Patents

Literature

5556results about How to "Improve ergonomics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

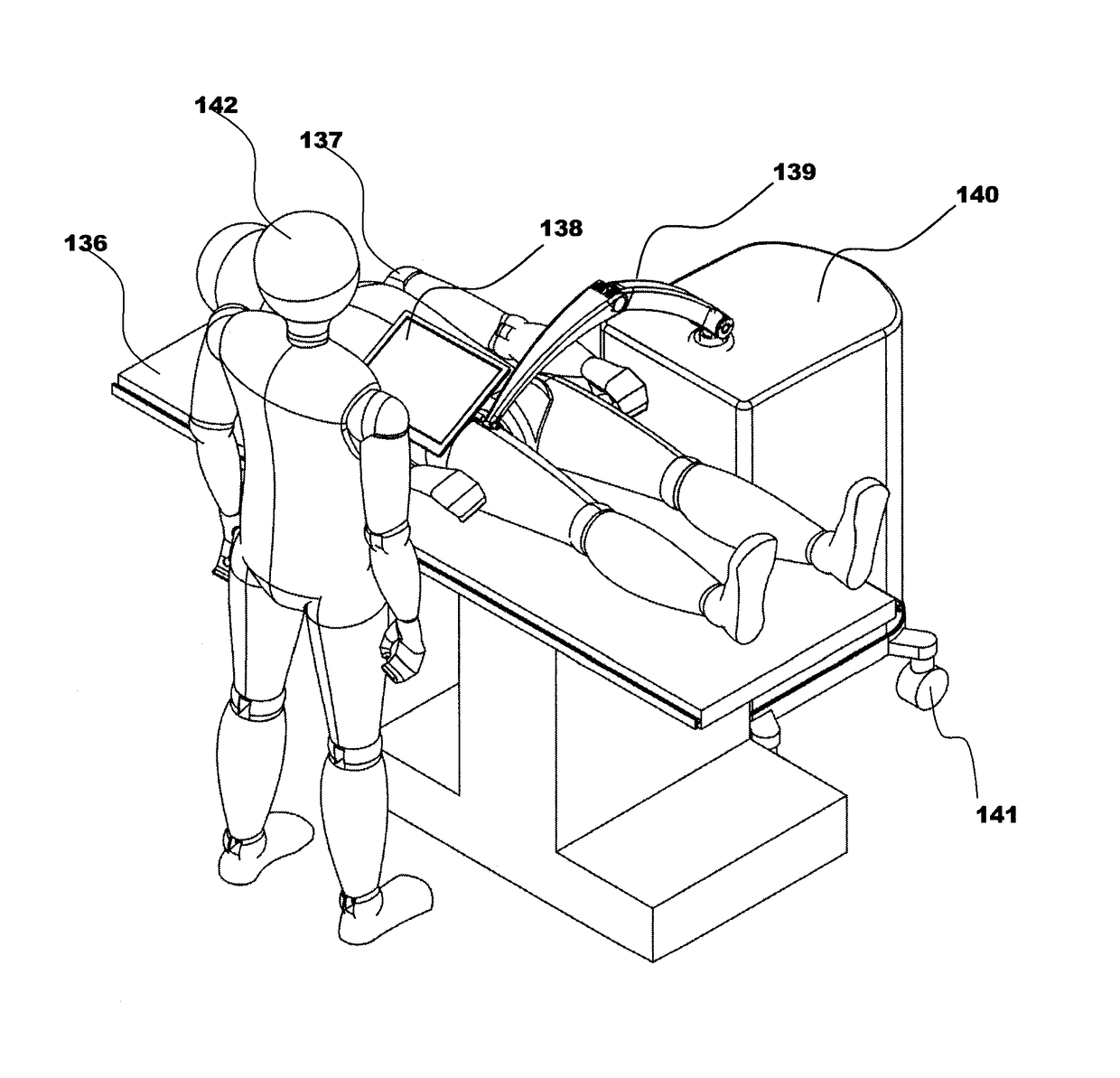

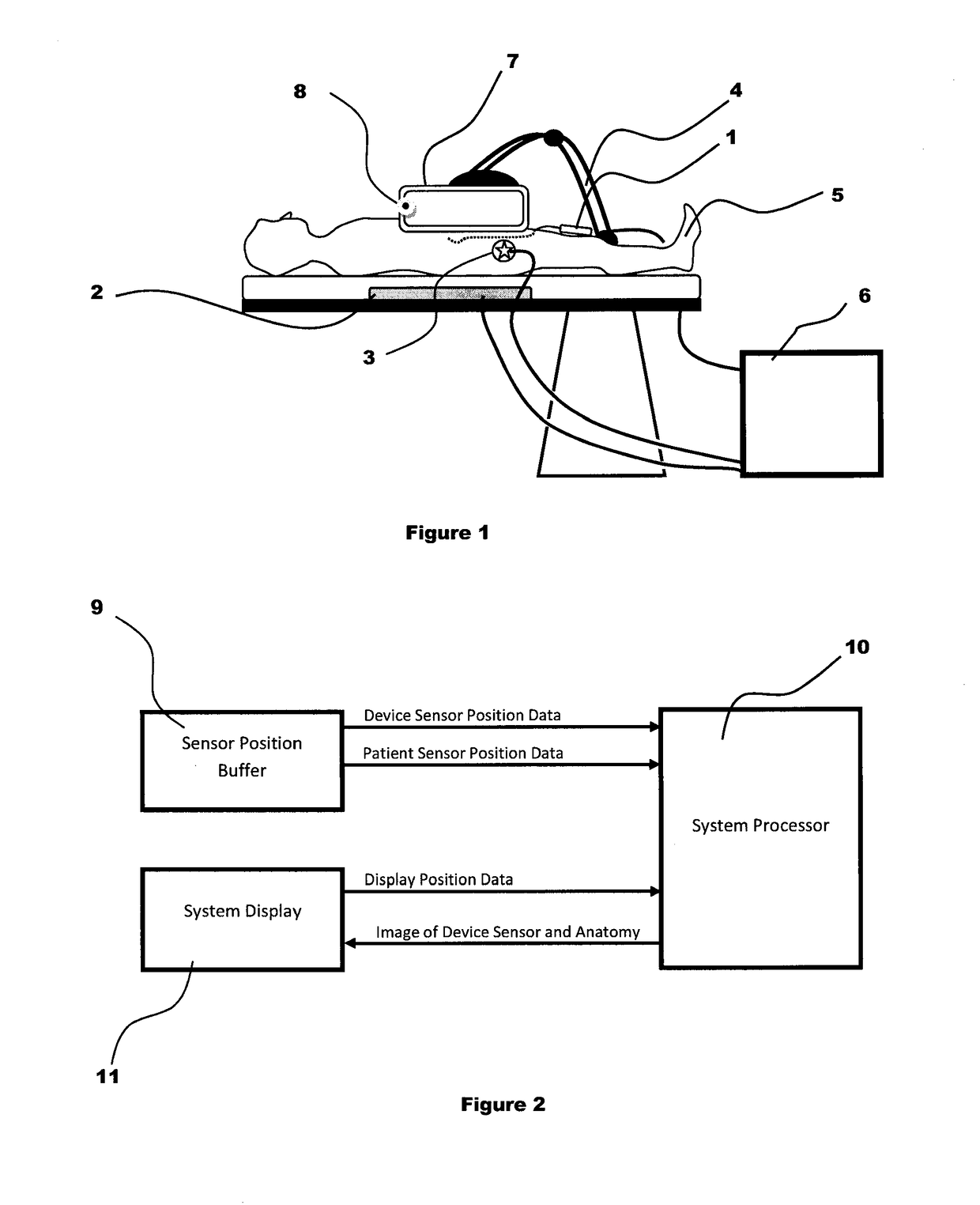

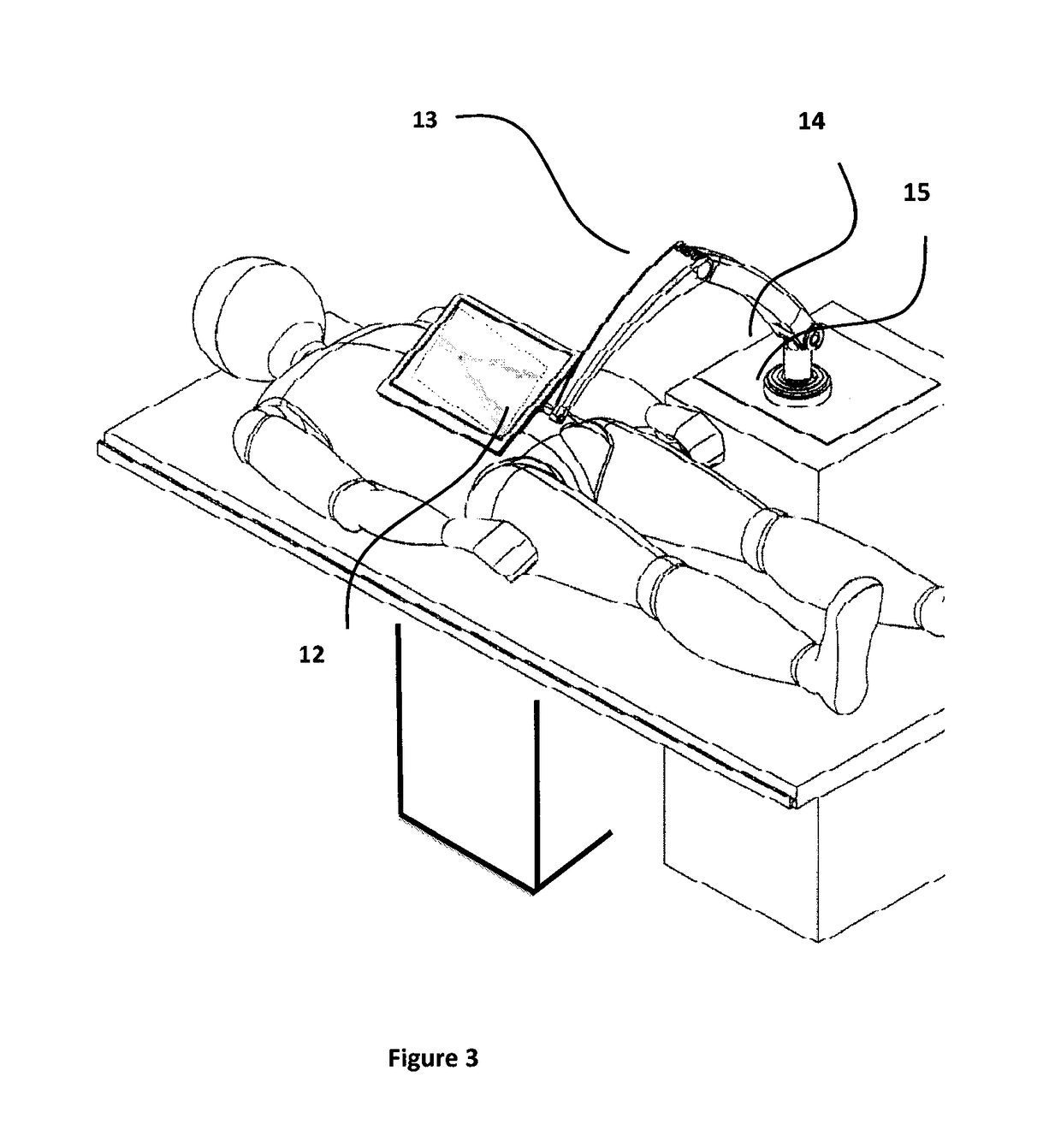

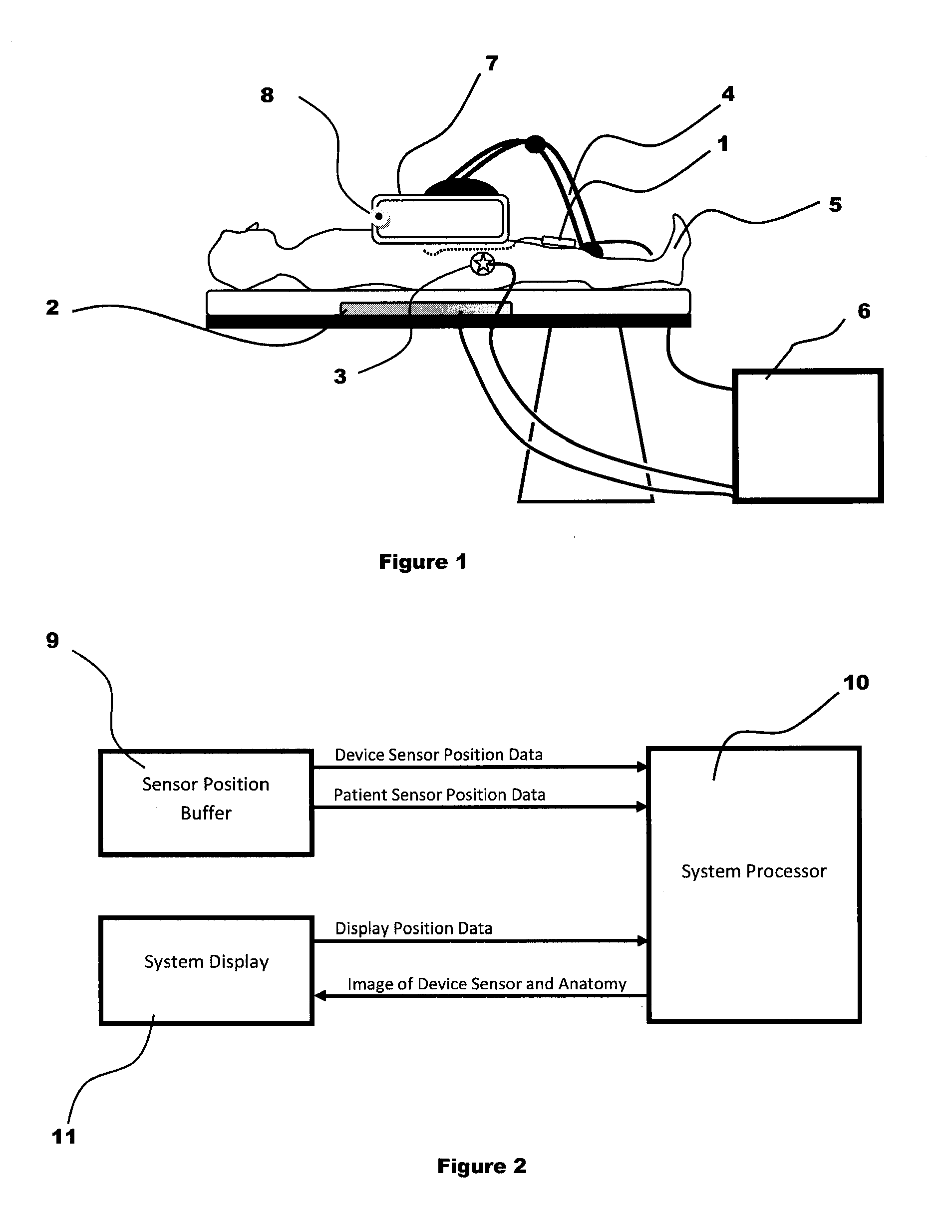

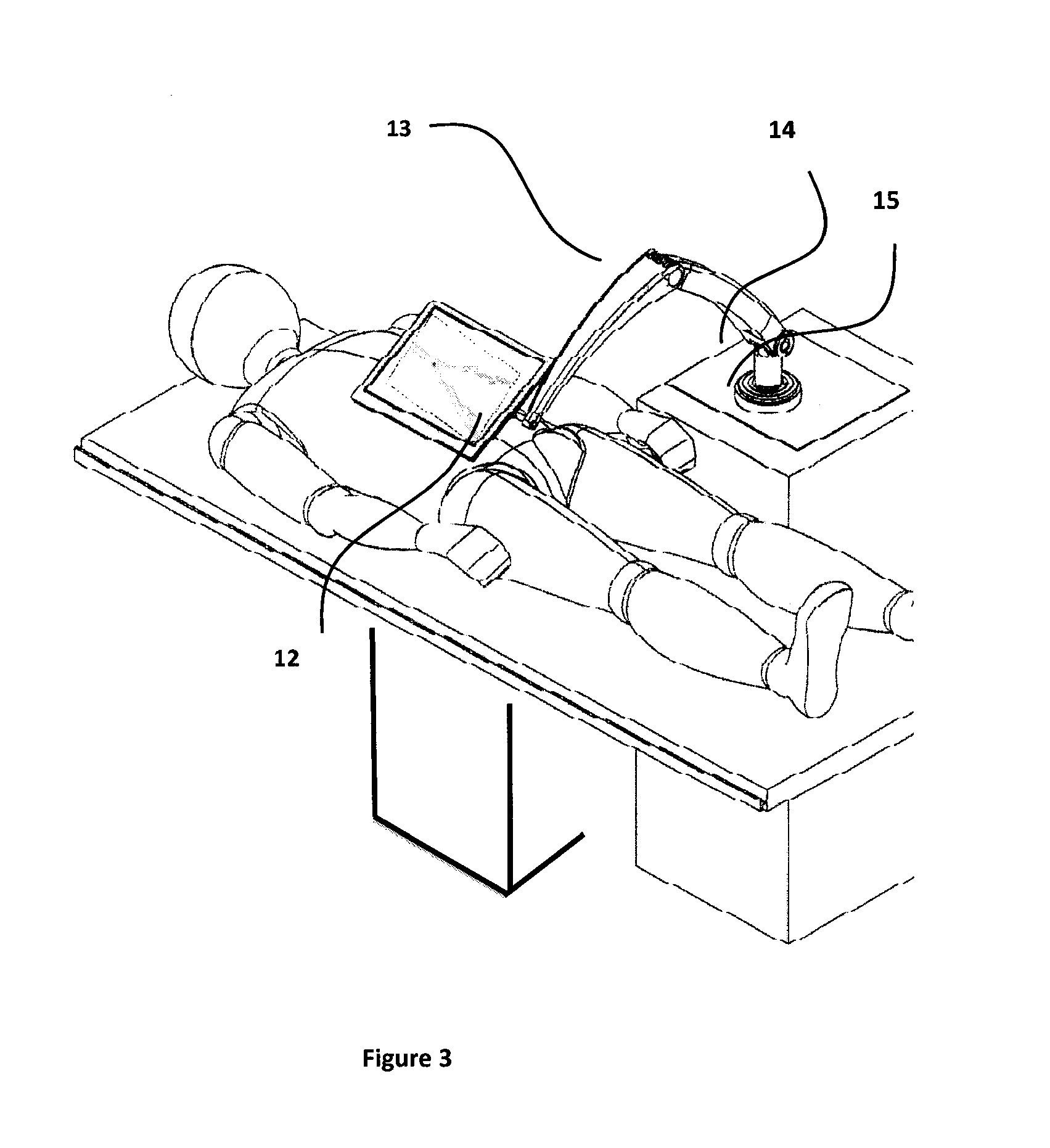

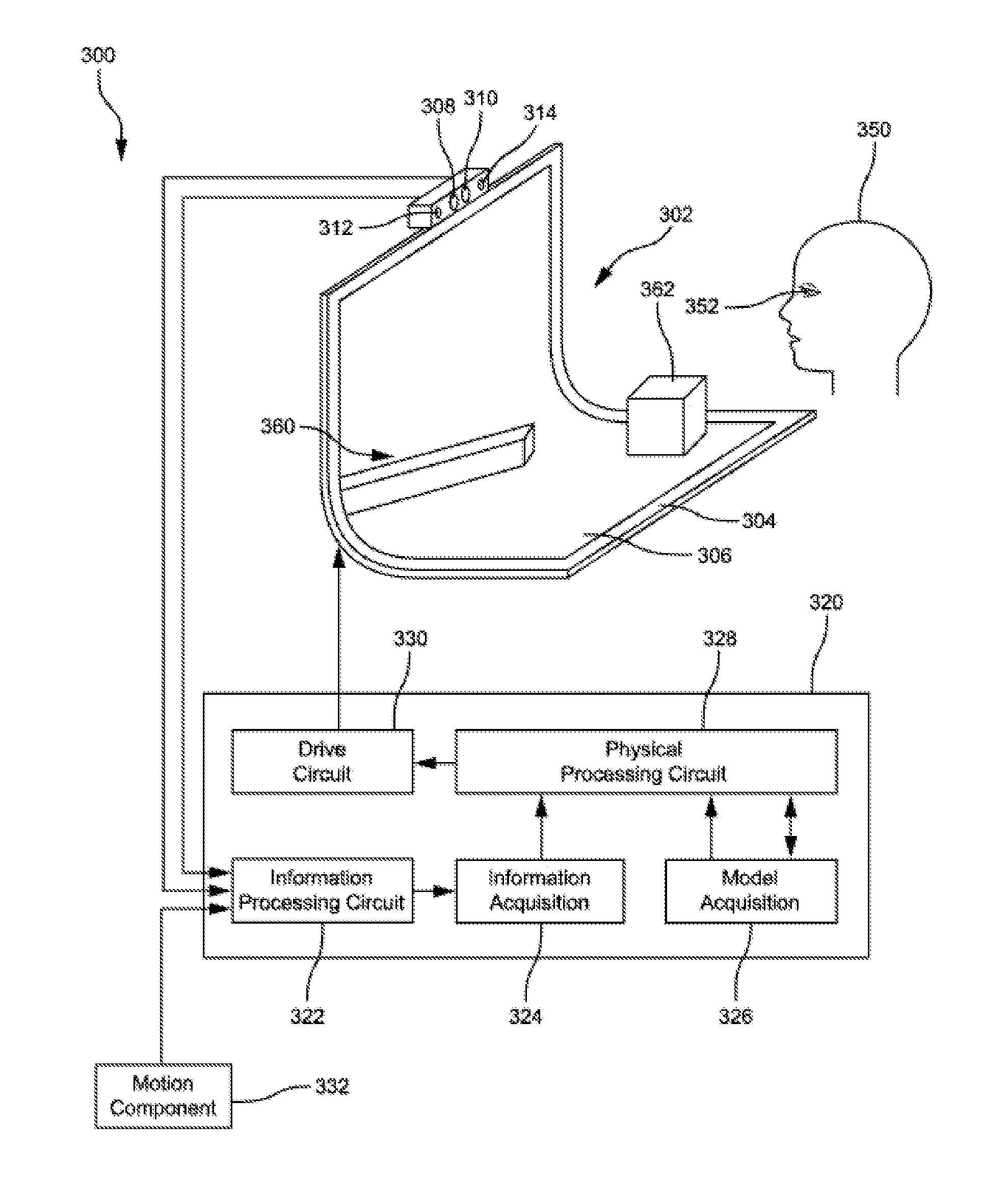

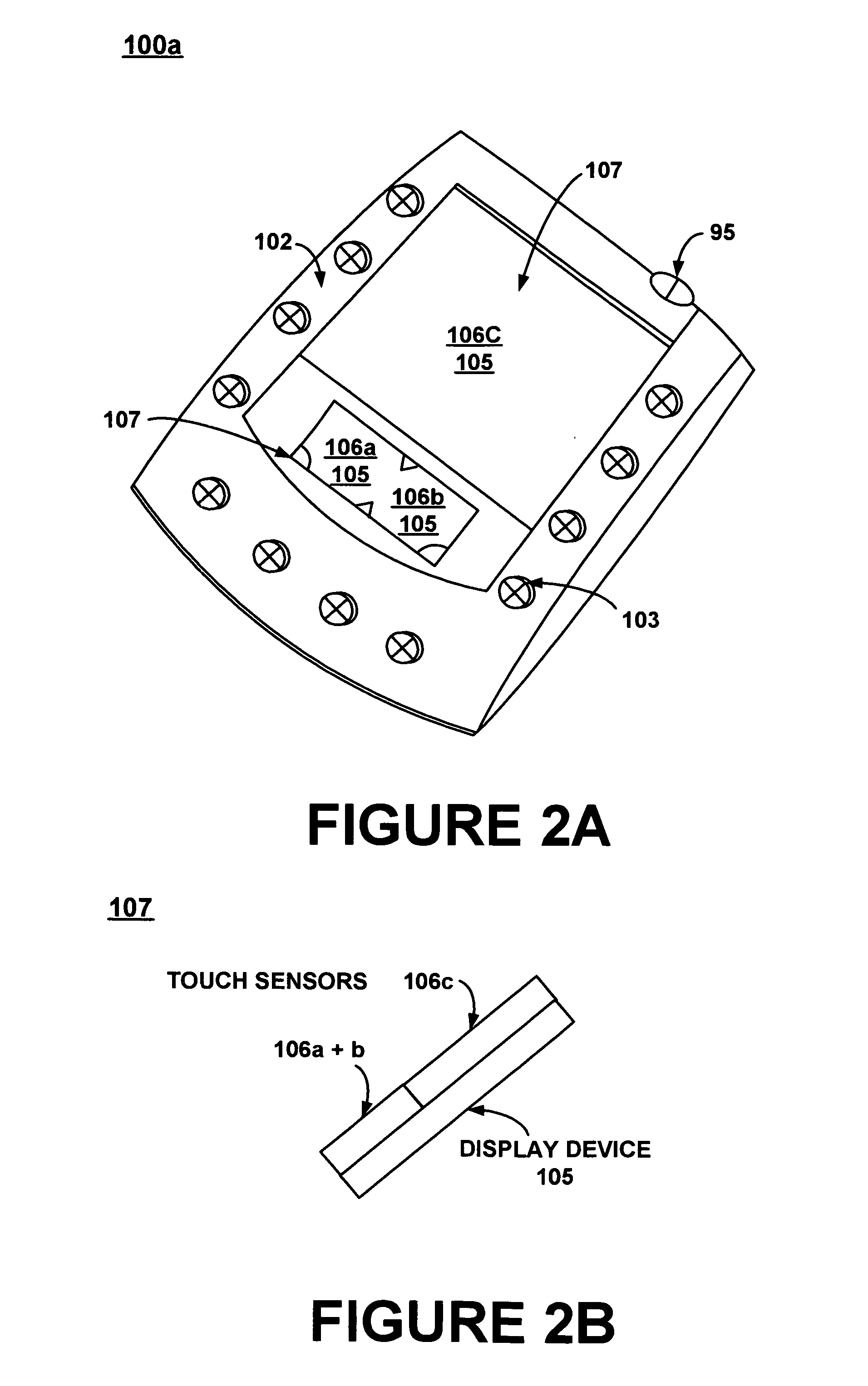

System and method for displaying anatomy and devices on a movable display

ActiveUS11020016B2Increase functional anatomical workspaceImprove ergonomicsMechanical/radiation/invasive therapiesDiagnostic recording/measuringHuman bodyRadiology

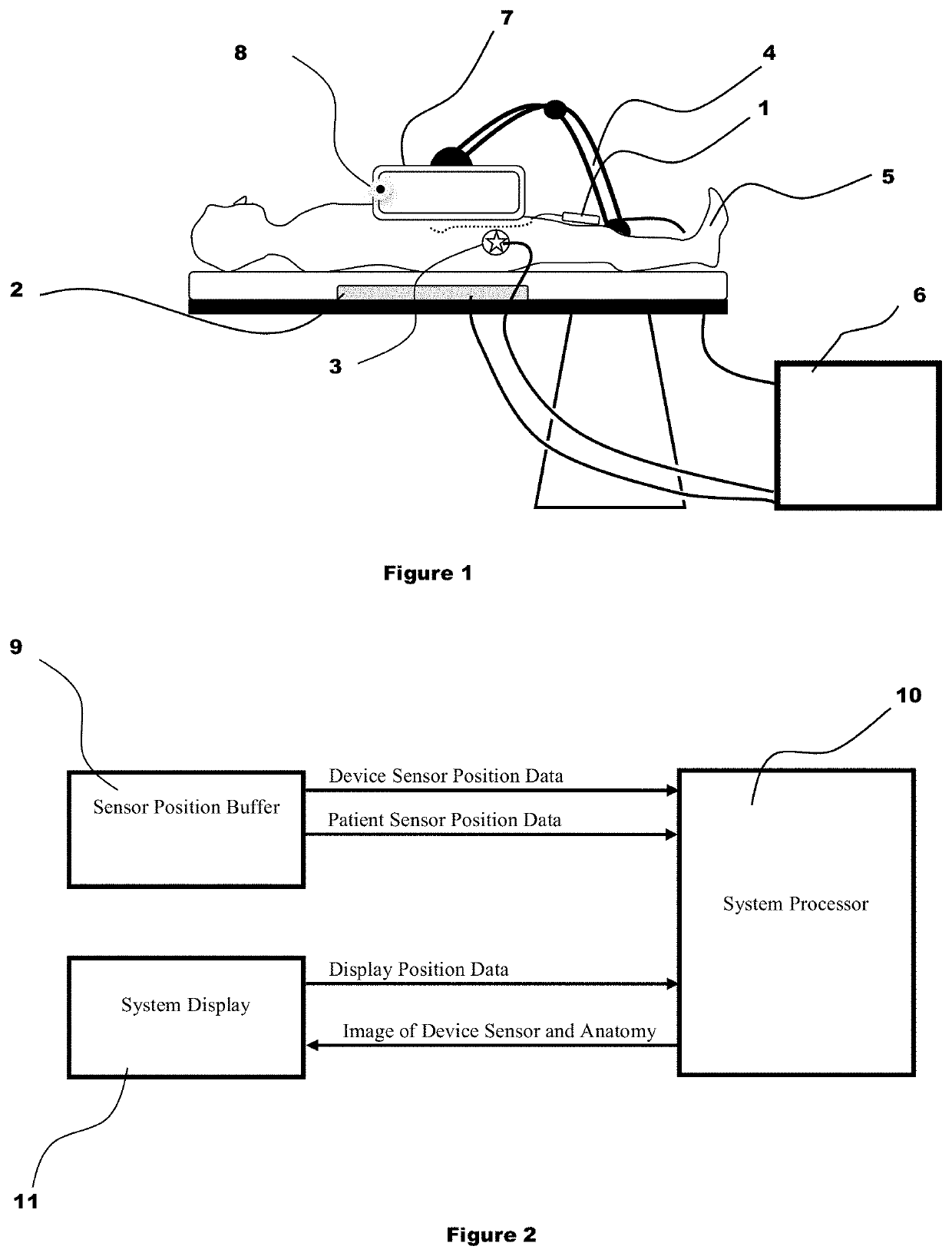

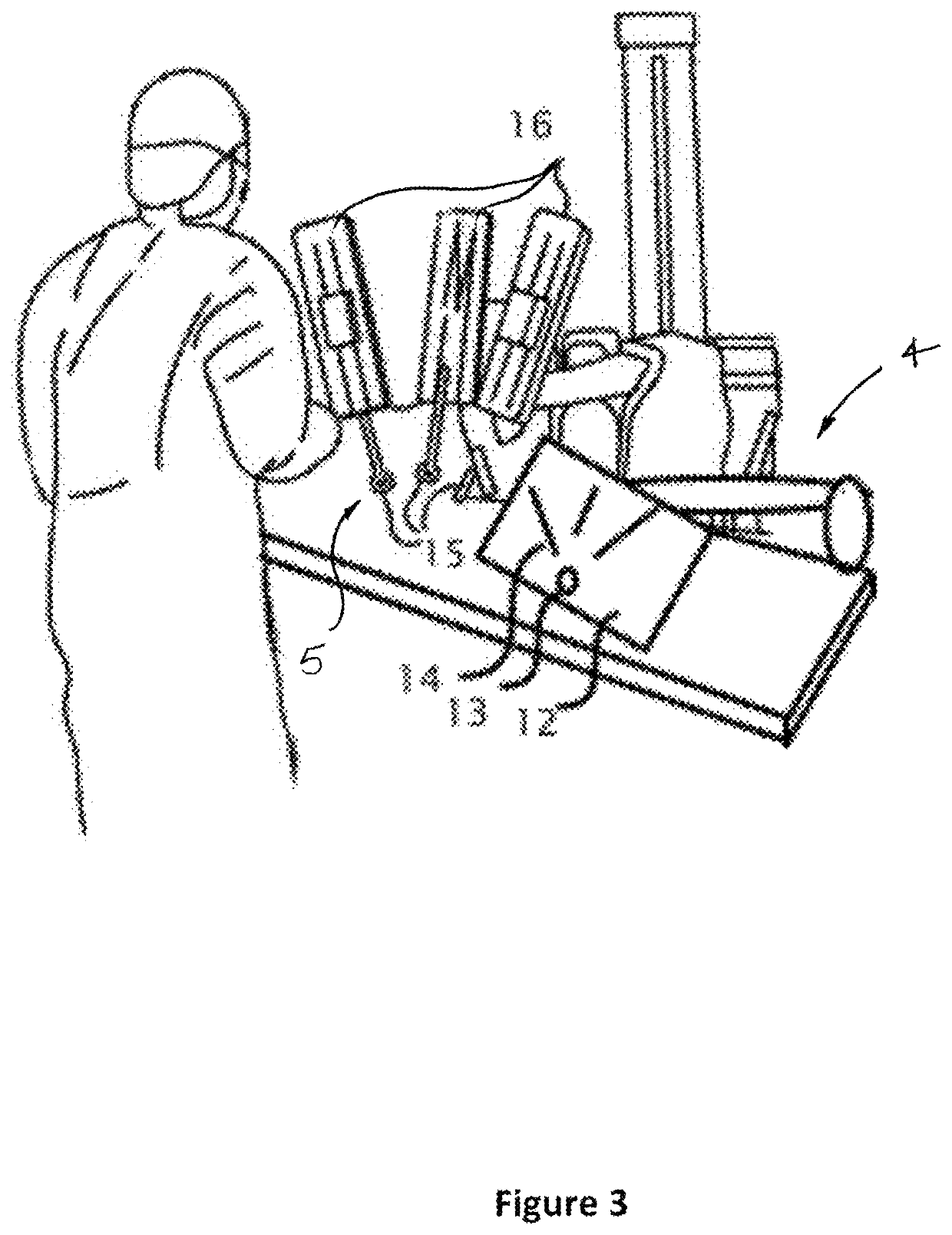

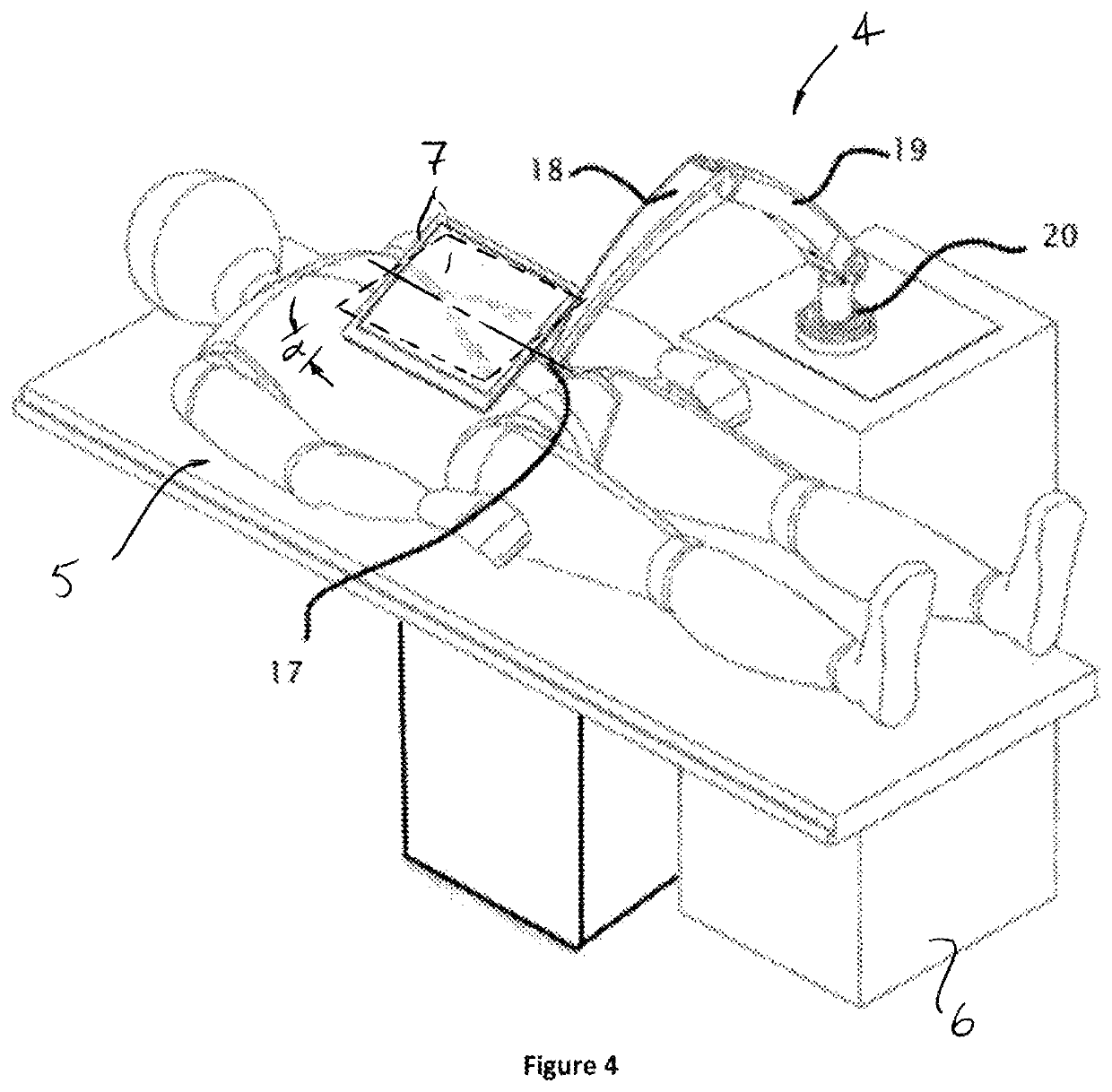

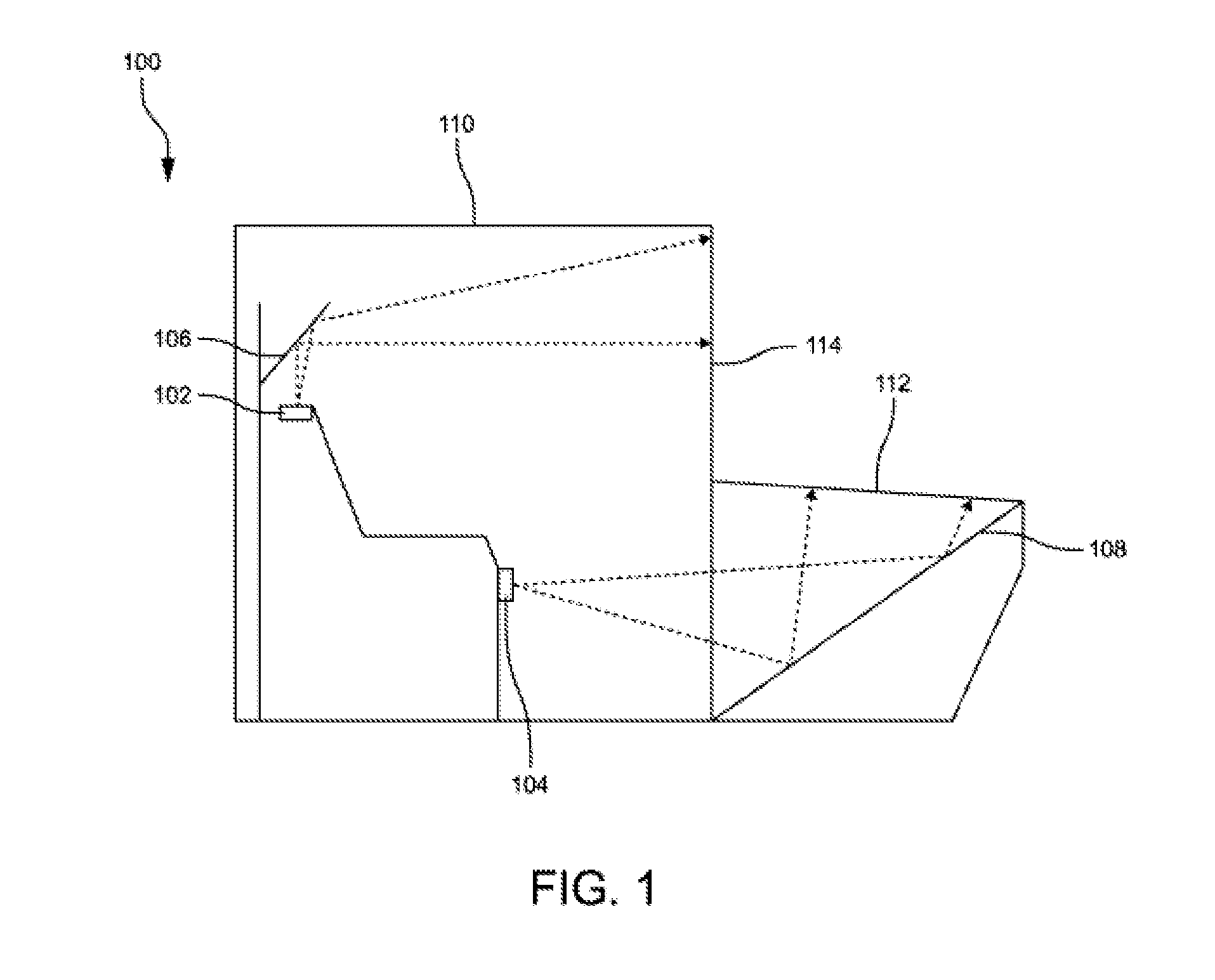

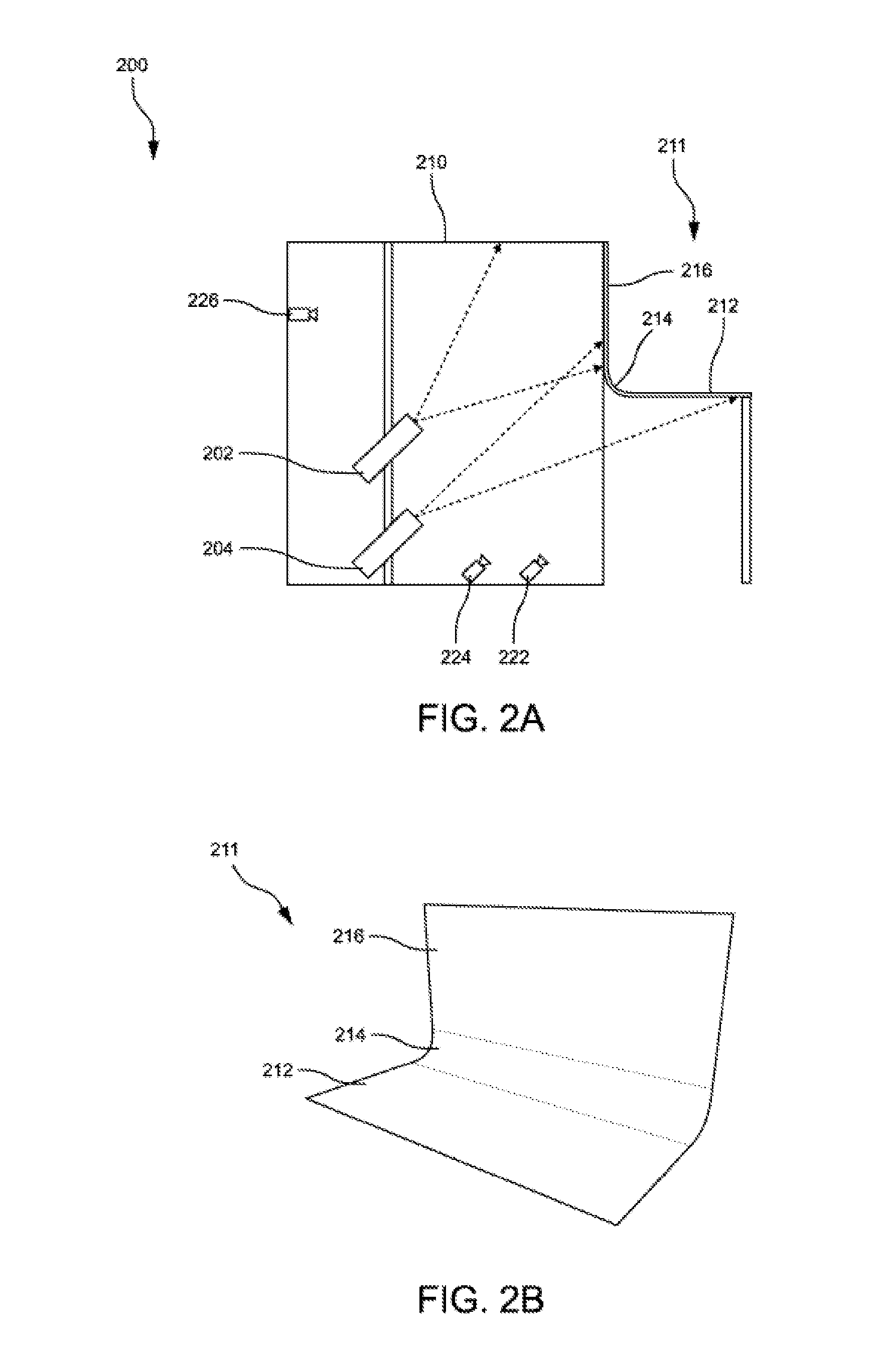

An image display system is provided comprised of a virtual window system that creates a visual coherency between the patient's anatomical images and the actual patient by aligning the image on the display to the patient and then presenting the image to the user in a way that feels as if the user is looking directly into the patient through the display. The image shown within the image display system is dependent upon the position of the image display apparatus and the position of the user so that the display orientation of the image may be biased slightly toward the user to improve ergonomics and usability.

