High-capacity metal lithium powder composite cathode and preparation method thereof, and multi-layer composite electrode

A metal lithium powder, multi-layer composite technology, applied in the field of electrochemical power supply, can solve the problems of low volume specific capacity, loss of powdered advantages, high contact resistance, etc., to improve specific capacity, inhibit growth, and prevent internal short circuits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Preparation of high-capacity metal lithium powder composite negative electrode: under the protection of argon atmosphere, 30 grams of toluene as a solvent and 4.5 grams of polyvinylidene fluoride (PVDF) as a binder were mixed to make a glue solution, and 20 grams of lithium metal powder , 40 grams of graphite as the negative electrode powder, 0.5 grams of surfactant (polyvinylpyrrolidone (PVP)), 5 grams of acetylene black as the conductive agent are added to the glue, stirred evenly and then sprayed onto the surface of the current collector with the conductive glue layer , (that is, sprayed onto the surface of the conductive adhesive layer, wherein the current collector with the conductive adhesive layer can be prepared using existing technology or commercially available), dried and rolled at 120 ° C, that is, the high-capacity metal is completed on the surface of the conductive adhesive layer Preparation of lithium powder composite negative electrode, the specific capac...

Embodiment 2

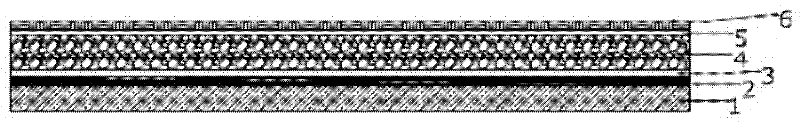

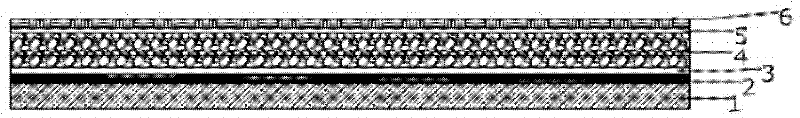

[0078] see figure 1 , a multilayer composite electrode, which is composed of a current collector 1, a conductive adhesive layer 2, a high-capacity metal lithium powder composite negative electrode 3, a hot-pressed graphite layer 4, an insulating protective layer 5 and a separator 6 distributed in sequence. Its preparation method is as follows:

[0079] Preparation of a current collector with a conductive adhesive layer: take a copper foil with a thickness of 10 μm as a current collector, mix 30 grams of sodium polyacrylate (PAA), 8 grams of water and 2 grams of Ca(OH) 2 Mix evenly to make 40 grams of glue A, mix 5 grams of acetylene black (SP) and 55 grams of water evenly to make 60 grams of conductive paste, take 40 grams of prepared glue A and add it to 60 grams of conductive paste and mix evenly Get conductive glue.

[0080] The conductive adhesive was coated on the surface of the copper foil current collector by the gravure printing method, and dried at 120°C to obtain a...

Embodiment 3

[0086] Adopt the preparation method of embodiment 1 to prepare multi-layer composite electrode, the difference is that the preparation of high-capacity metal lithium powder composite negative electrode adopts the following steps:

[0087] Under the protection of an argon atmosphere, mix and stir 95 grams of toluene and 4.5 grams of vinyl acetate to obtain a glue; add 15 grams of lithium metal powder, 75 grams of tin powder, and 5 grams of carbon nanotubes into the glue, stir well and then spray To the surface of the conductive adhesive layer, drying and rolling at 160°C, that is, the preparation of a high-capacity metal lithium powder composite negative electrode is completed on the surface of the conductive adhesive layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com