Patents

Literature

50results about How to "Reduce corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

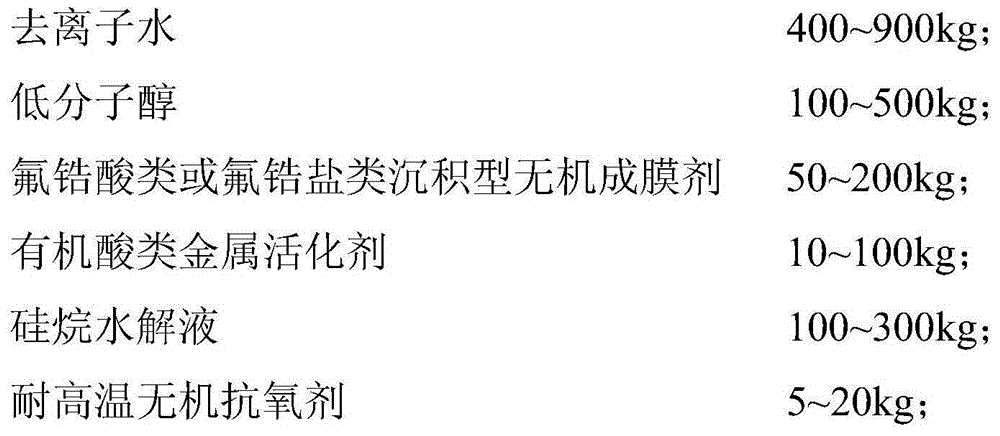

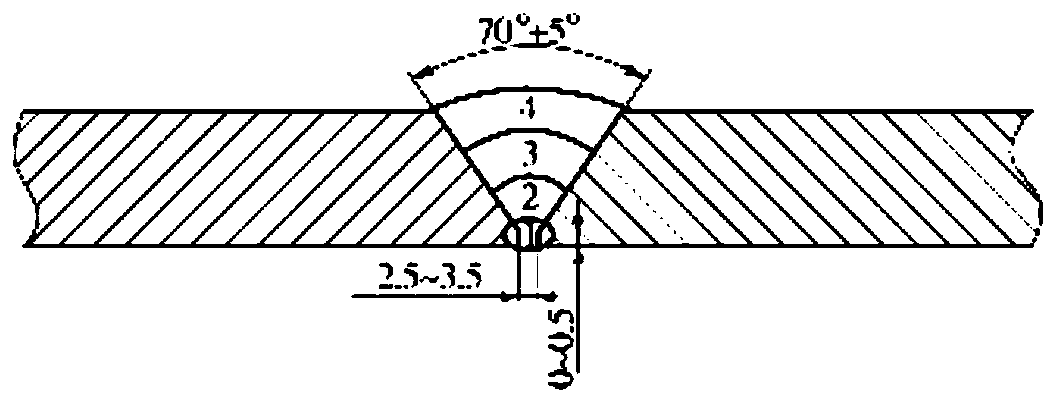

Non-chrome purified liquid

ActiveCN103205738AImprove corrosion resistanceGood resistance to high temperature yellowing propertiesMetallic material coating processesAntioxidantSilanes

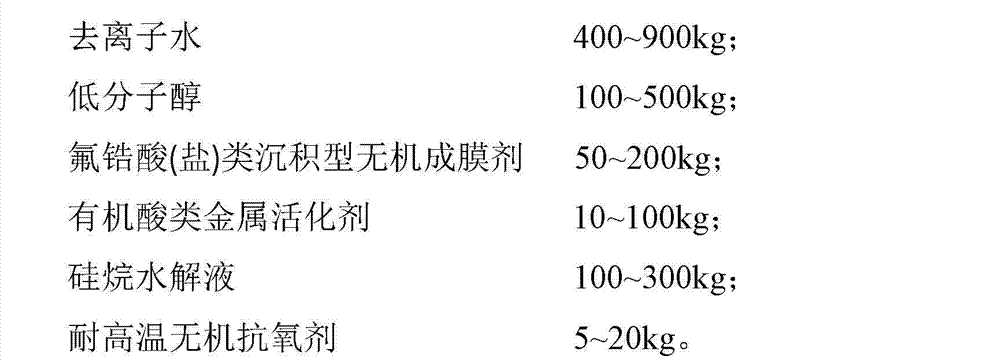

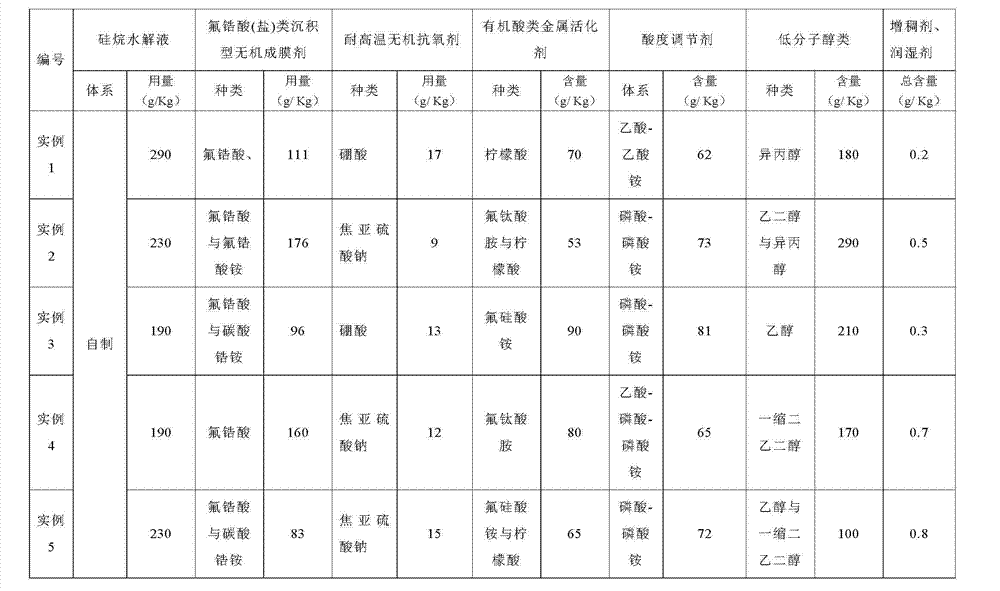

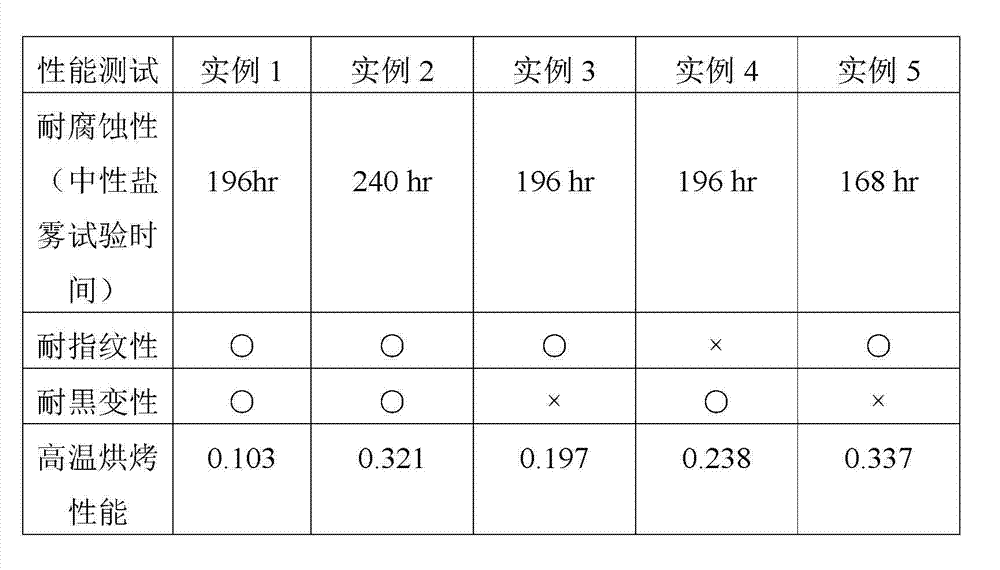

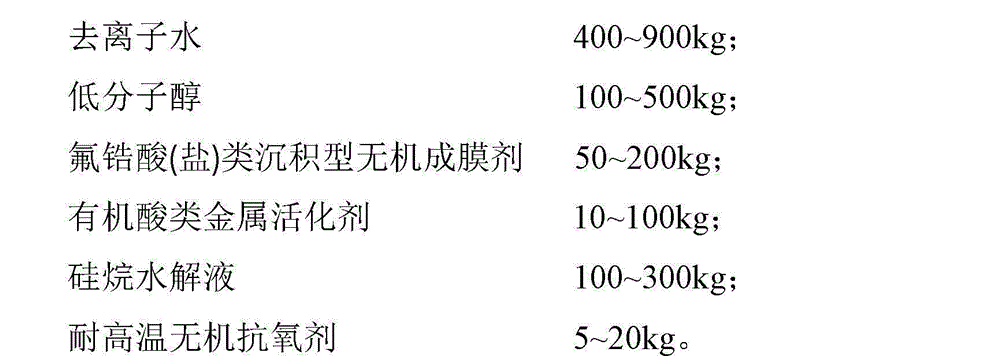

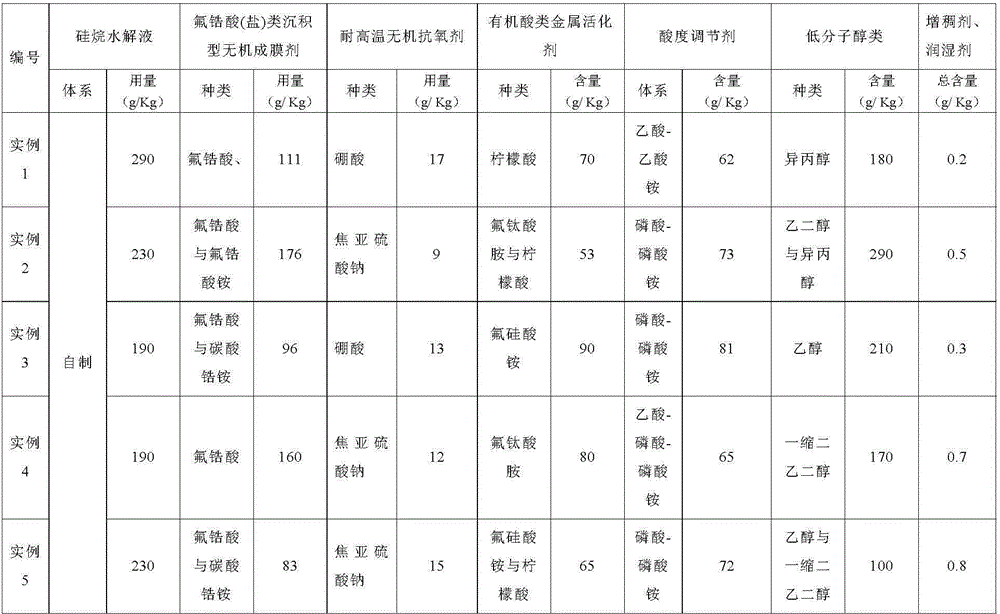

The invention discloses a non-chrome purified liquid. Components of each 1000kg of the non-chrome purified liquid include: 400-900kg of deionized water, 100-500kg of low molecular weight alcohol, 50-200kg of zirconium-fluoride-acid (salt) type sedimentary inorganic film-forming agent, 10-100kg of organic-acid type metal activator, 100-300kg of silane hydrolyzate and 5-20kg of high-temperature-resistant inorganic antioxidant. The non-chrome purified liquid is good in corrosion resistance, has good high-temperature and xanthochroia resisting features since the high-temperature-resistant inorganic antioxidant is added in without organic aqueous resin, is adaptable to surface passivation processing of galvanized and aluminum-zinc alloy plated type metal products, and is further adaptable to surface passivation processing of galvanized plates (the galvanized plates for computer cases and the like) with special requirements for high-temperature and xanthochroia resisting features.

Owner:武汉钢实硅钢浩源润滑油有限公司

Sea water corrosion resistant low-alloy cast iron

InactiveCN101225496AImproves corrosion resistance of cast ironReduce corrosion resistanceManganeseRare earth

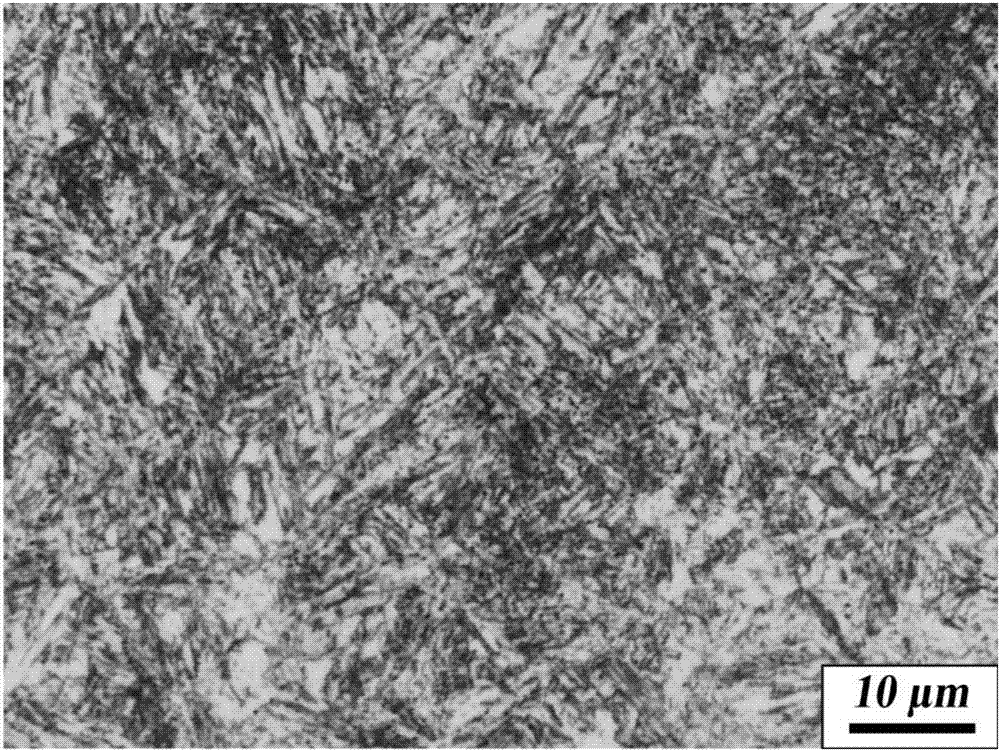

The invention discloses a seawater corrosion-resistant low alloy cast iron, which is mainly used for manufacturing components in seawater hydraulic projects. Adopting the weight percentage as unit, the seawater corrosion-resistant low alloy cast iron comprises 0.6 to 1.6 Ni, 1.5 to 3.0 Cr, 1.8 to 2.8 Si, 2.8 to 3.6 C, 0.6 to 1.0 Mn, 1.5 to 3.0 Cu, 0.1 to 0.3 RE, less than or equal to 0.4 Al, less than or equal to 0.1 Sb, less than or equal to 0.12 P, less than or equal to 0.06 S, and remaining part of Fe. The seawater corrosion-resistant low alloy cast iron has the advantages of improving corrosion resistant performance due to joint action of the cast iron chromium, nickel, copper and other alloy elements, reducing nickel content and cost, and improving corrosion resistant performance of the seawater corrosion-resistant cast iron compared with the Ni-Cr alloy corrosion resistant cast iron.

Owner:山东省耐磨耐蚀材料工程技术研究中心

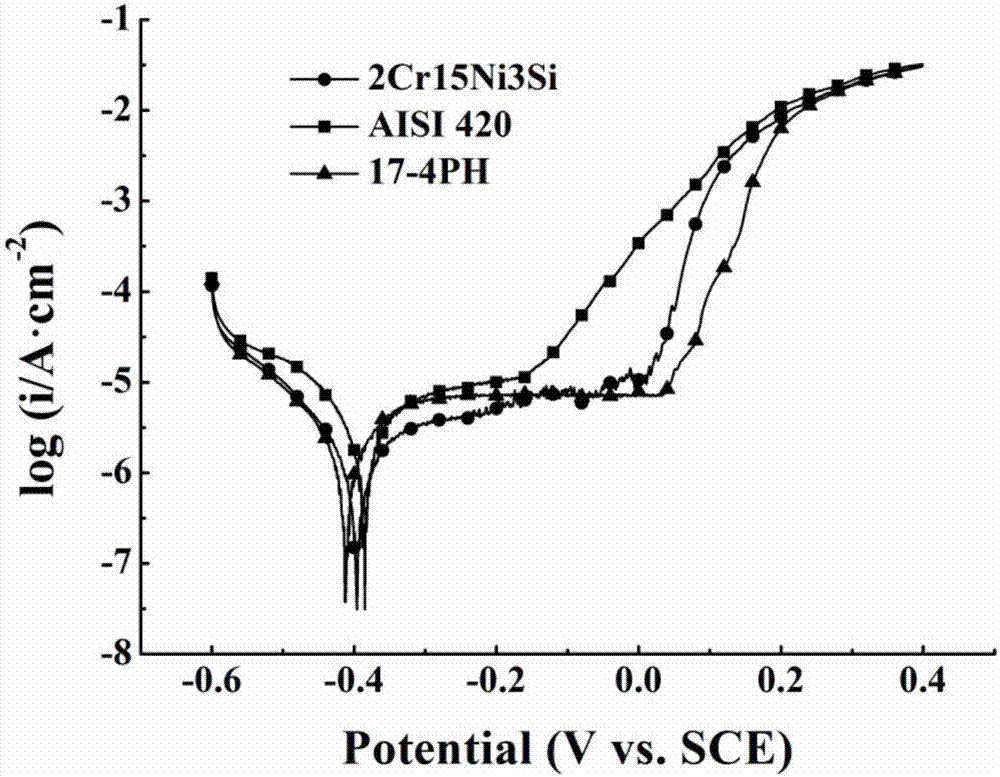

Ultrahigh-strength martensitic stainless steel and preparation method thereof

ActiveCN106906429AImprove mechanical propertiesImprove corrosion resistanceMartensitic stainless steelIngot

The invention discloses ultrahigh-strength martensitic stainless steel and a preparation method thereof. The ultrahigh-strength martensitic stainless steel is high in yield strength, high in tensile strength, good in ductility and good in impact toughness. The preparation method comprises the steps as follows: Step 1, a raw material is prepared from stainless steel components in percentage by weight according to the burnt value, is smelted in the vacuum environment and is poured to form a steel ingot; the steel ingot is prepared from components in percentage by weight as follows: 0.10%-0.25% of C, 11.0%-17.0% of Cr, 0.5%-2.0% of Mn, 1.1%-3.0% of Si, 0.1%-4.0% of Ni, 0.1%-0.3% of Cu, less than or equal to 0.02% of P, less than or equal to 0.02% of S and the balance of Fe and inevitable impurity elements; Step 2, forging of the steel ingot is started at 1,050-1,200 DEG C, the finish forging temperature ranges from 880 DEG C to 920 DEG C, the forging ratio is larger than or equal to 5, and air cooling is performed after forging; Step 3, a forging is subjected to heat preservation at 950-1,050 DEG C for 2-4 h, is subjected to water quenching and then is tempered at 200-300 DEG C for 2-4 h, and the ultrahigh-strength martensitic stainless steel is obtained after natural cooling.

