Patents

Literature

1178 results about "Vacuum induction melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum induction melting (VIM) utilizes electric currents to melt metal within a vacuum. The first prototype was developed in 1920. One of the few ways to induce a current within a conductor is through electromagnetic induction. Electromagnetic induction induces eddy currents within conductors by changing the magnetic field. Eddy currents create heating effects to melt the metal. Vacuum induction melting has been used in both the aerospace and nuclear industries.

Ultra pure electroslag remelting method for high-performance corrosion resistant alloy

ActiveCN102912151AImprove performanceImprove organizationIncreasing energy efficiencyCorrosion resistant alloySolution treatment

The invention relates to an ultra pure electroslag remelting method for a high-performance corrosion resistant alloy, and the method comprises the following steps of: preparing the following ingredient components of a self-fluxing electrode bar in parts by weight: 25-34 parts of Ni, 25-29 parts of Cr, 2.5-4.5 parts of Mo and 30-45 parts of Fe, and carrying out vacuum induction melting, so as to obtain the self-fluxing electrode bar; slowly melting the self-fluxing electrode bar in melted electroslag remelting slag charge comprising the following components in parts by weight: 55-80 parts of CaF2, 5-25 parts of CaO, 5-15 parts of Al2O3 and 5-10 parts of MgO, purifying, and recrystallizing in a crystallizer, so as to obtain an electroslag ingot; and forging the electroslag ingot into a bar material at the temperature of 1130+ / -5 DEG C, and carrying out solution treatment, so that the high-performance corrosion resistant alloy is obtained. By utilizing the ultra pure electroslag remelting method provided by the invention, the content of harmful elements such as sulphur and phosphorus in the alloy can be reduced, the impurity distribution of the alloy is improved, fining of structure can be facilitated, and the hot workability and yield of the alloy can be improved.

Owner:CHONGQING MATERIALS RES INST

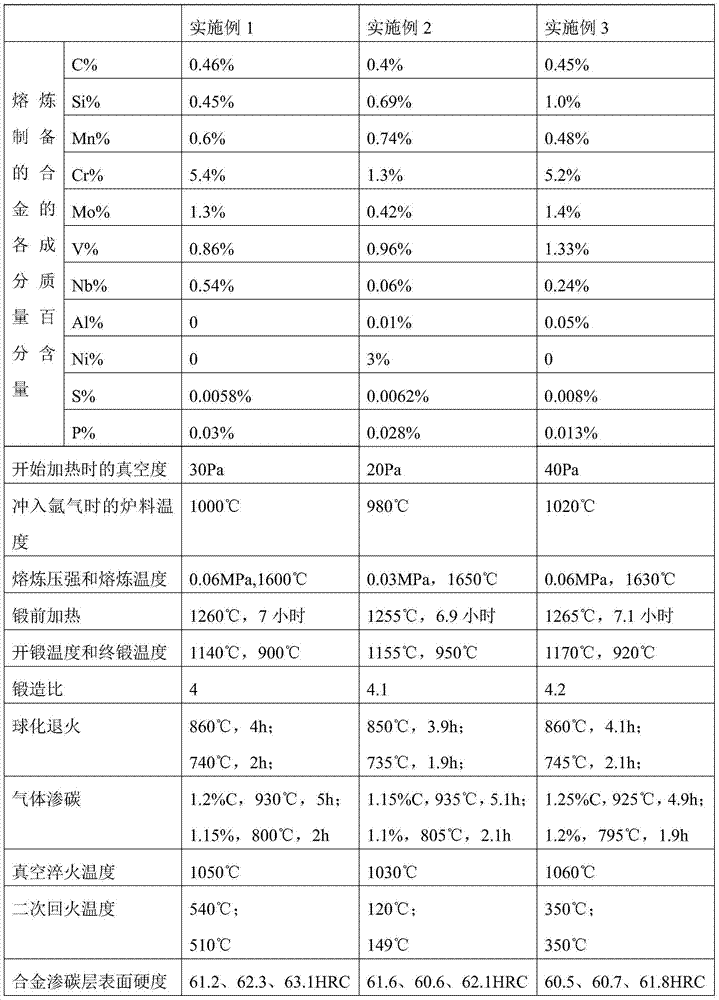

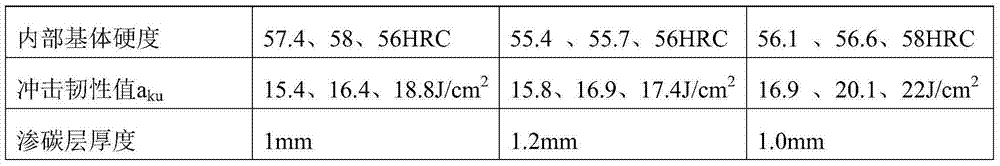

Alloy for cutter ring of disk type hobbing cutter and preparation method thereof

The invention relates to an alloy for a cutter ring of a disk type hobbing cutter, which comprises the following components in percentage by mass: 0.4-0.46% of C, 0.45-1.0% of Si, 0.48-0.74% of Mn, 1.3-5.4% of Cr, 0.4-1.4% of Mo, 0.86-1.33% of V, 0.06-0.54% of Nb, 0-0.05% of Al, 0-3% of Ni, no more than 0.009% of S, no more than 0.03% of P and the balance of Fe. The preparation method comprises the following steps: performing vacuum induction smelting on the raw materials, casting, forging, performing spheroidal annealing, performing gas carburization, performing vacuum quenching, and performing double tempering. The carburized layer of the prepared cutter ring of a disk type hobbing cutter is 1mm thick, the surface hardness of the carburized layer can be up to 60-63HRC, the internal average hardness is higher than 55HRC, and the impact toughness aku is up to 15-22J / cm<2>; and the shield cutter ring is high in hardness and favorable in toughness.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD +1

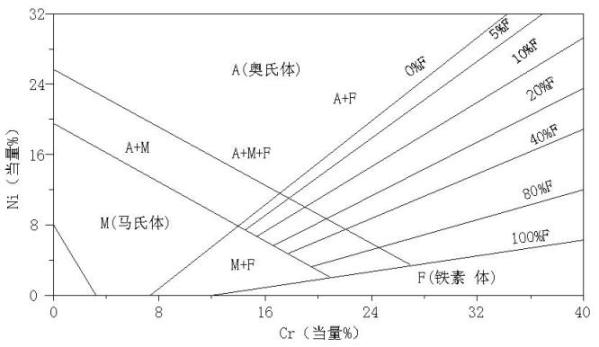

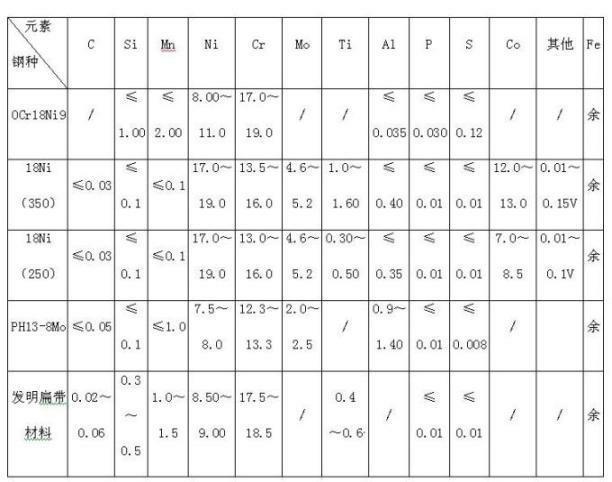

Martensite stainless steel and preparation method for flat strip of martensite stainless steel

ActiveCN102251191AHigh strengthHigh hardnessIncreasing energy efficiencySolution treatmentMartensitic stainless steel

The invention discloses martensite stainless steel and preparation method for flat strips of martensite stainless steel. The martensite stainless steel comprises following chemical components by weight percentage: C 0.02 to 0.06%, Si 0.3 to 0.5%, Mn 1.0 to 1.5%, Ni 8.5 to 9.0%, Cr 17.5 to 18.5%, Ti 0.4 to 0.6%, P no more than 0.009% and S no more than 0.009%, with the balance being Fe. The preparation method for flat strips of the martensite stainless steel comprises the following steps: a) weighing above-mentioned chemical components at desired weight percentage; b) carrying out vacuum induction melting; c) carrying out casting to obtain remelt electrode bars; d) carrying out electroslag remelting to obtain steel ingots; e) forging steel ingots into billets; f) processing billets into round strips; g) carrying out solid solution treatment; h) drawing treated blanks into wires; i) preparing flat strips. According to the invention, equivalents of nickel and chromium are strictly controlled, the ratio of C to Ti and alloy elements are optimized, EVR smelting is carried out and such alloying elements as C, Si, Mn and Ti are added, thereby enabling formation of a metastable austenite structure; a predeformed phase-changed martensite wire material is obtained by wire drawing; and the ultra high strength deformed flat strips of martensite stainless steel are obtained by flat strip rolling.

Owner:CHONGQING MATERIALS RES INST

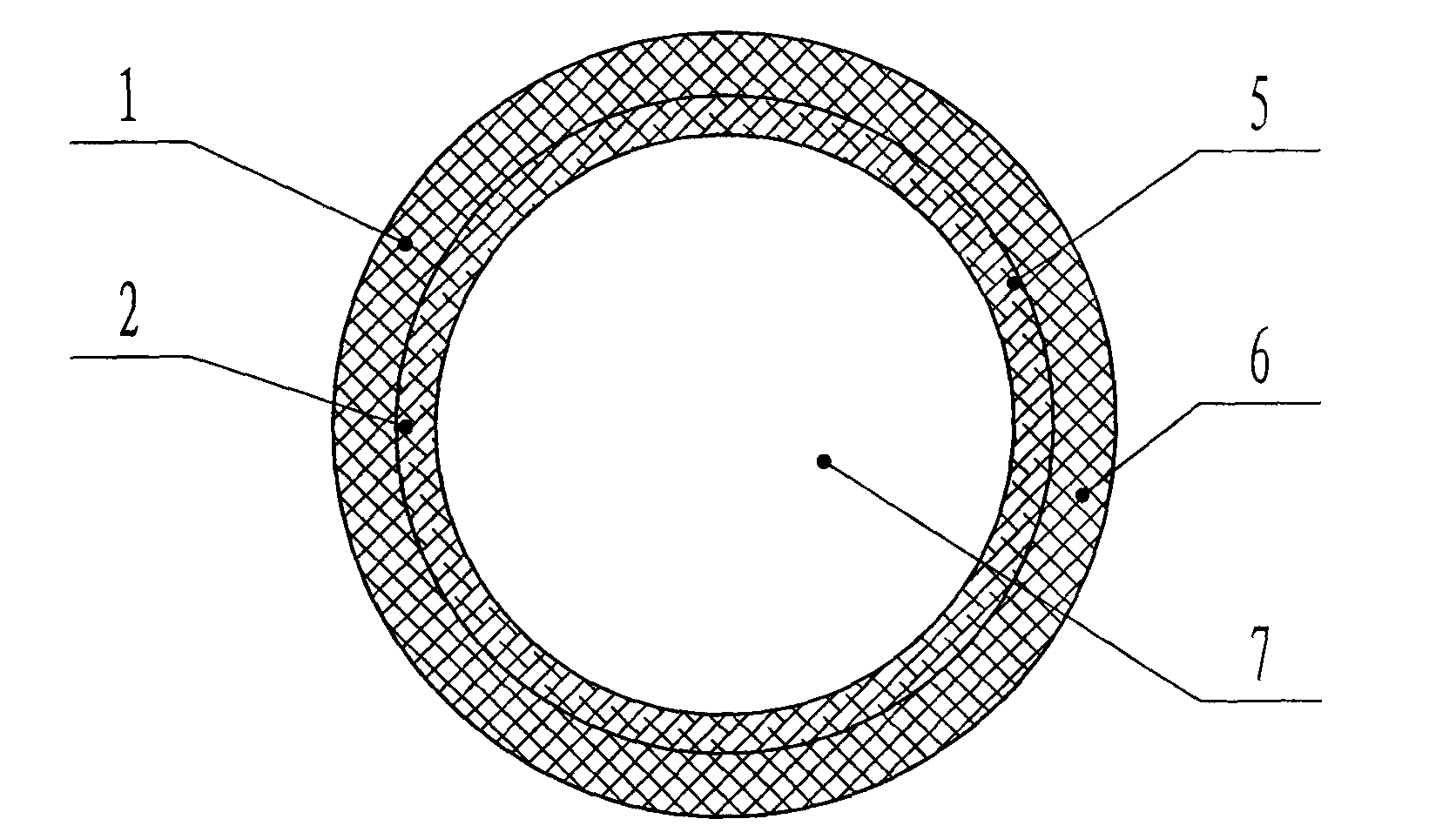

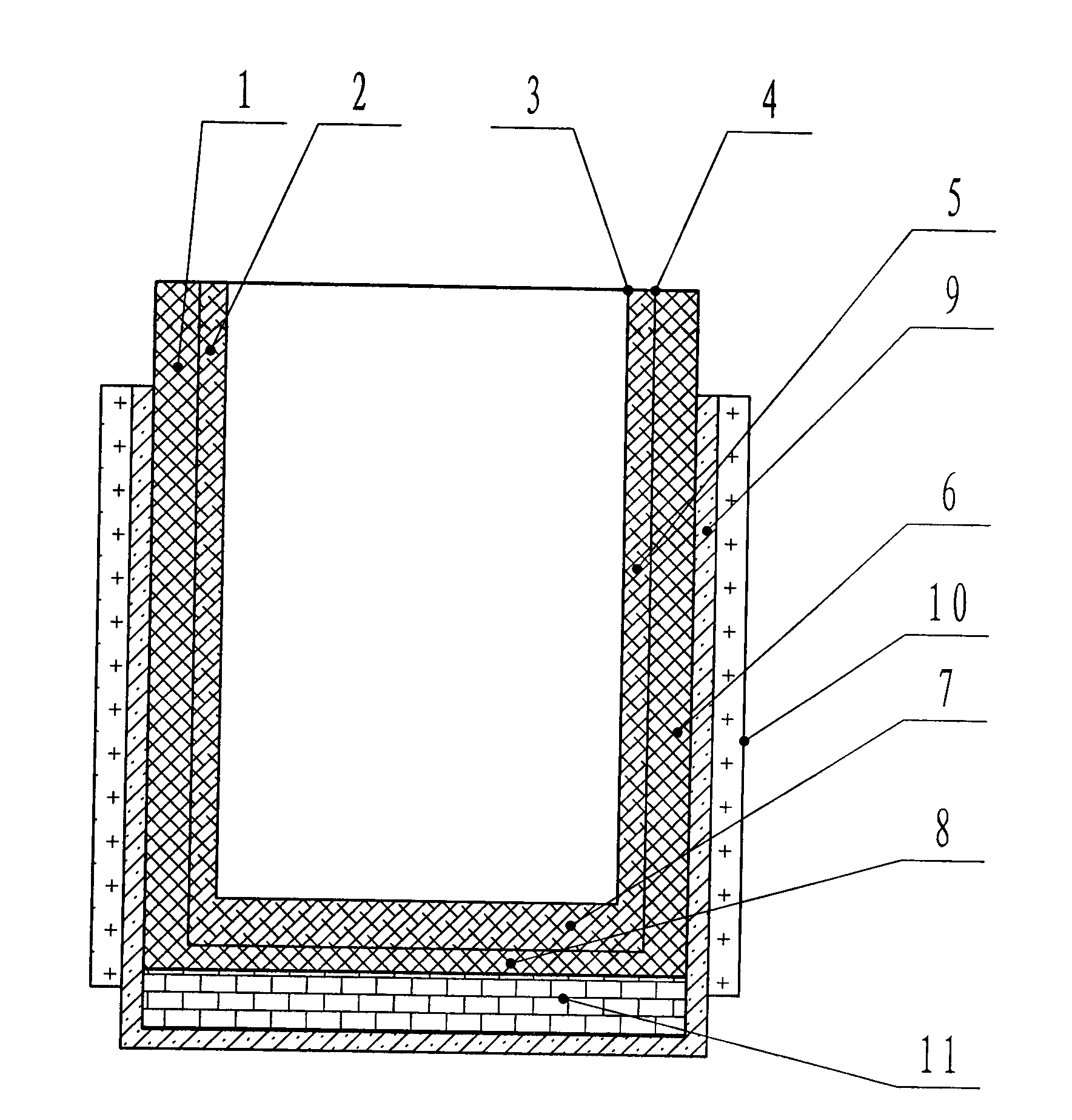

Crucible for fusing titan and method of preparation thereof

The invention relates to a crucible for fusing titanium and a production method thereof, mainly used for fusing titanium alloy as well as for fusion cast of other special alloys. Highly stable compounds (yttrium oxide, calcium zirconate or cerium sulphide, etc.) are used as the outer layer of the crucible for fusing titanium; refractory metals (tungsten, molybdenum or tantalum) and the like are combined with the compounds to form transition gradient coating; hot spray processes (laser cladding, plasma spraying, etc.) are used for spraying the transition layers and the transition gradient coating onto the inner surface of a graphite container layer by layer to form a firm and compact composite coating with good thermal shock resistance. By adopting the crucible of the invention to carry out vacuum induction fusion of titanium and titanium alloy, the fused alloy has uniform component, the fusion process consumes less energy and the crucible produces less contamination to the molten titanium.

