Patents

Literature

39results about How to "Shortened diffusion channel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

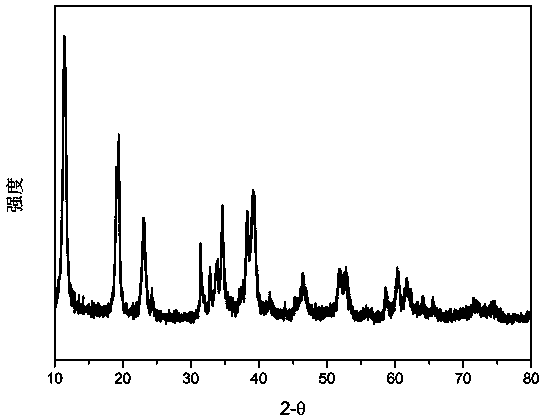

Core-shell structure nickel-cobalt-manganese ternary positive electrode material precursor and preparation method thereof

ActiveCN108878818AGuaranteed charge and discharge capacityGuaranteed rate performanceSecondary cellsPositive electrodesLithiumManganese

The invention discloses a core-shell structure nickel-cobalt-manganese ternary positive electrode material precursor and a preparation method thereof. The ternary positive electrode material precursoris a core-shell structure particle with an average particle diameter of 5-12 [mu]m. The chemical formula of a core is Ni<x>Co<y>Mn<1-x-y>(OH)<2>, wherein <x> is greater than or equal to 0.6 and is less than or equal to 0.9, <y> is greater than or equal to 0.1 and is less than or equal to 0.4, and <1-x-y> is greater than or equal to 0. The chemical formula of a shell is Ni<x>Co<y>Mn<1-x-y>CO<3>, wherein <x> is greater than or equal to 0.4 and is less than or equal to 0.7, <y> is greater than or equal to 0.1 and is less than or equal to 0.4, and <1-x-y> is greater than 0. A ternary positive electrode material made by lithium mixing and sintering of the core-shell structure nickel-cobalt-manganese ternary positive electrode material precursor is assembled into a battery, and excellent electrochemical performance is exhibited. The preparation method is simple in process, low in cost and suitable for industrial production.

Owner:ZHUJI PAWA NEW ENERGY

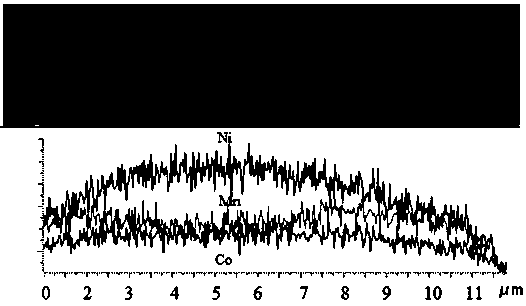

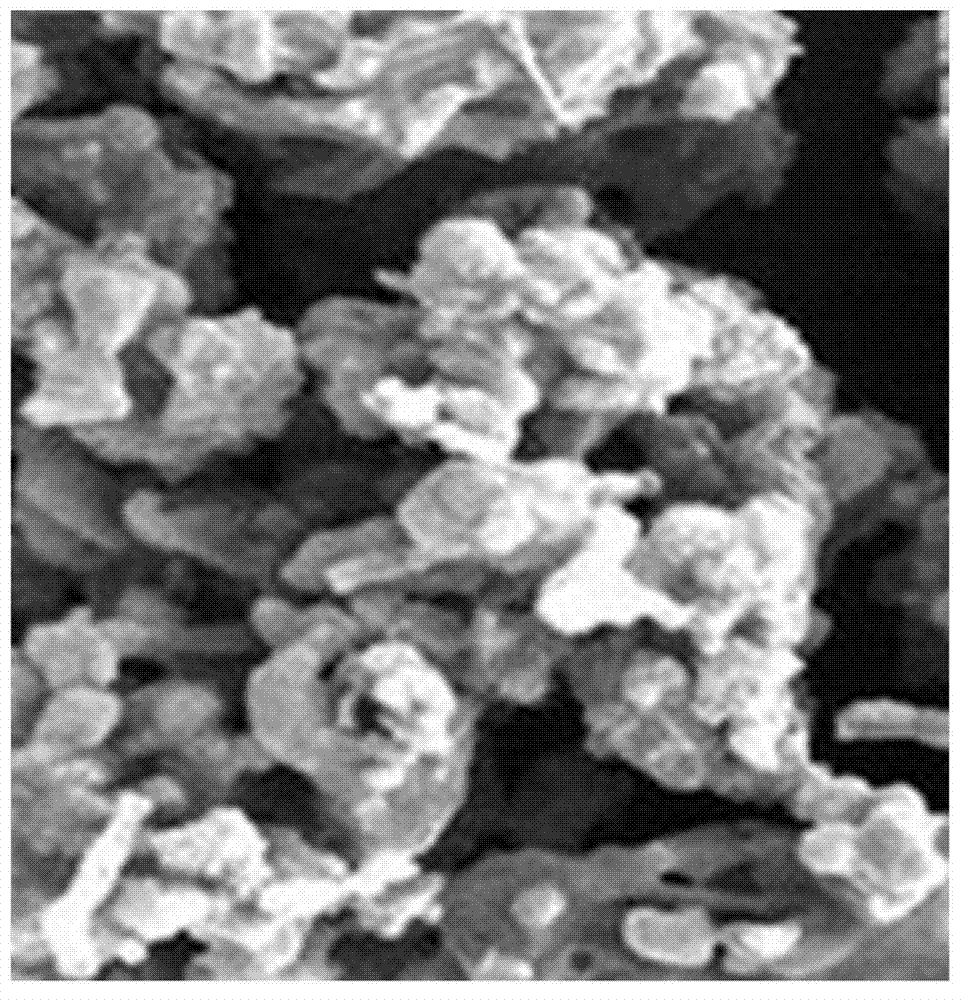

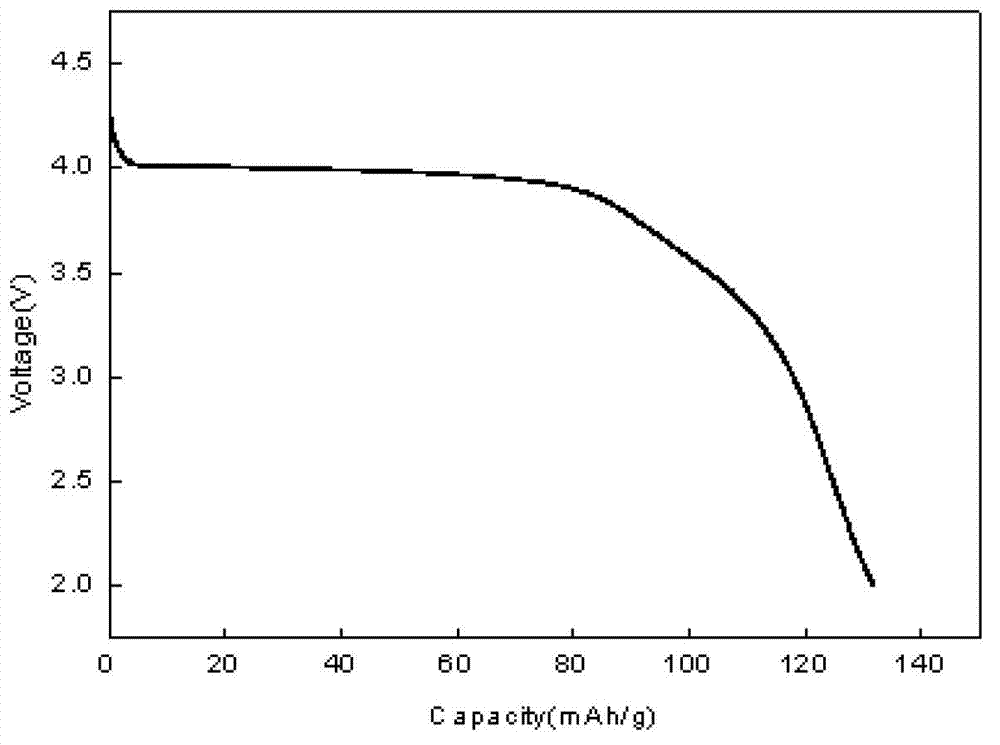

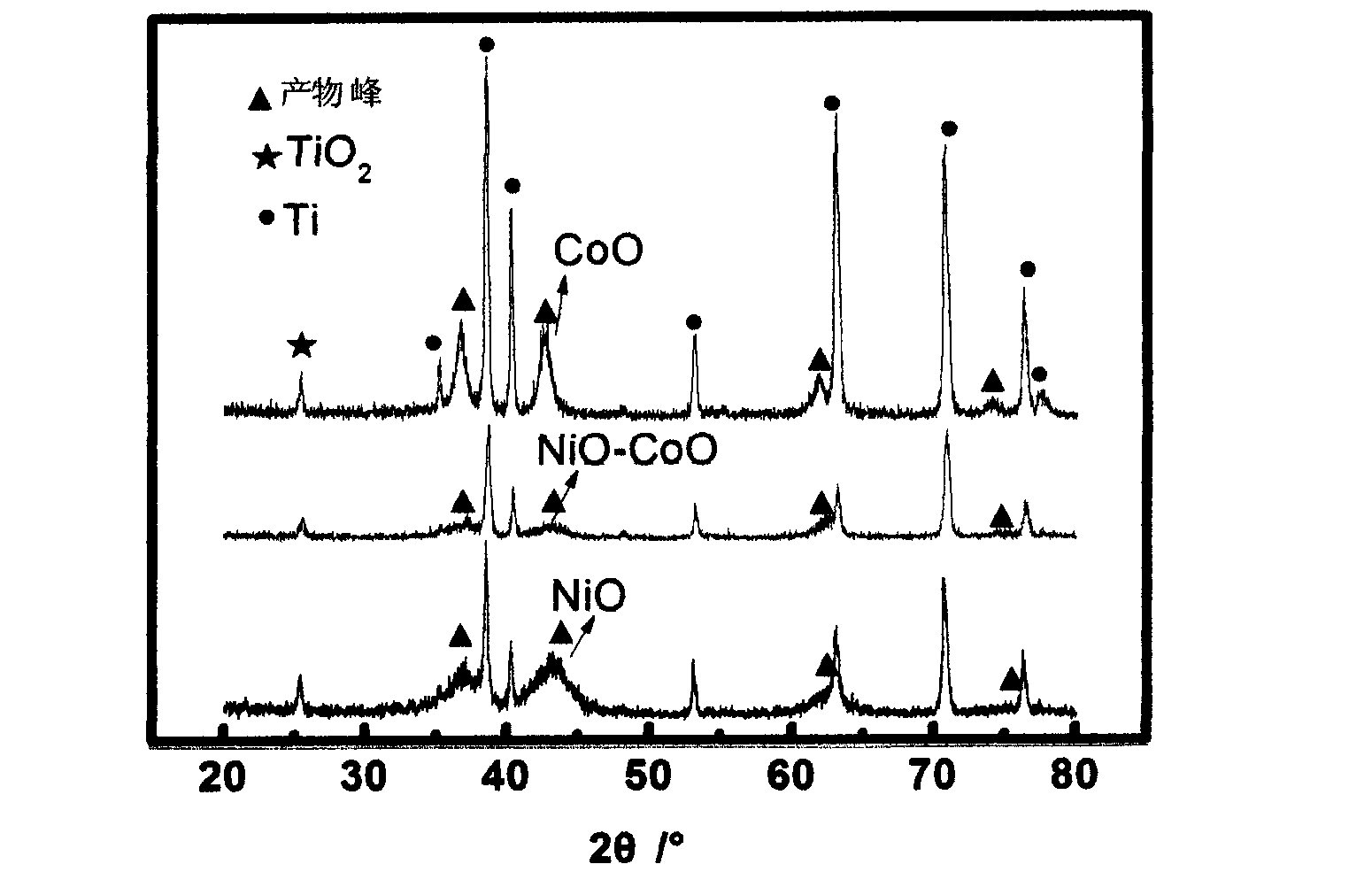

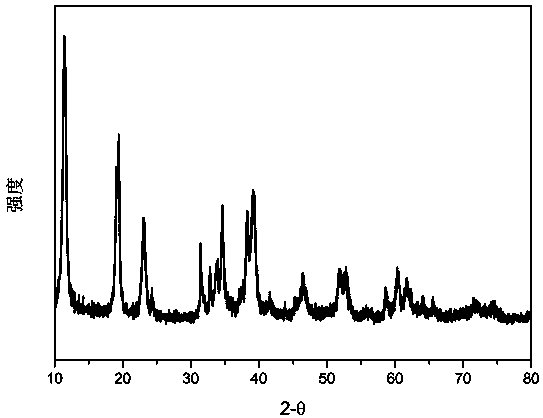

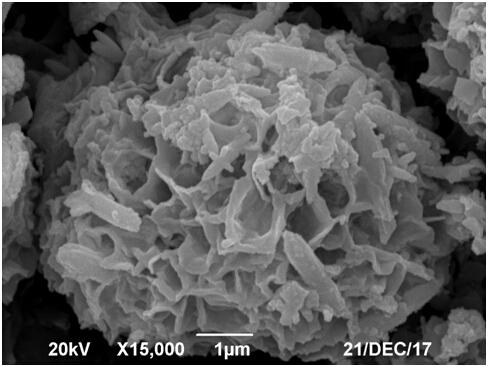

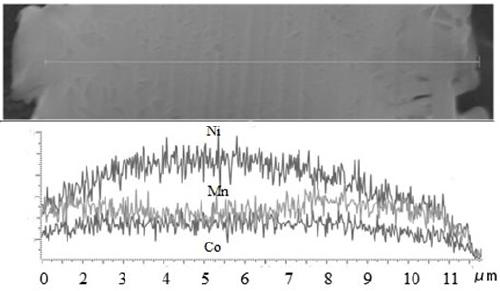

Core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material precursor and preparation method thereof

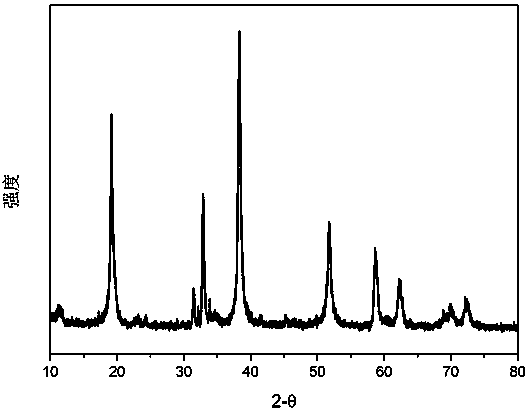

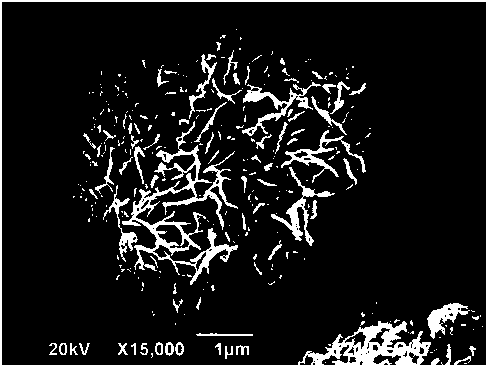

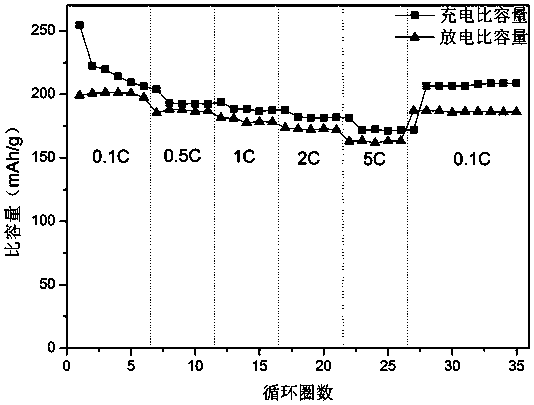

ActiveCN108793268AIncrease capacityShortened diffusion channelCell electrodesSecondary cellsHydroxideSpecific discharge

The invention discloses a core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material precursor and a preparation method thereof. The ternary positive electrode materialprecursor is core-shell structure particles with the average particle size of 4-12 [mu]m, wherein an inner core is hydroxide precipitates of nickel, cobalt and manganese, a shell layer is carbonate precipitates of nickel, cobalt and manganese, the nickel content decreases gradually from the center of the core-shell structure particles to the surface of the shell layer, the manganese content increases gradually from the center of the core-shell structure particles to the surface of the shell layer, and the cobalt content is distributed evenly between the center of the core-shell structure particles and the shell layer. The invention also discloses the preparation method of the ternary positive electrode material precursor. A ternary positive electrode material obtained after the ternary positive electrode material precursor is mixed with lithium and calcined is assembled into a battery, at 0.1 C, the first discharge capacity can reach 198 mAh / g and still keeps at 182 mAh / g after the battery is circulated for 100 cycles, and the specific discharge capacity can reach 176.3 mAh / g at 5 C. The method is simple in process, low in cost and suitable for industrialized production.