Owner:XI AN JIAOTONG UNIV

Intermediate-carbon high-speed cutting saw blade matrix steel and production method thereof

The invention discloses an intermediate-carbon high-speed cutting saw blade matrix steel and a production method thereof. The steel comprises the following components in percentage by weight: 0.20-0.40% of C, 0.10-0.30% of Si, 0.45-0.63% of Mn, not more than 0.010% of P, not more than 0.005% of S, 0.008-0.020% of Ti, 0.80-1.20% of Cr, not more than 0.005% of N, 0.020-0.050% of Al, 0.10-0.20% of Ni, 0.030-0.050% of V and the balance of Fe and inevitable impurities, wherein Als / N is not less than 30%, Mn +Cr is 1.45-1.85. The production method comprises the following steps of: desulfurizing molten iron, smelting in a converter, carrying out vacuum treatment, casting continuously, hot-rolling continuously, cooling, coiling, leveling, quenching and tempering. Facts prove that the steel has pure steel quality, strong toughness, high wearing resistance and low cost at the same time. The production method of the steel is simple in process and stable in product property.

Owner:WUHAN IRON & STEEL (GROUP) CORP

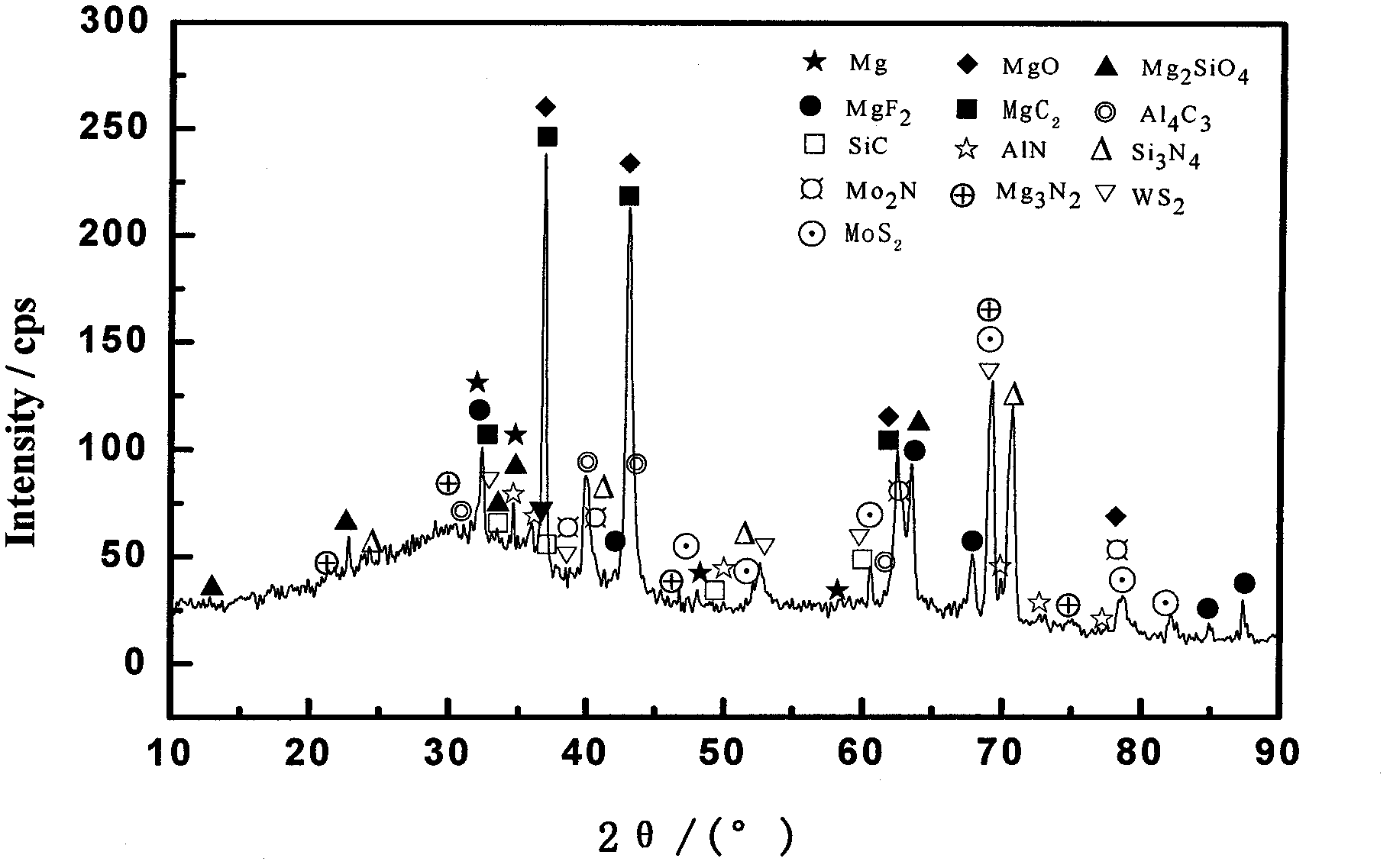

Preparation method of composite film on surface of magnesium alloy and solution formula for preparation method

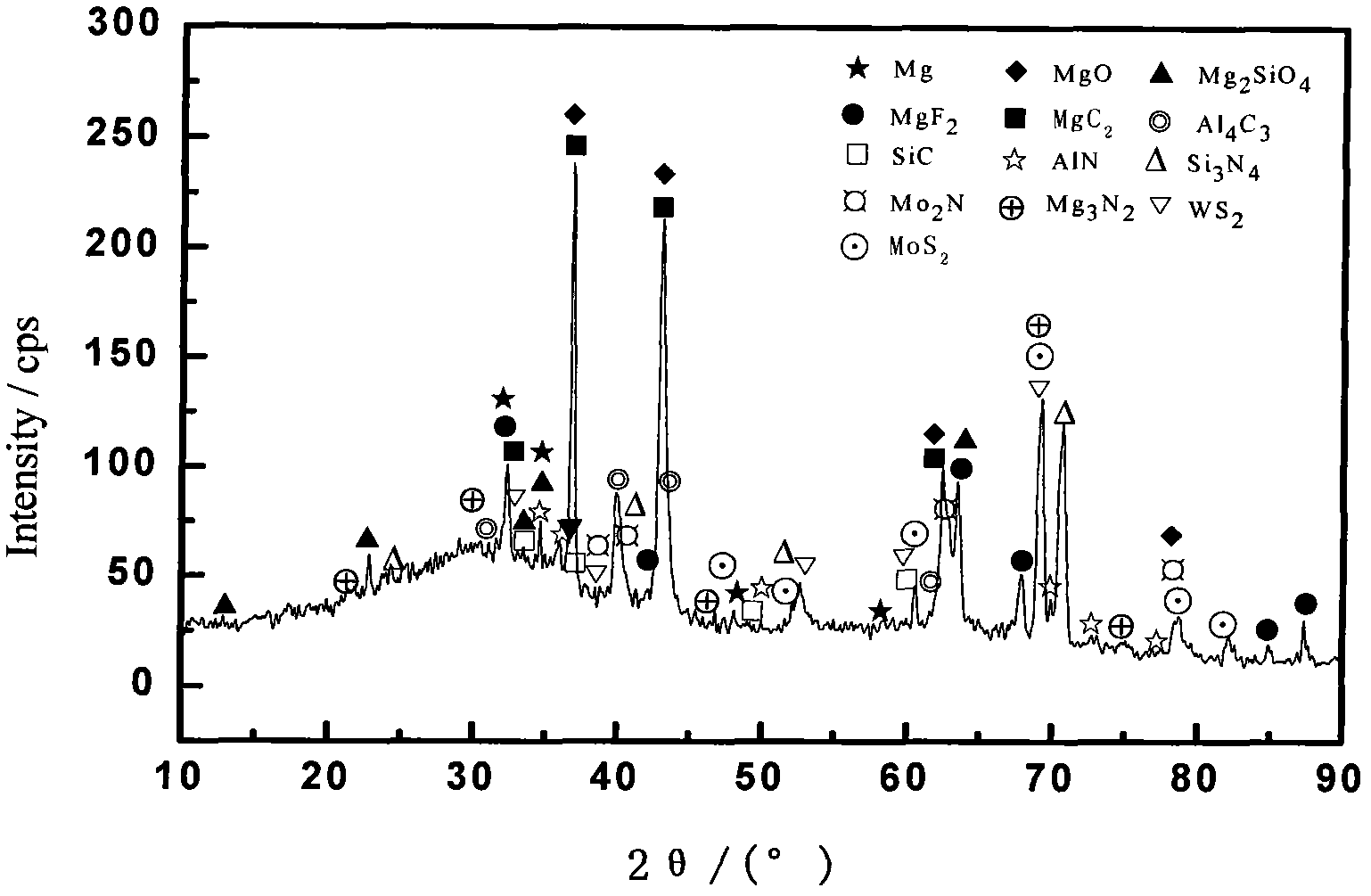

InactiveCN102321906AImprove performanceImprove carrying capacityAnodisationFriction reductionPlasma electrolytic oxidation

The invention relates to a preparation method of a composite film on the surface of a magnesium alloy and a solution formula for the preparation method. The preparation method comprises the following steps of: (1) placing a polished and washed magnesium alloy work piece into electrolyte containing elements to be permeated and then carrying out plasma electrolytic permeation treatment to form a surface modified layer containing distributed permeated elements on the surface of the magnesium alloy work piece; (2) washing the processed work piece, placing the processed work piece into alkaline electrolyte and carrying out plasma electrolytic oxidation treatment; and finally, obtaining a composite film on the surface of the work piece, wherein the composite film has excellent combination properties, such as high hardness, corrosion resistance, wear resistance and friction reduction. The solution formula for the preparation method is as follows: the electrolyte for carrying out the plasma electrolytic permeation treatment contains 10-140 g / L of compound A containing elements C, N, B and S to be permeated and 2-30 g / L of sodium hydroxide; and the compound A is one or combination of more of formamide, urea, ethanolamine, borax and thiourea.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Production method of composite material stirring wing

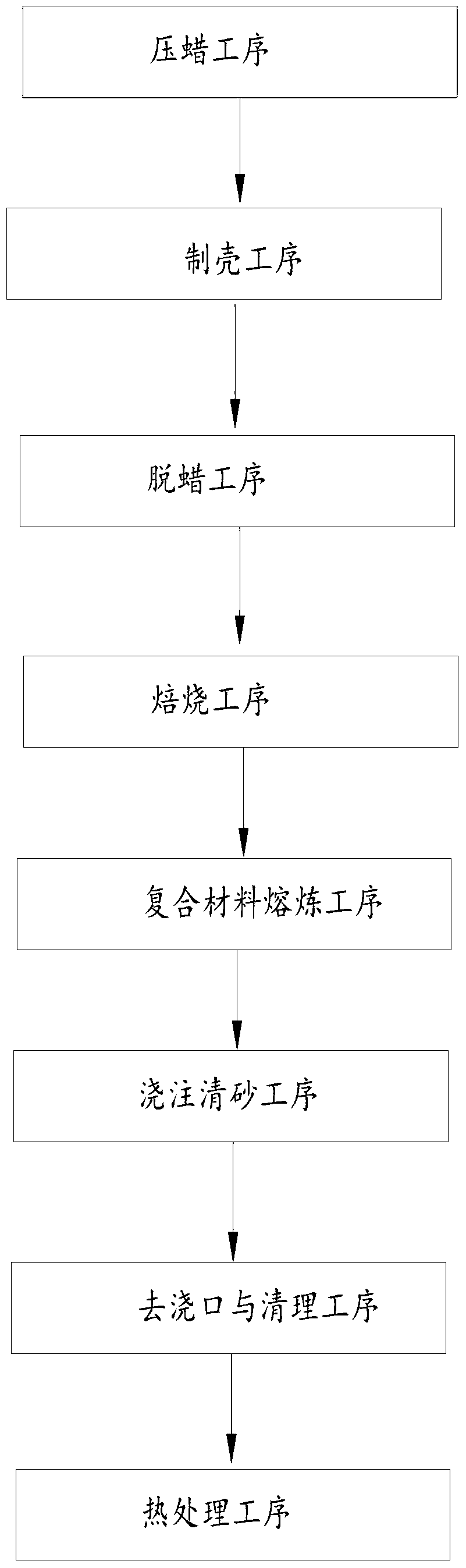

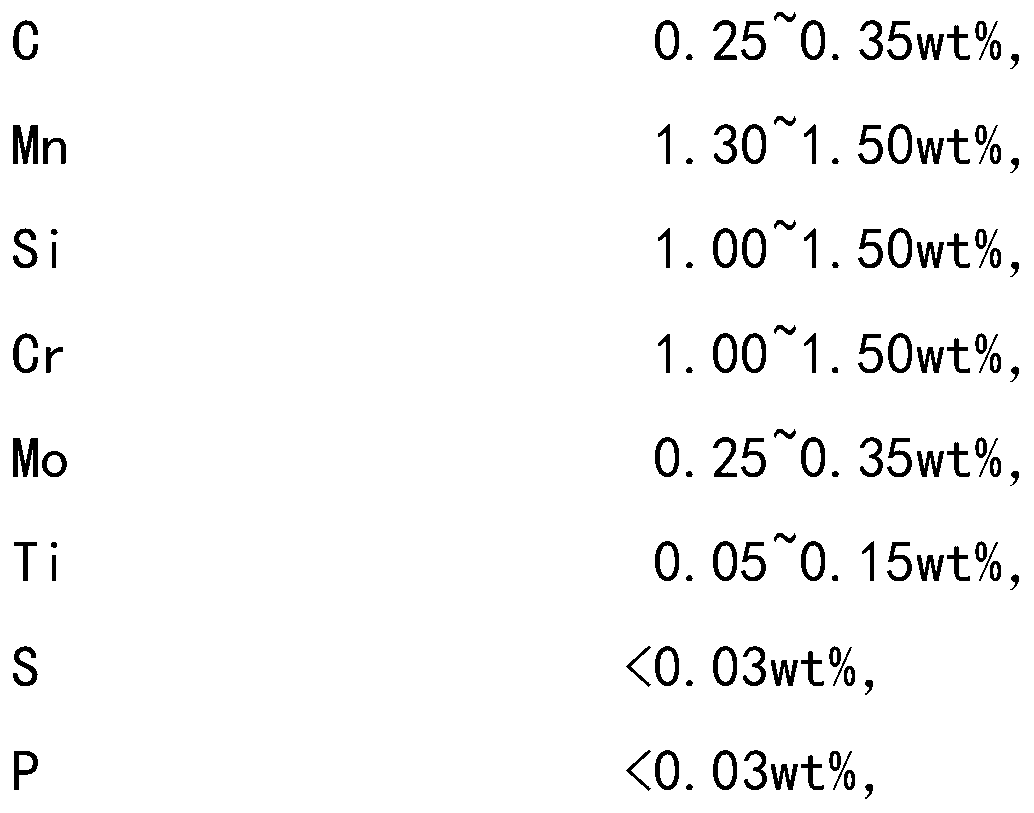

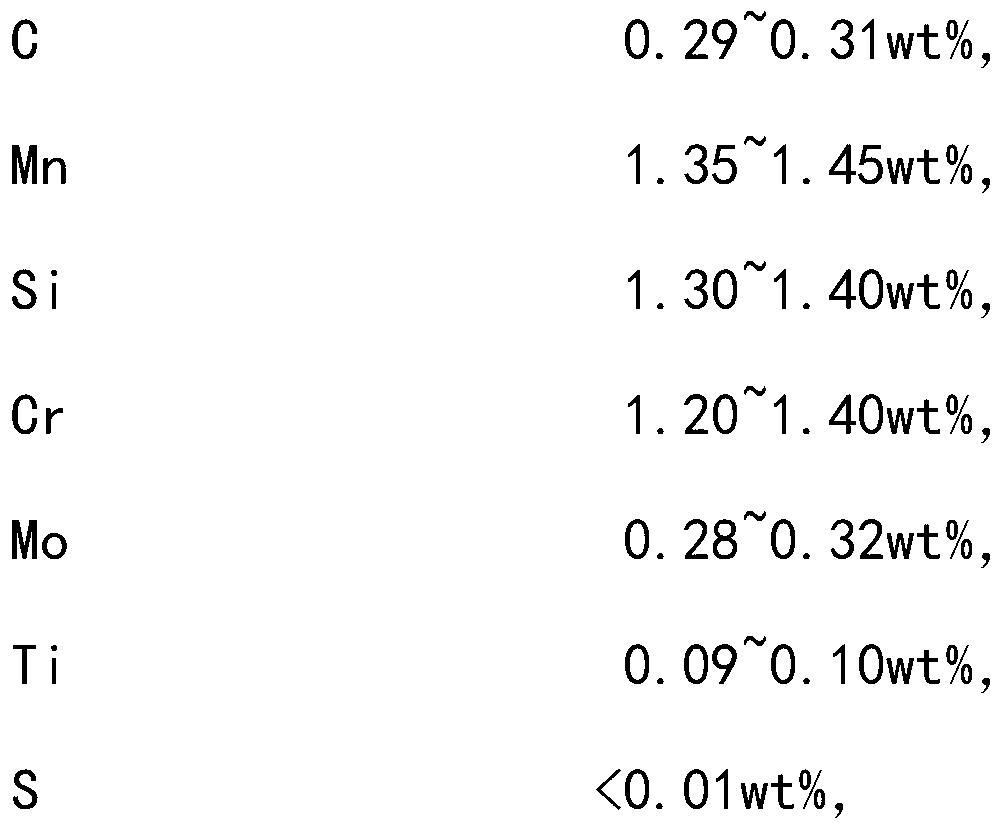

InactiveCN103252449AImprove mechanical propertiesImprove mechanical properties; adding C can improve the compactness of the material structureFoundry mouldsFoundry coresWaxSmelting process

The invention provides a production method of a composite material stirring wing. The method comprises the following steps of: (1) wax pressing process; (2) shell making process; (3) dewaxing process; (4) roasting process; (5) composite material smelting process; (6) clean sand pouring process; (7) sprue removing and cleaning process; and (8) heat treatment process. The production method can be used for producing the stirring wing with high safety and reliability, and the high-quality composite material stirring wing can be produced by the method.

