Patents

Literature

1193 results about "Sodium bisulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium bisulfite (or sodium bisulphite, sodium hydrogen sulfite) is a chemical compound with the chemical formula NaHSO₃. Sodium bisulfite is a food additive with E number E222. This salt of bisulfite can be prepared by bubbling sulfur dioxide in a solution of sodium carbonate in water. Sodium bisulfite in contact with chlorine bleach (aqueous solution of sodium hypochlorite) will generate heat and form sodium bisulfate and sodium chloride.

Method for synthesizing taurine

InactiveCN101486669AHigh yieldReduce chanceSulfonic acid preparationSodium IsethionateSodium bisulfite

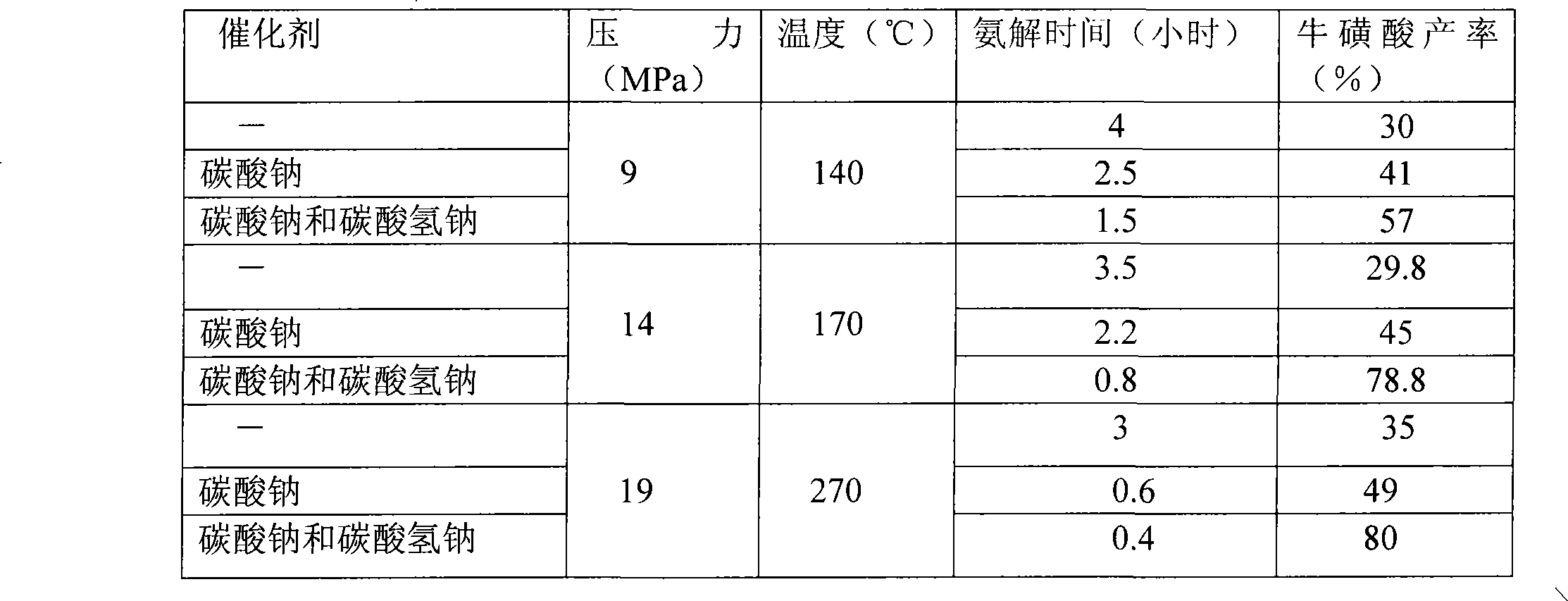

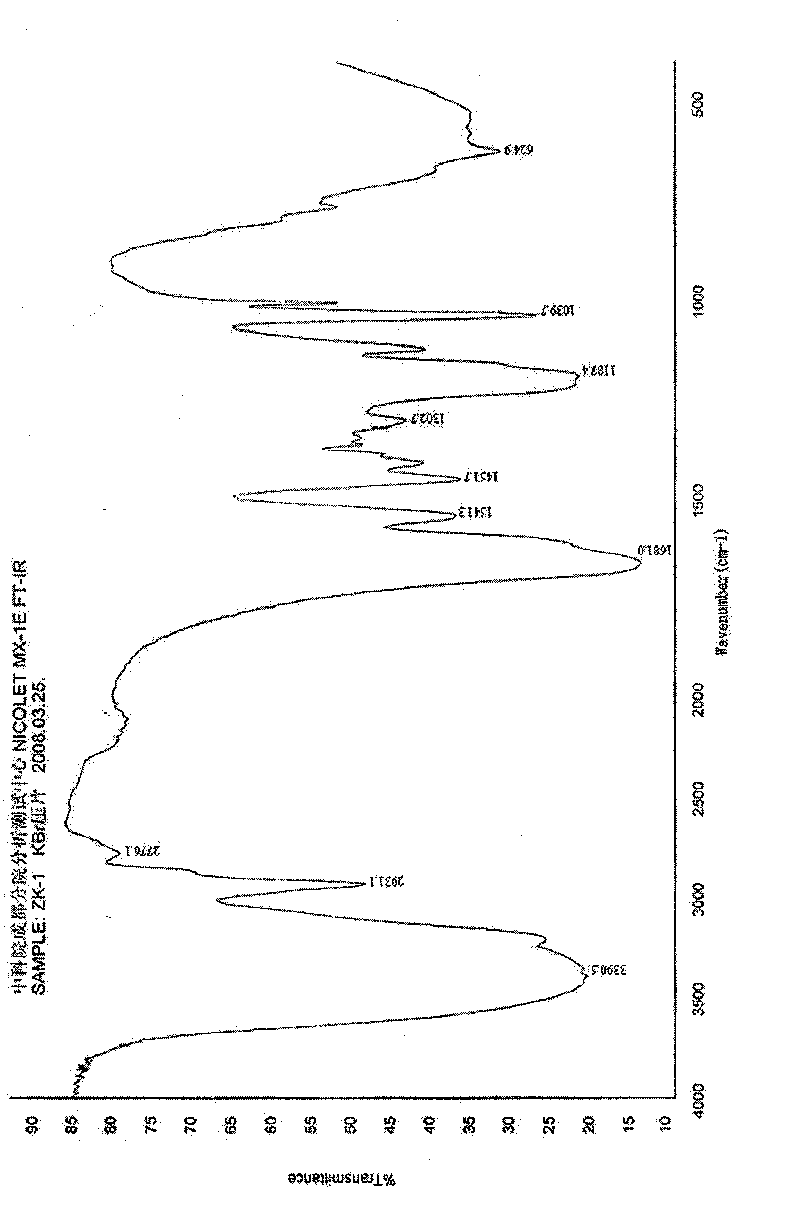

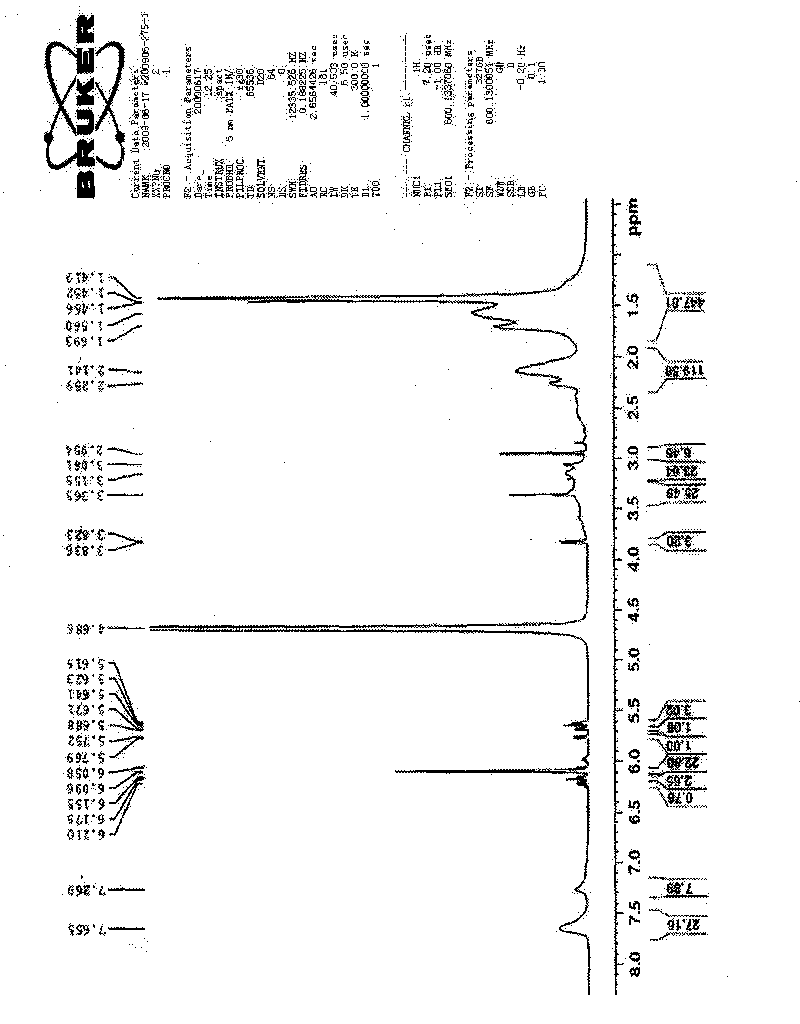

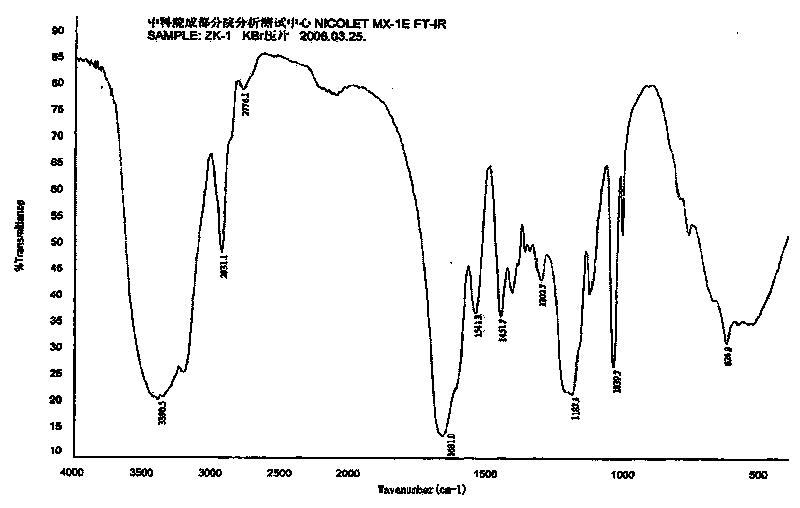

The invention relates to a method for synthesizing taurine. The production technique comprises the steps: A. sodium bisulfite, epoxyethane and sodium hydroxide are placed in a reaction kettle to produce sodium isethionate through reaction; sodium isethionate reacts with liquid ammonia at temperature of 260 DEG C and 270 DEG C and a pressure of 18.5MPa to 19MPa to synthesize and produce sodium 2-amino ethyl sulfonate; B. a sodium 2-amino ethyl sulfonate solution is added with sulphuric acid and goes through centrifugal filtration, thus obtaining the rough crystals of taurine; and C. the rough crystals of taurine are refined and dried. The method has the advantage that by changing the temperature and pressure for reaction, the yield of sodium 2-amino ethyl sulfonate (the intermediate product for synthesizing and preparing taurine) is improved; the occurrence possibility of side reaction is lowered; and the content of impurities is obviously reduced.

