Patents

Literature

915 results about "Carbon substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

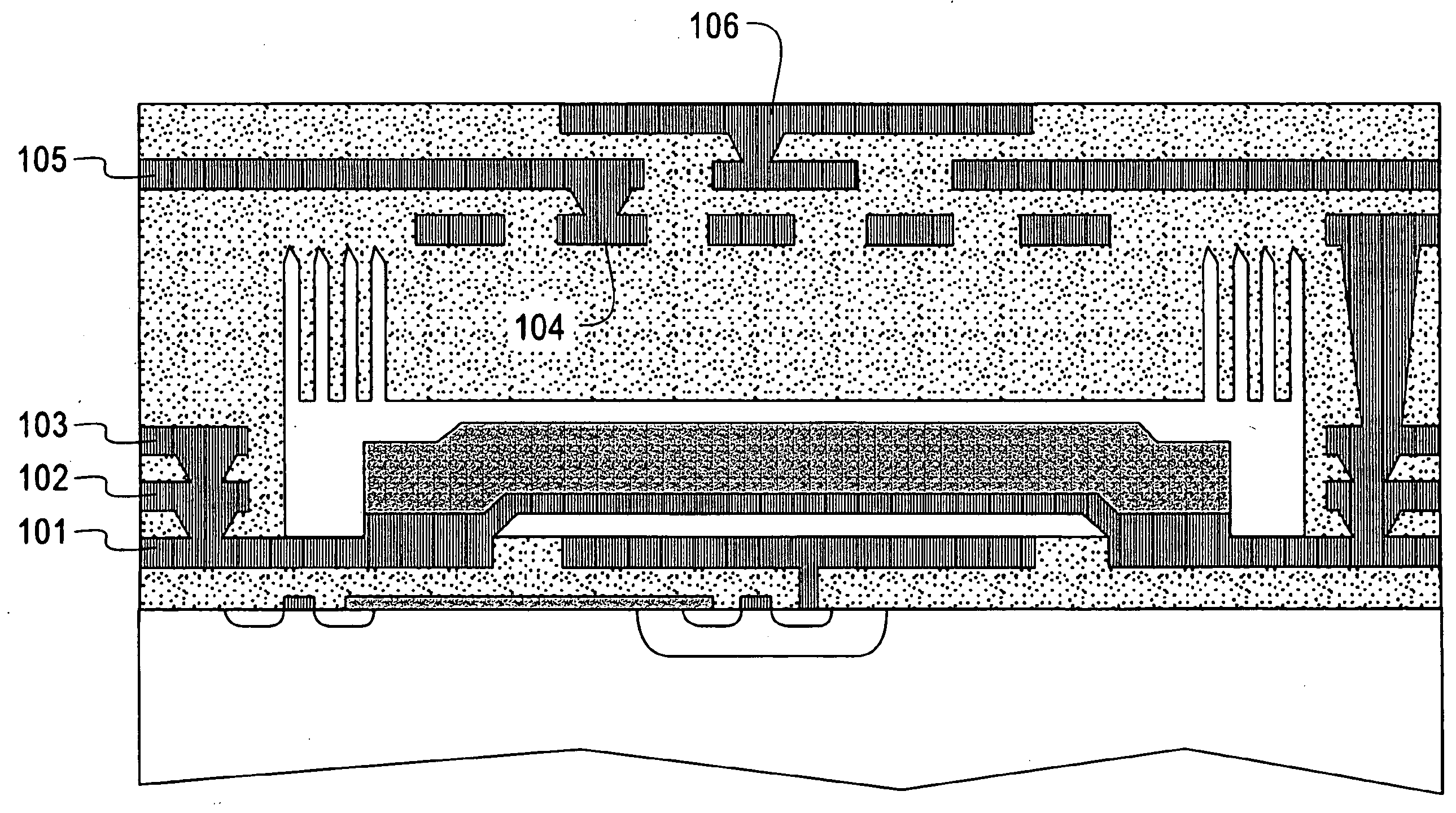

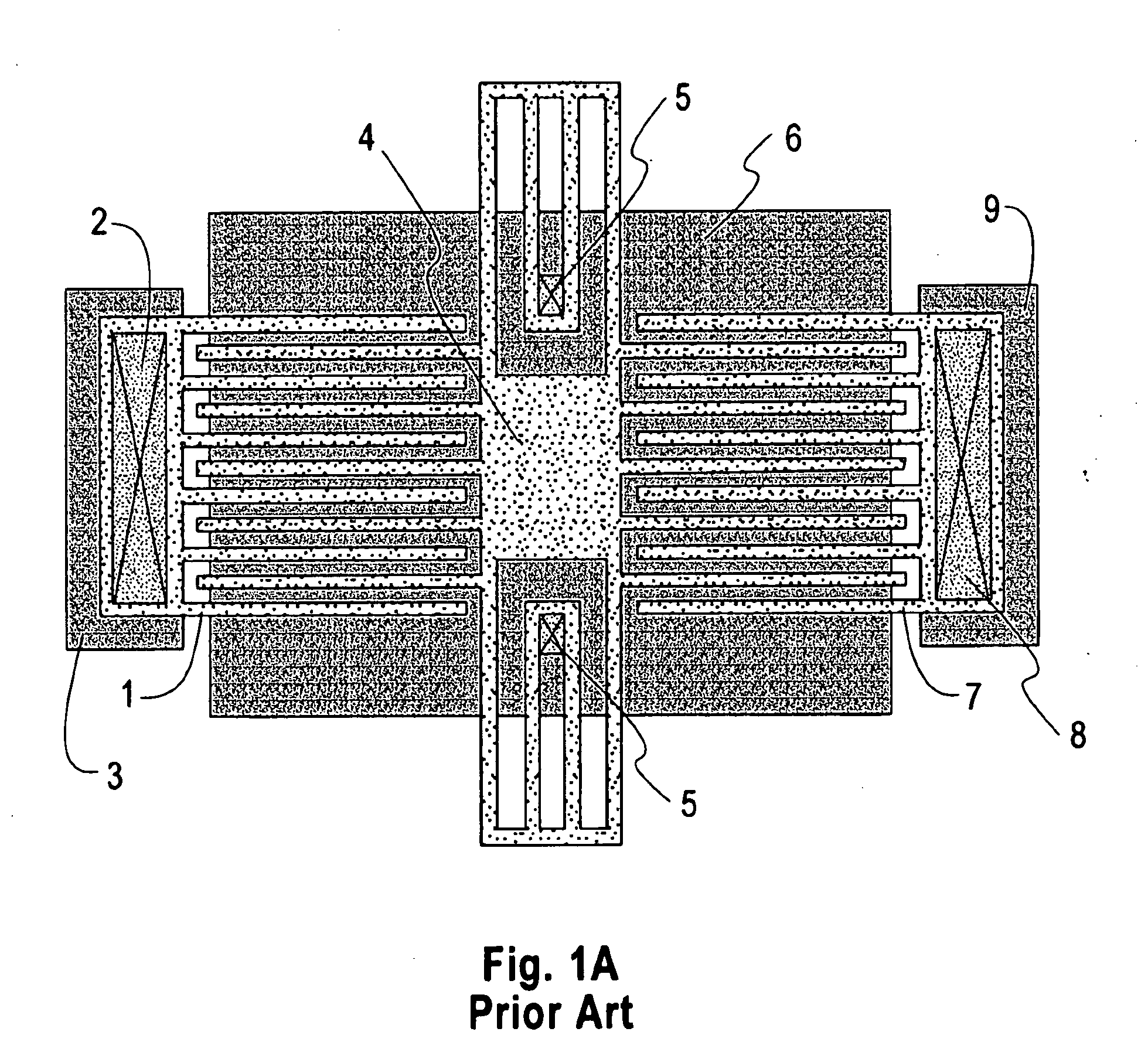

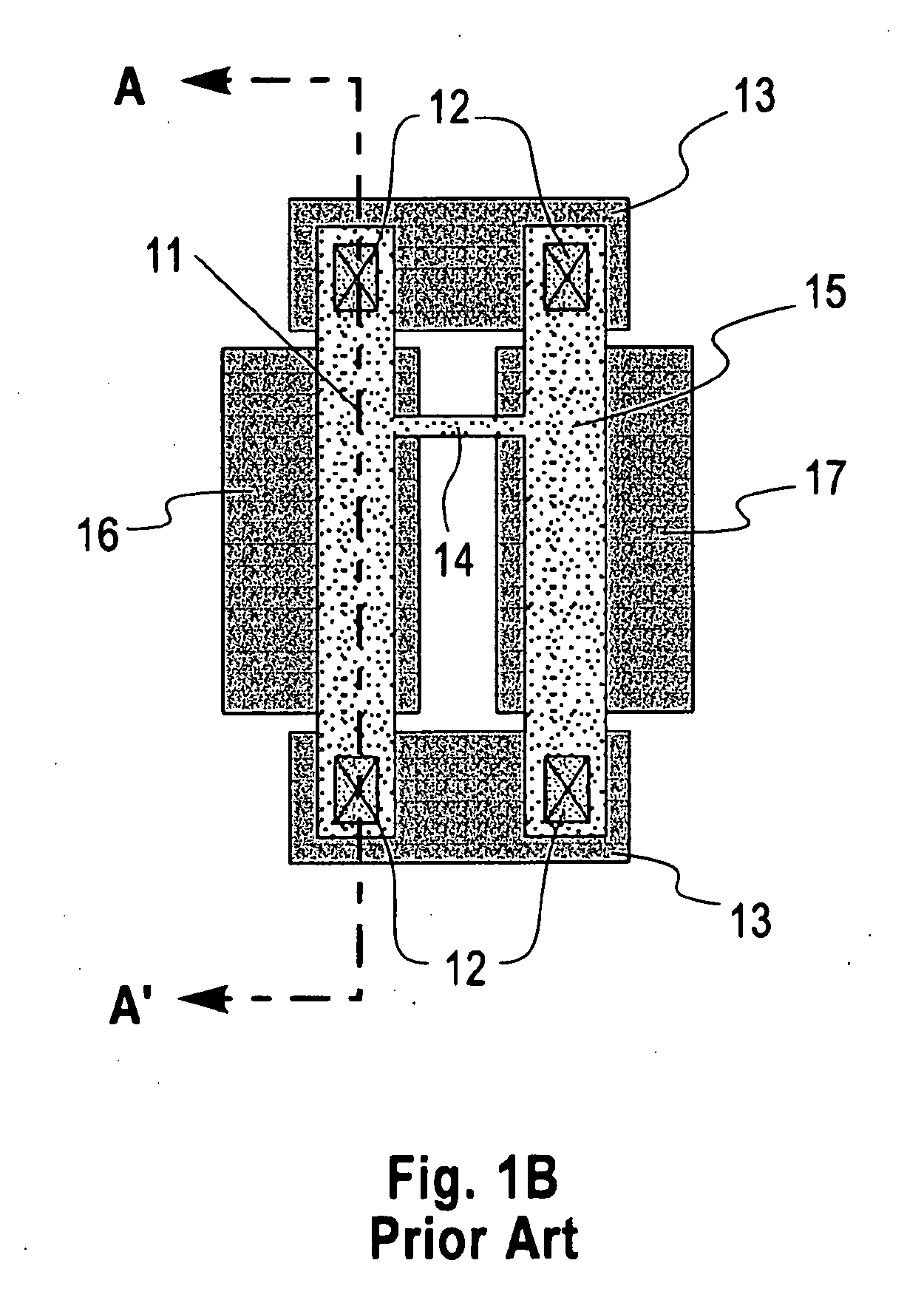

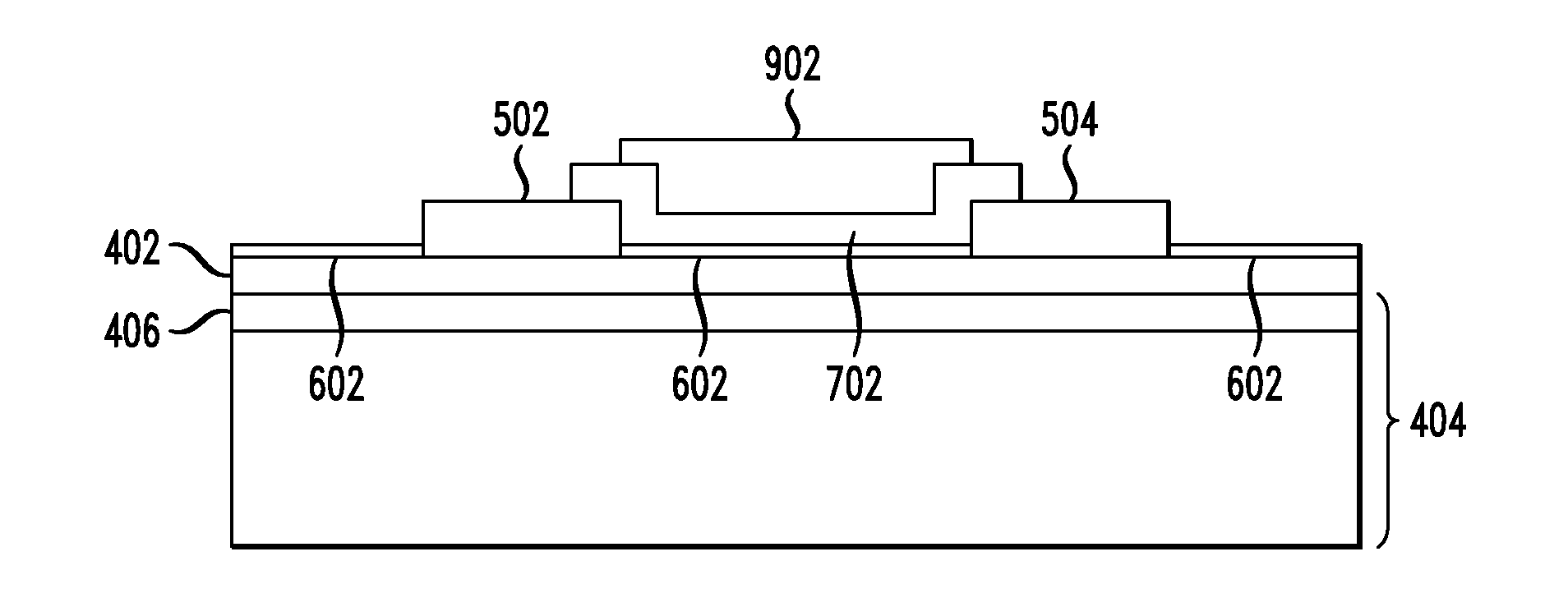

Low temperature bi-CMOS compatible process for MEMS RF resonators and filters

InactiveUS20090108381A1Impedence networksSemiconductor/solid-state device detailsMetal interconnectOxygen plasma

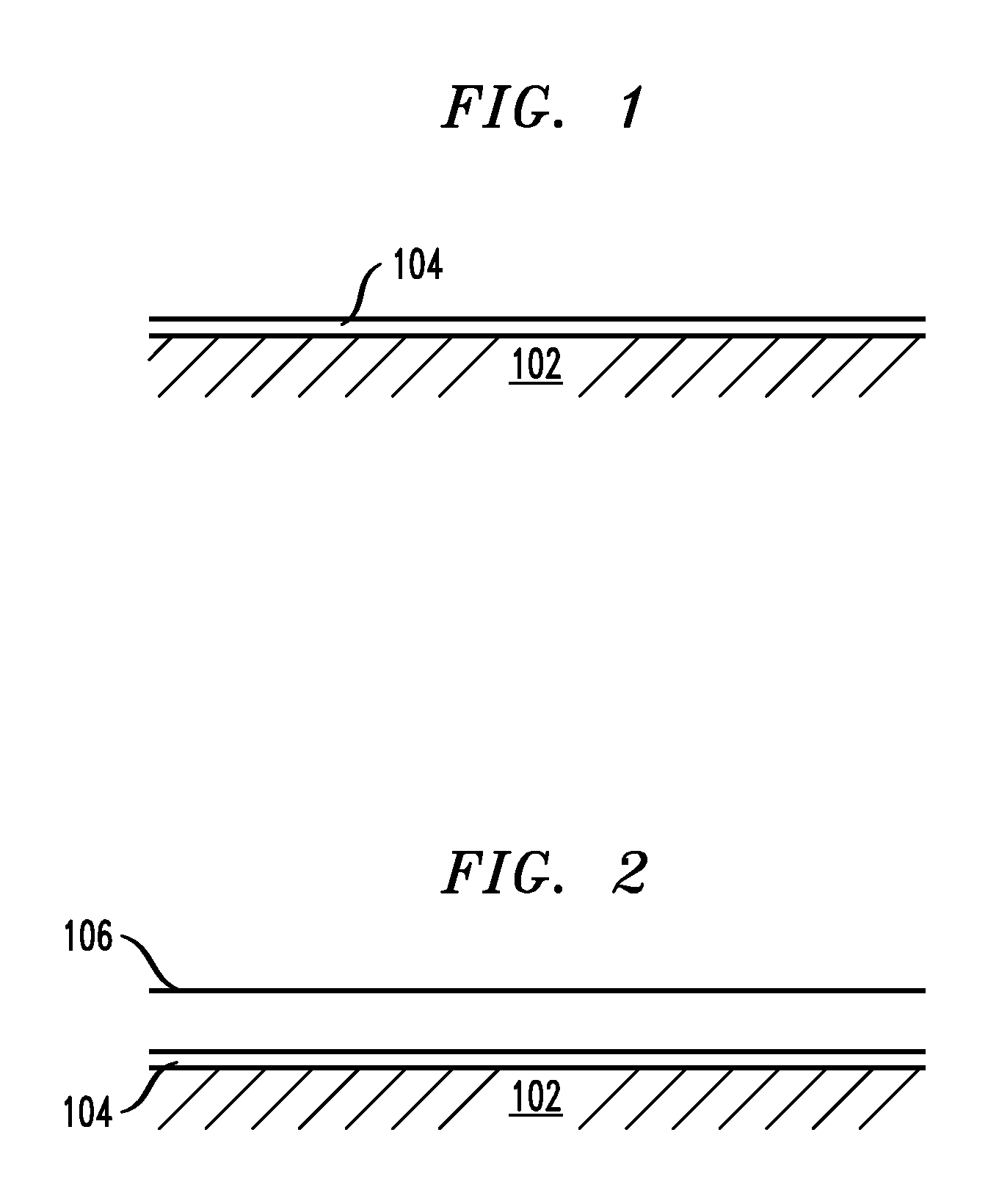

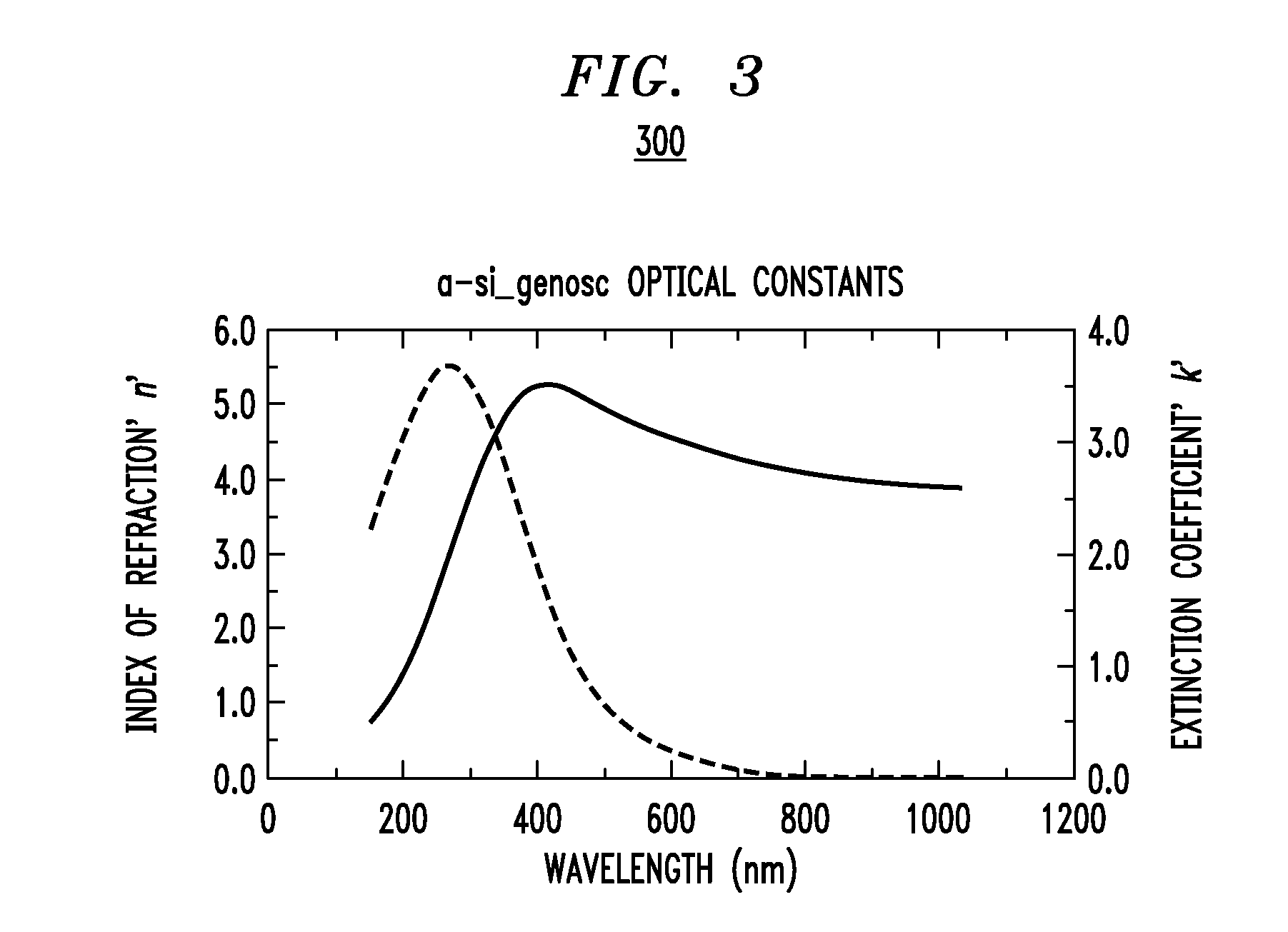

A method of formation of a microelectromechanical system (MEMS) resonator or filter which is compatible with integration with any analog, digital, or mixed-signal integrated circuit (IC) process, after or concurrently with the formation of the metal interconnect layers in those processes, by virtue of its materials of composition, processing steps, and temperature of fabrication is presented. The MEMS resonator or filter incorporates a lower metal level, which forms the electrodes of the MEMS resonator or filter, that may be shared with any or none of the existing metal interconnect levels on the IC. It further incorporates a resonating member that is comprised of at least one metal layer for electrical connection and electrostatic actuation, and at least one dielectric layer for structural purposes. The gap between the electrodes and the resonating member is created by the deposition and subsequent removal of a sacrificial layer comprised of a carbon-based material. The method of removal of the sacrificial material is by an oxygen plasma or an anneal in an oxygen containing ambient. A method of vacuum encapsulation of the MEMS resonator or filter is provided through means of a cavity containing the MEMS device, filled with additional sacrificial material, and sealed. Access vias are created through the membrane sealing the cavity; the sacrificial material is removed as stated previously, and the vias are re-sealed in a vacuum coating process.

Owner:IBM CORP

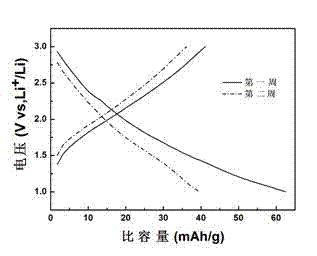

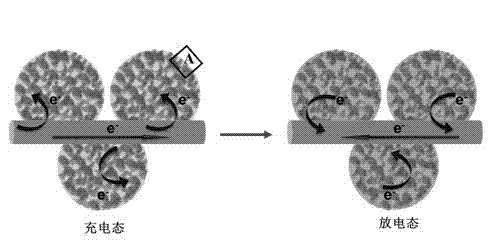

Carbon/silicon/carbon nano composite structure cathode material and preparation method thereof

The invention discloses a carbon / silicon / carbon nano composite structure cathode material and a preparation method thereof, belonging to the technical field of electrochemical power supply technologies. The cathode material consists of a carbon-based conductive substrate, nano silicon and a nano carbon coating layer, wherein the nano silicon is uniformly distributed on the carbon-based conductive substrate; the nano carbon coating layer is arranged on the surface of the nano silicon; the carbon-based conductive substrate is porous carbon, a carbon nanotube or graphene; the nano silicon exists in the state of nanoparticles or nano films; the weight percentage of the nano silicon in the cathode material is 10-90 percent; and the thickness of the nano carbon coating layer is 0.1-10 nanometers. The preparation method comprises the following steps of: depositing nano silicon on the carbon substrate in a reaction space in oxygen-free atmosphere by adopting a chemical vapor deposition process; and coating nano carbon on the surface of the nano silicon by adopting the chemical vapor deposition process. In the obtained carbon / silicon / carbon composite cathode material, the volume change of a silicon electrode material is controlled effectively in the charging and discharging processes, the electrode structure is kept complete, the circulation volume is large, the circulation service life is long, and the electrochemical performance is high.