Owner:SHANGHAI UNIV

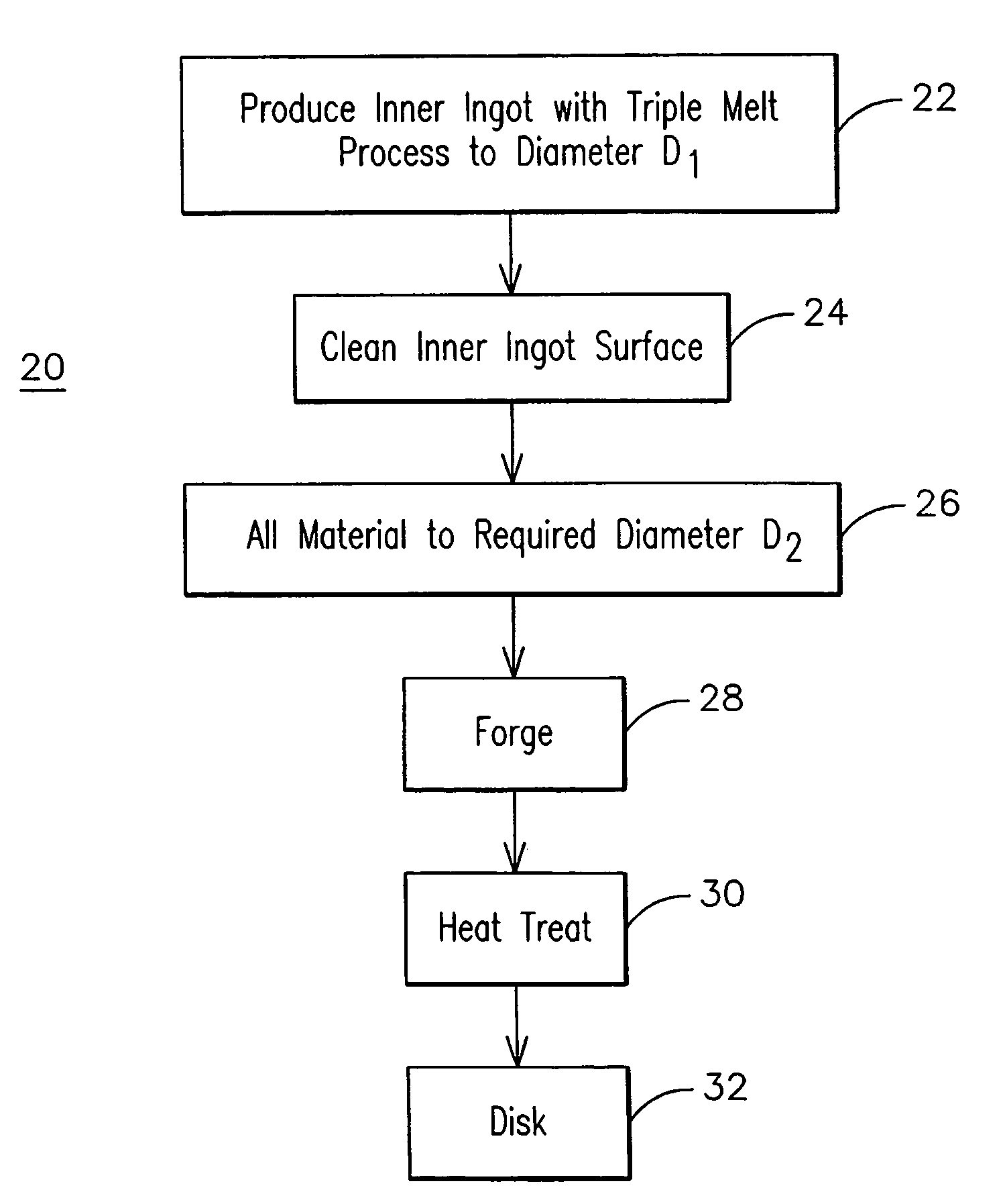

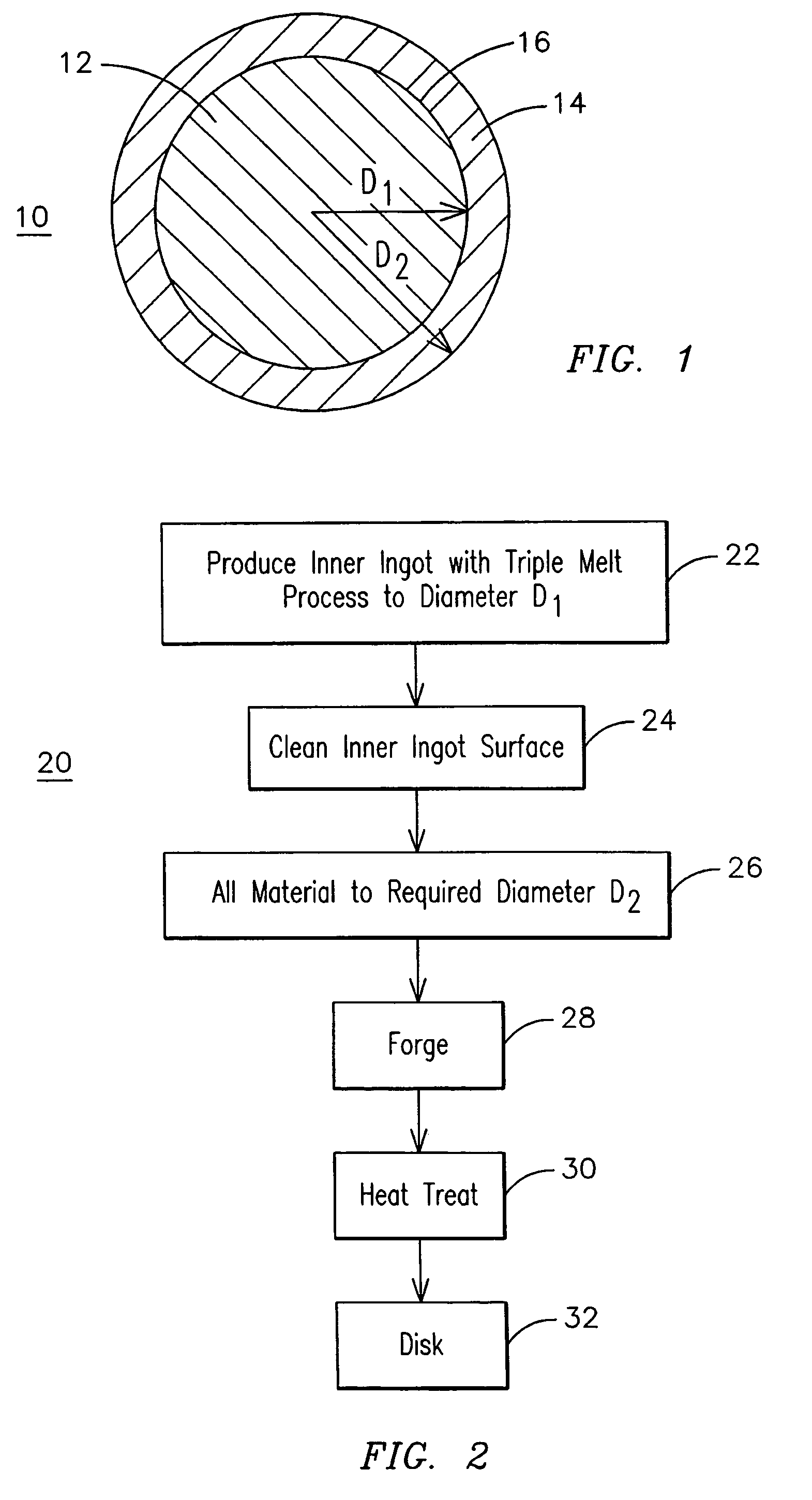

Method of manufacturing a rotating apparatus disk

InactiveUS7316057B2Semiconductor/solid-state device detailsSolid-state devicesDeposition processVacuum arc remelting

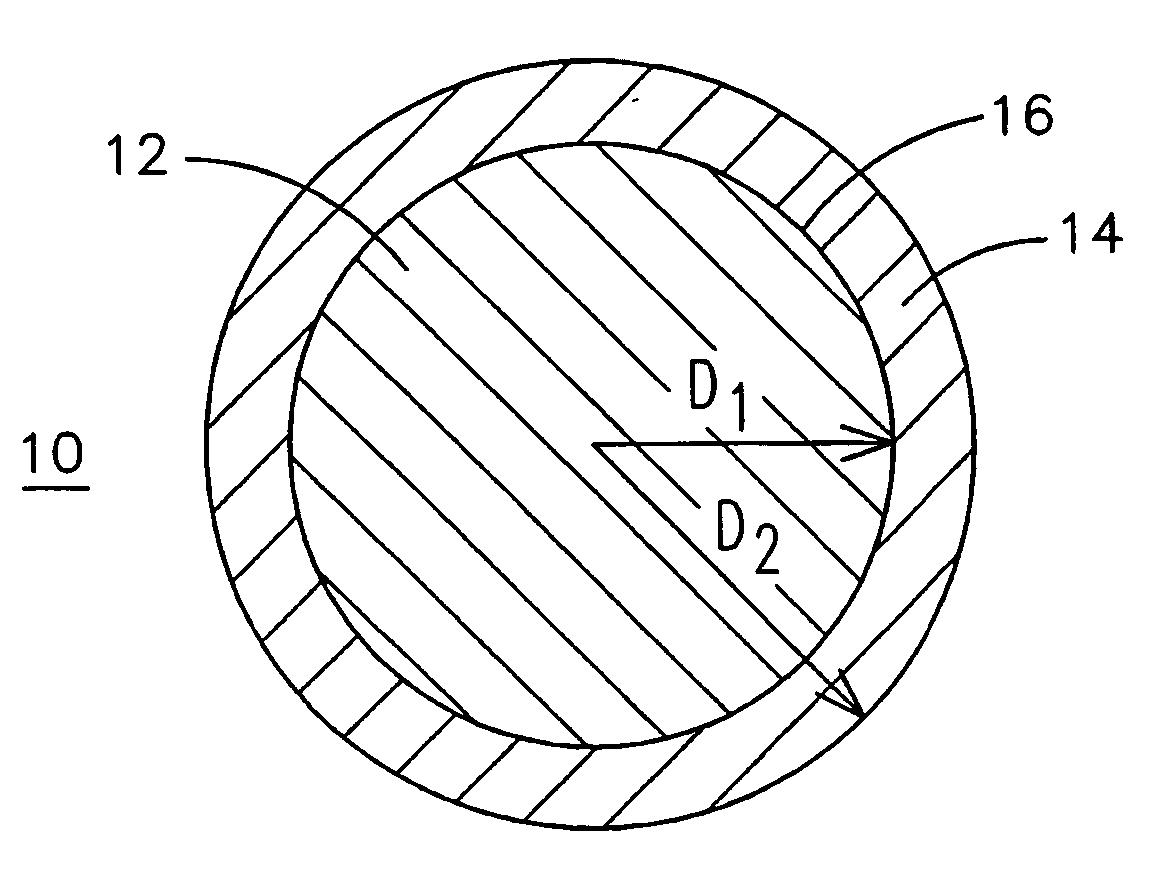

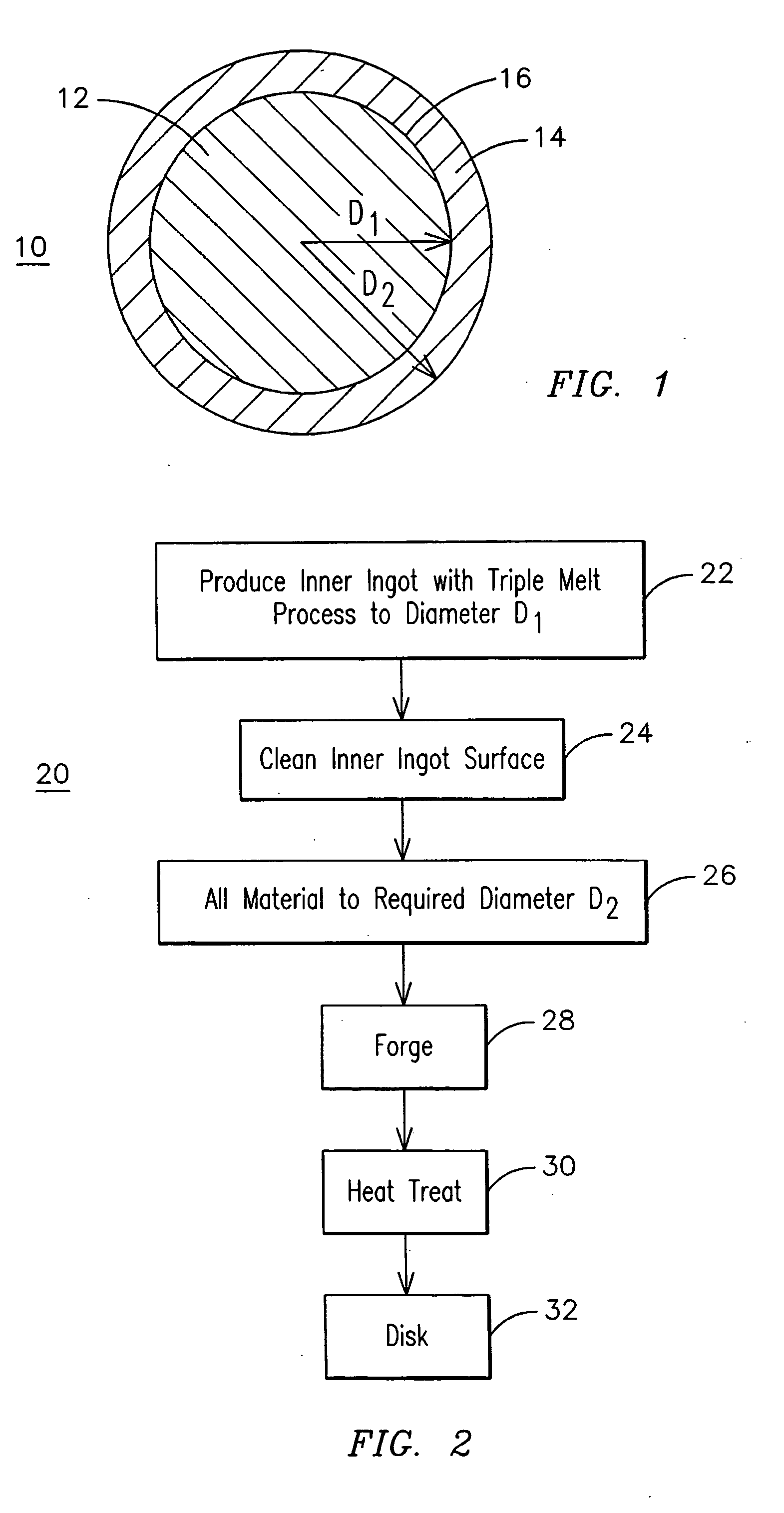

A method (20) of fabricating a large component such as a gas turbine or compressor disk (32) from segregation-prone materials such as Alloy 706 or Alloy 718 when the size of the ingot required is larger than the size that can be predictably formed without segregations using known triple melt processes. A sound inner core ingot (12) is formed (22) to a first diameter (D1), such as by using a triple melt process including vacuum induction melting (VIM), electroslag remelting (ESR), and vacuum arc remelting (VAR). Material is than added (26) to the outer surface (16) of the core ingot to increase its size to a dimension (D2) required for the forging operation (28). A powder metallurgy or spray deposition process may be used to apply the added material. The added material may have properties that are different than those of the core ingot and may be of graded composition across its depth. This process overcomes ingot size limitations for segregation-prone materials.