Owner:ZHUJI PAWA NEW ENERGY

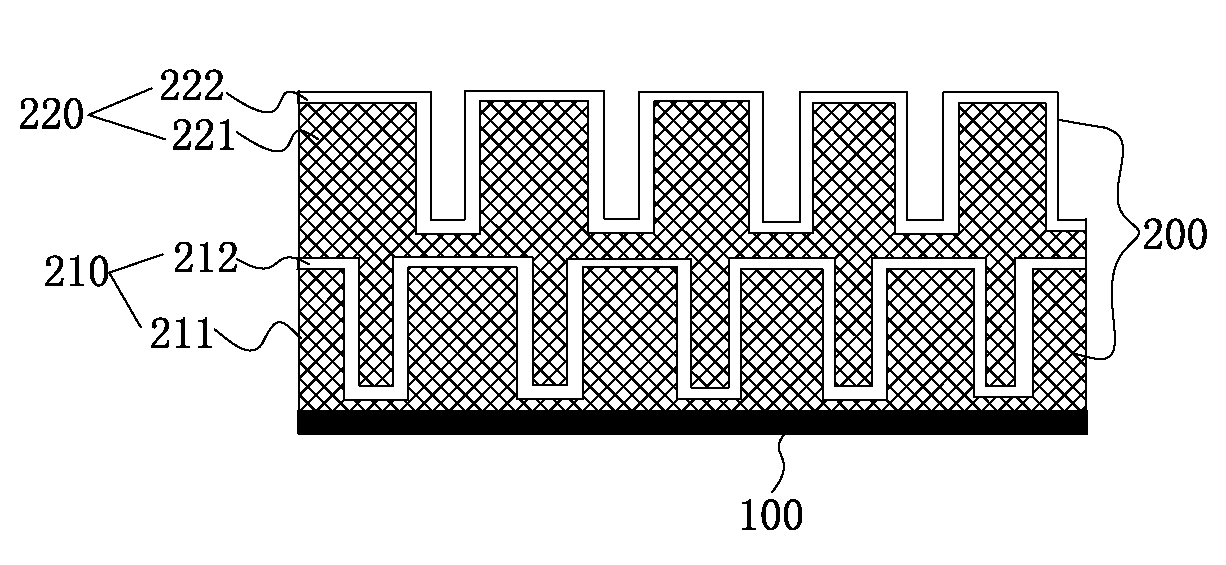

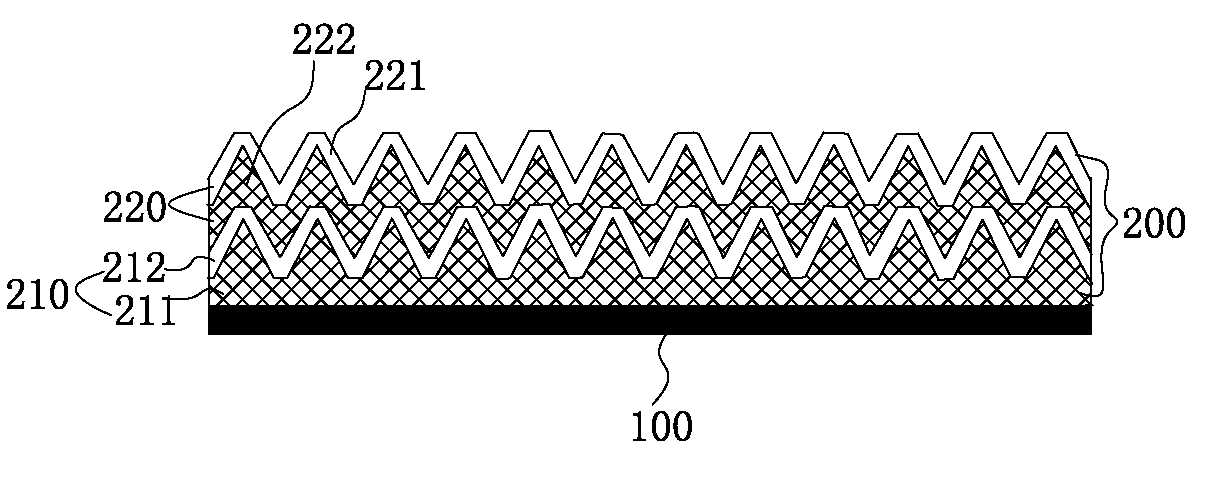

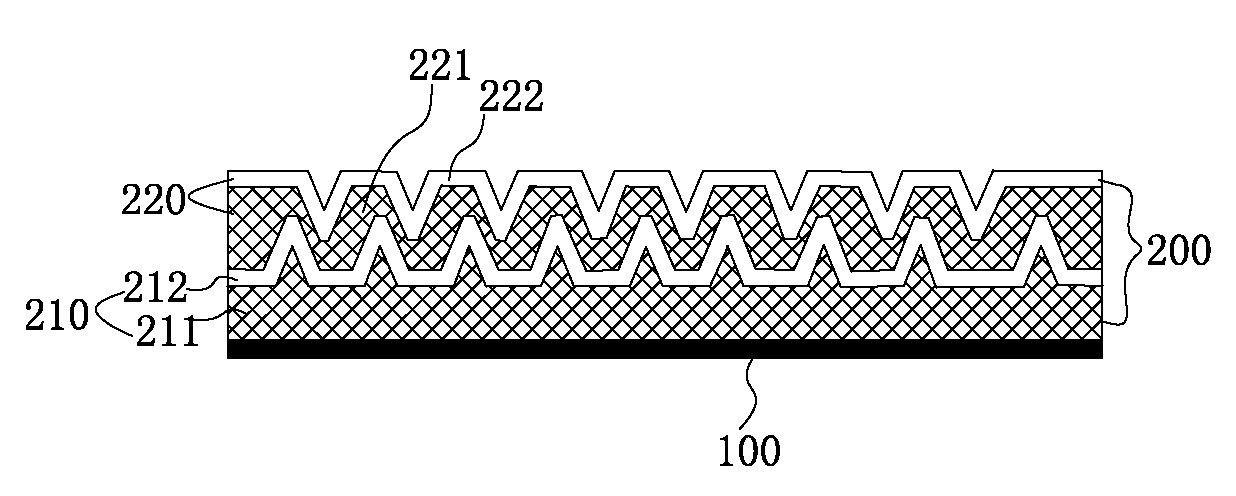

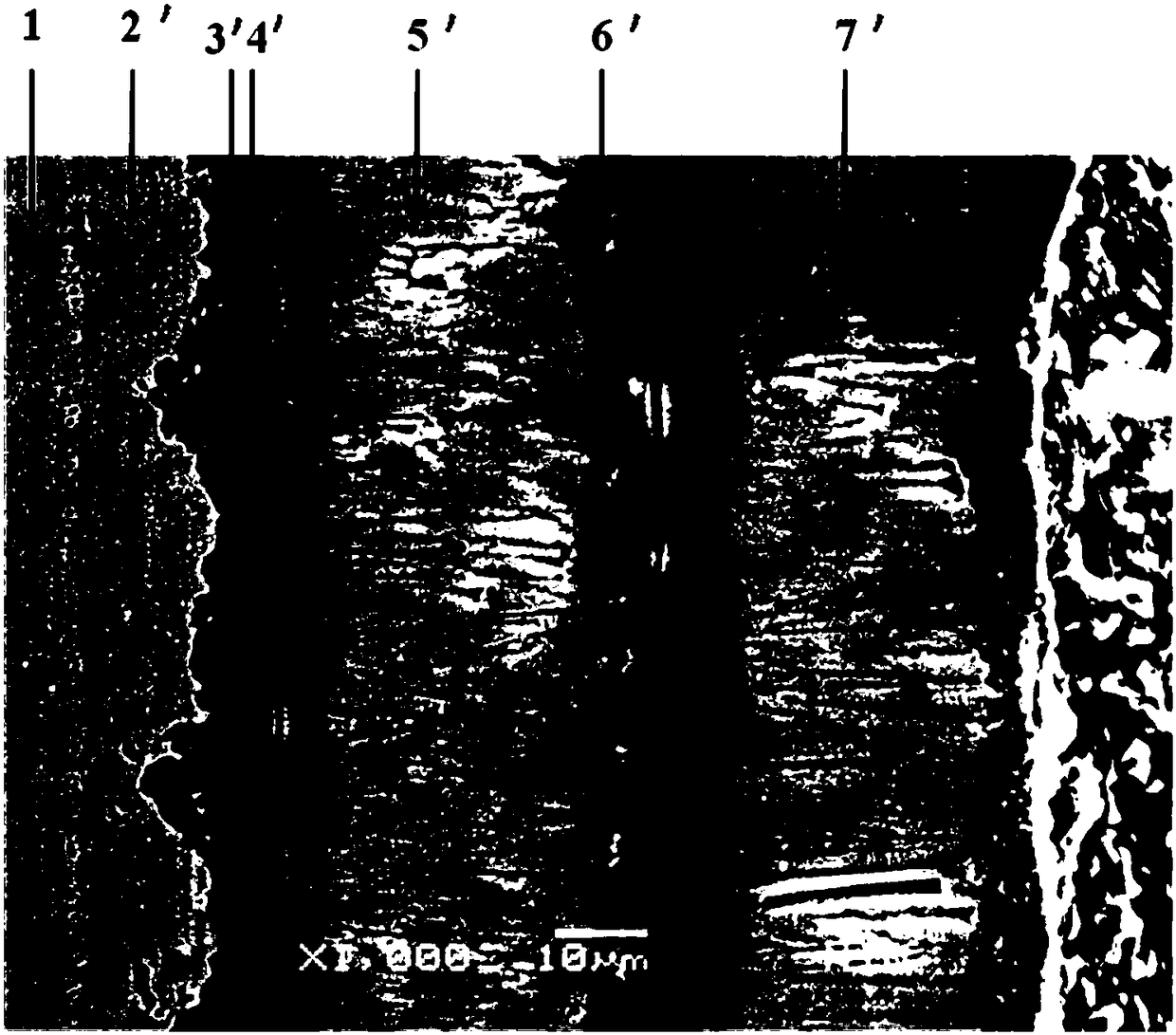

Packaging process of flexible semiconductor film electronic device

ActiveCN103996629AEnhanced scatteringReduce transmittanceSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingThin membraneComposite material

The invention discloses a packaging process of a flexible semiconductor film electronic device. The packaging process comprises a water and oxygen blocking layer preparation working procedure, wherein a water and oxygen blocking layer is formed by one or more water and oxygen blocking units in a stacking mode, each water and oxygen blocking unit comprises an organic blocking layer and an inorganic blocking layer, an uneven morphology structure is arranged on the surface of each organic blocking layer, and each inorganic blocking layer is arranged on the upper surface of the corresponding organic blocking layer. The uneven morphology structure on the surface of an organic film is a regular pattern or an irregular pattern. The uneven morphology structure on the surface of each organic blocking layer is formed in a photoetching mode or physical embossing mode or through particle addition. The uneven morphology structure of the surface of each organic blocking layer is of a rectangular structure or zigzag structure or arc structure. The flexible semiconductor film electronic device is simple in manufacturing process and high in water and oxygen blocking performance, and the device can be kept to be thin while the good water and oxygen isolation performance of the device can be achieved.

Owner:GUANG ZHOU NEW VISION OPTO ELECTRONICS TECH

Carbon compound cathode material for ultracapacitor battery

InactiveCN101740230AGood lithium ion intercalation/extraction cycle performanceExcellent Capacitive Energy Storage PerformanceElectrolytic capacitorsFiberCapacitance

The invention discloses a carbon compound cathode material for an ultracapacitor battery, comprising a nuclear layer and a shell layer, wherein the shell layer accounts for the total weight of 10-40 percent; the nuclear layer is made of graphite materials subjected to surface nanometer treatment; and the shell layer is made of a porous carbon material. The surface nanometer treatment of the nuclear layer is to form a nano carbon fiber, a cabon nanotube or a nano hole on the surface of natural graphite, artificial graphite or an in intermediate phase carbon microsphere material in situ; and the porous carbon material comprises a three-dimensional structure that millipores are distributed on a carbon organism. Metal elements are doped in the shell layer. The component formula is reasonable; the prepared material has the nuclear and shell structures in which the metal elements are doped; meanwhile, the invention has favorable characteristics of energy accumulation by using double electric layers and lithium ion stripping / embedding, can effectively improve the high multiplying power and the power density of a lithium ion battery, meets the double requirements of the ultracapacitor battery on energy accumulation by using the lithium ion and double electric layers of the cathode material, can be used as a cathode of a high-performance lithium ion battery, and has favorable high multiplying power charge-discharge performances and industrial prospect.

Owner:CENT SOUTH UNIV +1

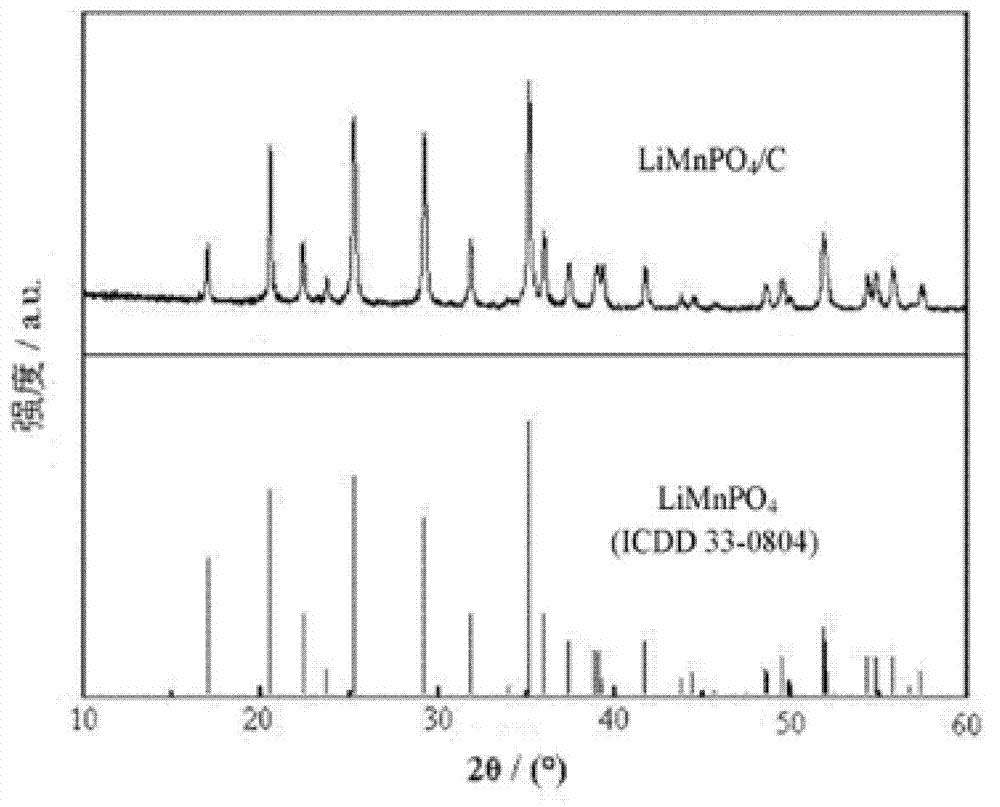

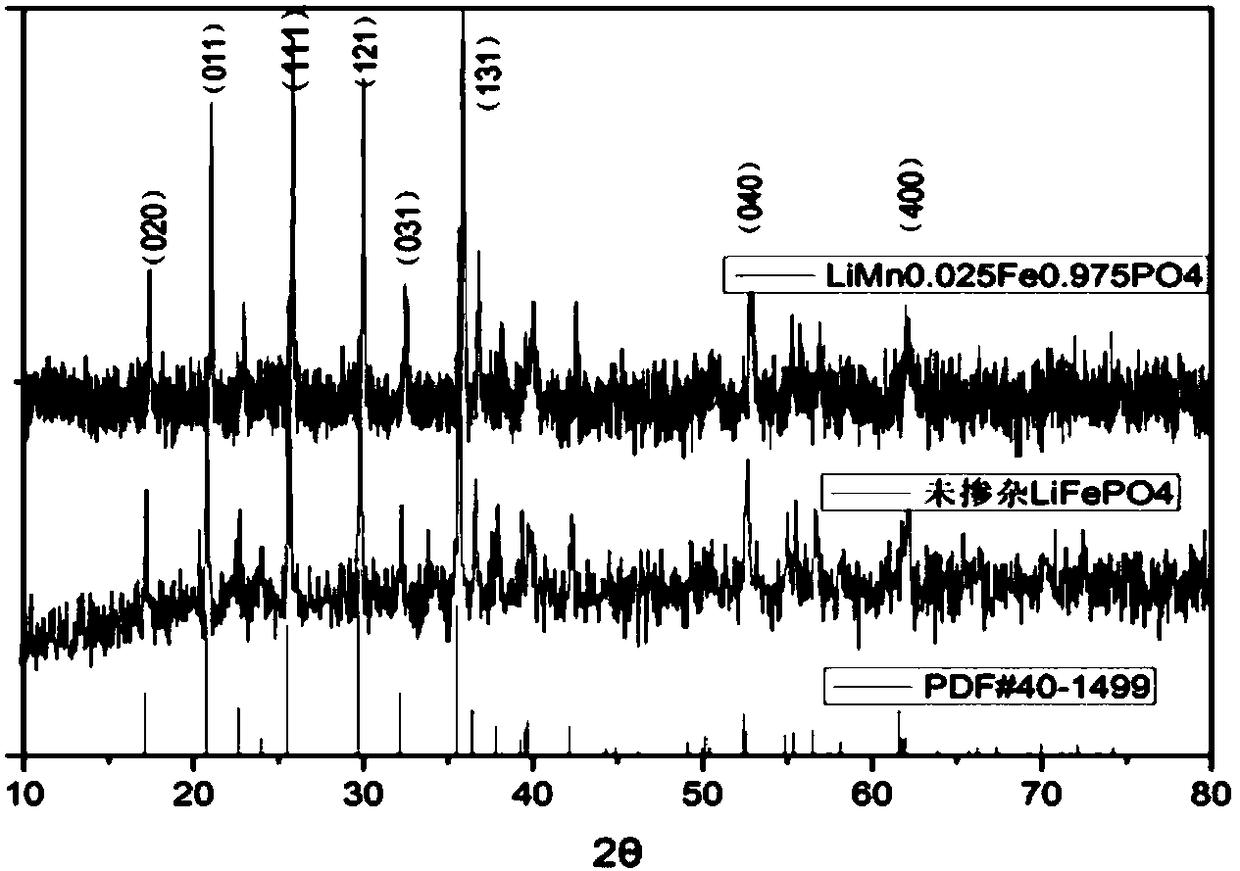

Method for synthesizing manganese phosphate lithium sol-gel doped with other metal ions

The invention relates to a method for synthesizing manganese phosphate lithium sol-gel doped with other metal ions. The method comprises the following steps: (1) dissolving a lithium source compound, a manganese source compound, a metal ion compound, a carbon source compound, a phosphorus source compound and a complexing agent in deionized water, wherein the molar ratio of the complexing agent to the lithium source compound is 0.5-2.5; (2) stirring a settled solution strongly and evaporating the solution until a viscous substance is obtained, and performing drying and ball milling on the viscous substance in a blasting drying box to obtain a mixed powder; and (3) transferring the mixed powder into a ceramic boat, and performing calcinations under the atmosphere of indifferent gas under the temperature of 500-800 DEG C for 1-24 hours to obtain a manganese phosphate lithium product doped with other metal ions. The method provided by the invention has the advantgages of improving the electric conductivity of materials effectively and largely improving the cycle performance of materials, has also the advantages of good evenness of the synthesized manganese phosphate lithium sol-gel doped with the other metal ions, low production cost, simple operation and easiness to realize commercialized production.