Owner:TSINGHUA UNIV

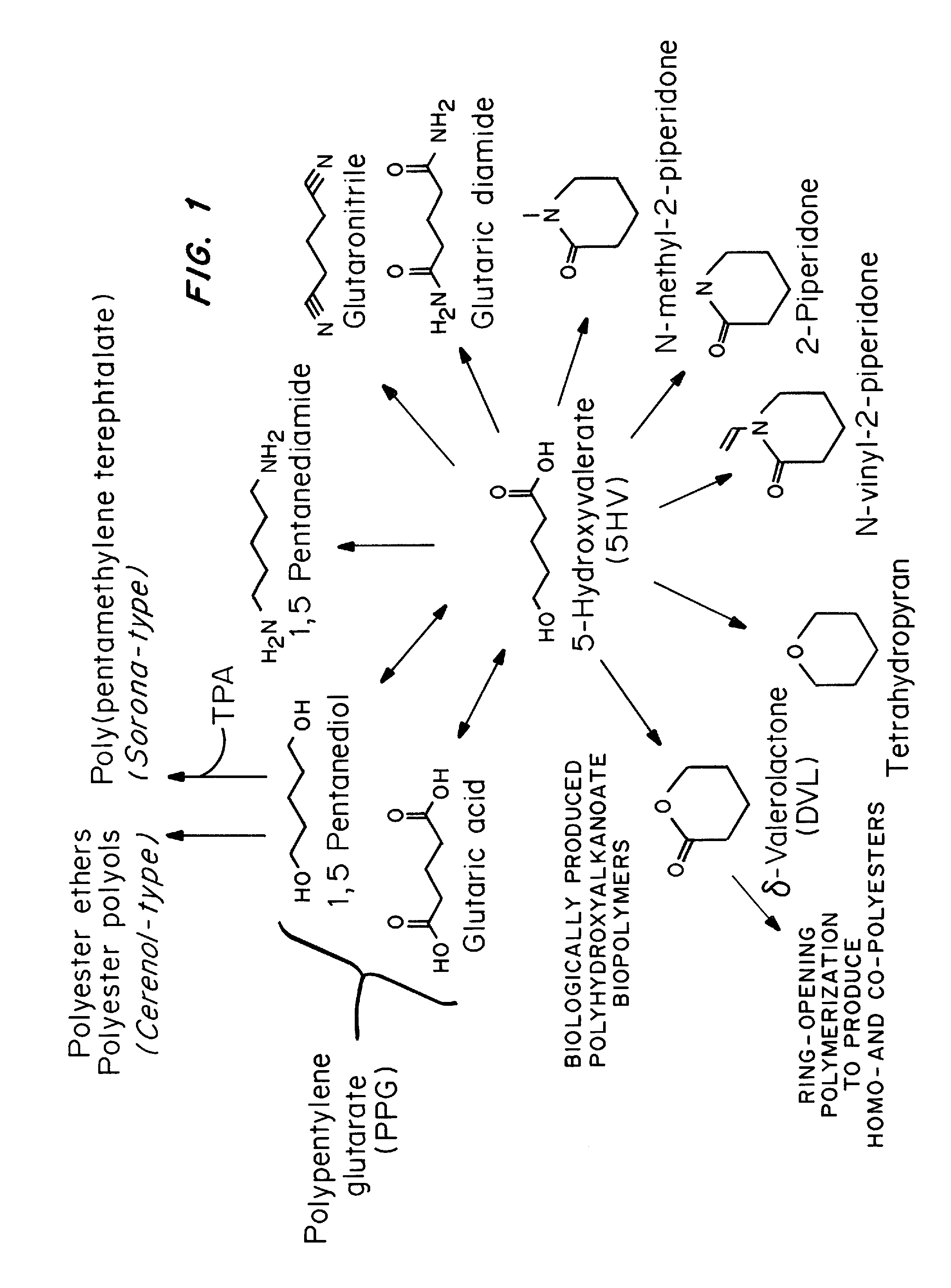

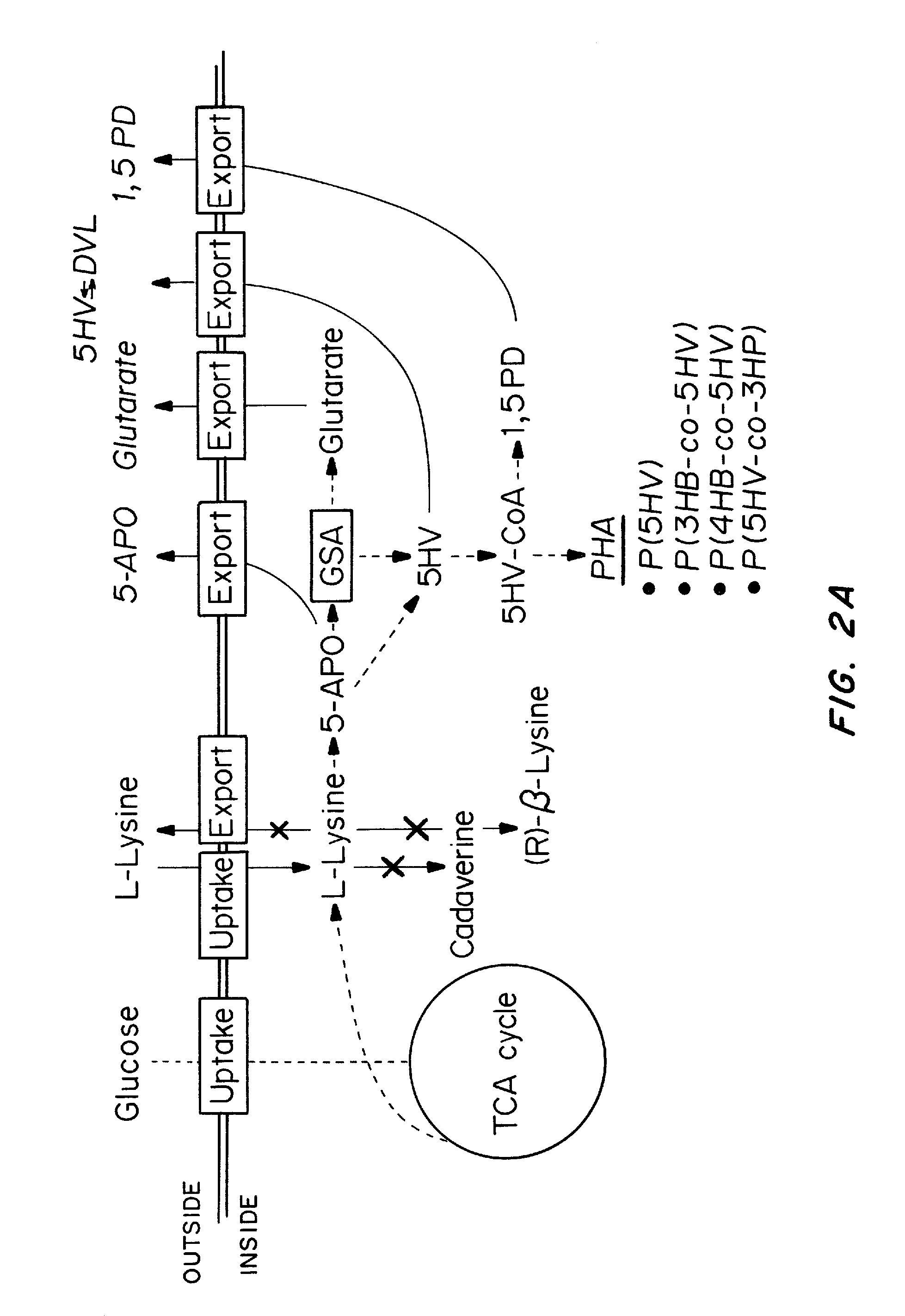

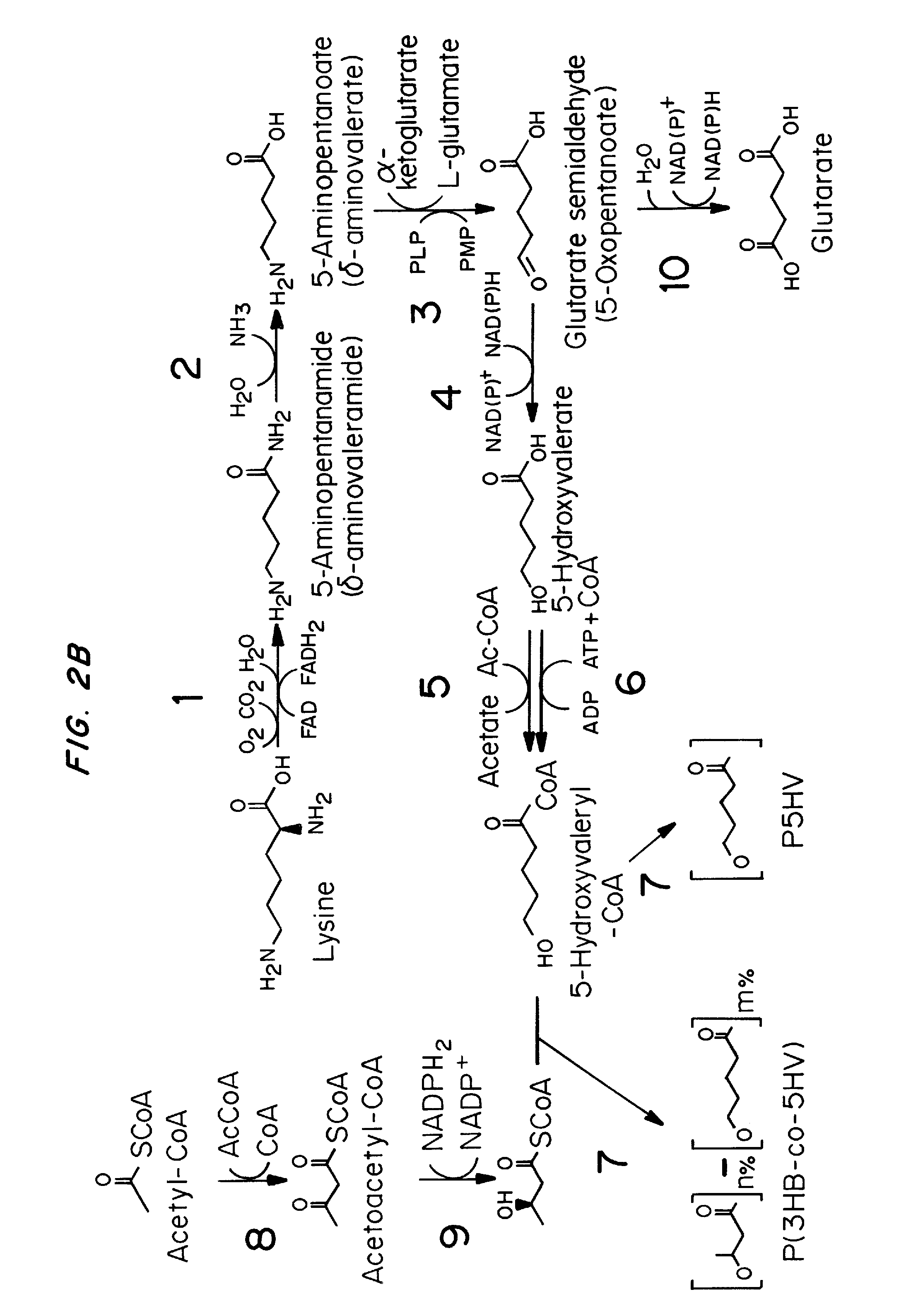

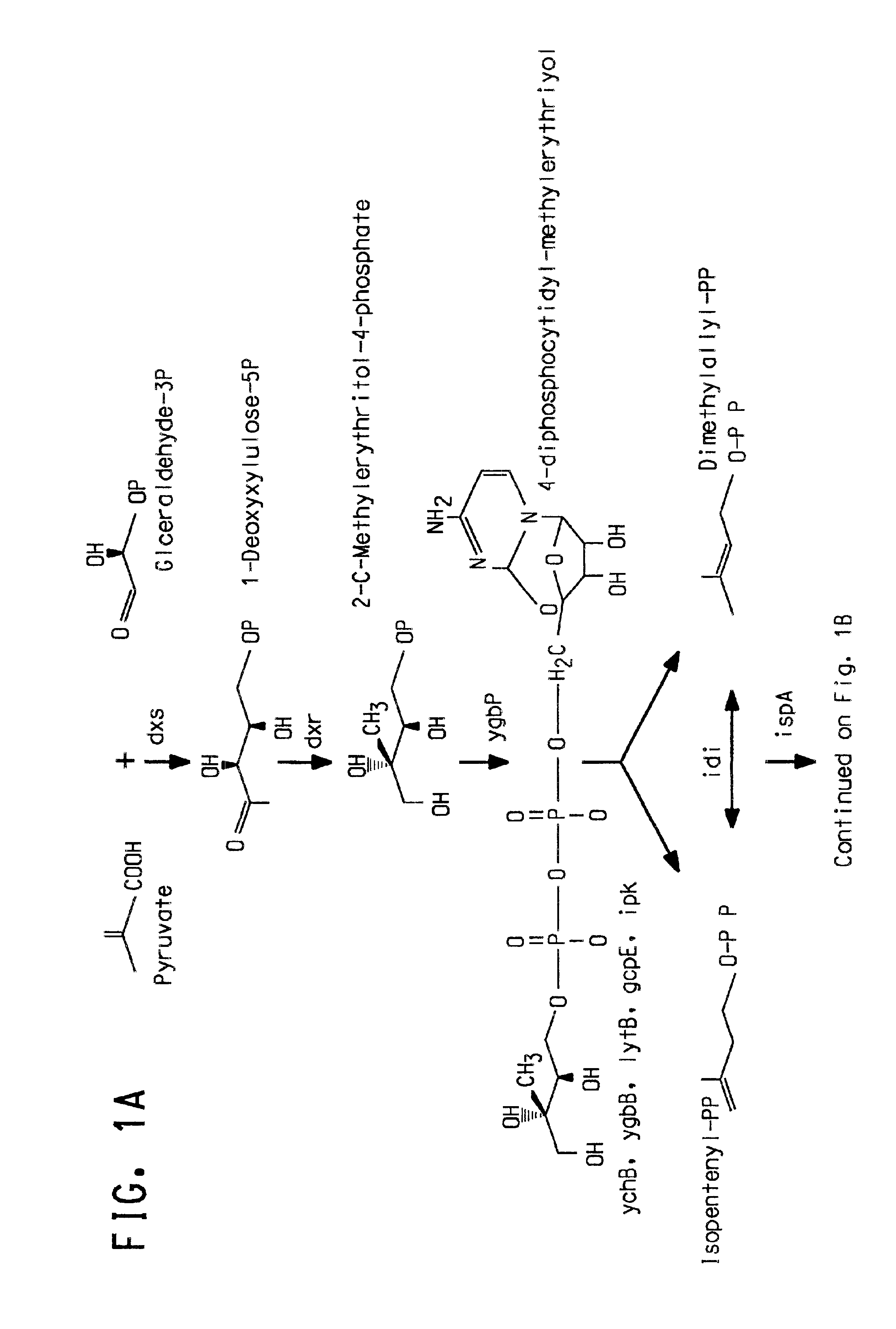

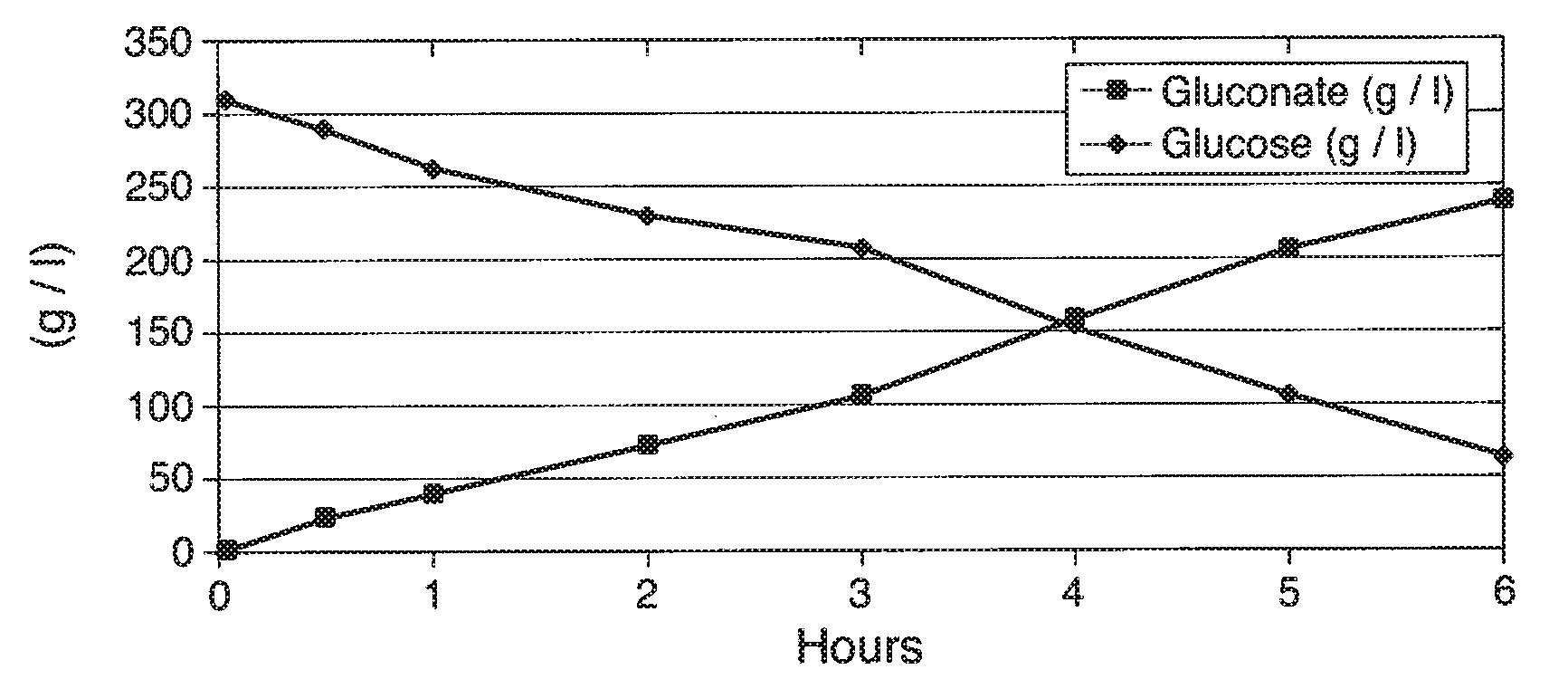

Green process and compositions for producing poly(5HV) and 5 carbon chemicals

Recombinant hosts for producing polyhydroxyalkanoates and methods of producing polyhydroxyalkanoates from renewable carbon substrates are provided. Certain recombinant hosts that produce 5 carbon chemicals such as 5-aminopentanoate (5AP), 5-hydroxyvalerate (5HV), glutarate, and 1,5 pentanediol (PDO) are also provided. One embodiment provides a recombinant host expressing a gene encoding a heterologous enzyme selected from the group consisting of a polyhydroxyalkanoate synthase and a 5-hydroxyvalerate-CoA (5HV-CoA) transferase, wherein the host produces a polymer containing 5-hydroxyvalerate. Preferably, the host expresses both a polyhydroxyalkanoate synthase and a 5HV-CoA transferase. The host can be prokaryotic or eukaryotic. A preferred prokaryotic host is E. coli. The polymers produced by the recombinant hosts can be homopolymers or copolymers of 5-hydroxyvalerate. A preferred copolymer is poly(3-hydroxybutyrate-co-5-hydroxyvalerate).

Owner:CJ CHEILJEDANG CORP

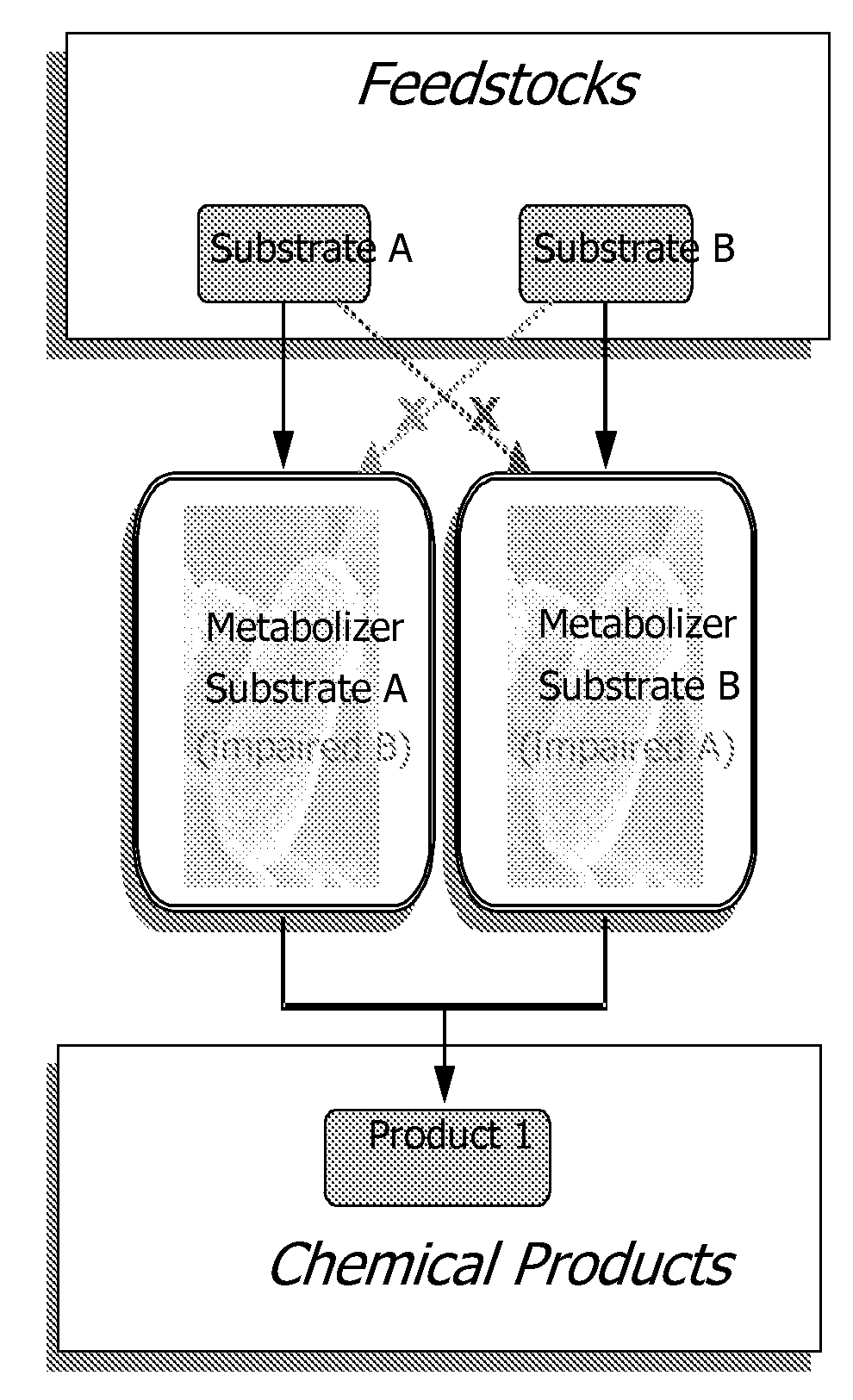

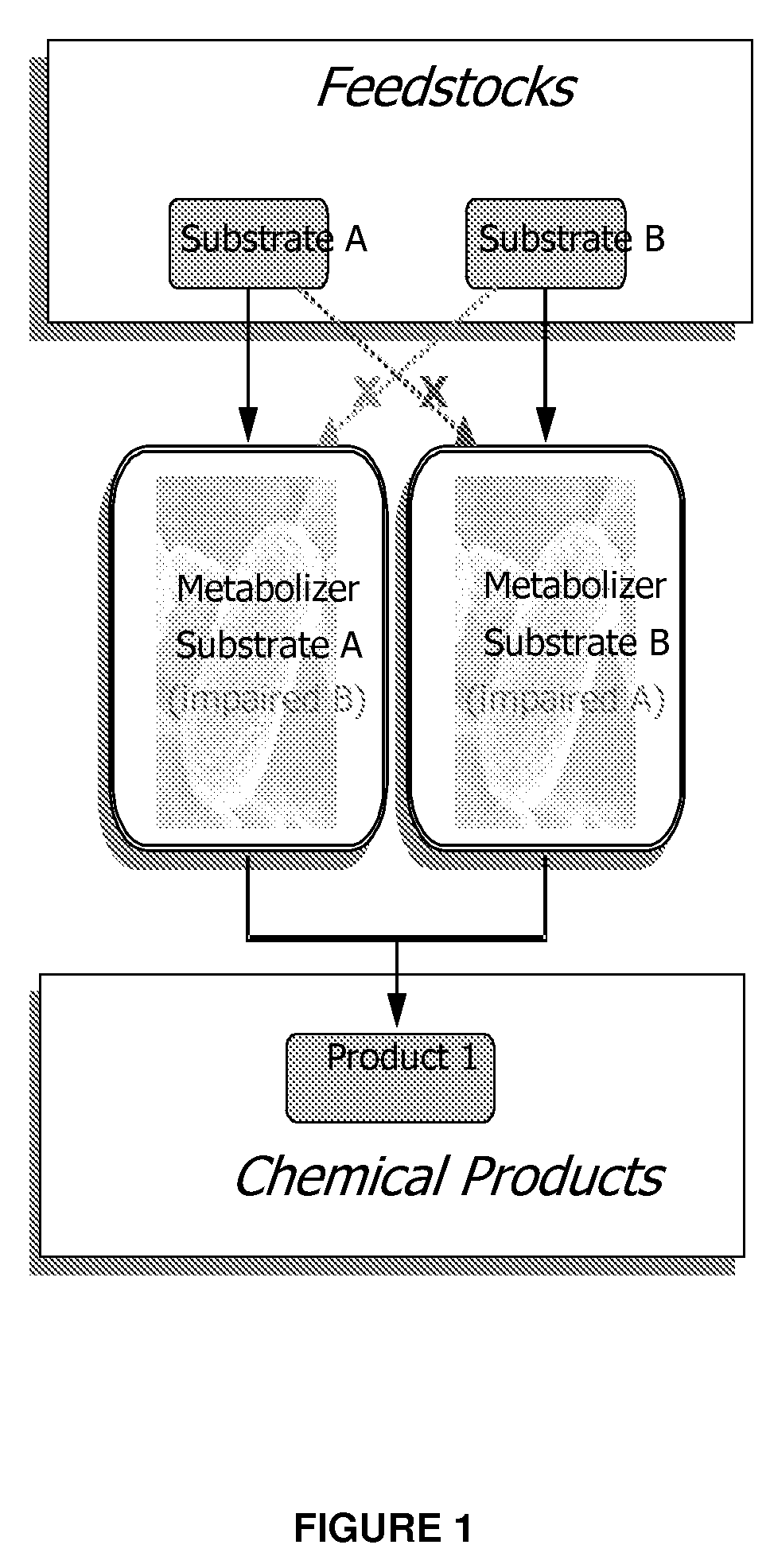

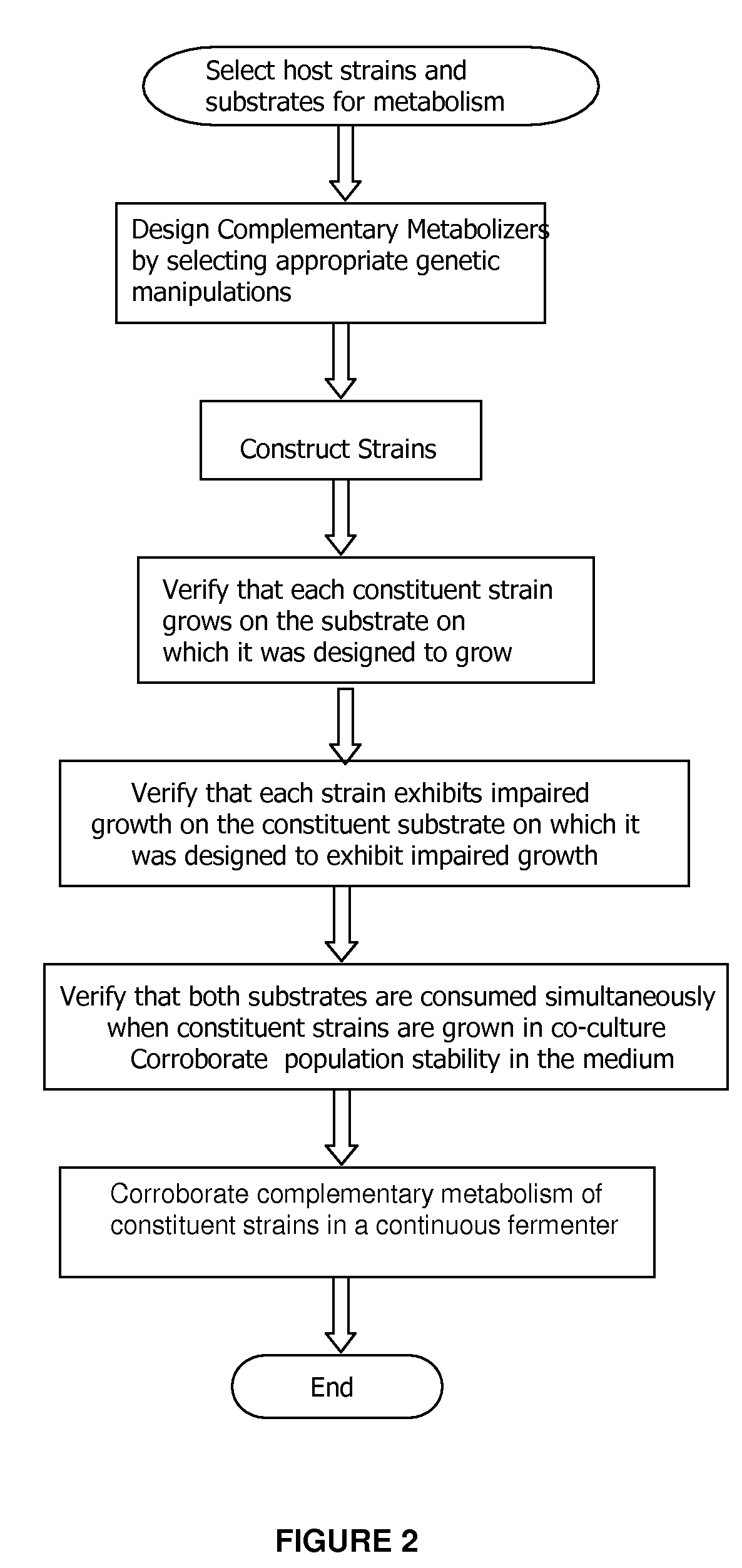

Complementary metabolizing organisms and methods of making same

InactiveUS20090023182A1Impaired metabolic capacityIncrease metabolic rateFermentationMicrobiology processesOrganismBiology

