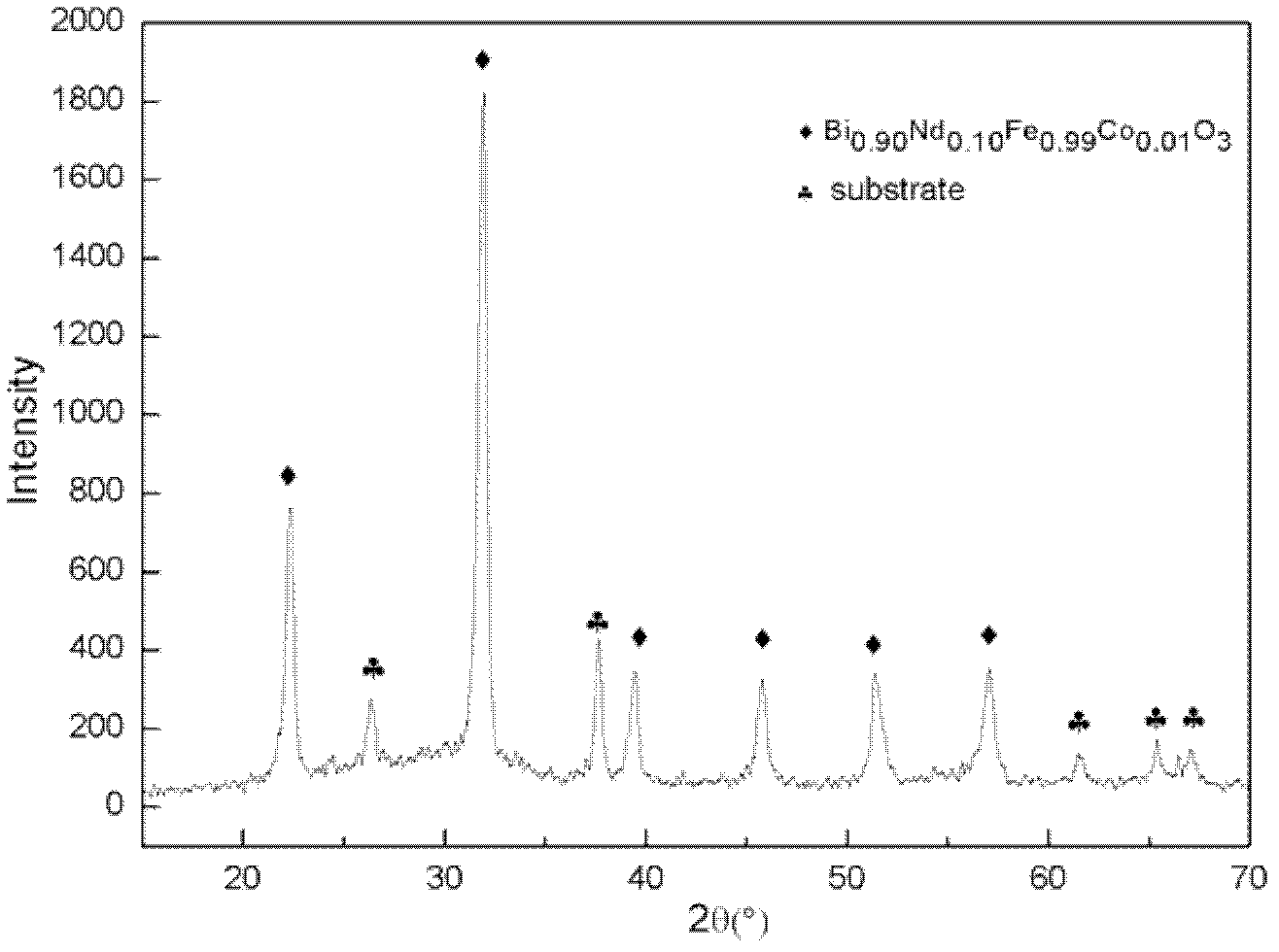

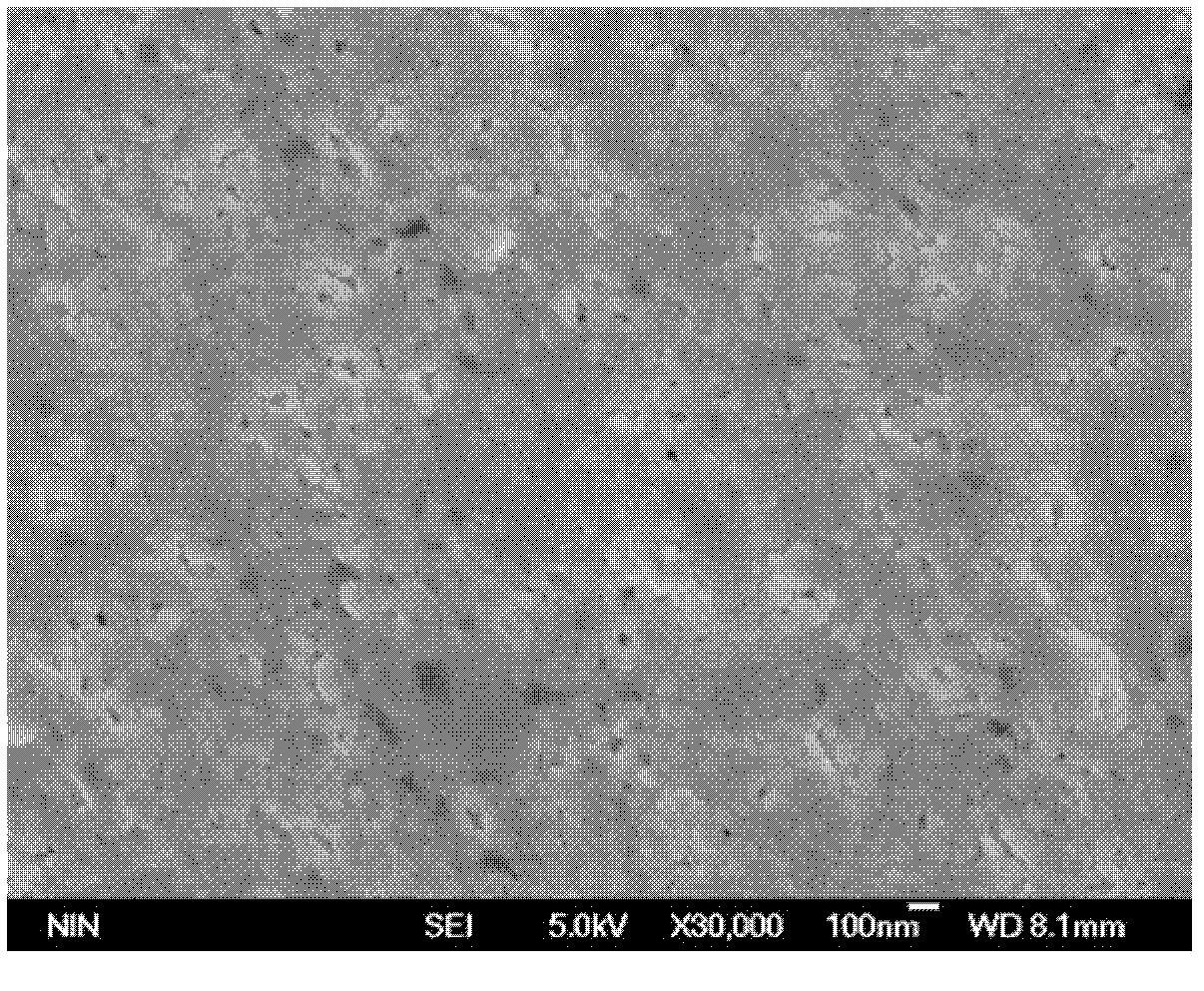

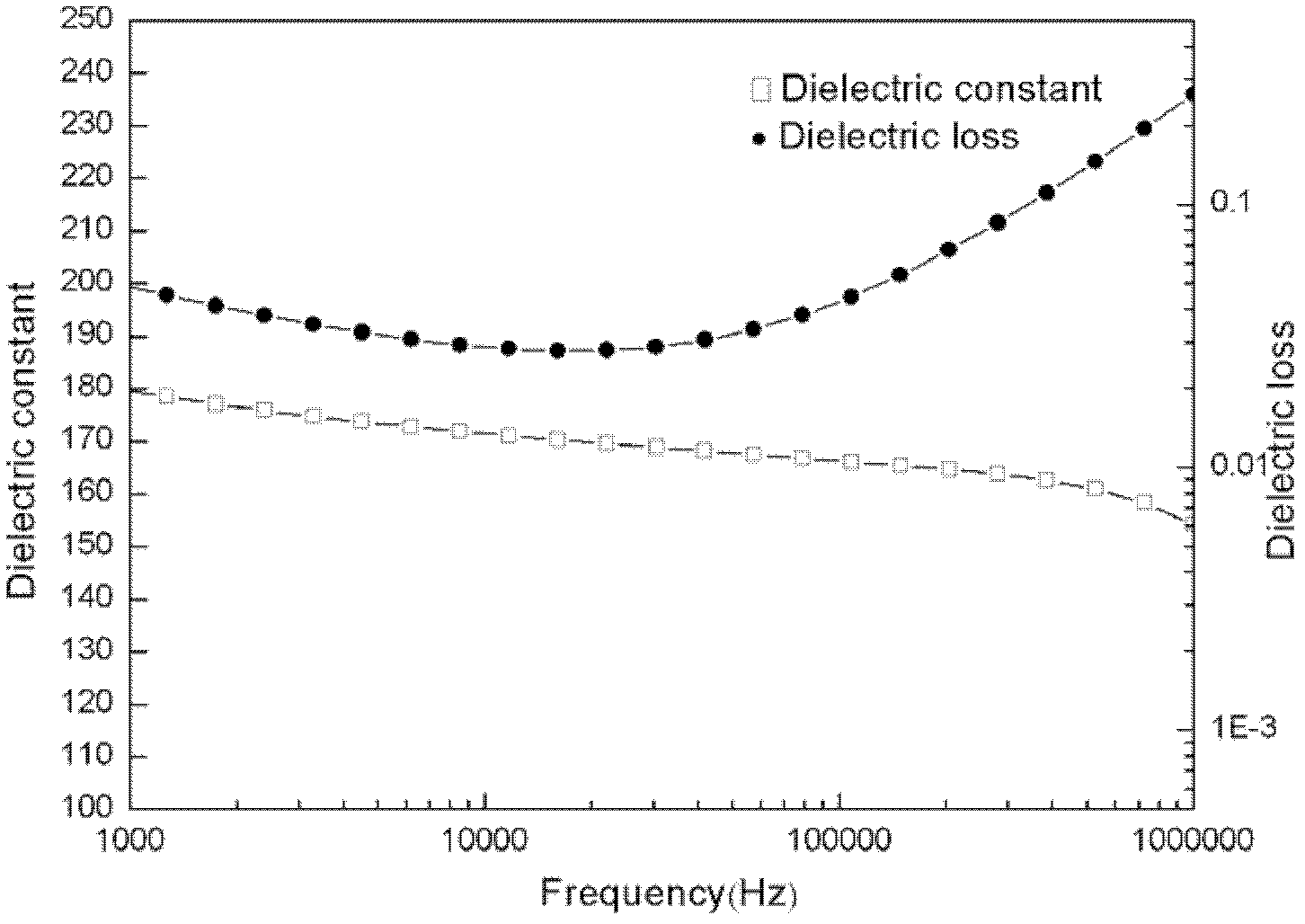

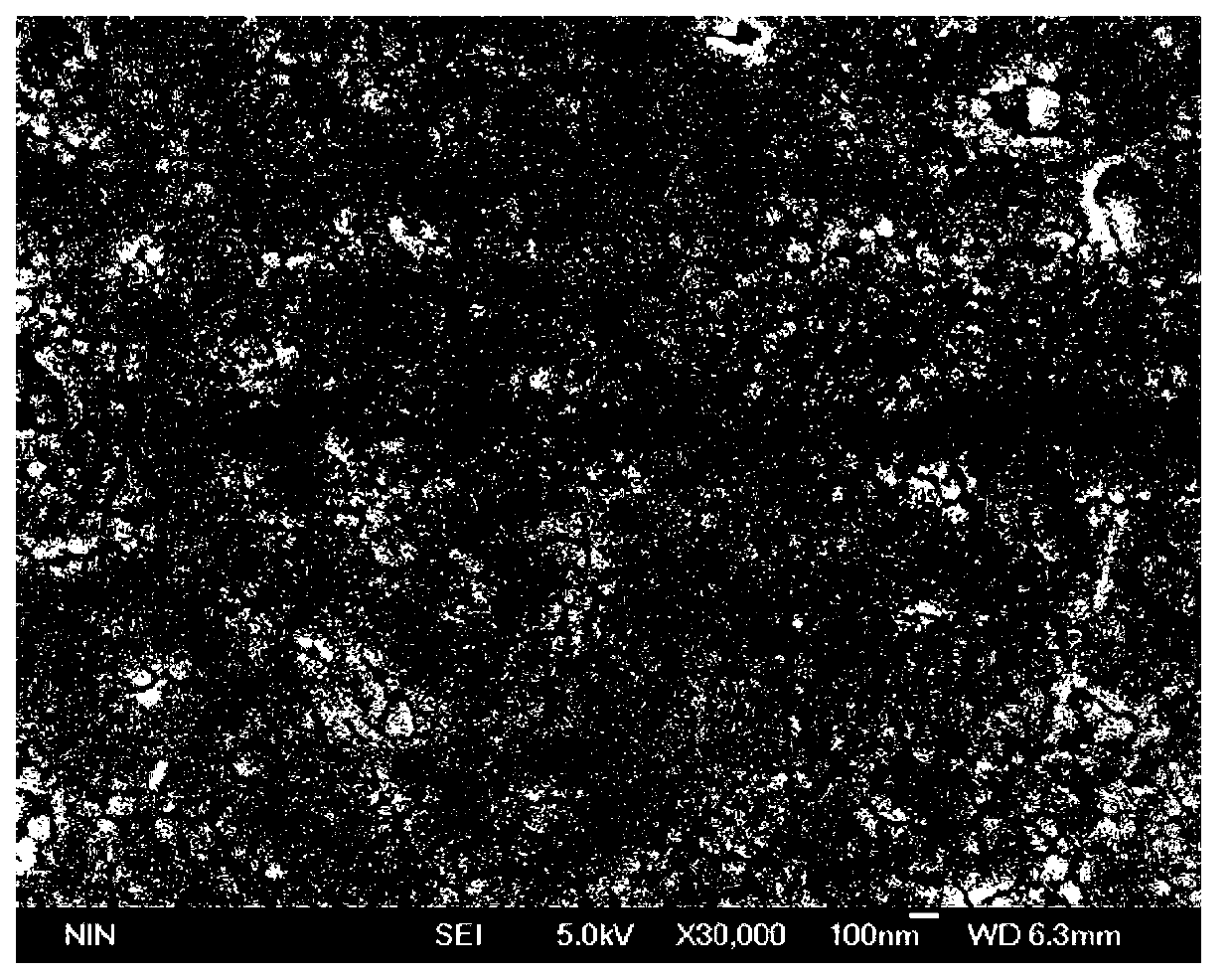

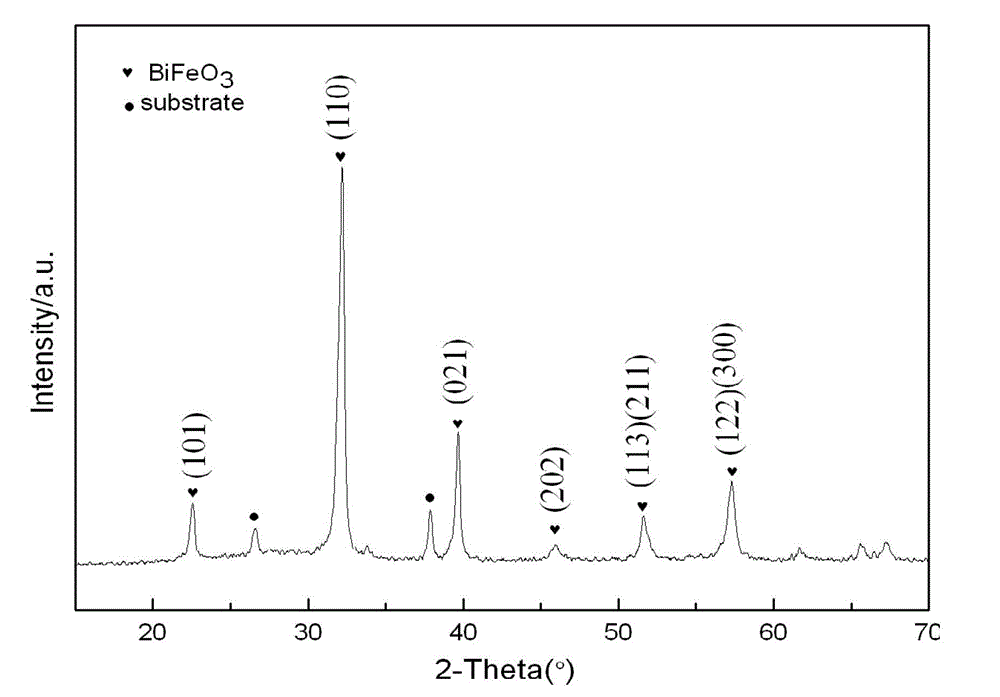

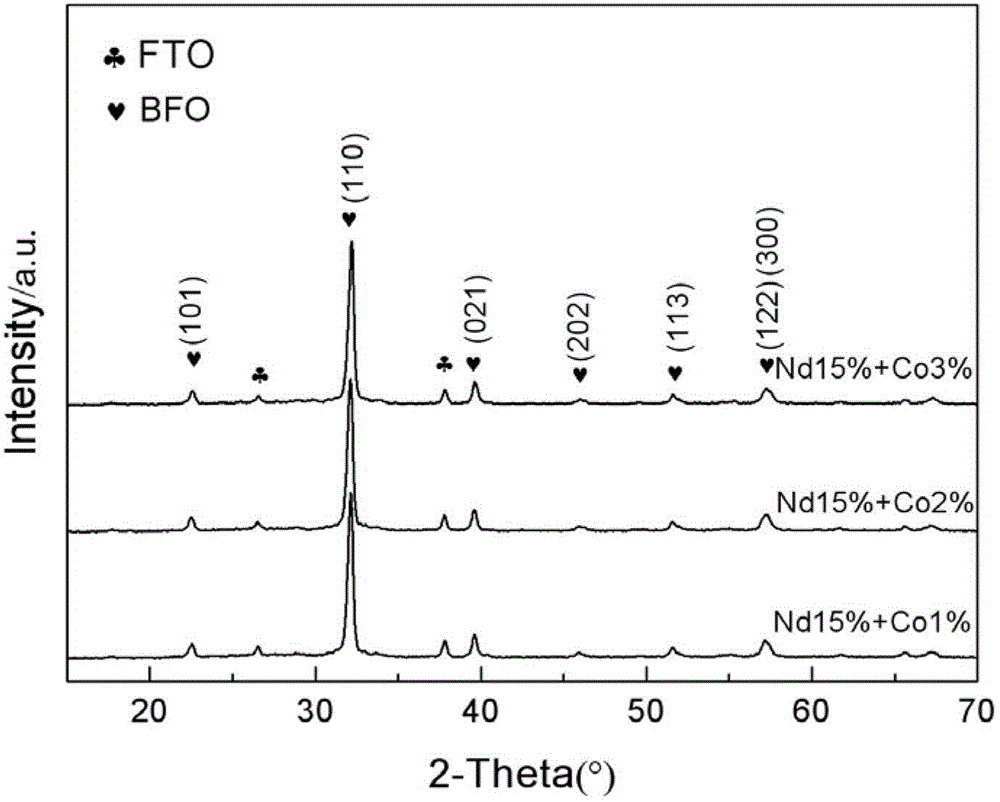

Method for preparing Nd/Co-codoped BiFeO3 film on FTO (fluorine-doped tin oxide)/glass substrate surface