Owner:TIANJIN YOULIANG LITHIUM ENERGY TECH

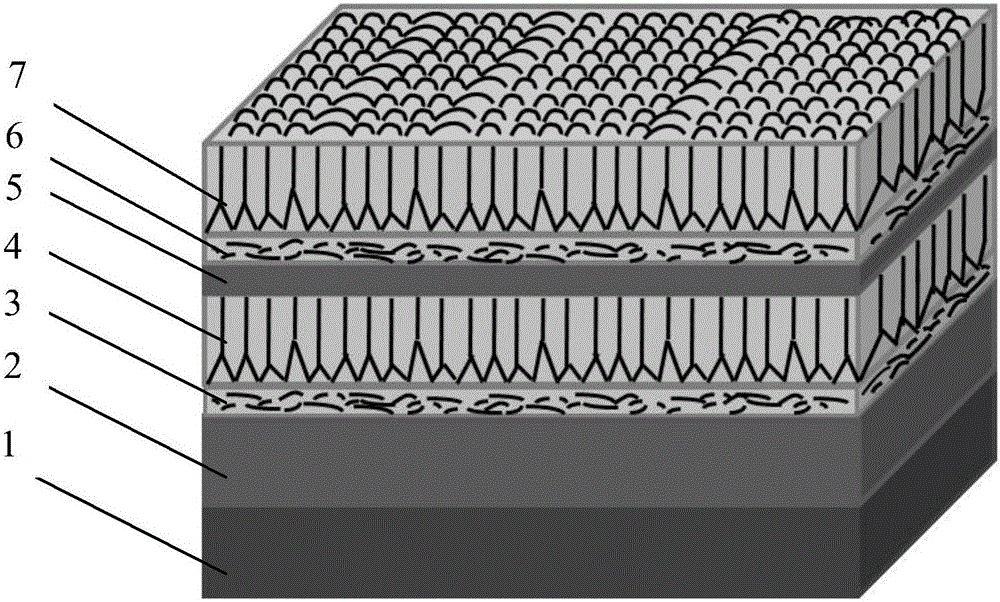

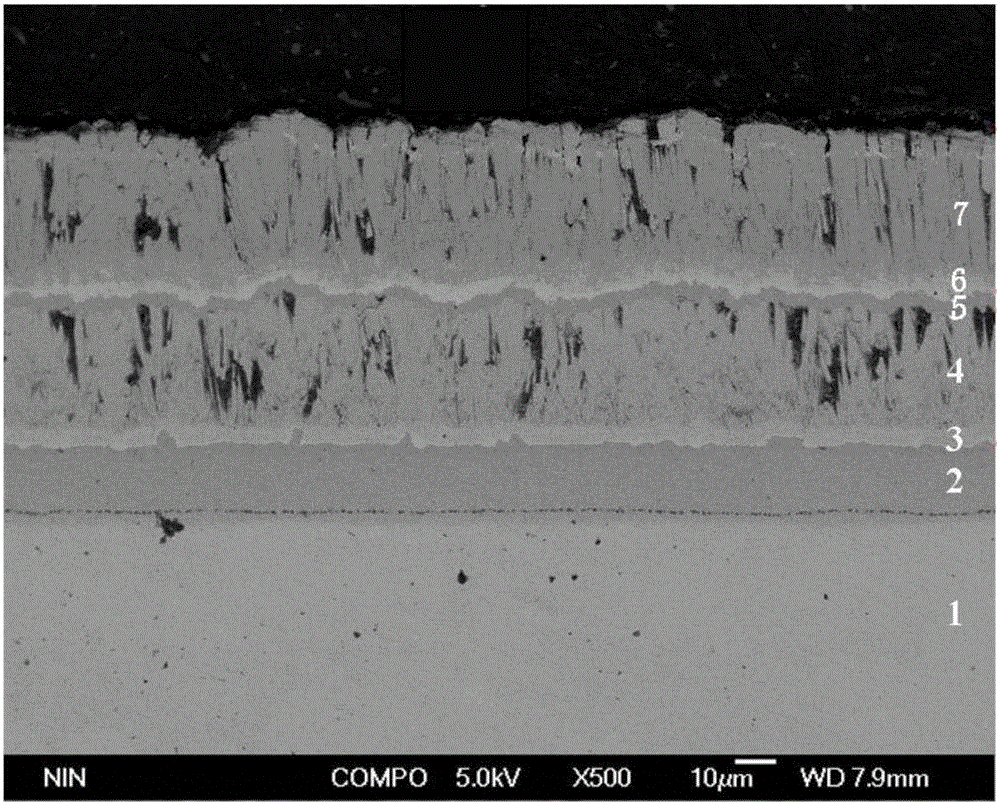

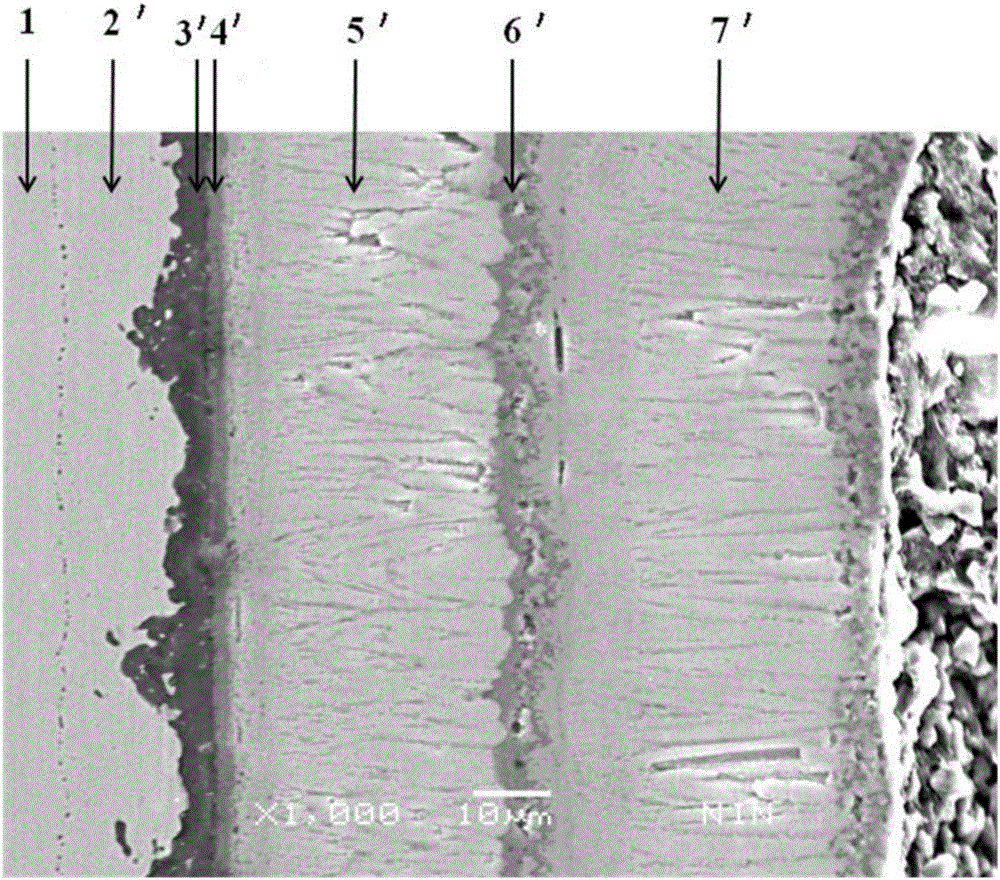

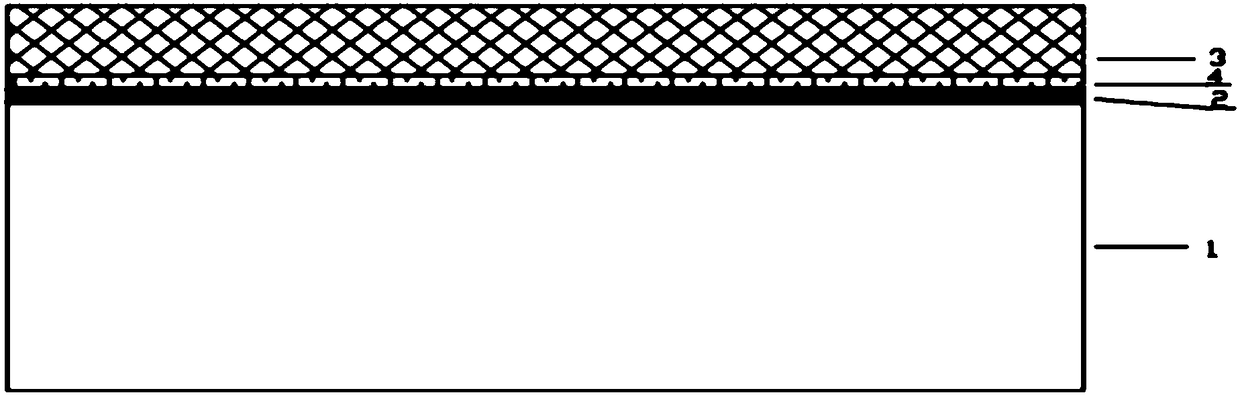

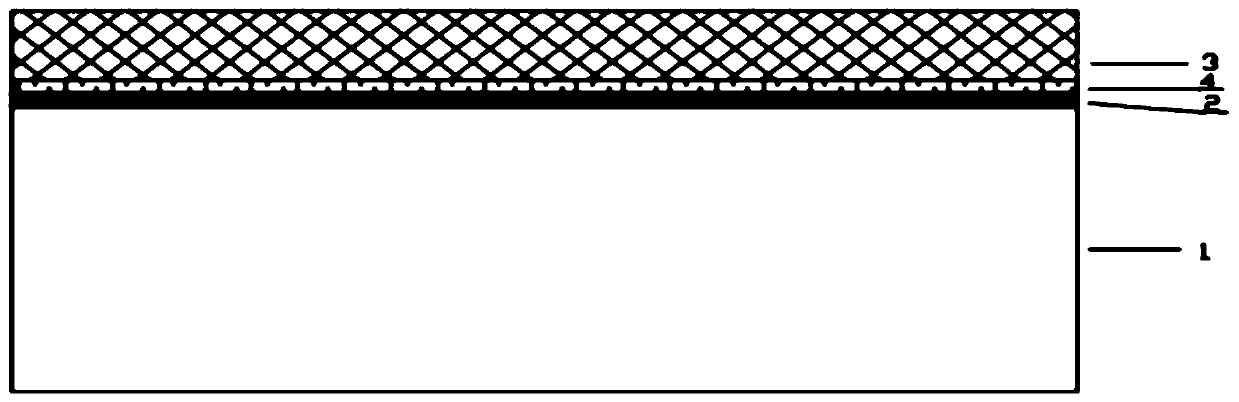

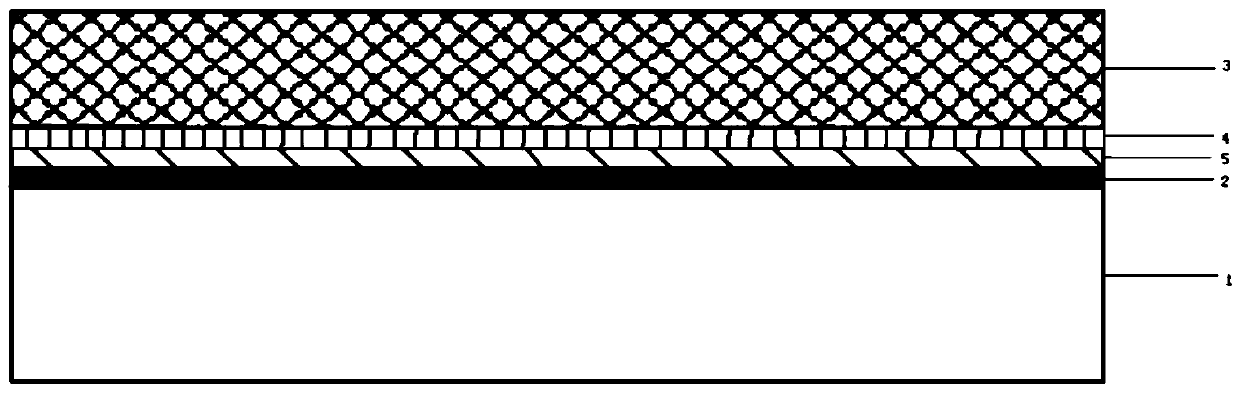

High temperature oxidation-resistant thermal barrier coating layer with composite structure and preparation method thereof

ActiveCN105734500AShortened diffusion channelReduce spreadVacuum evaporation coatingSputtering coatingCrystal structureOxidation resistant

The invention provides a high temperature oxidation-resistant thermal barrier coating layer with a composite structure. The high temperature oxidation-resistant thermal barrier coating layer comprises a metal bonding layer, a first ceramic layer, a second ceramic layer, a metal deposition layer, a third ceramic layer and a fourth ceramic layer deposited at the top of a high-temperature alloy basal body in sequence; the first ceramic layer and the third ceramic layer are both isometric crystal structures; the second ceramic layer and the fourth ceramic layer are both columnar crystal structures; components of the ceramic layers are ZrO2 with stable Y2O3; components of the metal bonding layer are MCrAlY; and components of the metal deposition layer are MCrAlY or NiAl, wherein M is Ni or / and Co. The invention further provides a method for preparing the high temperature oxidation-resistant thermal barrier coating layer. The high temperature oxidation-resistant thermal barrier coating layer has multiple layers of laminated isometric crystal and columnar crystal structures, and is excellent in oxygen resistance and thermal shock resistance; and the preparation method is simple in process, excellent in repeatability and easy to operate.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

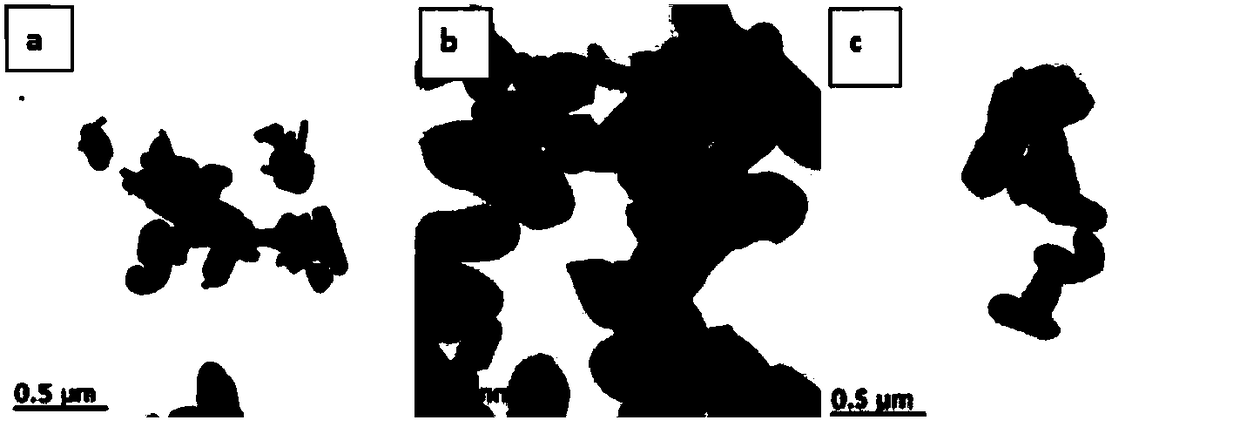

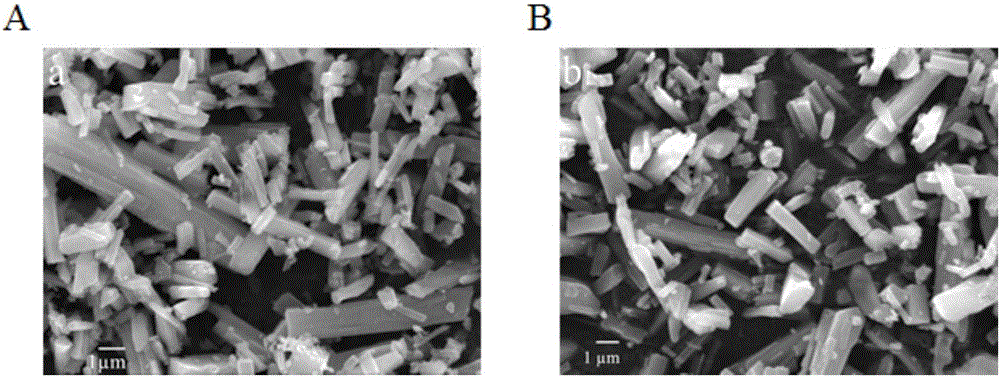

Preparation method of manganese-doped lithium iron phosphate electrode material

The invention discloses a preparation method of a manganese-doped lithium iron phosphate electrode material. The method comprises the steps of using a precipitation method to synthesize a lithium ironphosphate precursor under the condition of stirring by respectively taking lithium hydroxide monohydrate, ferrous sulfate heptahydrate and phosphoric acid as a lithium source, an iron source and a phosphorus source, using ascorbic acid as a reducing agent and part of a carbon source and taking ethylene glycol as a stabilizing agent and a reducing agent of a solvothermal method; then, dropwise dripping manganese sulfate monohydrate, used as a doped manganese source, into a precursor solution; after that, dropwise dripping ammonia water into the solution to adjust the pH of the solution to 7-10, carrying out a hydrothermal reaction, then washing, and drying to obtain the nano-rod-shaped uniform manganese-doped lithium iron phosphate electrode material with good dispersibility. The preparation method provided by the invention is simple in process, wide in raw material source and beneficial to large-scale industrial production; the prepared manganese-doped lithium iron phosphate cathode material has excellent rate capability and excellent cycle performance, is stable in charge-discharge voltage platform, and has a higher specific capacity.

