Patents

Literature

1661 results about "Coal water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal water slurry refers to the new coal-based fuel which appears in the 70s. It combines 65% coal, 34% water and 1% chemical additives. After certain technological processing, the coal water slurry is with the following advantages: low ash and sulfur; lower temperatures of the combustion flame center; high combustion efficiency; low discharge of ash, SO₂ and NOₓ comparing with fuel and coal. For the long-term consideration of energy strategy, most countries start the research, development and storage of coal water slurry and even achieve the commercial use.

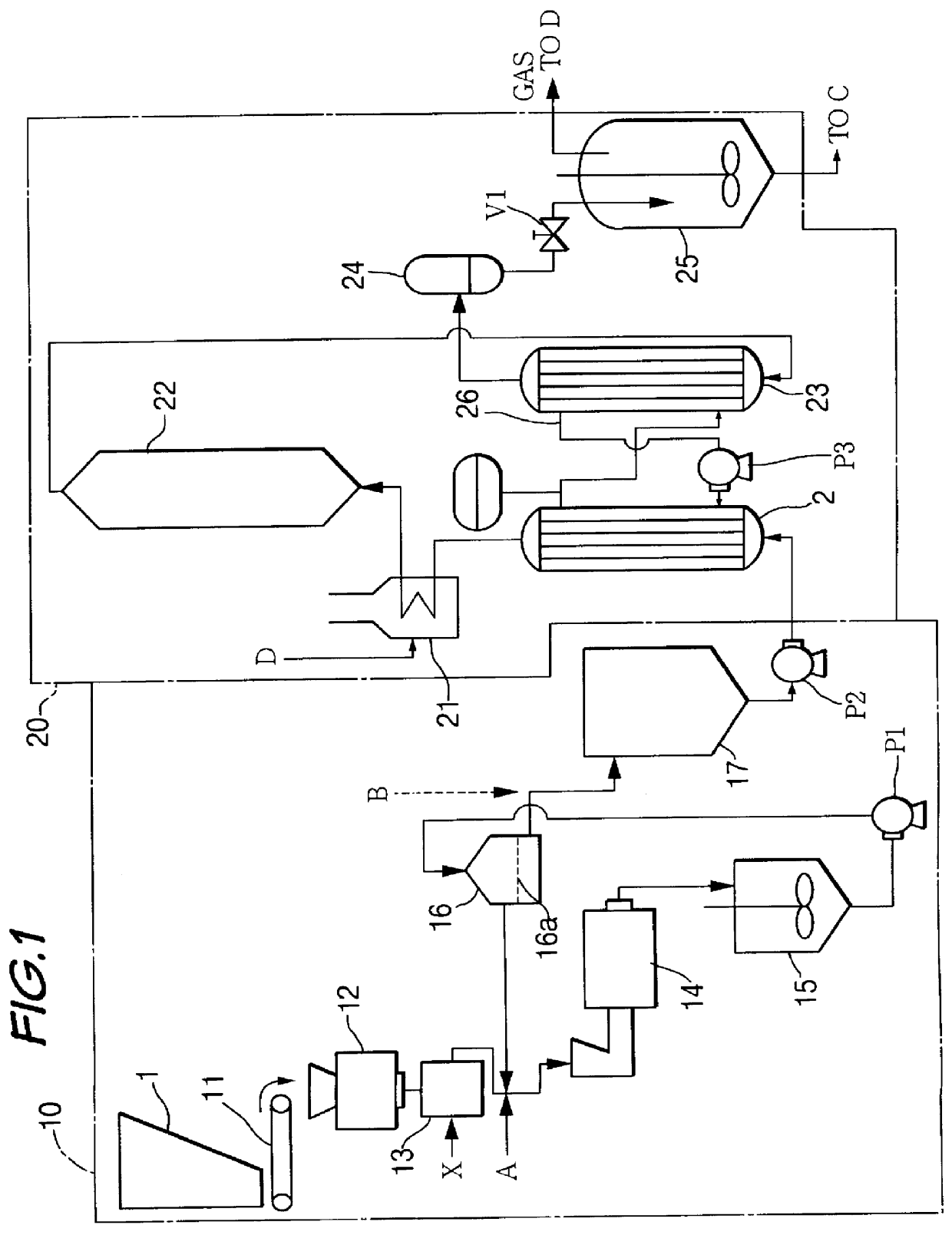

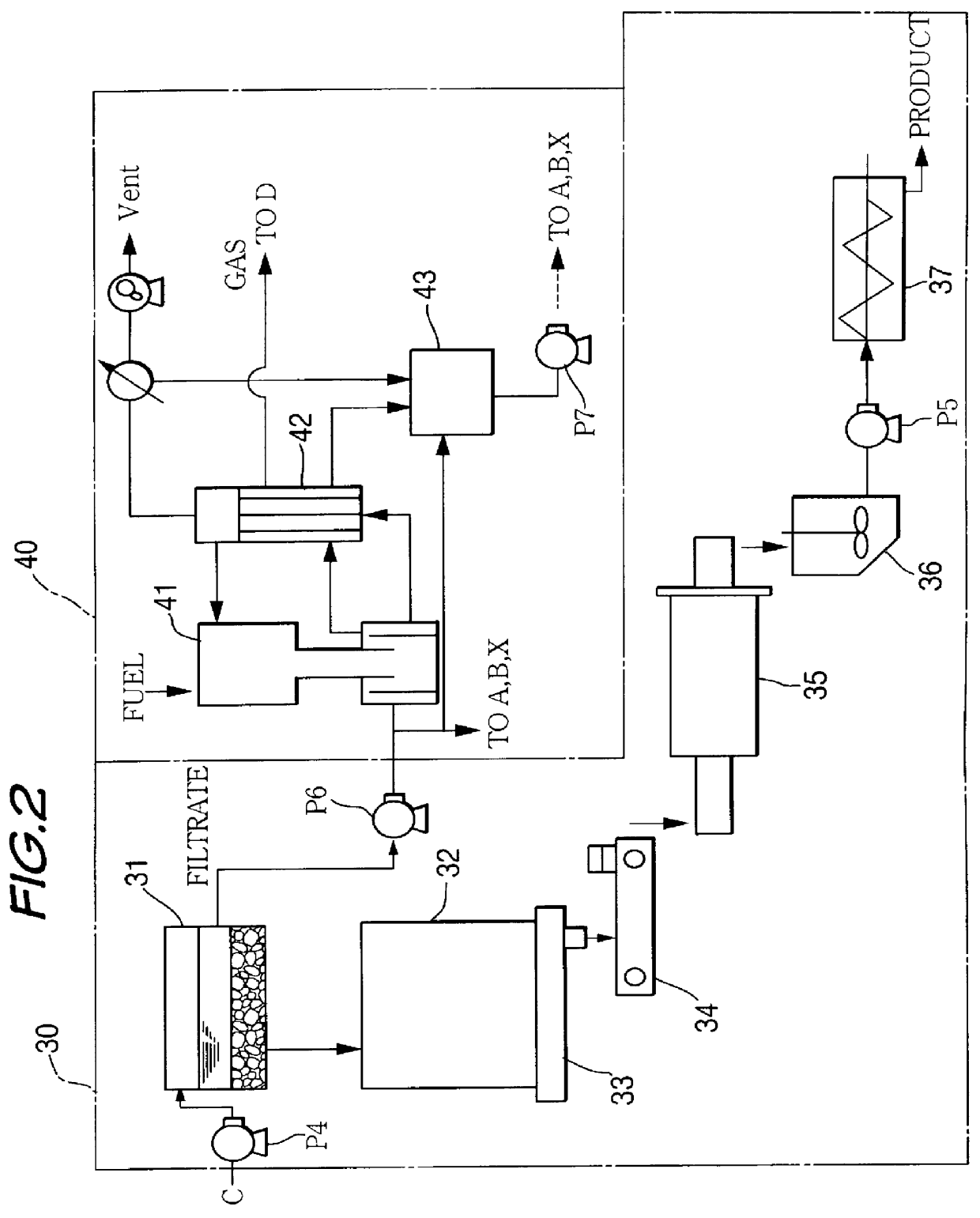

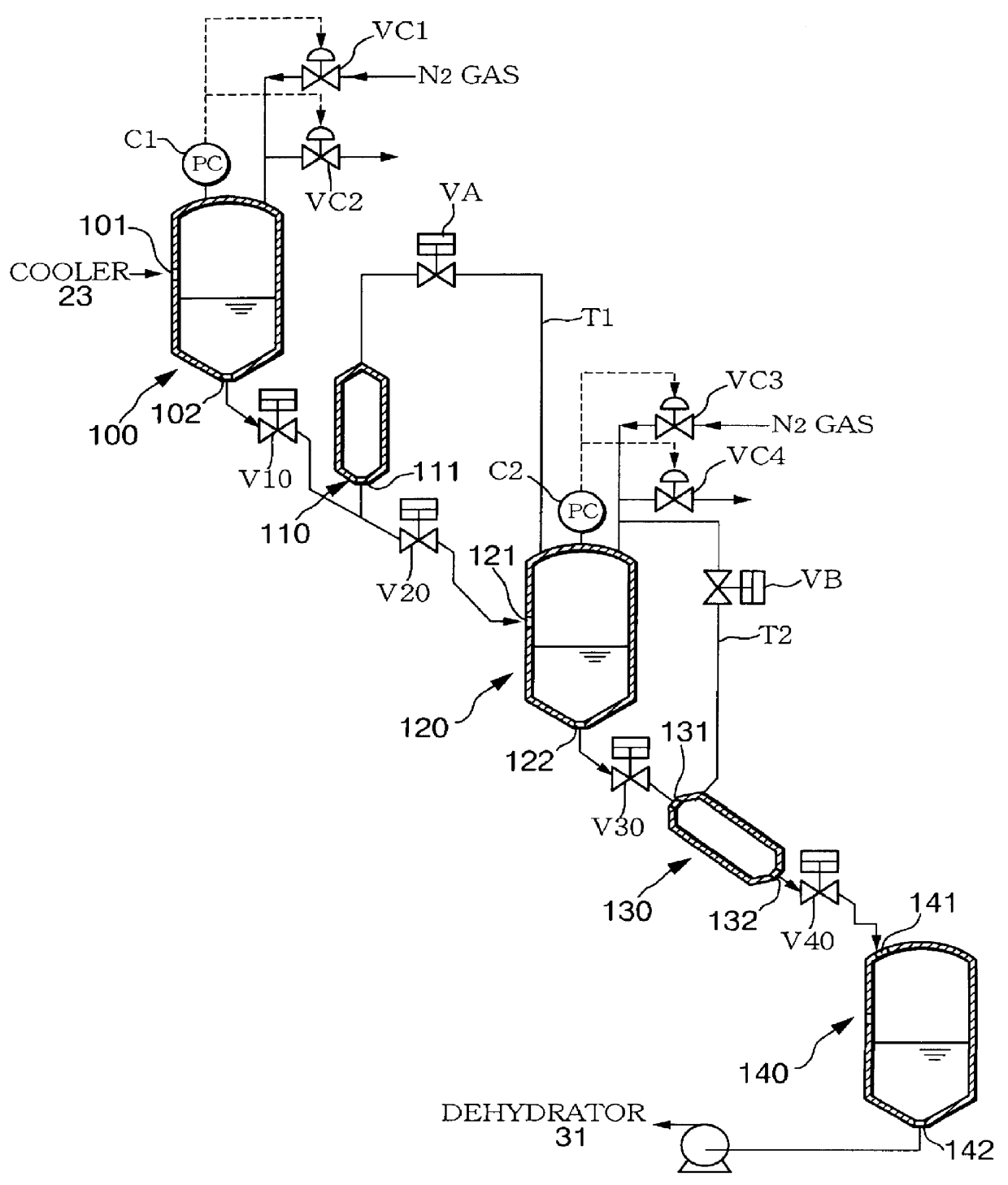

Coal-water slurry producing process, system therefor, and slurry transfer mechanism

In a coal-water slurry producing system, low grade coal is wet-ground to not greater than 3 mm in particle size to produce a ground coal slurry. An upgrading treatment is applied to the ground coal slurry under a pressurized hydrothermal atmosphere not less than 300 DEG C. to produce an upgraded coal slurry. The upgraded coal slurry is subjected to a dehydration treatment to produce an upgraded coal cake and a filtrate. A final coal-water slurry is produced from the upgraded coal cake. The filtrate is recycled for producing the ground coal slurry. A slurry transfer mechanism is provided in the coal-water slurry producing system for ensuring a stable transfer of the upgraded coal slurry from a high-pressure slurry vessel to a low-pressure slurry vessel.

Owner:JGC CORP

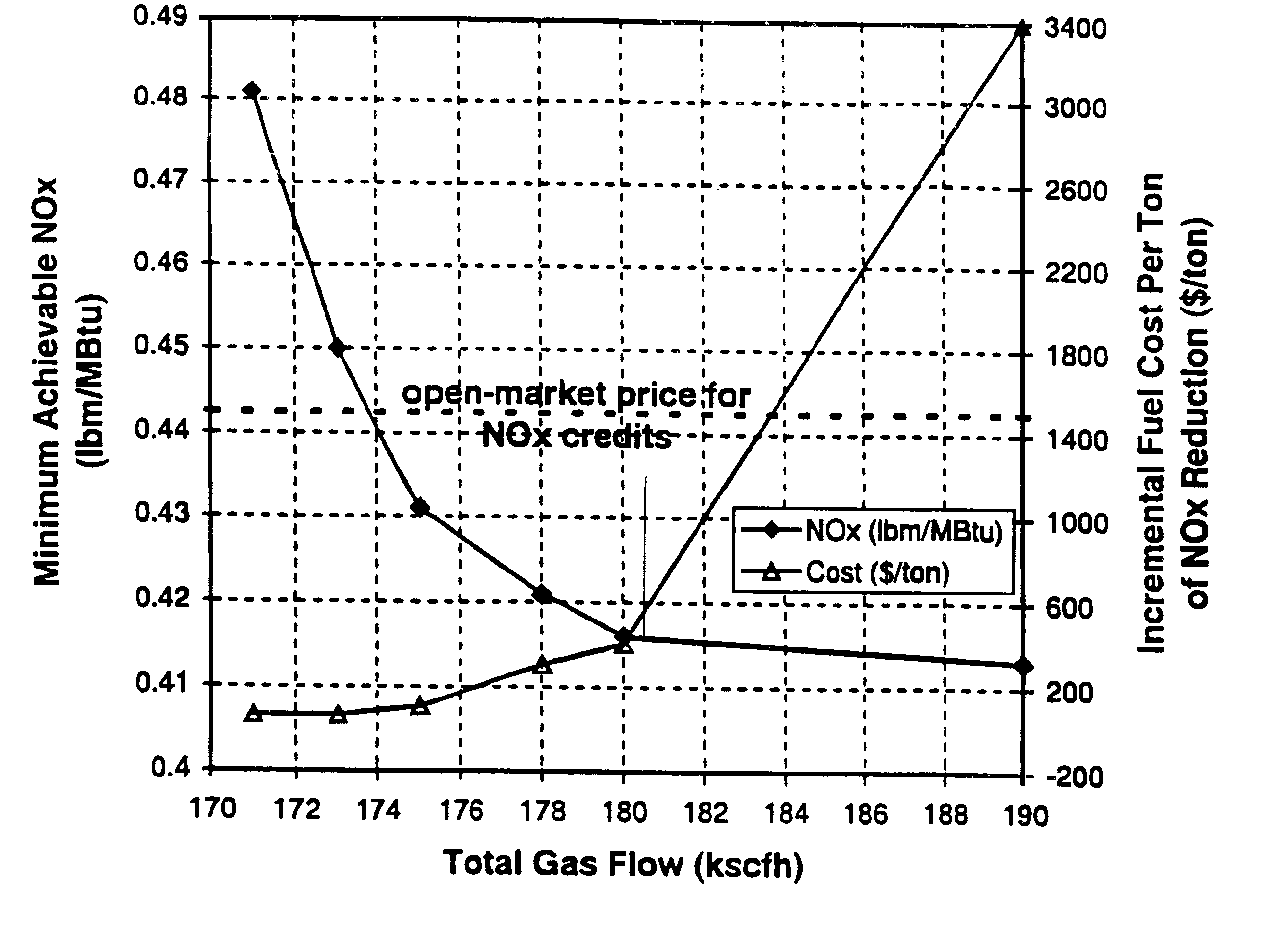

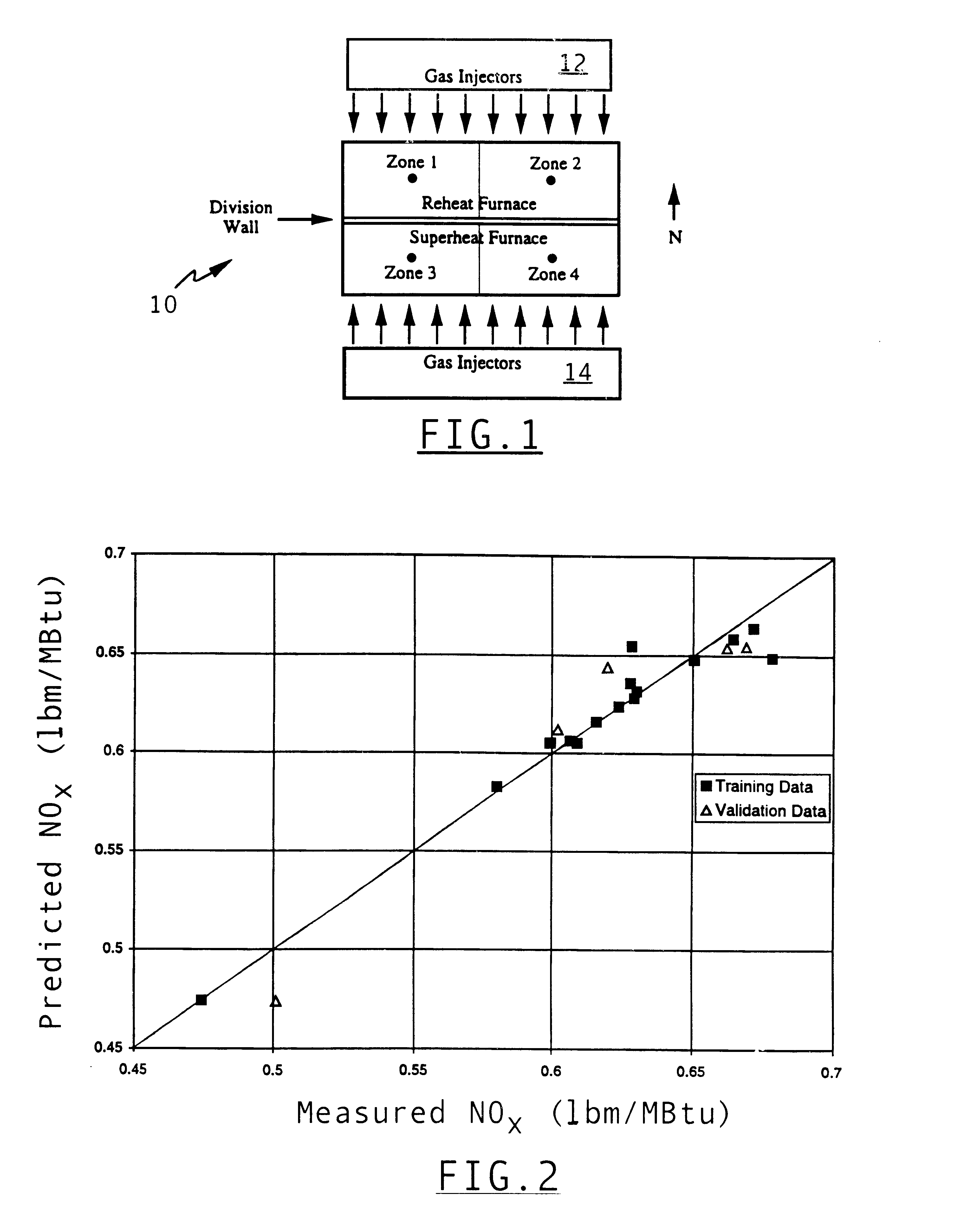

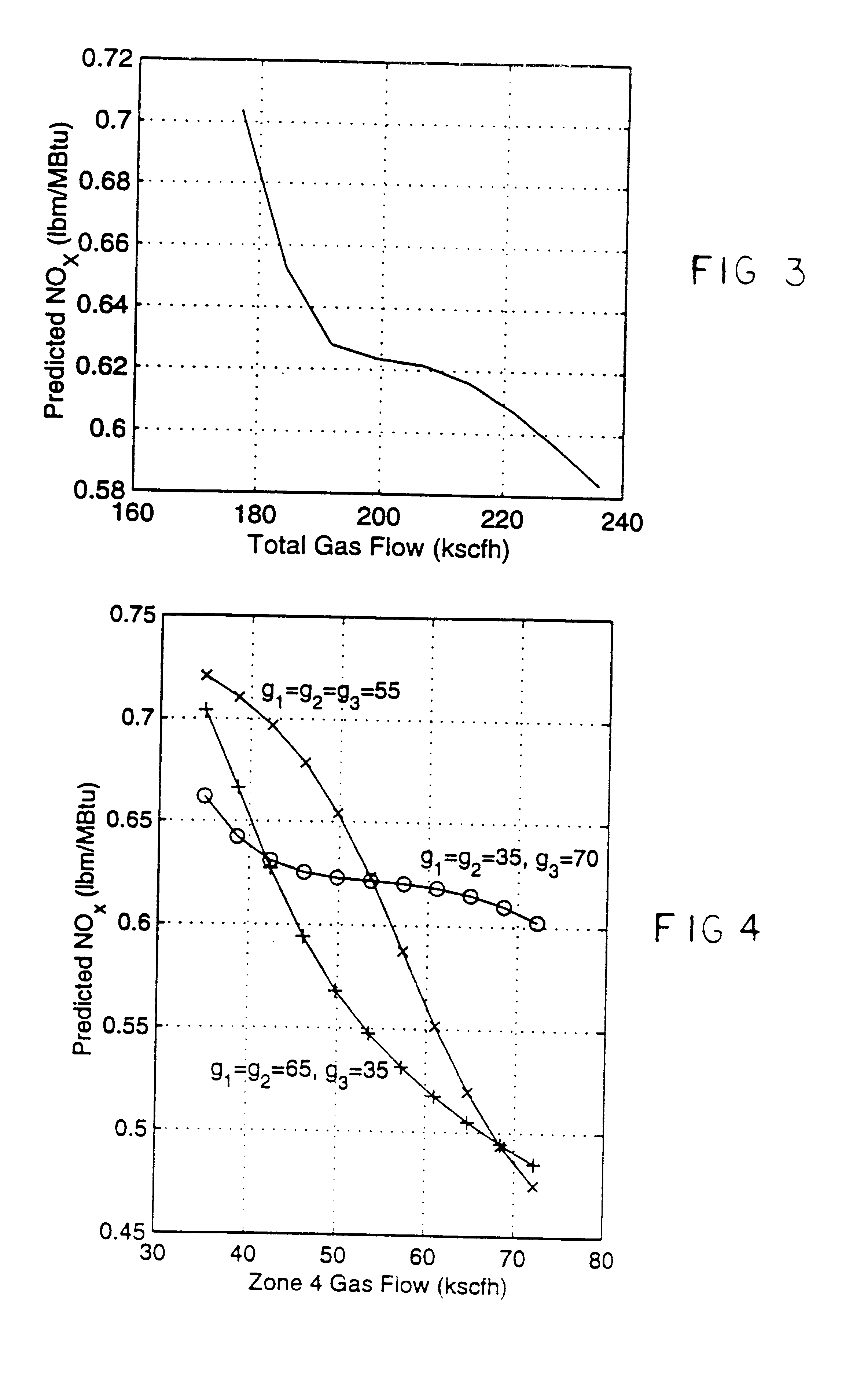

Intelligent emissions controller for substance injection in the post-primary combustion zone of fossil-fired boilers

InactiveUS6507774B1Emission reductionReduce pollutant emissionsSampled-variable control systemsCombustion signal processingWater oil emulsionU s economy

The control of emissions from fossil-fired boilers wherein an injection of substances above the primary combustion zone employs multi-layer feedforward artificial neural networks for modeling static nonlinear relationships between the distribution of injected substances into the upper region of the furnace and the emissions exiting the furnace. Multivariable nonlinear constrained optimization algorithms use the mathematical expressions from the artificial neural networks to provide the optimal substance distribution that minimizes emission levels for a given total substance injection rate. Based upon the optimal operating conditions from the optimization algorithms, the incremental substance cost per unit of emissions reduction, and the open-market price per unit of emissions reduction, the intelligent emissions controller allows for the determination of whether it is more cost-effective to achieve additional increments in emission reduction through the injection of additional substance or through the purchase of emission credits on the open market. This is of particular interest to fossil-fired electrical power plant operators. The intelligent emission controller is particularly adapted for determining the economical control of such pollutants as oxides of nitrogen (NOx) and carbon monoxide (CO) emitted by fossil-fired boilers by the selective introduction of multiple inputs of substances (such as natural gas, ammonia, oil, water-oil emulsion, coal-water slurry and / or urea, and combinations of these substances) above the primary combustion zone of fossil-fired boilers.

