Patents

Literature

4039 results about "Composite electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

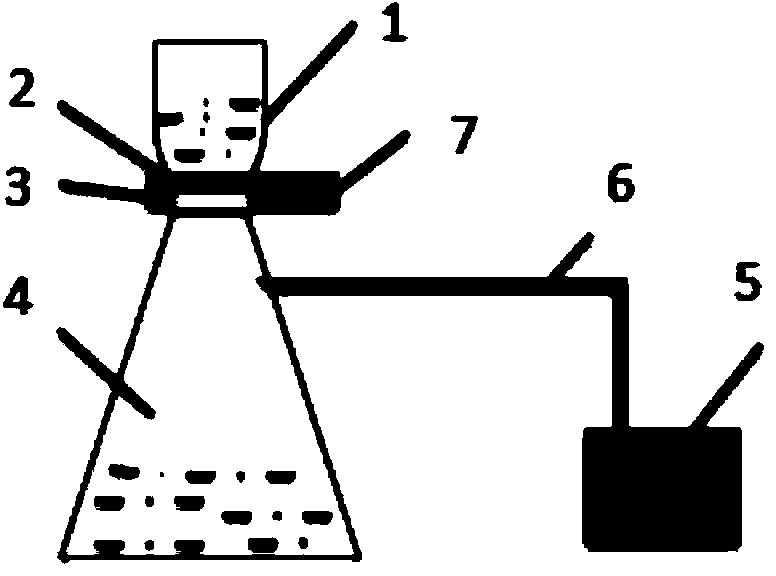

Microsensors for glucose and insulin monitoring

InactiveUS6893552B1Simultaneous measurementLacking and neededImmobilised enzymesBioreactor/fermenter combinationsOxidative enzymeD-Glucose

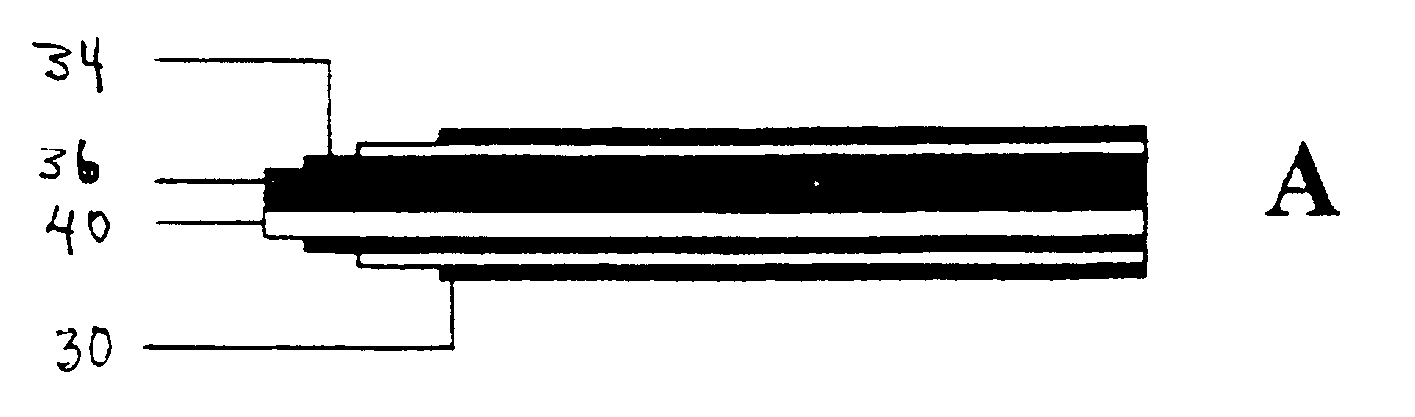

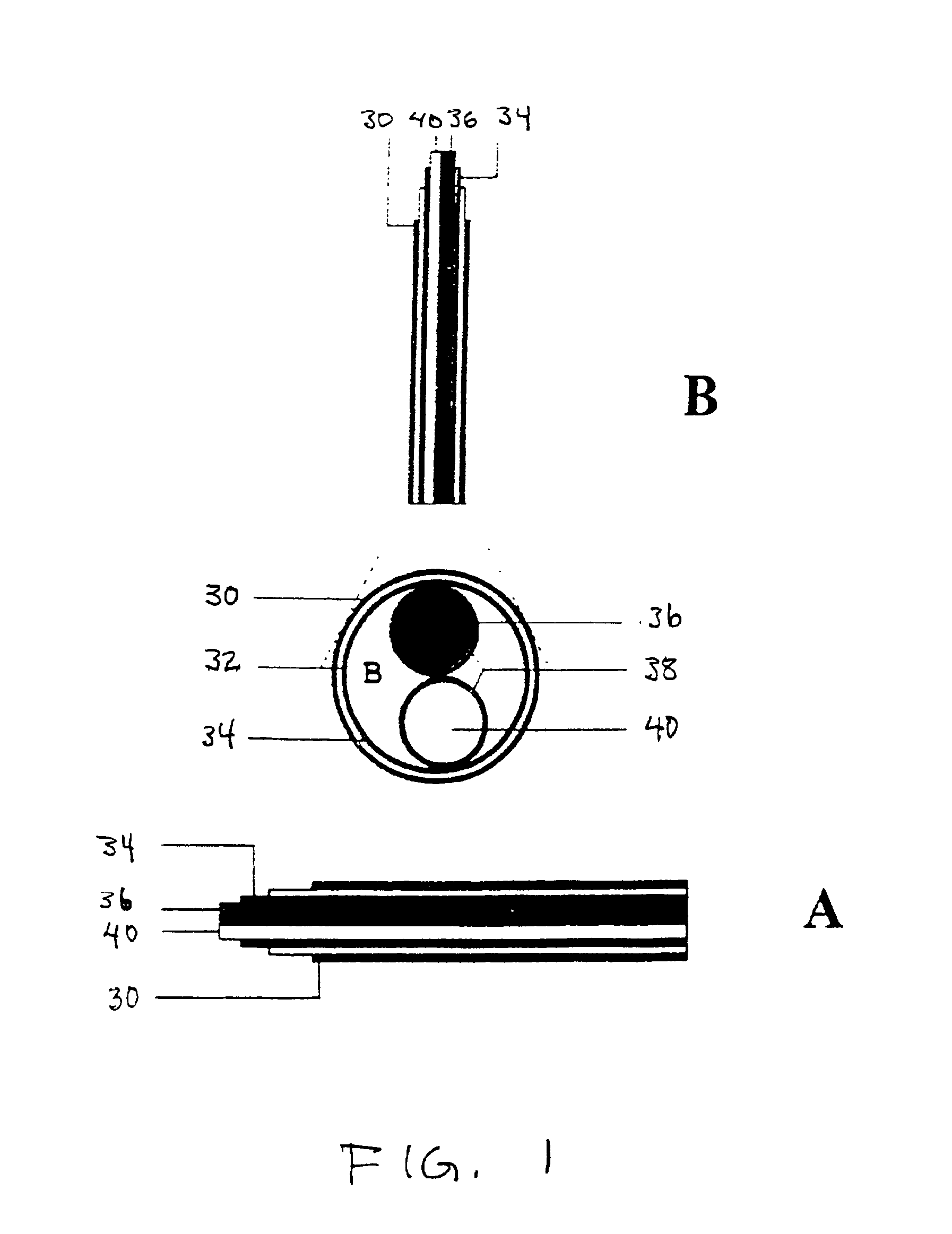

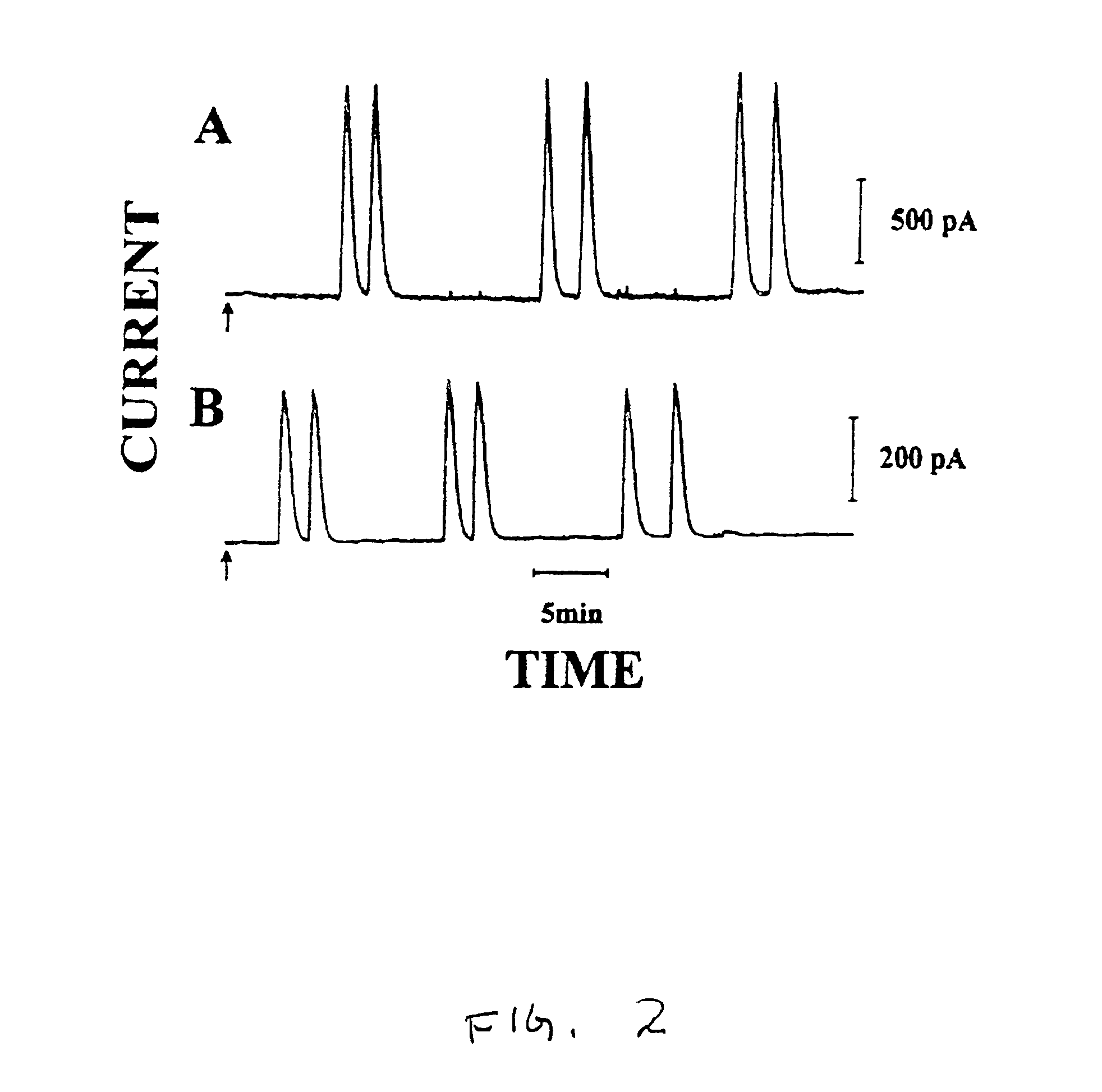

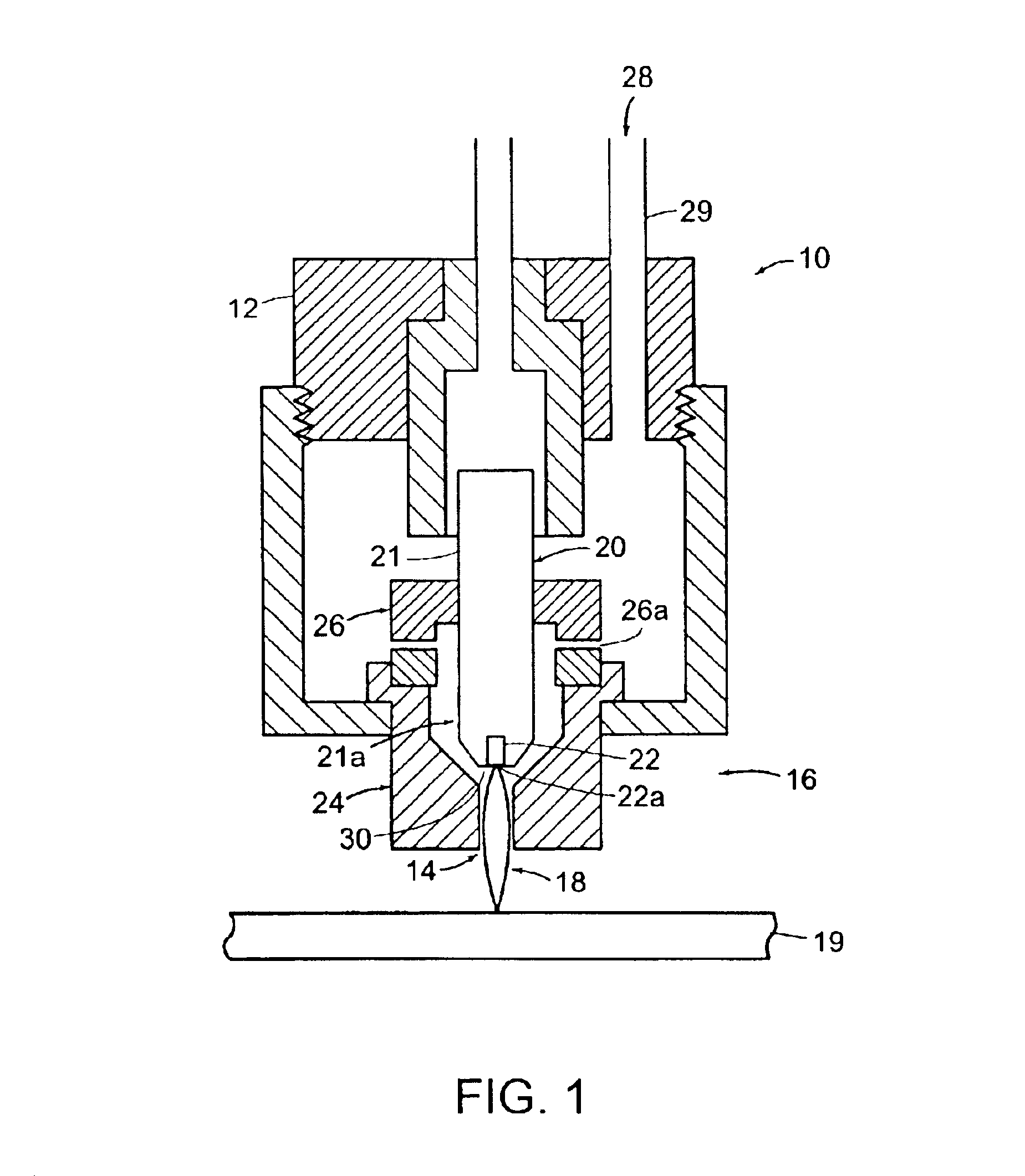

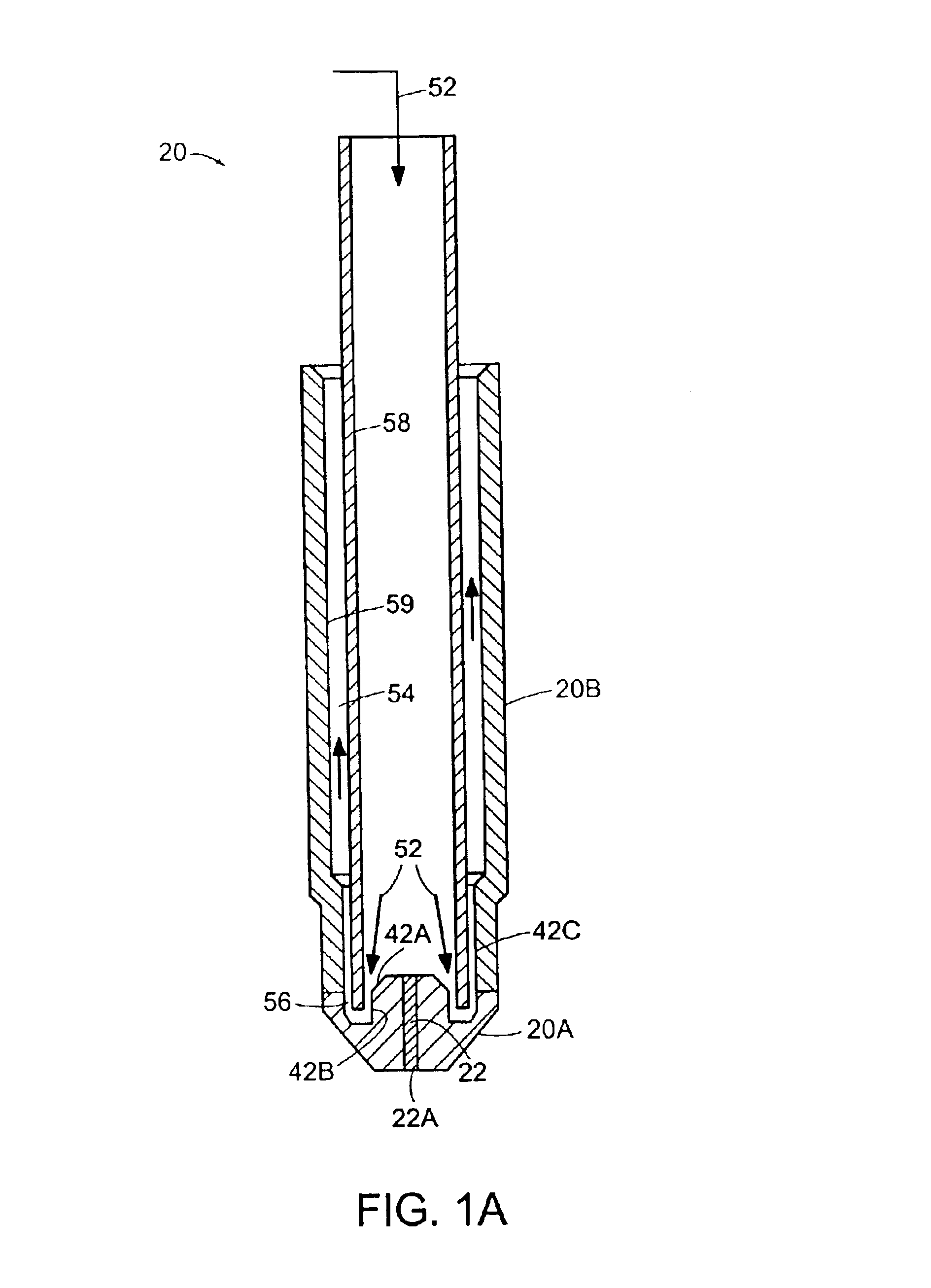

A dual sensor for the simultaneous amperometric monitoring of glucose and insulin, wherein the glucose probe is based on the biocatalytic action of glucose oxidase, and the insulin probe is based on the electrocatalytic activity of metal oxide. Further provided is an oxidase enzyme composite electrode with an internal oxygen-rich binder. The present invention also optionally includes metallizing components within the carbon paste to eliminate signals from interfering compounds. The present invention includes embodiments for both in vitro and in vivo uses.

