Patents

Literature

175 results about "Large format" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large format refers to any imaging format of 4×5 inches (102×127 mm) or larger. Large format is larger than "medium format", the 6×6 cm (2¼×2¼ inch) or 6×9 cm (2¼×3½ inch) size of Hasselblad, Mamiya, Rollei, Kowa, and Pentax cameras (using 120- and 220-roll film), and much larger than the 24×36 mm (0.95×1.42 inch) frame of 35 mm format.

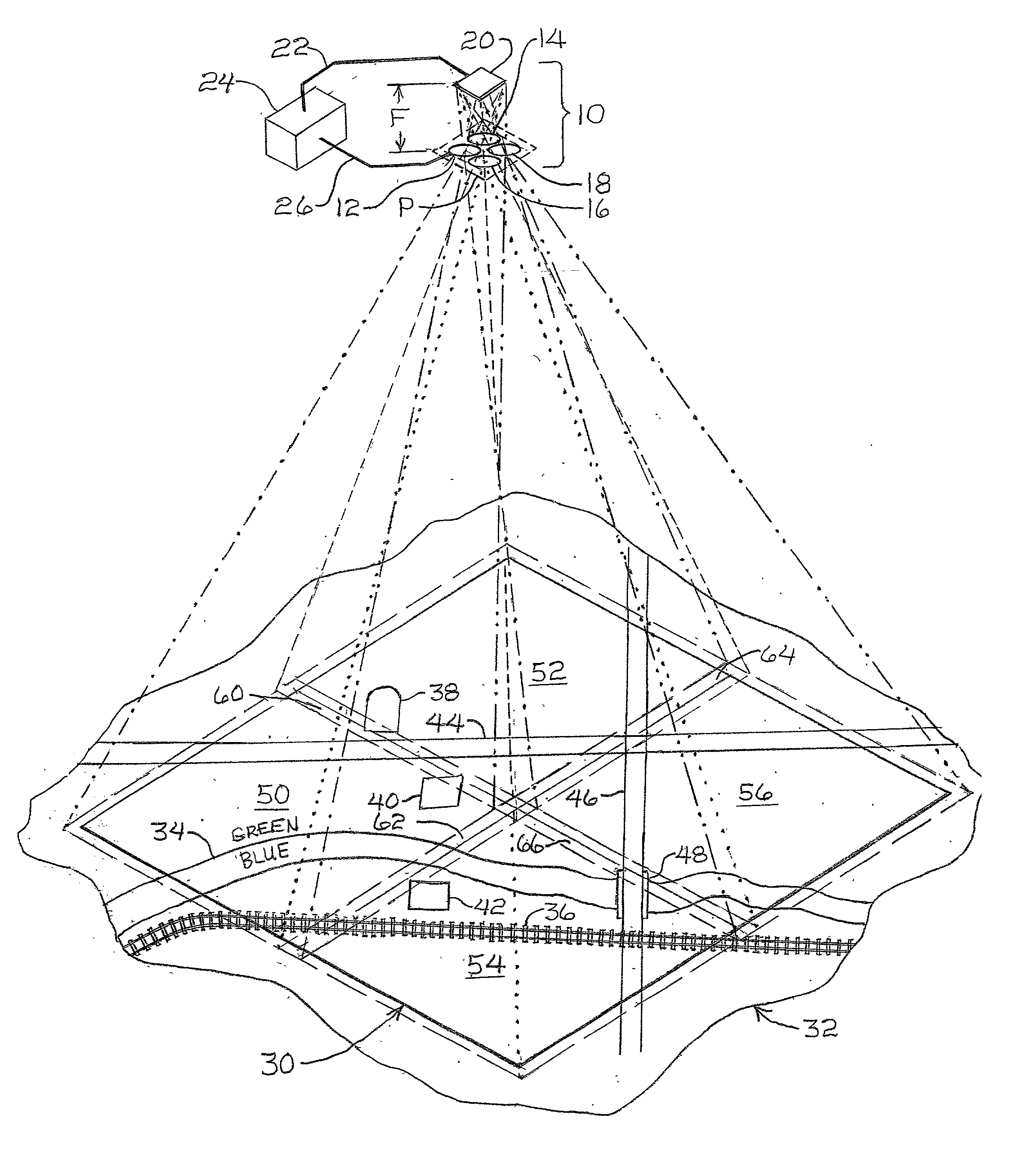

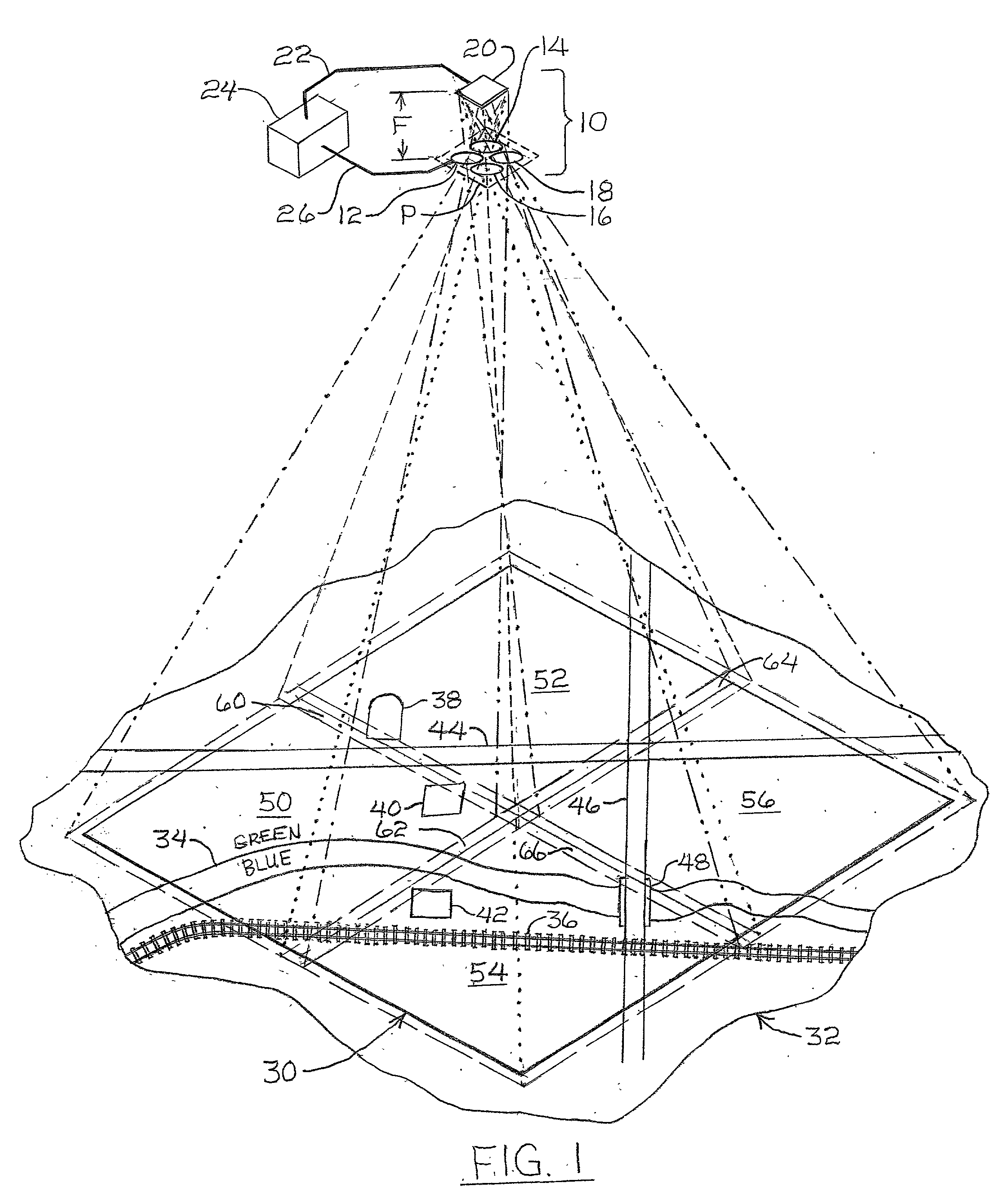

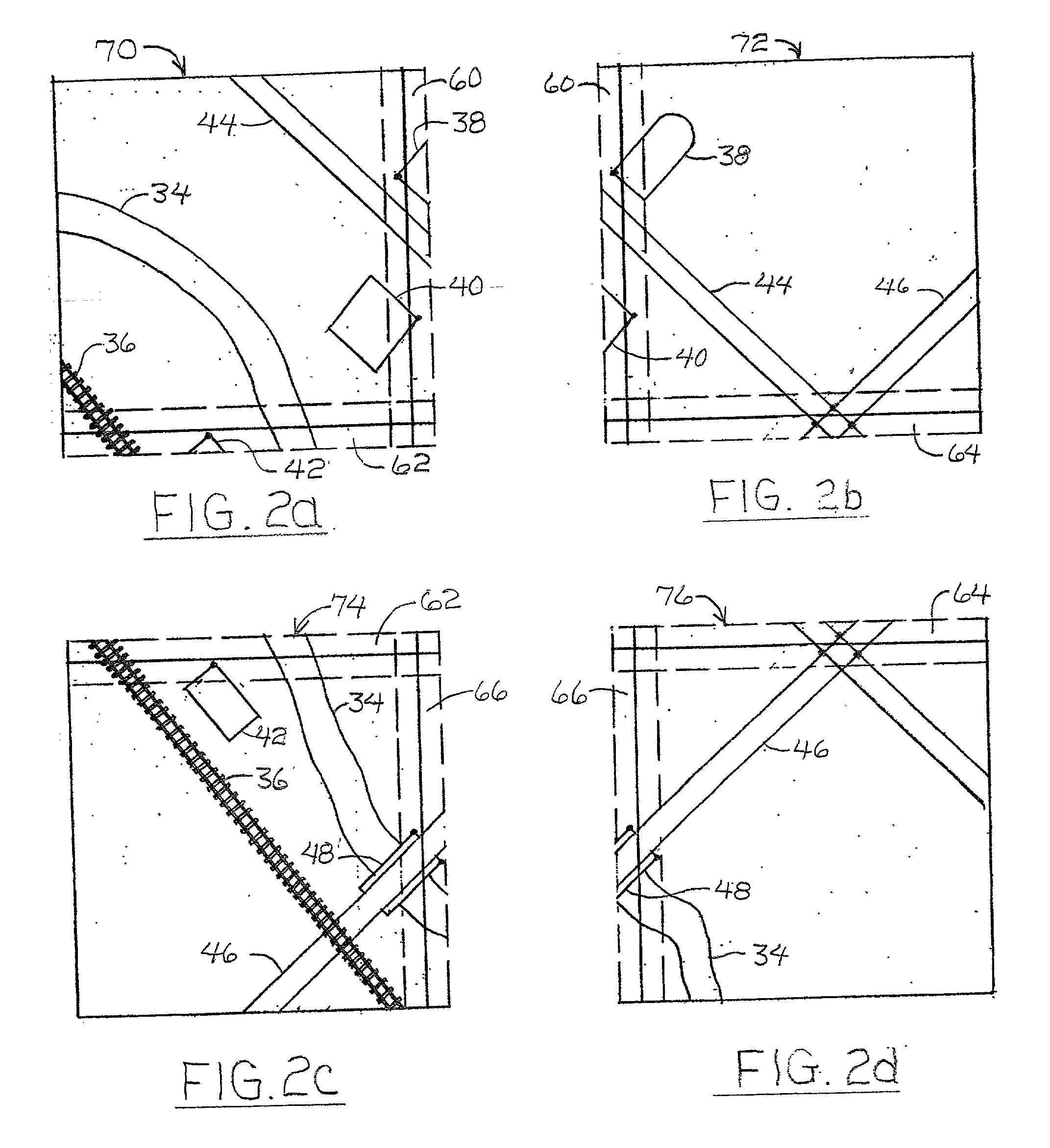

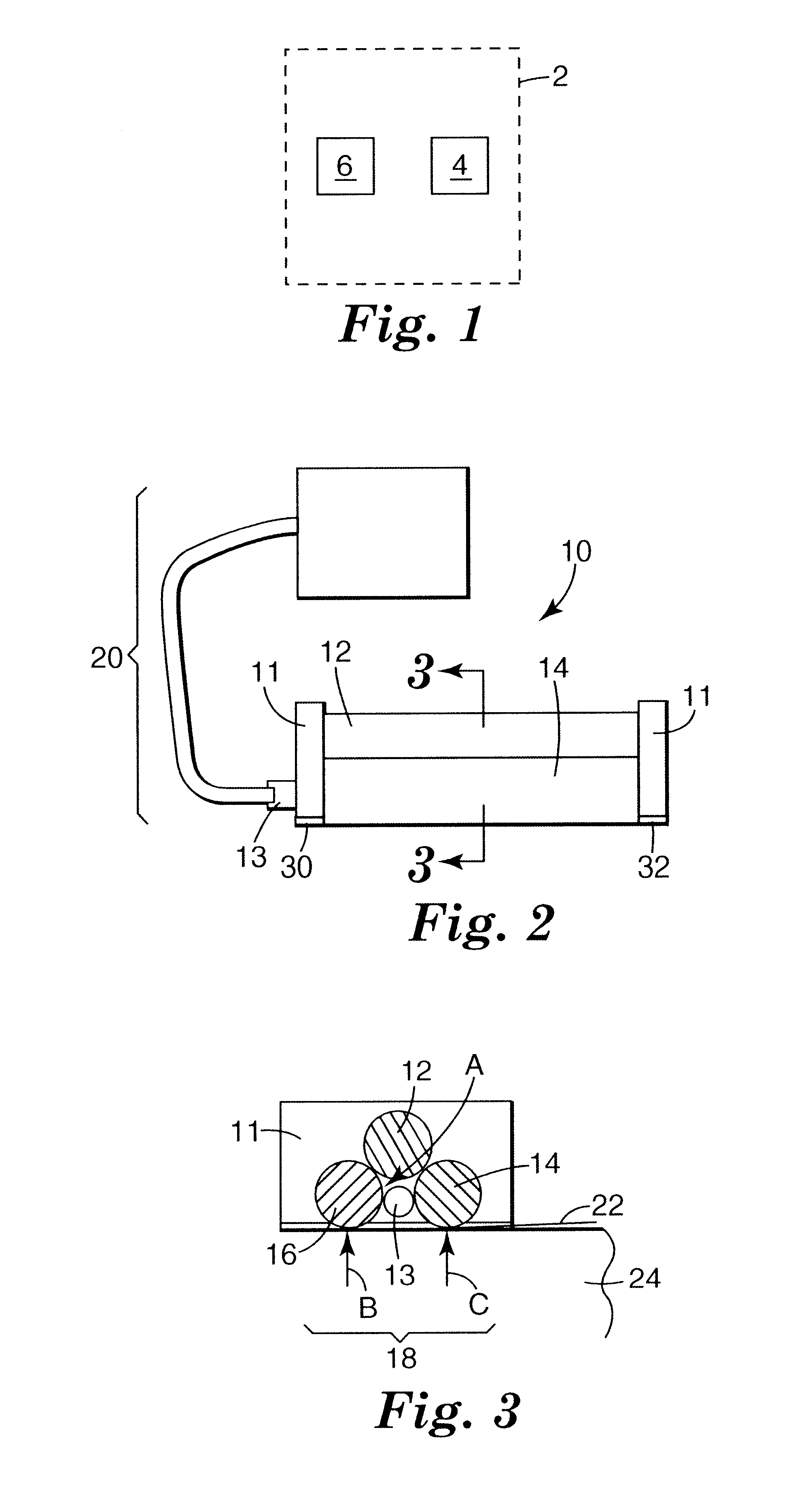

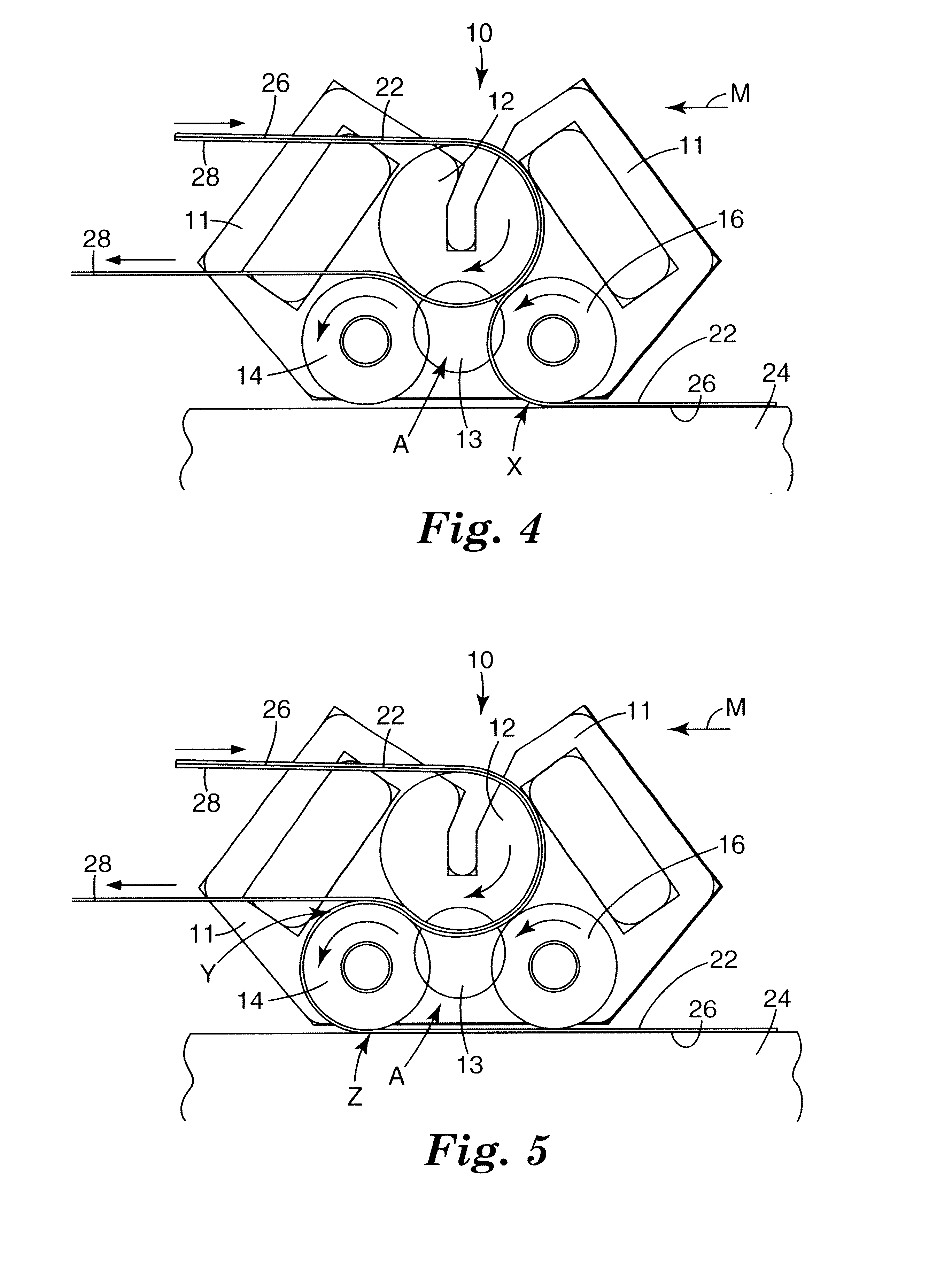

Self-calibrating, digital, large format camera with single or mulitiple detector arrays and single or multiple optical systems

InactiveUS20020163582A1High resolutionTelevision system detailsGeometric image transformationDigital signal processingAccelerometer