Owner:ENERGY SYST ASSOCD +1

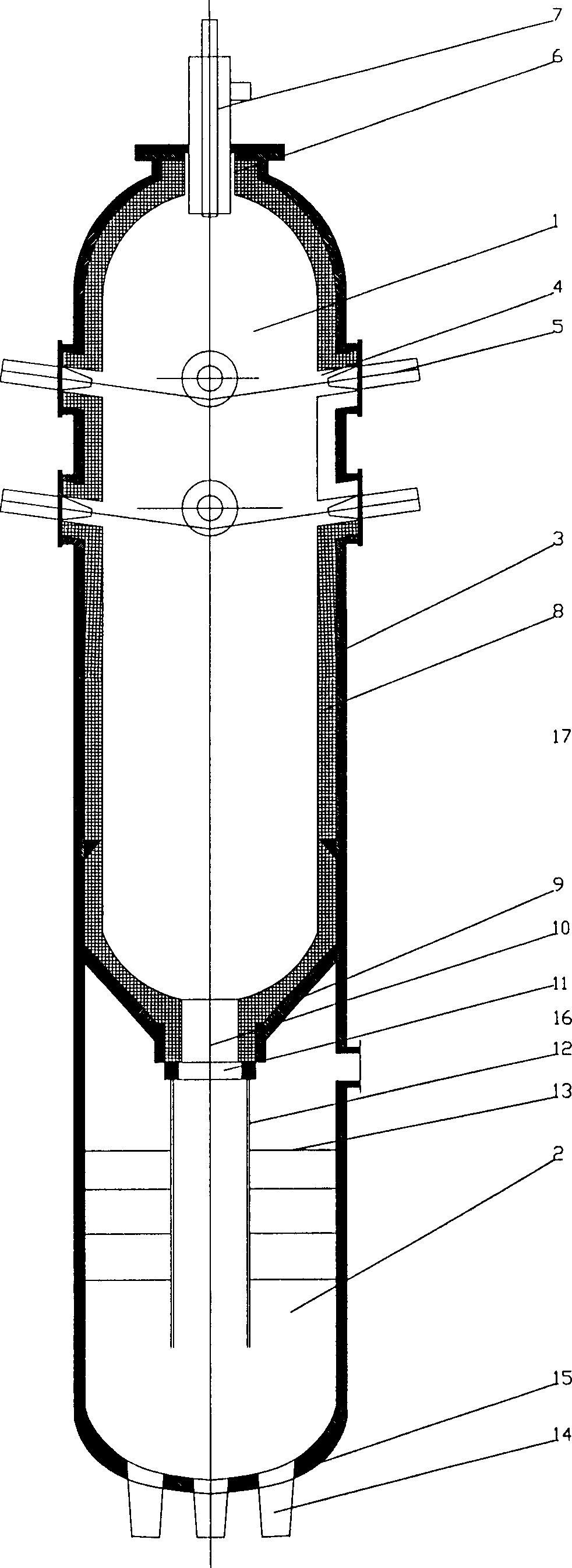

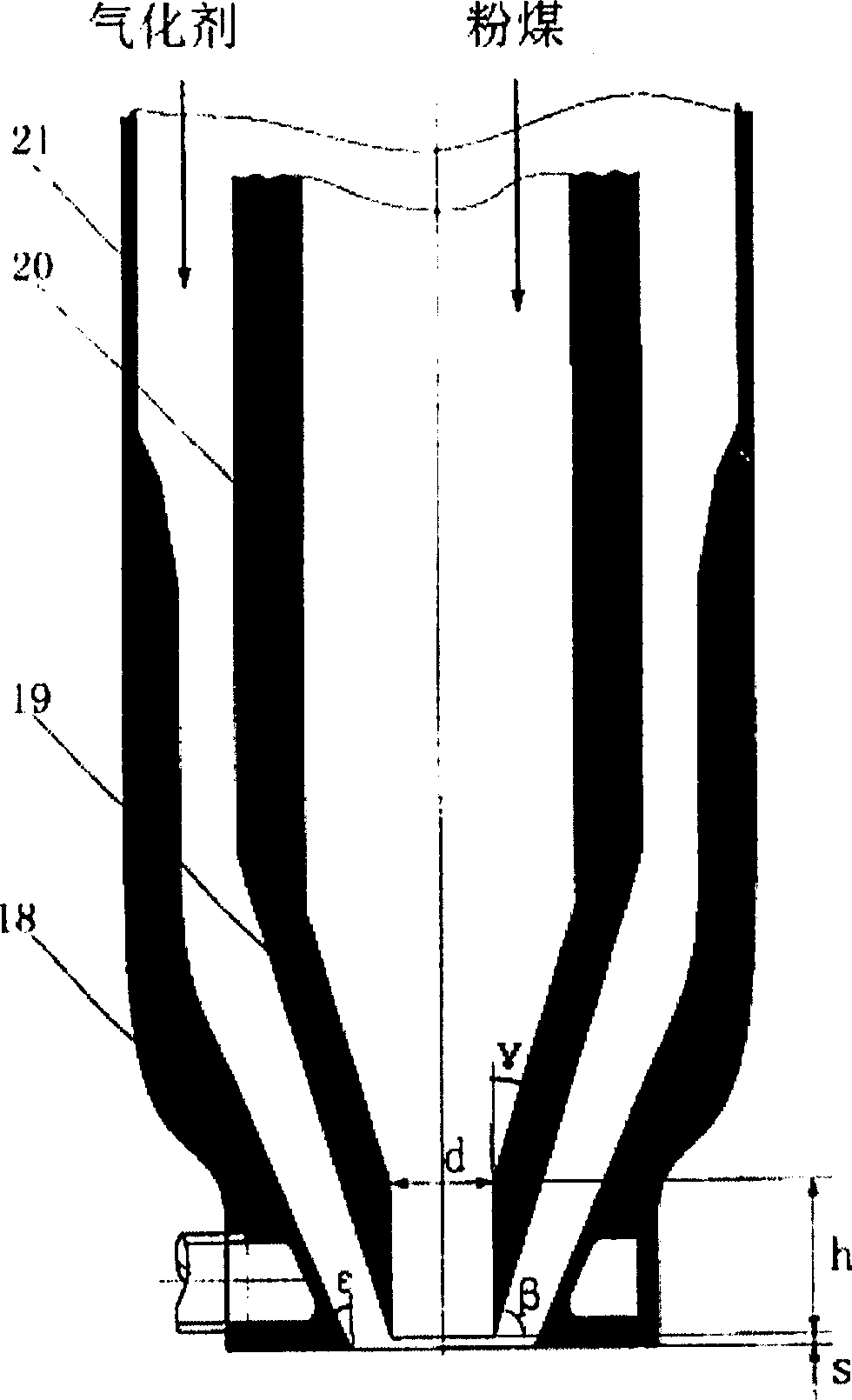

Multi-nozzle coal water mixture or fine coal gasifying furnace and its industrial application

ActiveCN1775920AUniform temperature distributionLess investmentCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterSlag

The invention discloses a plural muzzles coal water slurry or fine coal gasification furnace used for gasifying coal water slurry or fine coal. The gasification room is made up of case, process muzzle room, process muzzle, preheating muzzle room, and preheating muzzle. The case has firebricks in it and washing cooling room is made up of chilling circle, down take, vesicle breaking stick and roughing slag outlet. The transforming ratio of the furnace is over 98%, and is especially suited for large scale gasification produce technology that produces 3000-5000T / day.

Owner:EAST CHINA UNIV OF SCI & TECH

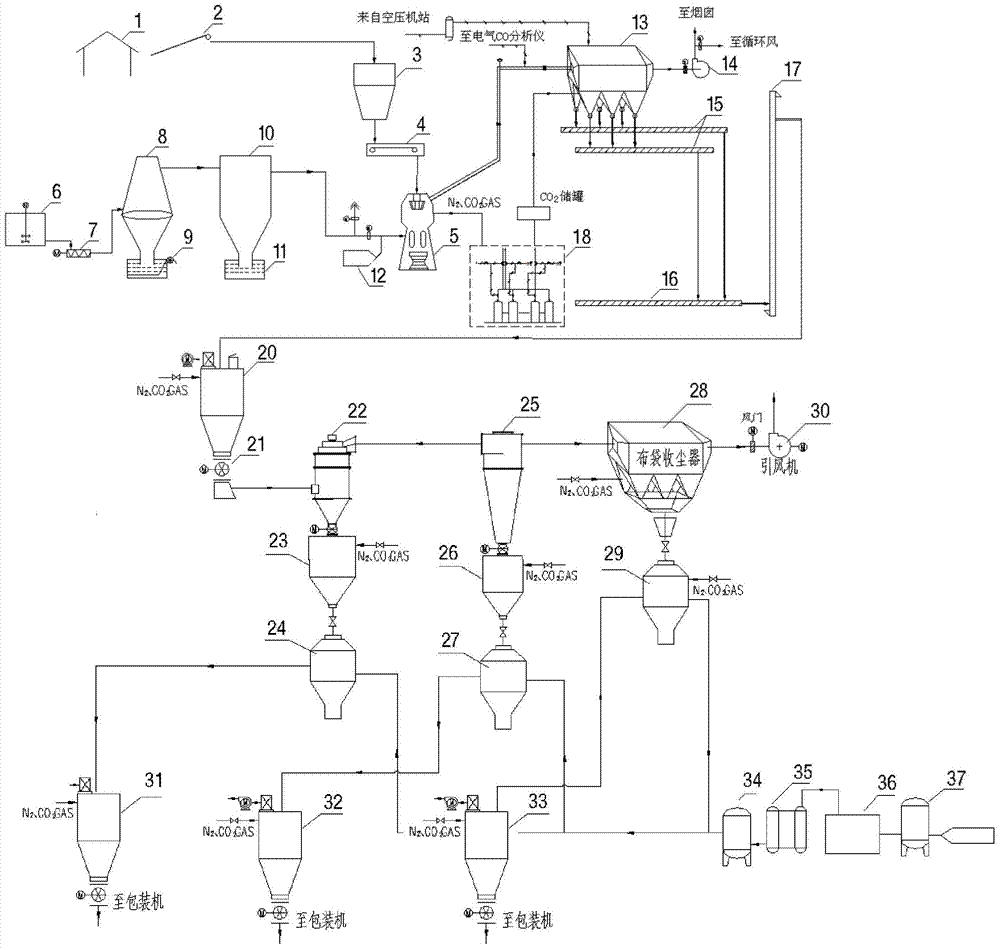

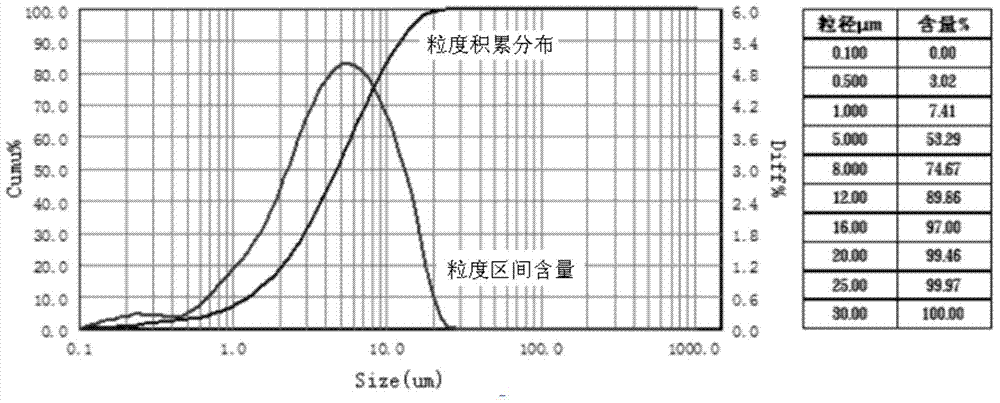

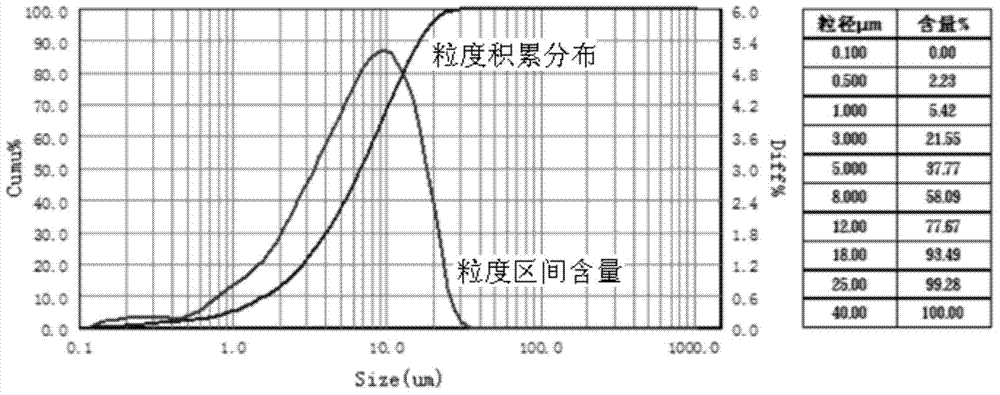

Method for preparing high concentration water-coal-slurry by low-rank coal

ActiveCN101173765AImprove particle size distributionReduce preparation energy consumptionLump/pulverulent fuel preparationHigh concentrationCoal water

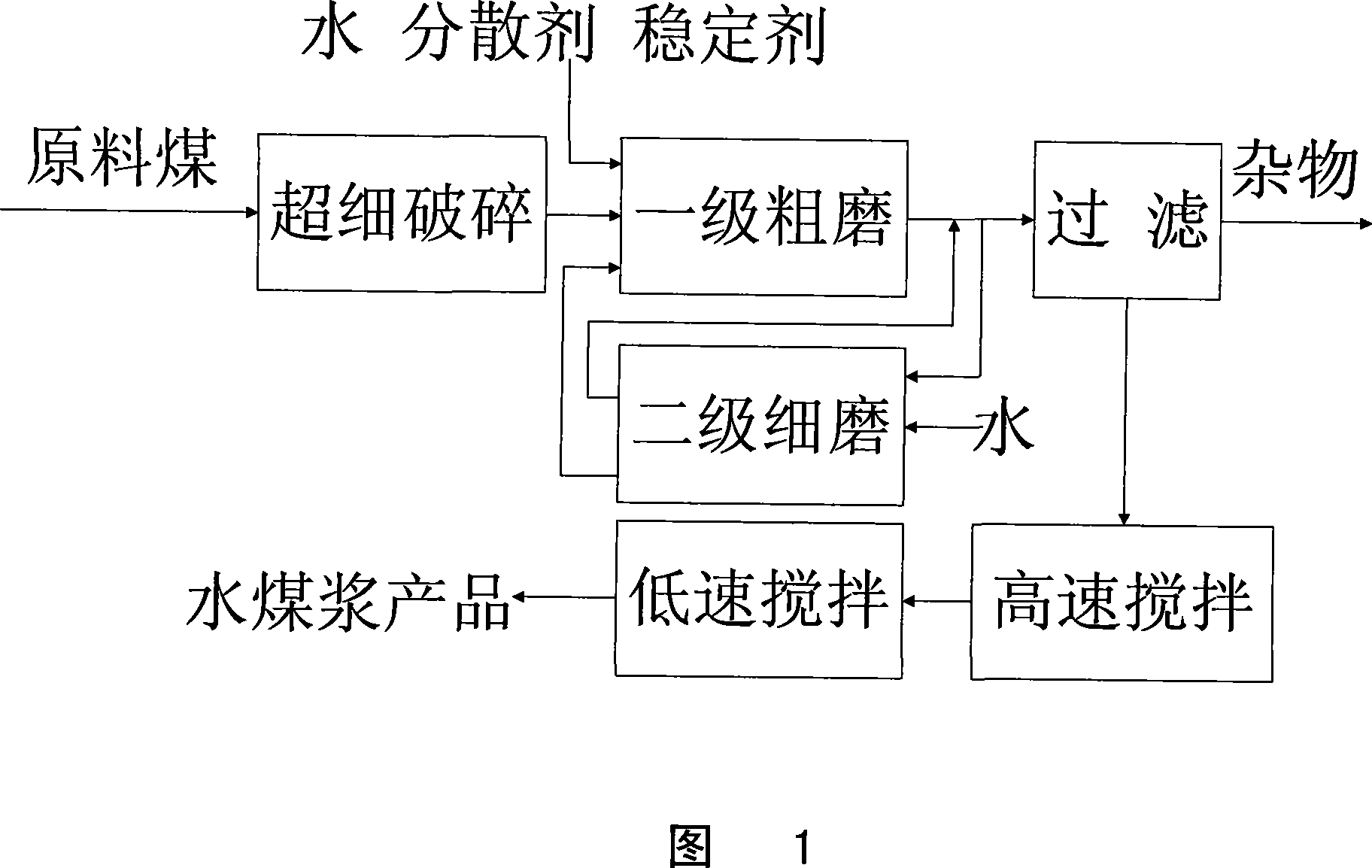

The invention relates to a method for preparing high-concentration coal-water slurry by using low-rank coal. The steps include: 1) ultrafine crushing of low-rank coal; 2; 3) wet coarse grinding of the mixture; 4) ① mix 10% to 30% of the total amount of coal slurry after coarse grinding with water in a mass ratio of 5:1 to 2, and then carry out Wet fine grinding; ②The coal slurry after wet coarse grinding other than wet fine grinding is directly sent to the filter device; 5) The coal slurry after step 4) ① fine grinding is processed in the following way: ①Return all the coal slurry to step 3 ) for circulating coarse grinding; or ② return part of the coal slurry to step 3) for circulating coarse grinding, and send another part of finely ground coal slurry directly into the filter device; or ③ directly send all the coal slurry into the filter device; 6) The coal slurry sent to the filter device is filtered through a 18-20 mesh filter, and then stirred at a high speed in the stirring device, left standing, or stirred at a low speed to obtain a high-concentration coal-water slurry product.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

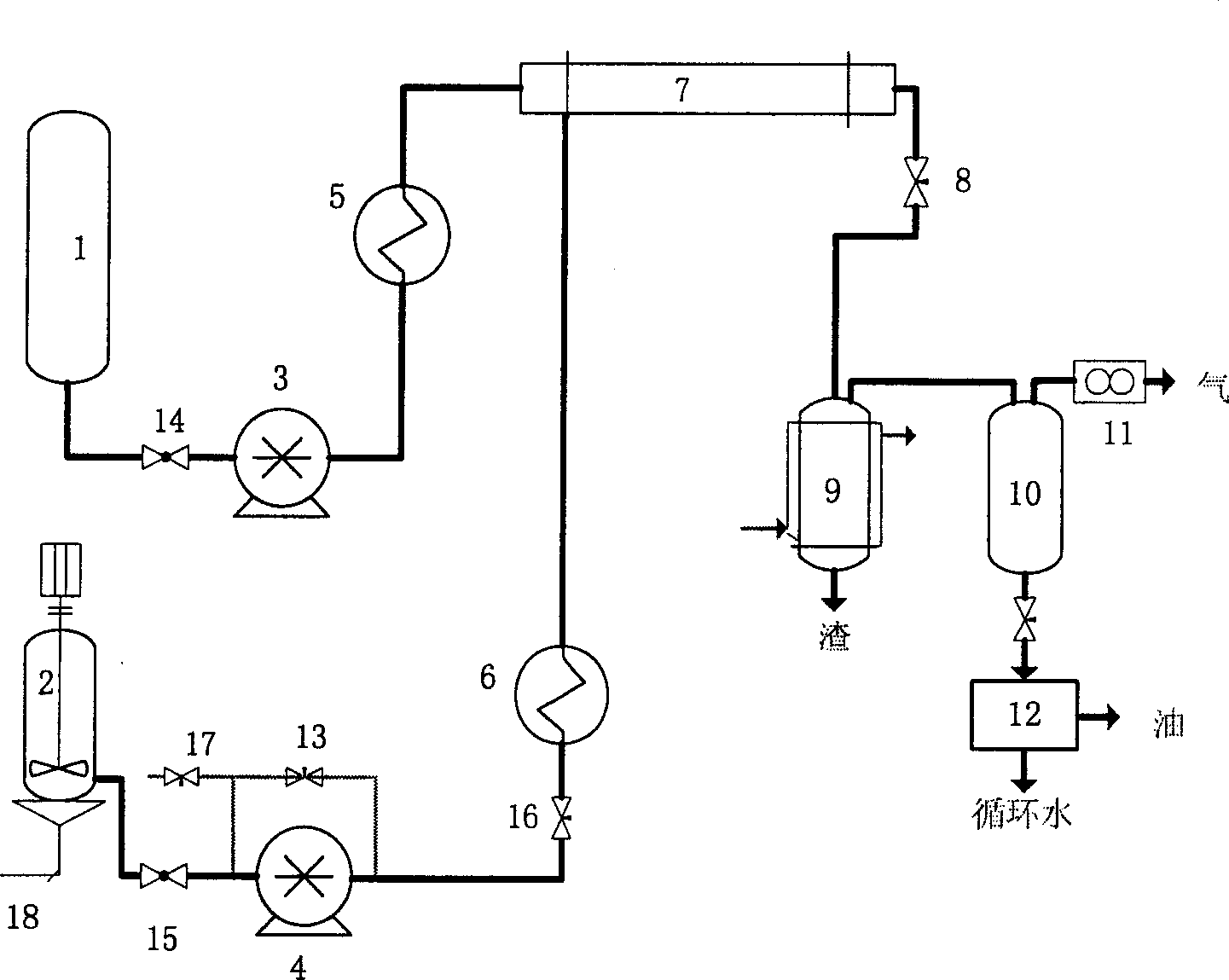

Method for continuous conversion of low-rank coal in subcritical water or supercritical water

ActiveCN1544580ANo emissionsQuick responseLiquid hydrocarbon mixture productionSolid solvent extractionCoal waterLower grade

The invention discloses a process for preparing coal water slurry or the mixture of coal water slurry with alkaline metal and / or alkaline earth oxides or hydroxides by the method of low level coal continuous transformation in subcritical or supercritical water which comprises, conducting continuous high pressure conveying of coal water slurry, charging into reaction system, usting the peculiarity of the hypercritical water to extracting and pyrolising low grade coal, converting it into useful product in gas, liquid and solid forms.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