Owner:AURIS HEALTH INC

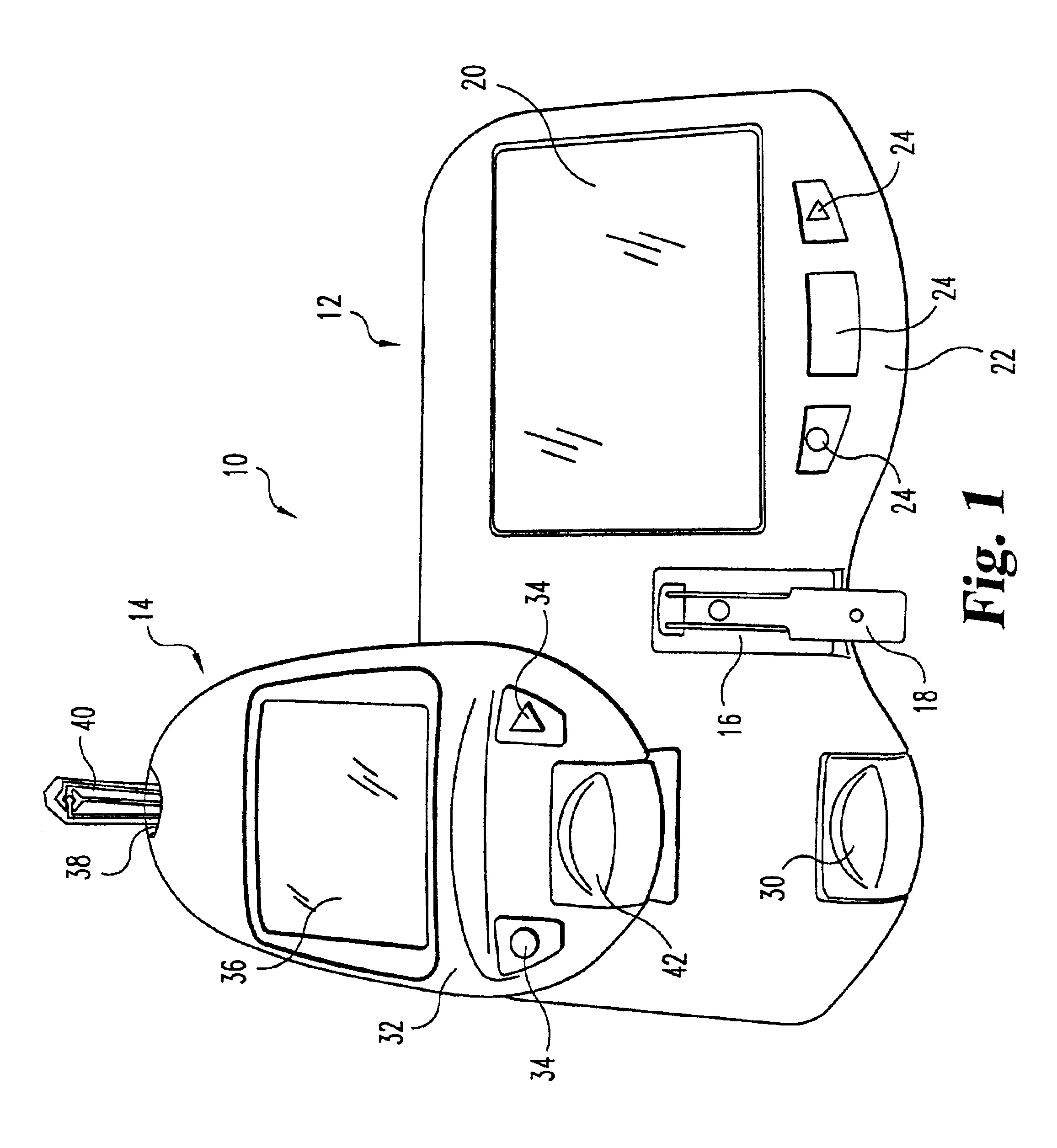

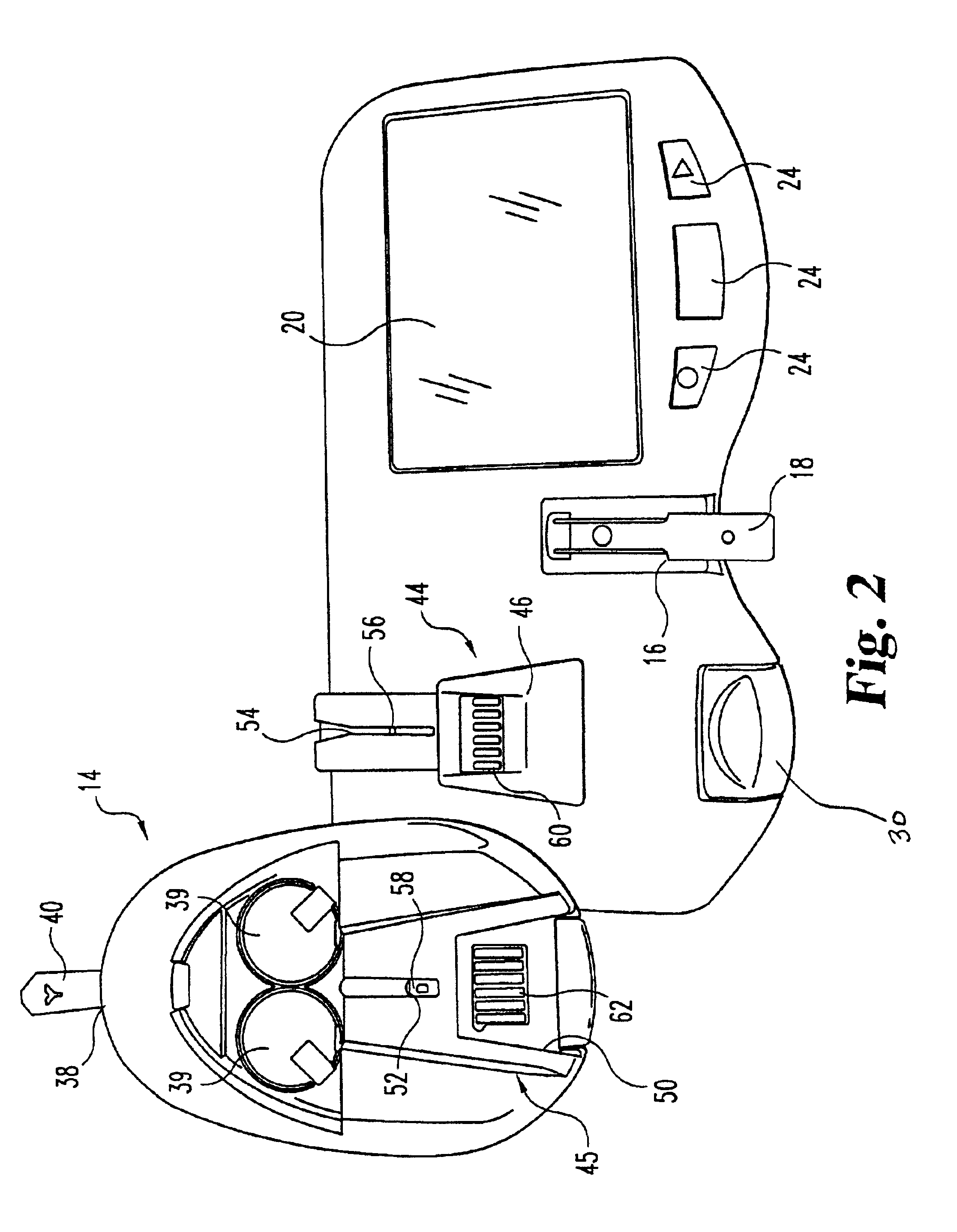

Body fluid test apparatus with detachably mounted portable tester

InactiveUS6849237B2Sacrificing abilityMonitor glucose levelImmobilised enzymesBioreactor/fermenter combinationsGlucose meter deviceHand held

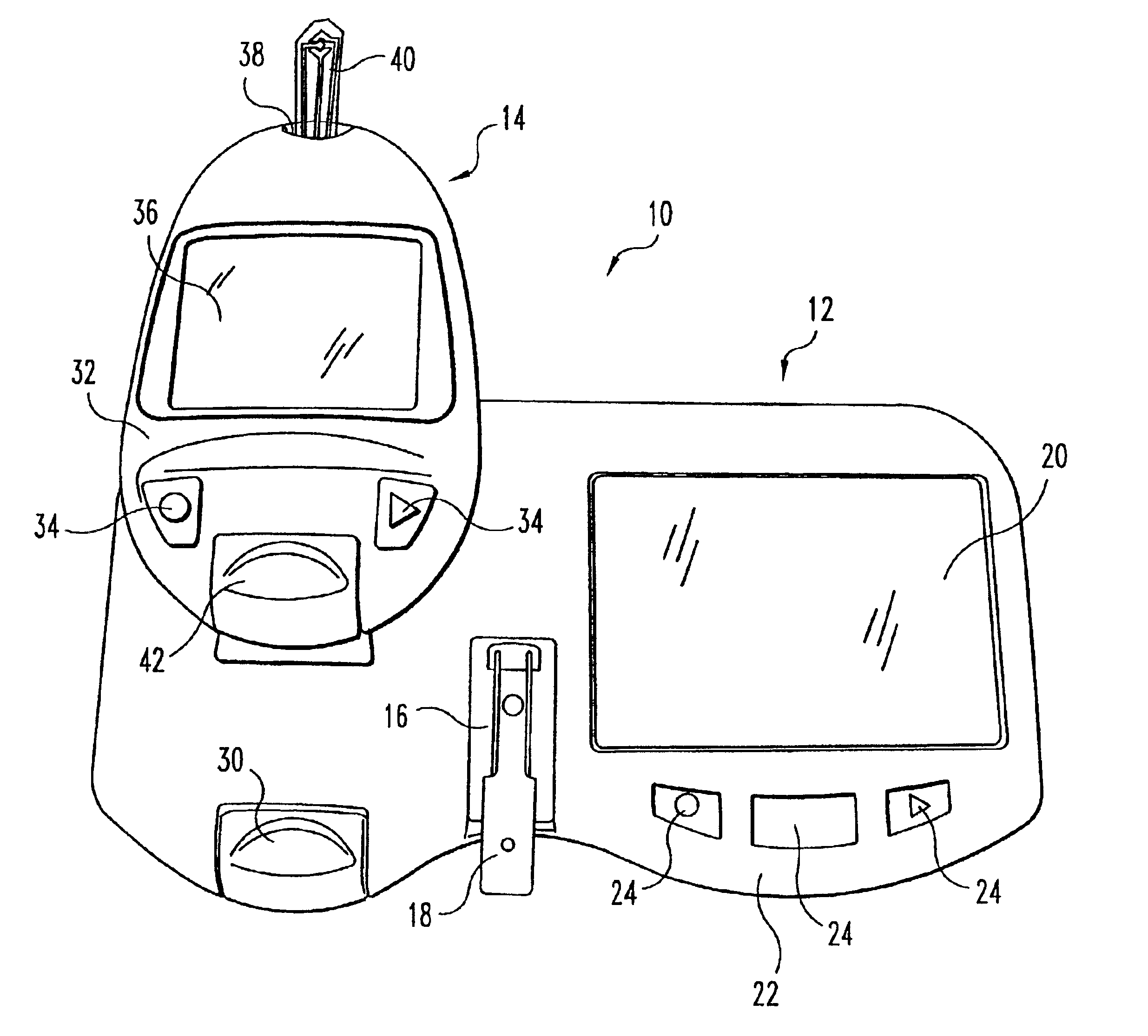

A test apparatus having a base which performs a plurality of tests for different analytes in body fluids. A portable tester, such as a glucose meter, is detachably mounted to the base and provides a convenient and ergonomic hand-held instrument which a diabetic may carry to frequently monitor blood glucose levels. When mounted or docked to the base, the portable tester is data linked to the base. The invention provides a communications network among the base, the portable tester and another device such as a PC. The portable tester can therefore be kept small and inexpensive since advanced computing and data storage capabilities are provided in the base or a PC.

Owner:POLYMER TECH SYST

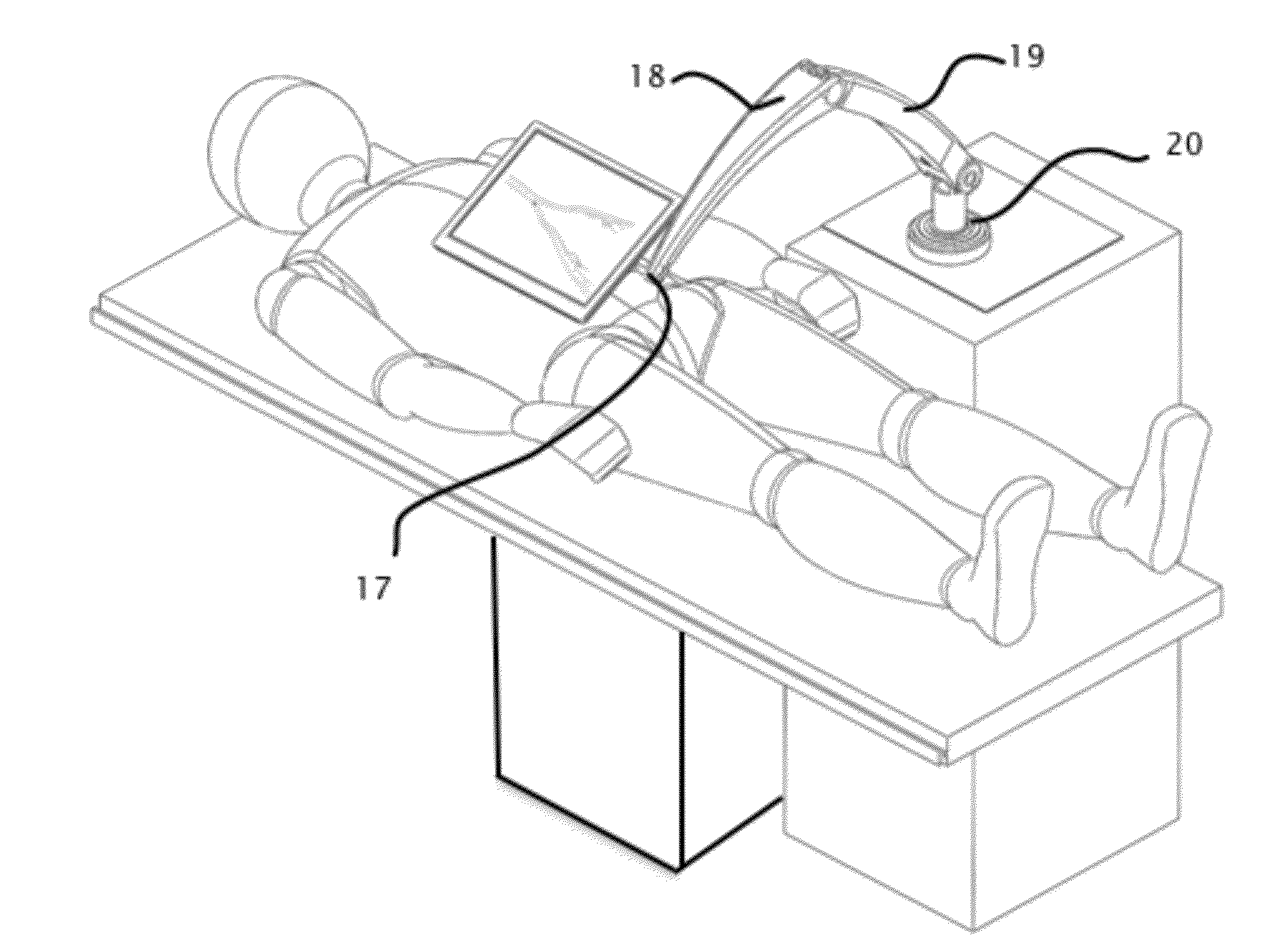

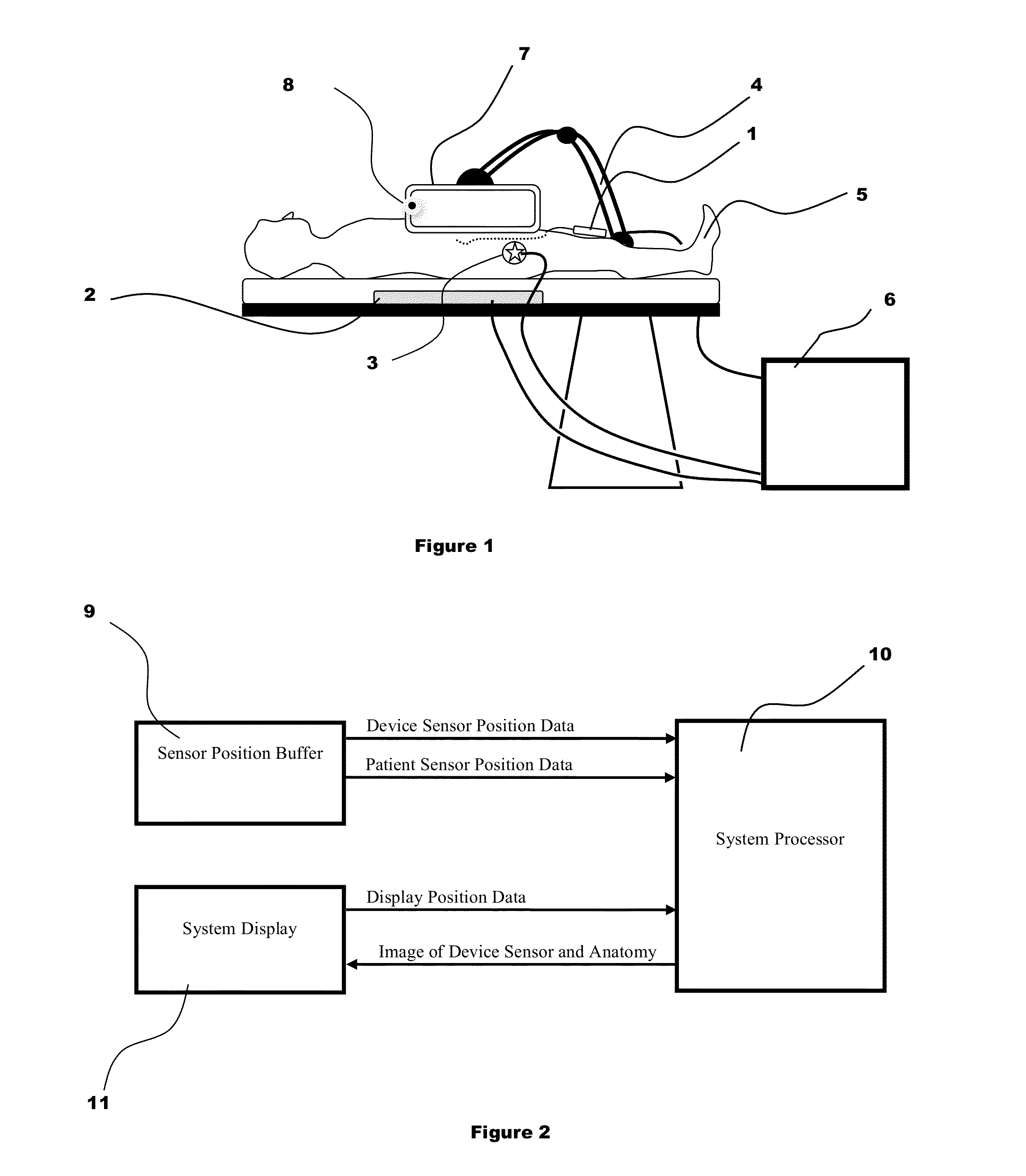

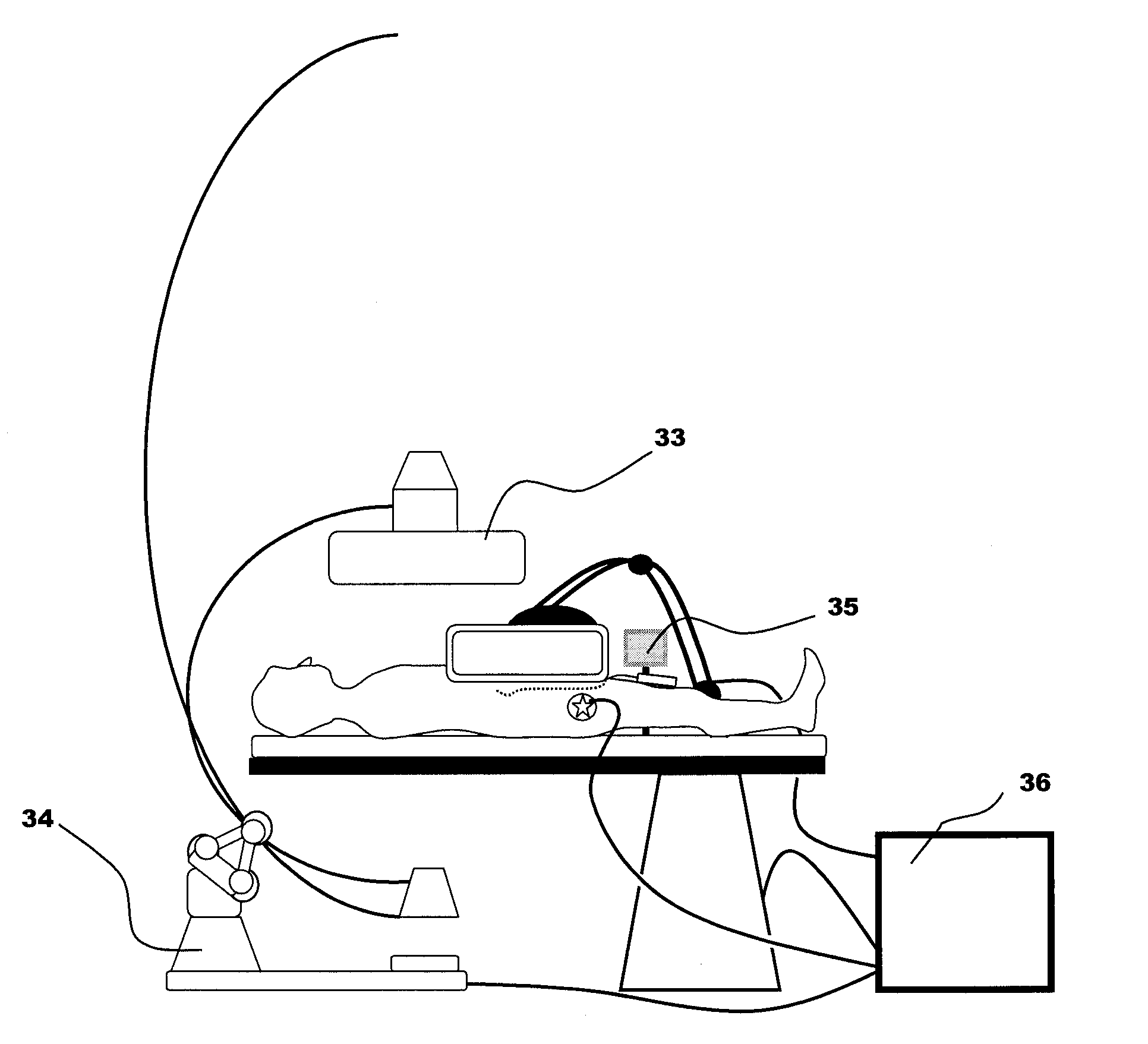

System and method for displaying anatomy and devices on a movable display

ActiveUS20140357984A1Easy to browseQuick selectionMechanical/radiation/invasive therapiesOrgan movement/changes detectionComputer graphics (images)Display device

An image display system is provided comprised of a virtual window system that creates a visual coherency between the patient's anatomical images and the actual patient by aligning the image on the display to the patient and then presenting the image to the user in a way that feels as if the user is looking directly into the patient through the display. The image shown within the image display system is dependent upon the position of the image display apparatus and the position of the user so that the display orientation of the image may be biased slightly toward the user to improve ergonomics and usability.

Owner:AURIS HEALTH INC

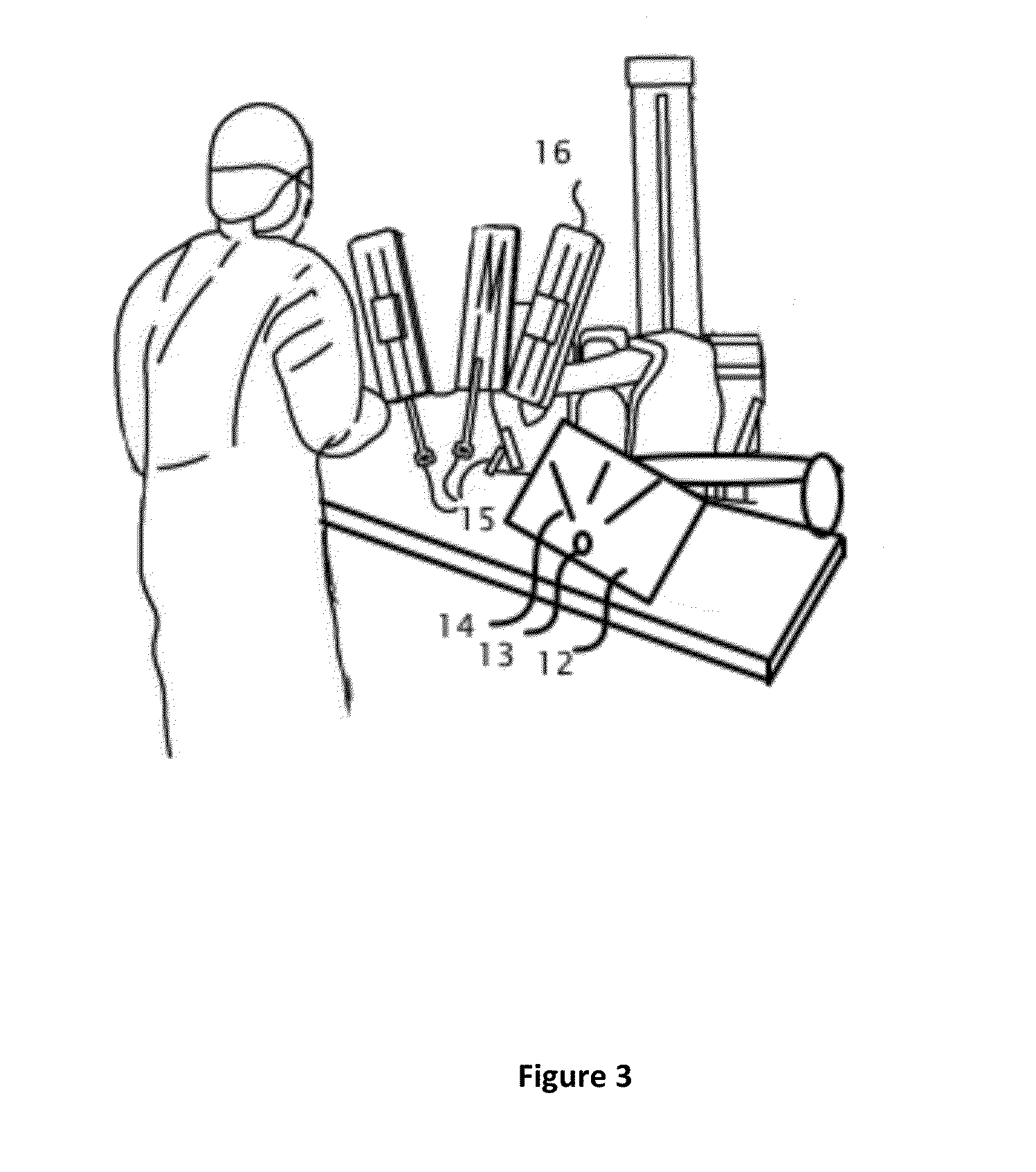

System and method for virtually tracking a surgical tool on a movable display

ActiveUS9918681B2Increase workspaceImprove ergonomicsUltrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsDisplay deviceVisual perception

The invention comprises a virtual window system that creates a visual coherency between the image of the patient and his or her anatomy and the patient by aligning the image of the patient anatomy on the display to the patient and presenting the image to the user that feels as if the user is looking directly into the patient through the display. The invention is designed to also display medical devices, such as a minimally invasive tool. The system substantially unifies the coordinate systems of the patient, the medical device, the display, and the physician's hands. The invention creates a visual coherency between the motion of the medical device in the image and the motion of the physician's hands manipulating the device. This invention also creates a visual coherency between the motion of the image in the display and of that display.

Owner:AURIS HEALTH INC

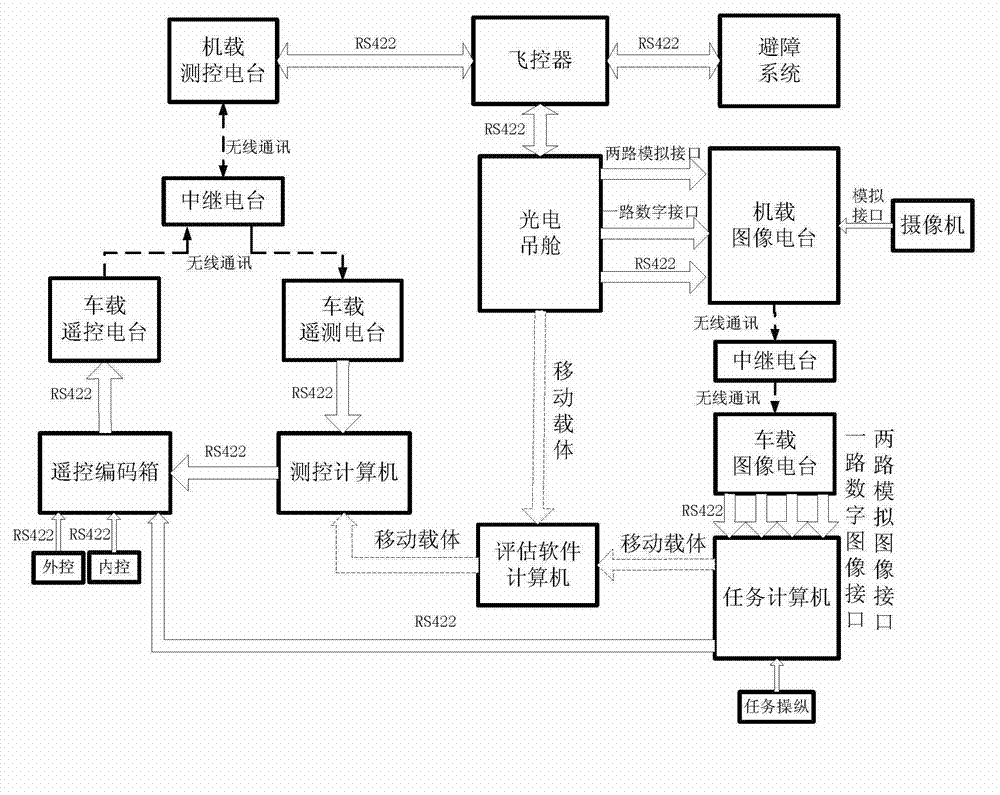

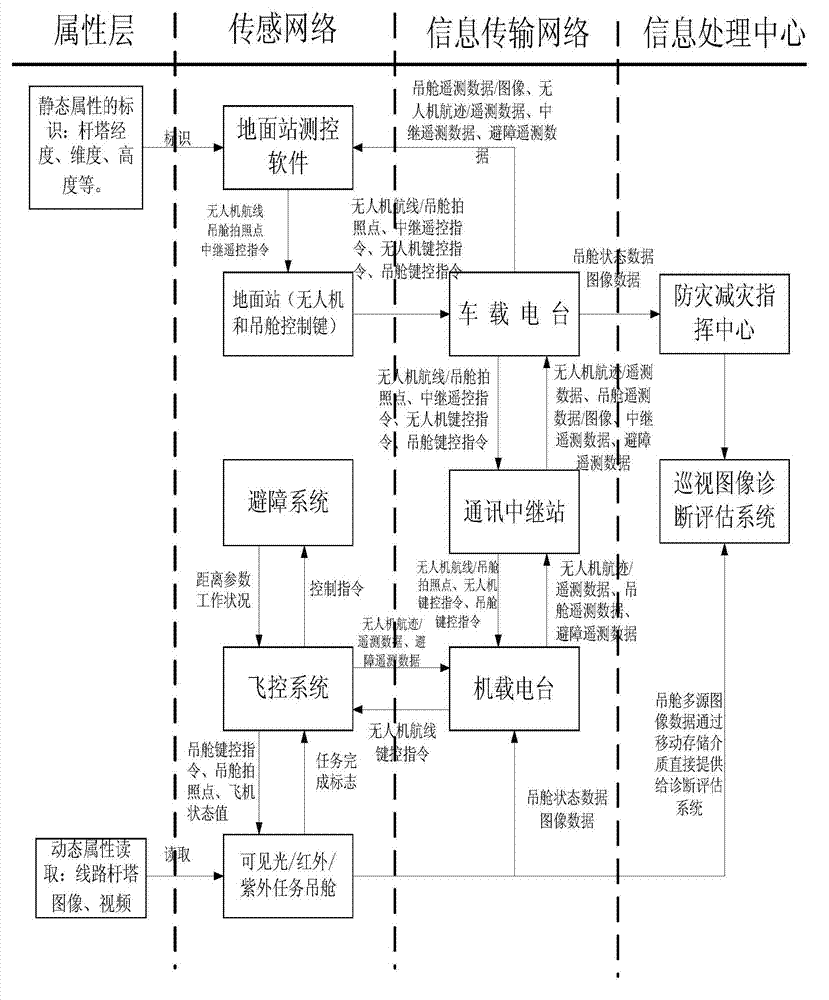

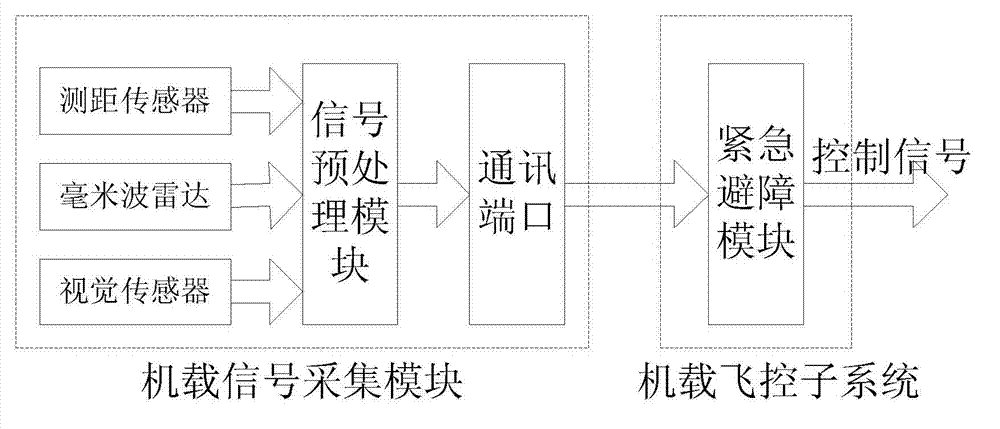

Special unmanned helicopter system suitable for routing inspection on power grid in mountain area

ActiveCN103078673AReduce grid failure rateReduce grid operating costsRadio transmissionTerrainGeographic information system