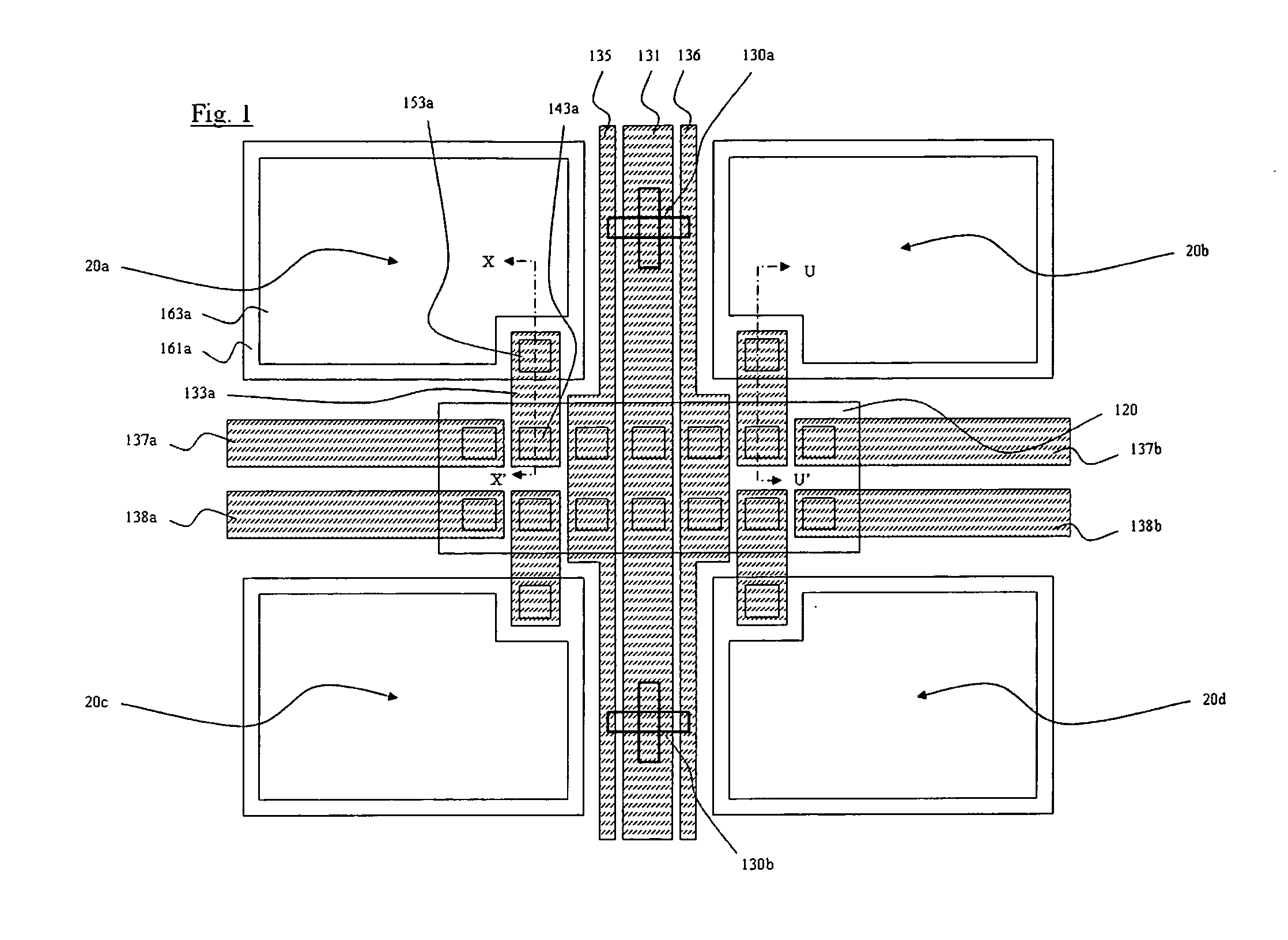

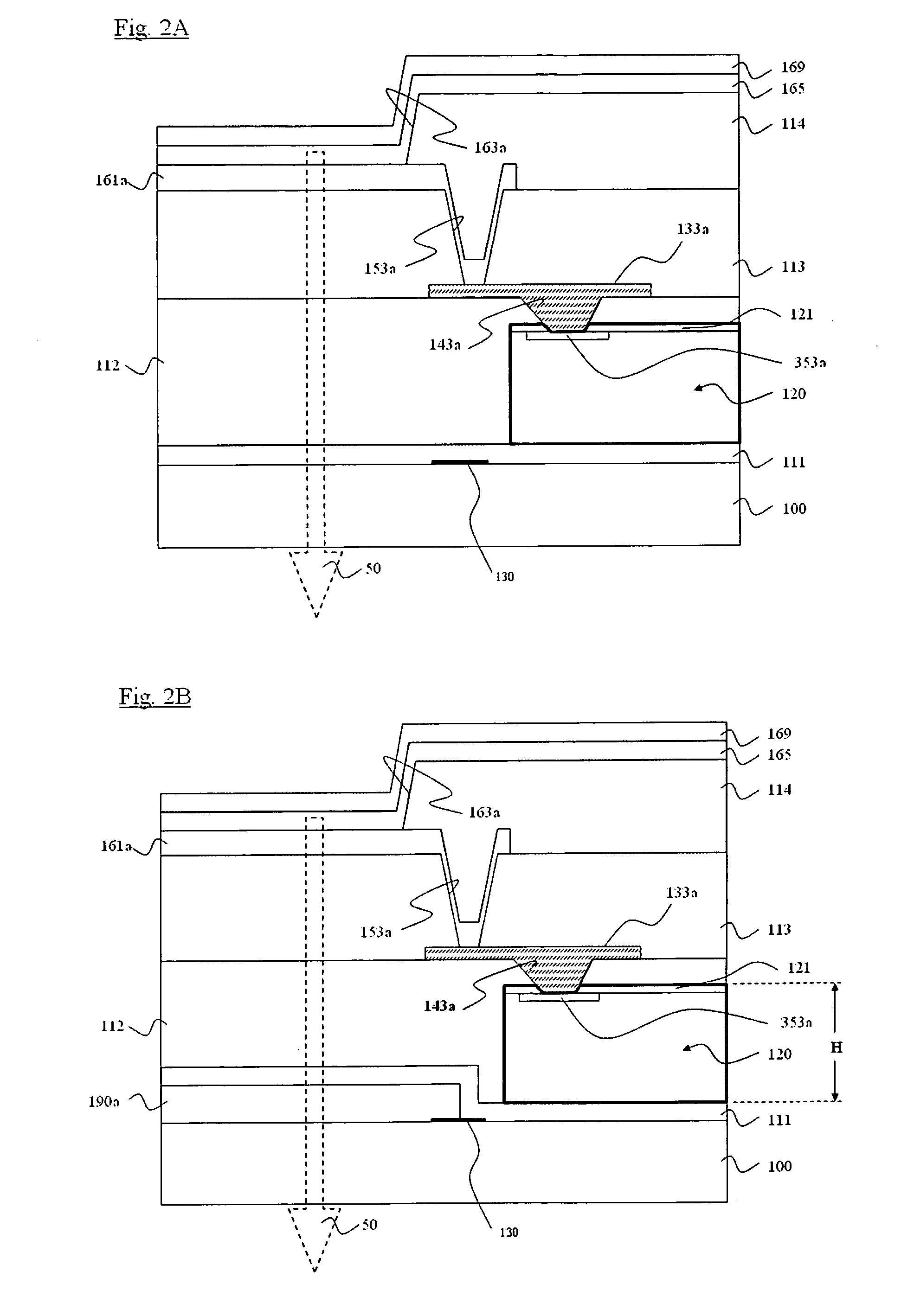

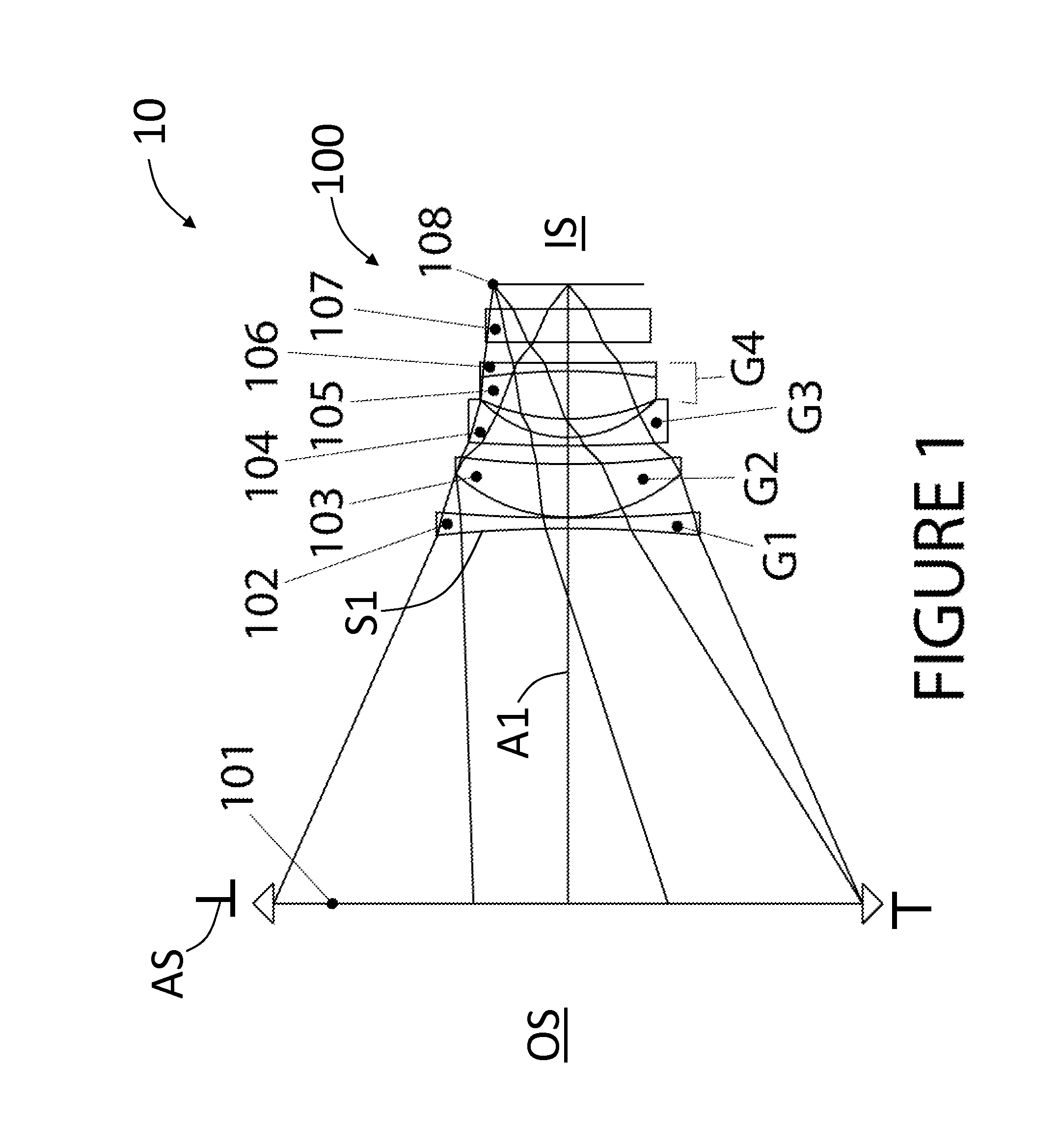

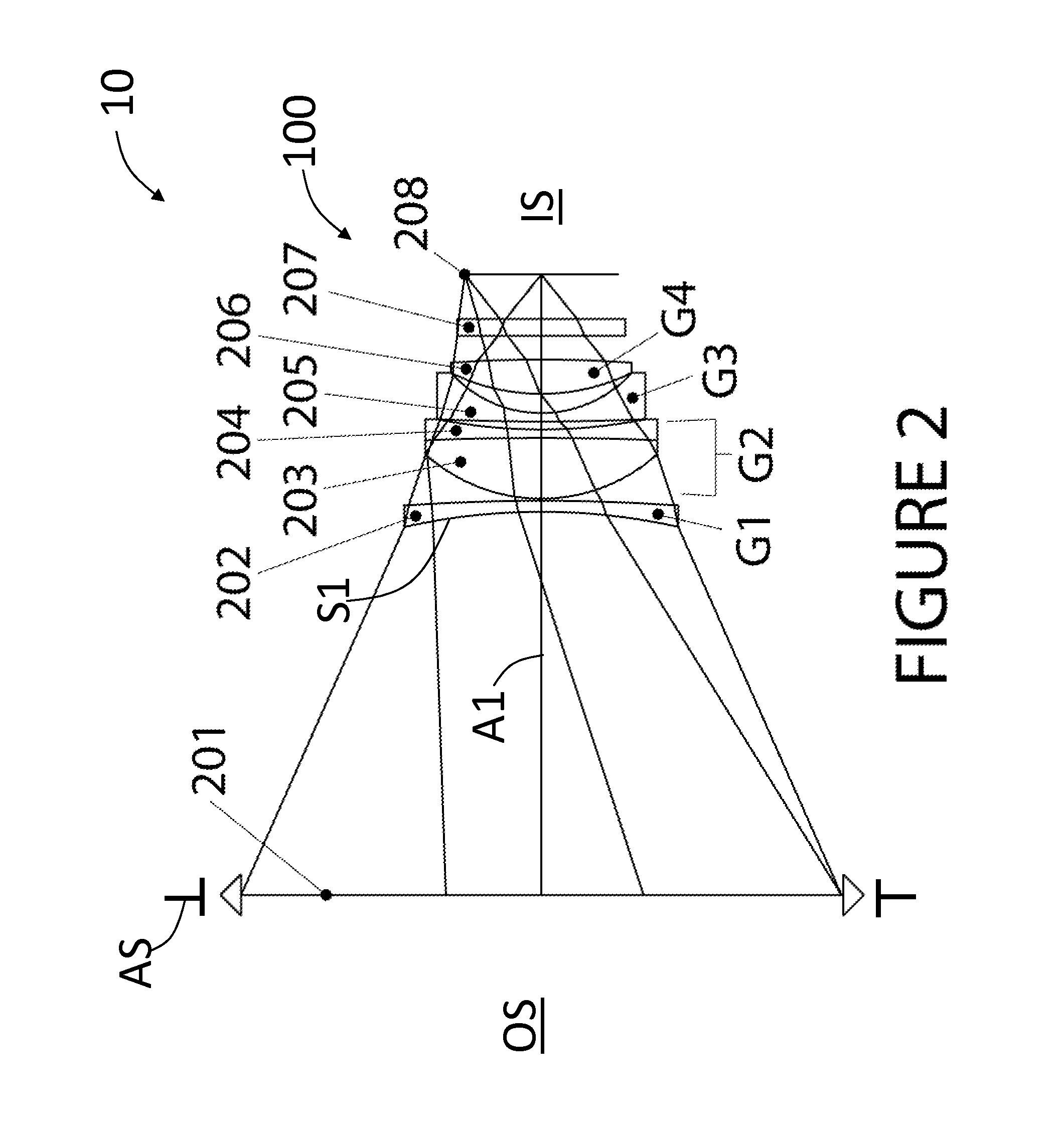

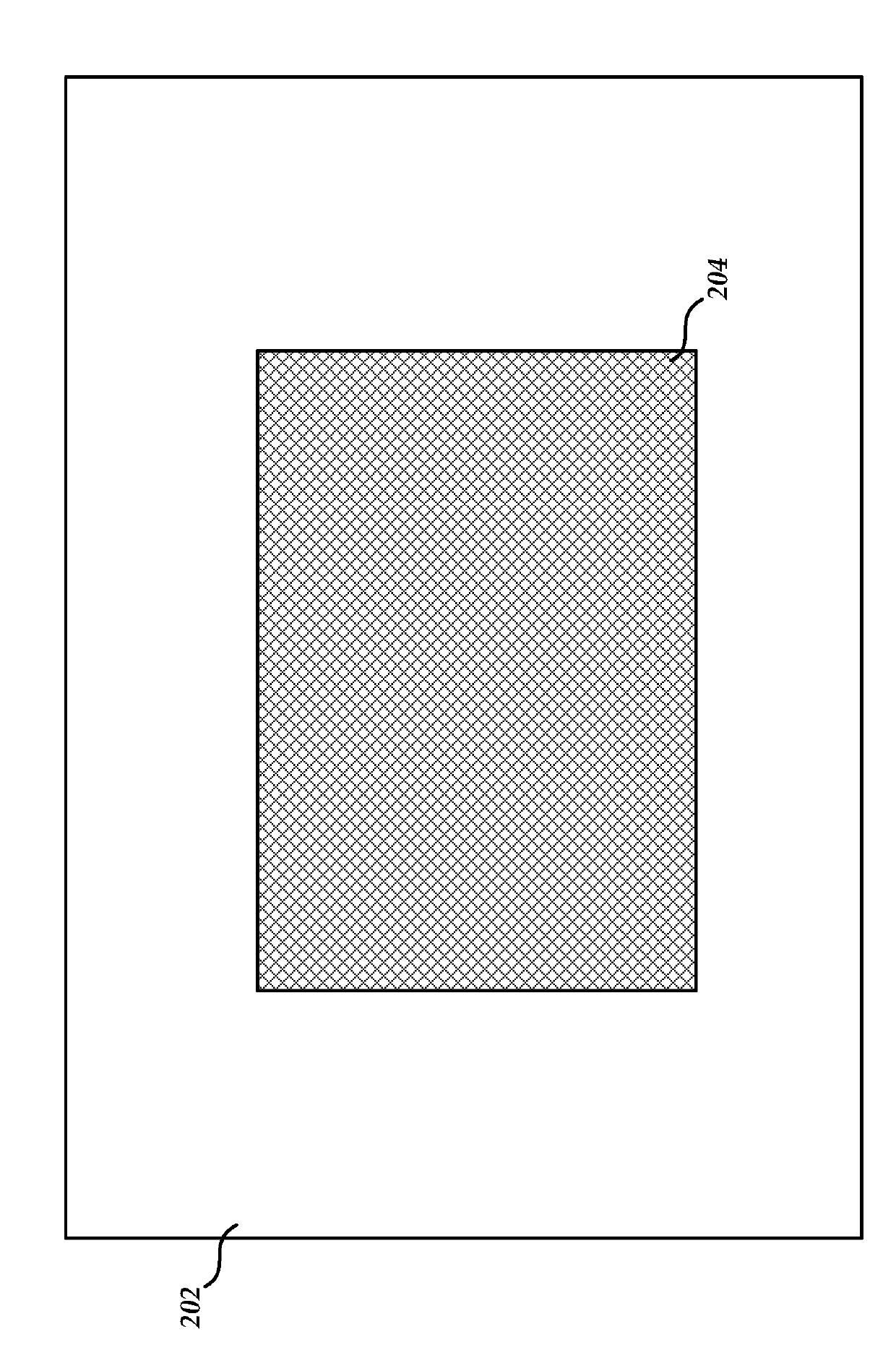

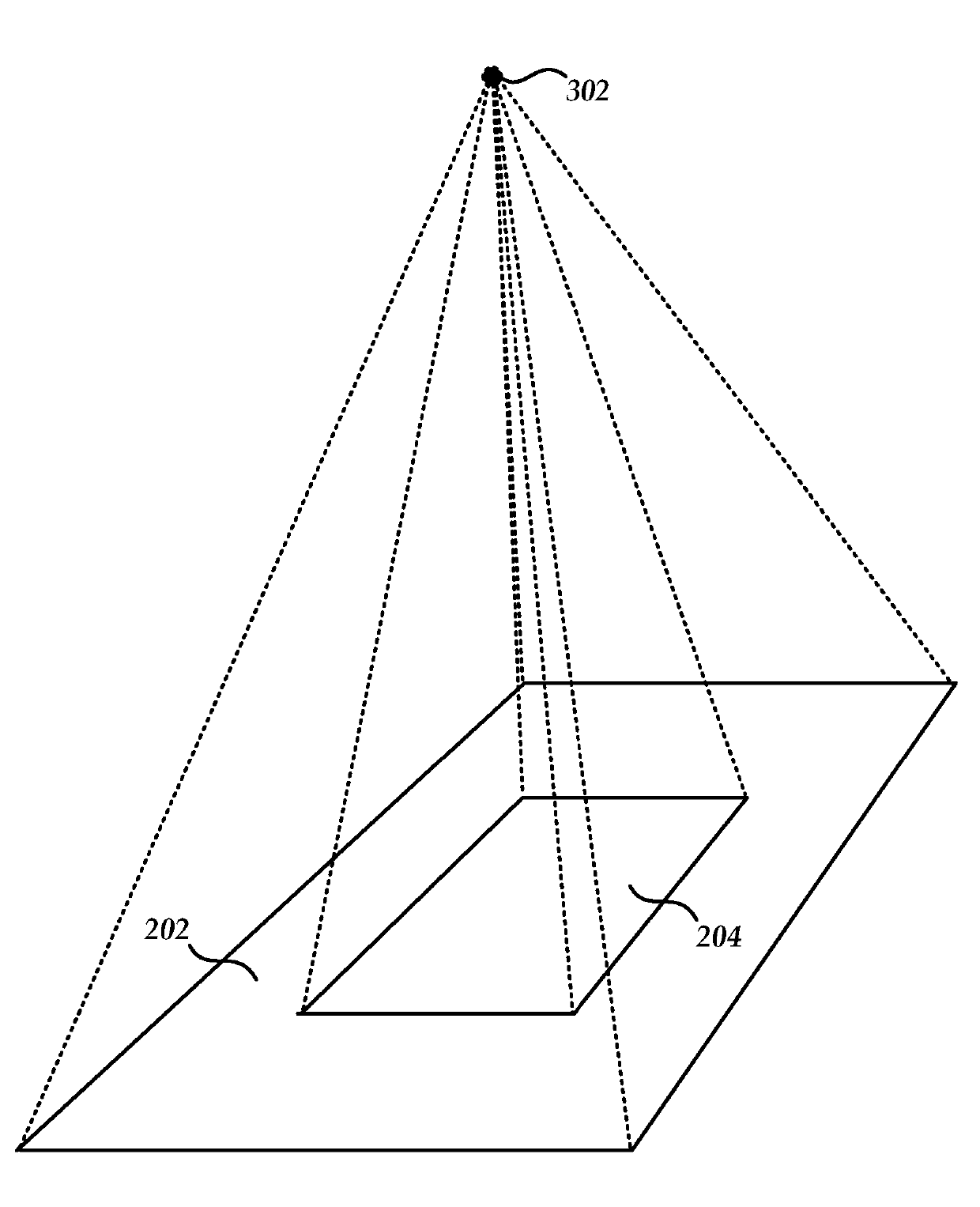

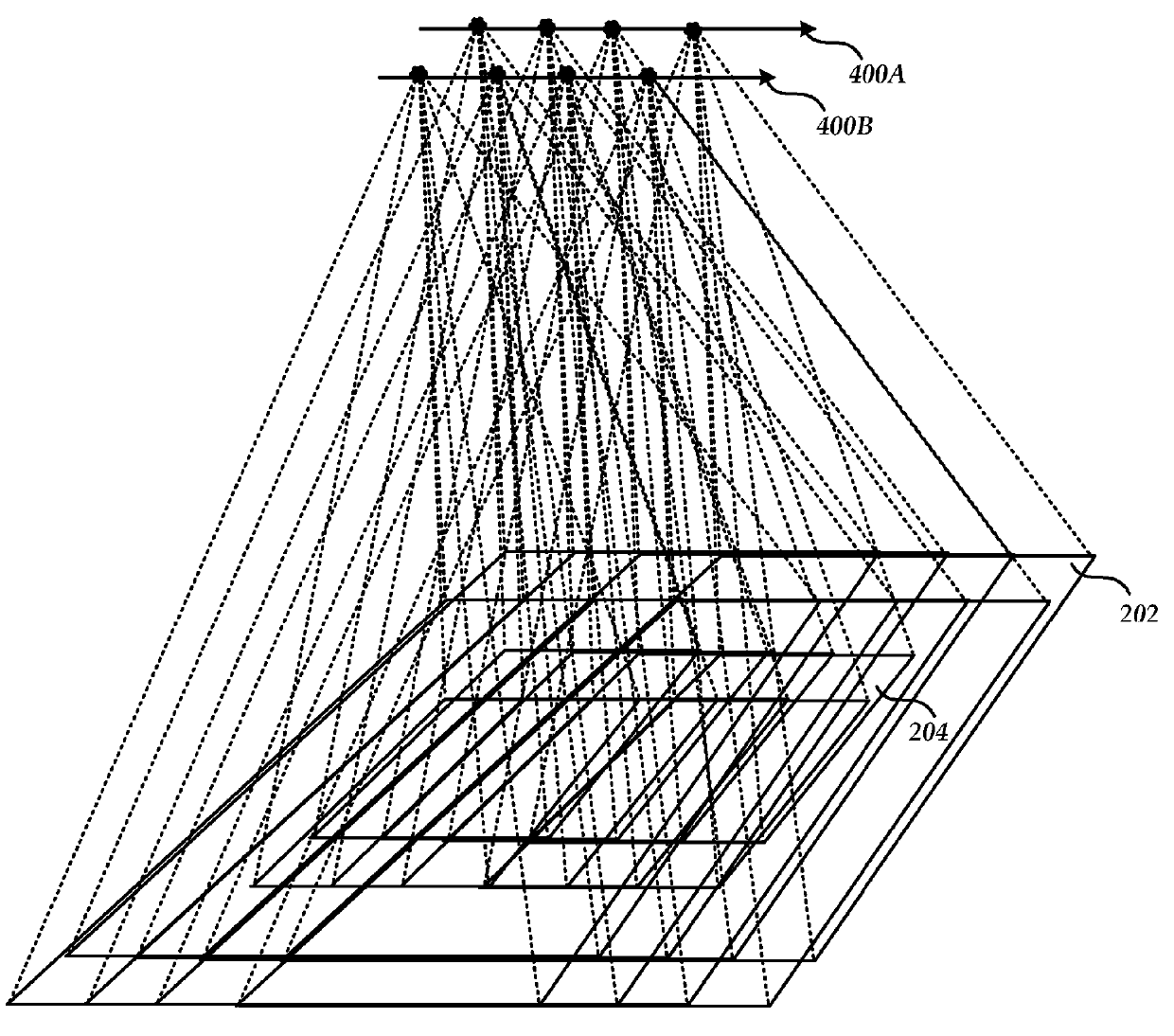

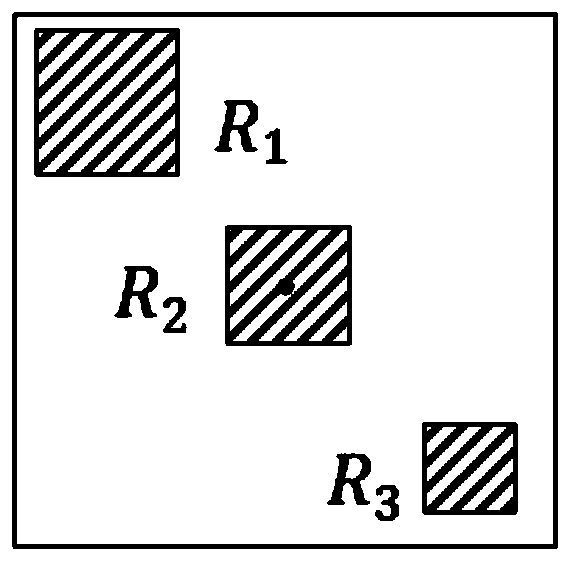

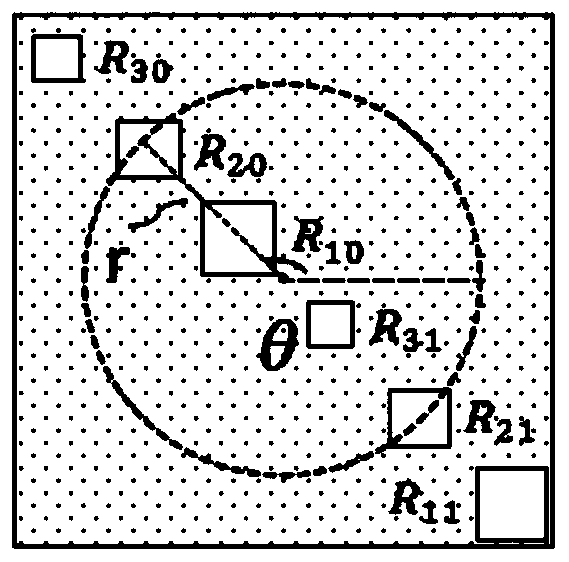

Large format, digital camera systems (10, 100, 150, 250, 310) expose single detector arrays 20 with multiple lens systems (12, 14, 16, 18) or multiple detector arrays (104, 106, 108, 110, 112, 114, 116, 118, 120, 152, 162, 172, 182, 252, 262, 272, 282, 322, 324) with one or more single lens systems (156, 166, 176, 186) to acquire sub-images of overlapping sub-areas of large area objects. The sub-images are stitched together to form a large format, digital, macro-image (80, 230'', 236'', 238'', 240''), which can be colored. Dampened camera carrier (400) and accelerometer (404) signals with double-rate digital signal processing (306, 308) are used.

Owner:VEXCEL IMAGING US INC

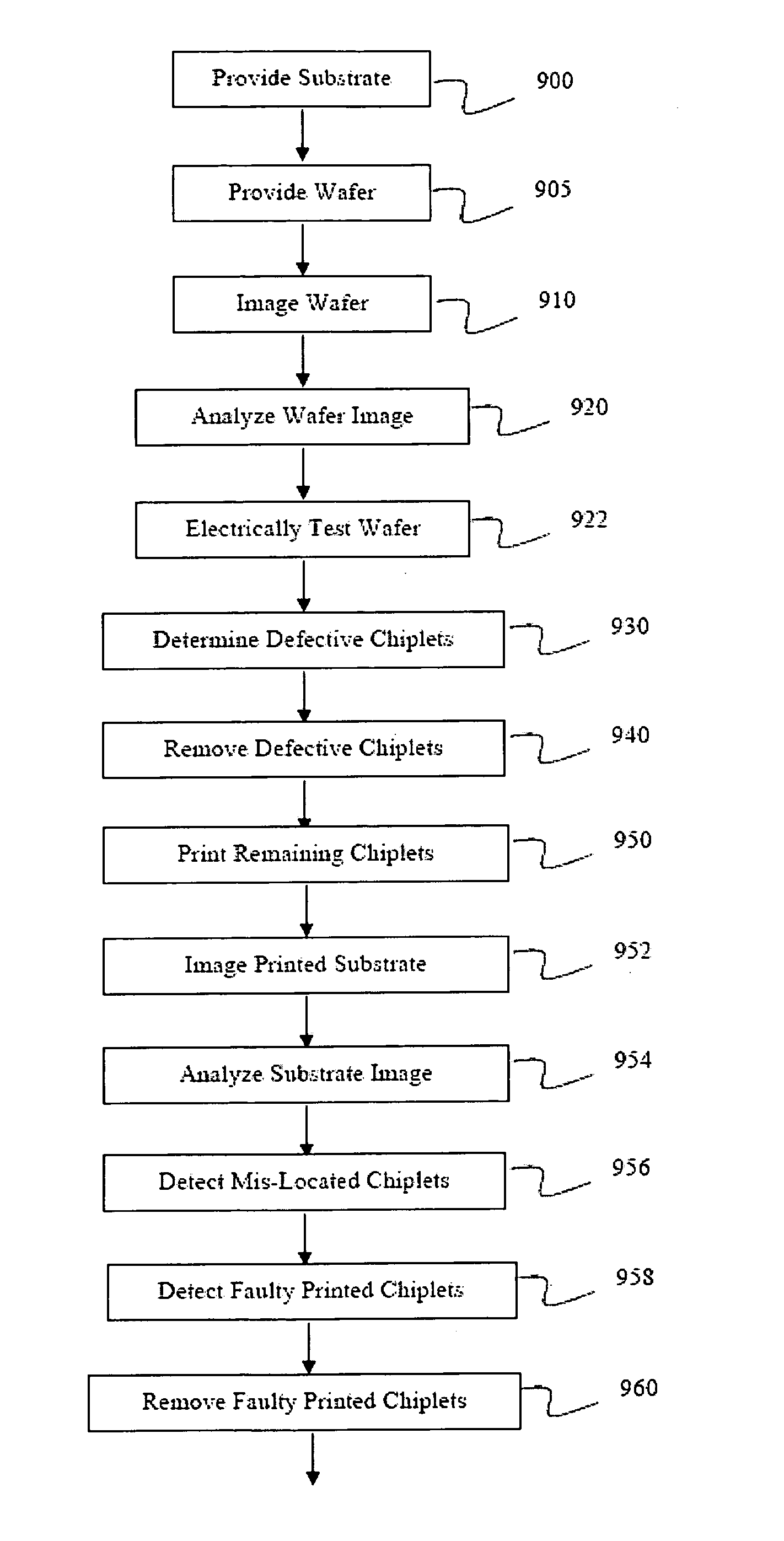

High-yield fabrication of large-format substrates with distributed, independent control elements

ActiveUS20120228669A1Semiconductor/solid-state device testing/measurementElectronic circuit testingElectrical and Electronics engineeringWafering

A large-format substrate with distributed control elements is formed by providing a substrate and a wafer, the wafer having a plurality of separate, independent chiplets formed thereon; imaging the wafer and analyzing the wafer image to determine which of the chiplets are defective; removing the defective chiplet(s) from the wafer leaving remaining chiplets in place on the wafer; printing the remaining chiplet(s) onto the substrate forming empty chiplet location(s); and printing additional chiplet(s) from the same or a different wafer into the empty chiplet location(s).

Owner:X DISPLAY CO TECH LTD

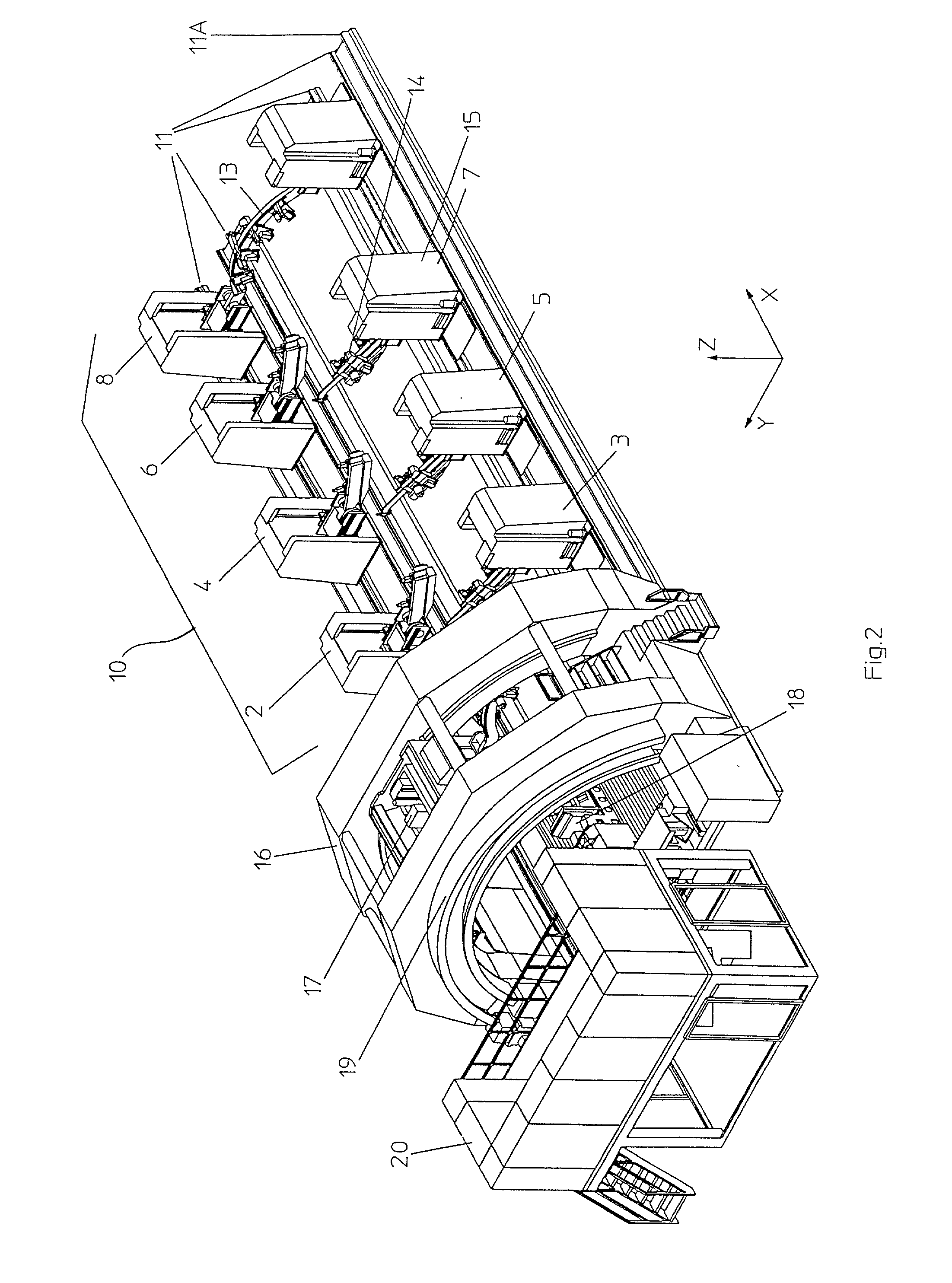

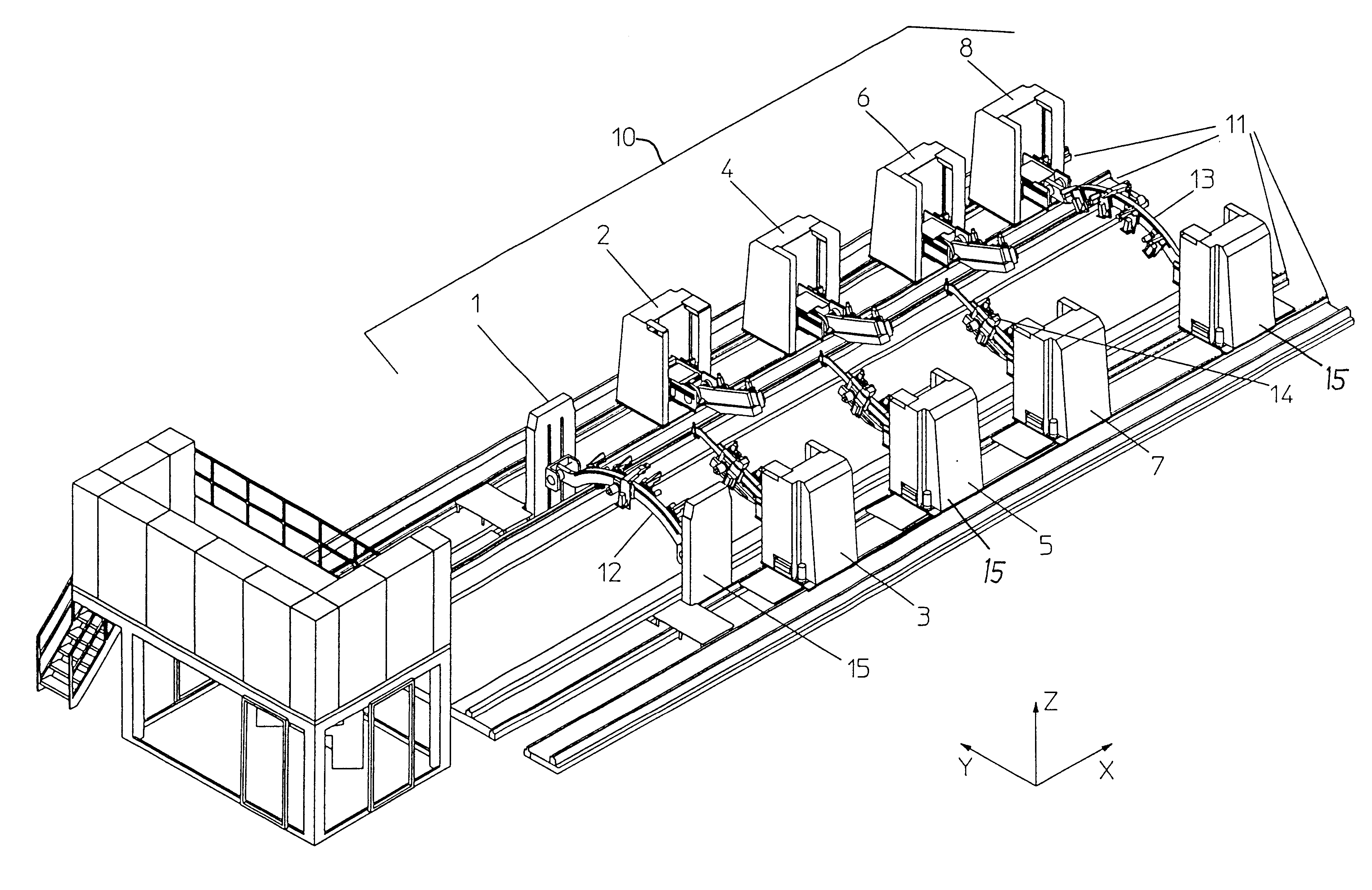

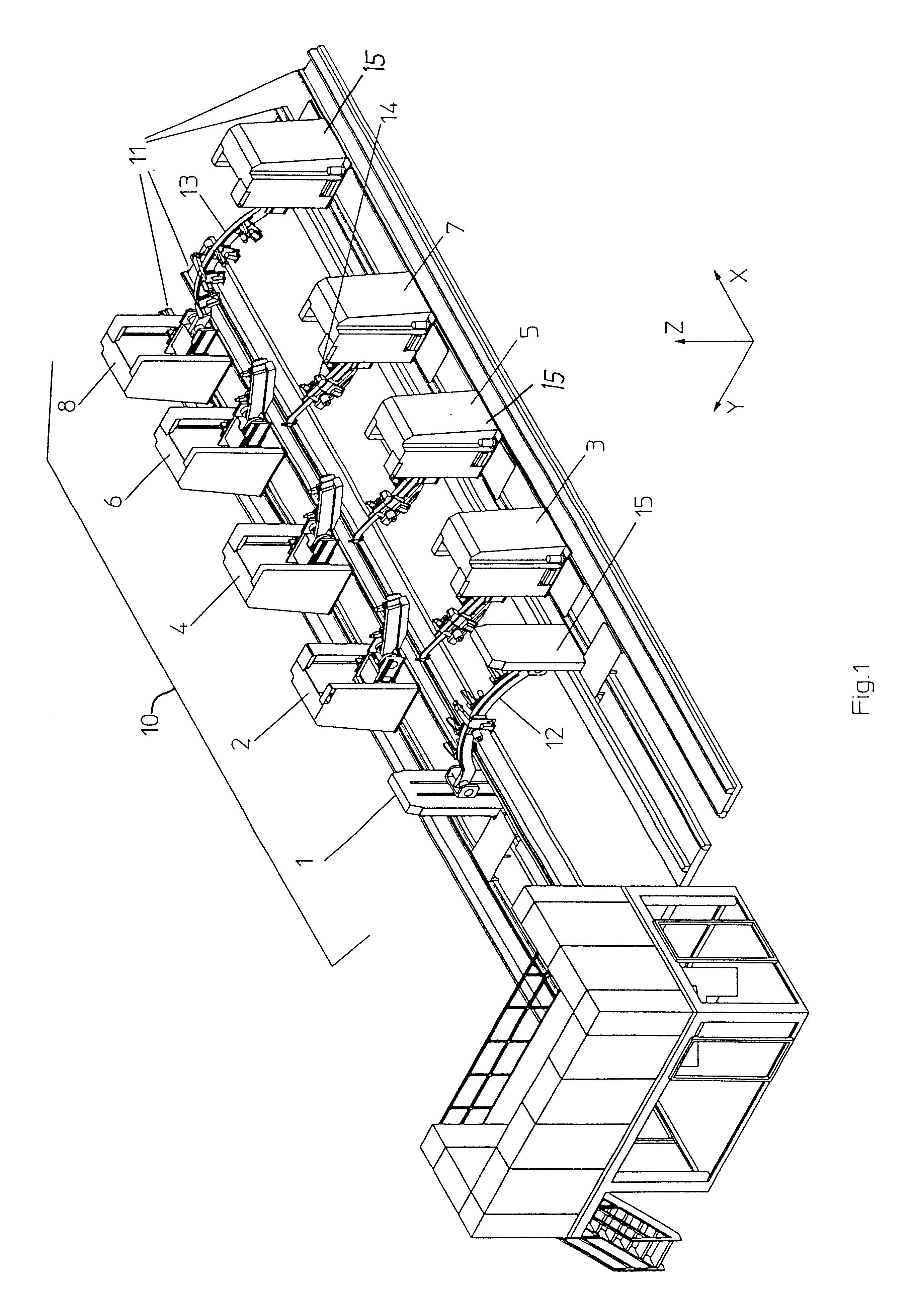

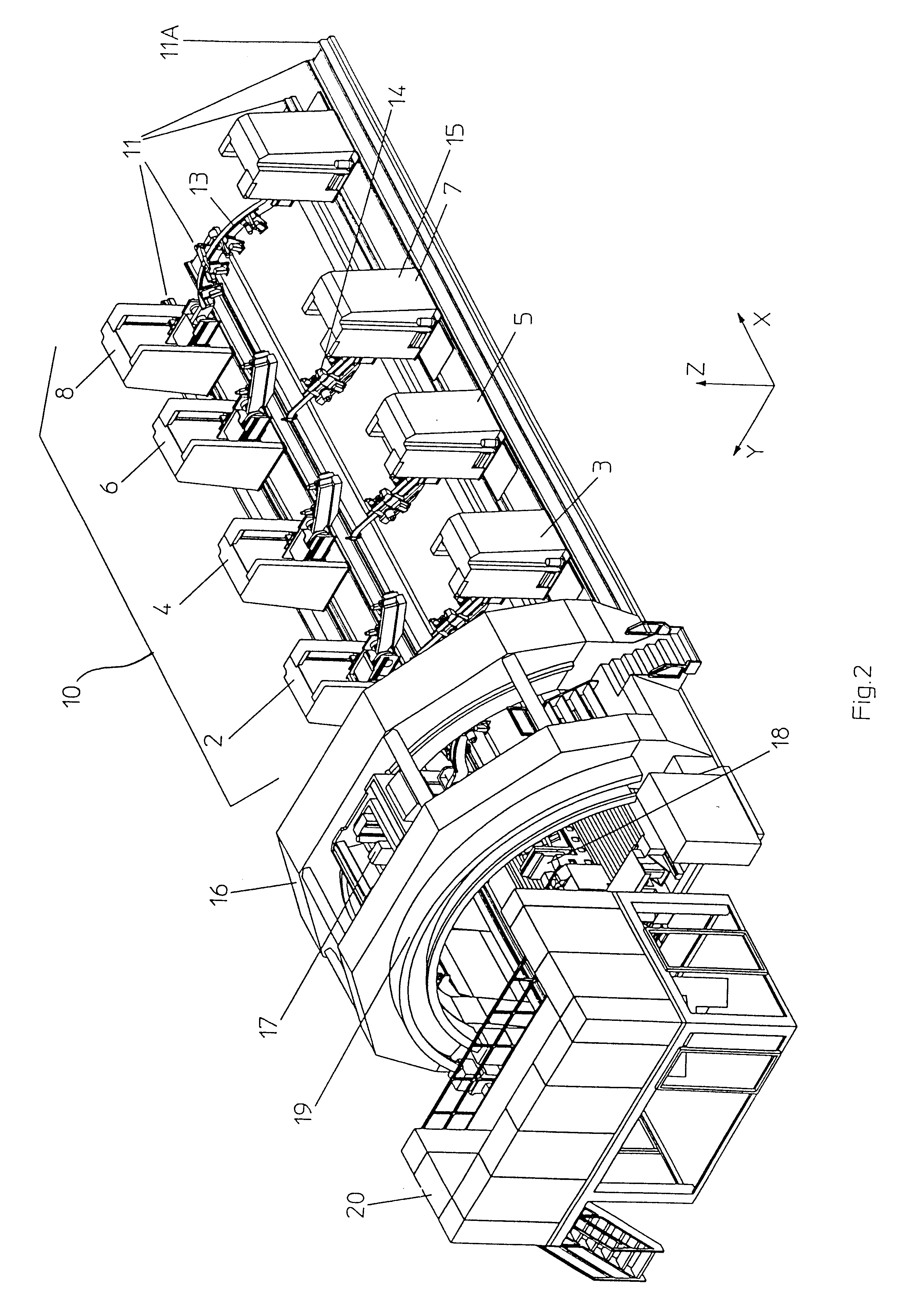

Versatile adaptable holding apparatus for holding large format workpieces

InactiveUS20020092149A1Precise positioningReduce usageLarge fixed membersPositioning apparatusRiveting machinesMachine