Owner:QINGDAO YUXIN VEHICLE ENG

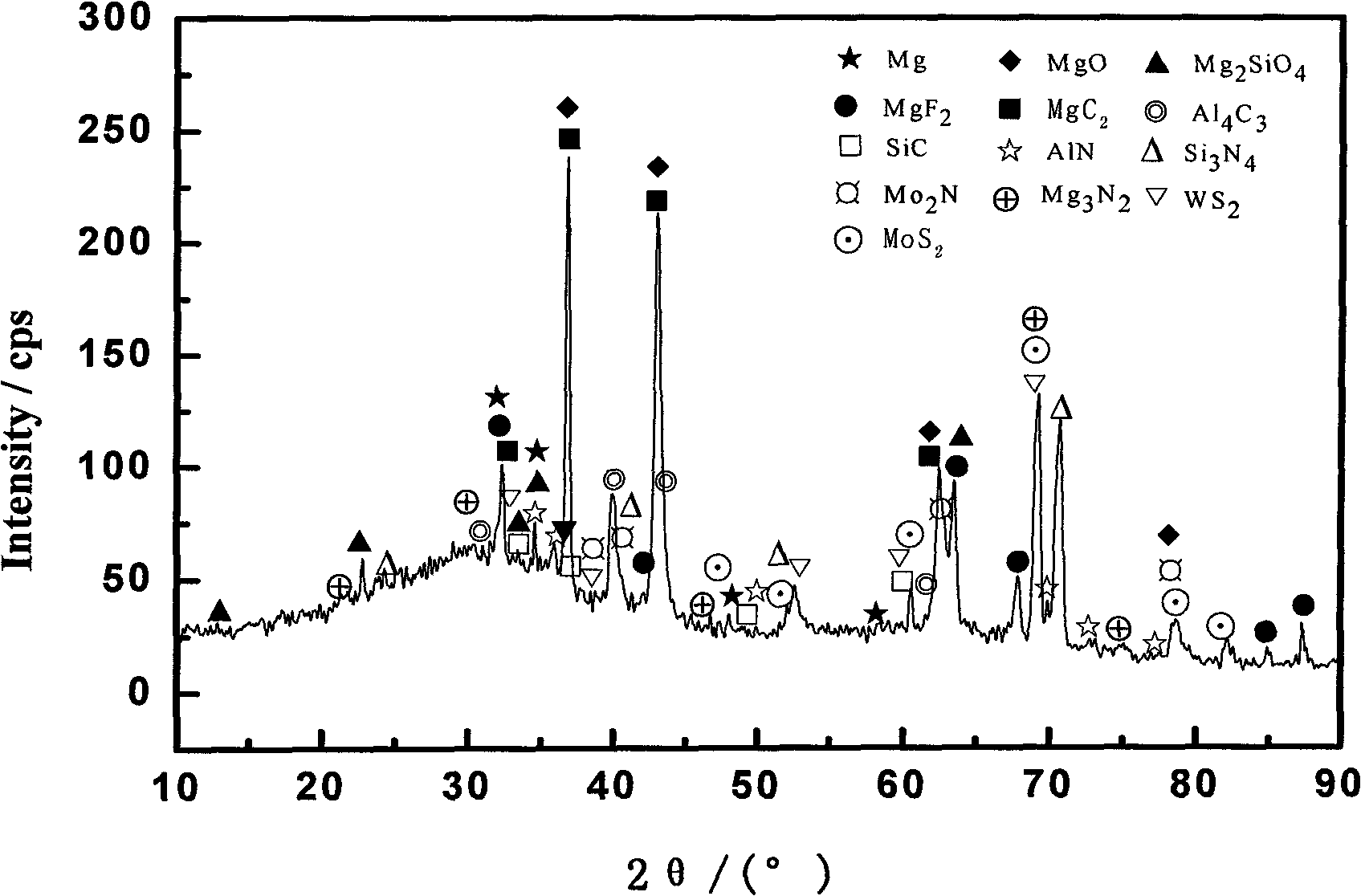

Preparation method of composite film on surface of metallic material and solution composition for preparation method

InactiveCN102321903AImprove carrying capacityImprove performanceAnodisationFriction reductionPlasma electrolytic oxidation

The invention relates to a preparation method of a composite film on the surface of a metallic material and a solution composition for the preparation method. The preparation method comprises the following steps of: (1) placing a polished and washed metal work piece into electrolyte containing elements to be permeated and then carrying out plasma electrolytic permeation treatment to form a surface modified layer containing distributed permeated elements on the surface of the metal work piece; (2) washing the processed work piece, then placing the processed work piece into alkaline electrolyte and carrying out plasma electrolytic oxidation treatment, and finally, obtaining a composite film on the surface of the work piece, wherein the composite film has excellent combination properties, such as high hardness, corrosion resistance, wear resistance and friction reduction. The solution composition for the preparation method is as follows: the electrolyte for carrying out the plasma electrolytic permeation treatment contains 10-140 g / L of compound A containing elements C, N, B and S to be permeated and 2-30 g / L of sodium hydroxide; and the compound A is one or the combination of more of formamide, urea, ethanolamine, borax and thiourea.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Hoop surface hot dip coating tin alloy process

InactiveCN105586557ALow melting pointImprove corrosion resistanceHot-dipping/immersion processesTinningMetal coating

The invention discloses a hoop surface hot dip coating tin alloy process. The hoop surface hot dip coating tin alloy process comprises the steps of sanding, alkali wash oil removal, acid pickling, plating assisting, preheating, hot dip coating and analysis and detection. According to the hoop surface hot dip coating tin alloy process, no harmful heavy metal ion or phosphorus or sediment exists, heating is not needed, the treatment time is short, the number of treatment steps is small, a surface adjusting procedure can be omitted, hot drip coating can be reused, and the adhesive force of a metal coating to a substrate is effectively improved.

Owner:大连新锋钢管厂

Preparation method of 5083-O-state battery case side plate for new energy automobile

The invention belongs to the technical field of aluminum alloy, and particularly discloses a preparation method of a 5083-O-state battery case side plate for a new energy automobile. The method comprises the following steps of adding prepared raw materials into a smelting furnace for smelting, and then conducting standing refining, slagging-off, degassing and filtering to obtain molten aluminum; casting the molten aluminum into an aluminum alloy cast ingot; conducting homogenizing heat treatment on the aluminum alloy cast ingot; after preheating, conducting hot rolling to obtain a hot-rolled blank with the thickness of 6.0 mm, wherein the hot rolling final temperature is 310 DEG C or above; and conducting cold rolling to obtain an intermediate cold-rolled coiled material with the thickness of 2.5 mm, conducting intermediate annealing, conducting cold rolling again to obtain an aluminum alloy coiled material with the thickness of 1.2 mm, conducting stretch bending alkali washing, water washing and drying on the aluminum alloy coiled material, conducting finished product annealing, conducting plate shape withdrawal and straightening, and conducting transverse shearing and slitting to obtain the side plate. The tensile strength of the prepared 5083 material can reach 280 MPa or above, the surface dyne value is 60 dyne or above, and meanwhile, good forming performance and good corrosion resistance are achieved.

Owner:郑州明泰实业有限公司

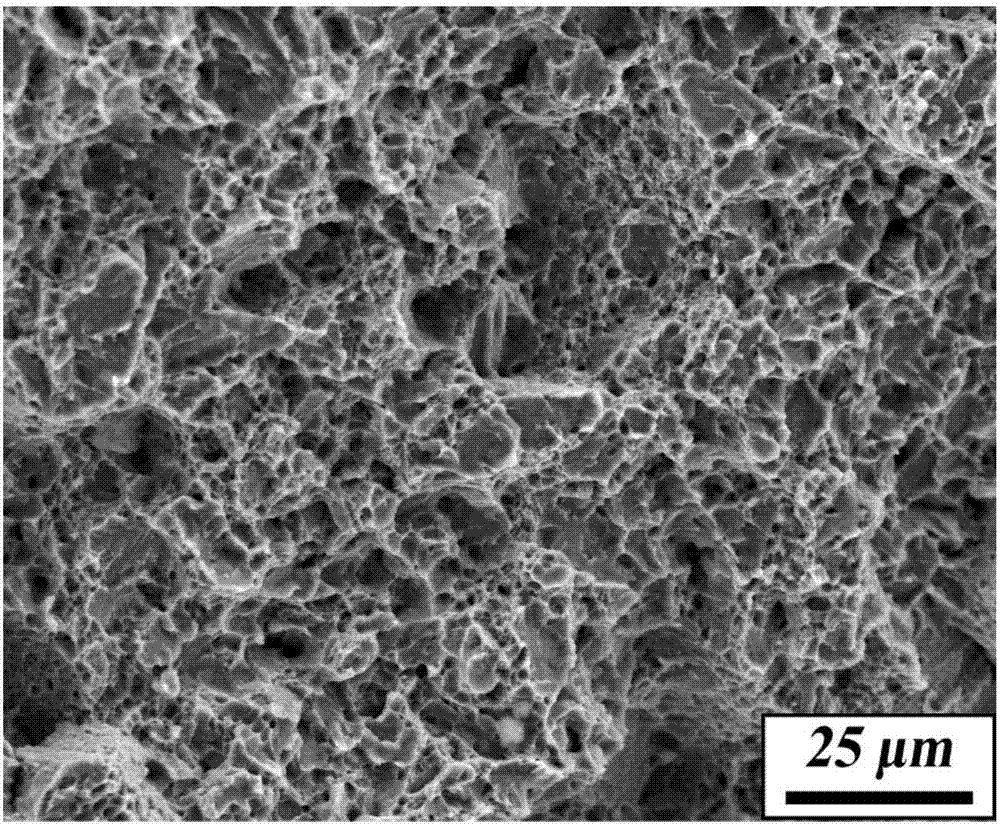

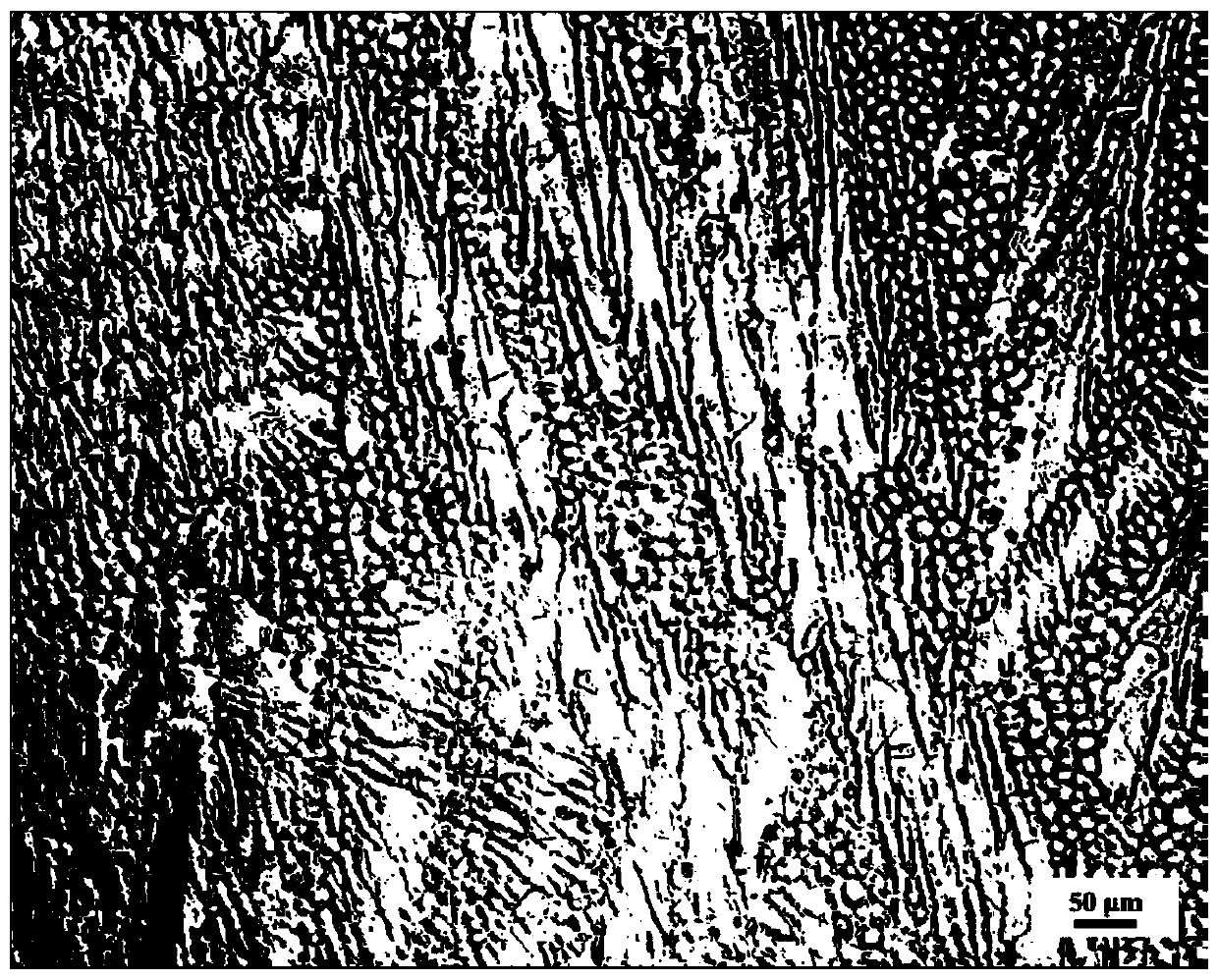

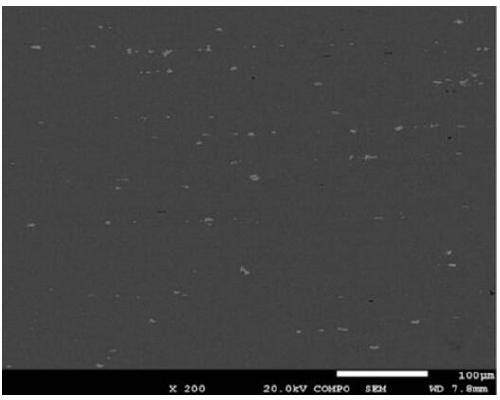

Ceramic enhanced type nickel-based composite coating and preparation method thereof