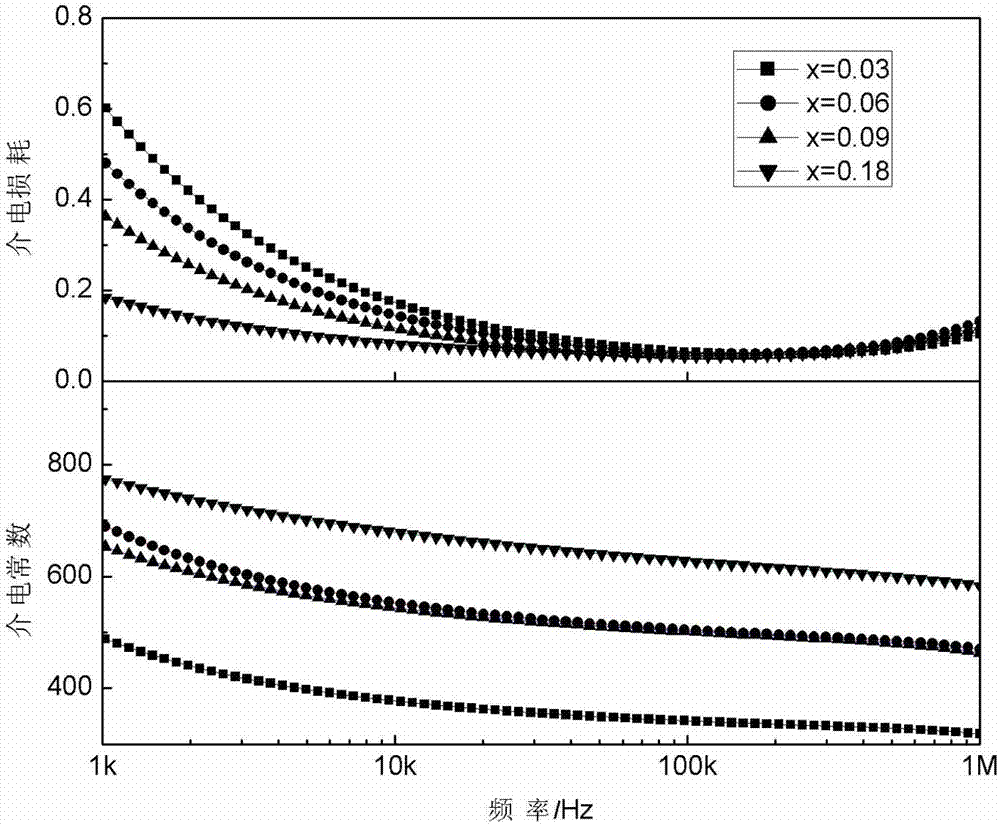

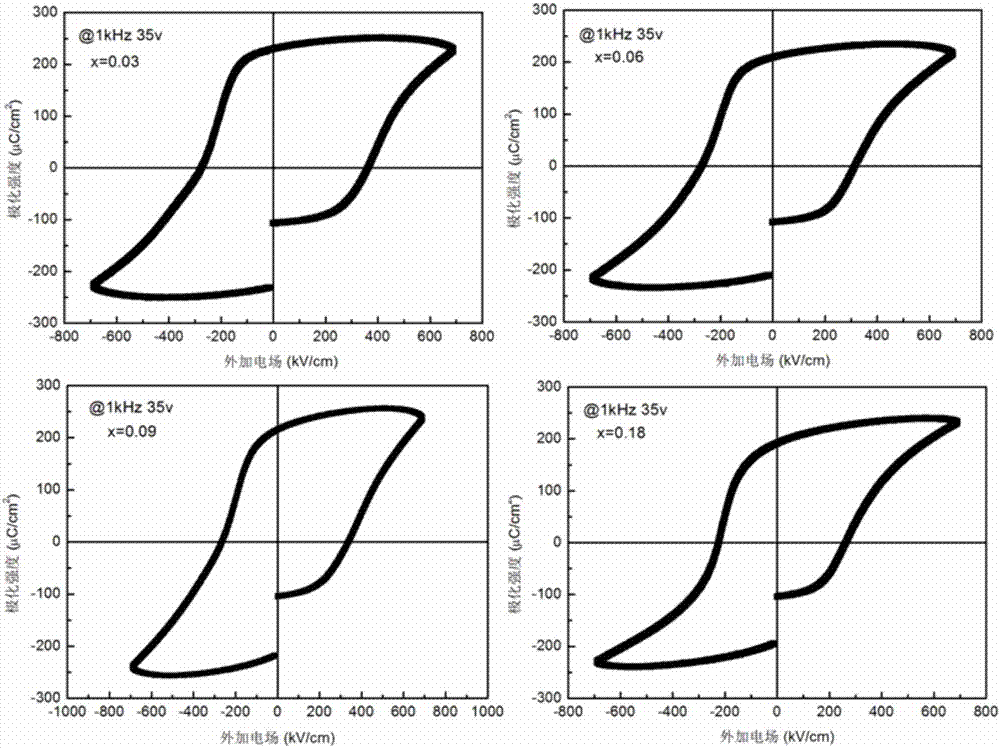

InactiveCN102534588AImprove uniformityExcellent dielectric propertiesSolid/suspension decomposition chemical coatingPolymer scienceAcetic anhydride

The invention provides a method for preparing an Nd / Co-codoped BiFeO3 film on an FTO (fluorine-doped tin oxide) / glass substrate surface, which comprises the following steps: after cleaning an FTO substrate, carrying out ultraviolet irradiation, and dissolving bismuth nitrate (8% excessive), ferric nitrate, neodymium nitrate and cobalt nitrate which serve as raw materials in mixed ethylene glycol monomethyl ether and acetic anhydride in a mol ratio of 0.98:(1-x):0.1:x (x=0.01-0.05), thereby obtaining a stable BiFeO3 precursor solution of which the metallic ion concentration is 0.1-0.5mol / L; and after spin coating, drying to obtain a dry film, preannealing, naturally cooling, repeating the process above to obtain the film with expected thickness, and finally, annealing to obtain the crystalline BiFeO3 film. In the invention, the facility requests are simple, the experiment conditions can be easily achieved, the prepared film has good uniformity, the doping amount is easy to control, andthe dielectric properties of the film can be greatly enhanced by doping.

Owner:SHAANXI UNIV OF SCI & TECH

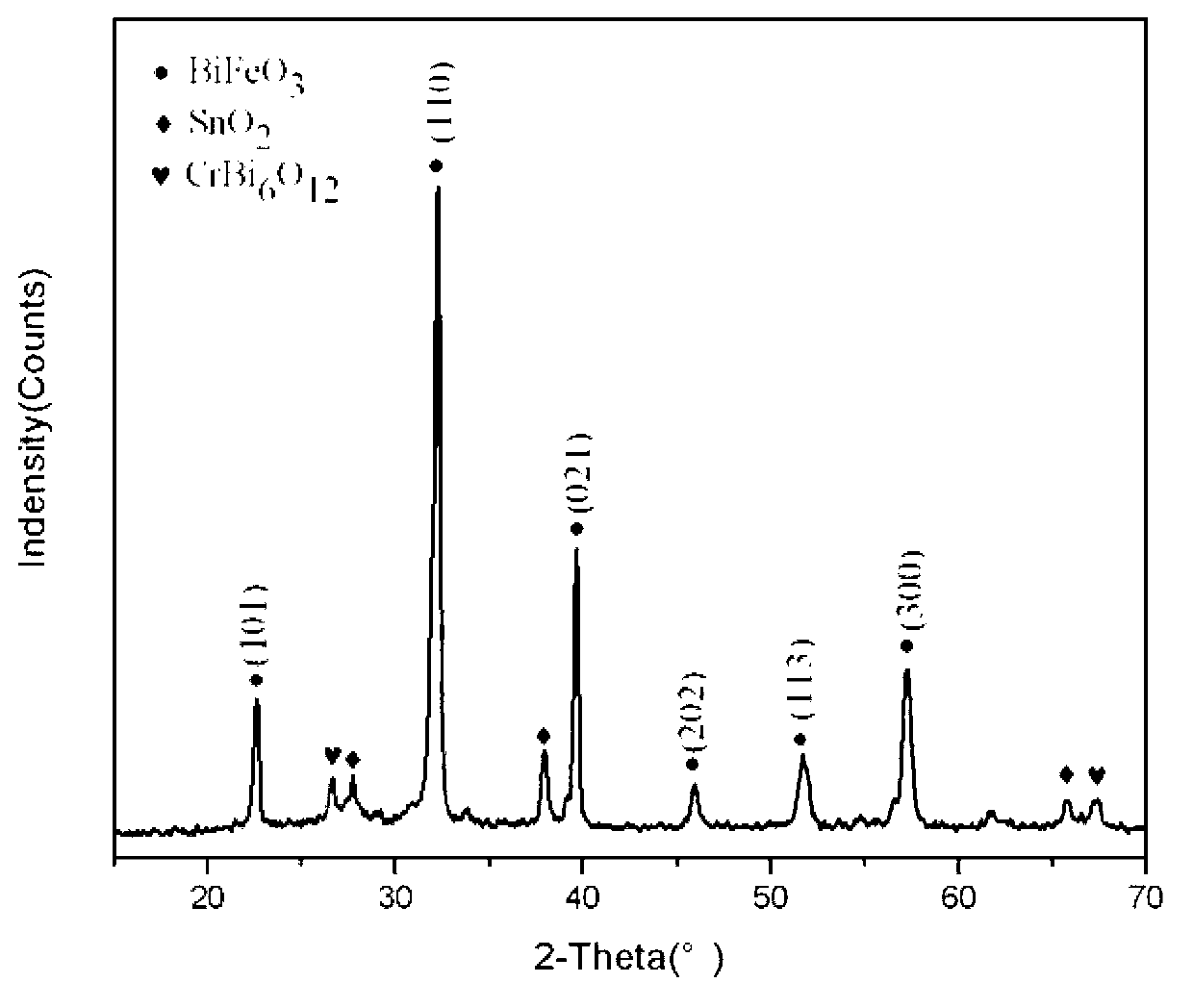

Method for preparing Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film via sol-gel process

The invention discloses a method for preparing a Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film via a sol-gel process. The method is carried out by the following steps of: washing an FTO (Fluorinedoped Tin Oxide) substrate and subsequently irradiating via ultraviolet light; using bismuth nitrate, ferric nitrate, samarium nitrate and chromic nitrate as raw materials (the bismuth nitrate excesses by 5%), dissolving the above raw materials in mixed ethylene glycol monomethyl ether and acetic anhydride according to a mole ratio of 0.90: (1-x):0.15:x (x is 0.00, 0.01, 0.02 or 0.03), then adding ethanol amine to adjust a viscosity and obtain a stable BiFeO3 (bismuth ferrite) precursor solution with a metal ion concentration of 0.003-0.3mol / L; and homogenizing and subsequently obtaining a dry film, then using a layer-by-layer annealing process to obtain a crystal-state Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film. The method disclosed by the invention has the advantages of simple device requirement, easy achievement of experiment condition, good uniformity of the prepared films and easy control of the doping amount, so that the ferroelectric performance of the film is greatly enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

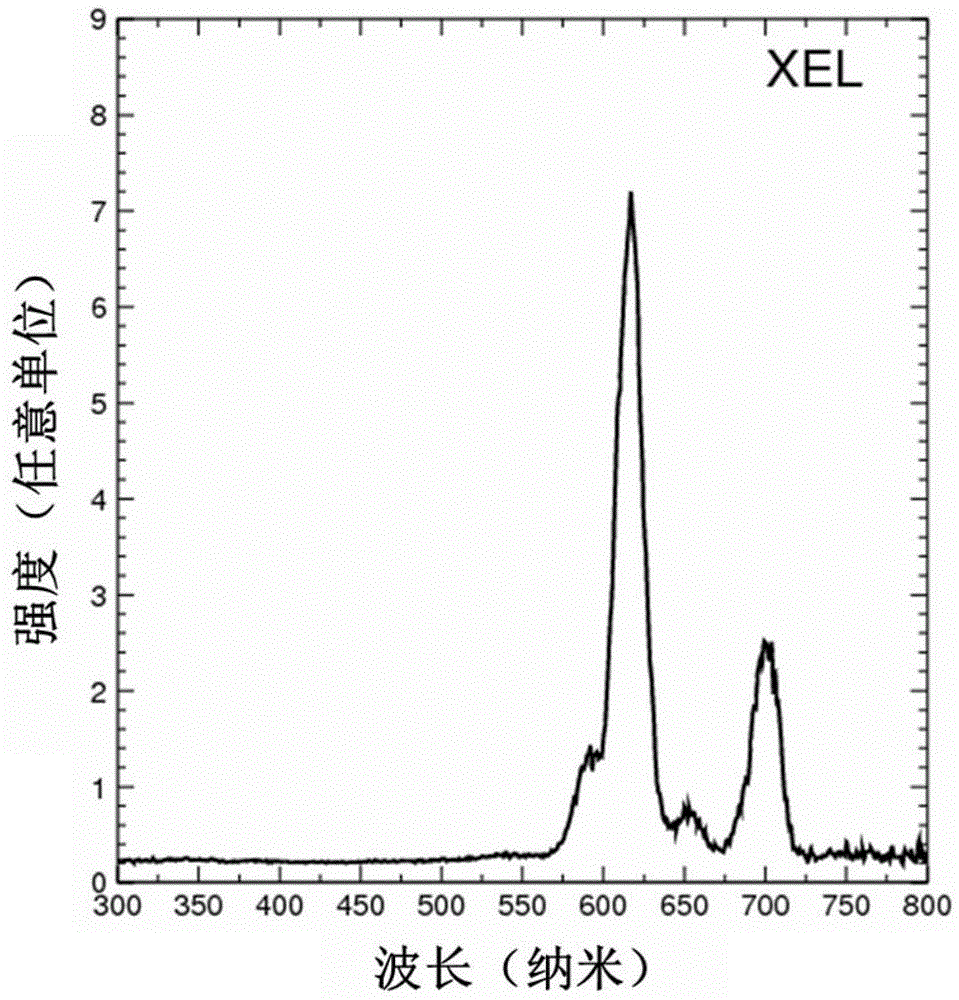

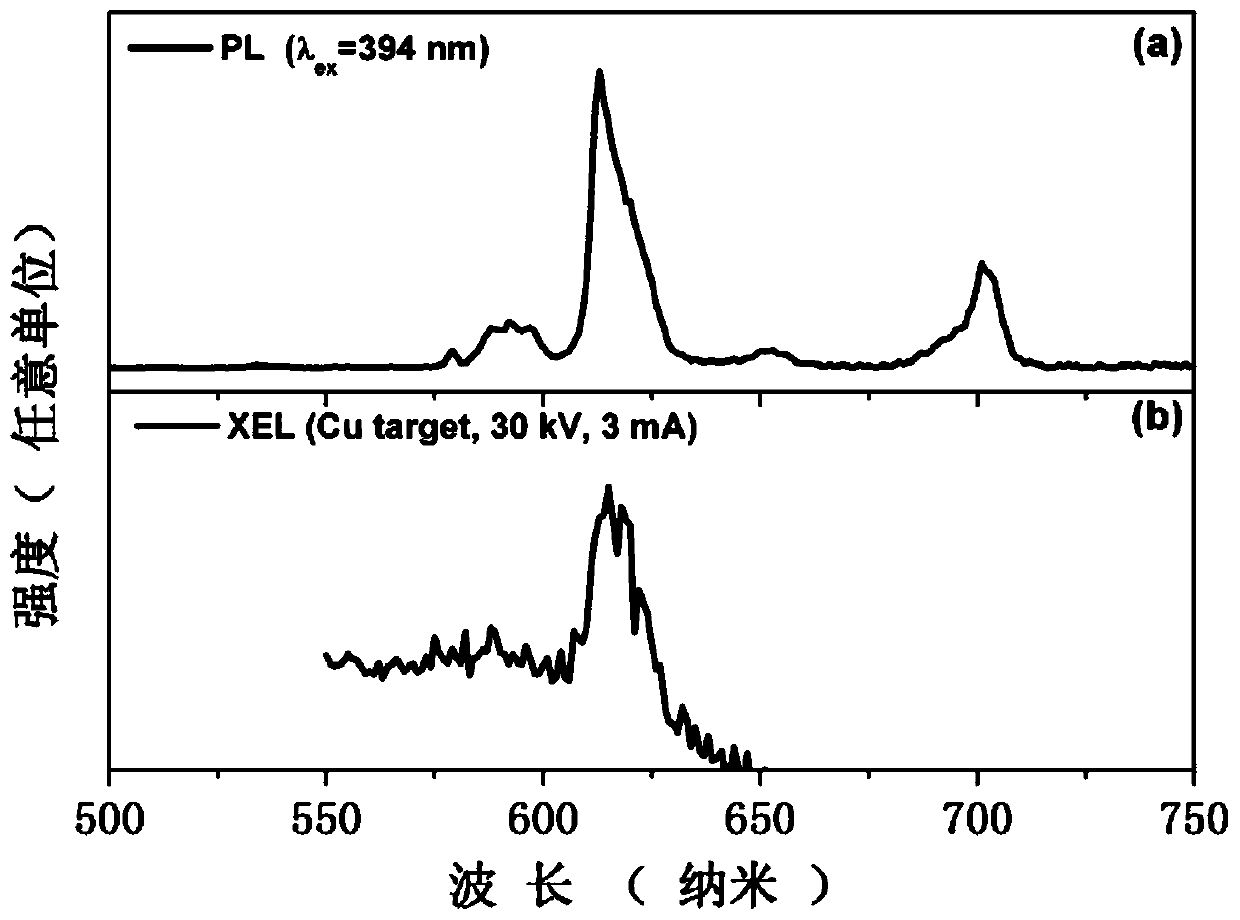

High-density gadolinium and tungsten borate scintillation glass and preparation method thereof

The invention relates to high-density gadolinium and tungsten borate scintillation glass and a preparation method thereof. The scintillation glass comprises a matrix Gd2O3-WO3-B2O3 and luminescence center Eu3+ ions dispersed on the matrix. The matrix comprises 20-25 mol% of Gd2O3, 40-60 mol% of WO3, 10-30 mol% of B2O2 and 0.05-5 mol% of Eu3+ ions. The radius of Gd3+ ions in the rare earth doped gadolinium and tungsten borate scintillation glass is moderate, and can be effectively subjected to solution treatment with the Eu3+ ions; Gd3+ can transfer energy to a Eu3+ luminescence center, and accordingly light emitting efficiency is improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing BiFe1-xCrxO3 ferroelectric film by using sol-gel method

The invention provides a method for preparing a BiFe1-xCrxO3 ferroelectric film by using a sol-gel method. The method comprises the following steps of: dissolving bismuth nitrate, ferric nitrate and chromic nitrate according to a molar ratio of 1.05: (1-x): x into a mixed solution containing ethylene glycol monomethyl ether, acetic oxide and cholamine, and magnetically stirring to obtain a stable BiFe1-xCrxO3 precursor with the metal ion concentration of 0.003-0.3mol / L, wherein x is equal to 0.00-0.03, and the volume ratio of the ethylene glycol monomethyl ether to the acetic oxide to the cholamine is 14: 5: 1. A film is prepared by spin-coating the BiFe1-xCrxO3 precursor on an FTO (Fluorine-doped Tin Oxide) / glass substrate by using a spin-coating method, and a crystalline BiFe1-xCrxO3 film is obtained by adopting a layer-by-layer annealing process. The method disclosed by the invention has simple requirements on equipment, and experimental conditions are easy to achieve; the prepared film is better in uniformity, and the doping amount is easy to control; and the ferroelectric property of the BiFeO3 film is improved through B-bit Cr doping.

Owner:盐城青墩津邦水务有限公司

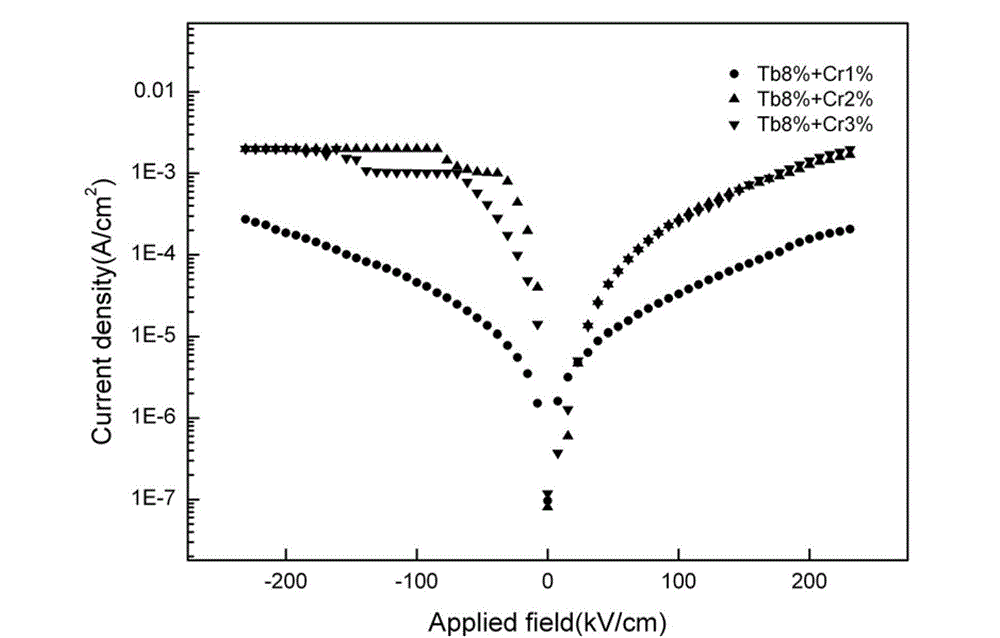

Preparation method of low-leakage current Bi0.92Tb0.08Fe(1-x)CrxO3 film

ActiveCN102976764AImprove multiferroic propertiesImprove electrical performanceAcetic anhydrideLow leakage

The invention provides a preparation method of a low-leakage current Bi0.92Tb0.08Fe(1-x)CrxO3 film. The method comprises the following steps of: dissolving bismuth nitrate, ferric nitrate, terbium nitrate and chromic nitrate at a molar ratio of 0.97:(1-x):0.08:x into the mixed solution of ethylene glycol monomethyl ether and acetic anhydride to form a mixed solution; adding ethanolamine into the mixed solution to adjust the viscosity and the complexing degree to obtain a stable BiFeO3 precursor liquid; and preparing a Tb and Cr co-doped crystalline BiFeO3 film by a spin-coating method and layer-by-layer annealing technology. The film is a crystalline Bi0.92Tb0.08Fe0.99Cr0.01O3 film, wherein the leakage current density is still kept below 10<-4>A / cm<2> in a 150kv / cm test electric field. According to the method provided by the invention, the requirements on equipment are simple, the experimental conditions are easy to realize, the prepared film has good uniformity, and the leakage current of the film is reduced through the co-doping of Tb and Cr.