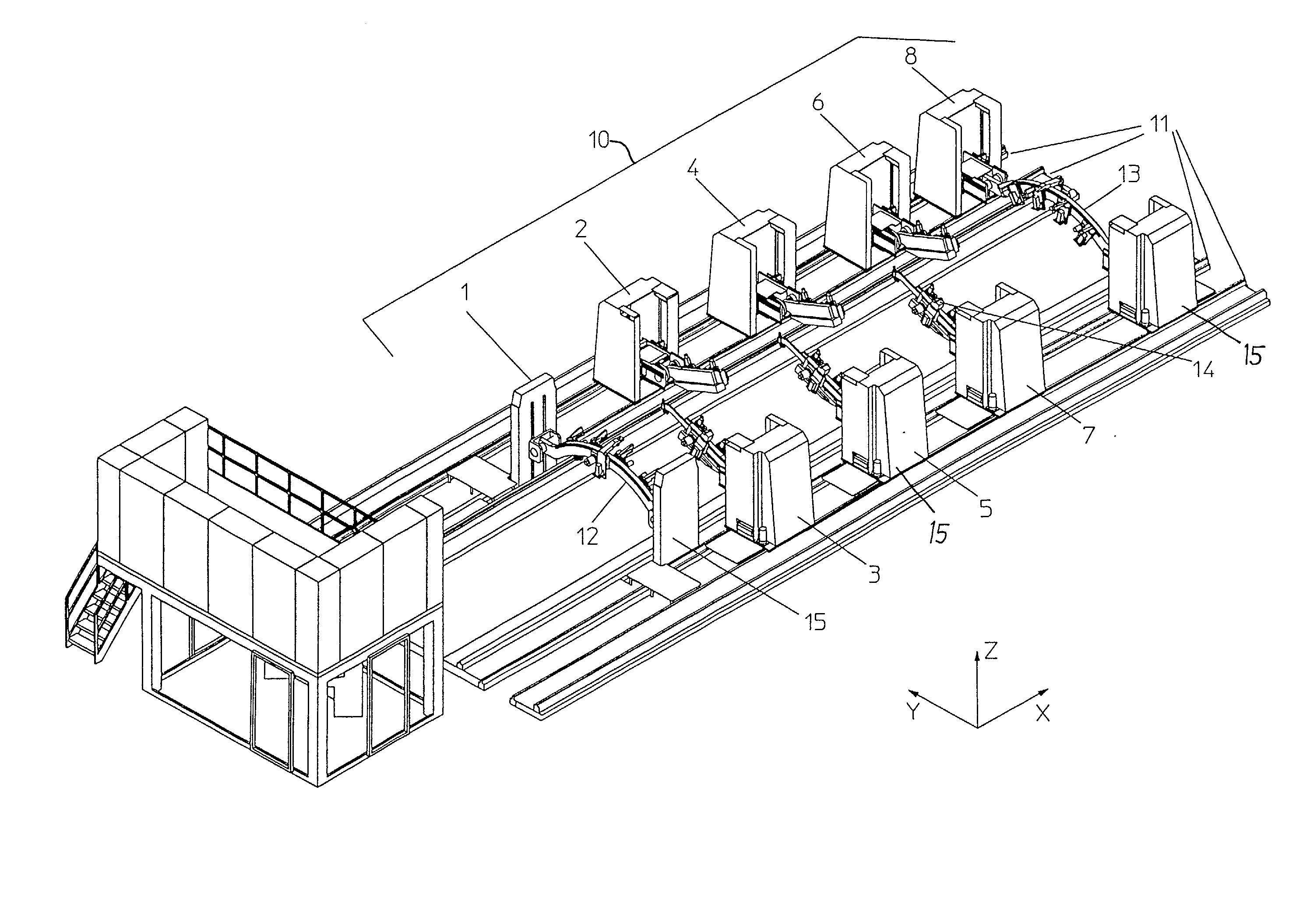

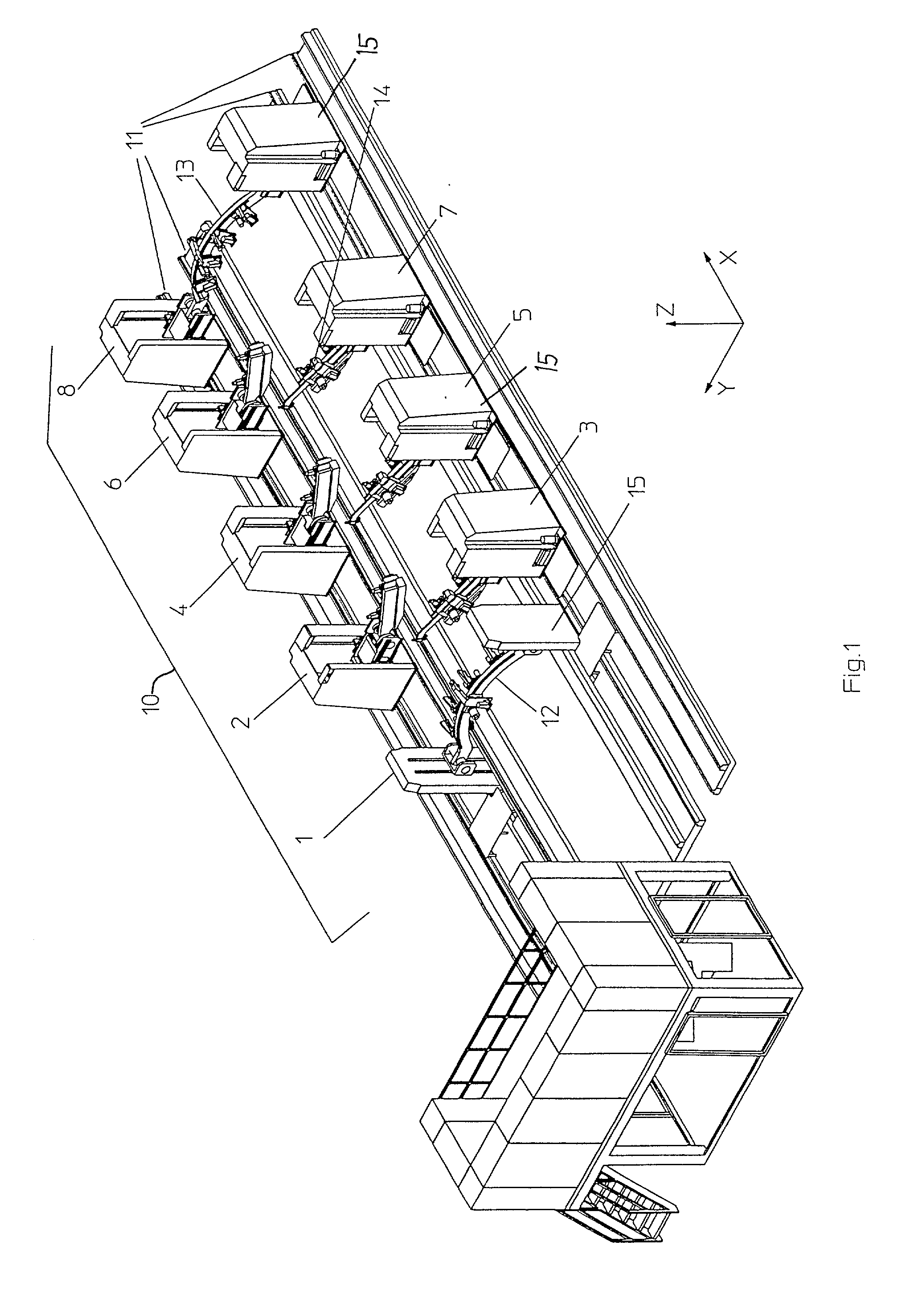

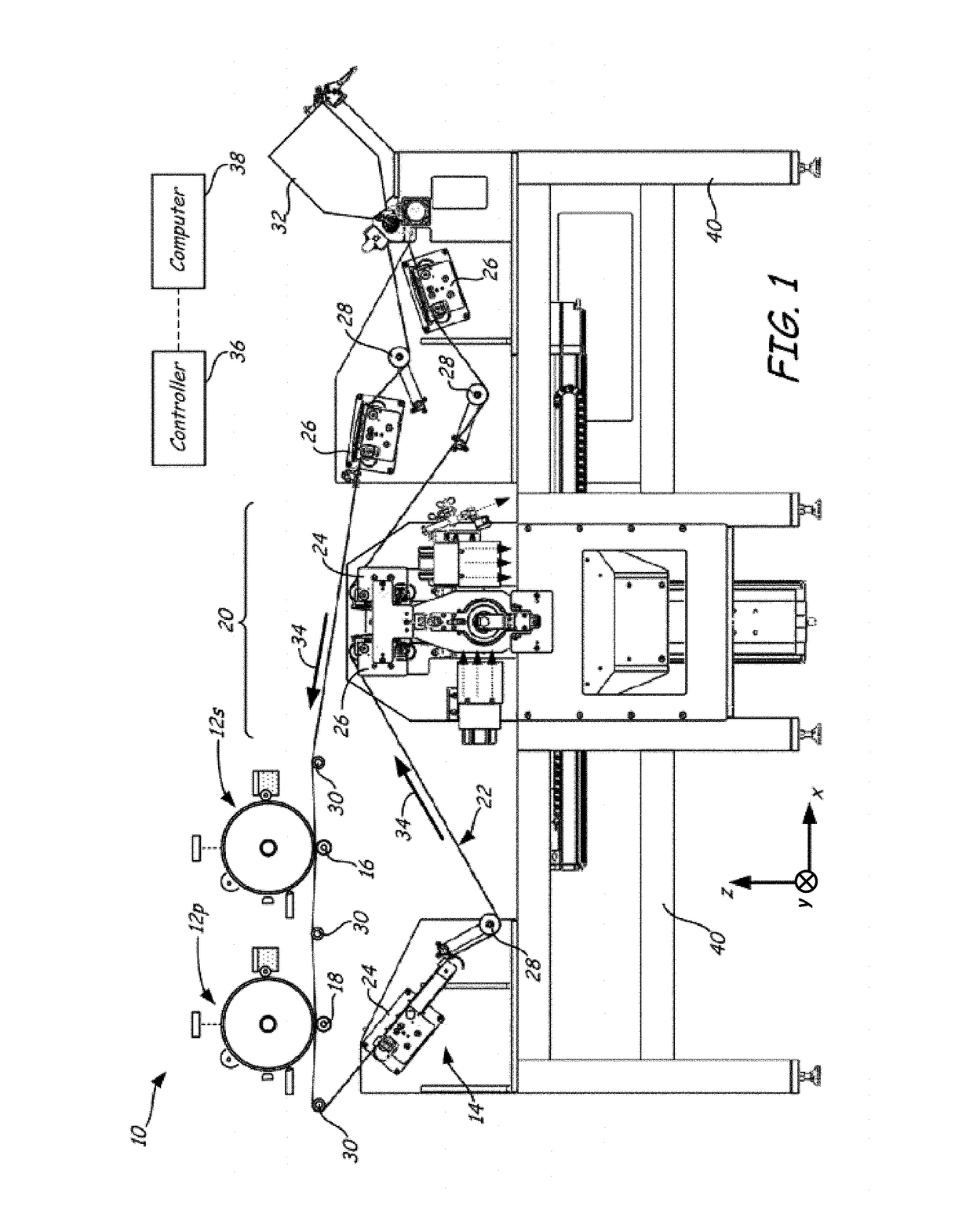

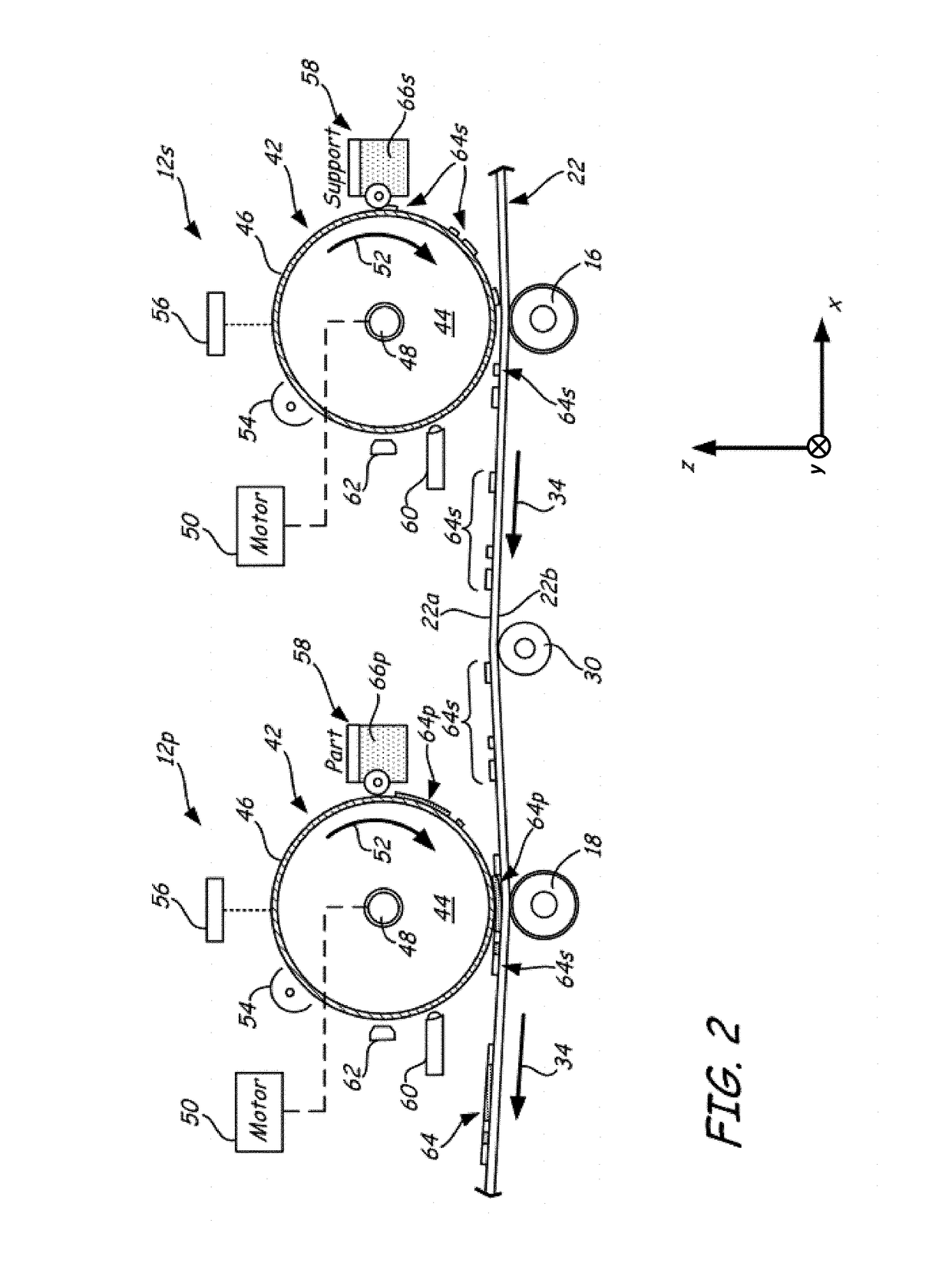

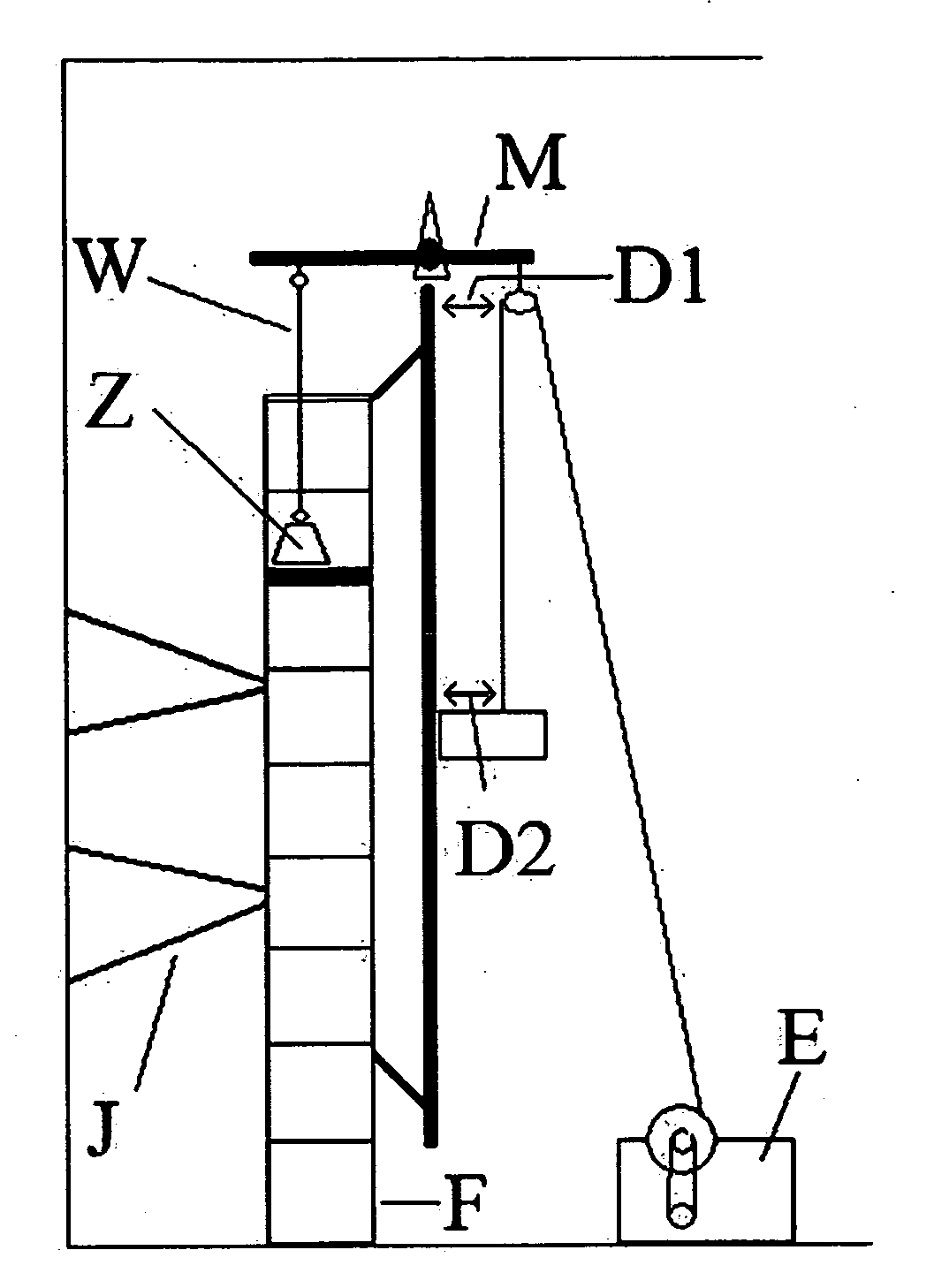

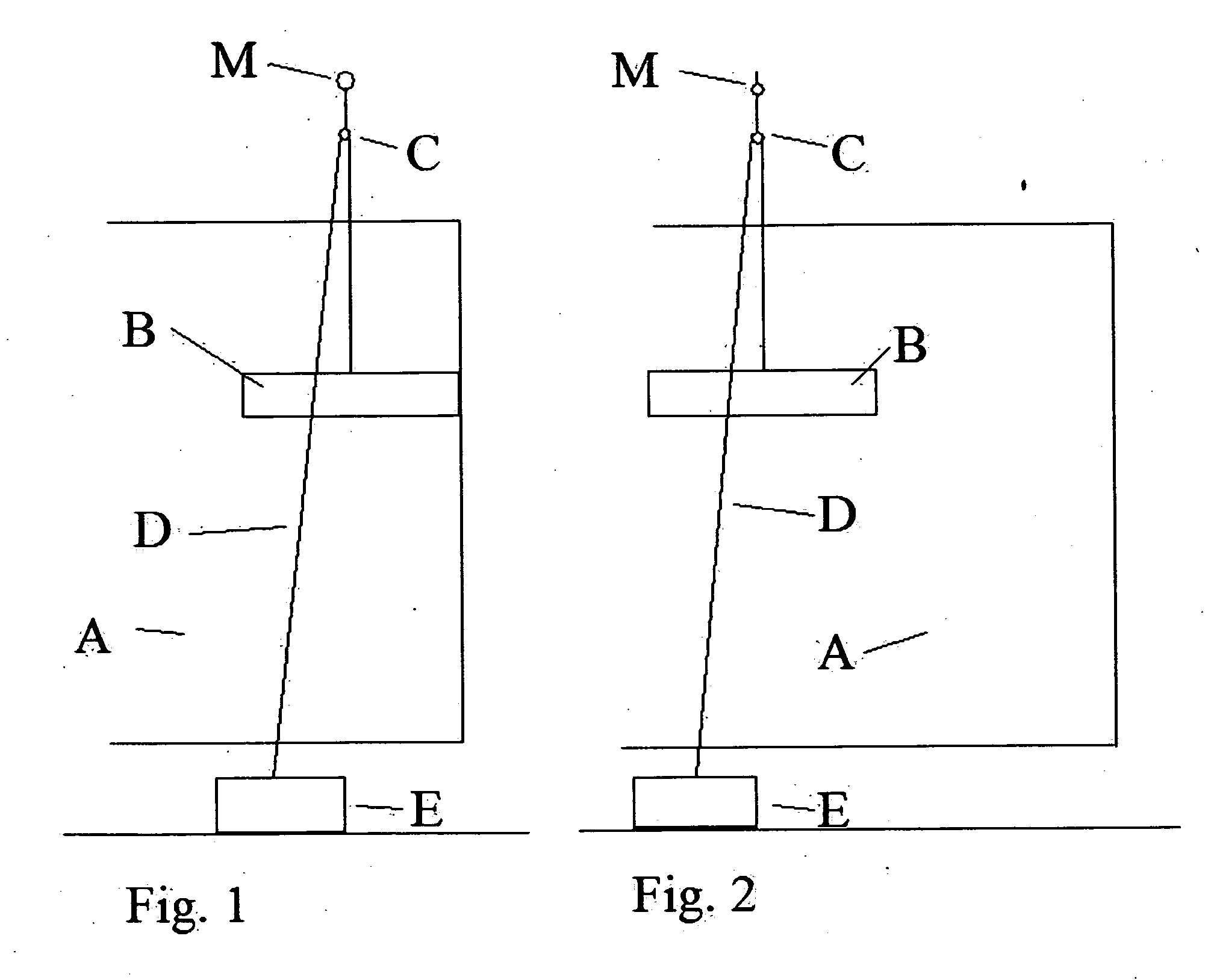

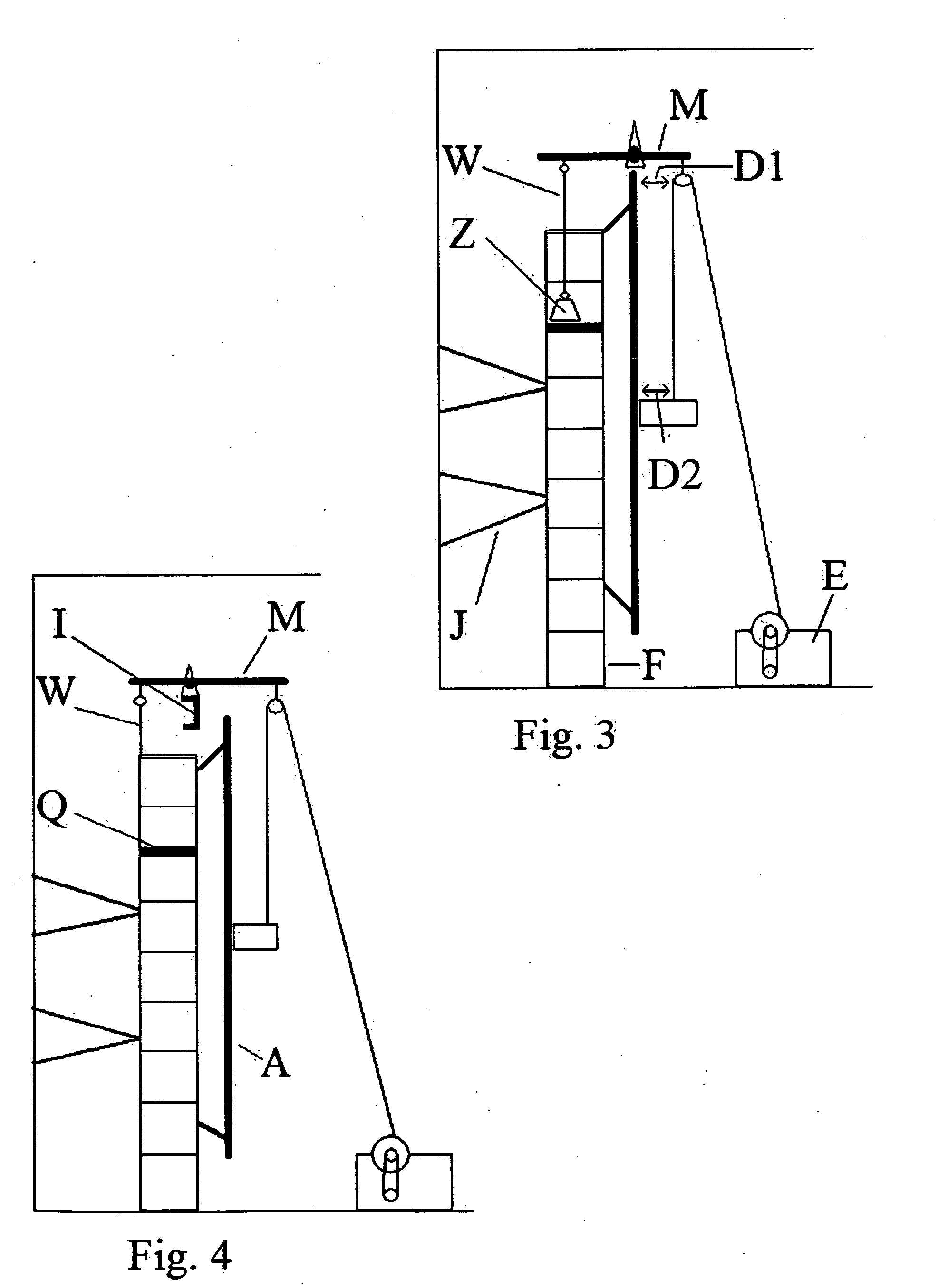

An apparatus for holding a large format workpiece includes first and second sets of support units on opposite sides of the workpiece. Each support unit includes a support arm carrying individual mounting fixtures such as suction units for suction-holding the workpiece. The support arm is pivotably mounted on a support column, which in turn is movable along a floor-mounted rail. A riveting machine includes an upper tool and a lower tool that are movable parallel to the floor-mounted rail. To make space for the machine to set rivets in the area that is supported by a given support arm, that support arm is released from the workpiece and moved away to allow the machine to carry out its riveting cycle at that area, while the greatest possible number of the other support units simultaneously remain in place and continue to support the workpiece.

