Patents

Literature

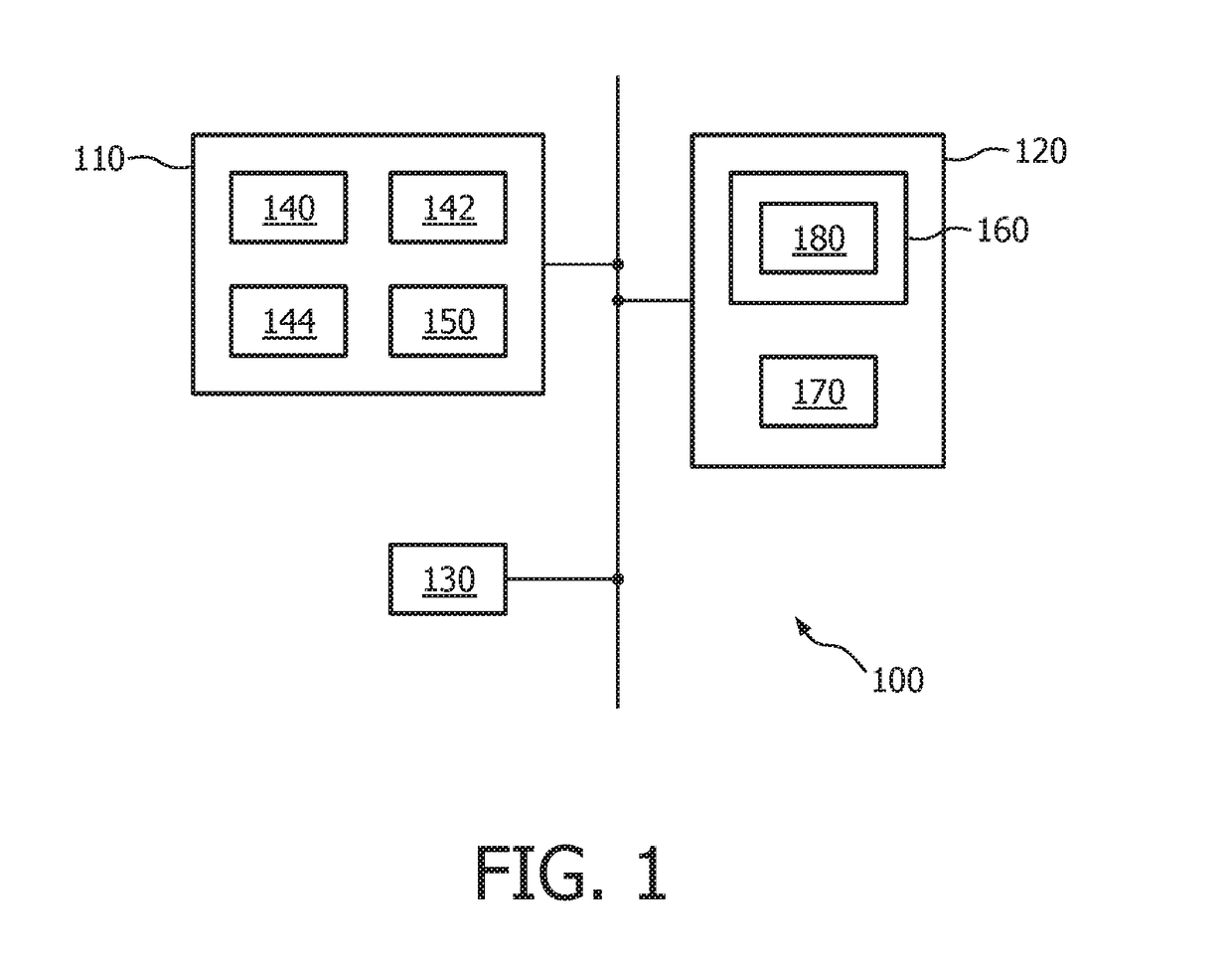

108 results about "Acoustic streaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acoustic streaming is a steady flow in a fluid driven by the absorption of high amplitude acoustic oscillations. This phenomenon can be observed near sound emitters, or in the standing waves within a Kundt's tube. It is the less-known opposite of sound generation by a flow. There are two situations where sound is absorbed in its medium of propagation: during propagation. The attenuation coefficient is α=2ηω²/(3ρc³), following Stokes' law (sound attenuation).

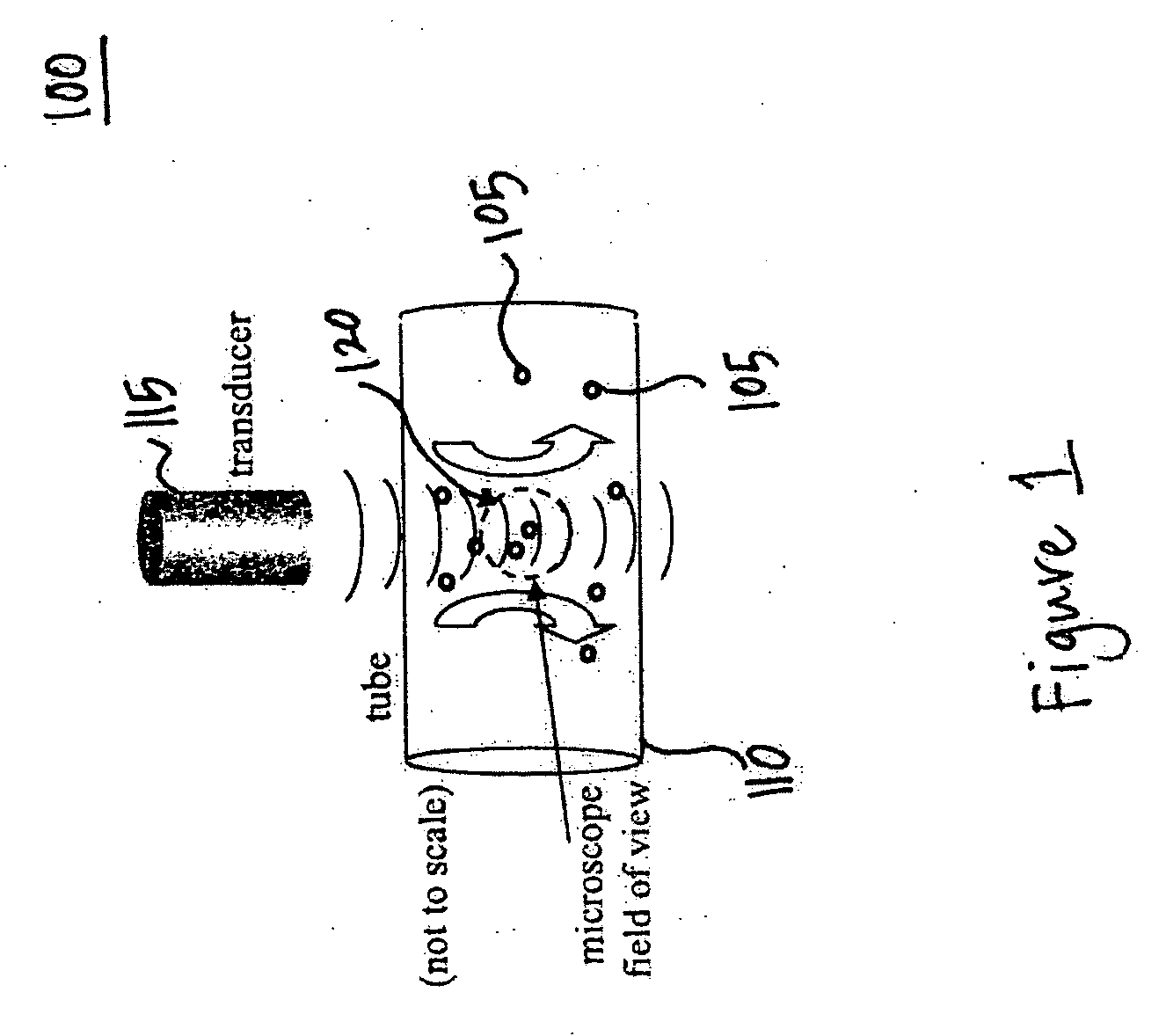

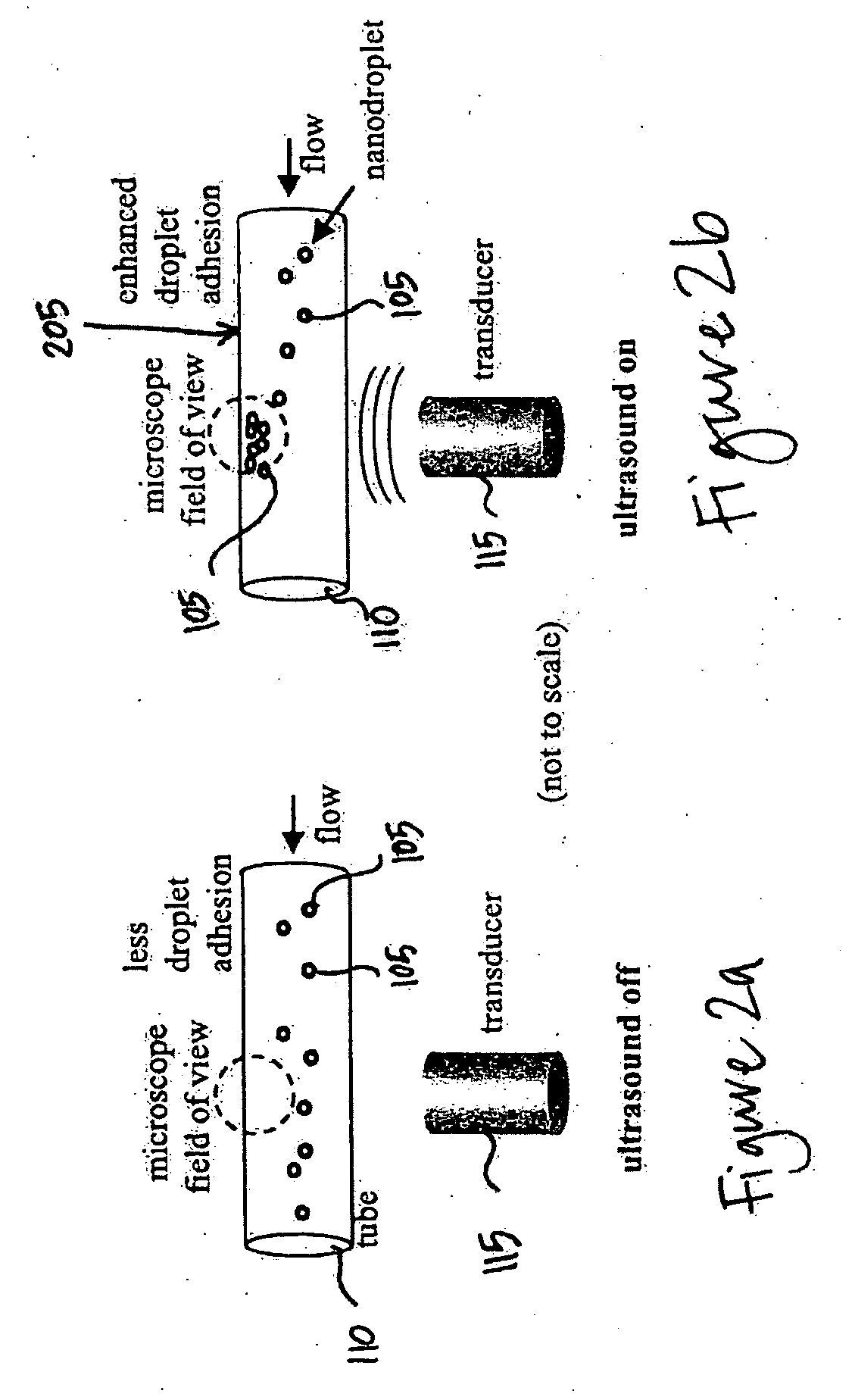

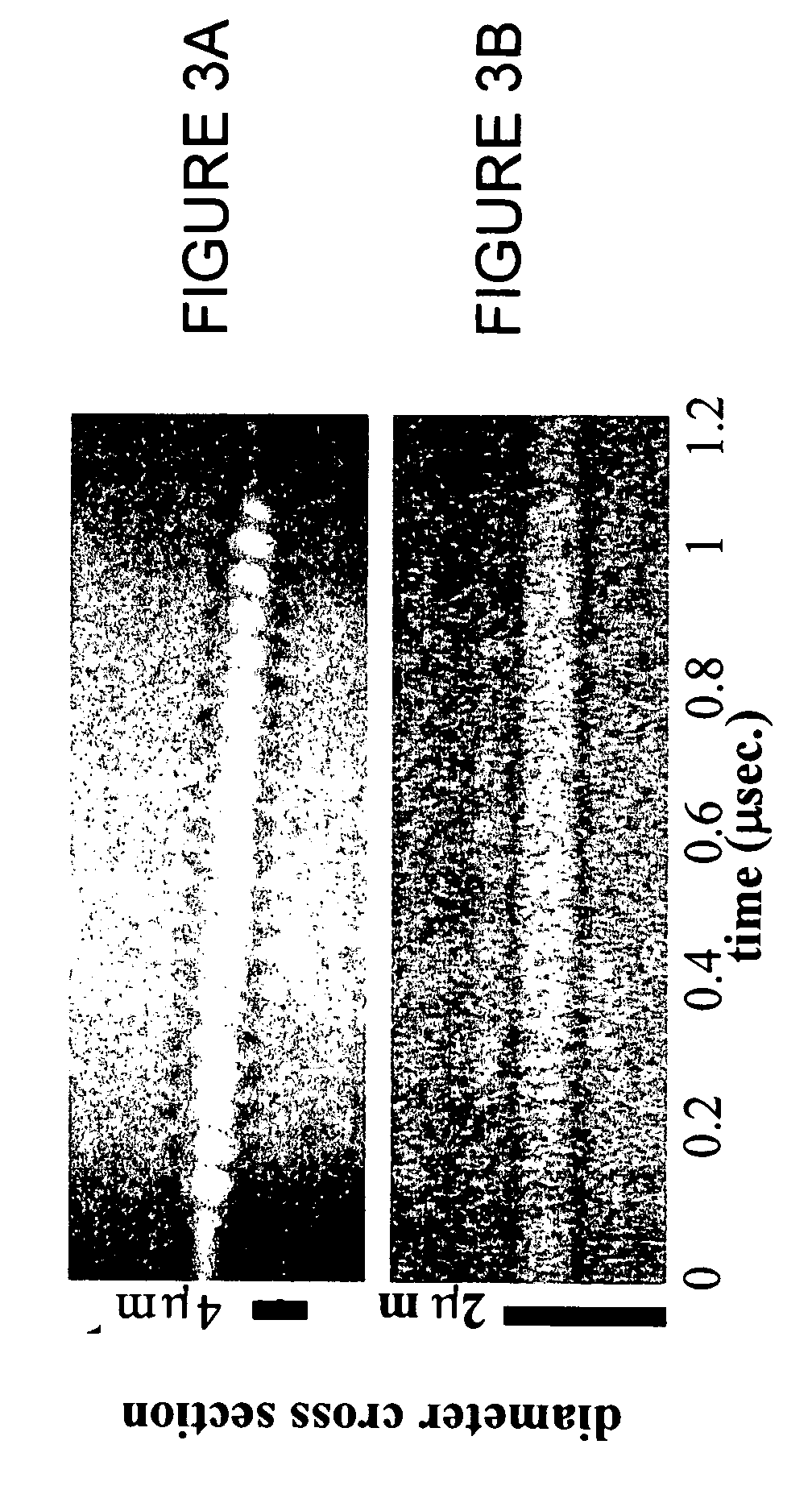

Ultrasonic concentration of carrier particles

InactiveUS20070071683A1Ultrasonic/sonic/infrasonic diagnosticsBiocideMembrane permeabilityMembrane permeabilization

Methods, compositions, and apparatus for localized delivery of compounds are provided. In certain embodiments, acoustic streaming force is used to direct carrier particles to a target site, mediate particle internalization, and release associate compounds. Ultrasound radiation is preferred as the source for the acoustic streaming force. Also encompassed are embodiments in which targeting and membrane permeability enhancement are combined with imaging of the treatment site.

Owner:RGT UNIV OF CALIFORNIA +1

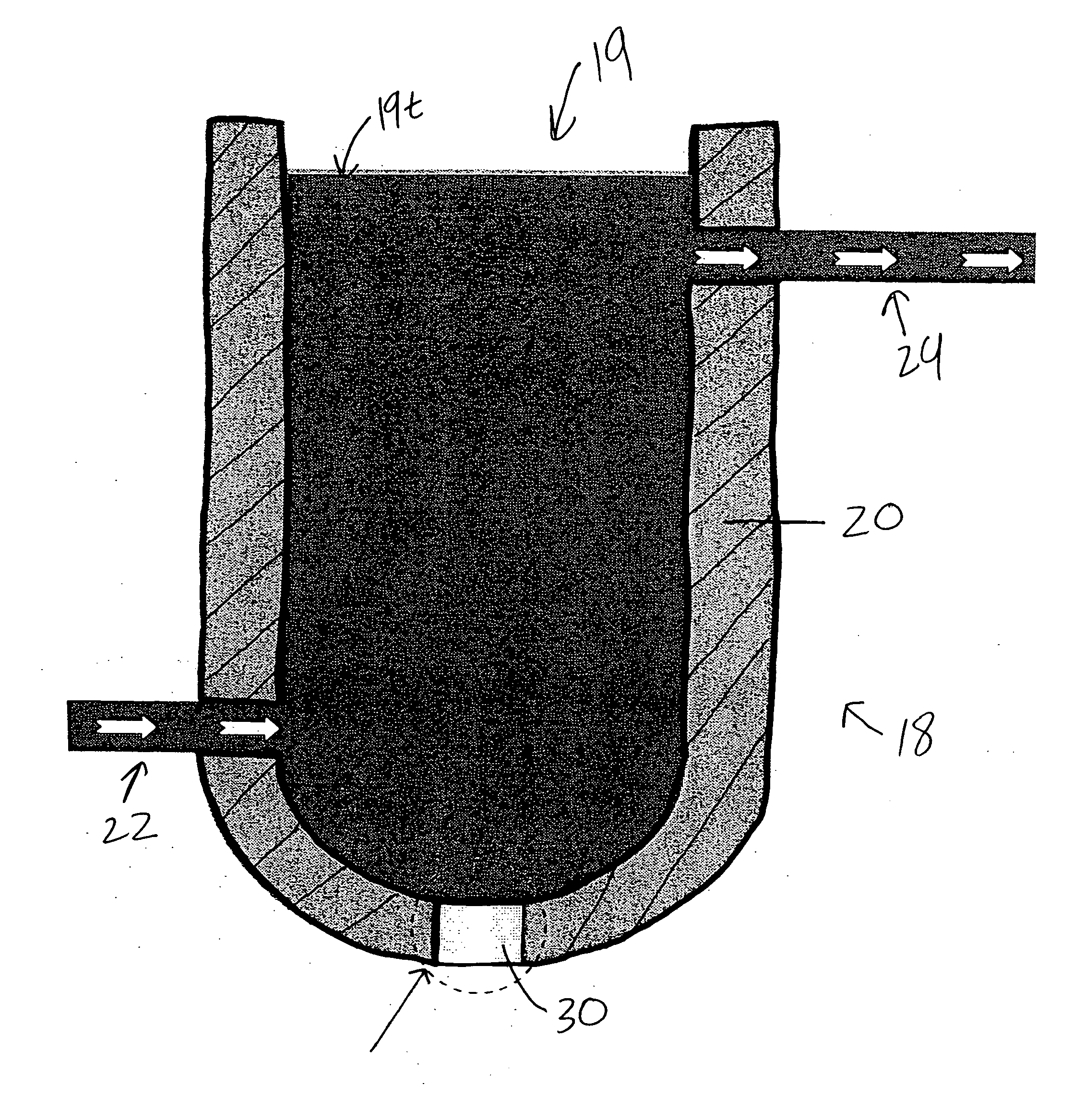

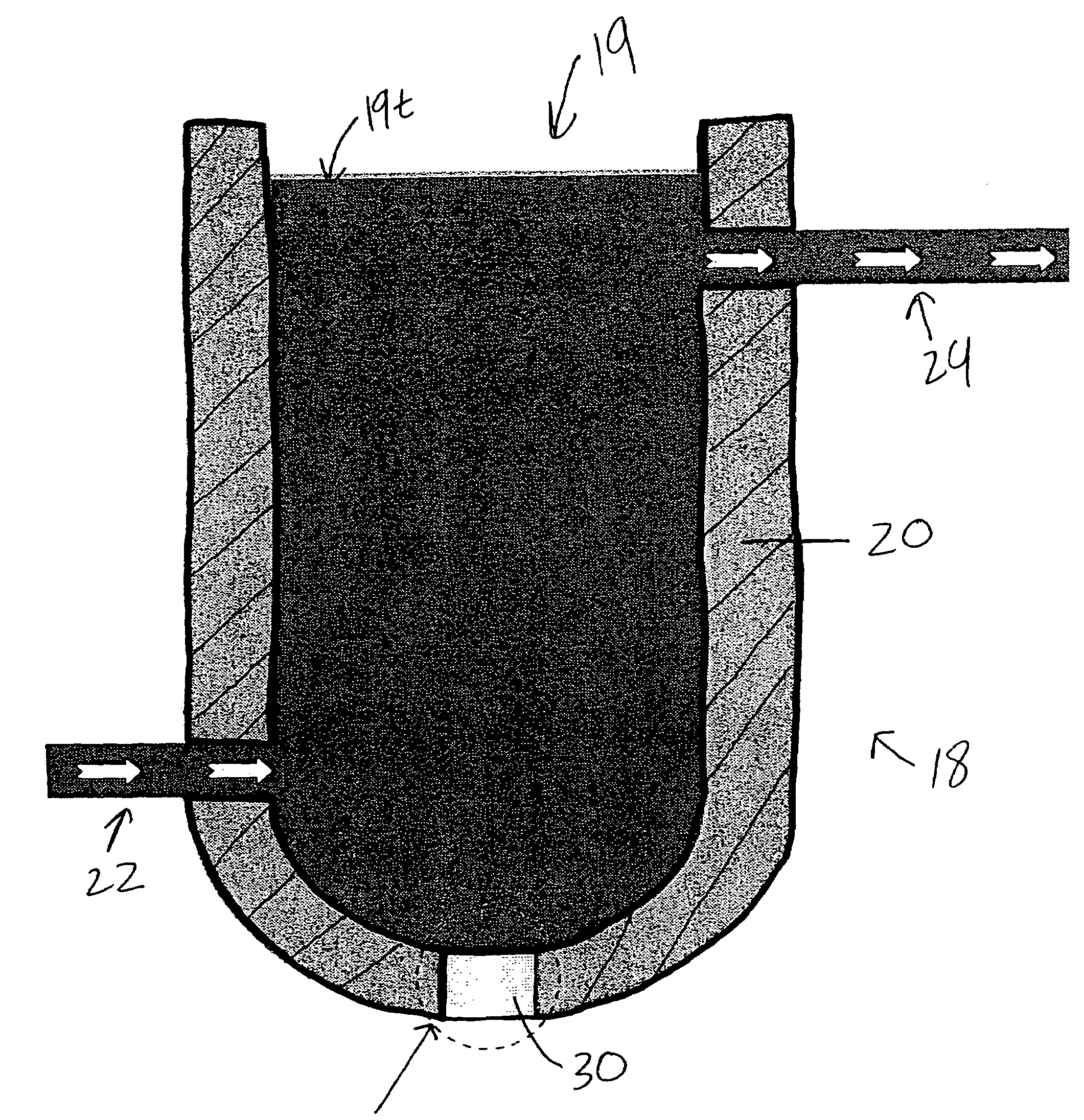

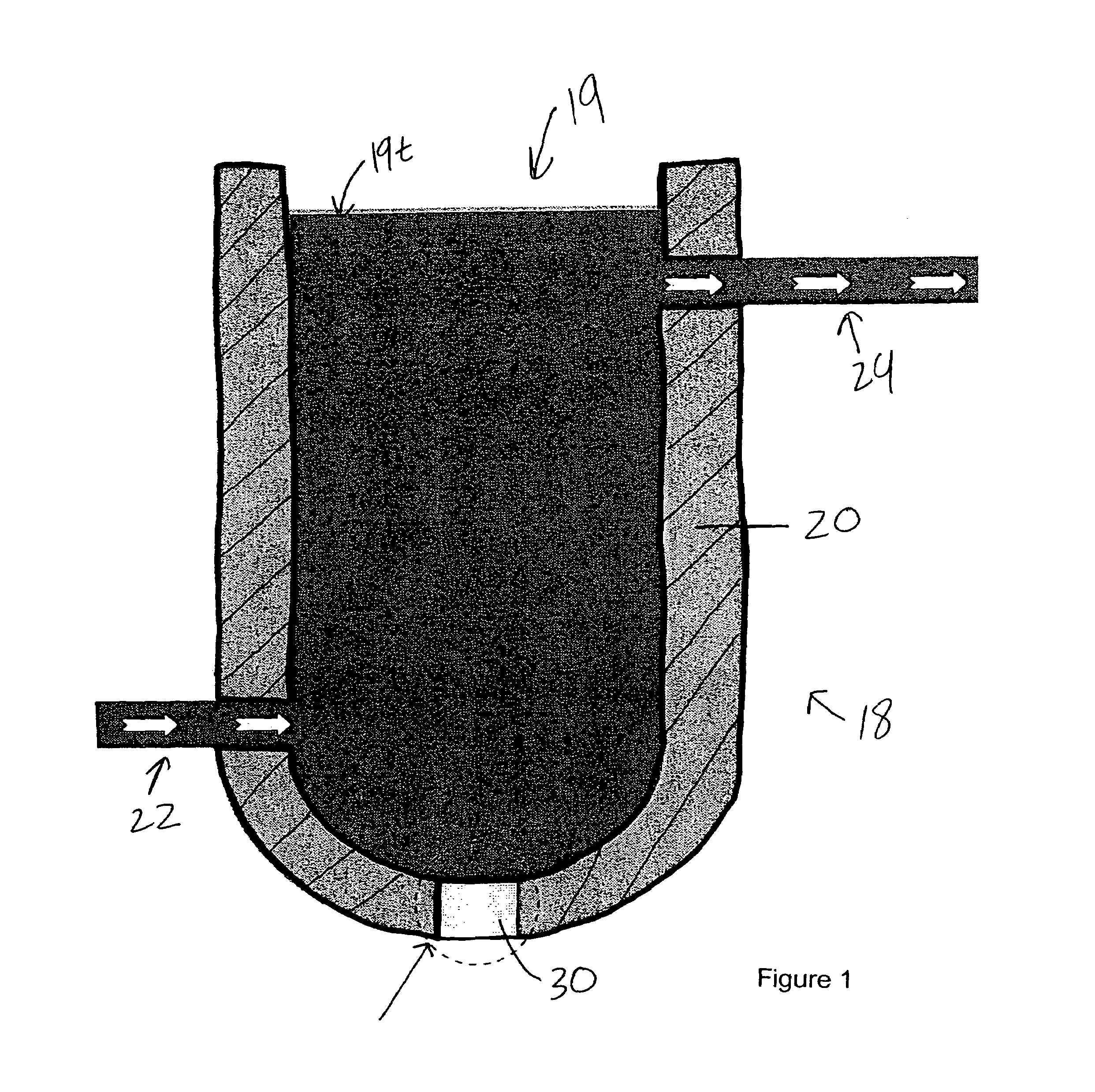

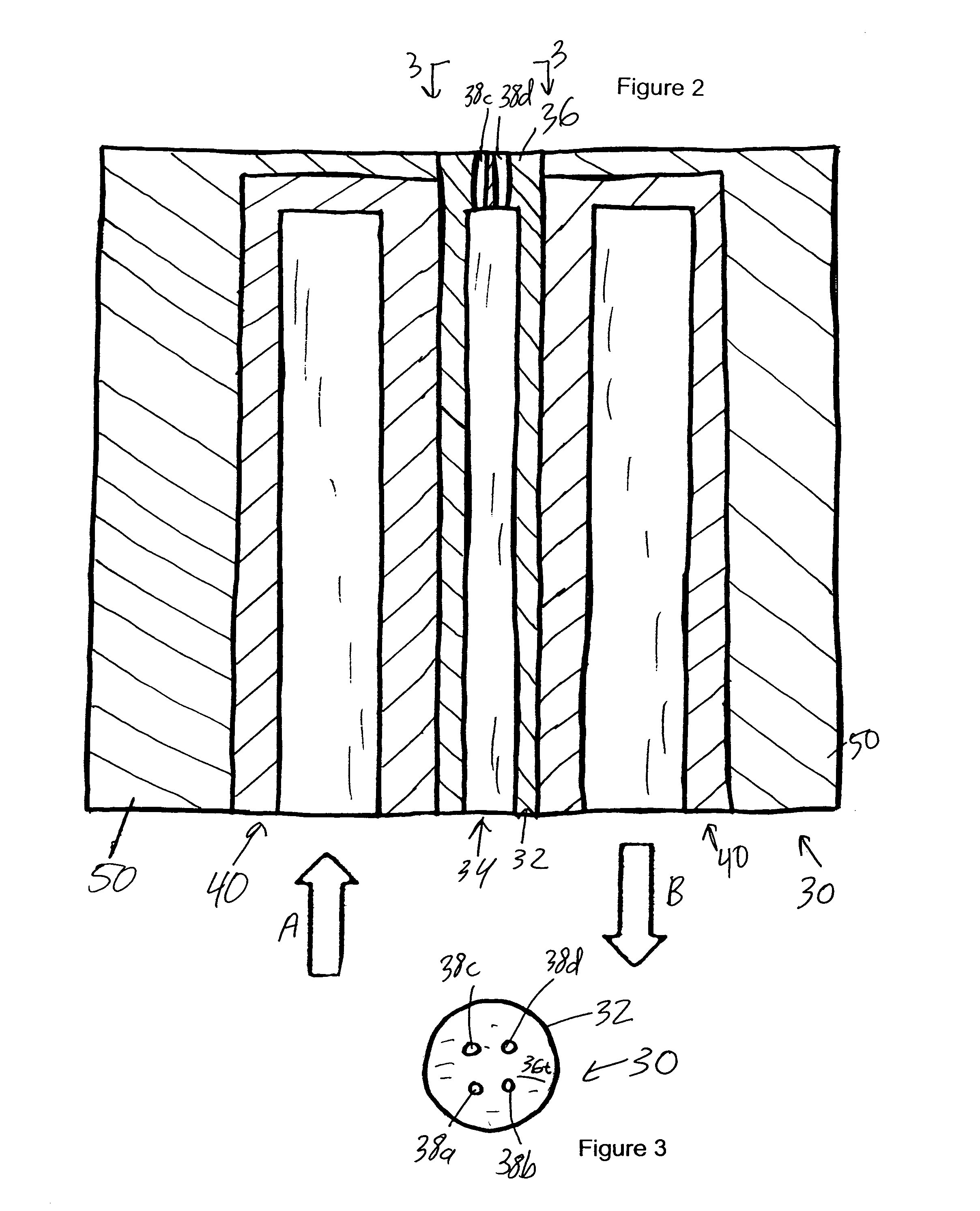

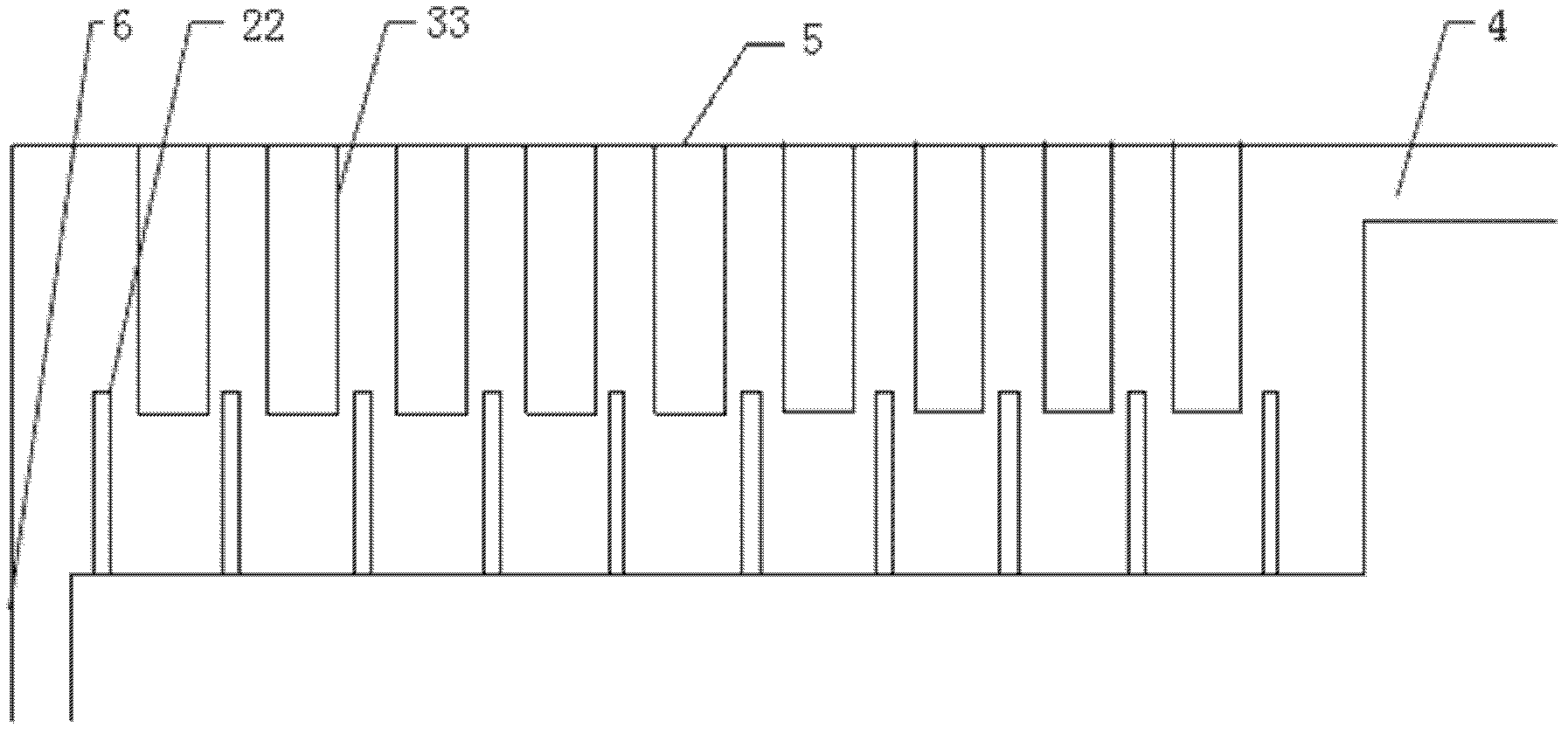

Degassing of molten alloys with the assistance of ultrasonic vibration

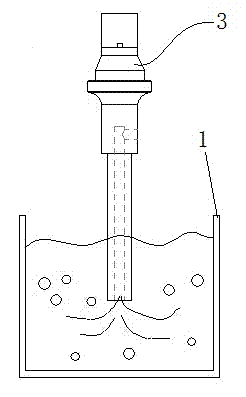

InactiveUS20070235159A1Reduce gas contentReduce heat transferMelt-holding vesselsLiquid degasificationNitrogen gasCavitation bubble

