Patents

Literature

879 results about "Nickel content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Austenoferritic stainless steel having a very low nickel content and a high tensile elongation

InactiveUS6096441ALow nickel contentImproved general propertyHeat treatment process controlElectric furnaceSulfurManganese

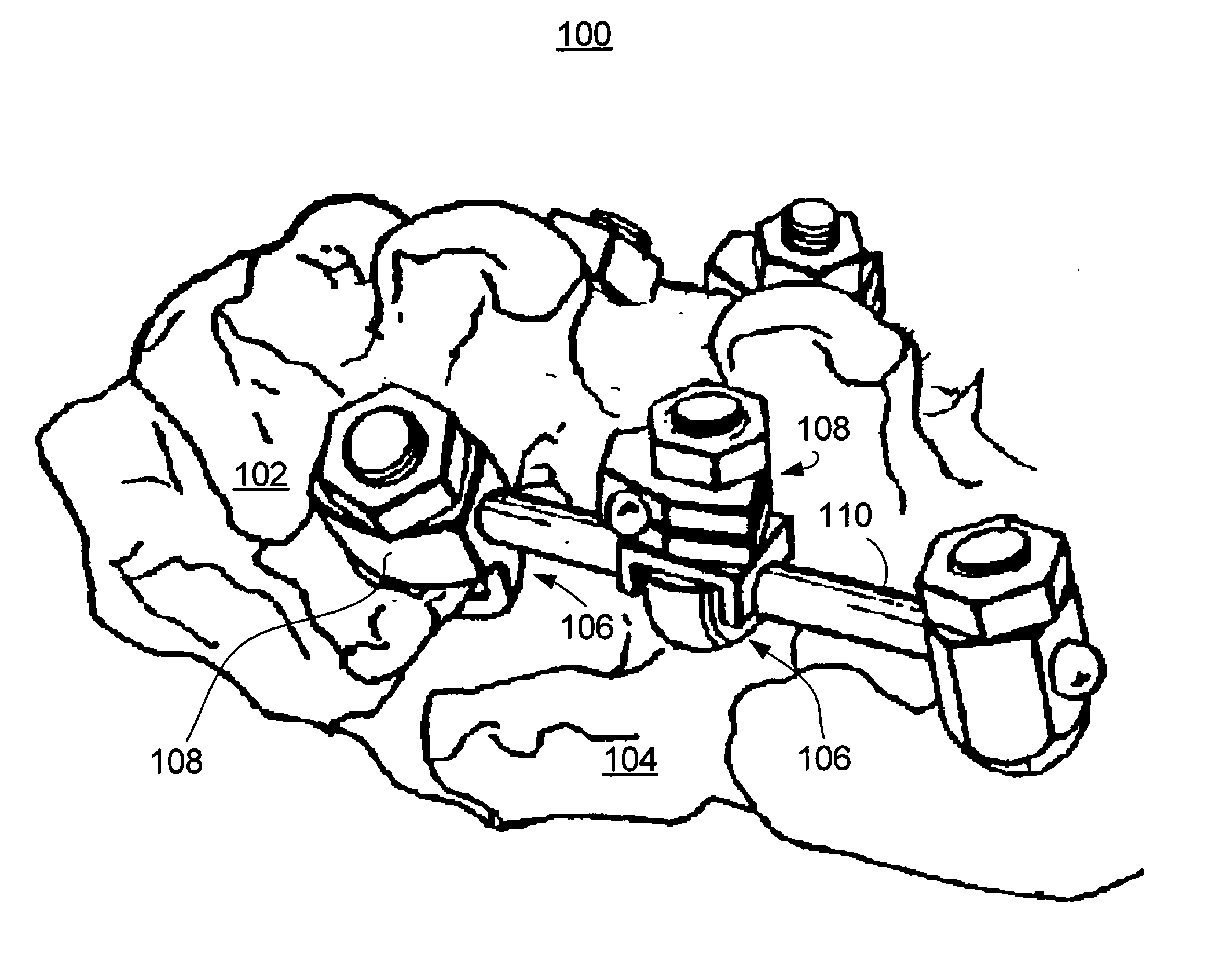

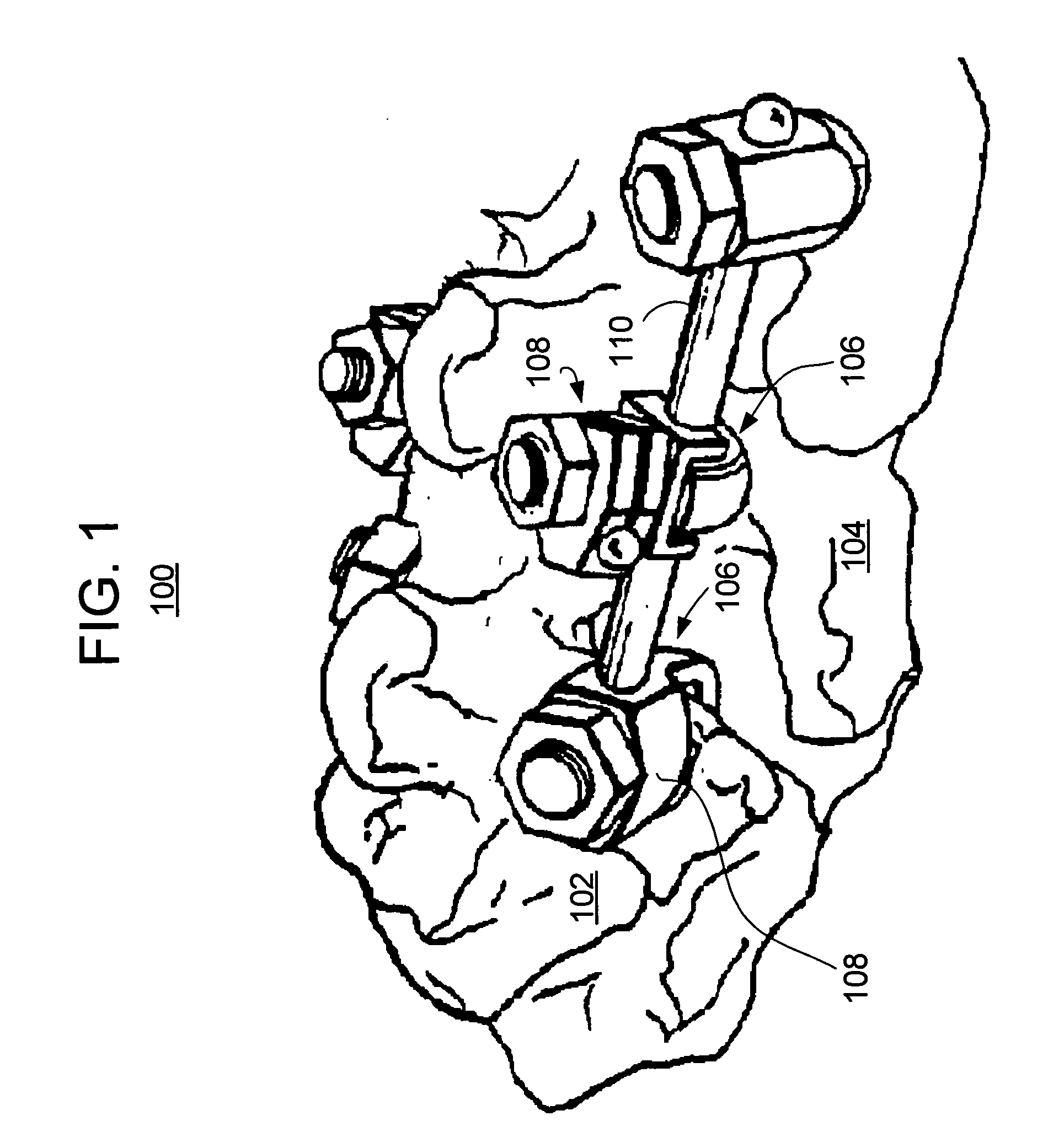

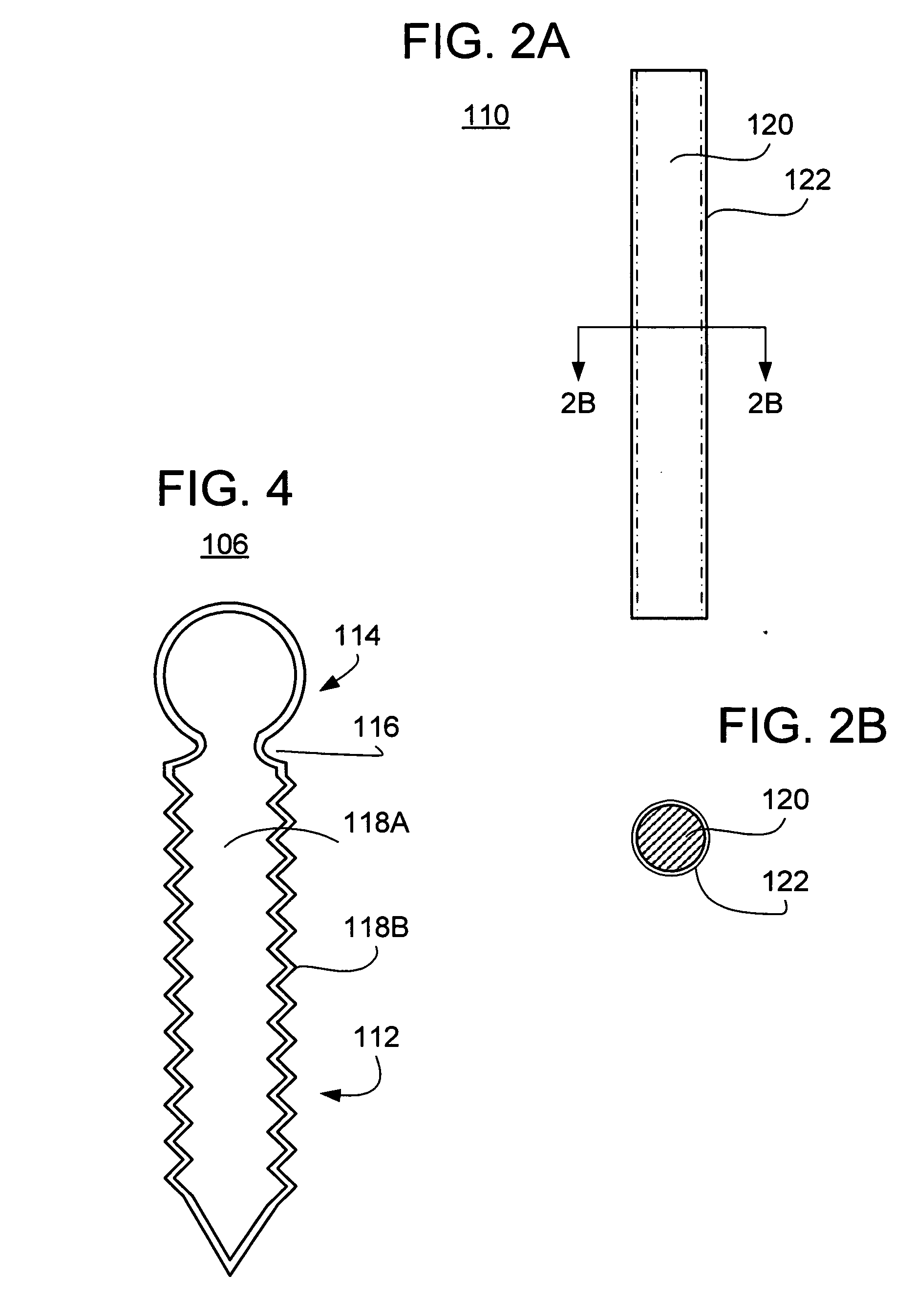

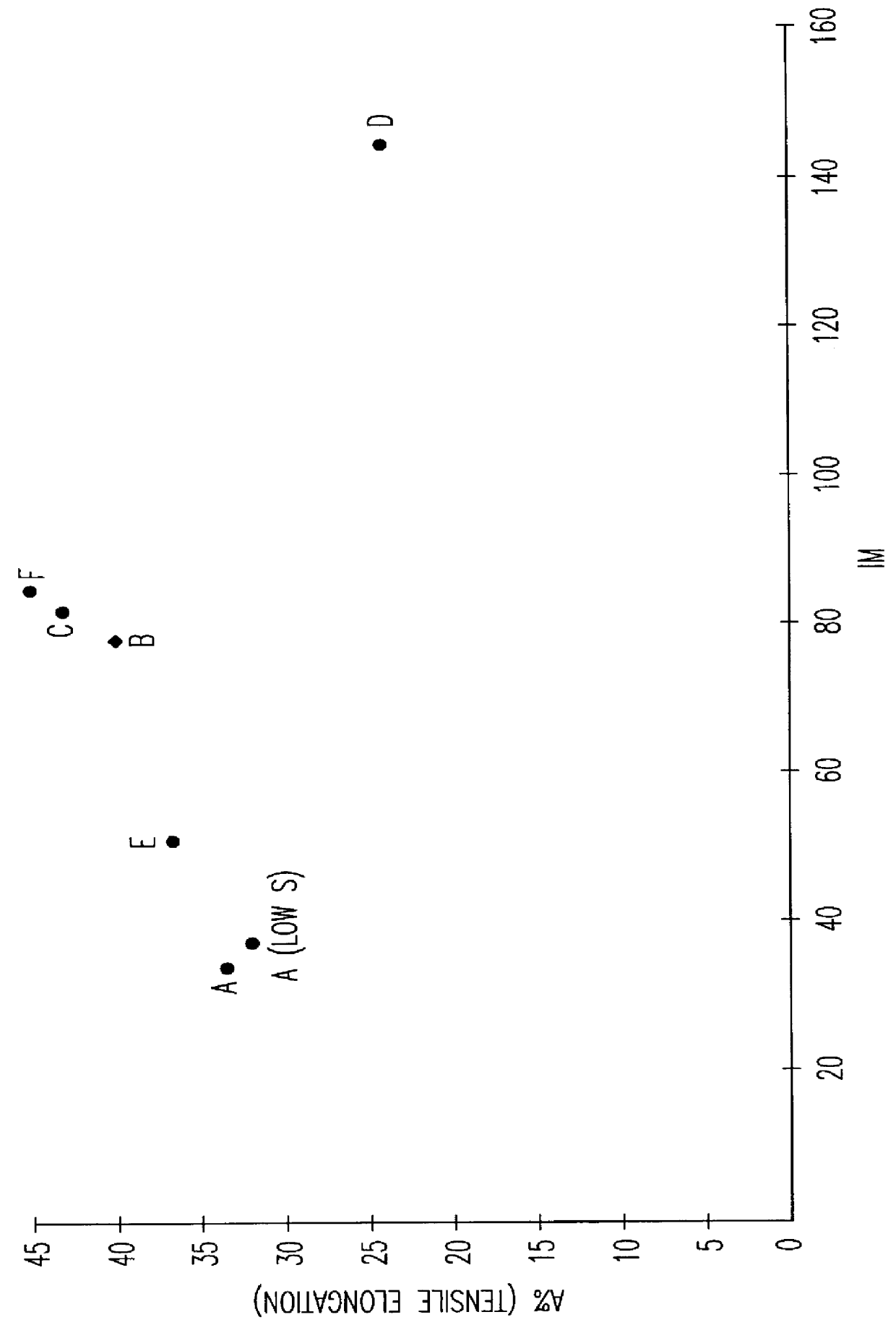

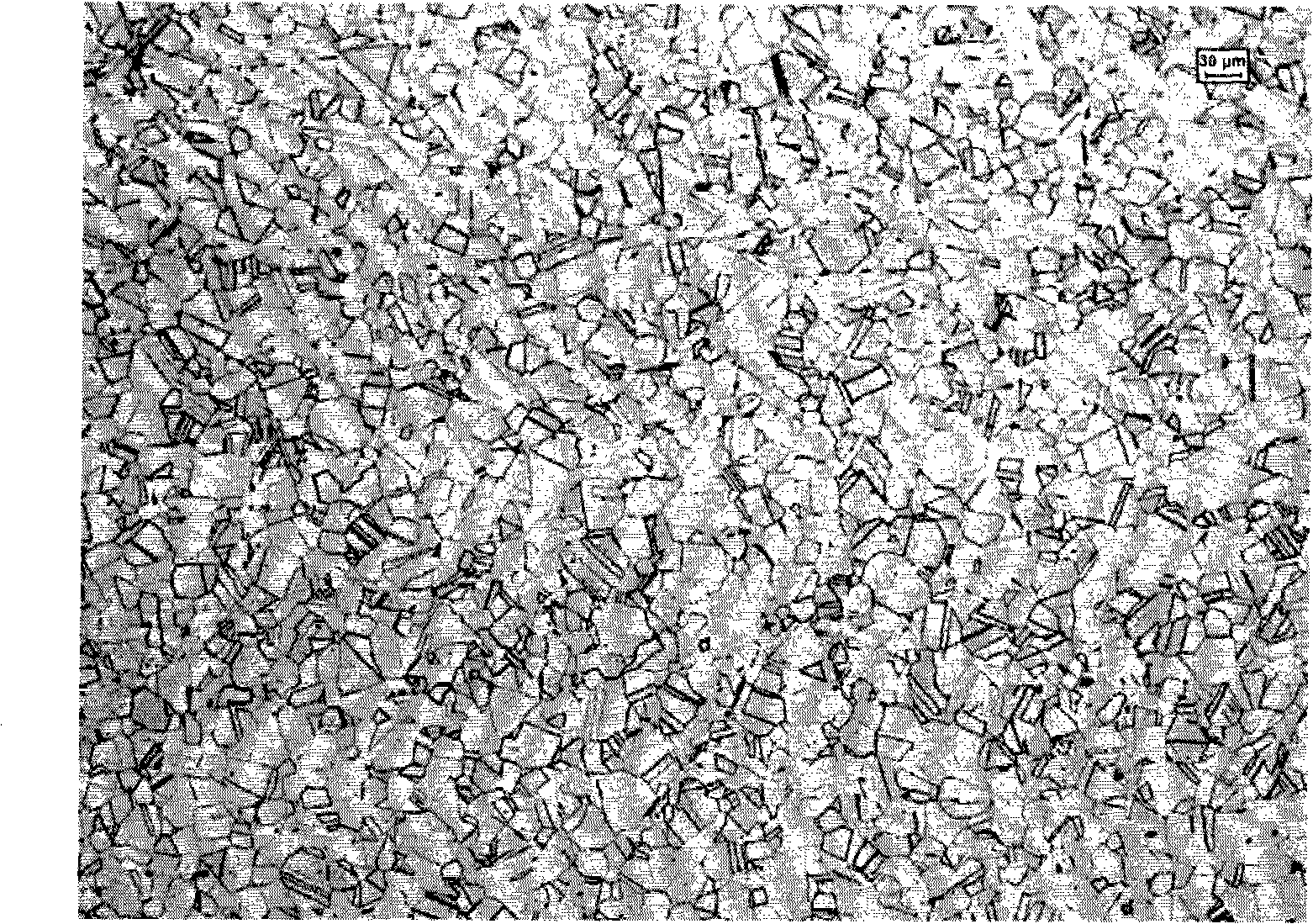

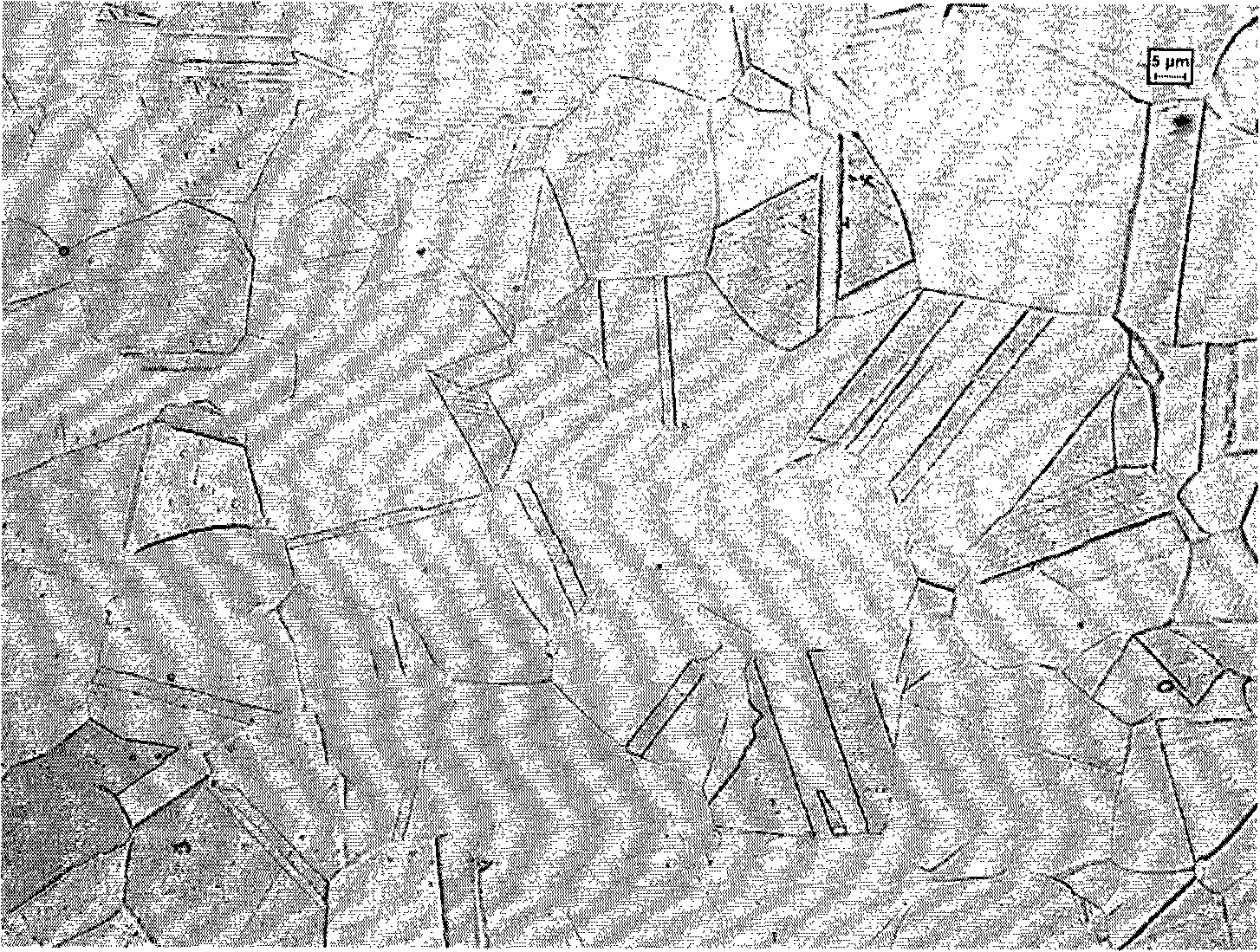

An austenoferritic stainless steel with high tensile elongation includes iron and the following elements in the indicated weight amounts based on total weight: carbon<0.04% 0.4%<silicon<1.2% 2%<manganese<4% 0.1%<nickel<1% 18%<chromium<22% 0.05%<copper<4% sulfur<0.03% phosphorus<0.1% 0.1%<nitrogen<0.3% molybdenum<3% the steel having a two-phase structure of austenite and ferrite and comprising between 30% and 70% of austenite, wherein Creq=Cr %+Mo %+1.5 Si % Nieq=Ni %+0.33 Cu %+0.5 Mn %+30 C %+30 N % and Creq / Nieq is from 2.3 to 2.75, and wherein IM=551-805(C+N)%-8.52 Si %-8.57 Mn %-12.51 Cr %-36 Ni %-34.5 Cu %-14 Mo %, IM being from 40 to 115.

Owner:UGITECH

Preparation of amines

InactiveUS6140539ASimplifies work-upIncreased space-time yieldOrganic compound preparationOrganic chemistry methodsHydrogenMetal

In a process for preparing amines, in which at least one compound containing at least one nitro group is reacted with hydrogen in the presence of a supported catalyst comprising, as catalytically active metal, nickel, if desired together with at least one metal of transition group I, V, VI and / or VIII, the reduced and stabilized supported catalyst comprises nickel crystallites having a bimodal nickel crystallite size distribution having maxima at 30-80 Angstr+E,uml o+EE m and 81-150 Angstr+E,uml o+EE m on a support comprising ZrO2, ZrO2-HfO2 and / or SiO2-ZrO2 and / or SiO2-ZrO2-HfO2 and in the reduced and passivated state has a nickel content of 60-80 percent by mass, an SiO2 content of 0-20 percent by mass, a ZrO2 content of 0-40 percent by mass, an HfO2 content of 0-4 percent by mass and after further reduction for one hour at 100 DEG C. has a degree of reduction of at least 70%.

Owner:BASF AG

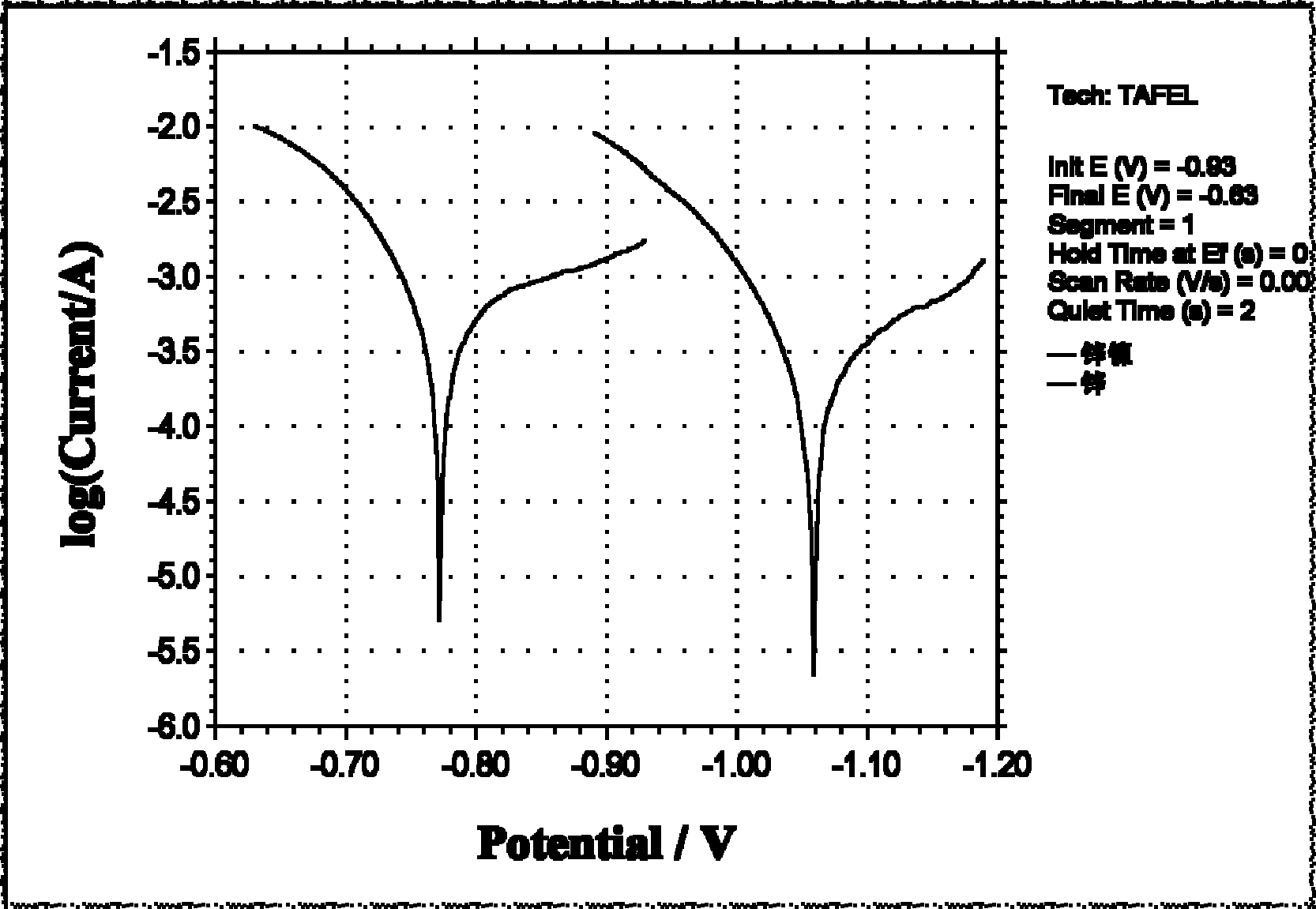

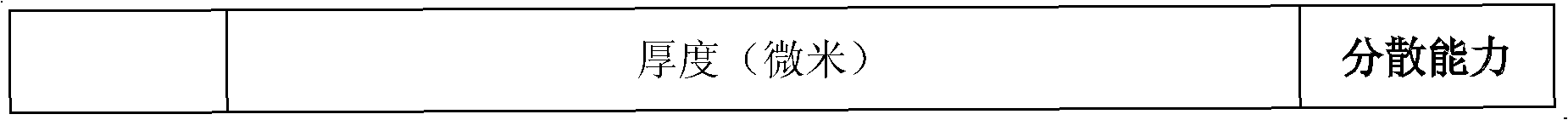

Alkaline electroplating Zn-Ni alloy additive, electroplating solution and preparation method

