Patents

Literature

822results about How to "Realize high value utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood fiber reinforced inflaming retarding foam material and machining method thereof

InactiveCN102061059AImprove use valueSolve the "Three Rural Issues"Chemical recyclingFirming agentSURFACTANT BLEND

The invention discloses a wood fiber reinforced inflaming retarding foam material and a machining method thereof. The composite foam material is prepared from the following components in parts by weight: 40-95 parts of foaming flame-retarded resin, 0.1-8 parts of curing agent, 0.5-8 parts of surfactant, 1-50 parts of wood fiber and 0.5-10 parts of flexibilizer. The wood fiber is treated by using a coupling agent and then dried, and the coupling agent accounts for 0.15-0.5 percent of the mass of the wood fiber. A naturally expanded foaming method or die foaming method is adopted. The wood fiber reinforced inflaming retarding foam material can be widely applied to fields of insulation of building outer wall bodies, architectural ornament, traffic vehicles, water ships, aerospace, electromechanical equipment, industrial sound absorption, heat preservation and shock absorption and the like, and is a composite foaming material with actual application value.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

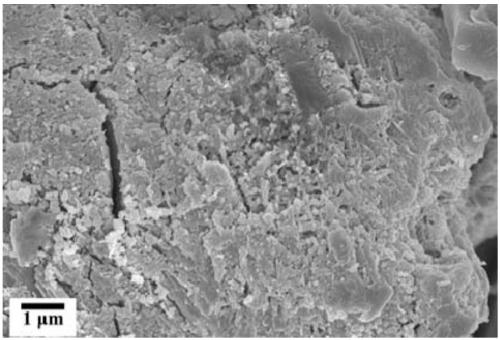

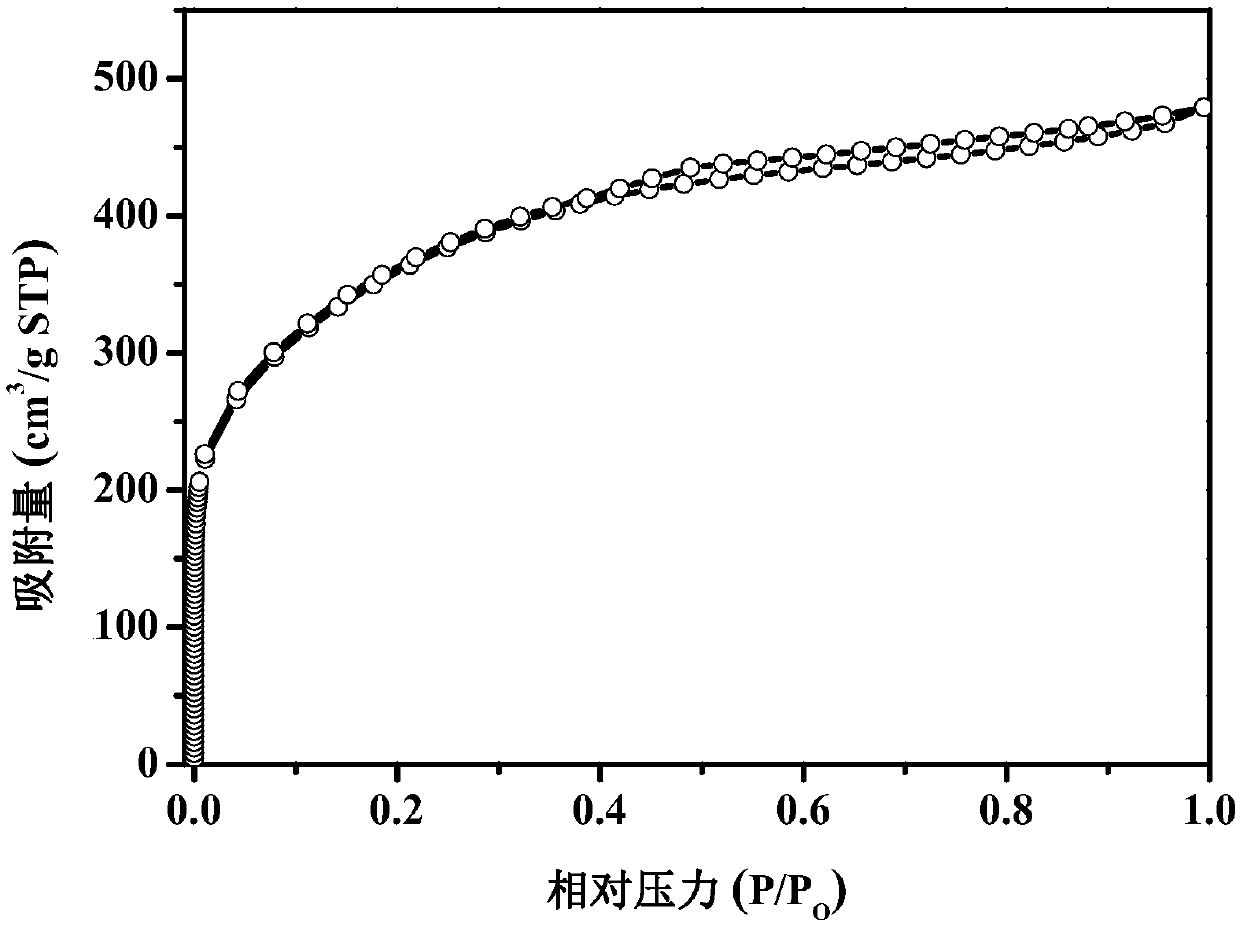

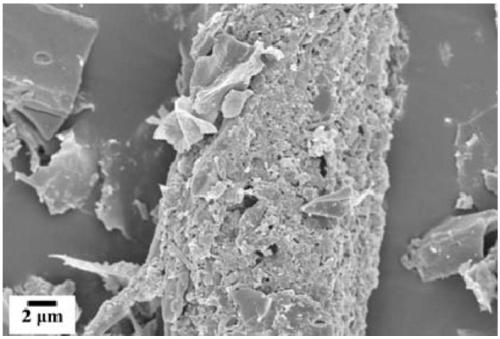

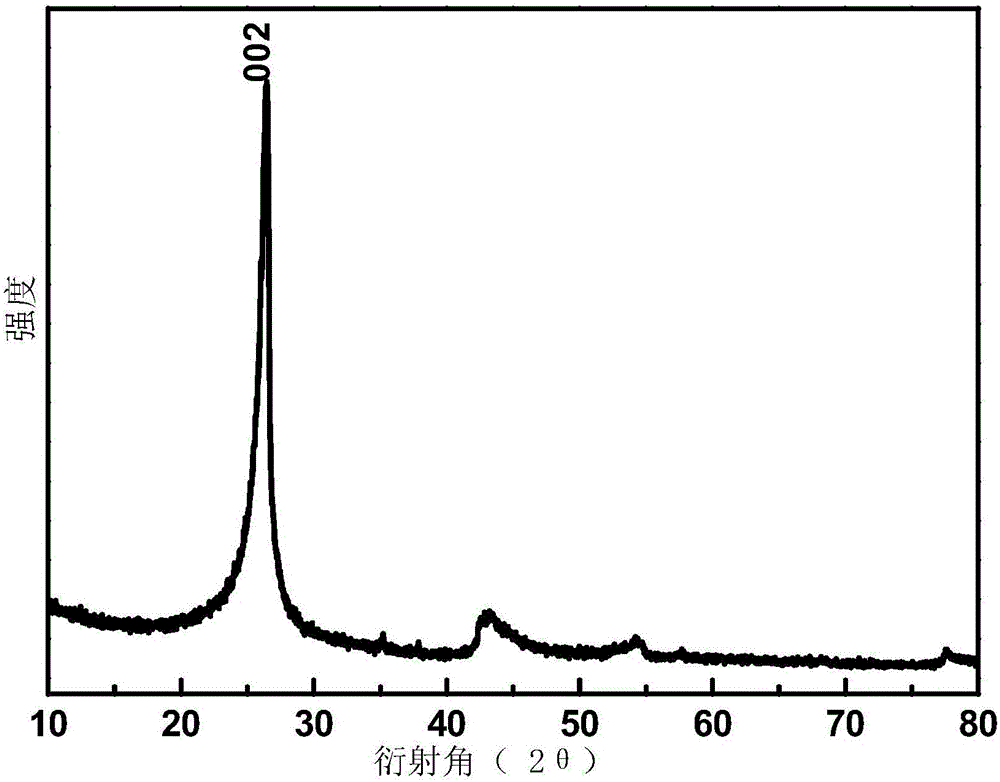

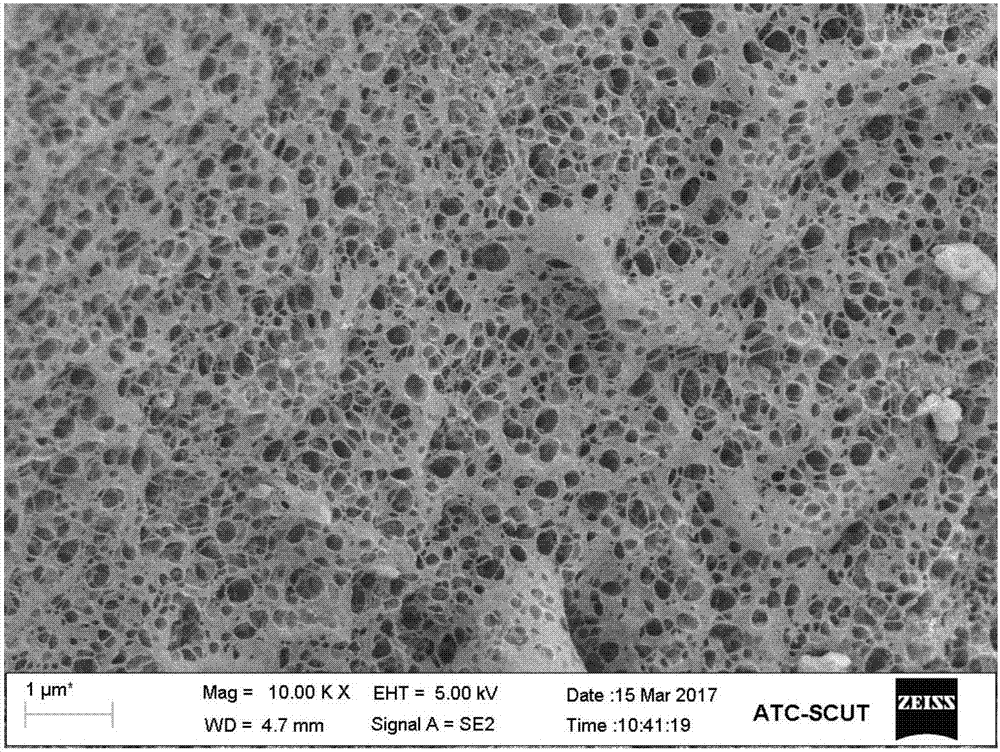

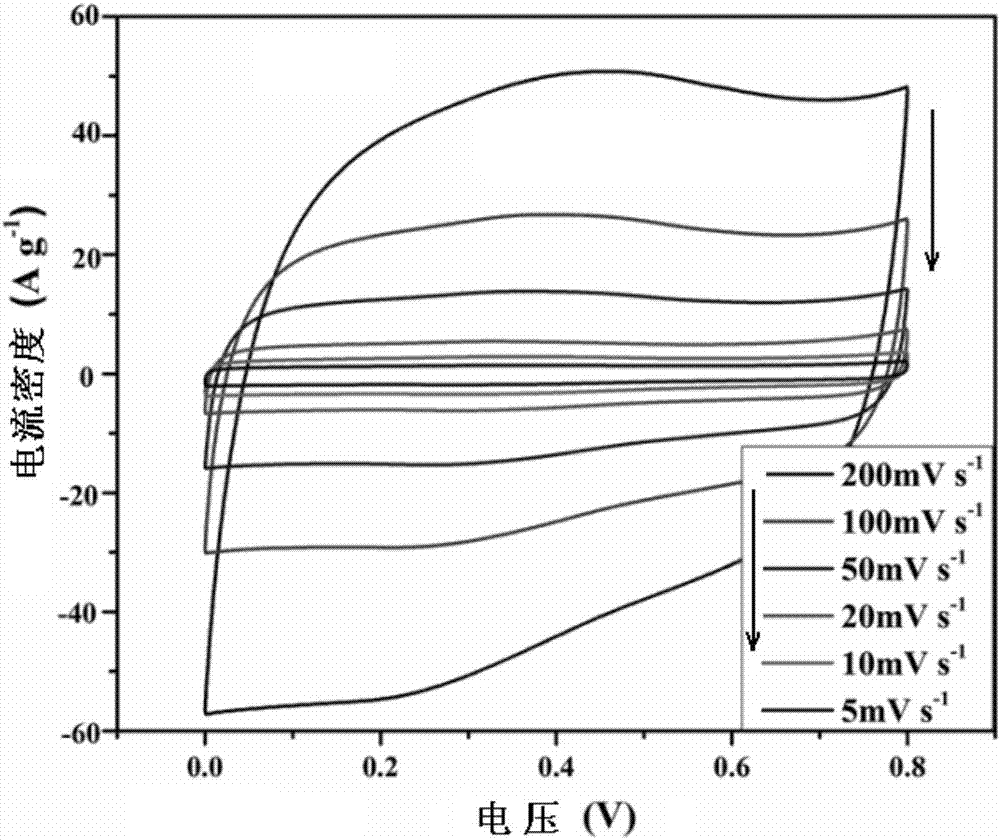

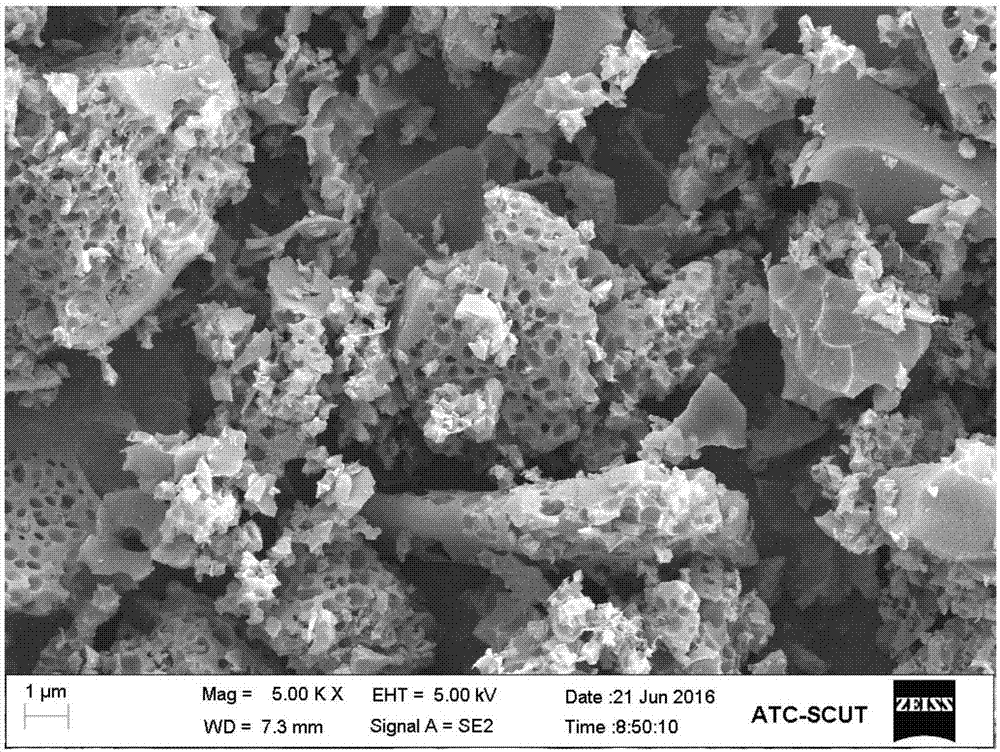

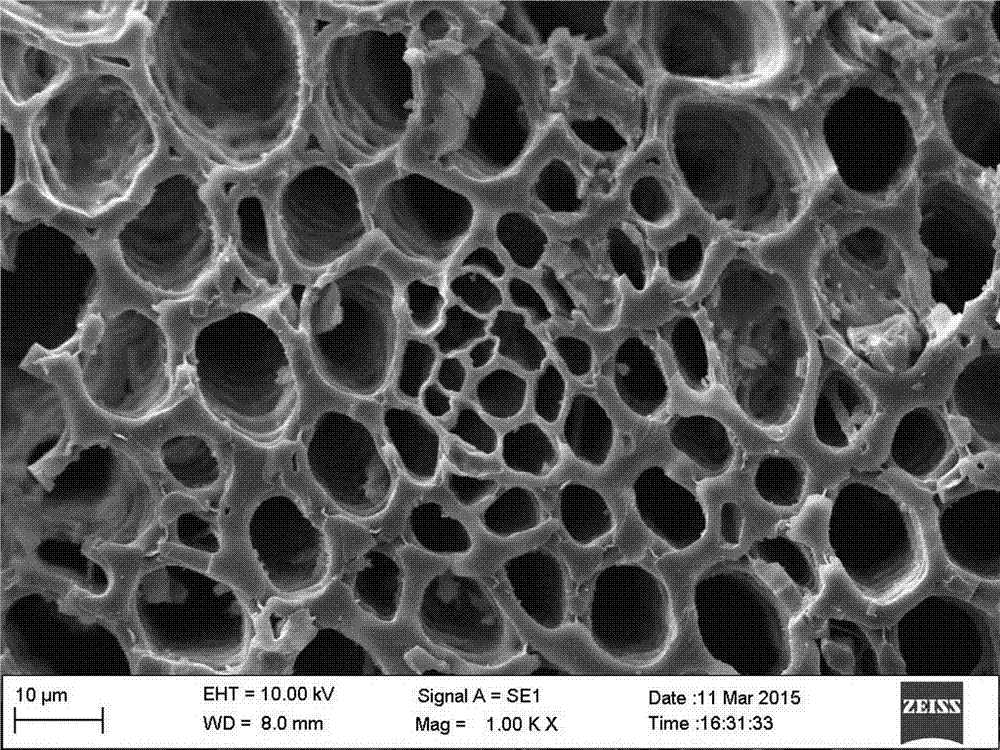

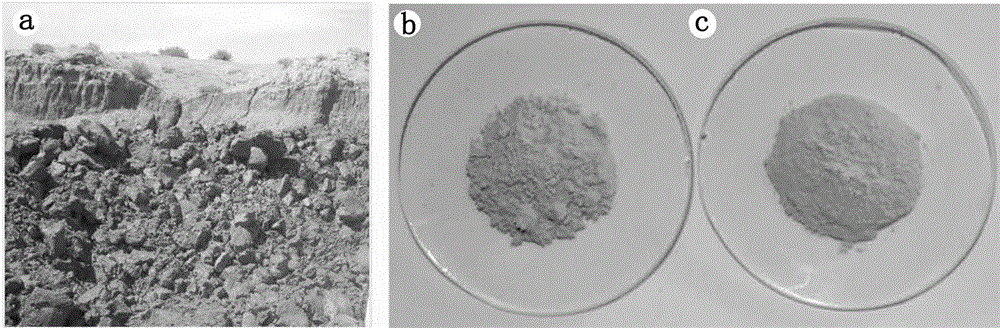

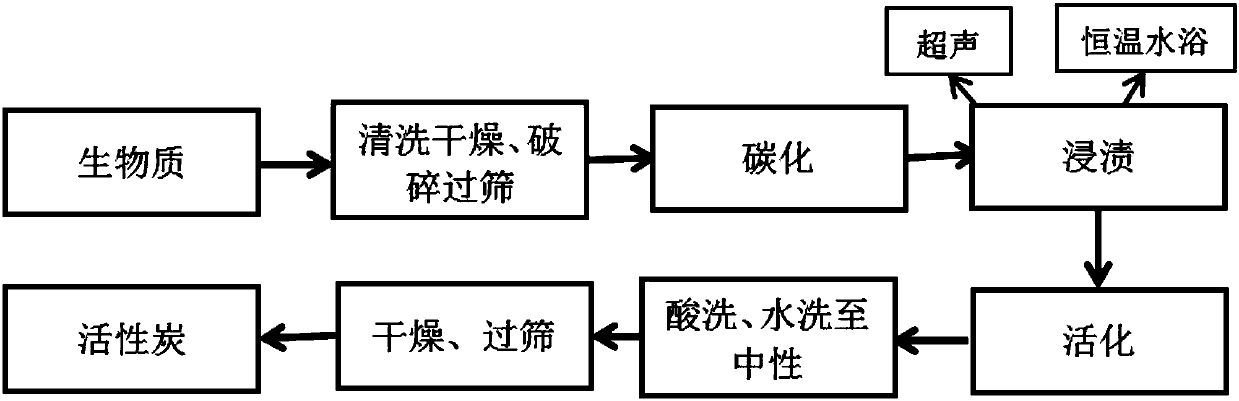

Biomass-based grading porous carbon and preparation method thereof

ActiveCN109516458ARealize high-value utilizationHigh porosityCarbon compoundsHybrid capacitor electrodesDouble saltBiomass

The invention discloses a biomass-based grading porous carbon and a preparation method thereof. The method comprises the following steps of shearing and sieving the biomass raw materials to 20 to 80 meshes; adding the materials into a double-salt system water solution; performing stirring; performing low-temperature hydro-thermal method pre-carbonization treatment for 5 to 20h at 180 to 300 DEG C;performing washing and filtering to obtain a pre-carbonization product; then raising the temperature to 600 to 1000 DEG C in inert atmosphere; performing carbonization activation treatment for 0.5 to8h; performing acid washing, alkali washing or ultrasonic treatment on the obtained product; then washing the materials by water to the neutral state; performing drying to obtain the biomass-based grading porous carbon. The hydrothermal carbonization is performed during the pre-carbonization; the double-salt system is used as a salt template and a pre-hole-forming agent; the adverse conditions are provided for the subsequent carbonization activation for preparing the porous carbon; the obtained porous carbon has high specific surface area and the loose three-dimensional connection pore passage structures; high electrical conductivity and good capacitive characters are realized; the biomass-based grading porous carbon can be applied to supercapacitors as carbon electrodes.

