Core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material precursor and preparation method thereof

A core-shell structure and cathode material technology, applied in the core-shell structure gradient nickel-cobalt-manganese ternary cathode material precursor and its preparation field, can solve the problems of complex preparation process, achieve simple process, improve electrochemical performance, and high capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

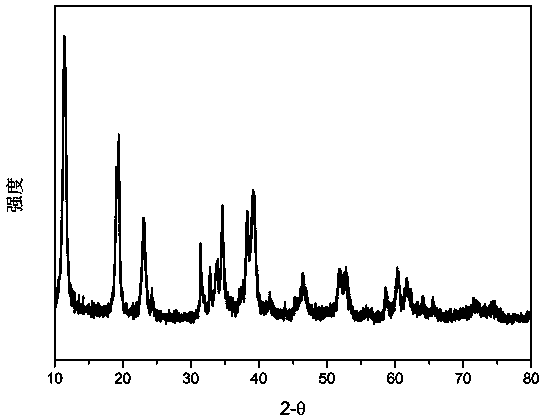

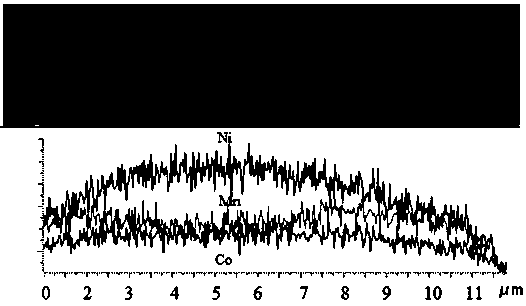

[0053] The precursor of the ternary positive electrode material is a core-shell structure particle with an average particle size of 10 μm; wherein, the inner core is a hydroxide precipitate of nickel-cobalt-manganese, the shell layer is a carbonate precipitate of nickel-cobalt-manganese, and the nickel content is reduced from the core-shell The center of the structure particle decreases gradually to the surface of the shell layer, the manganese content gradually increases from the center of the core-shell structure particle to the surface of the shell layer, and the content of cobalt is evenly distributed between the center of the core-shell structure particle and the shell layer; the average diameter of the inner core The average thickness of the shell layer is 2 μm; the shell layer has micropores with a pore diameter of 0.2-0.5 μm.

[0054] Example 1 of the preparation method of the core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material prec...

Embodiment 2

[0065] The precursor of the ternary positive electrode material is a core-shell structure particle with an average particle size of 12 μm; wherein, the inner core is a hydroxide precipitate of nickel-cobalt-manganese, and the shell layer is a carbonate precipitate of nickel-cobalt-manganese, and the nickel content is reduced from the core-shell The center of the structure particle decreases gradually to the surface of the shell layer, the manganese content gradually increases from the center of the core-shell structure particle to the surface of the shell layer, and the content of cobalt is evenly distributed between the center of the core-shell structure particle and the shell layer; the average diameter of the inner core The shell layer has an average thickness of 3 μm; the shell layer has micropores with a pore diameter of 0.1-0.4 μm.

[0066] Example 2 of the preparation method of the core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material ...

Embodiment 3

[0077] The precursor of the ternary positive electrode material is a core-shell structure particle with an average particle size of 11 μm; wherein, the inner core is a hydroxide precipitate of nickel-cobalt-manganese, and the shell layer is a carbonate precipitate of nickel-cobalt-manganese, and the nickel content is reduced from the core-shell The center of the structure particle decreases gradually to the surface of the shell layer, the manganese content gradually increases from the center of the core-shell structure particle to the surface of the shell layer, and the content of cobalt is evenly distributed between the center of the core-shell structure particle and the shell layer; the average diameter of the inner core The average thickness of the shell layer is 4 μm; the shell layer has micropores with a pore diameter of 0.1-0.5 μm.

[0078] Example 3 of the preparation method of the core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com