Patents

Literature

93results about How to "Control particle size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

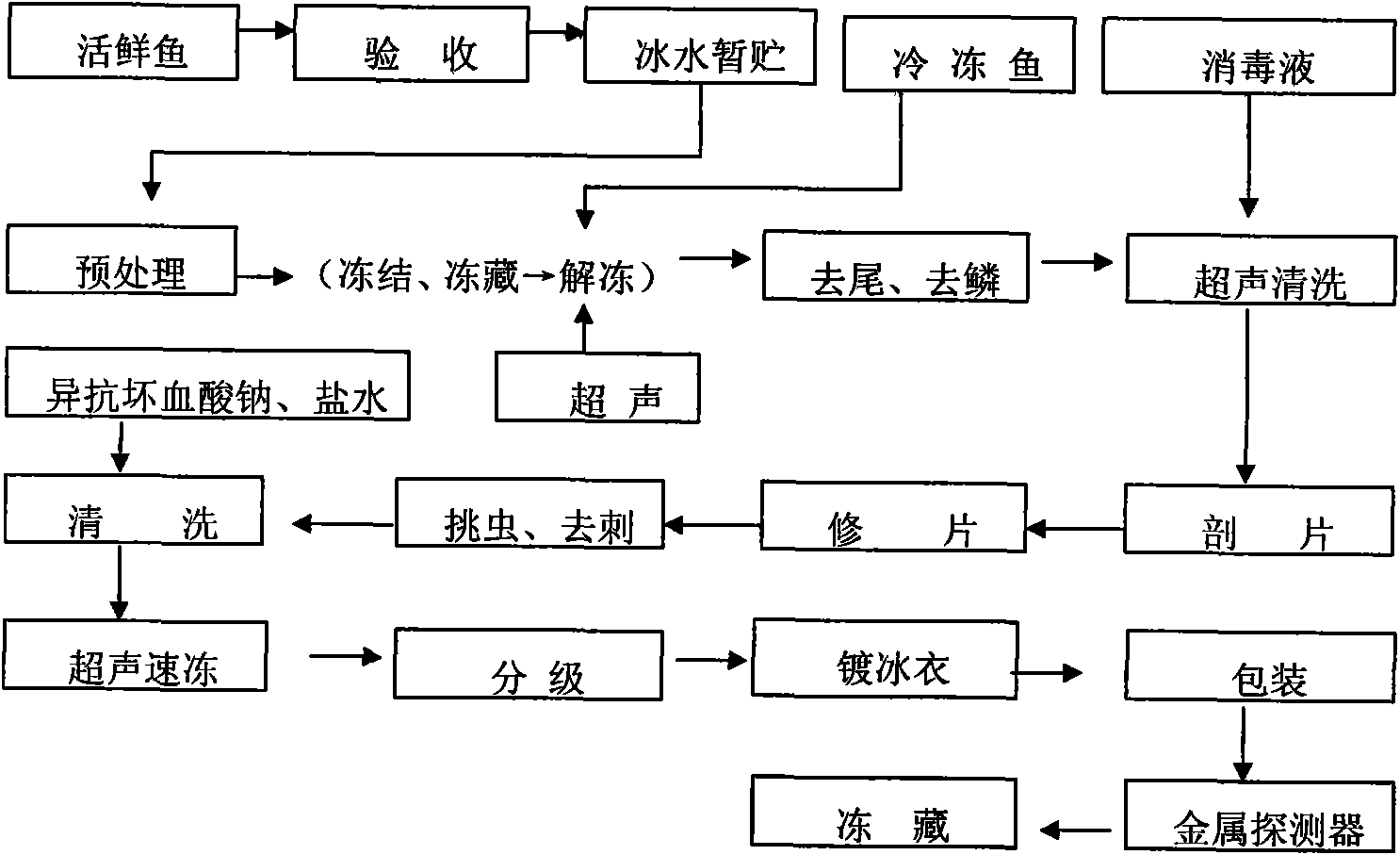

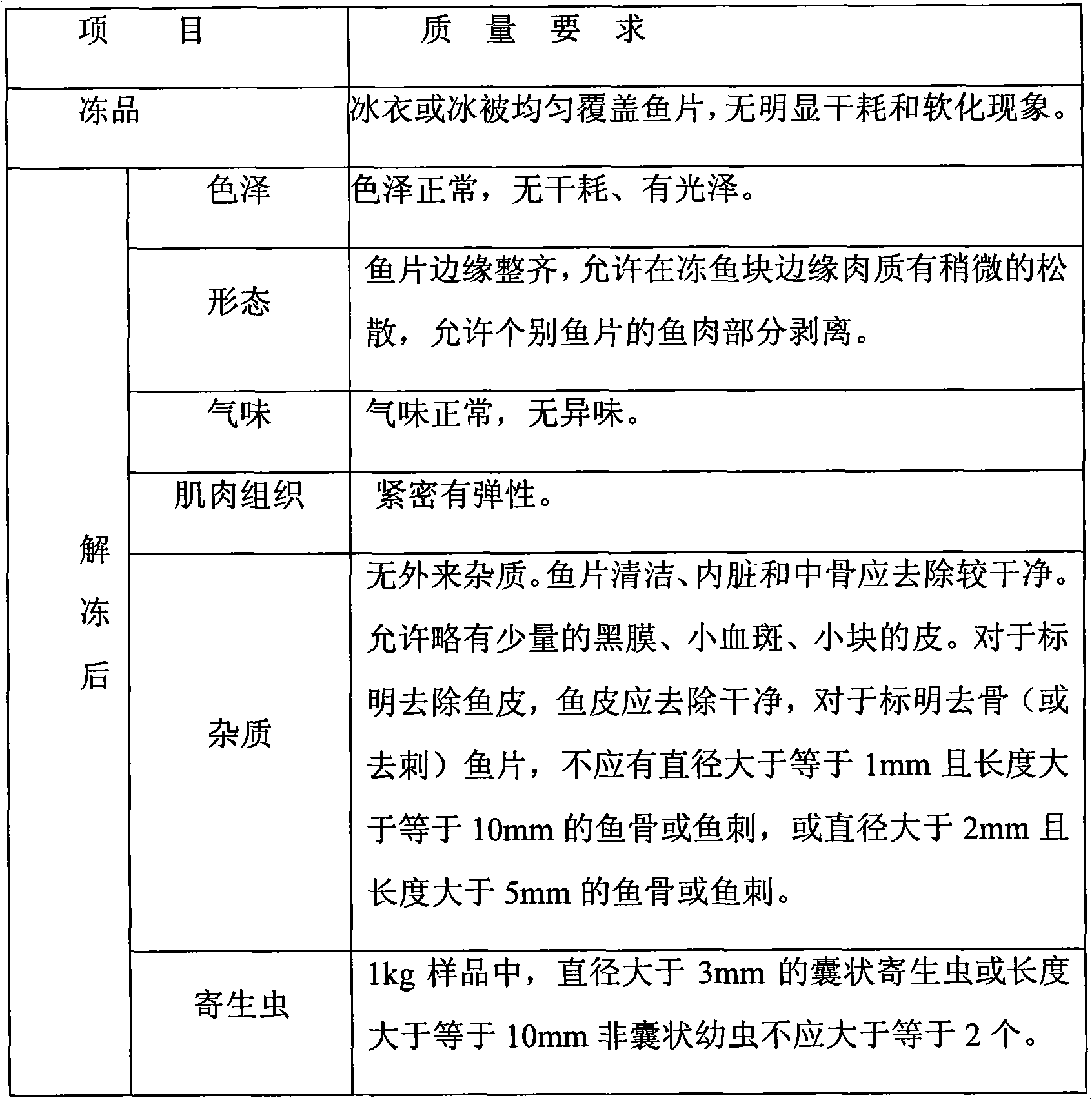

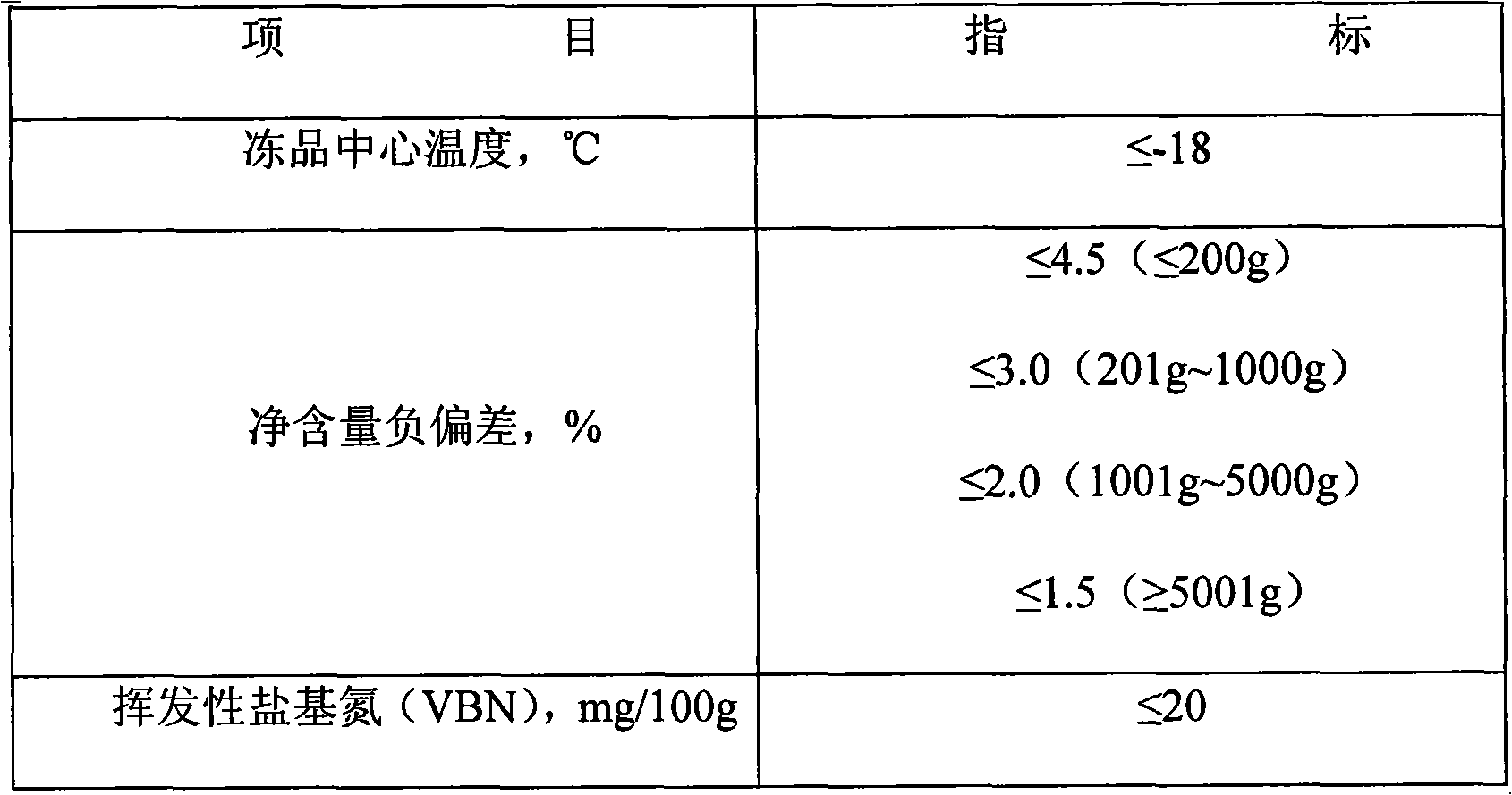

Processing method of sushi sashimi

InactiveCN101919539AExtended shelf lifeAvoid "cooking"Fish washing/descalingMeat/fish preservation by freezing/coolingIce waterAquatic product

The invention provides a processing method of sushi sashimi, which belongs to the field of processing of aquatic products. The processing method comprises the steps of taking a live fresh scaly fish as a raw material, carrying out acceptance, temporary storage in ice water and pretreatment, or taking a frozen scaly fish as the raw material, firstly carrying out ultrasonic thawing, further removing a tail, removing scales, carrying out ultrasonic cleaning, cutting into slices, trimming, picking out insects, removing bones, cleaning, carrying out ultrasonic quick freezing, classifying, glazing, packaging, carrying out metal detection, freezing, and carrying out other process steps for processing the sushi sashimi. The sushi sashimi processed by adopting the method has good quality, and the sensory, the physical and the chemical properties, as well as the safety sanitation quality are in line with requirements; furthermore, the processing method has short thawing time, short freezing time and high processing efficiency, and can be popularized in the processing of the aquatic products.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