Owner:SHAANXI UNIV OF SCI & TECH

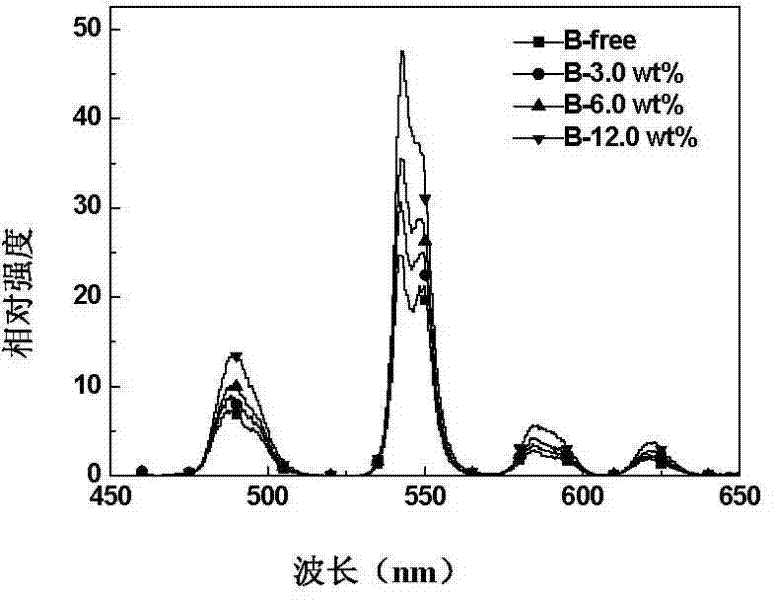

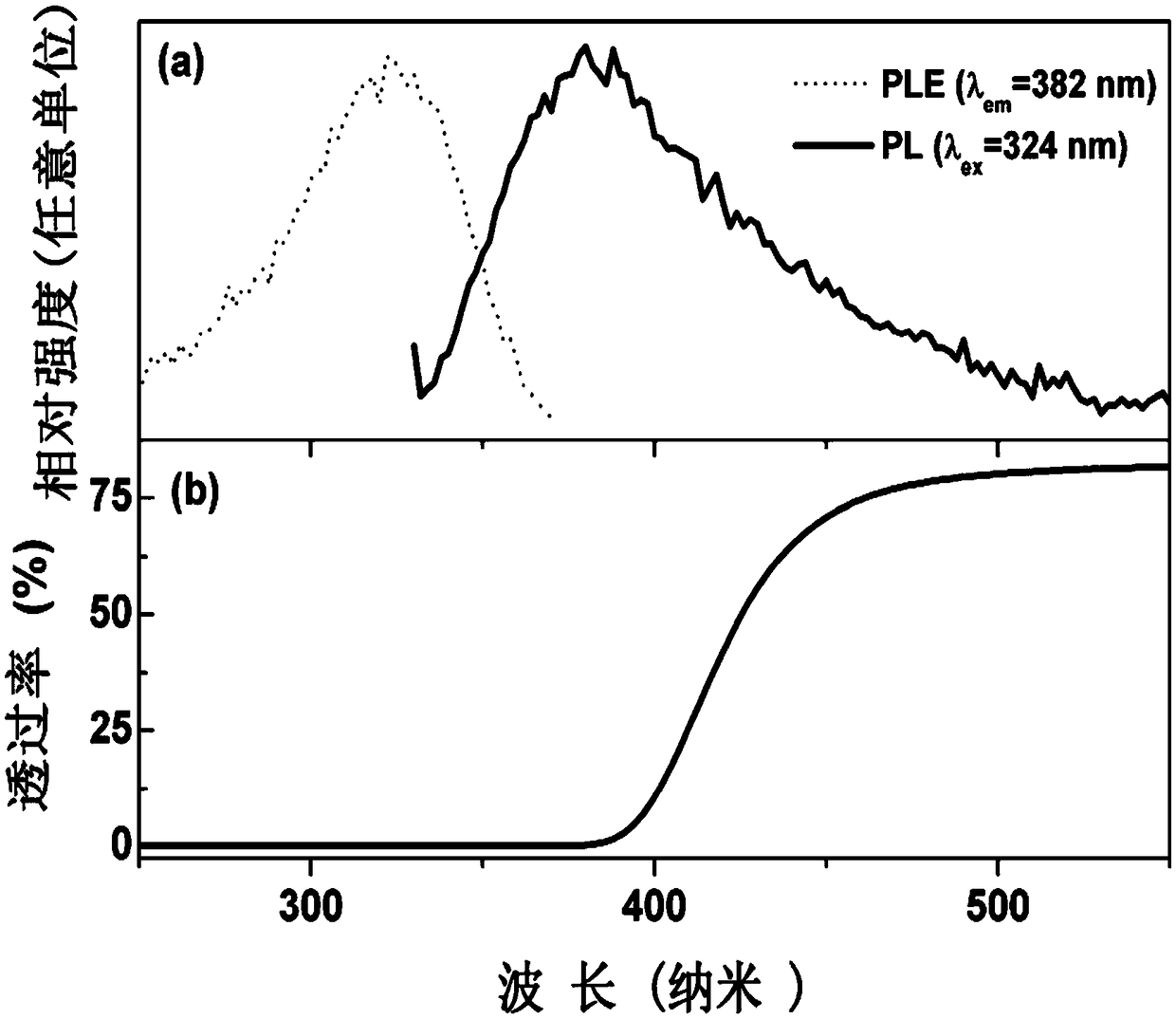

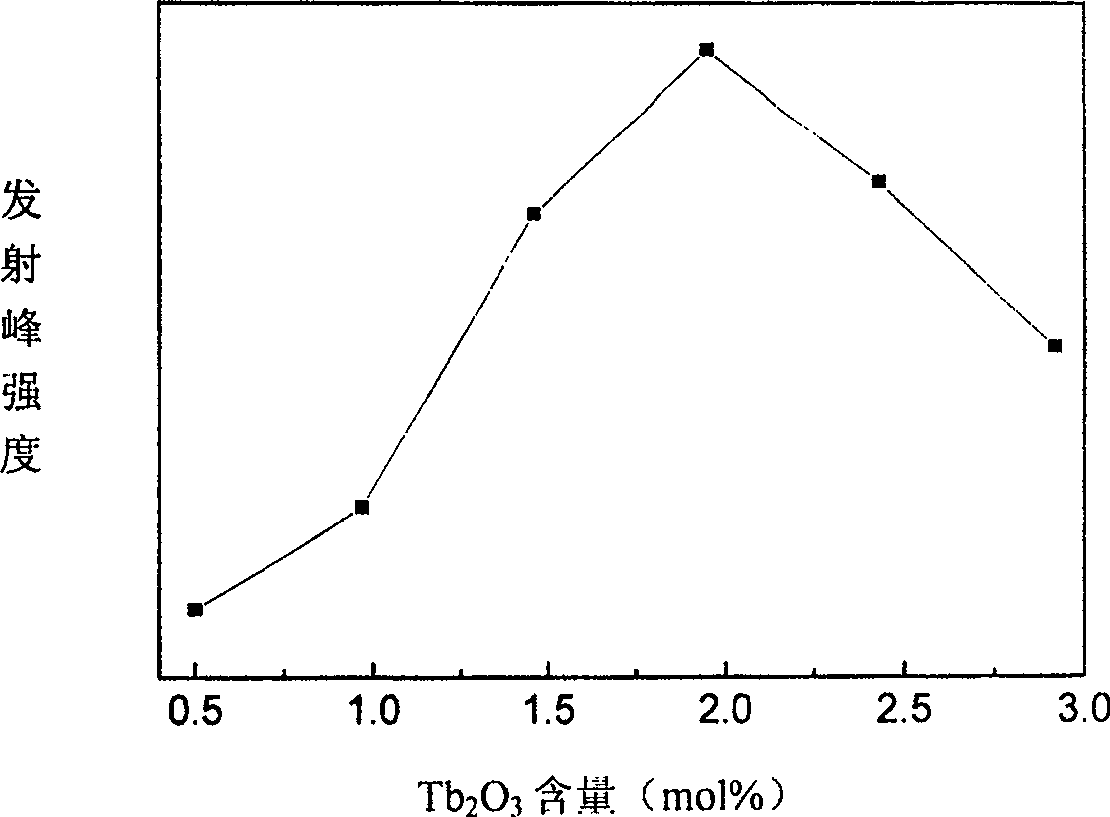

High-luminous-intensity terbium-activated silicate glass and preparation method thereof

InactiveCN102452793ASimple preparation processChemical composition is easy to controlLuminous intensitySilicate glass

The invention relates to high-luminous-intensity terbium-activated silicate glass and a preparation method thereof. The invention belongs to the field of luminescent materials. According to the invention, B2O3 with high phonon energy is added into a terbium-activated silicate glass formula; the mixture is well mixed; and preparation is carried out through high-temperature fusing and an annealing treatment. B2O3 takes 2-20% of a total weight of the glass formula. The glass and the method are advantaged in that: with he prepared terbium-activated silicate glass, the luminous intensity of Tb<3+> is effectively improved. The luminescent glass can be used in fields such as displaying, illumination and photoelectric devices.

Owner:TONGJI UNIV +1

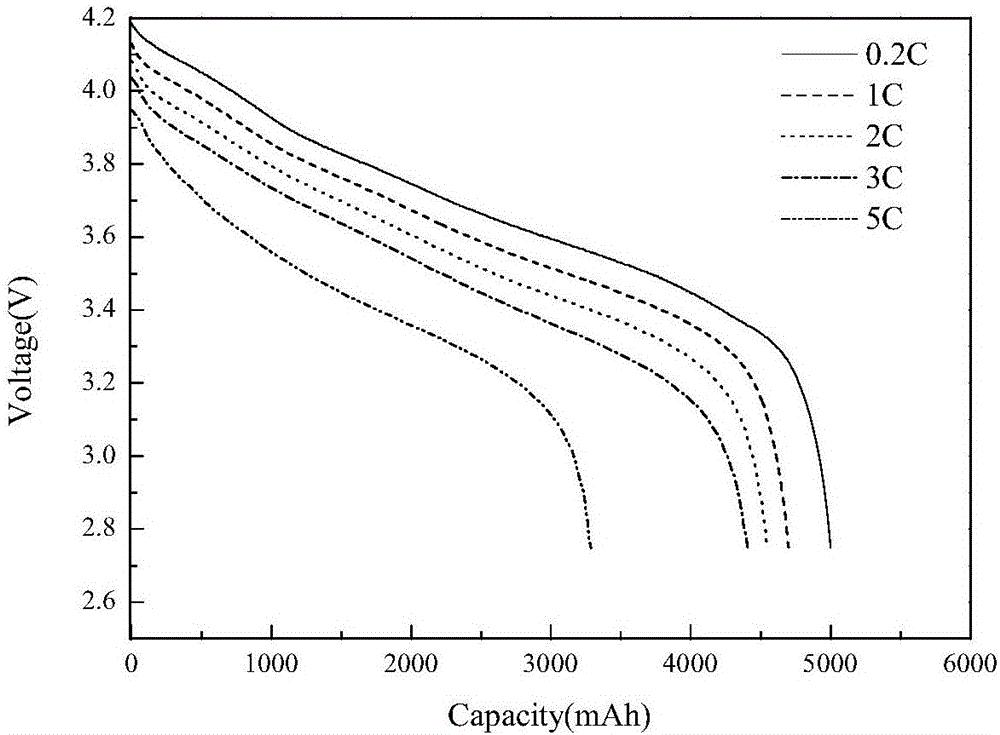

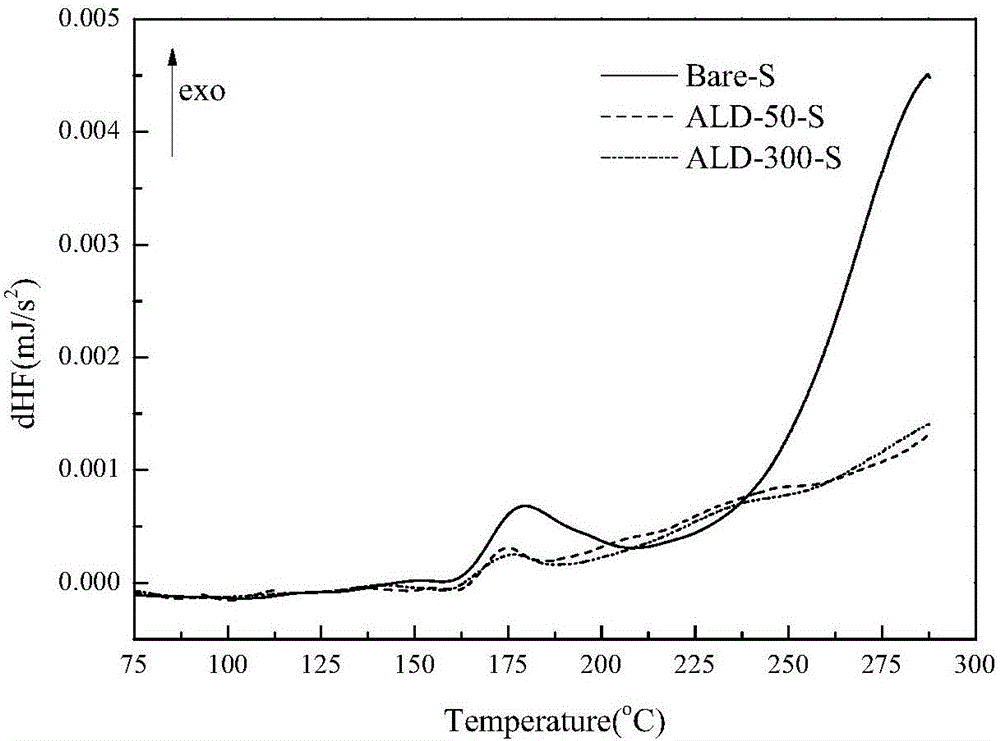

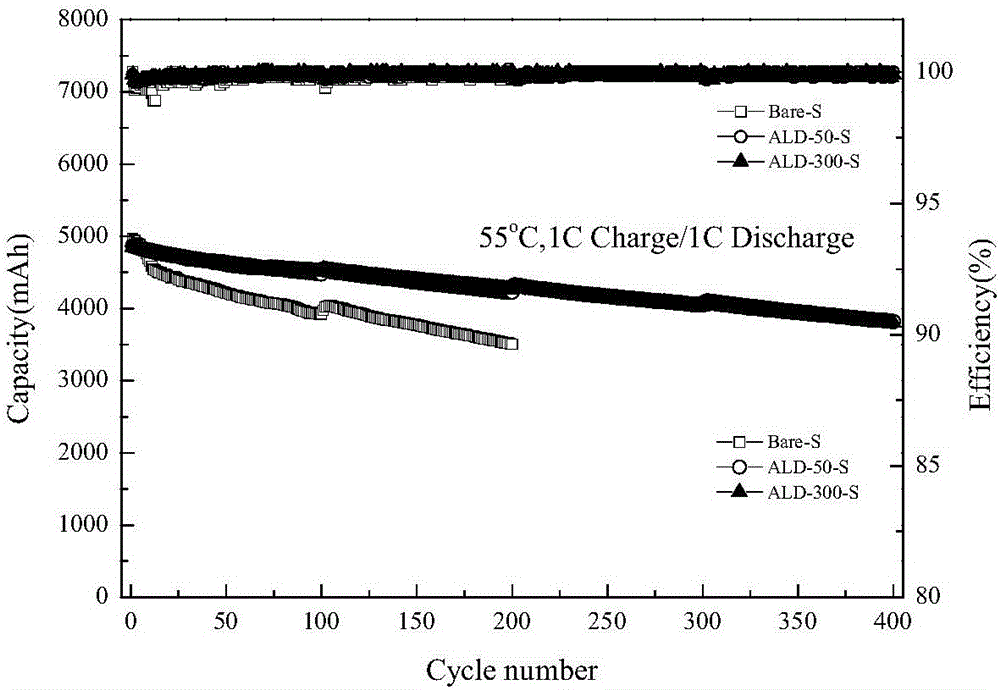

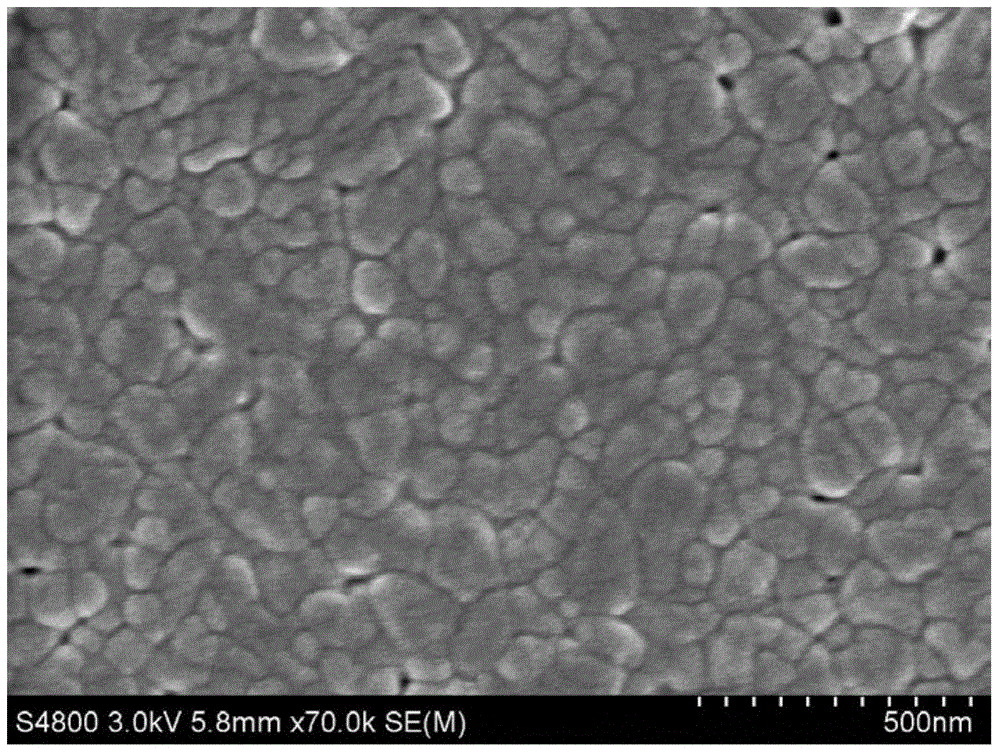

Atomic layer deposition modified lithium-ion battery and preparation method thereof

InactiveCN106384838AImprove high temperature stabilityImprove cycle stabilitySecondary cellsVapour deposition manufacturingPole pieceEngineering

The invention discloses an atomic layer deposition (ALD) modified lithium-ion battery and a preparation method thereof. According to the atomic layer deposition modified lithium-ion battery disclosed by the invention, a modification layer is formed on at least one surface of a positive electrode active material and a negative electrode active material; each modification layer is formed through adopting an atomic layer deposition process; or a modification layer is formed at least one surface of a positive electrode pole piece and a negative electrode pole piece, and each modification layer is formed through adopting the atomic layer deposition process.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

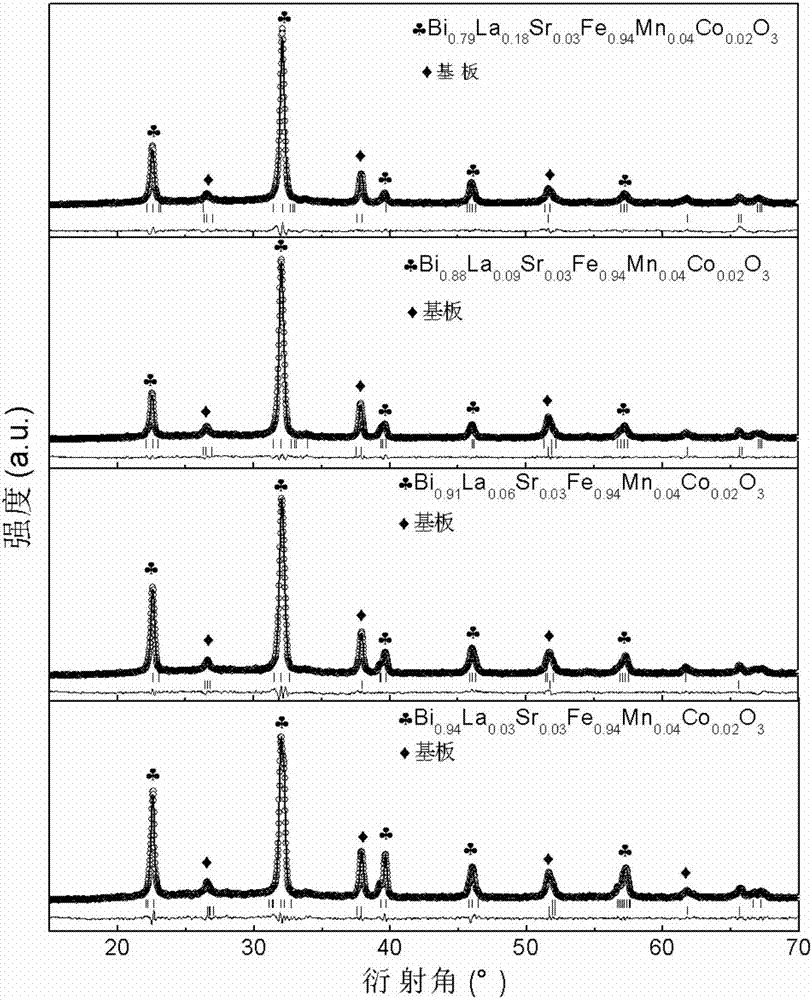

LaSrMnCo codoped bismuth ferrite multiferroic film and preparation method thereof