Owner:SOUTH CHINA NORMAL UNIVERSITY

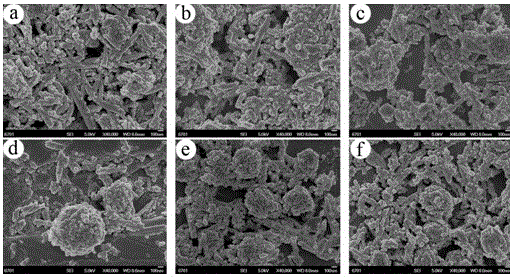

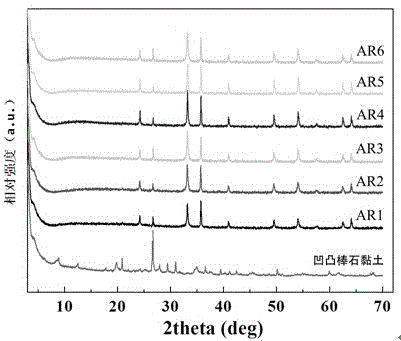

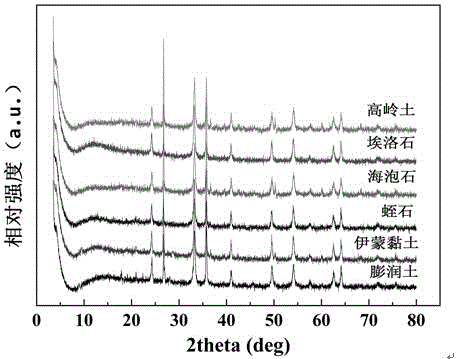

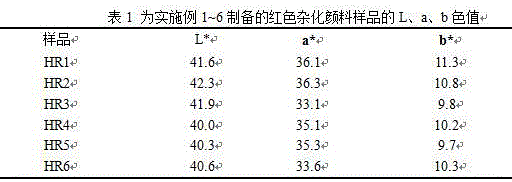

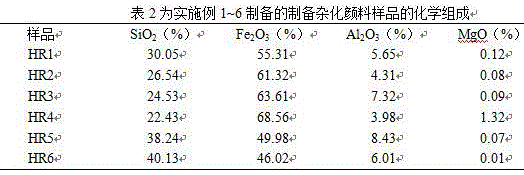

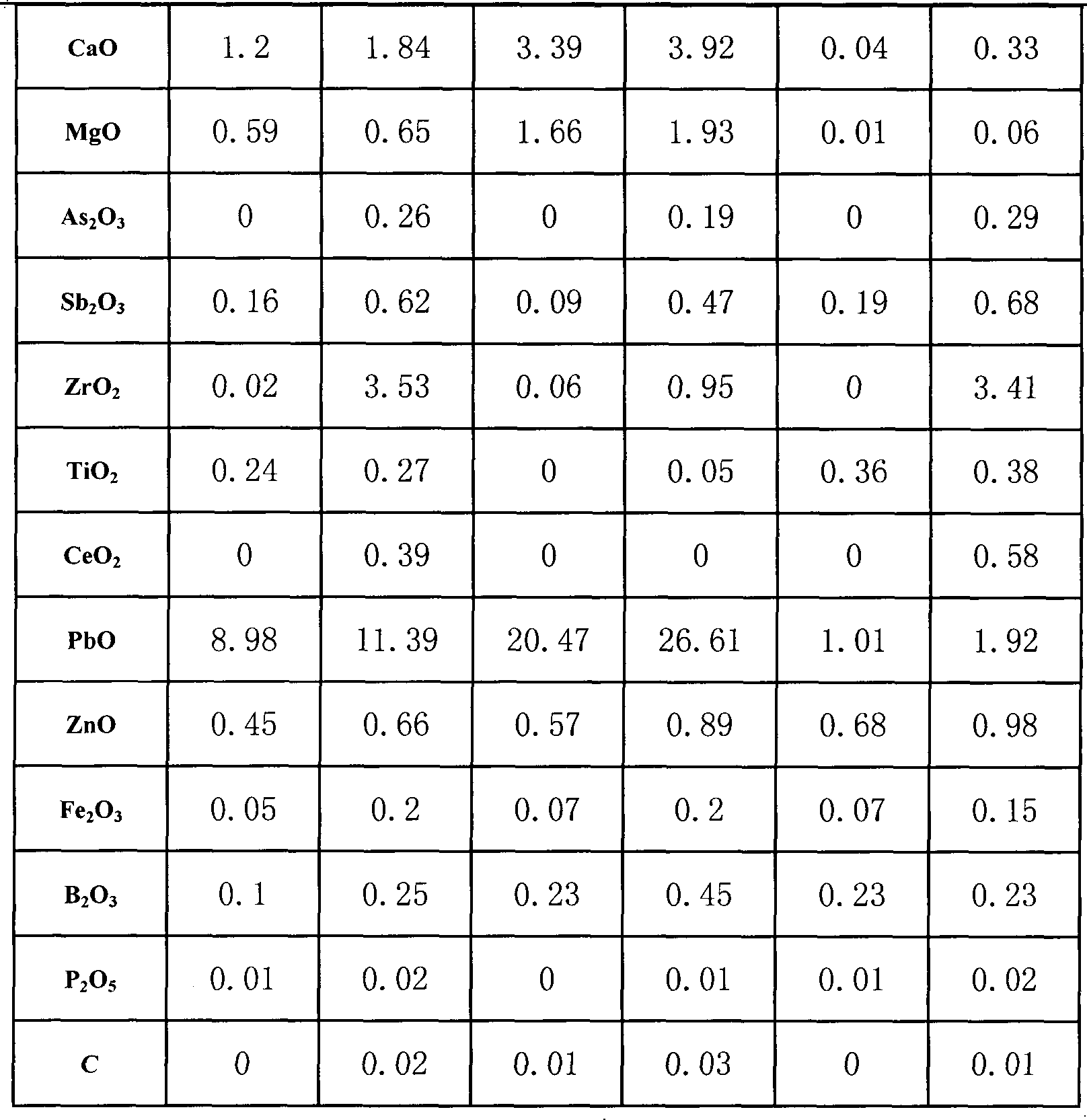

Method for preparing red hybridized pigment from red attapulgite clay

ActiveCN105802282AImprove stabilityUniform particle sizePigmenting treatmentPhysical chemistryMineralogy

The invention discloses a method for preparing red hybridized pigment from red attapulgite clay. The method comprises the following steps of: mixing pretreated red attapulgite clay ore with solid ferric salt, uniformly grinding, dispersing in water, adding an additive, stirring to disperse uniformly, performing ultrasonic treatment, further transferring into a hydrothermal reaction kettle for hydrothermal reaction, cooling to the room temperature, separating a solid product, washing, drying and crushing, thereby obtaining the red hybridized pigment. According to the method, the novel red hybridized pigment which takes silicon as a framework and is bright in color, good in stability and uniform in granularity can be prepared by virtue of the red of natural attapulgite clay self and crystal transfer of the ferric salt in the hydrothermal process, high-value utilization of the red ttapulgite clay resource is achieved, and red pigment with higher cost performance can be provided for multiple fields of pigment, paint, ceramic, restoration of cultural relics, coatings and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

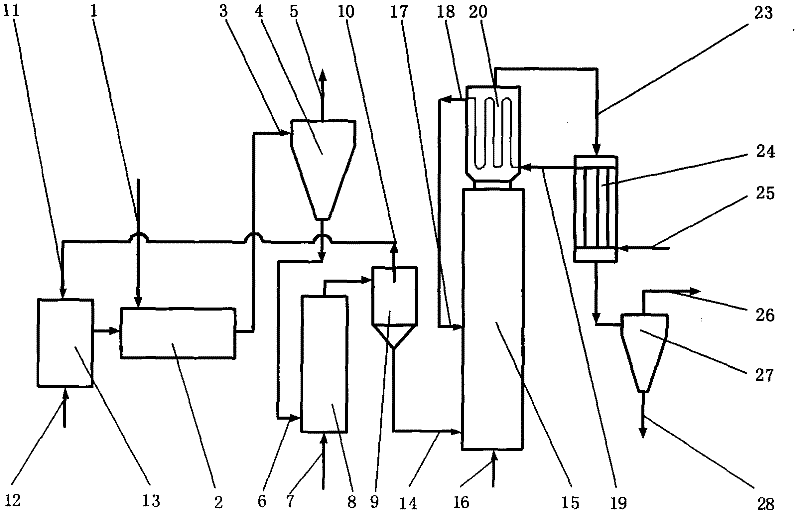

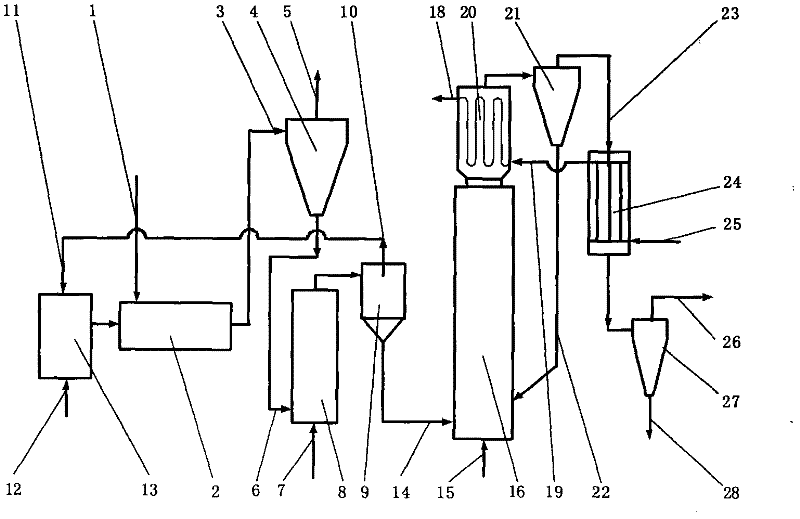

Processing method of cellulose industrial biomass waste and process device thereof

ActiveCN102311742AWide adaptabilityOvercome the disadvantages of difficult continuous processingWaste processingCarbon compoundsCellulosePorous carbon

The invention discloses a processing method and a process device of cellulose industrial biomass wastes, and the method comprises the following steps: feeding raw materials into a drying system continuously, supplying heat by high-temperature flue gas from the combustion of volatile matter precipitated in pyrolysis and carbonization so as to dry the raw materials; allowing the dried raw materials to enter a carbonization reactor for pyrolysis and carbonization, delivering the intermediate products of pyrolysis and carbonization to a riser reactor, preparing porous carbon-based adsorption functional material (namely active carbon), syngas (or called biomass gas), or steam under the action of an oxidative medium and an activator, or an oxidative medium and an gasifying agent, or an oxidative medium. The steam required by the system is prepared by the activated or gasified high-temperature gas-solid products through heat exchange, which can increase the energy recovery efficiency of the process; the process adopts a continuous running mode with complete self-heating, and realizes the high-value conversion of cellulose industrial biomass wastes.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

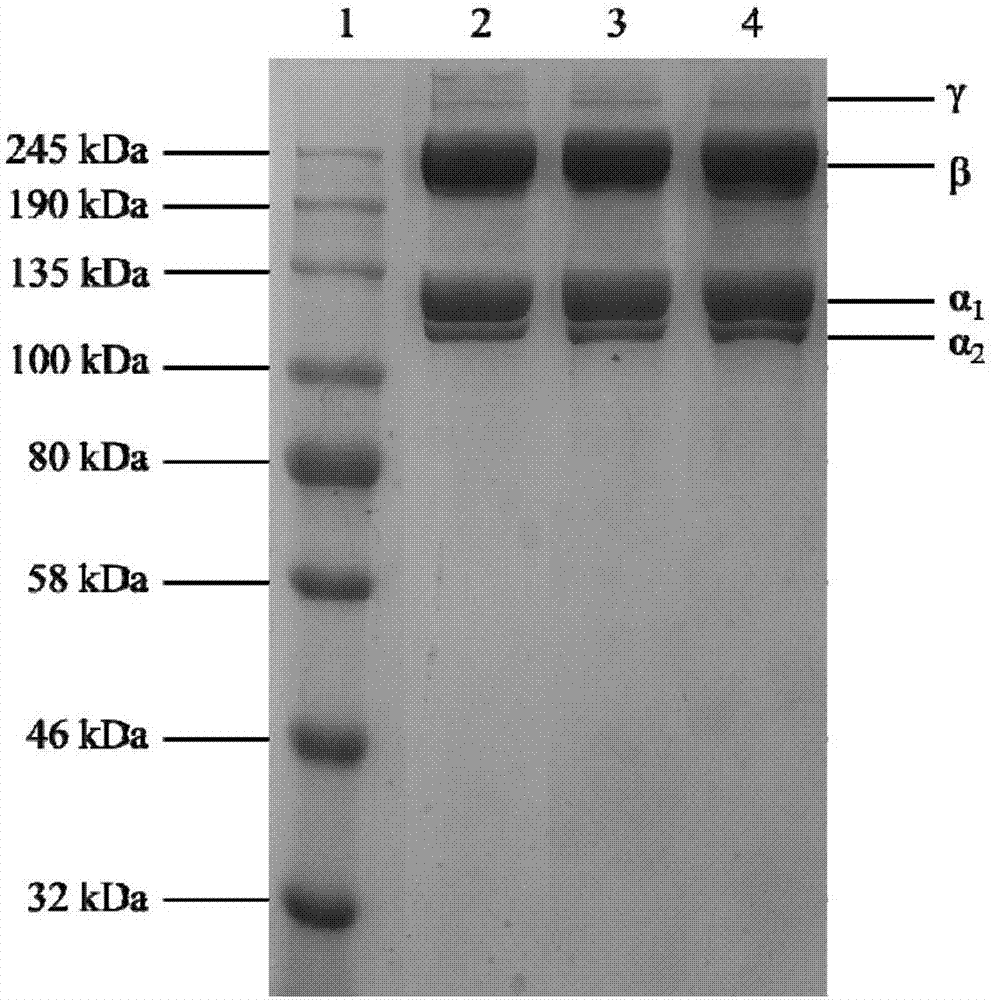

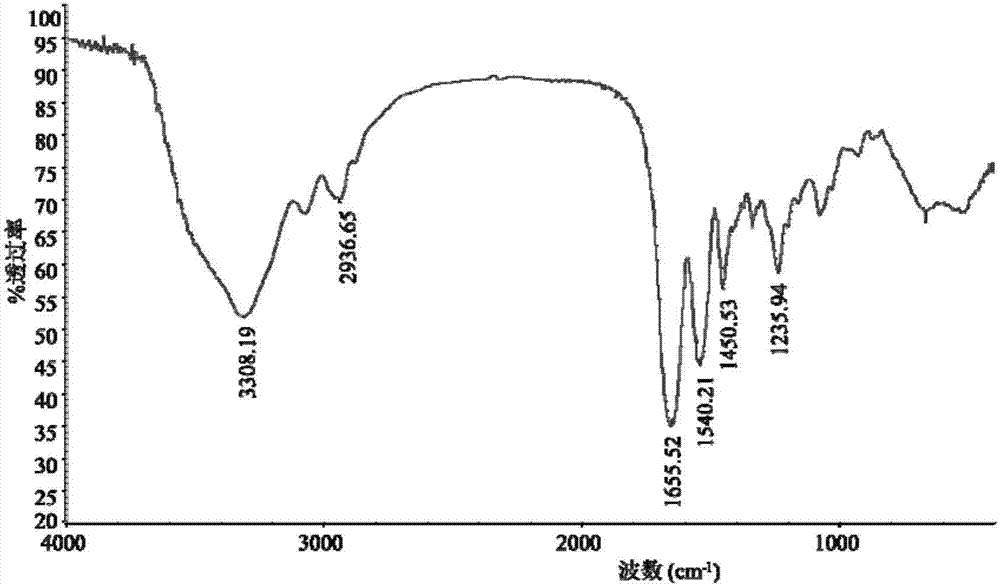

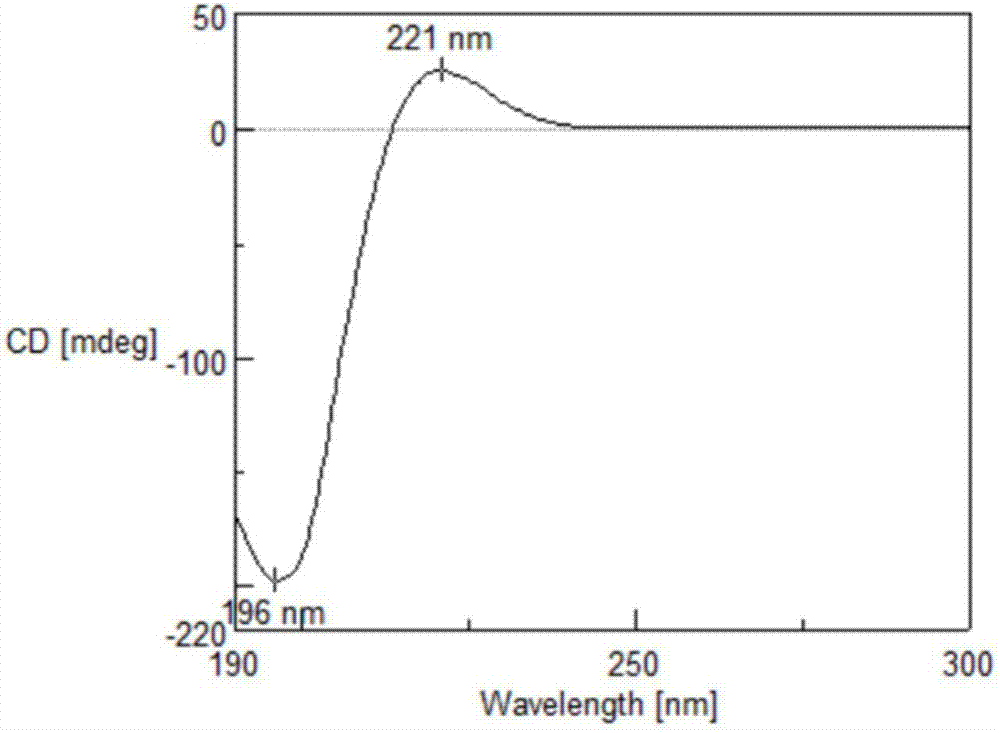

Method of extracting collagen and method of using collagen to prepare collagen protein

InactiveCN1903918ATake advantage ofRealize high value utilizationConnective tissue peptidesFreeze-dryingHydrolyzed collagen

The present invention discloses a method for extracting collagen and method for preparing collagen protein by using said collagen. Said method for extracting collagen includes the following steps: using Java tilapia skin as raw material, cutting said Java tilapia skin, adding n-hexane, defatting, using NaOH solution to remove heteroprotein, using acetic acid solution to extract collagen protein, concentrating and freeze-drying so as to obtain collagen. The method for preparing collagen protein by using extracted collagen includes the following steps: adding water to dissolve the collagen, then utilizing proteinase to make zymolysis, concentrating and spray-drying so as to obtain hydrolytic collagen protein.