Owner:SHAYANG TIANYI MEDICINE IND

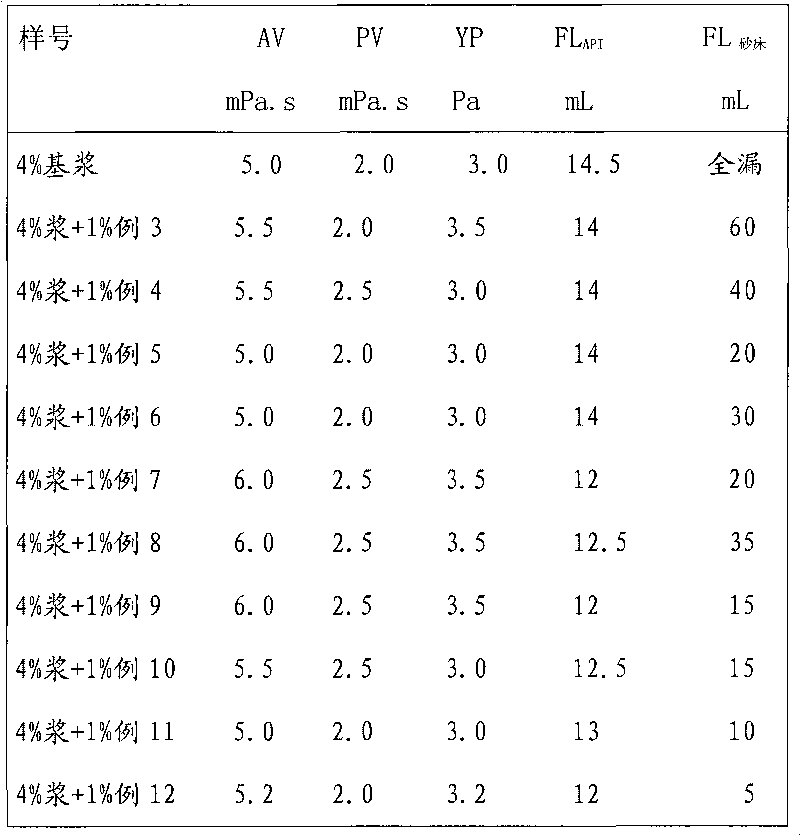

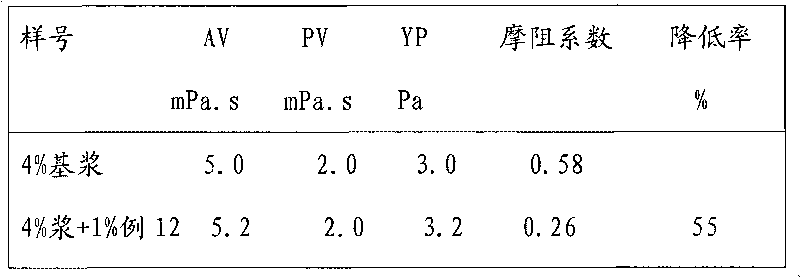

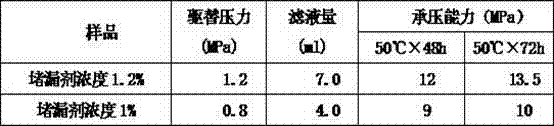

Drilling fluid plugging agent while drilling

The invention relates to a drilling fluid plugging agent while drilling, comprising 60-100 parts of plant fibers, 5-20 parts of asphalt, 5-15 parts of graphite and 5-20 parts of weak water absorbent gel by weight. The weak water absorbent gel is a polymer which has mean grain size of 200-20 meshes and water absorbent multiple of 10-100g.g-1 and is prepared by reacting 20-60 parts of monomer, 0.05-1.0 part of potassium peroxydisulfate, 0.05-1.0 part of sodium bisulfite, 0.005-0.5 part of methylene-bis-acrylamide and 2-10 parts of inorganic fillers by weight under constant temperature of 20-60 DEG C for 8-12h by way of aqueous solution polymerization, drying and pelleting, wherein the polymeric monomer is one or more of acrylamide, acrylic acid, dimethyl diallyl ammonium chloride and 2-acrylamide-2-methyl propanesulfonic acid. The plugging agent has little effect on the rheological property of the drilling fluid, can reduce the API filtration and the coefficient of friction resistance of the drilling fluid in an auxiliary manner and is suitable for controlling leakage of and plugging the windows with high density and narrow pressure.

Owner:PETROCHINA CO LTD

Extruded gluten based pet chew bodies

InactiveUS20050214349A1Facilitate easeEasy to storeAnimal feeding stuffAccessory food factorsFiberAdditive ingredient

A method of forming solid gluten-based pet chew is provided wherein a gluten mixture is heated to a maximum temperature of up to about 80° C. to create a substantially homogeneous and flowable mixture under extrusion processing conditions. The formulation includes from about 40-90% by weight of grain protein, from about 10-40% by weight plasticizer, and at least about 0.01 by weight of a reducing agent such as sodium bisulfite for cleaving disulfide bonds present in the grain protein. Dental health agents including an acidulent and a chelator are added to promote good dental health. Optional ingredients such as fillers, fiber, lubricant / mold release agents and colorants can also be used. The formulations can be processed in extrusion or injection molding equipment.

Owner:DERMAPET

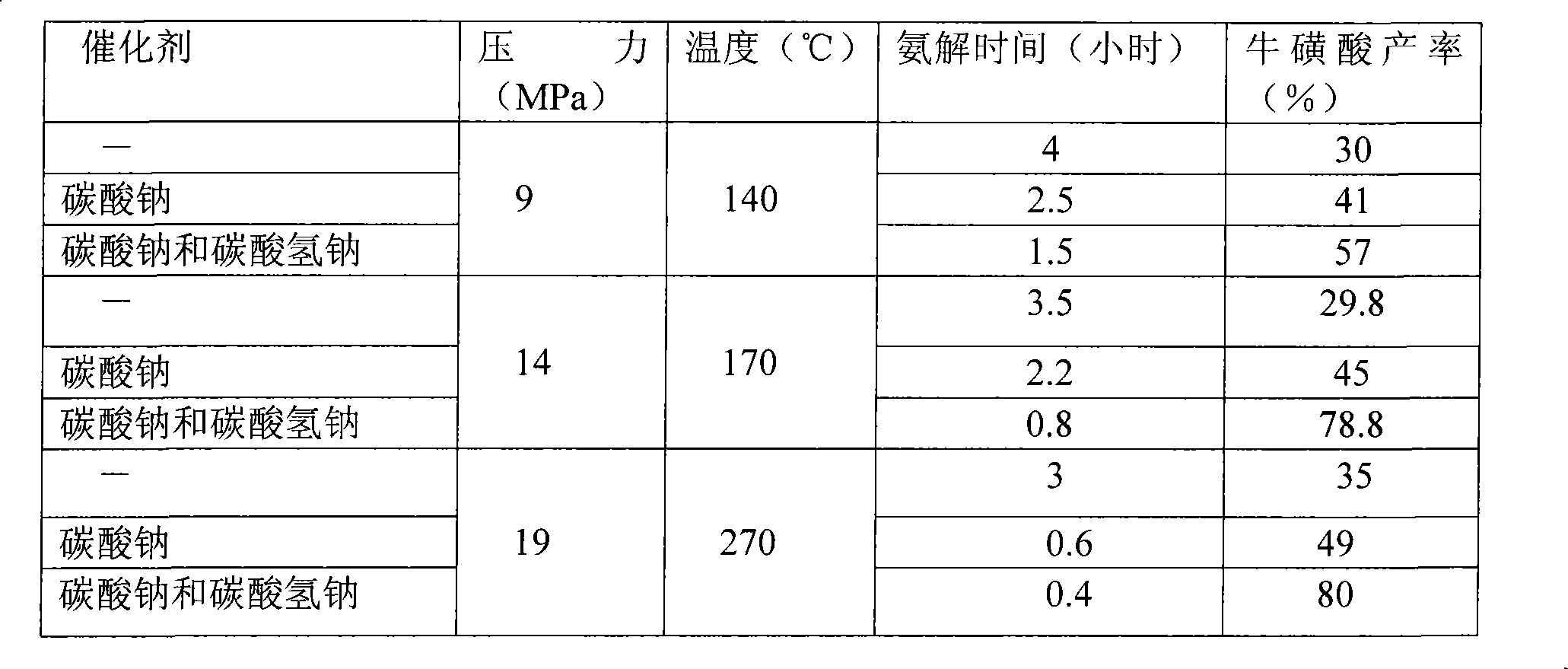

Synthesis of taurine

The invention relates to a method for synthesizing taurine, comprising the following steps: (1) according to the amount ratio of materials of 1:1 to 1:1.2, epoxy ethane and sodium bisulfite are subjected to addition reaction under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at a temperature between 75 and 85 DEG C to form hydroxyethyl sodium sulfonate; (2) the hydroxyethyl sodium sulfonate and liquid ammonia are subjected to ammonolysis reaction under 14 to 21MPa and at a temperature between 160 and 280 DEG C to generate sodium taurate, and the mass concentration of ammonia in the reaction liquid is 20 to 30 percent; and (3) neutralization: namely, the sodium taurate is neutralized by sulphuric acid to generate the taurine. The method for synthesizing the taurine has the advantages of short time, high yield and lower cost, and is easy for industrialized production.

Owner:王代龙 +1

Method for preparing taurine

The invention relates to a method for preparing taurine, comprising the following steps: epoxy ethane and sodium bisulfite are reacted under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at a temperature between 75 and 85 DEG C to form hydroxyethyl sodium sulfonate; the hydroxyethyl sodium sulfonate and liquid ammonia are subjected to ammonolysis reaction at under 14 to 21MPa and at a temperature between 160 and 280 DEG C to form ammonolysis solution containing sodium taurate; and the ammonolysis solution is evaporated to remove ammonia, neutralized by sulphuric acid, concentrated, crystallized, separated, pre-dried in a boiling drying device or a vibration fluidization drying device, and then added into a microwave drying device to be dried and sterilized to obtain the taurine. The method for synthesizing the taurine has the advantages of short time, high yield and lower cost, and is easy for industrialized production. The water content of a taurine wet product can be reduced to below 0.30 percent through combined application of pre-drying of the boiling drying device or the vibration fluidization drying device and microwave drying, and simultaneously the device has the function of sterilizing.

Owner:王代龙 +1

High temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid and preparation method thereof

The invention relates to high temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid of a high temperature and high pressure drilling and a preparation method thereof. Four monomers, namely, acrylamide (AM), 2-acrylamide-2-methyl propane sulfonic acid (AMPS), dimethyl diallylammonium chloride (DMDAAC) and styrenesulfonate (SSS) are used as raw materials, wherein the mole ratio of AM:AMPS:DMDAAC:SSS is (9-11):(3-4):(0.5-1.5):(1.0-1.5); ammoniumpersulfate-sodium bisulfite as an initiator is added and solution is copolymerized through a polymerization method to compose the fluid loss agent. The fluid loss agent provided by the invention has the advantages of ideal high temperature resistant (more than 220 DEG C) reducing filtrate performance, shale inhibition performance and stable fluid rheology performance and simple preparation method, convenient operation and higher yield.