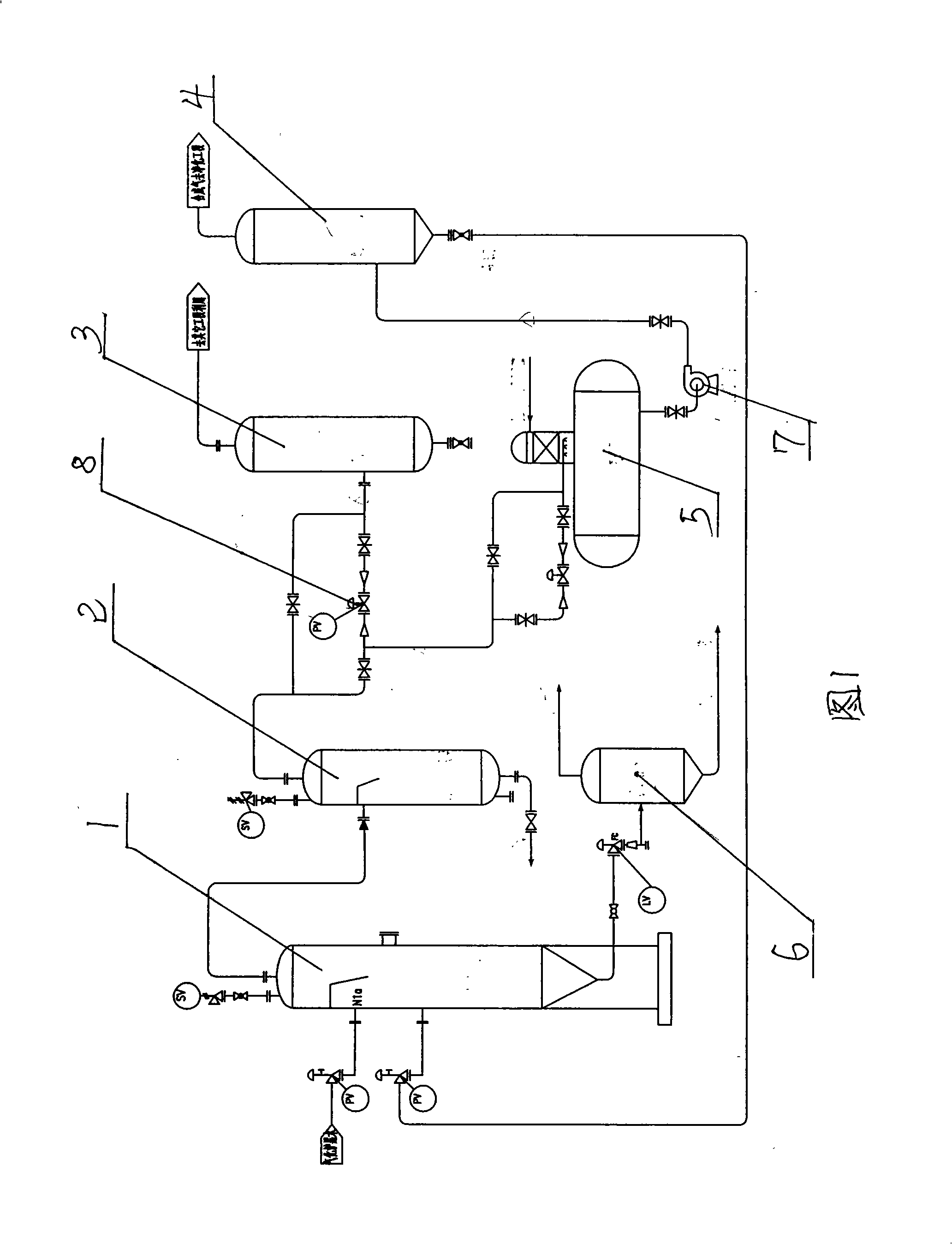

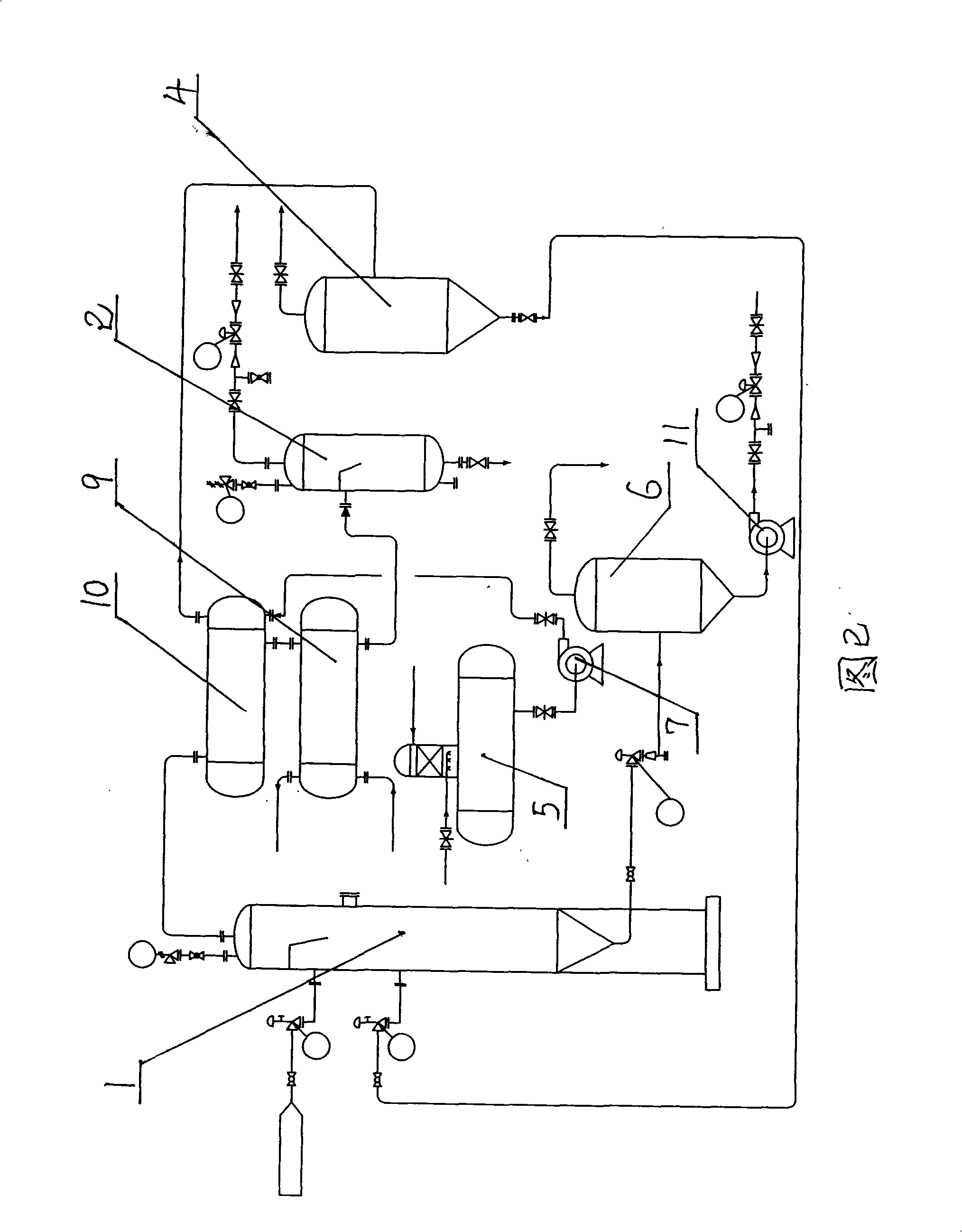

Grey water treatment technology for graded gasification furnace

InactiveCN101306899AImprove transfer efficiencyTake advantage ofMultistage water/sewage treatmentWater/sewage treatment by heatingGas phaseDeaerator

The invention belongs to the ash water processing technology for gasification of coal water slurry in gasified ash water, in particular relating to an ash water processing technique applied in a staged gasification furnace. The technique solves the problems in the prior art of complex structure, energy waste, trivial technological operation and so on. The method comprises the following steps that: black water exhausted from the staged gasification furnace and a syngas scrubber respectively enters into a high-pressure flash tank after decompressed by respective pipes; liquid phase after high-flash flash evaporation in the high-pressure flash tank passes through a pressure-reducing valve and enters into a vacuum flash tank for secondary flash evaporation; the liquid phase after vacuum flash evaporation in the vacuum flash tank enters into a settling tank the position of which is lower than that of the vacuum flash tank for settlement by means of gravity action; gas phase after high-flash flash evaporation in the high-pressure flash tank enters into a separator on the top of the high-flash tank for gas-liquid separation; and one part of separated gas phase enters into a deaerator and directly contacts the ash water for heat exchange, and the other part of the steam enters into a steam buffer tank through a pressure control valve. Compared with the prior flow, the adoption of the flow saves equipment investment by 3 million; and about 10 tons of steam is supplied in normal operation.