Owner:SOUTH CHINA UNIV OF TECH

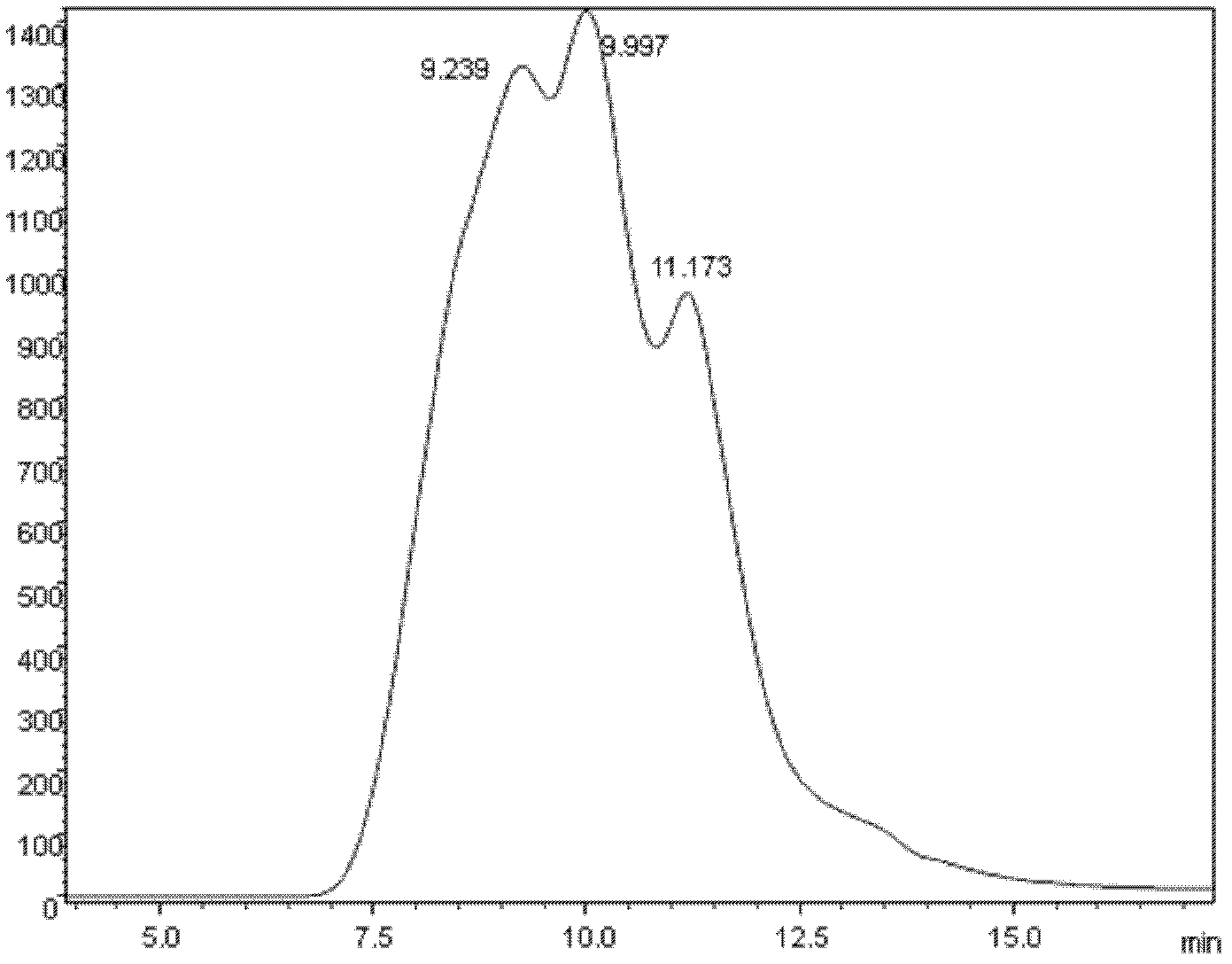

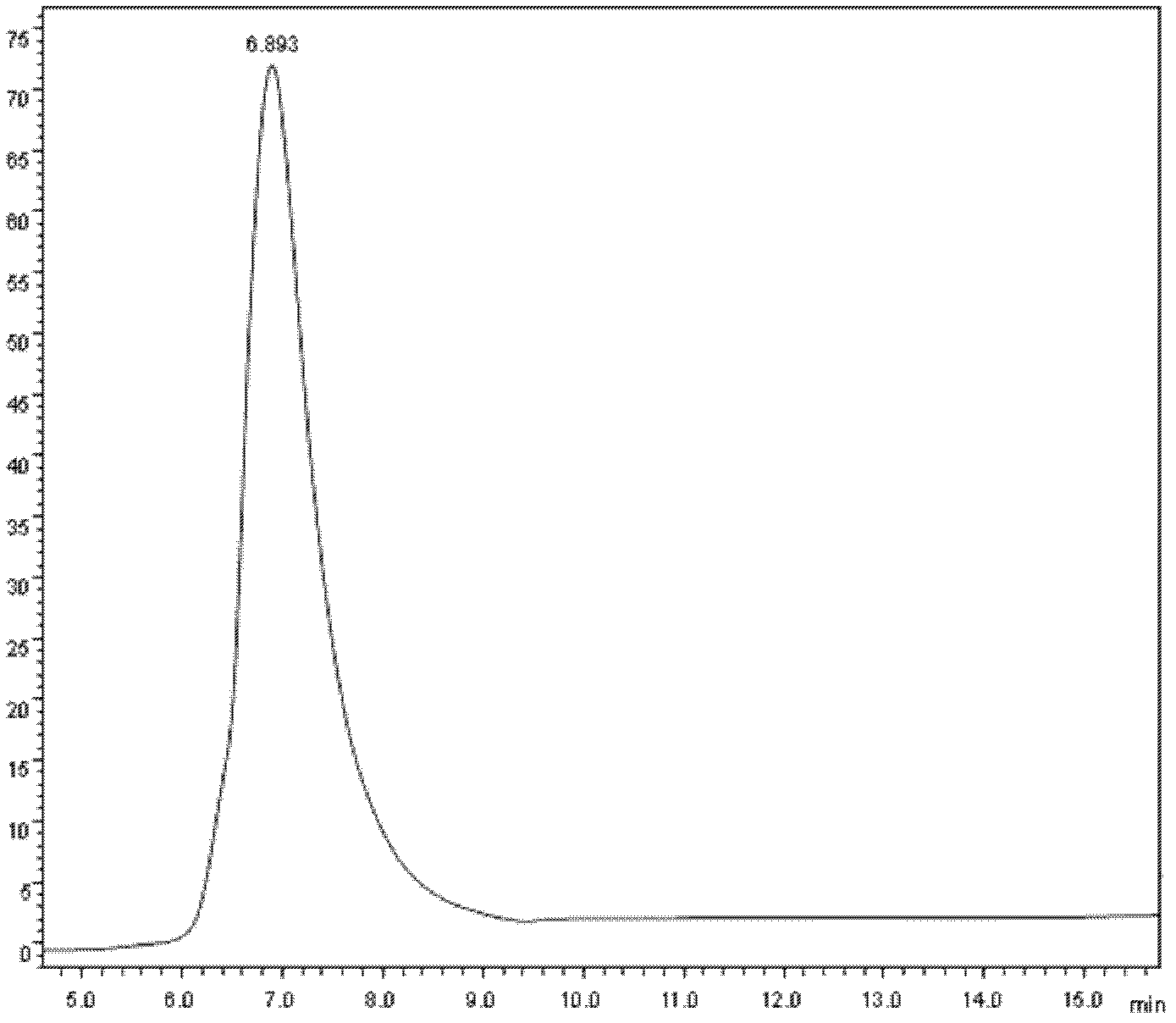

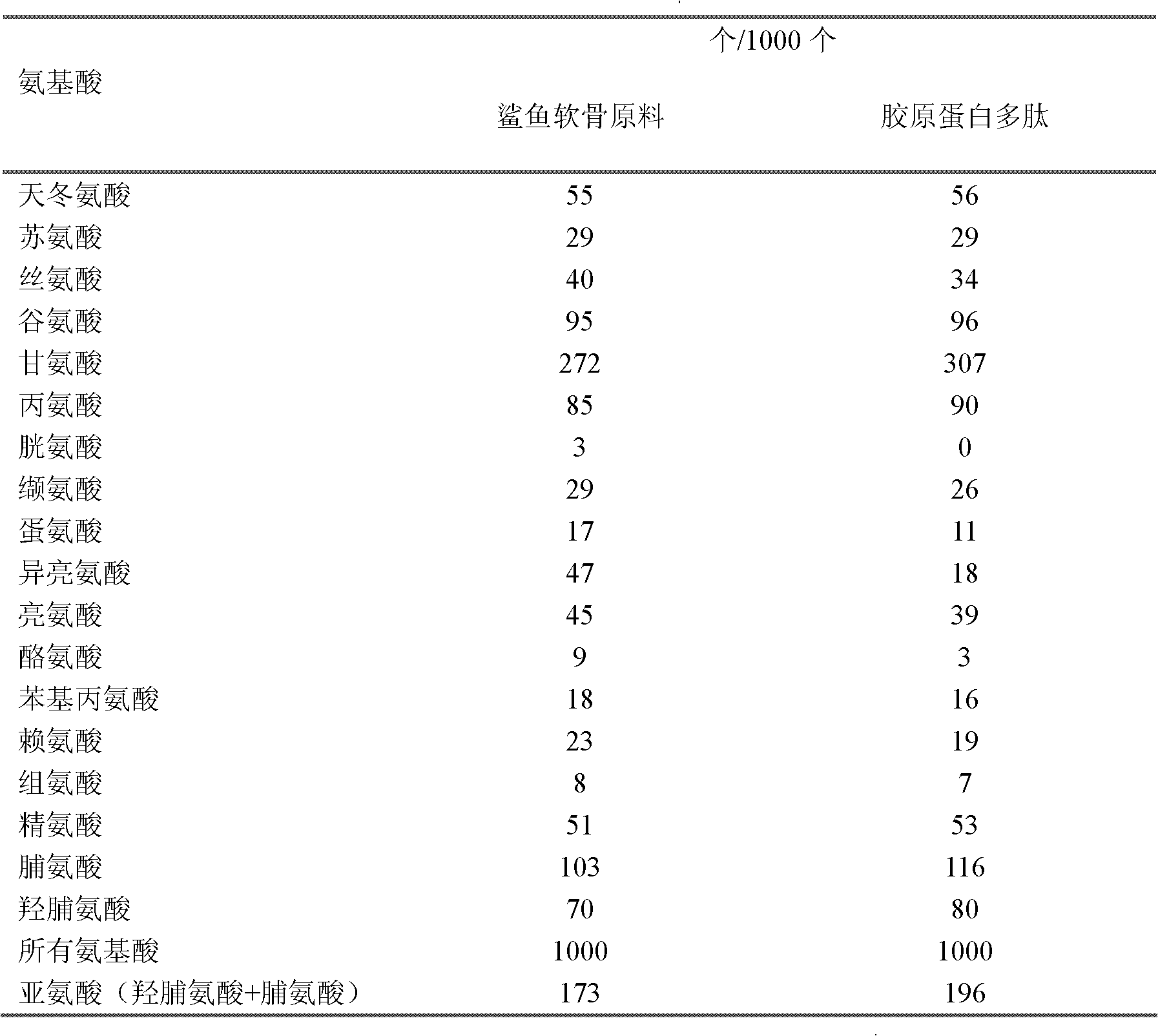

Method for preparing chondroitin sulfate and collagen polypeptide from animal cartilages

ActiveCN102533915ARealize high-value utilizationEfficient separation and extractionPeptide preparation methodsFermentationAlcoholUltrafiltration

The invention discloses a method for preparing chondroitin sulfate and collagen polypeptide from animal cartilages, which comprises the following steps: crushing animal cartilage materials to obtain cartilage powder; hydrolyzing the cartilage powder with protease, and then carrying out ultrafiltration and concentration to obtain a concentrated solution; passing the concentrated solution through an anion exchange resin column, and collecting an effluent solution A; eluting with pure water, and collecting a water washing solution B; merging the effluent solution A and the water washing solution B, carrying out ultrafiltration and concentration, and carrying out spray drying to obtain the collagen polypeptide; and eluting the anion exchange resin column with an NaCl solution, carrying out ultrafiltration and concentration on the eluent solution, carrying out alcohol precipitation, dehydrolyzing, and drying to obtain the chondroitin sulfate. The invention realizes the high-valued utilization of cartilage resources, can simultaneously and efficiently extract and separate the chondroitin sulfate and the collagen polypeptide, increases the added values of the products and reduces the environment pollution.

Owner:ZHEJIANG UNIV OF TECH

Waste crosslinked polyethylene recovered material and recovery method thereof

InactiveCN104385485AImprove melt fluidityImprove performancePlastic recyclingRecovery methodThermoplastic

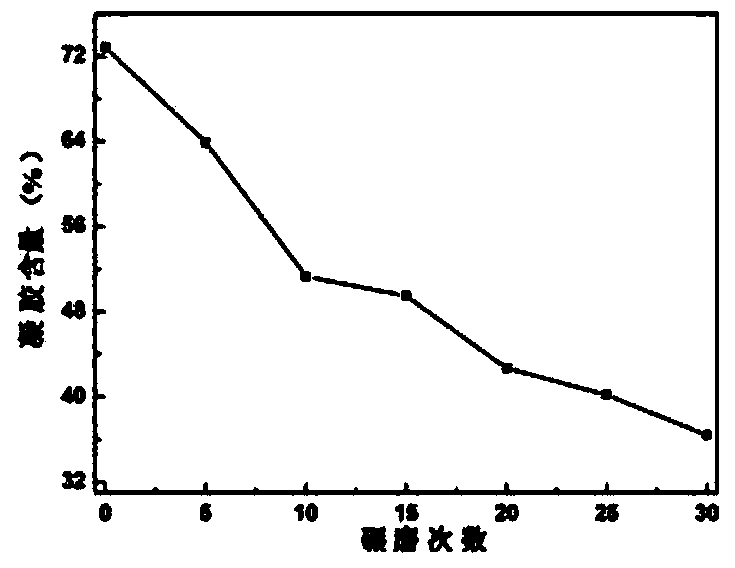

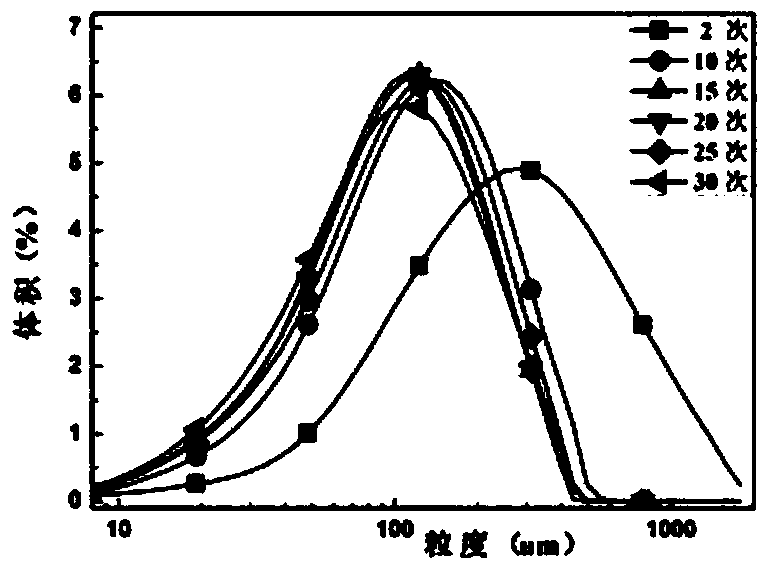

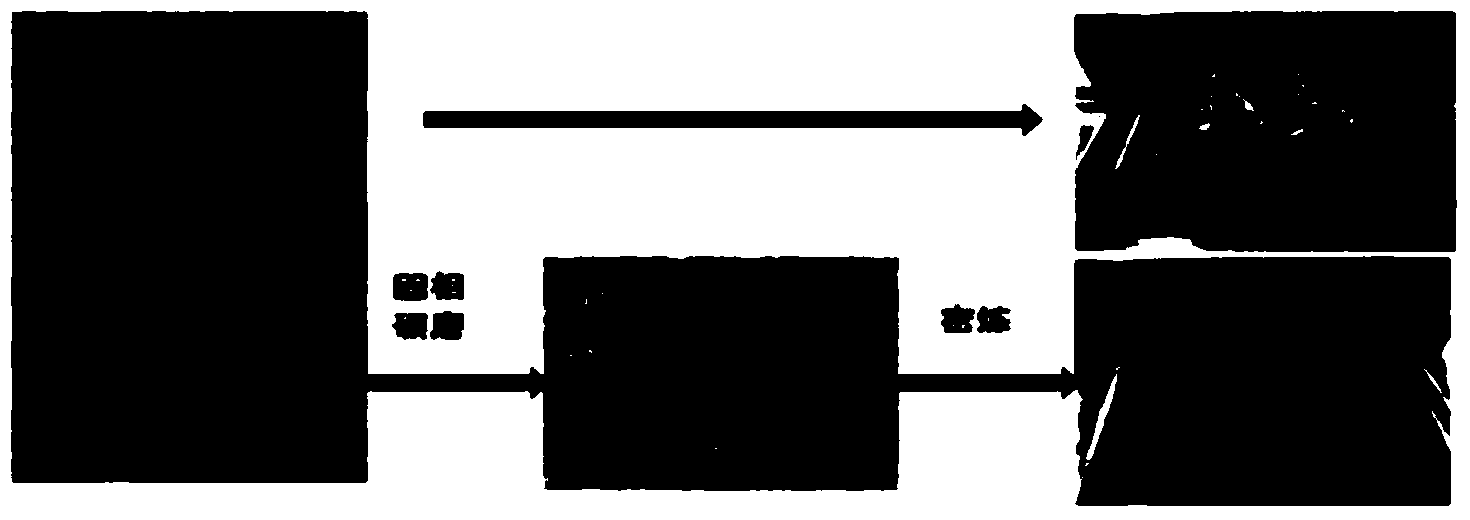

The invention discloses a waste crosslinked polyethylene recovered material and a recovery method thereof. The waste crosslinked polyethylene recovered material comprises the following steps of crushing waste crosslinked polyethylene to obtain particles with sizes of 0.5-2cm, and grinding the particles by a solid-state mechanochemical reactor to obtain powder of 100-500 meshes, wherein in grinding, a cooling cycle water temperature is controlled in a range of 5-30 DEG C, grinding pressure is controlled in a range of 10-50MPa, a grinding rotation rate is controlled in a range of 10-1000rpm and grinding frequency is 5-30. A Soxhlet extraction device test result shows that the powder has gel content less than 60%. The recovery method can selectively cut out C-O bonds and Si-O bonds in waste crosslinked polyethylene, cut out cross bonds of a three dimensional crosslinking structure, change the original insoluble and non-melting characteristic, improve material thermoplastic and fusion fluidity, and provides thermoplastic processability for the waste crosslinked polyethylene recovered material. The waste crosslinked polyethylene recovered material can be processed to form high-value recovered materials and products with excellent performances by conventional thermoplastic processing processes such as extrusion and rolling.

