Patents

Literature

181 results about "Laser polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-laser polishing and reinforcing method for surfaces of additive manufacturing metal parts

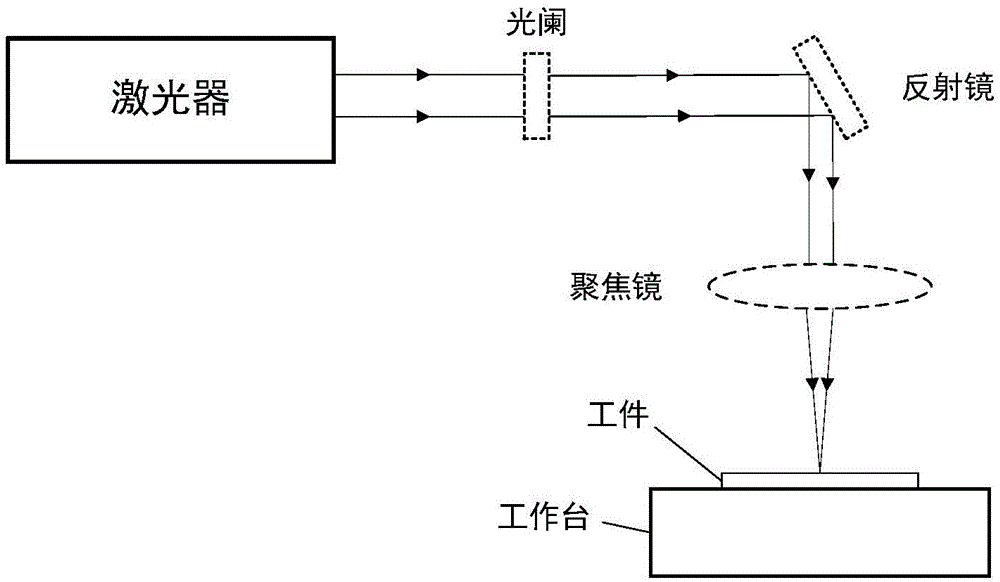

InactiveCN104109860AAchieving Surface Quality Polishing IssuesQuick polishSurface stressLaser scanning

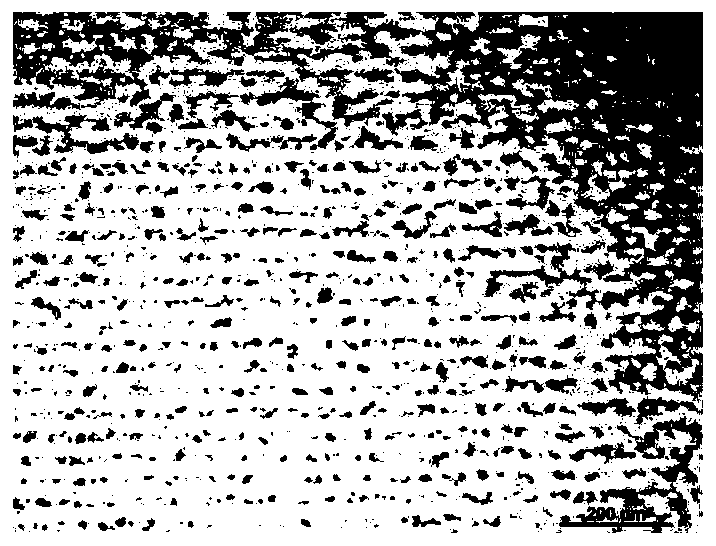

The invention discloses a multi-laser polishing and reinforcing method for surfaces of additive manufacturing metal parts, and the polishing on the surfaces of the additive manufacturing metal parts can be realized by repeatedly scanning and processing the surfaces of the additive manufacturing metal parts through utilizing millisecond pulse laser and nanosecond pulse laser; during the multi-laser scanning polishing process, the additive manufacturing metal parts are subjected to thermal preservation treatment, so that the stress on the surfaces of the additive manufacturing metal parts can be evenly distributed; laser scanning reinforcement is carried out on the surfaces of the laser-polished additive manufacturing metal parts, so that the stress state on the surfaces of the additive manufacturing metal parts can be changed into pressure stress from tensile stress, the anti-fatigue property of the additive manufacturing metal parts can be enhanced, and the usage performance of the metal parts can be met; compared with a manual polishing method, the multi-laser polishing and reinforcement efficiency of the additive manufacturing metal parts is high and is as 20 times as that of the manual polishing, the non-contact rapid polishing of the additive manufacturing metal parts can be realized, the tensile stress, caused by the laser polishing, of the additive manufacturing metal parts can be eliminated, and the anti-fatigue property of the additive manufacturing metal parts can be enhanced.

Owner:XI AN JIAOTONG UNIV

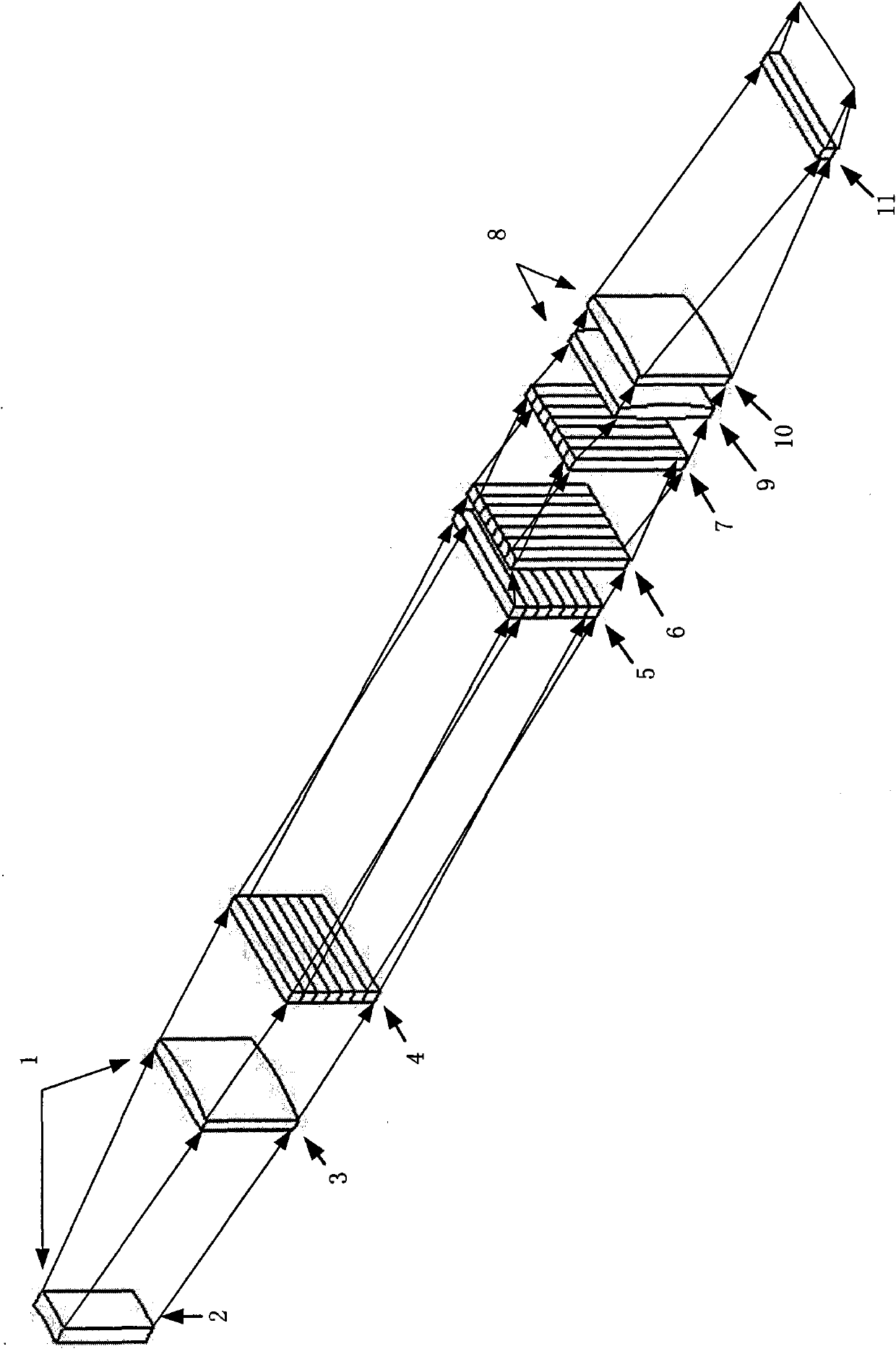

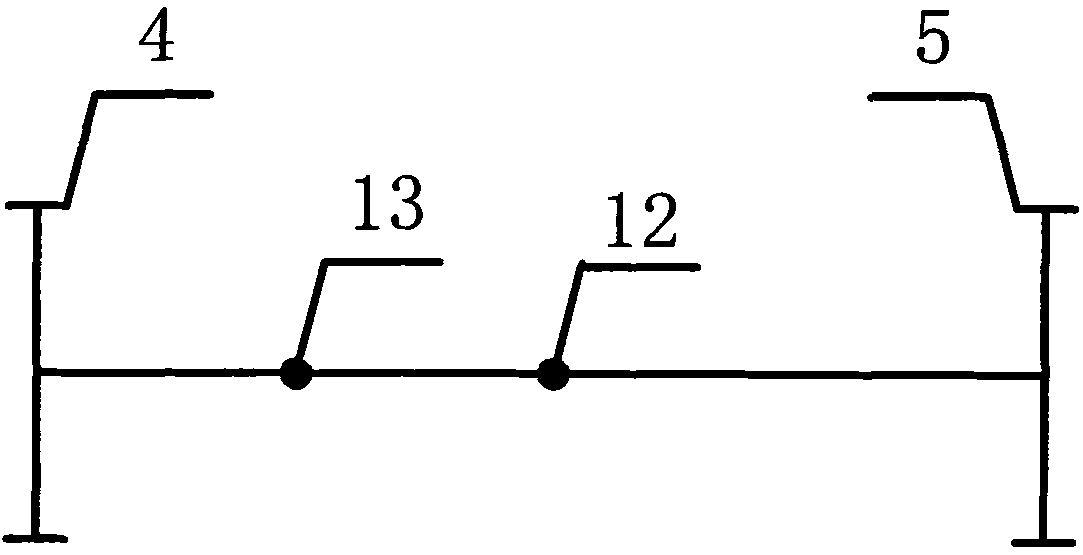

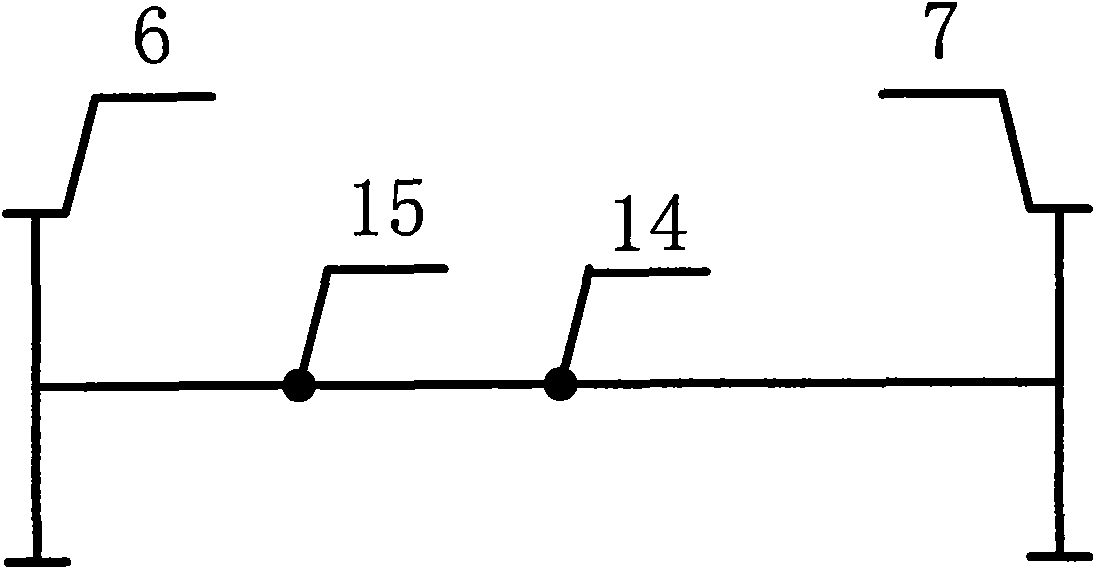

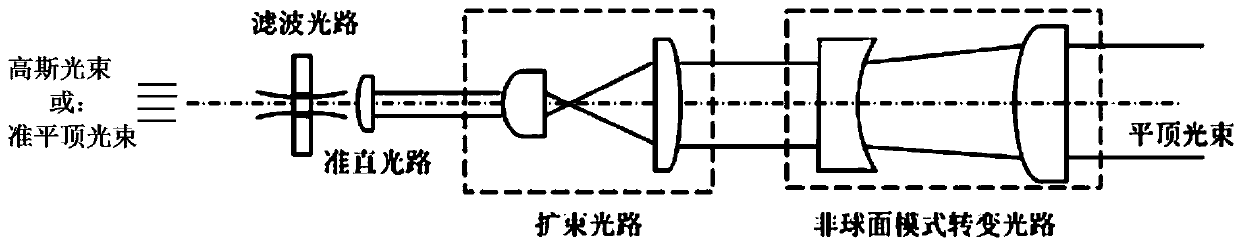

Laser beam transformation shaper outputting uniform linear spots

The invention discloses a laser beam transformation shaper outputting uniform linear spots, which is an optical system capable of transforming and shaping laser beams with irregular spot shapes and nonuniformly distributed energy into laser beams with uniformly distributed energy and the spot shape approaching a line, and is mainly applied to laser polishing, laser cleaning and laser induced material surface modification, and belongs to field of laser surface processing technology and application thereof. The laser beam transformation shaper comprises seven parts, namely a first part of a telescope system consisting of a plurality of circular lenses or cylindrical lenses, second, third, fourth and fifth parts consisting of a cylindrical lens array respectively provided with N cylindrical lenses, a sixth part consisting of two cylindrical lenses of which the generatrices are vertical mutually, and a seventh part consisting of cylindrical lenses or cylindrical lens combination. The laser beam transformation shaper transforms and shapes incident laser into linear laser spots with uniformly distributed spot energy, and greatly improves the efficiency of laser polishing, laser cleaningand laser induced material surface modification by matching high-speed movement of a work bench.

Owner:BEIJING UNIV OF TECH

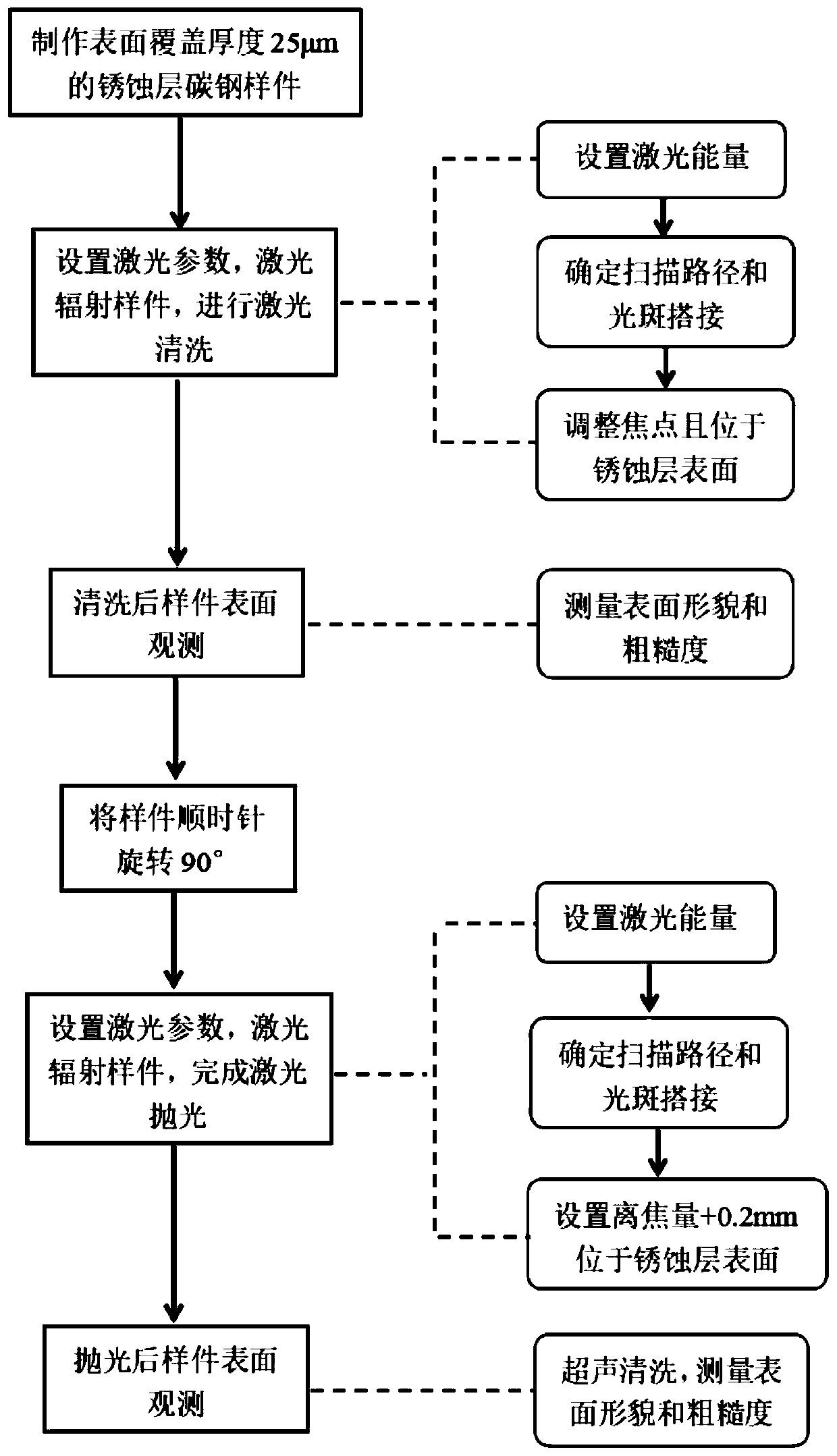

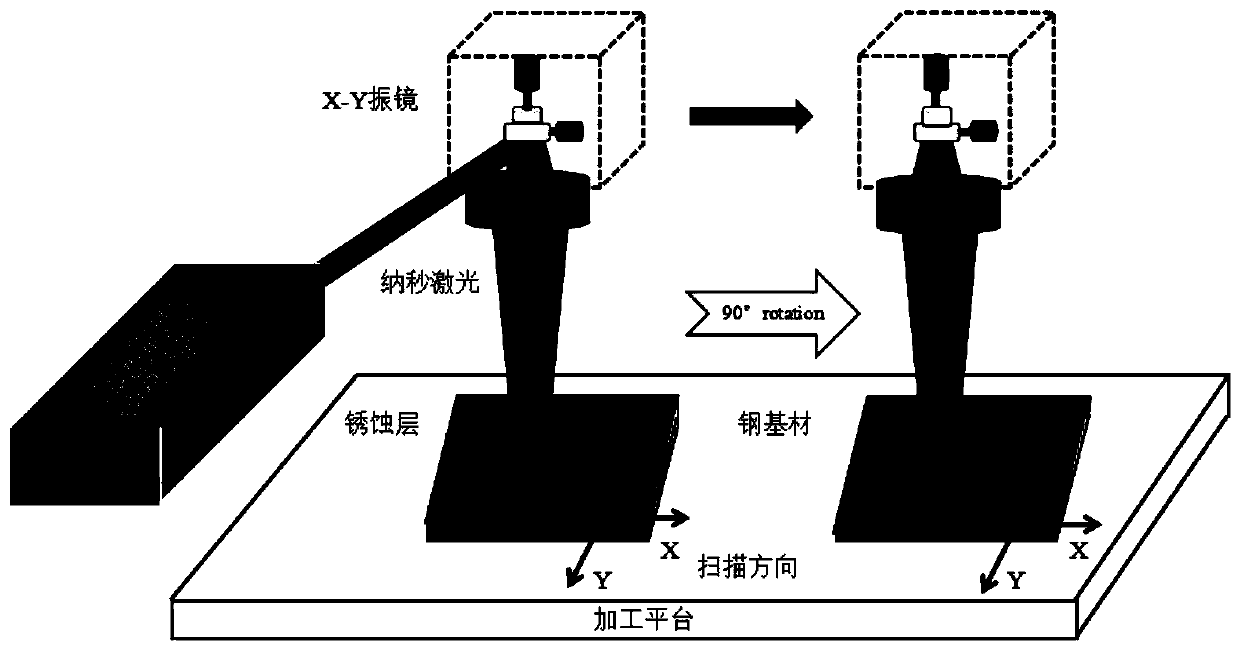

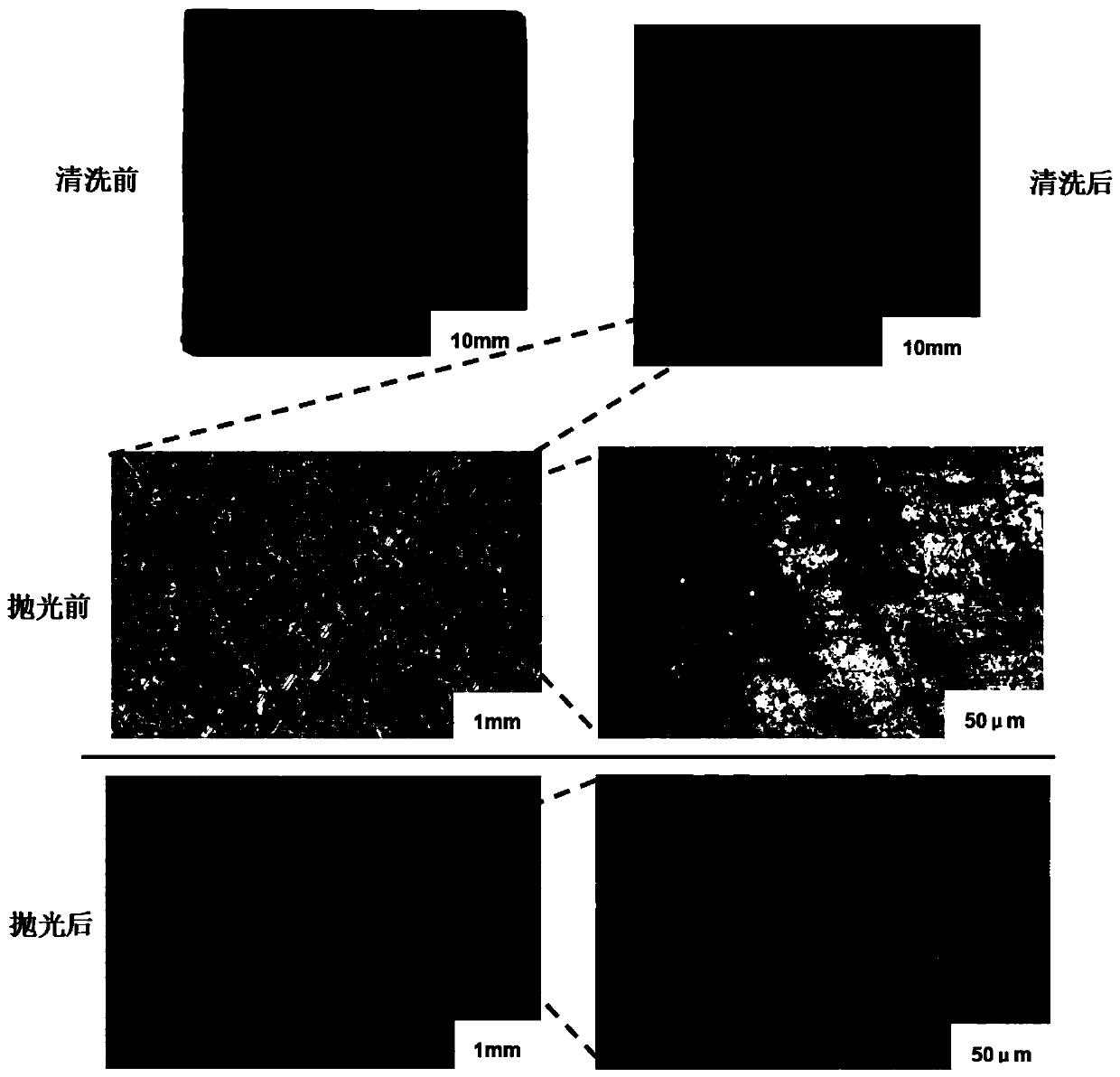

Laser cleaning and polishing composite processing method for surface of carbon steel

ActiveCN109773340AConditions that affect the performance of the matrixAvoid damageWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingNanosecond pulse

The invention discloses a laser cleaning and polishing composite processing method for the surface of carbon steel. By means of the method, laser cleaning and laser polishing processes are seamlesslycombined and used on the same equipment. The method can be widely applied to surface laser processing of steel parts. A nanosecond pulse laser with a certain output energy range is used, so that a corrosion layer can be evaporated; the corrosion layer on the surface of the carbon steel is quickly removed by utilizing primary laser treatment; and then laser parameters are adjusted to radiate a cleaned surface to enable a protruding fused object on the carbon steel to flow and fill and solidify a sunken part, and the polished surface with small roughness and improved performance is obtained. Therefore, defects in the prior art are overcome, fusion pits and micro-scale defects of the surface of the carbon steel after laser cleaning can be effectively repaired, the surface roughness is reduced, and the purposes of improving the laser processing efficiency of the carbon steel and keeping the surface performance are achieved.