The invention relates to an alkaline electroplating Zn-Ni alloy additive, an electroplating solution and a preparation method. The additive comprises the following components in parts by weight: 3.5 to 4.5 parts of nickel complex agent, 6 to 8 parts of nickel source, 7 to 8.5 parts of zinc complex agent, 1.5 to 2.5 parts of brightening agent and 0.2 to 0.3 part of throwing agent. The preparation method comprises the following steps: adding zinc oxide into dissolved sodium hydroxide, stirring and dissolving; adding the zinc complex agent, the nickel complex agent, nickel replenisher, the brightening agent and the throwing agent in turn; and stirring to ensure that the mixture is mixed uniformly so as to prepare the electroplating solution containing the additive. The alkaline electroplating Zn-Ni alloy additive can acquire excellent metal distribution and constant alloy composition within a wide current density range, has stable nickel content of the plating in a range of between 12 and 15 percent, excellent corrosion resistance which is over five times more than a conventional zinc coating, excellent dispersive power and higher current efficiency, and can be used for barrel plating or rack plating with small coating stress, high ductility and excellent brightness.

Owner:济南德锡科技有限公司

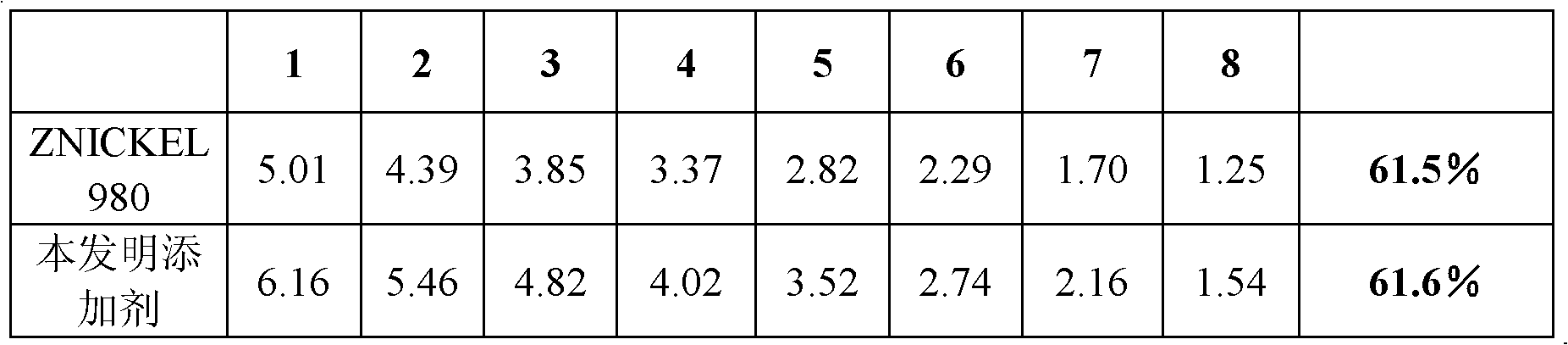

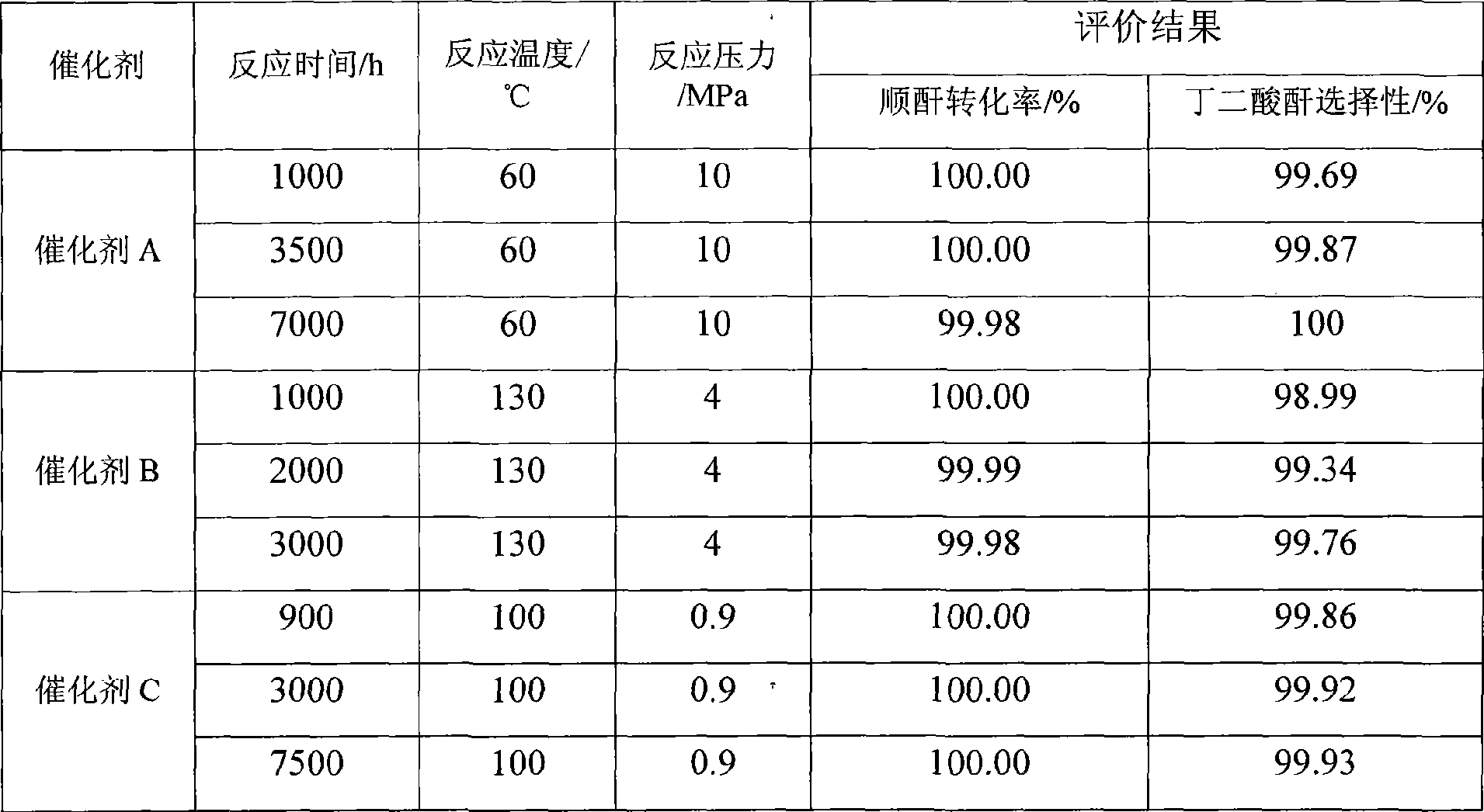

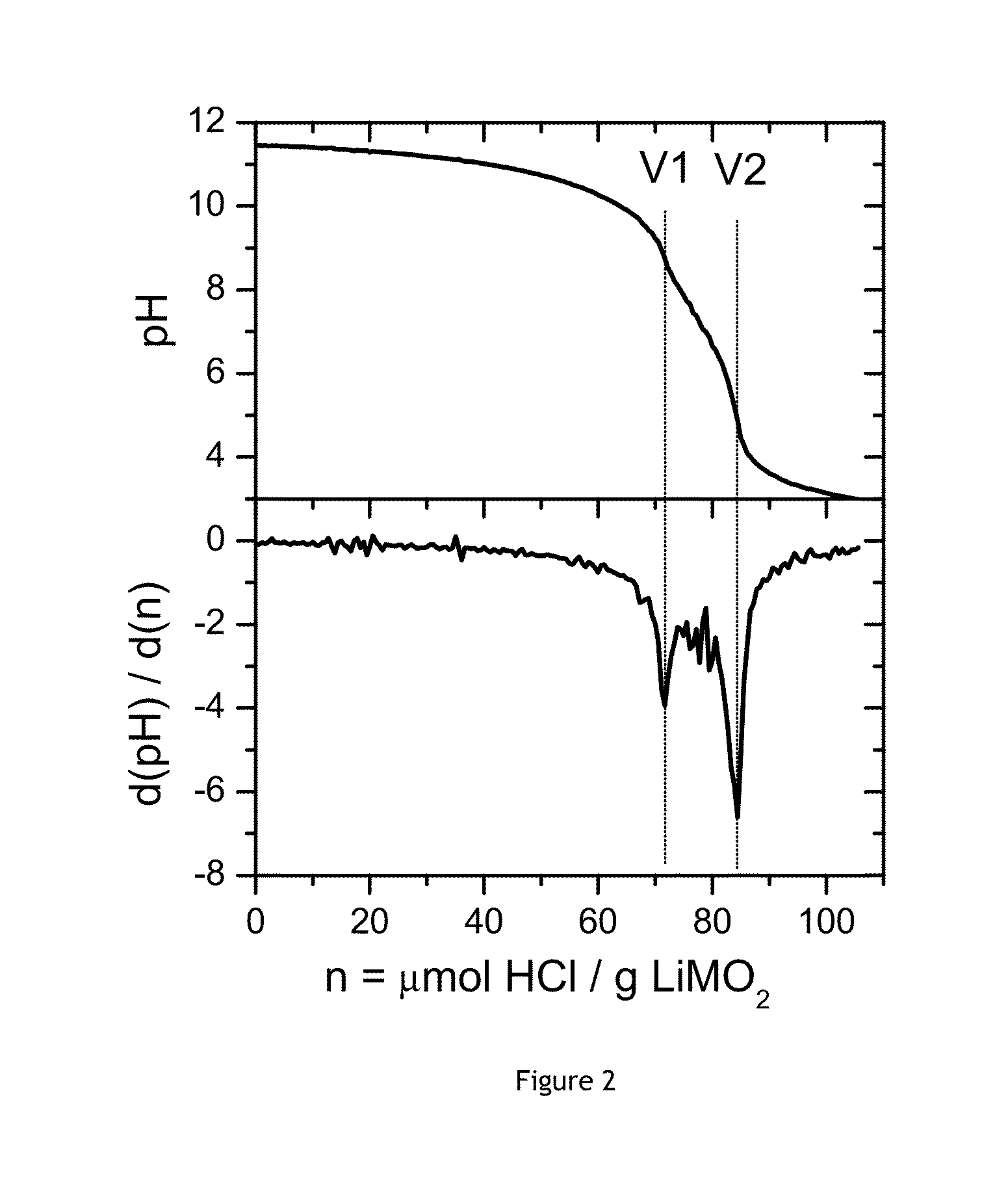

Preparation method of butanediol secondary hydrogenation catalyst by butynediol two-step hydrogenation

ActiveCN101306368AUniform depositionGood dispersionPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSURFACTANT BLEND

The invention provides a method for preparing a butanediol secondary hydrogenation catalyst through adopting the butynediol two-step hydrotreation, and the method comprises the following steps: an accelerant is introduced into an alumina carrier; the carrier is heated; mixed nickel complex solution containing organic nickel salt, inorganic nickel salt and surfactant is prepared; the mixed nickel salt solution is dipped on the heated carrier, and the catalyst product with the nickel content of 5-25 w% and the accelerant content of 0.001-6 w% can be obtained by drying, baking, deoxidizing and passivating. The catalyst can be used in the process of preparing the butanediol secondary hydrogenation by adopting the butynediol two-step hydrotreation, the carbonyl can be reduced to be lower than 0.2 mg (KOH)*g<-1>, and the contents of acetal and butylene glycol are enabled to be reduced to the lowest level. Through the subsequent rectification, the butylene glycol product with the purity more than or equal to 99.5 percent and the chromaticity lower than or equal to 10 AHPA can be produced.