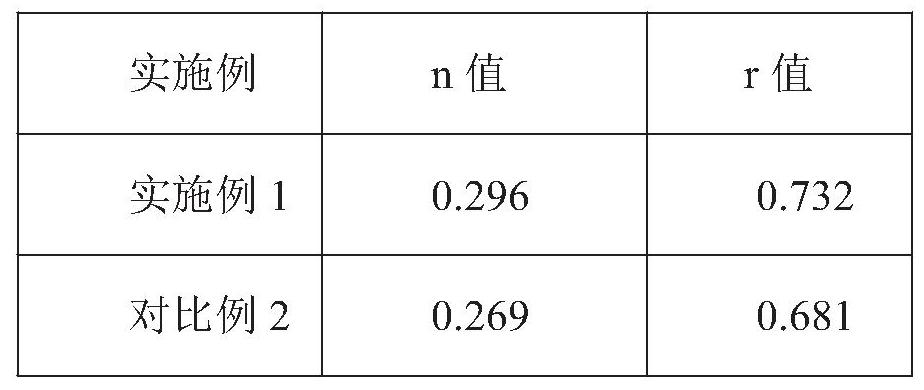

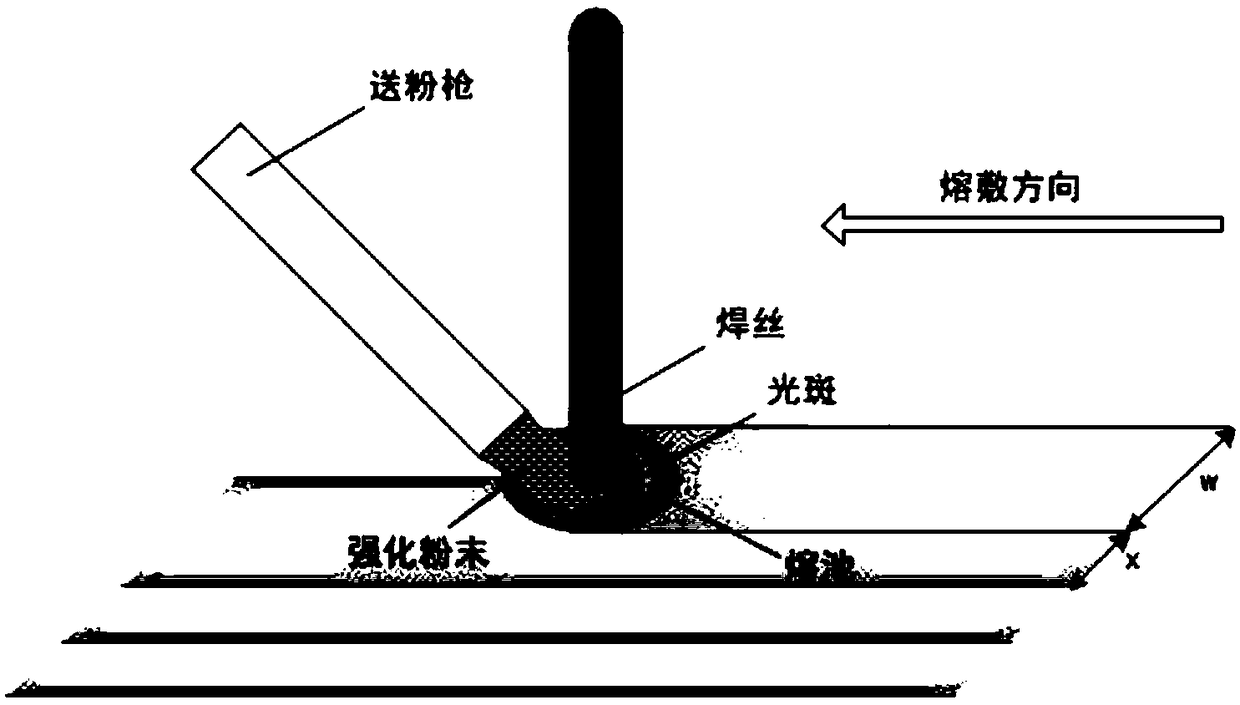

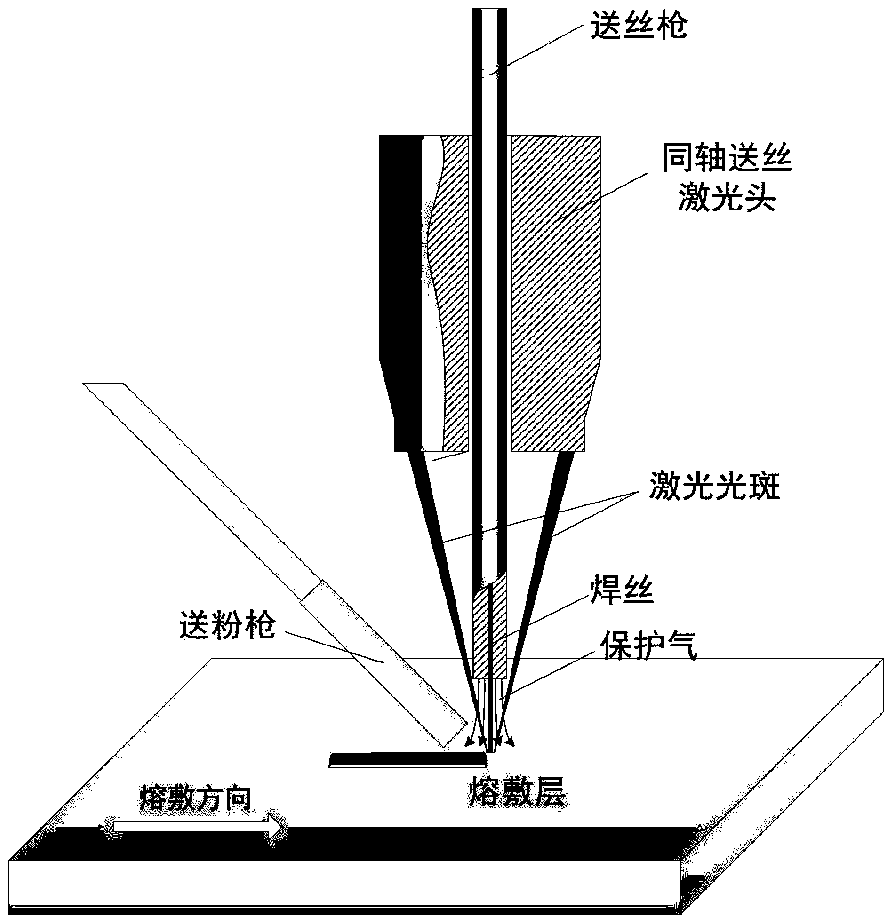

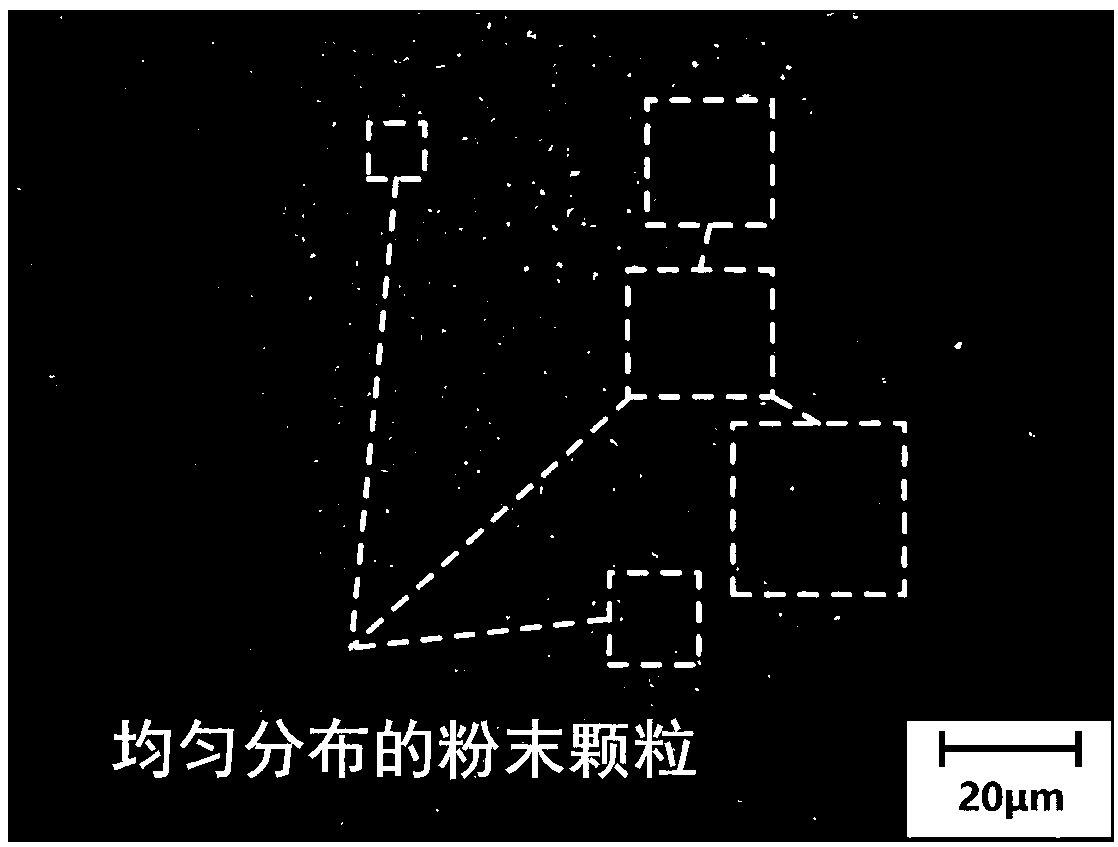

InactiveCN108505034AReduce corrosion resistanceComplete organizationMetallic material coating processesNickel alloyLaser

The invention provides a ceramic enhanced type nickel-based composite coating and a preparation method thereof. A non-powdery nickel alloy containing raw material and ceramic powder are melted and deposited on a matrix material and the ceramic enhanced type nickel-based composite coating is formed on the matrix material, wherein the mass percent content of nickel in the non-powdery nickel alloy containing raw material is greater than or equal to 30 percent. According to the method provided by the invention, the non-powdery nickel alloy containing raw material and the ceramic powder are adoptedin a melting and depositing process; laser melted conventional raw material alloy powder is avoided, and furthermore, a phenomenon that incomplete tissues are caused by air pores and cracks are easily generated in the melting and depositing process so that the corrosion resistance of the coating is reduced is avoided. A result of the embodiment provided by the invention shows that the composite coating obtained according to the technical scheme has no cracks and pores and has complete tissues.

Owner:HUAZHONG UNIV OF SCI & TECH

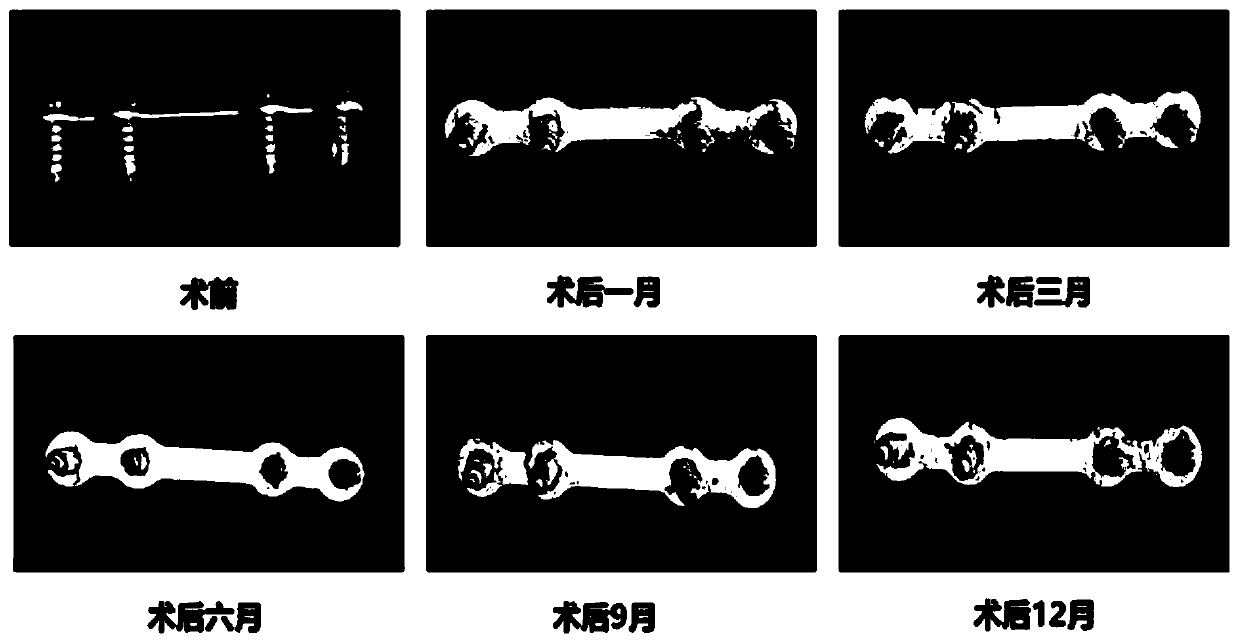

Degradable Zn-Ag series zinc alloy and preparing method and application thereof

InactiveCN110241330AReduce corrosion potentialImprove corrosion resistanceSurgeryTrace element compositionZinc alloys

The invention provides a degradable Zn-Ag series zinc alloy and a preparing method and application thereof. The zinc alloy is composed of Zn, Ag and a microelement. The mass percent of the Zn ranges from 89.85 to 99.4%, the mass percent of the Ag ranges from 0.01 to 10%, and microelement comprises one or multiple of Fe, Mg, Ca, Sr and Li. The mass percent of the microelement ranges from 0.01 to 0.55%. The method comprises the steps of heating metal zinc to be molten after burdening, adding metal silver, performing stirring until the metal silver is molten, adding the microelement, performing stirring, standing and pouring, and obtaining a zinc alloy cast ingot; and performing heat treatment and heat preservation on the zinc alloy cast ingot, and finally performing extrusion forming. The made zinc alloy has the higher strength and ultra-high plasticity, good anti-bacterium effect is achieved, and the alloy can serve as a degradable medical device implant to be applied into the human body to be subjected to non-toxic degradation.

Owner:湖南华耀百奥医疗科技有限公司

Microalloy element Nb reinforced double-phase stainless steel and preparation method thereof

InactiveCN110983164AImprove qualityImprove mechanical propertiesProcess efficiency improvementEconomic benefitsMetallic materials

The invention belongs to the field of stainless steel metal materials, and particularly relates to microalloy element Nb reinforced double-phase stainless steel and a preparation method thereof. The double-phase stainless steel is prepared from components in percent by mass including smaller than or equal to 0.03% of C, smaller than or equal to 1.0% of Si, smaller than or equal to 2.0% of Mn, smaller than or equal to 0.02% of S, smaller than or equal to 0.03% of P, 21%-23% of Cr, 4.5%-6.5% of Ni, 2.5%-3.5% of Mo, 0.03%-0.05% of Nb, 0.08%-0.20% of N and the balance Fe and inevitable impurities.According to the double-phase stainless steel, a trace of Nb element is added into 2205 double-phase stainless steel, the 2205 stainless steel has more excellent mechanical performance, meanwhile, the corrosion resistance of the 2205 double-phase stainless steel is not reduced, the cost of the double-phase stainless steel can be effectively reduced, the application range of the double-phase stainless steel is widened, the preparation method is simple, and important engineering application value and remarkable economic benefits are achieved.

Owner:FUZHOU UNIV

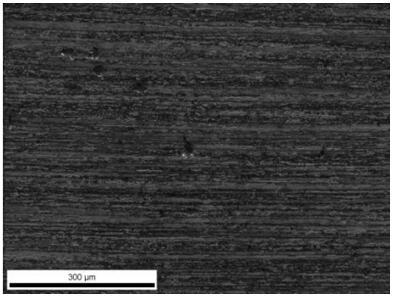

High-strength corrosion-resistant aluminum alloy for variable-diameter drill pipe body and manufacturing method of aluminium alloy

The invention discloses a high-strength corrosion-resistant aluminum alloy for a variable-diameter drill pipe body and a manufacturing method of the aluminium alloy. The aluminium alloy comprises, inpercentage by weight, Zn: 5.5-6.3%, Mg: 2.5-3.1 %, Cu: 0.5 to 0.9%, Fe: <=0.2%, Zr: <= 0.15%, Ti: <=0.1%, Mn: 0.1 to 0.3%, Cr: 0.1 to 0.25%, and the balance being Al and unavoidable impurities. An aluminum alloy variable-diameter drill pipe body prepared by manufacturing method of the invention has high strength, good corrosion resistance and fatigue resistance, and the technical indexes such as dimensional precision and concentricity are high in control level, and the prepared drill pipe body is stable in quality, good in overall performance, low in cost and conducive to industrial batch production and field application.

