1:1 type silicate mineral doped bismuth yellow hybridization pigment and preparation method thereof

A silicate mineral, bismuth yellow technology, applied in chemical instruments and methods, inorganic pigment processing, fibrous fillers, etc., can solve the problems of color and heat resistance production cost reduction, achieve the solution of agglomeration, expand application fields, The effect of avoiding the formation of free aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

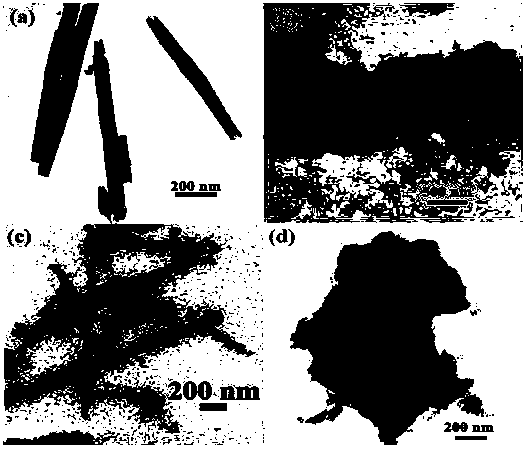

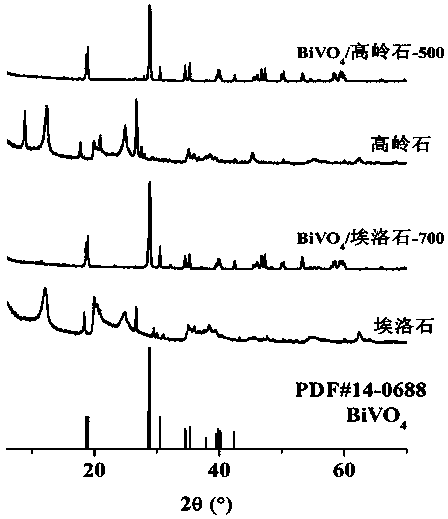

Embodiment 1

[0025] Dissolve 48.5 g of bismuth nitrate in 200 mL of 1 mol L -1 nitric acid solution, then add 100 g of dickite and stir for 1 h. Weigh 12.19 g of sodium metavanadate and dissolve in 50 mL of 1 mol L -1 Nitric acid solution, added to the bismuth nitrate solution dispersed with dickite under stirring, the pH value of the reaction system was slowly adjusted to 7.0 with sodium carbonate, stirred and reacted at room temperature for 8 h, and a yellow precipitate was obtained, which was filtered and washed. Placed directly in a muffle furnace and calcined at 300 °C for 2 h, a yellow powder bismuth yellow / dickite hybrid pigment was obtained, labeled as BiVO 4 / Dickite-300, its L*, a*, b* color values are shown in Table 1.

Embodiment 2

[0027] Dissolve 70.61 g of bismuth sulfate in 200 mL of 2 mol L -1 nitric acid solution, and then add 100 g halloysite and stir for 1.5 h. Weigh 18.39g sodium vanadate and dissolve in 50 mL 2 mol L -1Nitric acid solution, add it to the bismuth sulfate solution dispersed with halloysite under stirring, slowly adjust the pH value of the reaction system to 8.0 with potassium carbonate, stir and react at room temperature for 6 h, and obtain a yellow precipitate, which is filtered and washed Directly placed in a muffle furnace and calcined at 700 °C for 1 h, a bright yellow powder bismuth yellow / halloysite hybrid pigment was obtained, labeled as BiVO 4 / Halloysite-700, its L*, a*, b* color values are shown in Table 1.

Embodiment 3

[0029] Dissolve 31.5 g of bismuth chloride in 100 mL of 0.5 mol L -1 nitric acid solution, and then add 30 g of kaolinite and stir for 2 h. Weigh 11.70 g of ammonium metavanadate and dissolve in 50 mL of 0.5 mol L -1 Add it to the bismuth chloride solution dispersed with kaolinite under stirring, slowly adjust the pH value of the reaction system to 6.5 with sodium bicarbonate, stir and react at room temperature for 8 h, and obtain a yellow precipitate, which is After filtration and washing, the bismuth yellow / kaolinite hybrid pigment was obtained in the form of bright yellow powder, labeled as BiVO. 4 / Kaolinite-500, its L*, a*, b* color values are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com