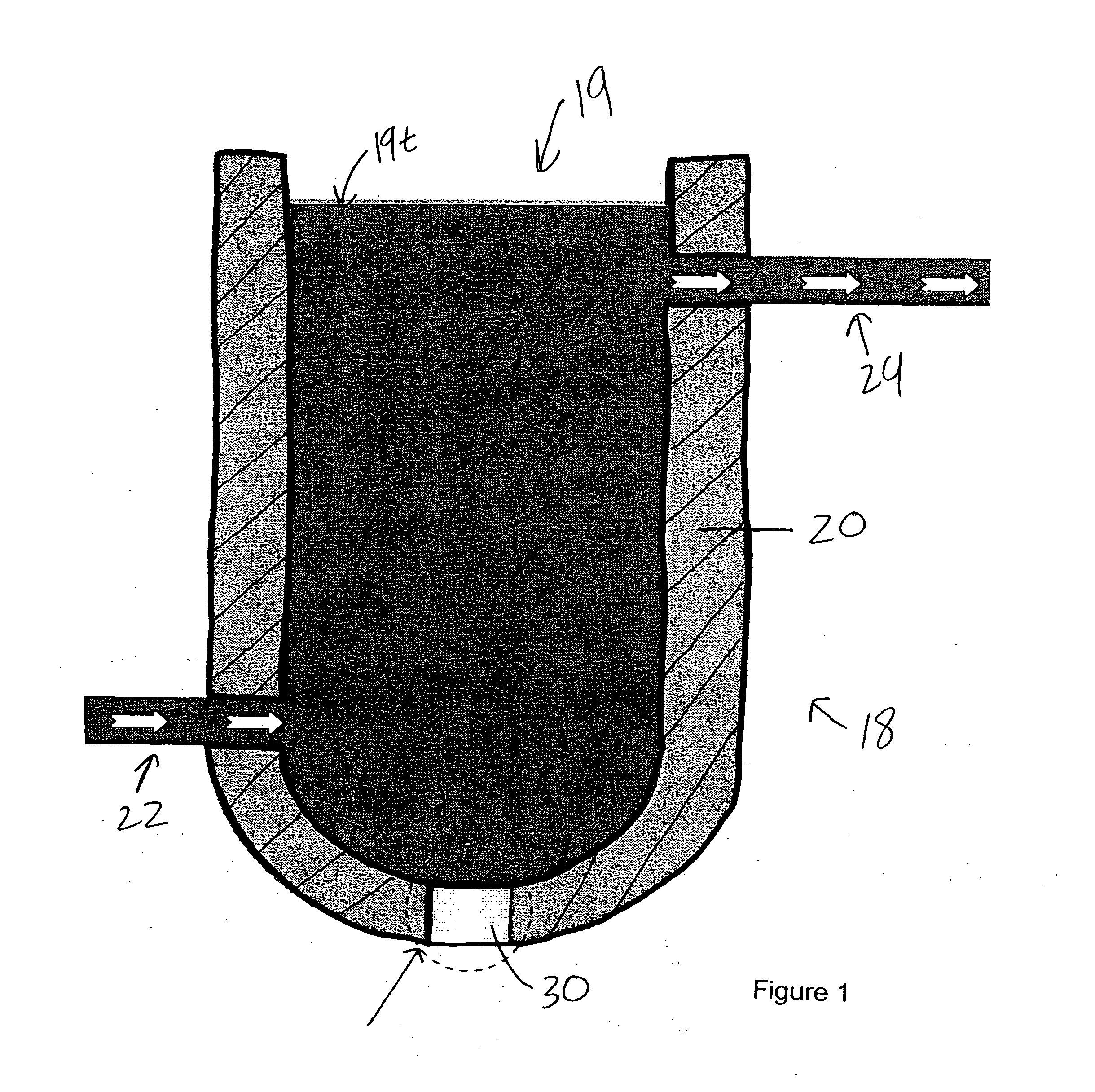

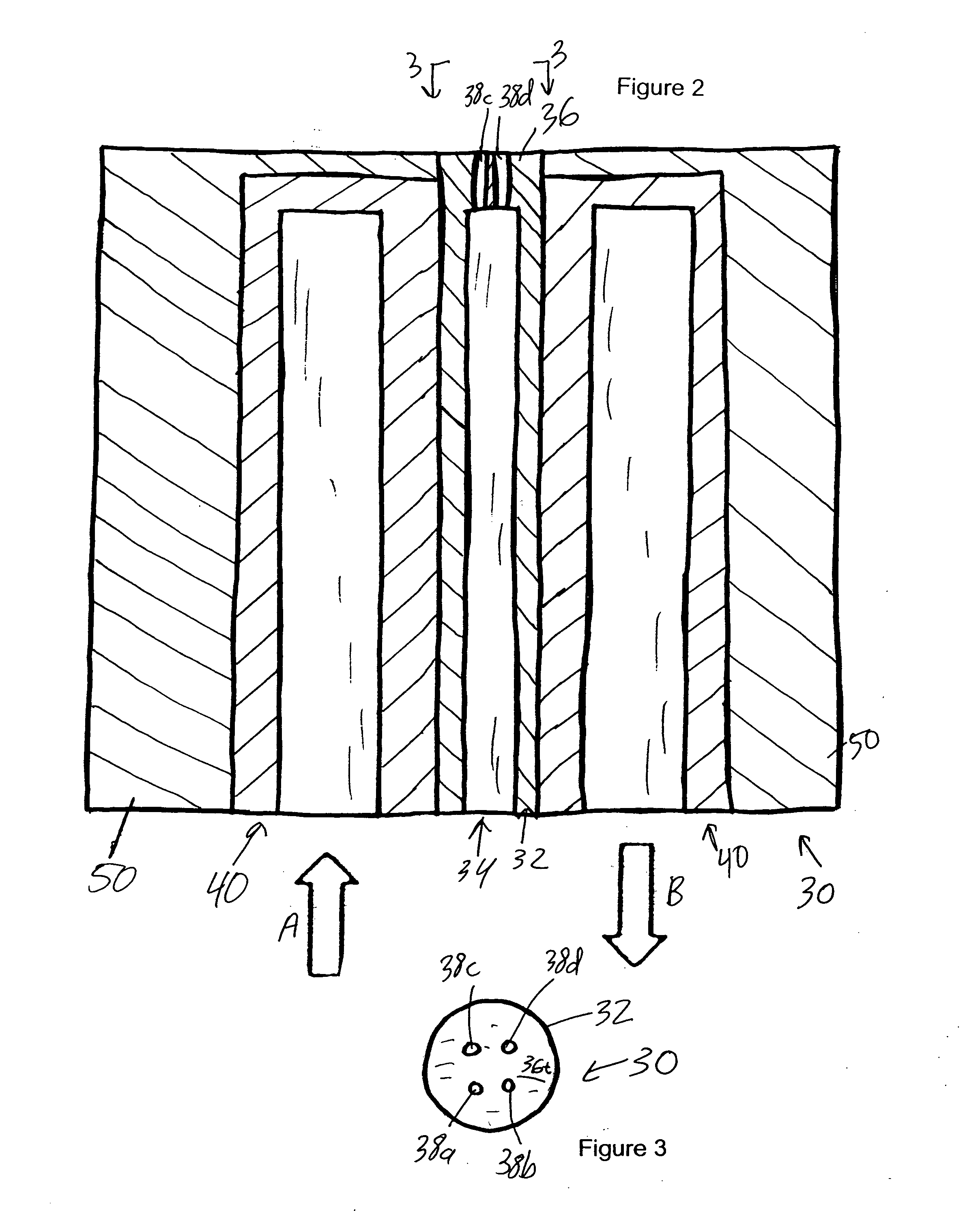

An apparatus and method are disclosed in which ultrasonic vibration is used to assist the degassing of molten metals or metal alloys thereby reducing gas content in the molten metals or alloys. High-intensity ultrasonic vibration is applied to a radiator that creates cavitation bubbles, induces acoustic streaming in the melt, and breaks up purge gas (e.g., argon or nitrogen) which is intentionally introduced in a small amount into the melt in order to collect the cavitation bubbles and to make the cavitation bubbles survive in the melt. The molten metal or alloy in one version of the invention is an aluminum alloy. The ultrasonic vibrations create cavitation bubbles and break up the large purge gas bubbles into small bubbles and disperse the bubbles in the molten metal or alloy more uniformly, resulting in a fast and clean degassing.

Owner:UNIV OF TENNESSEE RES FOUND +1

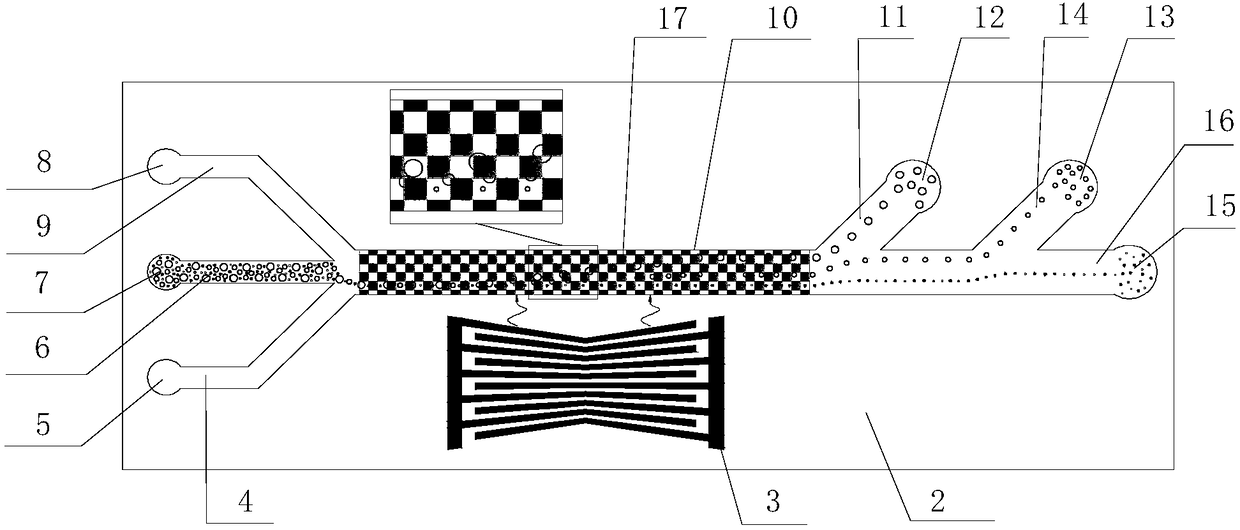

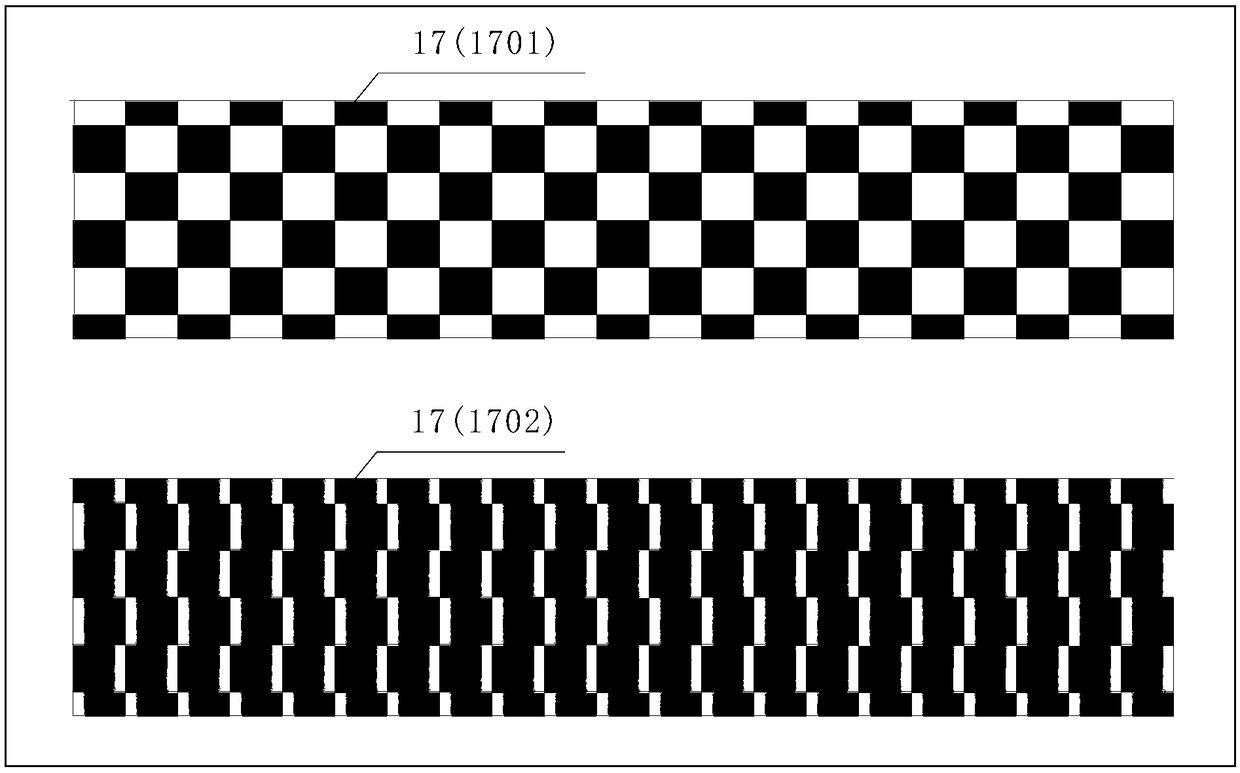

Microfluidic chip and cell screening method for screening specific cells

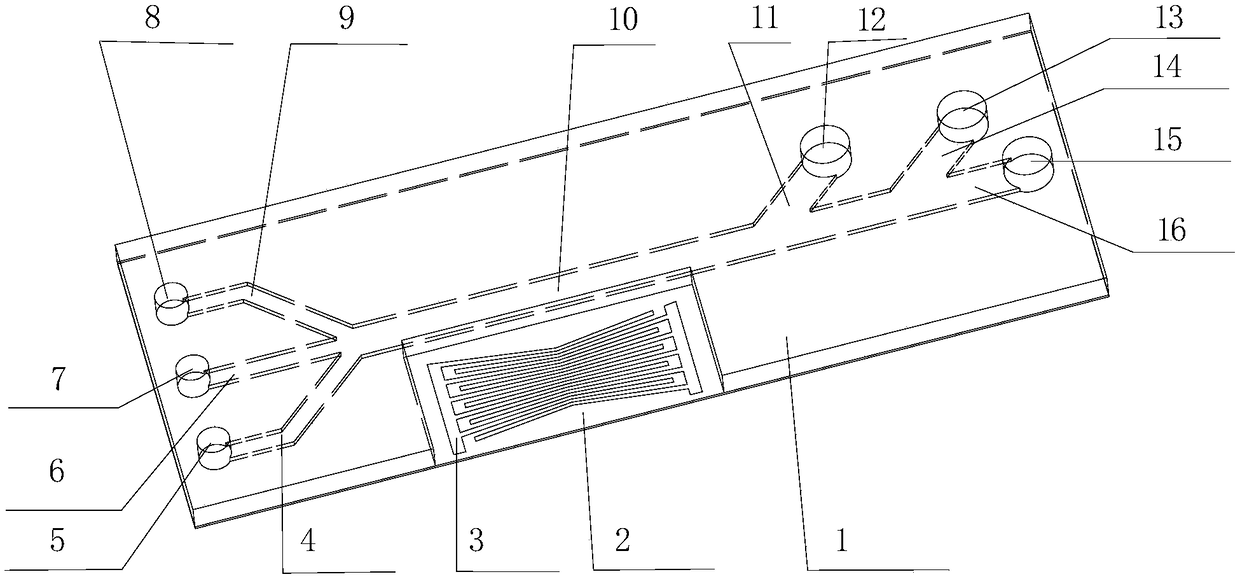

ActiveCN104195028ATo achieve the purpose of screening specificityCell dissociation methodsBioreactor/fermenter combinationsScreening methodAcoustic wave

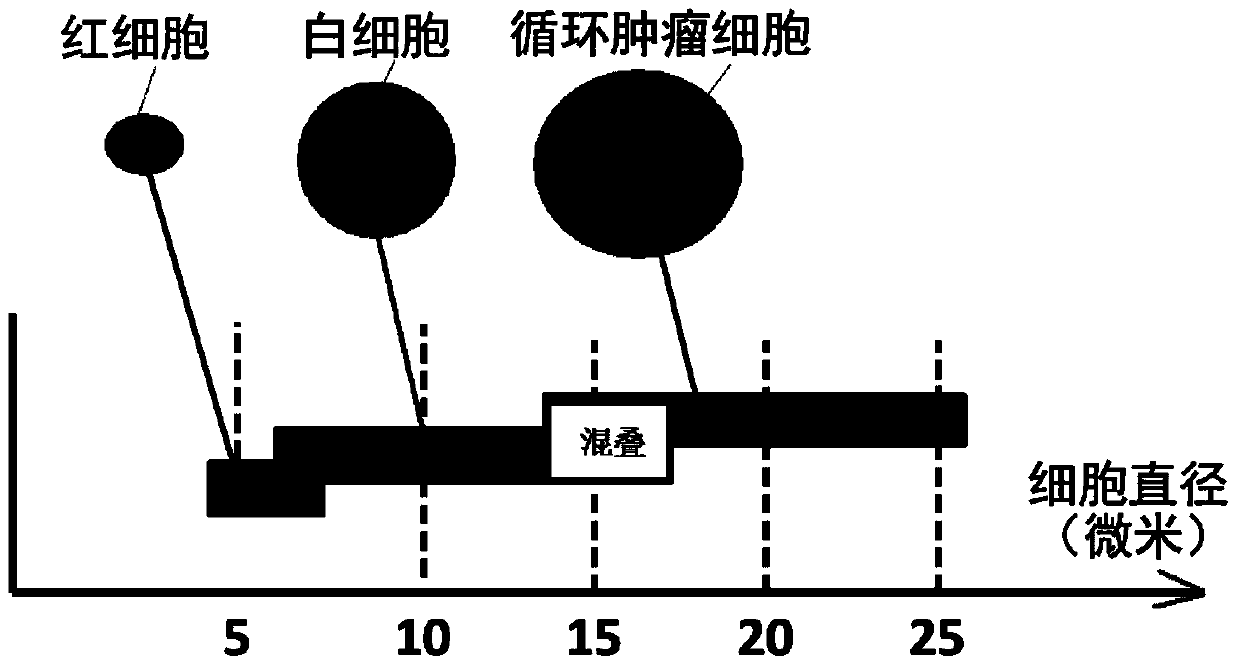

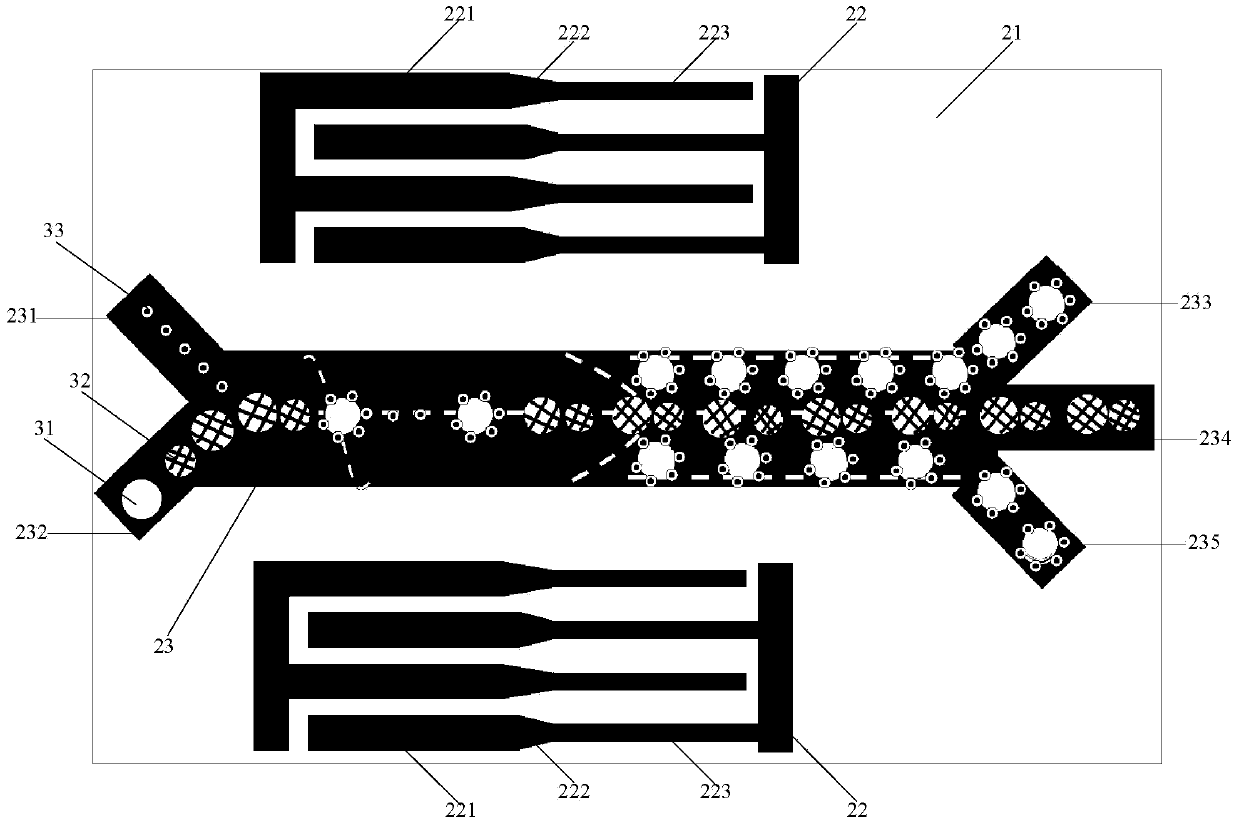

The invention discloses a microfluidic chip and a cell screening method for screening specific cells. The chip comprises a substrate, a cavity and an acoustic excitation source, wherein the cavity comprises a middle channel, an inlet and an outlet; the acoustic excitation source is positioned on the substrate and at two sides of the middle channel and comprises two parts which extend to a direction of the outlet along the middle channel, wherein the corresponding acoustic resonance frequency of the second part close to the outlet is integer multiples of the corresponding acoustic resonance frequency of the first part far away from the outlet. Based on an acoustic streaming effect formed by targeted microbubbles and asymmetric sound fields, the microbubbles are adhered to the surfaces of the specific cells, so that the enriched cells which flow past the first part can still move in a straight line and cannot diffuse due to a laminar flow characteristic of microfluidics, and the specific cells bonded with the targeted microbubbles can shift because the acoustic resonance frequency of the second part is different from that of the first part. Thus, the screening of the specificity of the specific cells in blood is realized.