Owner:NANJING UNIV OF SCI & TECH

High-entropy alloy diffusion barrier layer for Cu interconnect integrated circuit and preparation method of high-entropy alloy diffusion barrier layer for Cu interconnect integrated circuit

ActiveCN108336062AThin diffusion barrierUniform compositionSemiconductor/solid-state device detailsVacuum evaporation coatingHigh entropy alloysIntegrated circuit

The invention relates to the technical field of semiconductor integrated circuits, in particular to a high-entropy alloy diffusion barrier layer for a Cu interconnect integrated circuit and a preparation method of the high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit. The high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit sequentially comprises a Si substrate layer, a high-entropy alloy intermediate coating and a Cu film from bottom to top, wherein the high-entropy alloy intermediate coating sequentially comprises a third coating, a second coating and a first coating from bottom to top; the first coating is an AlCrTaTiZrMo high-entropy alloy coating; the second coating is a pure Ti coating; and the third coating is an AlCrTaTiZrMoNx high-entropy alloy coating. According to the high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit, improvement of the atomic bulk density is facilitated,generation of defects, such as vacancies is reduced, a diffusion channel for atoms is reduced, and the diffusion barrier performance and the heat stability of the high-entropy alloy coatings are improved.

Owner:SHANGHAI DIANJI UNIV

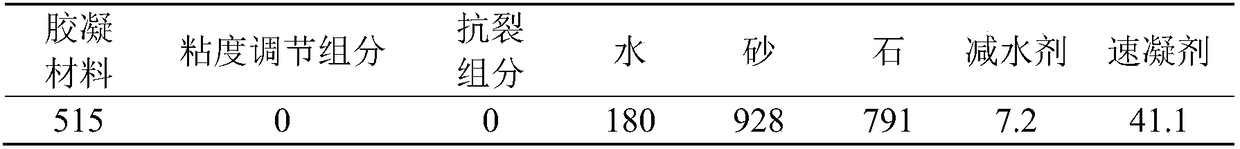

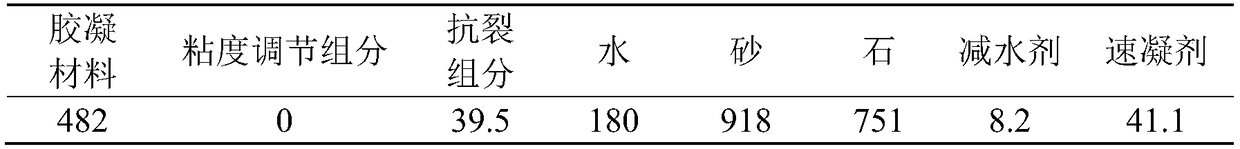

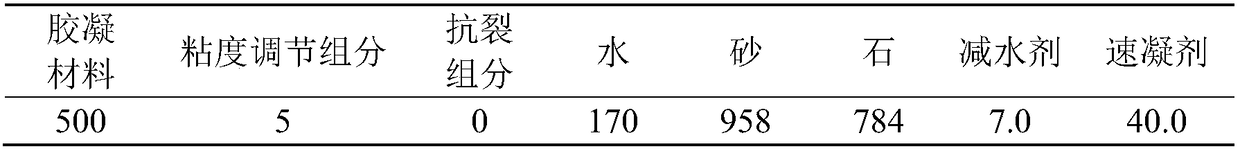

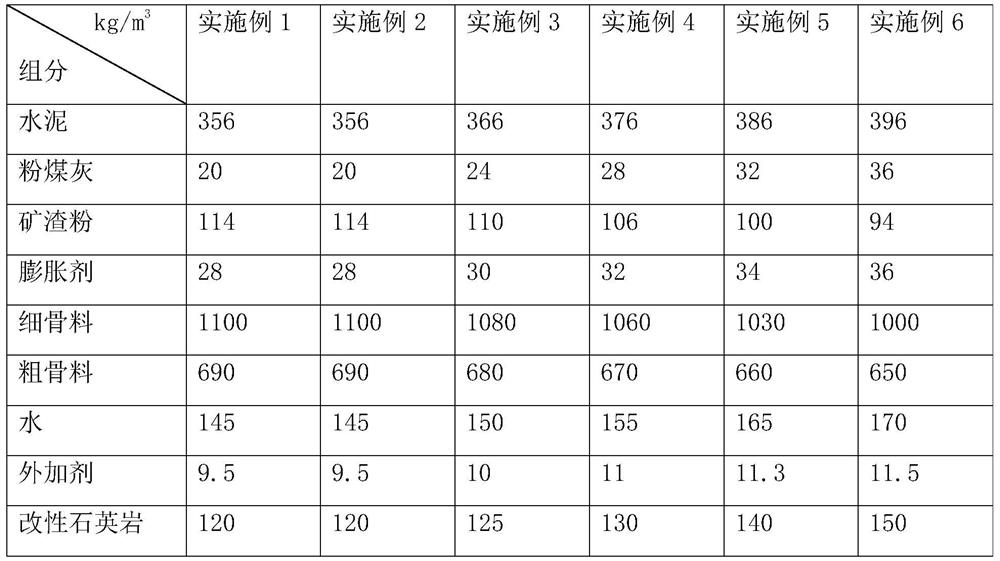

Low-viscosity, anti-cracking and high-strength wet-spraying concrete and preparation method thereof

The invention discloses low-viscosity, anti-cracking and high-strength wet-spraying concrete and a preparation method thereof. The wet-spraying concrete comprises the following components: 470-485kg / m<3> of a cementing material, 165-175kg / m<3> of water, 5-11kg / m<3> of a viscosity regulating component, 38.5-40.5kg / m<3> of an anti-cracking component, 8.0-8.5kg / m<3> of a water reducing component, 900-950kg / m<3> of fine aggregate, 750-780kg / m<3> of coarse aggregate and 40-42kg / m<3> of an alkali-free liquid accelerator. The wet-spraying concrete has 28d compressive strength of 65MPa or above; undera slump condition of 200mm plus or minus 10mm, the emptying time of an inverted slump cone is shorter than 15s; in an early anti-cracking test, the total cracking area per unit area is not greater than 250mm<2> / m<2>, and the cracking grade is L-IV; in a ring cracking test, no cracking occurs within 56d, and the cracking tendency is low. The wet-spraying concrete is high in strength, low in viscosity, good in anti-cracking performance and easy to pump and construct through spraying, and facilitates improvement on the bearing capacity and the water-proof performance of a sprayed concrete liningstructure.

Owner:NANJING HYDRAULIC RES INST

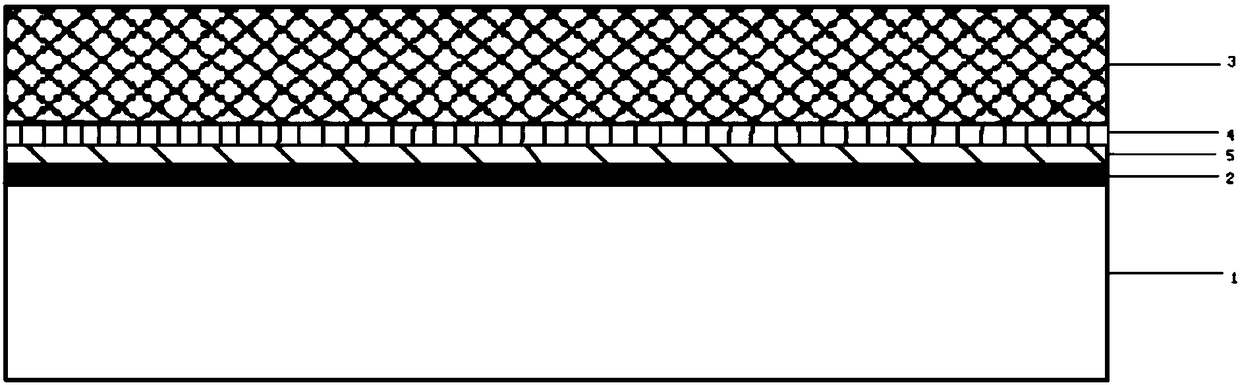

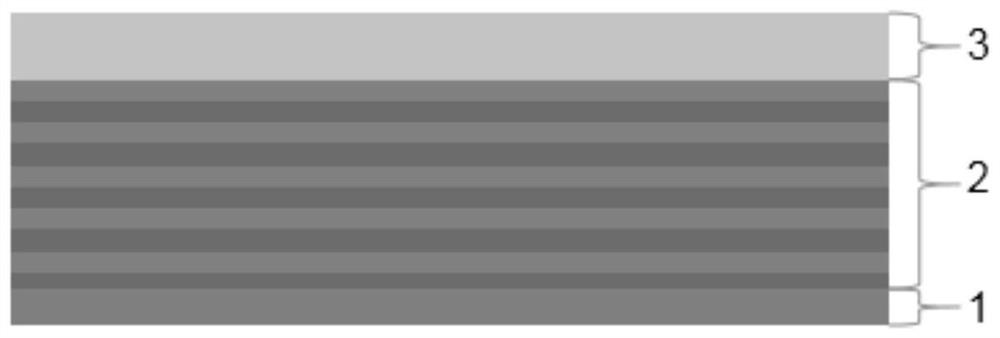

Fiber-reinforced ceramic matrix composite surface antioxidant/infrared stealth coating capable of resisting temperature of 1650 DEG C and preparation method thereof

ActiveCN111732457AGood compatibilityMinimizes differences in thermal expansion coefficientsLiquid surface applicatorsMolten spray coatingLayered structureOxidation resistant

The invention relates to the technical field of high-temperature infrared stealth materials and particularly discloses a fiber-reinforced ceramic matrix composite surface antioxidant / infrared stealthcoating capable of resisting the temperature of 1650 DEG C. The infrared stealth coating is of a layered structure and comprises a ceramic inner layer, a ceramic middle layer, a ceramic outer layer and a low-infrared-emissivity functional layer from bottom to top, wherein the ceramic inner layer is a mullite layer, the ceramic middle layer is a rare earth silicate layer, the ceramic outer layer isan 8YSZ layer, and the low-infrared-emissivity functional layer is a coating with Pt as a conductive phase and Bi2O3 as a binding phase. The invention further provides a preparation method of the fiber-reinforced ceramic matrix composite surface antioxidant / infrared stealth coating capable of resisting the temperature of 1650 DEG C. According to the infrared stealth coating, the oxidation resistance and the high-temperature stability of the composite material are improved, the infrared radiation intensity of a base material can be remarkably reduced, and the infrared stealth coating has excellent oxidation resistance and an infrared stealth function.

Owner:NAT UNIV OF DEFENSE TECH

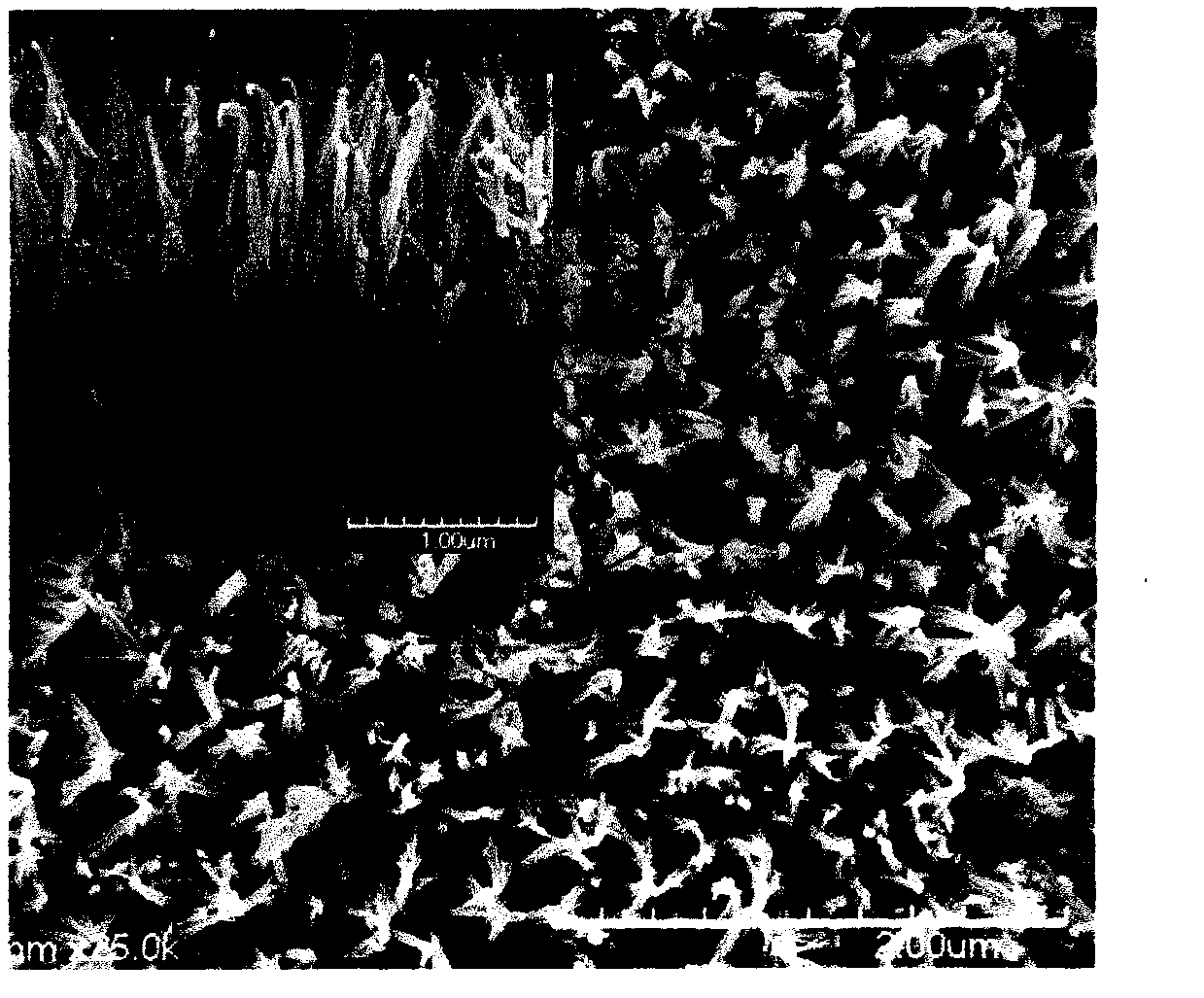

High-performance nickel-cobalt oxide composite nanowire film for super capacitor

InactiveCN102709060AIncrease transfer rateShortened diffusion channelElectrolytic capacitorsHybrid capacitor electrodesCapacitanceNickel salt

The invention discloses a high-performance nickel-cobalt oxide composite nanowire film for a super capacitor. Nickel salt and cobalt salt are used as raw materials, the nickel-cobalt composite nanowire film is generated on a metal titanium substrate, wherein the molar ratio of nickel salt and cobalt salt is 1-5:1-5. The film not only has the advantages of larger specific surface area, simplification in electrode preparation process, alkaline environment stability and the like, but also has excellent super capacitance performance, such as high quality specific capacity and favorable cycle performance, and is an excellent electrode material for the super capacitor in electrochemistry.