ActiveCN107117830AGood dielectricImprove ferroelectric propertiesCoatingsMANGANESE ACETATEAcetic anhydride

The invention provides a LaSrMnCo codoped bismuth ferrite multiferroic film and a preparation method thereof. A Bi(0.97-x)LaxSr0.03Fe0.94Mn0.04Co0.02O3 multiferroic film, namely the LaSrMnCo codoped bismuth ferrite multiferroic film, is prepared by taking bismuth nitrate, lanthanum nitrate, strontium nitrate, ferric nitrate, manganese acetate and cobalt nitrate as raw materials (bismuth nitrate of excessive 5 percent), taking ethylene glycol monomethyl ether and acetic anhydride as solvents and using a spin-coating method and a layer-by-layer annealing process. A sol-gel process is adopted, spin-coating and layer-by-layer annealing methods are adopted, equipment requirements are simple, experimental conditions are easy to realize, the film is suitably prepared on a large surface and an irregularly shaped surface, chemical components are accurately controllable, the multiferroic property of the BiFeO3 film can be improved, the prepared the LaSrMnCo codoped bismuth ferrite multiferroic film has high uniformity and is a multiferroic film with high residual polarization value and low coercive field, and the ferroelectric and dielectric properties of the film are effectively enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

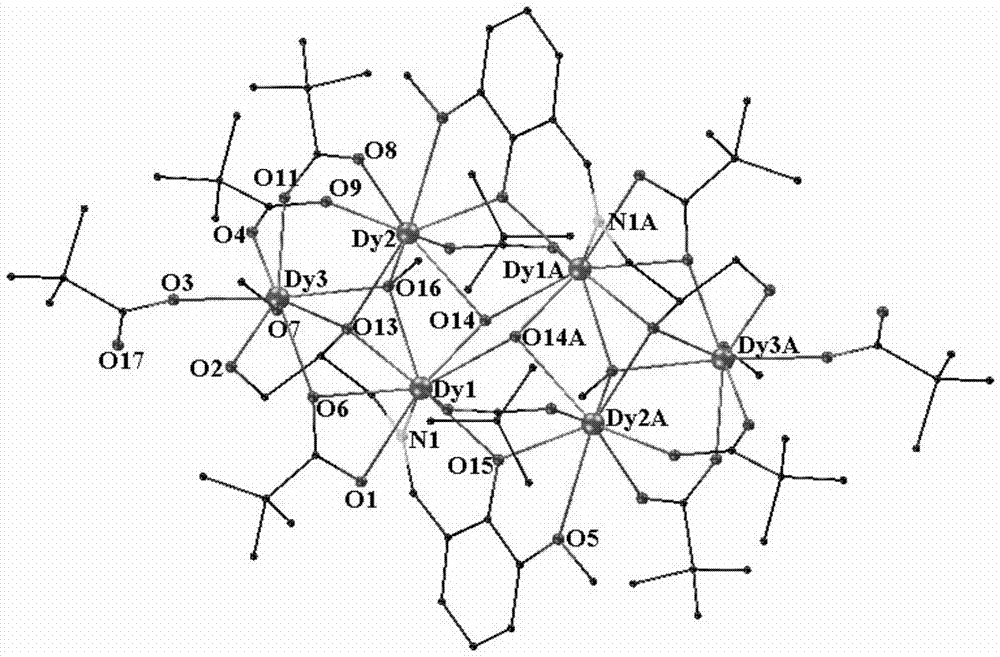

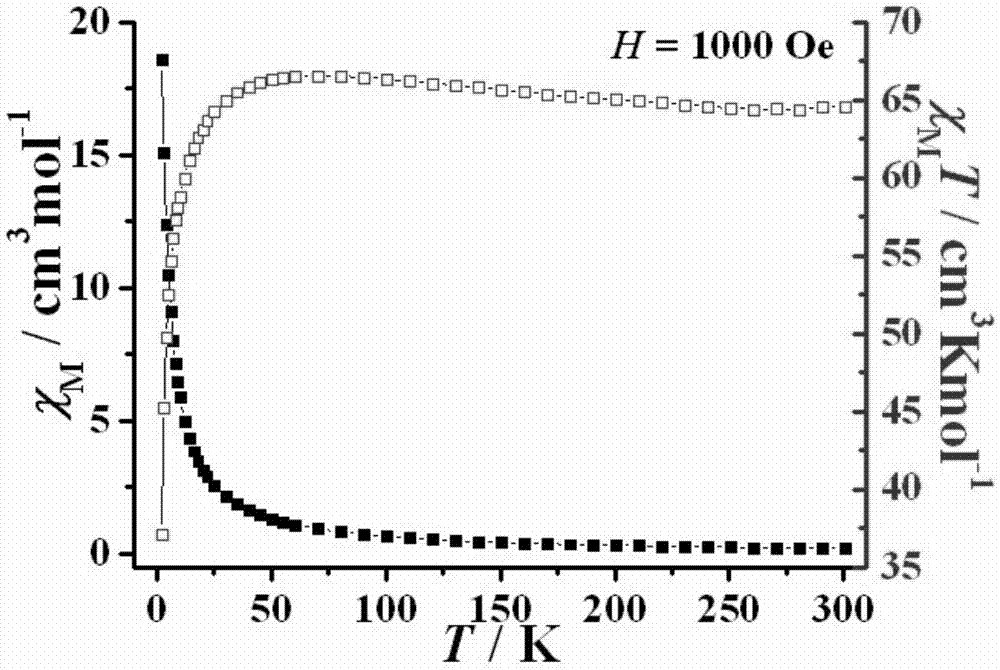

Rare-earth magnetic material and preparation method thereof

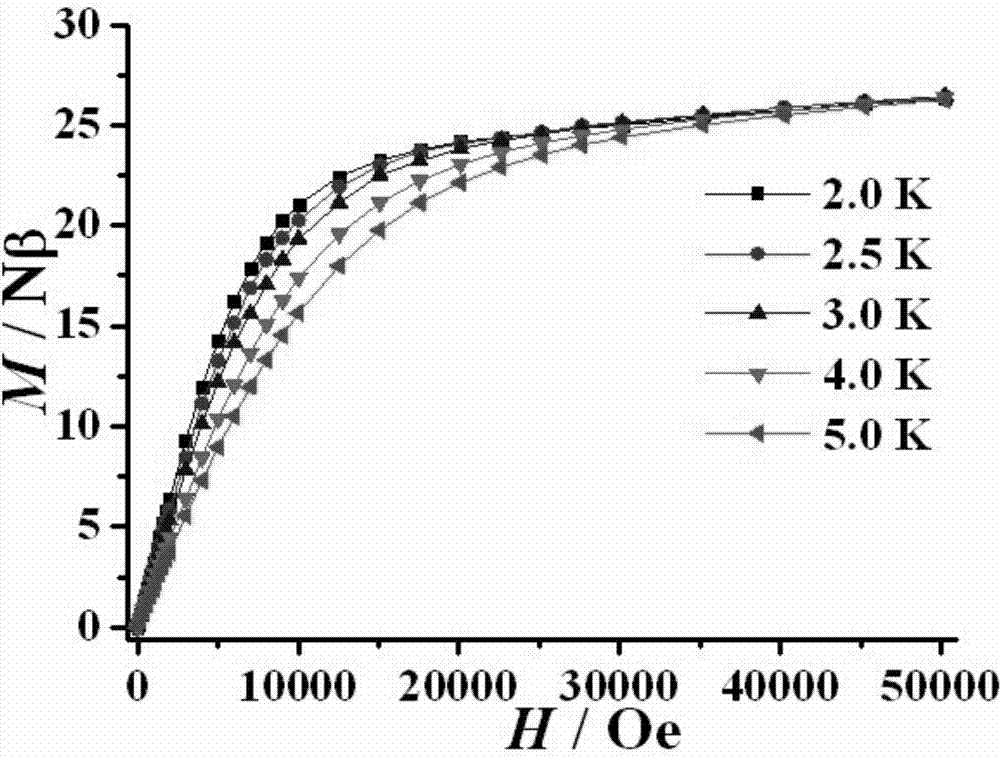

InactiveCN104332272AEasy to prepareLow costOrganic/organic-metallic materials magnetismRare earthParamagnetism

The invention discloses a rare-earth magnetic material and a preparation method thereof. The chemical formula of the rare-earth magnetic material is [Dy6L2(Mu3-OH2)2(Mu3-OCH3)2(piv)10(OCH3)2], L is 3-{[(2-hydroxy-3-methoxyphenyl)methylene]amino}-1,2-propylene glycol, and piv is trimethylacetic acid. The preparation method of the rare-earth magnetic material is as follows: with DyCl3 6H2O, the trimethylacetic acid and the 3-{[(2-hydroxy-3-methoxyphenyl)methylene]amino}-1,2-propylene glycol as materials and methanol and acetonitrile as solvents, the target product is prepared by solvothermal reaction after pH is regulated to be equal to 5.5 to 6.6. The magnetic properties of the rare-earth magnetic material described by the invention are as follows: ferromagnetic exchange exists between dysprosium ions in molecules, and the rare-earth magnetic material acts as paramagnetism on the whole; the method described by the invention is simple, the cost is low, the chemical constituents are easy to control, and repeatability is good.

Owner:GUANGXI NORMAL UNIV

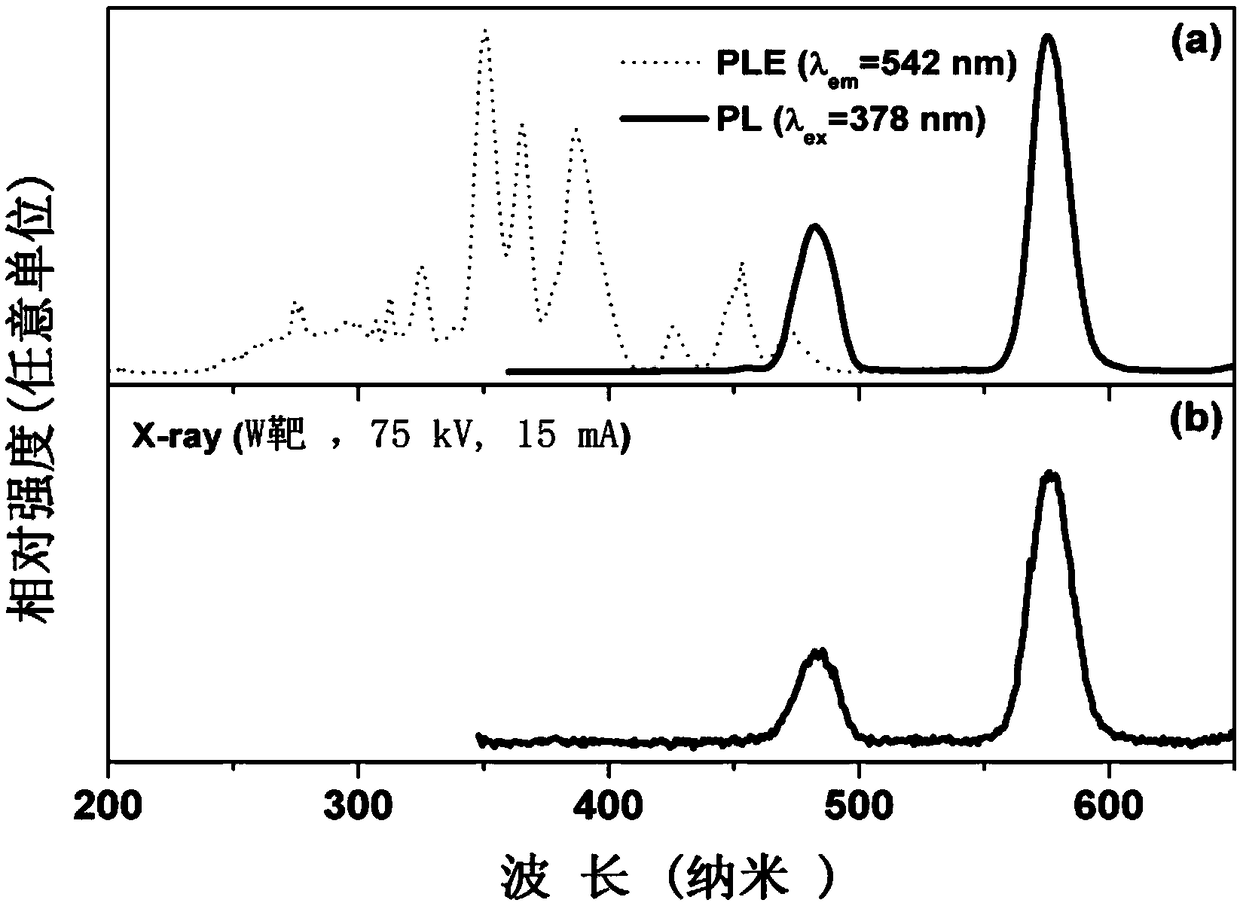

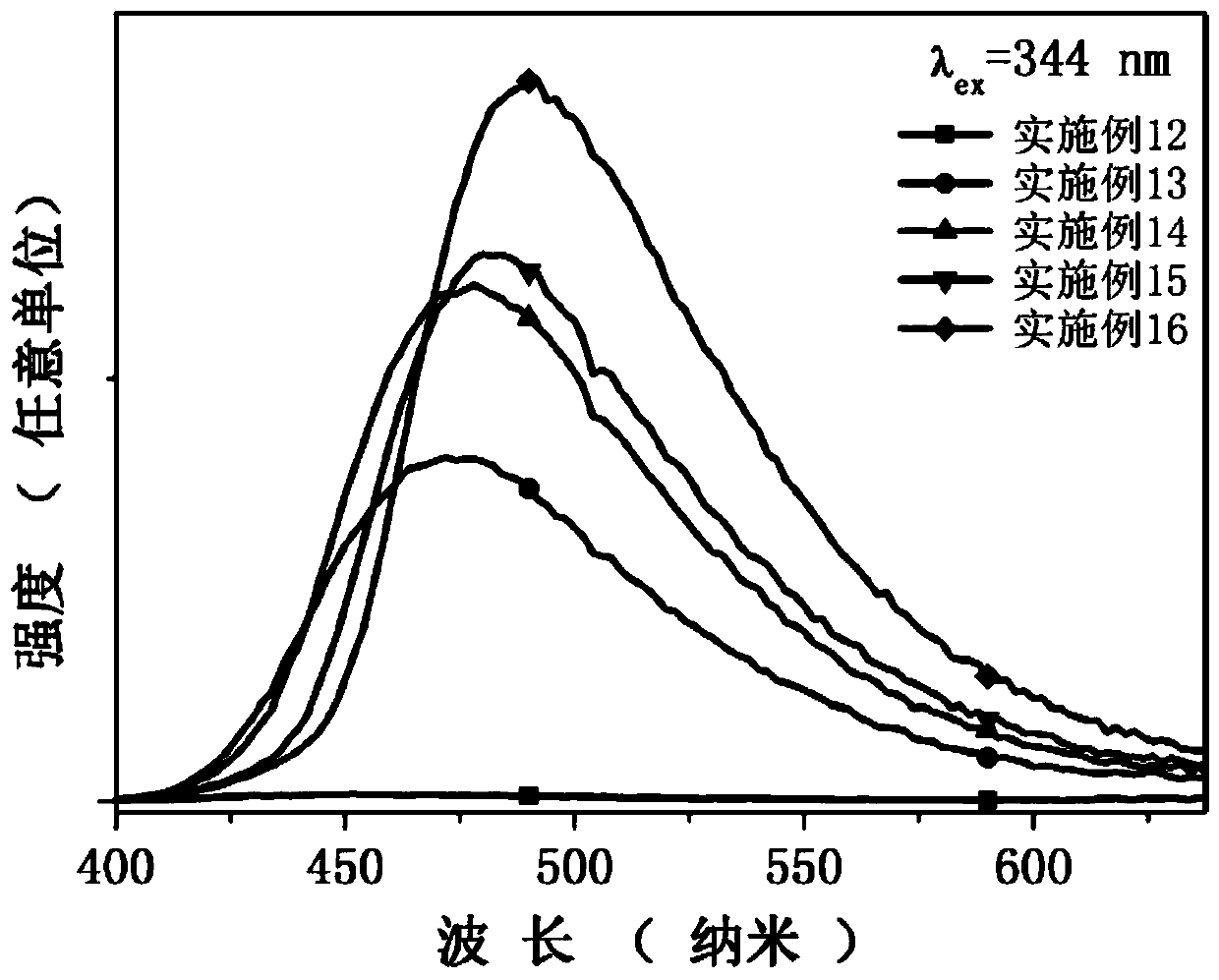

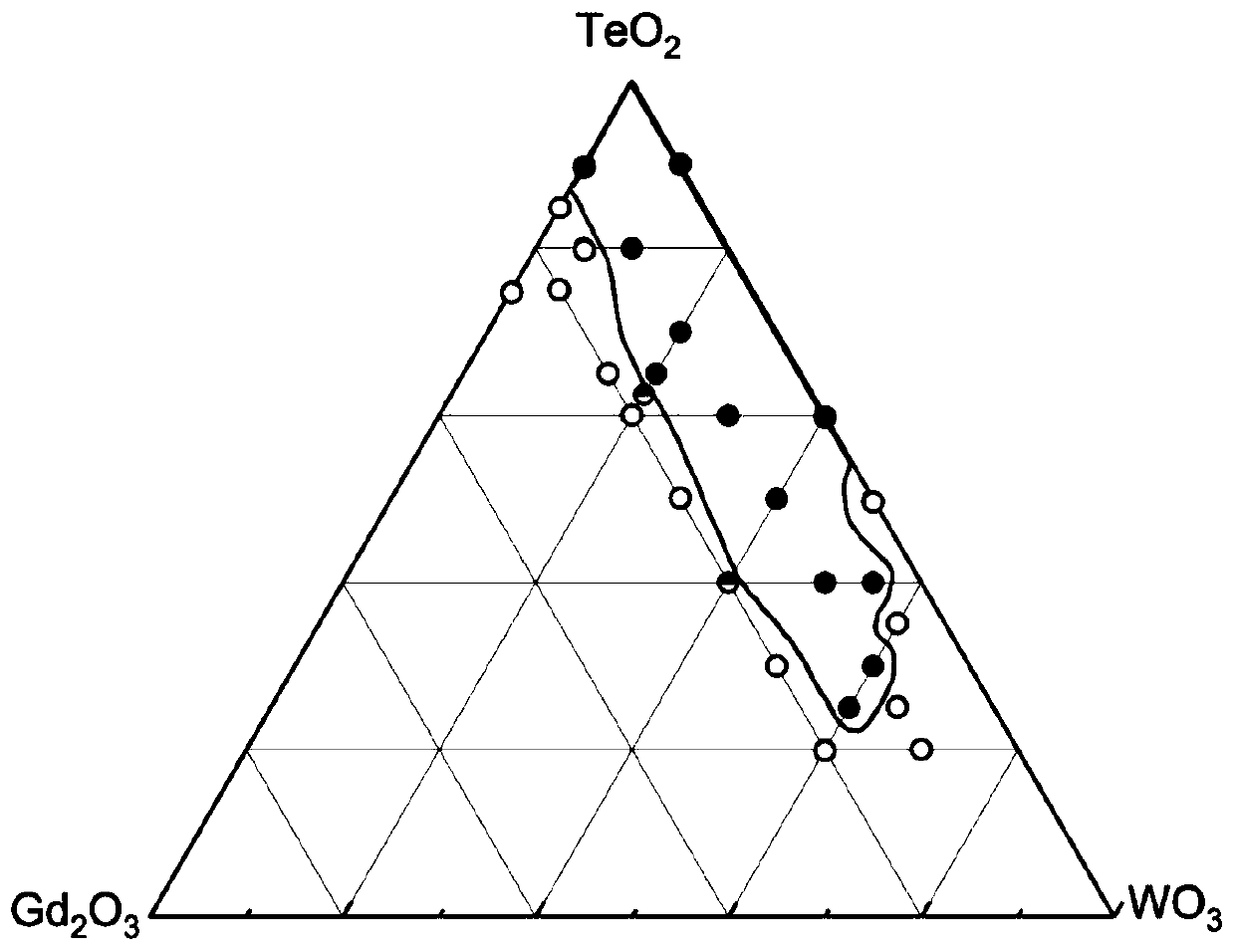

Ultra-high-density boron germanotelluriteb scintillation glass and preparation method thereof

ActiveCN108609848ASimple preparation processChemical composition is easy to controlGlass shaping apparatusHigh energyRare earth ions

The invention relates to ultra-high-density boron germanotelluriteb scintillation glass and a preparation method thereof. The ultra-high-density boron germanotelluriteb scintillation glass is characterized in that main components of a network former of the ultra-high-density boron germanotelluriteb scintillation glass (metered by mole percent) are 5-30 mol% of B2O3, 10-30 mol% of GeO2 and 5-20 mol% of TeO2, and the rest of 20-60 mol% of glass component consists of rare earth oxide or rare earth fluoride. Rare earth ions comprise Y3+, La3+, Ce3+, Pr3+, Nd3+, Pm3+, Sm3+, Eu3+, Gd3+, Tb3+, Dy3+,Ho3+, Er3+, Tm3+, Yb3+ and Lu3+, and the sum of the components is 100 mol%. The invention further discloses a method for preparing the boron germanotelluriteb scintillation glass which is rich in Gd2O3, and application of the ultra-high-density boron germanotelluriteb scintillation glass in X-ray medical imaging, industrial online detection, national safety supervision and high-energy physics or nuclear physics experiments.