Owner:SICHUAN UNIV

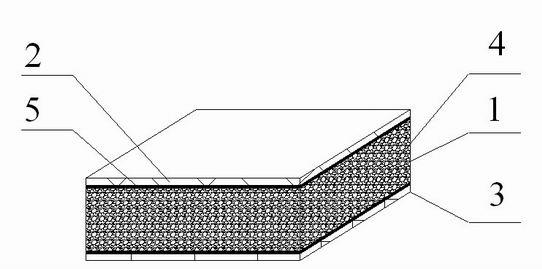

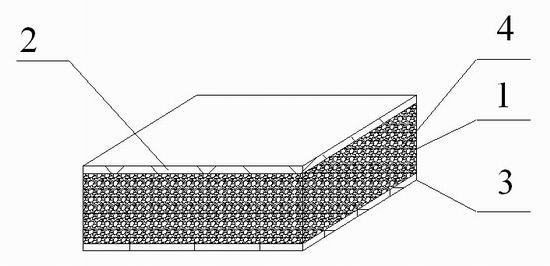

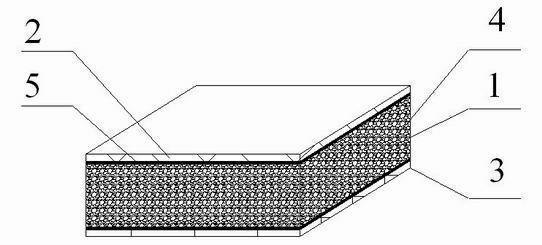

Wood fiber reinforced flame retardant foam composite plate and manufacturing method thereof

InactiveCN102114659AImprove use valueSolve the "Three Rural Issues"Wood working apparatusDomestic articlesAdhesive cementPhenolformaldehyde foam

The invention relates to a wood fiber reinforced flame retardant foam composite plate and a preparation method thereof. The external layer of the composite plate is a wood panel, and the foam core plate in the internal layer is a wood fiber reinforced phenol formaldehyde foam material or a melamine modified formaldehyde foam material. The wood fiber is treated by a coupling agent. The invention further relates to a manufacturing method of the plate. The wood panel is adhered to the external layer panel of the foam core plate. The plate can be manufactured by performing lamination thermal composition on the materials by using an adhesive, and also can be manufactured by directly foaming between fixed dual-layer panels. The foam core plate uses wood fiber reinforced phenol formaldehyde foam or melamine modified formaldehyde foam material. The flame retardant performance can accord with the specified standard. The foam core plate is flame retardant and small in smoke amount, generates no harmful gas, and meets requirement of environmental friendliness, so that the composite plate has excellent sound absorption and heat insulation properties. The fiber reinforced foam base material has an excellent mechanical property.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

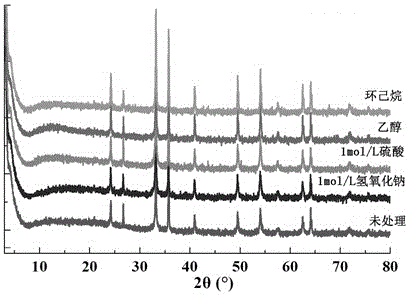

Method for preparing iron oxide red hybridization pigment by means of clay minerals

ActiveCN105694539ABright colorImprove stabilityPigment treatment with non-polymer organic compoundsClay mineralsStructural evolution

The invention discloses a method for preparing an iron oxide red hybridization pigment by means of clay minerals. According to the method, natural clay minerals are dispersed in water to form suspension liquid after being subjected to breaking, double rolling and ball milling, molysite and auxiliaries are then added, evenly dispersed and transferred into a hydrothermal reaction kettle, pH of the solution is controlled to be 0.5-4, reaction lasts for 5-60 h at the pressure of 2-8 MPa and the temperature of 160-300 DEG C, and programmed cooling is conducted at the rate of 10 DEG C / min to indoor temperature; the solid product is separated, washed, dried and smashed to generate the bright red hybridization pigment. Structural evolution and recombination are induced through hydrothermal reaction, reaction parameters are precisely controlled, exchange is conducted between Fe3+ and ions in clay minerals under the action of auxiliaries, in-situ formation of a crystalline phase is achieved, the novel silicon-aluminum iron oxide red hybridization pigment with bright color, high stability and uniform size is obtained, and the cost-effective red hybridization pigment is provided for multiple fields including coating, paint, ceramic and ink.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

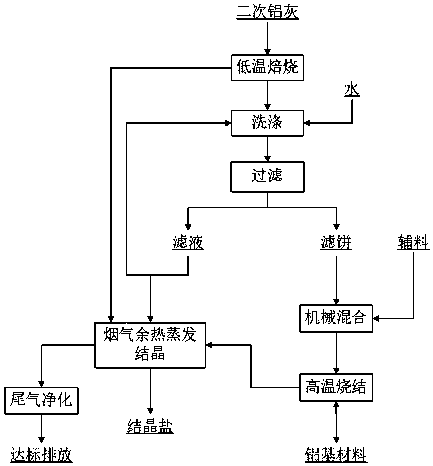

High-efficiency clean resource utilization method for quadratic aluminum dust

ActiveCN109179464AClean and efficient treatmentRealize high-value utilizationHuman health protectionCalcium aluminatesResource utilizationPotassium

The invention discloses a high-efficiency clean resource utilization method for quadratic aluminum dust. The method comprises the following steps: performing low-temperature roasting treatment on quadratic aluminum dust, removing harmful elements such as nitrogen, carbon and fluorine, pulping, washing, desalting and dehydrating the quadratic aluminum dust, removing sodium salt, potassium salt andother impurity components, washing brine and evaporating and crystallizing by utilizing flue gas waste heat. The purified quadratic aluminum dust can serve as a raw material to be directly utilized, and after the quadratic aluminum dust is mechanically mixed with auxiliary materials (calcium-based, silicon-based and magnesium-based), an aluminum based inorganic material is prepared at a high temperature, and the sintering exhaust gas realizes up-to-standard discharge by virtue of dust removal and dry defluorinated purification. According to the technology in the invention, the quadratic aluminum dust can be safely, cleanly and efficiently treated and converted into the high-value aluminum based inorganic material to the greatest degree, and environmental-friendly treatment and high-value resource utilization of the quadratic aluminum dust can be realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

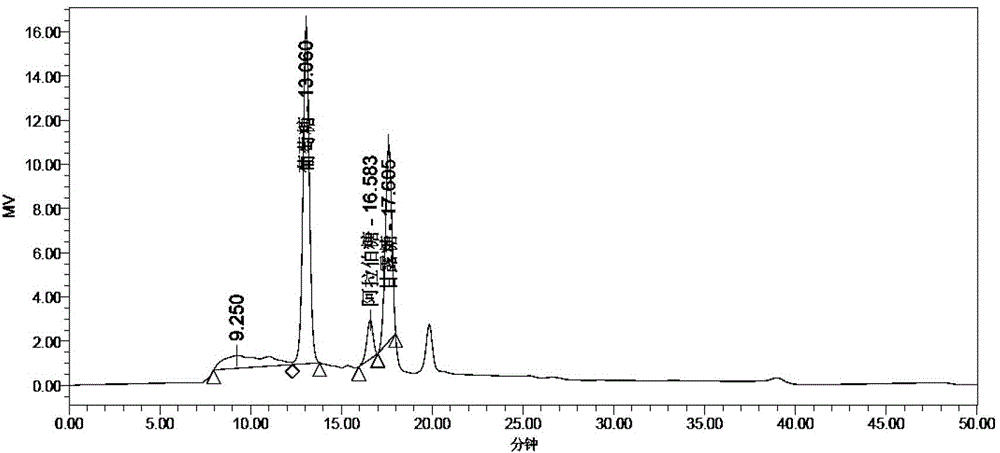

Method for separation of terylene-cotton blended fabrics and repolymerization of terylene

The invention discloses a separation method of (waste) terylene-cotton blended fabrics. The terylene-cotton blended fabrics are composed of polyethylene terephthalate and cotton fibers. The method comprises the following steps: carrying out an alcoholysis reaction on the terylene-cotton blended fabrics, ethylene glycol and an alcoholysis catalyst to obtain a reaction mixture, wherein the alcoholysis catalyst is zinc acetate; carrying out solid-liquid separation on the reaction mixture to obtain a solid matter and a liquid matter, wherein the solid matter is the cotton fibers; and carrying outa pre-polycondensation reaction and a final polycondensation reaction on the liquid matter in the presence of a polycondensation catalyst to obtain polyethylene terephthalate. By using the separationmethod disclosed by the invention, the (waste) terylene-cotton blended fabrics with various blending ratios are successfully separated to obtain the terylene and cotton fibers.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

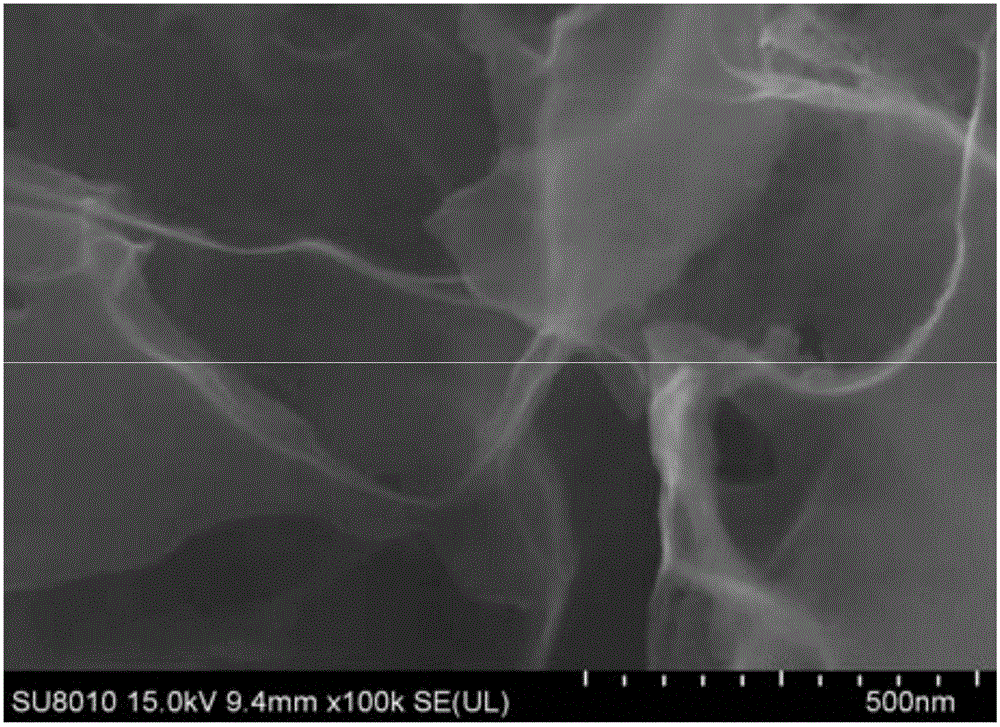

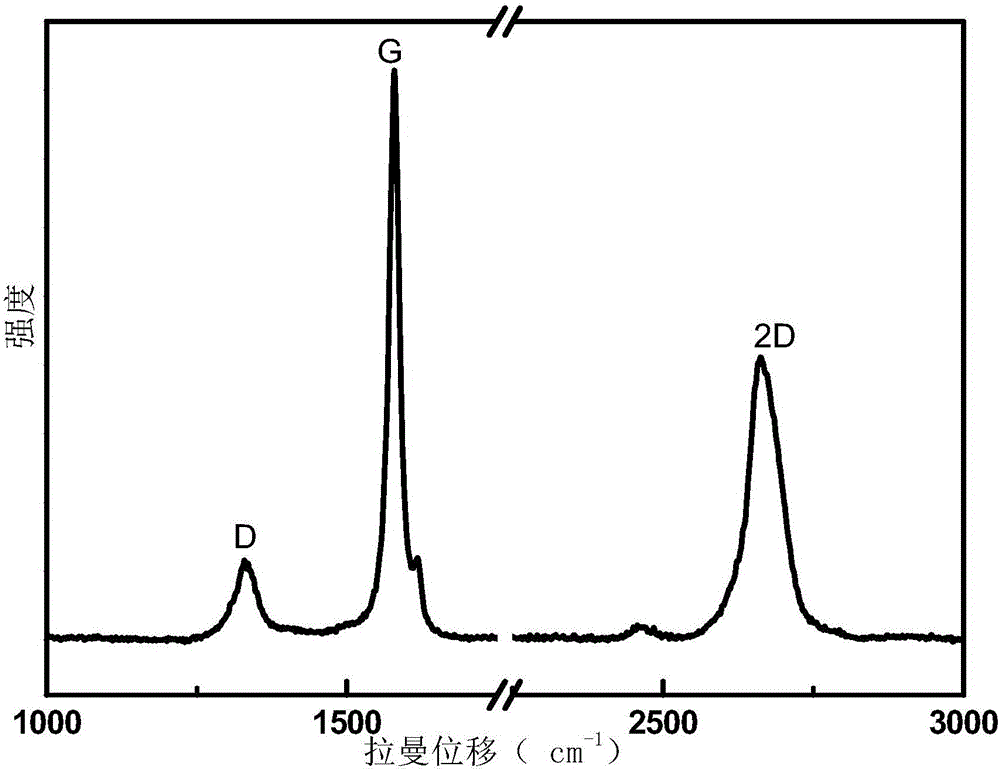

Method for preparing graphene by using lignin

The invention belongs to the technical field of carbon material manufacturing technology, and in particular relates to a method for preparing graphene by using lignin as a raw material. The method is as follows: a layered or powdered material is used as a substrate, the lignin and a catalyst precursor are alternately assembled on the surface of the substrate by a layer-by-layer electrostatic self-assembly method, then a lignin / catalyst precursor / substrate composite is put into a double-temperature-zone tubular furnace, a H2 / Ar mixed gas is introduced into the double-temperature-zone tubular furnace at a certain speed, at the same time the double-temperature-zone tubular furnace is heated by a certain procedure, after the double-temperature-zone tubular furnace is heated to target temperature, the temperature of the double-temperature-zone tubular furnace is held for a certain time, when the double-temperature-zone tubular furnace is cooled to room temperature, the sample is taken out, and is soaked in an acid for catalyst removal, and after a plurality of times of washing and vacuum drying, the graphene is obtained. The method has the advantages of simple process and convenient operation, and the prepared graphene is good in growth, controllable in layer number and considerable in yield.

Owner:SOUTH CHINA UNIV OF TECH

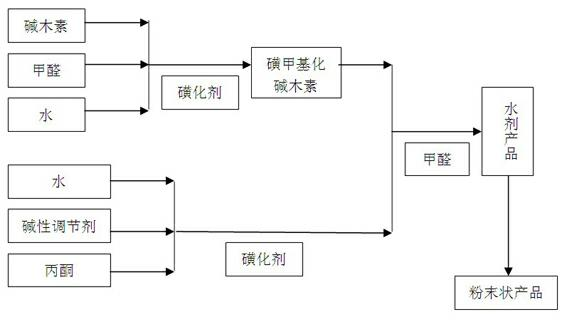

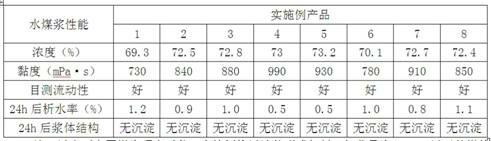

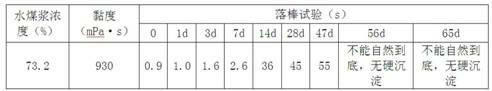

Sulfomethylated alkali lignin-formaldehyde-sulfonated acetone polymer coal water slurry additive

ActiveCN102585940AIncrease added valueRemove the burdenLiquid carbonaceous fuelsCoal waterPrepolymer

The invention discloses a sulfomethylated alkali lignin-formaldehyde-sulfonated acetone polymer coal water slurry additive and a preparation method thereof. The additive comprises the following components, by weight, 11.5-20.0 parts of alkali lignin, 4.9-10.0 parts of a sulfonating agent, 0.1-0.8 parts of an alkaline regulator, 4.5-10.0 parts of acetone, 5.4-13.5 parts of formaldehyde, and 47.3-67.2 parts of water. The preparation method comprises the following steps: 1, reacting the alkali lignin with a certain amount of formaldehyde and a certain amount of the sulfonating agent to prepare sulfomethylated alkali lignin; and 2, carrying out a catalytic sulfonation reaction on acetone by the alkaline regulator and the sulfonating agent to obtain a sulfonated acetone prepolymer, adding the prepared sulfomethylated alkali lignin and a formaldehyde solution, and carrying out a polymerization reaction to form the coal water slurry additive containing sulfo, hydroxy and alkyl active groups. So the product and the product stability are improved. The additive of the invention has the advantages of simple method, easily available raw materials, short production period, good stability, nontoxicity, no seasonal and regional restriction of the use, convenient storage and transportation, and realization of the high value utilization of lignin.

Owner:FUZHOU UNIV

Biomass-based nitrogen self-doped porous carbon material and preparation method and application thereof

The invention belongs to the technical field of material science and energy chemical engineering, and discloses a biomass-based nitrogen self-doped porous carbon material and a preparation method and application thereof. The preparation method includes the steps that chitin or chitosan is treated in high-temperature water at 180-300 DEG C for 2-24 hours, and a pre-carbonized product is obtained; the pre-carbonized product is mixed evenly with an activating agent aqueous solution, then the mixture is dried and heated to 600-1000 DEG C in an inert atmosphere for carbonization and activation for 0.2-10 hours, and the carbonized product is washed with an acid solution, then washed with water to be neutral and dried to obtain the biomass-based nitrogen self-doped porous carbon material. The high-temperature water treatment is conducted on chitin or chitosan, a favorable condition is thus provided for subsequent carbonization and activation for the preparation of the porous carbon material, and the nitrogen self-doped porous carbon material is excellent in super capacitor performance and CO2 adsorption property.

