GH4169 high-temperature alloy free-forged bar billet and preparation method thereof

A technology of GH4169 and superalloy, which is applied in the direction of metal processing equipment, etc., can solve the problems of poor composition uniformity of ingots and high equipment costs, and achieve the effect of small content of harmful impurity elements, uniform composition, and improved structure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of preparation method of GH4169 superalloy free-forging billet of the present invention, concrete operation process comprises the following steps:

[0036] Step 1, sequentially smelting GH4169 superalloy ingots through the triple smelting process of vacuum induction melting + electroslag remelting + vacuum consumable remelting to obtain GH4169 superalloy ingots with a diameter of 480 mm to 600 mm;

[0037] Step 2, the GH4169 superalloy ingot is heated in a natural gas furnace to a temperature of 1180°C to 1200°C for uniform treatment;

[0038] In step 2, the ingot high-temperature uniform treatment process is as follows:

[0039] First heat to 600°C-650°C, heat preservation coefficient is 0.6min / mm, then heat up to 1140°C-1160°C at a heating rate of 2°C-6°C / min, hold time ≥ 24h, then heat at 2°C-6°C / mm The heating rate of min is raised to 1180°C-1200°C, the holding time is ≥48h, and the furnace is cooled to 600°C-650°C at the end of the holding time, and then ai...

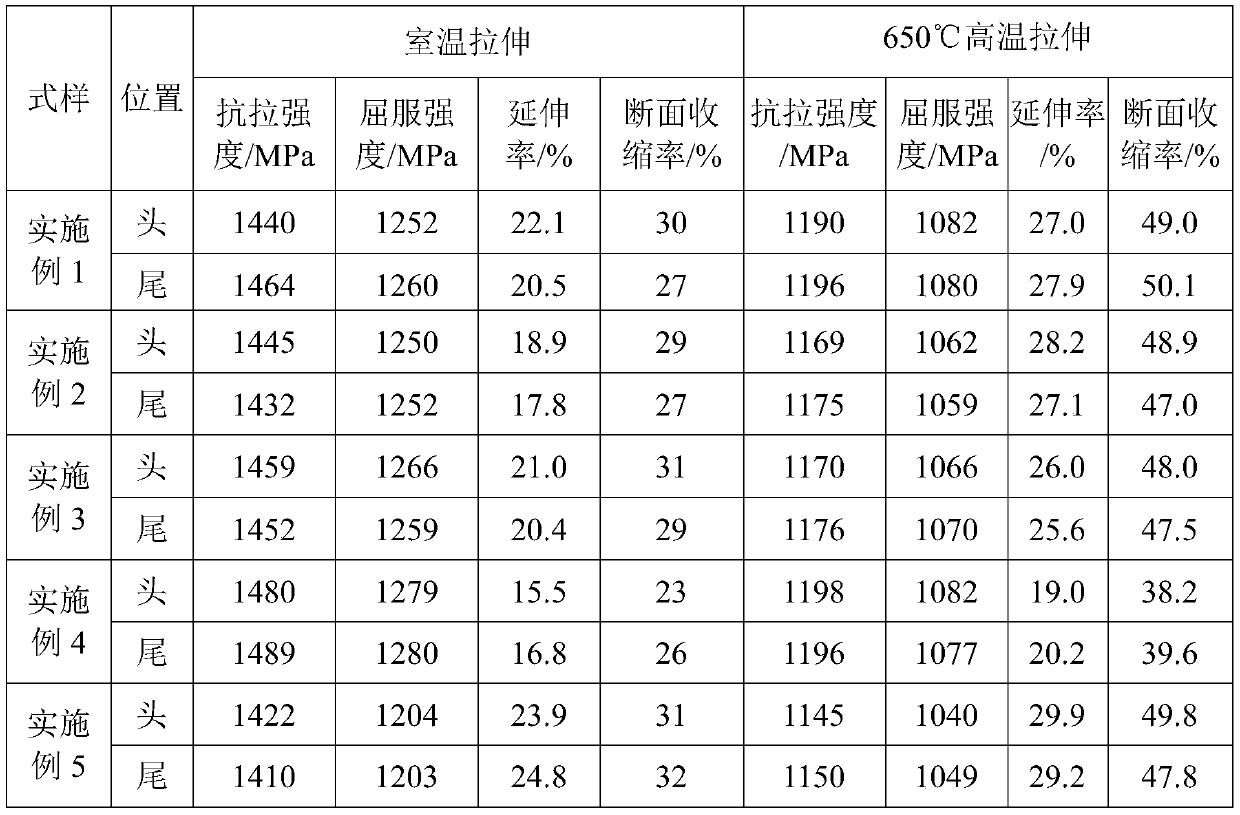

Embodiment 1

[0058] The diameter of the GH4169 alloy ingot smelted by vacuum induction melting + electroslag remelting + vacuum consumable remelting process is 490mm. The ingot homogenization process is as follows: heating to 650°C, holding for 300min, and then heating at a rate of 2°C / min Raise the temperature to 1150°C, hold for 24 hours, then raise the temperature to 1195°C at a heating rate of 6°C / min, hold for 48 hours, cool in the furnace to 650°C at the end of the hold, and then air cool;

[0059] Heat the GH4169 superalloy ingot cold material after the homogenization heat treatment to 650°C and keep it warm, then raise the temperature to 1100°C at a heating rate of 5°C / min and keep it warm. 1200→Φ600×800→Bafang 480×1180, the deformation of the first and second fires and single fires are 33% and 32% respectively. After completion, the hot material is quenched in water.

[0060] Heat the cold billet obtained after billet opening to 850°C and keep it warm, then raise the temperature ...

Embodiment 2

[0065] The diameter of the GH4169 alloy ingot smelted by vacuum induction melting + electroslag remelting + vacuum consumable remelting process is 530mm. 1160°C, holding time 28h, then heating up to 1190°C at a heating rate of 4°C / min, holding time 54h, furnace cooling to 630°C at the end of holding, then air cooling;

[0066] Heat the GH4169 superalloy ingot cold material after homogenization heat treatment to 630°C and keep it warm, then raise the temperature to 1090°C at a heating rate of 7°C / min and keep it warm, then open the billet, forging a total of 2 fires, and the deformation setting is as follows: Φ530× 1020→Φ660×655→Bafang 500×1080, the deformations of the 1st and 2nd single fires are 35% and 39% respectively. After completion, the hot material is quenched in water.

[0067] Heat the cold billet obtained after billet opening to 800°C and keep it warm, then raise the temperature to 1080°C at a heating rate of 7°C / min and then carry out 4 times of upsetting and draw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com