Owner:GUANGDONG UNIV OF TECH

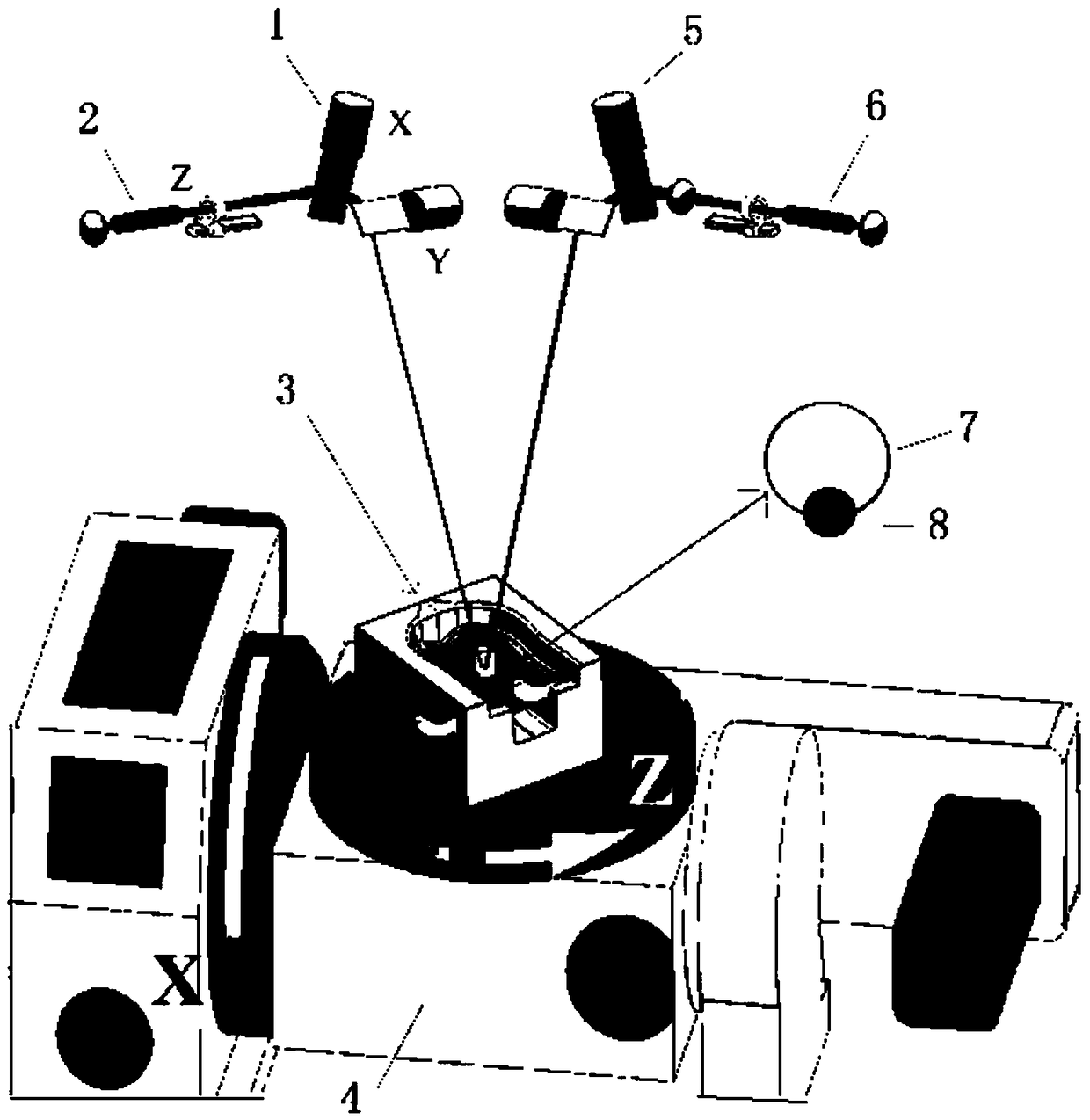

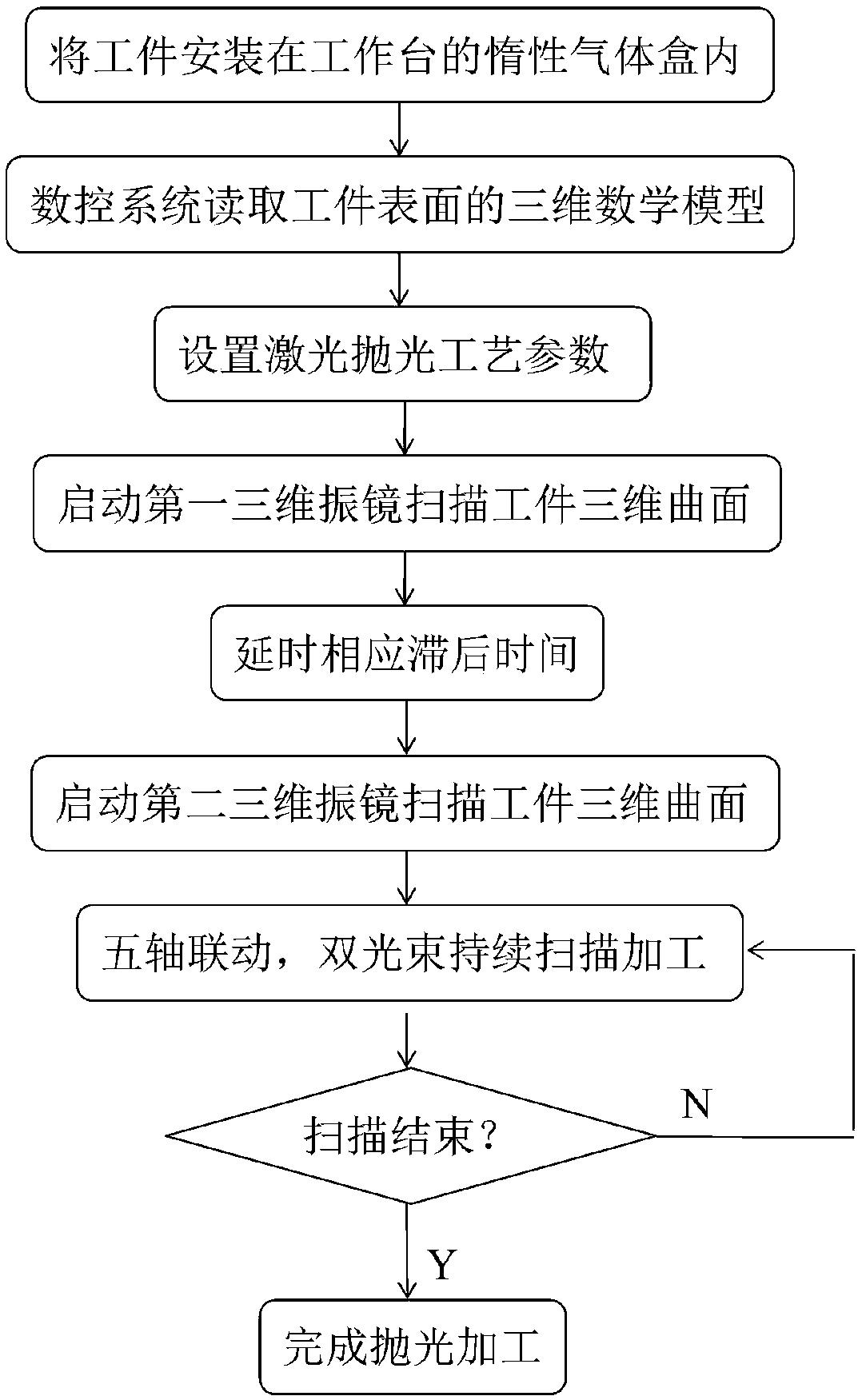

Double-beam five-axis numerically controlled laser polishing method

The invention discloses a double-beam five-axis numerically controlled laser polishing method. The method comprises the following steps that A, firstly, two three-dimensional galvanometer systems capable of performing three numerically controlled moving shafts are arranged on laser polishing equipment to form a double-beam three-dimensional galvanometer system, a fiber infrared continuous laser passes through the first three-dimensional galvanometer system and applies a focused light spot on a three-dimensional curved surface of a to-be-polished workpiece, a multi-band pulsed laser passes through the second three-dimensional galvanometer system and also applies a focused light spot on the three-dimensional curved surface of the to-be-polished workpiece. The double-beam five-axis numerically controlled laser polishing method has the advantages that 1, the method can be applied to laser polishing of a plastic injection mold cavity and a blow mold cavity; 2, laser polishing can be performed on a 3D glass shell of a mobile phone; 3, precise laser polishing can be performed on optical glass; 4, polishing can be performed on the three-dimensional curved surface of parts processed by additive manufacturing (3D printing); 5, laser polishing can be performed on the three-dimensional shaped curved surface of other product parts.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

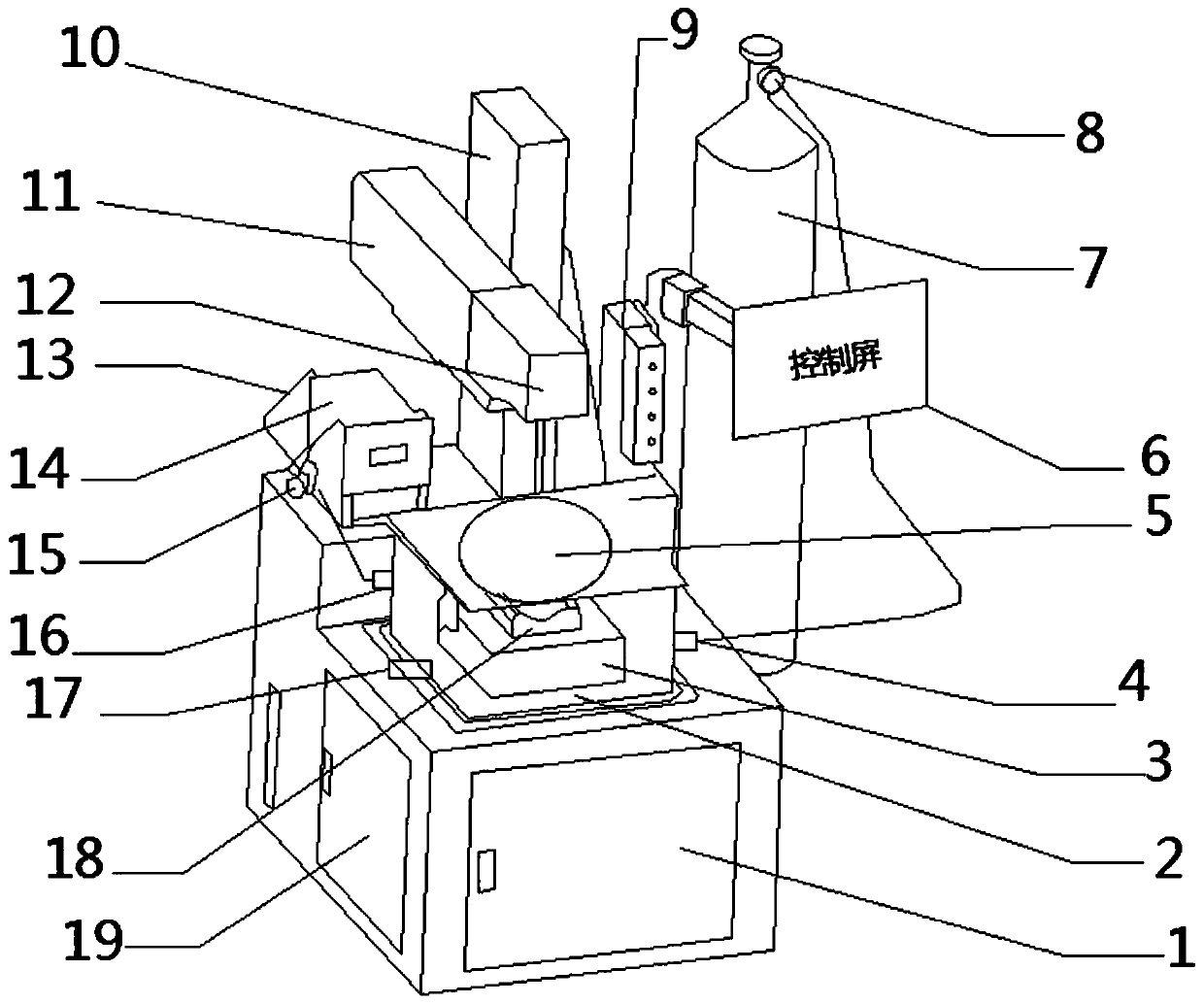

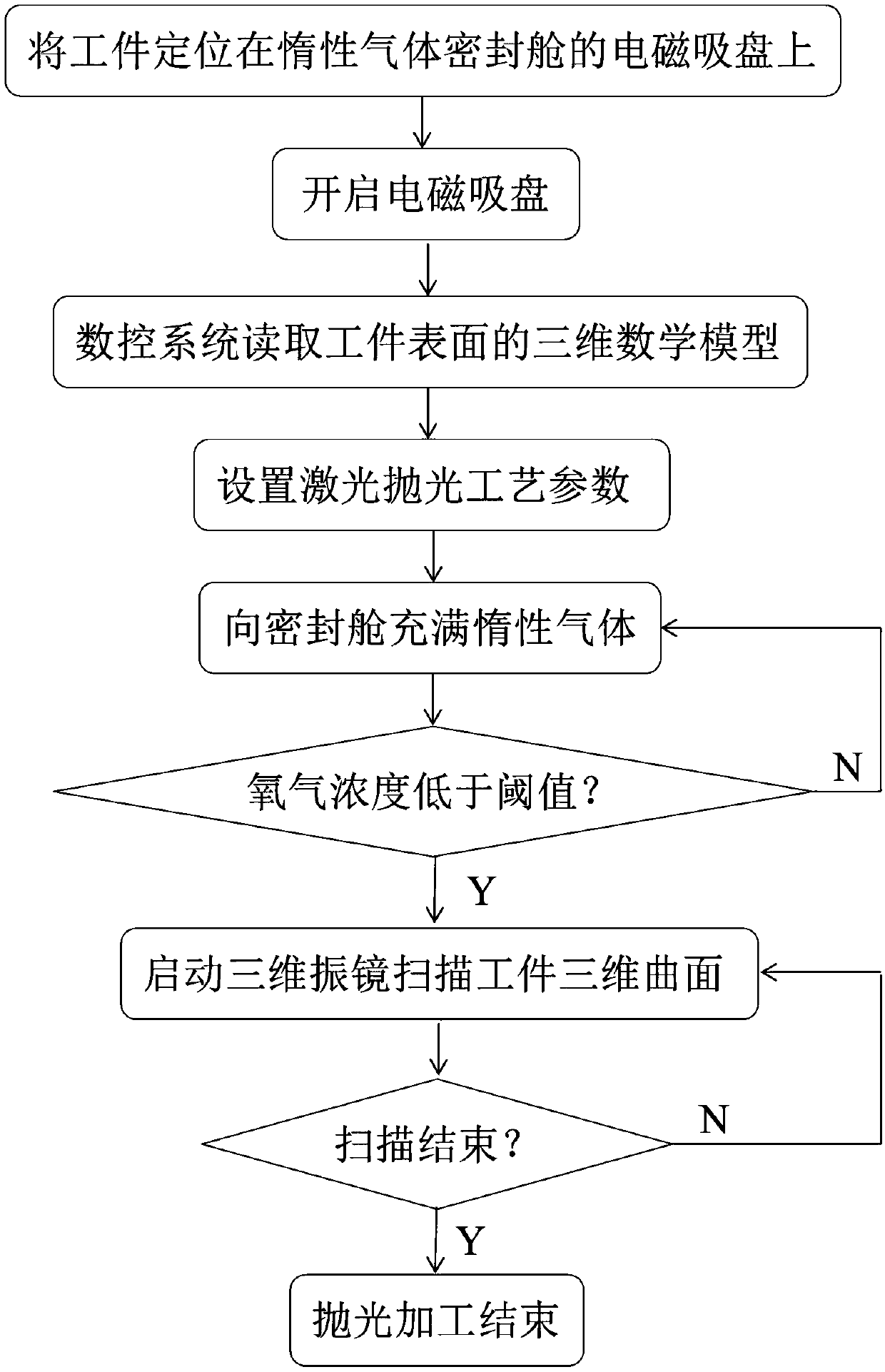

3D surface laser polishing method and device

The invention discloses a 3D surface laser polishing method and device. The device comprises a device lathe bed, an inert gas bottle, an oxygen concentration tester, a 3D galvanometer and an internalQBH collimator with a beam expander. An inner quasi flat top continuous laser device is arranged in the device lathe bed, an inert gas seal cabin is arranged above the device lathe bed, an electromagnetic chuck is arranged in the inert gas seal cabin, and the inert gas seal cabin is connected with an inert gas seal cabin air inlet pipe through an inert gas seal cabin air inlet valve. The device has the beneficial effects that firstly, 3D surfaces of a plastic injection molding mold cavity and a blowing plastic mold cavity are subjected to laser polishing; secondly, 3D surfaces of a general anddedicated structural part or metal parts of the device can be subjected to laser polishing; and thirdly, the metal 3D surface for decoration can be mechanically polished.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

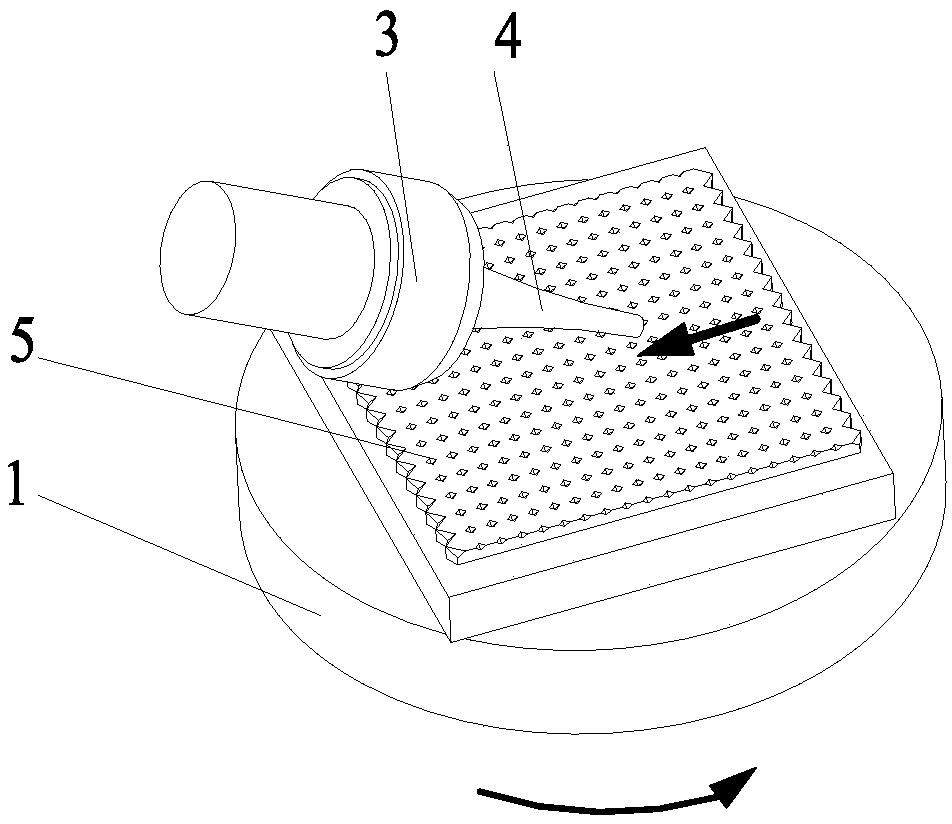

Additive manufacturing and surface polishing synchronous processing method and device

ActiveCN109926584AShort duration of actionNo heat effectAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyMachining process

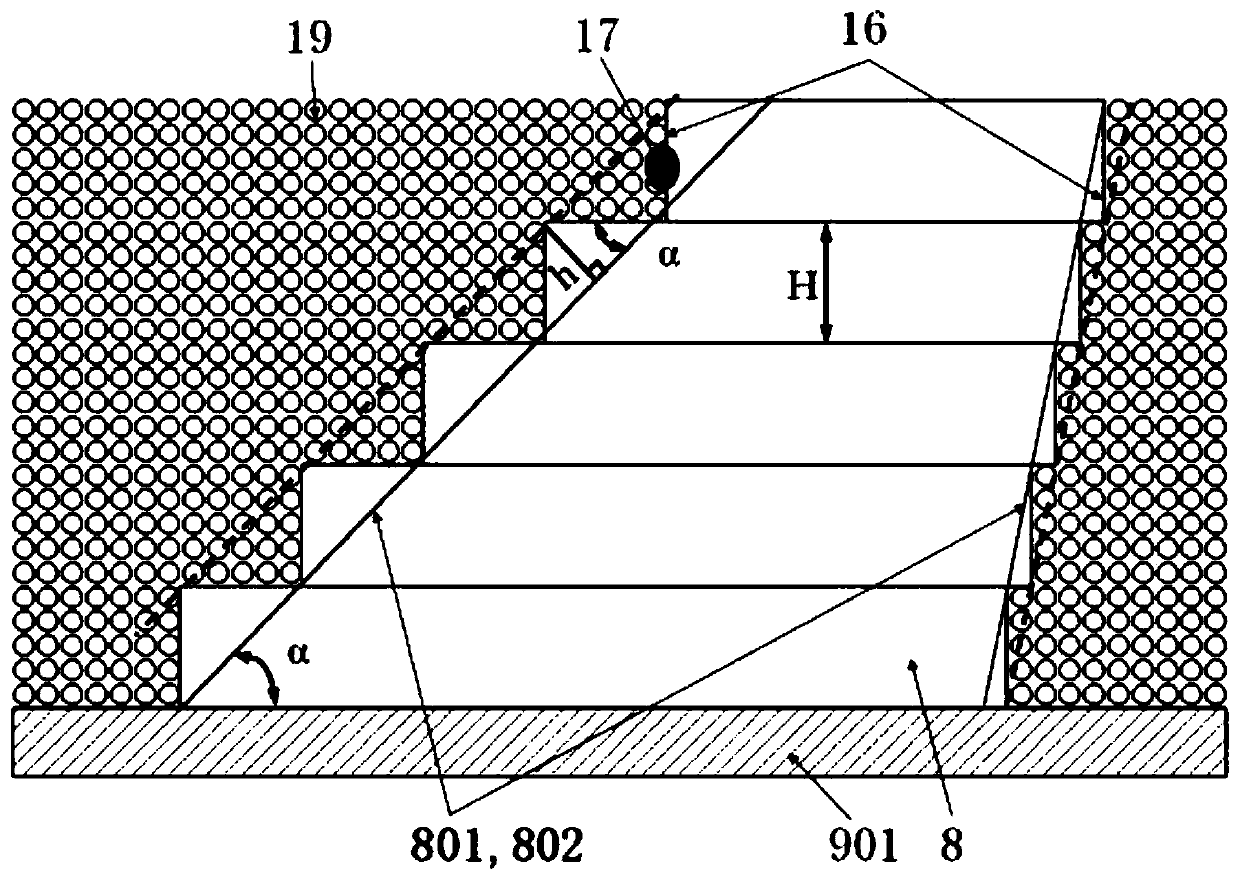

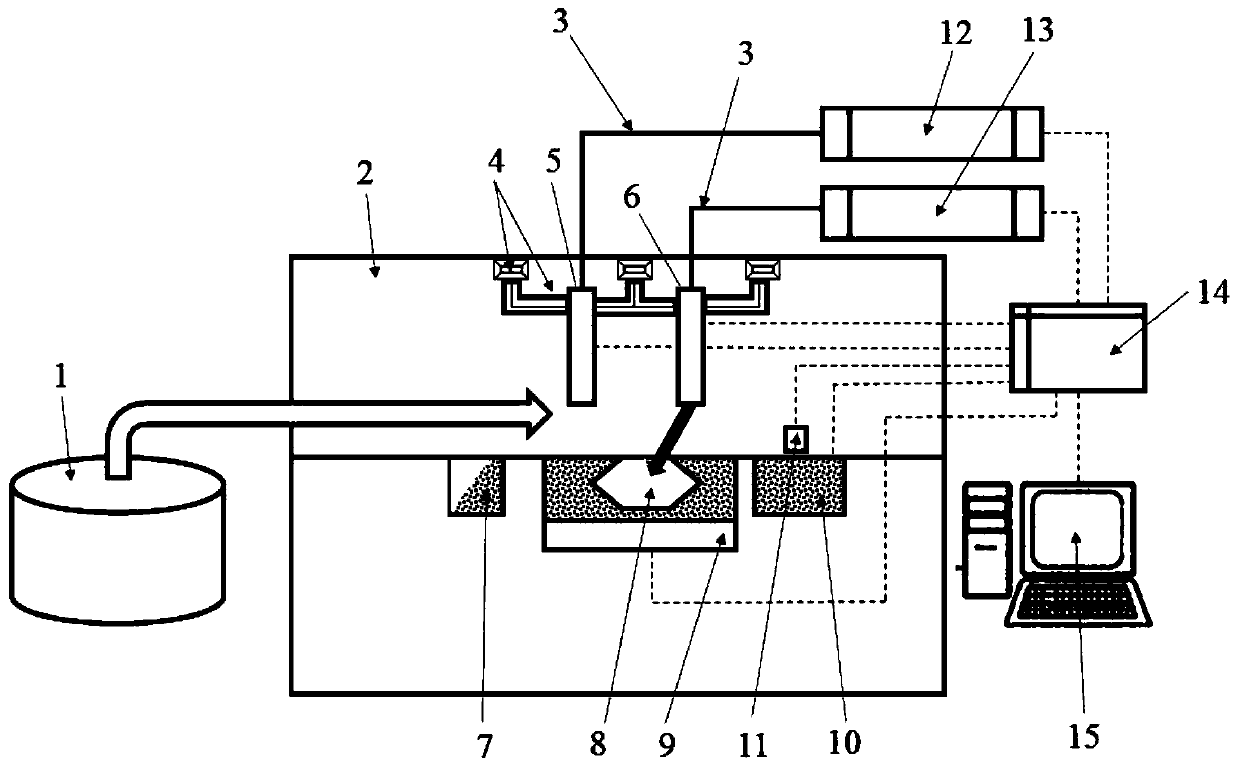

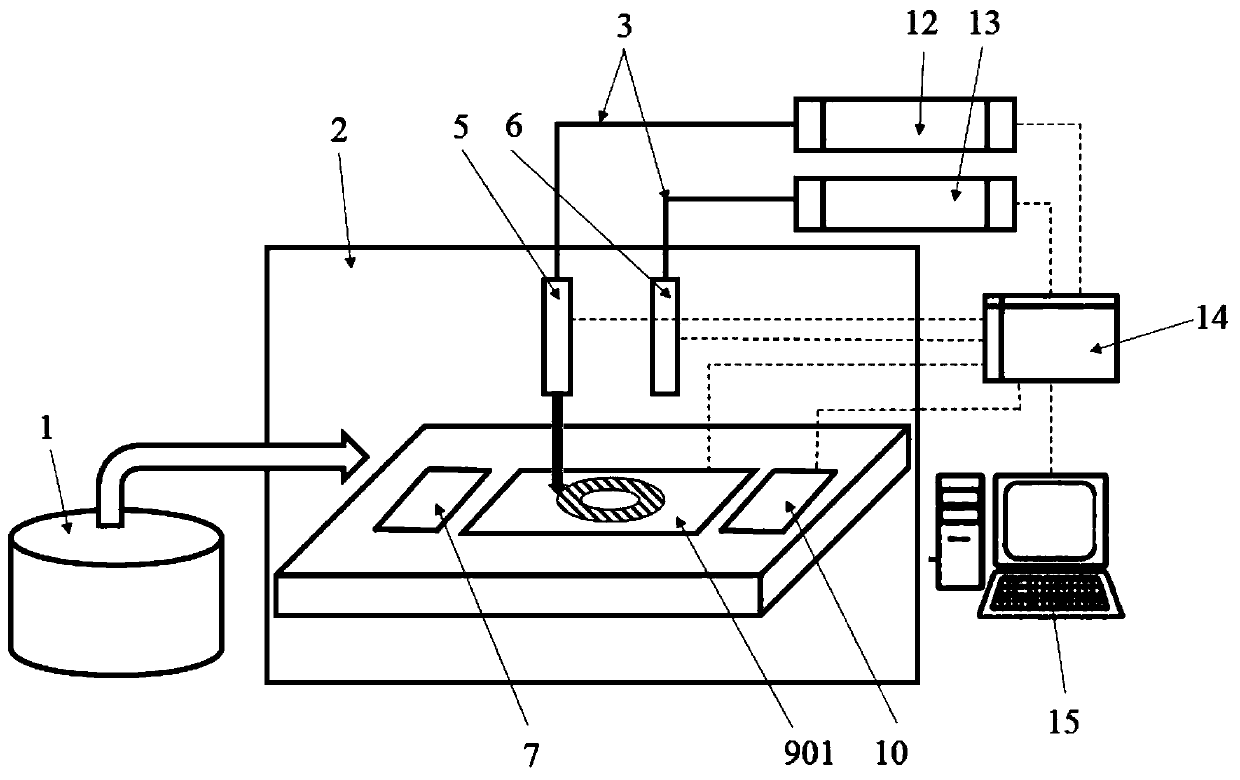

The invention provides an additive manufacturing and surface polishing synchronous processing method and device. The method is characterized in that after powder in a selected space at some slice layer is molten into a cladding layer by laser during layer-based forming processing of an additive manufacturing part, the inner outline surface and / or the outer outline surface of the cladding layer are quickly scanned and polished through laser so as to remove redundant materials in the selected areas on the inner outline surface and / or the outer outline surface, and then the cladding layer of the next slice layer can be formed and processed by laser until redundant materials in all selected areas on the inner outline surface and / or the outer outline surface of the whole additive manufacturing part are removed. With the adoption of the method, metal surface materials can be directly removed, and residual stress generated by additive manufacturing can be released; the technical route thatthe additive manufacturing technology and the surface polishing technology are synchronously carried out is capable of polishing the inner surface and the outer surface of any metal additive manufacturing part with a complex empty cavity; and the technical problem that the inner surface of an empty cavity of the part cannot be polished in later laser polishing or mechanical processing can be overcome.