The invention discloses a special unmanned helicopter system suitable for routing inspection on a power grid in a mountain area, which comprises a sensor network, an information transmission network and an information processing center. According to the special unmanned helicopter system suitable for routing inspection on the power grid in the mountain area, which is disclosed by the invention, in the complex terrain environment of the mountain area and under the complex weather conditions of the mountain area, a medium-sized special unmanned helicopter system suitable for routing inspection on the power grid in the mountain area and an application method thereof can be provided. According to the invention, effective fusion of cutting-edge advanced technologies such as an unmanned aerial vehicle platform technology, a data chain communication technology, a GIS (Geographic Information System) technology, a visible light / infrared / ultraviolet high definition shooting, storage and transmission technology, a distance measuring and sensing technology and an image diagnostic evaluation technology is sufficiently utilized to implement daily routing inspection on a power transmission line.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +3

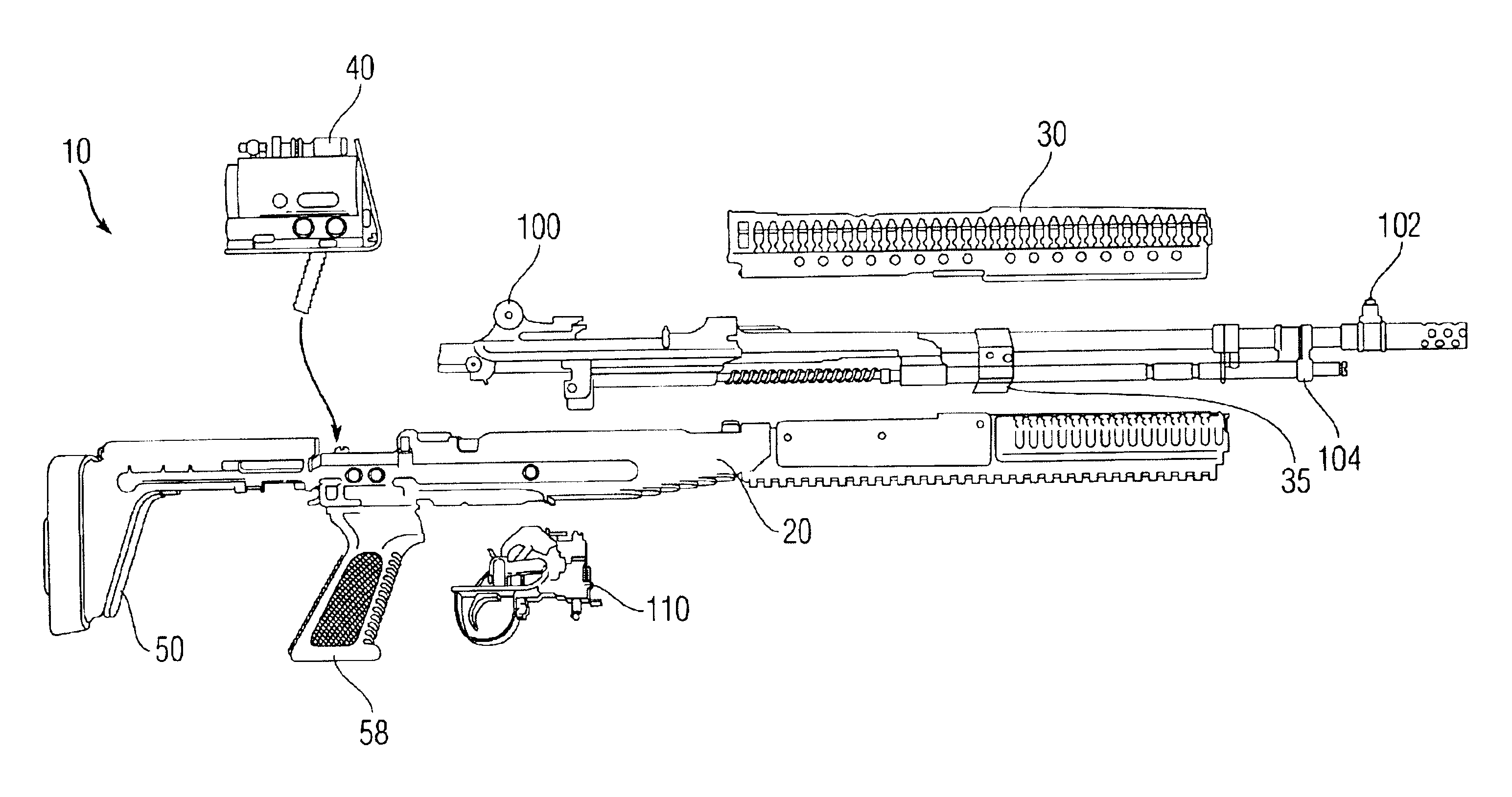

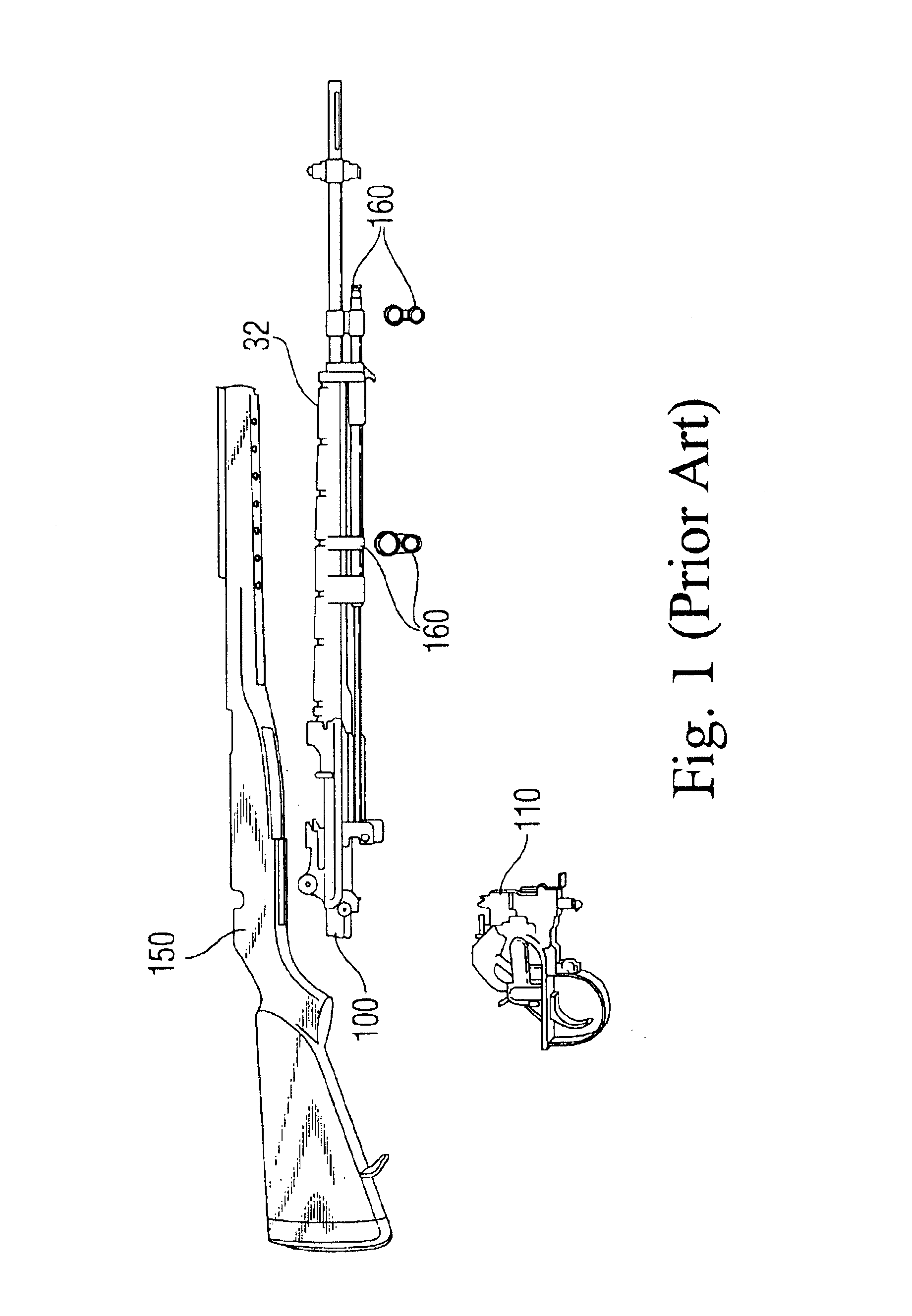

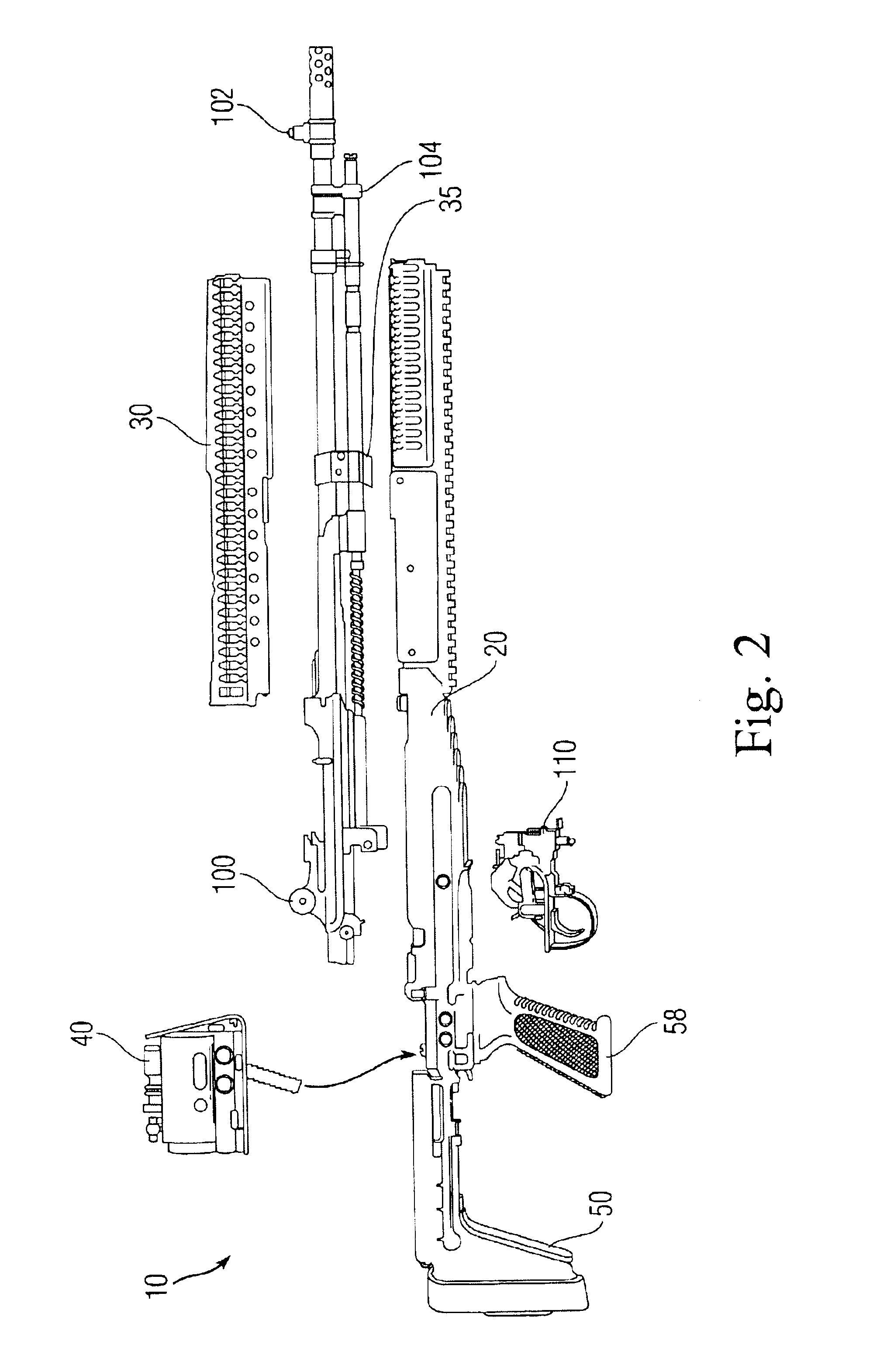

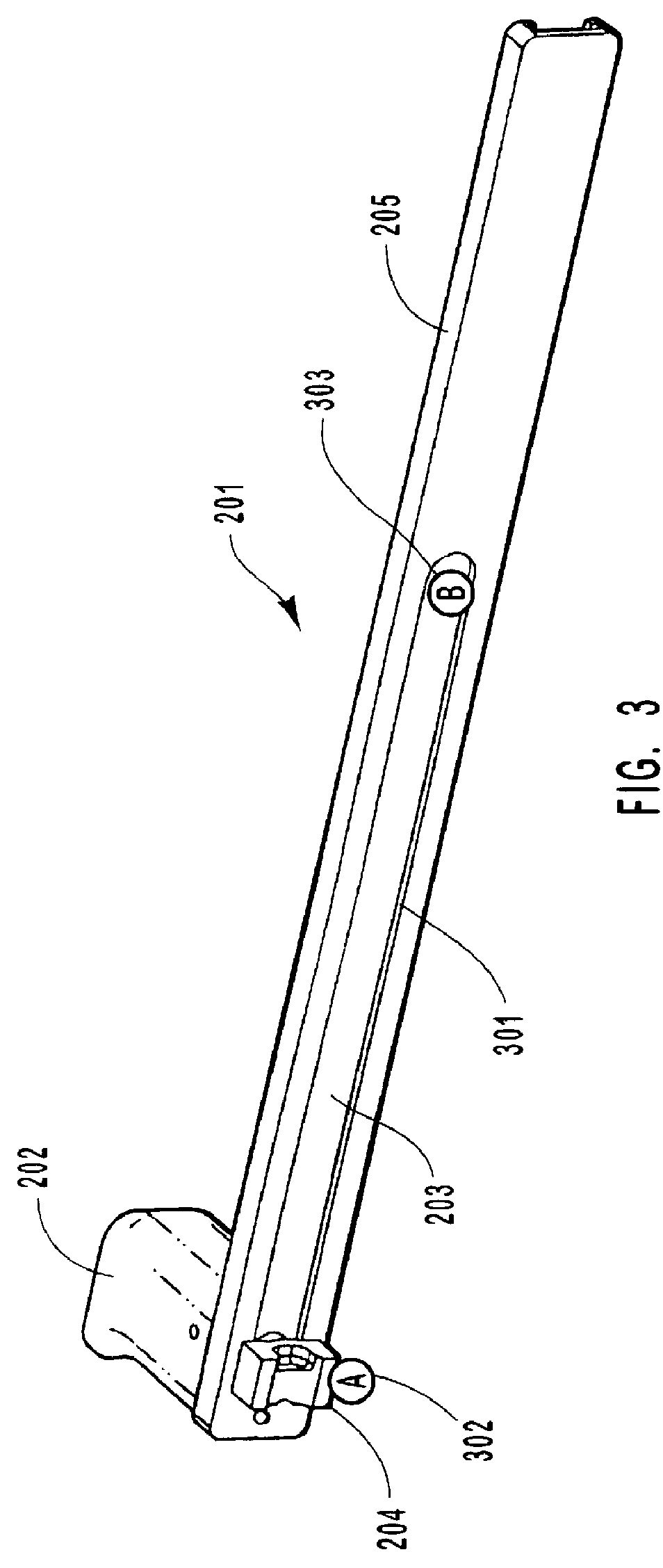

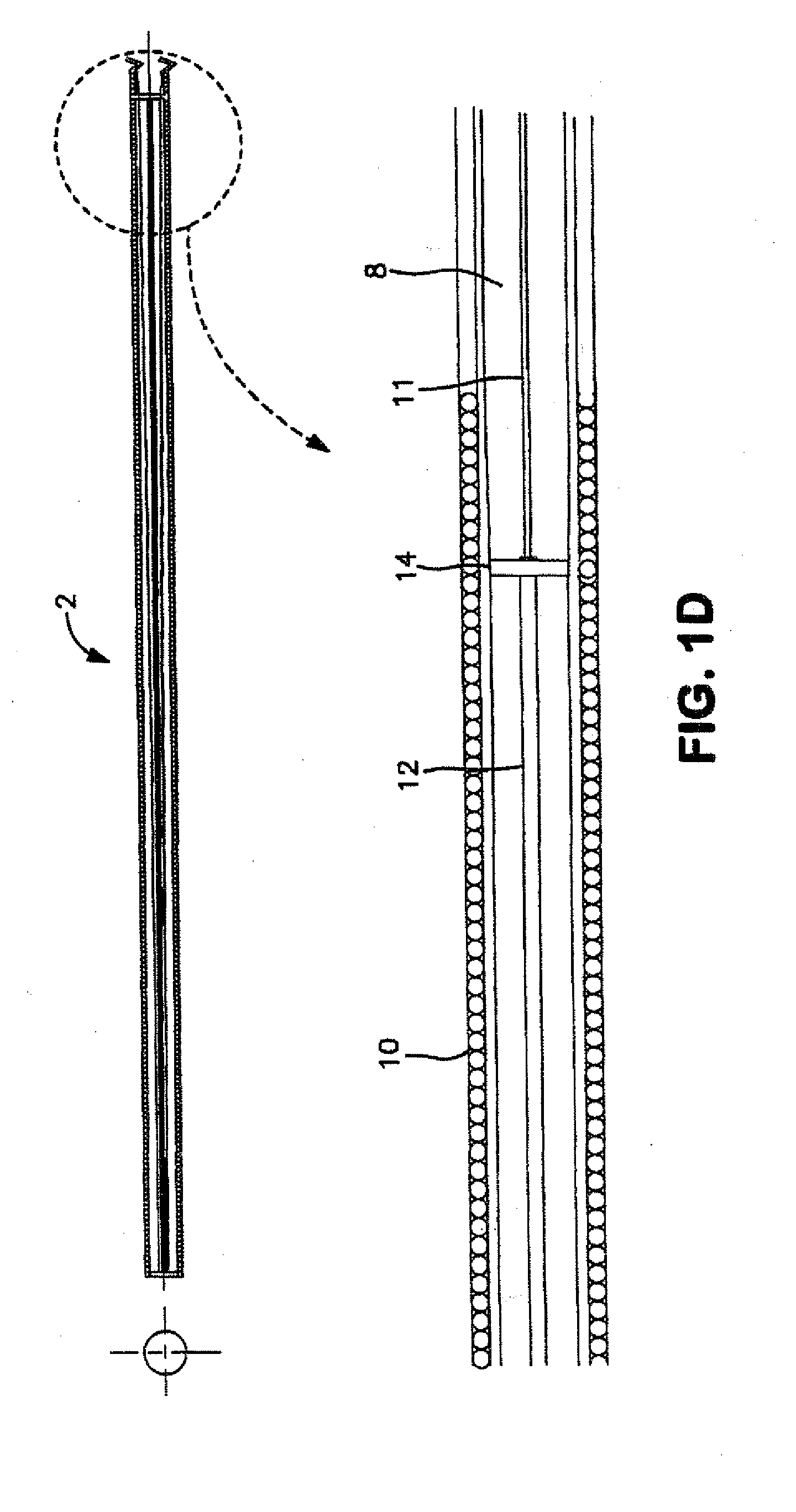

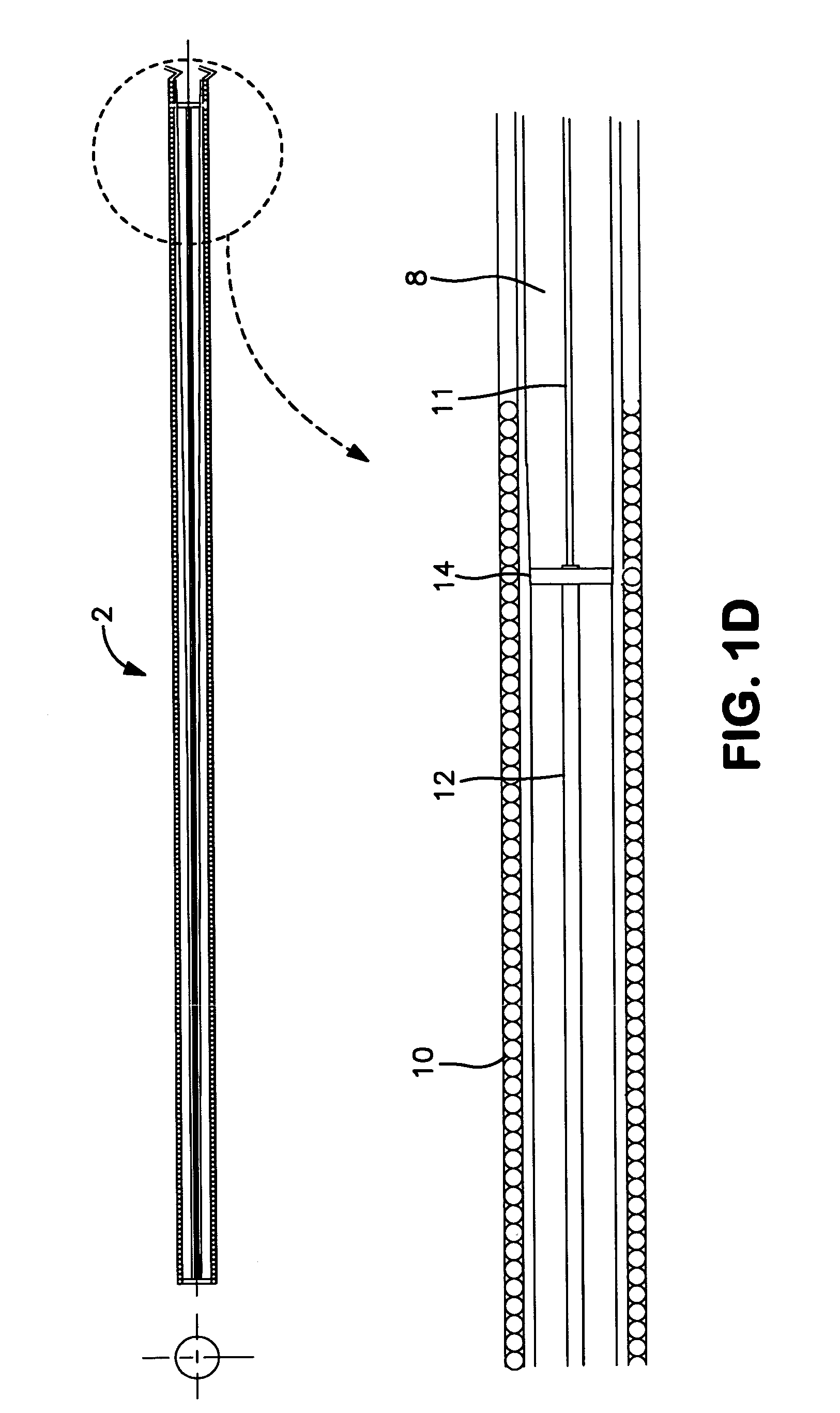

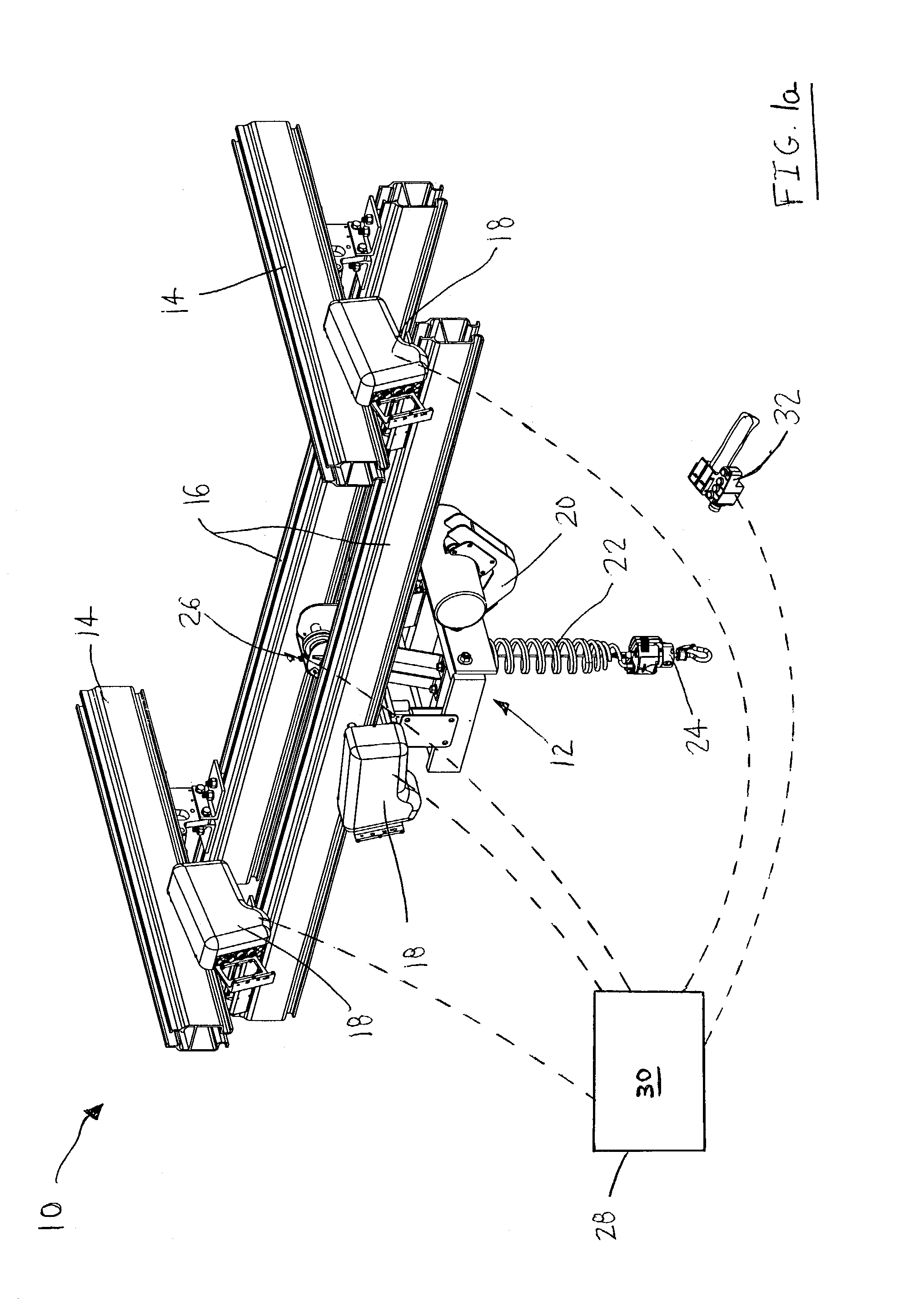

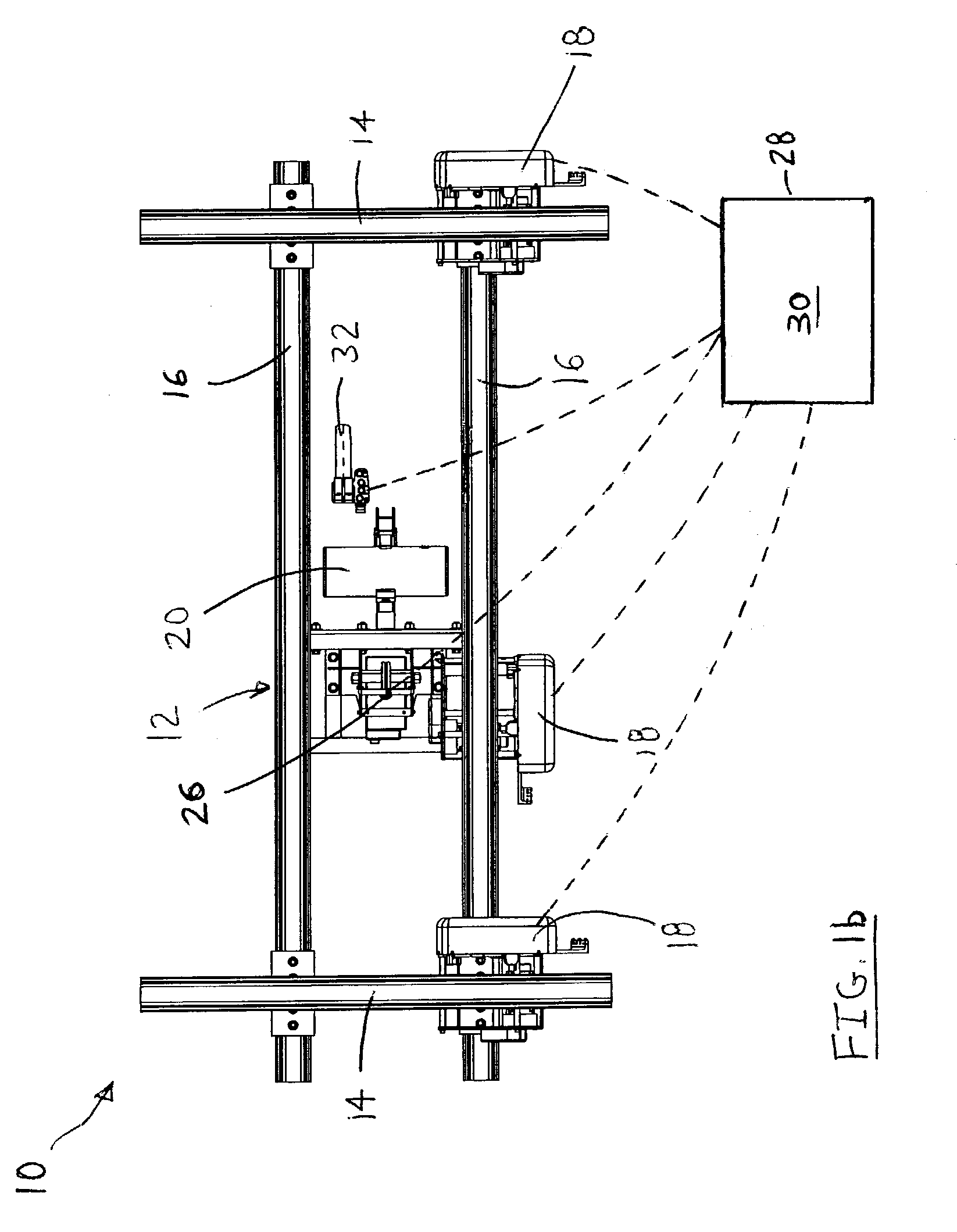

Replacement chassis stock system for firearms

Disclosed herein is a modular, replacement chassis stock system for an existing firearm's operating mechanism possessing a simple design and incorporating durable, commercially available components. The system comprises a chassis assembly with up to three integral mounting rails, a top rail, a replacement operating rod guide, a telescoping buttstock assembly, and a buttstock / grip mount assembly. The present invention may be used to replace the standard stock of an M-14 rifle (or copies thereof, such as the Springfield Armory M1A) such that the barrel is held in perfect alignment with up to five Mil Std 1913 pattern mounting rails. The telescoping buttstock assembly is adjustable in length via the use of a thumb lever release and includes an adjustable cheek-rest, an optionally adjustable buttpad, and a pistol grip. Auxiliary devices may be attached to the chassis stock system via the buttstock / grip mount assembly located above the pistol grip. The chassis stock system is secured at the rear of the barreled action by the installation of the trigger assembly and at the front by attaching it to the replacement operating rod guide.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

System and method for virtually tracking a surgical tool on a movable display

ActiveUS20130072787A1Increase workspaceImprove ergonomicsUltrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsDisplay deviceMedical device

The invention comprises a virtual window system that creates a visual coherency between the image of the patient and his or her anatomy and the patient by aligning the image of the patient anatomy on the display to the patient and presenting the image to the user that feels is if the user is looking directly into the patient through the display. The invention is designed to also display medical devices, such as a minimally invasive tool. The system substantially unifies the coordinate systems of the patient, the medical device, the display, and the physician's hands. The invention creates a visual coherency between the motion of the medical device in the image and the motion of the physician's hands manipulating the device. This invention also creates a visual coherency between the motion of the image in the display and display.

