Method for ultrasonic-assisted laser polishing of ceramic-based composite material

A laser polishing, ultrasonic-assisted technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult to discharge gasified substances and residues, high processing costs, low ultrasonic processing efficiency, etc., to reduce particle size Adhesion effect, improvement of machined surface quality, effect of improved material removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

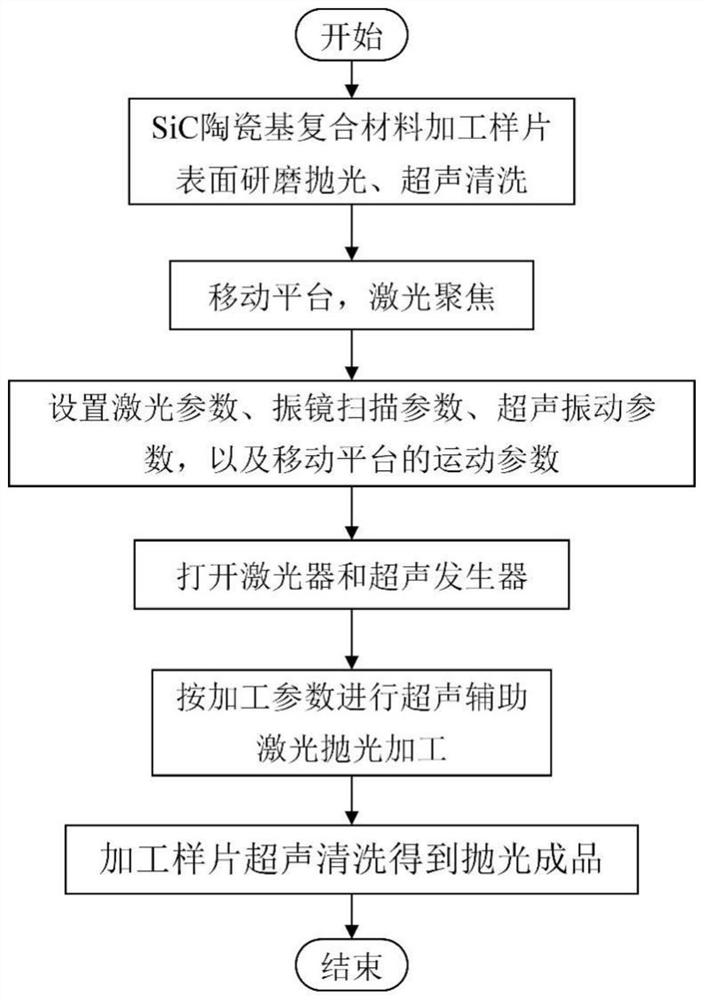

[0026] refer to figure 1 , a method for ultrasonically assisted laser polishing of ceramic matrix composites, comprising the steps of:

[0027] 1) Grinding and polishing the surface of the processed sample of SiC ceramic matrix composite material, and placing it in an organic solvent for ultrasonic cleaning for 10 to 15 minutes;

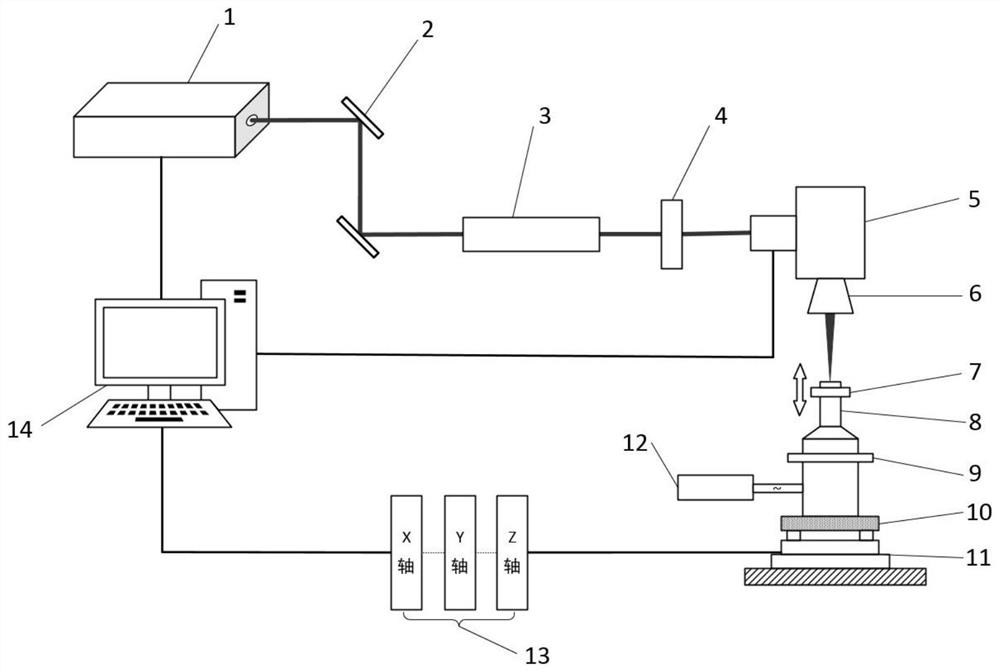

[0028] 2) After air-drying, fix the processing sample on the ultrasonic-assisted laser polishing processing device, refer to figure 2 , the ultrasonic-assisted laser polishing processing device includes a laser processing system, an XYZ high-precision mobile platform, an ultrasonic vibration auxiliary device and a fixture; the laser of the laser processing system is irradiated on the processing sample, and the processed sample is fixed on the ultrasonic vibration auxiliary device through the fixture, and the ultrasonic vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com