Owner:SHANGHAI UNIV OF ENG SCI

Method for laser-assisted polishing of CVD diamond

ActiveCN109590811AImprove polishing efficiencyImprove polishing qualityPolishing machinesMetal working apparatusLaser assistedGraphite

The invention relates to a method for laser-assisted polishing of a CVD diamond. The method comprises the following steps: first, selecting a suitable laser type according to the material property ofthe CVD diamond, and simulating the laser ablation of the CVD diamond so as to acquire suitable laser ablation parameters; then, carrying out laser rough polishing based on optimum laser process parameters; and finally, carrying out mechanical precision polishing by the adoption of a polishing disc till the required precision is achieved, so that a graphitization layer generated during the laser ablation process and surface defects such as microcracks can be removed. Through the method provided by the invention, the problems that the graphitization layer is easy to generate during the laser polishing process of the CVD diamond and the polishing efficiency of the mechanical polishing process is low can be solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

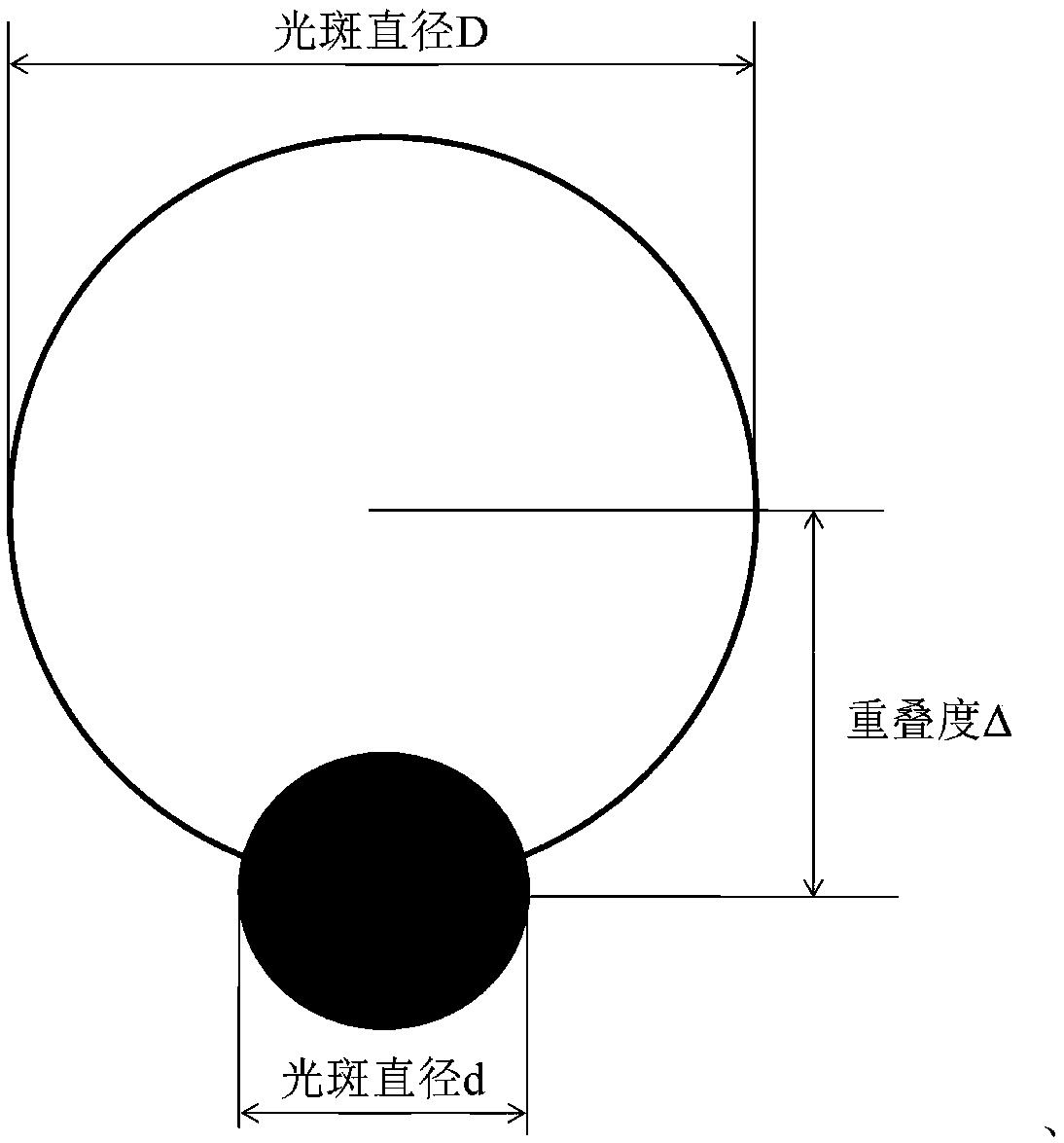

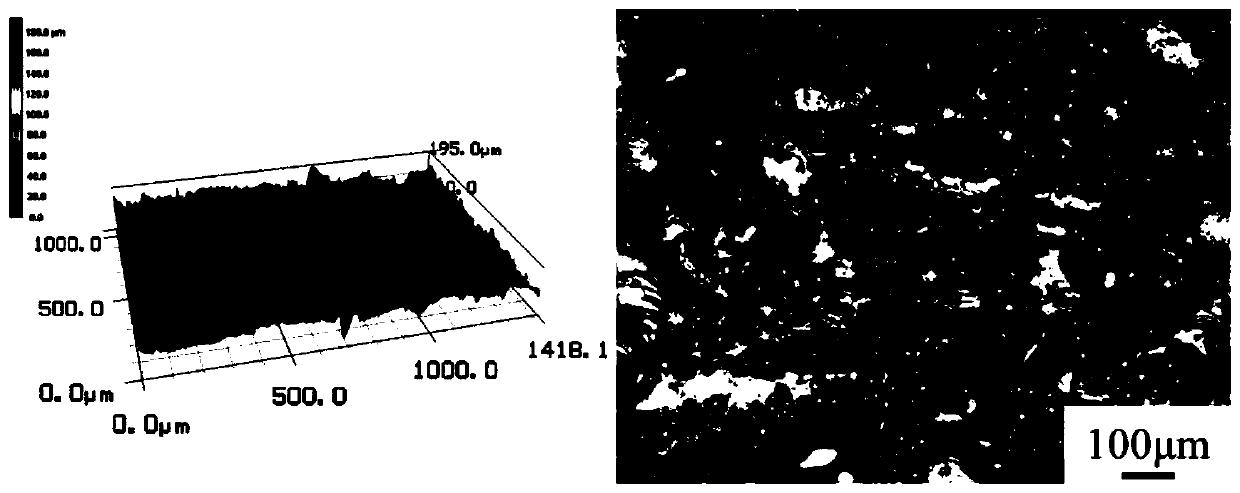

Ultrafast laser polishing method for ceramic matrix composites

ActiveCN108890138ASolve the problem of overlapping difficultiesGuaranteed uniformityLaser beam welding apparatusLaser processingOptoelectronics

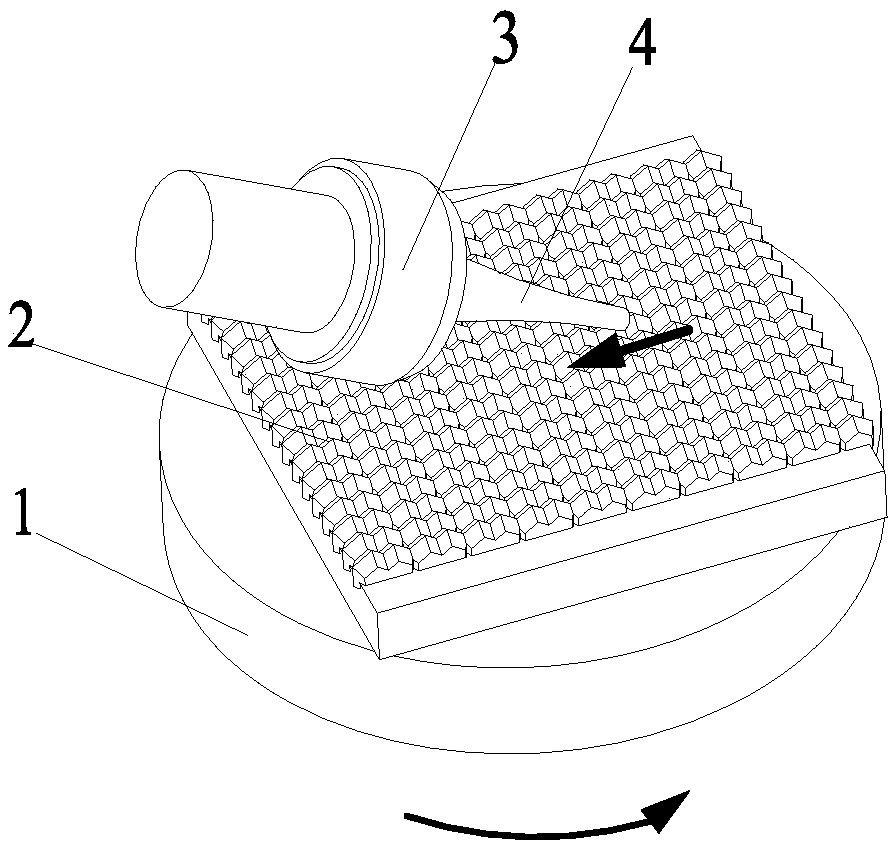

An ultrafast laser polishing method for ceramic matrix composite material At first, that proces sample of SiC ceramic matrix composite is fixed on the lase processing equipment, the laser processing equipment comprise an optical path system and a processing platform, the optical path system comprises a femtosecond laser, and the laser of the femtosecond laser acts on the processing platform afterpassing through a mirror, a beam expanding mirror, an aperture, a vibrating mirror and a field mirror assembly; The machining platform comprises a three-dimensional movement mechanism and a fixture inthe x, y and z axes directions relative to the worktable, an angular displacement table is installed in the three-dimensional movement mechanism, and the included angle between the y axis direction and the normal of the worktable can be changed by adjusting the angular displacement table to obtain a large incident angle of the laser beam; The laser parameters of the femtosecond laser, the scanning of the vibrating mirror and the movement of the three-dimensional moving mechanism are controlled by the computer to polish the sample. The invention utilizes the laser and the processing platform to work cooperatively, adjusts the transverse and longitudinal light spot overlap ratio according to the need, ensures the uniformity of the processing, and has high processing efficiency.

Owner:无锡超通智能制造技术研究院有限公司

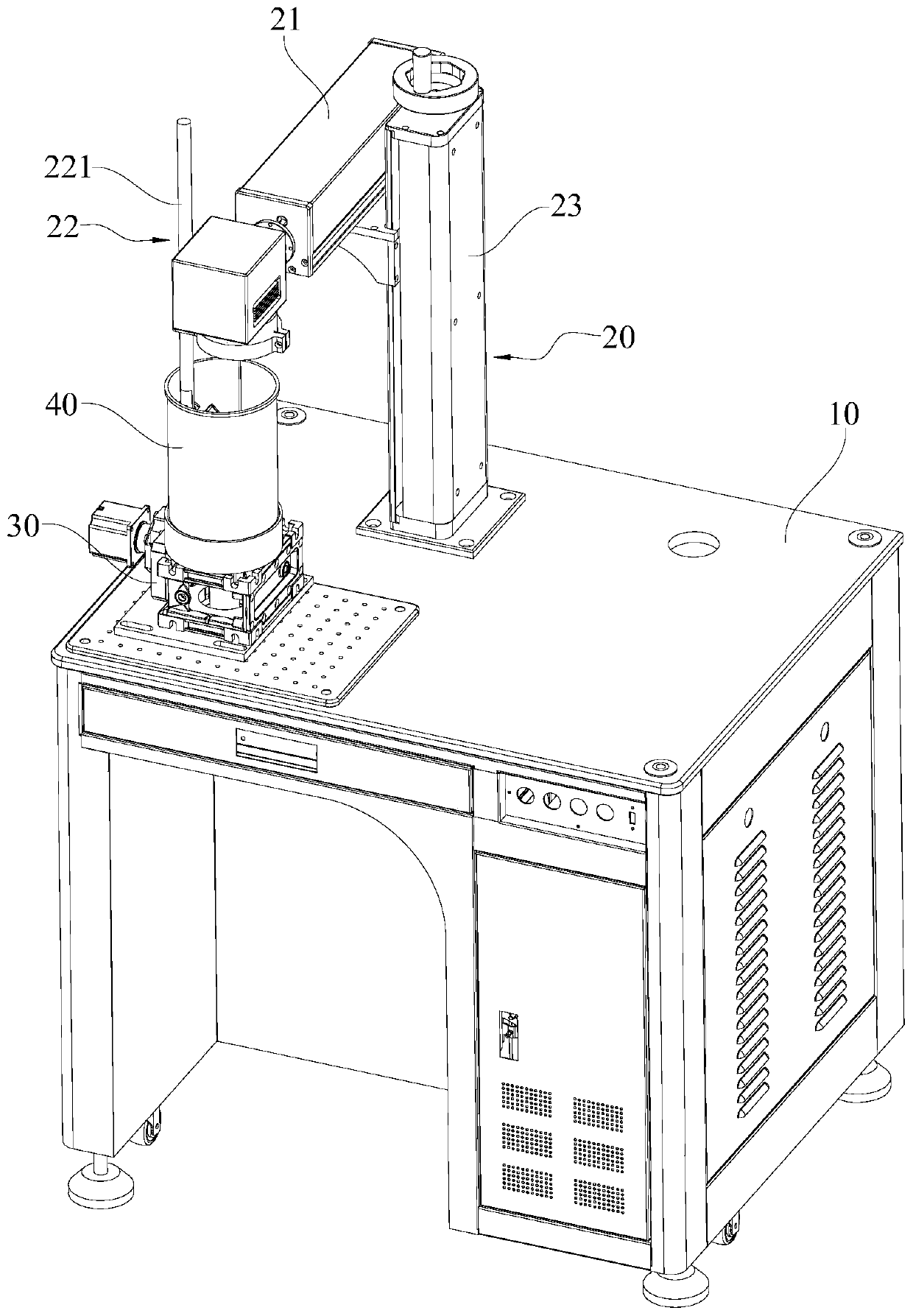

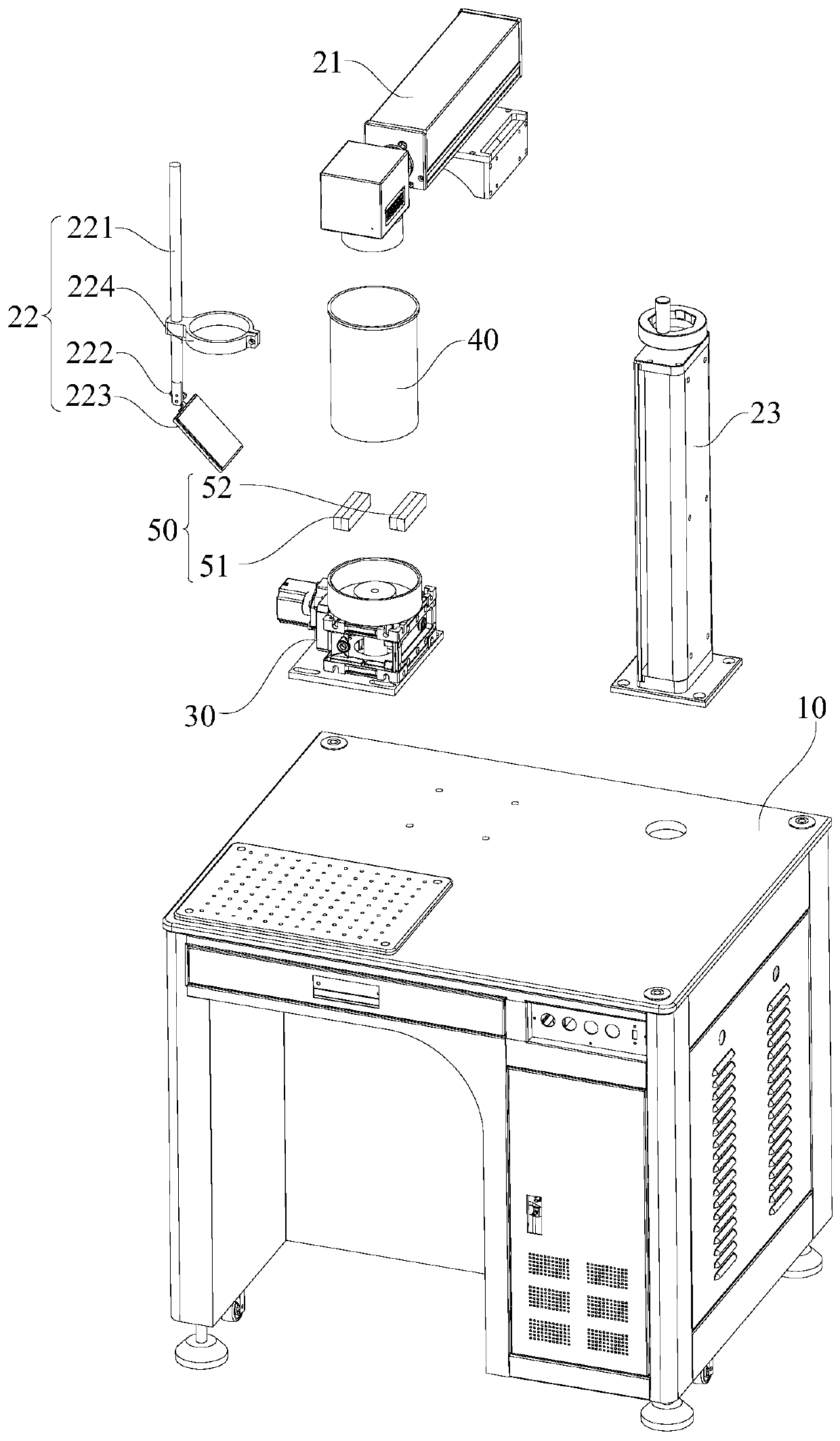

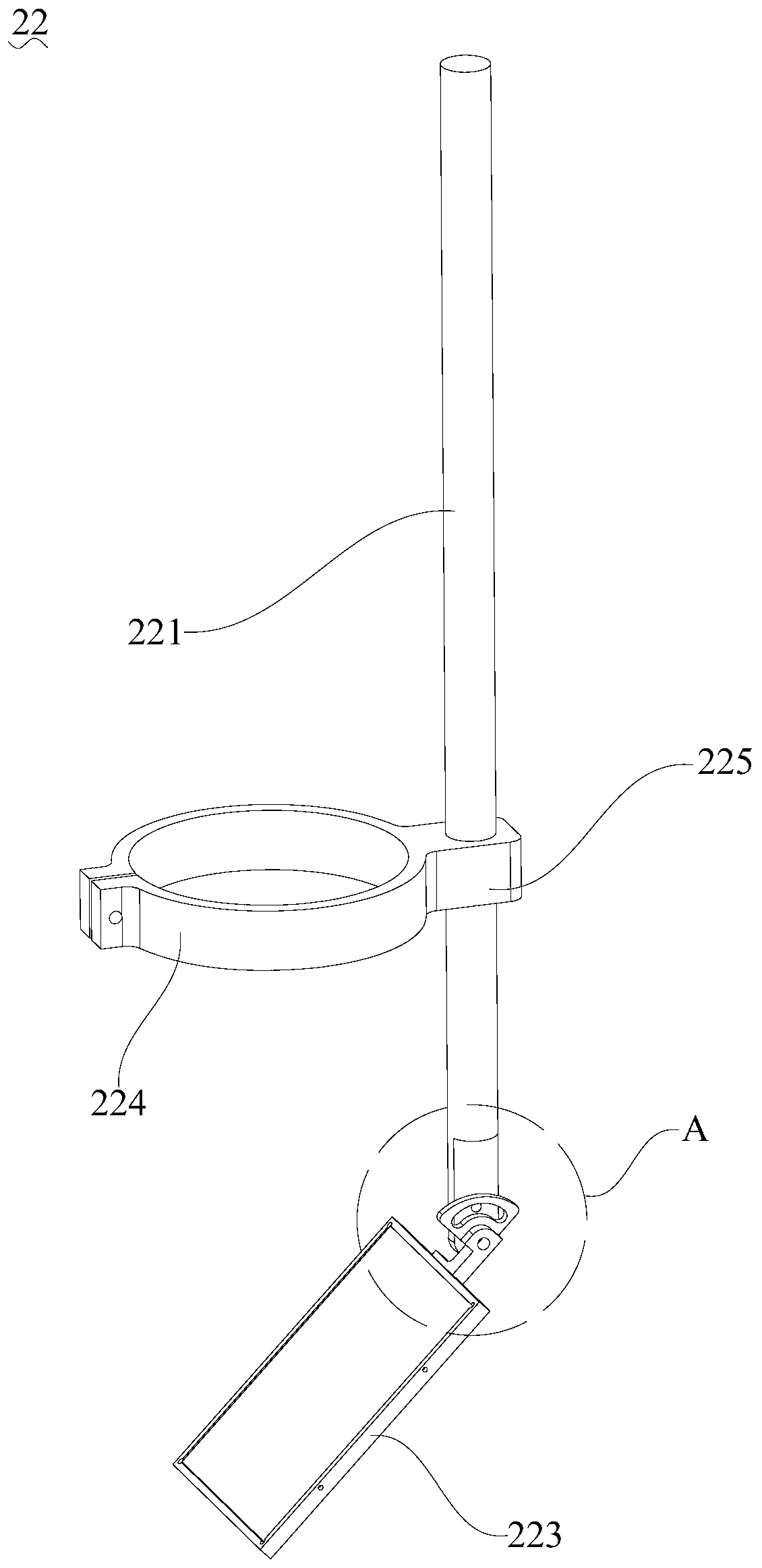

Ultrafast laser cleaning and fine polishing equipment for inner wall of component and control method

InactiveCN111266740AAchieve cleaningAchieve/or polishCleaning processes and apparatusLaser beam welding apparatusEngineeringErbium lasers

The invention belongs to the technical field of laser equipment, and particularly relates to ultrafast laser cleaning and fine polishing equipment for the inner wall of a component and a control method. The ultrafast laser cleaning and fine polishing equipment for the inner wall of the component comprises a main machine body, a laser system and a rotary clamping mechanism, the laser system comprises an ultrafast fiber laser, a laser head and a laser reflection mechanism, the ultrafast fiber laser is arranged in the main machine body, the laser head is electrically connected with the ultrafastfiber laser, the laser reflection mechanism comprises a fixing rod, a mirror bracket and a reflector, the fixing rod is arranged on the laser head, the mirror bracket is arranged at the lower end of the fixing rod, and the reflector is used for extending into an area defined by the inner ring wall of the to-be-machined component. When the ultrafast laser beam needs to be adjusted to act on the inner ring wall of the component to be machined, flexible adjustment of the position of the ultrafast laser beam acting on the inner ring wall of the component to be machined can be achieved only by vertically adjusting the relative positions of the fixing rod and the laser head and adjusting the position of the mirror bracket relative to the fixing rod, and efficient laser cleaning and laser polishing are achieved.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

