Method for improving strength and plasticity of high-nitrogen duplex stainless steel

A duplex stainless steel and high-nitrogen technology, applied in the field of steel alloy materials, can solve the problems of deterioration of plastic toughness and corrosion resistance of materials, affecting the safety of materials in service, and large residual stress of materials, so as to improve the comprehensive service performance and facilitate industrialization Effect of application, reduction of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

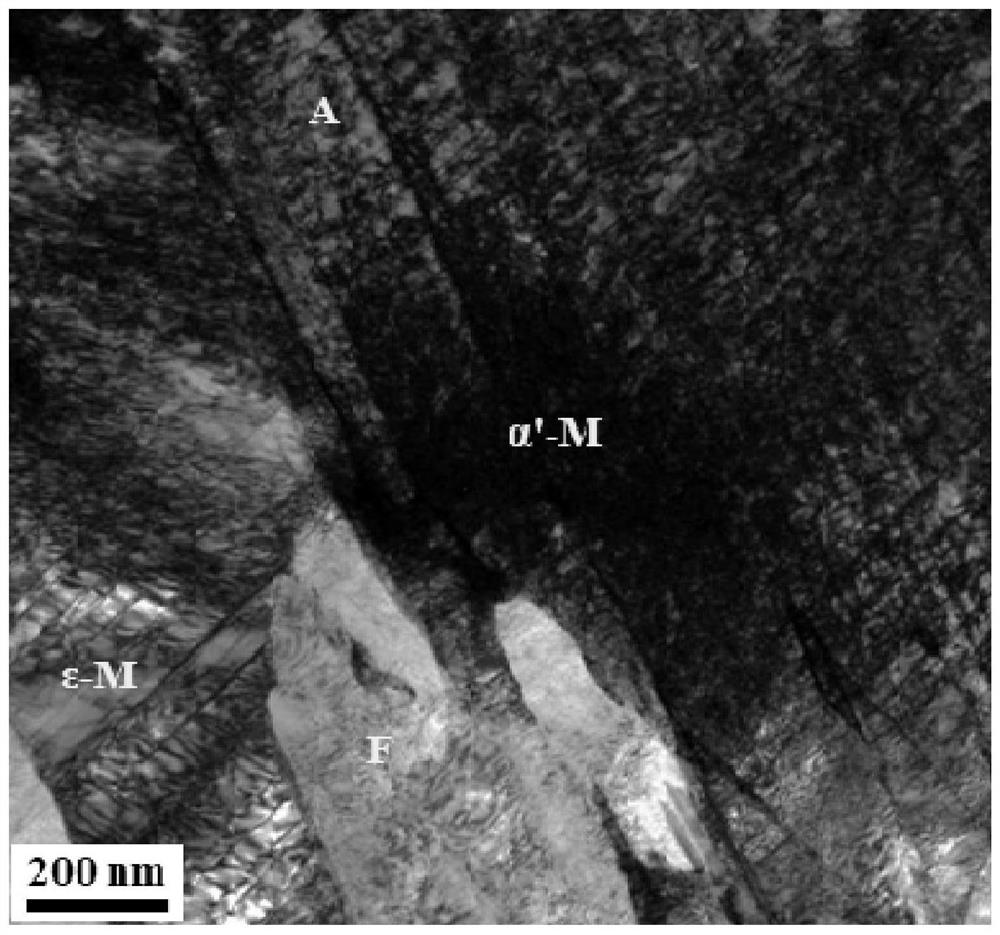

[0027] Such as Figure 1 to Figure 4 Shown is the first preferred embodiment of the present invention. The composition of the high-nitrogen duplex stainless steel in this embodiment is: C=0.02%, Cr=19.20%, Mo=0.01%, Ni=0.05%, Mn=6.13%, N=0.37%; the balance is iron and other unavoidable impurities.

[0028] The components according to the above content are placed in a vacuum induction melting furnace, and cast and melted under the protection of a nitrogen atmosphere to obtain an ingot of high nitrogen stainless steel.

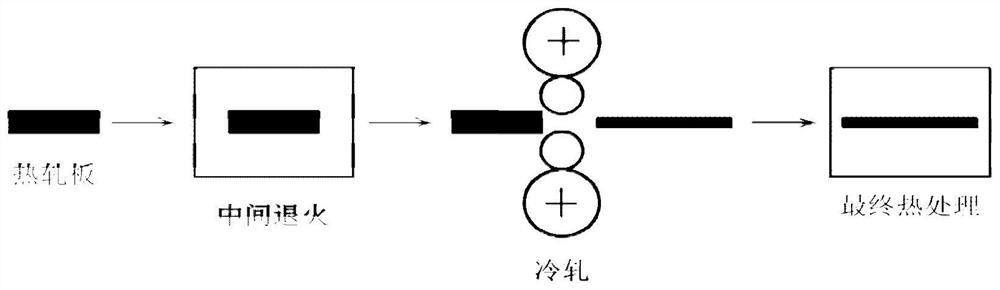

[0029] Such as figure 1 As shown, the method for improving the strong plasticity of the above-mentioned high-nitrogen duplex stainless steel includes the following steps in turn:

[0030] 1) The ingot of duplex stainless steel is hot-rolled, the initial temperature of hot rolling is 1200°C, and the final rolling temperature is 980°C. After hot rolling, it is water-cooled to inhibit the precipitation of brittle phases such as carbonitrides;

[0031]2) Homogen...