Owner:SOUTH CHINA UNIV OF TECH

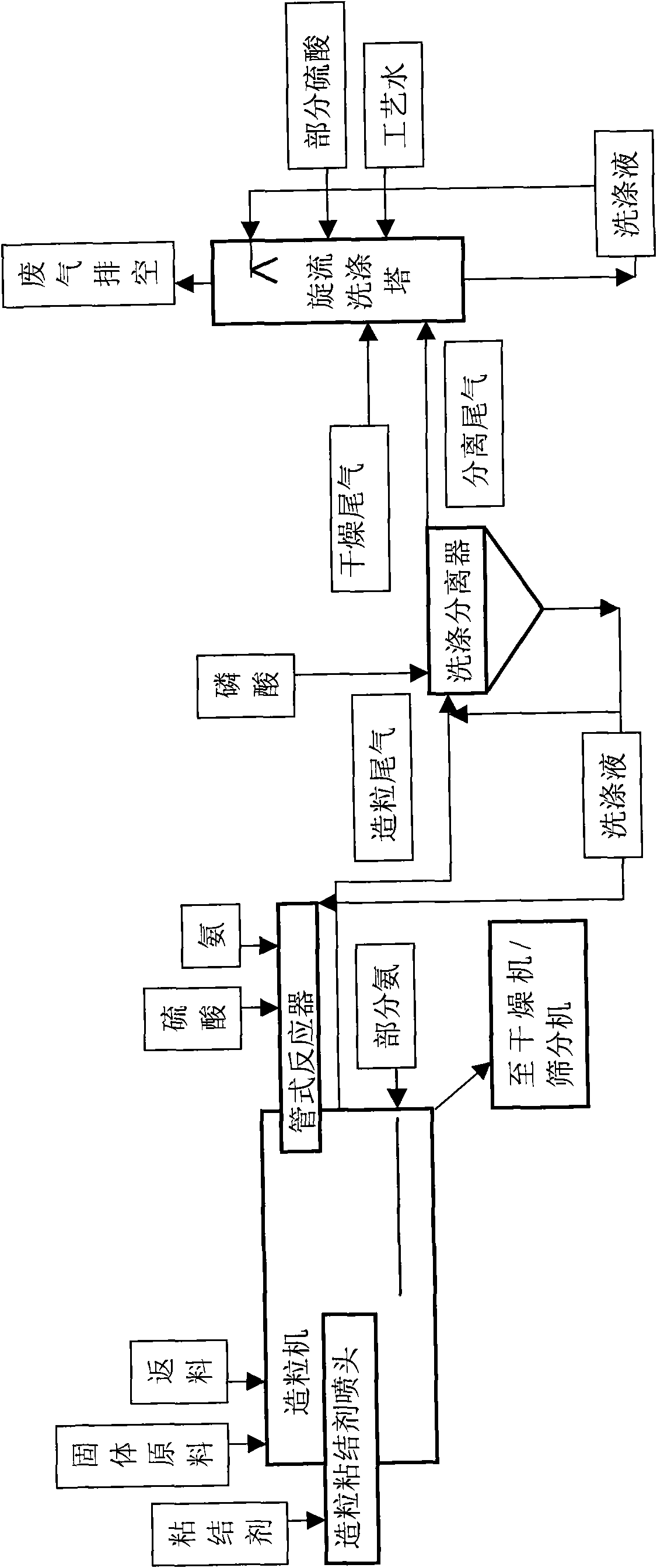

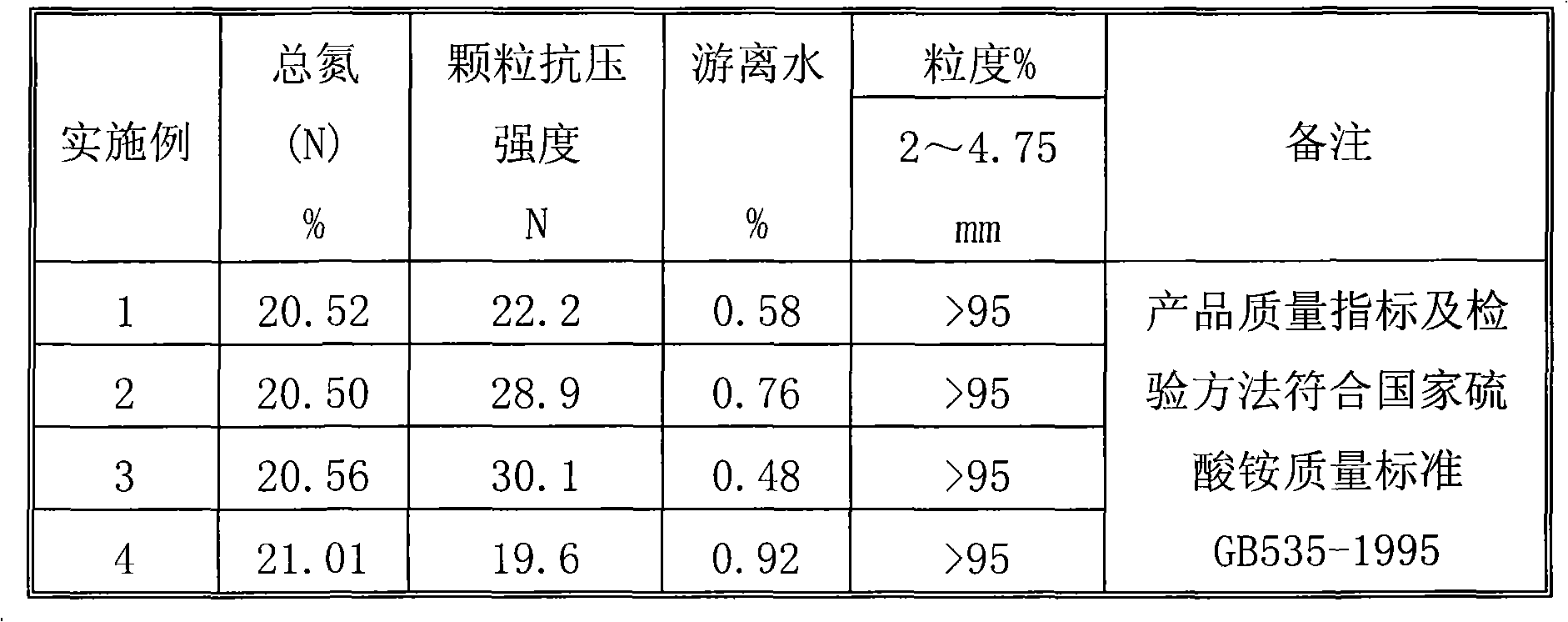

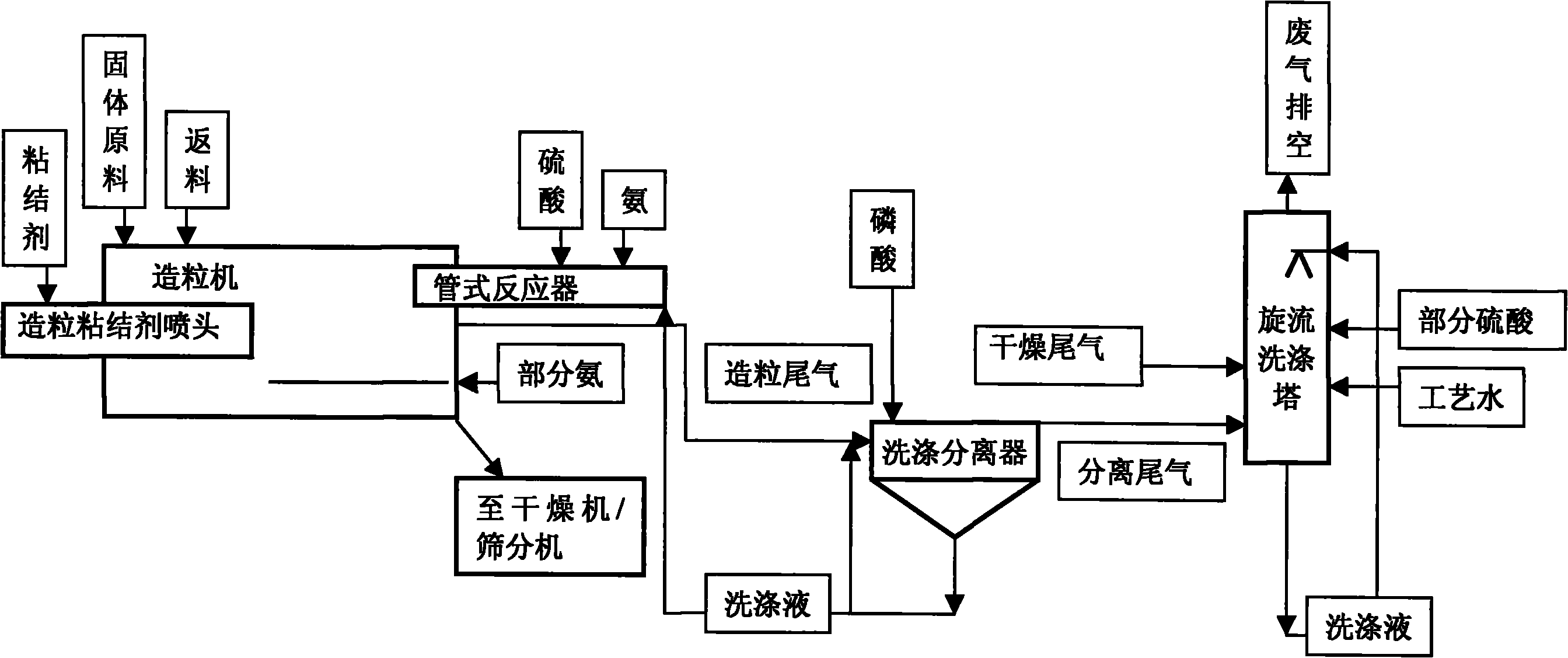

Preparation method of large-particle ammonium sulfate

InactiveCN101850989AReduce reaction loadControl water balanceAmmonium salt fertilisersAmmonia compoundsSlurryWater balance

The invention relates to a preparation method of large-particle nitrogenous fertilizers, in particular to a preparation method of large-particle ammonium sulfate, which comprises the following steps: firstly, adding 25-60 parts by weight of sulfuric acid, 7.6-16.5 parts by weight of ammonia and washing liquid from a gas-liquid separator to a tubular reactor for neutralization reaction; spraying high-temperature slurry formed after the reaction into a pelletizer; wherein, simultaneously, a solid material bed which comprises 20-70 parts by weight of solid material and rolls together with returns in the pelletizer can be installed in the pelletizer; spraying a pelleting binder through a spray nozzle and spraying the ammonium through an ammonium spraying shaft for pelleting to form wet solid material; fractionating the dried material after entering a sieving machine to sieve qualified particles and then cooling the particles to obtain the product. The invention reduces the reaction load of the tubular reactor; the system returns ratio is reduced, and the water balance is easier to control; simultaneously, the production cost is reduced, and recycling and the high-value utilization of industrial byproducts are realized by utilizing by-product powdery ammonium sulfate.

Owner:河北天人化工股份有限公司

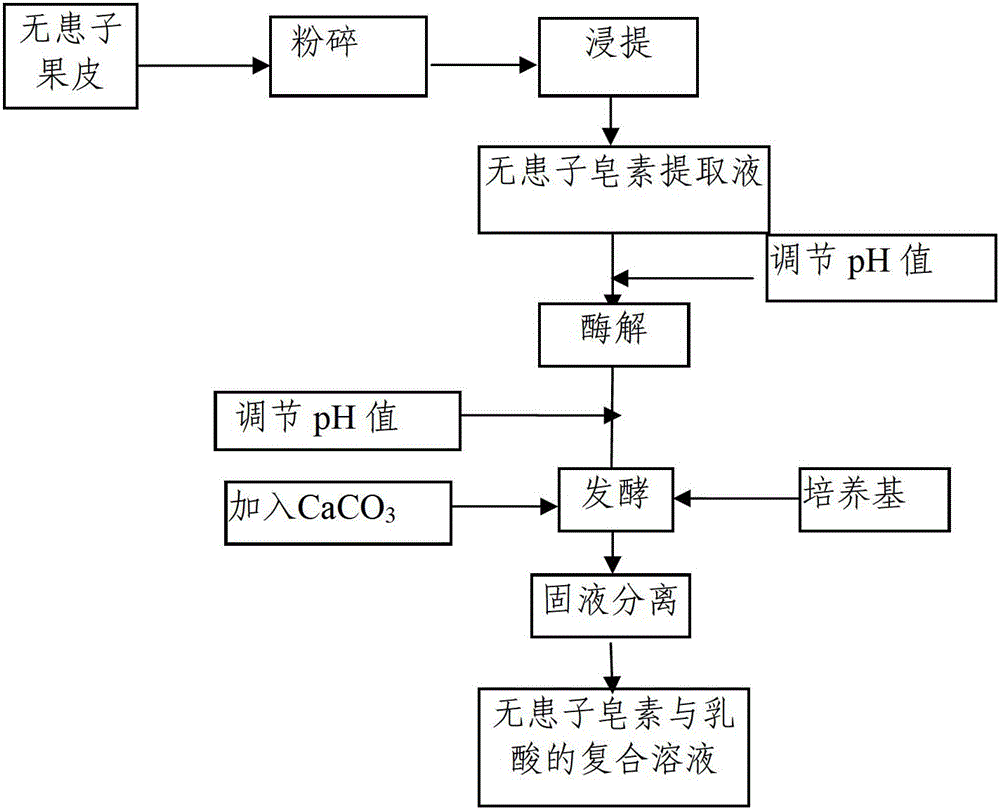

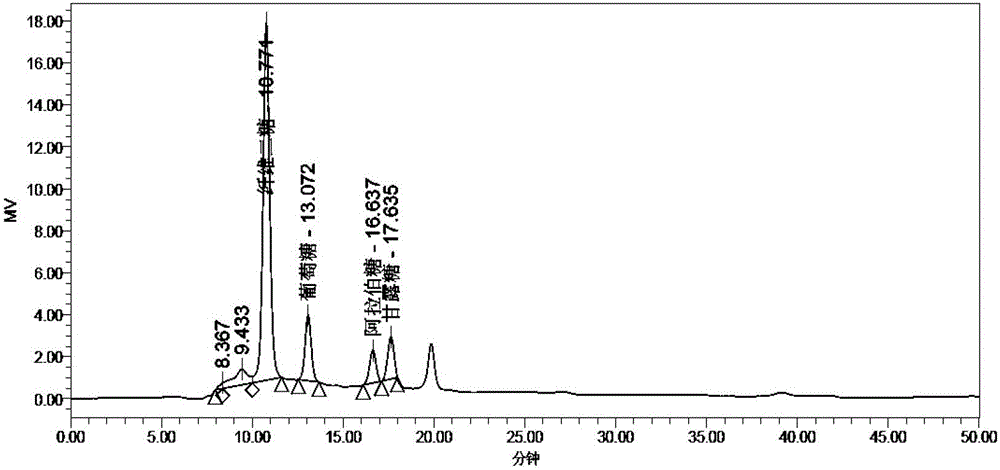

Fermentation and refining method for sapindus mukurossi saponin extract

ActiveCN102719491ARealize high-value utilizationTake advantage ofSugar derivativesSteroidsBiotechnologyLiquid product

The invention provides a fermentation and refining method for sapindus mukurossi saponin extract, which includes the following steps: sapindus mukurossi extract is enzymatically saccharified, and lactic acid bacteria are then used for inoculation and fermentation. The invention also provides a fermented and refined product of the sapindus mukurossi saponin extract. According to the characteristic of the sapindus mukurossi peel extract containing high-density cellobiose and mannose, in the fermentation and refining method, the sapindus mukurossi peel extract is enzymatically saccharified and fermented to convert carbohydrates and a small amount of protein in the sapindus mukurossi peel extract into lactic acid, consequently, sapindus mukurossi peels are sufficiently utilized, the compound product of sapindus mukurossi saponin and lactic acid is obtained, and the high-value utilization of sapindus mukurossi fruits is realized. According to the method, carbohydrates, protein and other interfering impurities in the aqueous sapindus mukurossi extract are directly converted into active components in the final product, the quality of the prepared refined sapindus mukurossi liquid product is stable, the purity of the refined sapindus mukurossi liquid product is high, and the refined sapindus mukurossi liquid product can be used in the preparation of liquid detergent or other liquid products.

Owner:广州德谷个人护理用品有限公司

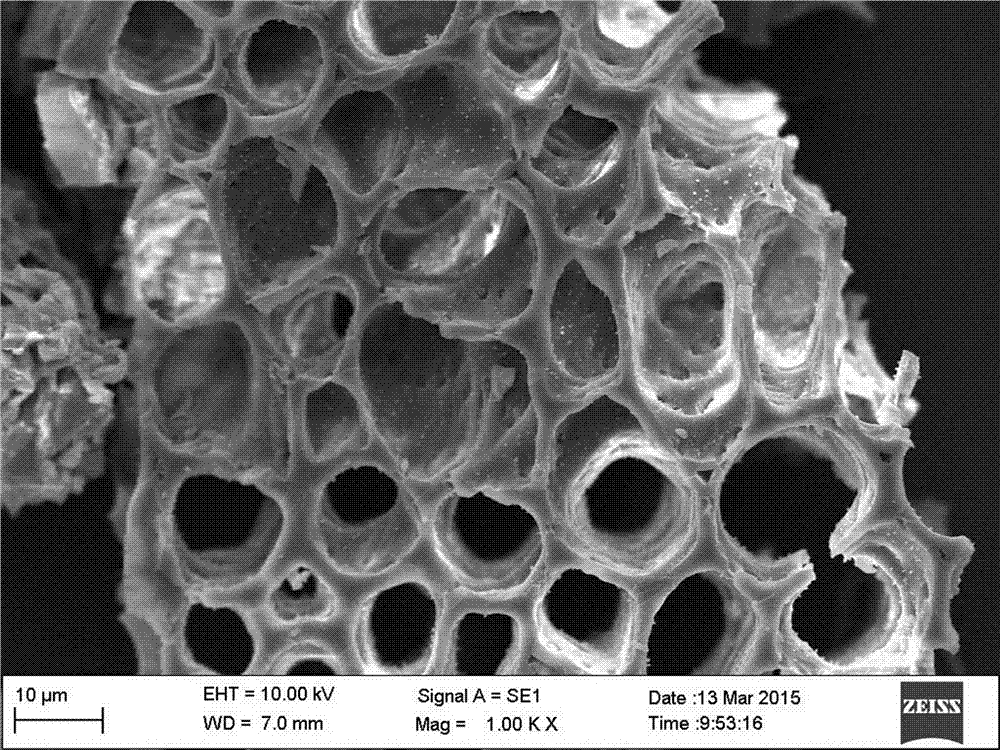

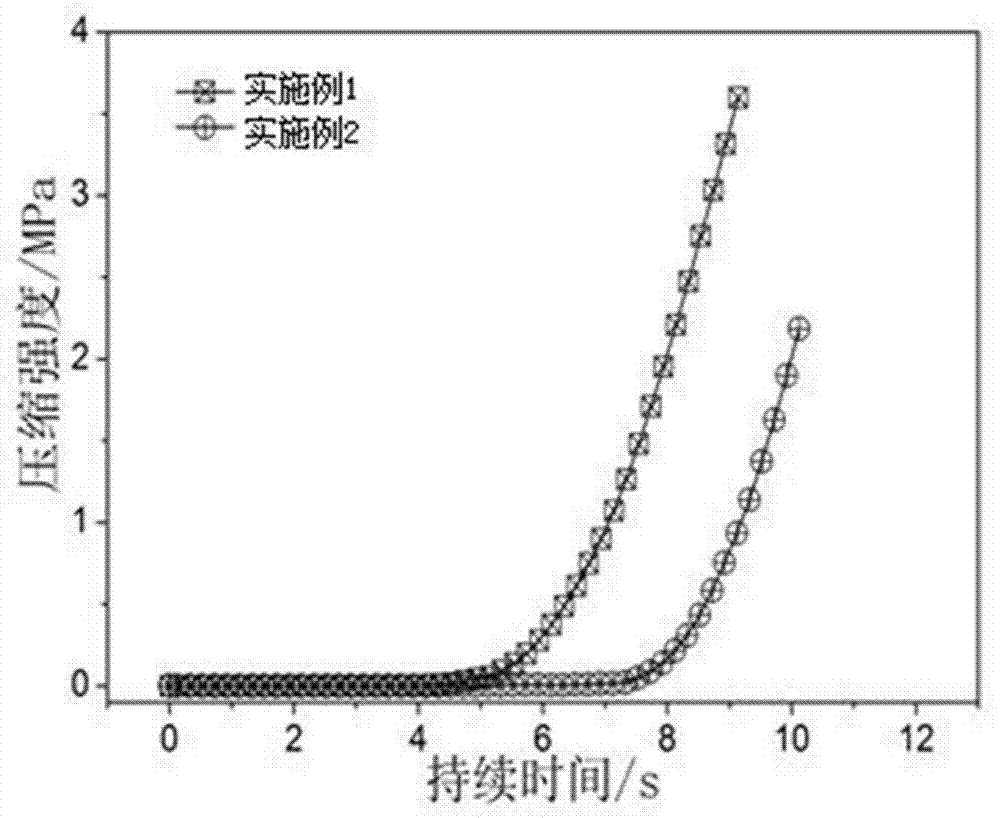

Method for preparing large-particle foam carbon by using corncob

The invention discloses a method for preparing large-particle foam carbon by using a corncob. The method specifically comprises the following steps: drying the corncob, crushing into corncob powder, and then mixing with a catalyst to react for 30-40 minutes; adding an adhesive to react for 60 minutes, then cooling and dehydrating to obtain biomass base expandable slurry; adding a surfactant, a foaming agent and a curing agent to mix and then pouring in a mold, foaming and curing for 15-30 minutes, and drying and curing for 20-30 minutes to obtain charring precursor; then charring at the temperature of 150-350 DEG C for 20-60 minutes, curing for 4 hours at 500-600 DEG C, washing an activation product to be neutral, and drying to obtain the large-particle foam carbon. The agricultural and forestry biomass material corncob is used as a foam carbon matrix, so the consumption of a petroleum base chemical product is reduced, and high value of low-value agricultural waste is realized; the prepared foam carbon has high aperture ratio, large specific surface and strong adsorption capacity and can be applied to the field of environmental engineering such as purification of polluted water body in place of conventional active carbon.