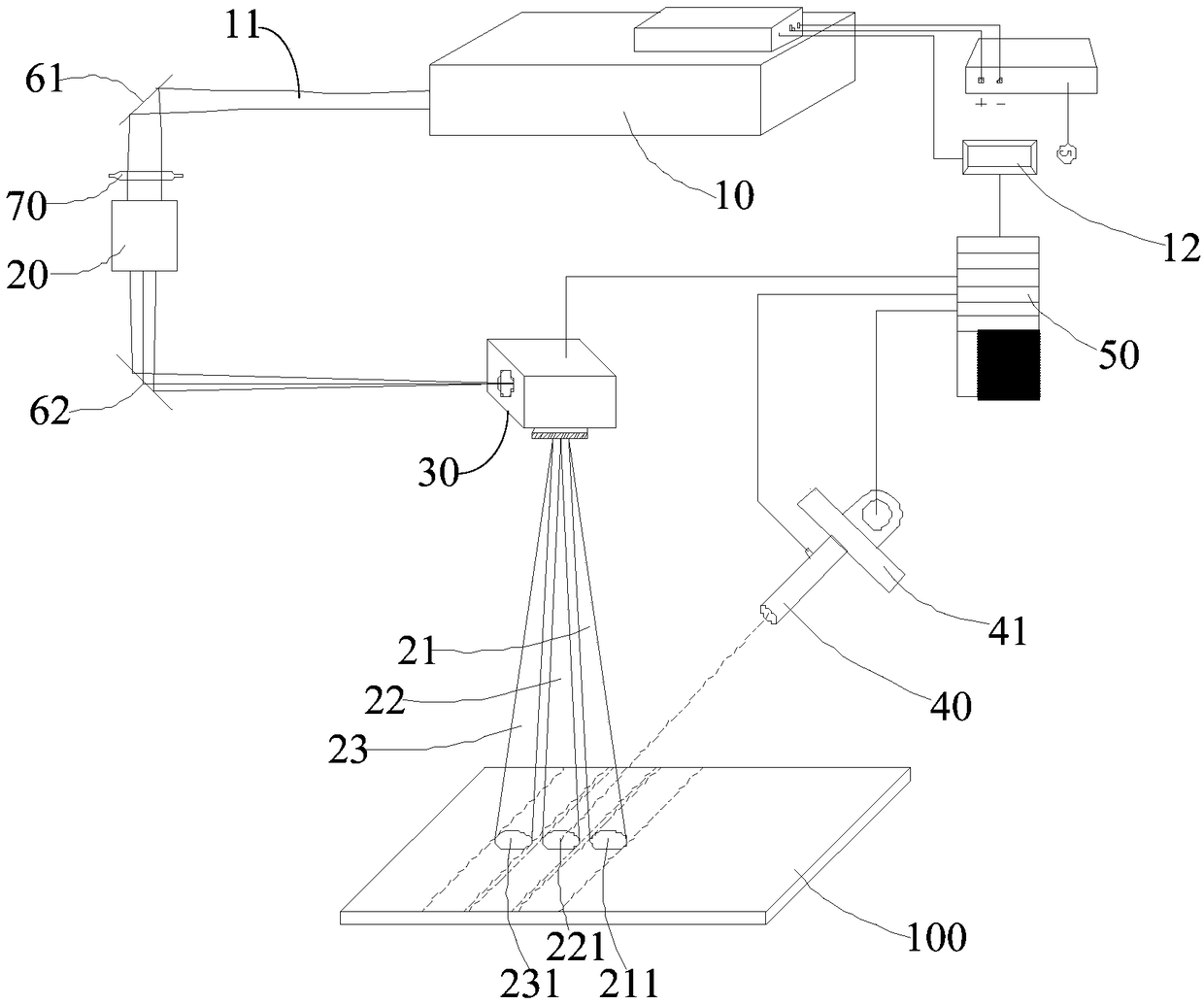

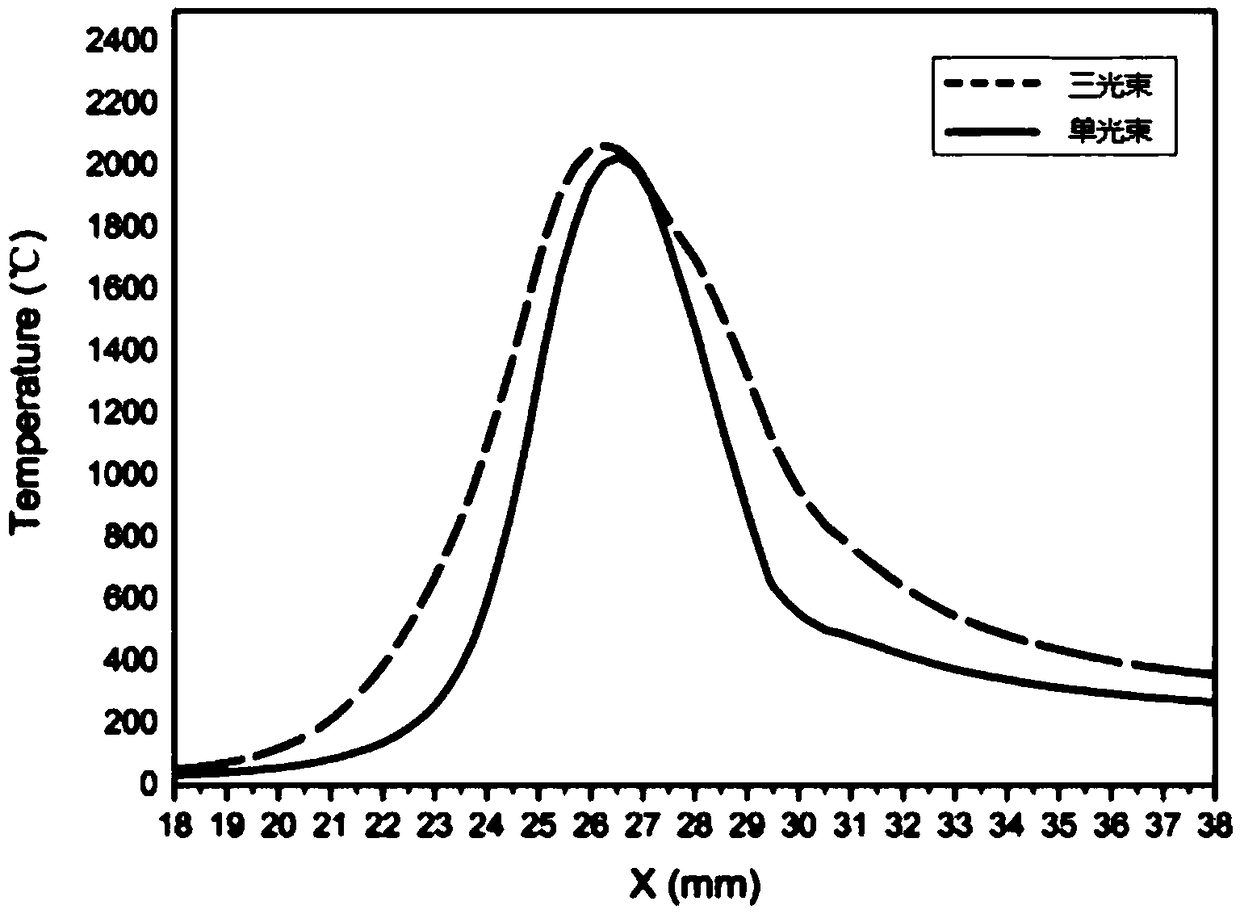

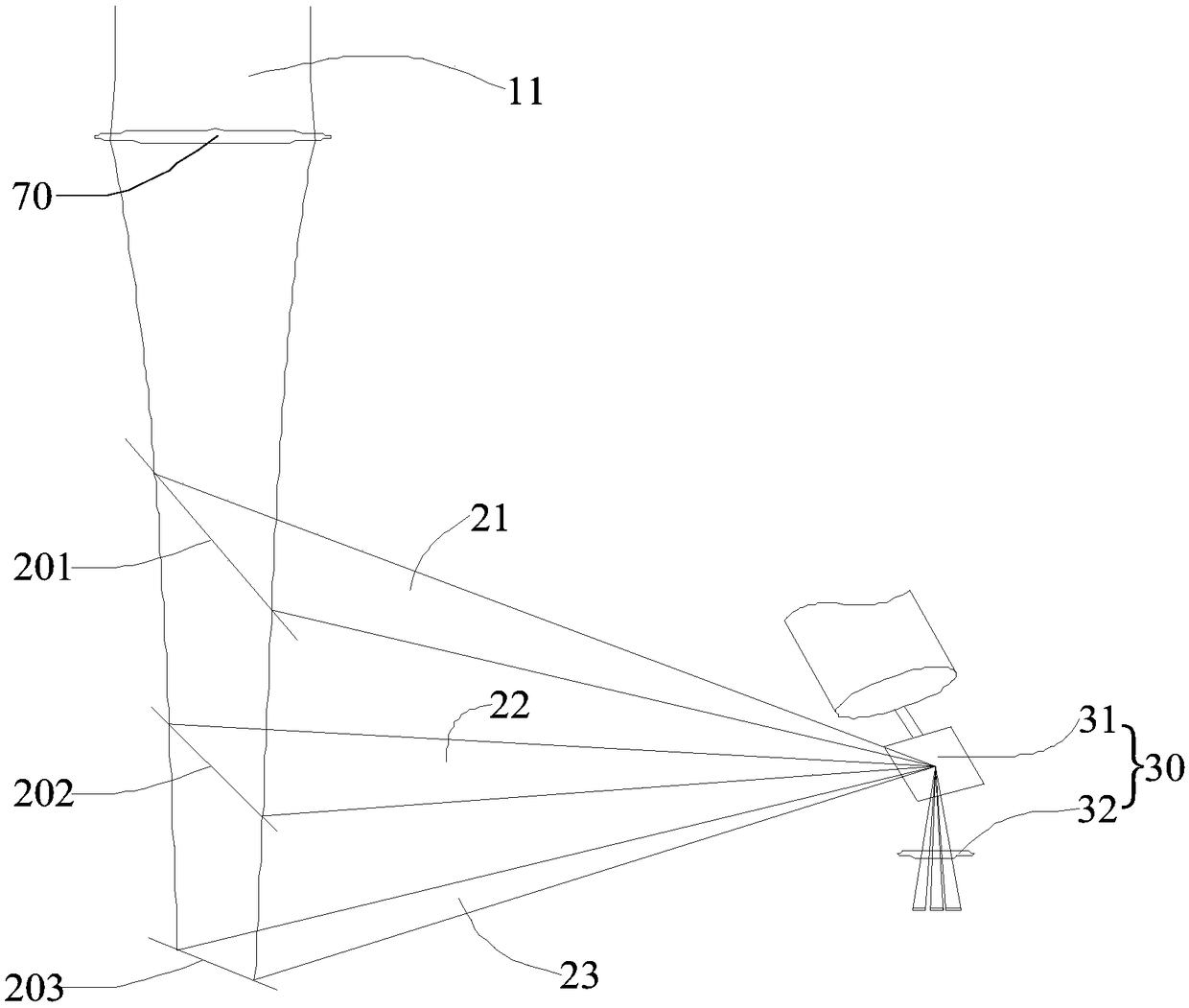

Laser polishing device and method

The embodiment of the invention provides a laser polishing device and method, and relates to the technical field of polishing. According to the laser polishing device, an initial light beam emitted bya laser is split into a first light beam, a second light beam and a third light beam by a beam splitter, then the first light beam, the second light beam and the third light beam are received througha scanner and projected to a to-be-machined component, and a preheating light spot corresponding to the first light beam, a polishing light spot corresponding to the second light beam and an annealing light spot corresponding to the third light beam are formed on the to-be-machined component, so that the to-be-machined component is preheated and annealed while polishing treatment is conducted, and the situation that in the polishing process of brittle materials such as glass, thermal stress is generated due to the large temperature gradient, and consequently, cracks are generated on the machined component is avoided.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

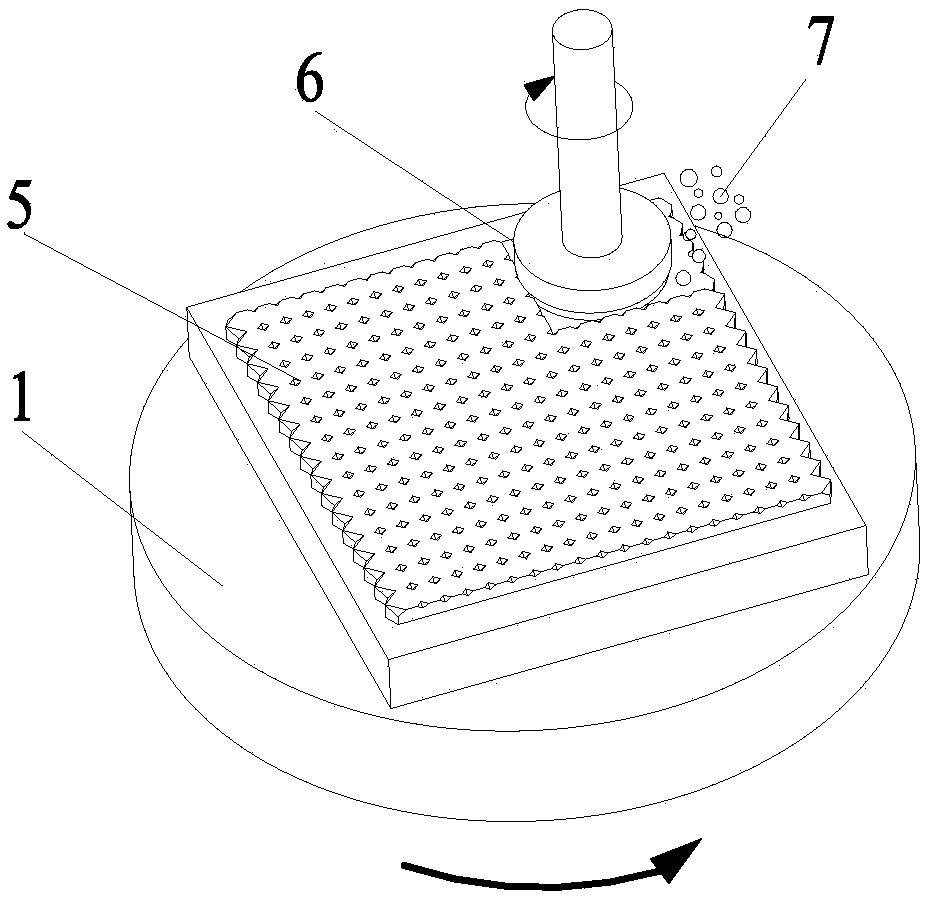

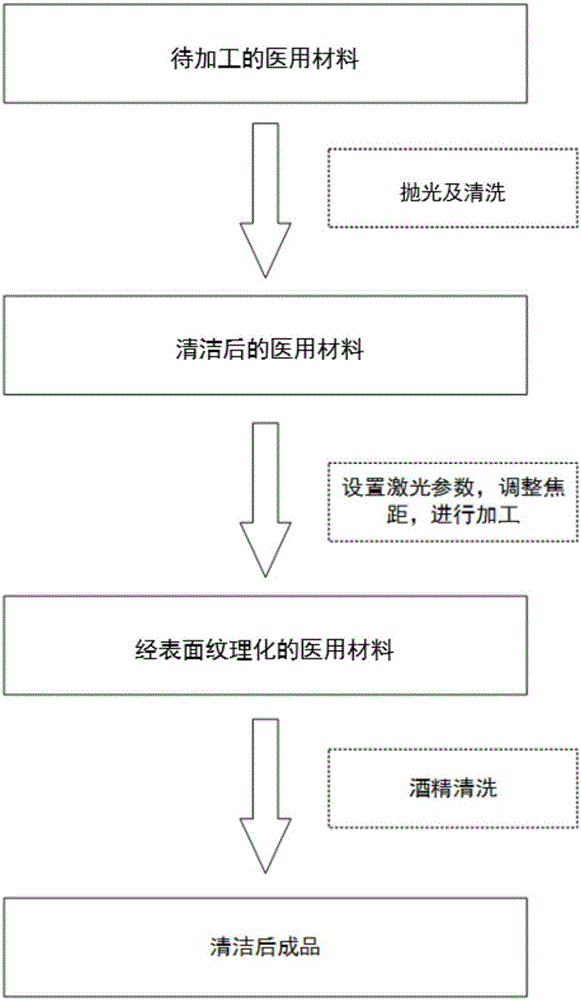

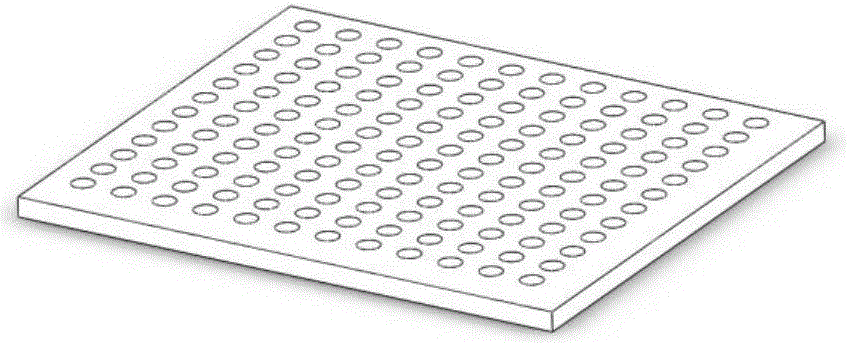

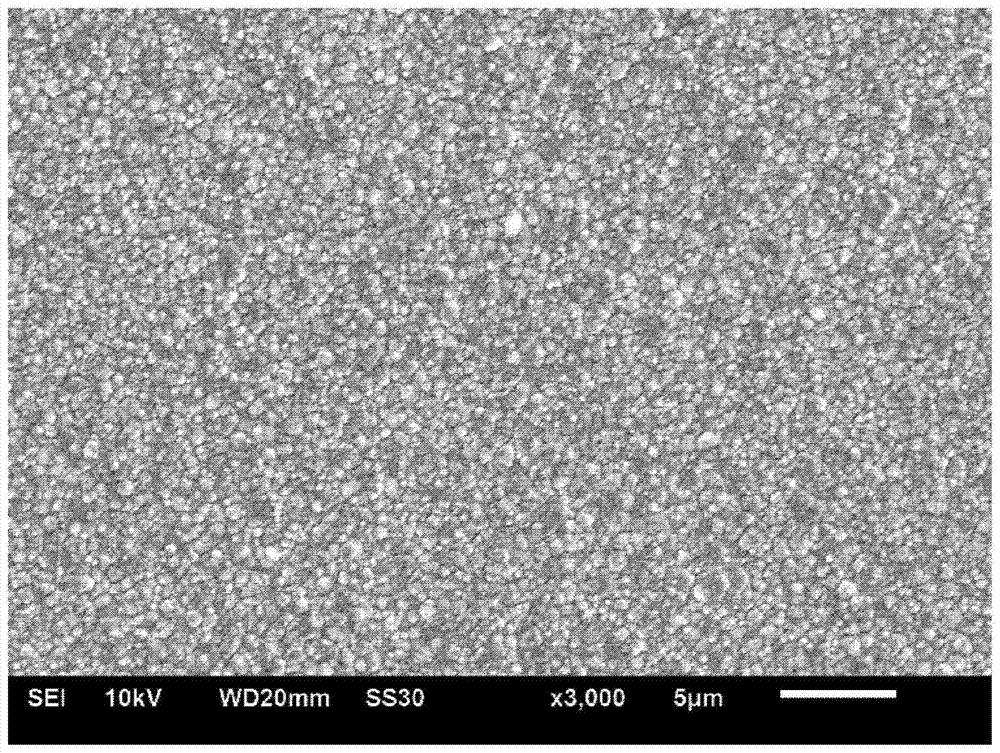

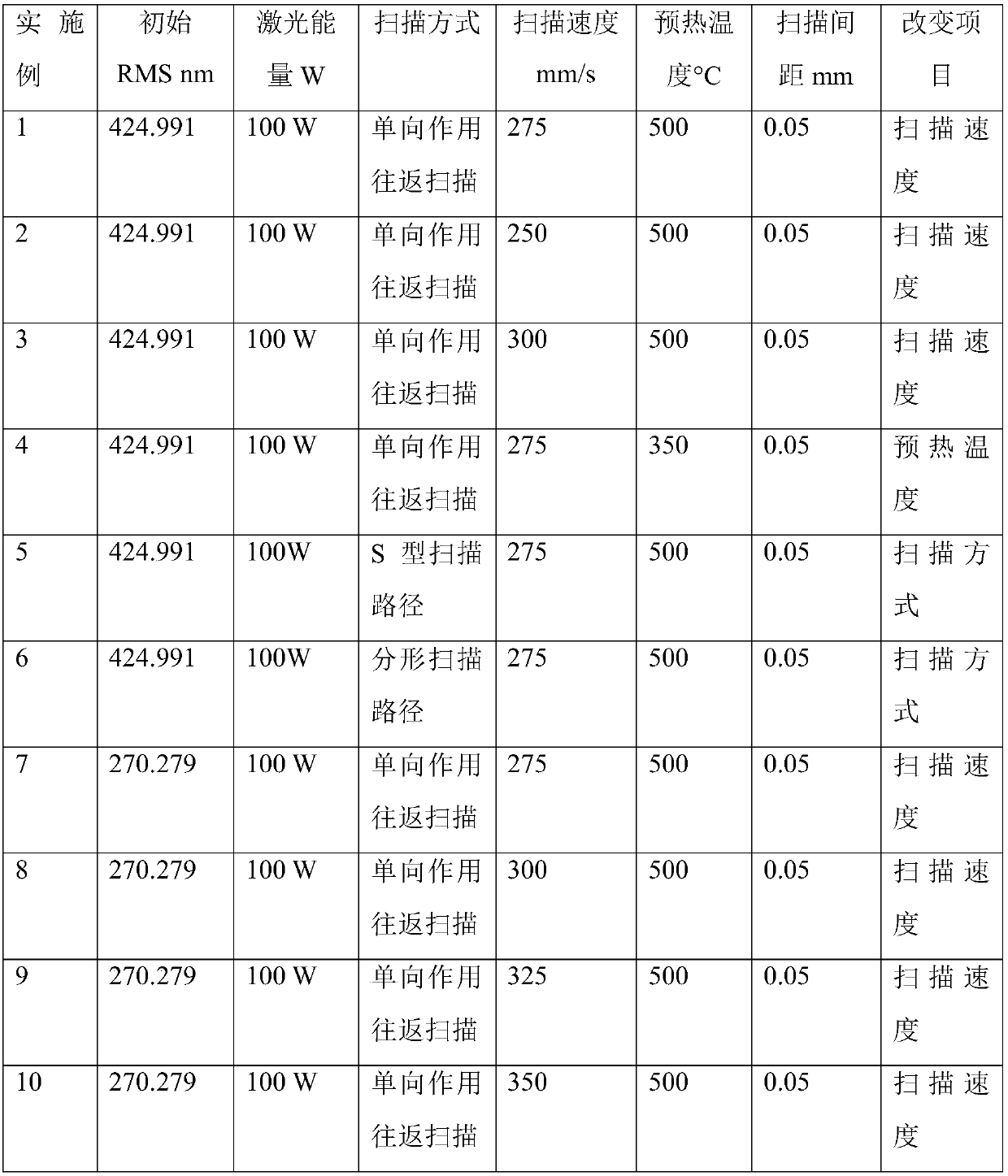

Laser veining method for improving surface cell adhesion of medical implants

ActiveCN106392332ALittle thermal impactNo chemical changeLaser beam welding apparatusCell adhesionChemical cleaning

The invention discloses a laser veining method for improving the surface cell adhesion of medical implants. The method comprises the steps that (1) the surface of a medical material is subjected to chemical cleaning and deoiling, and mechanical grinding and polishing or laser polishing in sequence, and then the surface is cleaned again; (2) the medical material cleaned in the step (1) is placed on a workbench of a laser processing system, laser parameters are set, the laser processing system is started, laser rays scan the surface of the medical material surface at a certain speed through galvanometer scanning, and finally a veined surface is obtained through laser ablation, specifically, the processing process is carried out under inert gas shielding; and (3) the processed medical material is cleaned. The method can be widely applied to the medical implants of specific applications, enables the surfaces of the implants to obtain better cell adhesion performance, and improves the medical effects of the implants.

Owner:BEIHANG UNIV

Composite polishing method based on laser and plasma

ActiveCN109366256ANo damageEasily brokenGrinding machine componentsLaser beam welding apparatusLaser processingMulti axis

The invention discloses a composite polishing method based on a laser and a plasma. The workpiece to be machined is fixed on the working table of the polishing system, then the laser beam is convergedto the surface of the workpiece to be processed through the laser polishing device to form a laser beam focal spot, and then a normal-pressure plasma beam is generated through the plasma polishing device to impact the surface of the workpiece to be processed to form a plasma impact region; adjusting the laser beam pointing direction and the plasma impact direction to enable the laser beam focal spot to be overlapped with the plasma impact region, and carrying out composite polishing on the surface of the workpiece to be processed; moving the focal spot of the laser beam through a multi-axis moving platform, and the plasma impact composite area finishes the polishing of the whole surface of the workpiece to be machined. According to the method, the modification and composite etching effects of the surface of the material on the surface of the material are achieved by utilizing the plasma in the ultrafast laser processing process, the surface machining quality is improved, and the bottleneck problem that the surface machining quality of the ultrafast laser is not high is solved, so that the high-quality and high-efficiency fine polishing of the surface of the material is realized.

Owner:WUHAN UNIV

Technological method for composite asynchronous polishing of ceramics using picosecond-nanosecond laser

ActiveCN109514076AAchieve initial flatteningEliminate microcracksWelding/soldering/cutting articlesLaser beam welding apparatusPicosecond laserMicro nano

The invention discloses a technological method for composite asynchronous polishing of ceramics using picosecond-nanosecond laser. The technological method comprises the steps of firstly, irradiatingthe ceramic surface to be machined through picosecond laser along a certain scanning trace, and removing micro protrusions of the ceramic surface, so that the preliminary flattening is achieved; meanwhile, generating a large number of micro-nano particles by using a removal mechanism for the electronic state of ceramic materials through picosecond laser, wherein the micro-nano particles exist at adjacent space areas of the irradiated ceramic surface; starting a low power nanosecond laser according to the preset time for tracing the scanning path of the picosecond laser, and irradiating and fusing the micro-nano particles uniformly distributed on the ceramic surface; and finally forming a compact and smooth fine-grain melted layer so that the polishing effect is achieved. According to the technological method, original pore cracks of the ceramic materials are repaired, and the shortcomings that a heat affected zone generated by traditional laser polishing is large and the material surface is liable to generate micro-cracks and pores are overcome; and low removal amount, high efficiency and accuracy and submicron-level fine polishing of the ceramic materials is achieved.

Owner:BEIJING UNIV OF TECH

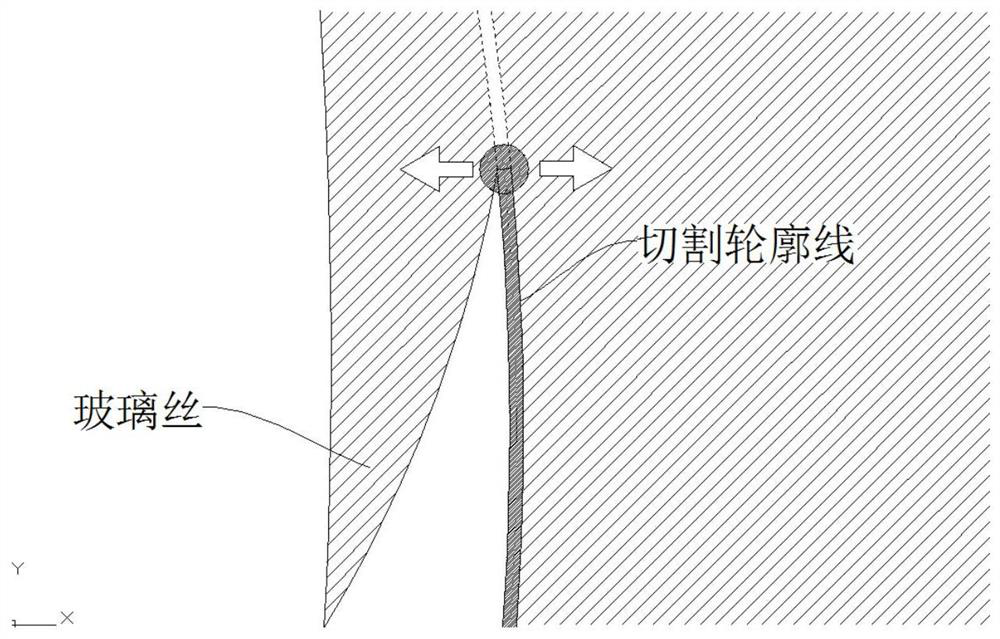

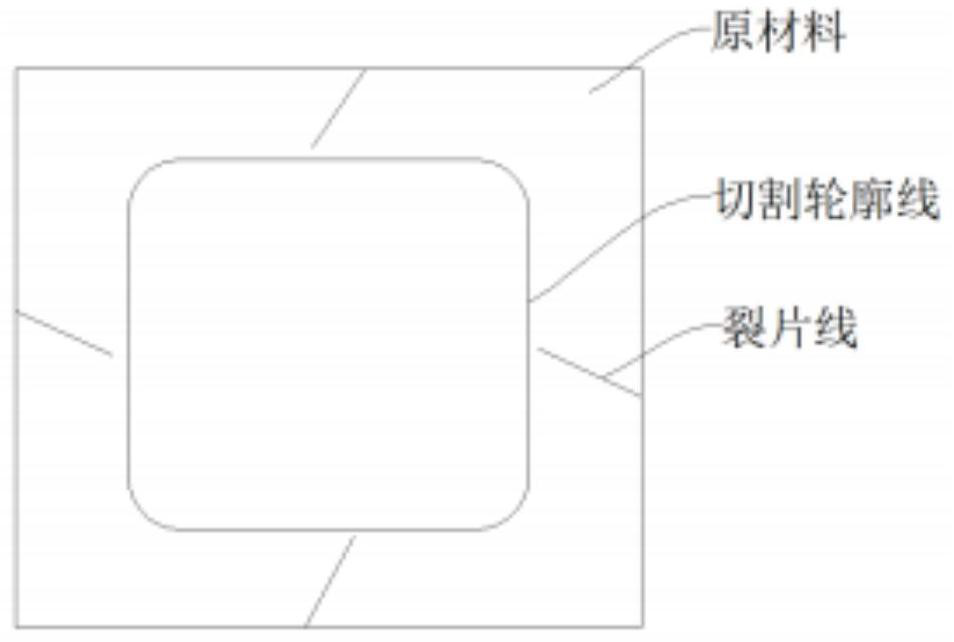

Method for laser polishing of glass and polishing processing method of glass hole and glass sheet

ActiveCN112404736ASolve micro-cracks on the cut surfaceFix bugsGlass severing apparatusLaser beam welding apparatusGlass chipCw laser

The invention provides a method for laser polishing of glass and a polishing processing method of a glass hole and a glass sheet. The method comprises the following steps of: irradiating a cutting contour line arranged on a glass plate by adopting first laser, and then cutting off the glass along the cutting contour line; and irradiating along a polishing contour line which is 0.3-1.2mm close to the cutting contour line by adopting second laser, and evaporating the glass on the two sides of the polishing contour line to obtain a polished glass product, wherein the second laser is CO2 continuous laser. According to the method, the defects of micro-cracks of a section caused by a conventional cutting mode can be overcome; the polishing contour line is directly irradiated by the CO2 continuous laser, so that glass bodies on the two sides of the polishing contour line are evaporated and removed, a smooth glass side section is obtained, and the mechanical property of the glass is improved;and the method can be applied to edge treatment of glass drilling, inner contour and outer contour, the plane quality of the side surface is optimized, and the potential fragment risk of the subsequent process is solved.