Owner:SOUTHWEST PETROLEUM UNIV

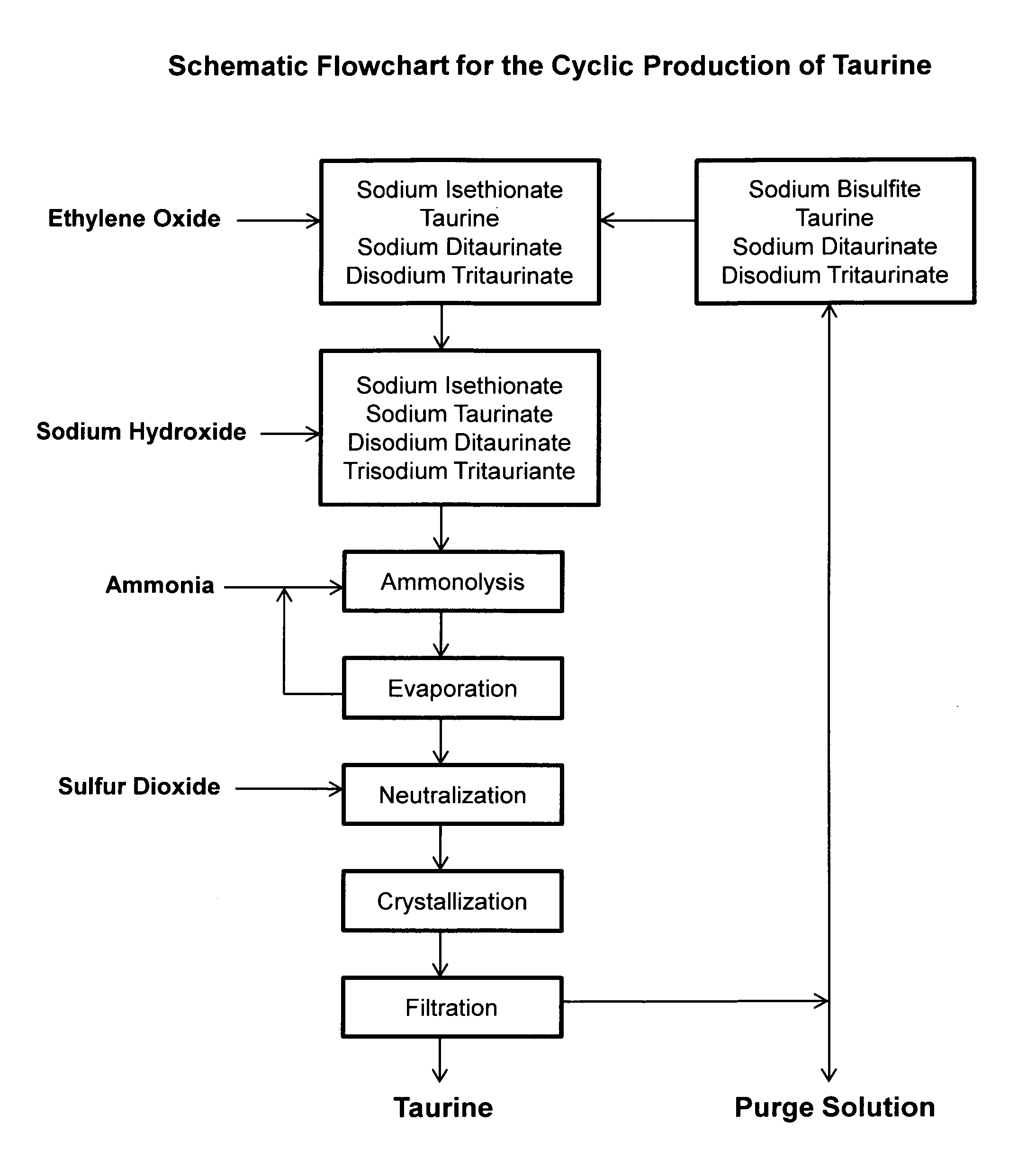

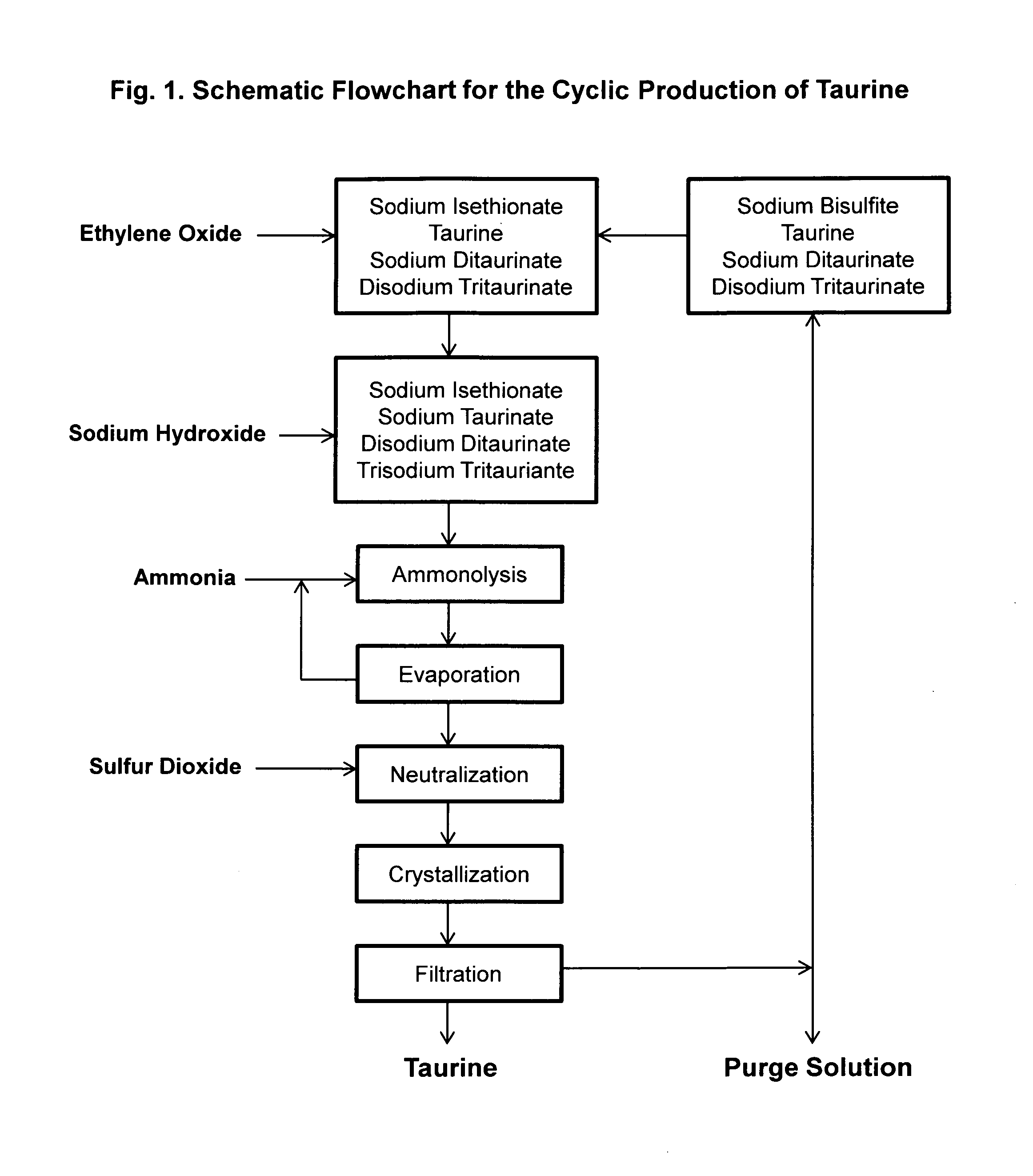

Cyclic process for the production of taurine from ethylene oxide

ActiveUS9061976B1Organic compound preparationSulfonic acids salts preparationCyclic processSodium dithionite

The present invention discloses a cyclic process for the production of taurine from ethylene oxide in a high yield of greater than 95% by continuously converting the byproducts of the ammonolysis reaction, sodium ditaurinate and sodium tritaurinate, to sodium taurinate. The cyclic process is completed by using sulfur dioxide or sulfurous acid to neutralize sodium taurinates to recover taurine and to regenerate sodium bisulfite, which is then reacted with ethylene oxide.

Owner:VITAWORKS IP LLC

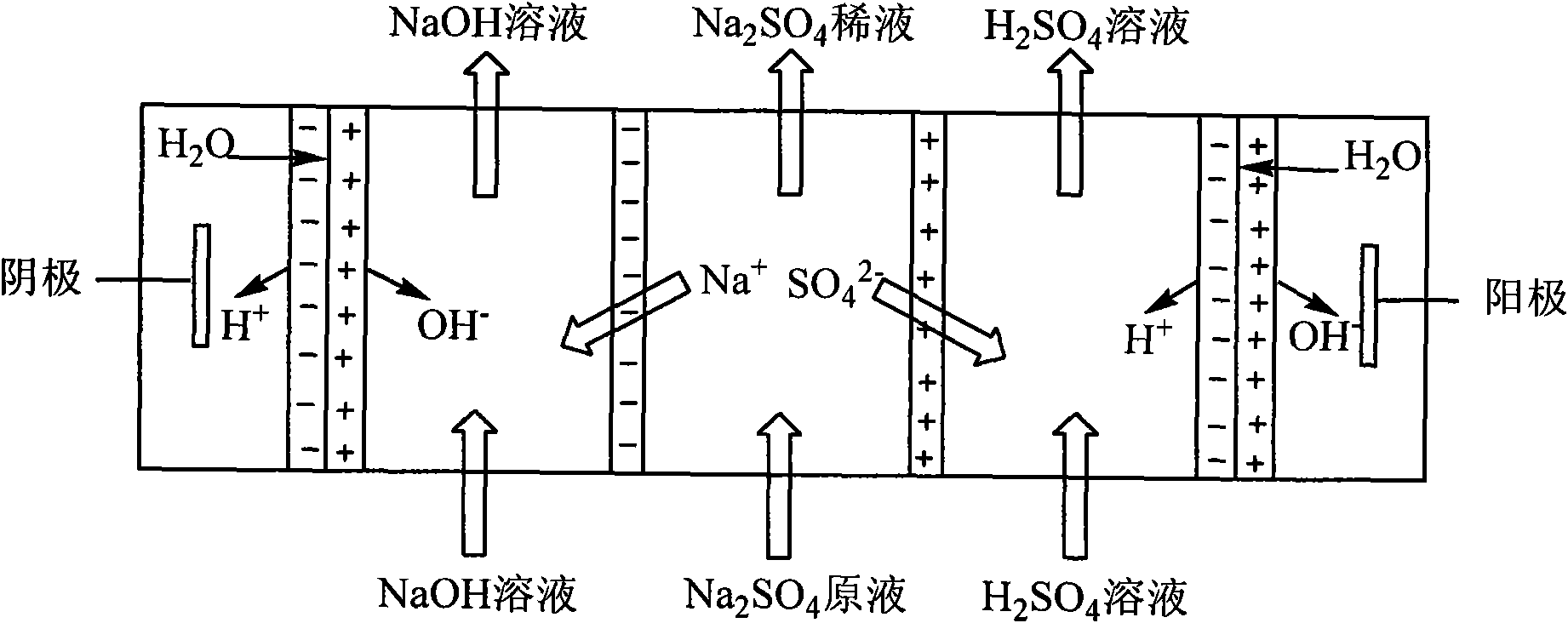

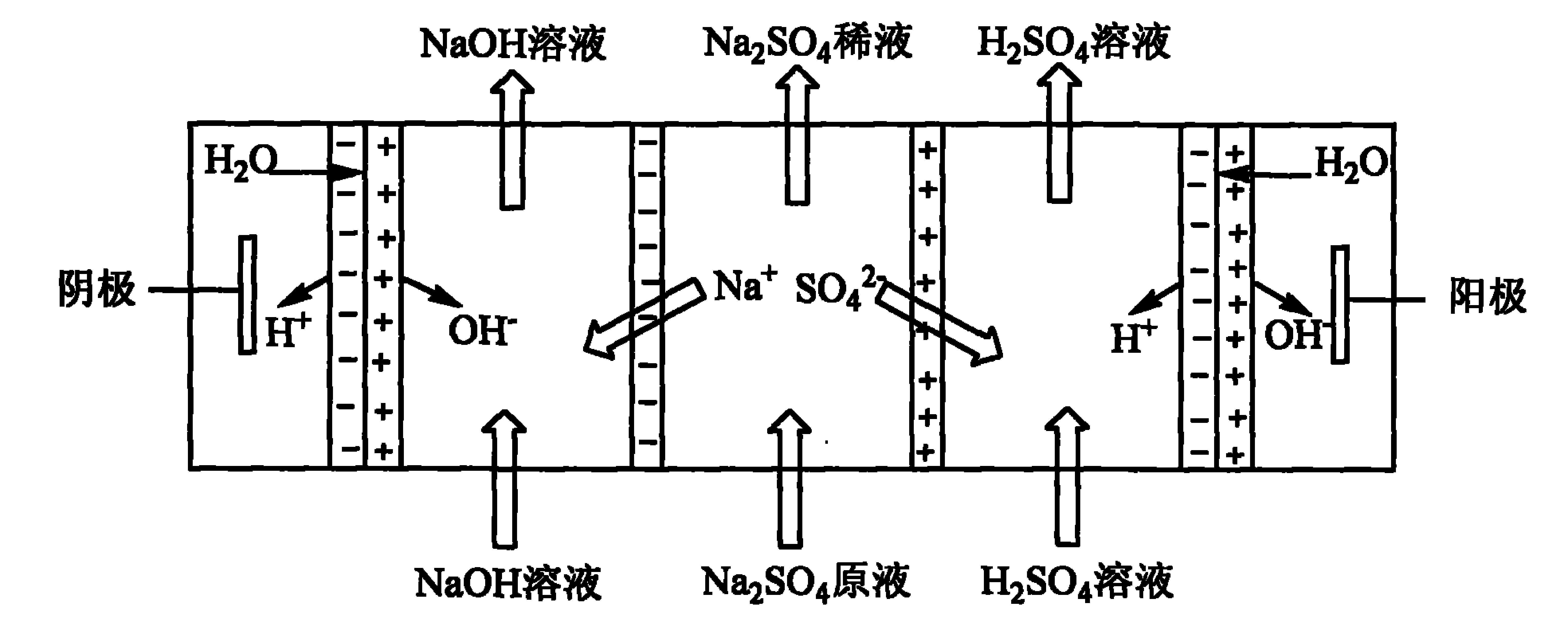

Reproduction method for sodium-base flue gas desulfurization liquid

InactiveCN102335553ALow costElectrolysis componentsDispersed particle separationElectrolysisResource utilization

The invention relates to a reproduction method for sodium-base flue gas desulfurization liquid, which is characterized in that the flue gas desulfurization liquid containing sodium sulphite and sodium bisulfite is oxidized to a solution containing sodium sulfate, the solution containing sodium sulfate is electrolyzed to a sodium hydroxide solution and a sulfuric acid solution by using bipolar membrane electrodialysis. According to the invention, the electrolytic conversion rate of sodium sulfate can reach more than 90%, the obtained sodium hydroxide solution can be used as absorption liquid for a flue gas desulfurization tower, the sulfuric acid by-product is produced simultaneously. By-product sulfuric acid can be used as sulfuric acid for treating high hardness and high alkalinity. The reproduction method for sodium-base flue gas desulfurization liquid is capable of achieving the purposes of strong brine zero-draining, comprehensive resource utilization and cost reduction.

Owner:CHINA PETROLEUM & CHEM CORP

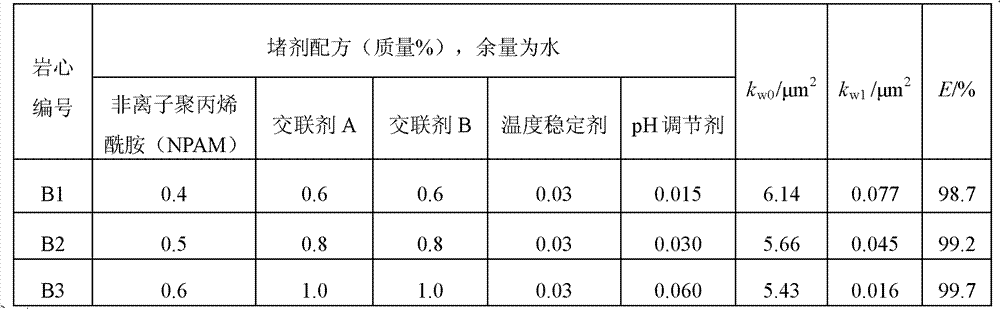

Gel plugging agent for deep profile control of higher temperature oil reservoir and preparation method of gel plugging agent

ActiveCN102807849AImprove temperature resistanceGelation time is shortDrilling compositionSodium bicarbonateCross-link

The invention relates to a gel plugging agent for deep profile control of a higher temperature oil reservoir, and a preparation method of the gel plugging agent. The gel plugging agent comprises 0.3-0.8 percent of nonionic polyacrylamide, 0.6-1.3 percent of a cross-linking agent A, 0.45-1.44 percent of a cross-linking agent B, 0.02-0.04 percent of a temperature stabilizer and 0.01-0.08 percent of a pH value regulator, wherein the cross-linking agent A is methenamine; the cross-ling agent B is hydroquinone or resorcinol; the temperature stabilizer is sodium thiosulfate, sodium bisulfite or sodium sulfite; and the pH regulator is sodium hydroxide, potassium hydroxide, sodium carbonate or sodium bicarbonate. The gel plugging agent disclosed by the invention has strong temperature resisting performance and can be used for the profile control operation of the high temperature oil reservoir with 100-160DEG C; the gel plugging agent has the characteristics of high strength after being gelatinized, stronger plugging capability for the stratum and favorable thermal stability; and in addition, after the gel plugging agent is stood at the temperature of 130 DEG C for 90 days, the strength change is little and gel breaking and hydration are avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