Owner:广州康臣药业有限公司

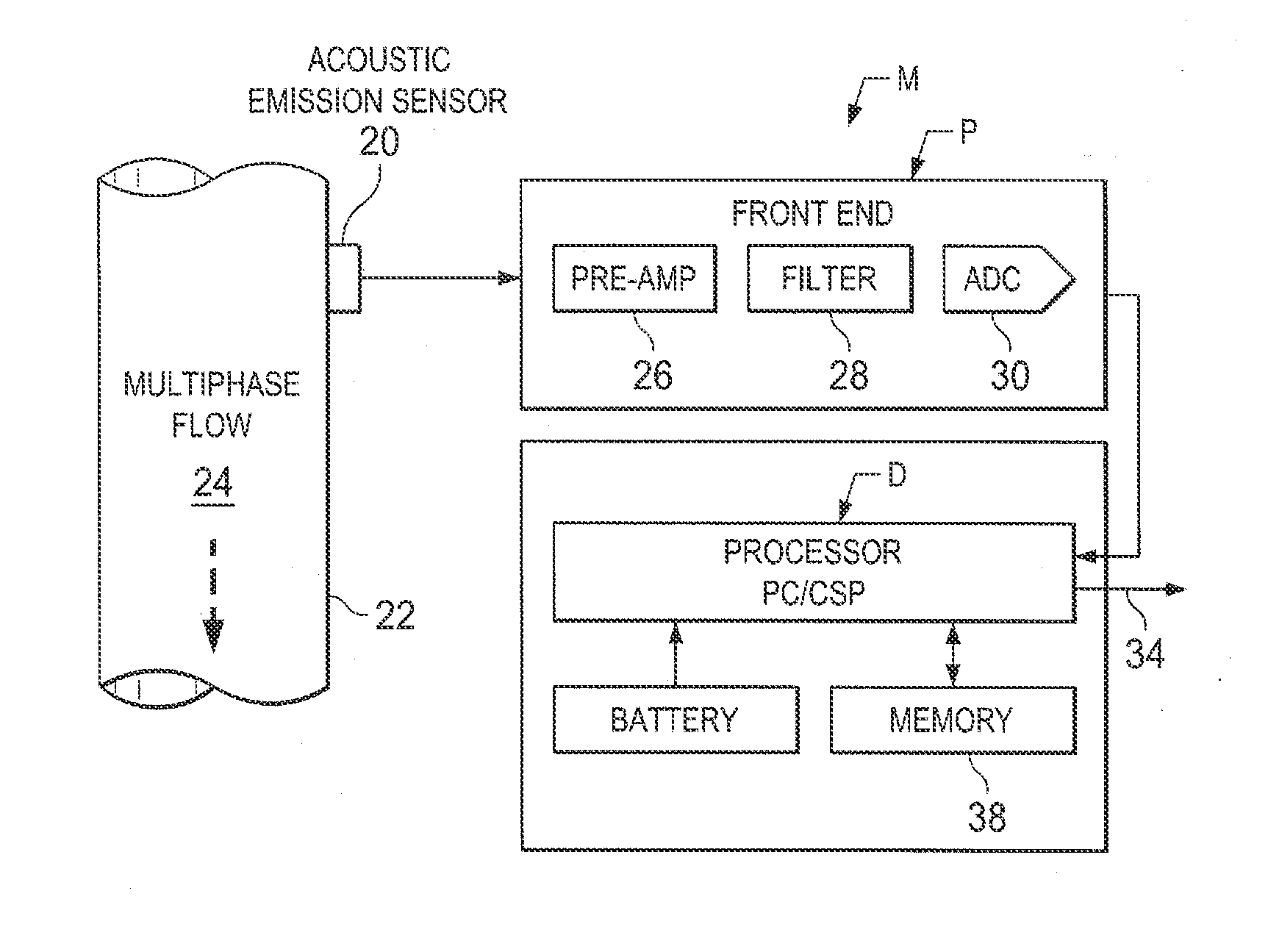

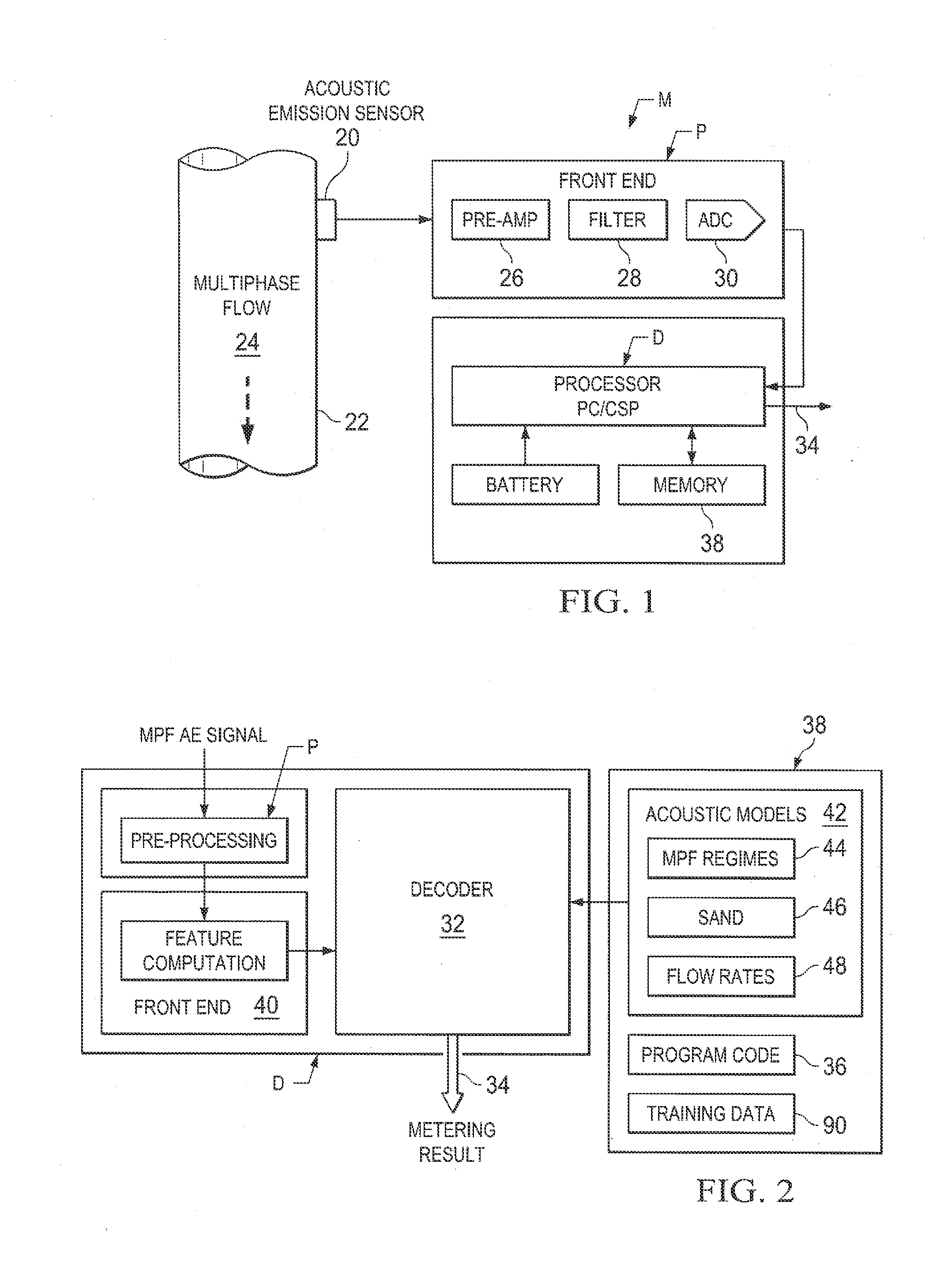

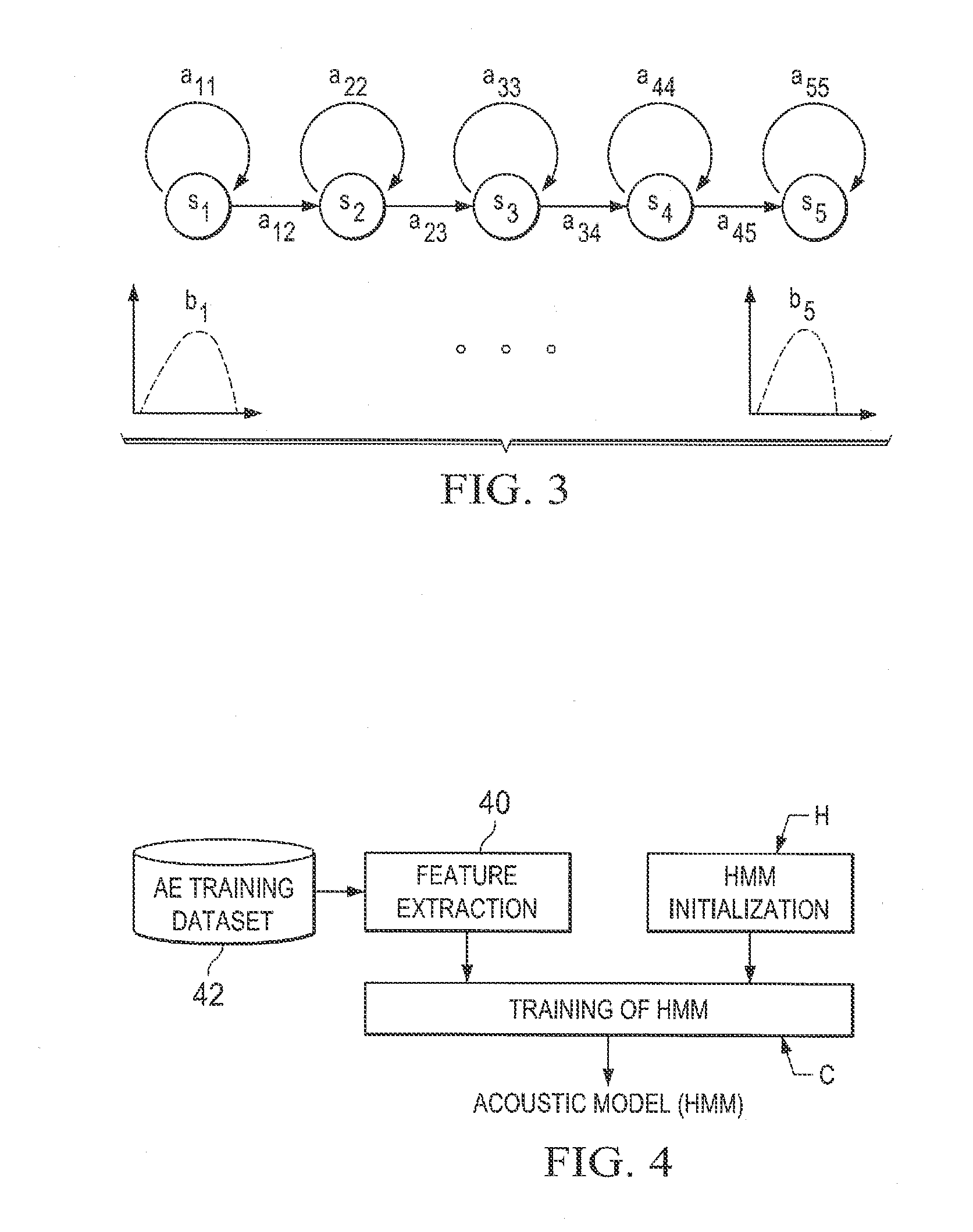

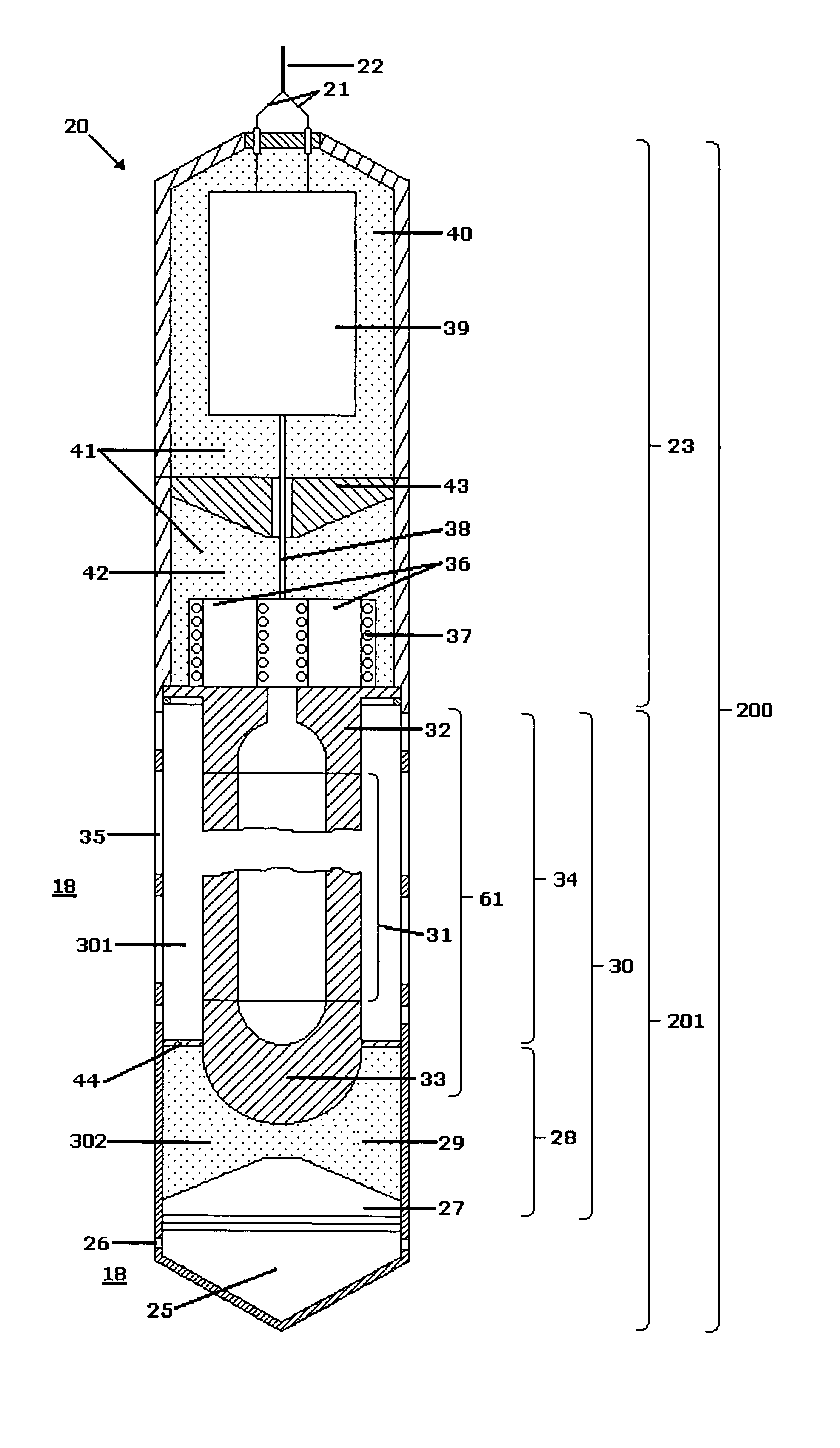

Virtual multiphase flow metering and sand detection

InactiveUS20150377667A1ConstructionsMaterial analysis using acoustic emission techniquesHide markov modelAcoustic emission

Virtual and non-invasive multiphase metering is performed for recognition of multiphase flow regimes of hydrocarbons and other fluids, flow rate, presence of sand, and other multiphase flow parameters. A passive acoustical detector system receives acoustical flow information in the form of acoustic emission signals, and a data processor processes and classifies the acoustical patterns. A statistical signal processing methodology is used. Acoustic models are provided for various flow regimes and flow patterns, using Artificial Intelligence methods including Hidden Markov Models and Artificial Neural Networks along with automated learning procedures. The metering can be used for downhole, top side and surface applications.

Owner:SAUDI ARABIAN OIL CO

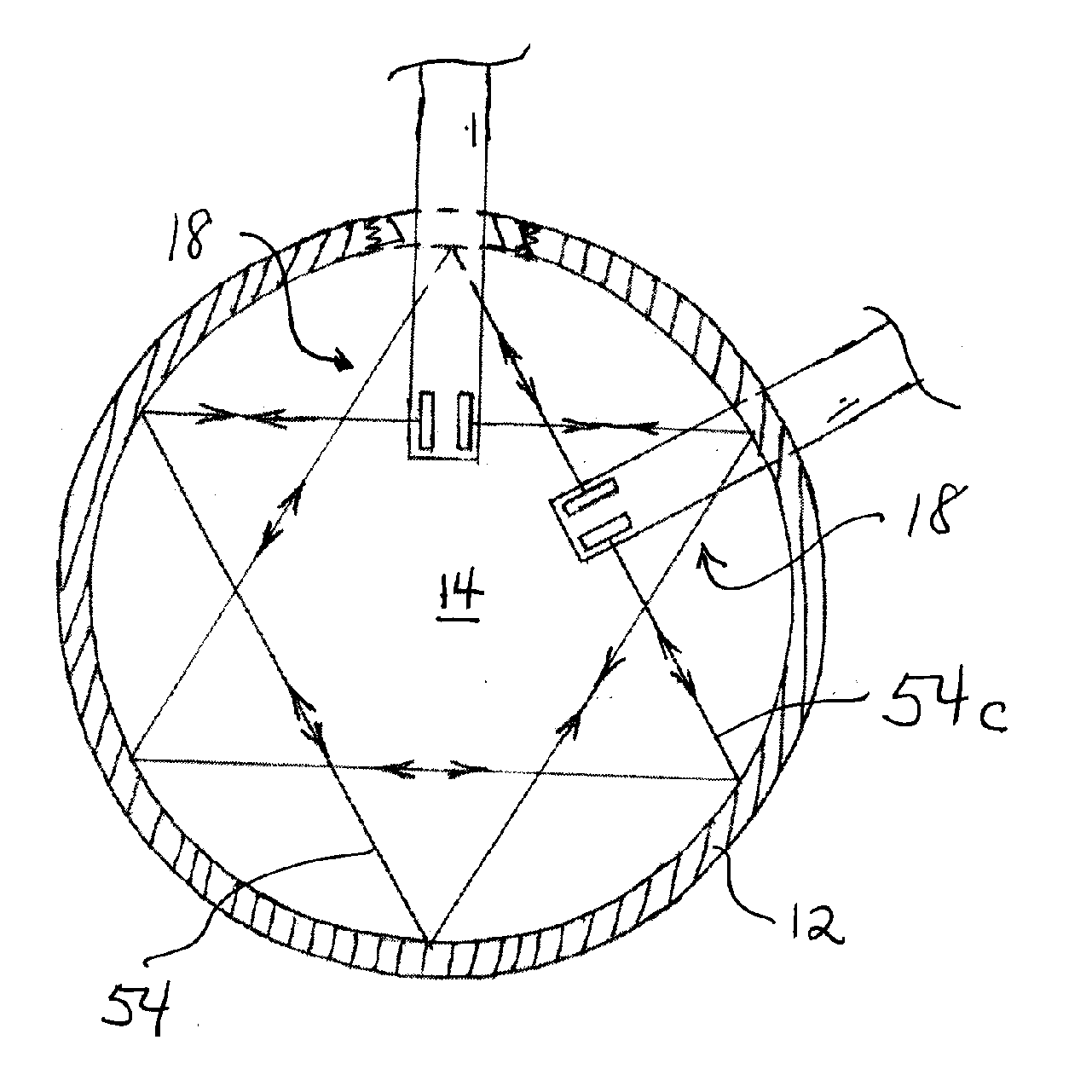

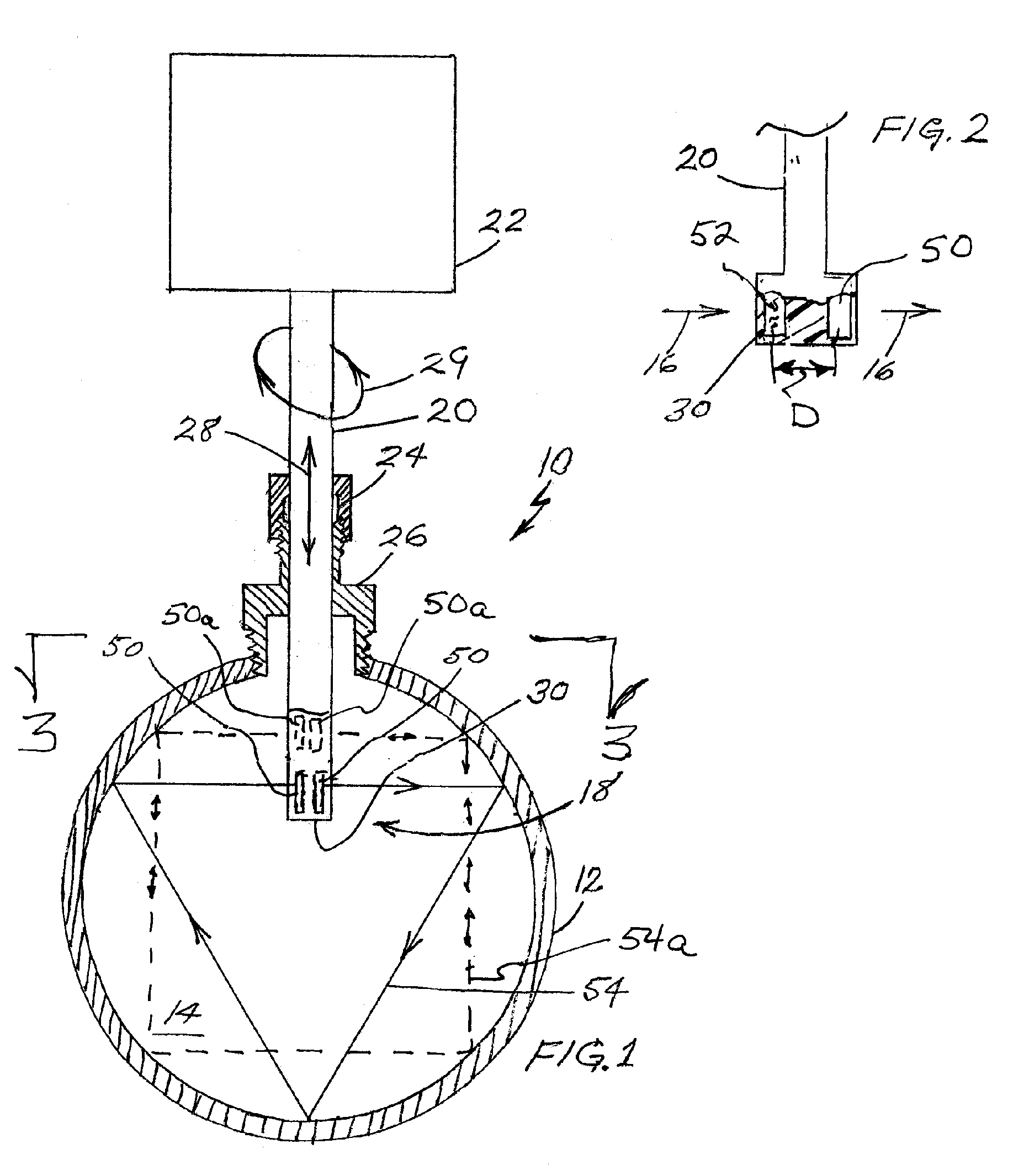

Degassing of molten alloys with the assistance of ultrasonic vibration

InactiveUS7682556B2Reduce gas contentReduce heat transferMelt-holding vesselsLiquid degasificationNitrogen gasCavitation bubble

An apparatus and method are disclosed in which ultrasonic vibration is used to assist the degassing of molten metals or metal alloys thereby reducing gas content in the molten metals or alloys. High-intensity ultrasonic vibration is applied to a radiator that creates cavitation bubbles, induces acoustic streaming in the melt, and breaks up purge gas (e.g., argon or nitrogen) which is intentionally introduced in a small amount into the melt in order to collect the cavitation bubbles and to make the cavitation bubbles survive in the melt. The molten metal or alloy in one version of the invention is an aluminum alloy. The ultrasonic vibrations create cavitation bubbles and break up the large purge gas bubbles into small bubbles and disperse the bubbles in the molten metal or alloy more uniformly, resulting in a fast and clean degassing.

Owner:UNIV OF TENNESSEE RES FOUND +1

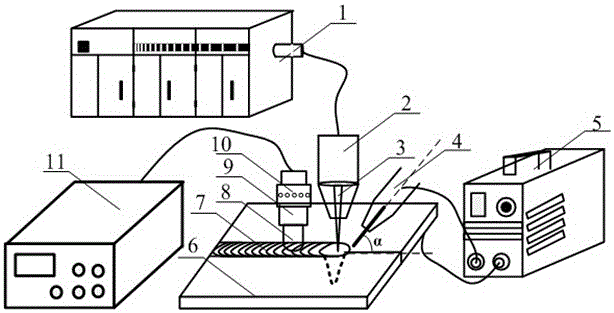

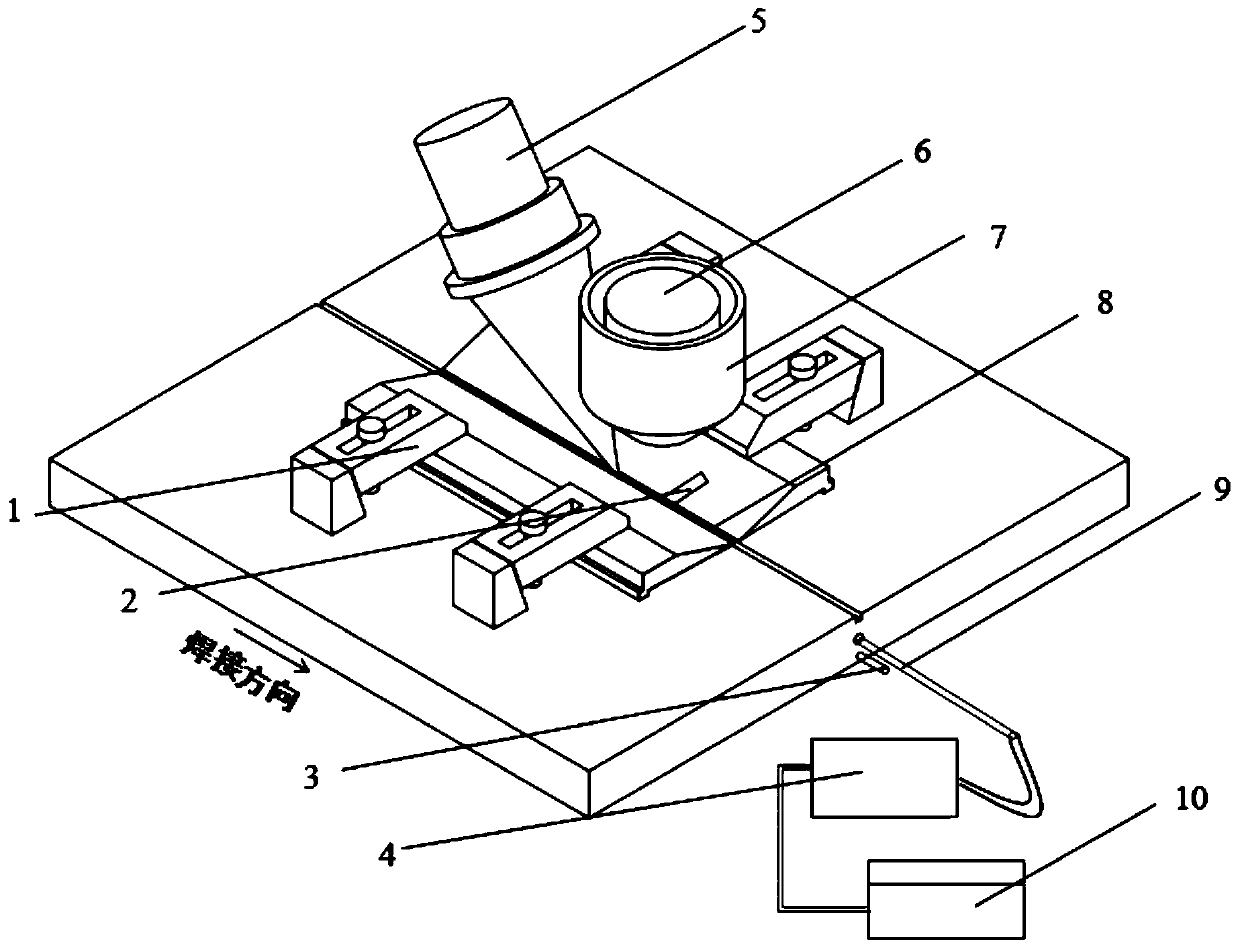

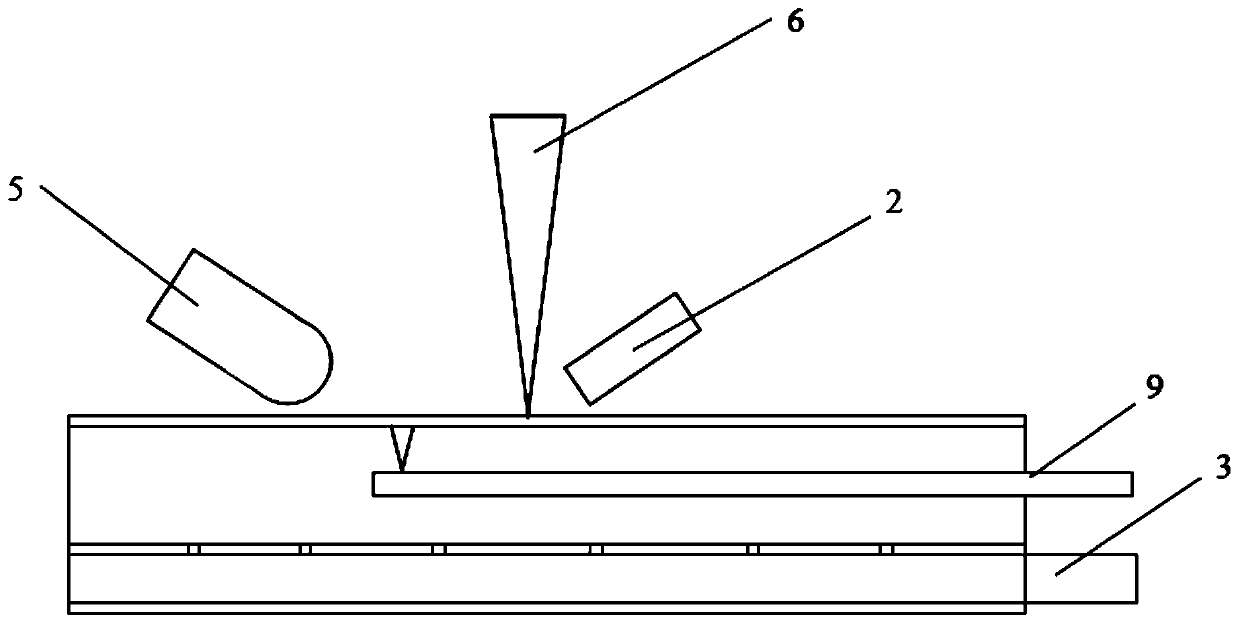

Ultrasonic assistec laser electric arc composite welding method of aluminum alloy

InactiveCN105710537AEfficient weldingPromote escapeWelding/soldering/cutting articlesLaser beam welding apparatusCavitationWelding residual stress

The invention relates to an ultrasonic assisted laser electric arc composite welding method of an aluminum alloy. On the basis of carrying out a welding scheme by combining TIG electric arc welding and laser welding, ultrasonic vibration pressure is introduced into a welding seam, wherein a designed vibration head is in direct contact with the welding seam, so that ultrasonic resources can be more sufficiently utilized, and gas in the welding seam can be rapidly escaped; most of gas in the welding seam is removed so that welding seam gas pore defects are reduced or avoided; tissue crystal grains of the welding seam are remarkably refined by utilizing cavitation effect and acoustic streaming effect caused by the fact that ultrasonic waves are transmitted in liquid, and furthermore, tissue alloy elements of the welding seam are more uniform, segregation is reduced, the strength and corrosion resistance performance of the welding seam are improved, and the performance of a welding connector is improved; and welding residual stress is effectively eliminated or reduced and the strength and corrosion resistance performance of the connector are enhanced, so that the efficient welding of the aluminum alloy is realized.

Owner:北京隆源自动成型系统有限公司

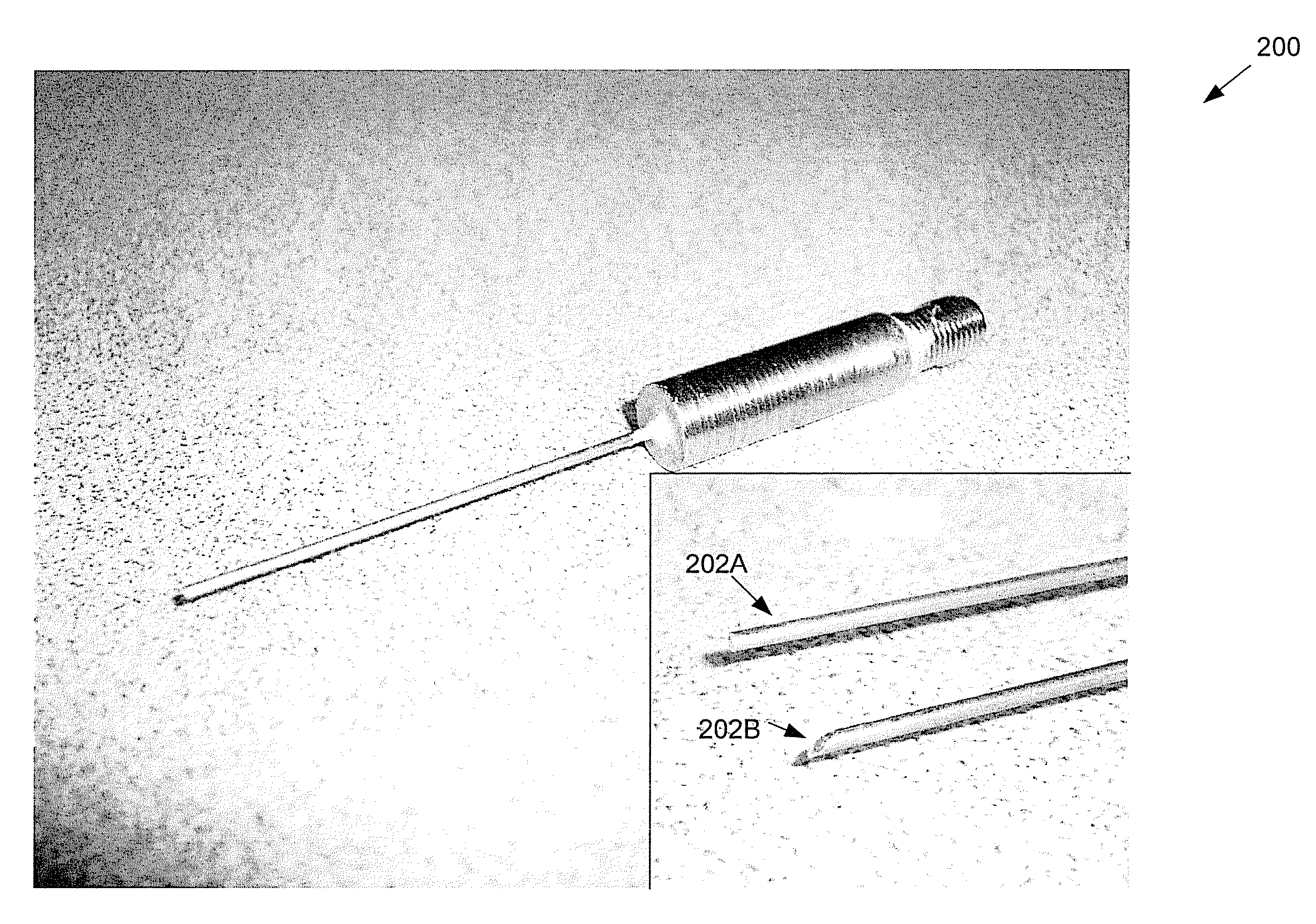

Thrombolysis In Retinal Vessels With Ultrasound

InactiveUS20080262512A1Reduce riskHigh resolutionImage enhancementLaser surgeryVenous occlusionBlood vessel

Systems and methods are described providing for the use of ultrasound energy to effect the dislodging of one or more blood clots inside blood vessels. Such clots can include those inside retinal vessels, especially in patients with central retinal vein occlusion. Embodiments of the present disclosure may be used for any retinal arterial or venous occlusion. In exemplary embodiments, a small probe can be inserted into the eye of a patient and placed over the retinal vessels. Acoustic streaming created by the probe can be directed to an area or region including targeted blood vessels, resulting in increased flow in one or more retinal veins and facilitating or effecting mechanical dislodging of one or more blood clots in the targets blood vessels. Exemplary embodiments can utilize ultrasonic energy produced at a frequency of approximately 44 MHz to 46 MHz with pulse repetition frequencies of approximately 100 Hz to 100 kHz.