Owner:KORNERSTONE MATERIALS TECH

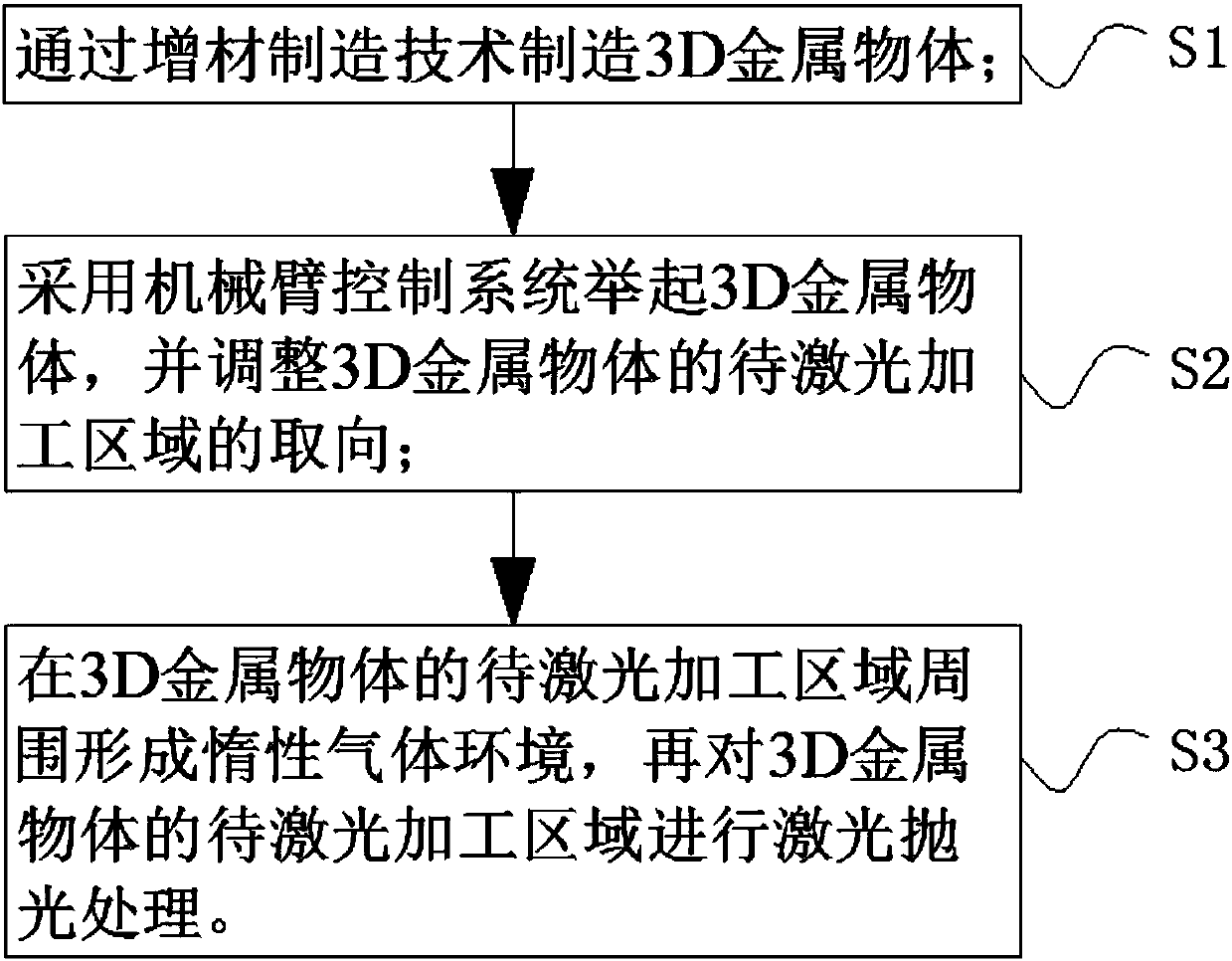

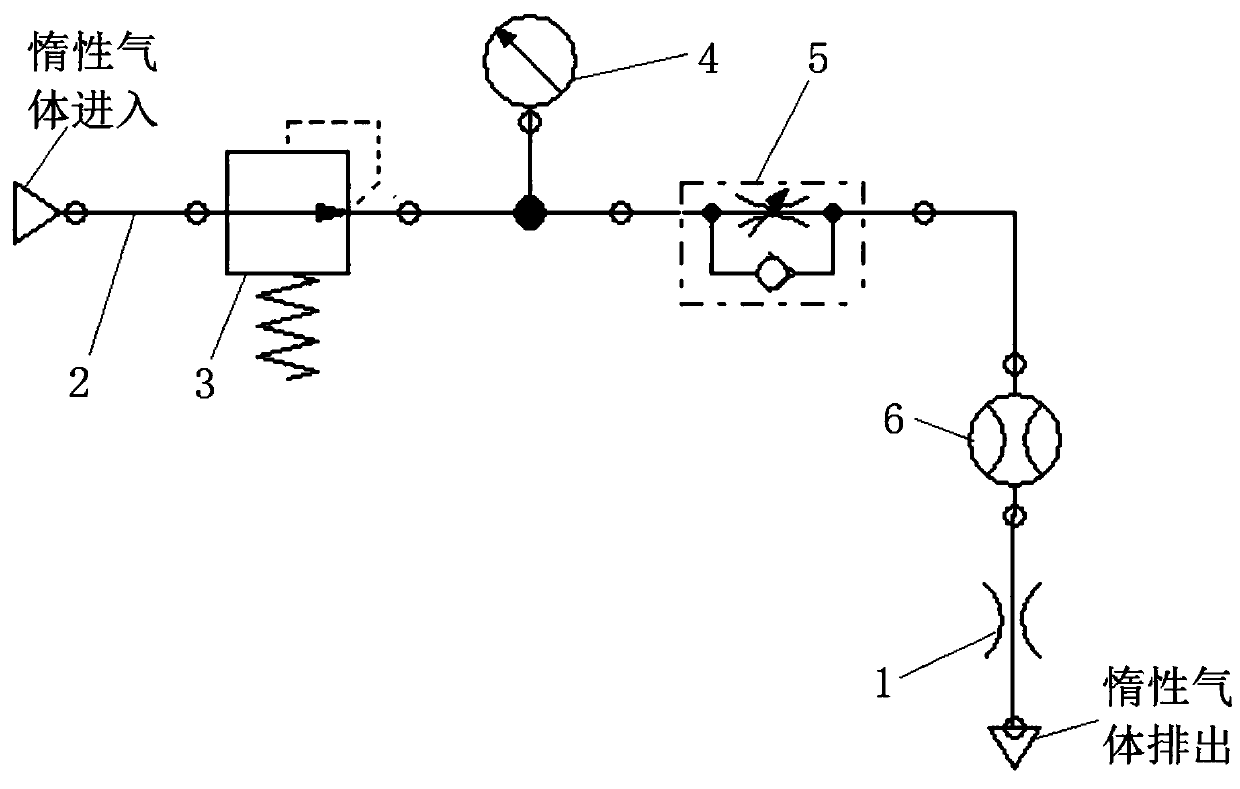

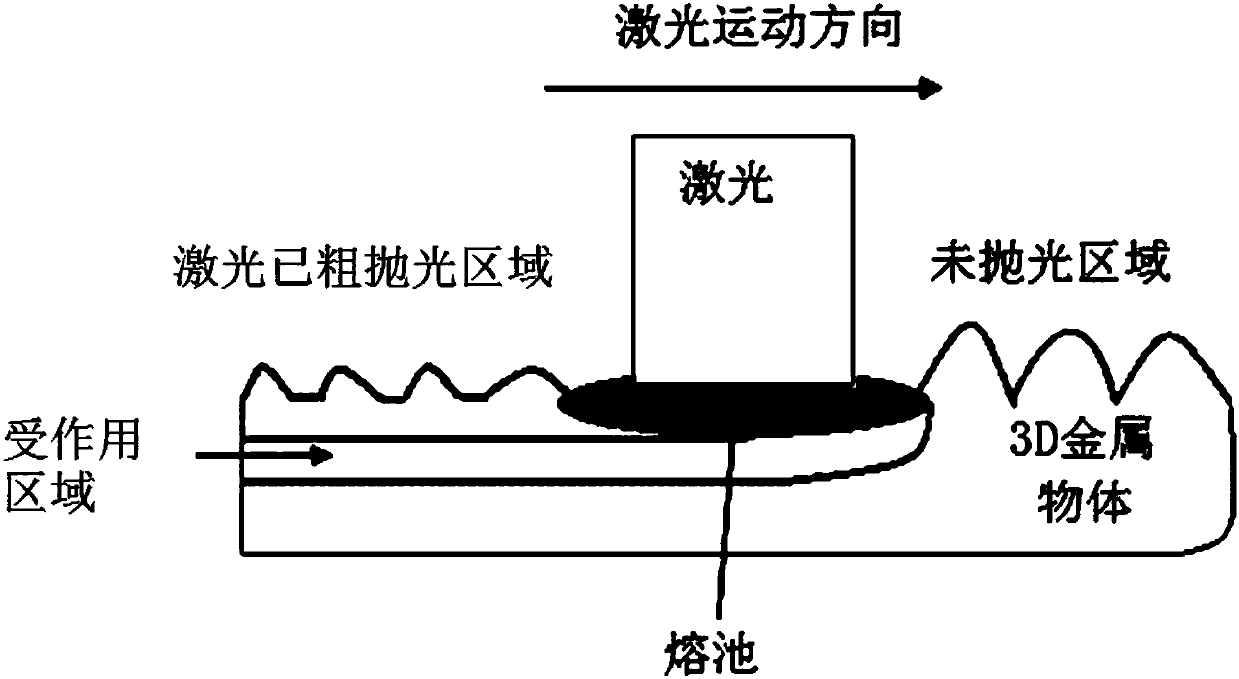

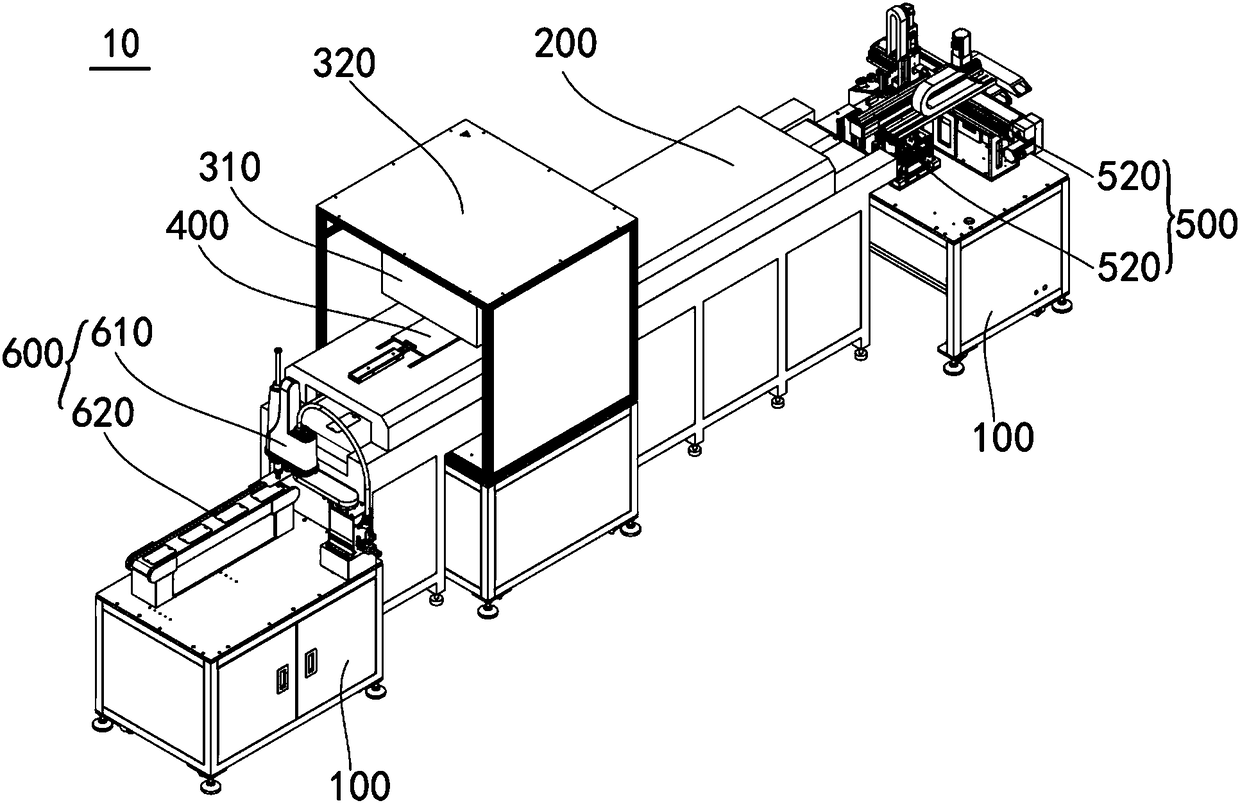

Laser polishing method

ActiveCN109759711APrecise airflow control functionHigh surface finishLaser beam welding apparatus3d printLaser processing

The invention provides a laser polishing method. The method comprises the following steps of S1, 3D metal objects are manufactured by additive manufacturing techniques; step S2, a mechanical arm control system is used to lift a 3D metal object, and adjusting the orientation of the laser processing region of the 3D metal object; and S3, an inert gas environment is formed around the laser processingregion of the 3D metal object, and laser radiation is carried out on the laser processing region of the 3D metal object. The novel laser polishing technology provides a highly flexible polishing solution for 3D printed metal products, the technology is advanced and strong in practicability, and the technical effect that the traditional metal polishing technology cannot be achieved is achieved.

Owner:THE HONG KONG POLYTECHNIC UNIV

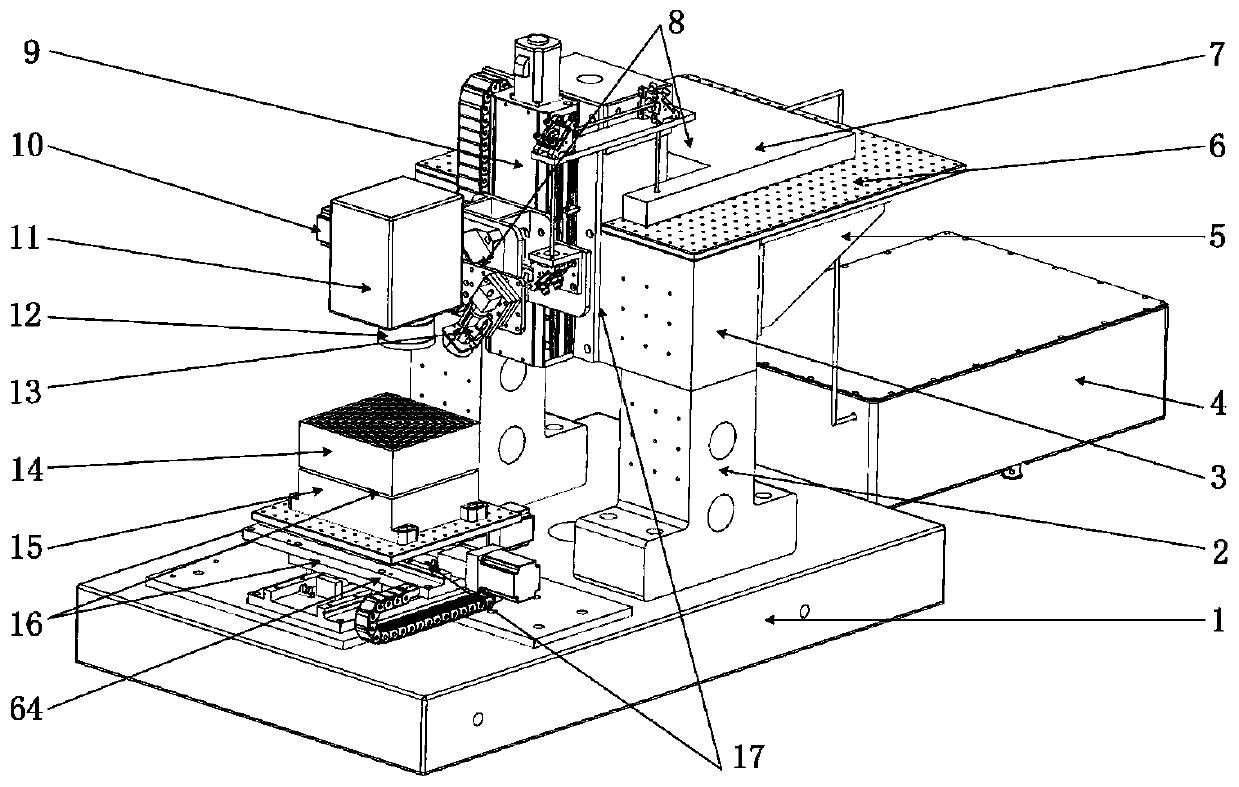

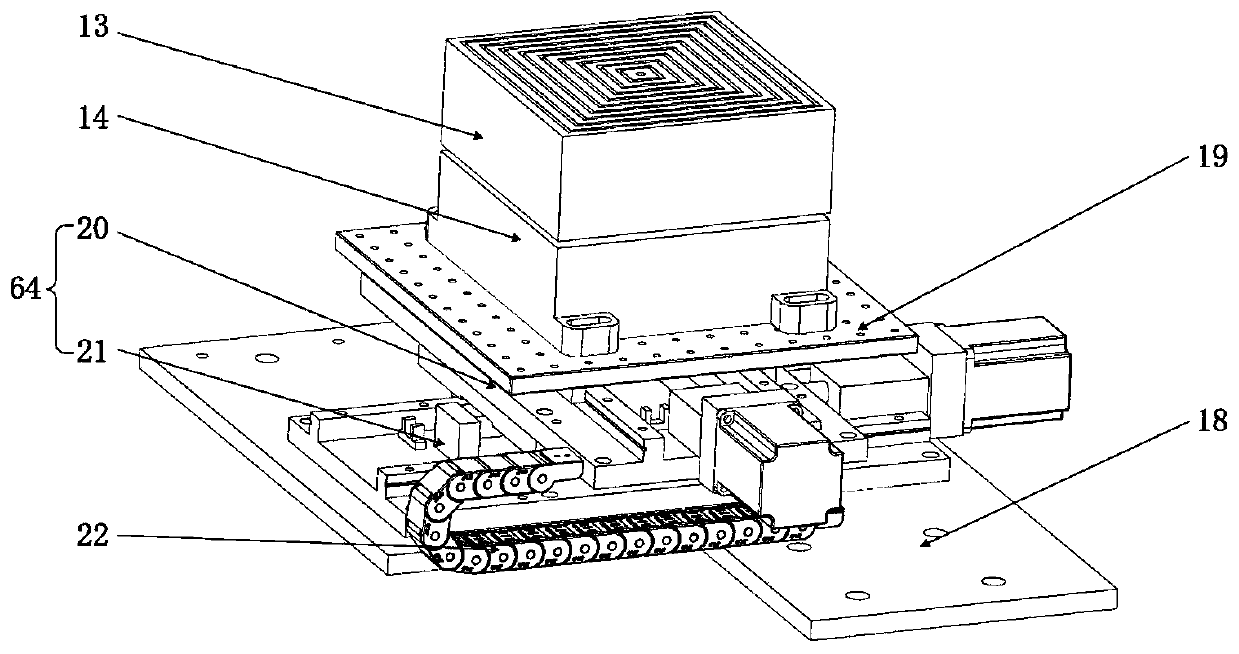

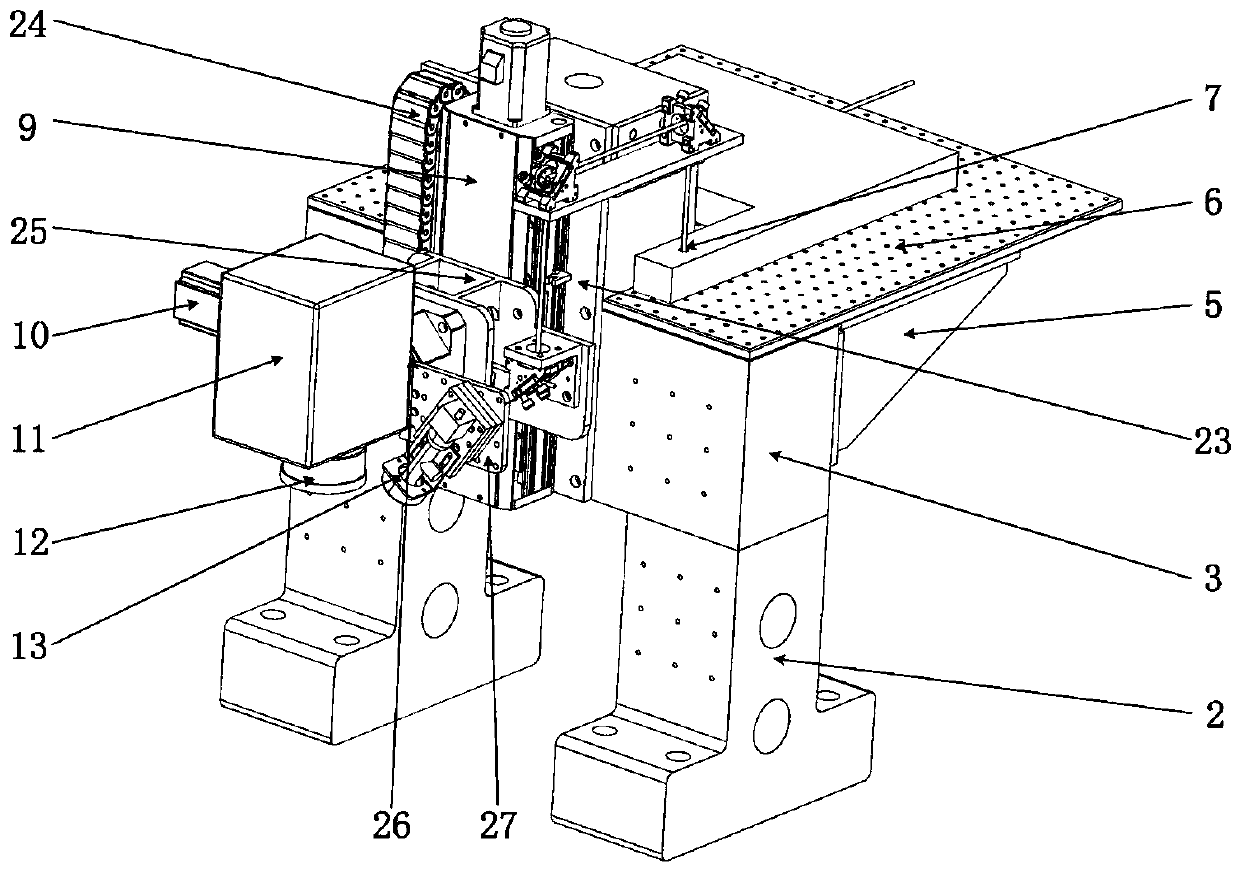

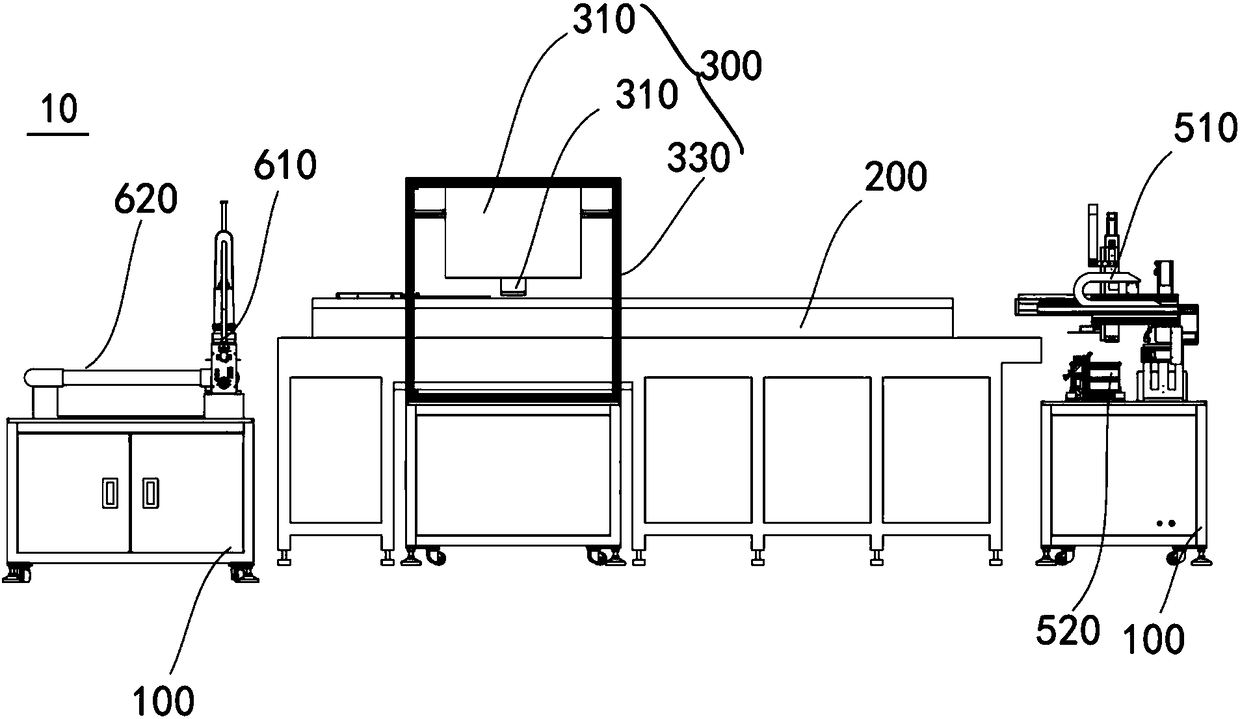

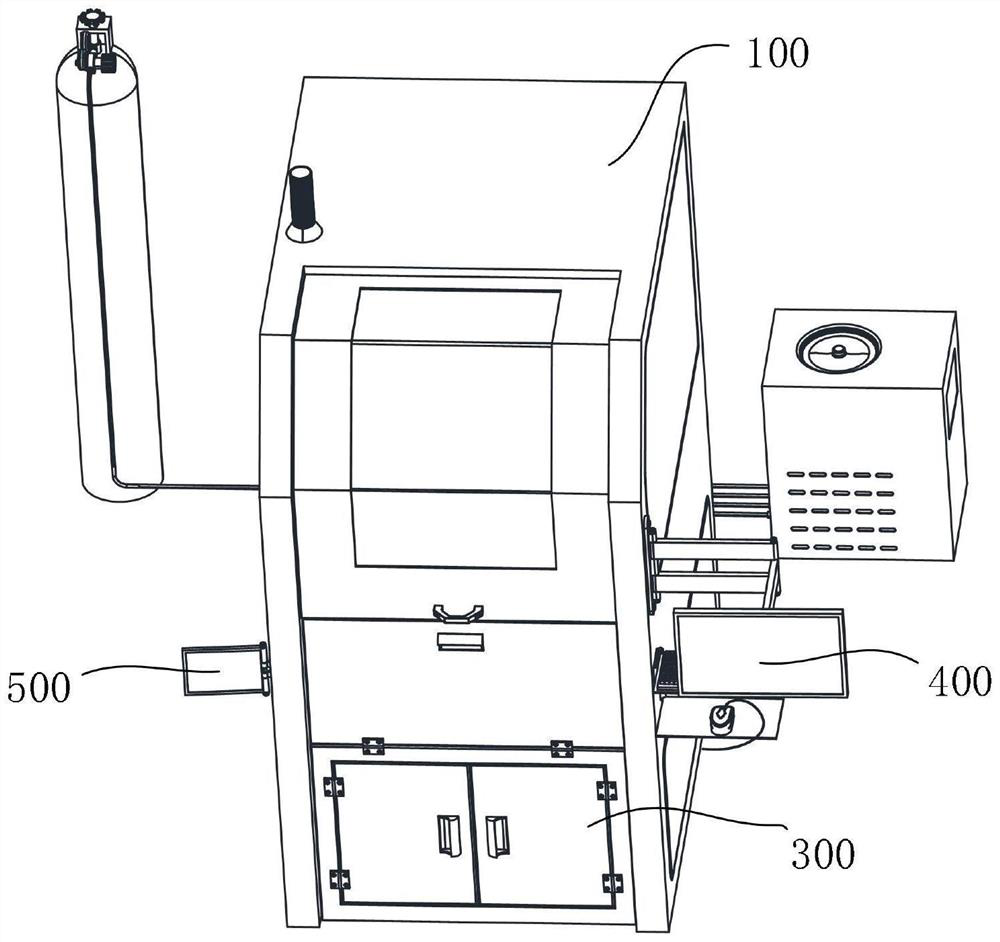

Laser polishing machining equipment

InactiveCN111168243AImprove stabilityReduce vibrationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltrasound assisted

The invention discloses laser polishing machining equipment. The equipment comprises a marble base, a laser, gantry columns, a gantry beam, rib plates, a light path bread board, a light path design part, an XY cross moving platform, a Z-axis sliding table, a B-axis hollow rotating platform, a galvanometer, a field lens, a visual detection part, a suction cup, an ultrasonic vibration device and thelike. Movement in three directions of an X axis, a Y axis and a Z axis and rotation in a B axis direction can be realized; and the equipment integrates the four-axis motion platform, the light path design, the visual inspection device, the ultrasonic vibration device and the like, can meet the requirements of various processes such as general laser processing, inclined laser processing and ultrasonic-assisted laser processing, and has a good application value. According to the laser polishing machining equipment, by adopting the design of the marble base and the gantry type structure, the layout is reasonable, the structure is compact, the appearance is elegant, the stability is good, the vibration is small, the reliability is high, the higher motion precision can be achieved, and the requirements of various laser processing technologies can be met.