Owner:山东兖矿轻合金有限公司

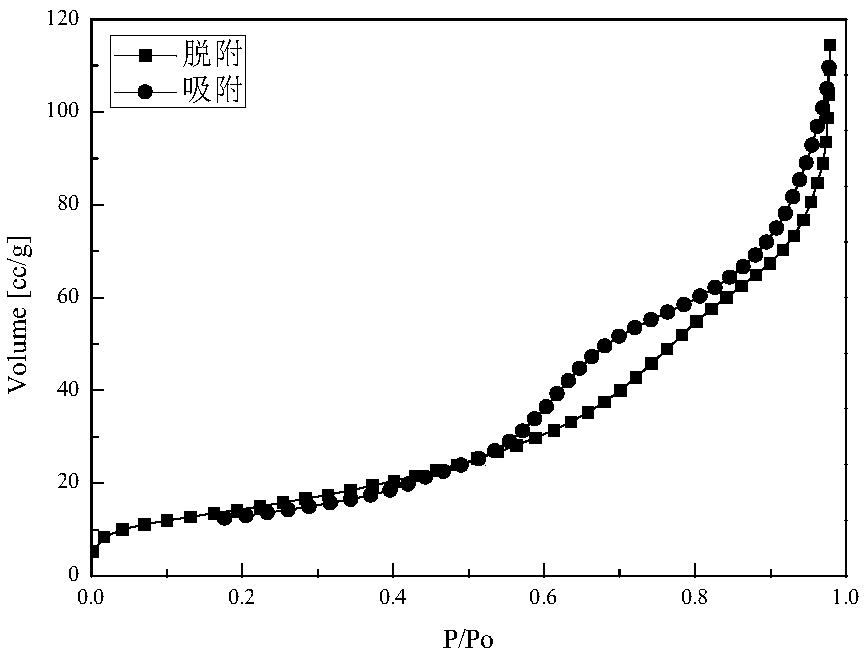

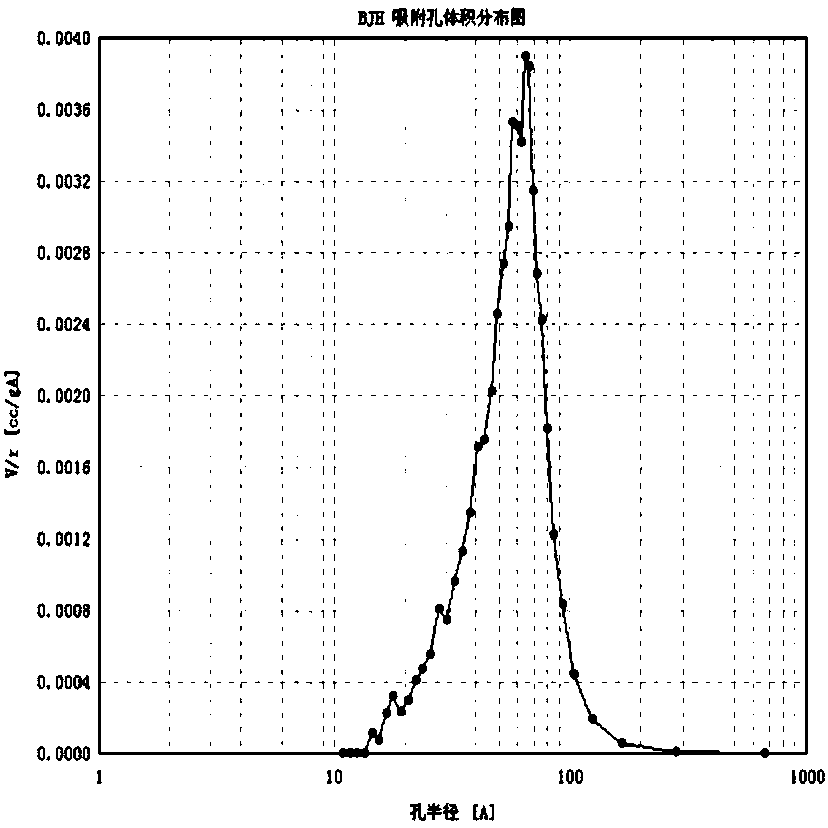

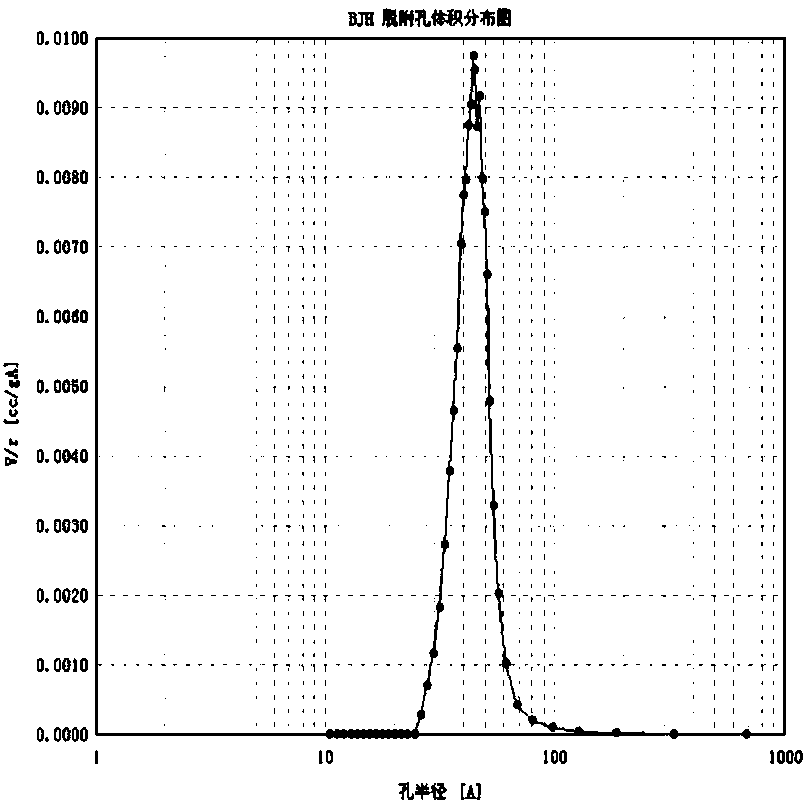

Preparation method for self-cleaning anti-corrosive coating on magnesium alloy surface

InactiveCN107556865AEasy to prepareEasy to operateAnti-corrosive paintsEpoxy resin coatingsEpoxySodium molybdate

The invention provides a preparation method for a self-cleaning anti-corrosive coating on a magnesium alloy surface. The preparation method is characterized in that a corrosion inhibitor is loaded onto a ZrO2 carrier with a mesoporous structure, the ZrO2 carrier is mixed with an epoxy resin glue solution, at last, the surface of a magnesium alloy matrix is coated with the mixed glue solution, andthe corrosion inhibitor is one or more of benzotriazole, hexamethylenetetramine, 2-mercaptobenzothiazole and sodium molybdate. ZrO2 loaded with the corrosion inhibitor is mixed with the epoxy resin glue solution, the surface of the magnesium alloy matrix is coated with the mixture, and room-temperature curing is performed to obtain a corrosion inhibitor-ZrO2 / epoxy resin coating. The novel coatinghas the functions of corrosion resistance and self-repairing, is environmentally friendly, and nontoxic and harmless, and is simple in preparation process and low in production cost.

Owner:HARBIN ENG UNIV

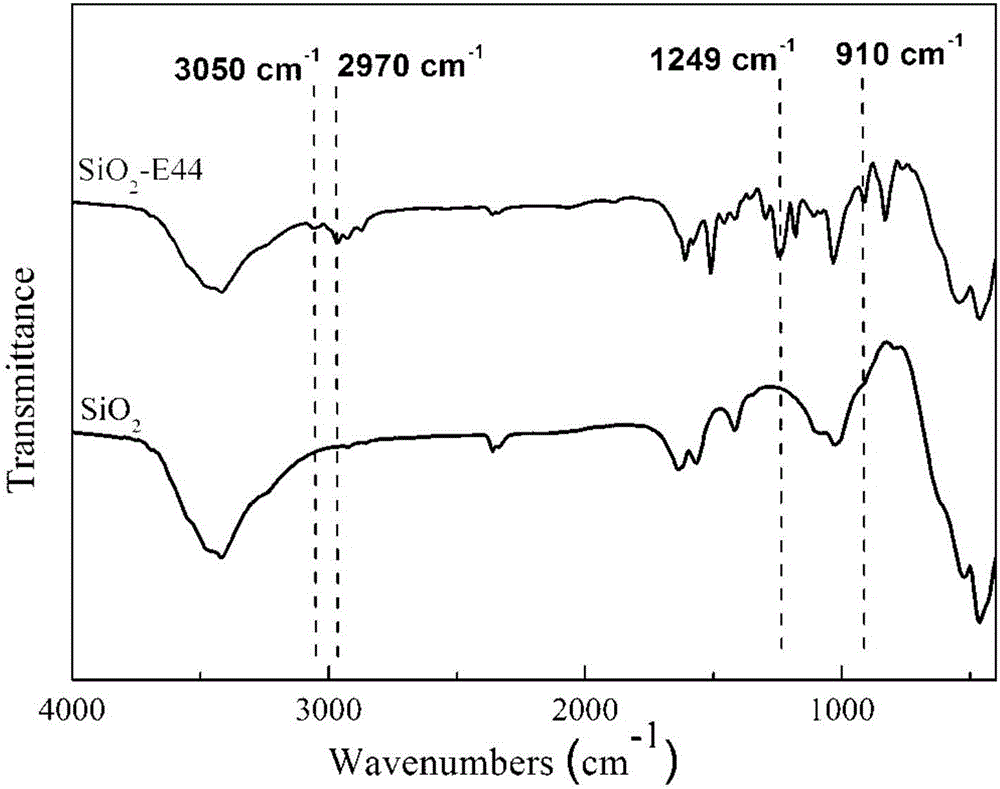

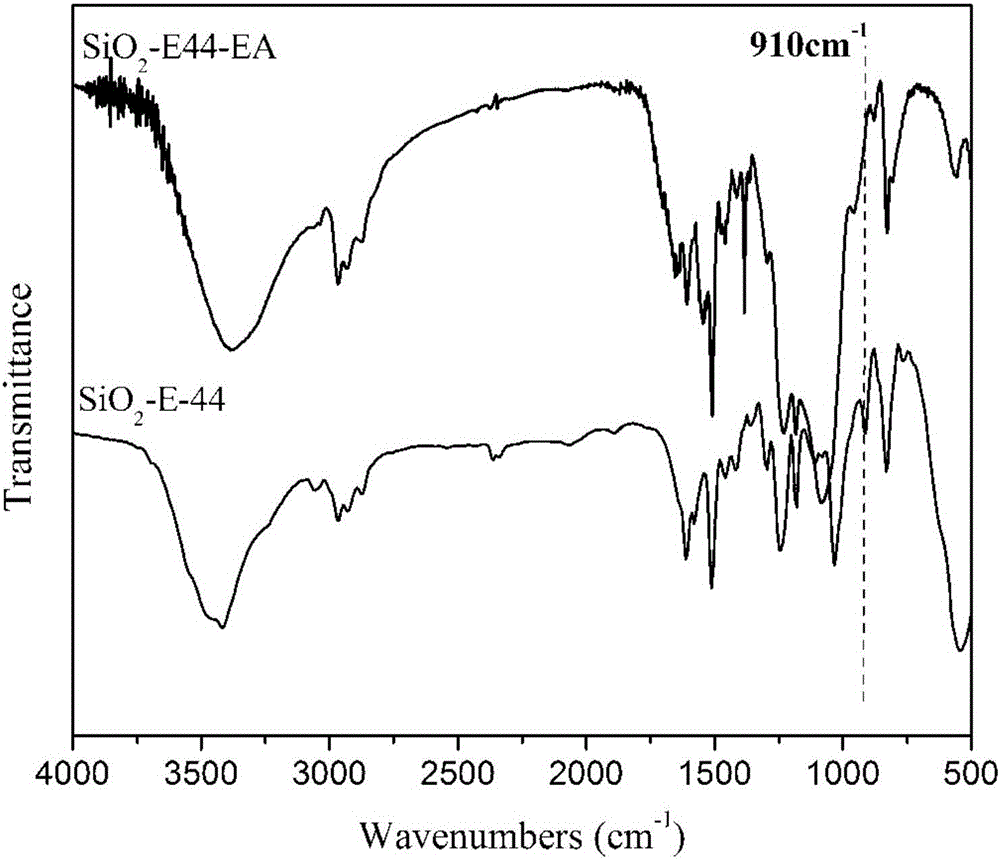

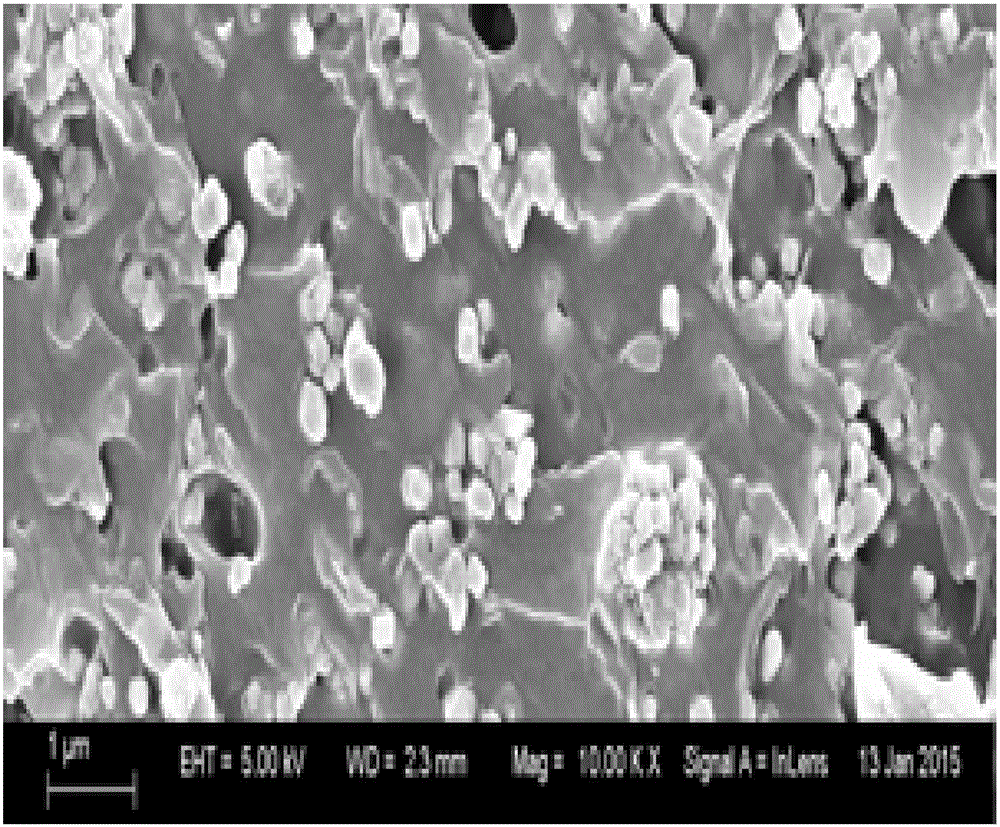

Nanometer filler for abrasion-resistant coatings and method for preparing nanometer filler

The invention belongs to the technical field of functional materials, and particularly relates to a nanometer filler for abrasion-resistant coatings and a method for preparing the nanometer filler. The nanometer filler for the abrasion-resistant coatings comprises nanometer silicon dioxide, isocyanate, epoxy resin, solvents and alkaline amine substances. A molar ratio of the nanometer silicon dioxide to the isocyanate to the epoxy resin is 1:1.5-3:1.5-3. The nanometer filler and the method have the advantages that epoxy resin molecules are led into the surfaces of the nanometer silicon dioxide by the aid of the isocyanate, so that nanometer silicon dioxide with epoxy resin grafted surfaces can be obtained; epoxy groups of the epoxy resin molecules are subjected to ring opening by the aid of alkaline ring opening reaction of the epoxy groups, so that hydroxyl capable of participating in crosslinking and solidifying can be formed, and modified nanometer silicon dioxide with hydroxyl flexible chain segment grafted surfaces can be ultimately obtained; the modified nanometer silicon dioxide can be directly added into the abrasion-resistant coatings for high-speed trains, accordingly, the toughness and the compactness of the coatings can be improved, and the water absorption of the coatings can be reduced.

Owner:CRRC QINGDAO SIFANG CO LTD

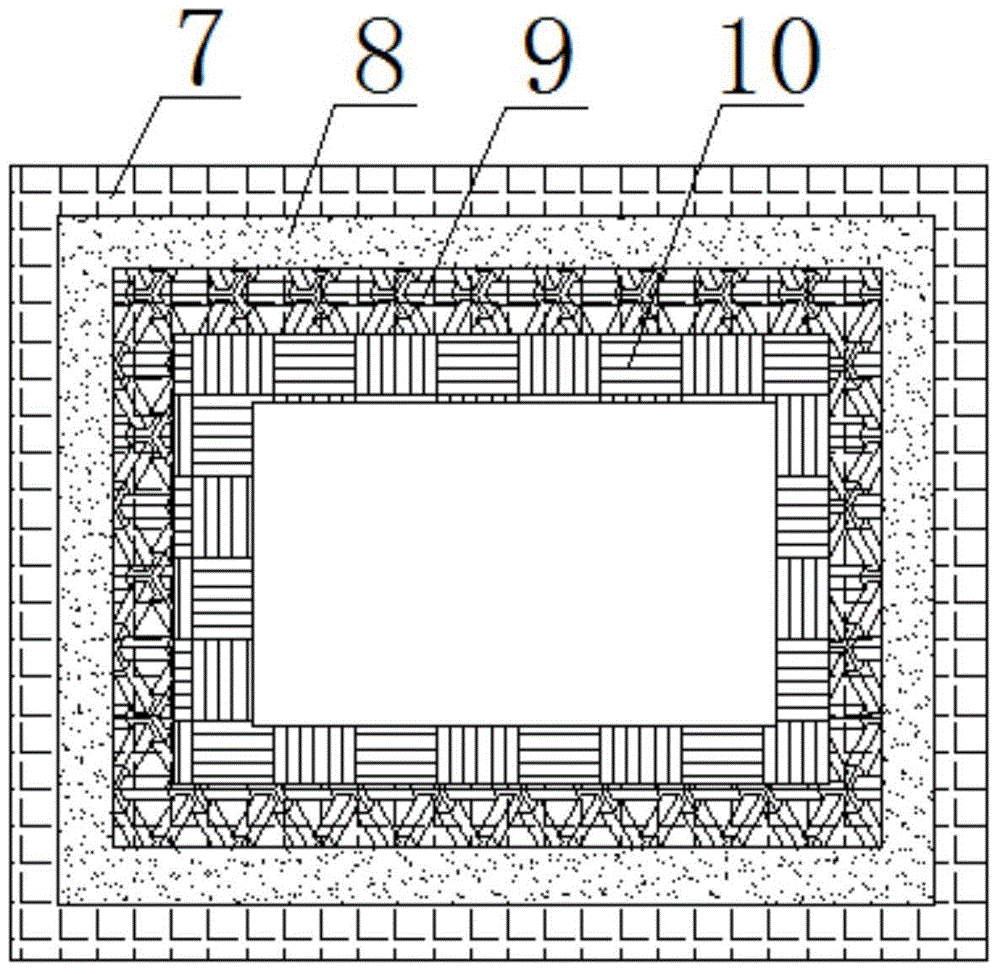

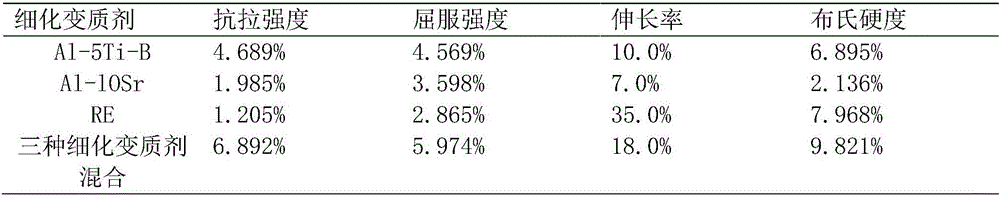

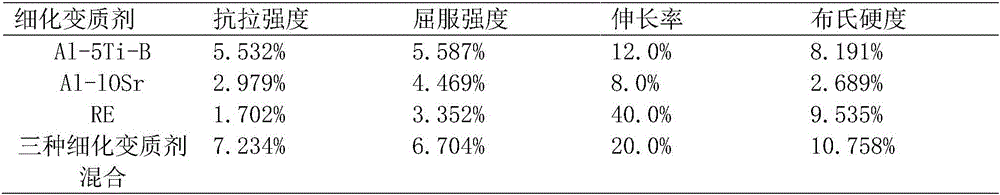

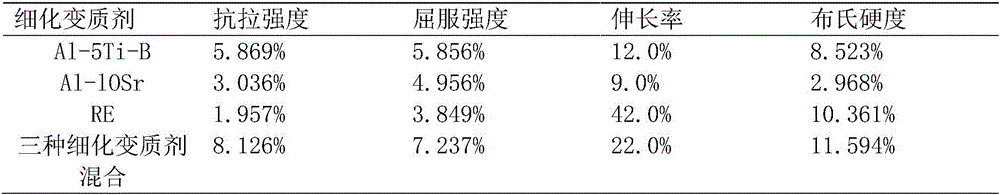

Novel high-strength and corrosion-resisting outer wall insulating decorative plate