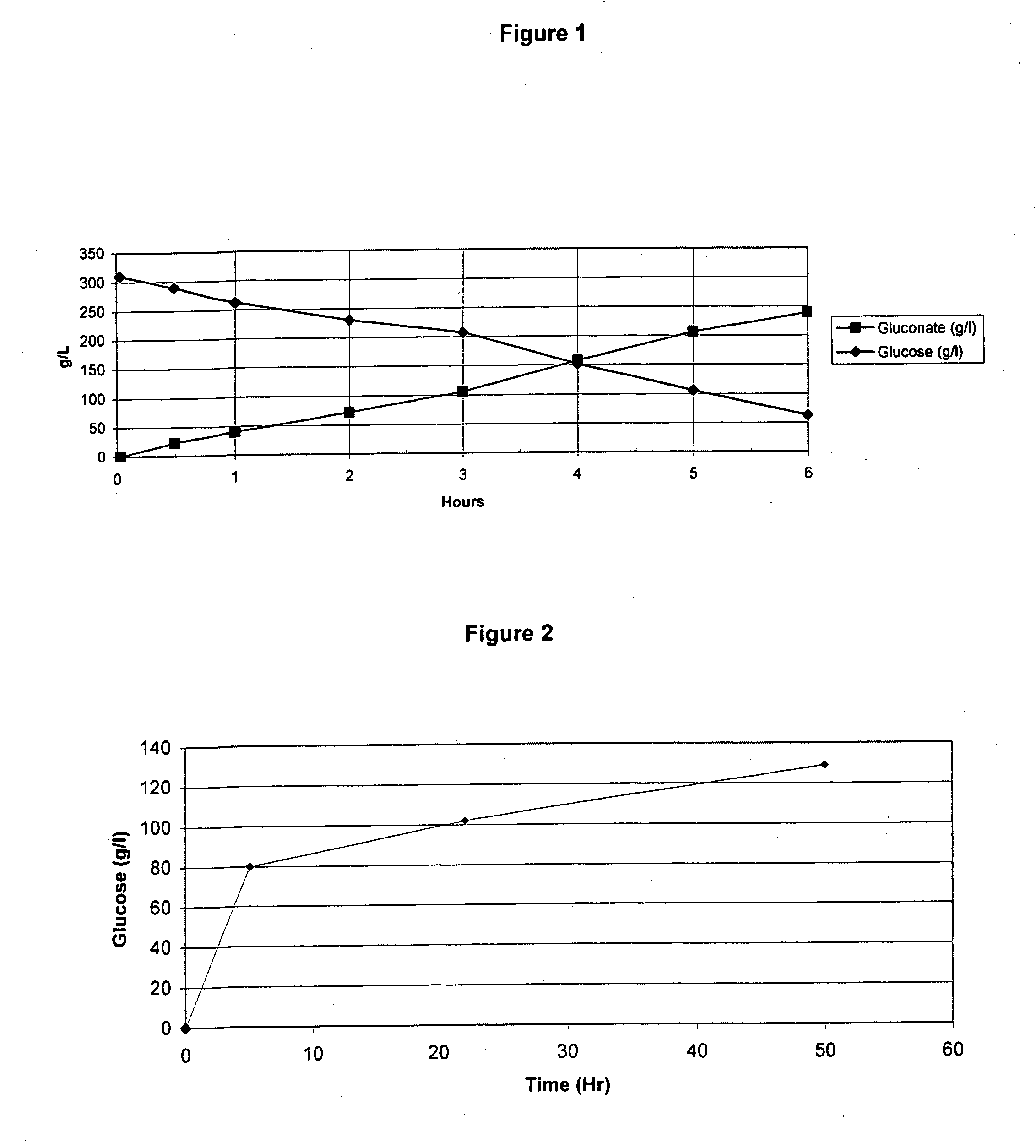

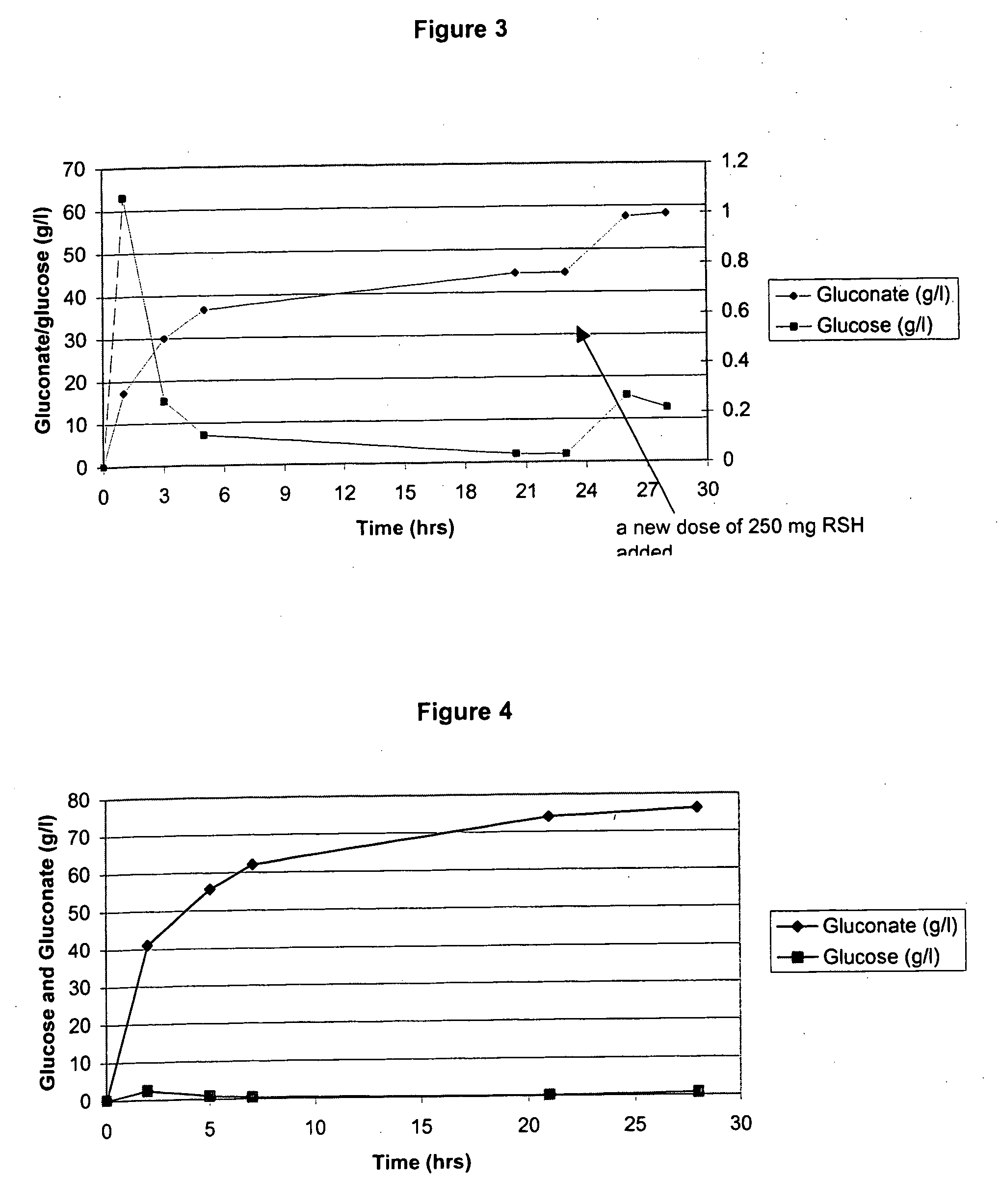

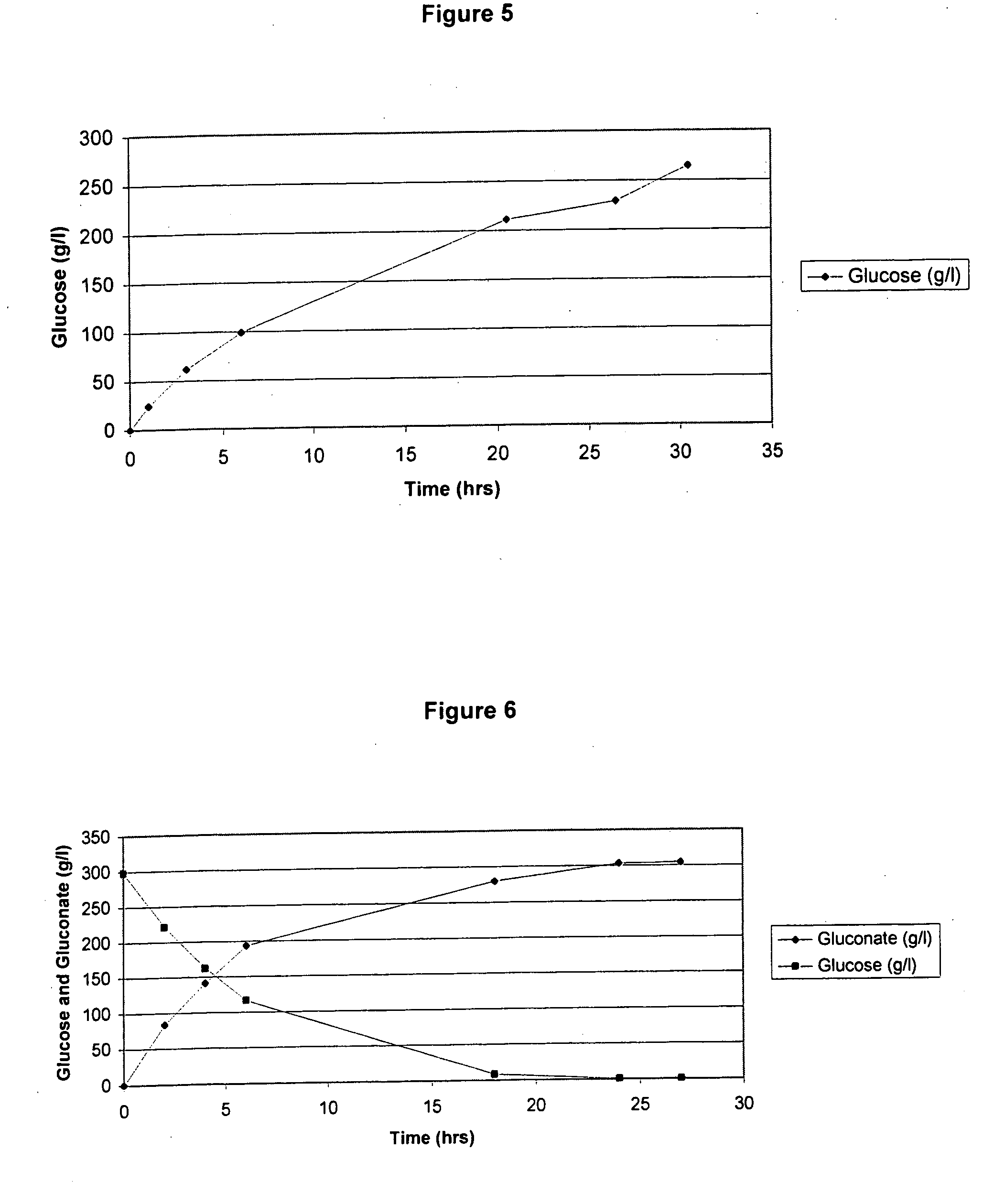

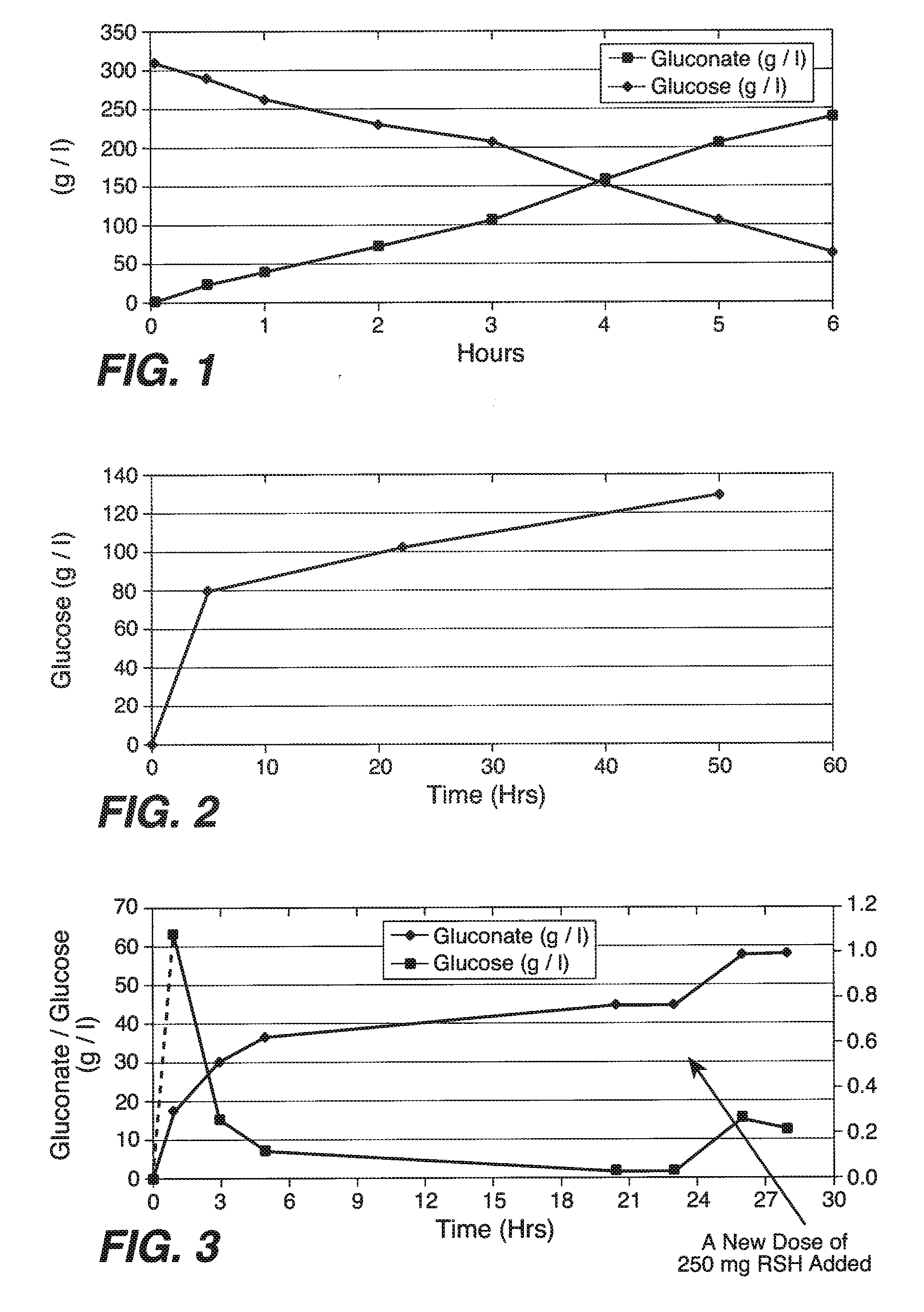

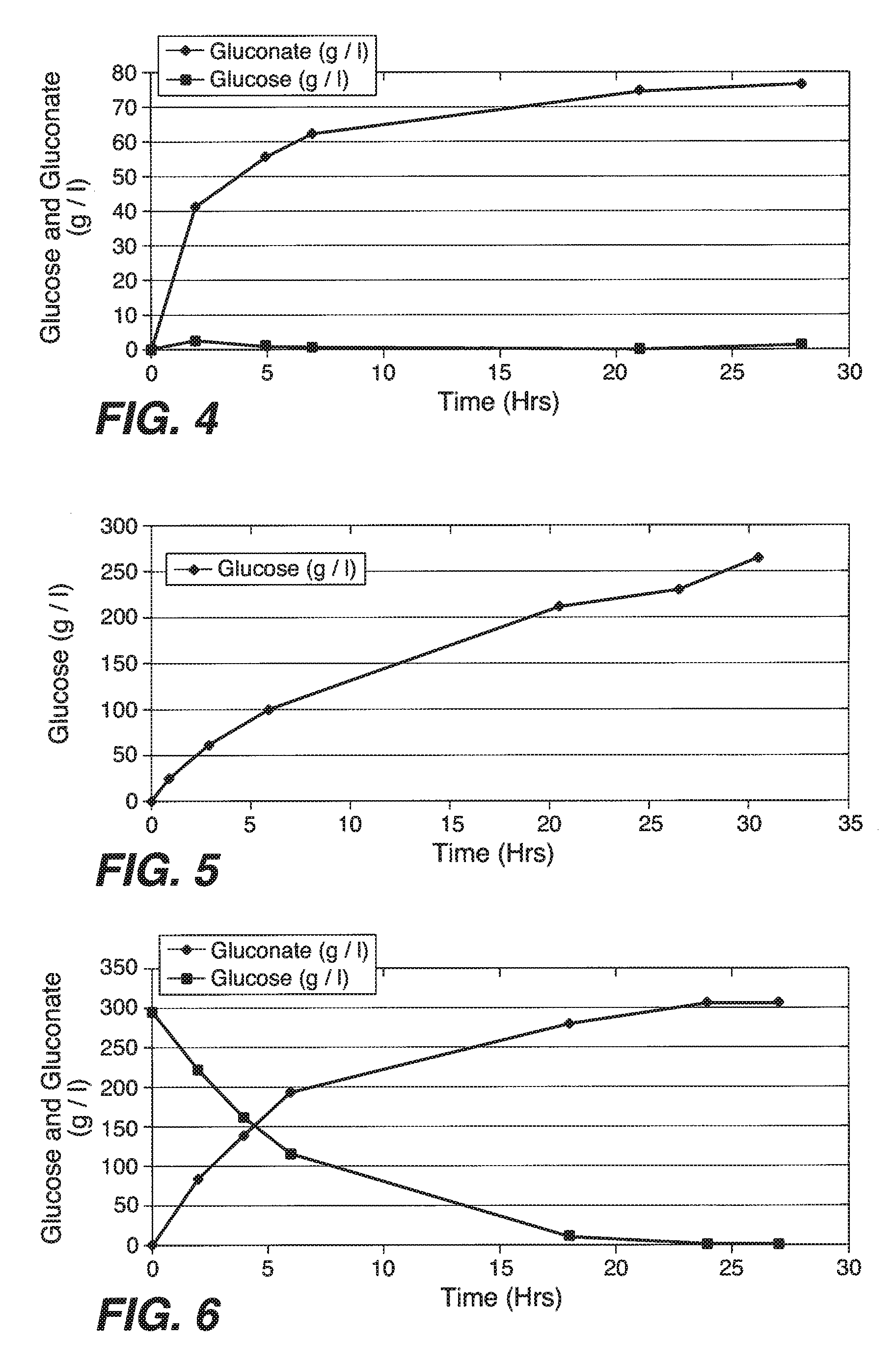

The invention provides a non-naturally occurring set of microbial organisms. The set of organisms includes: at least a first constituent complementary metabolizing organism (CMO) exhibiting the ability to metabolize a first carbon substrate and having substantially impaired metabolic capacity for a second carbon substrate, and at least a second constituent complementary metabolizing organism (CMO) exhibiting the ability to metabolize the second carbon substrate and having substantially impaired metabolic capacity for the first carbon substrate, wherein a co-culture of the at least first and second CMOs exhibit simultaneous metabolism of a mixture having the first and second carbon substrates compared to either CMO alone. Simultaneous metabolism of a mixture having first and second carbon substrates can include an enhanced rate of metabolism of the first and second substrates compared to either CMO alone. Also provided is a bioprocess for producing a chemical compound. The bioprocess includes co-culturing a non-naturally occurring set of microbial organisms in a mixture having at least a first and a second carbon substrate under conditions sufficient for biosynthesis of a target chemical compound, the set of non-naturally occurring microbial organisms including: at least a first constituent complementary metabolizing organism (CMO) exhibiting the ability to metabolize the first carbon substrate and having substantially impaired metabolic capacity for the second carbon substrate, and at least a second constituent complementary metabolizing organism (CMO) exhibiting the ability to metabolize the second carbon substrate and having substantially impaired metabolic capacity for the first carbon substrate, wherein a co-culture of the at least first and second CMOs exhibit simultaneous metabolism of a mixture having the first and second carbon substrates compared to either CMO alone. Simultaneous metabolism of a mixture having first and second carbon substrates can include an enhanced rate of metabolism of the first and second substrates compared to either CMO alone.

Owner:GENOMATICA INC

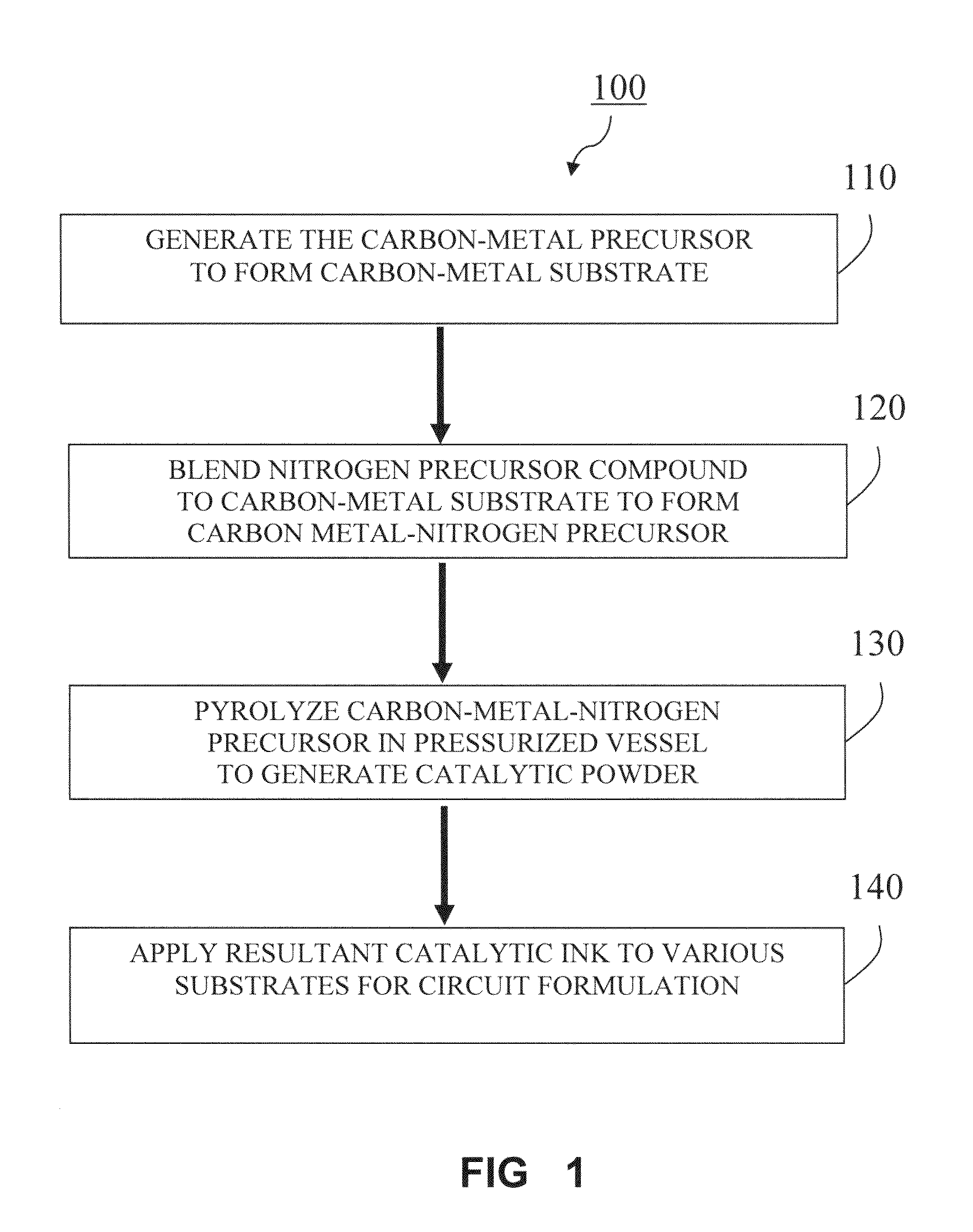

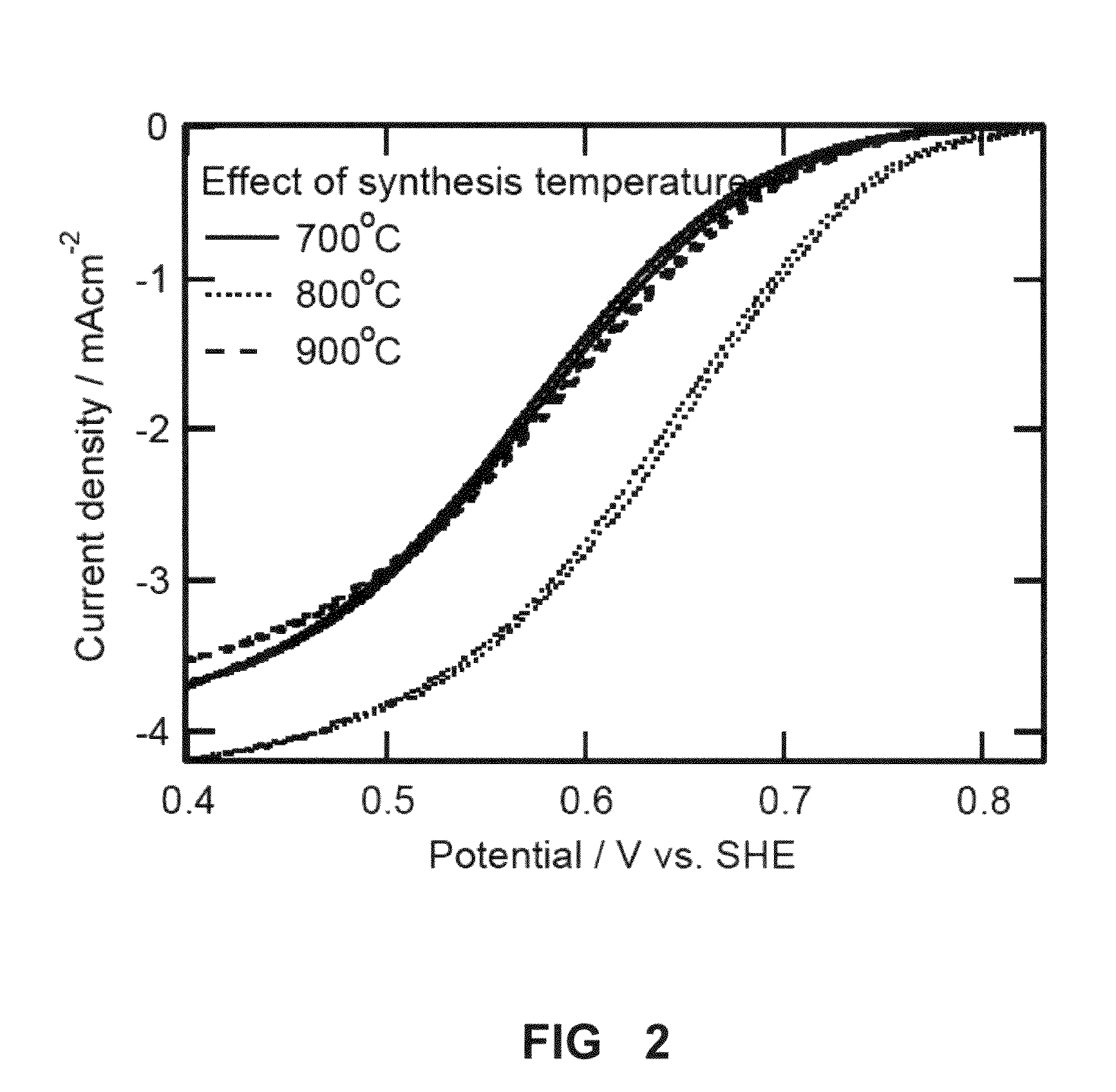

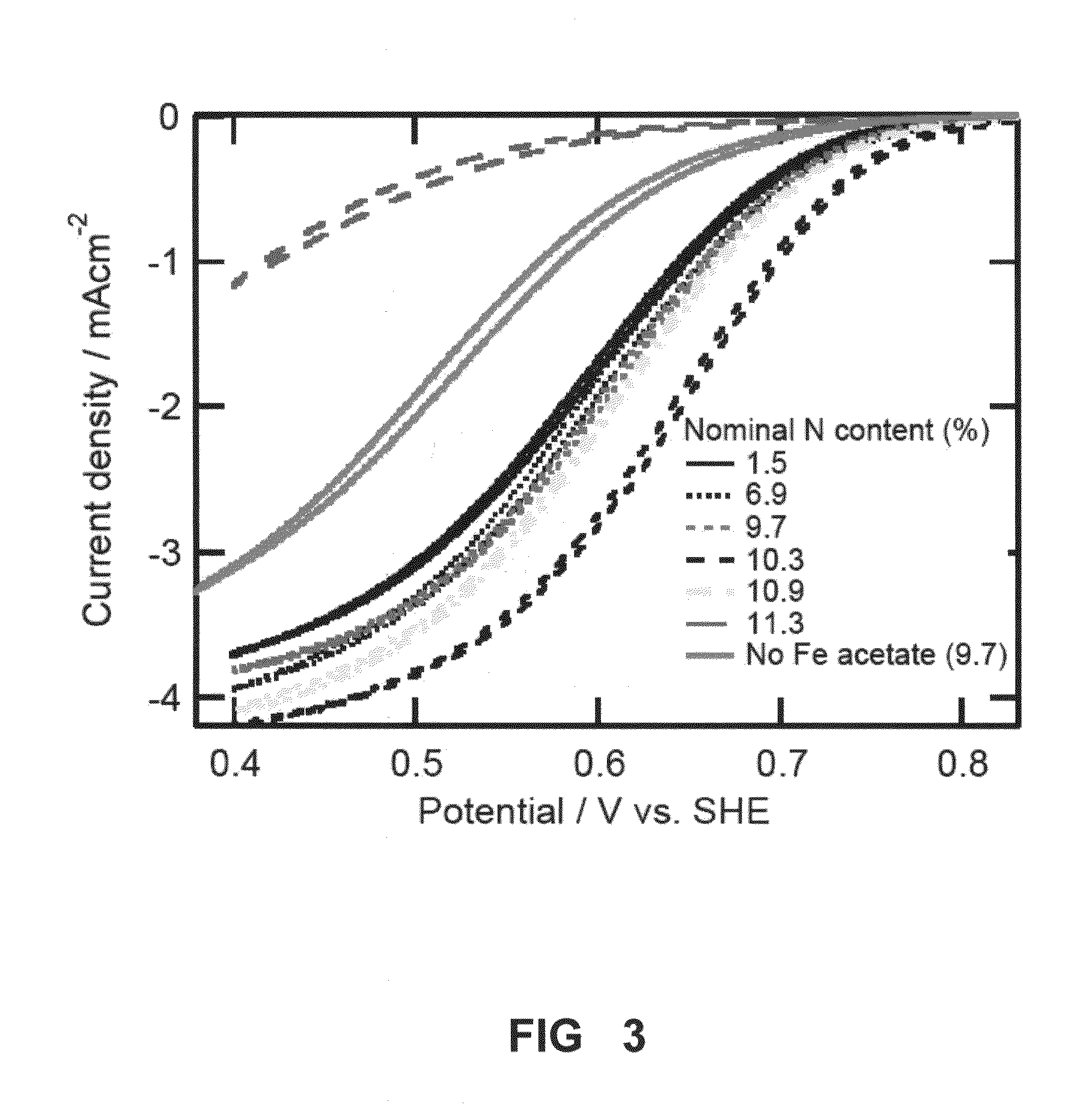

Novel catalyst for oxygen reduction reaction in fuel cells

InactiveUS20110287174A1High catalytic activityImprove usabilityFinal product manufactureCell electrodesFuel cellsNitrogen

A method for making a carbon-metal-nitrogen oxygen reducing cathode catalyst, the method comprising mixing a carbon source with a transition metal precursor to form a metal precursor loaded carbon substrate; adding a nitrogen precursor compound to the metal precursor loaded carbon substrate to form a carbon-metal-nitrogen precursor; and pyrolyzing the carbon-metal-nitrogen precursor in a closed vessel, thereby forming an oxygen reducing cathode catalyst. The carbon-metal-nitrogen catalyst requires no precious metal such as Pt, and also provides benefits such as controlled deposition of catalytically active nitrogenous compounds that can increase the catalytic activity of the catalyst when compared to gaseous deposition of nitrogen to the surface of the carbon support.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