Owner:山西丰喜肥业(集团)股份有限公司临猗分公司

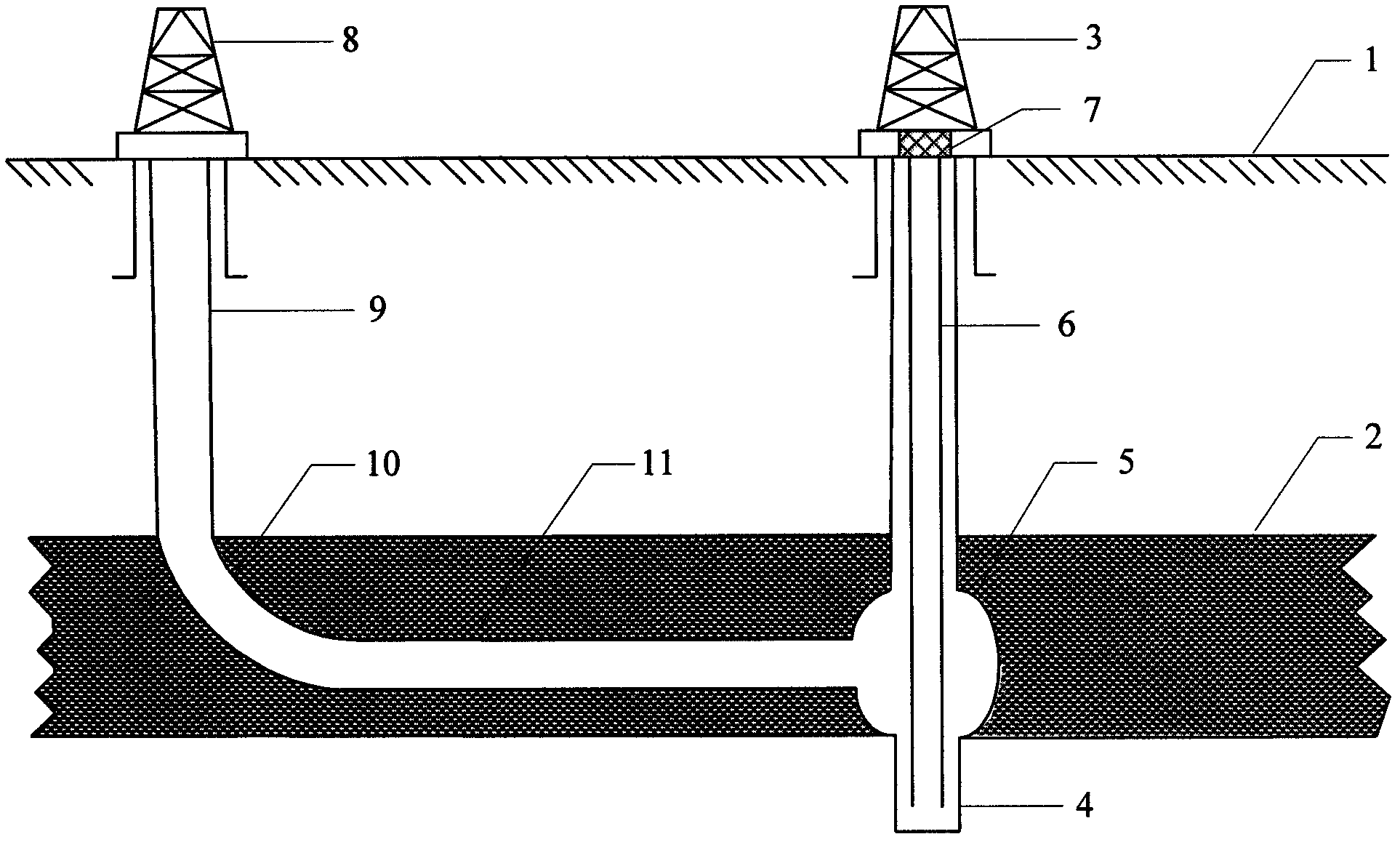

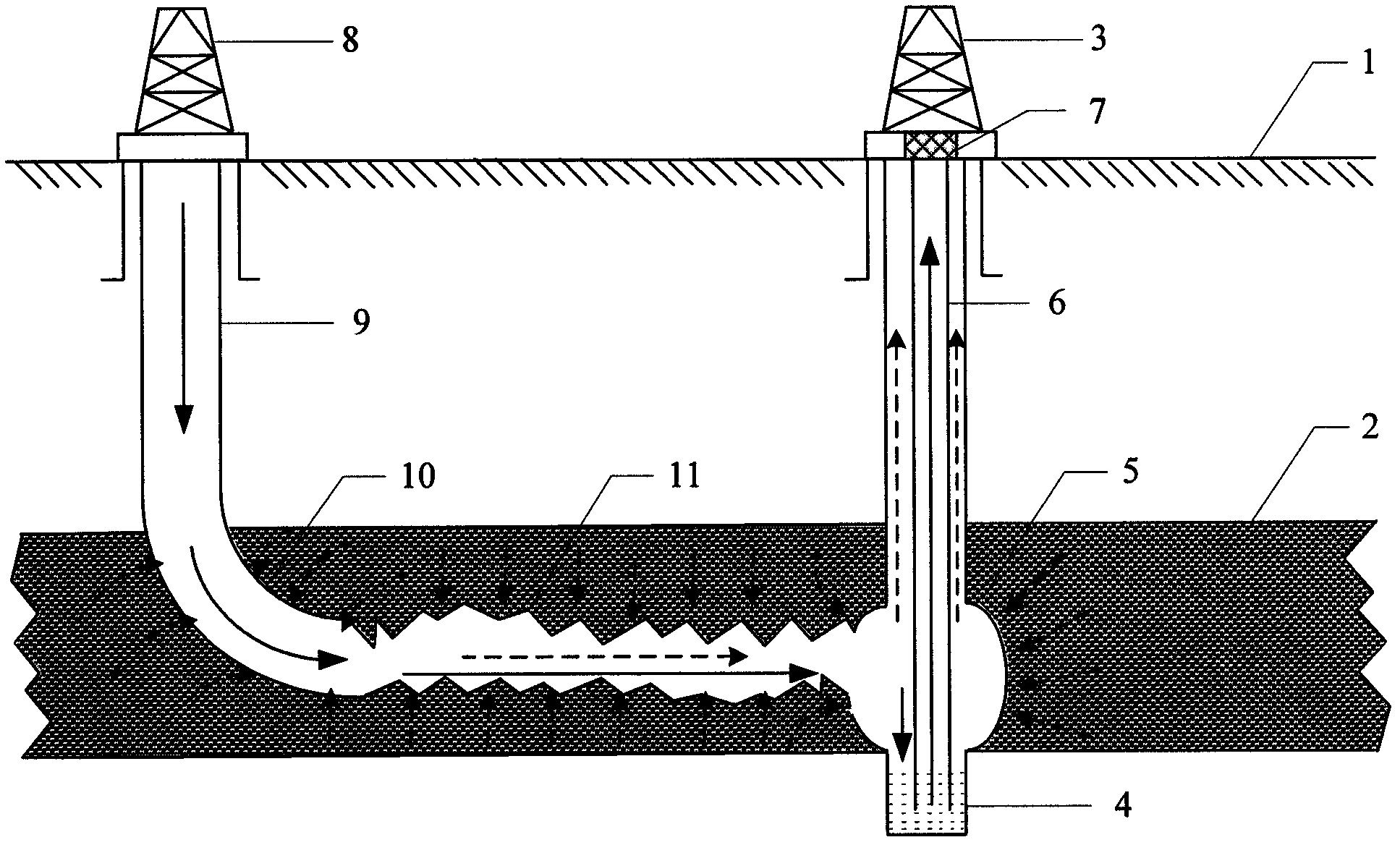

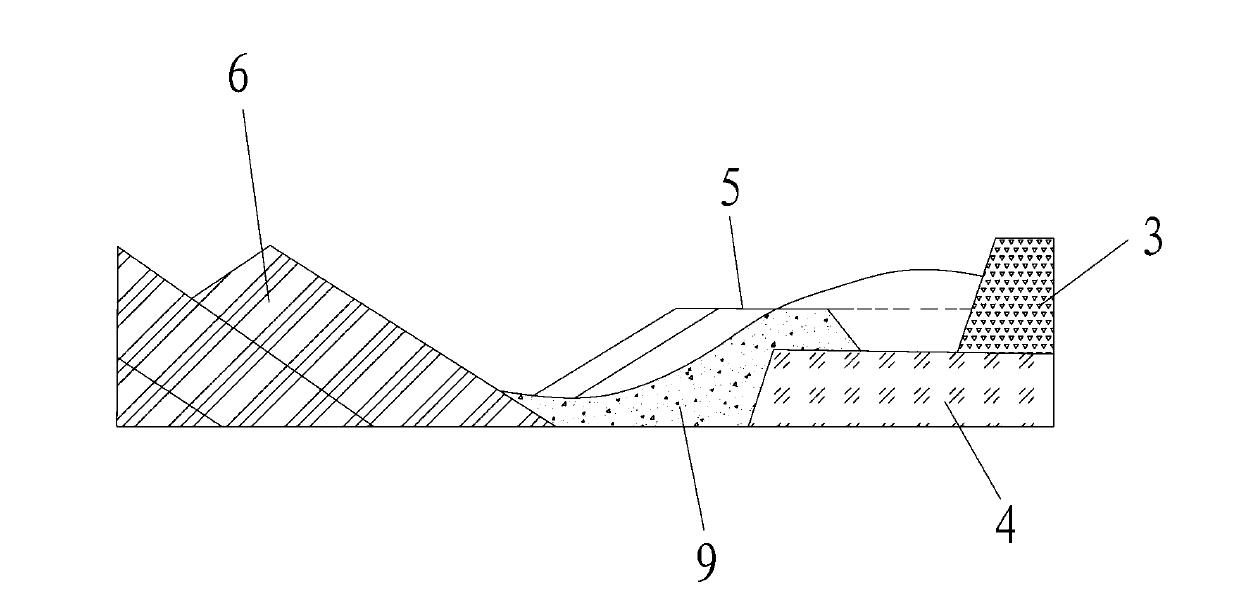

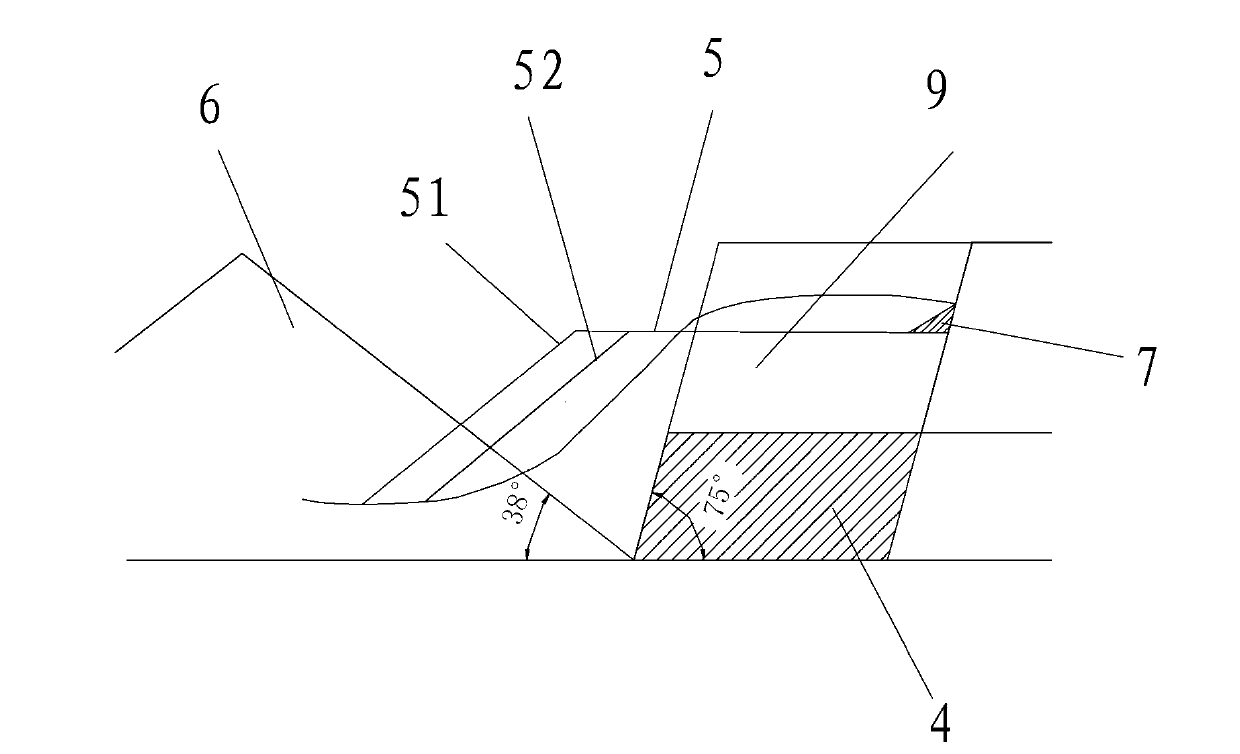

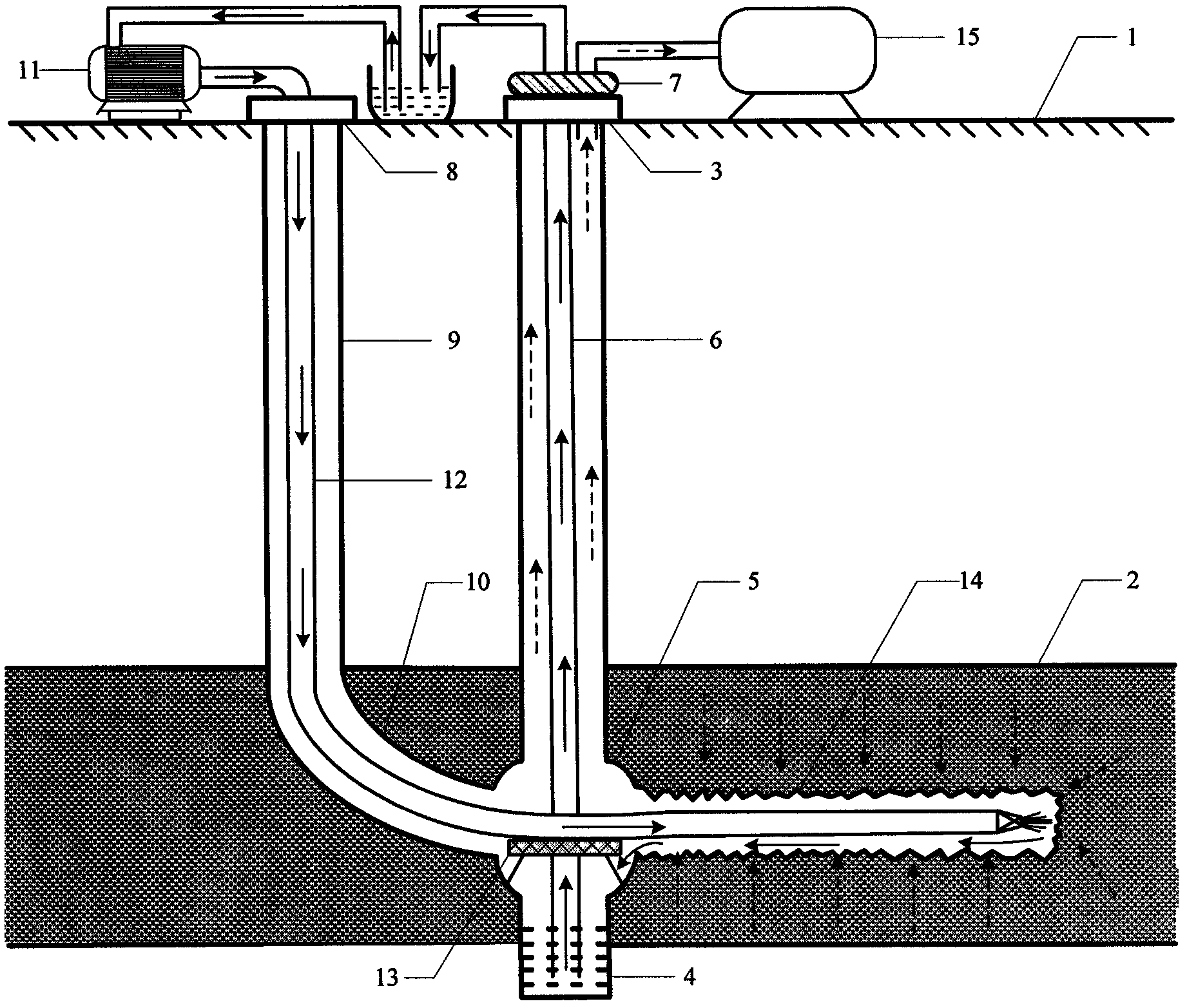

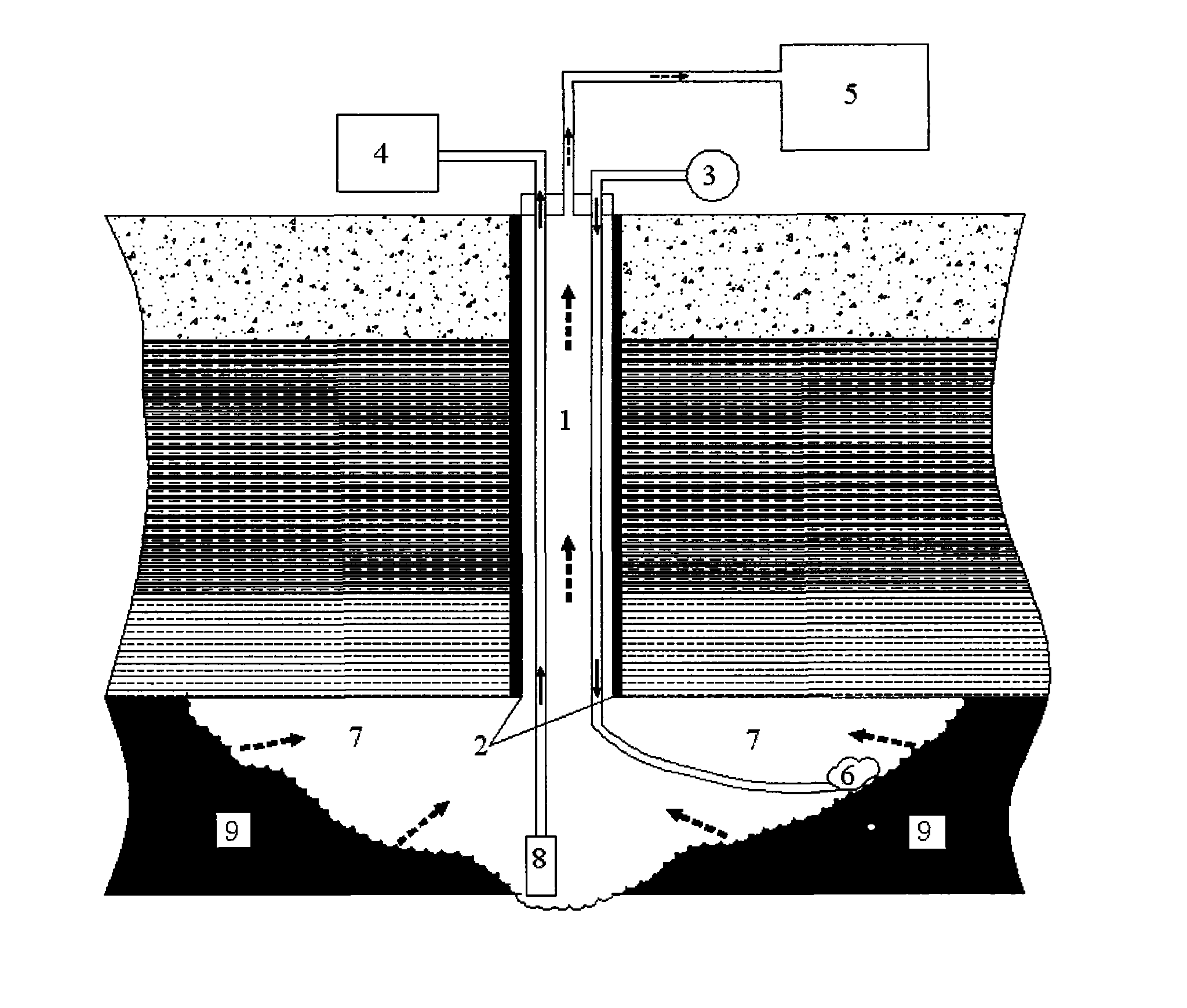

Method for mining coal bed gas by hydraulic washout of butted well in manner of pressure relief

InactiveCN102518411AOvercoming difficult to obtainOvercoming maintenance problemsLiquid/gas jet drillingFluid removalDirectional wellCoal water

The invention discloses a method for mining coal bed gas by hydraulic washout of a butted well in the manner of pressure relief, which comprises the following steps: firstly, drilling a drainage vertical well (3); digging the section of a target coal bed (2); forming a pocket (4) after passing through the coal bed; drilling a vertical well section (9) and a deviating section (10) of a horizontal directional well (8) and laying a casing pipe for well cementation; then, drilling a channel of a horizontal section (11) by using a conventional measure; butting the channel of the horizontal section (11) with the drainage vertical well (3) for barefoot well completion; continuously injecting water into the horizontal directional well (8) to wash the coal bed of the horizontal section (11); gathering coal water into the pocket (4); discharging the coal water through lifting equipment (6); when pulverized coal does not exist in the pocket (4), laying a water spray hose (12); by means of the action of high-pressure water jet, ejecting out a plurality of branch boreholes (13) at the horizontal section (11); continuously injecting the water to wash until the pulverized coal does not exist in the pocket (4) any longer; closing the horizontal directional well (8); and entering a conventional water draining and gas mining stage. The invention provides a new resolution for ground gas mining from soft low-permeability coal beds.

Owner:ZHENGZHOU UNIV

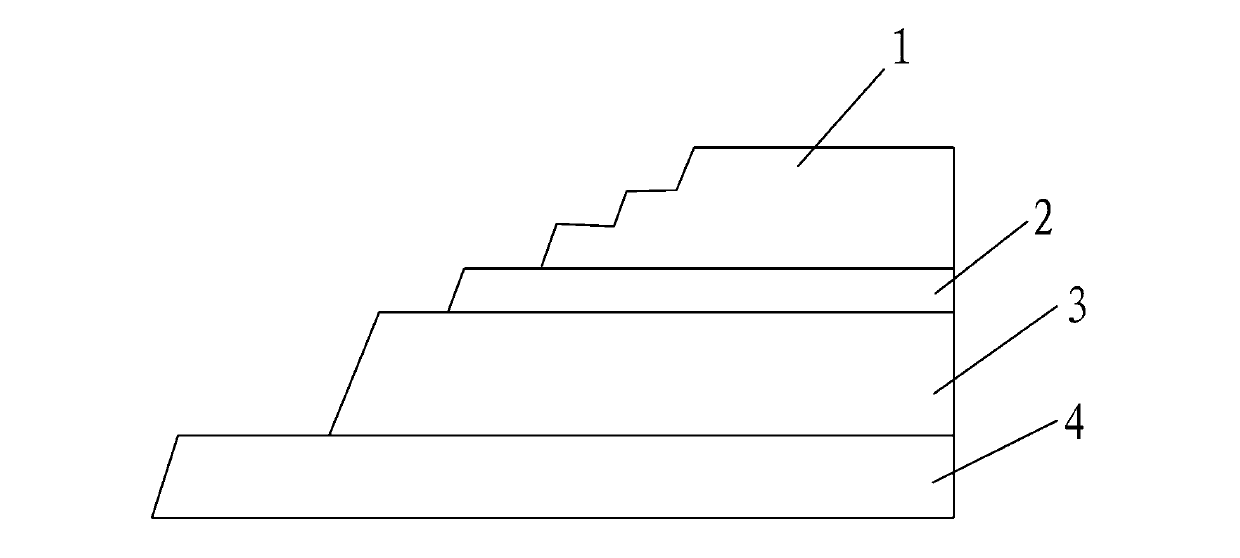

Open pit coal mine mining process

ActiveCN103216237AConvenience to workGuaranteed continuity of fitUnderground miningSurface miningCoal waterMining engineering

The present invention provides an open pit coal mine mining process, which comprises the following operation steps: 1, adopting a bucket wheel excavator to dig a loess layer on the upper portion, placing the dug loess onto a conveying belt of a belt type conveyor, and discharging the loess to an outer dump; 2, adopting a single bucket truck to convey crushed stone in a rock layer on the middle portion to the outer dump, and adopting the single bucket truck to convey into an inner dump until a rock layer on the lower portion is exposed after a pit formed by the rock layer on the middle portion has a enough space; 3, adopting a casting-blasting method to blast the rock layer on the lower portion, adopting a bulldozer to flatten the top surface of the blasting stack to form a combination extension platform, adopting a dragline to inversely stack the blasting amount into the inner dump, directly discharging the blasting amount into the inner dump with matching with the single bucket until a coal layer is exposed; and 4, adopting the single bucket truck to convey coal in the coal layer to a crushing plant, and then conveying the crushed coal to a designated location with a belt conveyor.

Owner:CHINA SHENHUA ENERGY CO LTD +1

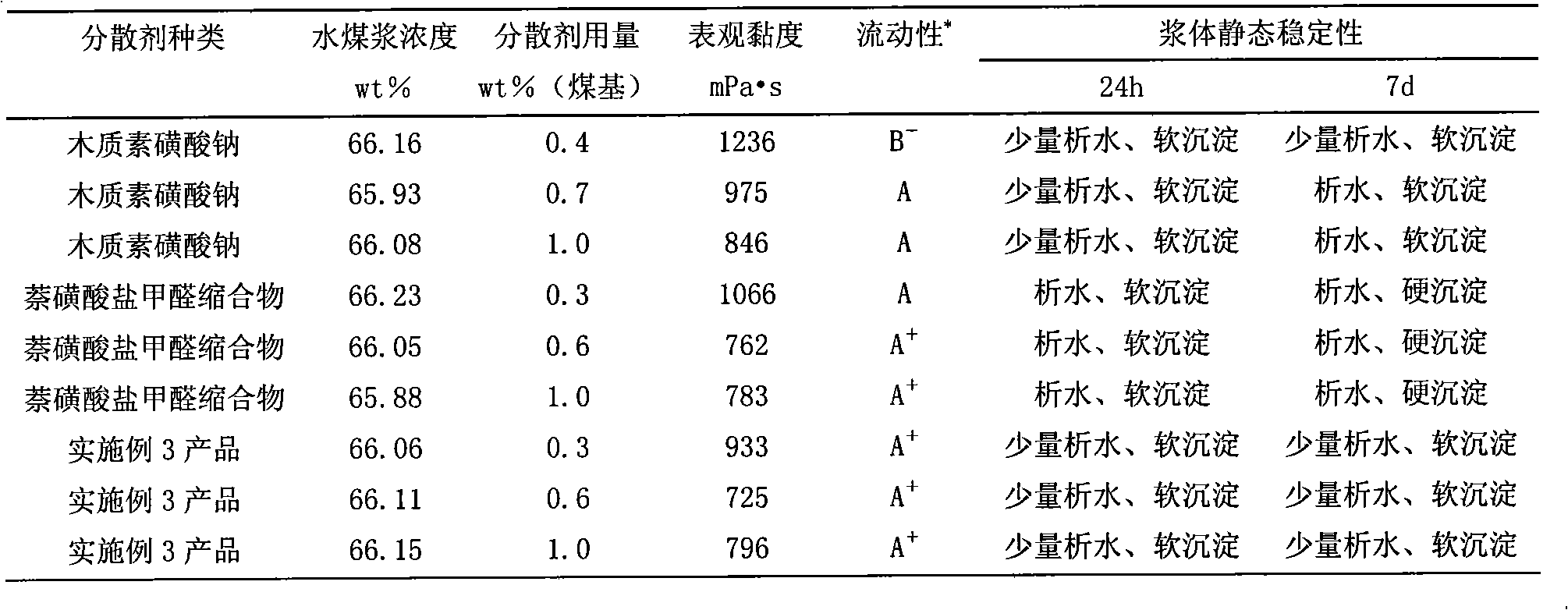

Special composite coal water slurry additive for coal gasification

InactiveCN103509617ALess unit consumptionHigh slurry concentrationLiquid carbonaceous fuelsPowder mixturePhosphate

The invention relates to a special composite coal water slurry additive for coal gasification, which is mixed and prepared from the following components in percentage by weight: 30-75% of lignosulfonate, 10-45% of sulfonate formaldehyde condensate, 5-15% of polyethenoxy ether, 5-25% of phosphate, 0-5% of pH regulator and 0-2% of stabilizer. The components are proportionally prepared into a solid powder mixture or a water solution with arbitrary concentration, and are added into dry-basis coal powder to be uniformly stirred, wherein the additive on dry basis accounts for 0.4-1.0 wt% of the dry-basis coal powder. The finished product coal water slurry prepared from the additive has the advantages of high slurry concentration, low viscosity, favorable rheological property, high stability and wide adaptability to coal types.

Owner:湖南东盈节能环保科技开发有限公司

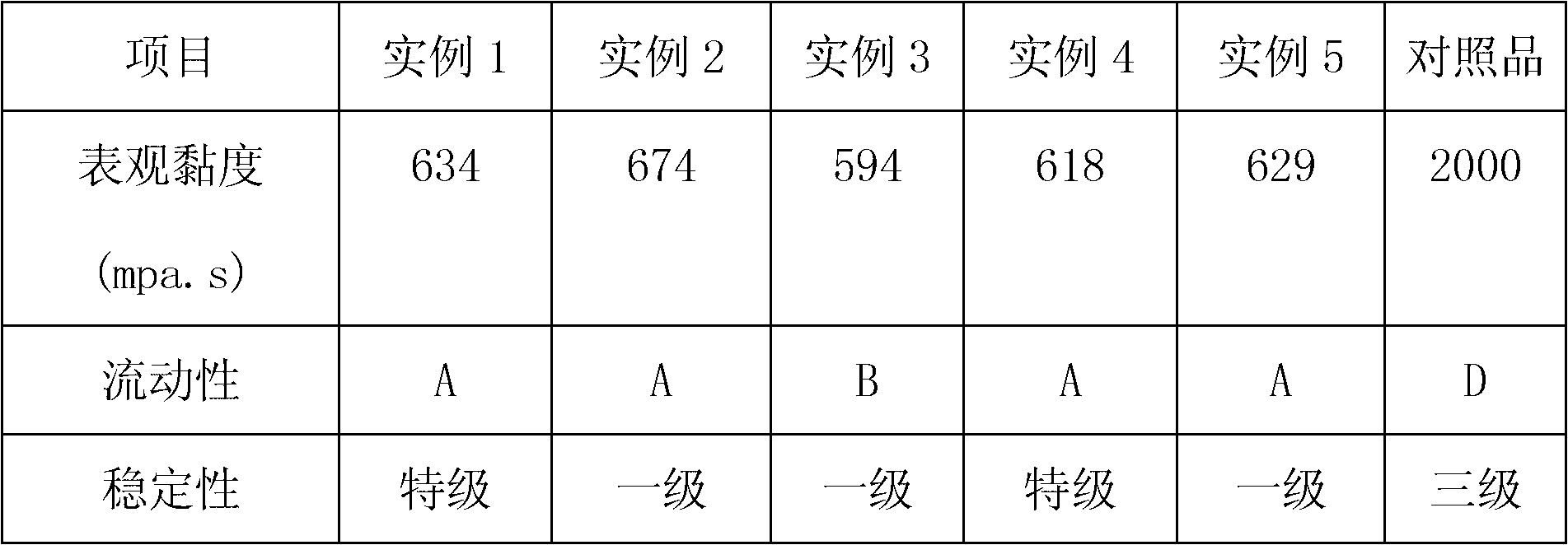

Coal water slurry additive and preparation method and application thereof

The invention discloses a coal water slurry additive and a preparation method and application thereof. The method is characterized in that the coal tar fraction wash oil is taken as the starting material, carries out sulfonation reaction with a sulfonating agent and then carries out polycondensation reaction with aminobenzene sulfonate, phenols and formaldehyde; and neutralization is carried out after reaction is completed. The method can greatly lower the production cost, and the obtained additive has the advantages of small mixing amount, excellent dispersibility, good slurry forming ability and stability and reduction of the stabilizing agent in the coal water slurry. The additive can not only be independently used for preparing the coal water slurry, but also be used by being compounded with other types of additives, such as naphthalene sulfonate-formaldehyde condensates, polycarboxylic acid additives or lignosulfonate and other anionic surfactants and synthesize the coal water slurry suitable for different types of coal by adjusting the production conditions. The coal water slurry prepared by the additive has the solid content between 63% and 70% and is easy to flow and clean. The viscosity of the coal water slurry is controlled below 1200mPa.s at the shearing rate of 100s<-1>.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD +1

Method for preparing high-efficiency water-reducing agent of poly-carboxylic acid

The invention discloses a preparation method for a polycarboxylate high-performance water reducer, comprising the following steps: based on weight proportion, mixing 5-50% of unsaturated carboxylic acid, a derivative a of the unsaturated carboxylic acid, 45-95% of polyoxyethylene vinyl propionate ester, a derivative b of the polyoxyethylene vinyl propionate ester, as well as 0-30% of propyl sulfonate c to prepare a mixed monomer solution; then adding the initiator which takes up 0.5-15% of the total weight of the mixed monomer solution, and the chain transfer agent which takes up 0-15% of thetotal weight of the mixed monomer solution into the mixed monomer solution so as to prepare the polycarboxylate high-performance water reducer through binary or ternary copolymerization. The polycarboxylate high-performance water reducer disclosed in the invention can be widely applied to grout, mortar, concrete, gypsum and coal-water slurry, so that the mixed material can have higher mobility tosignificantly reduce the actual water consumption in the mixing process and effectively improve the concrete strength and durability, thereby showing the advantages of low mixing amount, high dispersion and high slump retaining performance.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Terpolymer dispersants and preparation technique and use thereof

InactiveCN101391194AGood dispersionImprove thermal stabilityTransportation and packagingMixingSolubilityDispersion stability

The invention discloses a terpolymer dispersing agent with high dispersion and stability, low preparation cost and environmental protection as well as a preparation process and applications thereof. The terpolymer dispersing agent is prepared through free radical copolymerization of acrylic acid, sodium styrene sulfonate, hydroxypropyl acrylate or 2-hydroxyethyl methacrylate, the number average relative molecular weight of the terpolymer is between 2000 and 40000, and the dispersing agent has advantages of high thermal stability, good water solubility, excellent adaptability to acid and alkali and good dispersion stability, and also has good dispersion effects to calcium carbonate, zinc oxide, barium sulfate, titanium dioxide and pesticide Atrazine water dispersible granules and fipronil water dispersible granule, and can be widely used in the pesticide, pigment, dyestuff, coal water slurry and other industries. In addition, the preparation process has the advantages of simple operation, short cycle, environmental protection and low cost, and is suitable for the industrial scale production.

