Coal water slurry dispersing agent made from black-liquor of straw pulping in paper-making and preparation thereof

A papermaking black liquor and dispersant technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems that restrict the popularization and application of lignin-based coal-water slurry dispersants, and the poor viscosity-reducing performance of coal-water slurry dispersion. , It is difficult to meet the production requirements and other problems, and achieve the effects of excellent dispersion and viscosity reduction performance, excellent slurry stability and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

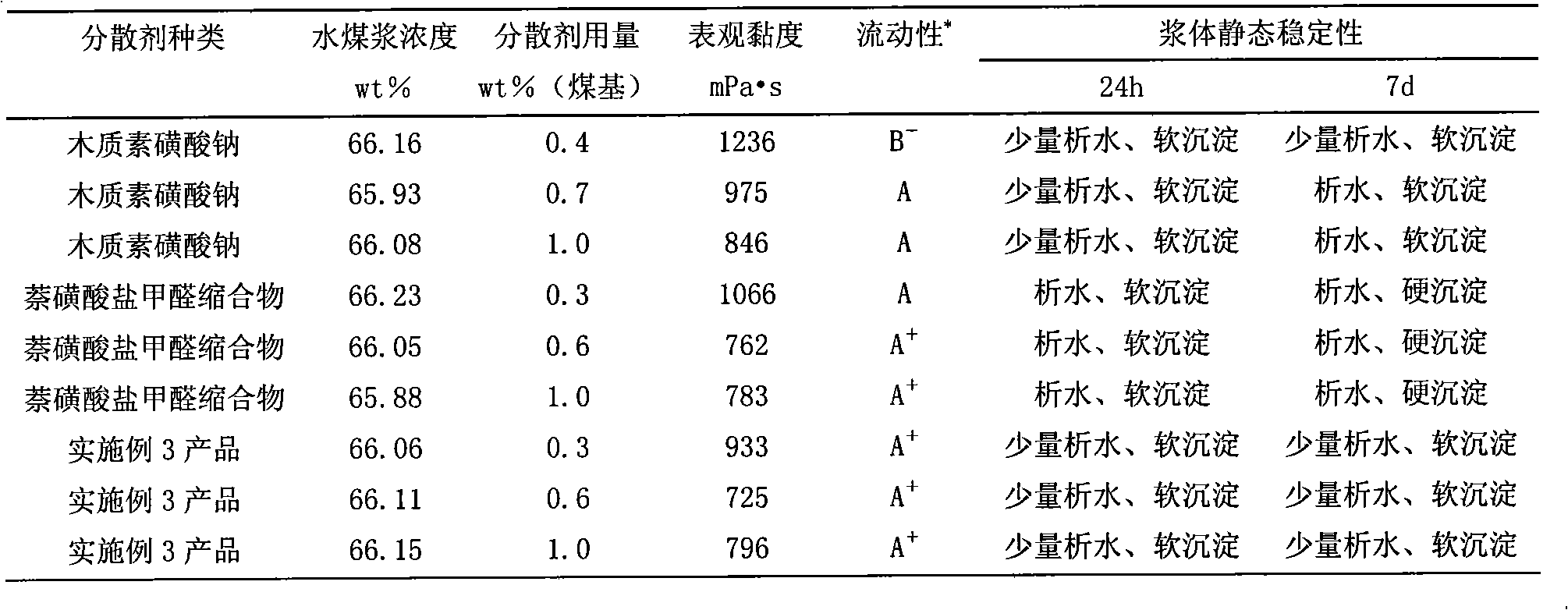

[0035]Get 15 grams of urea and dissolve it in 50 grams of water, join in 200 grams of wheat straw pulp concentrated black liquor (solid content 55%, wherein lignin content 26.5%, effective alkali content 24.6%, ash content 11.2%), add sodium hydroxide to adjust pH to 10.5, during which 20 g of formaldehyde was added dropwise, and then reacted at 80° C. for 1 hour to obtain an intermediate reaction solution A. Dissolve 25 grams of ammonium sulfite in 46.5 grams of water, add 15 grams of acetylacetone, after fully dissolved, add sulfuric acid to adjust the pH to 9, react at 50°C for 0.8 hours, add 10 grams of glyoxal, and react at 65°C for 1 hour , to obtain the intermediate reaction solution B. The intermediate reaction solution A and the intermediate reaction solution B were mixed, sodium hydroxide was added to adjust the pH to 11, 15 g of formaldehyde was added dropwise, and the polycondensation reaction was carried out at 85° C. for 3 hours. After the reaction is completed,...

Embodiment 2

[0037] Get 10 grams of dimethyl urea and dissolve it in 20 grams of water, join in 200 grams of straw pulp concentrated black liquor (solid content 55%, wherein lignin content 26.5%, effective alkali content 24.6%, ash content 11.2%), add sulfuric acid Adjust the pH to 10, add 20 g of acetaldehyde dropwise during this process, and then react at 90° C. for 1.5 hours to obtain an intermediate reaction solution A. Dissolve 50 grams of sodium metabisulfite in 120 grams of water, add 20 grams of acetone, add sodium hydroxide to adjust the pH to 11 after the dissolution is complete, react at 70°C for 0.5 hours, add 10 grams of formaldehyde, and react at 50°C for 0.7 hours to obtain Intermediate reaction solution B. The intermediate reaction solution A and the intermediate reaction solution B were mixed, sodium hydroxide was added to adjust the pH to 10.5, 10 g of formaldehyde was added dropwise, and the polycondensation reaction was carried out at 90° C. for 3 hours. After the reac...

Embodiment 3

[0039] Get 20 grams of acetone in 50 grams of water, join in 200 grams of wheat straw pulp concentrated black liquor (solid content 55%, wherein lignin content 26.5%, effective alkali content 24.6%, ash content 11.2%), add sodium hydroxide to adjust pH To 12, 20 grams of polyoxymethylene was added dropwise during this process, and then reacted at 75° C. for 2 hours to obtain an intermediate reaction solution A. Dissolve 15 grams of sodium bisulfite and 25 grams of sodium sulfite mixture in 80 grams of water, add 12 grams of acetophenone, add sulfuric acid to adjust the pH to 10.5 after the dissolution is complete, react at 85 ° C for 1 hour, add 10 grams of formaldehyde, at 55 The reaction was carried out at ℃ for 0.6 hours to obtain the intermediate reaction solution B. The intermediate reaction solution A and the intermediate reaction solution B were mixed, sodium hydroxide was added to adjust the pH to 11, 14 g of glutaraldehyde was added dropwise, and the polycondensation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com