Owner:ARROWHEAD CENT

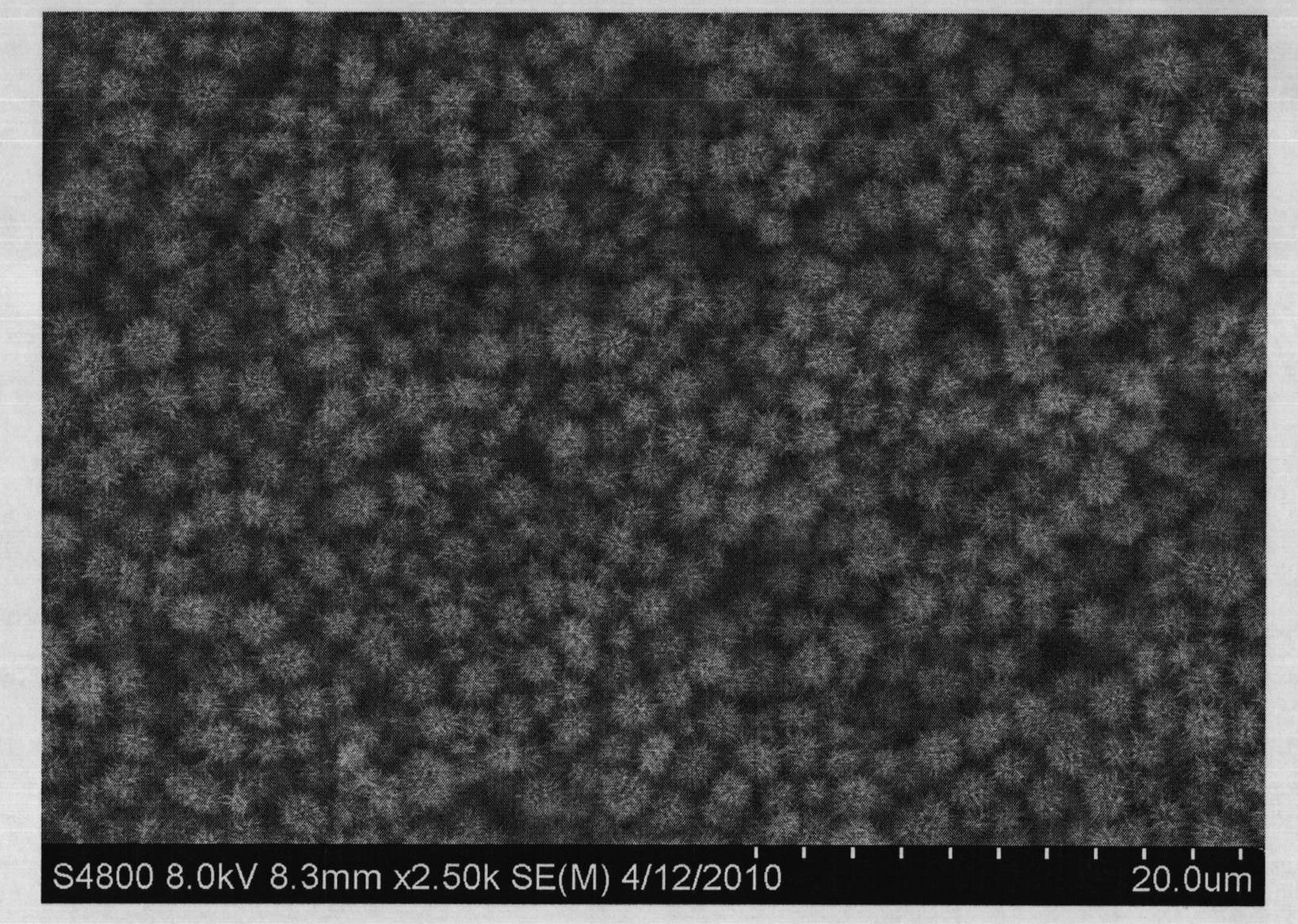

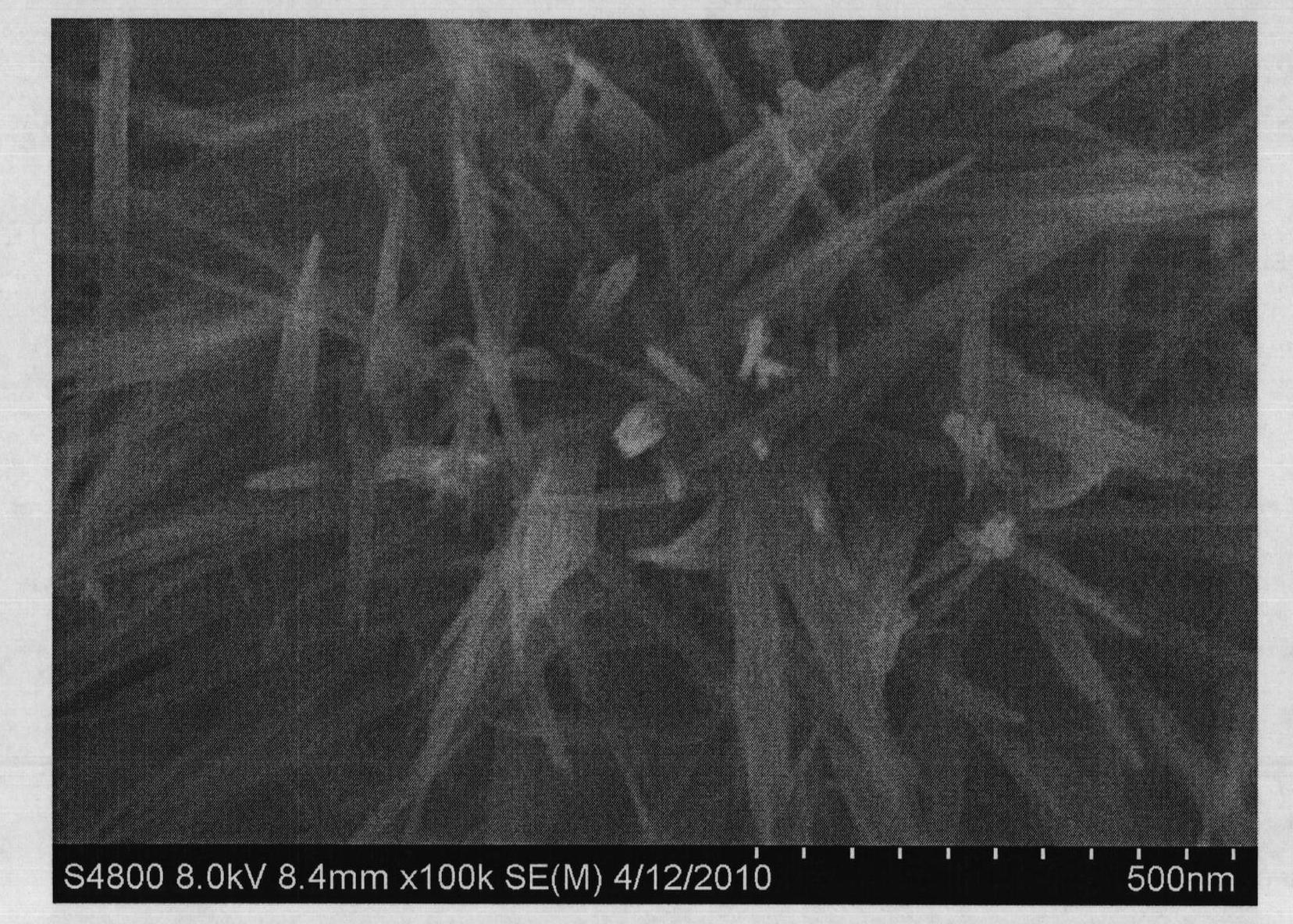

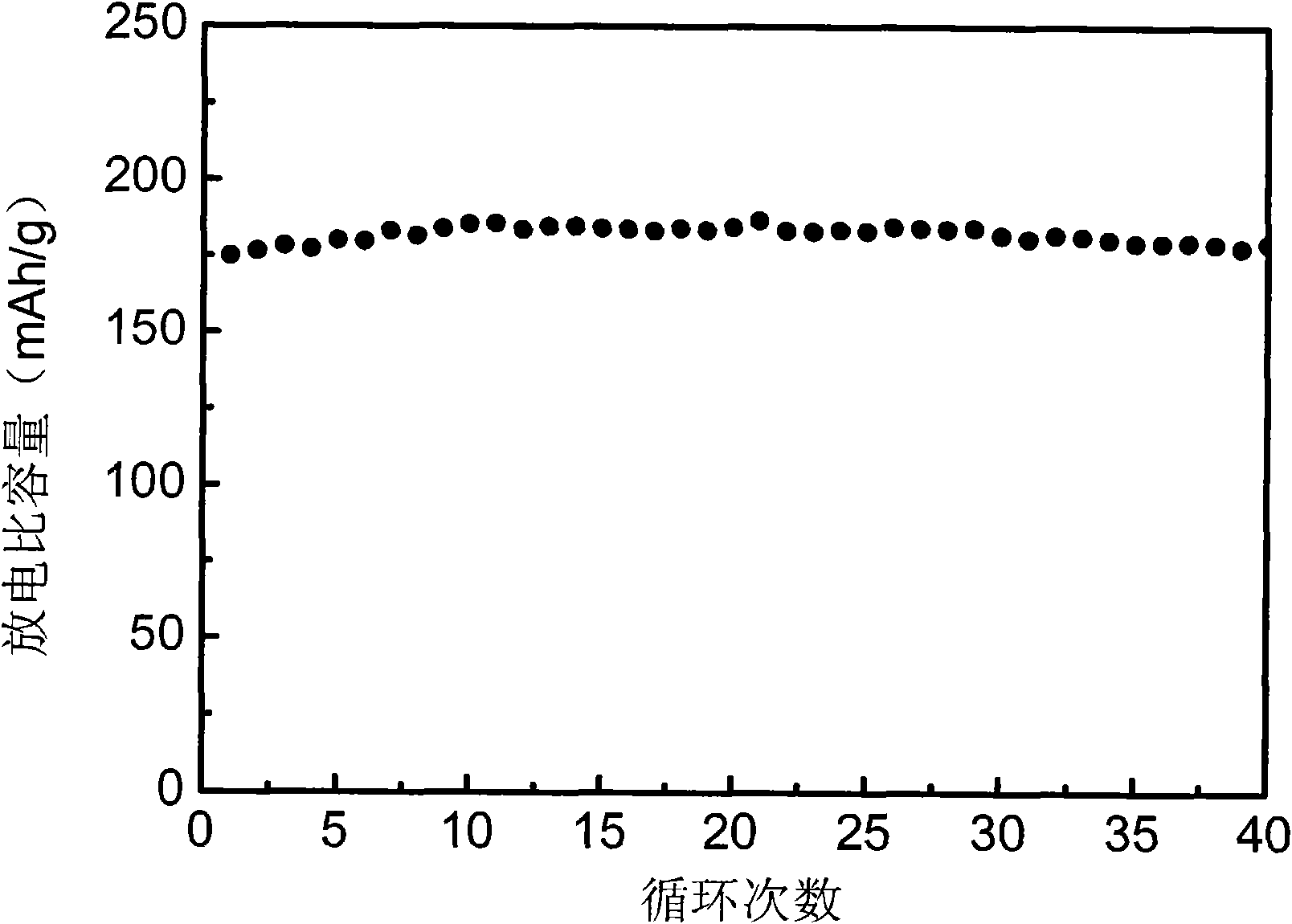

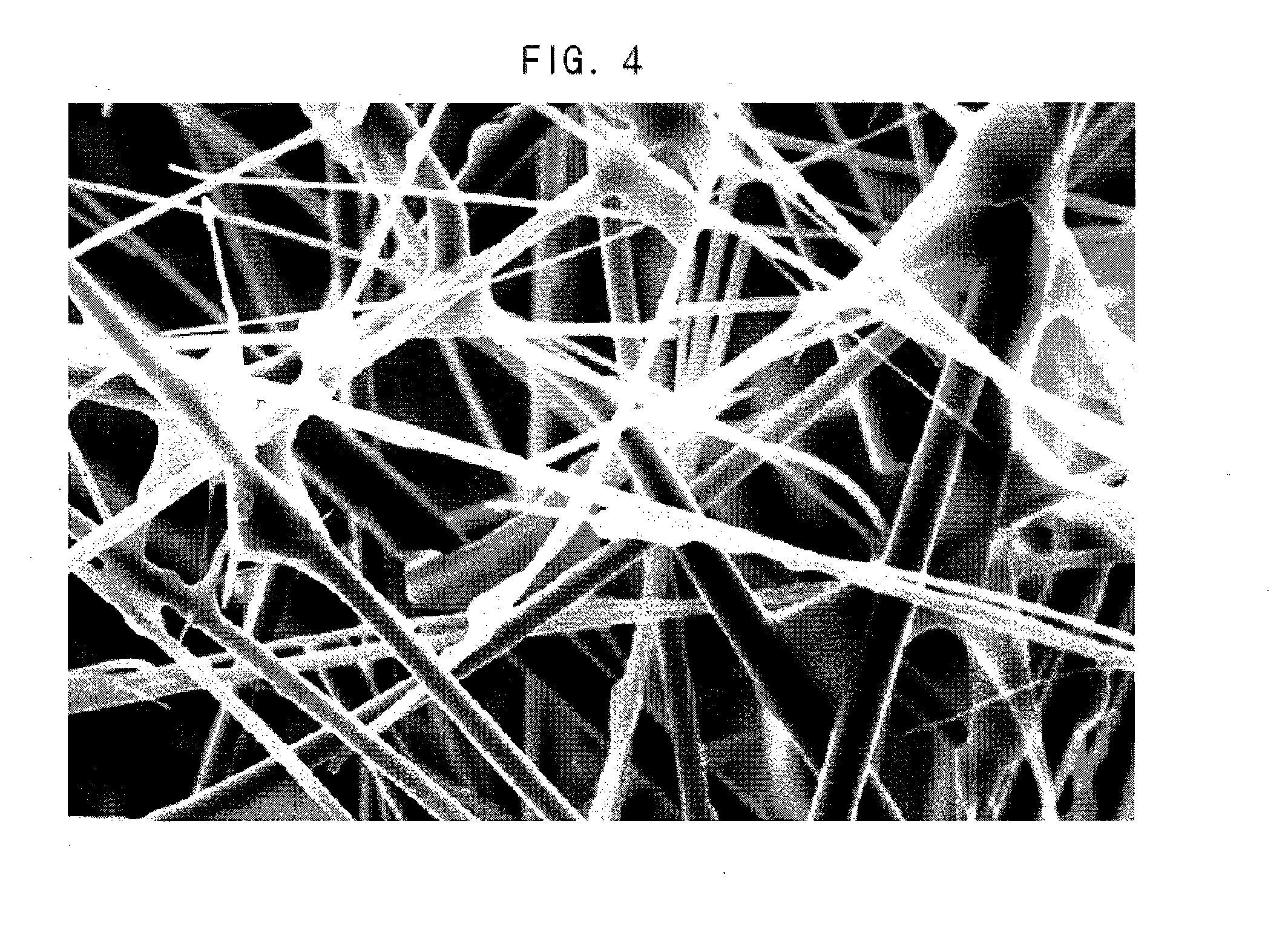

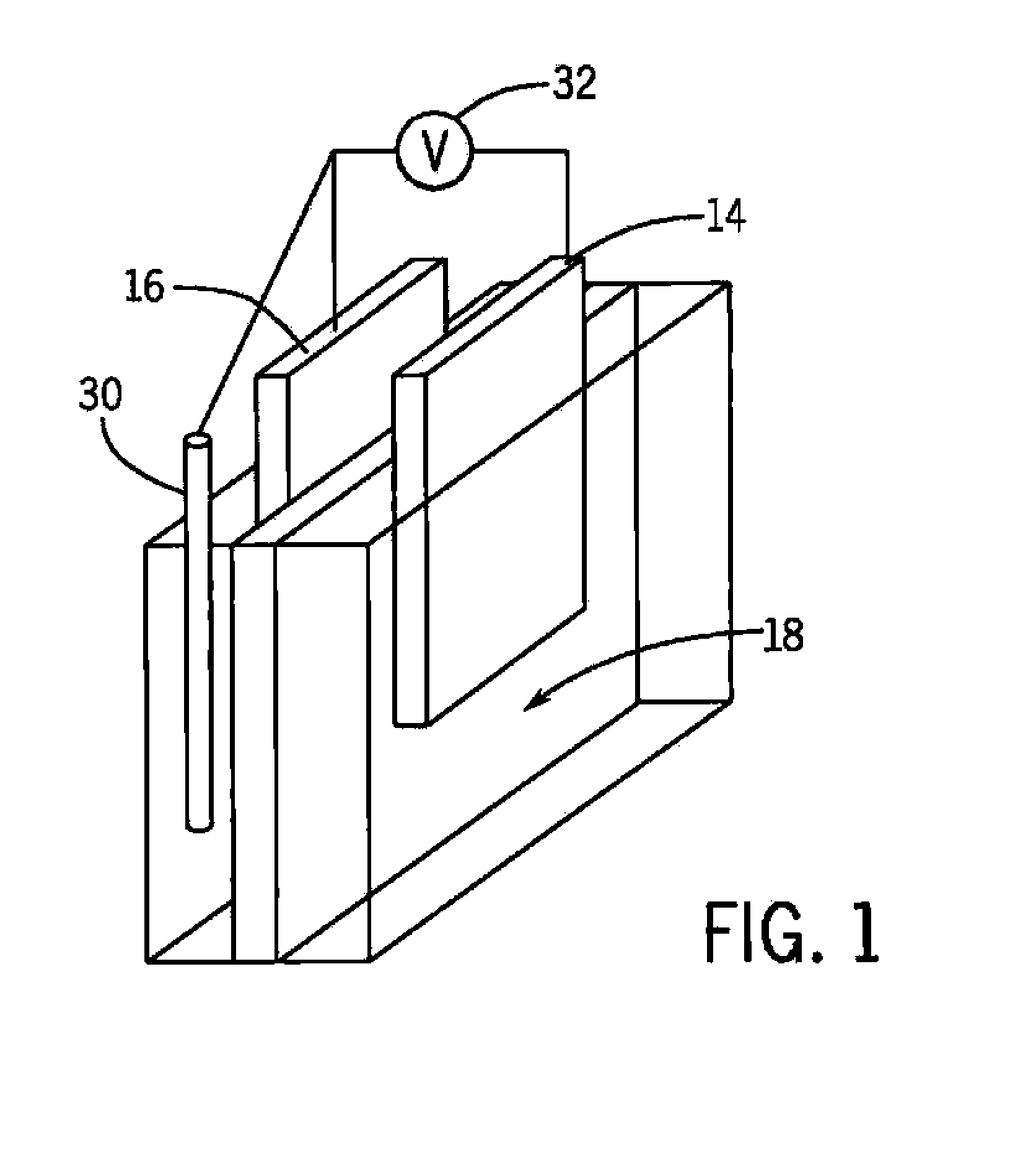

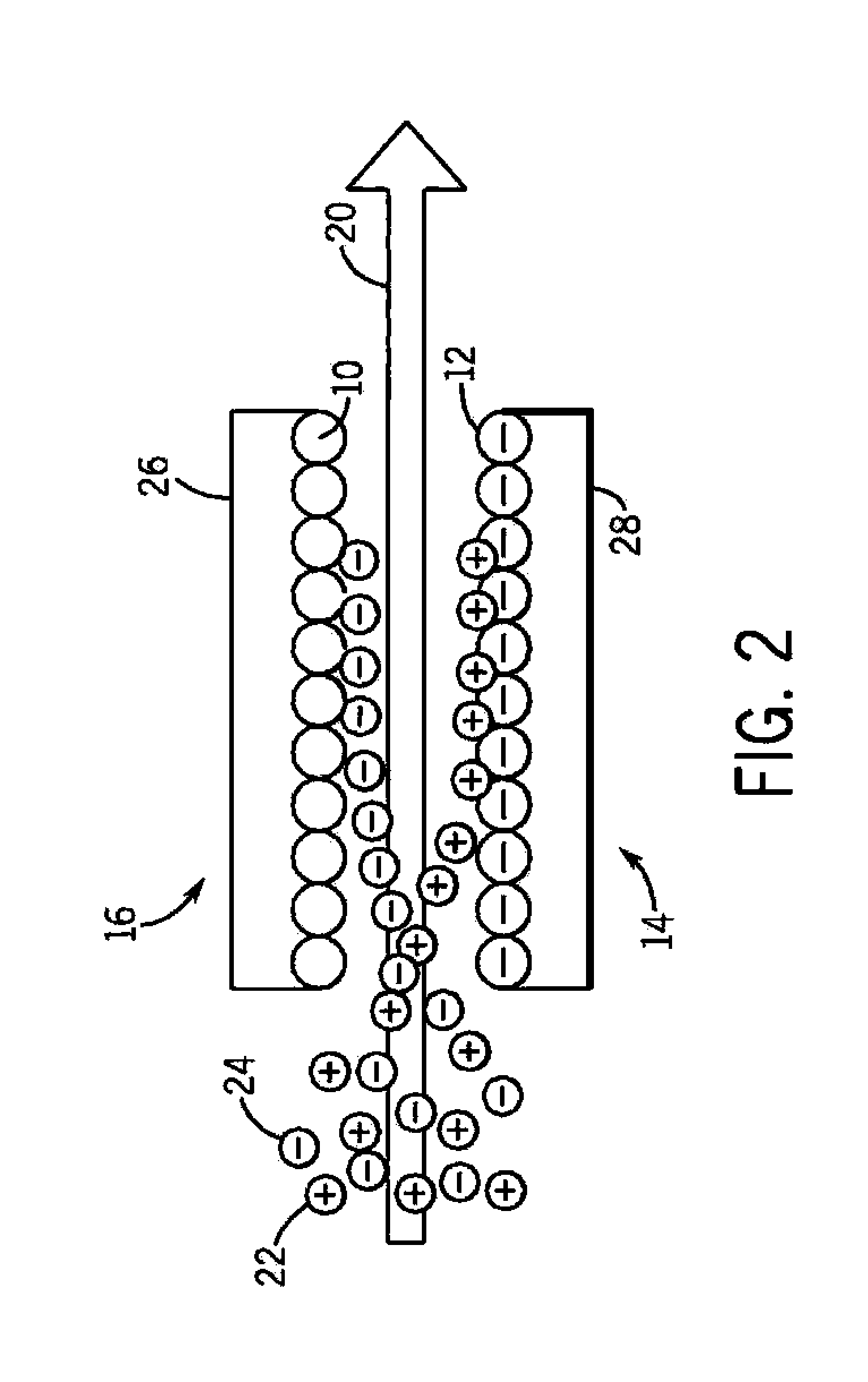

Conductive nanocomposite-based electrodes for lithium batteries

ActiveUS20090305135A1High specific capacityHigh reversible capacityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon layerComposite electrode

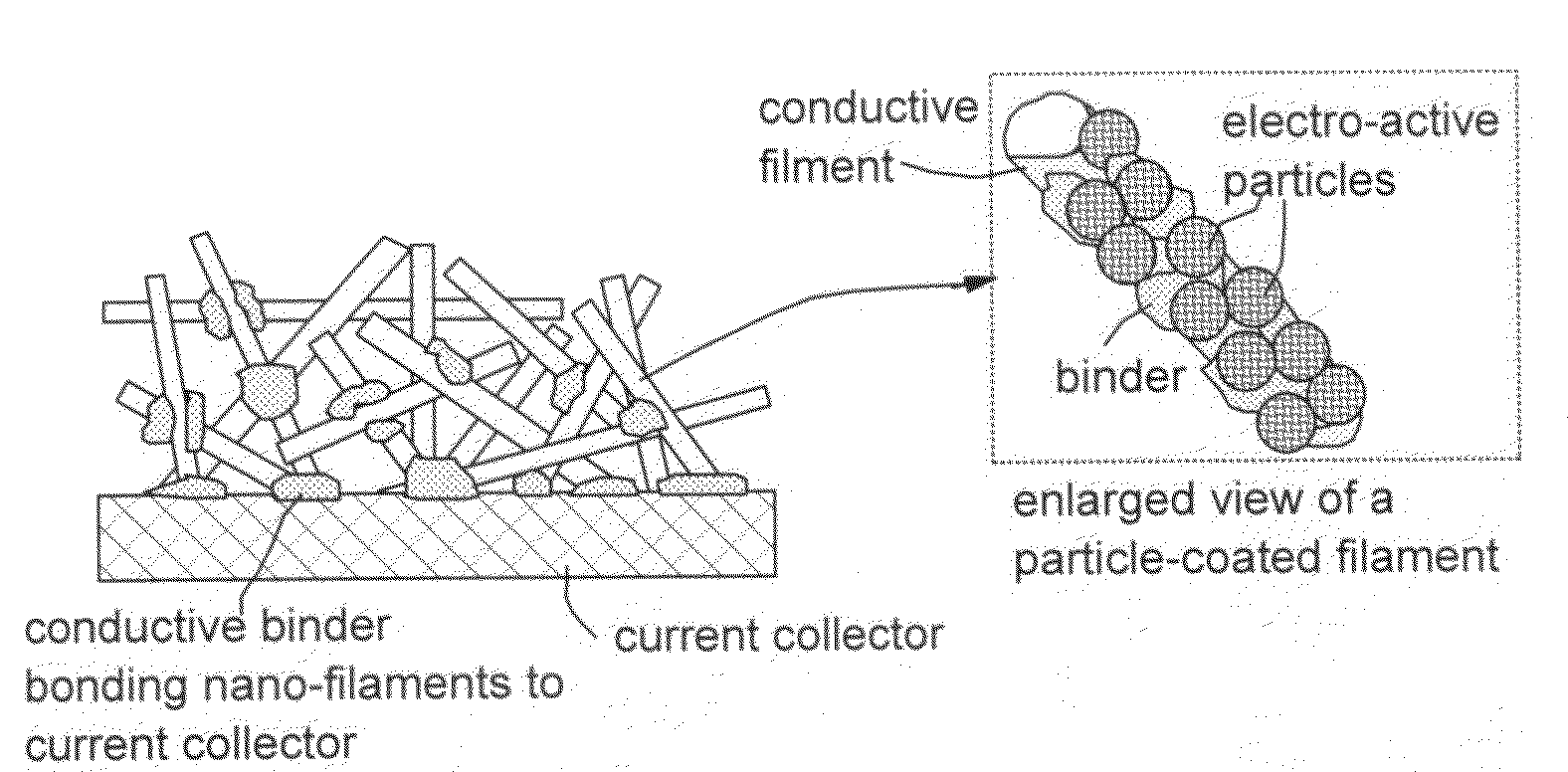

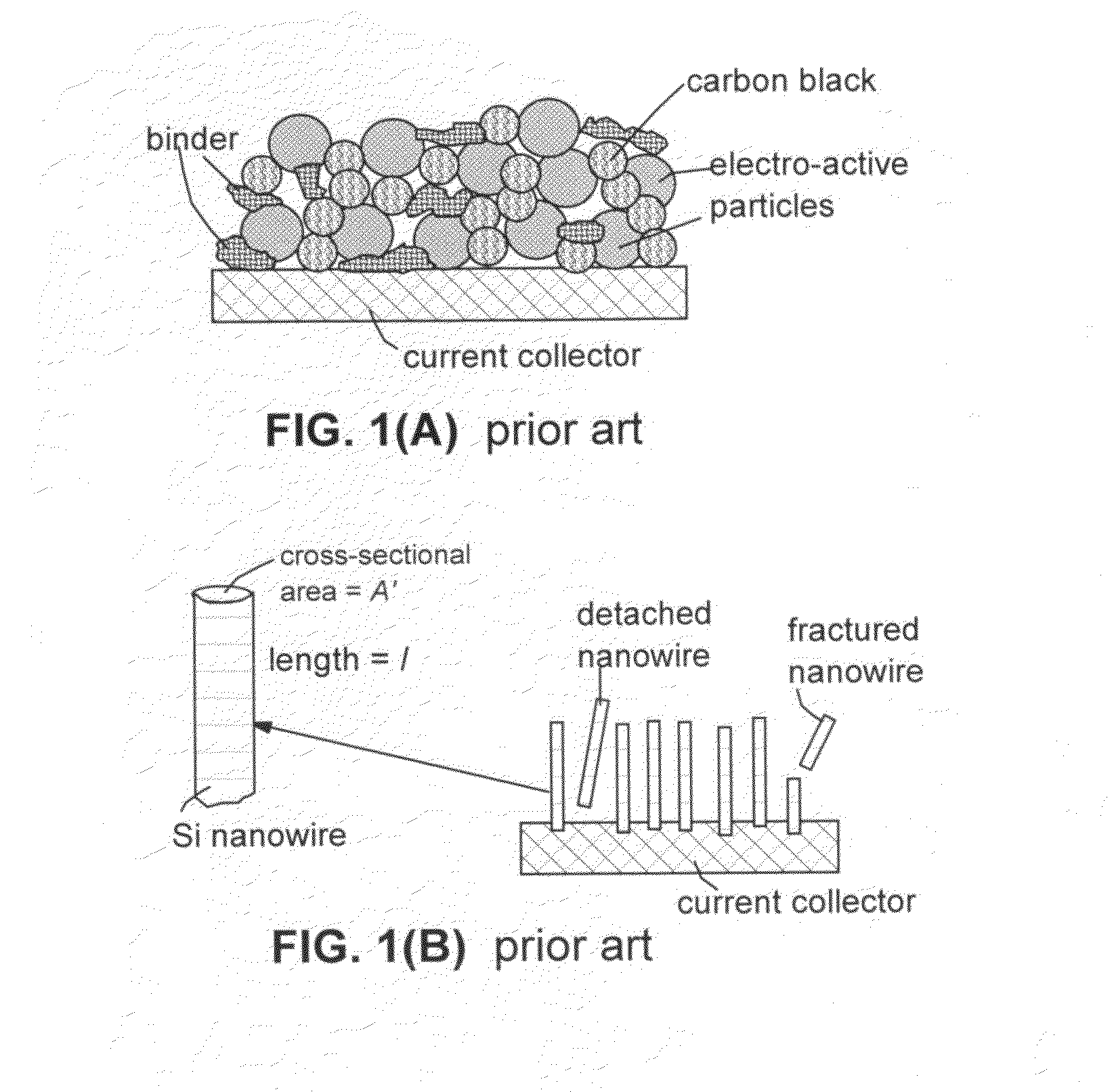

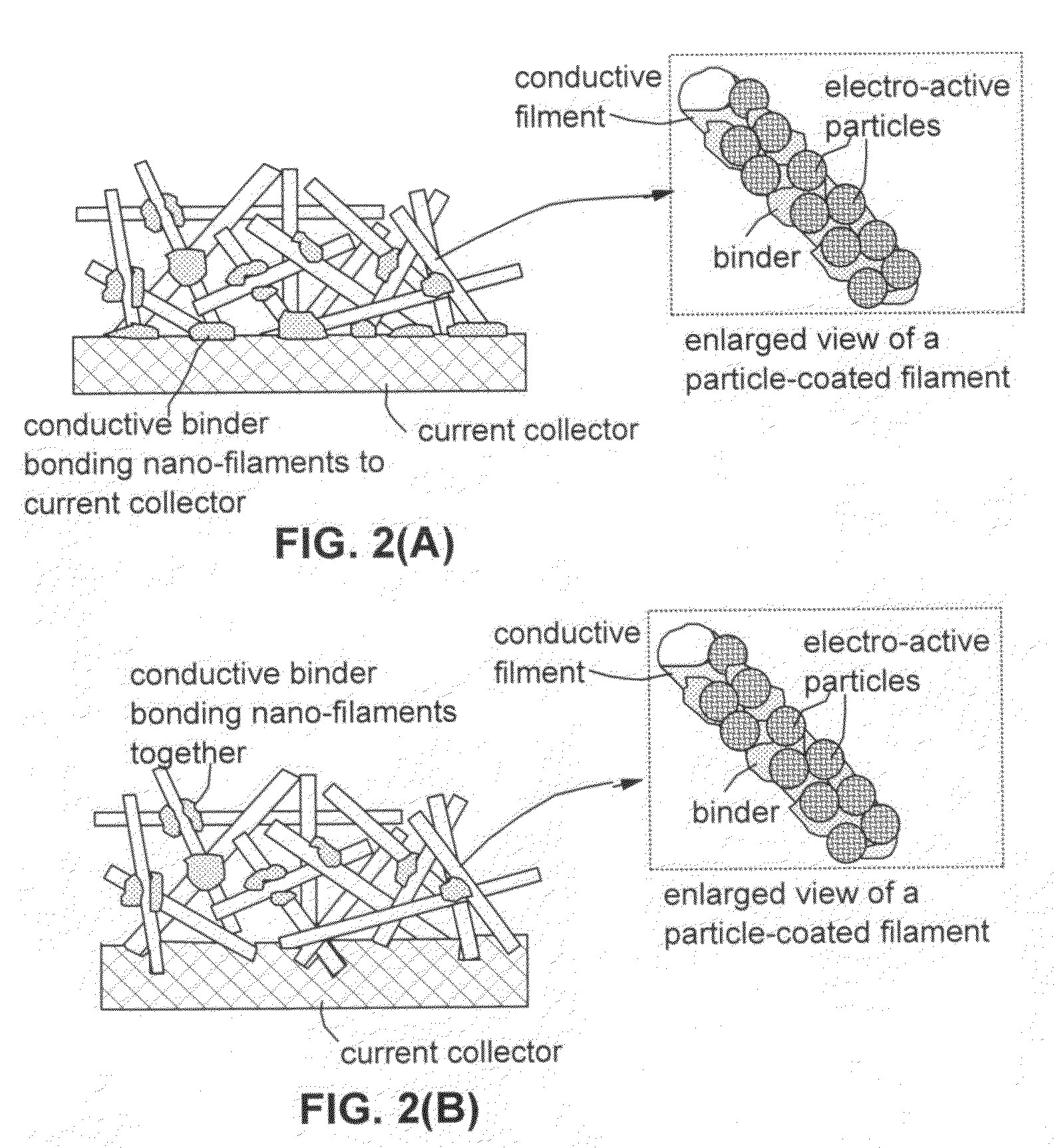

This invention provides a nanocomposite-based lithium battery electrode comprising: (a) A porous aggregate of electrically conductive nano-filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a three-dimensional network of electron-conducting paths, wherein the nano-filaments have a diameter or thickness less than 1 μm (preferably less than 500 nm); and (b) Sub-micron or nanometer-scale electro-active particles that are bonded to a surface of the nano-filaments with a conductive binder material, wherein the particles comprise an electro-active material capable of absorbing and desorbing lithium ions and wherein the electro-active material content is no less than 25% by weight based on the total weight of the particles, the binder material, and the filaments. Preferably, these electro-active particles are coated with a thin carbon layer. This electrode can be an anode or a cathode. The battery featuring such an anode or cathode exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

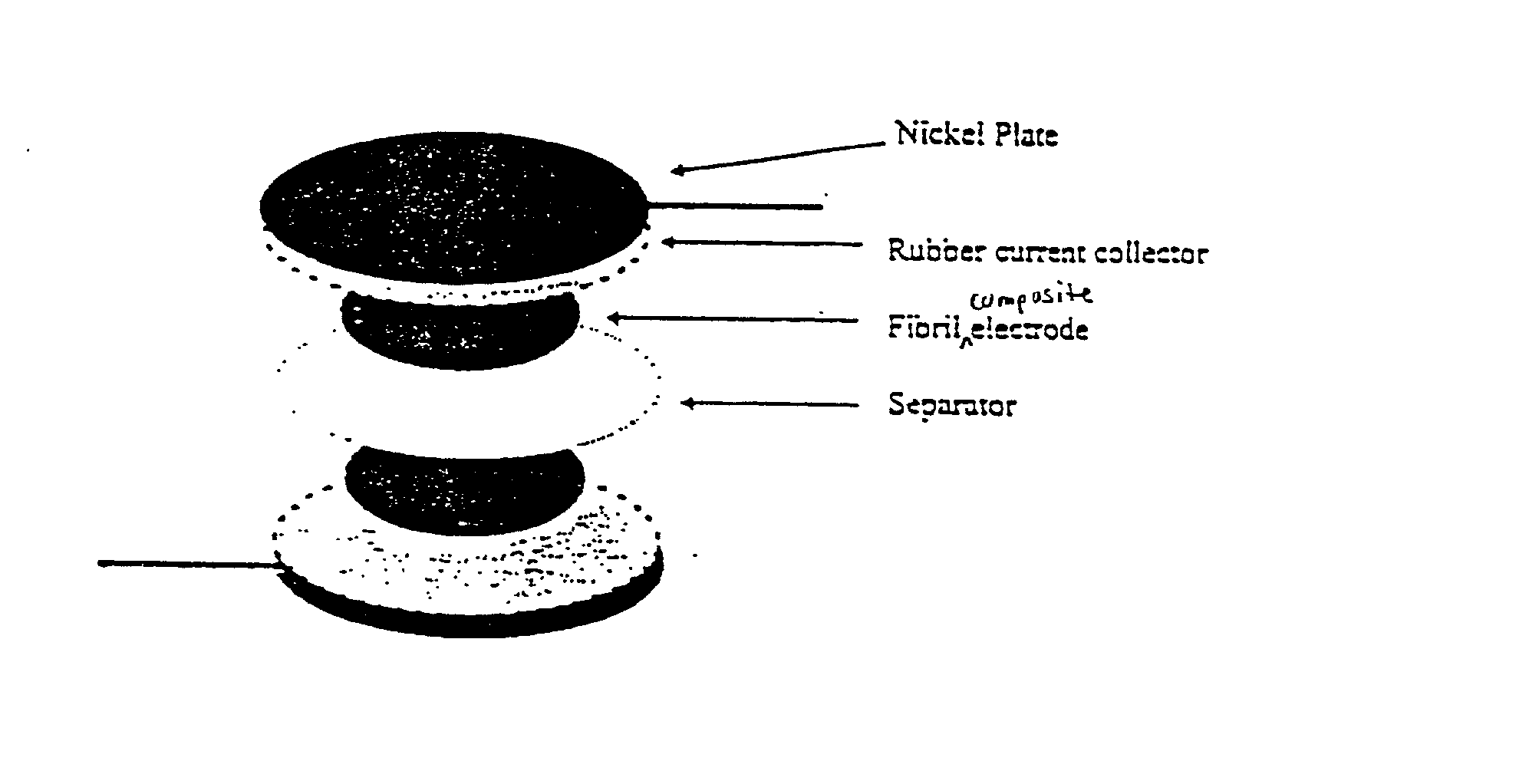

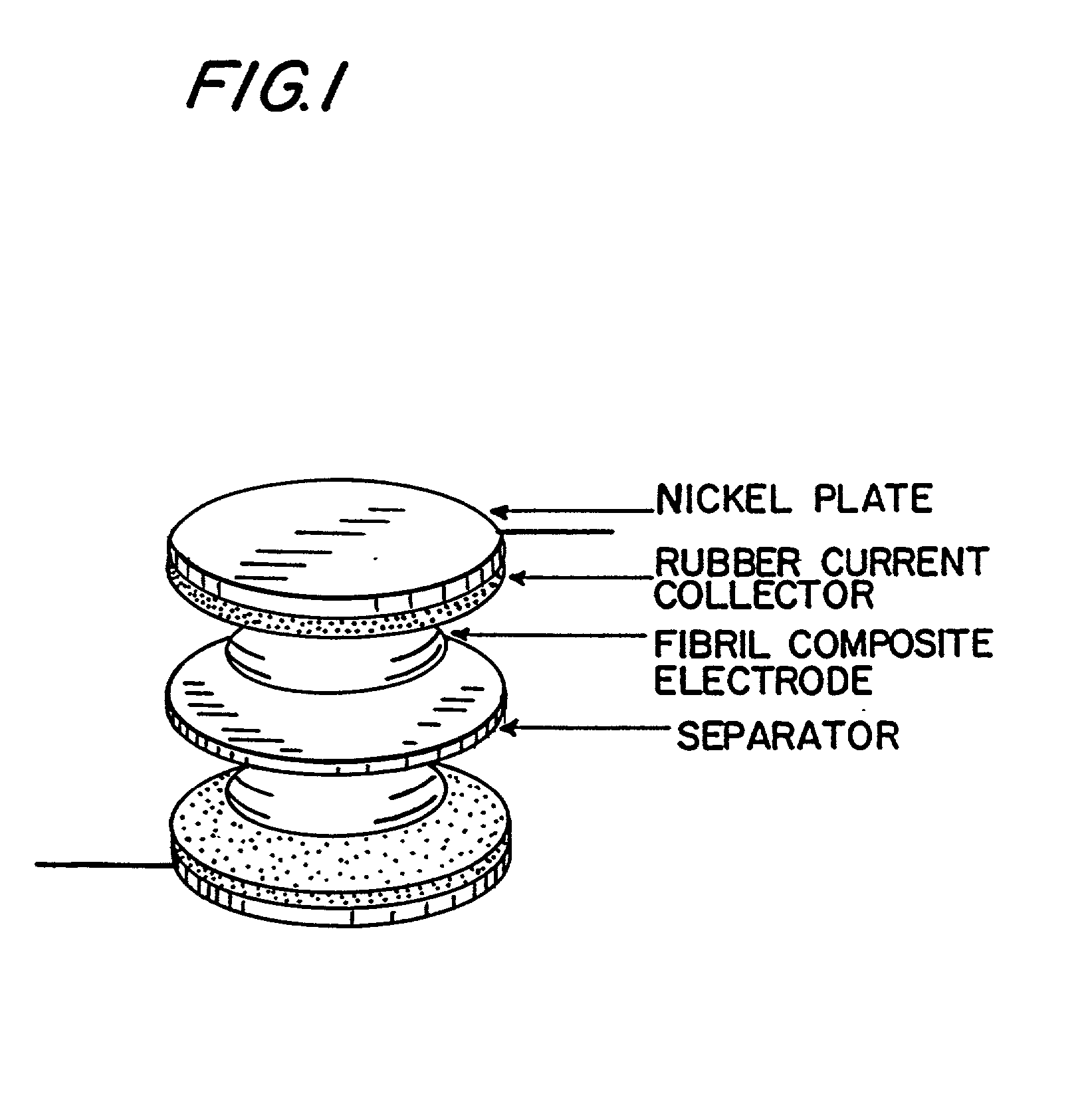

Fibril composite electrode for electrochemical capacitors

Owner:HYPERION CATALYSIS INT

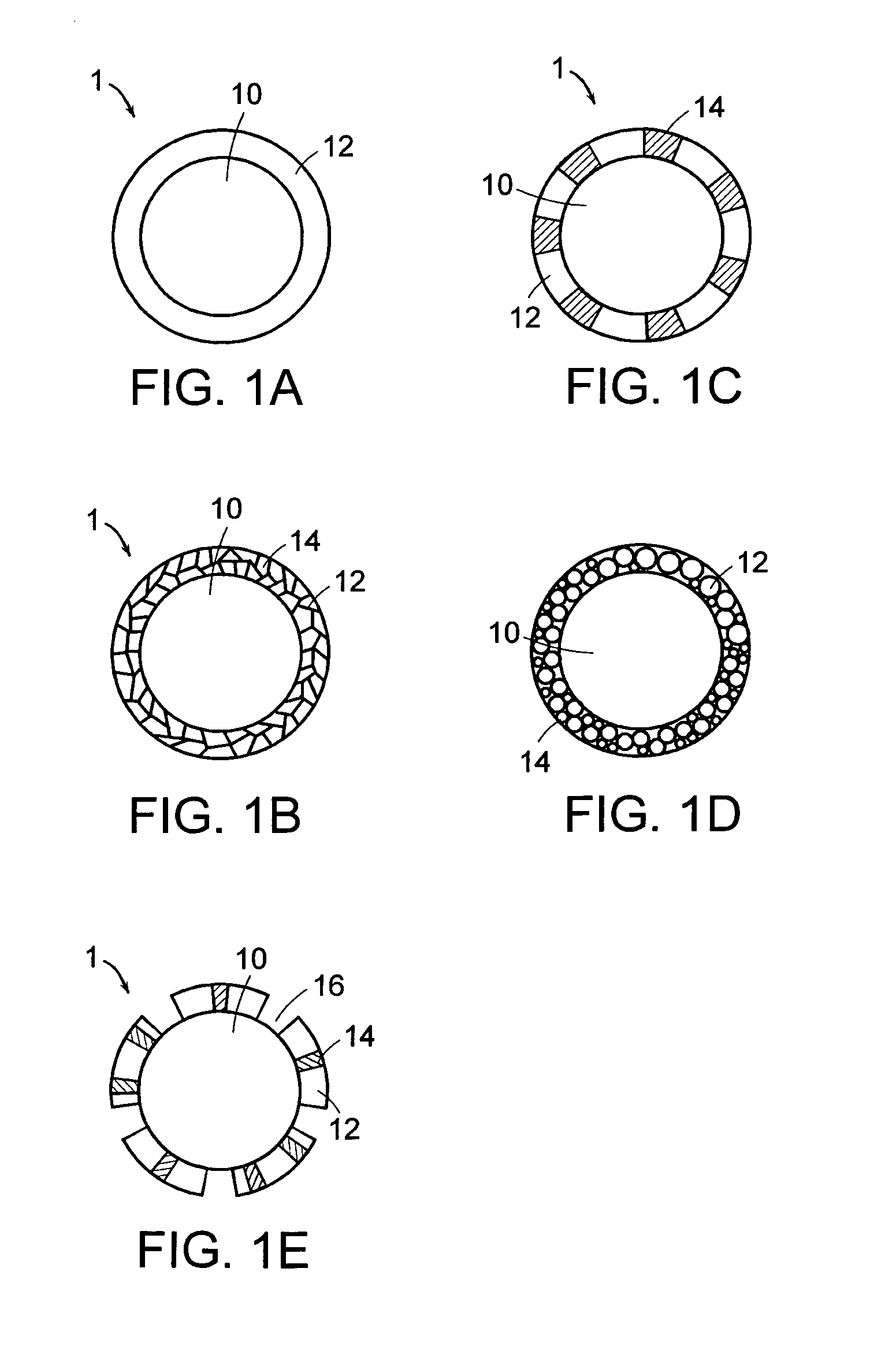

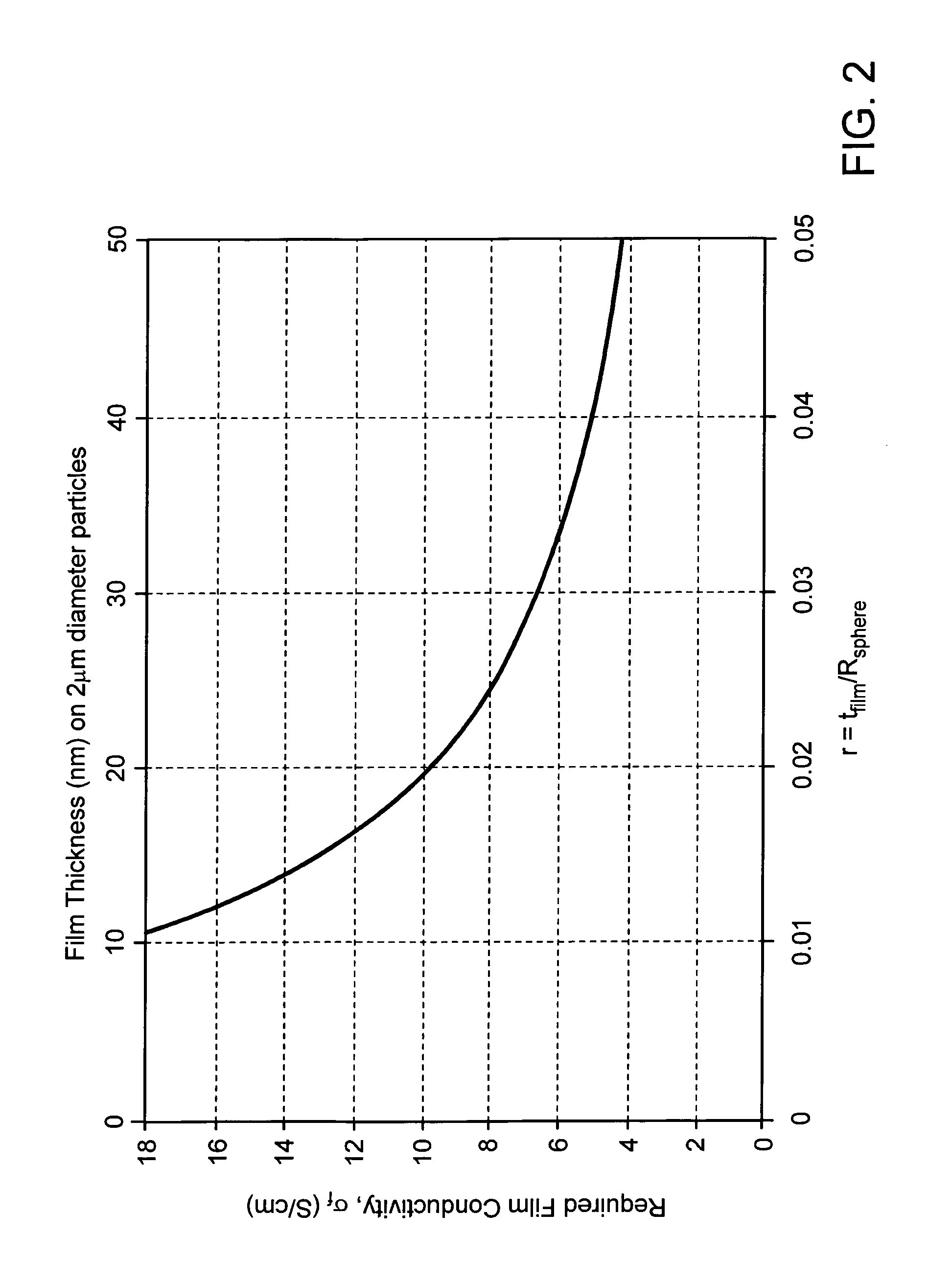

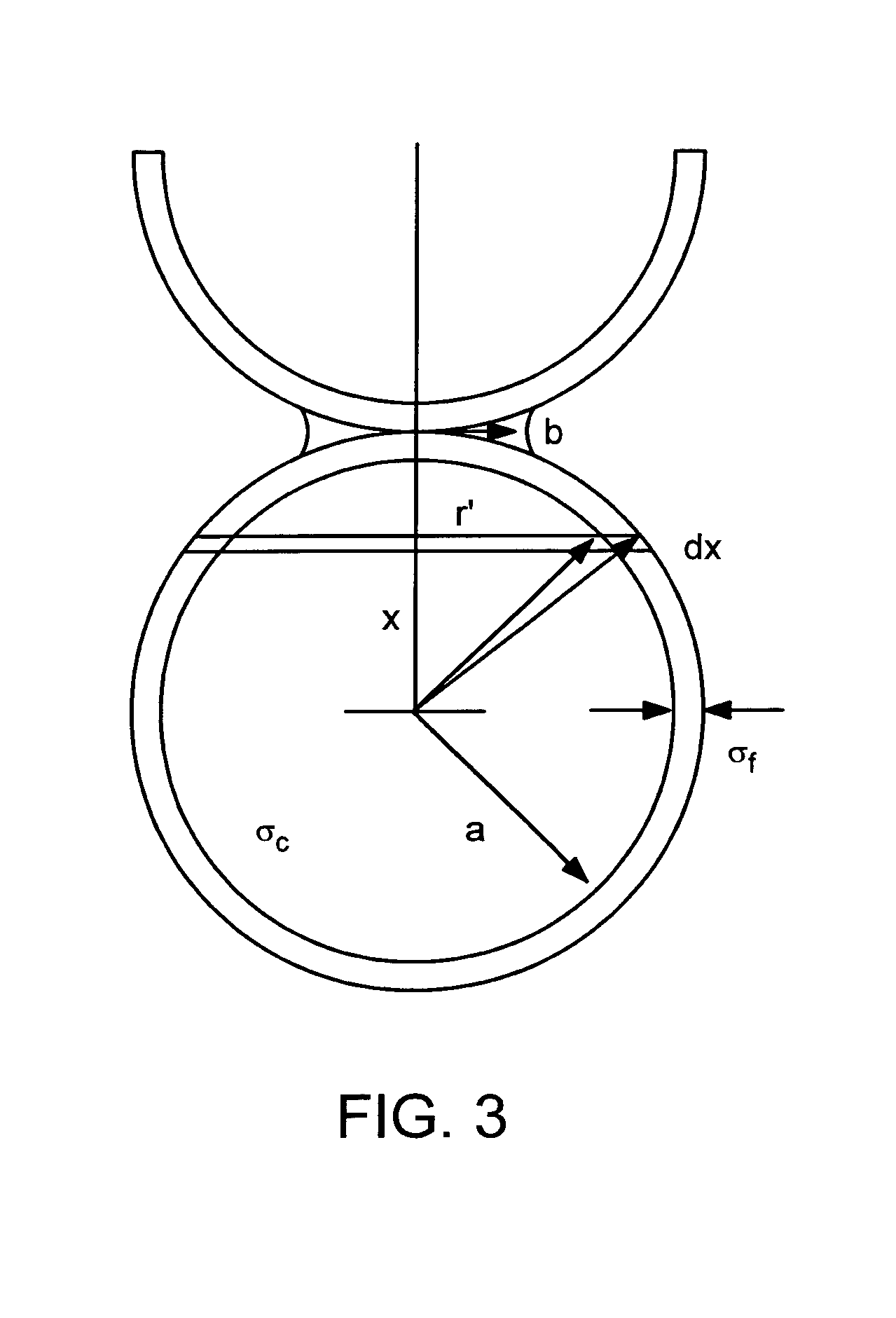

Coated electrode particles for composite electrodes and electrochemical cells

InactiveUS7087348B2Precise positioningImprove conductivityMachining electrodesHybrid capacitor electrodesComposite electrodeRefractive index

Electrodes for use in electrochemical devices are disclosed. More particularly coated electrode particles for use in solid electrochemical cells and materials and systems for improving electronic conductivity and repulsive force characteristics of an electrode network are disclosed. An article containing a plurality of distinct first particles that form an electrode network in which the distinct first particles are coated with a system of electrically conductive material is also disclosed. In some embodiments, the coating layer also includes a low refractive index material. In some embodiments, the coating layer of the electroactive material includes a plurality of second particles.