Owner:AURIS HEALTH INC

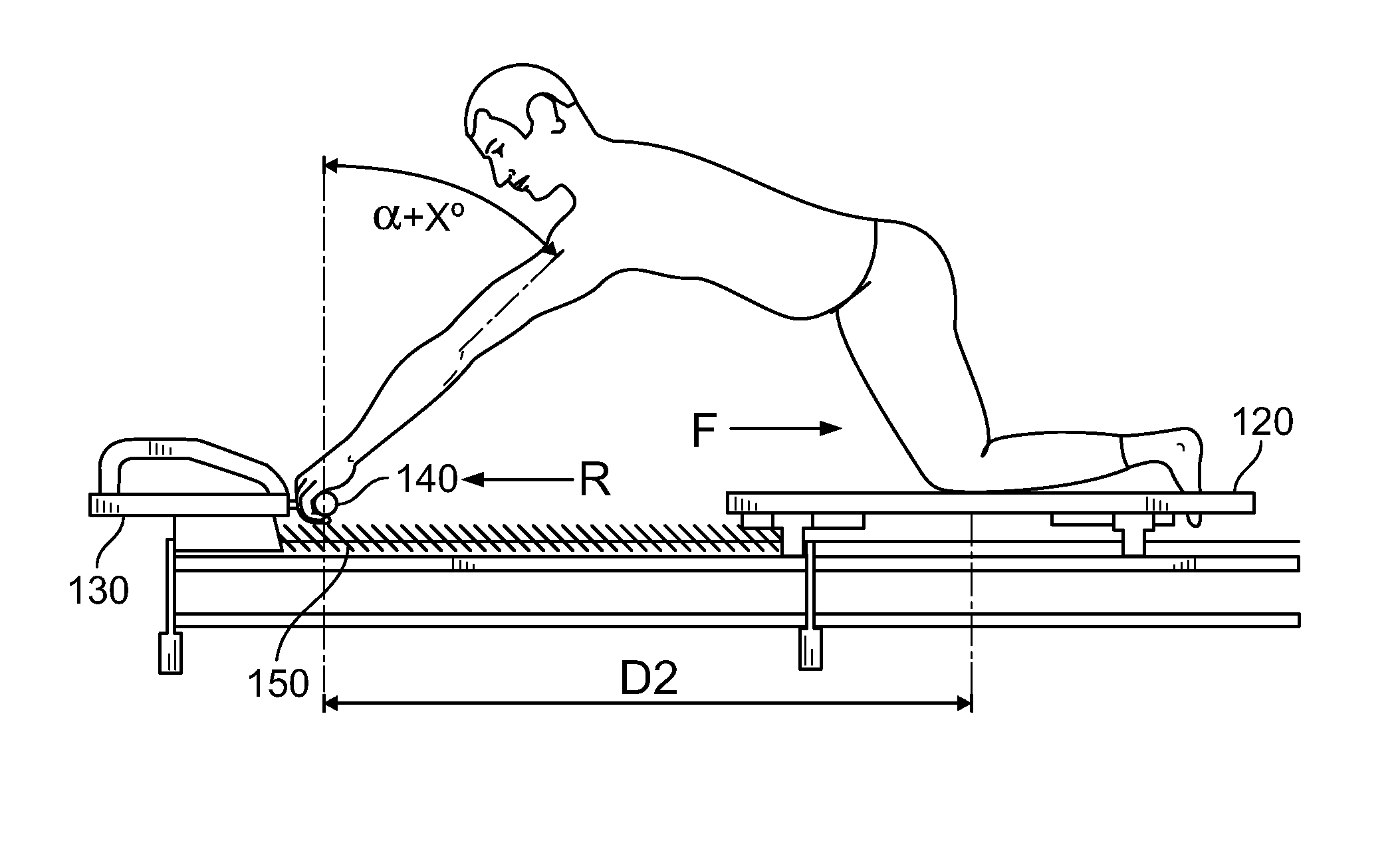

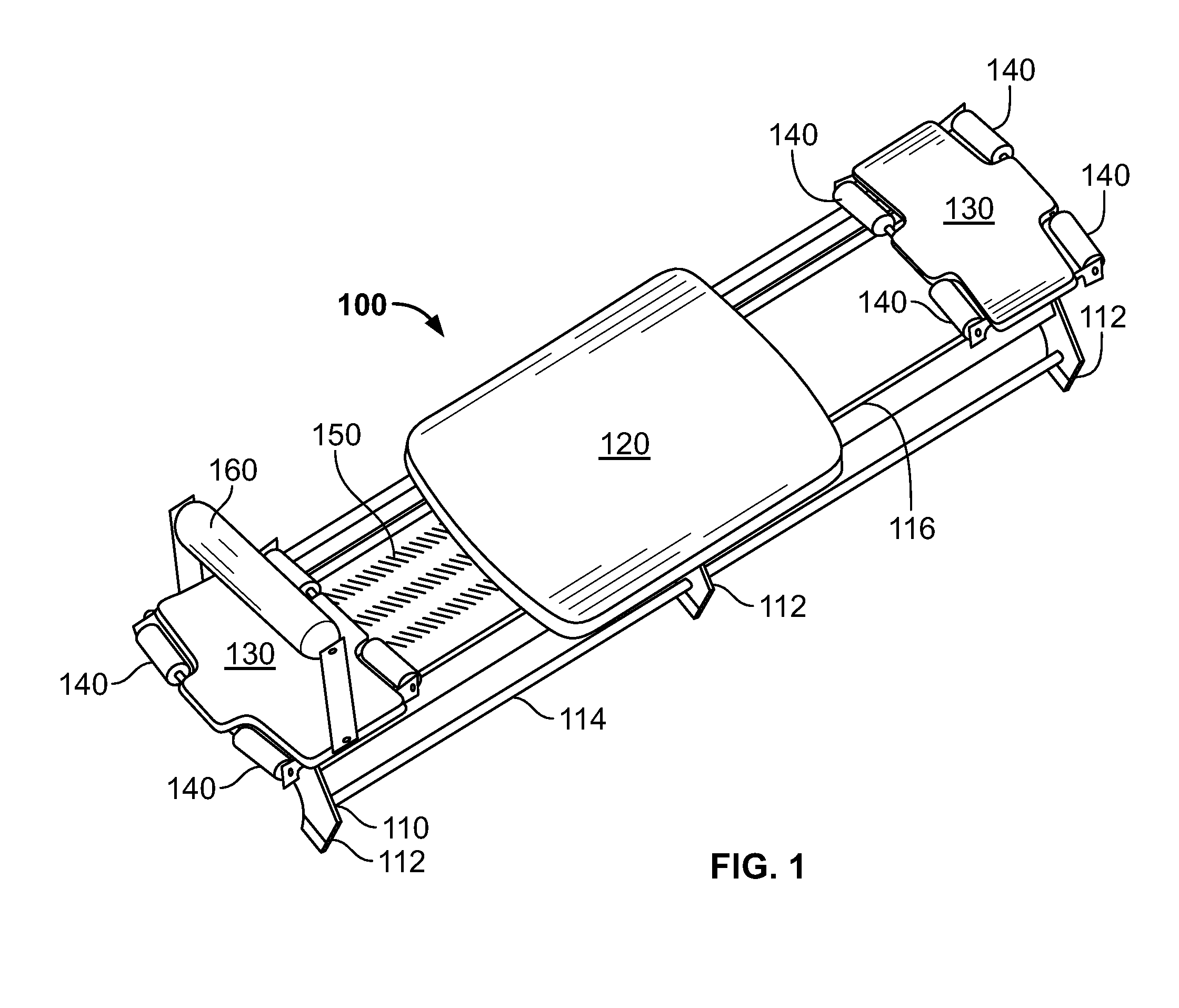

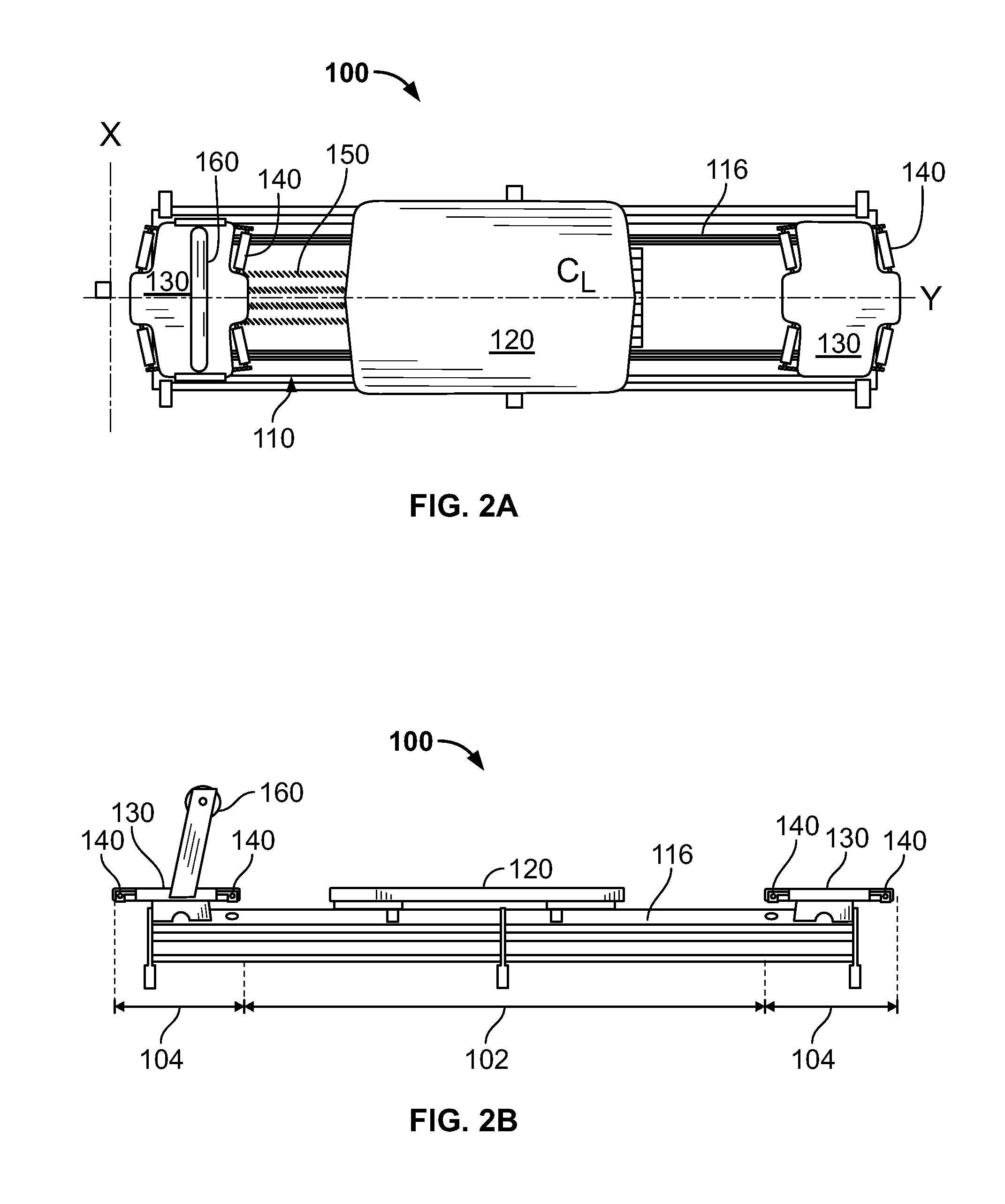

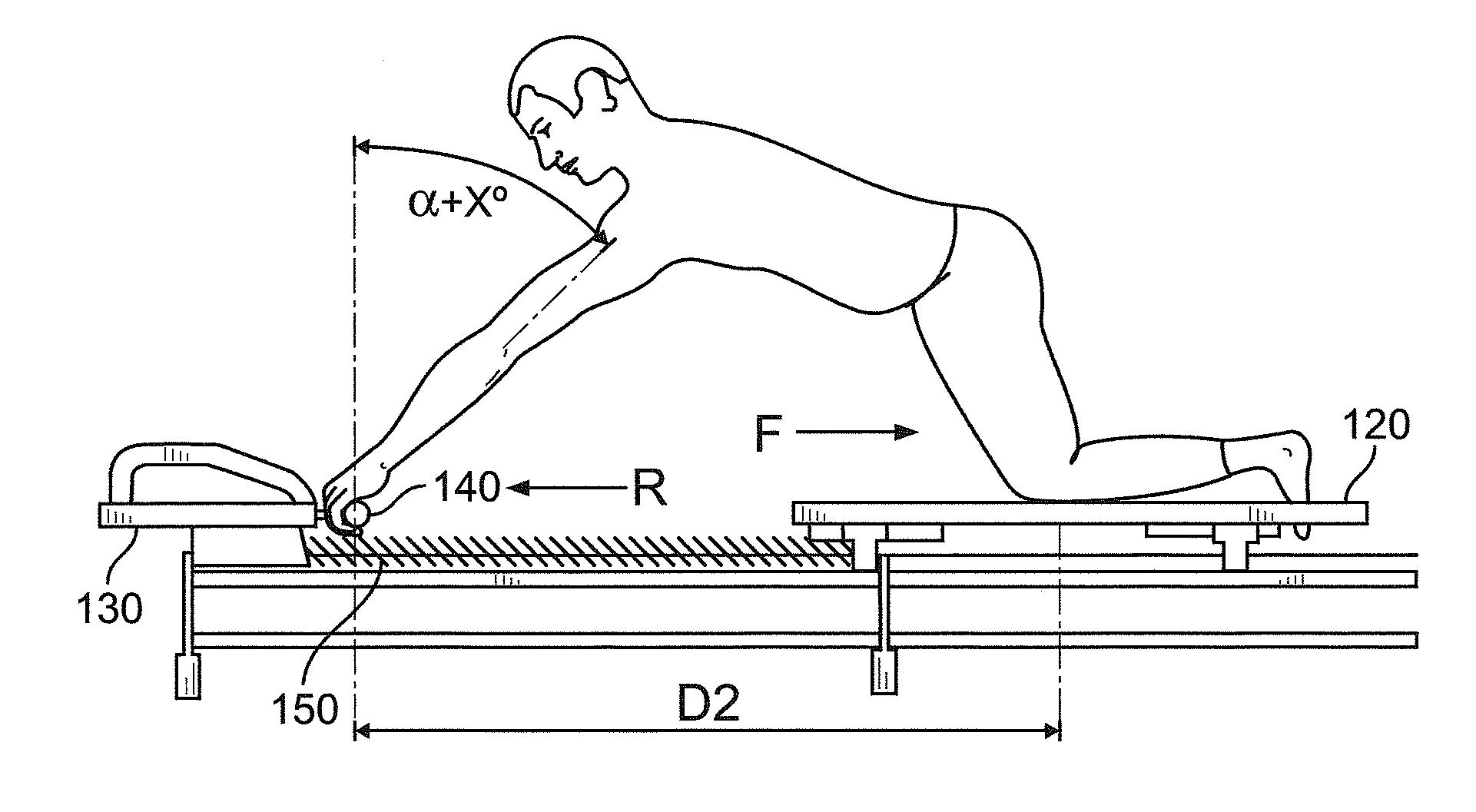

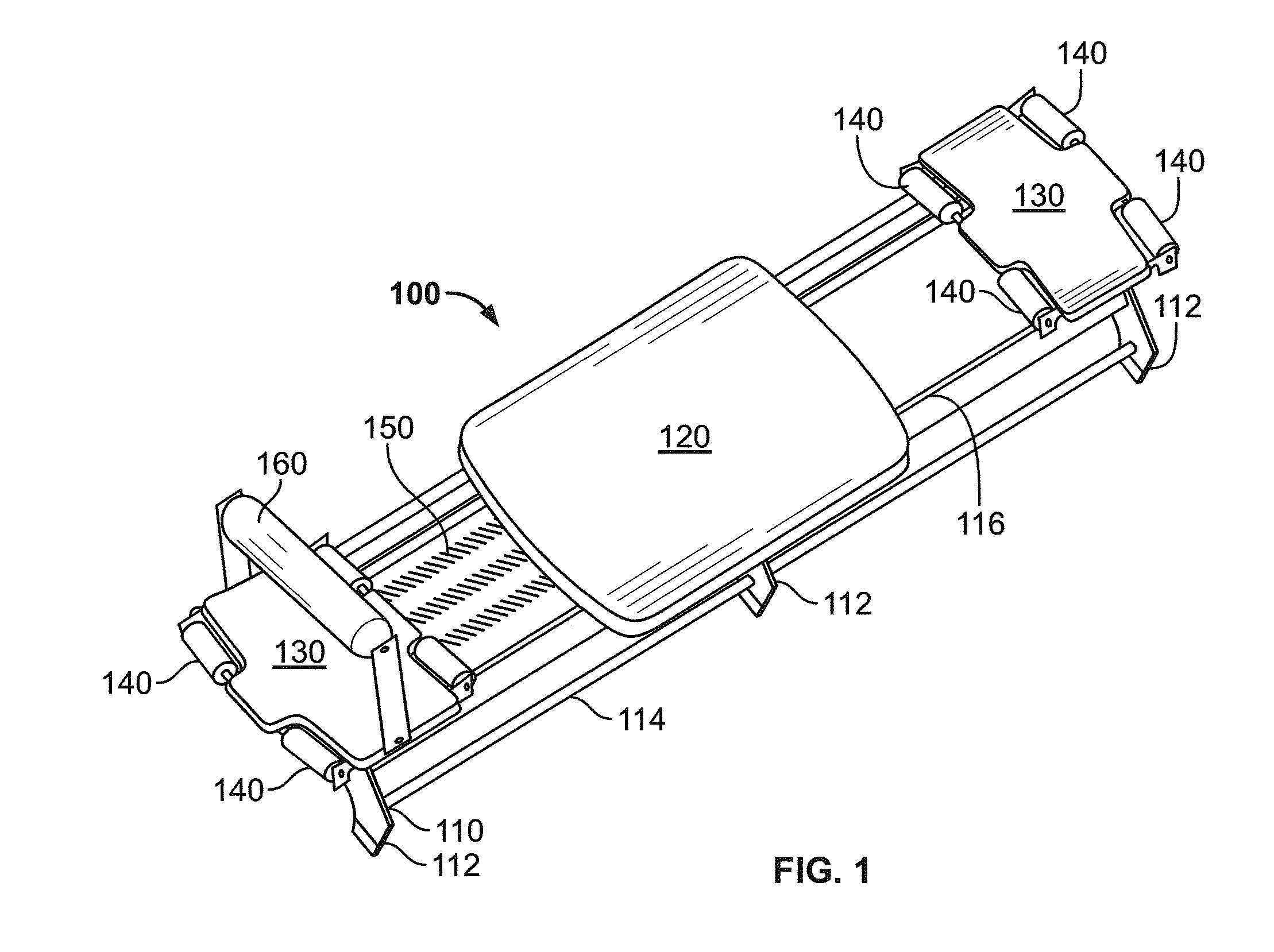

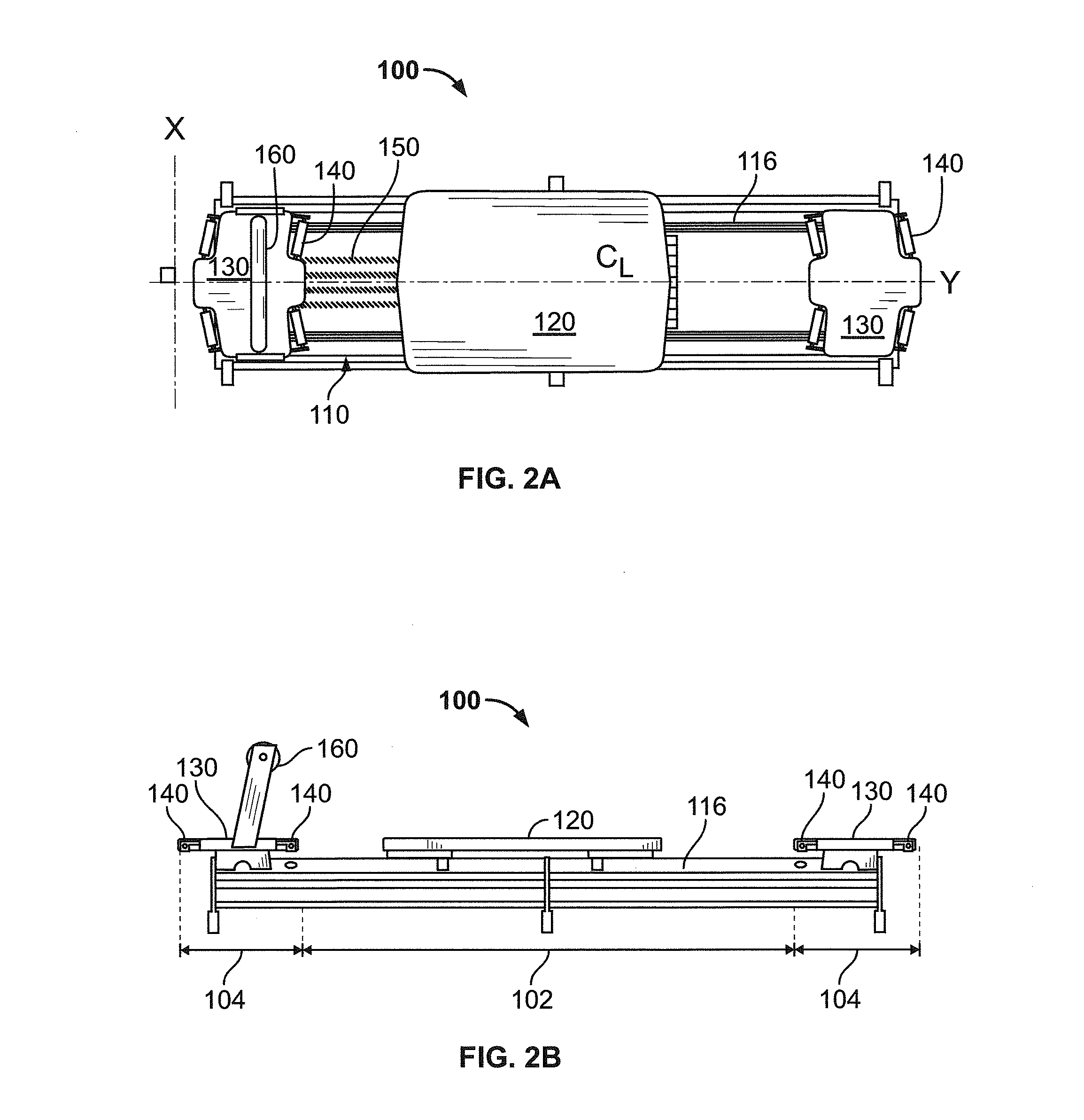

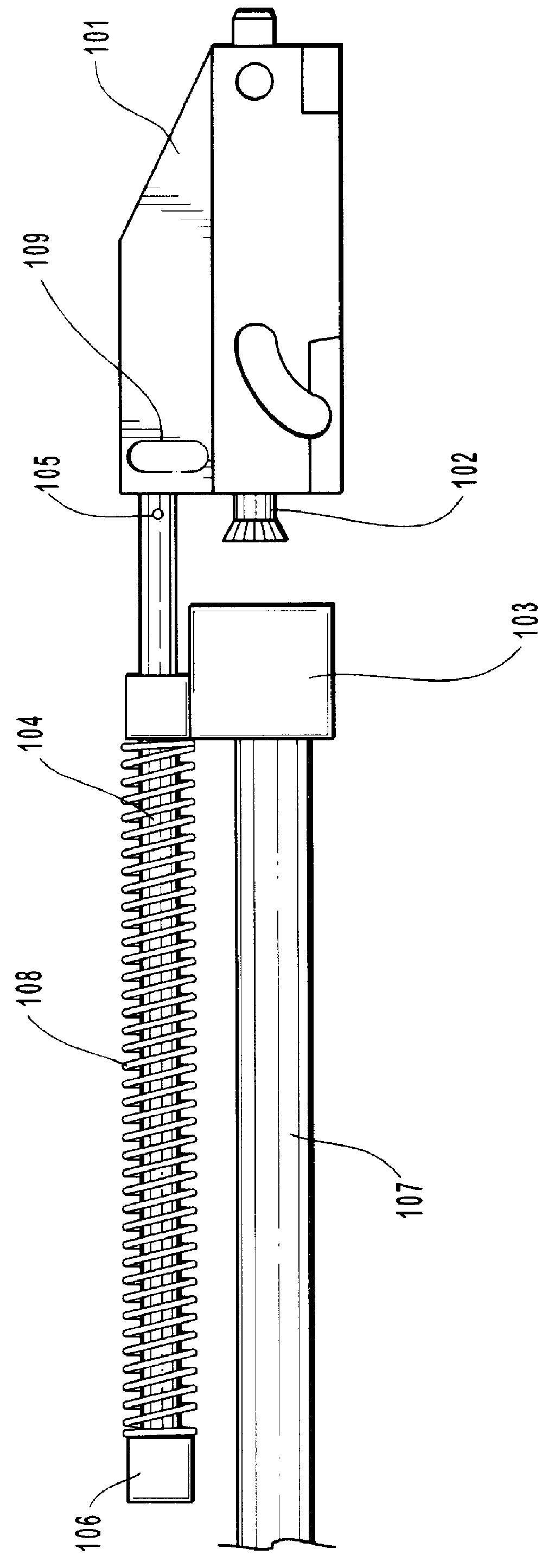

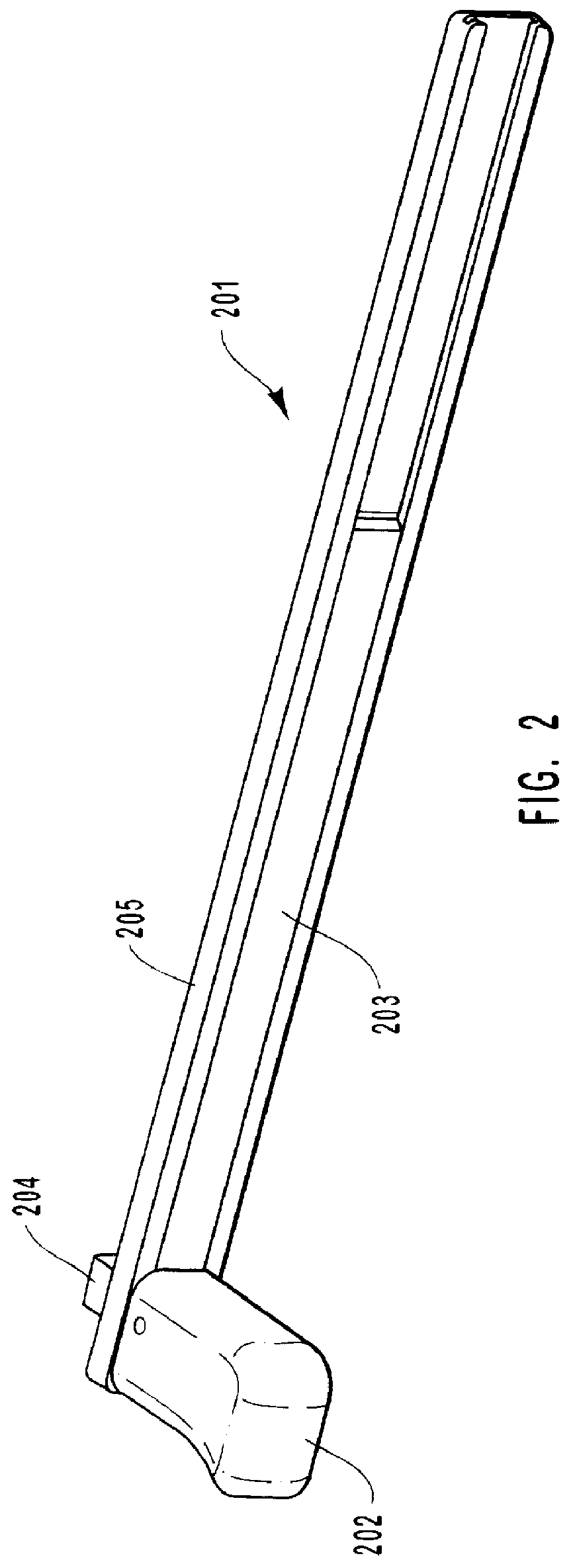

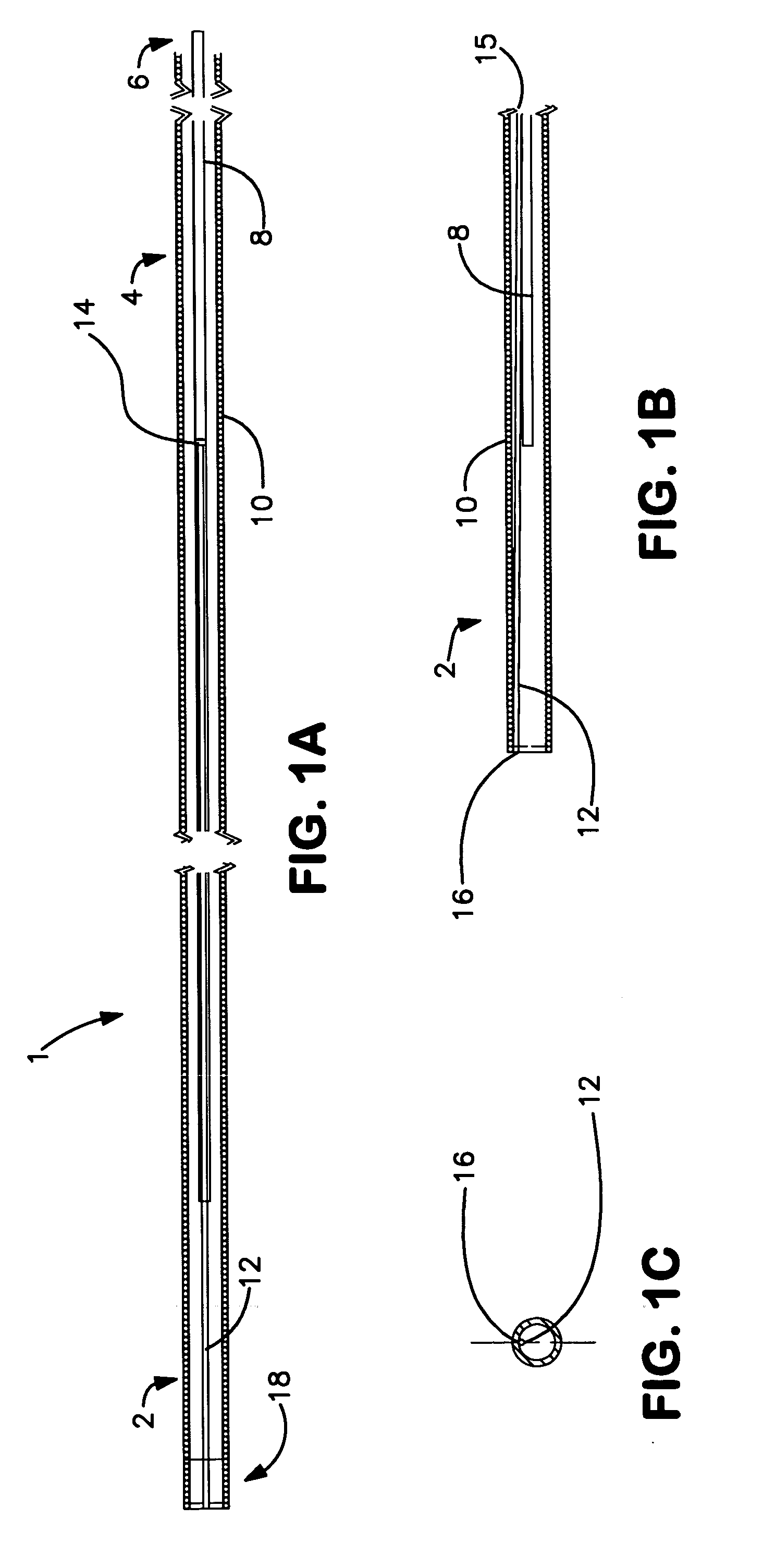

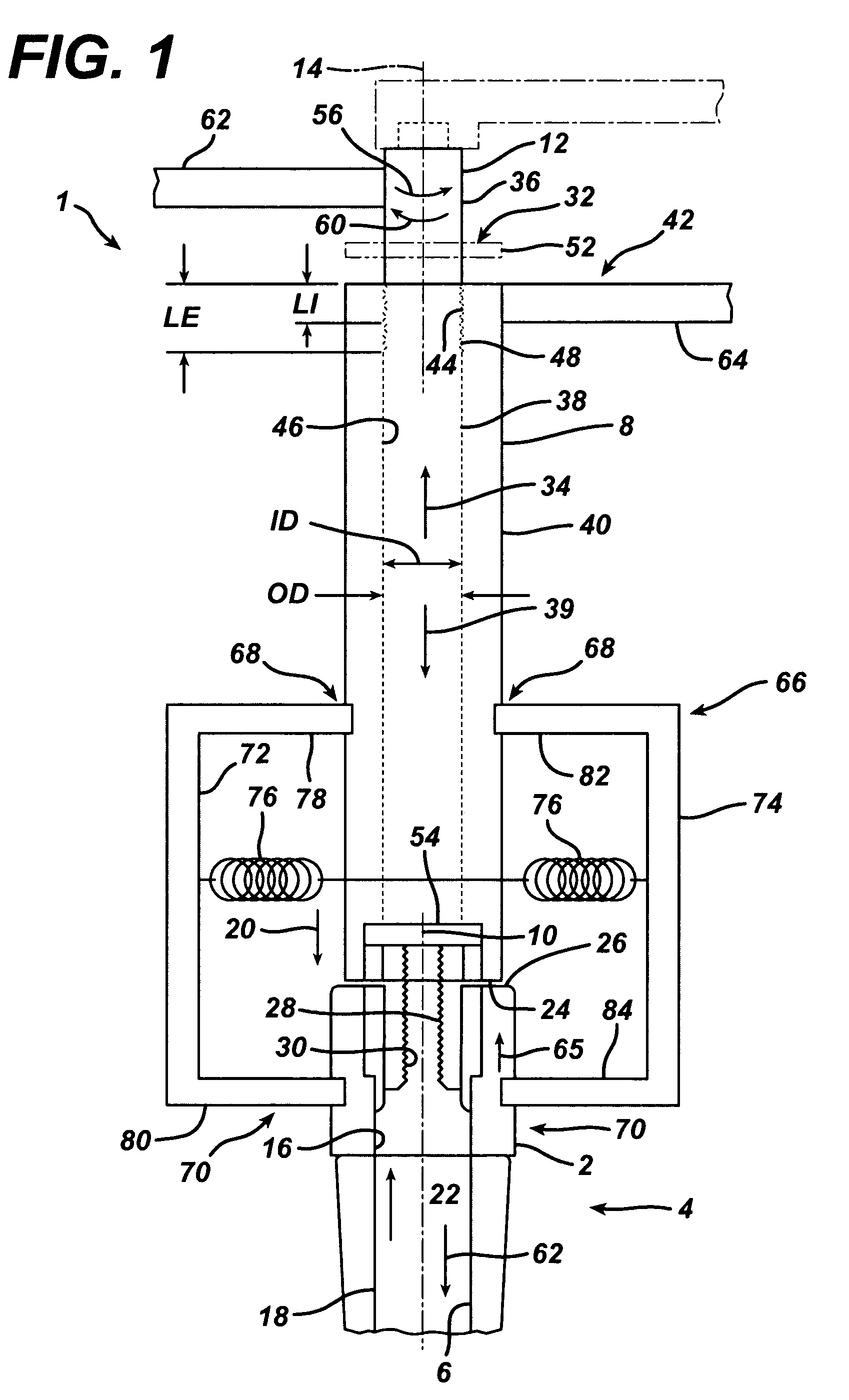

Exercise Machine Ergonomic Handle System

ActiveUS20160008657A1Improve ergonomicsFlexible cuttingResilient force resistorsStiltsHand heldEngineering

An exercise machine ergonomic handle system for providing hand-holds for the performance of exercises with reduced flexion and / or extension of the hand and wrist and reduced ulnar and / or radial deviation so as to reduce injury and allow application of full strength to the exercise machine. The exercise machine ergonomic handle system generally includes a longitudinally extending frame, a carriage that moves upon a first longitudinal portion of the frame, and at least one pair of ergonomic handles positioned on a second longitudinal portion of the frame. The ergonomic handles rotate about an axis to prevent flexion and / or extension, and can be positioned at a width and / or angle that reduces ulnar and / or radial deviation.

Owner:LAGREE TECH INC

Exercise Machine Ergonomic Handle System

ActiveUS20150065318A1Improve ergonomicsFlexible cuttingStiltsMuscle exercising devicesHand heldEngineering

An exercise machine ergonomic handle system for providing hand-holds for the performance of exercises with reduced flexion and / or extension of the hand and wrist and reduced ulnar and / or radial deviation so as to reduce injury and allow application of full strength to the exercise machine. The exercise machine ergonomic handle system generally includes a longitudinally extending frame, a carriage that moves upon a first longitudinal portion of the frame, and at least one pair of ergonomic handles positioned on a second longitudinal portion of the frame. The ergonomic handles rotate about an axis to prevent flexion and / or extension, and can be positioned at a width and / or angle that reduces ulnar and / or radial deviation.