Owner:SHANXI UNIV

Catalyst for continuous production of succinic anhydride from hydrogenation of maleic anhydride and preparation method thereof

ActiveCN101502802AHigh yieldHigh activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFixed bedHigh activity

The invention provides a catalyst for continuously producing butanedioic anhydride by maleic anhydride hydrogenation. The catalyst is a nickel loaded catalyst prepared by an equivalent-volume impregnation method, wherein in the catalyst, the content of nickel is 13 to 20 weight percent, the content of accelerating agent is 1 to 7 weight percent, and a carrier is a composite oxide of SiO2 and Al2O3 or SiO2-Al2O3. A preparation method for the catalyst comprises the following steps: impregnating impregnation solution blended by ammonia water and active metal salt solution on a carrier subjected to baking pretreatment at a temperature between 400 and 800 DEG C by the equivalent-volume impregnation method to form the catalyst through drying, baking and reducing treatment. The catalyst is applied to continuously preparing the butanedioic anhydride by maleic anhydride hydrogenation on a fixed bed reactor, the conversion rate of maleic anhydride is more than or equal to 99.98 percent, and the selectivity of the butanedioic anhydride is more than or equal to 98.85 percent. The catalyst achieves the technical-scale continuous production of the butanedioic anhydride, and has the advantages of high activity, good selectivity, high yield (more than or equal to 98.83 percent) and long service life.

Owner:SHANXI UNIV

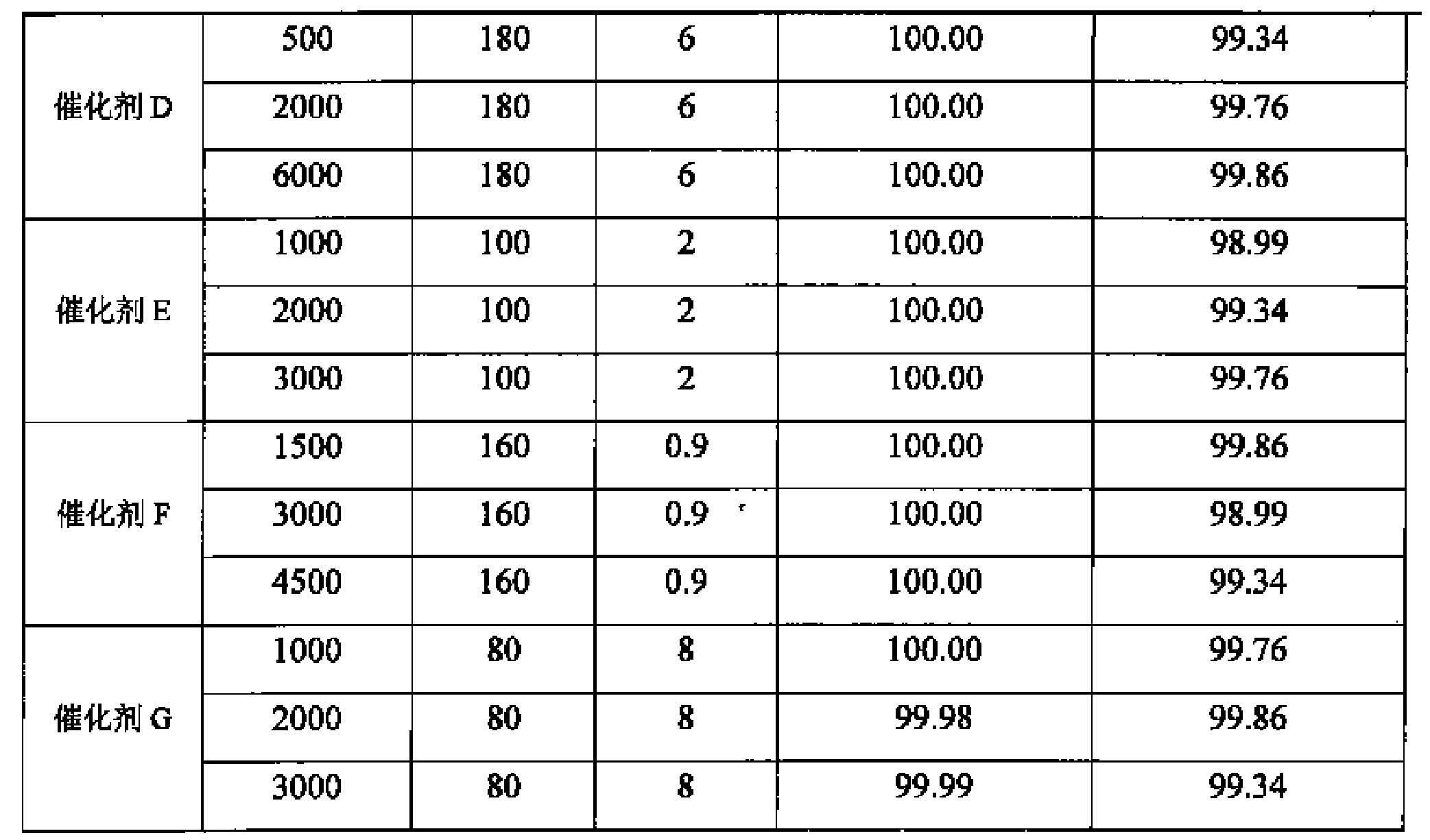

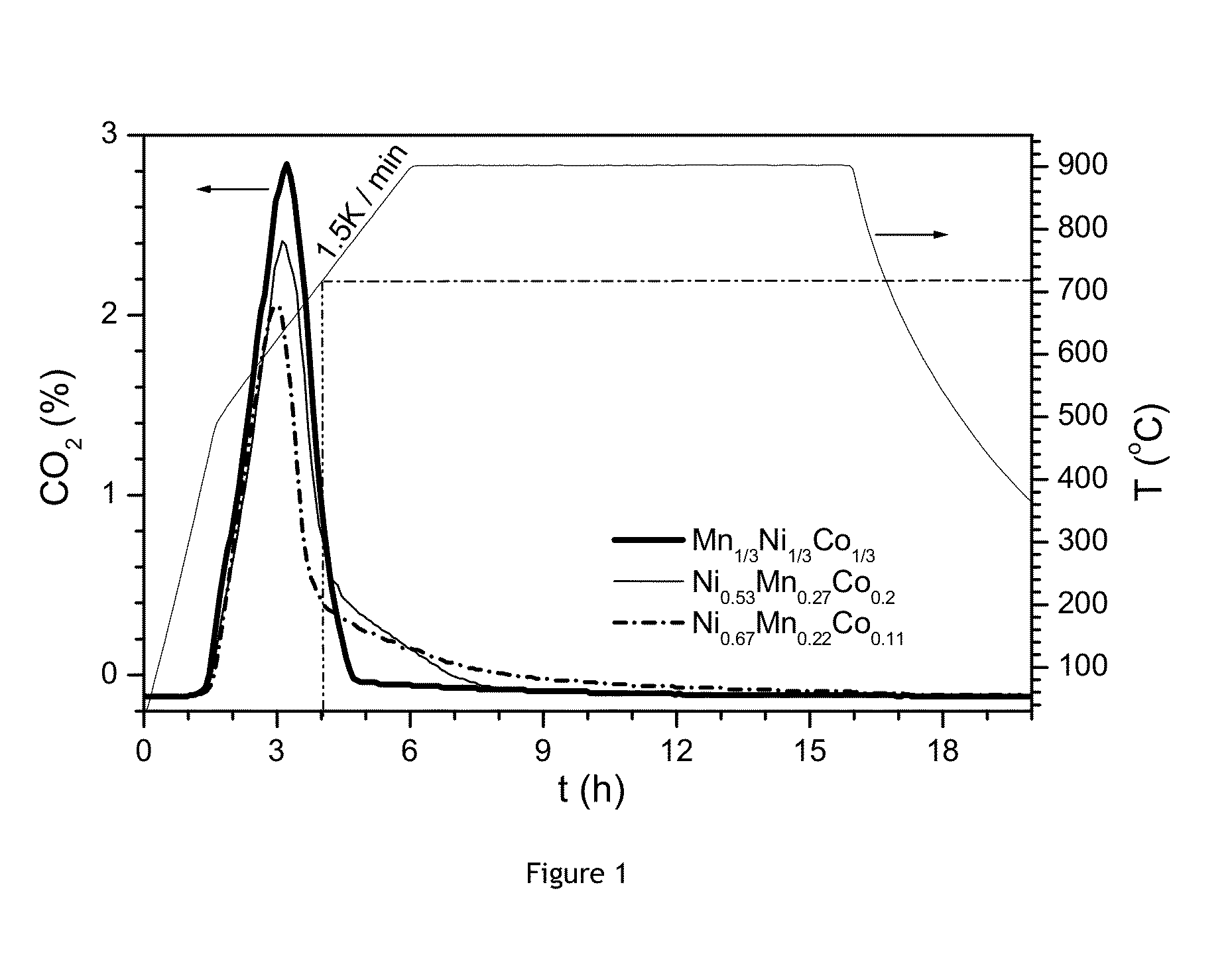

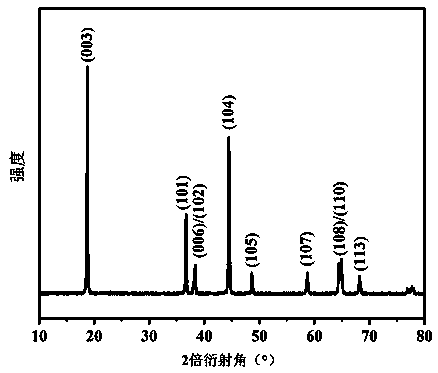

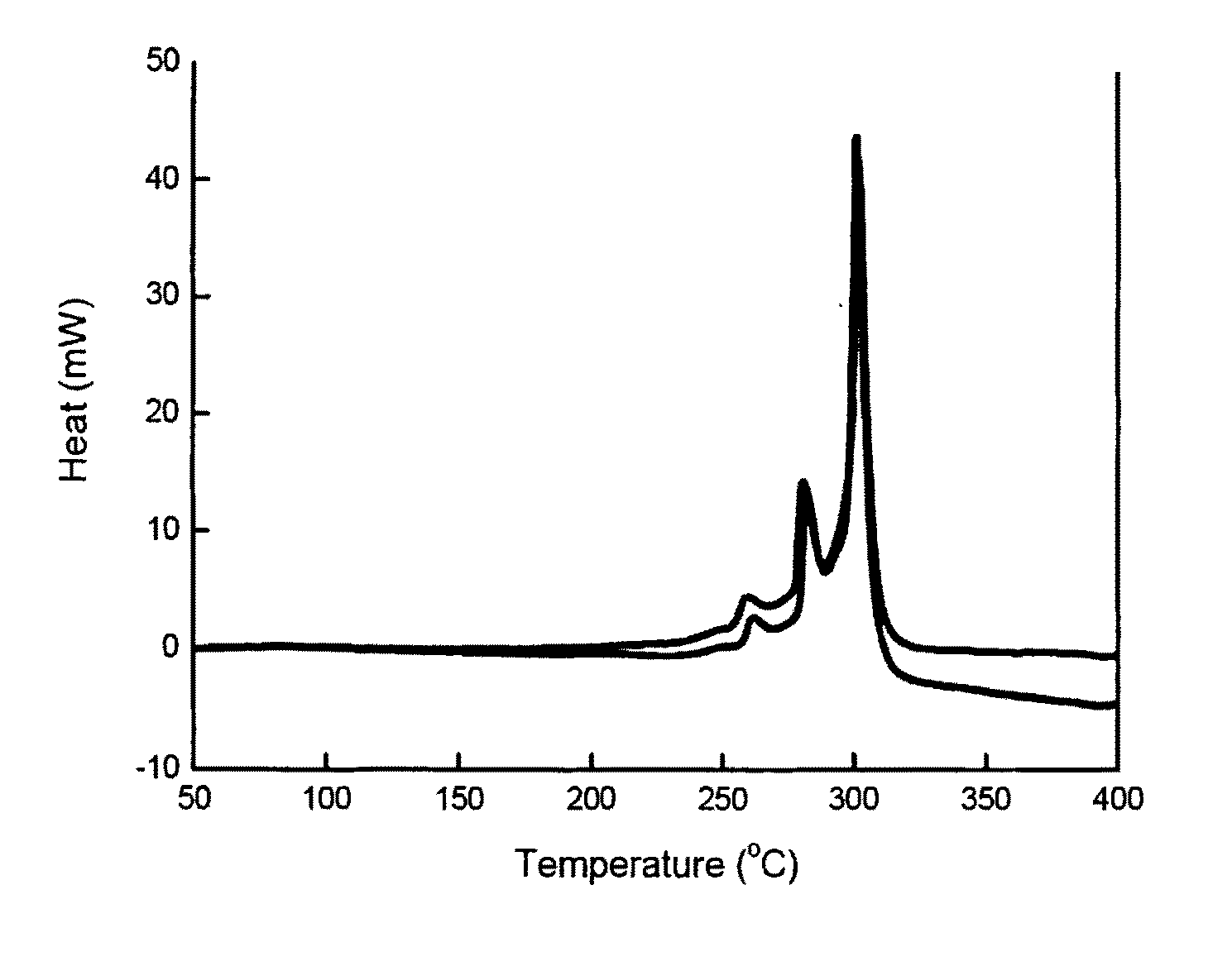

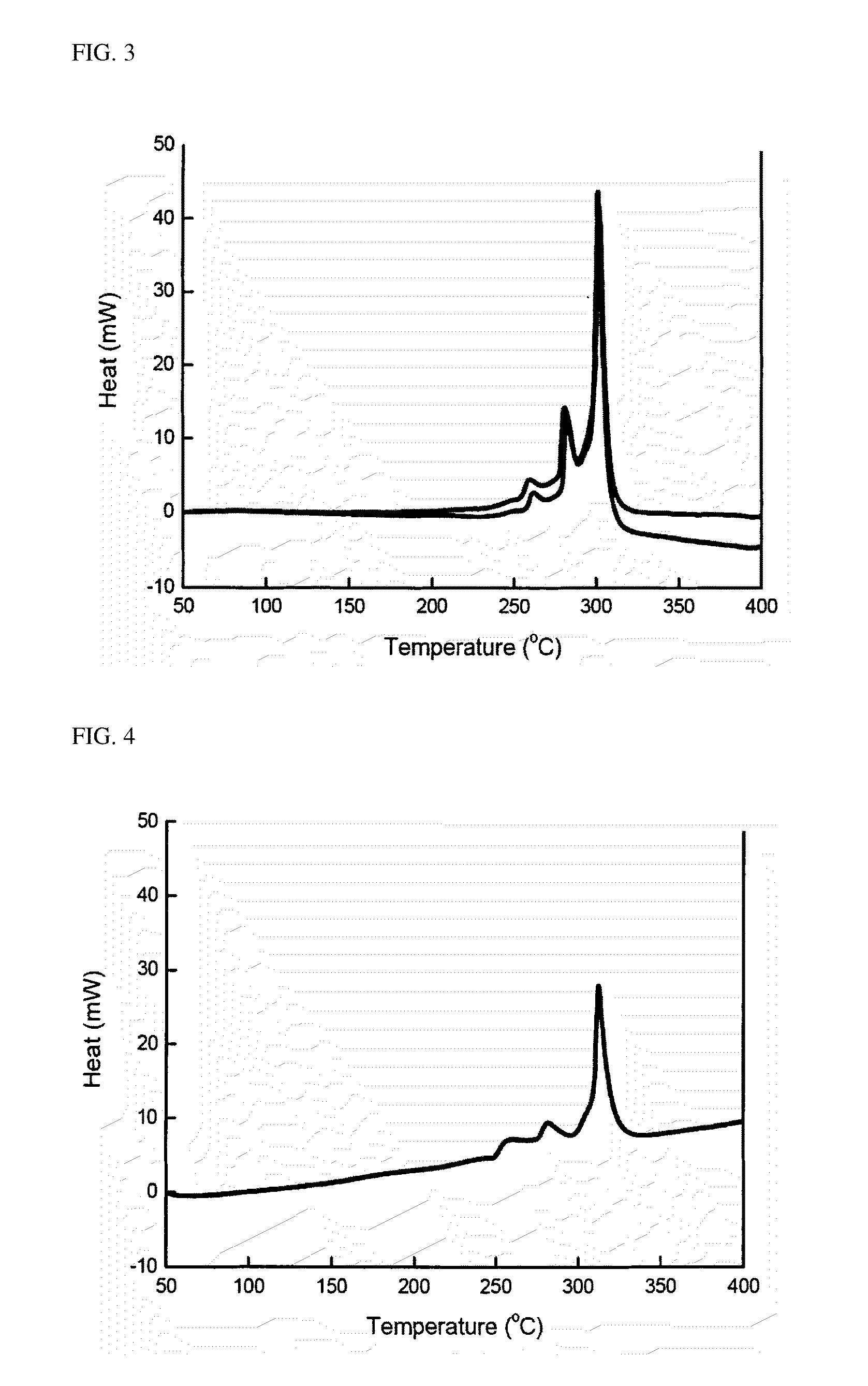

High nickel cathode material having low soluble base content

ActiveUS20140054495A1Improve performanceSecondary cell gas removalLi-accumulatorsDopantCathode material

The invention relates to cathode materials for Li-ion batteries in the quaternary phase diagram Li[Li1 / 3Mn2 / 3]O2—LiMn1 / 2Ni1 / 2O2—LiNiO2—LiCoO2, and having a high nickel content. Also a method to manufacture these materials is disclosed. The cathode material has a general formula Lia((Niz(Ni1 / 2Mn1 / 2)yCox)1-kAk)2-aO2, wherein x+y+z=1, 0.1≦x≦0.4, 0.36≦z≦0.50, A is a dopant, 0≦k≦0.1, and 0.95≦a≦1.05, and having a soluble base content (SBC) within 10% of the equilibrium soluble base content.

Owner:UMICORE AG & CO KG

Chromium-manganese-copper-molybdenum series austenite corrosion-resistant wear-proof stainless steel

The present invention discloses one kind of anticorrosive and antiwear Cr-Mn-Cu-Mo austenite stainless steel comprising C 0.06-0.11 wt%, Mn 14-19 wt%, Si 0-3 wt%, P not more than 0.054 wt%, S not more than 0.03 wt%, Cr 16-18 wt%, N 0.1-0.4 wt%, Cu 1.0-2.5 wt%, Mo 0-3 wt%, Ni 0-2 wt%, Re 0-0.22 wt%, and Fe and inevitable impurity for the rest. The Cr-Mn-Cu-Mo austenite stainless steel has high strength, high toughness, high wear resistance, low nickel content and relatively low production cost.