Owner:SIEMENS ENERGY INC

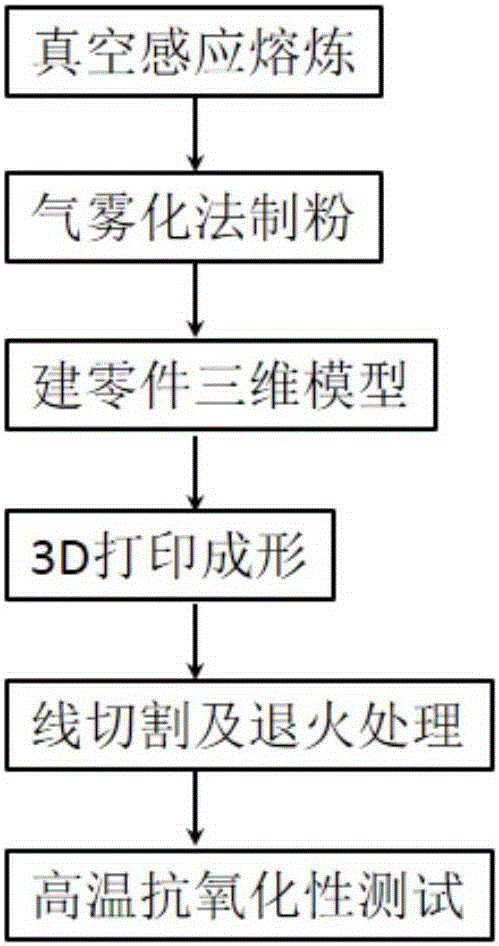

Method for preparing high temperature titanium alloy by adopting selective laser melting rapid formation technique

ActiveCN105154701AIncrease the content of low melting point elementsIncrease the content of melting point elementsIncreasing energy efficiencyManufacturing cost reductionSelective laser melting

The invention discloses a method for preparing high temperature titanium alloy by adopting a selective laser melting rapid formation technique. The method comprises the following steps: (1), preparing powder of elements in nominal chemical components of titanium alloy according to the mass proportion of all the elements, then carrying out vacuum induction melting; (2), milling titanium alloy formed by melting by adopting a gas atomization milling method; (3), establishing a part three-dimensional model, and importing the part three-dimensional model into selective laser melting rapid formation equipment; (4), placing powder into the selective laser melting rapid formation equipment, and carrying out part forming on a substrate; (5), separating the formed part from the substrate by adopting a wire cutting process, annealing the part, so as to improve the plasticity and the toughness of titanium alloy; (6), performing a high temperature oxidation test on the part, so as to determine the high temperature oxidation resistance of the novel titanium alloy. According to the method for preparing high temperature titanium alloy by adopting the selective laser melting rapid formation technique, provided by the invention, a high temperature titanium alloy part with a complex structural shape is quickly formed, and the characteristics of rapid manufacturing, accurate manufacturing and reduction of manufacturing cost and the like are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Hot-work die steel for extrusion wheel and manufacturing method thereof

InactiveCN102534391AImprove hardenabilityReduced temper softening resistanceMetal-working apparatusTemperingThermal fatigue

The invention relates to hot-work die steel for an extrusion wheel and a manufacturing method of the die steel. The invention adopts the technical scheme that the manufacturing method comprises the following steps: hot-forging after scrap steel or molten iron and scrap steel are smelted in an electric furnace and are subjected to electroslag remelting or vacuum induction melting and then carry out spheroidizing annealing at a temperature of 700-880 DEG C; quenching at a temperature of 1,020-1,120 DEG C and tempering at a temperature of 530-650 DEG C, wherein the hot-work die steel has a hardness of up to 40-52HRC and a tensile strength of up to 1,850-1,955MPa. The hot-work die steel comprises the following chemical components in percentage by weight: 0.30-0.50wt% of C, 0.80-1.20wt% of Si, 0.2-0.5wt% of Mn, 3.00-5.00wt% of Cr, 1.00-1.50wt% of Mo, 0.70-1.20wt% of V, 0.005-0.03wt% of N and less than 0.030wt% of P, less than 0.030wt% of S and the balances of Fe and inevitable impurities. The steel has the characteristics of low cost, good thermal fatigue property, high heat stability and excellent comprehensive property and can be used for manufacturing the extrusion wheel of a continuously-extrusion-molded coating machine and other hot-work dies.

Owner:WUHAN UNIV OF SCI & TECH

Smelting production method of low activation martensitic steel for fusion reactor

InactiveCN101328522AReduce manufacturing costMeet the design requirementsIncreasing energy efficiencyQuality levelSteel bar

The invention relates to a method for producing a low-activation martensitic steel for a fusion reactor by melting. The method comprises: step one, a charging material is smelted in a vacuum induction furnace: (1) when a vacuum degree is between 0.1 and 10 Pa, argon gas is passed through the vacuum induction furnace till the vacuum degree is between 0.005 and 0.08MPa, and a smelting temperature is between 1450 and 1650 DEG C; (2) alloys are added in sequence: firstly, pure Fe is melted; Cr and W are added into the furnace; then Ta and V are added into the furnace, and finally C and Mn are added into the furnace; simultaneously, the level of an oxygen content in the pure Fe is observed; before Cr is added, a little of C is added into the furnace for carrying out deoxidation treatment; (3) on-line detection is carried out to the compositions of alloy elements; the alloy elements are added according to a detection result; and (4) after the compositions are qualified, a mixture is cast under the vacuum at a casting temperature of between 1450 and 1550 DEG C. Step two, according to the compositions and the inner quality level of a cast ingot which is obtained by vacuum induction and melting, whether the cast ingot is remelted and refined in a vacuum electroslag remelting furnace or a common electroslag remelting furnace with argon protection. Step three, a needed CLAM steel bar material is prepared by the production of forging, cogging and hot rolling. The method has the characteristics of simple smelting operation, stable process and low production cost; the compositions and impurities of the produced CLAM steel meet the design requirement; and the method has no aliquation of the compositions and tissues and high degree of purity and is suitable for the application of the fusion reactor.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

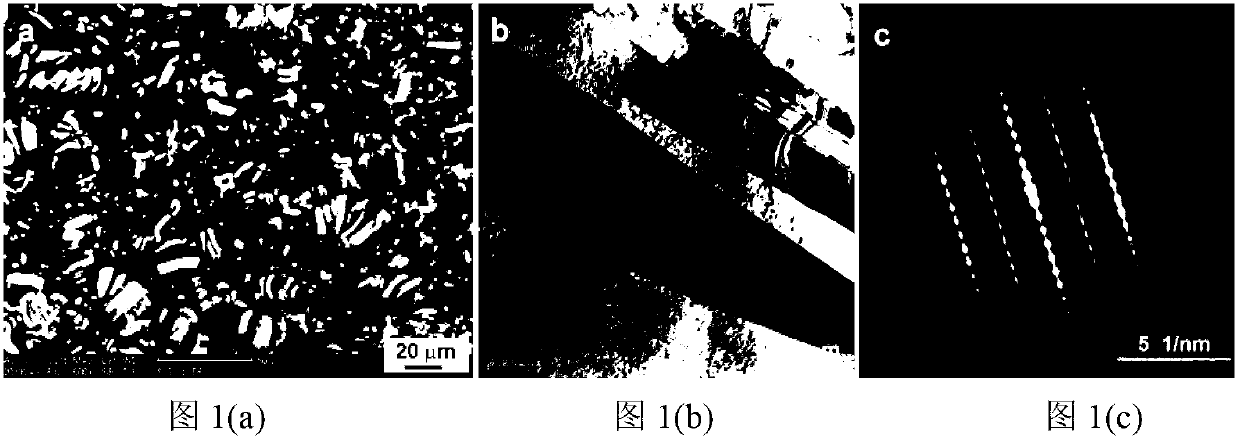

Oxide dispersion strengthening low activity ferrite/martensite steel and smelting method thereof

ActiveCN106756434ASufficient oxygen contentLow viscosityIncreasing energy efficiencyRare earthManganese

The invention discloses oxide dispersion strengthening low activity ferrite / martensite steel and a smelting technology and a smelting method of the oxide dispersion strengthening low activity ferrite / martensite steel, and belongs to the technical field of special steel metallurgy. The oxide dispersion strengthening low activity ferrite / martensite steel comprises raw materials including, by mass percent, 8.9%-9.1% of electrolytic chromium, 0.4%-0.5% of electrolytic manganese, 0.05%-0.08% of high-purity silicon, 0.08%-0.12% of high-purity graphite, 1.4%-1.6% of metal tungsten, 0.1% of metal tantalum, 0.18%-0.22% of metal vanadium, 0.1%-0.25% of sponge titanium, 0.2%-0.5% of high-purity rare earth yttrium, 1% of oxide scales and the balance high-purity low-sulfur low-phosphorus pig iron. A preparing method of the oxide dispersion strengthening low activity ferrite / martensite steel comprises material preparing, vacuum induction smelting, casting, forging and electroslag remelting processes, ODS-RAFM is prepared, and the large-specification ODS steel high in density, uniform in component, little in energy consumption, high in purity, stable in smelting method and capable of meeting the need of large nuclear power equipment is achieved.

Owner:NORTHEASTERN UNIV

Precision-investment casting method of titanium aluminum base alloy aircraft engine blade

A precision-investment casting method of a titanium aluminum base alloy aircraft engine blade relates to a preparation method of an aircraft engine blade and solves the problems of easy deformation, complicated processing procedures and low processing efficiency caused by the thin aircraft engine blades with diverse shapes when the existing blank processing mode is adopted. The invention adopts a water jacketed copper crucible vacuum induction melting centrifugal casting method to realize the preparation of the titanium aluminum base alloy aircraft engine blade. The aluminum content of the titanium aluminum base alloy is 46-48at%. Under vacuum argon shield, the melting is implemented and the melting power is 330-350kW in the melting process. With the centrifugal casting technology adopted, the casting is carried out by adopting a bottom casting type casting system and a casting system composed of blade type shells. The preheating temperature of a casting type shell is 400-600 DEG C and the shell cools with a furnace after casting, and the oxygen content of the alloy is 0.04-0.08% after casting. The method is simple in technology, low in processing cost and is applicable to processing various aircraft engine blades.

Owner:HARBIN INST OF TECH

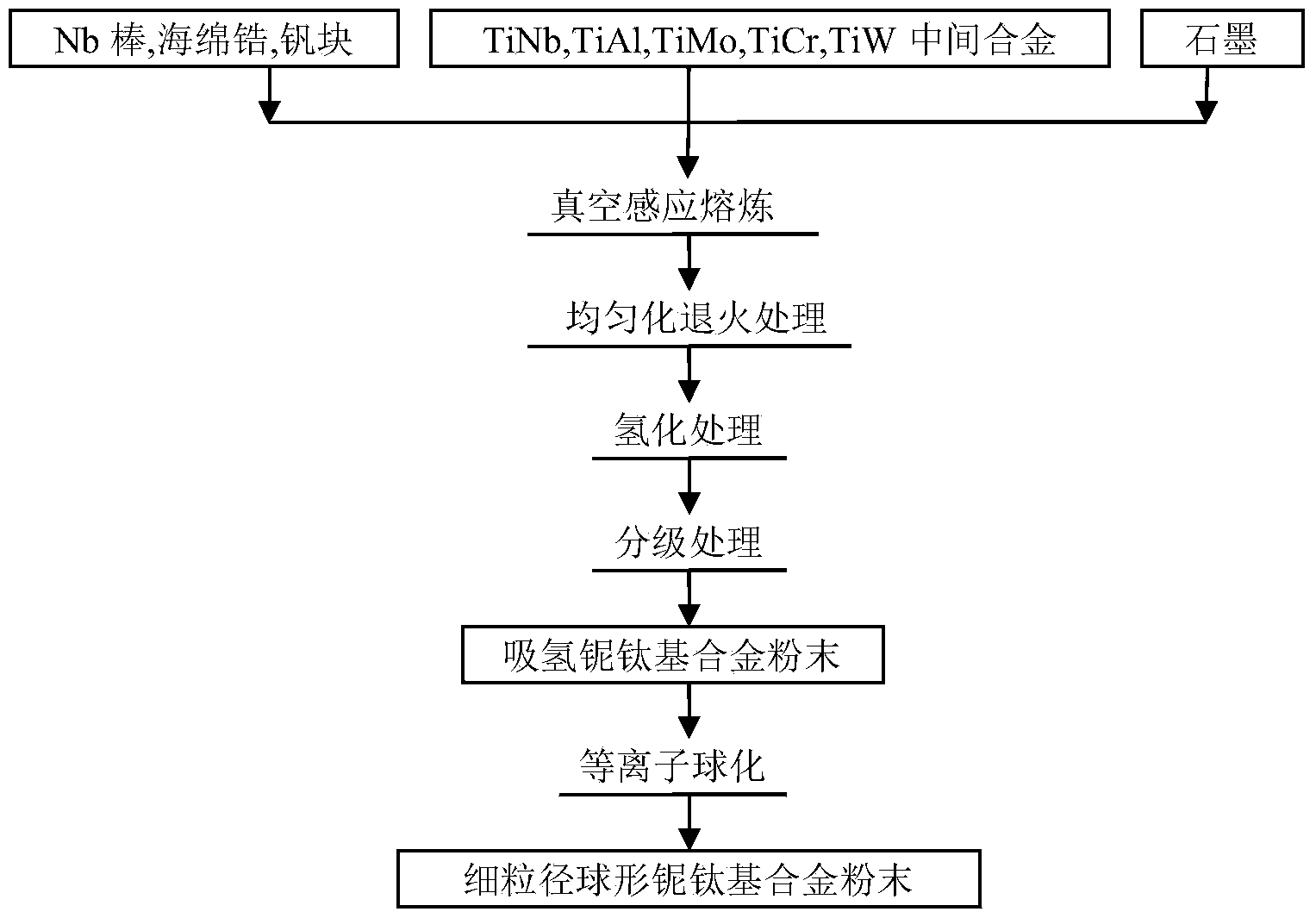

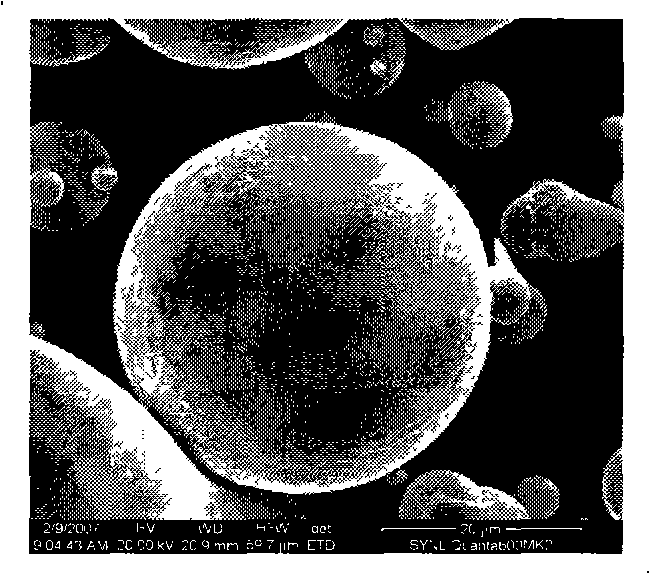

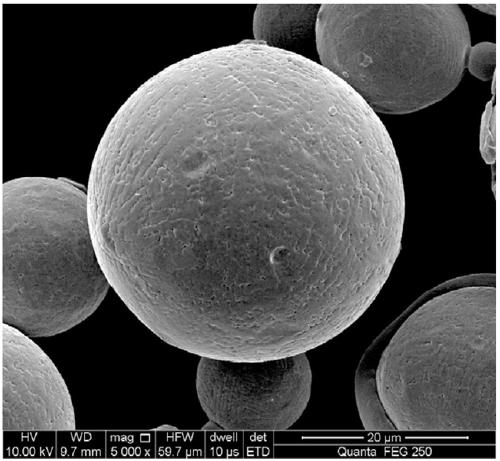

Method for manufacturing spherical niobium and titanium-based alloy powder with small particle size

The invention discloses a method for manufacturing spherical niobium and titanium-based alloy powder with a small particle size. The spherical niobium and titanium-based alloy powder is manufactured by the aid of vacuum induction melting, hydrogen treatment and plasma spheroidization technologies. The method includes firstly, manufacturing niobium and titanium-based spherical alloy ingots by the aid of the vacuum induction melting technology to realize a purification melting effect, reducing the quantity and the size of non-metallic inclusion to the greatest extent and performing homogenization thermal treatment on the niobium and titanium-based spherical alloy ingots to obtain ingots with uniform alloy contents; secondly, performing hydrogen treatment on the ingots to acquire hydrogen absorption niobium and titanium alloy powder; thirdly, sieving the hydrogen absorption niobium and titanium alloy powder, and then performing plasma spheroidization on the hydrogen absorption niobium and titanium alloy powder. The method has the advantages that output power, the powder feeding rate and the airflow rate are optimized in spheroidization procedures, accordingly, hollow powder can be prevented, and the fine powder yield can be increased; the spherical powder obtained by the method is excellent in dispersibility and flowability and uniform in particle size; the niobium and titanium-based alloy powder finally manufactured by the method is small in particle size, uniform in composition, good in flowability, high in spheroidization rate and low in oxygen content and is applicable to the technical field of injection molding, quick molding and thermal spraying.