Owner:AIRBUS OPERATIONS GMBH +1

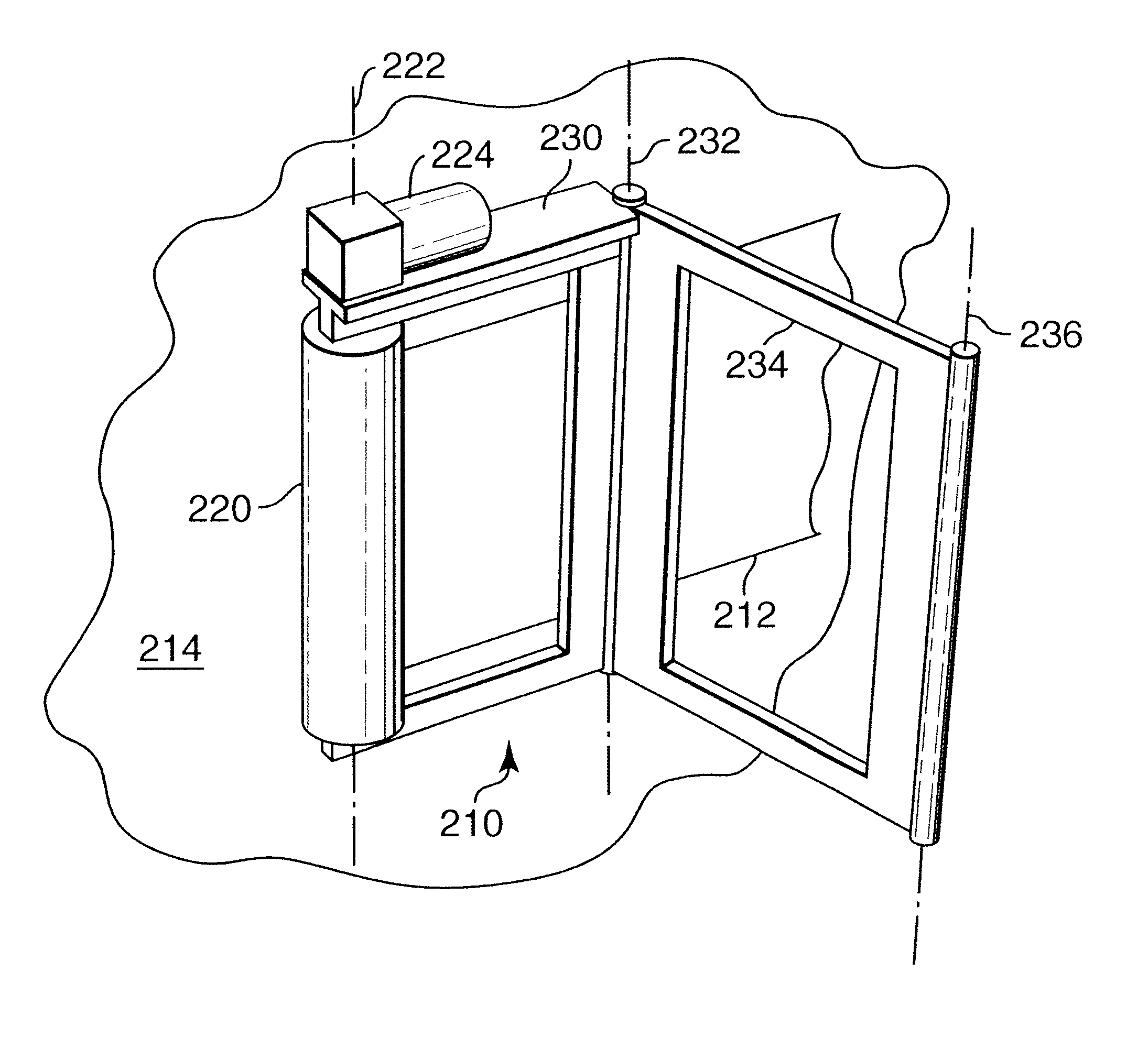

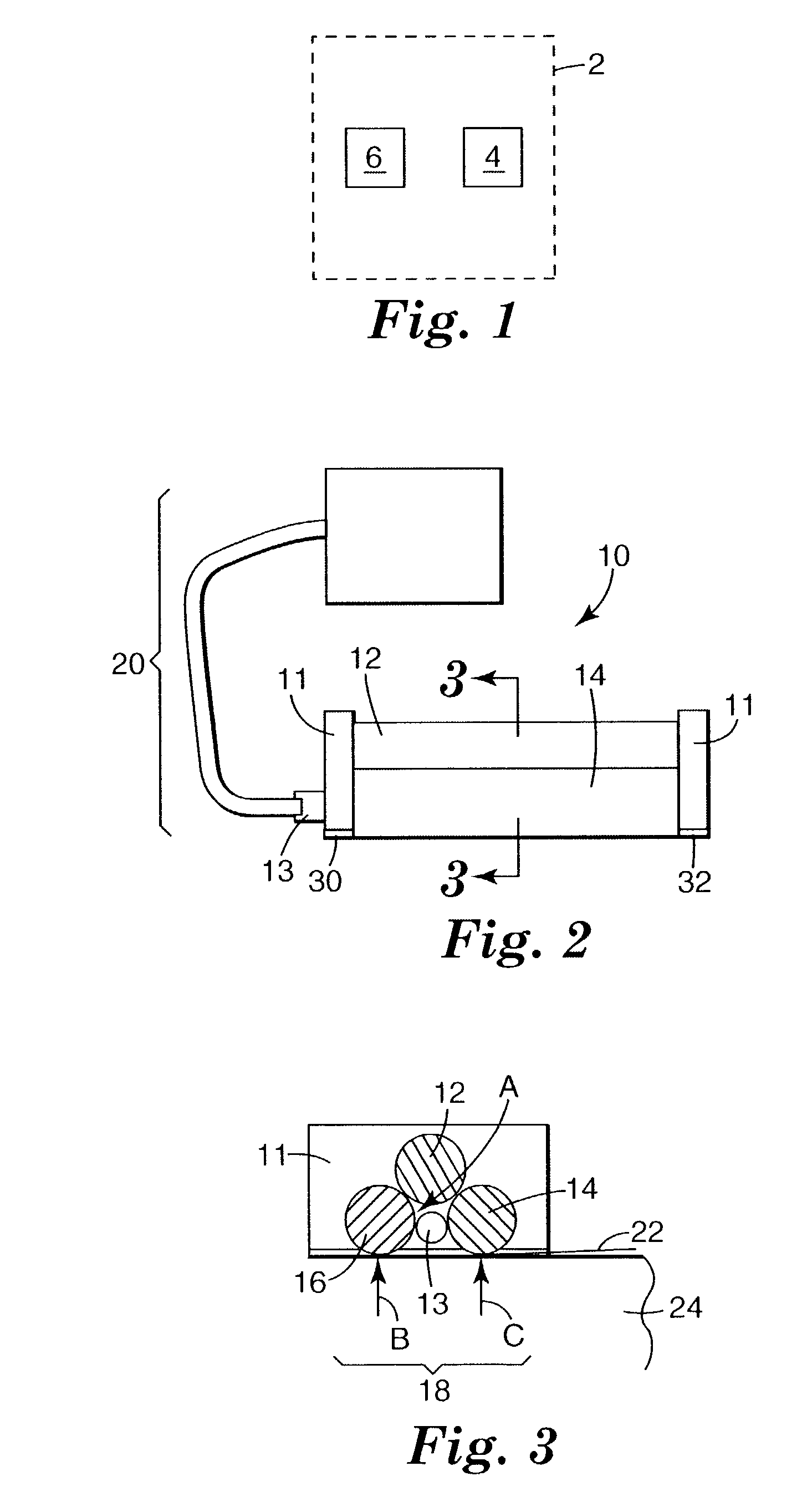

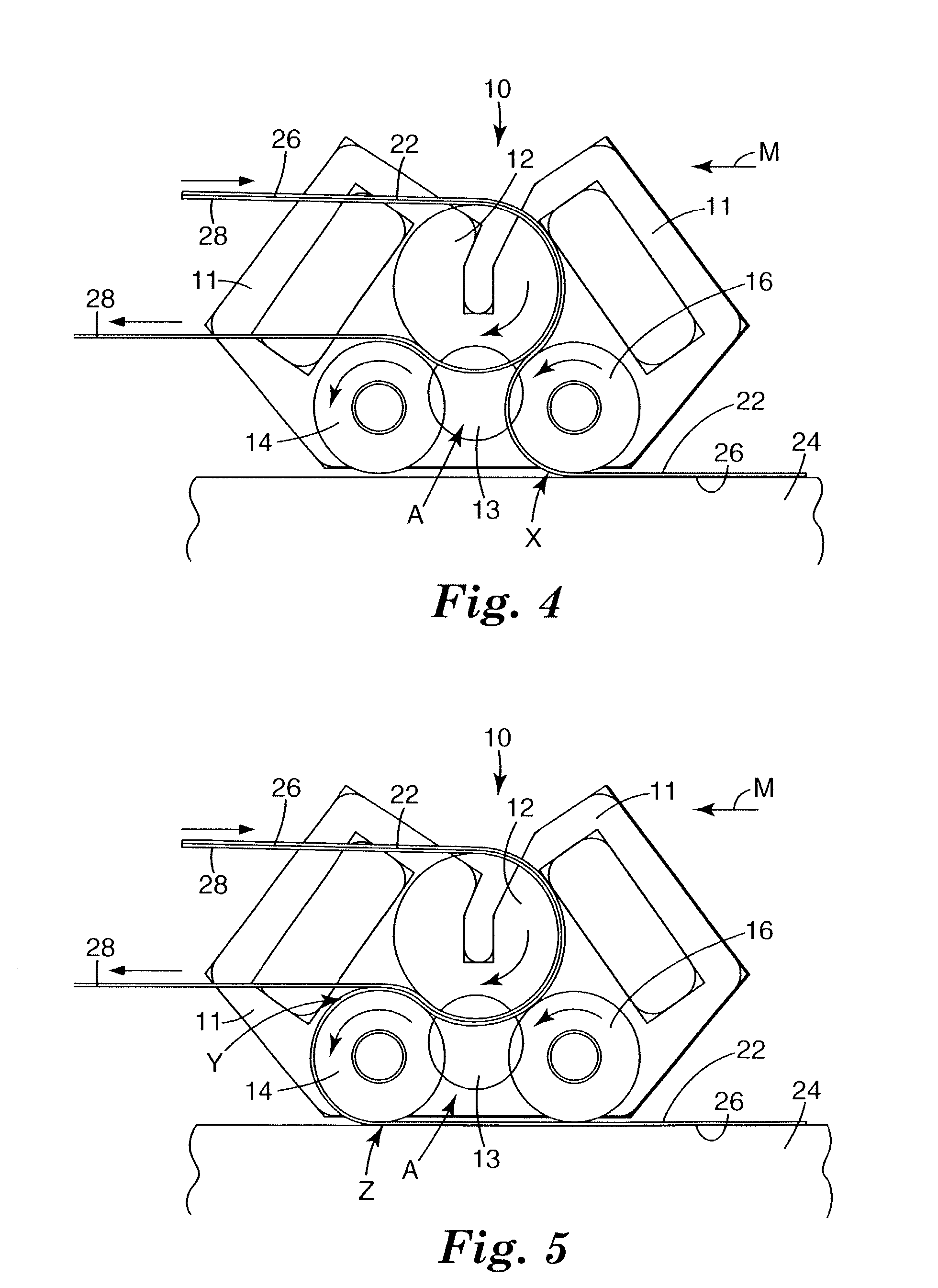

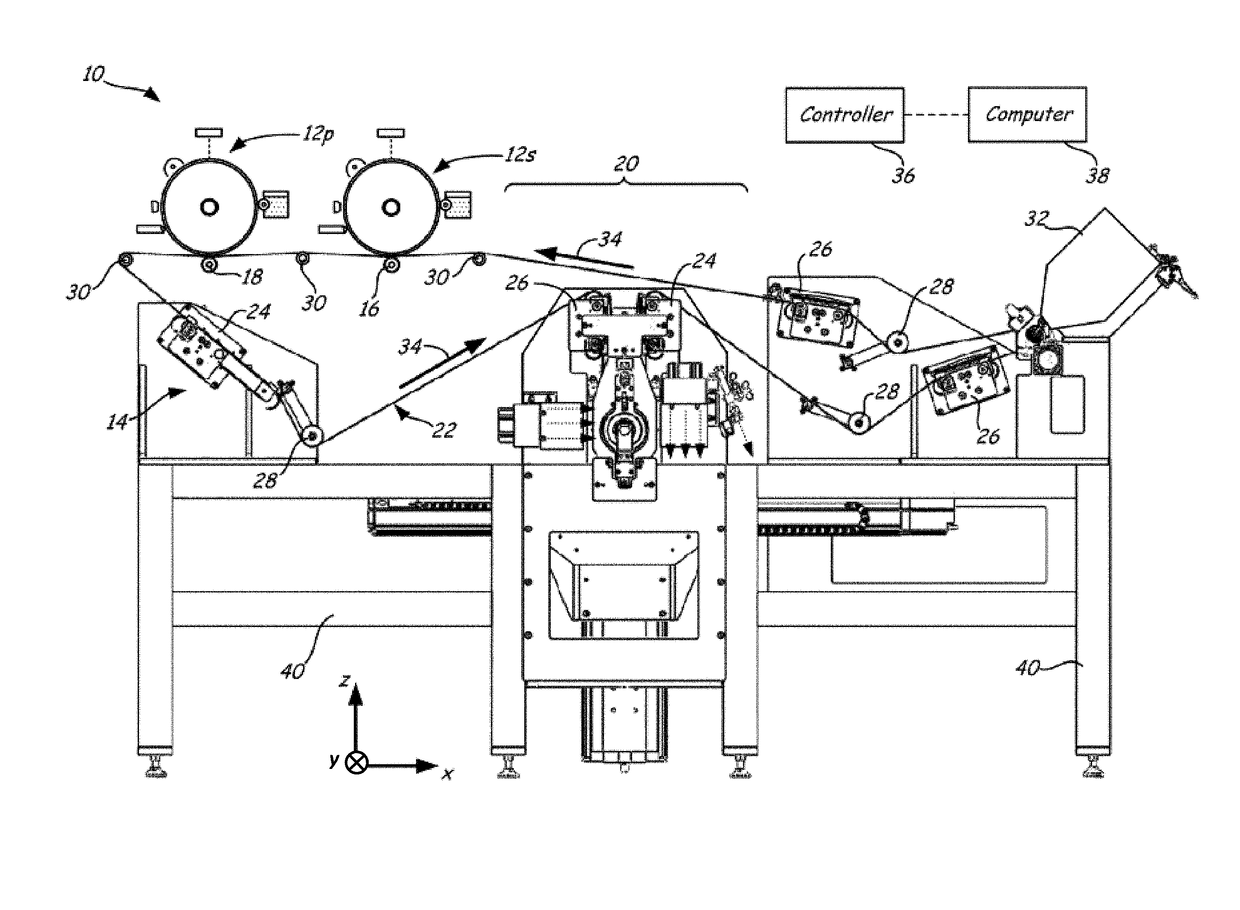

Film lamination and removal system and methods of use

InactiveUS6706131B2Good lookingIncreased durabilityMechanical working/deformationCovering/liningsVacuum assistedAdhesive

Vacuum-assisted film laminating and removal systems and methods of using the same. The systems include a vacuum-assisted laminator for applying large format films to substrates where lamination pressure is generated at least partially by a vacuum drawn in a vacuum cavity. The removal apparatus applies tension over the width of the adhesive film, thereby removing the film from the substrate along the release line that extends over the width of the film. The systems and methods can be used to apply and remove large-scale adhesive films from substrates.