Owner:江苏省方通新型不锈钢制品股份有限公司

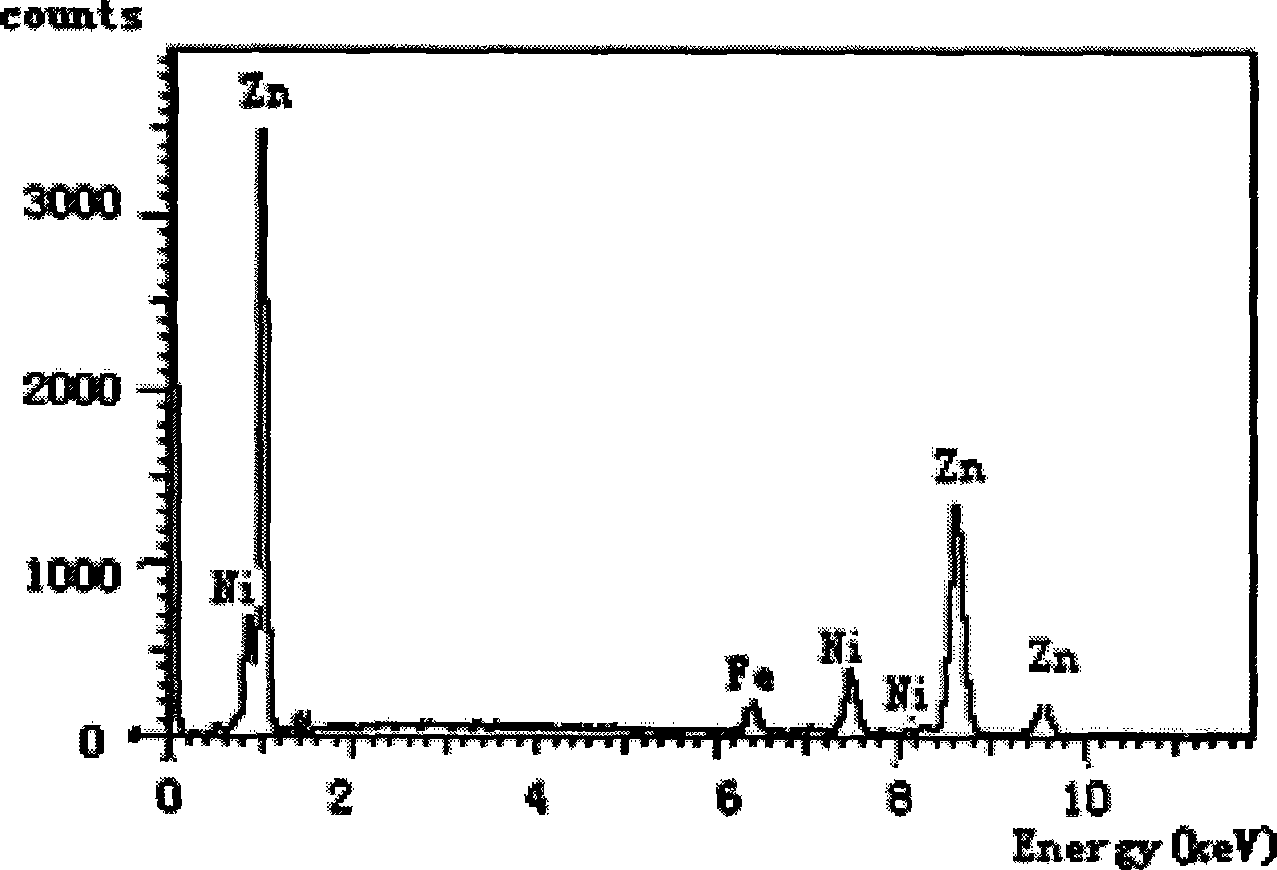

Method for plating zinc-nickel alloy in alkaline electroplate liquid

InactiveCN101240437ASolve the problem of large compositional changesImprove current efficiencyWater basedOrganic solvent

The invention discloses a method for electroplating alkaline Zn-Ni alloy, comprising the steps of: preparing alkali wash and acid wash, preparing electroplating Zn-Ni alloy plating solution, mechanical grinding, degreasing with organic solvent or water-based detergent, alkali washing, acid washing and electroplating. The invention provides a stable electroplating solution formula and complete electroplating process. The coating electroplated by the method is proved to have good flat surface, uniform coating distribution and alloy distribution, the coating is single gamma-phase, the nickel has a content of 10% to 15%; the coating has superior corrosion resistance, red rust appears on the non-passivated Zn-Ni coating after 1500 hours in a neutral salt spray test; compared with general alkali electroplating solution, the coating has high current efficiency, reaching up to 80% to 90%.

Owner:BEIHANG UNIV

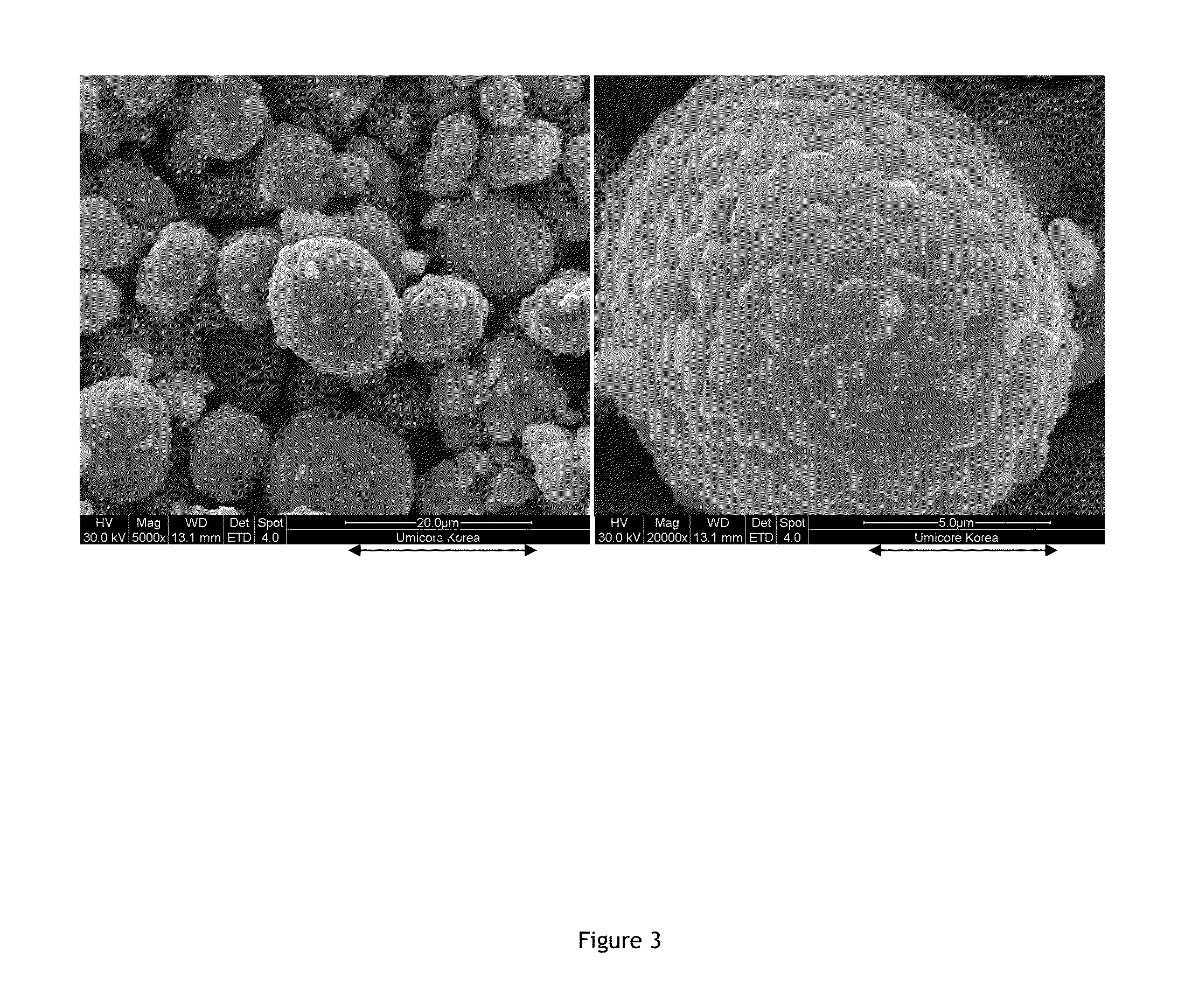

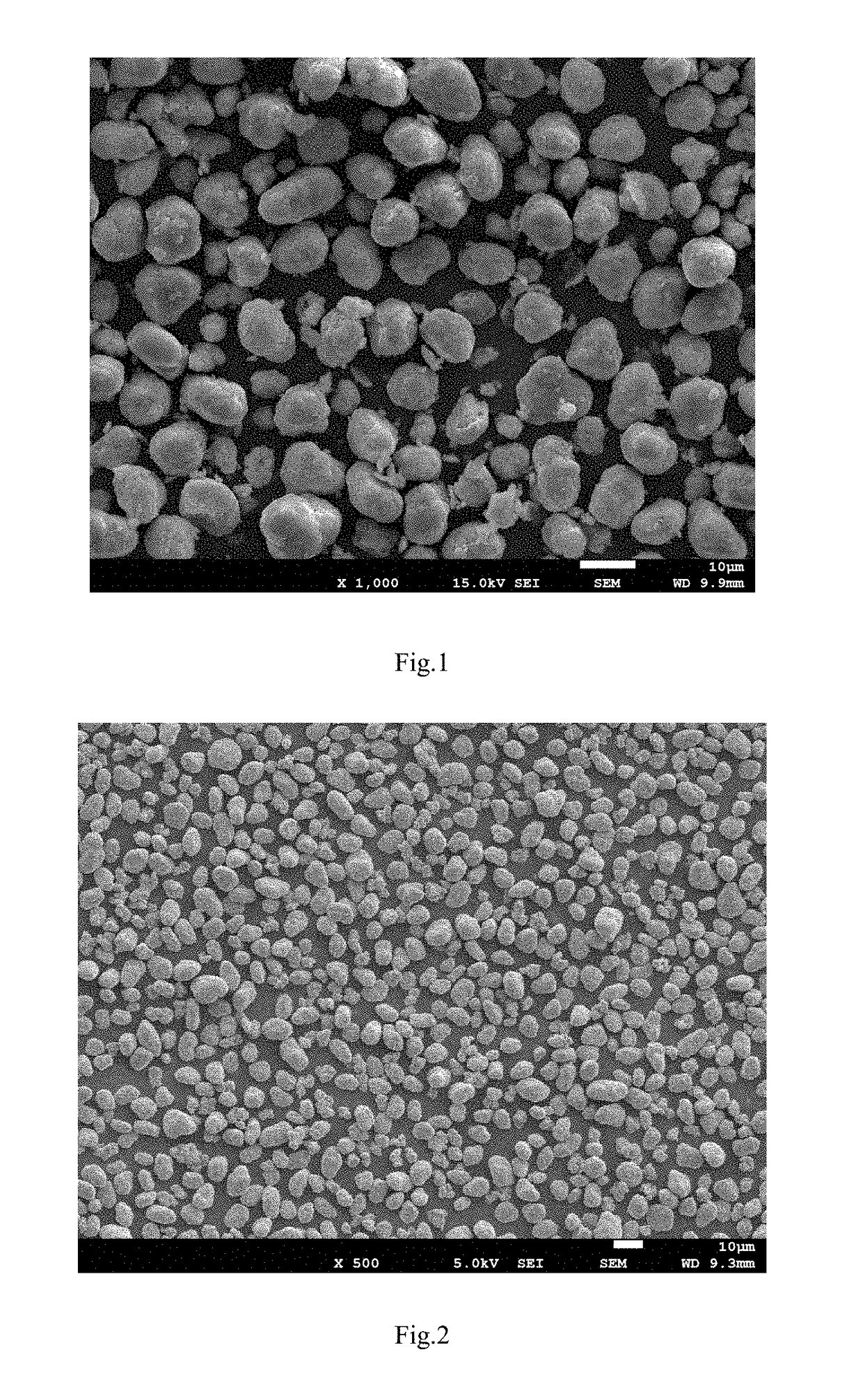

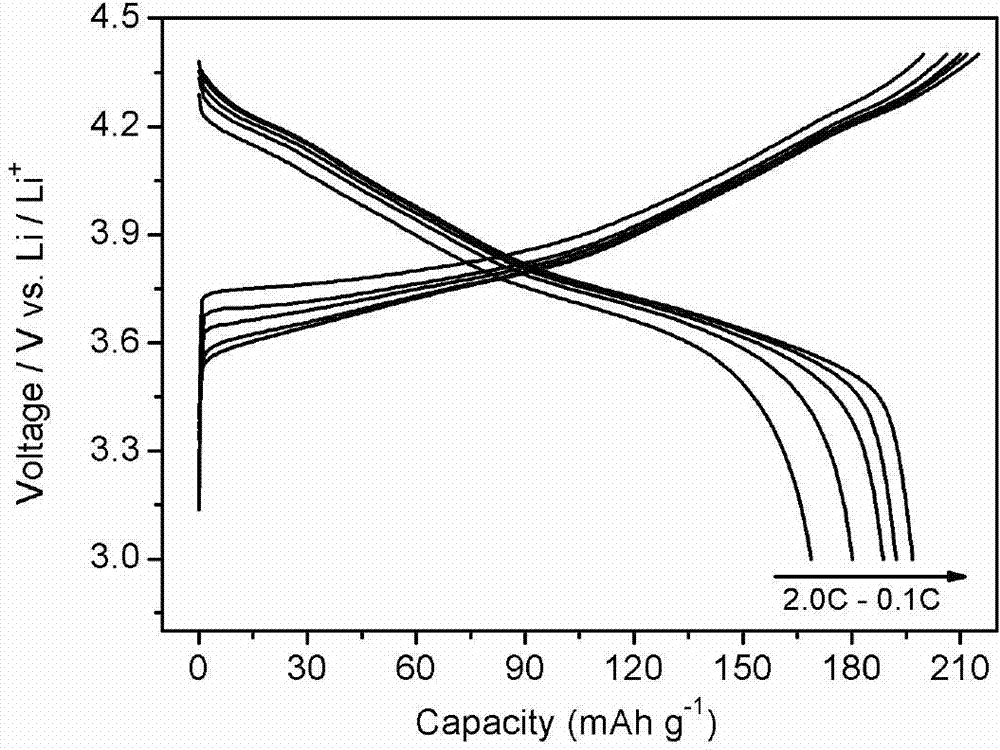

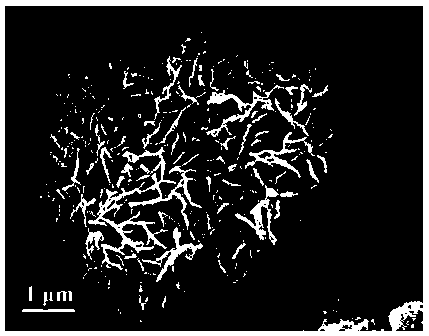

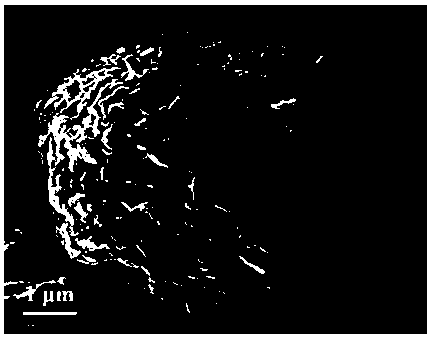

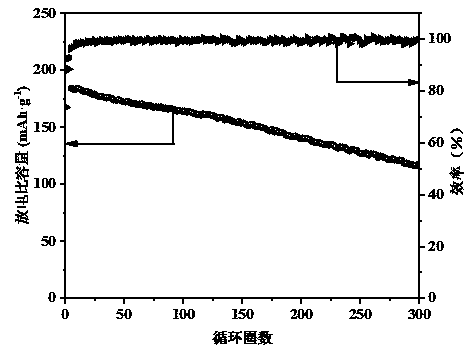

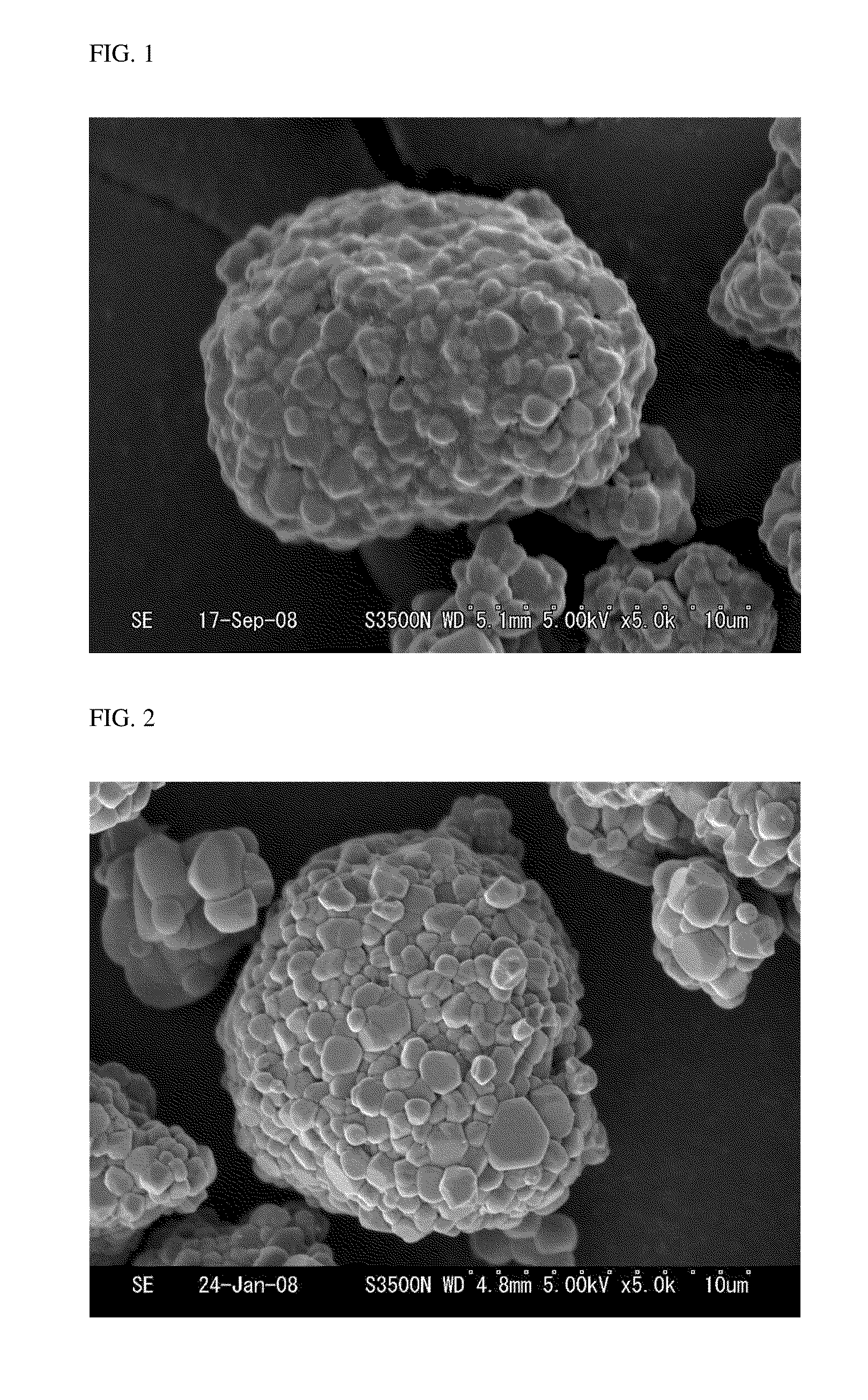

Nickel lithium ion battery positive electrode material having concentration gradient, and preparation method therefor

ActiveUS20170317344A1Improve securityImprove cycle capabilitySecondary cellsPositive electrodesElectrical batteryPhysical chemistry

A nickel lithium ion battery positive electrode material having a concentration gradient, and a preparation method therefor. The material is a core-shell material having a concentration gradient, the core material is a material having a high content of nickel, and the shell material is a ternary material having a low content of nickel. The method comprises: synthesizing a material precursor having a high content of nickel by means of co-precipitation, co-precipitating a ternary material solution having a low content of nickel outside the material precursor having a high content of nickel, aging, washing, and drying to form a composite precursor in which the low nickel material coats the high nickel material, adding a lithium source, grinding, mixing, calcining, and cooling to prepare a high nickel lithium ion battery positive electrode material. The obtained material has regular morphology, uniform coating, narrow particle size distribution range, gradient distribution of the concentration of the nickel element, high content of the nickel element in the core, and low content of the nickel element in the shell; the nickel element in the core guarantees the specific capacity of the material, and the shell coating material maintains the stability of the structure of the material, so as to improve the safety of the material in the charge and discharge process, and improve the cycle and rate performance of the material.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