Owner:CHONGQING UNIV

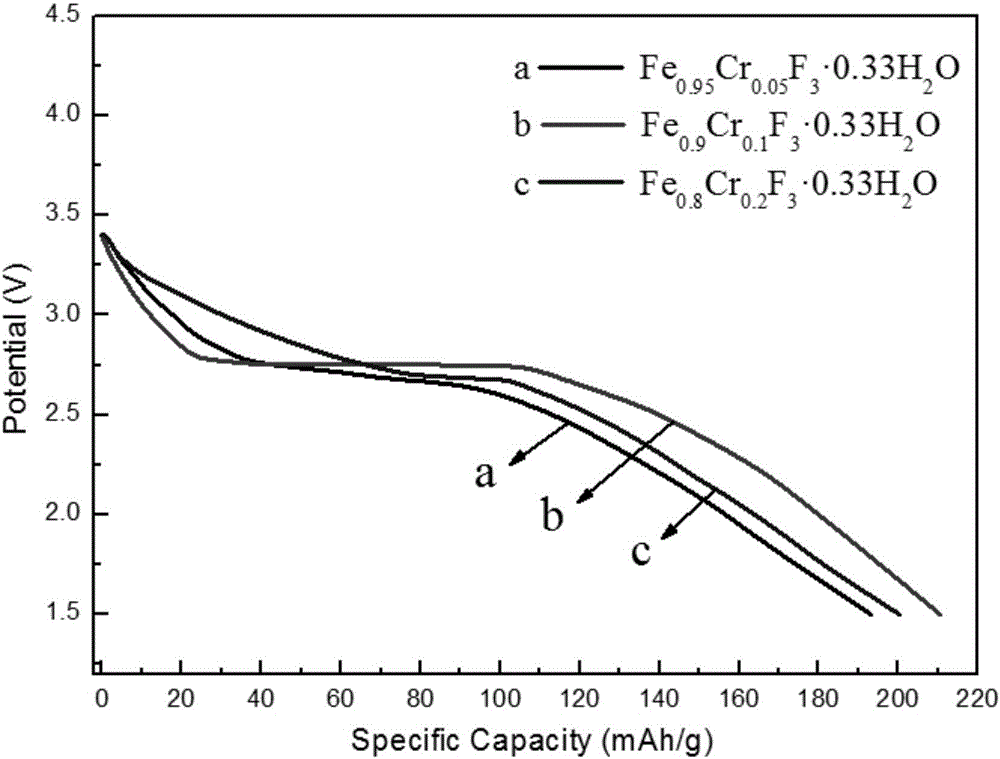

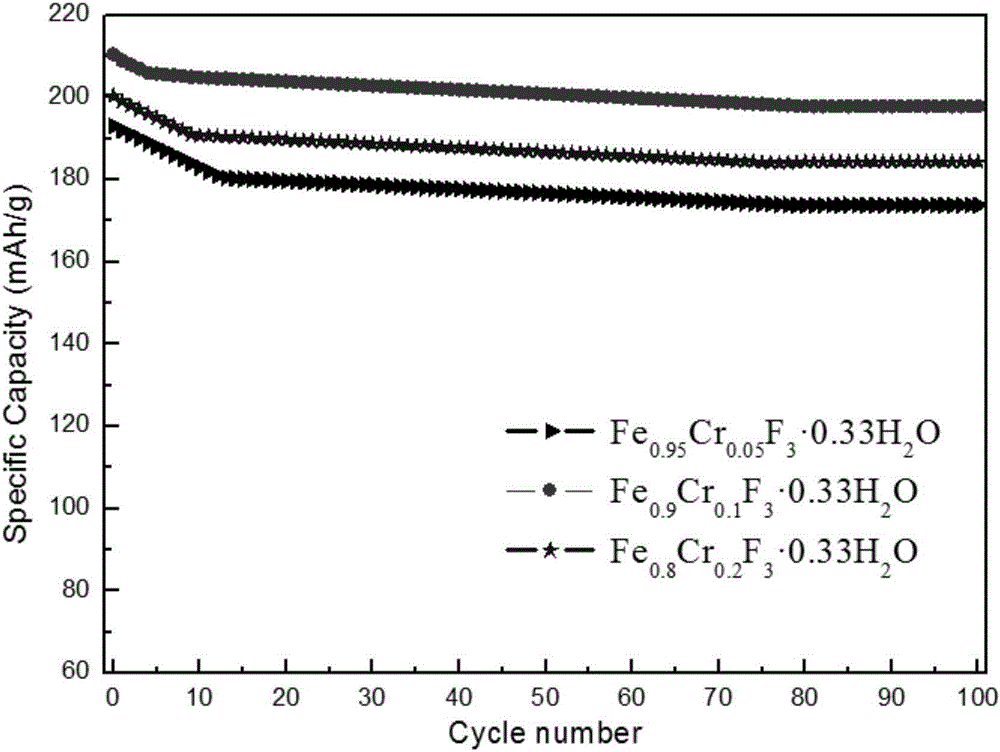

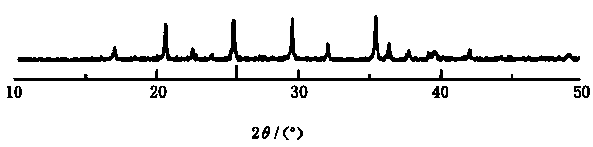

Modified ferric fluoride nano-composite anode material and preparing method and application thereof

ActiveCN106099074AImprove conductivityImprove diffusion abilityMaterial nanotechnologyCell electrodesPhysical chemistrySpecific discharge

The invention relates to the field of battery anode materials and discloses a modified ferric fluoride nano-composite anode material and a preparing method and application thereof. The modified ferric fluoride nano-composite anode material is prepared from a molysite alcohol solution, a villiaumite alcohol solution and chromic salt. The preparing method of the modified ferric fluoride nano-composite anode material comprises the following steps that firstly, the molysite alcohol solution is prepared; secondly, the villiaumite alcohol solution is prepared; third, the molysite alcohol solution and the villiaumite alcohol solution are mixed; fourthly, chromic salt is added, centrifuging is carried out after a mixing and stirring reaction, and precipitate is obtained and washed and centrifuged with absolute ethyl alcohol; fifthly, high-temperature drying is carried out, then a high-temperature reaction is carried out under the protection of inert gas, cooling is carried out, and the product is obtained. The modified ferric fluoride nano-composite anode material is high in specific discharge capacity, multiplying power and circulation stability. The preparing method of the modified ferric fluoride nano-composite anode material is simple in process, low in cost and beneficial to industrial production.

Owner:深圳鑫茂新能源技术股份有限公司

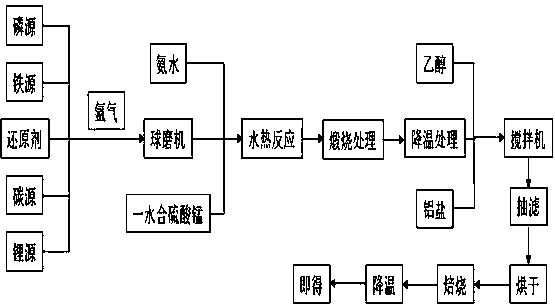

A preparation method of an alumina-coated manganese-doped lithium iron phosphate cathode material

InactiveCN109244424AShortened diffusion channelImprove electrical conductivity and charge and discharge capacityCell electrodesSecondary cellsCarbon sourceAluminium

The invention relates to the technical field of cathode materials for lithium ion batteries, in particular to a preparation method of an alumina-coated manganese-doped lithium iron phosphate cathode material, which comprises the following steps in turn: (1) ball milling a phosphorus source, an iron source, a lithium source carbon source and a reducing agent to obtain a manganese-doped lithium ironphosphate precursor; 2, adding a manganese source into a manganese-doped lithium iron phosphate precursor solution, successively dropping ammonia water, hydrothermal reacting, drying, calcining, andcooling to obtain that manganese-doped lithium iron phosphate material; 3) uniformly stirring that manganese doped lithium iron phosphate material and the organic solvent, adding aluminum salt solution in the stirring, and successively stirring, pumping, filter, drying, roasting, cooling to obtain an alumina coated manganese doped lithium iron phosphate cathode material; The alumina-coated manganese-doped lithium iron phosphate cathode material prepared by the invention can effectively improve the conductivity and the charge-discharge capacity, increase the electric contact area, and further improve the cycle performance of the lithium ion battery.

Owner:DONGGUAN UNIV OF TECH

Abrasion-resistant and corrosion-resistant concrete and preparation method thereof

The invention relates to the field of building materials, and particularly discloses abrasion-resistant and corrosion-resistant concrete and a preparation method thereof. The abrasion-resistant and corrosion-resistant concrete comprises the following components: cement, fly ash, slag powder, an expanding agent, fine aggregate, coarse aggregate, water, an additive and modified quartzite. The preparation method of the modified quartzite comprises the following steps: crushing quartzite, mixing the crushed quartzite with an acid solution, and conducting washing and roasting to obtain porous quartzite; atomizing and depositing an wear-resistant and corrosion-resistant additive on the porous quartzite to obtain quartzite particles; and (3) mixing carbide slag and the quartzite particles, and keeping the temperature at 950-1000 DEG C for 2-3 hours to obtain modified quartzite. The wear-resistant and corrosion-resistant additive is prepared from the following components: coal gangue, composite fibers, rice hull ash, a silane coupling agent KH-550 and a water repellent agent. The abrasion-resistant and corrosion-resistant concrete has the advantages of being good in sea wave and sediment abrasion resistance and chloride ion erosion resistance, high in impermeability and excellent in durability when being used for ocean engineering infrastructure construction.

Owner:青岛建一混凝土有限公司

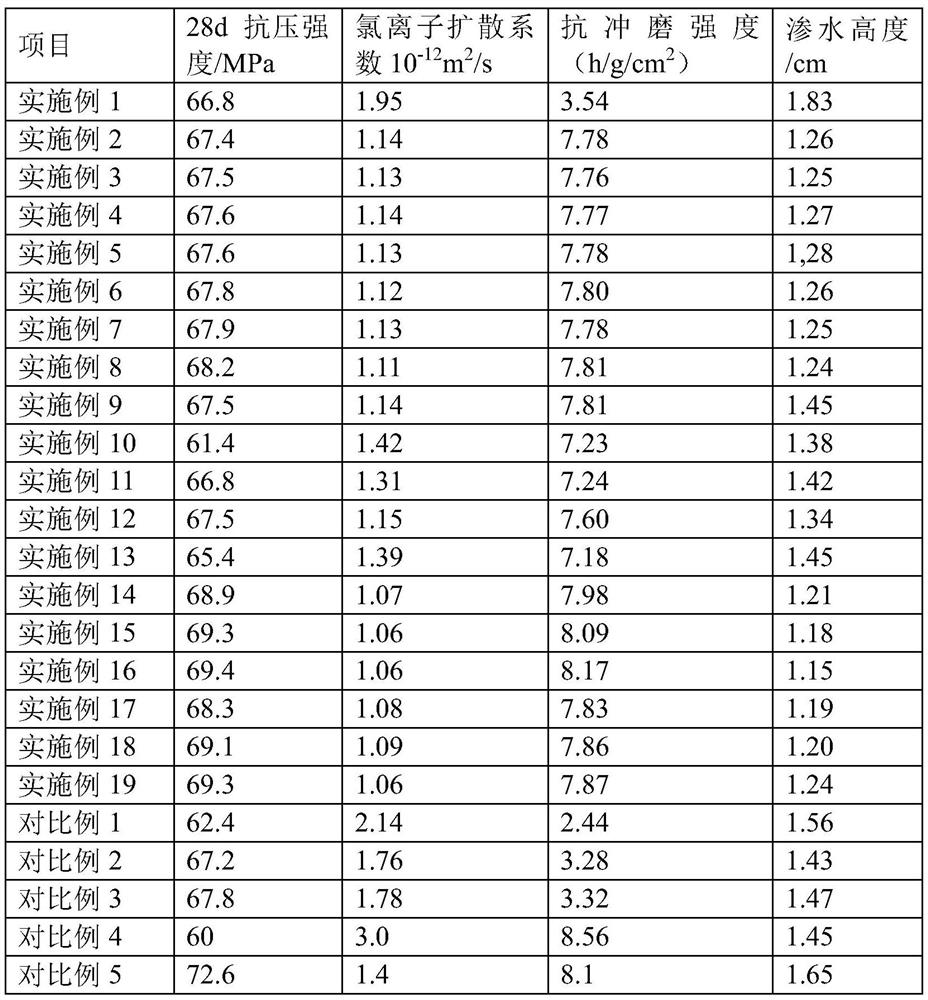

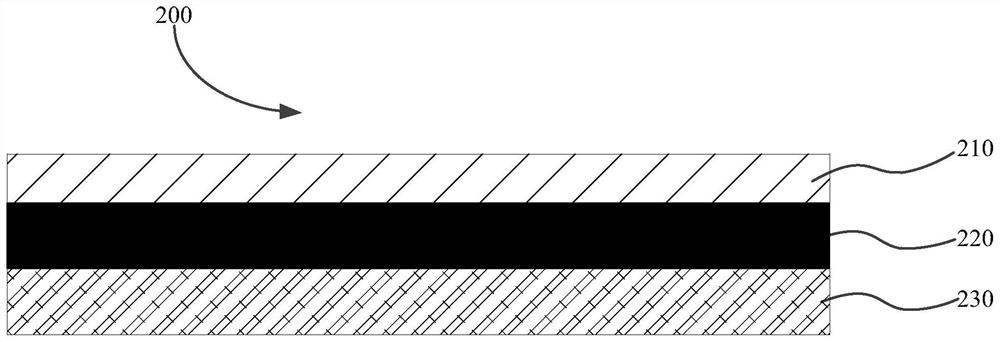

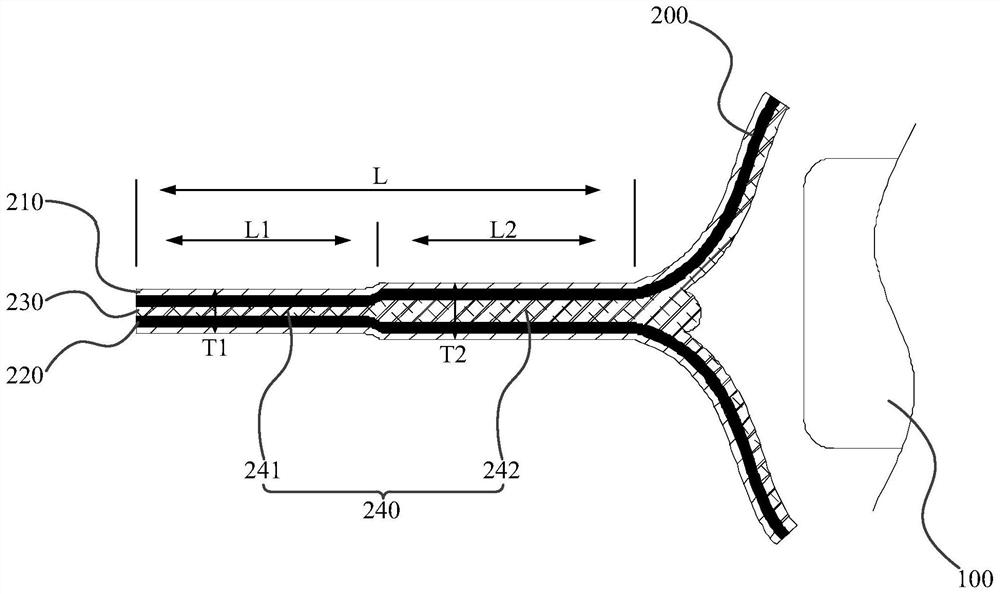

Soft package battery and preparation method thereof

PendingCN112599894AImprove waterproof performanceIncrease production costSynthetic resin layered productsCell component detailsEngineeringPlastic film

Embodiments of the invention provide a soft package battery and a preparation method thereof. The soft package battery provided by the invention comprises a battery cell and aluminum-plastic films, wherein the battery core is positioned between an upper-layer aluminum-plastic film and a lower-layer aluminum-plastic film; each aluminum-plastic film comprises a nylon layer, an aluminum layer and a PP layer which are arranged in a stacked mode, and the edges of the two layers of aluminum-plastic films are packaged in a hot melting mode to form a packaging part so as to allow the PP layers of thetwo layers of aluminum-plastic films to form an integrated structure; and the thickness of the PP layers at one end, away from the battery cell, of the packaging part is smaller than the thickness ofthe PP layer at the end, towards the battery cell, of the packaging part. The invention also provides the preparation method of the soft package battery. The preparation method comprises the followingsteps: providing the battery cell and the aluminum-plastic films; and packaging the edges of the two layers of aluminum-plastic films in a hot melting mode through an upper sealing head and a lower sealing head, wherein the packaging face of the upper sealing head forms a step face or an inclined face, and the packaging face of the lower sealing head and the packaging face of the upper sealing head are symmetrical along a horizontal plane. According to the soft package battery provided by the invention, the waterproof performance of the soft package battery is improved on the premise of not increasing production cost.

Owner:ZHUHAI COSMX BATTERY CO LTD

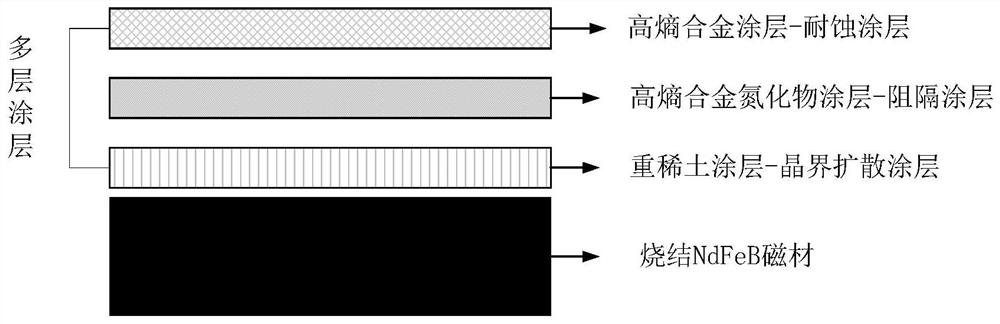

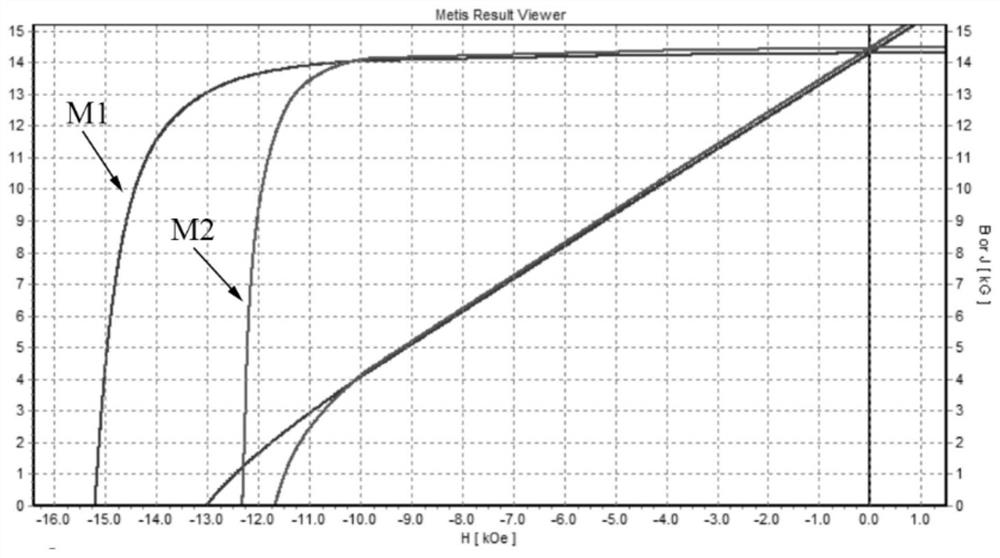

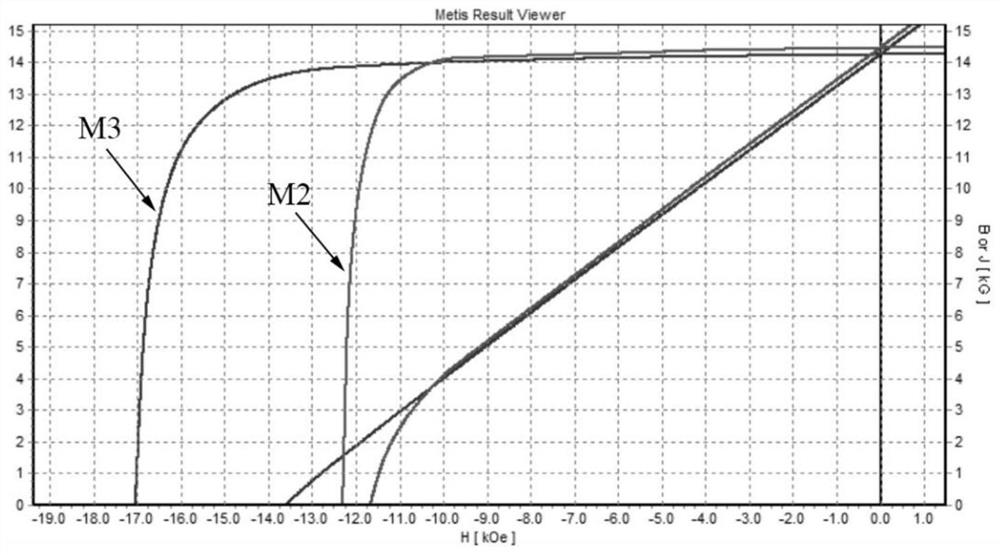

Method for simultaneously improving coercive force and corrosion resistance of sintered NdFeB