Owner:SHANGHAI NORMAL UNIVERSITY

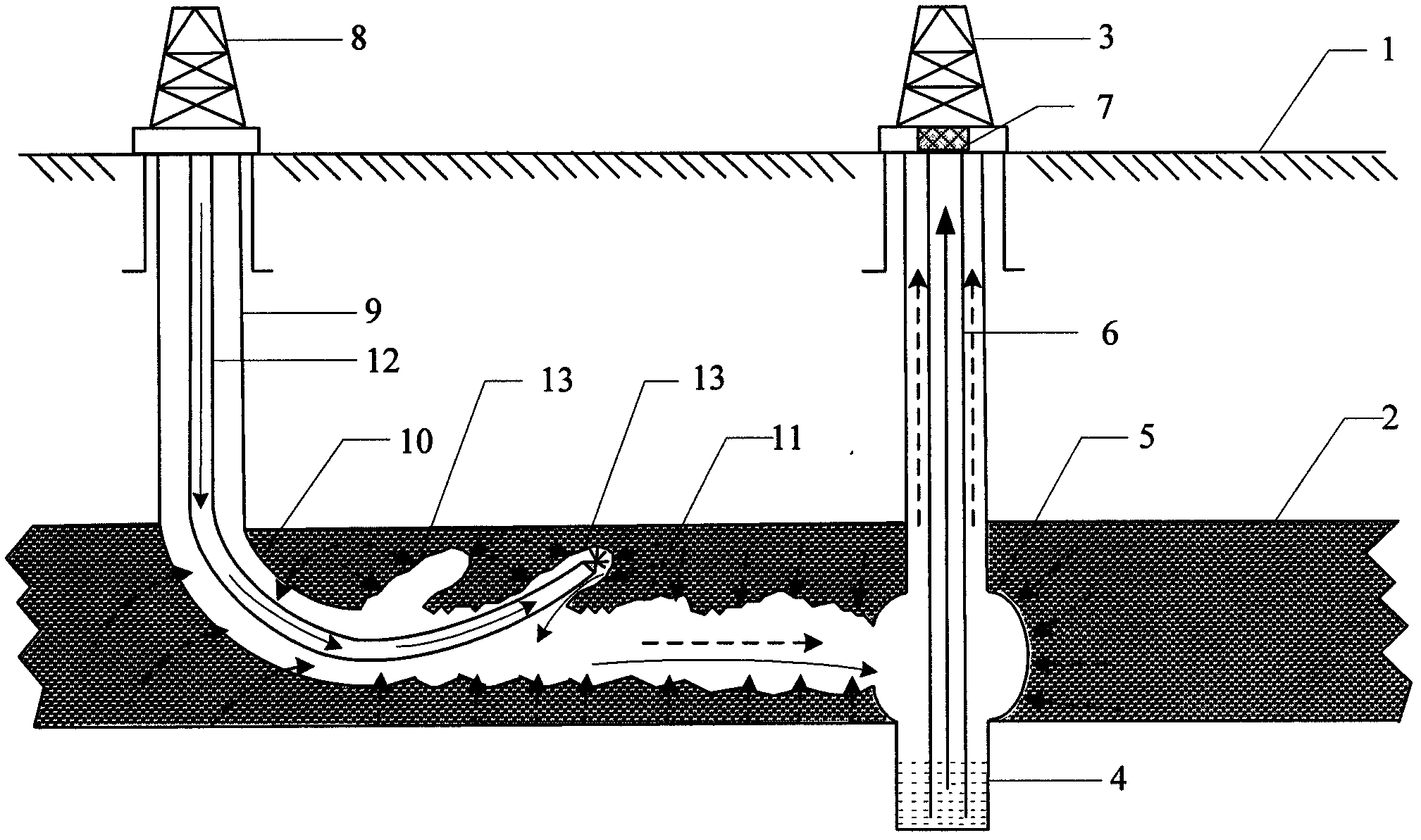

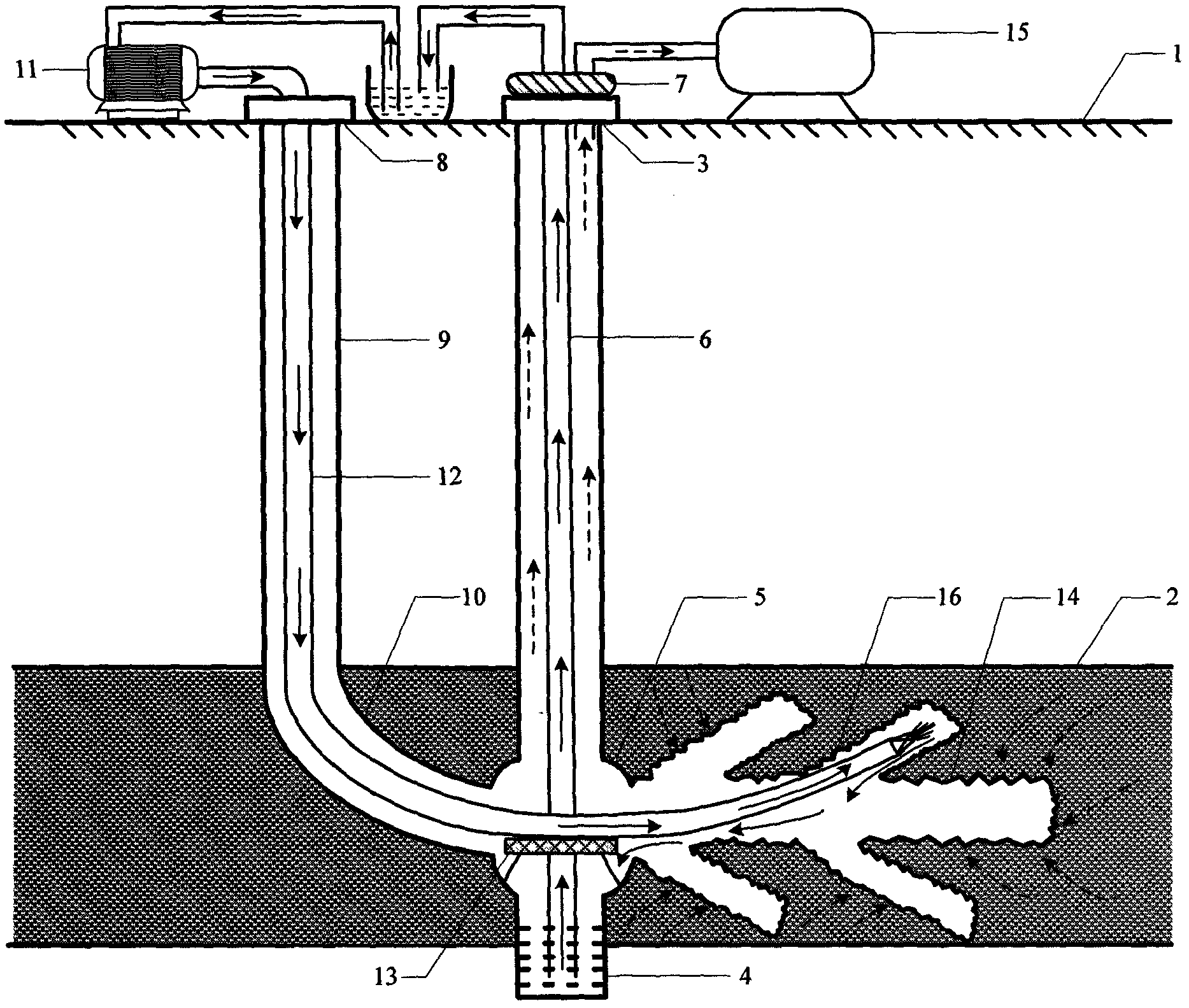

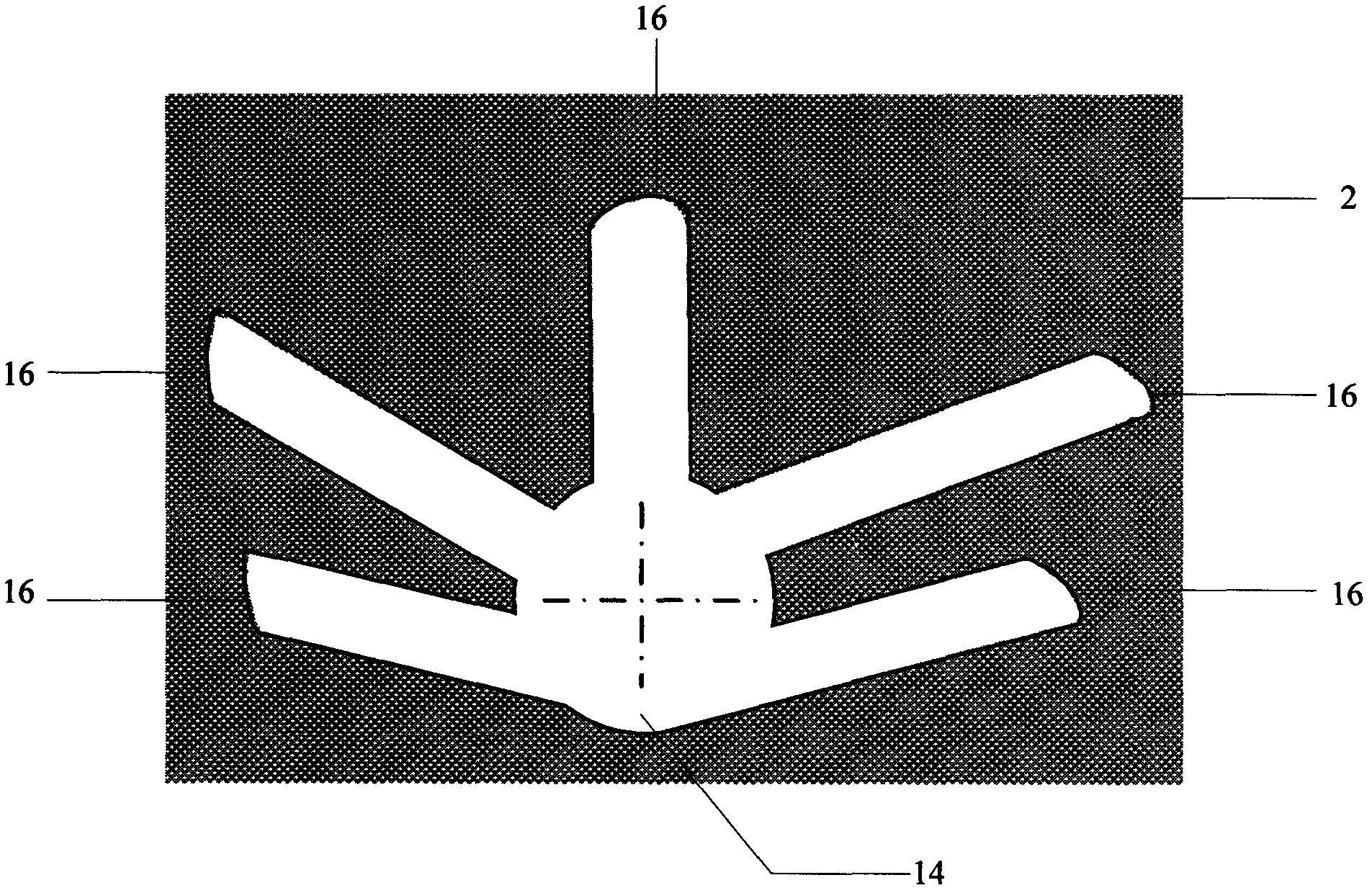

Method for exploiting coal-bed methane by utilizing water force of horizontal pinnate well of double well-shaft to scour, drill and relieve pressure

InactiveCN102425397AIncrease pressure relief spaceLow costLiquid/gas jet drillingFluid removalCoal waterWell cementing

The invention discloses a method for exploiting coal-bed methane by utilizing a water force of a horizontal pinnate well of a double well-shaft to scour, drill and relieve pressure. The method comprises the following steps: drilling a straight drainage well (3), digging a hole in a section of a target coal-bed (2) and forming a pocket (4) after passing through the coal-bed; drilling a straight well section (9) and a building section (10) of a horizontal pinnate well (8) and placing a casing pipe for fixing the well; placing a water-spraying hose (12) connected with a high-pressure water pump (11) into the horizontal pinnate well (8); passing through a cave (5), scouring the coal-bed with a high-pressure jetted water and drilling along a horizontal direction, thereby forming a horizontal sectional main well hole (14); changing a jetting direction, and jetting a plurality of branched well holes (16) around the horizontal sectional main well hole (14); causing coal water to flow back to the pocket (4) during a jetting process, and discharging the coal water through a lifting device (6); separating through a methane, coal and water separating device (7); collecting and storing the coal and methane; and reusing the water to jet flow and scour under the well. The invention provides a new solution for ground gas production on a mellow and low-seepage coal bed.

Owner:ZHENGZHOU UNIV

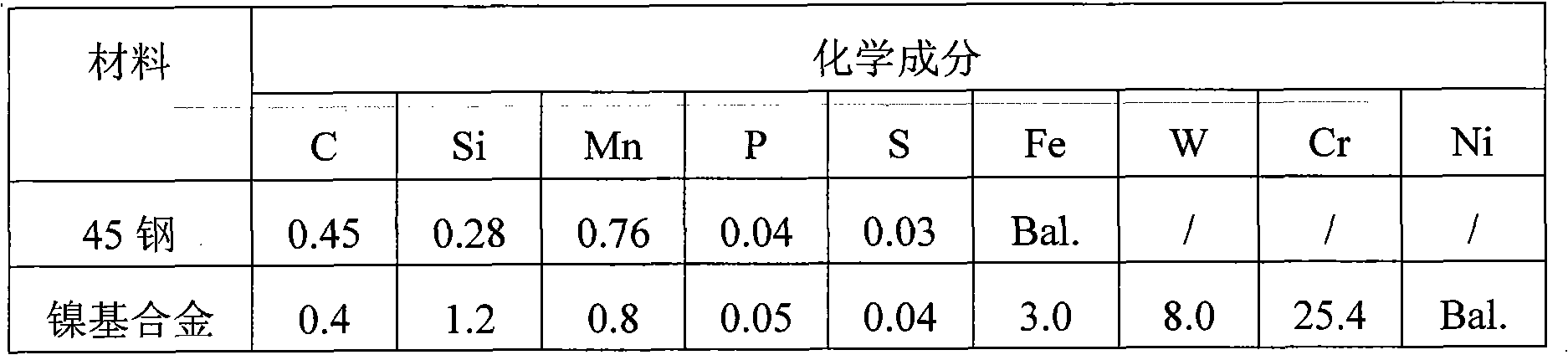

Method for cladding alloy on surface of metallic matrix

InactiveCN102115882AImprove performanceExtended service lifeMetallic material coating processesCoal waterHigh-temperature corrosion

The invention relates to a method for cladding an alloy on the surface of a metallic matrix. The method comprises the following step of: cladding a single path or multiple paths of alloy on the surface of the metallic matrix by adopting the laser cladding method under the protection of inert gases. Compared with the prior art, the invention has simple process and is convenient for operation; and the metal obtained from preparation is provided with a cladding layer with excellent performance, can meet special performance requirements of resisting high-temperature wire and high-temperature corrosion, can be used for producing a nozzle for a coal water slurry gasifier, and greatly prolongs the service life of the nozzle for the coal water slurry gasifier.

Owner:SHANGHAI UNIV OF ENG SCI

Aluminum chrome refractory material

The invention belongs to the technical field of refractory materials, in particular to an aluminum chrome refractory material, which takes white fused corundum as a body and is formed by adding scraps (the scraps are collected and crushed into the synthetic size) generated in the cold processing process of a dense chromic oxide product, Alpha-Al2O3 powder or chrome oxide green or white fused corundum powder and sintering at a high temperature in combination with an inorganic binding agent or an organic binding agent. A product obtained in the invention can be widely applied to a coal water slurry gasification furnace back lining, a hard carbon black reaction furnace inner lining, a residual oil gasification furnace inner lining in the petrochemical industry, a glass wool molten pool inner lining and the like, fully and effectively makes use of the scraps generated in the cold processing process of the dense chromic oxide product and has the characteristics of low impurity content, high refractoriness, excellent physical performance, good thermal shock resistance and strong erosion resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

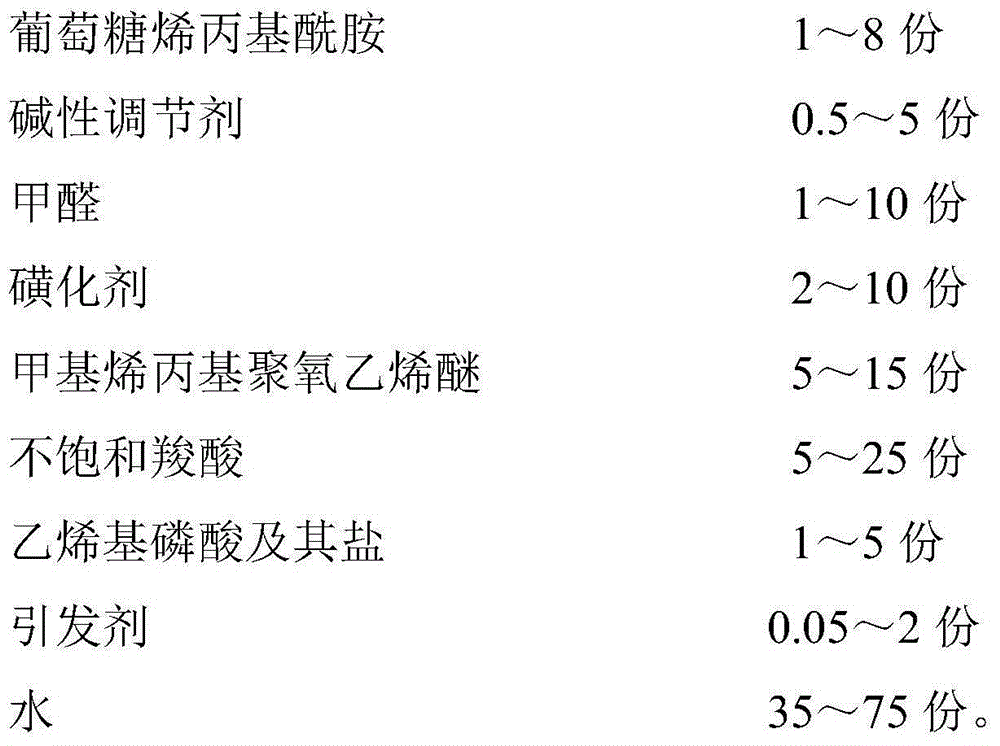

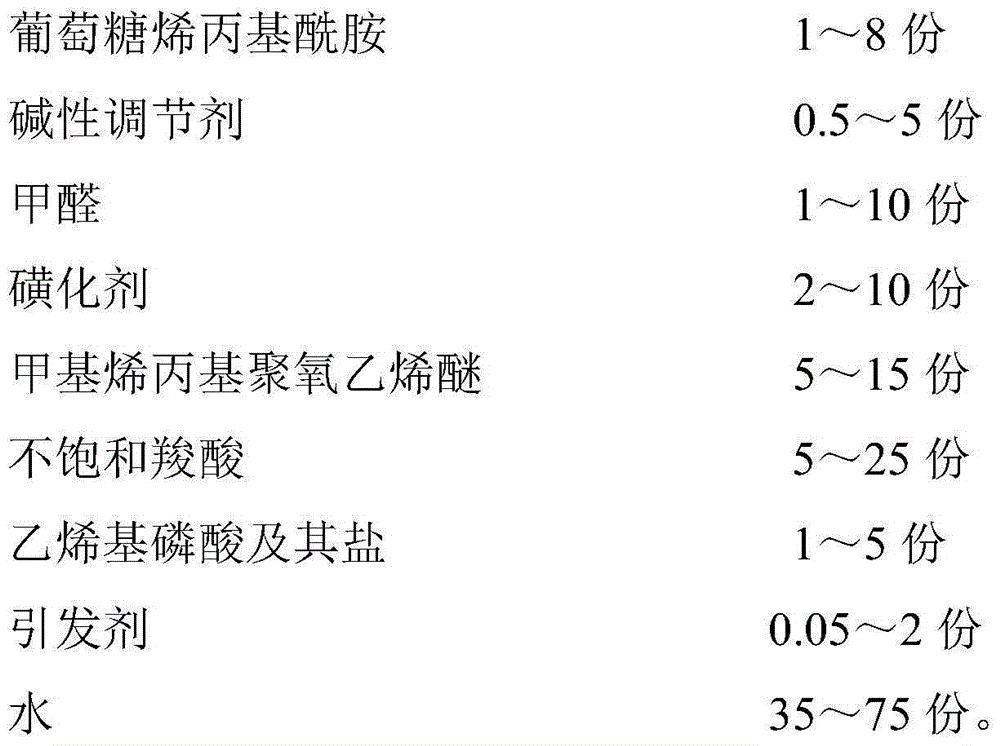

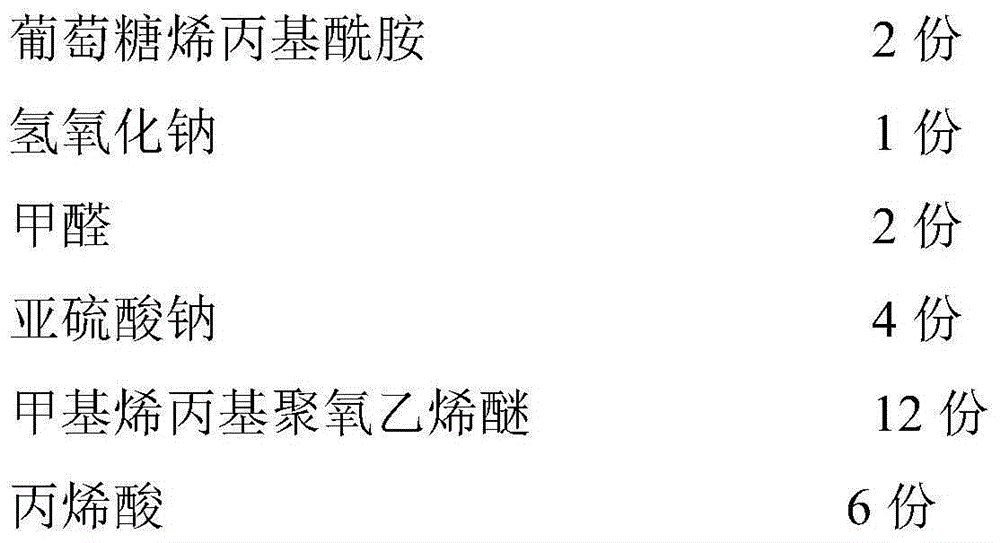

Coal water slurry additive and preparation method thereof

ActiveCN105154151AImprove stabilityImprove liquidityLiquid carbonaceous fuelsCoal waterPhosphoric acid

The invention provides a coal water slurry additive and a preparation method thereof. The method comprises the following steps: (1) adding glucose allyl amide, an alkaline regulator and water into a reaction kettle, starting stirring, and starting heating; (2) after the temperature rises to 55-70 DEG C, adding formaldehyde, continuing reacting for 0.1-1 hour, adding a sulfonating agent, and keeping the temperature for 0.1-1 hour; (3) continuing heating to 70-90 DEG C, adding methyl allyl polyethenoxy ether, unsaturated fatty acid, vinyl phosphoric acid and salt thereof, stirring uniformly, and dropwisely adding a 1-10 wt% initiator solution, wherein the initiator solution is prepared from the initiator and water, the dropwise addition time is controlled at 0.5-4 hours, and the dropwise addition temperature is controlled at 90-100 DEG C; and (4) after the dropwise addition, keeping the temperature to continue reaction for 1-4 hours, cooling and discharging to obtain the coal water slurry additive.

Owner:佛山市天亿化工有限公司

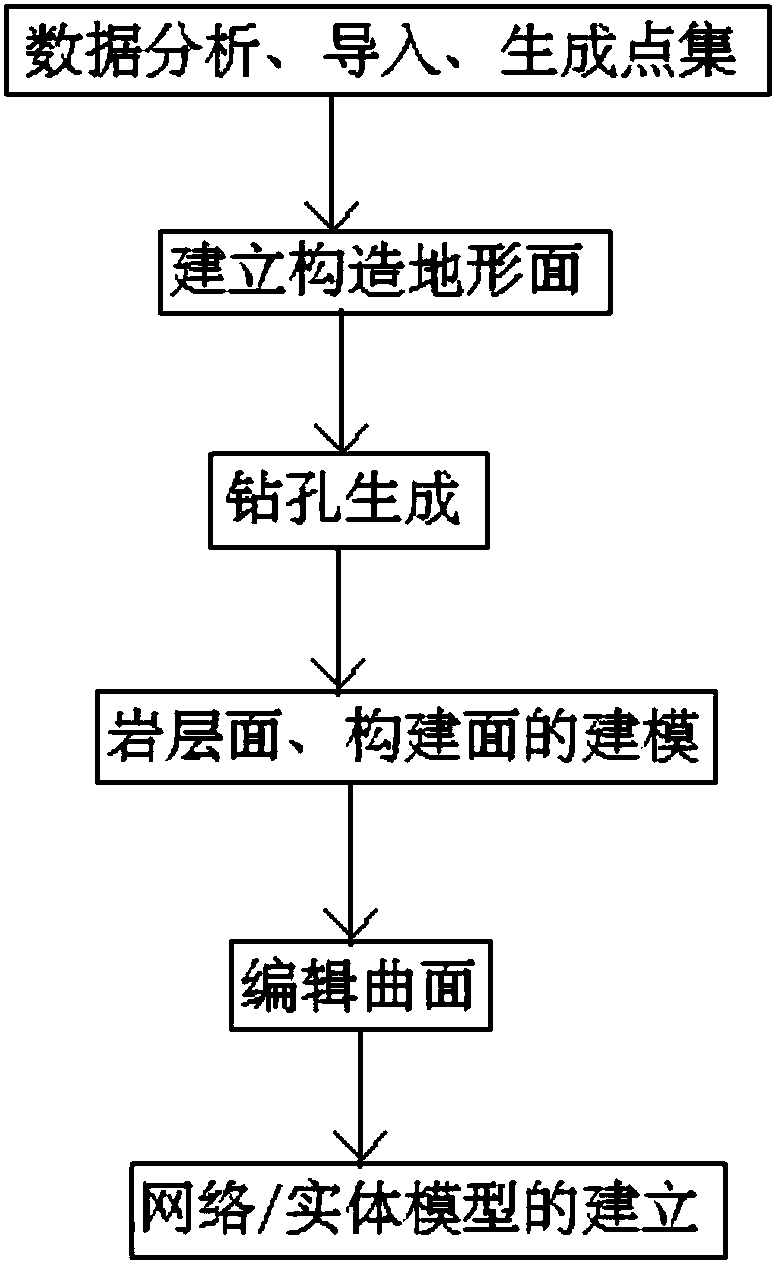

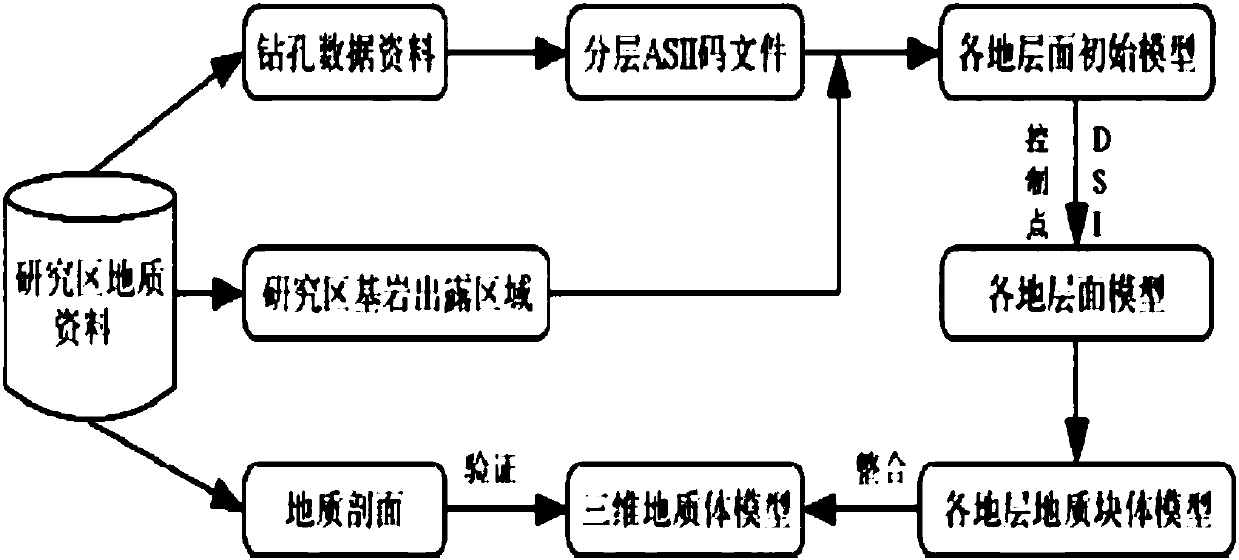

Three-dimensional geologic modeling method based on GOCAD (Geological Object Computer Aided Design)

The invention provides a three-dimensional geologic modeling method based on GOCAD (Geological Object Computer Aided Design). The method comprises the following processes that: 1) carrying out data analysis and importing, and generating a point set; 2) establishing and constructing a topographic surface; 3) generating a borehole; 4) carrying out modeling on a rock stratum surface and a construction surface; 5) editing a hook face; and 6) establishing a grid / entity model. By use of the method, field actual measurement discrete geological prospecting data can be used for fitting and interpolation, a three-dimensional geologic model with information, including terrains simulated at a ratio, a stratum boundary, attributes and the like, is established, geologic structure information can be specifically embodies through three-dimensional visualization, coal mine production and water prevention and treatment work can be visually guided through the visualization, a new meaning and method is provided for the analysis and the research of the water prevention and treatment work, and the method has an effective guidance meaning for the analysis of a mine coal water prevention and treatment scheme.