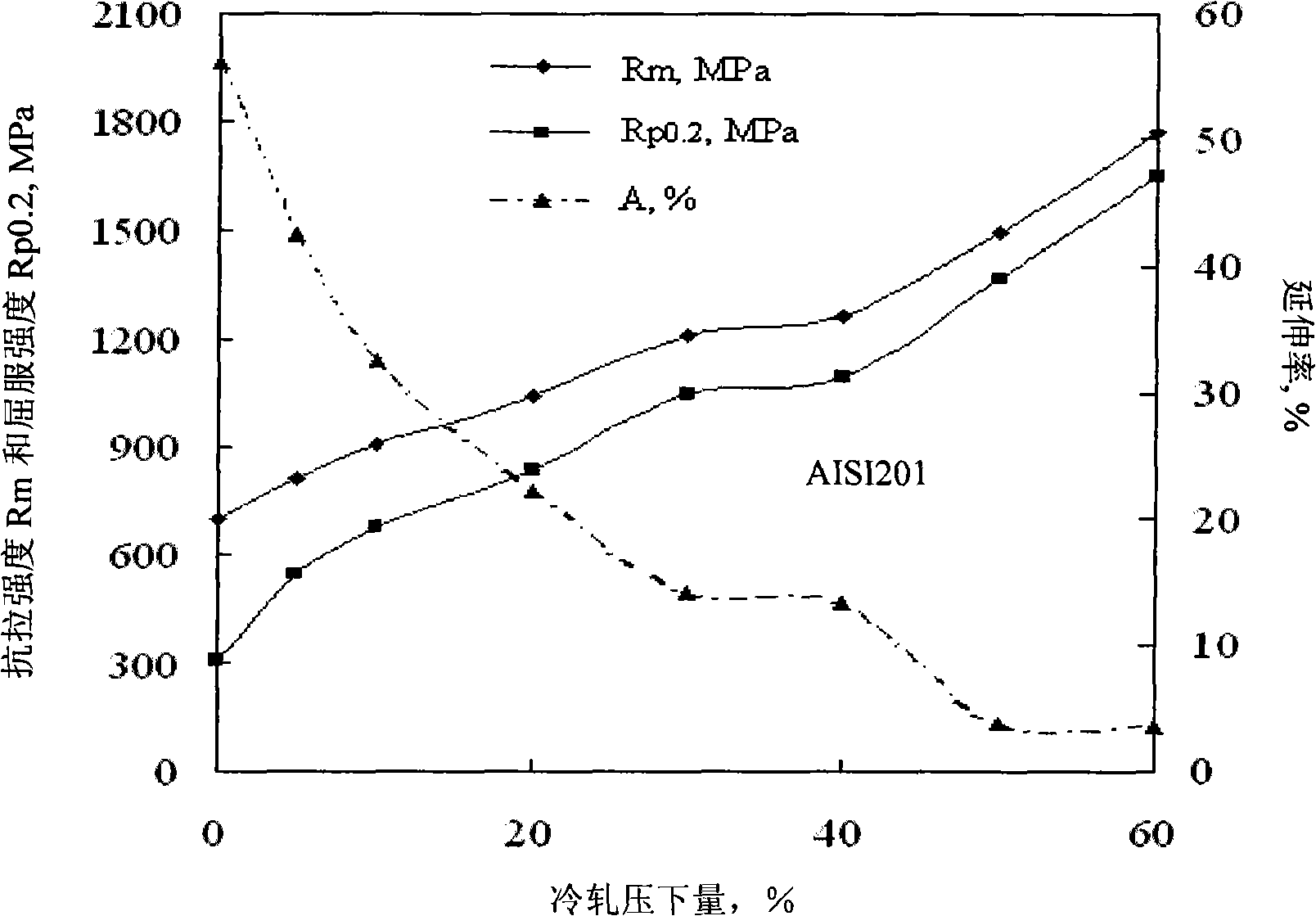

1000MPa grade nickel-saving type metastable austenite stainless steel

The invention provides 1000MPa class nickel-saving type metastable austenite stainless steel. The chemical components of the nickel-saving type metastable austenite stainless steel of the invention calculated by weight percentage include 0.06 to 0.15 percent of C, less than 1 percent of Si, 8 to 10 percent of Mn, 15 to 17 percent of Cr, 0.5 to 1.2 percent of Ni, 0.15 to 0.30 percent of N, less than 0.03 percent of P, less than 0.02 percent of S and the rest are Fe and unavoidable impurities. The room temperature yield stress of a cold processing state of the invention can reach 1250MPa, the anti-tension intensity can reach 1460MPa and the average room temperature extension rate can be maintained to be 16.8 percent. Under different states, the room temperature yield stress of the material is 370 to 1250MPa and the room temperature anti-tension intensity is 860 to 1460MPa. The room temperature anti-tension intensity of a cold-rolling solid solution state can reach over 1000MPa and the extension rate is larger than 40 percent. The invention has high intensity and excellent plasticity. The excellent room temperature mechanical performance of the 1000MPa class nickel-saving type metastable austenite stainless steel of the invention can be remarkably distinguished from the normal metastable austenite stainless steel and is suitable for weak-corrosion environments such as the fields of traffic, construction and hardware, etc., and can partially replace the austenitic stainless steels with high nickel contents like AISI304, AISI301 and AISI201, etc., so as to save the expensive metal nickel.

Owner:BAOSHAN IRON & STEEL CO LTD

Desulphurisation material

A particulate desulphurisation material is described comprising one or more nickel compounds, a zinc oxide support material, and one or more alkali metal compounds wherein the nickel content of the material is in the range 0.3 to 10% by weight and the alkali metal content of the material is in the range 0.2 to 10% by weight. A method of making the desulphurisation material is also described comprising the steps: (i)contacting a nickel compound with a particulate zinc support material and an alkali metal compound to form an alkali-doped composition, (ii)shaping the alkali-doped composition, and (iii)drying, calcining, and optionally reducing the resulting material. The desulphurisation material may be used to desulphurise hydrocarbon gas streams with reduced levels ofhydrocarbon hydrogenolysis.

Owner:JOHNSON MATTHEY PLC

Copper Foil for Printed Circuit and Copper-Clad Laminate

ActiveUS20100212941A1Easy to integrateIncrease temperatureNon-insulated conductorsElectrolytic inorganic material coatingEtchingCopper foil

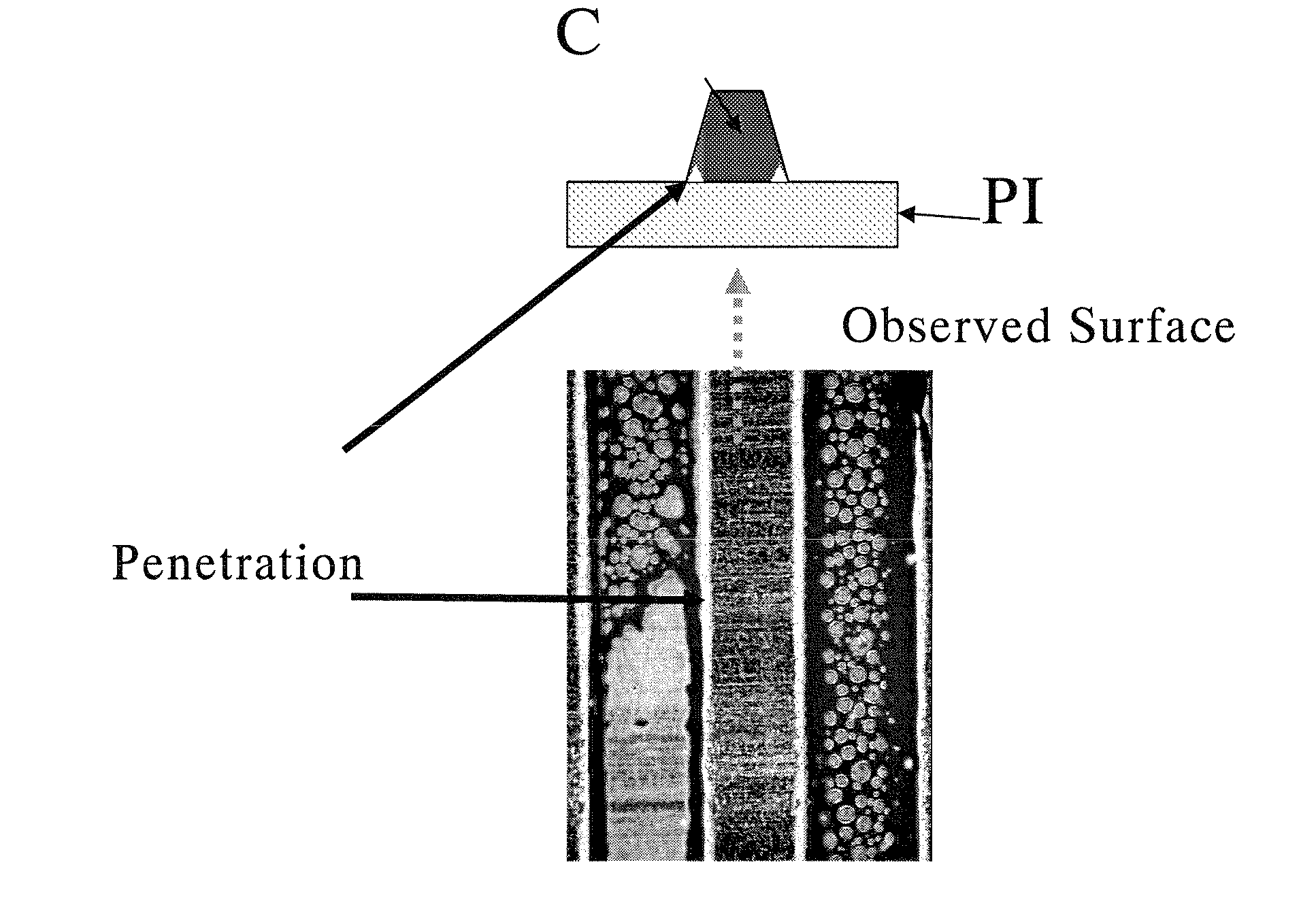

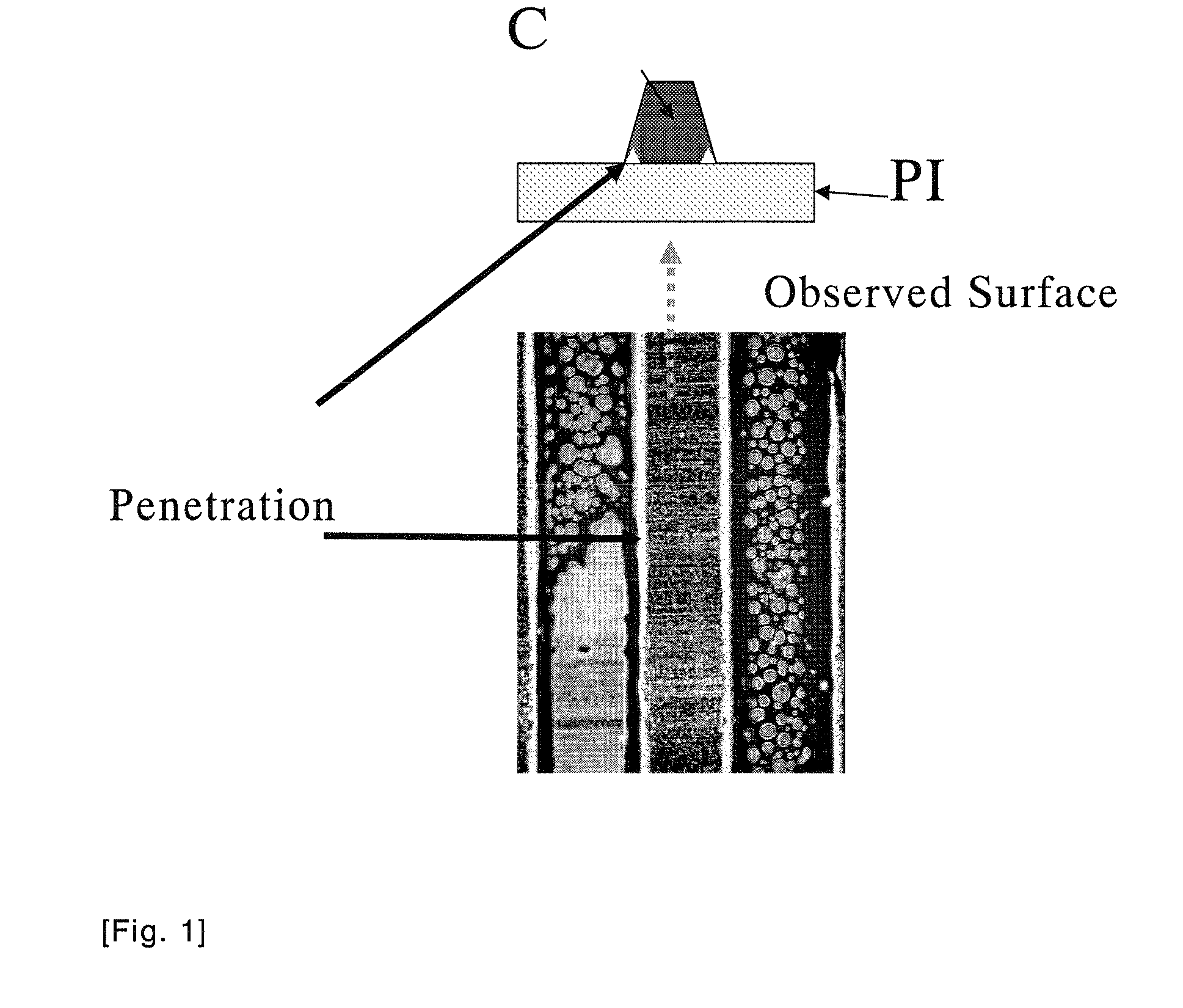

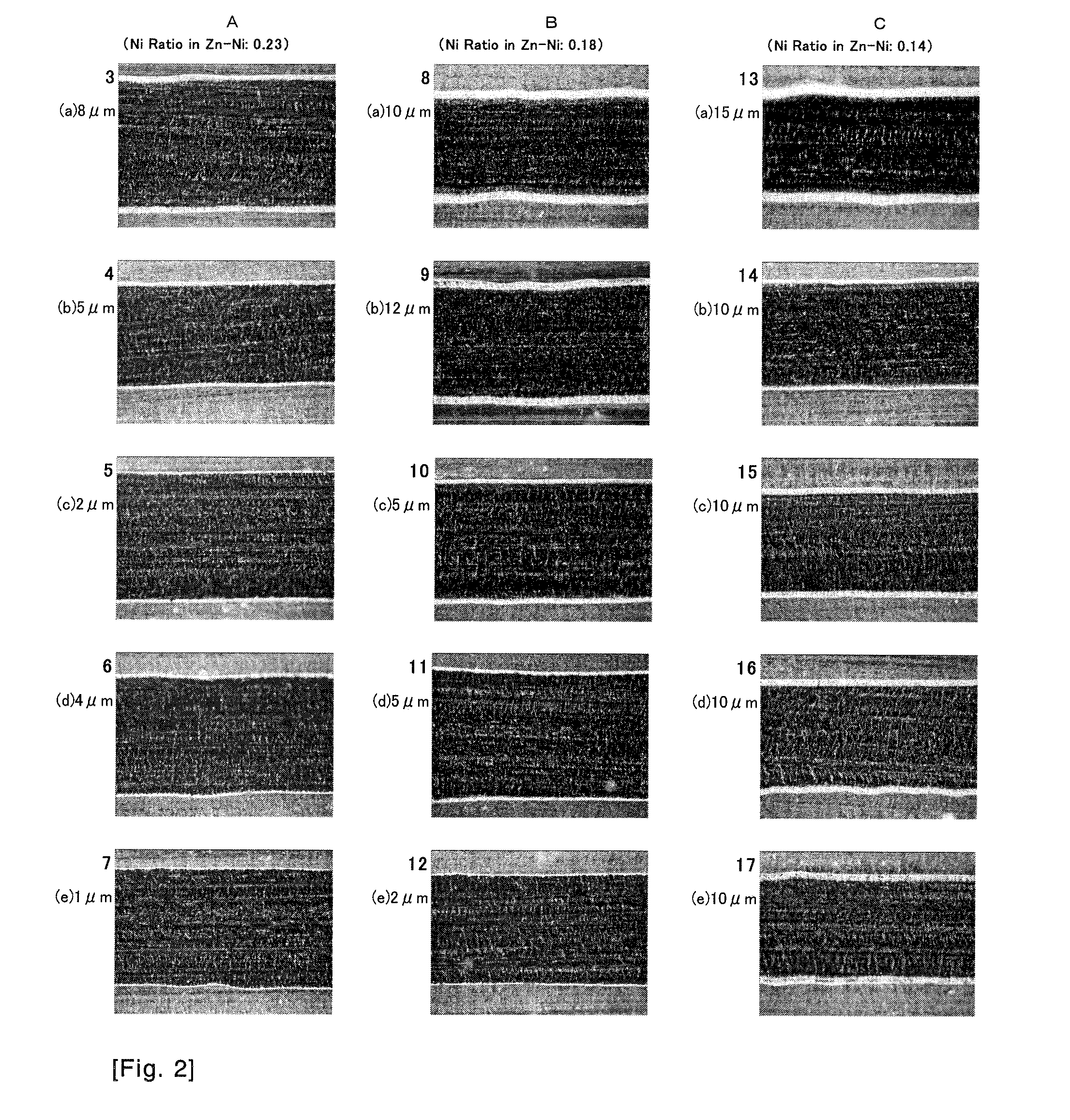

Provided is a copper foil for printed circuit comprising a roughened layer on a surface of a copper foil by way of copper-cobalt-nickel alloy plating, a cobalt-nickel alloy plated layer formed on the roughened layer, and a zinc-nickel alloy plated layer formed on the cobalt-nickel alloy plated layer, wherein the total amount of the zinc-nickel alloy plated layer is 150 to 500 μg / dm2, the lower limit of the nickel ratio in the alloy layer is 0.16, the upper limit thereof is 0.40, and the nickel content is 50 μg / dm2 or more.With the development of electronic equipment, the miniaturization and high integration of semiconductor devices have advanced further. This tendency has led to a demand for the adoption of a higher temperature in treatment in a production process of printed circuits and has led to heat generation during the use of electronic equipment after the productization. The present invention provides a technique that, even under these circumstances, the adhesive strength between a copper foil and a resin base material does not decrease and the penetration into a circuit edge part can be effectively prevented when performing the soft etching of a copper foil circuit.