Owner:UNIV OF SCI & TECH BEIJING

Method of manufacturing a rotating apparatus disk

InactiveUS20060075624A1Semiconductor/solid-state device detailsExtrusion containersDeposition processVacuum arc remelting

A method (20) of fabricating a large component such as a gas turbine or compressor disk (32) from segregation-prone materials such as Alloy 706 or Alloy 718 when the size of the ingot required is larger than the size that can be predictably formed without segregations using known triple melt processes. A sound inner core ingot (12) is formed (22) to a first diameter (D1), such as by using a triple melt process including vacuum induction melting (VIM), electroslag remelting (ESR), and vacuum arc remelting (VAR). Material is than added (26) to the outer surface (16) of the core ingot to increase its size to a dimension (D2) required for the forging operation (28). A powder metallurgy or spray deposition process may be used to apply the added material. The added material may have properties that are different than those of the core ingot and may be of graded composition across its depth. This process overcomes ingot size limitations for segregation-prone materials.

Owner:SIEMENS ENERGY INC

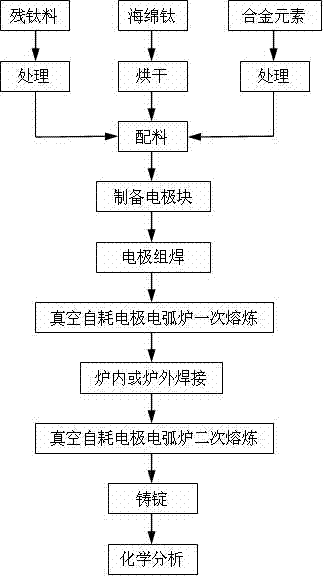

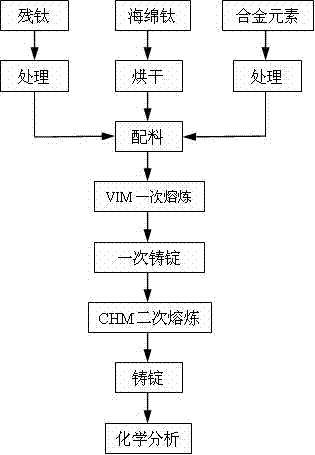

Preparation method of short-process titanium alloy Ti-Ni-Nb

The invention relates to an energy-saving high-efficiency short-procedure process for preparing a high-quality titanium alloy Ti-Ni-Nb. The energy-saving high-efficiency short-procedure process comprises a crucible vacuum induction melting (VIM) technology of titanium and a titanium alloy and a cold hearth melting (CHM) technology of titanium and the titanium alloy. The VIM technology is used for preparing a primarily cast ingot of titanium and the titanium alloy, and replacing vacuum consumable-electrode arc melting (VAR) electrode preparation of an alloy in the traditional preparation process and one-time smelting of the alloy, and the CHM technology is used for carrying out secondary refining of the primarily cast ingot of titanium and the titanium alloy and preparing the cast ingot of titanium and the titanium alloy, in a required shape. According to the energy-saving high-efficiency short-procedure process for preparing the high-quality titanium alloy Ti-Ni-Nb, the preparation procedure of the alloy can be simplified, and high-quality alloy cast ingots of multiple shapes are produced.

Owner:SHANGHAI UNIV

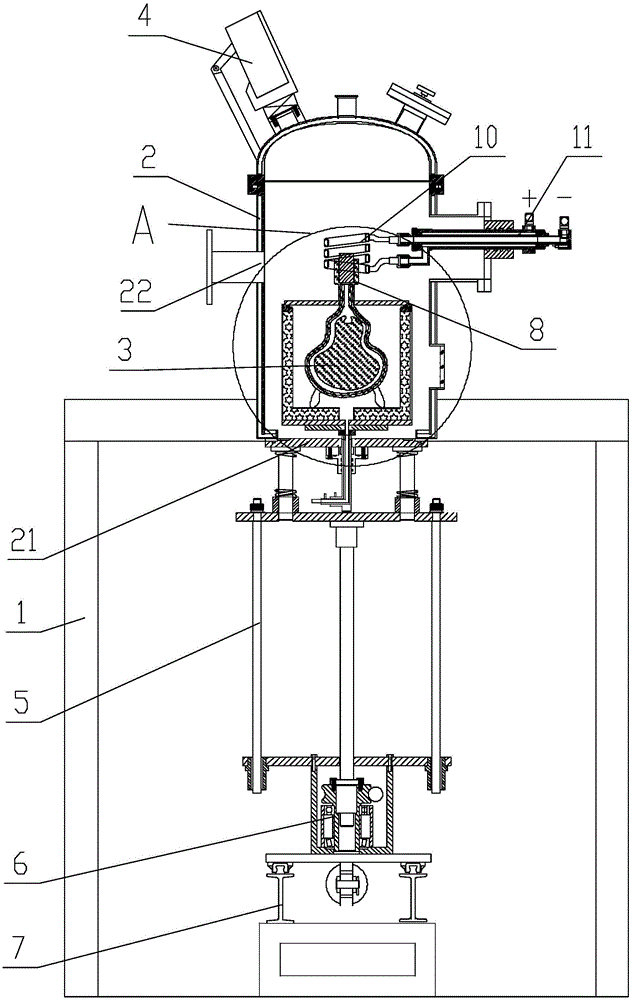

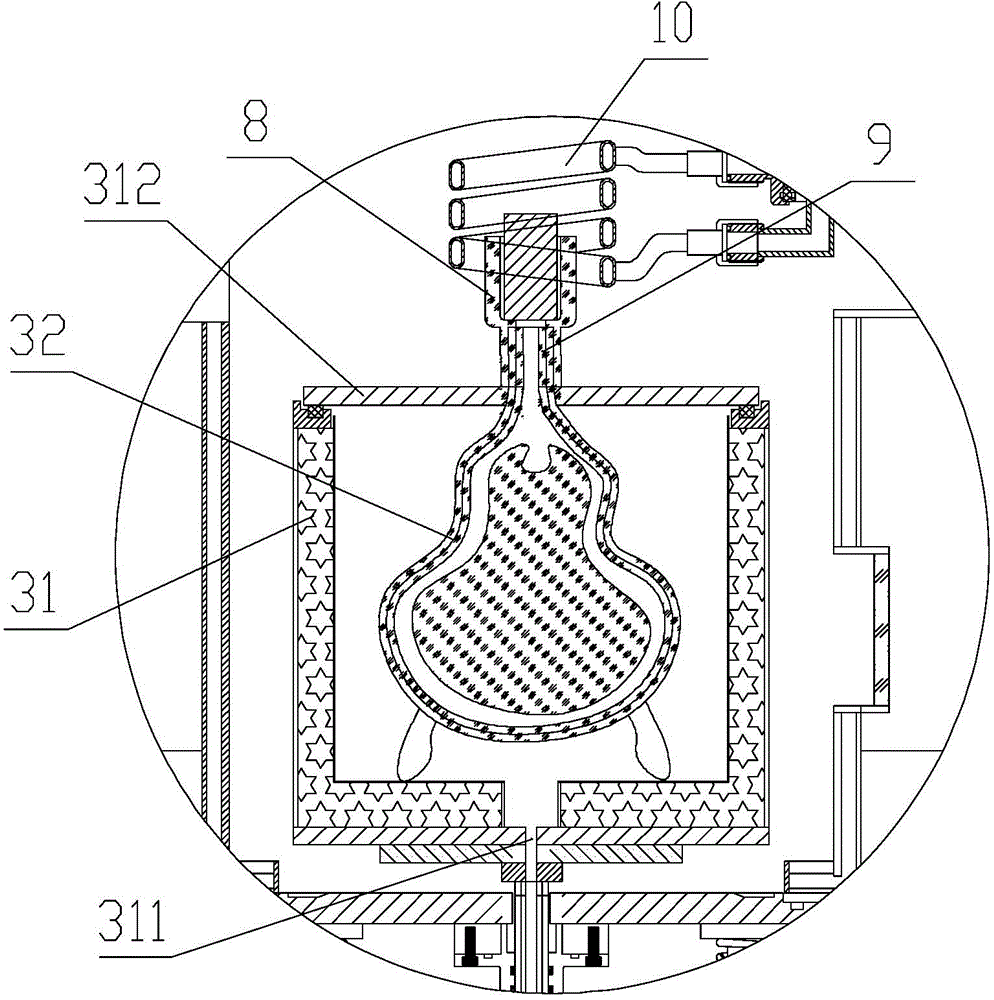

Titanium-based alloy induction melting bottom leakage type vacuum suction casting device and control method

The invention discloses a titanium-based alloy induction melting bottom leakage type vacuum suction casting device and a control method, relates to the technical field of titanium-based alloy melting suction casting and solves the problems of low efficiency, high cost, complicated technology and the like of an existing titanium-based alloy melting suction casting device. The titanium-based alloy induction melting bottom leakage type vacuum suction casting device provided by the invention can be used for carrying out vacuum induction melting on titanium-based alloy by adopting a ceramic crucible; since no any shielding effect works on an electromagnetic force by ceramic, all electromagnetic induction energy generated by an induction coil can totally act on titanium metal, energy saving and environment protection are realized, the utilization rate of metal raw materials is up to 60%-70%, and the metal cost is greatly reduced; an isolating layer is formed on the inner surface of a crucible body of the ceramic crucible, materials which are used for manufacturing the isolating layer comprise yttrium oxide, the yttrium oxide has good inertia on the titanium metal under high temperature and can be used for isolating ceramic materials which can react with the titanium metal during a melting process, and titanium-based alloy melting is enabled to be reliably proceeded.

Owner:北京博瑞杰特科技发展有限公司

Purification smelting method for nickel-based high-temperature alloy master alloy

A purification smelting method for a nickel-based high-temperature alloy master alloy comprises the following steps: (1) carrying out hydrochloric acid and ultrasonic treatment of a metal raw material; preparing CaO-CaF2 pre-melted slag; and uniformly mixing the pre-melted slag and a pure nickel powder, and pressing into a block; (2) placing the raw material and the press block together into a crucible, and vacuumizing; adding C, Nb, Ti and Al after melting; filling with argon gas, adding B and Zr until an alloy liquid is molten again, and pouring into a steel mold, to obtain a high temperature alloy ingot; and removing oxide scale and risers of the ingot, to obtain a high temperature alloy concentrate; and (3) putting the concentrate into a copper crucible; vacuumizing, melting, and rapidly solidifying, to obtain the high temperature alloy master alloy. Slag refining is performed during vacuum induction smelting, and the sulfur and phosphorus content is low; the copper crucible can avoid the pollution of the crucible to an alloy melt; magnetic suspension can promote non-metallic inclusions to float upwards; the content of oxygen and nitrogen is low, so the amount of non-metallic inclusions formed in the cooling and solidification processes of the alloy liquid is reduced; the conventional mature smelting device is used, and the operation is convenient.

Owner:UNIV OF SCI & TECH BEIJING

Magnesium-lithium alloy with enhanced long-period structure phase and preparation method thereof

ActiveCN103122431AMeet the requirements of various applicationsHigh strengthAlloy substrateMass content

The invention provides a magnesium-lithium alloy with an enhanced long-period structure phase and a preparation method thereof. The method adopts pure Mg, pure Li, pure Zn and Mg-Y intermediate alloy as raw materials and comprises the following steps of: proportionally putting the raw materials into a vacuum induction melting furnace, filling a protective gas, heating and smelting, and casting the smelted melt into a metal die to obtain an as-cast alloy; performing heat treatment at 490-510 DEG C for 5-10 hours to obtain a casting alloy with an LPSO structure phase through phase transformation; and performing extrusion deformation processing at 260-280 DEG C to obtain a magnesium-lithium alloy which comprises the following components in percentage by mass: 5.5-10% of Li, 4-10% of Y, 1-4% of Zn, less than 0.03% of inevitable impurities Fe, Cu, Ni and Si in total and the balance of Mg, wherein the mass content ratio of Y to Zn is 1-6. According to the invention, by reasonably selecting the alloy elements, the LPSO structure phase is introduced into a magnesium-lithium alloy substrate, and a magnesium-lithium alloy material with low density, high strength, high plasticity and good heat resistance is prepared.