Embodiment 2

[0037] The difference between this embodiment and the above-mentioned embodiment 1 is only that: the process parameters in the method for improving the strong plasticity of the above-mentioned high-nitrogen duplex stainless steel are different, specifically, the annealing time in step 4) is 30s.

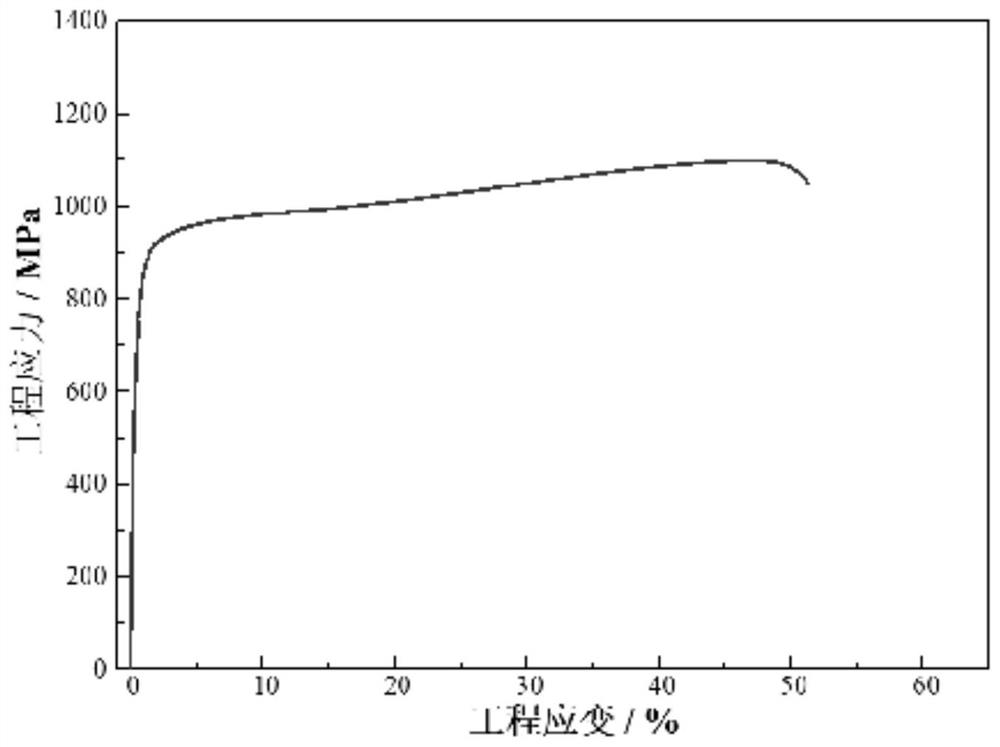

[0038] The high-nitrogen duplex stainless steel in this embodiment has a tensile strength of 1000 MPa, a yield strength of 700 MPa, and an elongation after fracture of 58% after high-temperature rapid annealing. Due to the long annealing time, the crystal grain grows, the elongation increases, and the strength-plasticity product is 58GPa%. Compared with conventional solution treatment (1050°C, heat preservation for 300s, water cooling), the tensile strength is basically the same, but the yield strength is significantly improved, and the strength and plasticity product are slightly improved.

Embodiment 3

[0040] The difference between this embodiment and above-mentioned embodiment 1 is only:

[0041] The content of each component of the high-nitrogen duplex stainless steel is different. Specifically, according to the mass percentage, the high-nitrogen duplex stainless steel includes the following components: C=0.04%, Cr=22.8%, Mo=0.01%, Ni=1.5 %, Mn=7.8%, N=0.24%, and the balance is iron and other unavoidable impurities.

[0042] The process parameters in the method for improving the strong plasticity of the above-mentioned high-nitrogen duplex stainless steel are different. Specifically, the initial temperature of hot rolling in step 1) is 1250° C., and the final rolling temperature is 1000° C.; the annealing temperature in step 2) is 1050° C. ℃; the total reduction rate in step 3) is 65%.

[0043] Using conventional solution treatment (1050°C, heat preservation for 300s, water cooling), the tensile strength of the high-nitrogen duplex stainless steel is 950MPa, the yield str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com