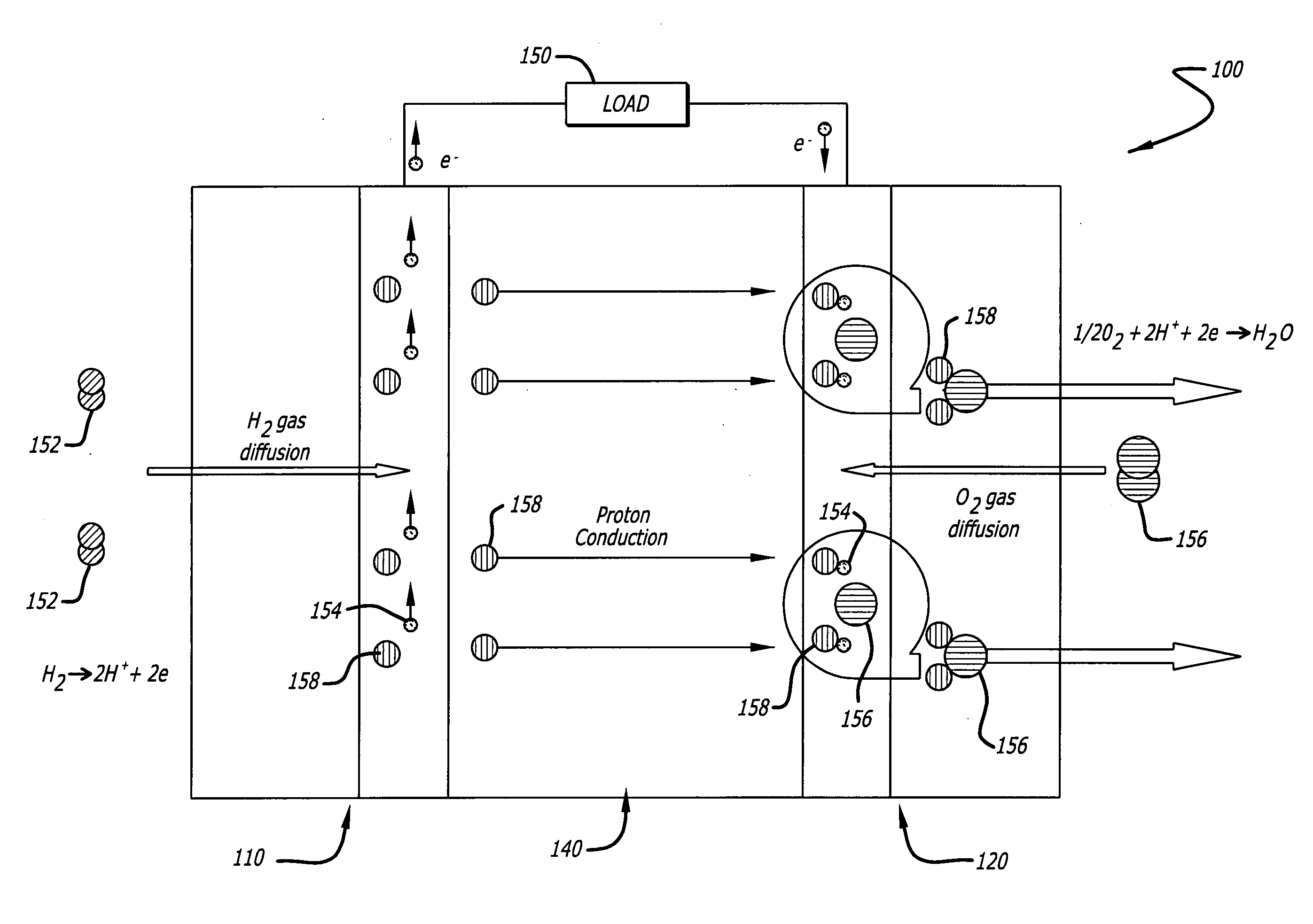

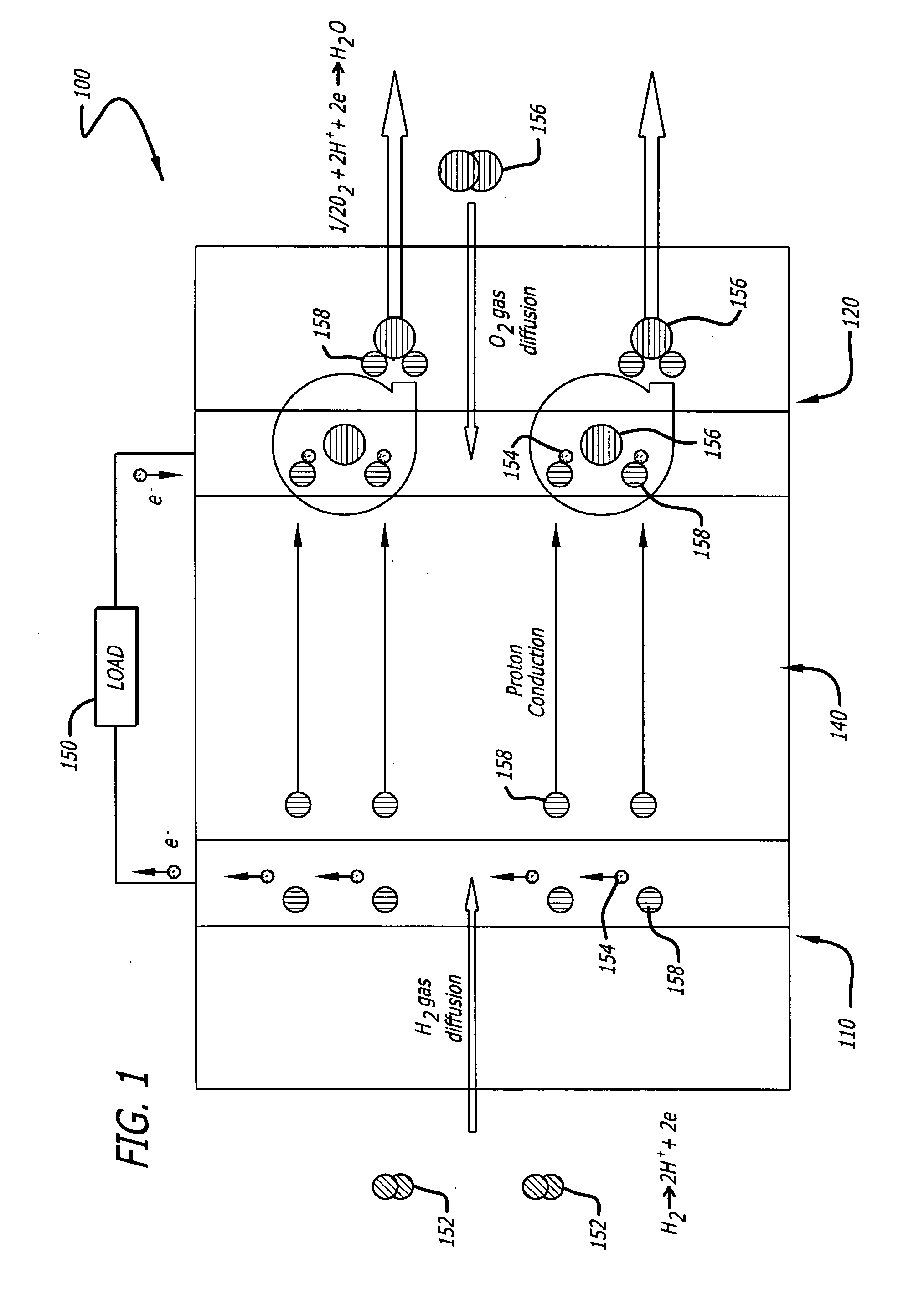

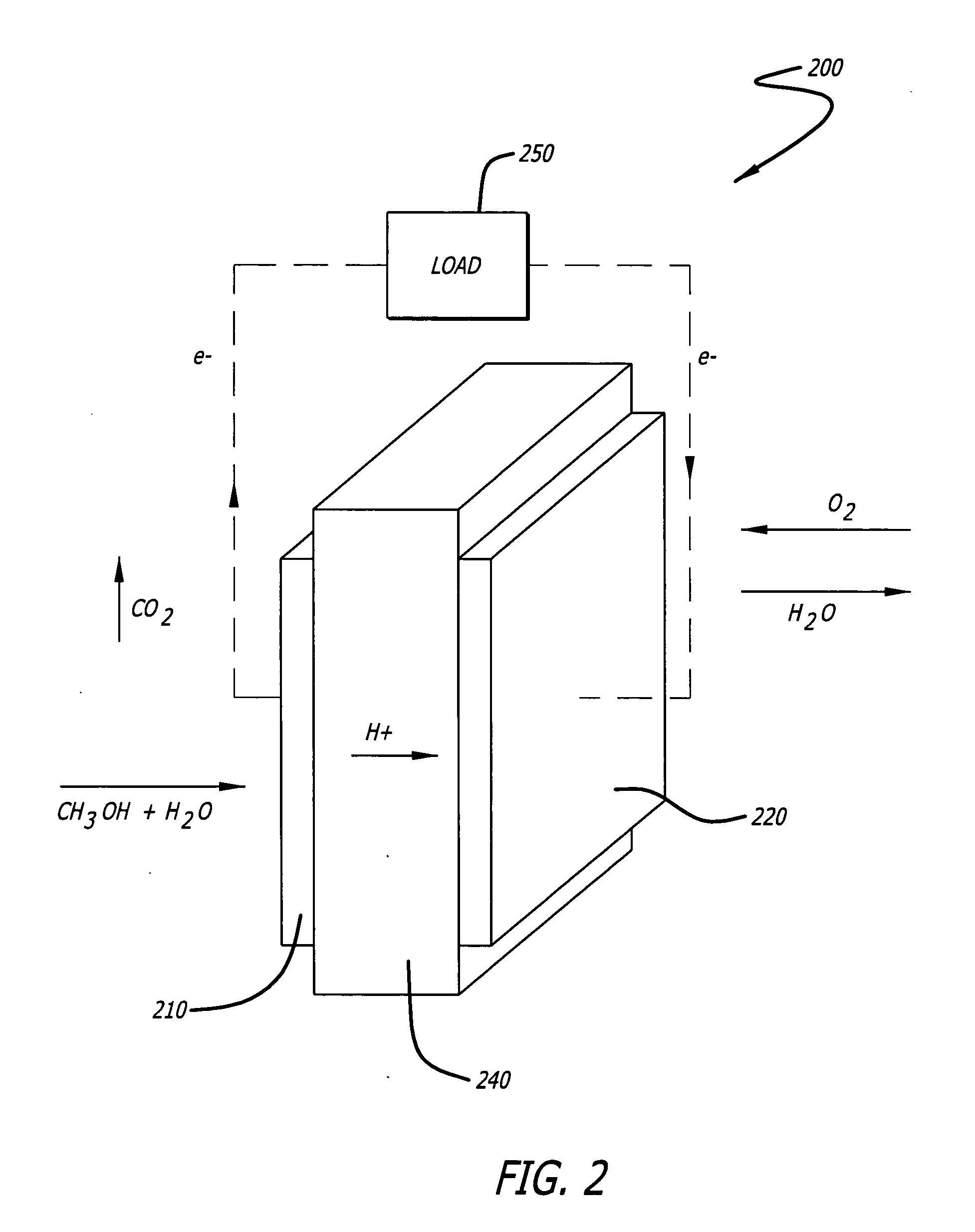

Carbon based electrocatalysts for fuel cells

InactiveUS20100159305A1High utilization rateHigh power densityActive material electrodesCoatingsHot pressPrecious metal

Novel proton exchange membrane fuel cells and direct methanol fuel cells with nanostructured components are configured with higher precious metal utilization rate at the electrodes, higher power density, and lower cost. To form a catalyst, platinum or platinum-ruthenium nanoparticles are deposited onto carbon-based materials, for example, single-walled, dual-walled, multi-walled and cup-stacked carbon nanotubes. The deposition process includes an ethylene glycol reduction method. Aligned arrays of these carbon nanomaterials are prepared by filtering the nanomaterials with ethanol. A membrane electrode assembly is formed by sandwiching the catalyst between a proton exchange membrane and a diffusion layer that form a first electrode. The second electrode may be formed using a conventional catalyst. The several layers of the MEA are hot pressed to form an integrated unit. Proton exchange membrane fuel cells and direct methanol fuel cells are developed by stacking the membrane electrode assemblies in a conventional manner.

Owner:RGT UNIV OF CALIFORNIA

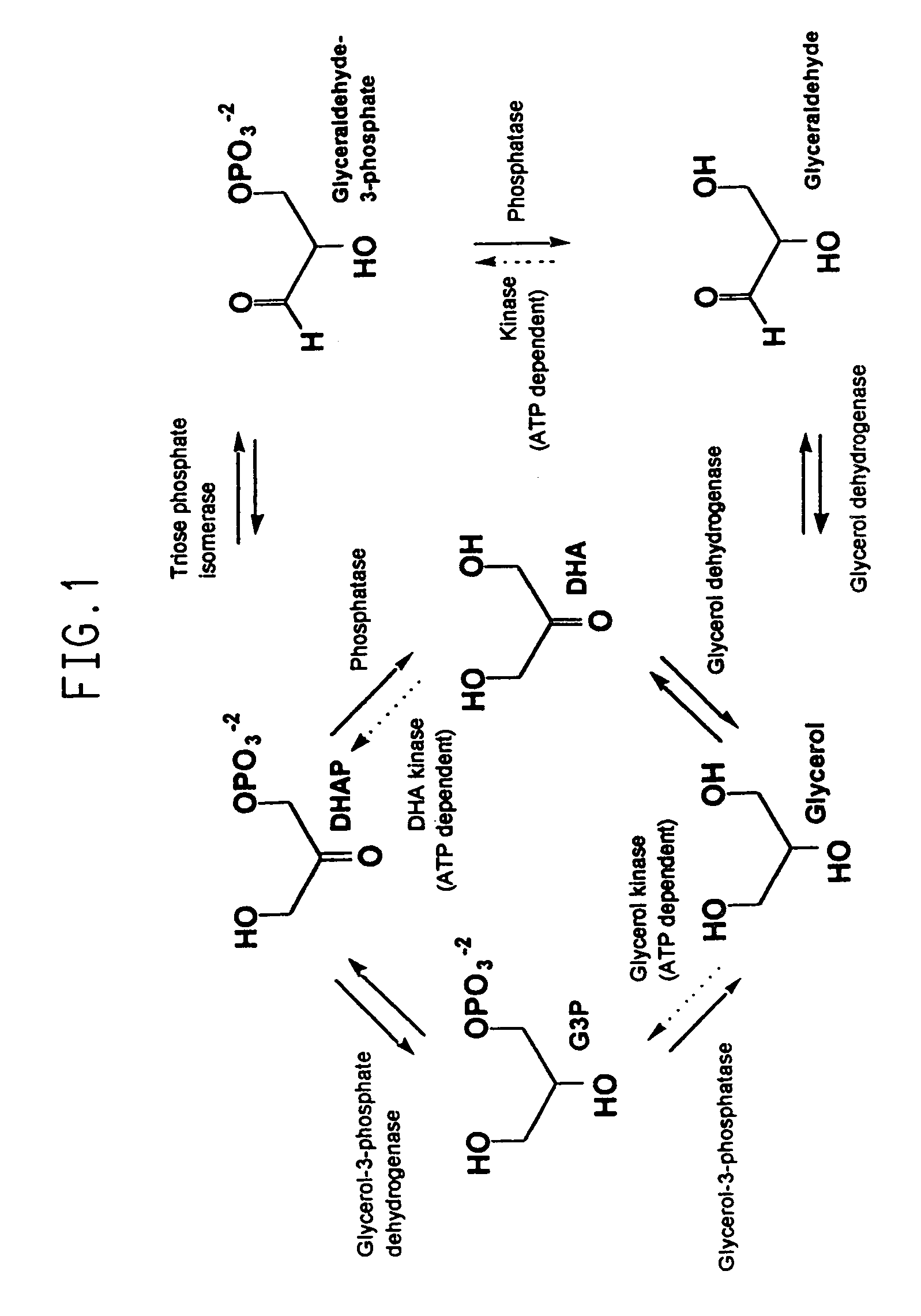

Transformed microorganisms and genes useful in the production of glycerol and 1,3-propanediol

Recombinant organisms are provided comprising genes encoding a glycerol-3-phosphate dehydrogenase and / or a glycerol-3-phosphatase activity useful for the production of glycerol from a variety of carbon substrates. The organisms further contain disruptions in the endogenous genes encoding proteins having glycerol kinase and glycerol dehydrogenase activities.

Owner:EI DU PONT DE NEMOURS & CO +1

Methods for producing end-products from carbon substrates

InactiveUS20070141660A1Improve processing efficiencyAvoiding catabolic repressiveBacteriaBiofuelsCelluloseIn vivo

The present invention provides means for the production of desired end-products of in vitro and / or in vivo bioconversion of biomass-based feed stock substrates, including but not limited to such materials as starch and cellulose. In particularly preferred embodiments, the methods of the present invention do not require gelatinization and / or liquefaction of the substrate.

Owner:CHOTANI GOPAL K +4

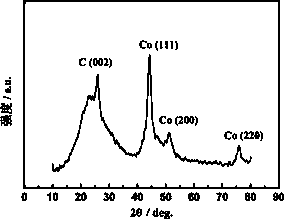

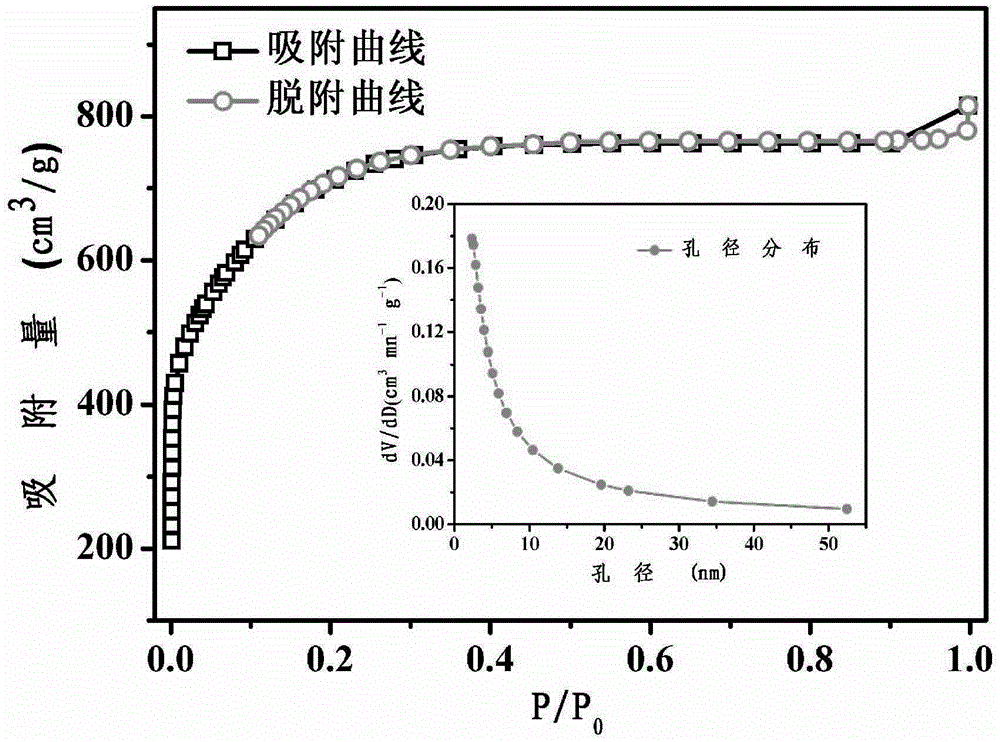

Porous nano composite material for fuel cell oxygen reduction catalyst

InactiveCN103811775AImprove cycle stabilityEasy to operateMaterial nanotechnologyPhysical/chemical process catalystsPorous carbonOxygen

The invention discloses a porous nano composite material for a fuel cell oxygen reduction catalyst, and is an M-N-C porous nano composite material, wherein M in M-N-C refers to base metal ferrum, cobalt or nickel, N refers to nitrogen, and C refers to carbon; small-particle-size metal nano particles are uniformly dispersed and embedded in a nitrogen-doped porous carbon carrier material; the base metal nano particles have the particle size range being 5-100nm; the mass percentage of nitrogen contained in the porous carbon carrier is 3-7%. The porous nano composite material for the fuel cell oxygen reduction catalyst, which is provided by the invention, has the advantages that because of the in-situ nitrogen doping of a carbon substrate, the implant of base metal nano particles in uniform distribution and the formation of the porous structure with high specific area, the catalytic oxygen reduction capability of the porous nano composite material is improved obviously, and the cycle stability of the material is improved; a precursor prepared by the composite material is low in cost, is easy to prepare, is controlled easily in the preparation process, is simple to operate, and facilitates industrial large-scale production.

Owner:NANKAI UNIV

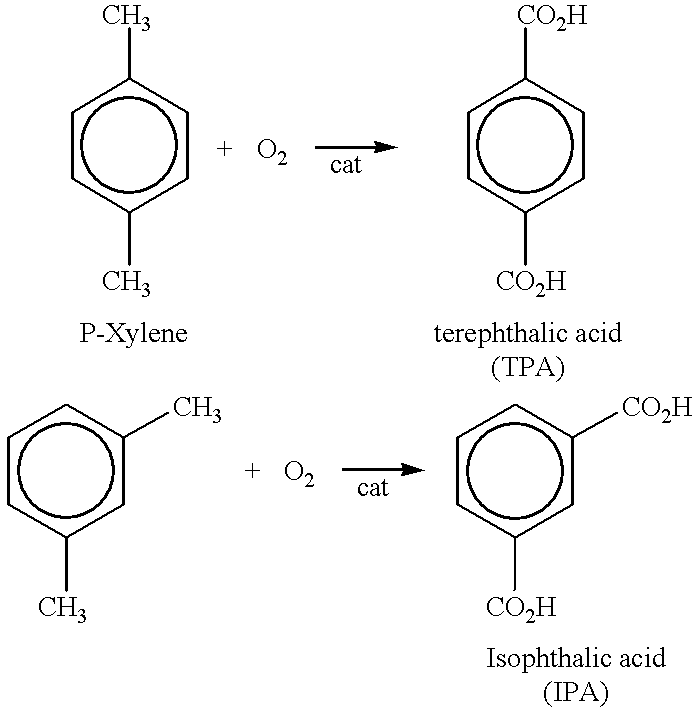

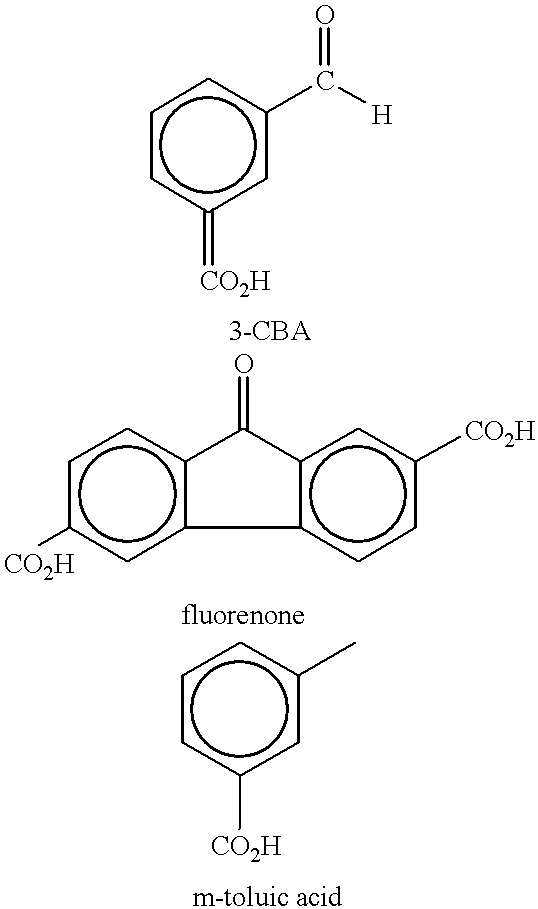

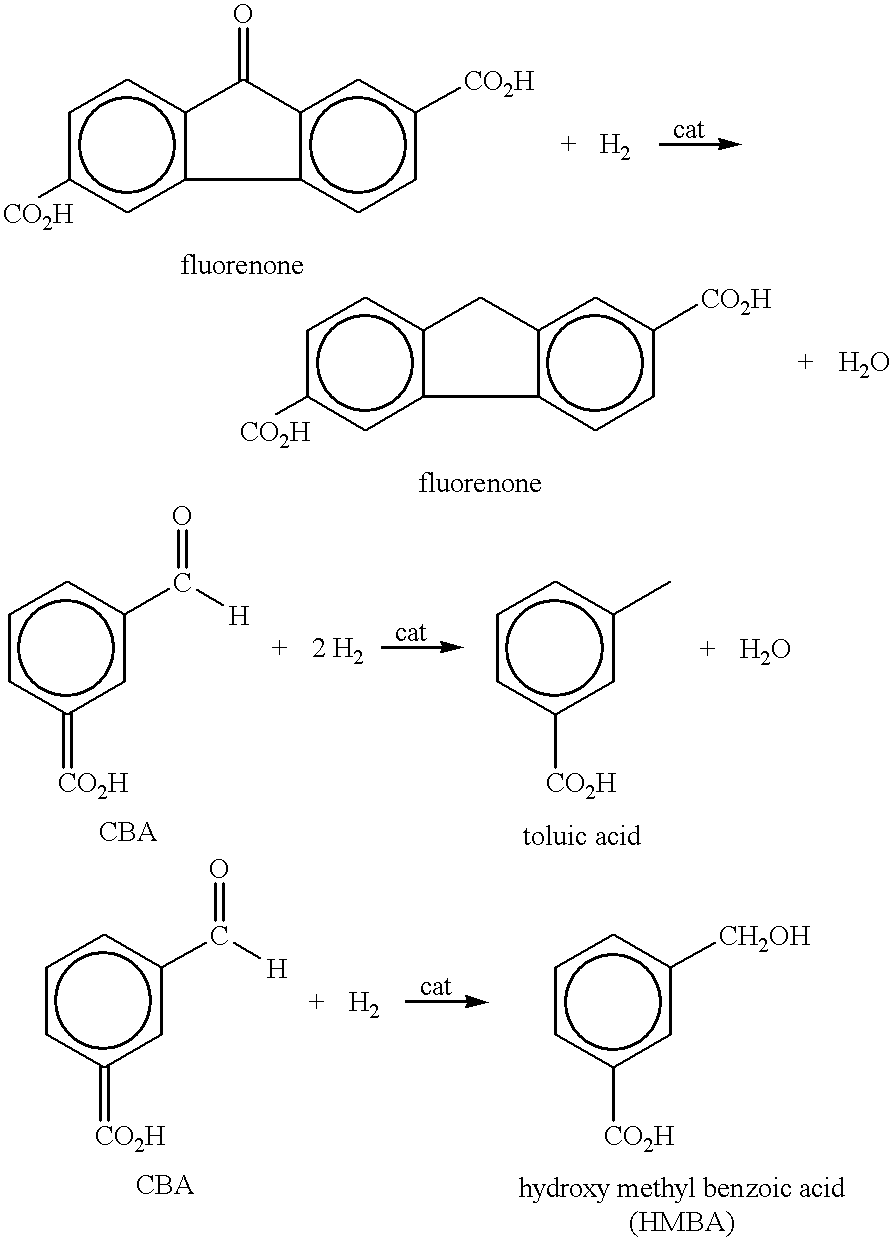

Method of purifying aromatic dicarboxylic acids

InactiveUS6265608B1MinimizationReduce usageOrganic compound preparationCarboxylic compound separation/purificationPalladium catalystCarboxylic acid

An aromatic dicarboxylic acid is purified by oxidizing m-xylene or p-xylene to produce crude isophthalic acid or crude terephthalic acid, respectively. The products of the oxidizing step are hydrogenated in the presence of a palladium catalyst. Carbon monoxide is introduced during the hydrogenation step. The palladium catalyst is provided on a carbon substrate. The products of the oxidizing step are dissolved in a solvent, which may be water, prior to the hydrogenation step. The products of the oxidizing step may be dissolved at an elevated temperature, above the normal boiling point of the solvent. The oxidation step produces isophthalic acid, 3-carboxybenzaldehyde and fluorenones in the case of oxidizing m-xylene and produces terephthalic acid, 4-carboxybenzaldehyde and fluorenones in the case of oxidizing p-xylene. It may be helpful to monitor the disappearance of 3-carboxybenzaldehyde in the case of oxidizing m-xylene and 4-carboxybenzaldehyde in the case of oxidizing pxylene, and reducing the amount of carbon monoxide when the rate of disappearance is below a predetermined minimum. After the hydrogenation step, the isophthalic acid or terephthalic acid may be crystallized. The carbon monoxide may be maintained at a concentration of 100 to 500 ppm based on added hydrogen and carbon monoxide. Other aromatic dicarboxylic acids may also purified by this procedure.

Owner:GRUPO PETROTEMEX DE C V

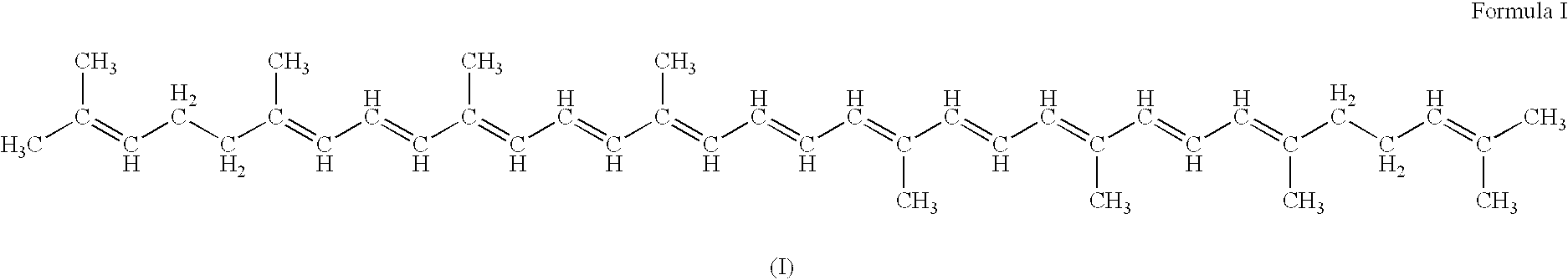

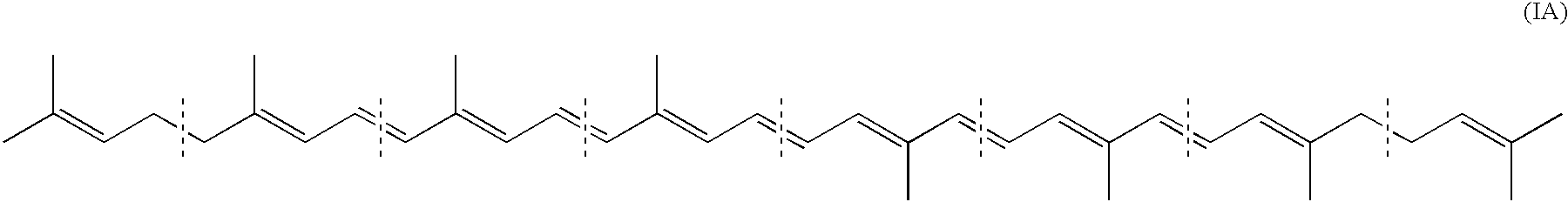

Carotenoid production from a single carbon substrate

A method for the production of carotenoid compounds is disclosed. The method relies on the use of microorganisms which metabolize single carbon substrates for the production of carotenoid compounds in high yields.