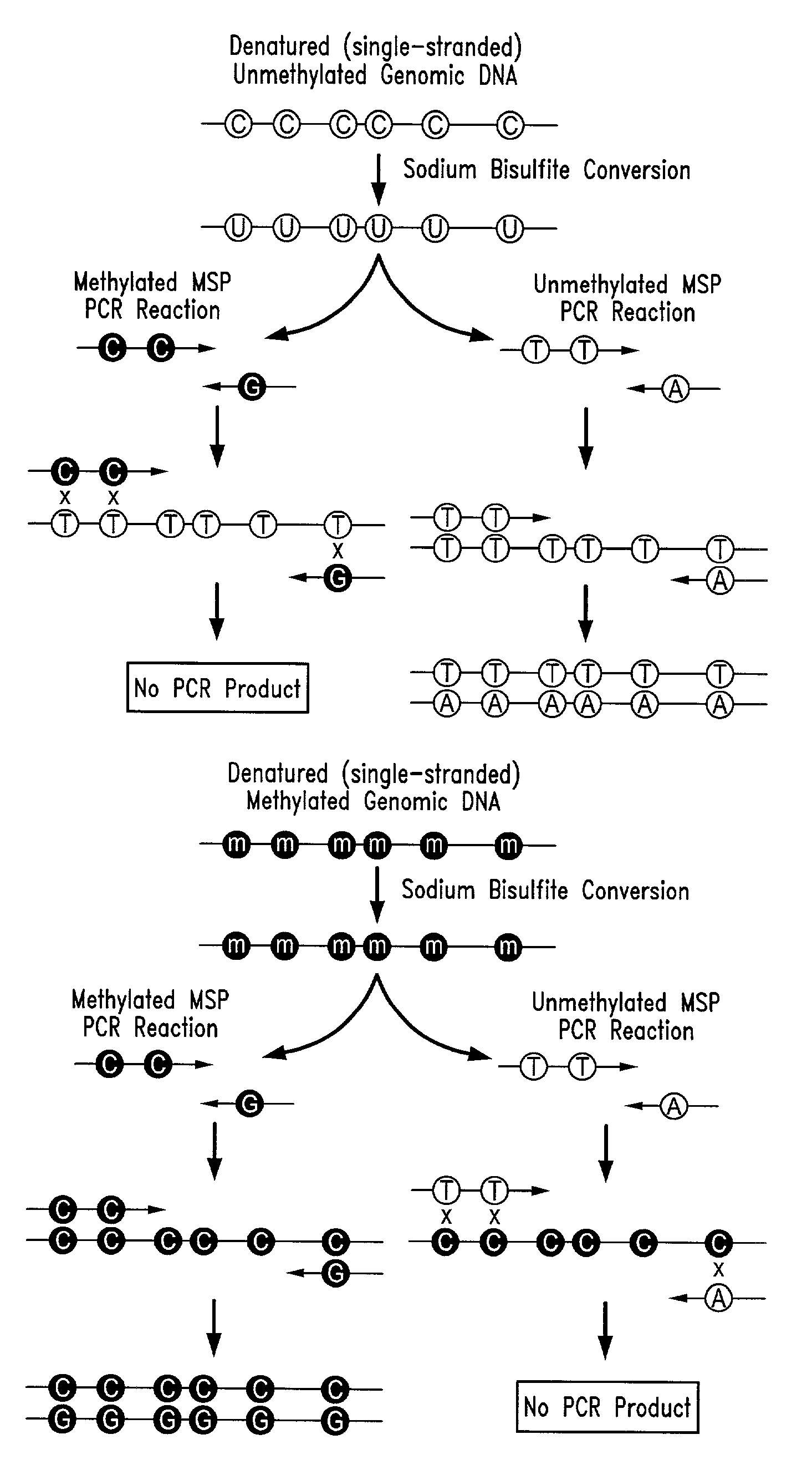

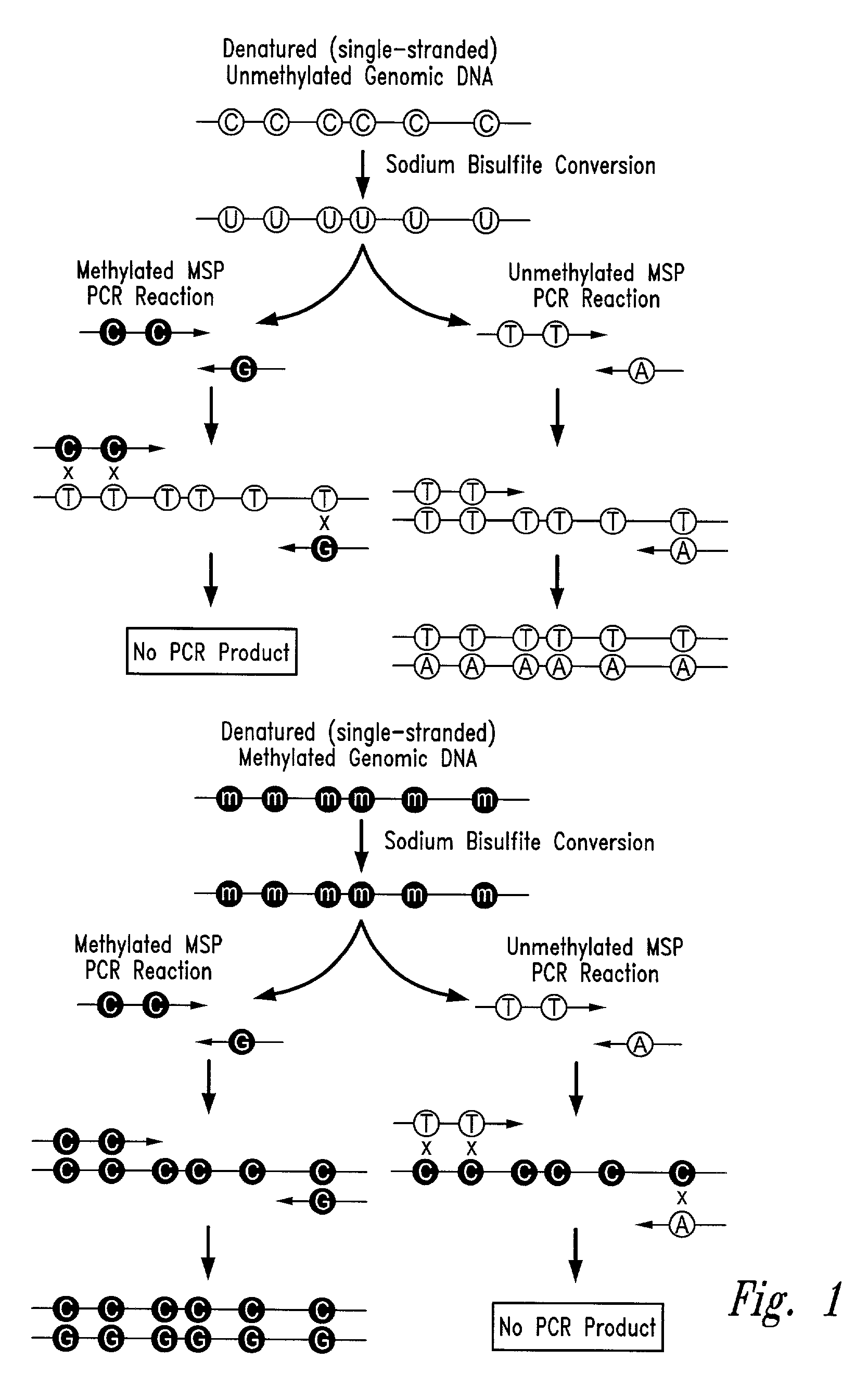

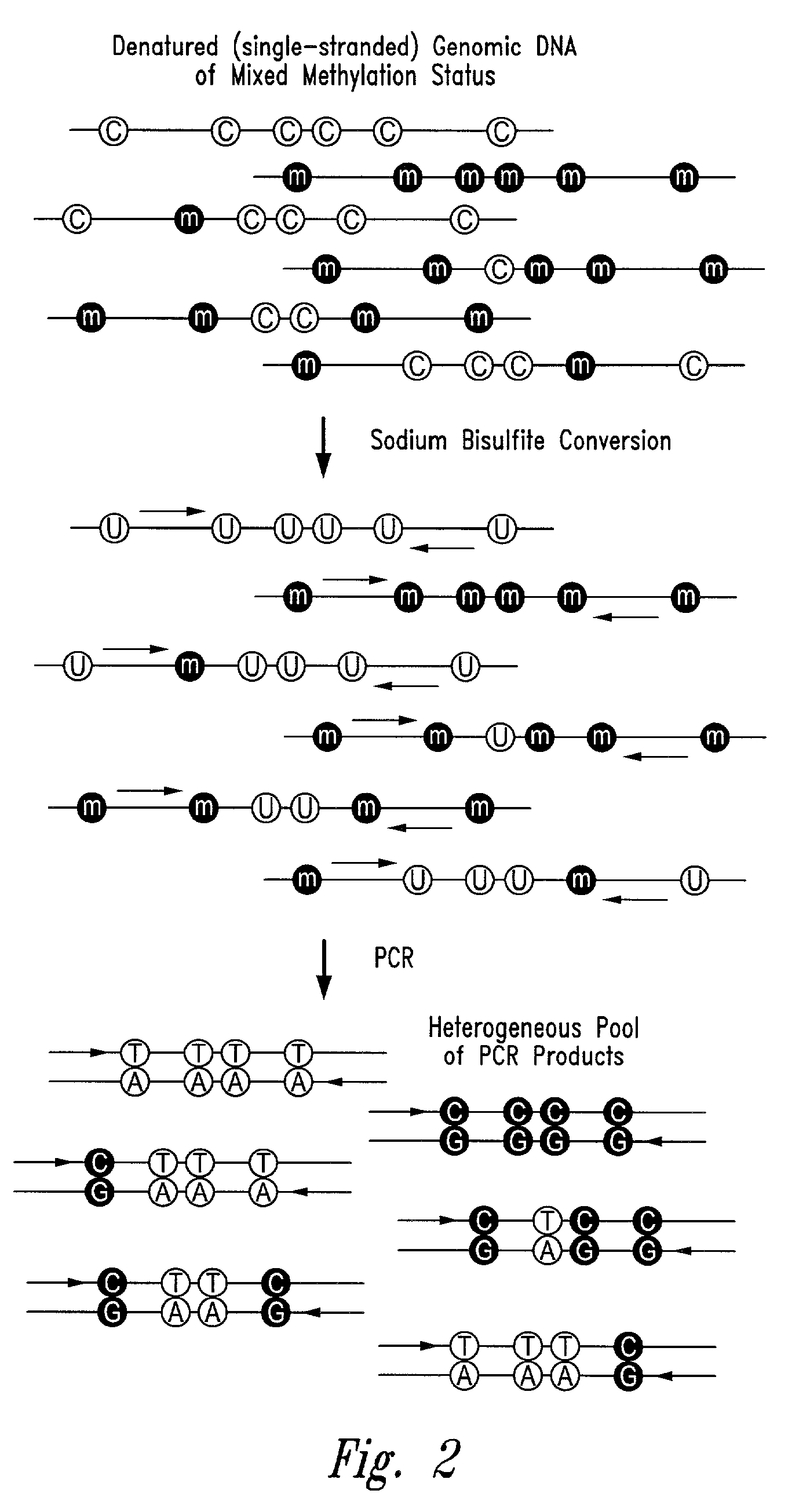

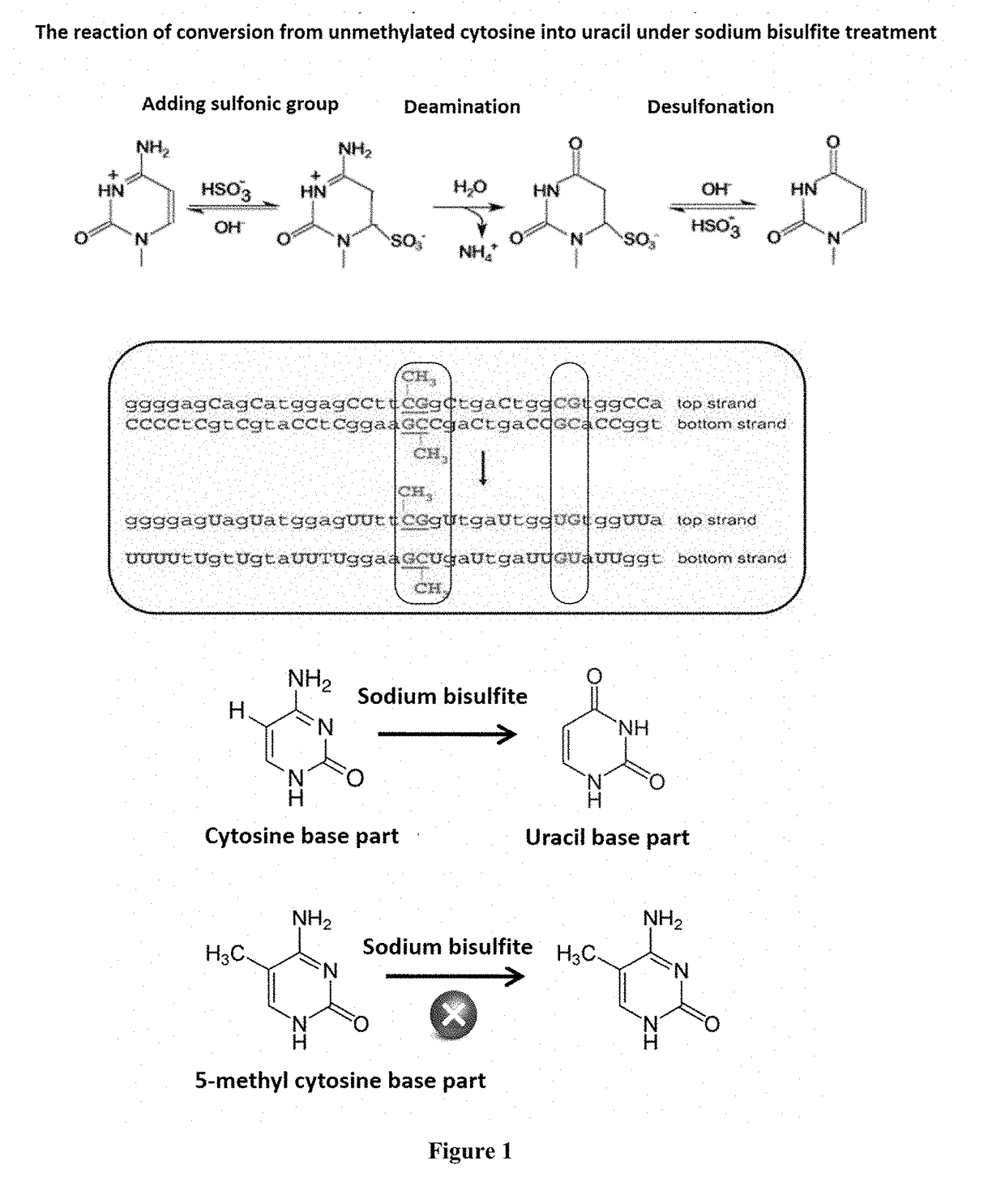

Process for high throughput DNA methylation analysis

InactiveUS7112404B2Sugar derivativesMaterial analysis by observing effect on chemical indicatorDNA methylationHybridization probe

There is disclosed an improved high-throughput and quantitative process for determining methylation patterns in genomic DNA samples based on amplifying modified nucleic acid, and detecting methylated nucleic acid based on amplification-dependent displacement of specifically annealed hybridization probes. Specifically, the inventive process provides for treating genomic DNA samples with sodium bisulfite to create methylation-dependent sequence differences, followed by detection with fluorescence-based quantitative PCR techniques. The process is particularly well suited for the rapid analysis of a large number of nucleic acid samples, such as those from collections of tumor tissues.