Owner:LAGREE TECH INC

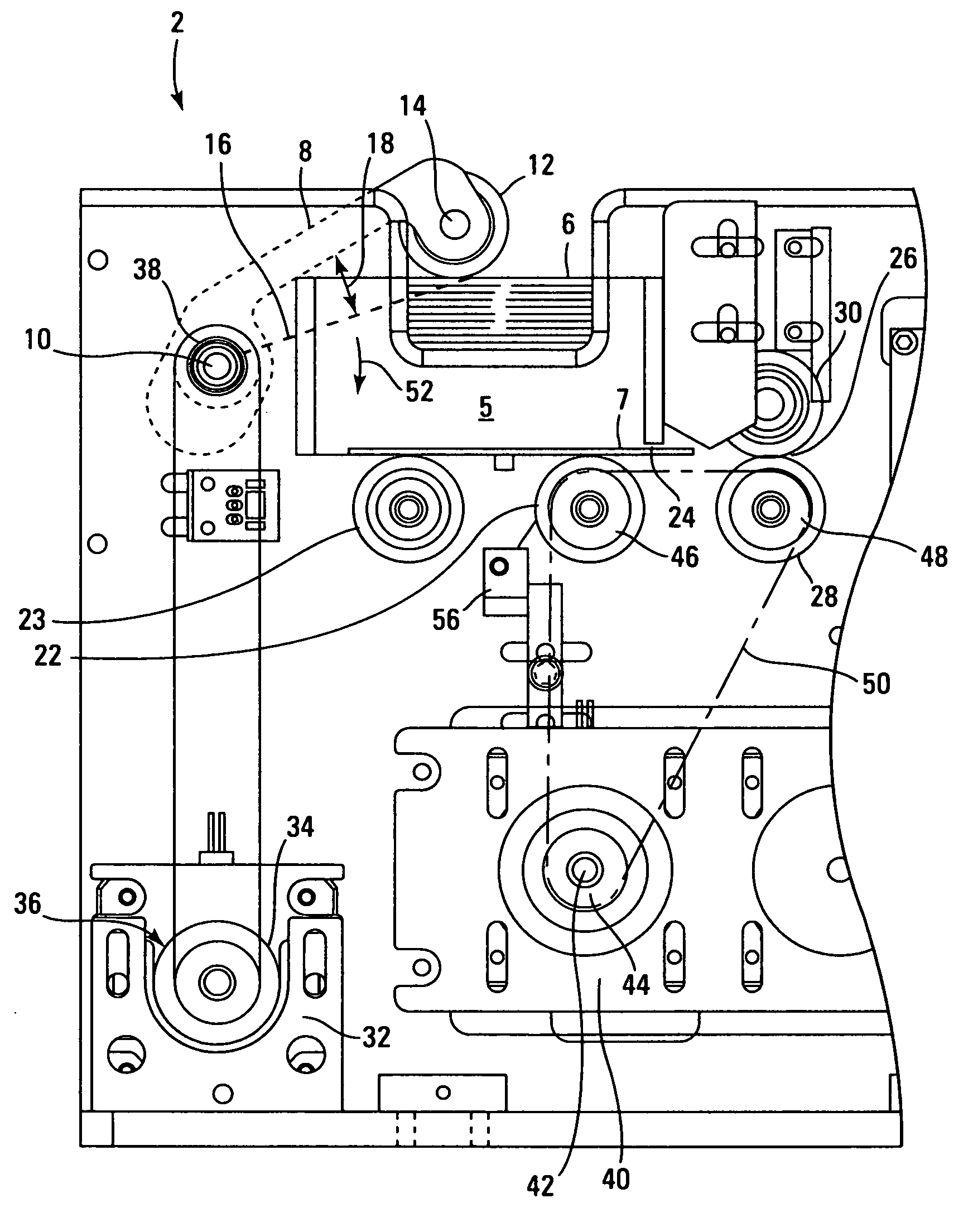

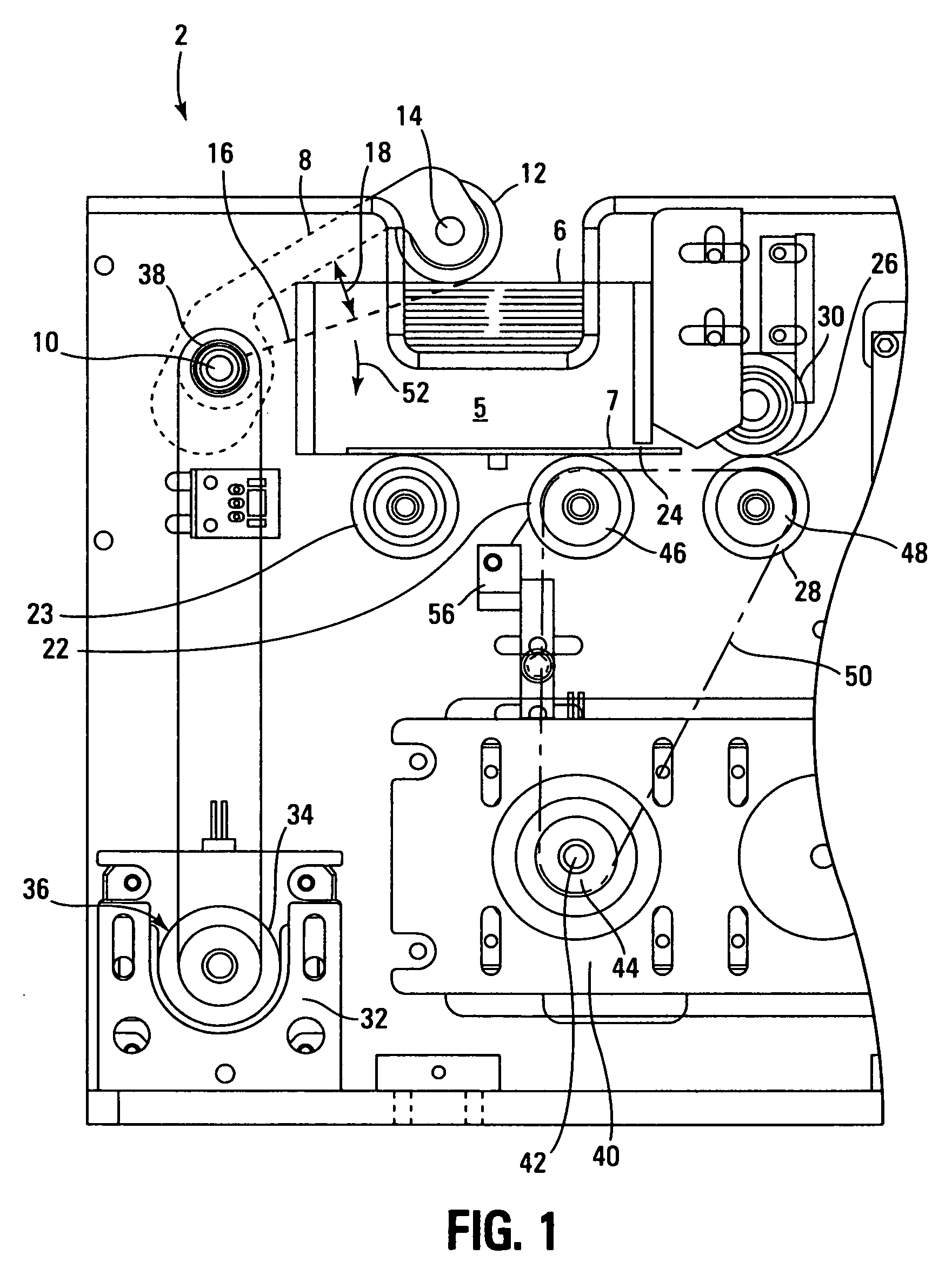

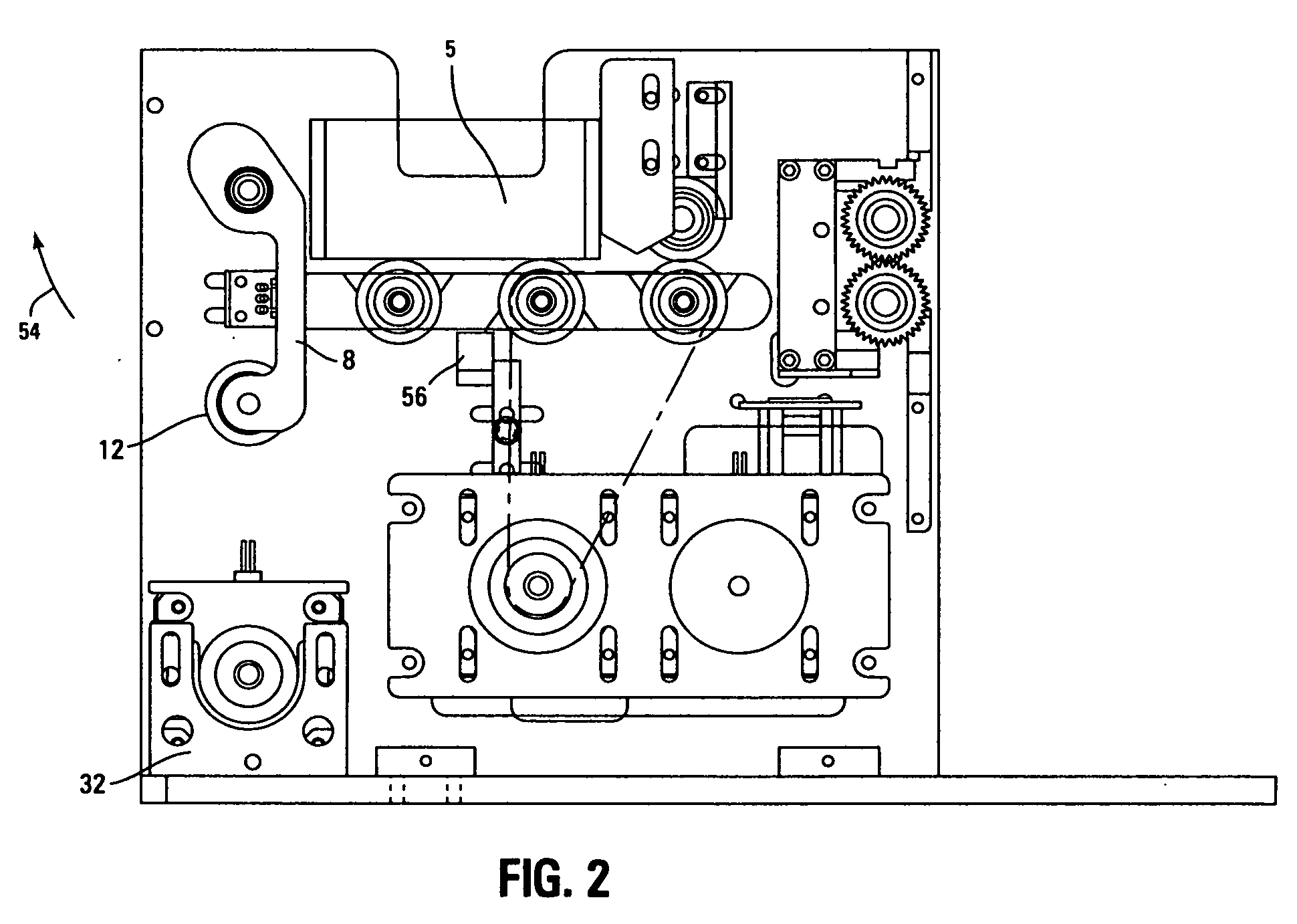

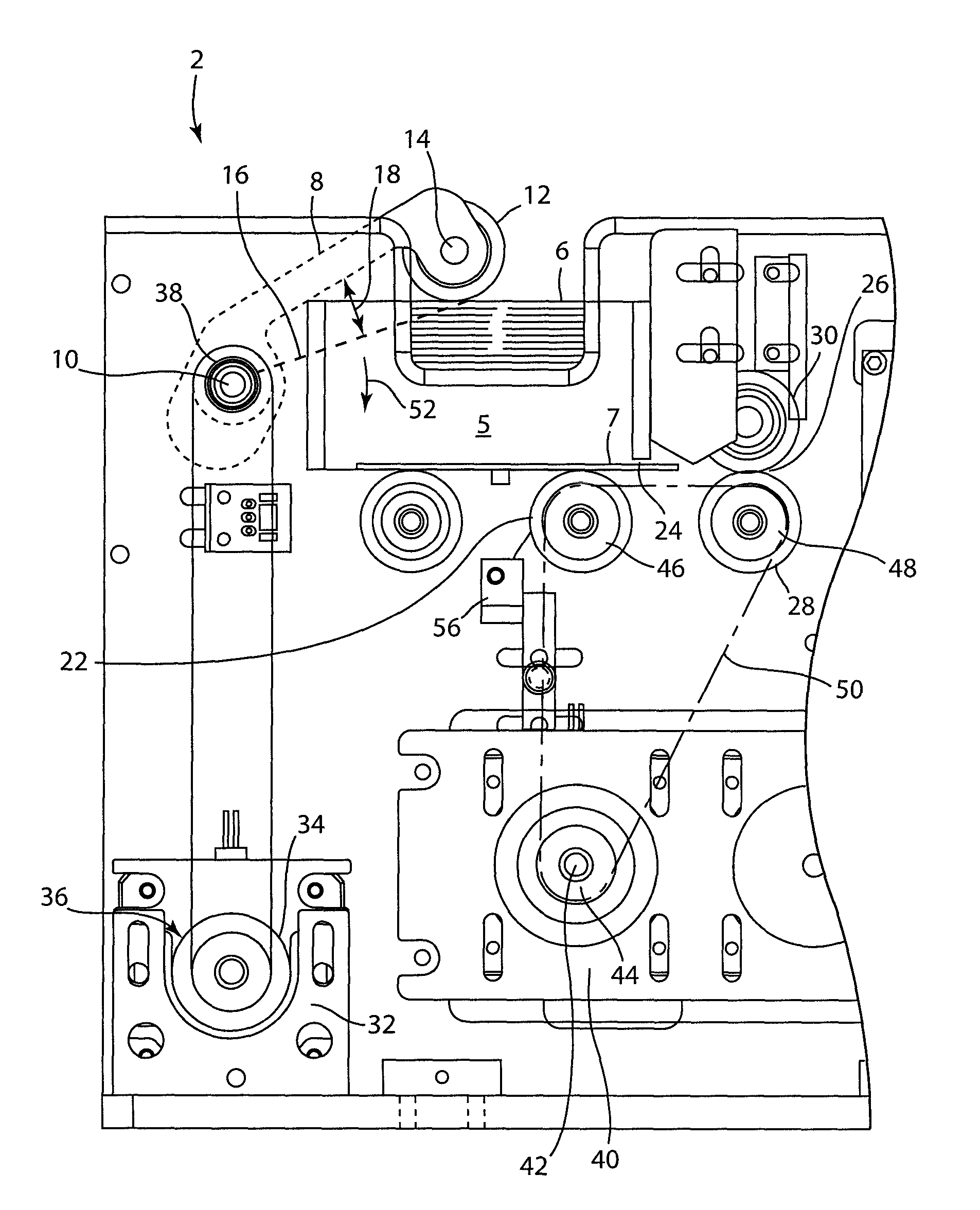

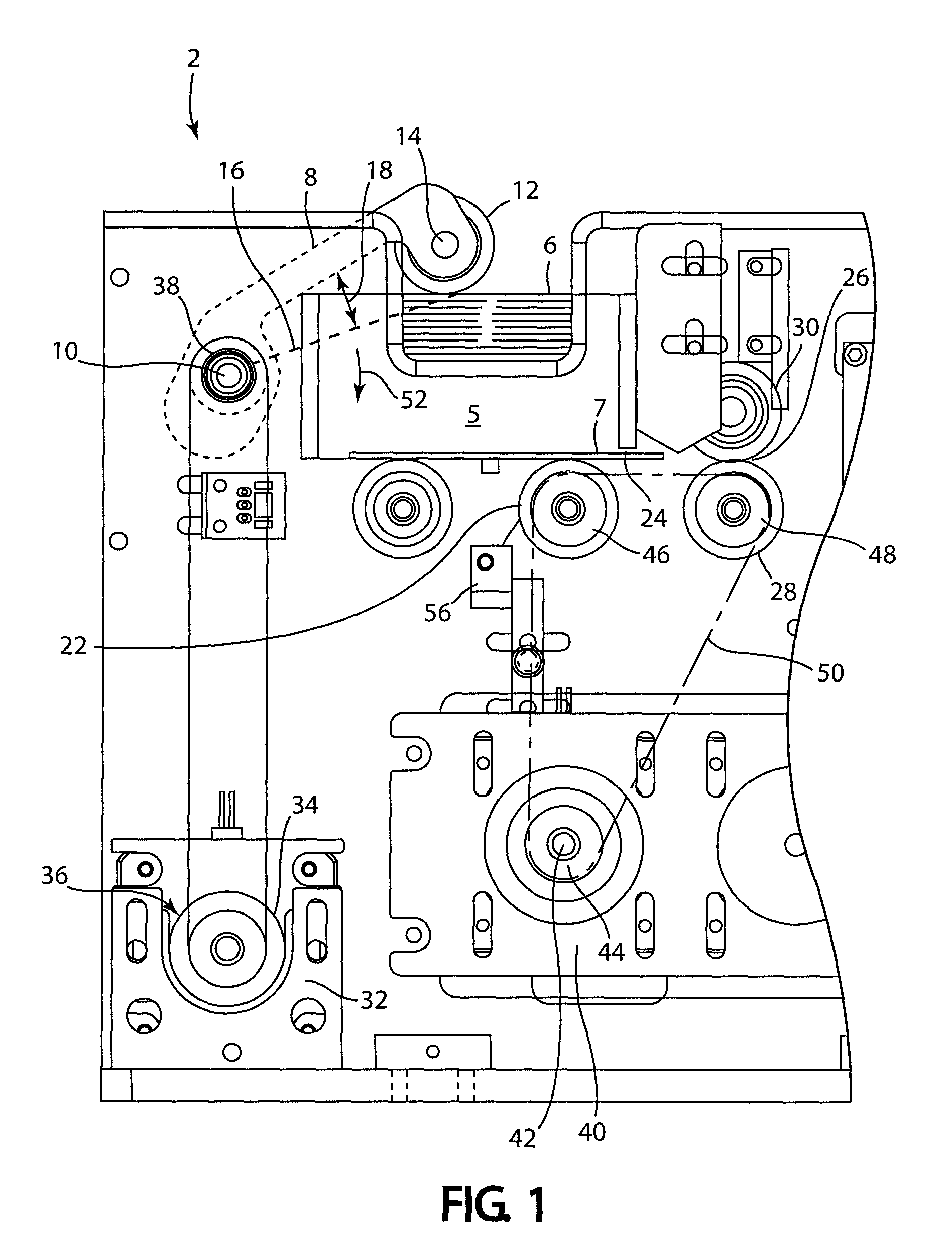

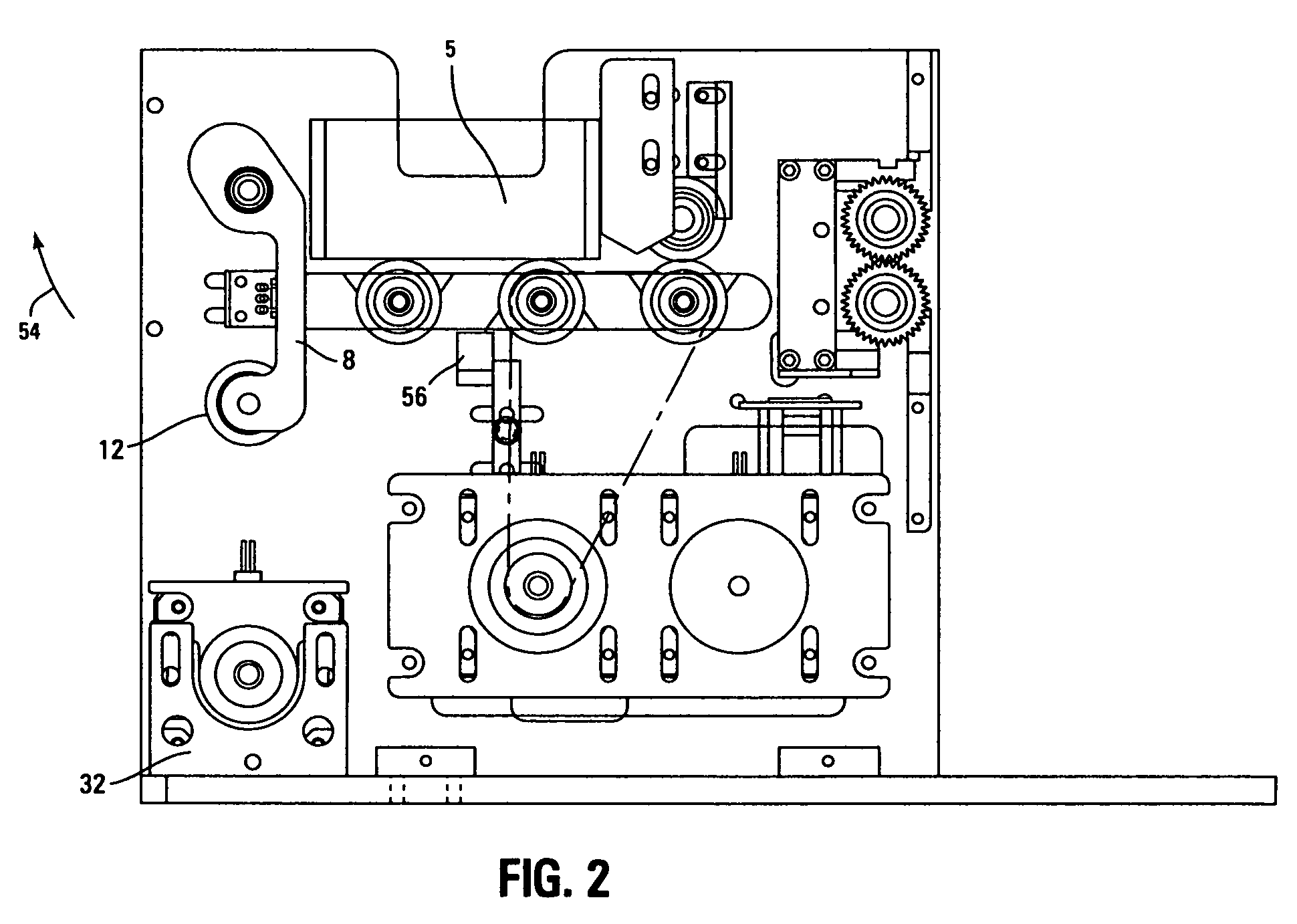

Card weight for gravity feed input for playing card shuffler

A card feeding device for feeding cards into a card handling device is disclosed. Examples of card handling devices include shufflers, card sorters, card delivery devices and card verification devices. The device includes a card infeed area that supports a stack of cards. The card infeed area has a card support surface. Included in the device is a card removing system that removes cards individually from the bottom of the stack. A pivoting arm presses against a card at the top of the stack. At least one sensor is provided that detects at least one of a position of the arm and a presence of a card in the card infeed area. A method of shuffling cards is also disclosed. The method includes the steps of providing cards to be shuffled into a card infeed area as a stack with a top and bottom and removing cards one-at-a-time from the bottom of the stack and moving the removed cards to a shuffling zone. Cards are then shuffled. The stack of cards is stabilized by a pivoting arm capable of pressing against the top of the stack in an engaged position. The pivot arm may be automatically rotated from a first card engaging position to a second recessed position.

Owner:LNW GAMING INC

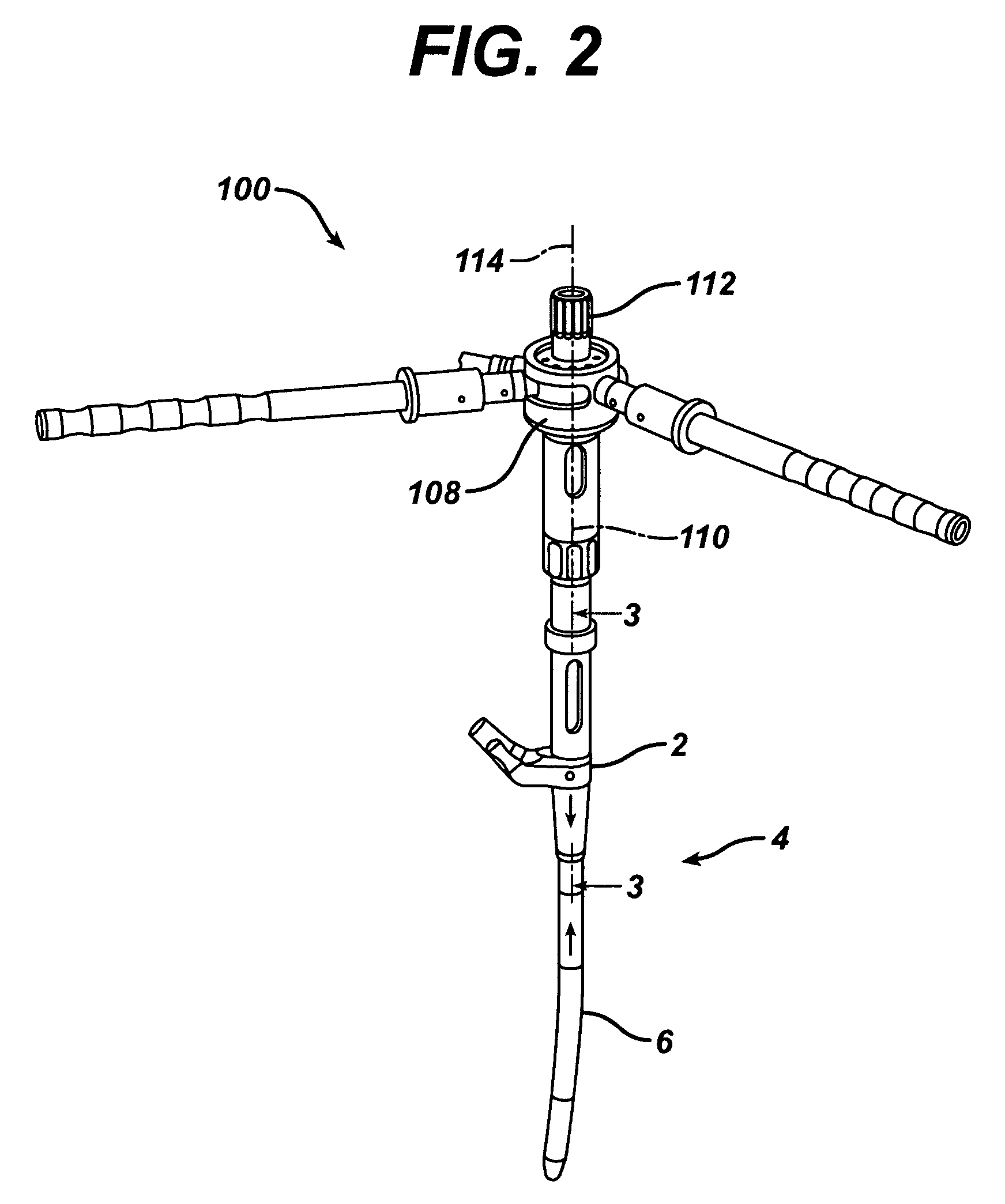

Compact operating system for automatic rifles

InactiveUS6019024AQuick and easy to disassembleQuickly and easily and and reassembledBreech mechanismsSoftware engineeringRifle

An operating system for automatic rifles is described which permits a user to easily remove and replace the bolt and bolt carrier from the rifle, without requiring the user to employ special tools. This invention permits the user to reconfigure the rifle to fire a wide range of different calibers of cartridges, as well as to reconfigure the rifle to feed ammunition from either the top or the bottom of the firearm. This invention further improves the reliability and decreases the manufacturing cost of the operating system by reducing the number of required components. This invention also provides an ergonomic, left hand sided, non-reciprocating cocking handle. The cocking handle assembly is provided with a slot cover which keeps debris from entering the interior of the rifle.

Owner:RMDI

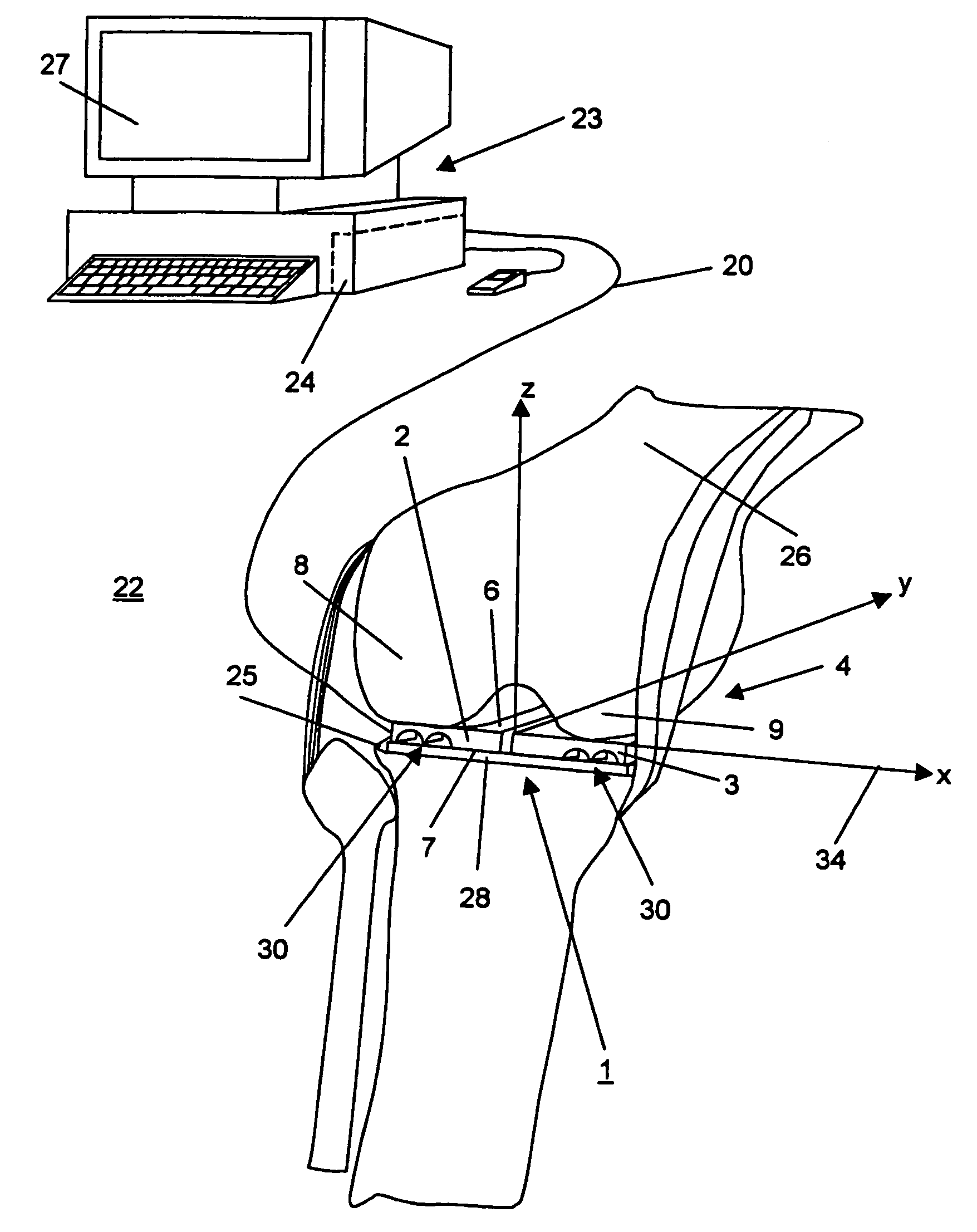

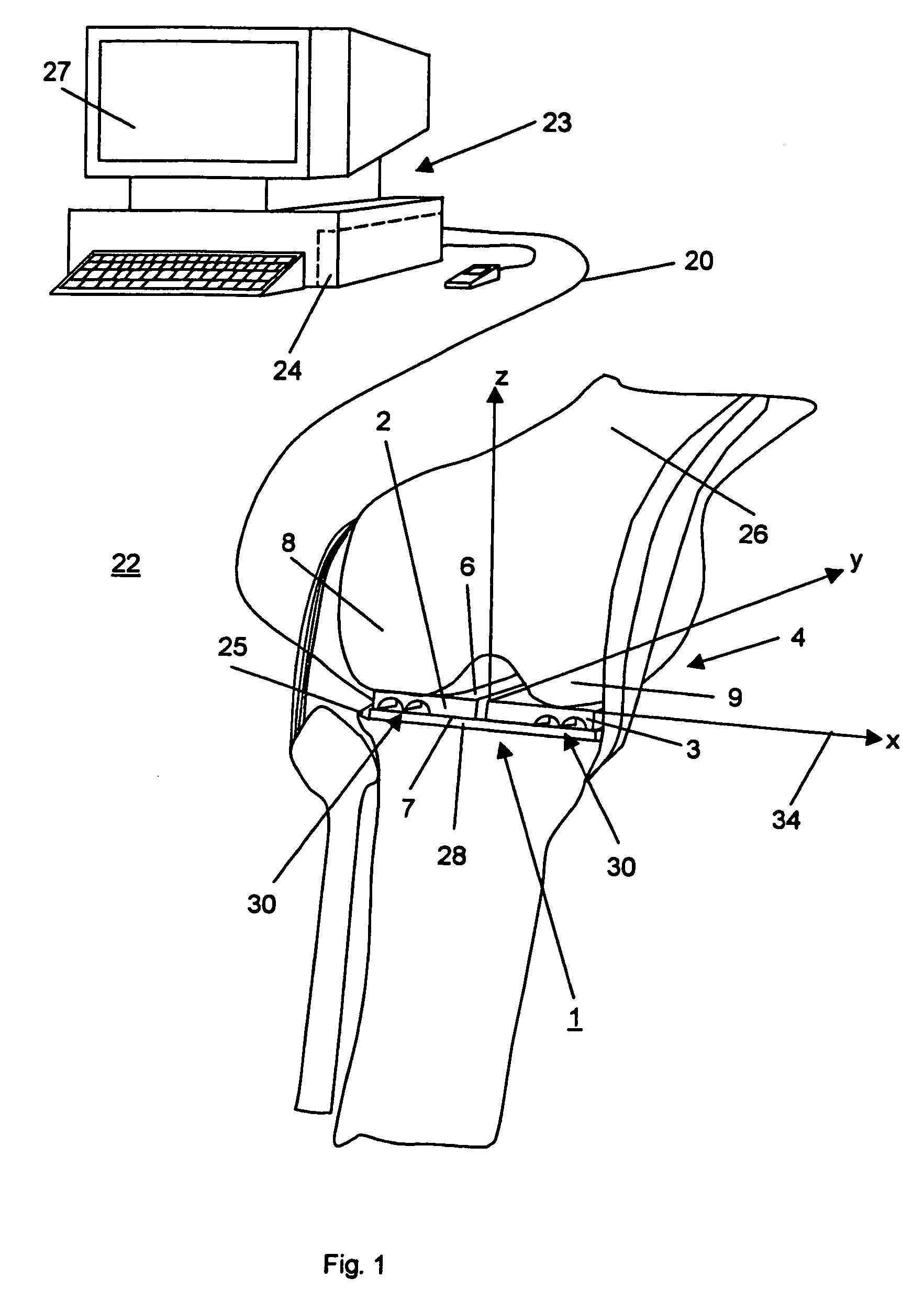

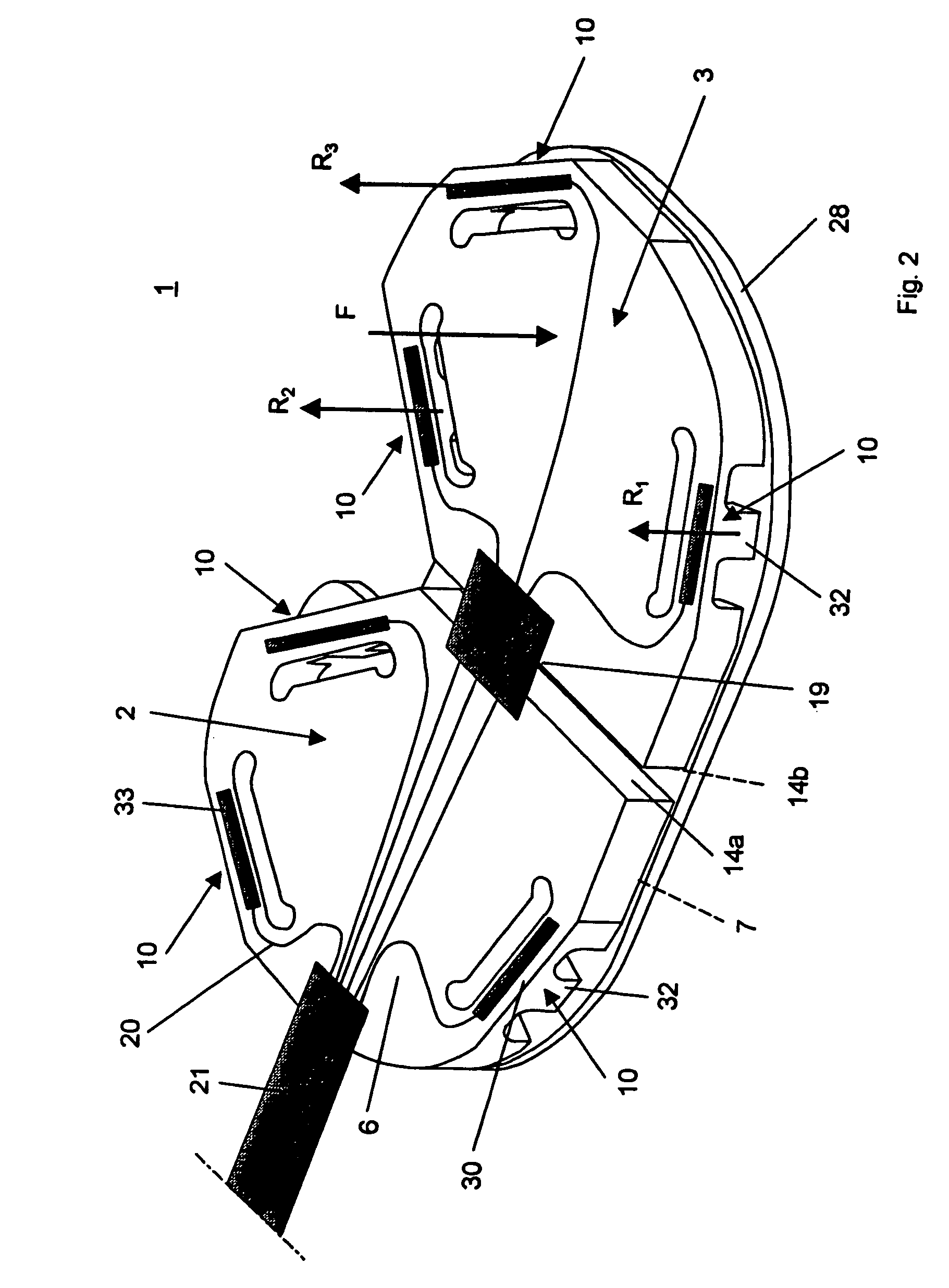

Device for measuring tibio-femoral force amplitudes and force locations in total knee arthroplasty

ActiveUS7412897B2Improve balanceImprove ergonomicsSurgeryForce measurementTotal hip arthroplastyPhysical medicine and rehabilitation

A probe used during a total knee arthroplasty for measuring forces and locations of their points of application and thereby moments includes two load sensitive plates t to be inserted in one joint-compartment of a knee joint each and each being provided with a top surface and a bottom surface. At least two load sensors may be situated on the top surfaces and / or the bottom surface of each load sensitive plate.

Owner:SYNTHES USA

Card weight for gravity feed input for playing card shuffler

ActiveUS8353513B2Reduce the overall heightImprove ergonomicsCard gamesComputer hardwareSupport surface

A card-feeding device for feeding cards into a card-handling device is disclosed. Examples of card-handling devices include shufflers, card sorters, card delivery devices and card verification devices. The device includes a card infeed area that supports a stack of cards. The card infeed area has a card support surface. Included in the device is a card-removing system that removes cards individually from the bottom of the stack. A pivoting arm presses against a card at the top of the stack. At least one sensor is provided that detects at least one of a position of the arm and a presence of a card in the card infeed area. A method of shuffling cards is also disclosed. The method includes the steps of providing cards to be shuffled into a card infeed area as a stack with a top and bottom and removing cards one at a time from the bottom of the stack and moving the removed cards to a shuffling zone. Cards are then shuffled. The stack of cards is stabilized by a pivoting arm capable of pressing against the top of the stack in an engaged position. The pivot arm may be automatically rotated from a first card-engaging position to a second recessed position.

Owner:LNW GAMING INC

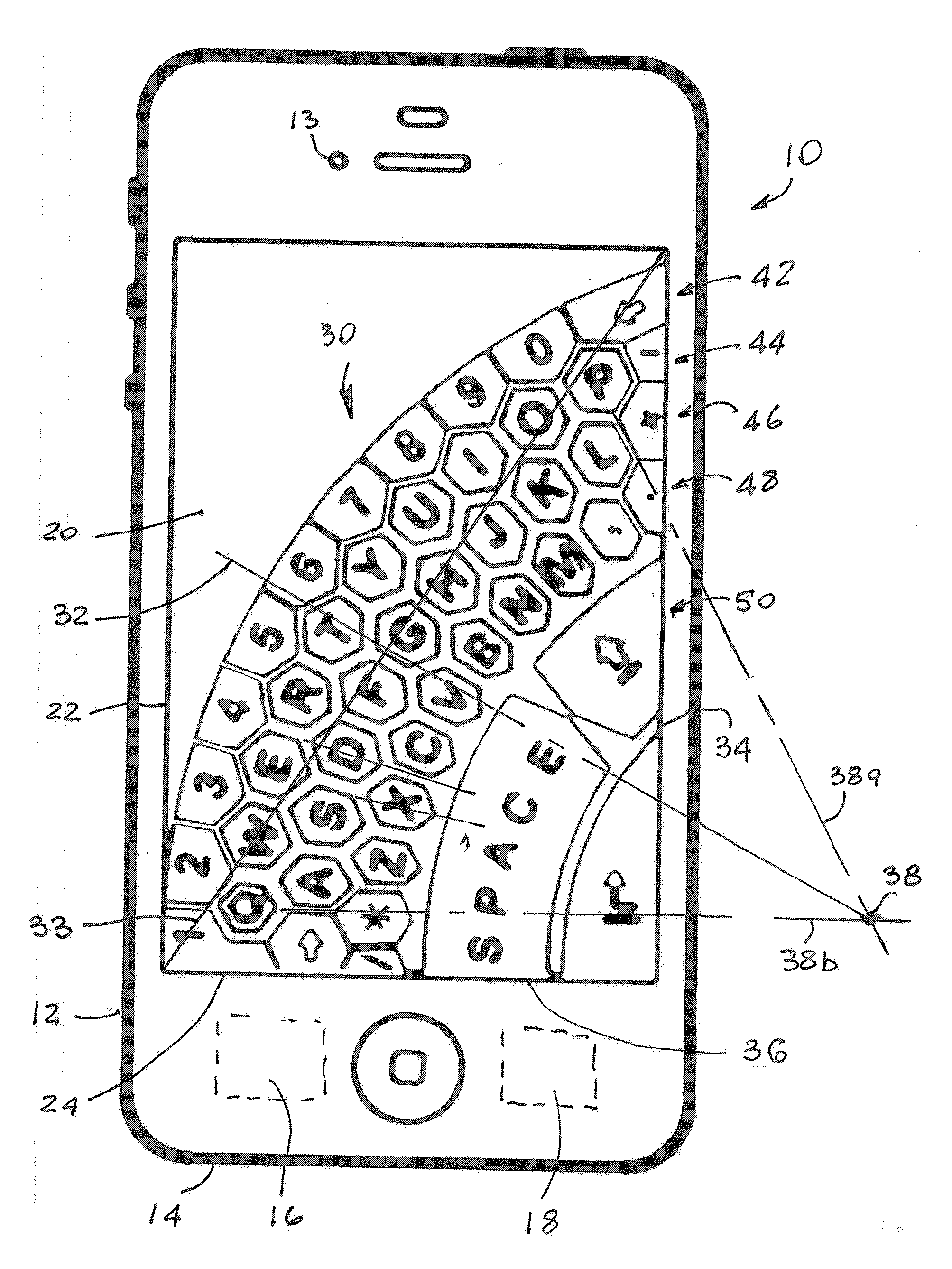

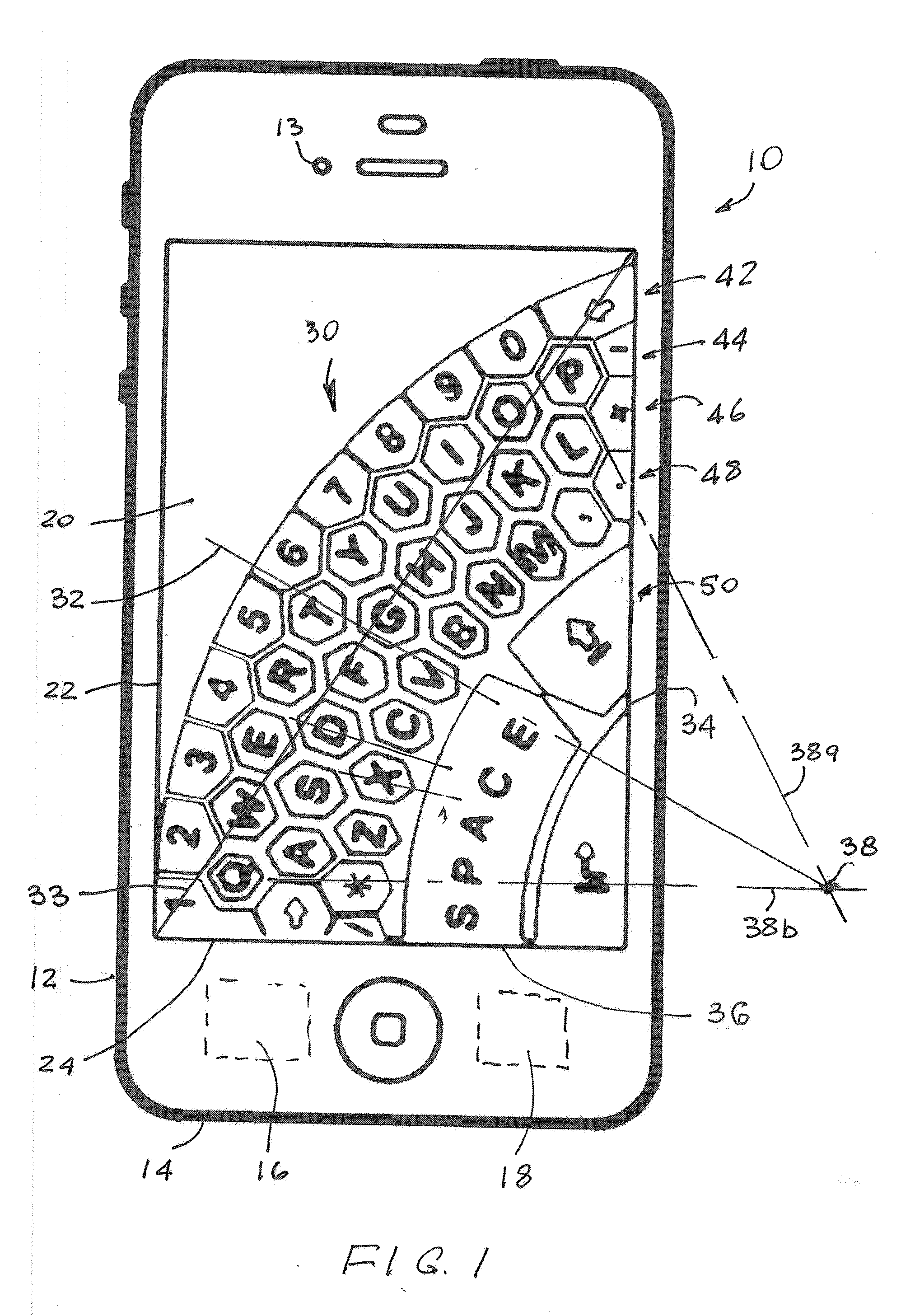

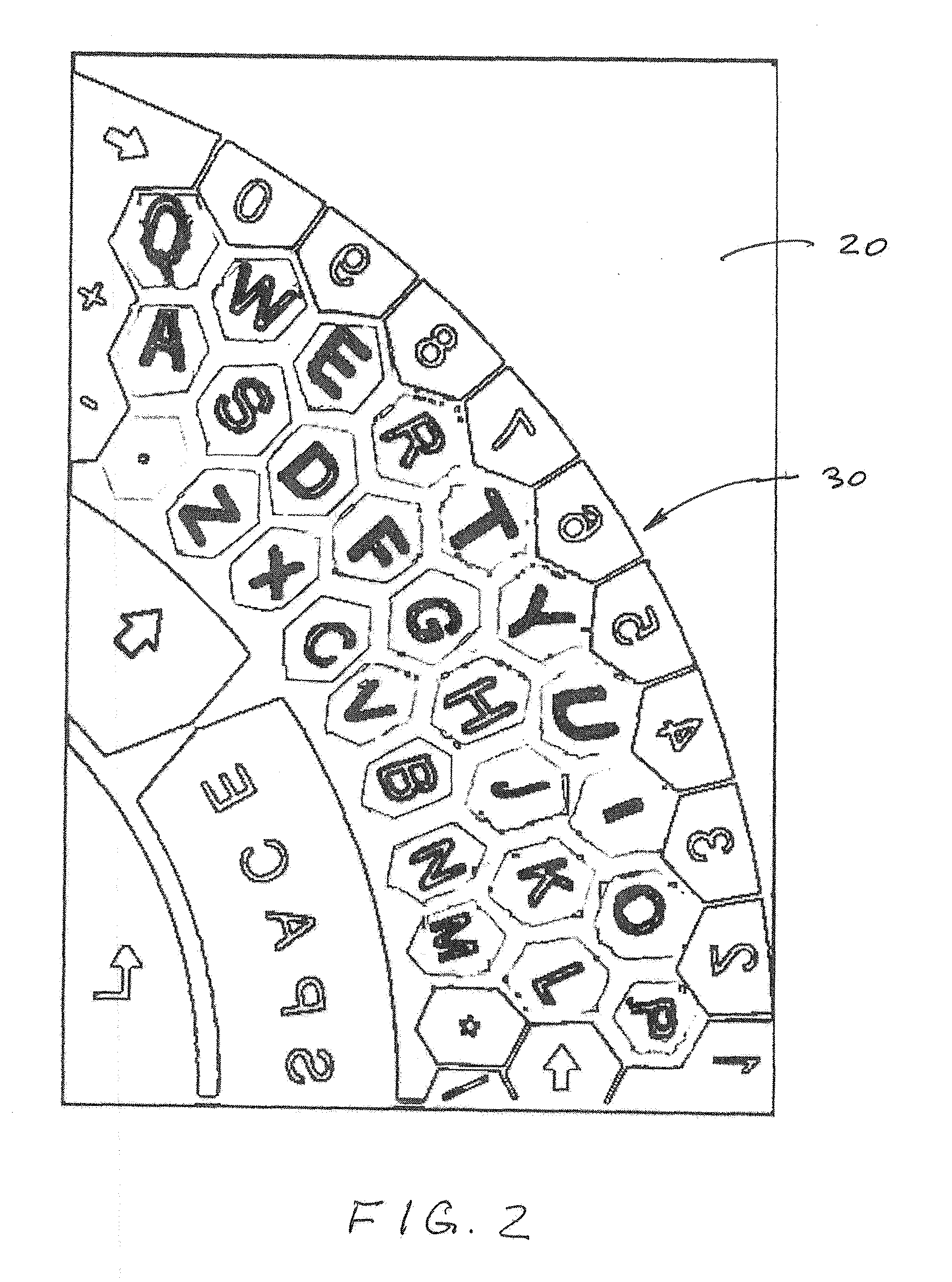

On-Screen Diagonal Keyboard

ActiveUS20130234949A1Easy to reachEasy to useInput/output for user-computer interactionCathode-ray tube indicatorsDiagonalSharp angle