Owner:XI AN JIAOTONG UNIV

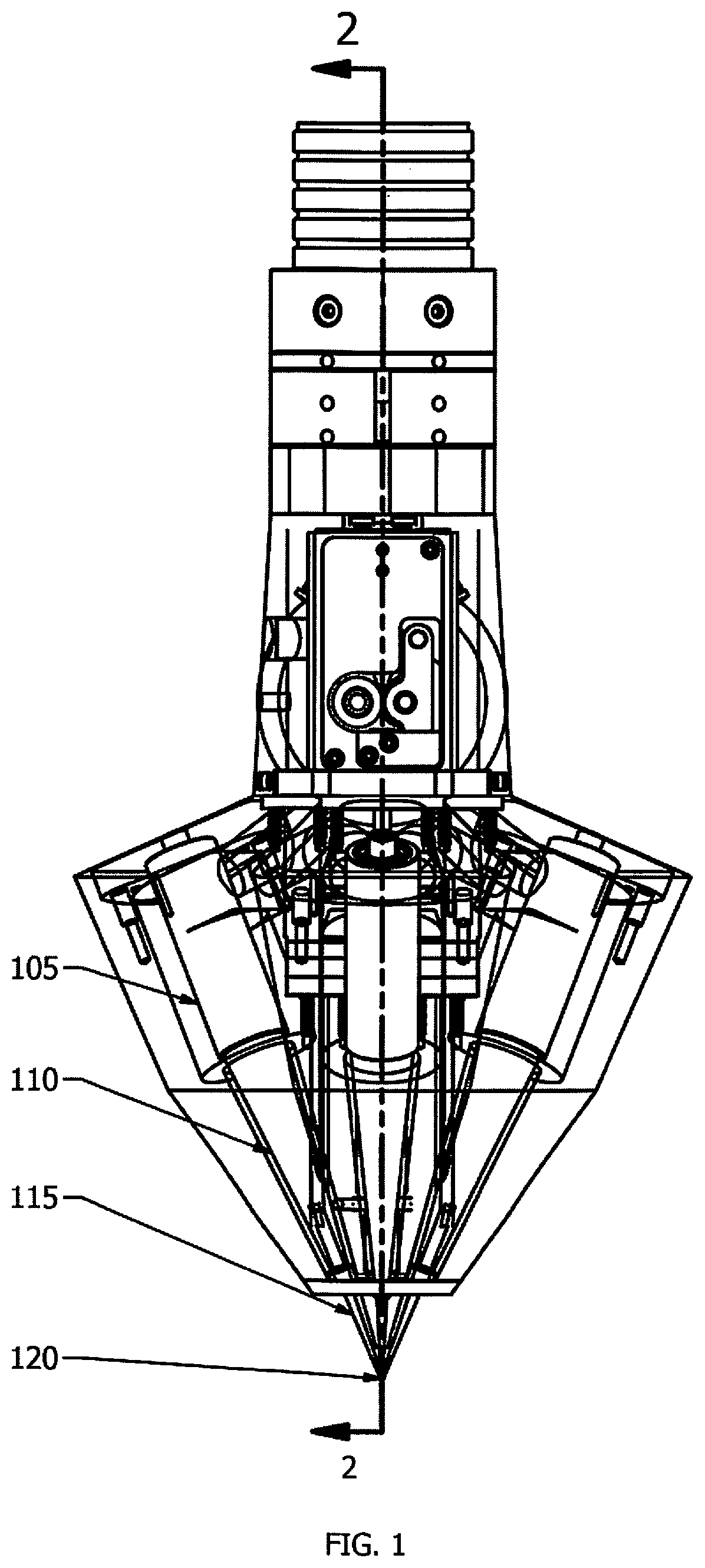

Multi-mode laser device for metal manufacturing applications

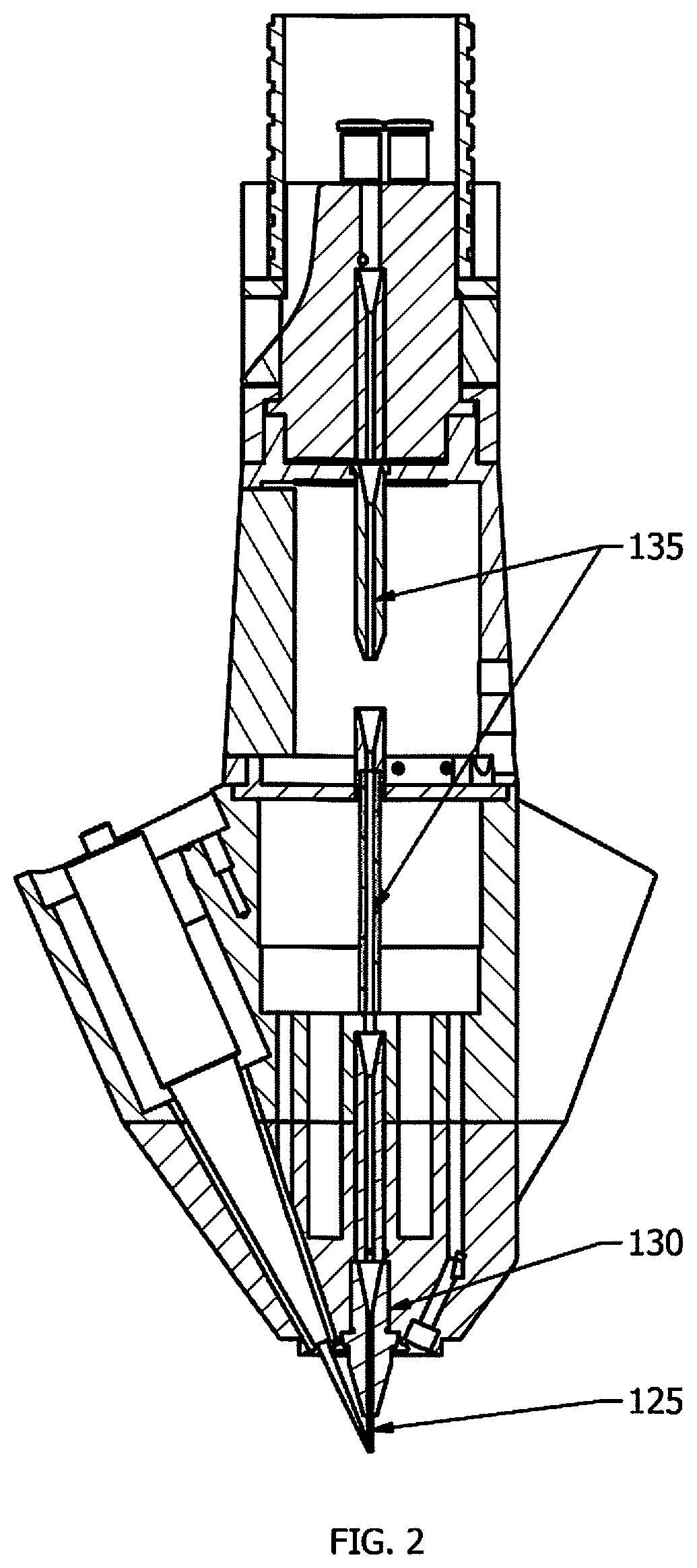

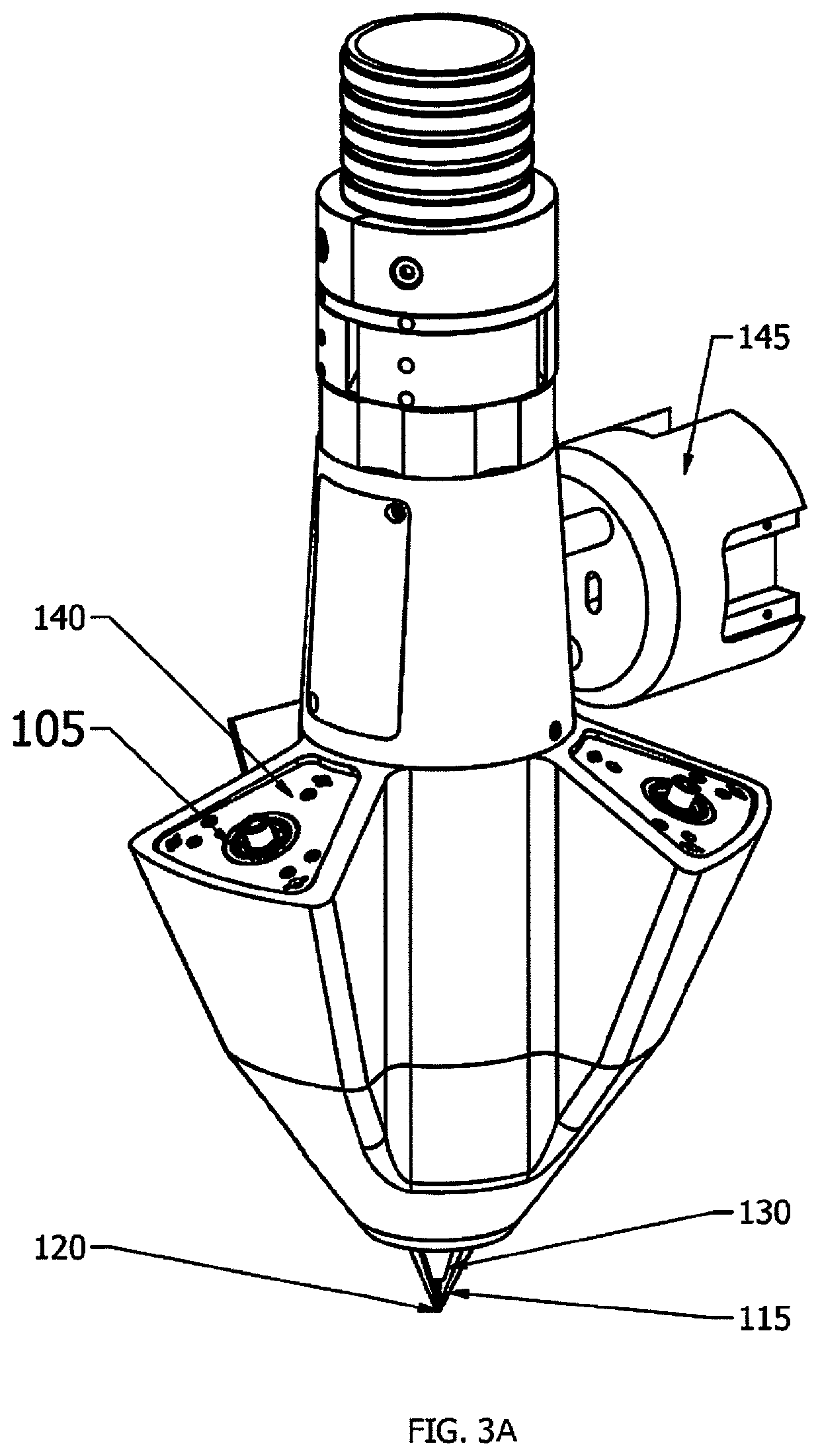

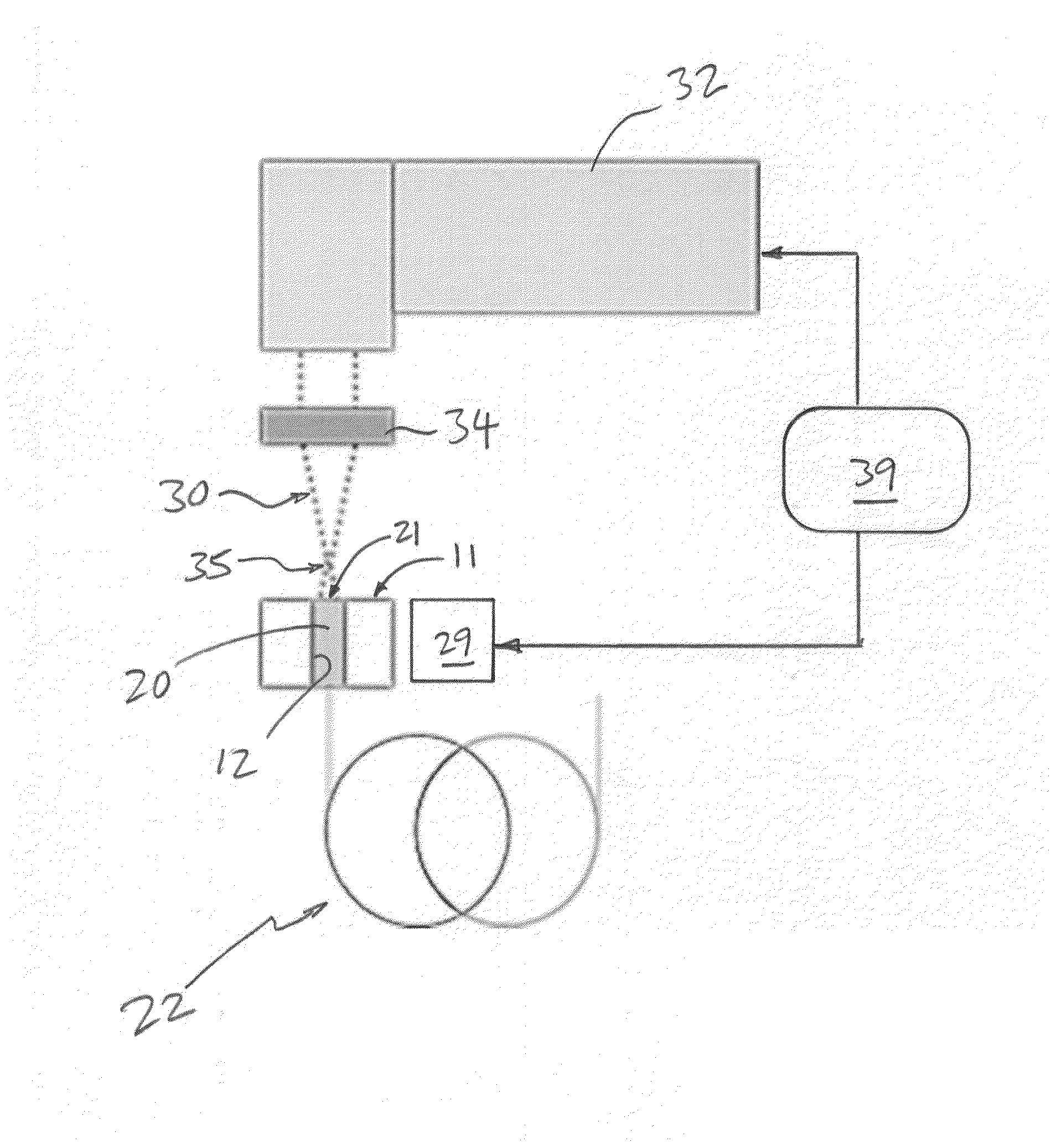

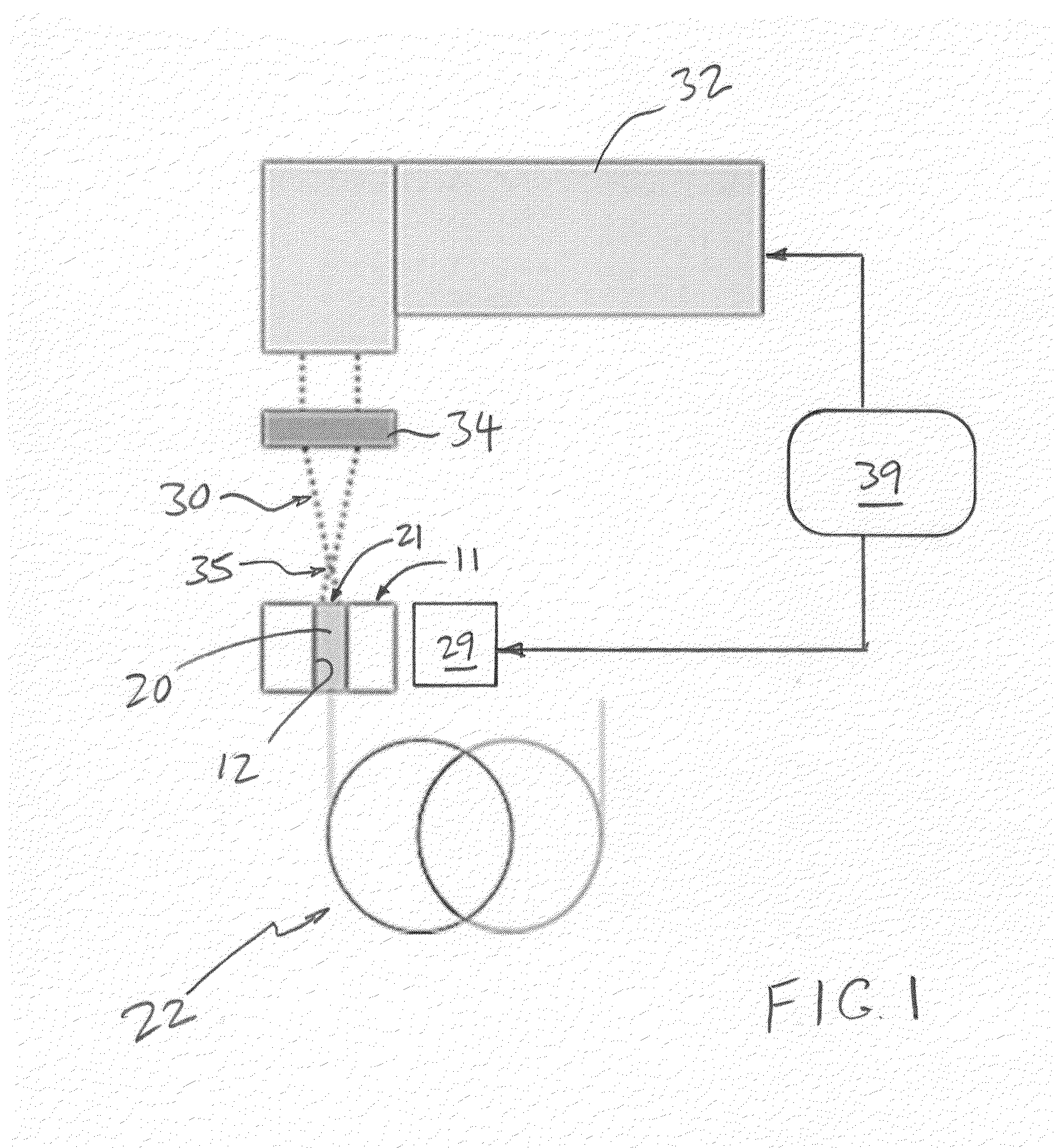

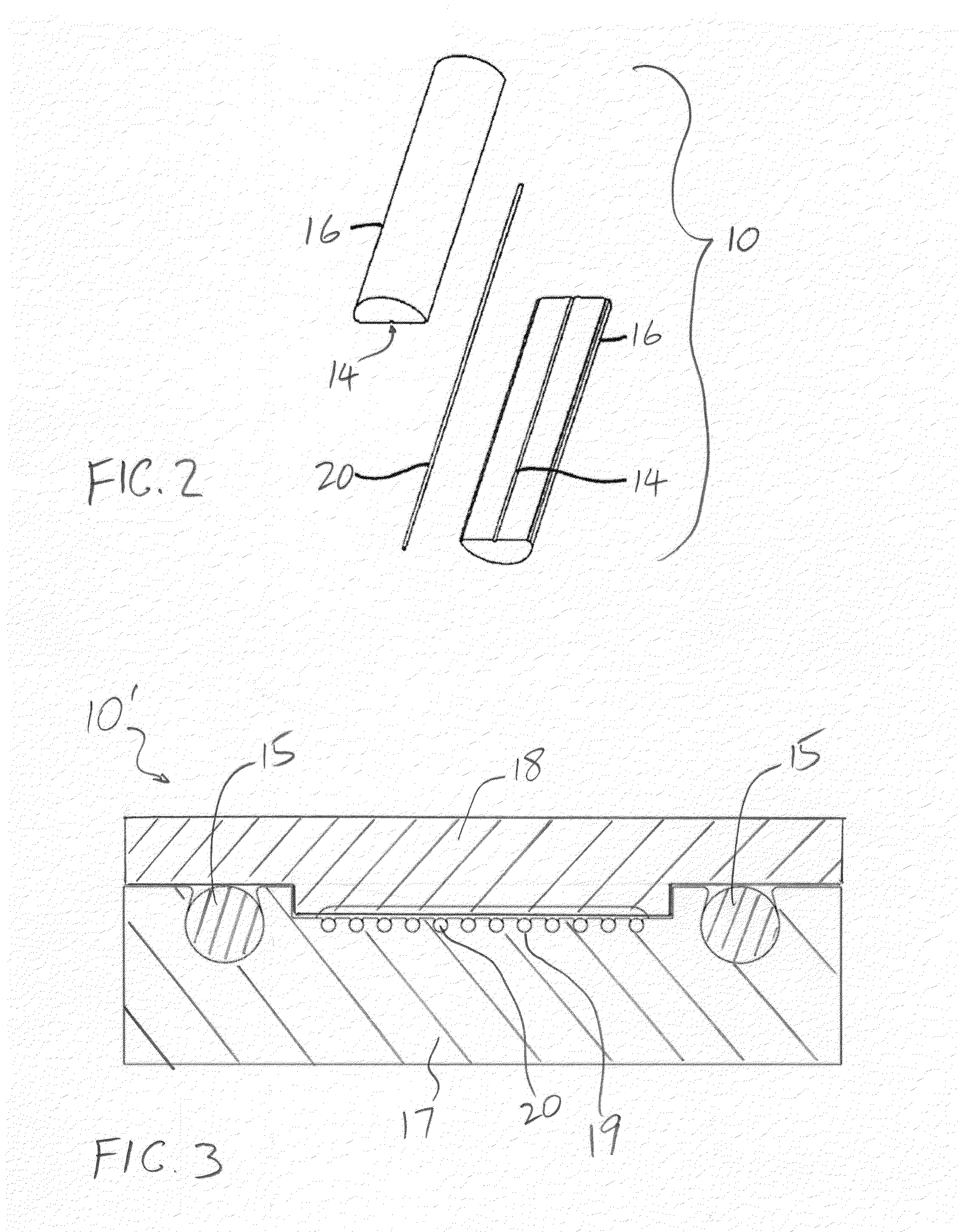

ActiveUS20210001402A1Efficient powerFacilitate depositionAdditive manufacturing apparatusIncreasing energy efficiencyShielding gasEngineering

Disclosed is a multi-mode laser device for metal manufacturing applications including additive manufacturing (AM), laser cladding, laser welding, laser cutting, laser texturing and laser polishing. The multi-mode laser device configures off-axis, solid-state diode or diode-pumped lasers into an array to perform precision controlled, direct metal deposition printing, cladding, laser welding, laser cutting, laser texturing and laser polishing through a single device. Dual-mode printing, cladding and welding capability using metal wire and powder feedstock sources in the same device is provided with in-line control, precision wire feed driver / controller, adjustable shield gas diffuser, and nozzles tailored to wire feedstock diameter.

Owner:DIRECTED METAL 3D SL

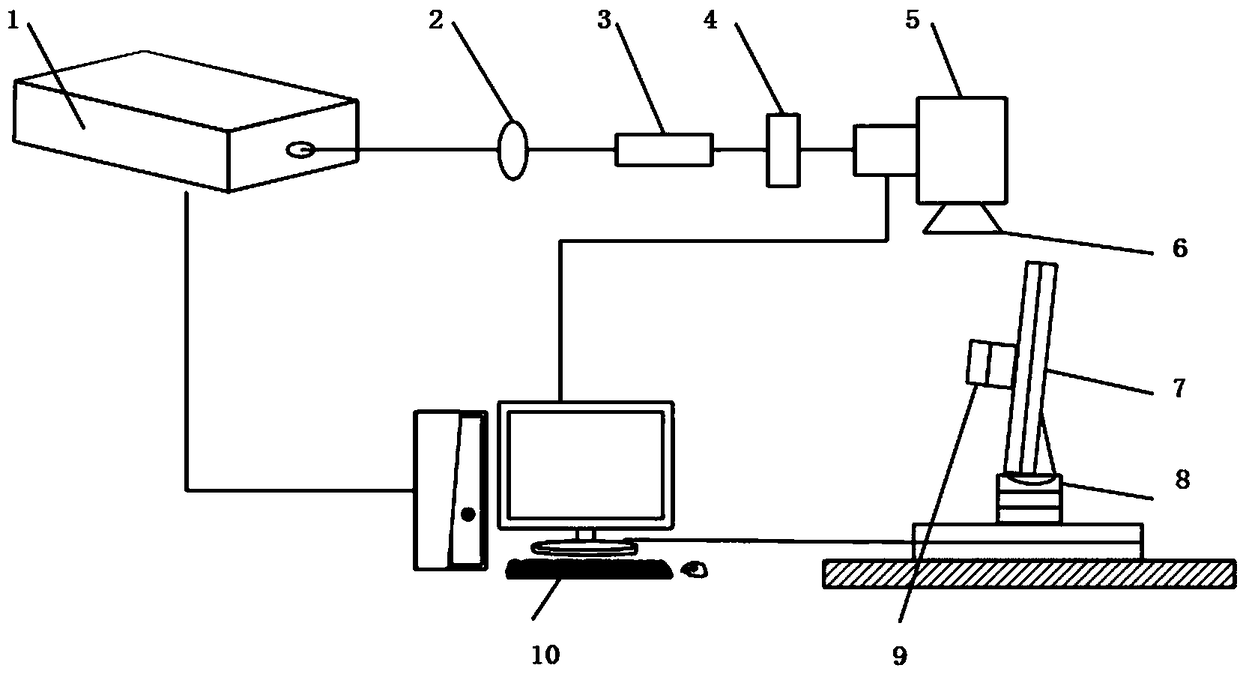

Method for laser polishing of surface of silicon wafer

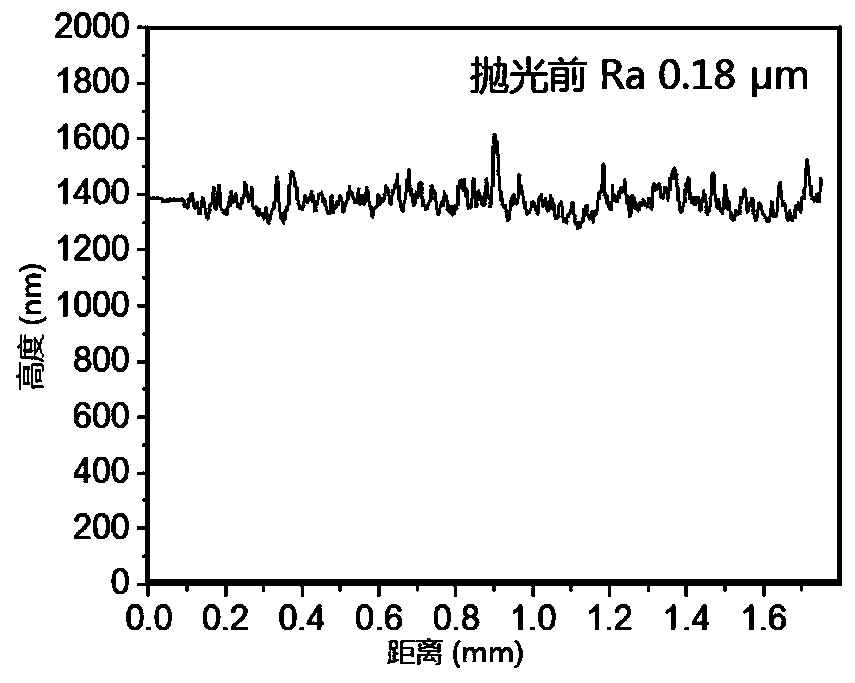

ActiveCN109693039ASimple processImprove processing efficiencySemiconductor/solid-state device manufacturingLaser beam welding apparatusLaser scanningLaser polishing

The invention relates to a method for laser polishing of the surface of a silicon wafer, and belongs to the technical field of surface polishing of semiconductor materials. The method comprises the steps that firstly, the silicon wafer is ultrasonically cleaned and blow-dried by cold air; then the surface of the silicon wafer is subjected to scanning processing through a set laser scanning processpath and laser processing parameters by utilizing a laser surface polishing technology; and after processing is completed, ultrasonic cleaning and cold air blow-drying are conducted, and thus the high-precision laser-polished surface is obtained. The preparation method is simple in process, high in efficiency, flexible and controllable, and has great repeatability, and industrialization application is easy to realize.