Owner:3M INNOVATIVE PROPERTIES CO

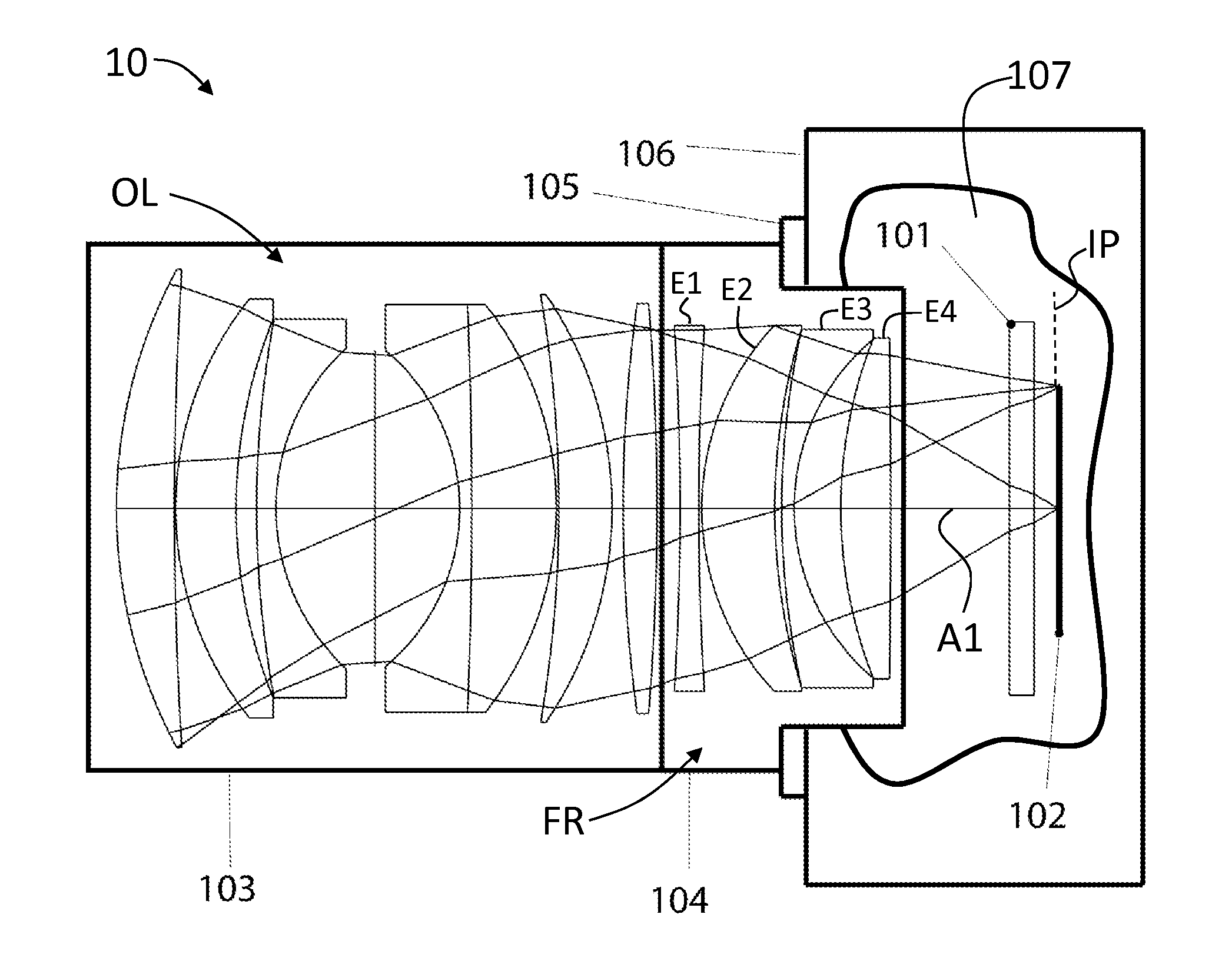

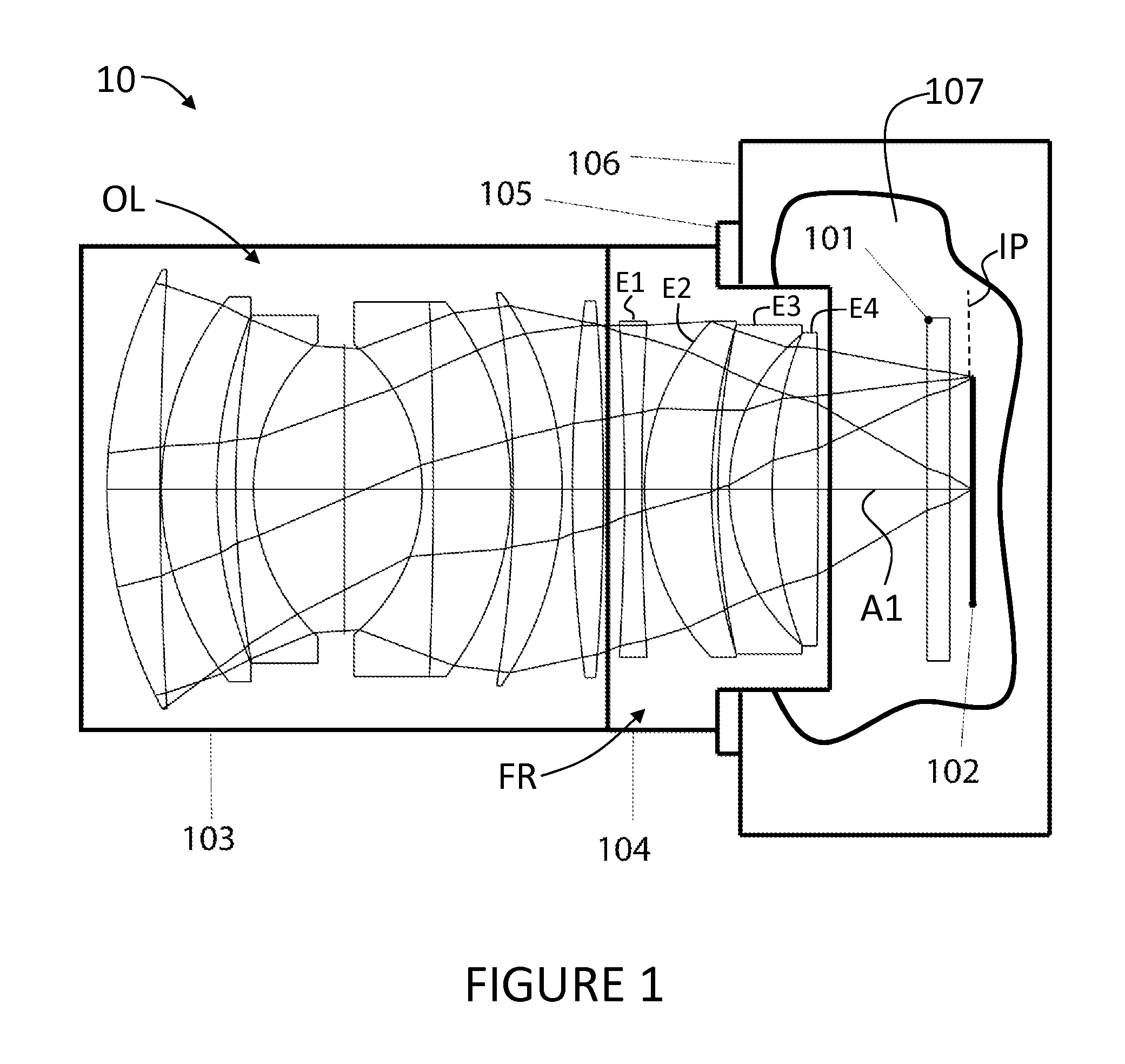

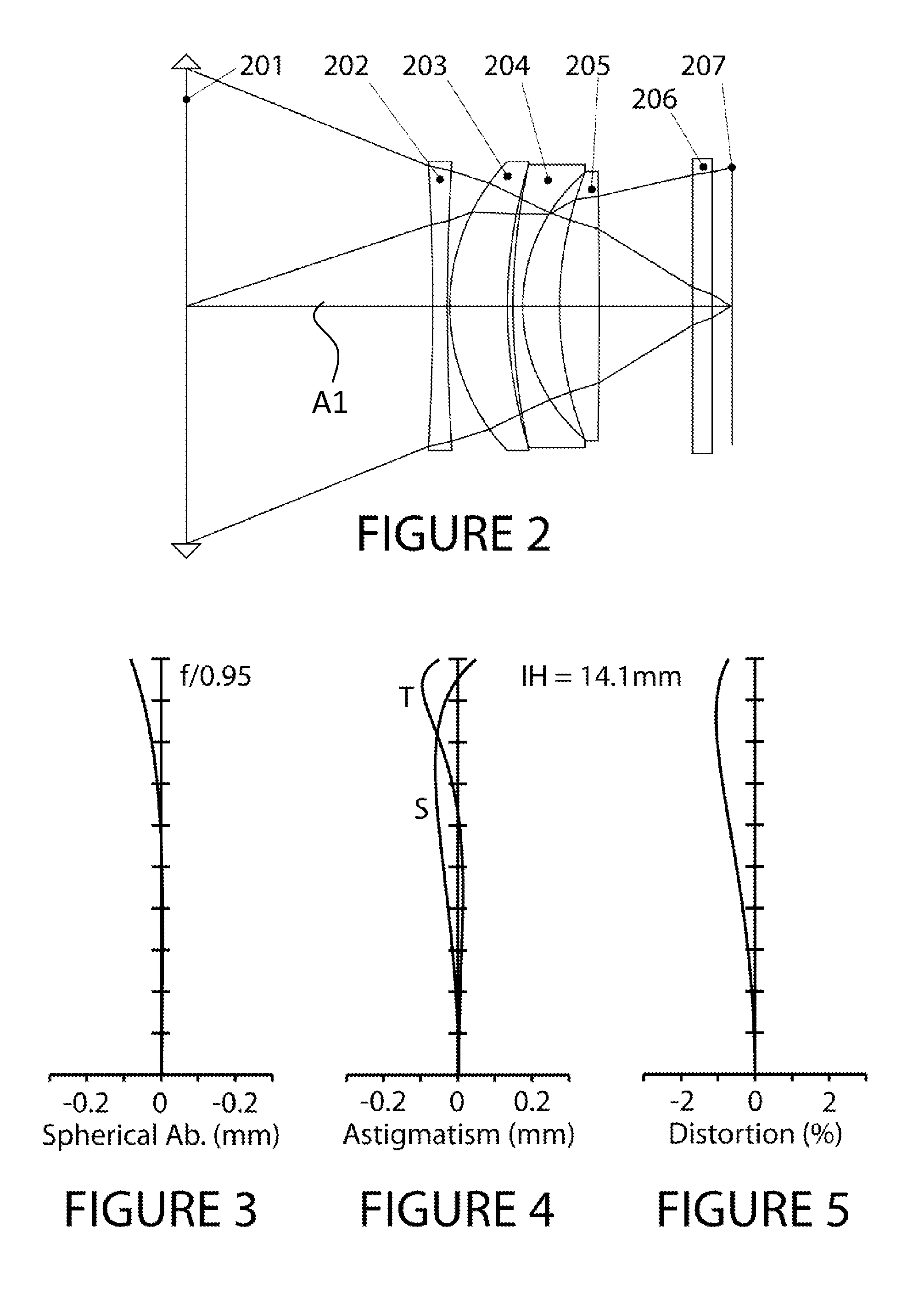

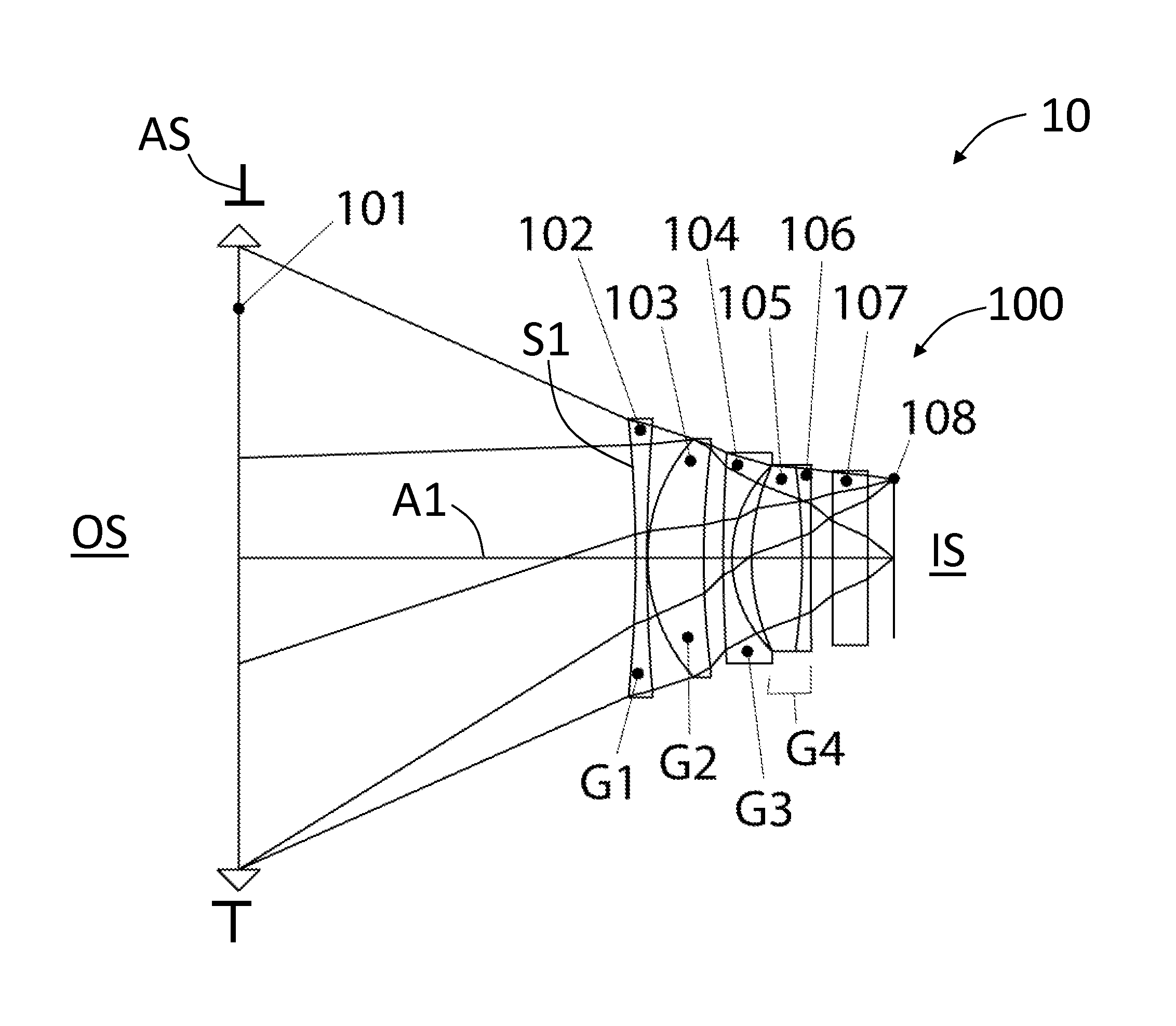

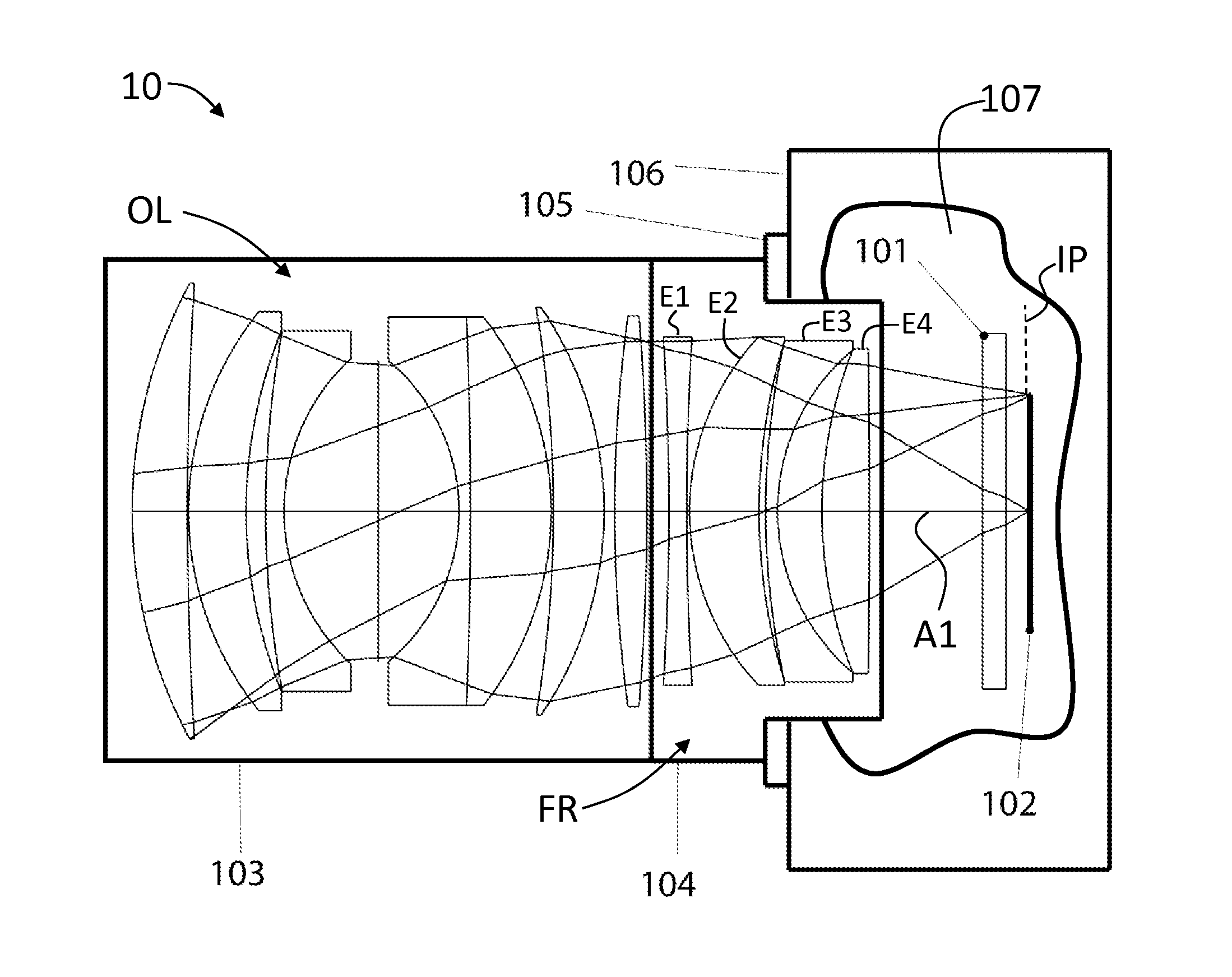

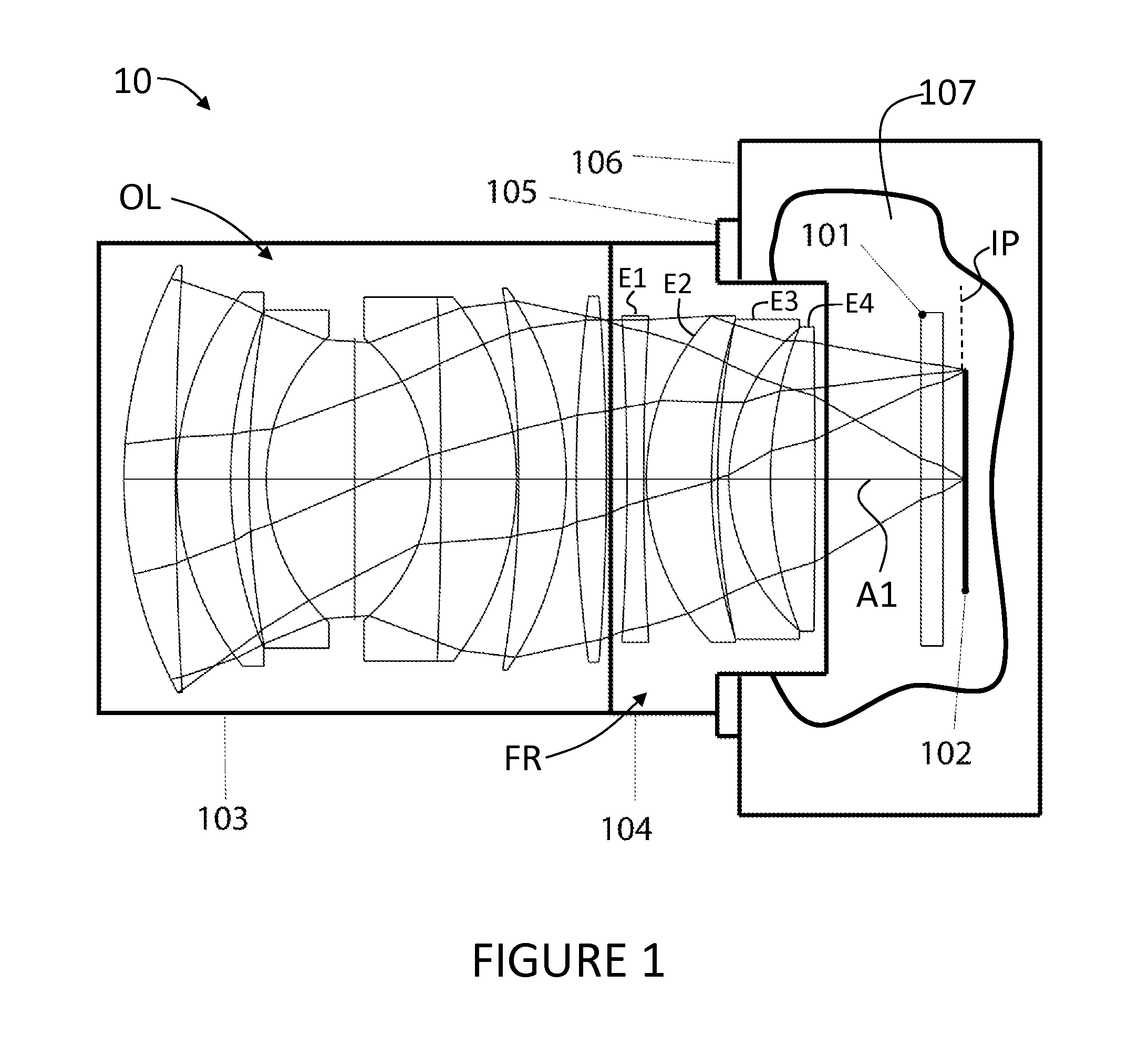

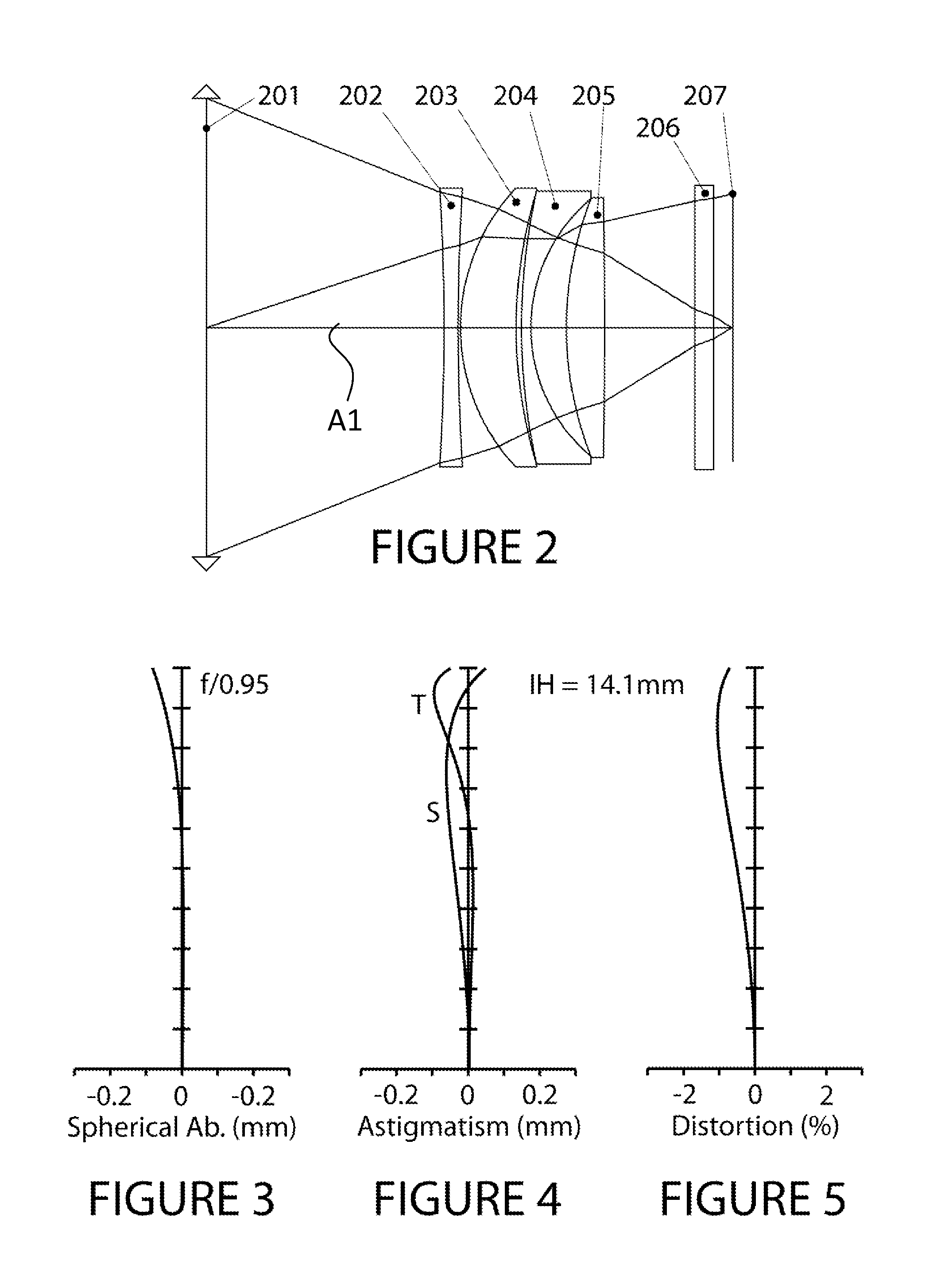

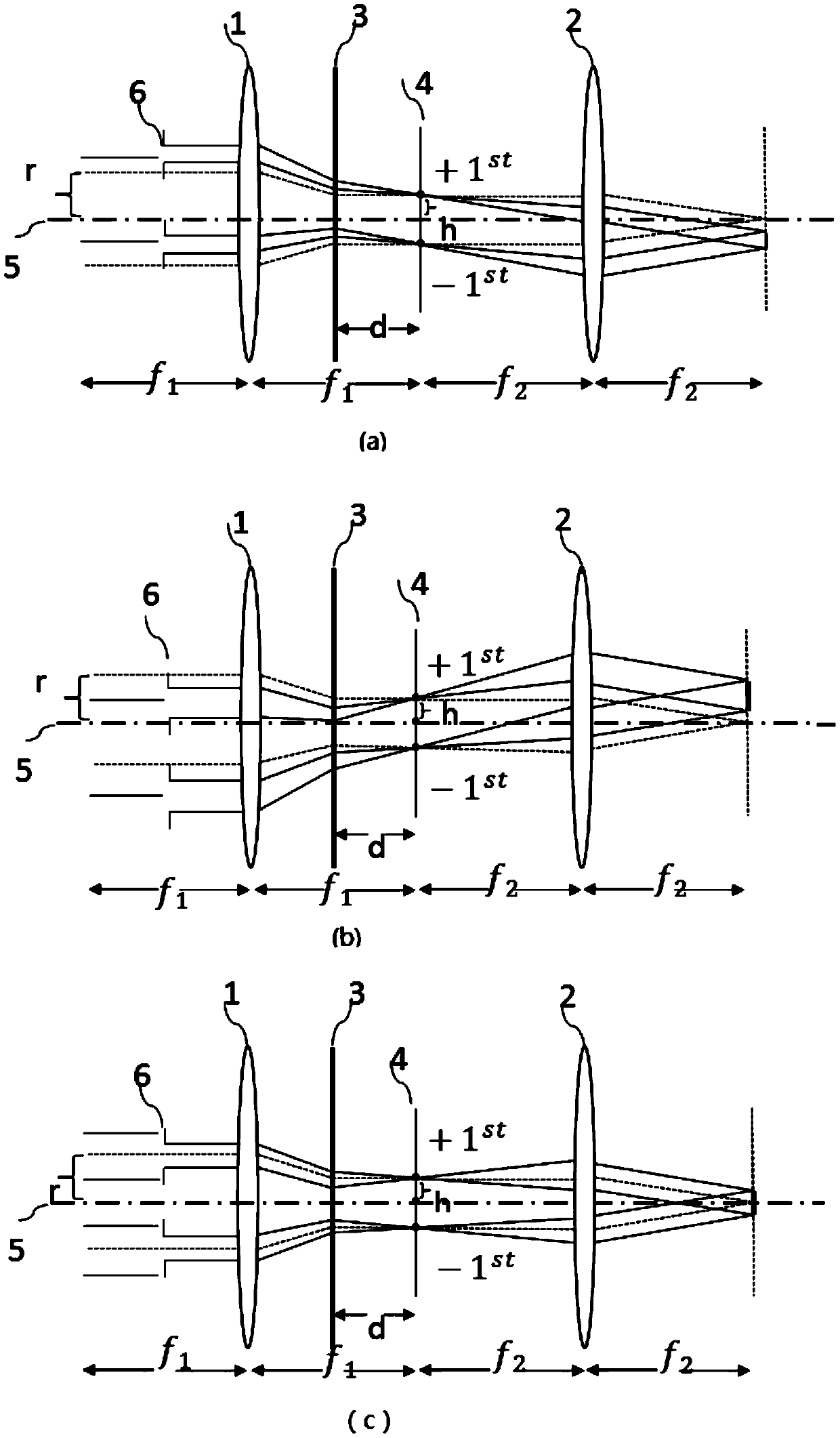

Optical attachment for reducing the focal length of an objective lens

InactiveUS20130064532A1Shorten focal lengthReduce focal ratioCamera body detailsOptical elementsMagnificationPhysics

An optical attachment configured to be operably attached to the image side of an objective lens to reduce the focal length and focal ratio of the objective lens. The focal-reducing attachment includes four lens elements and has a magnification of between 0.5 and 1. The focal-reducing lens can work with objective lenses having relatively large working distances for a large format size as well as with cameras having a smaller format size and relatively small permissible working distance.

Owner:CALDWELL PHOTOGRAPHIC

Optical attachment for reducing the focal length of an objective lens

InactiveUS8903232B1Reduce aberrationImprovement in optical correctionCamera body detailsOptical elementsPhysicsAngular aperture

An optical attachment having five or six elements and configured to be operably arranged on the image side of an objective lens to reduce the focal length and focal ratio of the objective lens is disclosed. The optical attachment is particularly suitable for adapting objective lenses designed with a relatively large working distance for a large format size to cameras having a smaller format size and relatively small permissible working distance. The optical attachments disclosed herein have high image quality at large aperture over a large field of view, and can be well-corrected for all major aberrations.

Owner:CALDWELL PHOTOGRAPHIC

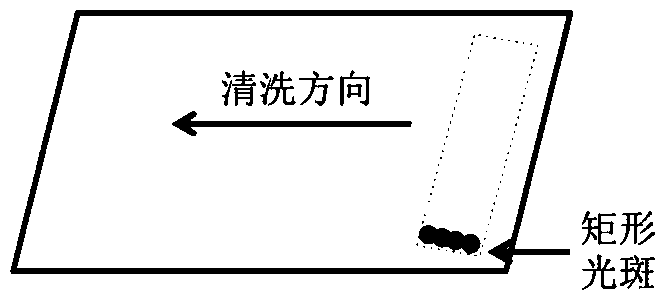

Multi-laser-head intelligent laser cleaning method and device

ActiveCN111420938AEasy to cleanImprove cleaning efficiencyCleaning processes and apparatusImaging processingSurface cleaning

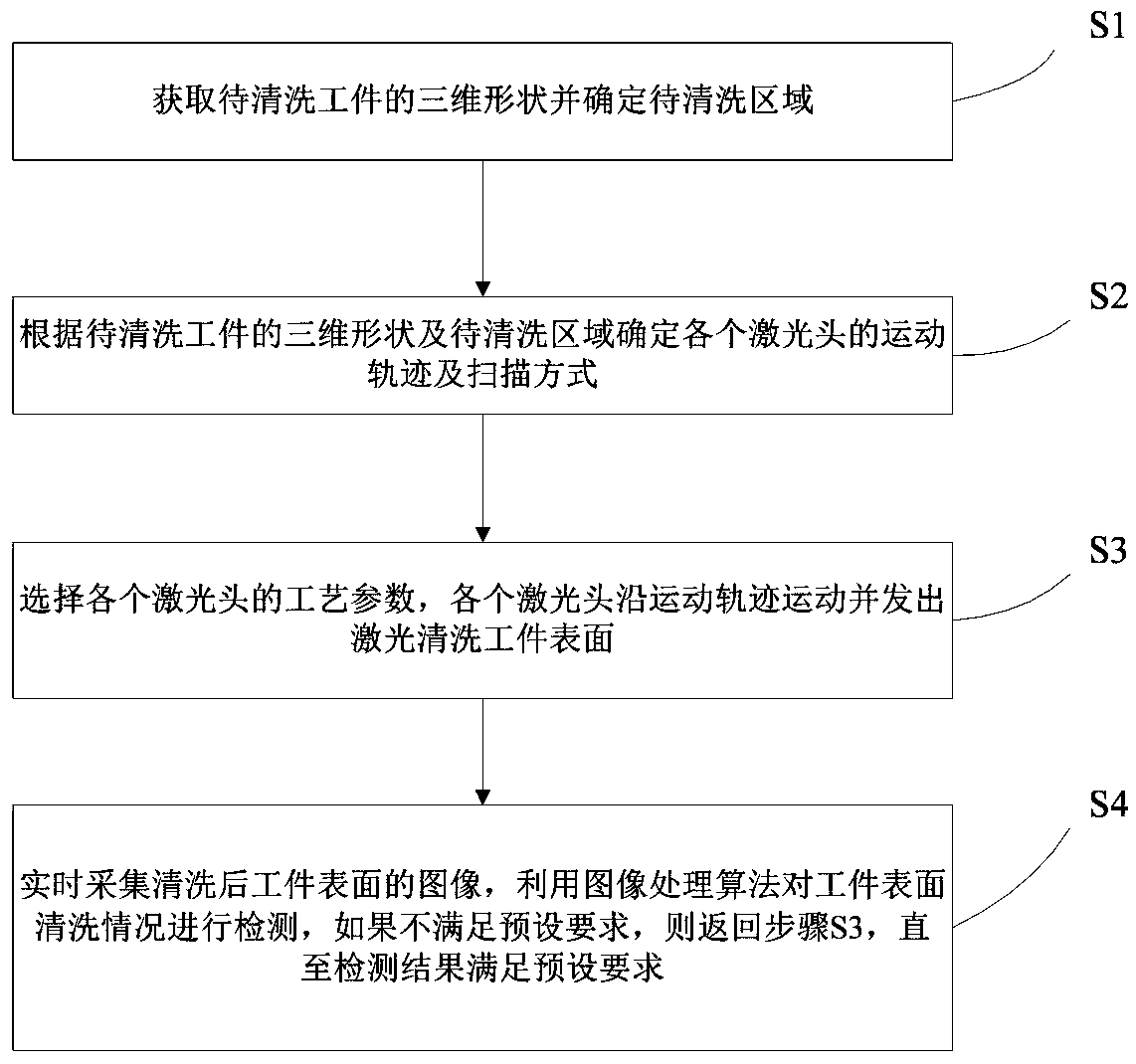

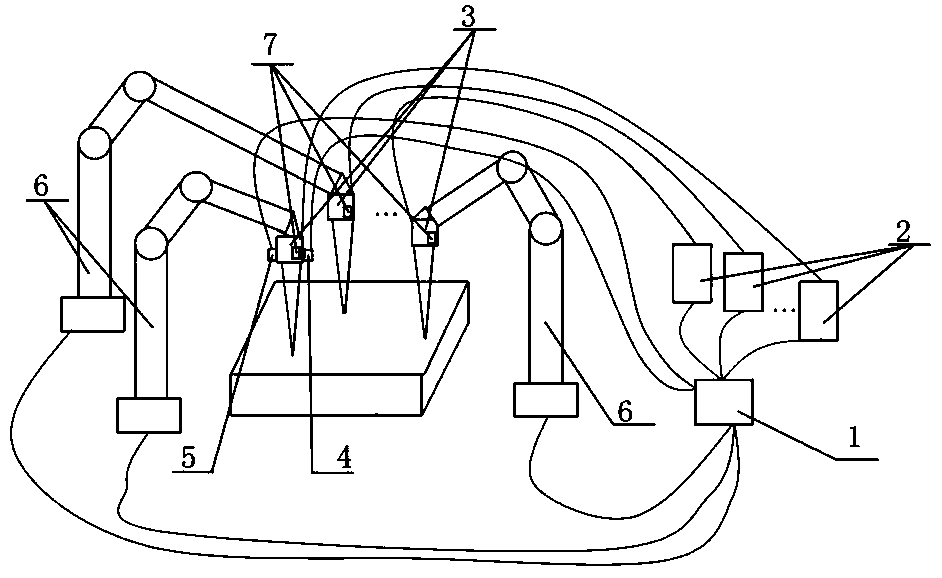

The invention discloses a multi-laser-head intelligent laser cleaning method. The method comprises the steps of S1, acquiring a three-dimensional shape of a to-be-cleaned workpiece, and determining abe-cleaned area; S2, determining a motion track and a scanning mode of each laser head according to the three-dimensional shape of the to-be-cleaned workpiece and be-cleaned area; S3, selecting technological parameters of all laser heads, and moving all the laser heads along the motion track and emitting laser to clean the surface of the workpiece; and S4, acquiring an image of the cleaned workpiece surface in real time, detecting the workpiece surface cleaning condition by using an image processing algorithm, and if the preset requirement is not met, returning to the step S3 until the detection result meets the preset requirement. The multiple laser heads can be matched with one another to clean dirt on the surface of the workpiece, and the laser cleaning method is particularly suitable for cleaning surfaces with large breadth and complex shape and structure, and has the advantages of being high in cleaning efficiency, good in cleaning quality and the like.

Owner:ZHUZHOU NAT INNOVATION RAILWAY TECH CO LTD

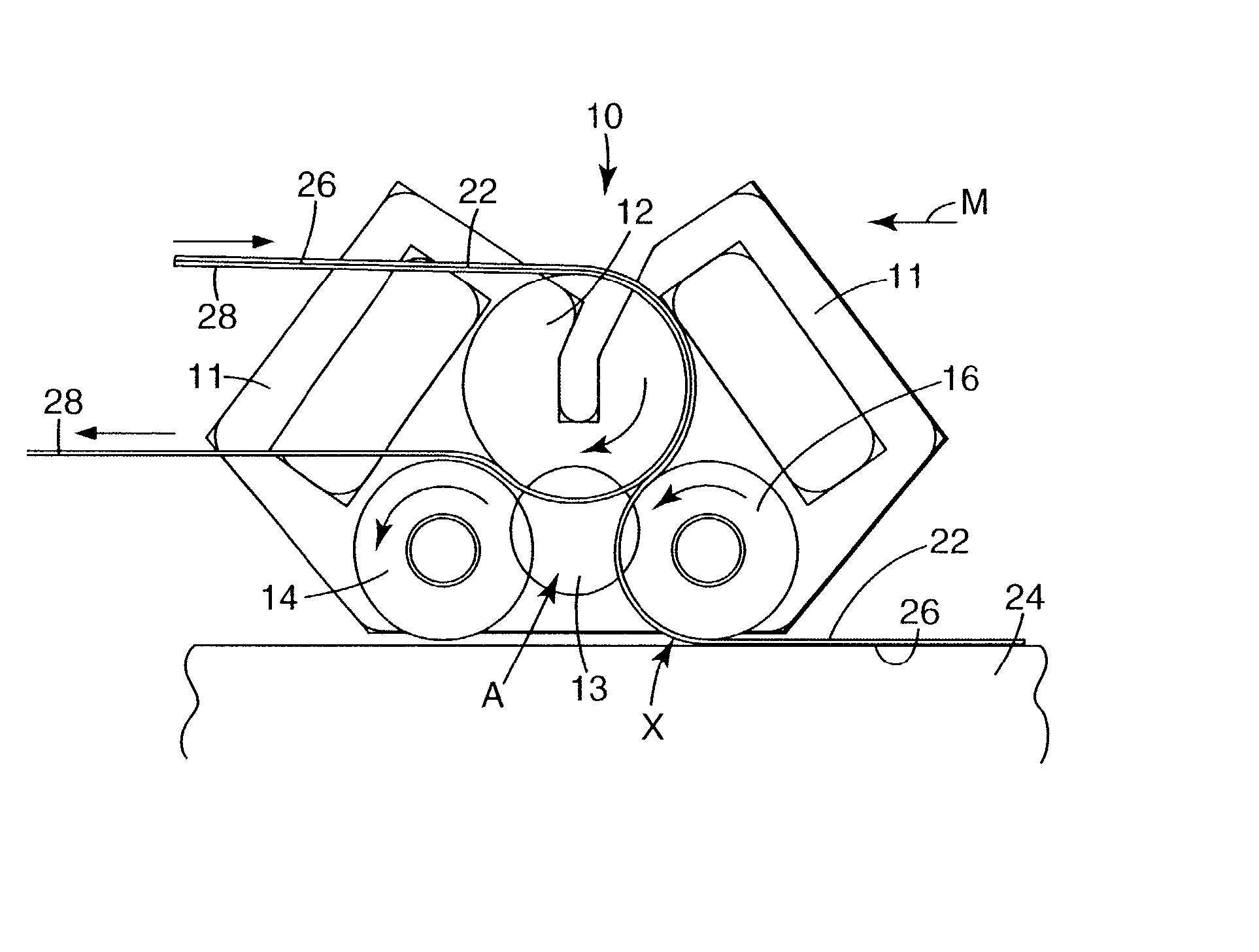

Film lamination and removal system and methods of use

InactiveUS20030015298A1Reduce riskReduce and prevent likelihoodMechanical working/deformationCovering/liningsVacuum assistedAdhesive

Vacuum-assisted film laminating and removal systems and methods of using the same. The systems include a vacuum-assisted laminator for applying large format films to substrates where lamination pressure is generated at least partially by a vacuum drawn in a vacuum cavity. The removal apparatus applies tension over the width of the adhesive film, thereby removing the film from the substrate along the release line that extends over the width of the film. The systems and methods can be used to apply and remove large-scale adhesive films from substrates.

Owner:3M INNOVATIVE PROPERTIES CO

Optical attachment for reducing the focal length of an objective lens

An optical attachment configured to be operably attached to the image side of an objective lens to reduce the focal length and focal ratio of the objective lens. The focal-reducing attachment includes four lens elements and has a magnification of between 0.5 and 1. The focal-reducing lens can work with objective lenses having relatively large working distances for a large format size as well as with cameras having a smaller format size and relatively small permissible working distance.

Owner:CALDWELL PHOTOGRAPHIC

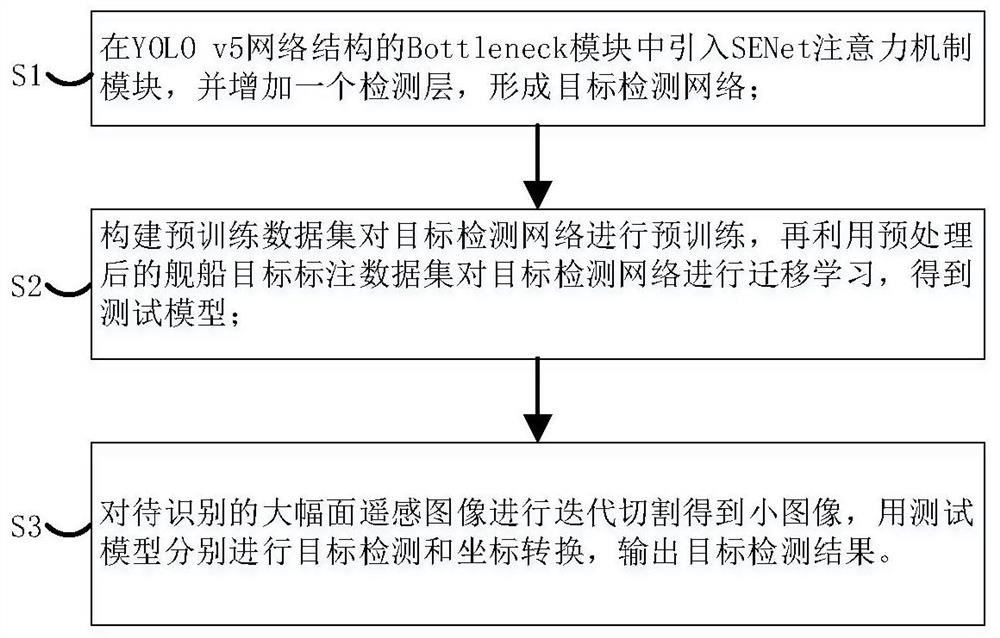

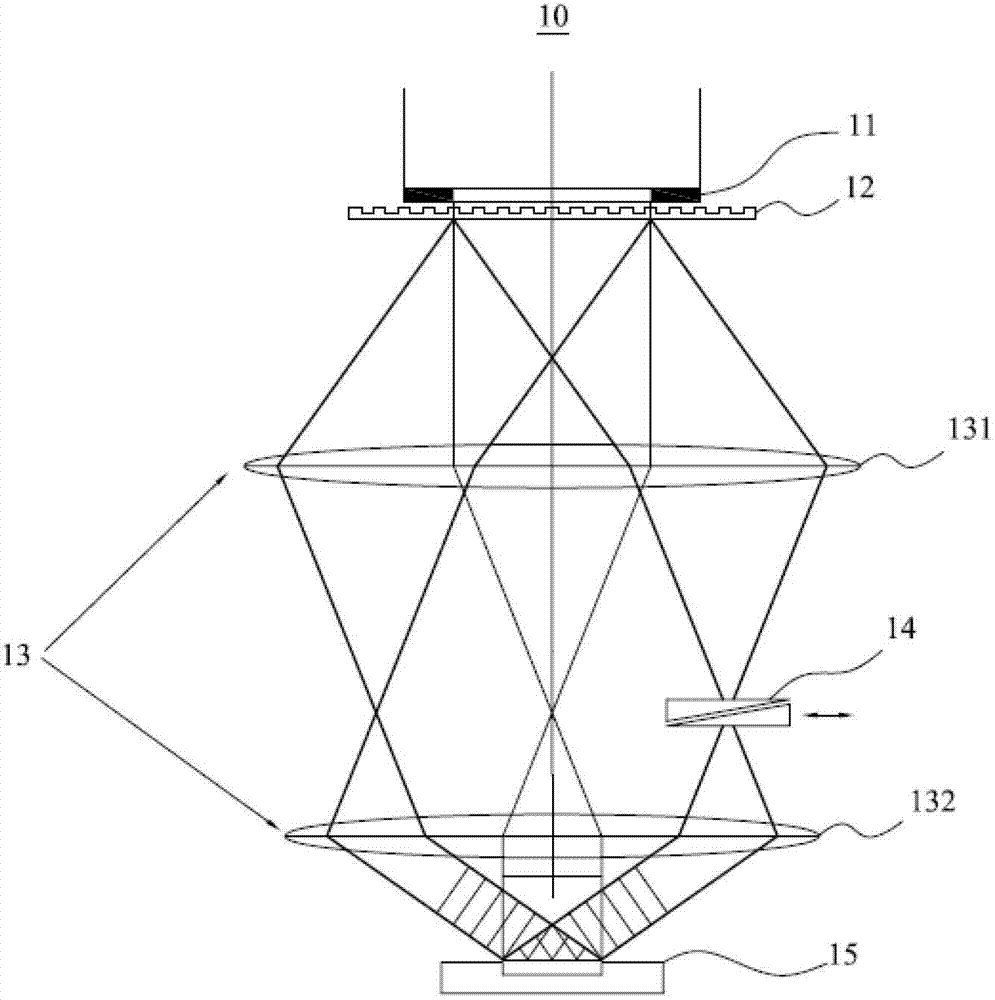

Large-format remote sensing image ship target detection method and system under small sample condition

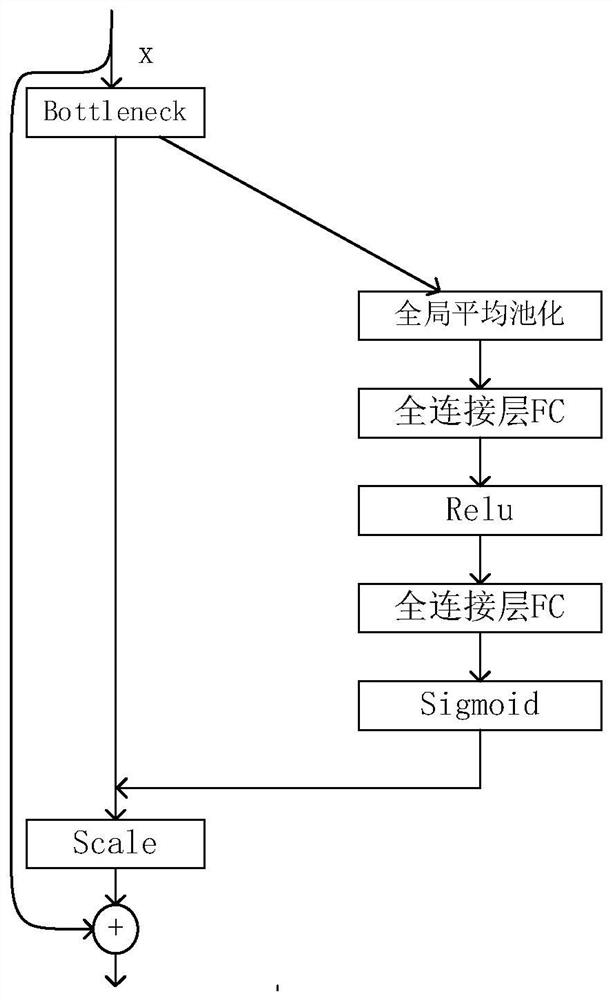

PendingCN112580439AImprove accuracyHigh precisionScene recognitionNeural architecturesPattern recognitionData set

The invention discloses a large-format remote sensing image ship target detection method and system under a small sample condition. The method comprises the steps: introducing an SENet attention mechanism module into a Bottleneck module of a YOLO v5 network, adding a detection layer, and forming a target detection network; constructing a pre-training data set to perform pre-training on the targetdetection network, and performing transfer learning on the target detection network by using the preprocessed ship target annotation data set to obtain a test model; and carrying out iterative cuttingon the large-format remote sensing image to be recognized to obtain a small image, respectively carrying out target detection and target coordinate conversion by using the test model, and outputtinga target detection result. According to the method, effective training of a network model and large-format image quick detection can be completed by using small-batch image target samples, and the accuracy and robustness of ship target detection are maintained.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

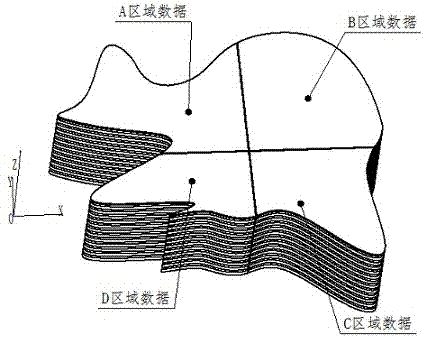

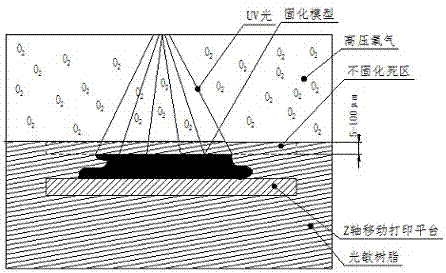

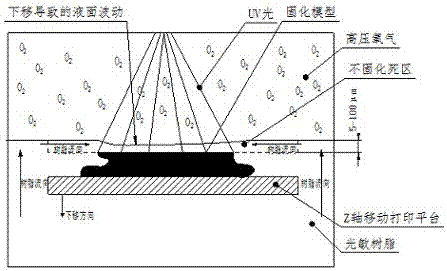

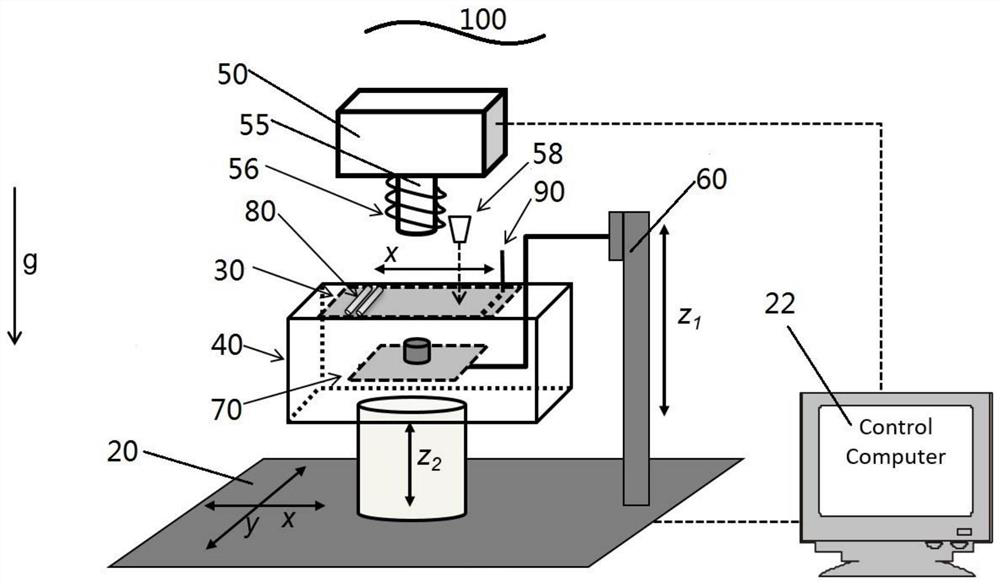

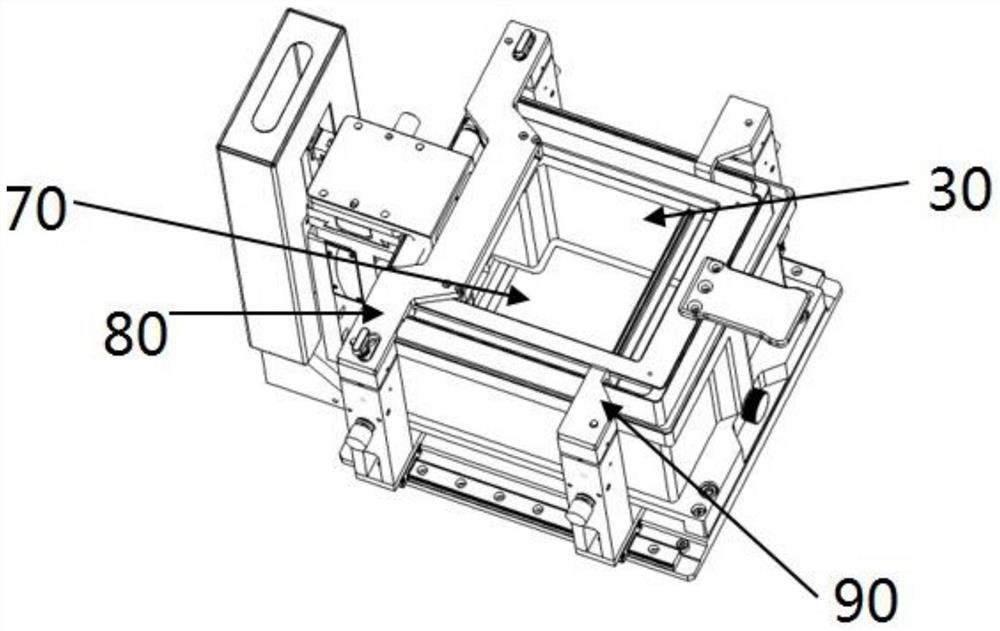

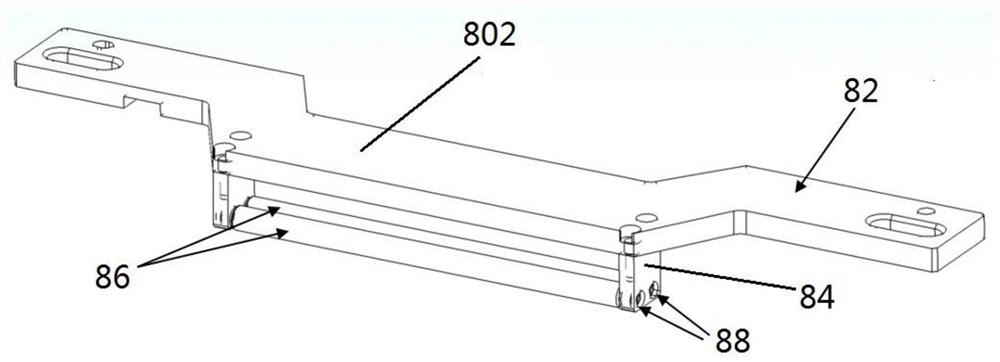

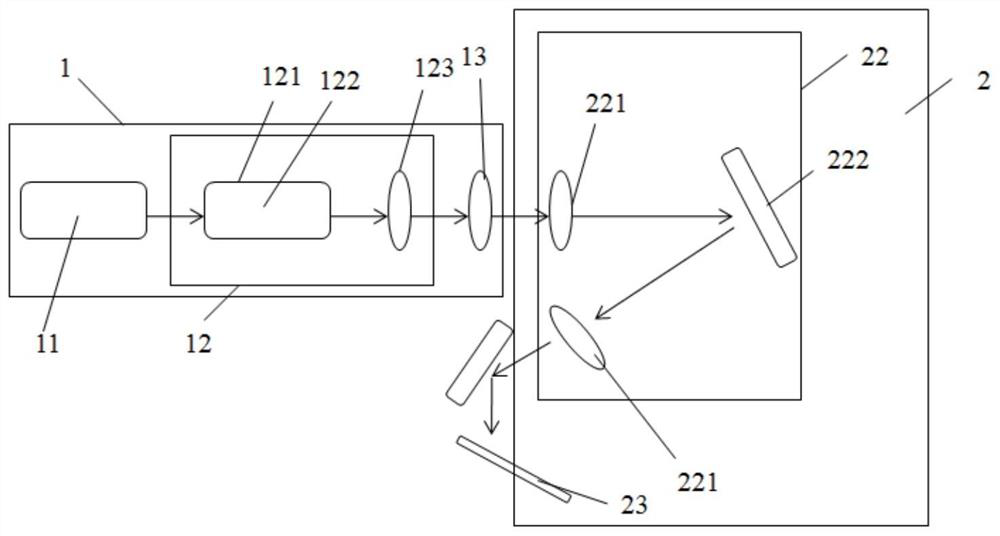

Large-format rapid 3D printing method and device based on DLP photo-curing

PendingCN107283825AFast Stereocuring 3D PrintingAdditive manufacturing apparatusManufacturing environment conditioningHigh pressure oxygenProjection system

The invention provides a large-format rapid 3D printing method and device based on DLP photo-curing. The large-format rapid 3D printing method based on DLP photo-curing comprises the steps that four groups of DLP projection system components are adopted to constitute a large-sized format projection system ( the large-format projection system for short), the large-format projection system is controlled by a computer to continuously play UV images of 365-405 nm layer by layer, the UV images enable photosensitive resin to be cured layer by layer, a Z-axis printing platform descends layer by layer, and then a three-dimensional object is formed through such reciprocating iteration. The large-format projection system is placed on the upper portion of the whole device system, a seal component cavity is arranged on the lower portion, the upper portion of the seal component cavity restrains generation of bubbles through high-pressure oxygen and forms a curing dead zone, under the action of the dead zone and the high-pressure oxygen, the liquid level can be kept stable; and meanwhile, under the action of a balance box and a liquid level laser ranger, on the premise of not lowering the precision, the large-format rapid 3D printing device greatly improves the printing speed and the printing format.