Owner:JIANGSU ACAD OF AGRI SCI

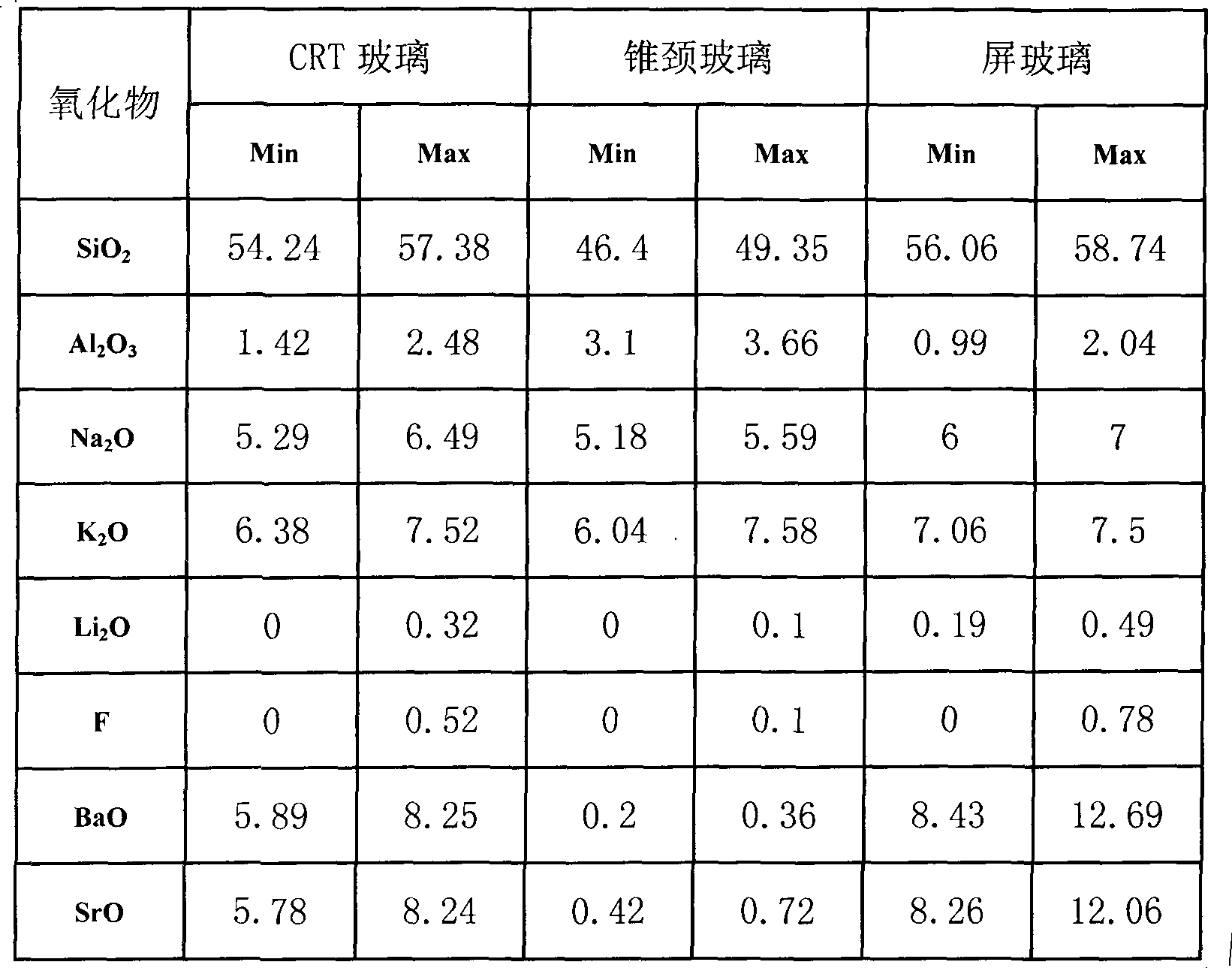

Anti-radiation building putty powder and preparation method thereof

The invention provides anti-radiation building putty powder and a preparation method thereof. Color picture tube glass and reinforced ingredients are mixed in proportion and ground till the particle size is 60 to 100 meshes to obtain ground powder; the ground powder is further mixed with cement in proportion to obtain ground anti-radiation building putty powder; the ground powder can be further calcined and mineralized and then mixed with the cement in proportion to obtain sintered anti-radiation building putty powder, so that the anti-radiation building putty powder can obtain higher chemical stability and use safety. By the method, the waste color picture tube glass is turned into resources, and the harmless disposal, recycling and high-value utilization of the waste color picture tube glass are implemented. The anti-radiation building putty powder can be widely applied to the surface treatment of a radiation protection body and a radioactive building material (building).

Owner:YANCHENG INST OF TECH +2

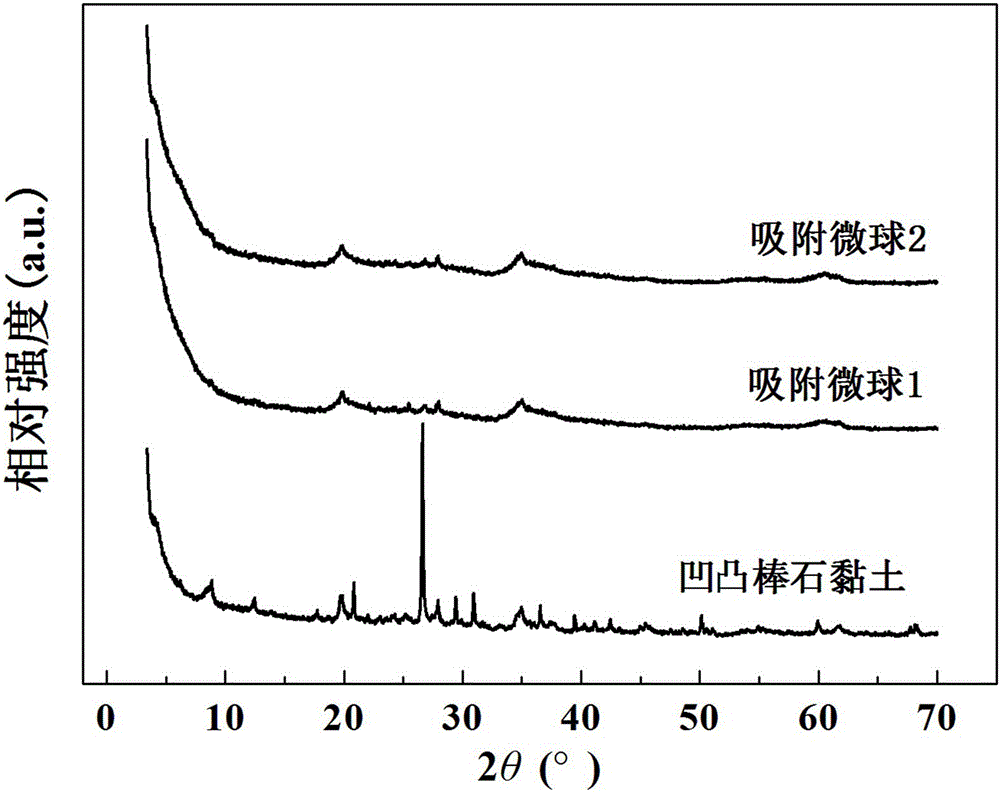

Method for preparing micro-nano hybrid mesoporous adsorbing microspheres by utilizing red attapulgite clay

ActiveCN105664843AImprove adsorption capacityNarrow pore size distributionOther chemical processesAlkali metal oxides/hydroxidesMicro nanoMycotoxin

The invention discloses a method for preparing micro-nano hybrid mesoporous adsorbing microspheres by utilizing red attapulgite clay. The method comprises the steps of mixing the read attapulgite clay with silicate, and grinding, performing microwave heating at 80 to 140 DEG C, and activating for 0.5 to 4h; dispersing the obtained solid into an organic acid aqueous solution according to the solid-to-liquid ratio of 1 to 9.5, then adding a metal salt water solution, and uniformly stirring; transferring the obtained suspension liquid into a hydrothermal reactor provided with a tetrafluoroethylene liner, reacting at temperature of 160 to 260 DEG C for 2 to 48h, and cooling to the normal temperature at the speed of 10 DEG C / min; performing separating, washing, drying and smashing on a product to obtain the adsorbing microspheres. According to the method disclosed by the invention, the red attapulgite clay with abundant reserves, low grade and deep color and luster is subjected to treatment to obtain a spherical amorphous silicate adsorbing material with the mesoporous structure, and a product is large in specific surface area, uniform in pore diameter distribution, can be used for adsorption and enrichment or desorption of antibiotic, mycotoxin, dye and heavy metal, and has a wide application prospect in environmental restoration, wastewater treatment and feed additives.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ultrasonic auxiliary purification method of xylose in eucalyptus hot water prehydrolysis liquid

ActiveCN108411044AHigh purityRealize high-value utilizationXylose productionPurification methodsHydrolysate

The invention discloses a purification method of xylose in eucalyptus hot water pretreatment hydrolysate. In the purification method, a method of combination of physics, chemistry and biology of combination of ultrasonic treatment synergized with calcium hydroxide and ultrasonic treatment synergized with secondary activated carbon adsorption and laccase is adopted to treat the eucalyptus hot waterprehydrolysis liquid, dissolved organic matters such as lignin and furfural and impurities except the xylose in the prehydrolysis liquid are separated and removed to the maximum, and the purity of the xylose in the prehydrolysis liquid is improved, so that the problems of low purity of the xylose, difficulty in removal of fermentation inhibitors and high production cost in the subsequent xylose high-value use process are solved, the utilization value of the eucalyptus hot water prehydrolysis liquid is increased, and high-value utilization of hemicellulose components of broad-leaved woods suchas eucalyptus is realized.

Owner:QILU UNIV OF TECH

Method for preparing magnetic cellulose aerogel by utilizing waste paper

ActiveCN106589444ALow densityHigh porosityOther chemical processesFatty-oils/fats refiningIndustrial equipmentDissolution

The invention discloses a method for preparing magnetic cellulose aerogel by utilizing waste paper. An ultra-light multi-porous gas magnetic hydrophobic aerogel adsorbing material is prepared by using waste paper fibres in life as a raw material; waste paper regenerated cellulose gel is prepared by utilizing an microwave auxiliary ionic liquid dissolution method; black red waste paper cellulose aerogel is obtained through magnetic modification and hydrophobic and oleophobic modification. The magnetic cellulose aerogel disclosed by the invention can effectively remove a variety of organic pollutants and oily materials leaked in water; the absorption multiplying power is high; oil is absorbed thoroughly; an adsorbing material is non-toxic and harmless; the adopted magnetic collecting method is simple and easy to use; secondary pollution is low; the preparation method is simple in process and mild in conditions; waste can be changed into treasure by conventional industrial equipment and low-cost raw materials; the emission of waste water, waste gas and waste residues is avoided in a production process; the method has a wide popularization application value and social significance.

Owner:FUZHOU UNIV

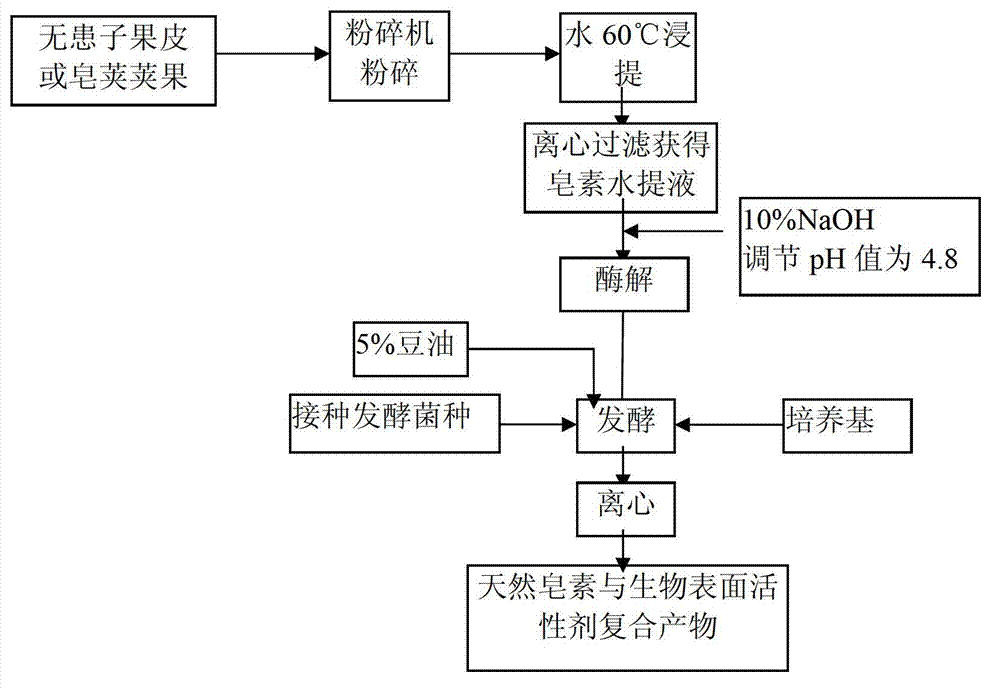

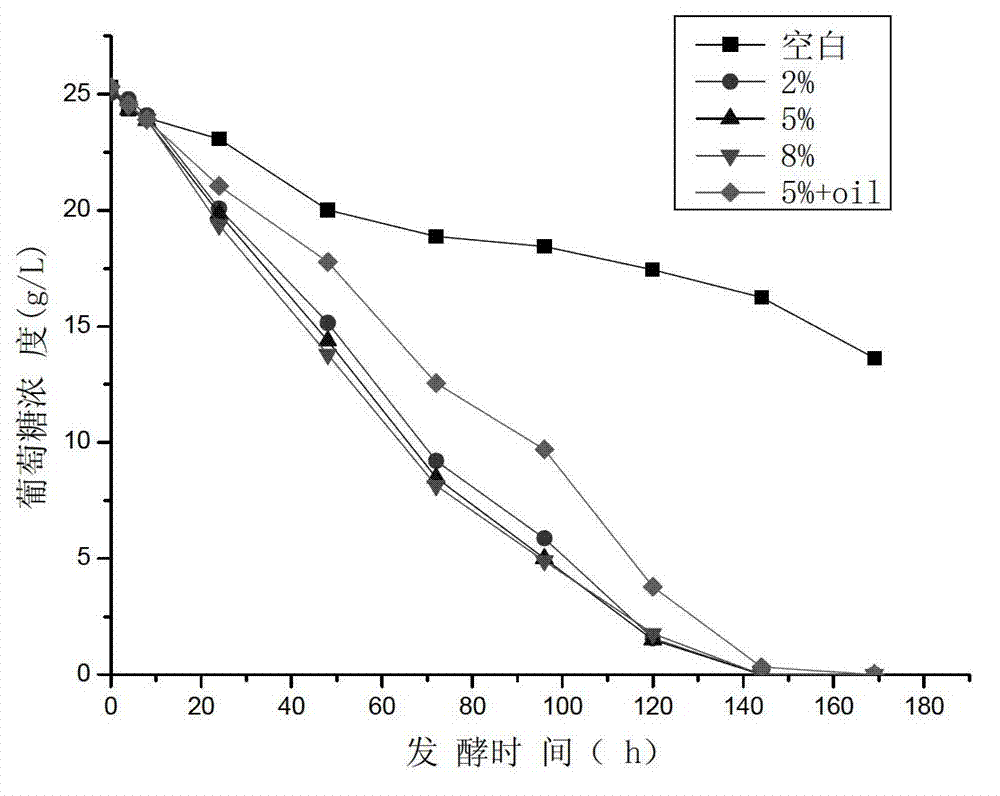

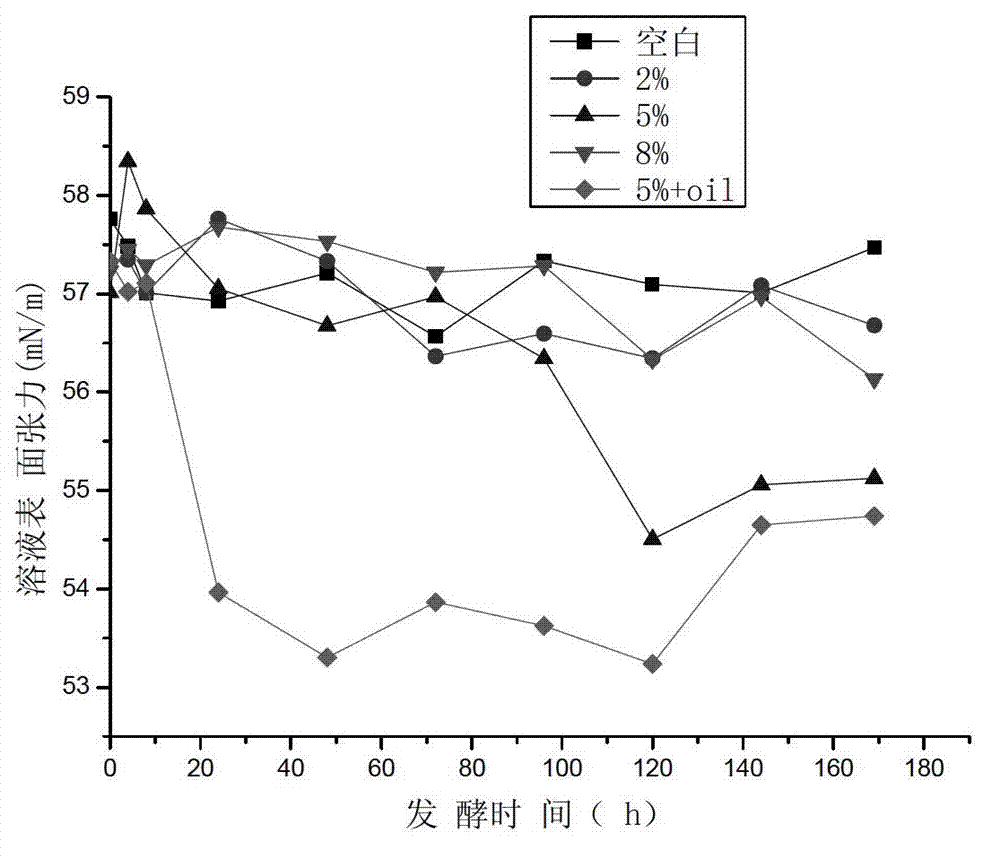

Method for extracting natural saponin and biosurfactant composite product

ActiveCN103088101AIncrease productivitySimple processTransportation and packagingMicroorganism based processesHigh concentrationYeast

The invention provides a method for extracting a natural saponin and biosurfactant composite product. According to the fact that soapberry or Chinese honeylocust water extract contains cellobiose and monosaccharide in high concentration, the cellobiose is subjected to enzyme hydrolysis, water extraction enzyme hydrolysate is taken as a substrate, hilly candida and pseudomonas aeruginosa are inoculated, sophorolipid and rhamnolipid are produced by fermentation, the natural surfactant and biosurfactant composite product is obtained, and a practicable and efficient technical route is provided for preparing a natural saponin liquid detergent or other liquid products.