Owner:JX NIPPON MINING& METALS CORP

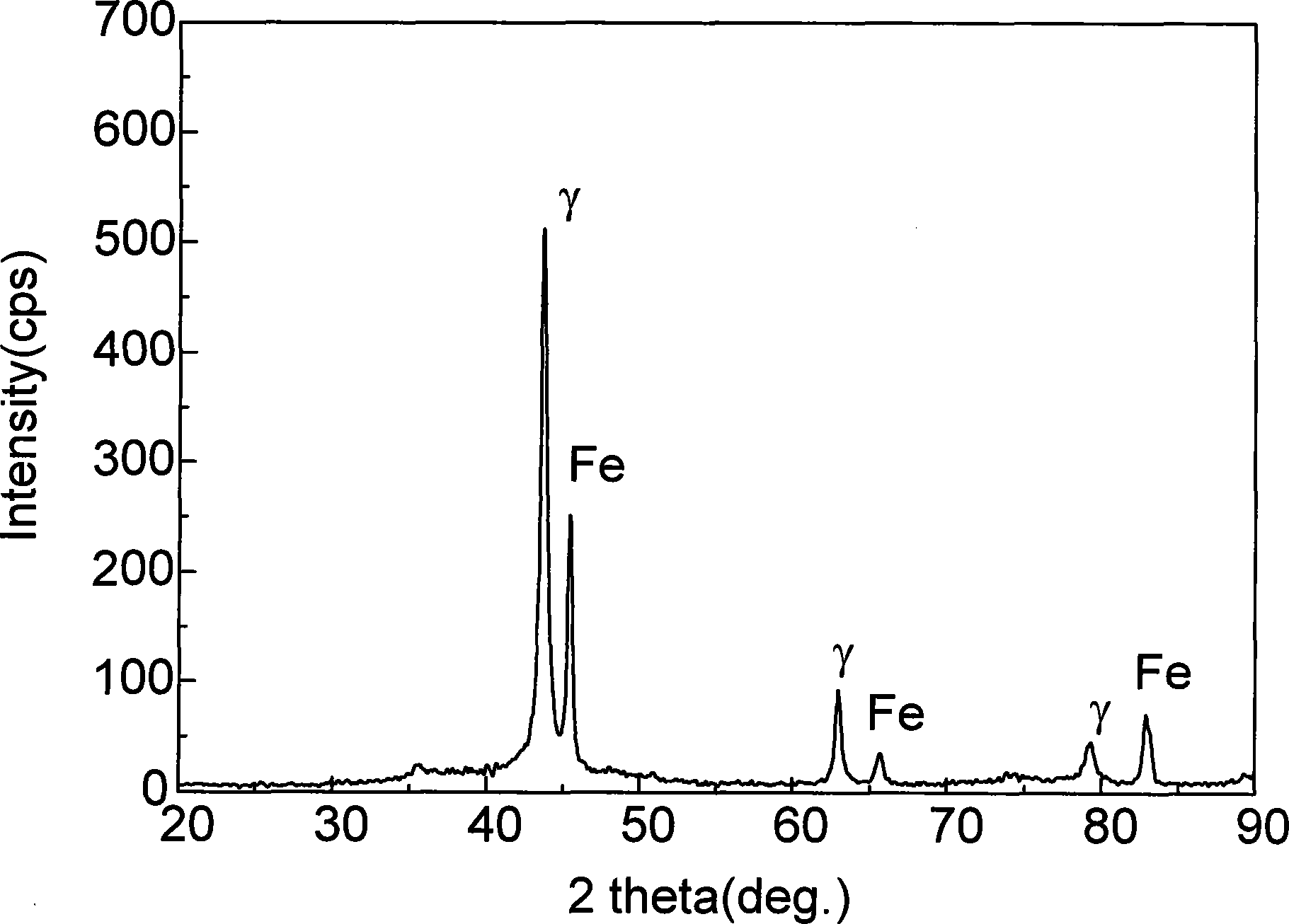

Method for preparing high-performance iron nickel magnetically soft alloy by using powder metallurgy process

The invention discloses a method for preparing high-performance iron nickel magnetically soft alloy by using a powder metallurgy process, which belongs to the technical field of powder metallurgy. The method comprises the following steps of: 1, uniformly mixing various powder such as iron powder, nickel powder, molybdenum powder, silicon powder, copper powder, cobalt powder, chrome powder, niobium powder, tungsten powder, aluminum powder and titanium powder according to a certain ratio, wherein the nickel content ranges from 30 to 78 percent; or the alloy powder prepared according to a certain alloy component ratio is directly used as a raw material; 2, forming the powder which is obtained by step 1 into a blank with a certain shape by using a powder metallurgy forming method; 3, sintering the formed blank, which is obtained by the step 2, under the pressure of between 0 and 1,000 MPa and at the temperature of between 600 and 1,500 DEG C for 10 to 4,000 minutes; and 4, processing the sintered body obtained by the step 3 under the pressure of between 0 and 4,000 MPa and at the temperature of between 600 and 1,600 DEG C for 0 and 4,000 minutes. The method has the characteristic that: by improving the sintering and thermal treatment systems, the material density is improved, the micro texture and structure of the material are improved, the impurity content is reduced, and the magnetically soft alloy product with the maximal magnetic conductivity of no less than 40 mH / m and with the coercive force of no more than 20 A / m can be prepared.

Owner:UNIV OF SCI & TECH BEIJING

White-colored copper alloy with reduced nickel content

Disclosed is a white-colored copper alloy comprising by weight up to 30% zinc, up to 20% manganese, up to 5% nickel with the balance copper. This alloy may have from 6% to 25% zinc, from 4% to 17% manganese, from 0.1% to 3.5% nickel and the balance copper. The balance copper in the alloy may further contain at least one of: up to 0.5% of at least one of the group which consists of Sn, Si, Co, Ti, Cr, Fe, Mg, Zr, and Ag; and up to 0.1% of at least one of the group which consists of P, B, Ca, Ge, Se, Te. It may also contain up to 0.3% Zr by weight. The alloy may have an electrical conductivity greater than 2.5% IACS at eddy current gauge exciting frequencies between 60 kHz and 480 kHz.

Owner:PMX IND

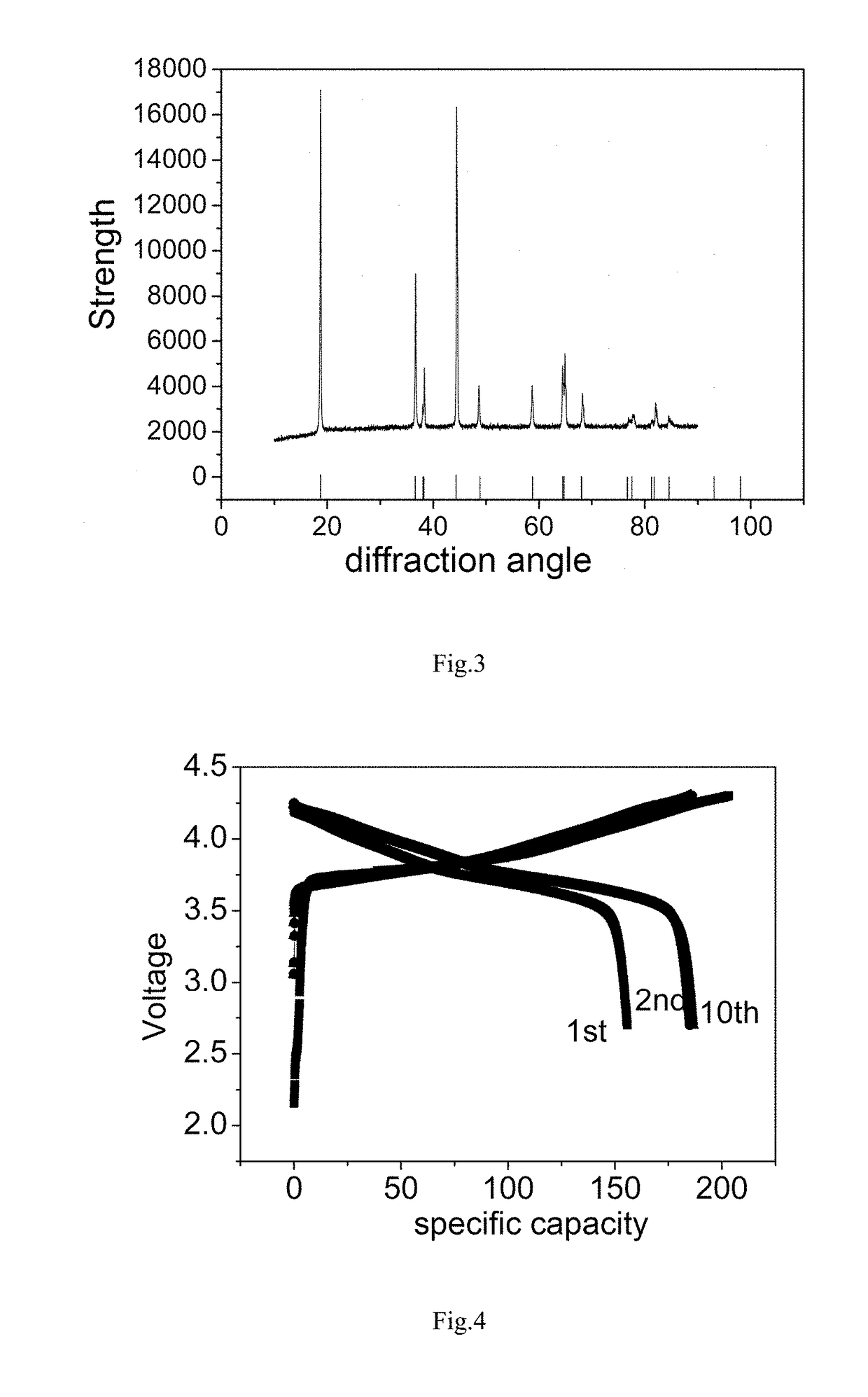

Core-shell polynary lithium ion battery anode material distributed in all-concentration gradient way and preparation method thereof

ActiveCN104852026AImprove securityInhibited DiffusionCell electrodesSecondary cellsManganeseConcentration gradient

The invention relates to a core-shell polynary lithium ion battery anode material distributed in an all-concentration gradient way and a preparation method thereof, and belongs to the field of lithium ion battery anode materials. The structural formula of the anode material is LiaNixCoyMn1-x-yO2@LibNimConMn1-m-nO2, wherein a is more than or equal to 0.9 and less than or equal to 1.2, x is more than or equal to 0.6 and less than or equal to 0.9, y is more than or equal to 0.05 and less than or equal to 0.4, b is more than or equal to 0.9 and less than or equal to 1.2, m is more than or equal to 0.2 and less than or equal to 0.7, and n is more than or equal to 0.1 and less than or equal to 0.6. The anode material is spherical or sphere-like, and is of a core-shell structure; a core part is an all-concentration gradient part being 2-10 microns in diameter; a shell part is a protective layer part being 0.5-2 microns in thickness; the concentration of the protective layer part is an all-concentration gradient end-point concentration; and from the center of a core to the surface of a shell, the nickel content decreases gradually while the cobalt content and manganese content increase gradually. The material has the advantages of low cost, high cycle performance, high safety performance, high discharge capacity and the like. Moreover, the core-shell polynary lithium ion battery anode material is simple in process flow, and easy for realizing industrial production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

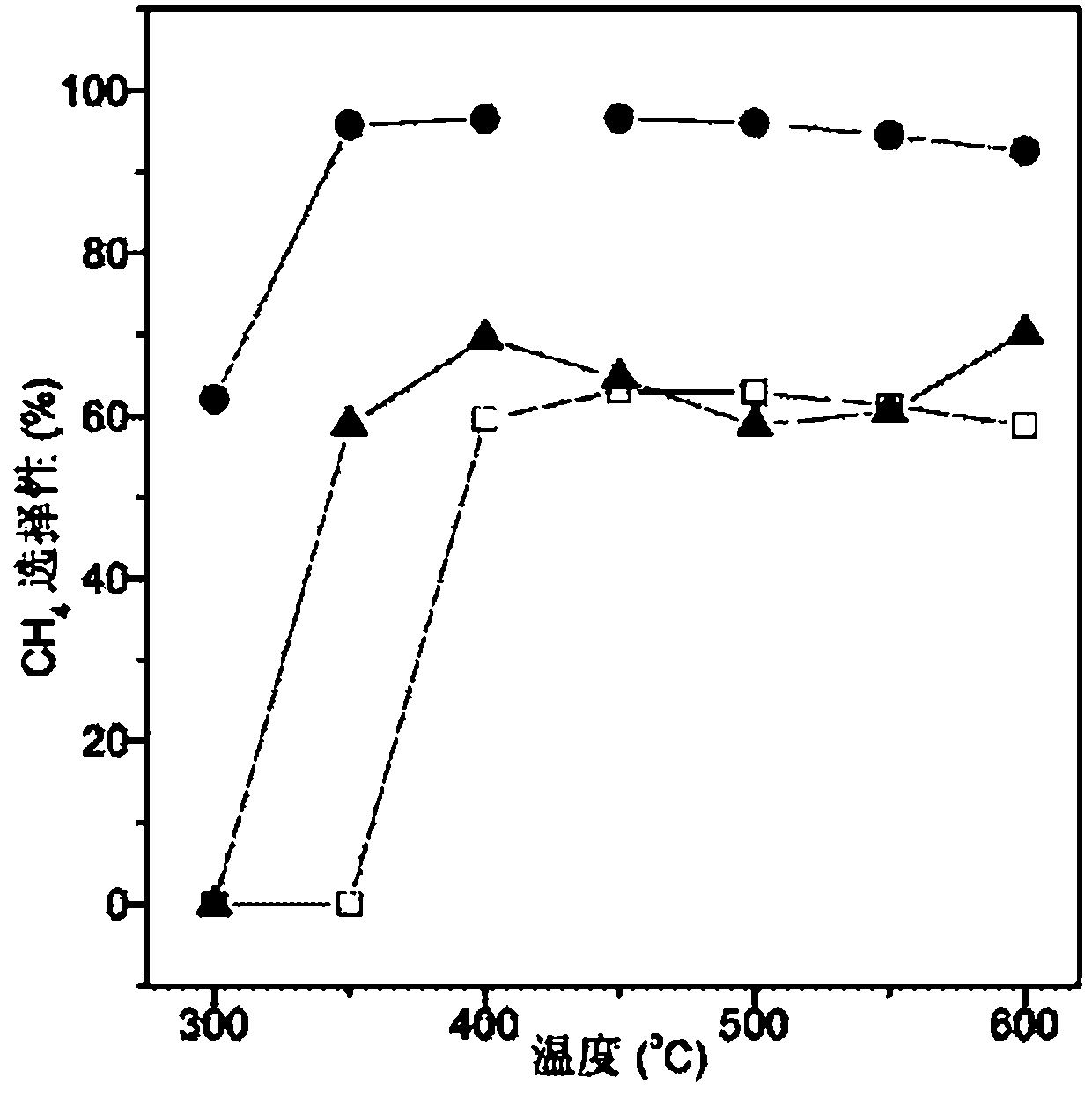

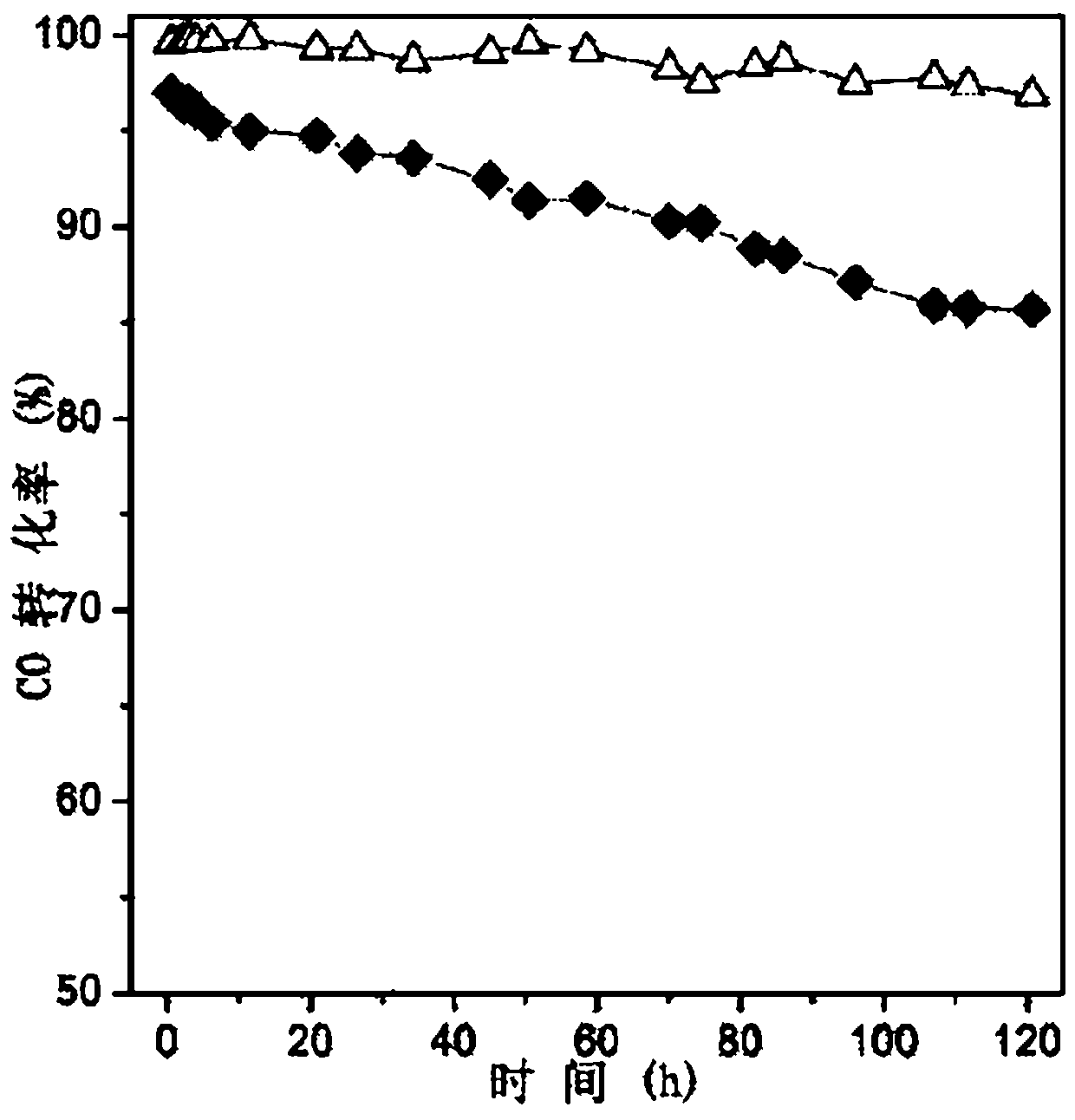

Perovskite supported nickel base methanation catalyst and preparation method thereof

ActiveCN102513115AReduced activityImprove anti-sintering performanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationMethanation

The invention relates to the field of methanation catalysis, particularly a syngas complete methanation catalyst and a preparation method thereof. The catalyst is prepared by using perovskite-type substances as a carrier, NiO as an active component, and rare-earth oxides as an auxiliary agent, and loading the active component and the auxiliary agent on the carrier by using an immersion method. The catalyst comprises 1-70 wt% of NiO, 0-15 wt% of rare-earth oxide, and the balance of perovskite. The catalyst disclosed herein has the advantages of high catalytic activity, strong anti-carbon formation and anti-sintering property, low nickel content, and low cost, and is especially suitable for high-concentration CO methanation reaction systems at high pressures.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

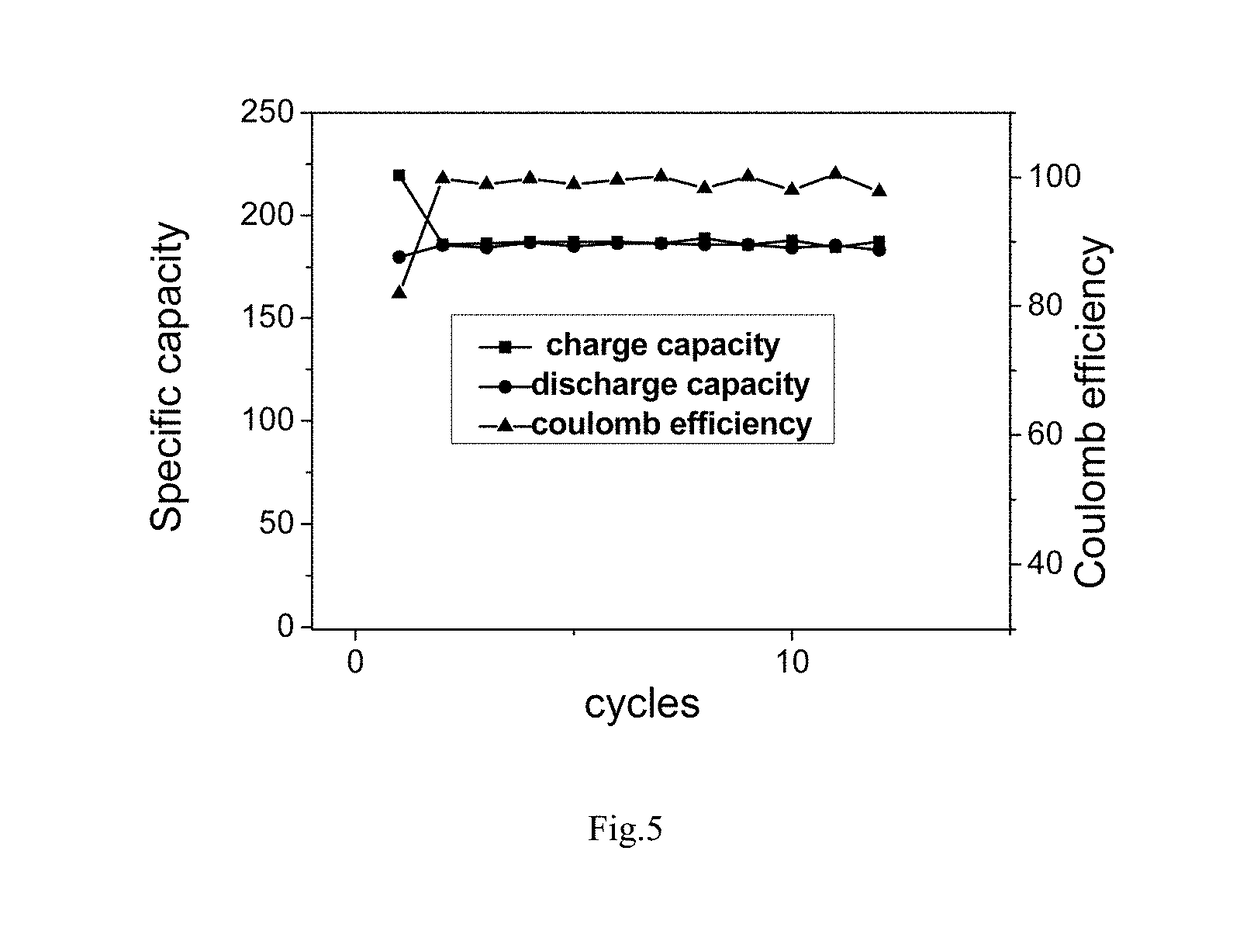

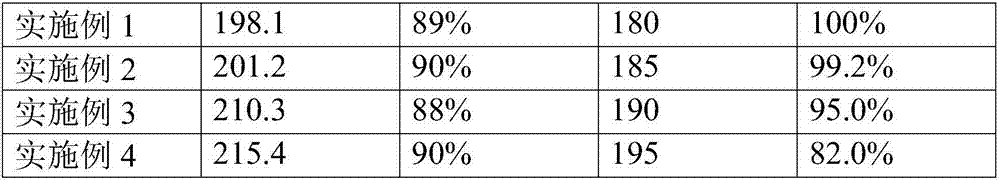

Lithium ion battery cathode material and preparation method thereof

ActiveCN107394160AImprove surface structureReduce surface residual alkali contentMaterial nanotechnologyCell electrodesTwo stepLithium-ion battery