Owner:A123 SYSTEMS LLC

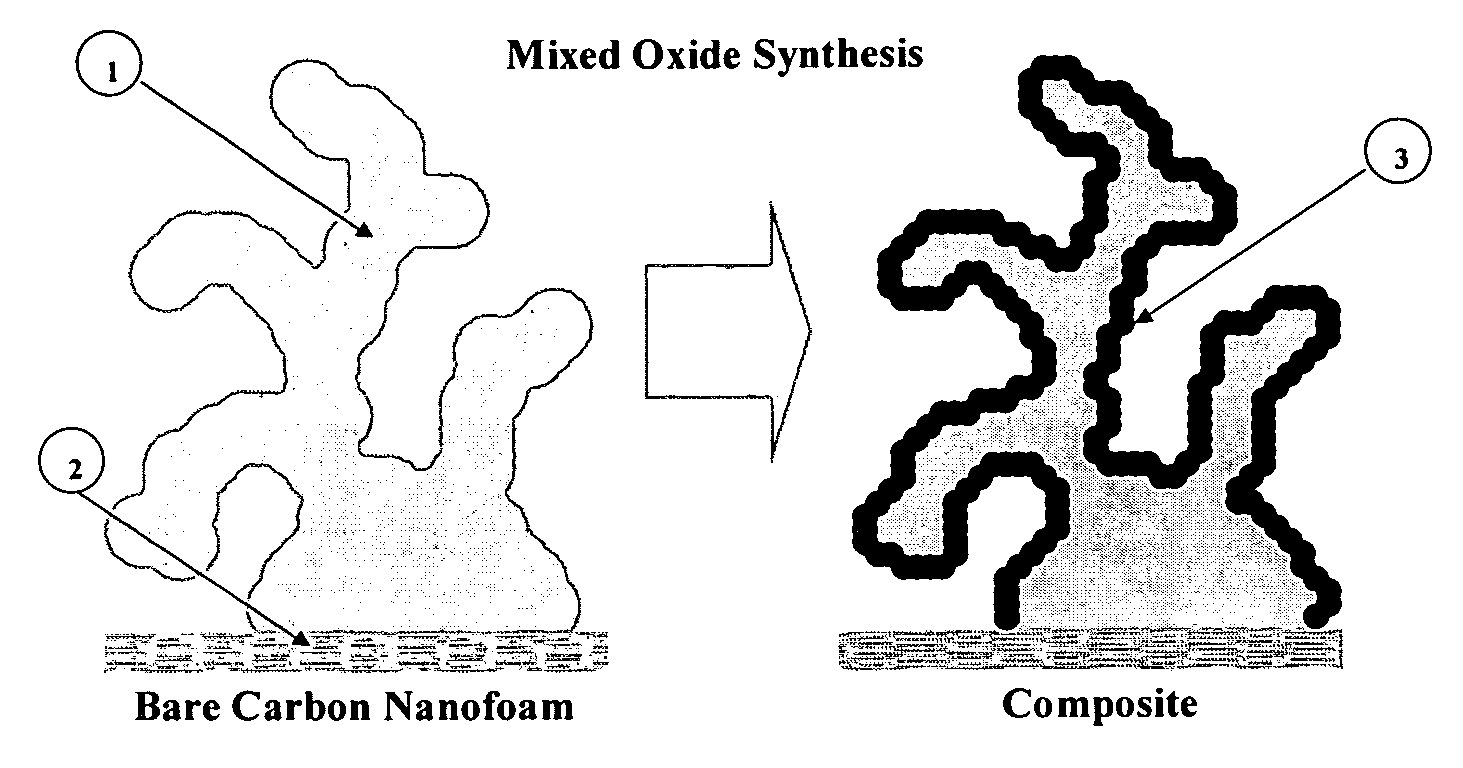

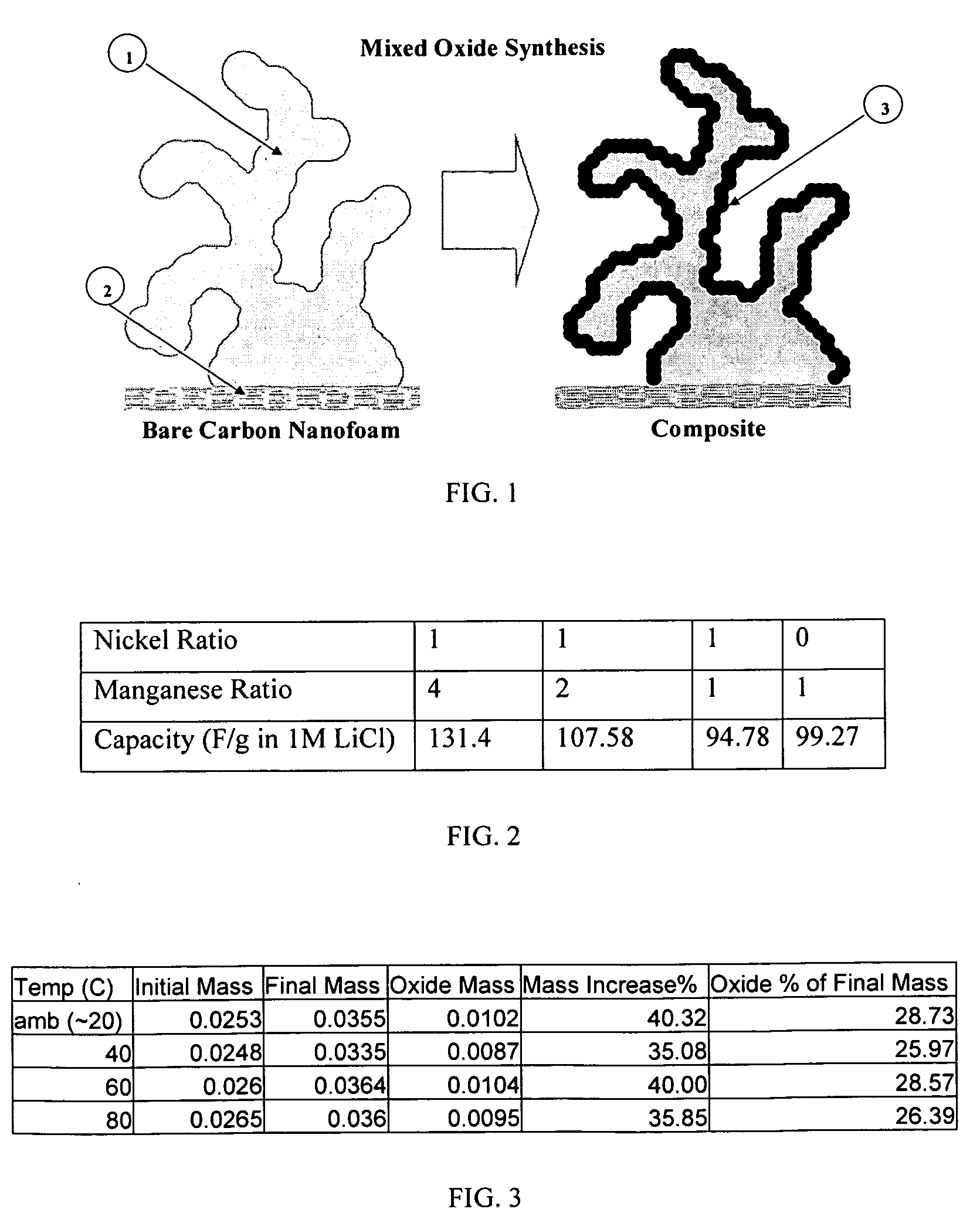

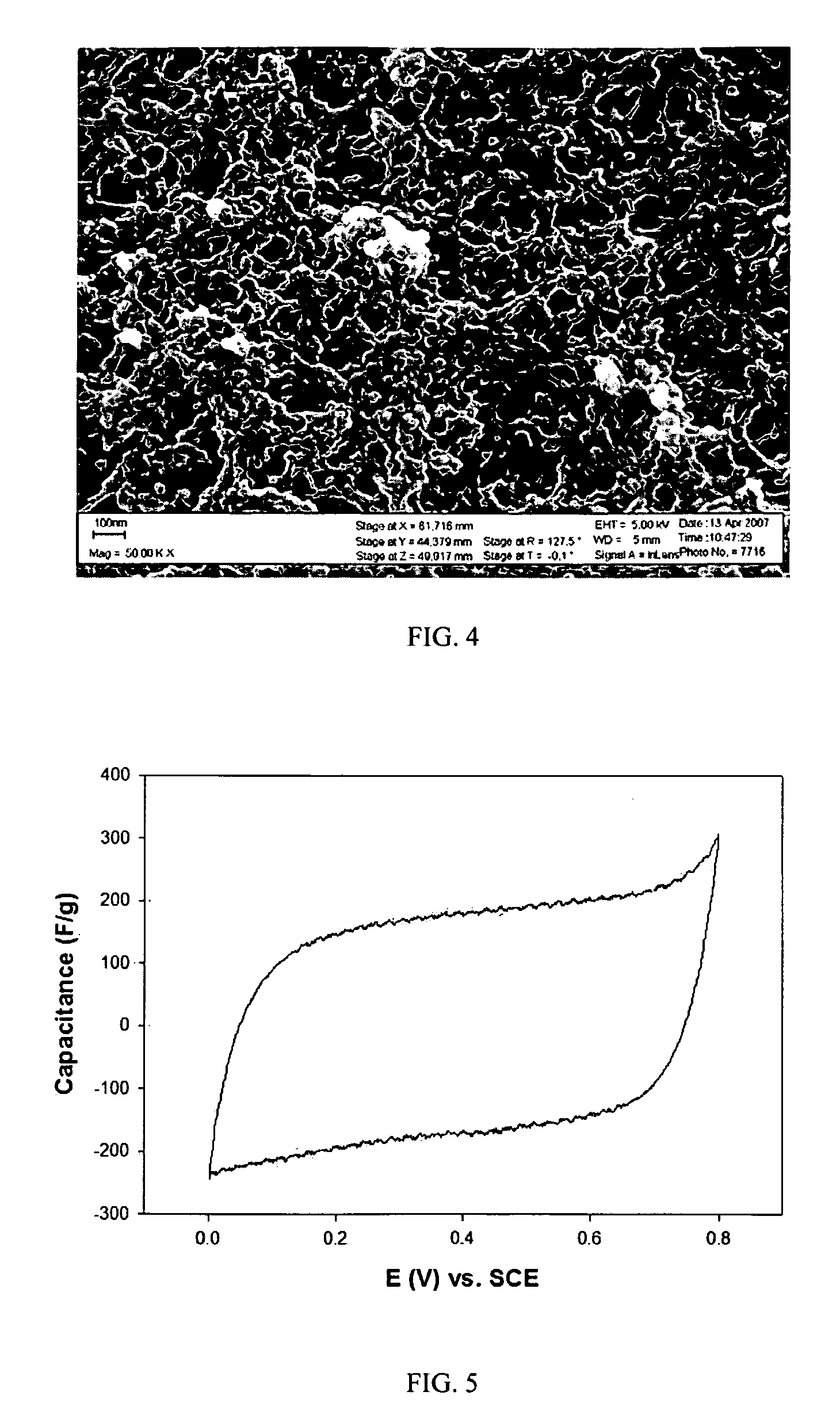

Composite electrode comprising a carbon structure coated with a thin film of mixed metal oxides for electrochemical energy storage

InactiveUS20090185327A1Increase capacityProlong lifeLiquid electrolytic capacitorsFinal product manufactureComposite electrodeMixed oxide

A composite electrode is created by forming a thin conformal coating of mixed metal oxides on a highly porous carbon structure. The highly porous carbon structure performs a role in the synthesis of the mixed oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of mixed metal oxides. The metal oxide mixture shall include two or more metal oxides. The composite electrode, a process for producing said composite electrode, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said composite electrode are disclosed.

Owner:SEYMOUR FRASER WADE

Lithium titanate composite electrode material with surface coating layer

InactiveCN101764209AChange physical propertiesChange chemical propertiesCell electrodesMagnesium phosphateMagnesium orthophosphate

The invention relates to a battery electrode material, in particular to a lithium titanate composite electrode material with surface coating layer; in the lithium titanate composite electrode material with surface coating layer, the electrode material is composed of lithium titanate particles and a coating layer coated with the surface of the lithium titanate particles; the particle size of the lithium titanate particles is 100nm-95mum, the average thickness of the surface coating layer is 0.2nm-5m, and the particle diameter of the composite electrode material is 0.1-100mum; the material of the surface coating layer is one or mixture of more than one kind of insulation oxide, insulation composite oxide, aluminium phosphate, magnesium phosphate, lithium fluoride, lithium phosphate or LiMPO4, wherein M is magnesium, ferrum, cobalt, nickel, chromium, titanium or vanadium; in the invention, by carrying out surface coating treatment to the surfaces of the existing lithium titanate particles, a layer of protective film is formed on the surface, so as to change the physical and chemical characteristics of the surface of the lithium titanate active material, the surface can not be reacted with electrolyte even if under overpotential condition, so as to avoid ballooning and ensure the capacity and the circularity of the battery not to be reduced.

Owner:SUZHOU PHYLION BATTERY

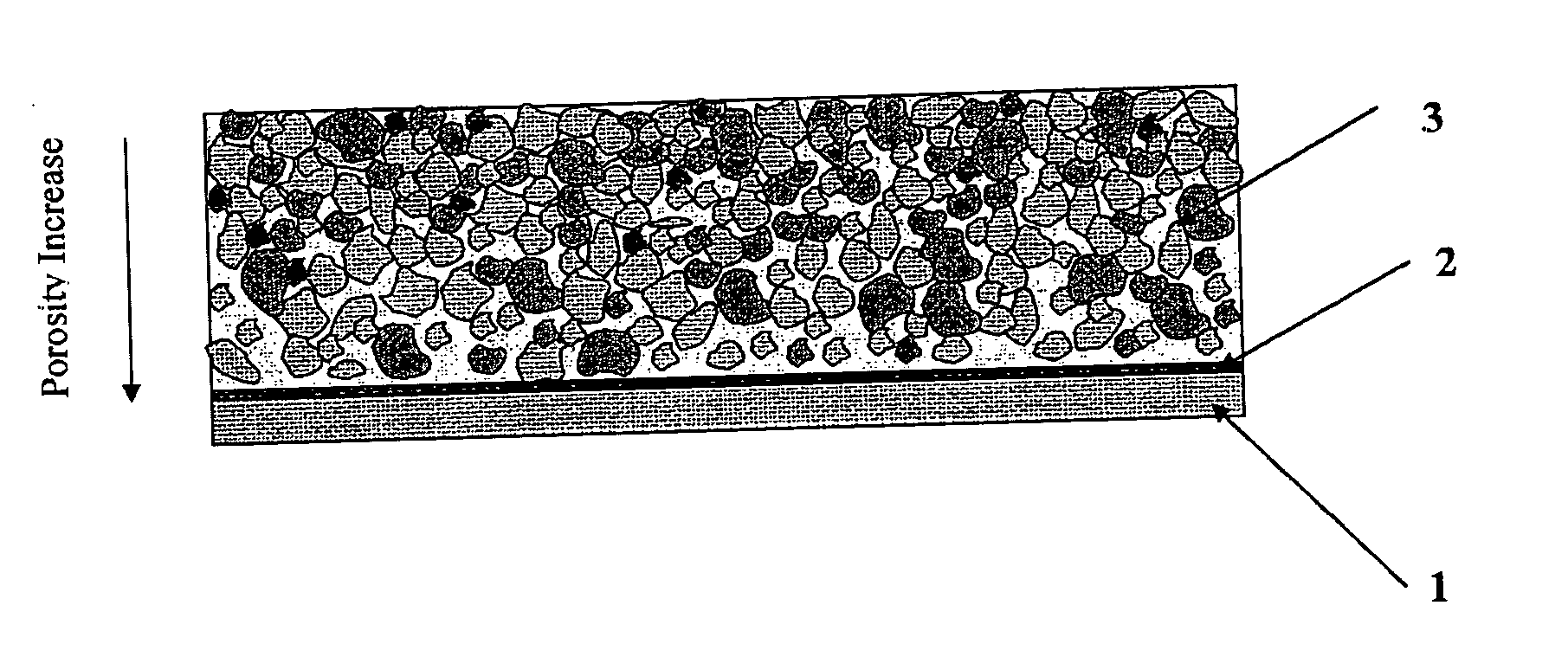

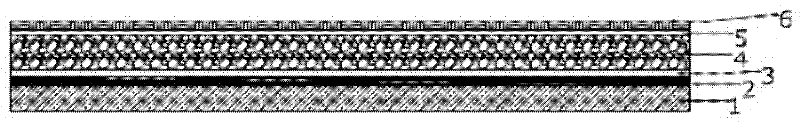

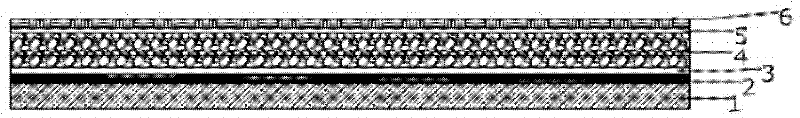

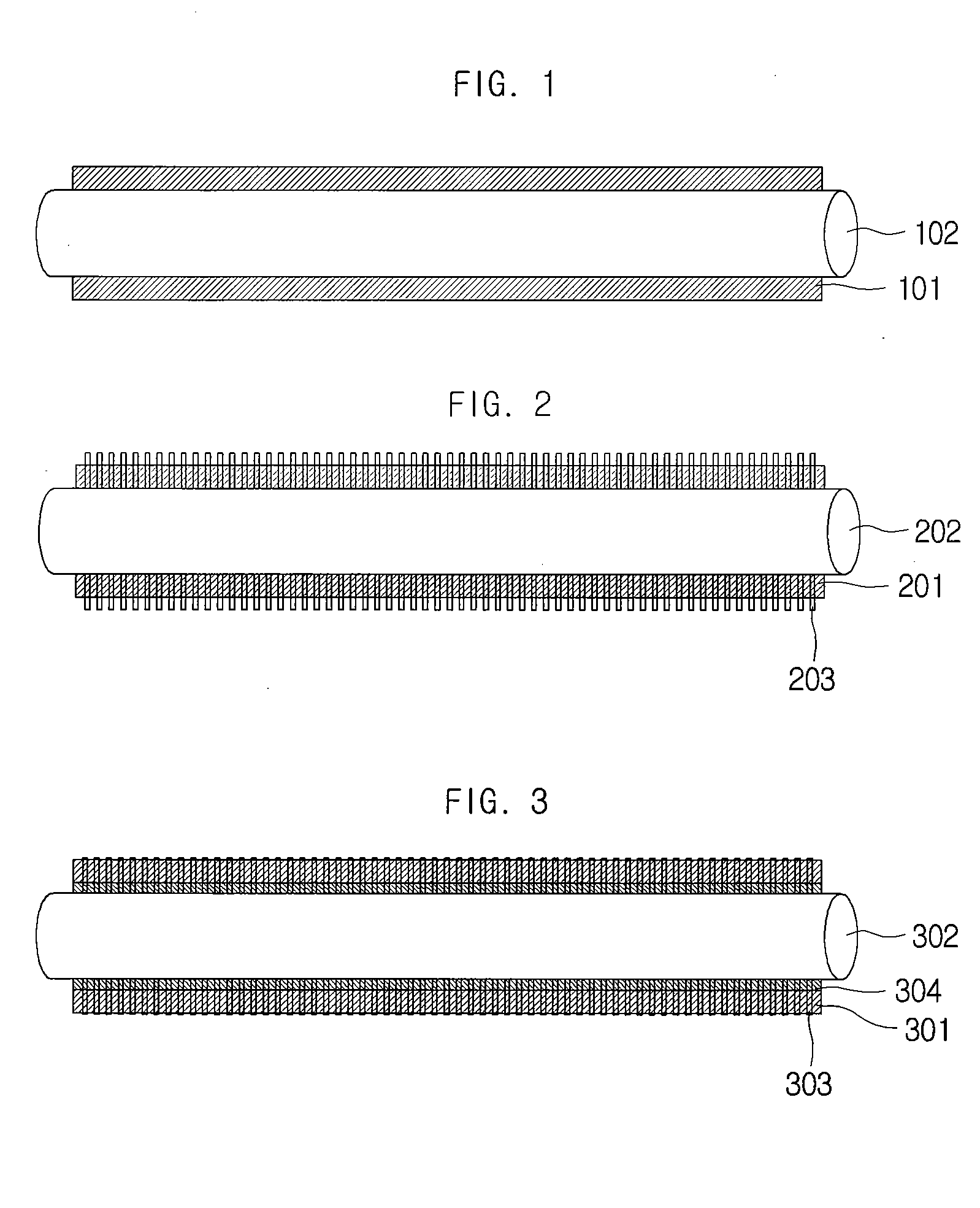

Battery electrode structure and method for manufacture thereof

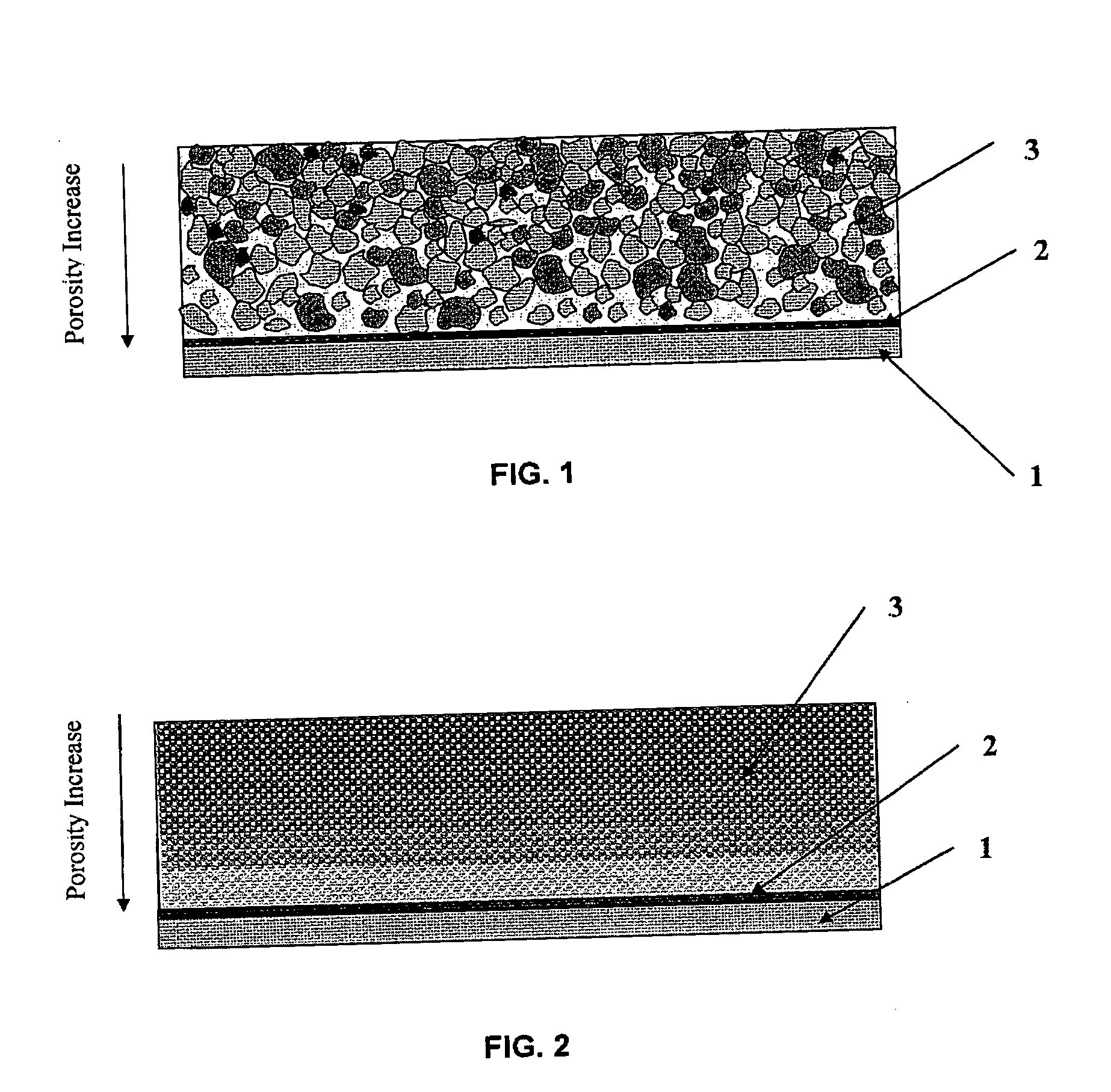

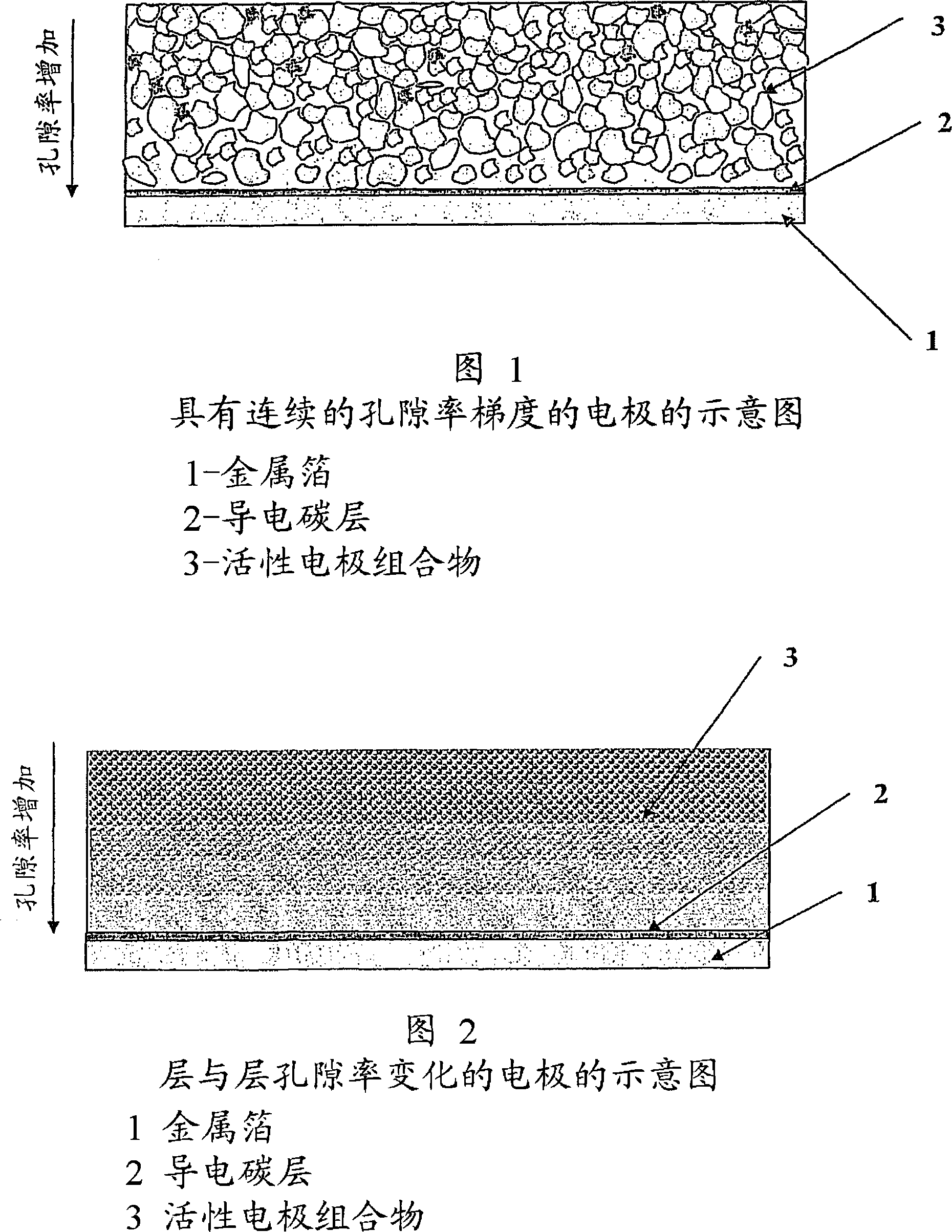

InactiveUS20060024579A1Increase energy densityReduce porositySecondary cellsActive material electrodesPorosityComposite electrode

There are disclosed solid composite electrodes with electrode active layers that include an electrode active material, an optional election conductive material, an optional binder and other optional additives. The solid composite electrodes are formed by the deposition of an electrode composition (slurry) onto a current collector in one or many layers. The electrode structure may be characterised by a porosity of the electrode composition layer that decreases in a direction from the back side of the layer (close to the current collector) towards the outer side of the layer. The gradient of the decrease in the porosity is controlled by the content of solid substance in the slurry, by the composition of the solvent in the slurry, by the temperature of the layer drying after deposition, as well as by the pressing or calendering conditions for each layer. The electrode structures can be used in for example chemical sources of electric energy such as primary (non-rechargeable) as well as secondary (rechargeable) batteries.

Owner:OXIS ENERGY

Multi-element composite nano-material, preparation method thereof and application thereof

ActiveCN103117175AComponents are easy to controlImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention provides a multi-element composite nano-material for a super capacitor, and a preparation method of the nano-material. The nano-material comprises a carbon material, metal oxide and conducting polymer, and components of the nano-material can be two or more than two materials. By the aid of the characteristics such as fine electrical conductivity, long cycle life and high specific surface area of the carbon material, high pseudo-capacitance of the metal oxide and low internal resistance, low cost and high operating voltage of the conducting polymer, different types of electrode materials generate synergistic effects, advantages are mutually combined, shortcomings are mutually weakened, the energy storage characteristics of an electric double-layer capacitor and a pseudo-capacitor are simultaneously made full use of, a composite electrode material with high power density, fine circulating stability and higher energy density is prepared, and the multi-element composite nano-material is excellent in comprehensive performance when used for an electrode of the super capacitor, has the advantages of simple preparation process, short cycle, low cost and the like, and is suitable for large-scale industrial production.