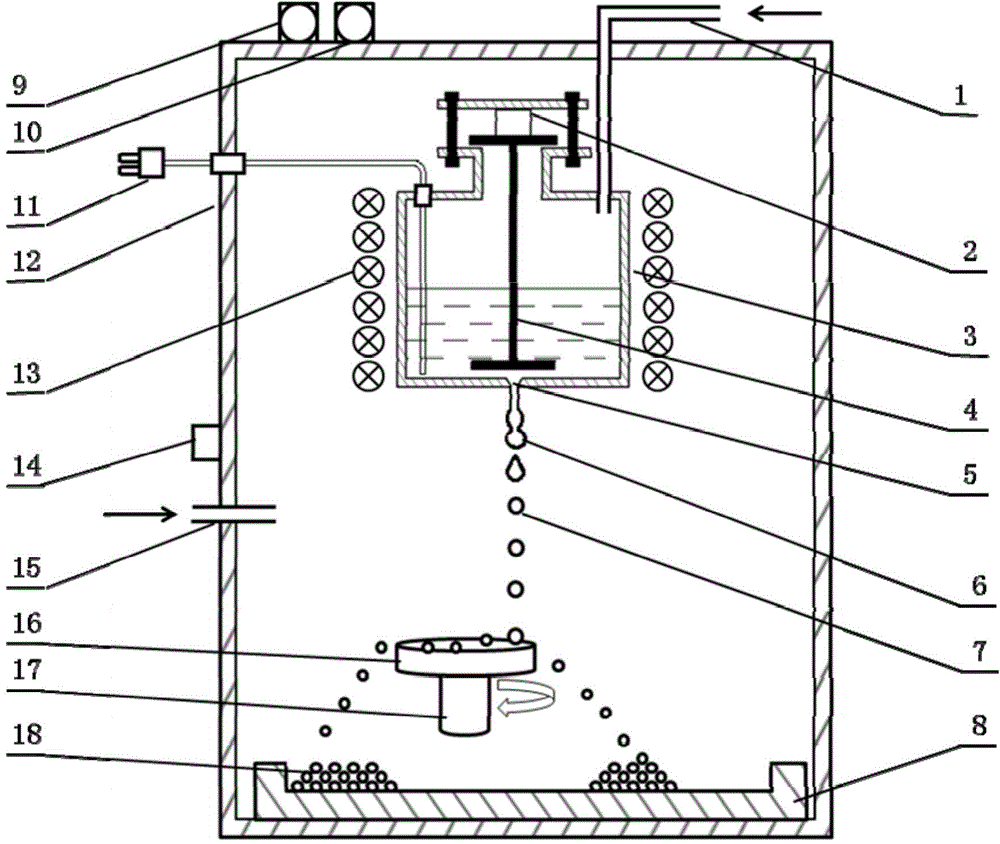

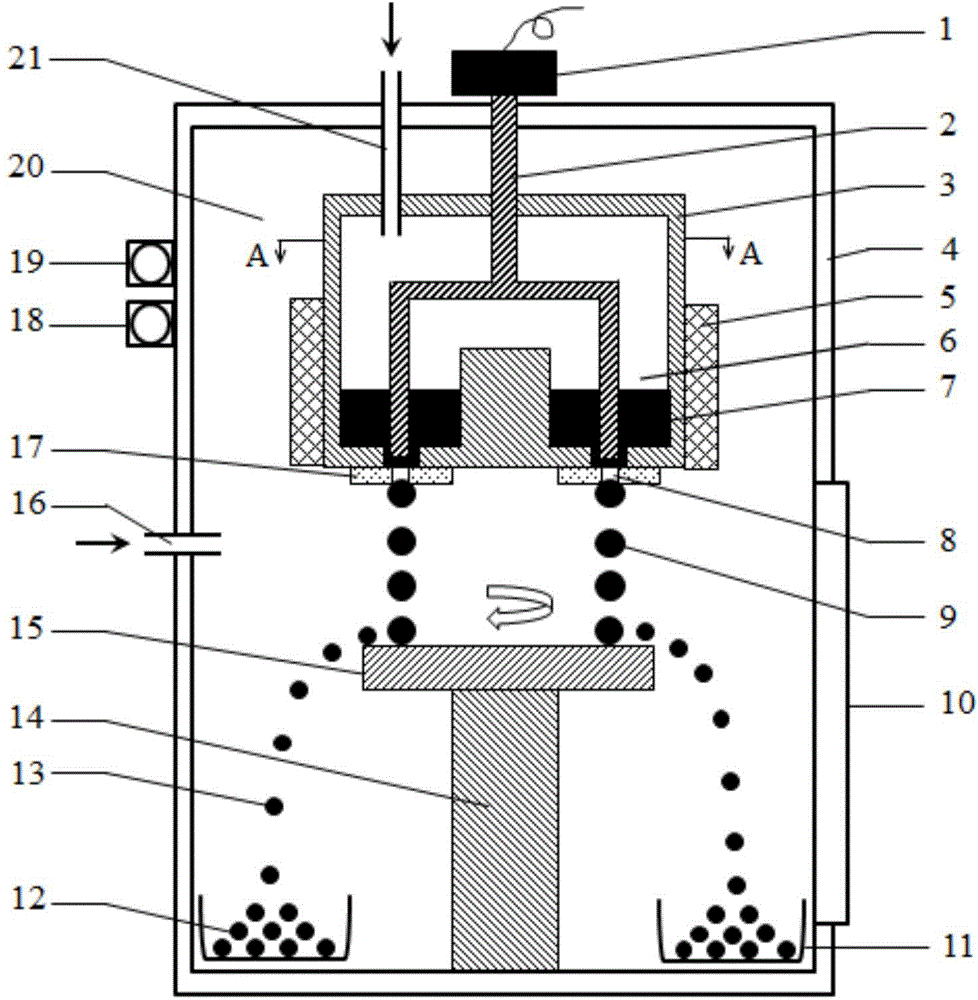

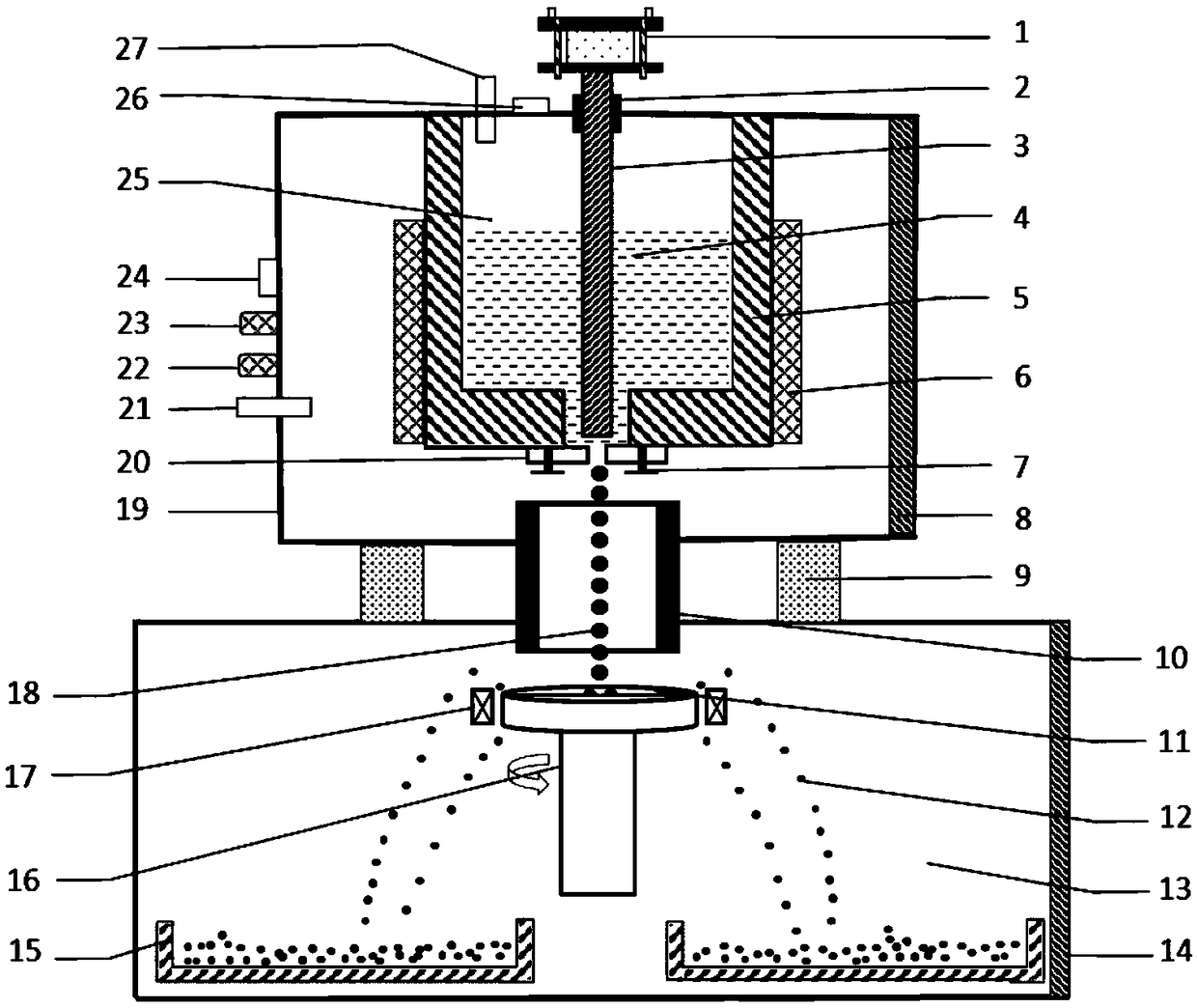

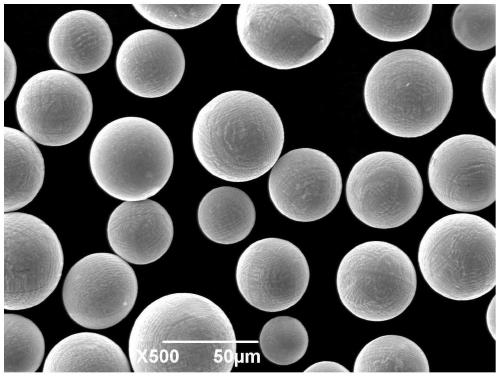

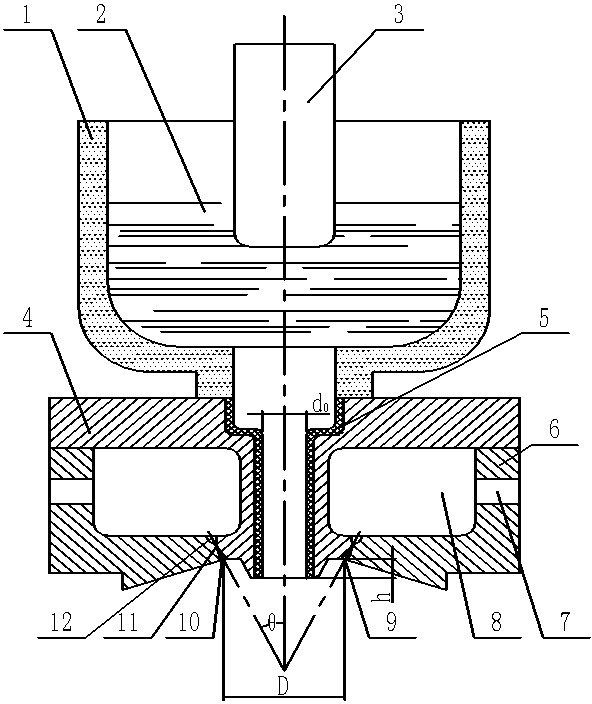

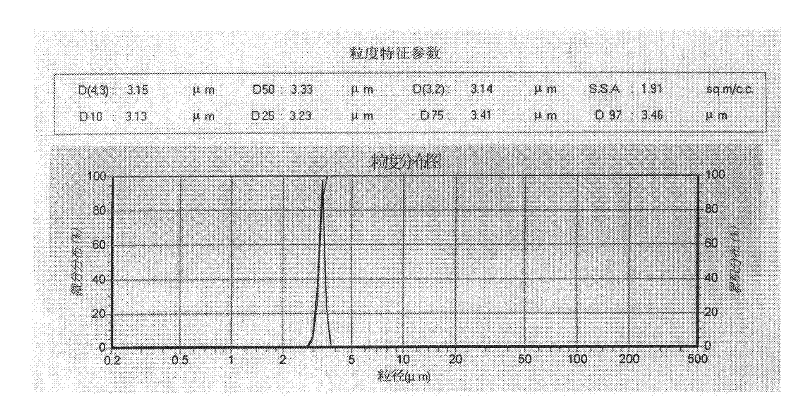

Method and device for preparation of superfine spherical metal powder on basis of uniform droplet spray method

The invention discloses a device for preparation of superfine spherical metal powder on the basis of a uniform droplet spray method. The device comprises a shell, a crucible and a powder collection area, and the crucible and the powder collection area are arranged in the shell. The device is characterized in that a thermocouple is arranged in the crucible, sensing heaters are arranged outside the crucible, and a nozzle with small holes is arranged at the bottom of the crucible; the powder collection area comprises a collection plate and a rotary circular plate, the collection plate is arranged at the bottom of the shell, and the rotary circular plate is connected with a motor and arranged above the collection plate. The invention further discloses a method for preparation of the superfine spherical metal powder. The method for preparation of the superfine spherical metal powder is mainly combined with the uniform droplet spray method and a centrifugal atomization method to prepare metal power narrow in particle size distribution interval, high in sphericity, excellent in liquidity and spreadability, controllable in size, free of satellite droplets and accordant with the utilization requirement on 3D (three-dimensional) printing.

Owner:DALIAN UNIV OF TECH +1

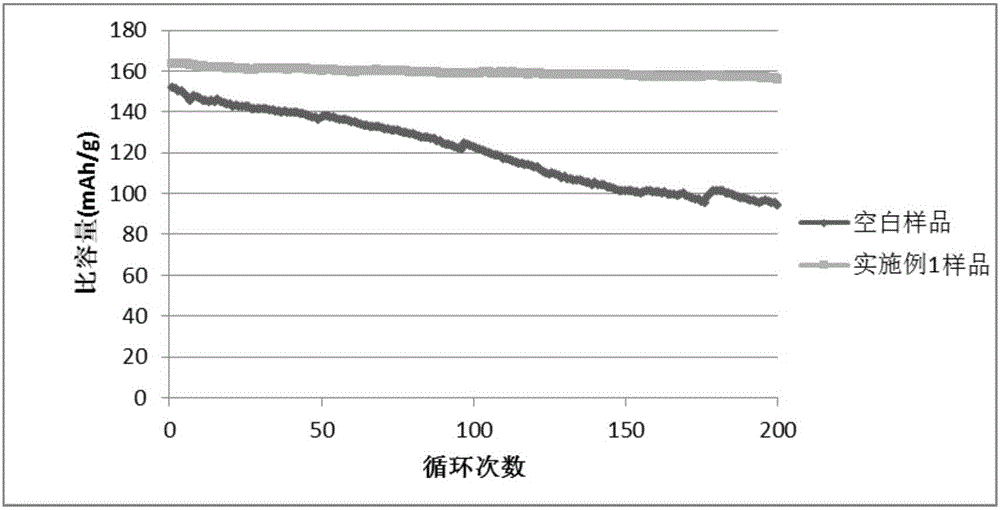

High density ultrafine composite ferric lithium phosphate anode material and preparation method

ActiveCN1907844AChemical composition is easy to controlEasy to dopeCell electrodesPhosphorus compoundsIron saltsOrganic compound

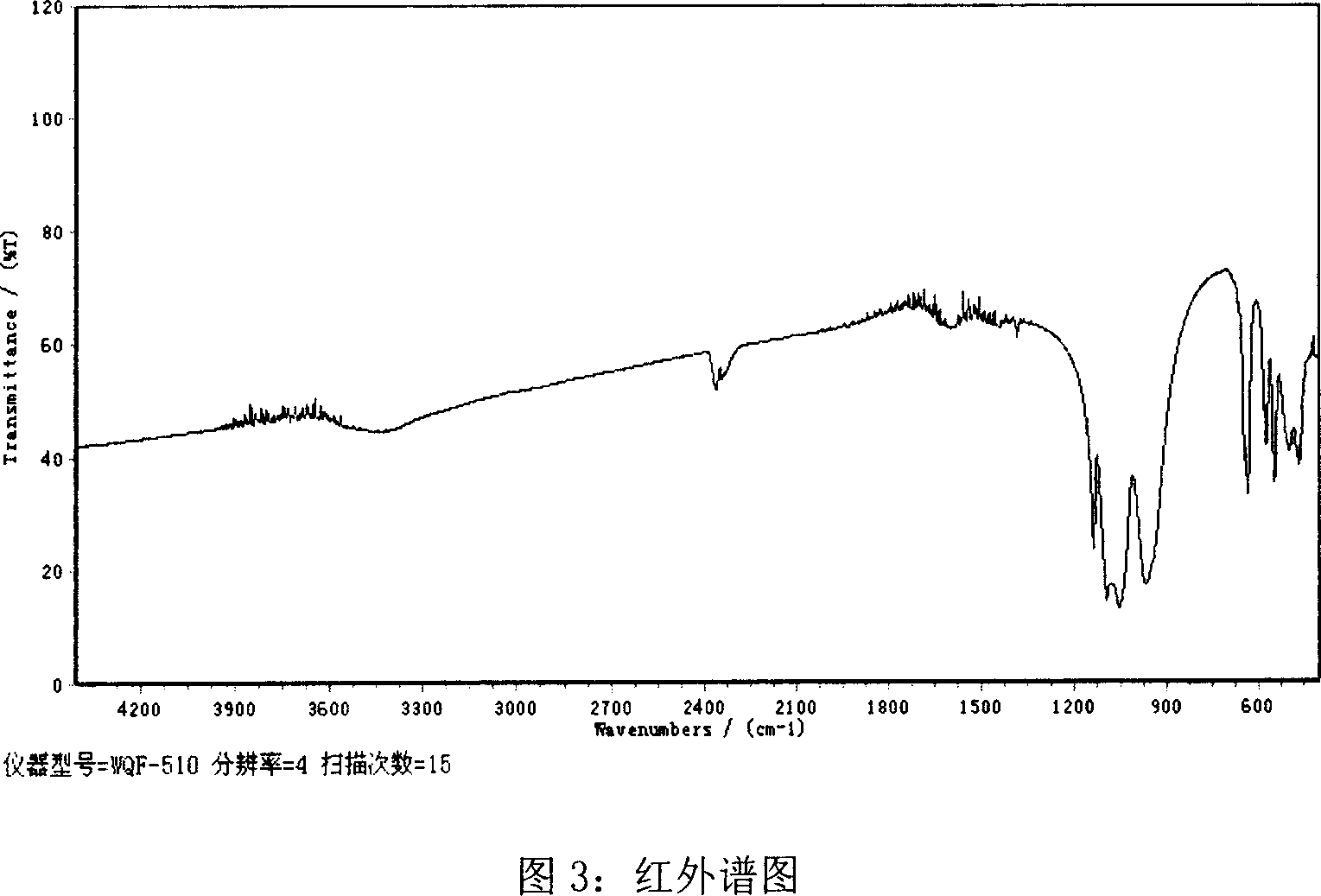

This invention belongs to battery field, which relates to ultra-micro compound lithium iron phosphate cathode material with high density and its fabrication method. Said cathode material is prepared by mixing iron salt, lithium salt and phosphates at a P / Li / Fe ratio of 1-1.1:1-1.1:1-1.1, adding conductive additives containing dopant element and carbon-bearing organic compound, adding organic acid as carrier, adjusting pH, controlling solution temperature in reactor to form sol, separating the sol to obtain nano-precursor and placing it into micorwave oven under protection of inert gas, and obtaining the final product. It is easy to control the chemical component, phase composition and particle size distribution. The conductive additive can be well-distributed. The method also has the advantages of short reaction time, low energy consumption during synthesis process and low cost. The obtained composite has high purity and good compatibility with electrolyte, excellent conductive property and charge and discharge property with large current, and good structure stability,thermal stability and cycle performance.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

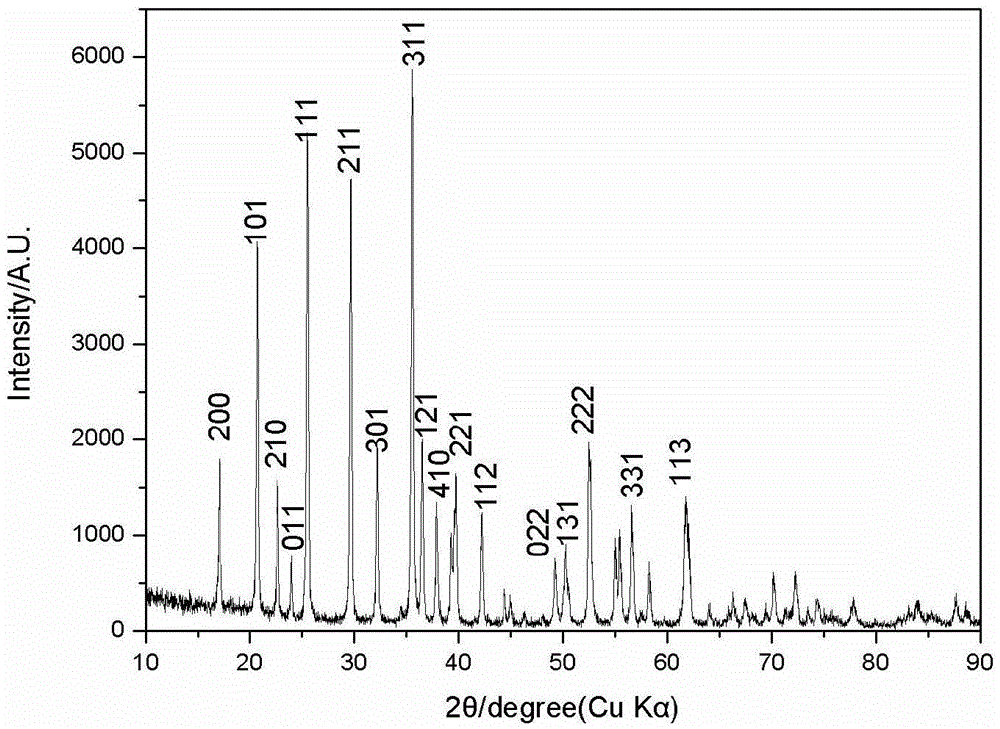

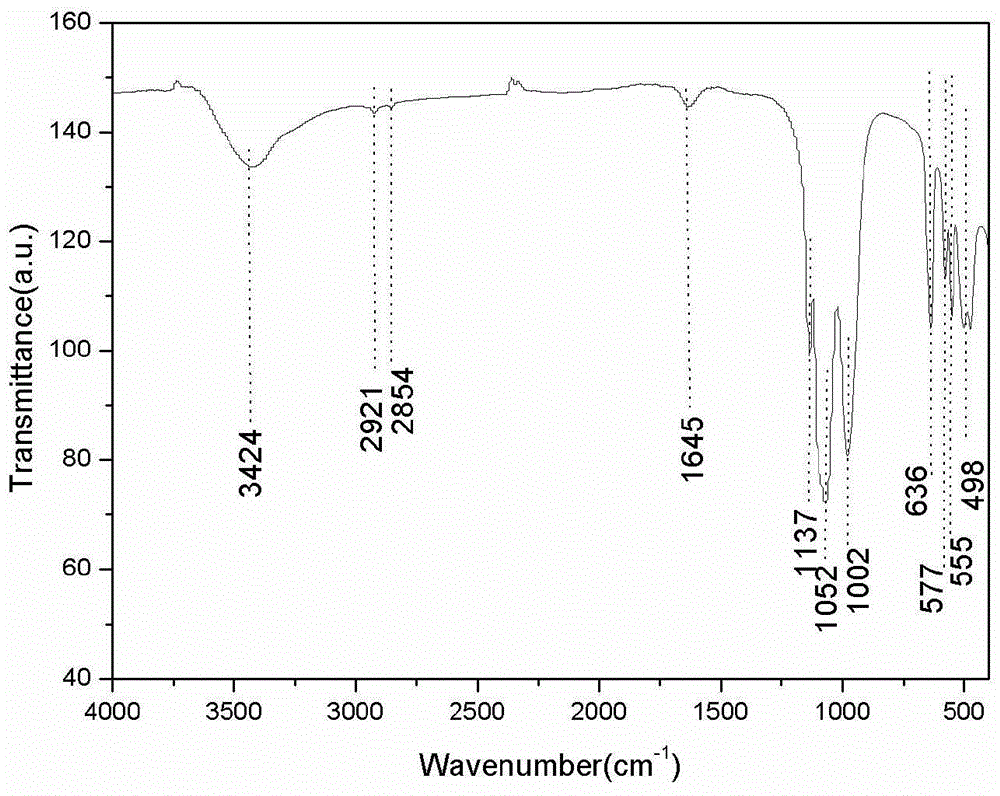

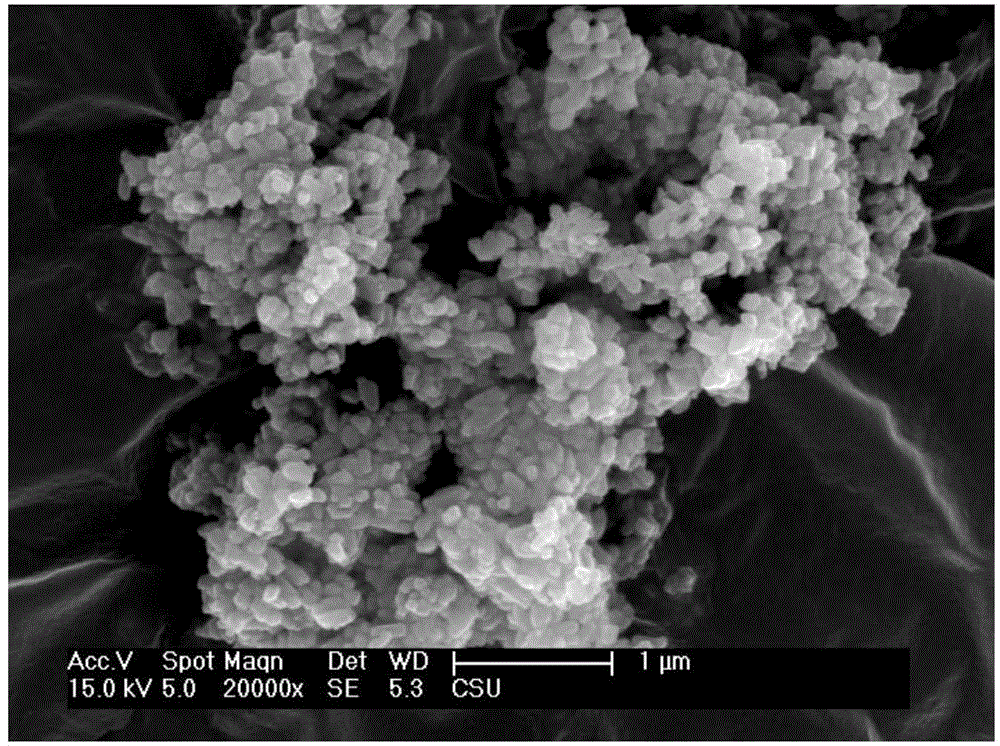

Shape-controllable nano lithium titanate composite and preparation method thereof and lithium ion battery

InactiveCN105870437AImprove conductivity and stabilitySuppress flatulenceCell electrodesSecondary cellsLithium carbonateCarbon source

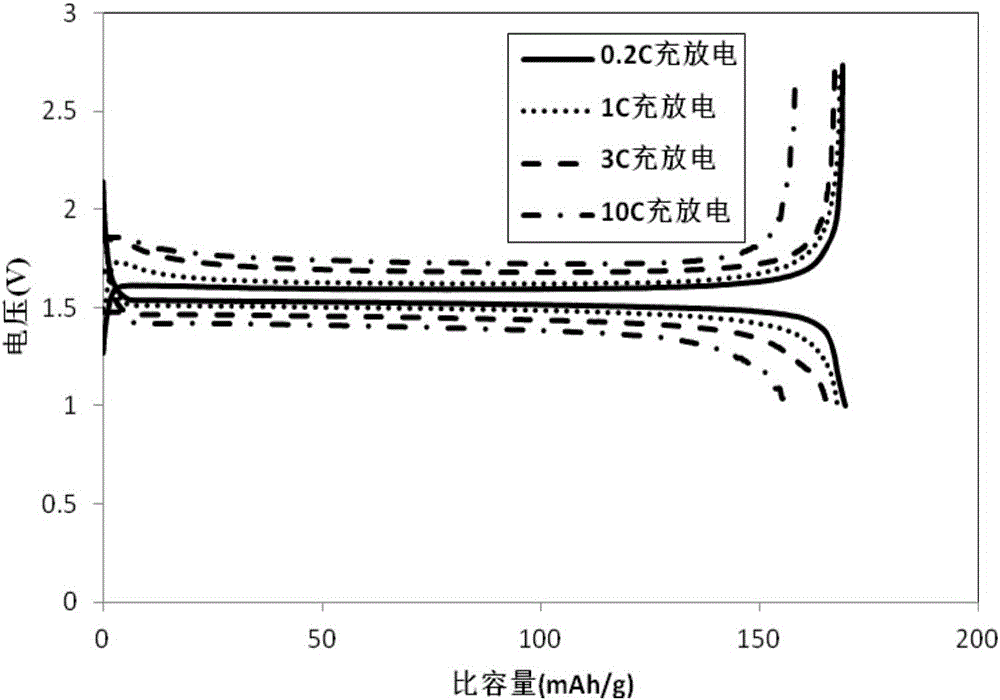

The invention relates to shape-controllable nano lithium titanate composite and a preparation method thereof and a lithium ion battery. The preparation method includes (1) uniformly mixing a lithium source and a titanium source, sintering and cracking all mixtures to obtain a precursor of lithium titanate composite; (2) adding the precursor of lithium titanate composite into dispersion media that is then added with organic carbon source, grinding until particle size of the precursor of lithium titanate composite in all mixtures reaches the nano scale, and obtaining lithium titanate composite pulp; (3) drying, cracking and sintering the lithium titanate composite pulp to obtain the product. Through grinding the precursor of lithium titanate composite to the nano scale and adjusting the second sintering process, particle size of the product can be effectively controlled and particle shape can be so changed. In addition, with doping, carbon wrapping, and oxide wrapping, composite modification of the lithium titanate composite can be realized. Therefore, performance about capacity, magnification, cycling and so on of the lithium titanate is optimized.