Owner:BEIHANG UNIV +1

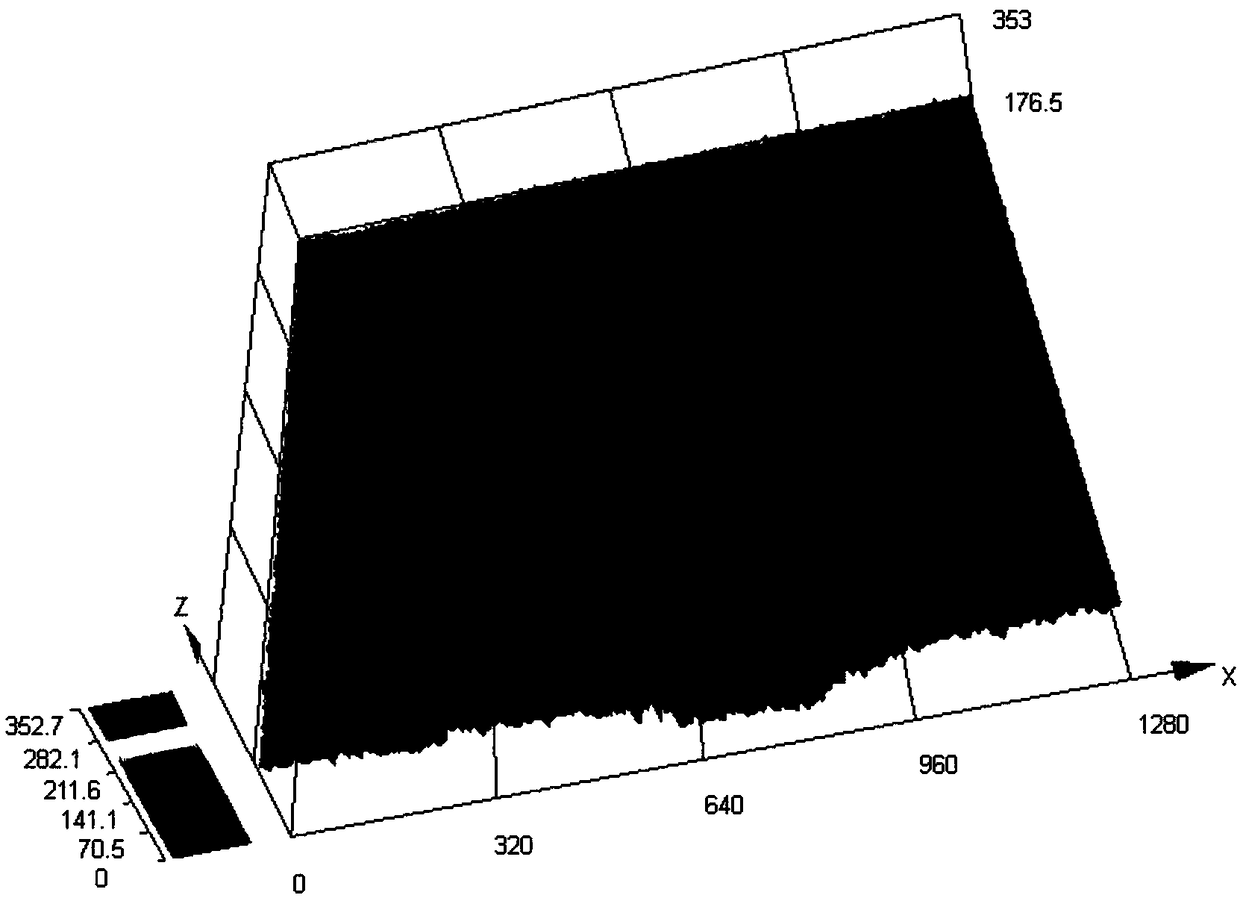

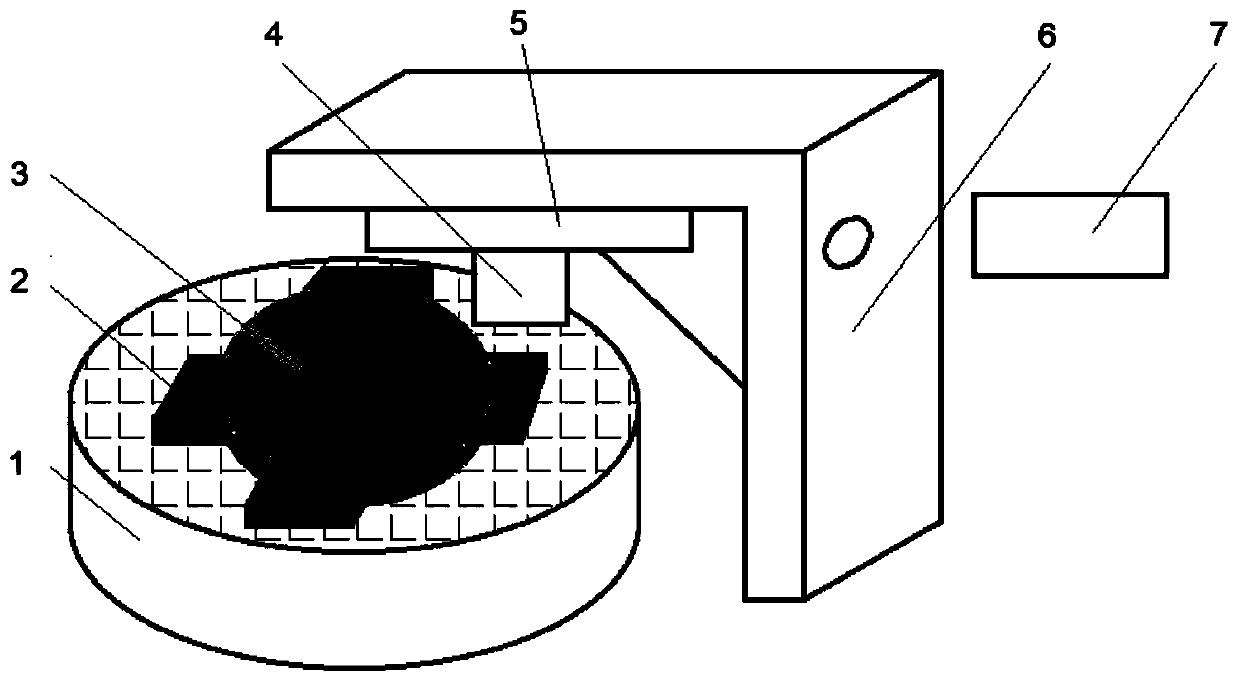

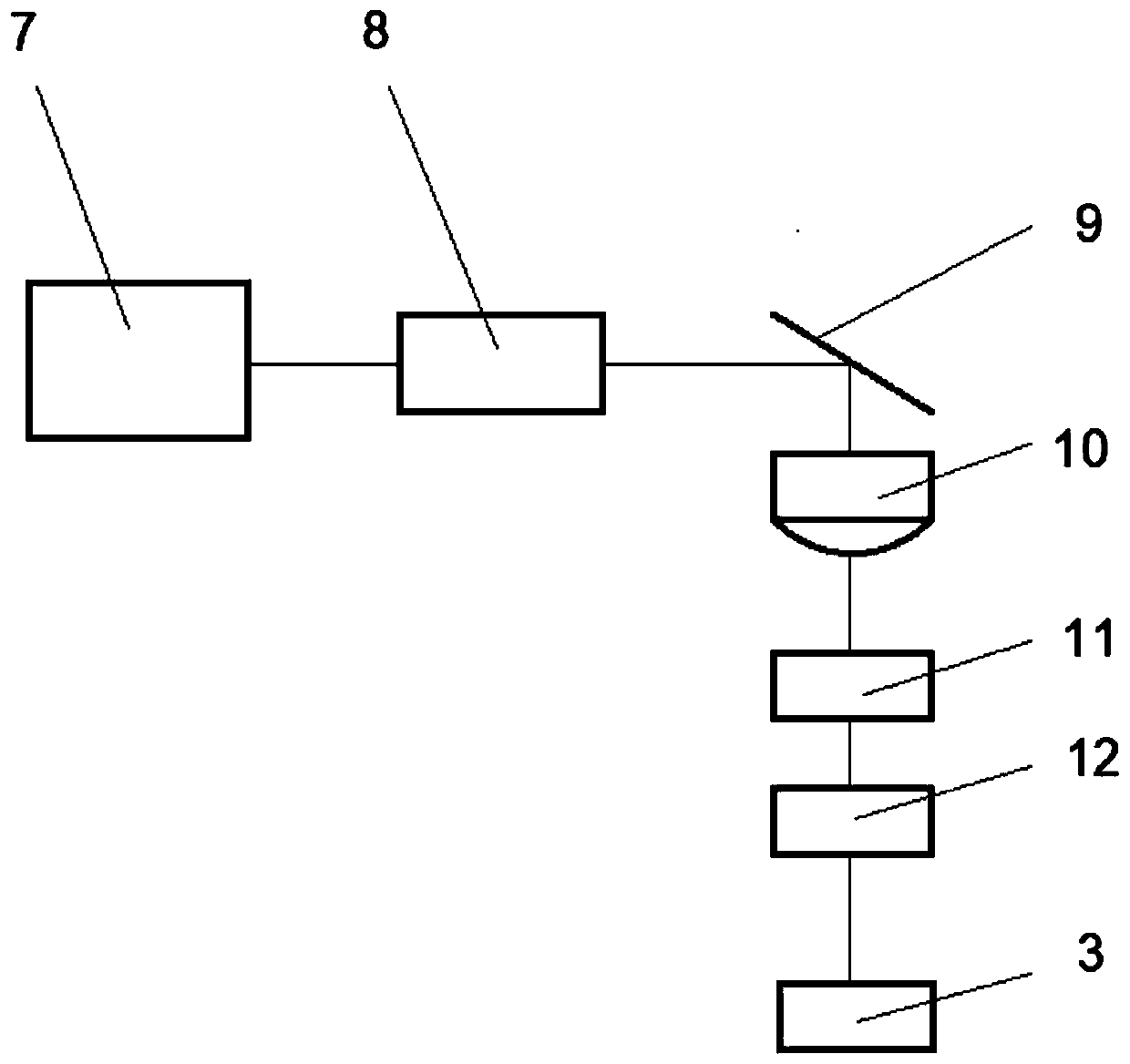

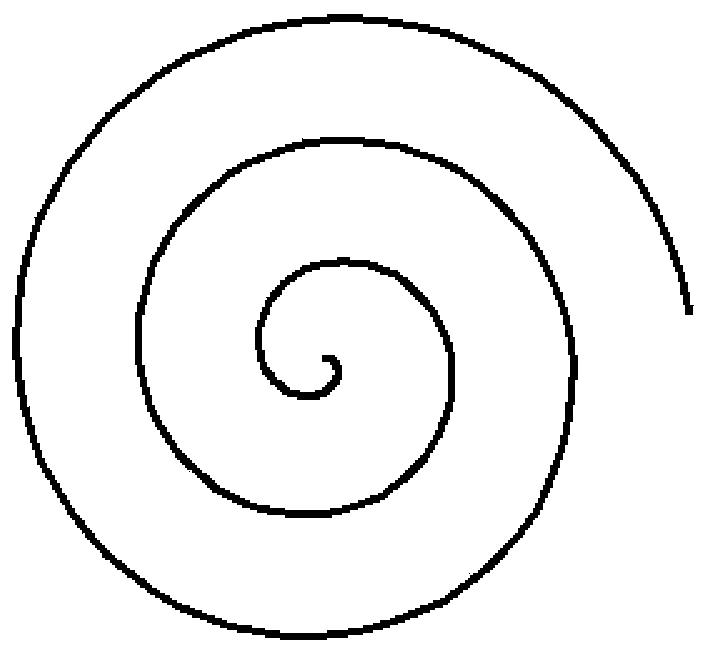

Meter-stage large-opening-diameter optical element CO2 laser polishing device and polishing method

ActiveCN111318808ACause secondary pollutionReduce residual stressLaser beam welding apparatusLinear motionLight beam

The invention relates to a meter-stage large-opening-diameter optical element CO2 laser polishing device. On the basis that an optical element does constant-speed motion on a worktable, laser penetrates through a hole in a support, through a reflecting mirror, a light beam is transmitted to a vibrating mirror system composed of a vibrating mirror and a focusing mirror, machining of the optical element is systematically achieved, the reflecting mirror, the vibrating mirror and the focusing mirror which are integrated are mounted on the support and do linear motion in the direction where the laser is incident from the hole, light path transmission cannot be affected by motion of the vibrating mirror system, motion track rough positioning formed by worktable motion and vibrating mirror systemmotion can be achieved well, the self motion of the vibrating mirror system achieves precise positioning of the motion track, according to the device, through the manner of spiral track machining andchanging of parameters, the optical element is scanned, through a fusion and gasifying combined manner, the surface of the optical element is polished, and the device can achieve linear or circumference motion of the meter stage or above.

Owner:NANJING UNIV OF SCI & TECH

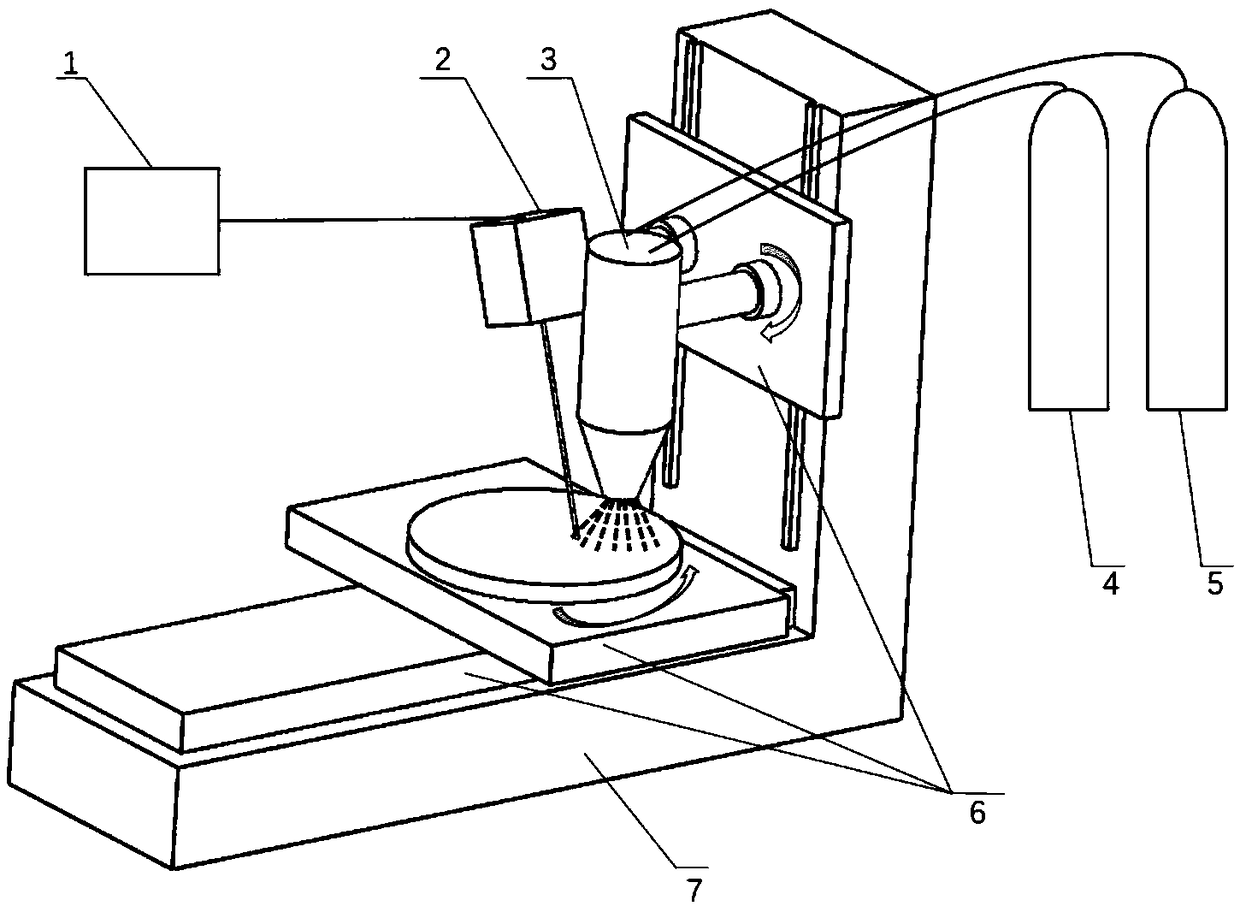

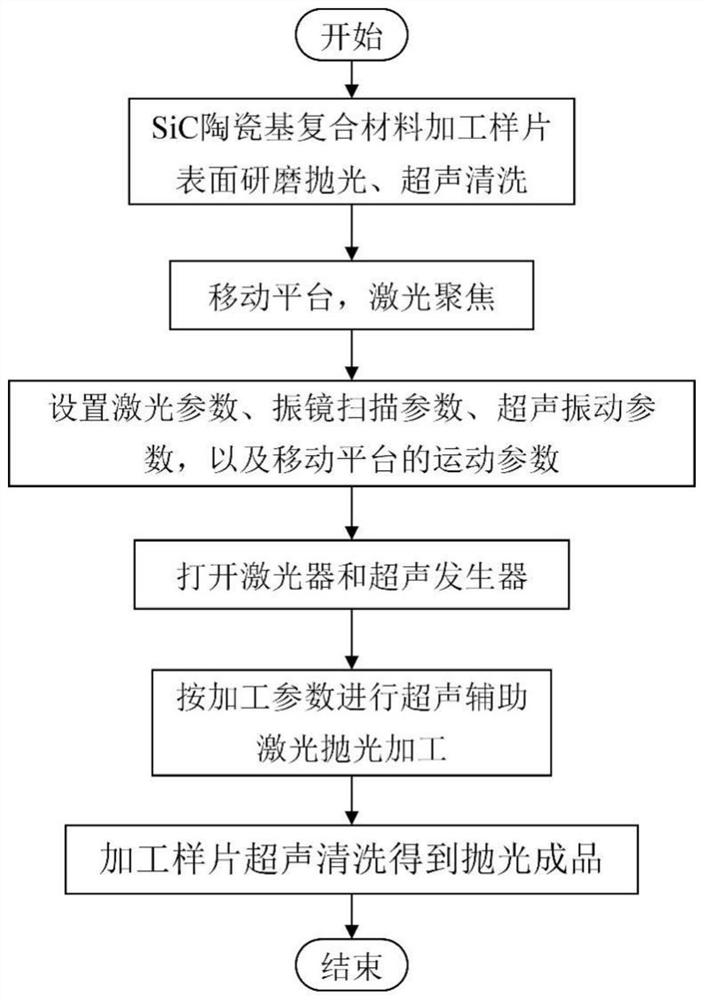

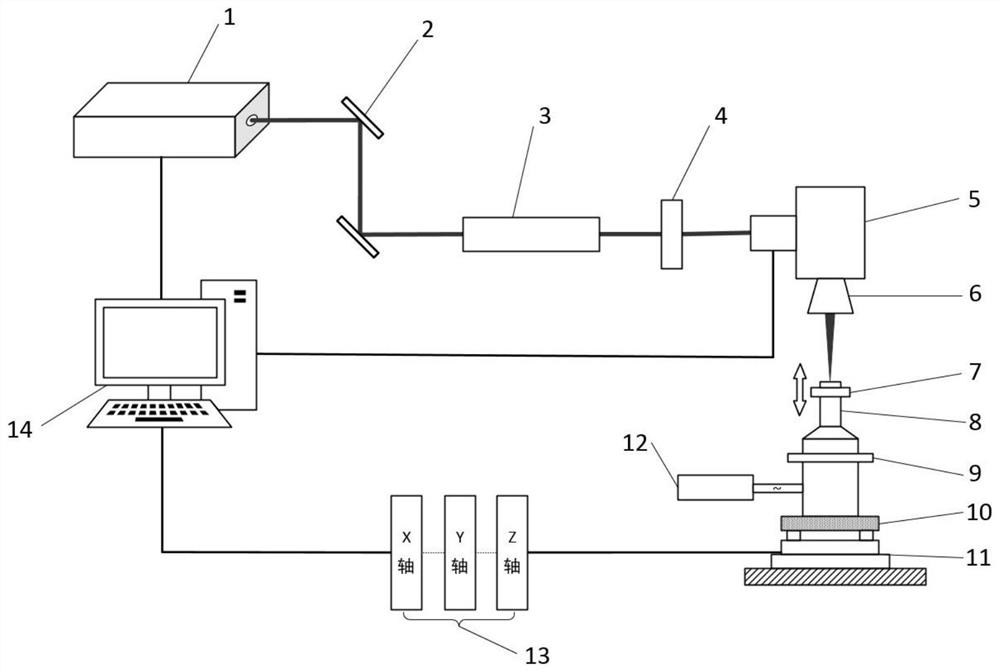

Method for ultrasonic-assisted laser polishing of ceramic-based composite material

InactiveCN111716005AAvoid shieldingAvoid scattering effectsLaser beam welding apparatusFemto second laserMaterial removal

The invention discloses a method for ultrasonic-assisted laser polishing of a ceramic-based composite material. The method comprises the following steps of firstly, grinding and polishing the surfaceof a machined sample wafer of a SiC ceramic-based composite material, and carrying out ultrasonic cleaning; fixing the machined sample wafer on an ultrasonic-assisted laser polishing processing device, and moving a platform to focus the laser to an initial machining position; setting a laser parameter, a galvanometer scanning parameter, an ultrasonic vibration parameter and a motion parameter of an XYZ high-precision mobile platform, starting a femtosecond laser and an ultrasonic generator, and carrying out ultrasonic-assisted laser polishing machining on the machined sample wafer by using theadjusted parameters; and after polishing is completed, carrying out ultrasonic cleaning on the machined sample wafer again. According to the method, the laser machining method and the ultrasonic machining method are combined, the effects of acoustic streaming, cavitation and the like of ultrasonic waves are fully utilized, the problems of defects such as a recast layer and surface cracks caused by the plasma effect and the particle adhesion effect in the laser polishing process are solved, the laser machining process is optimized, and the material removal rate and the polished surface qualityare improved.

Owner:XI AN JIAOTONG UNIV

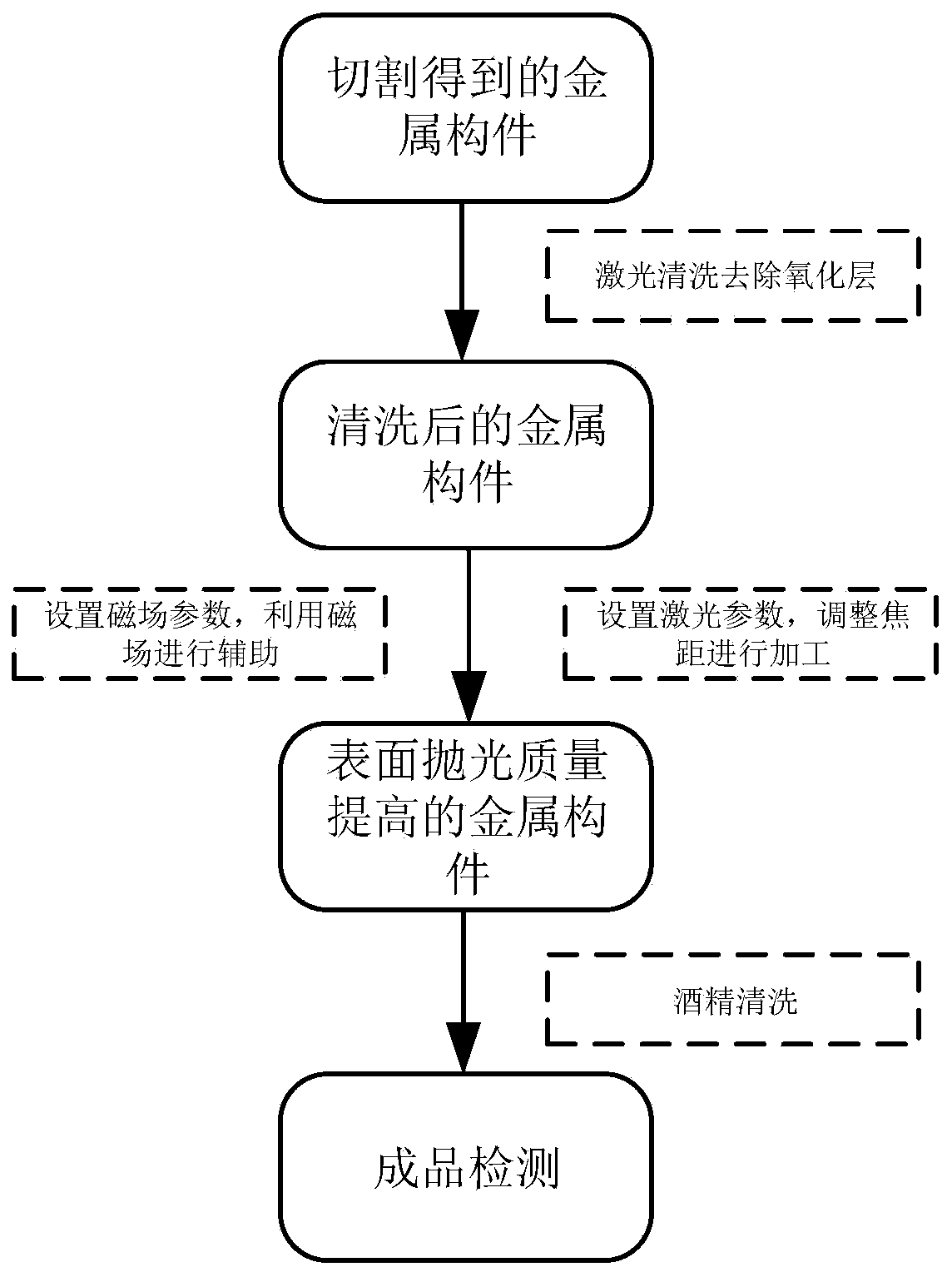

Magnetic field auxiliary laser polishing method based on existing laser processing equipment

InactiveCN109967863ANo pollution in the processEasy to operateLaser beam welding apparatusLaser processingHardness

The invention relates to a magnetic field auxiliary laser polishing method based on existing laser processing equipment. Compared with existing polishing technology, introduction of an auxiliary magnetic field obviously improves the surface quality of a polishing piece. The magnetic field auxiliary laser polishing method based on the existing laser processing equipment comprises the following steps that 1, a pollution layer or an oxidation layer of the material surface is removed by adopting laser cleaning technology; 2, a magnetic field parameter is arranged, the polishing piece is placed ina stable magnetic field after the communicating and stable magnetic field is formed; and 3, a laser processing optimized parameter is arranged, polishing treatment is carried out on the material surface under the magnetic field auxiliary action. The auxiliary magnetic field can adjust and control molten pool flowing and plasma moving in the processing process, negative effect generated by mutual action of a laser and materials is effectively reduced, so that the surface of the polishing piece obtains fine and uniform microstructures, the strength, hardness, corrosion resistance and the like ofthe material surface are improved, the processing technology and processing areas of the laser are adjusted flexibly, the processing precision is high, the efficiency is high, and the cost is low.

Owner:BEIHANG UNIV

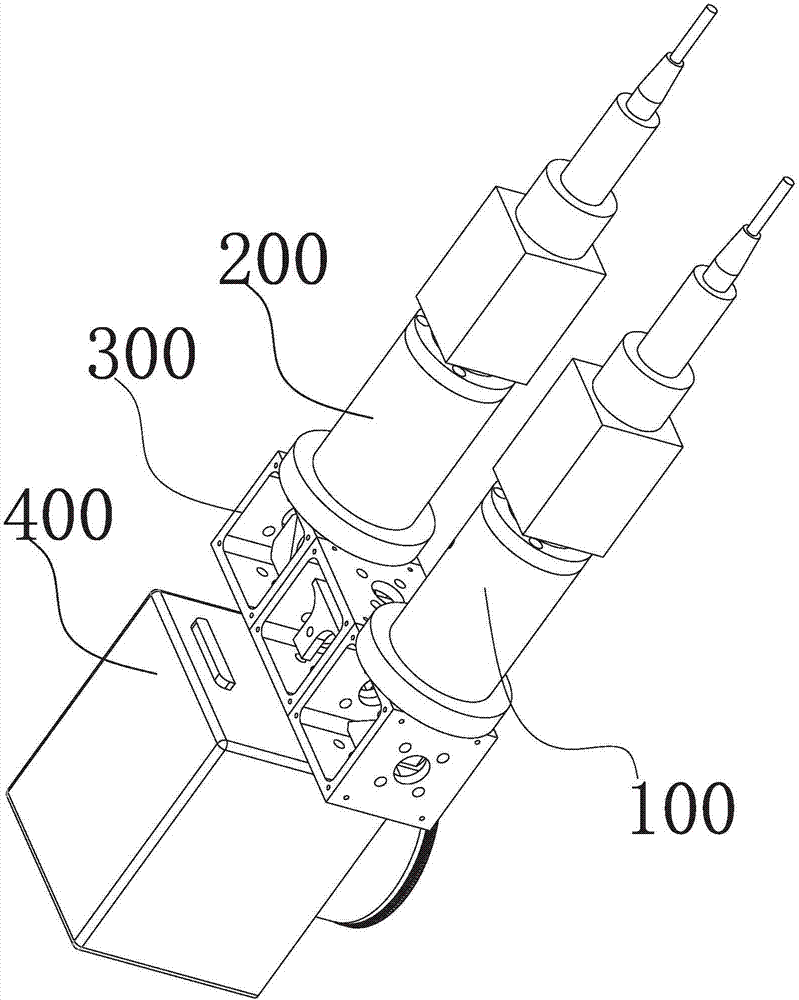

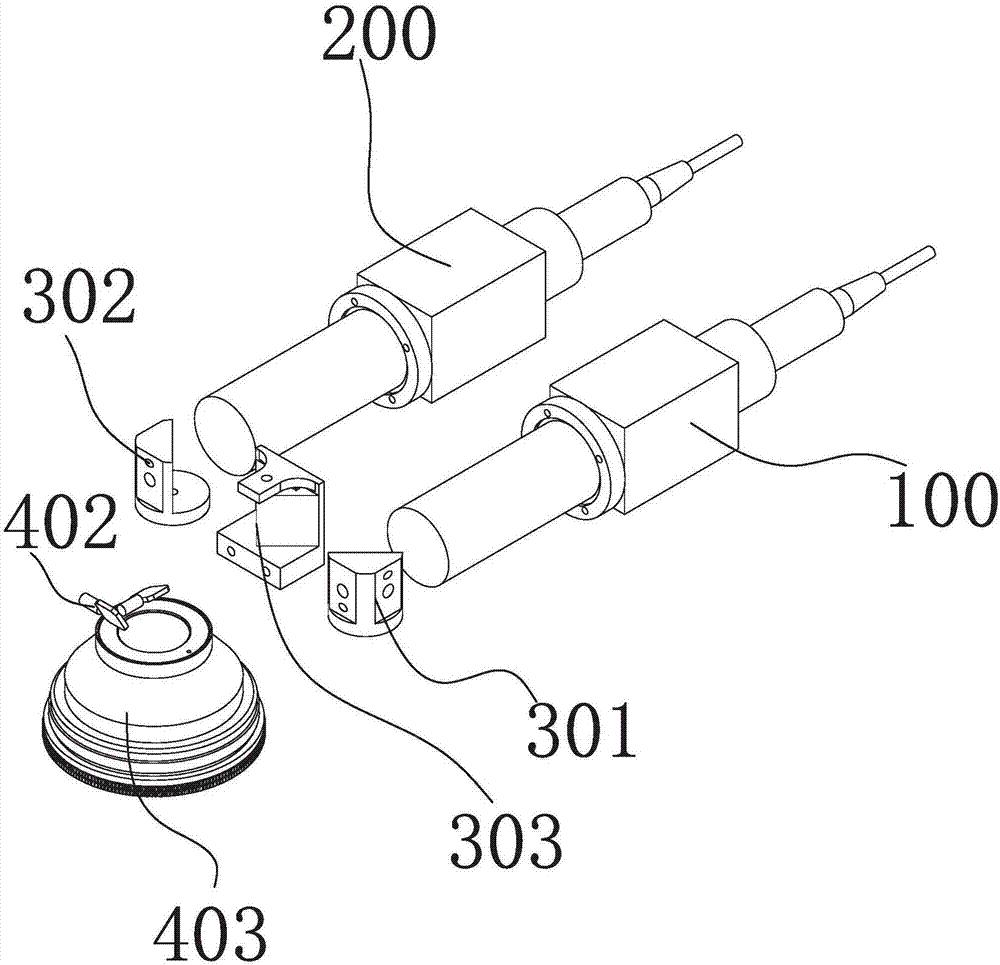

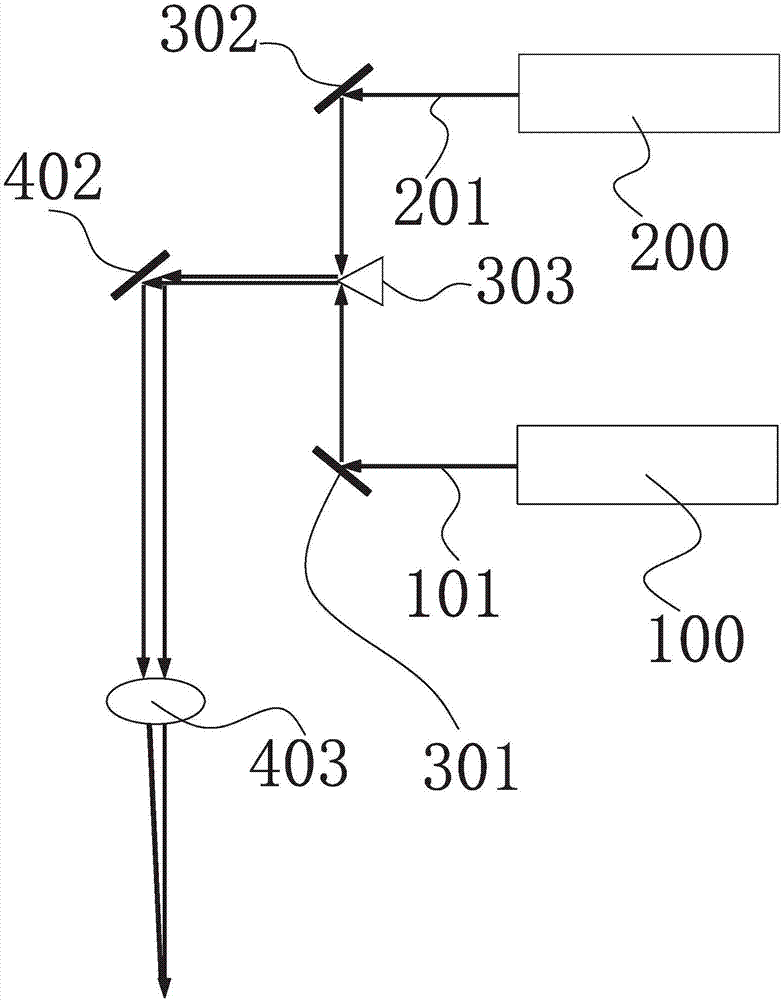

Laser polishing machine and polishing method using same

InactiveCN107363409AImprove flatnessImprove the finishLaser beam welding apparatusLight beamLaser scanning