Belonging to the technical field of lithium ion batteries, the invention discloses a lithium ion battery cathode material and a preparation method thereof. The chemical molecular formula of the cathode material is Lix(NiaCobMnc)1-yMyO2, wherein x is greater than or equal to 0.96 and smaller than or equal to 1.04, y is greater than or equal to 0.01 and smaller than or equal to 0.06, a is greater than or equal to 0.8 and smaller than or equal to 0.9, and a+b+c=1, M has a general formula of BzM'1-z, M' is composed of one or several of the following elements: Al, Mg, Ti and Zr, and z is greater than or equal to 0.1 and smaller than or equal to 0.5. The cathode material is coated by a layer of compound containing L, B, Ni, Co and Mn, the content of B in the outermost surface of the coating layer is at least two times that of the B in the innermost layer of the coating layer. According to the invention, the high capacity cathode material is acquired from a high nickel content ternary system, additionally multielement doping is employed to stabilize the crystal structure of the material, and then by means of washing, boron element surface modification and two-step sintering process, the material surface structure can be improved, and the surface residual alkali content can be reduced to improve the interface stability. The whole technological process of the invention is simple, and is easy for large scale production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method of joining ceramic or graphite to metal with an alloy having high nickel or cobalt content, alloys for joining the same, and products formed therewith

A brazed product has a metal substrate, a ceramic or graphite substrate, and a brazing alloy containing one of a high nickel content and cobalt content joining the ceramic or graphite substrate to the metal substrate. A method of joining these materials include providing a metal layer coating of titanium or nickel on the surface of the ceramic or graphite substrate to be joined or using a high nickel content or high cobalt content and containing titanium. The brazing alloy contains a high nickel content 70-95% by weight, or a high cobalt content between 45-55% by weight. This brazing alloy can contain titanium in the range between 0.5-5% by weight.

Owner:THOMAS SANDIN CONSULTING

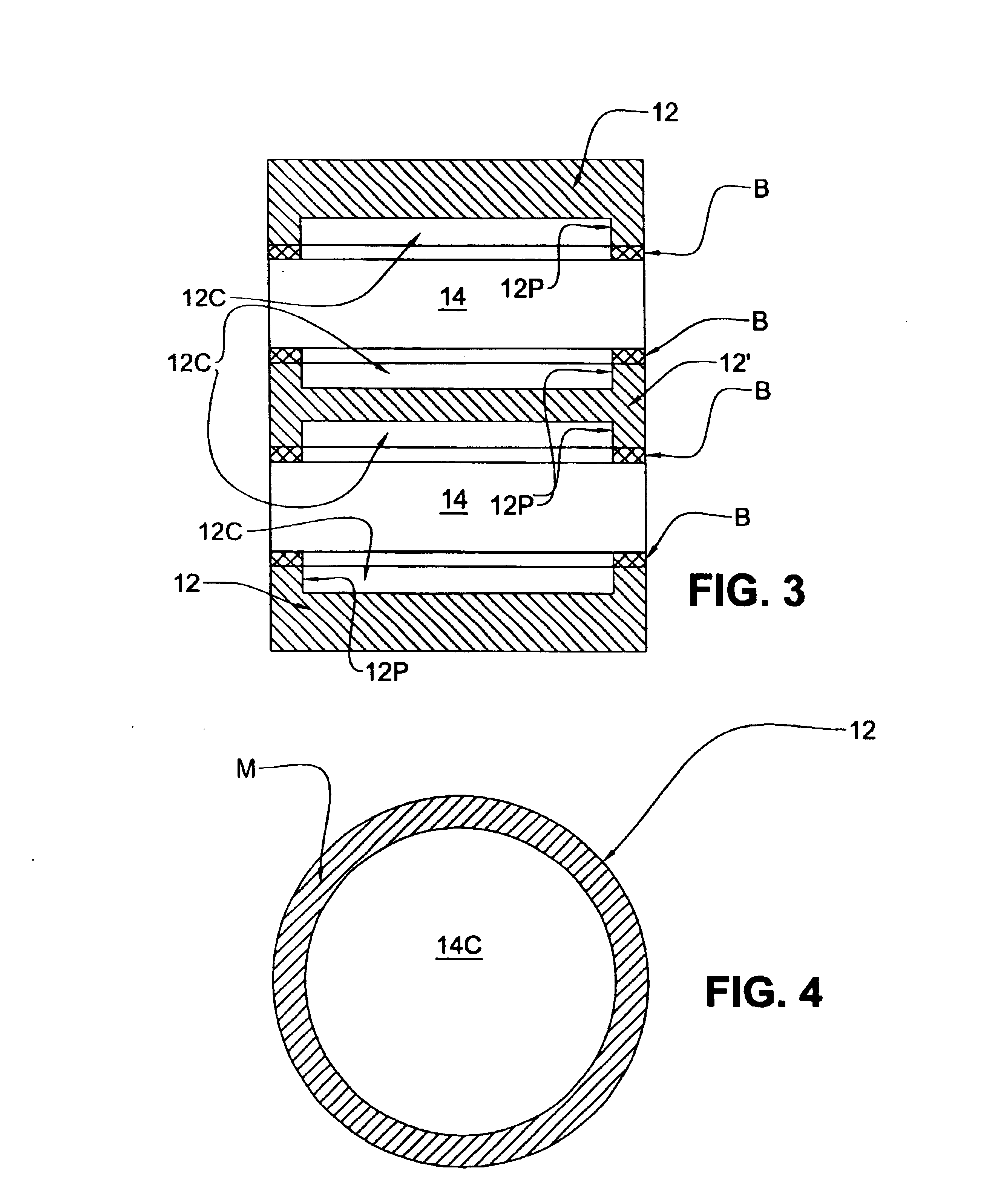

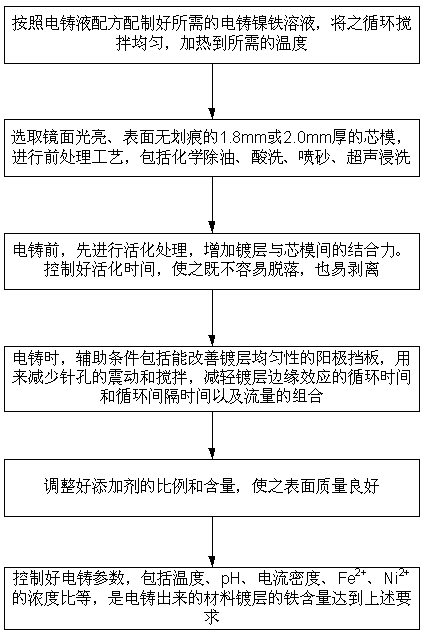

Vapor plating metal mask plate prepared from nickel-iron alloy

InactiveCN103205680ALow costLow coefficient of linear thermal expansionVacuum evaporation coatingSputtering coatingThermal expansionHigh surface

The invention discloses a vapor plating metal mask plate prepared from a nickel-iron alloy. The metal mask plate is a nickel-iron alloy mask plate prepared by an electroforming process. The nickel-iron alloy material include two elements: nickel and iron, wherein the iron content is 40%-70%, and the nickel content is 30%-60%. With similar physical properties to invar alloy plates, the vapor plating mask plate provided in the invention has high surface brightness, high uniformity, and good surface quality, and has lower cost than the mask plate made from an invar alloy, so that the cost is saved. Meanwhile, the mask plate provided in the invention has a small linear thermal expansion coefficient, thus meeting the vapor plating requirement. In addition, the mask plate involved in the invention has the characteristics of high hardness and high magnetism.

Owner:KUN SHAN POWER STENCIL

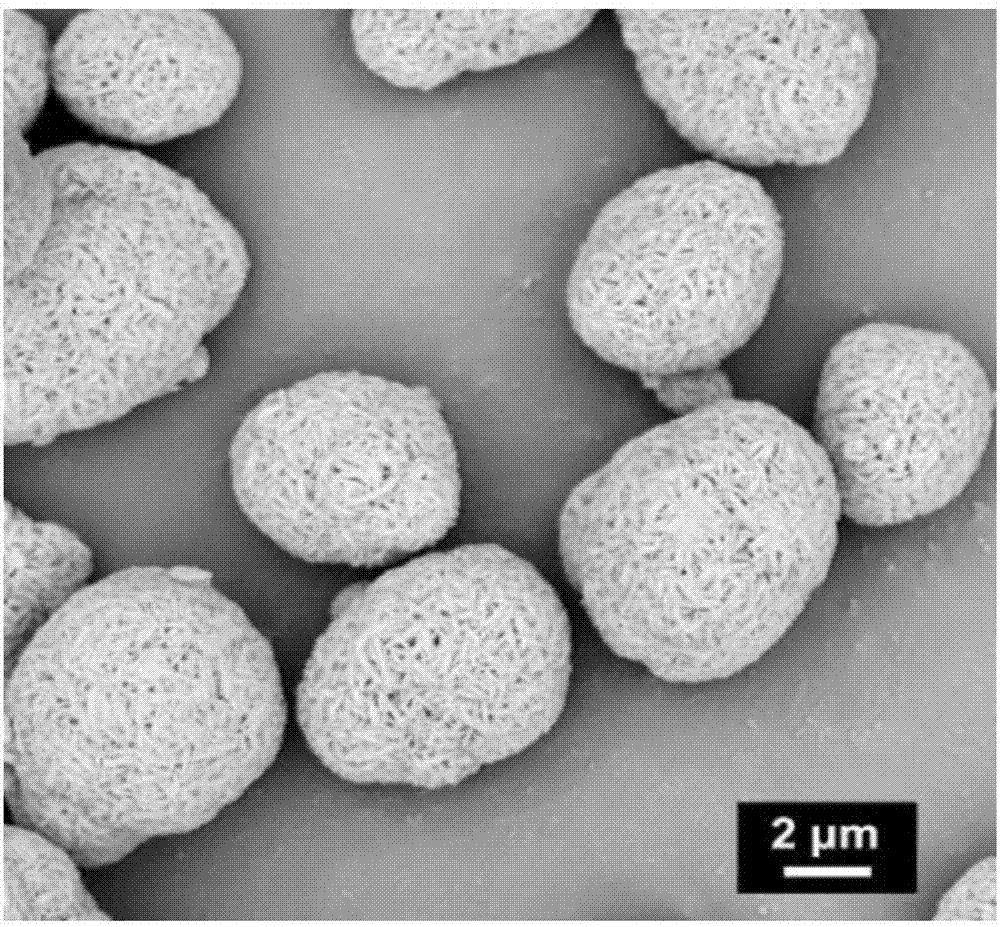

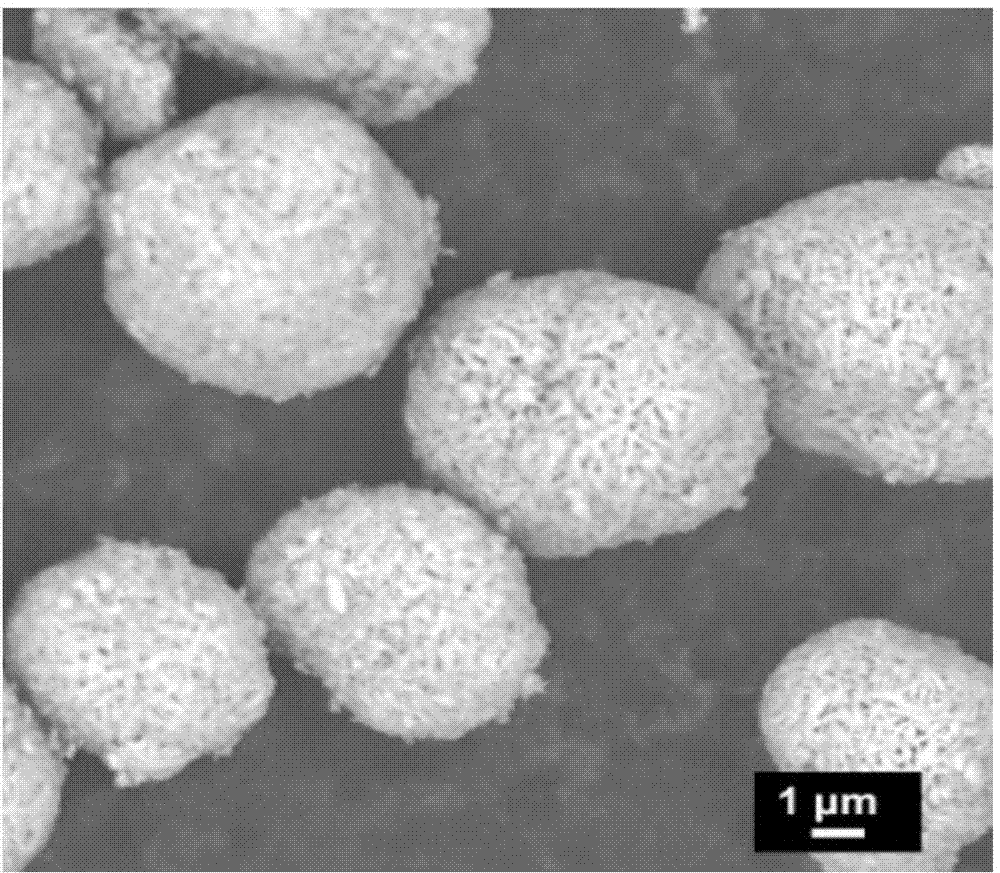

Core-shell structure high nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material and preparation method thereof

ActiveCN110518219AUniform size distributionStable charging and discharging performancePositive electrodesLi-accumulatorsManganeseCharge discharge

The invention provides a core-shell structure high nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material and a preparation method thereof. The quaternary positive electrode material is spherical particles with an average particle size of 8-10 microns, the diameter of the inner core is 4-6 microns, the thickness of the shell layer is 2-3 microns and the surface ofthe shell layer is sheet-shaped. The nickel content gradually decreases from the center of the core to the surface of the shell structure, the manganese content gradually increases from the center ofthe core to the surface of the shell structure, the cobalt content is uniformly distributed and the aluminum content is uniformly or gradient distributed. The preparation method comprises the follow steps: a low nickel solution I is continuously added into a high nickel solution so that the nickel content in the high nickel solution is continuously reduced, and then the low nickel solution I is continuously pumped into an ammonia aqueous solution to form a continuous reaction system with reduced nickel content, and further hydroxide and carbonate are successively used as precipitants and ammonia water is used as a complexing agent to successively coprecipitate to generate a precursor with a core-shell structure; and then the precursor is sintered with lithium so as to prepare the core-shell structure high nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material. The battery assembled by the positive electrode prepared by the core-shell structure high nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material has high capacity, excellent cycle and rate performance and highly reversible charge-discharge reaction.

Owner:CENT SOUTH UNIV

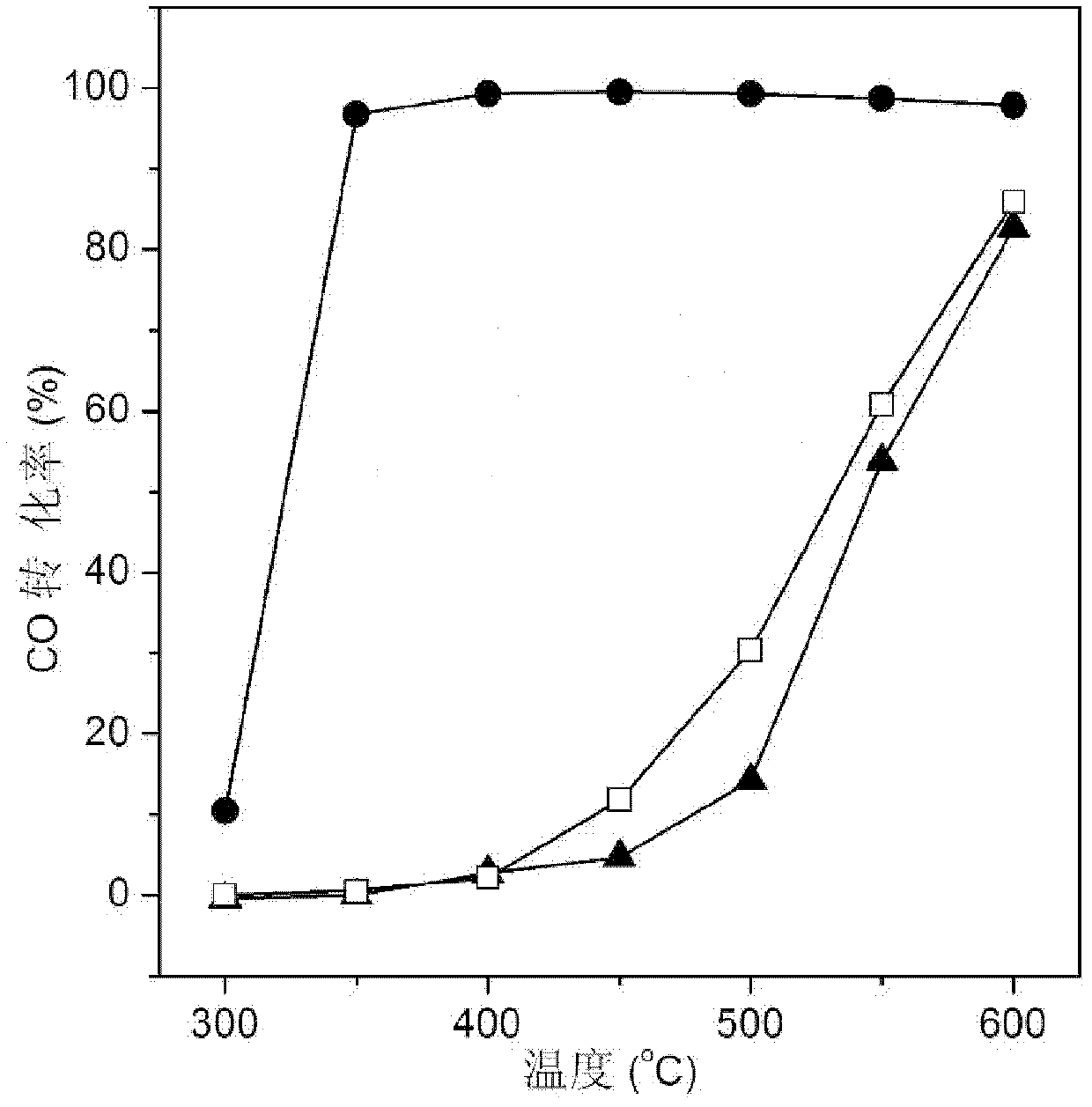

Methanation catalyst and preparation method thereof

ActiveCN102463119AHigh catalytic activityImprove catalytic stabilityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsCooking & bakingNickel salt