Owner:UNIV OF SOUTHERN CALIFORNIA

Method for preparing water absorption polymer with high liquid absorption speed, dispersity and dried degree

The invention discloses a preparation method of absorbent polymer which is characterized in high speed rate of liquid absorption, good dispersibility and high dry-touch degree. Acrylic acid is added into sodium hydroxide aqueous solution, which is uniformly mixed with acrylamide and then crosslinking agent, and foam stabilizer aqueous solution is added; while being aerated with nitrogen gas, the solution is ordinally added with polymerization initiator azodi (2-amidinopropane hydrochloride) aqueous solution, ammonium persulphate aqueous solution, sodium bisulfite aqueous solution and uniformly mixed; the aeration of nitrogen gas is stopped, and when the temperature of the solution is raised to 35 to 45 DEG C, the solution is added with foamer aqueous solution and uniformly mixed, so that porous gel is obtained; when the temperature is raised to 100 DEG C to 110 DEG C, the porous gel is put in the temperature environment of 80 to 90 DEG C for two the three hours; after being cooled down, the porous gel is taken out of a container, scissored into pieces, dried, crumbled and filtered, and grains are collected; crosslinking treatment agent is sprayed on the surface of grains, and after stirring and heating, the absorbent polymer is obtained. In three minutes, the volume of saline absorbed by the product prepared by the invention can reach 70 ml / gSAP.

Owner:段梦麟

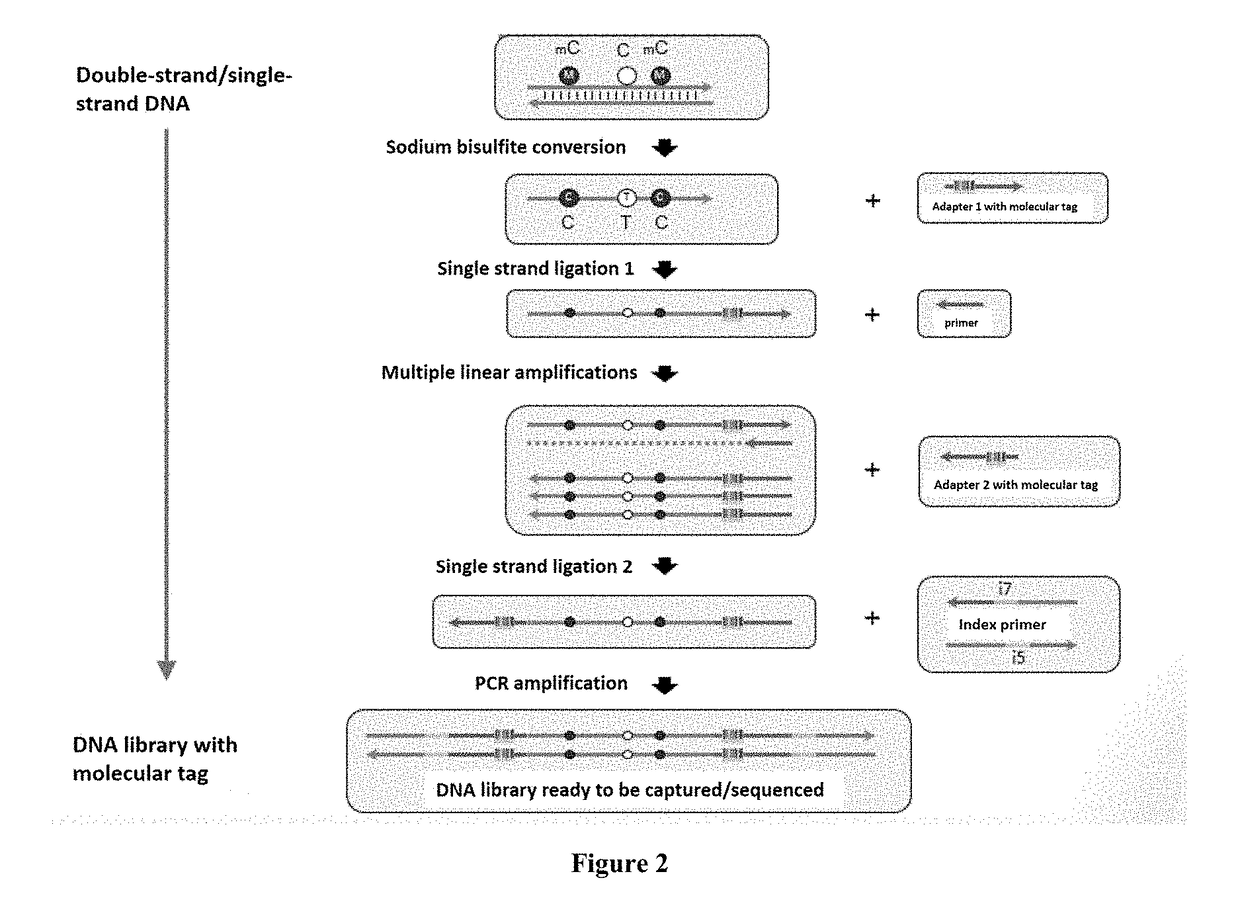

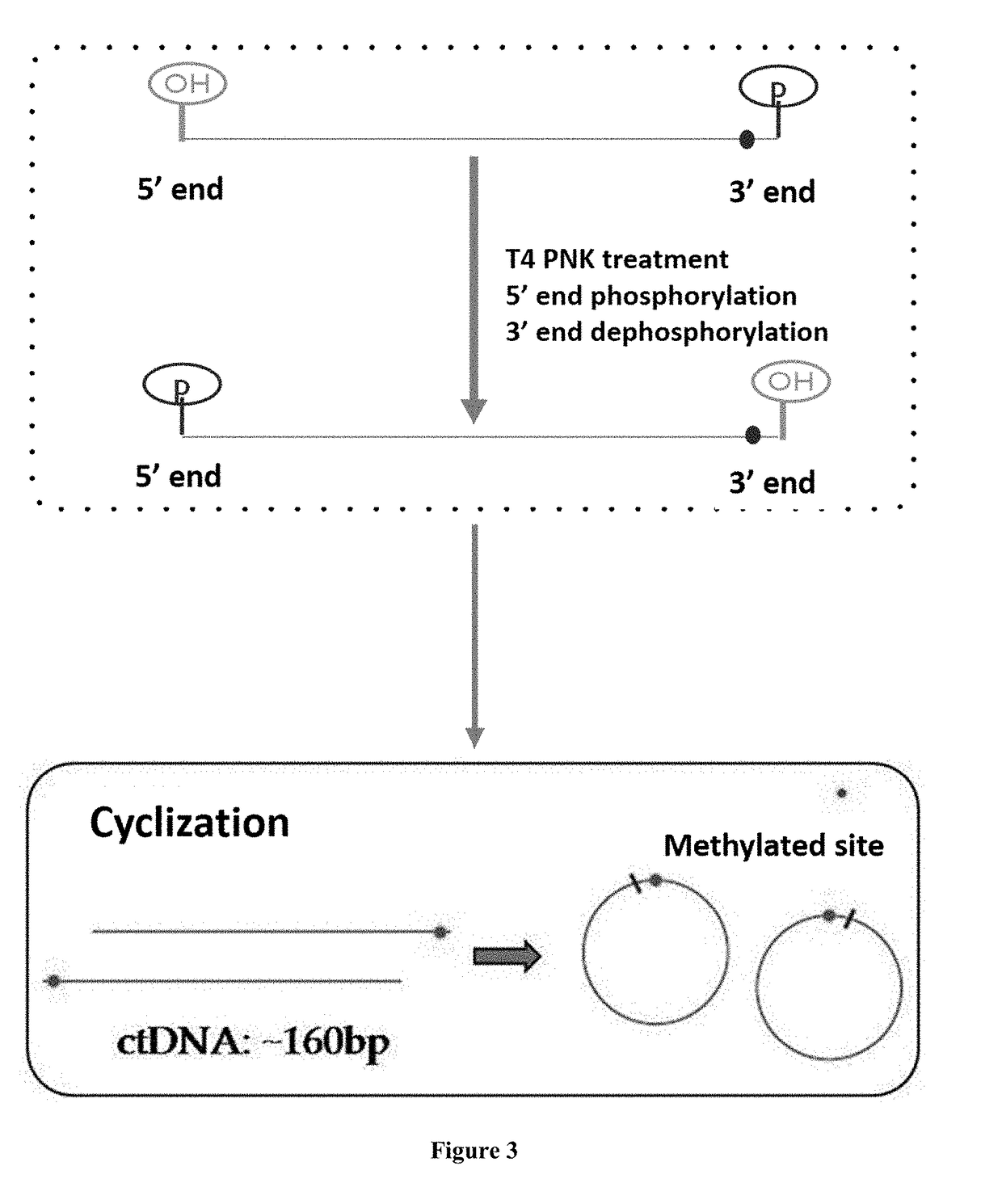

Method for Detecting Methylated DNA

InactiveUS20170218458A1Microbiological testing/measurementLibrary member identificationDNA fragmentationSingle strand

The present application discloses a method of detecting the methylation of specific genome regions in a DNA fragment from a sample containing DNA. The method includes treating the DNA fragment containing specific genome regions with sodium bisulfite and obtaining single-strand DNA fragment; attaching an adapter to one or both ends of the single-strand DNA fragment; optionally cyclizing the adapter-attached single-strand DNA fragment; preparing the single-strand DNA fragment with attached adapter into a DNA sequencing library containing the specific genome regions; sequencing the DNA sequencing library to identify the sequence of the single-strand DNA fragment. The present application also discloses a kit for detecting the methylation of specific genome regions in a DNA fragment from a sample containing DNA, and the use of single strand ligating agent in preparing a kit for detecting the methylation of specific genome regions in a DNA fragment.

Owner:ANCHORDX MEDICAL CO LTD

Chemical cleaning method of ultrafiltration membrane

The invention discloses an ultrafiltration membrane chemical cleaning method and aims at an ultrafiltration membrane that is used for processing purified PTA waste water. The invention uses an acid lotion prepared by citric acid and sodium bisulfite for dissolving and eluting inorganic pollutants that are formed by cobalt and manganese ion hydroxide, deposited and absorbed on the surface of the ultrafiltration membrane, and uses an alkaline oxidative lotion that contains sodium hypochlorite for dissolving and eluting organic colloid pollutants that are deposited and absorbed on the surface of the ultrafiltration membrane. The ultrafiltration membrane chemical cleaning method can effectively elute the pollutants, recover the running flux and running pressure of the ultrafiltration membrane, and ensure stable running of the purified PTA waste water in an ultrafiltration process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of producing swellable, non-aging starch maleates, biologically degradable starch maleates as well as use

The aging of swellable starch maleates is reduced by reacting with one or more singly and / or multiply functional nucleophiles as in a Michael condensation reaction. Mixtures of mercaptoethanol and 1,2-bis-(2-mercaptoethoxy)-ethane or mixtures of sodium bisulfite and pentaerythrite-tetrakis-(2-mercaptoacetate) are preferred. The decrease of the retention capacity [SRV] in the reaction products after 100 days is preferably <10%. The products find use as biodegradable, non-aging superabsorbers.