Owner:HARBIN ENG UNIV

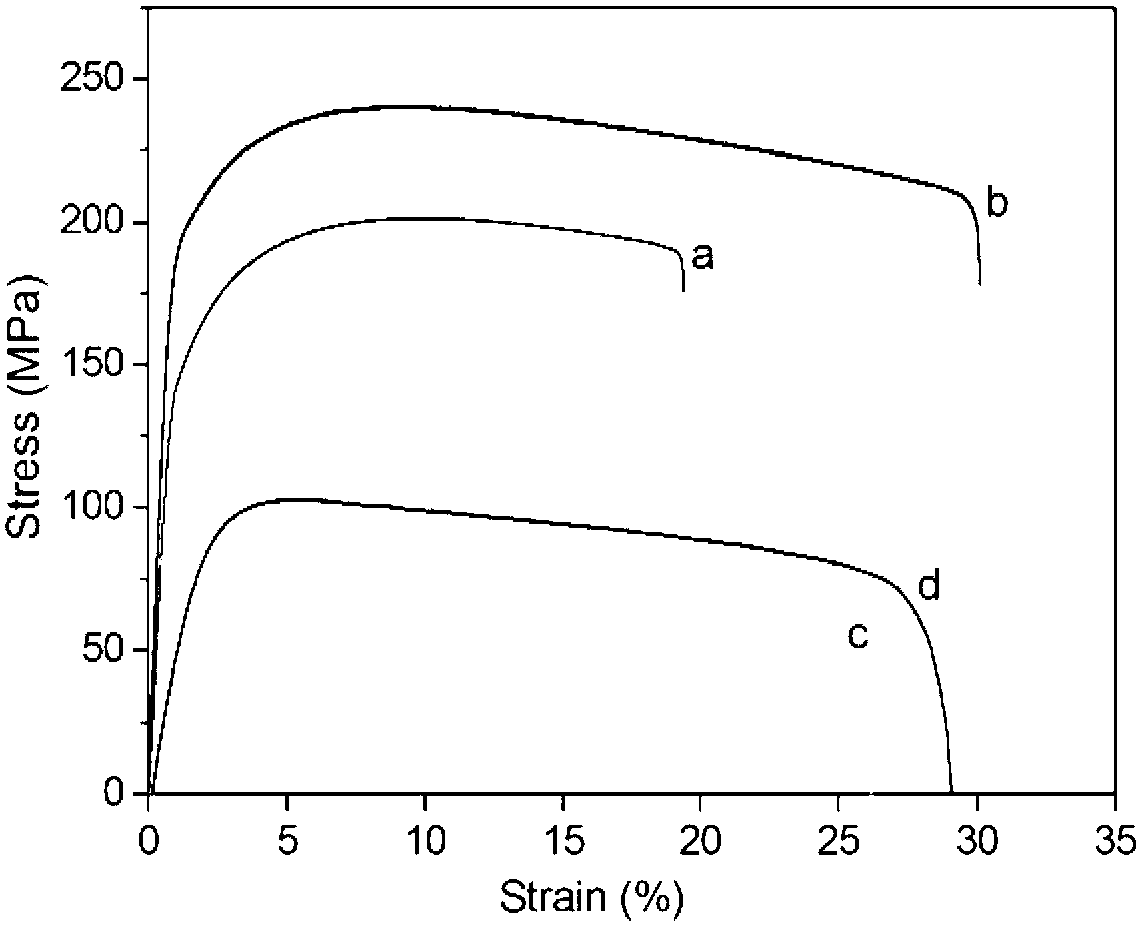

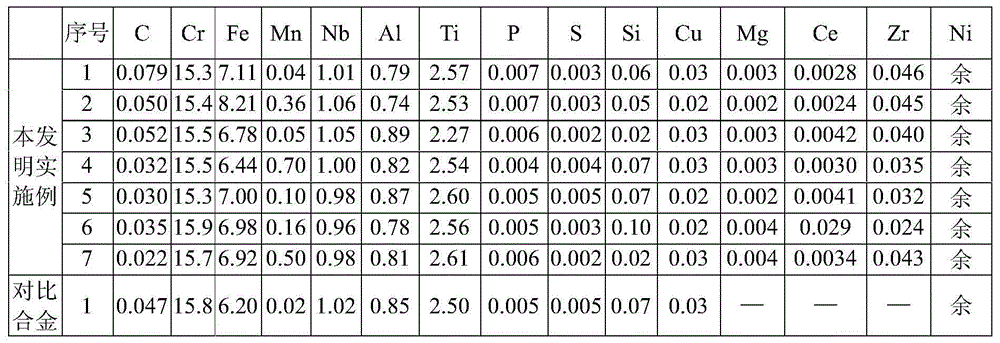

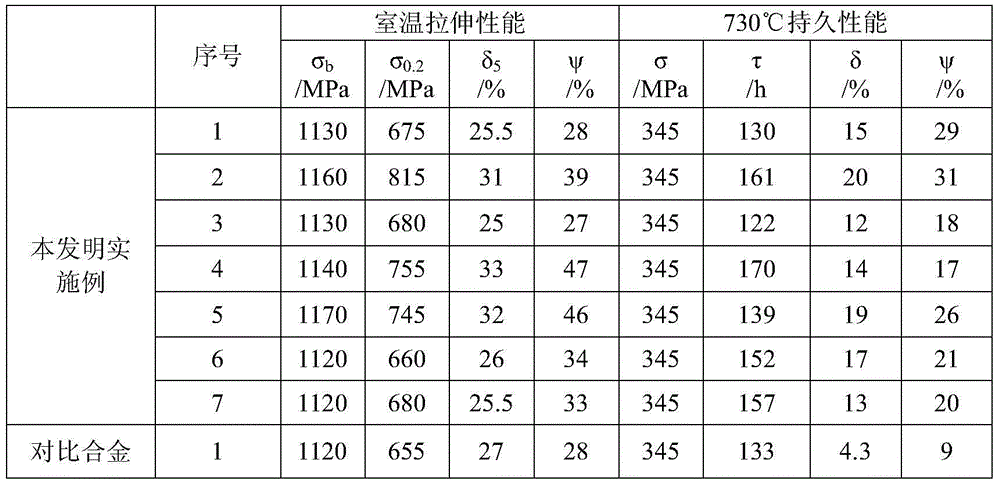

High-strength nickel-base superalloy and manufacturing method thereof

The invention discloses a high-strength nickel-based superalloy and a manufacturing method thereof. The alloy comprises the following components by weight percentage: C0.02-0.08; Cr14.0-17.0; Fe5.0-9.0%; Al0 .50~1.30; Ti2.25~2.75; Nb0.7~1.2; Mn0.02~1.0; Mg0.001~0.006; Ce0.001~0.03; Zr0.01~0.06; ≤0.30; Cu≤0.30, the balance is nickel and unavoidable impurities. The manufacturing method of the alloy is vacuum induction melting and heat treatment. The invention has the advantages that it can significantly reduce the failure of components during use, and has good application prospects.

Owner:宝钢特钢有限公司

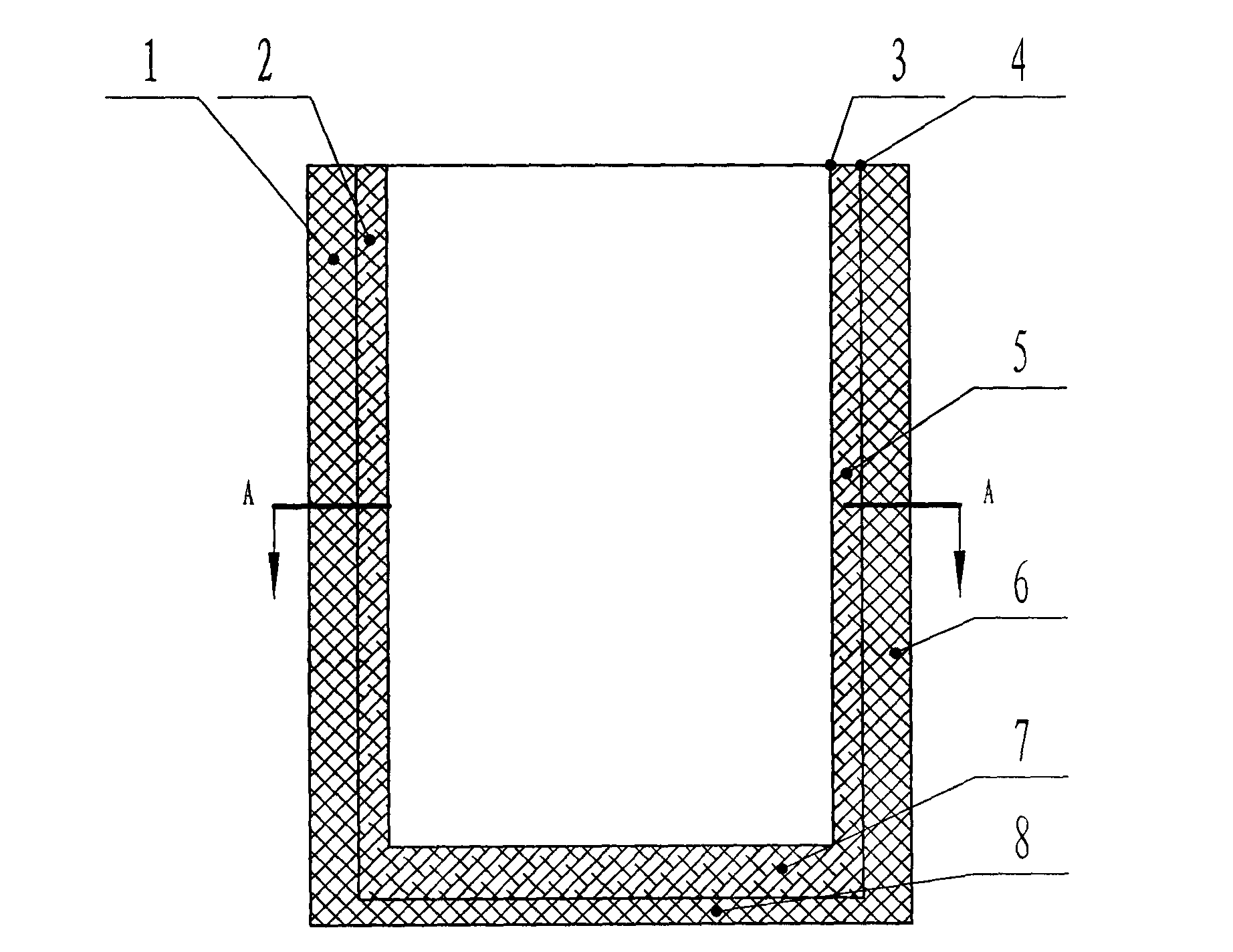

Crucible for vacuum induction melting and manufacturing method thereof

The invention relates to a crucible for vacuum induction melting and a manufacturing method thereof. The crucible is tied on a bottom brick in an induction coil of a vacuum induction furnace. The crucible is characterized by being designed as a double-layered composite structure, wherein the inner layer is an inner shell which is used for melting and made of high-chemically stable crucible material with low decomposing pressure; and the outer layer is an outer shell which is made of low-cost crucible material and has the functions of heat insulation and support. The manufacturing method comprises the following steps in sequence: (1) paving a layer of outer shell material of the crucible at the bottom of the tied crucible, paving a layer of inner shell material of the crucible, and rammingthe material of the crucible; (2) mounting a graphite core, and placing a thin cylinder between the graphite core and an asbestos insulation layer; (3) tying the inner and outer shells of the crucible, and adding the inner shell material of the crucible between the graphite core and the thin cylinder and ramming the inner shell material of the crucible, and then adding the outer shell material ofthe crucible between the graphite core and the asbestos insulation layer; and (4) roasting the induction coil by electrifying the induction coil, and extracting the graphite core after cooling. The crucible manufactured by the manufacturing method of the crucible for vacuum induction melting has low cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method and equipment for removing phosphorus and metal impurities in ganister sand through vacuum induction melting

The invention belongs to the field of polycrystalline silicon purification in the metallurgical method. The method for removing phosphorus and metal impurities in ganister sand through vacuum induction melting comprises the steps of firstly removing the phosphorus impurity in the polycrystalline silicon through smelting the ganister sand in the induction heating mode under high vacuum state, then conducting ingot stretching, and then removing the metal impurities in the ganister sand through the directional solidification technology. The method disclosed by the invention is simple, the ganister sand is smelted with good impurity removal effect and high removal efficiency since the phosphorus and metal impurities in the polycrystalline silicon are removed through the vacuum induction melting and directional solidification technology, the characteristic of high temperature of the inductance coil heating is effectively used; and the method is simple and easy, integrates the double effects of phosphorus removal and metal removal, is high in yield and stable in purification effect, and is suitable for mass industrial production.

Owner:DALIAN UNIV OF TECH

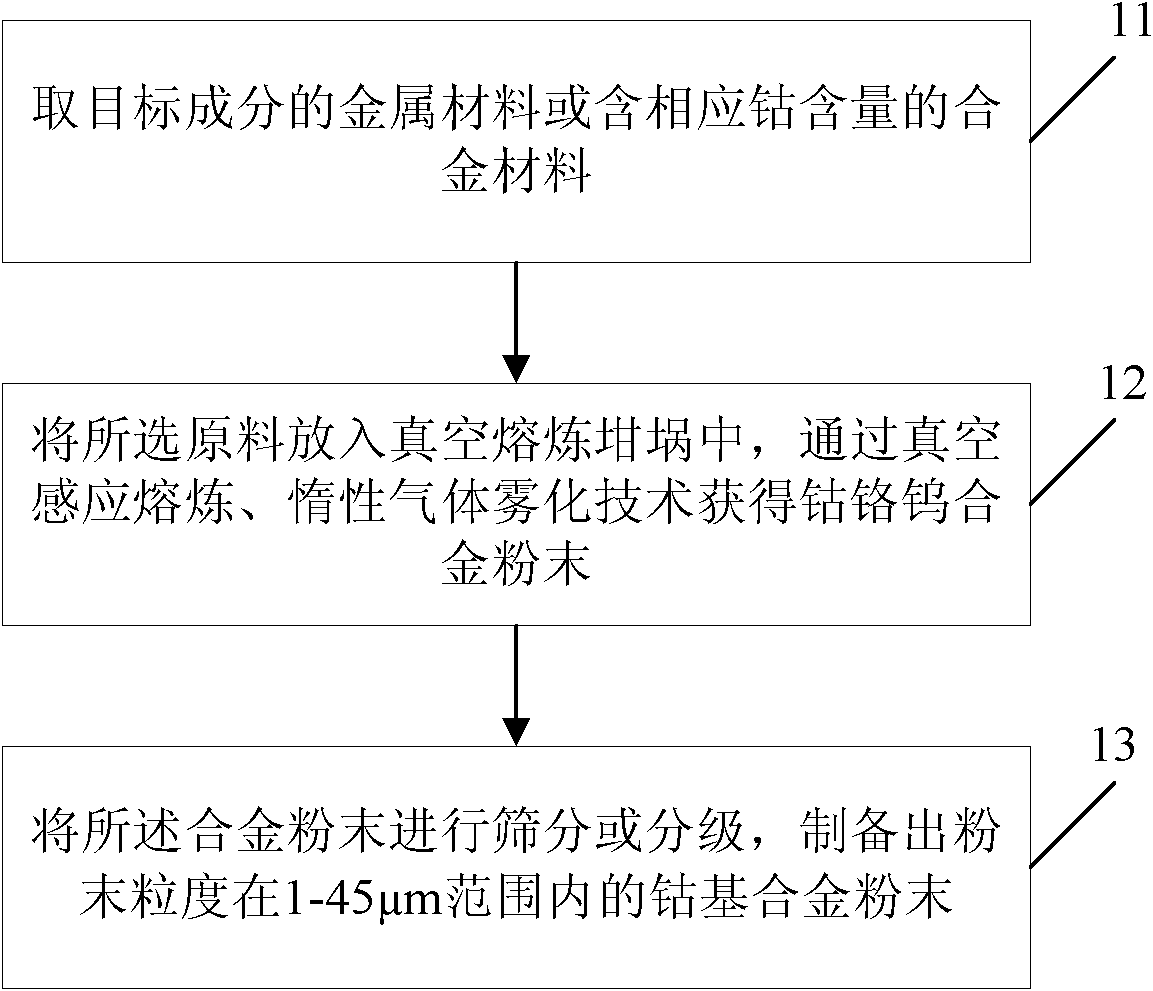

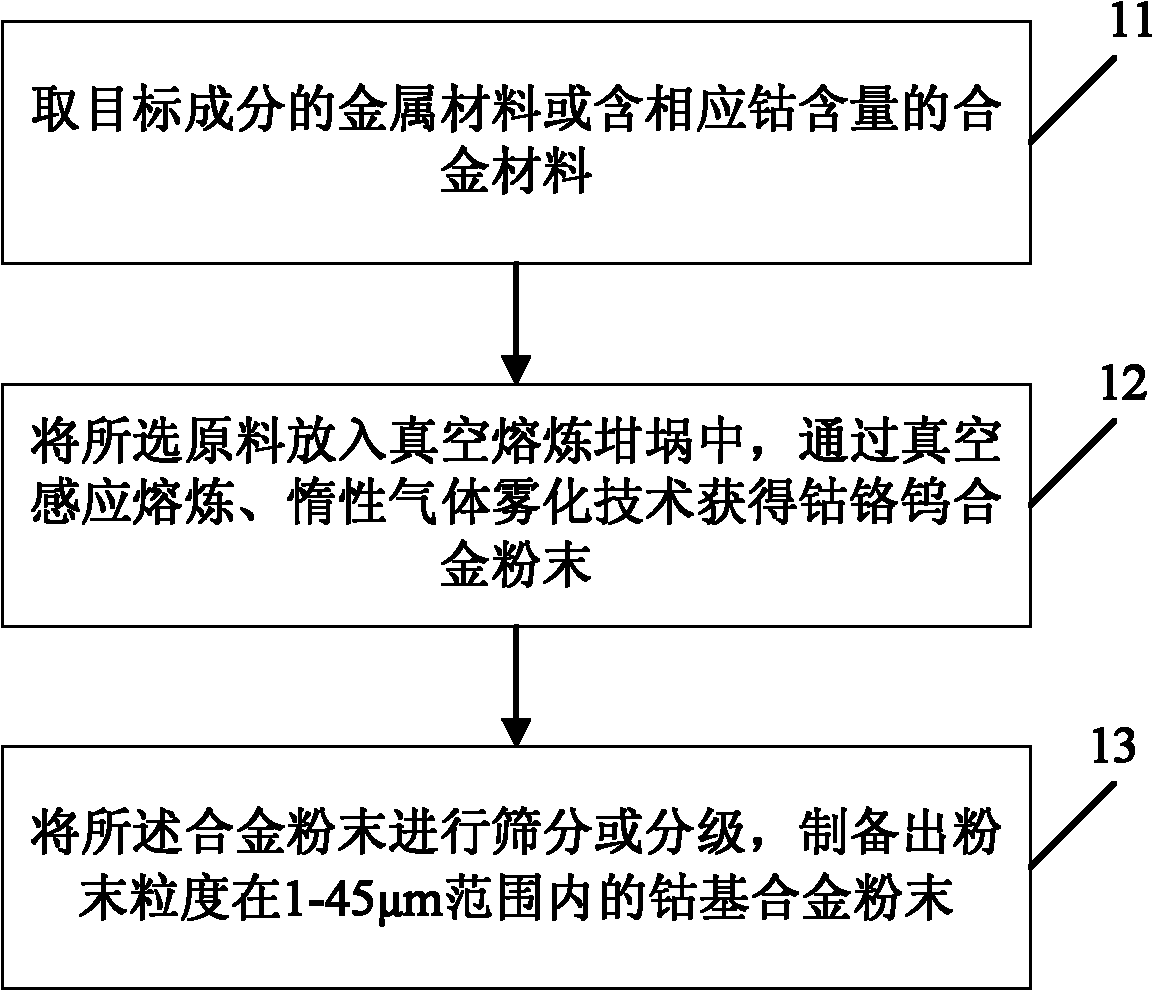

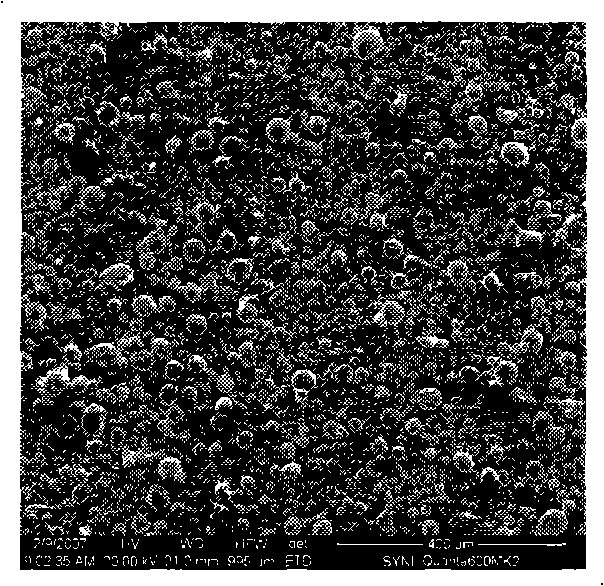

Production method of fine particle sized cobalt-base alloy powder

The invention relates to a production method of fine particle sized cobalt-base alloy powder, which comprises the steps that: firstly, metal materials of targeted components or alloy materials which contain the corresponding cobalt content are taken; the selected raw materials are placed into a crucible, and the cobalt-base alloy powder is obtained through the vacuum induction melting and inert gas atomization technologies; and screening or grading is carried out, so the cobalt-base alloy powder with the powder size within 1-45mu m is produced. The problems of high oxygen content of fine powder, bad apparent density and fluidity, low powdering rate during the coating, low coating density and bonding strength and the like of the existing fine particle sized cobalt-base alloy powder are solved, and the quality of a cobalt-base alloy powder product is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