The invention discloses a methanation catalyst and a preparation method thereof. The methanation catalyst comprises the following components: a) nickel oxide, wherein nickel content is 5-50wt%; b) manganese oxide, wherein manganese content is 0.1-15wt%; c) at least one of oxides of beryllium, manganese, calcium, strontium, barium, lanthanum and cerium, wherein metal content is 0.5-20wt%; the components a) and b) are distributed within the range from the surface of carrier particles to a position 1 / 2 radius away from the center, and the component c) is distributed into the whole carrier particles. The preparation method disclosed by the invention comprises the following steps of: 1) mutually dissolving nickel salt and / or manganese salt with organic acid, preparing salt of the component c) into aqueous solution; and 2) dipping supported components nickel, manganese and the component c), wherein the component c) is independently supported, and baking and sintering decomposition treatment are carried out after supporting every time. The catalyst disclosed by the invention can maintain better catalytic activity and stability in a wider temperature range and has good catalytic effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

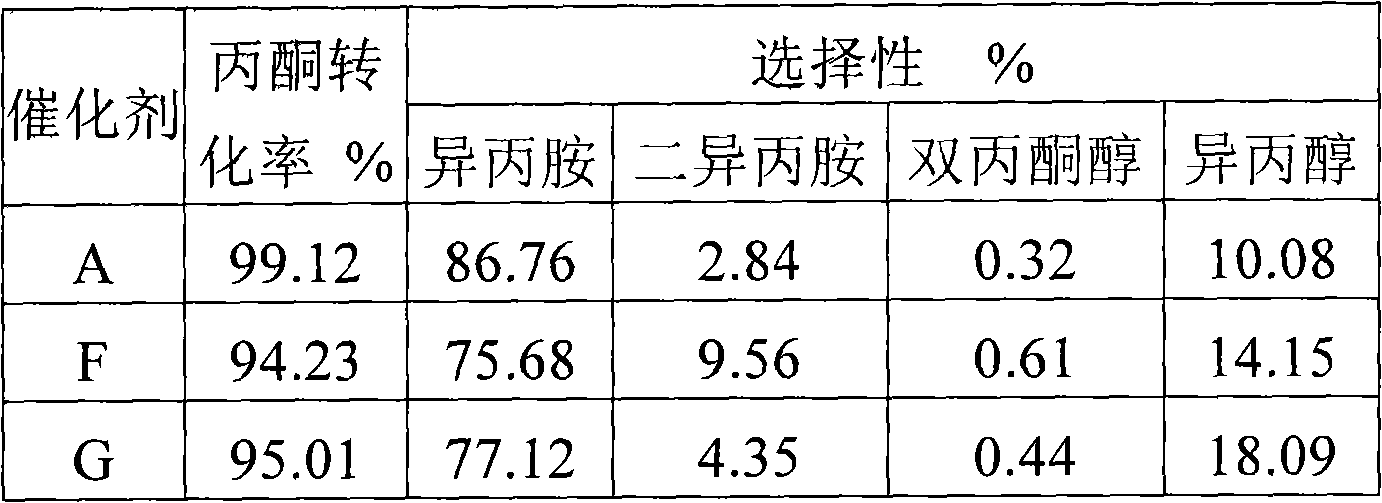

Method for synthesizing isopropamide

ActiveCN101880236AReduce generationSimple production processOrganic compound preparationPreparation by reductive alkylationFatty amineReaction temperature

The invention discloses a method for synthesizing isopropamide, belonging to the technical field of synthesizing fatty amine. In order to improve the conversion efficiency and the selectivity of catalysts for synthesizing isopropamide, propanone or isopropanol is used as the raw material, in the presence of hydrogen and a nickel-based catalyst, amination is carried out to synthesize isopropamide under the conditions that the reaction temperature is 110-200 DEG C, the reaction pressure is 0.1-1.0MPa, and the mole ratio of propanone or isopropanol to hydrogen to ammonia is 1:(1-5):(1-5), wherein the catalyst contains a carrier and nickel active components loaded on the carrier, and over 90 percent of the nickel active components are distributed in a region with the depth of 0.7 mm from the surface of the carrier. The method in the invention can ensure that the conversion efficiency of the propanone is improved, has higher propanone conversion efficiency under the condition of same nickel content and better selectivity, reduces the generation amount of diisopropylamine, simplifies the production process flows of the isopropamide, and lowers the production cost of the isopropamide.

Owner:CHINA PETROLEUM & CHEM CORP +1

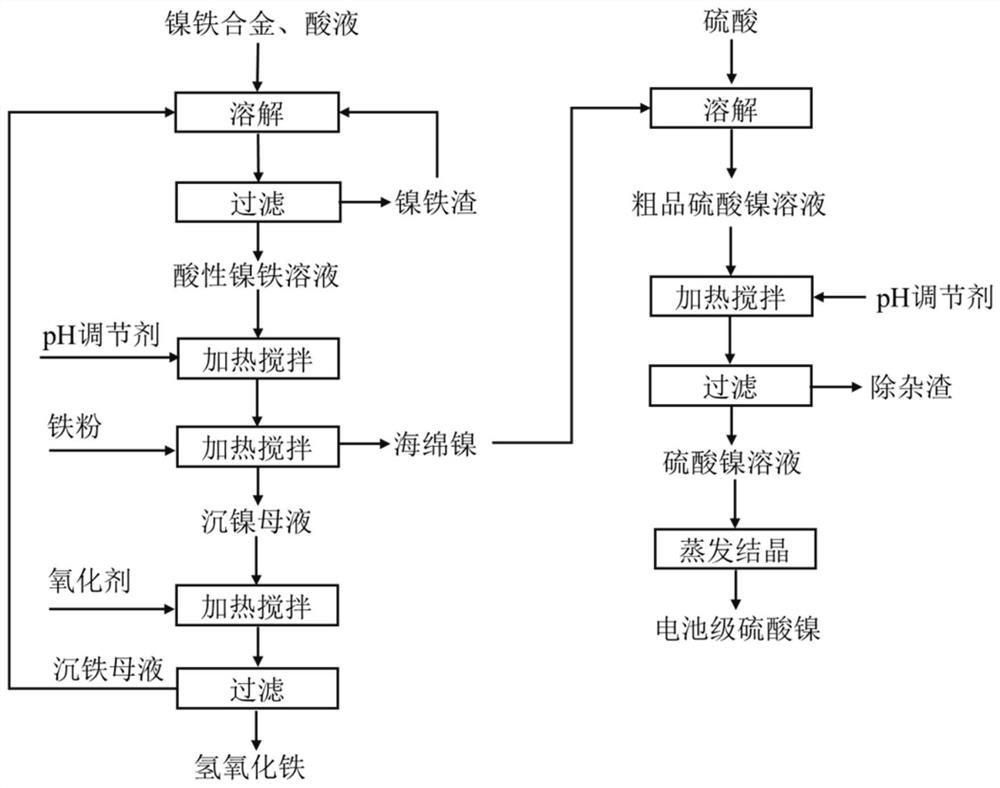

Method for separating nickel and iron from nickel-iron alloy and application

ActiveCN112941314AAchieve separationHas economic valueIron oxides/hydroxidesNickel sulfatesFerric hydroxideIron powder

The invention belongs to the field of hydrometallurgy, and discloses a method for separating nickel and iron from a nickel-iron alloy and application. The method comprises the following steps: dissolving the nickel-iron alloy in an acid solution, filtering, and taking filtrate to obtain an acidic nickel-iron solution; adjusting the pH value of the acidic nickel-iron solution, heating, stirring, adding iron powder, and continuously heating and stirring to obtain sponge nickel and nickel precipitation mother liquor; enabling the nickel precipitation mother liquor to be subjected to oxidation iron precipitation to obtain ferric hydroxide slag and iron precipitation mother liquor; and dissolving sponge nickel into sulfuric acid, filtering, collecting filtrate, heating, and adjusting the pH value to obtain a nickel sulfate solution; According to the method, after the nickel-iron alloy is dissolved by using the acid liquor, nickel in the solution is replaced by iron powder to obtain sponge nickel, the nickel precipitation mother liquor is oxidized to generate ferric hydroxide, the nickel content is lower than 0.4%, the iron precipitation mother liquor can be returned to a leaching section, and the sponge nickel is subjected to acid dissolution, impurity removal and evaporative crystallization to obtain a battery-grade nickel sulfate product.

Owner:HUNAN BRUNP RECYCLING TECH +2

Sea water corrosion resistant low-alloy cast iron

InactiveCN101225496AImproves corrosion resistance of cast ironReduce corrosion resistanceManganeseRare earth

The invention discloses a seawater corrosion-resistant low alloy cast iron, which is mainly used for manufacturing components in seawater hydraulic projects. Adopting the weight percentage as unit, the seawater corrosion-resistant low alloy cast iron comprises 0.6 to 1.6 Ni, 1.5 to 3.0 Cr, 1.8 to 2.8 Si, 2.8 to 3.6 C, 0.6 to 1.0 Mn, 1.5 to 3.0 Cu, 0.1 to 0.3 RE, less than or equal to 0.4 Al, less than or equal to 0.1 Sb, less than or equal to 0.12 P, less than or equal to 0.06 S, and remaining part of Fe. The seawater corrosion-resistant low alloy cast iron has the advantages of improving corrosion resistant performance due to joint action of the cast iron chromium, nickel, copper and other alloy elements, reducing nickel content and cost, and improving corrosion resistant performance of the seawater corrosion-resistant cast iron compared with the Ni-Cr alloy corrosion resistant cast iron.

Owner:山东省耐磨耐蚀材料工程技术研究中心

Duplex stainless steel with pitting corrosion resistance and favourable cold temperature flexibility and manufacturing method thereof

InactiveCN101684542AImprove solubilityDecreased low temperature toughnessChemical compositionRoom temperature

The invention discloses a duplex stainless steel with pitting corrosion resistance and favourable cold temperature flexibility and a manufacturing method thereof. The duplex stainless steel comprisesthe following components in mass percentage: 0.01-0.10% of C, 0.2-1.0% of Si, more than 0% and less than 1.5% of Mn, 20.0-22.0% of Cr, 1.8-4.0% of Ni, 0.08-0.2% of N, more than 0% and less than 0.5% of Mo, less than or equal to 1.0% of one or more than one of W and Cu and the balance Fe and inevitable impurities. The invention controls Mn content below 1.5% until zero and simultaneously adjusts the content of elements of N, Ni and the like to ensure that steel has high strength, favourable corrosion resistance and favourable impact toughness at room temperature and low temperature when steel contains no or small amount of noble element Mo; meanwhile, the duplex stainless steel has low cost and small hot working difficulty, can be largely applied in the fields of buildings along the coast,petrochemical industry and the like and can replace 304 austenitic stainless steel of which the nickel content is above 8% at room temperature and lower temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

Magnesium ion doped gradient nickel cobalt lithium manganate anode material and preparation method thereof

ActiveCN109686938AUniform size distributionEvenly distributedCell electrodesSecondary cellsManganateReaction temperature

The invention relates to a magnesium ion doped gradient nickel cobalt lithium manganate anode material and a preparation method thereof. The chemical formula of the anode material is LiNixCoyMnzMg (1-x-y-z) O2, wherein x is more than 0.5 and less than 0.9, y is more than 0.05 and less than 0.20, z is more than 0.05 and less than 0.30, and 1-x-y-z is more than 0; the nickel content is gradually reduced from the center to the surface of the anode material particles, the manganese content is gradually increased from the center to the surface of the anode material particles, and the contents of cobalt and magnesium are uniformly distributed in the anode material. The invention also discloses a preparation method of the anode material. The anode material has the advantages that the structure and the cycle performance are stable in the charging and discharging process, the capacity is higher, and the charging and discharging reaction is highly reversible. The method has the advantages of simple process, low reaction temperature and low raw material cost, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

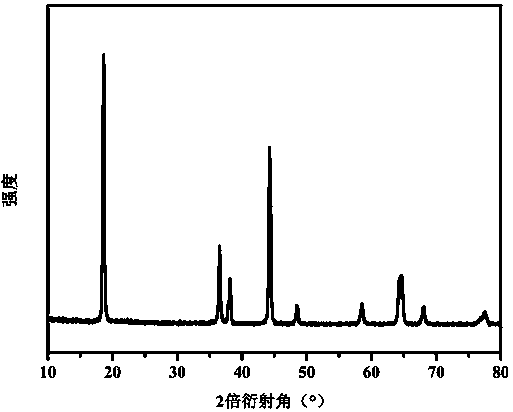

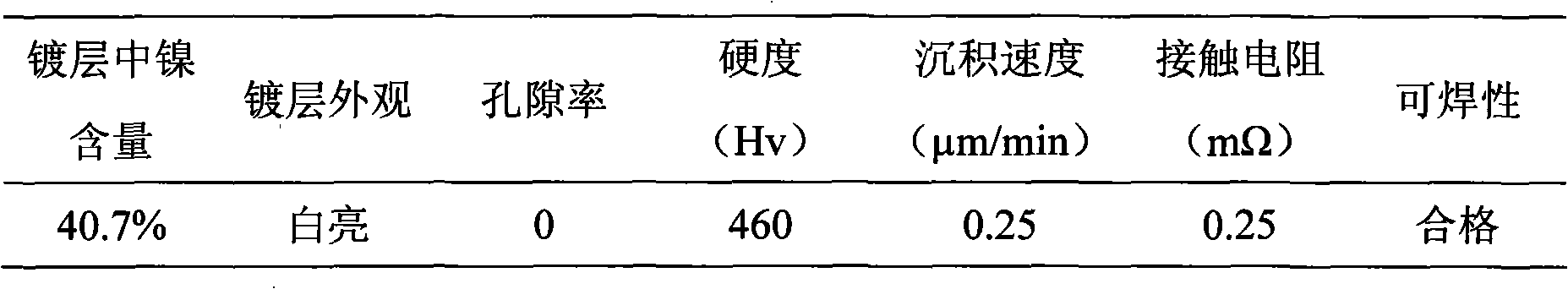

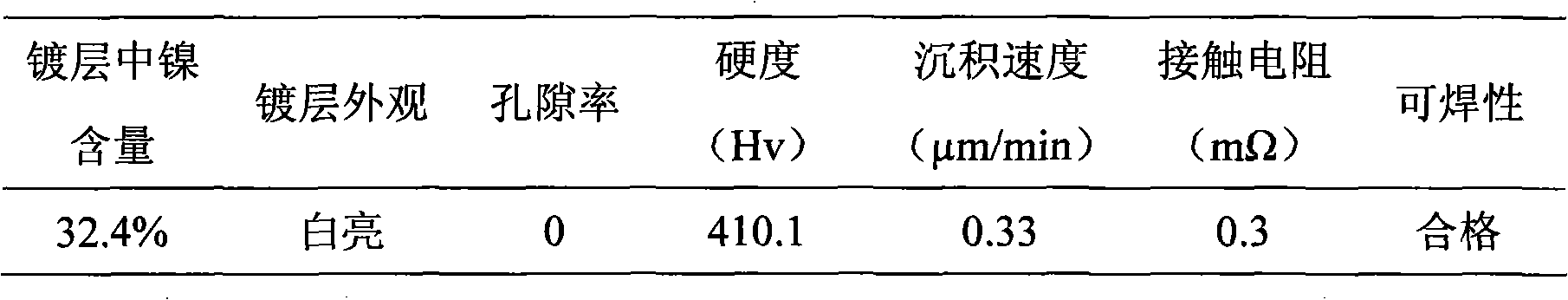

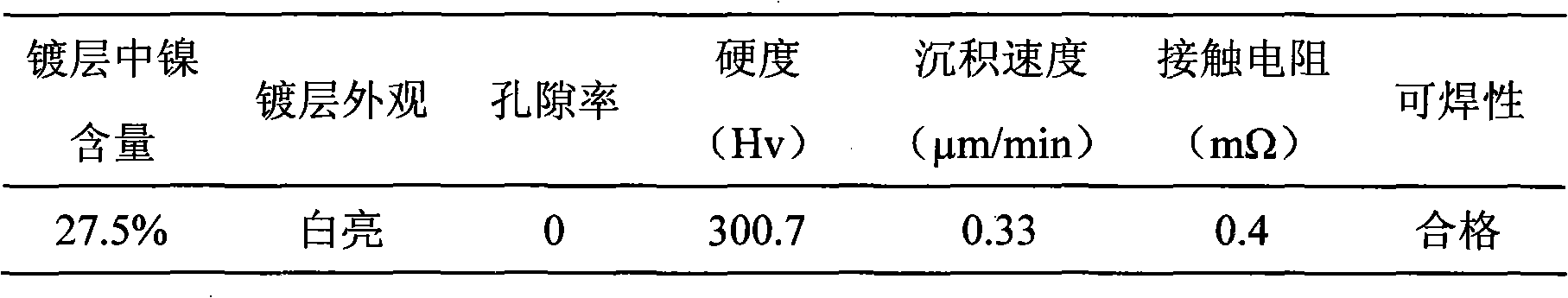

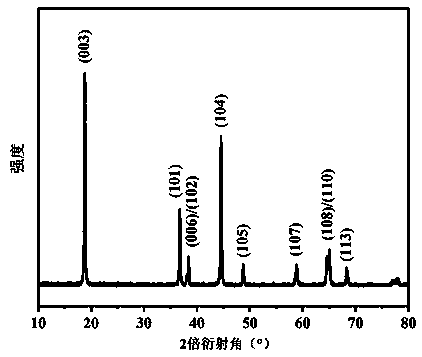

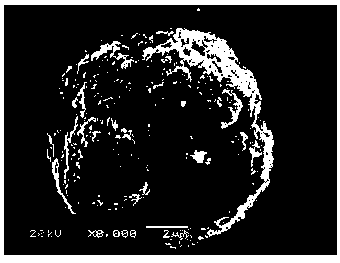

Electrolyte of electroplating palladium-nickel alloy

The invention relates to electrolyte of an electroplating palladium-nickel alloy, in particular to electrolyte. The invention provides electrolyte which can electroplate bright, compact and needle-hole-free electroplating palladium-nickel alloy with different nickel contents (10 to 40 percent), which comprises major salt, complexing agent, additive, conductive salt and pH stabilizer; the major salt comprises a palladium salt and a nickel salt, calculating at the metal palladium, the content of the palladium salt is 1 to 10 g / L, and the mol ratio of the palladium salt and the nickel slat is 1: 1 to 3; the concentration of the complexing agent is 0.2 to 1.0 mol / L; the content of the additive is 0.01 to 1.0 g / L; the content of the conductive salt is 20 to 100 g / L; and the pH stabilizer is of 20 to 50 g / L boric acid or 30 to 90 g / L pyroborate.

Owner:XIAMEN UNIV

High-nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material and preparation method thereof

ActiveCN110518220AUniform size distributionEvenly distributedPositive electrodesLi-accumulatorsManganeseCharge discharge

The invention provides a high-nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material and a preparation method thereof. The positive electrode material is spherical particles with an average particle size of 5-8 microns, the nickel content of the positive electrode material gradually decreases from the center to the surface of the spherical particles, the manganesecontent gradually increases from the center to the surface of the spherical particles, the cobalt content is uniformly distributed in the spherical particles and the aluminum content is uniformly or gradiently distributed in the spherical particles. The preparation method comprises the steps: the solution I with low nickel content is continuously added into the solution II with high nickel content, then the solution II with gradually decreasing nickel content is continuously pumped into the ammonia aqueous solution to form a continuous reaction system with decreasing nickel content, and then the precursor with gradient change of nickel, cobalt, manganese and aluminum content is precipitated in an inert gas environment by taking hydroxide as the precipitant and ammonia water as the complexing agent; and then the nickel cobalt manganese aluminum hydroxide precursor is sintered with lithium so as to prepare the high-nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material. The quaternary positive electrode material obtained by the preparation method has high capacity, excellent cycle and rate performance and highly reversible charge-discharge reaction.

Owner:CENT SOUTH UNIV

Cathode active material for lithium secondary battery

ActiveUS20110065003A1Increase battery capacityImprove high temperature stabilityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithiumConductive polymer

Disclosed herein is a cathode active material based on lithium nickel-manganese-cobalt oxide represented by Formula 1, wherein the lithium nickel-manganese-cobalt oxide has a nickel content of at least 40% among overall transition metals and is coated with a conductive polymer at a surface thereof. A lithium secondary battery having the disclosed cathode active material has advantages of not deteriorating electrical conductivity while enhancing high temperature stability, so as to efficiently provide high charge capacity.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com