Owner:EI DU PONT DE NEMOURS & CO

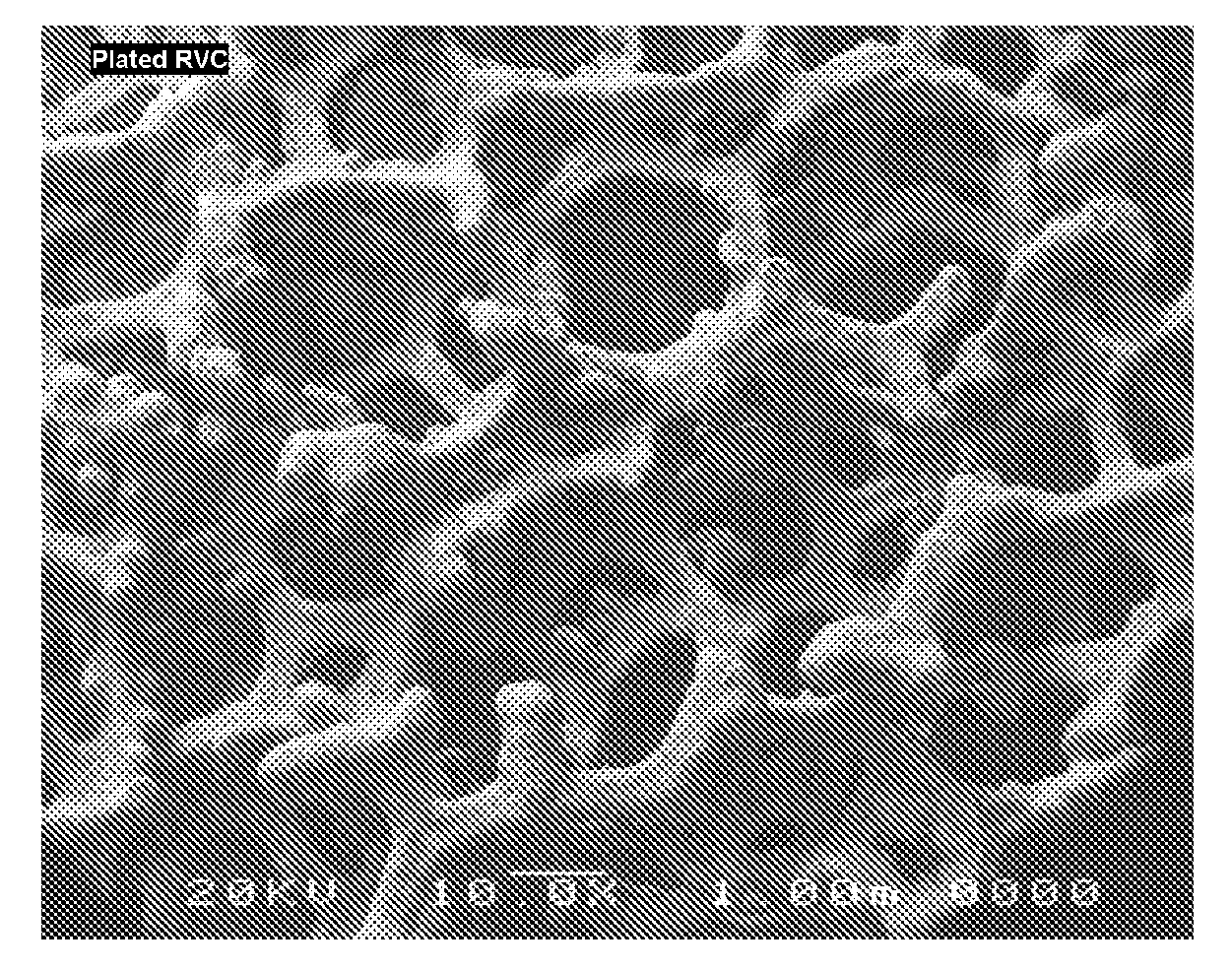

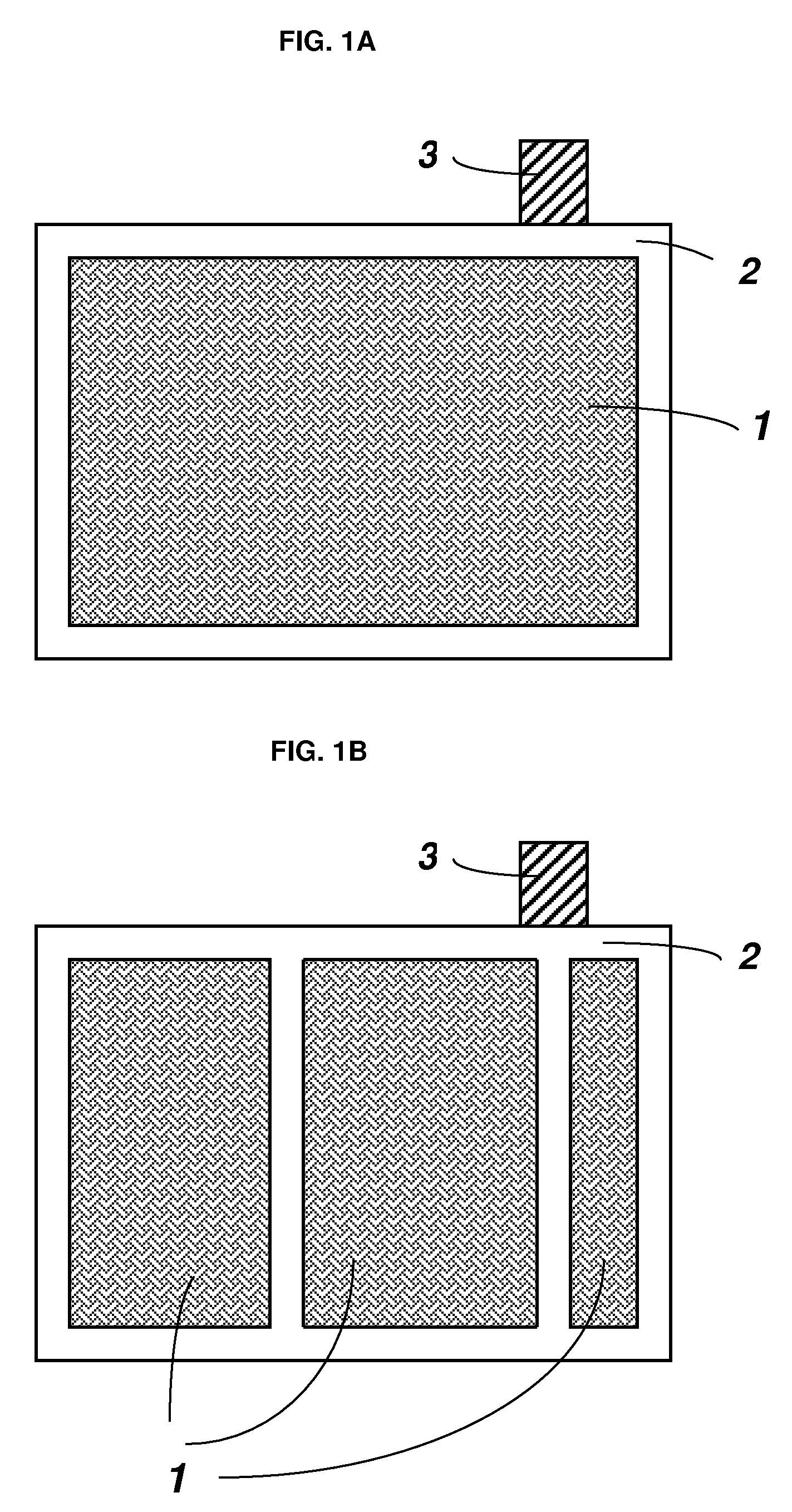

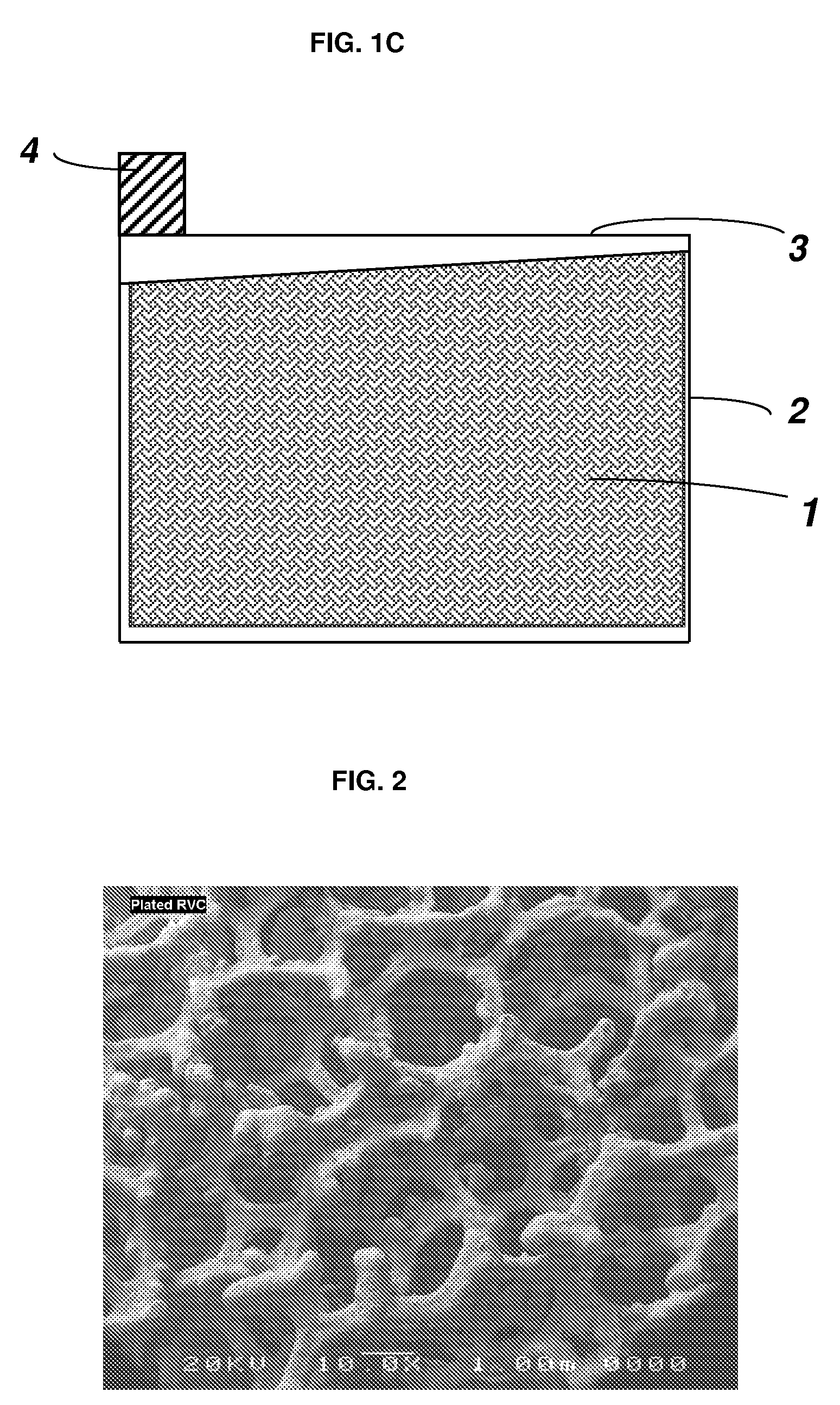

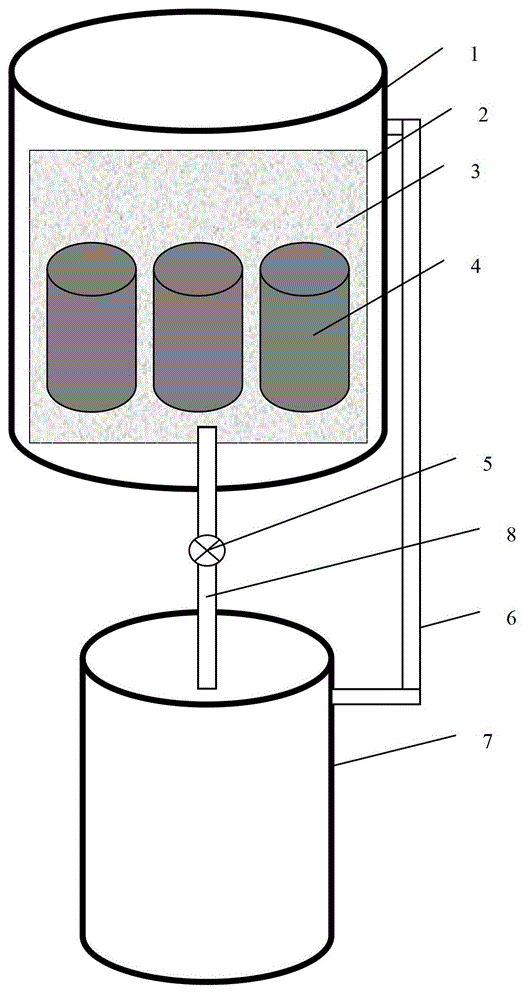

Current Collector Structure and Methods to Improve the Performance of a Lead-Acid Battery

InactiveUS20060292448A1Improve performanceAchieve recyclabilityElectrode carriers/collectorsLead-acid accumulator electrodesGraphiteMetal foam

A current collector of a battery includes a reticulated substrate having a circuitous network of pores and a metal applied to at least a portion of the reticulated substrate. The reticulated substrate may be a non-metal foam substrate, such as, for example, a carbon foam substrate, a reticulated vitreous carbon substrate or a graphite foam substrate.

Owner:GYENGE ELOD +2

Composite coating carbon/carbon composite material crucible and preparation method thereof

The invention discloses a composite coating carbon / carbon composite material crucible comprising a carbon / carbon composite material crucible, a silicon carbide coating adhered on the inner surface of the carbon / carbon composite material crucible, a silicon coating adhered on the silicon carbide coating, and a silicon nitride coating adhered on the silicon coating. Also, the invention discloses a preparation method of the composite coating carbon / carbon composite material crucible. According to the invention, silicon nitride is combined with the silicon carbide composite coating, such that corrosion of silicon-containing steam upon the inner profile of the carbon / carbon composite material crucible can be effectively inhibited, and crucible service life is greatly improved. With a chemical vapor reaction method, SiC coating in-situ production is achieved. Compared with a traditional SiC coating prepared with a CVD method, the bonding strength with the carbon / carbon substrate is higher. Also, excessive Si coating is produced on site, such that Si source is provided for the production of the silicon nitride coating. The silicon nitride coating produced with high-purity nitrogen has improved bonding strength, such that corrosion resistance of the crucible is further improved.

Owner:XIAN CHAOMA SCI TECH

Resin isobaric liquid-phase impregnation densification method for rapidly filling pores inside carbon/carbon composite material

The invention relates to a resin isobaric liquid-phase impregnation densification method for rapidly filling pores inside a carbon / carbon composite material. The method comprises the following steps of by using a PIP (precursor impregnation and pyrolysis) process and a vacuum autoclave with an isobaric impregnation recovery device, and taking nitrogen as a protective gas, using an impregnating solution to impregnate a carbon fiber perform or low-density C / C body workpiece in a vacuum; allowing the impregnating solution to infiltrate into the workpiece at nitrogen pressure; isobarically recovering excess impregnating solution; continuing to isobarically heat to thermally set resin; and then carbonizing the resin into a carbon substrate for filling the pores inside the workpiece. The carbon / carbon composite material component with the required density is obtained by multiple circulating operations. The period of the method is short, and the excess impregnating solution which does not filtrate into the workpiece is isobarically recovered, so that the resin is prevented from reversely filtrating, the resin consumption and pure nitrogen consumption are reduced, and the densification efficiency and the densification uniformity are improved.

Owner:山东道普安制动材料有限公司

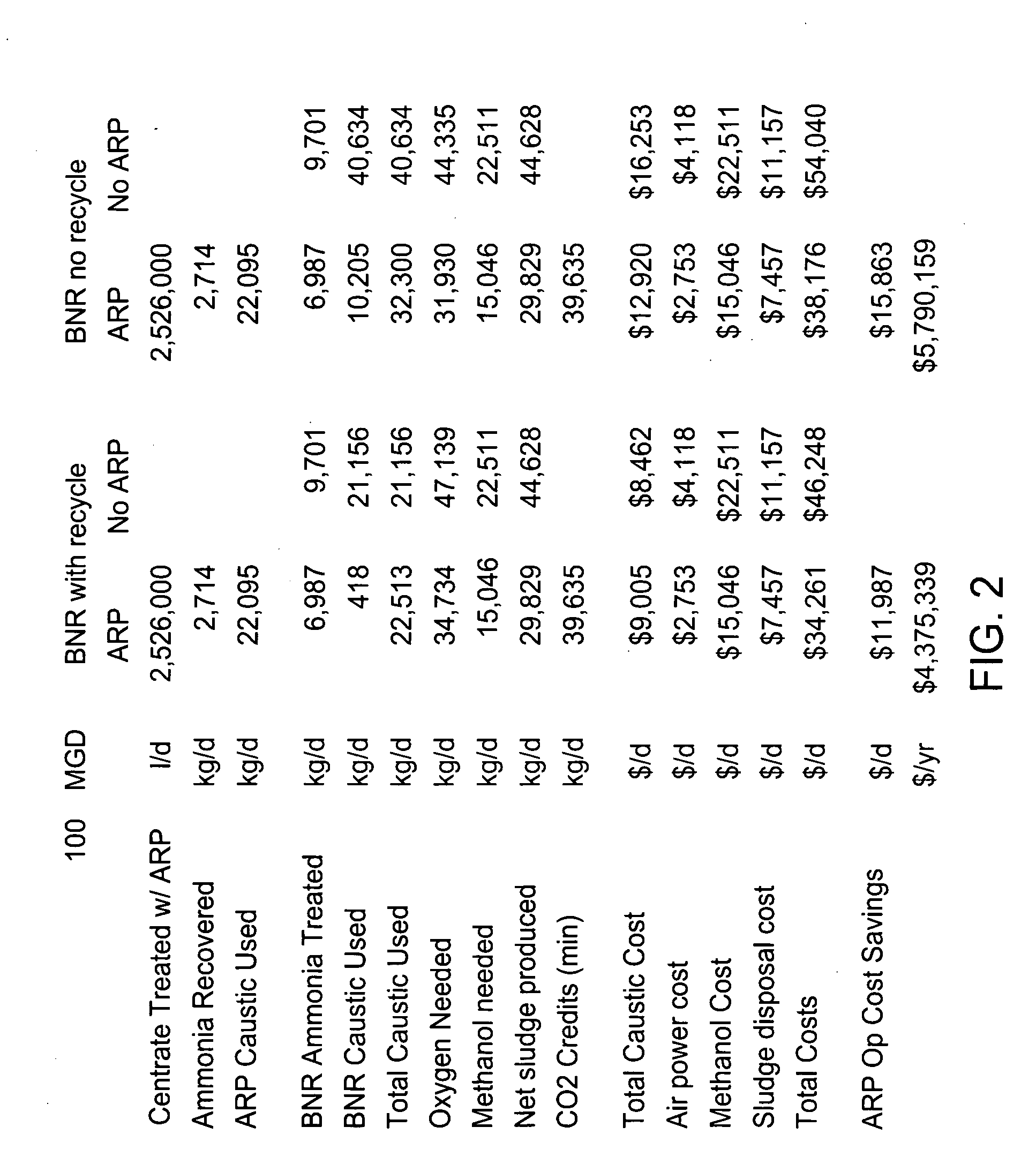

Integrating recycle stream ammonia treatment with biological nutrient removal

InactiveUS20080156726A1Reducing negative environmental impactReduce operating costsLiquid degasificationWater contaminantsRecovery methodAlkalinity

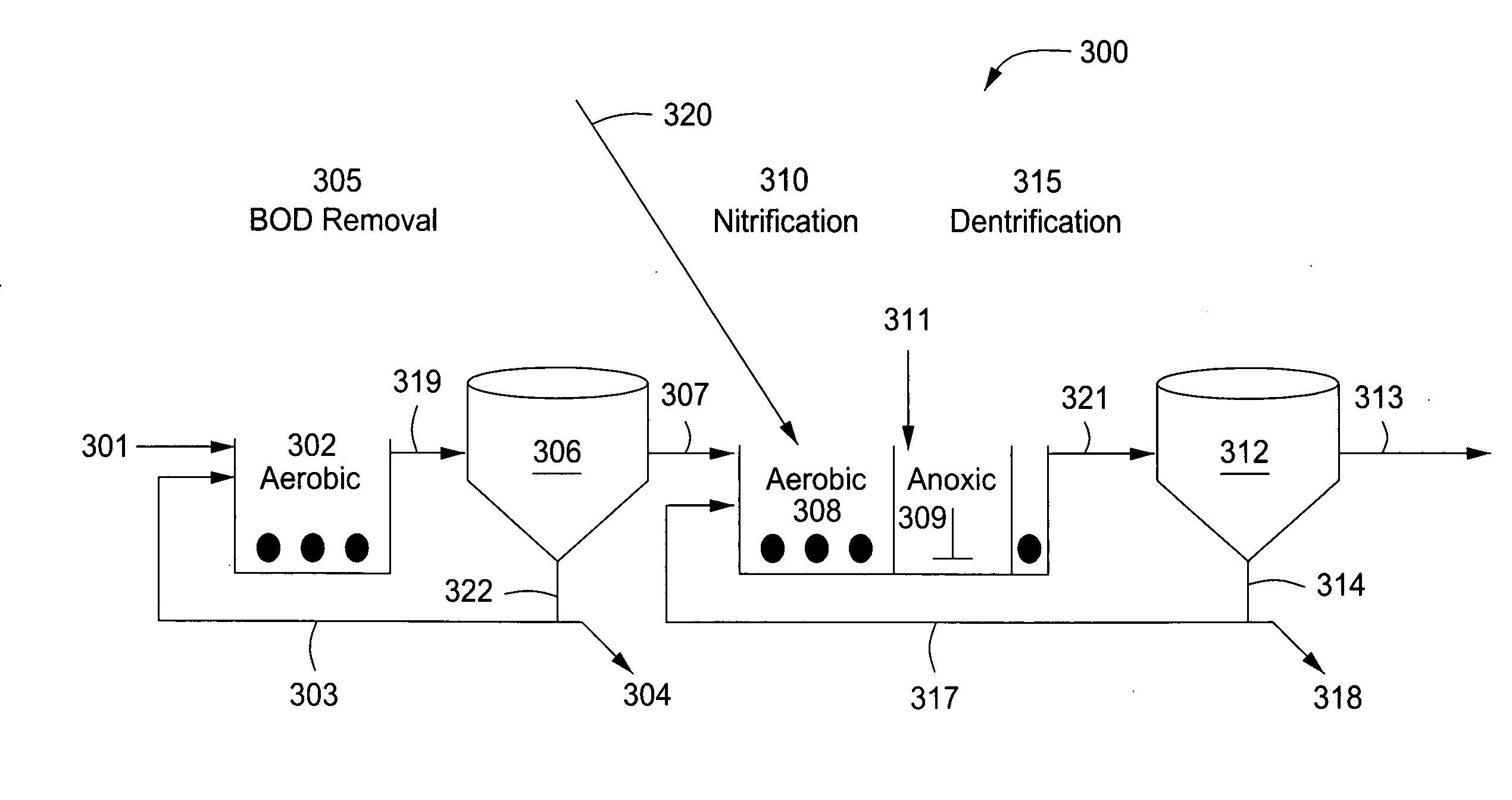

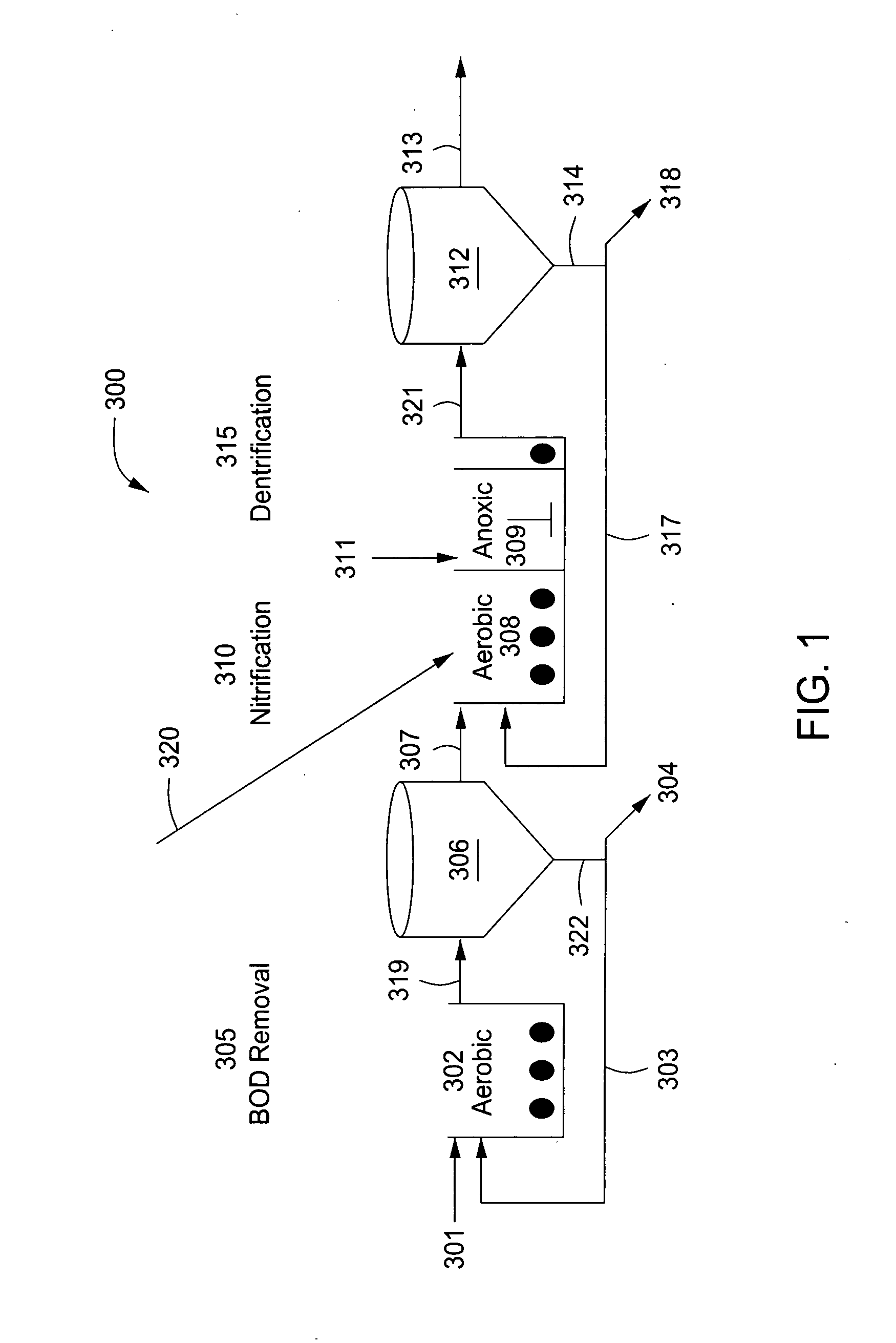

Embodiments include a method and apparatus for recovering ammonia and nitrogen from a waste stream. Embodiments further include recovering ammonia using an ammonia recovery process and a biological nitrogen recovery process. In some embodiments, a return stream from the ammonia recovery process may be used to provide alkalinity, carbon substrate, and / or biological oxygen demand to the biological nitrogen recovery process. In some embodiments, a hydrothermal sludge process may be used to further treat the waste stream and provide additional return to the ammonia recovery system. Other embodiments include an ammonia recovery system for conducting the ammonia recovery process, a biological nitrification and / or denitrification system for conducting the biological nitrogen recovery process, and an optional hydrothermal sludge processing system.