Owner:中国煤炭地质总局水文地质局

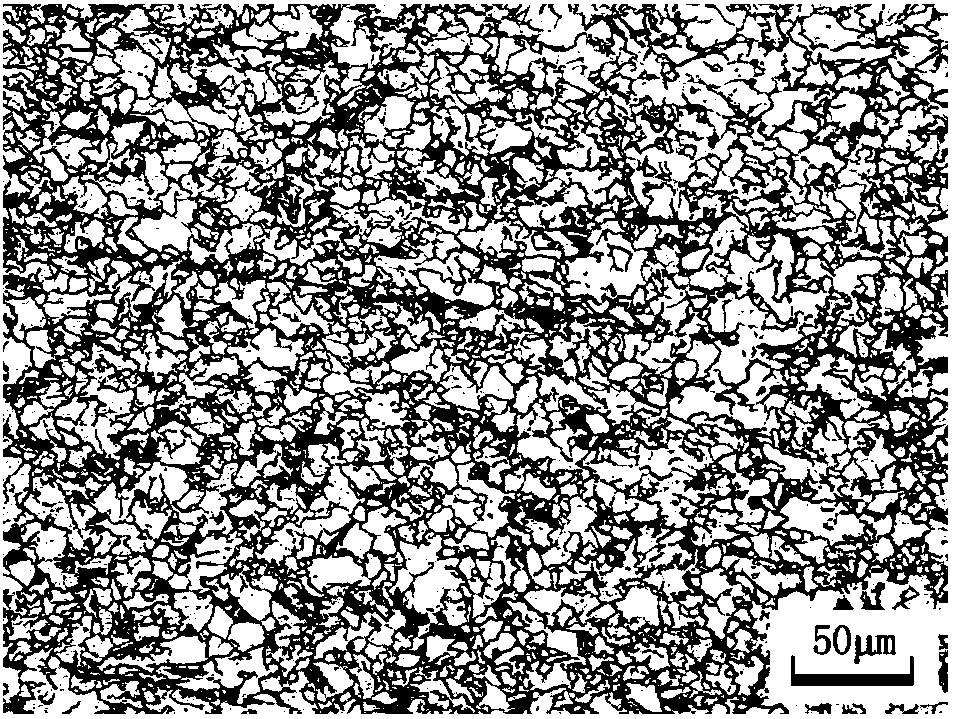

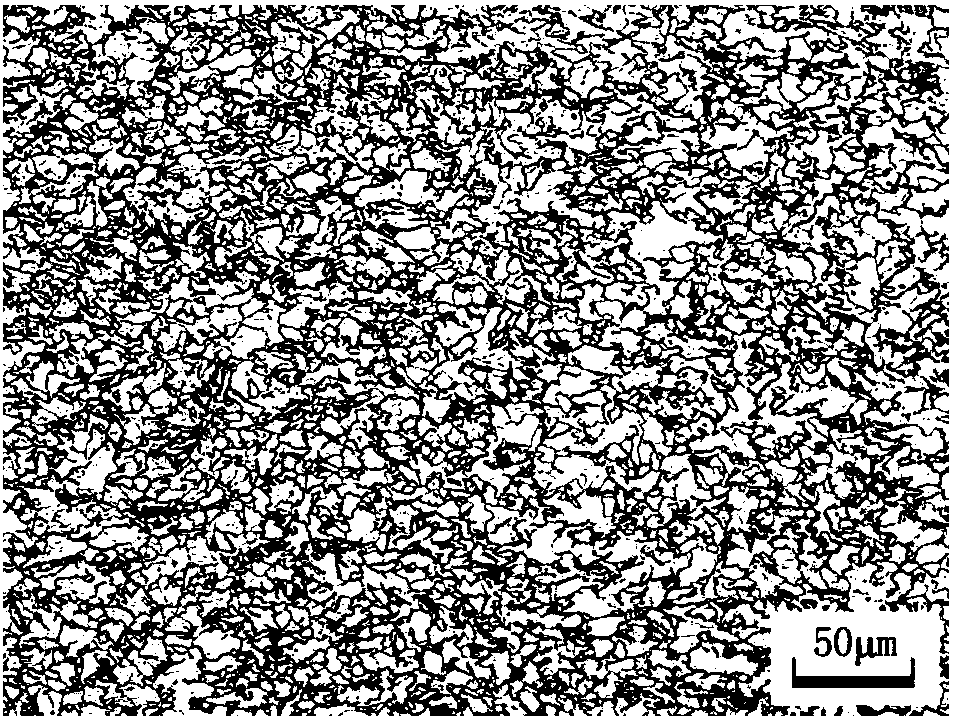

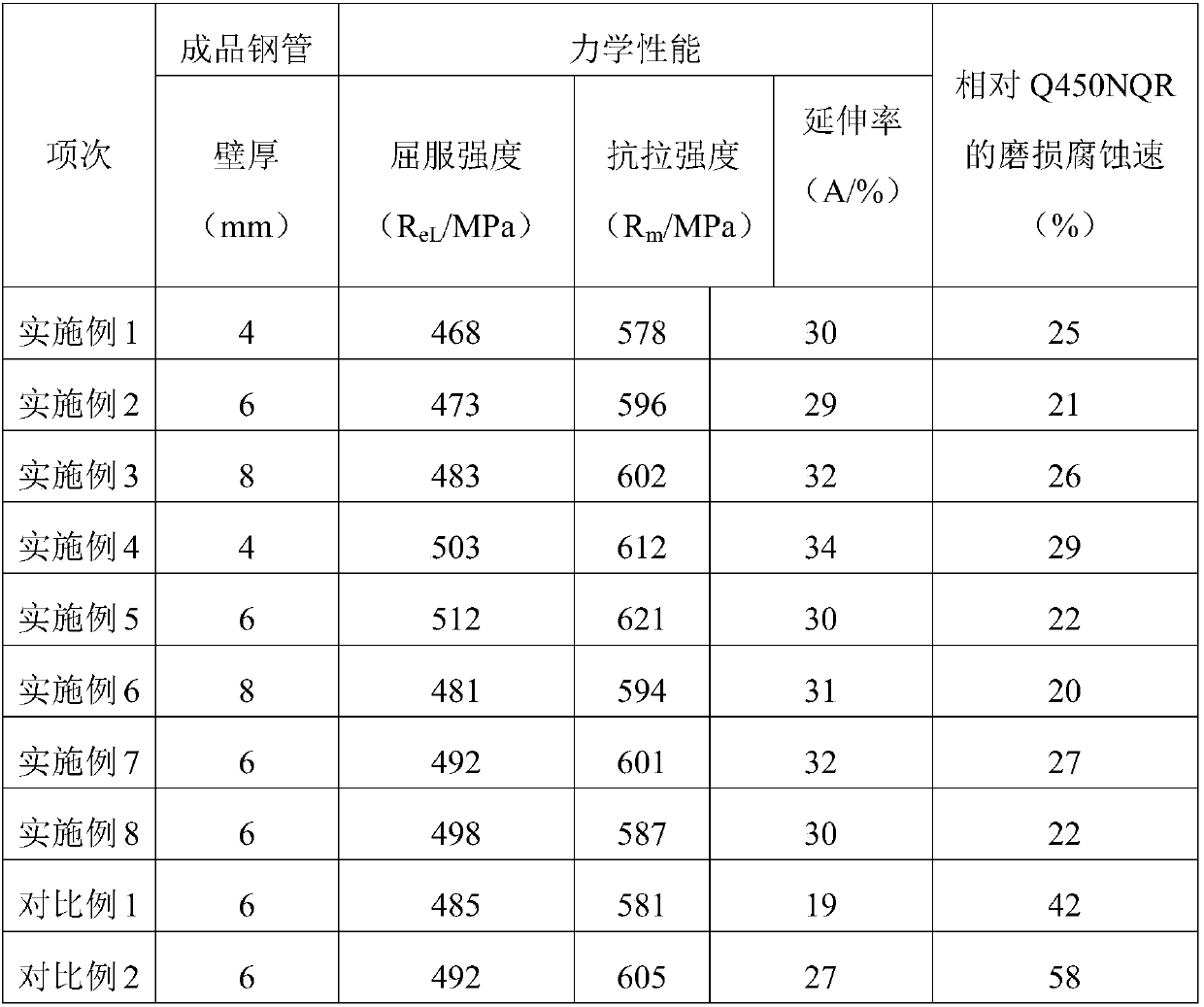

Coal-water abrasion and corrosion resistant steel plate for railway coal transport vehicle and manufacturing method thereof

The invention discloses a coal-water abrasion and corrosion resistant steel plate for a railway coal transport vehicle and a manufacturing method thereof. The coal-water abrasion and corrosion resistant steel plate comprises the chemical components of, by weight, 0.01-0.15% of C, 0.10-0.50% of Si, 0.20-1.0% of Mn, 0.020% or less of P, 0.010% or less of S, 0.20-0.60% of Cu, 0.50-1.5% of Ni, 0.20-2.0% of Cr, 0.030-0.10% of Sb, 0-0.25% of Mo, 0-0.05% of Nb, 0-0.05% of V, 0-0.10% of Ti, 0-0.005% of B and the balance Fe and impurities, wherein C, Cr and Ni need to meet the relation of 1.6%<=12C+Cr / Ni<=2.8%. The steel plate is manufactured through the ten steps of blast-furnace iron melting, molten iron pre-desulfuration, converter smelting, LF+RH refining, plate blank continuous casting, cast blank slow cooling, plate blank heating, hot continuous rolling, laminar flow cooling and reeling, the yield strength of the steel plate is 450 MPa grade, the steel plate is excellent in mechanical performance, the service life of the steel plate under the coal-water abrasion and corrosion environment can be greatly prolonged, and the obvious competition advantage in the railway coal transport vehicle carriage manufacturing industry is achieved.

Owner:武汉钢铁有限公司

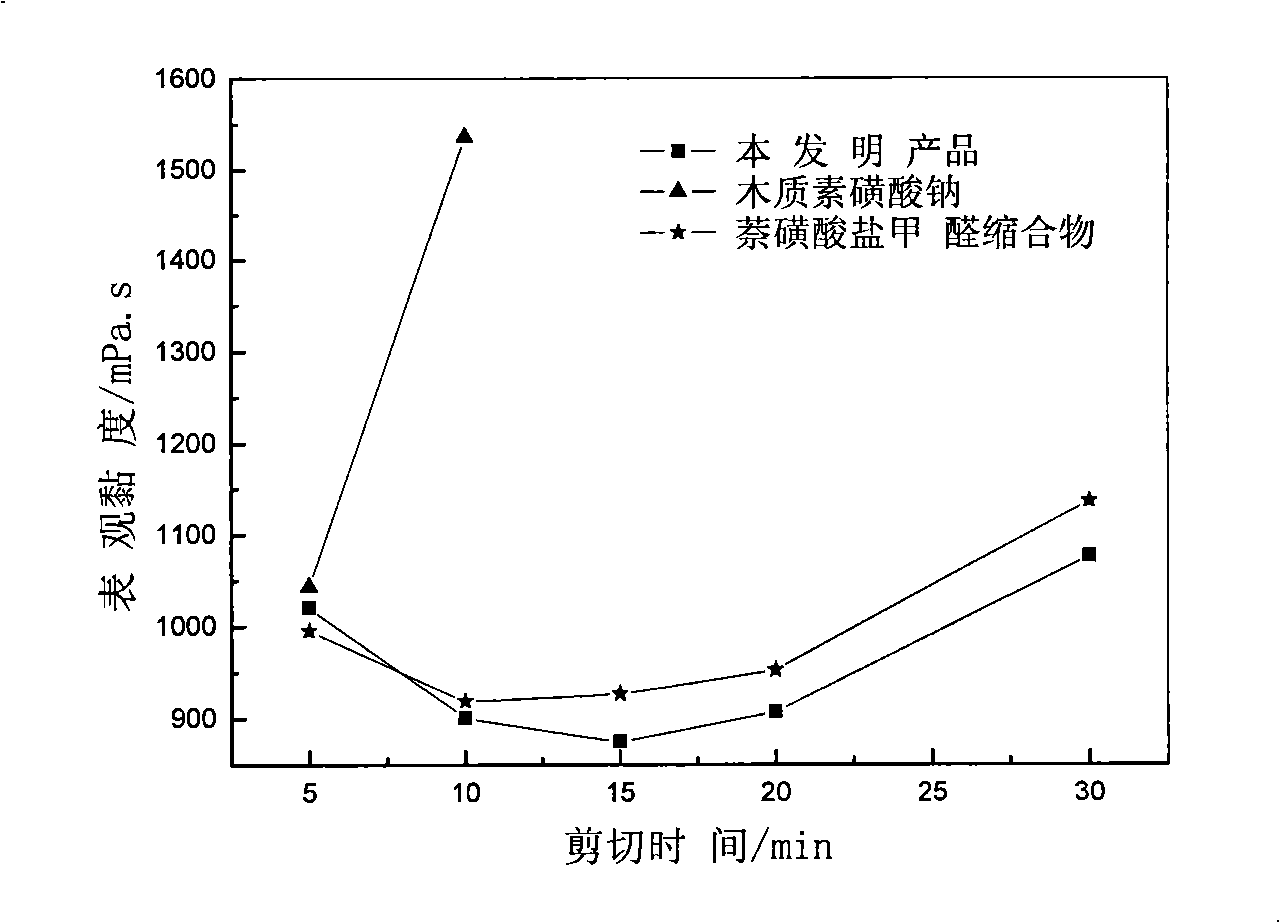

Coal water slurry dispersing agent made from black-liquor of straw pulping in paper-making and preparation thereof

InactiveCN101322927AReduce manufacturing costEasy to operate and controlTransportation and packagingMixingSolubilitySulfonate

The invention discloses a straw pulp papermaking black liquor water-coal slurry dispersant and a preparation method thereof. The prescription of the water-coal slurry dispersant is counted by mass portion and includes 20 portions of condensed straw pulp papermaking black liquor of 50 to 60 percent; 25 to 50 portions of aldehydes, 20 to 60 portions of carbonyl compounds and 25 to 50 portions of sulfonating agents. The preparation method thereof is to prepare the water-coal slurry dispersant by carrying out graft sulfonation and polycondensation on the condensed straw pulp papermaking black liquor, the aldehydes, the carbonyl compounds and a sulfonating agent. The materials of the invention have abundant sources and low cost; the production cost is low; the water-coal slurry dispersant prepared by the invention has excellent water solubility and surface activity as well as excellent slurry preparing performance to the water-coal slurry under a lower addition; the dispersing viscosity reduction performance of the water-coal slurry dispersant is far superior to lignin sulfonate; aiming at different coal varieties, the water-coal slurry dispersant achieves or exceeds the efficiency of naphthyl sulfonate formaldehyde condensate; besides, the anti-shearing performance of a slurry body is excellent; the application range to the coal varieties is broad; the water-coal slurry dispersant is novel, effective and environment-friendly.