Owner:STOCKHAUSEN GMBH & CO KG DEGUSSA-HUELS AKTIENGESE

Chemical cleaning method of reverse osmosis membrane

ActiveCN101721916AEffective elutionThe process is continuous and stableSemi-permeable membranesGeneral water supply conservationReverse osmosisChemical cleaning

The invention relates to a chemical cleaning method of a reverse osmosis membrane. In the method, aiming at a reverse osmosis membrane for processing PTA refining wastewater, inorganic pollutants which are formed by cobalt ions, manganese ions, hydroxide thereof and the like and are deposited and adsorbed on the surface of the membrane are dissolved and eluted by using acid rinse prepared by citric acid and sodium bisulfite; organic colloid pollutants deposited and adsorbed on the surface of the membrane are dissolved and eluted by using alkaline rinse containing sodium dodecyl benzene sulfonate and sodium hydroxide. The method can elute the pollutants on the surface effectively, restore operating flux, operating pressure and desalination rate of the reverse osmosis membrane, and ensure that the process of processing the reverse osmosis membrane for the PTA refining wastewater is stable in operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

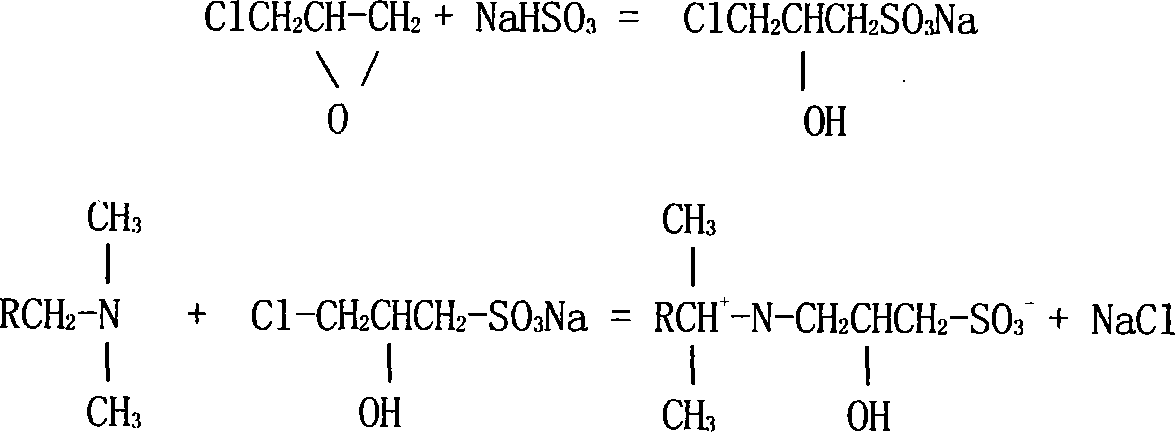

Method for preparing foaming agent used for oil gas field drilling and extracting

InactiveCN101215462AImprove conversion rateImprove performanceOrganic chemistryTransportation and packagingBetaineSurface-active agents

The invention relates to a process for preparing sponging agent which is adopted by oil gas field drills and used in the drilling technology of oil and natural gas and in geothermal drilling wells. The process is the synthetic technology for improving the sponging agent, lowers the producing cost, increases the foamability and the foam stability, and is realized by two-step synthesis. The invention is characterized in that: firstly, adding epoxy chloropropane, sodium bisulfite, deionized water and alkali catalyst into a catalyst case , heating to 60-85 DEG C under mixing, reacting for 2-3 hours, processing reactants into water solution which contains 3-chlorine-2-hydroxypropyl sodium sulfonate whose concentration is 30% with the deionized water after the reactants are aged for 1hour in 70 DEG C, then, adding long-chain tertiary amine into the mixed solution of the water solution which is prepared by the above process, anionic surface active agent and water, heating to 75-95 DEG C under mixing, and reacting for 7-9 hours, preparing the sponging agent which takes N-alkyl-N and N-dimethyl hydroxypropyl sulfo betaine as main components. The reaction time of the invention is greatly shortened, the tertiary amine percent conversion is high, the surfactivity is increased, the foaming performance of the product is good, and the invention can be used for sponging agent formula which is needed in the oil field gas drills.

Owner:榆林康隆石油技术服务股份有限公司

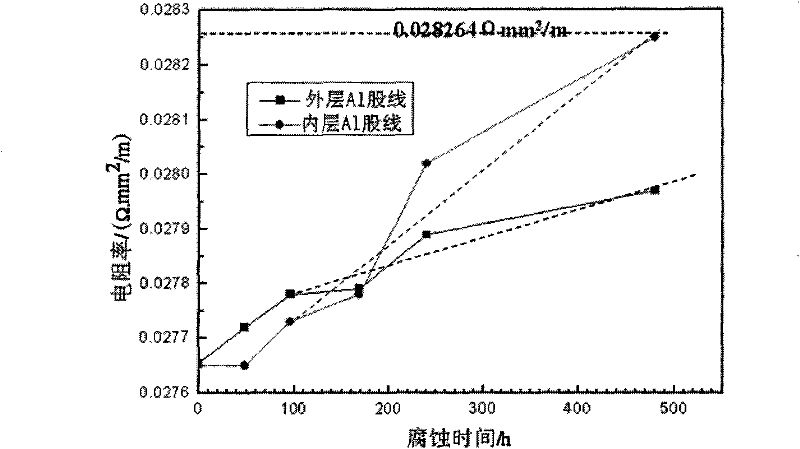

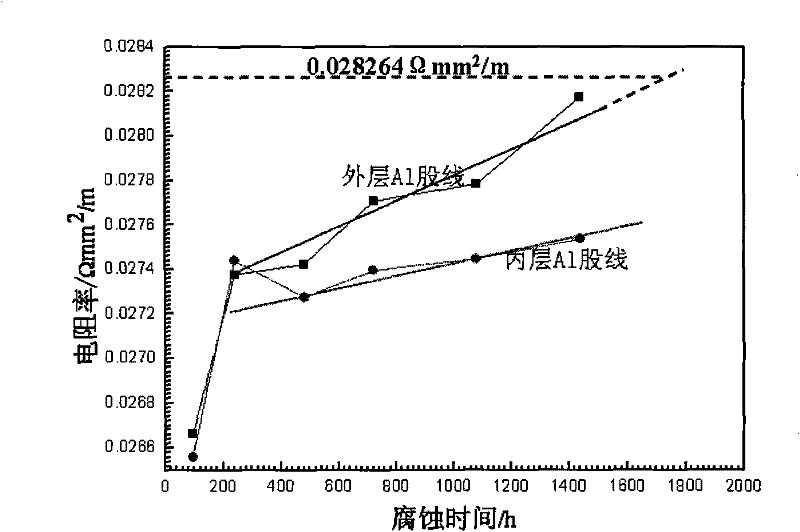

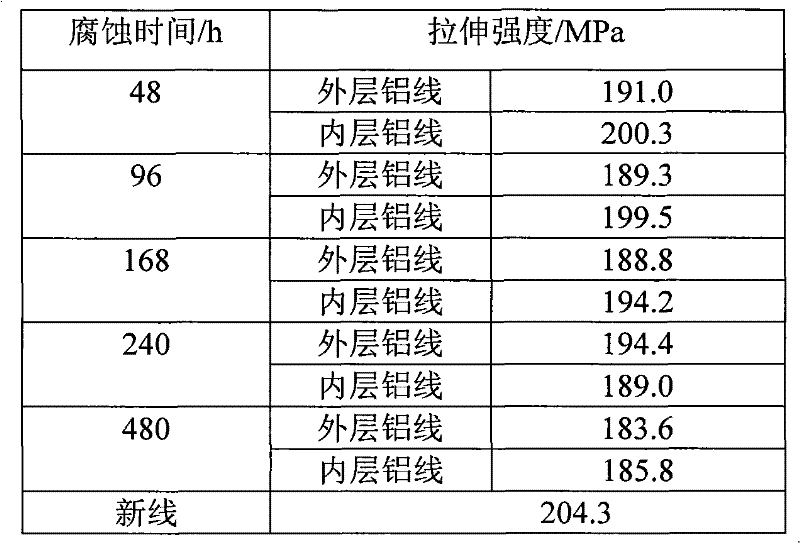

Evaluation Method of Corrosion Condition of Steel-cored Aluminum Stranded Aerial Conductor

InactiveCN102279148AWeather/light/corrosion resistanceMaterial resistanceSodium bisulfiteLaboratory test

The invention discloses a method for evaluating the corrosion status of steel-cored aluminum strand overhead conductors, which includes: (1) sodium chloride and sodium bisulfite+sodium chloride solution used to simulate corrosion conditions in coastal areas and industrial pollution areas (2) Laboratory accelerated corrosion test of unserviced ACSR overhead conductors; (3) Test of tensile strength and electrical conductivity of the inner and outer aluminum strands of corroded conductors to obtain the performance of overhead conductors under given conditions Changes with corrosion time; (4) Tensile strength and electrical conductivity tests of the inner and outer layers of aluminum strands of steel-reinforced aluminum stranded aerial conductors that have served in seaside and industrial polluted areas for different periods of time. Under certain conditions, the relationship between the performance and the corrosion time is simulated to simulate the relationship between the corrosion status and the service time of the actual service wire; Analyze the stranded overhead wires, evaluate the corrosion state and the remaining service life of the wires, and propose a treatment plan for the wires in service.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

Method for producing cation modified polyurethane color stabilizer

The invention discloses a modified polyurethane color fixing agent of basic ion, which is prepared by PEG600, PPG2000, TDI, DMPA, methyl ethyl ketone, calcium trisodium diethylenetriamine pentoacetate, epichlorohydrin, acetone, isopropanol, sodium bisulfite, water and glacial acetic acid. The process for preparation comprises polyurethane prepolymerization reaction, modified chain extending reaction, blocking reaction, emulsion reaction, removing solvent and the like. The modified polyurethane color fixing agent of ion of the invention can form net-shaped cross bonding with woven fabric, and the invention adopts sodium acid sulfite to be blocking agent, which guarantees that when in application, enough isocyanate bonds are supplied to form chemical crosslinking with hydroxyl group and carboxy group with cloth surface, the invention improves various color stabilities of dyed fabric, meanwhile, the invention keeps soft hand feeling of fabric.

Owner:NANTONG UNIVERSITY +1

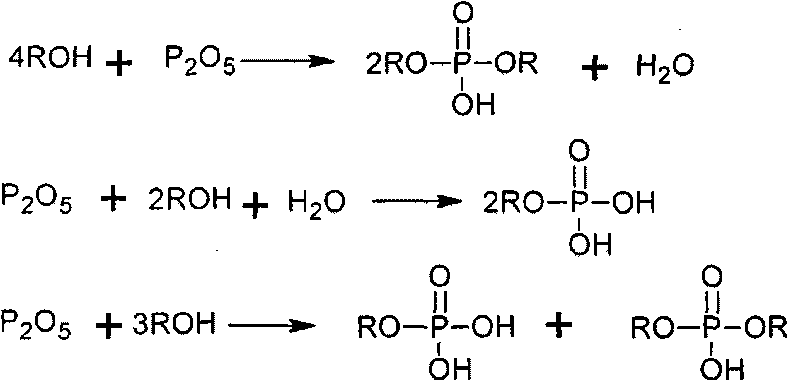

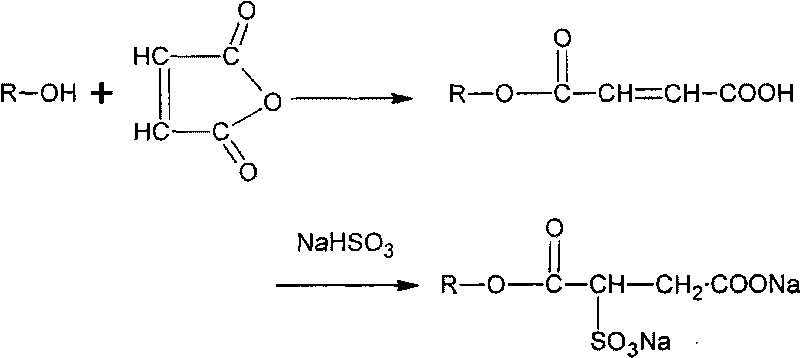

Composite leather greasing agent and preparation method thereof

InactiveCN101760570AHigh content of active substancesExcellent comprehensive fatliquoring performanceLeather impregnationVegetable oilAlkylphosphate

The invention provides a composite leather greasing agent used for a leather greasing work procedure and a preparation method thereof. The composite greasing agent comprises two ingredients: alkyl phosphate and disodium sulfosuccinate. The preparation method comprises the following steps: making hydroxylated animal and vegetable oil and modifiers thereof take phosphorylation reaction with phosphorus pentoxide; then, making obtained materials take monoester reaction with maleic anhydride; and next, making obtained materials take sulphitation reaction with sodium bisulfite to obtain the composite leather greasing agent with the two ingredients of alkyl phosphate and disodium sulfosuccinate. The composite leather greasing agent has the characteristics of high active matter content, strong combination capability with leather and good comprehensive greasing performance. The production process of the composite leather greasing agent is simple, and the discharge of the three wastes does not occur in the production process.

Owner:WENZHOU UNIVERSITY

Mobile water purification system and method

InactiveUS20150166385A1Reduce risk of damageIrreparably damagedUltrafiltrationTreatment involving filtrationFiltrationUltrafiltration

A mobile water purification system is configured as modules to be air-lifted to a site requiring potable water. Raw water is pumped to a pre-treatment module that separates suspended solids and preferably oxidizes organic contaminants. At least one, and preferably two or more filtration modules coupled in parallel, then remove contaminants using ultrafiltration and / or reverse osmosis, and pass treated water to a storage tank. A control system operates valves to stagger backwashing of filtration modules, allowing one such module to be backwashed while allowing others to continue filtering water. The control system can selectively bypass a reverse osmosis unit, and disable related booster pumps, depending upon raw water quality. During backwash cycles, sodium bisulfite is added to fill water directed into ultrafiltration units to neutralize free chlorine present in backwash fluid.