InactiveCN105714167AAvoid enteringLower melting temperatureCovering/liningsHeat proofingOctadecyltrichlorosilaneHigh intensity

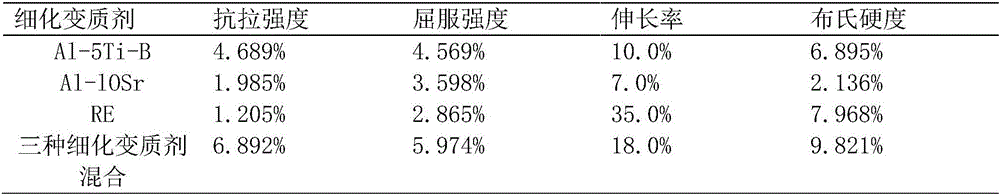

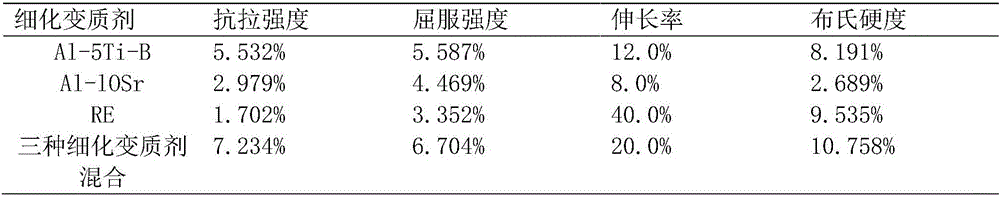

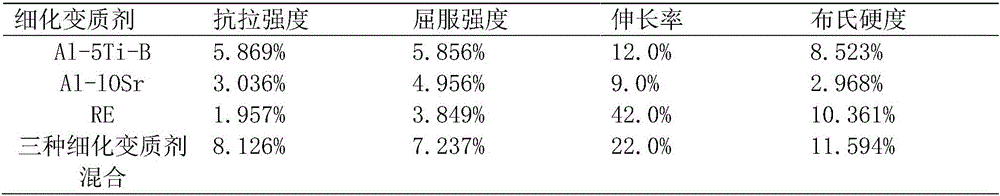

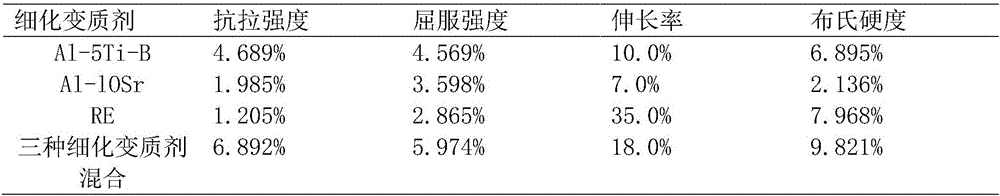

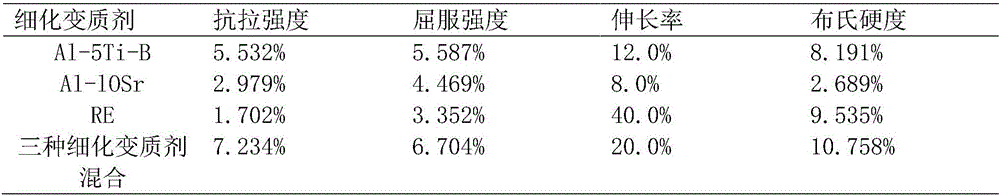

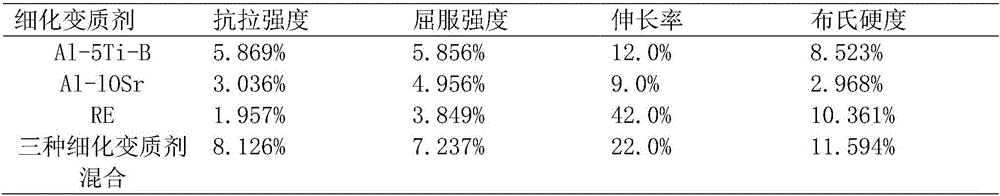

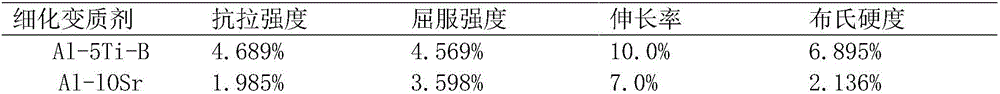

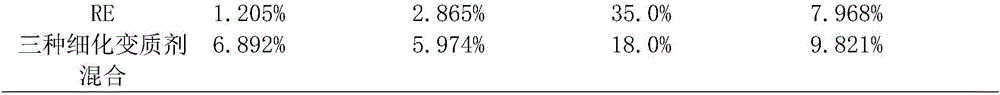

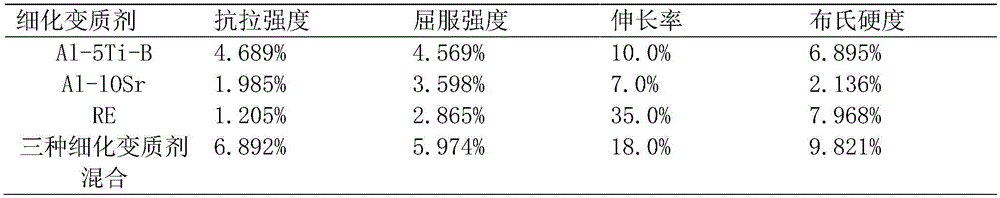

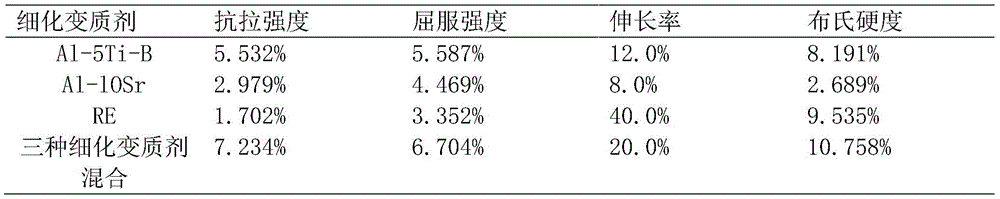

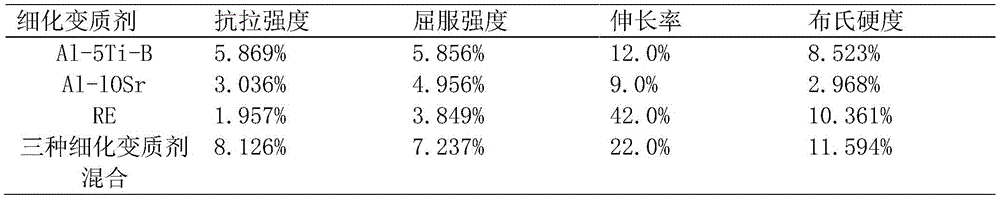

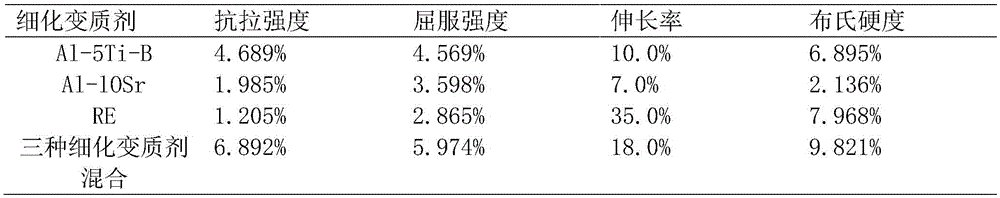

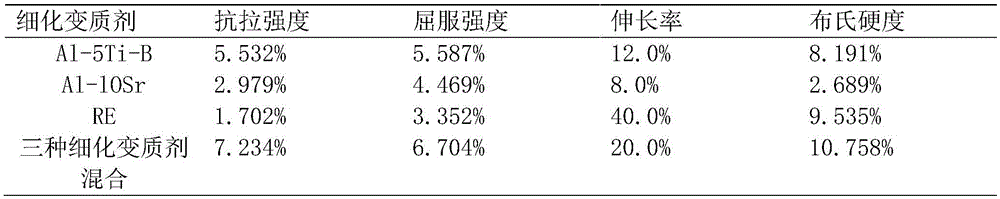

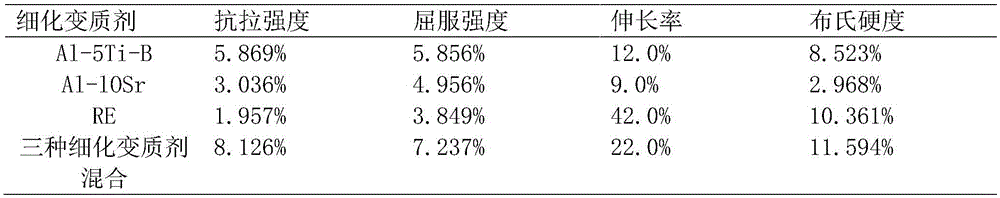

The invention discloses a novel high-strength anti-corrosion exterior wall thermal insulation decorative board, comprising a thermal insulation layer and a decorative layer, the decorative layer is arranged on one side of the thermal insulation layer, the thermal insulation layer is wrapped by an aluminum plate, and the center is filled with thermal insulation material , the aluminum sheet percentage includes Mg0.2%, Si 2.0%, Cu4.0%, Mn0.2%, Fe0.2%, Zr0.1%, Er0.1%, Cr0.01%, Ni0.01%, Ti0.1%, Al balance. The aluminum plate is through (1) smelting; (2) adding Al-5Ti-B, Al-lOSr and RE three kinds of metal refinement modifiers to add refinement modifiers; (3) standing for 2h under the condition of 100MPa to form a casting Ingot; (4) five hot rolling, three cold rolling under ultrasonic vibration; (5) C and V laser modification and (6) octadecyltrichlorosilane solution surface treatment to obtain the finished product. The invention utilizes multiple means to modify and process the material of the aluminum plate, so that the aluminum plate can still maintain the integrity of the oxide film when corroded under severe working conditions, avoid metal failure, and meet the requirements of today's industrial development.

Owner:董超超

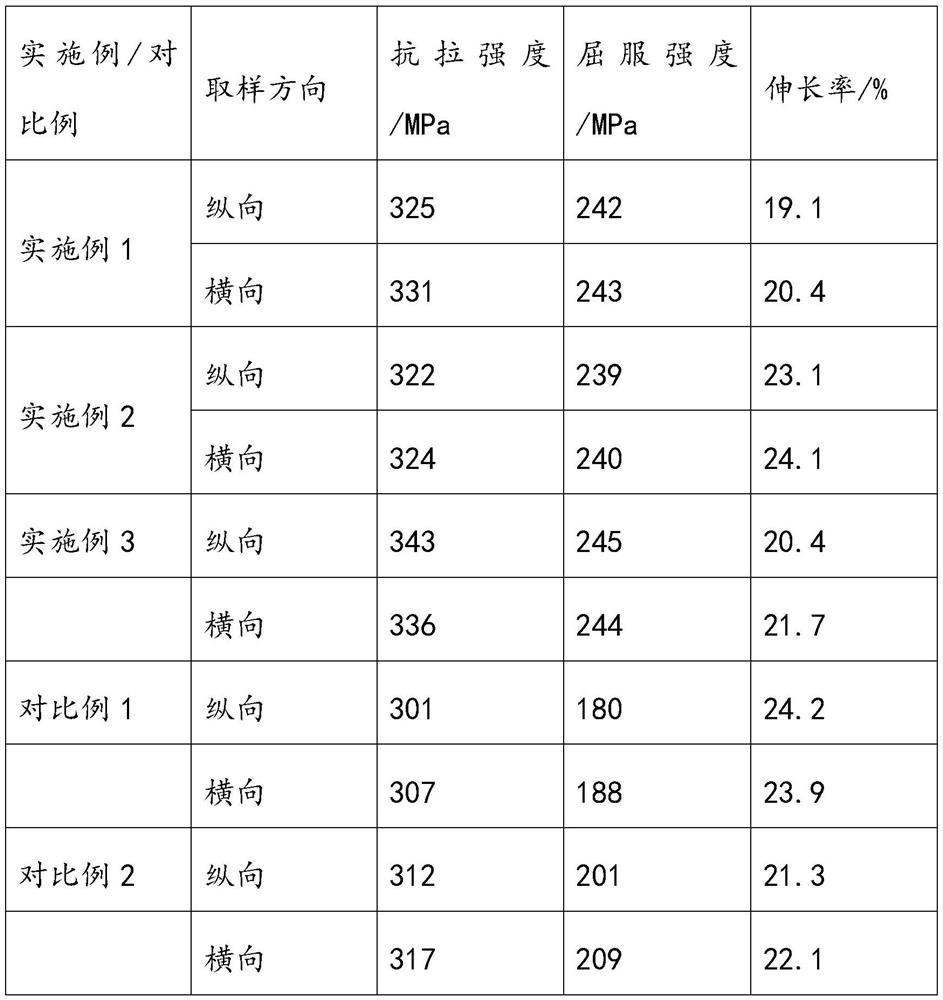

Magnesium alloy thick plate and preparation method thereof

ActiveCN112481536ASolve rolling difficultiesSolve the mechanical propertiesThick plateMagnesium alloy

The invention aims to provide a preparation method of a novel magnesium alloy thick plate. The alloy comprises, by mass, 3.5-5.0% of Al, 2.0-3.5% of Zn, 0.1-0.8% of Mn, 0.01-0.80% of RE, 0.001-0.090%of Ca, less than or equal to 0.005% of Fe, less than or equal to 0.05% of Si, less than or equal to 0.005% of Cu, less than or equal to 0.005% of Ni and the balance Mg, and the total content of impurities does not exceed 0.1%, wherein the sum of the Al content and the Zn content satisfies the condition that Al+Zn is greater than or equal to 6% and less than or equal to 8%. Aiming at a novel Mg-Al-Zn alloy system, a forming process for preparing the large-size magnesium alloy thick plate with low anisotropy and high strength is developed to satisfy urgent demands of such fields as aerospace, weaponry and automobiles on the magnesium alloy thick plate with low cost and high performance.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