Owner:中科(马鞍山)新材料科创园有限公司

Impregnated sintered solid state composite electrode, solid state battery, and methods of preparation

InactiveUS20150056520A1Electrode thermal treatmentSolid electrolyte cellsComposite cathodeComposite electrode

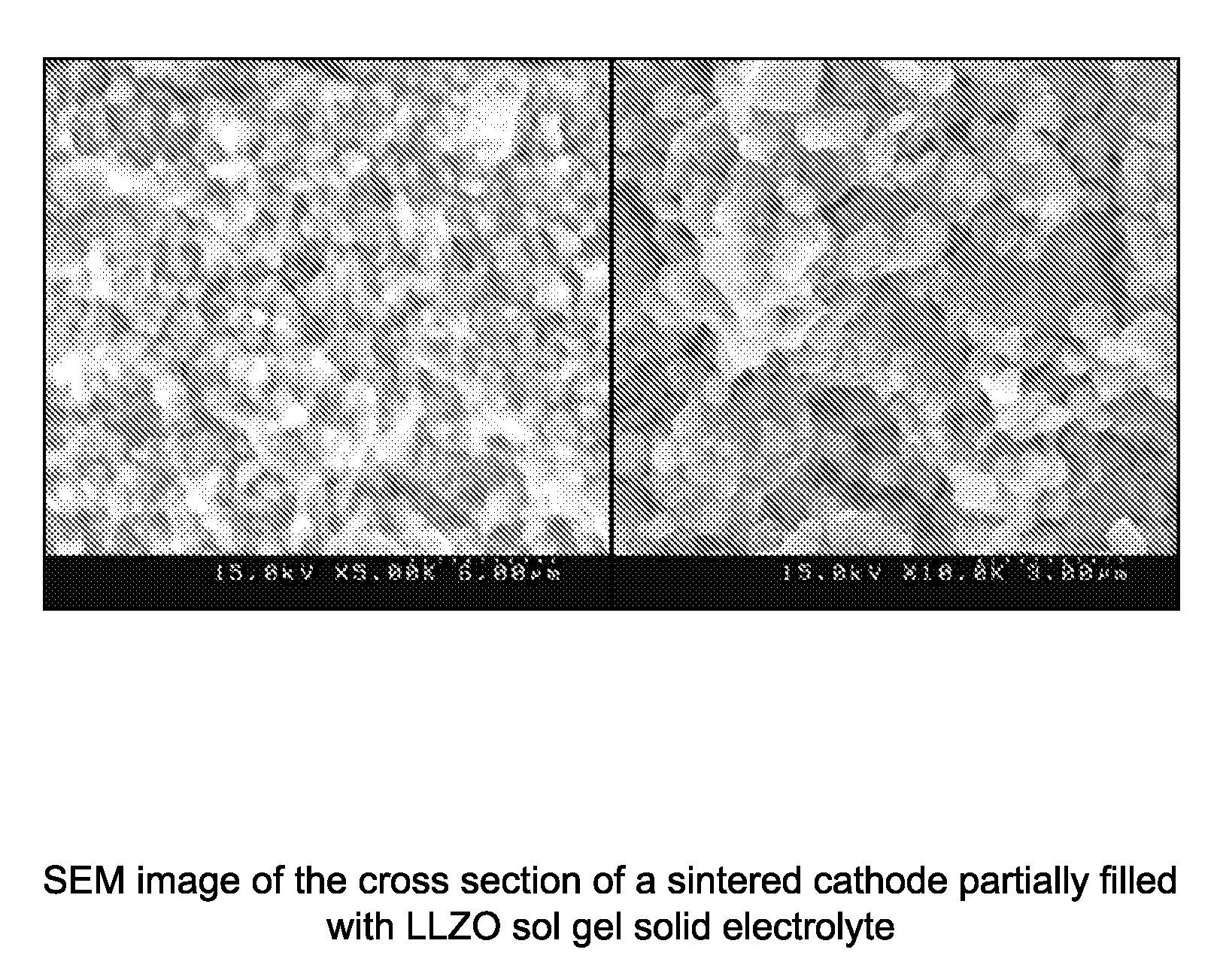

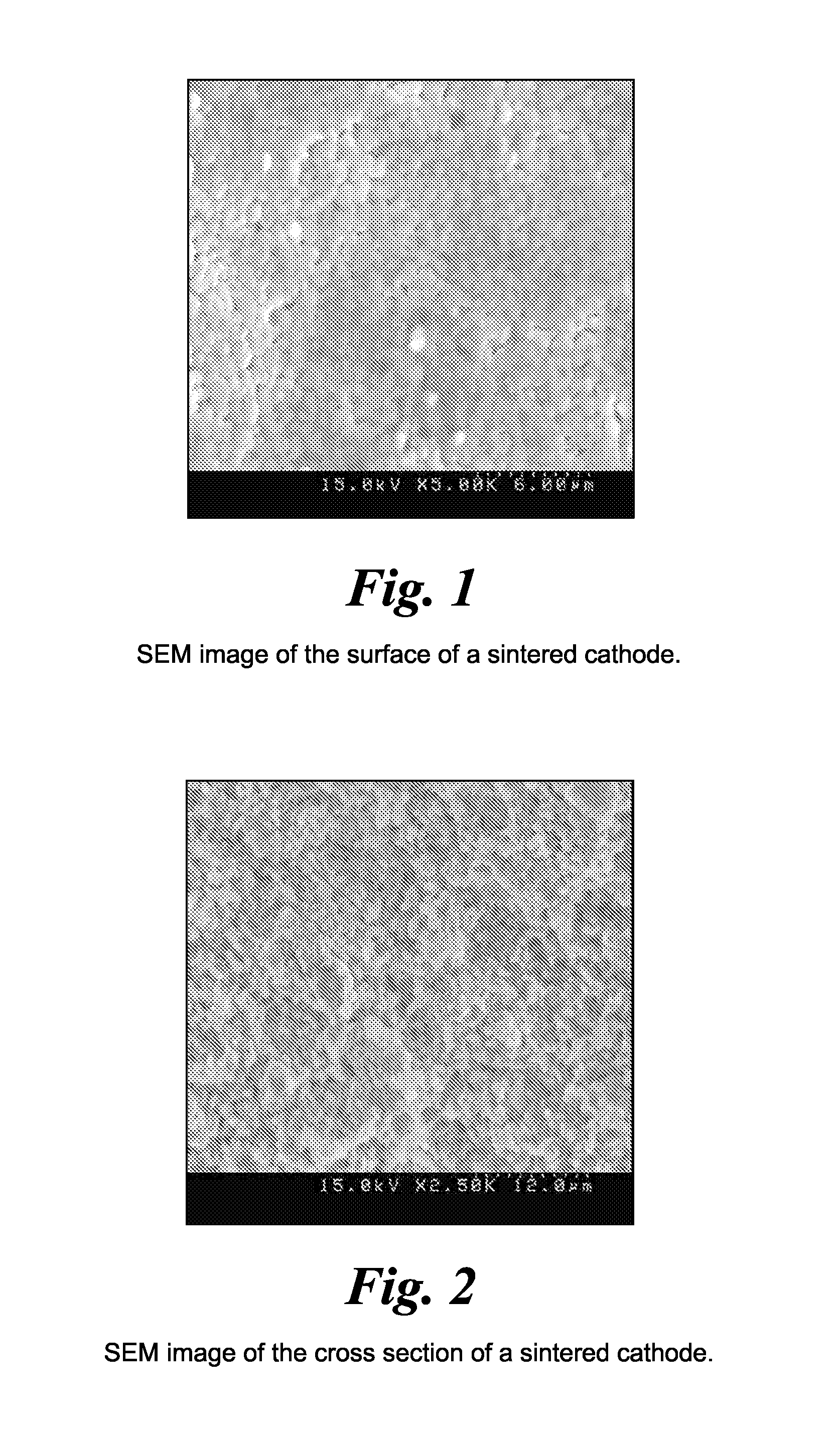

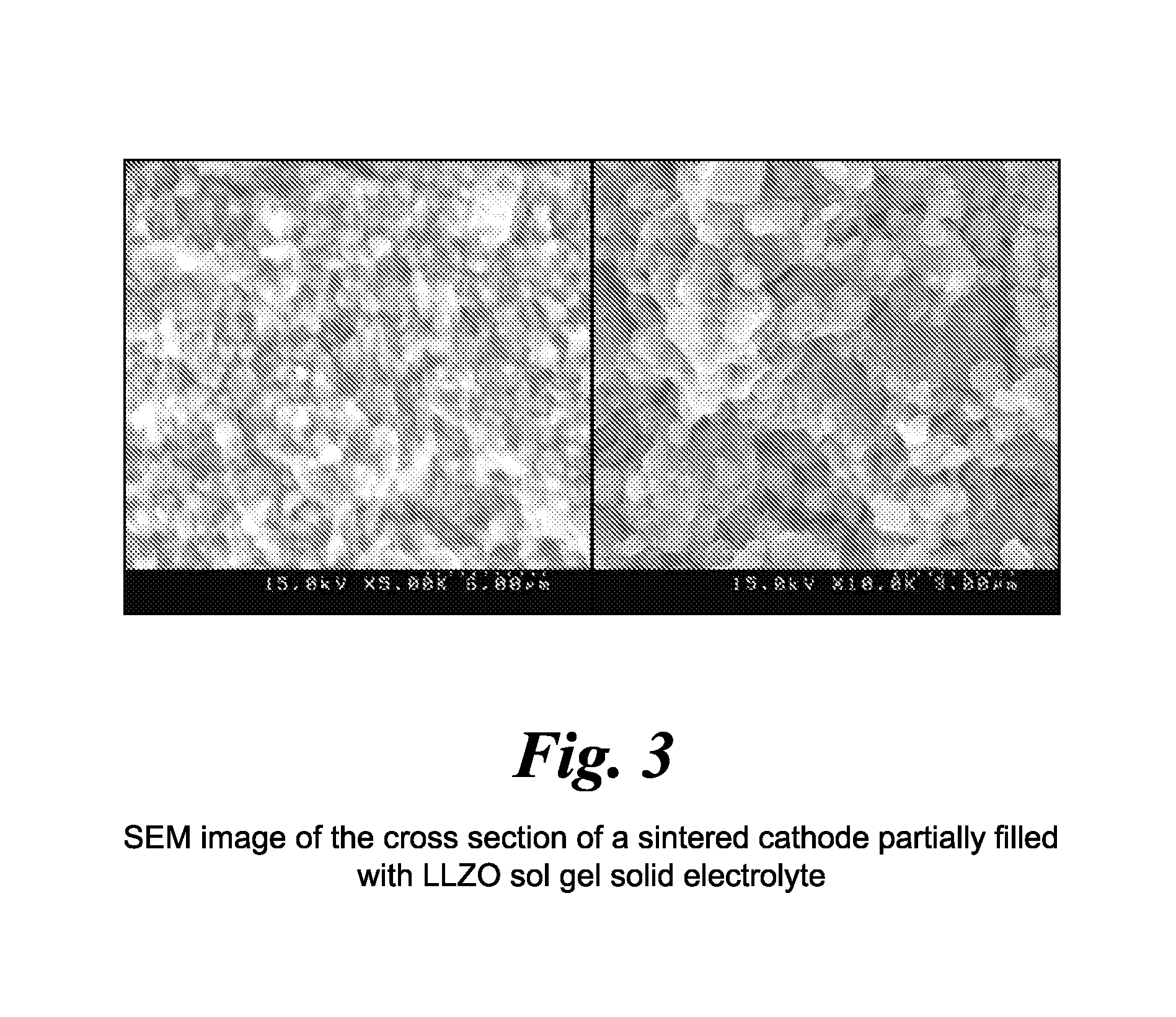

An impregnated solid state composite cathode is provided. The cathode contains a sintered porous active material, in which pores of the porous material are impregnated with an inorganic ionically conductive amorphous solid electrolyte. A method for producing the impregnated solid state composite cathode involves forming a pellet containing an active intercalation cathode material; sintering the pellet to form a sintered porous cathode pellet; impregnating pores of the sintered porous cathode pellet with a liquid precursor of an inorganic amorphous ionically conductive solid electrolyte; and curing the impregnated pellet to yield the composite cathode.

Owner:JOHNSON IP HLDG LLC

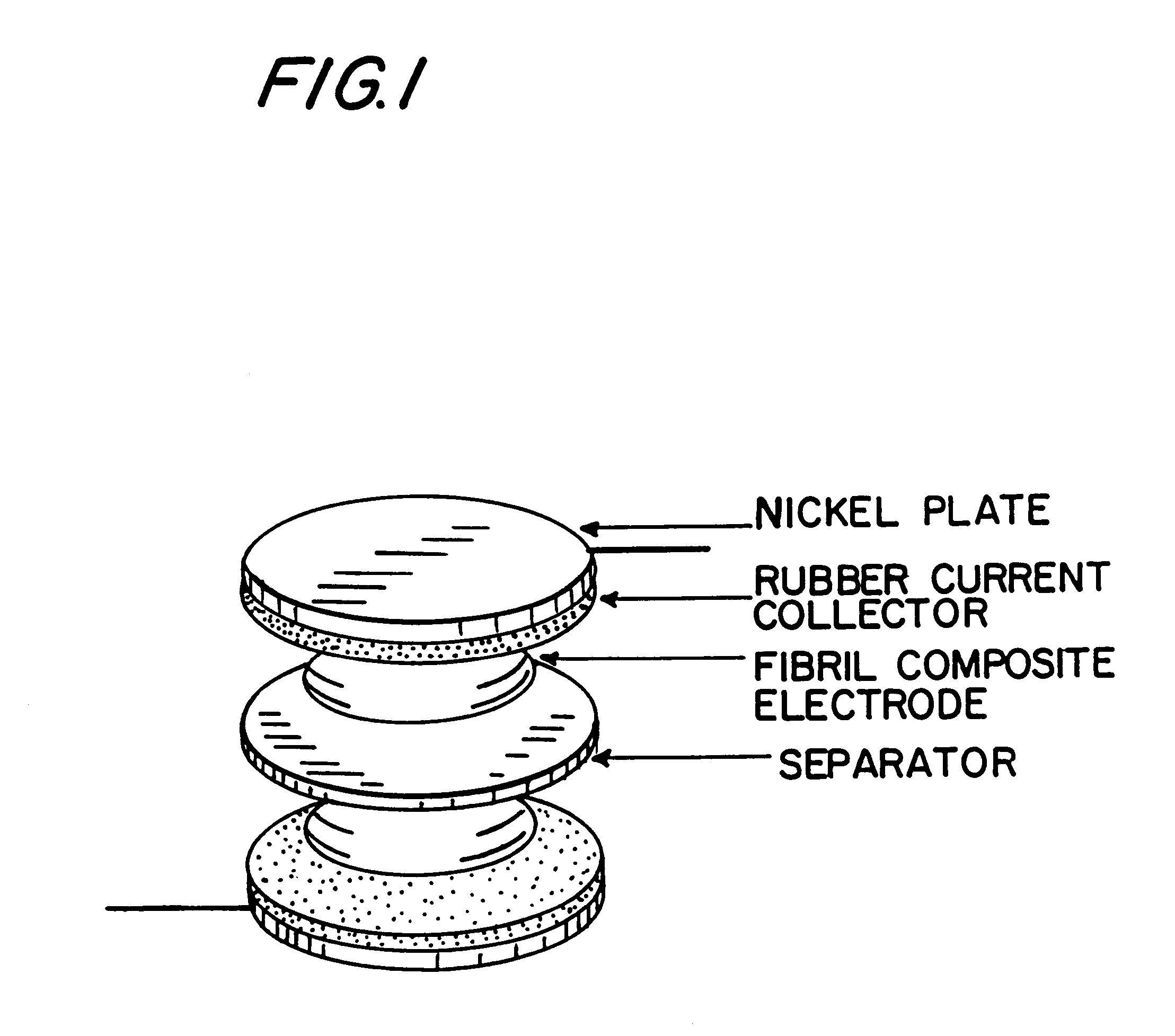

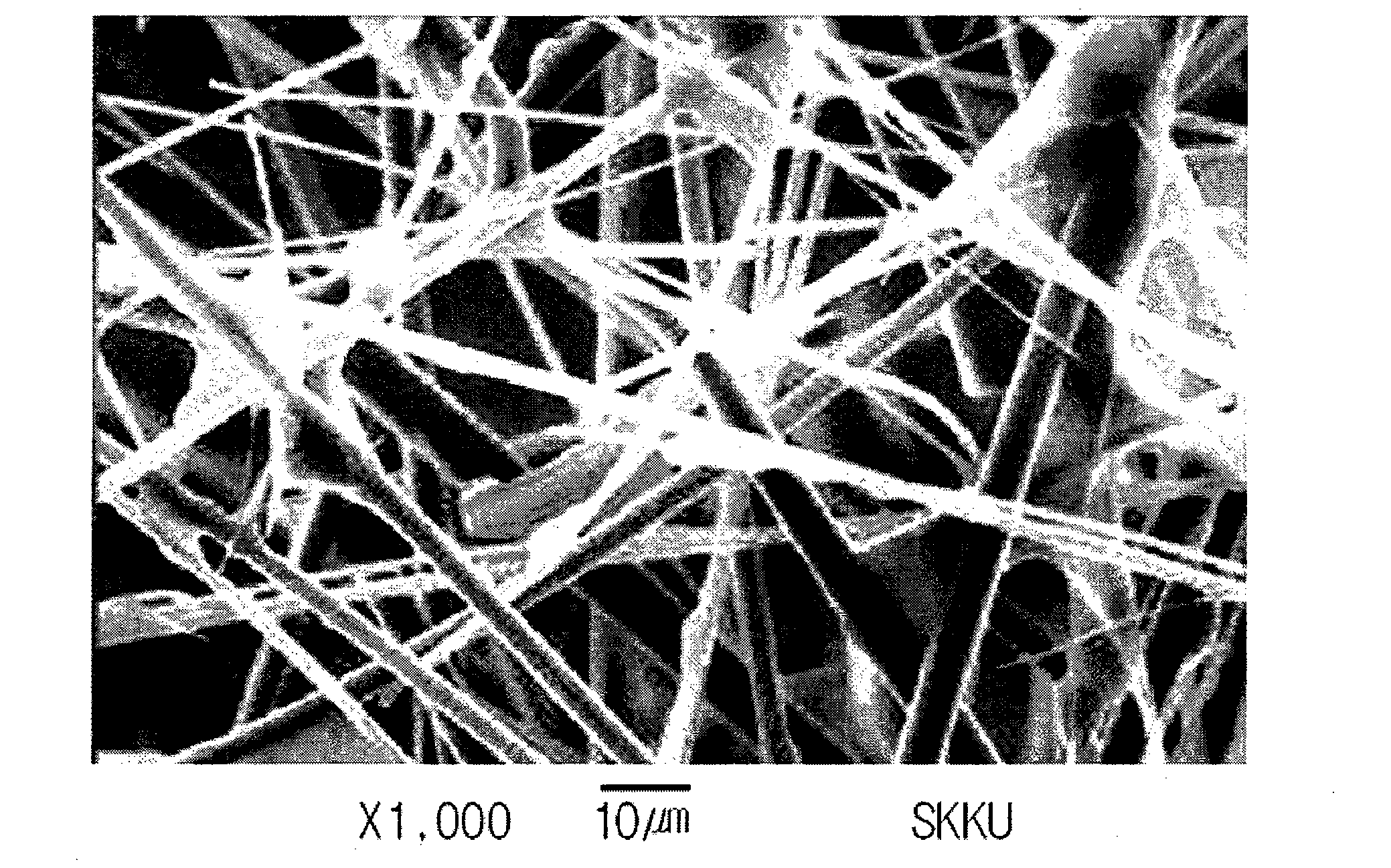

Fibril composite electrode for electrochemical capacitors

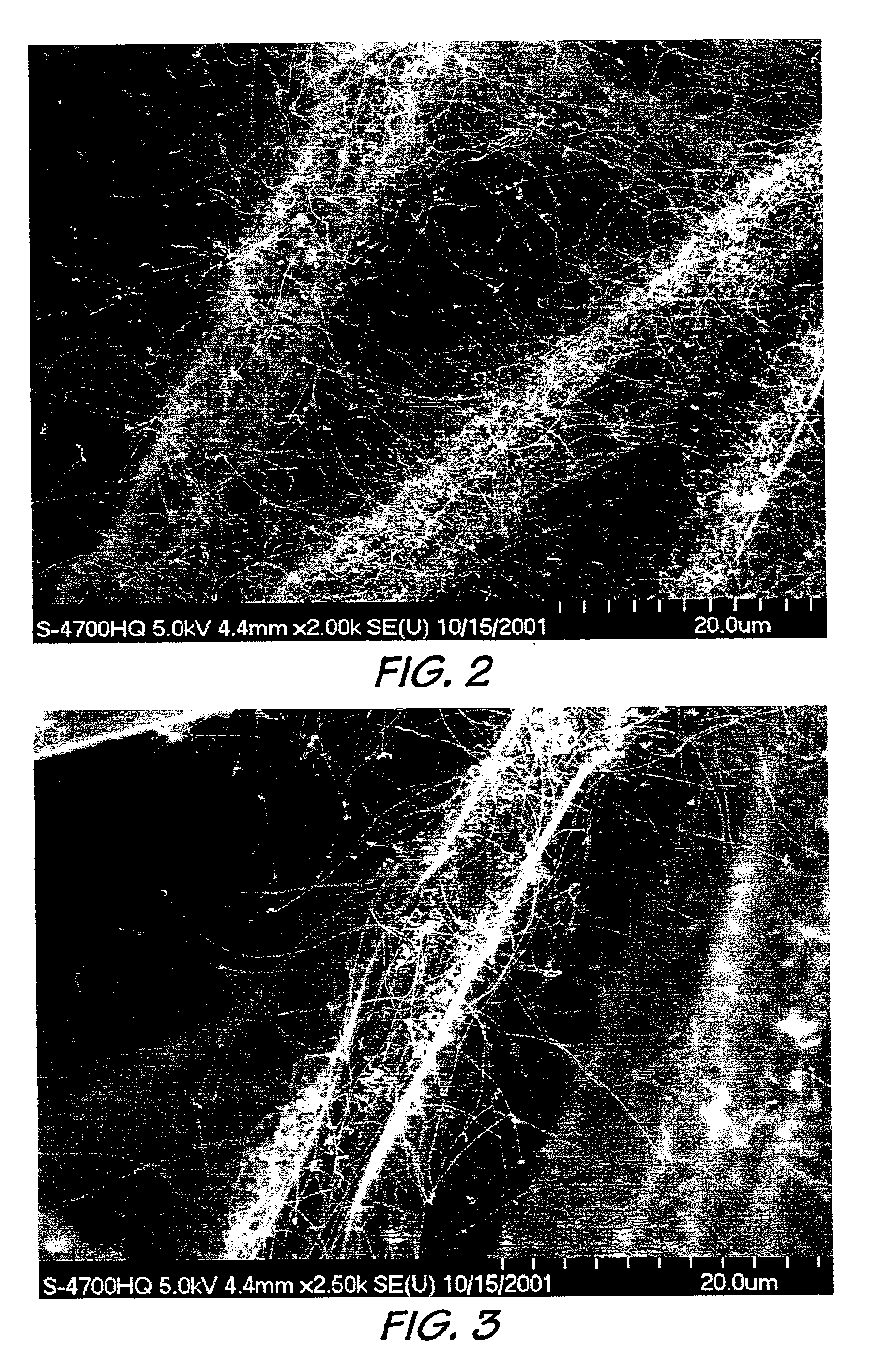

InactiveUS20020008956A1Improve electrochemical performanceReadily and highly dispersible in polar solventsNon-fibrous pulp additionNanotechComposite electrodeCarbon nanofiber

Composite electrodes comprising carbon nanofibers (fibrils) and an electrochemically active material are provided for use in electrochemical capacitors. The fibril composite electrodes exhibit high conductivity, improved efficiency of active materials, high stability, easy processing, and increase the performance of the capacitor. A method for producing the composite electrodes for use in electrochemical capacitors is also provided.

Owner:HYPERION CATALYSIS INT

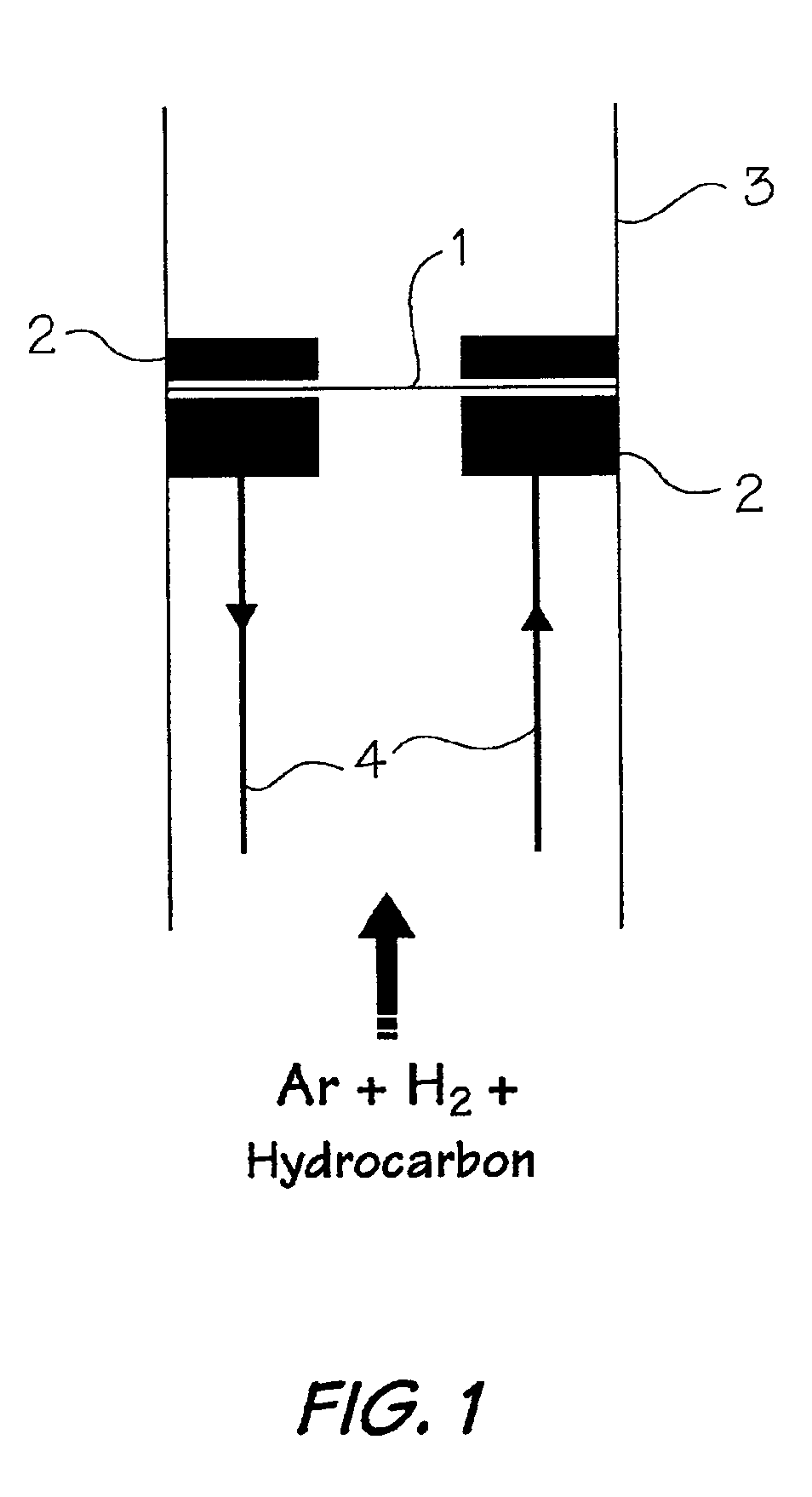

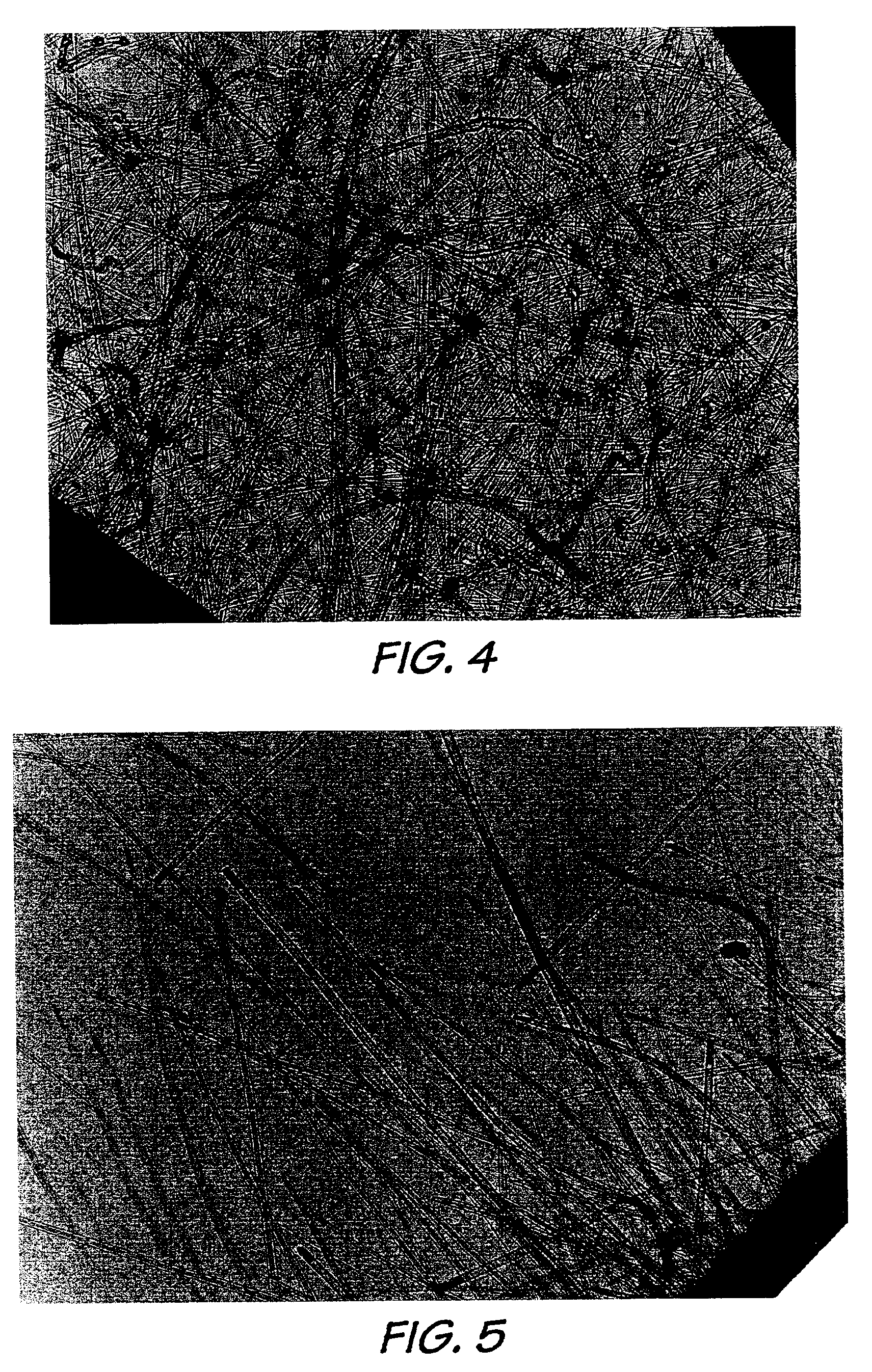

Process for preparing carbon nanotubes

InactiveUS6887451B2Speed up the processMaterial nanotechnologyEnergy inputComposite electrodeSilanes

Carbon nanotubes are produced using a silane procedure, in which a substrate such as carbon paper or stainless steel mesh is immersed in a silane solution of a metal catalyst, preferable Co:Ni in a 1:1 ratio; and a feedstock gas containing a carbon source such as ethylene is fed through the substrate and the catalyst deposited thereon while the substrate is heated by applying an electrical current thereto. Thus, a reaction occurs between the catalyst and the gas to yield carbon nanotubes supported on the conductive substrate. These composite electrodes may be used in electrochemistry or in field emitting applications.