Owner:DOHENY EYE INST

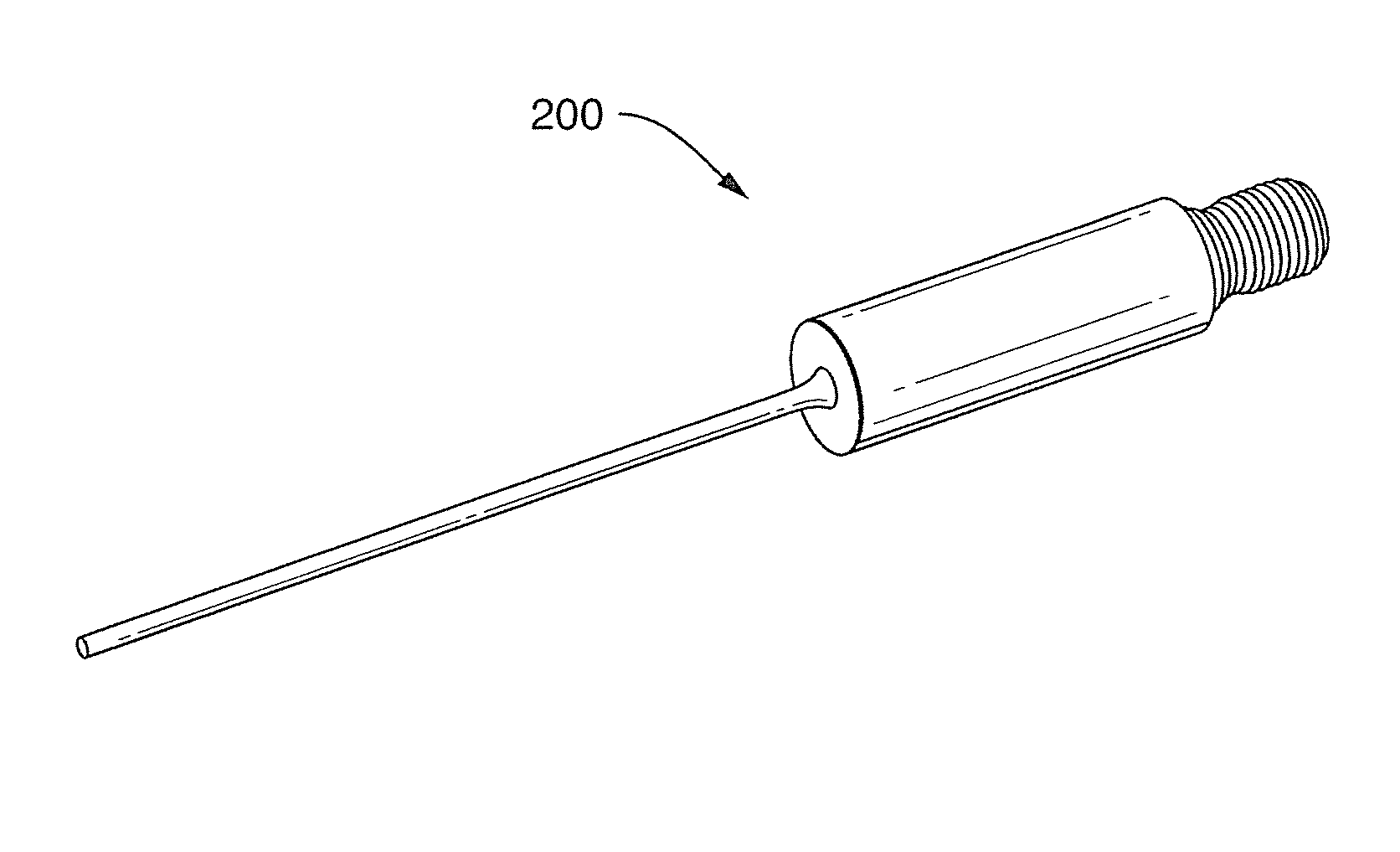

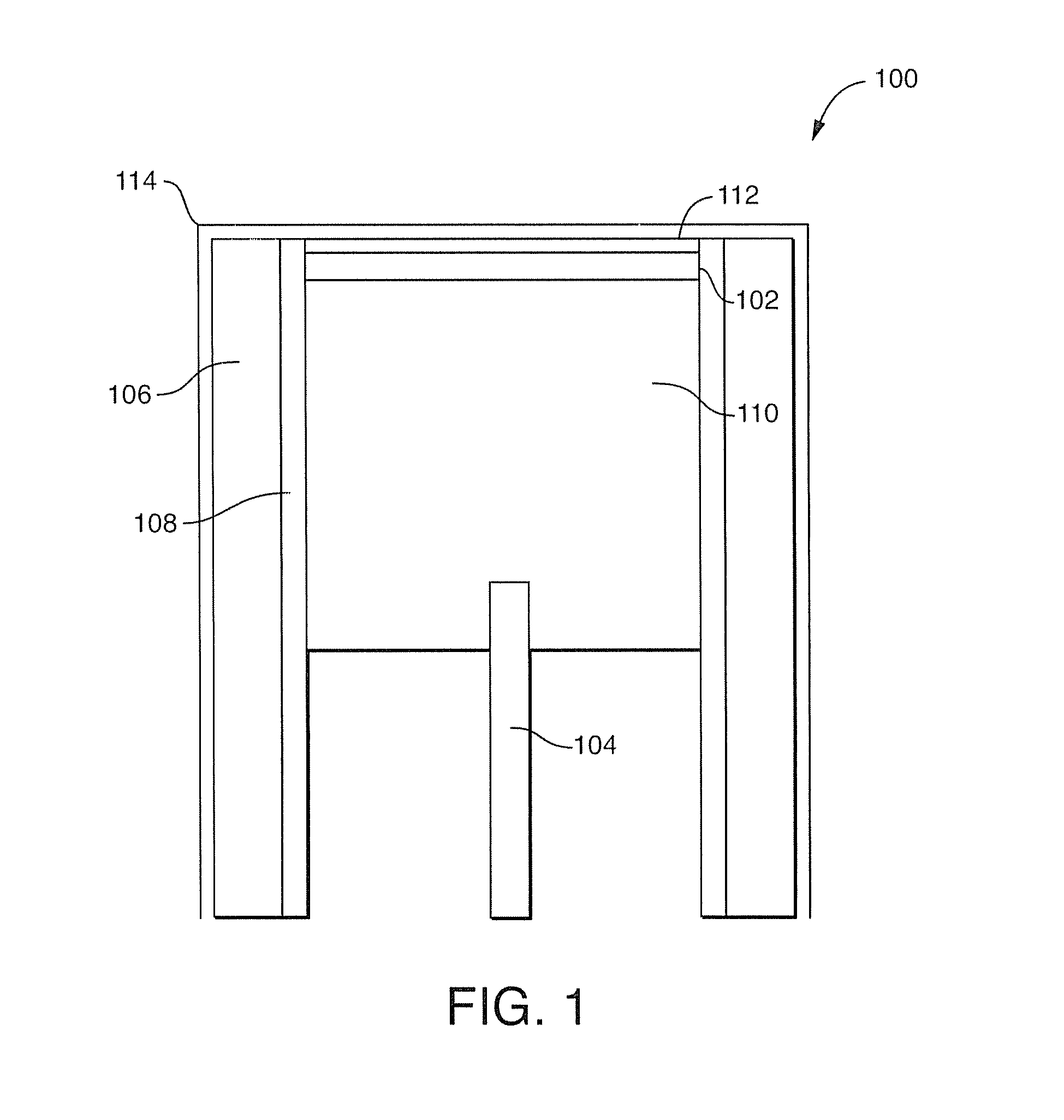

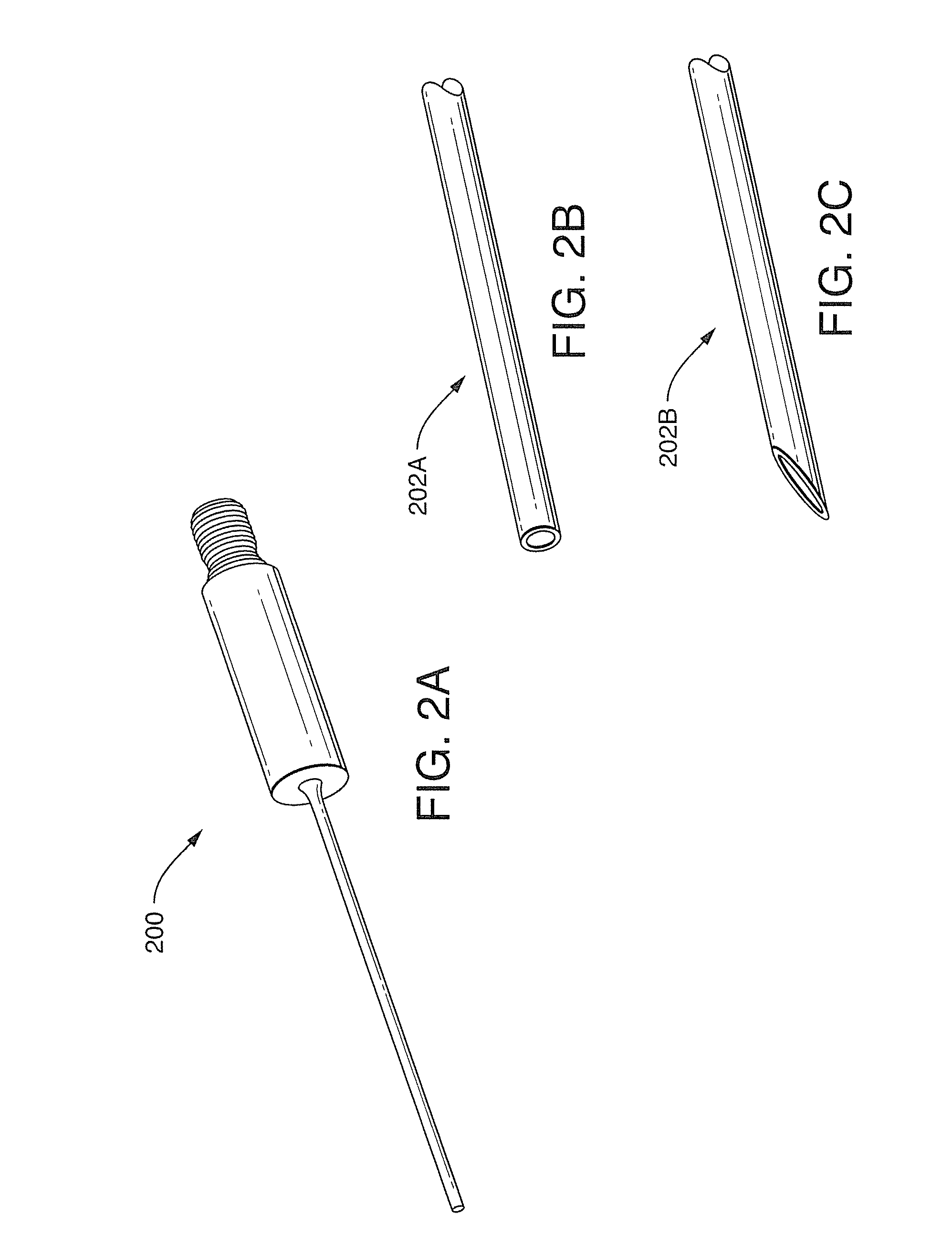

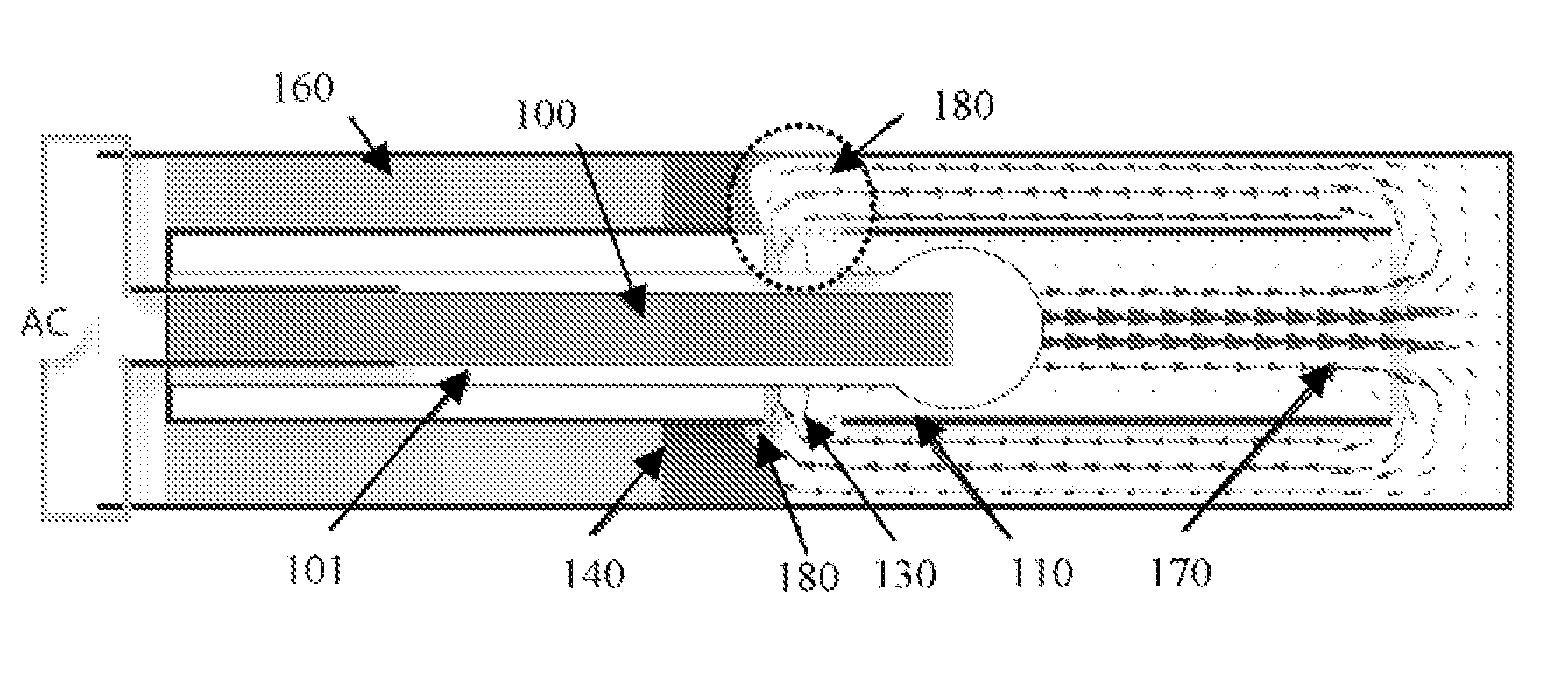

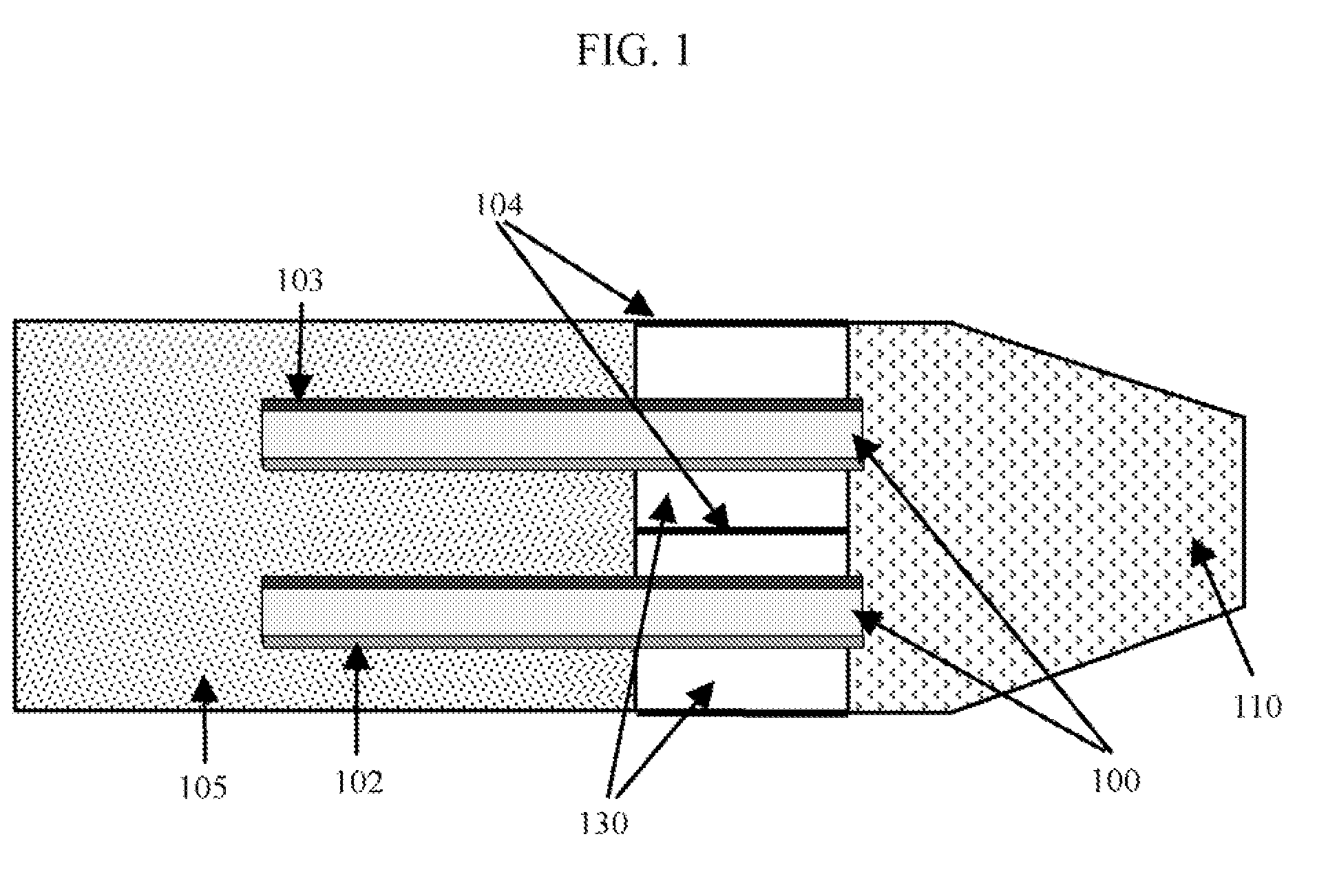

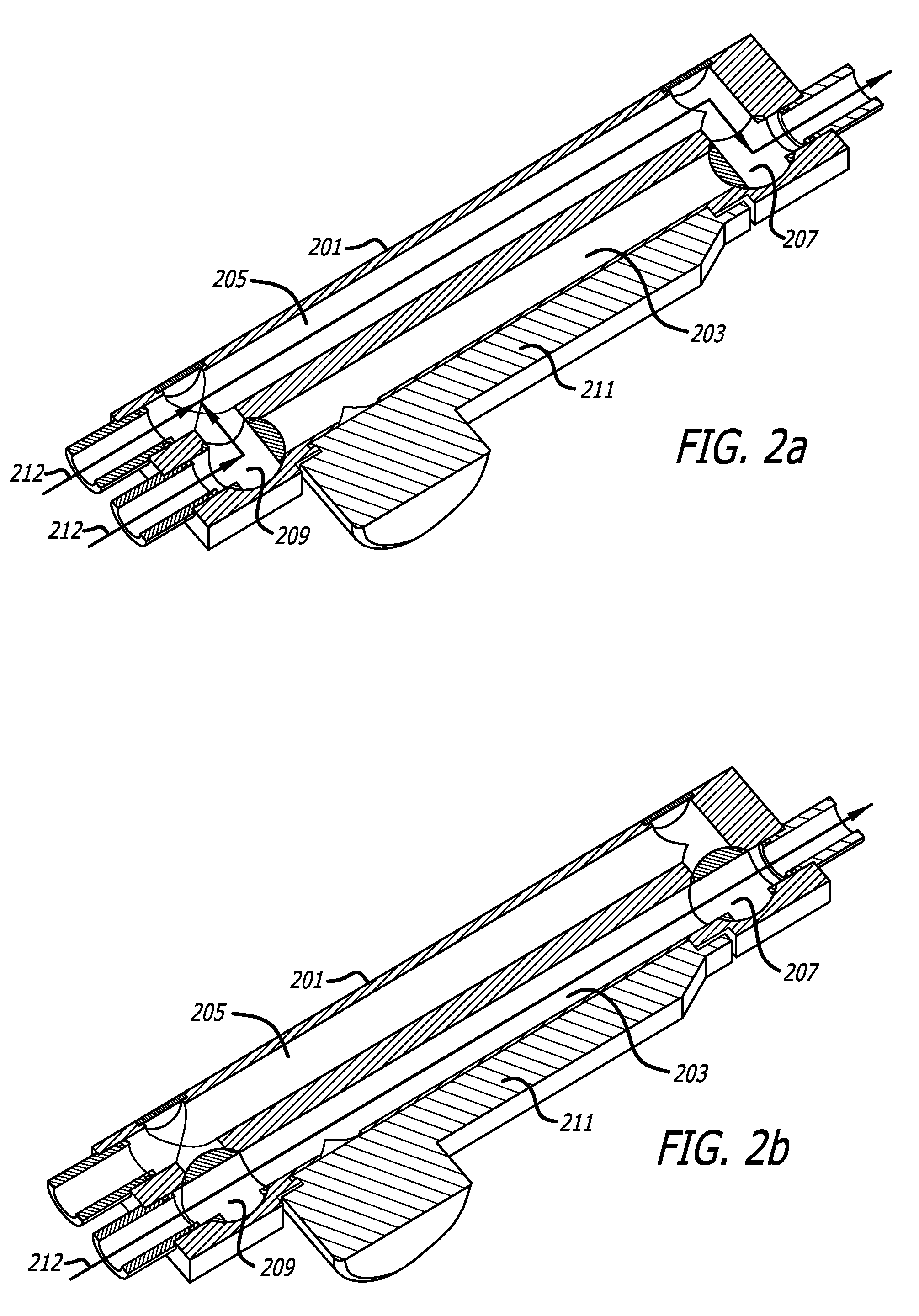

Thrombectomy microcatheter

The present invention is an ultrasonic thrombectomy catheter that produces physical forces (shear rates) strong enough to emulsify obstructions such as thrombi and emboli without causing damage to arterial walls. This is accomplished by properly arranging piezoelectric transducers within a catheter and a tubular catheter head separated by a gap to generate acoustic streaming that simultaneously emulsifies the obstruction and sweeps resulting debris into a catheter lumen for removal. The open gap may be formed by supporting struts that connect the catheter to the catheter head. The design of the catheter tip allows the fabrication of catheters capable of removing partial or complete blockages from arteries and other vessels having diameters as small as 2 mm.

Owner:CFD RES CORP

Thrombolysis in retinal vessels with ultrasound

InactiveUS20140243712A1Reduce riskHigh resolutionUltrasound therapyEye surgeryVenous occlusionBlood vessel

Systems and methods are described providing for the use of ultrasound energy to effect the dislodging of one or more blood clots inside blood vessels. Such clots can include those inside retinal vessels, especially in patients with central retinal vein occlusion. Embodiments of the present disclosure may be used for any retinal arterial or venous occlusion. In exemplary embodiments, a small probe can be inserted into the eye of a patient and placed over the retinal vessels. Acoustic streaming created by the probe can be directed to an area or region including targeted blood vessels, resulting in increased flow in one or more retinal veins and facilitating or effecting mechanical dislodging of one or more blood clots in the targets blood vessels. Exemplary embodiments can utilize ultrasonic energy produced at a frequency of approximately 44 MHz to 46 MHz with pulse repetition frequencies of approximately 100 Hz to 100 kHz.