Owner:北京泰和九思科技有限公司

Preparation method and applications of super-hydrophobic SiO2 aerogel powder

InactiveCN104003406AControl particle size distributionParticle size distribution can be adjustedSilicaCoatingsActive agentOil phase

The invention relates to a preparation method and applications of super-hydrophobic SiO2 aerogel powder. The method is implemented through the following steps: preparing a silicon source solution, an oil phase, a surfactant and a surfactant aid into a microemulsion; then, neutralizing the microemulsion until the pH value is 6-10 so as to form wet microgel particles; sequentially carrying out ageing, washing and solvent exchange on the wet microgel particles; finally, modifying the obtained product by using a silane modifier, and drying gel at normal pressure and temperature so as to obtain aerogel powder. The method is capable of preparing aerogel powder by using a microemulsion, the particle size of aerogel powder prepared by using the method is uniformly distributed, and prepared aerogel powder has the characteristics of controllable particle size distribution, short preparation period, and capability of being dried at normal pressure and temperature.

Owner:WUHAN UNIV OF TECH

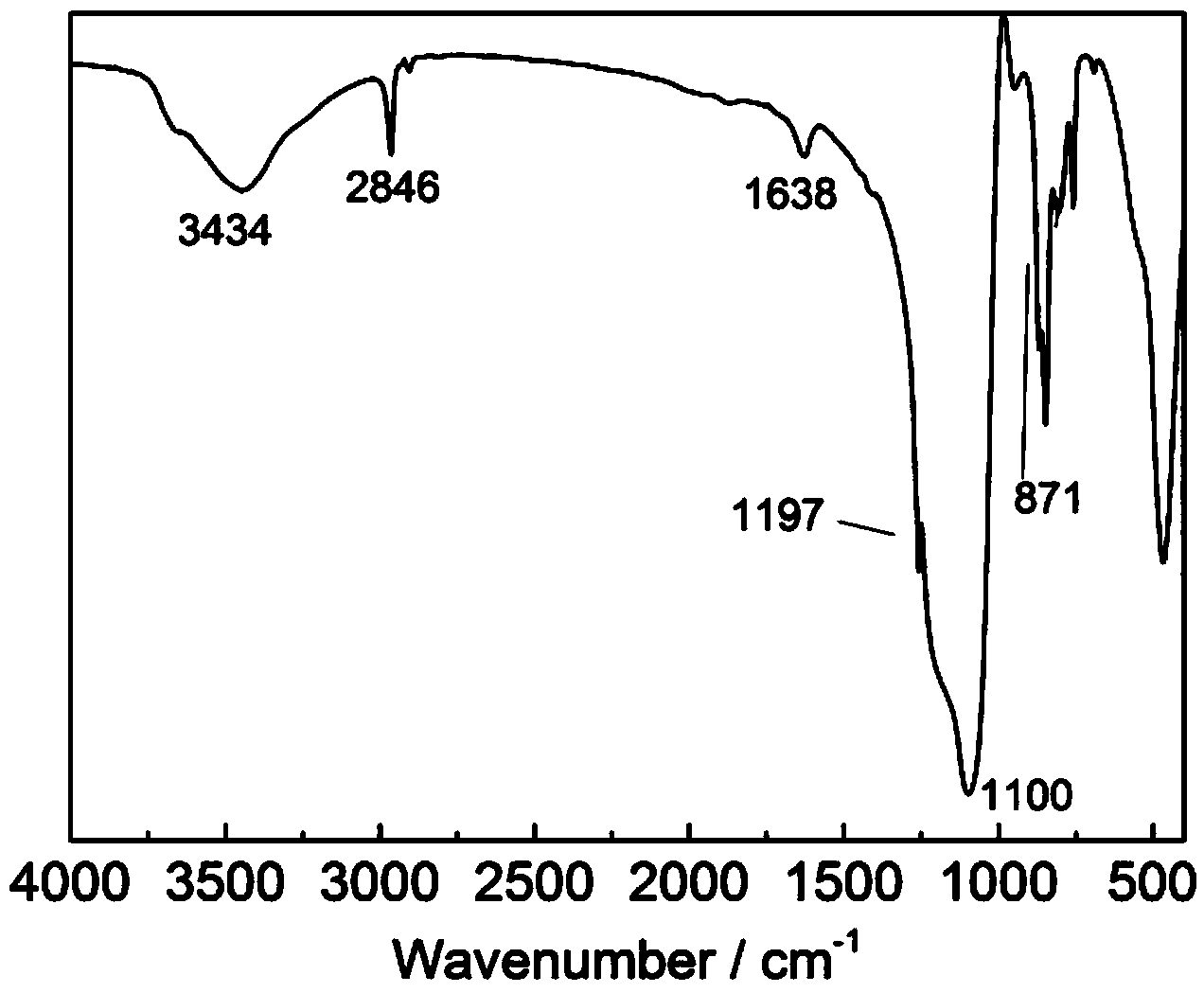

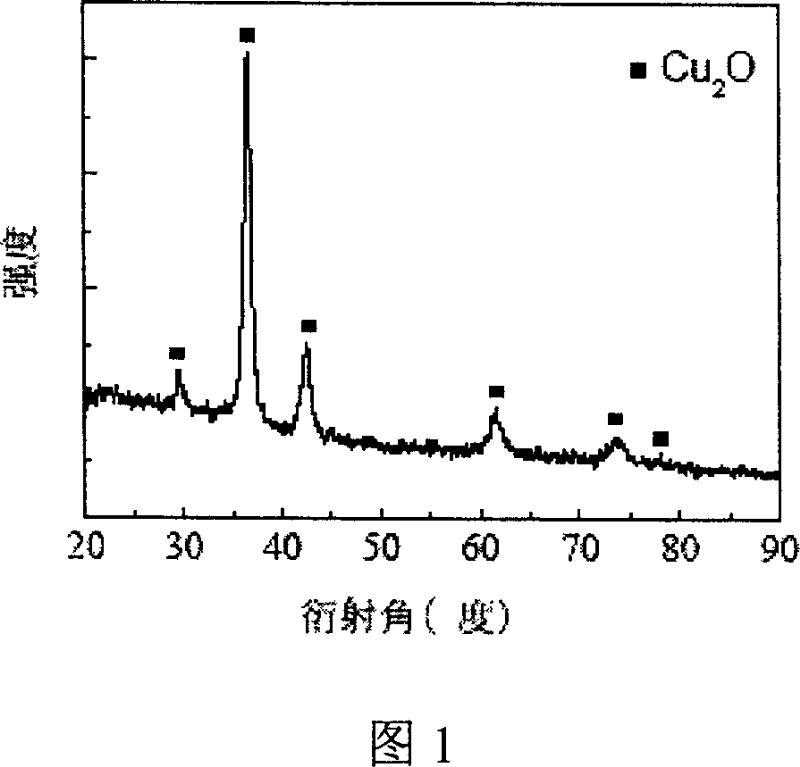

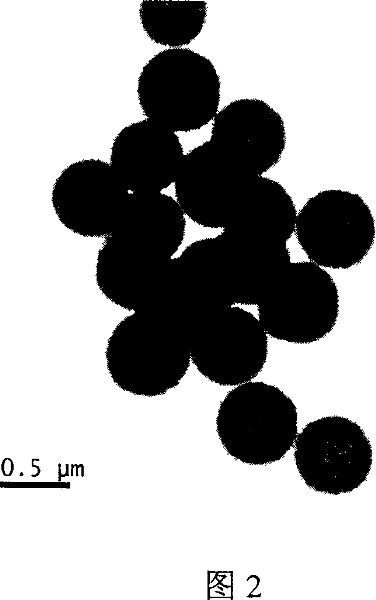

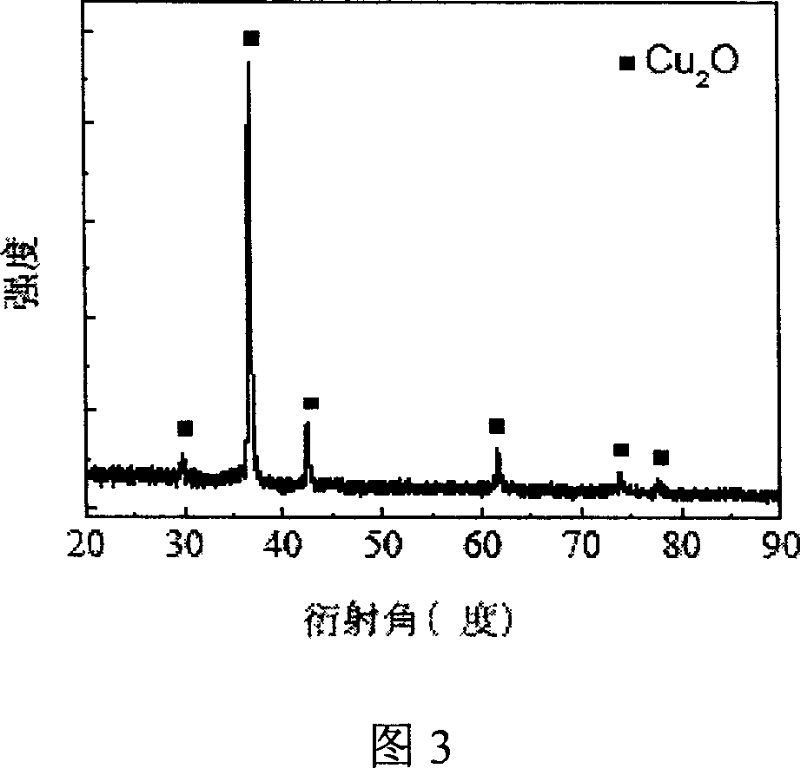

Method for preparing monodispersed copper-protoxide hollow microsphere by aqueous phase cluster soft mold plates process

InactiveCN101041456AQuick restoreControl particle size distributionNanostructure manufactureCopper oxides/halidesHydrazine compoundMicrosphere

The invention discloses a preparing method of monodisperse cuprous oxide hollow submicroballoon with aqueous phase cluster soft mold plates method in preparing technical domain of inorganic functional material, which comprises the following steps: forming cluster with polyvinyl pyrrolidon and dodecyl sodium sulfate; setting the cluster as soft mold plate; mixing water solution of nantokite with water solution of cluster soft mold plate; adjusting pH value; using hydrazine hydrate as reducer; deacidizing copper ion quickly; getting copper-protoxide hollow submicroballoon colloidal solution; making the soft mold plate with the function of controlling outlook and size of particle during reacting course; whizzing; depositing; washing with deionized water and absolute ethyl alcohol; getting copper-protoxide nanometer particle with grain diameter at 11-22 nm; self-assembling; forming monodisperse cuprous oxide hollow submicroballoon with diameter of particle at 400-550 nm.

Owner:JIANGNAN UNIV

Preparation method of neodymium-iron-boron magnet

InactiveCN106782974ASolve mass productionControl particle size distributionInorganic material magnetismBatch productionAluminium

The invention provides a preparation method of a neodymium-iron-boron magnet, relating to the field of production of the neodymium-iron-boron magnet. By virtue of processes of formula optimization, oriented molding, magnet oxygen content control and the like, the invention provides a preparation method of a high-performance sintering neodymium-iron-boron magnet, which solves the problem of batch production of high-performance sintering neodymium-iron-boron products. The preparation method comprises the following steps: weighing 30.0-31.5% of praseodymium and neodymium, 0.9-1.0% of boron, 0-2.0% of terbium, 0.03-0.60% of aluminum, 0.05-0.25% of copper, 0.3-1.5% of cobalt, 0-0.2% of zirconium, 0-0.3% of niobium, 0.05-0.3% of gallium and 62.35-68.67% of iron, and melting and casting to obtain a cast sheet; putting the cast sheet into a rotary hydrogen smashing furnace for processing to obtain coarse powder; adding a lubricating agent into the coarse powder for grinding to obtain fine powder; adding a lubricating agent and an antioxidant into the fine powder, and mixing the powder with a double-cone powder mixer to obtain powder; and making a mold to obtain a billet product, and sintering and cooling to obtain a finished product.

Owner:ZHEJIANG ZHONGKE MAGNETIC IND

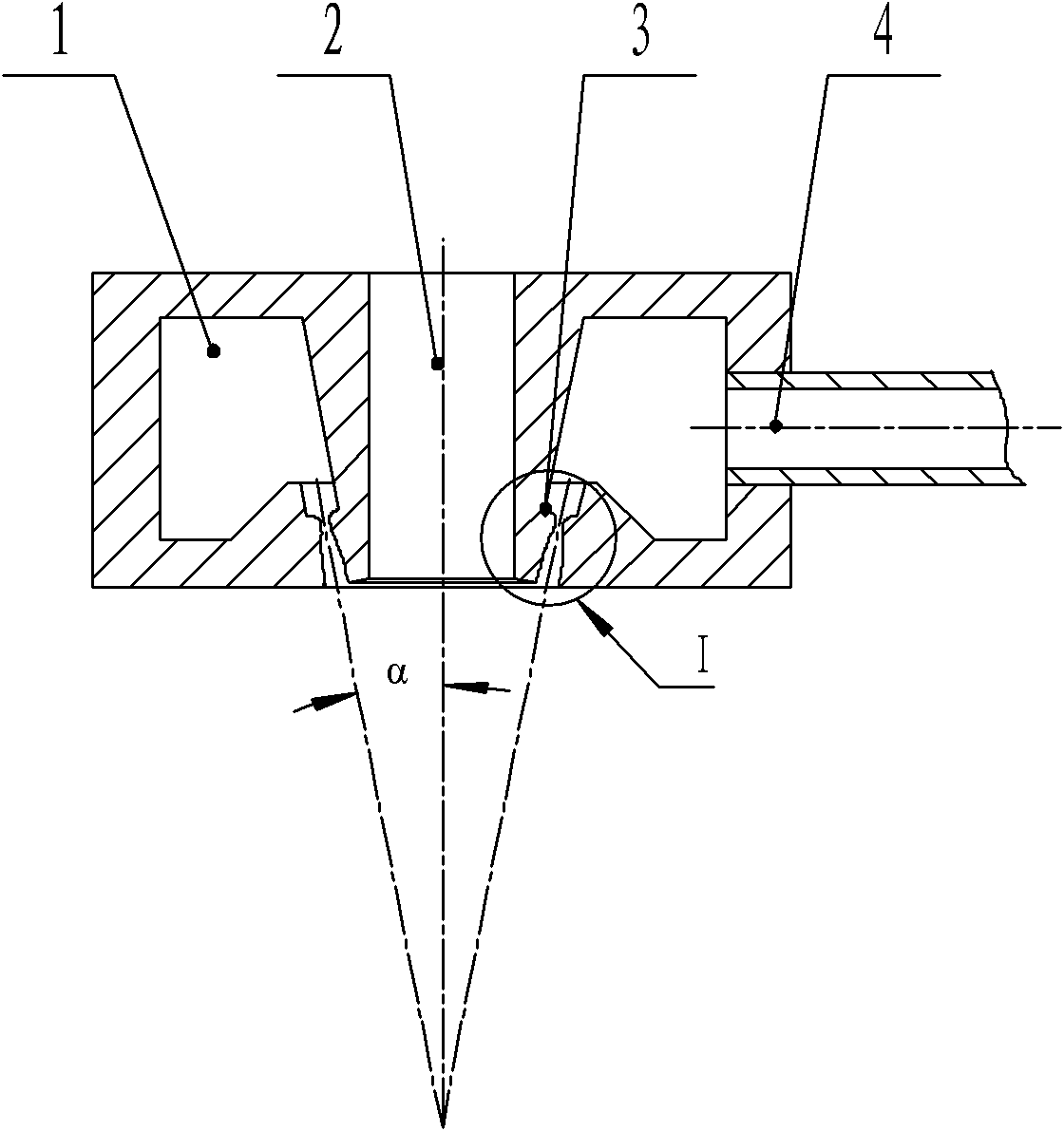

Circumferential seam type supersonic nozzle for metal gas atomization

ActiveCN102581291AUniform velocity distributionReduce turbulenceLiquid spraying apparatusShock waveGas cylinder

A circumferential seam type supersonic nozzle for metal gas atomization comprises a gas inlet pipe (4) connected with an external gas bottle. The gas inlet pipe is connected with an annular gas chamber (1) of the nozzle, the center of the nozzle is provided with a central hole (2), a supersonic gas spray pipe (3) of a circumferential seam structure is formed on the inner chamber wall and the outer chamber wall below the gas chamber and comprises stabilizing sections, contracting sections, throats and diffusion sections, a seam profile consists of symmetric curves, the profile of the whole spray pipe is the seam profile formed by the curves AB, BC and CD to take the axis of central hole (2) as the symmetry axis, the profile rotates by 360 degrees around the axis of the central hole (2) so that a curved surface is obtained, and an included angle alpha ranging from 0 degree to 6 degrees but not equal to 0 degree is formed by an extension line of a central line of each seam passage and the axis of the central hole of the nozzle in the profile of the gas spray pipe (3) passing through the axis of the central hole of the nozzle. The supersonic nozzle for gas atomization has the advantages that gas flow is uniform, turbulence level is low, and shock waves are absent in a flow field.

Owner:有研增材技术有限公司

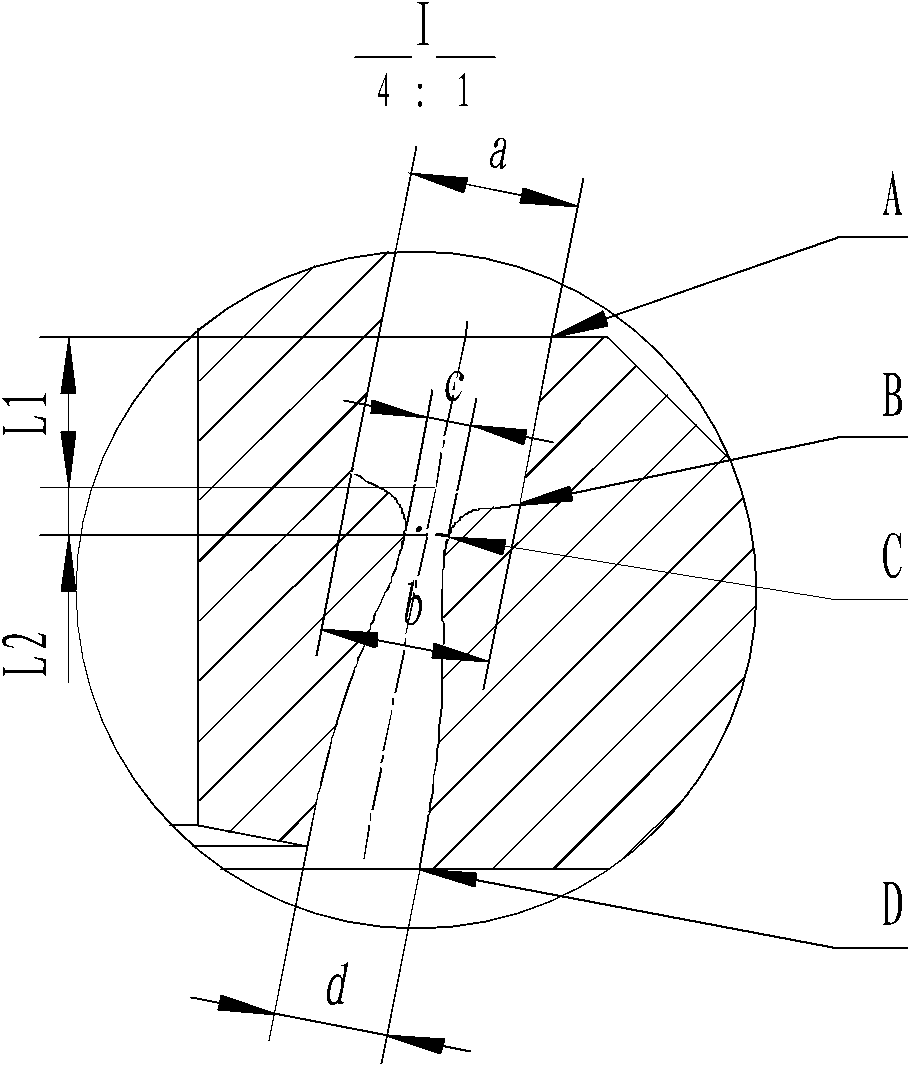

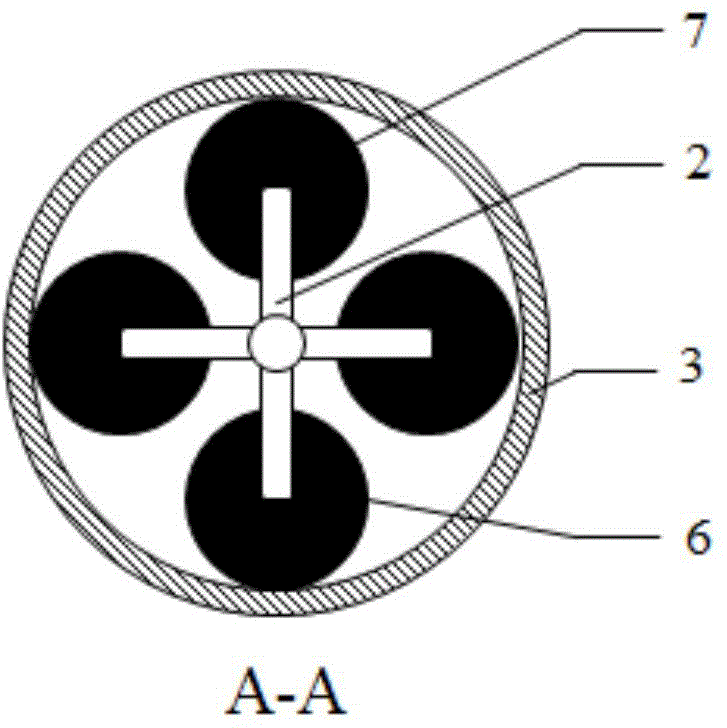

Method and device for efficiently preparing superfine spherical metal powder with high melting point

The invention discloses a device for efficiently preparing superfine spherical metal powder with a high melting point. The device comprises a shell, and a crucible and a powder collecting area which are arranged in a chamber of the shell, and is characterized in that a plurality of melting pools with the same volume are formed inside the crucible, and gaskets with small holes which are communicated with the chamber are fixed at the bottoms of the melting pools; a transmission rod comprises transmission support rods with the number the same as that of the melting pools, and the bottoms of the transmission support rods are aligned with circular holes in the gaskets with small holes; a thermocouple is arranged inside the crucible, and an induction heater is arranged outside the crucible; and the powder collecting area comprises a rotating disk which is used for atomizing metal droplets and is arranged at the bottom of the chamber and connected with a motor, and a collecting tank is also formed in the bottom of the chamber. The invention also discloses a method for efficiently preparing superfine spherical metal powder with the high melting point. By mainly combining a pulse micropore injection method with a centrifugal atomization method, the method can be used for preparing superfine spherical metal powder which is narrow in particle size distribution interval, high in sphericity, good in spreadability and liquidity, and high in production efficiency, and meets the 3D printing and using requirements.