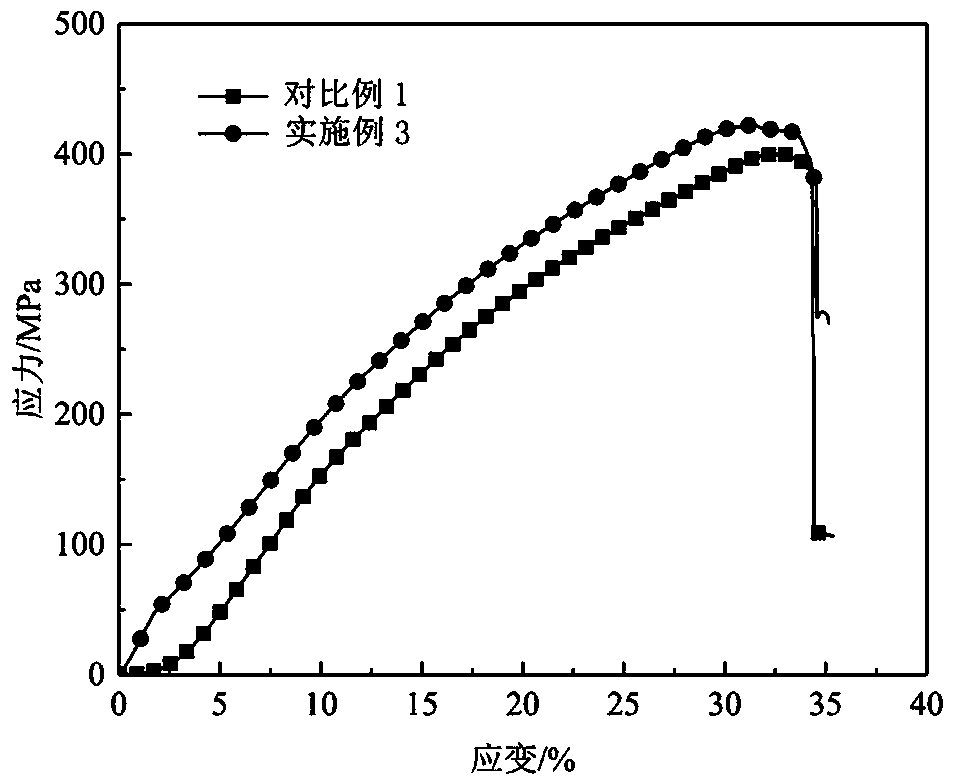

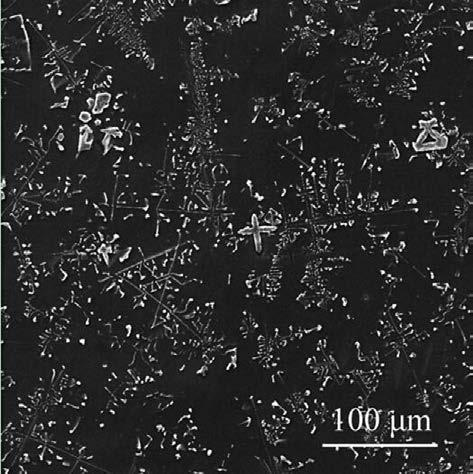

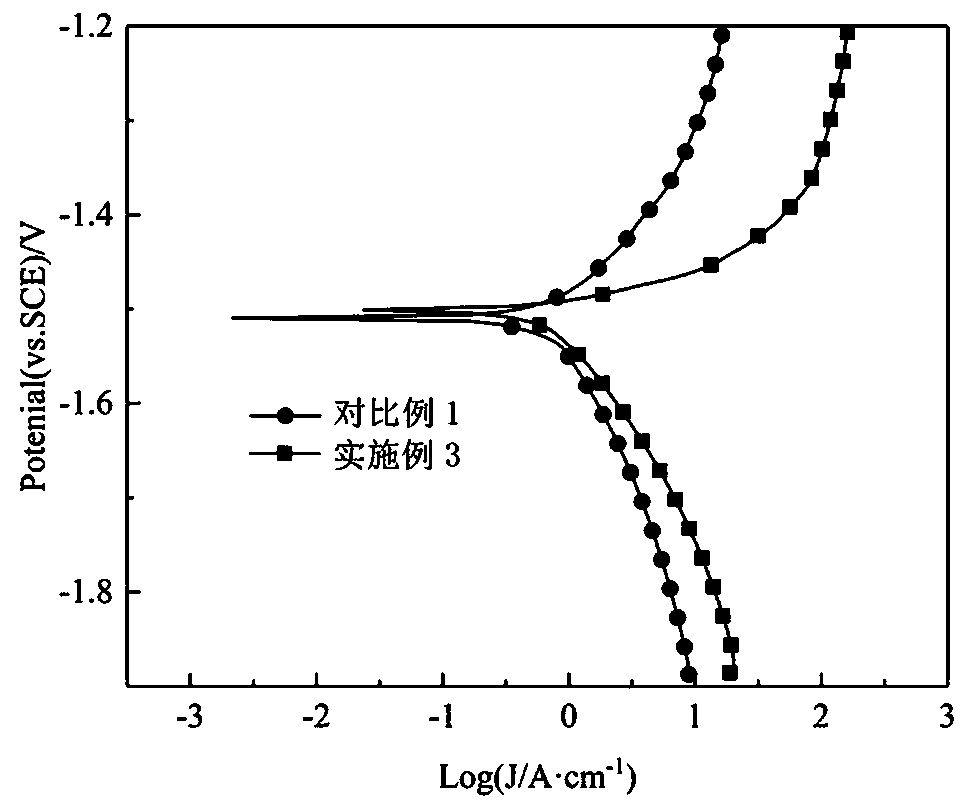

High-strength and rapid-corrosion magnesium alloy and preparation method thereof

InactiveCN110016598AHigh strengthIncrease corrosion rateConstructionsFluid removalMetal alloyPotassium

The invention relates to the technical field of metal alloy materials, and particularly relates to a high-strength and rapid-corrosion magnesium alloy, and a preparation method thereof. The alloy is composed of the following components in percentage by weight: 2%-8% of Al, 0.5%-7% of Ge and the balance magnesium. According to the high-strength and rapid-corrosion magnesium alloy, and the preparation method thereof, the strength and the corrosion speed of the magnesium alloy are increased by adequately utilizing the action of the elements Al and Ge, and the mechanical property of the magnesiumalloy is remarkably improved, and the corrosion speed of the magnesium alloy is remarkably increased through few alloy element adding types and low adding amounts. The compressive strength of the magnesium alloy is capable of reaching 416-431MPa; the corrosion speed in 3% potassium chloride solution at 90 DEG C is capable of reaching 537-582 mm / a; the performance requirement of a fractured ball can be met; and the magnesium alloy can be used as a structural member, and can also be rapidly dissolved under a specific condition.

Owner:TAIYUAN UNIV OF TECH

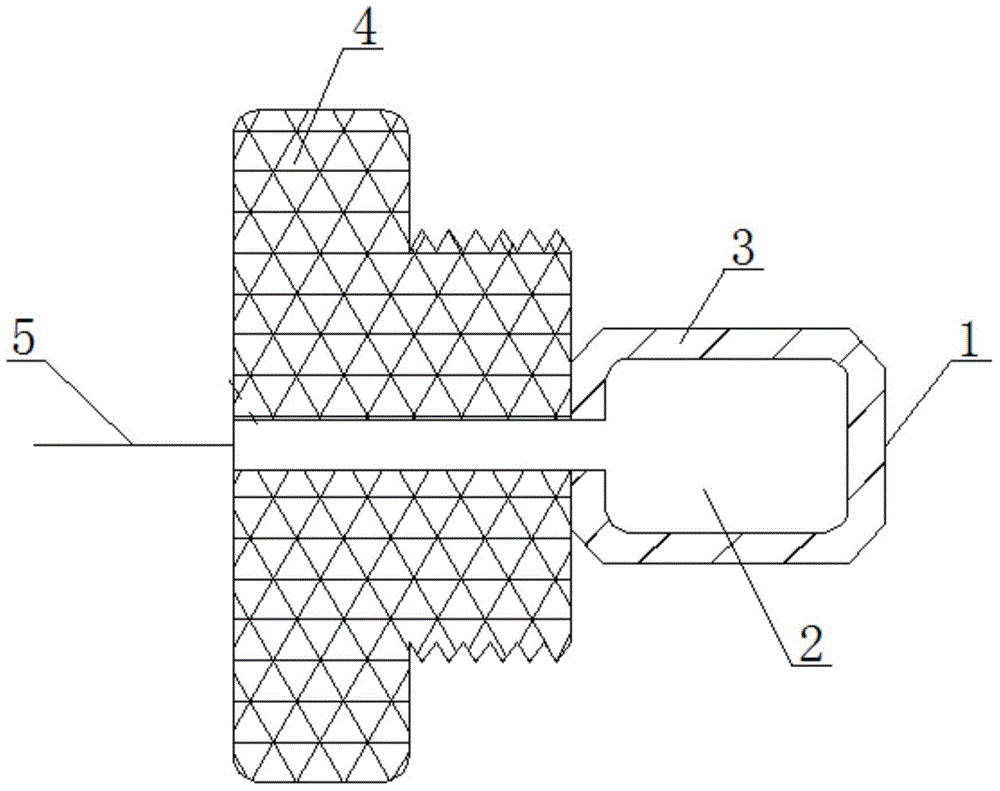

Anti-corrosion temperature sensor

InactiveCN105043567AReduce corrosion resistanceDoes not affect thermal conductivityThermometer detailsThermometers using electric/magnetic elementsElectrochemical responseElectrical resistance and conductance

The invention provides an anti-corrosion temperature sensor, including a body and a plug which are mutually connected. The body is composed of a protection shell and a thermistor. The thermistor is positioned in the protection shell, and the plug is led out through a lead. The protection shell comprises a stainless steel layer, a graphite layer, an active metal layer and a heat-conducting insulation material layer from outside to inside, wherein the active metal layer refers to metal which is more active than stainless steel. With the adoption of the protection shell structure, the active metal layer is enabled to have a chemical or electrochemical reaction first as electrons of the stainless steel layer are conducted to a magnesium thin sheet layer due to corrosion, thereby reducing the corrosion resistance of the stainless steel layer, and meanwhile, the oxidized active metal layer cannot affect the thermal conductivity of the whole temperature sensor. The invention is simple and reasonable in structure.

Owner:WUHAN UNIV OF TECH

Novel high-strength corrosion-resistant aluminum alloy pipeline

InactiveCN105734371AAvoid enteringLower melting temperatureMetallic material coating processesRigid pipesOctadecyltrichlorosilaneMaterials science

The invention discloses a novel high-strength anti-corrosion aluminum alloy pipeline. The aluminum alloy pipeline comprises Mg0.2%, Si2.0%, Cu4.0%, Mn0.2%, Fe0.2%, Zr0.1% by weight percentage , Er0.1%, Cr0.01%, Ni0.01%, Ti0.1%, Al balance. The aluminum alloy pipeline is through (1) smelting; (2) adding Al-5Ti-B, Al-lOSr and RE three kinds of metal refinement modifiers to add refinement modifiers; (3) standing for 2h under the condition of 100MPa Forming an ingot; (4) Five hot rolling, three cold rolling under ultrasonic vibration; (5) C and V laser modification and (6) Octadecyl trichlorosilane solution surface treatment to obtain a finished product. The invention utilizes multiple means to modify and process the material of the aluminum alloy pipe, so that the aluminum alloy pipe can still maintain the integrity of the oxide film when corroded under severe working conditions, avoid metal failure, and meet the requirements of today's industrial development.

Owner:董超超

Novel high-strength corrosion-resistant aluminum alloy door and window

InactiveCN105803278AAvoid enteringLower melting temperatureWindow/door framesMetallic material coating processesCorrosion resistantHigh intensity

The invention discloses a novel high-strength corrosion-resistant aluminum alloy door and window. The novel high-strength corrosion-resistant aluminum alloy door and window comprises an aluminum alloy frame. The aluminum alloy frame comprises, by weight, 0.2% of Mg, 2.0% of Si, 4.0% of Cu, 0.2% of Mn, 0.2% of Fe, 0.1% of Zr, 0.1% of Er, 0.01% of Cr, 0.01% of Ni, 0.1% of Ti, and the balance Al. A finished product is obtained after the aluminum alloy frame is subjected to (1) smelting, (2) adding of three metal refinement modifiers of Al-5Ti-B, Al-10Sr and RE, (3) two hours of standing under the condition of 100 MPa, and forming of a cast ingot, (4) five passes of hot rolling, and three passes of cold rolling under ultrasonic vibration, (5) modification with C laser and V laser, and (6) surface treatment with a octadecyltrichlorosilane solution. According to the novel high-strength corrosion-resistant aluminum alloy door and window, various methods are used for conducting modification and treatment on materials of the aluminum alloy frame, the completeness of an oxidation film can still be kept when the aluminum alloy frame is subjected to corrosion under adverse working conditions, so that metal failure is avoided, and the requirements of current industrial development are met.

Owner:董超超

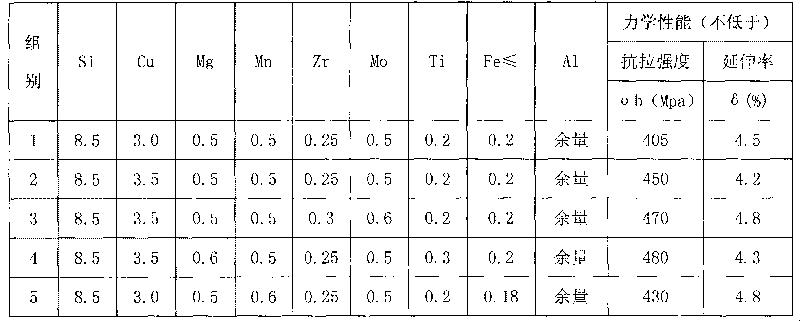

Aluminum casting alloy with strong mechanical performance

The invention relates to an aluminum casting alloy with strong mechanical performance, which is characterized by comprising 7.5-9.5 percent of silicon, 2.8-4.2 percent of copper, 0.4-0.6 percent of magnesium, 0.4-0.6 percent of manganese, 0.2-0.4 percent of zirconium, 0.5-0.7 percent of molybdenum, 0.15-0.35 percent of titanium, less than or equal to 0.25 percent of iron, less than or equal to 0.15 percent of others, and the remaining is aluminum. The performance index of the invention is capable of reaching that the tensile strength is more than or equal to 400 MPa, and the elongation percentage is more than or equal to 4; and the utility model is suitable for the housing of a middle-pressure or a high-pressure gear pump.

Owner:HEFEI CHANGYUAN HYDRAULICS

Method for improving strength and plasticity of high-nitrogen duplex stainless steel