Owner:DOHENY EYE INST

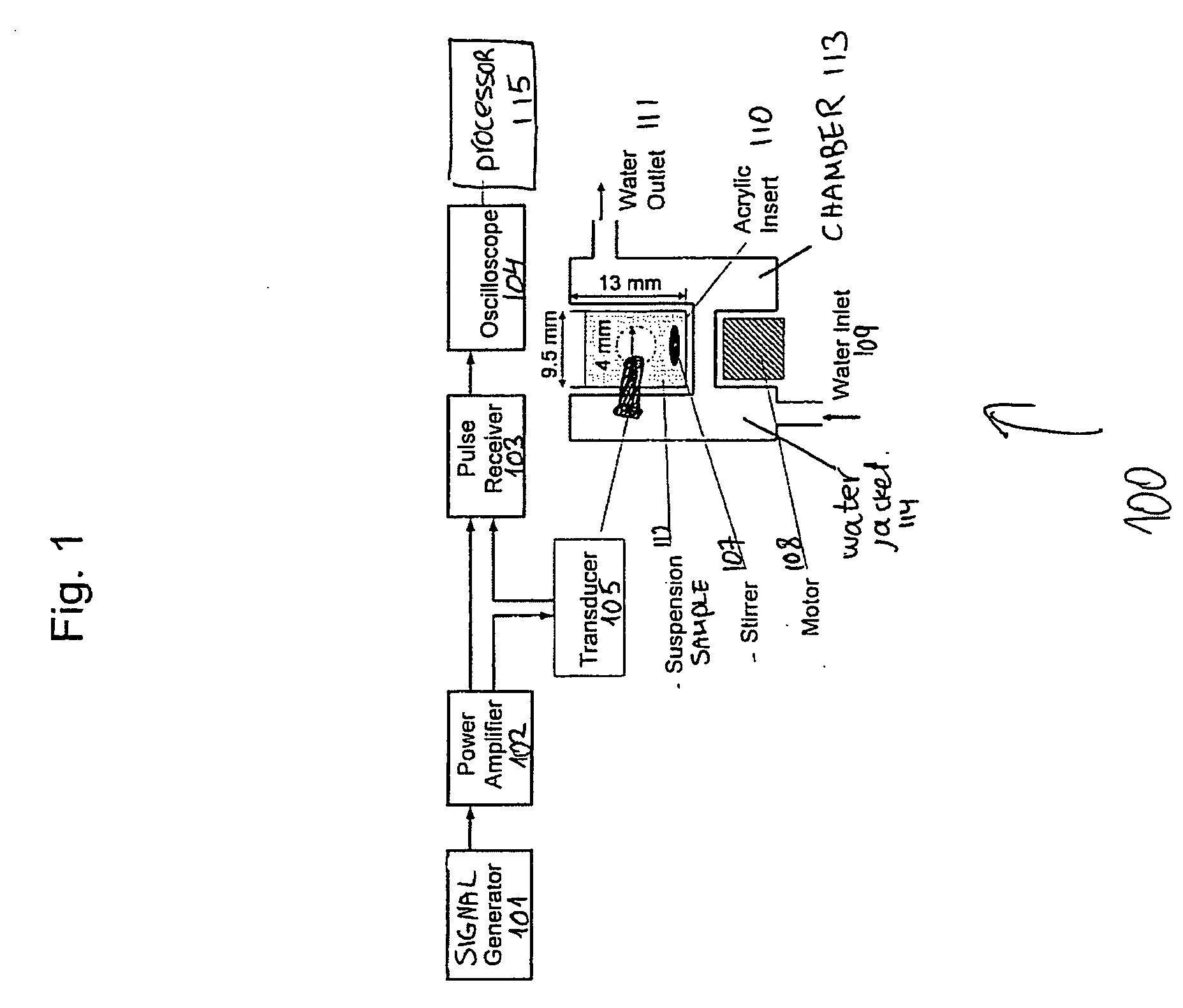

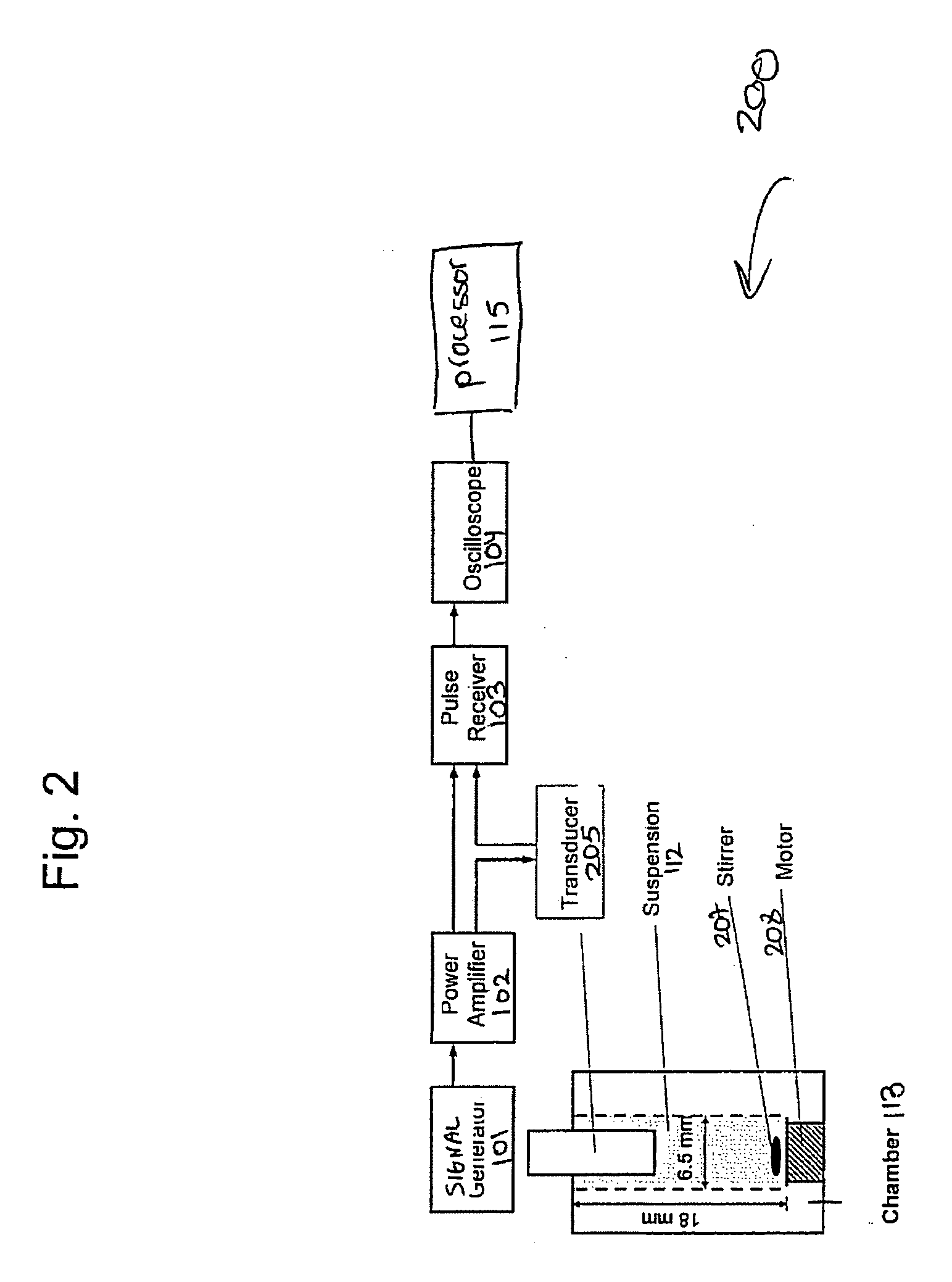

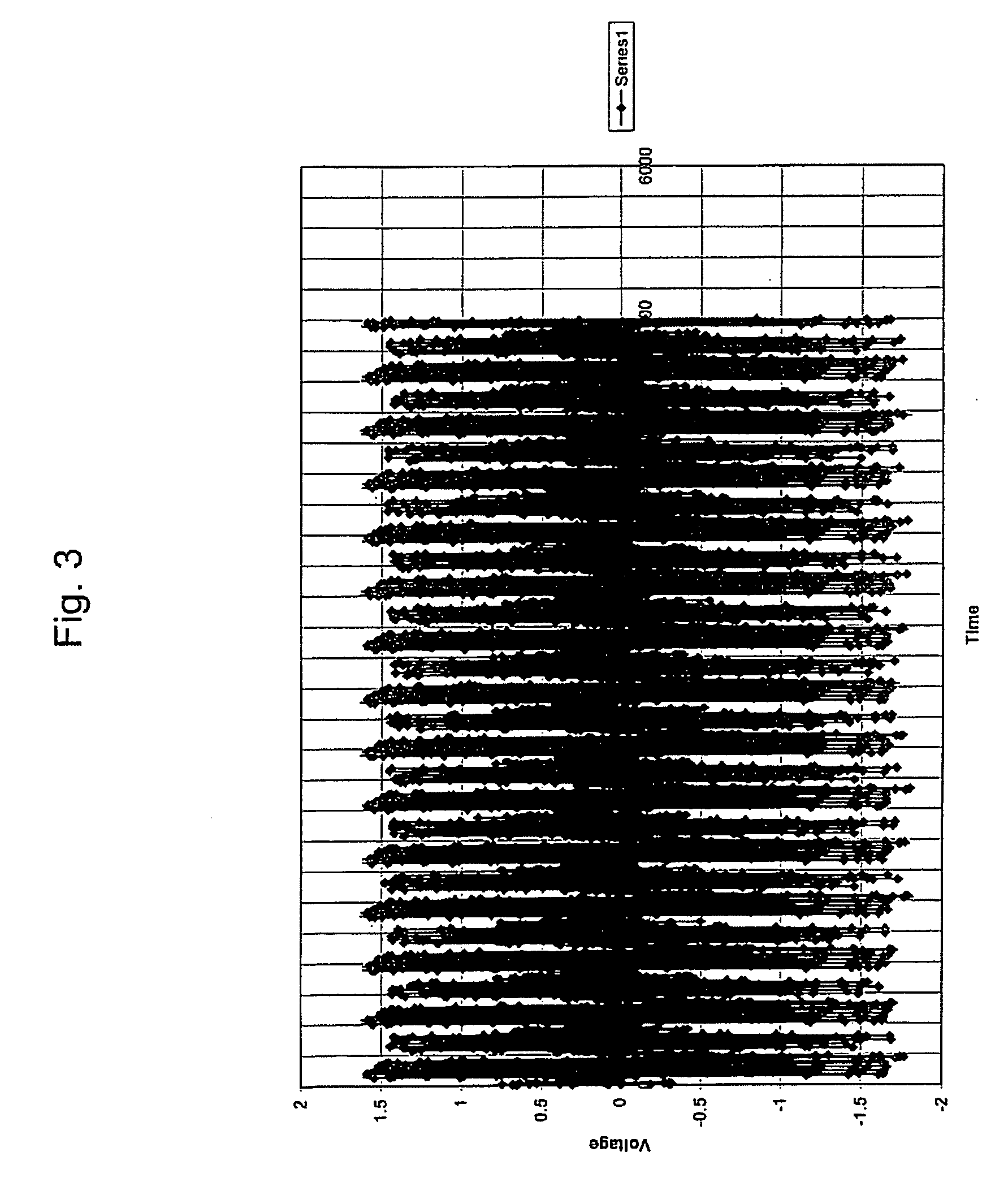

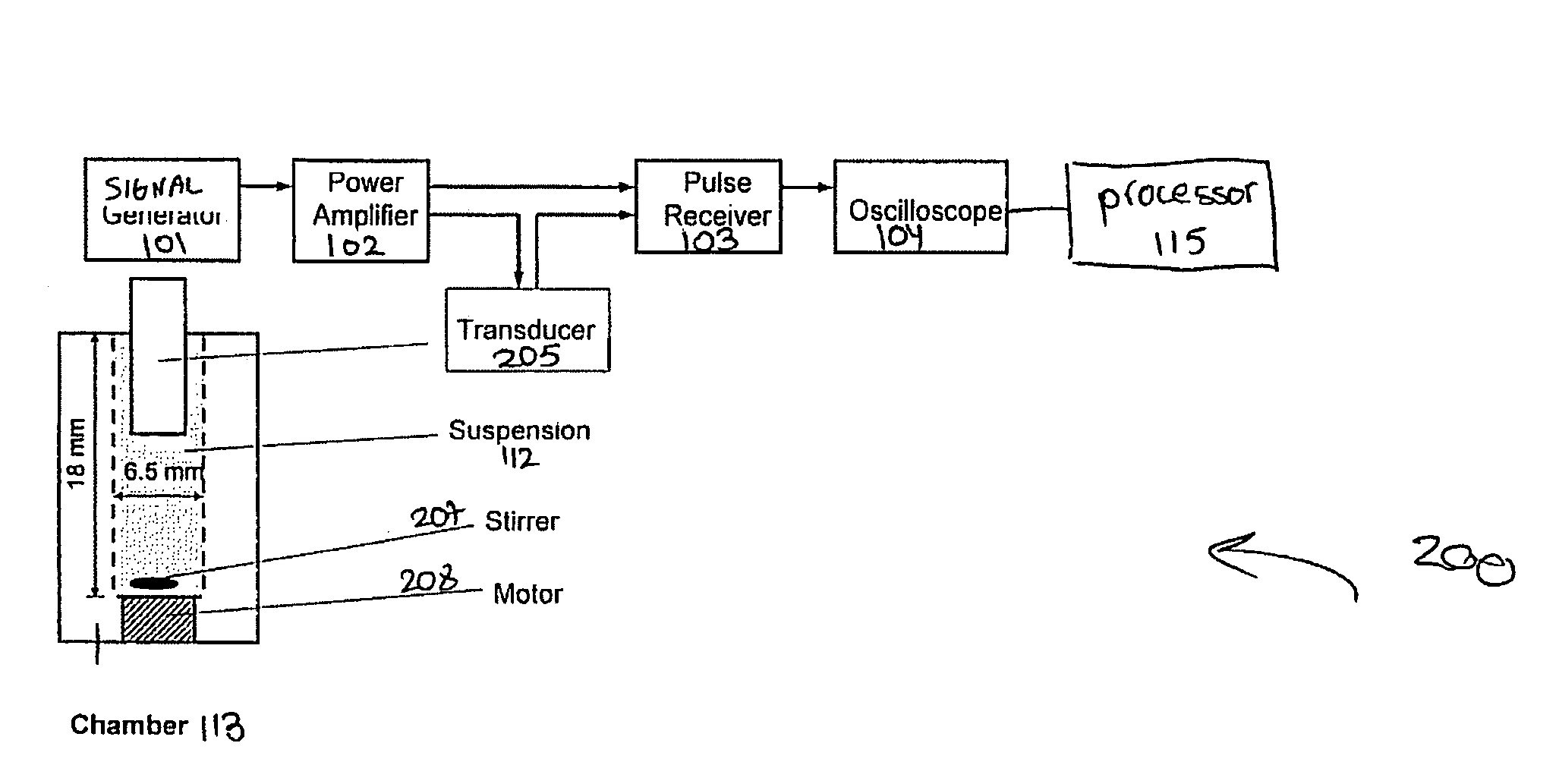

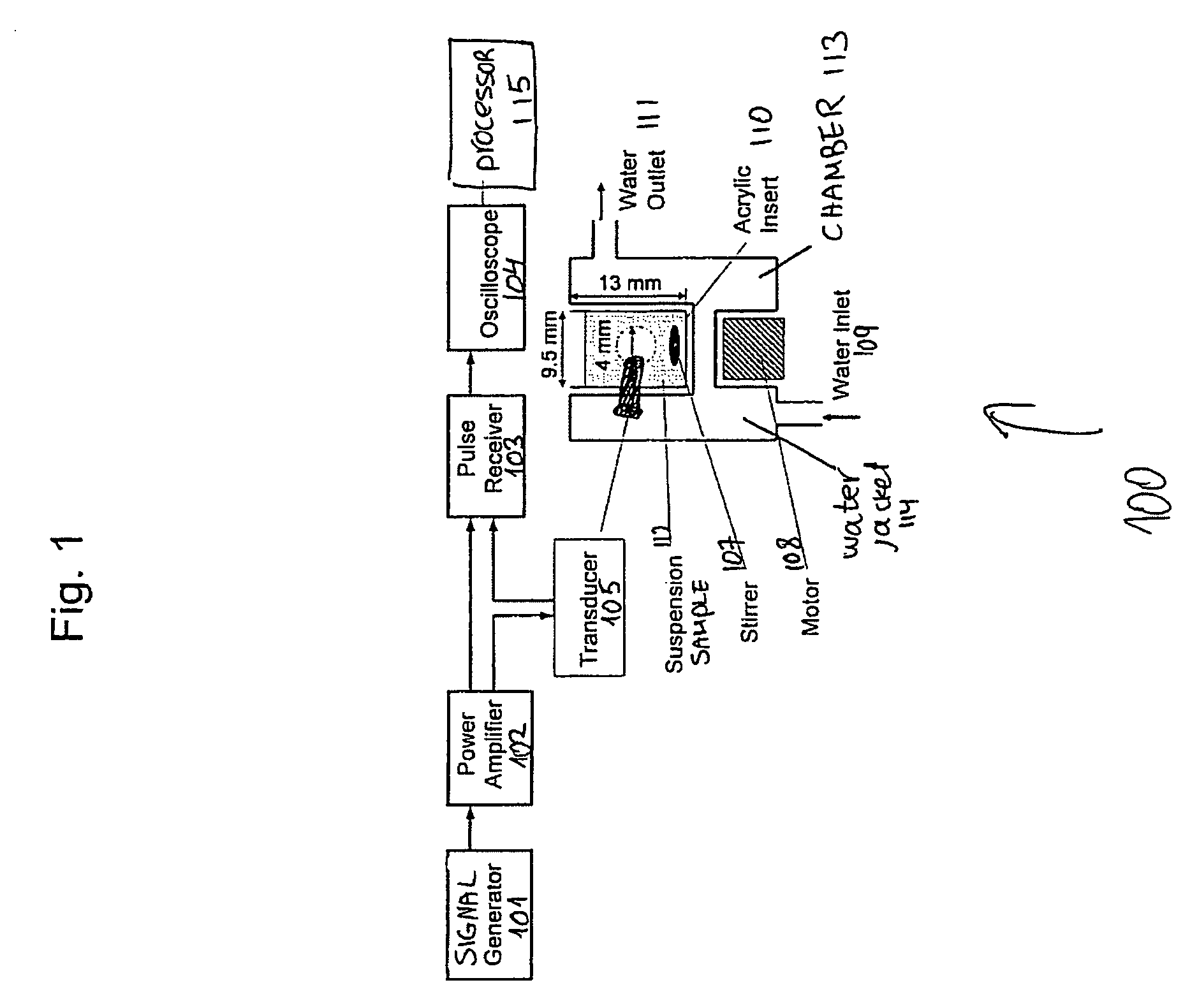

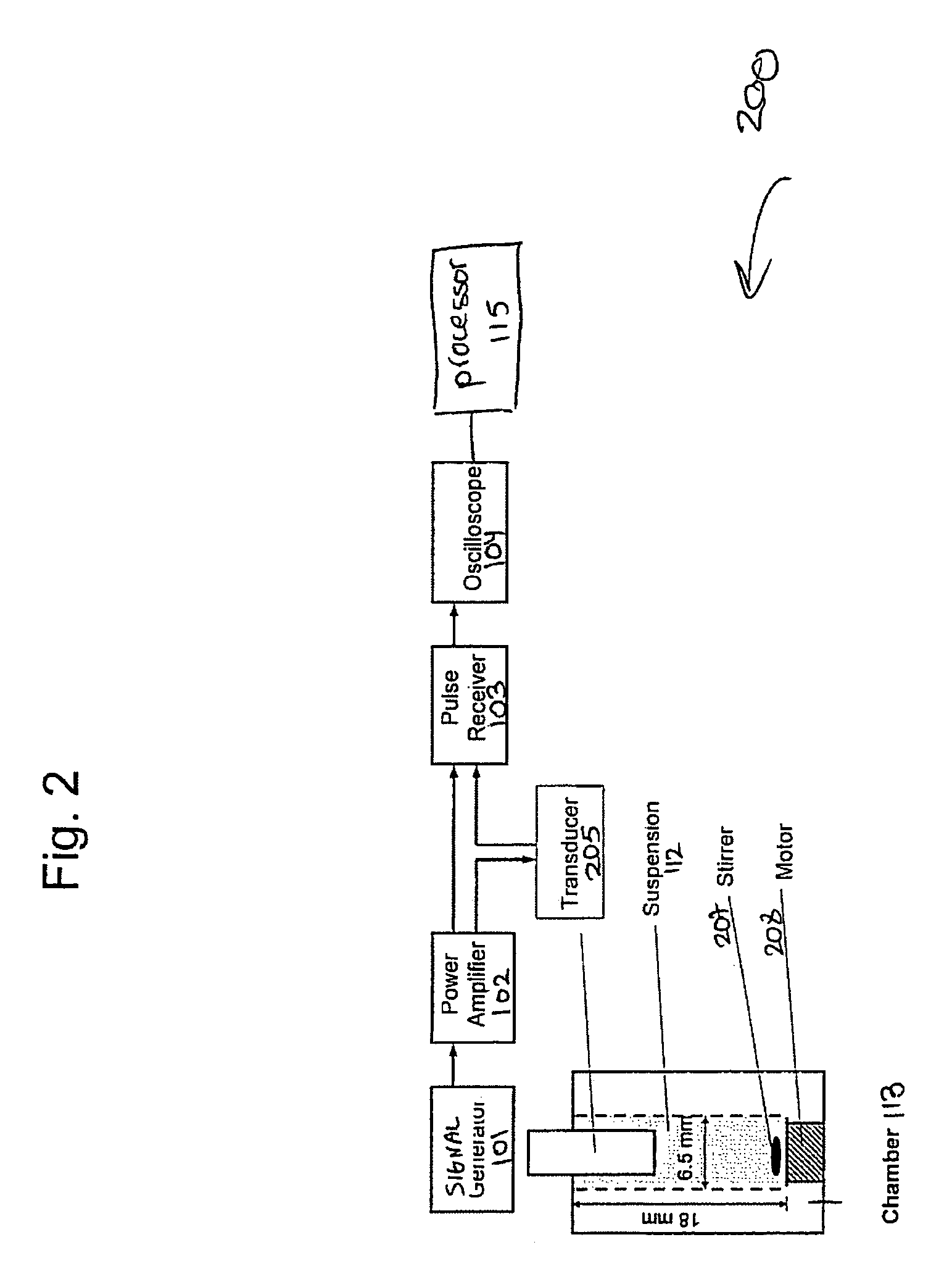

System and method for ultrasonic measuring of particle properties

ActiveUS20060178581A1Improve the level ofSmall volumeUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationAcoustic energy

Devices, systems and methods for measuring and detecting properties of a variety of particles or cells in suspension. Properties, such as, for example, velocity of particles, concentration and / or size may be measured according to the methods of the invention. Acoustic energy may be introduced to a focal zone and narrow band interrogating signals may be used. The acoustic energy may cause movement or streaming of the fluid or suspension. The acoustic streaming may allow a Doppler effect measurement without any other source of velocity.

Owner:PRODYNE CORP +1

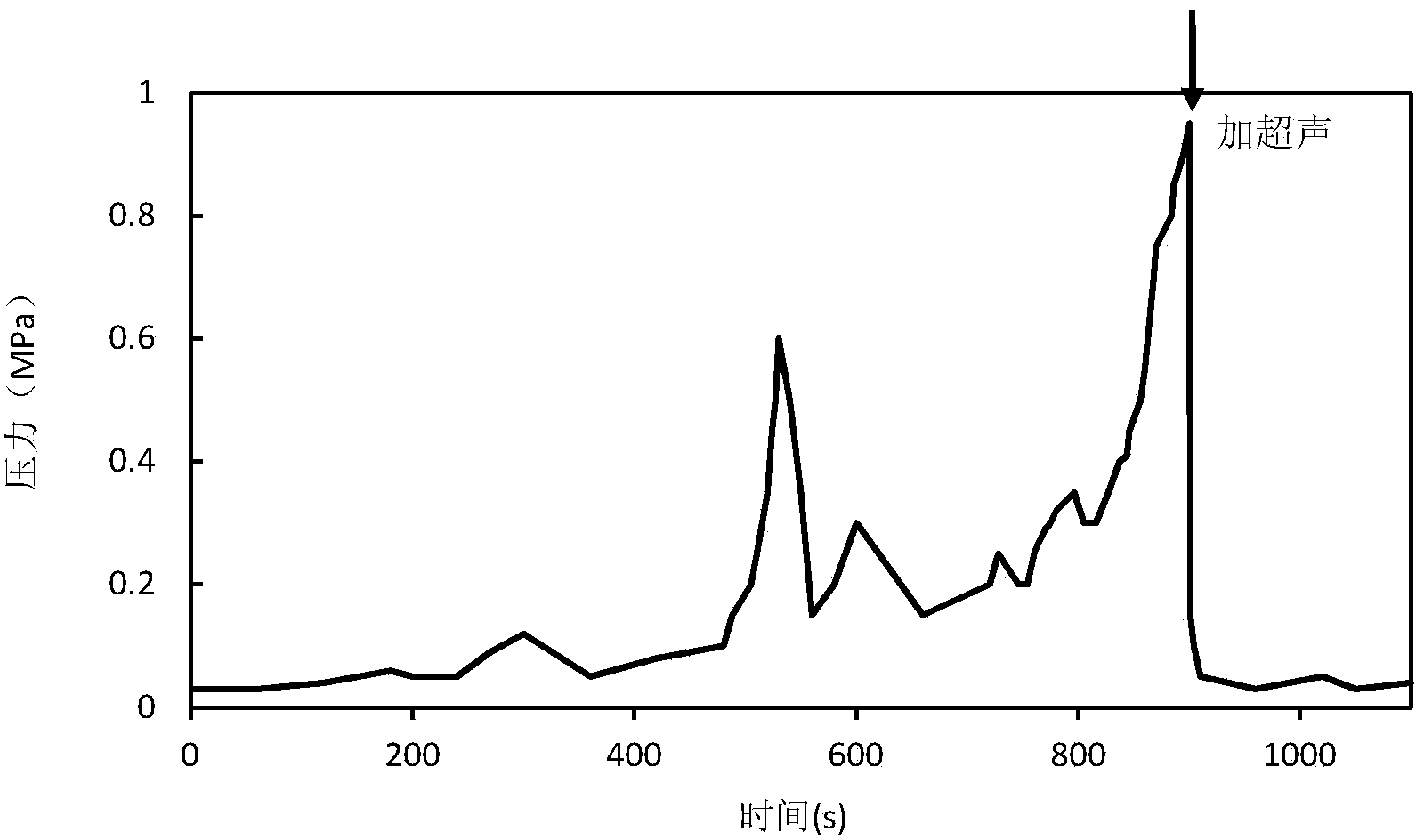

Method for enhancing gas-liquid process in micro-reactor

ActiveCN104162395AImprove mass transfer coefficientImprove absorption rateEnergy based chemical/physical/physico-chemical processesMicroreactorGas liquid reaction

The invention relates to a method for enhancing a gas-liquid process in a micro-reactor. The method comprises the following steps: applying ultrasound of a specific frequency to a gas-liquid micro-reactor in which gas liquid two-phase flow is bubble flow, slug flow, slug annular flow, stirring flow or annular flow; and regulating and controlling the transverse equivalent diameter of a gas phase in the gas-liquid two-phase flow and the ultrasonic frequency till a product of the ultrasonic frequency and the transverse equivalent diameter of the gas phase is up to 1-40 mm.kHz. According to the method, disturbance and acoustic streaming are caused in liquid by using the ultrasound and the cavitation effect of the gas phase, so that gas-liquid mass transfer is enhanced; and meanwhile, agglomeration between a solid or a sticky substance in fluid or the adhesion to the wall surface of a micro channel can be broken, so that blockage is prevented and dredged. The method for enhancing the gas-liquid process disclosed by the invention is suitable for the fields of various gas-liquid reactions, gas absorption, gas separation and purification, and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

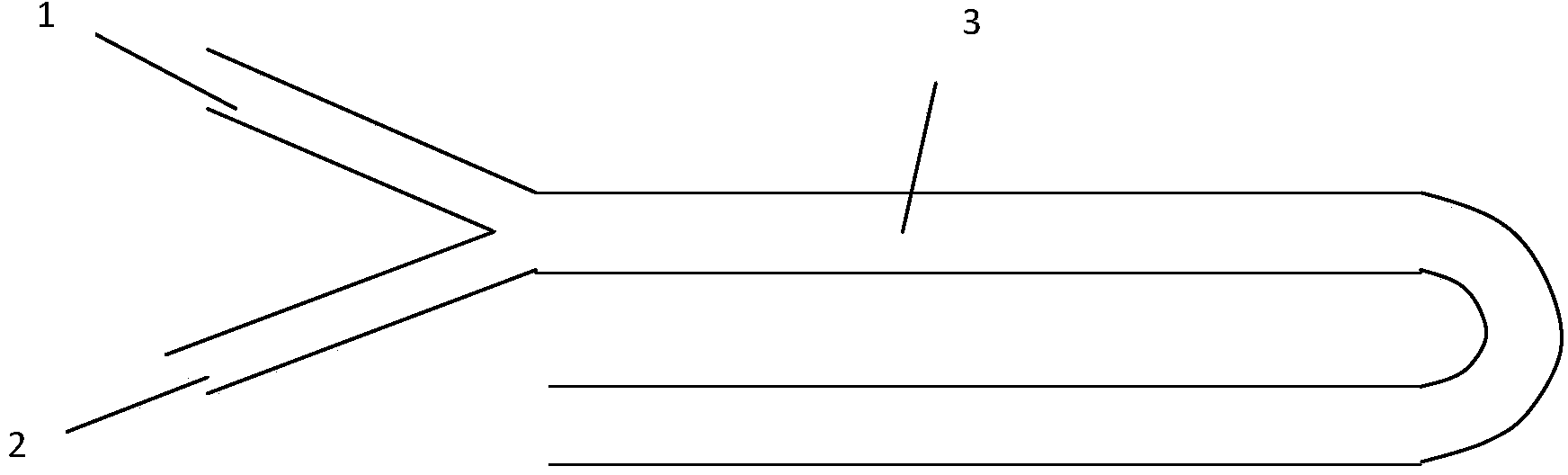

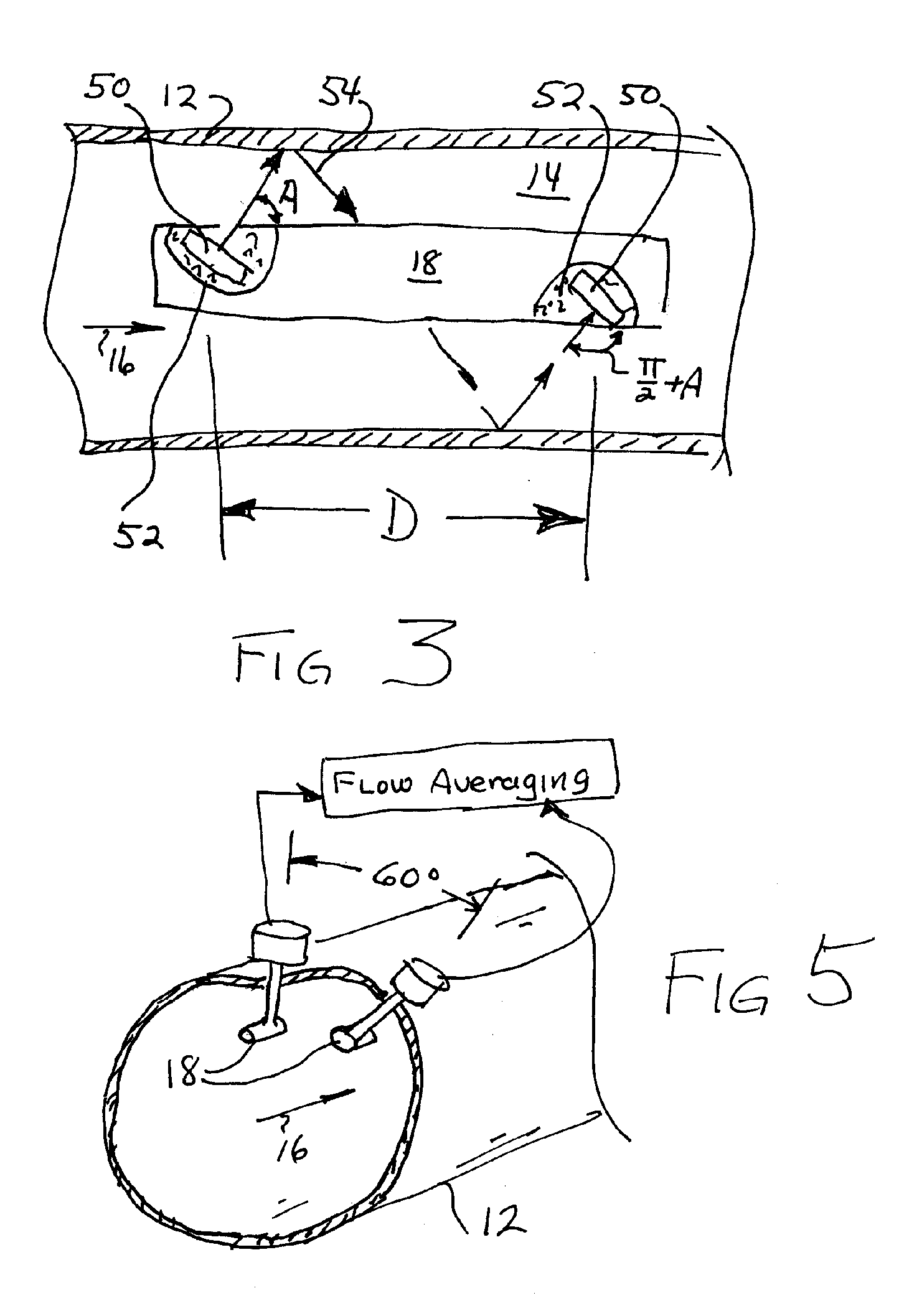

Acoustic Flow Sensor

InactiveUS20060059999A1High volume accuracyImprove liquidityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesFlow transducerProbe type

A probe type acoustic transit-time flow sensor has paired transducers arranged to generate quasi-helical acoustic beams making a plurality of reflective contacts with a pipe's interior wall. The transducers in each pair are spaced apart along the flow axis so that transit-time measurements can be used both to measure the internal diameter of the pipe and to determine a flow rate. These measurements are combined to yield a volumetric flow rate. Various numbers of pairs of transducers can be put on a single probe or on multiple probes and used to provide a more accurate representation of a flow profile and therefore a more accurate volumetric flow determination.

Owner:ONICON INC

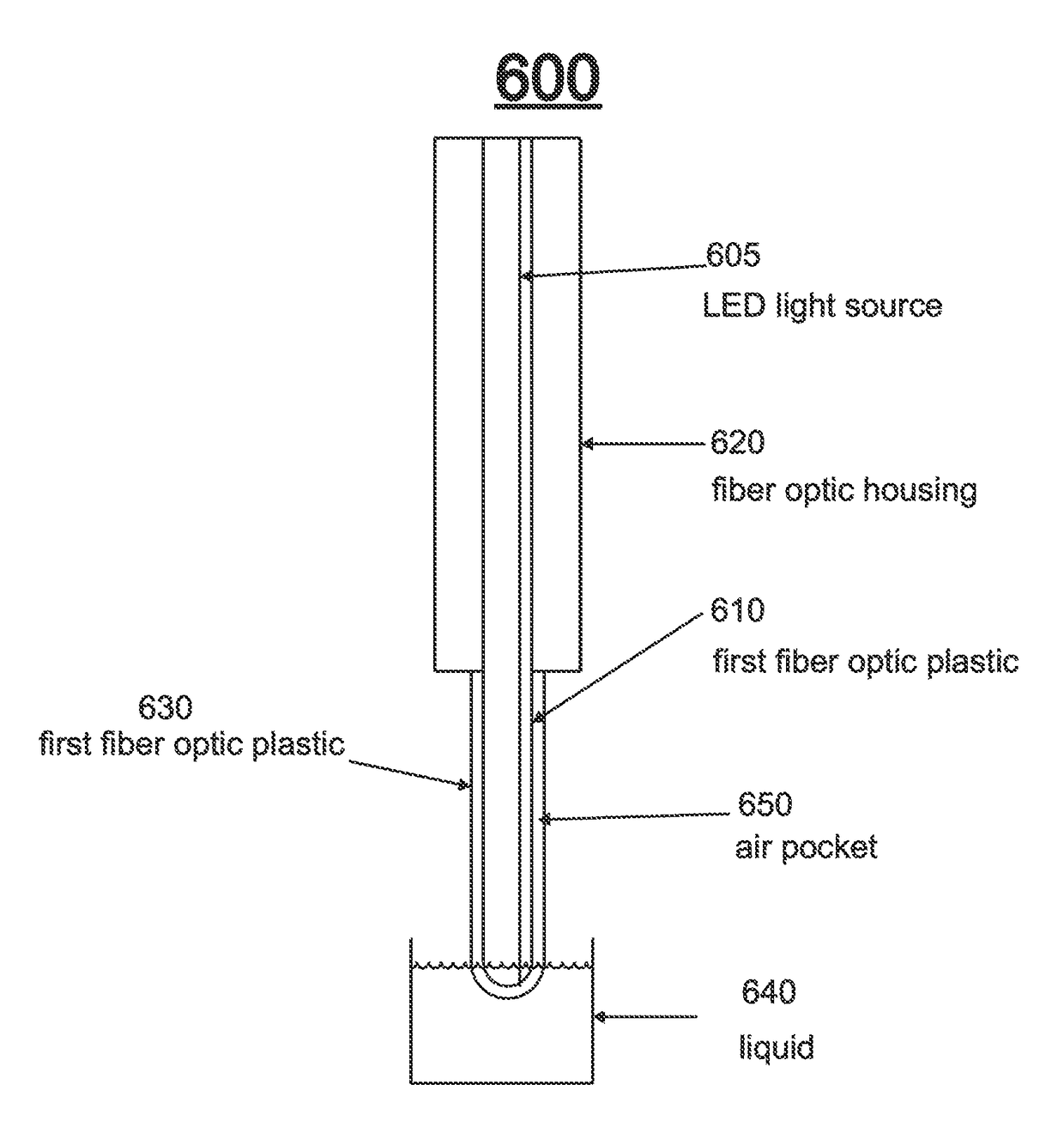

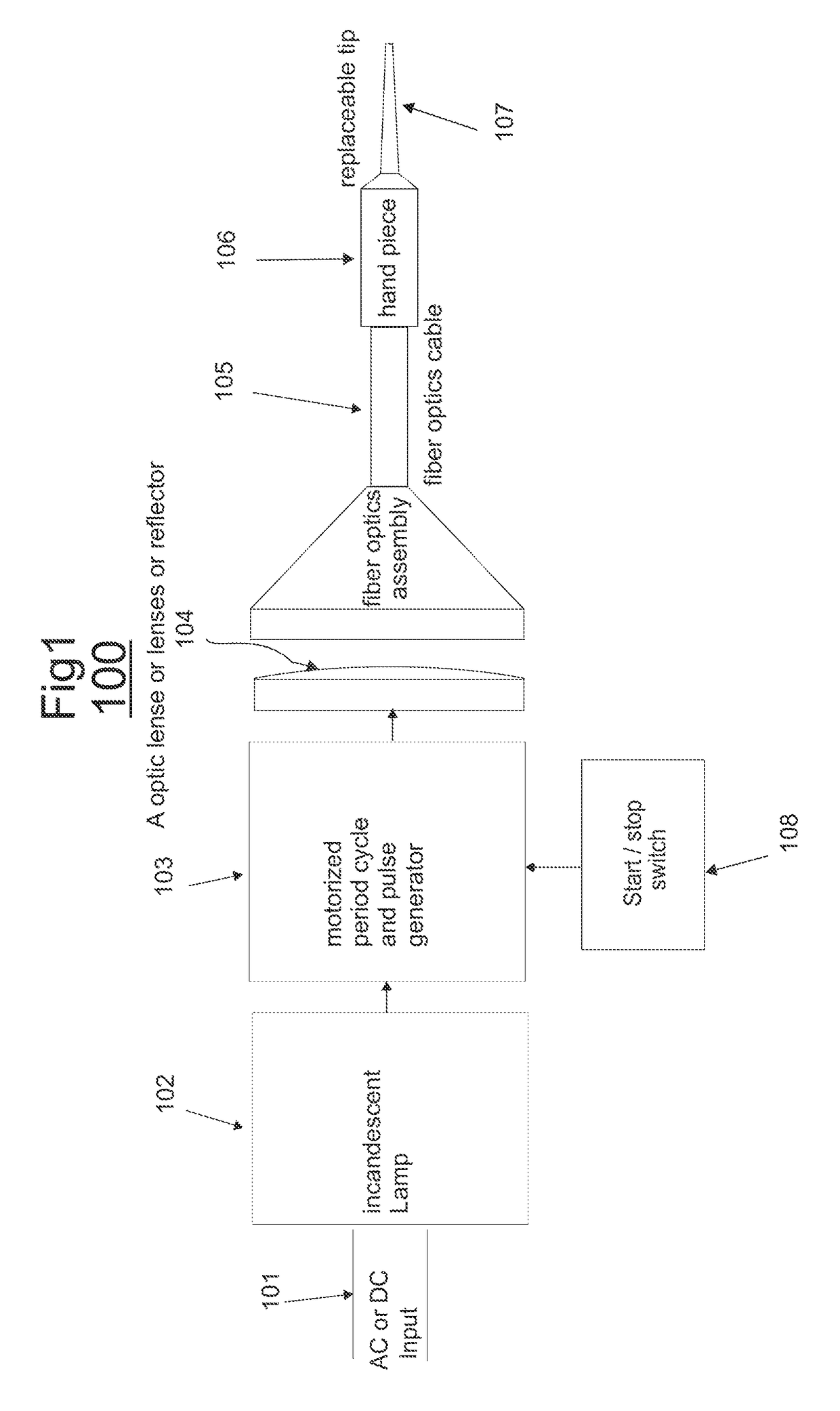

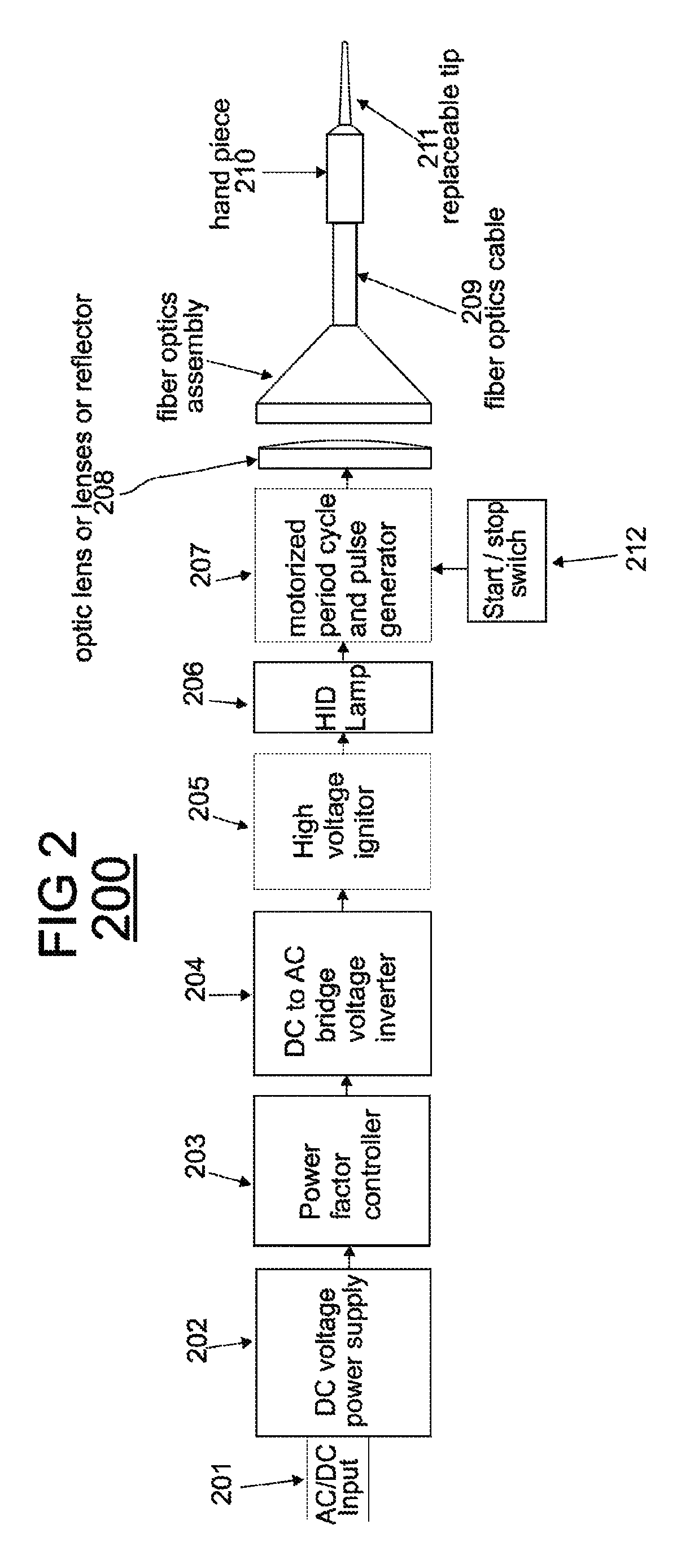

Photon induced acoustic streaming device and method

A device and method of using a device for photon-induced endodontic and periodontic applications includes a power source, a trigger coupled to the power source and circuit elements initiated by the trigger. The circuit elements include a timing circuit and a driver. A light source is coupled to the circuitry elements wherein and driver controls the period, cycle, and pulse generation of the light source to create photon induced acoustic waves. The optical assembly includes a fiber optic cable and an output tip and is coupled to the light source. This optical assembly refracts light from the light source and photon induced acoustic waves exit the output tip in a pre-determined pattern.