Owner:DALIAN UNIV OF TECH +1

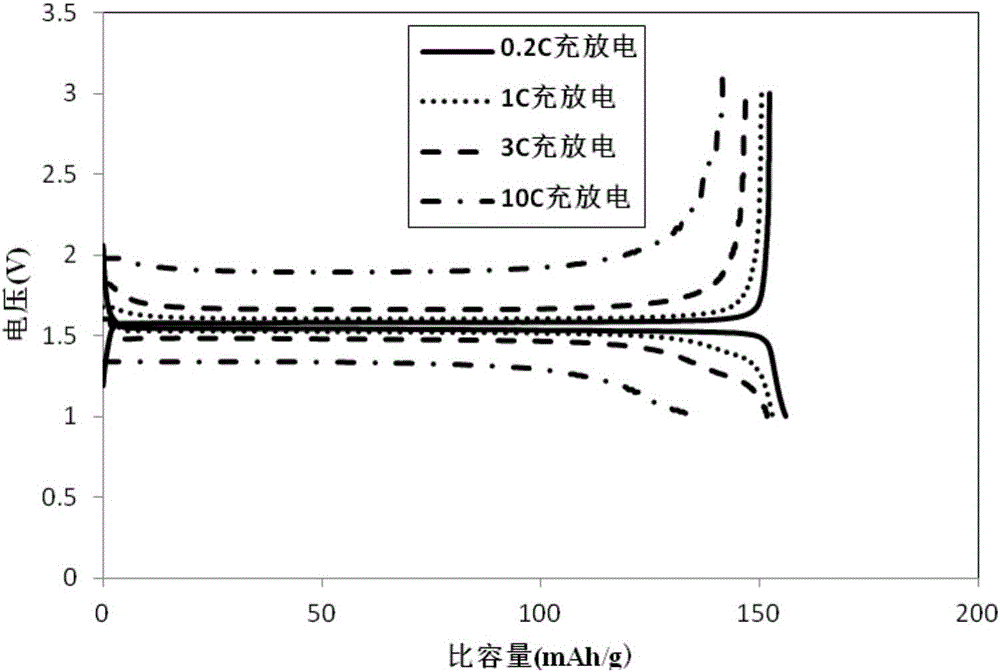

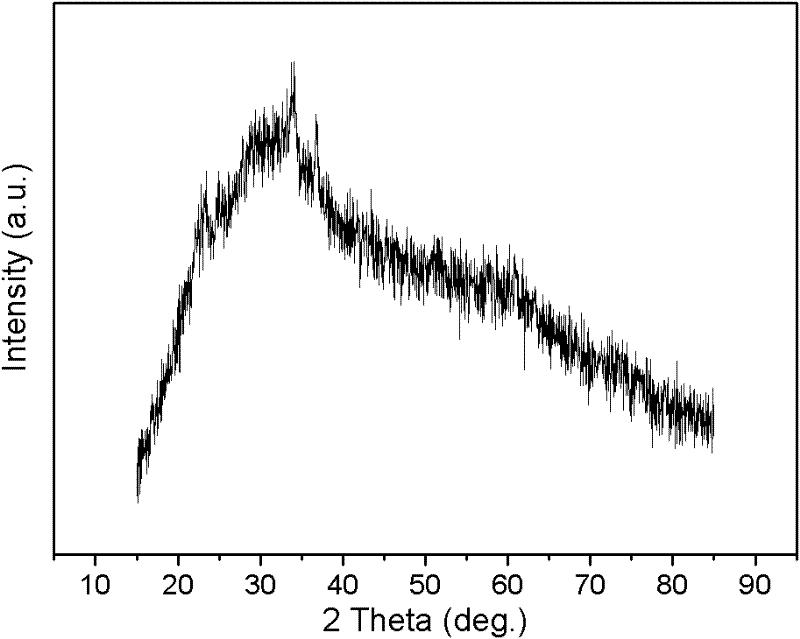

Method for preparing nanocrystal lithium iron phosphate anode material through co-precipitation

ActiveCN102249210AControl Particle SizeControl particle size distributionCell electrodesNanotechnologyLithium iron phosphateMetallurgy

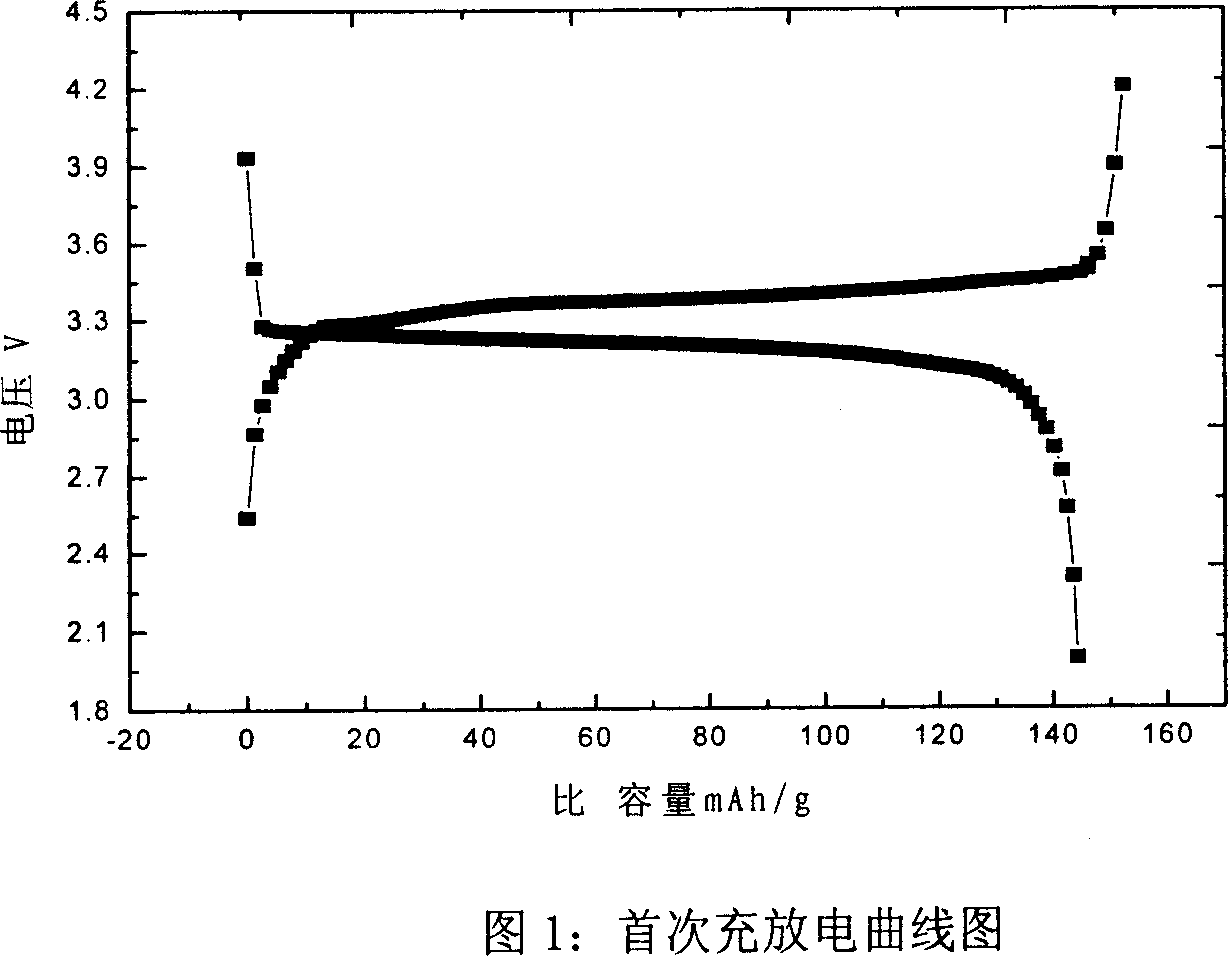

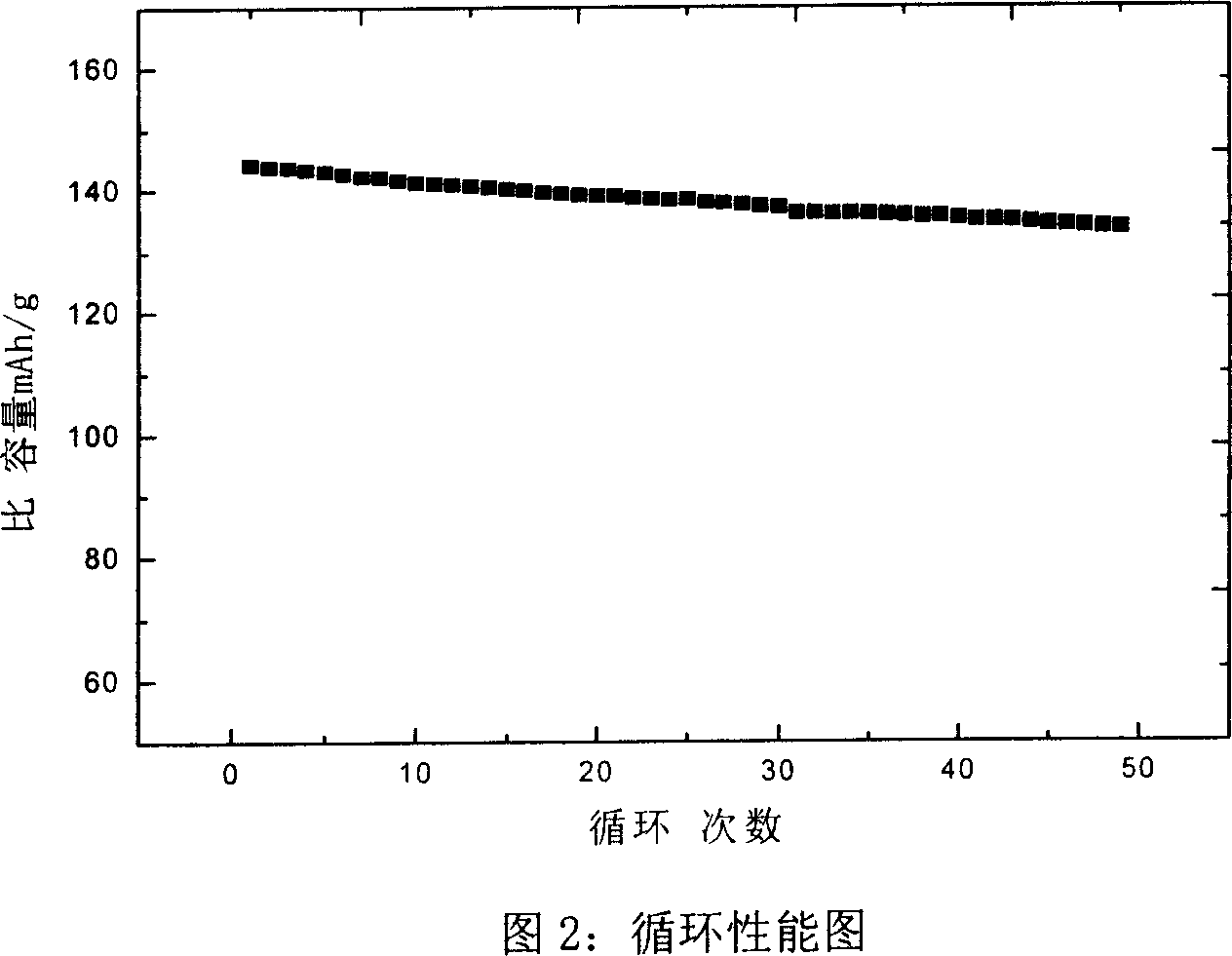

The invention discloses a method for preparing a nanocrystal lithium iron phosphate anode material through co-precipitation, which comprises the following steps of: 1, mixing crude materials, and stirring at high speed to obtain a precursor solution; 2, standing the precursor solution, cleaning, filtering and drying to obtain precursor powder; 3, adding an organic carbon source into the precursor powder and uniformly blending, and drying obtain the precursor powder which is coated by the organic carbon source; 4, roasting and cooling to obtain the organic carbon-coated nanocrystal lithium iron phosphate anode material; 5, mixing an inorganic carbon source with an anode material, adding adhesive and uniformly stirring to obtain an anode sizing agent; and 6, coating the anode sizing agent onto an aluminum foil substrate, drying and pressing to obtain a carbon-coated nanocrystal lithium iron phosphate anode material. With the adaption of the carbon-coated nanocrystal lithium iron phosphate anode material prepared by the method disclosed by the invention, assembled button half-cells have excellent chemical properties. The first discharge capacity achieves 155 mAh / g to 165 mAh / g at 0.1C; and a discharge platform is flat and about 3.4 V.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

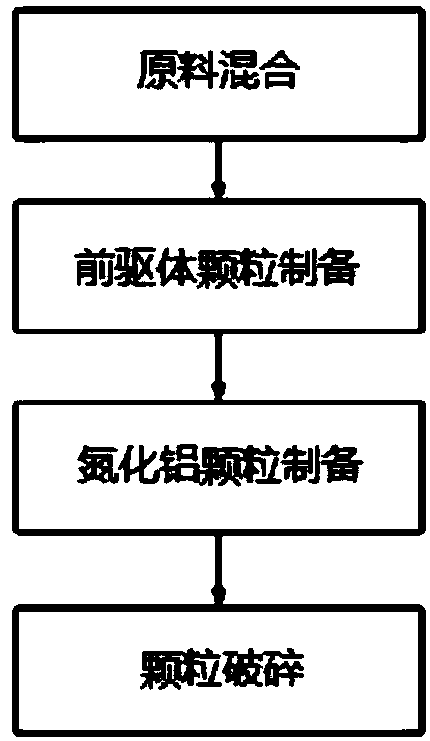

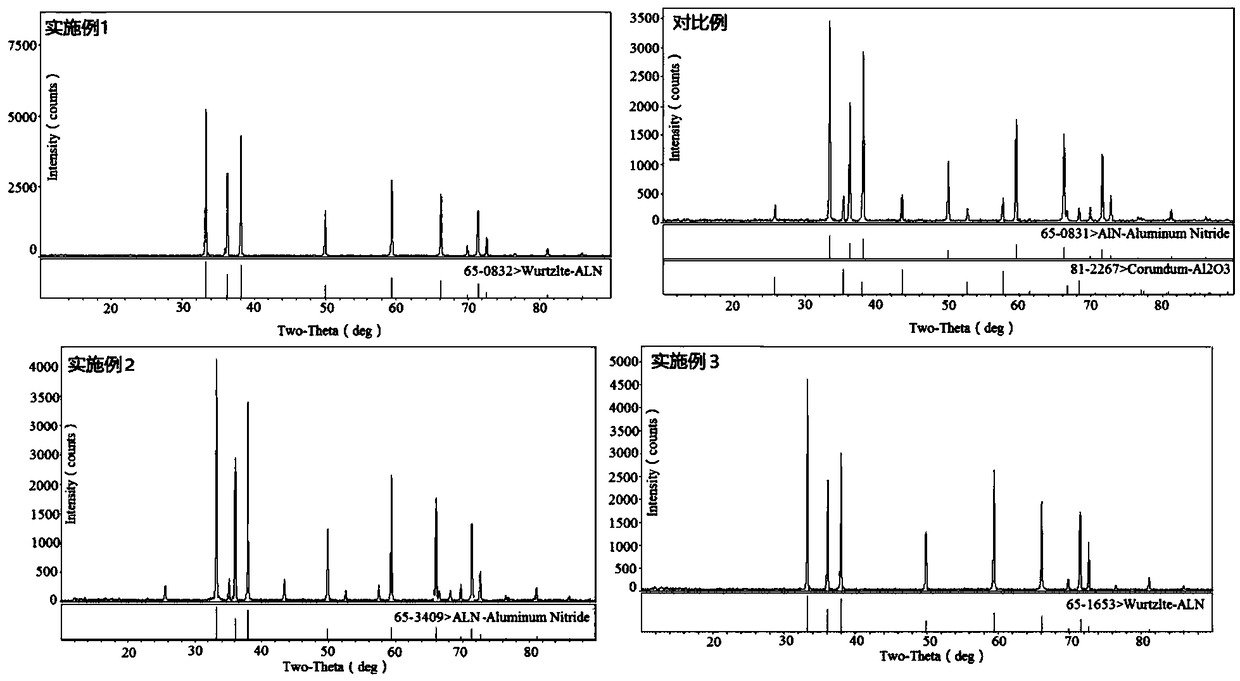

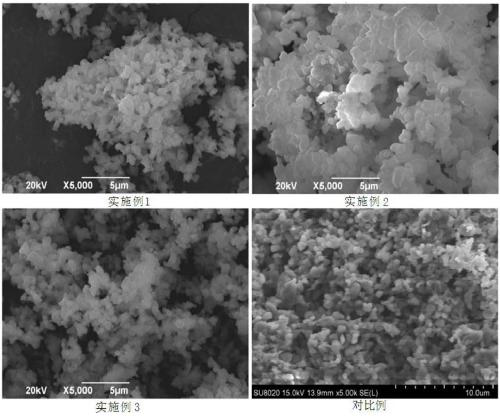

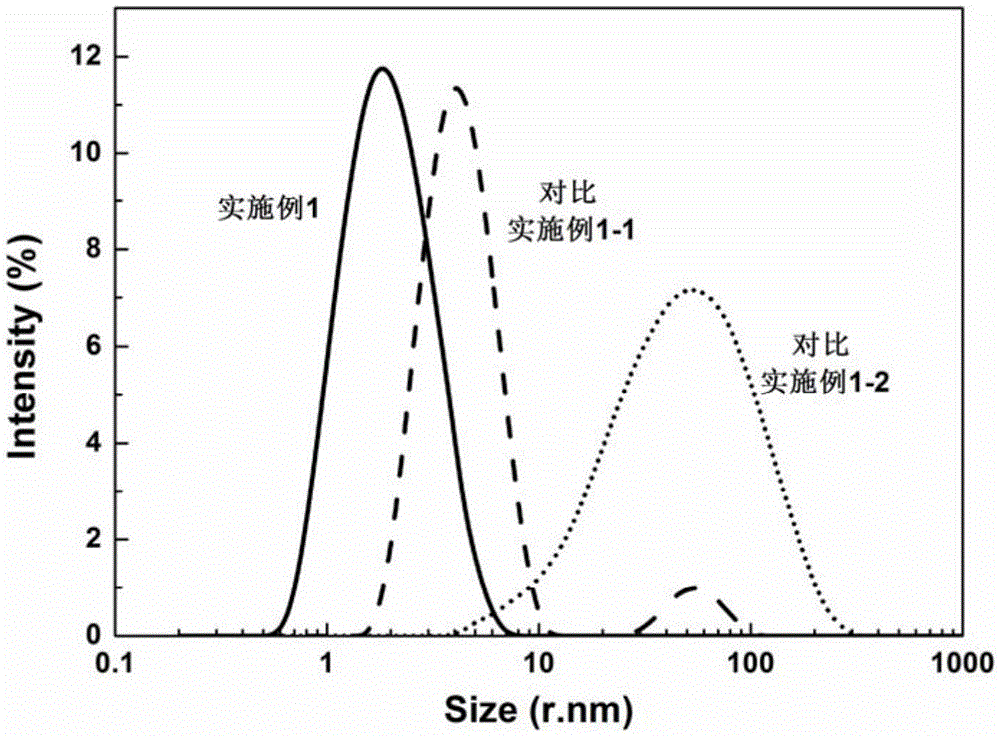

Aluminum nitride powder as well as preparation method and application thereof

The invention discloses a preparation method of aluminum nitride powder. The preparation method comprises the following steps: carrying out uniform mechanical mixing on an aluminum source with a carbon source; enabling precursor granules to continuously react in a nitrogen environment to obtain carbon-containing aluminum nitride granules, and carrying out calcining decarbonization so as to obtainaluminum nitride granules; crushing the aluminum nitride granules, thereby obtaining aluminum nitride powder. The precursor granules continuously react, a sufficient nitrogen channel is reserved in the material piling process in a synthesis process, a nitrogen atmosphere is in sufficient contact with the granules, inverted nitrogen flows form a compulsive gas path to carry away generated CO rapidly, materials are in sufficient contact with the nitrogen atmosphere constantly, the reaction time is greatly shortened, sufficient reactions can be ensured, and the purity of the finally prepared aluminum nitride powder is improved. The invention further discloses the aluminum nitride powder prepared with the method and application of the aluminum nitride.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