Owner:广州德谷个人护理用品有限公司

Compound multilayer medical dressing of aquatic biological source crosslinking collagen

ActiveCN107233613AWide variety of sourcesIncrease profitConnective tissue peptidesSurgical adhesivesFreeze-dryingCollagen sponge

The invention discloses an aquatic biological source medical collagen with high purity and activity, and is capable of solving the problems of a natural collagen dressing that the mechanical strength is bad, the degradation resistance ability is weak and the wound is easily infected by microorganisms. An acid extraction method and a method of removing telopeptide by pepsase are used for extracting the collagen, the extraction ratio is improved by the ultrahigh pressure treatment and a tissue mashing method, and through a series of purification operations, such as decellularization, protein elimination, degreasing, repeated salting out, dialysis, degerming, decoloration and heat source removal, the medical collagen with the high purity and activity is prepared. A netlike collagen sponge with uniform pores is prepared by a vacuum freeze-drying technology, and the collagen sponge is modified by a physical crosslinking and chemical crosslinking mode so as to prepare the inner layer, and is compounded with a chitosan outer layer film and a medical non-woven fabric base cloth layer, finally a compound multilayer medical dressing finished product is obtained by Co-60 sterilization.

Owner:OCEAN UNIV OF CHINA

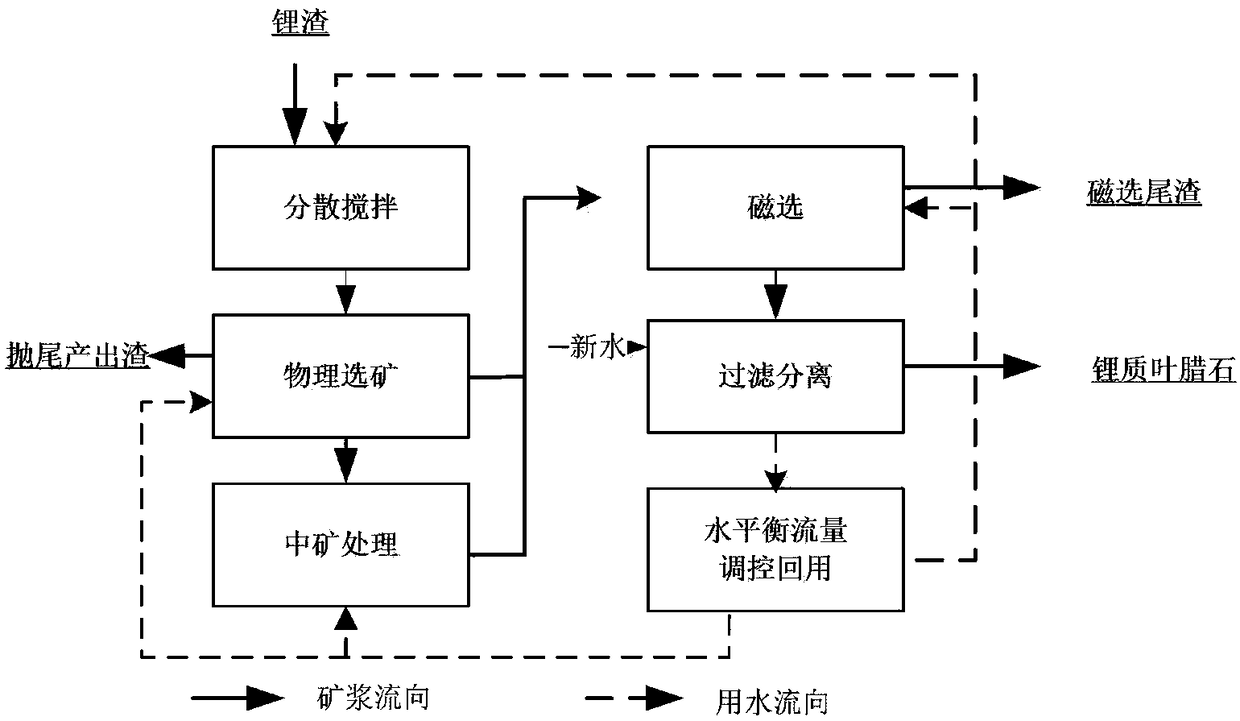

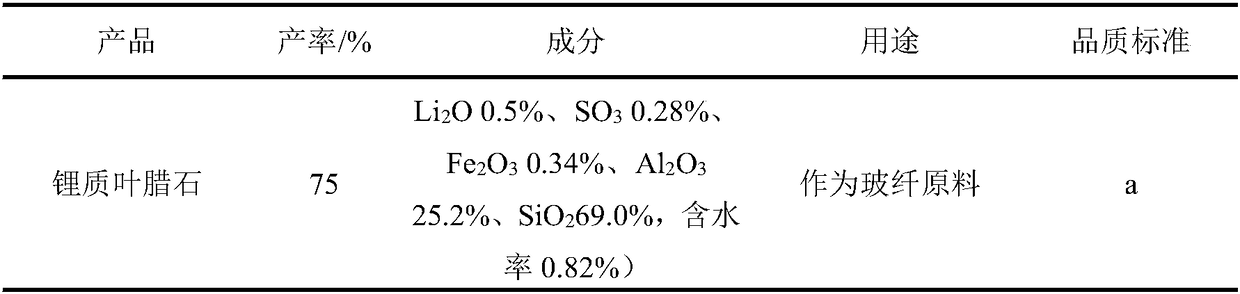

High-valued comprehensive utilization method of lithium slag

The invention provides a high-valued comprehensive utilization method of lithium slag, in particular to mineral waste residues obtained by lithium extraction of spodumene by a sulfuric acid method. The high-valued comprehensive utilization method comprises the following steps: firstly, carrying out size mixing and stirring on the lithium slag and enabling sulfate mineral in the lithium slag to bein a dispersed suspension state; secondly, carrying out desulfurizing treatment on a product obtained in the first step by using a physical ore dressing mode to obtain desulfurized slurry and tailingdiscarding produced slag and enabling the sulfur content of slag phase in the desulfurized slurry to be smaller than or equal to 0.5 percent; thirdly, under the condition that the magnetic field strength is 0.5 to 2.0T, carrying out magnetic separation on the desulfurized slurry obtained in the second step to obtain magnetic separation slurry and magnetic separation tailings and reducing the content of ferric oxide in the magnetic separation slurry to be smaller than or equal to 0.05 percent; then concentrating, filtering and drying the obtained magnetic separation slurry to obtain a pyrophyllite raw material for glass fibers. The treatment method of the lithium slag, disclosed by the invention, has the advantages of greenness and environmental protection, obvious economic benefits and capability of realizing the leap of high-valued recycling of the lithium slag.

Owner:TIANQI XINLONG CO LTD

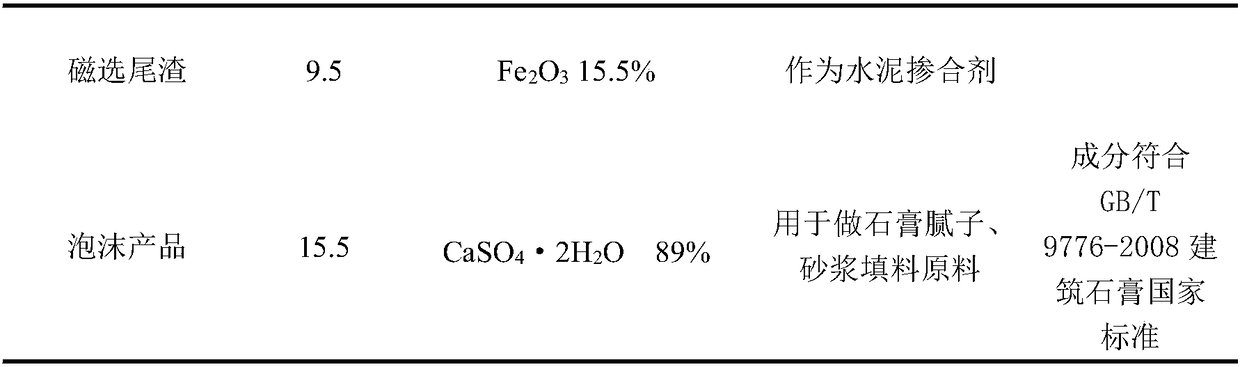

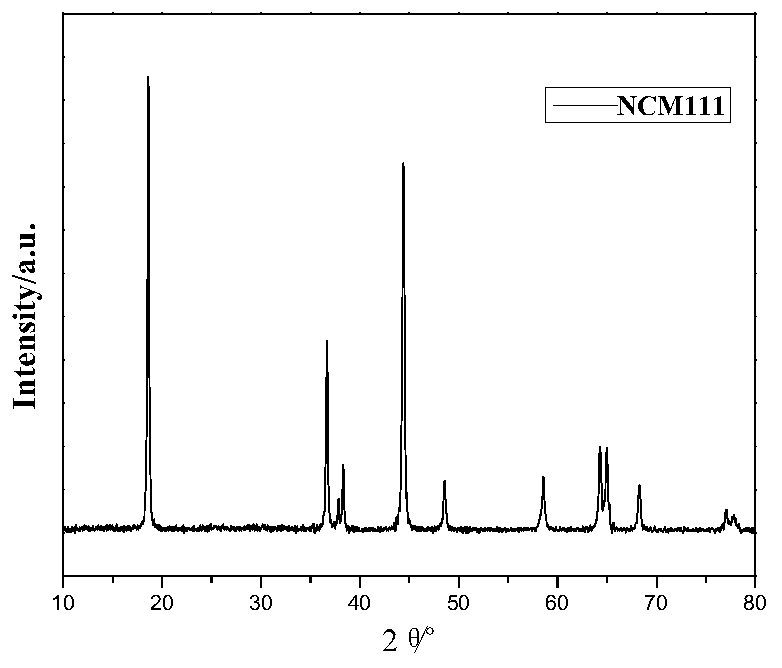

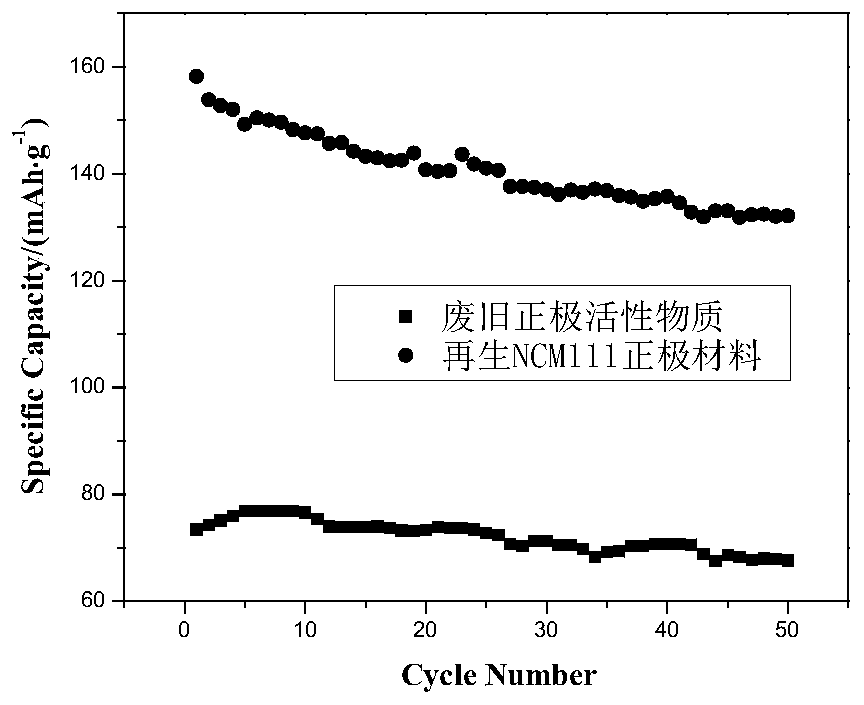

Method for recycling waste lithium battery positive electrode material under assistance of biomass waste

ActiveCN111430829AEasy to separateImprove crystal phasePositive electrodesWaste accumulators reclaimingSocial benefitsEnvironmental engineering

The invention discloses a method for recycling a waste lithium battery positive electrode material under the assistance of biomass waste, and belongs to the technical field of resource cyclic utilization. According to the method, the biomass waste is used as a reducing agent, and the recovery of a waste power lithium battery and the regeneration of a ternary positive electrode material are organically combined, so that the cyclic utilization of the waste power lithium battery is realized at low cost. The method is short in technological process and low in synthesis cost and is suitable for large-scale production, and the regenerated nickel-cobalt-manganese ternary positive electrode material is excellent in performance and has the very good economic benefits and social benefits.

Owner:湖南烯富环保科技有限公司

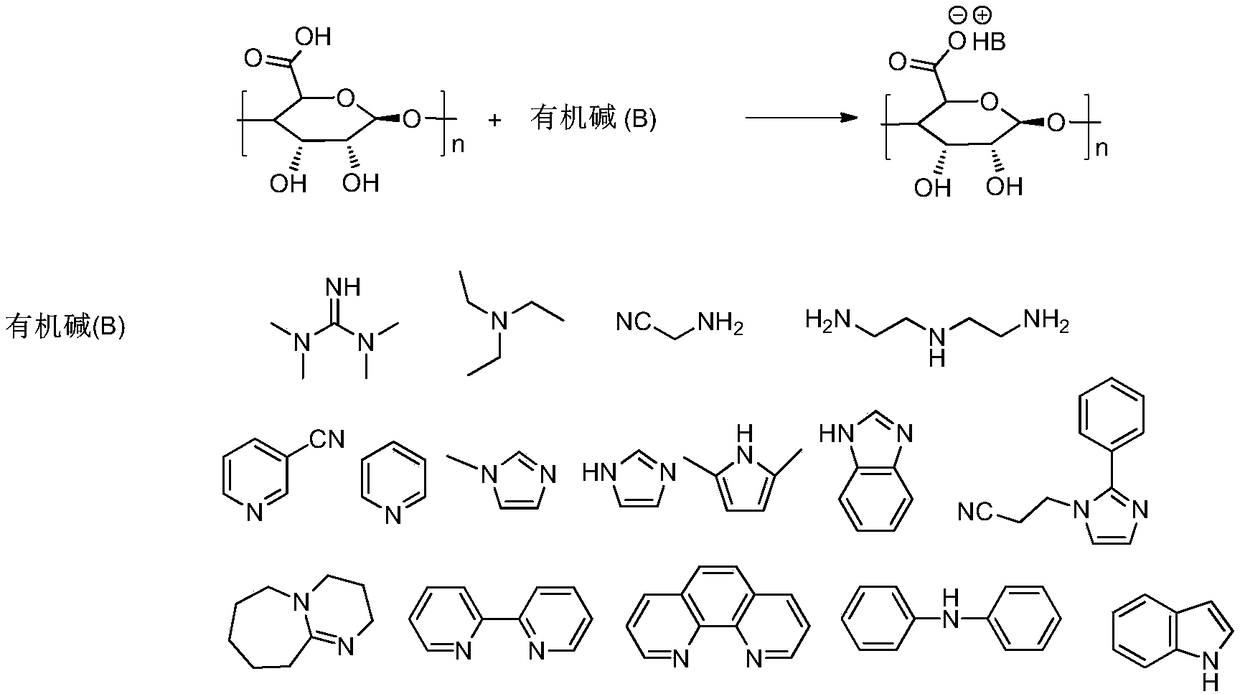

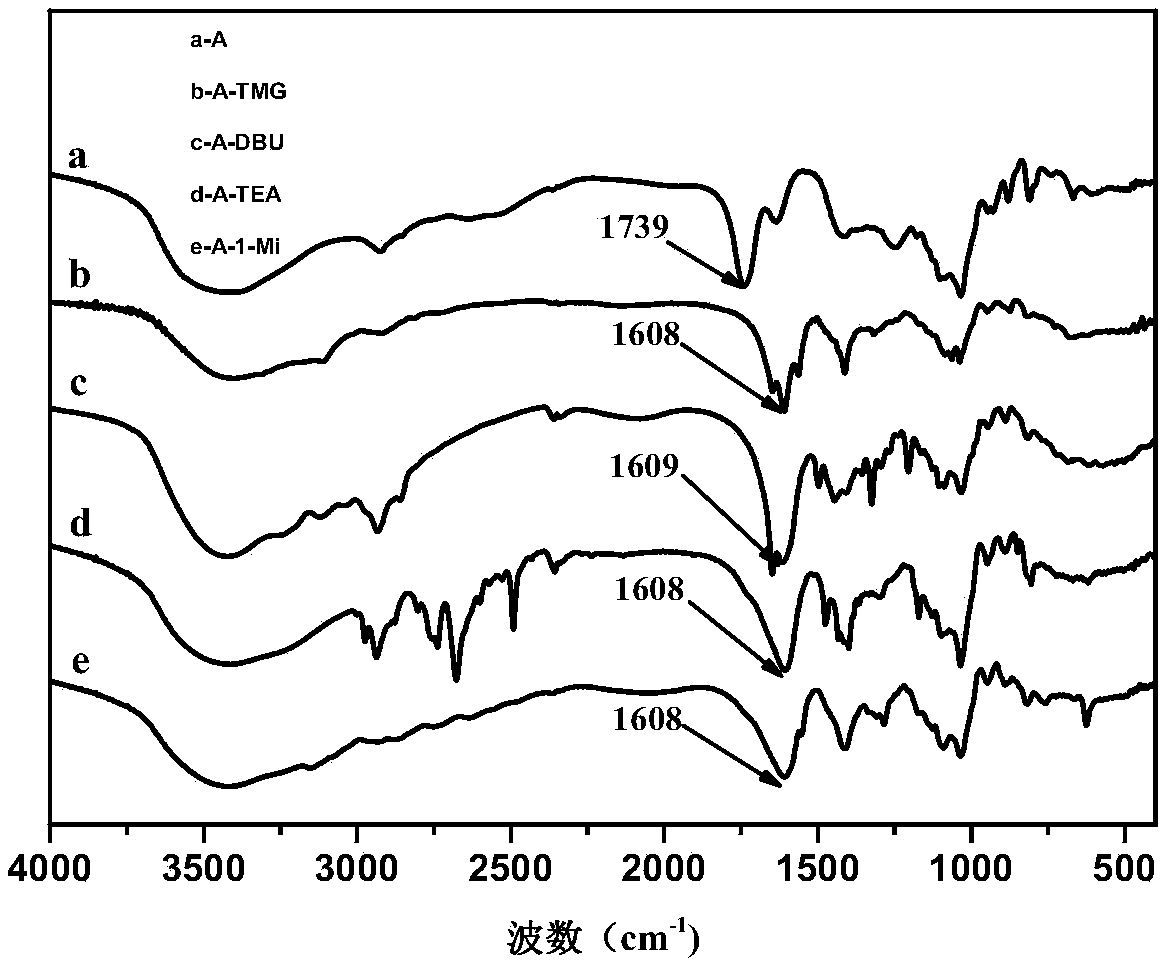

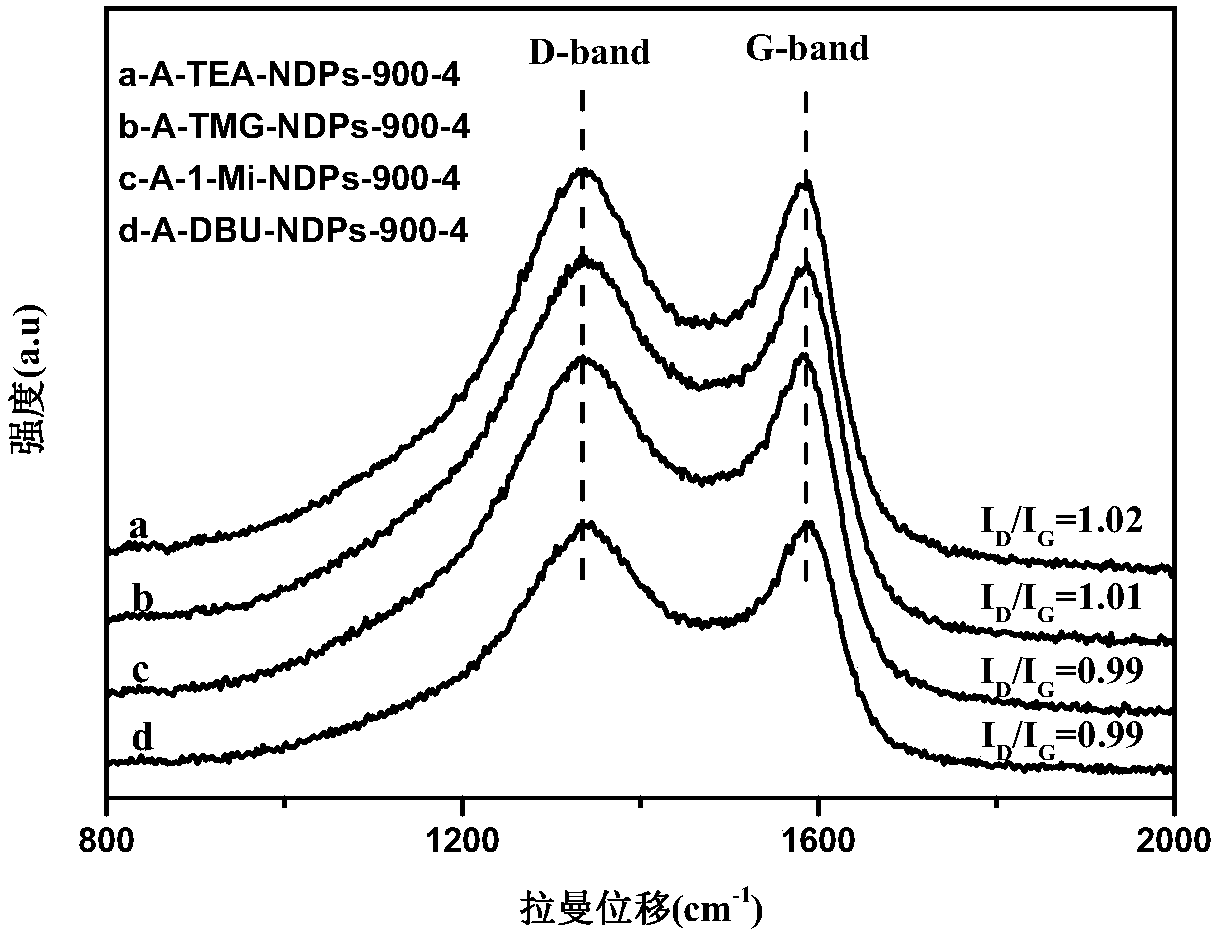

Preparation method and application of nitrogen-doped porous carbon material

ActiveCN108128765ASolve uncontrollable key problemsRealize high-value utilizationHybrid capacitor electrodesCarbon preparation/purificationPorous carbonProton