Owner:G&H TECH LLC

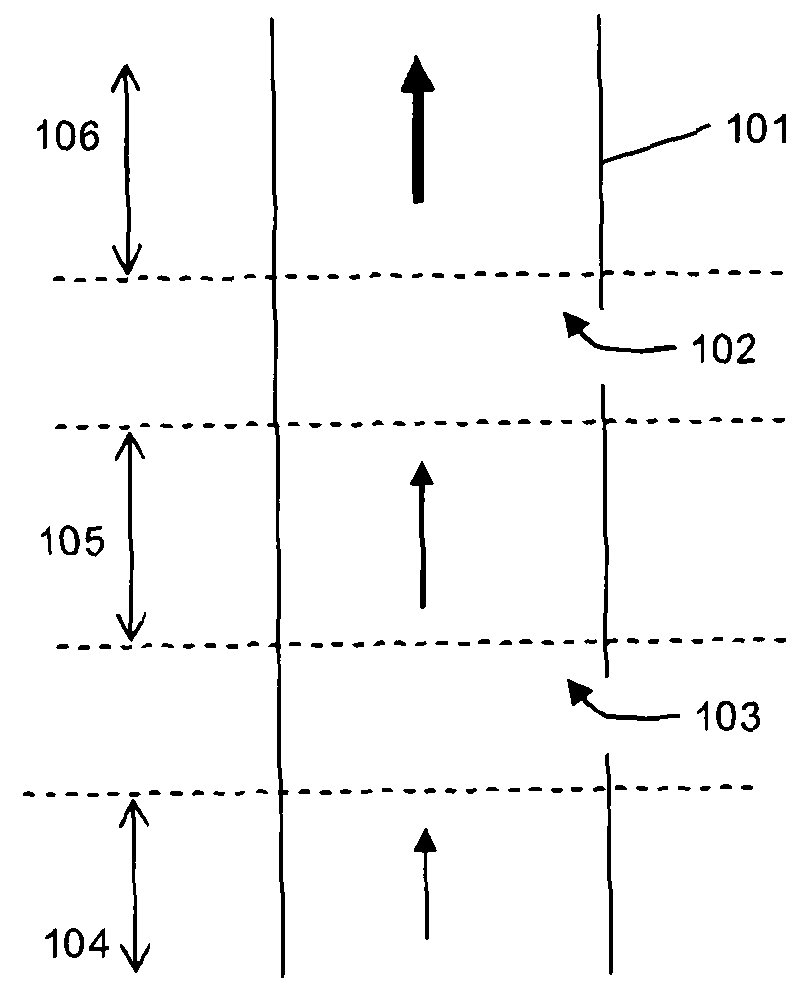

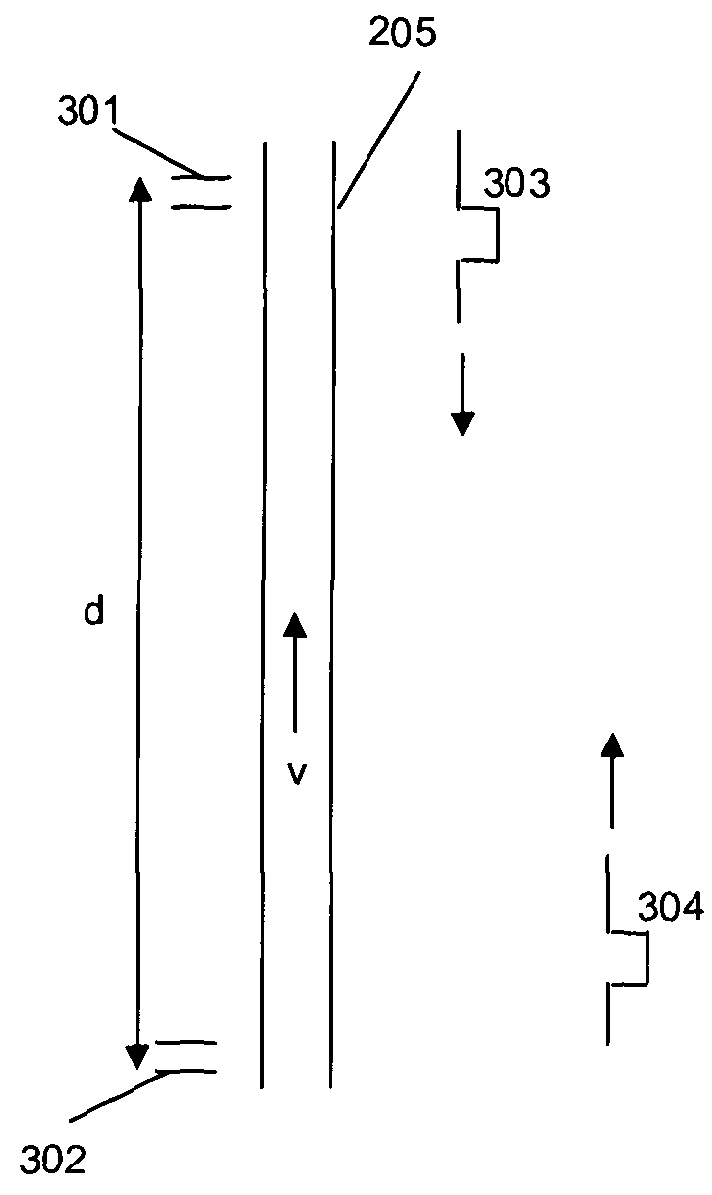

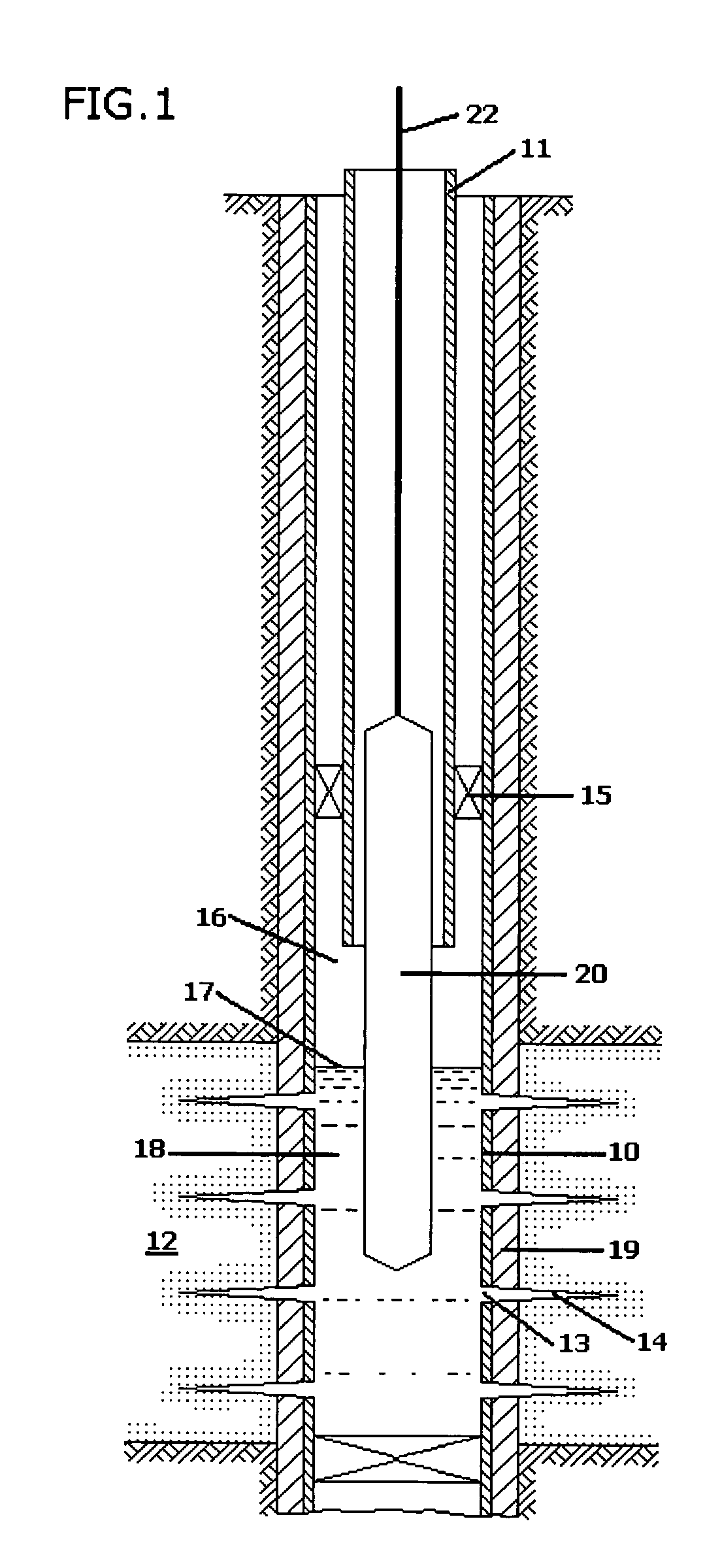

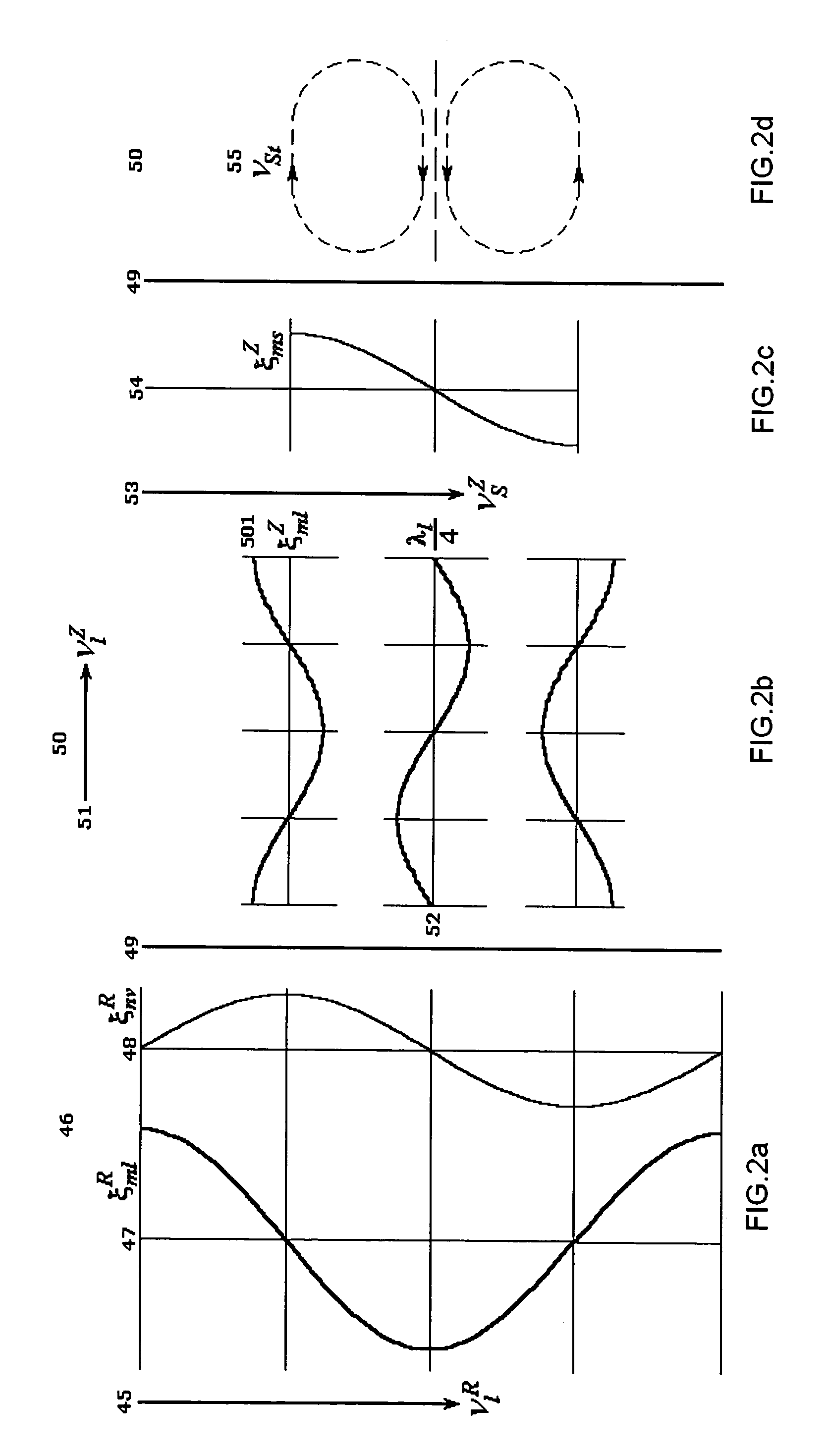

Techniques for distributed acoustic sensing

ActiveUS9250112B2Improve resolutionVelocity increasesSubsonic/sonic/ultrasonic wave measurementVolume/mass flow measurementFiberDistributed acoustic sensing

The application describes techniques for monitoring the rate of flow of fluid in a conduit (205) using fiber optic distributed acoustic sensing which are especially applicable to flow in oil and gas wells. The techniques also allow for calibration of the position of the channels of a fiber optic distributed acoustic sensor arranged along a fluid carrying conduit. The techniques comprise introducing a first acoustic stimulus (303) travelling in one direction and a second acoustic stimulus (304) travelling in the opposite direction. Flow of the fluid (v) results in a difference in the propagation velocity of the two acoustic stimuli. The first and second acoustic stimuli create a standing wave and the beat effect due to the flow induced wavelength variation is detected and used to determine flow rate. The acoustic stimulus may be introduced to travel through the conduit to provide the first stimulus and to reflect from the end of the conduit and travel back as the second acoustic stimulus.

Owner:OPTASENSE HLDG LTD

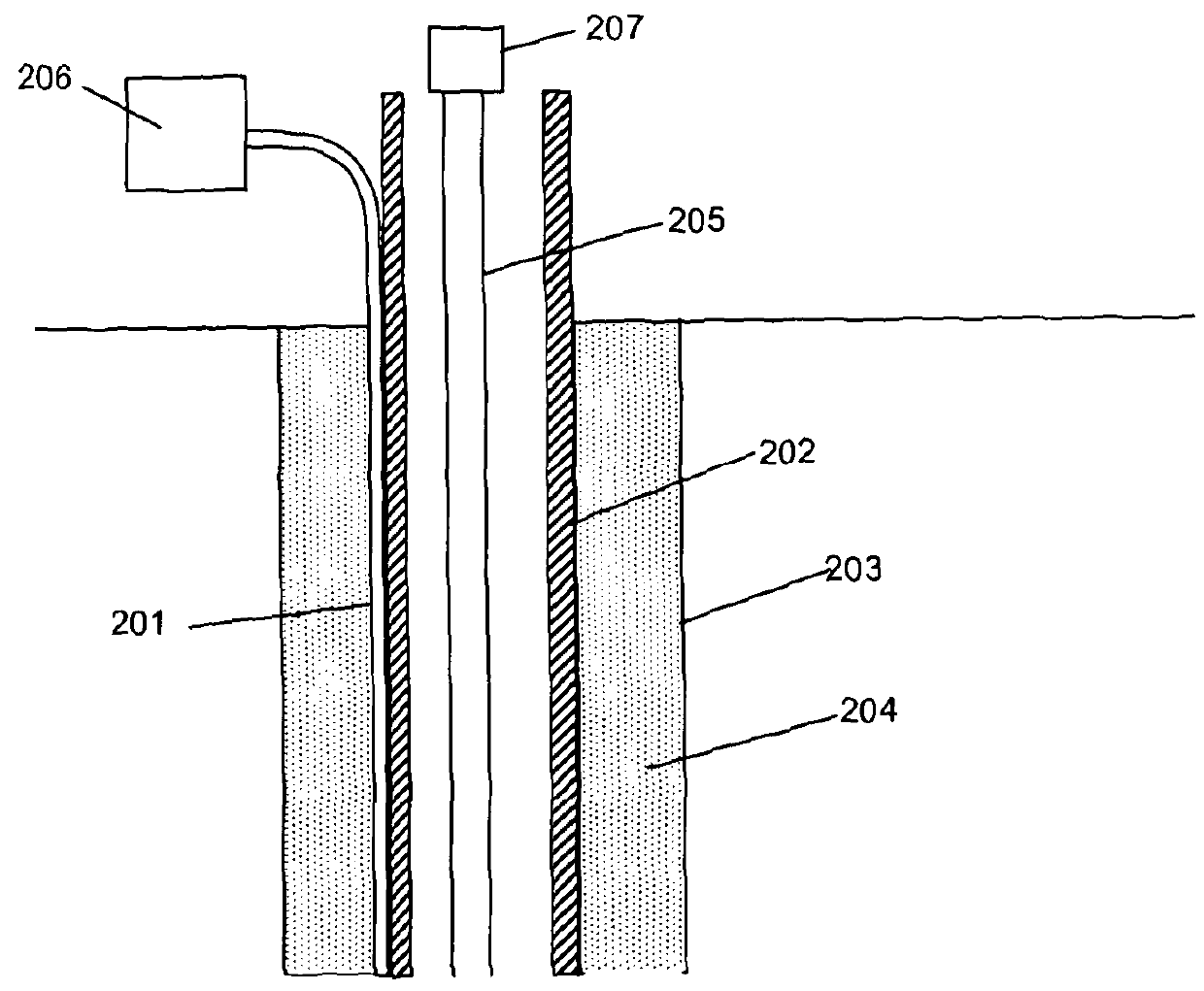

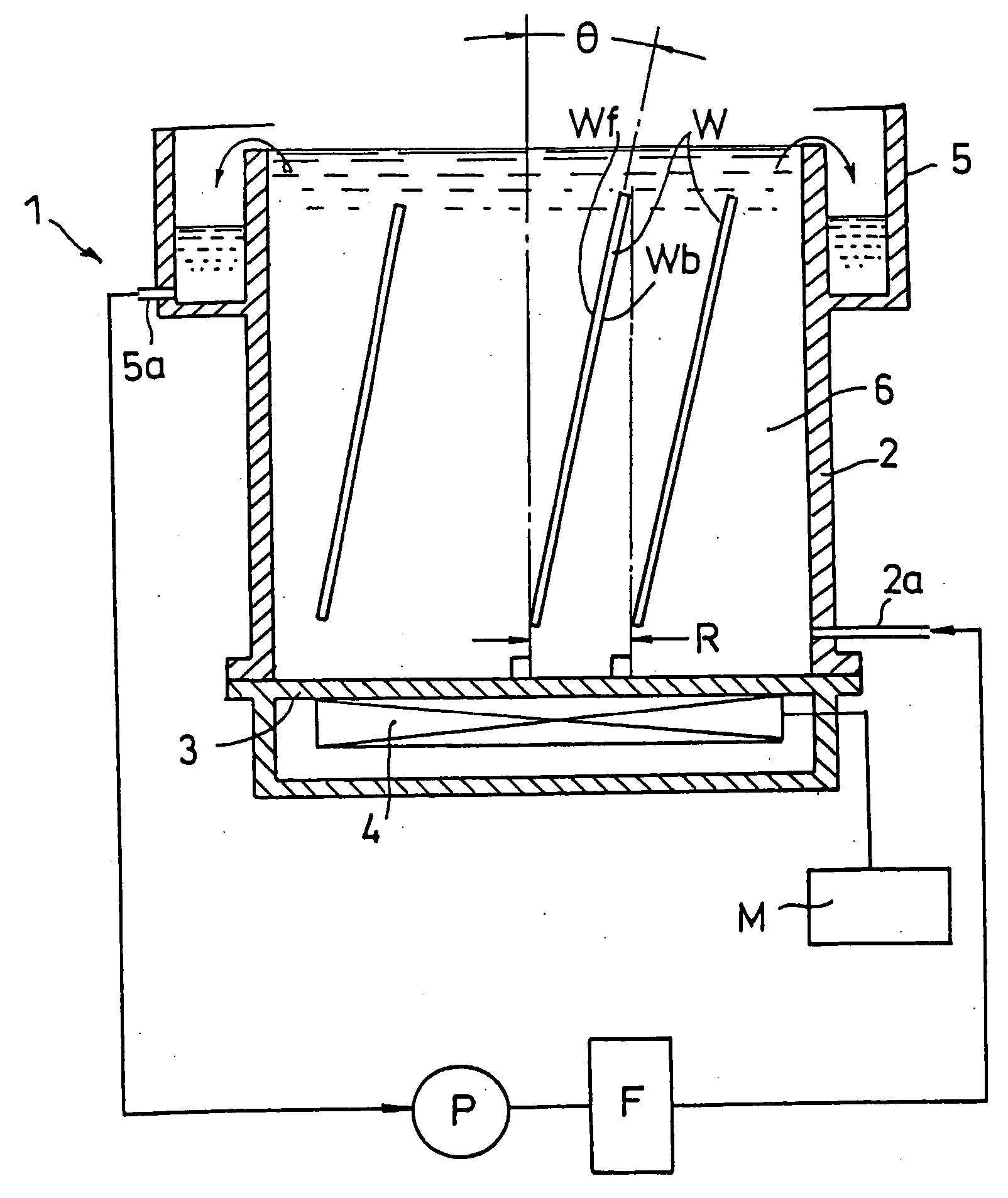

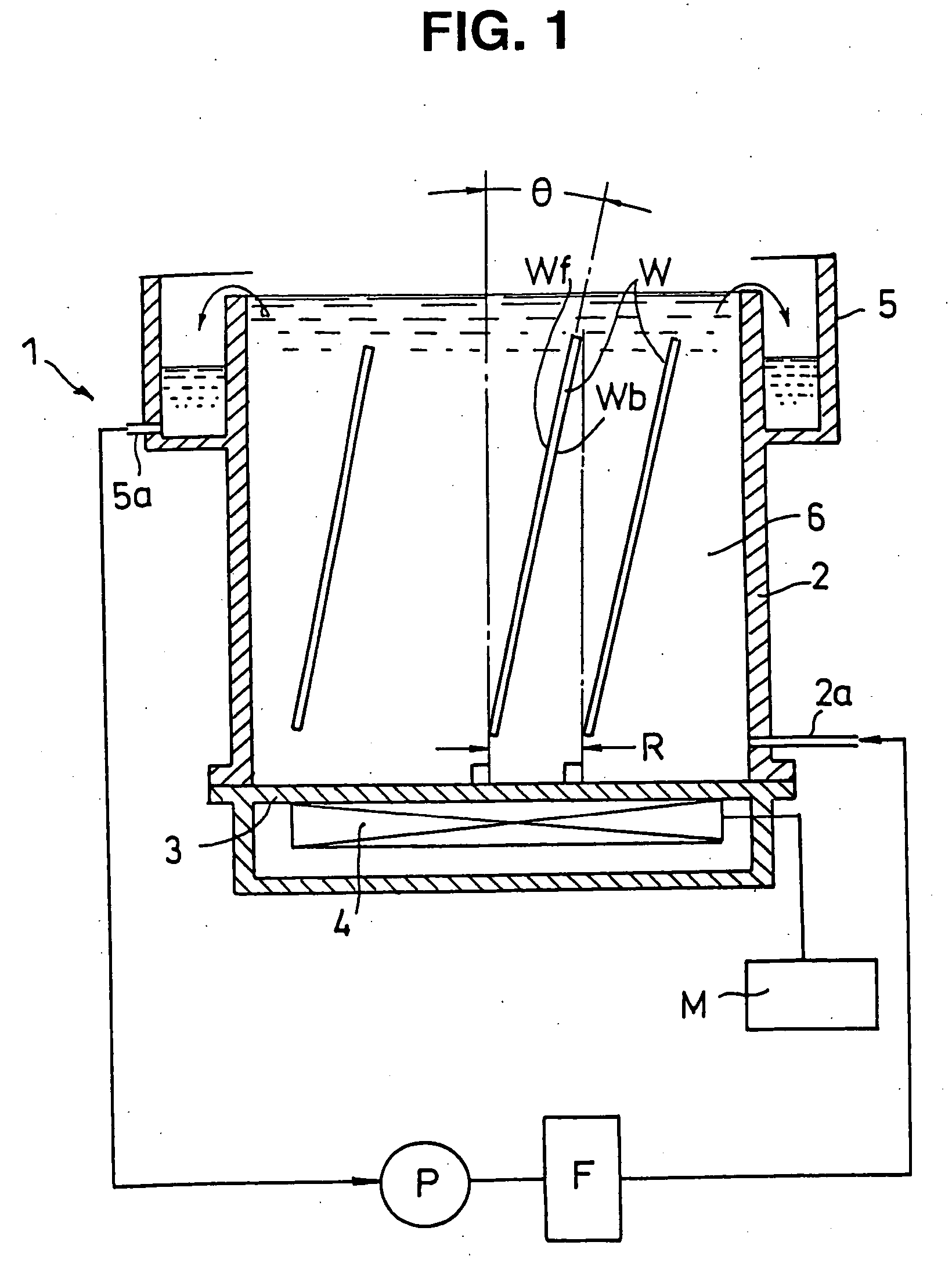

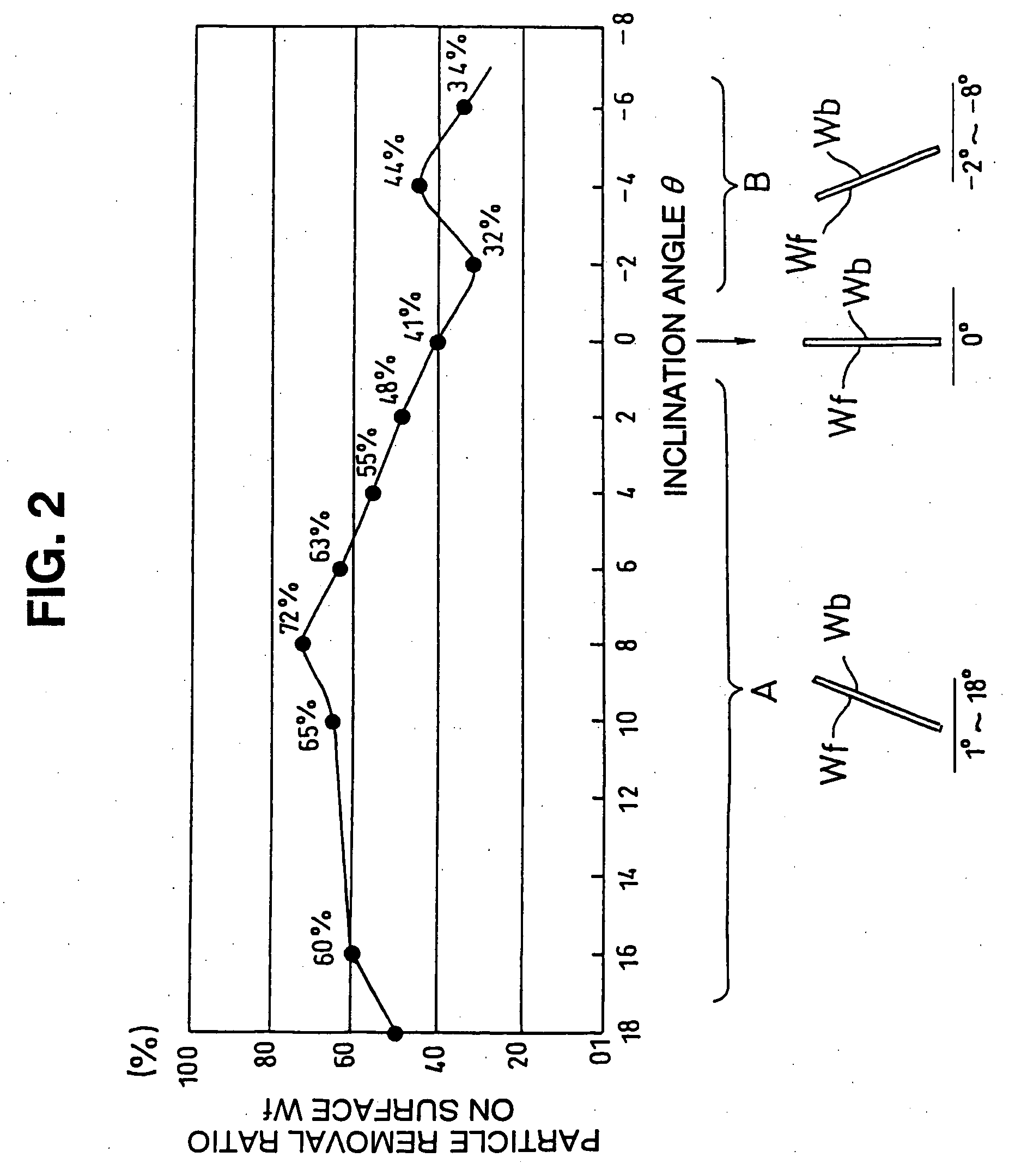

Method for cleaning substrate and apparatus therefor

InactiveUS20050121051A1Efficient removalEasy to operateSemiconductor/solid-state device manufacturingElectrostatic cleaningEngineeringUltrasonic vibration

A substrate cleaning method and an apparatus therefor capable of increasing a particle removal ratio at which particles firmly adhering to a substrate are removed therefrom and increasing a throughput. A substrate such as a wafer or the like placed in a cleaning tank filled therein with a cleaning liquid is cleaned by an ultrasonic vibration. Cleaning of the substrate is carried out in such a manner that an ultrasonic vibration is applied to the substrate from a bottom of the cleaning tank, during which application the substrate is kept at a predetermined inclination angle with respect to a direction of acoustic streaming in the cleaning liquid formed by propagation of an ultrasonic wave.

Owner:KAIJOO KK

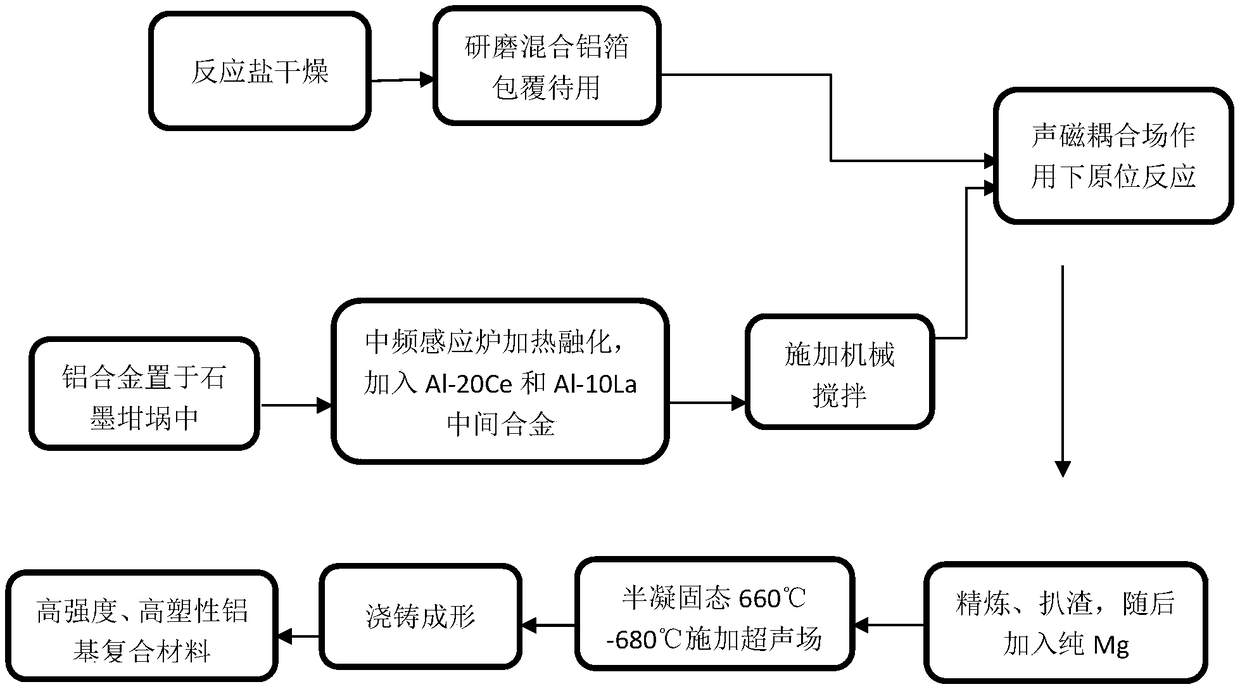

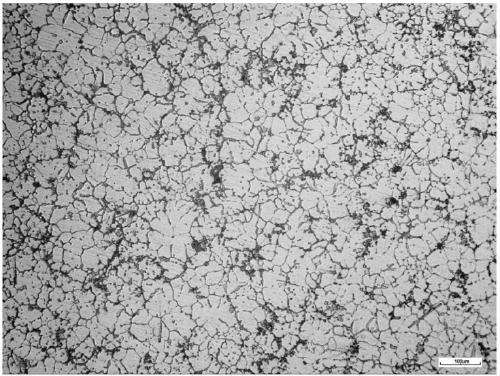

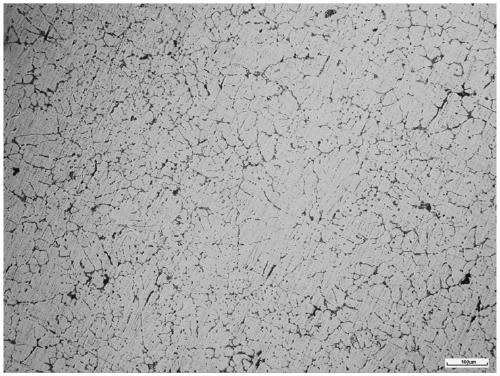

Method for regulating and controlling preparation of in situ binary nanoparticle enhanced aluminum based composite material

The invention relates to an in situ binary nanoparticle enhanced aluminum based composite material, in particular to a method for regulating and controlling the preparation of the in situ binary nanoparticle enhanced aluminum based composite material. A melt direct reaction method is used for preparing the binary nanoparticle enhanced aluminum based composite material; the aluminum alloy melting process uses mechanical stirring; rare earth middleintermediate alloy is added; through mechanical stirring, the melt generates vortex; the rare earth intermediatemiddle alloy is fast dispersed into the melt; in addition, the melt temperature can be more uniform. In the reaction process, an acoustic magnetic coupling field is exerted; through sound flow movement in two different directions, the uniform distribution of the enhanced particles in the metal melt in the whole melt is ensured; an ultrasonic field is exerted in the semi-solidified state; the continuous growth of the particles can be effectively inhibited, so that the distribution is more uniform; the prepared composite material is subjected to solid dissolution reinforcement through heat treatment, so that the grain particle dimension is smaller; the nanometer particles realize the scattered distribution in the crystals and on the crystal boundary; in addition, the particle and substrate interfaces are pure and achieves pollution-free effects; finally, the in-situ aluminum-based composite material is obtained.