Owner:JINGGANGSHAN UNIVERSITY

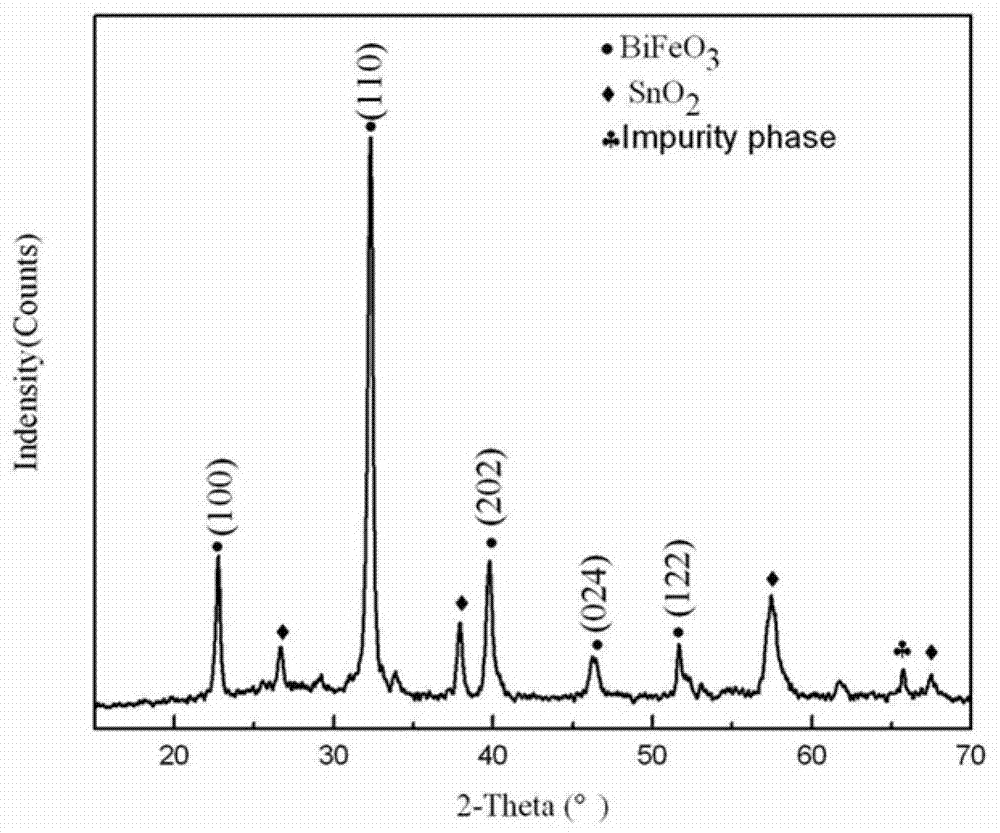

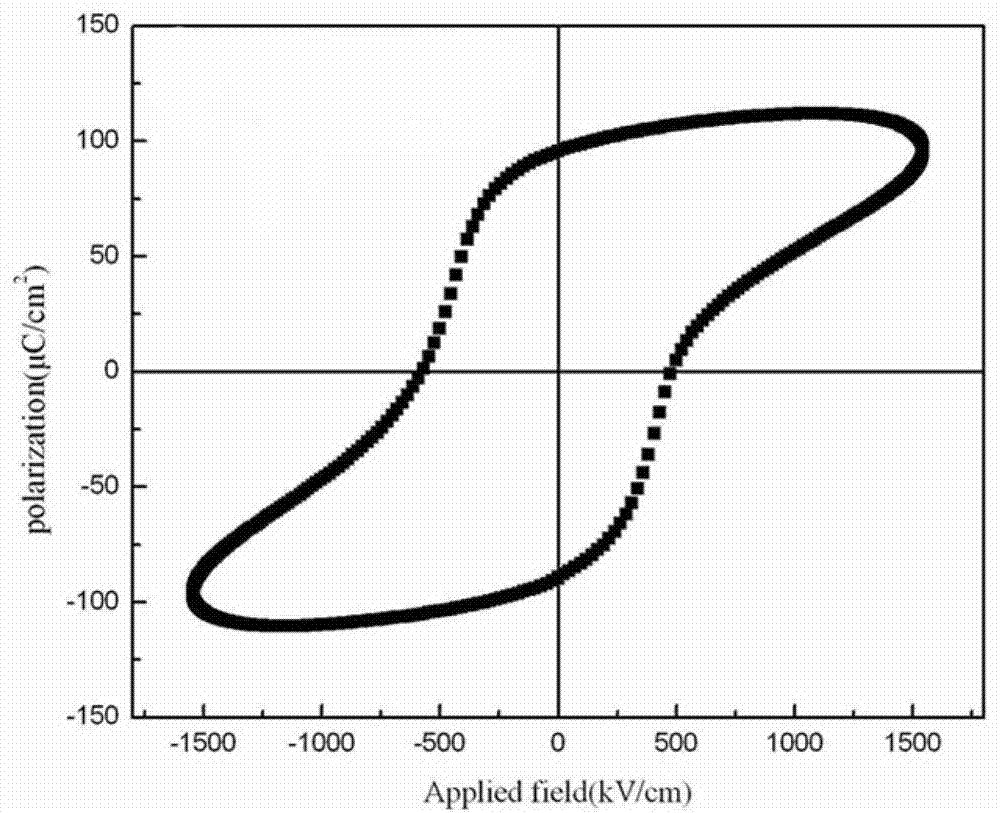

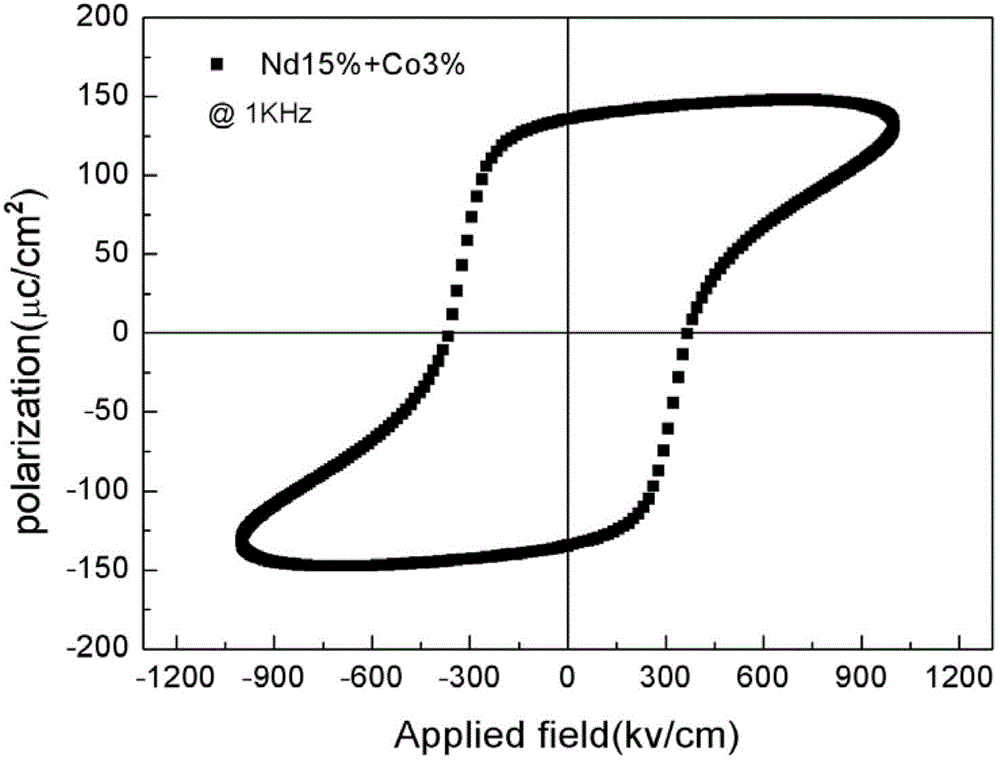

Method for preparing high-remanent-polarization BiFeO3 film with preferentially growing (110) crystal face by sol-gel process

ActiveCN103060887AImprove ferroelectric propertiesWell mixedFrom gel statePolycrystalline material growthAcetic anhydrideCobalt(II) nitrate

The invention provides a method for preparing a high-remanent-polarization BiFeO3 film with preferentially growing (110) crystal face by a sol-gel process, which comprises the following steps: dissolving bismuth nitrate, ferric nitrate, neodymium nitrate and cobalt nitrate used as raw materials in a mol ratio of 0.90:(1-x):0.15:x (x=0.01-0.03) in mixed ethylene glycol monomethyl ether and acetic anhydride (in a volume ratio of 3:1) to obtain a stable BiFeO3 precursor solution with the metal ion concentration of 0.3 mol / L, wherein bismuth ions are 5% excessive to compensate the volatilization in the film annealing process; and evenly coating the BiFeO3 precursor solution on an FTO (fluorine-doped tin oxide) substrate, drying to obtain a dry film, and carrying out layer-by-layer quick annealing at 550 DEG C to obtain the crystalline BiFeO3 film with expected thickness. The facility requests are simple, the experimental conditions can be easily achieved, and the BiFeO3 film with preferentially growing (110) crystal face, of which the remanent polarization is higher than 130 mu C / cm<2>, can be prepared by accurately controlling the solvent ratio of the precursor solution and the codoping of the A-B position.

Owner:SHAANXI UNIV OF SCI & TECH

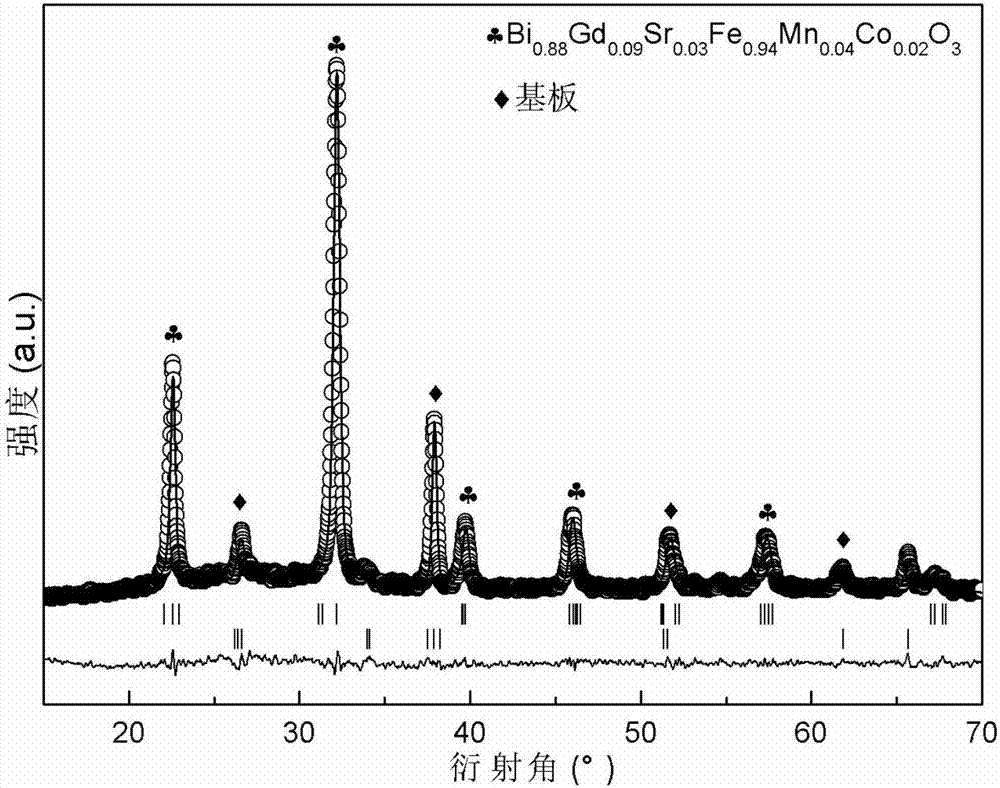

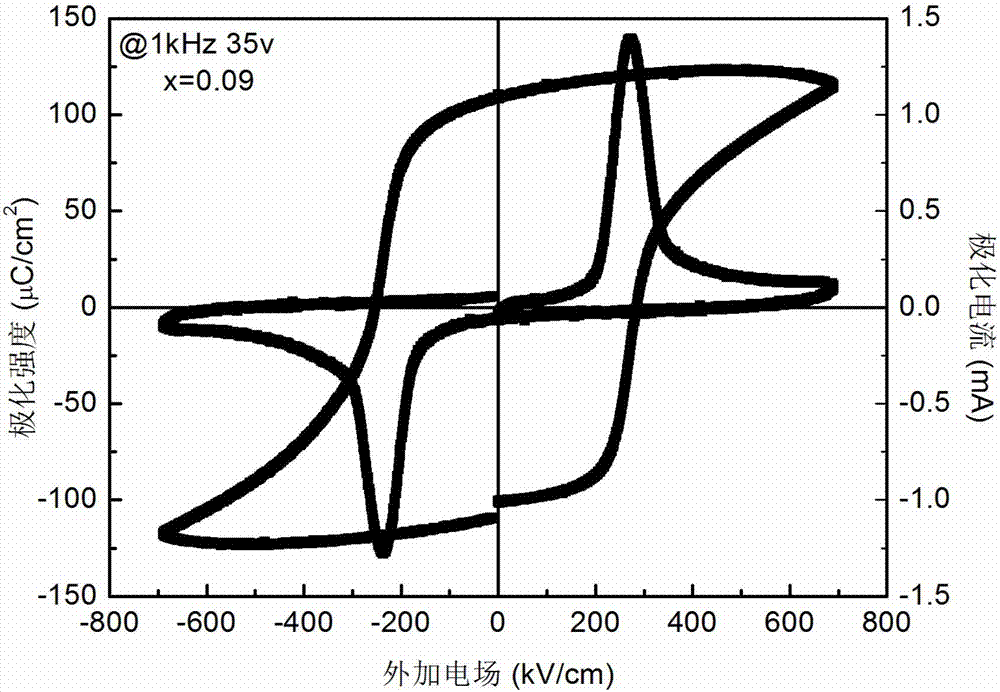

GdSrMnCo codoped bismuth ferrite multiferroic film and making method thereof

ActiveCN107032631AGood dielectricImprove ferroelectric propertiesCoatingsMANGANESE ACETATEAcetic anhydride

The invention provides a GdSrMnCo codoped bismuth ferrite multiferroic film and a making method thereof. The Bi0.97-xGdxSr0.03Fe0.94Mn0.04Co0.02O3 multiferroic film that is the GdSrMnCo codoped bismuth ferrite multiferroic film is made from bismuth nitrate, gadolinium nitrate, strontium nitrate, ferric nitrate, manganese acetate and cobalt nitrate (5% excessive bismuth nitrate) through a spin coating technology and a layer-by-layer annealing technology by using ethylene glycol monomethyl ether and acetic anhydride as a solvent. The method which adopts a sol-gel process and the spin coating and layer-by-layer annealing technologies has the advantages of simple device requirements, easiness in realization of experimental conditions, suitableness for making a film on a large surface and a surface with an irregular shape, accurate and controllable chemical components, and improvement of the multiferroic performance of a BiFeO3 film; and the produced GdSrMnCo codoped bismuth ferrite multiferroic film has good uniformity and has the ferroelectric stability changing with the applied voltage.

Owner:SHAANXI UNIV OF SCI & TECH

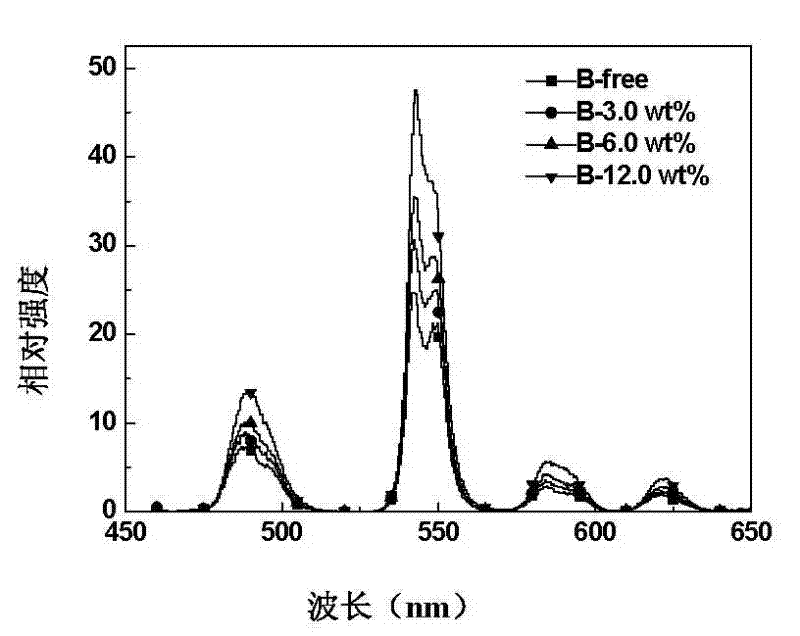

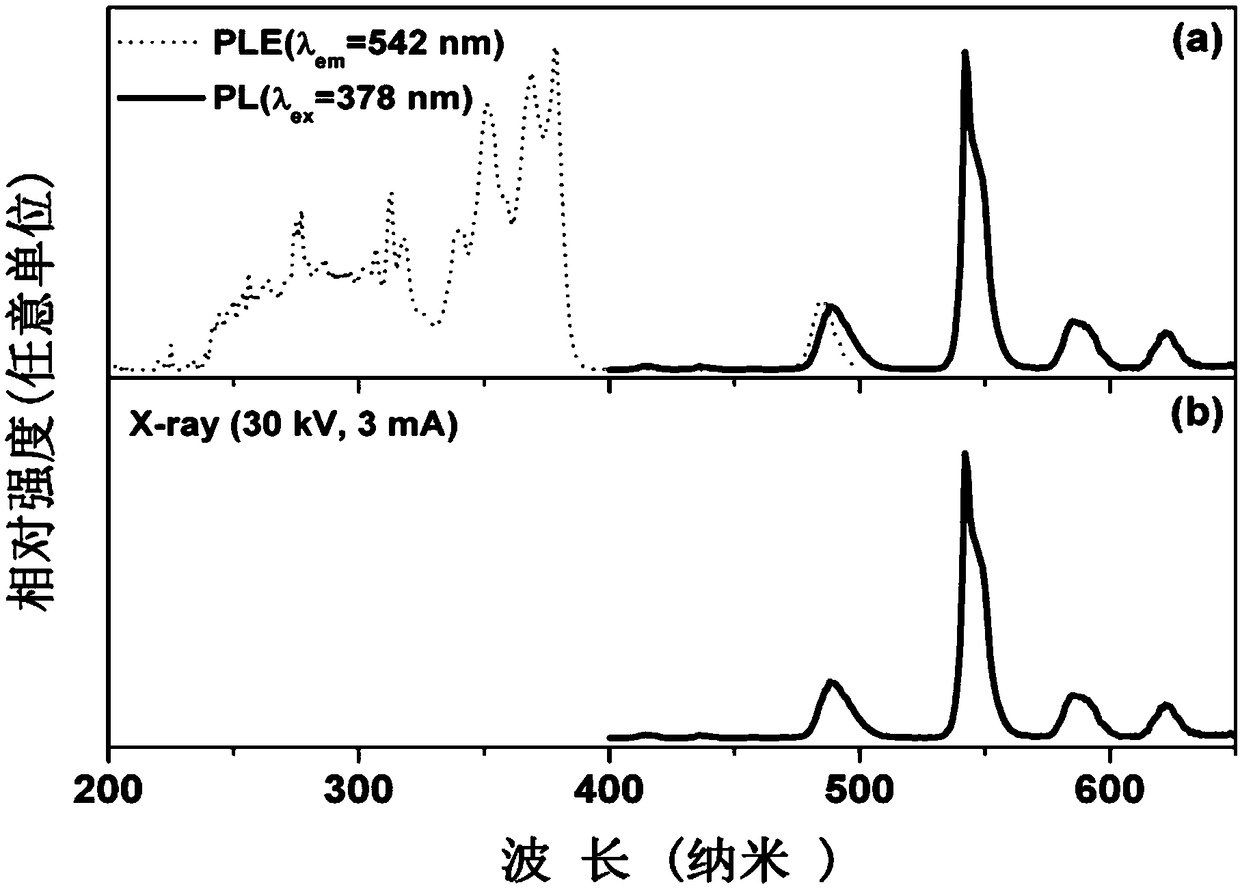

Flicker glass of silicate activated by terbium, and preparation method

InactiveCN100522855CSimple preparation processChemical composition is easy to controlGlass pressing apparatusFiberLuminous intensity

A terbium-activated silicate scintillation glass with silicate as the matrix, wherein Tb3+ is introduced into the scintillation glass as the active ion, Gd3+ as the sensitizer, BaF2 as the flux, prepared by melting method, shaped and annealed into, wherein, the formula of the scintillation glass is (by mole percentage): SiO2 (50-80mol%); BaO (10-25mol%); BaF2 (1.2-6.0mol%); Na2O+K2O+Li2O (1 -12mol%); Al2O3 (0.1-1.2mol%); Tb2O3 (0.2-4mol%); Gd2O3 (0.2-3mol%). The preparation method of the scintillating glass includes mixing the formula evenly and melting at 1400-1450°C for 3-6 hours; pouring the molten glass into a preheated mold to shape it; Heat preservation for 3 hours and annealing treatment. The advantages are: simple process, easy adjustment of components, good chemical stability, can be drawn into optical fibers, high luminous intensity, and emission peak near 550nm, which is of great value for X-ray real-time imaging and nuclear technology applications.