Owner:CHORNENKY TODD E

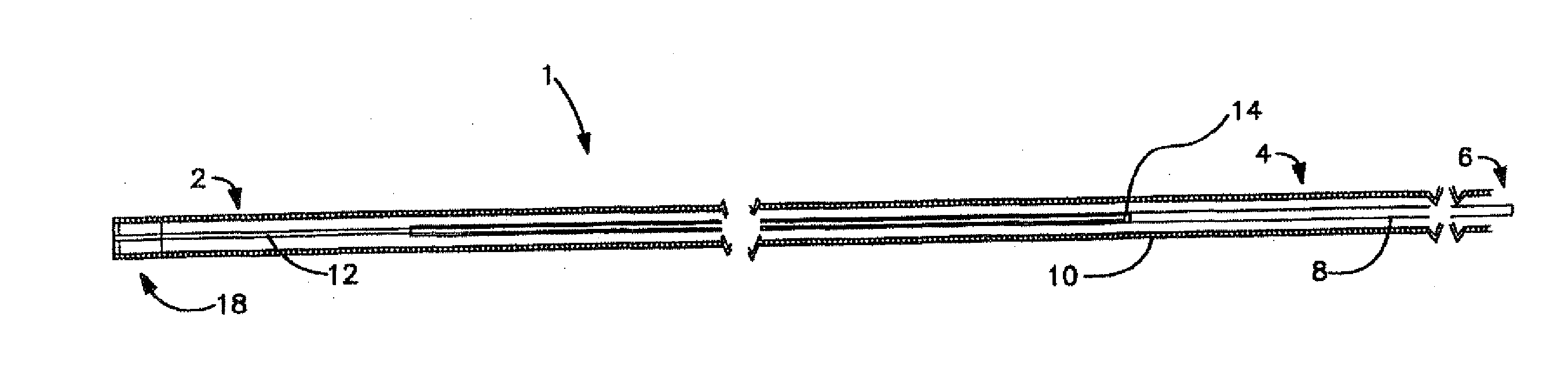

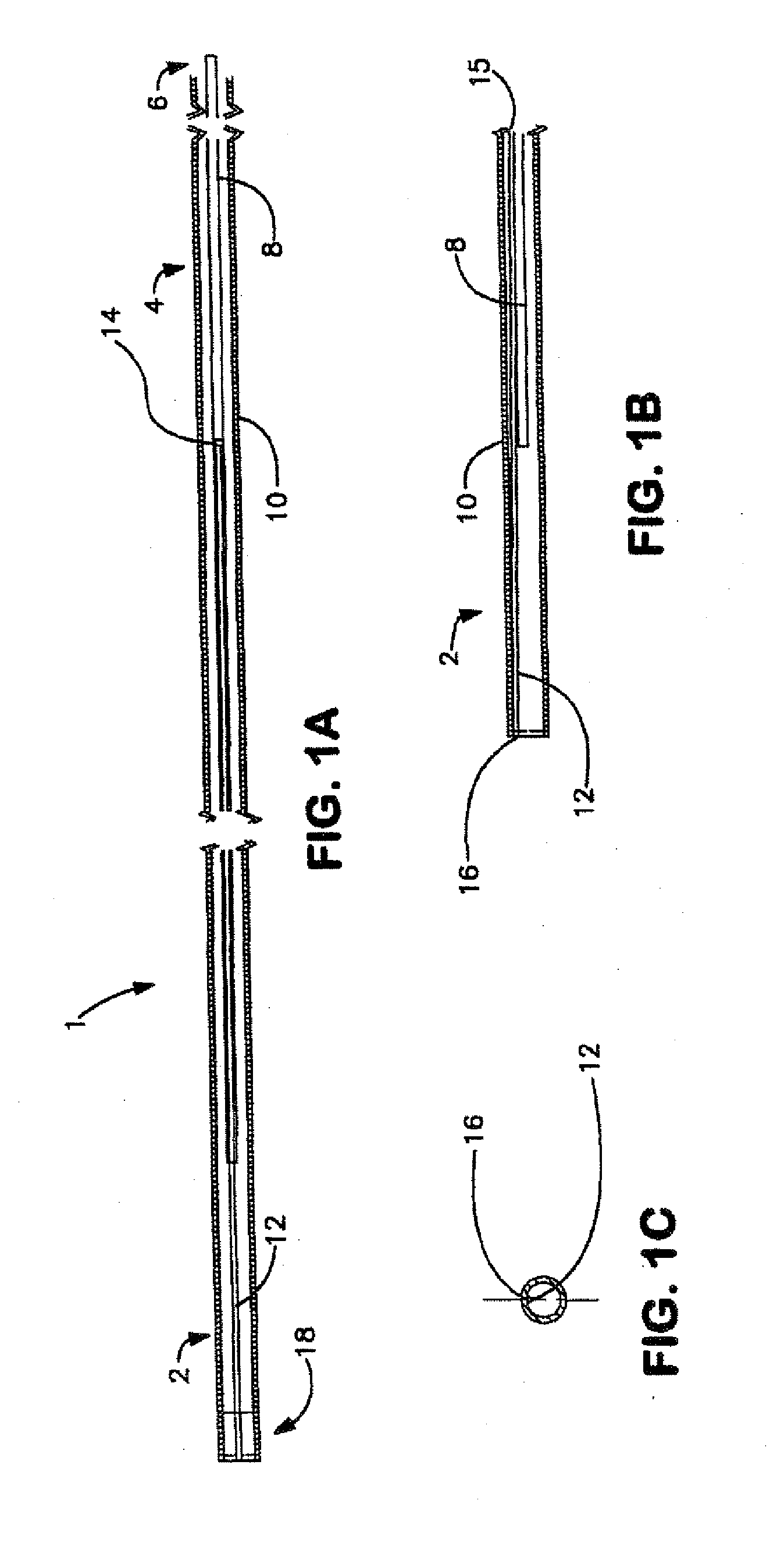

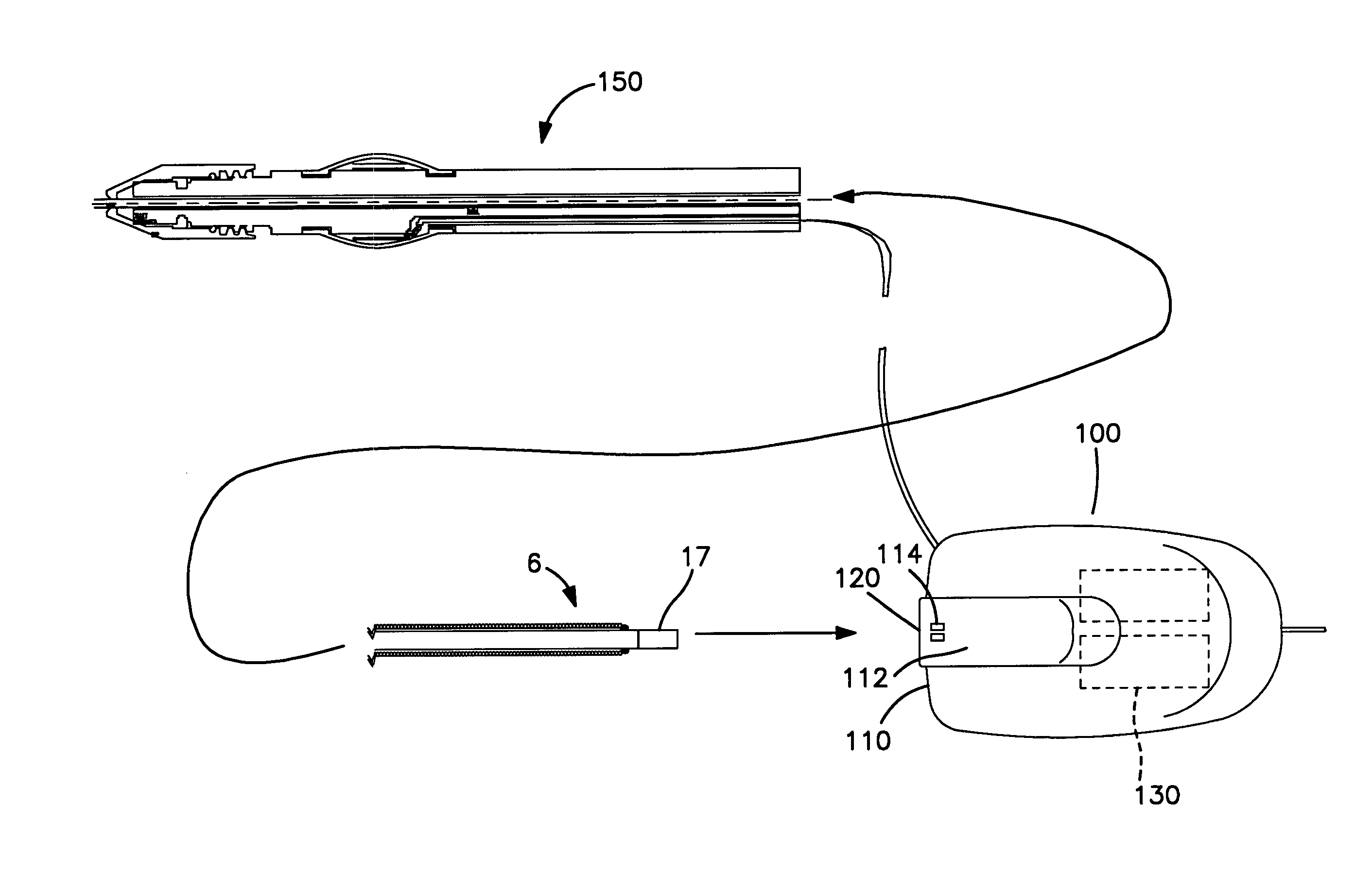

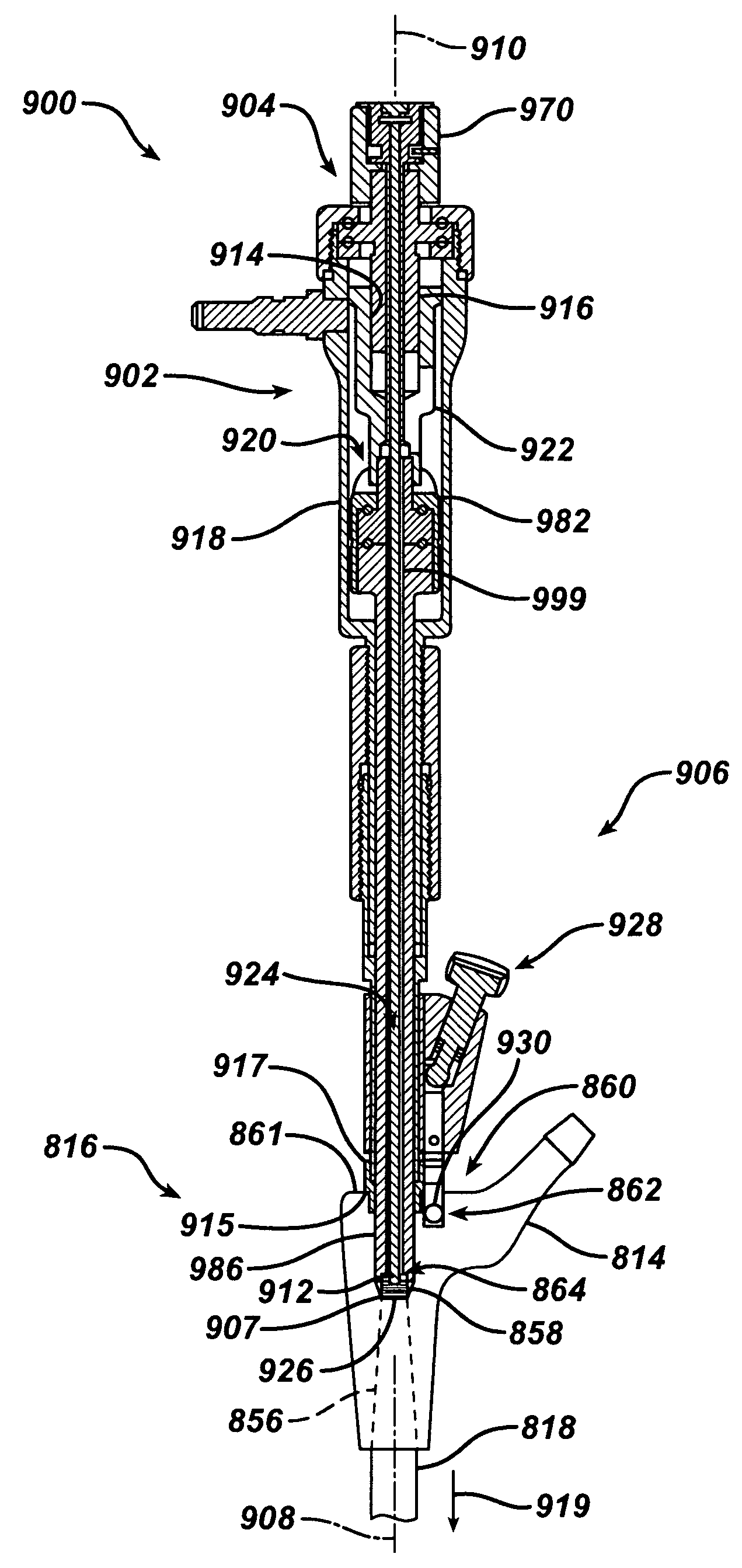

Vascular guidewire control apparatus

ActiveUS20120271198A1Shorten the timeSaving of other resourceGuide wiresDiagnostic recording/measuringEngineeringControl theory

A controller for use with a guidewire, such as a vascular guidewire, provides a mechanism for gripping and applying a torque to the guidewire without the need to thread the guidewire axially through the controller and at a location close to a point of access of the guidewire. In one embodiment, the controller includes a side-access, multi-part assembly including a collet or other gripping element that applies a uniform radially inward force on the guidewire. In another embodiment, for use with guidewires having active electrically controllable elements, the controller integrally or removably incorporates a switch or other mechanism to initiate an energized state. The controller thereby permits ergonomic, single-handed control of an electronically steerable guidewire, including axially displacing, torquing and steering the guidewire.

Owner:THE CLEVELAND CLINIC FOUND

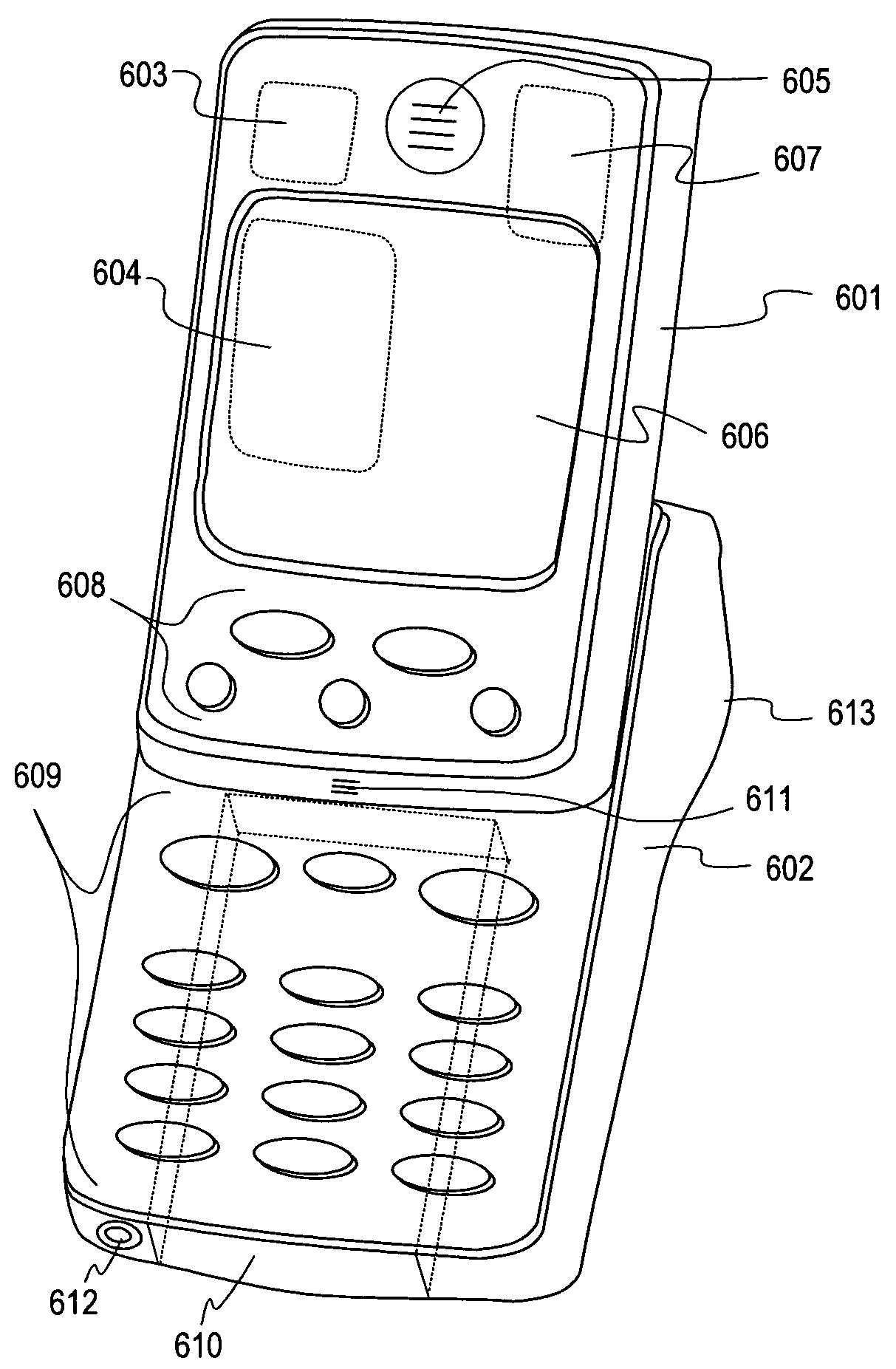

Telescopic telephone

InactiveUS6961593B1Easy to useImprove ergonomicsCordless telephonesDevices with multiple keyboard unitsRadiotransmitterEngineering

A telephone including a first part and a second part attached thereto, the second part being movable in relation to the first part between a first position and a second position. The telephone further includes in the first part a radio transmitter / receiver and a connected antenna, and in the second part an arrangement for attaching the battery to the second part.

Owner:NOKIA TECHNOLOGLES OY

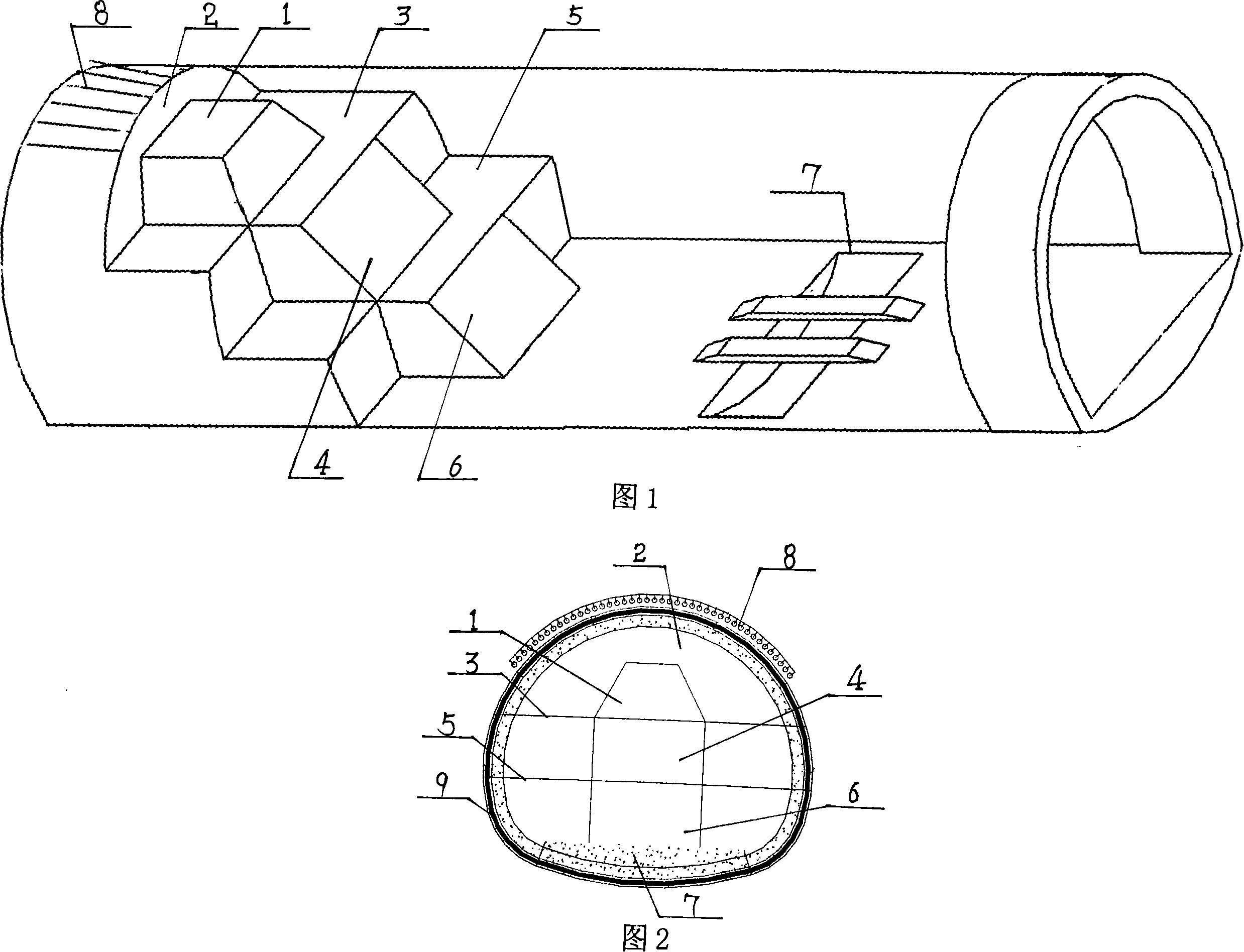

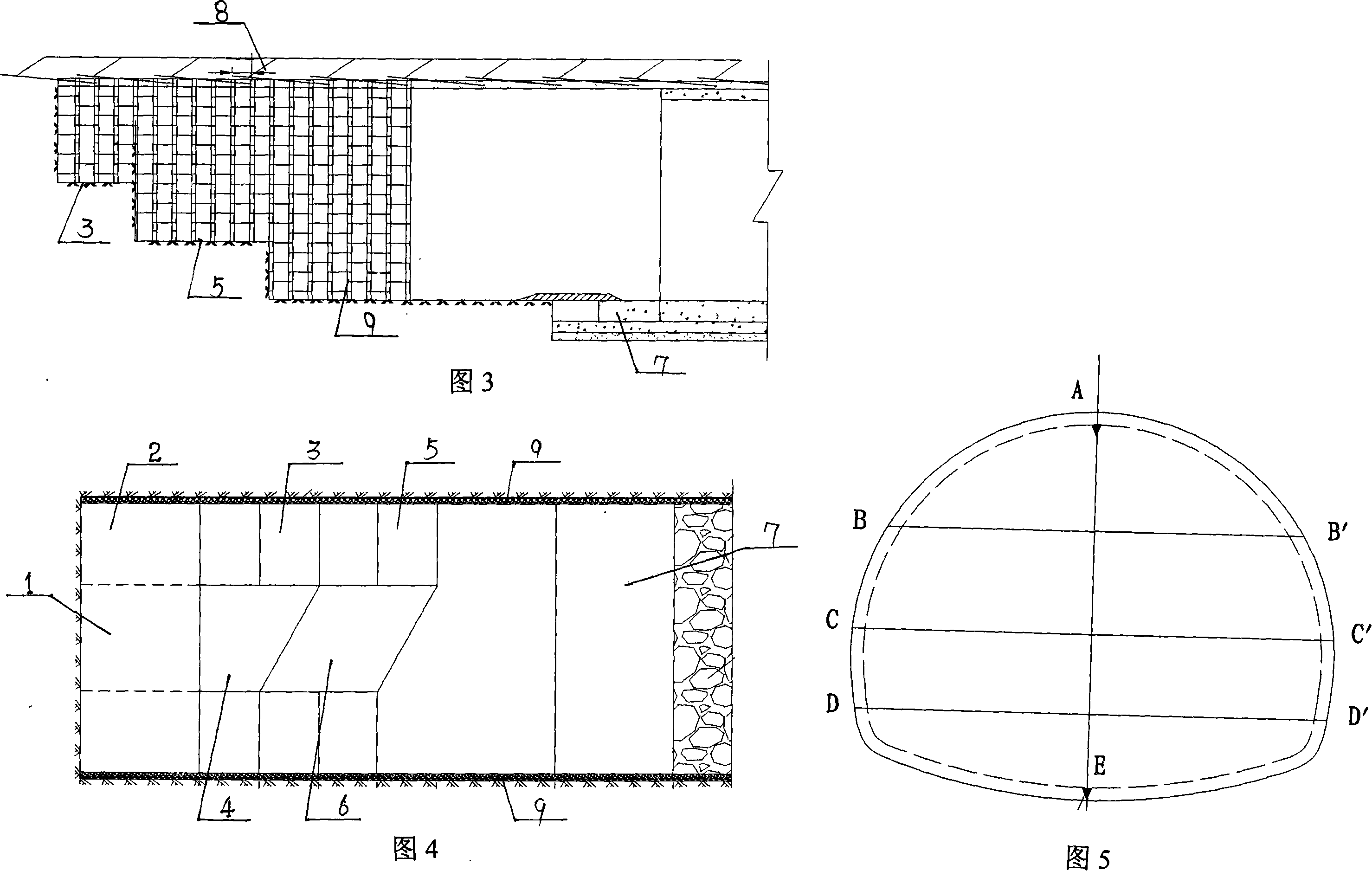

Tunnel dredging method suitable for railway large section IV, V class rock tunnel

ActiveCN101105131ASimple and fast operationLarge construction spaceUnderground chambersTunnel liningRailway tunnelRock tunnel

The invention relates to the technical field of railway tunnel construction, specifically a digging method of IV and V-class surrounding rock railway tunnel with large cross section, aiming to solve the problems of the existing railway tunnel digging method including narrow operation space, low work efficiency, inflexible construction method, instable construction progress, high deformation potential of surrounding rock, and inconvenient operation. The method comprises performing leading support, digging arc-shaped pilot tunnel and preserving core soil; staggeredly digging left / right side walls of middle sidestep and preserving core soil; staggeredly digging left / right side walls of lower sidestep and preserving core soil; sequentially digging upper, middle and lower sidesteps and preserving core soil; and digging inverted arch and carrying out preliminary support. The invention has large construction space and high work efficiency, and can perform multi-job parallel operation. When the geologic conditions are changed, the invention can be flexibly and timely converted to other construction method. Preservation of core soil and left / right staggeredly digging are helpful to the stability of the digging working face. When the surrounding rock has large deformation, the invention can adjust closure time as soon as possible under the prerequisite of assuring safety and meeting requirements of clearance cross section.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Flexible ceramic wear-resistant heat-proof dual-anticorrosive coating

InactiveCN1528844AIncreasing the thicknessReduce the probability of water seepageAnti-corrosive paintsEpoxy resin coatingsCoated surfaceSaline water

The invention is a kind of flexible ceram wearing and heat resisting heavy corrosion preventing paint, which is made up of epoxy resin and several kinds of ceram powder, rust-protection paint and firming agent, the weights of each ingredient are: (1) epoxy resin: 100; (2) additive: 50-120; (3) rust protection paint: 8-25; (4) ceram powder: 100-200; (5) compound solvent: 40-70; paint: firming agent=(35-50):1. The paint needn't base coat, it can be painted directly or brushed on the surface of metal under normal temperature, it has excellent wearing and corrosion prevention performance, impact resisting performance and flexibility, it can insulate acid, alkali, salt, saline water. The surface is smooth; it can be applied to oil pipe, oil pot, and chemical device, ship, wheel vane, pump, dust catcher, etc.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

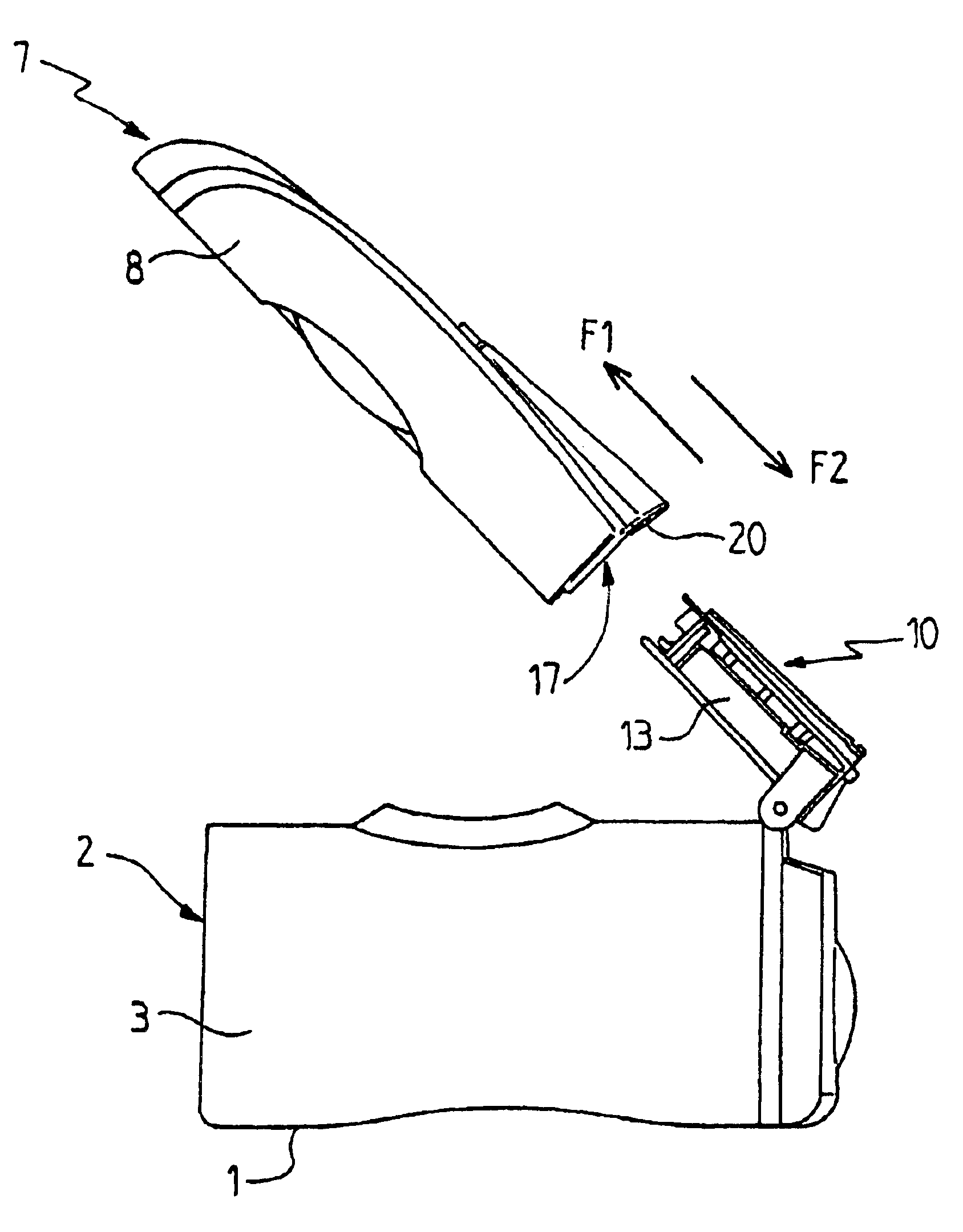

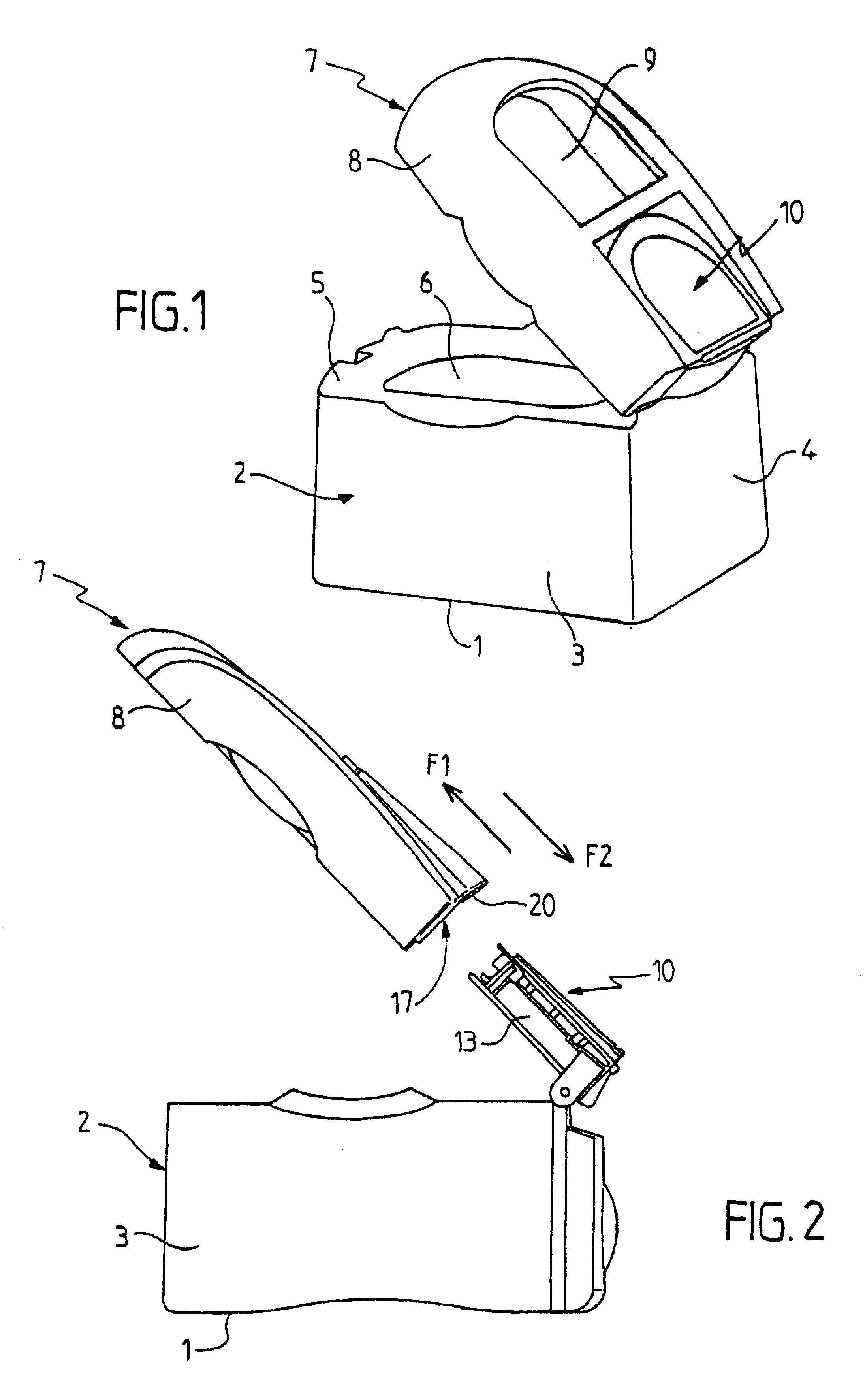

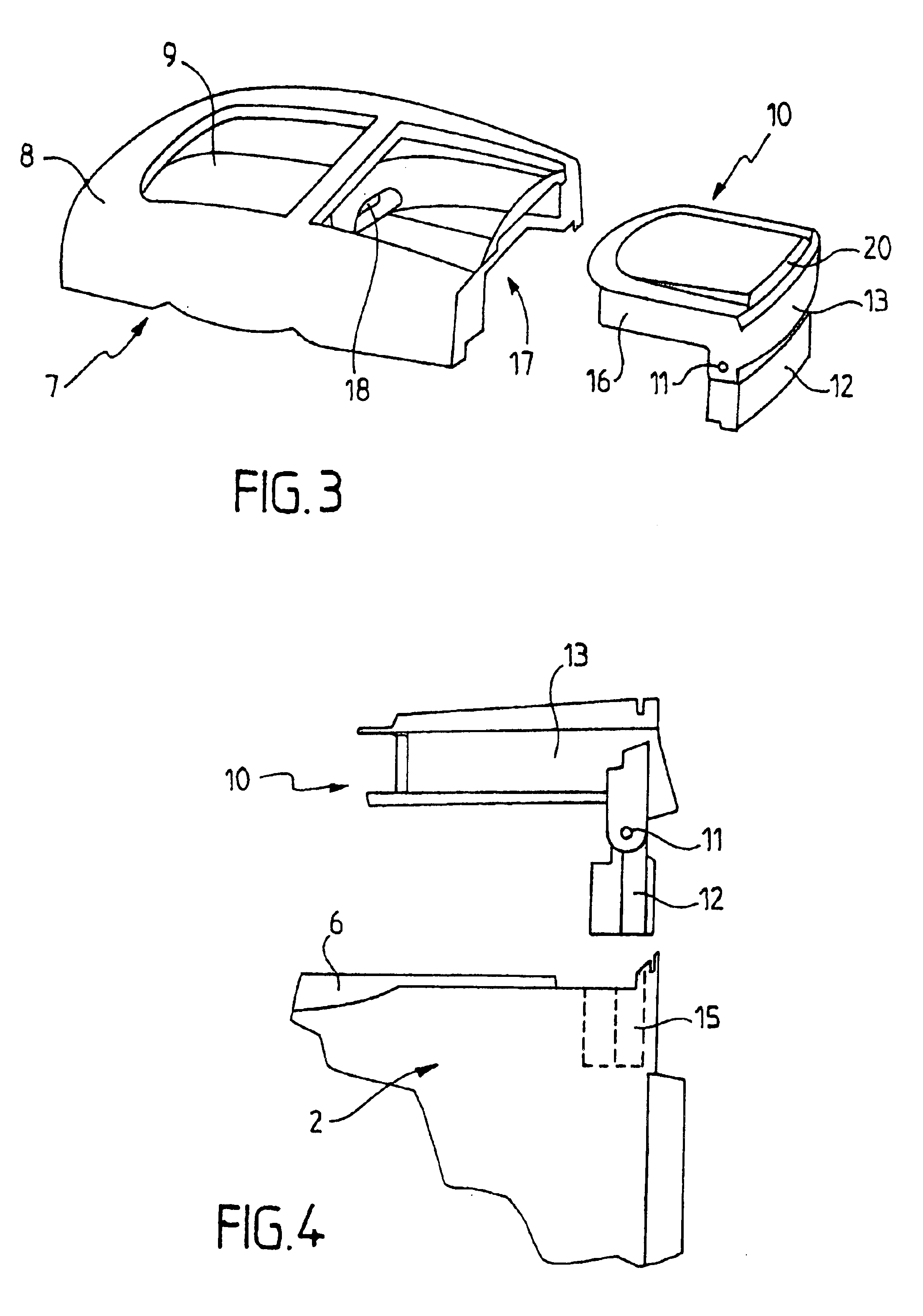

Cooking appliance having a lid that is separable from the filter device

A food-cooking appliance having a main body in which a cooking bowl (6) is mounted and a lid (7) removably mounted to the main body and designed to close the main body in a substantially airtight manner during cooking. The food-cooking appliance also includes odor treatment means (10) for treating cooking odors, which means are associated with the lid (7), and heater means. The lid (7) is removably mounted to be removable from the main body and from the cooking odor treatment means (10) so as to be separable simultaneously from the main body and from the odor treatment means (10).