ActiveCN112680695AAvoid failureImprove coercive forceVacuum evaporation coatingSputtering coatingSurface engineeringSputtering

The invention belongs to the field of sintered NdFeB magnetic material surface engineering, and discloses a method for simultaneously improving coercive force and corrosion resistance of sintered NdFeB. The method specifically comprises the following steps of: (1) conducting coating pretreatment; (2) cleaning a glow plasma; (3) depositing a grain boundary diffusion layer-heavy rare earth coating; (4) depositing a barrier layer-high-entropy alloy nitride coating; (5) depositing a corrosion-resistant layer-high-entropy alloy coating; (6) conducting vacuum heat treatment; and (7) after a sample is cooled to room temperature, taking out the sample to finish the treatment of the sintered NdFeB magnetic material. According to the method, a novel multi-layer coating is prepared on the surface of the sintered NdFeB magnetic material through magnetron sputtering, wherein in the bottommost layer, a heavy rare earth coating is adopted as a grain boundary diffusion coating; in the outermost layer, a high-entropy alloy coating is adopted as a corrosion-resistant coating; and in the middle layer, a high-entropy alloy nitride coating is adopted as a barrier coating. After the multi-layer coating composed of the three coatings is subjected to vacuum heat treatment, the problem that the coercive force and the corrosion resistance of sintered NdFeB cannot be improved at the same time can be solved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Method for obtaining ferritic heat-resisting steel with the characteristic of austenite structure

ActiveCN103555905AInitial size refinementImprove organizational stabilityRoom temperatureLarge deformation

The invention relates to a method for obtaining ferritic heat-resisting steel with the characteristics of an austenite structure, and belongs to the technical field of heat-resisting steels. A large deformation+heat treatment process is adopted, and the technical parameters controlled in process steps are as follows: heating 9%-12% Cr steel to 1100-1200 DEG C at 20 DEG C / s, and keeping temperature for 30-120 minutes; then cooling to 500-800 DEG C at 10 DEG C / s, keeping the temperature for 3-15 seconds, deforming at the deformation rate of 1s<-1> and the deformation amount of 70%-90%, immediately quenching to room temperature after the deformation is completed; then tempering at 650-800 DEG C for 1-5 hours, and air-cooling to room temperature. The method disclosed by the invention is used for preparing the 9%-12% Cr steel and a large-caliber boiler pipe thereof. According to the invention, the initial size of a precipitated phase is obviously thinner than the initial size of a precipitated phase treated through the traditional heat treatment mechanism, a ferrite structure has characteristics similar to the characteristics of the austenite structure, belongs to an equilibrium state and is small in interface quantity and less in diffusion channel; a base body has good structure stability in a long-time service process.

Owner:CENT IRON & STEEL RES INST

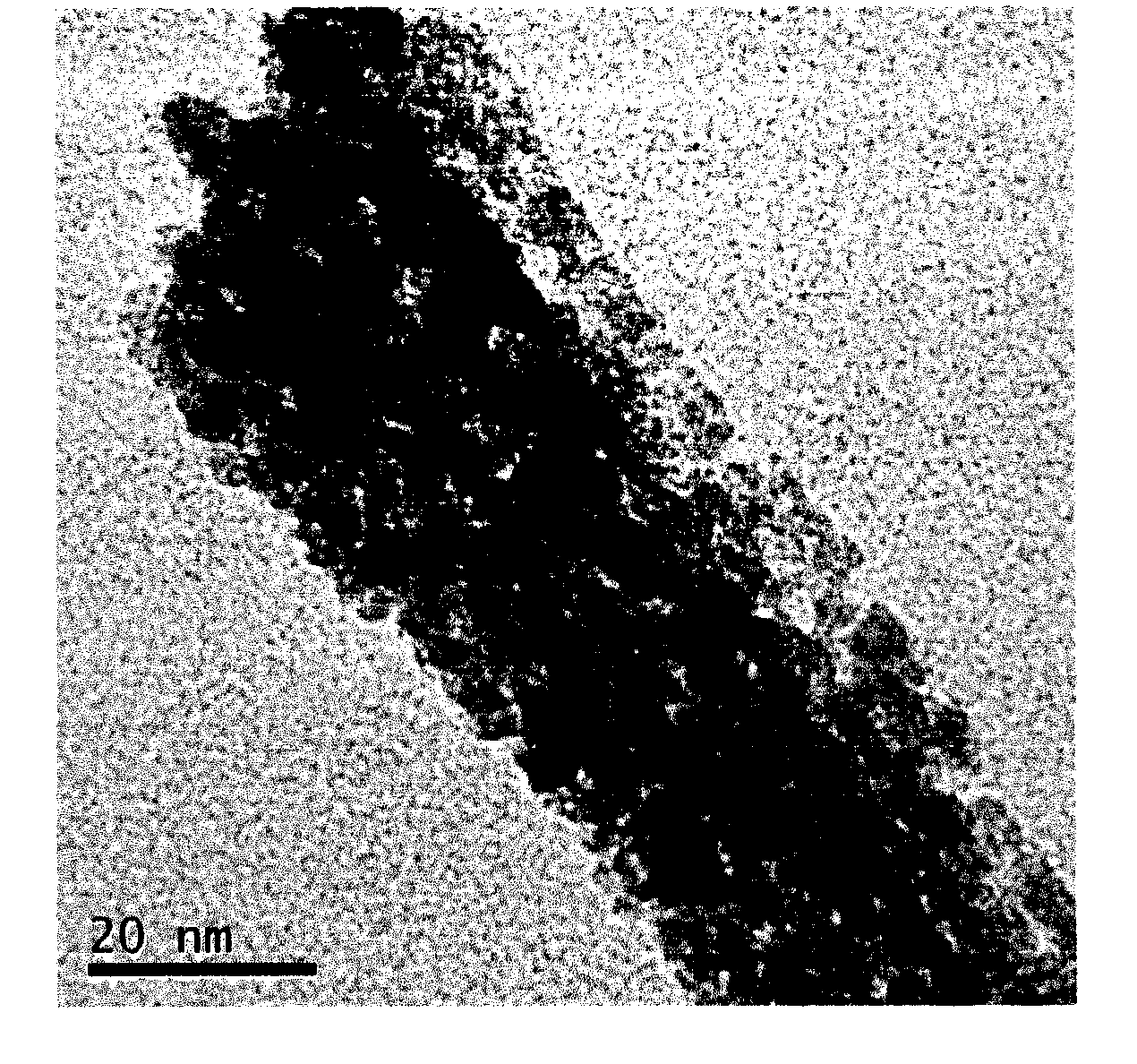

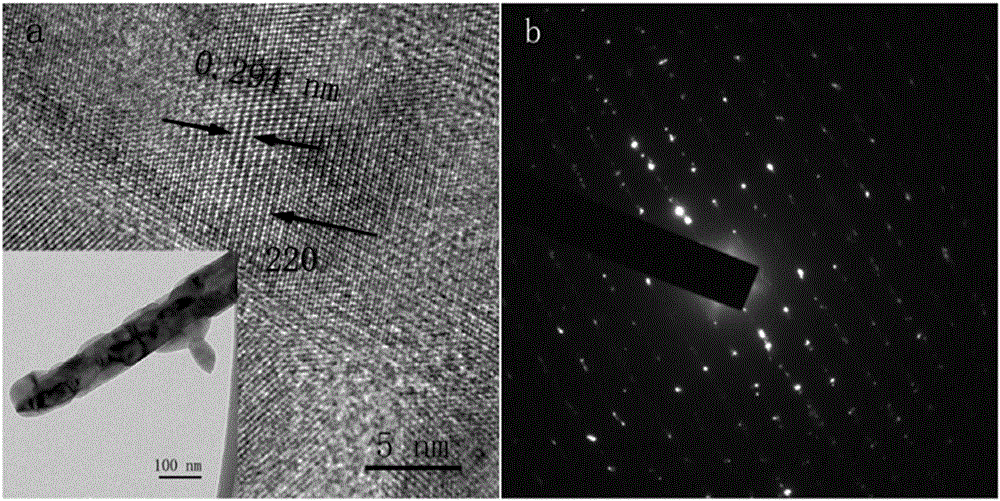

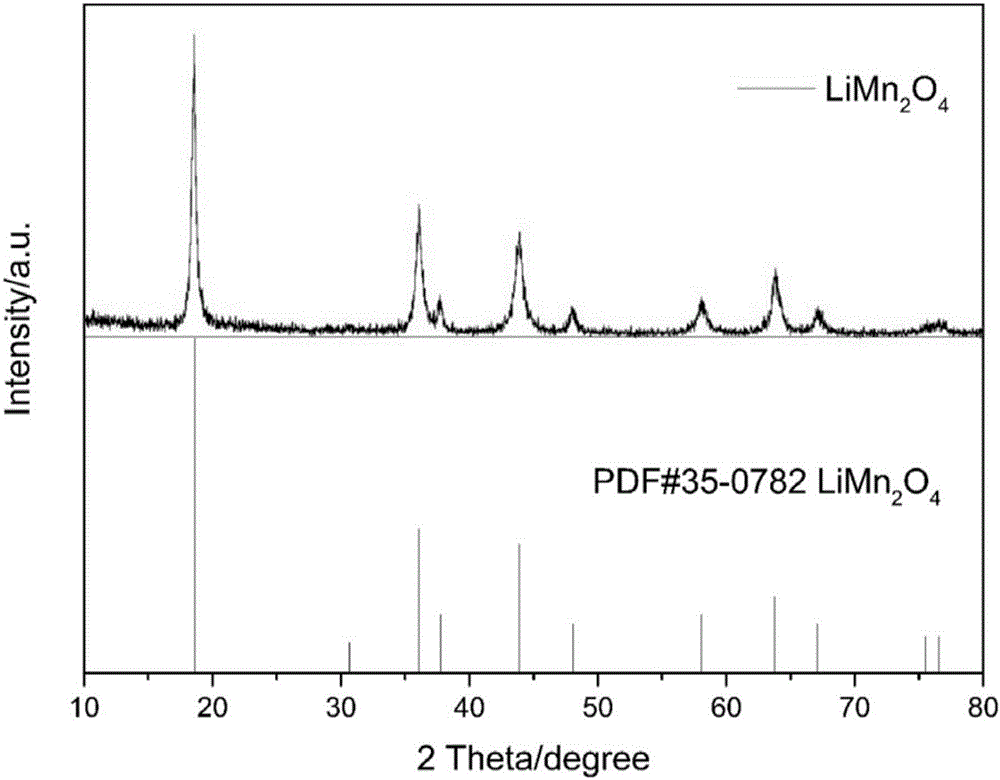

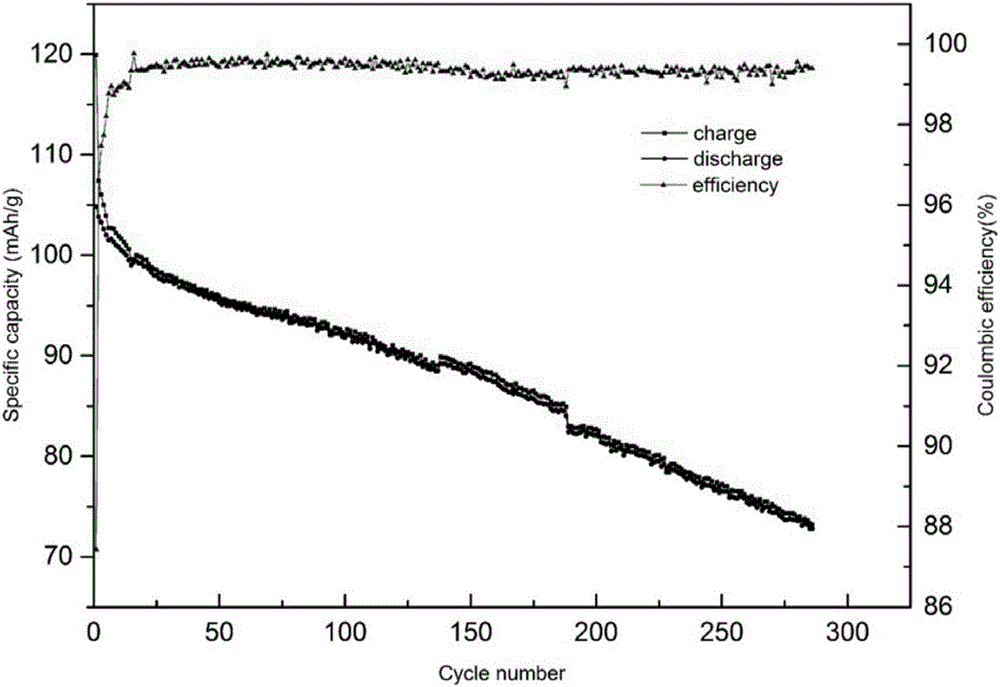

Preparation method of one-dimensional nanowire type lithium manganate positive electrode material

InactiveCN107434263AImprove structural stabilityShortened diffusion channelMaterial nanotechnologySecondary cellsNanowireManganate

The invention relates to a lithium ion battery material, and concretely relates to a preparation method of a one-dimensional nanowire type lithium manganate positive electrode material. The preparation method comprises the following steps: 1, preparing a manganese source compound solution, and adding an additive; 2, processing the prepared manganese source compound solution through a hydrothermal technology to obtain nanowire type alpha-MnO2, and washing and drying the nanowire type alpha-MnO2; and 3, mixing, stirring and drying the nanowire type alpha-MnOw, a lithium source compound and a solvent. The initial discharge capacity of the spinel structured LiMn2O4 nanowire prepared through the method is 104.8 mAh / g during1C rate charge and discharge. 87.6% Of the initial capacity is still kept at 150 cycles. 75% Of the initial capacity is kept during 3 C rate charge and discharge.

Owner:湖南电将军新能源有限公司

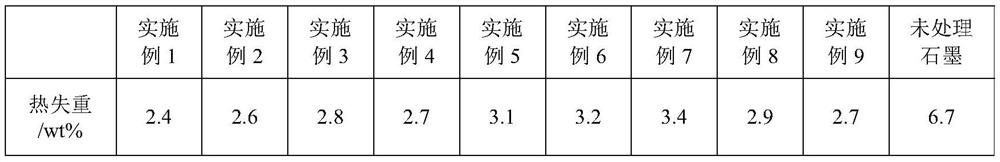

Preparation method of high-temperature-resistant graphite material

PendingCN113307264AImprove high temperature oxidation resistanceHigh bonding strengthGraphiteInorganic saltsPhosphate

The invention discloses a preparation method of a high-temperature-resistant graphite material. The preparation method comprises the following steps: step 1, removing impurities on the surface of graphite; 2, performing inorganic salt impregnation on the graphite; and 3, carrying out heat treatment on the graphite impregnated with the inorganic salt. Compared with the prior art, the preparation method has the positive effects that the preparation process is simple, the cost is low, the main components of the used impregnation liquid are phosphate and borate, the high-temperature oxidation resistance of the impregnation liquid is mainly derived from a series of changes generated by decomposition of the borate and phosphate at high temperature, a layer of stable oxidation-resistant coating covers the surface or pores of the graphite, channels for oxidizing gas to diffuse into the graphite are reduced, and the high-temperature oxidation resistance of the graphite is improved. The prepared anti-oxidation coating covered by the graphite powder has good bonding strength with graphite.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