Owner:HENNESY MECHANICAL SALES

Lost circulation material for malignant loss and preparation method

InactiveCN102504776AExcellent shear thinning propertiesEffective residencyDrilling compositionPotassium persulfateTemperature resistance

The invention relates to a lost circulation material for effectively plugging fractured and crushed stratum malignant loss in the drilling process and a preparation method. The invention adopts the technical scheme that a raw material for preparing the lost circulation material comprises the following components: 8 to 12 grams of hexadecyl dimethyl allyl ammonium chloride, 16 to 18 grams of acrylamide, 6 to 12 grams of styrene sodium sulfate, 0.2 to 0.4 gram of sodium dodecyl benzene sulfonate, 0.2 to 0.4 gram of potassium persulfate / sodium bisulfite, 16 to 20 grams of bentonite clay, and 239 to 279 grams of fresh water. The preparation method of the lost circulation material comprises the following steps of: firstly, dissolving recrystallized hexadecyl dimethyl allyl ammonium chloride, acrylamide and styrene sodium sulfate in the water; filling N2, adding an initiator and performing the reaction for 24 hours; precipitating, soaking and drying by using acetone so as to obtain white copolymer; and adding sodium dodecyl benzene sulfonate and bentonite clay into the copolymer and the water to obtain the lost circulation material. The lost circulation material can be used for plugging a leakage zone, has strong crushing resistance and strong temperature resistance and mineralization resistance degree and is suitable to be used for carrying out plugging on a big crack in the drilling process.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing resin type water-retaining preparation

InactiveCN1640901AAvoid destructionLow reaction temperatureOrganic fertilisersSoil conditioning compositionsPotassium persulfatePotassium hydroxide

The resin type water keeping agent is prepared with starch, acrylic acid and acrylamide as main material, oxidation-reduction system of potassium persulfate and sodium bisulfite as initiator, N, N-methylene bisacrylamide as crosslinking agent and through ternary grafting copolymerization. The preparation process includes the steps of: 1) gelatinizing starch, neutralizing acrylic acid with potassium hydroxide, cooling to room temperature and mixing with acrylamide aqua and gelatinized starch in a reactor; 2) adding crosslinking agent and initiator for polymerization under N2 protection; 3) regulating pH with alkali solution to neutral, washing the grafted product, drying and crushing to obtain white granular resin product. The resin type water keeping agent has fast water absorption, high water absorption rate and no destruction to soil structure, and can provide potash fertilizer.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

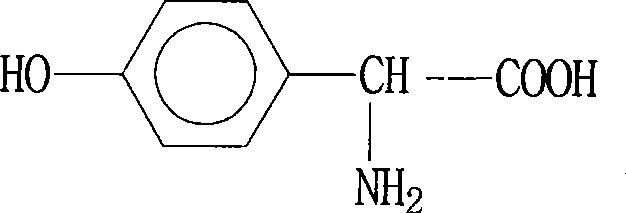

P-hydroxybenzene glycine synthesis technology

InactiveCN101362703AOrganic compound preparationAmino-carboxyl compound preparationSulfite saltHydroxylamine Hydrochloride

The invention belongs to the field of pharmaceutical chemical engineering intermediate production, which relates to a synthesis technology of p-hydroxyphenylglycine (HPG). The purpose of the invention is achieved by the following steps: phenol, glyoxylic acid, water and sulfamic acid carry out the one-pot braise reaction under the action of catalysts such as benzene sulfonic acid, p-toluenesulfonic acid, o-toluenesulfonic acid, and the like; after the reaction is finished, a small amount of reducing substances such as sodium sulfite, sodium bisulfite, hydroxylamine hydrochloride, and the like, are added; finally, the PH value is adjusted by alkali, the mother liquor separation is washed by large amount of water and then washed by organic solvents such as methanol, ethanol, acetone, glacial acetic acid, and the like; the obtained product HPG is white powder, wherein, the content of NPLC is equal to or more than 98.5, which can meet the requirement of splitting. The method has the advantages of low production cost, simple operation, stable quality, etc.

Owner:谢建中

Cyclopropene preservative with double functions of anticorrosion and keeping freshness

The cyclopropene consists of: 1-methyl cyclopropene 0.3-4 weight portions, preservative 5-40 weight portions, stabilizer 60-90 weight portions, slow releasing agent 0-20 weight portions and excipient 0-5 weight portions. The preservative is one or several of 2-aminobutane, phosphate of 2-aminobutane, hydrochloride of 2-aminobutane, sulfate of 2-aminobutane, lactate of 2-aminobutane, sodium pyrosulfite, potassium pyrosulfite, sodium bisulfite, potassium bisulfite and propyl isothiocyanate; the release controlling agent is one or several of lime, sodium bicarbonate, soda lime, reductive microcrystal alditol acid lignin polyacrylamide; and the stabilizer is one or several of cyclodextrin, rosin, silica gel and lac. The slow releaseing preservative has obvious functions of resisting rot and keeping freshness.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

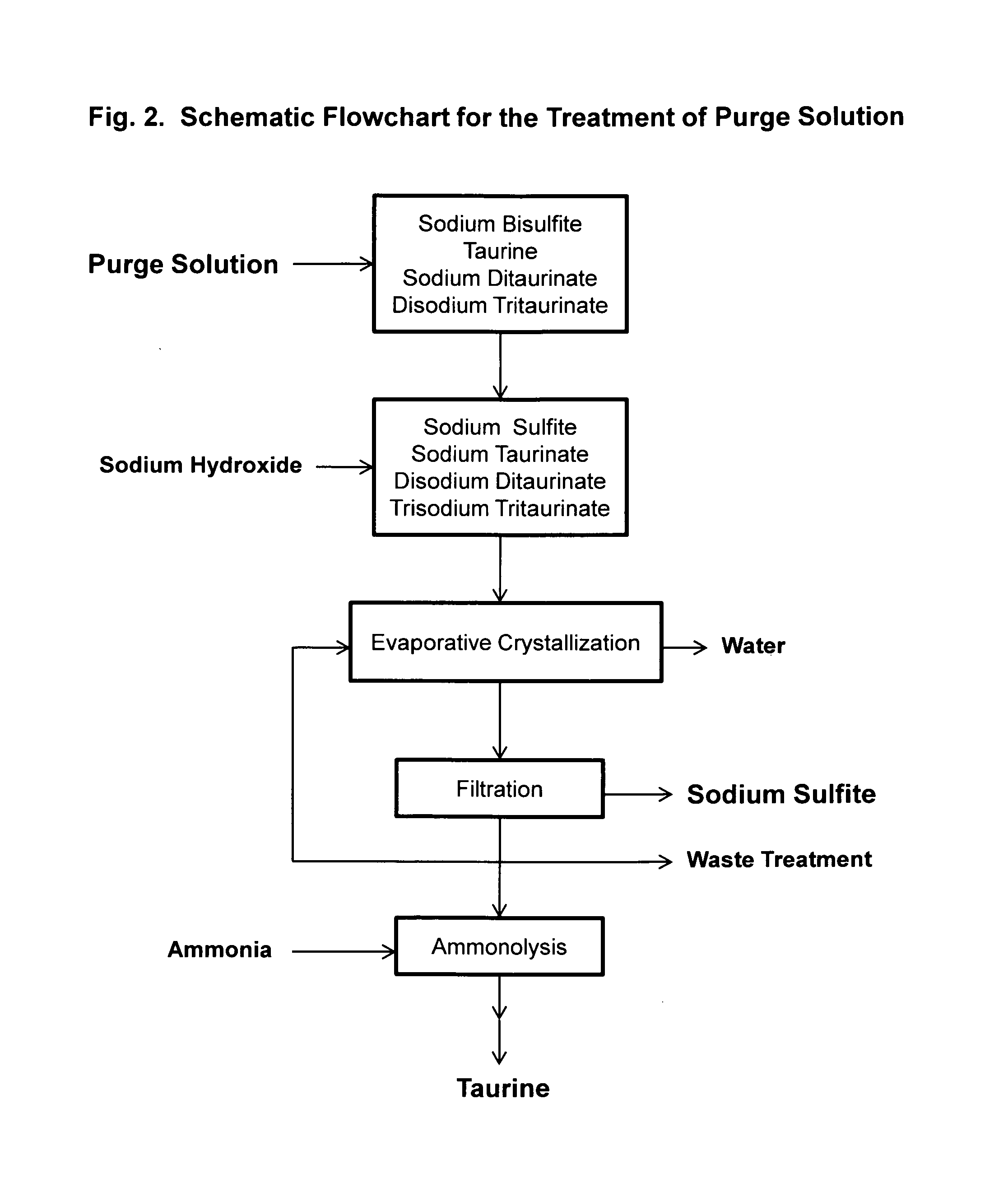

Recycling process for preparing taurine through ammonolysis of sodium hydroxyethanesulfonate

ActiveCN109020839ASolve the problem of three wastes pollutionIncrease incomeSulfonic acids salts preparationEnergy inputLiquid wasteTaurine

Owner:吴江

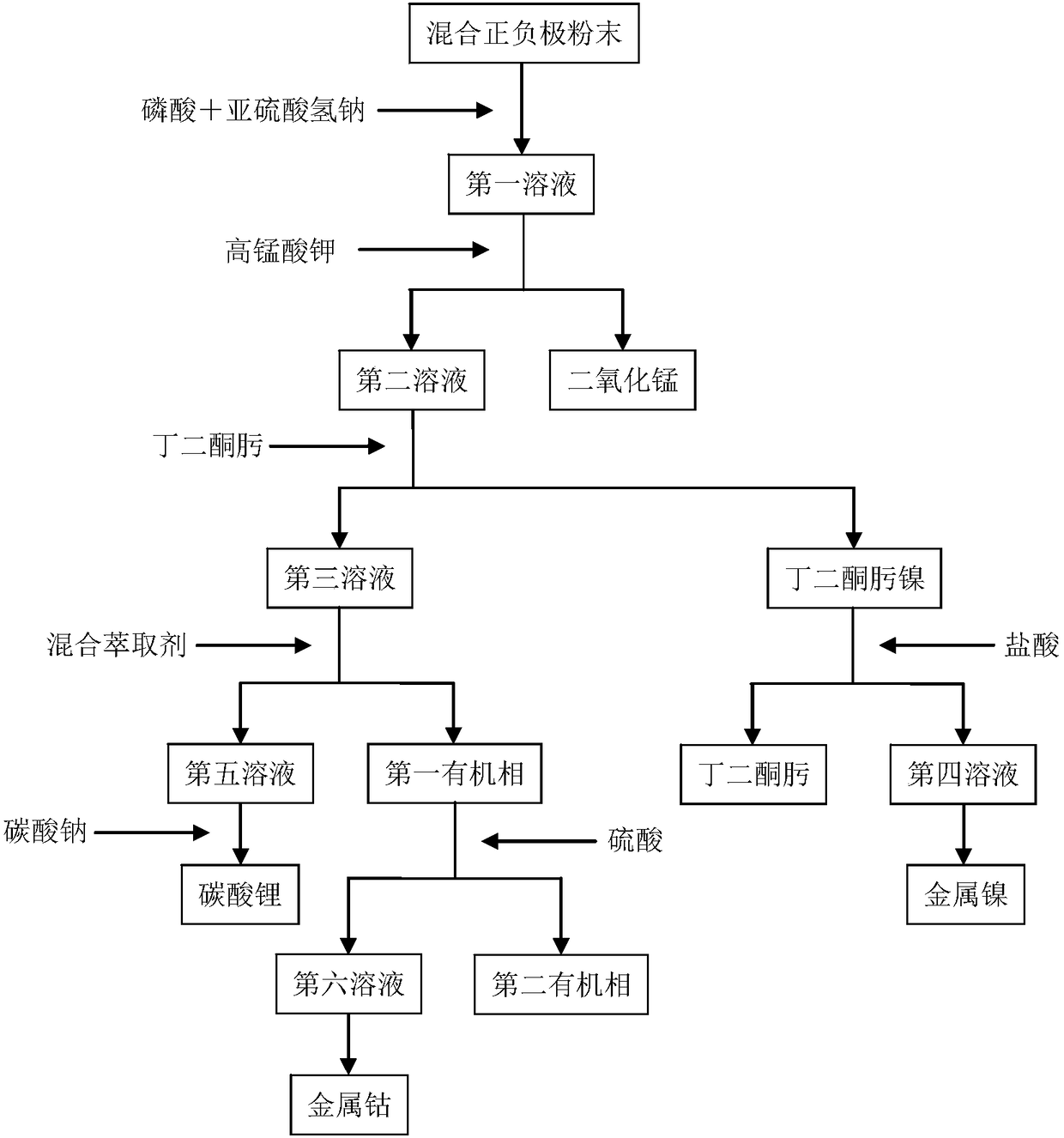

Method for recovering metal materials in waste ternary power batteries

ActiveCN108193050AImprove reducibilityReduce corrosionPhotography auxillary processesWaste accumulators reclaimingPurification methodsPhosphoric acid

The invention relates to a method for recovering metal materials in waste ternary power batteries, and belongs to the technical field of battery material recovery and cyclic utilization. The method comprises the steps that positive and negative electrode mixed powder, phosphoric acid solution and the like react with each other, filtering is conducted to obtain a first solution; a potassium permanganate solution is added into the first solution for recovering manganese dioxide, a second solution is obtained, a butanone oxime solution is added into the second solution, butanone oxime nickel precipitation and a third solution are obtained, butanone oxime nickel is dissolved in hydrochloric acid, separating is conducted to obtain a fourth solution, and the fourth solution is subjected to electrodeposition to recover metal nickel; then mixed extractant is used for extracting cobalt ions in the third solution, separating is conducted to obtain an organic phase and a fifth solution, cobalt inthe organic phase is extracted by using sulfuric acid, a sixth solution is obtained, and the sixth solution is subjected to electrodeposition to recover metal cobalt; and a sodium carbonate solutionis added to the fifth solution, and lithium carbonate is recovered. The method for recovering the metal materials in the waste ternary power batteries adopts a mild and stable phosphoric acid-sodium bisulfite system; the multiple purification methods of precipitation, extraction and electrodeposition are used without interference to each other, and the separation effect is good; and the recoveredproducts have many types, and application is wide.

Owner:中国人民解放军陆军防化学院

Carboxyl acid modified melamine high-efficiency water-reducing agent

The invention discloses a novel melamine super plasticizer modified by carboxylic acid. The melamine super plasticizer is made by reacting a primary material of melamine with amino sulfonic acid, sodium bisulfite, salicylic acid, citric acid, phenol, self-made sulphonating agent, formaldehyde and caustic soda liquid at a certain temperature and a certain pH value. The novel melamine super plasticizer modified by carboxylic acid has the characteristics of high water reducing rate, good adaptability and good water retentivity and has better effect when used in large concrete member having relatively high requirement on surface finish quality and high-strength concrete and self-compacting concrete.