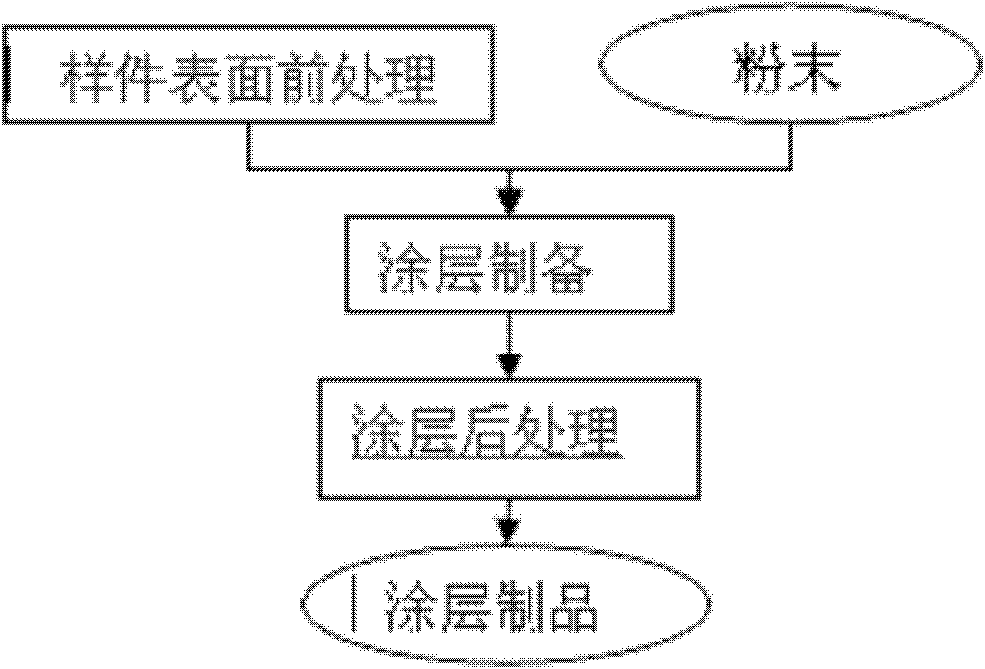

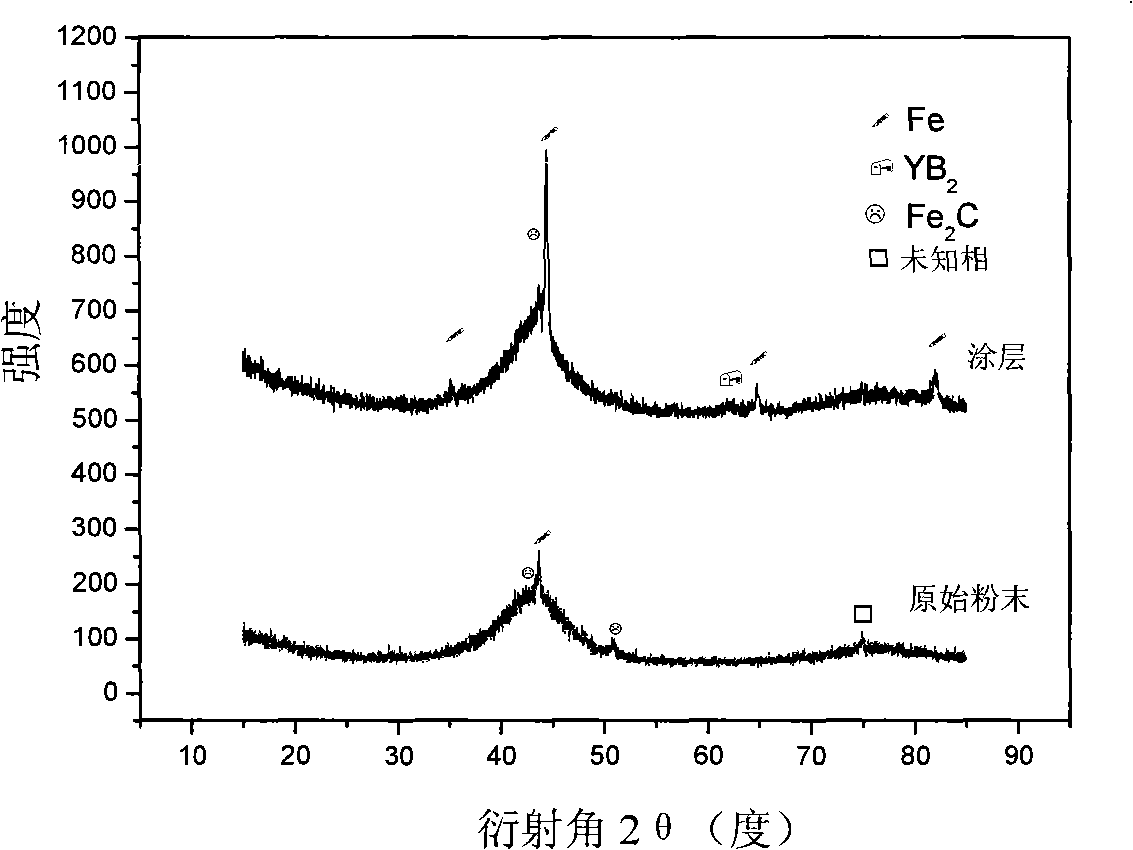

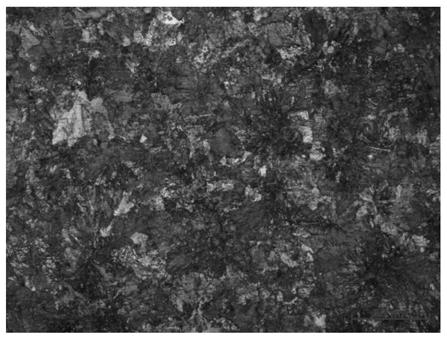

Preparation of non-magnetic high corrosion resistant amorphous steel coating

InactiveCN101323951AImprove mechanical propertiesGood physical propertiesMolten spray coatingHeat inorganic powder coatingSurface engineeringVoid ratio

The invention relates to a ferrous alloy with strong performance of glass formation and a technique method for preparing the coating of the amorphous alloy, in particular to a preparation method of non-magnetic amorphous steel coating with the performance of high anticorrosion and wearing resistance. The method of the invention solves the problem that large brittleness is existed in Fe-based large bulk of amorphous alloy and is a restriction as the structural material to go to engineering application, while the invention causes the application of bulk amorphous alloy to surface engineering field (especially amorphous alloy coating) to be possible. By adopting the Fe-based bulk amorphous alloy to prepare Fe-based amorphous alloy coating, firstly, mater alloy is produced by a method of vacuum induction melting according to needed components; then gas atomization technology is adopted to prepare amorphous alloy powder; supersonic thermal spray technology is adopted to prepare Fe-based amorphous alloy coating. The non-magnetic amorphous steel coating with high anticorrosion performance and wearing resistance produced by the invention is uniform, has low void ratio (less than 0.1 percent), is non-magnetic and has the performance of high anticorrosion and wearing resistance as well as vast application prospect to shell material of ships.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-purity titanium-nickel alloys with shape memory

The invention includes an alloy containing equivalent amounts of nickel and titanium. The alloy has shape memory and a metallic purity of at least about 99.995%, and comprises less than about 200 ppm of gases. The invention also includes an alloy comprising titanium and nickel where the titanium and nickel amounts are non-equivalent. The alloy has shape memory and has a metallic purity of at least 99.995%, and contains less than about 200 ppm of gases. The invention further includes a method of producing a shape memory alloy. Titanium is provided having a metallic purity of at least 99.999% and nickel is provided having a metallic purity of at least 99.99%. The titanium and nickel are combined utilizing at least one melting event independently selected from e-beam melting, vacuum arc melting, vacuum induction melting, induction skull melting and plasma melting.

Owner:HONEYWELL INT INC

Preparation method for nickel-base superalloy powder for laser forming

ActiveCN108941588AHigh sphericityHigh yieldAdditive manufacturing apparatusTransportation and packagingOxygen contentHot Temperature

The invention discloses a preparation method for nickel-base superalloy powder for laser forming, and belongs to the field of superalloy and powder metallurgy. According to the preparation method, vacuum induction melting and argon atomization powder making technologies are adopted, and the nickel-base superalloy powder suitable for laser forming is prepared. The nickel-base superalloy powder prepared through the method is high in small grain size powder, high in degree of sphericity, low in oxygen content, good in flowing performance, free of hollow defects, less in satellite powder and capable of meeting the technical requirement for laser forming.

Owner:CENT SOUTH UNIV

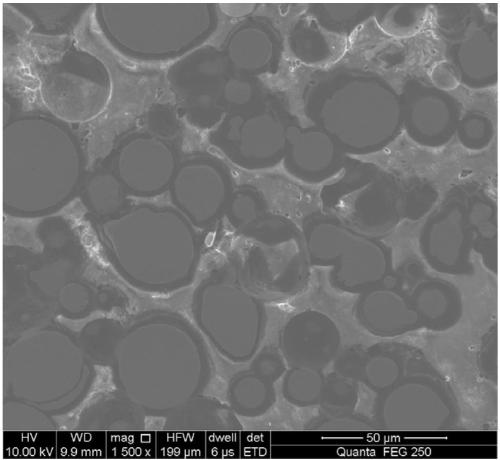

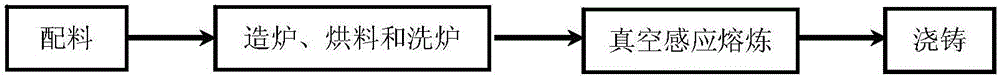

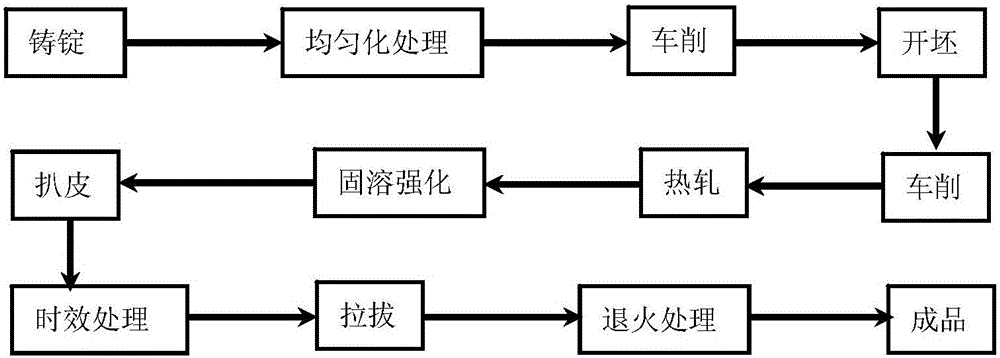

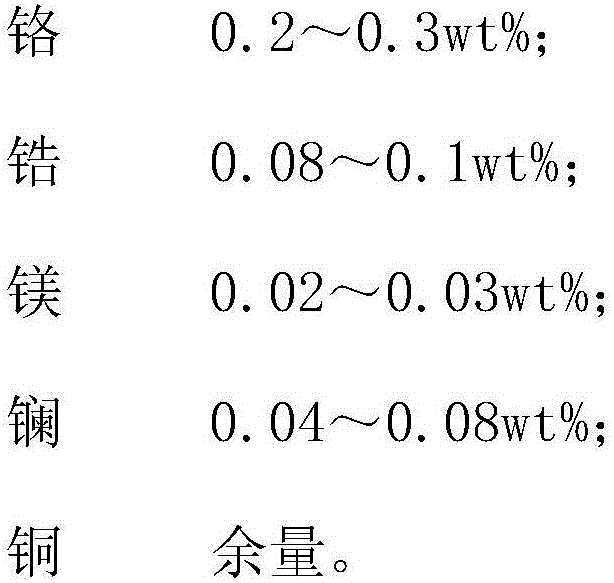

Multi-element micro-alloyed high-strength high-conductivity copper alloy and preparation technique thereof

ActiveCN106435249AHigh resistivityExcellent breaking forceConductive materialMetal/alloy conductorsSolution treatmentMaterials preparation

The invention relates to the field of copper alloy conductors, in particular to a multi-element micro-alloyed high-strength high-conductivity copper alloy and a preparation technique thereof. The multi-element micro-alloyed high-strength high-conductivity copper alloy comprises 0.2-0.3wt% of chromium, 0.08-0.1wt% of zirconium, 0.02-0.03wt% of magnesium, 0.04-0.08wt% of lanthanum and the balance copper. The multi-element micro-alloyed high-strength high-conductivity copper alloy preparation technique comprises the following steps of (1) materials preparation, (2) furnace forging, (3) material drying and furnace washing, (4) vacuum induction smelting, (5) casting, (6) homogenizing annealing treatment, (7) cogging, (8) hot rolling, (9) solution treatment, (10) peeling, (11) cold deforming, (12) aging treatment, (13) drawing, and (14) finished product acquiring after annealing treatment. The multi-element micro-alloyed high-strength high-conductivity copper alloy is reasonable in design and convenient to operate, a prepared copper alloy conductor has good electrical resistivity, pulling strength and tensile strength, and thus the production requirement is met.

Owner:CHANGZHOU HENGFENG SPECIAL CONDUCTOR CO LTD

Preparing method for in-situ synthesis TiC-Ti5Si3 particle reinforcement Ti-based composite material

The invention relates to the field of Ti-based composite materials, in particular to a preparing method for an in-situ synthesis TiC-Ti5Si3 particle reinforcement Ti-based composite material. The preparing method includes the specific steps that firstly, materials are weighed; secondly, mixed powder of Ti powder and SiC powder is prepared; thirdly, loading is conducted; and fourthly, vacuum induction melting is conducted, and the in-situ synthesis TiC-Ti5Si3 particle reinforcement Ti-based composite material is obtained after cooling. According to the preparing method, the in-situ synthesis Ti-based composite material high in performance can be prepared by adjusting the content of reinforcement phases and components of a titanium alloy base body, and secondary molding can also be conducted with the combination of the technology of hot forging, hot rolling, hot extruding and the like. The preparing method has the advantages that the technology is simple, cost is low, and industrial production is easy to achieve.