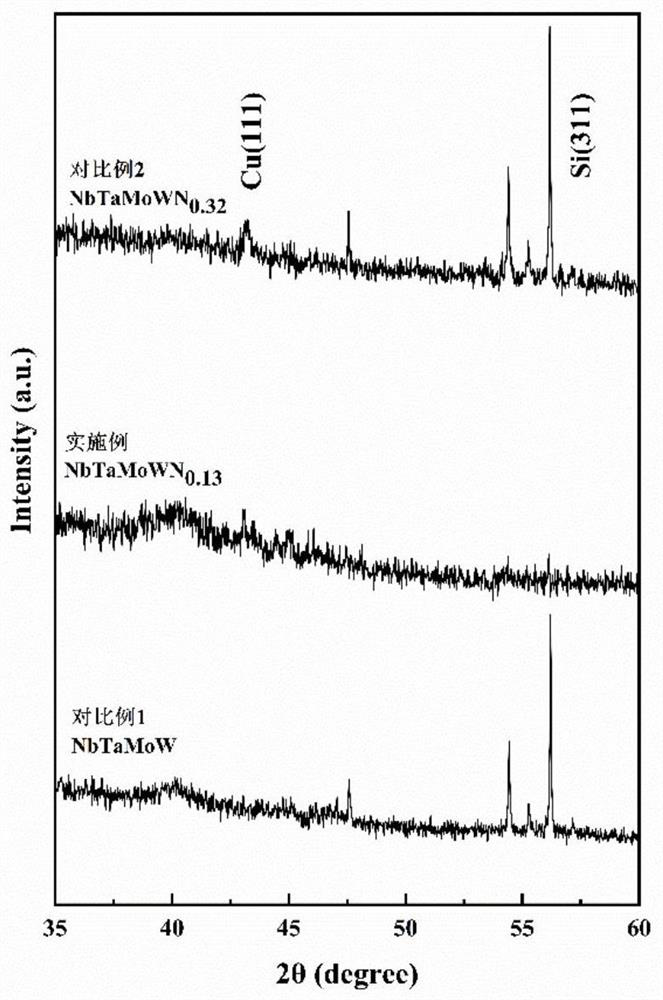

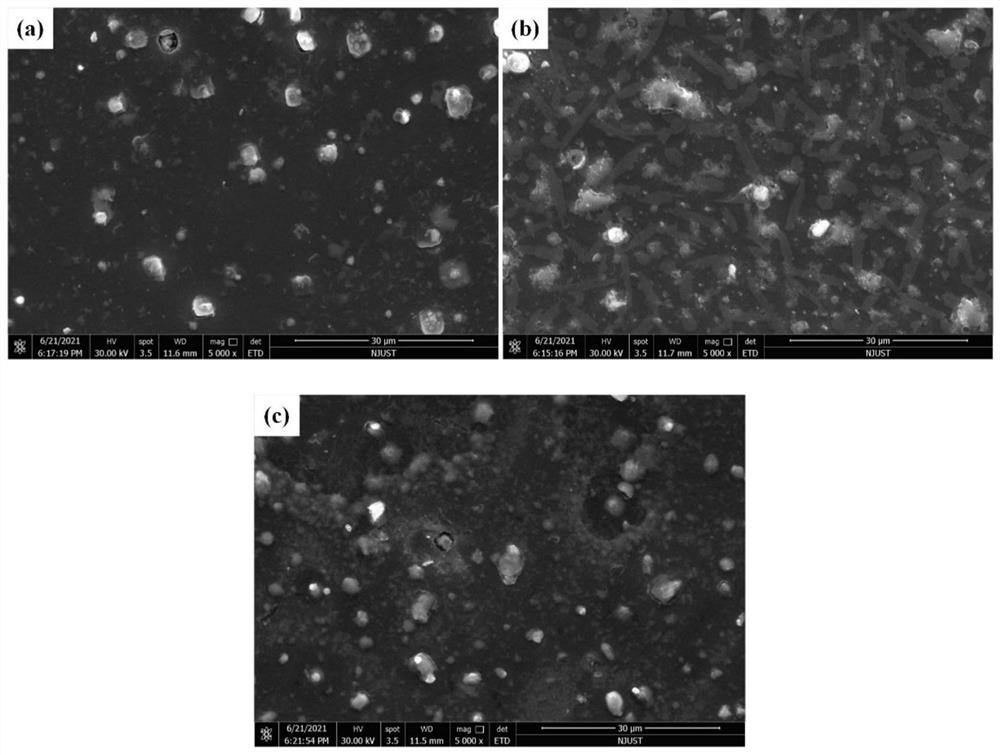

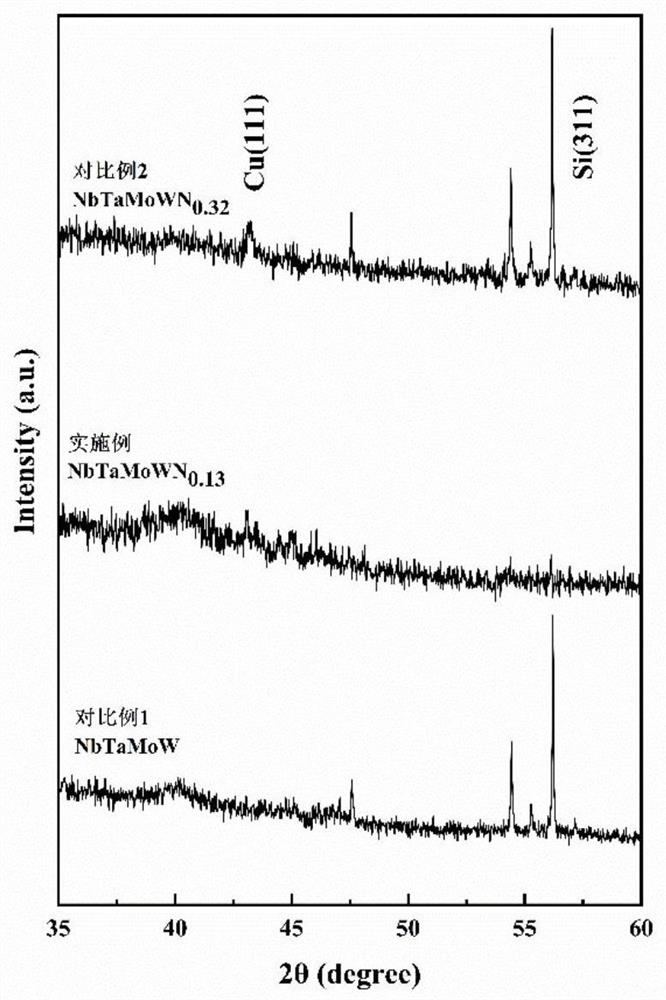

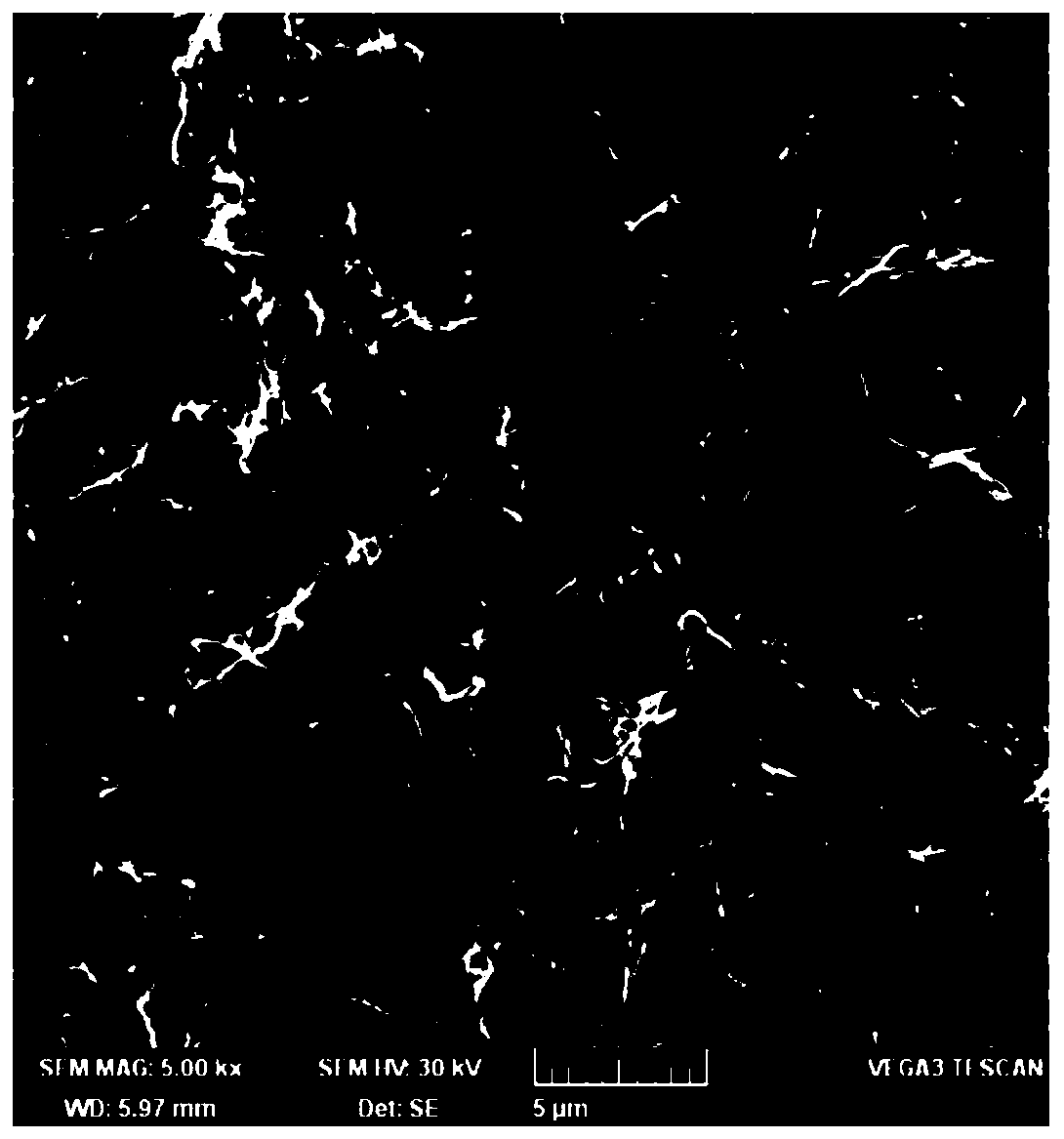

NbTaMoWNx nitride coating with high-temperature diffusion shielding performance and preparation method thereof

PendingCN113957385ADifficult to spreadInhibitionVacuum evaporation coatingSputtering coatingHigh entropy alloysHeat stability

The invention discloses an NbTaMoWNx nitride coating with high-temperature diffusion shielding performance and a preparation method thereof. According to the method, NbTaMoW high-entropy alloy is used as a magnetron sputtering target material, and the NbTaMoWNx nitride coating with the high-temperature diffusion shielding performance is prepared by adopting a direct-current magnetron sputtering method under the atmosphere of Ar and N2. The NbTaMoWNx nitride coating is prepared by adopting the direct-current magnetron sputtering method, the process is simple, convenient and rapid, the repeatability is good, and the prepared NbTaMoWNx nitride coating is of an amorphous phase structure, is small in thickness, has good thermal stability, electrical performance and high-temperature diffusion shielding performance, and can be applied to an integrated circuit to serve as a diffusion shielding layer in a Cu-Si device.

Owner:NANJING UNIV OF SCI & TECH

Copper current collector surface nanocrystallization method

ActiveCN109817892ASimple methodImprove controllabilityMaterial nanotechnologyElectrode manufacturing processesCarbon depositNanostructure

The invention relates to the field of lithium ion batteries, in particular to a copper current collector surface nanocrystallization method. The method comprises the following steps: 1) preparing an eroded copper matrix and pre-matrix; 2) reducing the pre-matrix to prepare a porous template; 3) depositing active metal to prepare an activated template; 4) preparing a precursor by utilizing an anodedissolution principle; and 5) calcining to prepare a copper current collector with active metal and carbon deposited on the surface and forming a nano structure. The method is simple, high in repeatability and good in controllability; the three-dimensional nano-copper is electrochemically inert and stable in structure; due to the structure of the three-dimensional nano-copper, diffusion channelsof lithium ions are greatly reduced, polarization is reduced, and the cycle performance and the rate capability can be improved to a great extent; the electrochemical performance of the electrode material is further improved by depositing active metal elements and further improving the specific surface area of a nano structure of the electrode material; and the negative electrode material preparedby the method does not need a binder or a conductive agent, so that the specific capacity of a battery is improved.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of water-resistant inorganic sodium silicate adhesive

InactiveCN110172302AReduce adhesionImprove bindingNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveGlucose polymers

The invention discloses a preparation method of a water-resistant inorganic sodium silicate adhesive, and belongs to the technical field of inorganic adhesion materials. By weight, 50-60 parts of sodium silicate, 10-12 parts of sodium fluorosilicate, 5-8 parts of a reducing agent, 40-60 parts of water, 5-8 parts of polydimethyl siloxane, 3-4 parts of a dispersing agent, 15-22 parts of modified powder and 8-15 parts of a modified glucose solution are weighed in sequence; the water is mixed with the modified glucose solution, the modified powder and the reducing agent are added, and after stirring is conducted for a reaction, a billet liquid is obtained; the billet liquid is mixed with the sodium fluorosilicate, the sodium silicate and the dispersing agent are added, and the water-resistantinorganic sodium silicate adhesive is obtained after stirring and mixing. By means of the method, the obtained water-resistant inorganic sodium silicate adhesive has excellent adhesion properties andwater resistance.

Owner:宋昆昆

Method for preparing composite carbon cathode material for super-capacitor battery

InactiveCN101763944BGood lithium ion intercalation/extraction cycle performanceExcellent Capacitive Energy Storage PerformanceElectrolytic capacitorsChemical platingElectrical battery

The invention relates to a high-rate lithium-ion battery and a method for preparing a composite carbon cathode material for a super-capacitor battery. The method comprises the following steps: coating a surface-nano-crystallized core with a porous carbon coat provided with macro-pore / meso-pore / micro-pore three-dimensional layer pores; doping metal particles on the surface of the coat; and carrying out low-potential treatment, wherein the three steps are sequentially achieved by a template-based method, a combined method comprising dipping, chemical plating and physical mixing, and an electrochemical method of lithium pre-doping respectively. The process of the invention has the advantages of simple method and convenient operation; the prepared material has a core-coat structure and doped metallic elements, and meanwhile, the material has good performance in double-layer electric energy storage and lithium-ion intercalation and de-intercalation energy storage and effectively improves the high-rate performance and power density of the lithium-ion battery; the material meets the requirements of super-capacitor batteries in both the lithium-ion energy storage and double-layer electricenergy storage of the cathode material; accordingly, the material can be used as the cathode of a high-performance lithium-ion battery; and the material has good performance in high-rate charging / discharging, so the material has a good prospect for industrialization.

Owner:CENT SOUTH UNIV +1

A high temperature oxidation resistant thermal barrier coating with composite structure and its preparation method

ActiveCN105734500BShortened diffusion channelReduce spreadVacuum evaporation coatingSputtering coatingCrystal structureOxidation resistant

The invention provides a high temperature oxidation-resistant thermal barrier coating layer with a composite structure. The high temperature oxidation-resistant thermal barrier coating layer comprises a metal bonding layer, a first ceramic layer, a second ceramic layer, a metal deposition layer, a third ceramic layer and a fourth ceramic layer deposited at the top of a high-temperature alloy basal body in sequence; the first ceramic layer and the third ceramic layer are both isometric crystal structures; the second ceramic layer and the fourth ceramic layer are both columnar crystal structures; components of the ceramic layers are ZrO2 with stable Y2O3; components of the metal bonding layer are MCrAlY; and components of the metal deposition layer are MCrAlY or NiAl, wherein M is Ni or / and Co. The invention further provides a method for preparing the high temperature oxidation-resistant thermal barrier coating layer. The high temperature oxidation-resistant thermal barrier coating layer has multiple layers of laminated isometric crystal and columnar crystal structures, and is excellent in oxygen resistance and thermal shock resistance; and the preparation method is simple in process, excellent in repeatability and easy to operate.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