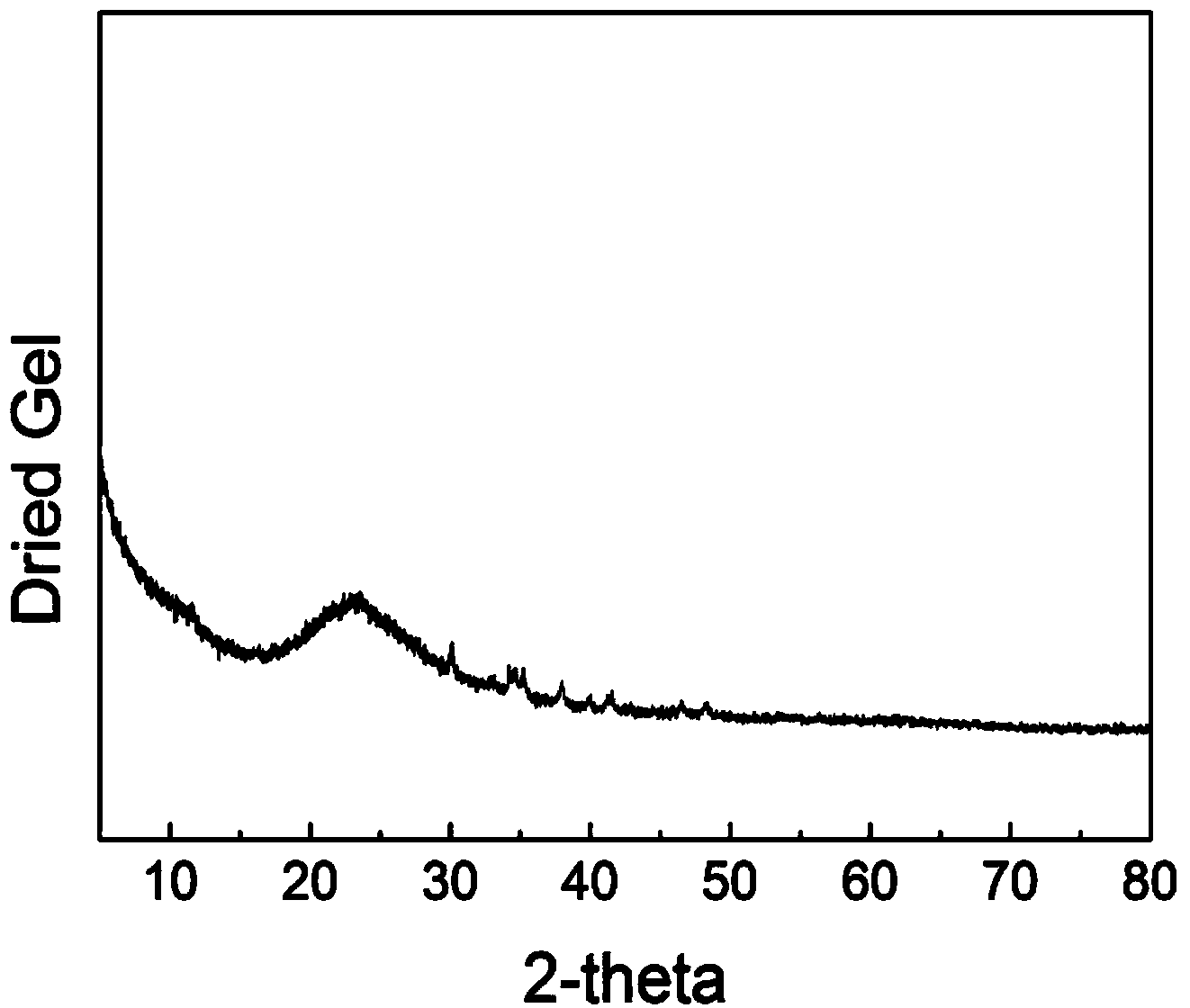

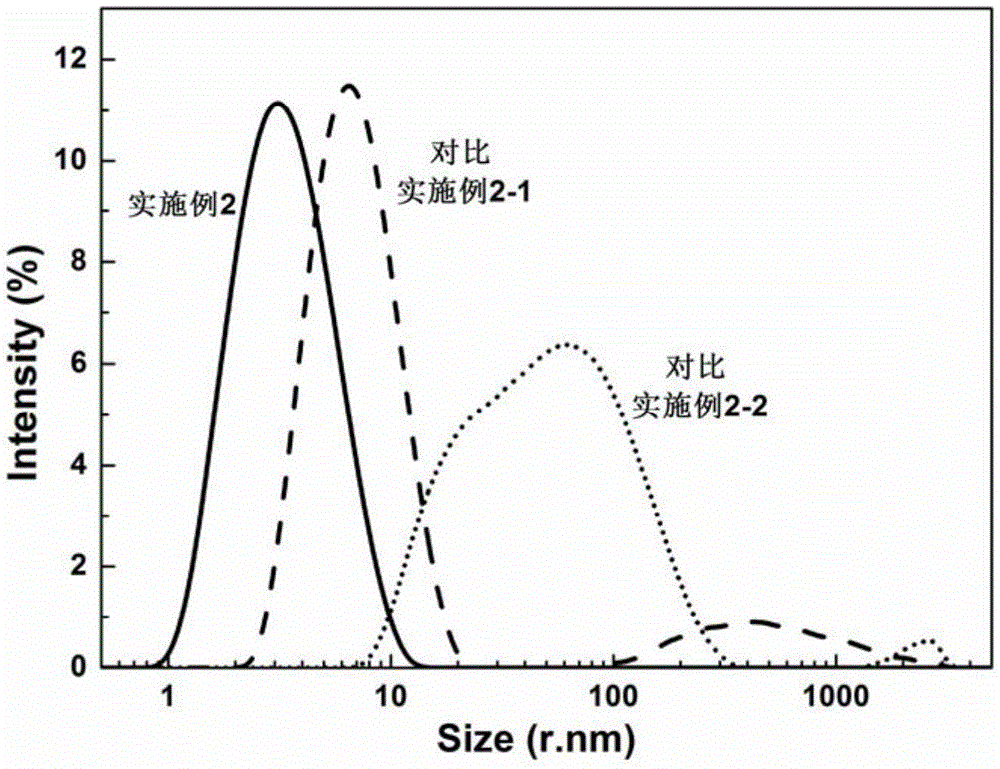

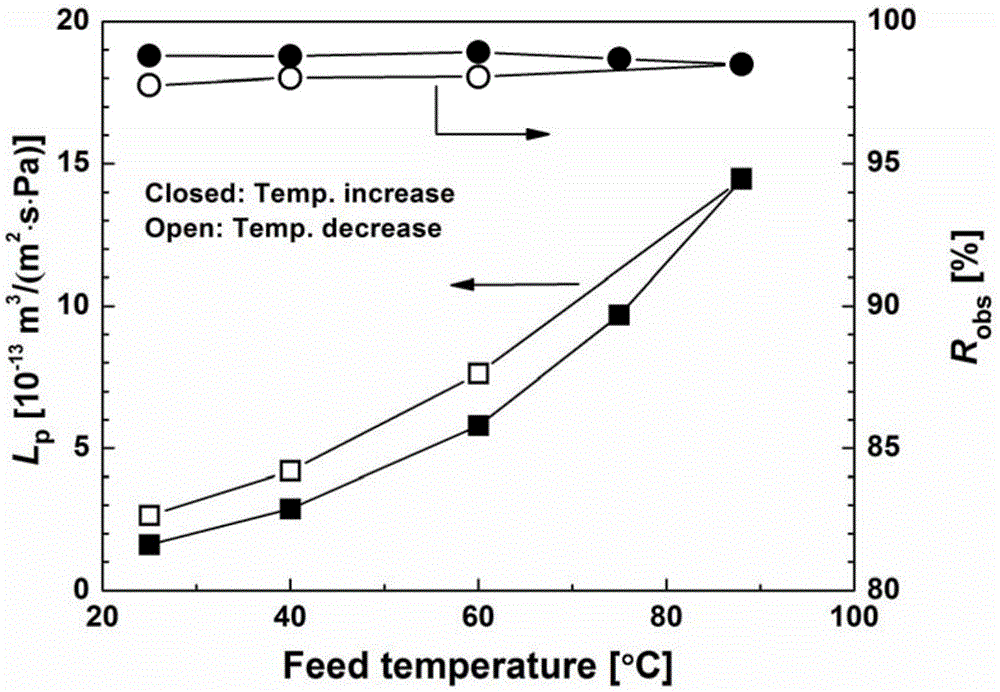

Preparation method and application of organosilicone sol based on pH swing

ActiveCN105597561AEnhanced network structureLarge particle sizeMembranesSemi-permeable membranesWater bathsAlcohol

The invention belongs to the field of preparation of inorganic membrane materials, in particular to a preparation method and application of an organosilicone sol based on pH swing. The preparation method comprises the following steps of adding an organosilicone source precursor into absolute ethyl alcohol; after stirring in water bath, adding deionized water; on the premise of continuous stirring in the water bath, adjusting the pH of the system to acidity by using acid and reacting for one hour; adjusting the pH of the system to weak acidity or neutrality, and reacting for one hour to prepare the organosilicone sol of which particle size distribution is extremely-narrow and stable; gelatinizing the sol into a membrane for reverse osmosis desalination. The organosilicone reverse osmosis membrane shows excellent hydrothermal stability and salt rejection rate.

Owner:CHANGZHOU UNIV

Component for olefinic polymerization loaded on nano carrier as well as its preparing method and application

A catalyst for the polymerization of olefin is a reaction product of magnesium compound, titanium compound and electronic donor compound, which are carried by a carrier whose average granularit is less than 100 nm. Its advantages are high polymerizing activity, uniform and controllable polymer granularity.

Owner:CHINA PETROLEUM & CHEM CORP +1

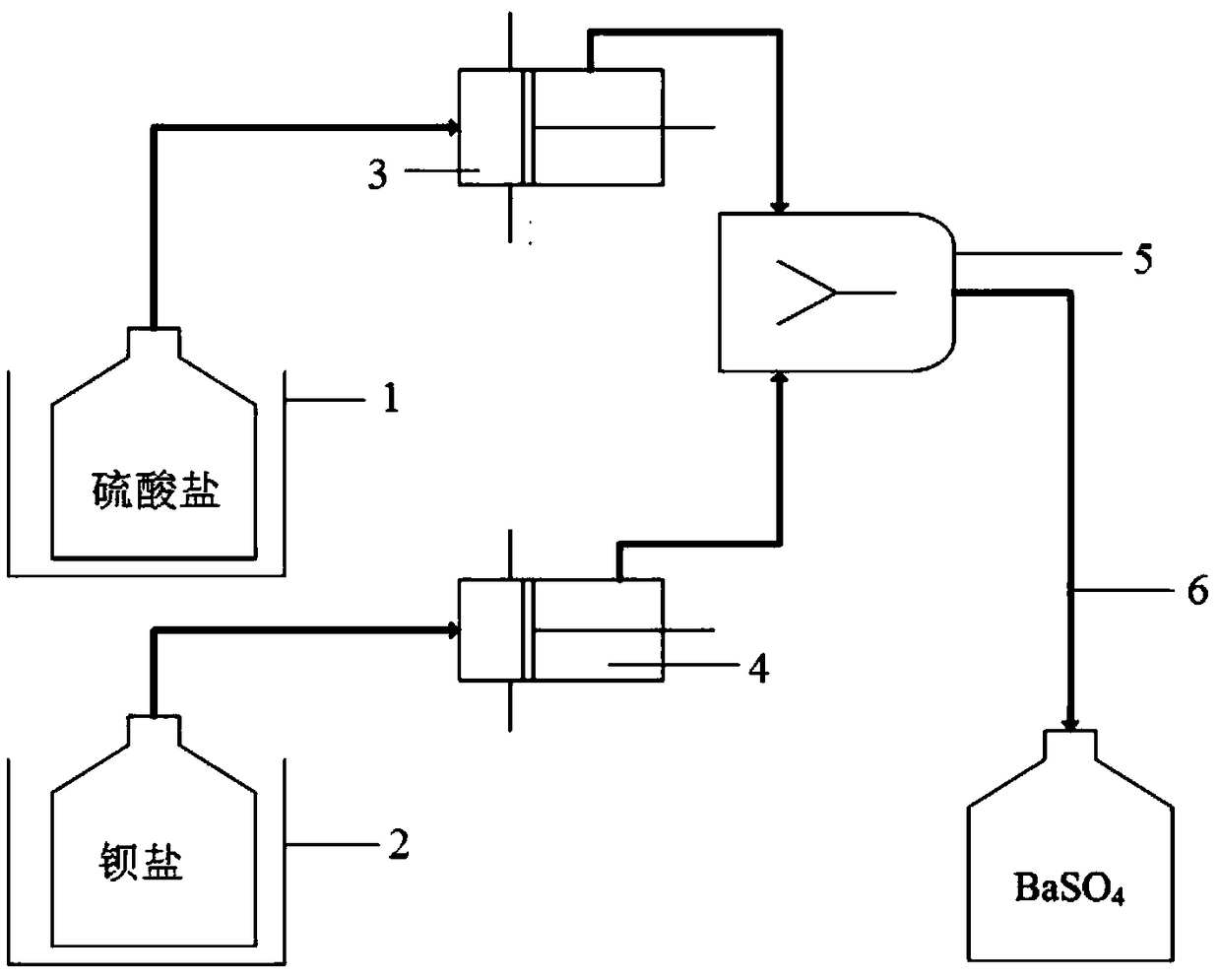

Method for preparing barium sulfate particles through microchannel method

ActiveCN108862355ALarge specific surface areaShort stayMaterial nanotechnologyCalcium/strontium/barium sulfatesBarium dichlorideBarium salt

The invention belongs to a method for preparing barium sulfate particles through a microchannel method in the technical field of nanomaterial preparation. The method comprises the following steps: introducing a sulfate water solution and a barium salt water solution into a microchannel reactor for reacting and ageing, and centrifuging, washing and drying an obtained reaction solution, thus obtaining the barium sulfate particles, wherein selected sulfate is sodium sulfate, ammonium sulfate or sodium persulfate, and barium salt is barium chloride, barium acetate or barium nitrate. The morphologyand the particle size distribution of the obtained barium sulfate particles are controllable, and industrial application of medical dry films can be met to a larger extent.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

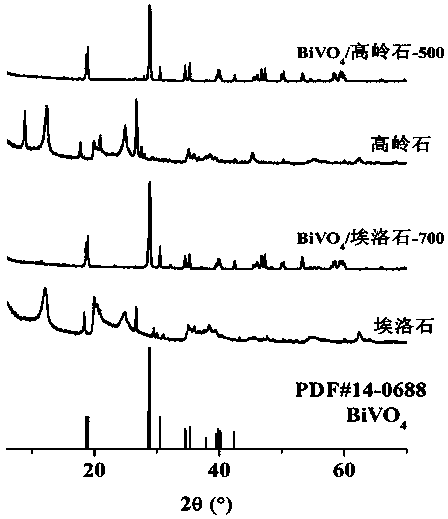

1:1 type silicate mineral doped bismuth yellow hybridization pigment and preparation method thereof

ActiveCN107760063AGood coloring effectSmall particle sizeInorganic pigment treatmentSilicate mineralsMuffle furnace

The invention discloses a 1:1 type silicate mineral doped bismuth yellow hybridization pigment which is prepared by dissolving bismuth salt into a nitrate solution; uniformly dispersing 1:1 type silicate minerals; dissolving a vanadium source into a nitric acid water solution or an alkali water solution; putting into a bismuth solution with silicate minerals; adjusting the pH value of a reaction system to be 7-10; performing stirring reaction so as to obtain yellow precipitate; and filtering, washing, and performing calcining treatment in a muffle furnace, thereby obtaining the 1:1 type silicate mineral doped bismuth yellow hybridization pigment. Due to adoption of the 1:1 type silicate minerals, by virtue of the doping action of components Al2O3 and SiO2 of the minerals to crystal latticeof BiVO3, the color performance of the bismuth yellow pigment is improved, the particle sizes and the particle size distribution of bismuth nanoparticles are effectively controlled, and the generation of free aggregates is avoided; and meanwhile, the production cost of the bismuth yellow pigment is greatly reduced, the high value utilization of the 1:1 type silicate minerals is achieved, and theapplication range of the bismuth yellow pigment is widened.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

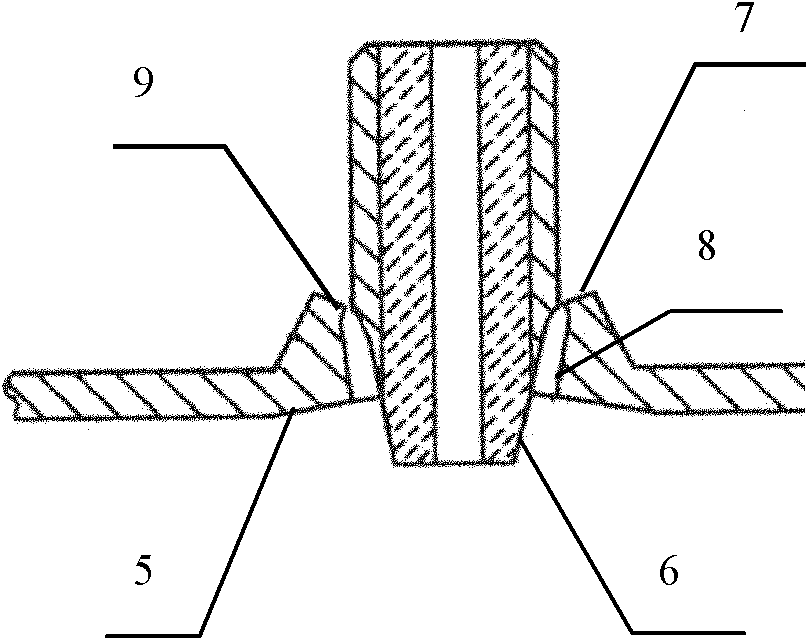

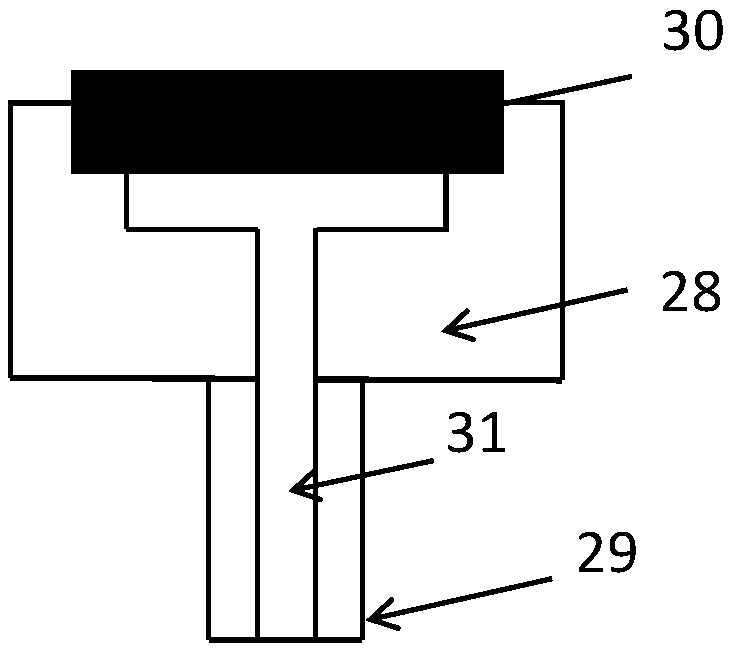

Device and method for preparing spherical metal powder for 3D printing

The invention provides a device and method for preparing spherical metal powder for 3D printing. The device for preparing the spherical metal powder comprises a shell, a crucible and a collecting bin,wherein the crucible is arranged in the shell, and the collecting bin is arranged on the lower portion of the shell. The device for preparing the spherical metal powder for the 3D printing is characterized in that a rotating disc arranged in a powder collection area is of a inlaying structure, materials with poor thermal conductance are selected as a substrate part of the rotating disc, metal materials with a wetting angle less than 90 degrees with liquid drops are selected to be inlayed into a main part to be used as an atomized plane, and a ventilation hole is formed in the rotating disc. The invention further discloses a method for preparing the spherical metal powder for the 3D printing, a pulse microporous injection method and a centrifugal atomization method are mainly combined, a rotating disc structure is matched, and the surface of the rotating disc is subjected to induction heating, so that molten metal breaks through a split mode of traditional molten metal, a fibrous splitmode which can be realized only when an atomization medium is an aqueous solution or an organic solution is realized, high melting point metal powder which meets requirements is prepared, the particle size is fine and grain size is controllable, the sphericity is high, no satellite droplet is achieved, the mobility and the spreadability are good, and the preparation method is suitable for industrialized production.