Owner:SOUTH CHINA UNIV OF TECH

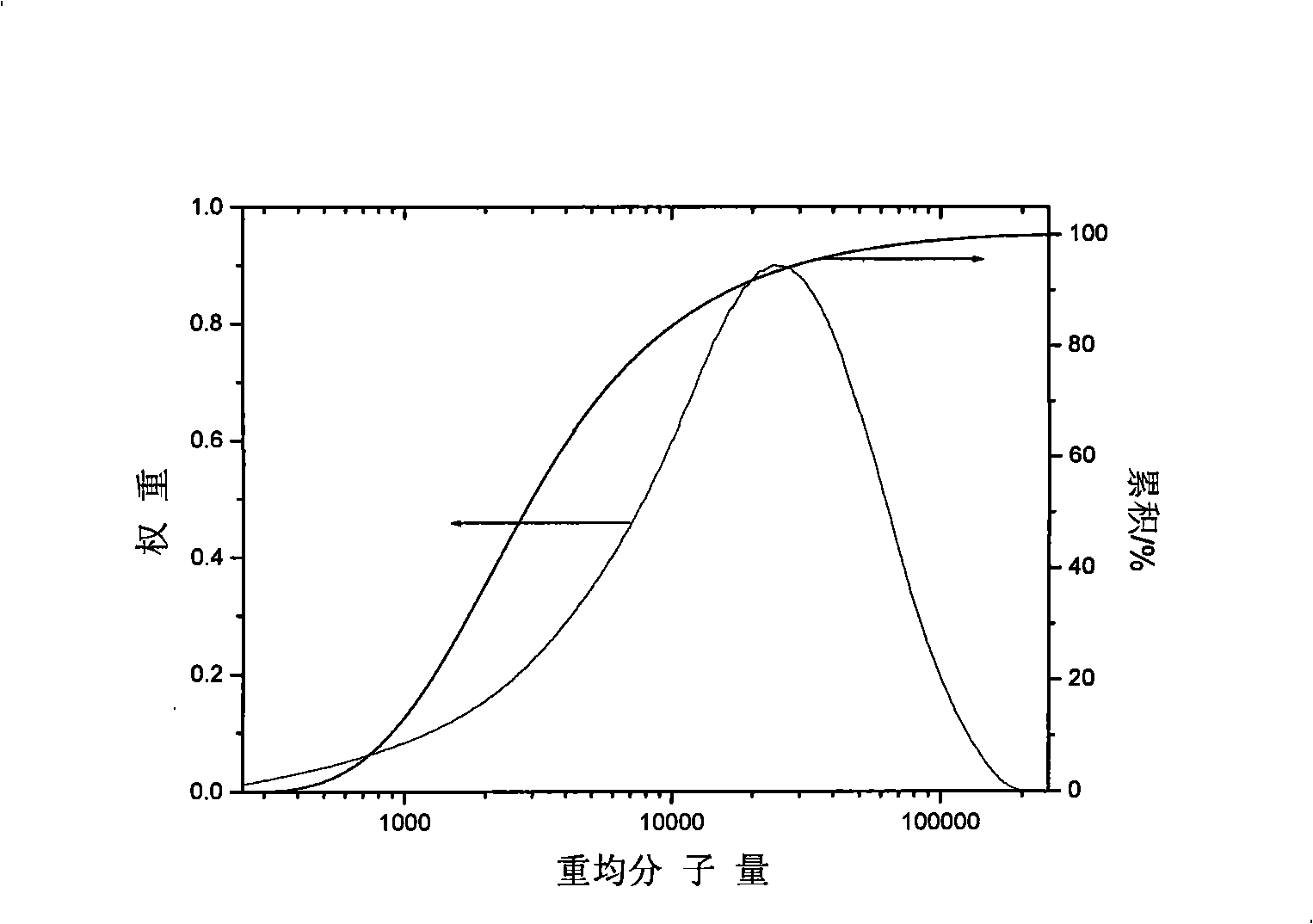

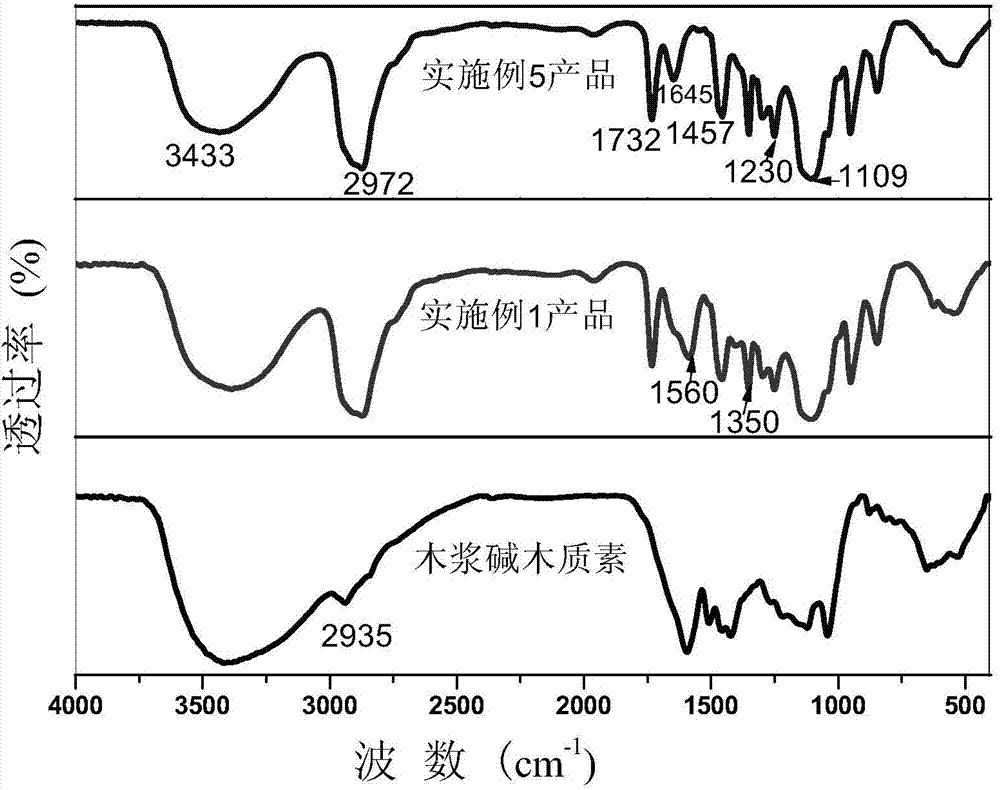

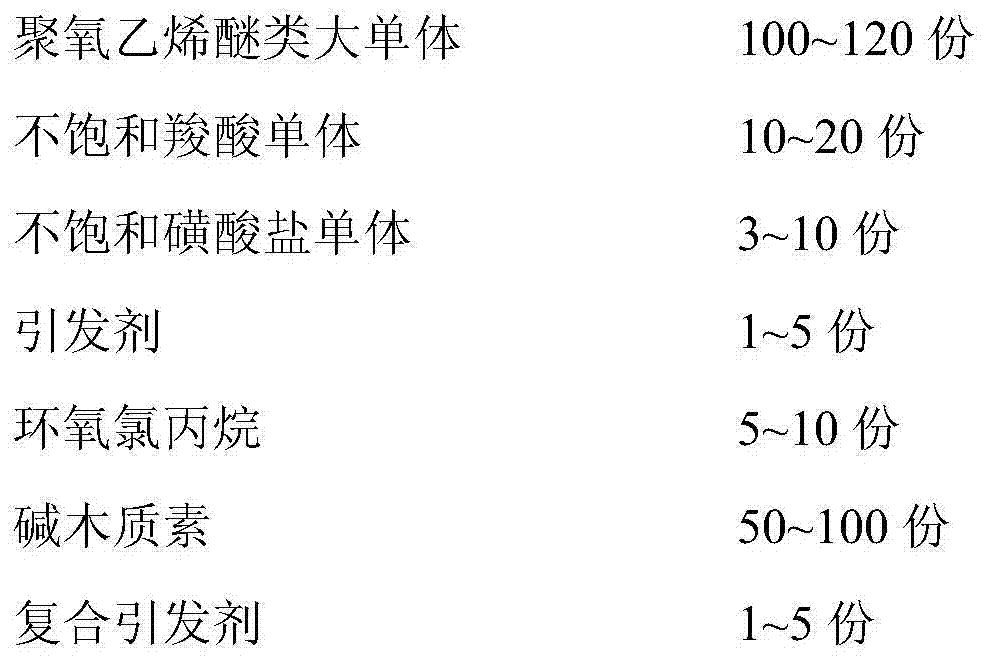

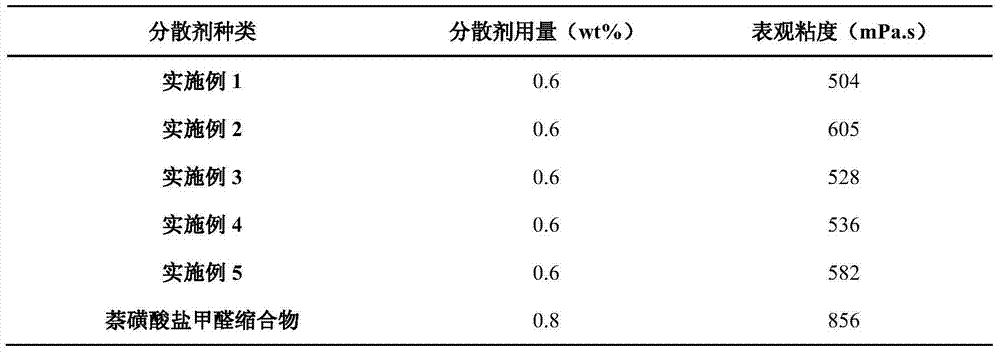

Preparation method of alkali lignin modified polycarboxylic acid-type coal water slurry dispersant

ActiveCN104327280AStay decentralizedReduce usageLiquid carbonaceous fuelsDispersion stabilityLiquid product

The invention relates to a preparation method of an alkali lignin modified polycarboxylic acid-type high-efficiency coal water slurry dispersant. The method comprises the steps: at the temperature of 50-80 DEG C, carrying out a copolymerization reaction of a polyoxyethylene ether macromonomer, an unsaturated carboxylic acid monomer, an unsaturated sulfonate monomer and an initiator for 2-3 h in an aqueous solution, adjusting the temperature to 30-50 DEG C, adding epoxy chloropropane, carrying out a reaction for 0.5-1 h, adding an alkaline regulator, adjusting the pH value to 10-12, adding an alkali lignin solution with the mass concentration of 20-50%, adjusting the reaction temperature to 60-80 DEG C, dropwise adding a composite initiator aqueous solution with the mass concentration of 2%, carrying out a reaction for 1-3 h, and thus obtaining a liquid product. The product has the dispersion viscosity reduction performance on coal water slurry superior to that of a naphthalenesulfonate formaldehyde condensation compound, and has good dispersion stability on coal slurry; and while original dispersive ability and other characteristics of the polycarboxylic acid-type dispersant are maintained, the production cost is reduced, and the usage amount of non-renewable resources and toxic materials is lowered.

Owner:SOUTH CHINA UNIV OF TECH

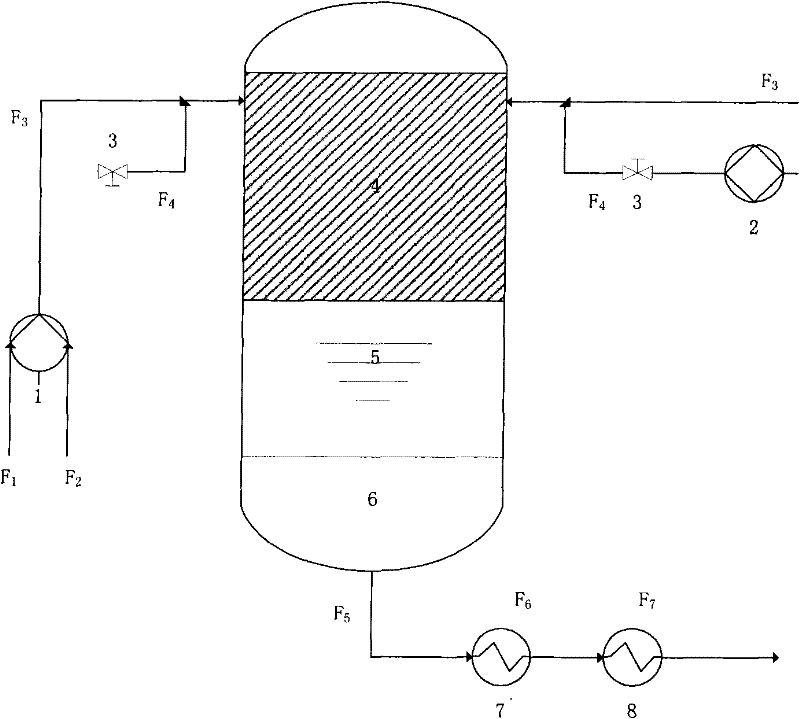

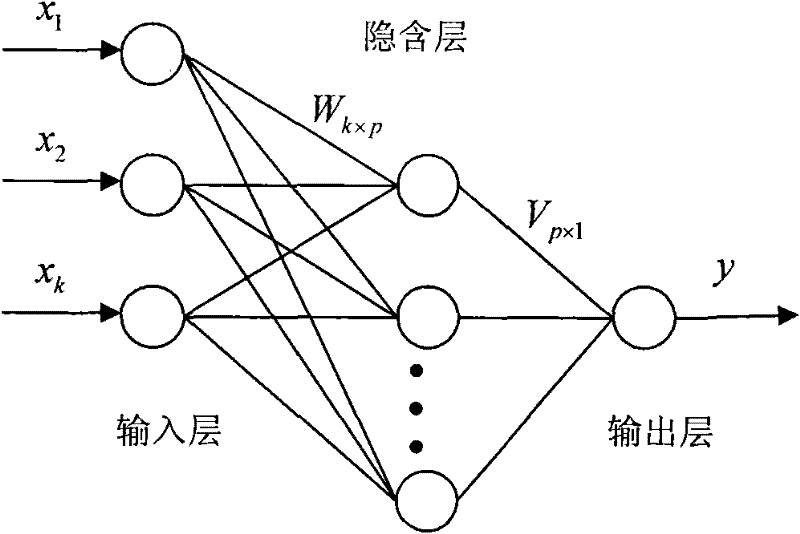

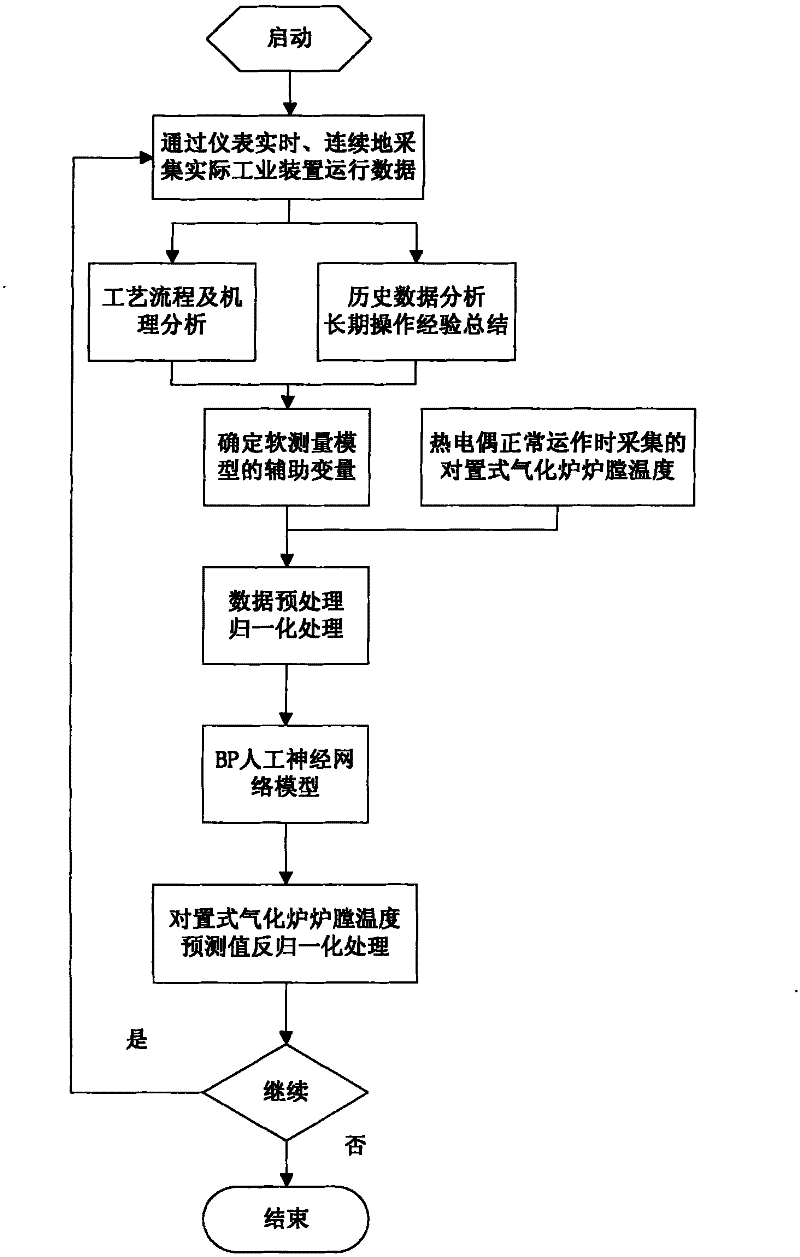

Soft measurement method for fire box temperature of multi-nozzle opposed coal water slurry gasification furnace

ActiveCN102175345AEmission reductionImprove conversion efficiencyThermometer applicationsNeural learning methodsCoal waterSpray nozzle

The invention relates to a soft measurement method for fire box temperature of a multi-nozzle opposed coal water slurry gasification furnace. The method comprises the following steps of: choosing a plurality of measurable process status auxiliary variables, including dried basis coal, oxygen flux at furnace entrance center, coal to oxygen ratio and content of H2, Co and CH4 synthesized at an exit, as input variables of a soft measurement model; simultaneously, acquiring practical operation data of an industrial device, and preprocessing the acquired data; and based on a BP artificial neural network, choosing a 6*6*1 three-layer network topology to train the model through a Levenberg-Marquardt learning algorithm so as to implement the soft measurement for the fire box temperature of the multi-nozzle opposed coal water slurry gasification furnace. The soft measurement technology can provide effective fire box temperature information for the multi-nozzle opposed coal water slurry gasification furnace so as to guide optimal running operations in a gasification process, and the method is also suitable for the soft measurement for the fire box temperature of coal water slurry gasification furnaces of other prior technologies.

Owner:EAST CHINA UNIV OF SCI & TECH

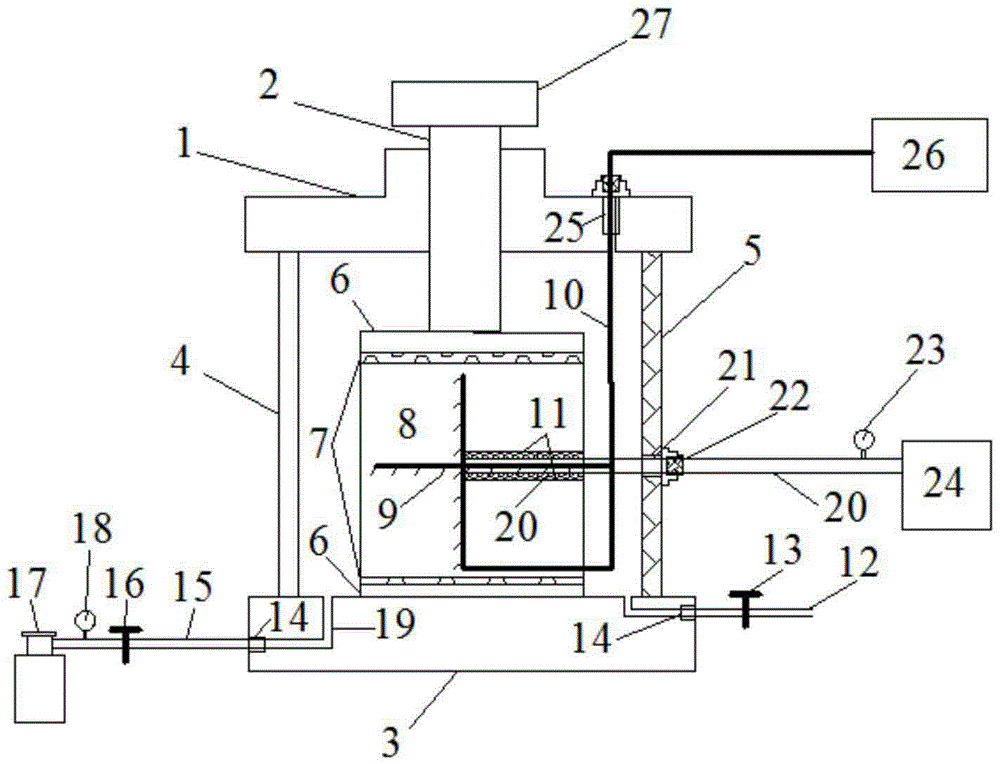

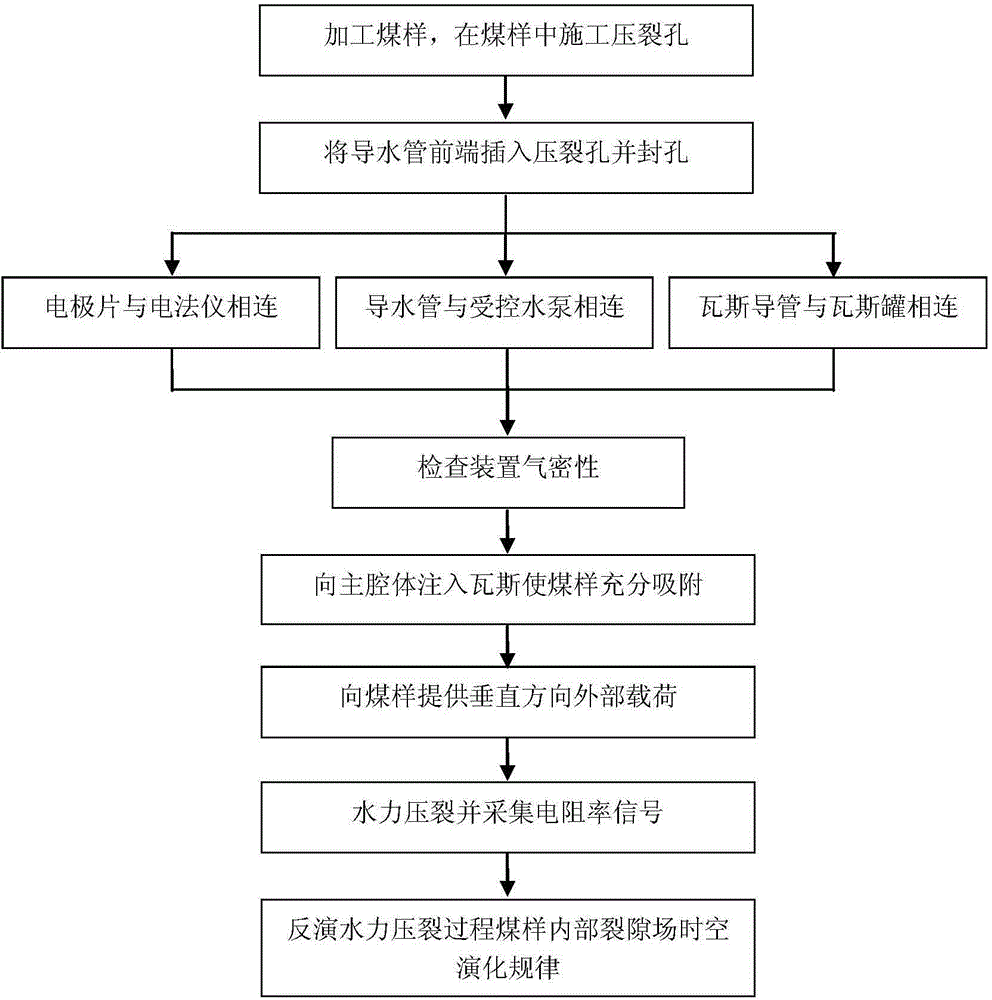

Gas coal hydrofracture field time-space monitoring device and method

InactiveCN104020192AFully reflect liquidityComprehensive reflection of diffusionMaterial resistanceCoal waterThree-dimensional space

The invention discloses a gas coal hydrofracture field time-space monitoring device and method. The device comprises a main cavity body, a crustal stress simulation module, a gas charging and discharging module, a hydrofracture module and a resistivity testing module which are arranged on the main cavity body, wherein the crustal stress simulation module is used for simulating the stress state of a coal body under a filed condition; the gas charging and discharging module is used for charging gas into a coal body; the hydrofracture module is used for providing pressure water for the coal body; the resistivity testing module is used for testing resistivity signals in a hydrofracture process of a coal sample. A coal sample obtained at the field is put into the main cavity body of the device, and gas is charged into the main cavity body, so that the coal sample adsorbs the gas fully, and external load is applied; high-pressure salt water is injected into preset drill holes in the coal sample and the preset drill holes are fractured; meanwhile the resistivity variation in the coal sample in the process is tested; the distribution in a three-dimensional space and the time-space evolution process of a fracture of the coal body are monitored continuously by the sensitive response to the salt water by resistivity. Additionally, the device also can determine the reasonable water injection pressure of the coal sample under different conditions.

Owner:CHINA UNIV OF MINING & TECH

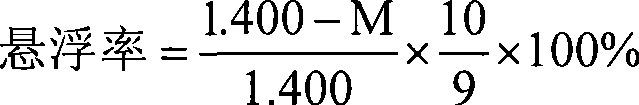

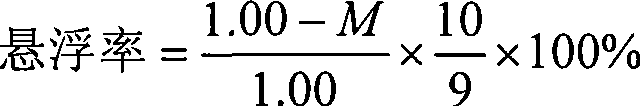

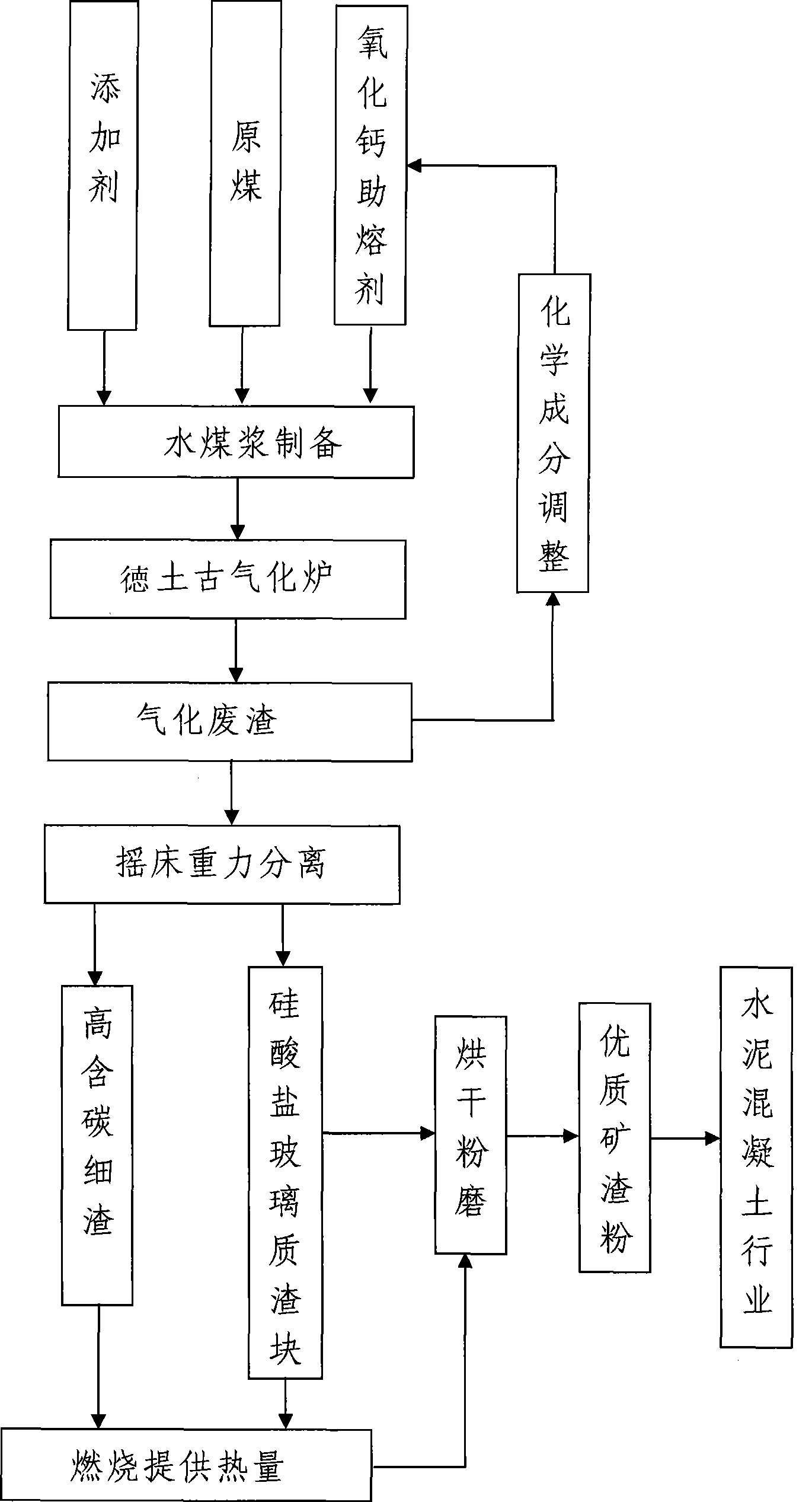

Comprehensive utilization method of coal water slurry gasified waste residue on Texaco gasifier

InactiveCN101456689AGood modification effectTake advantage ofSolid waste managementCement productionHigh carbonSlag

The invention provides a comprehensive utilization method for gasified waste residue of Texaco furnace water coal slurry, which is characterized in that enough fluxing agent is added during preparation and gasification of the water coal slurry; without changing a Texaco gasification process, the alkali coefficient of the generated waste residue is larger than 1.0, and then high carbon-containing granules and silicate glass slag blocks are separated by a gravity separation method; the waste residue is dried during grinding of the silicate glass slag blocks by using the heat value of the high carbon-containing granules; and finally obtaining the high-activity slag powder used for the cement or concrete industry, wherein the specific surface area of the slag powder is larger than 350m<2> / kg, and the moisture content is less than 1 weight percent, so the aim of effectively utilizing the gasified waste residue of the Texaco furnace water coal slurry is achieved. The method has the advantages of simple process, high utilization rate of the waste residue, and good economic benefit.