Owner:HER MAJESTY THE QUEEN AS REPRESENTED BY THE MINIST OF NAT DEFENCE OF HER MAJESTYS CANADIAN GOVERNMENT

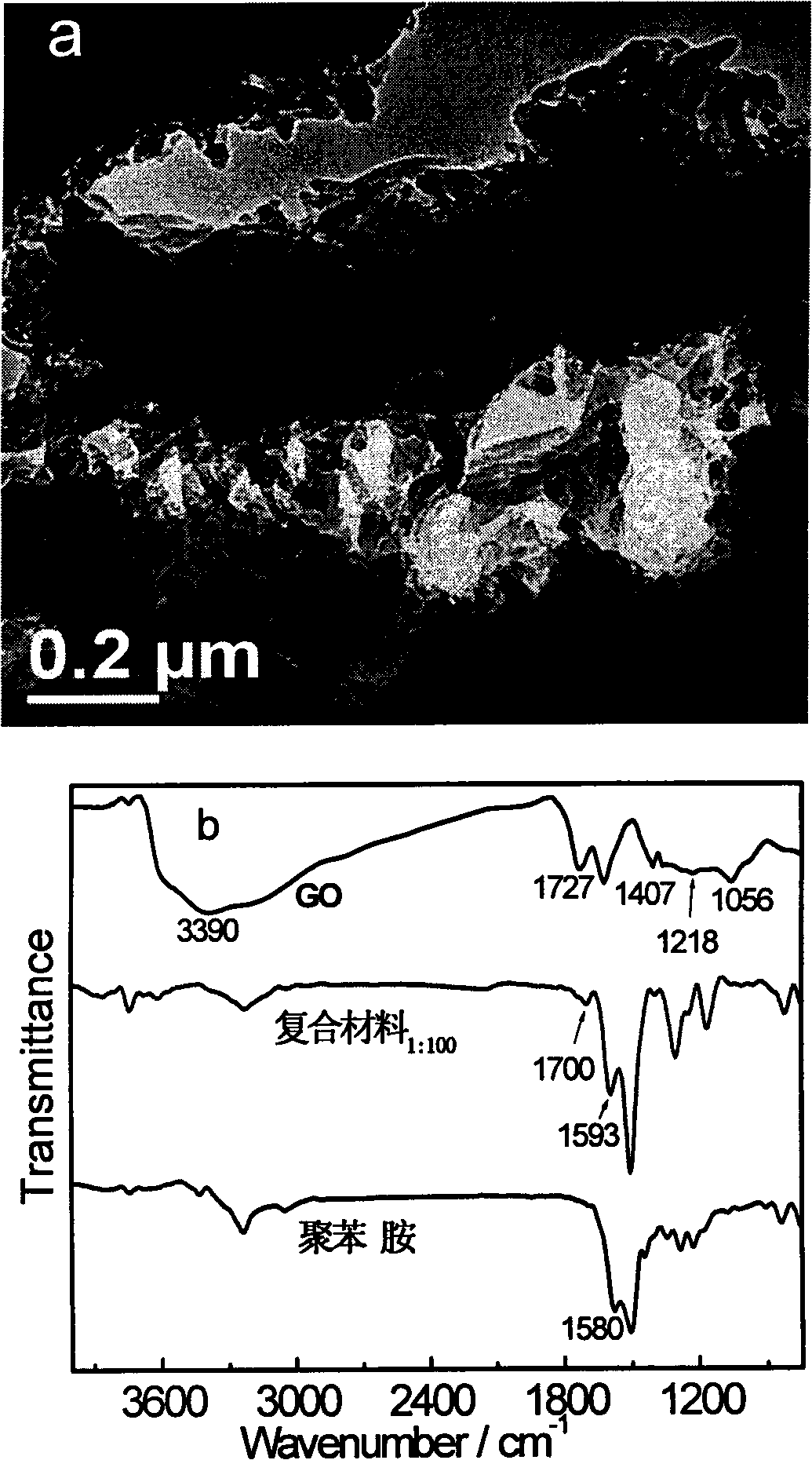

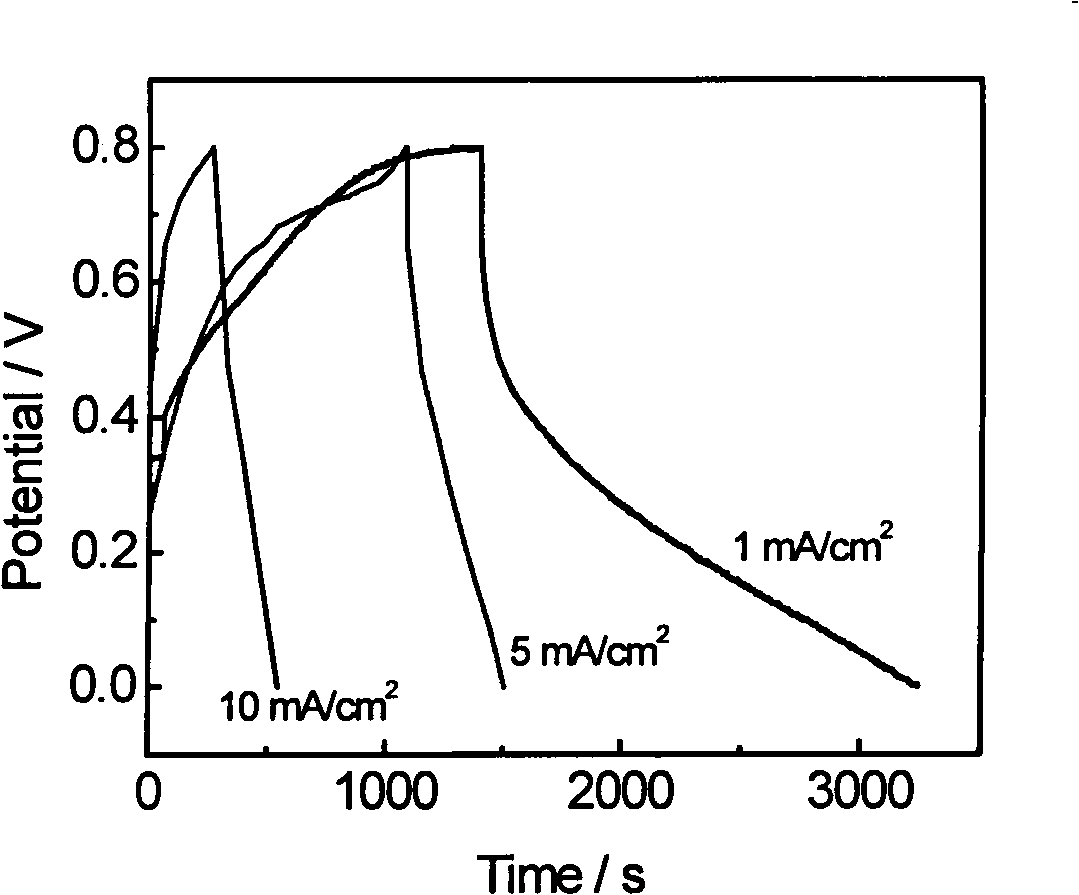

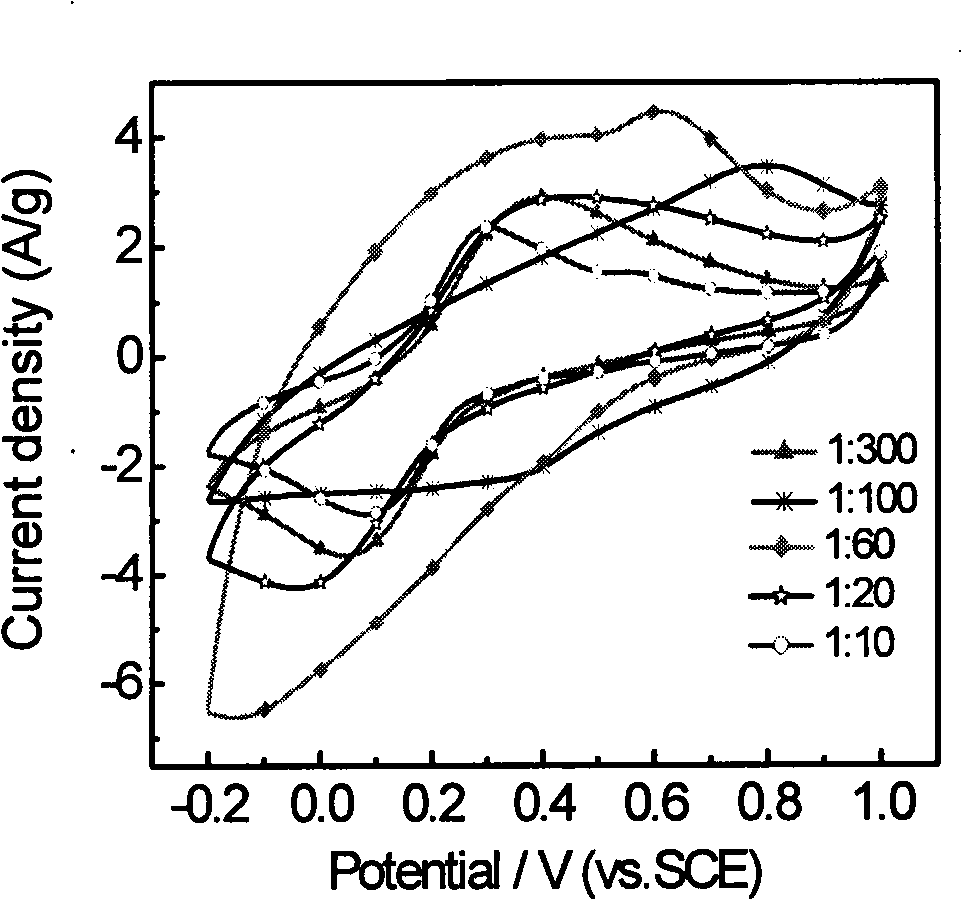

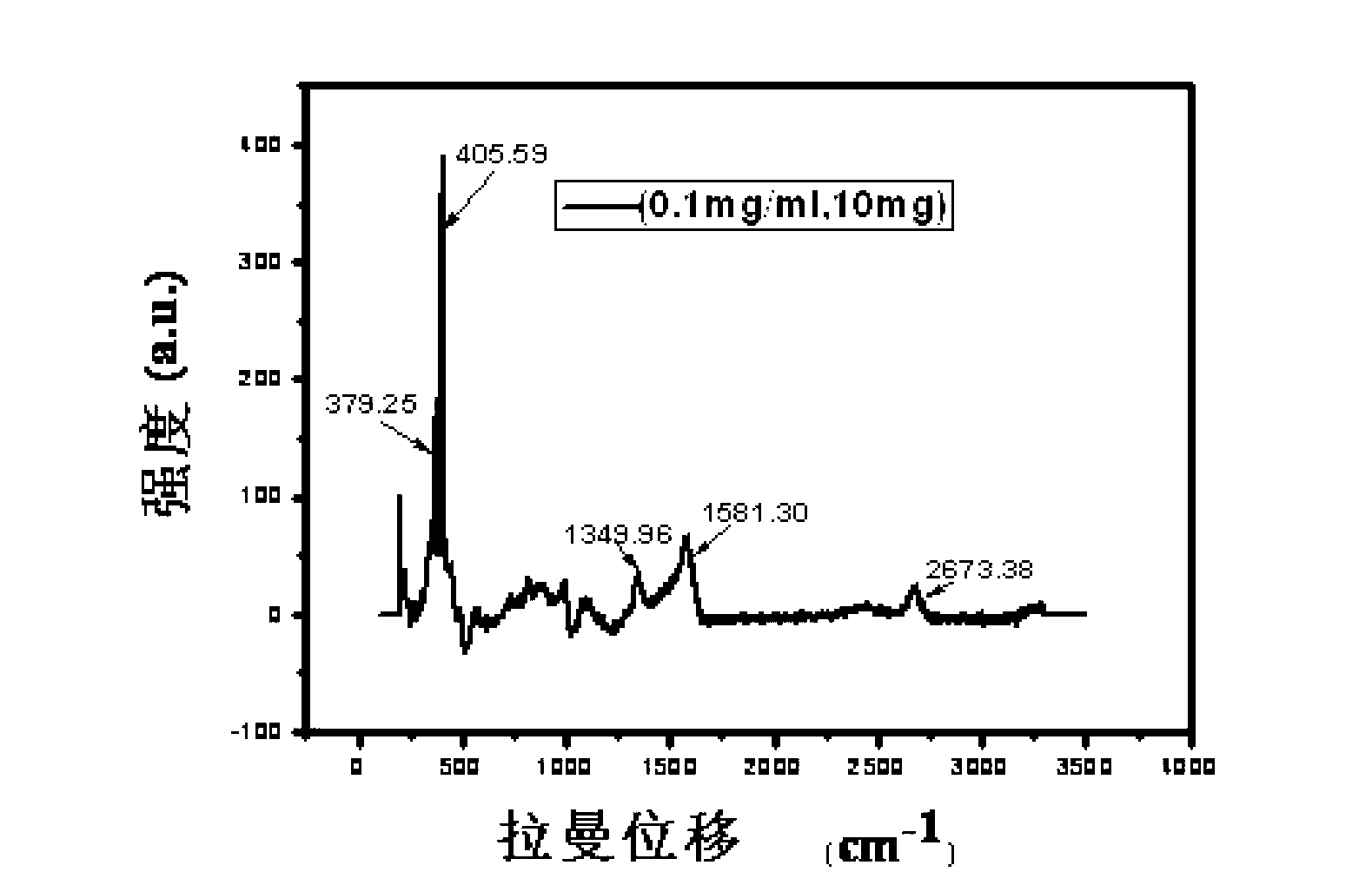

Oxidized grapheme/polyaniline super capacitor composite electrode material and preparation method and application thereof

ActiveCN101527202AImprove double layer capacitanceExcellent supercapacitor performanceElectrolytic capacitorsHybrid capacitor electrodesPolyaniline compositeAniline

The invention discloses an oxidized grapheme / polyaniline super capacitor composite electrode material and the preparation method and the application thereof. The preparation method comprise the following steps: firstly, adding oxidized graphite to water for ultrasonic dispersion so as to form an oxidized grapheme solution with uniformly dispersed single pieces; at room temperature, dropping aniline to the obtained oxidized grapheme solution for continuous ultrasonic dispersion to from a mixed solution; at a low temperature condition, adding hydrogen peroxide, ferric trichloride and a hydrochloric acid solution dropwise to the mixed solution, and stirring the solution for polymerization; and after the reaction is finished, centrifugating, washing and roasting the obtained mixed solution in vacuum to obtain the oxidized grapheme / polyaniline super capacitor composite electrode material which is used as the electrode material of an electricity storage system of a super capacitor and a battery. The oxidized grapheme / polyaniline super capacitor composite electrode material with good electrochemistry performance is obtained by the method, and the specific capacity of the oxidized grapheme and the polyaniline is greatly improved. In addition, the addition of the oxidized grapheme improves the charge and discharge service life of the polyaniline.

Owner:NANJING UNIV OF SCI & TECH

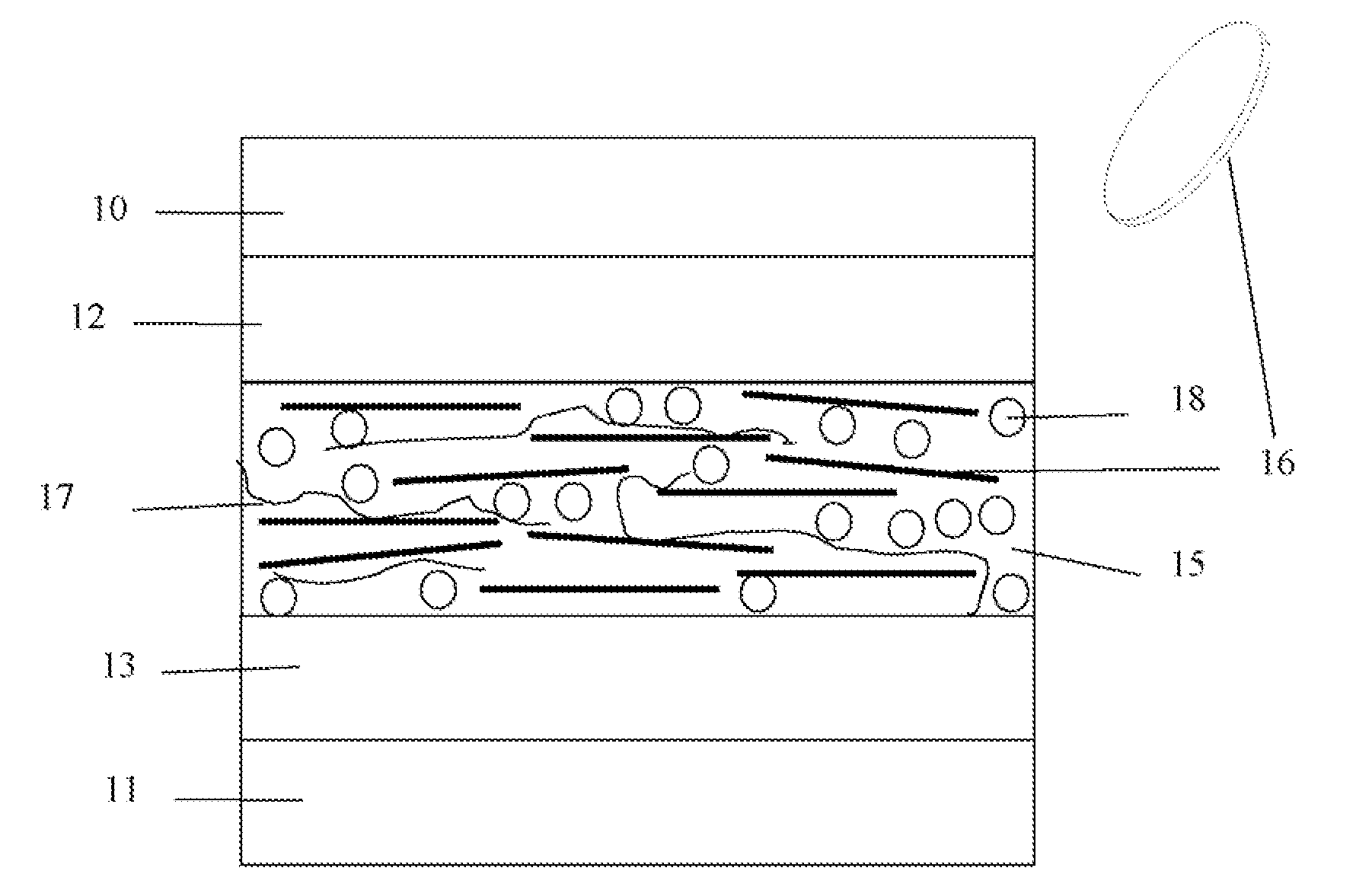

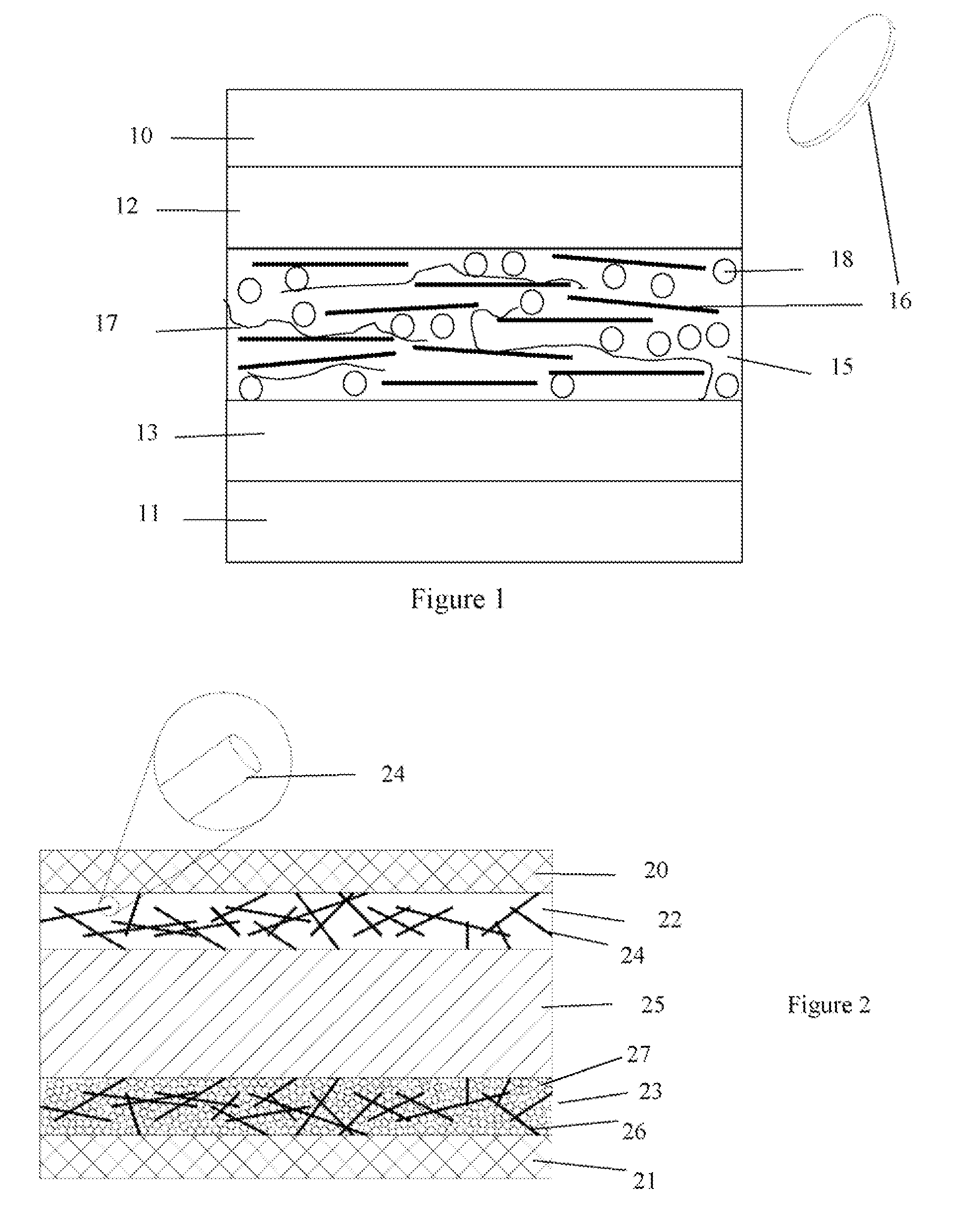

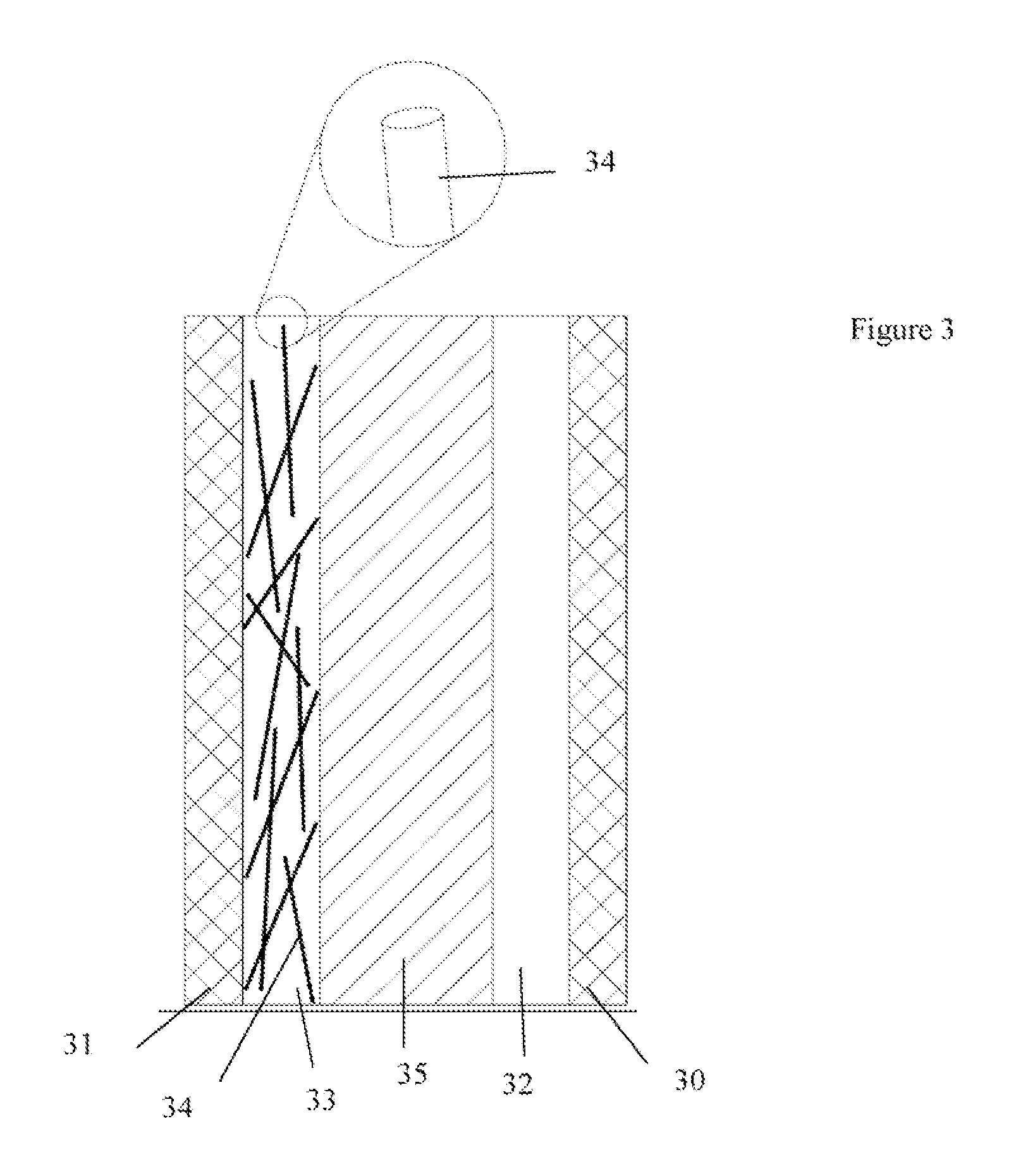

Composite electrode and electrolytes comprising nanoparticles and resulting devices

ActiveUS20100039690A1Improve electronic conductivityReduce power consumptionGenerators/motorsNon-linear opticsComposite electrodeNanoparticle

This invention discloses novel electrochromic devices and polymer actuator materials where nanoparticles are used to make composites. In particular, the said nanoparticles are wire shaped and disc shaped. These composites allow EC devices to be made with improved performance, particularly display devices could be made that consume low power and can be manufactured at low cost.

Owner:AJJER

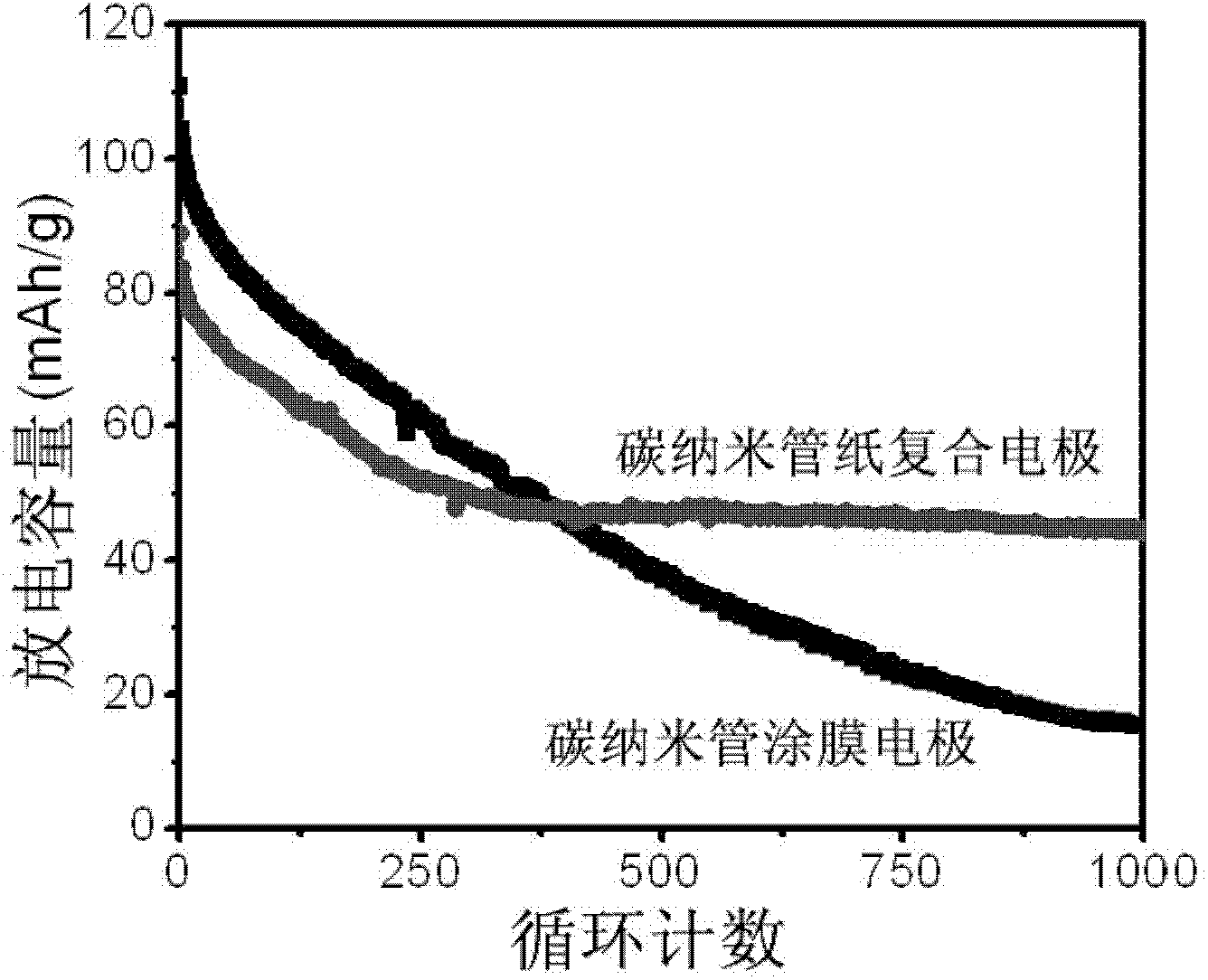

Self-supporting flexible carbon nano-tube paper composite electrode material for lithium ion battery

InactiveCN102593436AImprove performanceGood electronicsCell electrodesCarbon nanotubeSodium-ion battery

The invention discloses a self-supporting flexible carbon nano-tube paper composite electrode material for a lithium ion battery. A carbon nano-tube paper network of the material is formed by using interlaced carbon nano-tubes, and active anode material particles or cathode material particles of the lithium ion battery are compounded with carbon nano-tube paper to form the carbon nano-tube paper composite electrode material. In the electrode material, the carbon nano-tubes form an efficient three-dimensional conductive network, so that a better electron channel is provided for active material particles with low electrical conductivity. Because a bonding agent and a current collector are not needed, the electrode material has a higher active material ratio, and the performance of the electrode material is further improved. Meanwhile, the high mechanical property of the carbon nano-tube paper makes the composite electrode material show flexible characteristics, and as a flexible electrode material, the self-supporting flexible carbon nano-tube paper composite electrode material is hopeful to be widely used in next-generation flexible electronic equipment.

Owner:TSINGHUA UNIV

Composite electrode for a plasma arc torch

InactiveUS6841754B2Improve heat transfer performanceImprove thermal conductivityElectric discharge heatingArc welding apparatusMetallic materialsCopper electrode

A plasma arc torch that includes a torch body having a nozzle mounted relative to a composite electrode in the body to define a plasma chamber. The torch body includes a plasma flow path for directing a plasma gas to the plasma chamber in which a plasma arc is formed. The nozzle includes a hollow, body portion and a substantially solid, head portion defining an exit orifice. The composite electrode can be made of a metallic material (e.g., silver) with high thermal conductivity in the forward portion electrode body adjacent the emitting surface, and the aft portion of the electrode body is made of a second low cost, metallic material with good thermal and electrical conductivity. This composite electrode configuration produces an electrode with reduced electrode wear or pitting comparable to a silver electrode, for a price comparable to that of a copper electrode.

Owner:HYPERTHERM INC

Combined electrode of battery and preparation method thereof

InactiveCN103730630AImprove electronic conductivityImprove ionic conductivityActive material electrodesElectrolyte layer coatingSolid state electrolyteElectrical battery

The application relates to the field of energy storage materials, and discloses a combined electrode with ultrahigh electron and ionic conductivity and a preparation method thereof. The combined electrode is formed in a manner that a battery active material is uniformly tied in a three-dimensional multi-hole network formed by carbon nano tubes which are connected in a crossing manner, and meshes and the surface of the active material are filled or coated with a solid electrolyte material. According to the combined electrode, the carbon nano tubes, which are communicated with one another, can form an ultrahigh electrical transmission network, on the one hand, a solid electrolyte can provide the ultrahigh lithium-ion transmission capacity while not influencing the connection of the carbon nano tubes and the conductive capacity of the electrode; on the other hand, the three-dimensional network formed by the carbon nano tubes is also fixed by virtue of the solid electrolyte, the formation of a solid electrolyte interface is controlled, and an active material is protected under the high charge-discharge voltage. The combined electrode has the high reversible capacity and the enhanced rate capability, and can meet the requirement of a power automobile or a mixed power automobile.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Transition metal oxide/ graphene nanometer composite electrode material used for lithium battery and preparation method thereof

InactiveCN102339994AImprove conductivityLower internal resistanceCell electrodesSolventLithium-ion battery

The invention relates to a transition metal oxide / graphene nanometer composite electrode material used for a lithium battery and a preparation method thereof. The transition metal oxide / grapheme nanometer composite electrode material is the transition metal oxide modified by grapheme or graphene oxide, wherein the transition metal oxide and the grapheme or the graphene oxide can be connected in a physical packaging or chemical bonding mode. One of the following methods is adopted: 1. evenly mixing a precursor and graphene (or graphene oxide) required by preparing the transition metal oxide at the mass ratio of 0.01: 100 to 50: 100 in a solvent, and reacting at a certain temperature and pressure to obtain the nanometer composite electrode material; and 2. fully mixing the graphene (or graphene oxide) and the transition metal oxide at the mass ratio of 0.01: 100 to 50: 100 in a solvent, and drying to obtain the nanometer composite electrode material. The preparation method is simple, is easy to operate and is suitable for large-scale production, the prepared electrode material has higher lithium-ion and electron conductivity, and the assembled lithium battery has the advantages of high lithium battery specific capacity and good cycle performance and is suitable for the lithium battery electrode material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

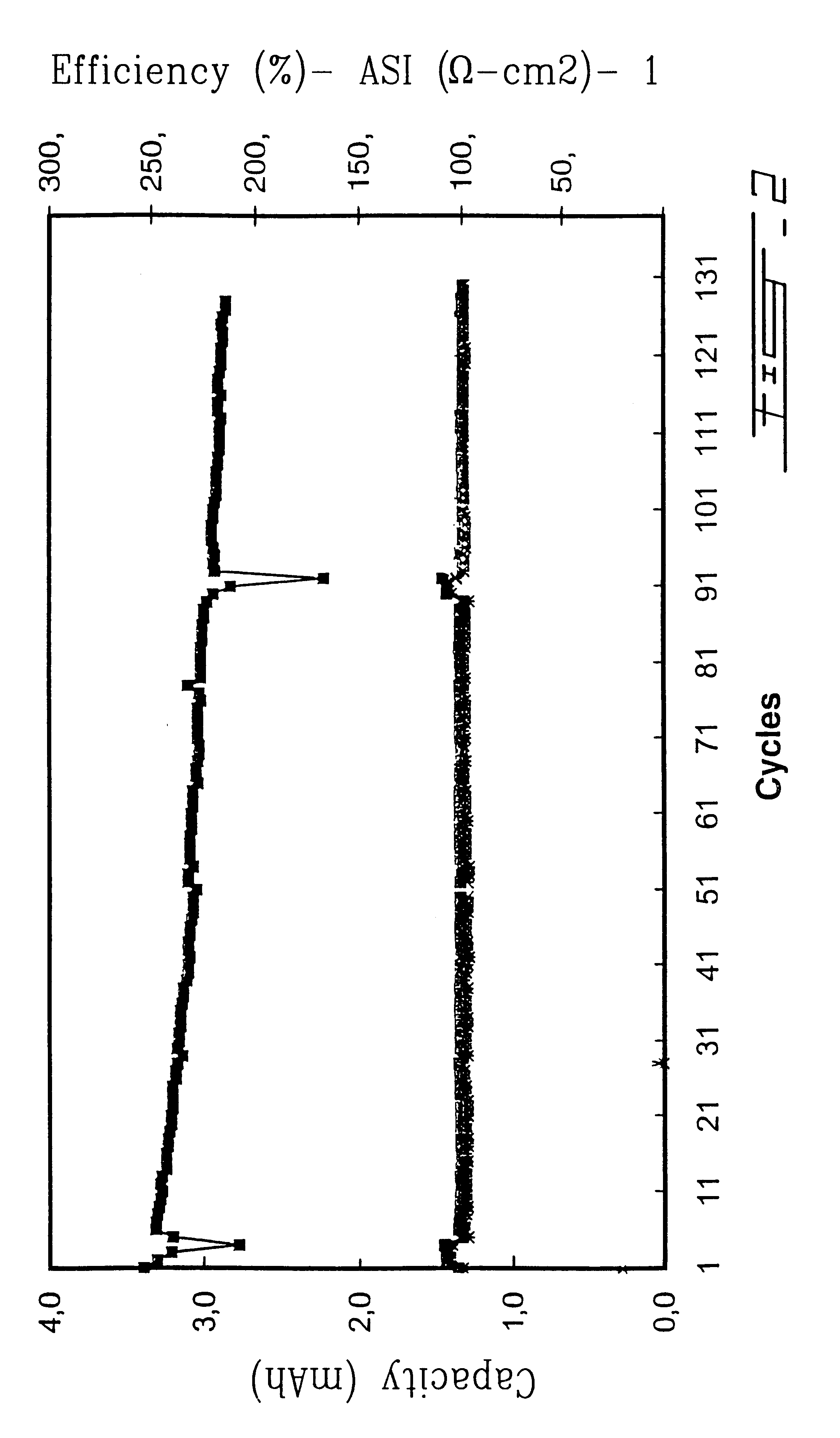

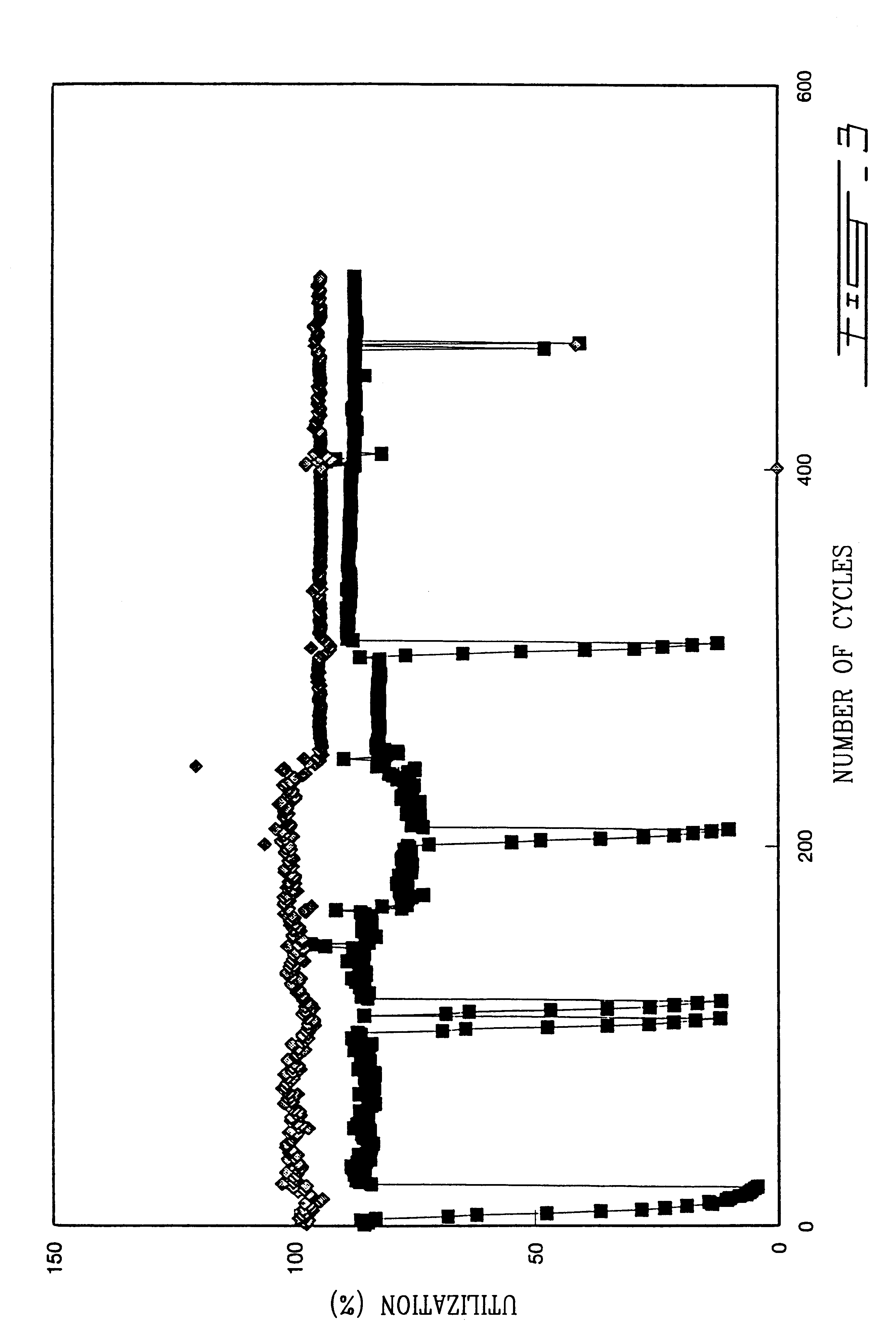

Improvements relating to electrode structures in batteries

ActiveCN101002351ASolve the real problemImprove electrochemical utilizationElectrode rolling/calenderingFinal product manufacturePorosityComposite electrode

There are disclosed solid composite electrodes with electrode active layers that include an electrode active material, an optional electron conductive material, an optional binder and other optional additives. The solid composite electrodes are formed by the deposition of an electrode composition (slurry) onto a current collector in one or many layers. The electrode structure is characterised by a porosity of the electrode composition layer that decreases in a direction from the back side of the layer (close to the current collector) towards the outer side of the layer. The gradient of the decrease in the porosity is controlled by the content of solid substance in the slurry, by the composition of the solvent in the slurry, by the temperature of the layer drying after deposition, as well as by the pressing or calendering conditions for each layer. The electrode structures can be used in chemical sources of electric energy such as primary (non-rechargeable) as well as secondary (rechargeable) batteries.