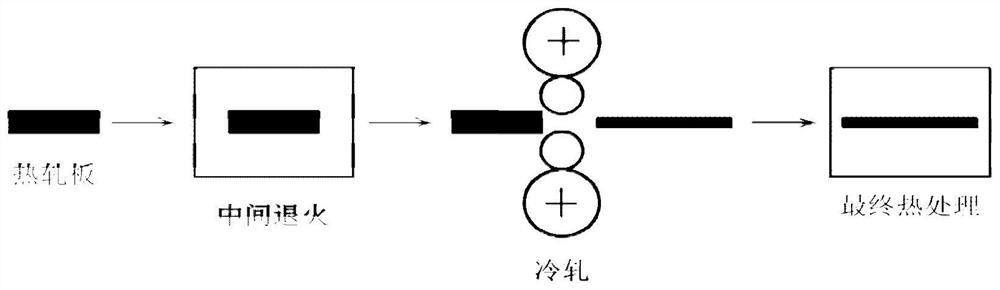

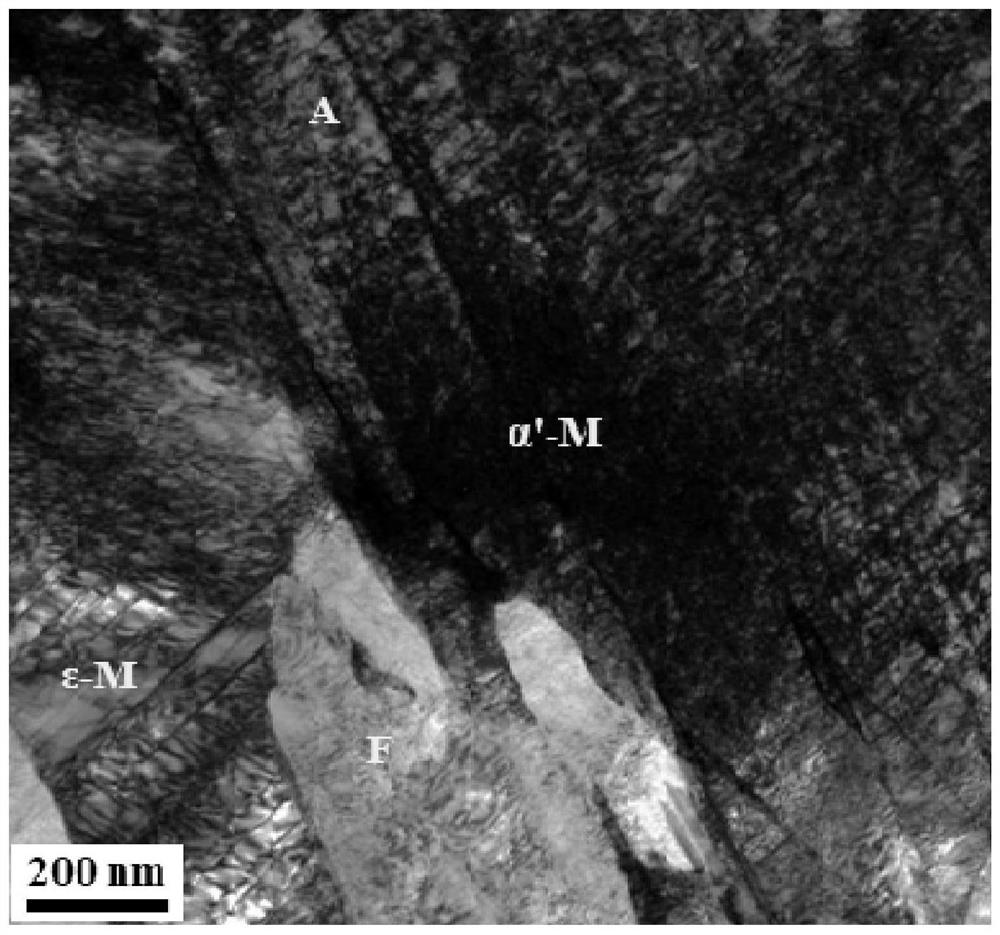

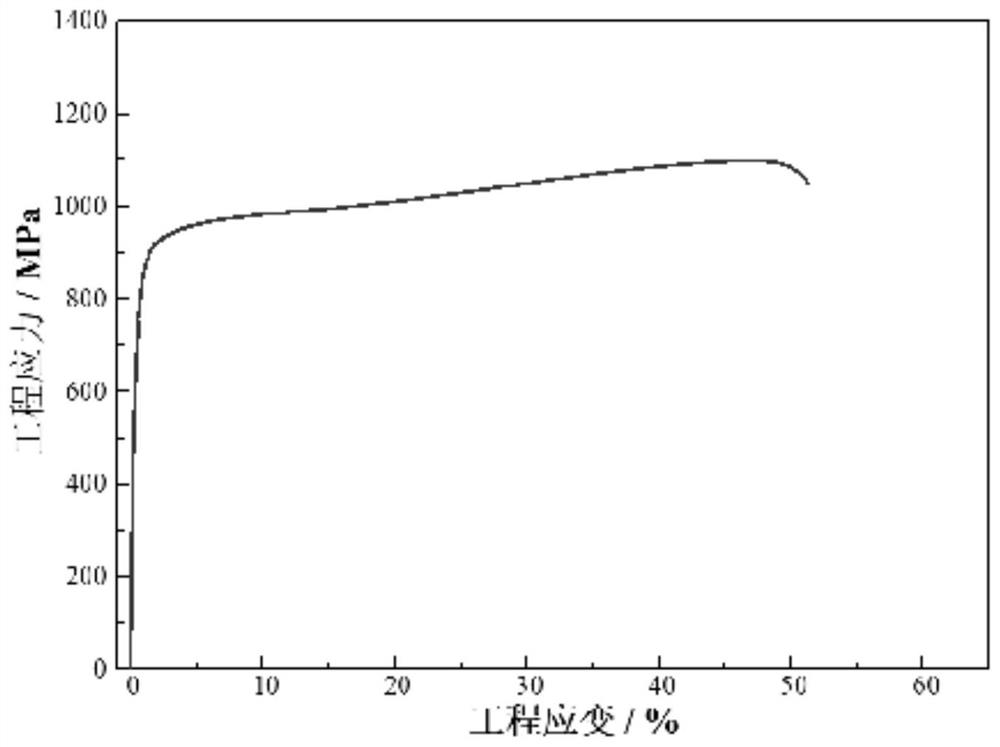

The invention relates to a method for improving the strength and plasticity of high-nitrogen duplex stainless steel. The steel is characterized by sequentially comprising the following steps that 1, hot rolling is carried out on a cast ingot of the duplex stainless steel, and water-cooling treatment is carried out after hot rolling; 2, the hot-rolled duplex stainless steel is subjected to homogenization solution annealing treatment, the annealing temperature ranges from 1050 DEG C to 1200 DEG C, and the heat preservation time ranges from 1 hour to 4 hours; 3, the duplex stainless steel treated in the step 2 is subjected to cold rolling treatment, and the total reduction rate ranges from 60% to 80%; and 4, the duplex stainless steel obtained after cold rolling is subjected to high-temperature rapid annealing treatment, the annealing temperature ranges from 1100 DEG C to 1200 DEG C, the annealing time ranges from 10 seconds to 90 seconds, and then water cooling is conducted. By means of TRIP effect strengthening, fine grain strengthening and back stress strengthening, the strength and plasticity matching problem of the high-nitrogen duplex stainless steel is effectively solved, and the yield strength, the tensile strength and the ductility of the high-nitrogen duplex stainless steel are improved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

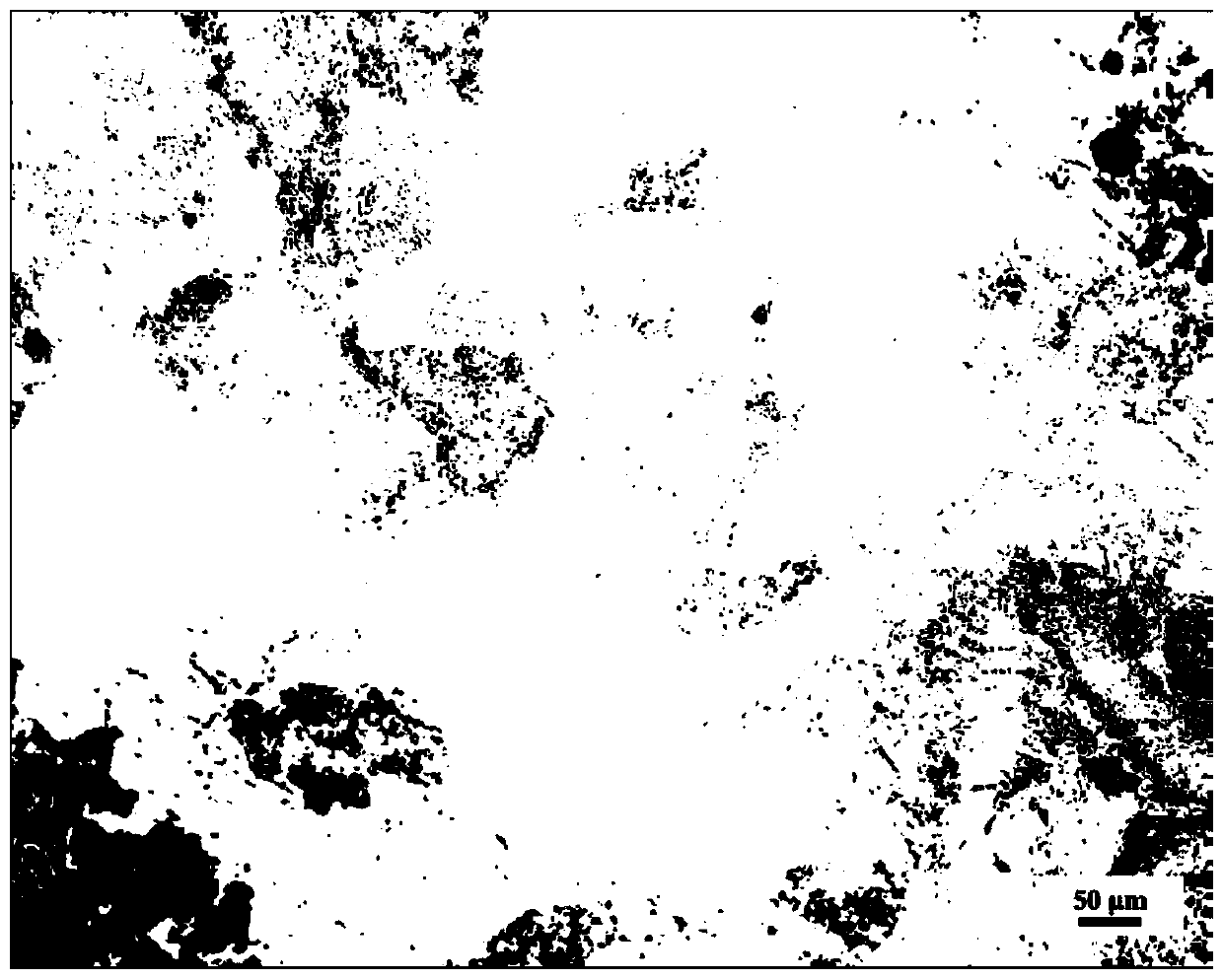

Anti-corrosion Mg-Ni base high-damping alloy and alloying method thereof

InactiveCN101603136AAccelerated corrosionReduce corrosion resistanceElectrode potentialSolid solution

The invention discloses an anti-corrosion Mg-Ni base high-damping alloy and an alloying method thereof. Mg-Ni high-damping alloy serves as the basis, other alloy elements are added to improve the anti-corrosion performance of the alloy. The alloy elements of the invention are 3wt% of Ni, 0.25-1wt% of Mg-Ni-Mn ternary magnesium alloy of Mn, wherein, Ni and Mn are respectively added in the form of preliminary alloy containing Mg-30wt% of Ni and Mg-5.5wt% of Mn, and Mg is industrial pure magnesium. The invention is obtained by preheating, painting protective coating, smelting, refining and shaping, the solidification structure of the obtained alloy is alpha-Mg+eutectic structure (alpha-Mg+Mg2Ni), Mn is totally in solid solution so as to enter a substrate to improve the electrode potential of alpha-Mg, so that the anti-corrosion performance of the alloy is improved. Meanwhile, the content of Mn in the alloy elements is not high, which brings small effect on alloy damping performance, so that alloy the can keep higher damping performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A chrome-free passivation solution

ActiveCN103205738BHigh temperature yellowing resistanceReduce corrosion resistanceMetallic material coating processesChromium freeOrganic acid

Owner:武汉钢实硅钢浩源润滑油有限公司

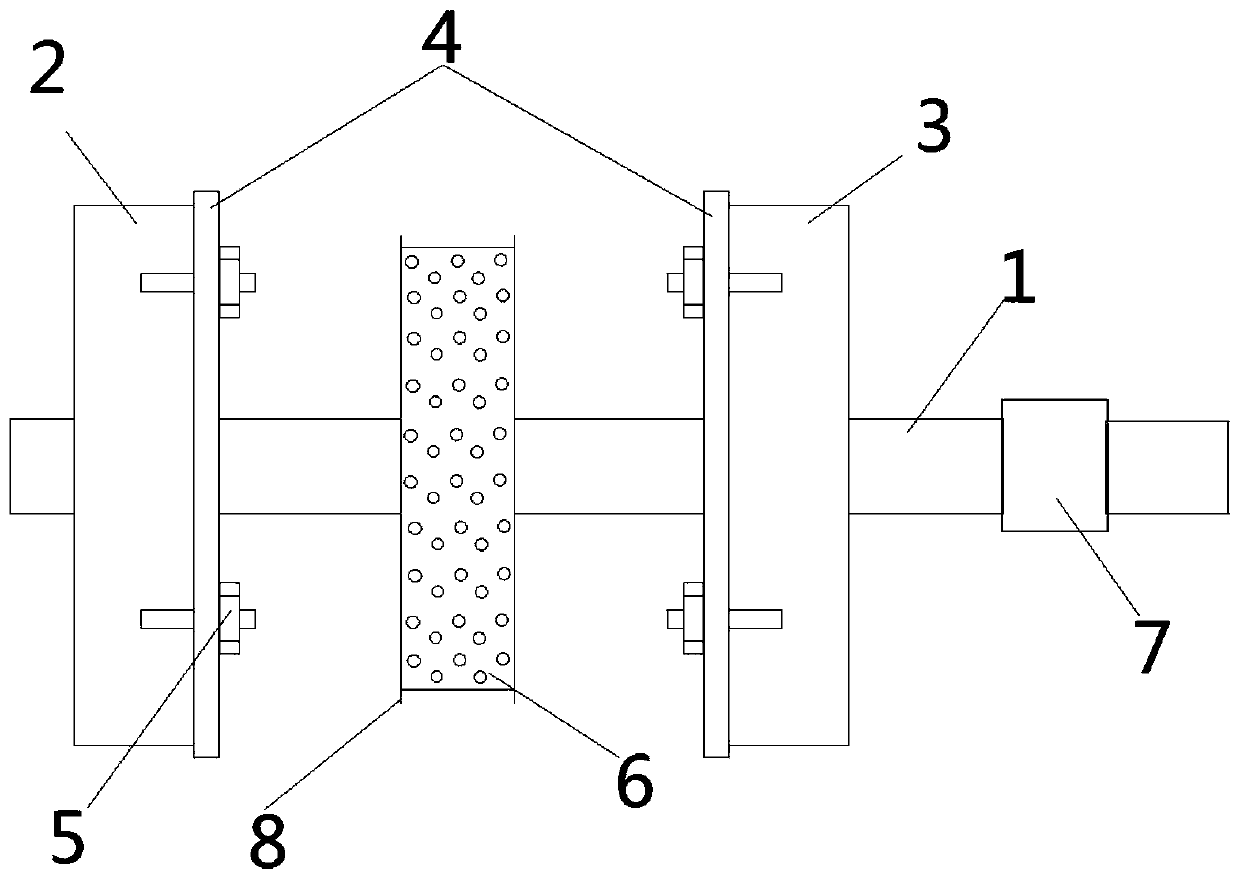

Welding method of nickel-base alloy steel pipeline

The invention discloses a welding method of a nickel-base alloy steel pipeline. A groove of a pipeline to be welded is treated, the angle of the groove of the pipeline to be welded is 70-75 degrees, the poor mobility of material liquid metal is avoided, the groove of the pipeline to be welded and the outer surface of the pipeline to be welded are polished and cleared, the situation that an oxidization layer exists on a weld opening is prevented, then after the pipeline is located and fixed, argon is adopted for protecting the groove of the pipeline to be welded, layering welding is adopted, and the situation that due to the improper welding temperature, as a result, metal grain of weld seams is thick and large, and the mechanical performance and corrosion resisting performance of the weldseams are lowered. According to the method, the scheme is reasonable, the data is reliable and explicit, the problem of 800 H welding quality can be effectively solved, the welding quality is improved, a left gas blocking baffle, a right gas blocking baffle and the inner wall of the pipeline to be welded are utilized for forming a sealing structure, then multiple gas output holes in a gas conveying pipe are utilized for inflating argon into the weld opening, the stable argon environment atmosphere is provided for welding, the device is simple in structure, and stability of the welding environment is ensured.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

Novel high-strength corrosion-resistant building curtain wall framework

InactiveCN105861895AAvoid enteringLower melting temperatureWallsMetallic material coating processesOctadecyltrichlorosilaneIngot casting

The invention discloses a novel high-strength anti-corrosion building curtain wall frame. The curtain wall frame comprises Mg0.2%, Si 2.0%, Cu4.0%, Mn0.2%, Fe0.2%, Zr0.1% by weight percentage, Er0.1%, Cr0.01%, Ni0.01%, Ti0.1%, Al balance. The curtain wall frame is through (1) smelting; (2) adding Al-5Ti-B, Al-lOSr and RE three kinds of metal refinement modifiers to add refinement modifiers; (3) standing for 2h under the condition of 100MPa to form Ingot casting; (4) five hot rolling and three cold rolling under ultrasonic vibration; (5) modification by C and V lasers and (6) surface treatment with octadecyltrichlorosilane solution to obtain finished products. The present invention uses various means to modify and process the material of the curtain wall frame, so that the curtain wall frame can maintain the integrity of the oxide film even under harsh working conditions, avoid metal failure, and meet the requirements of today's industrial development.

Owner:董超超

Novel high-strength anti-corrosion aluminum alloy safety guardrail

InactiveCN105648292AAvoid enteringLower melting temperatureLiquid surface applicatorsMetallic material coating processesOctadecyltrichlorosilaneHigh intensity

The invention discloses a novel high-strength anti-corrosion aluminum alloy safety guardrail. The safety guardrail comprises components in percentage by weight as follows: 0.2% of Mg, 2.0% of Si, 4.0% of Cu, 0.2% of Mn, 0.2% of Fe, 0.1% of Zr, 0.1% of Er, 0.01% of Cr, 0.01% of Ni, 0.1% of Ti and the balance of Al. The safety guardrail is obtained through the following steps: (1) smelting is performed; (2) three metal refinement modifiers including Al-5Ti-B, Al-lOSr and RE are added; (3) a mixture is left to stand for 2 h under the condition of 100 MPa, and an ingot is formed; (4) five-pass hot rolling is performed, and three-pass cold rolling is performed under ultrasonic vibration; (5) laser modification is performed with C and V; (6) a finished product is obtained after surface treatment with a n-octadecyltrichlorosilane solution. Various means are used for modifying and treating the material of the safety guardrail, so that completeness of an oxide film can be still kept under corrosion of the safety guardrail in severe working conditions, metal failure is avoided, and requirements for current industrial development are met.

Owner:董超超

Thin-walled aluminum profile for rail train bodies

ActiveCN110819857AEvenly distributedImprove corrosion resistanceAxle-box lubricationRailway bodiesMechanical engineeringMaterials science

The invention discloses a thin-walled aluminum profile for rail train bodies. The thin-walled aluminum profile is prepared from components including, by weight, 0.66%-0.72% of Si, 0.18%-0.24% of Fe, 0.24%-0.3% of Mn, 0.42%-0.46% of Mg, 0.04%-0.08% of Cr, 0.04%- 0.08% of Ti, 0.03%-0.05% of Cu, 0.14%-0.2% of La, 0.12%-0.16% of Sr, 0.05%-0.08% of Ce and the balance Al. The thin-walled aluminum profile for the rail train bodies has the excellent tensile strength, fatigue strength, ductility and corrosion resistance, has the good comprehensive performance, can better meet the use requirements of the rail train bodies and can prolong the service life of the rail train bodies and improve the safety of the rail train bodies.

Owner:ANHUI XIN FA ALUMINUM PROD

Novel high-strength corrosion-resistant aluminum alloy video monitoring unit

InactiveCN105624491ALower melting temperatureSave resourcesMetallic material coating processesCorrosion resistantSurface finishing

The invention discloses a novel high-strength corrosion-resistant aluminum alloy video monitoring unit which comprises a protective shell. The protective shell comprises the following components in percentage by weight: 0.2% of Mg, 2.0% of Si, 4.0% of Cu, 0.2% of Mn, 0.2% of Fe, 0.1% of Zr, 0.1% of Er, 0.01% of Cr, 0.01% of Ni, 0.1% of Ti and the balance of Al. The protective shell is prepared by the following steps: (1) smelting; (2) adding three metal refinement modifiers Al-5Ti-B, Al-lOSr and RE; (3) standing under 100 MPa for 2 hours to form a cast ingot; (4) carrying out five-pass hot rolling, and carrying out three-pass cold rolling under ultrasonic vibrations; (5) modifying by using C and V lasers; and (6) carrying out surface treatment by using an octadecyl trichlorosilane solution to obtain the finished product. Multiple means are utilized to modify and treat the material of the protective shell, so that the protective shell can still keep the oxidation film complete under severe corrosion working conditions, thereby avoiding the metal inactivation and satisfying the requirements for industrial development at present.

Owner:董超超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com