Owner:南京壹千零壹号自动化科技有限公司

Versatile adaptable holding apparatus for holding large format workpieces and method

InactiveUS6775897B2Precise positioningReduce usageLarge fixed membersMetal working apparatusEngineeringRiveting machines

Owner:AIRBUS OPERATIONS GMBH +1

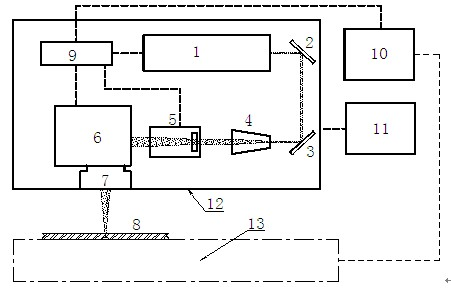

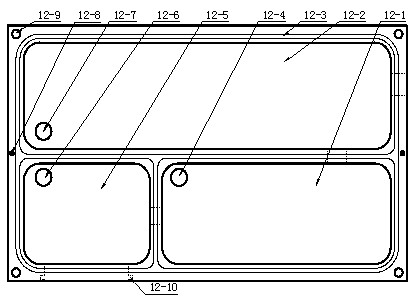

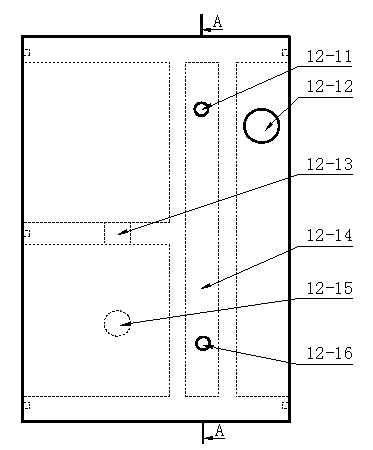

Integral laser cutting head

InactiveCN102689098AStable structureSmall amount of deformationLaser beam welding apparatusLaser processingControl system

The invention relates to an integral laser cutting head for laser processing of materials, comprising a laser, a first reflector, a second reflector, an extender lens, a dynamic focusing mechanism, a high-speed scanning vibrating mirror, an F-Theta field lens, a laser and scanning control system and a rectangular sealed box body, wherein the laser, the first reflector, the second reflector, the extender lens, the dynamic focusing mechanism, the high-speed scanning vibrating mirror, the F-Theta field lens and the laser and scanning control system are sealed in the box body. The integral laser cutting head has the characteristics of stable structure, constant temperature constant humidity and no dust, can guarantee an ideal working environment required by the operation of the laser, can work independently for small-range cutting operation and can be matched with an X-Y platform to carry out large-range cutting operation.

Owner:上海致凯捷激光科技有限公司

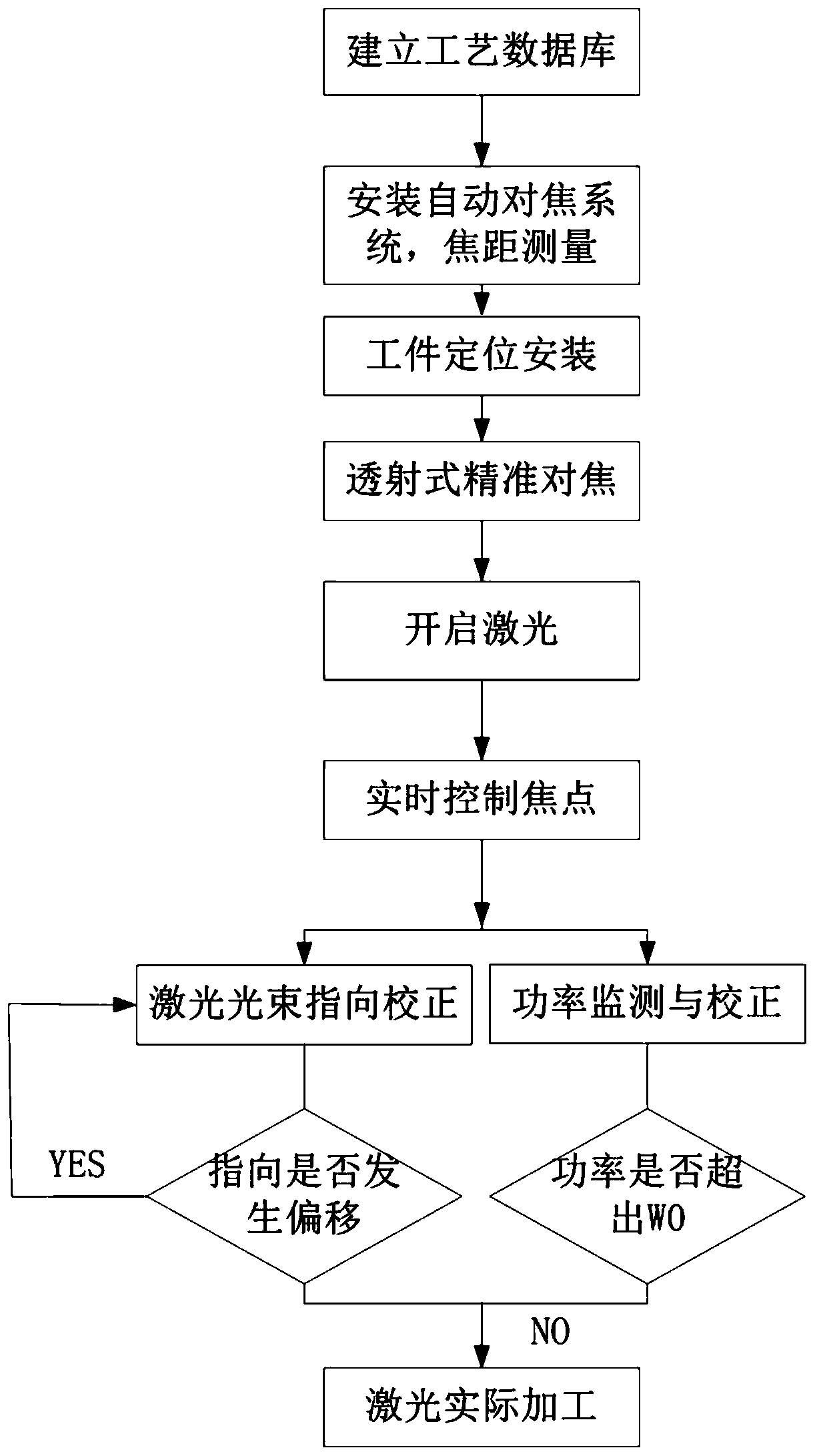

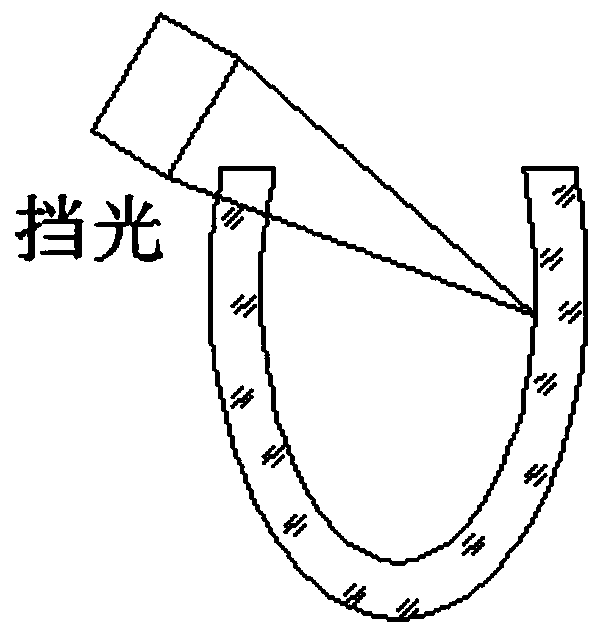

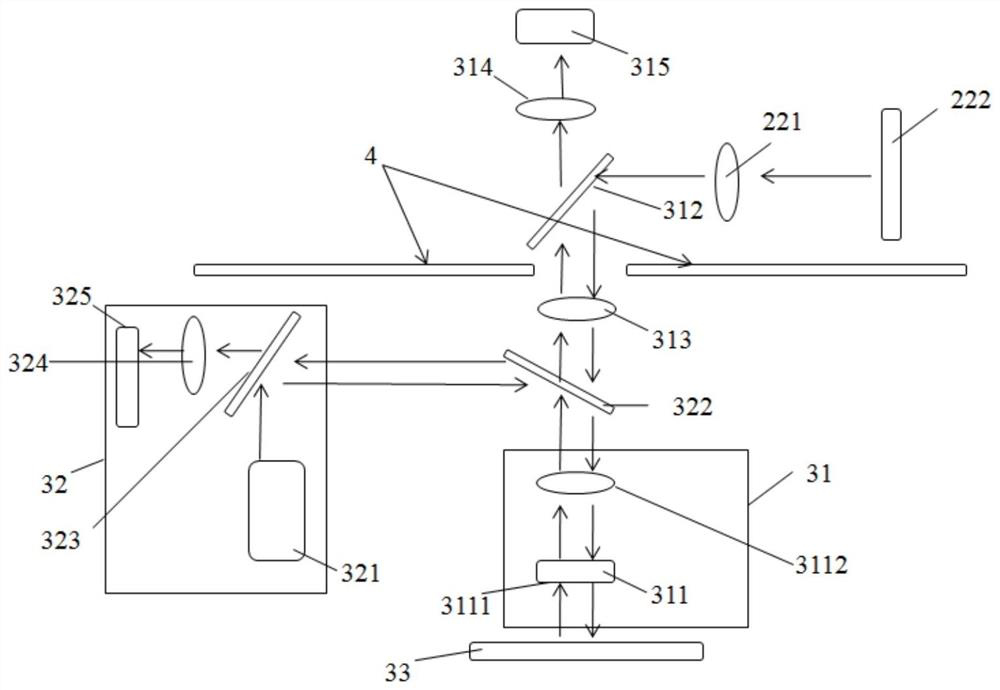

Method for machining micro-nano structure with antireflection function of large-format transparent curved surface part and system

ActiveCN110434470AHigh precisionImprove consistencyLaser beam welding apparatusNano structuringLaser processing

The invention relates to a method for machining a micro-nano structure with an antireflection function of a large-format transparent curved surface part and a system. The problems that the surface ofthe antireflection micro-nano structure of the large-format curved surface part is low in precision and poor in consistency are solved. When in machining, a process database is established firstly, and the heating effect damage laser damage threshold value w0 of the laser power on a material substrate is confirmed; secondly, the rear working distance L1, the workpiece positioning and installing, the transmission type precise focusing, the laser machining parameters setting of a laser machining system are sequentially measured, and transmission type machining is carried out; in the machining process, automatic focusing of the laser can be realized, the floating of the laser power in the machining process can be detected on line in real time, and the pointing deviation of a machining light beam can be further monitored in real time. When a functional micro-nano structure is required to be manufactured on the inner surface of a non-spherical transparent medium, the machining mode is compared with a traditional mode of directly machining from the inner surface, and the method has the advantages of simplicity, high precision, high efficiency and the like.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI +1

Large format digital camera with multiple optical systems and detector arrays

A large format digital camera has a primary camera system configured for collecting panchromatic image data and a secondary camera system configured for collecting color image data. The secondary camera system has an optical system that has a longer focal length than the optical system of the primary camera system. The resolution of the secondary camera system is greater than the resolution of the primary camera system. The footprint of images produced by the primary camera system is larger in size than the footprint of images produced by the secondary camera system. Images produced by the primary camera system offer information for performing image-based georeferencing by means of photogrammetric triangulation. Images produced by the secondary camera system offer a high-resolution narrow angle color image suitable for use in ortho image production.

Owner:VEXCEL IMAGING US INC

Metasurface color holography preparation method and optical system

The invention relates to a metasurface color holography preparation method, which comprises the following steps of on the basis of a pixel structure or pixel distribution, respectively layering and extracting a color target object image to obtain the corresponding multiple image layers; respectively obtaining a micro-nano structure and a micro-nano structure combination corresponding to each imagelayer, and obtaining a change relationship between the micro-nano structures and the micro-nano structure combinations among the layers; according to the combination of the micro-nano structure and aprimary color micro-nano structure of any image layer, realizing the simultaneous preparation of intra-layer multiple pixel micro-nano structures of the image layer by utilizing photoetching of spaceor / and phase modulation; and according to the change relationship of the micro-nano structures and the micro-nano structure combinations among the layers, realizing the simultaneous preparation of the micro-nano structures and the micro-nano structure combinations of the rest layers in a time-sharing manner by utilizing space or / and phase real-time regulation and control. According to the invention, the simultaneous preparation of multiple pixel micro-nano structures and the time-sharing preparation of the layered pixel combinations are realized, so that the large-format rapid preparation ofcolor holography can be realized.

Owner:SUZHOU UNIV

Large format electrophotographic 3D printer

ActiveUS20170210070A1Increase the areaAdditive manufacturing apparatusElectrographic process apparatusBrickComputer printing

A three-dimensional part and associated support structure is constructed using an electrophotography-based additive manufacturing system. A support layer is developed using a first electrophotography engine, and a part layer is developed using a second electrophotography engine. The developed support and part layers are transferred to a transfer medium and moved into alignment with a tile region of a layer transfusion assembly, where the transferred part and support layers are transfused to previously-printed layers. This process is repeated for a plurality tile regions and for a plurality of layers to construct a three-dimensional part having a footprint larger than a maximum printable area of the first and second electrophotography engines.

Owner:EASTMAN KODAK CO

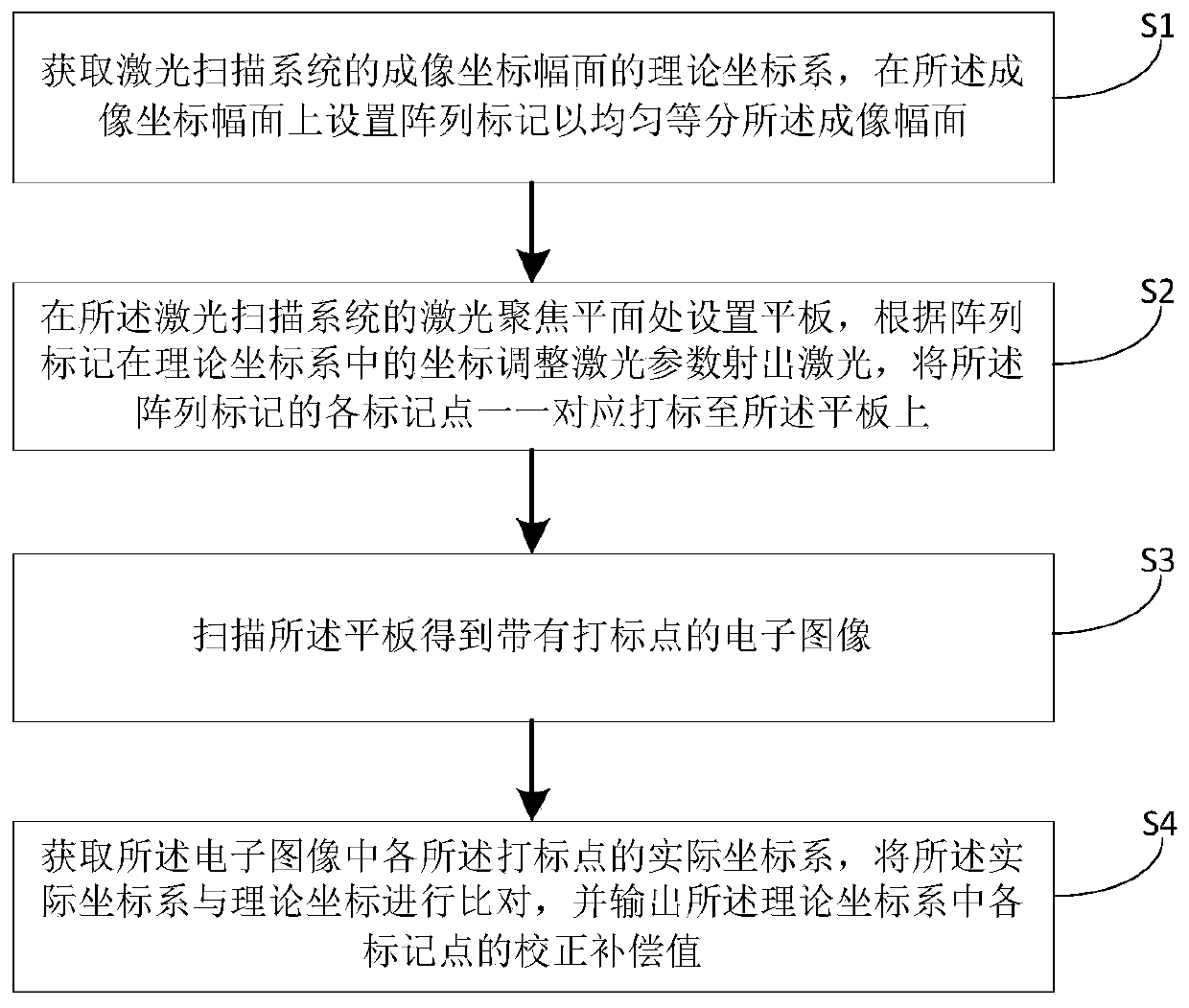

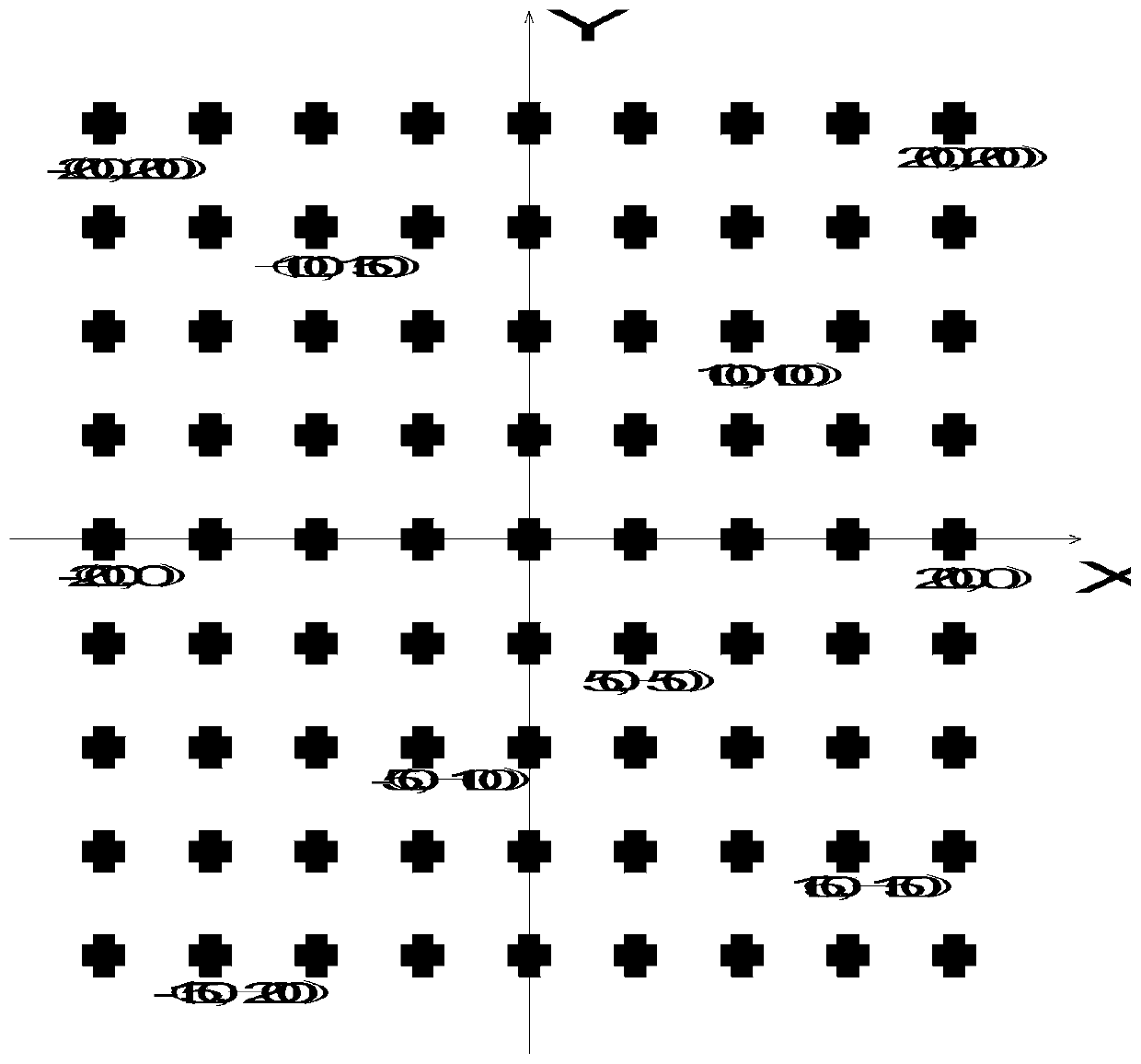

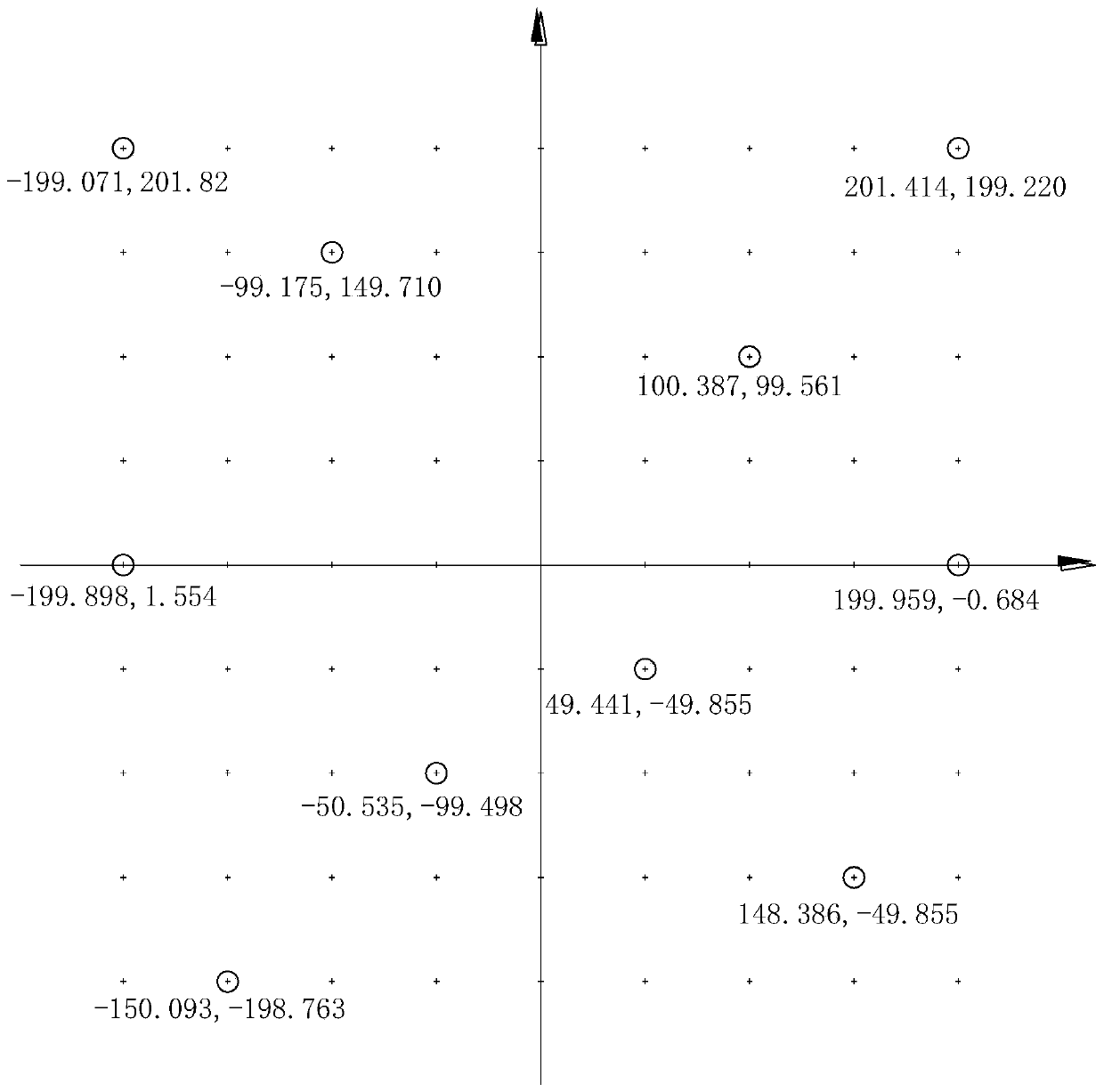

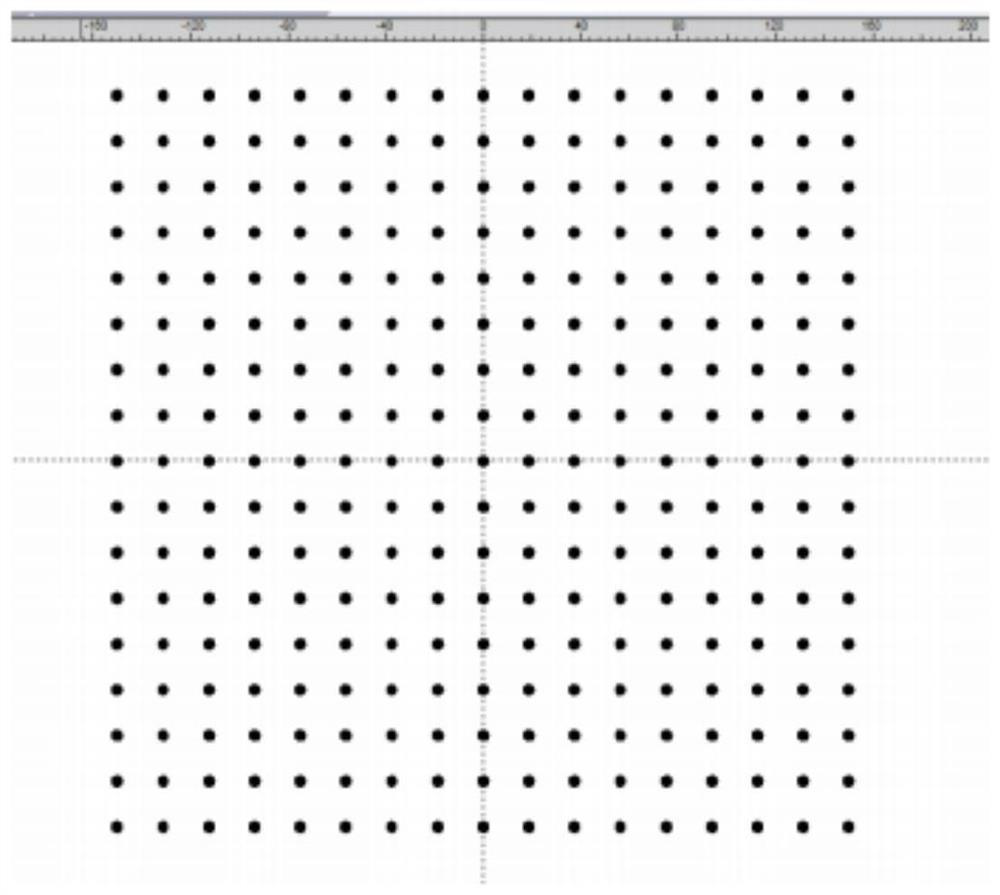

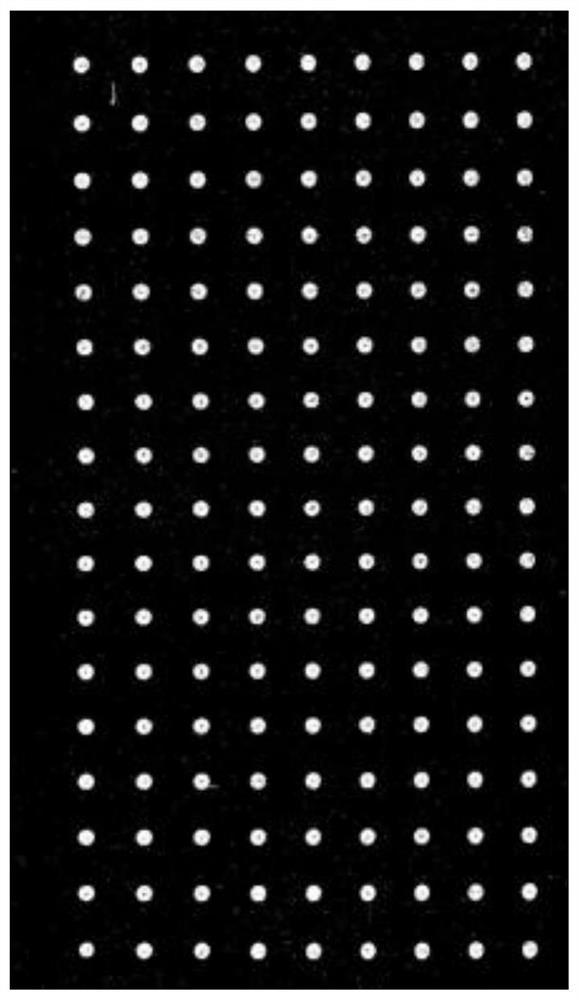

Correction method of large-format laser scanning system

The invention belongs to the technical field of laser precision machining, and particularly provides a correction method of a large-format laser scanning system, which comprises the following steps: acquiring a theoretical coordinate system of an imaging coordinate format of the laser scanning system, and setting array marks on the imaging coordinate format to uniformly and equally divide the imaging format; arranging a flat plate on a laser focusing plane of the laser scanning system, adjusting laser parameters according to coordinates of the array marks in the theoretical coordinate system to emit laser, and making the marking points of the array marks on the flat plate in a one-to-one correspondence mode; scanning the flat plate to obtain an electronic image with the marking points; andacquiring an actual coordinate system of each marking point in the electronic image, comparing the actual coordinate system with a theoretical coordinate, and outputting a correction compensation value of each marking point in the theoretical coordinate system. According to the scheme, the cost is low, the influence of a mechanical structure on the correction precision is avoided, new factors influencing the correction precision are not introduced, and correction can be carried out anytime and anywhere.