Owner:FASSBENDER ALEXANDER G

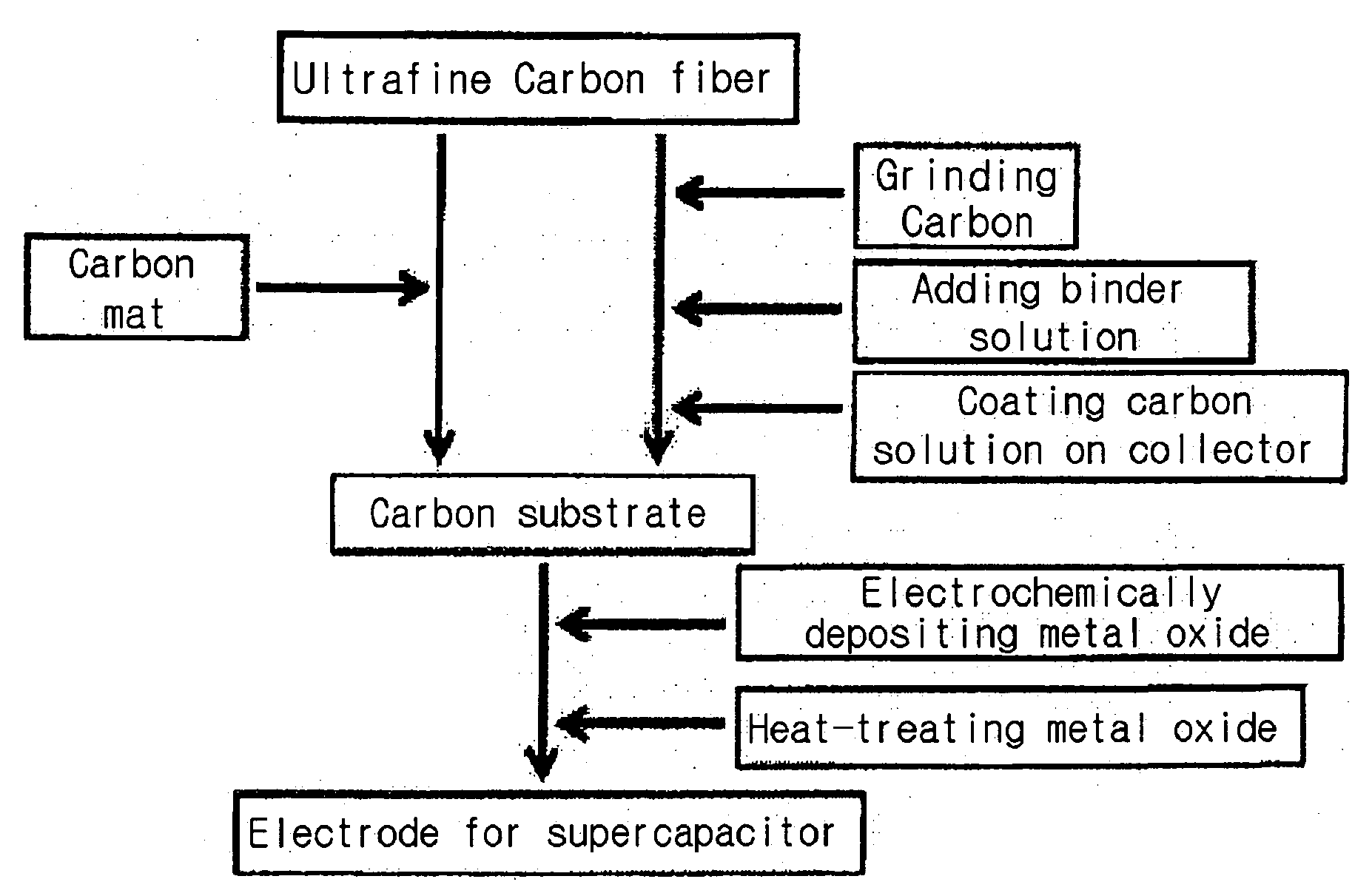

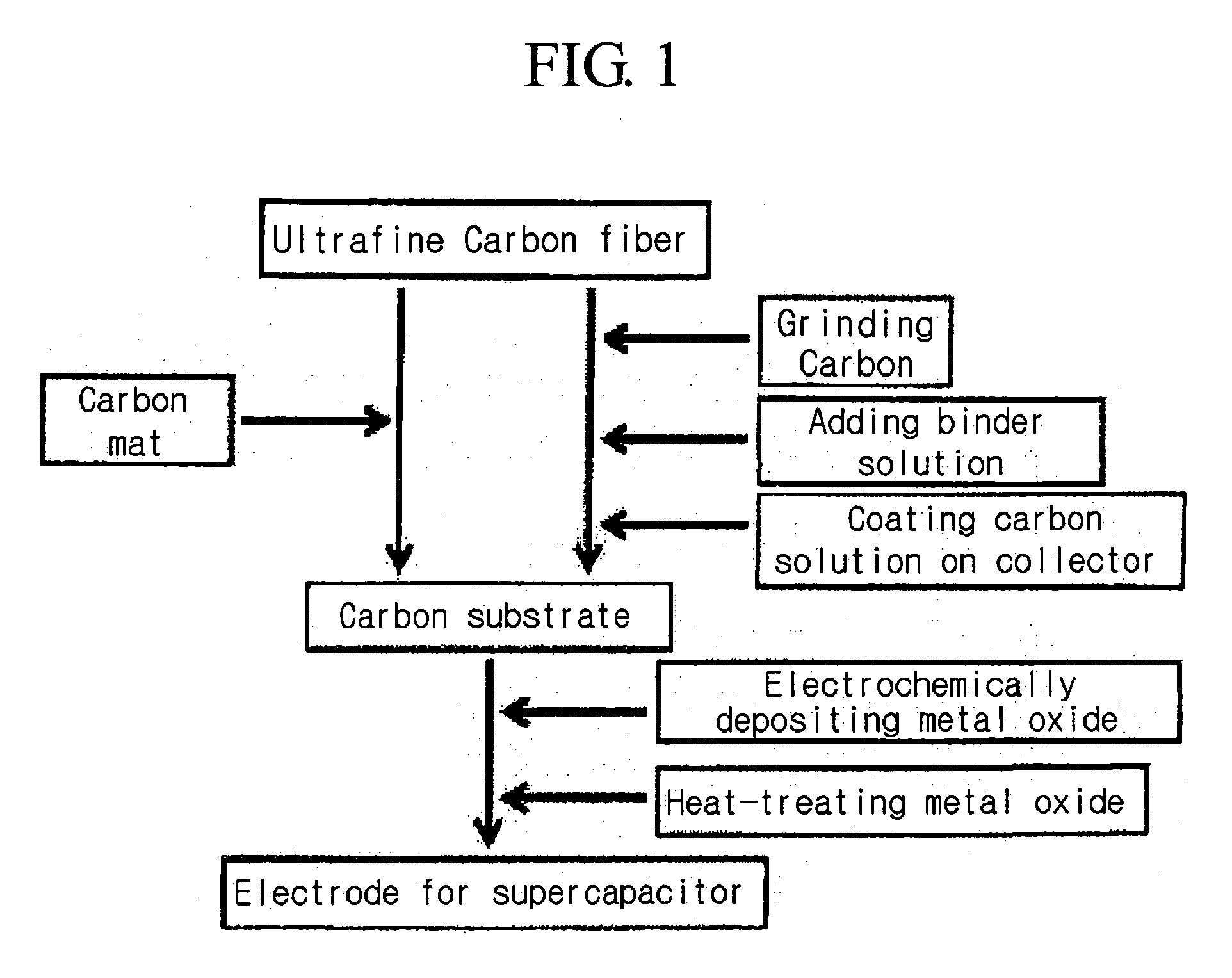

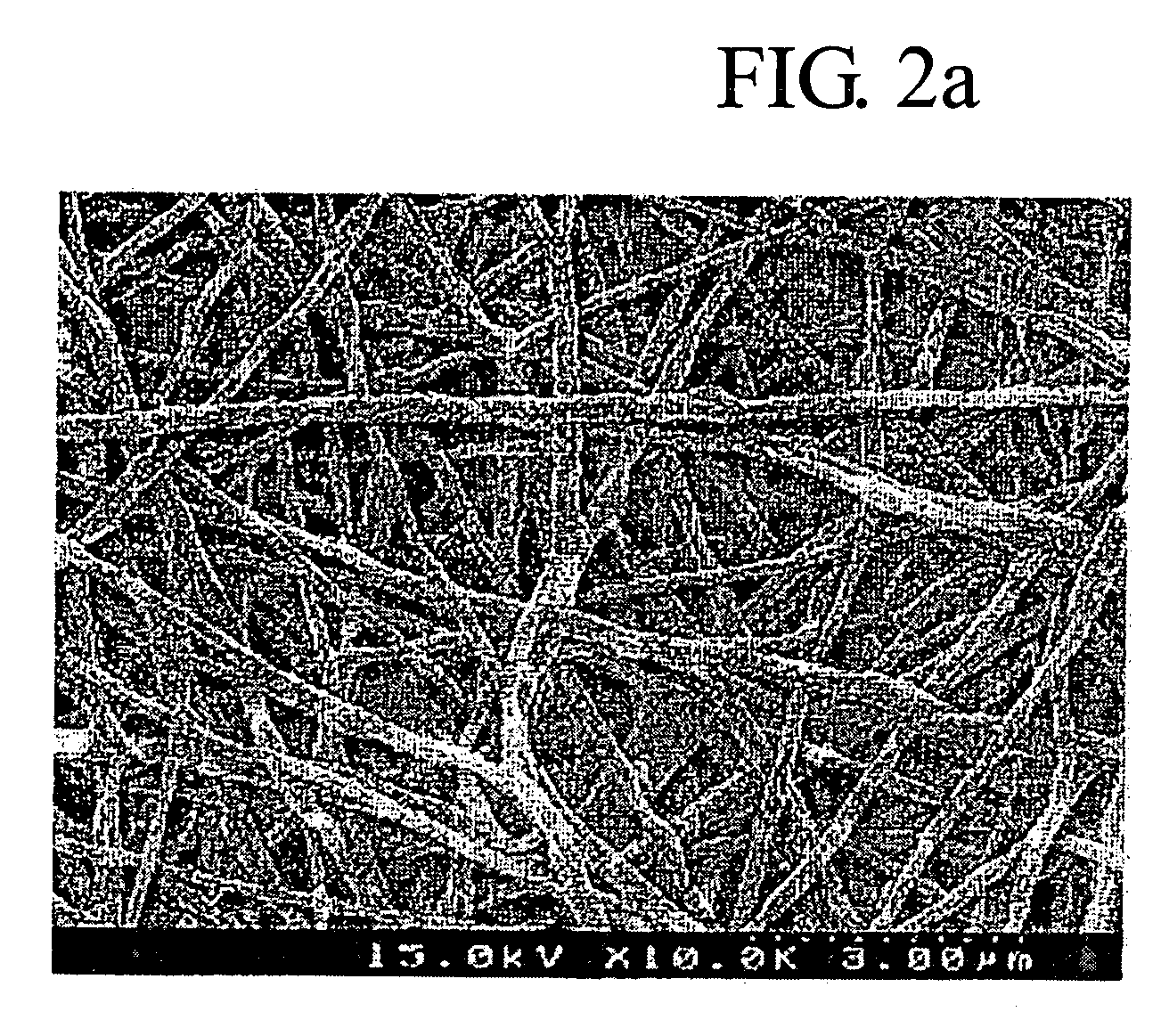

Electrode for supercapacitor having metal oxide deposited on ultrafine carbon fiber and the fabrication method thereof

ActiveUS20080251971A1High specific capacitanceImprove conductivityMaterial nanotechnologyElectric discharge heatingFiberCapacitance

The present invention discloses an improved electrode for a supercapacitor and a method of preparation thereof. The inventive electrode comprises a collector, a carbon substrate disposed on the collector comprising ultrafine carbon fibers having a specific surface area of at least 200 m2 / g (BET) and a d002 value of 0.36 nm or less, and a metal oxide thin layer formed on the carbon substrate. The electrode of the subject invention retains a high specific capacitance during high-speed charging and discharging cycles.

Owner:KOREA INST OF SCI & TECH

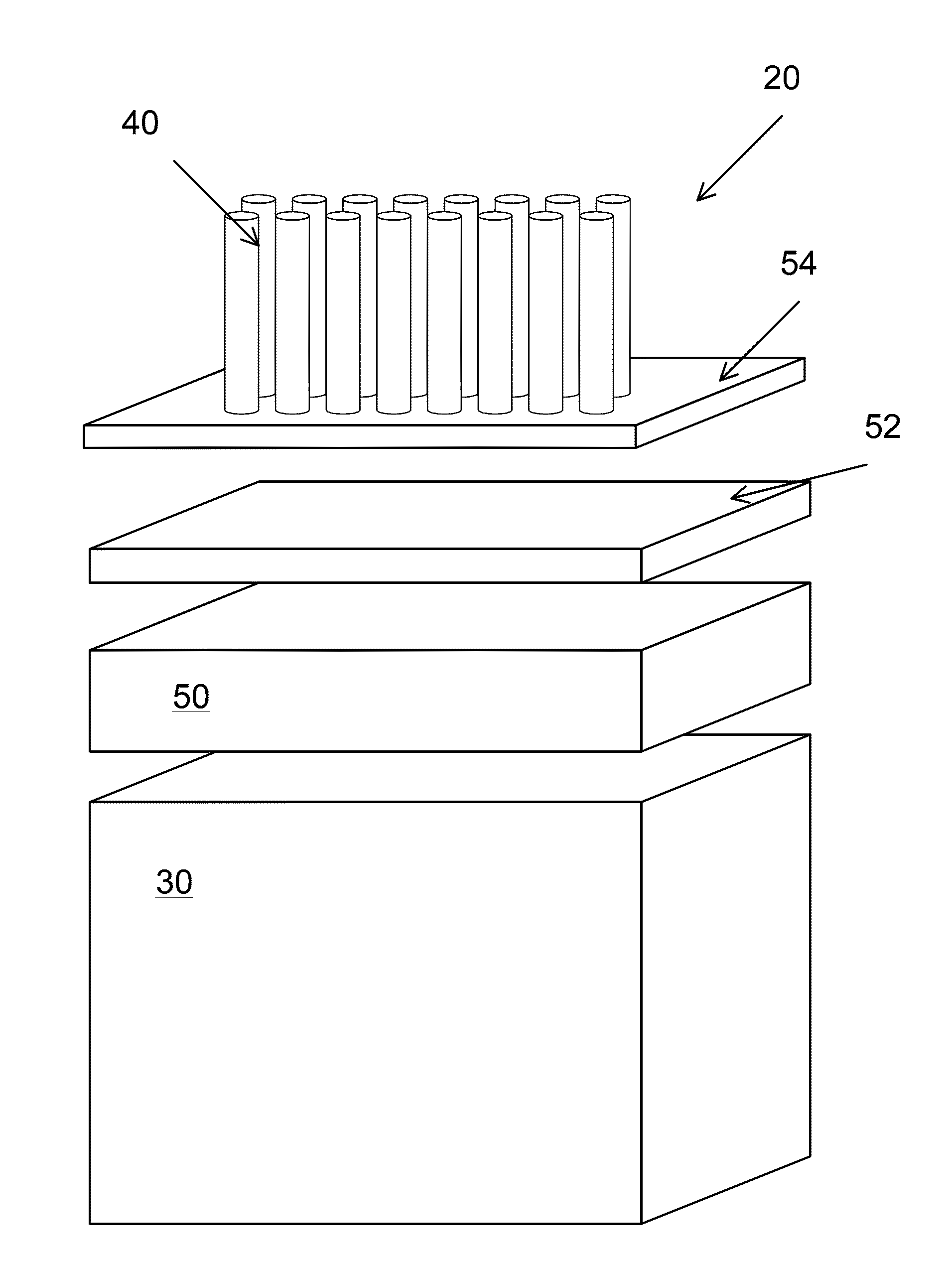

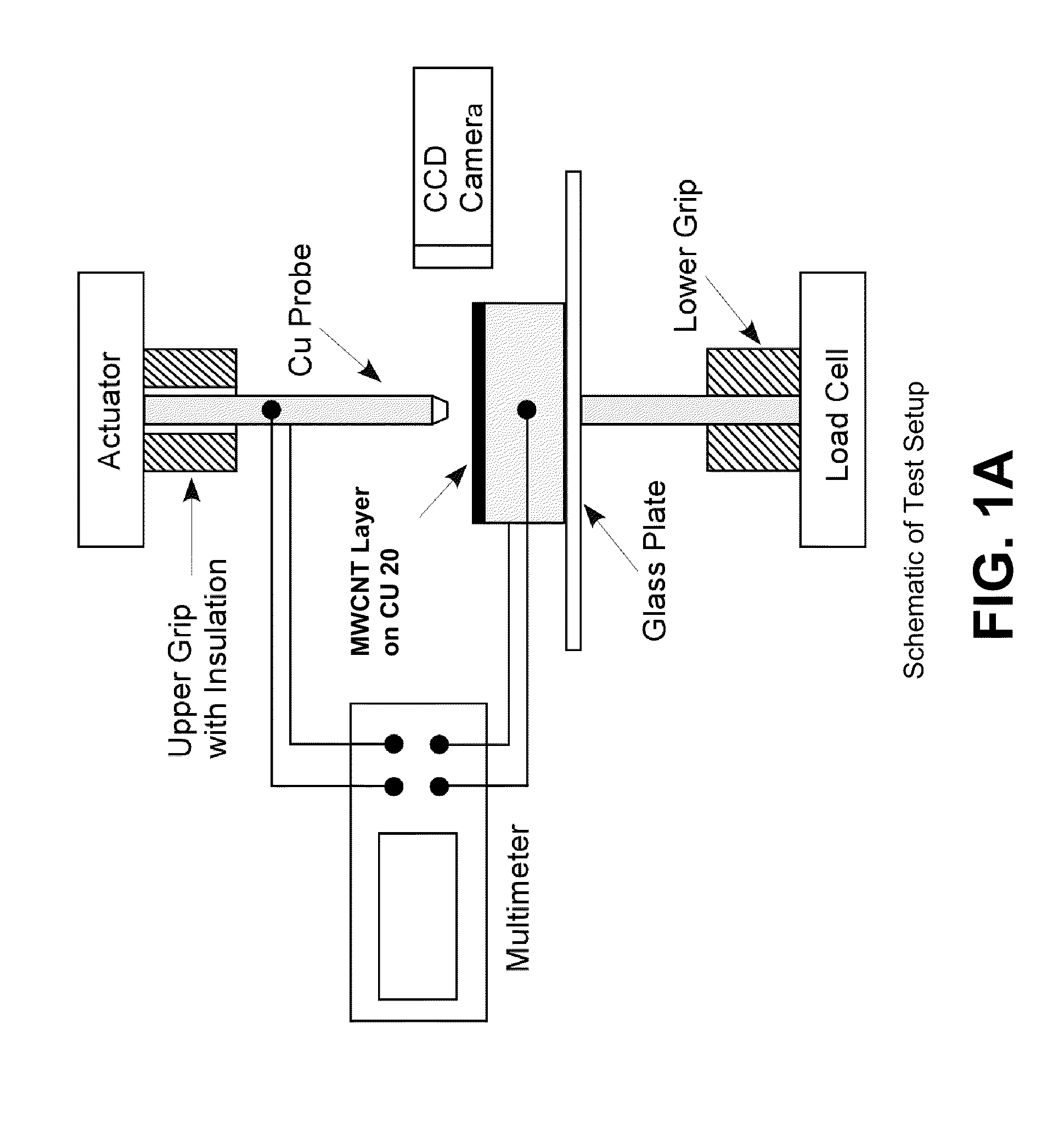

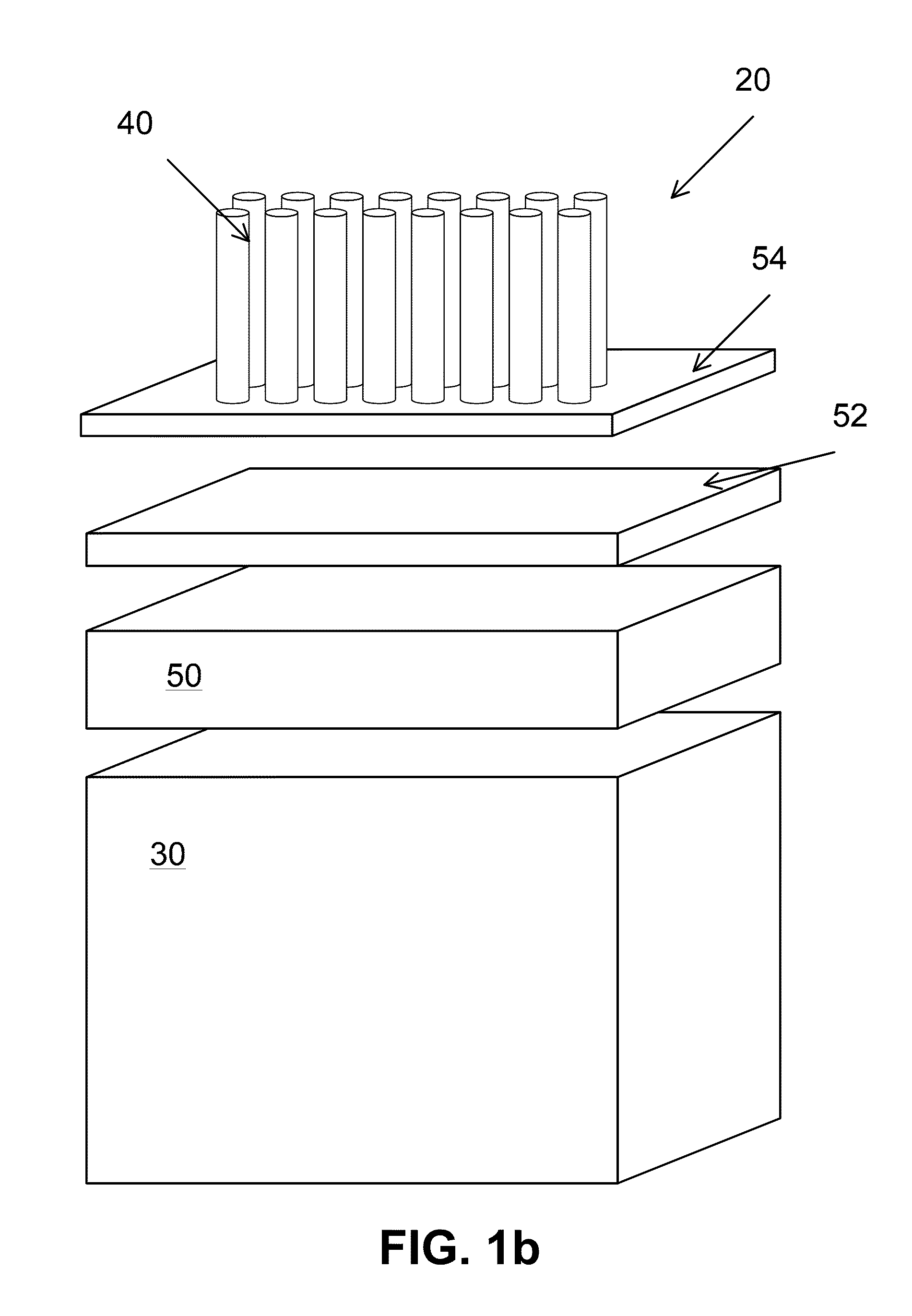

Methods for attaching carbon nanotubes to a carbon substrate

ActiveUS20100200208A1Reduce thermal (or electrical) interface resistanceHigh axial and in-plane thermal conductivityMaterial nanotechnologyLiquid surface applicatorsCarbon nanotubeGraphite

Vertically oriented carbon nanotubes (CNT) arrays have been simultaneously synthesized at relatively low growth temperatures (i.e., <700° C.) on both sides of aluminum foil via plasma enhanced chemical vapor deposition. The resulting CNT arrays were highly dense, and the average CNT diameter in the arrays was approximately 10 nm, A CNT TIM that consist of CNT arrays directly and simultaneously synthesized on both sides of various types of foil has been fabricated. The TIM is insertable and allows temperature sensitive and / or rough substrates to be interfaced by highly conductive and conformable CNT arrays. The use of foil, including substrates fabricated from carbon (CNT woven arrays, exfoliated graphite sheets, bucky paper, and the like) is disclosed.

Owner:PURDUE RES FOUND INC

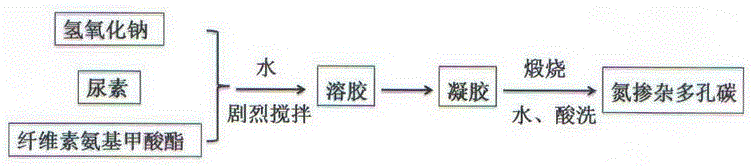

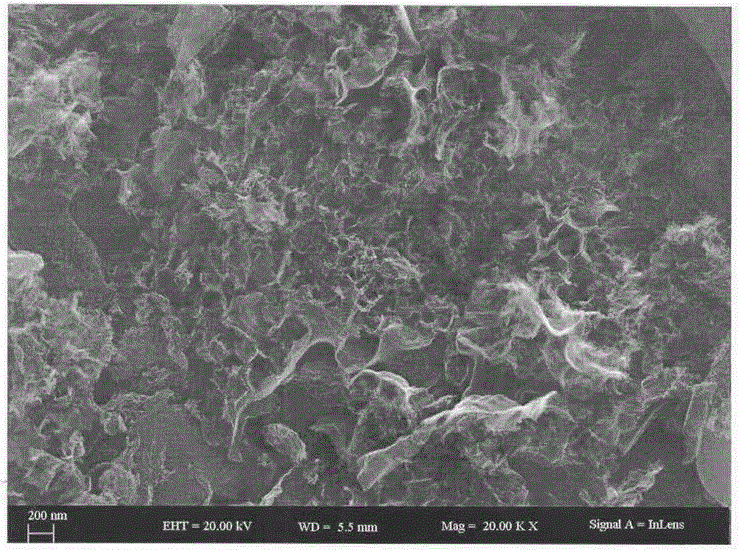

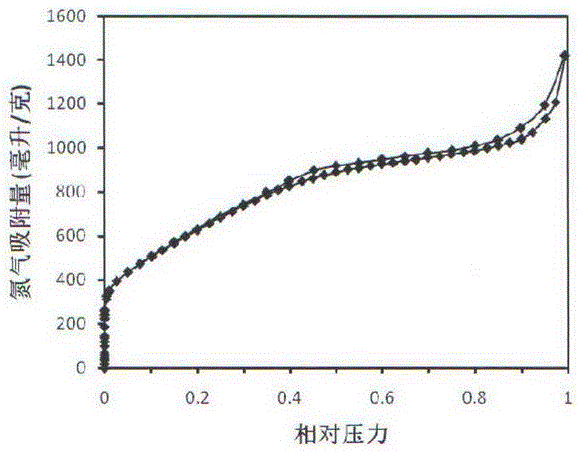

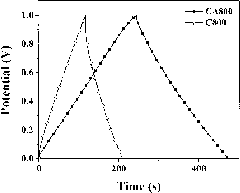

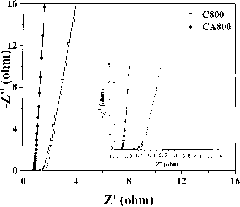

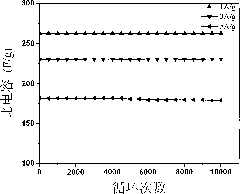

Application and preparation method of biomass-based nitrogen-doped porous carbon

InactiveCN106629655ASimple processImprove stabilityHybrid capacitor electrodesCarbon preparation/purificationCelluloseCarbamate

The invention discloses application and a preparation method of biomass-based nitrogen-doped porous carbon. The method includes: taking cheap cellulose carbamate as a raw material and urea as a nitrogen source, well mixing with sodium hydroxide solution, drying to form sol, and performing high-temperature calcination to obtain the porous-structure biomass-based nitrogen-doped porous carbon high in specific surface area and pore volume. According to electron microscopy images, the prepared material is in a three-dimensional inner-crosslinked porous structure; according to XPS and elemental analysis, nitrogen is successfully doped into a carbon substrate, the nitrogen content is 7.7-15.5%, and the specific surface area is 700-3700m<2> / g; according to supercapacitor experiments, the biomass-based nitrogen-doped porous carbon is great in electrochemical performance; according to pollutant adsorption experimental data, the material is high in adsorption rate and adsorption capacity in adsorption of dye pollutant methylene blue, and the adsorption capacity reaches 1520mg / g. The method is simple in preparation, the raw materials are renewable, and low cost is realized. In addition, sodium carbonate which is a by-product is obtained by washing of calcined samples, so that cost can be effectively reduced, and economic benefits are increased.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

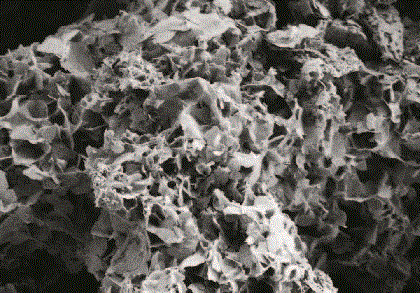

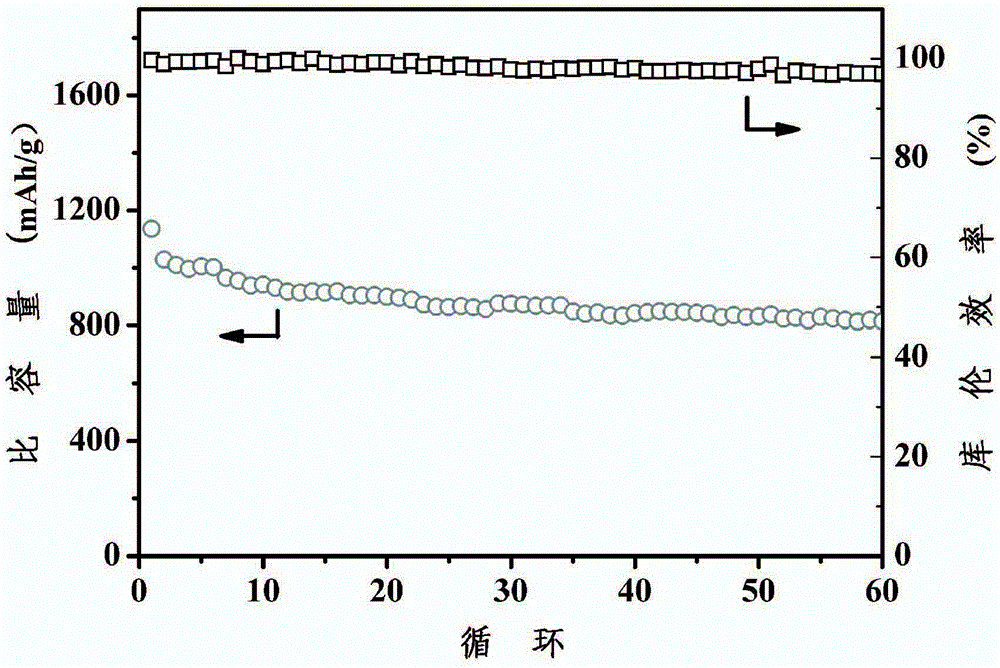

Nitrogen-enriched carbon based/sulfur composite cathode material used for lithium sulphur batteries, and preparation method thereof

InactiveCN105336930ASimple preparation processEffective compoundElectrode carriers/collectorsElectrical batteryPorous carbon

The invention discloses a nitrogen-enriched carbon base / sulfur composite cathode material used for lithium sulphur batteries, and a preparation method thereof, and belongs to the field of new generation energy storage. The nitrogen-enriched carbon-based / sulfur composite cathode material comprises a nitrogen-enriched porous carbon-based carrier prepared by taking fibroin as a nitrogen-rich carbon source, and a conductive network, possesses large specific surface area, high porosity, and excellent electrical conductivity; the nitrogen-enriched porous carbon-based carrier is activated with potassium hydroxide; and the nitrogen-enriched carbon base / sulfur composite cathode material is prepared via holt melting sulfur filling. The preparation method is simple, is friendly to the environment, and is suitable for industrialized production; the nitrogen-enriched carbon base / sulfur composite cathode material used for lithium sulphur batteries possesses high energy density, excellent cycling performance, and excellent rate capability, and possesses wide application prospect in the fields such as mobile communication and portable digital products, electric automobiles, and energy storage devices.