Owner:SEB SA

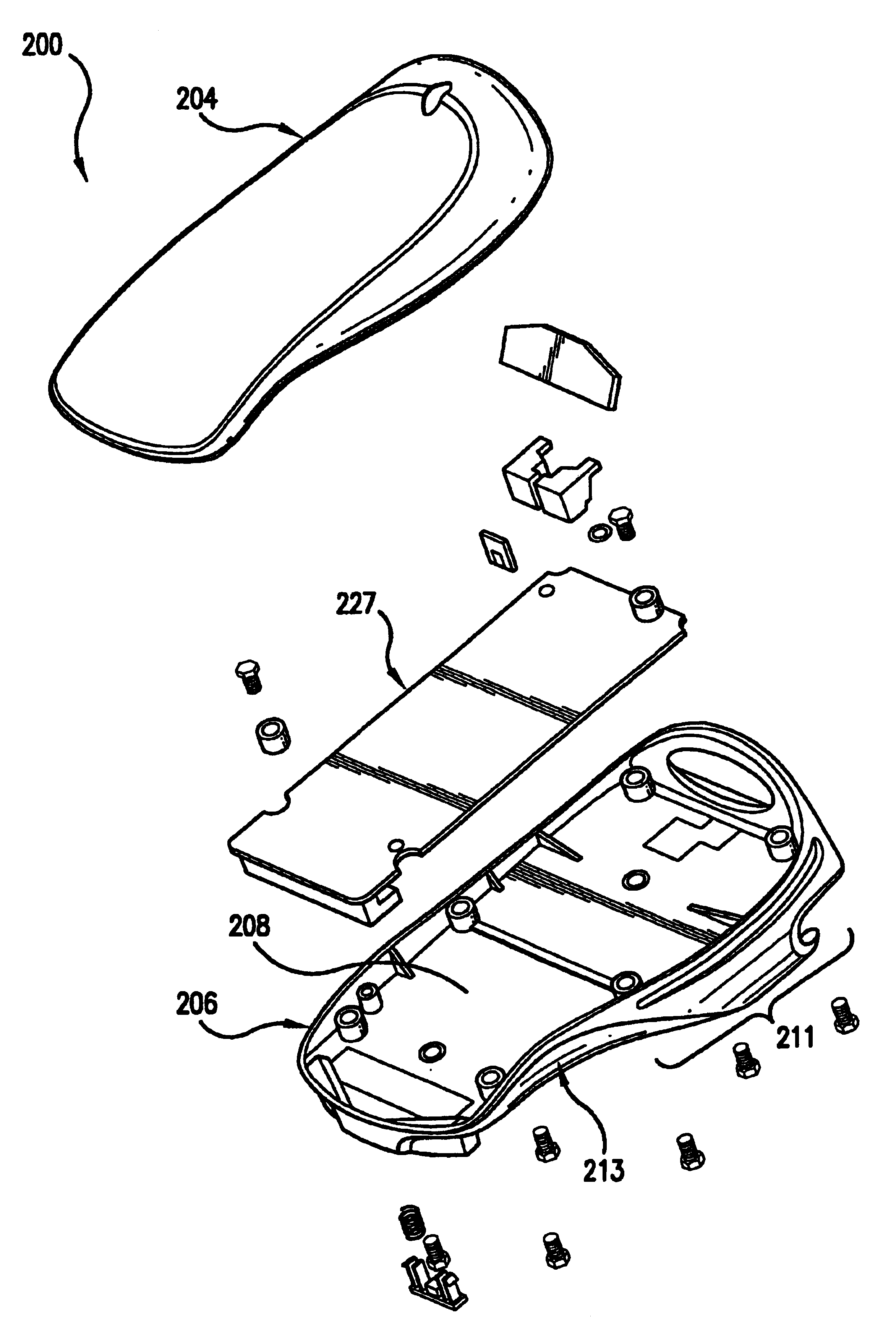

Adapter unit having a handle grip for a personal digital assistant

InactiveUS6837435B2Increased mechanical robustnessEasy to slideElectrolytic capacitorsDigital data processing detailsEngineering

The present invention relates generally to an adapter unit for a personal digital assistant. More specifically, this invention relates to an adapter unit that has a handle grip. The adapter unit provides additional functionality, and improved ergonomics and increased ruggedness to the personal digital assistant.

Owner:SYMBOL TECH LLC

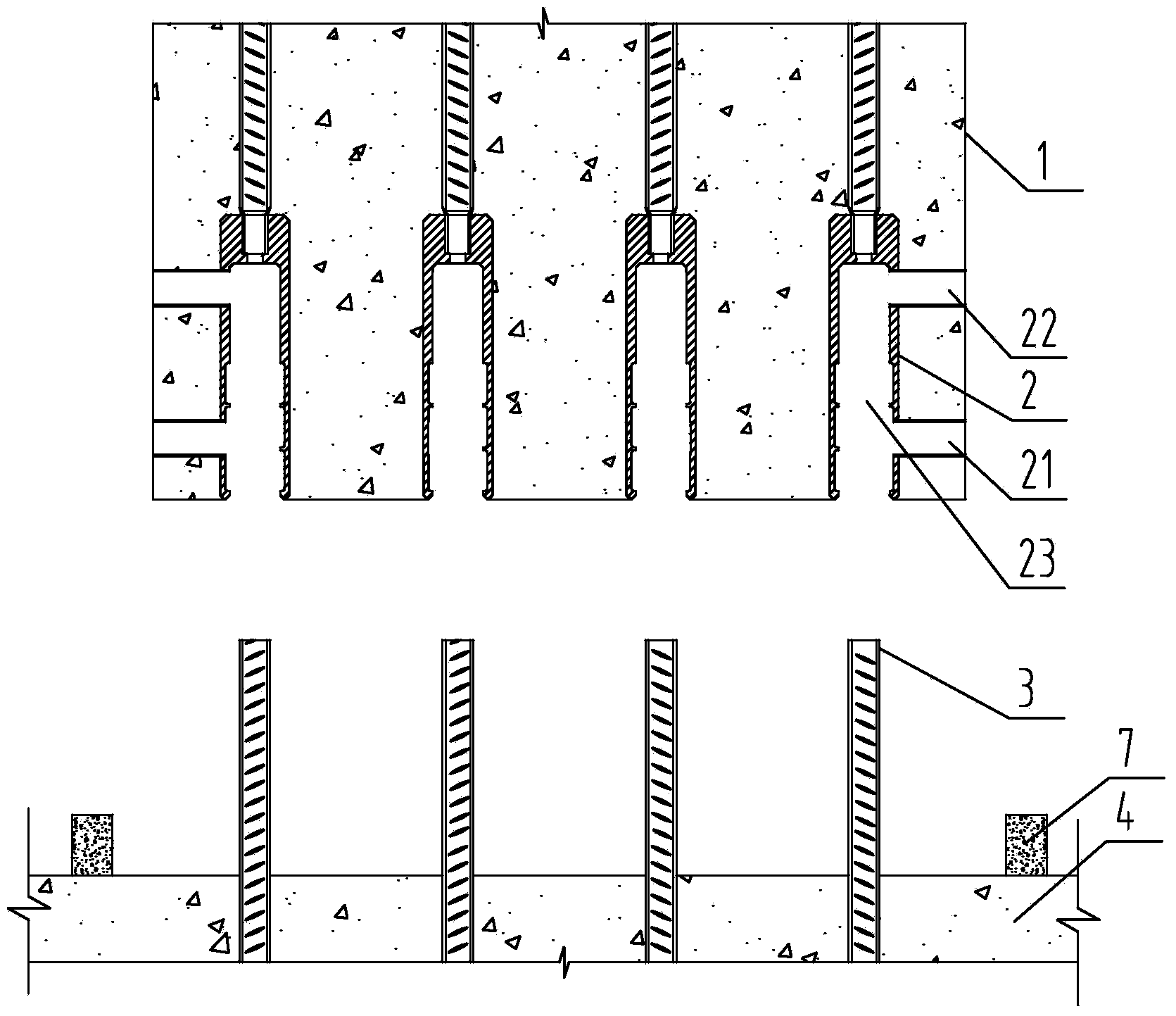

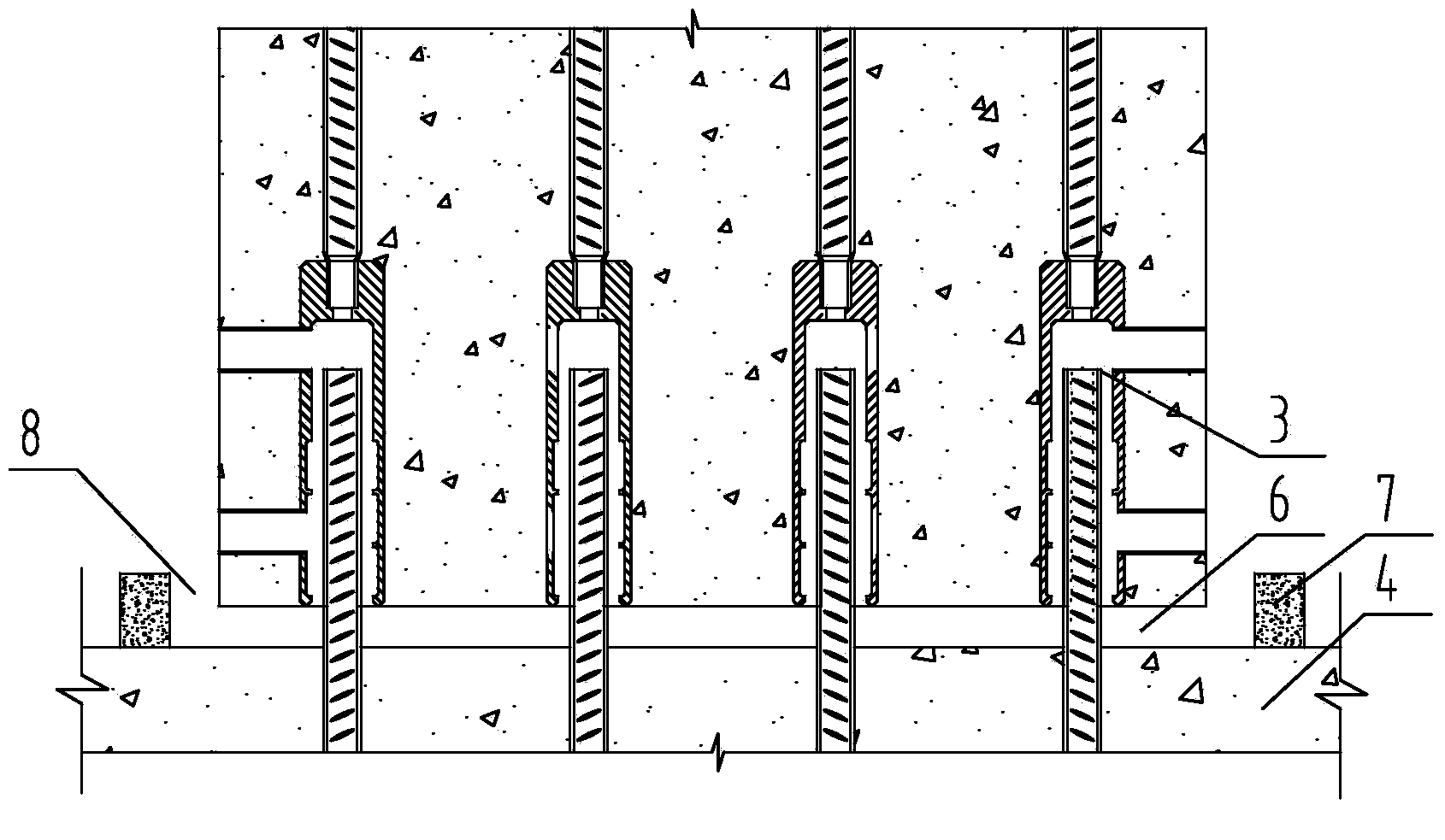

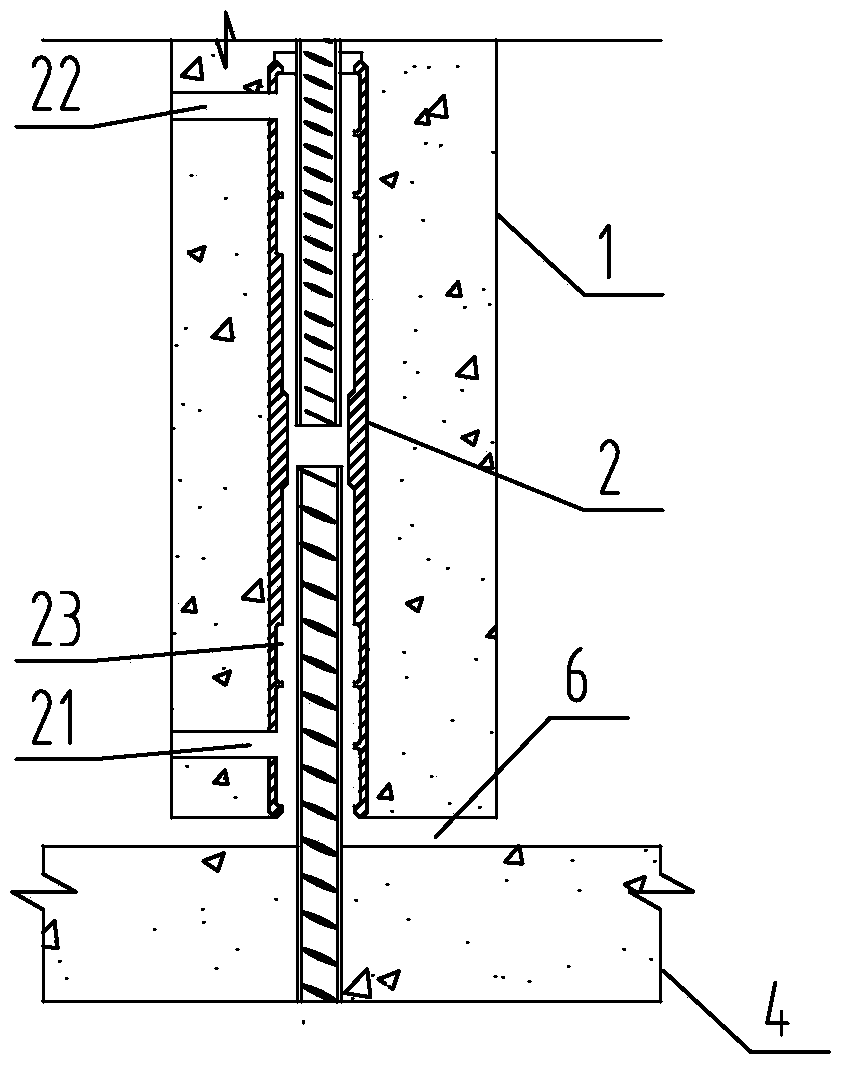

Grouting connection construction method

ActiveCN104314314AFast constructionImprove efficiencyBuilding reinforcementsBuilding material handlingRebarPrecast concrete

The invention discloses a grouting connection construction method which is used for connecting vertical reinforcements of an assembled concrete structure. The grouting connection construction method includes the steps: firstly, embedding a plurality of grouting connection devices at one end of a precast concrete unit to be connected in advance; secondly, lifting the precast concrete unit and then manufacturing a grouting box dam; thirdly, grouting horizontal gaps and then grouting the grouting connection devices. The grouting connection devices are connected with connection reinforcements extending out of a lower unit. Plugging grouting of the horizontal gaps and grouting of the grouting connection devices can be performed within the same day, so that the mounting efficiency of the precast concrete unit is greatly improved, the grouting connection construction method can be implemented in a subzero temperature environment even in winter, construction difficulty is reduced, and working efficiency is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Flexible display device and computer with sensors and control approaches

InactiveUS20160014403A1Brighter presentationQuality improvementDigital data processing detailsColor television detailsDisplay deviceData memory

Embodiments of a flexible electronic visual display device and a flexible mobile computer having such a display device are disclosed. The basic electronic visual display device comprises a flexible display device, at least one control system, at least one three-dimensional sensor, a flexible housing containing the electronic components, and an adjustment means for the housing. In some embodiments, the flexible display device can have additonal sensors of various types, a projector, a wireless communication interface, and a wireless power supply. For independent use some embodiments of the flexible electronic visual display device can also comprise an electronic module including at least one processor and at least one data memory, and also at least one electrical energy storage device being contained in the housing as well. This permits the flexible electronic display device to provide a broad range of functionalities and application possibilities, and to assume novel functionalities and applications.

Owner:STROETMANN CHRISTIAN

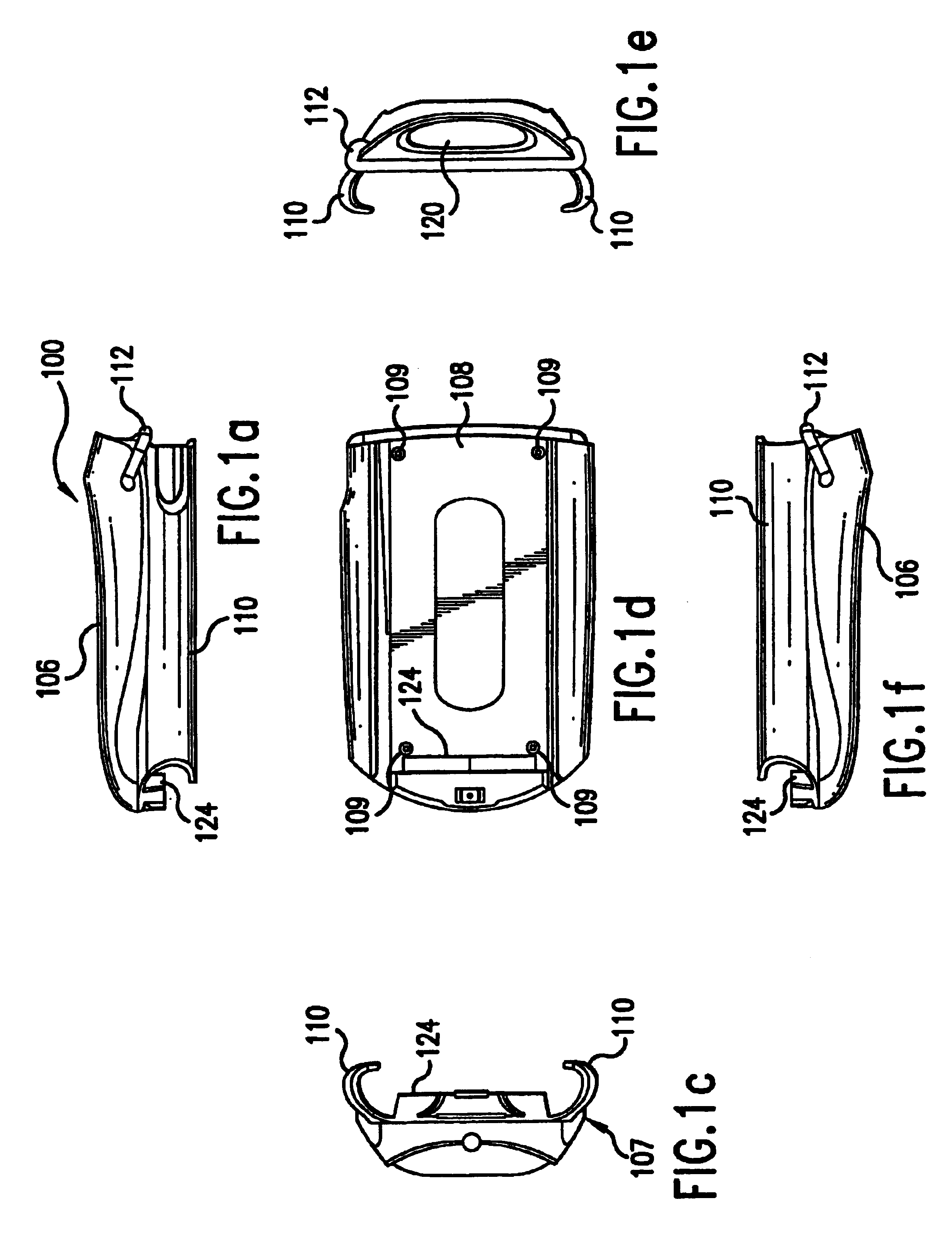

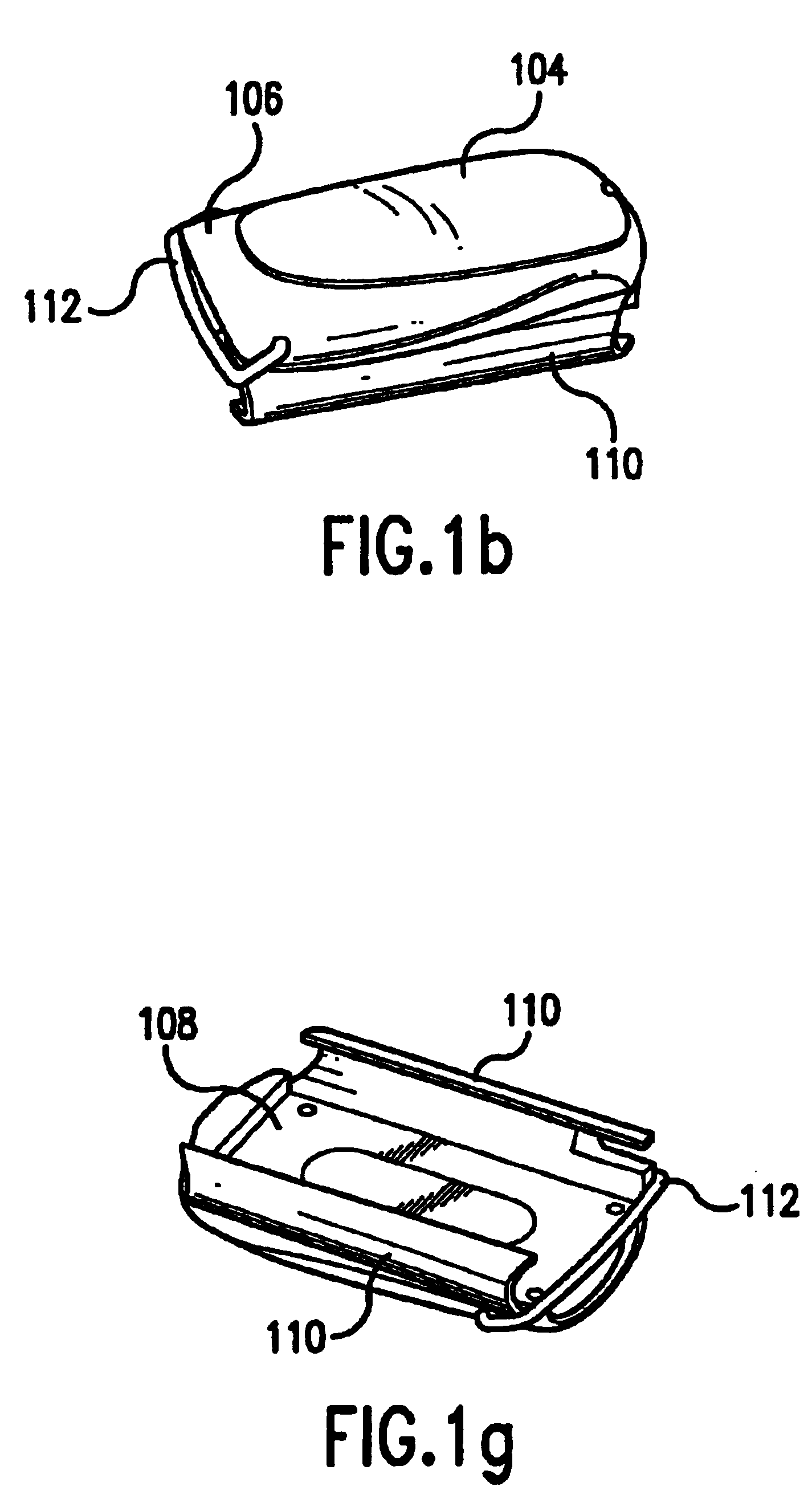

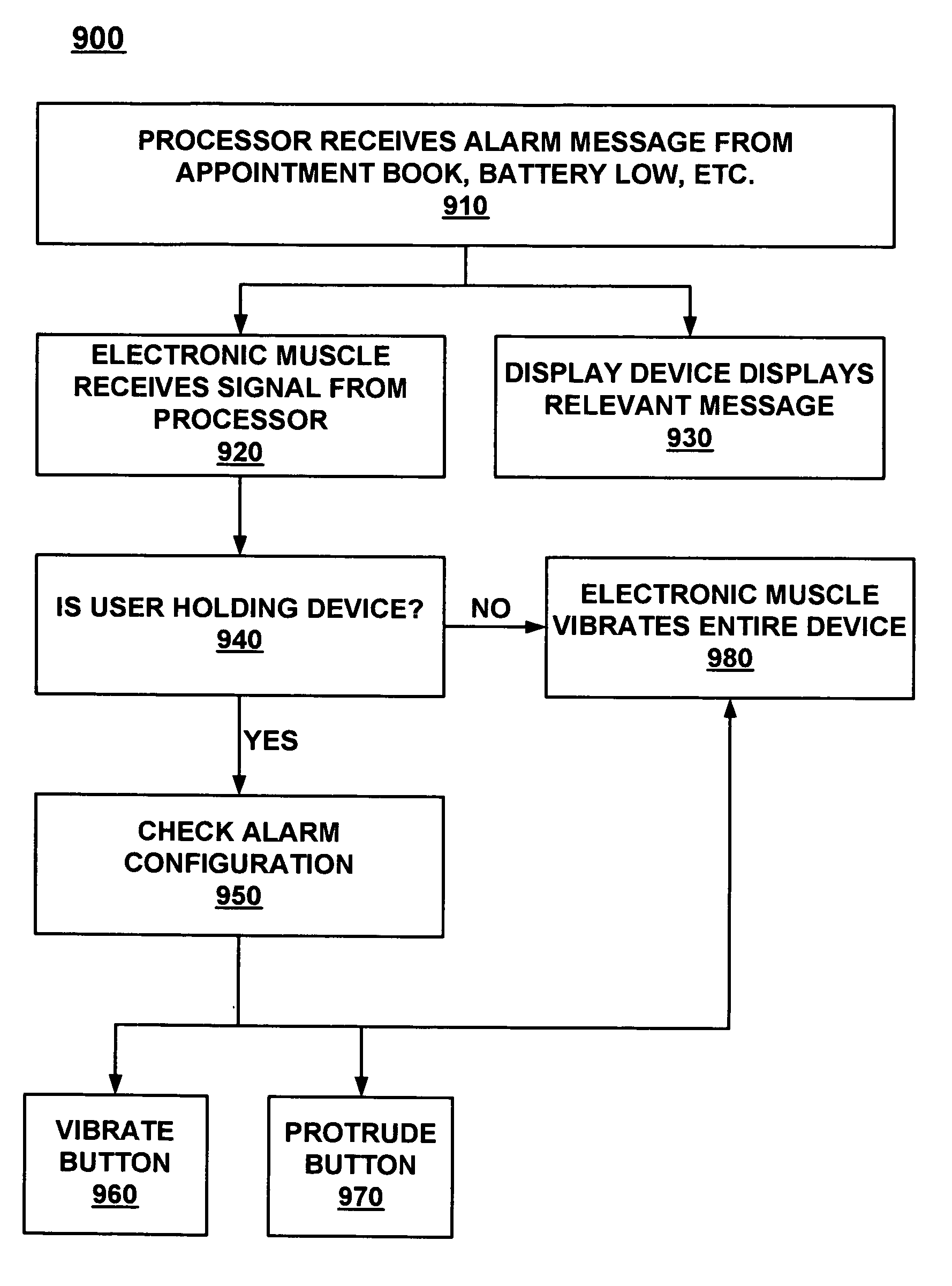

Entering and exiting power modes and activating hand writing presentation display triggered by electronic muscle material

InactiveUS7068256B1Improve ergonomicsCathode-ray tube indicatorsPower supply for data processingEngineeringMuscle material

A portable computer system contained within a housing that comprises an electronic muscle material for performing a plurality of functions. The electronic muscle can sense when the portable computer is being handled. When handled, the electronic muscle material can cause the portable computer system to enter a power-on mode and, conversely, when no longer being handled it can cause the portable computer system to exit the power-on mode. When handled, the electronic muscle material can further detect the left- or right-handedness of the user and, based on the handedness, can generate function buttons or other alterations to accommodate the user's hand preference and finger placement. The placement of the user's hand in a location on the electronic muscle material which indicates preparation to write can activate a selectable graffiti display area on the touch screen.

Owner:QUALCOMM INC

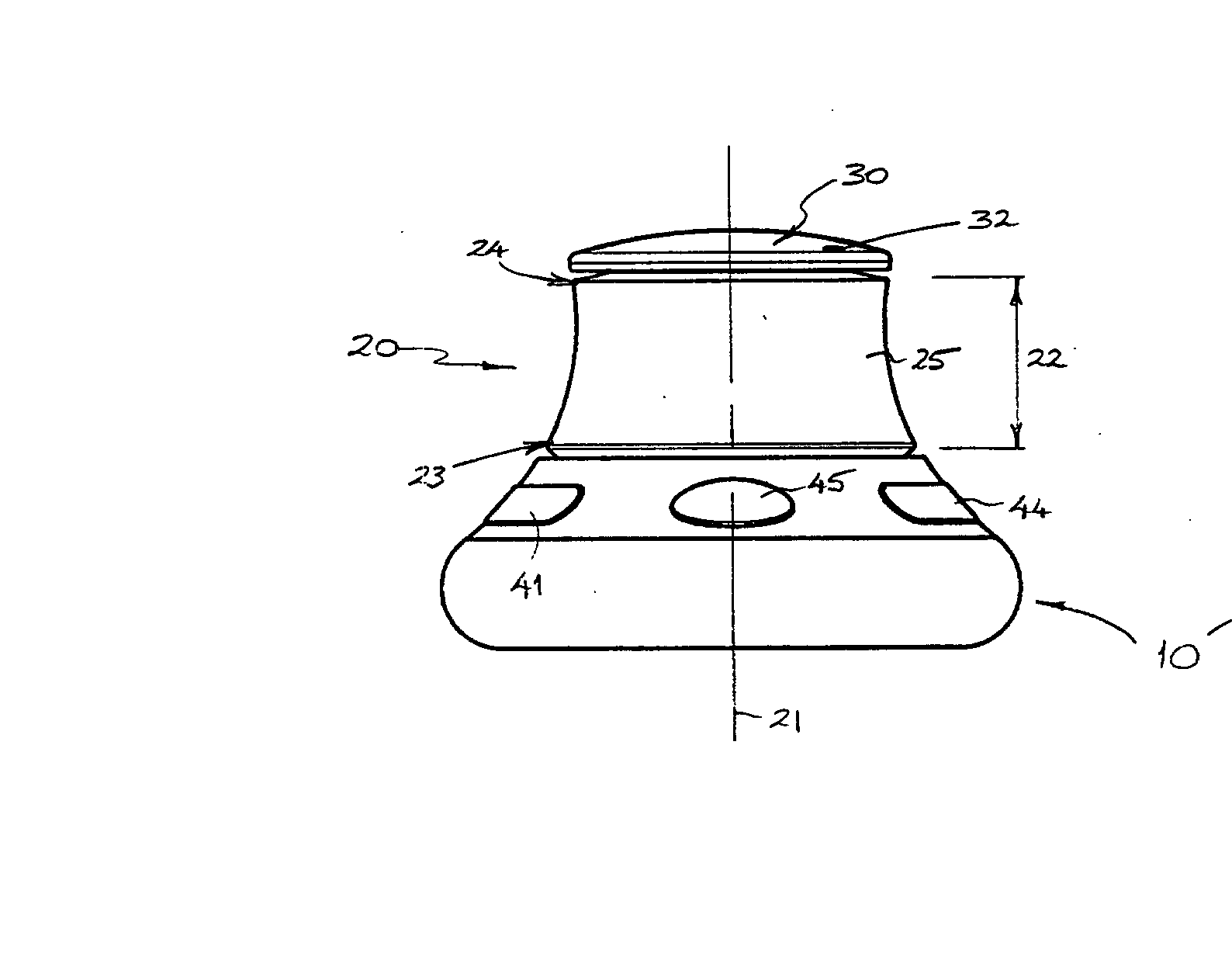

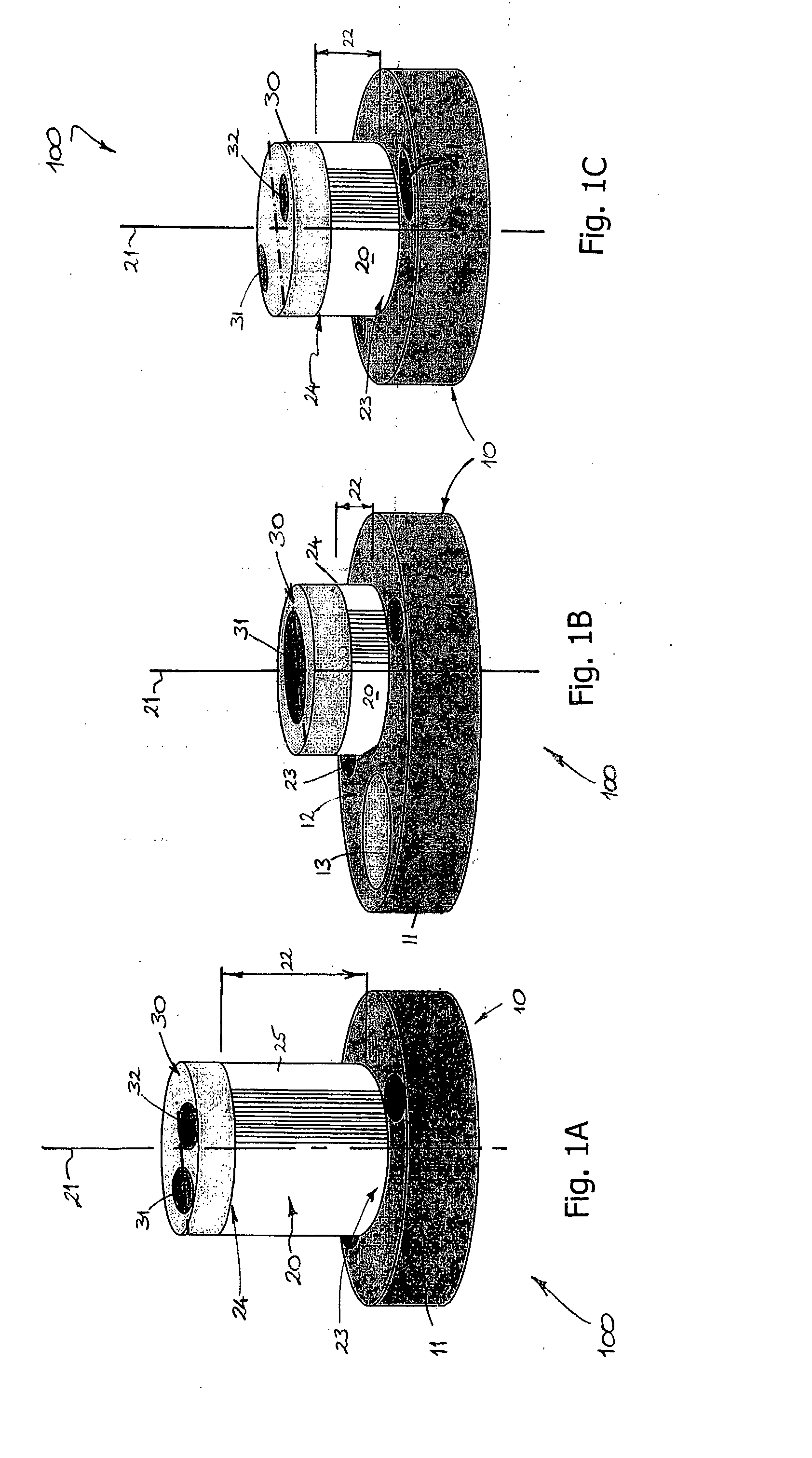

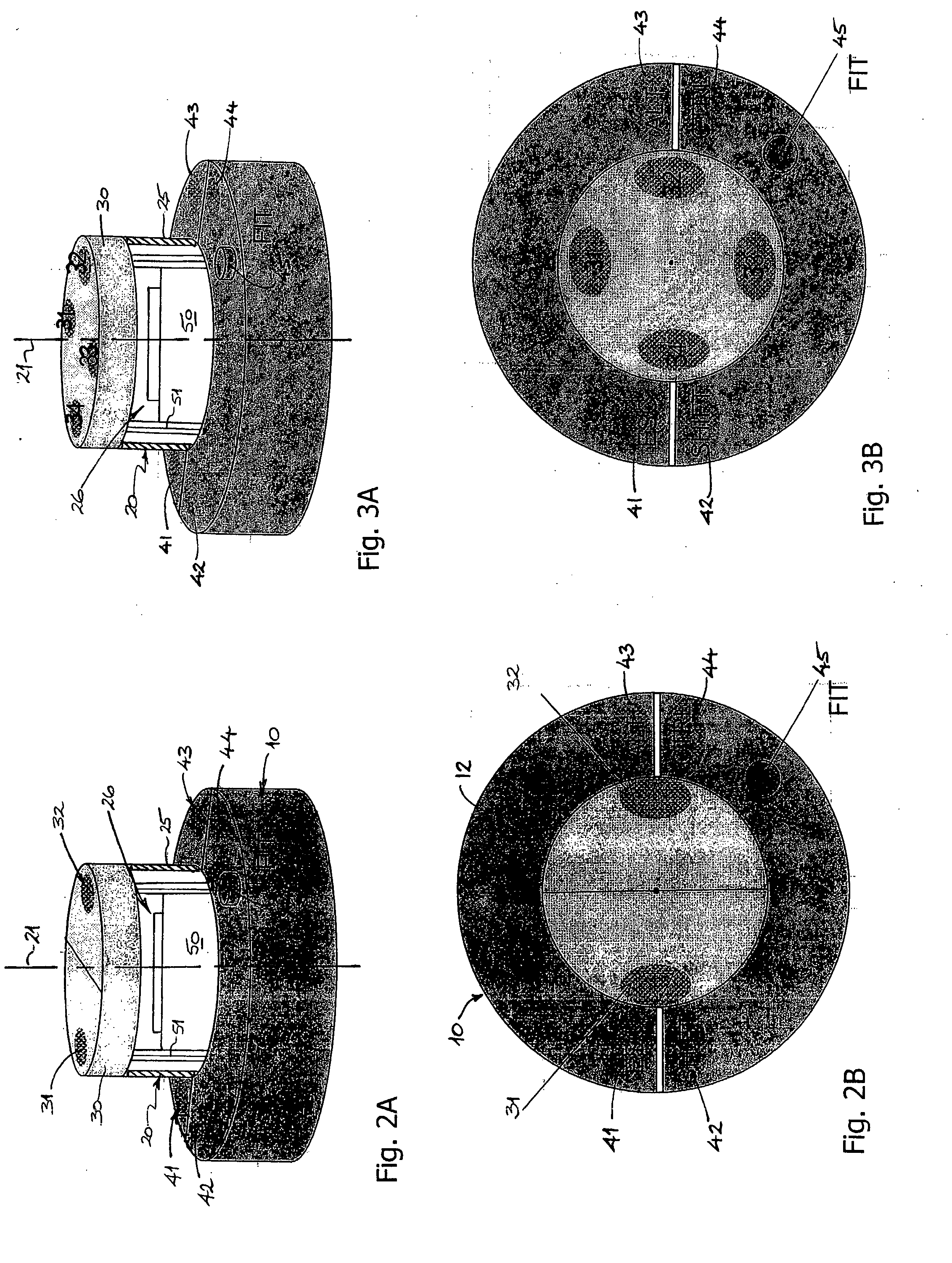

User Interface Device

InactiveUS20080001919A1Improve ergonomicsEnhance comfort and gripControlling membersCathode-ray tube indicatorsEngineeringUser interface

The present invention provides a device (100) for manual input of control signals in a computer-related environment, the device comprising: a base (10) for supporting the device on a surface; a first input member (20) mounted on the base (10) for rotary movement about an axis (21) extending generally upwardly from the base (10), the first input member (20) having an axial extent (22) from an end region (23) proximal the base (10) to an end region (23) distal from the base and enclosing a central space (26) within which a sensor arrangement (50) is housed for detecting and interpreting rotary movement of the first input member (20) relative to the base, the first input member (20) having an opening at each of its proximal and distal end regions (23, 24); and a pair of second input members (31, 32) provided at or adjacent said distal end region (24) of the first input member (20), each of said second input members (31, 32) comprising a switch or relay adapted to be actuated by application of finger pressure. Rotary movement of the first input member (20) and / or actuation of the second input members (31, 32) is adapted to generate a corresponding control signal within the computer environment.