Owner:TAIYUAN UNIV OF TECH

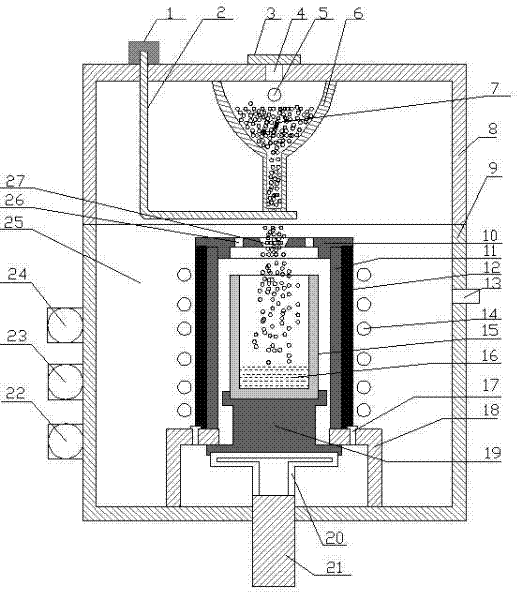

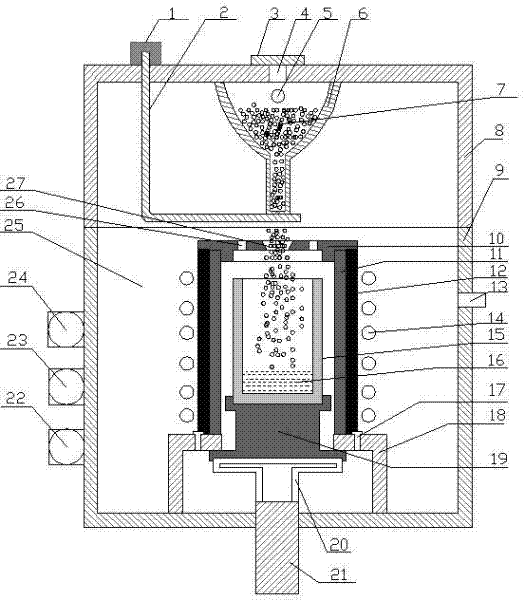

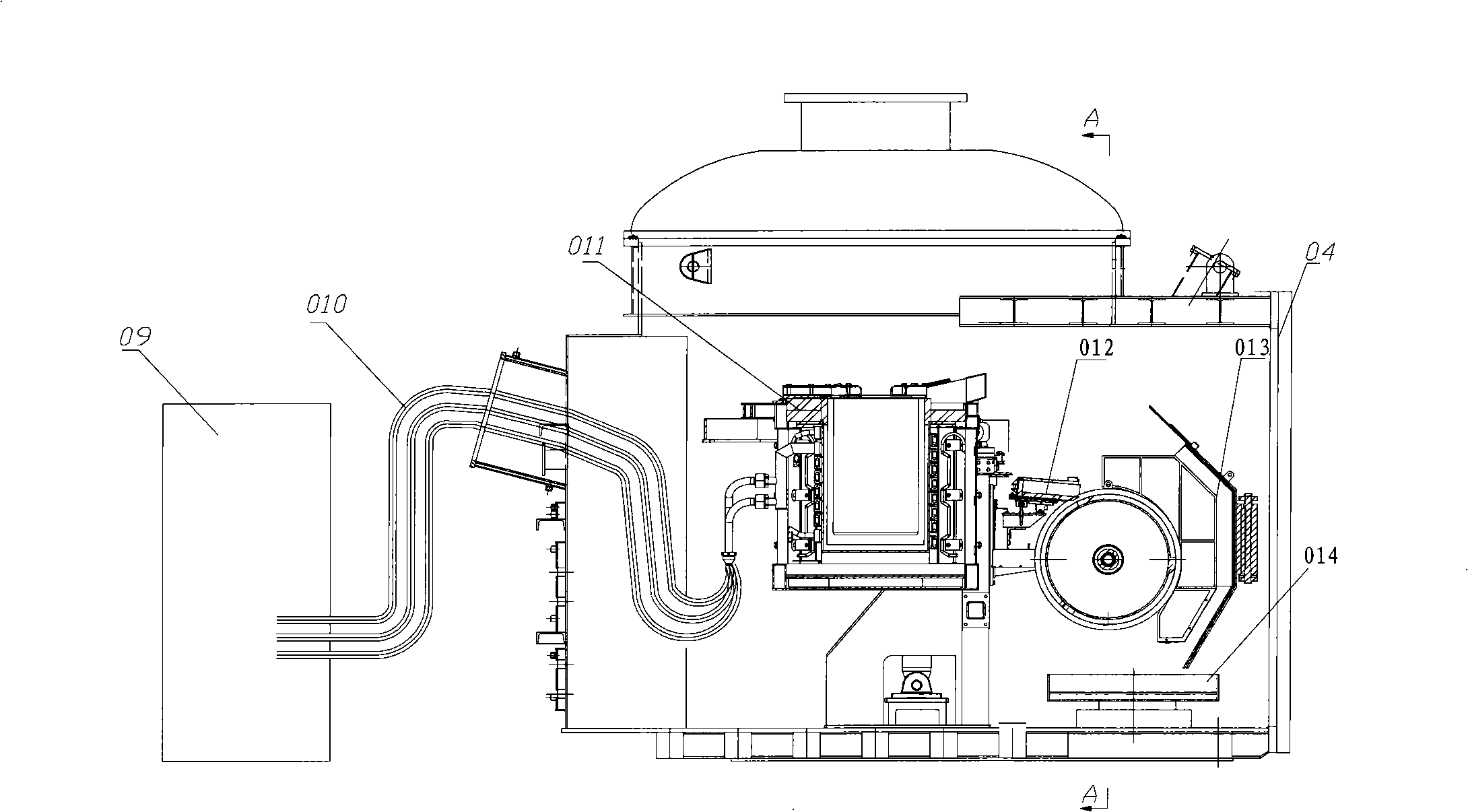

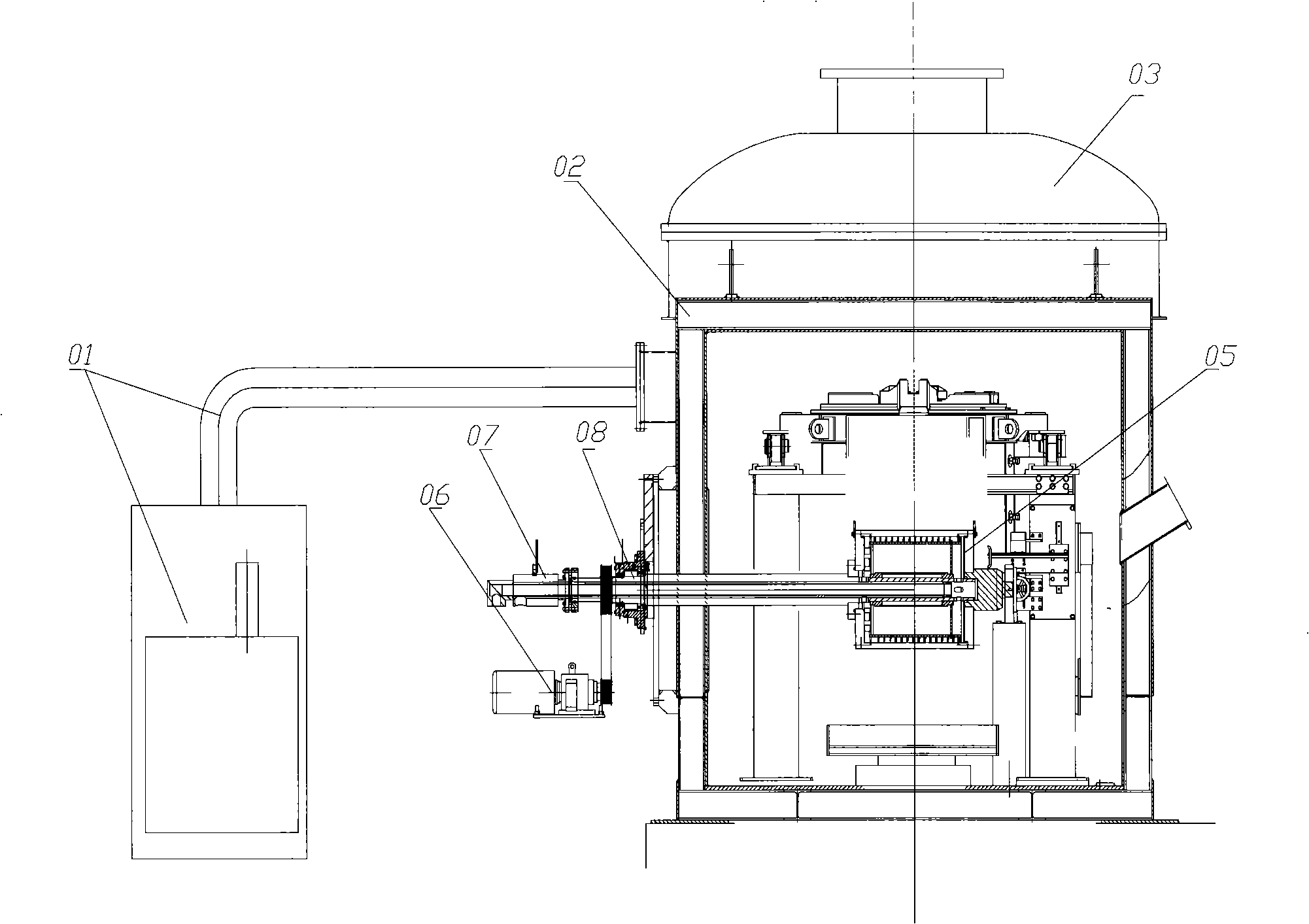

Vacuum induction smelting furnance

ActiveCN101347836AUniform thicknessUniform cooling effectCasting plantsCharge manipulationCooling effectFlap valve

The invention discloses a vacuum induction melting furnace, which relates to a crucible furnace that is suitable for charging treatment in vacuum or special atmosphere. The invention provides an improved vacuum induction melting furnace with better casting cooling effect and good productivity, which comprises a vacuum melting chamber, a medium frequency coil furnace, a set of vacuum pump and a corresponding vacuum pipeline system, a electric control system, a medium frequency power supply system, a hydraulic cylinder control system, a cooling system, and a pit discharging system. The cooling system is provided with a tundish feed divider, a belt wheel cooling mechanism, a baffle cooling mechanism and a turning wheel cooling mechanism. The pit discharging system comprises a medial chamber box, an inner container, an outer container, a walking car, a hydraulic lifting cylinder, a pit track, a flap valve and a guide shell. The guide shell and the flap valve are arranged in the medial chamber box, the outer container is fixedly arranged on the walking car, and the inner container is sheathed at the inner wall of the outer container.

Owner:厦门嘉鹭金属工业有限公司

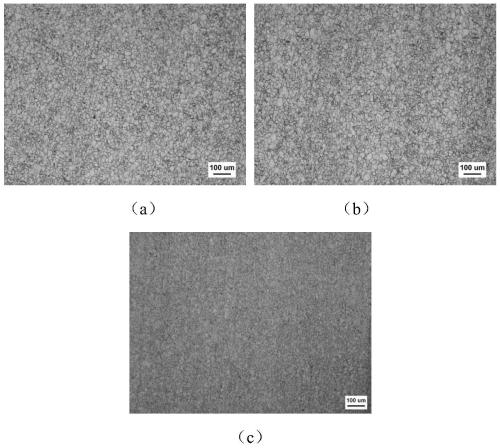

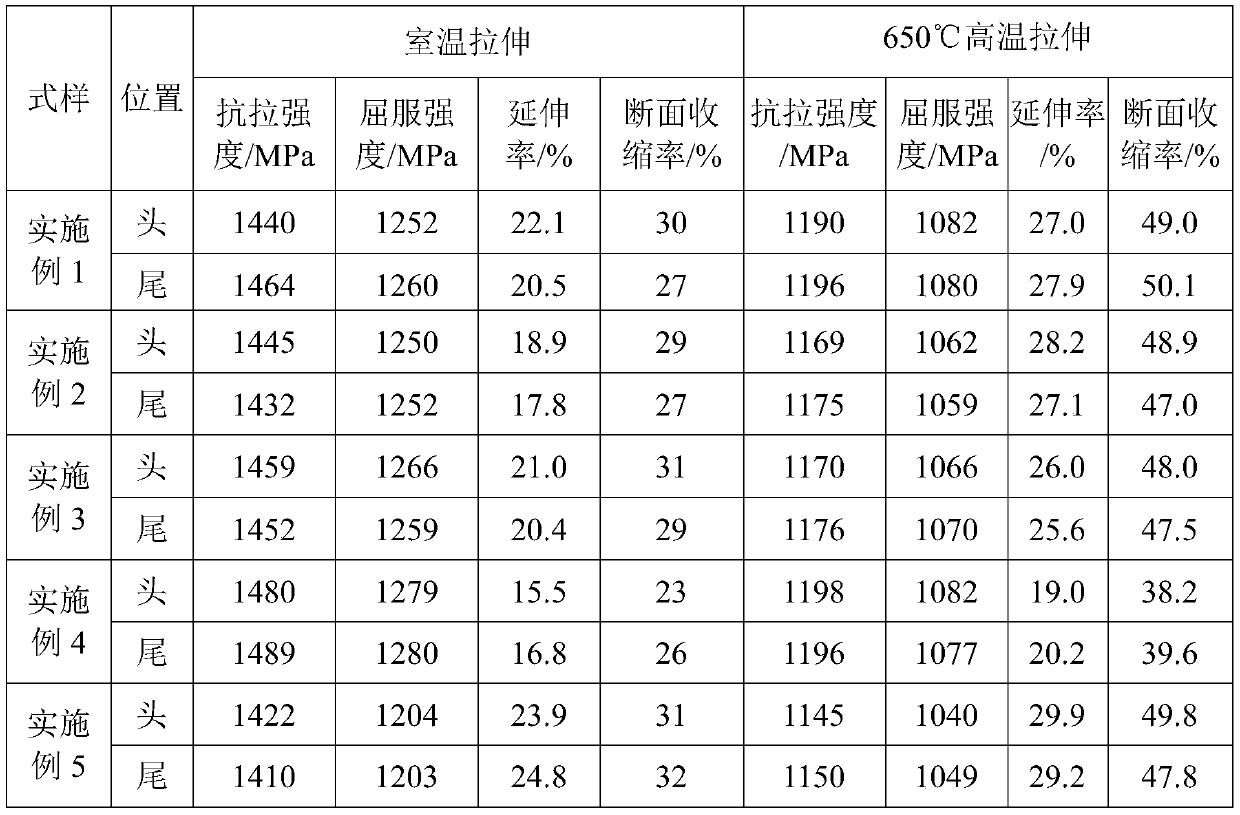

GH4169 high-temperature alloy free-forged bar billet and preparation method thereof

ActiveCN110449541ALow elemental contentImprove tissue uniformityMetal-working apparatusSmelting processIngot

The invention discloses a GH4169 high-temperature alloy free-forged bar billet. The GH4169 high-temperature alloy free-forged bar billet is characterized in that the specification is phi 250mm-350mm,the flaw detection level is not lower than phi 0.4dB-6dB, and the grain size is grade 8-9. The invention further discloses a preparation method of the bar billet. The preparation method comprises thefollowing steps that firstly, GH4169 high-temperature alloy cast ingots are smelted through a combined triple smelting process of vacuum induction smelting, electroslag remelting and vacuum self-consuming remelting, and high temperature homogenization treatment is carried out; secondly, upsetting, stretching, cogging and forging are carried out on the GH4169 high-temperature alloy cast ingots; then the billet materials obtained after cogging are deformed by upsetting and stretching, and the billet materials with the diameter of 400mm-500 mm are obtained; and finally, continuous remelting drawing forging is carried out on the billet materials obtained after upsetting and stretching at high-temperature to obtain the GH4169 high-temperature alloy free-forged bar billet with the diameter of 250mm-350mm. According to the preparation method , the grain size of the bar billet is controlled to be grade 8-9, the grain size grade difference from an edge part to a core part is controlled to be 1grade or within, and the structure uniformity of the large bar billet is improved.