Owner:江苏华工激光科技有限公司

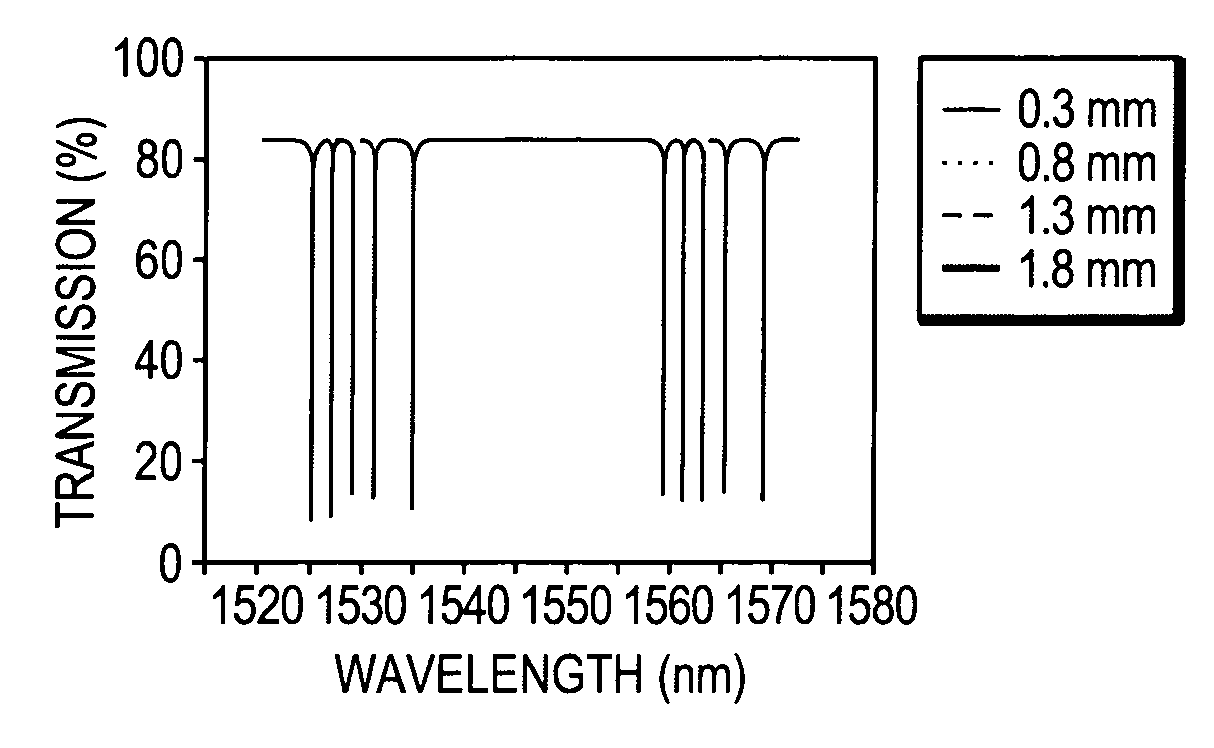

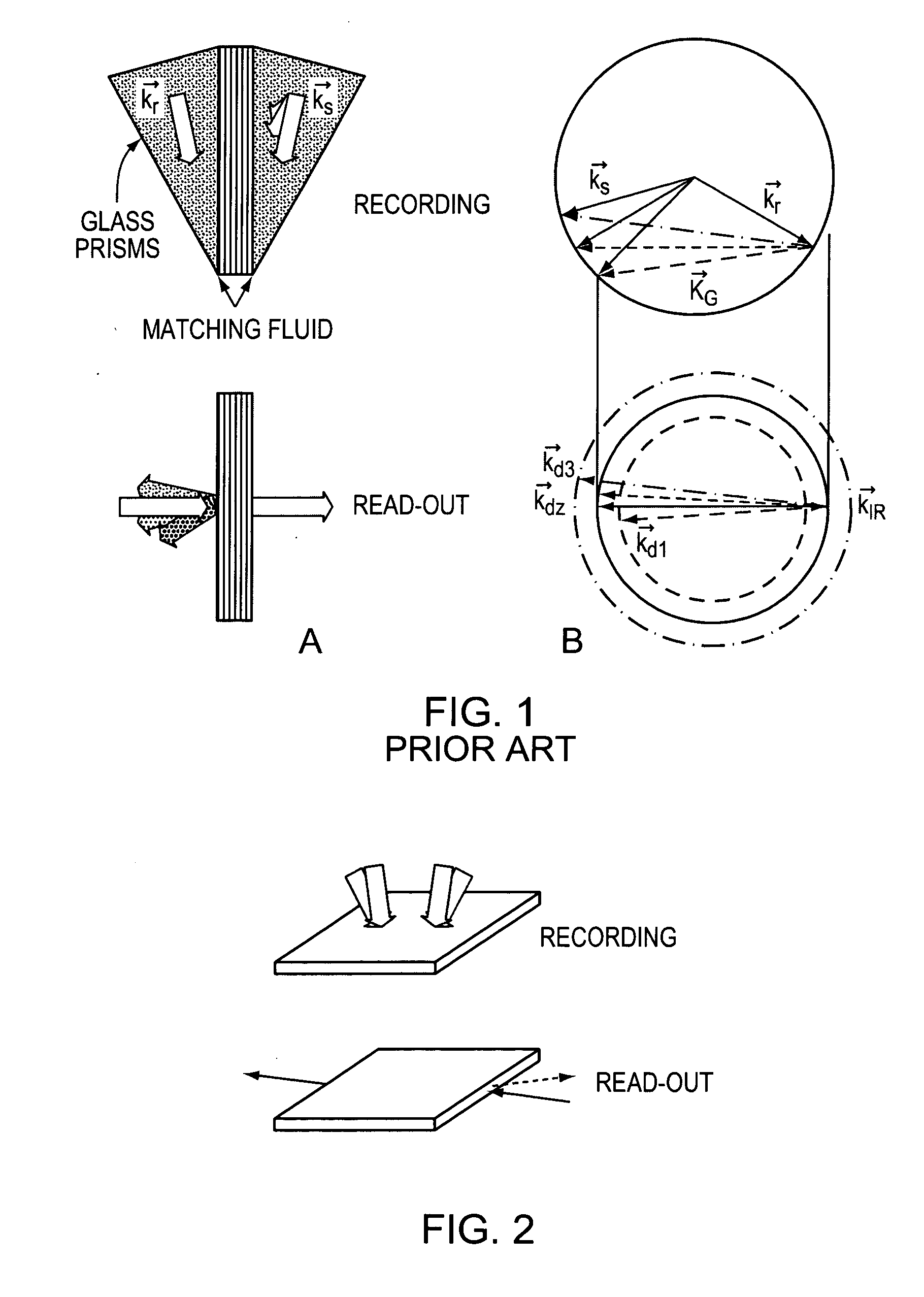

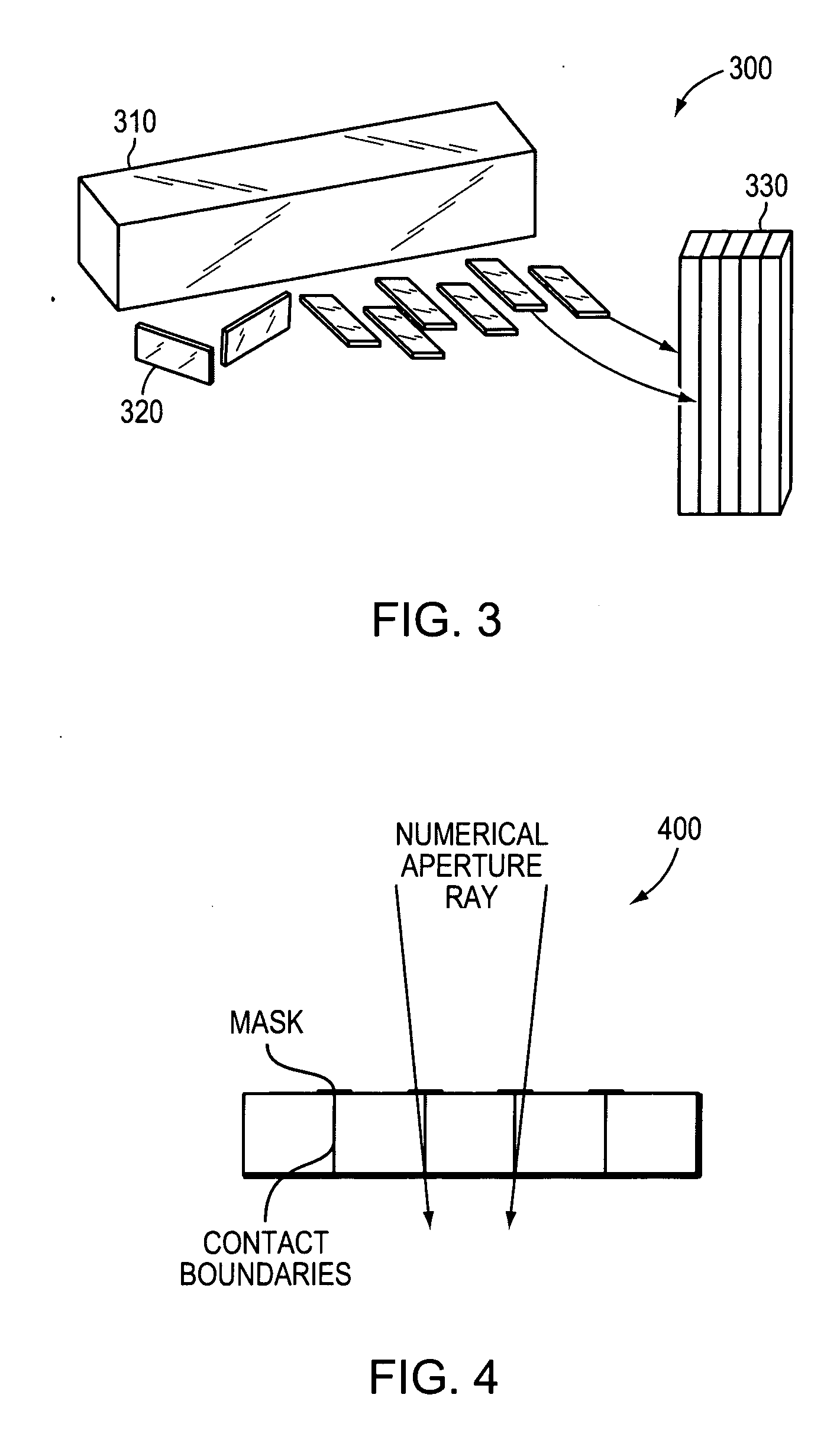

Efficient multi-line narrow-band large format holographic filter

Narrow-line holographic filters that can include a plurality of lines and that can be structured to provide a large aperture device. Materials that can be used to construct filters include glasses, photorefractive crystals such as lithium niobate and photorefractive thick polymers. The filters are fabricated by assembling a plurality of elements having the same one or more narrow line holographic filter patterns written thereon, in mutual orientation such that each element has a surface defined by a length and a width adjacent a corresponding surface of a neighboring element, and has a surface defined by a thickness and one of a length and a width accessible to impinging illumination. Filters exhibiting a plurality of characteristic narrow lines, and having arbitrarily large apertures can be fabricated. Methods of fabricating and using the filters are described.

Owner:CALIFORNIA INST OF TECH

Resin coating 3D printing method and system

ActiveCN111873433AImprove printing efficiencyFlow fastManufacturing platforms/substrates3D object support structuresPhoto irradiationResin coating

The invention relates to a resin coating 3D printing method and system. The resin coating 3D printing method comprises the steps that a 3D digital model of a sample to be printed is generated, and the3D digital model is cut into an image sequence; an image is controlled to be sent to an exposure system, wherein the exposure system projects the image to the surface of a transparent film through aprojection lens; the exposure system drives light to irradiate the projected image, and a curing layer is generated through exposure; after one layer is printed, the sample descends to be separated from the transparent film, the return distance of a sample table is the printing thickness of a next layer, a film rolling device is controlled to roll or rotate on the surface of the transparent film,a printing material is moved away, the transparent film is flattened, a laser displacement device is controlled to detect the state or position of the transparent film, and if the transparent film isflattened, the film rolling device is controlled to move out of a projection area; and a gap between the sample and the transparent film is filled with resin required for printing the next layer, andexposure printing is repeated in sequence until printing is finished. According to the resin coating 3D printing method and system, the film rolling device is arranged, the transparent film is flattened through the film rolling device, and high-speed and large-format machining can be conducted.

Owner:BMF NANO MATERIAL TECH CO LTD

Three-beam interference lithography method and system

InactiveCN102736451AImprove processing efficiencyLow costPhotomechanical exposure apparatusMicrolithography exposure apparatusComplex amplitudeLevel structure

The invention discloses a three-beam interference lithography method and a system. The method comprises that: a laser beam is divided into three beams by phase grating and then N times of interference exposure are realized on surface of a workpiece; a dislocation value of two adjacent exposure positions is dI / N, wherein N is an odd number greater than or equal to 3, and dI is a light intensity distribution cycle after the exposure; and the three beams are respectively a first beam, a second beam and a 0 beam with the same complex amplitude. With the three-beam interference lithography method of the invention, a large-size precision multi-level structure can be directly prepared in photoresist with high processing energy efficiency and the components used are easily obtained and have low cost. In addition, by adopting the three-beam interference exposure, the grating and the system have no zero elimination requirement and are easy to prepare.

Owner:SUZHOU UNIV

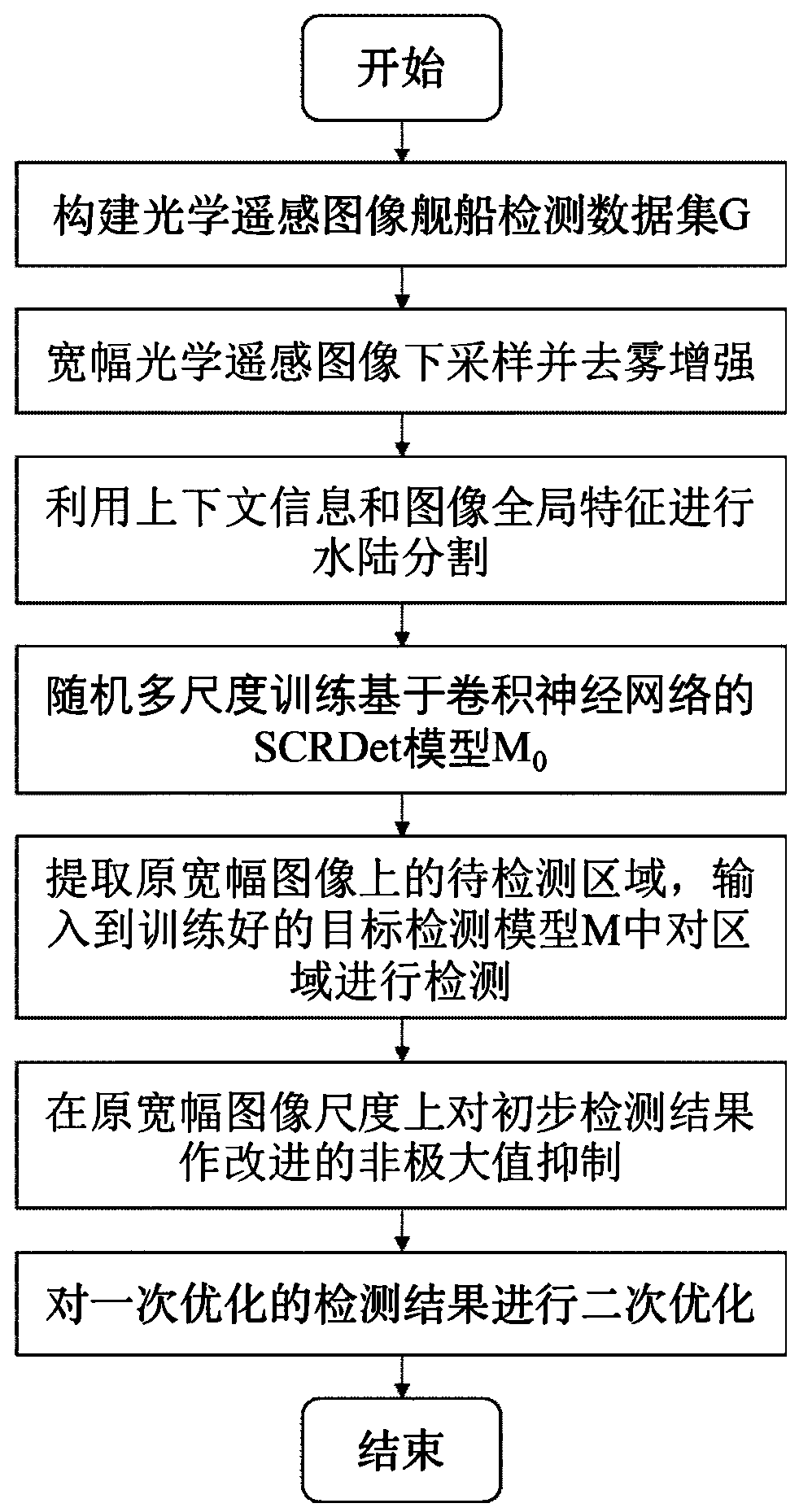

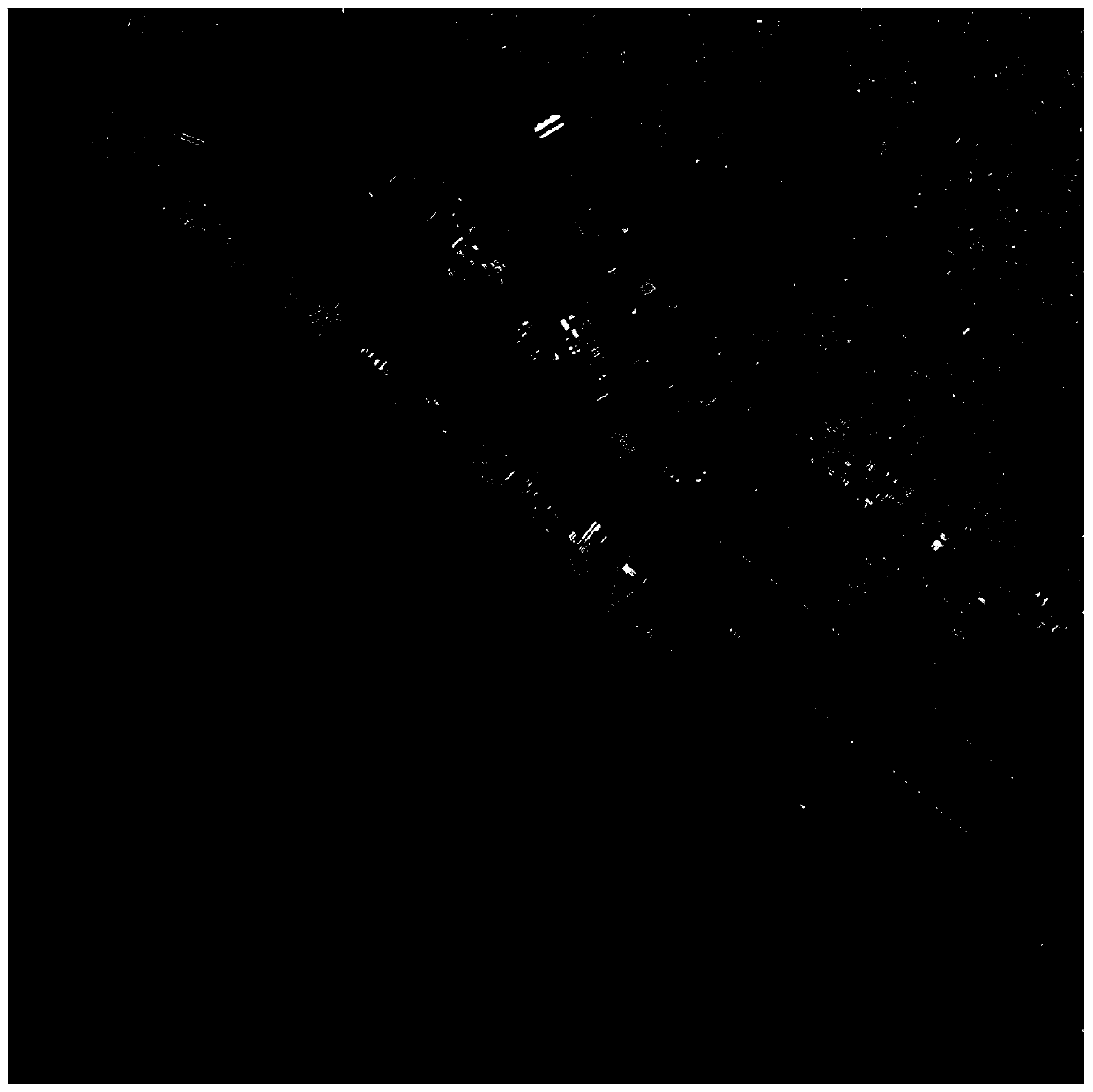

Remote sensing image ship detection method based on block extraction

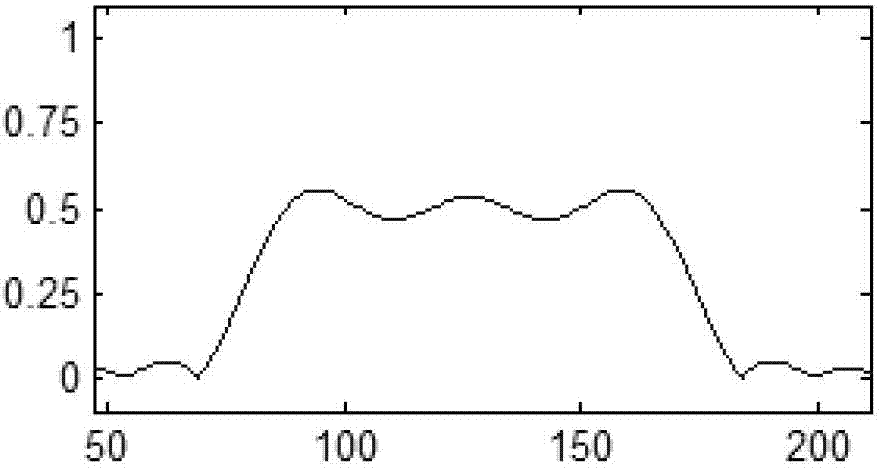

ActiveCN111027511AKeep targetOptimize water and land segmentation resultsImage enhancementImage analysisData setImage scale

The invention discloses an optical remote sensing image ship detection method based on block extraction of interest, and mainly solves the problems of low detection precision and more false alarms inthe prior art. The method comprises the following steps: constructing an optical remote sensing image ship detection data set; carrying out downsampling and defogging enhancement on the wide remote sensing image, and carrying out land and water segmentation by using context information and image global features; training an SCRDet-based target detection model by using the constructed data set; according to the land and water segmentation result, scanning the original wide remote sensing image by using a partially overlapped sliding window to extract an interested block as a to-be-detected area, and inputting the to-be-detected area image into the detection model to obtain an area detection result; mapping a region result to an original wide image scale, and performing improved non-maximumsuppression to optimize a preliminary detection result; and optimizing the detection result again according to the structural characteristics of the ship. The method is high in detection precision and low in false alarm rate, and can be used for acquiring ship targets of interest and positions thereof in large-format remote sensing images.

Owner:XIDIAN UNIV

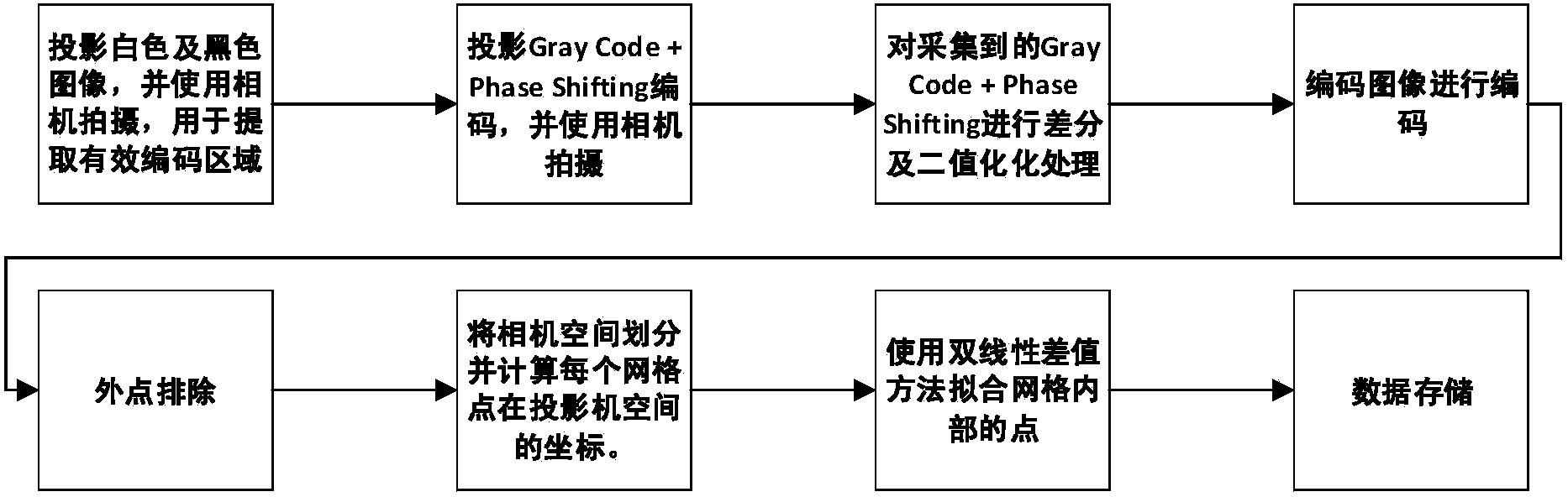

Large-width free surface multi-projection automatic splicing method

ActiveCN103533278ASolve the requestResolution timeTelevision system detailsColor television detailsCamera imageOptical scanning

The invention discloses a large-width free surface multi-projection automatic splicing method. By using the large-width free surface multi-projection automatic splicing method, automatic projection splicing fusion can be carried out on an uneven large-width free surface. In the invention, according to positions of an effective projection region and a region to be subjected to projection, a corresponding relation between a camera image space and a display image space is established; a corresponding relation between each projector image space and the camera image space is established by using an encoding structure optical scanning method; and thus, a corresponding relation between each projector image space and the display image space is obtained, so that points in the display image space can be mapped to corresponding positions in the corresponding projector image spaces. The large-width free surface multi-projection automatic splicing method can be widely applied to the fields of big show, large-scale activities, city image advertising and the like, overcomes the defects of high personnel requirement, long regulation time and the like of a conventional manual free surface splicing system, can replace the pure manual free surface splicing system abroad and greatly reduces manufacturing cost of a culture performance product.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

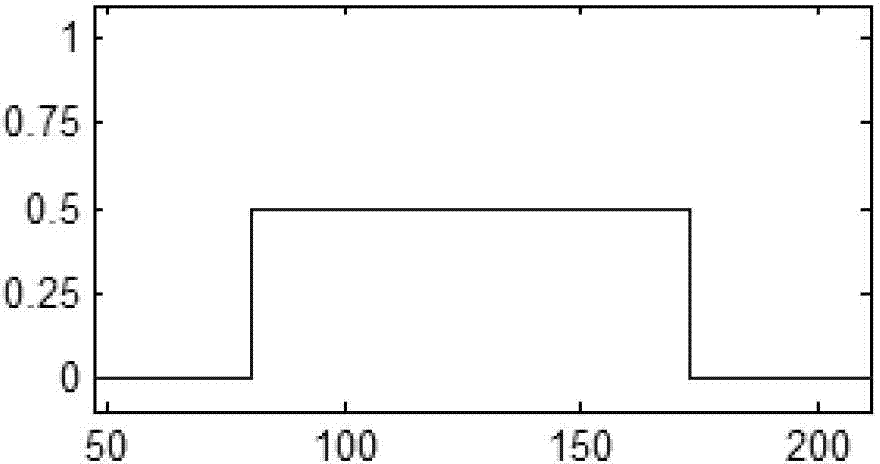

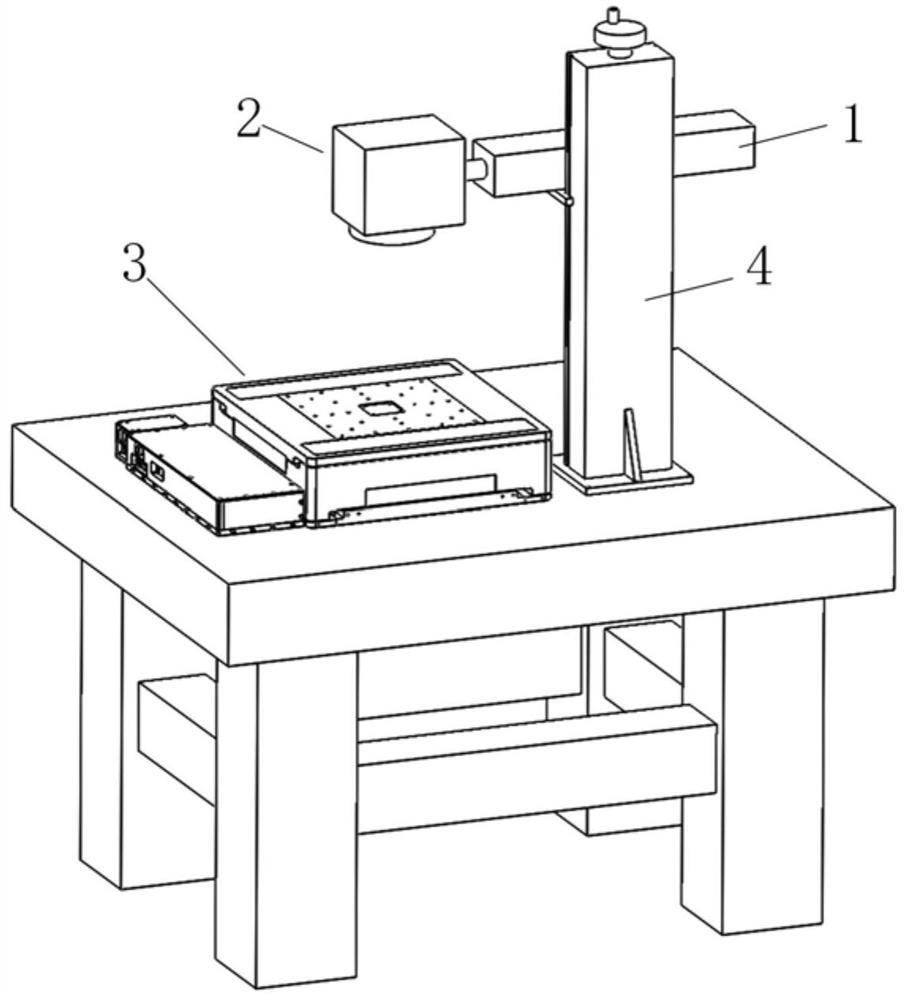

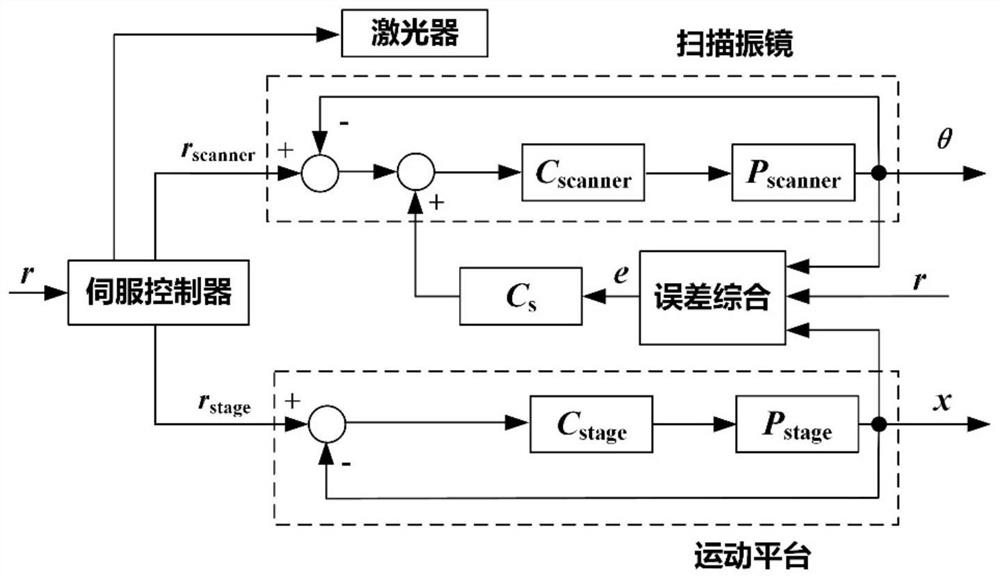

Large-format laser polishing system for metal additive component and machining method

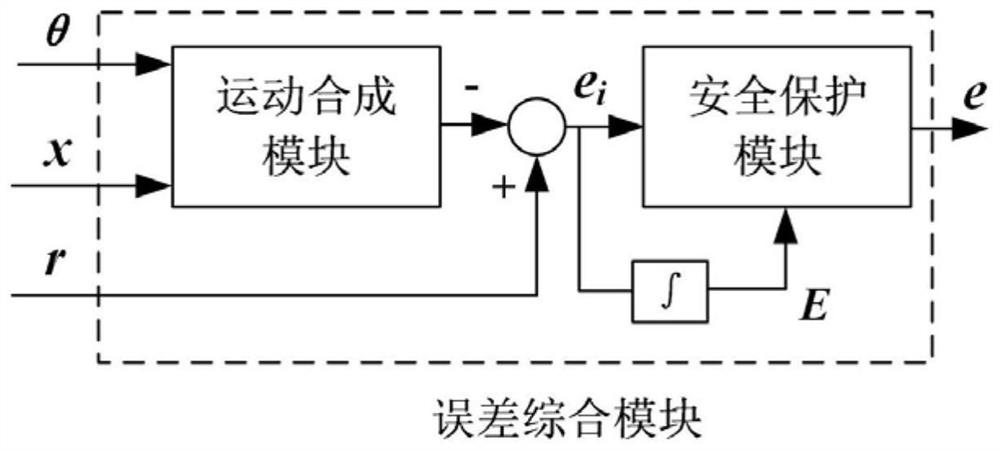

ActiveCN112276365AMovement precisionFast Error CompensationLaser beam welding apparatusLoop controlHigh bandwidth

The invention discloses a large-format laser polishing system for a metal additive component and a machining method, which are capable of achieving large-area precision polishing of a to-be-machined workpiece. The polishing system mainly comprises a laser, an XY digital scanning galvanometer, an XY servo motion platform, an embedded servo control system, a high-bandwidth driver, a computer and anoptical lifting platform. The machining process comprises the steps that a scanning track and a scanning speed are determined according to the size and polishing parameters of a to-be-machined metal additive component; movement tracks of two systems of the XY digital scanning galvanometer and the XY servo motion platform are determined; and the XY digital scanning galvanometer and the XY servo motion platform are controlled by the embedded servo control system to realize closed-loop control, and a master-slave control architecture is adopted. According to the system and the method, automatic distribution of reference tracks of the galvanometer and the motion platform of the large-format laser polishing system is achieved, a master-slave control strategy is introduced on the basis of the two closed-loop subsystems of the galvanometer and the motion platform, and the polishing quality and the polishing efficiency of large-format laser polishing are improved.