Owner:ZHEJIANG SCI-TECH UNIV

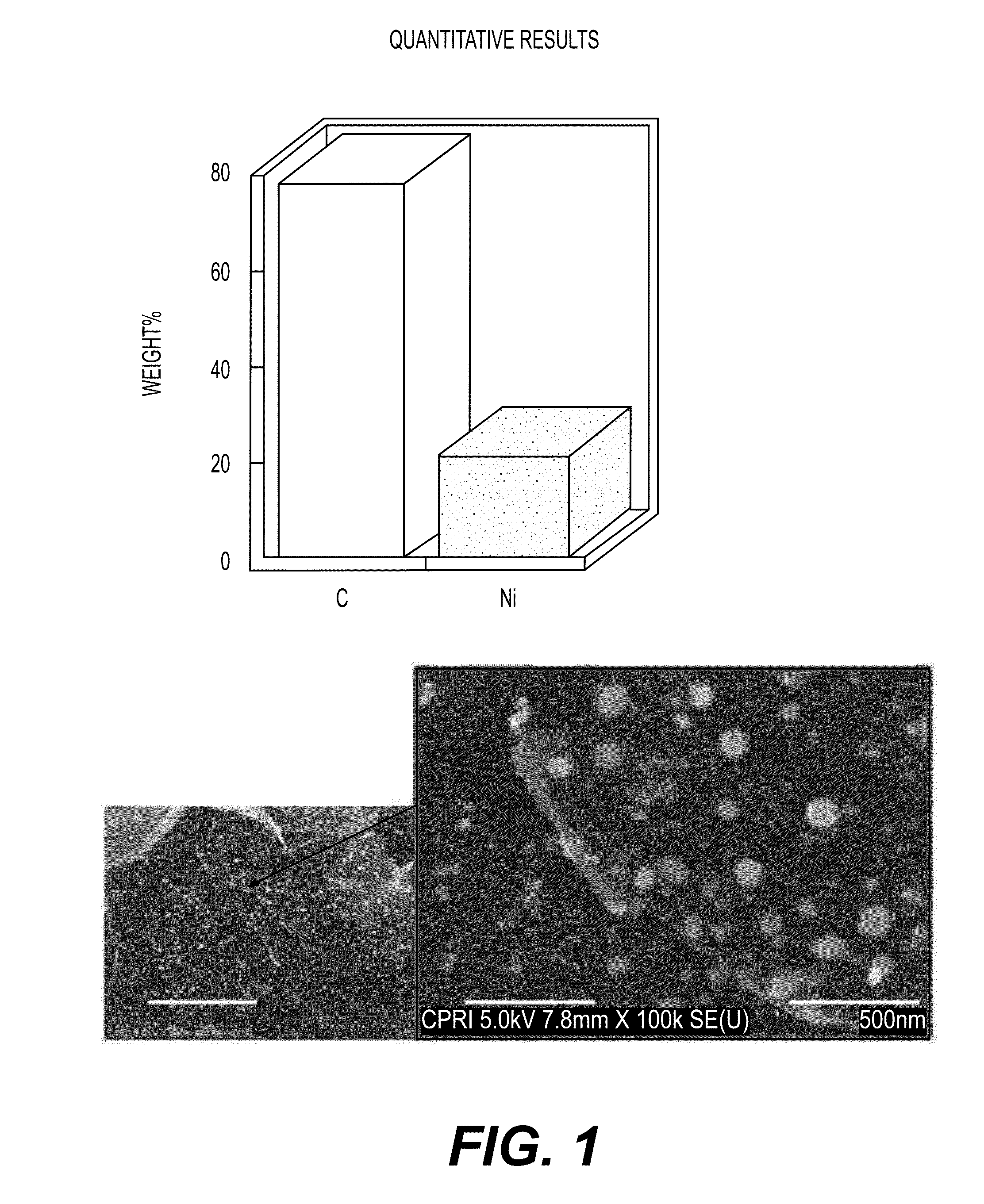

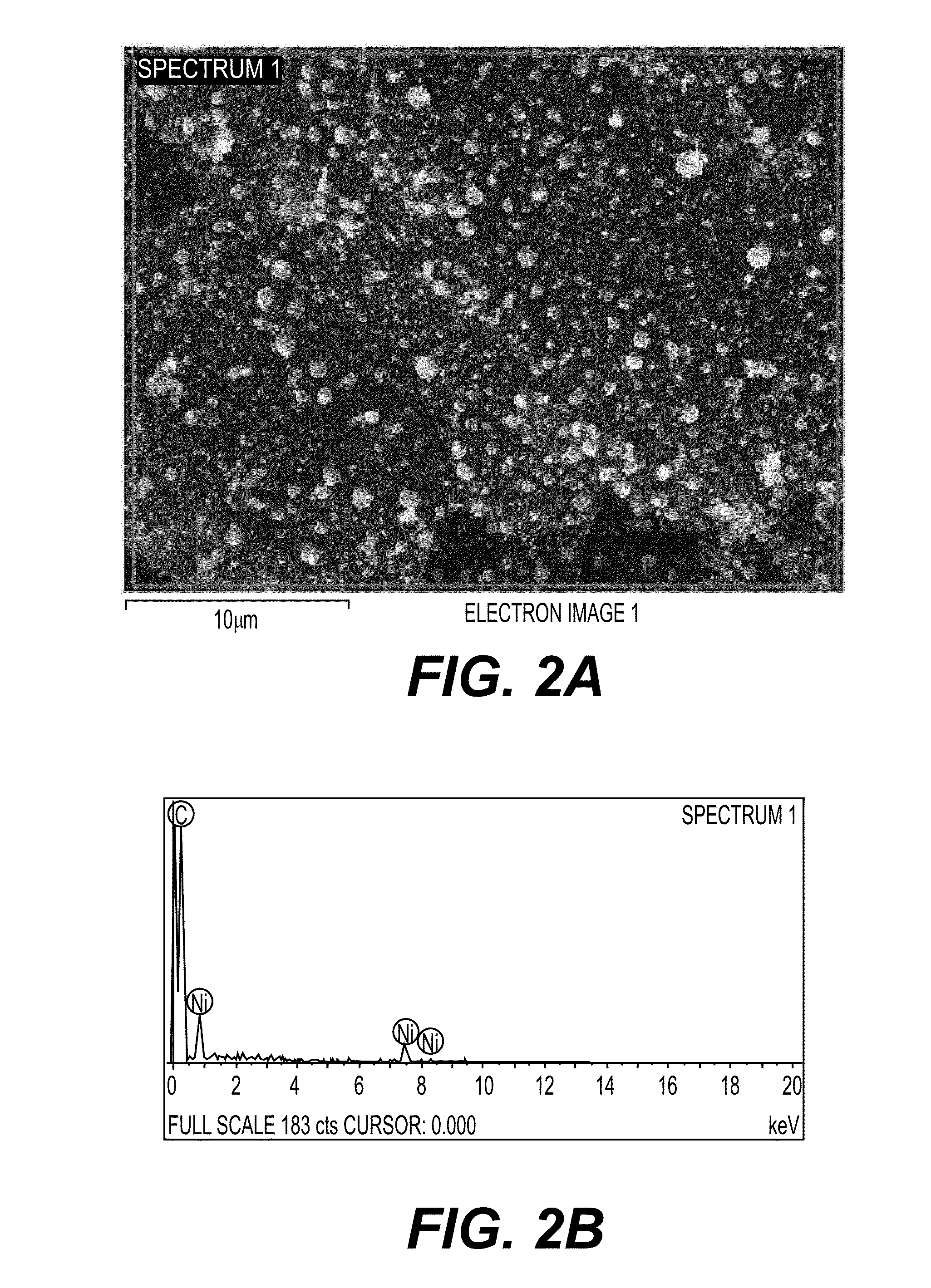

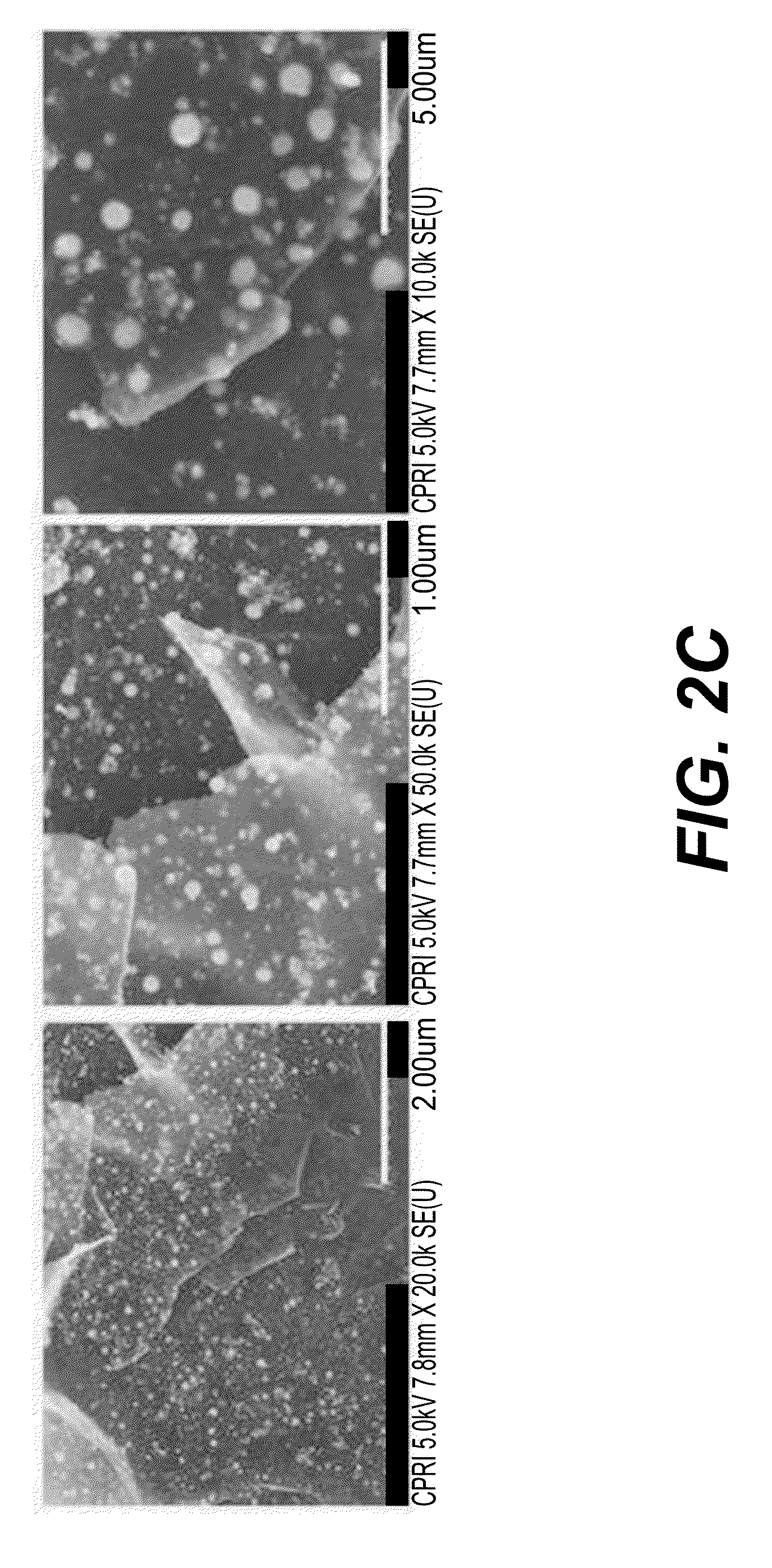

Graphene-nano particle composite having nanoparticles crystallized therein at a high density

InactiveUS20150179294A1Improve mechanical propertiesImprove electrical characteristicsSynthetic resin layered productsConductive materialNanoparticle ComplexHigh density

The present invention relates to a graphene-nanoparticle composite having a structure in which nanoparticles are crystallized at a high density in a carbon-based material, for example, graphene, and, more particularly, to a graphene-nanoparticle composite capable of remarkably improving physical properties such as contact characteristics between basal planes of graphene and conductivity since nanoparticles are included as a large amount of 20 to 50% by weight, based on 100% by weight of graphene, and a method of preparing the same.

Owner:CHEORWON PLASMA RES INST

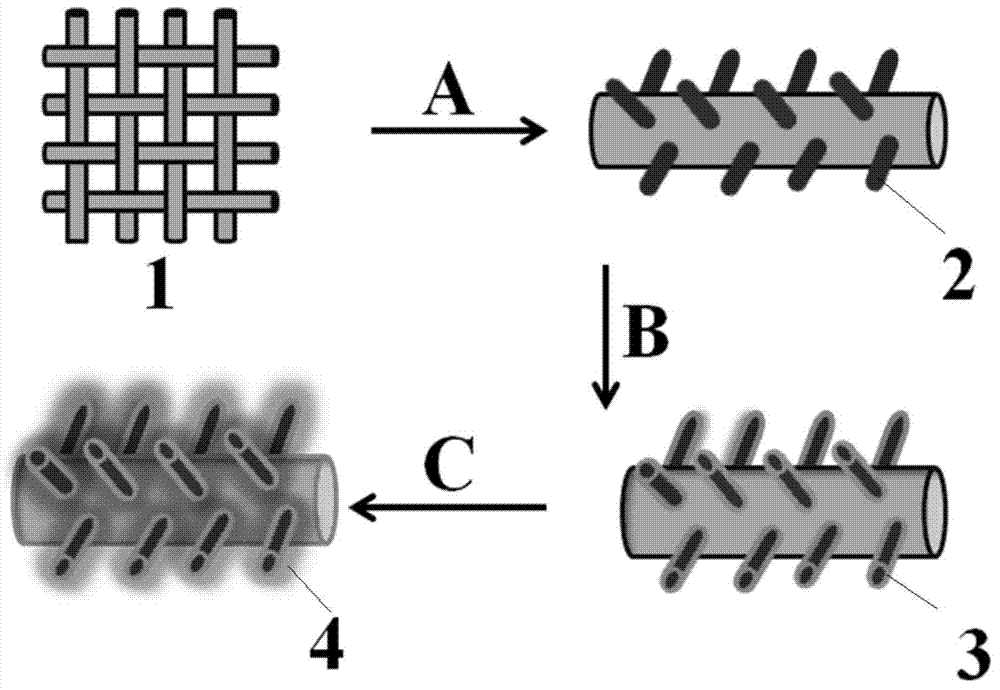

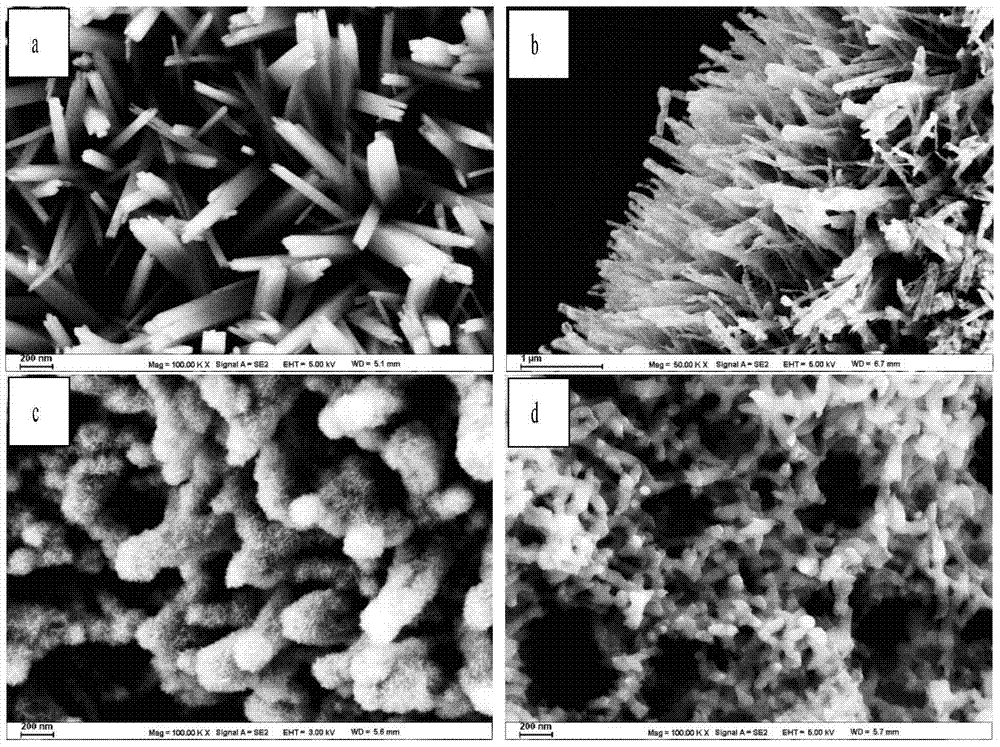

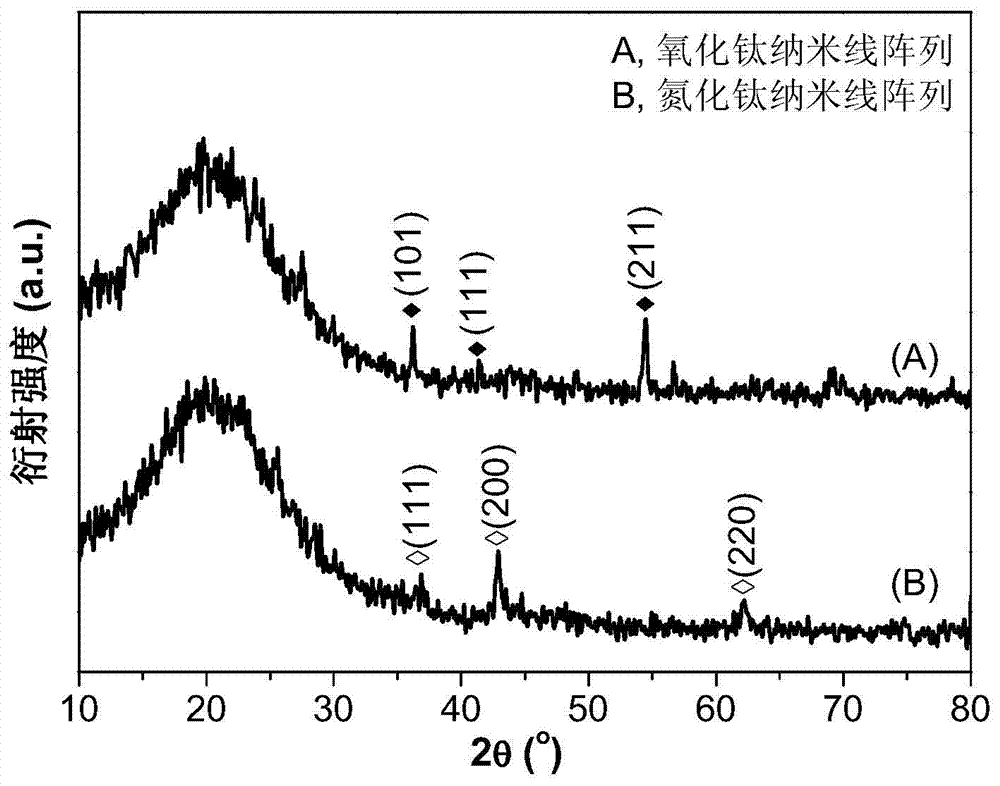

Polyaniline-manganese dioxide-titanium nitride nanowire array composite material and preparation method and application thereof

InactiveCN104240967AExtensive practical application valueExtensive productivityHybrid capacitor electrodesHybrid/EDL manufactureTitanium nitrideSupercapacitor

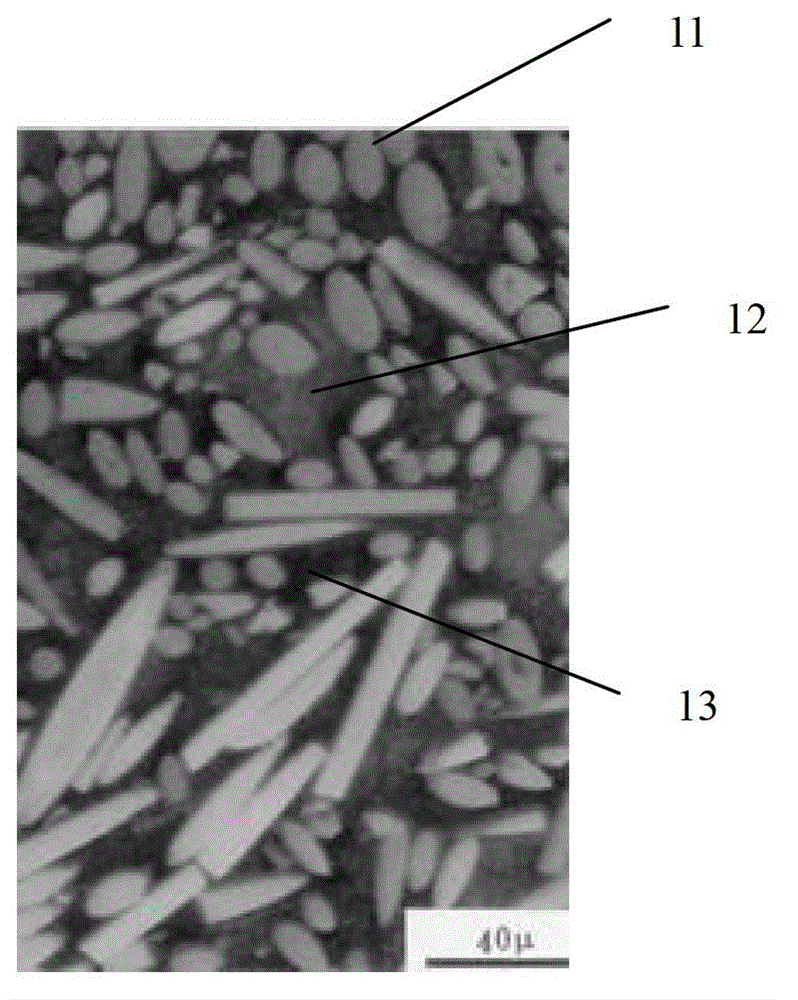

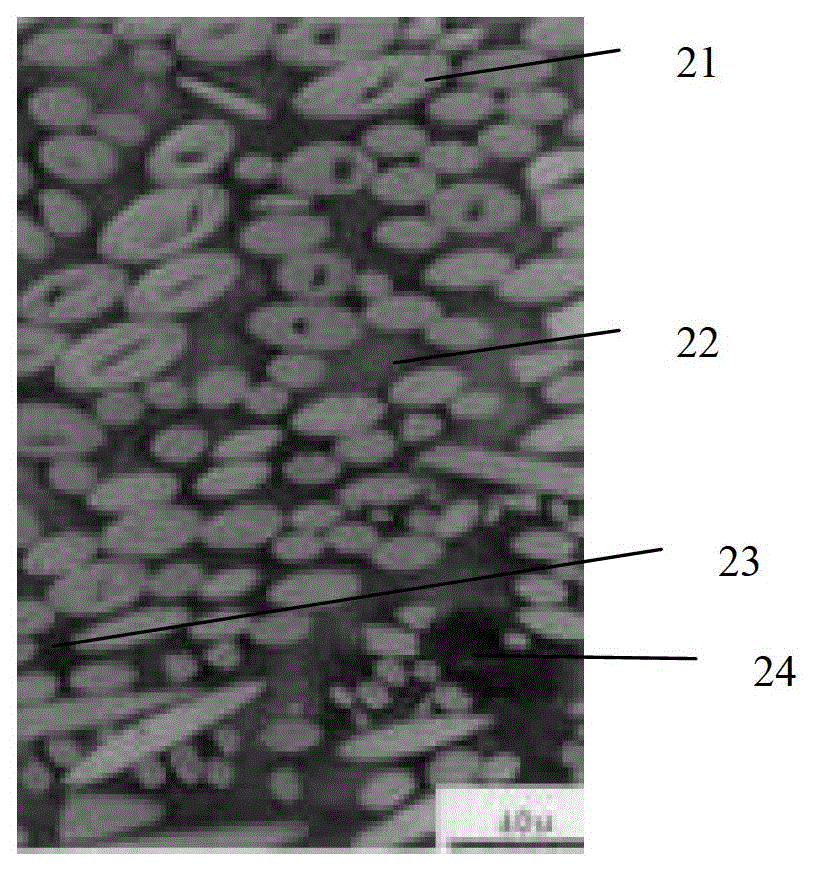

The invention provides a polyaniline-manganese dioxide-titanium nitride nanowire array composite material which comprises a carbon substrate (1), a titanium nitride nanowire array (2), a villiform manganese dioxide nano-film (3) and a coralliform polyaniline nanofiber (4). The titanium nitride nanowire array (2) is perpendicularly arranged on the surface of the carbon substrate (1) and connected with the carbon substrate (1) to form an integral structure, the manganese dioxide nano-film (3) coats the surface of the titanium nitride nanowire array (2), and the coralliform polyaniline nanofiber (4) is adhered on the surface of the manganese dioxide nano-film (3). The invention further provides a preparation method of the composite material and application of the composite material in a supercapacitor. The polyaniline-manganese dioxide-titanium nitride nanowire array composite material has features of an orderly-arranged porous structure, is regular and controllable in shape and appearance, can be directly applied to an electrode material of the supercapacitor and has wide actual application value and industrial production prospect.

Owner:SOUTHEAST UNIV

Methods for producing end-products from carbon substrates

InactiveUS20090181433A1Improve processing efficiencyAvoiding catabolic repressiveBacteriaBiofuelsCelluloseEngineering

The present invention provides means for the production of desired end-products of in vitro and / or in vivo bioconversion of biomass-based feed stock substrates, including but not limited to such materials as starch and cellulose. In particularly preferred embodiments, the methods of the present invention do not require gelatinization and / or liquefaction of the substrate.

Owner:GENENCOR INT INC

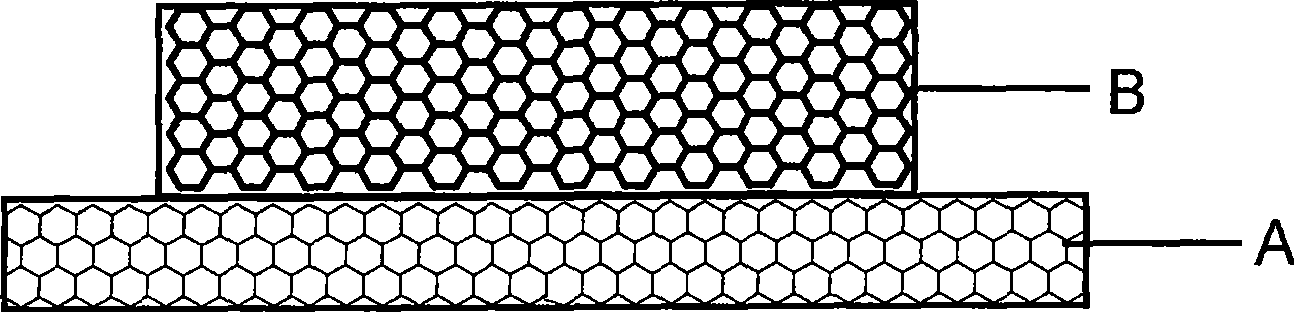

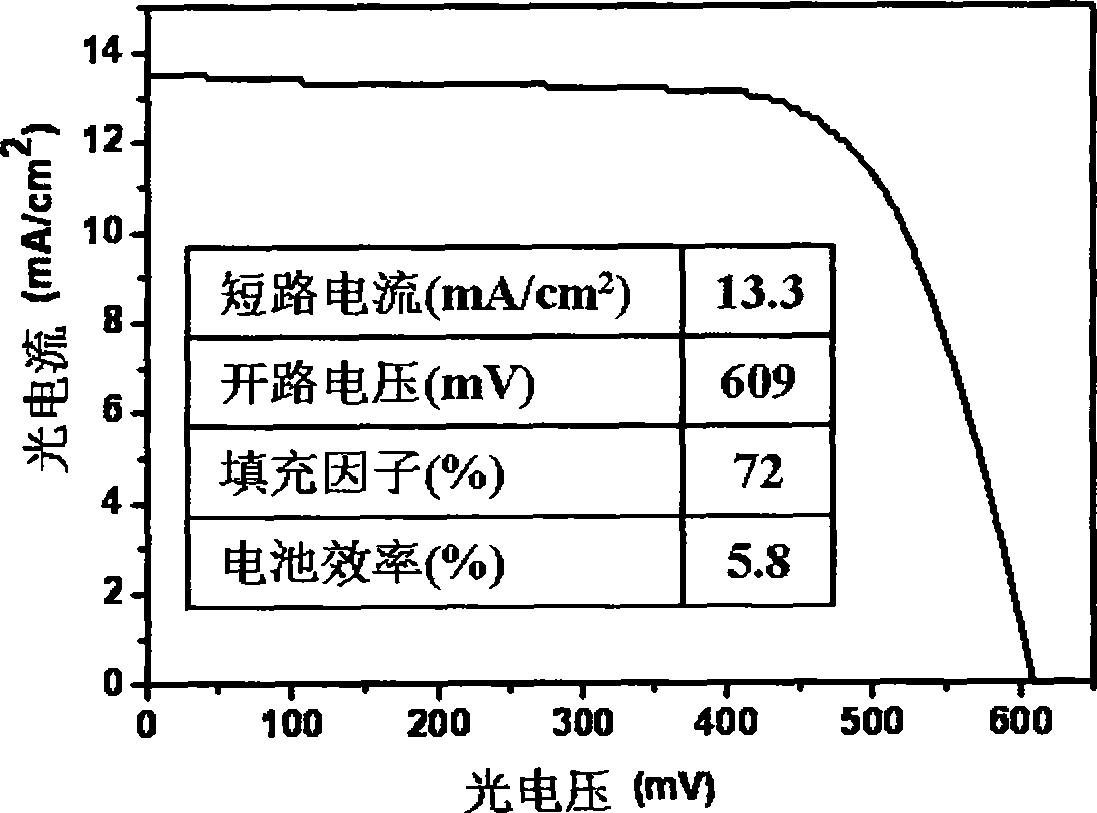

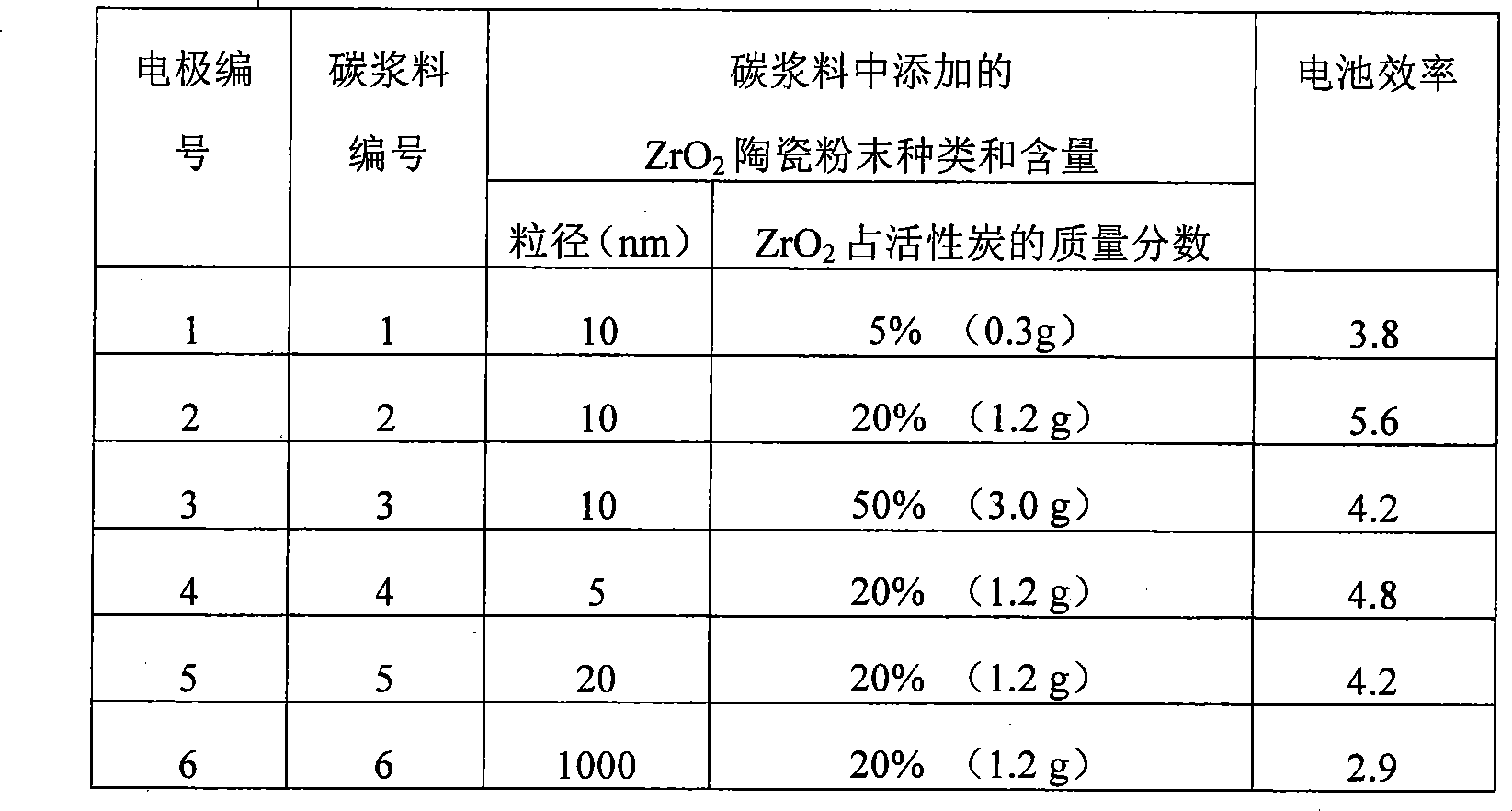

Full carbon counter electrode dye-sensitized solar cell and preparing method

ActiveCN101388294AGood mechanical properties such as friction resistanceImprove mechanical propertiesLight-sensitive devicesElectrode manufacturing processesElectrical batteryFilm coating

The invention relates to an all carbon counter electrode for a dye-sensitized solar cell and a process for preparation, wherein the all carbon counter electrode is formed by a carbon substrate A and a carbon catalytic active layer B which is coated on the carbon substrate. The process for preparing the all carbon counter electrode comprises firstly dispersing carbon catalytic active material and making into carbon paste according to the process of preparing carbon paste disclosed by the patient closure number CN101188257A, then transferring to the clean carbon substrate A through the methods of screen painting, spread coating, rotary film coating, film dropping or Czochralski method, and finally preparing the all carbon counter electrode through drying or kilning. The all carbon electrode of the invention can reduce series resistance and interface resistance, thereby increasing the short-circuit current (Jsc), filling factor (FF) and photoelectric transformation efficiency of the dye-sensitized solar cell. The substrate material adopted by the all carbon counter electrode of the invention has smaller resistance, can reduce using or avoid using metal flow concentration leads, and simplifies preparation technology.