Owner:DALIAN UNIV OF TECH +1

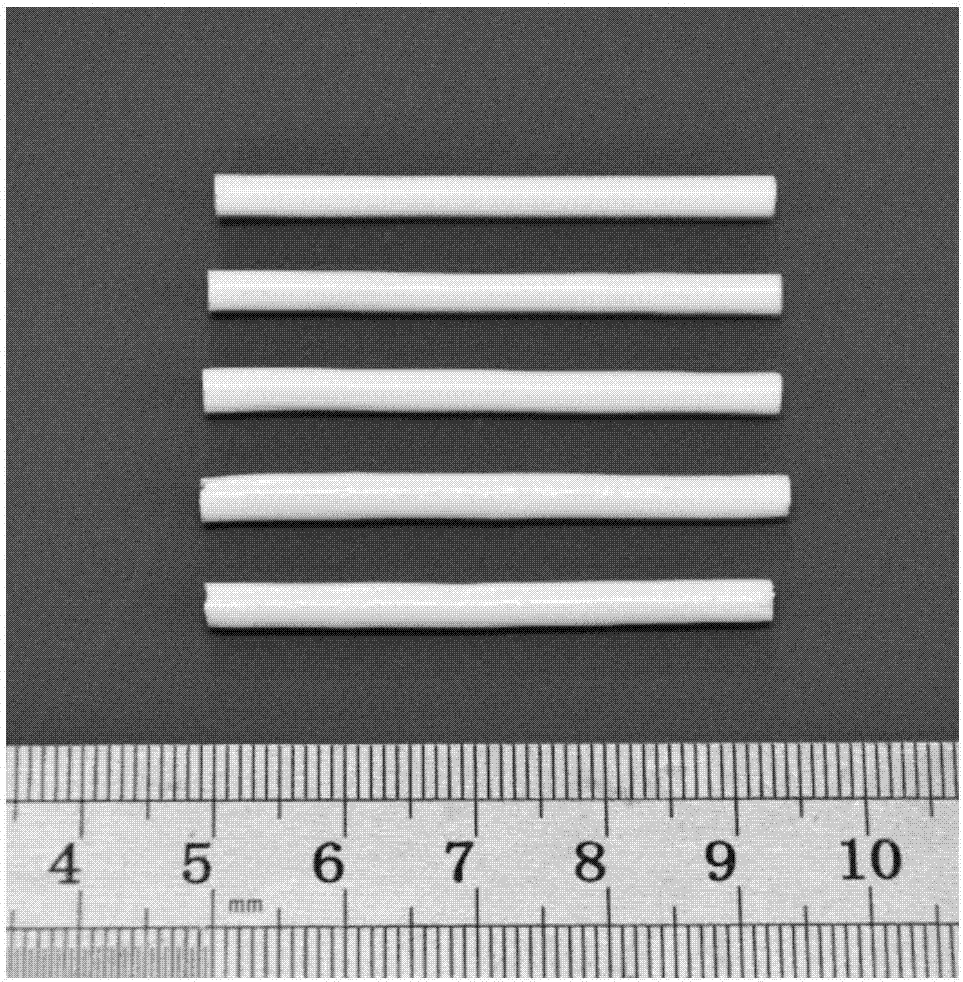

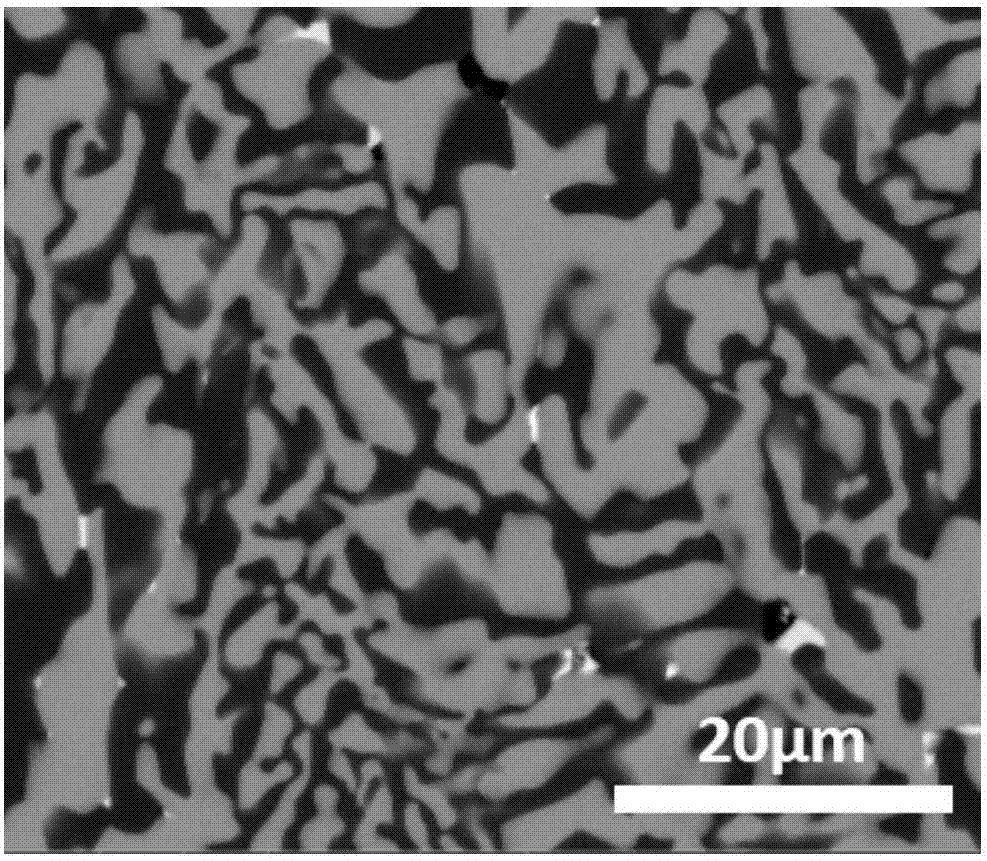

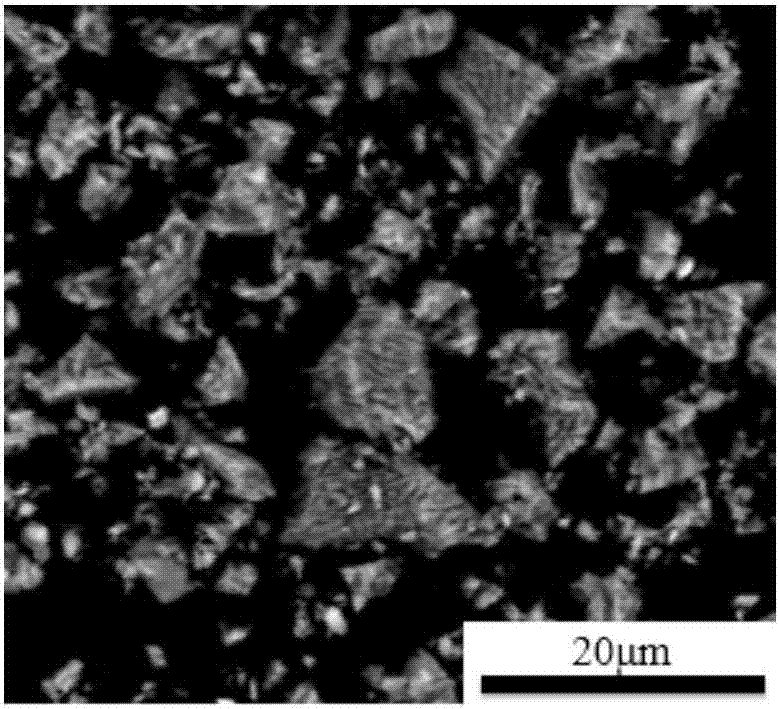

Preparation method of oxidecocrystal structureceramic powder

The invention discloses a preparation method of oxideeutecticstructureceramic powder. The method comprises the following steps: preparing an eutecticmaterial with fine and uniform tissue through a laser floating zone melting technology, then preserving a microcosmiceutectic structure with strong interface bonding into eutectic powder through crushing and screening, and further preparing eutectic powder with certain particle size distribution, thereby effectively reserving an eutecticstructure in an initial eutectic sample into a sinteredeutectic crystalthrough reasonable collocation of lamellar spaces and eutectic powder particle size of the initial eutectic sample. Theoxideeutecticstructureceramic powder is in a typicaleutectic morphology; eutecticmaterials with different lamellar spaces are obtained by changing the withdrawal rate during a laser floating zone melting process; eutectic powder with differentparticle size distribution is obtained through the combination of the withdrawal rate and ball milling time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

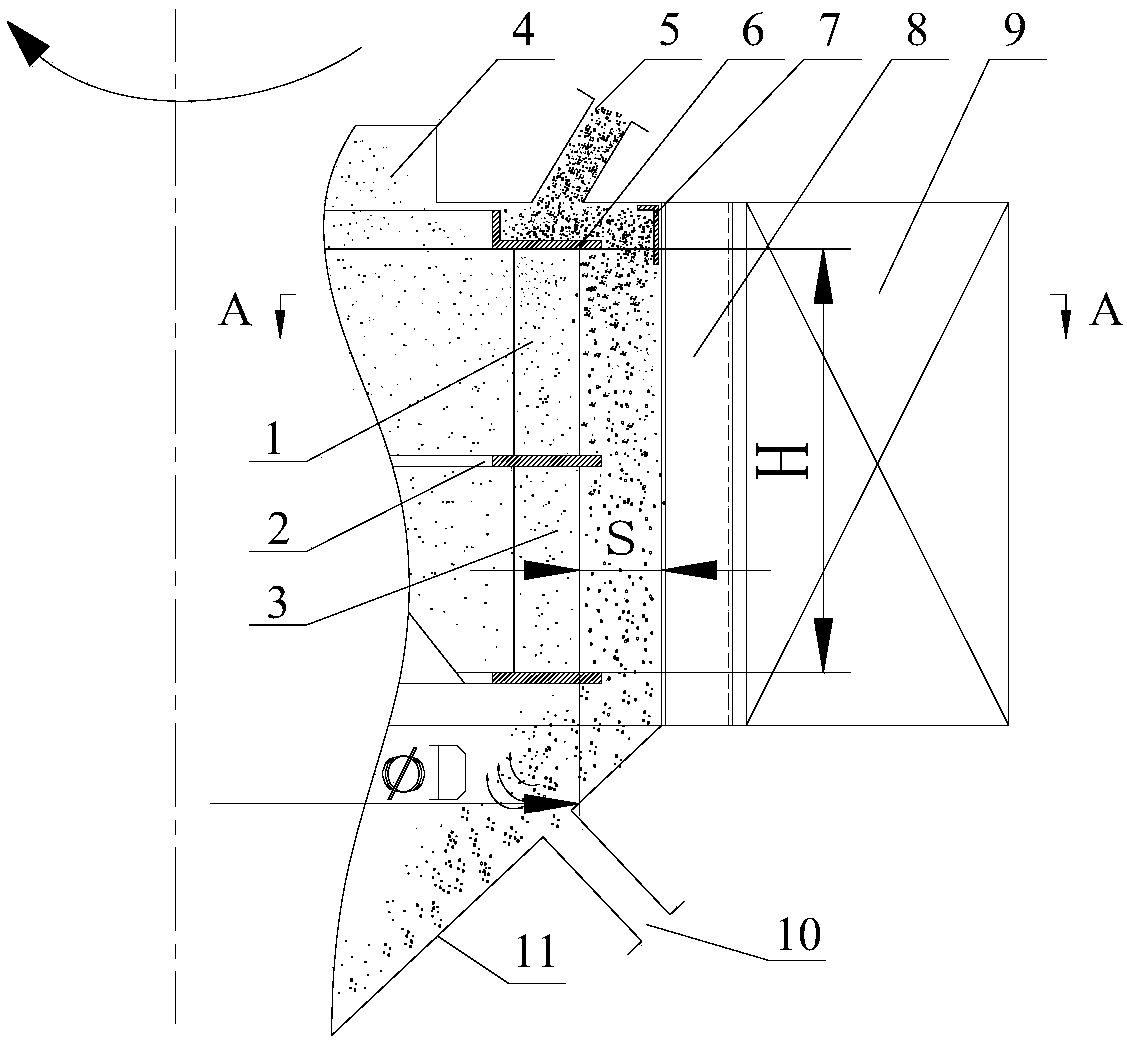

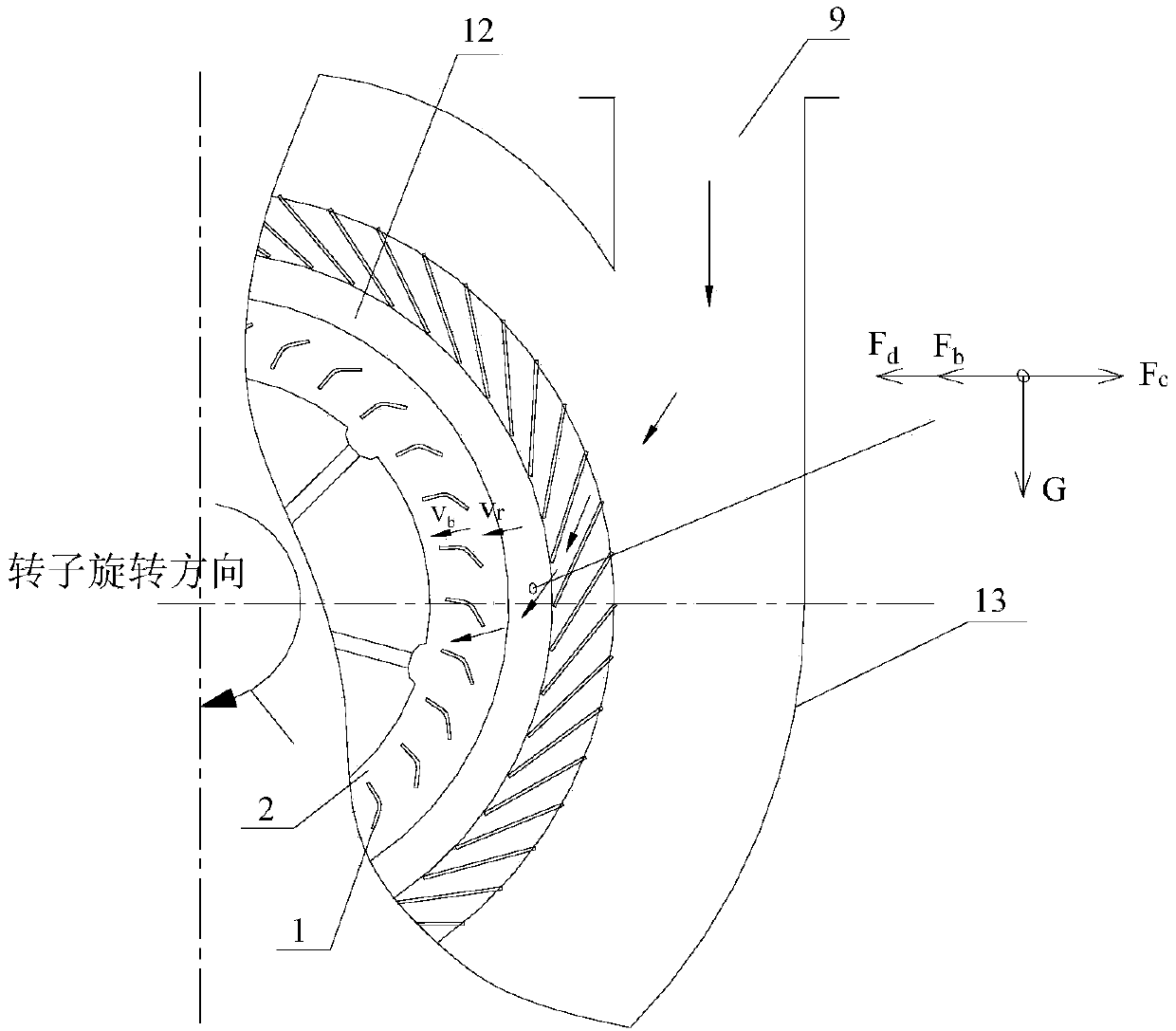

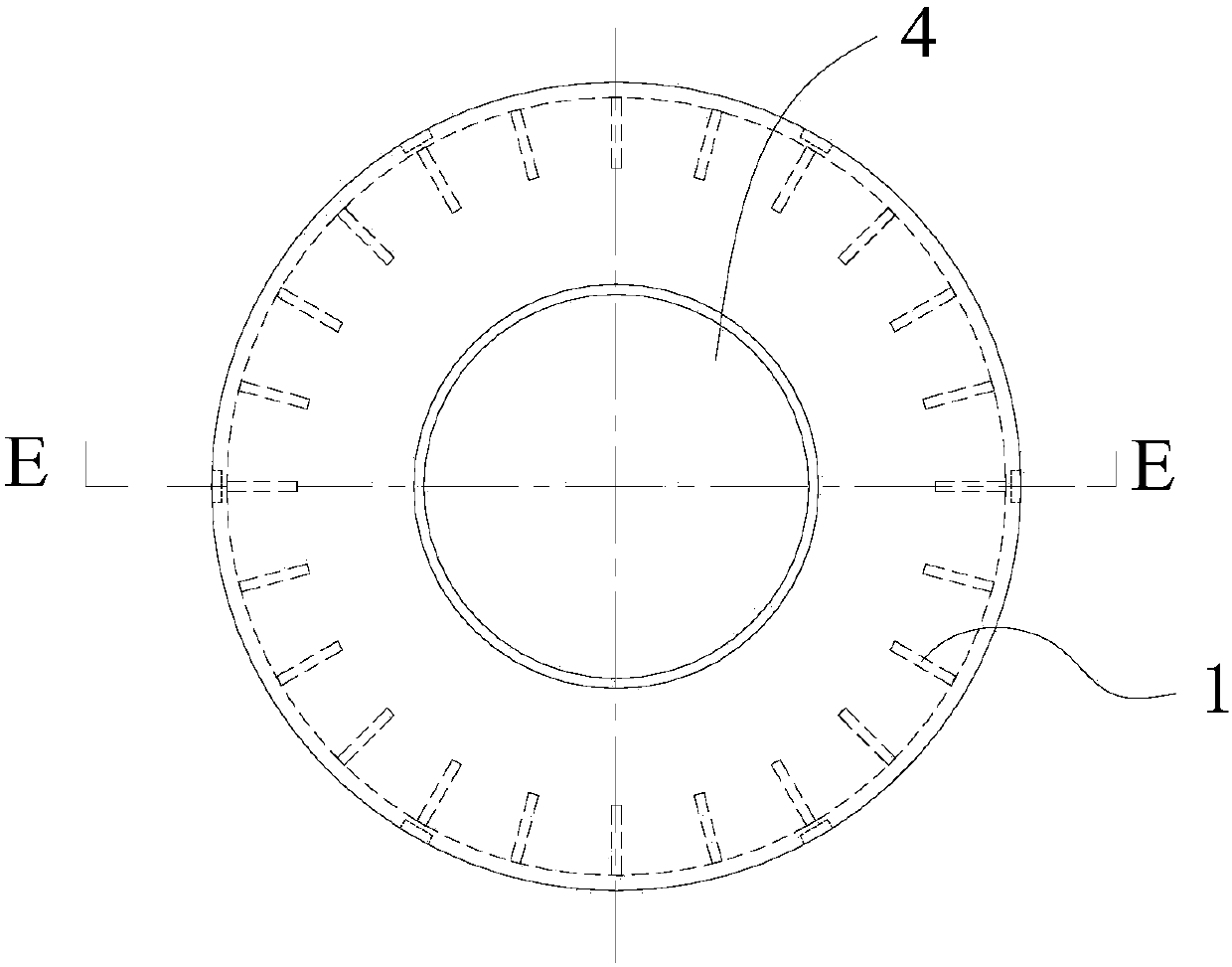

Radial efficient powder selecting machine and design method of powder selecting machine

PendingCN107913849AReduce resistanceImprove powder selection efficiencyGas current separationMechanical engineeringIndustrial engineering

The invention relates to a radial efficient powder selecting machine. The radial efficient powder selecting machine comprises a powder selecting machine shell, a finished product outlet formed in theupper part of the powder selecting machine, an intake port and a feed port connected to the powder selecting machine shell, a thick powder collecting cone positioned at the lower end of the powder selecting machine shell, a powder selecting machine rotor mounted in the powder selecting machine shell, movable blades arranged above and below the powder selecting machine rotor, and static blades mounted on the powder selecting machine shell and opposite to the movable blades; the movable blades comprise outer wind fin sections and inner wind fin sections; and the outer wind fin sections and the inner wind fin sections are in arc transition. The invention further provides the radial efficient powder selecting machine and a design method of the powder selecting machine. The technical effects ofthe radial powder selecting machine synthesize CFD theoretical analysis, laboratory tests and industrial application production data, and mainly embody on such aspects as low resistance, high powderselecting efficiency and high selecting clearness.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Preparation method of metallic oxide coated battery cathode material

InactiveCN106848321AFully contactedControl particle size distributionCell electrodesMetalMaterials science

The invention relates to a preparation method of a metallic oxide coated battery cathode material. The preparation method comprises the steps as follows: a cathode material substrate is coated with a coating liquid in an air-stream mill in an impinging stream manner, and a coated material precursor is obtained; the obtained coated material precursor is sintered and the metallic oxide coated battery cathode material is obtained. According to the preparation method, the battery cathode material is coated with a metallic oxide in the impinging stream manner by the aid of air-stream mill equipment, the coating rate and coating uniformity of the metallic oxide are increased, meanwhile, the coating process is controlled by adjusting parameters of the air-stream mill, and the preparation method is simple and can be applied to industrial production.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