Owner:3DCONNEXION

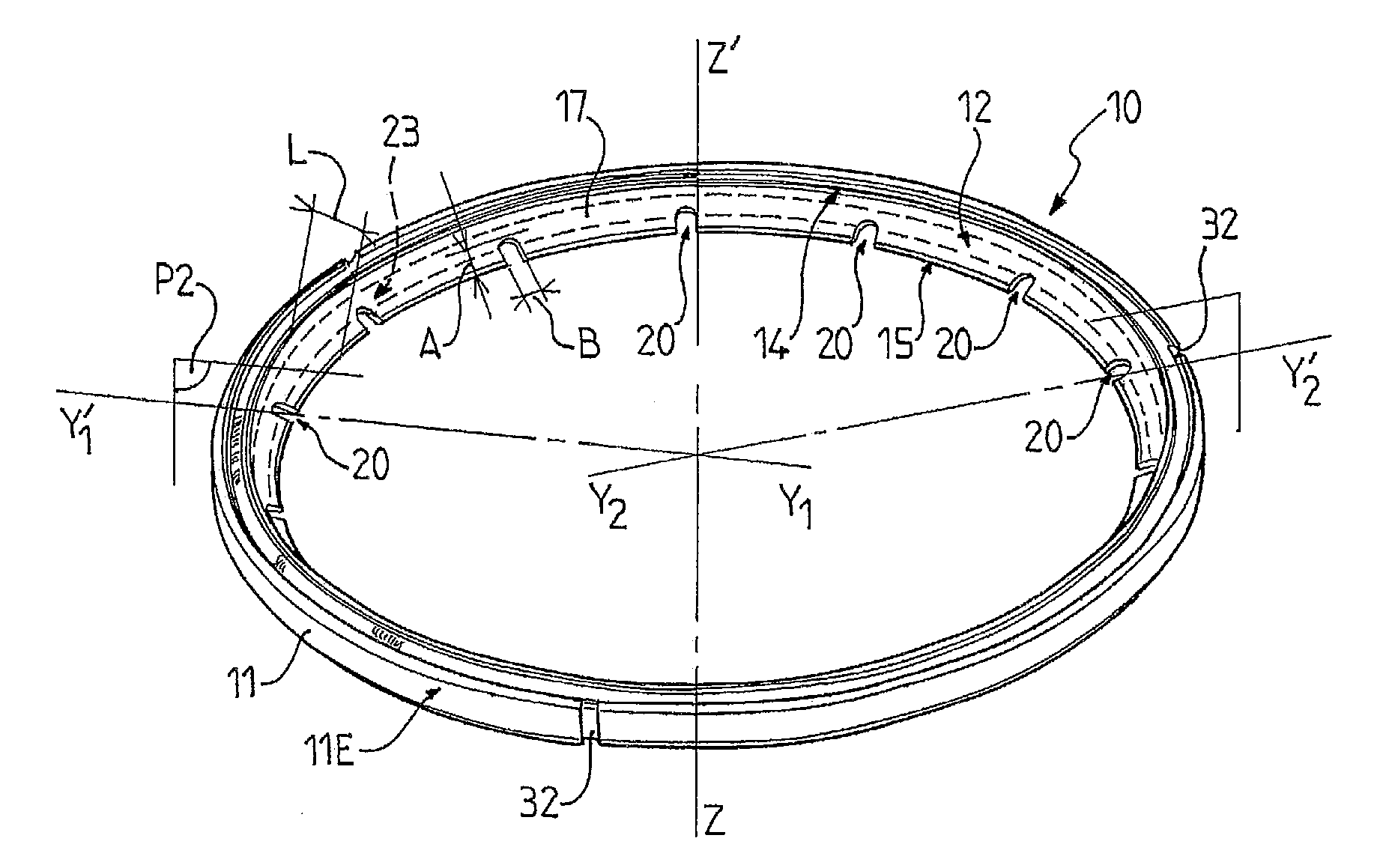

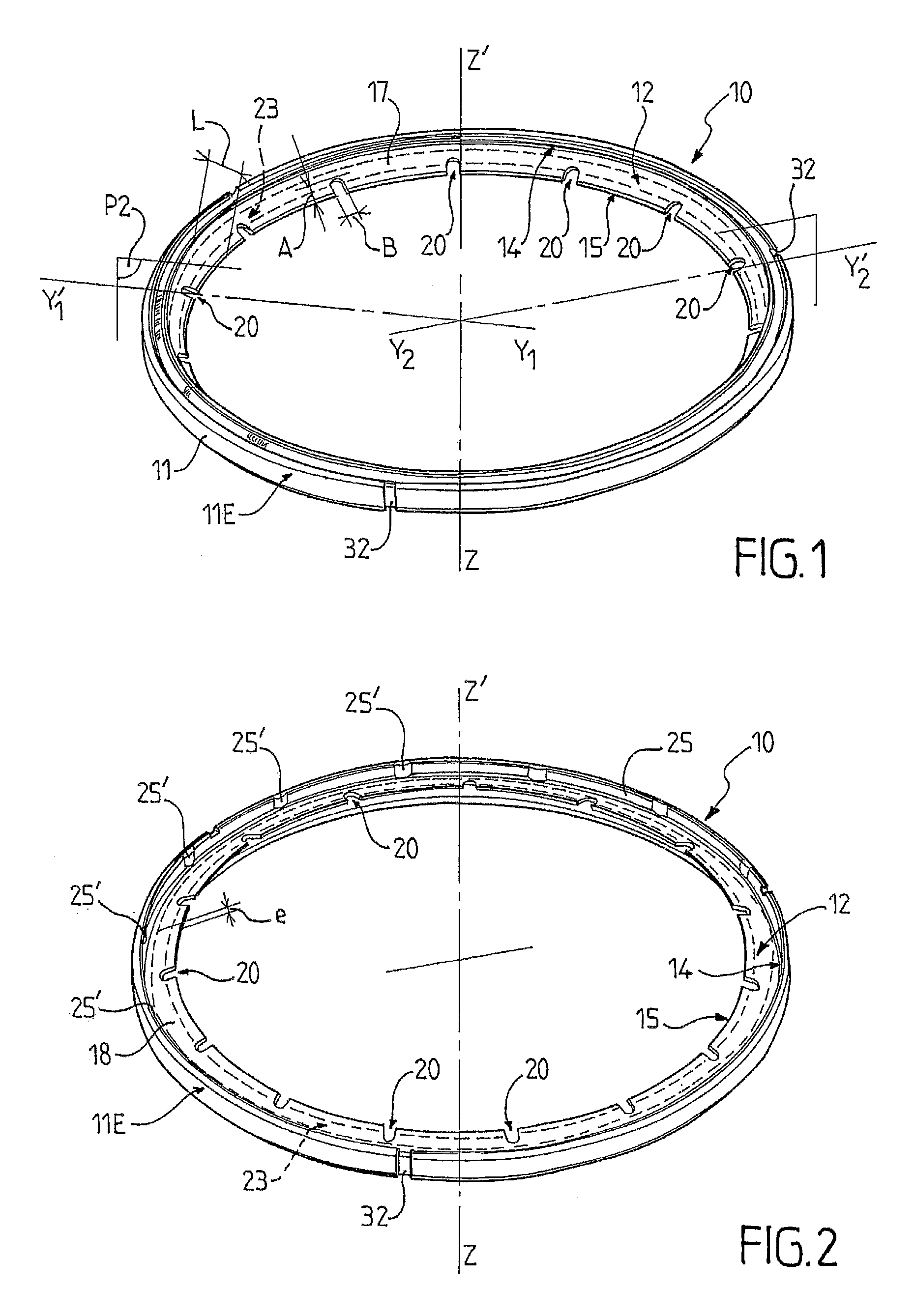

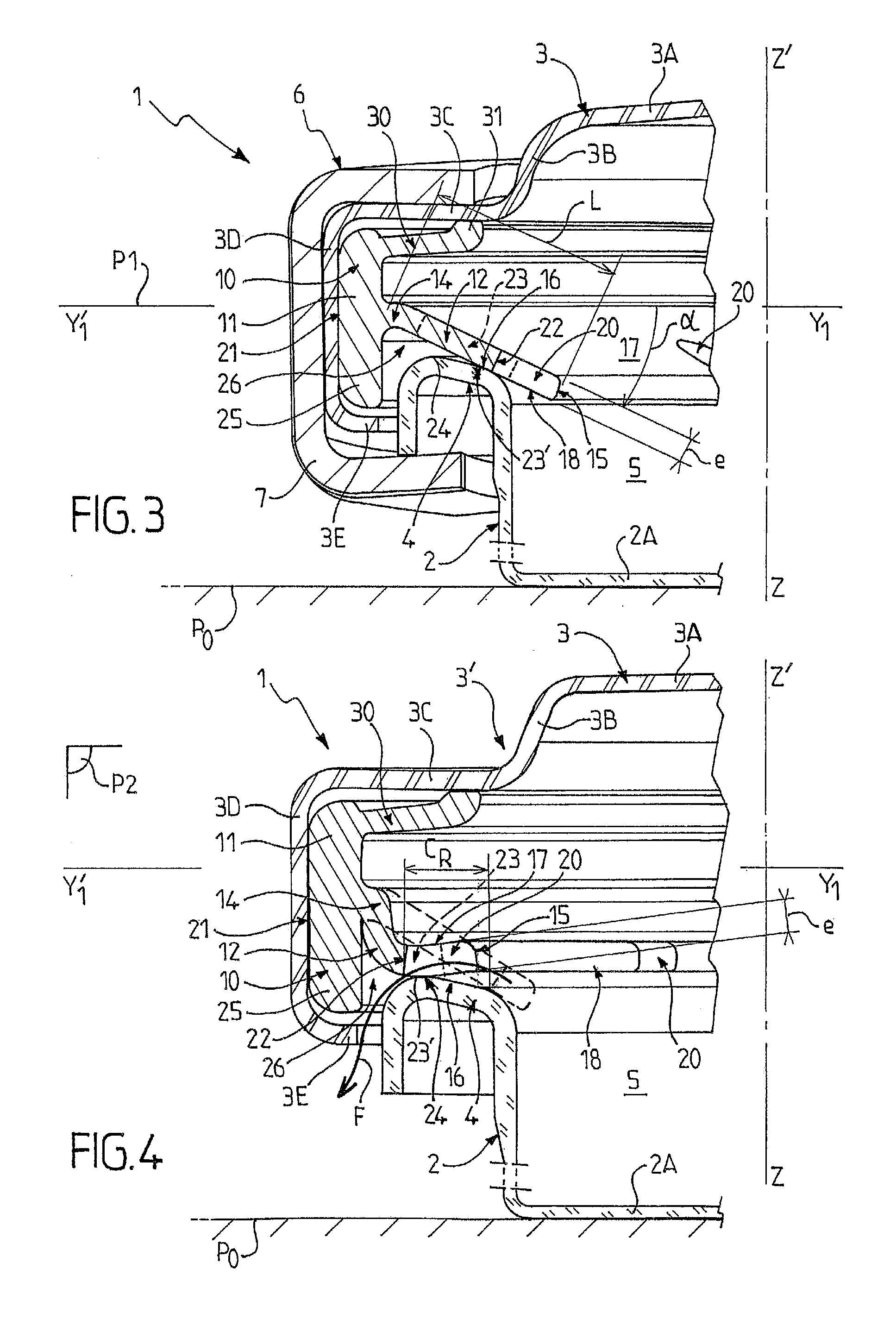

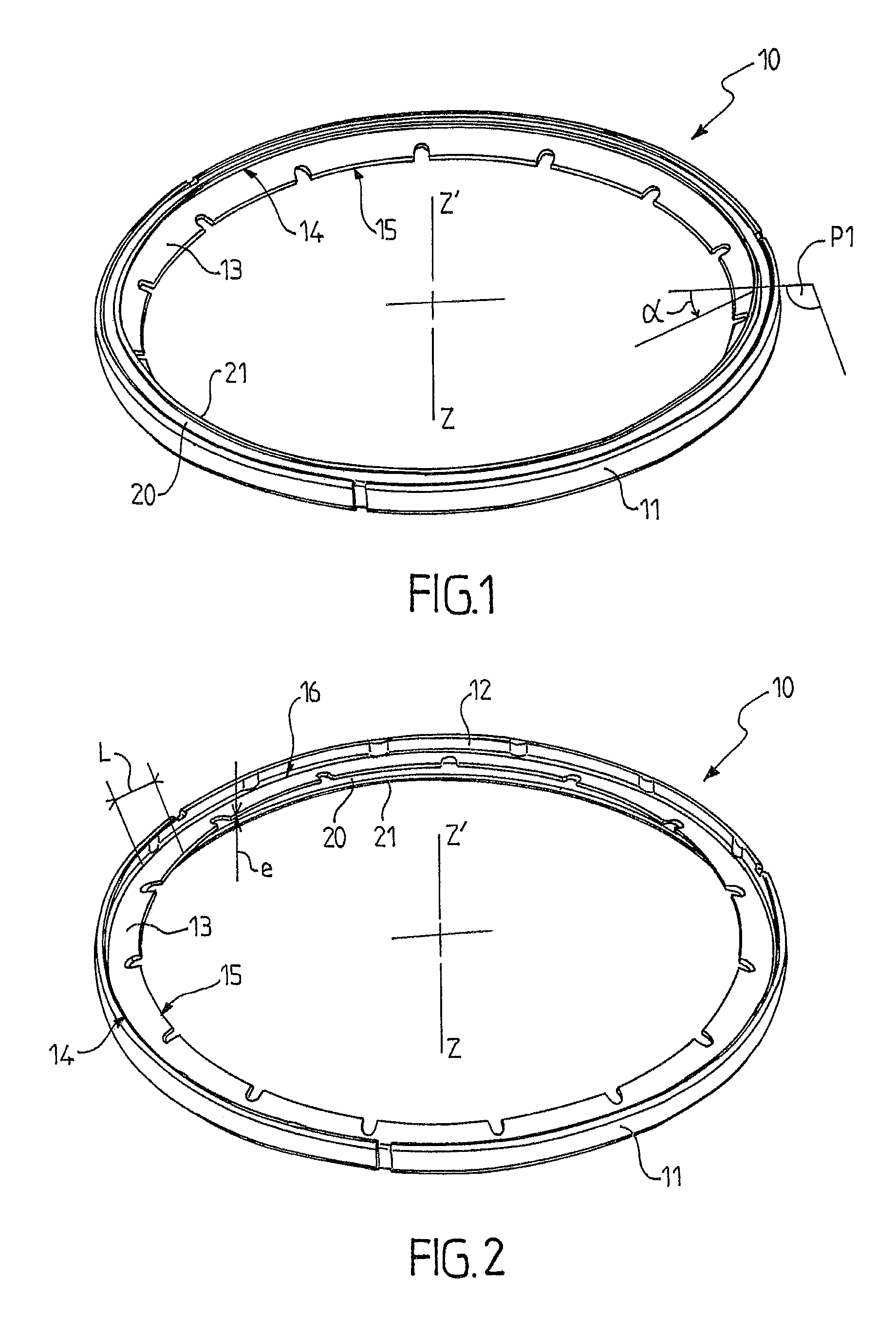

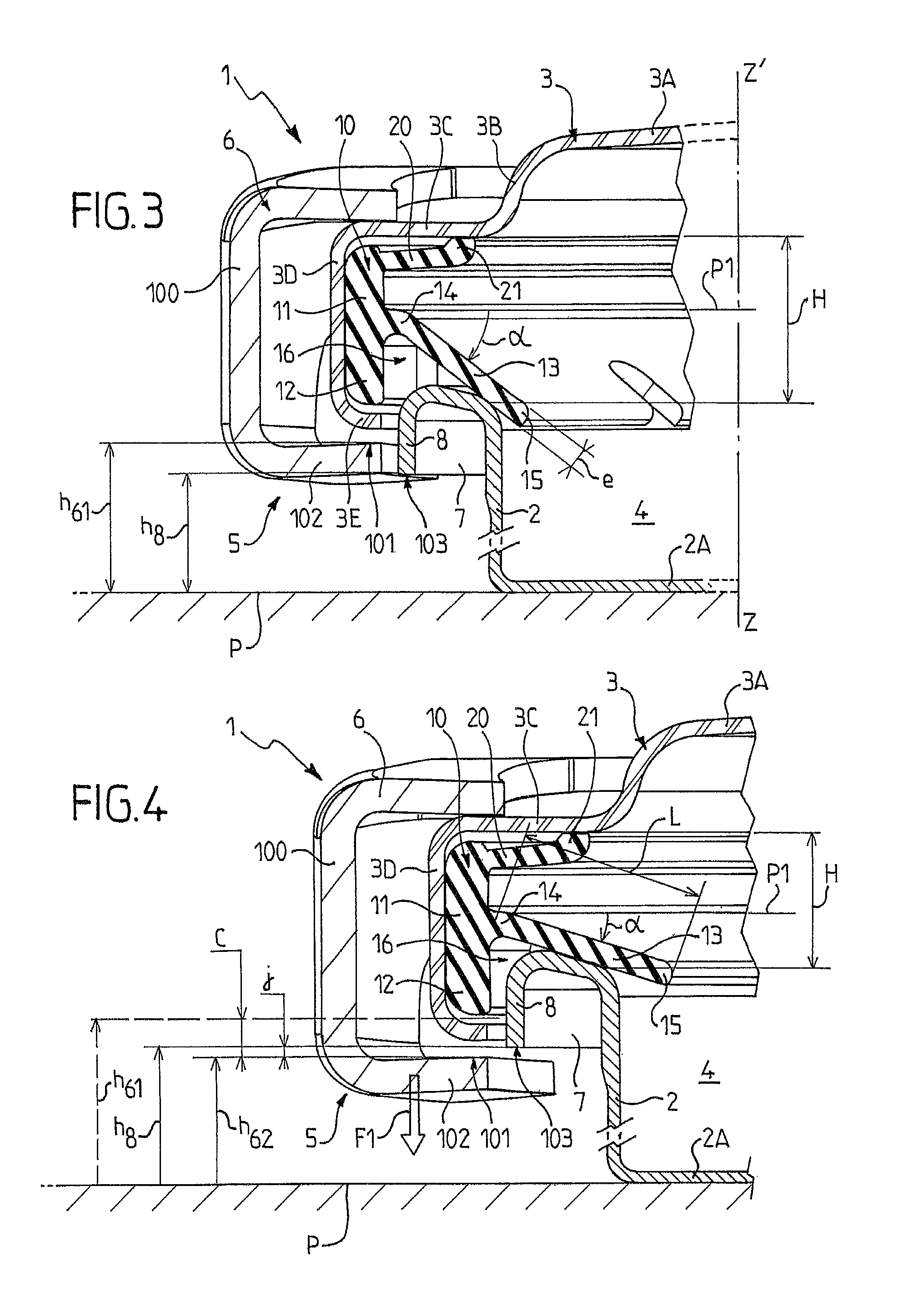

Pressure cooker gasket having a flexible skirt provided with notches

Provided is a sealing gasket for a cooking utensil for cooking food under pressure, the utensil includes a vessel and a lid that define a cooking enclosure. The gasket having a heel from which at least a first lip projects that is provided with at least one escape window notch that passes through its thickness, and in that the first lip forms a differential movement member enabling the escape window notch to effect a relative movement relative to the heel when the pressure prevailing inside the cooking enclosure exceeds a predetermined threshold, which relative movement enables said escape window notch to open up a leakage orifice via which the cooking enclosure is put into communication with the outside of the utensil. Cooking utensils for cooking food under pressure such as a pressure cooker are provided.

Owner:SEB SA

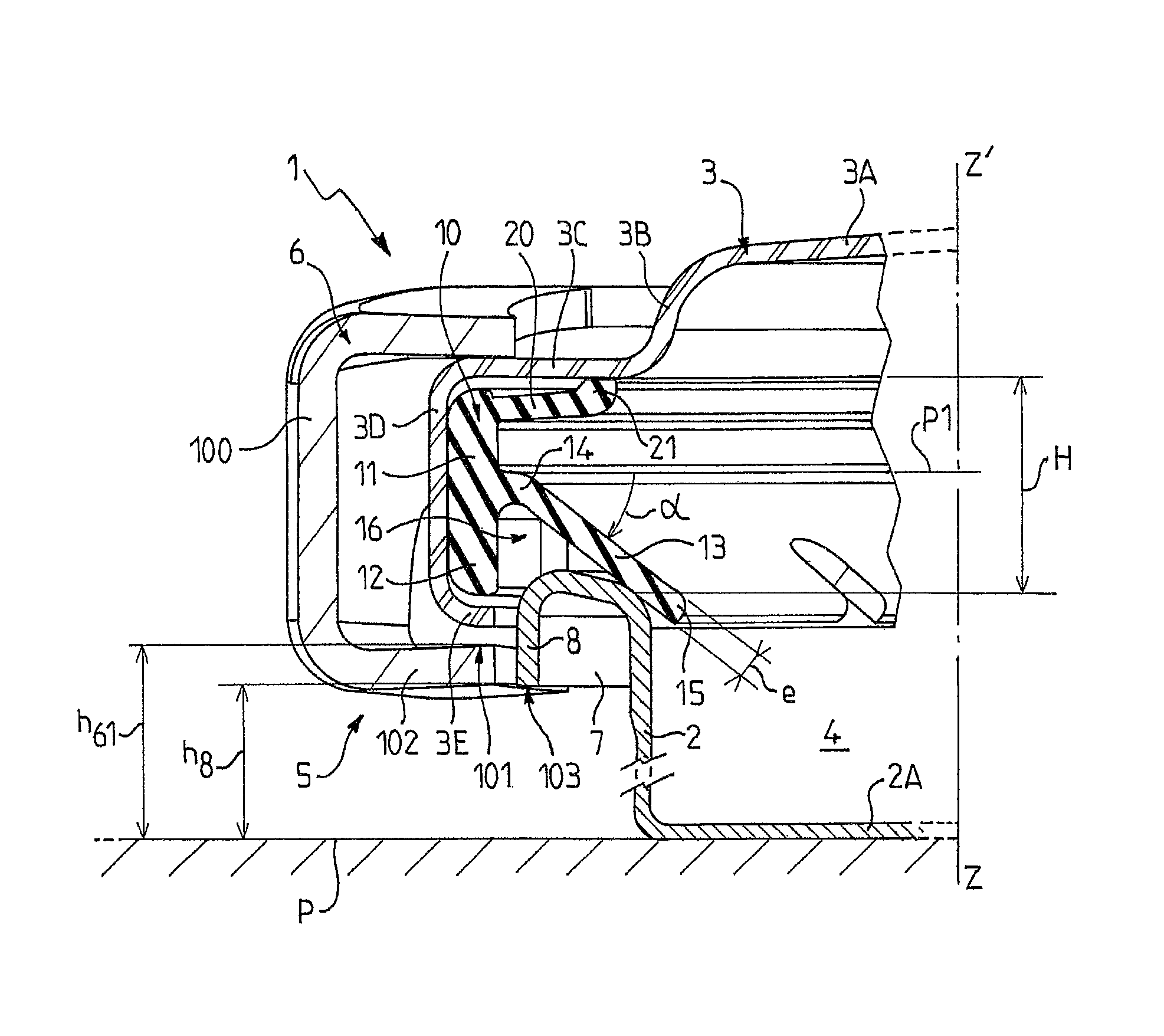

Vertically depressible joint and pressure-cooker provided with one such joint

InactiveUS8931402B2Place and to lock the lid on the vessel particularly simplySimple and robust structureEngine sealsMeat/fish preservationCookerGasket

Owner:SEB SA

Vascular guidewire control apparatus

InactiveUS20050277851A1Shorten the timeSaving of other resourceGuide wiresInfusion syringesAxial displacementElectric control

A controller for use with a guidewire, such as a vascular guidewire, provides a mechanism for gripping and applying a torque to the guidewire without the need to thread the guidewire axially through the controller and at a location close to a point of access of the guidewire. In one embodiment, the controller includes a side-access, multi-part assembly including a collett or other gripping element that applies a uniform radially inward force on the guidewire. In another embodiment, for use with guidewires having active electrically controllable elements, the controller integrally or removably incorporates a switch or other mechanism to initiate an energized state. The controller thereby permits, among other advantages, ergonomic, single-handed control of an electronically steerable guidewire, including axially displacing, torquing and steering the guidewire.

Owner:WINDCREST

Assembly tool for modular implants and associated method

InactiveUS7582092B2Easy to holdSimple optimum ergonomics.Joint implantsFemoral headsJoint arthroplastyProsthesis

An assembly tool for assembly of a first component of a prosthesis to a second component of the prosthesis for use in joint arthroplasty is provided. The tool includes a first member operably associated with the first component and a second member. The second member is operably associated with the second component. At least one of the first member and the second member are adapted to provide for the assembly of the first component of the prosthesis to the second component of the prosthesis. The second member is operably associated with the first member for relative motion between the first member and the second member for assembly of the first component of the prosthesis to the second component. The tool also includes an angular orientation feature cooperating with at least one of the first member and the second member for at least one of replicating and measuring the relative angular orientation of the first component with respect to the second component.

Owner:DEPUY PROD INC

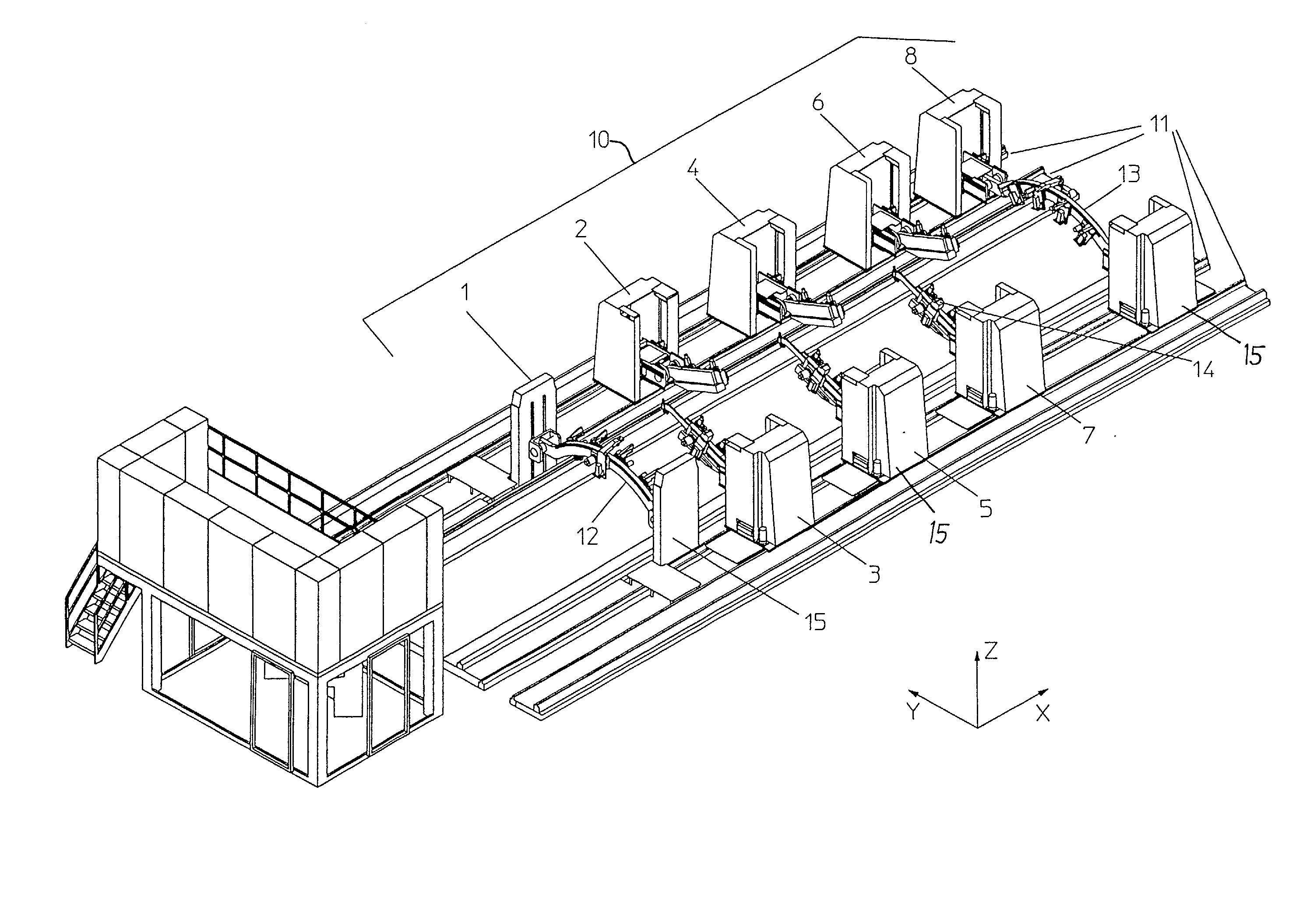

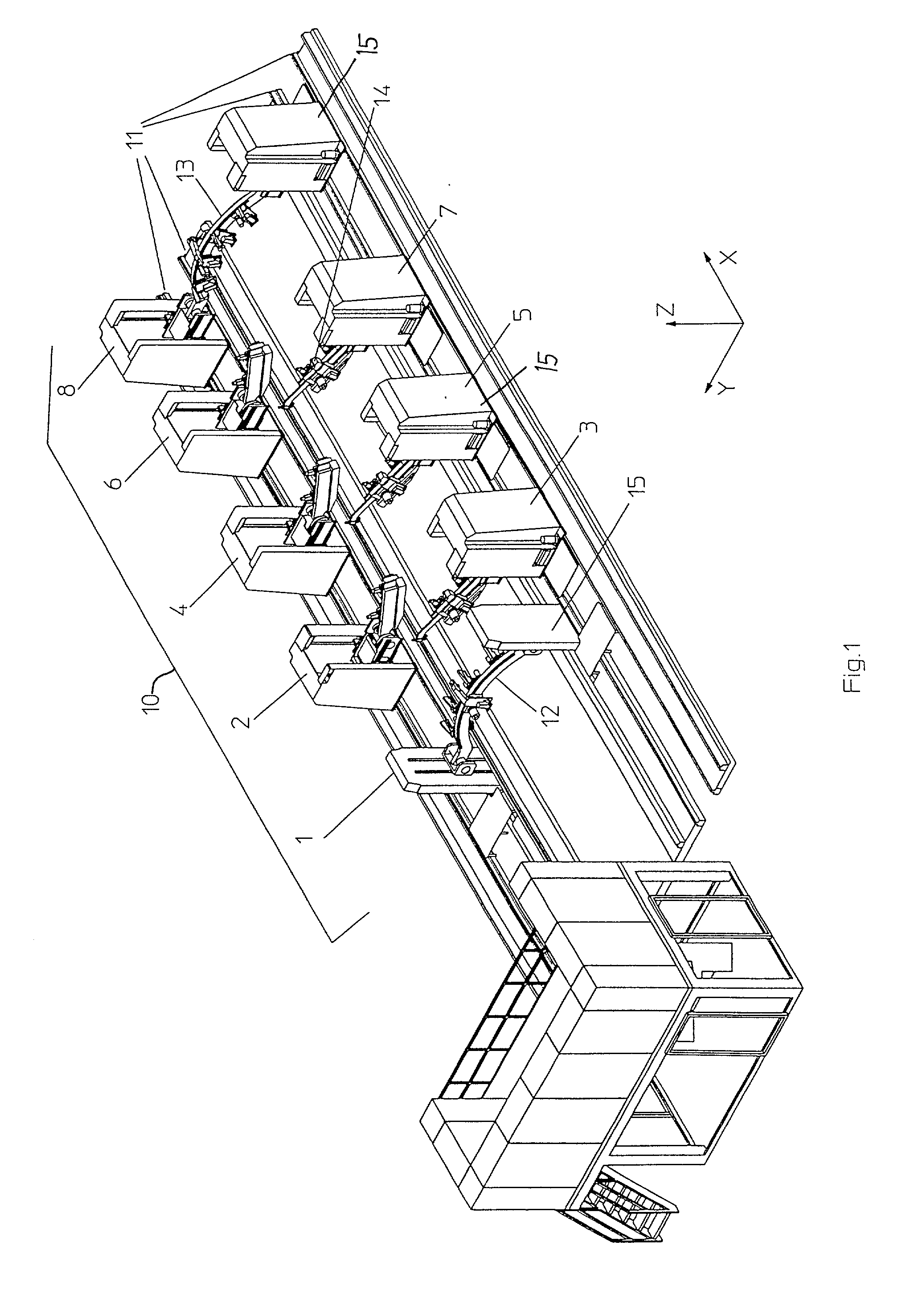

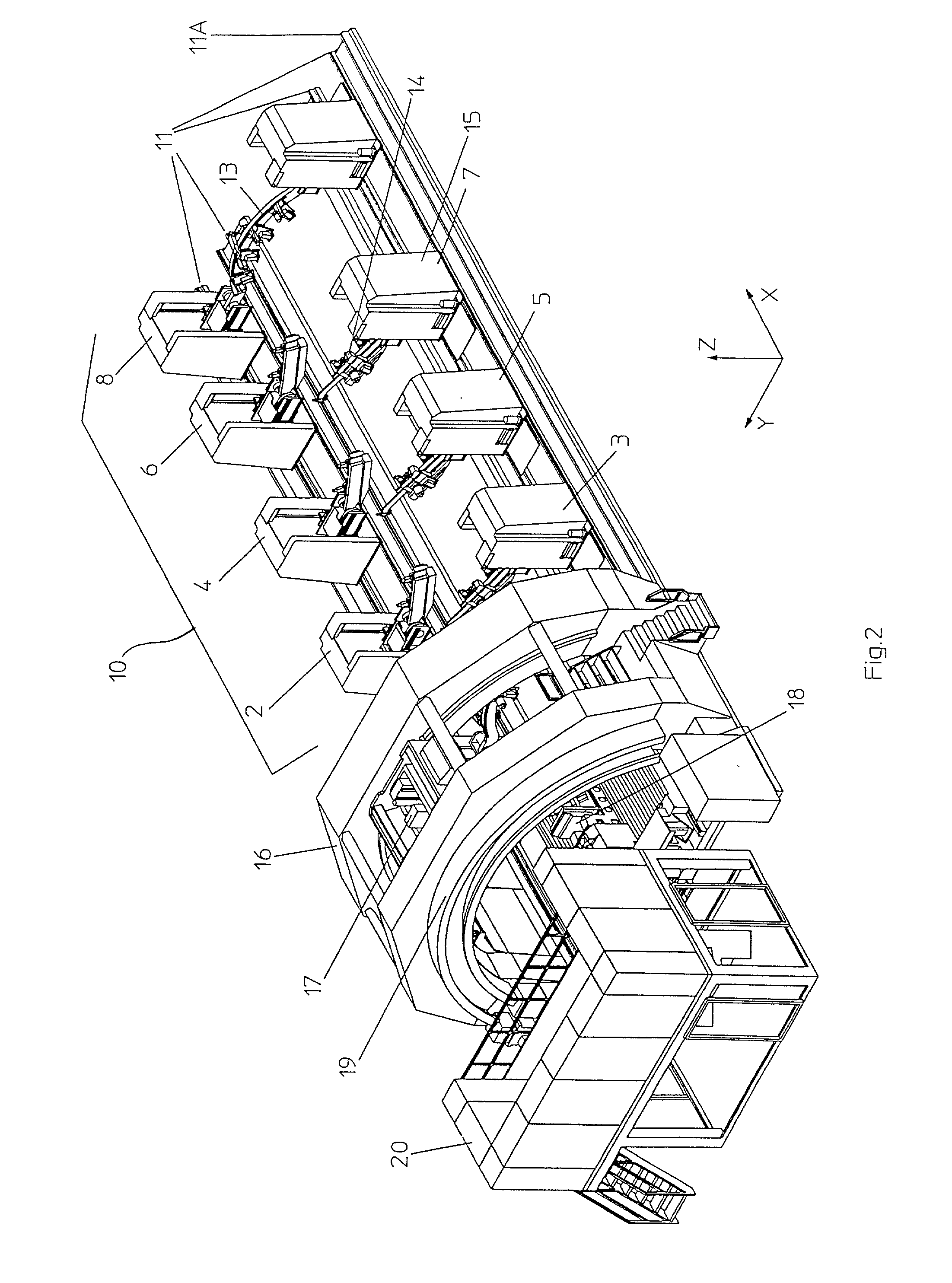

Versatile adaptable holding apparatus for holding large format workpieces

InactiveUS20020092149A1Precise positioningReduce usageLarge fixed membersPositioning apparatusRiveting machinesMachine

An apparatus for holding a large format workpiece includes first and second sets of support units on opposite sides of the workpiece. Each support unit includes a support arm carrying individual mounting fixtures such as suction units for suction-holding the workpiece. The support arm is pivotably mounted on a support column, which in turn is movable along a floor-mounted rail. A riveting machine includes an upper tool and a lower tool that are movable parallel to the floor-mounted rail. To make space for the machine to set rivets in the area that is supported by a given support arm, that support arm is released from the workpiece and moved away to allow the machine to carry out its riveting cycle at that area, while the greatest possible number of the other support units simultaneously remain in place and continue to support the workpiece.

Owner:AIRBUS OPERATIONS GMBH +1

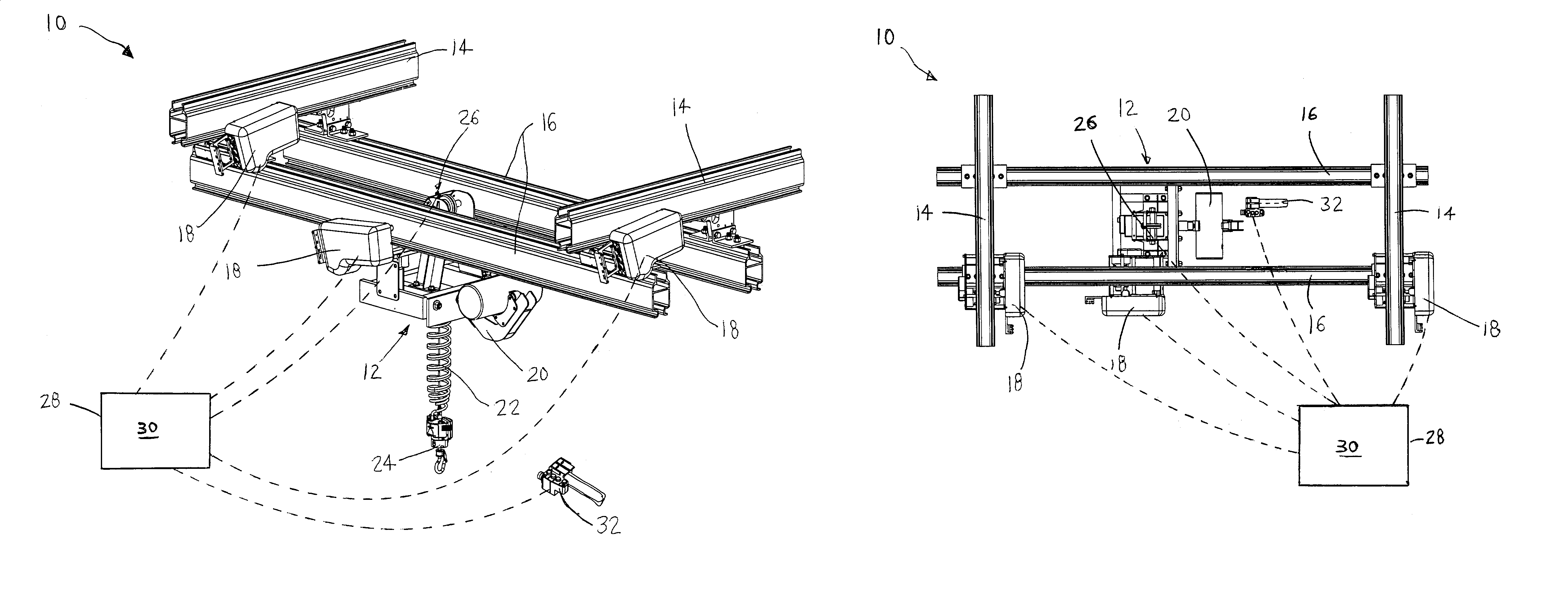

Methods and apparatus for manipulation of heavy payloads with intelligent assist devices

InactiveUS7185774B2Improve ergonomicsDigital data processing detailsPortable liftingEngineeringPayload

An intelligent assist method and apparatus are disclosed. The intelligent assist method includes imparting a manual force to a suspended object, determining an angle at which the suspended object is manually forced, generating motorized power to move the object in accordance with the angle at which the suspended object is forced, and inputting a signal to continue the motorized power and enable the object to continue moving on accordance with the angle at which the suspended object is manually forced.

Owner:NORTHWESTERN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com