Owner:JOHNSON MATTHEY PLC

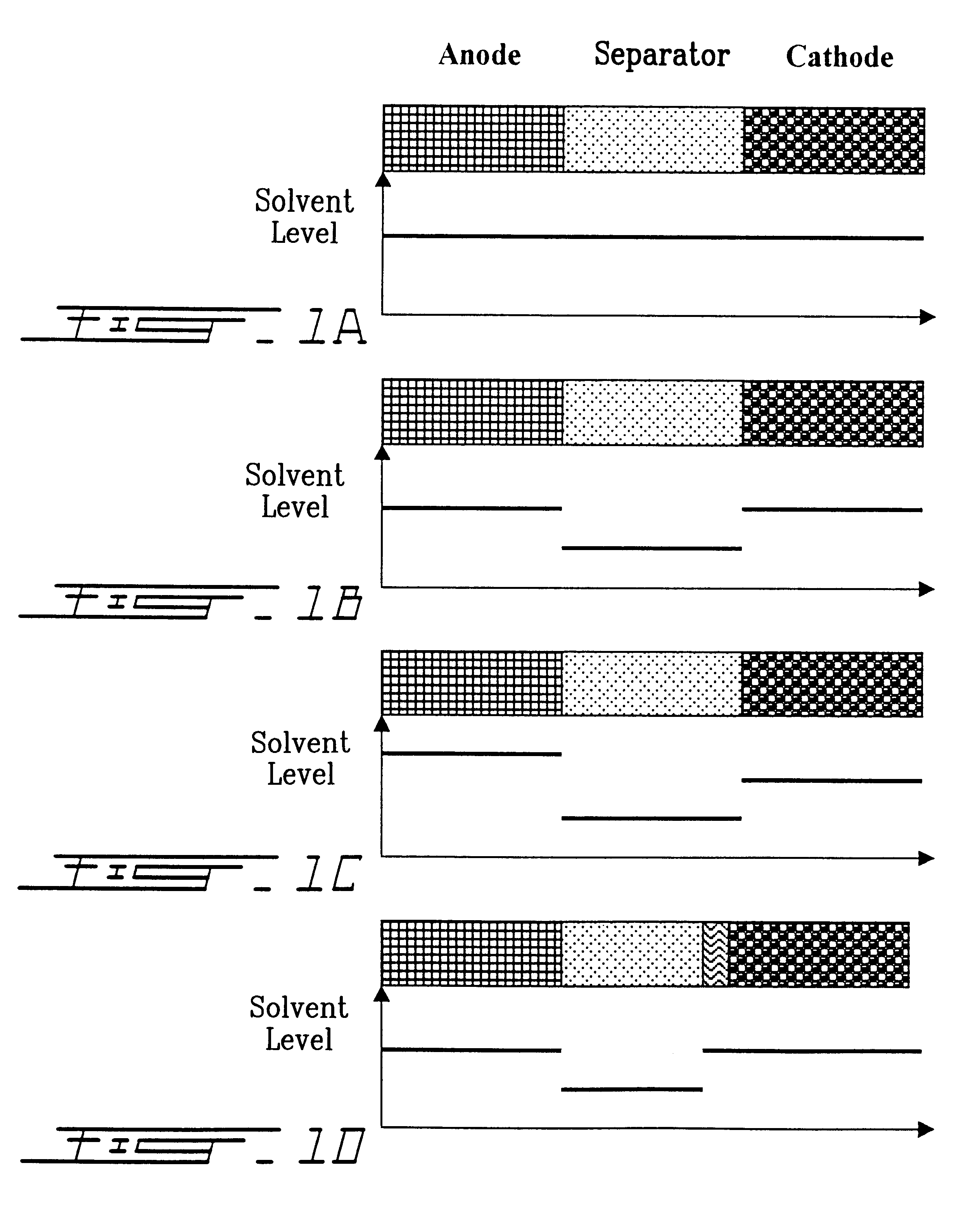

Electrolytic composition with polymer base for electrochemical generator

The invention concerns an aprotic electrolytic composition located in the separator and in at least one composite electrode containing a powder of an active electrode material, and if necessary an electronic conduction additive of an electrochemical generator The electrolytic composition comprises a first polymer matrix consisting of a polyether and at least a second polymer matrix, macroscopically separated, and also at least an alkaline salt as well as a polar aprotic solvent: The polymer matrices are capable of being swollen by at least one of the polar aprotic solvents. The solvent or mixture of solvents is unevenly distributed between the polymer matrices. The invention also concerns an electrochemical generator comprising a negative electrode and positive electrode reversible to alkaline ions and a separator with polymer electrolyte, the electrolytic component of which is the composition described above. The invention further concerns the manufacture in two or three steps of a sub-assembly of an electrochemical generator by coating an electrode support with a composite electrode containing the second matrix, followed by a surface coating on the electrode resulting from the preceding step with a solution containing the first polymer matrix so as to form the separator wholly or partly.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Liquid phase deposition of contacts in programmable resistance and switching devices

ActiveUS7566643B2High densityHigh resistivitySemiconductor/solid-state device manufacturingComposite electrodeConductive materials

Owner:OVONYX MEMORY TECH LLC

Graphene/molybdenum disulfide composite electrode material and preparation method thereof

The invention relates to the fields of a novel chemical electric power source and a new energy material, and particularly discloses a graphene / molybdenum disulfide composite electrode material and a preparation method of the composite electrode material. The preparation method comprises the steps of: (1) preparing graphite oxide from graphite as a raw material by an oxidation and intercalation method; (2) dissolving prepared graphite oxide with deionized water, carrying out ultrasonic stripping to obtain a graphene oxide solution, then adding DMF (dimethyl formamide) and molybdate, finally adding a reducing agent, and dispersing uniformly to obtain a mixed solution; and (3) transferring the mixed solution to a reaction kettle, keeping the temperature in the temperature condition of greater than or equal to 180 DEG C for 5-10h, centrifuging and washing the product to remove DMF, and drying to obtain the graphene / molybdenum disulfide composite electrode material product. The preparation method of the graphene / molybdenum disulfide composite electrode material is simple, uniform in reaction system and low in production cost, and is particularly suitable for requirements of industrial large scale production; and the prepared product graphene / molybdenum disulfide composite electrode material has better electrochemical performances.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

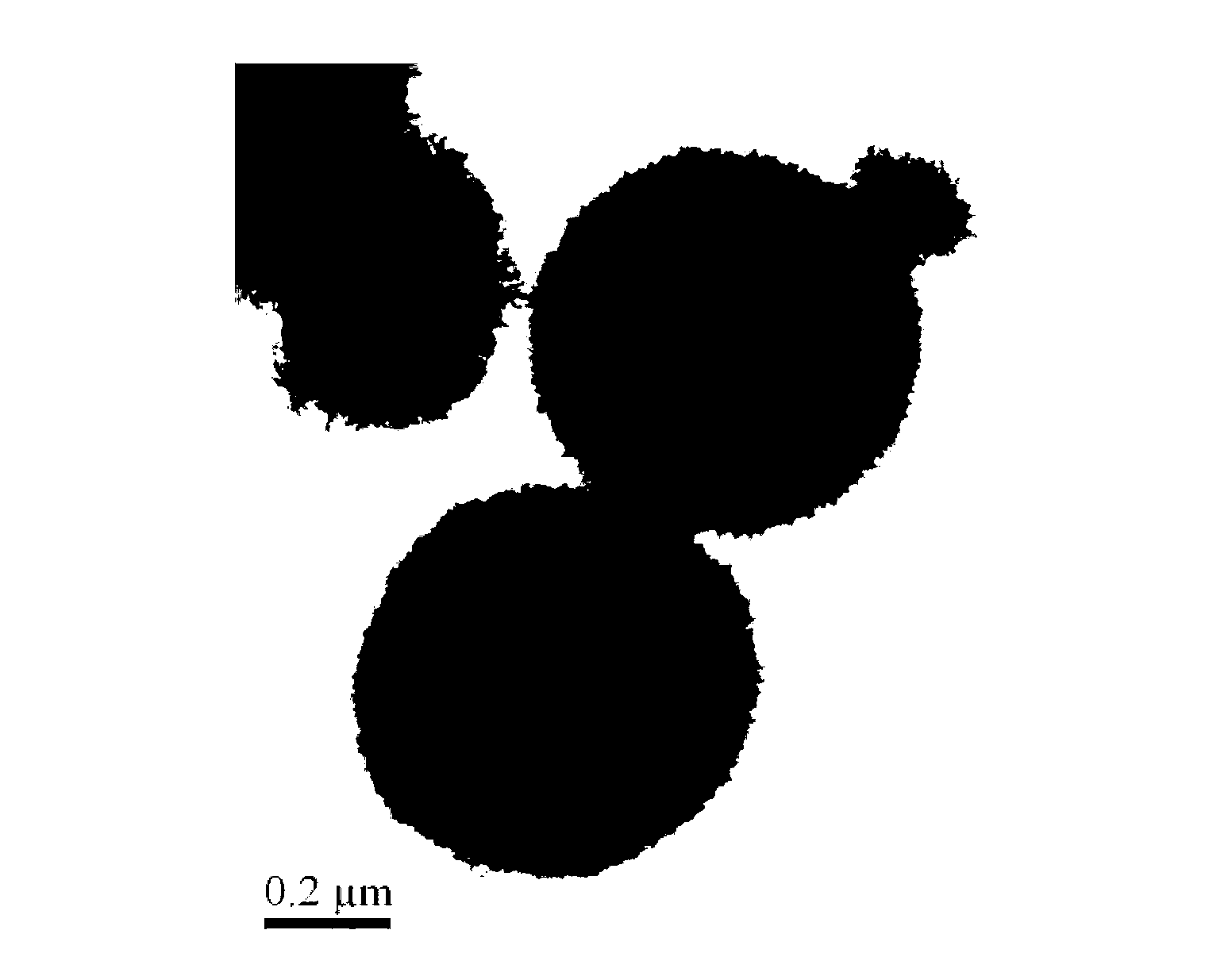

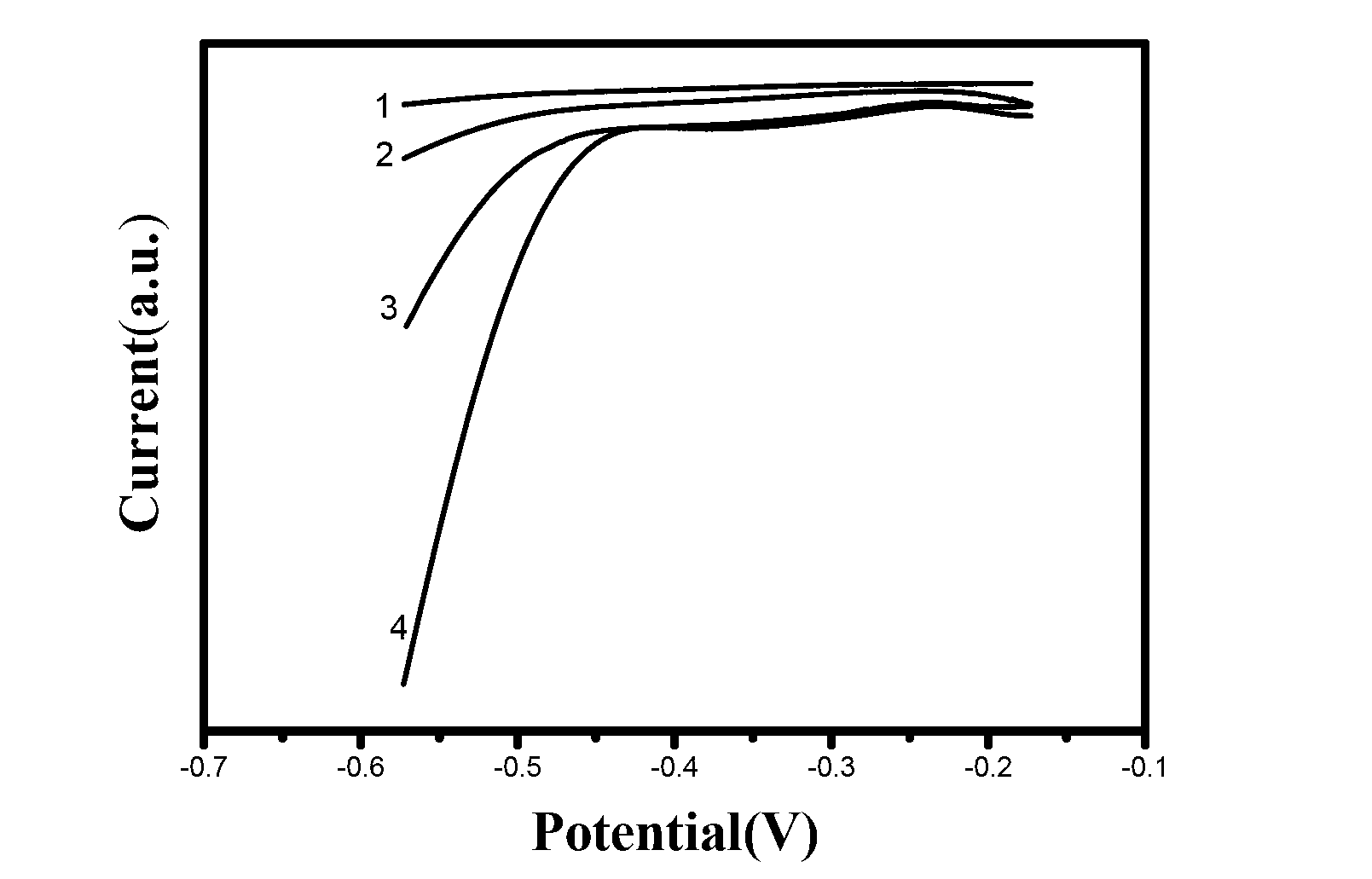

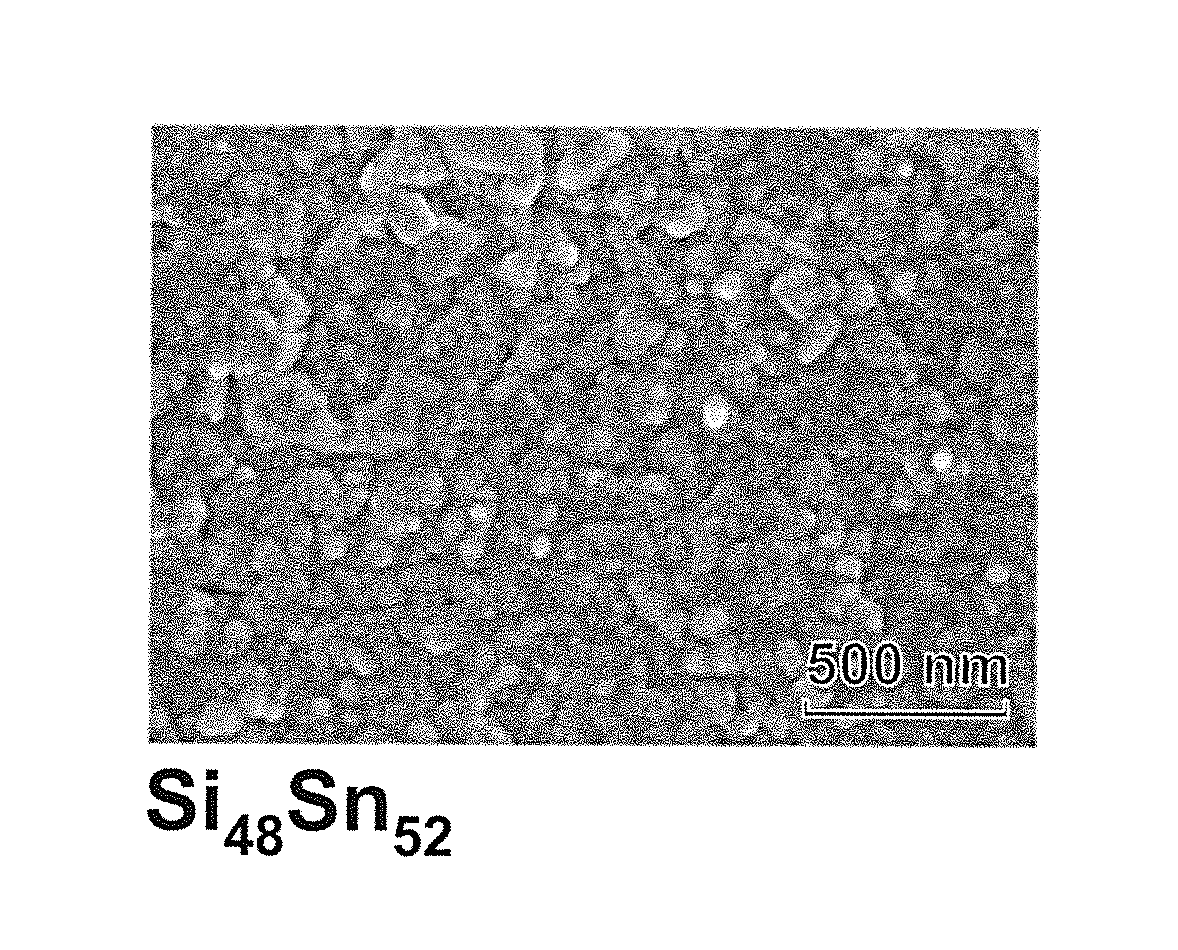

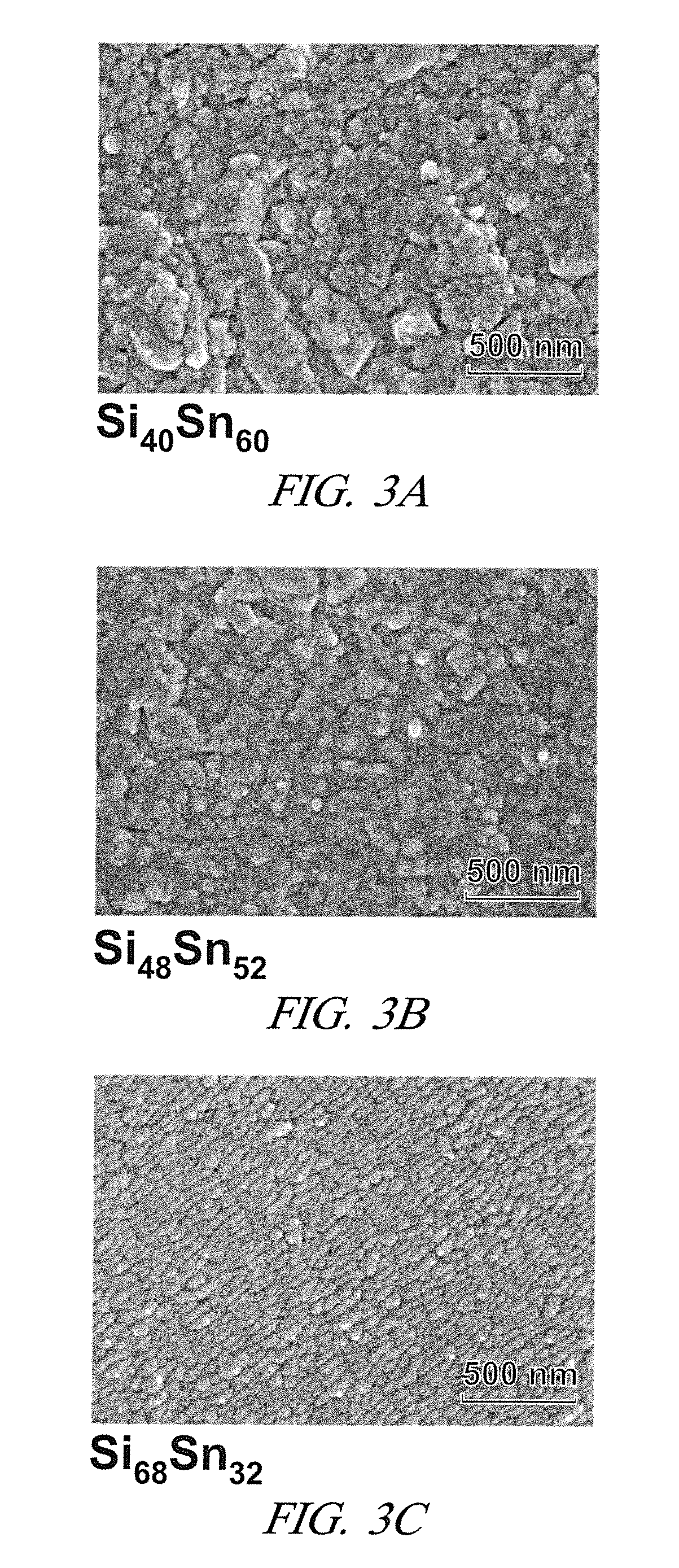

Phase separated silicon-tin composite as negative electrode material for lithium-ion batteries

ActiveUS9142830B2Reduce stressMitigate the fracture of the larger composite particlesMaterial nanotechnologyConductive materialComposite electrodeAmorphous phase

A composite of silicon and tin is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery. This electrode material is formed such that the silicon is present as a distinct amorphous phase in a matrix phase of crystalline tin. While the tin phase provides electron conductivity, both phases accommodate the insertion and extraction of lithium in the operation of the cell and both phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. In general, roughly equal atomic proportions of the tin and silicon are used in forming the phase separated composite electrode material.

Owner:GM GLOBAL TECH OPERATIONS LLC

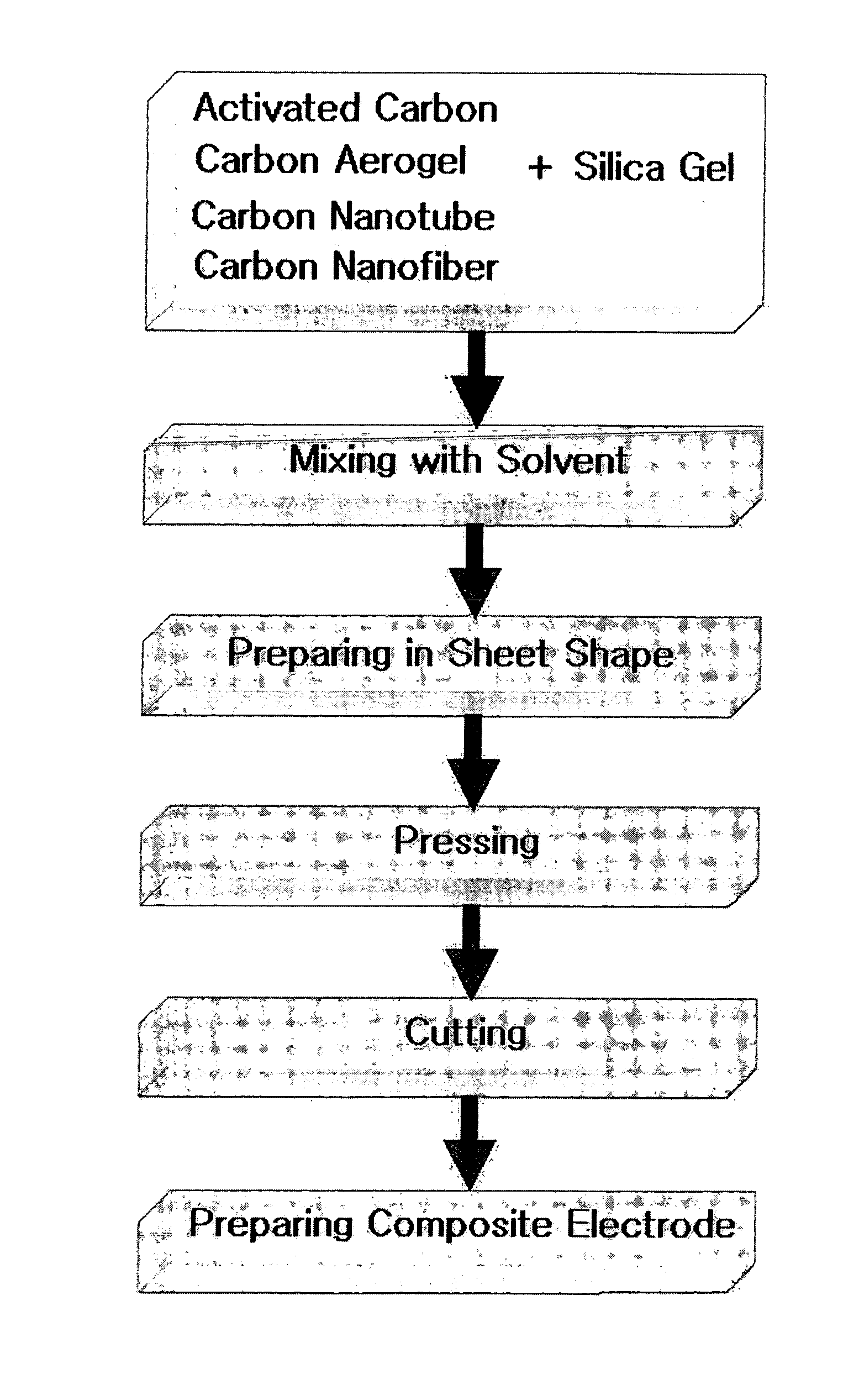

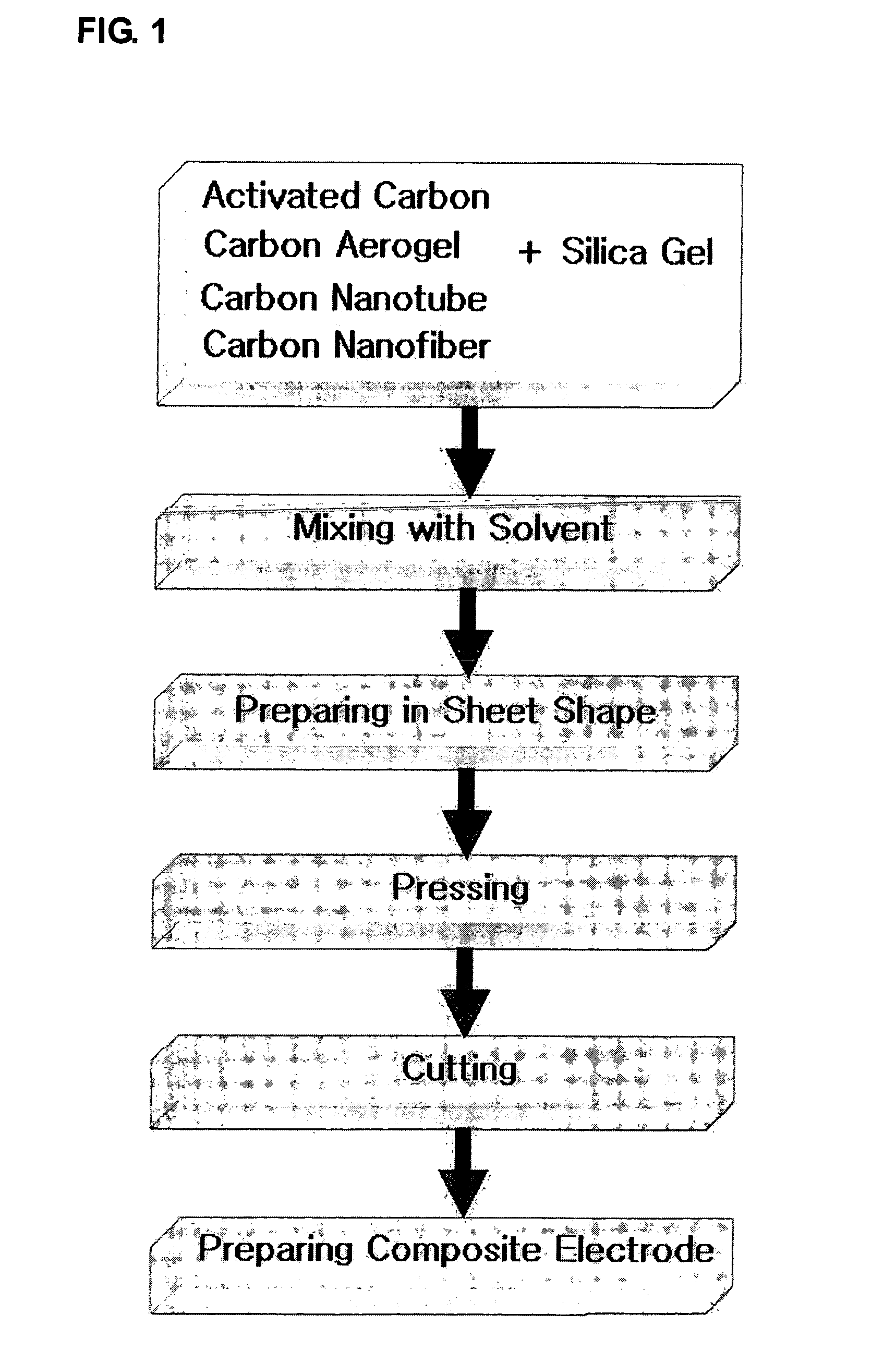

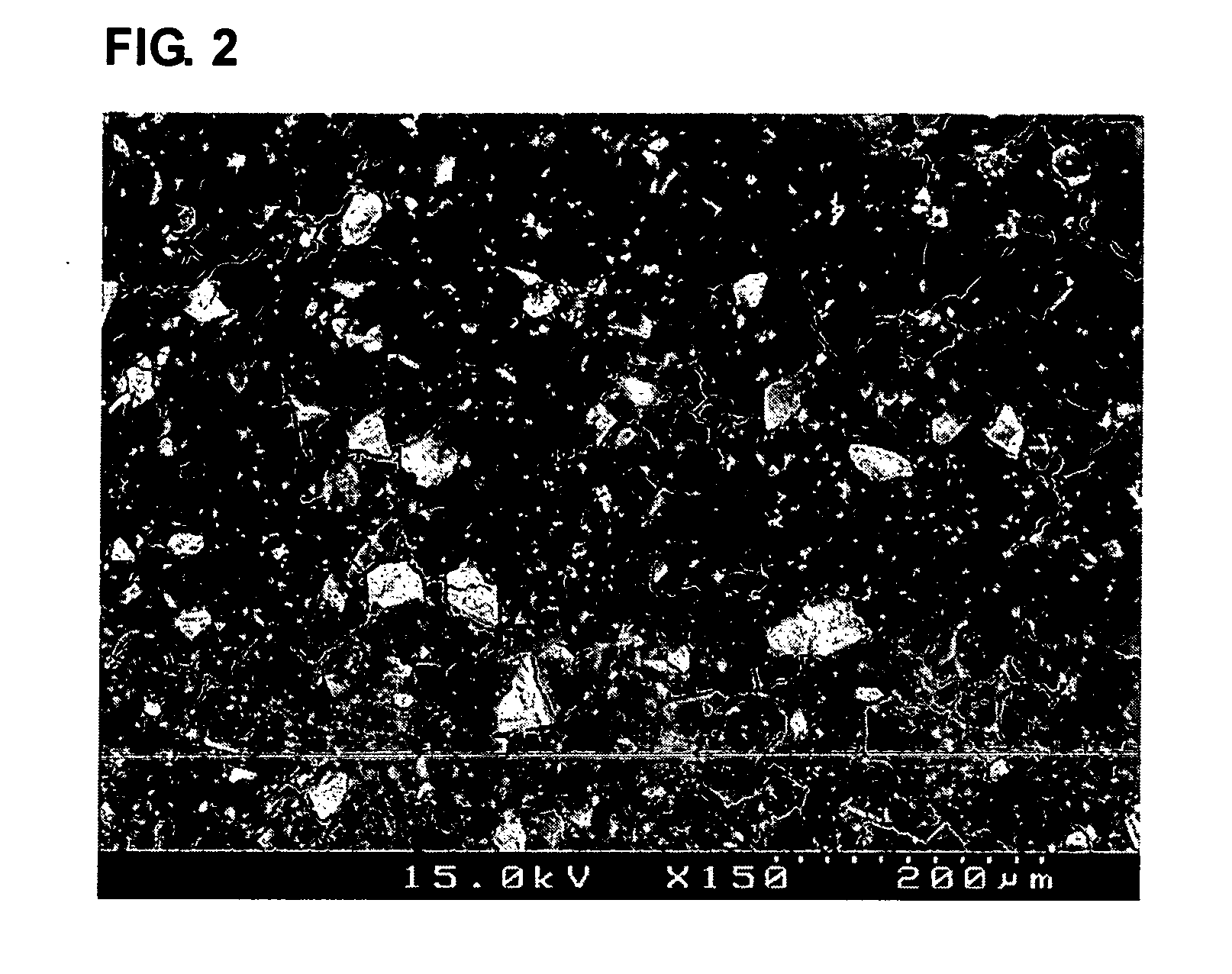

Carbon-porous media composite electrode and preparation method thereof

InactiveUS20050155216A1Improve hydrophilicitySimple processMaterial nanotechnologyElectrolytic capacitorsWater useCapacitance

The present invention discloses a carbon-porous media composite electrode material, a composite electrode using the same and a preparation method thereof. The carbon-porous media composite electrode can be applied for a device such as a secondary battery, a capacitor or the like, or for preparing ultra pure water using a capacitive deionization process, purifying salty water or the like.