The invention discloses a preparation method and an application of a nitrogen-doped porous carbon material. A series of alginic acid proton ionic liquids are prepared based on the presence of a carboxyl group in the molecular structure of alginic acid by using a reaction of the carboxyl group and organic bases having different structures, the reaction is mild, the structures of the alginic acid proton ionic liquids can be easily and conveniently adjusted by regulating the structures of the organic bases in order to achieve the purpose of regulating the content and the kind of nitrogen in the nitrogen-doped porous carbon material and a precursor thereof, the alginic acid is doped with nitrogen in situ at the molecular level to solve the key problem of uncontrollability of a carbon source and a nitrogen source in order to realize the high-value utilization of a nitrogen-containing carbon material, and the alginic acid-based nitrogen-containing carbon material can be successful individually used as an electrode material, and can be successfully applied to the field of energy storage.

Owner:GUIZHOU UNIV

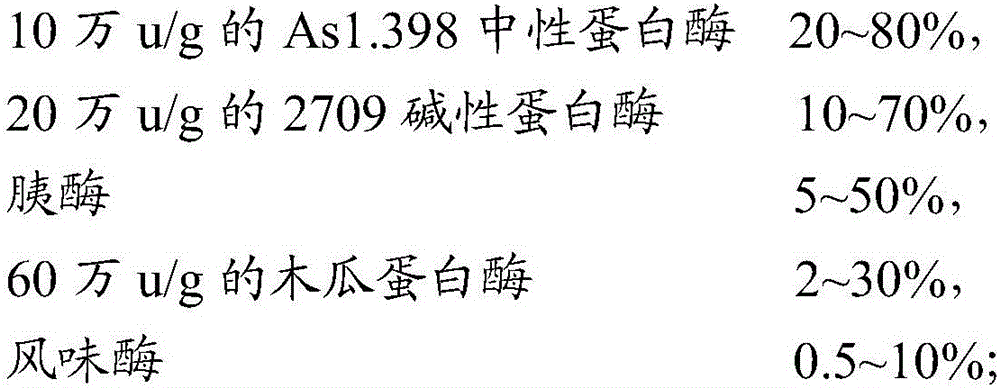

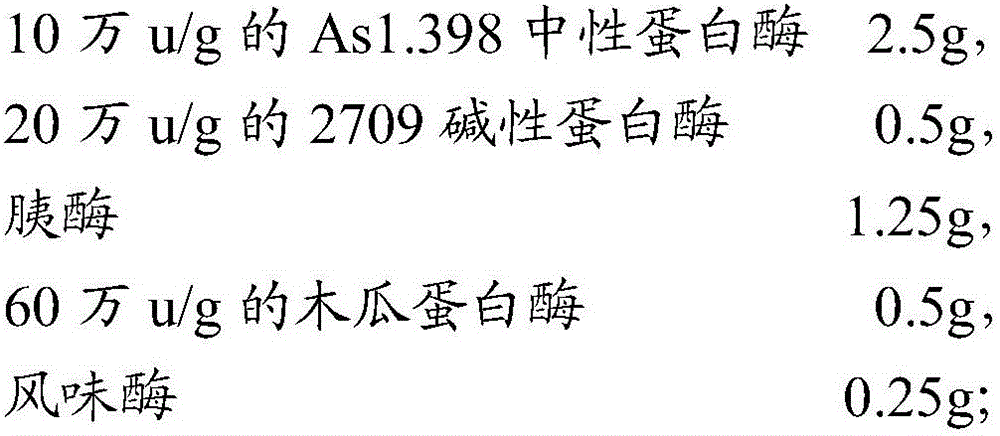

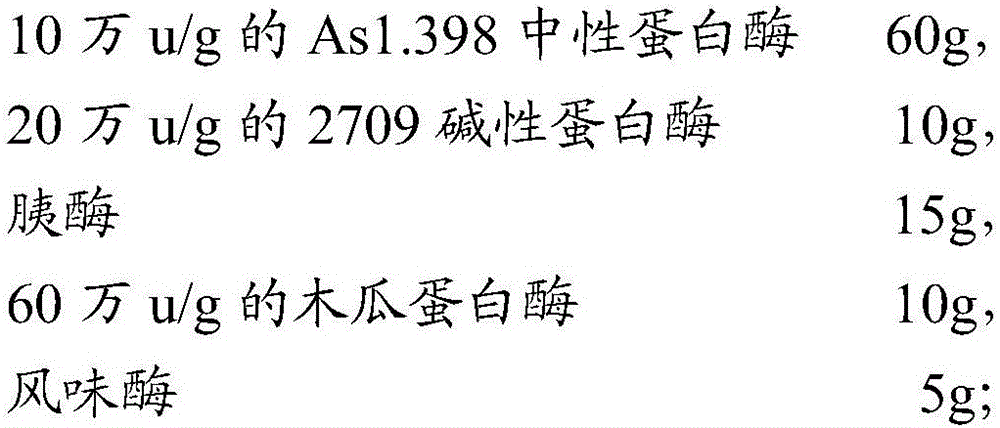

Method for extracting oligopeptide from algae to prepare alga oligopeptide powder

InactiveCN106119327AEasy extractionEffective enzymatic hydrolysisPeptide preparation methodsFermentationPectinaseFiltration

The invention provides a method for extracting oligopeptide from algae to prepare alga oligopeptide powder. The method includes steps: cleaning, airing and grinding algae to obtain alga powder; adding water for pulp grinding; heating alga pulp, adjusting pH to 3.3-4.0, adding pectinase, and stirring for enzymolysis; adding NaOH, adjusting pH to 7.0-9.0, adding compound protease, and stirring for enzymolysis; heating for enzyme deactivation, and performing solid-liquid separation and liquid phase collection; treating clear liquid according to a membrane filtration method, and collecting permeation liquid; subjecting the permeation liquid to electrodialysis, activated carbon refining, decarburization, evaporative concentration and drying to obtain the alga oligopeptide powder. The method is simple in process and reasonable in design, and small peptides are extracted from algae by enzymolysis to provide products beneficial to human health; high-value utilization of algae is realized, alga utilization rate is increased to make full use of natural resources, and influences of sea water quality and neritic organisms due to large-scale growth of algae are reduced.

Owner:DALIAN SHENLAN PEPTIDE TECH R & D CO LTD

Method for producing freeze thaw resisting ground water permeable bricks from gold and antimony mine tailings

ActiveCN105967753ANo color differenceRealize high value utilizationSolid waste managementCeramic shaping apparatusFreeze thawingBrick

The invention discloses a method for producing freeze thaw resisting ground water permeable bricks from gold and antimony mine tailings. The water permeable bricks with the advantages of high strength, high water permeability, good freeze thaw resistance and beautiful color are produced by using fine gold and antimony mine tailings with high content of silicon as basic raw materials, and adding certain amounts of cement, fly ash, river sands, an air entraining agent and an inorganic pigment. The production method comprises the following steps: producing a water permeable brick base blank; producing a water permeable brick coloring layer blank; digesting the above two blanks; carrying out wheel grinding; carrying out compaction molding and autoclaved curing. The produced water permeable brick has the advantages of high compressive strength, high water permeability and good freeze thaw resistance, is especially suitable for high and cold regions in western China, accords with national relevant standards, has certain environmental protection significance, and opens up a new way for comprehensive utilization of mine tailing resources.

Owner:CENT SOUTH UNIV

Method for preparing super capacitor based on biogas residue active carbon produced after biomass anaerobic dry fermentation

InactiveCN107644742ARealize high-value utilizationHigh specific capacitanceCarbon compoundsHybrid capacitor electrodesCapacitanceBiological activation

The invention discloses a method for preparing a super capacitor based on biogas residue active carbon produced after biomass anaerobic dry fermentation. The method for preparing the super capacitor based on the biogas residue active carbon after biomass anaerobic dry fermentation performs preprocessing on the biogas residues after biomass anaerobic dry fermentation, then performs high temperaturecarbonization and activation, and immerse an obtained activated product with acid and wash and dry the obtained activated product to obtain an activated carbon as a material of the electrode of the super capacitor. The active carbon prepared through the invention has an aperture structure on which micro holes and middle holes are distributed, has a relatively high specific surface area and has relatively high specific capacitance and cycling stability and is a relatively ideal electrode material of the super capacitor. The method for preparing the super capacitor based on biogas residue active carbon produced after biomass anaerobic dry fermentation uses the biogas to prepare a super capacitor so as to realize high value utilization of the biogas residual and the obtained active carbon isstable in structure and developed in pores, has a relatively high specific capacitance and cycle stability and is a relatively ideal electrode material of the super capacitor.

Owner:HEFEI UNIV OF TECH

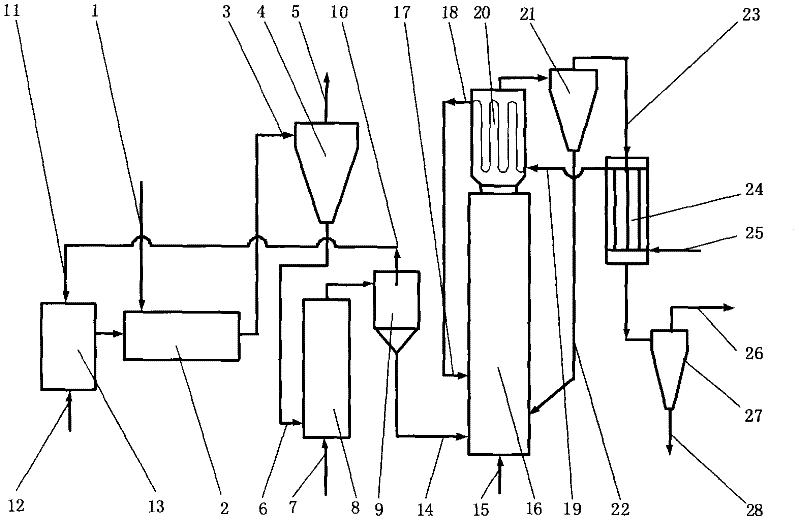

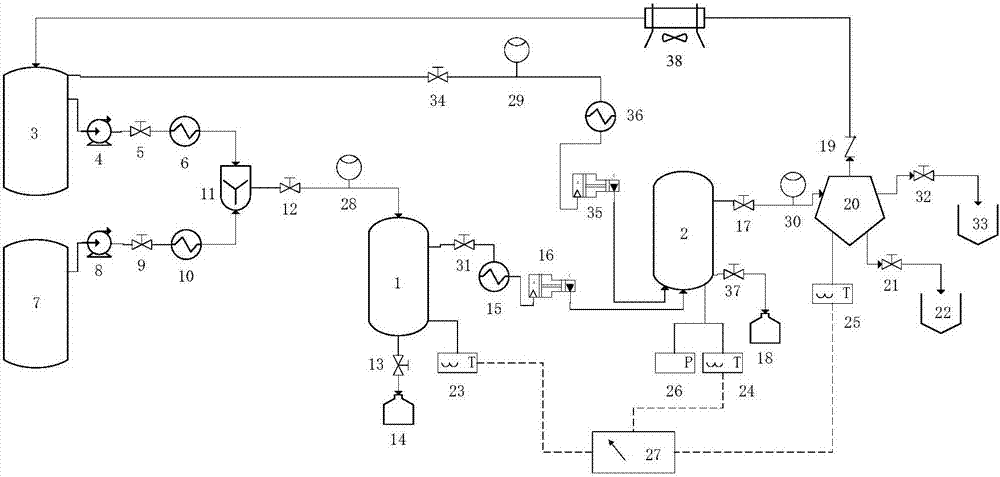

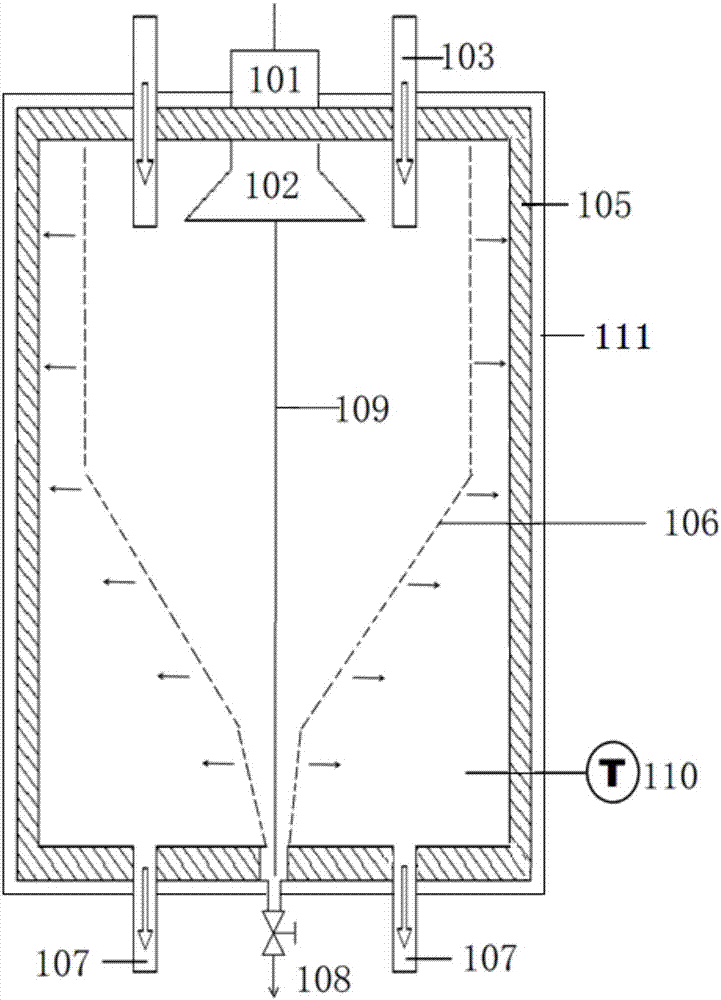

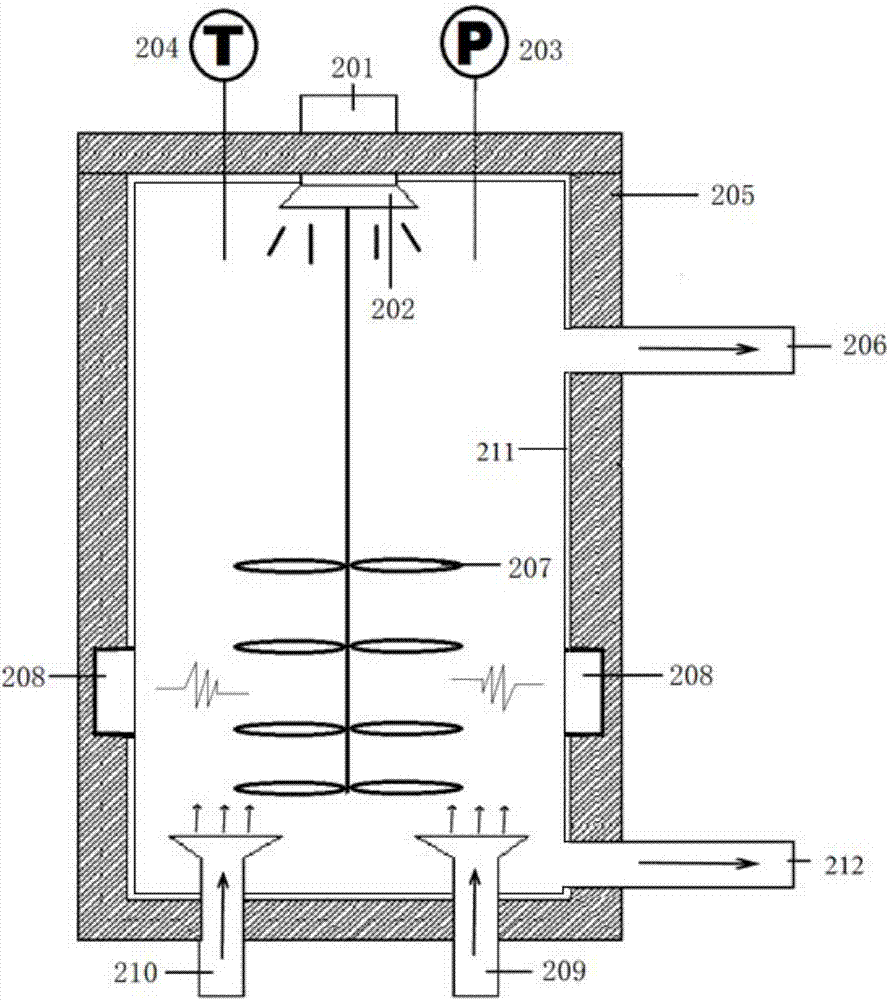

Catalytic cracking oil slurry pretreatment system and pretreatment method by utilization of system

ActiveCN106929096AAvoid wastingAchieve high valueTreatment with plural serial refining stagesProcess equipmentPretreatment method

A catalytic cracking oil slurry pretreatment system and a pretreatment method by the utilization of the system are disclosed. The invention relates to the field of comprehensive utilization of catalytic cracking oil slurry, specifically to a catalytic cracking oil slurry pretreatment device, a system thereof and a pretreatment method. The invention aims to solve the problem of low efficiency during the process of catalytic cracking oil slurry pretreatment. The system comprises a solvent tank, a catalytic cracking oil slurry tank, a mixer, an ultrasonic centrifuge device, an ultrasound-assisted microwave-enhanced supercritical extraction device, a separator, a solid particle gathering tank, a heavy components collector and a light components collector. Through a raw material mixing unit, a solid-liquid separation unit, a solvent extraction unit, a components separation unit and a solvent recovery unit, catalyst granules and oil slurry are separated, and separation of light and heavy components of oils and precision cutting extraction are realized. The method has advantages of simple process equipment and good separation effect.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com