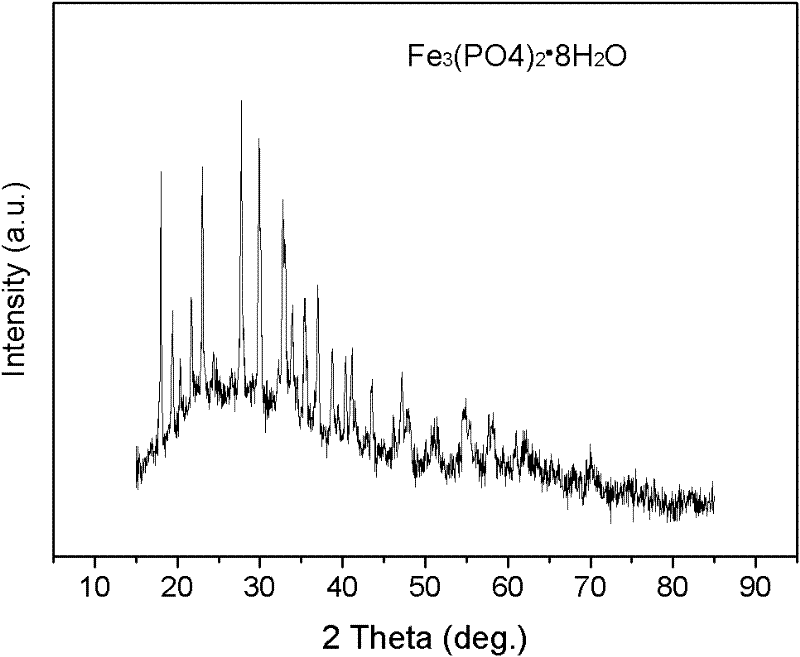

Method for preparing lithium iron phosphate by hydrothermal method and lithium iron phosphate prepared by method

PendingCN105529439AEasy to prepareInhibit particle growthCell electrodesWater soluble polymersWater soluble

The invention discloses a method for preparing lithium iron phosphate by a hydrothermal method and the lithium iron phosphate. The method disclosed by the invention comprises the following steps: only adding a lithium source, an iron source, a phosphorus source and a natural neutral water-soluble polymer to a reaction system solution; and filtering the reaction system solution after the reaction system solution reacts in a reaction kettle, so as to obtain an LiFePO<4> product. According to the method disclosed by the invention, a traditional surfactant and a strongly organic reducing substance are replaced with the natural neutral water-soluble polymer, the shape and form, the particle size and the particle size distribution of a lithium iron phosphate product can be simply and effectively controlled; impurities caused by oxidation of ferrous iron at a high temperature can also be prevented; the pH value of a reaction system is not affected by the neutral water-soluble polymer; the reducing substance formed by cracking at the high temperature also plays a role in inhibiting particle growth; and the production quality of the lithium iron phosphate is improved. With the lithium iron phosphate as a cathode material for a lithium-ion battery, the specific discharge capacity is high; the cycle performance is good; and a foundation is laid for application of the lithium-ion battery in the field of an industrial large battery.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

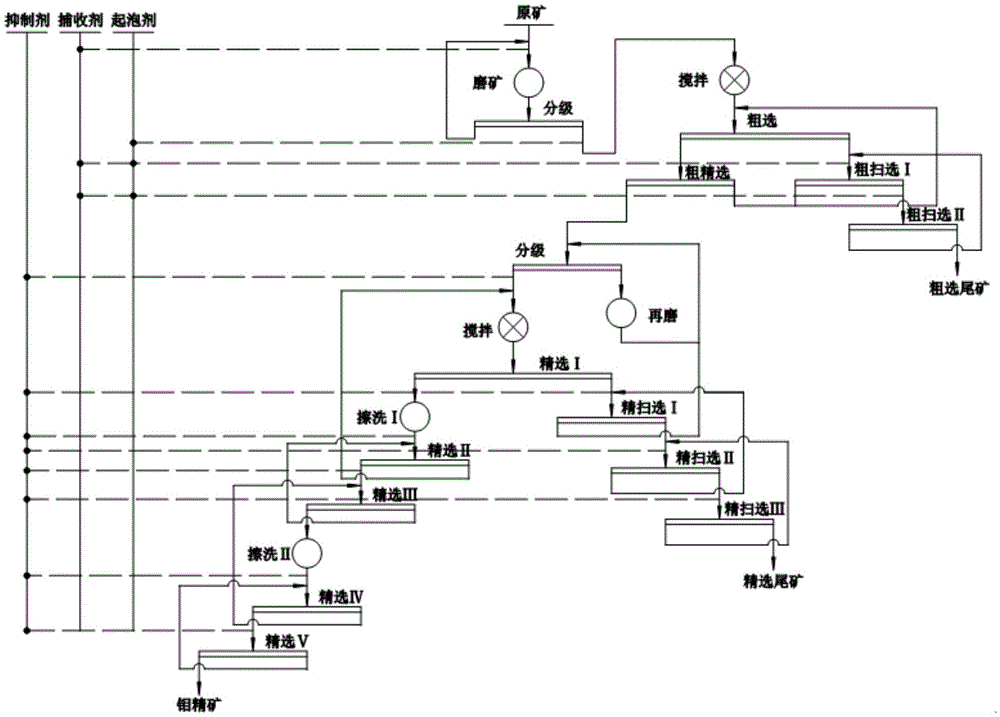

Process for separating molybdenum from lead in high-lead molybdenum ore

InactiveCN105597945AEnhanced inhibitory effectControl flotation speedFlotationGalenaMaterials science

The invention discloses a process for separating molybdenum from lead in high-lead molybdenum ore. The process comprises the following step: performing primary classification on crude ore after primary grinding. The process further comprises the following steps: firstly, feeding overflow of primary classification into a flotation machine or a flotation column for roughing so as to obtain rougher foams and rougher tailings, and adding a phosphorus-Nokes inhibitor into roughing; secondly, feeding the rougher tailings into the flotation machine for primary rough scavenging; thirdly, feeding the tailings after primary scavenging into the flotation machine for secondary rough scavenging; fourthly, performing rough concentration on the rougher foams so as to obtain rough concentrate, feeding the rough concentrate into a hydrocyclone for secondary classification, regrinding the bottom flow after secondary classification, and feeding back to the hydrocyclone for reclassification; fifthly, concentrating the overflow after secondary classification. As the phosphorus-Nokes is added into the roughing operation to pre-inhibit galena, a remarkable galena inhibition effect can be achieved, technical indexes such as the rough concentrate molybdenum recycling rate and the yield are equivalent to those of an original process, and no adverse effect can be caused to concentration.

Owner:JINDUICHENG MOLYBDENUM CO LTD

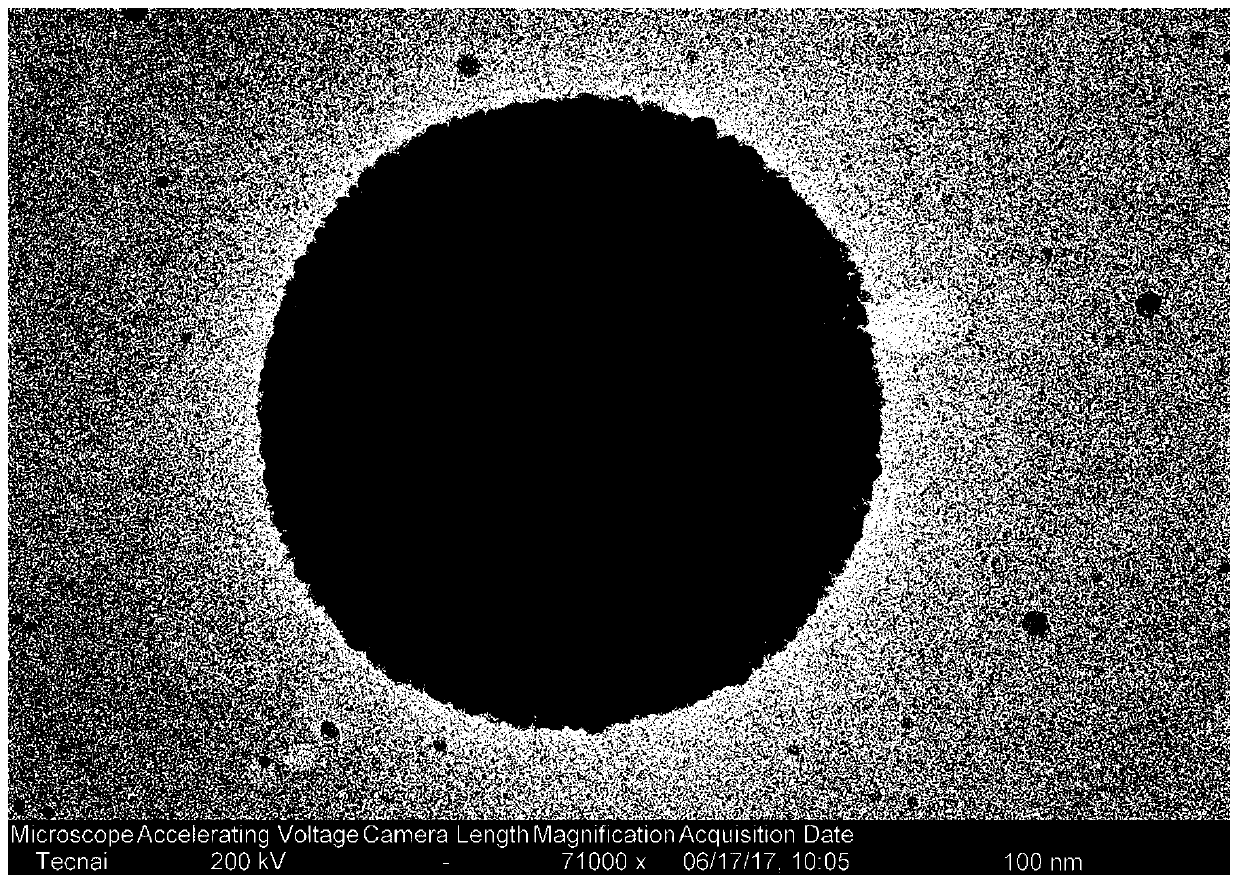

Method for preparing large batch of binary superlattice emulsion balls

InactiveCN110316696AEasy to separateOvercoming the inability to scale up mass productionSpecific nanostructure formationMaterial nanotechnologyEmulsionNanoparticle

The invention provides a method for preparing a large batch of binary superlattice emulsion balls. The method includes: by pyrolysis, preparing a series of monodisperse and size-adjustable inorganic colloid nanocrystalline particles with organic molecular ligands on surfaces, and by an emulsion assembling method, directly preparing a large batch of the binary superlattice emulsion balls which areordered in height and are provided with single structures. The method is simple and high in repeatability, conditions for the method are easy to control, large-scale production can be realized, the problem of multiphase coexistence during binary superlattice preparation can be solved effectively, and the method also can be applied to assemblies of various inorganic nanometer particles and is highin universality. The prepared binary superlattice material is widely applied to energy storage and transformation, biological marking and imaging, photoelectric devices and the like.

Owner:FUDAN UNIV

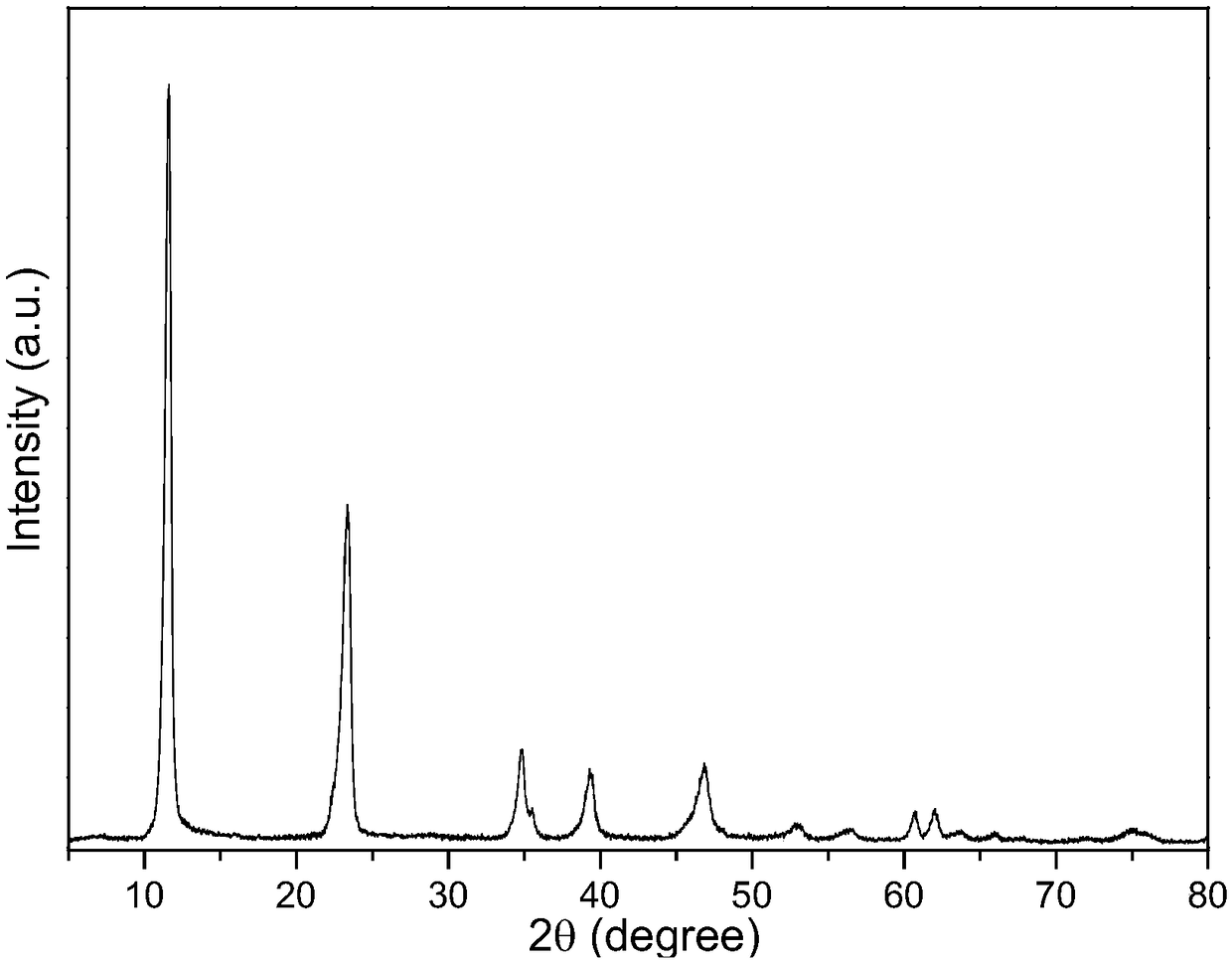

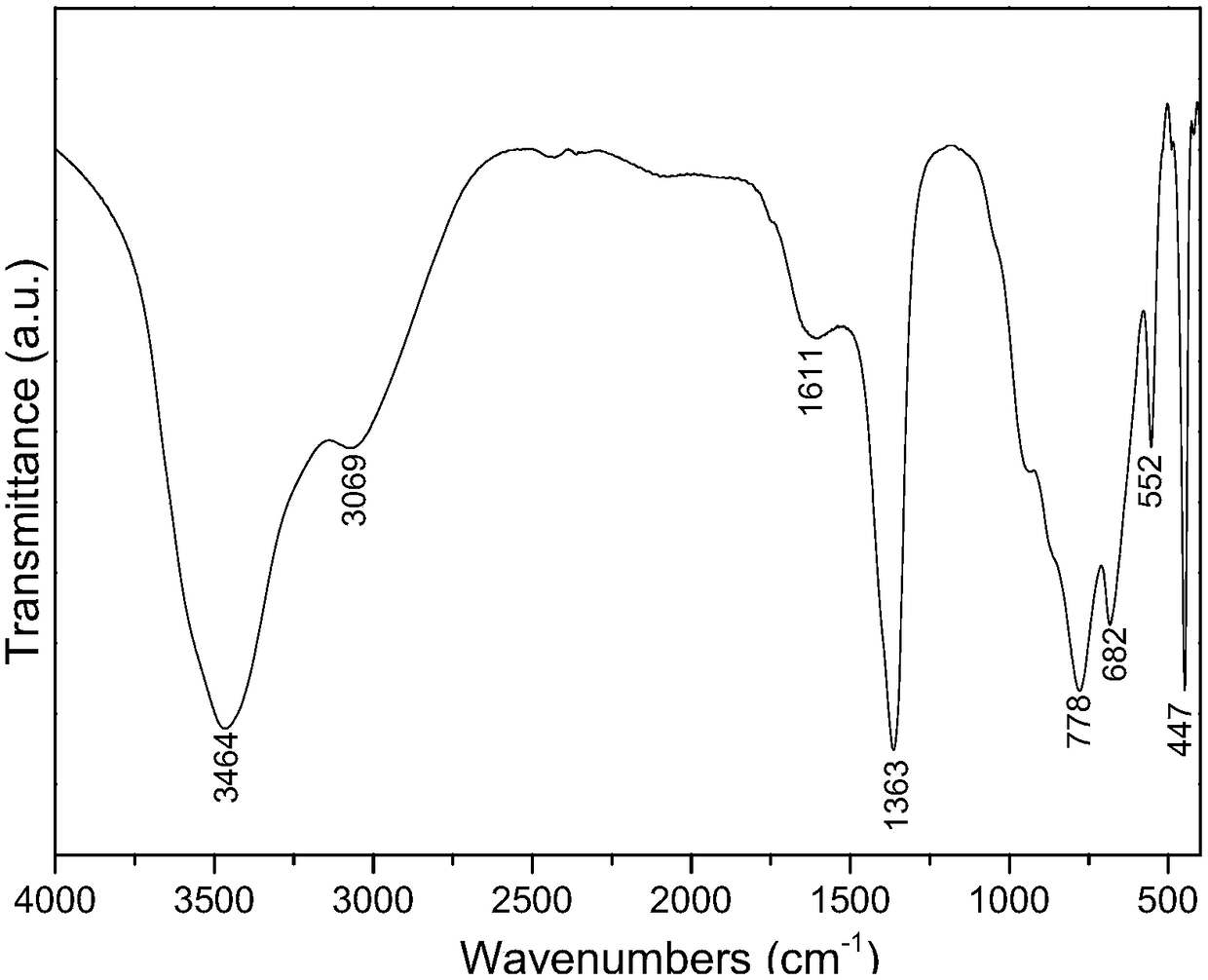

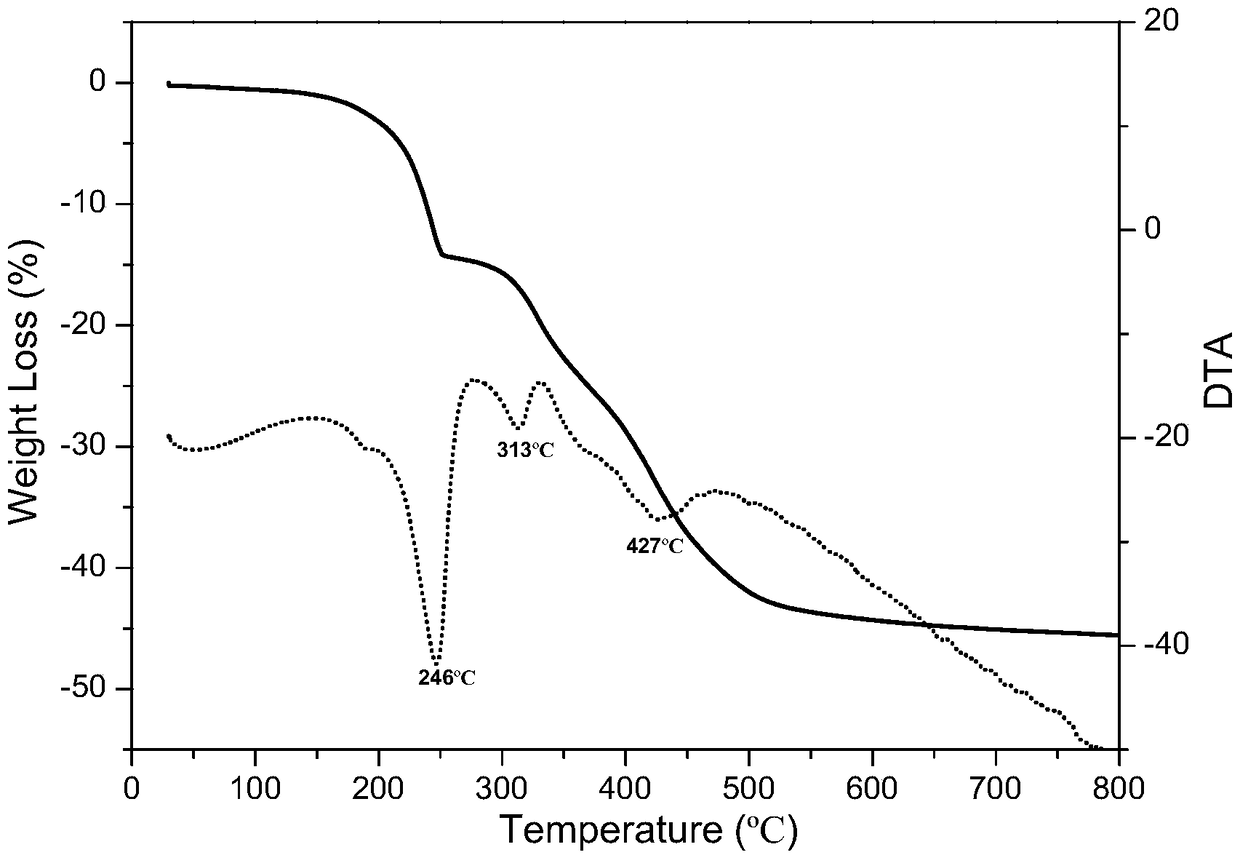

Preparation method for carbonate type hydrotalcite compound powder

InactiveCN108946773AControl particle size distributionHigh reactivityAluminium-carbonate compoundsCobalt compoundsUltrasonic assistedDivalent metal