Owner:KOREA INST OF SCI & TECH

High-capacity metal lithium powder composite cathode and preparation method thereof, and multi-layer composite electrode

InactiveCN102201565AHigher quality than capacityQuality improvementNon-aqueous electrolyte accumulator electrodesAdhesiveTin

The invention discloses a high-capacity metal lithium powder composite cathode and a preparation method thereof and a multi-layer composite electrode. The high-capacity metal lithium powder composite cathode comprises the following components in part by weight: 1 to 80 parts of metal lithium powder, 10 to 90 parts of cathode powder, 1 to 10 parts of conductive agent, 1 to 4.5 parts of adhesive and 0 to 0.5 part of surfactant. By compounding the metal lithium powder with materials such as graphite, soft carbon, hard carbon, tin and oxides thereof, silicon and oxides thereof and the like, mass ratio capacity and volume ratio capacity of a cathode material are improved, using amount of active substances is reduced, and the battery specific capacity is improved; the specific capacity of the cathode can be adjusted by adjusting the rate of metal lithium to the graphite; short circuit in a battery caused by piercing of a diaphragm through metal dendritic crystal growth can be effectively prevented through the separation of an insulating protective layer, so that the safety performance of the battery is improved; and the metal lithium powder is counteracted with irreversible capacity loss of the cathode, and primary Kulun efficiencies of the graphite, the hard carbon, the soft carbon, the tin, the silicon and other cathode materials are improved.

Owner:EC POWER LLC

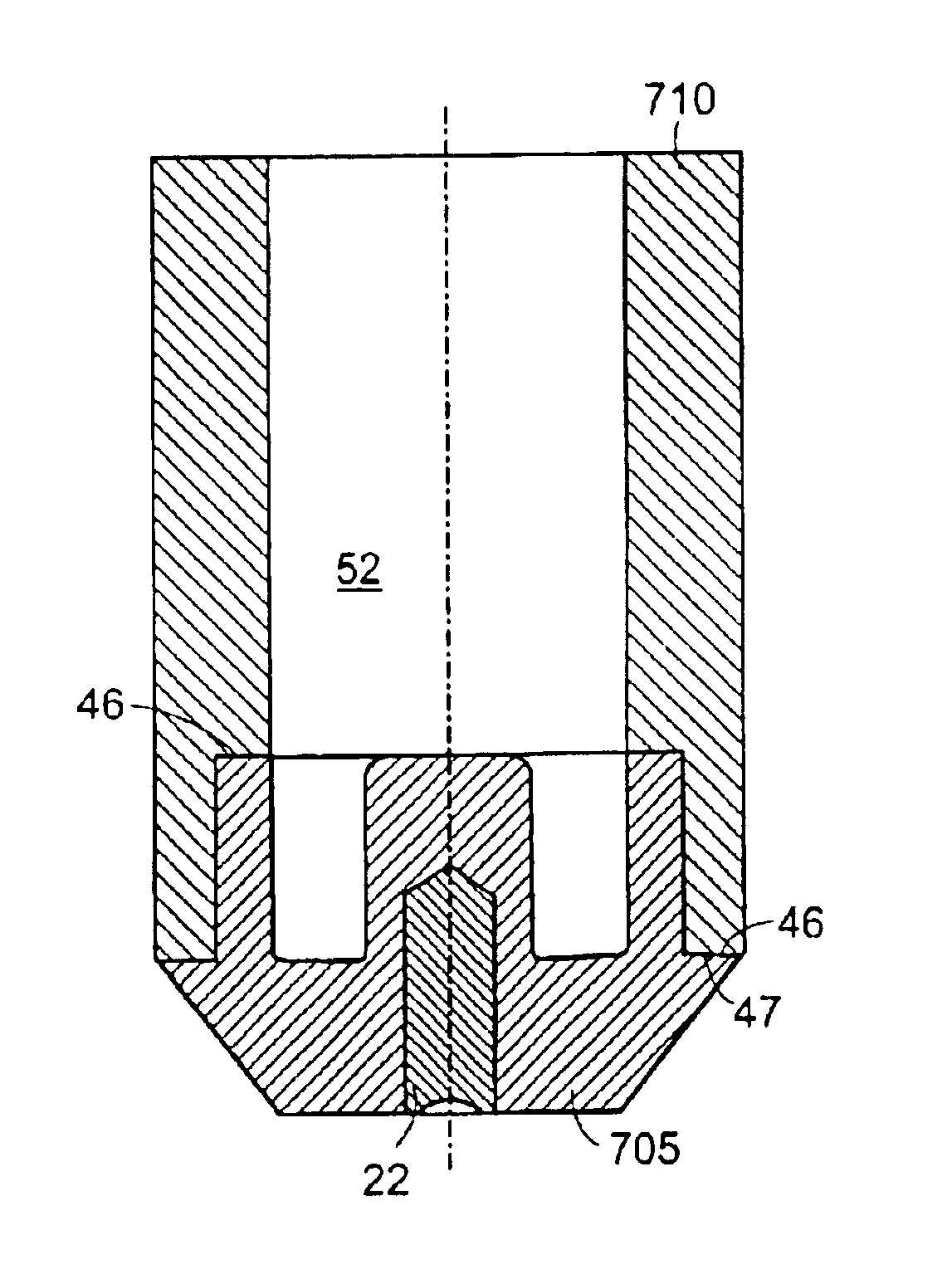

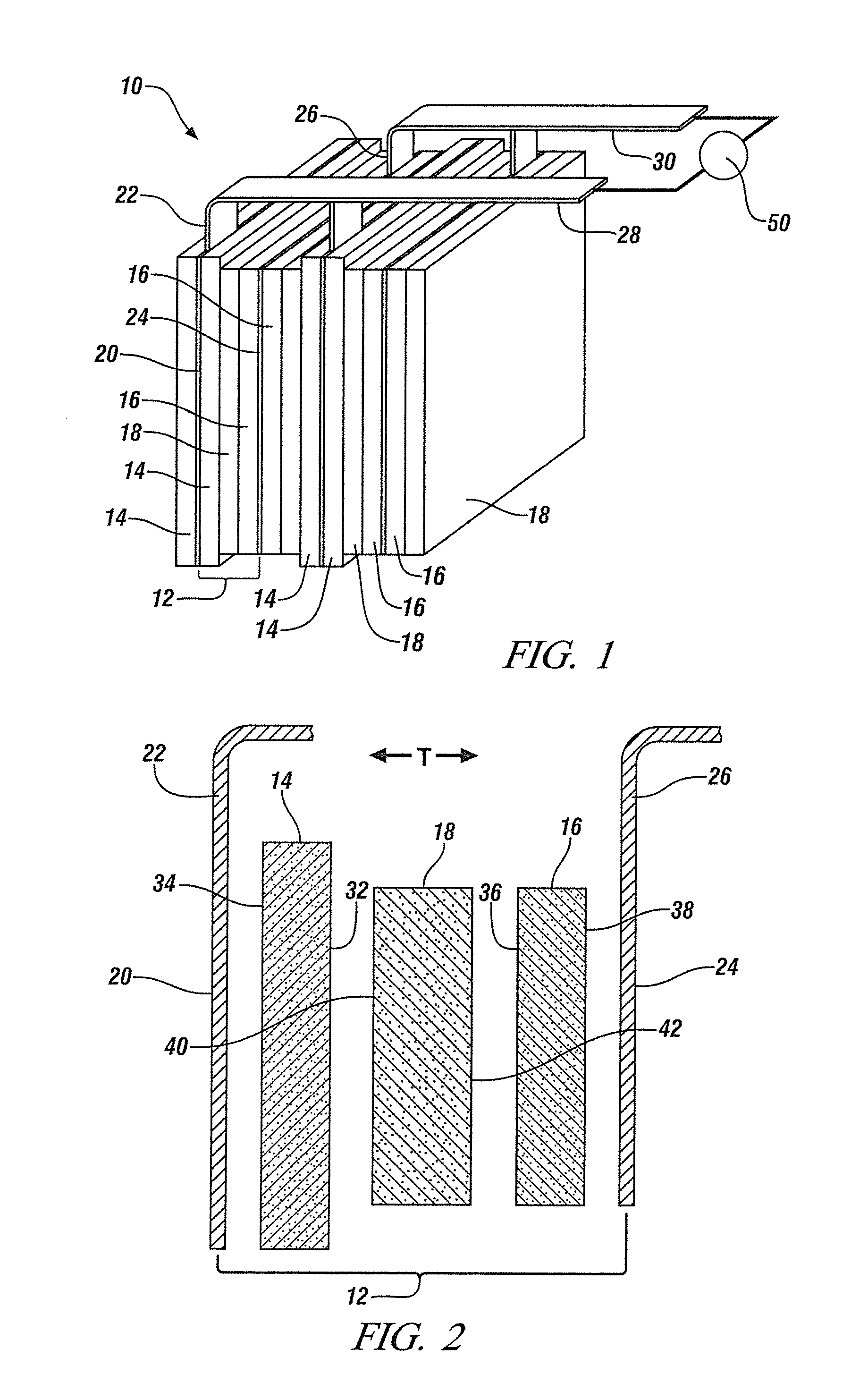

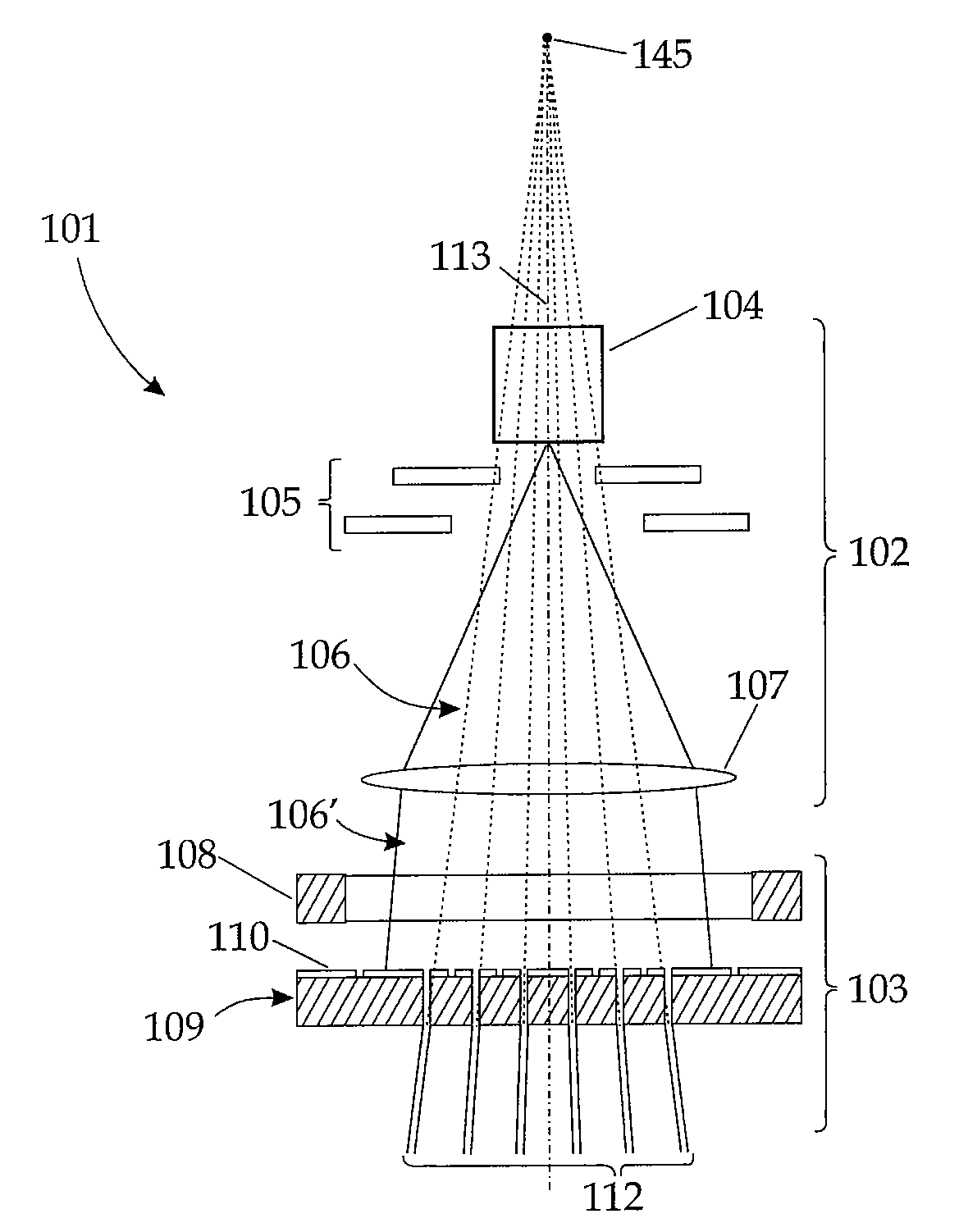

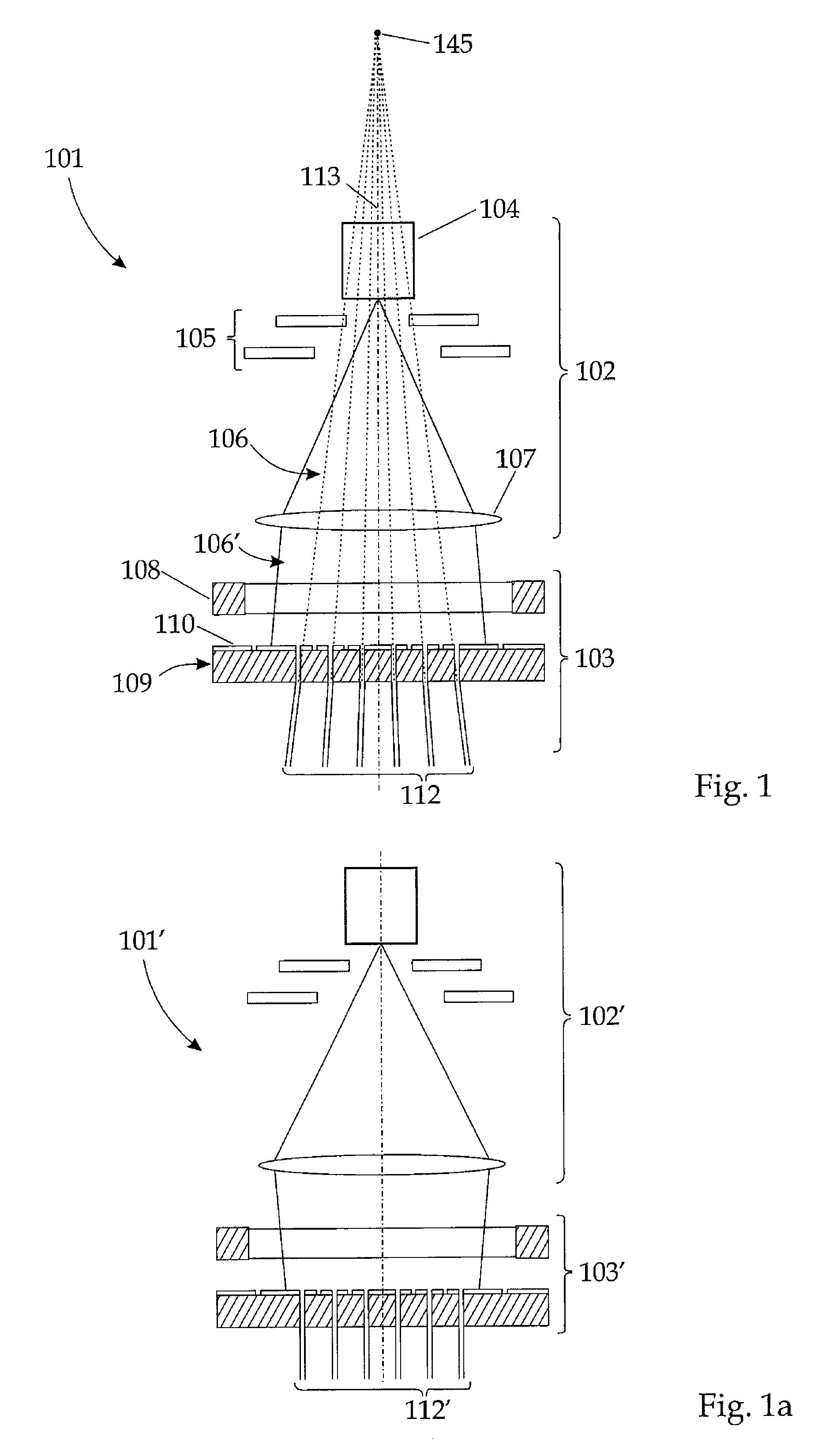

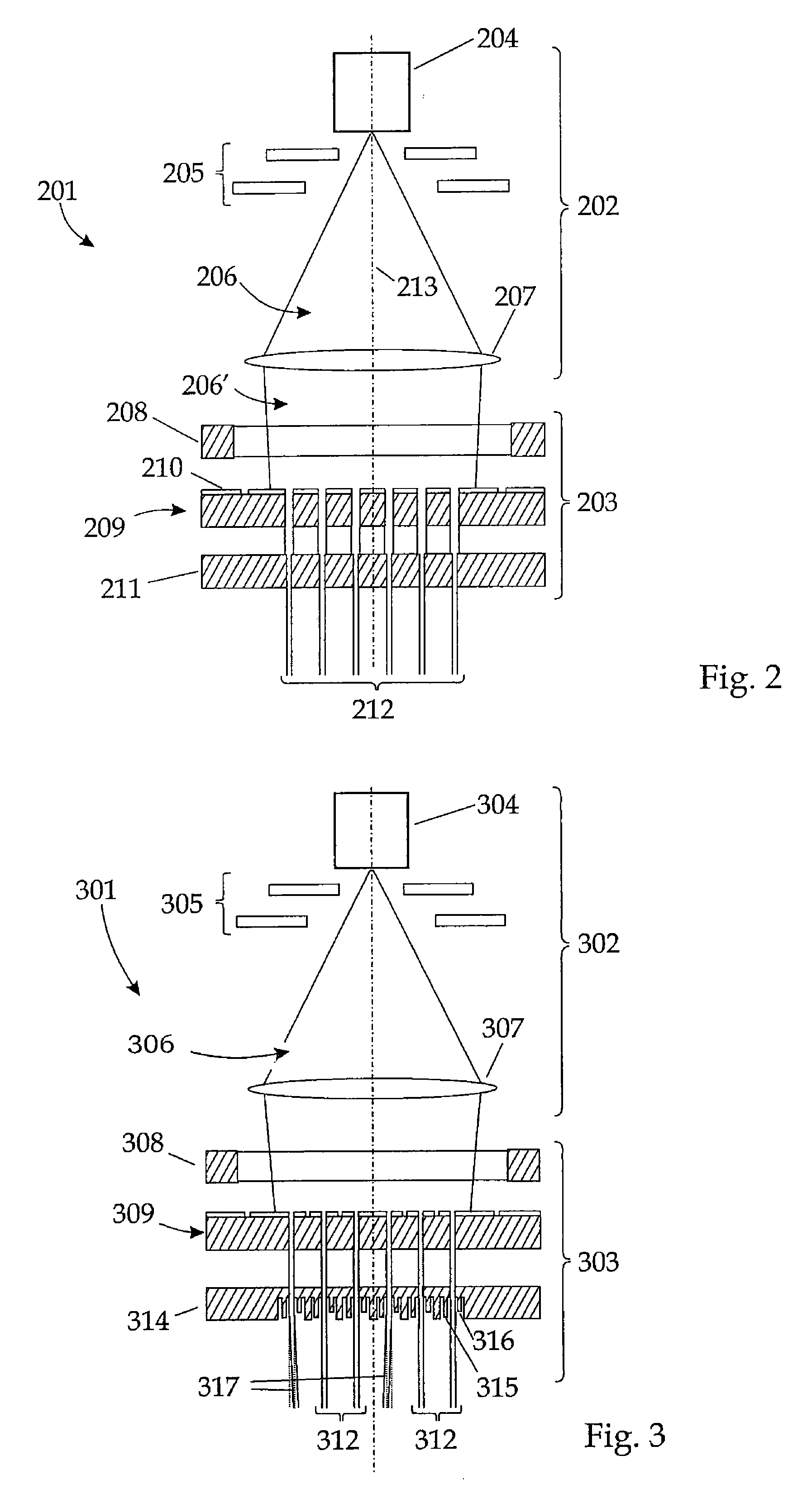

Multi-beam source

ActiveUS8183543B2Reduce various aberration effectReduce the spread angleThermometer detailsStability-of-path spectrometersBeam splitterBeam source

A multi-beam source for generating a plurality of beamlets of energetic electrically charged particles. The multi-beam source includes an illumination system generating an illuminating beam of charged particles and a beam-forming system being arranged after the illumination system as seen in the direction of the beam, adapted to form a plurality of telecentric or homocentric beamlets out of the illuminating beam. The beam forming system includes a beam-splitter and an electrical zone device, the electrical zone having a composite electrode composed of a plurality of substantially planar partial electrodes, adapted to be applied different electrostatic potentials and thus influencing the beamlets.

Owner:IMS NANOFABTION

Composite electrode and method for manufacturing the same

InactiveUS20100273051A1Large specific surface areaImprove high temperature stabilityElectrochemical processing of electrodesElectrolytic capacitorsComposite electrodeConductive polymer

A composite electrode and a method for manufacturing the same are disclosed. By using a composite electrode that includes a porous support made of ceramic or metal and a conductive polymer or a metal oxide formed on a surface of the porous support, a capacitor or secondary cell that provides increased charge / discharge capacity and increased energy / output density, as well as high-temperature stability and high reliability, can be manufactured.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