Owner:CHANGAN UNIV

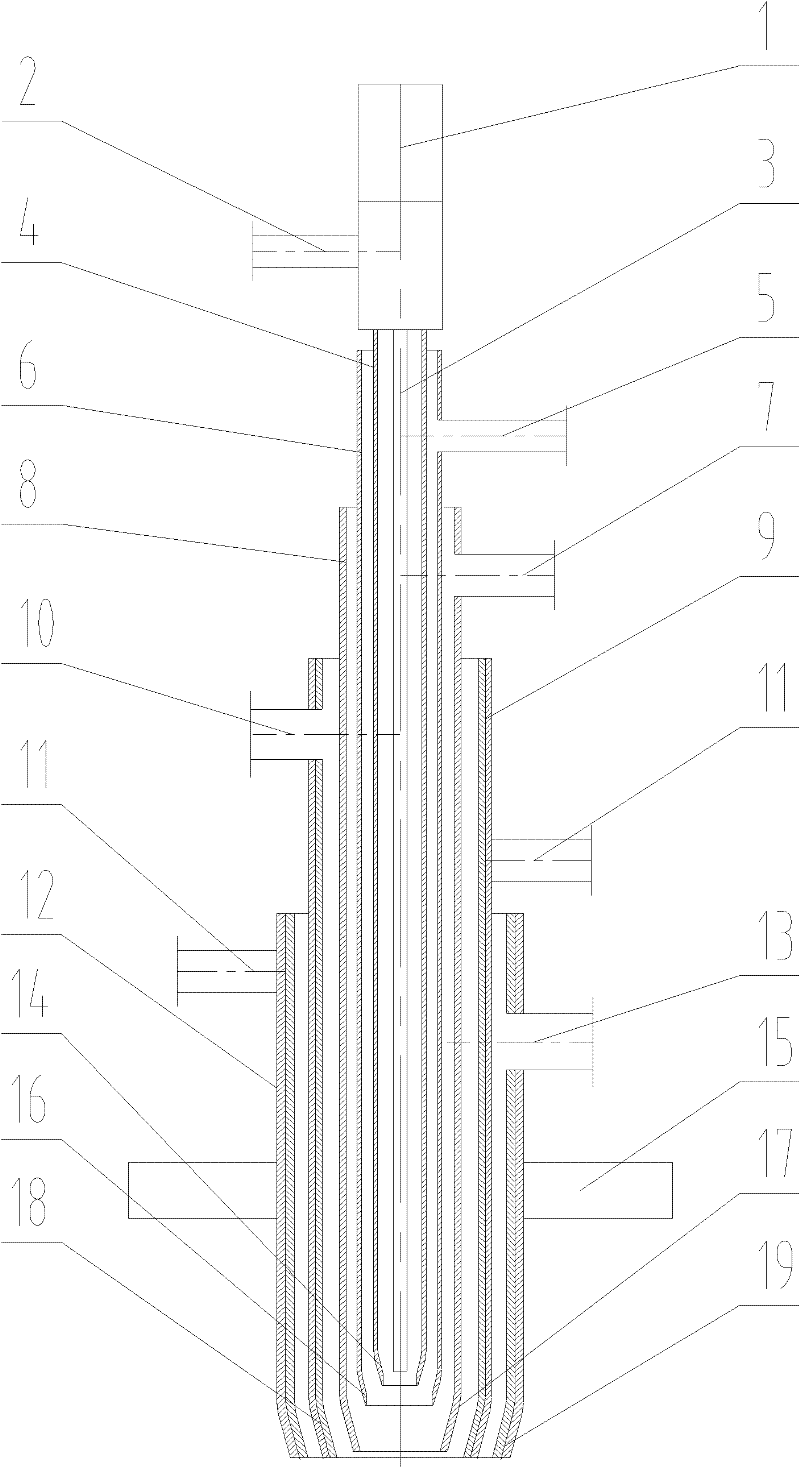

Combustion nozzle combination device of multi-channel coal water slurry gasification furnace

InactiveCN102408919AThe control logic is clear, simple and reliableReduce labor intensityGranular/pulverulent flues gasificationOxygenHigh pressure

The invention belongs to the coal chemical industry field of coal water slurry gasification, and specifically discloses a combustion nozzle combination device of a multi-channel coal water slurry gasification furnace. The combustion nozzle combination device comprises a high-voltage electric igniter connected with an electric ignition rod, wherein the high-voltage electric igniter is connected to an ignition nozzle through an ignition gas channel and an ignition gas pipe; a central oxygen channel is connected to a central oxygen pipe and nozzle, and is wrapped outside the ignition gas channel, the ignition gas pipe and the ignition nozzle; a coal water slurry channel is connected to a coal water slurry pipe and nozzle, and is wrapped outside the central oxygen pipe and nozzle; an outer annular oxygen channel is connected to an outer annular oxygen pipe and a combustion nozzle, and is wrapped outside the coal water slurry pipe; and a preheated gas channel is connected to a preheated gas pipe and nozzle, and is wrapped outside the outer annular oxygen pipe. By adding the ignition gas channel, the preheated gas channel, the electric ignition rod and a high-voltage power supply for the electric ignition rod based on the existing device, the invention simplifies the technical process, realizes the continuous operation of the combustion nozzle in accordance with a process of igniting, preheating and combusting coal water slurry, saves the production cost, and improves the operation safety and reliability.

Owner:BEIJING AEROSPACE PROPULSION INST

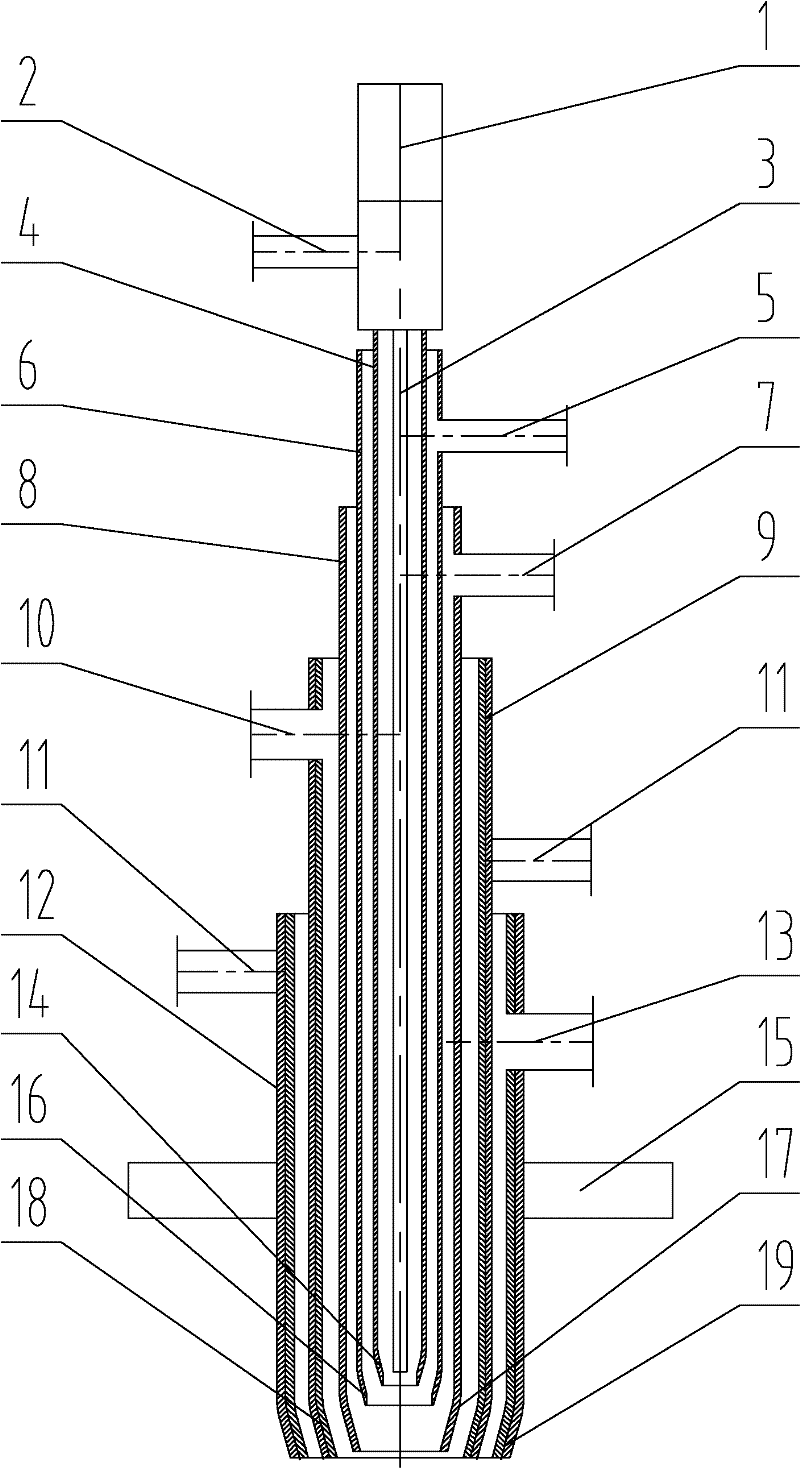

System and method for preparing ultrafine pulverized coal

InactiveCN103537355AIncrease productionReduce electricity consumption costsCombination devicesGrain treatmentsCoal waterProcess engineering

The invention discloses a system and a method for preparing ultrafine pulverized coal. The system comprises a fine pulverized coal preparation system and an ultrafine pulverized coal separation system. The fine pulverized coal preparation system comprises a vertical-type grinding machine. The vertical-type grinding machine is communicated with a bucket elevator. The bucket elevator is communicated with the ultrafine pulverized coal separation system. The ultrafine pulverized coal separation system comprises a pulverized coal surge bin. The pulverized coal surge bin is communicated with a grading machine. The grading machine is communicated with a cyclone separator. The cyclone separator is communicated with a pulse bag-type dust collector. The grading machine is communicated with a fine pulverized coal finished-product bin. The cyclone separator is communicated with an ultrafine pulverized coal finished-product bin 1#. The pulse bag-type dust collector is communicated with an ultrafine pulverized coal finished-product bin 2#. The method comprises fine pulverized coal preparation and ultrafine pulverized coal separation extraction. Through three-grade separation extraction adopting the grading machine, the cyclone separator and the pulse bag-type dust collector, the ultrafine pulverized coal is divided into different grades of ultrafine pulverized coal. The ultrafine pulverized coal obtained by the system and the method has a low cost and does not burn easily. The graded ultrafine pulverized coal can satisfy requirements on particle size graduation of coal water slurry master batch. The system and the method can realize industrial production.

Owner:SHENMU ZHANGJIAMAO COAL MINING CO LTD OF SHAANXI COAL & CHEM IND GRP

Sludge coal water slurry and process for making same

The invention discloses a sludge coal water slurry and process for making same which comprises, charging urban water treatment sludge, end product coal water slurry and dispersing agent into tubular grinding machine for grinding and mixing, filtering with a filter, loading sludge slurries with grain size smaller than 0.5mm to special-purpose slurry boiler for combustion.

Owner:青岛海众元亨热能有限公司

Coal water slurry addition agent, preparation method thereof and coal water slurry based on same

InactiveCN101812338AGood dispersionImprove stabilityLiquid carbonaceous fuelsPotassium hydroxideSodium hydroxide

The invention discloses a coal water slurry addition agent, a preparation method thereof and coal water slurry based on the same. The addition agent comprises the following components in percentage by weight: 55-90% of dispersant, 5-44% of stabilizer and 0.1-5% of PH regulator; the dispersant is one or mixture of several of polystyrene sulfonate and polyacrylate; the stabilizer is Arabic gum; and the PH regulator is sulfuric acid, nitric acid, sodium hydroxide or potassium hydroxide. The coal water slurry adopting the addition agent is the coal powder water slurry with the concentration of 68 percent which is prepared by enabling the weight of the addition agent to be 0.5-1.2% of the weight of dry-base coal powder, adding water and stirring well. The coal water slurry addition agent has good dispersibility and stability, the raw materials for preparing the addition agent has wide source and low cost, the preparation method is simple and easy to realize, and the addition agent has wide application range for coal types, low cost, low concentration and good stability. The coal water slurry which is prepared by adopting the addition agent has the apparent viscosity of 760mPa.s and can be stably stored for more than 30 days at 25DEG C and at the shear rate of 100S-1.

Owner:SHAANXI UNIV OF SCI & TECH

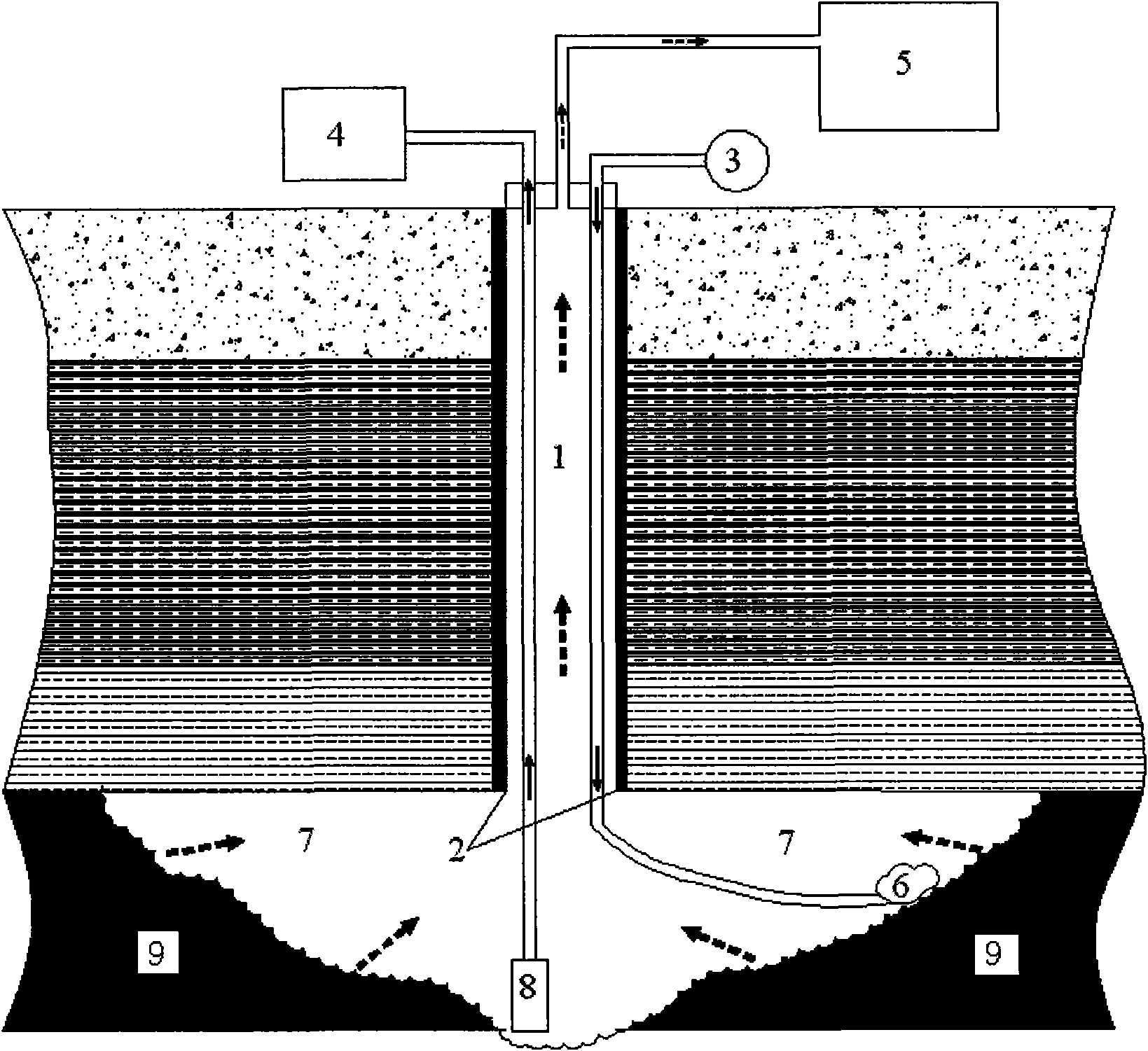

Method for exploiting coal bed gas by hydraulic drilling and pressure relieving

The invention discloses a method for exploiting coal bed gas by hydraulic drilling and pressure relieving. The method comprises the following steps of: drilling a large-caliber well to the coal bed(9), building a coal bed gas exploitation well(1) capable of adding water, discharging water and discharging gas, making a sleeve pipe(2) arranged on the drilling well, and performing mechanical drilling at the bottom of the well; making a well-sealing device arranged on an opening of the coal bed gas exploitation well(1), and making a ground water pump(3), a coal-water separating device(4) and a gas storage device(5) arranged; distributing water-discharging devices(8) and flushing robots(6) on both sides in the coal bed gas exploitation well(1), wherein the flushing robots(6) are connected with the ground water pump(3) by soft water pipes and can continuously flush the coal down in caves at the bottom of the well to form a pressure relieving space(7); discharging the coal-water mixture to the coal-water separating device(4) by the water-discharging devices(8); and discharging the coal bed gas continuously generated by the coal bed(9) after pressure relieving to the gas storage device(5) by the coal bed gas exploitation well(1). The method has the advantages of easily solving the problem of early exploiting the coal bed gas in the coal mass with looseness, extremely low permeability and high bursting, eliminating bursting risk and lowering a gas content of the coal mass.

Owner:ZHENGZHOU UNIV +2

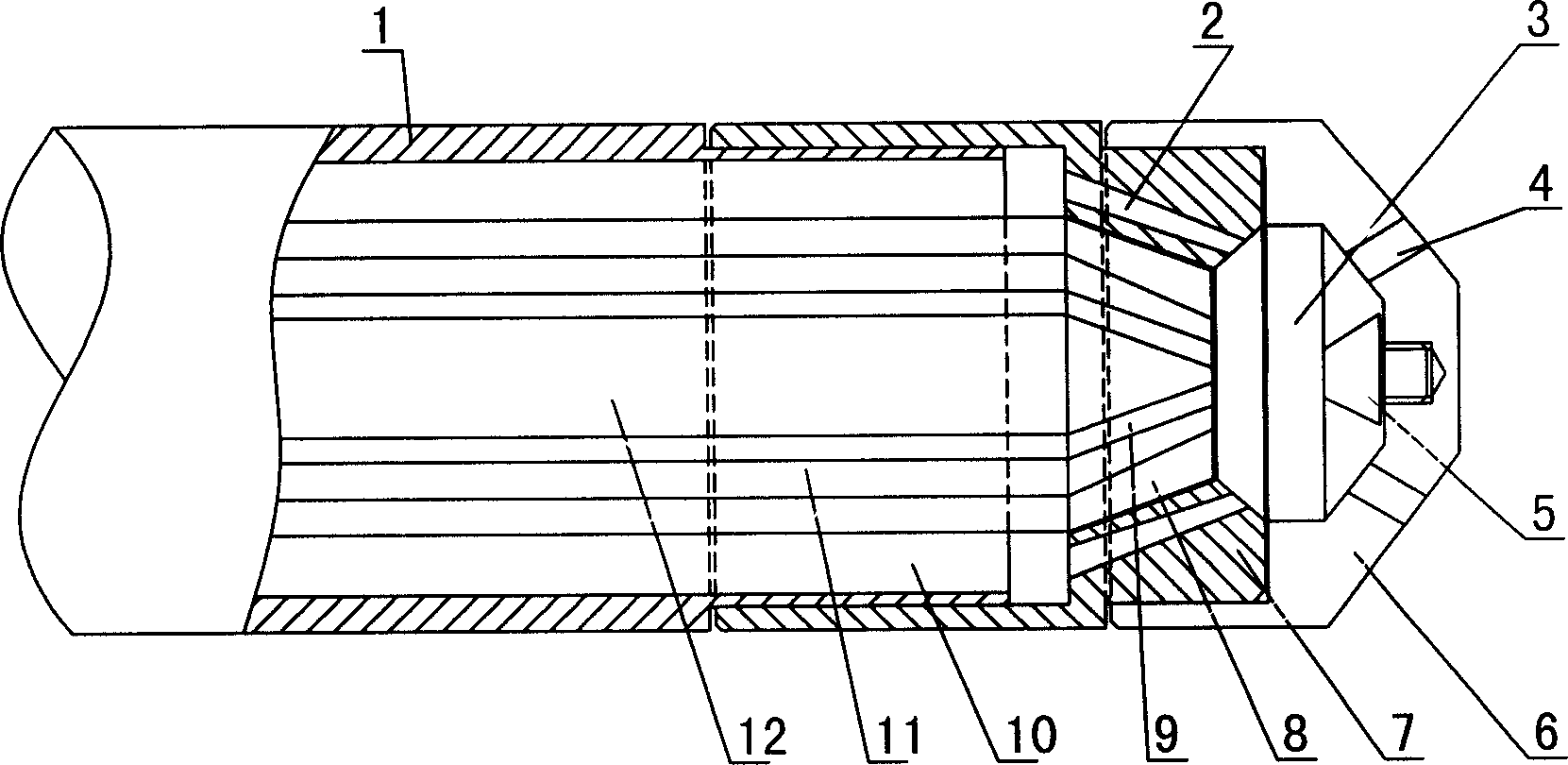

Coal-water fluid gasifying spray nozzle

InactiveCN1752521ALarge load adjustment rangeEasy to adjustLiquid fuel feeder/distributionLump/pulverulent fuel feeder/distributionInterior spaceCoal water

The present invention relates to a combustion device, and is aimed at providing a coal-water slurry gasification nozzle. It is characterized by forming central tube oxidant channel whose section is concentric ring-tubular structure, medium ring coal-water slurry channel and outer ring oxidant channel: the tail end of central tube oxidant channel is reducing-formed central tube nozzle, the medium ring coal-water slurry channel and outer ring oxidant channel are reducing-formed medium ring tube nozzle and outer ring tube spray head, the outer ring tube spray head is connected with atomizing head on which the jet orifices are uniformly distributed.

Owner:ZHEJIANG UNIV

Preparation method of anion sulfonate type coal water slurry dispersant

The invention discloses a preparation method of an anion sulfonate type coal water slurry dispersant. A terpolymer is prepared from an anion monomer and a sulfonate monomer as reaction monomers under the action of an initiator and a chain transfer agent through free radical polymerization. By using the dispersant obtained by the preparation method disclosed by the invention, coal water slurry with solid content of 60-70% has excellent dispersion and stabilization effects; and the dispersant is suitable for various coal species, in particular slurrying of coal with poor quality.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com