Owner:JIANGSU UNIV

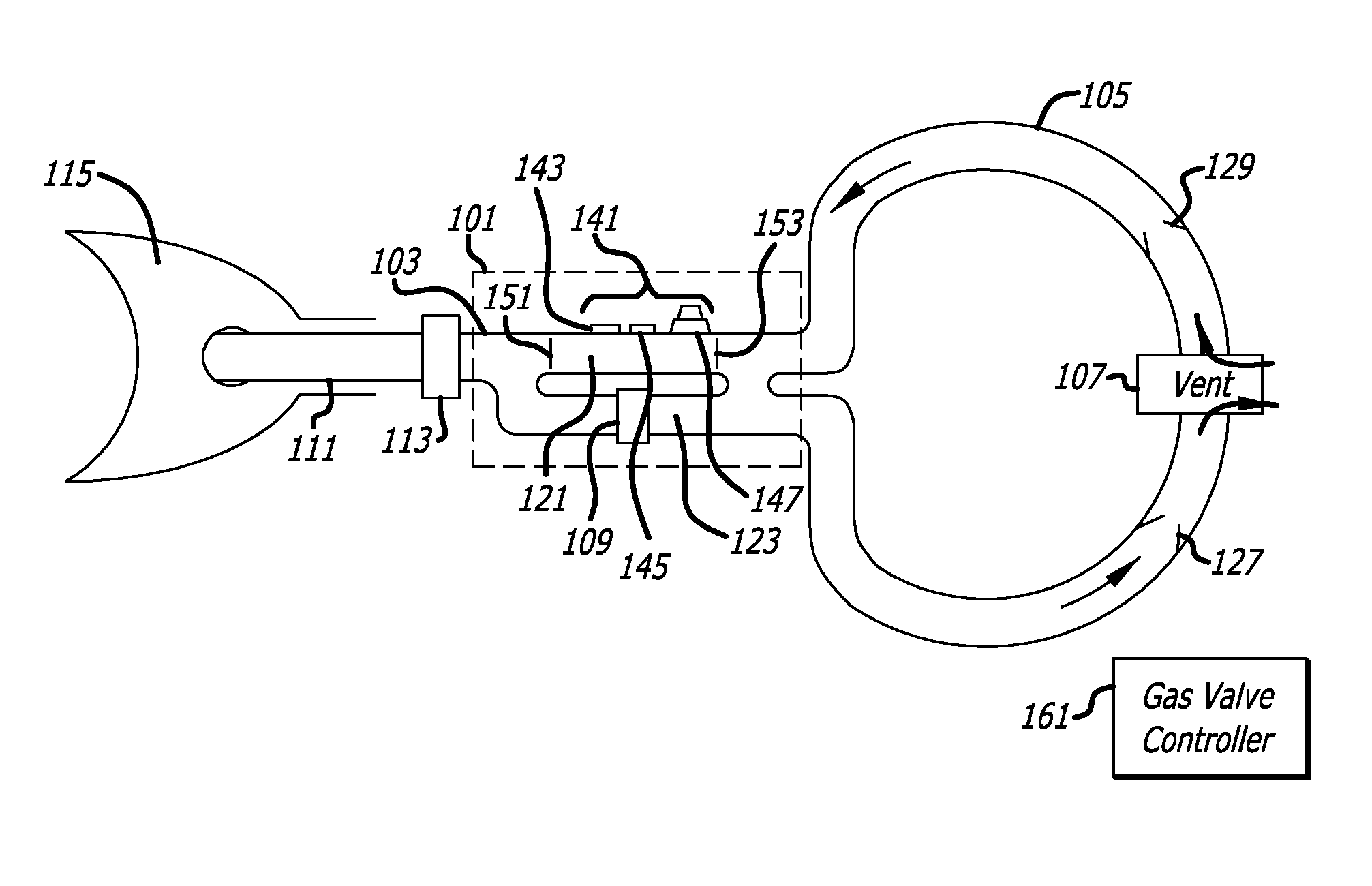

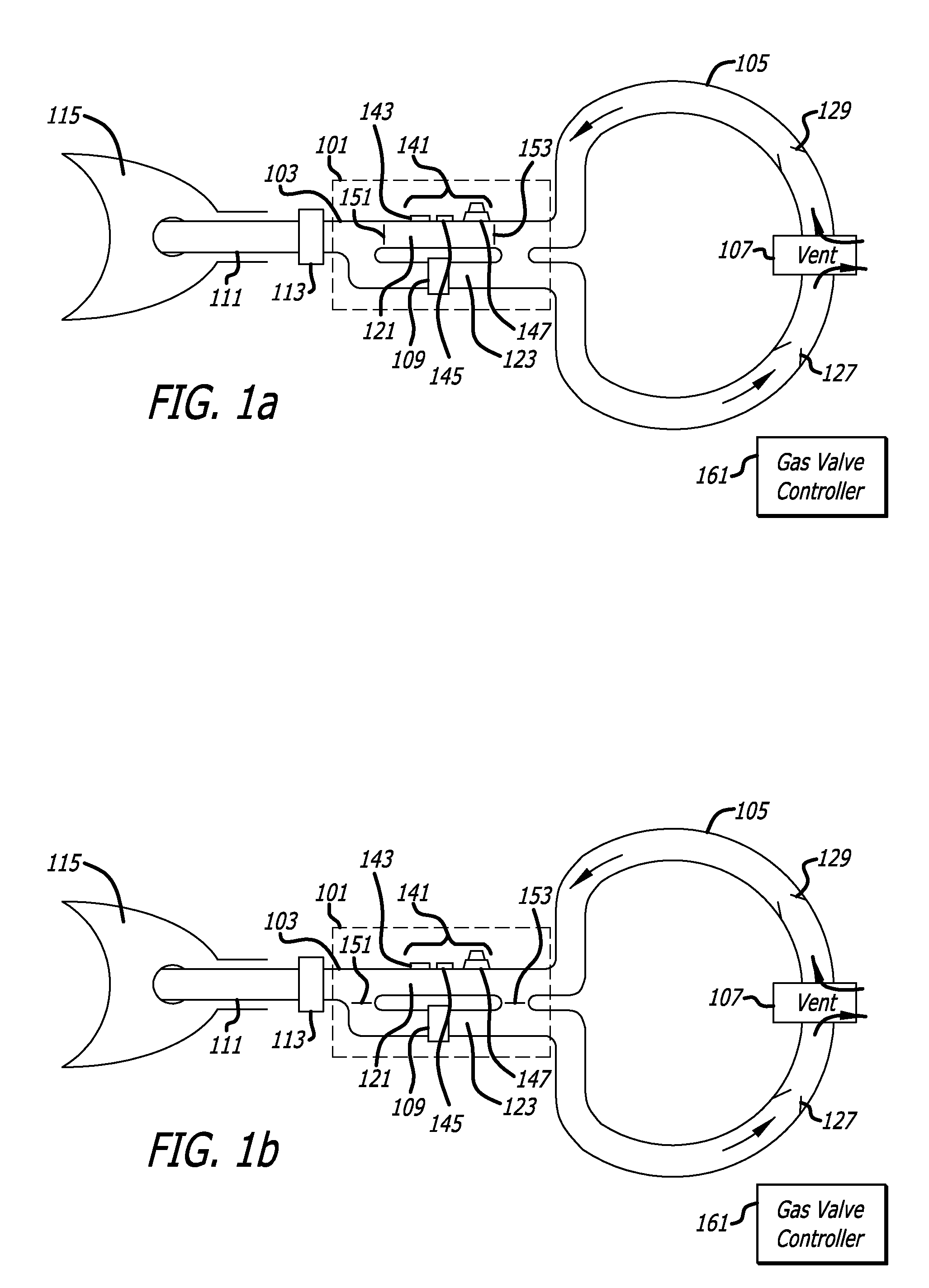

Breathing circuit with embedded acoustic reflectometer

InactiveUS20090318805A1Ultrasonic/sonic/infrasonic diagnosticsTracheal tubesMedicineBreathing circuits

An instrument may continuously monitoring acoustic reflections from within and / or beyond an intubation tube positioned within the mouth of a patient while the patient is breathing. The instrument may include an acoustic reflectometer configured to detect the acoustic reflections. An acoustic flow channel may contain the acoustic reflectometer within it. The acoustic flow channel may be configured to acoustically couple the acoustic reflectometer to an end of the intubation tube, but to substantially block the free flow of expiratory gas from the end of the intubation tube through the acoustic flow channel. A gas flow channel may be separate from the acoustic flow channel and may be configured to allow the free flow of expiratory gas from the end of the intubation tube through the gas flow channel.

Owner:UNIV OF SOUTHERN CALIFORNIA

System and method for ultrasonic measuring of particle properties

ActiveUS7543480B2Improve the level ofLittle generationUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationAcoustic energy

Devices, systems and methods for measuring and detecting properties of a variety of particles or cells in suspension. Properties, such as, for example, velocity of particles, concentration and / or size may be measured according to the methods of the invention. Acoustic energy may be introduced to a focal zone and narrow band interrogating signals may be used. The acoustic energy may cause movement or streaming of the fluid or suspension. The acoustic streaming may allow a Doppler effect measurement without any other source of velocity.

Owner:PRODYNE CORP +1

Variable frequency ultrasonic semi-continuous casting method for magnesium alloy

The invention belongs to the field of light alloy machining, and particularly relates to a variable frequency ultrasonic semi-continuous casting method for magnesium alloy. The method comprises the steps of alloy smelting, melt delivery and consolidation forming under ultrasonic treatment. Magnesium alloy melt is treated in a real-time variable frequency ultrasonic field introduced in the semi-continuous casting process, and the quasi real-time tracking of the resonant frequency of metal melt is achieved; and liquid cave melt is subjected to the ultrasonic resonance treatment continuously in the whole semi-continuous casting process, so that the continuous ultrasonic high-efficiency treatment of the magnesium alloy melt is achieved in the solidification process. In the method provided by the invention, an ultrasonic radiation rod is extended into the magnesium alloy melt in the magnesium alloy semi-continuous casting process, so that the cavitation effect and acoustic streaming effect produced by the variable frequency ultrasonic field directly act on the magnesium alloy melt solidifying. With the method provided by the invention, the magnesium alloy solidification behavior can be changed obviously, the structure is refined, and the uniformity of the billet solidification structure as well as the mechanical property of magnesium alloy billets are improved; and the billet casting defects are reduced obviously, and the quality of the magnesium alloy billets is improved greatly.

Owner:NORTHEASTERN UNIV +1

Laser welding method combining ultrasonic welding with chilling

ActiveCN110860795AReduce longitudinal residual stressReduce residual tensile stressLaser beam welding apparatusWelding residual stressUltrasonic welding

The invention belongs to the field of welding, and relates to a laser welding method combining ultrasonic welding with chilling. According to the method, cooling water is applied to the back surface of a welding seam with a certain distance behind a molten pool in the welding process, and ultrasonic vibration is applied to the front surface; the temperature and the flow of the cooling water are determined according to the welding mode used; and the ultrasonic application position, power and force are adjusted according to the mechanical properties of sample materials. According to the method,the welding residual stress can be effectively reduced, and air holes and cracks are reduced, so that the fatigue performance of the welding seam is improved, and meanwhile, transverse and longitudinal deformation of welding is reduced. Longitudinal residual stress and deformation can be effectively reduced through chilling and welding. The ultrasonic impact can counteract the transverse stress caused by chilling and welding, and further inhibit longitudinal stress, so that deformation is effectively reduced; and the acoustic streaming effect and cavitation effect of the ultrasonic can refinecrystal grains and reduce the air holes and cracks, so that the fatigue performance of the welding seam is improved.

Owner:DALIAN UNIV OF TECH

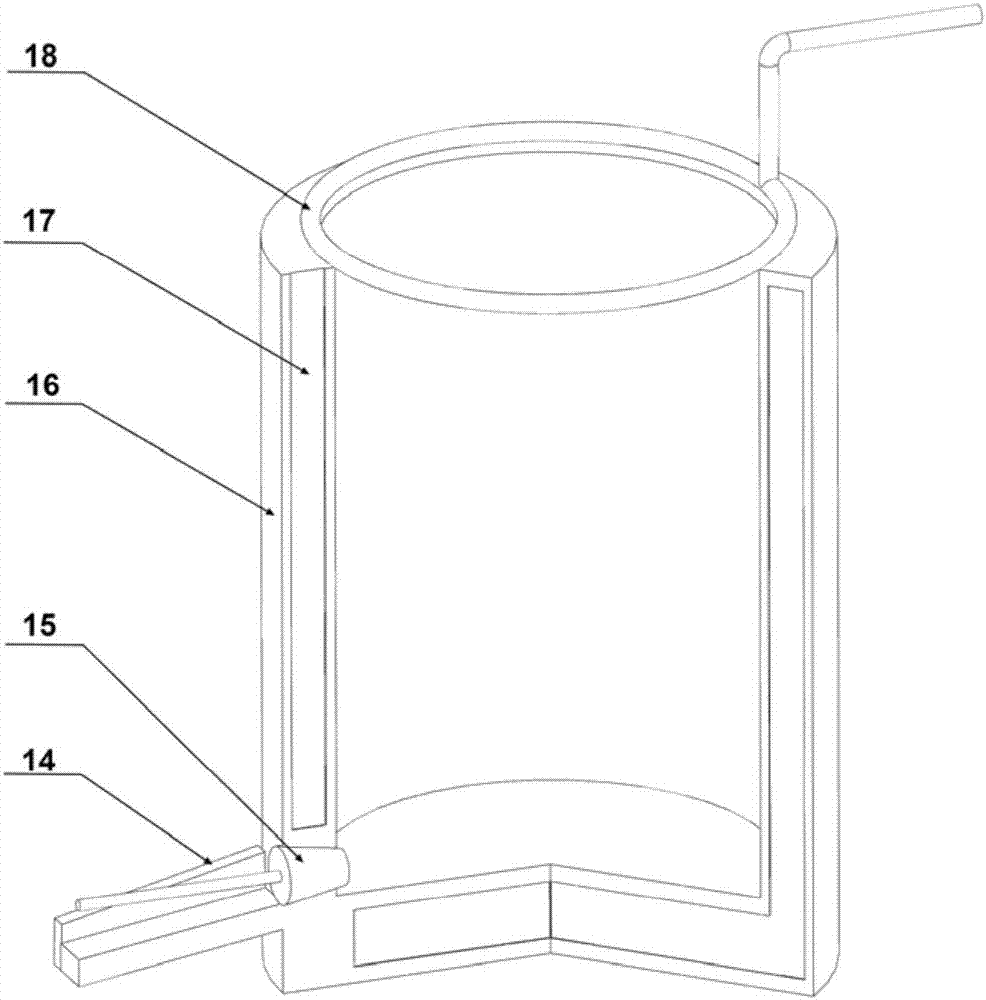

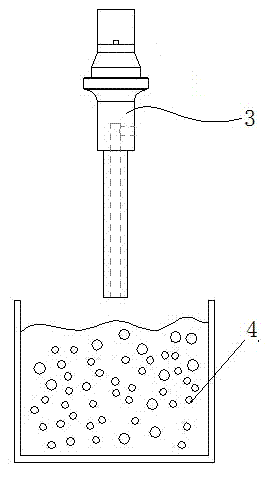

Preparation method of alloy semisolid slurry

The invention belongs to the technical field of semisolid processing and casting forming of metals / alloys, and in particular relates to a preparation method of alloy semisolid slurry. According to the preparation method, a molten alloy is filled into a slurry container, at least one group of ultrasonic vibration devices is operated in the slurry container, and at least one group of cooling gases is introduced into the slurry container. The alloy semisolid slurry is prepared by changing the parameters of the ultrasonic vibration devices and the quantity of the cooling gases. A round, tiny and uniform non-dendritic crystalline structure can be quickly prepared by combining an ultrasonic acoustic streaming effect with a cooling gas cooling effect, and the introduced inert gas for cooling also a purification effect on the slurry. The preparation method provided by the invention can be used for preparing various kinds of alloy semisolid slurry of aluminum, magnesium, zinc, copper, tin and the like, and is simple, efficient and economical in process, and the prepared slurry is pure and pollution-free.

Owner:冯睿

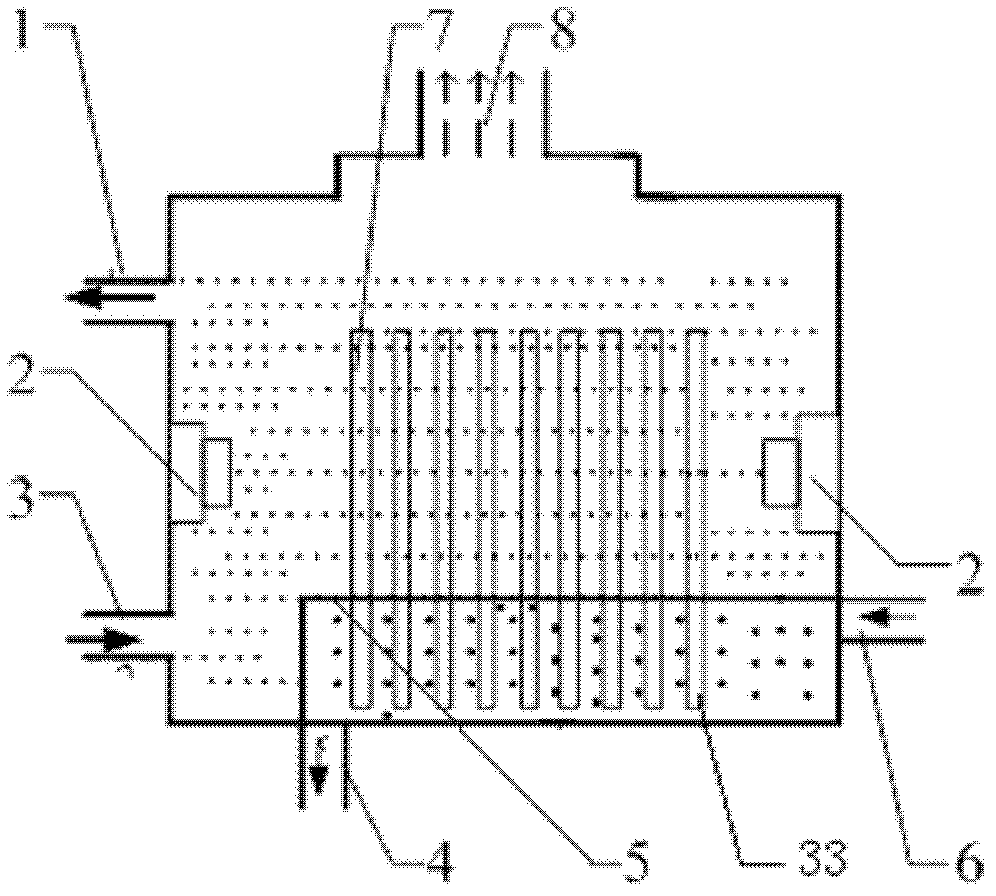

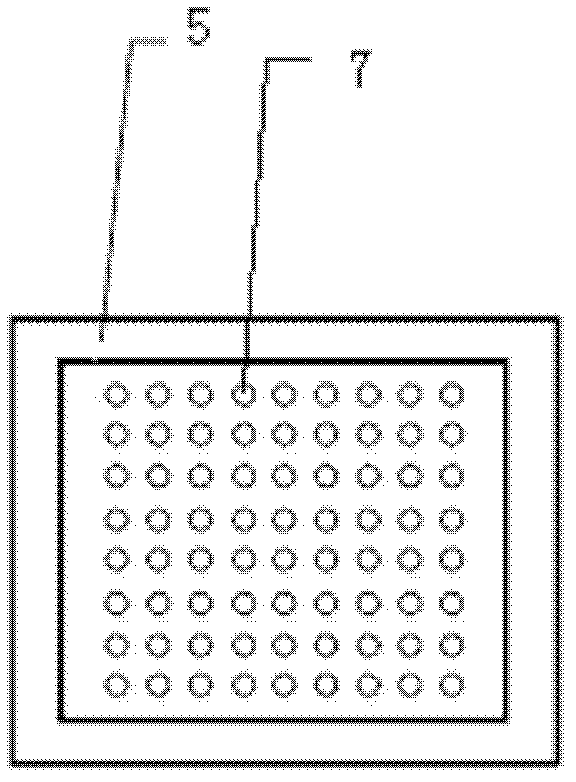

Acoustic surface wave sorting chip undergoing special wettability optimization

ActiveCN108285869AHigh-throughput enrichmentHigh Purity SortingBioreactor/fermenter combinationsBiological substance pretreatmentsHigh fluxAcoustic radiation force

The invention discloses an acoustic surface wave sorting chip undergoing special wettability optimization. According to the chip, through fusion of some characteristics of wettability optimization, abroadband / variable frequency interdigital transducer technique and hydraulic sorting and an acoustic surface wave sorting method, cell / particle high-flux enrichment and specific cell / particle high-purity sorting are achieved. During working of the chip, effects of a sound field and acoustic radiation force are achieved on fluid and cells / particles in a micro-channel through acoustic surface wave which is generated by an interdigital transducer. Therefore, by implementing special wettability optimization treatment on the base of a sorting channel, differences in surface tension, adhesive force,shear force, wall slippage and the like can be caused in various wettability micro-area interfaces. Cells, which pass through a sorting area in a lined-up form, can deviate away from an original streamline trajectory under actions of an acoustic streaming effect, the acoustic radiation force, the adhesive force (Stokes force) and the like; and through a coupling effect of the special wettabilityoptimization base, deviation speed and distance of the cells / particles is increased, and a sorting flux and efficiency are improved.

Owner:JILIN UNIV

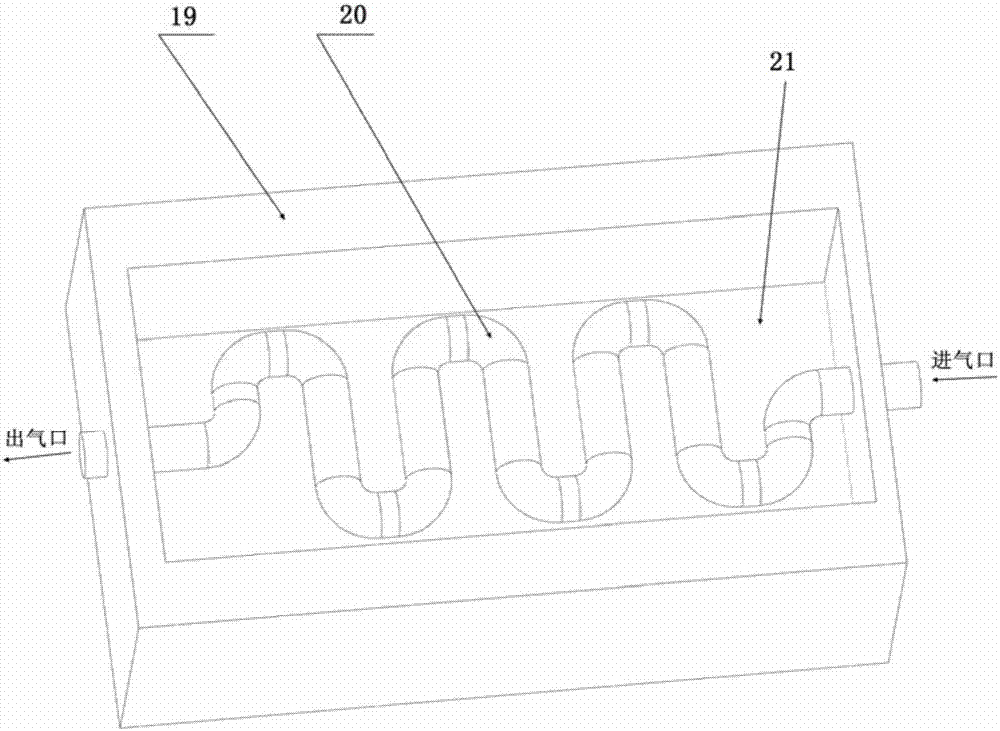

Ultrasonic-strengthened generator for absorption refrigerator

InactiveCN102384605AImprove performanceReduce maintenance costsSolar heat devicesClimate change adaptationCavitationLithium bromide

The invention discloses an ultrasonic-strengthened generator for an absorption refrigerator. A heater is arranged in a shell; the heater comprises a heat exchange water box and heat exchange tubes; columnar dead holes which extend inwards a box body are distributed on one end face of the box body of the heat exchange water box; condensation ends of the heat exchange tubes 7 are exposed outside the heat exchange water box, and evaporation ends of the heat exchange tubes 7 are arranged in the columnar dead holes; and a solar energy hot water inlet and a solar energy hot water outlet are arranged on the side wall of the heat exchange water box. In the ultrasonic-strengthened generator for the absorption refrigerator, the heat exchange tubes are used as heat exchange elements, and a lithium bromide solution is heated by a heating heat source through the heat exchange tubes, therefore, the heated uniformity of the lithium bromide solution is improved. Furthermore, a group of ultrasonic generators are arranged in the generator for the absorption refrigerator to provide an ultrasonic field for the lithium bromide solution; and the use efficiency of the low-quality heat source and the refrigeration efficiency of the refrigerator are improved by adopting the acoustic streaming effect and the cavitation effect of ultrasonic waves to strengthen a heat and mass transfer process of the lithium bromide solution. The ultrasonic-strengthened generator for the absorption refrigerator can be applied in absorption refrigerators which are driven by the low-quality heat source, such as solar energy, waste hot water, waste gas and the like.

Owner:SOUTH CHINA UNIV OF TECH

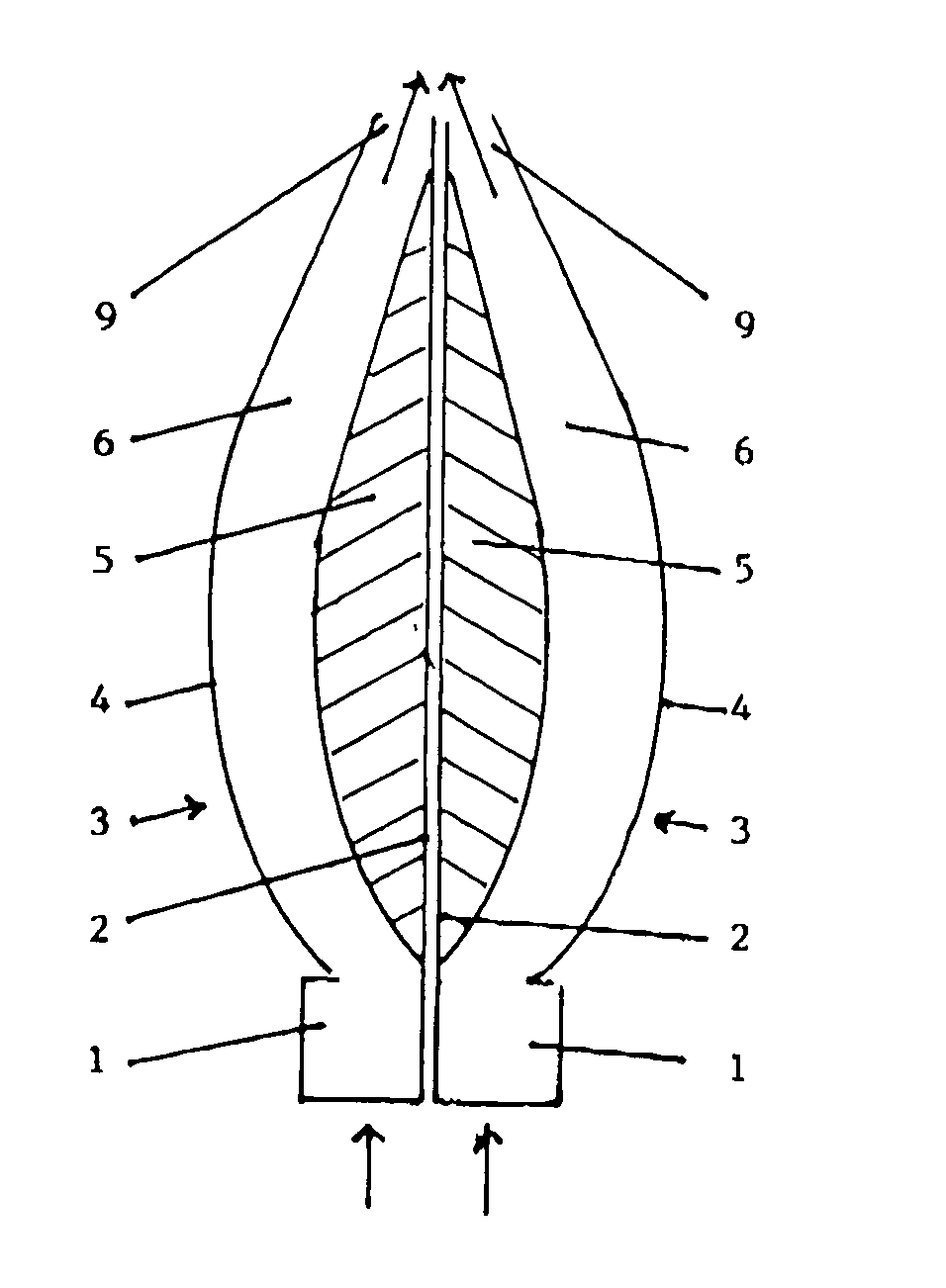

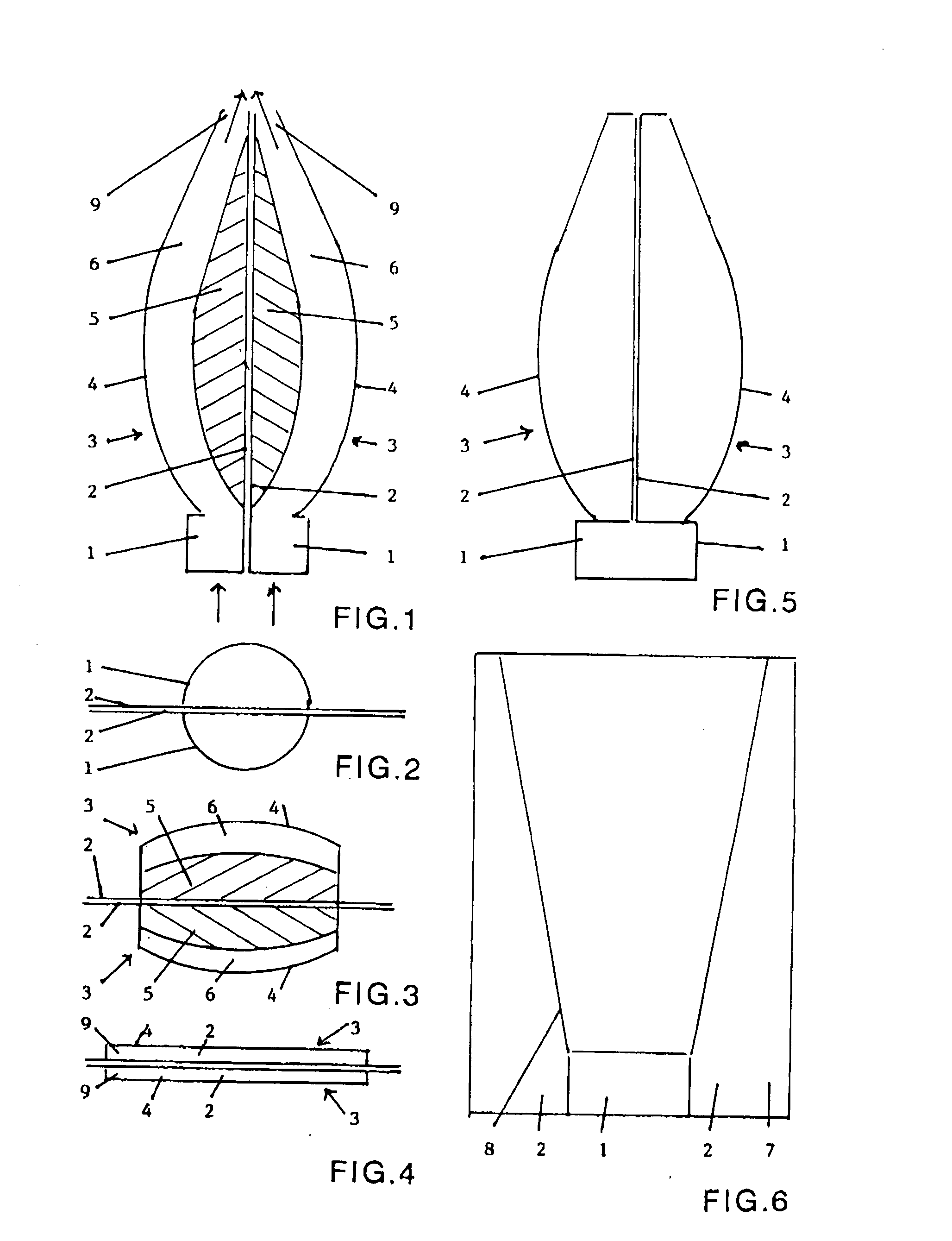

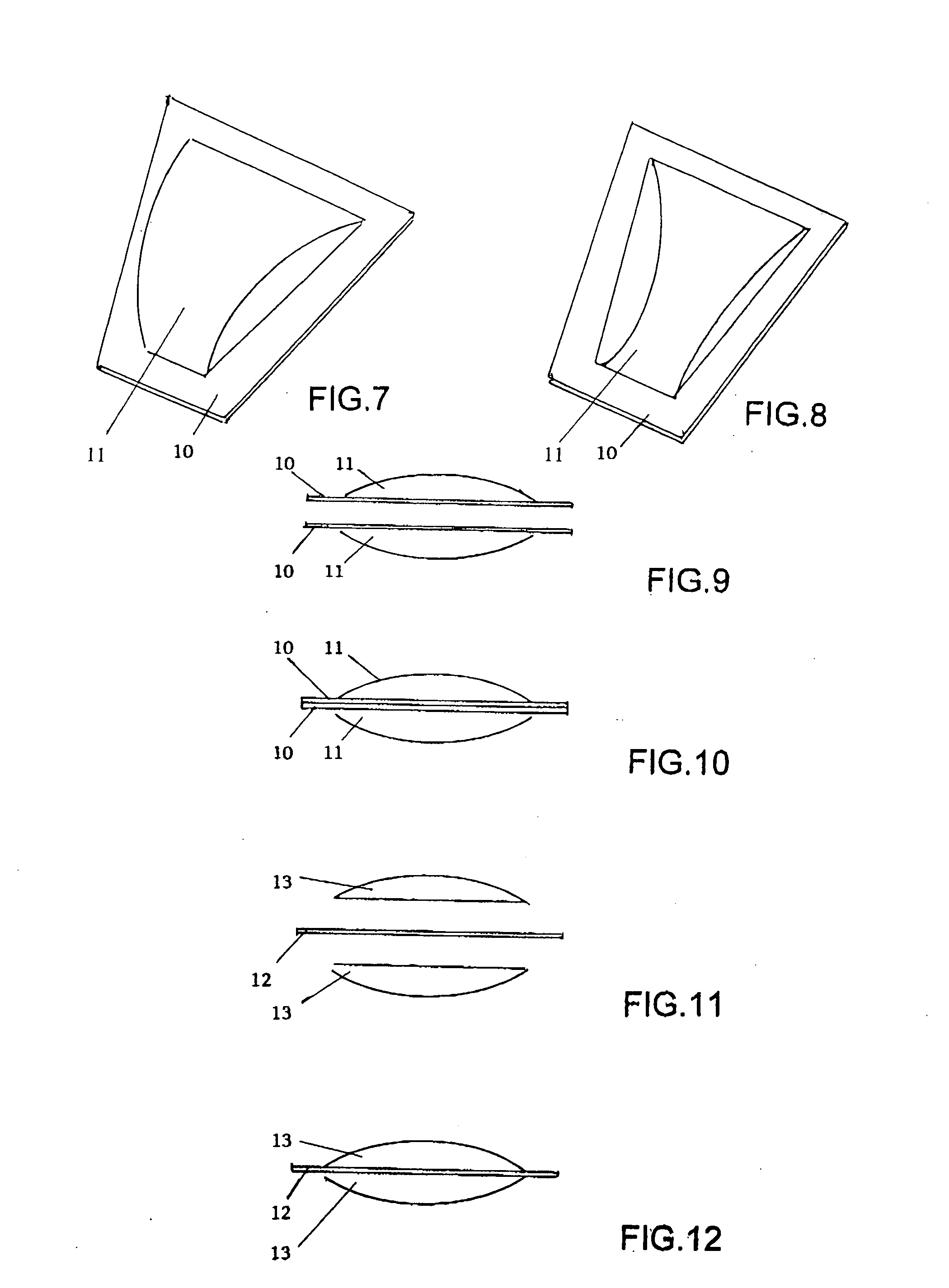

Acoustic transformer and method for transforming sound waves

InactiveUS20080006476A1Production becomes particularly simple and economicalReduce manufacturing costSound producing devicesFrequency/directions obtaining arrangementsTransformerAcute angle