Owner:TONGJI UNIV

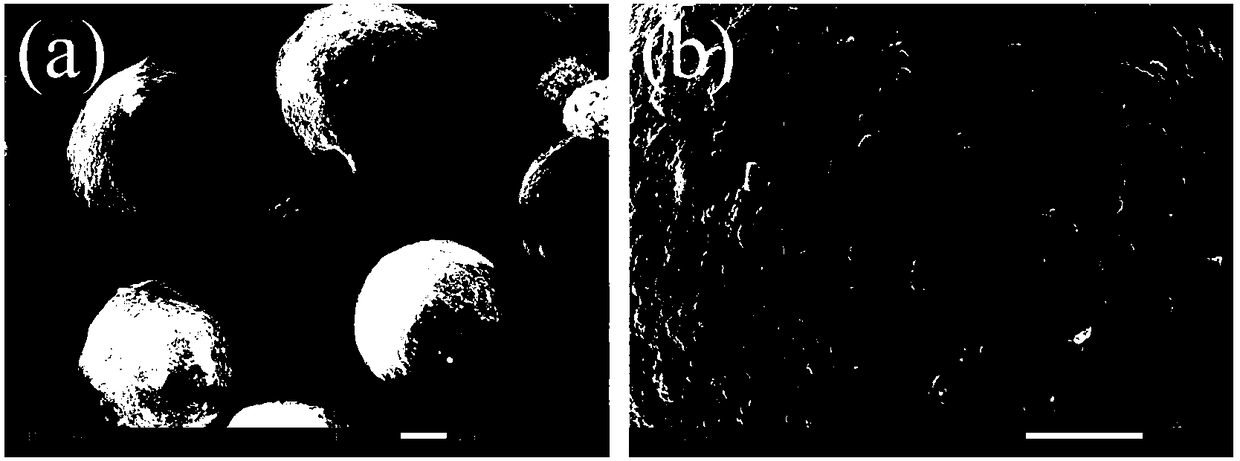

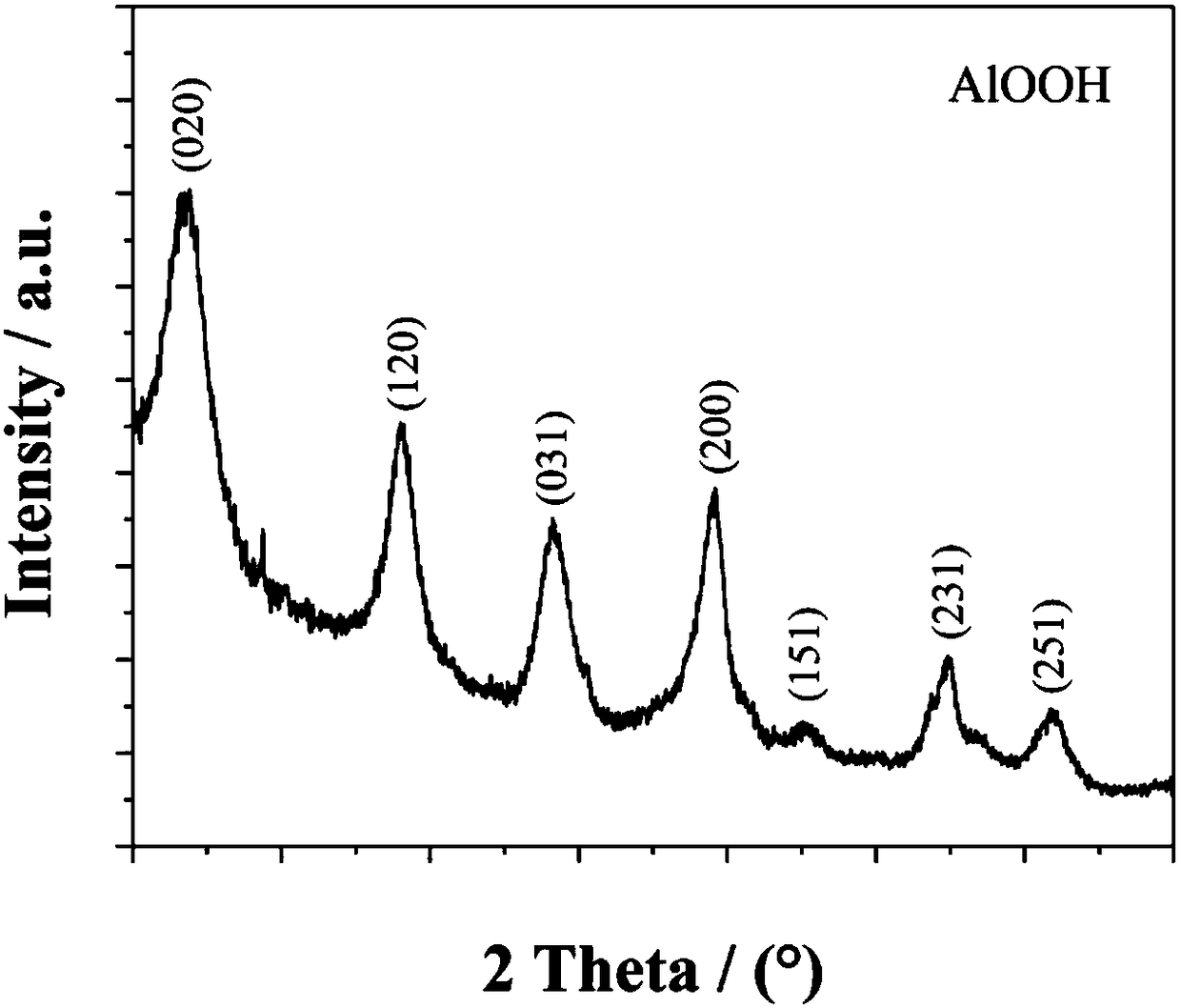

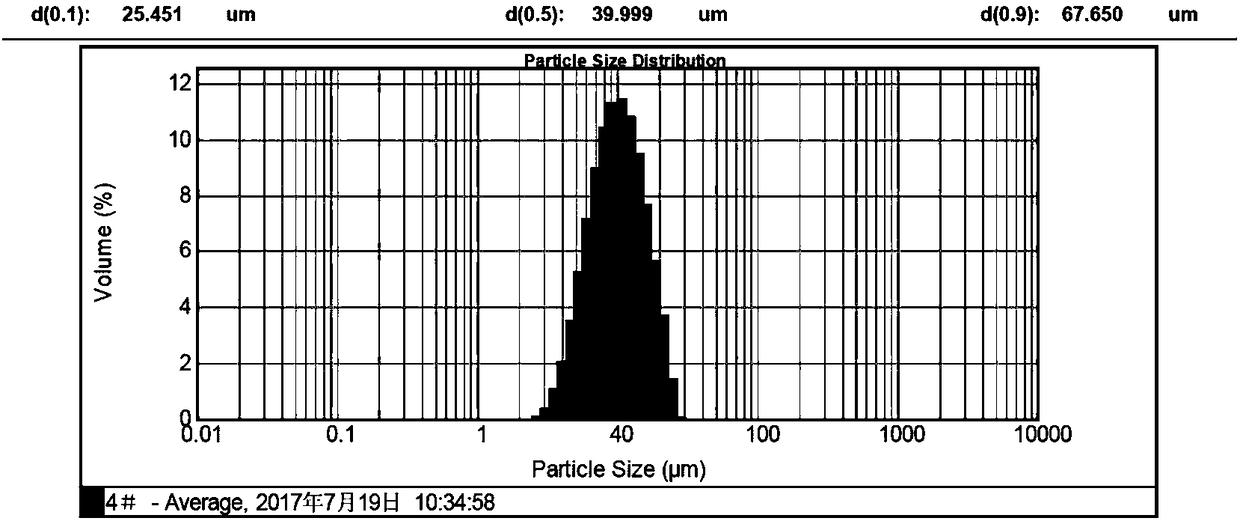

Al2O3/TiO2 precursor composite thermal spraying powder and preparation method thereof

InactiveCN108358613AImprove uniformityNarrow particle size distributionThermal sprayingComposite ceramic

The invention belongs to the field of thermal spraying preparation of functional coating layers, and in particular, relates to a novel Al2O3 / TiO2 precursor composite thermal spraying powder and a preparation method thereof. An Al2O3 / TiO2 precursor comprises AlOOH and Ti(OH)4 respectively with a mass ratio of 6.52:1 to 2.27:1; the particle size of the thermal spraying powder is 20-70 [mu]m, and themedian particle size D50 is 40 [mu]m. A sol-gel method is adopted, and organic metal salts are made into sols and then are compounded, so the uniformity of all components in the powder is effectivelyimproved; the method is applied to the preparation of an Al2O3 / TiO2 composite ceramic coating layer, TiO2 components are uniformly distributed, and thus the microhardness of the ceramic coating layeris effectively improved.

Owner:WUHAN UNIV OF TECH

Phosphate scintillation glass for thermal neutron detection and preparation method thereof

The invention relates to phosphate scintillation glass for thermal neutron detection and a preparation method thereof. The scintillation glass is prepared by virtue of a high-temperature melting process; the scintillation glass comprises a substrate and a light emitting center; the composition system of the substrate is Li2O-B2O3-P2O5, wherein the proportions of the components in the substrate are as follows: 20-60mol% of Li2O, 0-80mol% of B2O3 and 0-55mol% of P2O5, and the sum of the proportions of the components is 100%; and the light emitting center is Ce<3+> ions, and the molar content of the Ce<3+> ions relative to the sum of the molar weights of the components in the substrate is 0.05-5mol%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

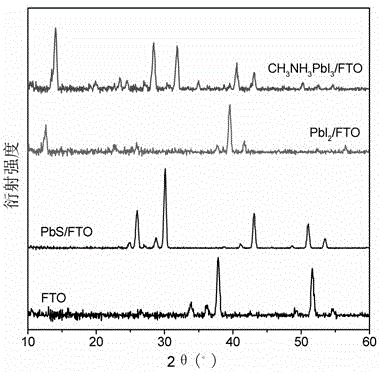

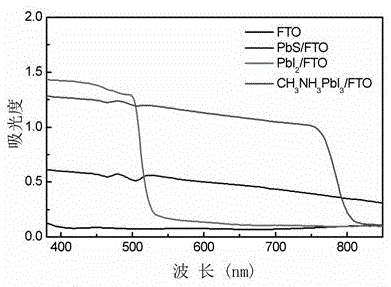

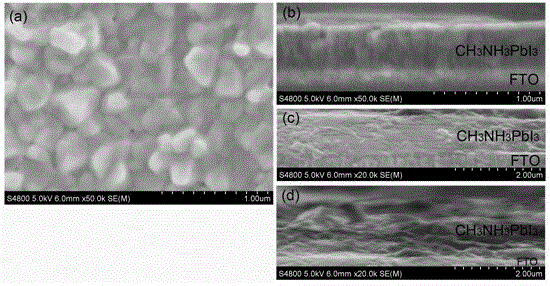

Preparation method of organic-inorganic hybrid perovskite thin film

InactiveCN105552237AControllable areaControllable shapeSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

The invention discloses a preparation method of an organic-inorganic hybrid perovskite thin film. Conductive glass is used as a substrate; a lead sulfide thin film is prepared by adopting an electro-deposition method; the lead sulfide thin film is used as a precursor; an iodine elementary substance is used as an iodizating agent for iodizating lead sulfide into lead iodide; and then the lead iodide reacts with methyl ammonium halide to obtain the perovskite thin film. The method disclosed by the invention can be operated in a large area; a film layer is controllable in area and shape, and an electro-deposition area and shape can be controlled by a method of corroding a conducting plane; a thickness of the film layer is controlled, and the thickness of the film layer can be conveniently controlled by regulating electro-deposition time; chemical components of the film layer are controllable, and the film layers with different components can be obtained by changing a ratio of I to Br in CH3NH3X solution, so that the perovskite thin films with different physical properties are obtained; and the obtained film layer is relatively uniform and has good compactness.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

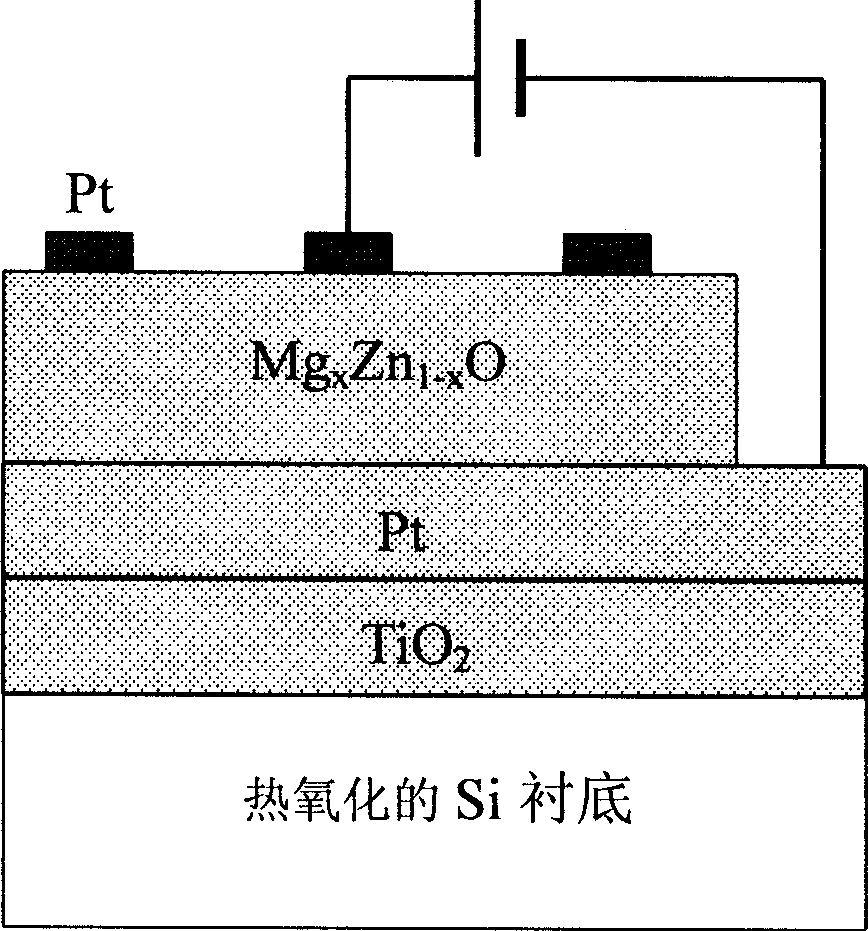

Non-volatile memory element and preparation method thereof

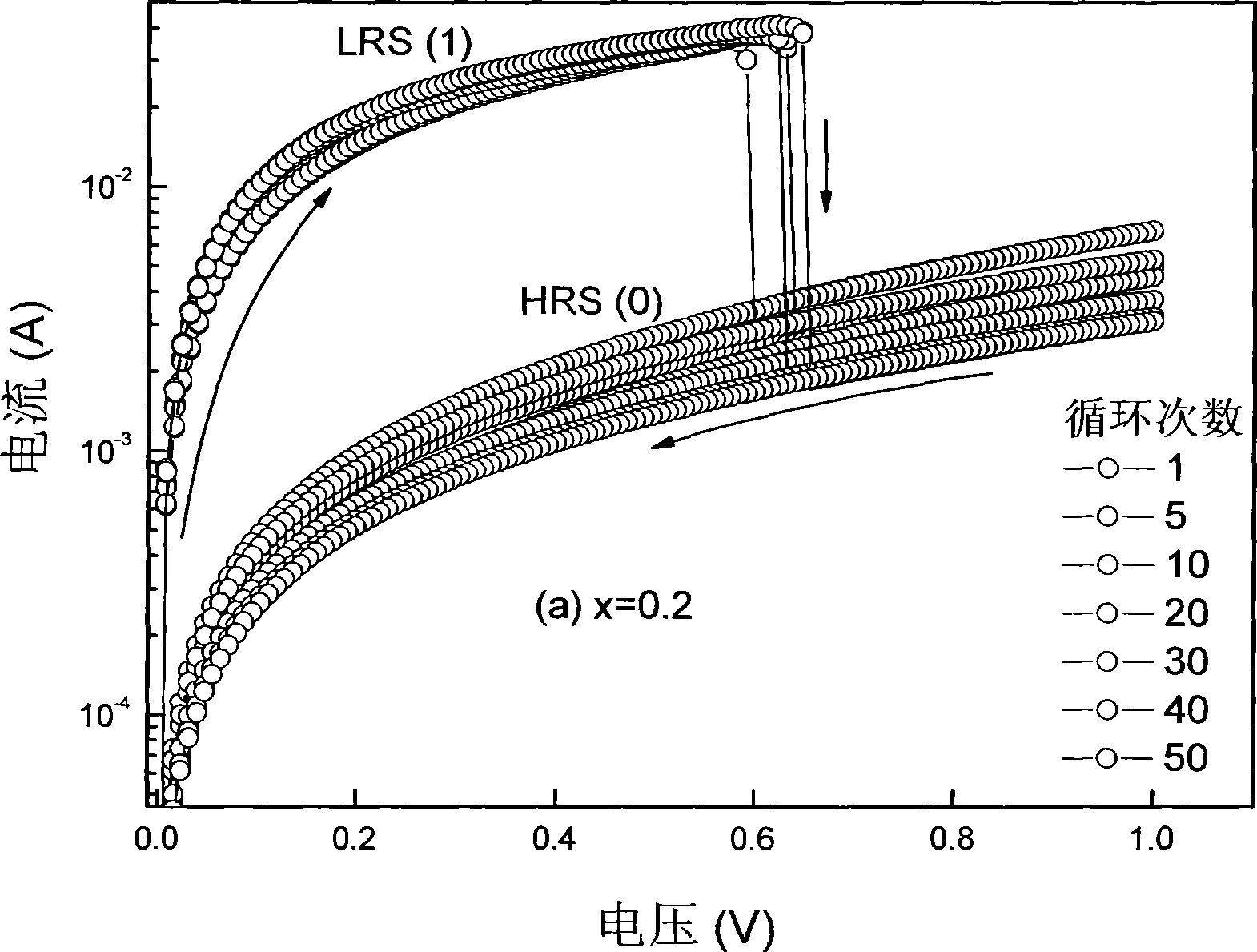

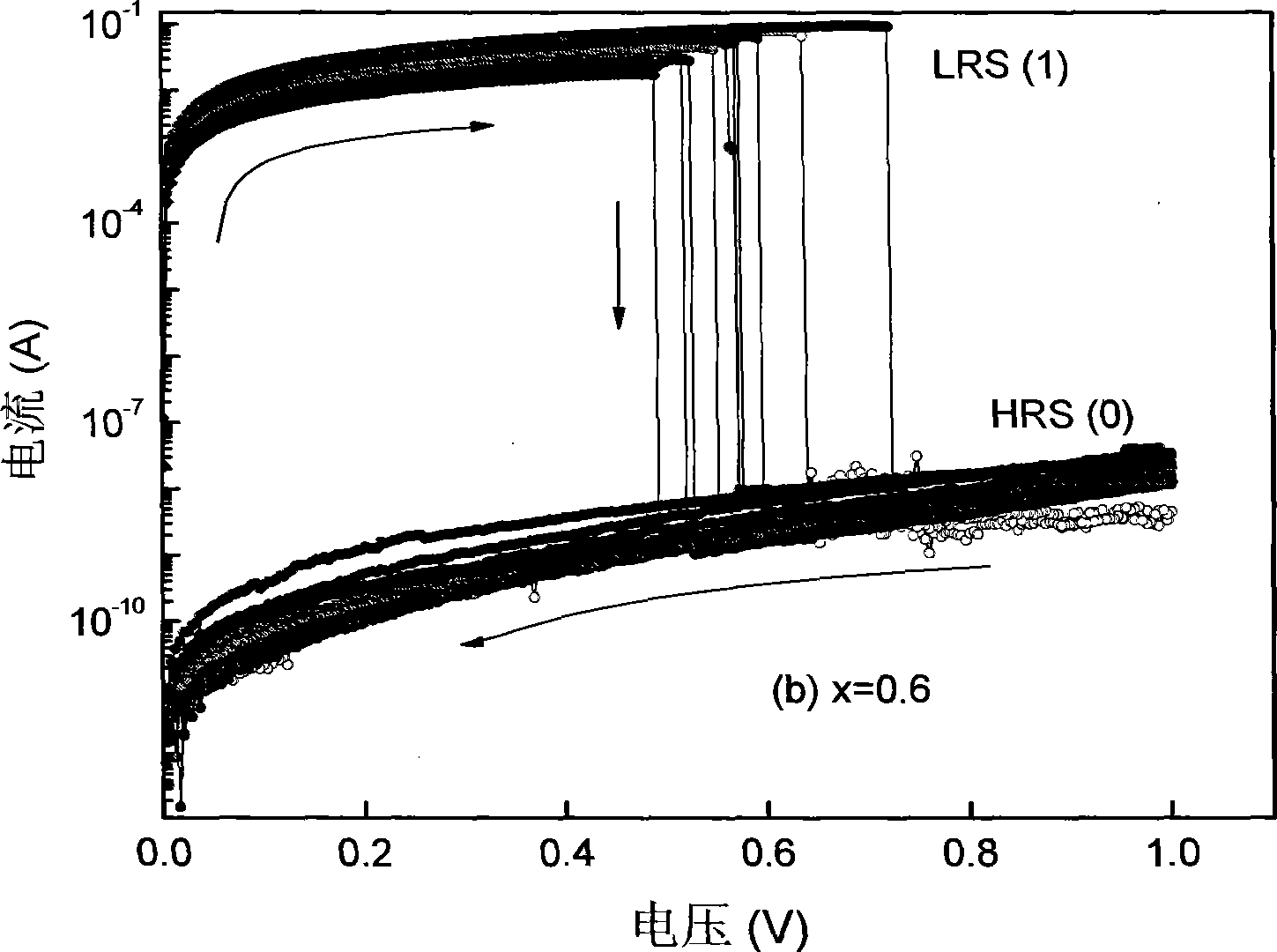

InactiveCN101452994AStable and repeatable resistive switching characteristicsInitialization current is smallElectrical apparatusRead-only memoriesSignal-to-noise ratio (imaging)Room temperature