Owner:TSINGHUA UNIV

Positioning marking method applicable to large format

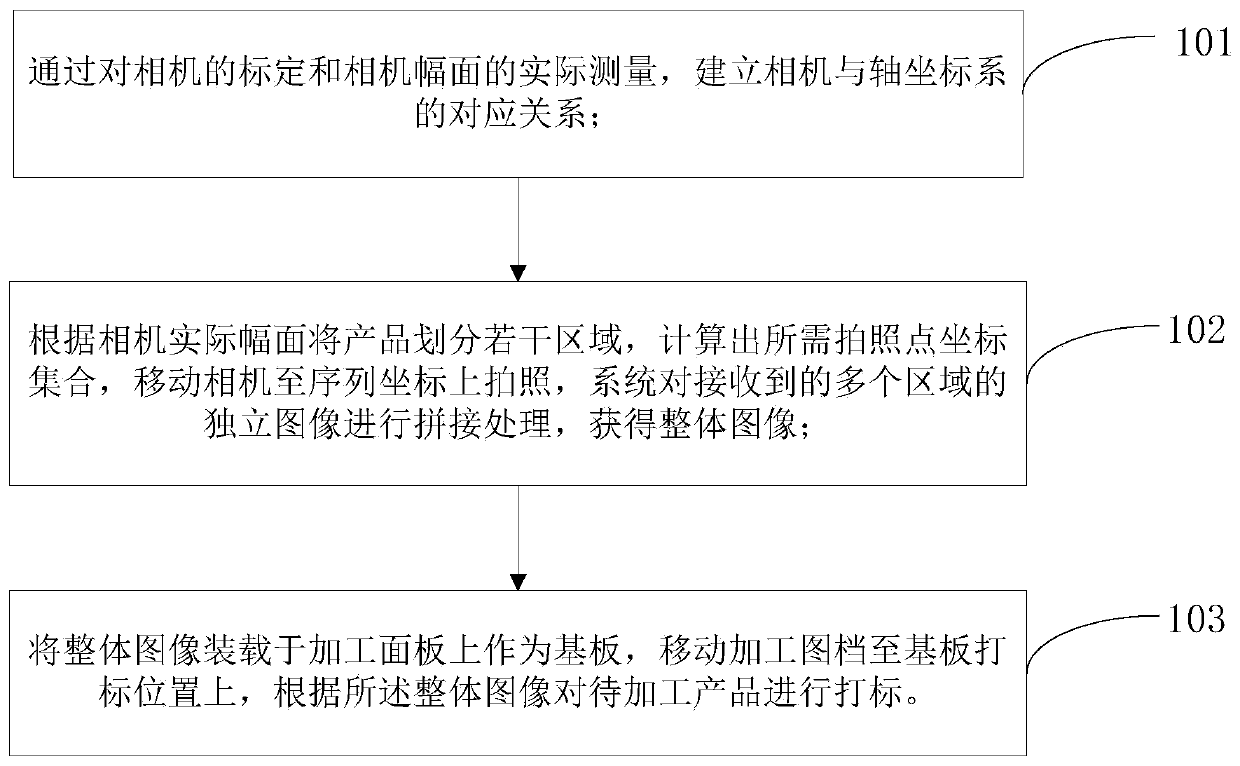

InactiveCN110977154AContinuous and accurate markingRealize positioning markingLaser beam welding apparatusLaser processingComputer graphics (images)

The invention relates to a positioning marking method applicable to a large format. The positioning marking method comprises the following steps: 101, by calibrating a camera and actually measuring the camera format, the corresponding relationship between the camera and an axis coordinate system is established; 102, a product is divided into a plurality of areas according to the actual format of the camera, a coordinate set of needed photographing points is calculated, the camera is moved to series coordinates to photograph, and a system splices received independent images of the multiple areas to obtain an integrated image; and 103, the integrated image is loaded on a processing panel to serve as a substrate, a processing drawing file is moved onto a marking position of the substrate, andthe to-be-processed product is marked according to the integrated image. The defects that in the prior art, due to the large workpiece format, the lens scanning area is limited, consequently high-precision and large-format marking cannot be achieved, and the application range of laser processing is limited are overcome, the positioning marking method is applicable to positioning marking of the large format, high-precision marking is achieved, and meanwhile assembly-line-type automation continuous and precise marking can be achieved.

Owner:苏州金橙子激光技术有限公司

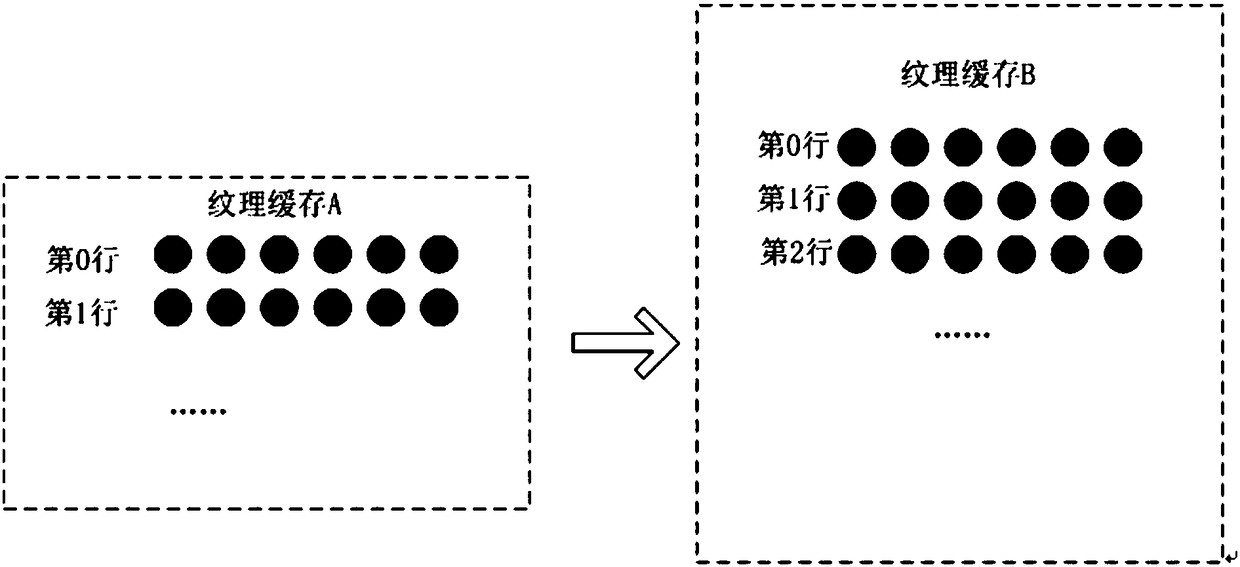

Method for quickly processing large-format video images through partial format data

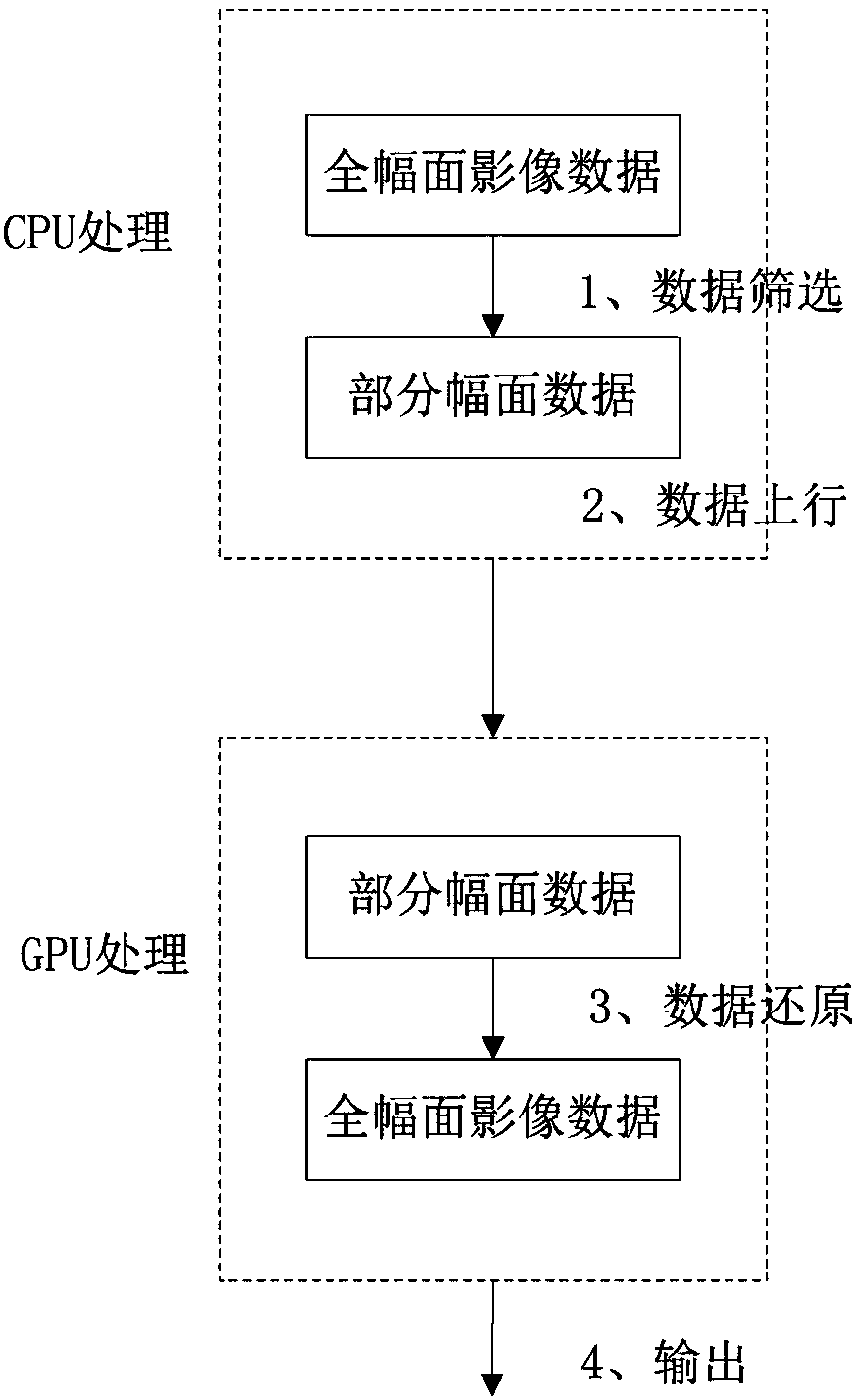

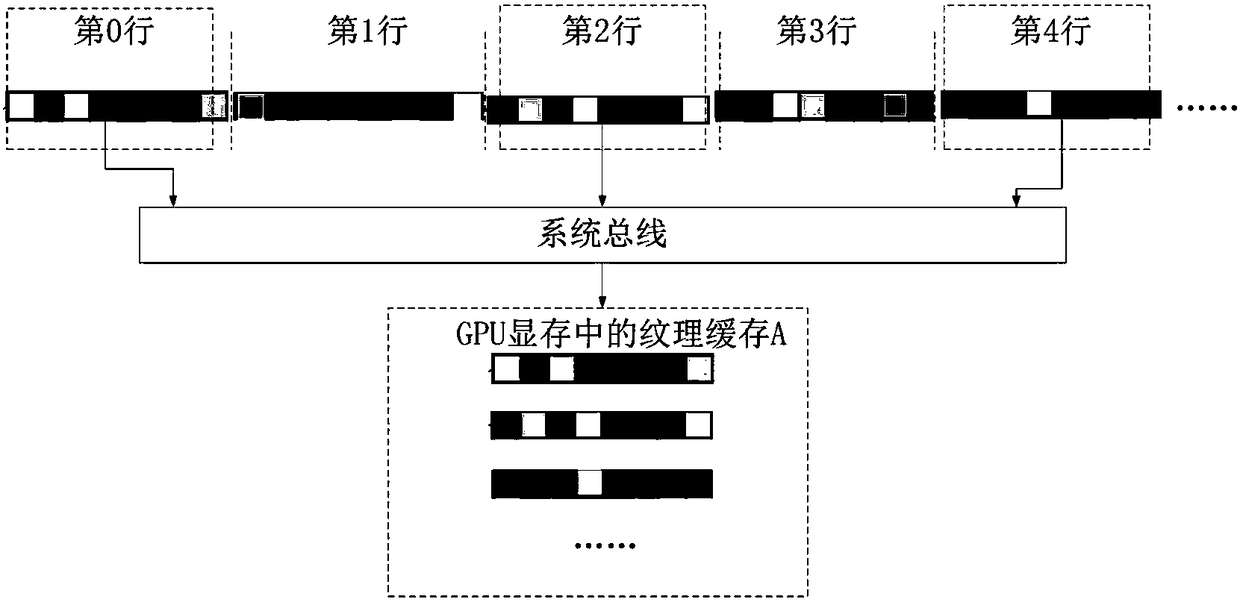

ActiveCN108259779ATaking into account real-timeTaking picture quality into considerationTelevision system detailsColor television detailsComputer graphics (images)Video image

The invention discloses a method for quickly processing a large-format video image through partial format data, a CPU is used for screening full-format image data to obtain partial-format image data;the CPU is used for uploading the partial format image data to a GPU; the GPU is used for reconstructing the partial format data into the full-format image data; and the GPU outputs the reconstructedfull-format image data. By the adoption of the method, rapid previewing can be realized, and the flexibility is high.

Owner:CHENGDU SOBEY DIGITAL TECH CO LTD

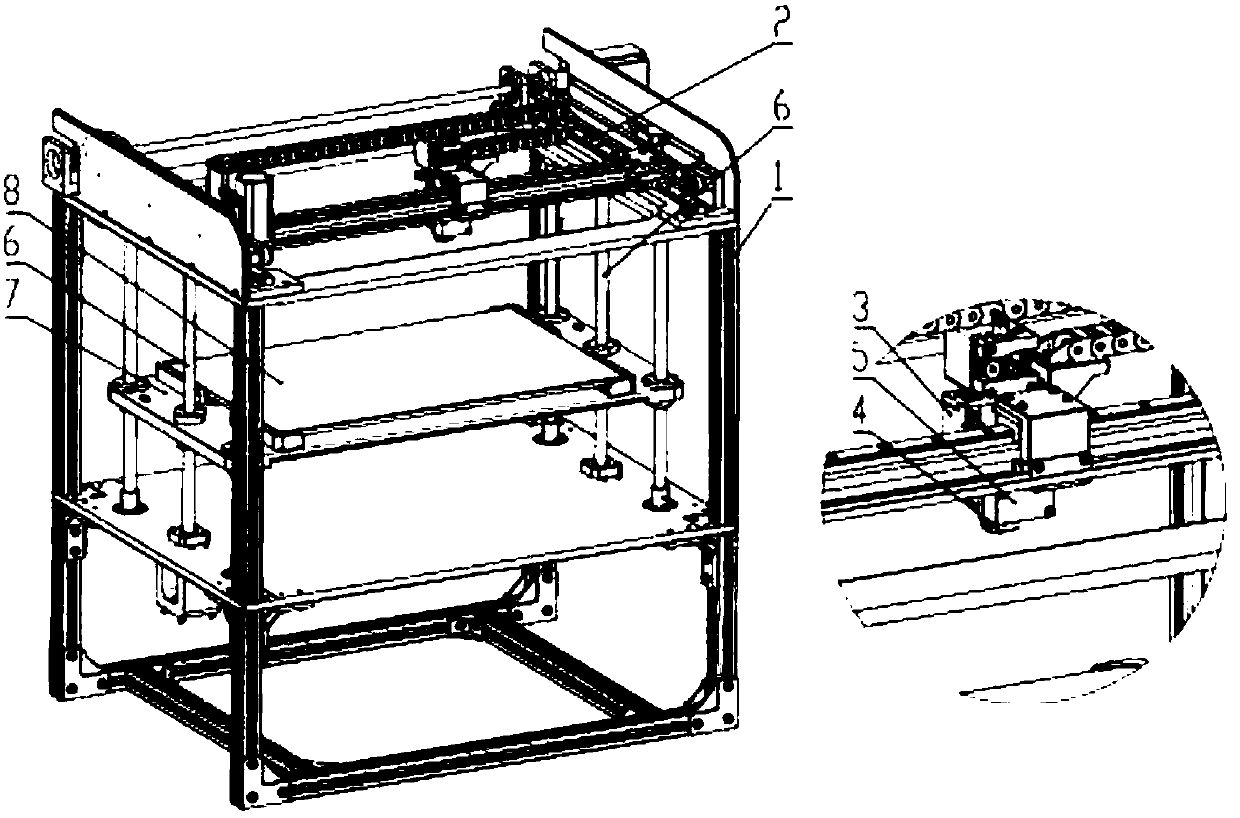

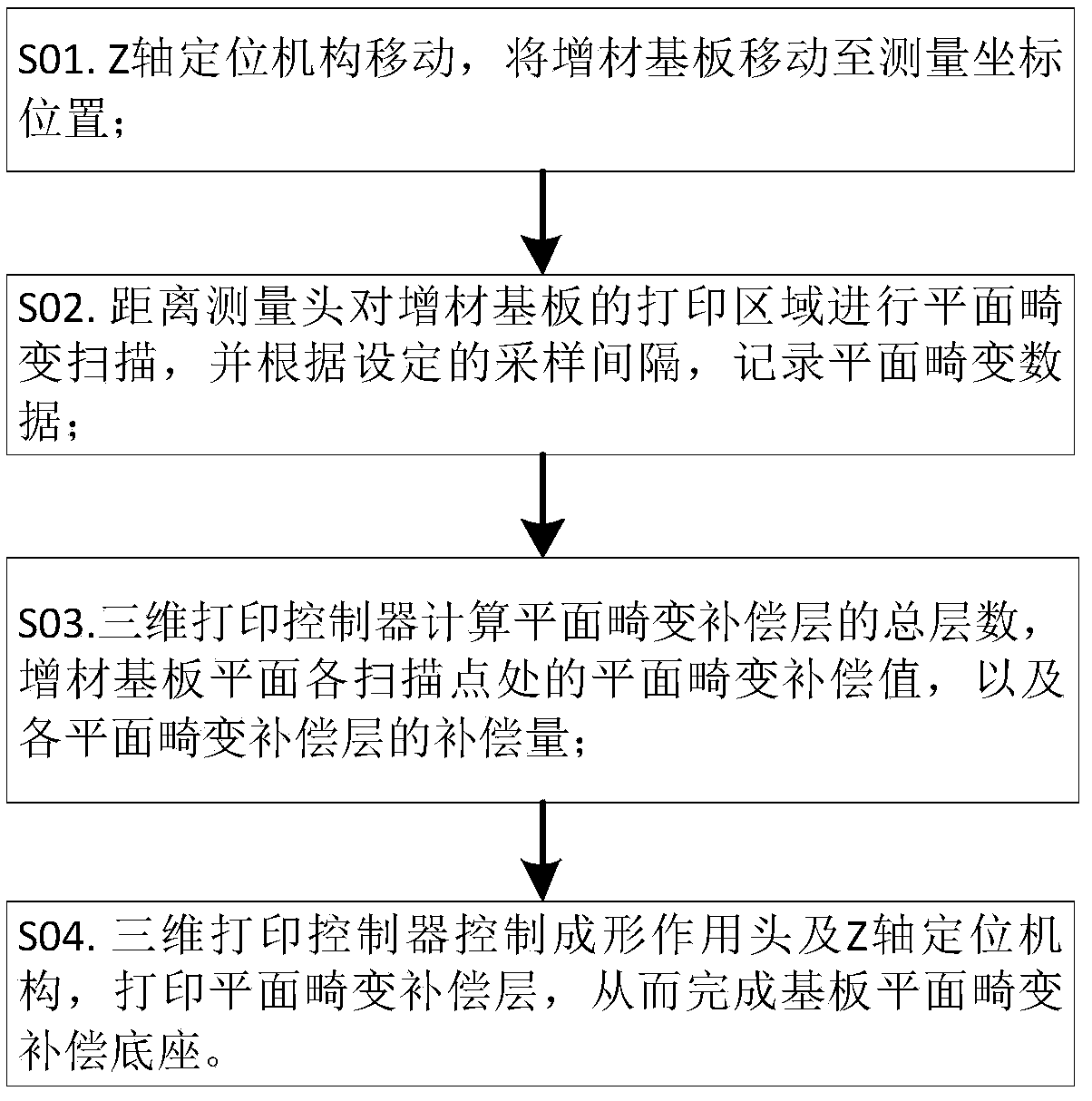

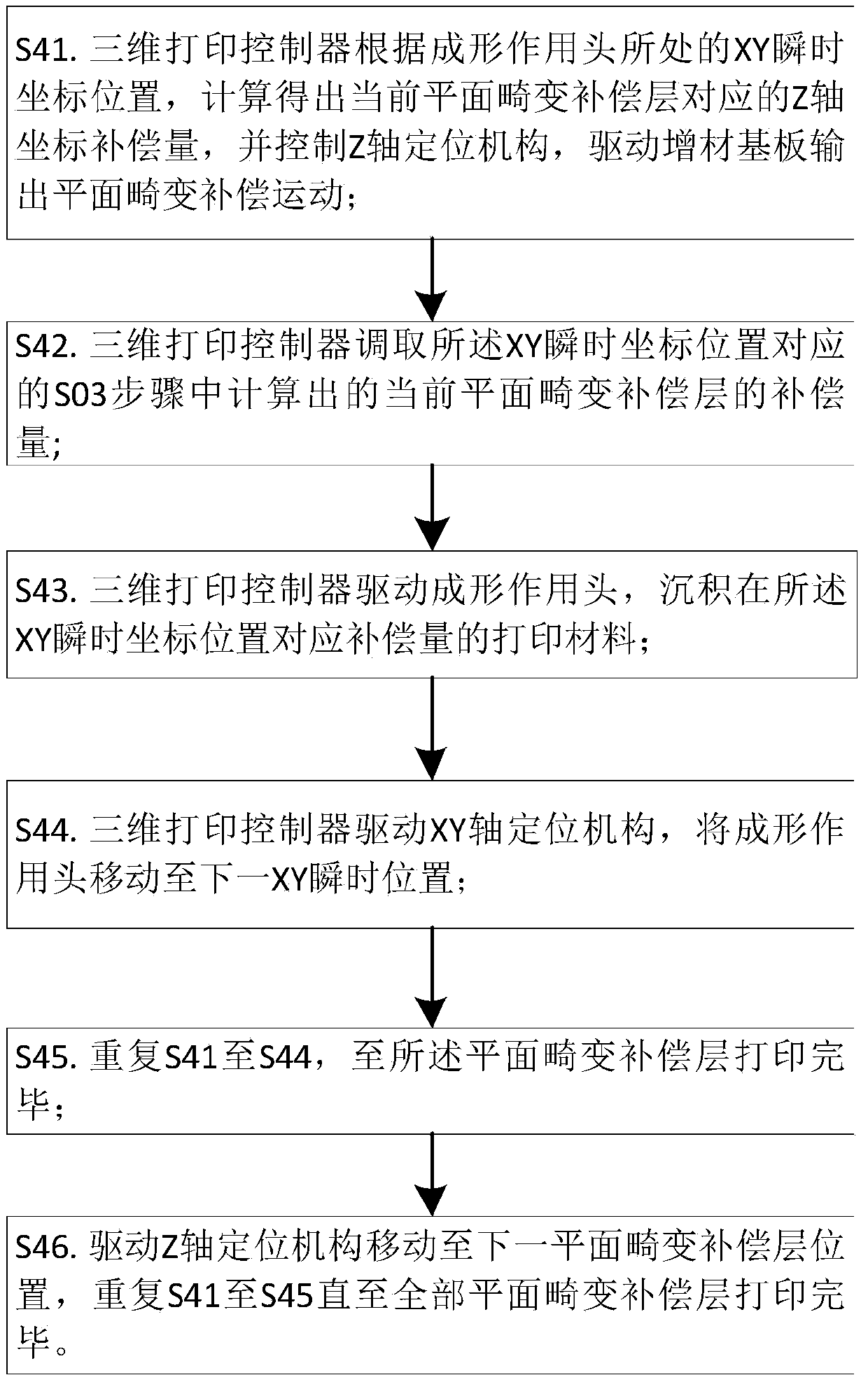

Additive substrate plane distortion compensating method

InactiveCN110962346AImprove flatnessReduce material costsManufacturing platforms/substratesManufacturing data aquisition/processing3 dimensional printingLarge format

The invention discloses an additive substrate plane distortion compensating method. A distance measuring head is used, and plane distortion data on the surface of an additive substrate are scanned andmeasured; parameters such as a plane distortion compensation value are calculated by a three-dimensional printing controller, and a forming action head is controlled to follow additive substrate surface distortion and implement deposition operation; in the process of printing a plane distortion compensation base, by real-time adjustment of the deposition compensation amount of the forming actionhead, plane distortion of the additive substrate is cumulatively compensated layer by layer; and finally an upper surface close to an ideal plane is obtained on the finally-completed plane distortioncompensation base, and upper surface is used as a reference plane for a three-dimensional printed part. By means of the method, high flatness of the additive substrate does not need to be ensured, complicated and precise multi-point leveling mechanisms are not needed, large-format deposition additive operation can be realized, and the material and processing cost of the additive substrate can be reduced.

Owner:PERA

Process for cleaning large format or giant screen movie screens

This invention relates to cleaning large format movie screens, such as vinyl screens and painted screens. There are different variations of the basic concept of using a cleaning head, cables, pulleys, an upper mounting bracket and a winch. In one instance a track may be used instead of a cable. The winch is connected to the cleaning head using cables and is used to move the cleaning head vertically across the screen through pulleys and other arrangements.

Owner:1570 CINEMA SERVICES

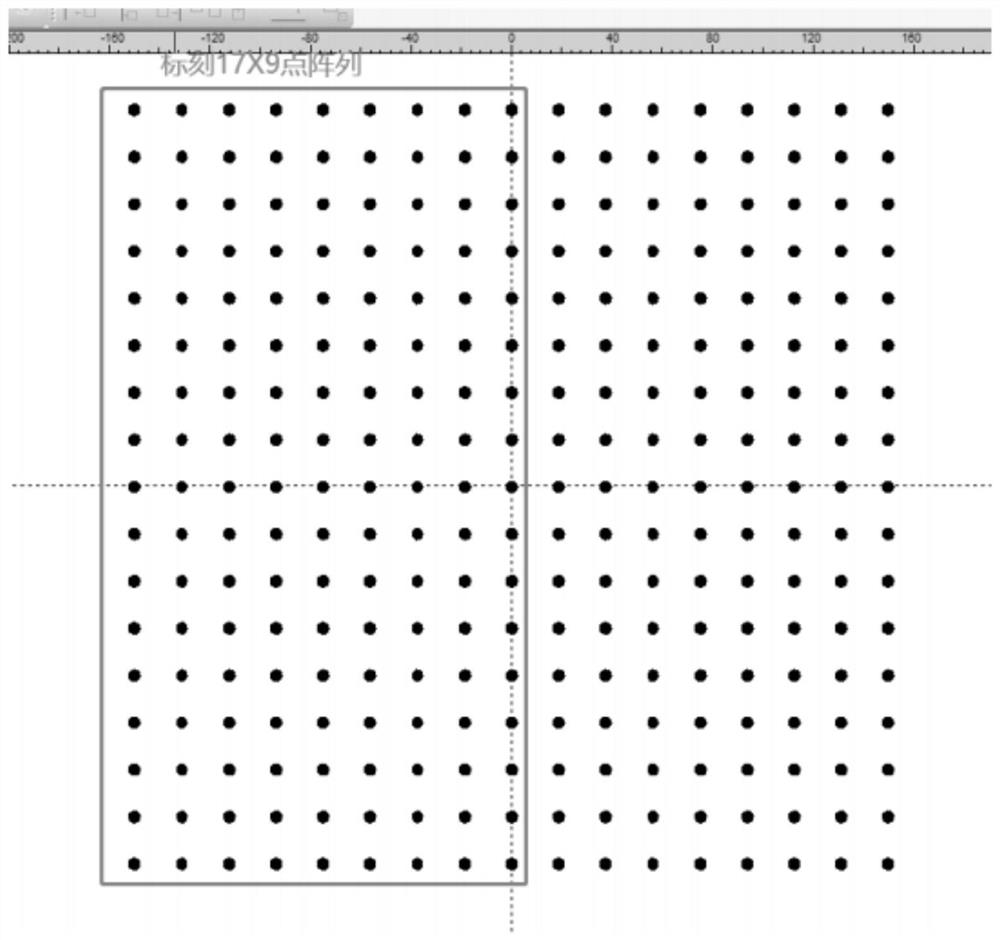

A3 breadth scanner-based regional scanning large-breadth galvanometer correction system

PendingCN114260560ASolve the acquisition problemAvoid situations that require custom scannersTransmissionLaser beam welding apparatusComputer hardwareLaser processing

The invention provides a regional scanning large-format galvanometer correction system based on an A3 format scanner, and the system comprises the steps: marking a circular array file according to the size of a to-be-corrected format, designing 17 rows and 17 columns of marked circular array files, and marking mark points on a first correction target A and a first correction target B through a to-be-corrected galvanometer; the maximum width is scanned through a two-dimensional scanner, the correction target A and the correction target B are the same galvanometer laser processing equipment, and actual coordinates of all points of the target A and the target B are obtained through an image recognition algorithm; finally, a correction file of the galvanometer is generated through the actual coordinates of 17 * 17 to complete correction, rapid multi-point correction of the galvanometer laser processing equipment with the breadth of 300 mm or above is achieved, manual measurement of coordinates of multiple points as before is not needed, errors and time waste caused by manual measurement are avoided, and the accuracy of the measurement is improved. And data in the whole process can be backed up and recorded through the server.

Owner:BEIJING JCZ TECH

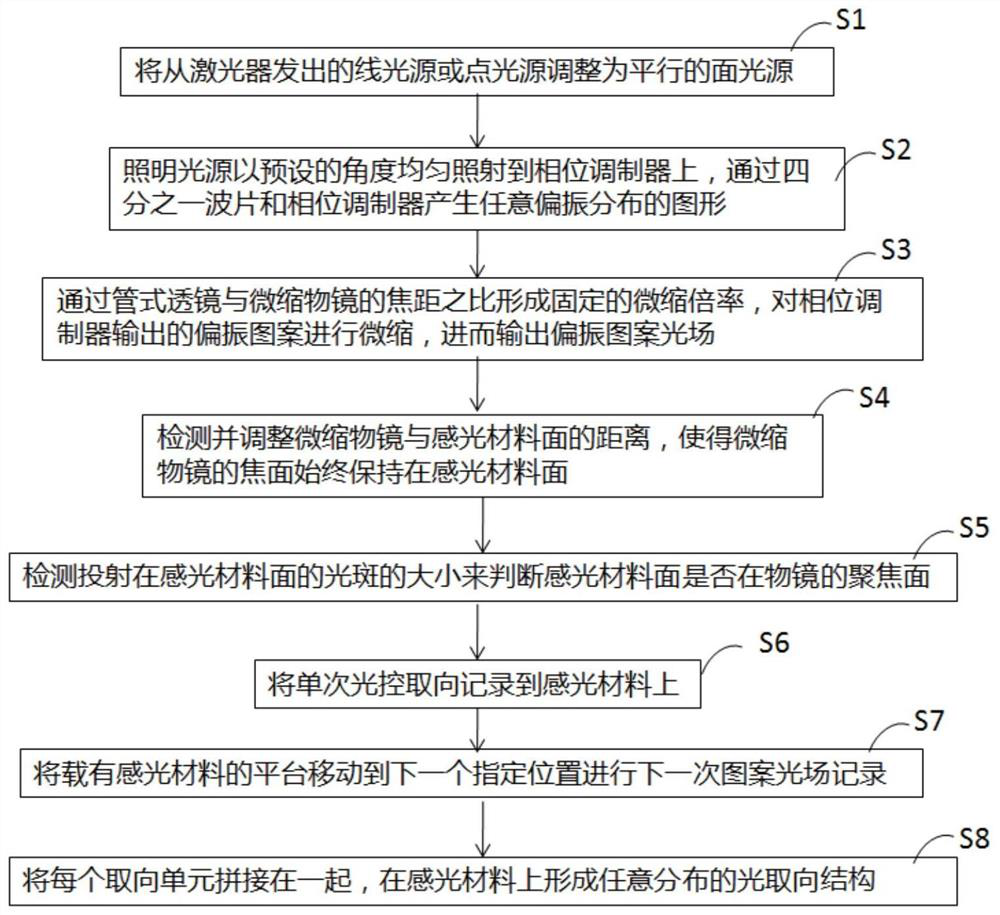

Large-format optical polarization pattern generation device and generation method

ActiveCN112241070AOvercome flexibilityFocus real timeNon-linear opticsOptical elementsLight spotImage detection

The invention discloses a large-format optical polarization pattern generation device which comprises an illumination component, a polarization pattern generation component, a miniature imaging component and an imaging detection and splicing component which are connected in sequence. The illumination component is used for realizing single polarization collimation of uniform surface light spots; the polarization pattern generation part comprises a quarter-wave plate and a phase modulator and is used for outputting a polarization pattern; the miniature imaging component is used for miniaturizingthe polarization pattern output by the polarization pattern generation part and writing the miniaturized polarization pattern into the photosensitive material; the imaging detection and splicing component comprises an imaging detection sub-part and a focal length calibration sub-part; and the imaging detection sub-part comprises a double-light-path pattern monitoring imaging assembly and a pattern splicing assembly. The integrated optical system, the motion control system and the detection system have the advantages that the single-exposure polarization pattern is high in precision, optionally controllable and high in efficiency, large-area optical polarization patterns can be realized, and the like.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com