The invention provides a preparation method for carbonate type hydrotalcite compound powder. The method comprises the following steps: taking divalent metal oxide or hydroxide and trivalent metal hydroxide as main raw materials; compounding with divalent metal carbonate (normal salt or subcarbonate) of the same metal of the divalent metal oxide or hydroxide, for supplying carbonate; directly compounding the hydrotalcite compound with regular structure and uniform grain size through one-step ultrasonic-assisted hydrothermal reaction. The preparation method belongs to atom economy reaction; thereaction speed is high; no waste is discharged during the process; the product can be directly dried without washing, so that water resource can be greatly saved; the method has the characteristics ofsimple technological process, environmental protection and easiness in industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

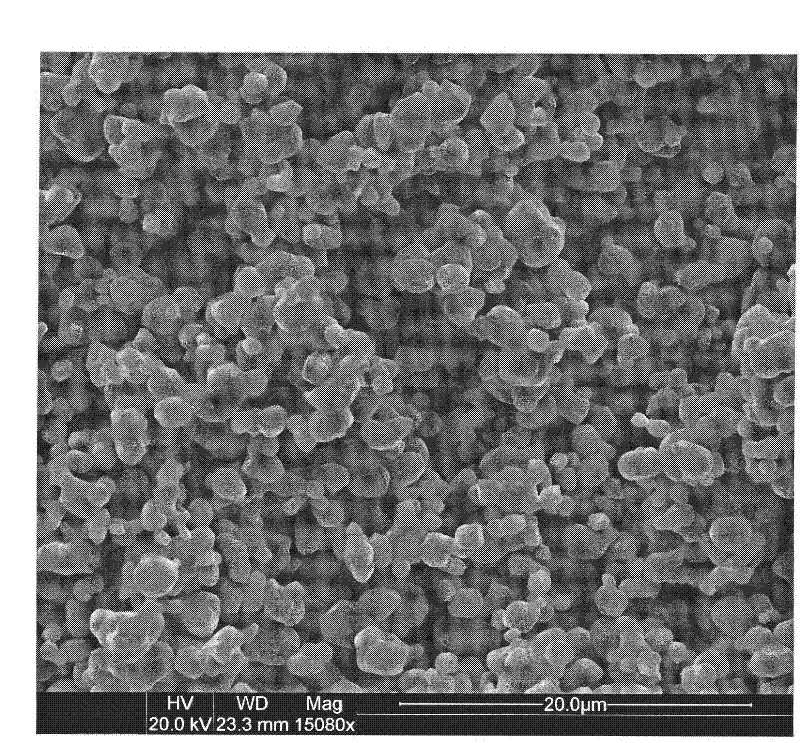

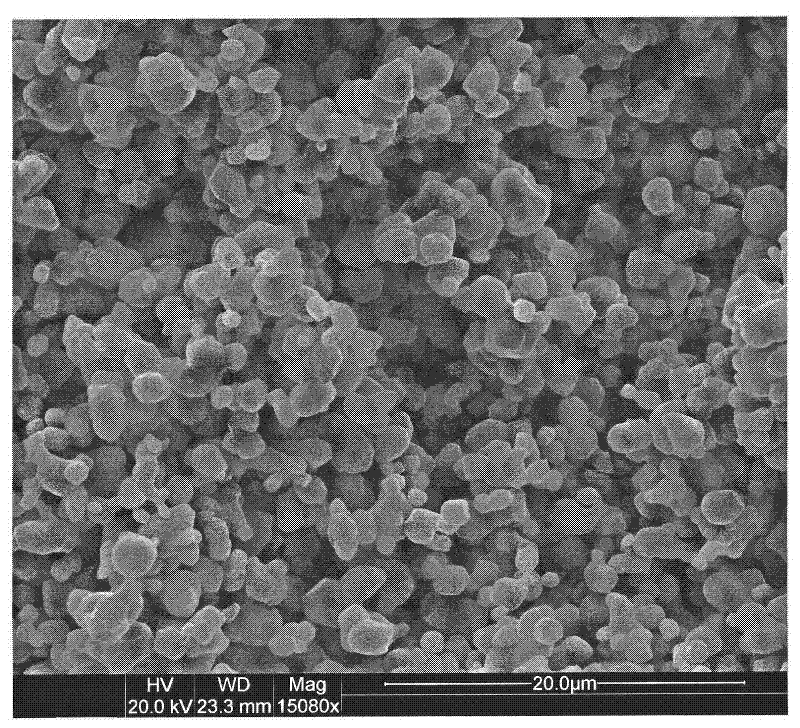

Preparation method of ferronickel-based alloy spherical powder for 3D printing

ActiveCN111570812AReduced propensity to formDrop high temperature stretchAdditive manufacturing apparatusTransportation and packagingChemical compositionMetal sphere

The invention discloses a preparation method of ferronickel-based alloy spherical powder for 3D printing. The preparation method comprises the following steps that 1) burdening is conducted by using the following chemical composition proportion of, in percentage by mass, 44.77%-51.5% of Ni, 18%-20% of Fe, 21.0%-22.5% of Cr, 1.0%-2.0% of Co, 8.0%-9.5% of Mo, 0.5%-1.0% of W, 0%-0.02% of C, 0%-0.01%of Mn and 0%-0.2% of Si; 2) the ingredients in the step 1) are prepared into an alloy ingot by adopting a vacuum induction melting horizontal continuous casting process, a shrinkage cavity defect at the head of the alloy ingot is removed, and then the alloy ingot is machined into an electrode bar; 3) the electrode bar in the step 2) is placed in a plasma rotating electrode powder making machine toform metal spherical powder; and 4) the prepared metal spherical powder is screened by adopting an ultrasonic vibrating screen under the protection of high-purity argon to obtain the ferronickel-based alloy spherical powder for the 3D printing.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

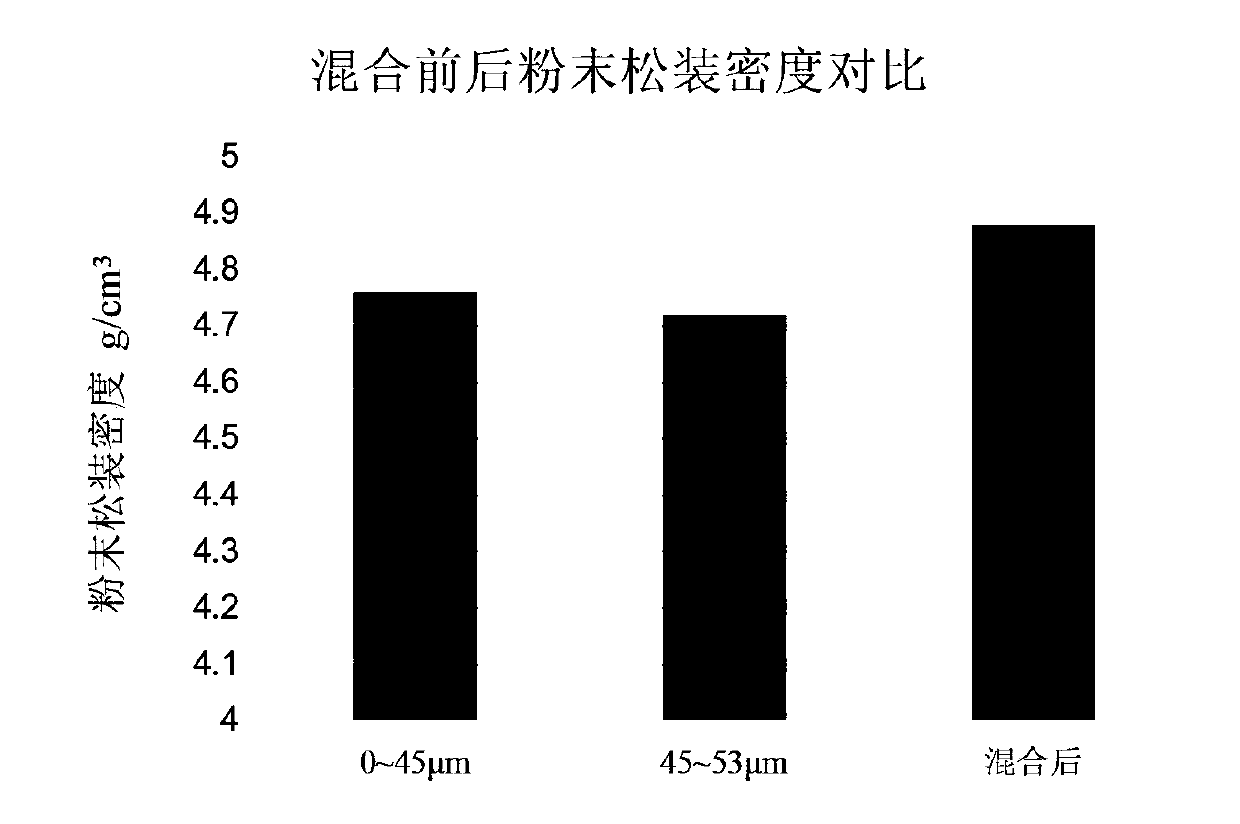

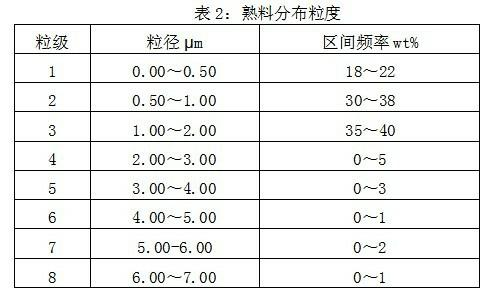

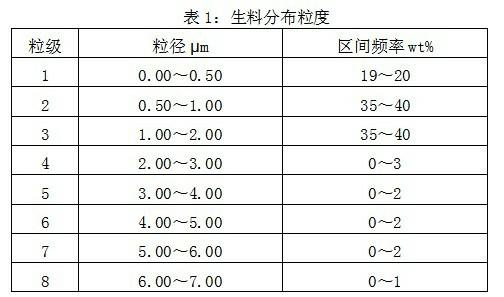

Preparation method of calcined kaolin with high oil absorption

ActiveCN102491356AControl break-up particle size distributionControl particle size distributionSilicon compoundsDepolymerizationGranularity

The invention discloses a preparation method of calcined kaolin with high oil absorption. According to the preparation method, coal-series kaolinite or kaolin undergoes screening, ore washing, crushing, milling, grinding and spray drying to obtain a raw material. the raw material undergoes depolymerization, breaking and calcining to obtain a clinker. And finally the clinker undergoes depolymerization and breaking. By the adoption of the preparation method, the calcined kaolin with its oil absorption being greater than 100ml / 100g can be obtained by proportioning fine raw ore, optimizing, depolymerizing and breaking the raw material, controlling loose unit weight of the raw material, controlling the broken particle size distribution of the raw material, controlling the calcining condition, controlling loose unit weight of the clinker, controlling the particle size distribution of the clinker and the like. There is no need to add a medicament during the preparation process. The product residue on sieve will not exceed standard. The product obtained has no corrosion, has low viscosity, and is easy to disperse in a solution.

Owner:唐山麦迪逊高岭土股份有限公司

Preparation method of calcined kaolin with low abrasion value

InactiveCN102862995AOptimizing the wet grinding processControl break-up particle size distributionSilicon compoundsSolid contentWet grinding

The invention discloses a preparation method of calcined kaolin with a low abrasion value. Coal-series kaolin rock or kaolin is screened, washed, smashed, ground, wet-ground and dried to obtain raw materials, the raw materials are depolymerized, scattered and calcined to generate mature materials, and finally the mature materials are depolymerized and scattered to generate finished products. The coal-series kaolin rock or kaolin is coal-permian concomitant coal-series kaolin rock or kaolin, and molar ratio of silicon to aluminum is SiO2 / Al2O3=1.9-2.1. Solid content of wet grinding mud is 42-50%, mud particle size (-2mu,%)>=93%, D50=0.3-0.8mu m. The particle size of the depolymerized and scattered raw materials is (-2mu,%)>=91.5%, D50=0.4-0.9mu m. By matching raw ore scientifically, optimizing raw material wet grinding process and controlling raw material scattering particle size distribution, a raw material abrasion value is controlled effectively, and the calcined kaolin with a low Einlehner abrasion value is obtained. Drug is not required in a preparation process, operation is convenient, cost is low, performance of product whiteness and covering power and the like can not be affected, and obtained products are easy to diffuse in a solution.

Owner:唐山麦迪逊高岭土股份有限公司

Preparation method of novel lithium ion battery cathode material

InactiveCN107293731AHigh purityControl particle size distributionCell electrodesSecondary cellsFreeze-dryingSolvent

The invention discloses a preparation method of a novel lithium ion battery cathode material. The method includes the following steps: 1) producing lithium carbonate; 2) mixing a cobalt salt with a complexing agent, adding the mixture as well as a precipitator into a reactor, performing a reaction to produce a solid, and sintering the solid with the lithium carbonate to prepare a lithium cobalt oxide material; 3) mixing deionized water and ethylene glycol, as solvents, with graphene oxide to obtain a graphene oxide dispersant, adding the self-made lithium cobalt oxide material, and performing ultrasonic treatment to obtain a mixed dispersant; 4) dropping the mixed dispersant to a receiving solution, of which temperature is controlled by a low-temperature freeze bath, successively performing freeze-drying and vacuum-drying to obtain a solid, adding the solid to a crosslinker solution for treatment, and treating the solid in a hydrazine hydrate solution; 5) drying the solid to prepare the lithium ion battery cathode material. The lithium ion battery cathode material has high stability, large specific capacity and excellent rate capability and cycle performance.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

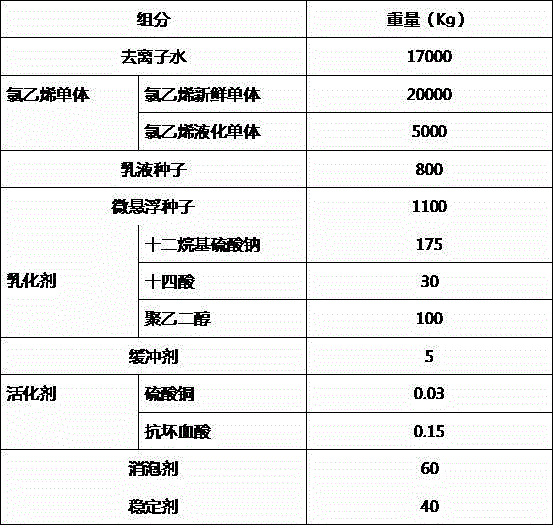

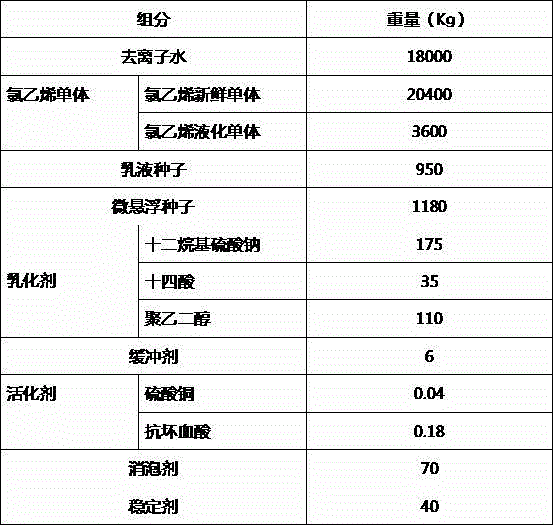

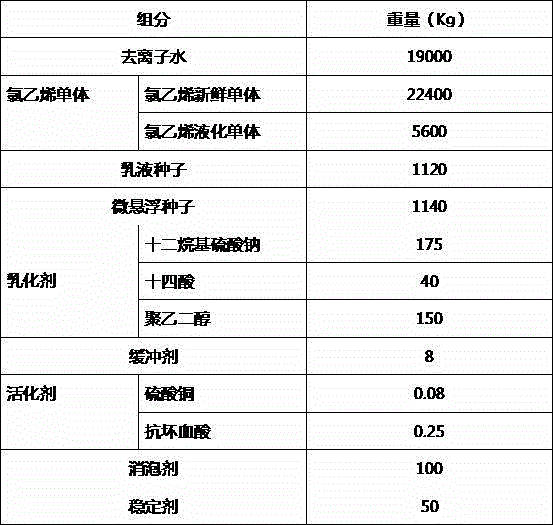

Low-viscosity high-foaming type polyvinyl chloride paste resin PB110-3 and production method thereof

The invention discloses low-viscosity high-foaming type polyvinyl chloride paste resin PB110-3 and a production method of the low-viscosity high-foaming type polyvinyl chloride paste resin PB110-3. The paste resin is prepared by, by weight, 17000-19000 parts of deionized water, 23000-28000 parts of vinyl chloride monomer, 690-1120 parts of emulsion seeds, 920-1400 parts of microsuspension seeds, 0.17-0.33 part of activating agents, 290-365 parts of emulsifying agents, 20-50 parts of stabilizing agents, 50-100 parts of antifoaming agents and 5-8 parts of buffering agents, wherein the temperature of the deionized water ranges from 40 DEG C to 60 DEG C, the vinyl chloride monomer is composed of vinyl chloride fresh monomer and vinyl chloride liquid monomer, the vinyl chloride liquid monomer accounts for 10% to 20% total quantity of the vinyl chloride monomer, the weight of the emulsion seeds is 3% to 4% total quantity of the vinyl chloride monomer, and the weight of the microsuspension seeds is 4% to 5% total quantity of the vinyl chloride monomer. The low-viscosity high-foaming type polyvinyl chloride paste resin PB110-3 and the production method make up for the blank in the technical field of a low-viscosity high-foaming effect of the polyvinyl chloride paste resin PB110-3, and the application range of the paste resin is enlarged.

Owner:ANHUI TIANCHEN CHEM

Supersonic atomizer for preparing iron-based spherical metal powder through crucible gas atomization method

The invention discloses a supersonic atomizer for preparing iron-based spherical metal powder through a crucible gas atomization method, and relates to the field of metal powder material preparation.The supersonic atomizer comprises a crucible, a plunger, an upper cover, a liquid guide pipe, a lower cover, gas feeding holes, a gas cavity and a Laval type circular seam; the liquid guide pipe is installed at the center of the upper cover, and the lower cover is arranged under the upper cover; the two gas feeding holes are oppositely formed in the side face of the lower cover; the gas cavity isdefined by the upper cover and the lower cover in a sealed mode and communicates with the upper cover and the lower cover; the Laval type circular seam formed by the upper cover and the lower cover together with the main axis of the atomizer as the center is arranged; and the crucible is filled with molten metal, and after the plunger is removed, the molten metal enters the atomizer through the liquid guide pipe to be atomized by gas flow sprayed out of the Laval type circular seam. The supersonic atomizer has the advantages that the gas flow is uniform and consistent, the turbulence scale issmall, and no impact wave exists in the flow field.

Owner:安徽哈特三维科技有限公司

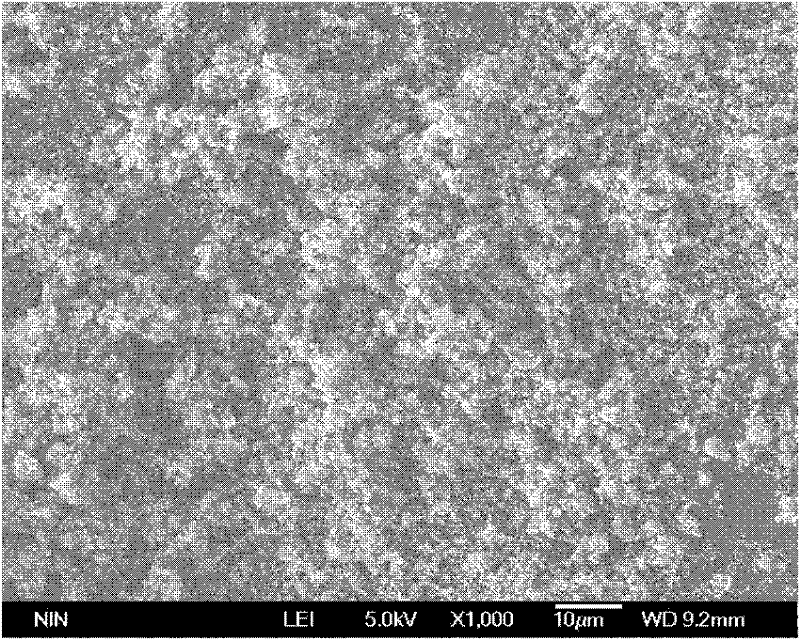

Battery-grade cobaltosic oxide preparation method

InactiveCN101913659BHigh densityHigh chemical purityCobalt oxides/hydroxidesReaction temperatureSpherical shaped

Owner:JIANGSU DONGXIN ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com