The invention relates to a laser polishing machine. The laser polishing machine comprises a first group of laser light source systems, a second group of laser light source systems, a light integrating prism system, a laser scanning system and a filed lens, wherein the laser scanning system is mounted at a common end of the first group of laser light source systems and the second group of laser light source systems; the light integrating prism system is mounted between the first group of laser light source systems and the second group of laser light source systems; the light integrating prism system comprises a first group of reflecting mirrors, a second group of reflecting mirrors and a prism used for integrating light; the laser scanning system comprises a laser scanning galvanometer; and a first group of reflecting mirrors, a second group of reflecting mirrors as well as the light integrating prism system are positioned on the same horizontal line. During working, the light integrating prism system is utilized for integrating laser generated by the first group of laser light source systems and the second laser light source systems into a laser light beam, and the laser light beam is focused on the surface of a workpiece for being repeatedly subjected to laser scanning polishing treatment under co-action of the laser scanning galvanometer and the field lens, so that a metal workpiece surface with high smoothness and high degree of finish is conveniently processed out.

Owner:佘志荣

Method of laser polishing a connectorized optical fiber and a connectorized optical fiber formed in accordance therewith

ActiveUS20160187592A1Effective and efficient and reliable approachSmall sizeOptical articlesCoupling light guidesFiberLaser beams

Laser polishing is achieved by directing laser beam perpendicular at the fiber end face in a connectorized optical fiber having a metal ferrule. The spot size of the laser beam is larger than the bare optical fiber diameter, providing a more uniform spatial distribution of the radiation energy over the fiber end face. The metal ferrule provides heat conduction to prevent excessive heat built up at the fiber tip, which would lead to undesirable surface defects and geometries. The connectorized optical fiber may be pre-shaped prior to laser polishing. Subsequent laser polishing flattens the fiber end face.

Owner:SENKO ADVANCED COMPONENTS

Porous hydrophilic stainless steel heat exchange tube and surface treatment method thereof

ActiveCN104117833AImprove stabilityExtended service lifeCorrosion preventionHeat transfer modificationElectrolysisEvaporation

The invention discloses a surface treatment method for a porous hydrophilic stainless steel heat exchange tube. The method includes the following steps that liquid phase plasma electrolysis or laser polishing or sand blasting treatment is carried out on a stainless steel tube to achieve surface roughening; chemical electrolysis or sol modified electroplating treatment is conducted on the roughened steel tube surface; a stainless steel heat exchange tube and a heat exchanger with the stainless steel heat exchange tube are obtained through the steps. According to the method, porous and recess microstructures can be obtained from surfaces of various stainless steel tubes, and reinforcement evaporation and boiling heat transfer are greatly improved; continuous strong hydrophilic performance can be obtained from the surfaces of various stainless steel tubes, water film spreading is accelerated, the thickness of a water film can be reduced, and therefore heat exchange efficiency is improved; metal surfaces more resistant to pitting corrosion, chloridion stress corrosion and concentration difference micro cell corrosion can be obtained from the surfaces of various stainless steel tubes, overall stability of a heat exchanger unit is improved, and the service life of the heat exchanger unit is prolonged.

Owner:FULL DIMENSION POWER TECH

Laser polishing method of mobile phone display screen glass

The invention discloses a laser polishing method of mobile phone display screen glass. According to the method, laser is adopted for polishing the mobile phone display screen glass, a beam shaping step is used for optimizing a laser source, a pre-heating step is used for solving the problem that the mobile phone display screen glass is fragile under thermal action, and non-contact nondestructive high-quality efficient polishing is conducted on the mobile phone display screen glass. The efficient economic novel method is provided for processing for obtaining the nondestructive smooth mobile phone display screen glass.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Glass polishing system and method

ActiveCN108436254ASave human effortImprove polishing efficiencyLaser beam welding apparatusTunnel kilnConveyor belt

The invention discloses a glass polishing system and method. The system comprises a stand, a tunnel kiln and a laser polishing device, wherein the tunnel kiln comprises a preheating station for preheating a glass workpiece before polishing, an annealing station for annealing and cooling the polished glass, a heating part, a conveyor belt and an annealing part; the heating part is used for heatingthe glass workpiece on the conveyor belt; the annealing part is arranged on the stand and is positioned above the conveyor belt, and the annealing part is used for annealing the glass workpiece subjected to laser polishing; the laser polishing device is provided with a laser polishing part which is arranged on the stand; the laser polishing part and the annealing part are sequentially distributedin the conveying direction of the conveyor belt; and the laser polishing part is positioned above the conveyor belt and is used for performing laser polishing on the glass workpiece on the conveyor belt. The glass polishing system is high in production efficiency.

Owner:MAXFORD TECH LTD +1

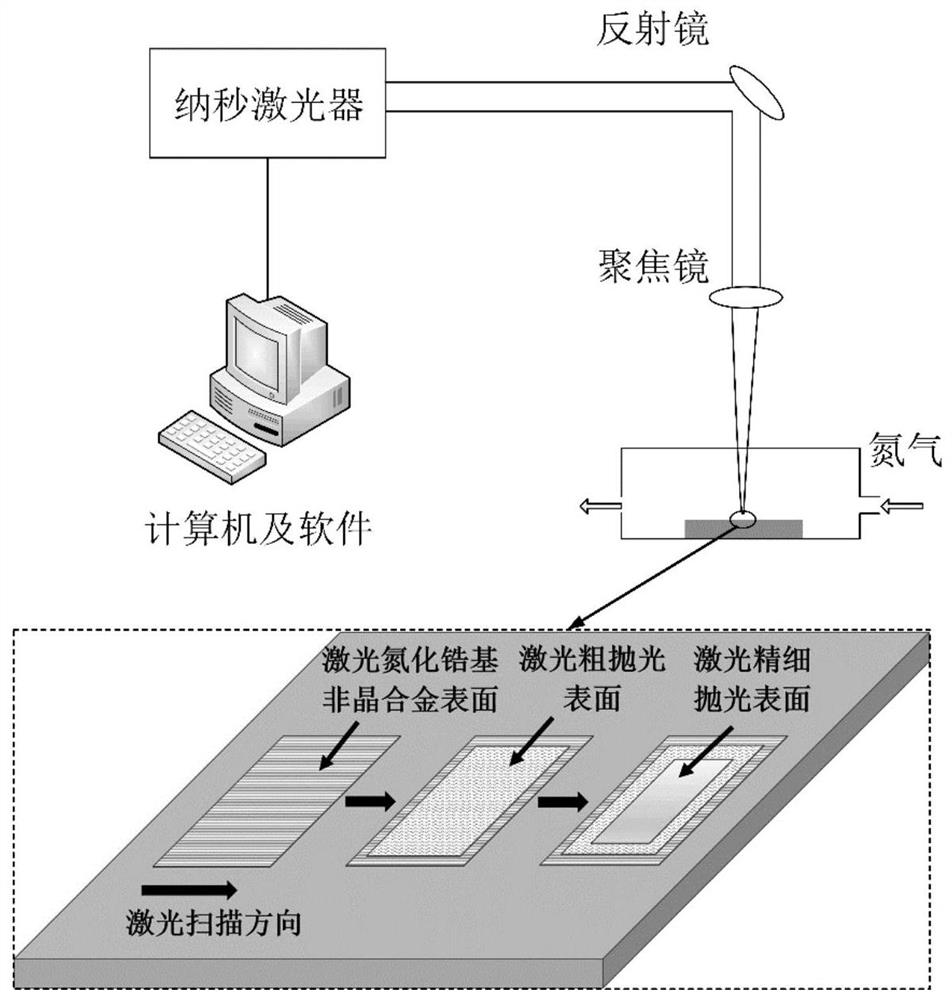

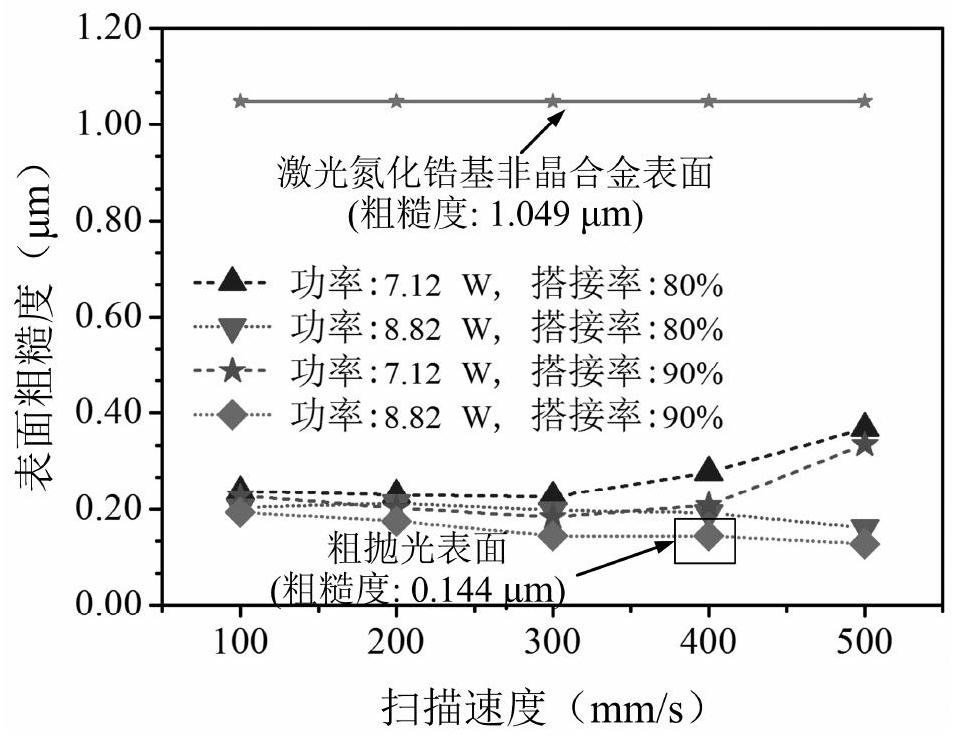

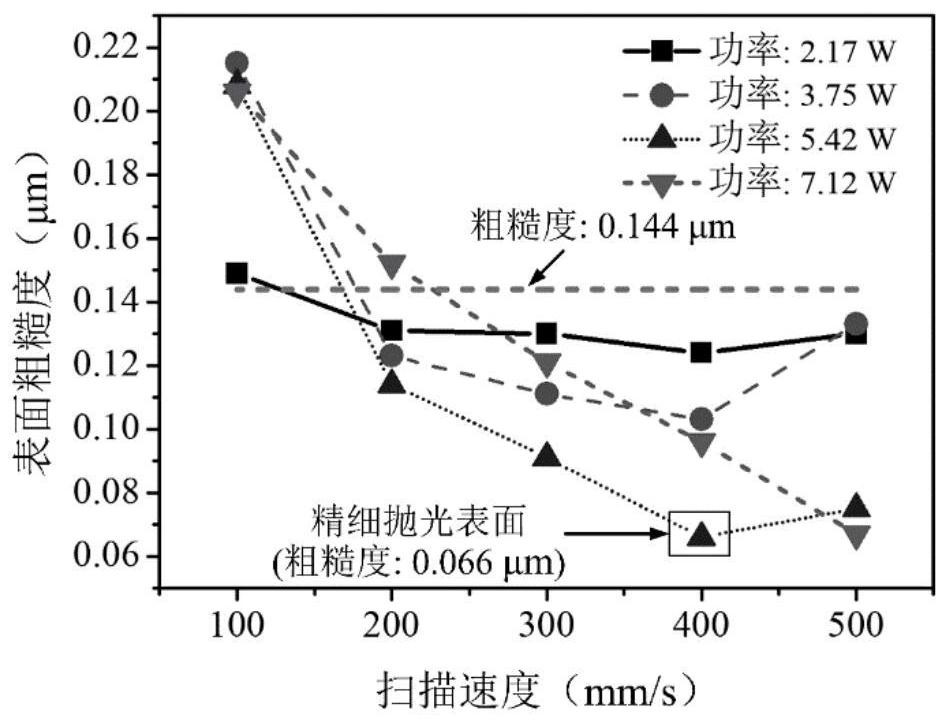

Method for realizing laser zirconium nitride-based amorphous alloy surface planarization through laser polishing

ActiveCN113275740AReduce roughnessRoughness controlLaser beam welding apparatusLaser polishingNitriding

The invention relates to a method for realizing laser zirconium nitride-based amorphous alloy surface planarization through laser polishing, and belongs to the technical field of amorphous alloy surface modification. The surface of a laser zirconium nitride-based amorphous alloy is subjected to laser polishing in a nitrogen atmosphere by utilizing heat generated by focusing laser on the surface of a material, so that the surface is re-melted, and the surface roughness is reduced. The method effectively solves the problem of poor surface quality of the existing laser zirconium nitride-based amorphous alloy. The surface roughness of the laser zirconium nitride-based amorphous alloy is regulated and controlled by changing laser polishing parameters. The method is simple in implementation process, high in efficiency and high in practicability, and can be applied to reducing the surface roughness of the laser zirconium nitride-based amorphous alloy and enhancing the practical application of the laser zirconium nitride-based amorphous alloy.

Owner:JILIN UNIV

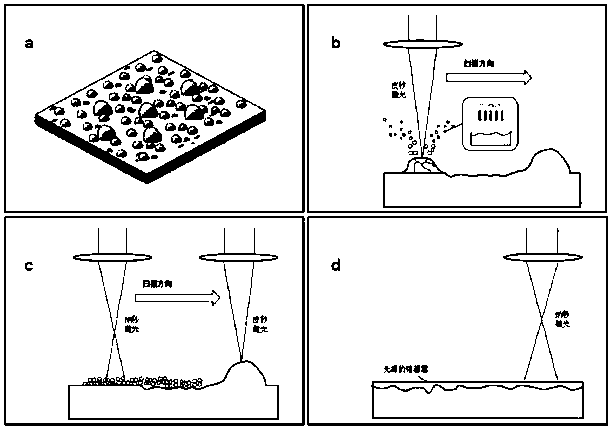

Evaporation-fusion composite laser polishing method capable of realizing peak clipping and then valley filling of metal surface

PendingCN112589263ANo pollutionImprove polishing efficiencyLaser beam welding apparatusNanosecond laserNanosecond

The invention provides an evaporation-melting composite laser polishing method capable of realizing peak clipping and then valley filling of a metal surface. According to the method, nanosecond pulselaser is introduced to perform peak clipping treatment on a large-roughness surface, and then composite laser polishing is performed on the large-roughness surface in such a manner that the valley bottom is filled through continuous laser fusion, so that generation of microcracks is prevented; the pulse width of nanosecond laser is extremely short, so that the severe thermal influence cannot be caused by repeated scanning, the surface is bright after action, and the peak of the microscopic surface is cut down; then continuous laser fusion is adopted, the material is fused and flows to fill thevalley bottom, and finally, the flat and bright polished surface without microscopic thermal cracks is obtained. The method is high in polishing efficiency and environmentally friendly.

Owner:ZHEJIANG UNIV OF TECH

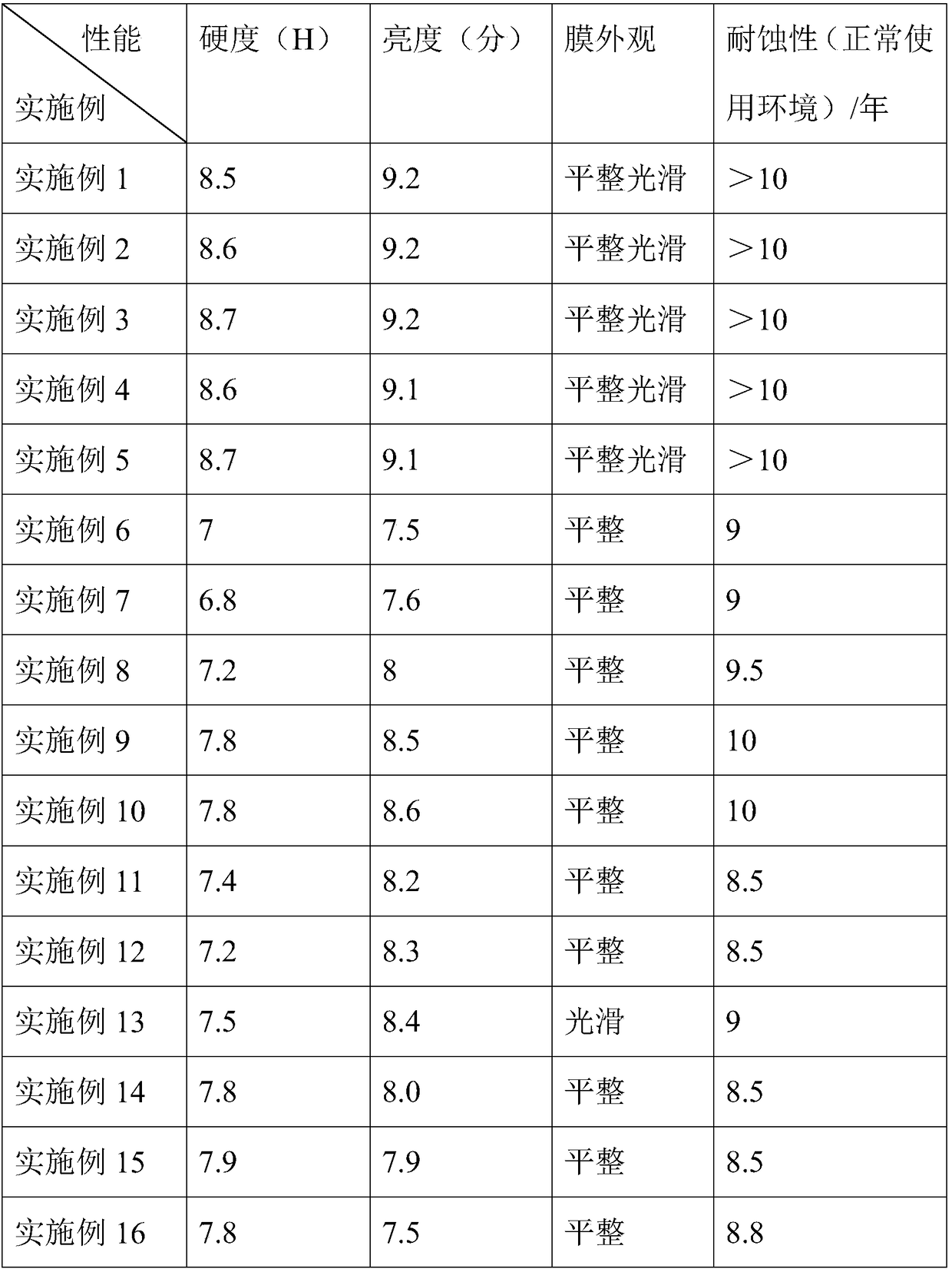

Surface treatment method capable of improving aluminium alloy corrosion resistance

InactiveCN108930032AGuaranteed durabilityLow corrosion rateAnodisationAbrasion apparatusCellulosePolyethylene glycol

The invention relates to an aluminium alloy surface treatment technology, and more specifically relates to a surface treatment method capable of improving aluminium alloy corrosion resistance, and belongs to the technical field of aluminium alloy surface treatment. The surface treatment method comprises following steps: pretreatment, platinization treatment, anodic oxidation treatment, hot water washing, cold hole sealing treatment, electrophoresis treatment, heat baking, and laser polishing treatment. A platinization solution adopted in the surface treatment method comprises 50 to 70g / L of tetrafluoroplatinic acid, 25 to 30g / L of polyethylene glycol, 25 to 40g / L of carboxyethyl cellulose, and 20 to 30g / L of polyacrylate. The surface treatment method is simple, is convenient in operation,low in cost, excellent in effect, and promising in application prospect, and is convenient for popularization and industrialization.

Owner:JIANGSU HEXING AUTOMOTIVE TECH

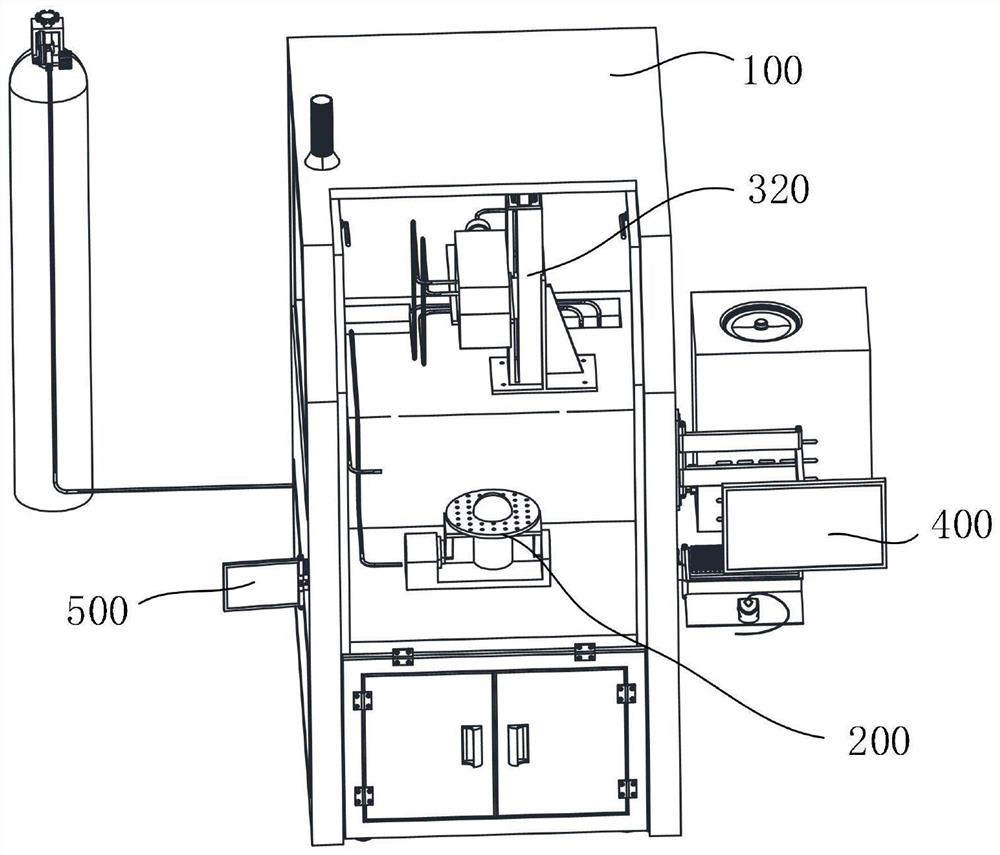

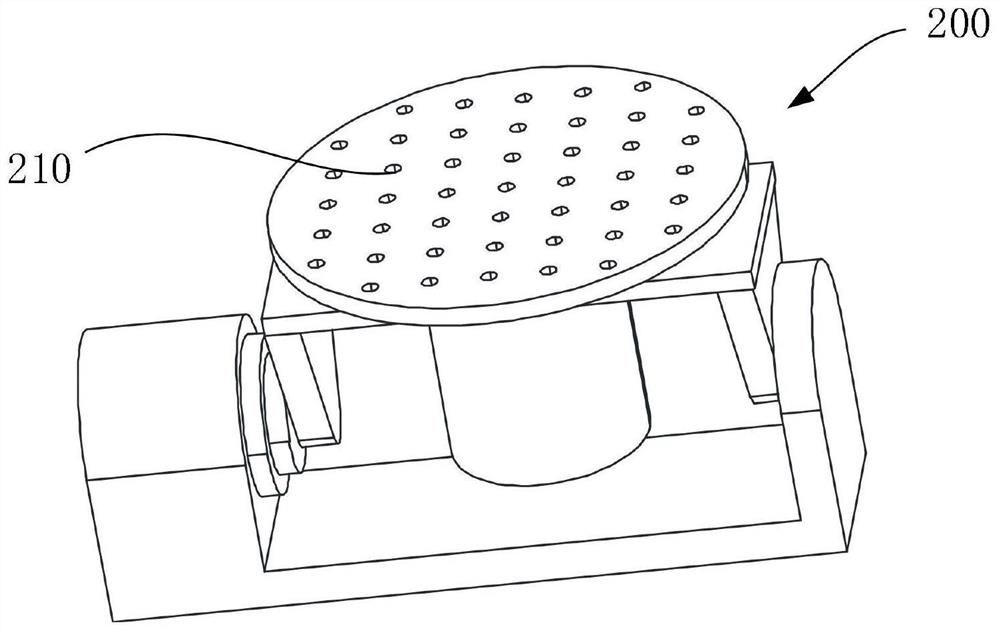

Laser polishing device and laser polishing method

PendingCN112756791AHigh precisionIncreased sensitivityLaser beam welding apparatusLaser transmitterControl system

The invention discloses a laser polishing device and a laser polishing method. The laser polishing device comprises a main machine box, a rotary clamping mechanism, a laser system, a first control system and a second control system; the rotary clamping mechanism is arranged in the main machine box and used for clamping a metal piece to be polished; the laser system is arranged in the main machine box, the laser system comprises a laser transmitter and a laser galvanometer assembly, and the laser transmitter is connected with the laser galvanometer assembly; the first control system is electrically connected with the laser transmitter and is used for controlling the laser transmitter to carry out laser polishing on the metal piece according to preset laser parameters and a preset polishing range; and the second control system is electrically connected with the laser galvanometer assembly and the rotary clamping mechanism and used for driving the laser galvanometer assembly to move and driving the rotary clamping mechanism to rotate, and multi-axis linkage is achieved.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com