The invention discloses a nonvolatile storage element. A sandwich-structure MgxZn1-xO thin-film nonvolatile storage element consists of an MgxZn1-xO thin film and Pt electrodes on the upper and lower surfaces of the MgxZn1-xO thin film, wherein x is equal to 0.6, 0.8 or 1. The invention also discloses a method for preparing the nonvolatile storage element. The method comprises the steps of preparing an MgxZn1-xO precursor solution, preparing the MgxZn1-xO thin film on a Pt bottom electrode, annealing the MgxZn1-xO thin film at 650 DEG C, cooling the MgxZn1-xO thin film to room temperature, plating the upper surface of the MgxZn1-xO thin film with the Pt electrodes after heat treatment, and forming a sandwich-structure MgxZn1-xO nonvolatile storage device. The MgxZn1-xO nonvolatile storage device provided by the invention has large high-low resistance ratio which reaches 10<7> to 10<9>, is favorable for raising the signal-to-noise ratio of the device, improving the properties of the device and simplifying a storage-state readout process, and is broad in application prospects.

Owner:SUN YAT SEN UNIV

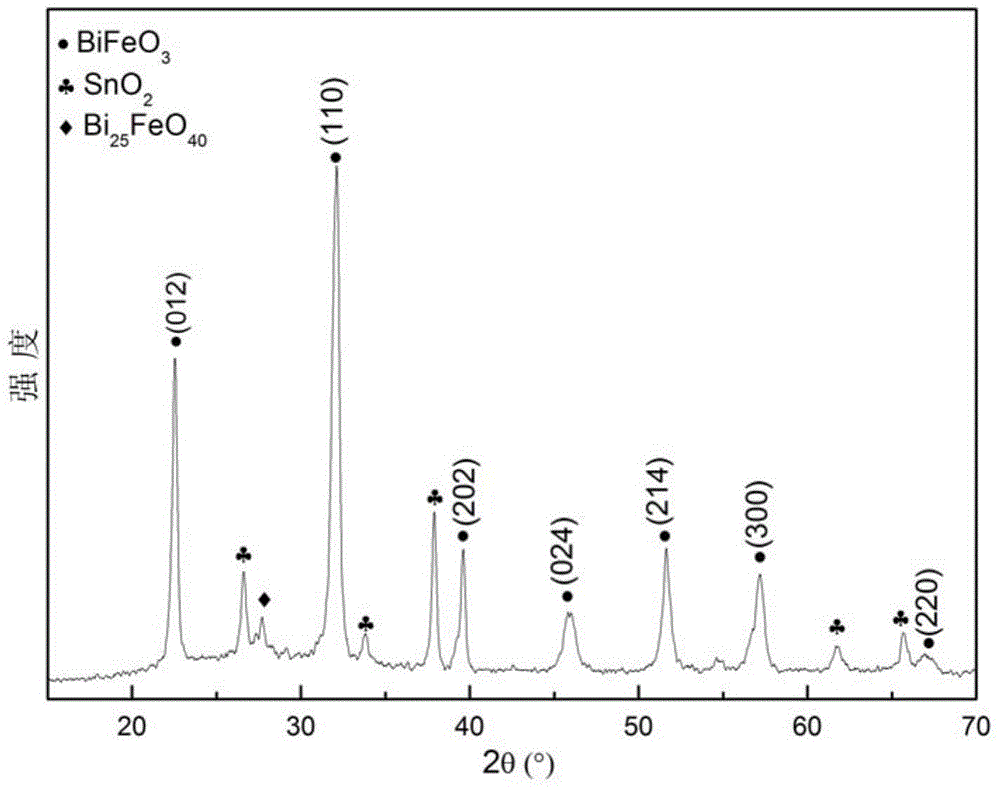

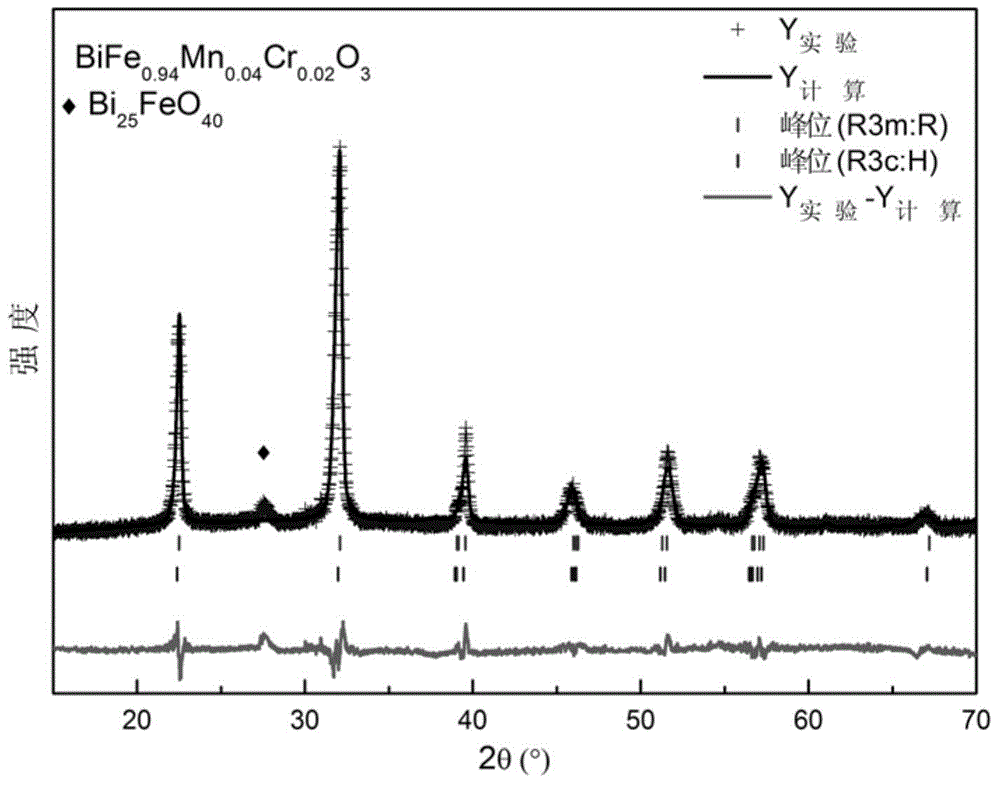

BiFe0.96-yMn0.04CryO3 ferroelectric film with high remanent polarization and high dielectric constant and preparation method thereof

ActiveCN103601249AIncreased polarizationImprove surface topographyIron compoundsAcetic anhydrideUltimate tensile strength

The invention relates to a BiFe0.96-yMn0.04CryO3 ferroelectric film with high remanent polarization and high dielectric constant and a preparation method thereof. The method comprises the steps of mixing bismuth nitrate, ferric nitrate, manganese acetate and chromic nitrate according to the mole ratio of 1.05: (0.96-y): 0.04: y, then, dissolving a mixture into mixed ethylene glycol monomethyl ether, and then, adding acetic anhydride, so as to obtain a BiFe0.96-yMn0.04CryO3 precursor solution with the metal ion concentration of 0.003-0.3mol / L; uniformly dispensing the BiFe0.96-yMn0.04CryO3 precursor solution on a FTO / glass substrate, of which the surface reaches atomic cleanliness, by adopting a spin-coating method, so as to prepare a film, then, drying to obtain a dry film, and then, adopting a layer-by-layer annealing process, thereby obtaining the crystalline BiFe0.96-yMn0.04CryO3 film. The method has the advantages that the requirements for equipment are simple, the experimental conditions are easily met, the prepared film is relatively good in uniformity and easy in doped amount control, and the ferroelectric properties and dielectric properties of the film can be improved greatly.

Owner:SHAANXI UNIV OF SCI & TECH

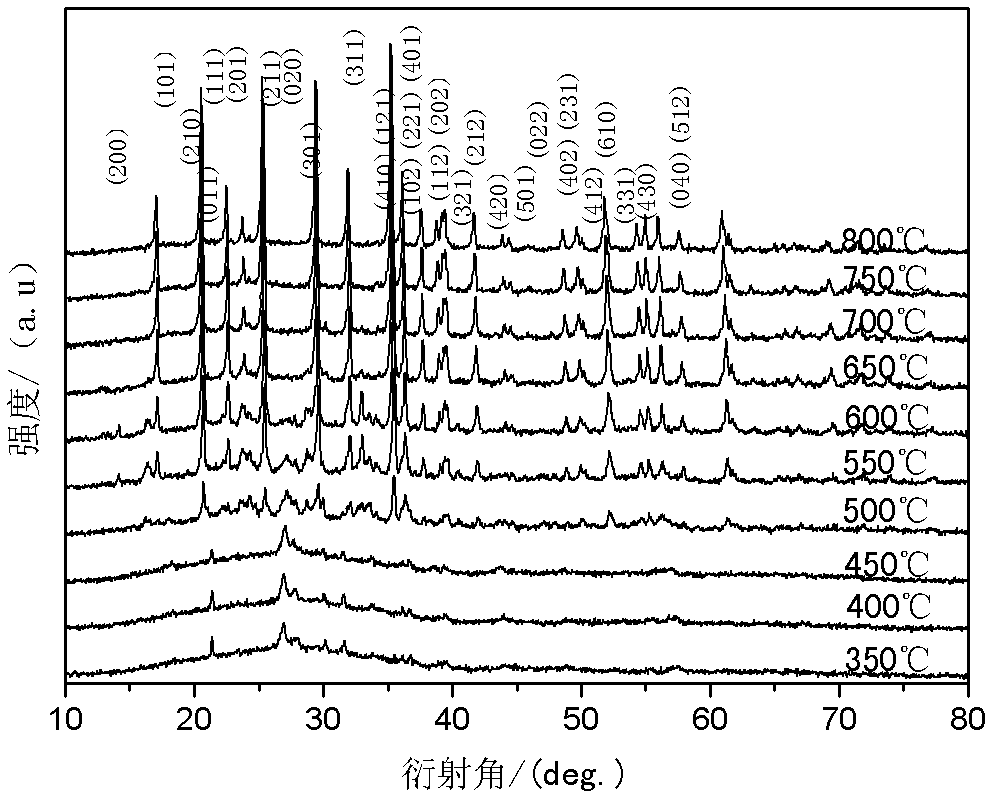

Preparation methods of NH4Fe1-xMxPO4 and LiFe1-xMxPO4/C materials

ActiveCN106477546AEvenly dispersedControllableCell electrodesSecondary cellsFerrous iron compoundHigh rate

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

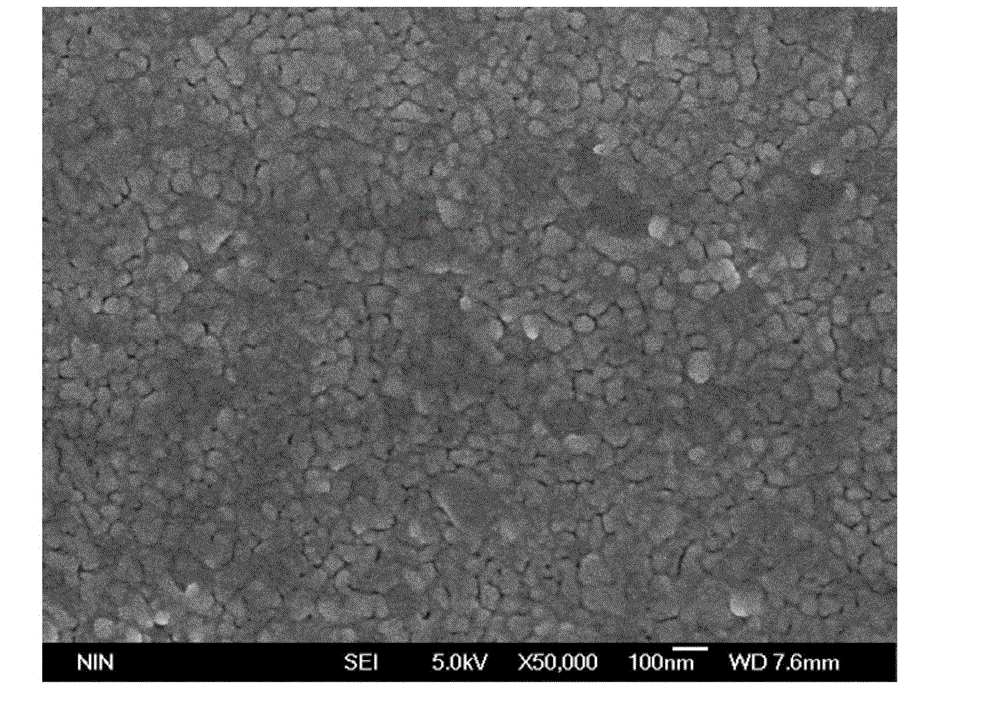

Non-volatile resistance memory element and preparation method thereof

InactiveCN101562228AStable and repeatable resistive switching characteristicsReduce divergenceElectrical apparatusDigital storageHigh resistanceHeterojunction

The invention discloses a non-volatile resistance memory element and a preparation method thereof. The memory element comprises a NiO / Mgx Zn (1-x) O (x=0.4-1) p-n heterojunction thin-film layer as well as Pt electrodes which are respectively arranged on the upper and the lower surface of the heterojunction thin-film layer. The resistance memory element has stable and repeatable resistance switch characteristic, can be switched between two states of high resistance and low resistance with the corresponding voltage values distributed within the range of 0.55-0.6V, and has smaller radiation degree which is lower than 1V, so as to meet the requirements of practical application. Furthermore, the ratio between the high resistance and the low resistance of the memory element is higher and reaches 10, so that higher signal-to-noise ratio of devices can be guaranteed. Meanwhile, the memory element has lower initial current which is 1muA. The preparation method adopts a sol-gel method and has simple operation, low cost and manageable chemical composition; and the prepared film has no cracking, good compactness and even crystal grain distribution.

Owner:SUN YAT SEN UNIV

Production technology for remanufacturing tobacco leaves by adopting paper-making method utilizing waste tobacco stems

The invention relates to the technical field of cigarette manufacturing, and in particular relates to a production technology for remanufacturing tobacco leaves by adopting a paper-making method utilizing waste tobacco stems. The production technology comprises the following steps: material collecting, material pretreatment, extraction separation, pulping, coating, thermal-radiation drying, and finished product packaging. According to the production technology, the broken tobacco fragments and tobacco stems generated in the cigarette manufacturing and processing are utilized as raw materials, and are prepared into the functional tobacco material with the artificial adjustability through the process including the steps of extraction, puling, coating, drying and the like and by utilizing the paper-making method and principle; the processed product has the advantages of small density, low tar release amount, controllable chemical components and the like, after the product is applied to the cigarette, the effect of reducing the consumption of the raw material and the production cost is achieved, further, the tar content of the cigarette is greatly reduced, the perniciousness of the cigarette is reduced, and the smoking quality of the cigarette can be regulated. To sum up, the production technology for remanufacturing tobacco leaves by adopting the paper-making method utilizing the waste tobacco stems is simple and convenient, has few steps, and is high in production efficiency and low in cost.