An acoustic transformer for transforming sound waves generated by, for example, a round membrane, into a rectangular wave front with reduced interfering resonances is provided in a form of a waveguide with a generally circular entrance and a generally rectangular exit defined by outer walls. The sound waves, arriving from the radiating membrane, are divided geometrically into two flows of sound waves of generally semicircular cross section. Each of the two flows of sound waves is deformed individually into a rectangular shape. Subsequently, the flows of sound waves are brought together once again at an acute angle. The division of the sound flow of circular cross section into two sound flows of semicircular cross section creates two sound flows, which already have a straight side surface. The two sound flows are passed into curved sound guides, which initially have a generally semicircular cross section and then gradually change over into a generally rectangular cross section. A displacement structure which is approximately elliptical in cross section, thickens gradually and, after reaching a maximum, falls off once again, is disposed to protrude inward of the approximately straight and flat wall of each of the sound guides. Each of the displacement structures along with a corresponding one of the outer walls provides a sound channel, which initially is semicircular in cross section, with a bent cross section of uniform thickness and then stretches into a rectangular cross section at an end thereof.

Owner:KLING MARTIN +1

Electroacoustic method and device for stimulation of mass transfer processes for enhanced well recovery

ActiveUS7059403B2Highly efficient acousticImprove liquidityFluid removalVibration devicesPorous mediumAcoustic energy

Owner:SONOPLUS

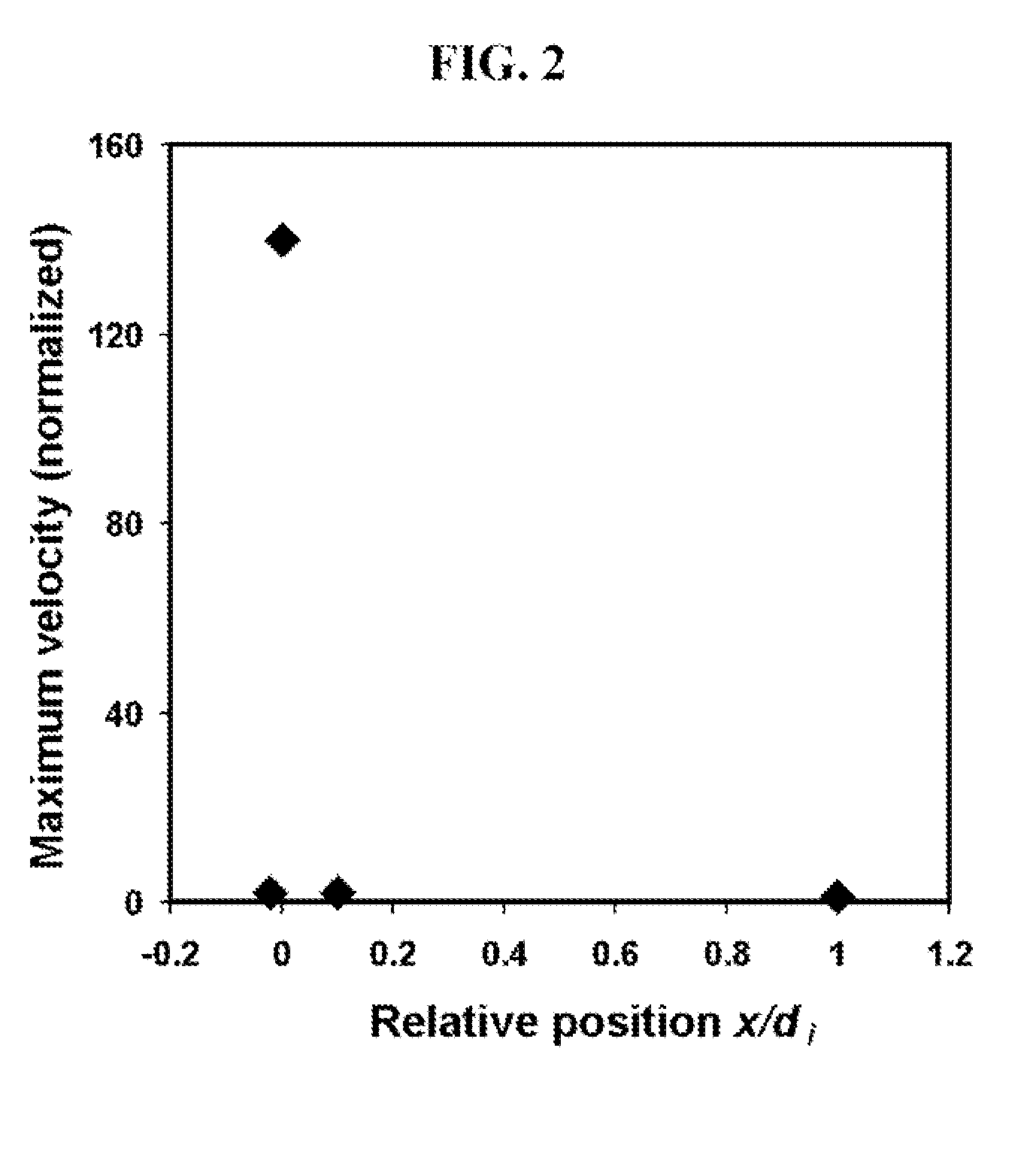

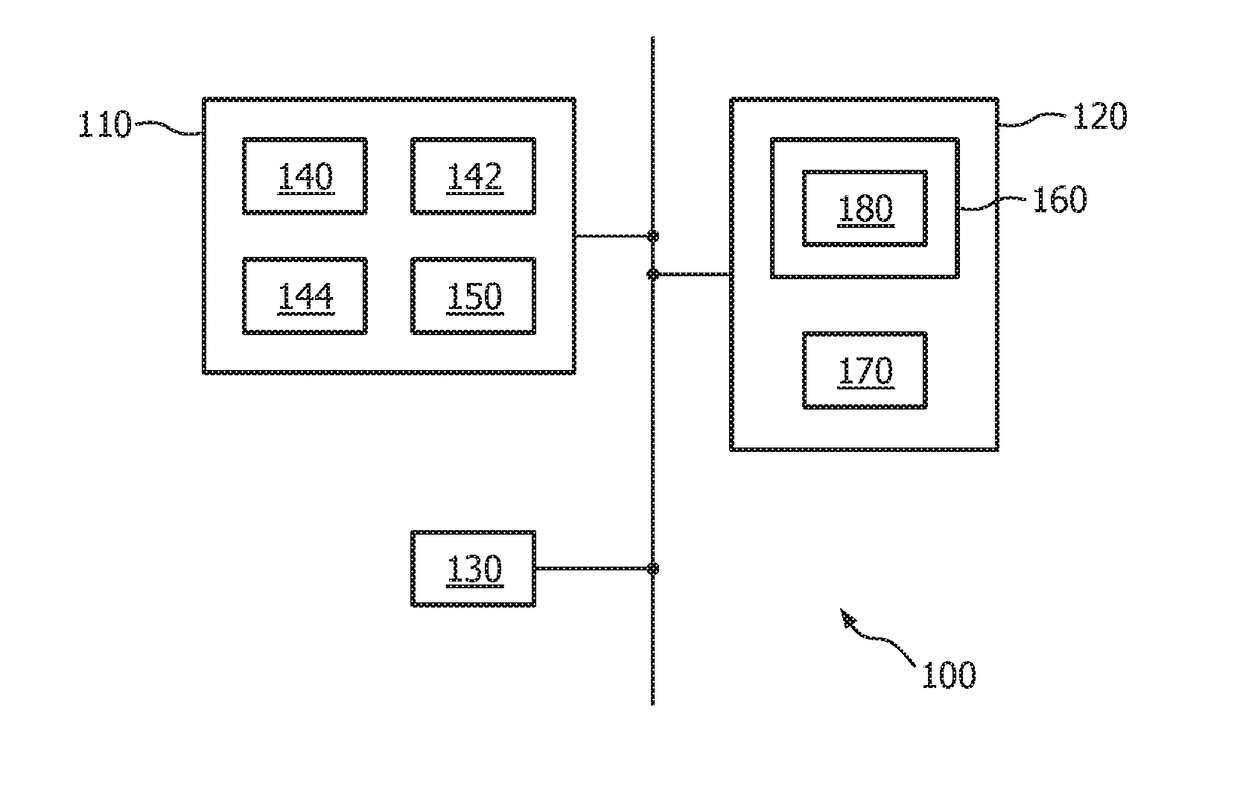

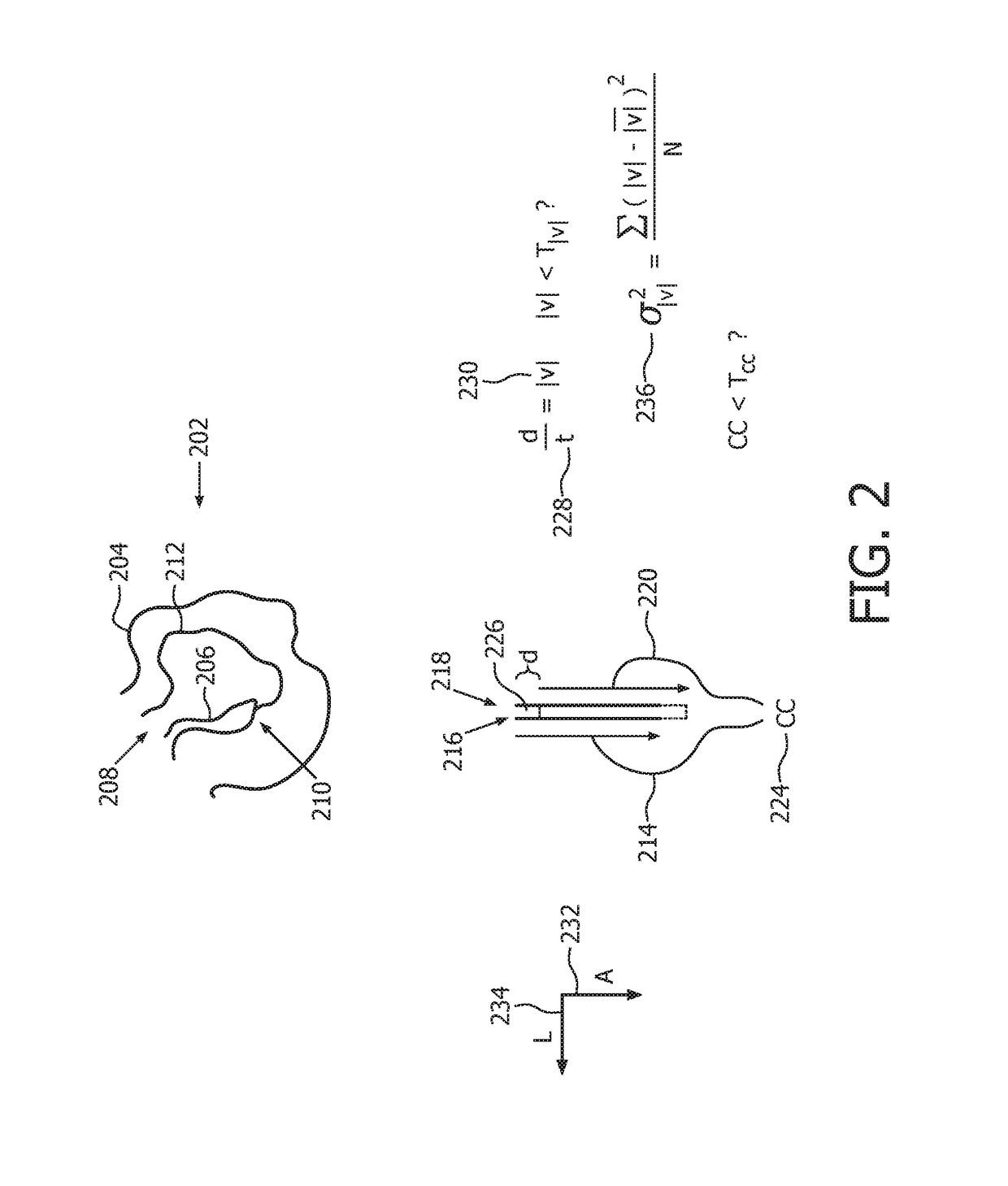

Acoustic streaming for fluid pool detection and identification

ActiveUS20170273658A1Inexpensive and fast and safe and convenient modalityReduce fieldImage enhancementImage analysisRelative displacementUltrasound attenuation

Ultrasound-based acoustic streaming for deciding whether material is fluid is dependent upon any one or more of a variety of criteria. Examples are displacement, speed (230), temporal or spatial flow variance, progressive decorrelation, slope or straightness of accumulated signal to background comparisons over time, and relative displacement to adjacent soft tissue. Echogenicity-based area identification is combinable with the above movement characteristic detection in the deciding. Fluid pool identification is performable from the area-limited acoustic streaming testing and ultrasound attenuation readings. Candidates from among the areas (210) are screenable based on specific shapes or bodily organs detected. Natural flow can be excluded from streaming detection by identification of blood vessels (206). Processing for each FAST ultrasound view (202), or for the entire procedure, is performable automatically, without need for user intervention or with user intervention to identify suspected areas.

Owner:KONINKLJIJKE PHILIPS NV

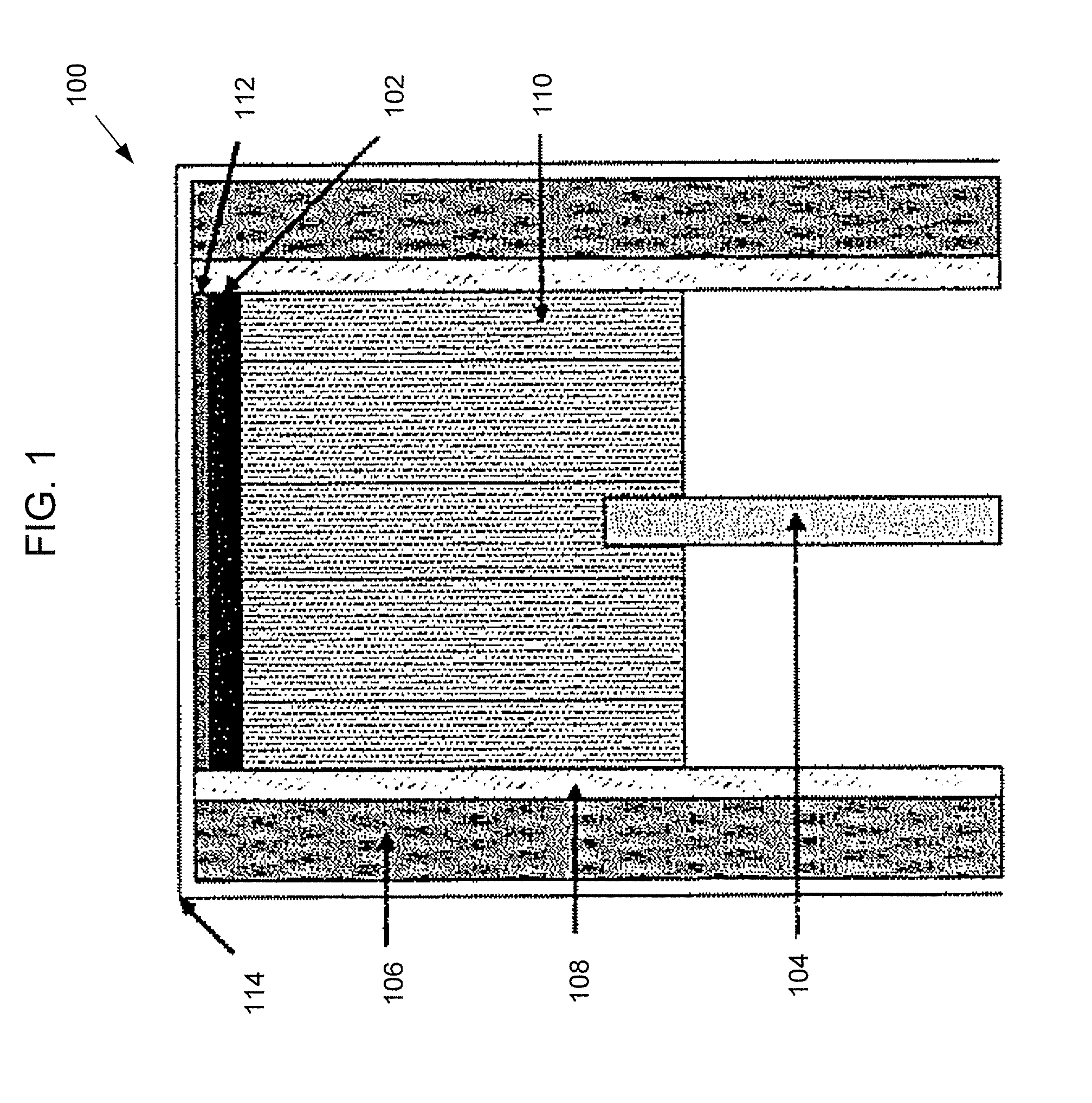

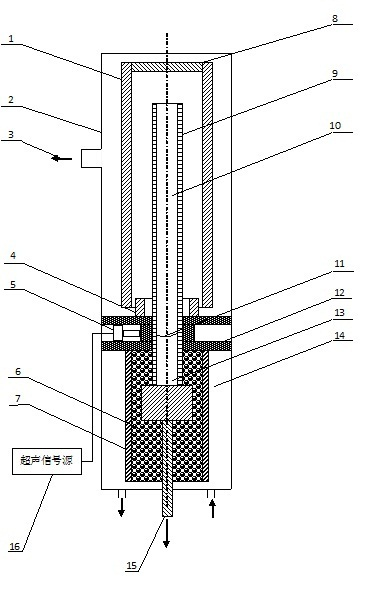

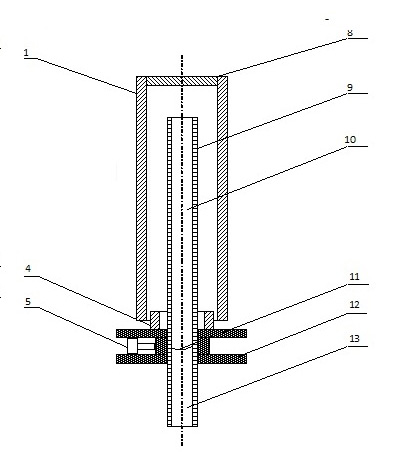

Method and device for directionally solidifying liquid/solid interface based on ultrasonic wave modulation

InactiveCN102357654AGuaranteed normal growthImprove quality and efficiencyPolycrystalline material growthFrom frozen solutionsInsulation layerEngineering

The invention provides a method and device for directionally solidifying a liquid / solid interface based on ultrasonic wave modulation. In the method, a group of ultrasonic waves is added near a peripheral liquid / solid interface of a crystallizer; the ultrasonic waves spread in a liquid phase to form a sound current; and the sound current forces the liquid phase to flow and stirs the liquid phase. The intensity of the sound current is related to the transmitting power and frequency of ultrasonic waves; and by modulating the transmitting power and frequency of the ultrasonic waves, a flat liquid / solid interface can be obtained. The device has the characteristics that a group of ultrasonic wave transmitting probes are added in a heat insulation layer at the lower end of a furnace, and the probes are externally connected with an ultrasonic signal source. By adjusting the applied ultrasonic waves to accurately control the melt to flow, the radial temperature and solute of the liquid / solid interface are re-distributed uniformly so as to ensure that the solidification material grows in a flat interface manner, the shortcomings are reduced, and the crystal quality and preparation efficiency are improved.

Owner:SHANGHAI UNIV

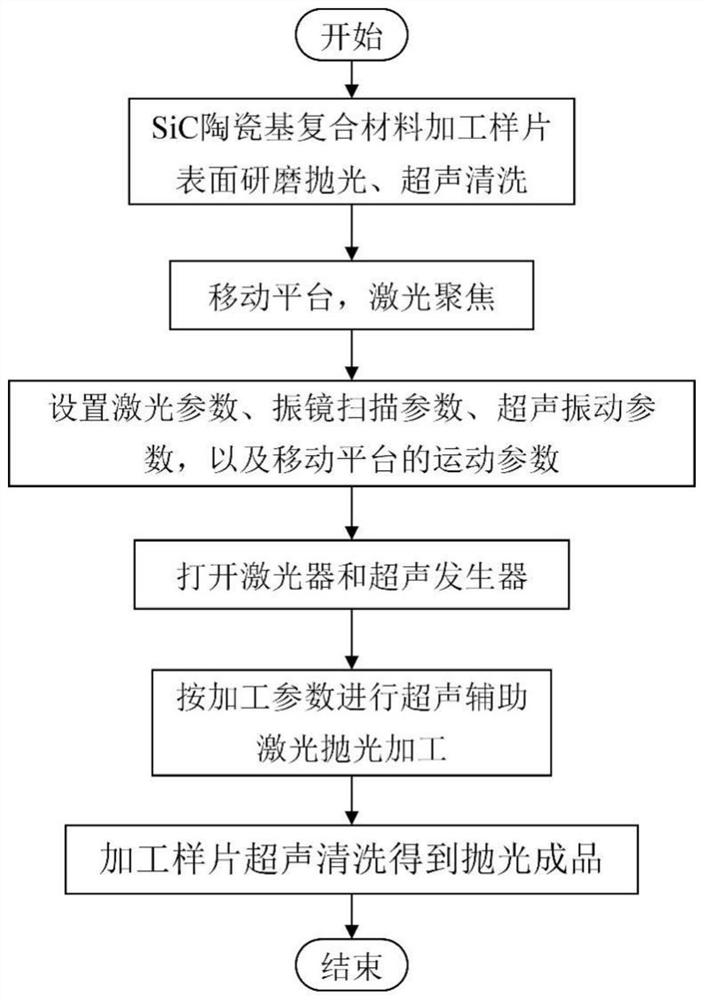

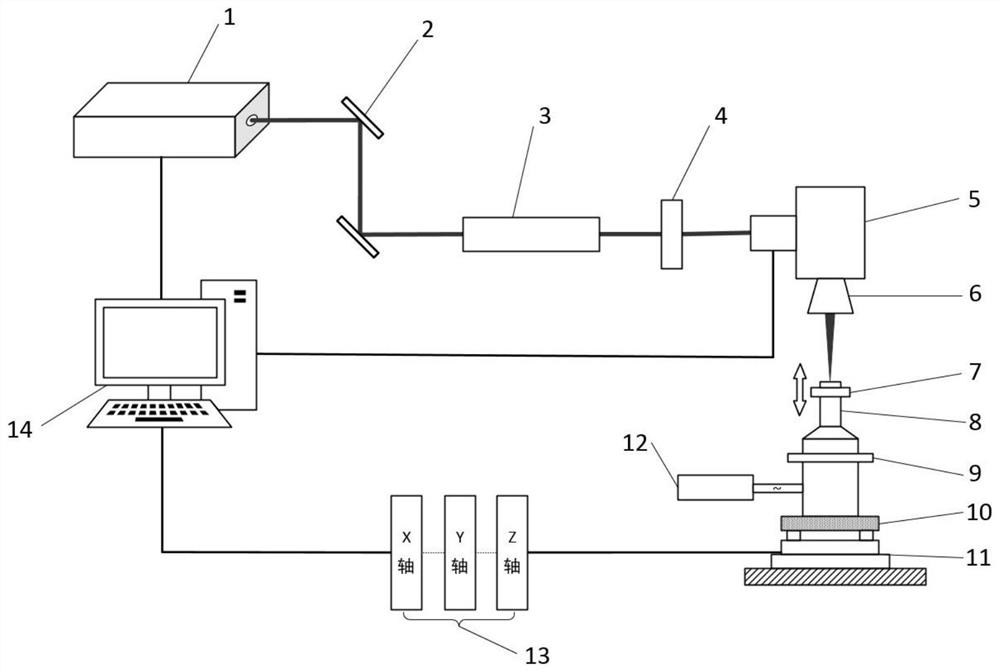

Method for ultrasonic-assisted laser polishing of ceramic-based composite material

InactiveCN111716005AAvoid shieldingAvoid scattering effectsLaser beam welding apparatusFemto second laserMaterial removal

The invention discloses a method for ultrasonic-assisted laser polishing of a ceramic-based composite material. The method comprises the following steps of firstly, grinding and polishing the surfaceof a machined sample wafer of a SiC ceramic-based composite material, and carrying out ultrasonic cleaning; fixing the machined sample wafer on an ultrasonic-assisted laser polishing processing device, and moving a platform to focus the laser to an initial machining position; setting a laser parameter, a galvanometer scanning parameter, an ultrasonic vibration parameter and a motion parameter of an XYZ high-precision mobile platform, starting a femtosecond laser and an ultrasonic generator, and carrying out ultrasonic-assisted laser polishing machining on the machined sample wafer by using theadjusted parameters; and after polishing is completed, carrying out ultrasonic cleaning on the machined sample wafer again. According to the method, the laser machining method and the ultrasonic machining method are combined, the effects of acoustic streaming, cavitation and the like of ultrasonic waves are fully utilized, the problems of defects such as a recast layer and surface cracks caused by the plasma effect and the particle adhesion effect in the laser polishing process are solved, the laser machining process is optimized, and the material removal rate and the polished surface qualityare improved.

Owner:XI AN JIAOTONG UNIV

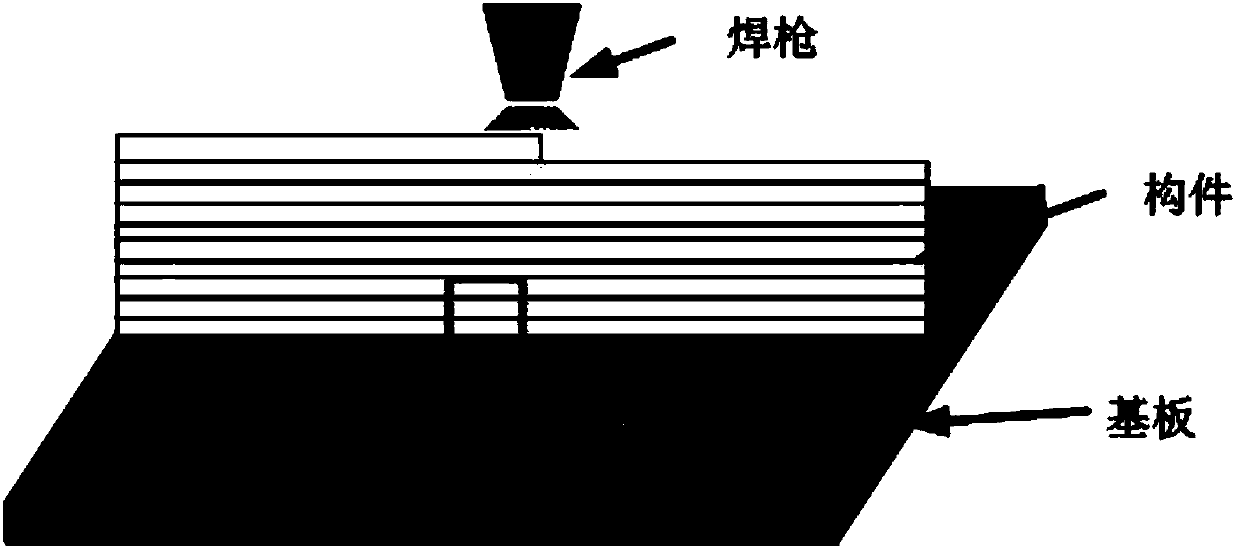

CMT-ultrasonic vibration composite additive manufacturing method

InactiveCN110480125AImprove mechanical propertiesAdditive manufacturing apparatusArc welding apparatusUltrasonic vibrationMechanical property

The invention discloses a CMT-ultrasonic vibration composite additive manufacturing method. A substrate is ultrasonically vibrated when CMT arc additive manufacturing is performed. After ultrasonic vibration, a fine and uniform component with a non-dendritic structure can be obtained. Under the cavatition and the acoustic streaming effect of ultrasonic vibration, a molten pool is ultrasonically vibrated before solidification, a large amount of fine bubble cores are generated, and the fine bubble cores are reserved to form a core-forming core, so that a solidification structure is refined; andduring the solidification process, the dendritic crystals are broken due to the ultrasonication, so that a fine and uniform structure is formed, and the mechanical property of the component is effectively improved.

Owner:TIANJIN UNIV

Carbon-aluminum interface wetting and structure regulating and controlling device and method under ultrasonic field coupling

A carbon-aluminum interface wetting and structure regulating and controlling device and method under ultrasonic field coupling are provided. The device comprises a vacuum cover, an object stage, a crucible, a radiator, a coupler, a liquid adding device, a heating resistance and a thermocouple; the radiator is connected with the coupler and an ultrasonic power supply; the object stage is assembled together with a thread screw rod and a drive motor; the vacuum cover is communicated with an atmosphere control device, an inert gas system and a vacuum pump system through valves. The method comprises the steps: placing a carbon substrate in the crucible; adjusting an atmosphere in the vacuum cover; adding a metal melt into the crucible, and adjusting the height of the object stage; vacuumizing; introducing an inert gas to the normal pressure; heating through the heating resistance; controlling the carbon substrate to rotate so as to make a metal melt oxide film ruptured; and carrying out ultrasonic coupling of the metal melt. The device and the method are integrated with acoustic streaming and cavitation of an ultrasonic field, and obtain ideal interface structure control conditions through optimization of acoustic field collaborative conditions and optimization of wetting and interface reaction conditions.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com