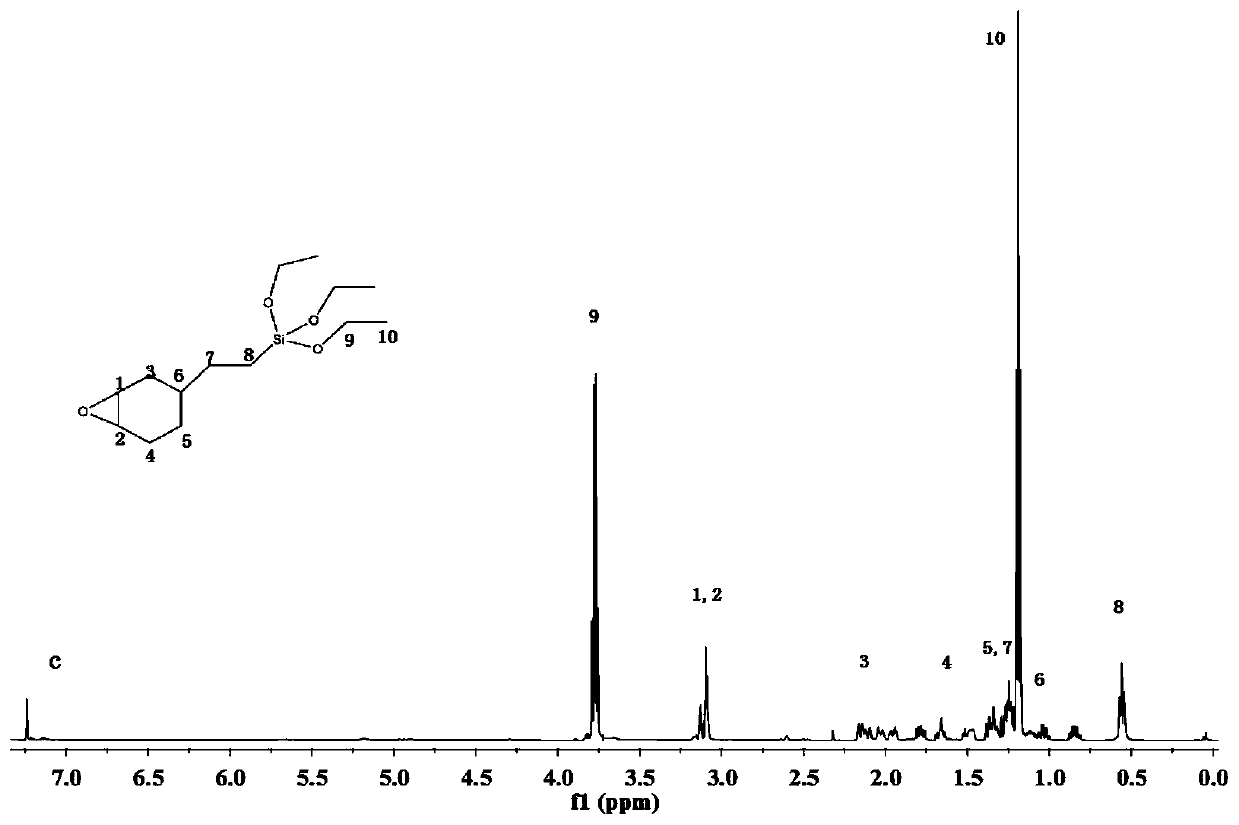

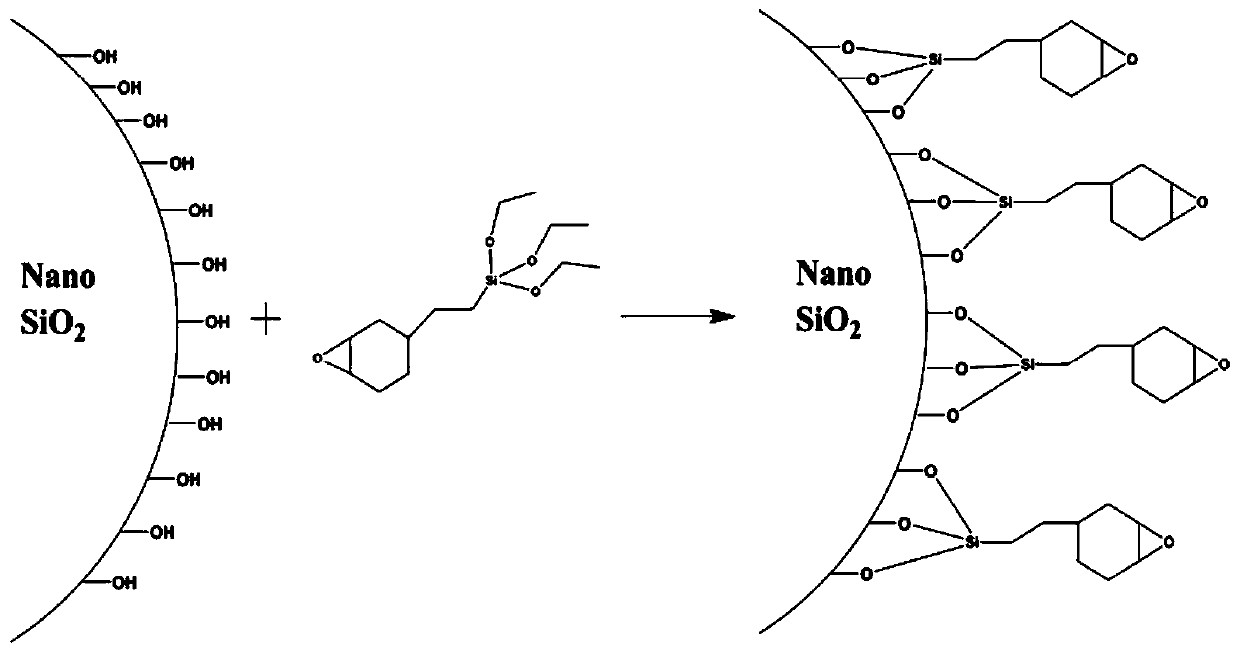

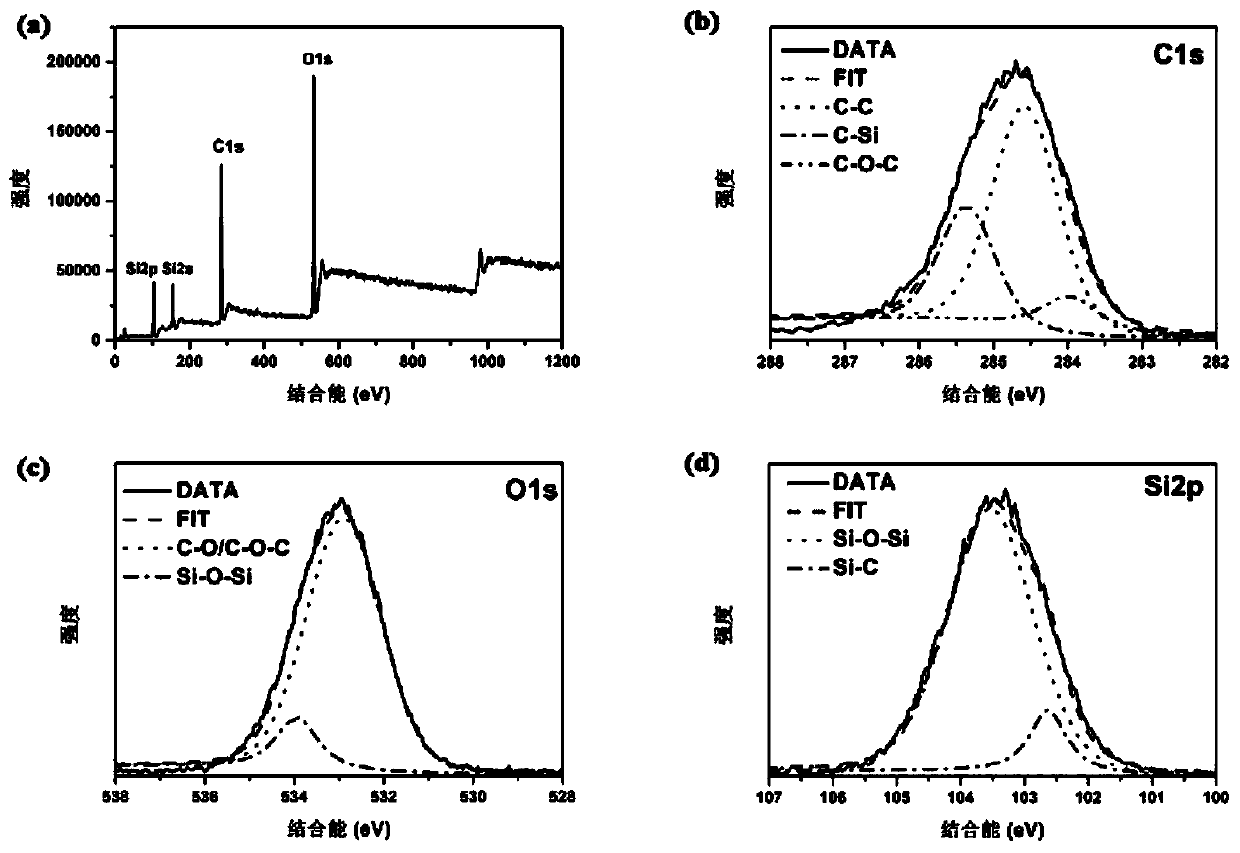

A kind of preparation method with high corrosion resistance epoxy resin coating

ActiveCN107722792BImprove interface compatibilitySolve the problem of poor dispersionGroup 4/14 element organic compoundsAnti-corrosive paintsPolymer scienceNano sio2

Owner:JILIN UNIV

A method for preparing a high-entropy alloy diffusion barrier layer for Cu interconnection integrated circuits

ActiveCN108336062BHigh bulk densityShortened diffusion channelSemiconductor/solid-state device detailsSolid-state devicesHigh entropy alloysAlloy coating

The invention relates to the technical field of semiconductor integrated circuits, in particular to a high-entropy alloy diffusion barrier layer for a Cu interconnect integrated circuit and a preparation method of the high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit. The high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit sequentially comprises a Si substrate layer, a high-entropy alloy intermediate coating and a Cu film from bottom to top, wherein the high-entropy alloy intermediate coating sequentially comprises a third coating, a second coating and a first coating from bottom to top; the first coating is an AlCrTaTiZrMo high-entropy alloy coating; the second coating is a pure Ti coating; and the third coating is an AlCrTaTiZrMoNx high-entropy alloy coating. According to the high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit, improvement of the atomic bulk density is facilitated,generation of defects, such as vacancies is reduced, a diffusion channel for atoms is reduced, and the diffusion barrier performance and the heat stability of the high-entropy alloy coatings are improved.

Owner:SHANGHAI DIANJI UNIV

A Zr-based high-entropy alloy coating that improves the life of a hot forging die and its preparation method

ActiveCN113025966BDense tissueImprove bindingVacuum evaporation coatingSputtering coatingHigh entropy alloysDiffusion wear

The embodiment of the invention discloses a Zr-based high-entropy alloy coating and a preparation method thereof for improving the service life of a hot forging die, belonging to the technical field of metal surface treatment. The Zr-based high-entropy alloy coating refers to the primer layer, the transition layer and the functional layer, and the thicknesses are respectively 200-400nm, 2000-4000nm, and 1000-2000nm. The film layer of the present invention is composed of multi-principal elements with different atomic radii, and has a compact structure, which reduces the diffusion channels of atoms, improves the diffusion barrier performance of the coating, and reduces the diffusion wear of the mold, and the composition is from the substrate to the surface of the film layer. The content of nitrides in the ZrTiN~AlCrSiN transition layer increases linearly and continuously, which improves the matching of the film structure and performance. There is no composition difference interface in the film layer, which ensures high adhesion, high hardness and Simultaneous realization of high thermal shock resistance.

Owner:安徽智模新材料科技有限公司

Preparation method and application of silicon-based composite negative electrode material for lithium ion battery

ActiveCN109301224BIncrease the speed of diffusionShortened diffusion channelMaterial nanotechnologyCell electrodesCarbon compositesHeteropoly acid

The invention discloses a preparation method and an application of a lithium ion battery silicon-based negative electrode material, and belongs to the field of electrochemical materials and new energyresources. The preparation method of the negative electrode material includes the steps: (1) dispersing nano-silicon and conductive macromolecules in an organic solvent to obtain mixed solution, andperforming spray-drying and high-temperature heat treatment on the mixed solution to obtain a silicon / amorphous carbon composite material; (2) collectively dispersing the silicon / amorphous carbon composite material and heteropoly acid in the organic solvent, and spray-drying mixture to obtain silicon / amorphous carbon composite material adsorbed by the heteropoly acid; (3) collectively dispersing the composite material acquired in the step (2) and the conductive macromolecules again, and spray-drying mixture to obtain the silicon-based negative electrode material with a multilayer structure ofsilicon / amorphous carbon / heteropoly acid / conductive macromolecule. The negative electrode material is simple in preparation route and has high charging and discharging capacity and excellent circulation performance and potential application prospects in the field of high-performance lithium ion batteries.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

Core-shell structure gradient nickel-cobalt-manganese ternary cathode material precursor and preparation method thereof

The invention discloses a core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material precursor and a preparation method thereof. The ternary positive electrode materialprecursor is core-shell structure particles with the average particle size of 4-12 [mu]m, wherein an inner core is hydroxide precipitates of nickel, cobalt and manganese, a shell layer is carbonate precipitates of nickel, cobalt and manganese, the nickel content decreases gradually from the center of the core-shell structure particles to the surface of the shell layer, the manganese content increases gradually from the center of the core-shell structure particles to the surface of the shell layer, and the cobalt content is distributed evenly between the center of the core-shell structure particles and the shell layer. The invention also discloses the preparation method of the ternary positive electrode material precursor. A ternary positive electrode material obtained after the ternary positive electrode material precursor is mixed with lithium and calcined is assembled into a battery, at 0.1 C, the first discharge capacity can reach 198 mAh / g and still keeps at 182 mAh / g after the battery is circulated for 100 cycles, and the specific discharge capacity can reach 176.3 mAh / g at 5 C. The method is simple in process, low in cost and suitable for industrialized production.

Owner:ZHUJI PAWA NEW ENERGY

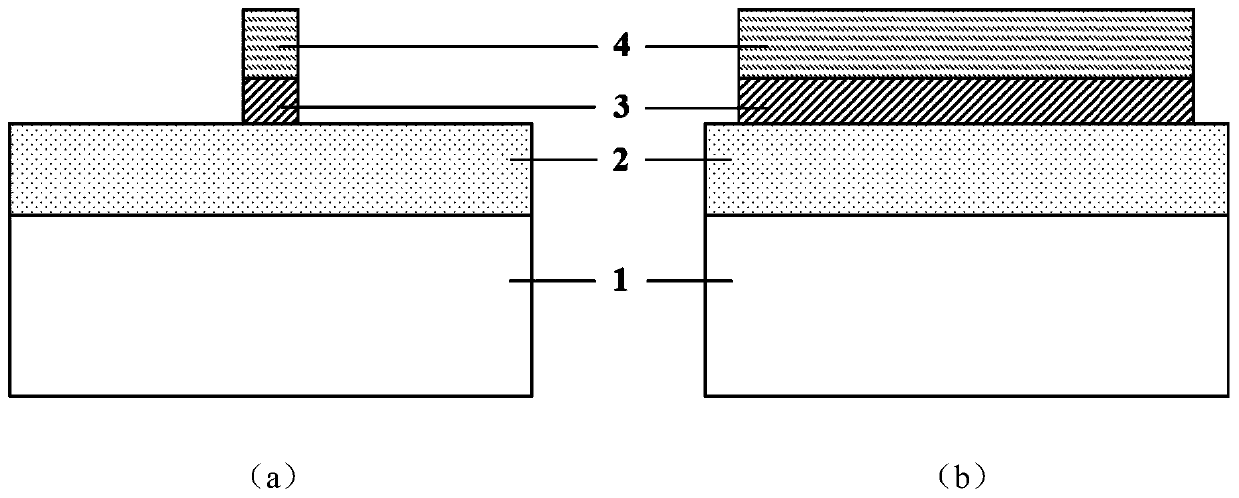

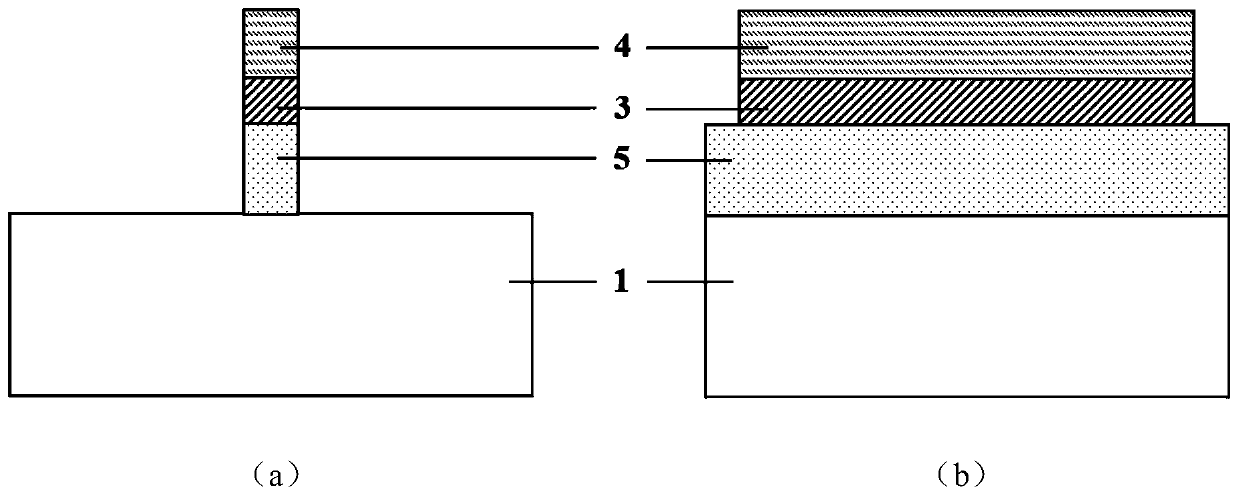

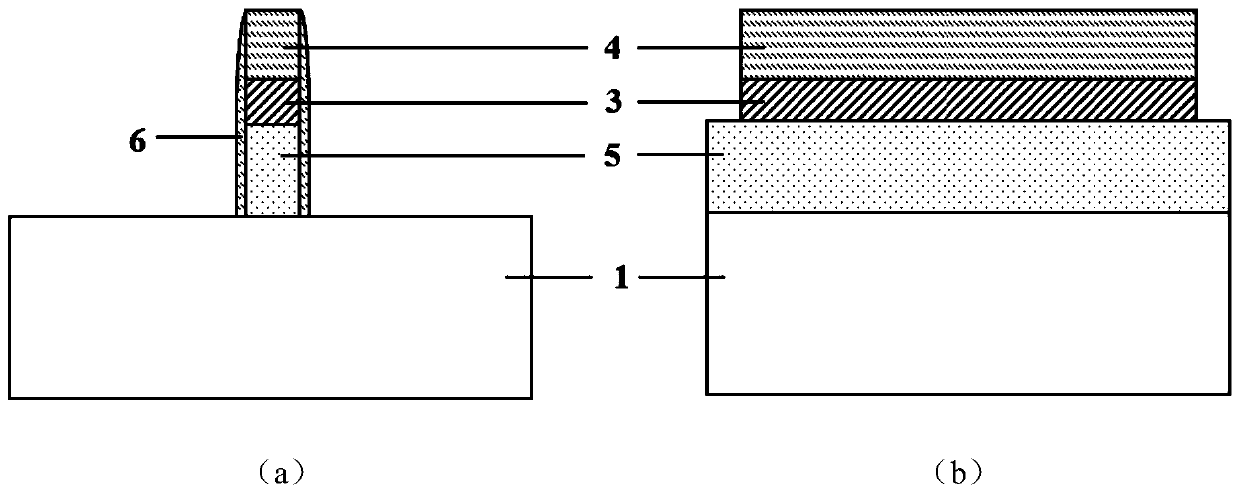

A germanium silicon channel fin field effect transistor and its preparation method

ActiveCN106952959BImprove mobilityShortened diffusion channelSemiconductor/solid-state device manufacturingSemiconductor devicesCharge carrier mobilityEngineering

The invention discloses a germanium-silicon channel fin type field effect transistor and a preparation method thereof. According to the germanium-silicon channel fin type field effect transistor, a body-on-insulator (BOI) structure is formed through thermal oxidation; a current leakage channel between a source and a drain is cut off; a leakage current of a device can be effective suppressed; the buried oxide layer area of the germanium-silicon channel fin type field effect transistor is smaller than that of an SGOI FinFET; and a heat dissipation effect can be improved. Moreover, in an oxidization process, a germanium accumulation technology is beneficial for improving a germanium component in a channel; the carrier mobility is improved; and an on state current is improved.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com