Owner:CHANGDE ZHENGYANG BIOTECH CO LTD

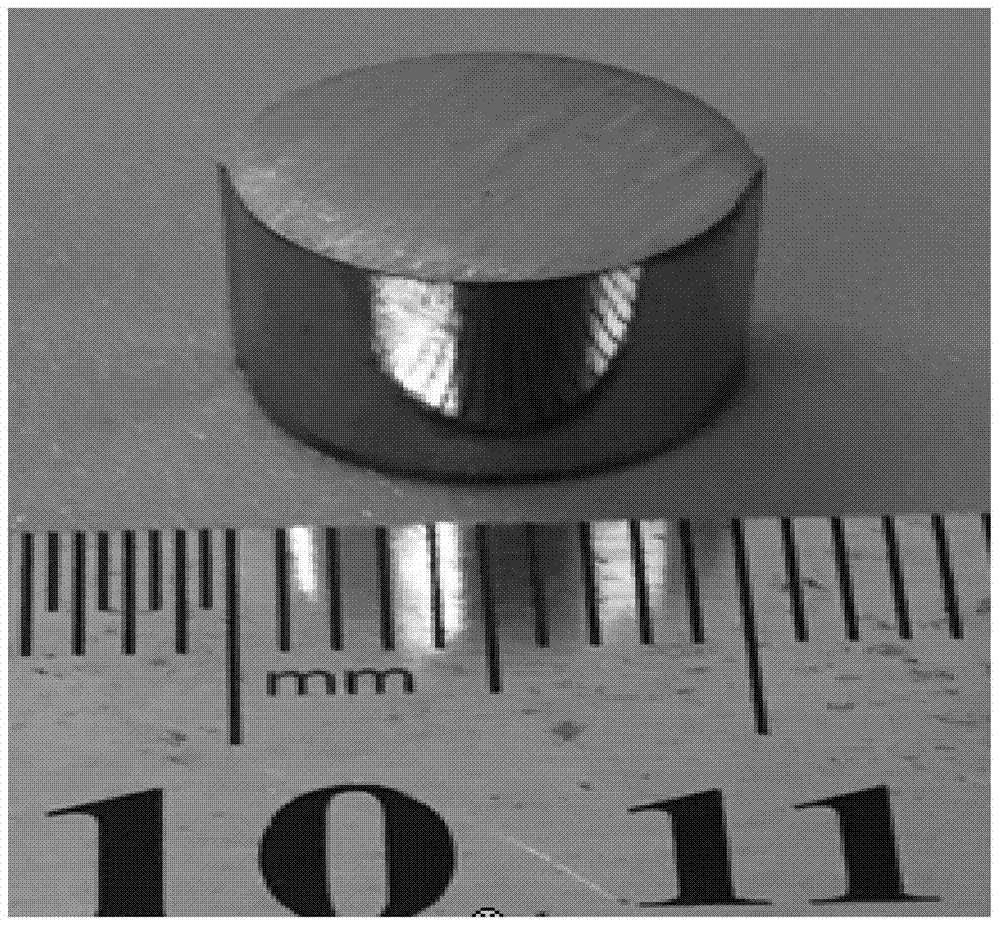

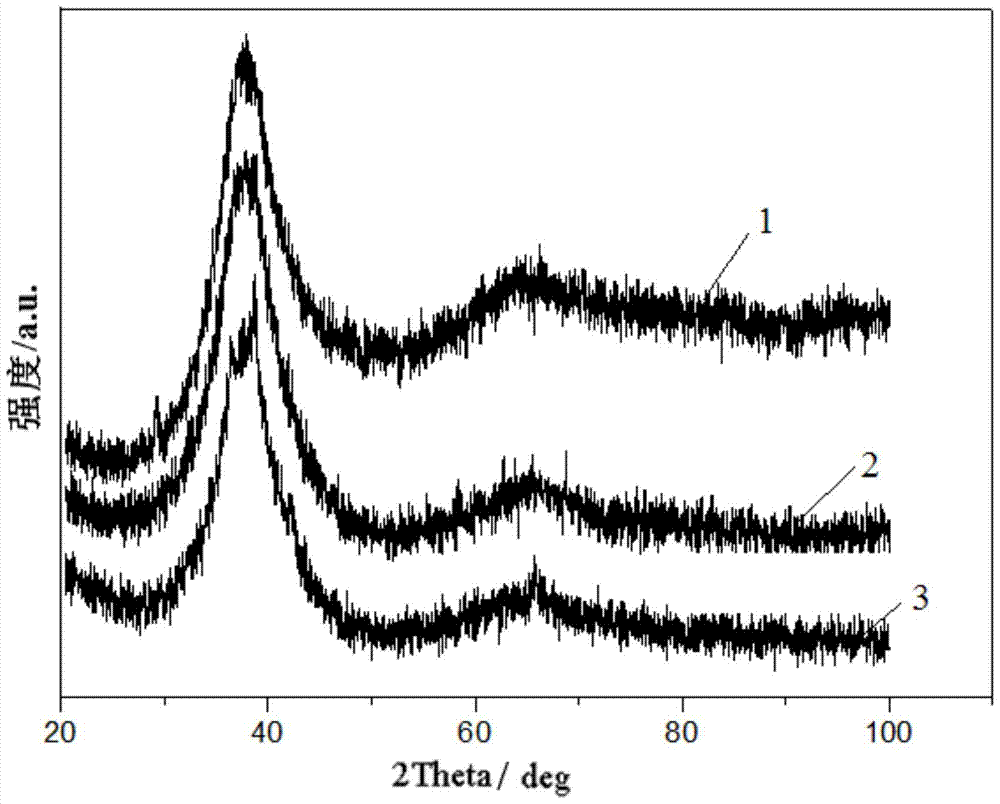

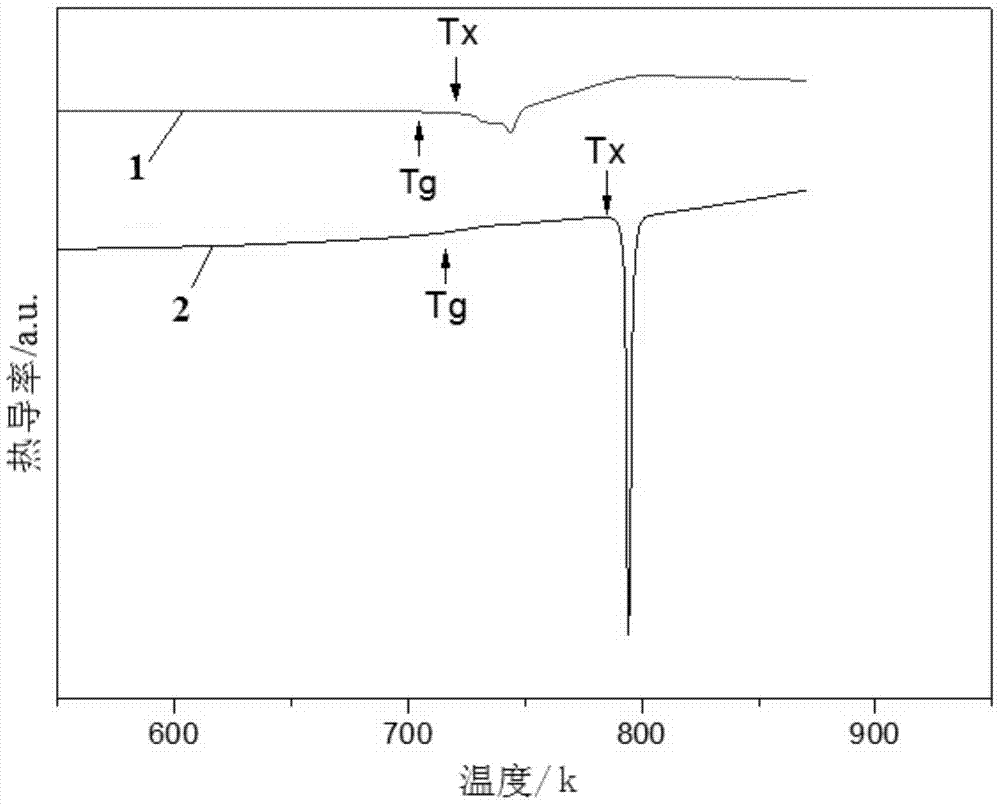

A method for solid-liquid bonding of dissimilar bulk amorphous alloys

ActiveCN104959575BChemical composition is easy to controlSimple processChemical compositionInsertion stent

The invention relates to a method for connecting dissimilar bulk amorphous alloys in a solid-liquid state, relating to a method for connecting dissimilar bulk amorphous alloys. The purpose of the present invention is to solve the technical problems that the existing method for connecting dissimilar bulk amorphous alloys needs to control many process parameters, complicated operation steps and poor economical practicability. The present invention: use the method of vacuum smelting copper mold casting to prepare bulk amorphous alloy ingots A and B respectively, and then adopt the method of solid-liquid connection to make bulk amorphous alloys A and B in the mold with brackets inside The solid-liquid connection is realized, and the dissimilar bulk amorphous alloy rods are finally obtained. Advantages of the present invention: 1. The present invention makes full use of heat transfer and solute diffusion, and realizes the metallurgical combination of heterogeneous amorphous alloys in the solid-liquid state at the atomic scale. The process is simple, easy to operate, the size is controllable, and the chemical composition of the alloy can be controlled It can be widely used in industrial production, which can further broaden the application of bulk amorphous alloys in the engineering field.

Owner:HARBIN INST OF TECH

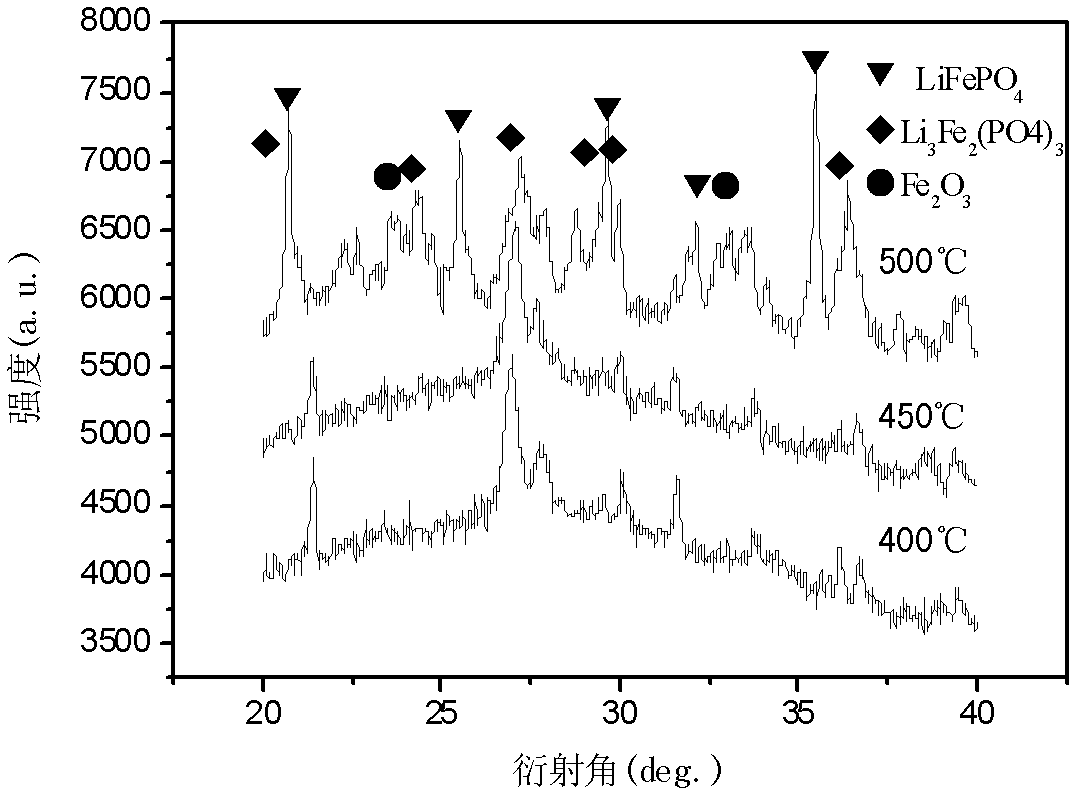

Preparation method of anode material lithium iron (II) phosphate for lithium ion cell

ActiveCN103187567AChemical composition is easy to controlAvoid uncontrollableCell electrodesPhosphateSlurry

The invention discloses a preparation method of anode material lithium iron (II) phosphate for a lithium ion cell. The preparation method mainly comprises the following two steps: (1) synthesis of precursor Li3Fe2(PO4)3, blending a lithium source, an iron source and a phosphorus source according to that the molar ratio of Li to Fe to P is 3:2:3, taking deionized water, absolute ethanol or acetone as a medium, ball-milling for 0.5-24 h, drying the obtained slurry, thermally treating for 3-24 hours at the temperature of 500-900 DEG C to obtain the precursor Li3Fe2(PO4)3; and (2) blending the obtained precursor Li3Fe2(PO4)3 and iron powder according to the molar ratio of 1:1, taking deionized water, absolute ethanol or acetone as the medium, ball-milling for 0.5-24 h, drying the obtained slurry, placing the dried slurry into a high-temperature furnace, under the atmosphere of inoxidizability, baking the dried slurry for 5-24 h at the temperature of 500-800 DEG C, and at last preparing the lithium iron (II) phosphate material. By adopting the principle that the lithium iron (II) phosphate material is synthesized by oxidation reduction between zero-valent iron and ferric iron source Li3Fe2(PO4)3 at high temperature, firstly, the pure phase Li3Fe2(PO4)3 intermediate is synthesized in advance, and then reacted with the zero-valent iron to synthesize the lithium iron (II) phosphate, so that the reaction process is easy to control. The synthesized product Li3Fe2(PO4)3 is high in chemical purity, good in electrochemical performance and high in batch stability.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

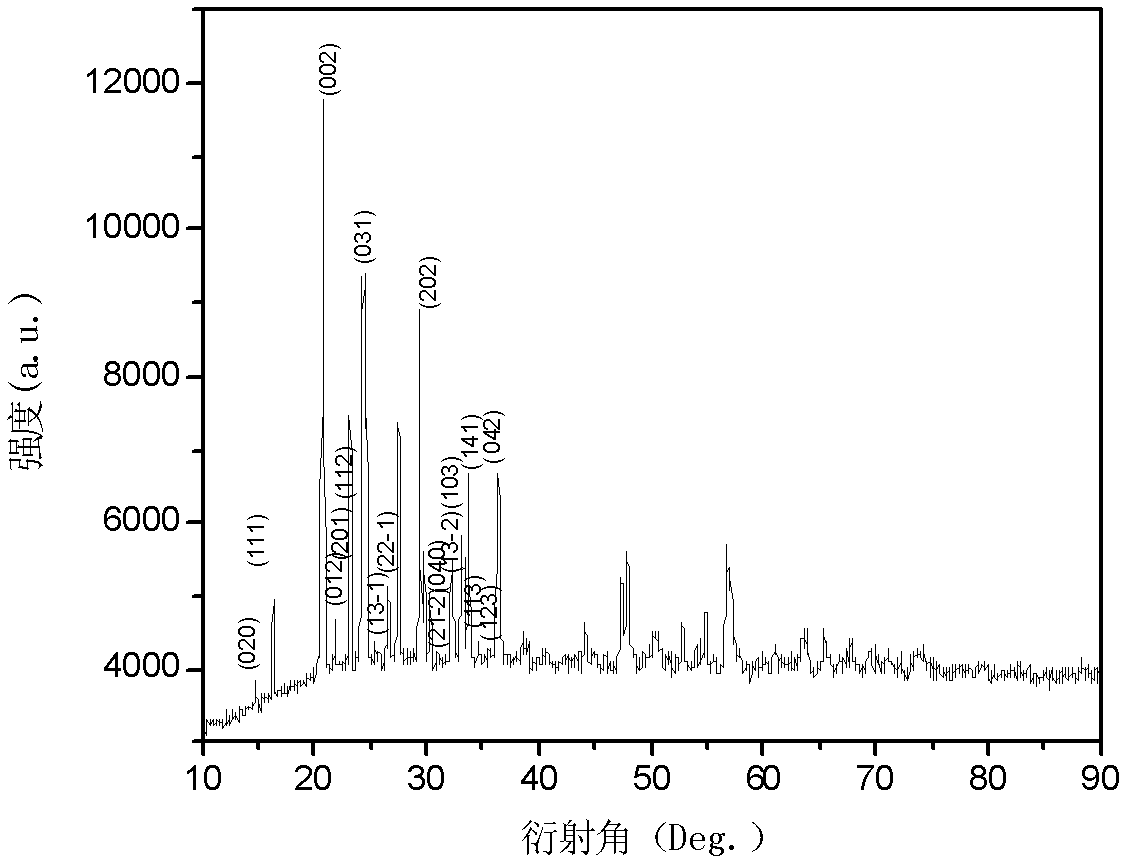

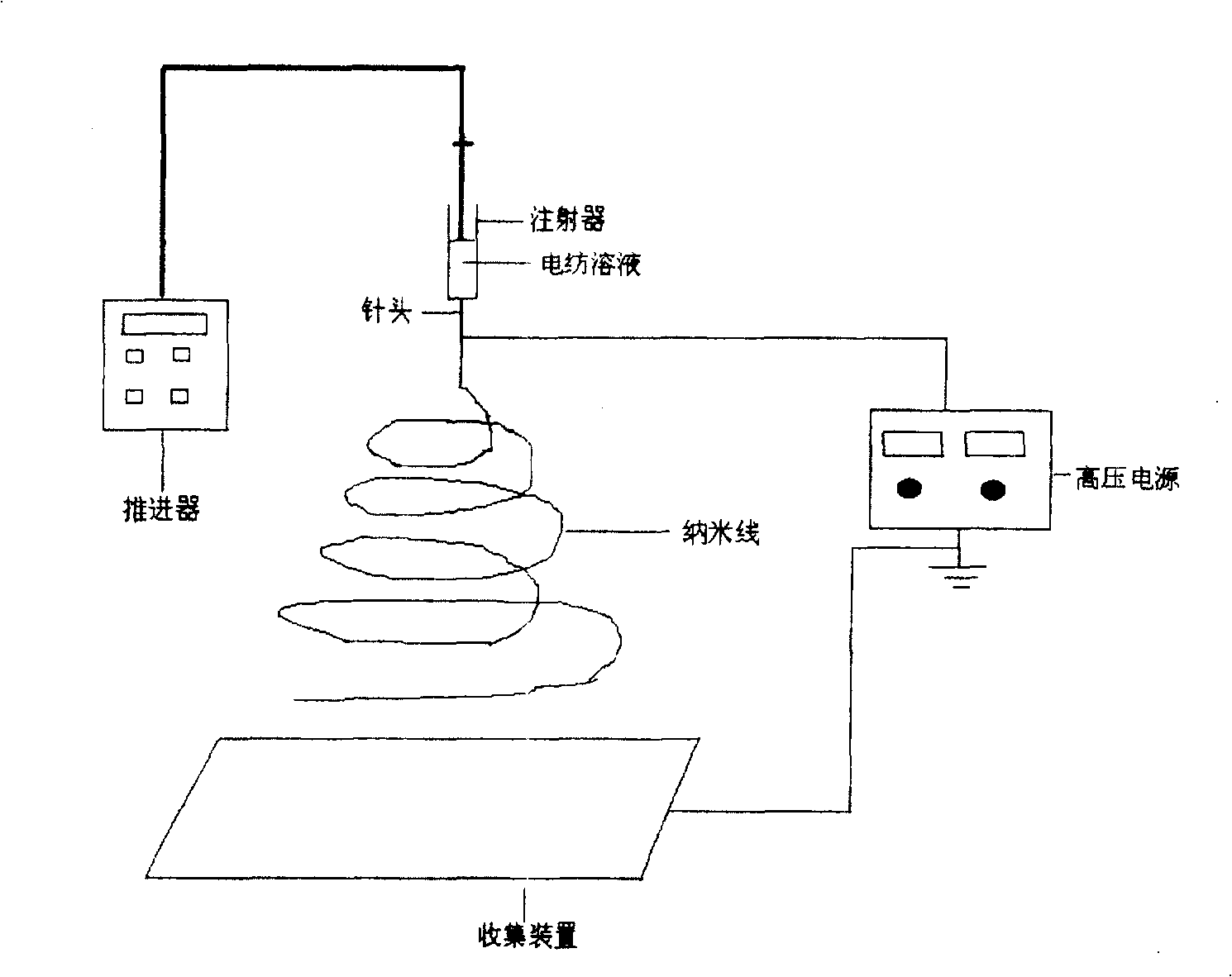

Method for preparing lanthanide series rare earth ions doped with bismuth titanate non-plumbum ferroelectric nano-wire

The invention is provides a simple, convenient, and inexpensive method for producing lanthanide series rare earth ion adulterating bismuth titanate non-lead ferro-electricity nanowire, including 1) preparing the electrospinning precursor solution that preparing the lanthanide series rare earth ion adulterating bismuth titanate solution according to the formula of Bi4-xRxTi3O12 (R is lanthanide series rare earth element, 0 C04B 35 / 475 C04B 35 / 462 C04B 35 / 624 C04B 35 / 64 3 7 2 2007 / 4 / 29 101037330 2007 / 9 / 19 100427431 2008 / 10 / 22 2008 / 10 / 22 2008 / 10 / 22 Xiang Tan University Hunan 411105 Zhong Xiangli Liao Min Wang Jinbin Zhou Yichun yanyong 43114 The Patent Agency of Changsha City The People's Road, the City of Changsha (Yaoling), Hunan Province 410011

Owner:XIANGTAN UNIV

Divalent europium activated lithium borate scintillation glass and preparation method thereof

ActiveCN110451798AIncreased capture cross sectionImprove detection efficiencyGlass shaping apparatusAir atmosphereNeutron capture

The invention discloses divalent europium activated lithium borate scintillation glass for thermal neutron detection and a preparation method thereof, and relates to the field of inorganic rare earthluminescent materials. Trivalent europium (Eu<3+>) is doped into a lithium borate glass system, and transparent divalent europium (Eu<2+>) activated lithium borate scintillation glass can be preparedin the air atmosphere after a part of B2O3 in the glass is replaced by 0.1-5 mol% of BN. The lithium borate scintillation glass body comprises the following components in percentage: 0-66.67 mol% of Li2O, 0-100 mol% of B2O3, 0-8 mol% of BN, and the balance of externally doped rare earth Eu<3+> ions. The lithium borate glass is rich in compounds such as <6>Li and (or) <10>B with large neutron capture cross sections, and neutron energy can be efficiently captured by the scintillation glass through a nuclear reaction and is transmitted to a divalent europium ion light-emitting center, so that thepurpose of neutron detection is achieved. In addition, due to inherent transparency of the glass, the preparation process is simple, the components are easy to adjust, and the characteristics of lowcost, large volume and the like can be realized, so that the scintillation glass has important application values in the fields of neutron detection, neutron flight time, petroleum logging, nondestructive inspection, neutron photography and the like.

Owner:JINGGANGSHAN UNIVERSITY

High density tellurate scintillation glass and preparation method thereof

ActiveCN110451795AImprove luminous performanceEffectively adjust the emission wavelengthX-ray/infra-red processesGlass shaping apparatusHigh densityHigh energy

Belonging to the field of optical materials, the invention discloses a high density tellurate scintillation glass and a preparation method thereof. The tellurate glass comprises the following components: 25-100mol% of TeO2; 0-20mol% of Gd2O3; 0-17.5mol% of Lu2O3; 0-60mol% of WO3; and a rare earth ion activator. Specifically, the sum of the four components TeO2, Gd2O3, Lu2O3 and WO3 is 100mol%; wherein, the external or internal admixing concentration of the rare earth ion activator is 0.1-16mol% of the sum of the four components TeO2, Gd2O3, Lu2O3 and WO3. The invention also discloses a preparation method of the high density tellurate scintillation glass. The preparation temperature of the high density tellurate scintillation glass is not higher than 1000DEG C, and the density is 5.50-6.57g / cm<3>. The high density tellurate scintillation glass has wide application in X-ray medical imaging, industrial online detection, national security supervision, high energy physics or nuclear physicsexperiments.

Owner:JINGGANGSHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com