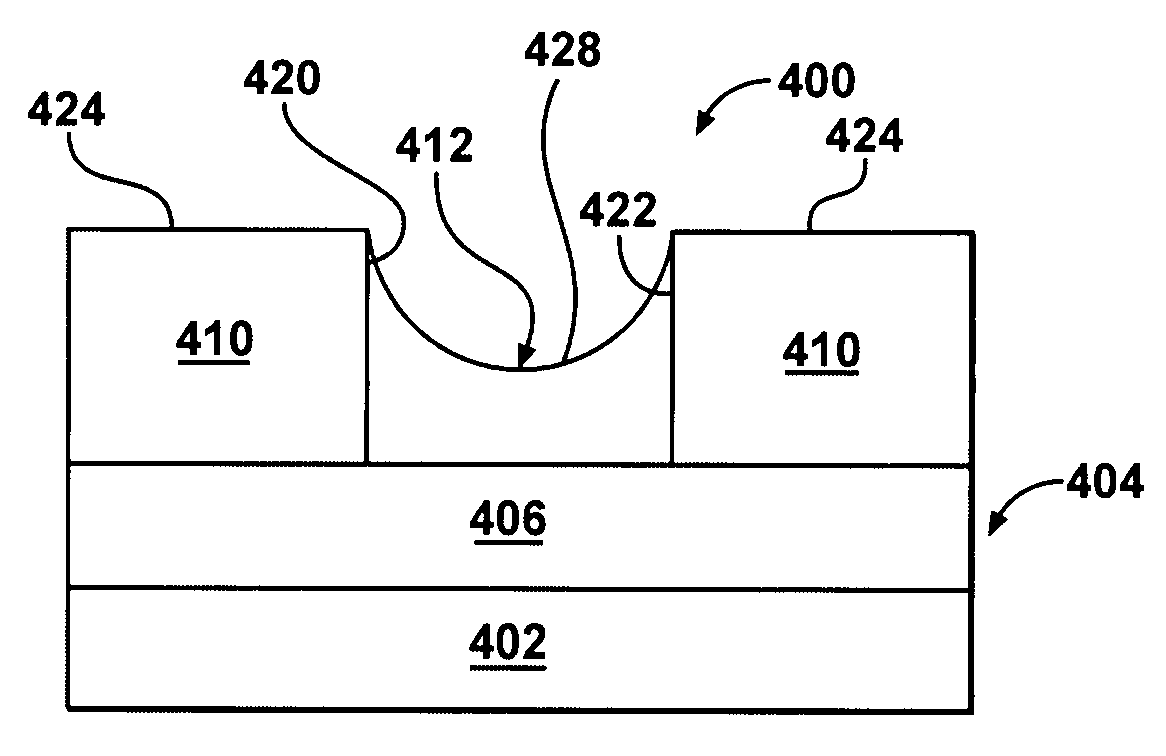

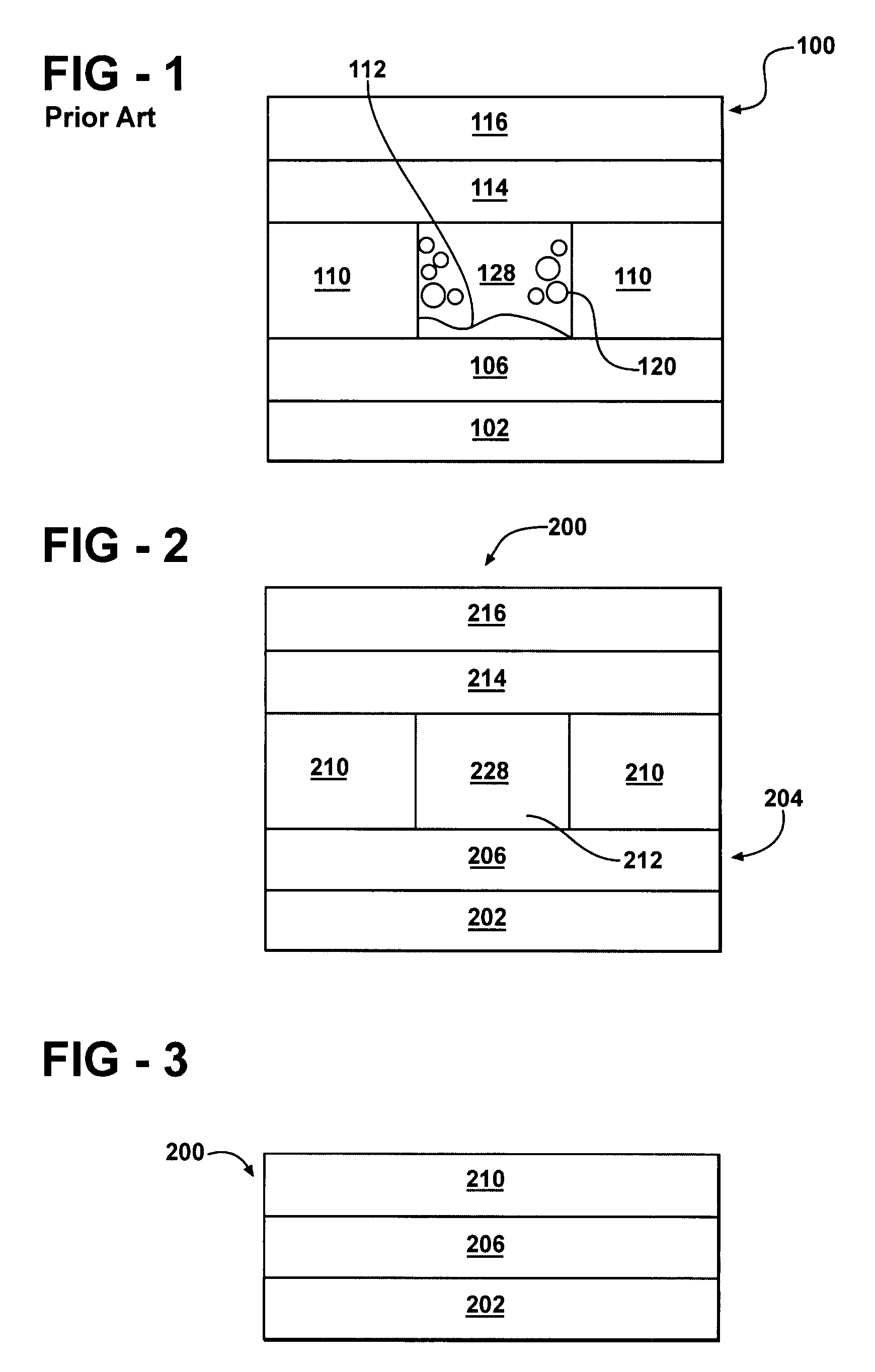

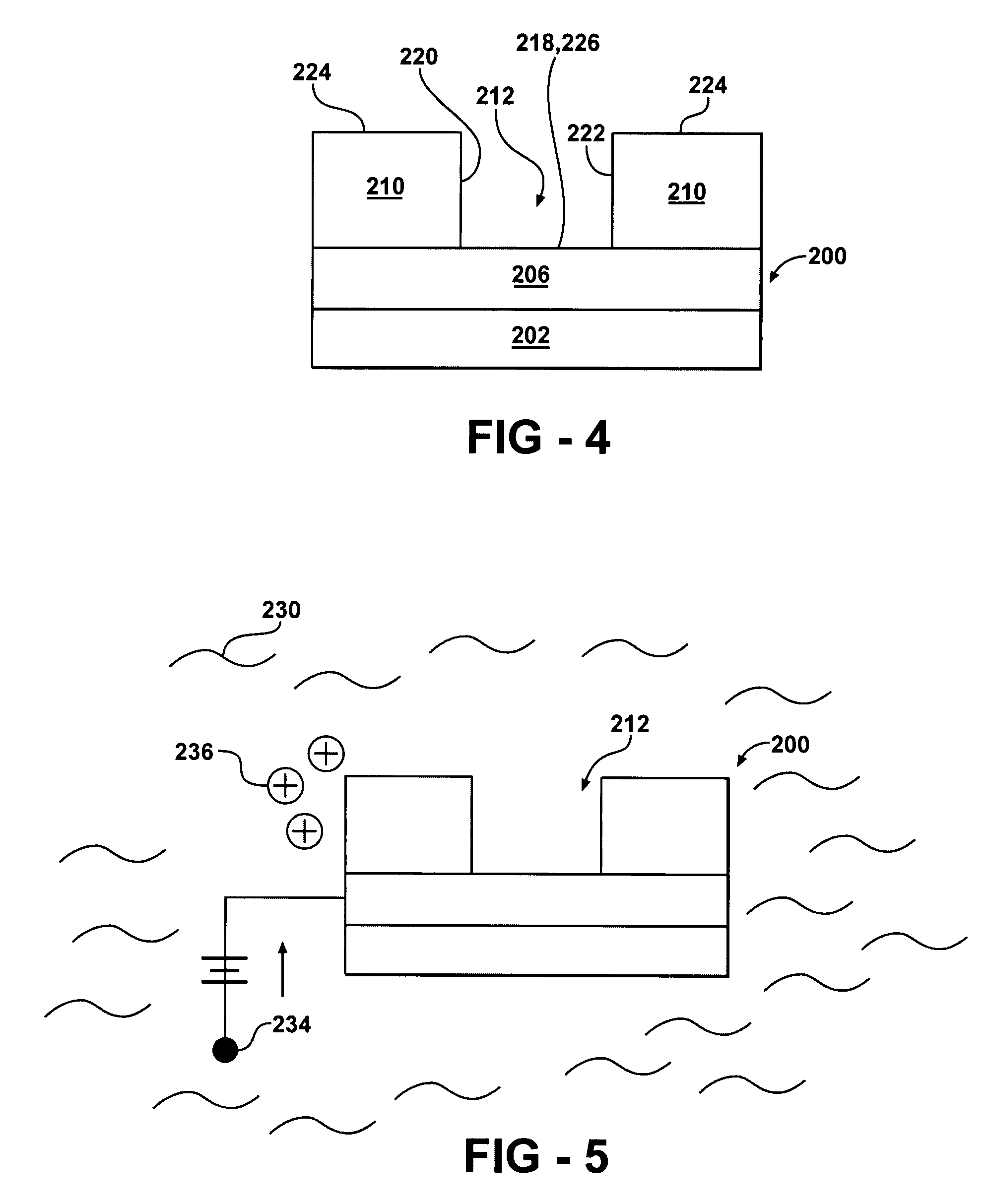

Method for fabricating composite electrodes

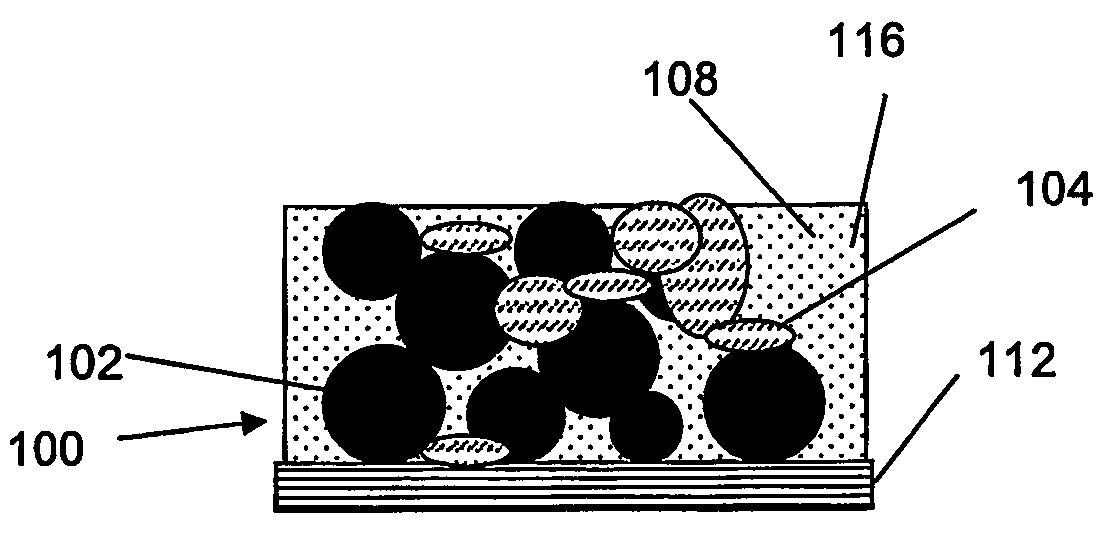

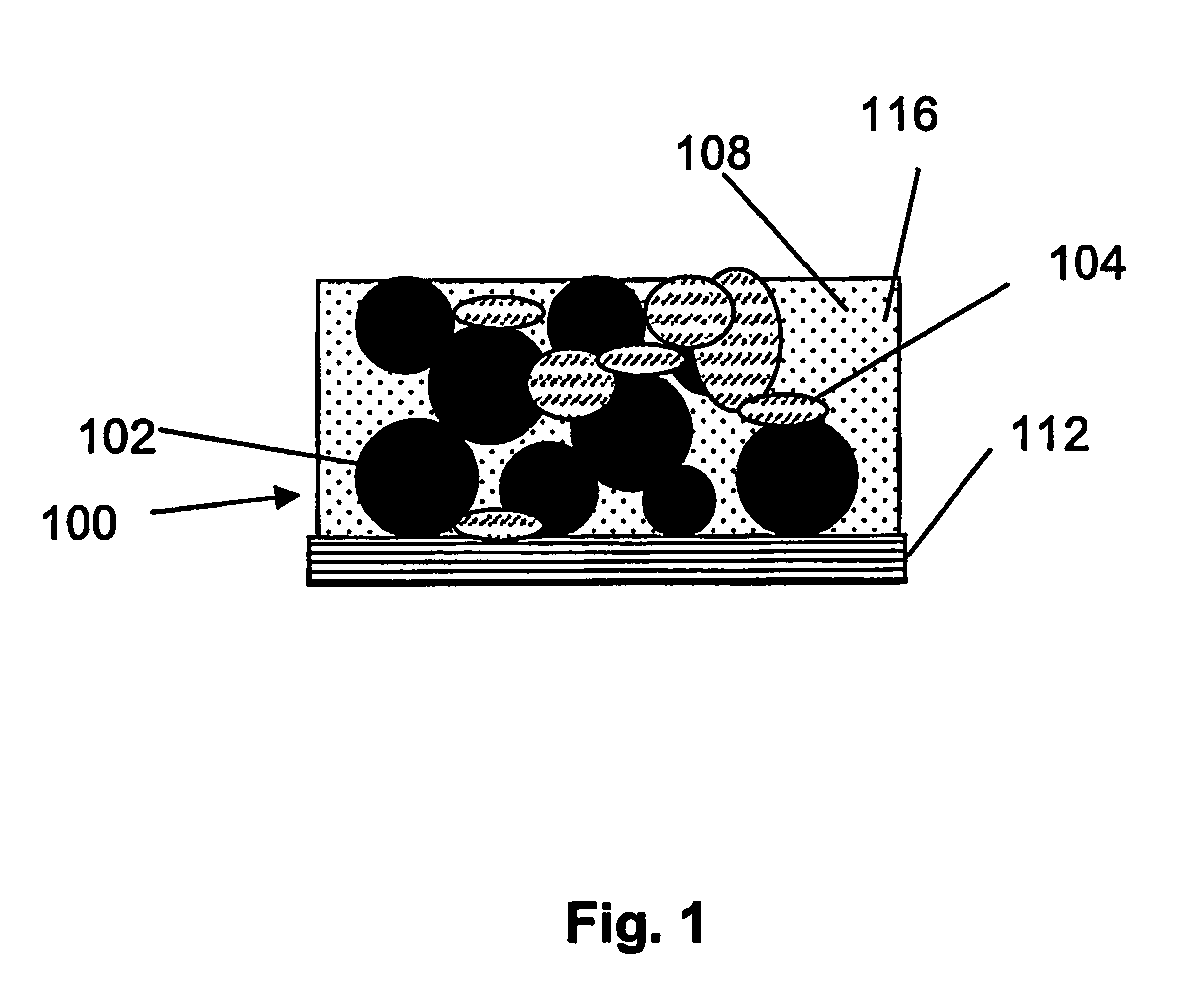

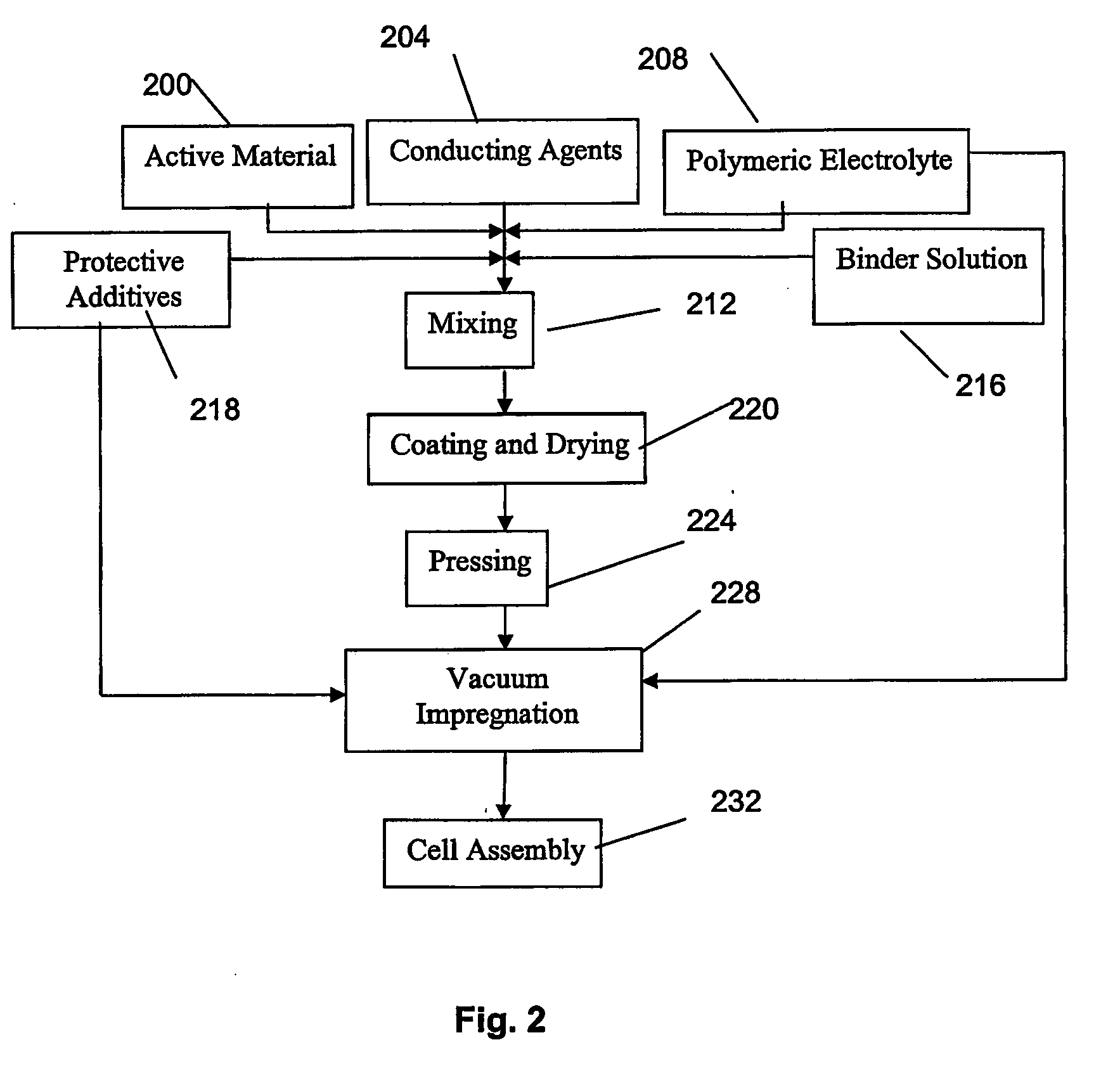

InactiveUS20050019656A1Effectively penetrate bulk of electrodeOvercome problemsFinal product manufacturePrimary cellsPolymer electrolytesComposite electrode

Disclosed is a method for manufacturing electrodes (100) for electrochemical devices such as batteries and capacitors in which a viscous polysiloxane polymer electrolyte (116) is incorporated into the slurry of materials forming the electrode (100). The optional addition of protective additives (218) to the slurry is also disclosed. A follow-on vacuum impregnation step (228) is disclosed to further improve penetration and wetting by the electrolyte (116).

Owner:QUALLIION LLC

Nanoporous Insulating oxide Deionization Device Having Electrolyte Membrane, and Method of Manufacture and Use Thereof

ActiveUS20080121531A1Avoid shortingCellsPolycrystalline material growthZeta potentialAlkaline earth metal

A nanoporous insulating oxide deionization device, method of manufacture and method of use thereof for deionizing a water supply (such as a hard water supply), for desalinating a salt water supply, and for treating a bacteria-containing water supply. The device contains two composite electrodes each constructed from a conductive backing electrode and a composite oxide layer being an insulating oxide or a non-insulating oxide and an intermediate porous layer. The composite layer being substantially free of mixed oxidation states and nanoporous and having a median pore diameter of 0.5-500 nanometers and average surface area of 300-600 m2 / g. The composite layer made from a stable sol-gel suspension containing particles of the insulating oxide, the median primary particle diameter being 1-50 nanometers. The difference in zeta potential, at a pH in the range of 6-9, being sufficient to suitably remove alkaline and alkaline earth cations (such as Ca2+ and Na1+), various organic and other inorganic cations and organic and inorganic anions from water, preferably household hard water. One composite layer being constructed from a mixture of Al2O3, MgAl2O4 and / or Mg-doped. Al2O3 particles, and the other composite layer being constructed from SiO2 or TiO2.

Owner:WISCONSIN ALUMNI RES FOUND

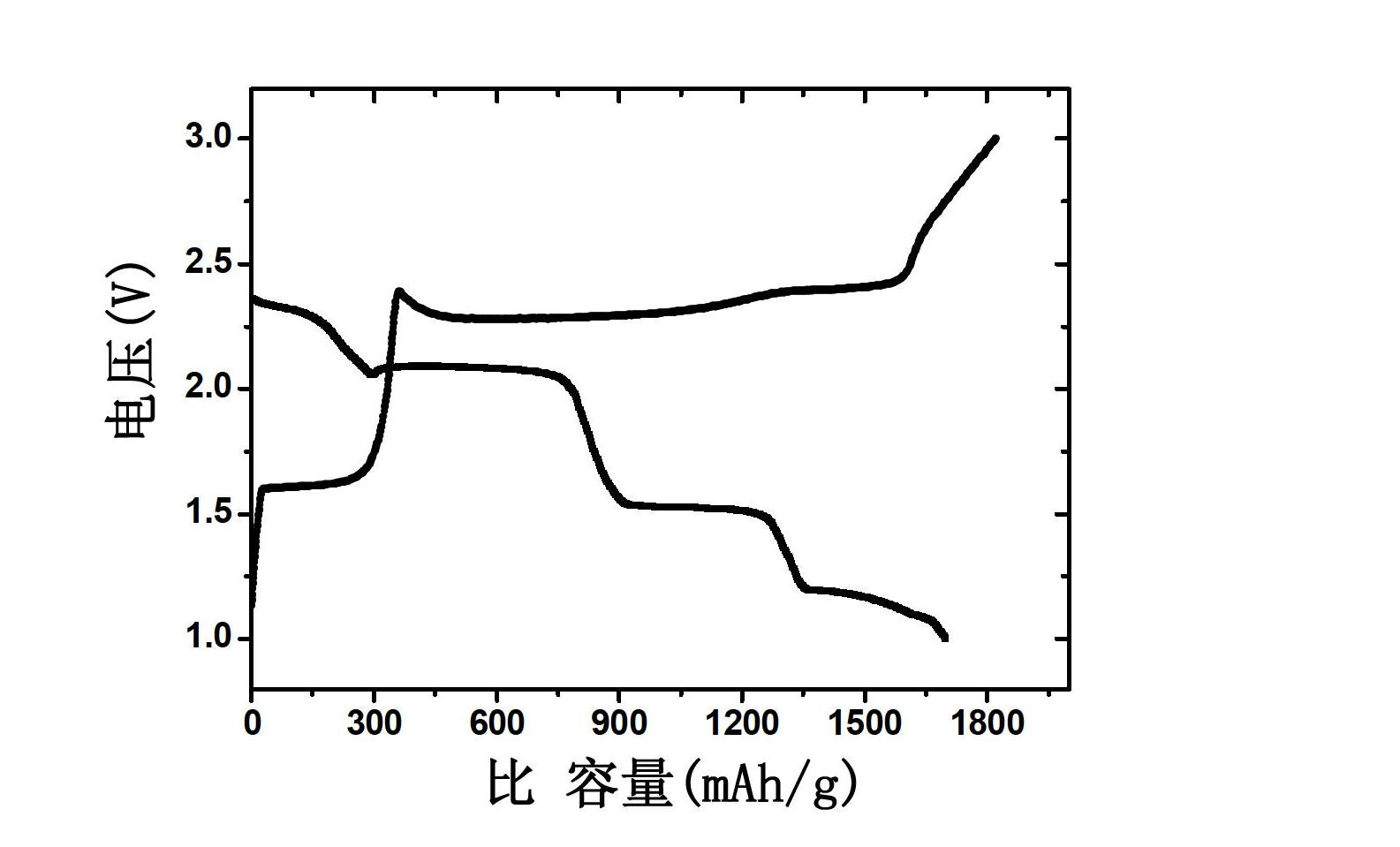

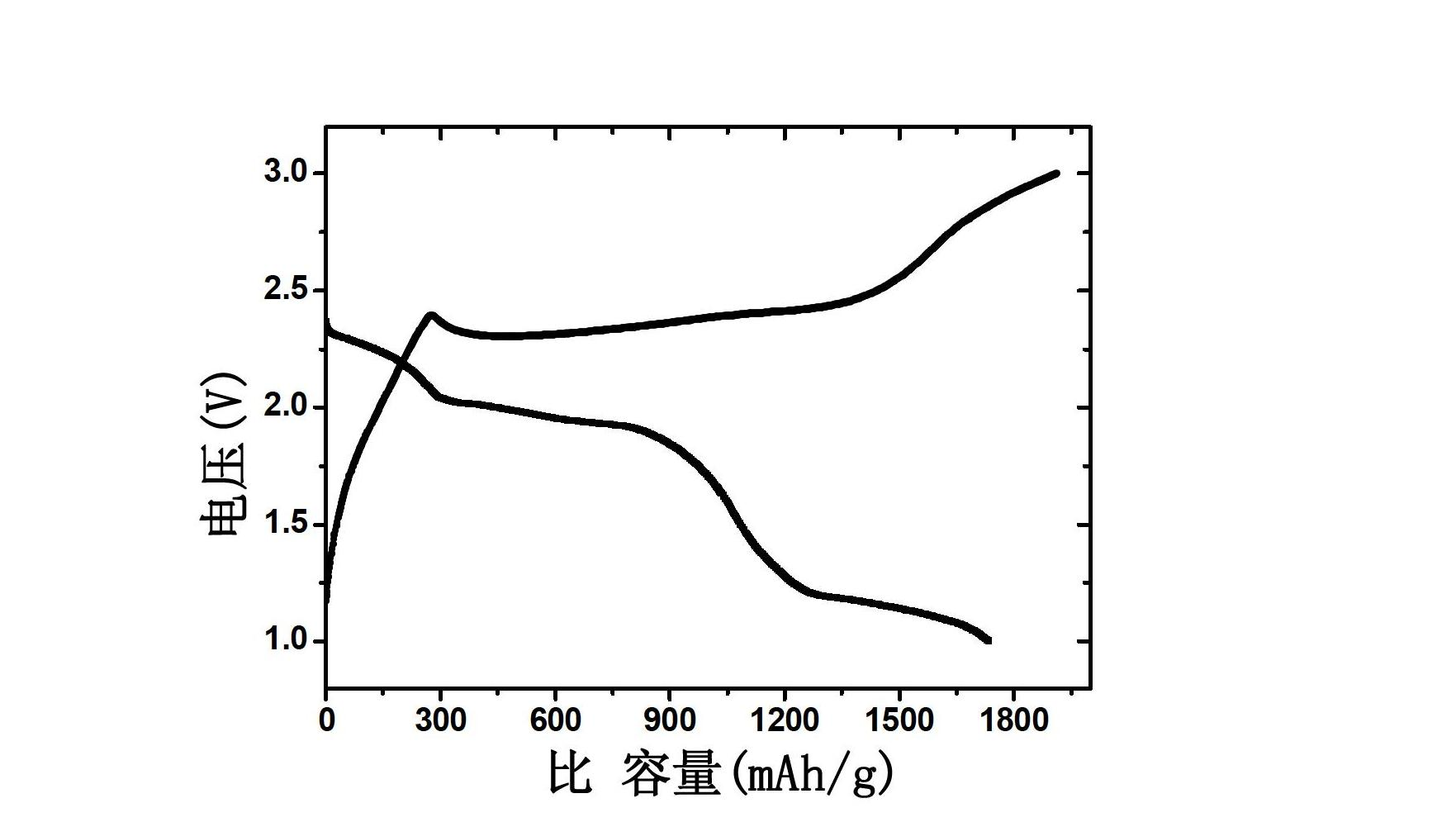

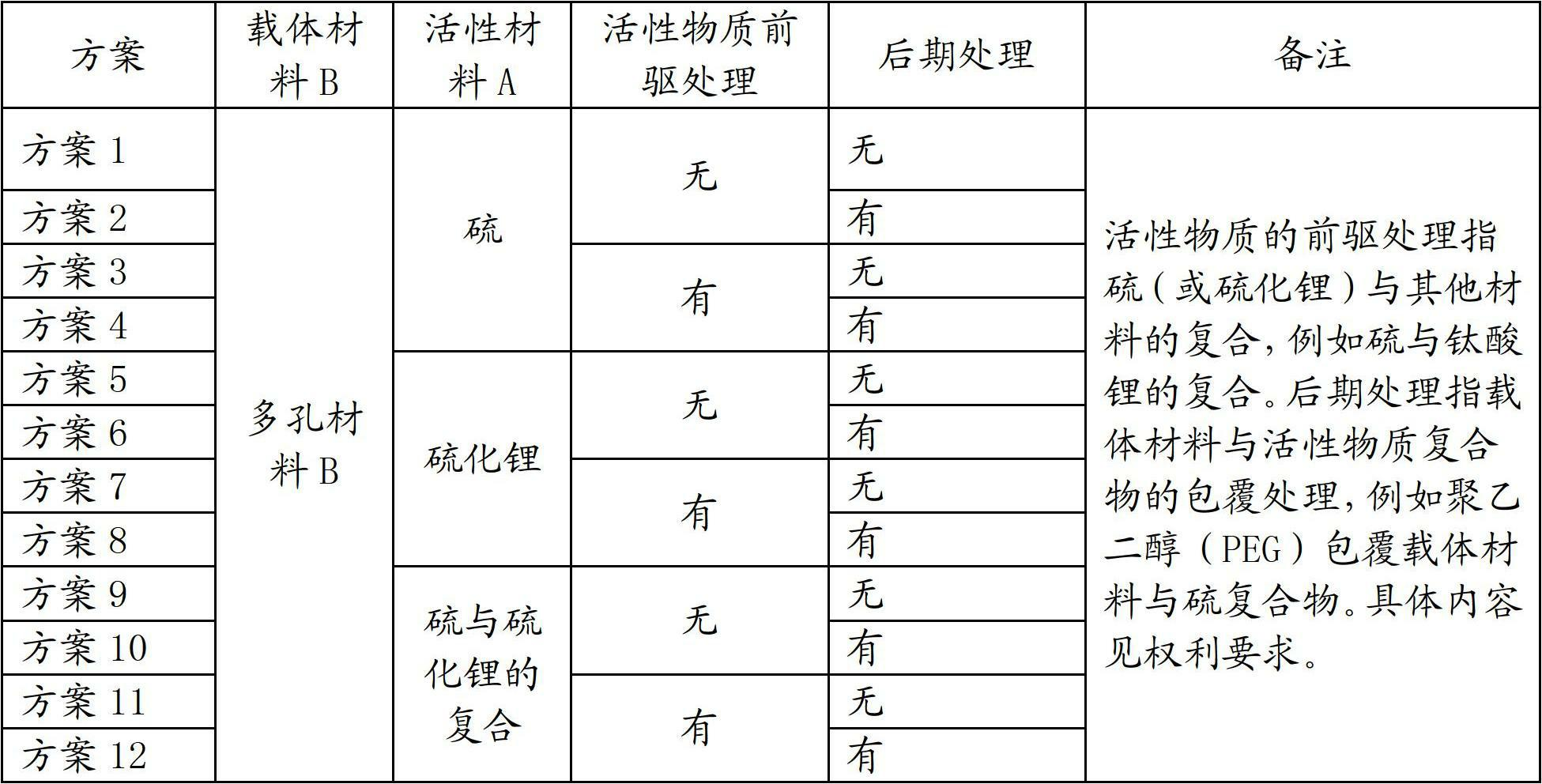

Lithium-sulphur battery anode material and preparation method thereof

InactiveCN102683659AImprove cycle performanceIncrease contentCell electrodesPorosityComposite electrode

The invention discloses a lithium-sulphur battery anode material, which adopts the technical scheme that elemental sulphur or lithium sulfide is loaded into one or various carrier materials to form a novel composite electrode for a lithium-sulphur battery. The carrier material (s) is (are) characterized in that within the operation voltage range of the elemental sulphur or the lithium sulfide, the carrier material (s) is (are) also provided with electrochemical activity, that is, is (are) provided with considerable lithium storage capacity, and simultaneously has (have) characteristics of high specific surface and high porosity. The invention also discloses a preparation method of the lithium-sulphur battery anode material. The system of the electrode solves problems that the carrier material of a conventional lithium-sulphur battery anode material is not provided with the electrochemical activity and is low in composite material specific capacity within the operation voltage range of the elemental sulphur or the lithium sulfide, and the integral specific capacity of the composite electrode and the energy density of the lithium-sulphur battery are improved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

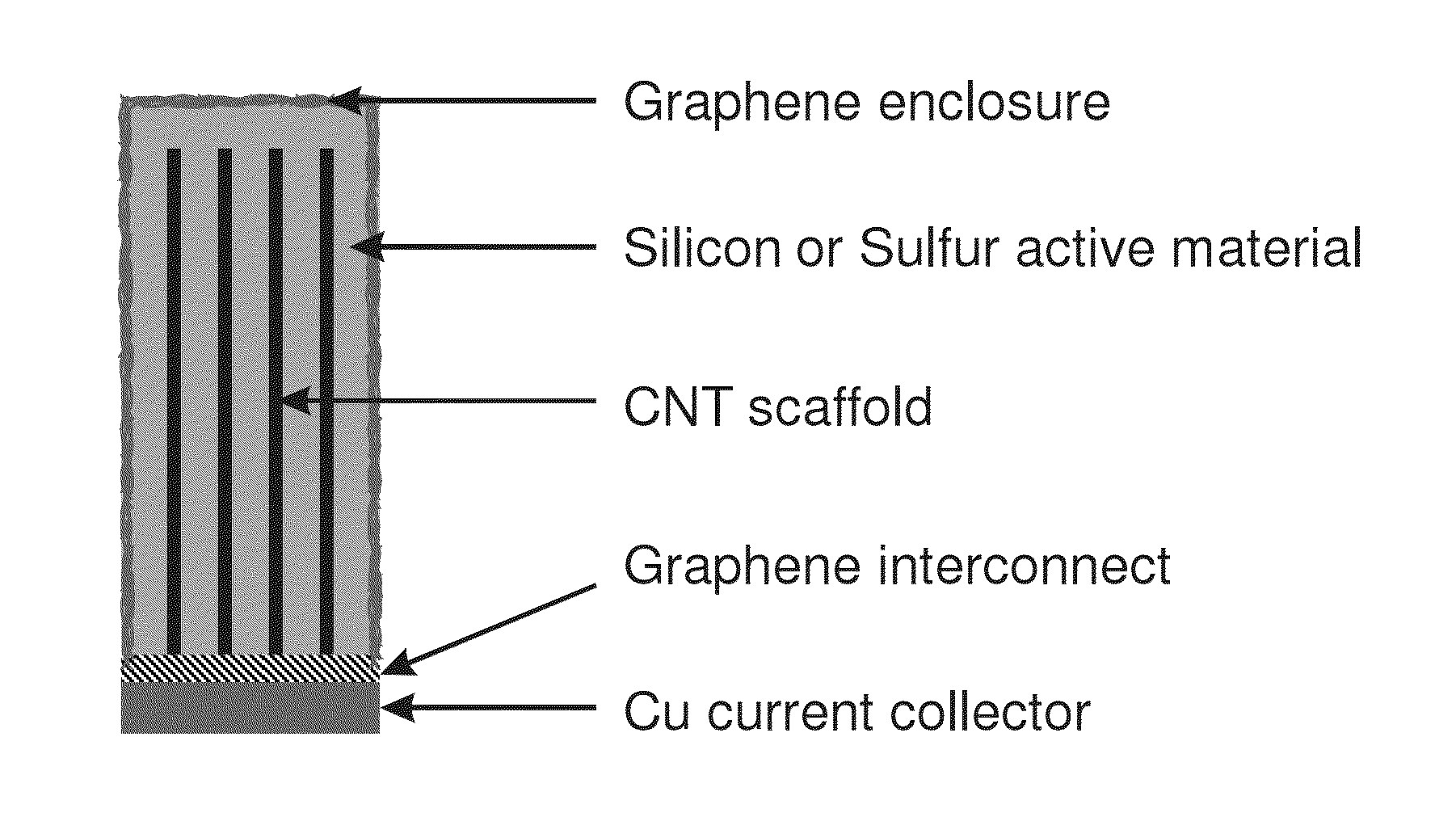

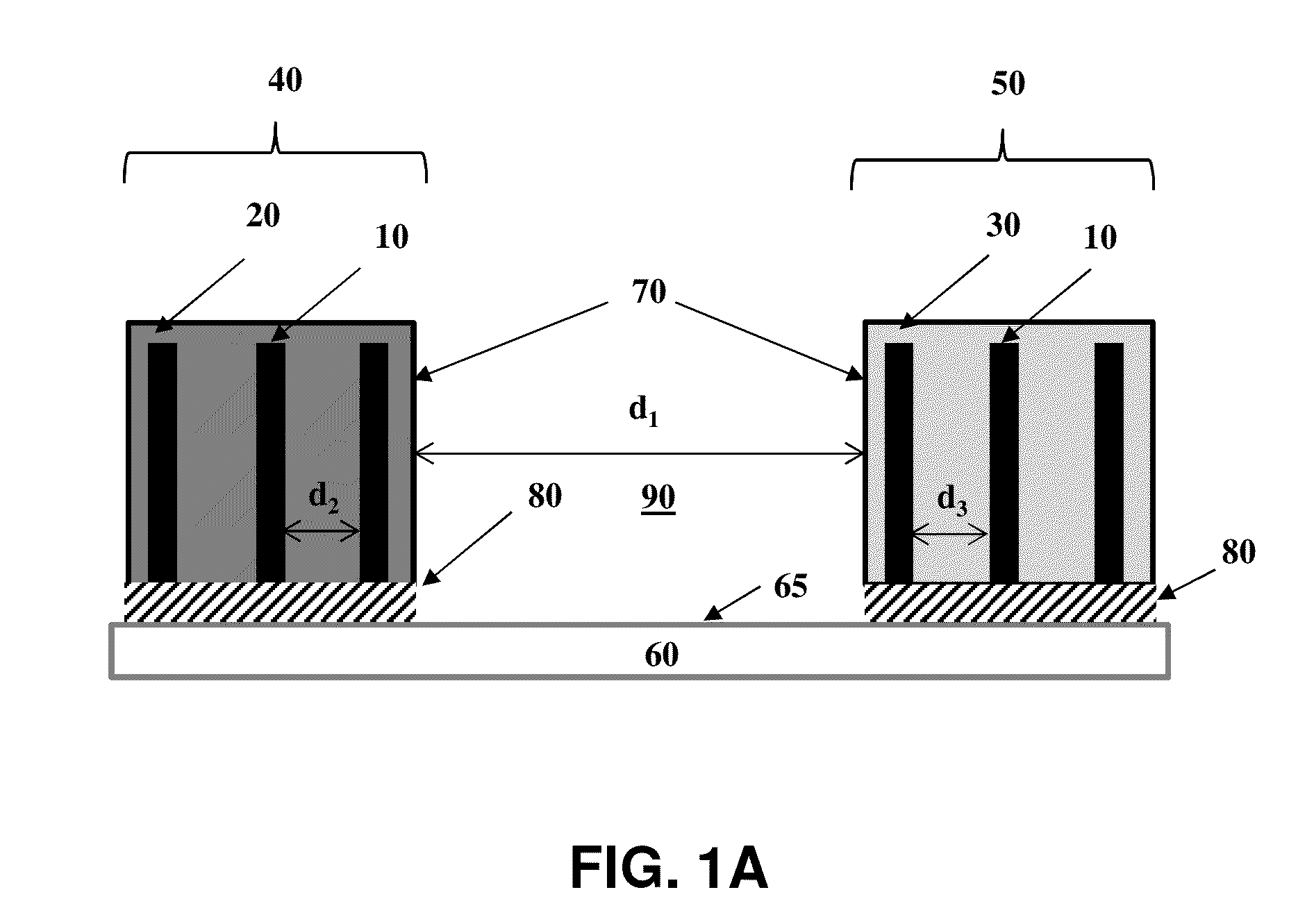

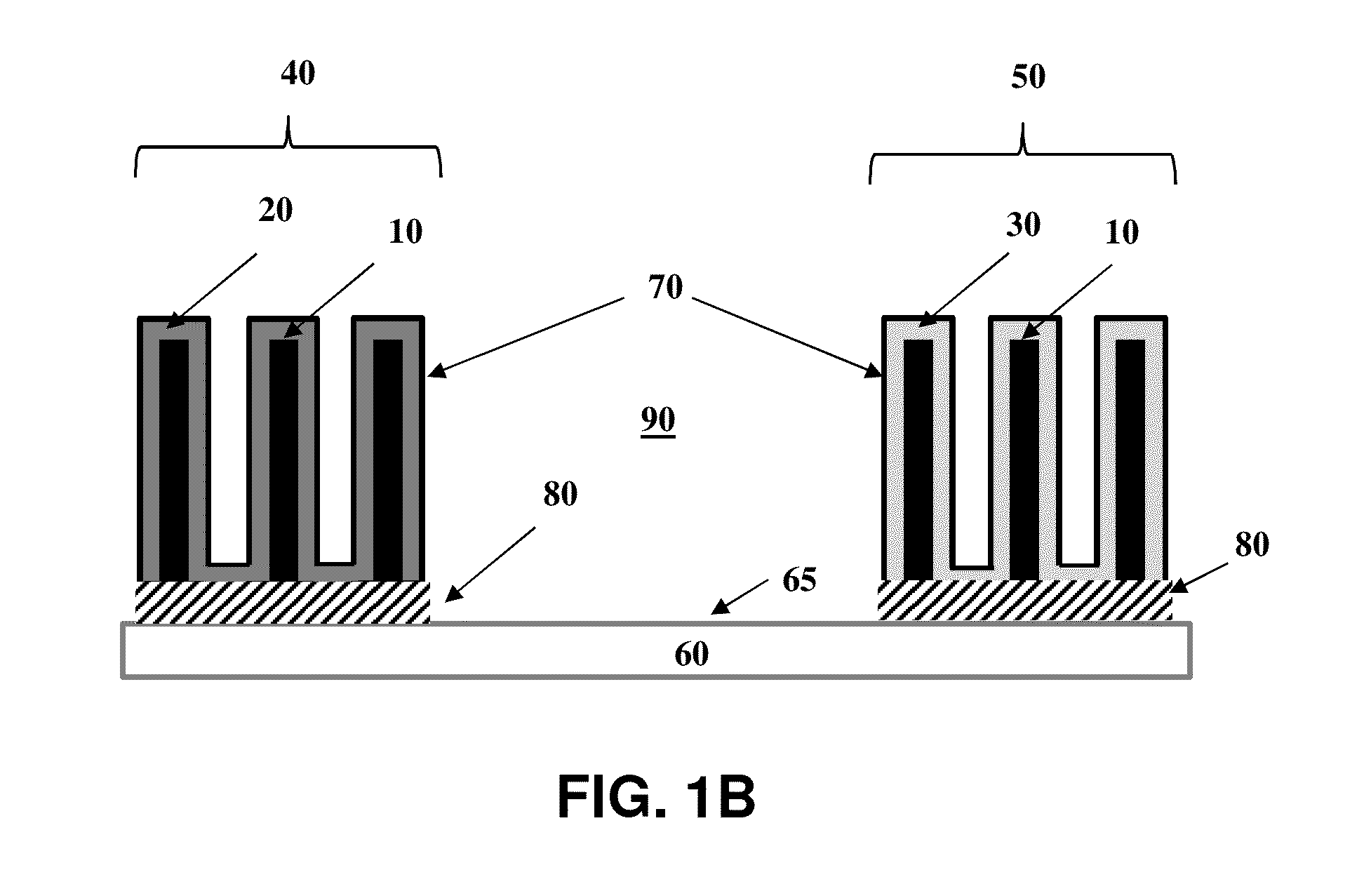

Carbon Nanotubes - Graphene Hybrid Structures for Separator Free Silicon - Sulfur Batteries

ActiveUS20150010788A1Improve power performanceImprove cycle lifeMaterial nanotechnologyFinal product manufactureMetallic lithiumDischarge rate

Provided herein are electrochemical systems and related methods of making and using electrochemical systems. Electrochemical systems of the invention implement novel cell geometries and composite carbon nanomaterials based design strategies useful for achieving enhanced electrical power source performance, particularly high specific energies, useful discharge rate capabilities and good cycle life. Electrochemical systems of the invention are versatile and include secondary lithium ion cells, such as silicon-sulfur lithium ion batteries, useful for a range of important applications including use in portable electronic devices. Electrochemical cells of the present invention also exhibit enhanced safety and stability relative to conventional state of the art lithium ion secondary batteries by using prelithiated active materials to eliminate the use of metallic lithium and incorporating carbon nanotube and / or graphene, composite electrode structures to manage residual stress and mechanical strain arising from expansion and contraction of active materials during charge and discharge.

Owner:CALIFORNIA INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com