Owner:西部超导材料科技股份有限公司

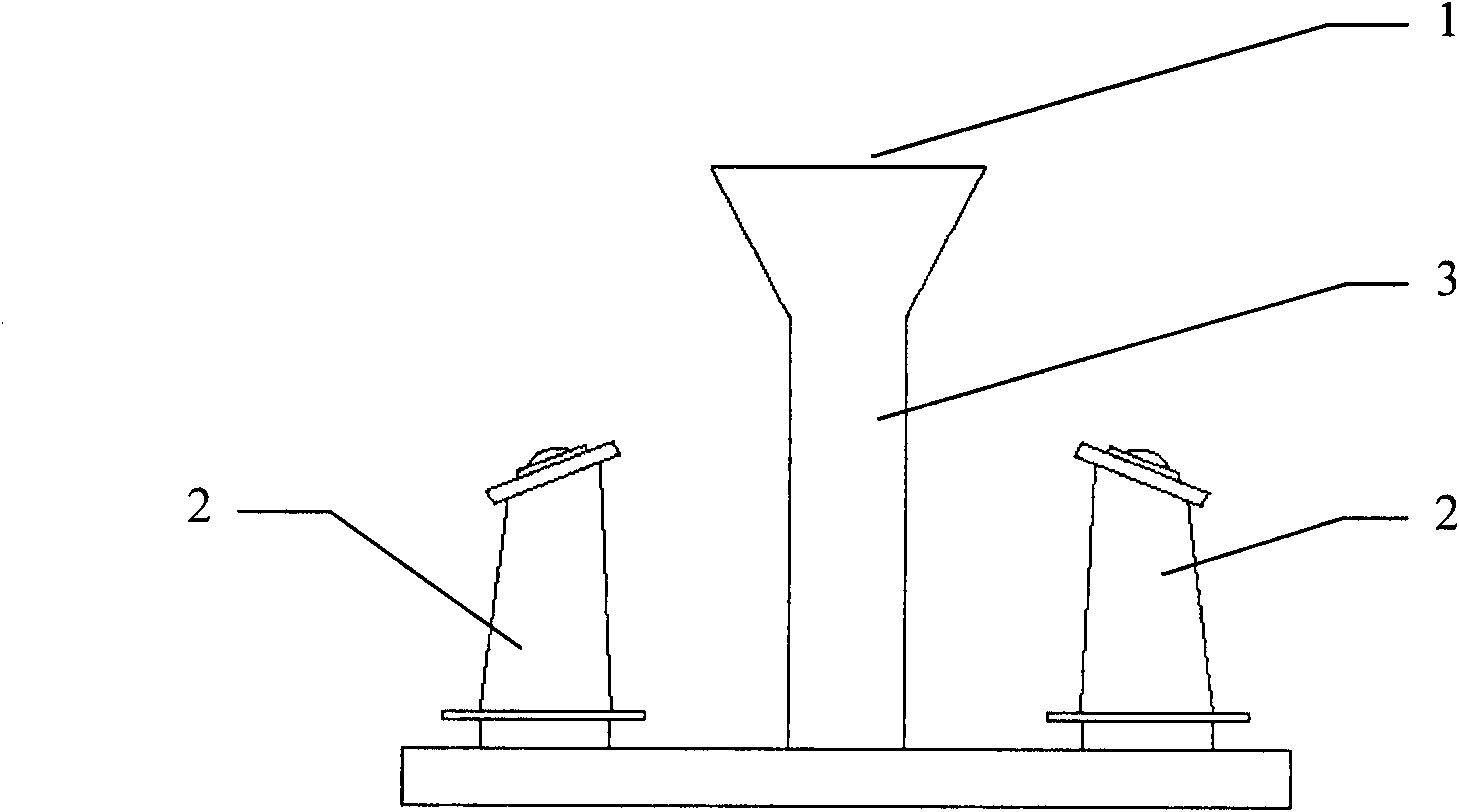

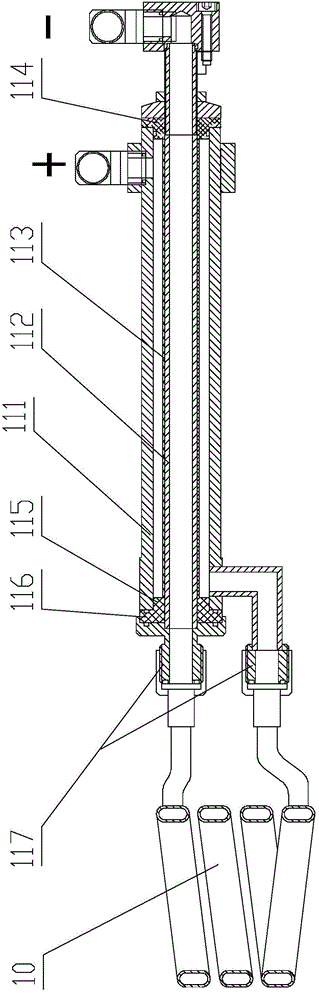

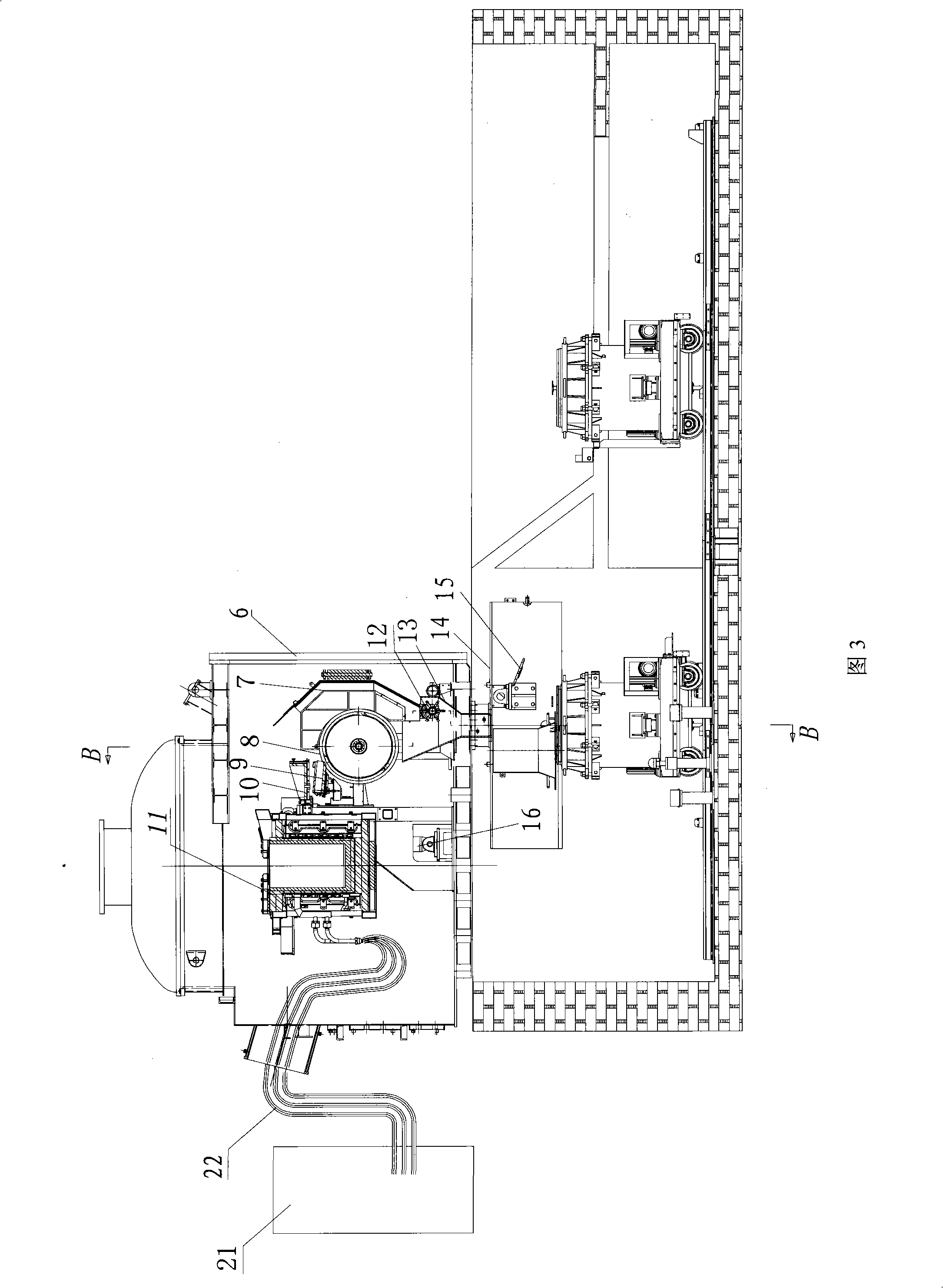

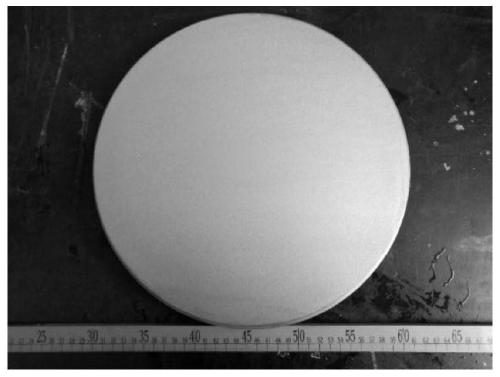

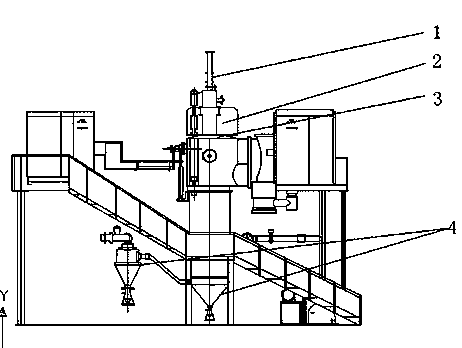

Process and equipment used for preparing high-purity spherical titanium and titanium alloy powder material

The invention discloses a process and equipment used for preparing a high-purity spherical titanium and titanium alloy powder material. The equipment comprises an electrode vertical conveying device 1, a vacuum induction melting device 2, a gas atomizer 3 and an atomizing tower 4, and is characterized in that the vertical displacement and the rotating speed of titanium and titanium alloy electrode bars entering a vacuum induction melting furnace are precisely controlled by the electrode vertical conveying device; the titanium and the titanium alloy electrode bars are molten into liquid in the induction furnace under a non-crucible contact state; the melting rate of the titanium and titanium alloy electrode bars can be adjusted through controlling the displacement speed of the titanium and titanium alloy electrode bars entering the melting furnace and the heating temperature in the induction furnace; when the metal liquid passes through a gas confluence focus of the high-pressure inert gas atomizer, a titanium and titanium alloy liquid phase flow is crushed into a superfine fogdrop state; under the effect of surface tension, liquid drops settle, cool and form the spherical superfine powder material in the atomizing tower and are separated and collected by a filter; the titanium and titanium alloy powder materials with different granularities and size distribution can be obtained through controlling atomizing gas pressure and flow. By using the process and the equipment, high-purity spherical magnesium, aluminum, nickel, chromium, tungsten, molybdenum and corresponding alloy powder and ceramic powder can be prepared.

Owner:CHANGSHA WEITE METALLURGY ENG TECH

Superfine extra-high-strength steel wire, steel wire rod, and production method of steel wire rod

ActiveCN110230008AGuaranteed StrengthGuaranteed toughnessFurnace typesHeat treatment process controlVacuum induction meltingChemical composition

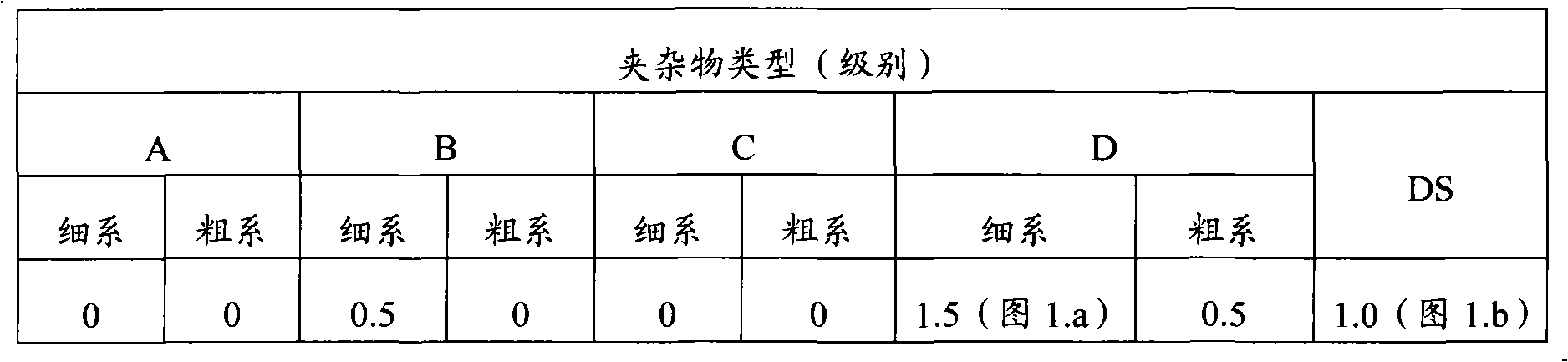

The invention discloses a superfine extra-high-strength steel wire, a steel wire rod for the superfine extra-high-strength steel wire, and a production method of the steel wire rod. The superfine extra-high-strength steel wire is prepared from the chemical components in percentage by mass: 0.90 to 0.96 percent of C, 0.12 to 0.30 percent of Si, 0.30 to 0.65 percent of Mn, 0.10 to 0.30 percent of Cr, less than or equal to 0.004 percent of Al, less than or equal to 0.001 percent of Ti, less than or equal to 0.01 percent of Cu, less than or equal to 0.01 percent of Ni, less than or equal to 0.01 percent of S, less than or equal to 0.01 percent of P, less than or equal to 0.0006 percent of O, less than or equal to 0.0006 percent of N, and the balance Fe and inevitable impurity elements, whereinthe size of an occluded foreign substance is less than or equal to 4mum, and the average density of the brittle occluded foreign substance is less than or equal to 2pieces / mm<2>. The steel wire rod for the superfine extra-high-strength steel wire can be used as base metal for producing the superfine extra-high-strength steel wire with the diameter being 50 to 60mum and the tensile strength beinglarger than or equal to 4500MPa, and the mileage without wire breakage is larger than or equal to 300km in the process of drawing to prepare the superfine extra-high-strength steel wire. The production method comprises the steps of vacuum induction melting, remelting, forging and steel rolling.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

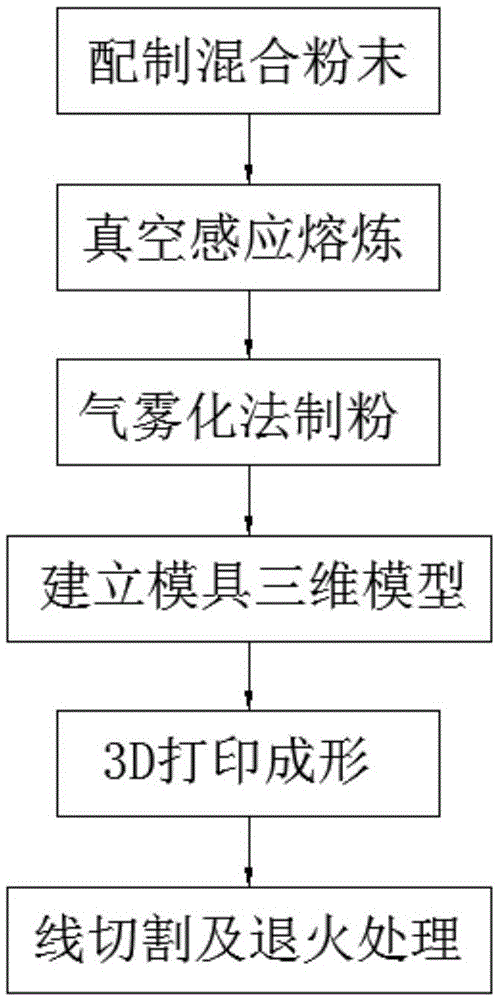

3D printing preparation method for injection mold

InactiveCN105562691AAvoid crackingAdd C elementAdditive manufacturing apparatusIncreasing energy efficiencyPolymer scienceEvaporation

The invention discloses a 3D printing preparation method for an injection mold. The 3D printing preparation method comprises the following steps that 1, mixed powder is prepared, and then vacuum induction melting is carried out, wherein the mixed powder is prepared from, by weight percent, 0.4% to 0.5% of C, 0.7% to 0.75% of Si, 0.35% to 0.45% of Mn, 14% to 15.6% of Cr, 0.25% to 0.35% of V and the balance Fe; 2, an atomization powder preparing method is adopted for preparing the powder; 3, a three-dimensional model is established; 4, the injection mold is formed; and 5, the formed injection mold is separated from a substrate, and then the injection mold is placed in a muffle furnace for annealing to improve the plasticity and toughness of the injection mold. According to the 3D printing preparation method, cracking of mold steel in the 3D printing process can be effectively restrained. Meanwhile, C is added to make up ingredient changes caused by element evaporation and carbonization of the injection mold under the action of lasers.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com