Owner:长春建工集团有限公司

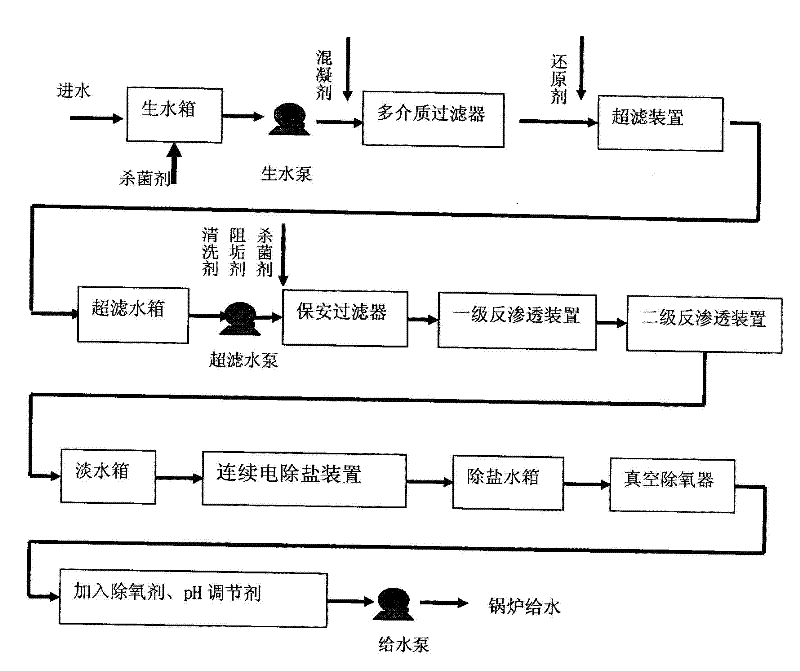

Novel water treatment method for boiler feedwater

ActiveCN102344215AAvoid breedingDecreased water conductivityGeneral water supply conservationMultistage water/sewage treatmentChlorine dioxideUltrafiltration

A novel water treatment method for boiler feedwater of the invention comprises the following steps: sterilization, that is adding liquid chlorine, sodium hypochlorite or stabilized chlorine dioxide into a raw water tank, controlling the residual chlorine amount in water to be 0.2-0.5 mg / L; filtration, that is adding a polyaluminium chloride coagulant before a multimedium filter with an amount of 10-20 mg / L, controlling the water turbidity of the ultrafiltration feedwater to be not more than 0.1 NTU and the SDI to be not more than 3; adding a reducing agent of sodium bisulfite before ultrafiltration with an adding amount of 3-5 mg / L; reverse osmosis, that is performing desalination treatment by a reverse osmosis membrane device, continuously adding a PTP-0100 scale inhibitor before a security filter with an adding amount of 3-5 mg / L; continuously adding a Micro Treat BIO bactericide with an adding amount of 3-5 mg / L; additionally adding cleaning agents of Dimamite and High Flux once a month with an amount of 3-5% of the water amount to be produced; desalination, that is performing desalination by an electrical desalination system (EDI); deoxygenation, that is performing deoxygenation by a vacuum deoxygenator, adding 10-20 microgram / L of deoxidants, controlling the agent residual amount to be 5-20 microgram / L, adding a corrosion-inhibiting pH regulator to control the pH value to be 8.8-9.3.

Owner:XINJIANG DELAND

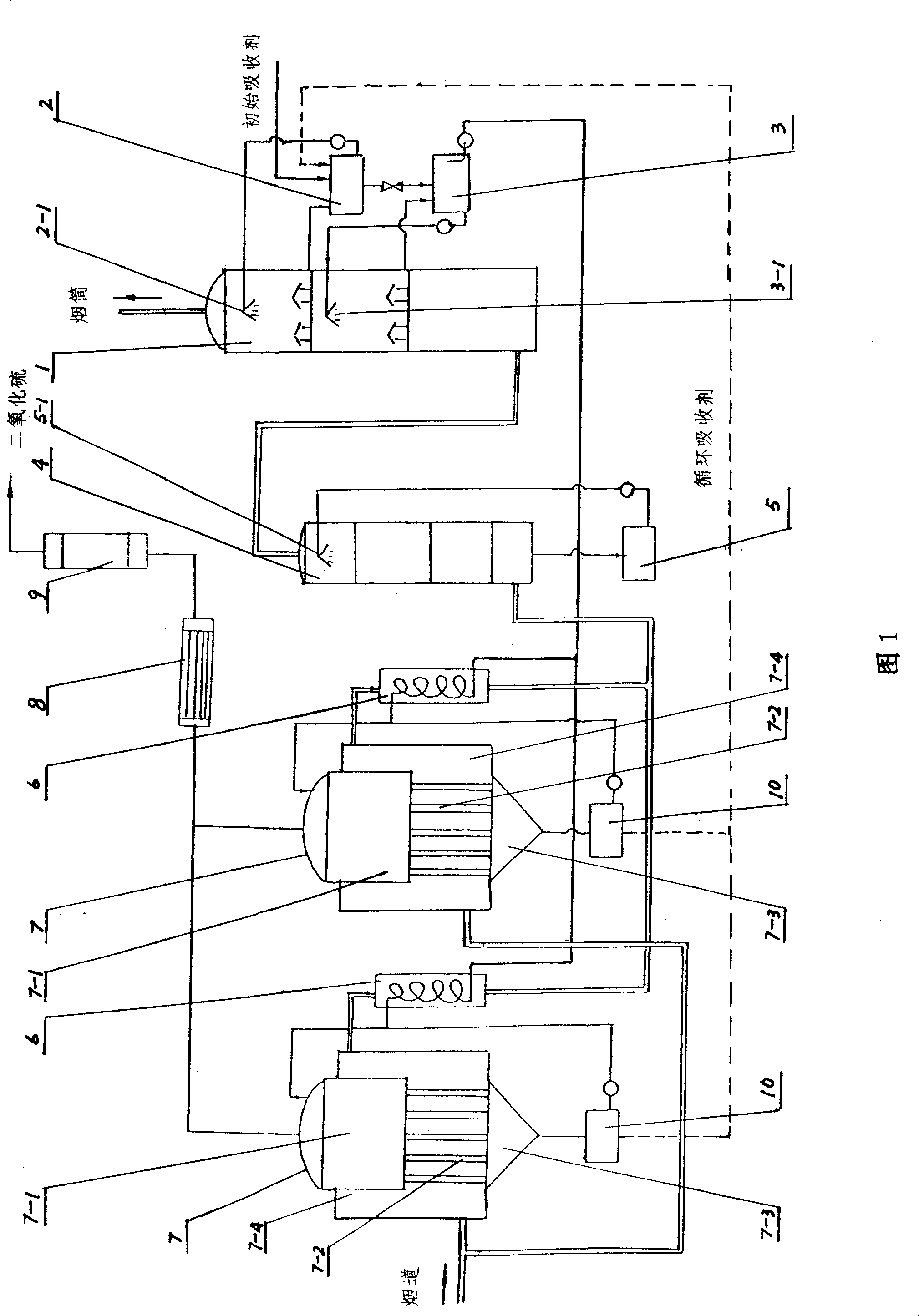

Energy-saving type sodium sulphite circulation desulfurizing device and method

InactiveCN101254392AImprove protectionLow running costDispersed particle separationCooling towerSulfite salt

The invention relates to an energy-saving sodium sulfite circulation and desulfurization device as well as the method thereof, the desulfurization device comprises a desulfurization tower as well as a first and a second absorption liquid circulation grooves, the top part of the desulfurization tower is communicated with a chimney, the lower part of the desulfurization tower is communicated with the top part of a washing and cooling tower, and the bottom part of the washing and cooling tower is communicated with a circulation washing groove. The invention is characterized in that the washing and cooling tower is communicated with a heat exchanger, which is then communicated with a flue after being communicated with a decomposed jacket reactor; the second absorption liquid circulation groove is communicated with a coil pipe in the heat exchanger, and the coil pipe is communicated with the reaction chamber of the decomposed jacket reactor; the lower part of the decomposed jacket reactor is communicated with a centrifuge. The invention has the desulfurization steps as follows: initial absorption liquid is prepared, the temperature of smoke is reduced, sulfur dioxide is absorbed, sodium bisulfite is decomposed, and sodium sulfite is recycled. The waste heat of the smoke is fully utilized, initial absorber is changed into circulation absorber to be used, the running cost is reduced, and the environment protection is favored.

Owner:向瑞先

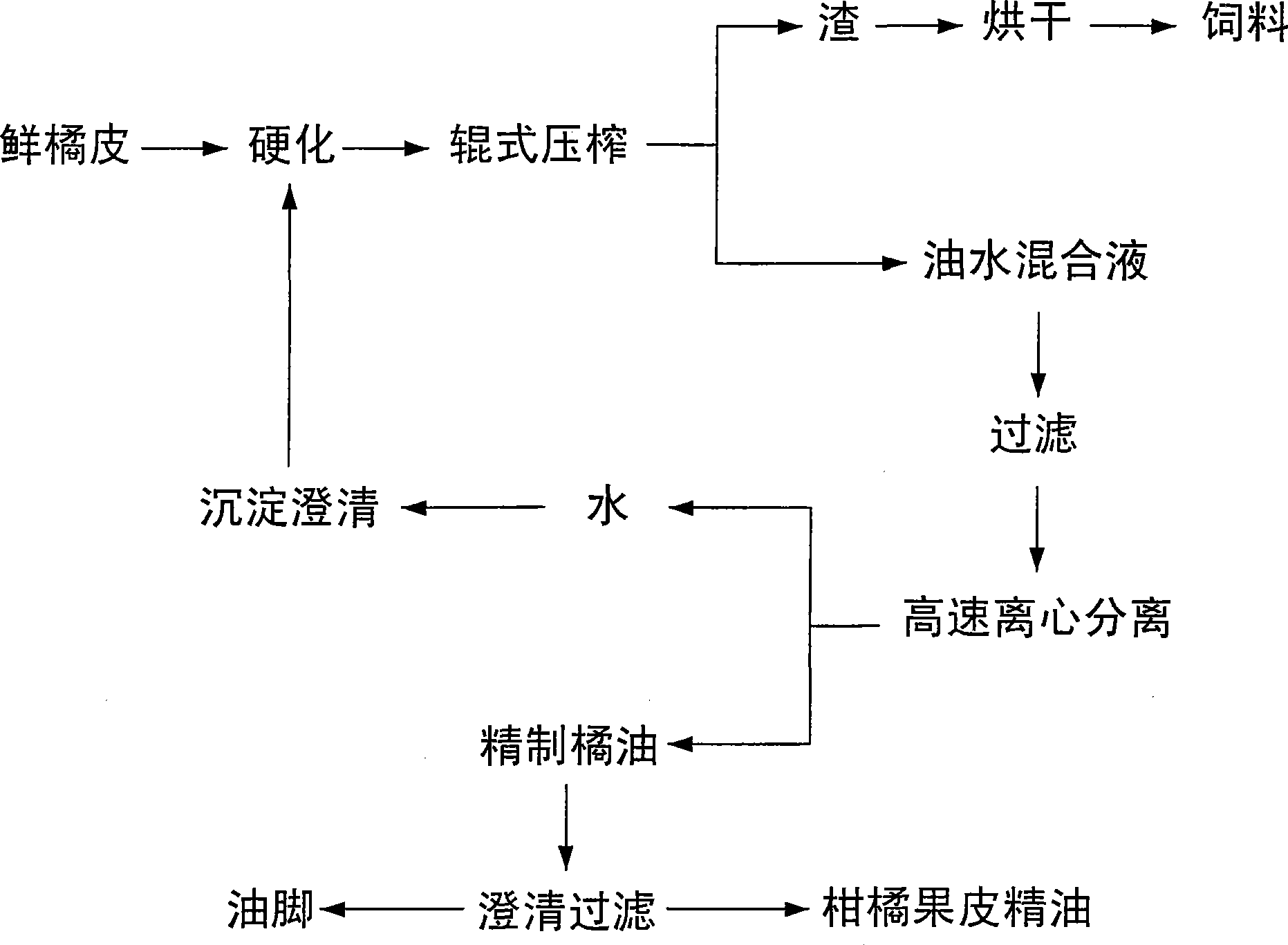

Extraction method of orange peel essential oil

The invention relates to an extraction method of essential oil from citrus peel, the extraction method is characterized in that hardening liquid is prepared by taking 99.04 percent to 99.26 percent of water, 0.1 percent to 0.2 percent of sodium benzoate, 0.5 percent to 0.8 percent of calcium chloride anhydrous and 0.04 percent to 0.06 percent of sodium bisulfite; 1 part of fresh citrus peel and 4 parts of the hardening liquid are further taken according to the proportion by weight, the even mixing is carried out to allow the citrus peel to be fully submerged in the hardening liquid, the time is 2 to 3 hours, the citrus peel is fished out from the hardening liquid after the completion of the soaking and crushed by using a roller crusher, the obtained citrus peel residues are directly or indirectly used as animal feeds after the drying, the mixed liquid of citrus oil and water which is obtained by crushing is filtered by using a filter net with 80 to 120 meshes, then a pipeline type high-speed centrifuge is used for separation under the rotation speed of 18000 turns / min to 20000 turns / min, the obtained water enters a sedimentation tank, big scraps are carried out the sedimentation, supernatant liquid is returned to a soaking tank of the citrus peel as hardening water, the obtained citrus oil is stored for more than 7 days at 3 DEG C to 8 DEG C, and the essential oil from the citrus peel is obtained after the filtration.

Owner:重庆檬泰生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com