Owner:深圳市华物光能技术有限公司

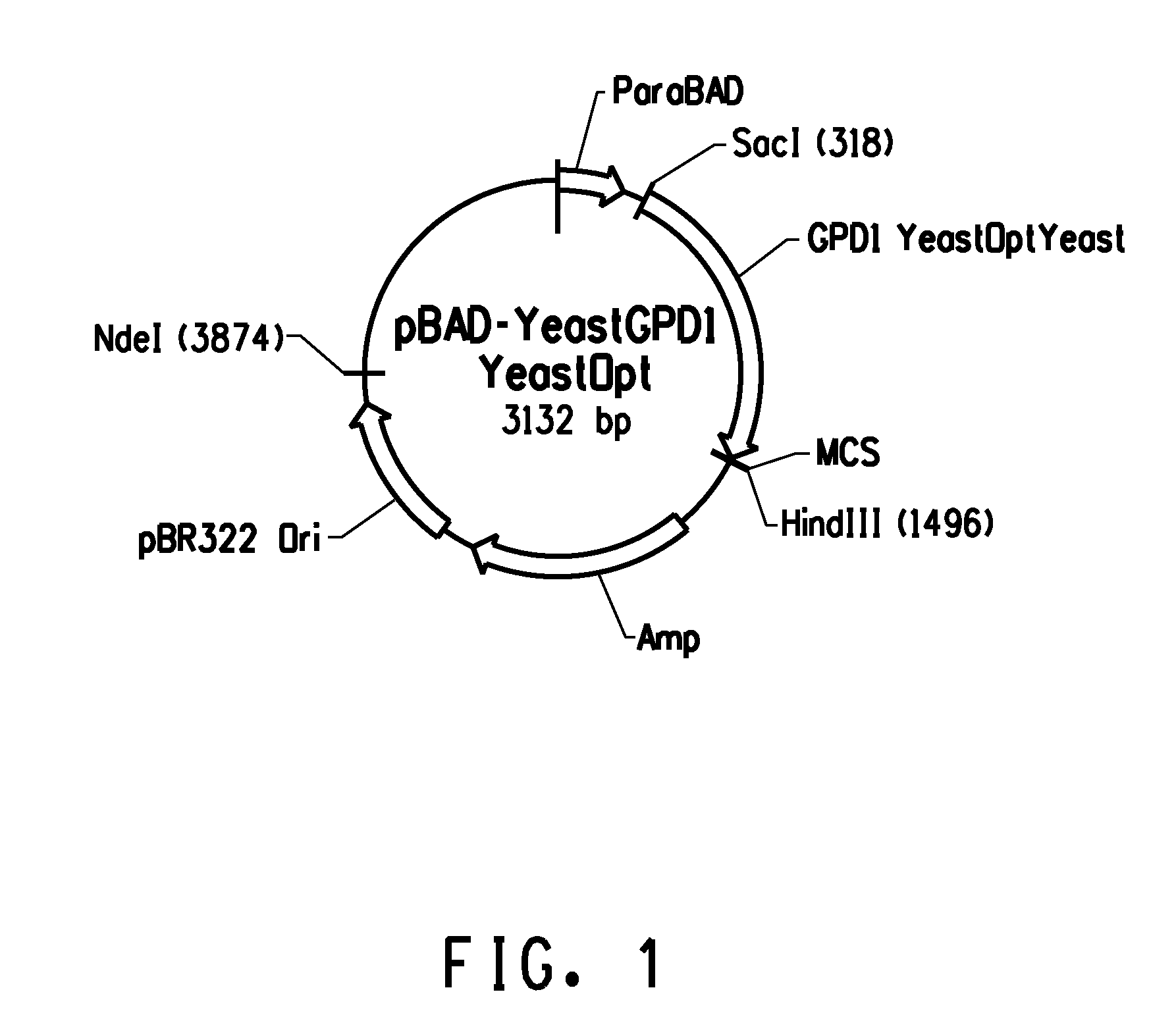

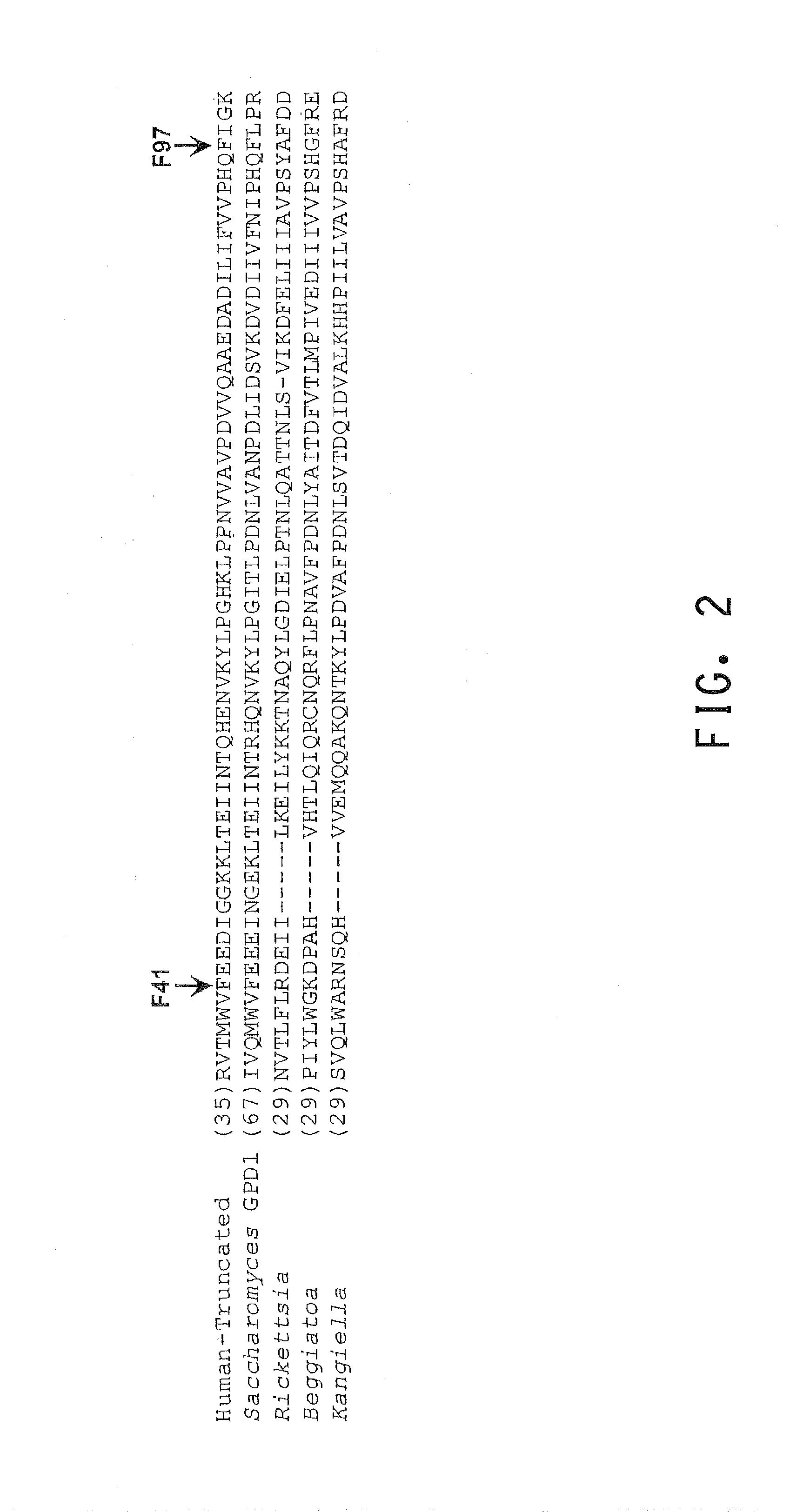

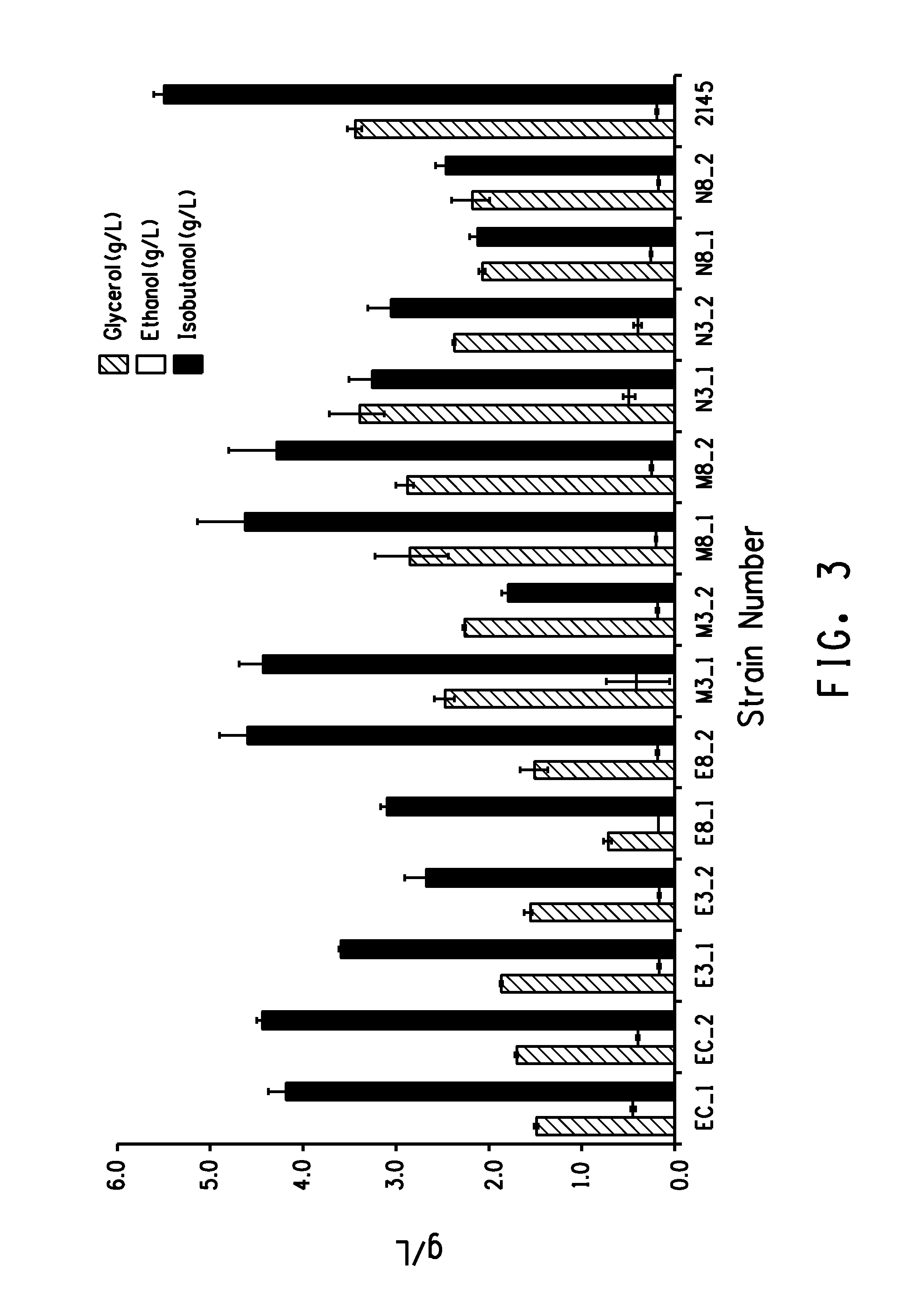

Glycerol 3- phosphate dehydrogenase for butanol production

ActiveUS20140273129A1Improved and increased production of butanolReduced and decreased production of glycerolBacteriaBiofuelsHeterologousMicroorganism

Provided herein are glycerol-3-phosphate dehydrogenase (GPD) enzymes with increased KM for NADH and GPD enzymes with substantially the same affinity for NADH and NADPH and / or are feedback inhibited by glycerol-3-phosphate. Also provided herein are recombinant microorganisms comprising a heterologous gene encoding GPD and a deletion or disruption in an endogenous gene encoding GPD. Also provided are recombinant microorganisms comprising a heterologous gene encoding GPD and a butanol biosynthetic pathway. Further provided are methods of producing butanol comprising providing the recombinant microorganisms described herein and contacting the recombinant microorganism with at least one fermentable carbon substrate under conditions wherein butanol is produced.

Owner:GEVO INC

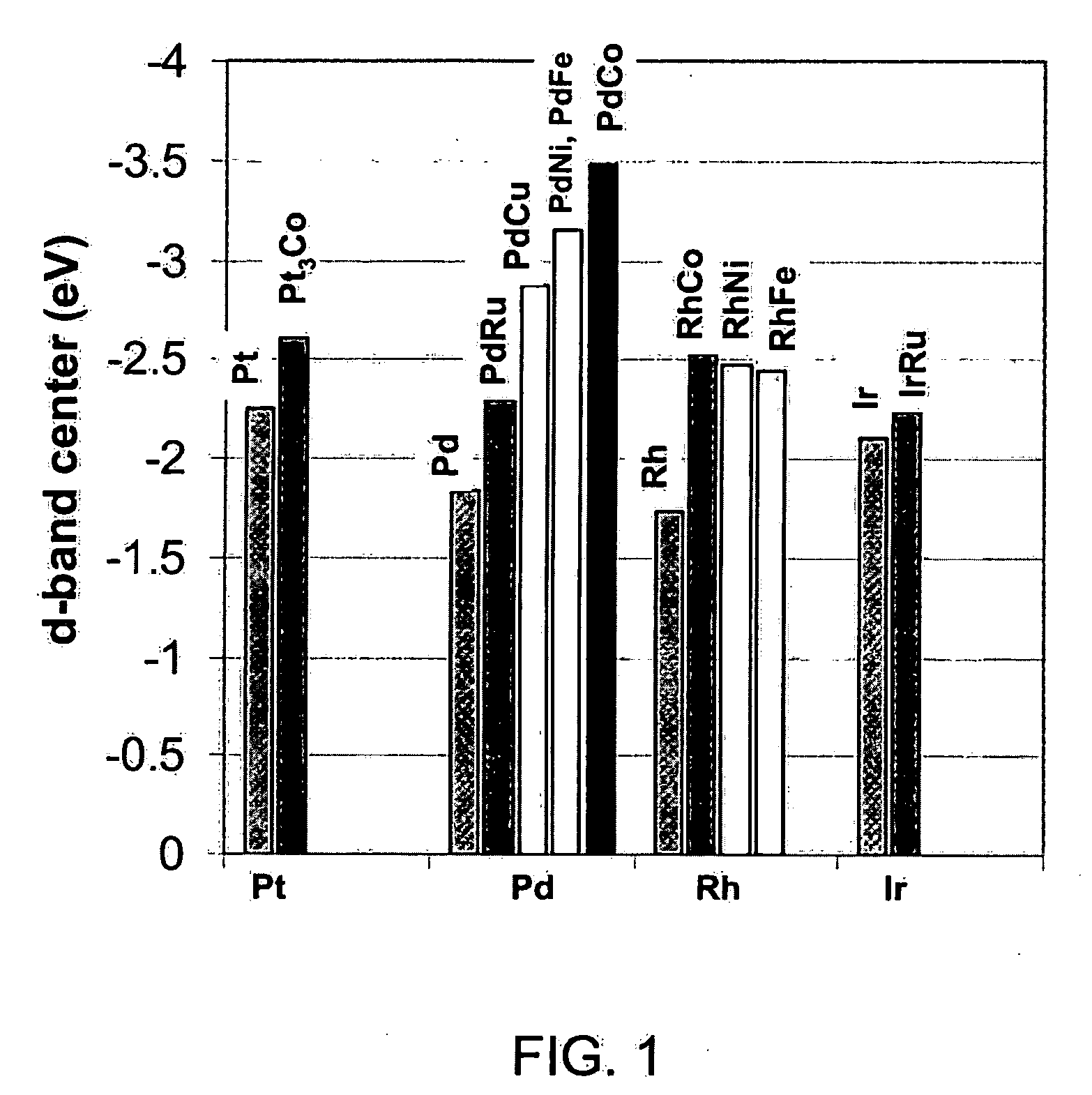

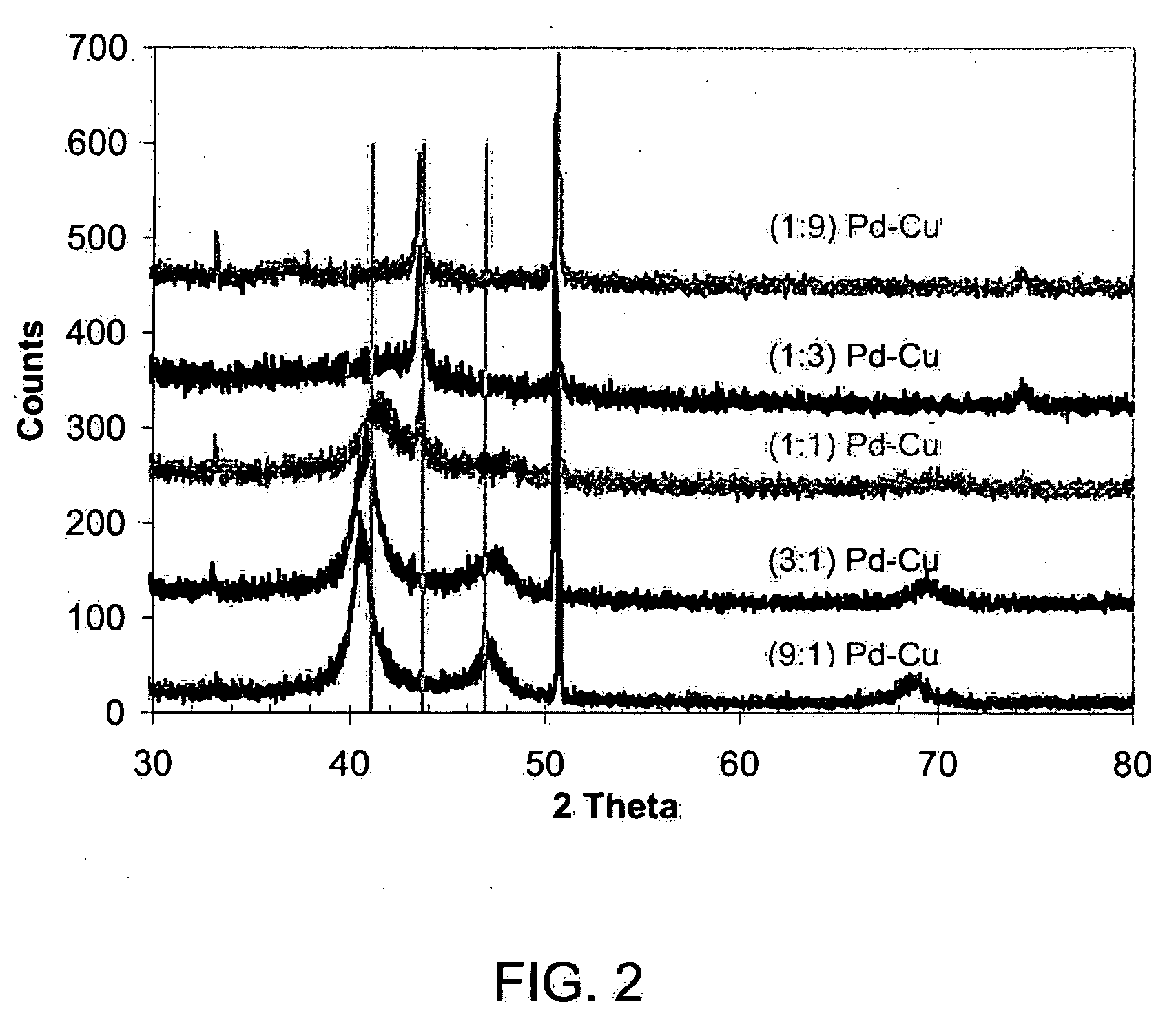

Non-platinum bimetallic polymer electrolyte fuel cell catalysts

ActiveUS20090192030A1Low costPromote formationCell electrodesCatalyst activation/preparationNon platinumAlloy

A polymetallic nanoparticle alloy having enhanced catalytic properties including at least one noble metal and at least one base metal, where the noble metal is preferentially dispersed near the surface of the nanoparticle and the base metal modifies the electronic properties of the surface disposed noble metal. The polymetallic nanoparticles having application as a catalyst when dispersed on a carbon substrate and in particular applications in a fuel cell. In various embodiments a bimetallic noble metal-base metal nanoparticle alloy may be used as an electrocatalyst offering enhanced ORR activity compared to the monometallic electrocatalyst of noble metal.

Owner:UCHICAGO ARGONNE LLC

Method to Improve Nucleation of Materials on Graphene and Carbon Nanotubes

ActiveUS20100301336A1Promote nucleationTransistorSemiconductor/solid-state device manufacturingCarbon nanotubeNucleation

Techniques for forming a thin coating of a material on a carbon-based material are provided. In one aspect, a method for forming a thin coating on a surface of a carbon-based material is provided. The method includes the following steps. An ultra thin silicon nucleation layer is deposited to a thickness of from about two angstroms to about 10 angstroms on at least a portion of the surface of the carbon-based material to facilitate nucleation of the coating on the surface of the carbon-based material. The thin coating is deposited to a thickness of from about two angstroms to about 100 angstroms over the ultra thin silicon layer to form the thin coating on the surface of the carbon-based material.

Owner:GLOBALFOUNDRIES US INC

Method for preparing porous carbon/nano metal oxide composite material

InactiveCN101038816AIncrease energy densityImprove power densityElectrode manufacturing processesFixed capacitor electrodesCapacitancePorous carbon

The invention relates to a method for preparing a lacunaris carbon / nanometer oxide composite material used in an ultra capacitor electrode. The prepared material is capable of evenly dispersing a nanometer oxide into a lacunaris carbon substrate. When the ultra capacitor electrode is prepared by the material, with a combination of a double-electric-layer capacitor and a metal oxide pseudocapacitance, the electrode can has a higher unit capacitor and a carbon framework can provide a favorable conductive passage for nanometer metal oxide particles dipersed in the carbon framework to reduce an equivalent internal resistance of the capacitor, thereby the capacitor has a high power and power density.

Owner:HARBIN ENG UNIV

Sulfur/carbon composite material for lithium-sulfur secondary battery and preparation method thereof

InactiveCN102969481AHigh reactivityIncrease profitElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesCarbon compositesDischarge efficiency

The invention discloses a sulfur / carbon composite material for a lithium-sulfur secondary battery and a preparation method thereof. The composite material is formed by compositing a micro-pore carbon substrate with a lithium ion conduction property and elemental sulfur filled in the micro-pore structure. The carbon substrate is used as an electronic conductor in the composite material, and is further used as a lithium ion conductor, so that sulfur electrode reaction is directly carried out on a sulfur / carbon solid-solid interface in a conversion reaction manner without directly contacting with electrolyte. Therefore, the problem of circulation caused by that a polysulfide intermediate product is dissolved in the electrolyte can be solved. Compared with the other sulfur / carbon composite electrode, the composite material has the advantages of high electrochemical capacity, good circulation stability, high charging and discharging efficiency and the like; and meanwhile, the preparation method is simple and low in cost, and has a good application prospect.

Owner:WUHAN UNIV

Active carbon-based material and preparation method thereof

InactiveCN101800131AImprove conductivityIncrease energy densityElectrolytic capacitorsHybrid capacitor electrodesCapacitanceHigh energy

The invention provides an active carbon-based material and a preparation method thereof. The carbon-based material comprises the following components based on parts by weight percent: 50-90% of carbon, 0.1-35% of oxygen, 0.1-35% of nitrogen, 0.0%-10% of sulphur, 0.0%-15% of phosphorus and 0.0-15% of boron. The preparation method comprises the following step of carbonizing doped or undoped polyaniline polymer at 500-1200 DEG C for 1-24h under the protection of inert gas. Heteroatom N, O, S, P, B, H and group thereof are induced to the carbon atom to change the chemical environment of the carbon atom and increase the space charge density of the carbon atom and the polarity of the material, so that the material has surface standard faraday capacitance and double electric layer capacitance, and has higher specific capacity, good electrical conductivity, and higher energy density and power density under the condition that the specific surface area is not increased. The preparation method of the active carbon-based material has the advantages of simple technology, easily-obtained raw materials, low cost, small pollution and being capable of being produced on a large scale.

Owner:XIANGTAN UNIV

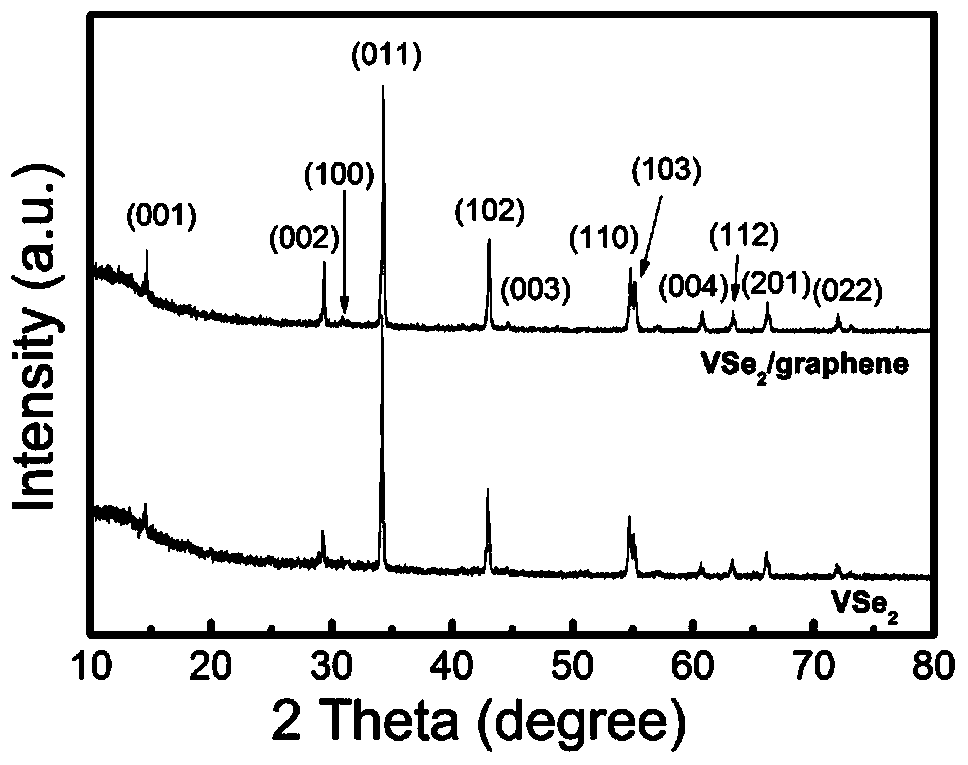

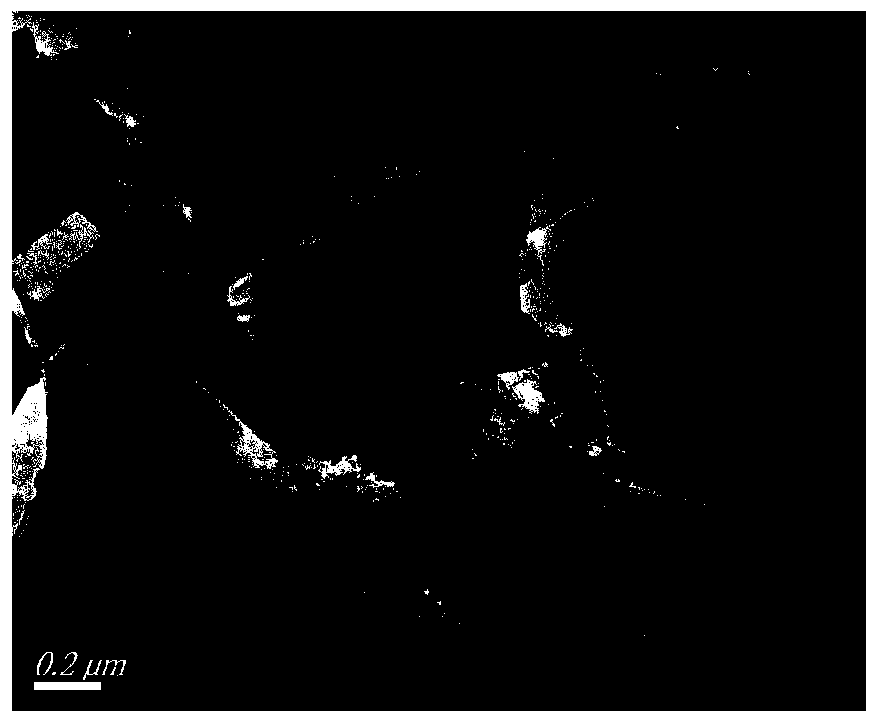

Vanadium selenide/carbon-based composite material, preparation method of material, and negative electrode of lithium ion battery

ActiveCN104051733AUniform particle distributionSmall particle sizeSecondary cellsNon-aqueous electrolyte accumulator electrodesHexagonal crystal systemHigh rate

The invention provides a vanadium selenide / carbon-based composite material, a preparation method of the material, and a negative electrode of a lithium ion battery. Vanadium selenide in the vanadium selenide / carbon-based composite material is of a hexagonal crystal system and is deposited on the surface of a carbon-based material, or the surfaces of vanadium selenide particles are at least partially coated with the carbon-based material to form vanadium selenide / carbon particles of a core shell-like structure; the vanadium selenide / carbon particles are connected through carbon nets to obtain the high conductivity. In the negative electrode of the power lithium ion battery, prepared from the vanadium selenide / carbon-based composite material provided by the invention, since selenide with the relatively large specific capacity is combined with the carbon-based material, the negative electrode has the characteristics of large capacity, high rate and high cyclic stability. Therefore, the negative electrode made of the composite material has the relatively large capacity, relatively long service life and relatively low price when applied to the lithium ion battery.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com